Patents

Literature

169results about How to "Easy to prefab" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

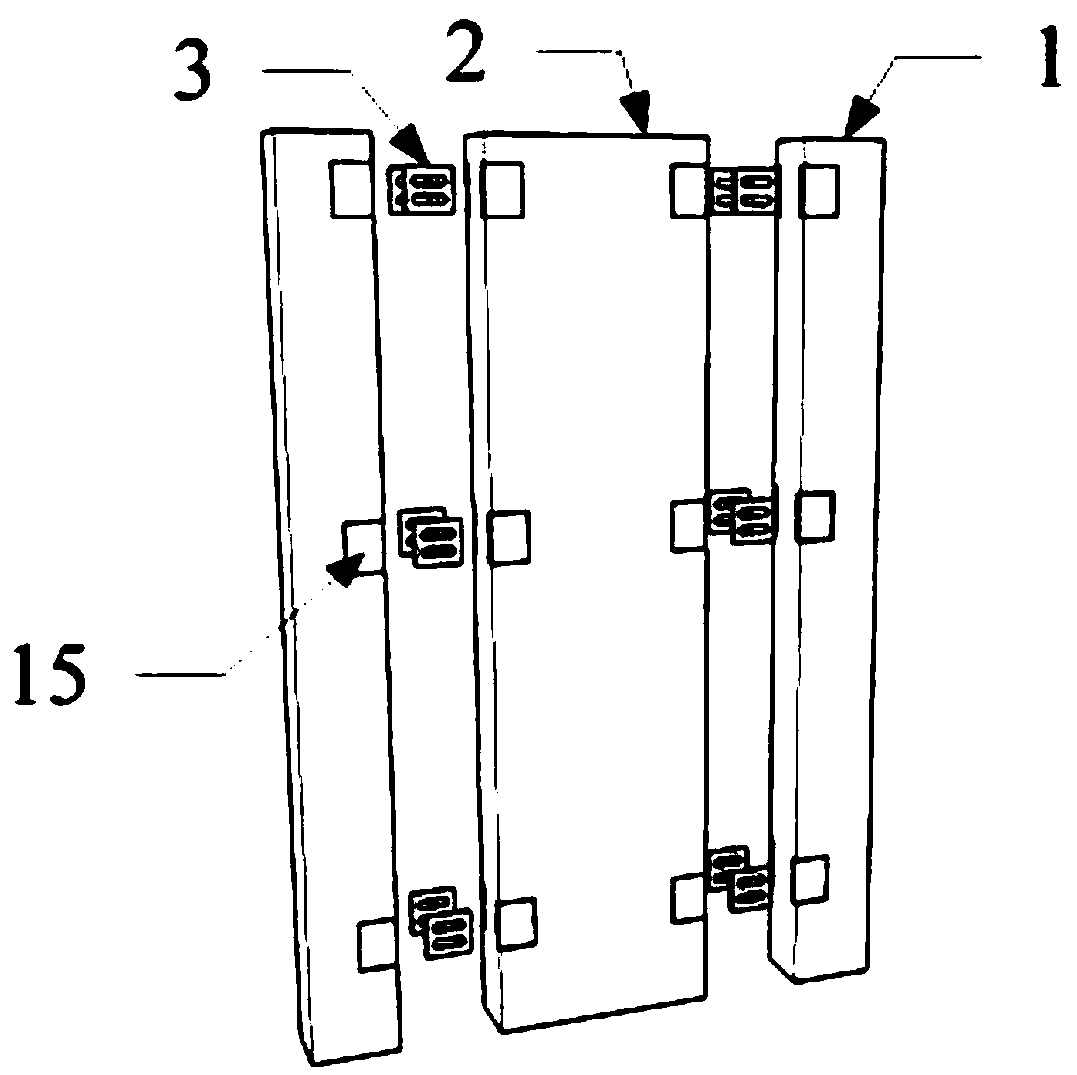

Assembled type gridding shearing wall structural system and construction technology of assembled type gridding shearing wall structural system

ActiveCN103924711ASimple structureLow input costWallsBuilding material handlingVertical edgeEngineering

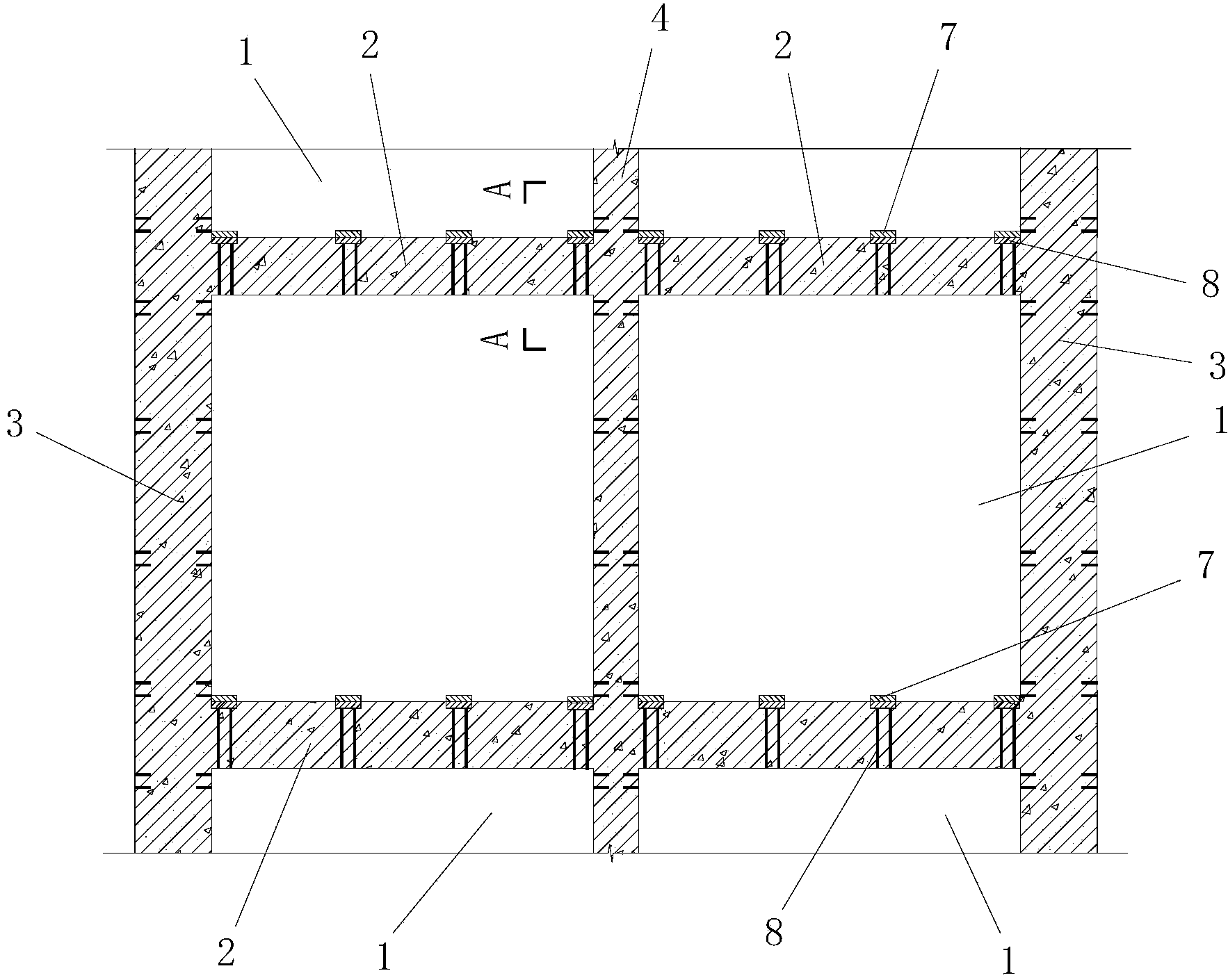

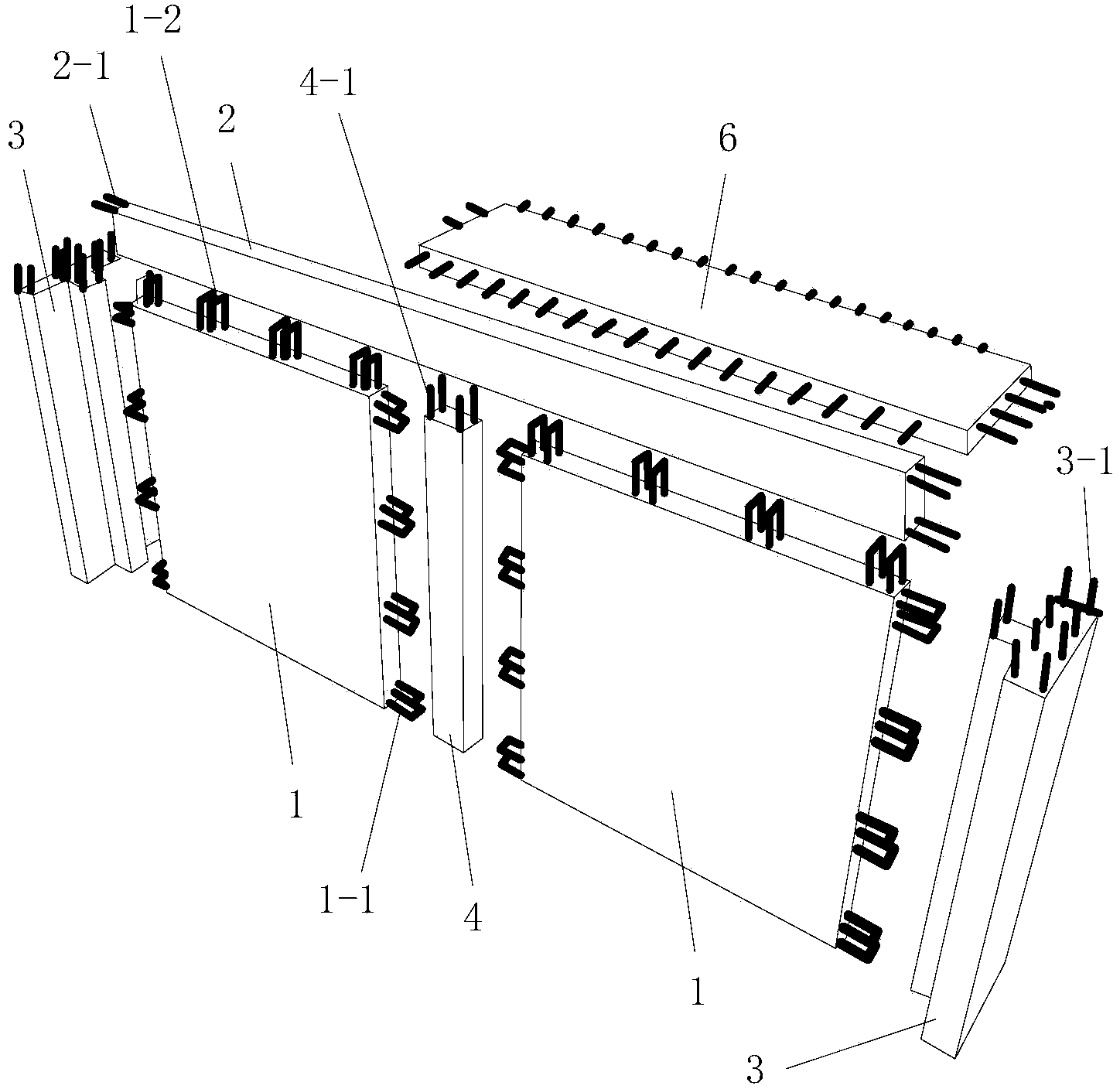

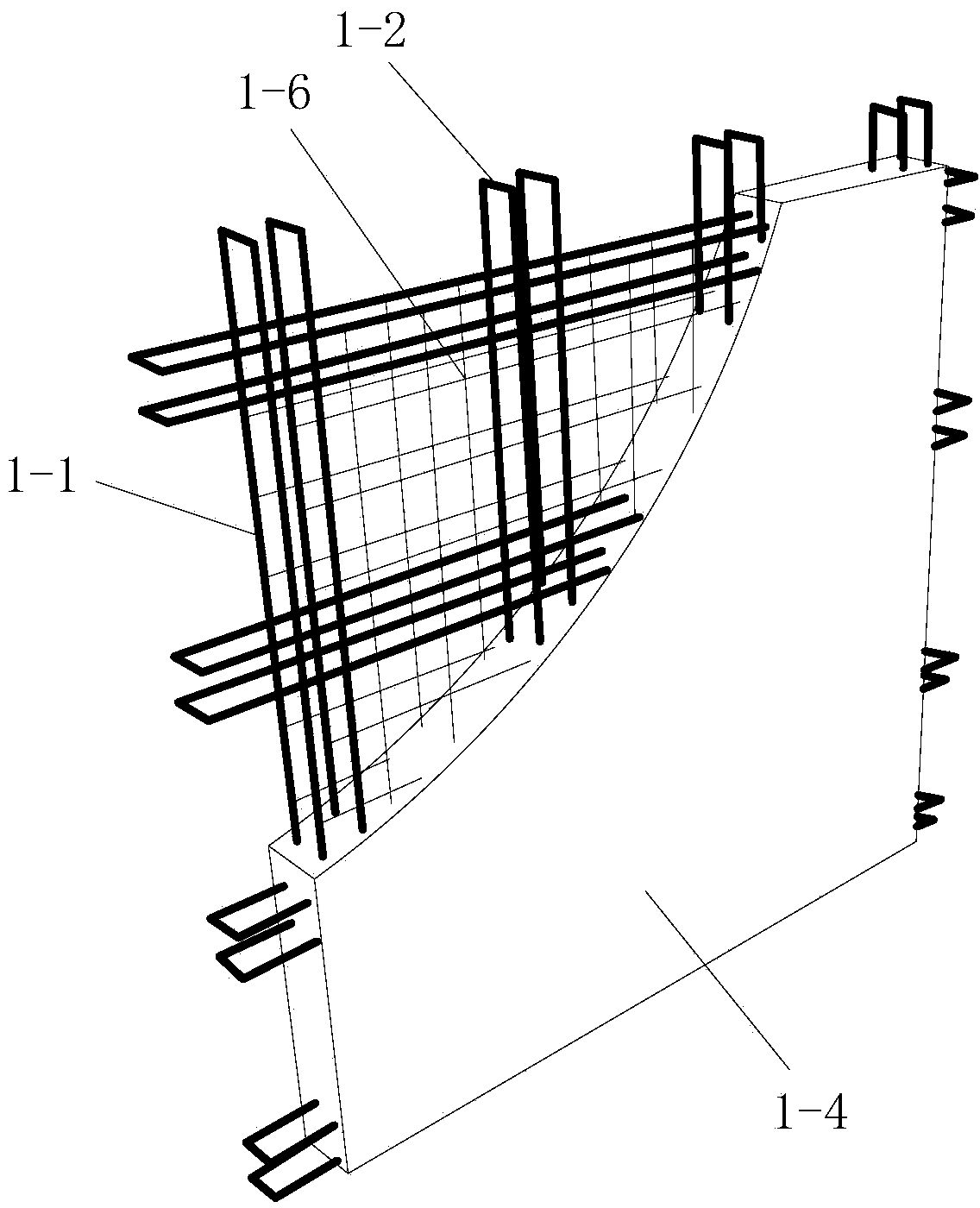

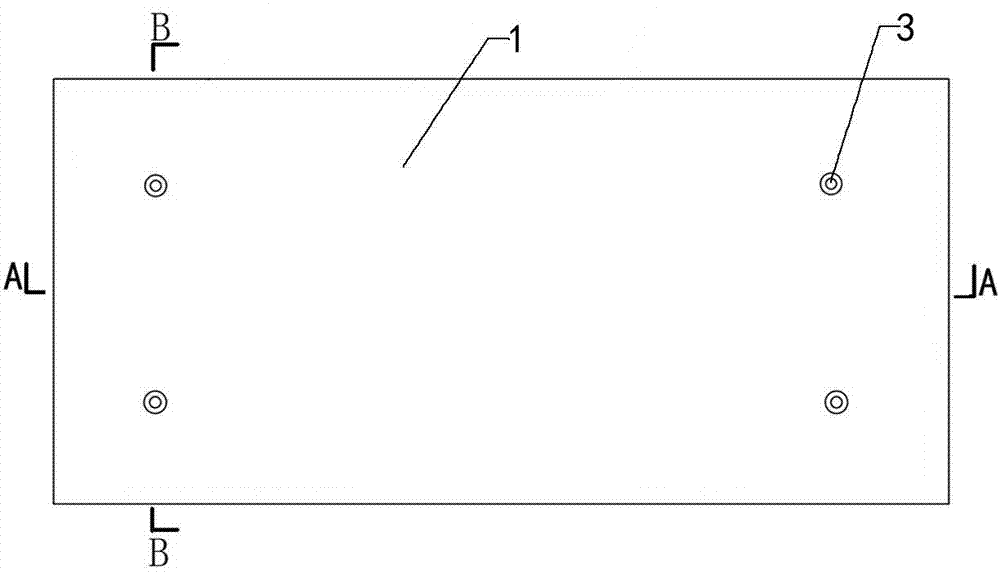

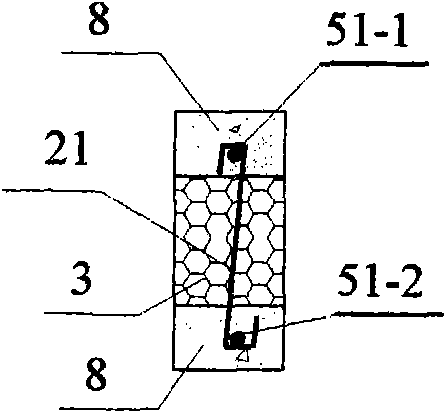

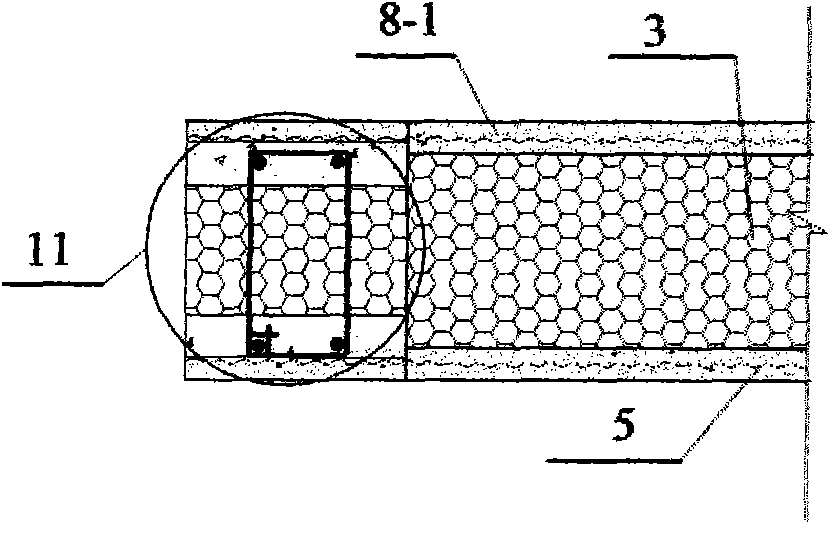

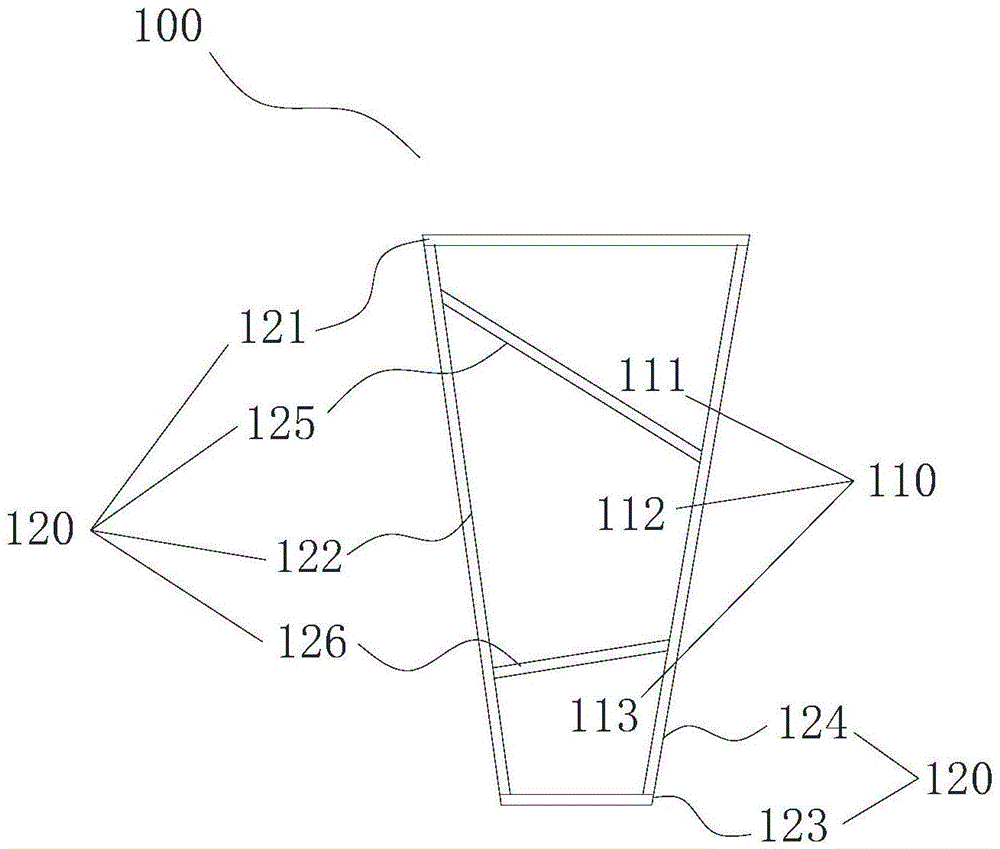

The invention discloses an assembled type gridding shearing wall structural system which comprises a plurality of shearing wallboards arranged from top to bottom. Each shearing wallboard comprises a shearing wall body, upper restraining hidden beams and two vertical edge restraining components, the shearing wall body is formed by a plurality of prefabricated gridding shearing wall main bodies in a spliced mode, every two adjacent prefabricated gridding shearing wall main bodies are connected through a connecting hidden column, and rectangular boxes on the internal framework of each prefabricated gridding shearing wall main body are respectively provided with a rectangular heat preservation board in an inlaid mode. A construction technology of the assembled type gridding shearing wall structural system includes the steps of (1) carrying out measuring and setting-out, (2) hoisting the prefabricated gridding shearing wall main bodies, (3) constructing the upper restraining hidden beams, the connecting hidden columns and the vertical edge restraining components, (4) constructing the shearing wallboard on the upper layer, and (5) repeating the steps till the construction process of the multiple shearing wallboards is completed. The assembled type gridding shearing wall structural system and the construction technology are reasonable in design, convenient to construct, low in investment cost and good in use effect, and multiple problems in traditional assembling of an integrated shearing wall structure can be effectively solved.

Owner:东莞市建安住宅工业有限公司

Fully prefabricated reinforced concrete bridge assembly structure and connecting method for same

ActiveCN103741604AImprove assembly rateReduce construction costsBridge erection/assemblyReinforced concreteBridge deck

The invention discloses a fully prefabricated reinforced concrete bridge assembly structure and a connecting method for the same. The fully prefabricated reinforced concrete bridge assembly structure is characterized by comprising prefabricated piles, prefabricated floor collar beams, prefabricated pier studs, prefabricated capping beams, prefabricated longitudinal beams, prefabricated composite bottom plates and prefabricated anti-collision barriers. The connecting method includes connecting the tops of the prefabricated piles with the bottoms of the prefabricated floor collar beams; upwardly connecting the prefabricated floor collar beams with the prefabricated pier studs; upwardly connecting the prefabricated pier studs with the prefabricated capping beams; erecting the prefabricated longitudinal beams on the prefabricated capping beams via bridge supports or fixing ends; supporting the prefabricated composite bottom plates on the prefabricated longitudinal beams, tying reinforcing steel bars of a bridge deck on the prefabricated composite bottom plates and integrally casting concrete on a site to form the bridge deck; mounting the prefabricated anti-collision barriers on the bridge deck. The fully prefabricated reinforced concrete bridge assembly structure and the connecting method have the advantages that components, except for the bridge deck, of the fully prefabricated reinforced concrete bridge assembly structure are of prefabricated structures, so that the bridge prefabricated rate can be greatly increased; common construction labor consumption can be reduced to the greatest extent, and the labor productivity can be improved; the construction period of the fully prefabricated structure can be greatly shortened, the bridge building cost can be reduced, and the bridge construction quality can be improved.

Owner:张利铨

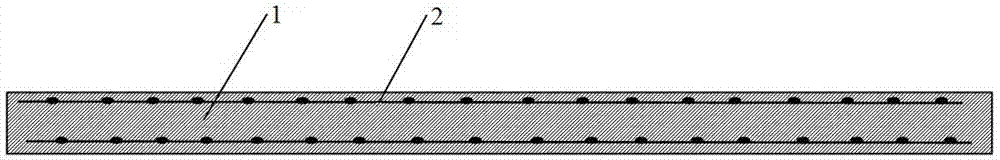

Fabricated type reactive powder concrete prefabricated pavement slab without reinforcing rib and manufacturing method thereof

ActiveCN104294728AStrong bending resistanceHigh compressive strengthSingle unit pavingsCeramic shaping apparatusWire gauzeWeather resistance

The invention discloses a fabricated type reactive powder concrete prefabricated pavement slab without a reinforcing rib and a manufacturing method thereof. A slab body is a material plate made from reactive powder concrete; layers of horizontal steel wire gauzes are respectively spread in the reactive powder concrete material plate and are close to upper and lower surfaces; hoisting embedded parts which run through in the vertical direction are respectively arranged at the four corners, wherein the two ends of the hoisting embedded parts are connected with lifting appliances. When the fabricated type reactive powder concrete prefabricated pavement slab without the reinforcing rib is manufactured, the fluidity of the reactive powder concrete is controlled to avoid deformation of the pavement slab in the later-period manufacturing process, and the fabricated type reactive powder concrete prefabricated pavement slab without the reinforcing rib is maintained naturally indoors to ensure the total quality of the pavement slab. Compared with a common concrete pavement slab, the pavement slab has the advantages of no reinforcing rib in structure, small thickness, portability, light weight, convenience in transportation and installation, high intensity, wear resistance, high bearing capability, good anti-impact performance, good anti-fatigue performance, good weather resistance, and fast and efficient construction, repeated use, and can be widely applied to road construction of temporary building living quarters.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

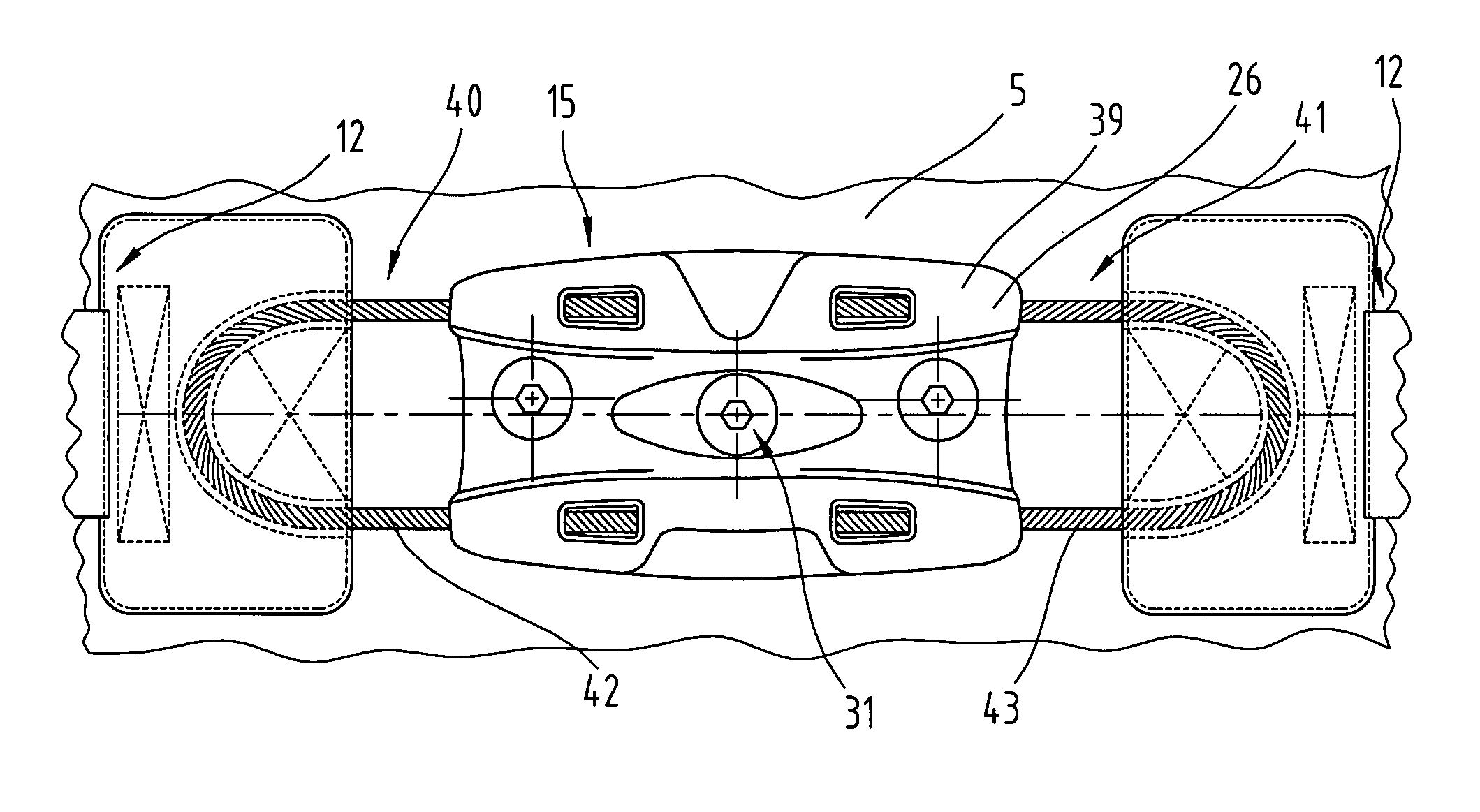

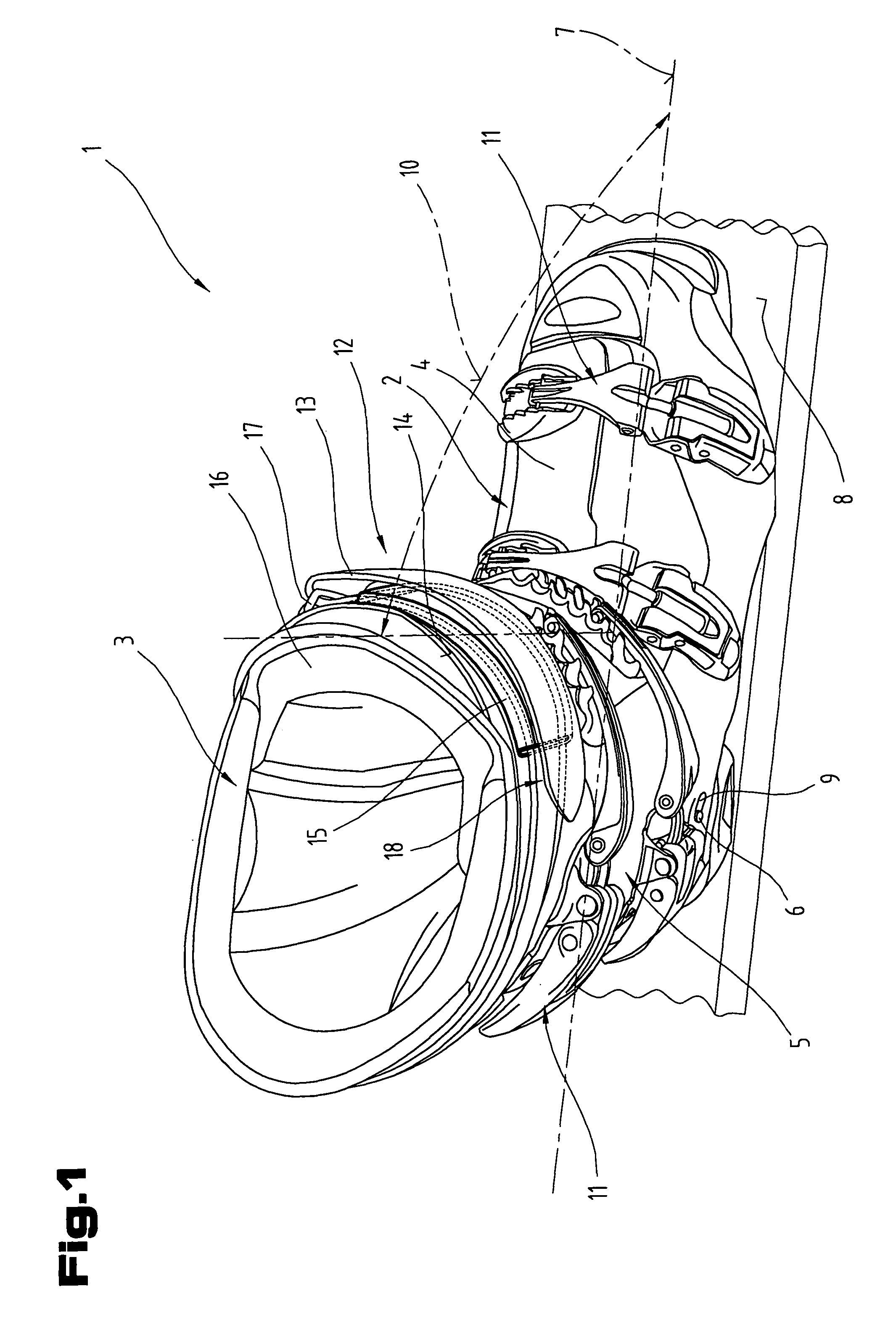

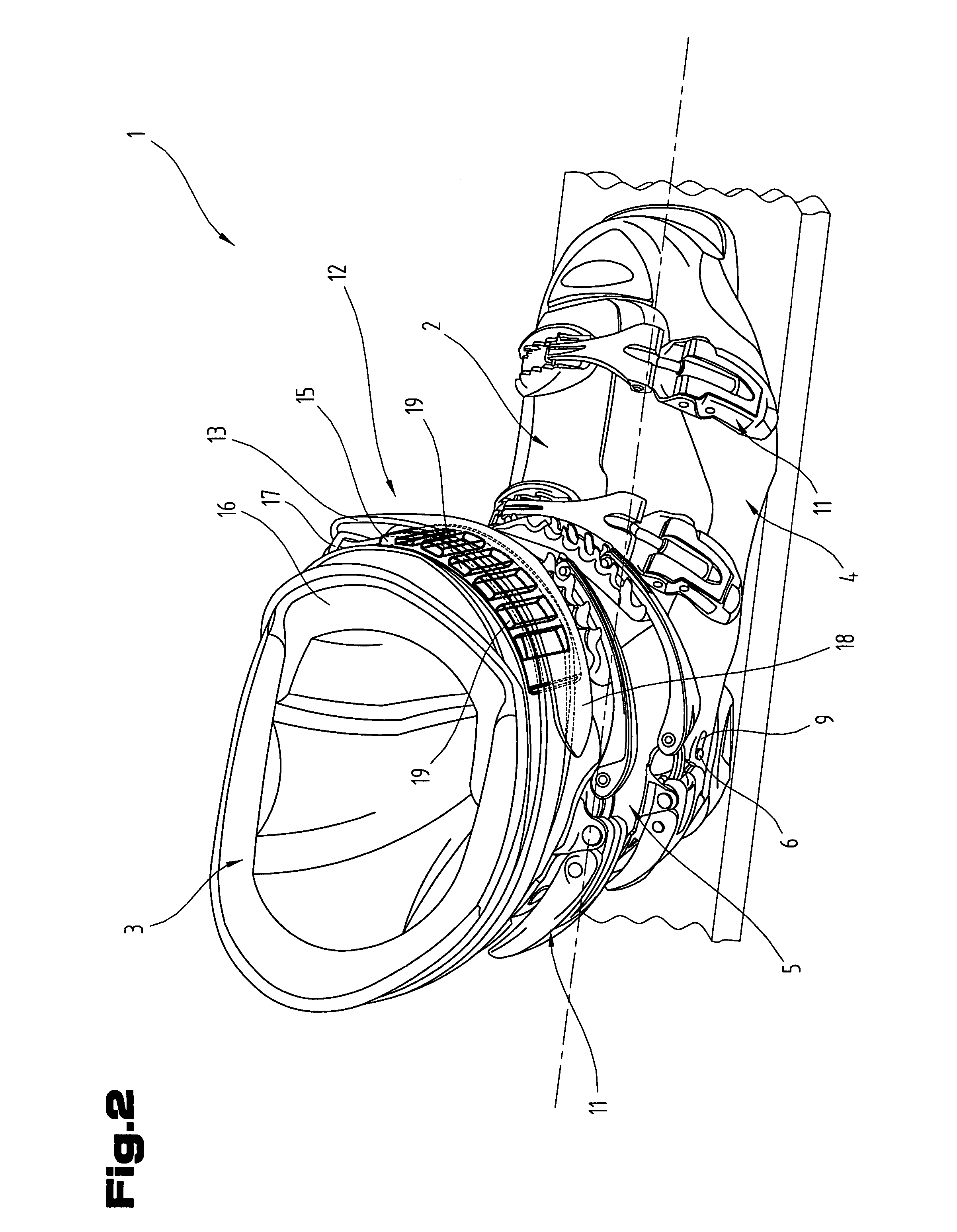

Sports shoe, in particular a ski shoe, with clamping means therefor

The invention relates to a sport shoe (1) with an outer shell (2) made from injection molded plastic, comprising a front foot shell (4) and a shoe cuff (5) adjoining it. At least partially accommodated in the shell (2) is a relatively soft elastic inner shoe (3). In particular, a ski shoe with at least one strap-shaped clamping means (12) disposed at least in a top end portion of the shoe cuff (5) and extending round the top end portion of the shoe cuff (5) is proposed. This strap-shaped clamping means (12) is of a non-stretch design within its entire longitudinal extension and the strap-shaped clamping means (12) is supported on at least one elastically flexible element (15) in the usage or active state, which is disposed between the shoe cuff (5) and the strap-shaped clamping means (12). Alternatively, the strap-shaped clamping means (12) is provided as a clamping means (12) extending at least partially round the shoe cuff (5) and is secured by at least one of its ends to an elastically flexible element (15) permanently mounted on the shoe.

Owner:ATOMIC AUSTRIA

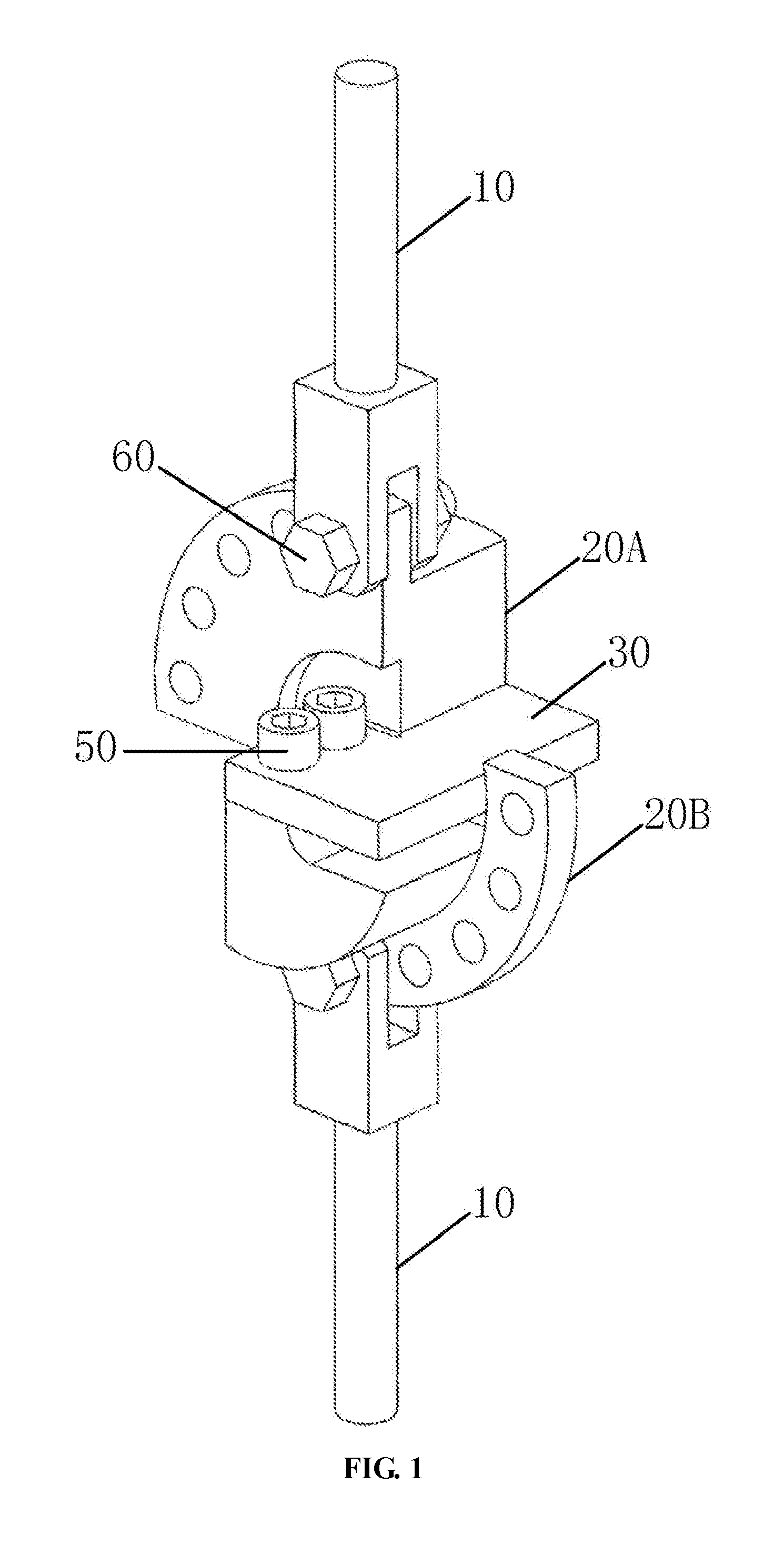

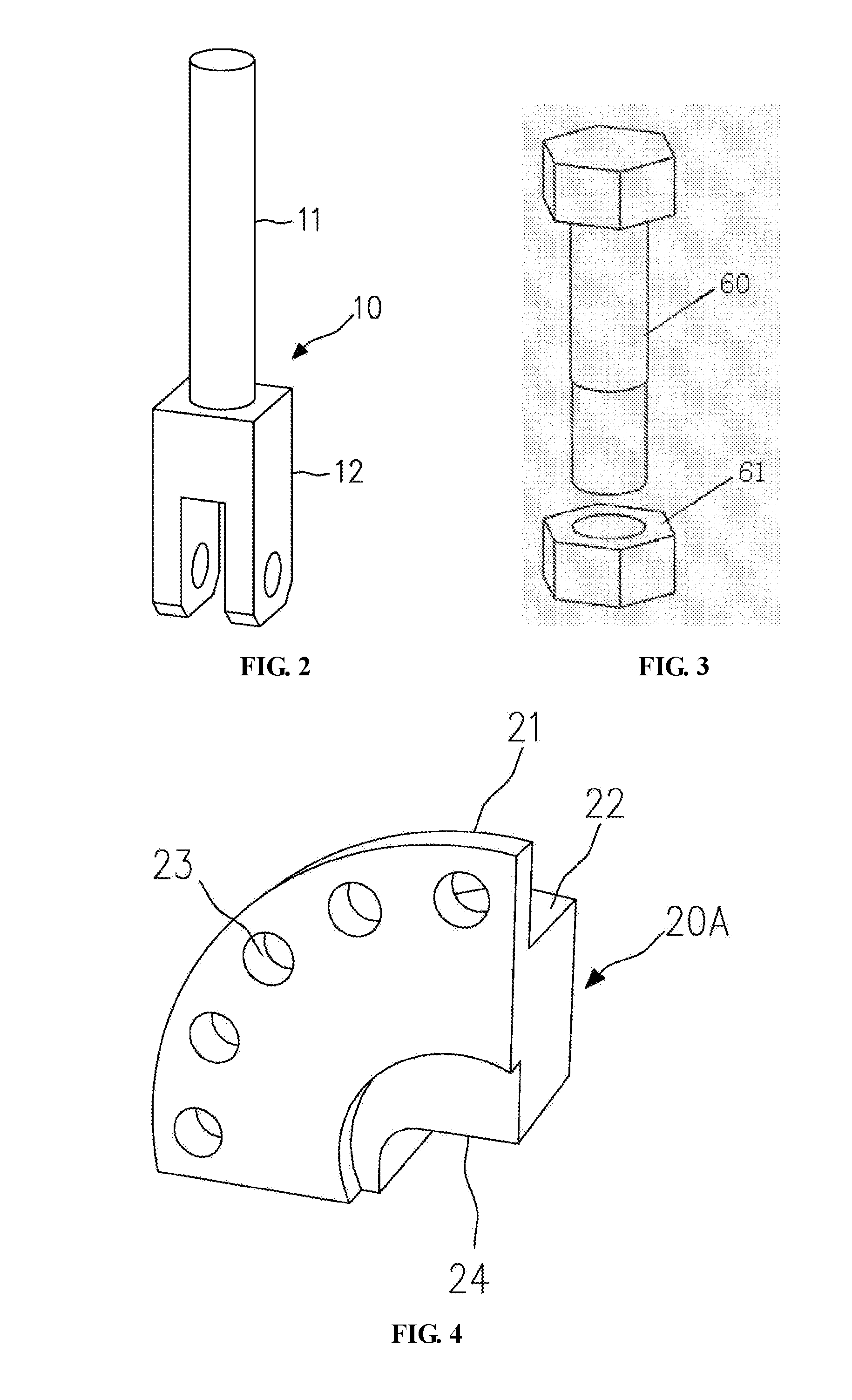

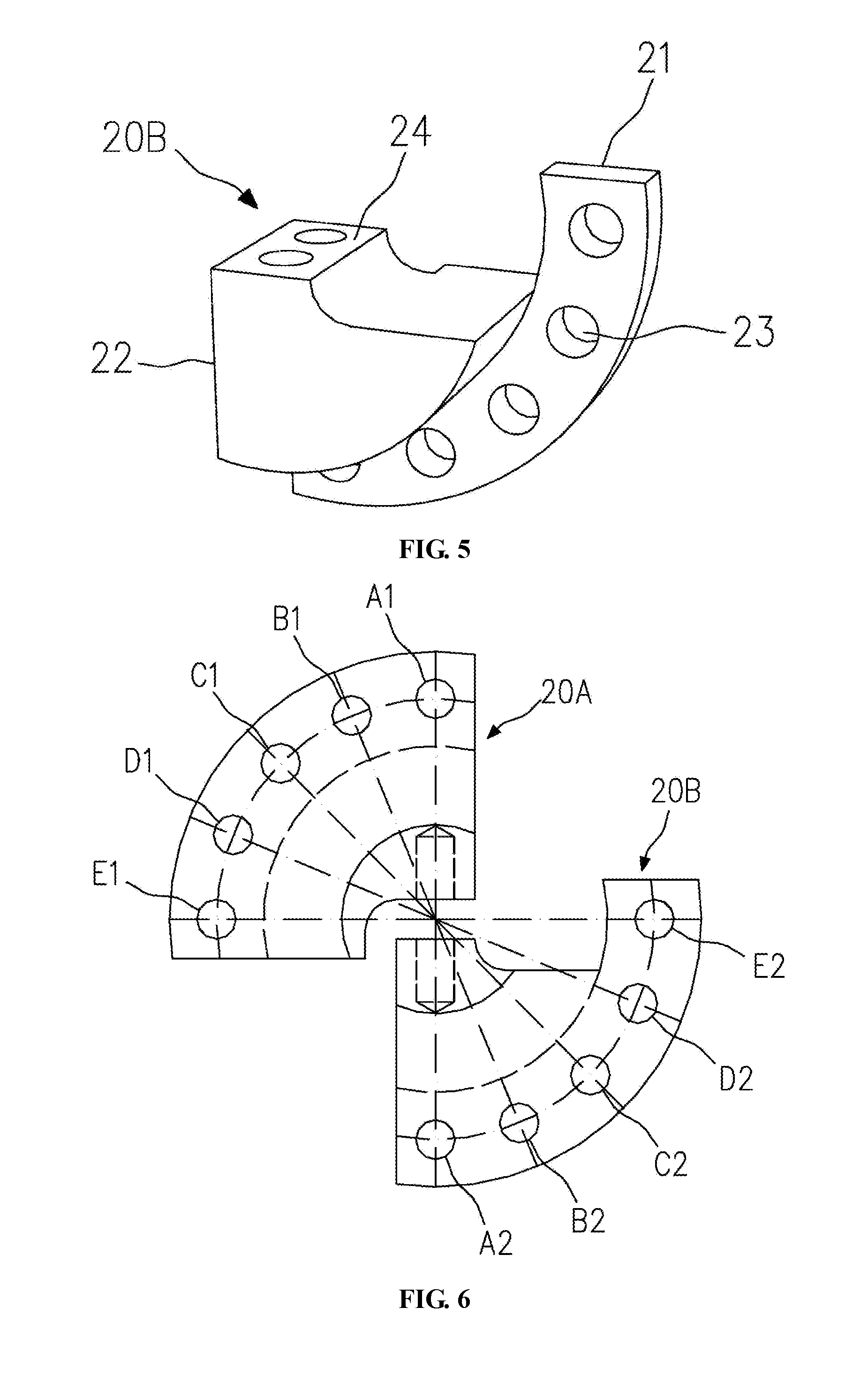

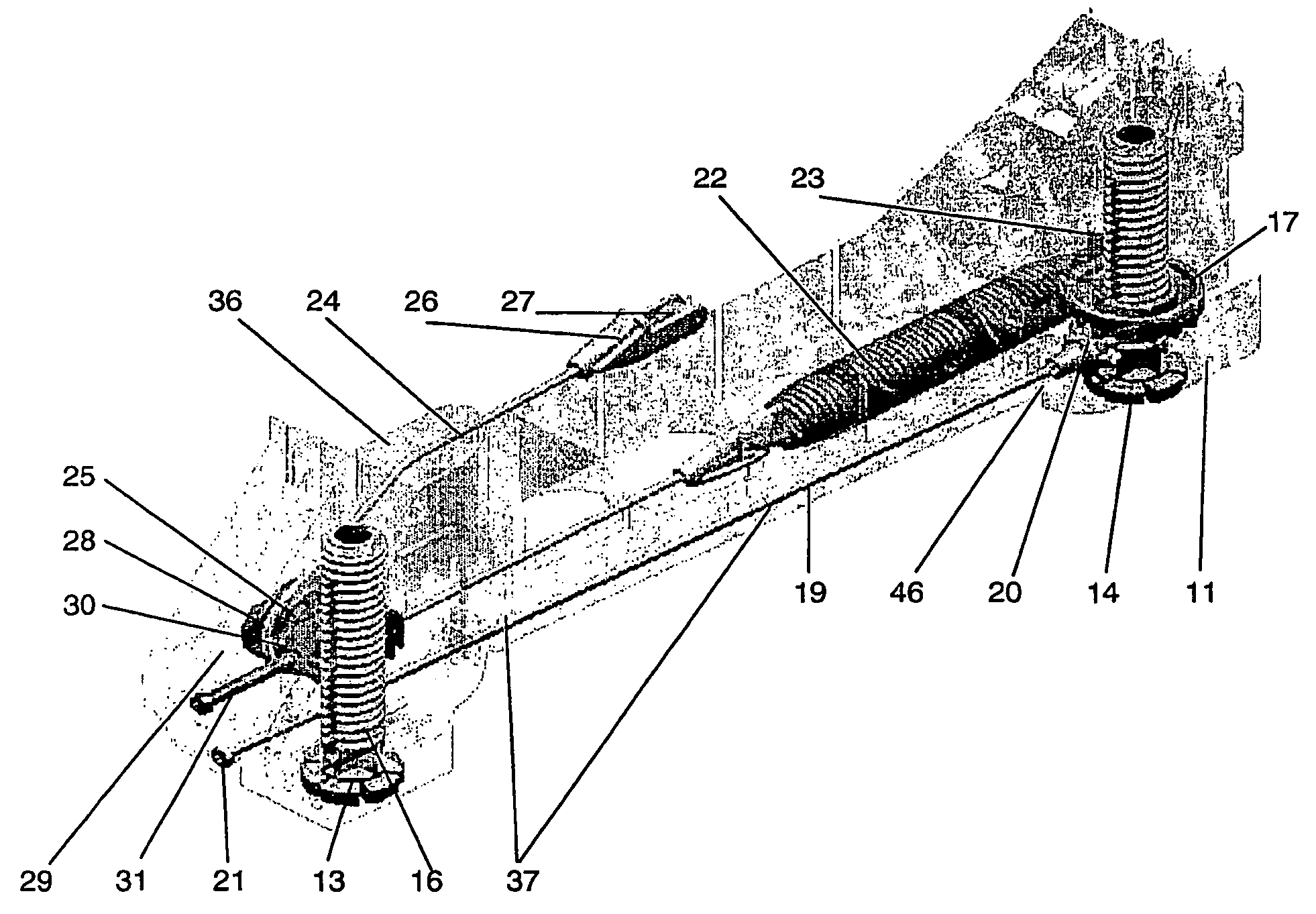

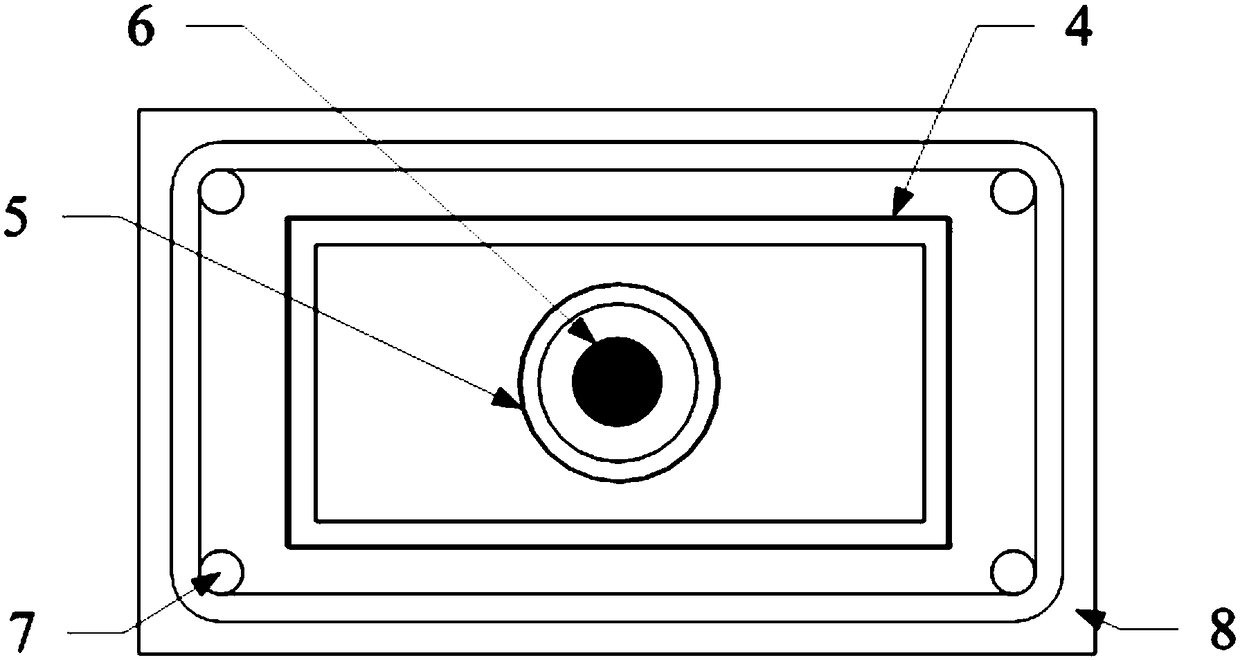

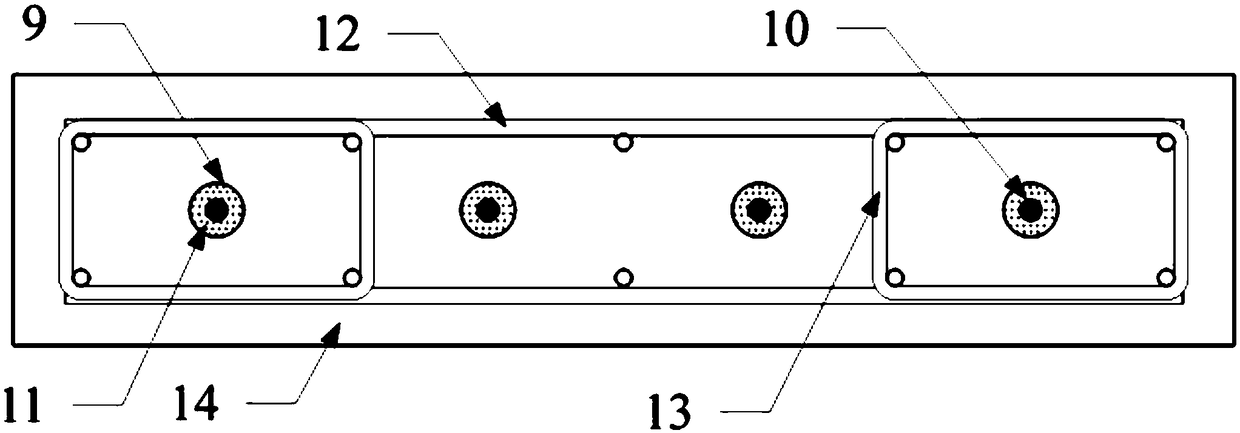

Device for testing mixed-mode fatigue crack growth rate

ActiveUS20160349161A1Efficient measurementEasy to testMaterial strength using repeated/pulsating forcesTension compressionTorsion fatigue

A device for testing mixed-mode fatigue crack growth rate comprises a plate-like specimen, and a first fixture mechanism for exerting stretch, shear and torsion actions on the specimen via a second fixture mechanism; the second fixture mechanism is used for clamping the specimen and enabling the specimen to generate a mixed-mode fatigue crack in cooperation with the first fixture mechanism; the device further comprises a fatigue crack measurement instrument for measuring and recording the length of mixed-mode fatigue crack generated on the specimen. With the help of a common tension-compression fatigue testing machine or a torsion fatigue testing machine, the device drives the first and second fixture mechanisms to exert stretch, shear and torsion actions on the specimen, thus, the requirements of those tests on mode I, mode II, mode III and mixed-mode fatigue crack growth rates can be fully satisfied, and a good foundation is laid for precisely predicting the fatigue life of critical mechanical parts and engineer components under complex working conditions.

Owner:HEFEI GENERAL MACHINERY RES INST

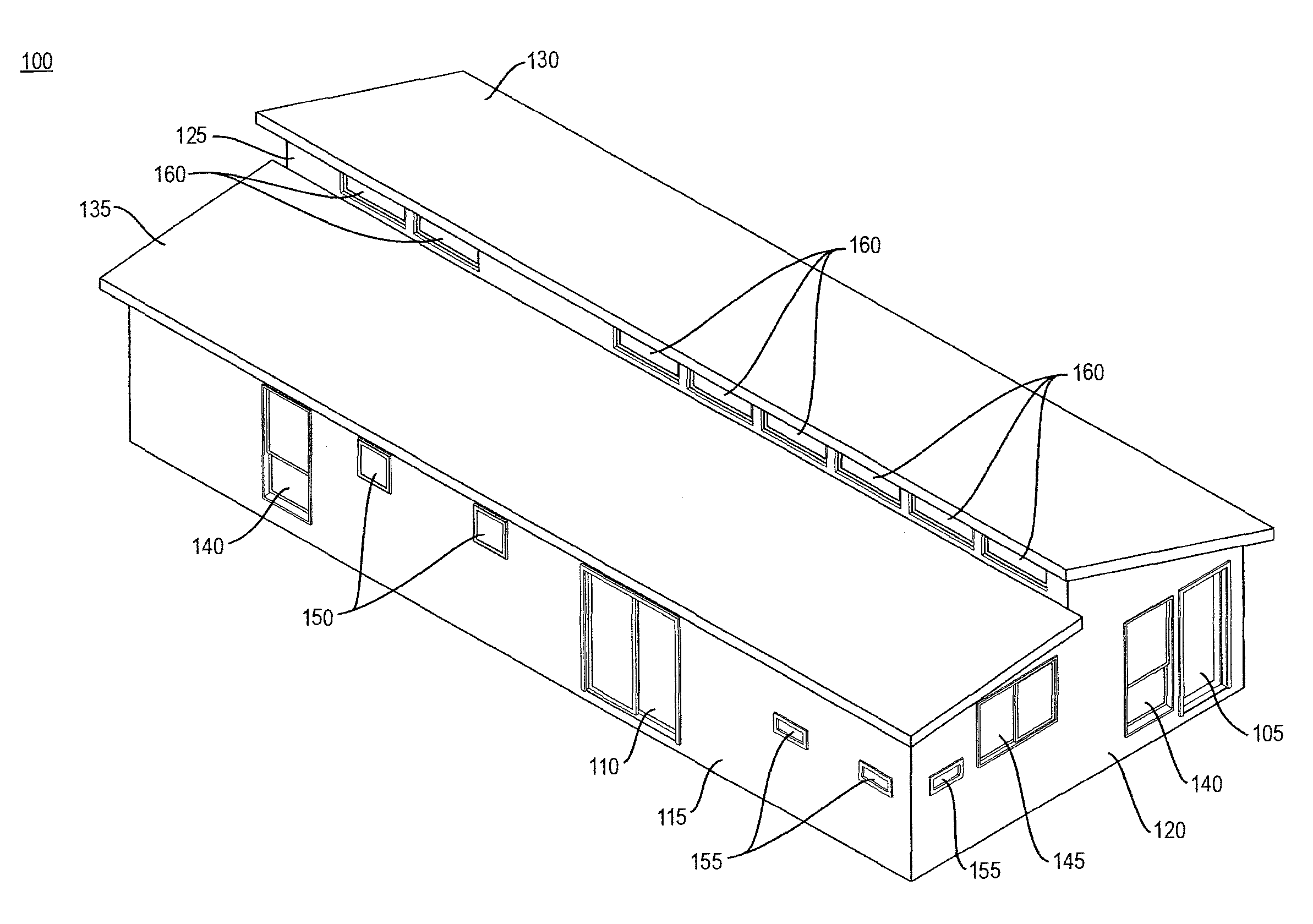

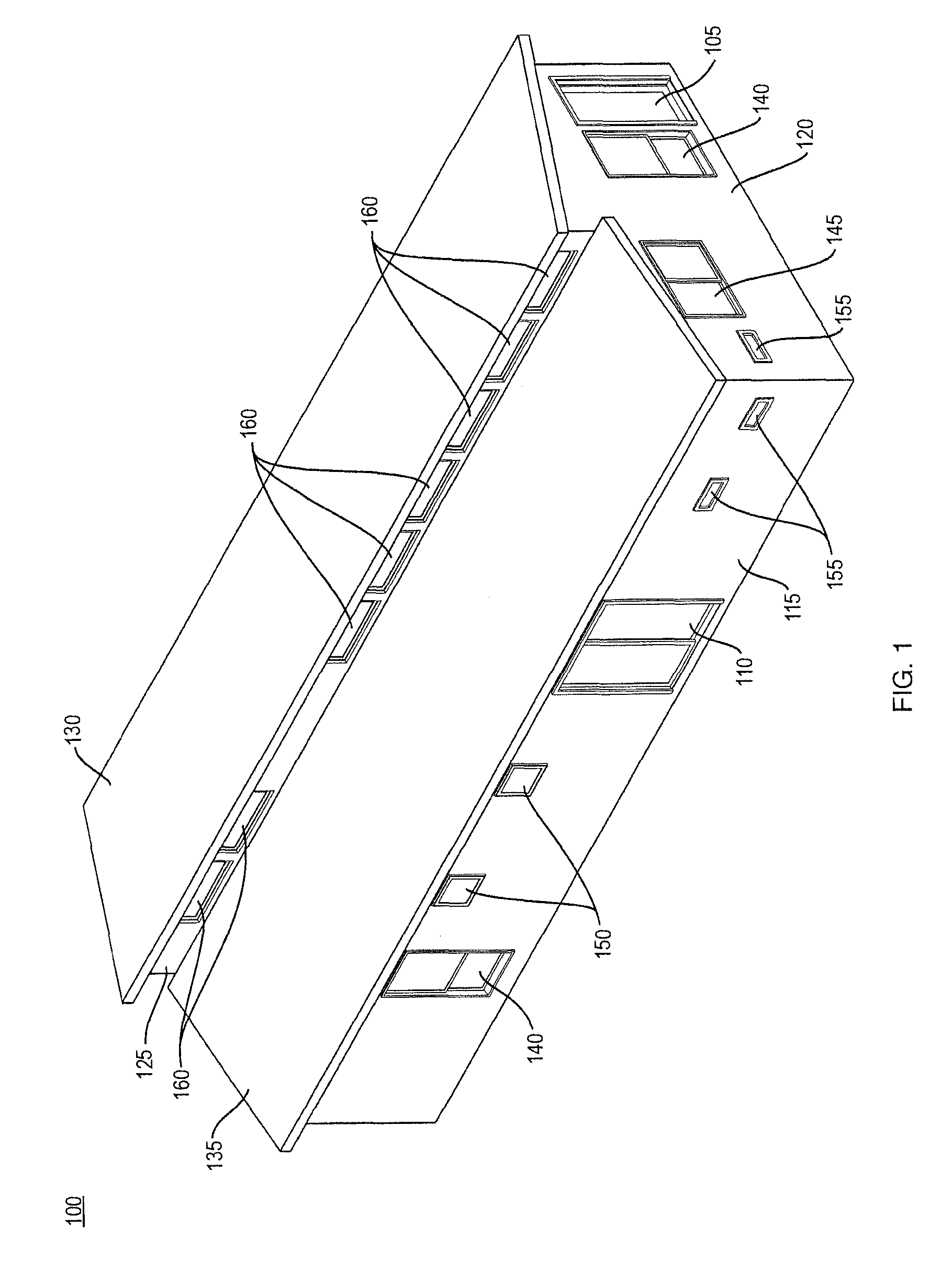

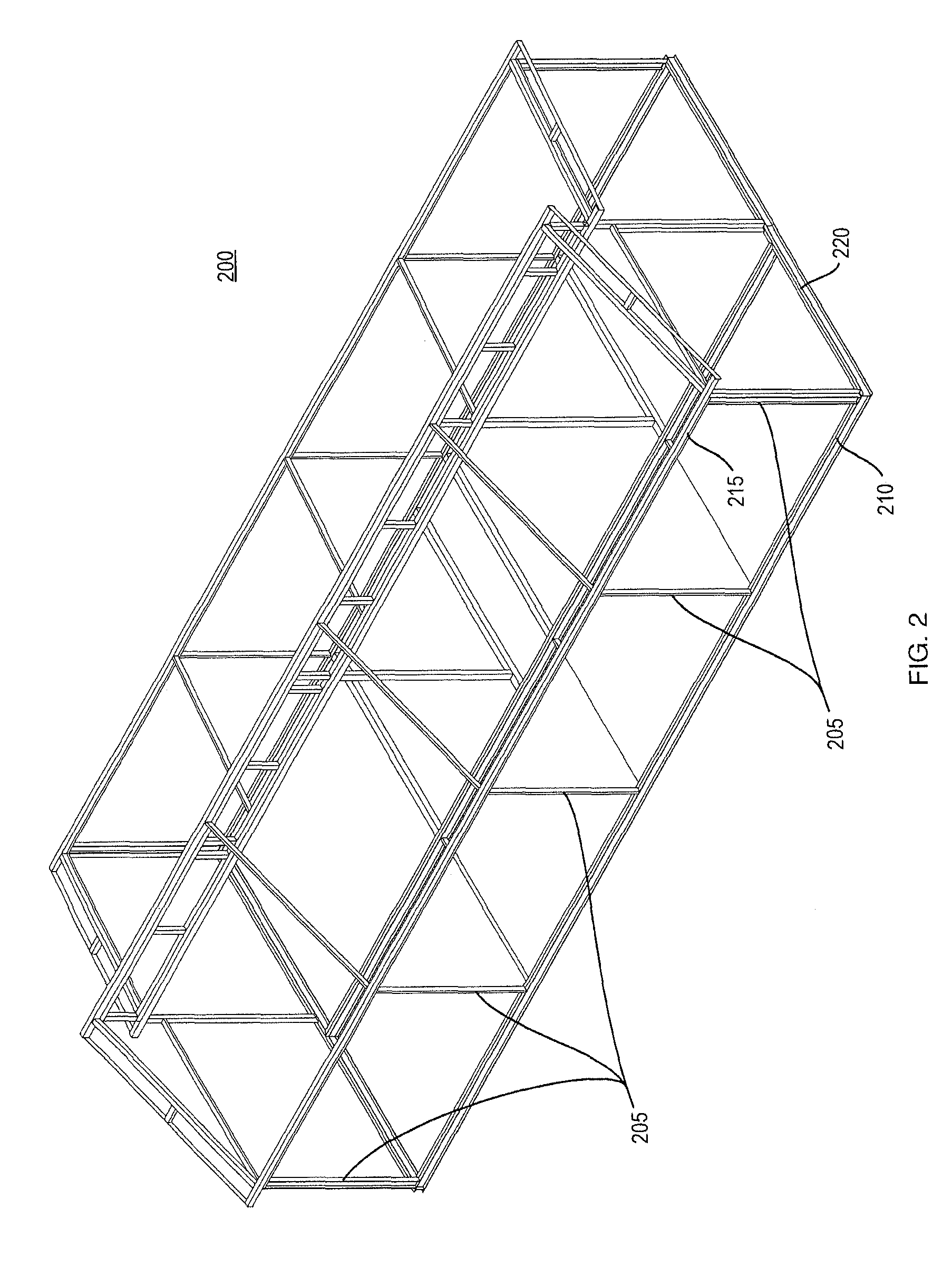

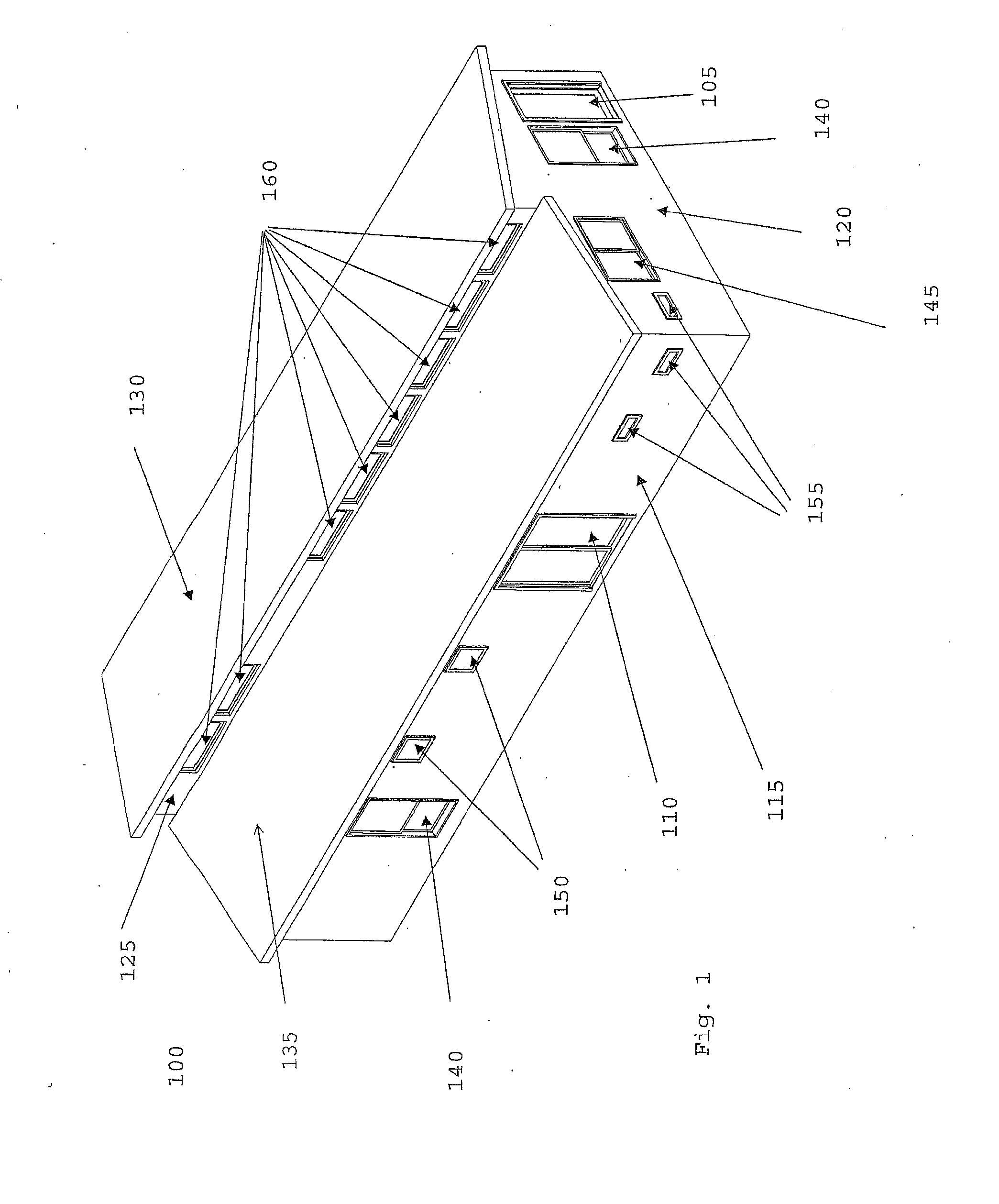

Foldable building units

InactiveUS20120279142A1Easy to prefabReduce and eliminate material damageBuilding roofsPublic buildingsArchitectural engineeringBuilding unit

Owner:BLU HOMES

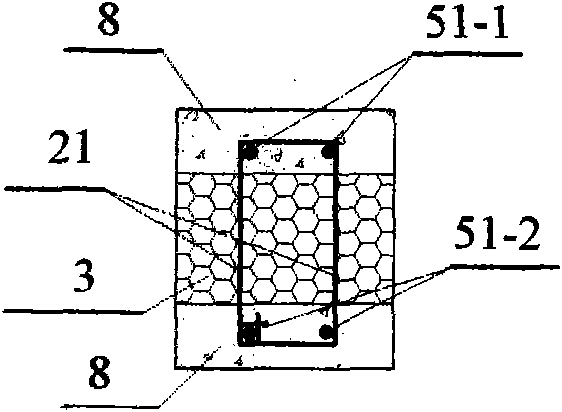

Lightweight composite column, lightweight composite beam and load bearing lightweight composite thermal-insulation wall body

The invention discloses a lightweight composite column, a lightweight composite beam and a lightweight composite thermal-insulation wall body. The invention relates to a composite thermal-insulation wall body for buildings. The purpose of the invention is to increase the bearing capacity of the lightweight composite thermal-insulation wall body and to cancel thermal bridges at openings. The lightweight composite column is formed by steel bars, a core layer, steel hoops and a protective layer, wherein the core layer is arranged between an internal protective layer and an external protective layer and is bonded with the internal protective layer and the external protective layer, the steel bars are arranged in the internal protective layer and the external protective layer and the steel hoops are tightly tied with the steel bars. The lightweight composite beam is formed by steel bars, a core layer, a protective layer and an alkali-resisting mesh, wherein the protective layer is arranged on the two sides and the upper part of the core layer and is bonded with the core layer; and the steel bars and the protective layer are wrapped and wound by the alkali-resisting mesh. The lightweight composite wall body is formed by beams or slabs of the main body structure of a building, lightweight composite columns, lightweight composite beams, lightweight boards and a leveling blanket, wherein the lightweight composite columns are anchored with the beams or slabs of the main body structure of the building, and the lightweight boards are arranged on the beams or slabs and are bonded with the columns; and the lightweight composite beams are arranged at openings and are connected with the lightweight composite columns. The composite wall body of the invention has the advantages that the thermal insulation performance is good, the manufacturing cost is low, the application scope is wide, the wall body reformation is promoted and the energy is saved.

Owner:吴淑环

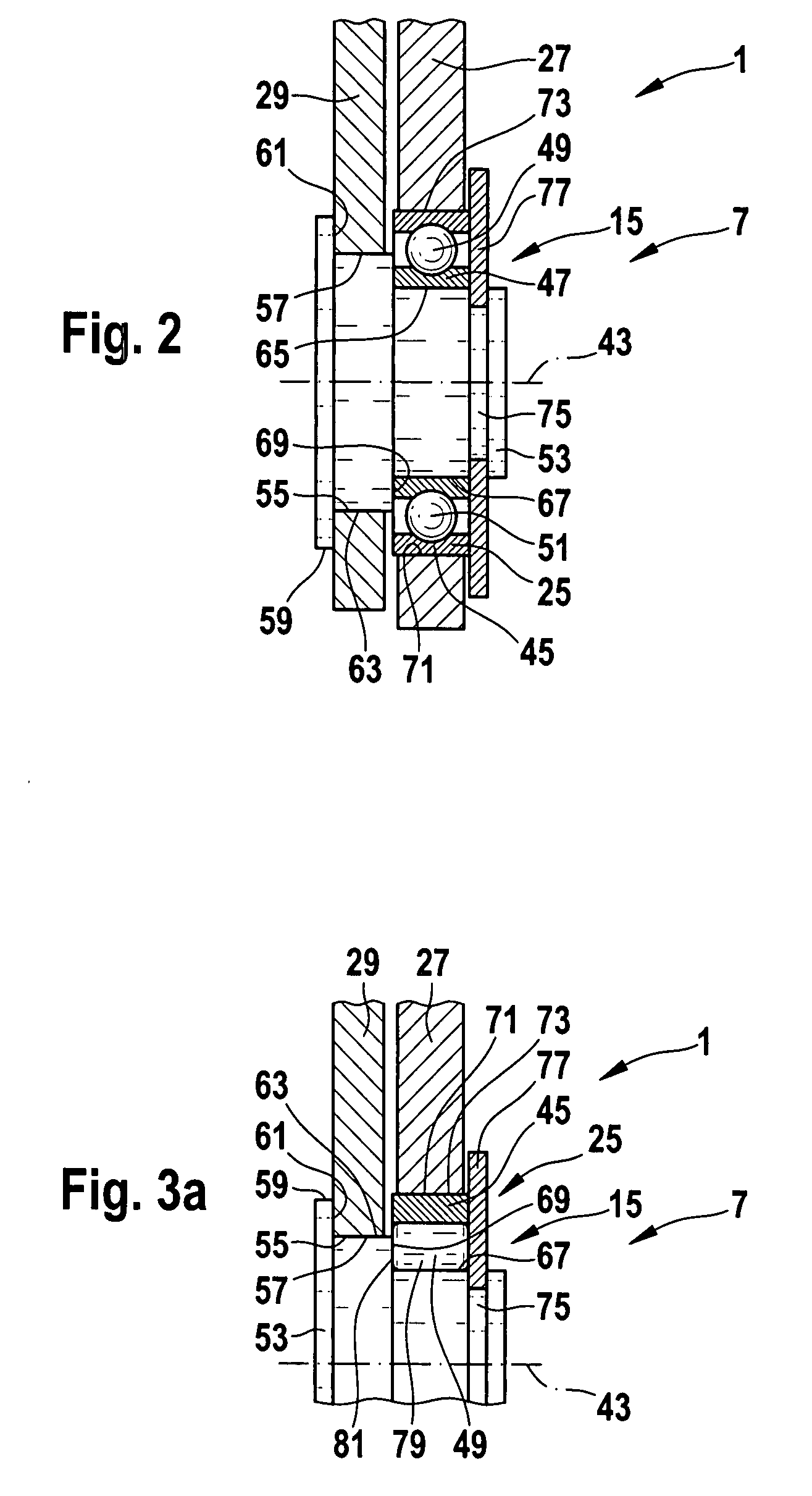

Joint arrangement

InactiveUS20070209160A1Reduce frictionMinimizing actuation forcePin hingesWing openersEngineeringMechanical engineering

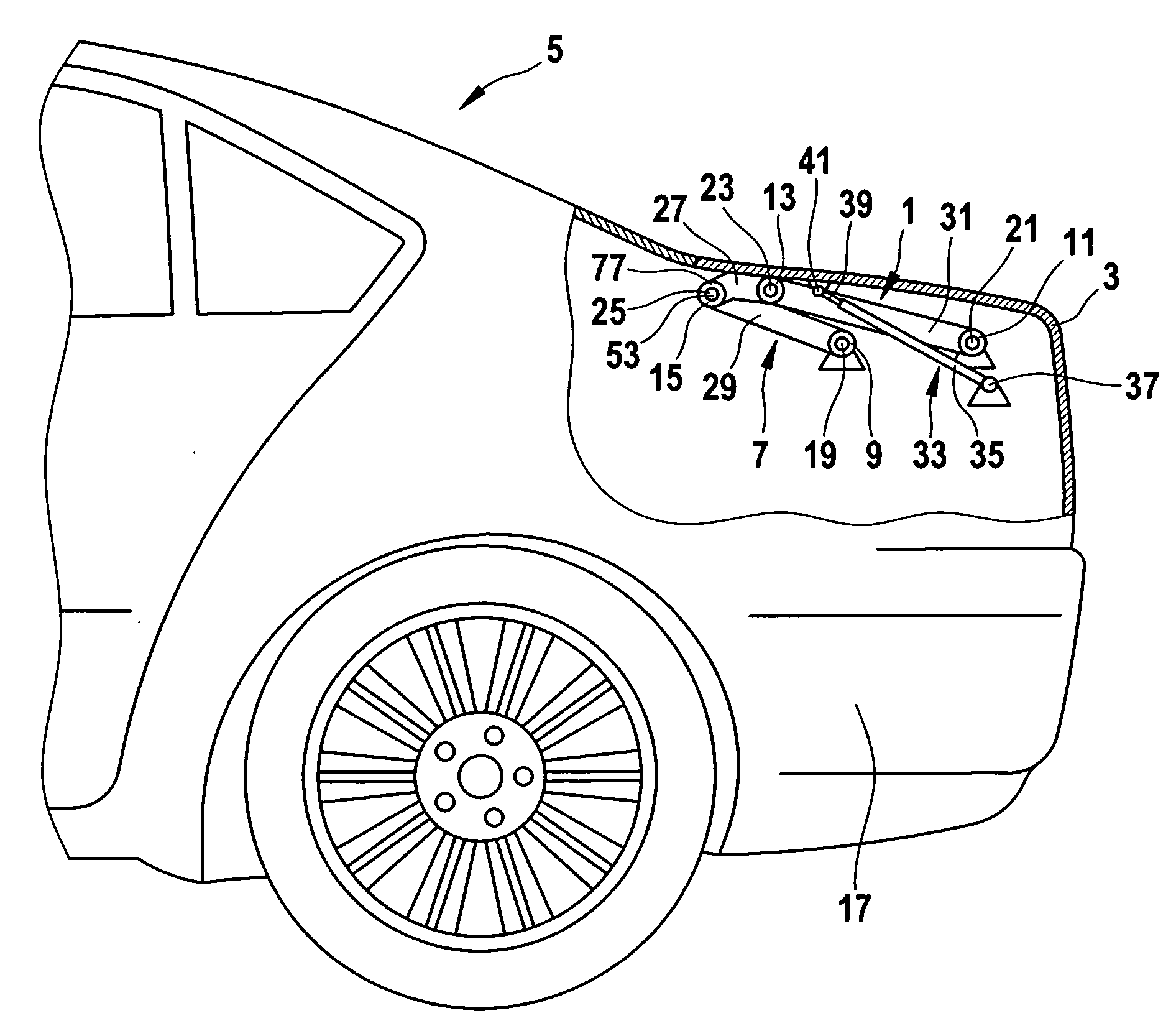

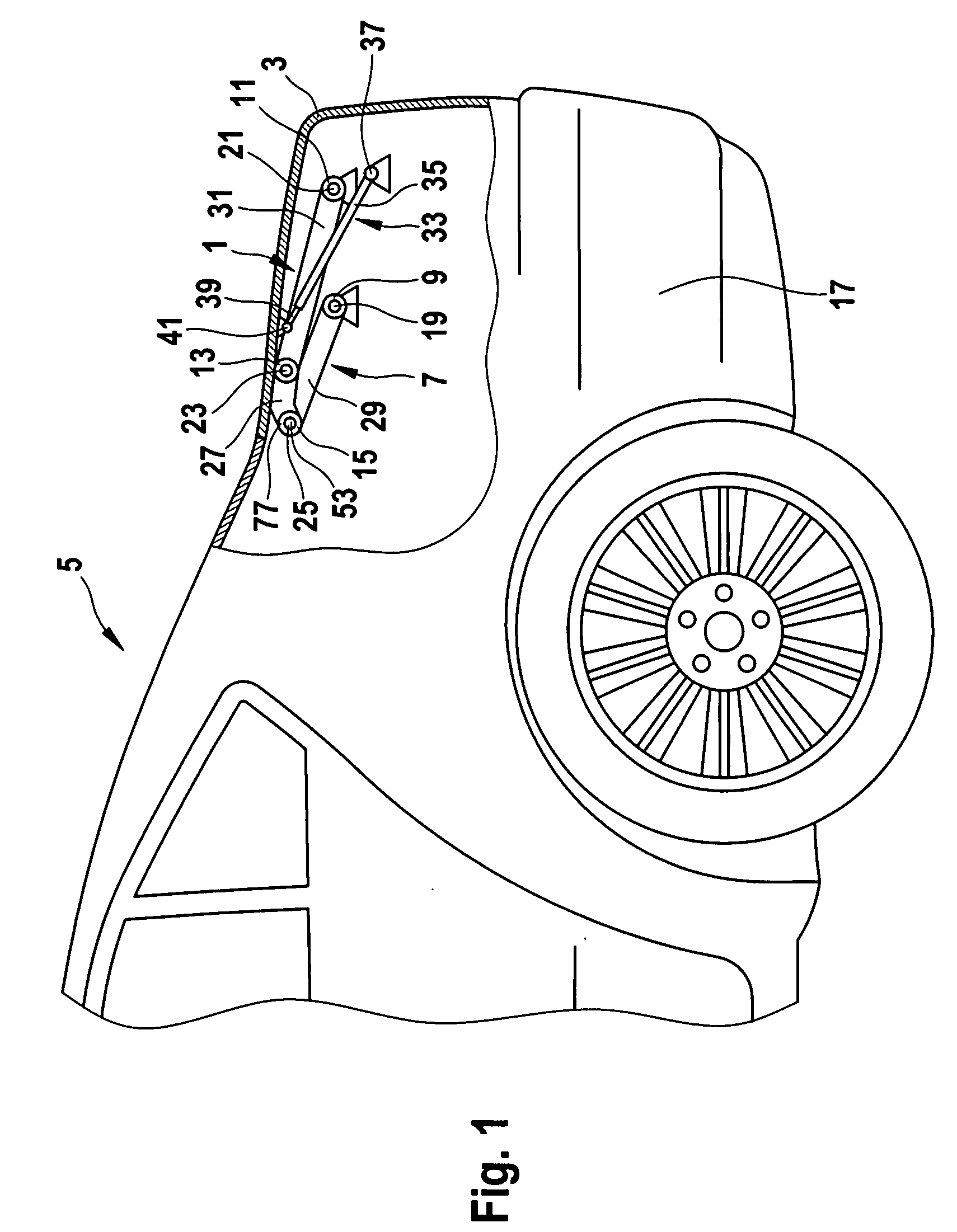

A multi-joint hinge for a motor vehicle having a body and a panel, the hinge allowing the panel to be moved between an open position and a closed position relative to the vehicle body. The hinge includes at joint having at least one roller bearing, and is preferably a four bar joint having two bearings mounted on the body and two bearings mounted on the panel.

Owner:STABILUS

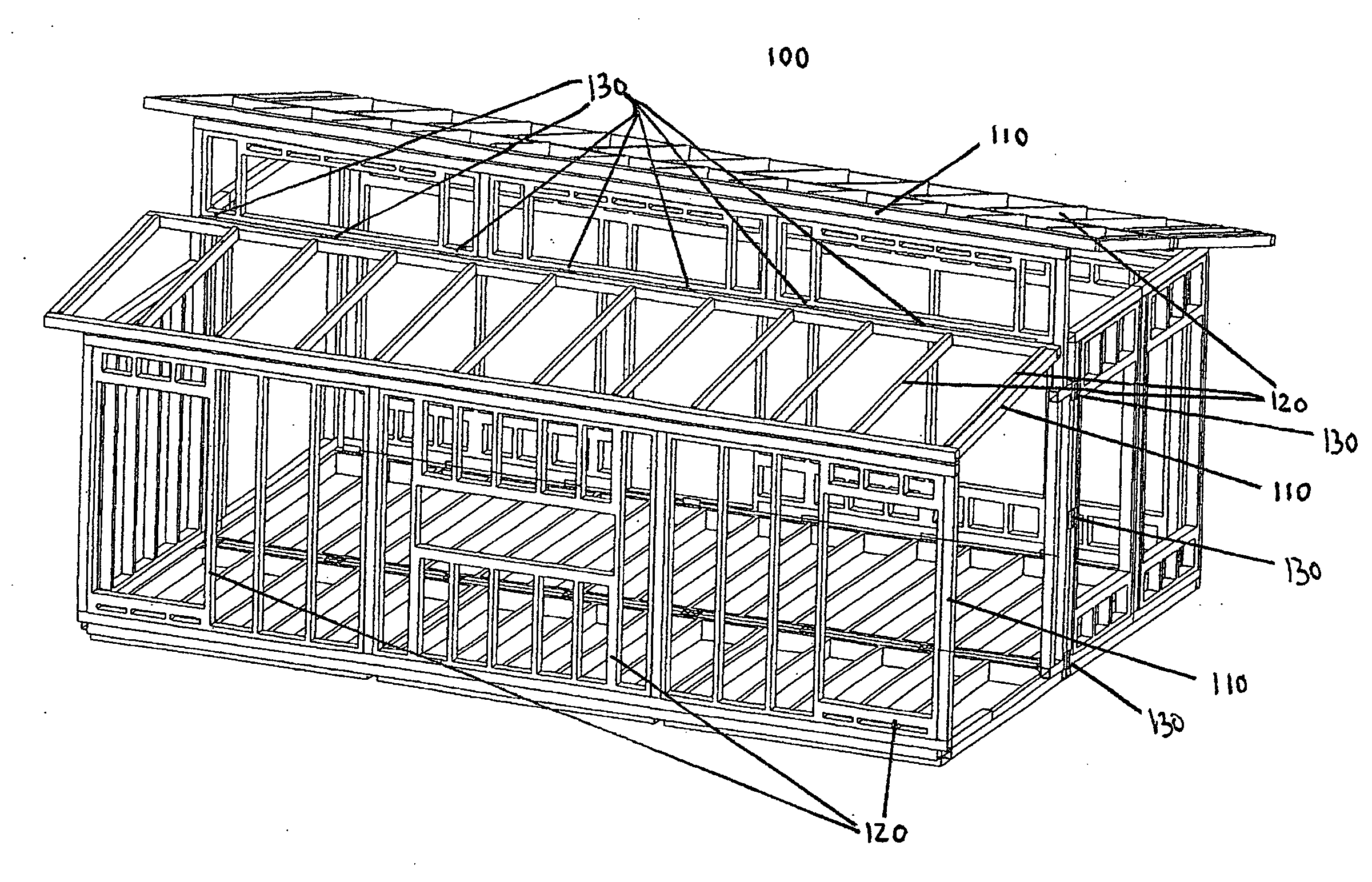

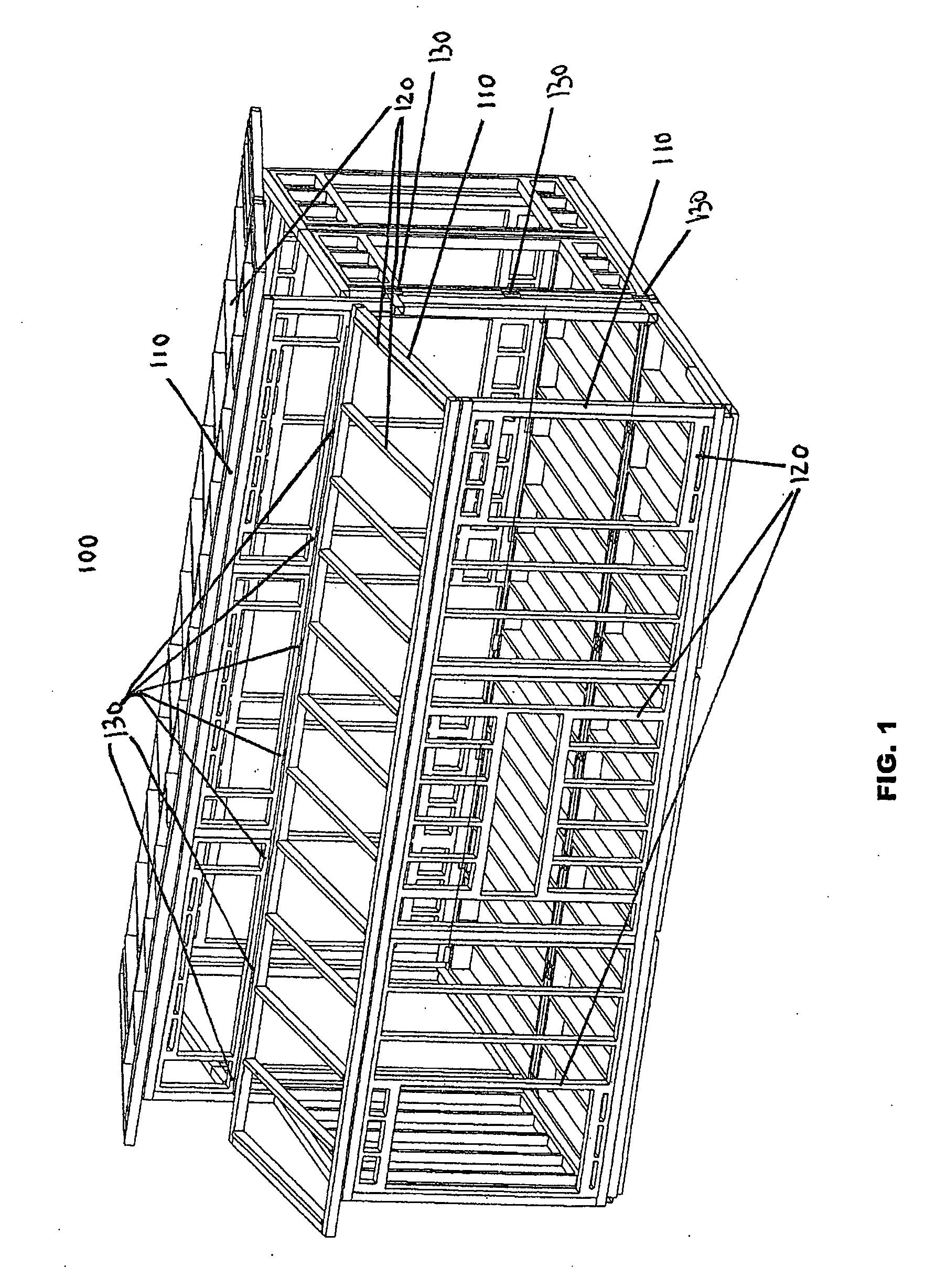

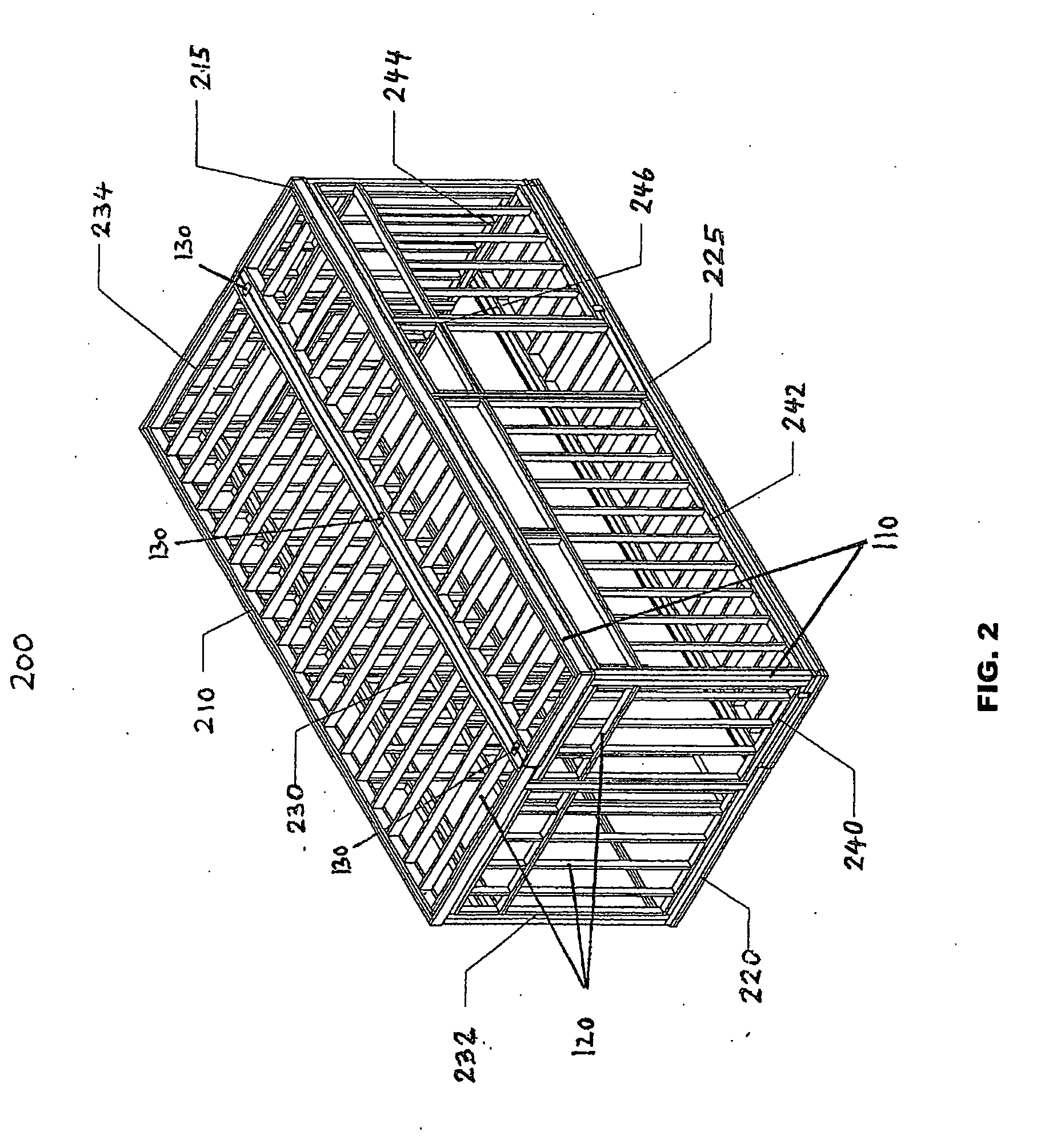

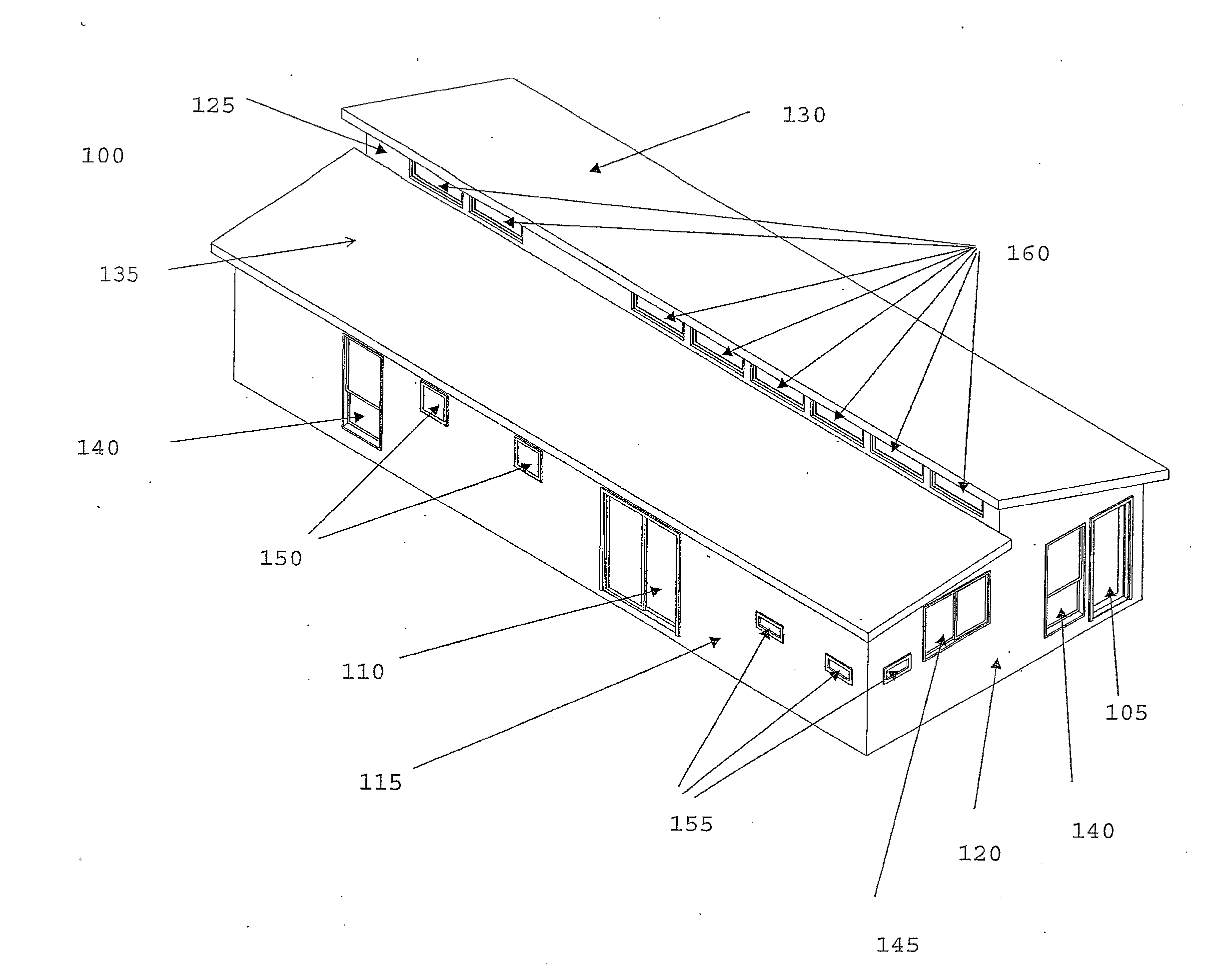

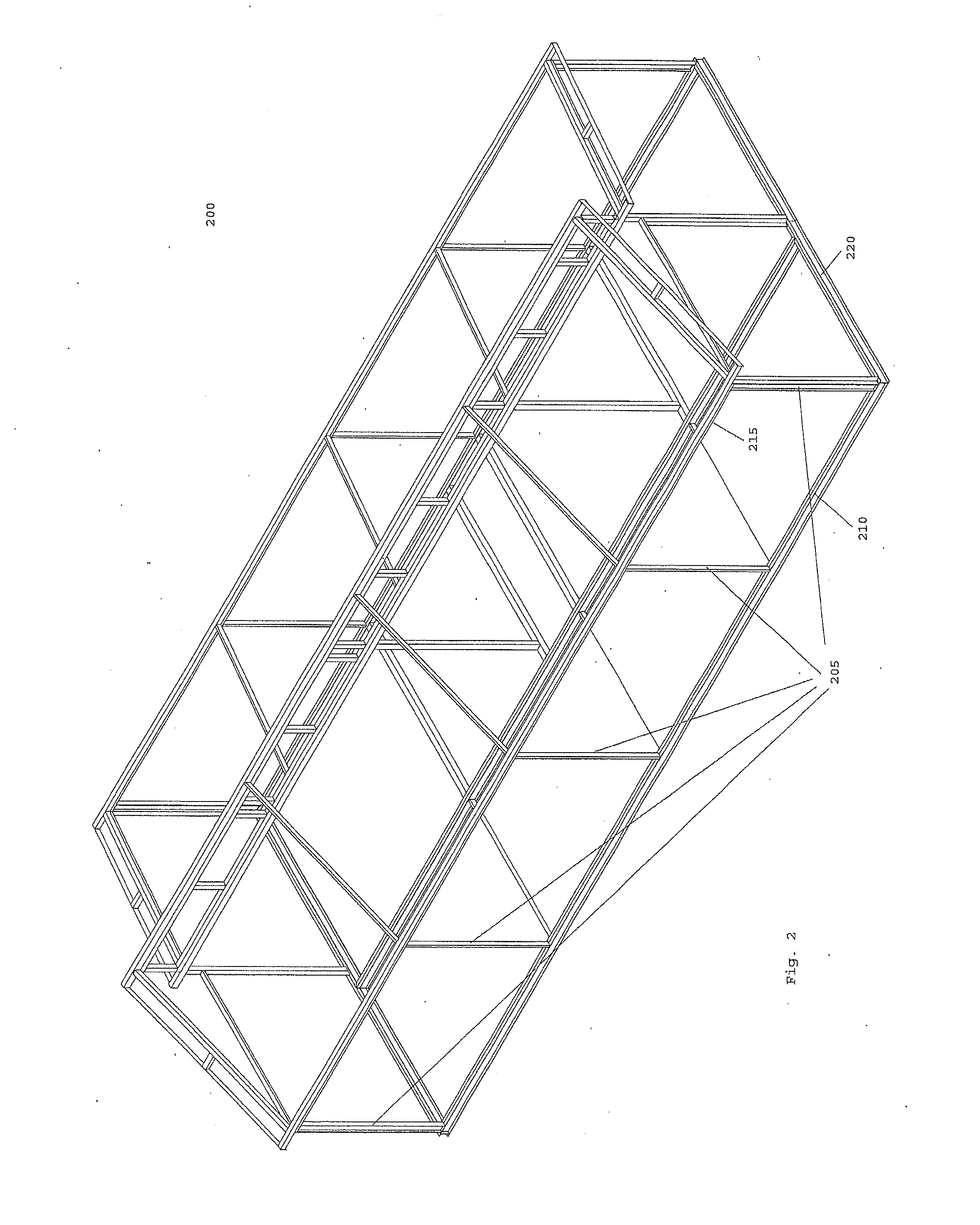

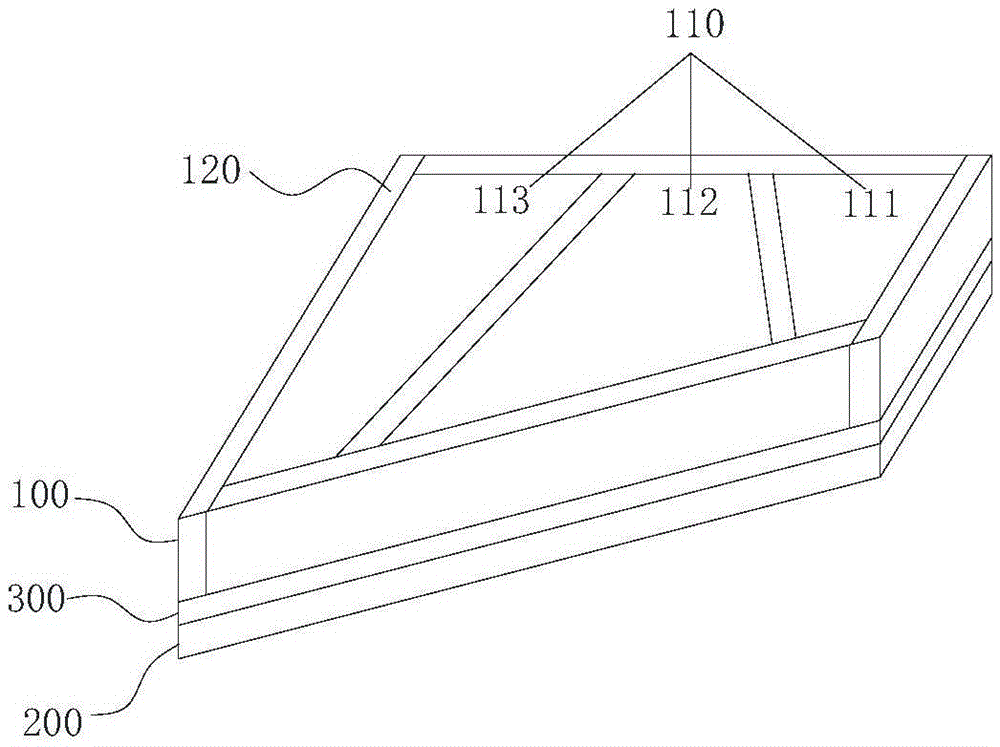

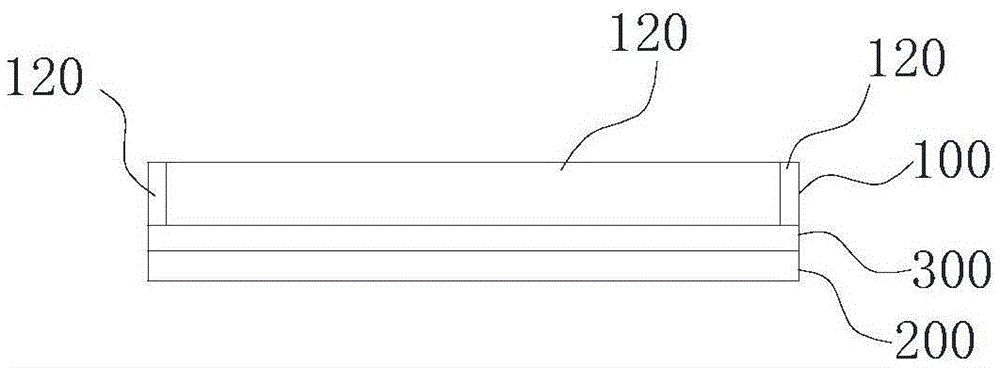

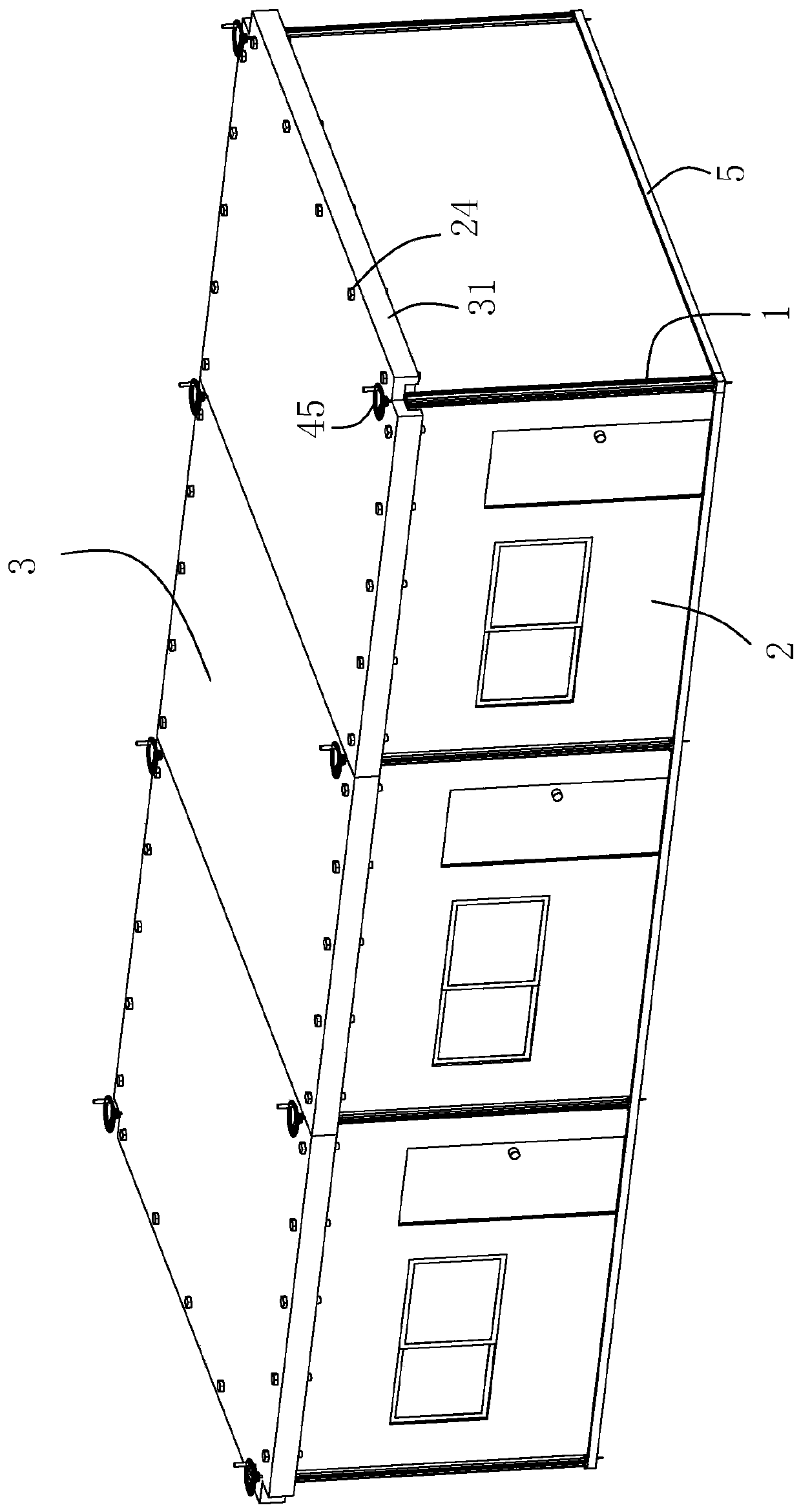

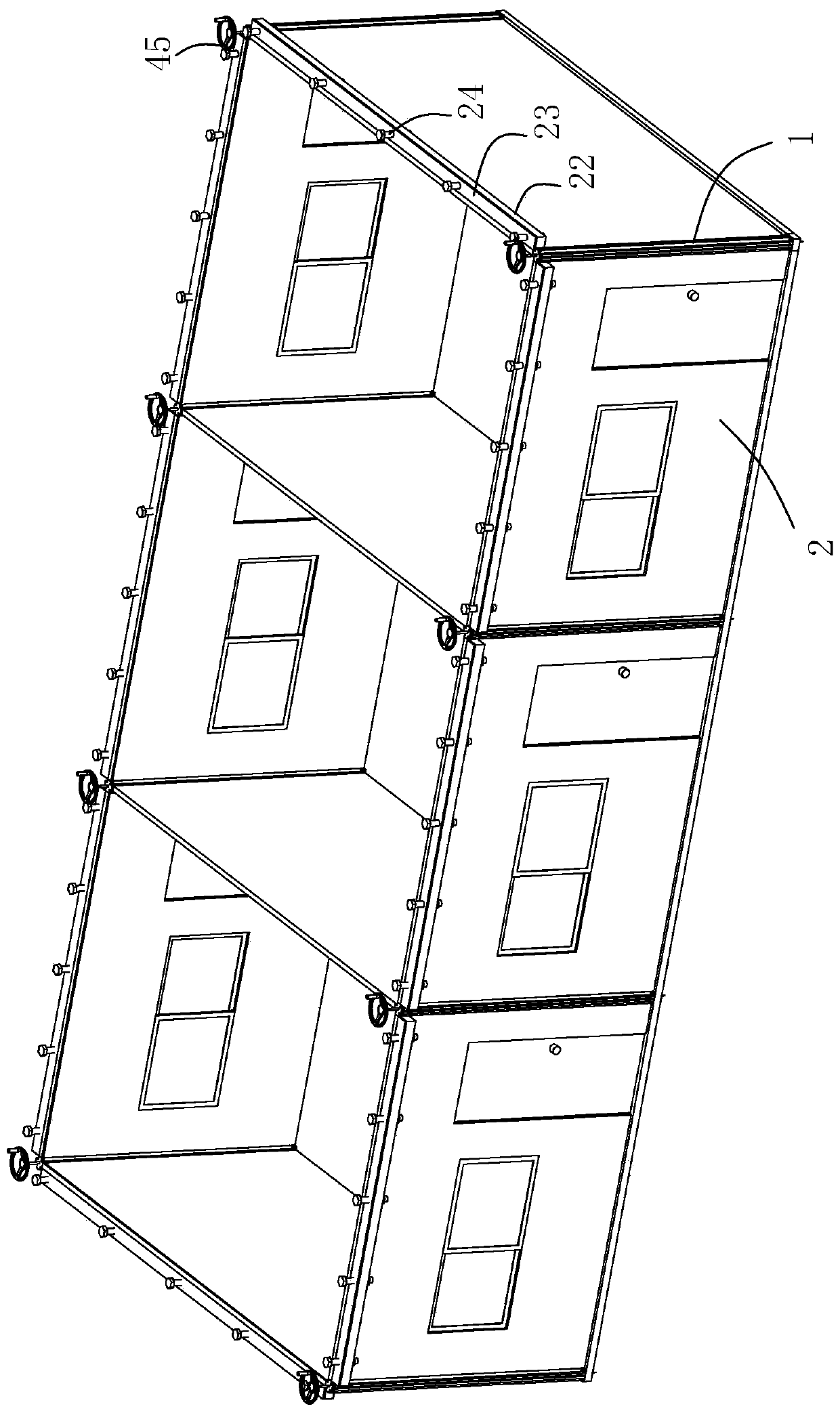

Foldable building units

InactiveUS8739475B2Easy to prefabReduce heat transferBuilding roofsRoof coveringConstruction engineeringArchitectural engineering

Foldable building units are provided based on structural frame and connection assembly designs that enable greater construction efficiency and flexibility. The structural frame and connection assembly designs allow for easier connection of frame elements in the prefabrication process of the foldable building units and for easier connection of frame elements at the building site, for example, of foldably connected frame elements after unfolding. They also allow for more finish in the prefabrication process, and / or less and faster work at the building site, for example, by enabling conventional structural lumber grids that can be continuous through the edges and corners of the building envelope for conventional exterior finishing, while providing a tight building envelope with reduced heat transfer, particularly, through the edges of the foldable building unit.

Owner:BLU HOMES INC

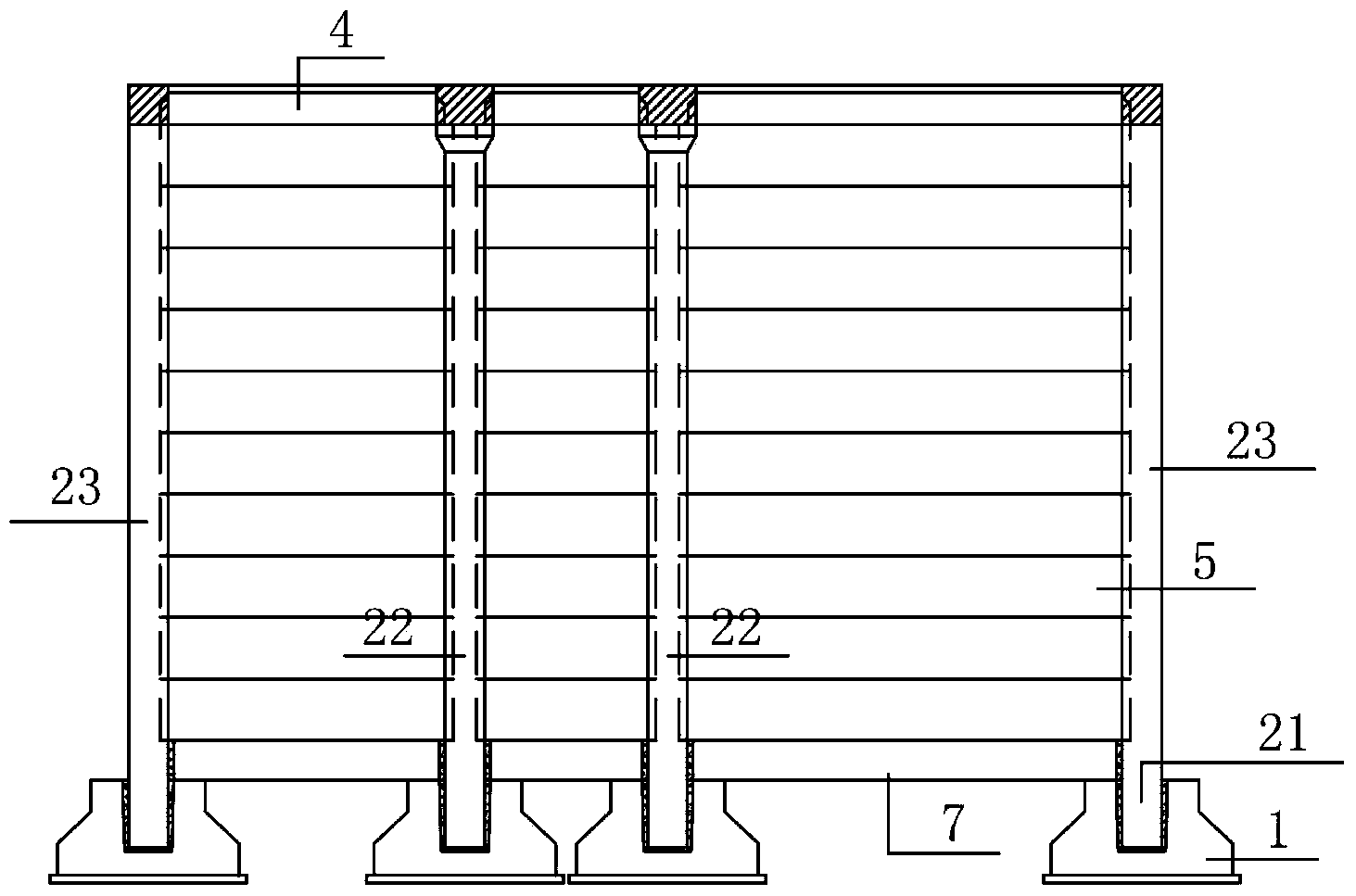

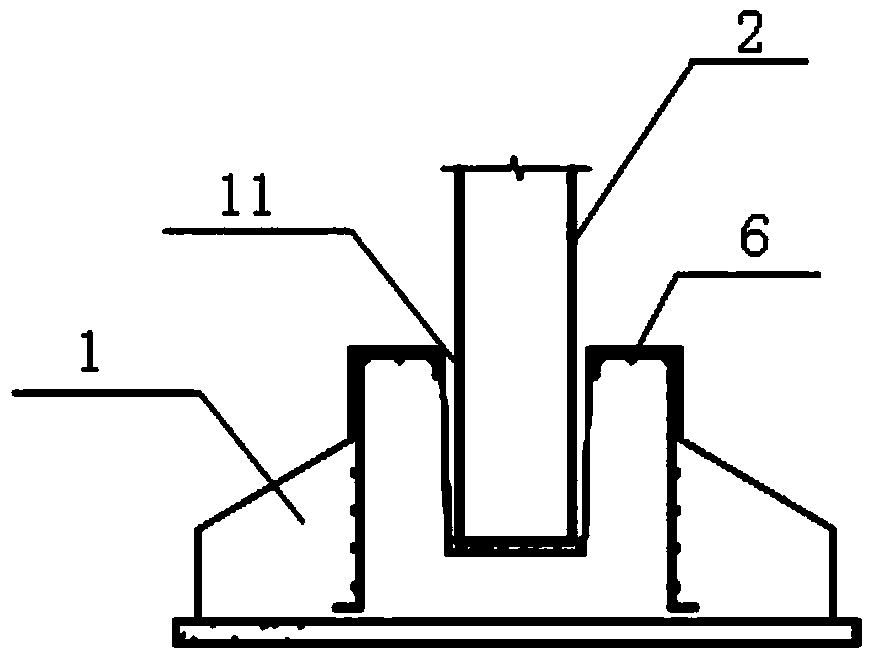

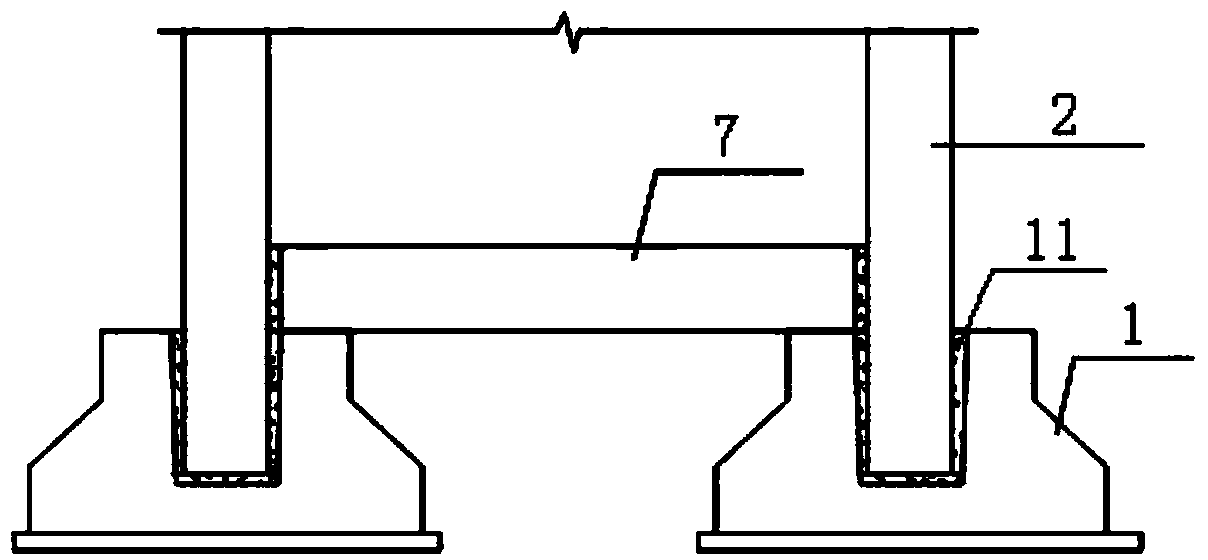

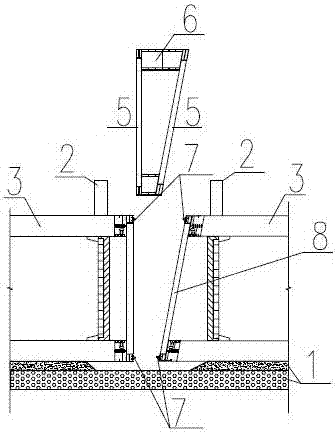

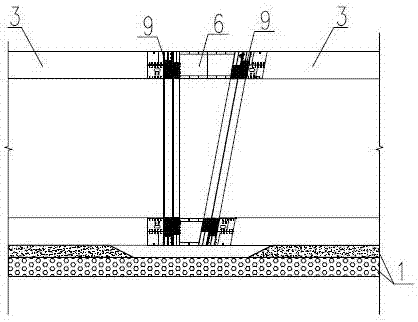

Assembly type firewall

The invention provides an assembly type firewall which comprises a plurality of foundations, a plurality of vertical supporting columns, a plurality of wall body beams and wall crown beams with first grooves arranged at the bottom. The foundations are of cast-in-place cup rim structures. The supporting columns are composed of base columns, middle columns or side columns from bottom to up in sequence. Two side surfaces corresponding to the middle columns are used for installation of I-shaped grooves of the wall body beams, and one side surface of the side columns is provided with second grooves. Two ends of each wall body beam are connected with the middle portions of adjacent two supporting columns. Two ends of each wall crown beam are connected with column tops of adjacent two supporting columns. The assembly type firewall further comprises wall boards connected with the outer walls of the supporting columns. The assembly type firewall is convenient to construct, improves the integrity of the supporting columns, ensures installation convenience and node integrity, reduces the number of node and installation procedures, improves safe reliability of the whole structure as well as the work efficiency, shortens the construction period and facilitates management on field safe and civilized construction.

Owner:STATE GRID CORP OF CHINA +2

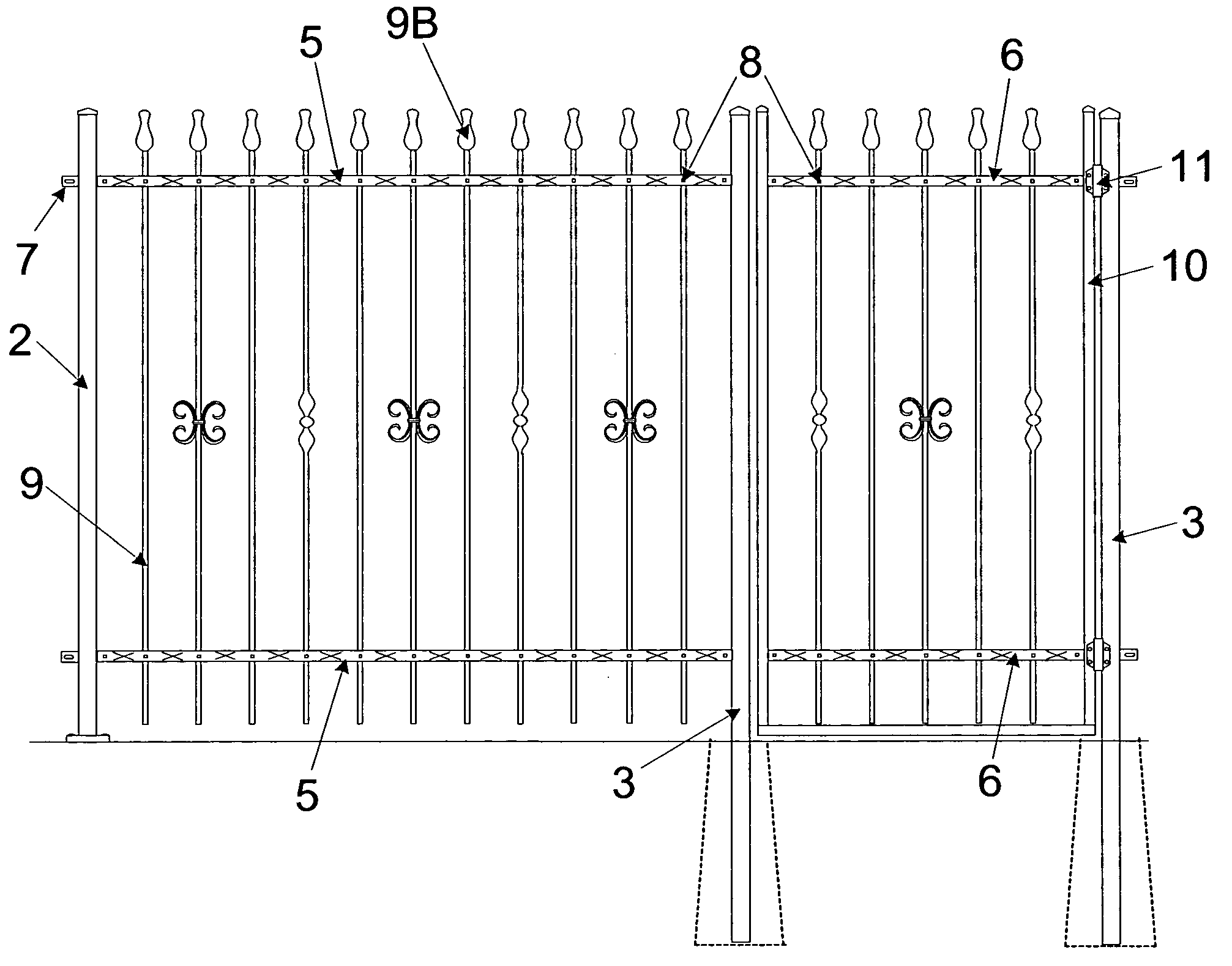

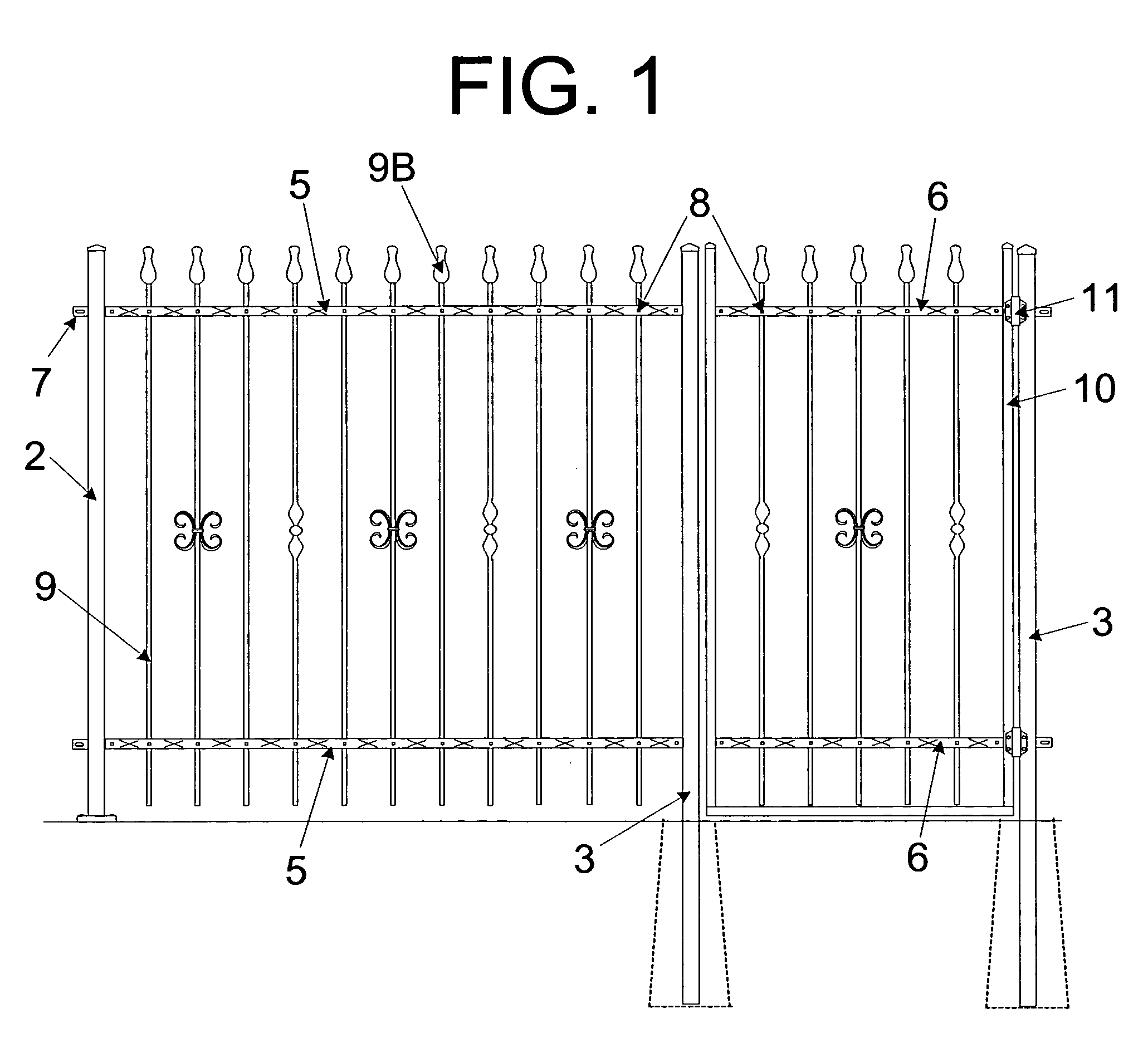

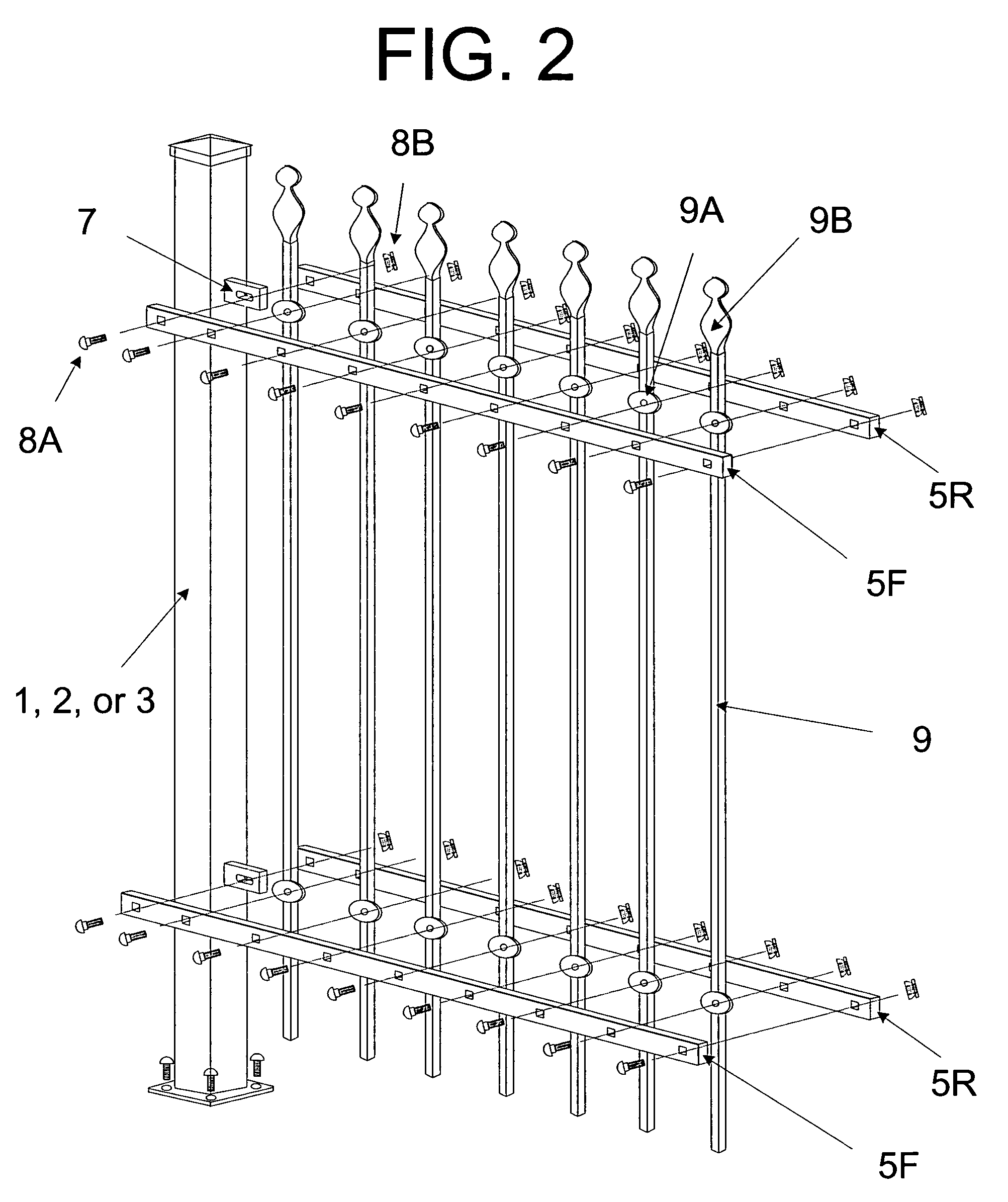

Modular railing, fence, gate, and security bars

InactiveUS20050236611A1Easy to prefabUnique ornamental appearanceBalustradesFencingSkill setsEngineering

The present invention includes modular fence, gate, railing, and security bar systems that can be easily prefabricated of a minimal number of parts, assembled at the installation site without the need for specialized skills or tools, and having a semi-customizable ornamental appearance that can be changed subsequent to the initial installation. A method of connecting the components by aligning holes formed in the rails with similar holes formed in pickets, balusters, and tabs; inserting a connecting bolt through the holes; and fastening nuts to the bolts is claimed. To add strength to the systems' connections, the pickets and / or balusters are formed to have flattened parts with a hole centered therein; the flattened part formed to fit between two rails. Another unique feature is the detachable head on the nut used to secure the connections. Once the head is detached, the connecting bolt and nut remaining have the appearance of a rivet.

Owner:VEREIDE DONALD W +1

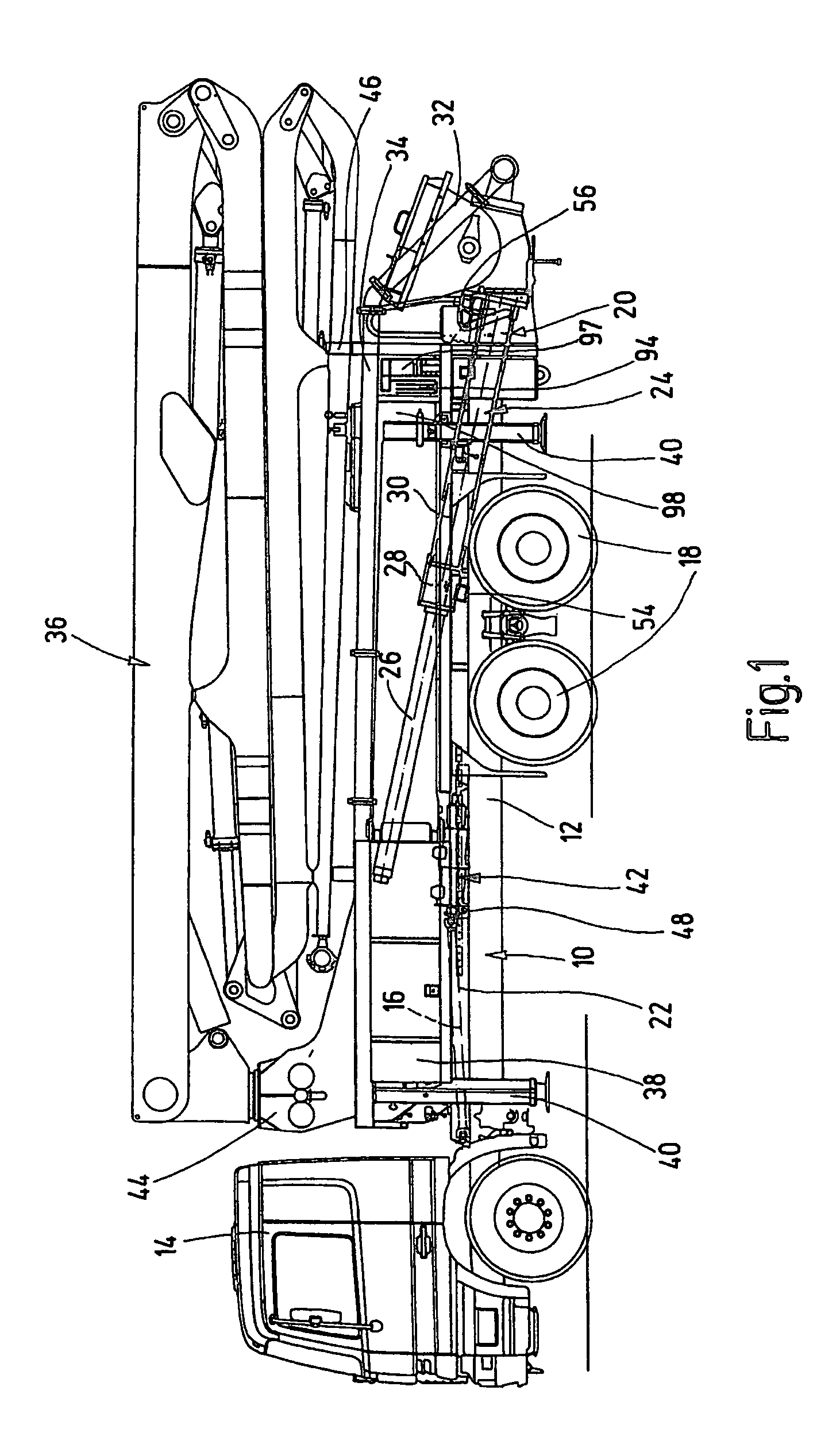

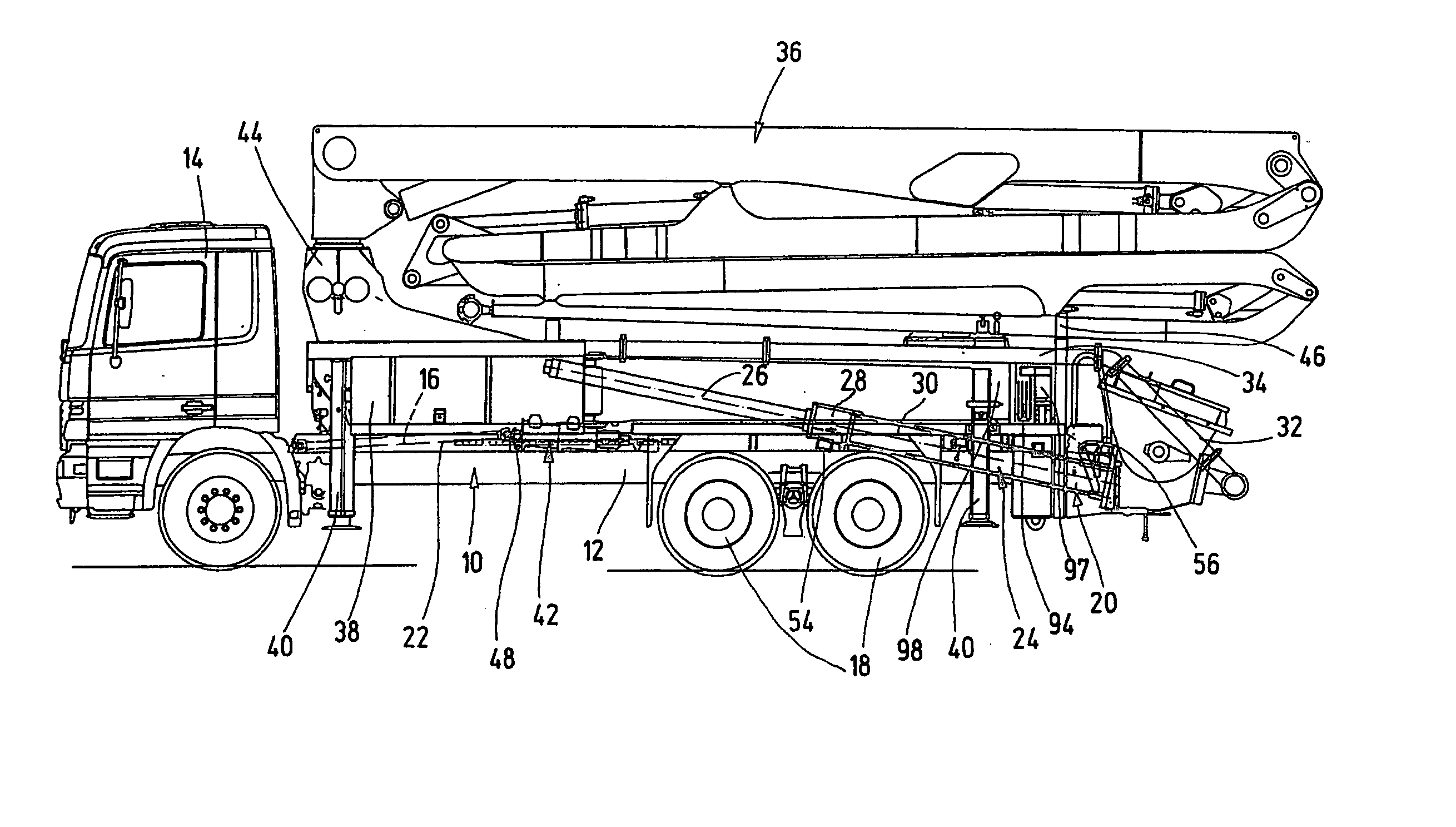

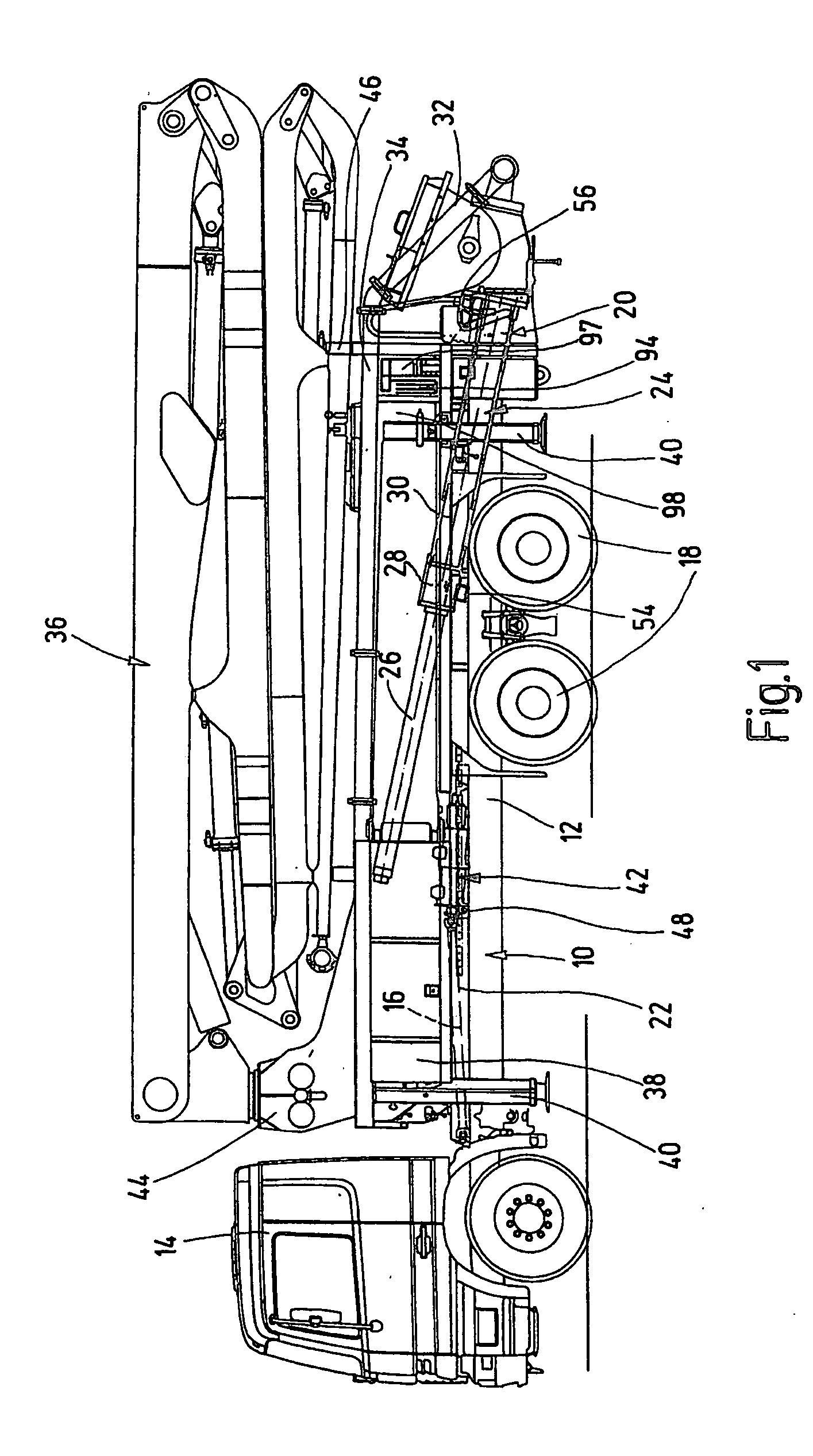

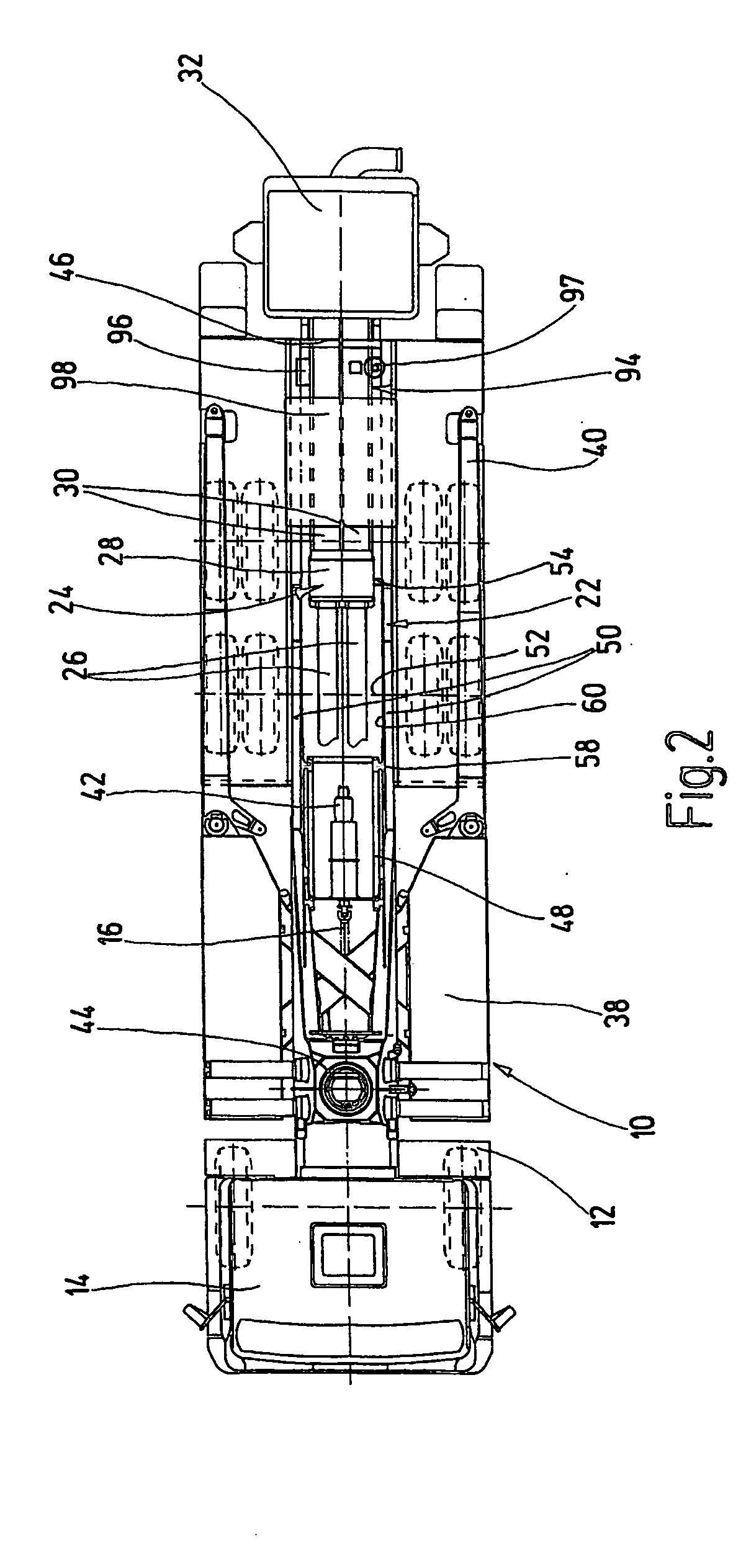

Mobile concrete pump and corresponding building frame

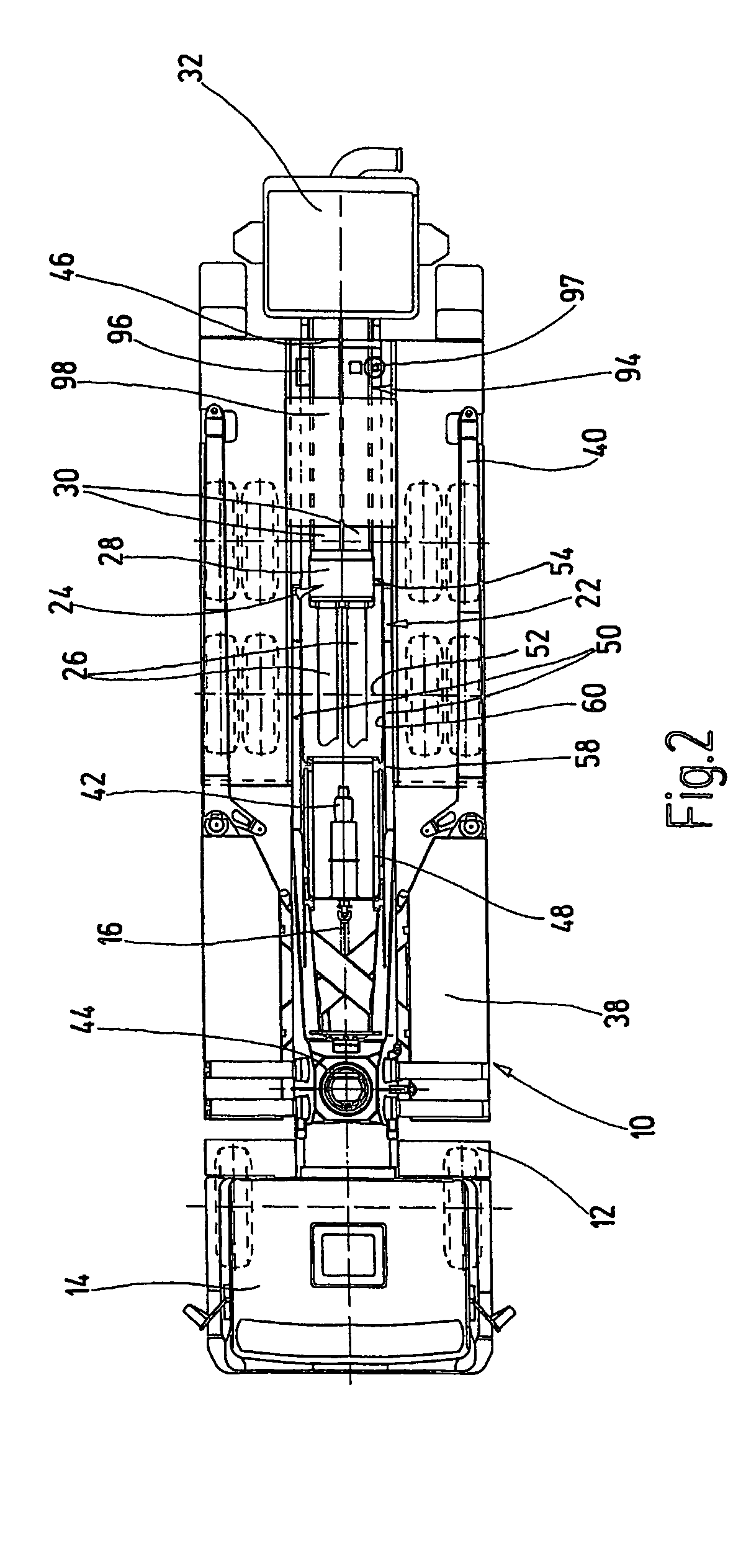

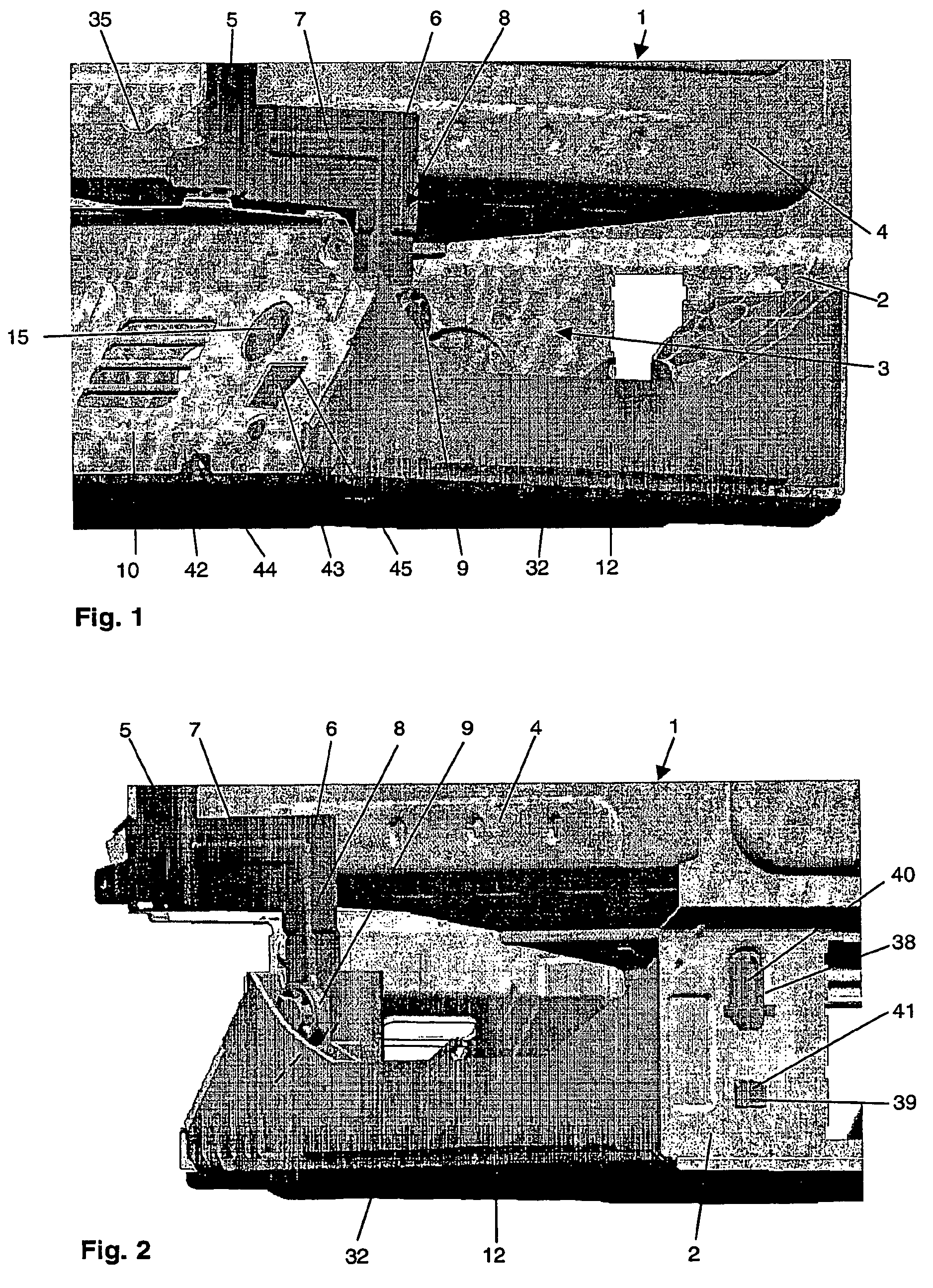

InactiveUS7654800B2Easy to prefabEasy to assembleConcrete transportationPositive displacement pump componentsFixed bearingConcrete pump

A mobile concrete pump including a building frame (22) arranged on the structure (12) of a truck chassis (10). The building frame (22) includes two longitudinal side members (50) mutually spaced apart by a free space (52) and resting on the chassis structure (12). The mobile concrete pump further comprises a driving assembly (42) for actuating the functional units, which are arranged with the core pump (24) in the free space zone (52) located between the two longitudinal side members (50). At least the core pump can be easily mounted and dismounted from the building frame (22). For this, the building frame (22) is provided with a floating bearing (54) which links the side members across the free space, as well as a fixed bearing (56) arranged at the rear end of the building frame and serving to support releasably the core pump (24) which is pre-assembled in modular manner.

Owner:PUTZMEISTER ENG GMBH

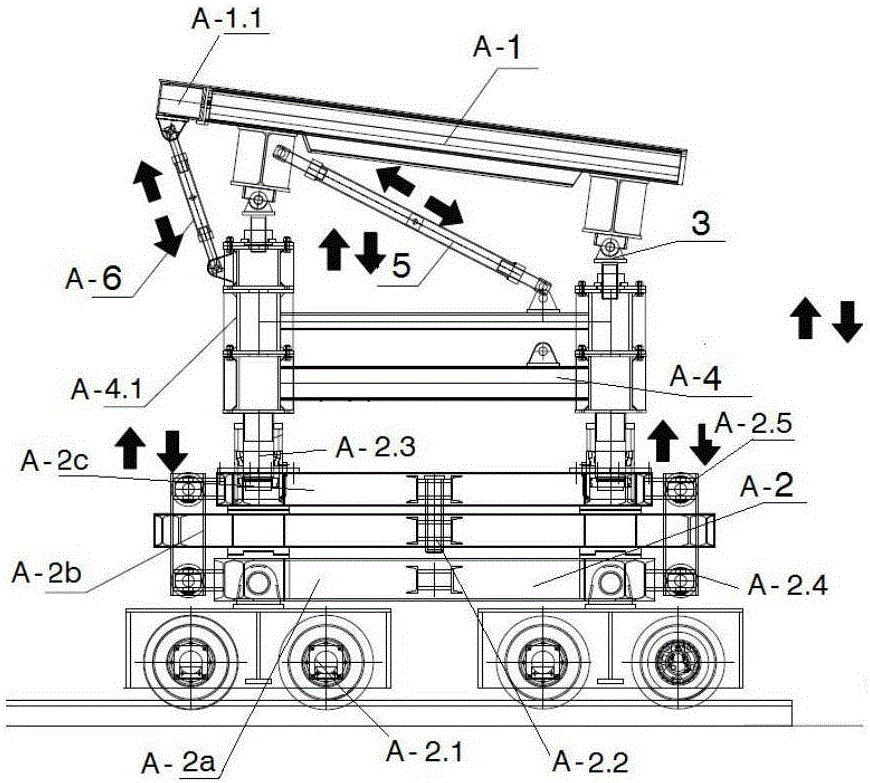

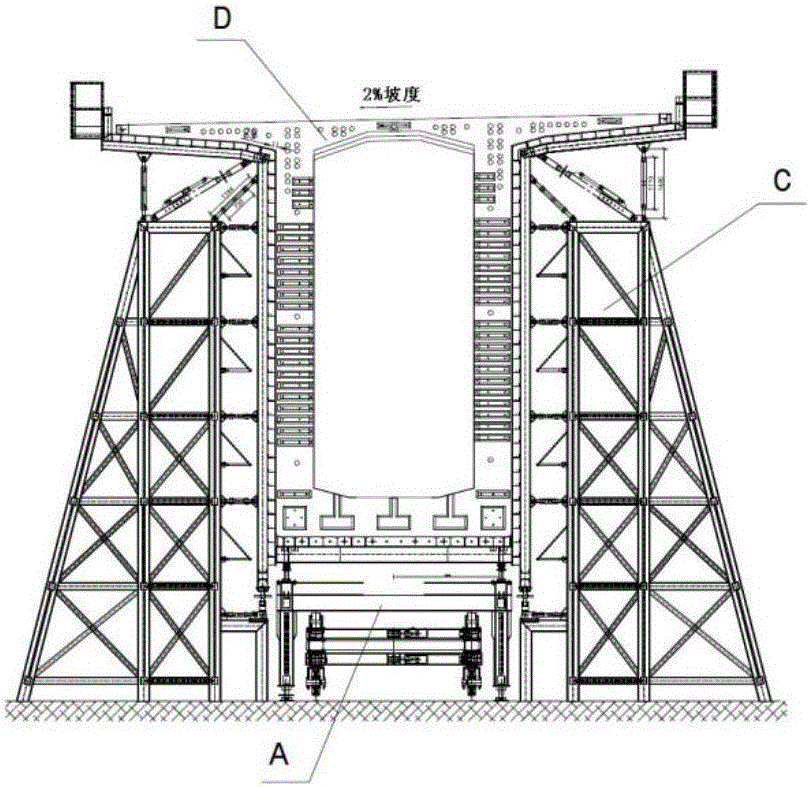

Prefabricated steel template system of large-span and ultrahigh distorted body matched box beam

ActiveCN106079039APrefab implementationEasy to prefabMouldsCeramic shaping mandrelsEngineeringUltimate tensile strength

The invention discloses a prefabricated steel template system of a large-span and ultrahigh distorted body matched box beam. The prefabricated steel template system is characterized in that a bottom die system comprises a bottom die and a bottom die adjusting device used for adjusting position and inclination angle of the bottom die; an inner die system comprises an inner die hydraulic system used for adjusting position of an inner die, and an inner die thread rotary rod system; a side die system comprises a side die adjusting mechanism used for adjusting position of a side die; and an end die template of an end die system comprises an end die fixing block section, en end die change block section and an end die ultrahigh change block section. According to the prefabricated steel template system, prefabricated templates of large-span sectional beams on a transition curve are prefabricated, sectional beams of bridges in special regions can be conveniently and quickly achieved through utilization of the system, the problems that the height change of the sectional beams is large and a cross lope changes of the prefabricated steel templates of which the sectional beams are ultrahigh and overweight are successfully solved, the construction cycle is shortened, and the labor intensity of constructors is effectively reduced.

Owner:CCCC SECOND HARBOR ENG

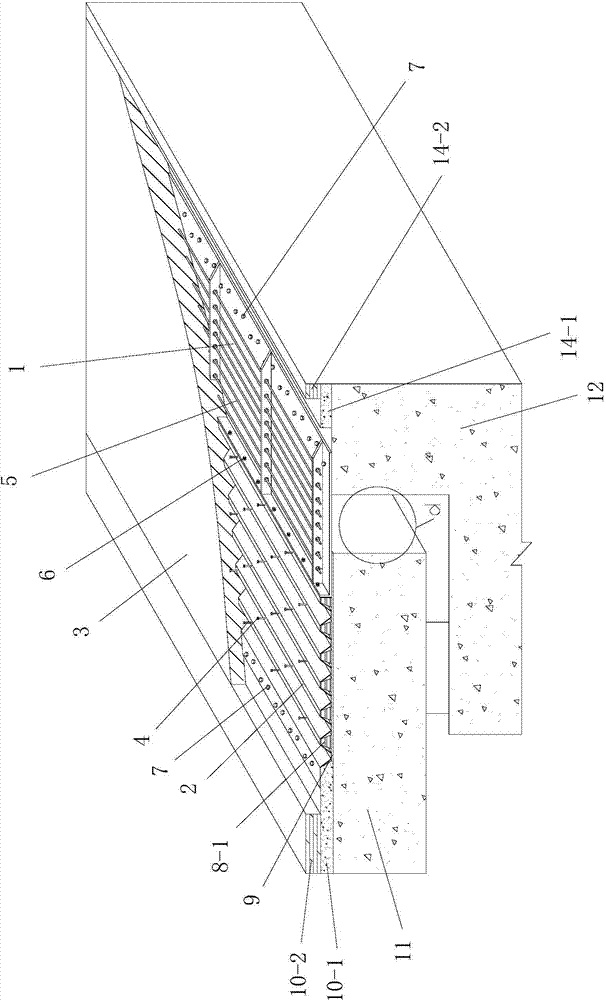

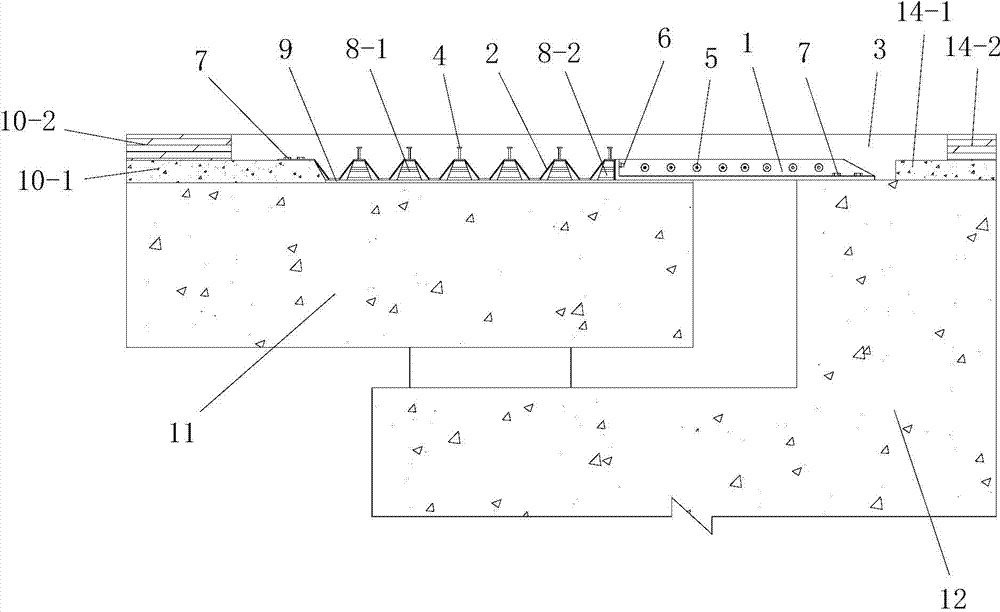

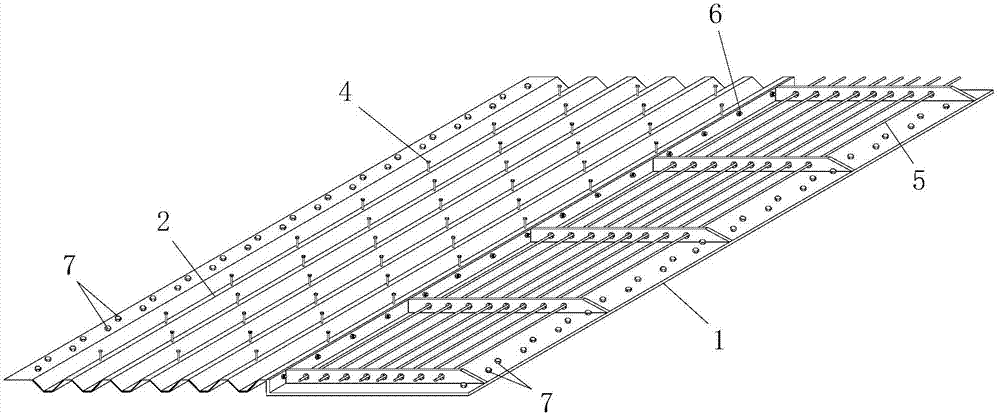

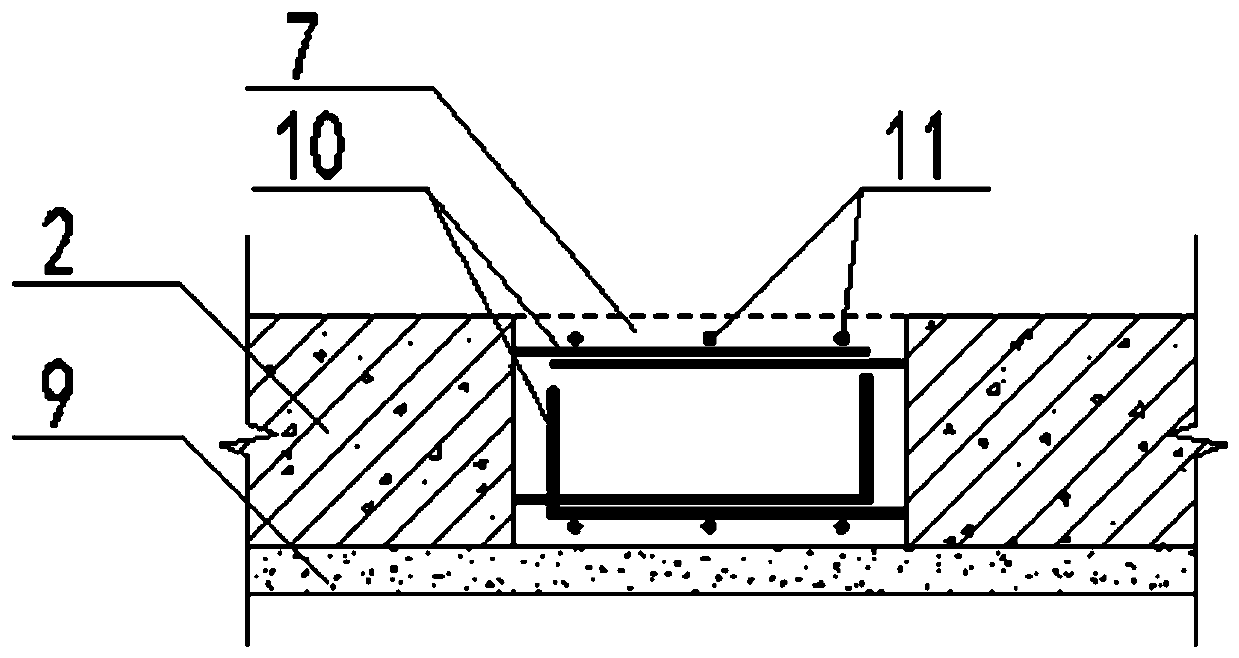

Stiffened joint-crossing plate based bridge deck jointless expansion device and construction method thereof

InactiveCN104674650ASimple structureReasonable designBridge structural detailsBridge erection/assemblyWave shapeExpansion joint

The invention discloses a stiffened joint-crossing plate based bridge deck jointless expansion device and a construction method thereof. The expansion device comprises a prefabricated expansion assembly and an expansion joint filler filled layer filled above the prefabricated expansion assembly, wherein the prefabricated expansion assembly is arranged on an expansion joint reserved between every two adjacent girder segments, and a sliding layer is laid on a girder exposed segment of each girder segment; the prefabricated expansion assembly comprises a stiffened joint-crossing plate and two wave-shaped expansion plates. A construction method for an expansion device to be repaired comprises the steps of cleaning an original bridge expansion device, constructing reserved mounting grooves, constructing the sliding layers, carrying out field assembly and mounting on the prefabricated expansion assembly and constructing the expansion joint filler filled layer. A construction method for an expansion device to be constructed comprises the steps of prefabricating the prefabricated expansion assembly, carrying out field assembly on the prefabricated expansion assembly, constructing the sliding layers, mounting the prefabricated expansion assembly and constructing bridge deck pavement structures and the expansion joint filler filled layer. The stiffened joint-crossing plate based bridge deck jointless expansion device and the construction method thereof have the advantages that the design is reasonable, the construction is convenient, the use effect is good, and multiple problems of the existing expansion devices can be solved.

Owner:XIAN HIGHWAY INST

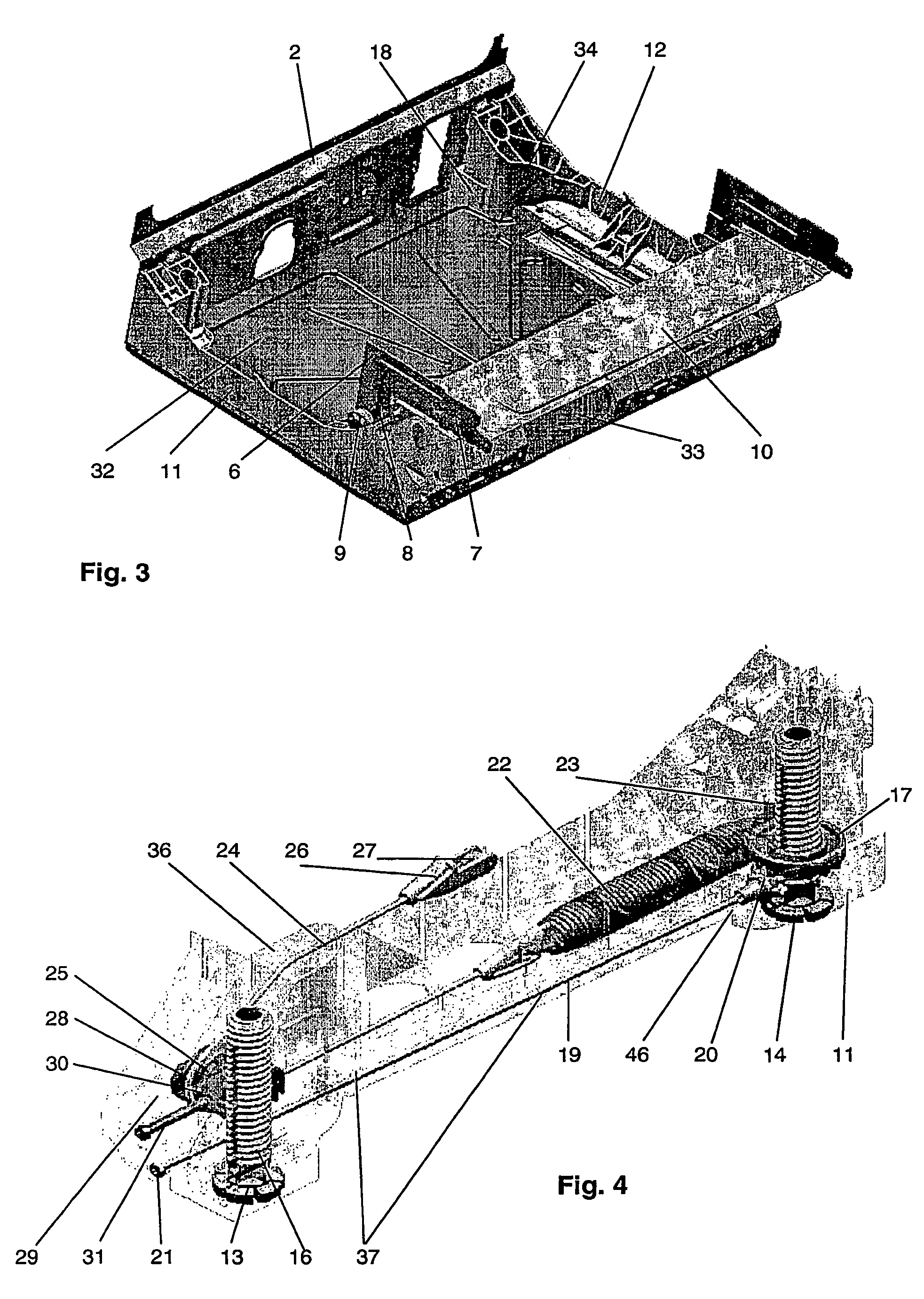

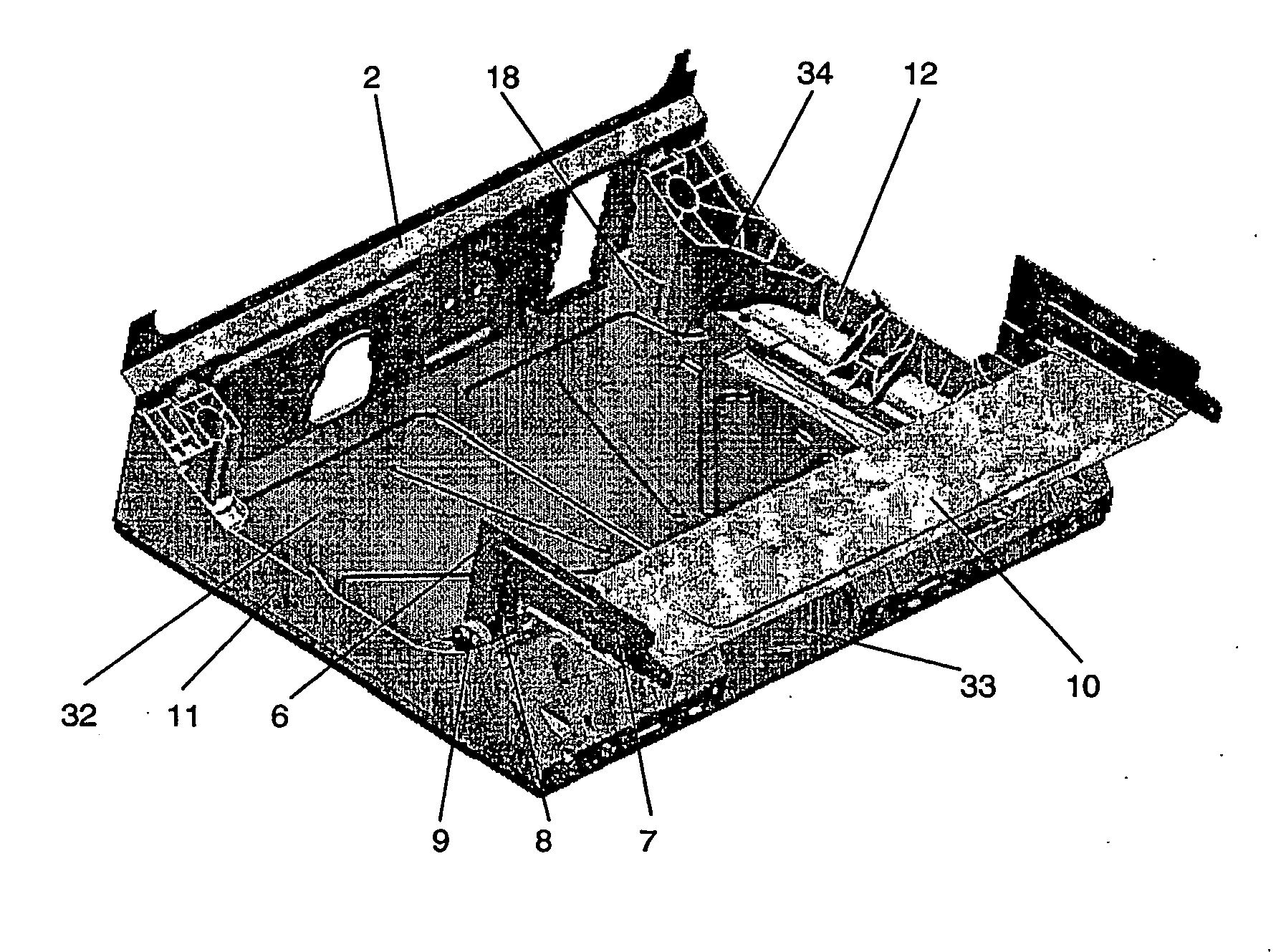

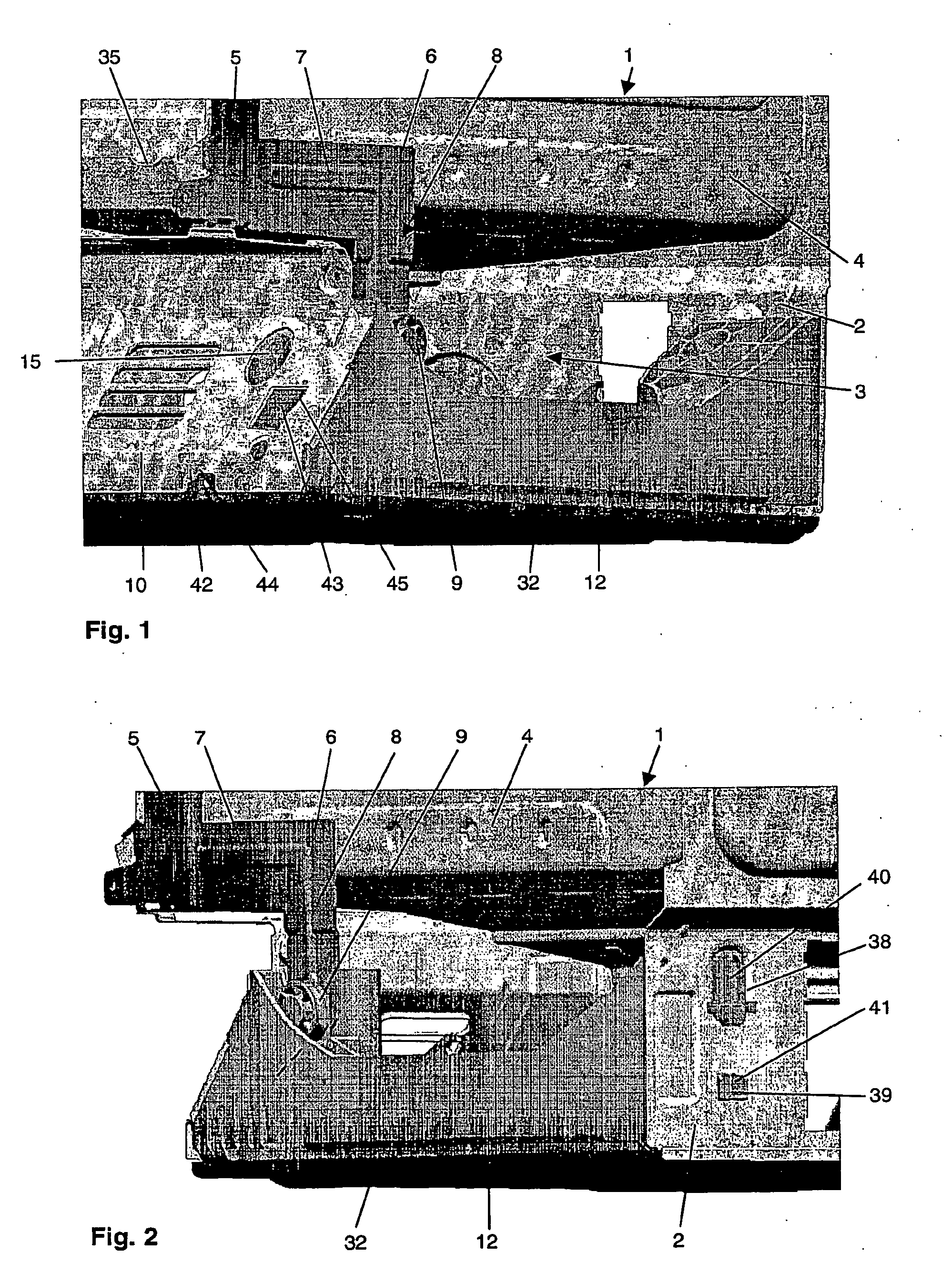

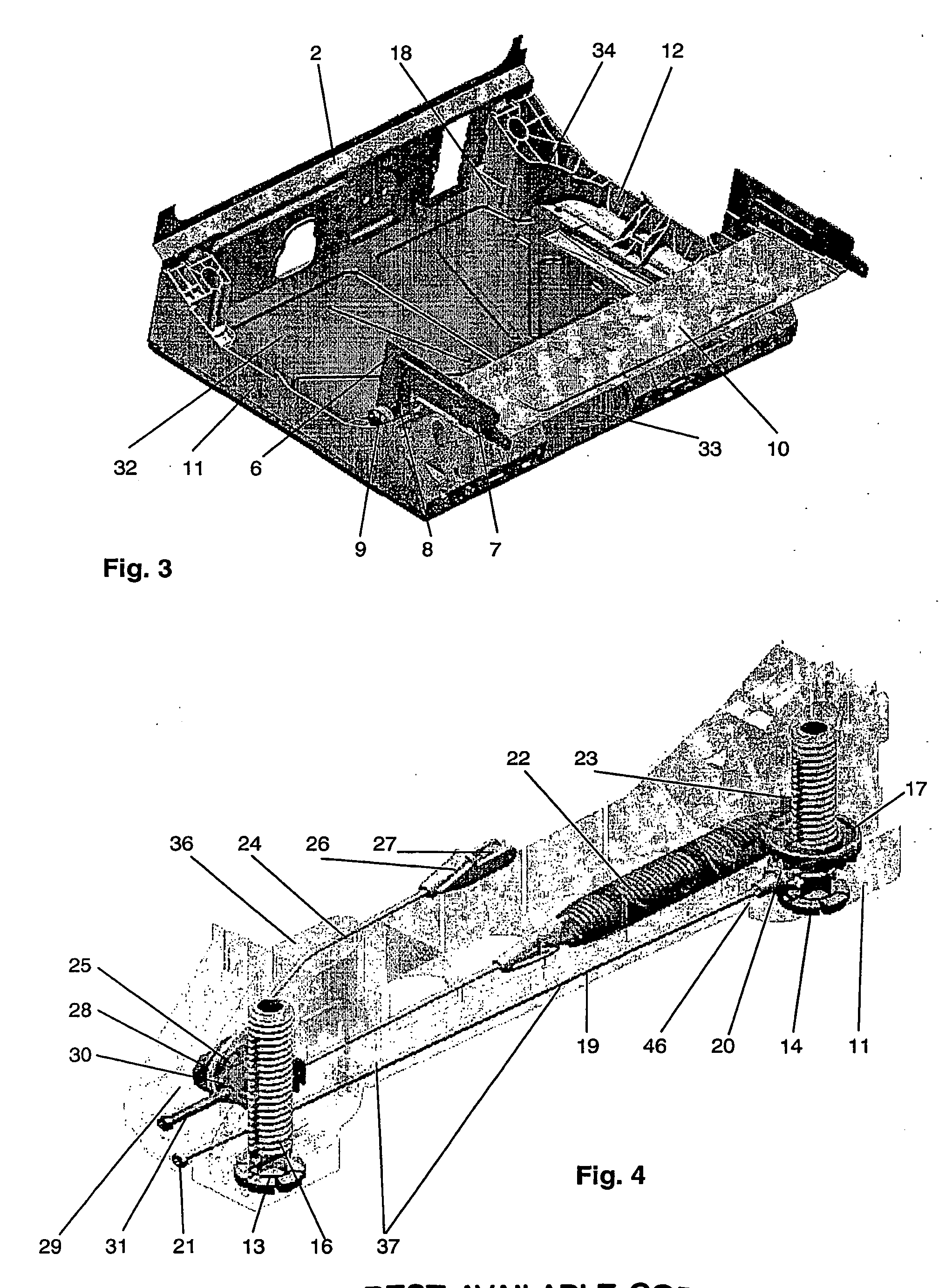

Dishwasher machine

InactiveUS7699064B2Easy to assembleEasy constructionTableware washing/rinsing machine detailsCleaning using liquidsHorizontal axisEngineering

The invention relates to a dishwasher having a rinsing container (1) which is sealable on its front side by an appliance door that is pivotable on its bottom section about a horizontal axis, whereby a base area (3) that extends beneath the rinsing container (1) is bordered at the bottom by collecting dish (32), at the rear by a cover (2) and at the front by a connecting strip (10), having appliance feet (13, 14) that are adjustable in height and having an adjustment device for varying the closing behavior of the appliance door. To design the entire base area (3) so that it is easy to assembly and nevertheless is readily accessible, it is proposed that the lateral borders of the base area (3) shall be formed by two base parts (11, 12), each of which is attached as a narrow receptacle housing for the appliance feet (13, 14), their height adjustment and the adjustment device and each of which is attached to the cover (2) and to the connecting strip (10).

Owner:MIELE & CO KG

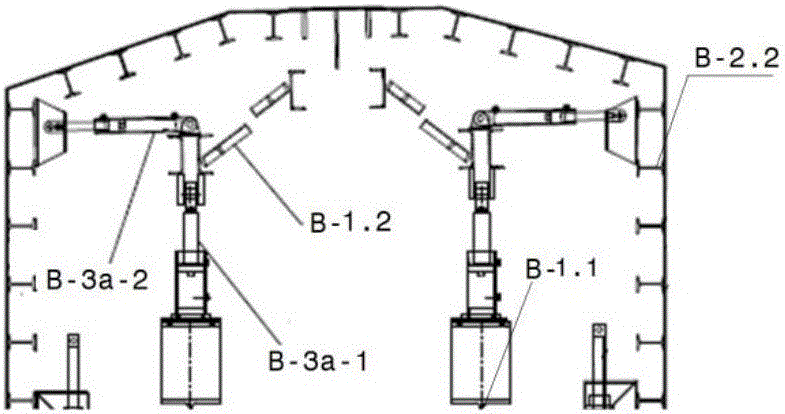

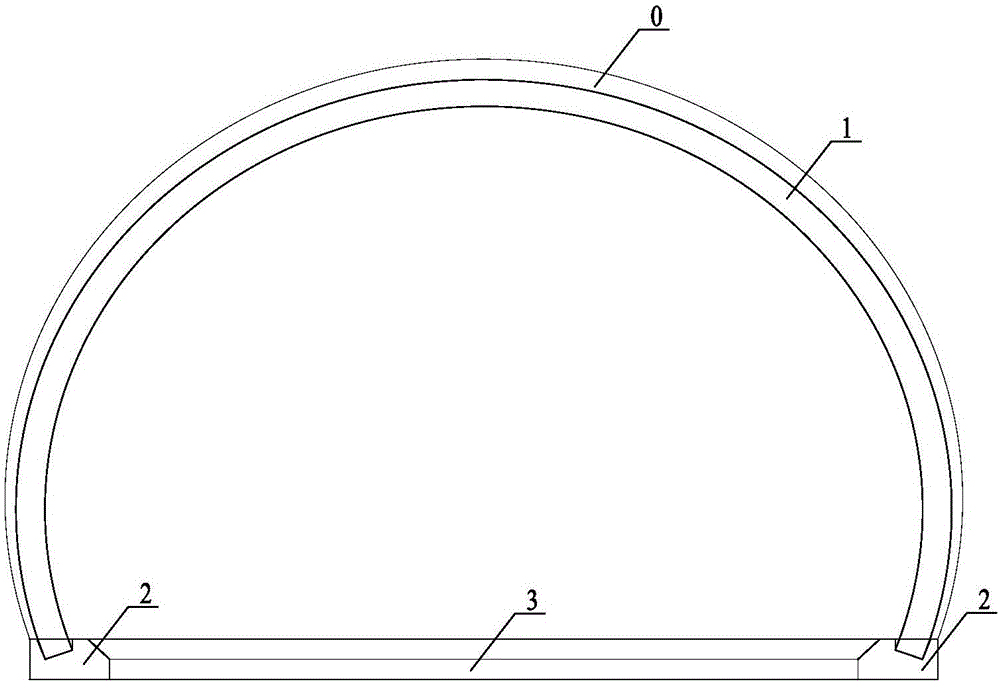

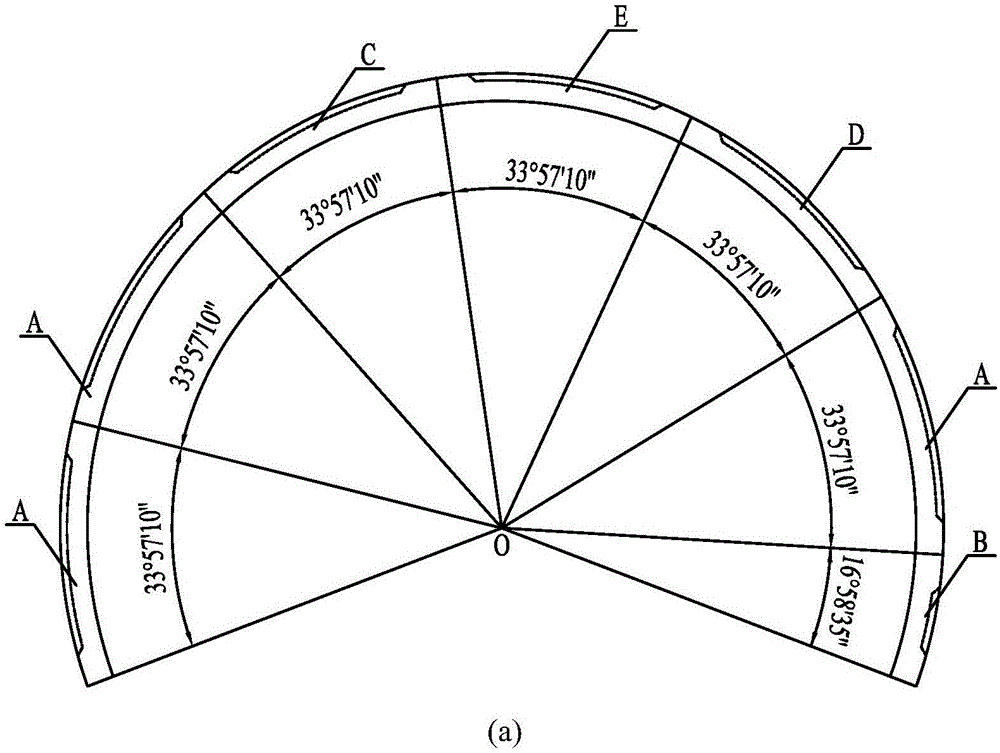

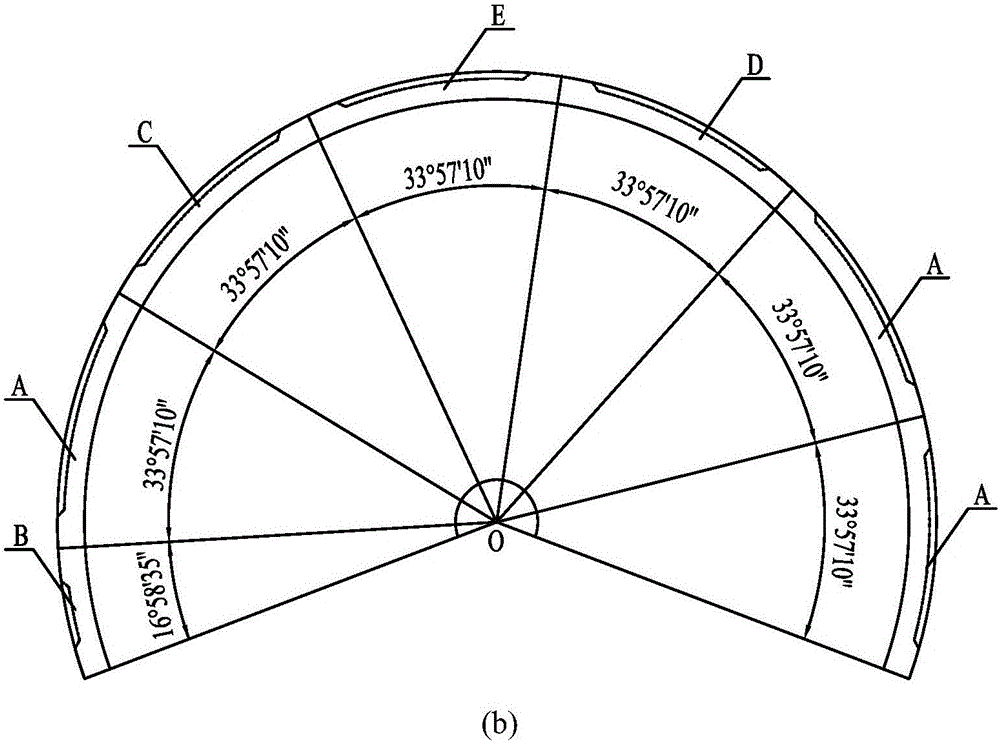

Full-section prefabricated lining structure for drilling and blasting method tunnel and construction method

ActiveCN106150519AReduce construction costsGuarantee the construction qualityUnderground chambersTunnel liningEngineeringLine structure

The invention provides a full-section prefabricated lining structure for a drilling and blasting method tunnel and a construction method. The lining structure is formed by connecting a plurality of single-ring full-section prefabricated lining structure bodies in the axial direction of the tunnel. Each single-ring full-section prefabricated lining structure body comprises a functional layer, a prefabricated lining arch ring, pedestals and a horizontal bottom beam, wherein the functional layer is arranged on the outer layer of the prefabricated lining arch ring and used for heat insulation, force transfer and / or water resistance, the two ends of the prefabricated lining arch ring are connected to the pedestals, the pedestals are connected to the two ends of the horizontal bottom beam, and a semicircular arch structure is formed. The full-section prefabricated lining structure replaces a cast-in-place secondary lining structure, the construction efficiency of the secondary lining structure in the drilling and blasting method tunnel is improved, the construction cost is reduced, and the mechanical strength of construction is improved.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

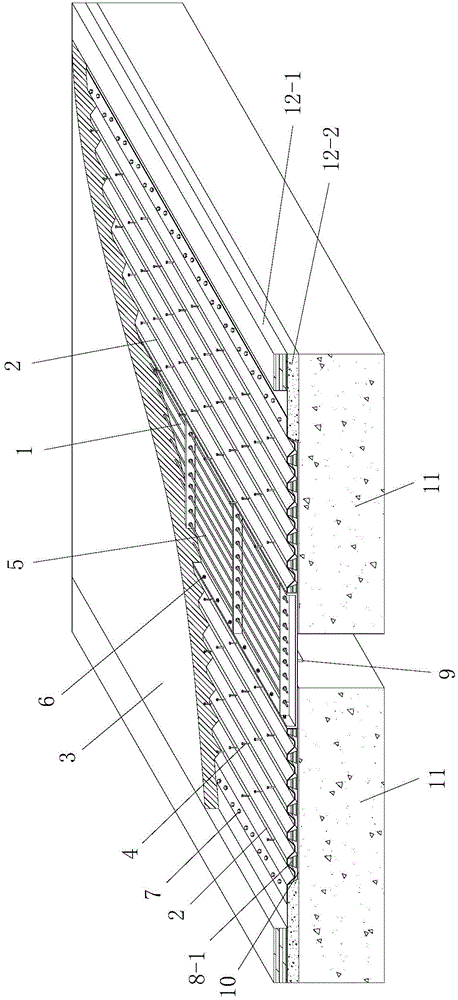

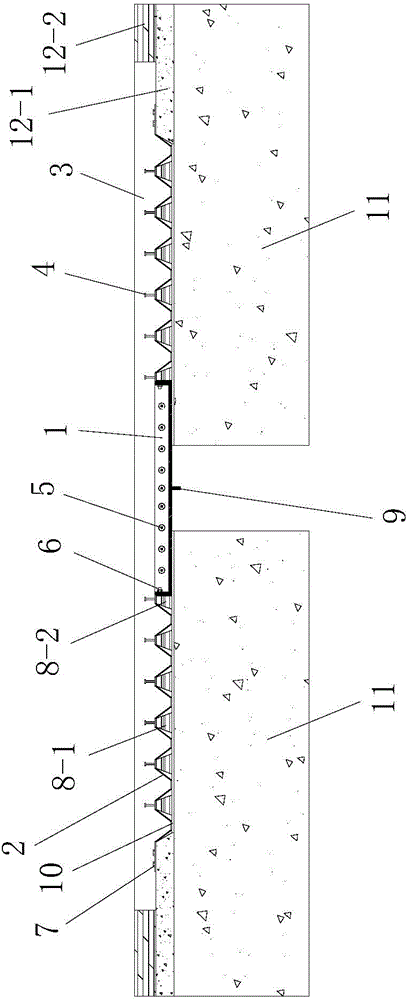

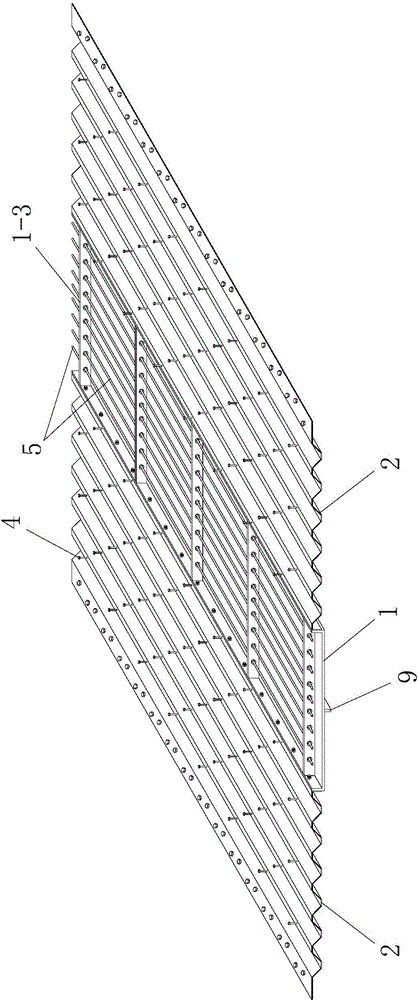

Warship board multilayer anti-detonation protection structure

ActiveCN103991518AIncreased damage areaReduce distortionVessel cleaningHullsDetonationUltimate tensile strength

The invention discloses a warship board multilayer anti-detonation protection structure. The warship board multilayer anti-detonation protection structure comprises a double-layer shell, a void compartment, a first liquid compartment and a second liquid compartment, wherein the double-layer shell, the void compartment, the first liquid compartment and the second liquid compartment are sequentially ranked from the outer side of a warship body to the inner side of the warship body, the water filling height h of the first liquid compartment and the water filling height h of the second liquid compartment are 70%-80% of a compartment height H, the void compartment is separated from the first liquid compartment through a first compartment separation plate, the first liquid compartment is separated from the second liquid compartment through a second compartment separation plate, the second liquid compartment is separated from an inner compartment of a warship through a third compartment separation plate, and the side, towards a compartment body, of the second liquid compartment is fixedly connected with a plurality of longitudinal box girders which are vertically ranked at intervals. The warship board multilayer anti-detonation protection structure with the structural style has the advantages of being light in weight, good in anti-detonation performance, high in residual intensity and the like, when a warship board is impacted by detonation, most detonation impact energy can be absorbed, the compartments of the warship are prevented from being damaged, and personal losses are avoided.

Owner:JIANGSU UNIV OF SCI & TECH

Abutment hidden expansion device and construction method thereof

InactiveCN104762873AWell formedSimple structureIn situ pavingsBridge structural detailsExpansion jointAbutment

The invention discloses an abutment hidden expansion device and a construction method thereof. The expansion device comprises a prefabricated expansion component arranged on an abutment expansion joint, and an expansion joint filler filling layer filled in the upper side of the prefabricated expansion component, wherein a bridge deck pavement structure is paved on a main beam; a slide layer is paved on an exposed section of the main beam; a road surface pavement layer is arranged at the outer side of the upper part of an abutment; the prefabricated expansion component comprises a reinforced joint plate and a waveform expansion plate; a construction method of an expansion device to be repaired comprises the steps of cleaning of an original bridge expansion device, construction of a reversed mounting groove, construction of the slide layer, field assembly and installation of the prefabricated expansion component and construction of the expansion joint filler filling layer; and a construction method of an expansion device to be constructed comprises the steps of prefabrication of the prefabricated expansion component, field assembly of the prefabricated expansion component, construction of the slide layer, installation of the prefabricated expansion component and construction of the bridge deck pavement structure and the expansion joint filler filling layer. The abutment hidden expansion device and the construction method thereof have the advantages of reasonable design, convenience for construction and good use effect, and can solve multiple problems in traditional expansion devices.

Owner:XIAN HIGHWAY INST

Foldable Building Units

InactiveUS20130133273A1Easy to prefabReduce heat transferPublic buildingsSpecial buildingArchitectural engineeringBuilding unit

Foldable building units are provided based on structural frame and connection assembly designs that enable greater construction efficiency and flexibility. The structural frame and connection assembly designs allow for easier connection of frame elements in the prefabrication process of the foldable building units and for easier connection of frame elements at the building site, for example, of foldably connected frame elements after unfolding. They also allow for more finish in the pre-fabrication process, and / or less and faster work at the building site, for example, by enabling conventional structural lumber grids that can be continuous through the edges and corners of the building envelope for conventional exterior finishing, while providing a tight building envelope with reduced heat transfer, particularly, through the edges of the foldable building unit.

Owner:BLU HOMES

Geometric art inlaid wall and floor decorative plate and manufacturing method thereof

The invention provides a geometric art inlaid wall and floor decorative plate, and belongs to the field of architectural ornament and decoration. The decorative plate comprises a stone decorating layer, metal inlaid strips, a binding layer and a compound layer, wherein the decorating layer is formed by fixedly arraying multiple geometric decorative blocks and the metal inlaid strips according to a preset type version. According to the technical scheme, the individual unit decorative plate product can be produced in a factory-like and industrial mode, and decorative schemes meeting various individual requirements can be realized conveniently and fast just by simply changing the shapes and arrangement of the metal inlaid strips and the decorative blocks in the preset type version. Moreover, the decorative plate has a more stable structure and a high-flatness decorative face, and decoration site splicing quality and efficiency are improved. Meanwhile, the invention further provides a manufacturing method of the geometric art inlaid wall and floor decorative plate. The decorative plate manufactured by adopting the method has the advantages of being provided with individual decorative art members, and being capable of being machined industrially in a factory, high in flatness and integrity, convenient to splice and the like.

Owner:SHANGHAI BUILDING DECORATION ENG GRP

Prefabricated gas film concrete shell and manufacturing method thereof

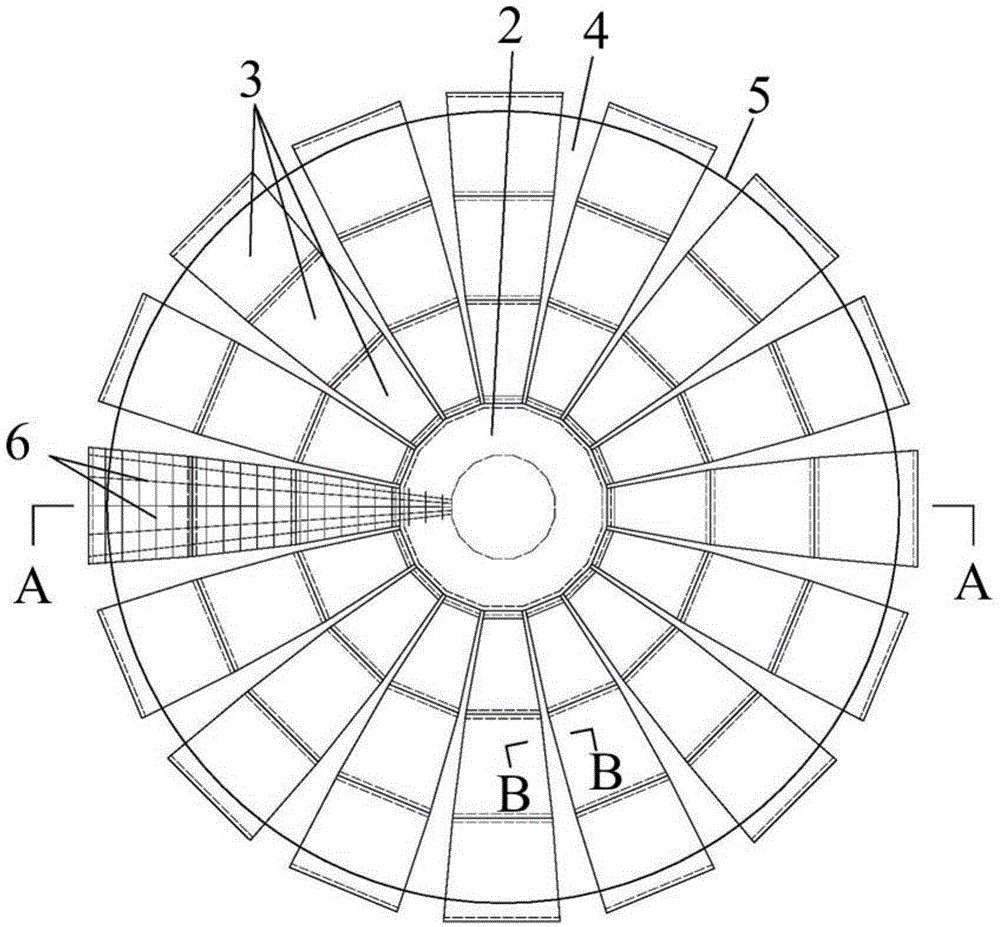

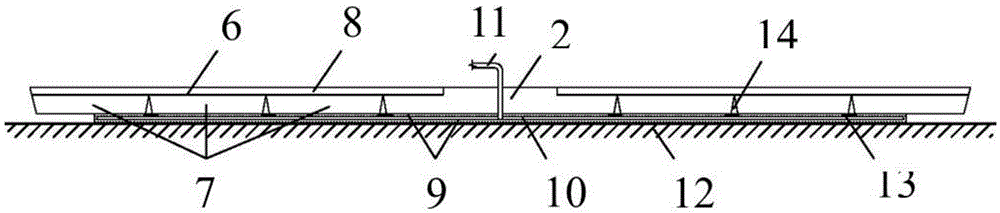

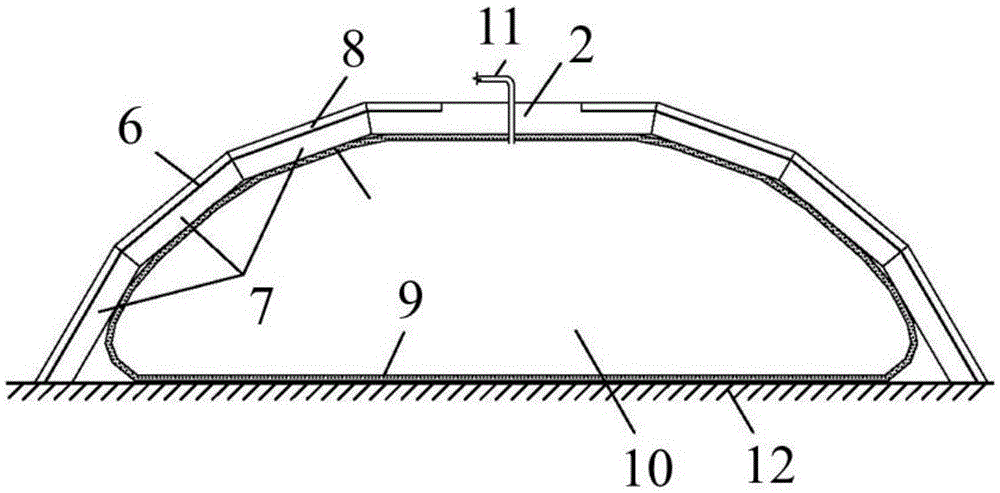

ActiveCN105604190AEasy to prepareHigh precisionArched structuresVaulted structuresSurface layerPrefabrication

The invention discloses a manufacturing method of a prefabricated gas film concrete shell. The manufacturing method includes a prefabrication stage, a planar assembly stage, an inflation jacking stage and a spatial assembly stage. The invention further discloses the prefabricated gas film concrete shell. The prefabricated gas film concrete shell comprises a block assembly, a tie grid and surface layer concrete, wherein the block assembly, the tie grid and the surface layer concrete form a shell body of the prefabricated gas film concrete shell, the tie grid is laid on the outer side of the block assembly, and the surface layer concrete is poured on the outer side of the tie grid. The prefabricated gas film concrete shell has the advantages that the manufacturing method is simple, precision is high, material and manpower consumption is small, and building cost is low, and can be applied to prefabricated structures in the fields of buildings, bridges, water projects and the like.

Owner:SHANGHAI JIAO TONG UNIV

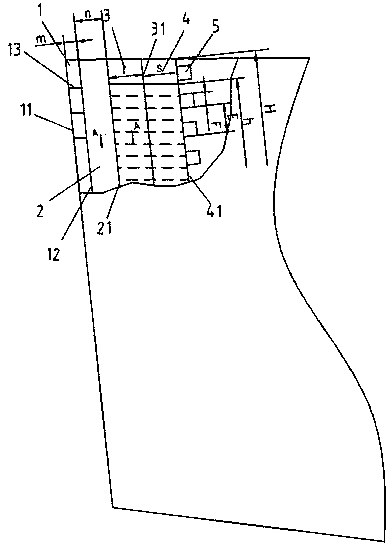

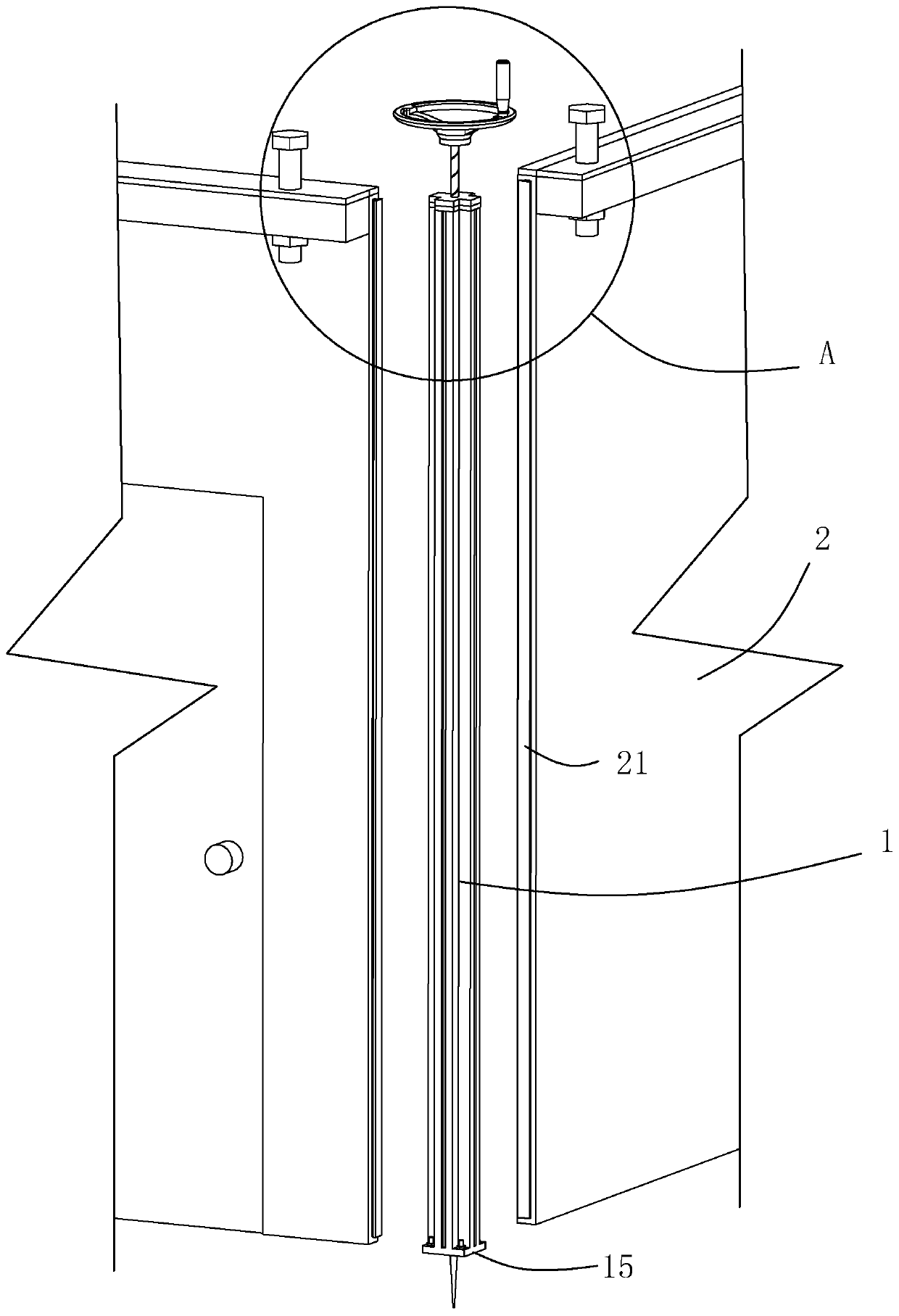

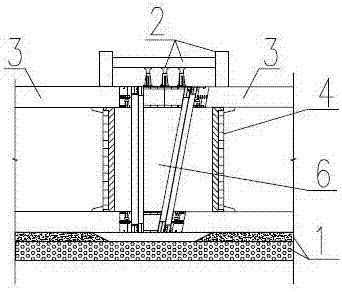

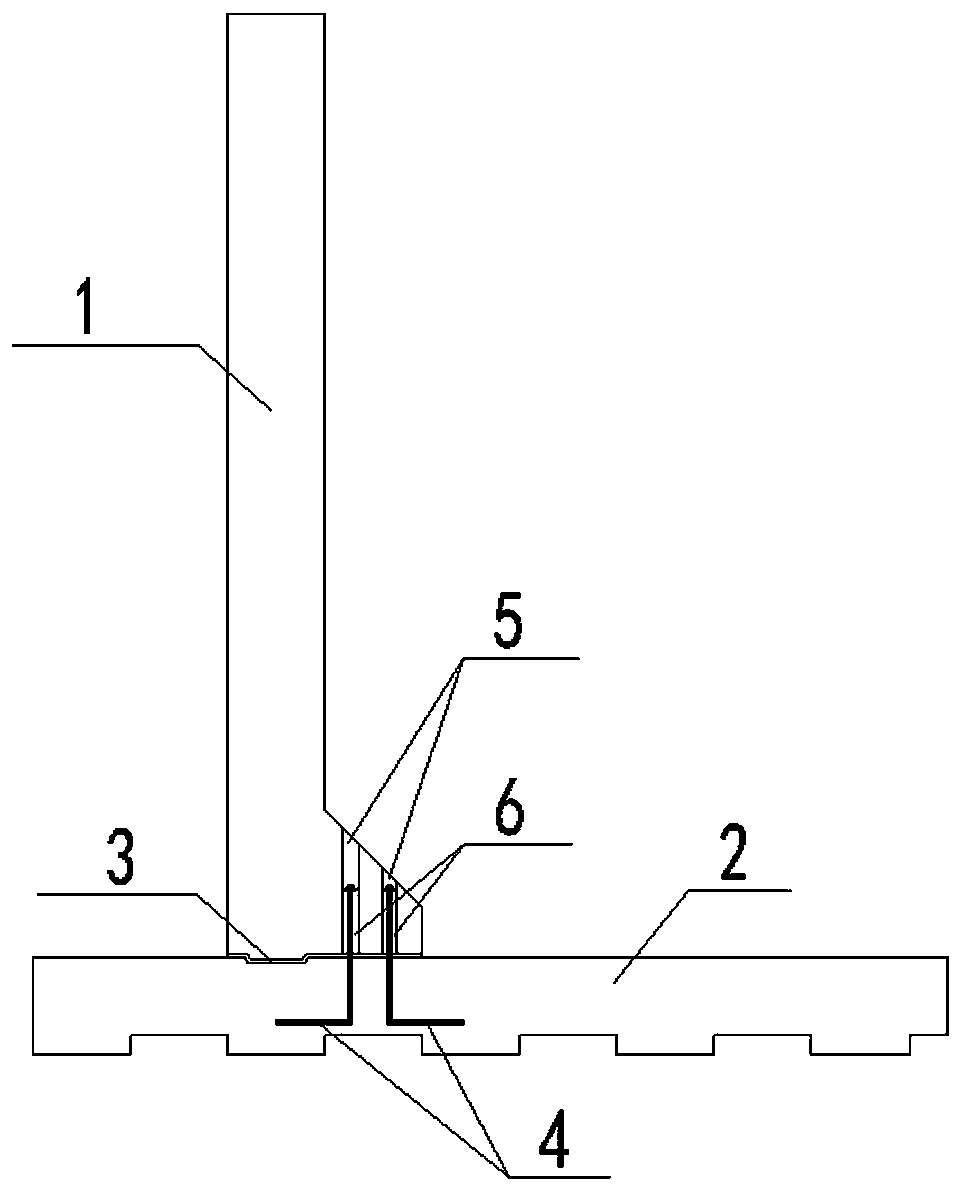

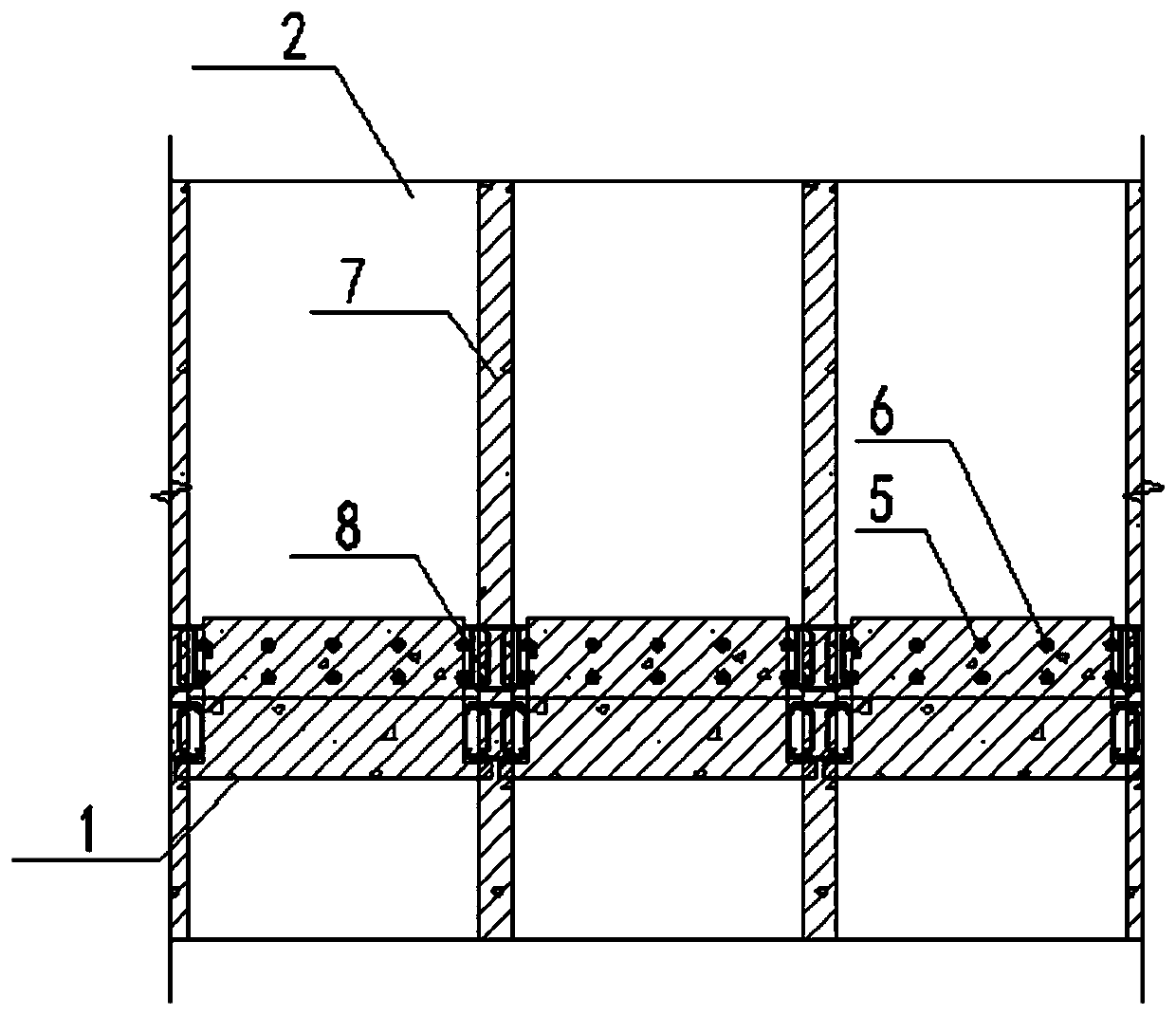

Temporary house used in housing construction project

ActiveCN110761413AEasy to prefabIncrease production capacityBuilding insulationsDwelling buildingThermal insulationArchitectural engineering

The invention relates to a temporary house used in a housing construction project. The temporary house includes a plurality of vertically-arranged columns arranged at equal intervals and wall plates arranged between the adjacent columns, the wall plates are vertically arranged, the side surfaces, perpendicular to the ground, of the wall plates and the columns are clamped, the side faces, facing the wall plates, of the columns are provided with clamping slots where the wall plates are clamped, long-strip-shaped sealing strips are slidably connected into the clamping slots, and the columns are internally provided with locking devices for pushing the sealing strips to abut against the side faces, located in the clamping slots, of the wall plates; and a roof is jointly overlapped above the wall plates, and the roof and the wall plates are fixedly connected. Through the arrangement, the temporary housing is quickly installed in the manner that the wall plates and the columns are clamped, meanwhile, gaps between the wall plates and the columns are plugged through the sealing strips, the sealing strips are extruded by the locking devices to generate deformation to further plug the gaps between the wall plates and the columns, the sealing performance of the wall plates and the columns is improved, and the indoor thermal insulation performance and sound insulation effect are further improved.

Owner:广东一业建设股份有限公司 +2

Structure form of final joint of immersed tunnel

InactiveCN106894449ASmall structure sizeEasy to prefabArtificial islandsUnderwater structuresWedge shapeWater pressure

The invention discloses a structure form of a final joint of an immersed tunnel and relates to the technical field of communication and transportation. A foundation pad is provided with adjacent long pipe sections on the two sides. The adjacent long pipe sections on the two sides are both provided with jack pushing systems. The end face on one side of one of the adjacent long pipe sections on the two sides is in a wedge shape, the end face on the other side of the other one of the adjacent long pipe sections on the two sides is a vertical end face, and the end faces on the two sides are both provided with steel end shells. A single-sided wedge-shaped block is inserted between the end faces on the two sides of the adjacent long pipe sections on the two sides. The end faces on the two sides of the adjacent long pipe sections on the two sides are provided with the first steel end shells. GINA water stops are mounted on the peripheries of the first steel end shells. The adjacent long pipe sections on the two sides are both internally provided with end sealing walls. The two sides of the single-sided wedge-shaped block are provided with second steel end shells. The immersed final joint is small in structure size and convenient to prefabricate, and the construction quality can be ensured easily; through the double-sided wedge shape, the construction difficulty is low, compression of the water stops is facilitated, and the final joint block is not liable to be squeezed out by water pressure; and the construction speed of underwater mating of prefabricated parts is high.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD

Prefabricated type cantilever retaining wall by grouting anchoring connecting method

PendingCN110055997AEasy to prefabImprove transportation space utilizationArtificial islandsUnderwater structuresRebarCantilever

The invention provides a prefabricated type cantilever retaining wall by a grouting anchoring connecting method. The prefabricated type cantilever retaining wall is spliced by a plurality of sectionsof retaining wall segments, the retaining wall segments comprises prefabricated bottom plates and prefabricated surface plates, the prefabricated bottom plates are internally provided with pre-buriedvertical reinforced steel bars, reserved holes which are matched with the pre-buried vertical reinforced steel bars are formed in the prefabricated surface plates, and a bed mortar material is paved on the prefabricated bottom plates; and the prefabricated vertical reinforced steel bars of the prefabricated bottom plates penetrate through the reserved holes of the prefabricated surface plates, a grouting material is poured in the reserved holes to enabled the surface plates and the bottom plates to be connected into an integral structure, and vertical connection among the segments of the retaining wall is connected through post-pouring joints of the surface plates and the bottom plates. According to the prefabricated type cantilever retaining wall by the grouting anchoring connecting method, prefabrication in a factory, transportation and installation on site are facilitated, the workloads of the connection of the reinforced steel bars on the site and pouring of concrete are reduced, and the construction periods of the retaining wall is shortened; and the connecting strength and stability of a wall body can be ensured, the connection is reliable, the structure is simple, the construction is convenient, the quality of the connection of prefabricated components is easy to ensured, and the prefabricated type cantilever retaining wall has good popularization value.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP +2

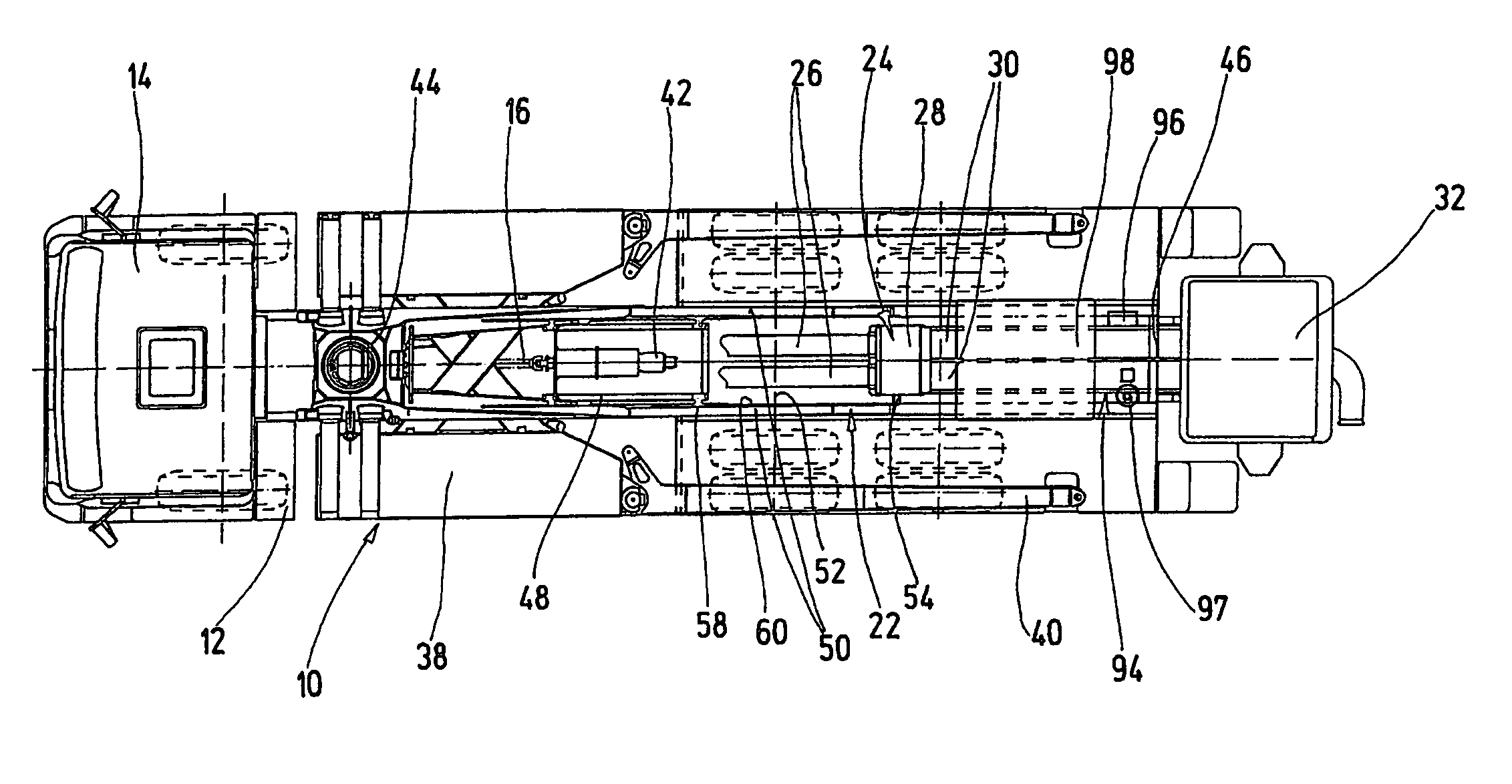

Mobile concrete pump and corresponding building frame

InactiveUS20050271522A1Reduce vibrationSaving connectionConcrete transportationPositive displacement pump componentsFixed bearingEngineering

The invention concerns a mobile concrete pump comprising a building frame (22) arranged on the structure (12) of a truck chassis (10) and serves to maintain a supporting device (38), a core pump (24) and functional units which form a distribution mast (36). The building frame (22) comprises two longitudinal side members (50) mutually spaced apart by a free space (52) and resting on said chassis structure (12). Said mobile concrete pump further comprises a driving assembly (42) for actuating the functional units, which are arranged with the core pump (24) in the free space zone (52) located between the two longitudinal side members (50). The invention aims at providing a mobile concrete pump whereof the building frame (22) can be easily mounted and dismounted. Therefore, said building frame (22) comprises a floating bearing (54) which links said side members across the free space, as well as a fixed bearing (56) arranged at the rear end of the building frame and serving to support releasably the core pump which is pre-assembled in modular manner. The building frame further comprises mounting means (62) designed to support releasably supporting carrier frames (48) of different sizes which link said side members across the free space (52) and which may be equipped in modular manner with various driving subassemblies (42).

Owner:PUTZMEISTER ENG

Dishwasher Machine

InactiveUS20070240744A1Compact designEasy to assembleTableware washing/rinsing machine detailsCleaning using liquidsEngineeringMechanical engineering

The invention relates to a dishwasher having a rinsing container (1) which is sealable on its front side by an appliance door that is pivotable on its bottom section about a horizontal axis, whereby a base area (3) that extends beneath the rinsing container (1) is bordered at the bottom by collecting dish (32), at the rear by a cover (2) and at the front by a connecting strip (10), having appliance feet (13, 14) that are adjustable in height and having an adjustment device for varying the closing behavior of the appliance door. To design the entire base area (3) so that it is easy to assembly and nevertheless is readily accessible, it is proposed that the lateral borders of the base area (3) shall be formed by two base parts (11, 12), each of which is attached as a narrow receptacle housing for the appliance feet (13, 14), their height adjustment and the adjustment device and each of which is attached to the cover (2) and to the connecting strip (10).

Owner:MIELE & CO KG

Rubber spacer light track structure with vibration reduction and noise reduction functions

ActiveCN104612000AIncrease lateral connection stiffness and section moment of inertiaImprove the bending performance of the sectionRailway tracksEngineeringElectrical and Electronics engineering

The invention discloses a rubber spacer light track structure with vibration reduction and noise reduction functions. The rubber spacer light track structure with the vibration reduction and noise reduction functions comprises a track beam, tracks and rubber pads, wherein the track beam comprises two track beam bodies which are used for fixing the tracks and arranged oppositely in parallel, the cross section of the track beam bodies is rectangular, and the extending direction of the track beam bodies is the same with the extending direction of the two tracks; connection rods used for increasing the anti-bending inertia moment of the track beam in the sectional direction are arranged between the track beam bodies, the multiple rows of connection rods keep flush with the top face and the bottom face of the track beam bodies, the sectional shape is set to be the same double-layer connection rods, the plane where the double-layer connection rods at any tow is perpendicular to the lateral face of the track beam bodies, and arc transition sections are arranged at the positions, connected with the track beam bodies, of the connection rods; each rubber pad is mainly formed by connecting multiple rubber layers made of high-damping rubber materials. The rubber spacer light track structure with the vibration reduction and noise reduction functions increases the transverse connection stiffness and the sectional anti-bending inertia moment of the track beam, and can greatly reduce environment vibration and noise.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST

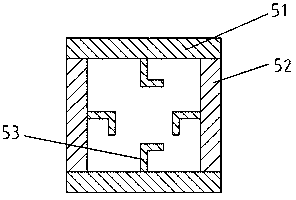

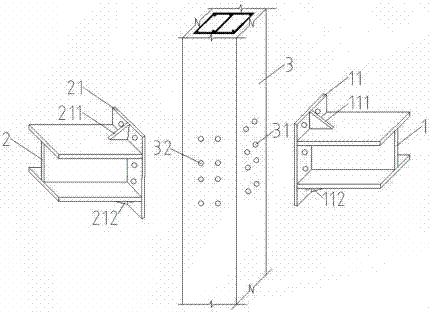

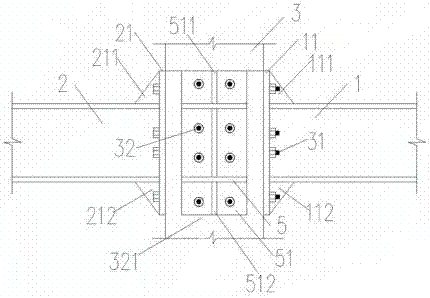

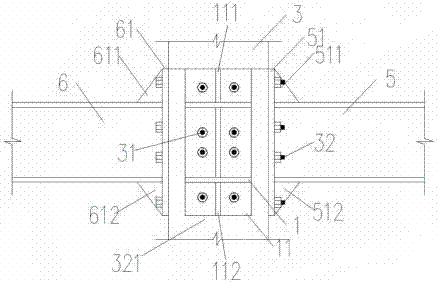

Novel assembly type reinforcing steel bar concrete column and steel beam connecting joints

InactiveCN107476430AAvoid damageReduce consumptionBuilding constructionsReinforced concrete columnSteel bar

The invention discloses novel assembly type reinforcing steel bar concrete column and steel beam connecting joints, and relates to the field of construction steel structure, civil construction technology and mechanical assembly. An end plate with reserved bolt holes is welded on the end part of a steel beam and the end plate is connected with a joint part where a pre-embedded high strength penetrating bolt is connected with the steel pipeline reinforced concrete column through high-strength bolts. According to the novel assembly type reinforcing steel bar concrete column and the steel beam connecting joints, bolt assembly is adopted, prefabricating and welding work is completed in a factory, and the quality is reliable; the anti-seismic performance is excellent, ductility and energy consumption capacity of the joints can be improved significantly; and plastic hinges are moved outward to avoid appearing at the beam end; and repairing or replacing after an earthquake is convenient.

Owner:南京清骐筑宇建筑科技有限公司

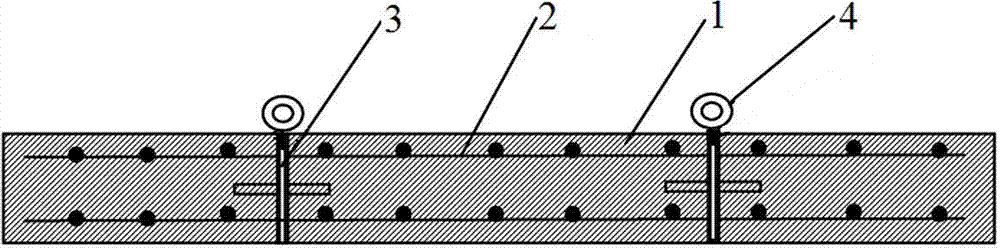

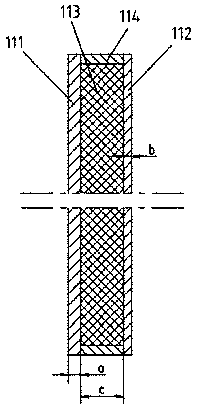

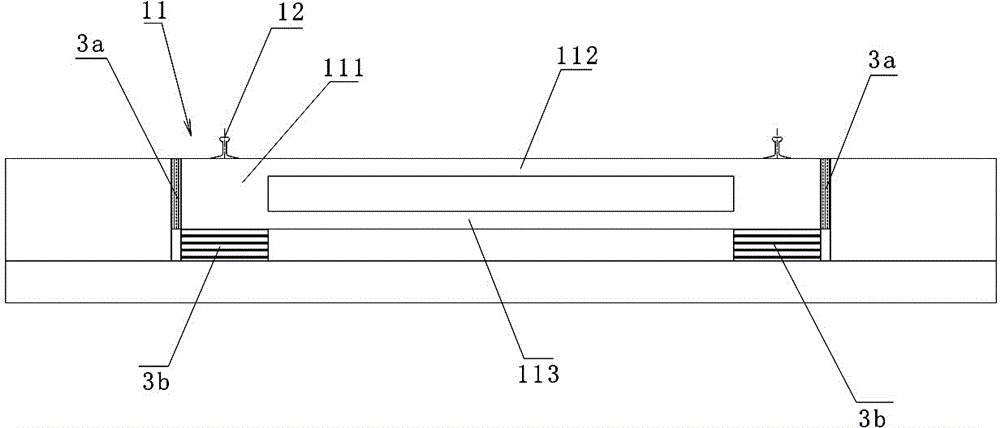

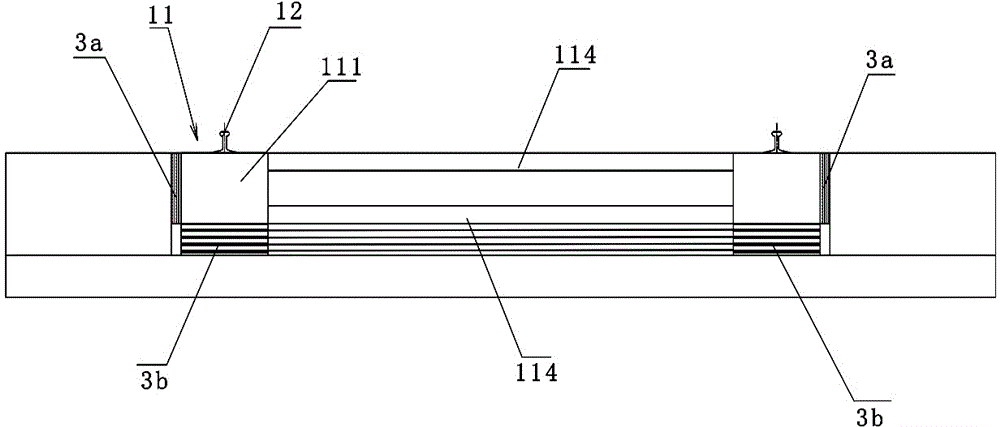

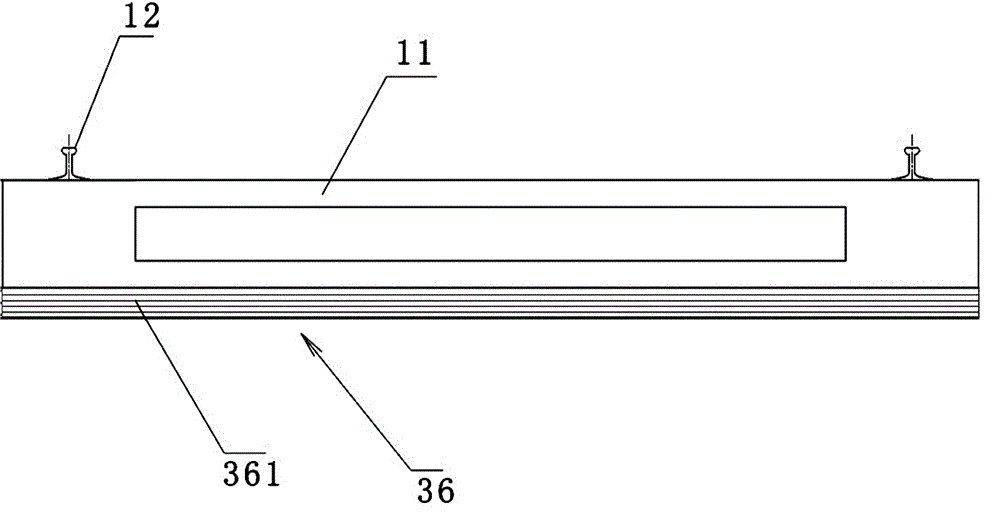

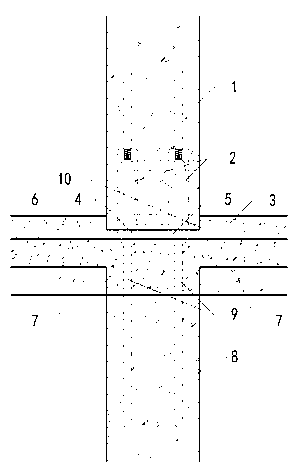

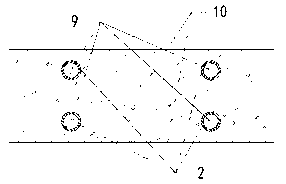

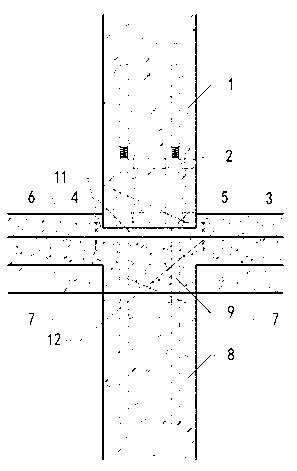

Plugging method for grout blanket at connecting position of upper layer and lower layer of assembling shear wall building

ActiveCN103243913AGuaranteed smoothStrong toughnessBuilding material handlingUltimate tensile strengthCement mortar

A plugging method for a grout blanket at a connecting position of an upper layer and a lower layer of an assembling shear wall building relates to a manufacturing method of a building structure. The method includes that first wood strips 11 are fixed on two sides of the grout blanket 4 through steel nails 12 to plug the two sides of the grout blanket 4 completely, then a high-strength grouting material 5 is filled in the grout blanket 4, and finally after the high-strength grouting material 5 is completely condensed to reach certain strength, the wooden strips 11 can be detached and recycled. The plugging method is suitable for a structure form at the connecting position of the upper layer and the lower layer of an assembling shear wall building structure. By using the wood strips for plugging, the surface of one side of the grouting blanket can be guaranteed to be smooth, the high-strength grouting material can fill the grouting blanket completely, and load between the upper layer and the lower layer is delivered completely. The toughness of the wood strips is better than that of cement mortar, and the wood strips have good impact resistance. The wood strips are convenient to prefabricate and install, suitable for assembling building construction and capable of being recycled, and materials are saved.

Owner:中国建筑东北设计研究院有限公司

Fabricated composite shear wall based on self-resetting composite end column-grouting anchor shear wall

PendingCN109403509AGive full play to the characteristics of bearing capacityImprove vertical bearing capacityWallsProtective buildings/sheltersPre stressRebar

The invention discloses a fabricated composite shear wall based on self-resetting composite end column-grouting anchor shear wall. The fabricated composite shear wall comprises self-resetting composite end columns, a grouting anchor shear wall, and energy dissipation connecting parts, wherein embedded double-layer concrete-filled steel pipe composite columns are connected in a pressed mode throughunbonded prestress, and inner steel pipes are taken as unbonded prestressed reinforced channels at the same time; the grouting anchor shear wall is connected by single row of reinforcing steel bars through grouting anchors, and shear wall reinforcing cages are made of factory-made steel meshes with stirrups; the energy dissipation connecting parts are made of high-strength steel plates with elliptical holes; the self-resetting composite end columns and the grouting anchor shear wall are connected through the energy dissipation connecting parts to form the integral fabricated composite shear wall. According to the fabricated composite shear wall based on the self-resetting composite end column-grouting anchor shear wall, the defects that existing 'equivalent cast-in-place' type fabricatedconcrete structure technologies have theoretical, technical and economic problems are overcome, and the prefabricated composite shear wall with efficient prefabricating, simplified construction and definite stress is realized.

Owner:NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com