Construction method of PK prestressed concrete overlapping slabs

A construction method and concrete technology, applied in the direction of floors, building components, buildings, etc., can solve the problems of complex fixtures, low efficiency, collisions, etc., and achieve the effect of optimizing support methods, satisfying reliability, and reducing hoisting costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

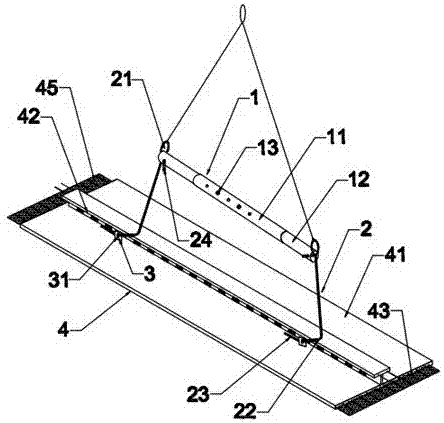

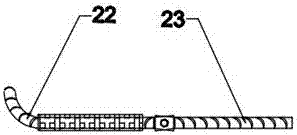

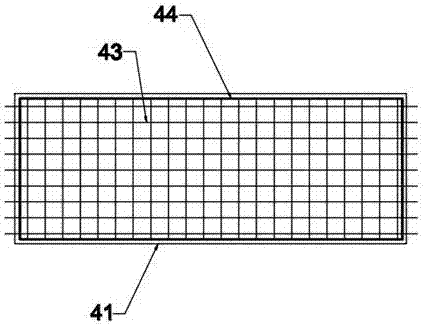

[0025] The PK prestressed concrete laminated slab construction method provided by the present embodiment includes the following steps: S1, prepare corresponding PK slabs 4 according to the requirements of the design drawings, and transport them to the construction site for stacking in batches; S2, design the PK slabs according to the drawings 4. Set up a height-adjustable support frame at the corresponding position to ensure that the PK boards 4 are pressed on the crossbars in the support frame; Lay until it is fully paved; S4, according to the design requirements of the drawings, reserve holes for installing water and electricity pipelines on the corresponding PK board 4; S5, perform sealing treatment at the junction of the PK board 4 and the beam-column formwork; S6, on the PK board 4 Arranging steel bars and pipelines; S7, pouring concrete on the PK slab 4; S8, removing the support frame and beam-column formwork erected in step 2.

[0026] Further, when stacking PK boards, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com