Patents

Literature

774 results about "Wire gauze" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A wire gauze is a sheet of thin metal that has net-like patterns or a wire mesh. Wire gauze is placed on the support ring that is attached to the retort stand between the Bunsen burner and the glassware to support the beakers, flasks, or other glassware during heating. Wire gauze is an important piece of supporting equipment in a laboratory as glassware cannot be heated directly with the flame of a Bunsen burner, and requires the use of a wire gauze to diffuse the heat, helping to protect the glassware. Glassware has to be flat-bottomed to stay on the wire gauze.

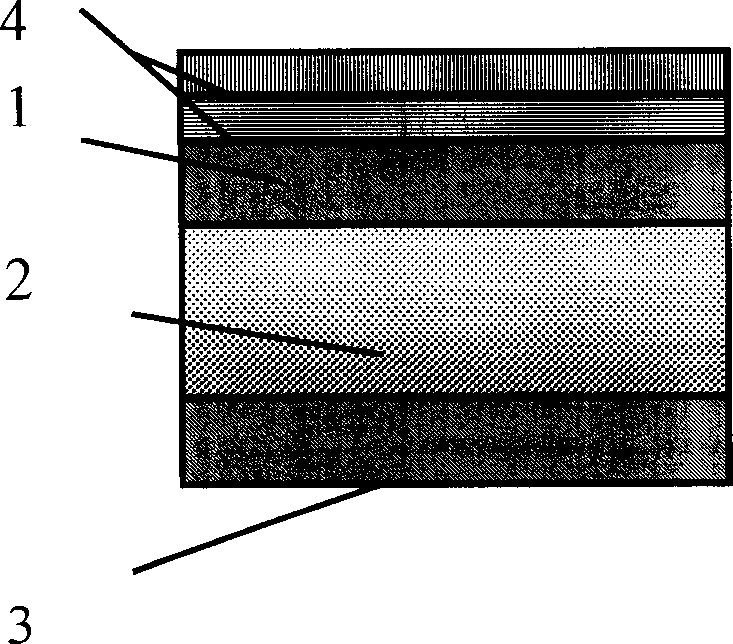

Metal polyporous material with gradient pore structure and preparation thereof

The invention provides a metal porous material with a gradient pore structure, which is formed by at least two porous layers with different pore diameter. The pore diameter of the metal porous material gradually decreases or gradually increases with the thickness direction of the material; a bottom layer of the porous layers is a macropore layer used as a support body; a surface layer of the porous layers is a pore layer used as a filtering precision control layer; the material of the macropore layer is a composite wire gauze, a metal fiber felt or a powder sintered metal porous material; and the material of the pore layer is superfine metal powder or superfine metal fiber. A method for preparing the metal porous material comprises a step of using spraying, dipping or centrifugal coating method to manufacture at least one pore layer on the surface of the support body. Compared with the prior metal porous material in the same grade, the metal porous material with the gradient pore structure has the advantages of obviously raising permeability coefficient, well solving the contradiction between the pore diameter and relative permeability coefficient of the metal porous material and having a simple process.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

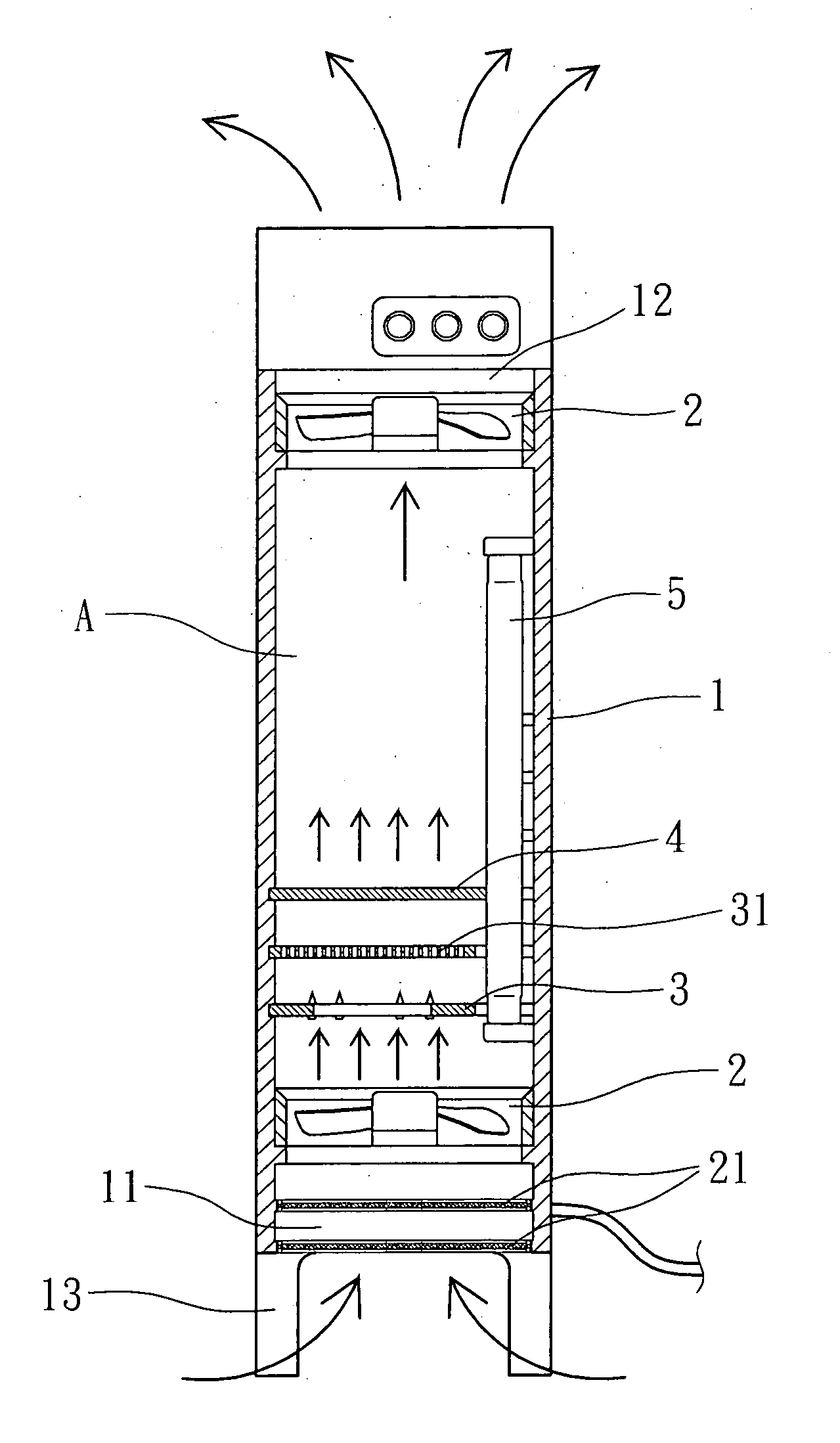

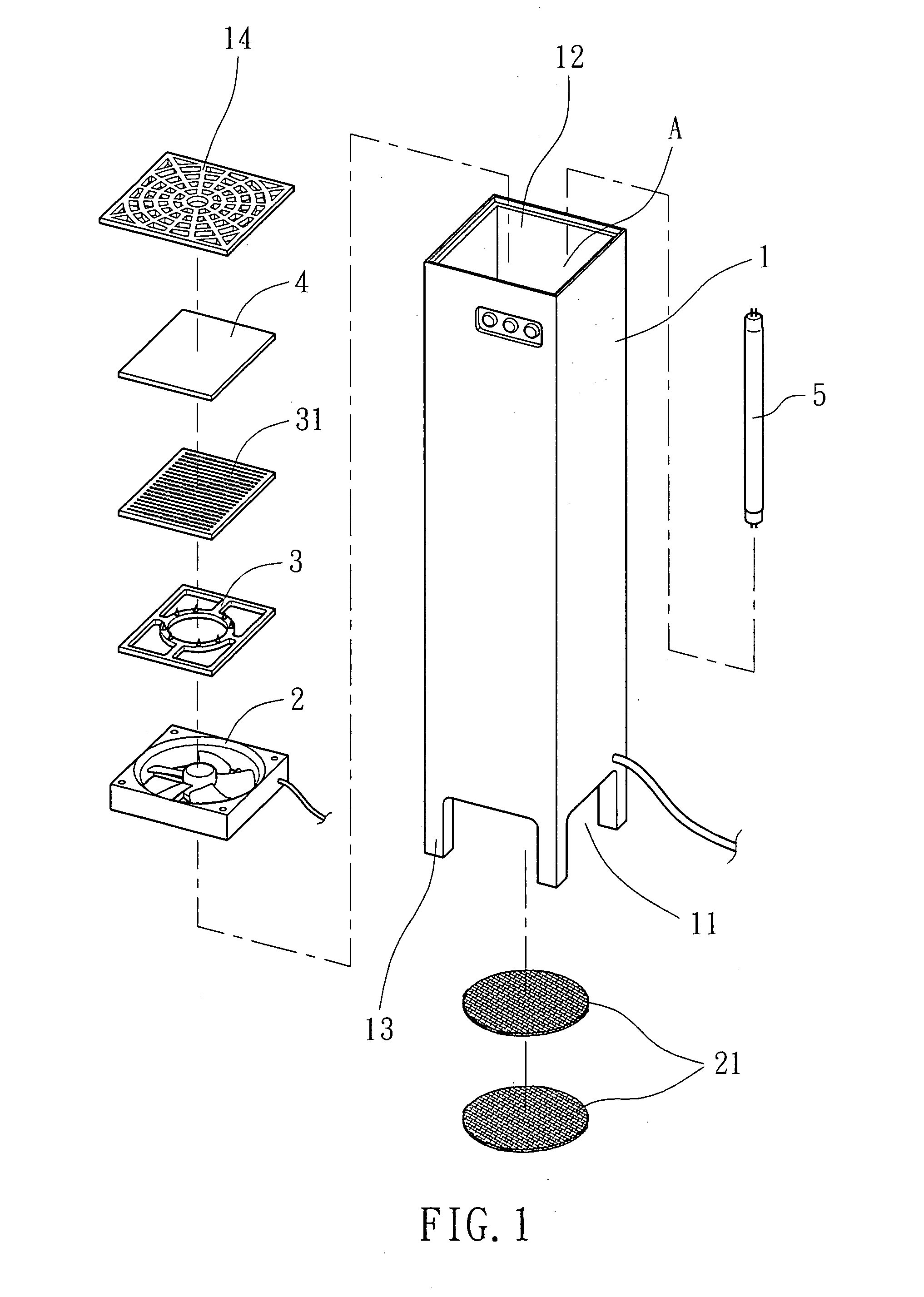

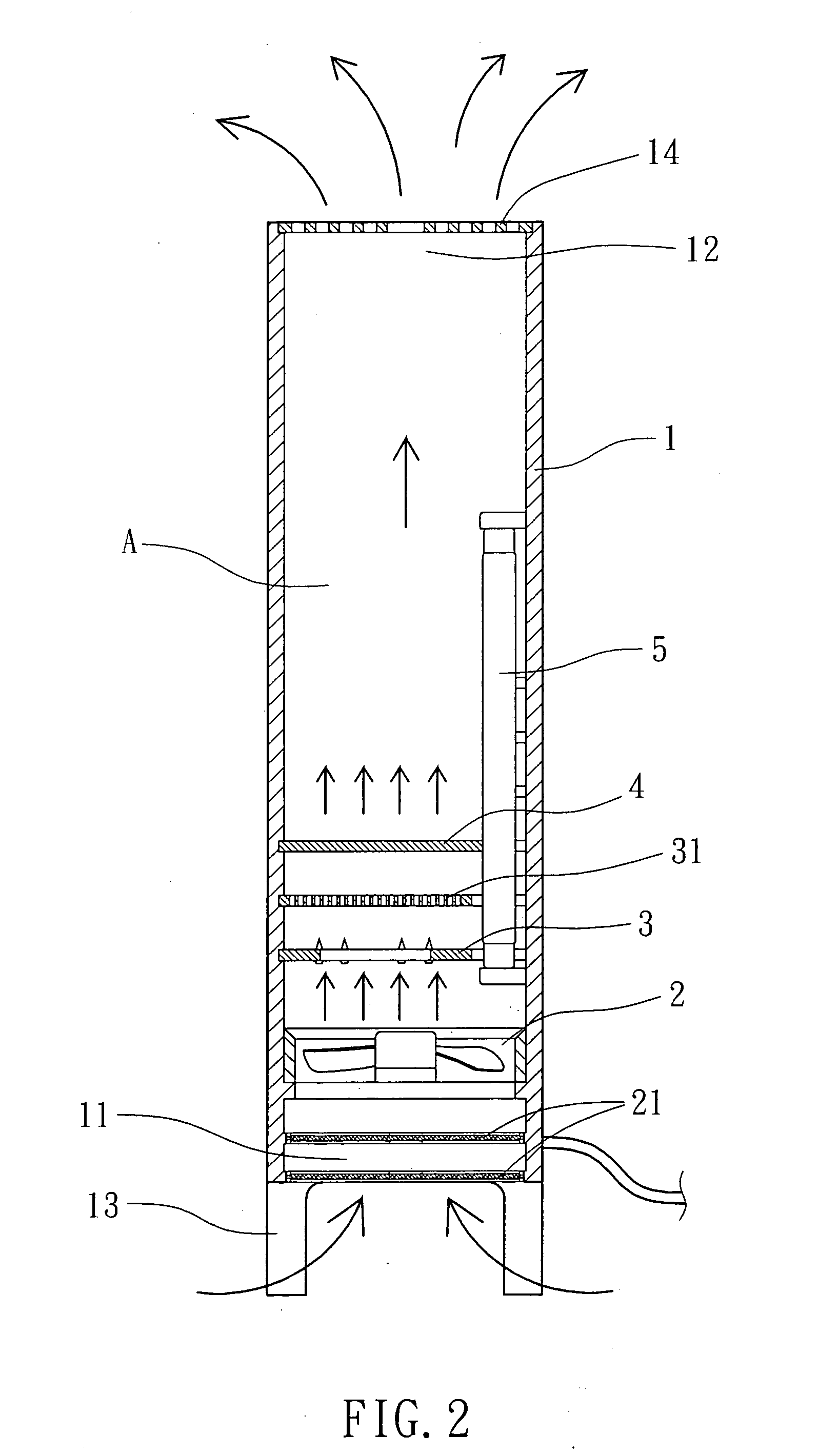

Air purifier

An air purifier includes a vertically disposed housing provided with a wire gauze filter, electric fans and air filter elements. The electric fans draw outside air around the floor vertically into the bottom air intake port toward the top air output port of the housing so that the flow of air, when passed out of the air output port, flows upwards to a certain elevation and is then diffused and lowered in all directions around the housing. By means of the traction of the flow of air, the pressure difference of the convection of air between the low air pressure and the high air pressure at the bottom and top sides of the housing, high concentration of car waste gas, micro dust particles, hair dust, micro fibers and other harmful industrial odors that fall to the floor due to the effect of gravity or floating nearly above the floor are sucked into the inside of the housing by the low air pressure zone at the open bottom side of the housing and then removed by the filter elements.

Owner:WU FU CHI

Hot melt conductor paste composition

InactiveUS6814795B2Freeze fastHigh densitySemiconductor/solid-state device detailsConductive materialScreen printingWire gauze

The present invention provides a hot melt conductor paste composition that includes conductive particles and glass particles dispersed in a thermoplastic polymer system. The hot melt conductor paste composition according to the invention is a solid at room temperature, but melts at a temperature of from about 35.degree. C. to about 90.degree. C. to form a flowable liquid that can be applied to a silicon substrate by screen printing. The hot melt conductor paste composition is particularly suitable for use in the fabrication of photovoltaic cells.

Owner:HERAEUS PRECIOUS METALS NORTH AMERICA CONSHOHOCKEN

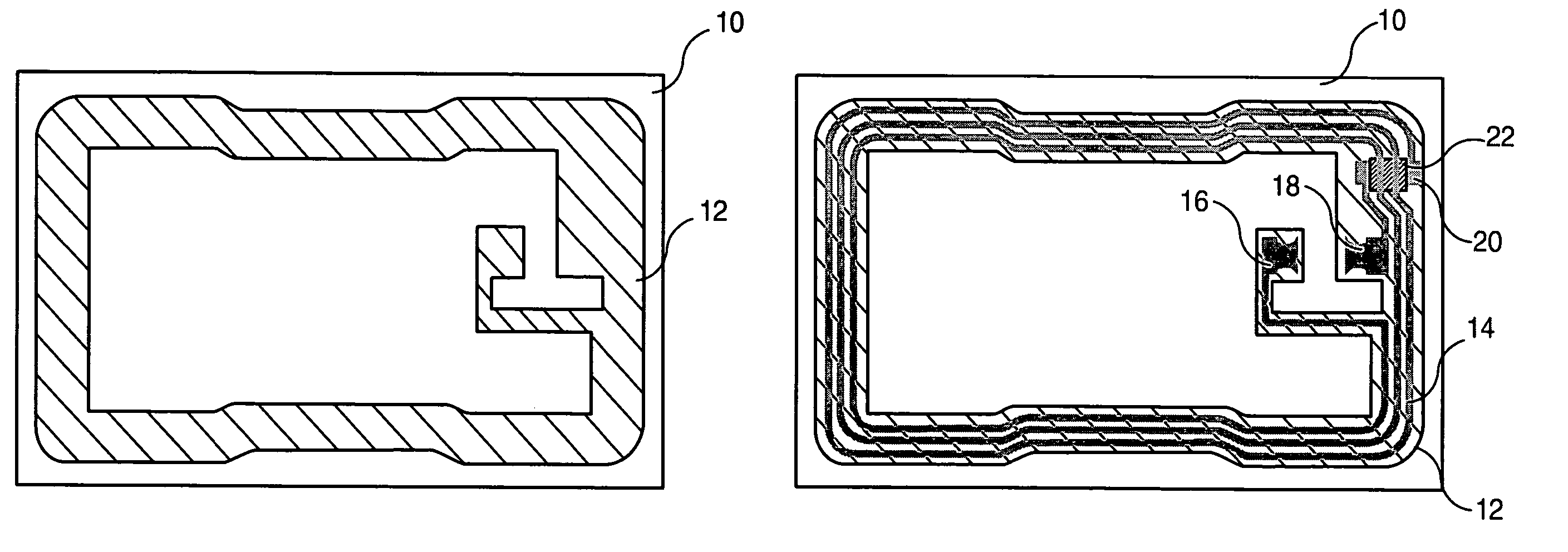

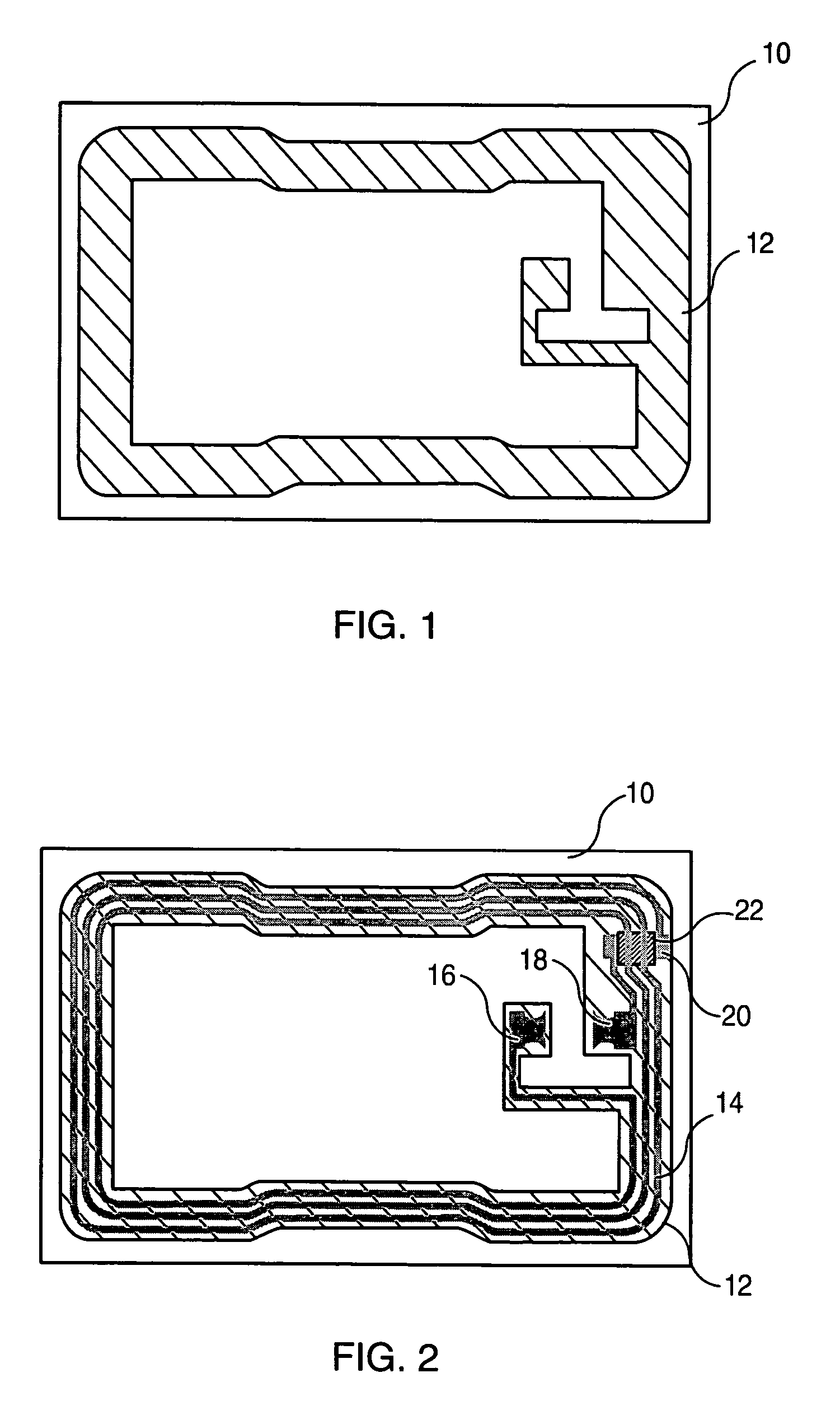

Method for making a smart card antenna on a thermoplastic support and resulting smartcard

Owner:ASK SA (FR)

Method for making high-temperature enamel firing porcelain printing making or oil painting

InactiveCN101376316ARealize standardized mass productionNever change colorDecorative surface effects2D-image generationWire gauzeWeather resistance

A method for producing a high-temperature enamel firing vitrolite oil painting comprises the following steps: inputting a color picture into a computer; processing and electronically scanning the color picture through the computer; outputting a film from a laser typesetter; sun curing a screen stencil; printing and manufacturing a piece of decal paper for ceramic ware; pasting the decal paper for ceramic ware to the porcelain board; and burning at a high temperature. The method is characterized in that photoshop software is applied when the color picture is processed and electronically scanned by the computer. The method for manufacturing the high-temperature enamel firing vitrolite oil painting can realize the standardized batch production of the high-temperature enamel firing vitrolite oil painting. The produced high-temperature enamel firing vitrolite oil painting has the same artistic effect as an ordinary oil painting, can present rich charm and texture of the color, and stable and deep senses of volume and space produced by the covering layer by layer from the shallow layer to the deep layer, and has clear strokes. Furthermore, the high-temperature enamel firing vitrolite oil painting has the characteristics of weathering resistance, ultraviolet ray irradiation resistance, acid and alkali detergent washing resistance, and never fading and changing color.

Owner:斯达高瓷艺发展(深圳)有限公司

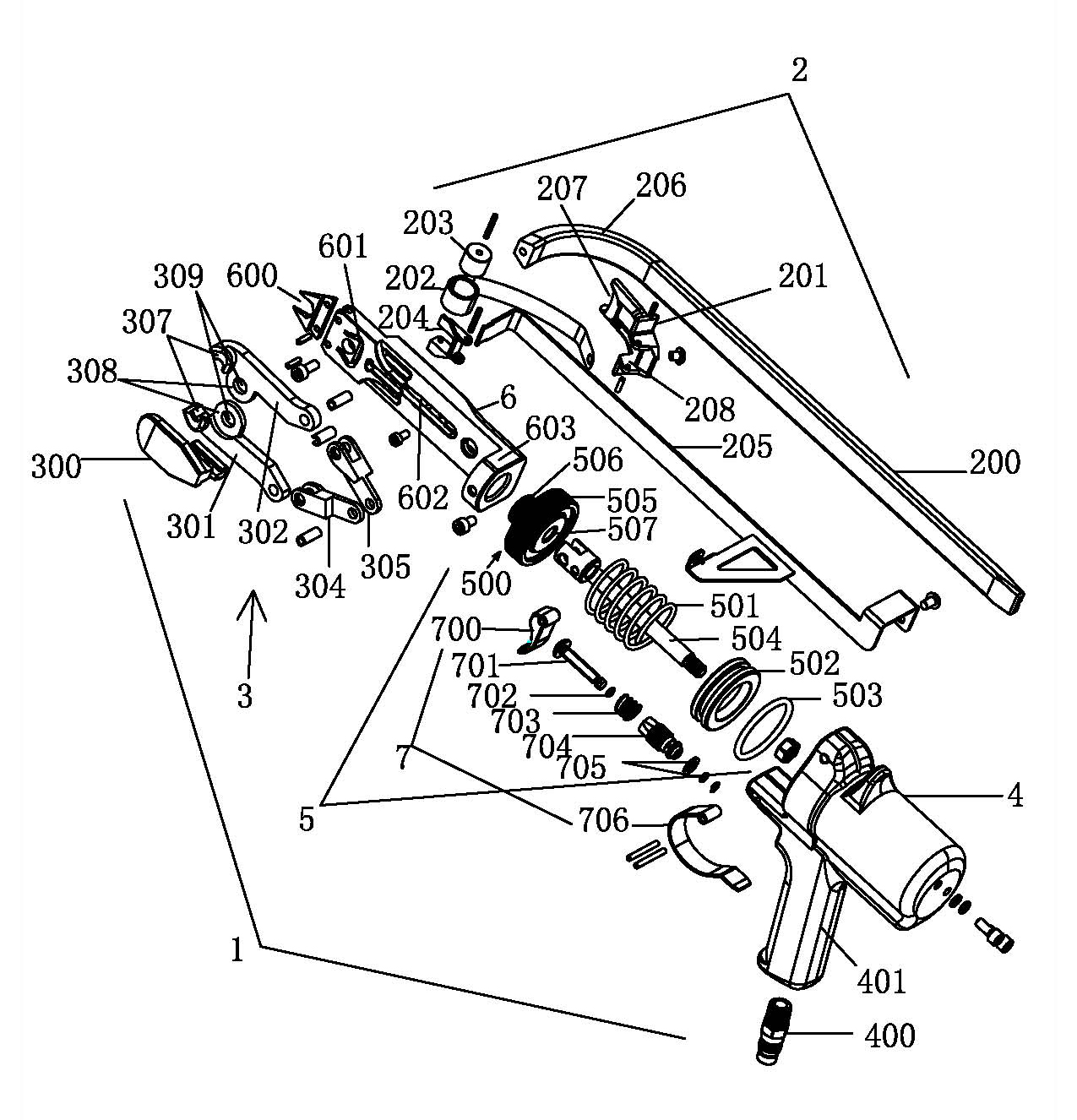

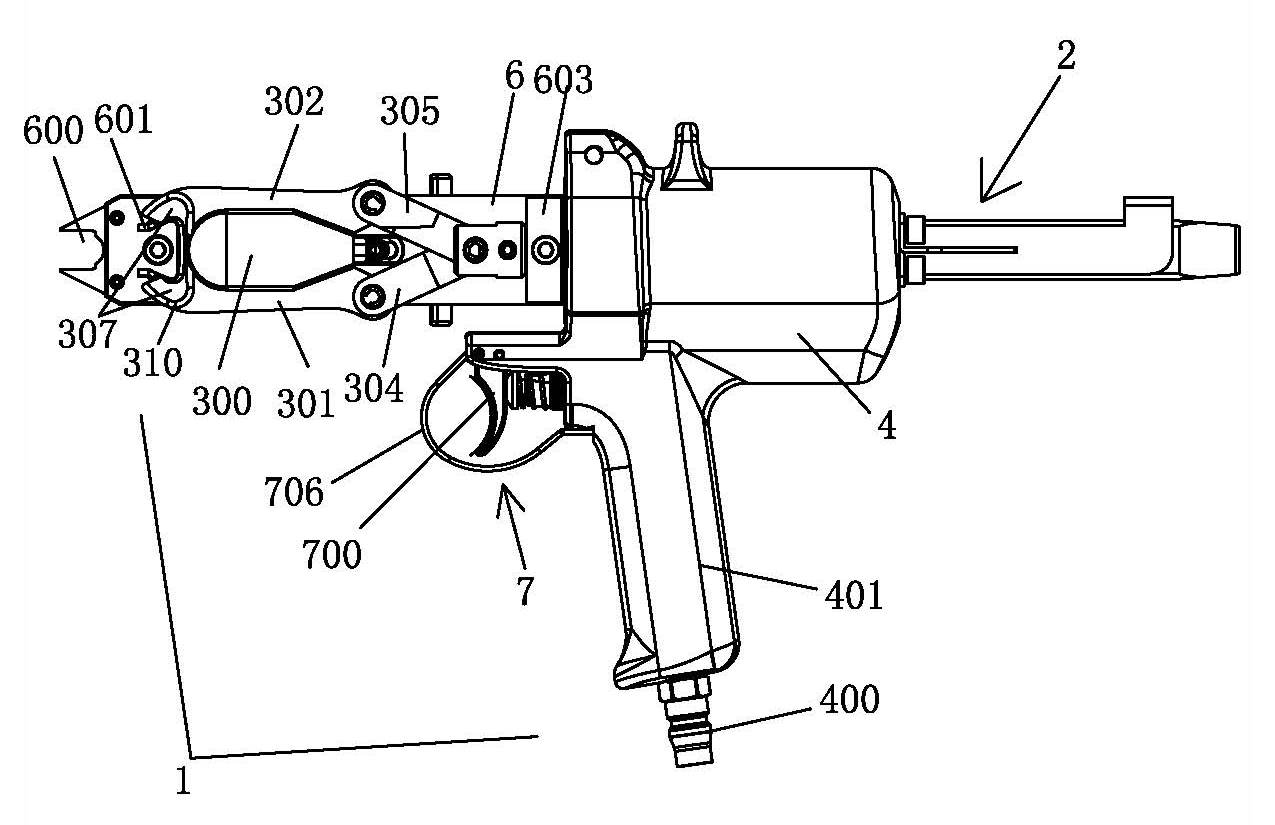

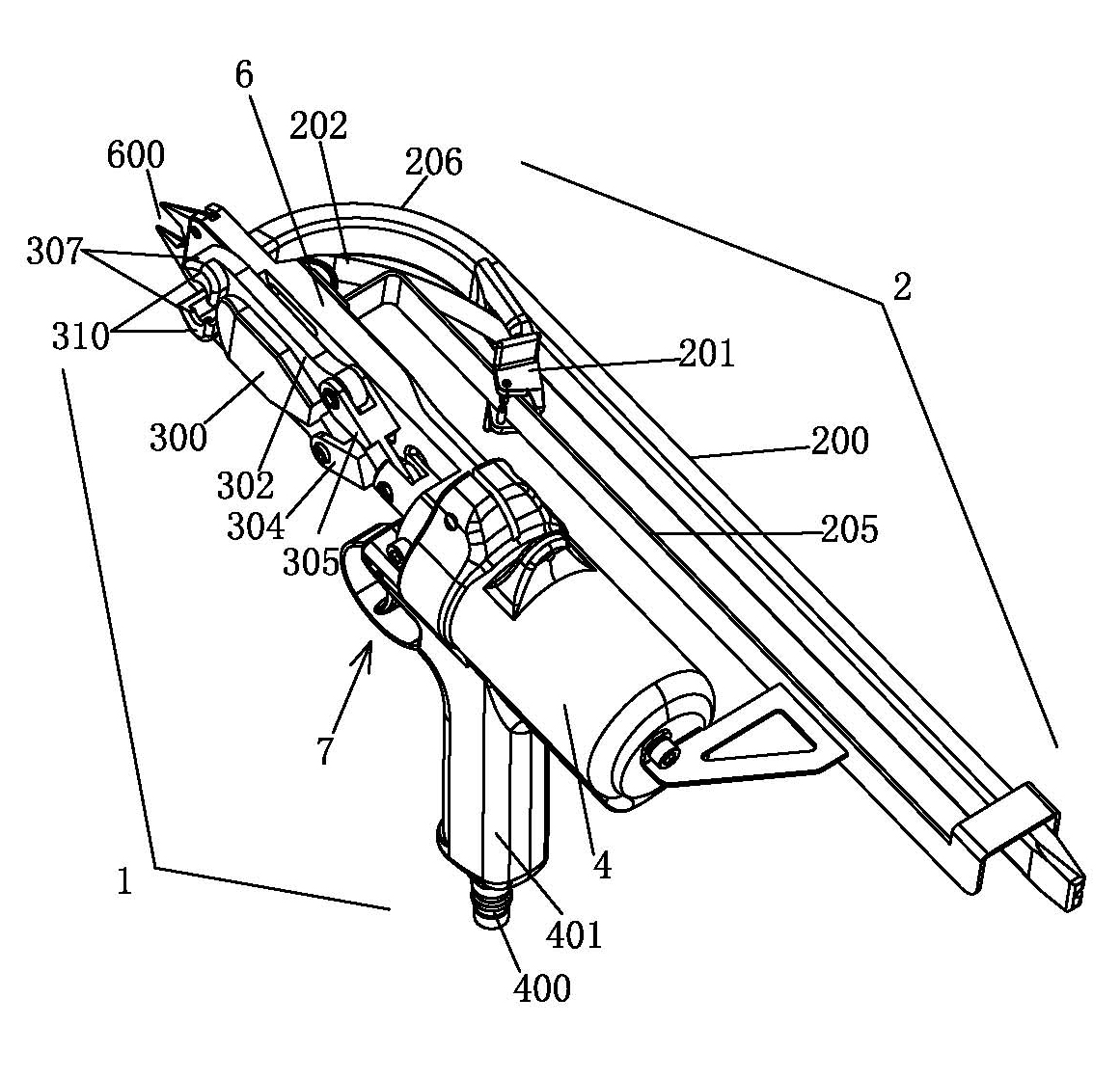

Pneumatic steel wire gauze gun

ActiveCN102350472ASmooth feedingNot easy to get stuckWire networkPortable power-driven toolsWire gauzeMechanical engineering

The invention relates to a pneumatic steel wire gauze gun. The pneumatic steel wire gauze gun provided by the invention comprises a pincers gun and a nail box, wherein the coiled spring of the nail box pulls back a nail feeder by installing the nail box at one side of a gun rack, so that a metal clamping slice nail is automatically delivered into a pincers mouth of the pneumatic steel wire gauze gun; a piston rod of a cylinder simultaneously pushes the rear ends of left and right connecting rods, and forces are transmitted to left and right clamping jaws at the front ends of the left and right connecting rods so as to drive a sliding block to slide forwards along a guide slot of the gun rack; when the front end of the sliding block abuts against the front end of the guide slot, the sliding block stops sliding; the rear ends of the left and right clamping jaws are pushed by the forces to stretch by taking the hinge pin of the sliding block as the fulcrum, so that pincers mouths of the left and right clamping jaws are closed, and the metal clamping slice nails arranged in the pincers mouths are pressed to be rolled. The pneumatic steel wire gauze gun provided by the invention has the advantages of automatic nail delivery, convenience in operation, time and labor conservation and high safety.

Owner:GUANGDONG MINGHUI PNEUMATIC TECH CO LTD

Construction method for preventing crack of infilled wall

ActiveCN102477797APrevent construction methodReasonable designCovering/liningsBuilding material handlingWire gauzeFiberglass mesh

The invention relates to a construction method for preventing crack of an infilled wall. The infilled wall comprises an inner wall and an outer wall. The method is characterized by comprising the following steps of: a, constructing the infilled wall; b, embedding a tie bar; c, suspending a hot dip galvanizing steel wire gauze; d, spraying bonding agent; e, paving fiberglass mesh; f, plastering mortar in a layering way; g, coating and polishing a putty layer; and h, painting paint, wherein the paint adopts emulsion paint which can be different according to design requirements and is painted for three times by a brush. The construction method for preventing crack of the infilled wall has the advantages that: the construction steps are reasonable in design, simple in operation, and safe and reliable in construction quality; and the infilled wall has no delaminating, hollowing, ash blasting or cracking.

Owner:MCC5 GROUP CORP SHANGHAI

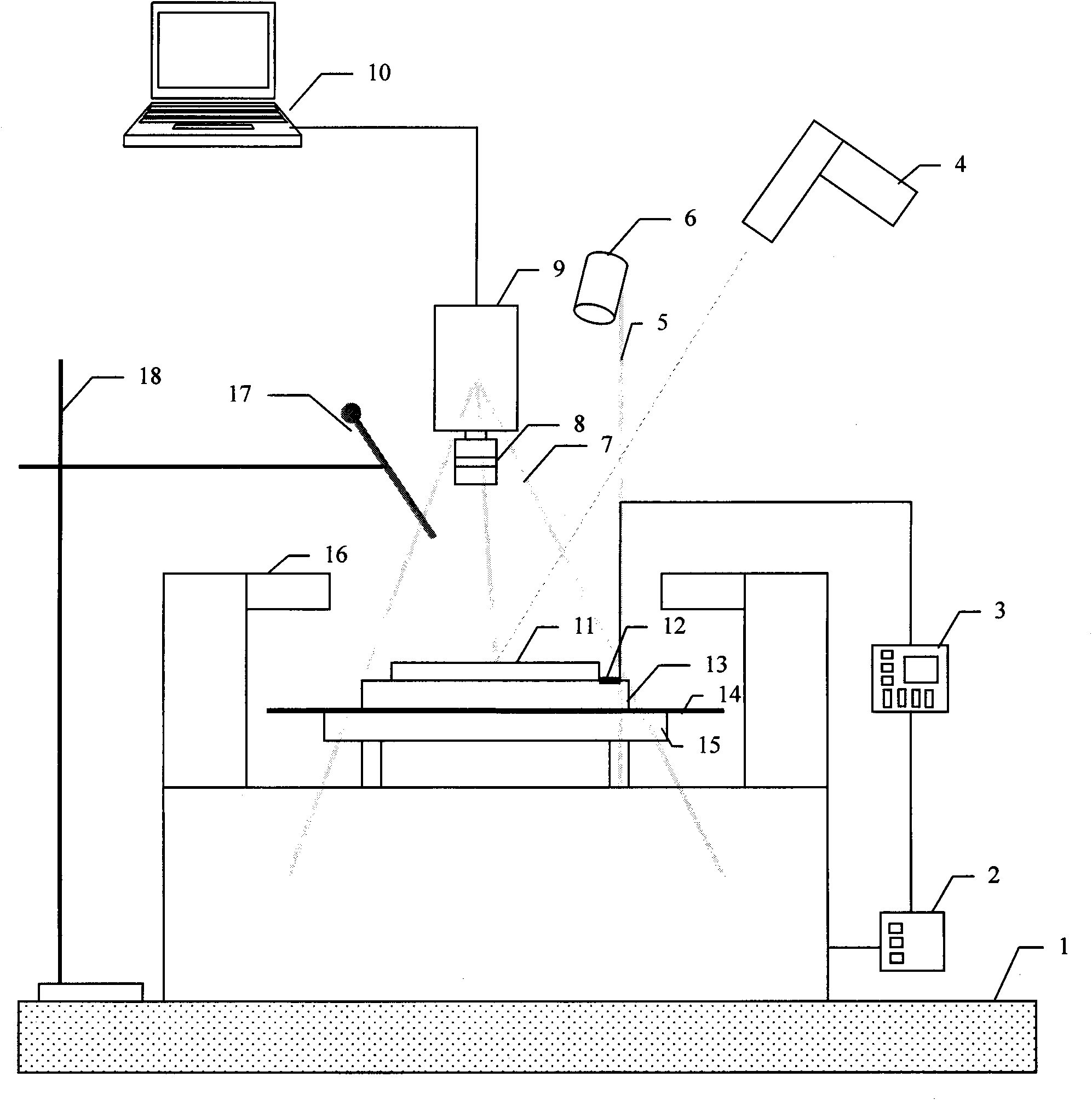

Method and device of measuring material thermal shock property

ActiveCN101666733AAccurate recordStable and reliable measurement environmentStrength propertiesStructural deformationWire gauze

The invention relates to a method and a device of measuring material thermal shock property, which belongs to the technical field of engineering materials, structural deformation and mechanics experiment. The measuring device comprises an air cushion precision optical platform, a temperature controlled switch, a PID temperature controller, an infrared radiation thermometer, an LED lamp bracket, anLED lamp, an A-frame, a lens, a high speed camera, a computer, a test piece, a thermoelectric pair, alumina ceramics, asbestos wire gauze, a heating furnace, a thermal insulation shield, a burette and a stand. The invention combines heating equipment and an optical photographic apparatus, masterly utilizes a digital image cross-correlation method and provides the method and the device of measuring material thermal shock property. The invention has novel train of thought, compact structure and complete system, and can realize quantitative analysis and measurement on the material thermal shockproperty.

Owner:TSINGHUA UNIV

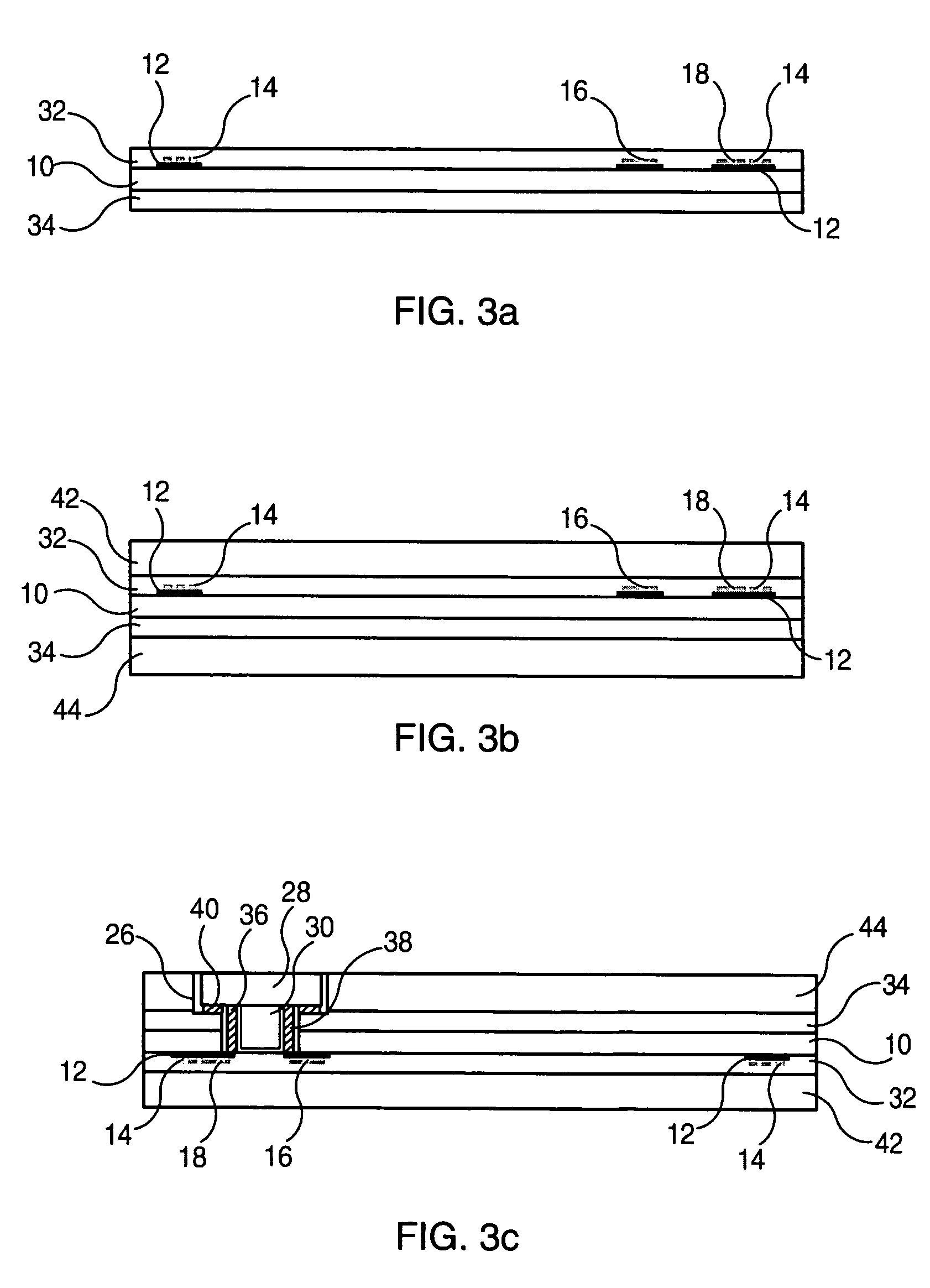

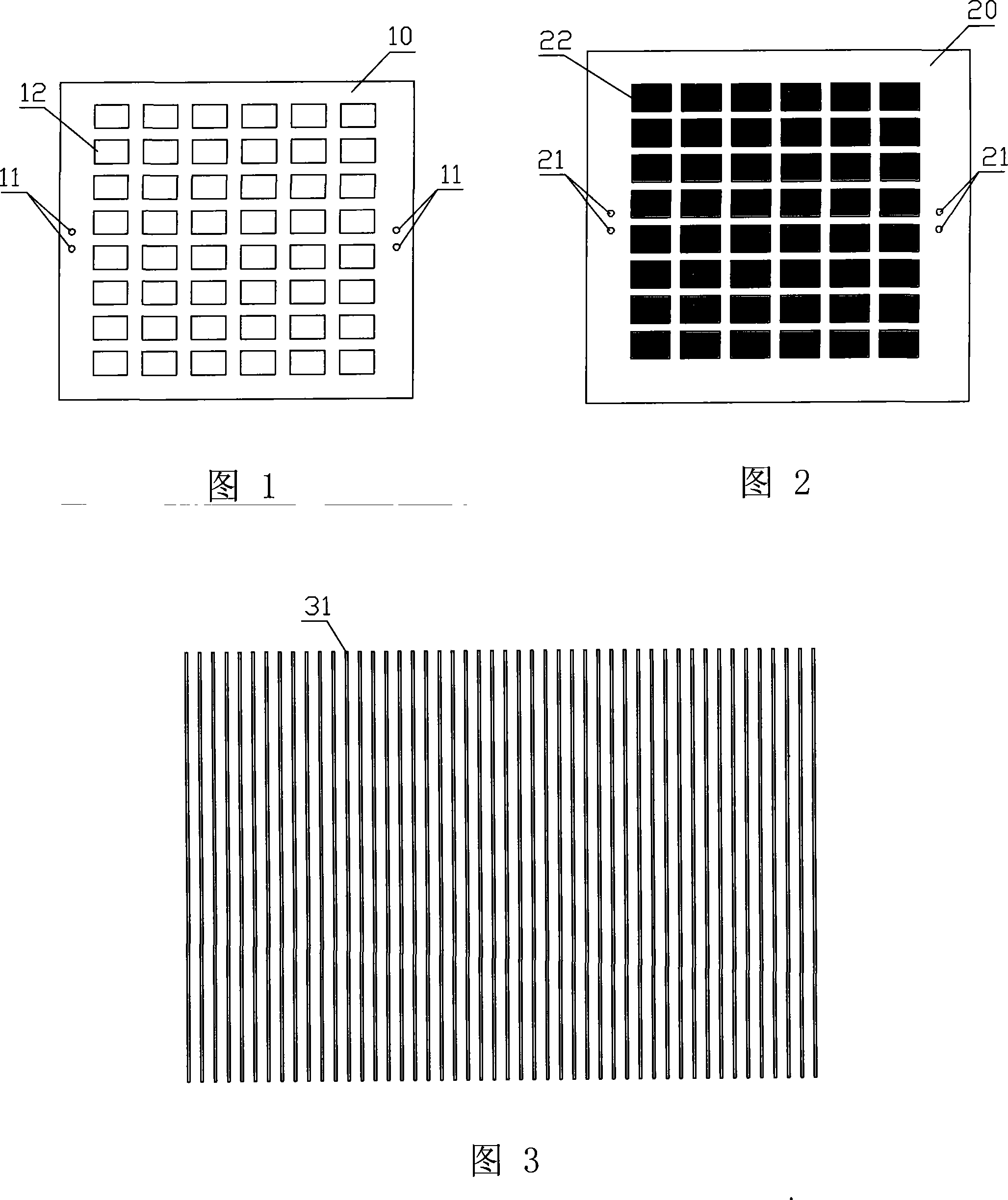

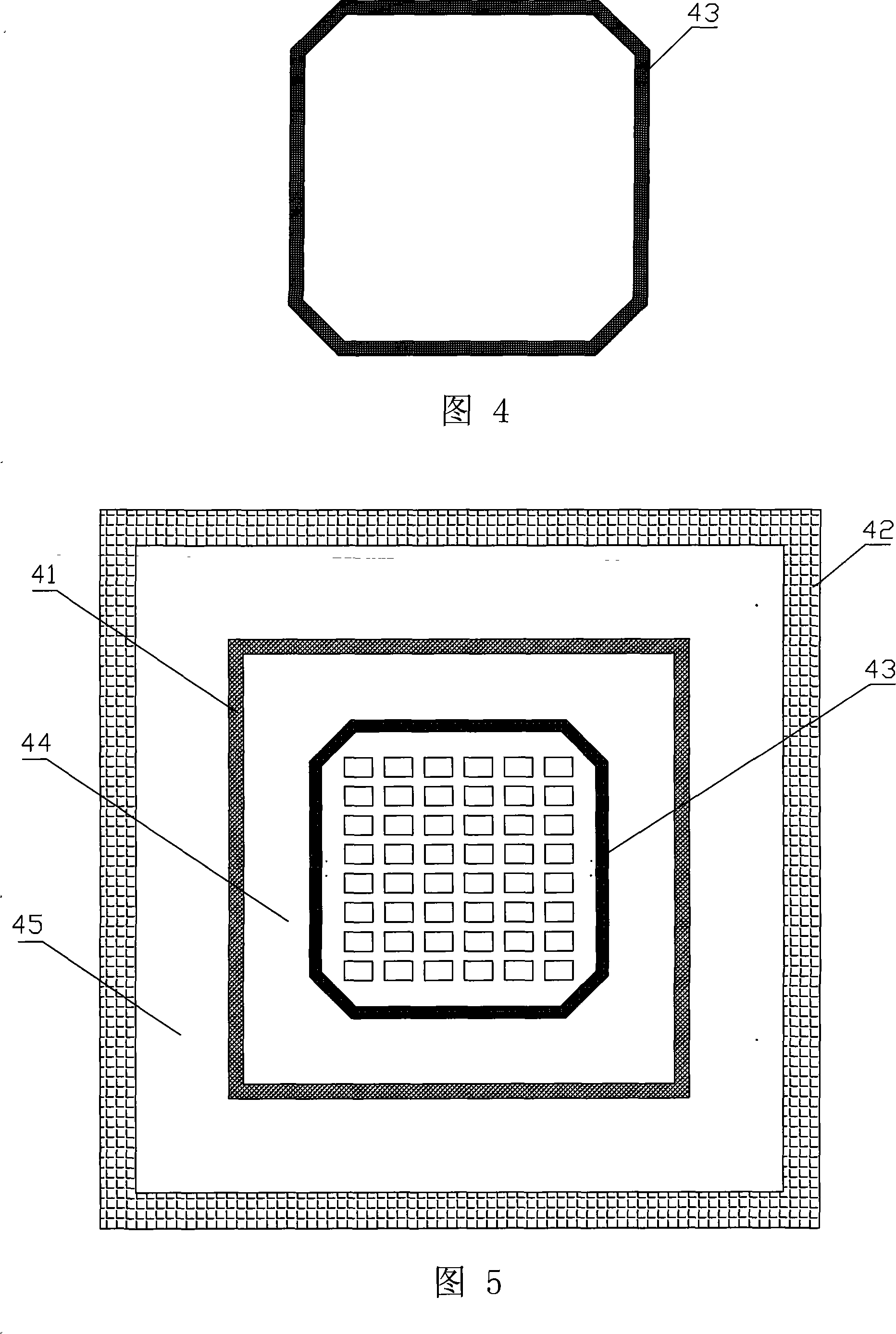

Method for preparing organic electroluminescent display mask plate

InactiveCN101250685AGuaranteed tensionReduce tensionVacuum evaporation coatingSputtering coatingWire gauzeSheet steel

The invention discloses a method for producing mask plates of organic electroluminescent displays, which comprises following steps: taking a sheet of magnetic conductive thin sheet steel, utilizing stainless steel etching or laser cutting to open holes on the thin sheet steel to form patterns, flatly spreading a silk screen on the thin sheet steel with the patterns, coating mucilage which is used to stretch the silk screen on the edge of the thin sheet steel, then, removing the silk screen on the region of thin sheet steel patterns, then, stretching the silk screen, taking a frame body, clinging the frame body on the stretched silk screen to form a net frame, tailoring along the outer margin of the net frame after bonding stably, cutting another magnetic conductive sheet steel into an outer frame of the mask plate which is needed, then, connecting the outer frame of the mask plate and the magnetic conductive thin sheet steel in the net frame, then, cutting off the silk screen, shedding the net frame, lastly, cutting off excess sheet steel along the outer margin of the outer frame of the mask plate, and finishing producing the mask plate. The method of the invention utilizes the silk screen to stretch the thin sheet steel, which lowers the production cost and simplifies the technological process, the net frame is more stably connected with the outer frame, the operation is comparatively simpler, and the precision is greatly increased.

Owner:TRULY SEMICON

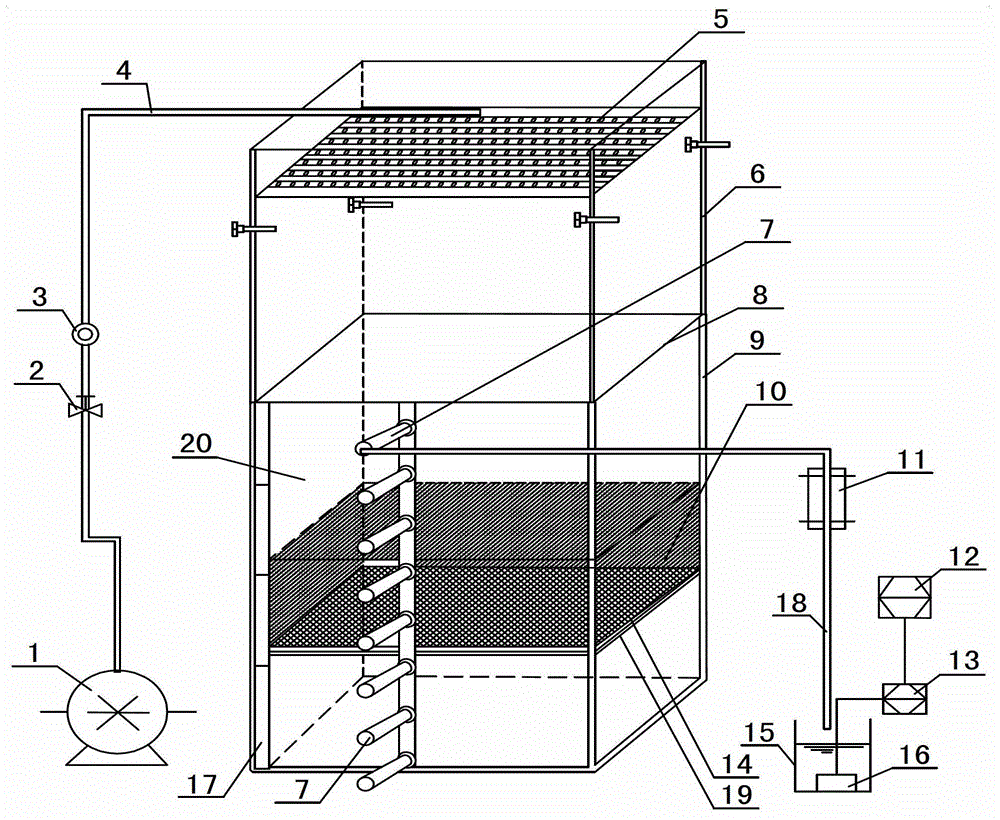

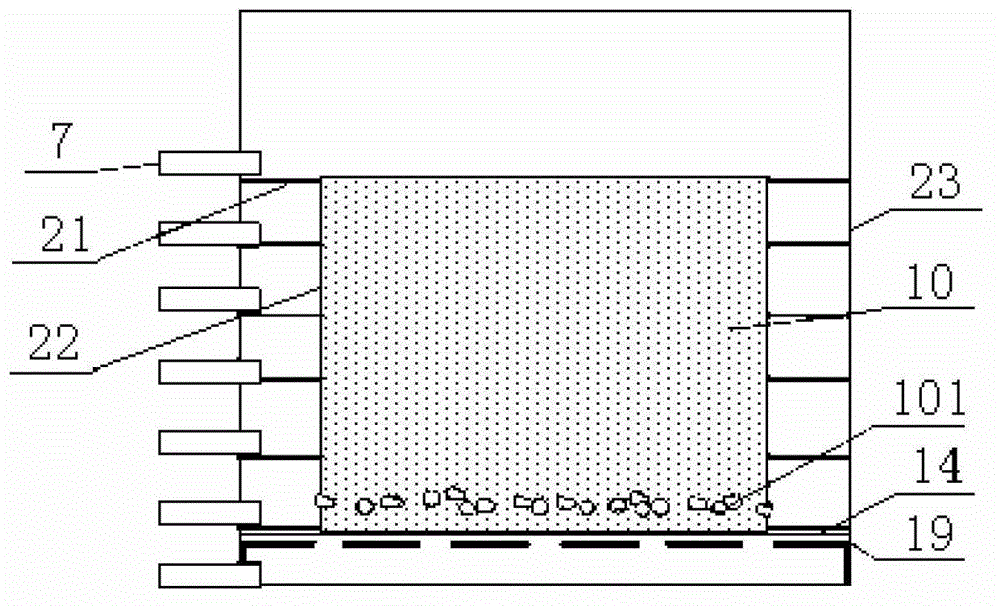

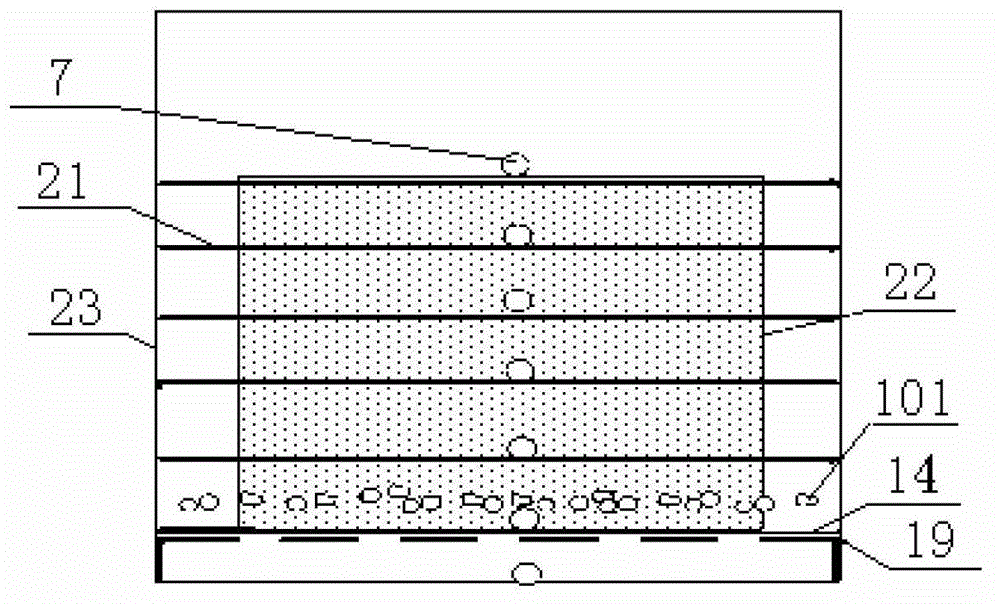

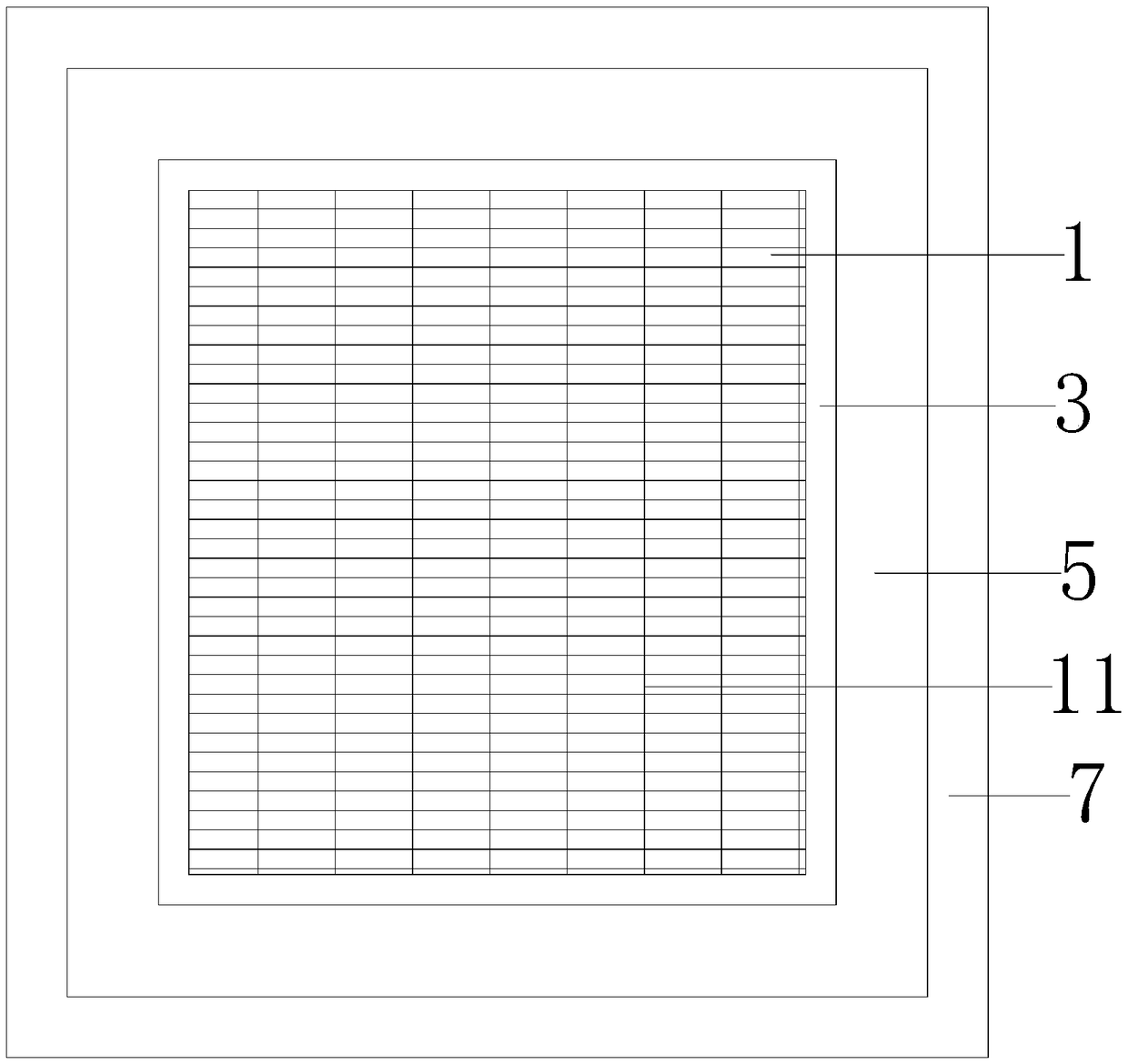

Artificial rainfall runoff and soil water motion simulation experimental system

InactiveCN102721800AAccurate collectionQuick collectionEarth material testingWire gauzeRainfall runoff

An artificial rainfall runoff and soil water motion simulation experimental system comprises a rainer, a runoff and soil water forming device, a water drainage device and a runoff volume measuring device. The rainer comprises a water supply device and a raindrop forming device; the water supply device adjusts water outlet strength by an adjusting valve and a flow meter; the raindrop forming device is a group of pipes with holes; the runoff and soil water forming device is a vertical container with a soil layer; the group of pipes with holes is arranged on the top of the vertical container and can be adjusted in a lifting manner; and the container comprises an inner wall on the inner layer and an outer wall on the outer layer, the inner wall consists of a water permeable steel wire gauze, the outer wall is made of a transparent material, the inner wall and the outer wall are connected with each other by a water impermeable layering steel plate, the water drainage device is arranged below the soil layer, a water leading pipe which is connected with the runoff volume measuring device is arranged outside the container, and the runoff volume measuring device performs data processing and operation by a computer. The artificial rainfall runoff and soil water motion simulation experimental system is convenient to carry, high in experimental efficiency, accurate and fast in operation and high in adaptability.

Owner:BEIJING NORMAL UNIVERSITY

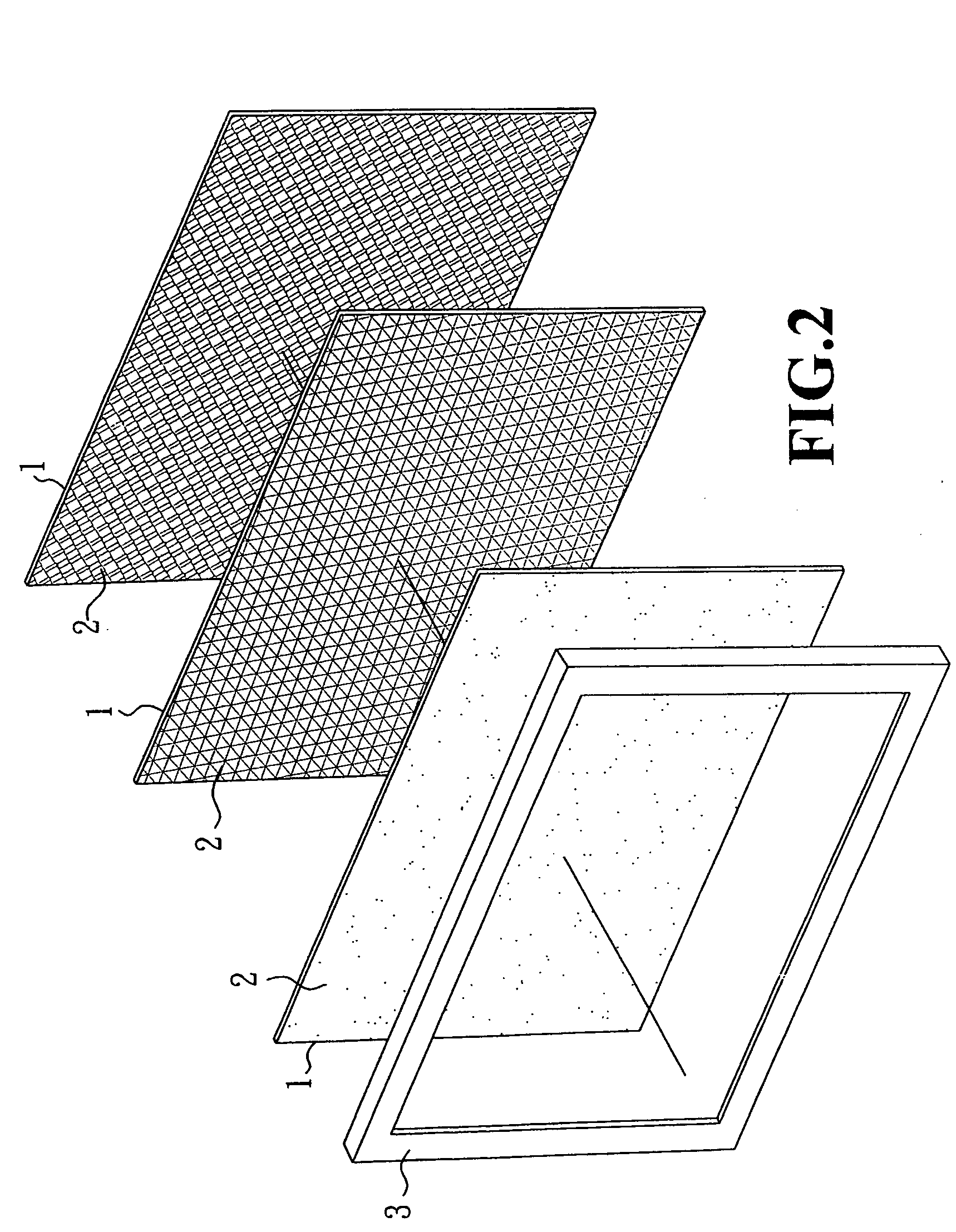

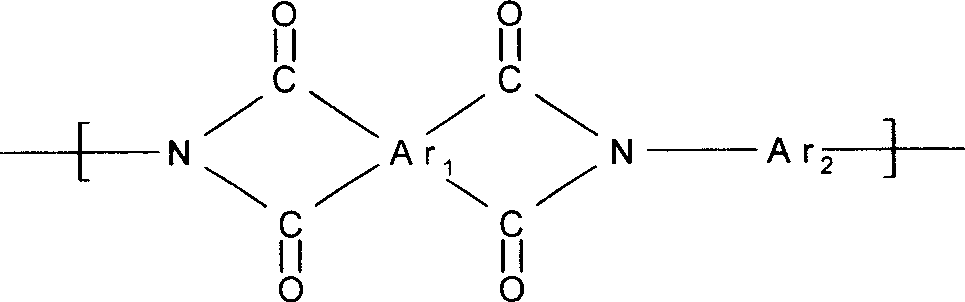

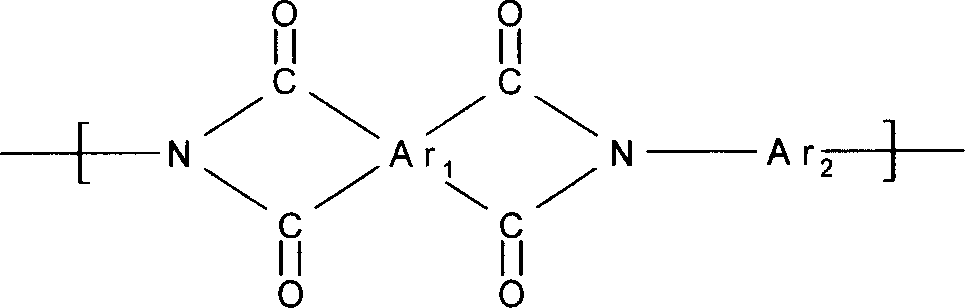

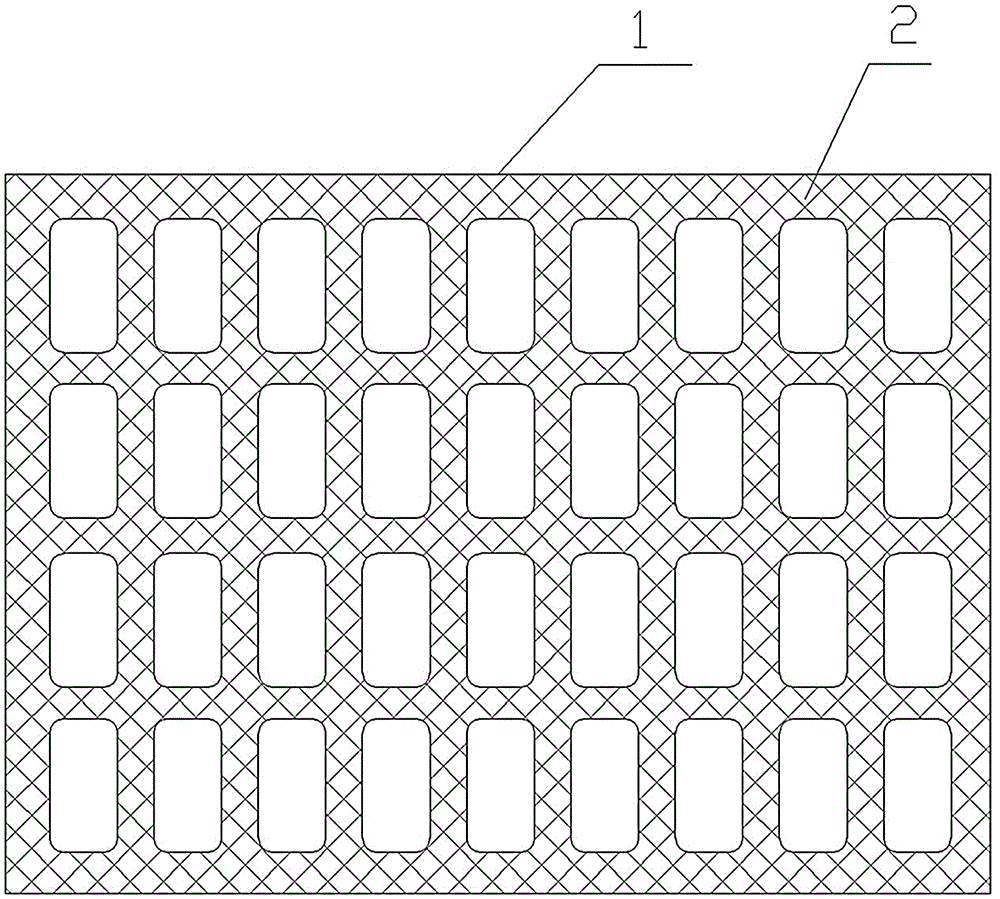

Polyimide solar net plate and manufacturing method

PendingCN108749276ADowngradeReduce manufacturing costScreen printersSynthetic resin layered productsWire gauzeScreen printing

The invention relates to a solar net plate, in particular to a polyimide solar net plate. The polyimide solar net plate comprises a net frame and a polyester wire net. The polyester wire net is tied to the bottom of the net frame. A silk screen printing hole is formed in the center of the polyester wire net, and the polyester wire net is in a concentric square shape. A stainless steel wire net anda polyimide film are further included. The polyimide film is fixed to the bottom face of the stainless steel wire net. A high-temperature glue layer is arranged between the polyimide film and the stainless steel wire net. The polyimide film is provided with a plurality of wire grooves, and a printing pattern is composed of the wire grooves. The top face of the stainless steel wire net is fixed tothe polyester wire net. The stainless steel wire net is larger than the silk screen printing hole and covers the silk screen printing hole, and a hot melt glue layer is arranged between the stainlesssteel wire net and the polyester wire net. The net plate manufacturing technology is simple, the manufacturing cost is low, the yield is high, the service life of the net plate is long, and frictionresistance and cross section sharpness are obviously improved; and the service life reaches 100,000 times or more, and the purchasing cost of printing net plates is reduced for battery piece manufacturers.

Owner:昆山良品丝印器材有限公司

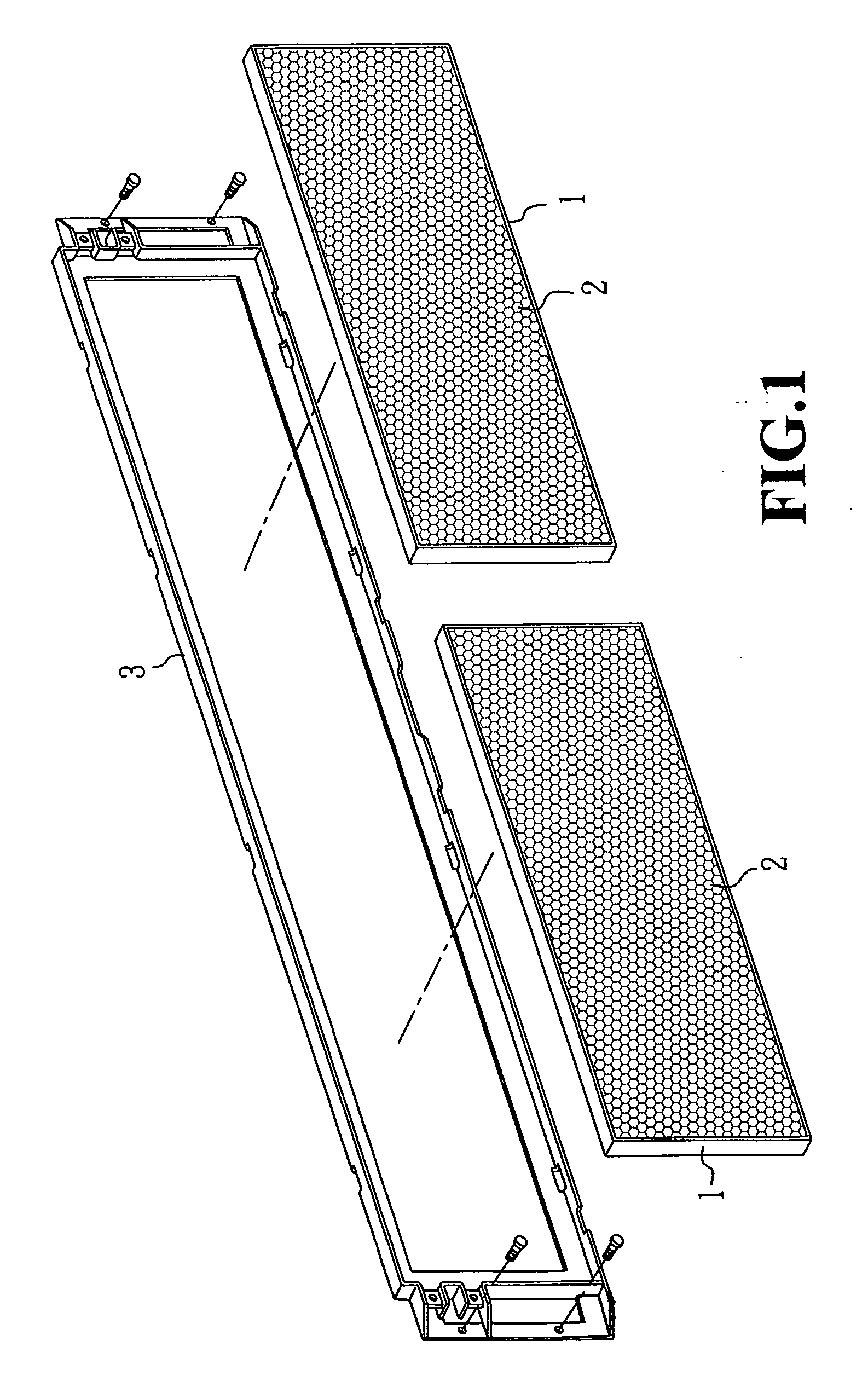

Wire gauze filter assembly

InactiveUS20060168924A1Efficient removalCombination devicesDispersed particle filtrationWire gauzeHoneycomb

A wire gauze filter assembly is disclosed to include an open frame, a plurality of wire gauze filter elements made of paper, nonwoven fabric, fire netting material, or plastics in the form of a meshed, honeycomb, or wave-like structure and mounted inside the open frame, and a filter compound selected from chitosan, photocatalyst, active carbon, nanometered gold, nanometered silver, bee propolis, nanometered TiO2Ag, nanometered TiO2Au, nanometered TiO2Pt, static filter compound, and / or their combination and coated on the wire gauze filter elements.

Owner:SUN SHIN CHING

Carrier-attached copper foil and printed board using the copper foil

InactiveUS6960391B2Avoid pollutionEasy to handleDecorative surface effectsPrinted resistor incorporationWire gauzeScreen printing

The present invention relates to a carrier-added copper foil and a print substrate using such copper foil characterized in comprising a resin layer and a functional material layer at least on a part of the copper foil. A carrier-added copper foil and a print substrate using such copper foil are obtained by forming an insulating layer and functional material layer having an area smaller than the area of the copper foil on the surface of the carrier-added copper foil with the screen printing method, thereby improving the handling of such copper foil, preventing the adhesion of contaminants such as resin powder on the copper foil surface during the cutting procedure, preventing scratches and dimples caused by foreign matter, and effectively preventing the generation of scratches, wrinkles and creases during the cutting, packaging and transportation procedures.

Owner:JX NIPPON MINING& METALS CORP

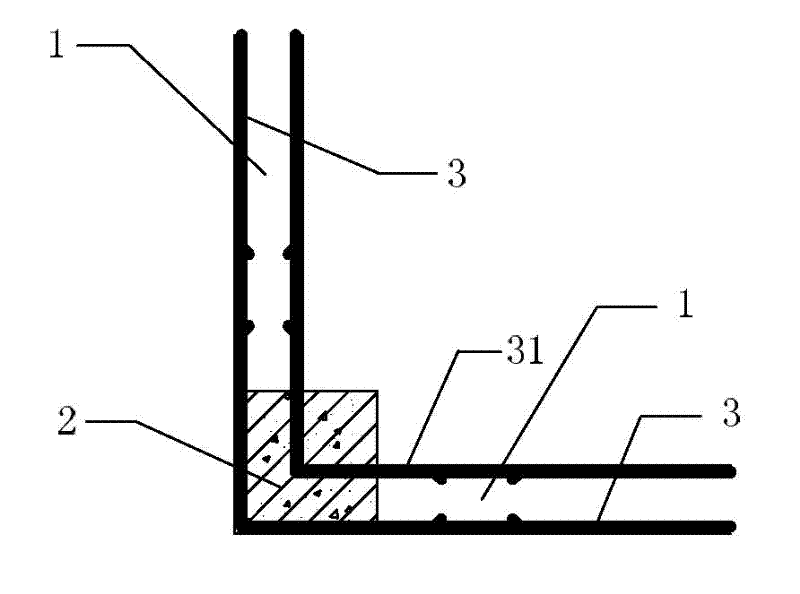

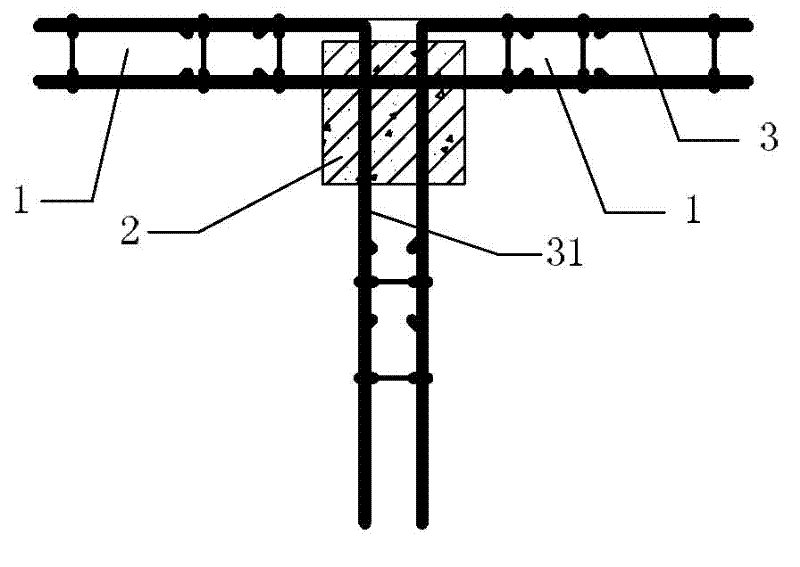

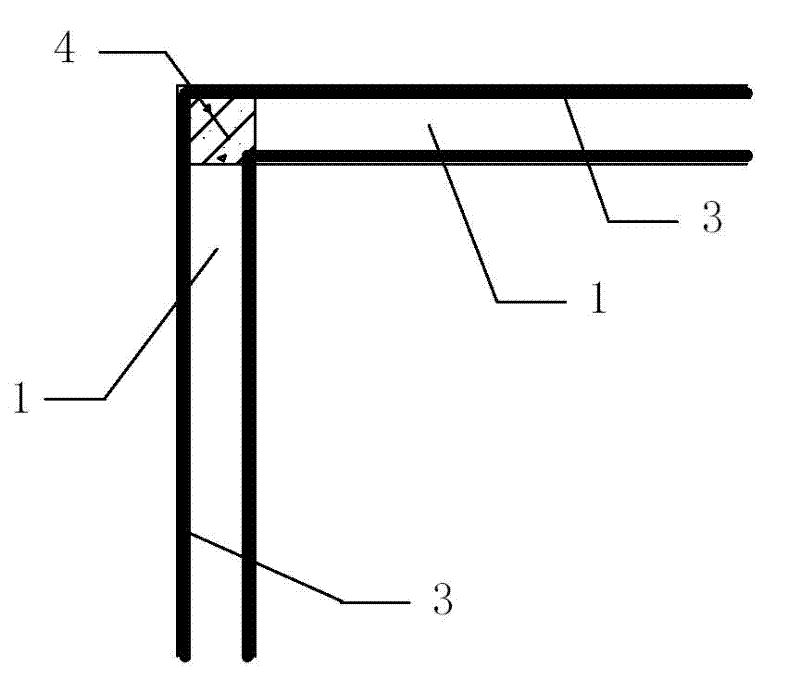

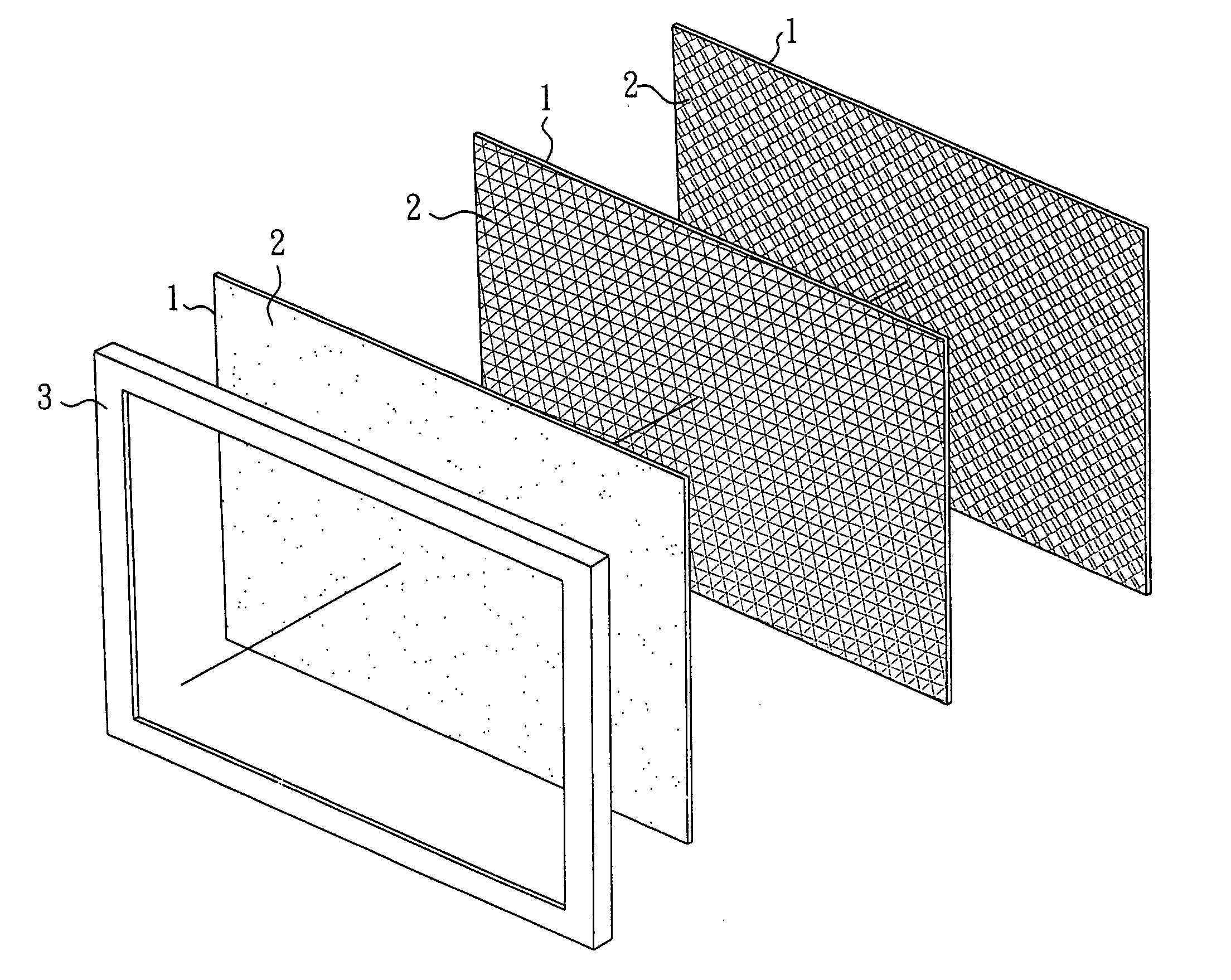

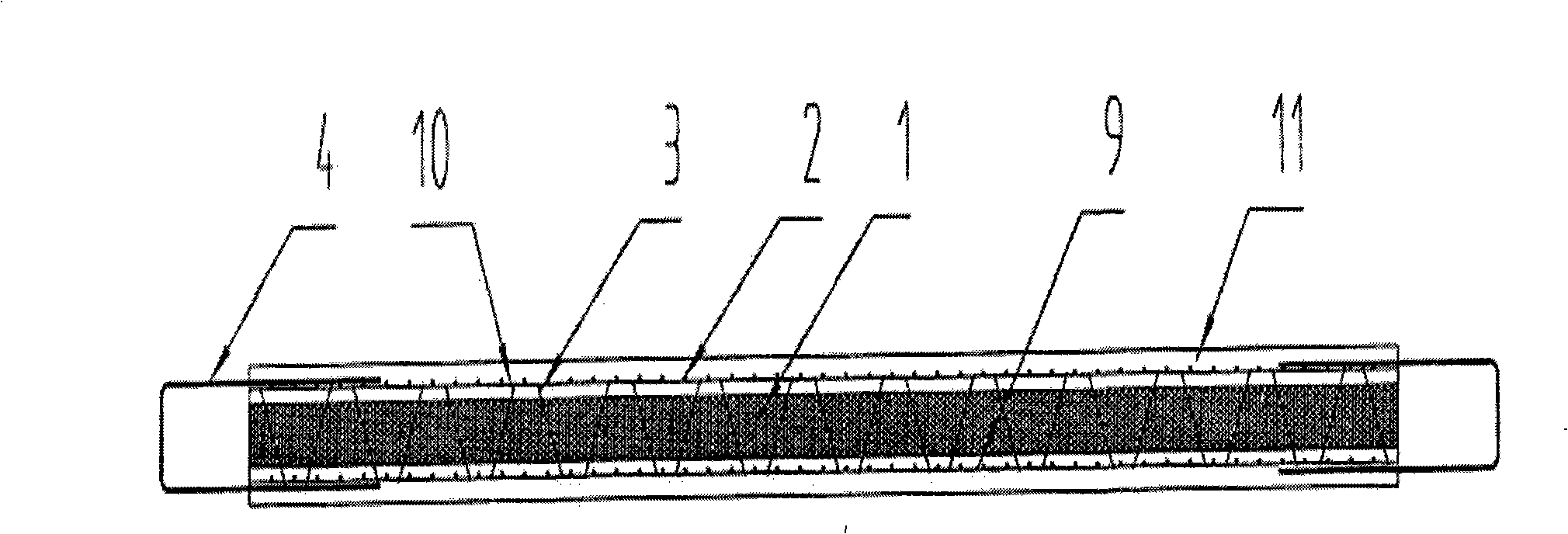

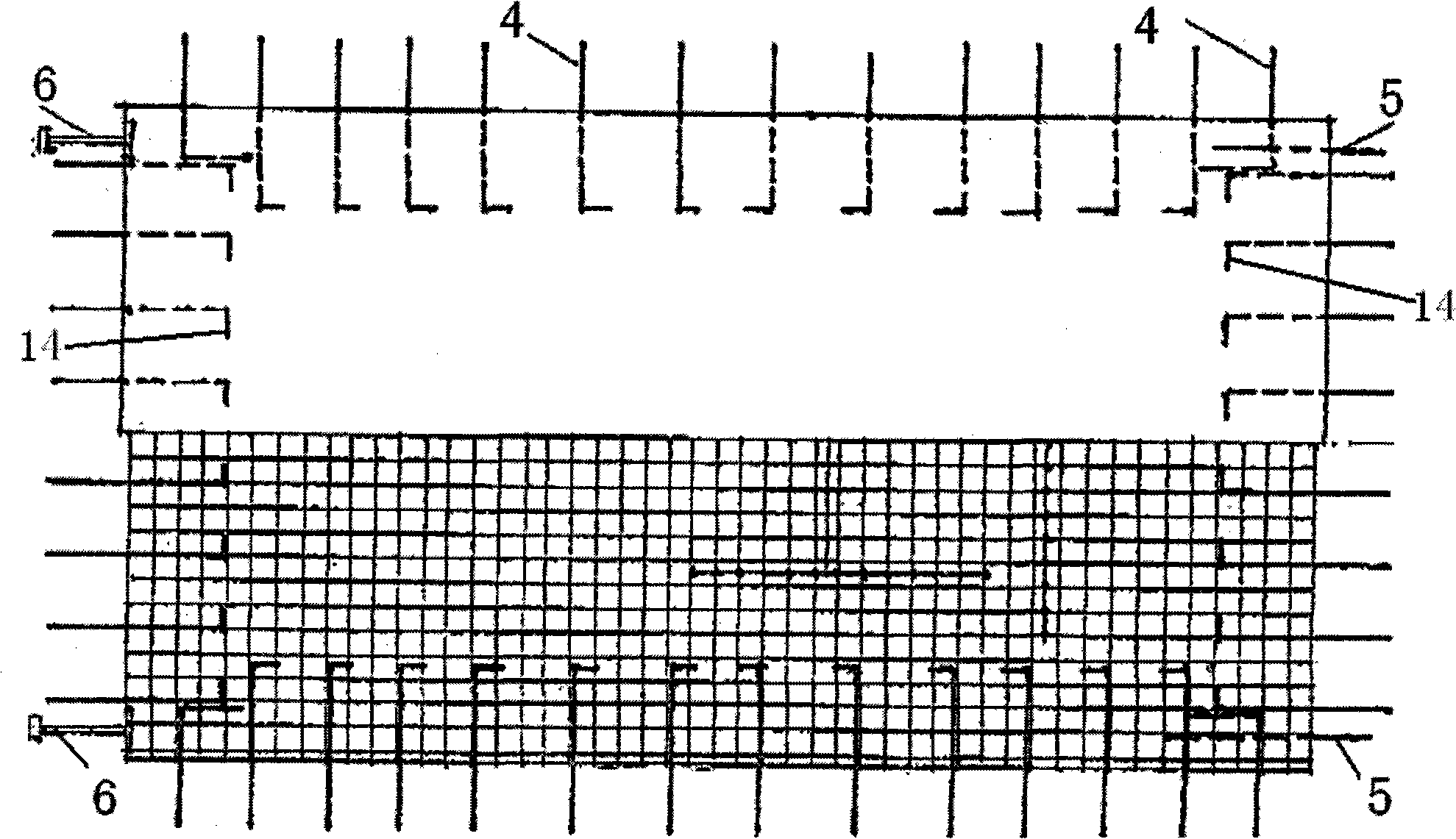

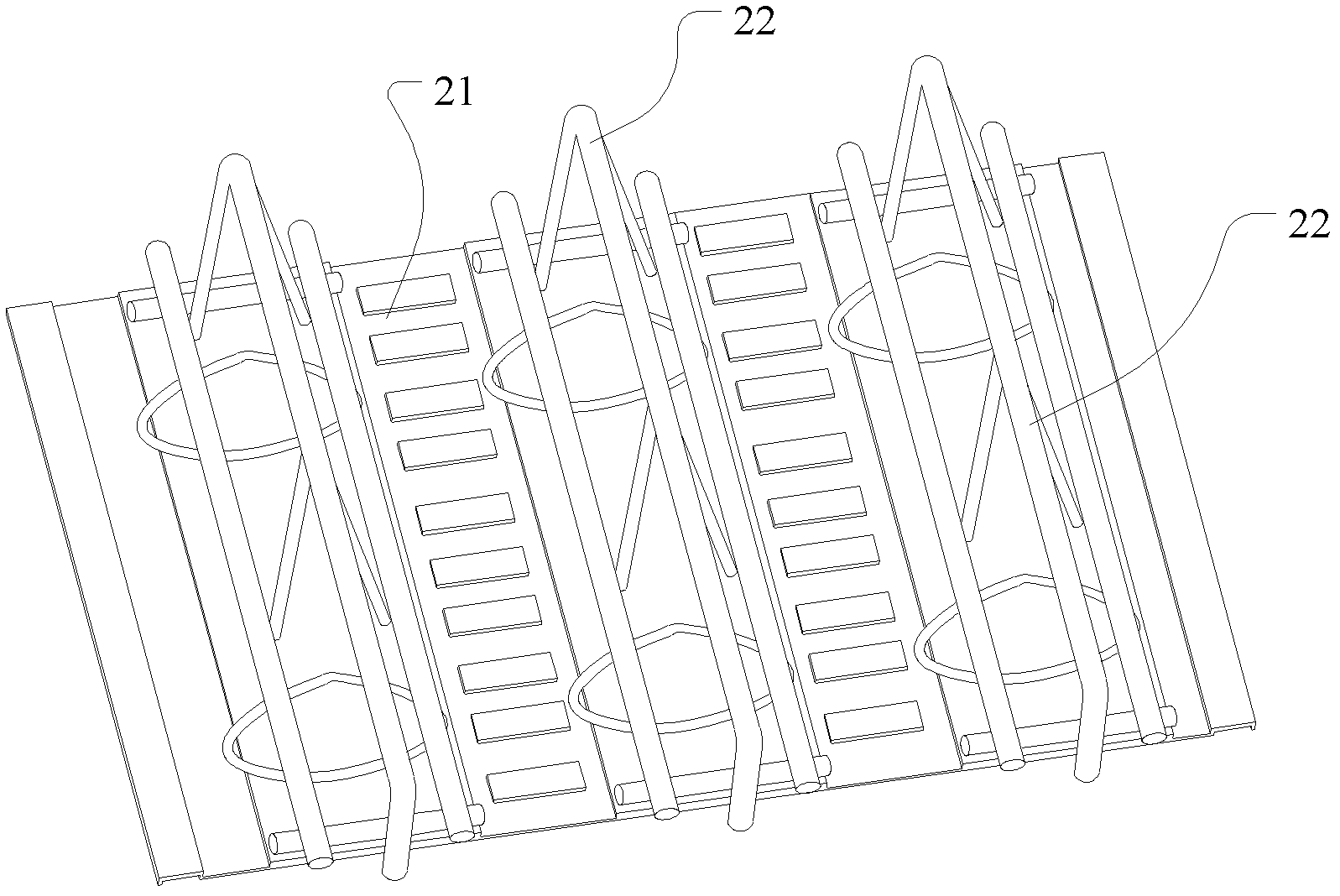

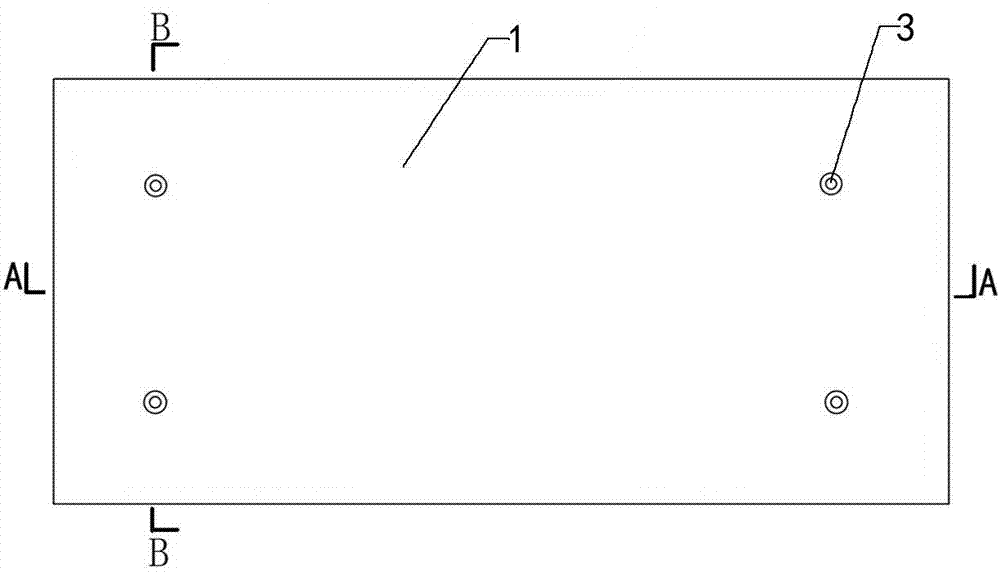

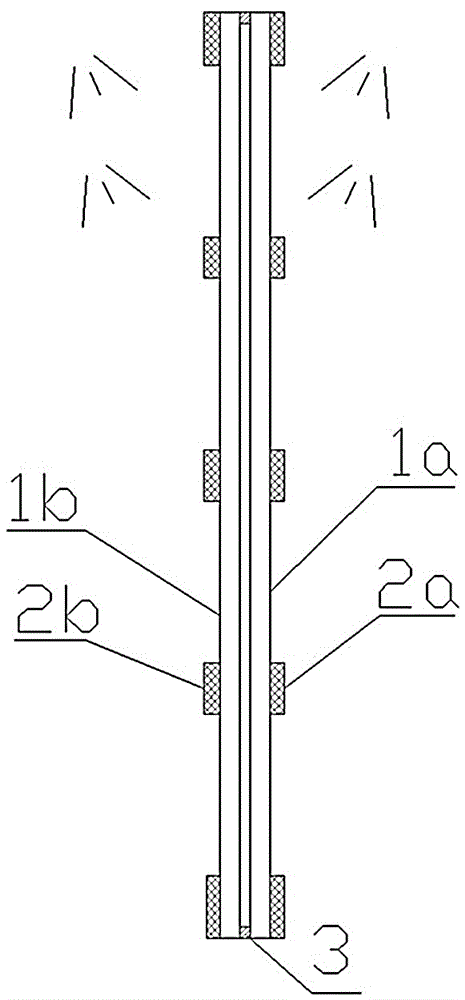

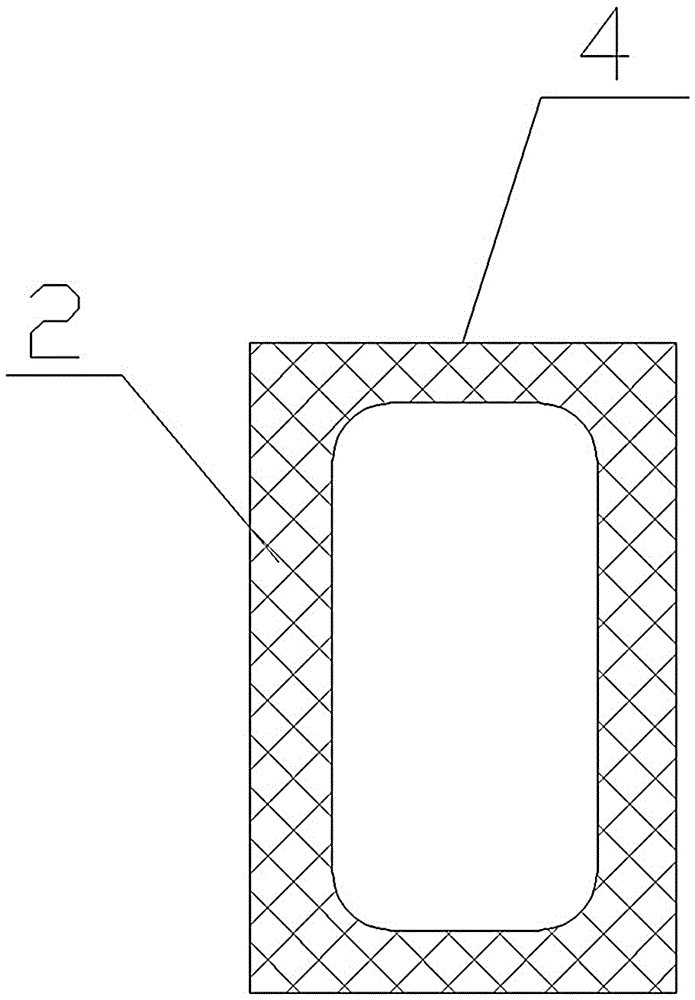

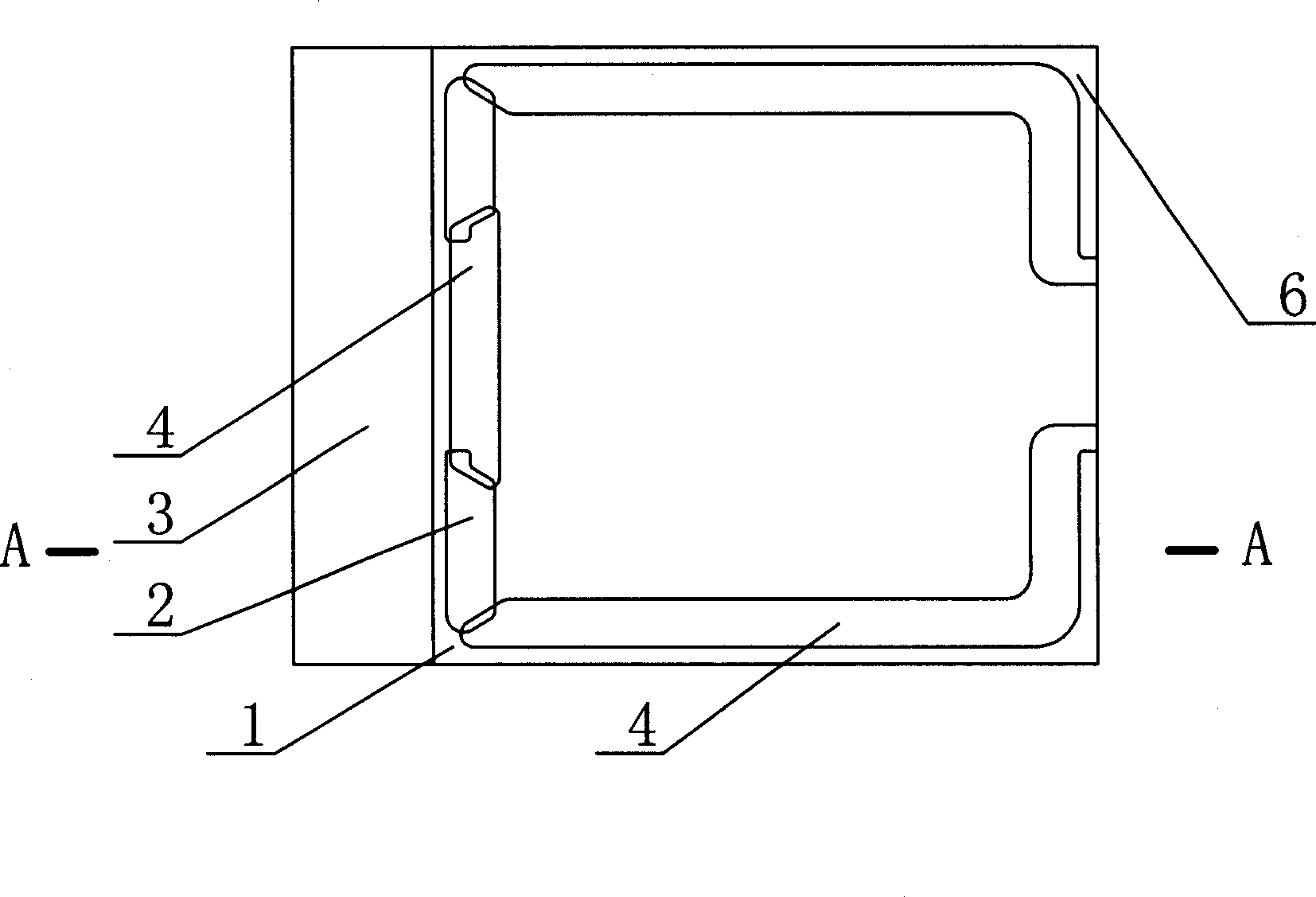

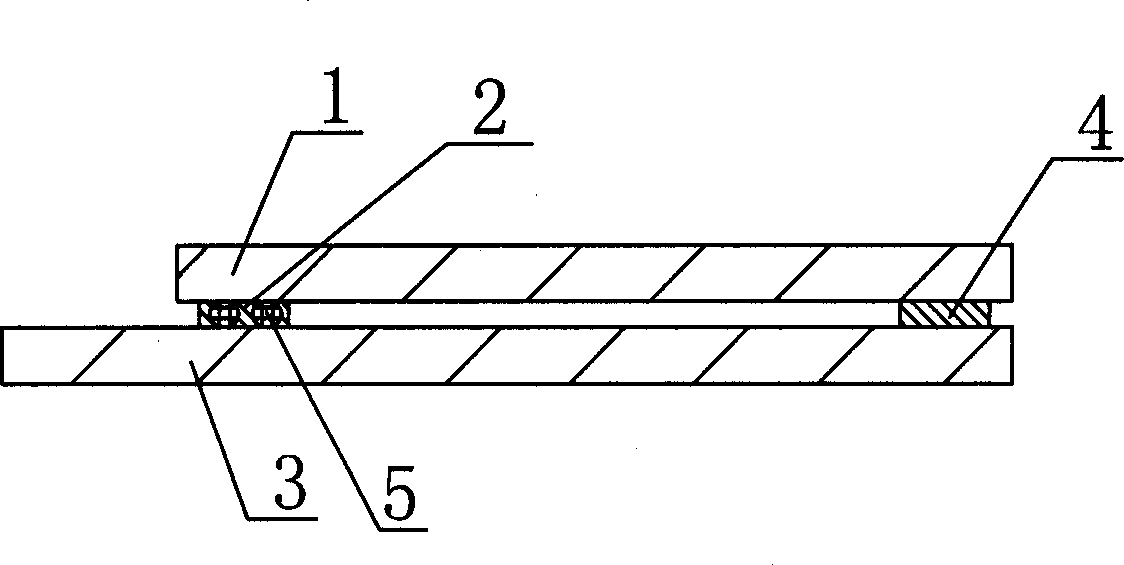

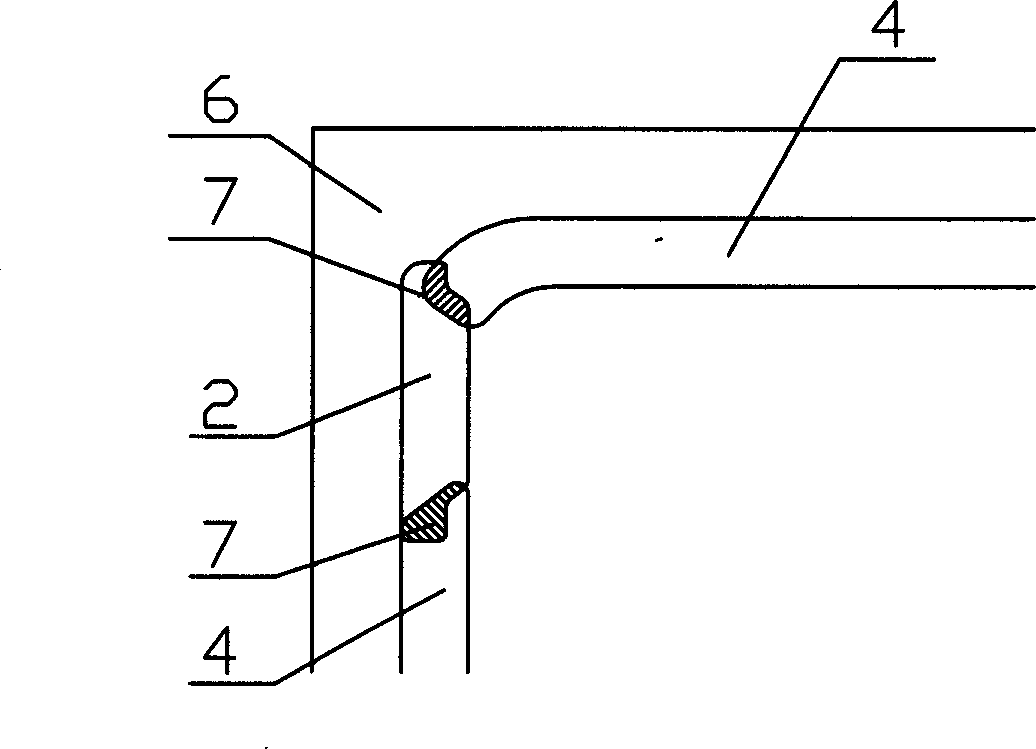

Network frame prefabricated composite board, sandwiched floor and its connection construction method

InactiveCN101260720AReasonable structureImprove bearing capacityConstruction materialWallsThree-dimensional spaceEngineering

The invention relates to a precast net rack sandwich wallboard and a connecting construction method for the same, belonging to the novel building material structure technical field. The precast net rack sandwich wallboard is characterized in that: the precast net rack sandwich wallboard comprises a core plate (1), wherein, a steel wire gauze (2) and a steel wire gauze (9) are respectively arranged on the upper surface and the lower surface of the core plate; the upper steel wire gauze and the lower steel wire gauze are fixedly connected with an inclined dowel bar (3) and an inclined dowel bar (10) which pass through the core plate to form a three-dimensional space net rack structure; U-shaped connecting reinforced rings (4) are arranged on the outsides of the upper steel wire gauze and the lower steel wire gauze along the circumference of the core plate; and a reinforced cement layer (11) in which the steel wire gauzes are coated through placement is formed between the steel wire gauzes and the core plate. The connecting construction method comprises the following steps: firstly, adjacent laminboards are butted on the construction site according to different positions; secondly, reinforcing steel bars (7) are inserted and fixedly connected; and thirdly, a bearing wall is formed by connection of cast-in-situ concrete columns. A parallel walling, an L-shaped walling, a T-shaped walling and a crossed walling are formed by connection and assembly according to different positions. The precast net rack sandwich wallboard and the connecting construction method can realize factory prefabrication and formation of a wall by placing on the construction site, and have light deadweight, large bearing capacity, quick construction, low manufacturing cost and safety and reliability.

Owner:山东龙新建材有限公司

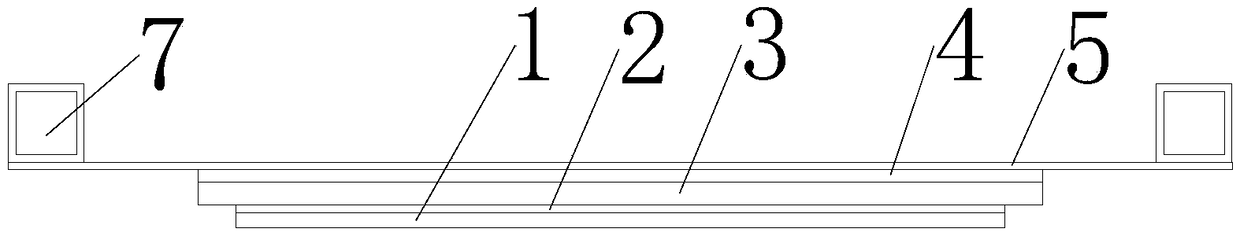

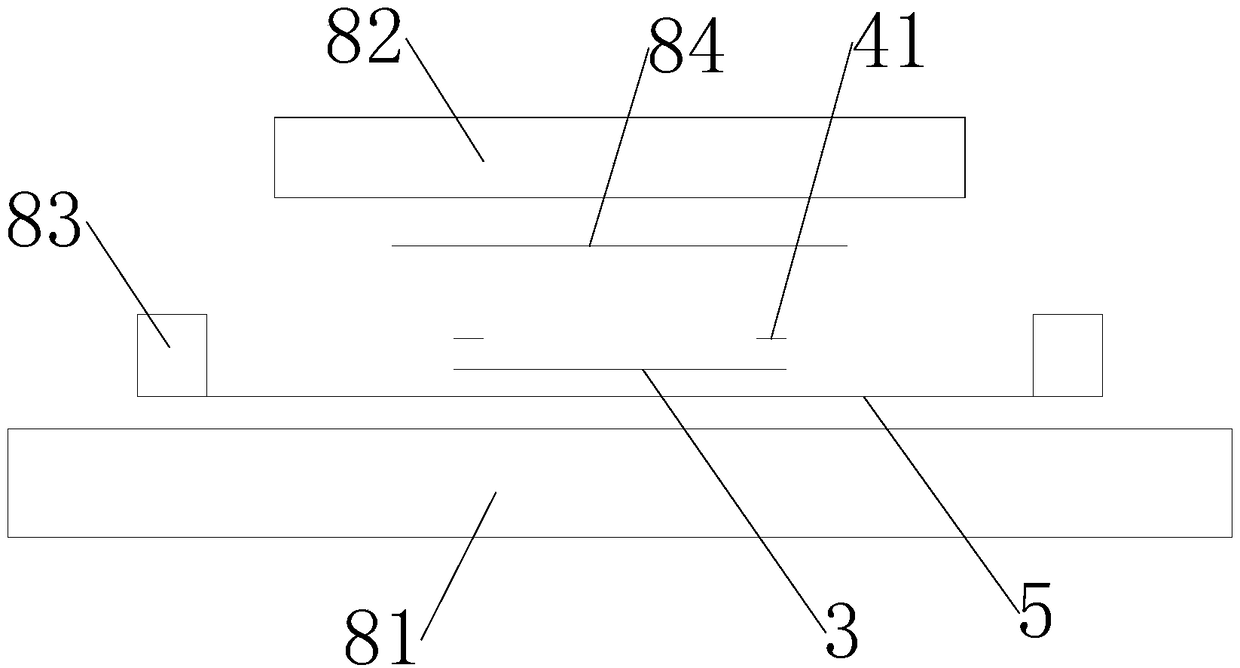

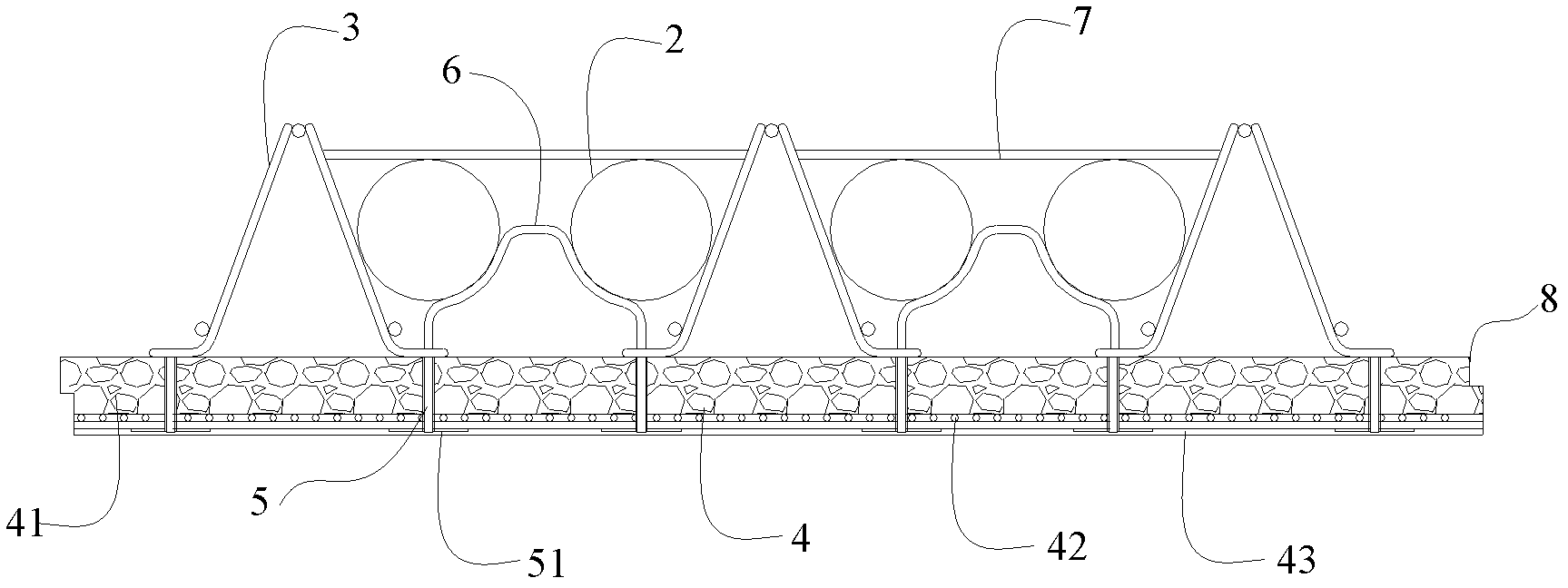

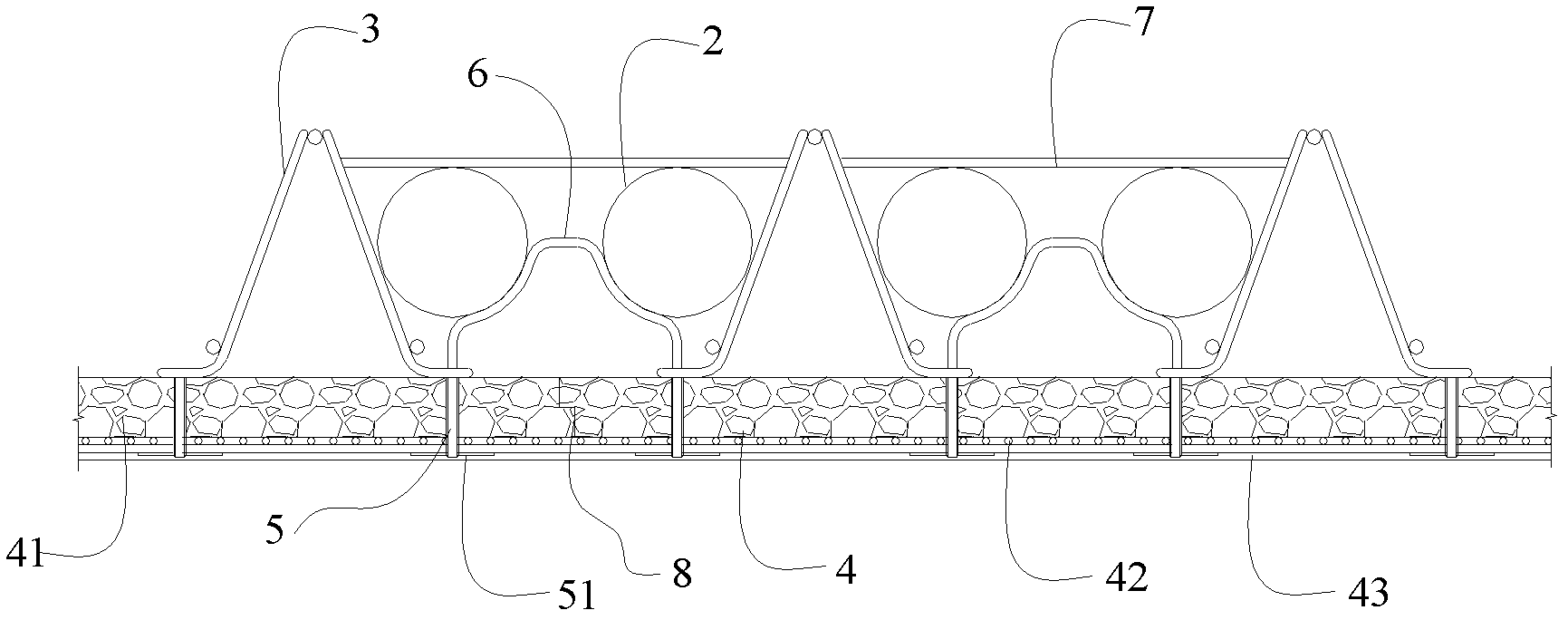

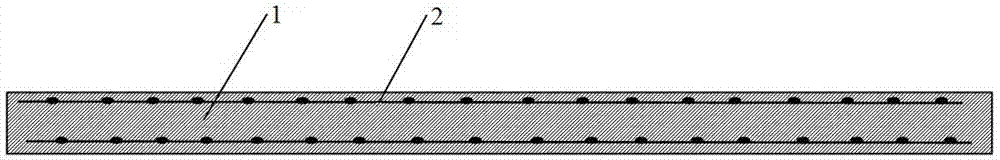

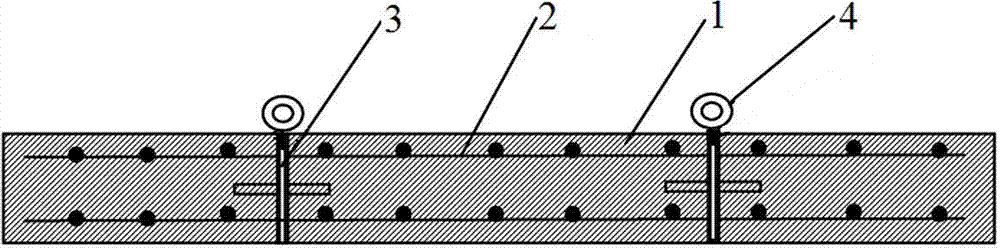

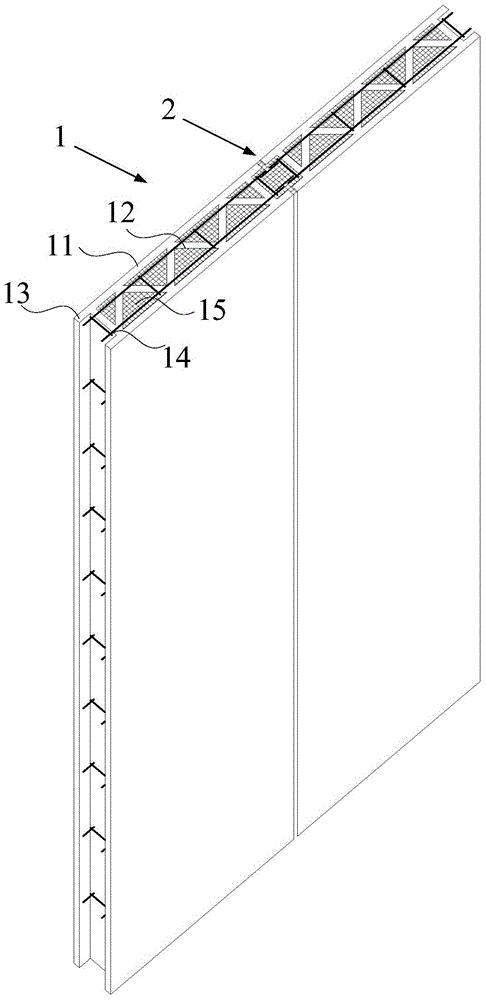

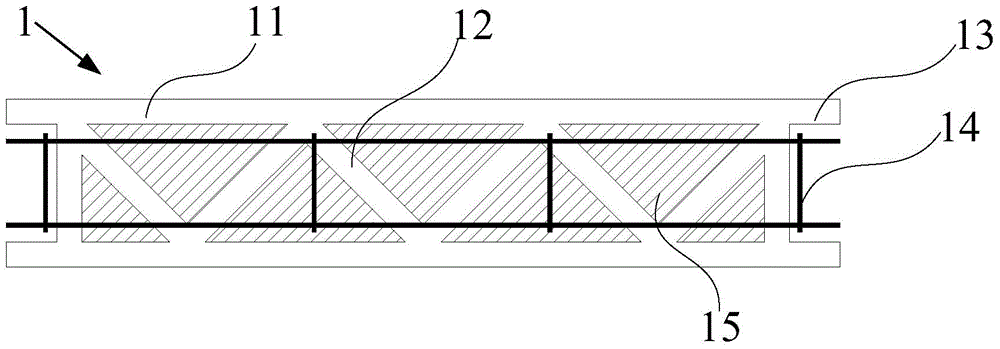

Self-supporting thermal insulation hollow floor slab and construction method thereof

InactiveCN102296736AReduce dosageWith heat preservation functionClimate change adaptationFloorsWire gauzeFloor slab

The invention discloses a self-supporting heat insulation hollow floor and a construction method thereof. The self-supporting heat insulation hollow floor comprises a plurality of frameworks consisting of bottom plates and multiple steel bar trusses erected above the bottom plates and connected with the bottom plates, the opposite ends of the bottom plates of the two adjacent frameworks are connected, and concrete is poured on the steel bar trusses. The self-supporting heat insulation hollow floor is characterized in that: the bottom plate comprises a steel wire gauze and heat insulation plates and / or sound insulation plates positioned on the steel wire gauze, and the bottoms of the steel bar trusses are connected with the bottom plates through a plurality of connectors. The self-supporting heat insulation hollow floor has the function of heat insulation or sound insulation; and meanwhile, the consumption of steel is reduced, so that the production cost is reduced. The invention has the advantages that: the construction method is simple in operation and is easy to learn and use.

Owner:CABR TECH CO LTD +2

Lightening fire resistant polymer porous membrane laminated composite material and manufacturing method thereof

InactiveCN101011874ALow densityGood heat insulationLamination ancillary operationsSynthetic resin layered productsWire gauzeFiber

The invention relates to a light heat resistant polymer porous film layer laminated composite material and its making. It is mainly made of porous polymer thin film and reinforced glass fiber, carbon fiber knitting and metal wire net. It firstly makes the porous polymer thin film through phase inversion or thermal phase separation, combining the glass fiber, carbon knitting fiber and metal wire net thorough dipping or heat pressure to make the single or multi layer laminated composite material. It is easy in process, equipment and realization. The made material is light, heat resistant, high in strength, low heat conductivity, good insulation, flexible, and good in machining.

Owner:ZHEJIANG UNIV

Fabricated type reactive powder concrete prefabricated pavement slab without reinforcing rib and manufacturing method thereof

ActiveCN104294728AStrong bending resistanceHigh compressive strengthSingle unit pavingsCeramic shaping apparatusWire gauzeWeather resistance

The invention discloses a fabricated type reactive powder concrete prefabricated pavement slab without a reinforcing rib and a manufacturing method thereof. A slab body is a material plate made from reactive powder concrete; layers of horizontal steel wire gauzes are respectively spread in the reactive powder concrete material plate and are close to upper and lower surfaces; hoisting embedded parts which run through in the vertical direction are respectively arranged at the four corners, wherein the two ends of the hoisting embedded parts are connected with lifting appliances. When the fabricated type reactive powder concrete prefabricated pavement slab without the reinforcing rib is manufactured, the fluidity of the reactive powder concrete is controlled to avoid deformation of the pavement slab in the later-period manufacturing process, and the fabricated type reactive powder concrete prefabricated pavement slab without the reinforcing rib is maintained naturally indoors to ensure the total quality of the pavement slab. Compared with a common concrete pavement slab, the pavement slab has the advantages of no reinforcing rib in structure, small thickness, portability, light weight, convenience in transportation and installation, high intensity, wear resistance, high bearing capability, good anti-impact performance, good anti-fatigue performance, good weather resistance, and fast and efficient construction, repeated use, and can be widely applied to road construction of temporary building living quarters.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Electromagnetic shielded observation window

InactiveCN1429070ANot easy to gatherHigh transparencyMagnetic/electric field screeningScreening apparatusWire gauzeDielectric

A viewing window of electromagnetic shielding is composed of single layer or multiple layer of metal wire mesh, single layer or multiple layer of optical film in quantum well structure and transparent backing material as each layer of metal wire mesh is fabricated by metal thin wire flared-out in single set or multiple set, any two pieces of thin wires in each set of metal thin wire will be in the same plane as parallel to each other; optical film will be metal dielectric media multilayer film contained single layer of metal film or multiple layer of metal film and it is structured by inducible layer which consists of two layer of different transparent media films laid at two sides symmetrically and functional layer which will be compounded in between the inducible layers laid symmetrically as well as it will be embedded on the surface of microwave cavity to be closely compounded with the microwave cavity.

Owner:李宏强 +1

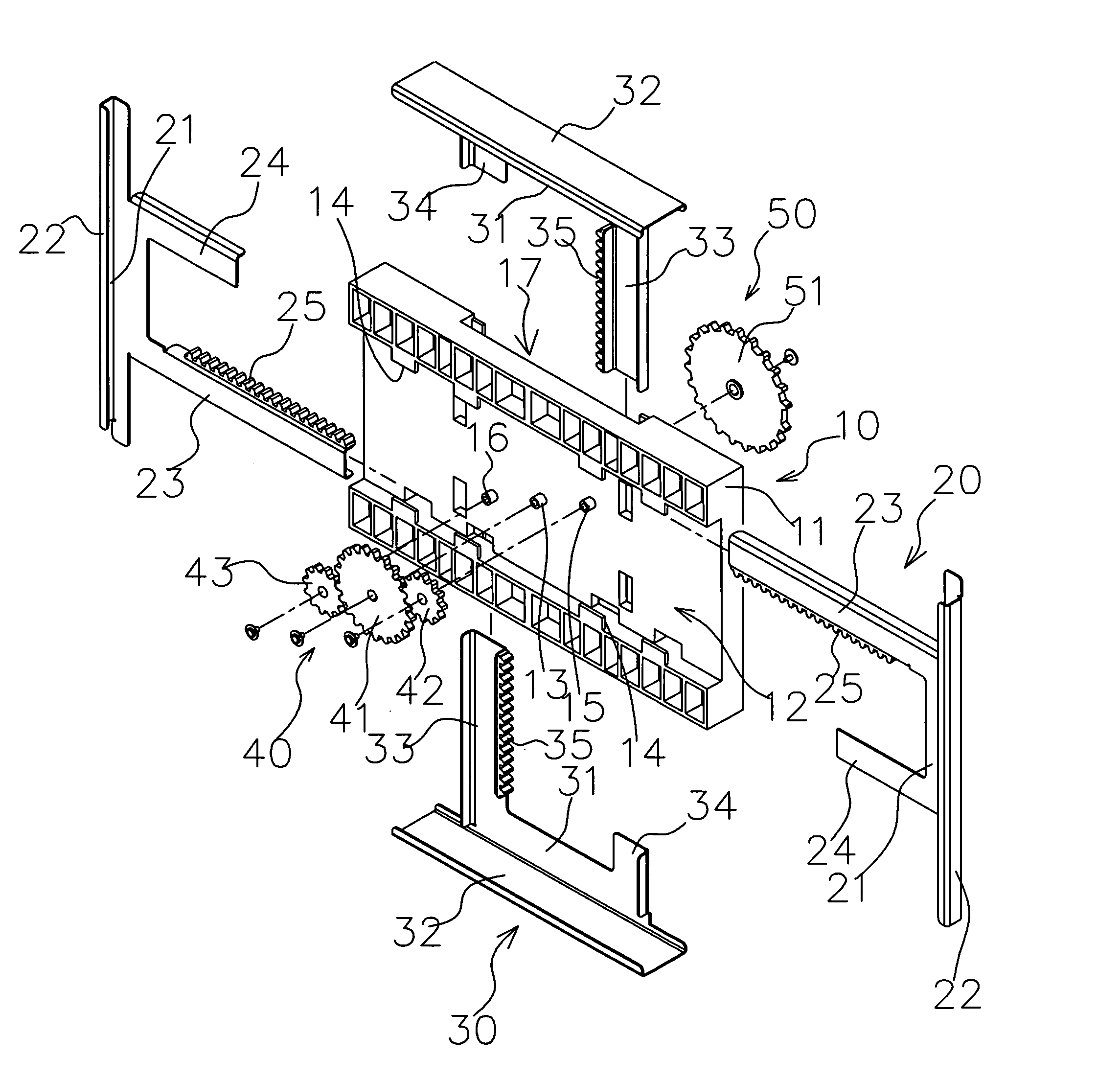

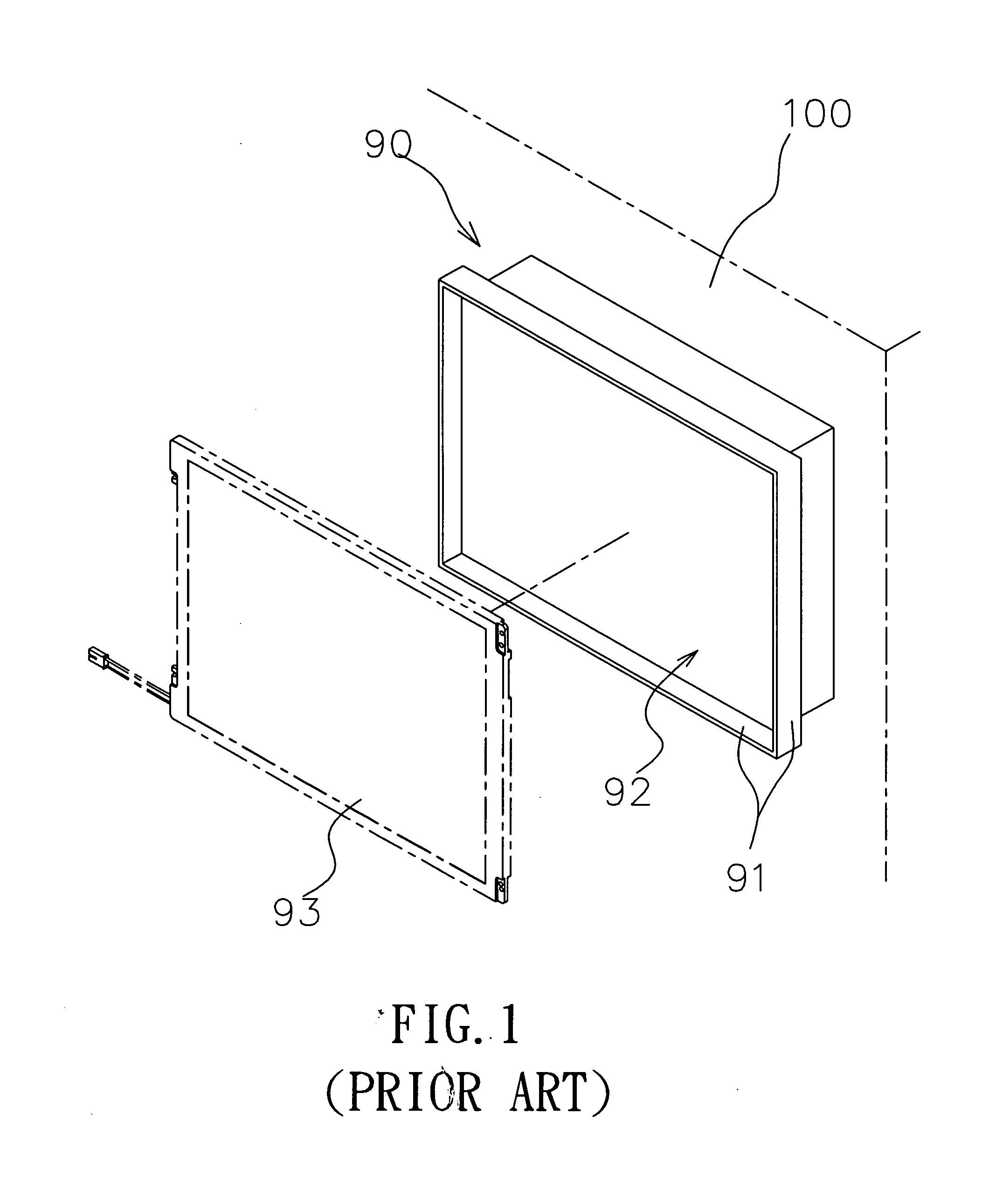

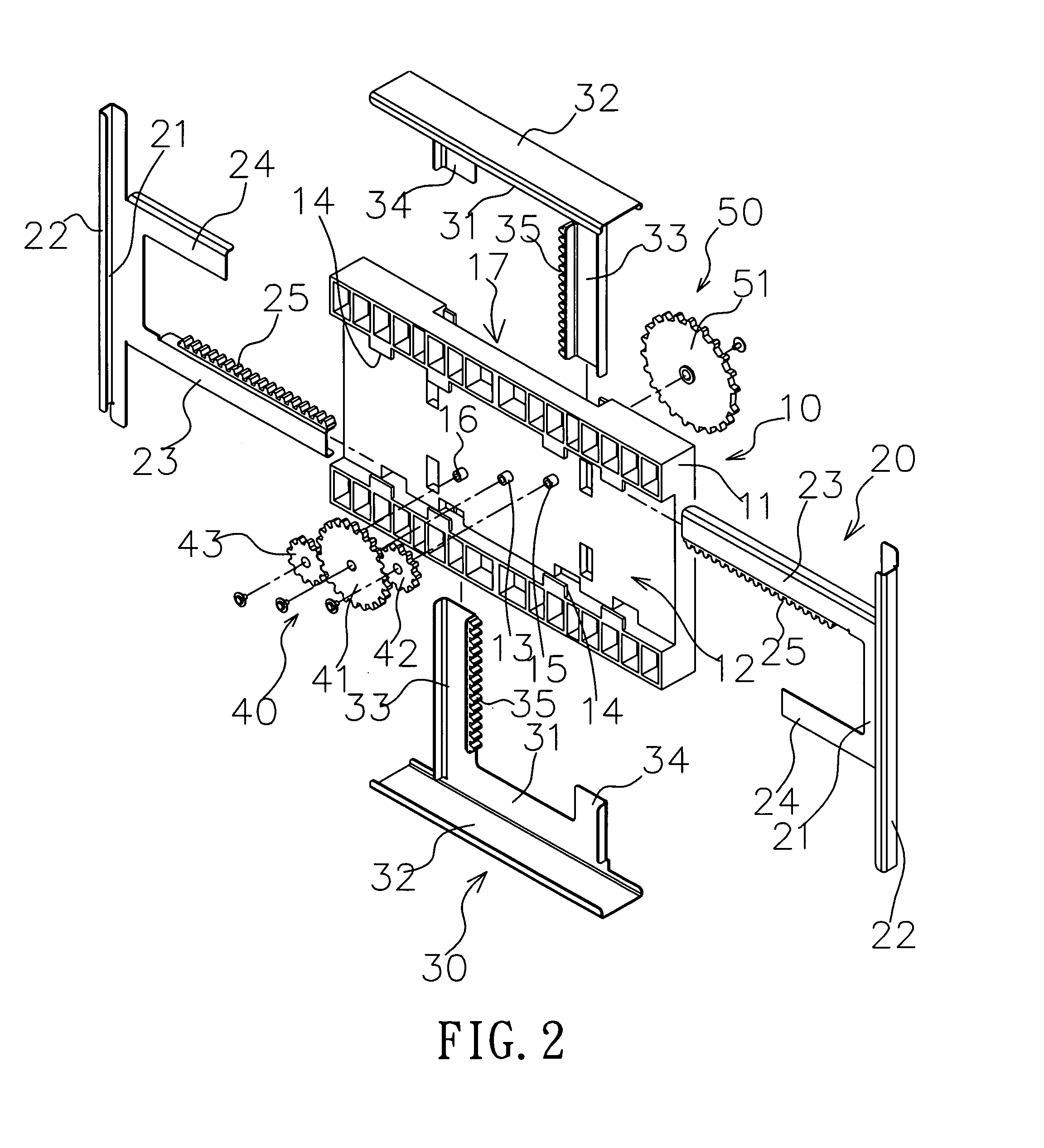

Roller type adjustable screen fixing apparatus

InactiveUS20100065704A1Inventory issueConveniently changedPicture framesDomestic mirrorsWire gauzeEngineering

Owner:PORTWELL

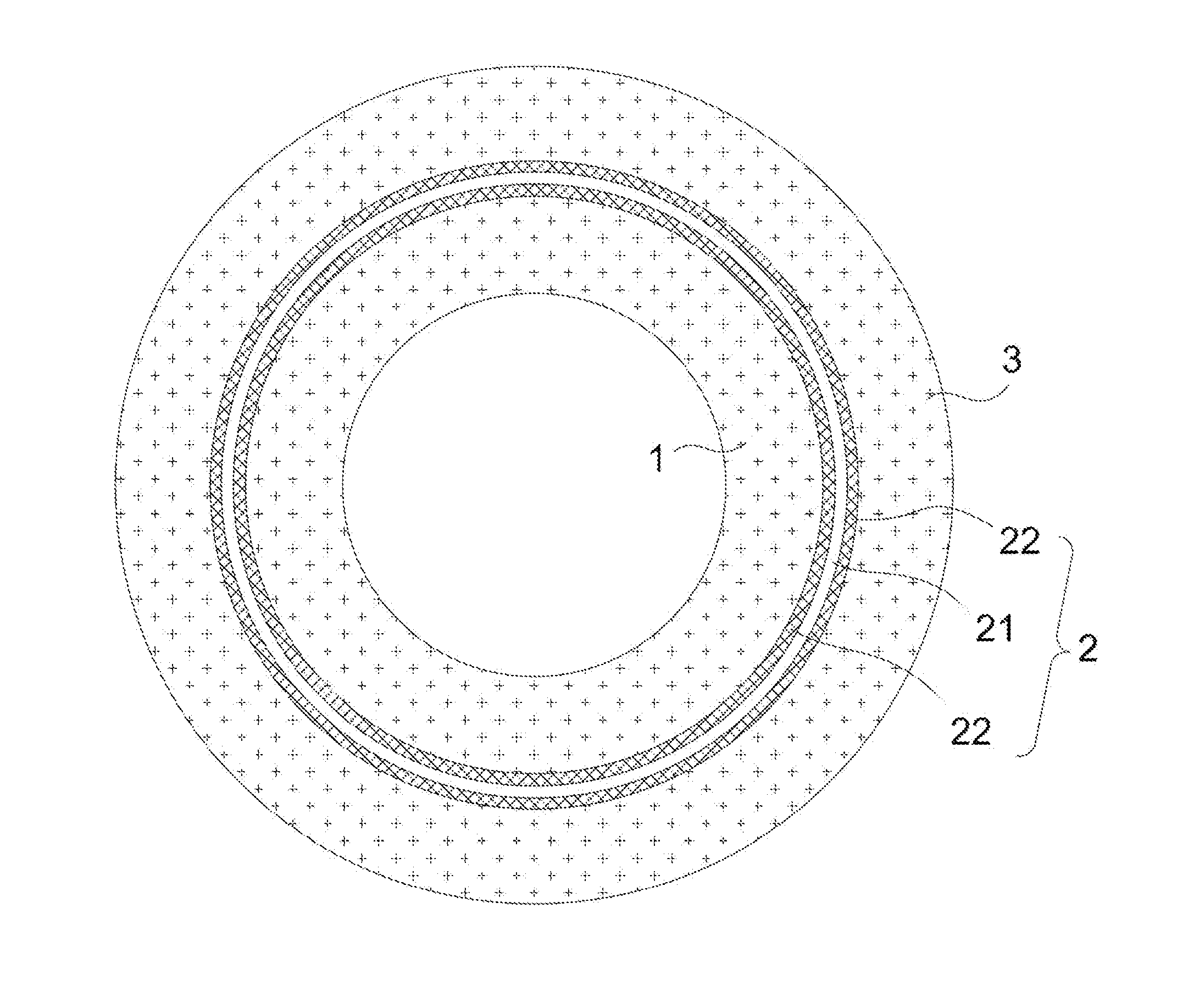

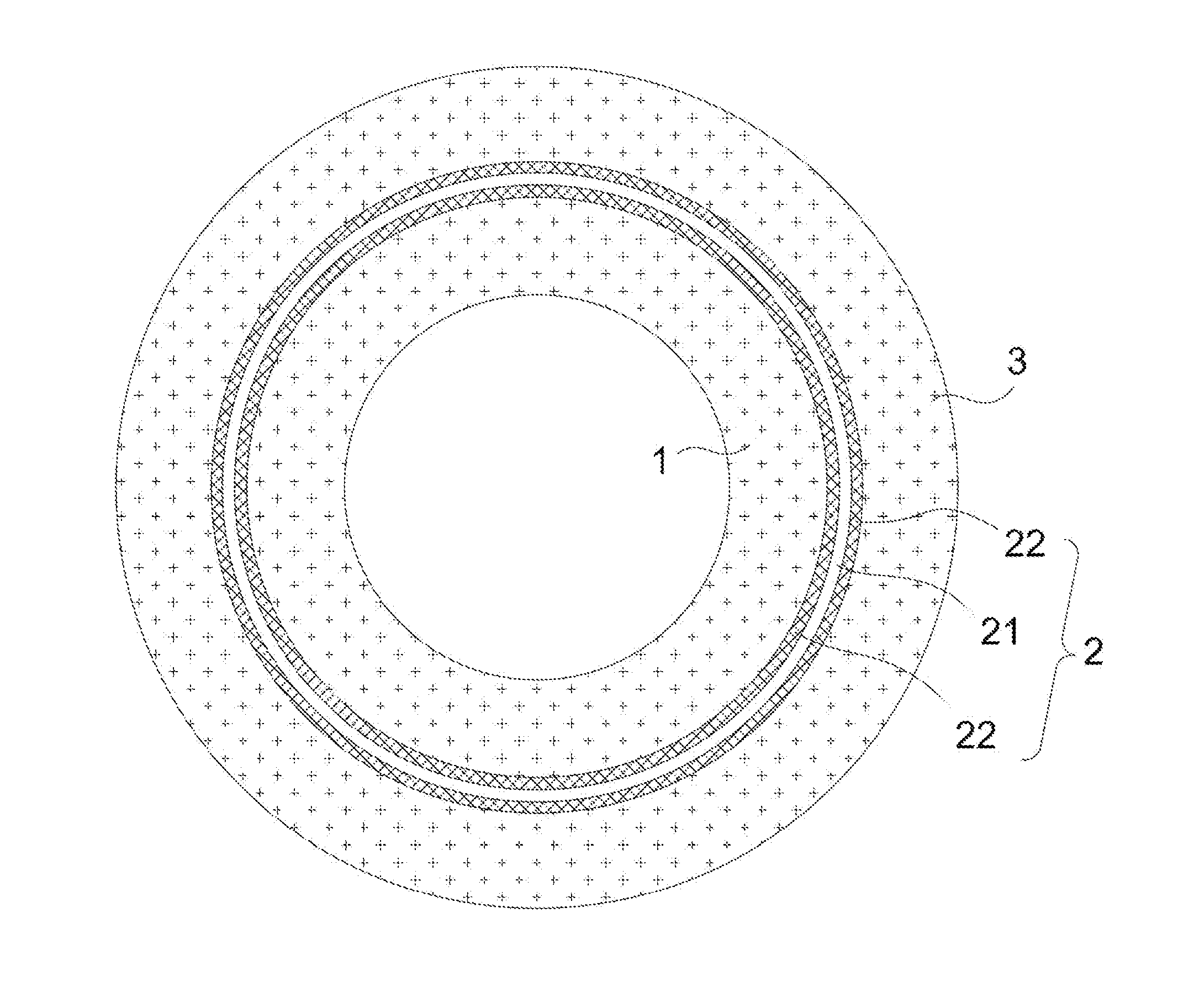

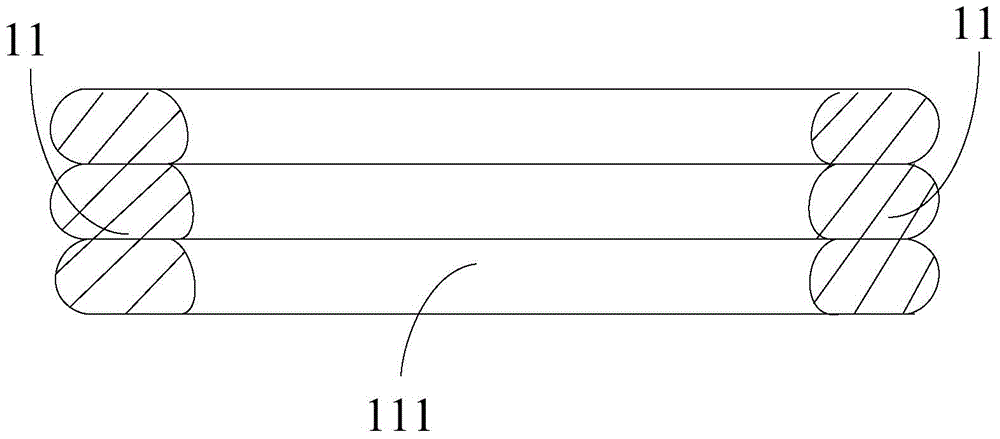

Wear-heat-resistant anti-bacterial anti-fouling steel wire framed pipe and manufacturing method thereof

ActiveUS20170030492A1Increase heatHigh compressive strengthPipe couplingsCouplingsWire gauzeHot melt

A wear-heat-resistant anti-bacterial anti-fouling steel wire framed pipe and a manufacturing method thereof are provided. The steel wire framed pipe includes: an anti-bacterial anti-fouling inner layer, an enhancement layer and a wear-heat-resistant outer layer from inside to outside in turn, wherein: the anti-bacterial anti-fouling inner layer is made from antifouling and antibacterial composite modified polyethylene; the wear-heat-resistant outer layer is made from wear-resistant cross-linked modified PE-RT; the enhancement layer includes an interlayer and two steel wire gauze layers respectively coating on an inner surface and an outer surface of the interlayer, and the interlayer is respectively bonded with the anti-bacterial anti-fouling inner layer and the wear-heat-resistant outer layer via hot-melt adhesive. The steel wire framed pipe provided by the present invention has high structural strength, wear-resistance, heat-resistance, and anti-bacterial and anti-fouling properties.

Owner:KANGTAI PLASTIC SCI & TECH GRP

Simple method for manufacturing ceramic-metal composite wear-resistant part

The invention discloses a simple method for manufacturing a ceramic-metal composite wear-resistant part. The simple method for manufacturing the ceramic-metal composite wear-resistant part is characterized by comprising the following steps of obtaining a steel wire gauze, stamping a groove in the steel wire gauze, filling ceramic particles in the groove after surface wetting treatment is conducted on the ceramic particles, taking another steel wire gauze to cover the first steel wire gauze so that the groove can be shielded and scattering of the ceramic particles can be avoided, fixing the steel wire gauze with the ceramic particles fixed on a corresponding position, need to be enhanced, of the mold cavity wear-resistant part, and pouring and casting matrix metal liquid to obtain the wear-resistant part. The simple method for manufacturing the ceramic-metal composite wear-resistant part has the advantages of being even in distribution of the ceramic particles, firm in combination with matrix metal, capable of giving full play to the characteristics of ceramic and metal and achieving high-resistant performance and high-impact-resistant performance, simple, easy and convenient to operate, capable of being produced in large scale or in batch, and low in cost.

Owner:CHONGQING LUOMAN NEW MATERIAL TECH CO LTD

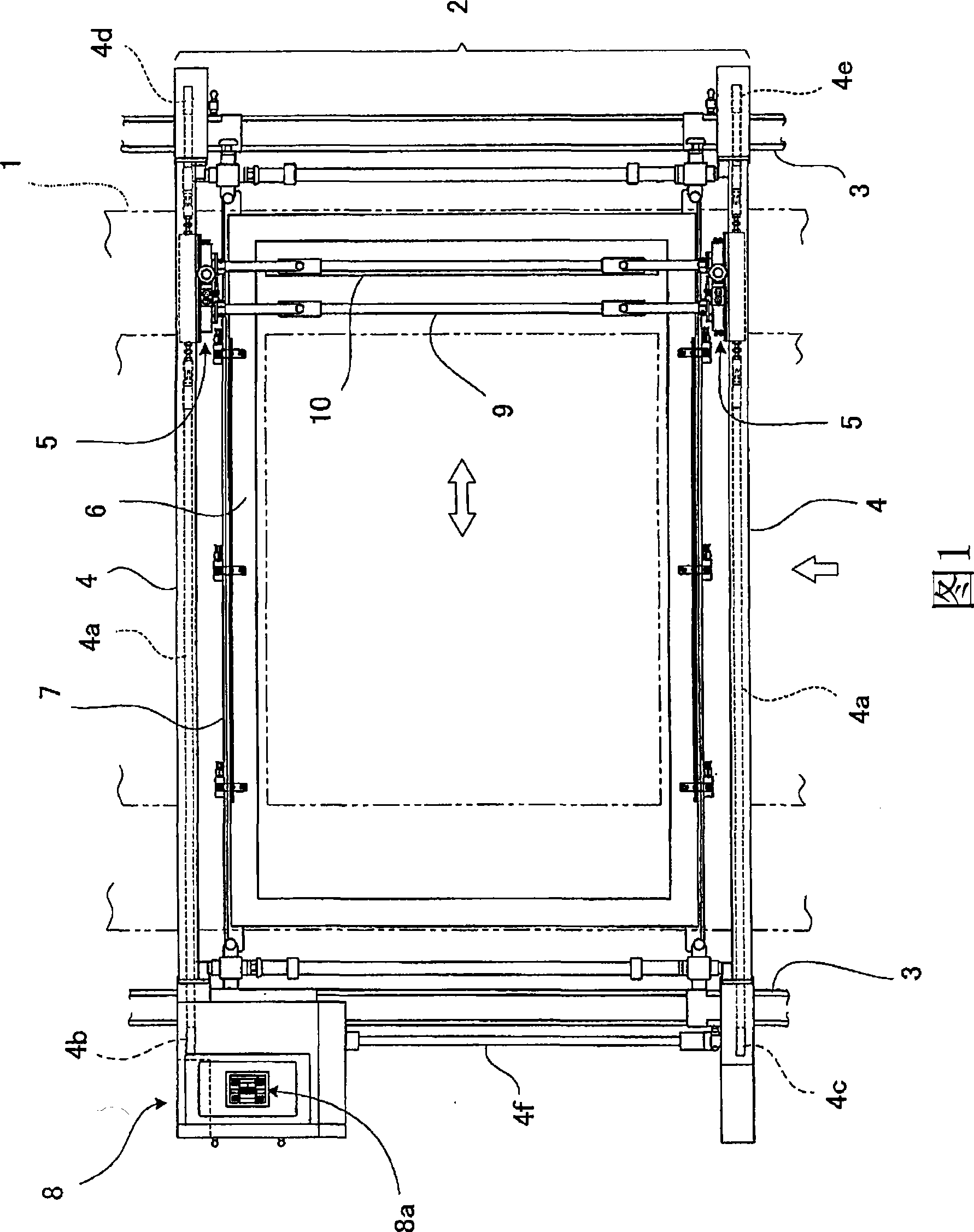

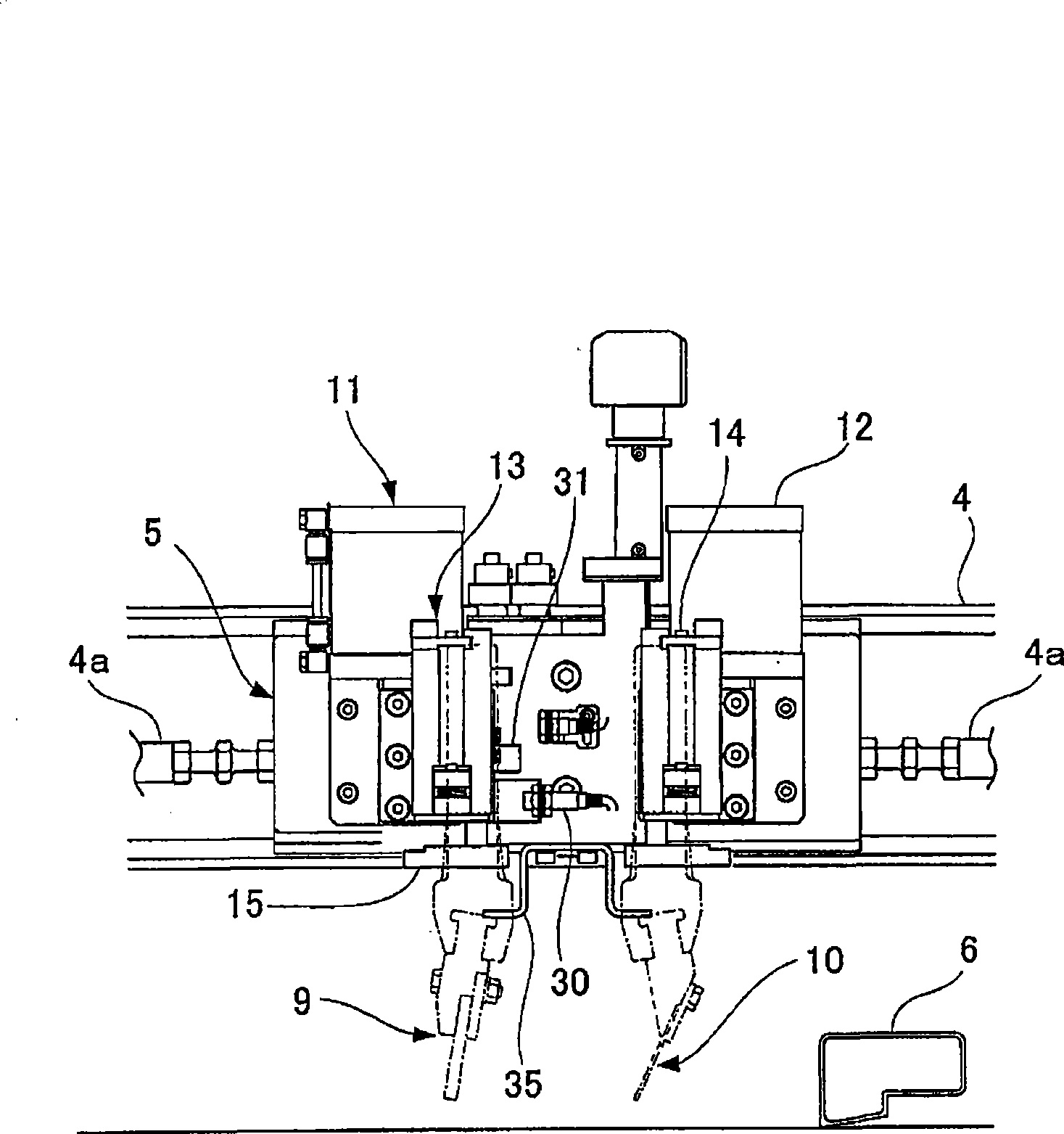

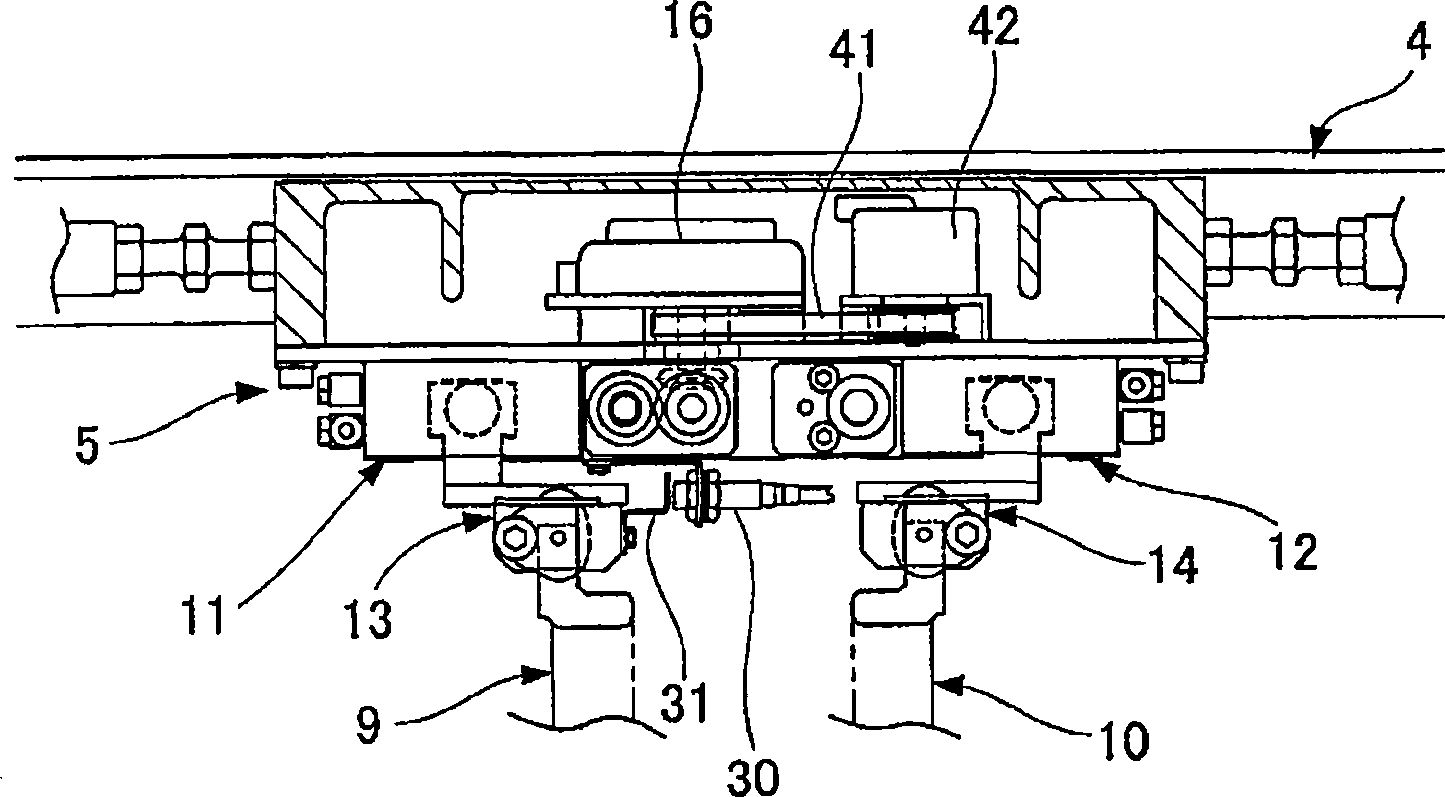

Arrangement for regulating pressure of scratch board in automatic silk screen dyeing machine

InactiveCN101439611AAdjust the amount of pressureReduce the frequency of failuresScreen printersWire gauzeScreen printing

The invention discloses a scraper pressure regulating device for regulating scraper pressure in an automatic screen printing and dyeing machine. The device comprises a cylinder driving the scraper to ascend or descend, an air pressure loop which switches the air pressure supplied to the cylinder to printing and dyeing pressure or pressure for pressurization origin determination which is lower than the printing and dyeing pressure; a movable limit block which is driven to rise or fall by a number controllable control motor in a height position controllable manner and stops the scraper from descending; a first detection device which detects the position of the movable scraper when the scraper is stopped from descending; an input device for externally inputting an expected height direction variable of the movable limit block; and a control device which controls the control motor according to the input from the input device by taking the position of the movable limit block which is detected by the first detection device when the air pressure loop switches the printing and dyeing pressure into the pressure for the pressurization origin determination.

Owner:TOSHIN KOGYO CO LTD

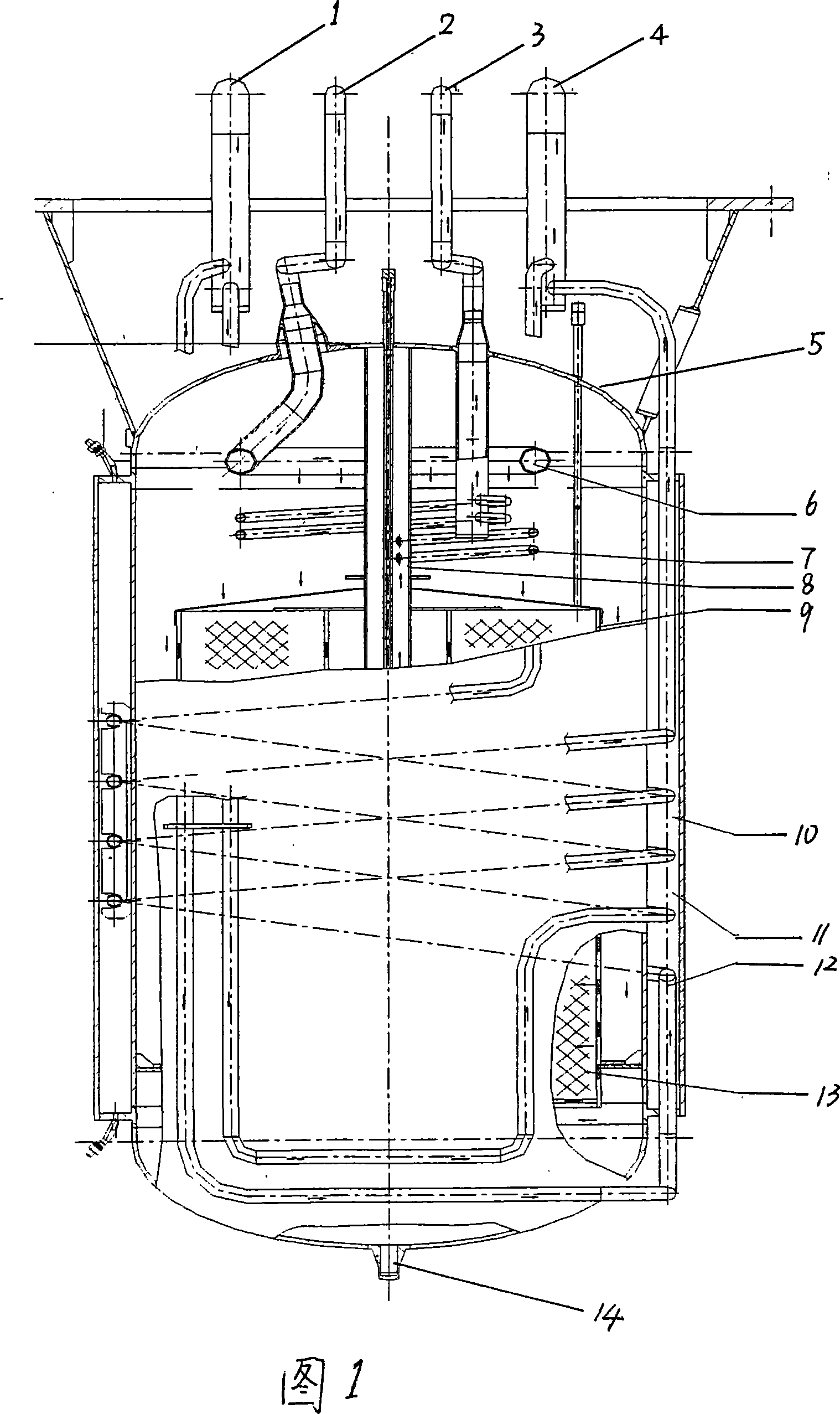

Cold trap for radiosodium on-line purifying

ActiveCN101231898ASuitable for in-line purificationImprove heat utilization efficiencyNuclear energy generationReactor fuel elementsWire gauzeEngineering

The invention discloses a cold trap used for on-line purification of radiosodium, which comprises an outer cylinder body. A wire gauze arranged in the outer cylinder body. A sodium inlet and a sodium outlet are arranged on the upper part of the outer cylinder body. A central return conduit is arranged inside the outer cylinder body communicating with the sodium outlet through a heat saving unit coil. The technical proposal provided by the invention makes the best of the temperature difference between the inlet and the outlet for heat exchange, thus improving the efficiency of heat utilization. On the premise that a reactor is not stopped, liquid sodium of high temperature is cooled, separated out, filtered, heated and so on. The invention can process a great deal of sodium and is applicable for on-line purification of a great deal of sodium.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

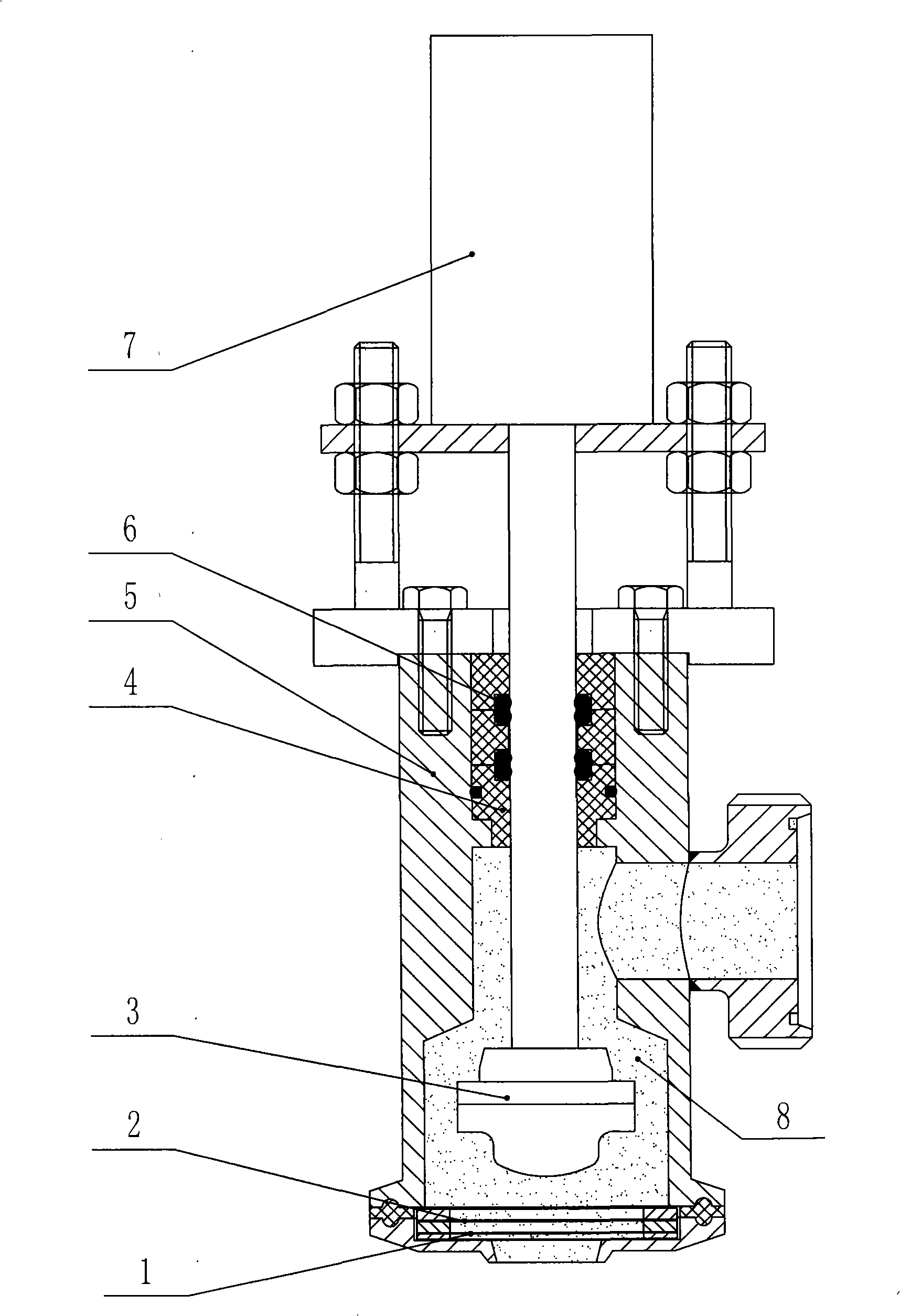

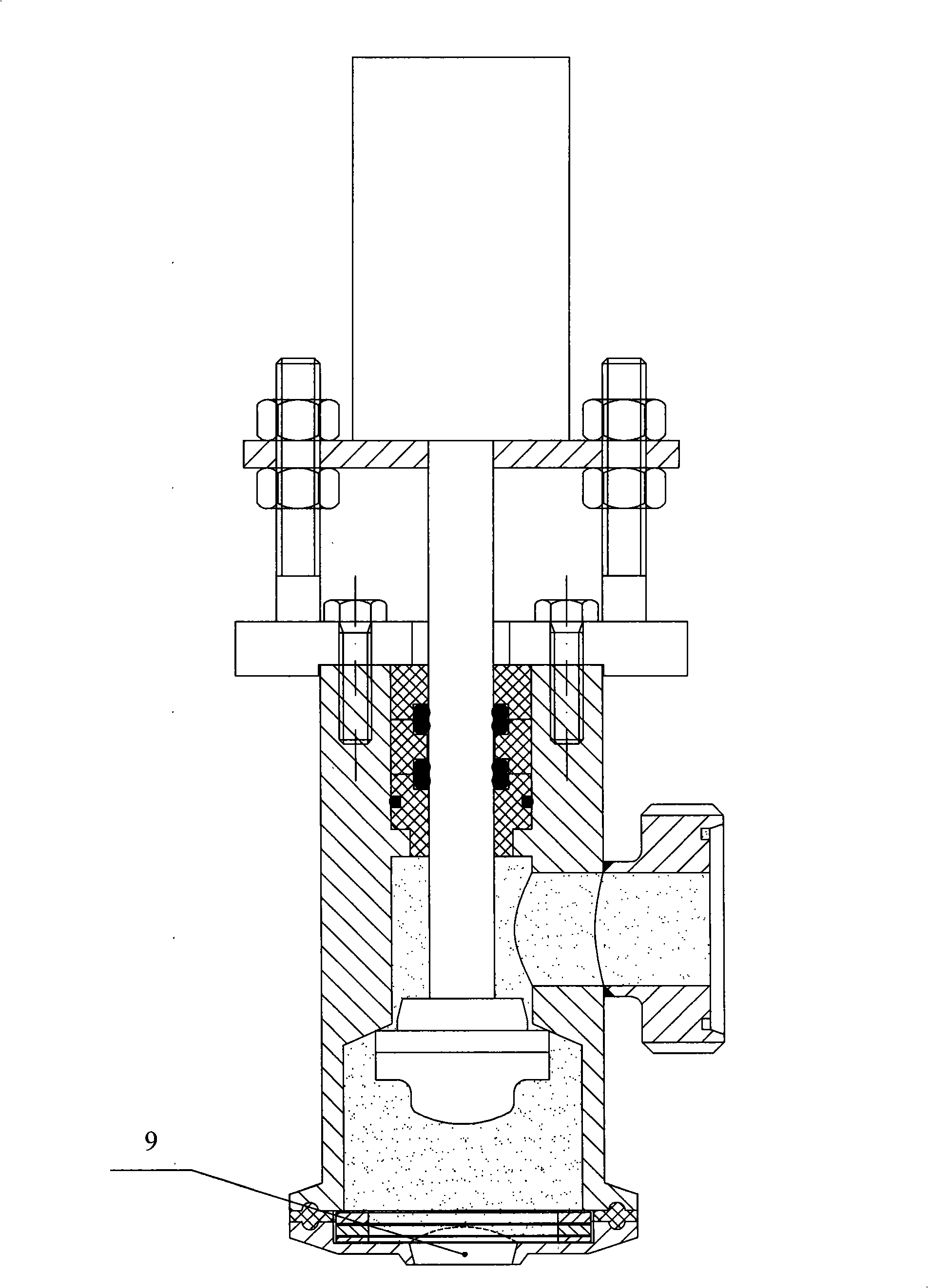

Inverse pumping type anti-leakage pouring valve

InactiveCN101403445ASimple structureSolve the problem of dripping backSpindle sealingsOperating means/releasing devices for valvesWire gauzeEngineering

The invention discloses a reverse pumping type anti-drip filling valve; the filling valve comprises a cylinder arranged in a valve body; a piston rod of the cylinder is fixed by a positioning ring of a valve core; the position of the material outlet of the valve body is provided with at least one layer of wire gauze; the valve core is in the valve body and above the wire gauze; on the positioning ring of the valve core, a sealing ring is arranged between the piston rod of the cylinder and the valve body; the amount of the wire gauze is two layers comprising a first layer wire gauze and a second layer wire gauze; the mesh amount of the first layer wire gauze and / or the second layer wire gauze is 20-30. The filling valve has simple structure, and solves the drip returning problem existing in the low-viscosity or high-viscosity fluid filling process reliably; moreover, the time for pumping the vacuum or blowing the residual materials after the filling is finished is not needed, and therefore the filling efficiency is improved.

Owner:FOSHAN HAITIAN FLAVOURING & FOOD CO LTD +1

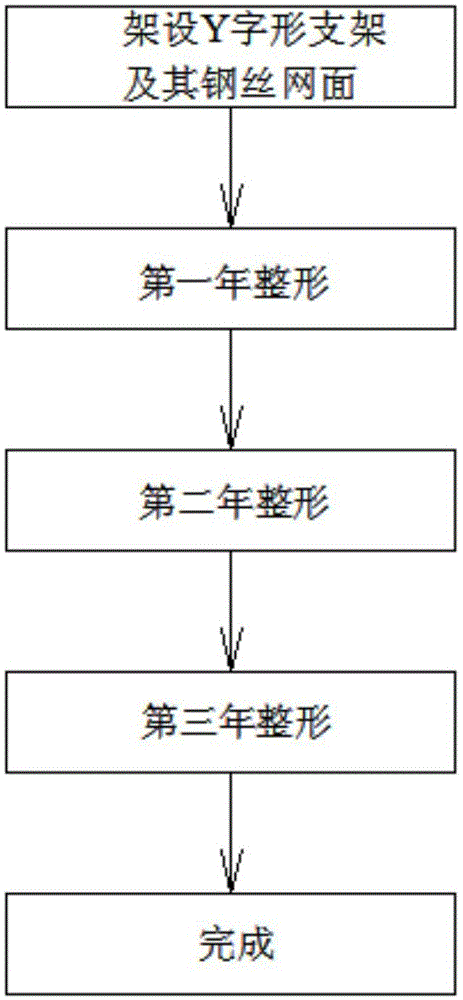

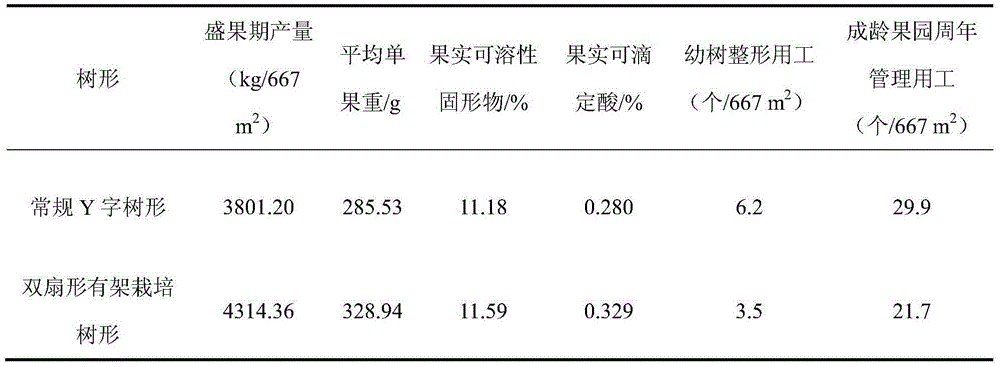

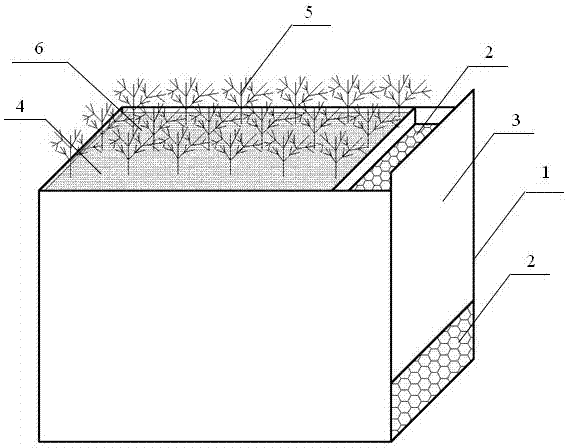

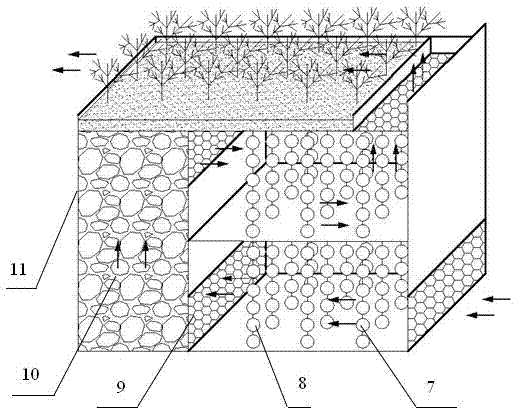

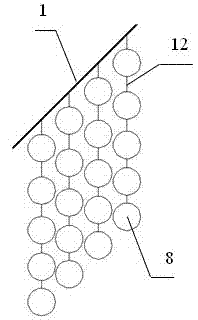

Double-sector trellis cultivation type pear tree form and shaping method thereof

ActiveCN105028105ALess branchedOrderly rowsCultivating equipmentsHorticulture methodsFruit treeWire gauze

The invention belongs to the field of fruit tree cultivation and fruit tree ecology and relates to a double-sector trellis cultivation type pear tree form and a shaping method thereof. Only two principal branches are reserved on a pear tree, a 90-degree included angle is formed between the two principal branches which are fixed to a Y-shaped support, and the two principal branches are symmetrically spread towards the space between lines; a base lateral branch is arranged on each of the two sides of the base of each principal branch, and a plurality of monopodium non-pruning type bearing branch groups are evenly arranged on and above the middle portion of each principle branch in a stagger mode; a 90-degree side angle is formed between each base lateral branch and the corresponding principal branch; a 90-degree base angle is formed between each monopodium non-pruning type bearing branch group and the corresponding principle branch, and the monopodium non-pruning type bearing branch groups are spread in parallel in the line direction; lateral branch bearing branch groups are formed on the base lateral branches through bud carving and non-pruning; weak shoots are taken as the main part of each principal branch, and the crown is spread to be sectors on the two sides of the Y-shaped support. The shaping method comprises the steps of erecting the Y-shaped support and a steel wire gauze surface, shaping at the first year, shaping at the second year and shaping at the third year. The method is convenient to operate and remarkable in effect.

Owner:CHANGLI INST OF POMOLOGY HEBEI ACADEMY OF AGRI & FORESTRY SCI

Portable combined constructed wetland purifying box for farmland drainage ditch

InactiveCN103288312AEasy to take outDoes not affect drainage capacityMultistage water/sewage treatmentWire gauzeConstructed wetland

The invention relates to a portable combined constructed wetland purifying box for a farmland drainage ditch. The portable combined constructed wetland purifying box is characterized in that a single portable combined constructed wetland purifying box frame is built through reinforcing steel bars, plastic plates and wire gauzes. The purifying box in the frame comprises a micro constructed wetland area, a biological cleaning ball area and an activated carbon adsorption area. Lateral sides of the single portable combined constructed wetland purifying box can be opened so as to facilitate regular replacing of fillers in the box. The portable combined constructed wetland purifying box is small in size, can be placed in the farmland drainage ditch conveniently and is convenient to move. A plurality of portable combined constructed wetland purifying boxes are connected in series and placed in the farmland drainage ditch, and farmland drainage water enters the boxes through water inlets of the purifying boxes and sequentially passes through the lower portions of the biological purifying ball areas, the activated carbon adsorption areas, the upper portions of the biological purifying ball areas and the micro constructed wetland areas to be purified and processed. The portable combined constructed wetland purifying box has the advantages of being capable of reducing the farmland non-point source pollution receiving water eutrophication degree and risks and reducing content of harmful substances such as heavy metal and pesticide residues in the farmland drainage so as to reduce damage of the harmful substances to receiving water aquatic organisms.

Owner:HOHAI UNIV

Manufacturing method of curved-surface touch screen glass cover plate

InactiveCN105528114AReduce processing difficultyImprove yield rateGlass severing apparatusInput/output processes for data processingWire gauzeScreen printing

The invention discloses a manufacturing method of a curved-surface touch screen glass cover plate. The manufacturing method of the curved-surface touch screen glass cover plate comprises the following steps: (a) washing a glass substrate; (b) carrying out silk-screen printing of acid-resistant ink on the surface of one side of the glass substrate, in which the acid-resistant ink is distributed at the edges of the periphery of each touch screen glass cover plate; (c) etching; (d) cutting the glass substrate; (e) carrying out ink removal treatment on the each separated touch screen glass cover plate; and (f) carrying out CNC engraving processing on the touch screen glass cover plate according to the curved-surface requirement to obtain the curved-surface touch screen glass cover plate. According to the manufacturing method of the curved-surface touch screen glass cover plate, a single-side thinning process is used for thinning to obtain the touch screen glass cover plate with a thin middle area and thick periphery; the CNC engraving is carried out according to the curved-surface requirement on the basis to obtain the glass of the curved-surface touch screen glass cover plate; compared with the conventional method for directly carrying out CNC engraving on the glass substrate, the method is used for carrying out CNC engraving after thinning; the process difficulty is greatly reduced; the yield of the product is increased; in addition, the thinning can be carried out in batch operation; the working efficiency is greatly improved.

Owner:凯盛科技股份有限公司

Liquid crystal display capable of preventing short circuit of electric gold ball, and preparation method

The invention discloses a LCD for preventing the short circuit of conductive metal balls, and the making method thereof. A liquid crystal empty box is made by aligning and binding transferring points made on upper and lower ITO glass substrates with sealing glue frame after sprayed with liners, then heat-pressing and curing, where the transferring points are arranged in a small frame range needing to lead out row electrodes and made of transferring sealing glue scattered with conductive metal balls by silk-screen. The invention can obviously raise finished product yield.

Owner:深圳市合力泰光电有限公司

3D printing internal parting wall and construction method of 3D printing internal parting wall

The invention discloses a 3D printing internal parting wall and a construction method of the 3D printing internal parting wall. The 3D printing internal parting wall comprises a plurality of prefabricated internal parting wall units formed according to the 3D printing technology and arranged side by side, first packing materials arranged in the prefabricated internal parting wall units, steel wire gauze sheets arranged in column space and second packing materials arranged in the column space, wherein butt joint grooves are formed in the two ends of each prefabricated internal parting wall unit, and the column space is formed by butt joint of every two adjacent butt joint grooves. A truss system is applied to an internal parting wall system, overall printing molding is achieved through a 3D printing machine, and the building requirements of walls with special-shaped building models are met; meanwhile, the performance of 3D printing materials is sufficiently played, the automatic degree is high, a large amount of manpower and a large number of materials are saved, and building rubbish is not generated. Continuous concave-convex lines are formed on the surfaces of the prefabricated internal parting wall units; the connection strength between the prefabricated internal parting wall units and the packing materials is improved; compared with a smooth surface, the force of friction is improved, and the combination strength is improved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

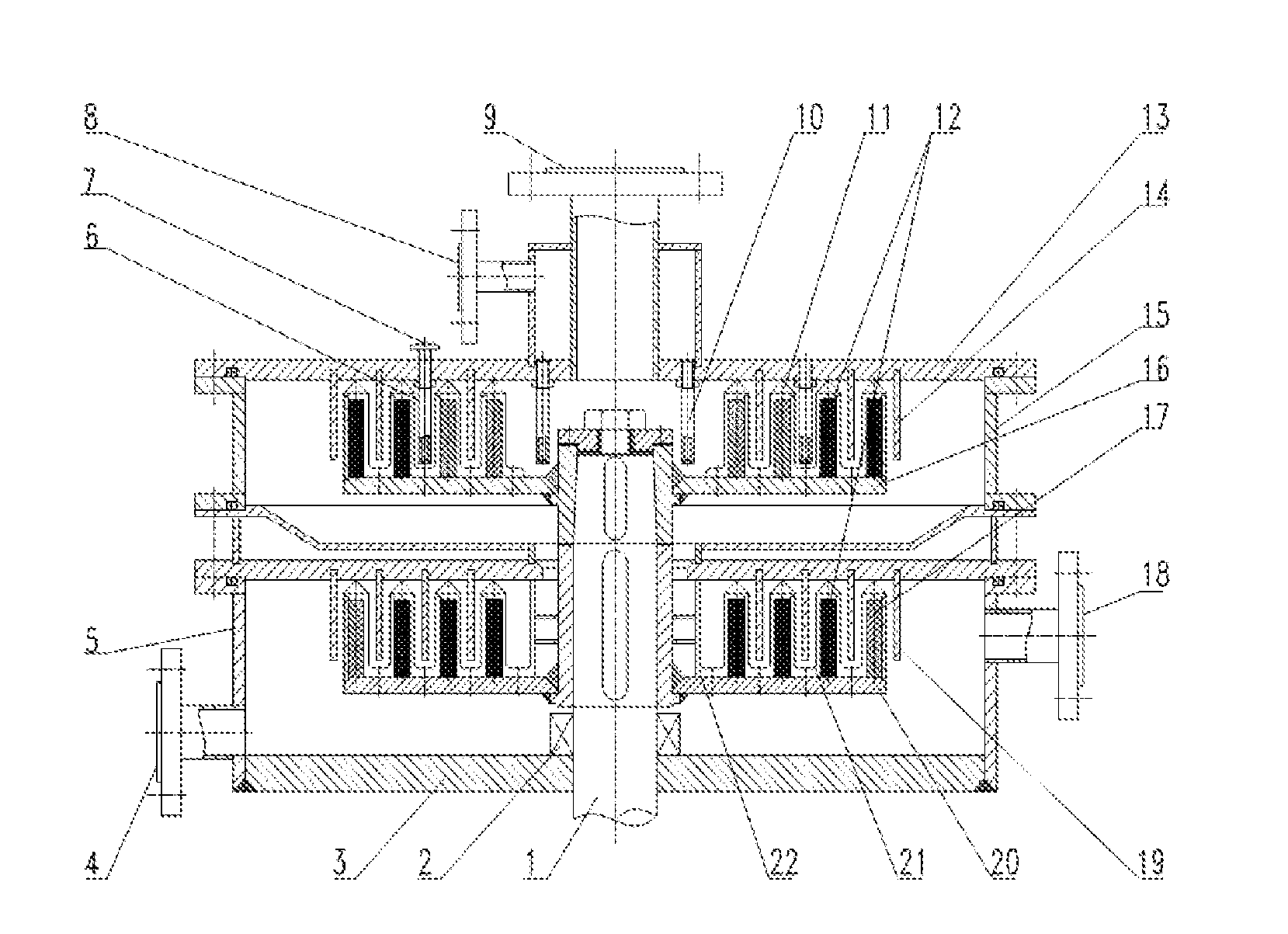

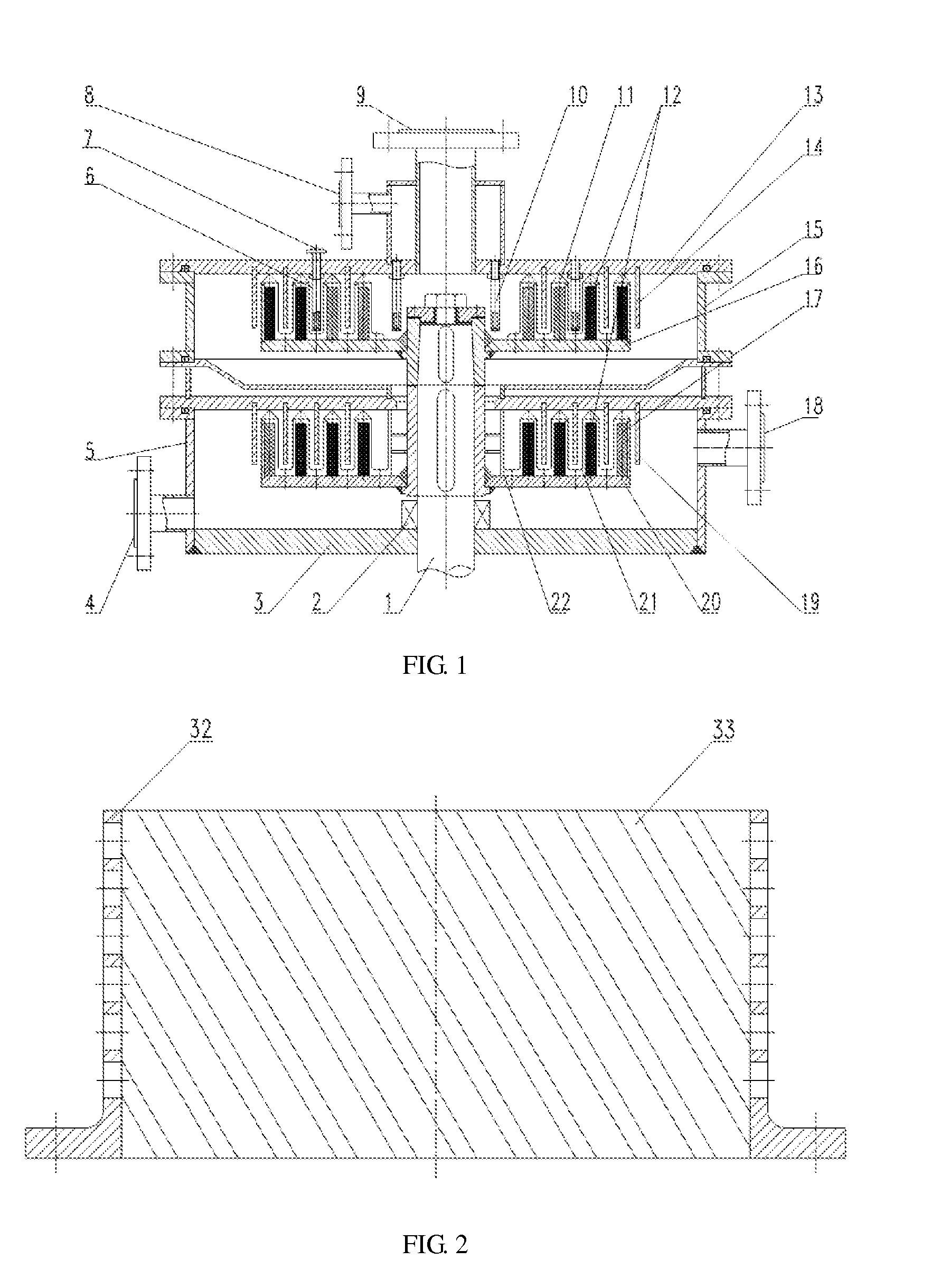

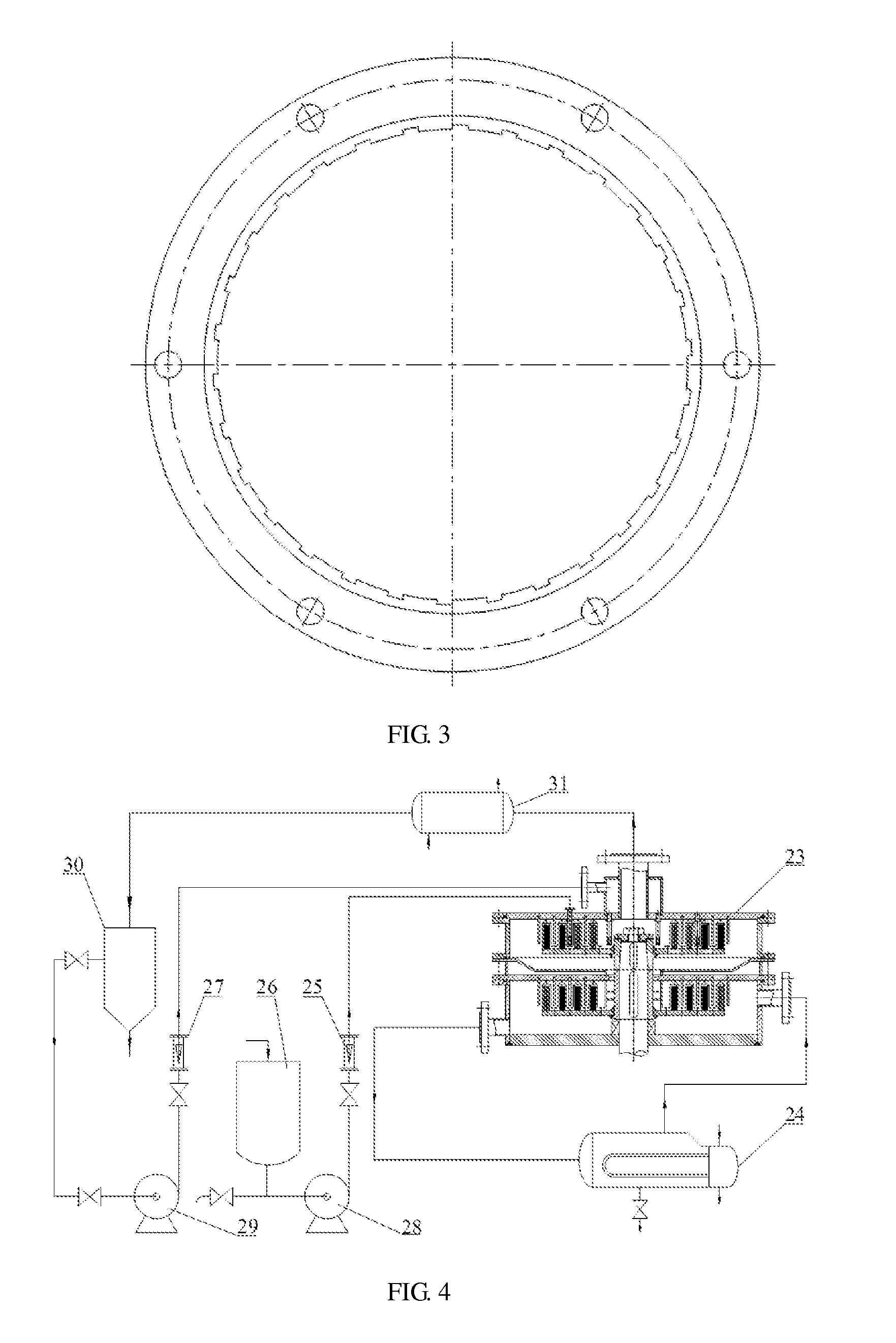

Reactive distillation apparatus for a multistage counter-current rotating bed and its application

ActiveUS20110214979A1Improve mass-transfer efficiencyImprove efficiency separationLiquid-gas reaction processesDistillation in rotating vesselsWire gauzeGas phase

The present invention discloses a reactive distillation apparatus for multistage counter-current rotating bed and its application, the apparatus comprises a closed shell, in the center of which a revolving shaft linking each shell section is set, the said shaft is provided with two or more rotors in series connection, a feeding inlet, a reflux inlet and an outlet of the gas phase are mounted on the top end face of the shell while a waste liquid outlet and an inlet of the gas phase are set on the bottom end face of the shell, the said shell consists of an upper section of the shell and a lower section of the shell along the axial direction, the said rotor consists of a rotating disc firmly connecting with the revolving shaft and a static disc mounted to the shell, a group of concentric dynamic filler rings but with different diameters are installed at intervals along the radial direction, wherein the wall of the dynamic filler rings is holed, and the ring clearance between the dynamic filler rings is configured with static rings fastened on the static disc; the filler filled in the said dynamic filler ring includes a catalytic filler and a wire gauze filler with the catalyst filler filled in the dynamic filler ring of the outer circle of the upper rotor and the inner circle of the lower rotor and the wire gauze filler filled in the rest of the dynamic filler rings, to make the whole rotor structure equivalent to the distillation section, reactive distillation section and stripping section; a feeding inlet is arranged on the top cover of the shell corresponding to the spray nozzle of raw material liquid; a rotating liquid distributor is arranged on the inner side of the innermost dynamic filler ring of the said lower rotor. The catalyst of the present invention not only plays the role of catalytic reaction, but also increases the interphase mass transfer area; the present invention improves the mass transfer efficiency and the separation efficiency of the reactive distillation process.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com