Patents

Literature

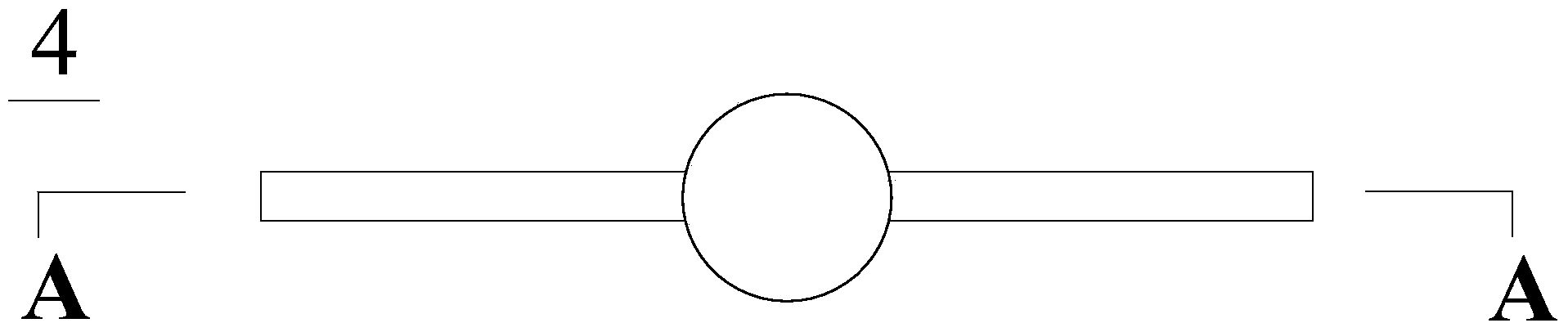

476results about How to "Strong bending resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoplastic elastomer and its production method

The invention provides a high elasticity thermal plasticity elastic body and the method to make. The weight proportion of the elastic body includes: plasticity ingredient styrene-butadiene-styrene block copolymer 100, filling naphthenic oil or white oil 40-60, modification agent 0-110, stabilizing agent 2-10, lubricant 2-65, and other bulk agent 10-300. The invention has advantages of low compression deformation, strong flexing resistance and good resilience.

Owner:闫俊龙

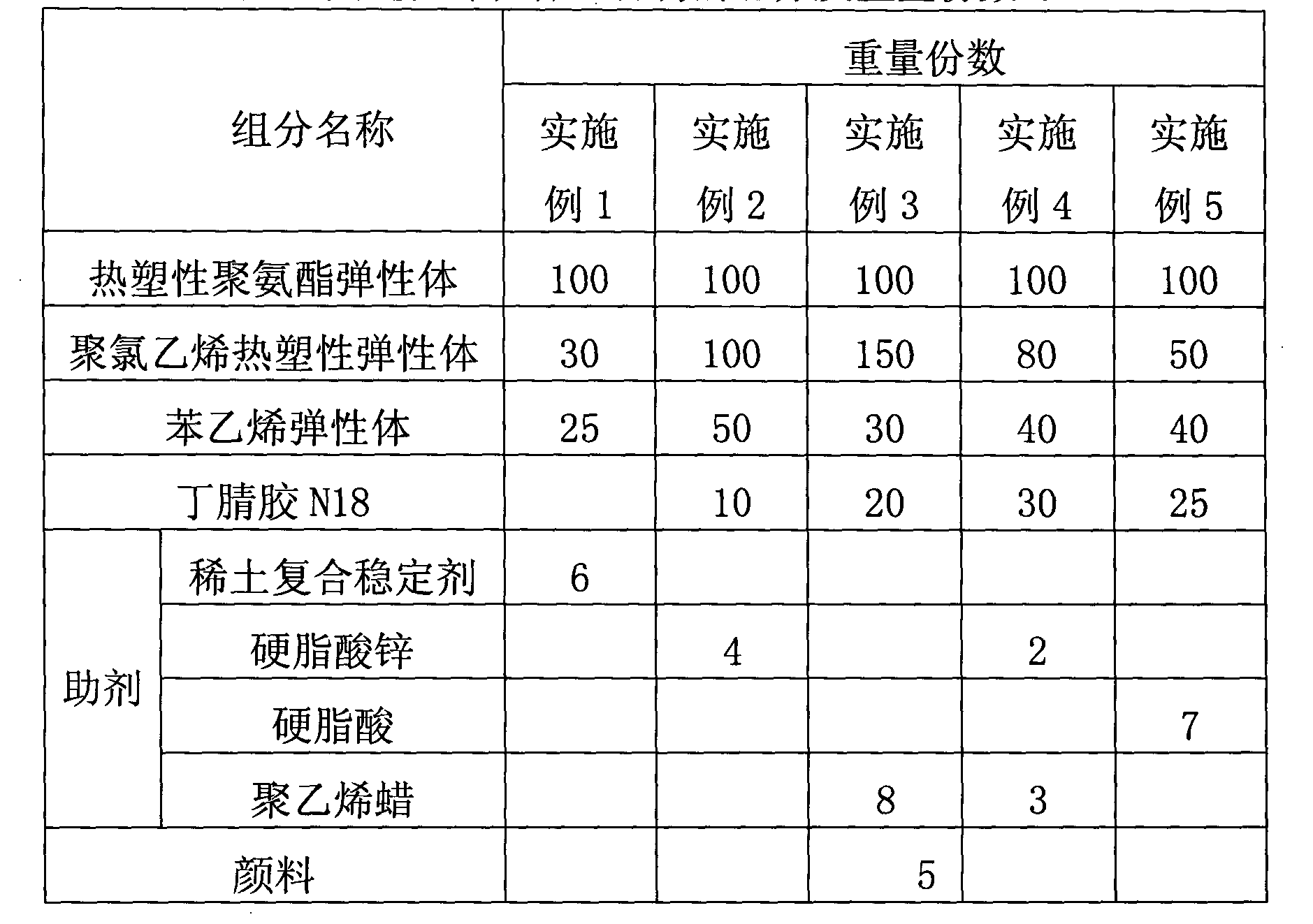

Thermoplastic elastomer composition

The invention discloses a thermoplastic elastomer composition which is plasticated by the following main components by weight: 100 parts of polyurethane thermoplastic elastomers, 30-150 parts of polyvinyl chloride thermoplastic elastomers, 25-50 parts of styrene elastomers, 0-30 parts of blend and 4-8 parts of auxiliaries, wherein the auxiliary is any one or more of a composite rare-earth stabilizer, zinc stearate, calcium stearate, stearic acid or polyethylene wax; and the blend is butyronitrile N18. The invention selects the thermoplastic elastomers with similar polarity and complementary properties to be synthesized and used and selects compatilizers to organically combine several best molecules with different structures, so that the generated novel thermoplastic elastomer has superior performance and appropriate price, can meet the requirements of market products and has wide application range because the product has the technical advantages of excellent oil resistance, resistance to low temperature of minus 35 DEG C, acid-alkali resistance, aging resistance and lower proportion than the vulcanized products with the same price.

Owner:营口巨成教学科技开发有限公司 +1

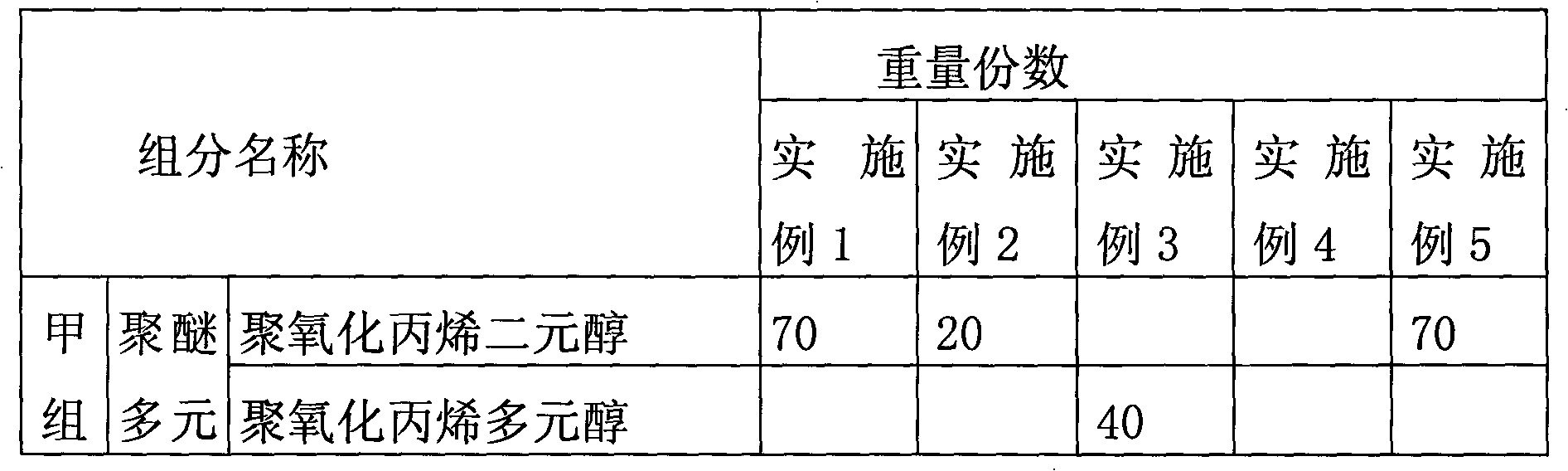

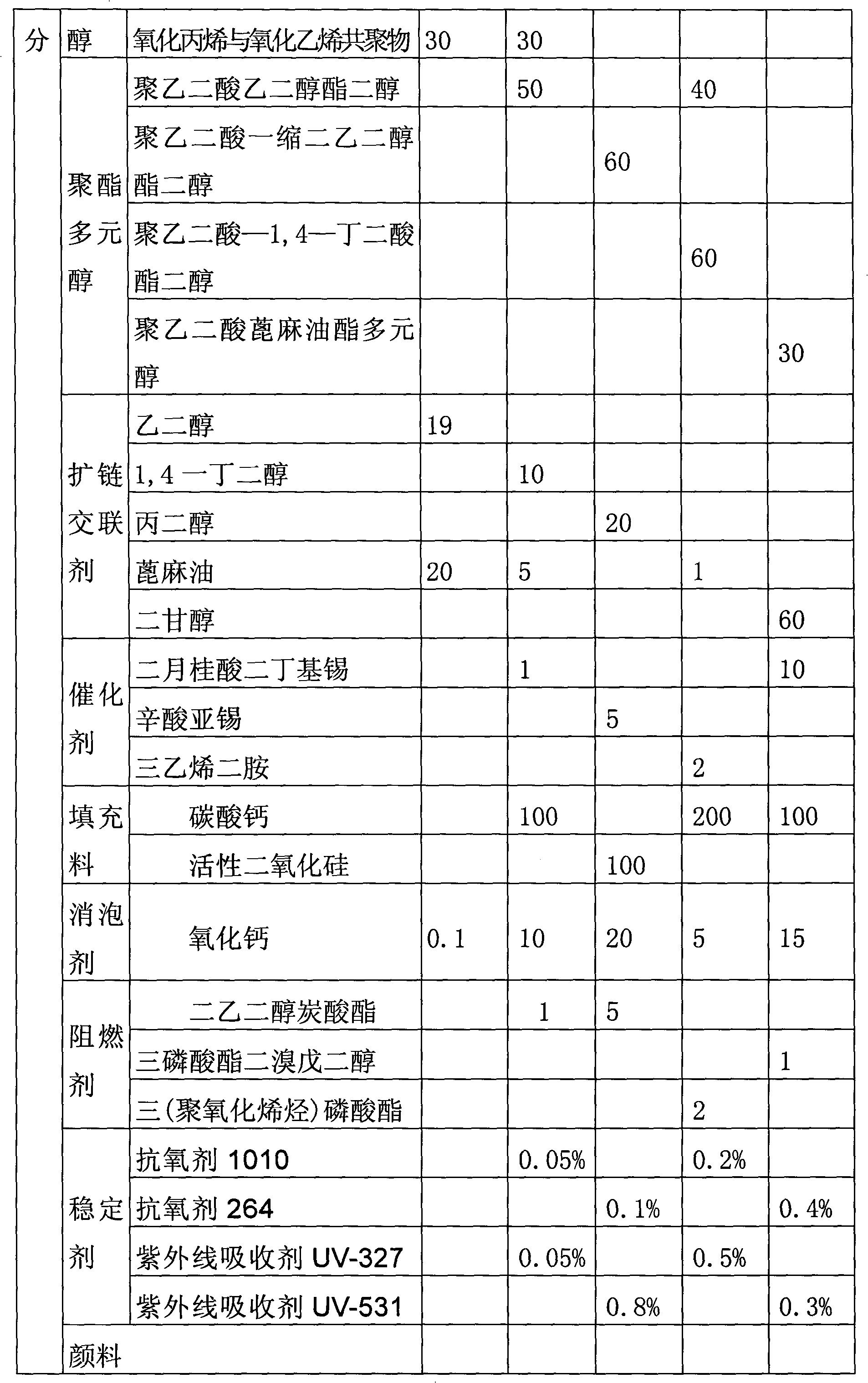

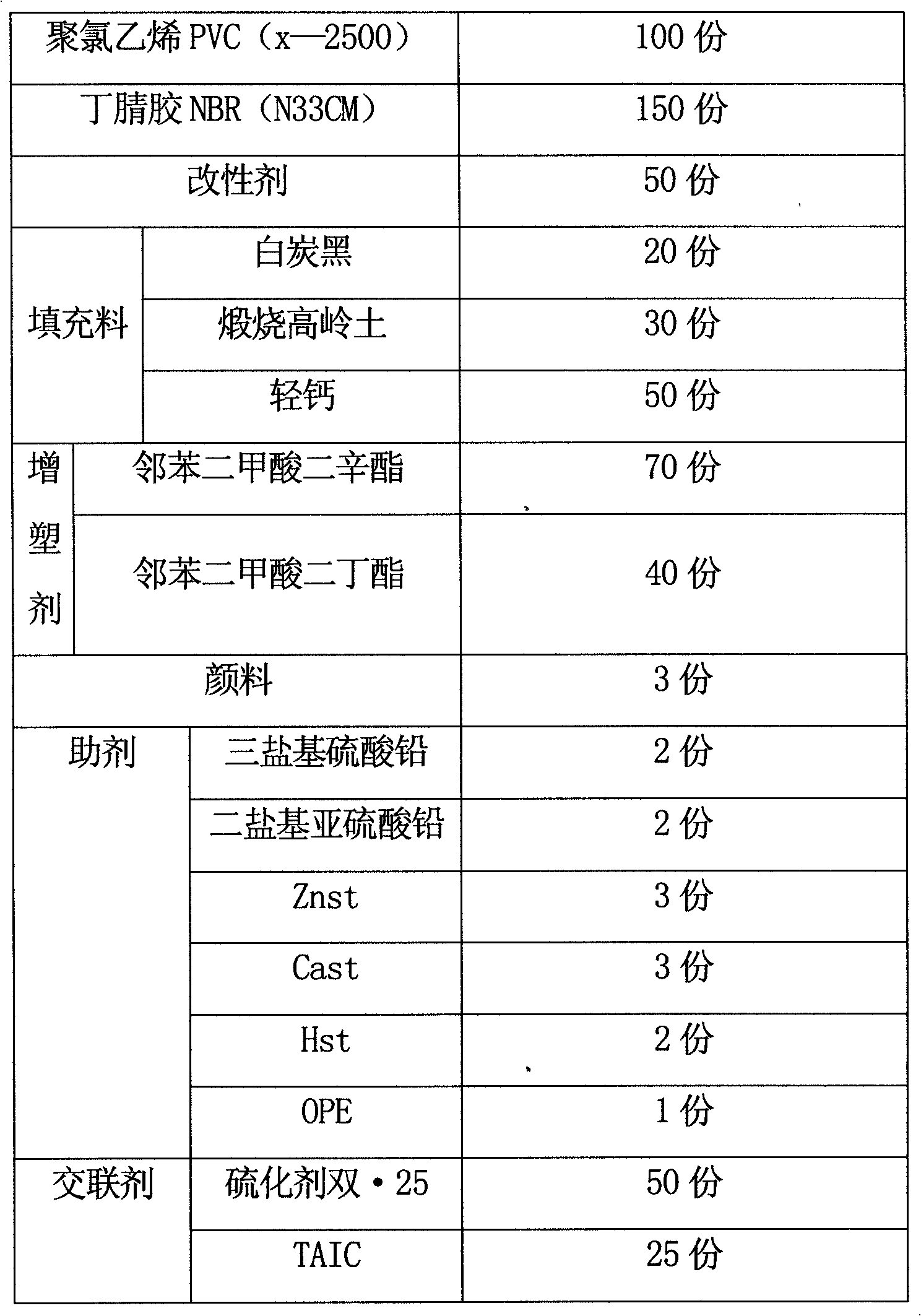

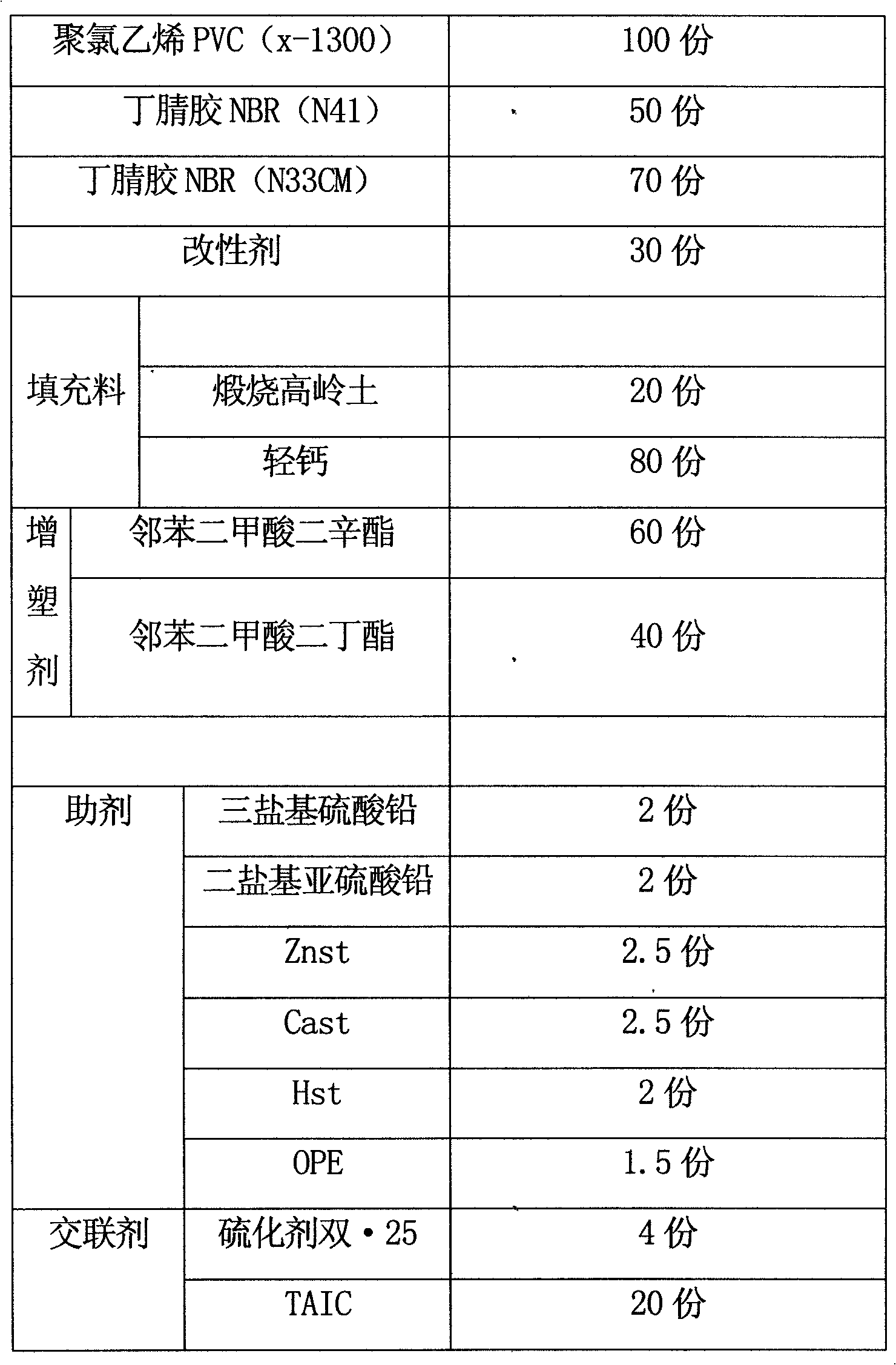

Oil-resistant and low temperature-resistant thermoplastic elastomer and production method

The invention provides an oil-resistant and low temperature-resistant thermoplastic elastomer and a production method according to the mechanism that the characters of a plurality of molecular materials are similar and compatible, mutually complementary and capable of mutually modifying. The oil-resistant and low temperature-resistant thermoplastic elastomer comprises the following components by weight parts: 100 parts of one or a plurality of polyvinyl chloride X-2000, X-2500, X1300 and X-1000, 40-150 parts of one or a plurality of nitrile butadiene rubber (NBR) N41, N33CM, N33M, N26 and N18,20-50 parts of modifier, 20-160 parts of filling agent, 70-150 parts of plasticizer, 15-75 parts of dynamic cross-linking agent, 0-5 parts of pigments and 8-20 parts of additives. The invention develops the modifier, selects the cross-linking agent and technological conditions of temperature, rotational speed and the like, thereby leading the product to achieve the technical requirements of oil resistance, low temperature resistance, acid-base resistance, aging resistance and smaller specific gravity than a vulcanized product with the same price. The elastomer can not only produce various oil-resistant pipes, ropes, wires and cables as well as sealing strips of aluminum-plastic doors and windows of vehicles, motor vehicles and buildings, but also manufacture various parts and products with different mechanical performance requirements on hardness, elasticity and the like through the different technologies of blow molding, extrusion molding, injection molding and the like.

Owner:NINGBO SUNLIGHT MOTOR PARTS

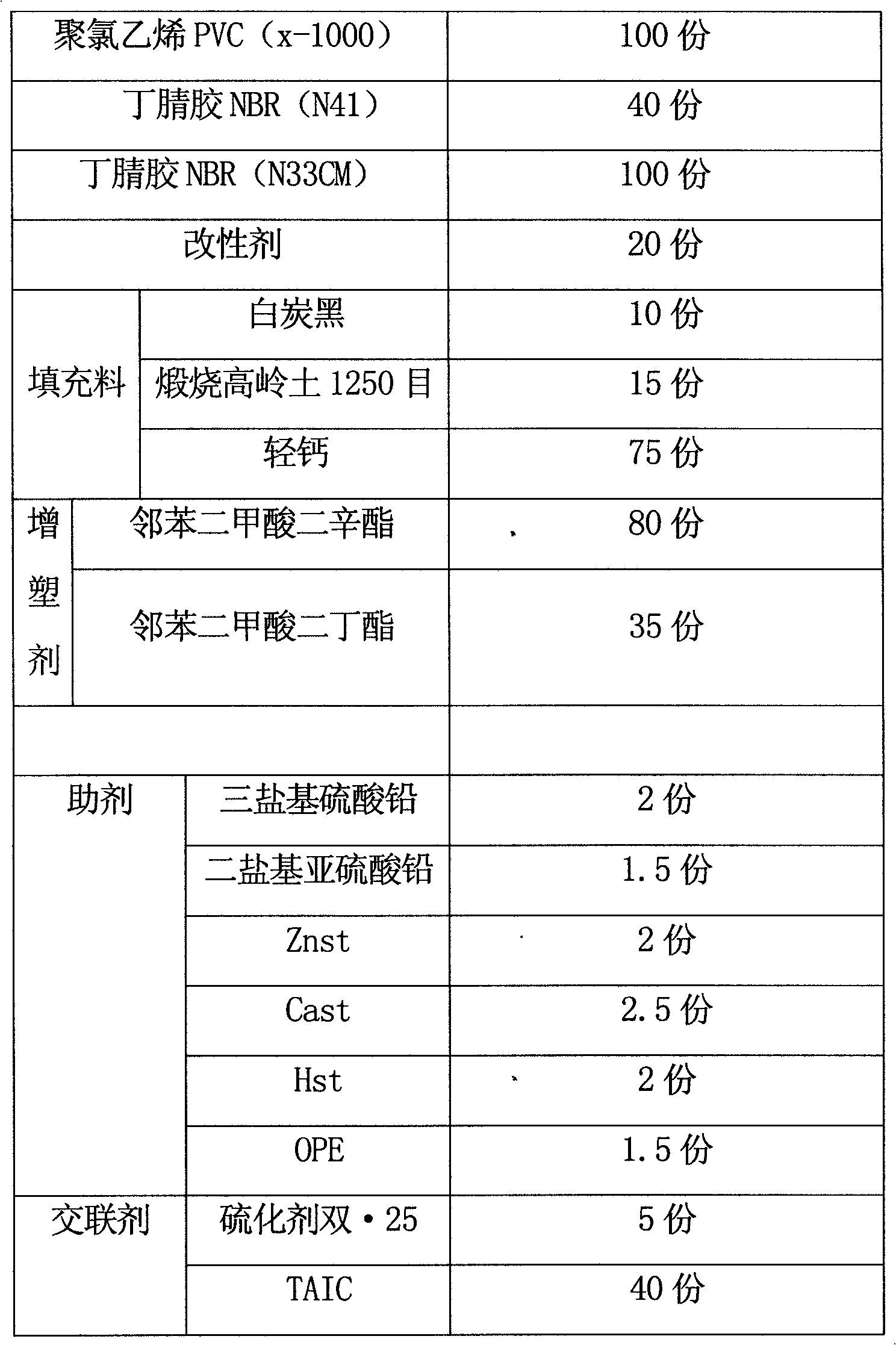

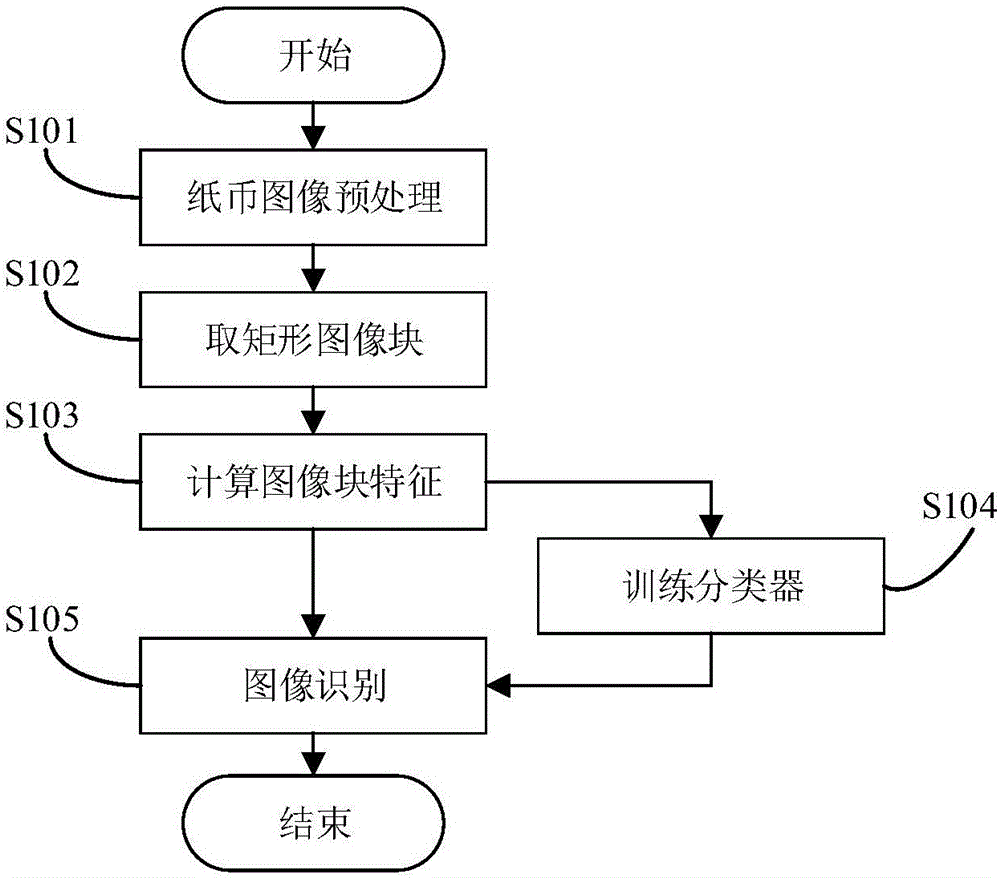

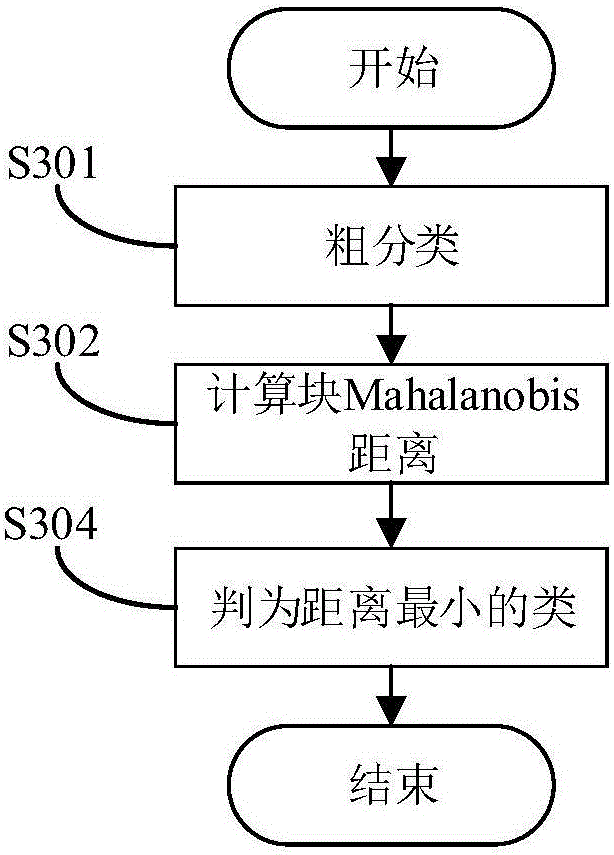

Banknote image recognition method

InactiveCN105894656ACalculation speedSolve the automatic identification problemPaper-money testing devicesCharacter and pattern recognitionFeature vectorImaging Feature

The invention provides a banknote image recognition method which trains a classifier by using a banknote image in a training set, which recognizes the currency type, the nominal value, the orientation, and the version of a banknote image to be tested by using the trained classifier, and which comprises the following steps of: 1) preprocessing the banknote image; 2) acquiring a plurality of image blocks in the banknote image; 3) computing the image feature of each image block in order to constitute feature vectors of the banknote image as the feature vectors of image blocks of the banknote image in the training set or the banknote image to be tested; 4) training the classifier by using the feature vector of each image block of the banknote image in the training set; and 5) inputting the feature vector of each image block of the banknote image to be tested into the classifier to recognize the banknote image. The banknote image recognition method is not required to a local difference between different banknotes but just required to extract corresponding features from the banknote image to perform subsequent recognition.

Owner:ZHEJIANG UNIV

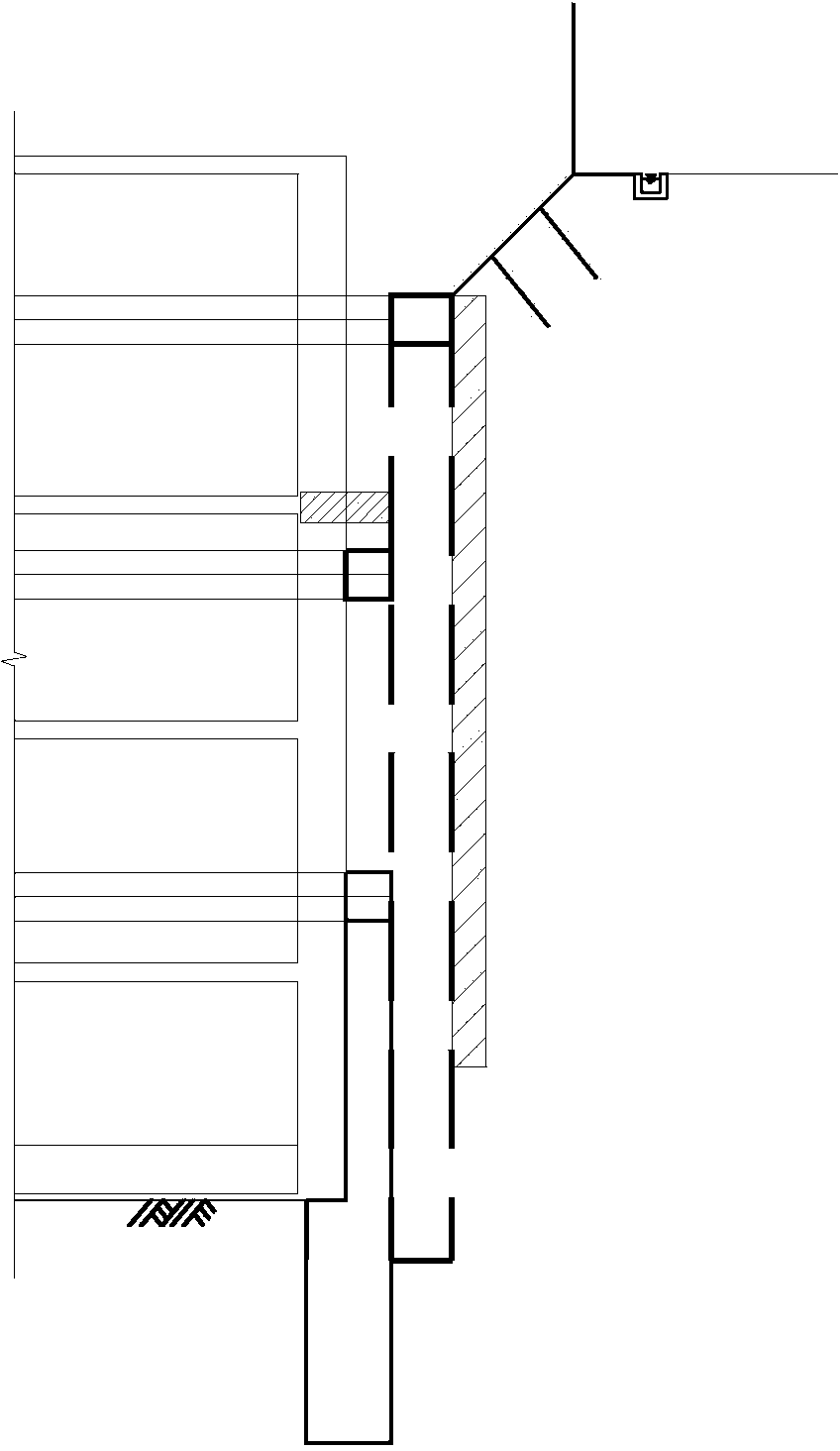

Manual hole digging non-uniform pile support construction technology

ActiveCN104264688AEasy constructionDoes not affect the constructionProtective foundationExcavationsBasementProof construction

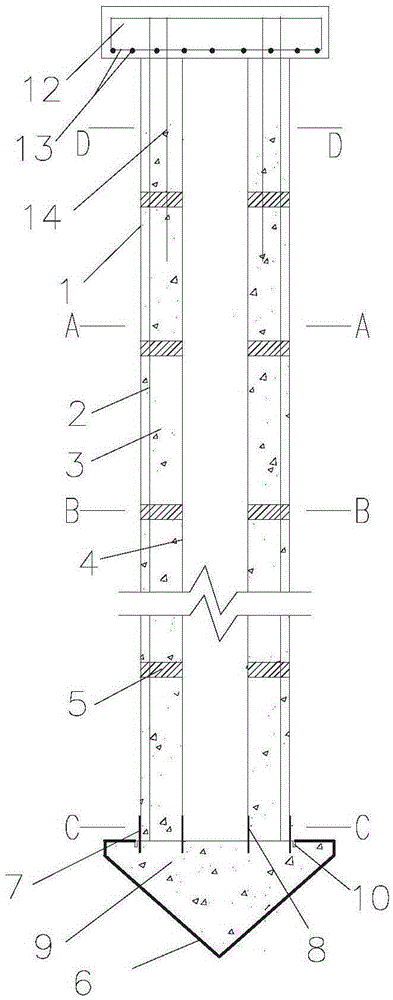

The discloses a manual hole digging non-uniform pile support construction technology for construction along the inner side of the former support structure, the construction steps are as follows: (1) digging the first order, the second order and the third order hole digging piles according to the process of every three for one; (2) forming crown beam at the top of pile for enhancing support structure integral rigidity, having layering construction for horizontal support or anchor cable according to the design calculation requirement, after getting the design strength requirement, excavating the foundation trench earthwork to the bottom in the foundation trench; (3) making level for the manual hole digging non-uniform pile, having the water proof construction, making the basement bottom plate, casting the bottom plate concrete with the former support pile; (4) removing the second strengthening anchor cable or removing the support, finishing the basement structure; (5) extending the rebar in the hollow part of the manual hole digging pile into the basement bottom plate as basement structure pile and anti-floating pile. The manual hole digging non-uniform pile support construction technology solves the problem that the big diameter strengthening support pile construction machinery cannot be contained for the inner support at upper part or convex waist beam while the remain construction space between the support pile and the basement outer side line is small.

Owner:GUANGZHOU URBAN PLANNING & DESIGN SURVEY RES INST

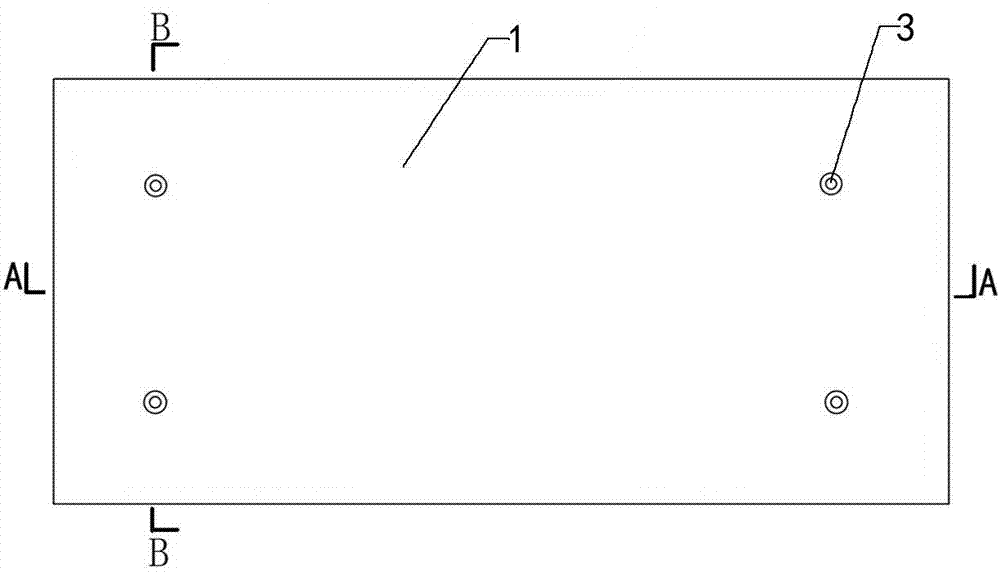

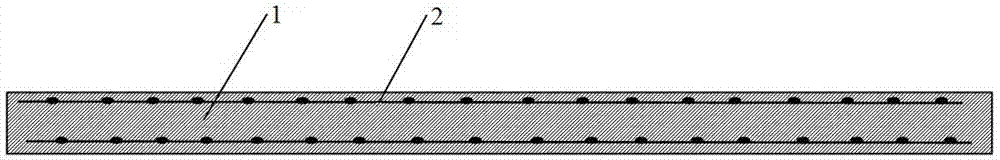

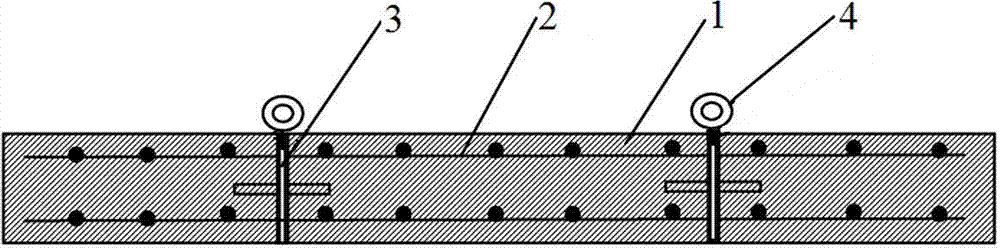

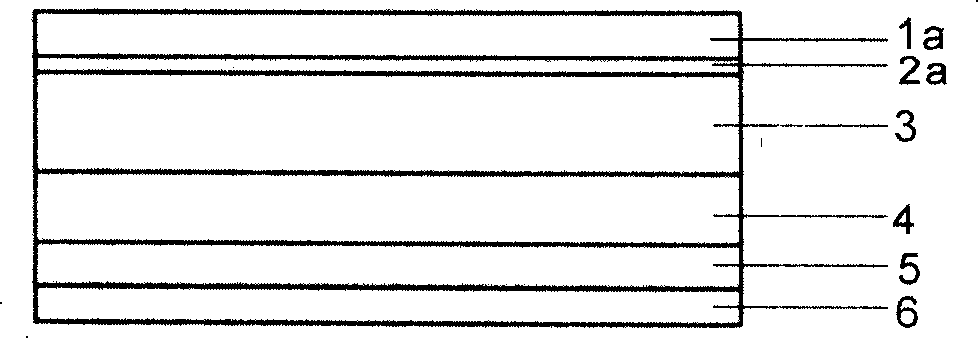

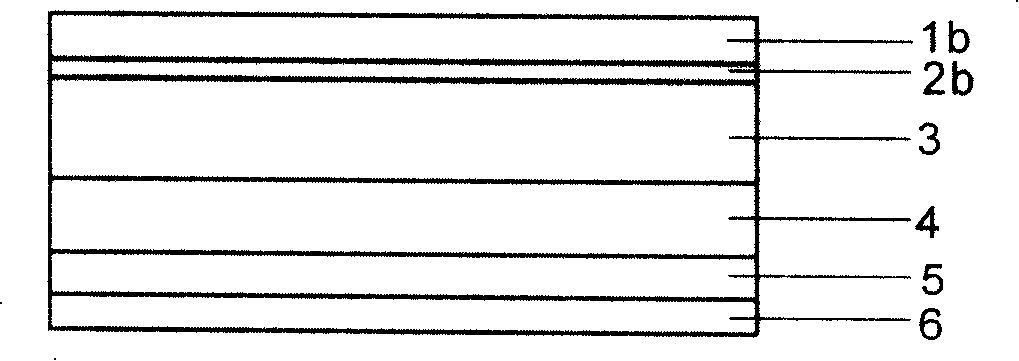

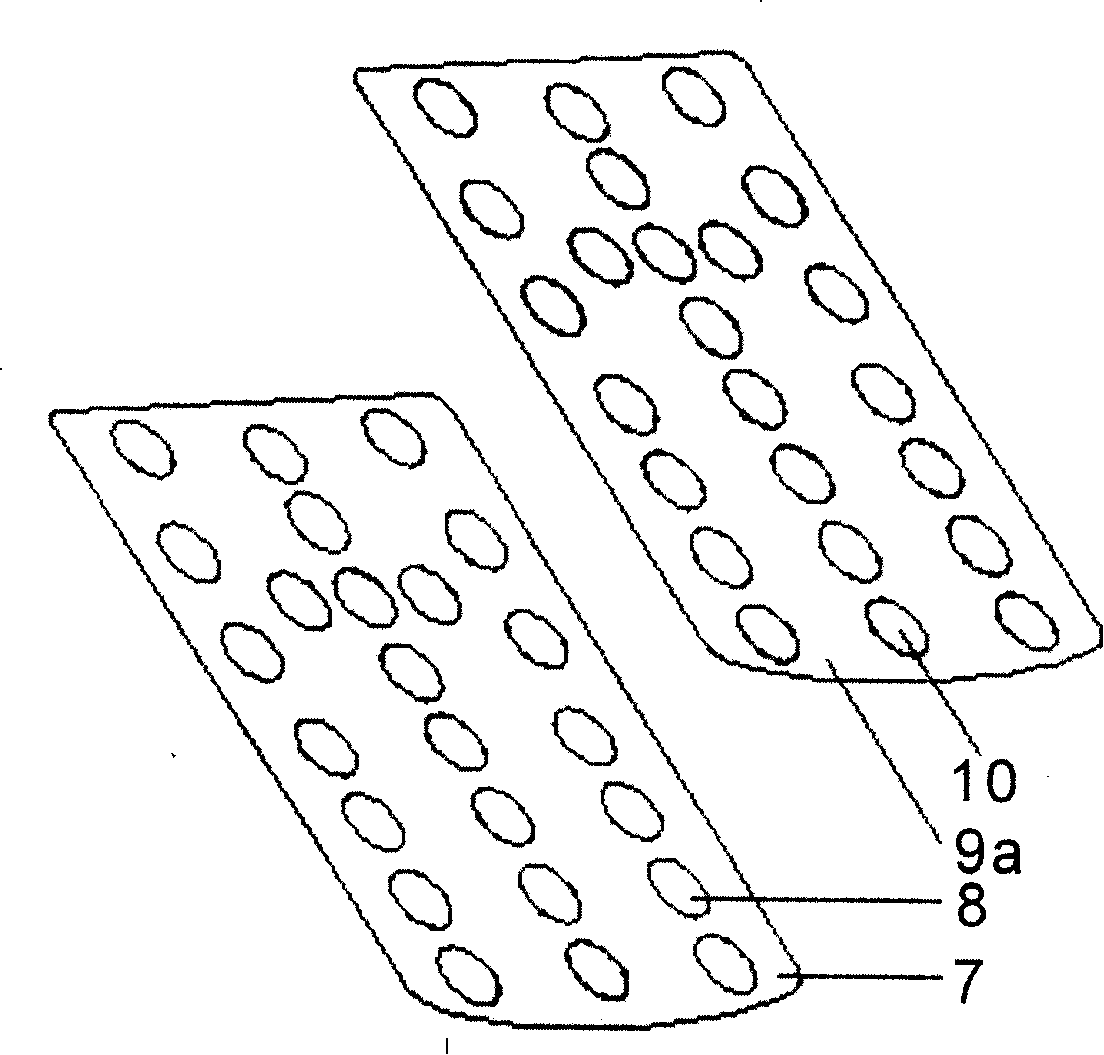

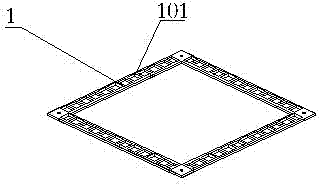

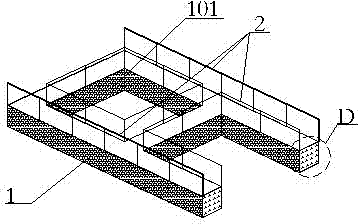

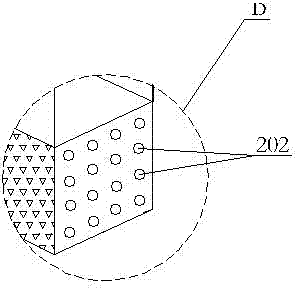

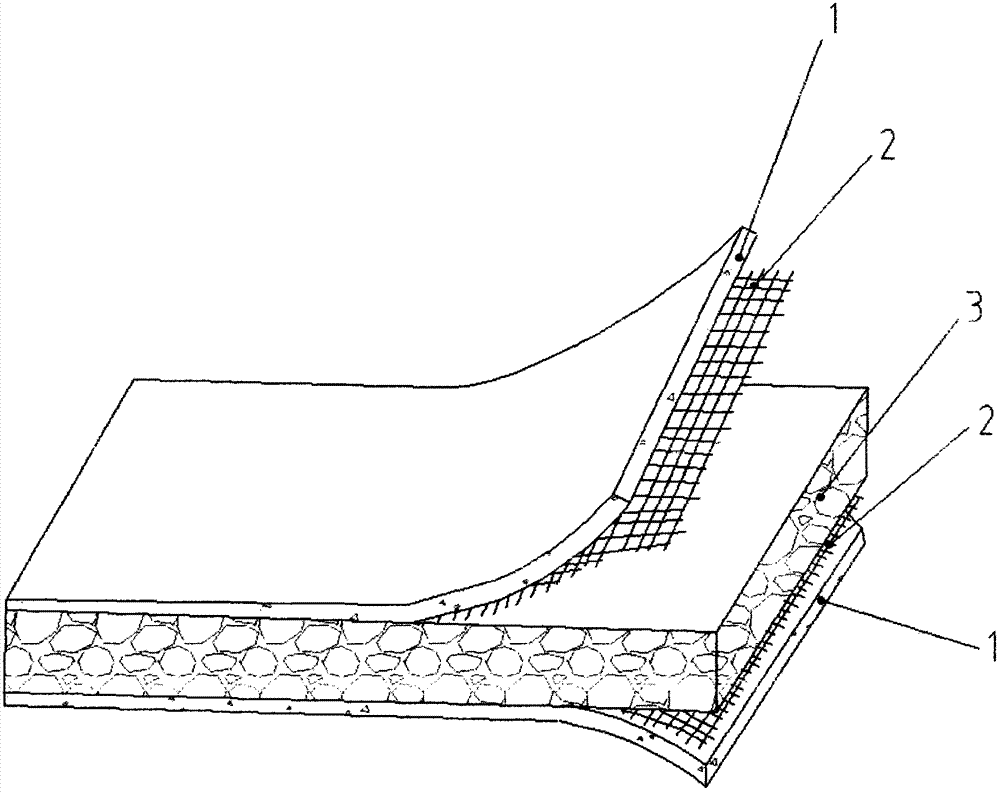

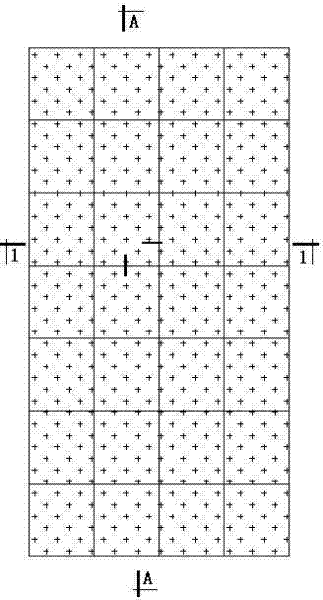

Fabricated type reactive powder concrete prefabricated pavement slab without reinforcing rib and manufacturing method thereof

ActiveCN104294728AStrong bending resistanceHigh compressive strengthSingle unit pavingsCeramic shaping apparatusWire gauzeWeather resistance

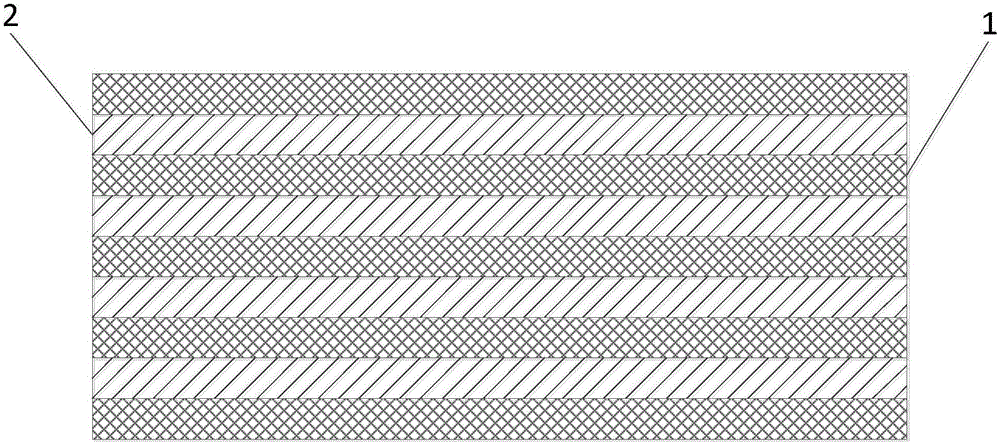

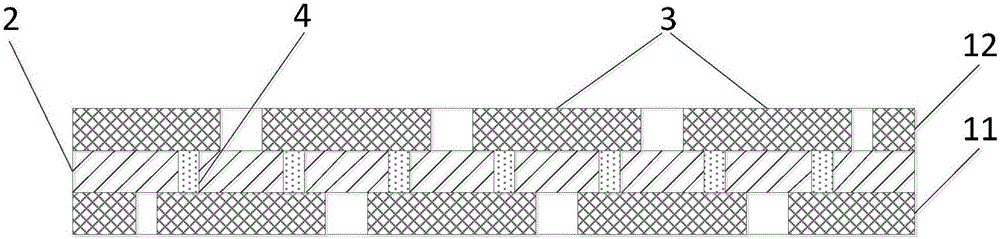

The invention discloses a fabricated type reactive powder concrete prefabricated pavement slab without a reinforcing rib and a manufacturing method thereof. A slab body is a material plate made from reactive powder concrete; layers of horizontal steel wire gauzes are respectively spread in the reactive powder concrete material plate and are close to upper and lower surfaces; hoisting embedded parts which run through in the vertical direction are respectively arranged at the four corners, wherein the two ends of the hoisting embedded parts are connected with lifting appliances. When the fabricated type reactive powder concrete prefabricated pavement slab without the reinforcing rib is manufactured, the fluidity of the reactive powder concrete is controlled to avoid deformation of the pavement slab in the later-period manufacturing process, and the fabricated type reactive powder concrete prefabricated pavement slab without the reinforcing rib is maintained naturally indoors to ensure the total quality of the pavement slab. Compared with a common concrete pavement slab, the pavement slab has the advantages of no reinforcing rib in structure, small thickness, portability, light weight, convenience in transportation and installation, high intensity, wear resistance, high bearing capability, good anti-impact performance, good anti-fatigue performance, good weather resistance, and fast and efficient construction, repeated use, and can be widely applied to road construction of temporary building living quarters.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

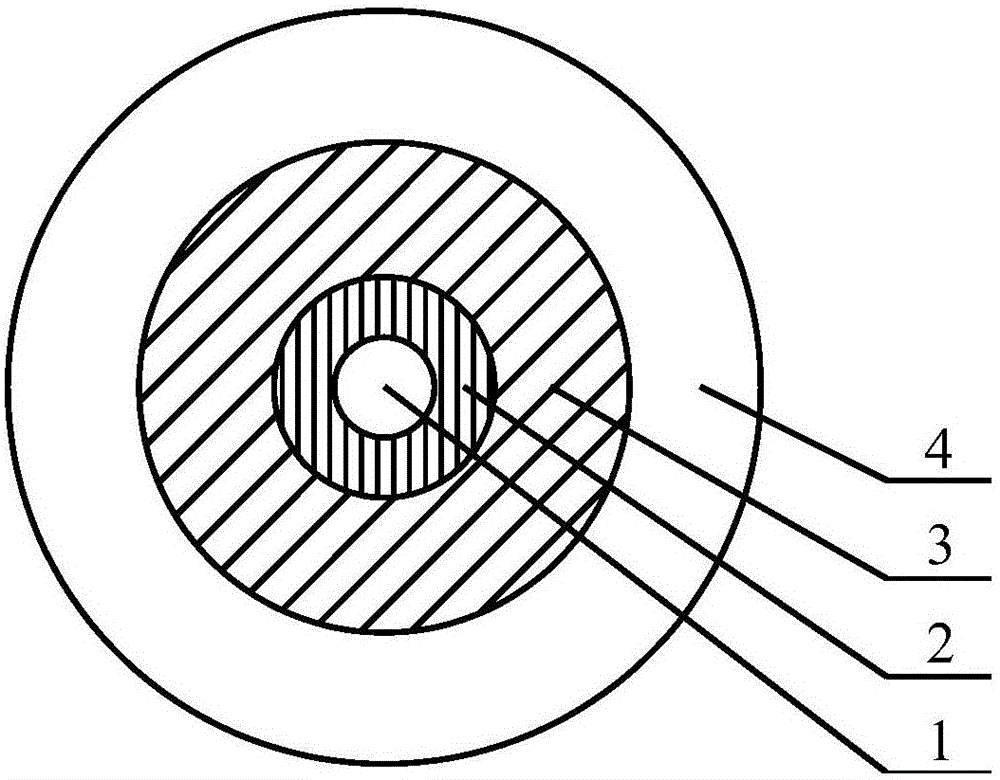

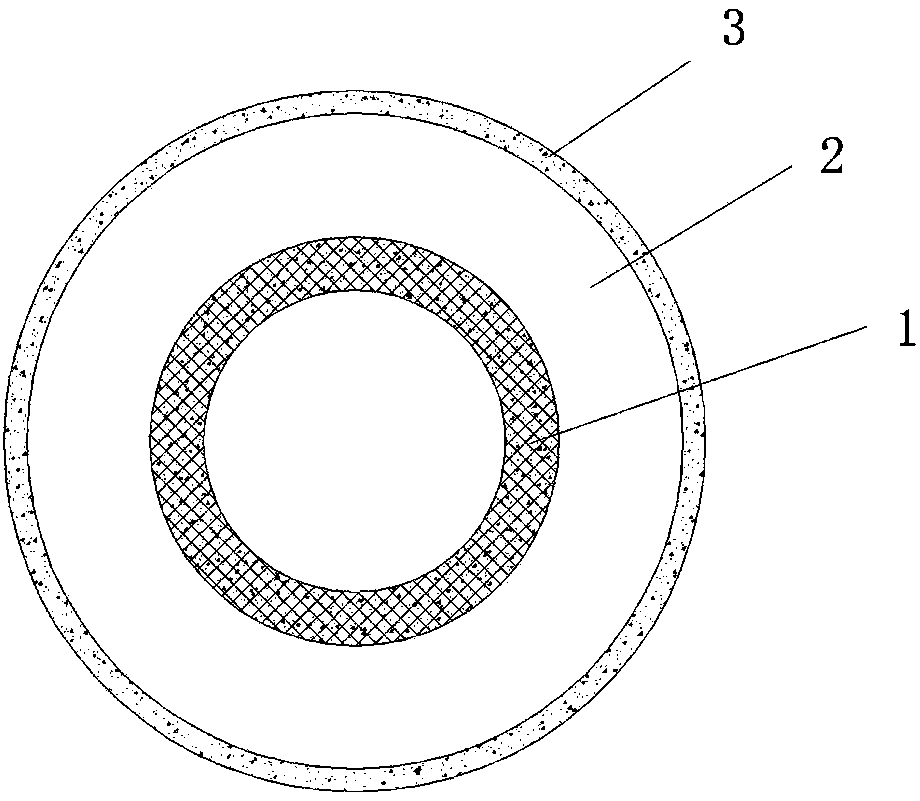

Bend-insensitive radiation-resistant single-mode fiber

ActiveCN105676349AReduce additional lossStrong bending resistanceGlass optical fibreOptical fibre with multilayer core/claddingRadiation resistantMetal impurities

The invention discloses a bend-insensitive radiation-resistant single-mode fiber and relates to the field of a single-mode fiber. The single-mode fiber comprises a core layer, an inner wrapping layer and an outer wrapping layer, which are arranged in sequence from the inside out. The core layer, the inner wrapping layer and the outer wrapping layer are made of quartz material. The inner wrapping layer comprises a first fluorine-doped inner wrapping layer and a second fluorine-doped inner wrapping layer arranged in sequence from the inside out. The core layer and the first fluorine-doped inner wrapping layer are germanium-undoped, and other metal impurities and phosphorus concentration are lower than 0.1 ppm; in mass percent, the doped fluorine content in the core layer is 0-0.45%, and chlorine content is 0.01%-0.10 %; fluorine content in the first fluorine-doped inner wrapping layer is 1.00%-1.55%; and the fluorine content in the second fluorine-doped inner wrapping layer is 3.03%-5.00%. Compared with an existing radiation-resistant single-mode fiber, additional loss of the single-mode fiber under a bending state is greatly reduced, and bending-resistant performance thereof is better, that is, the single-mode fiber is insensitive to bend; and meanwhile, the radiation-resistant capability of the single-mode fiber is better.

Owner:WUHAN POST & TELECOMM RES INST CO LTD +1

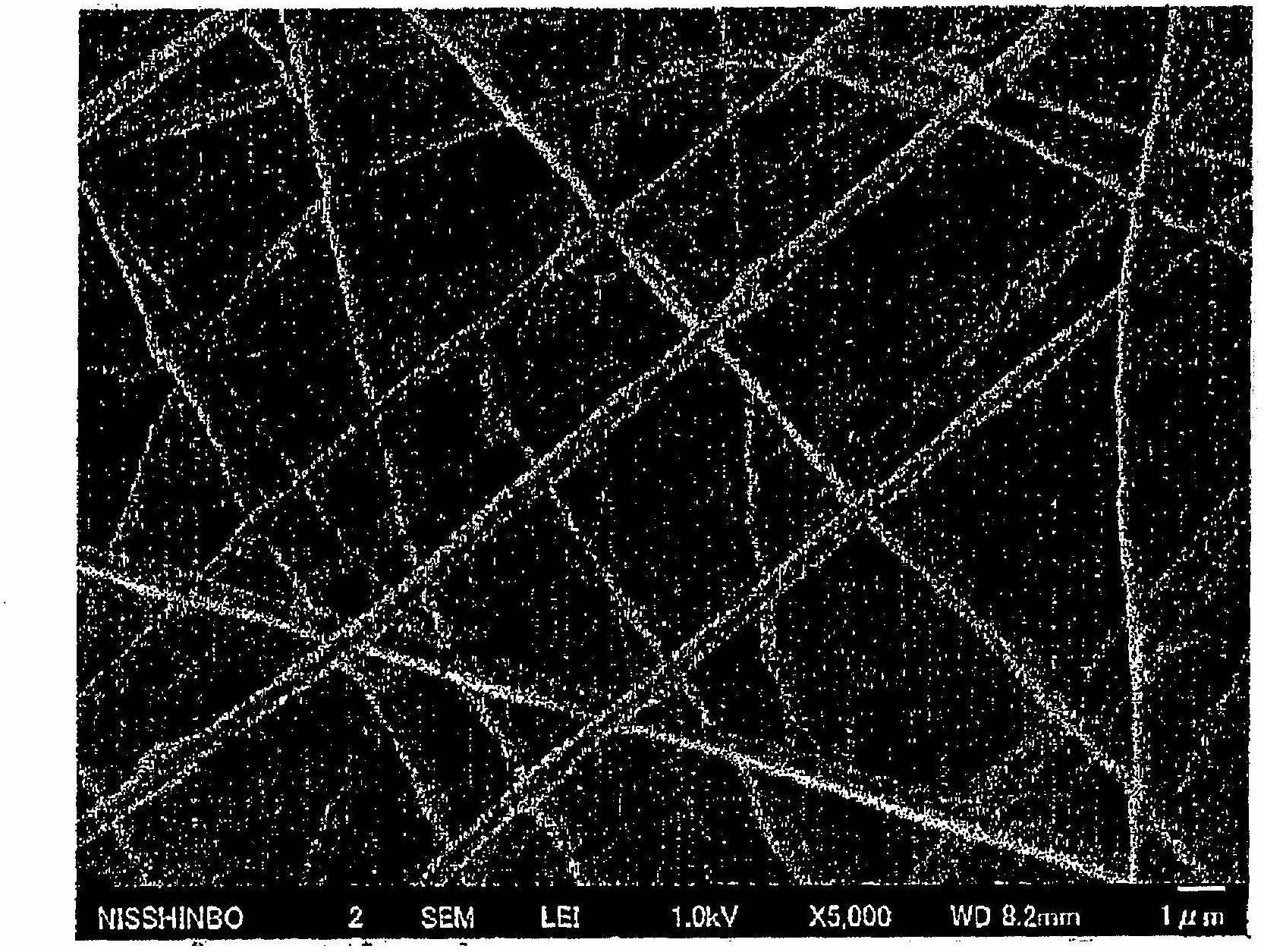

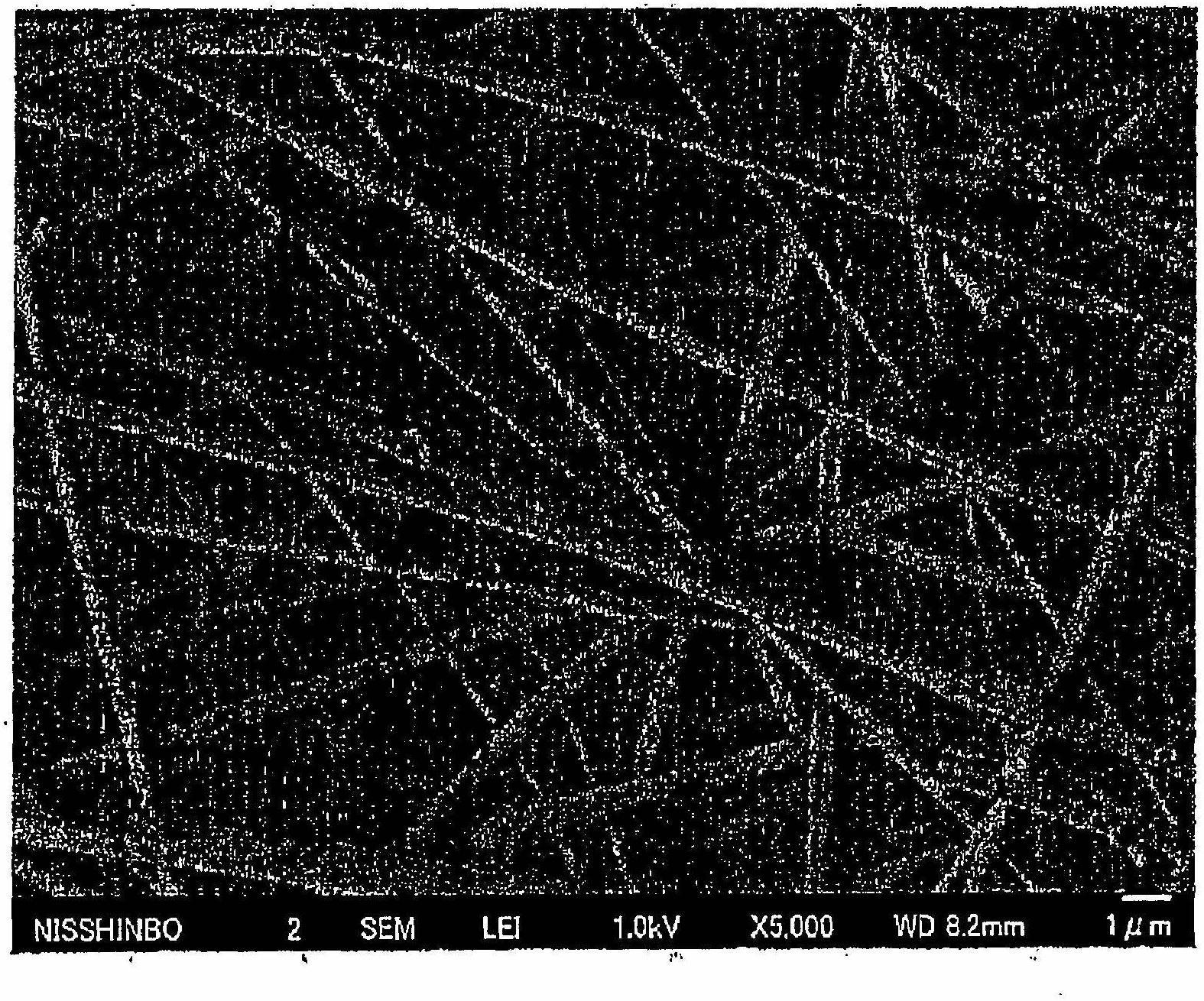

Flexible carbon fiber nonwoven fabric

ActiveCN102652192AStrong bending resistanceManufacturing process can be simplifiedReactant parameters controlOther chemical processesSimple Organic CompoundsPolymer science

Owner:NISSHINBO IND INC

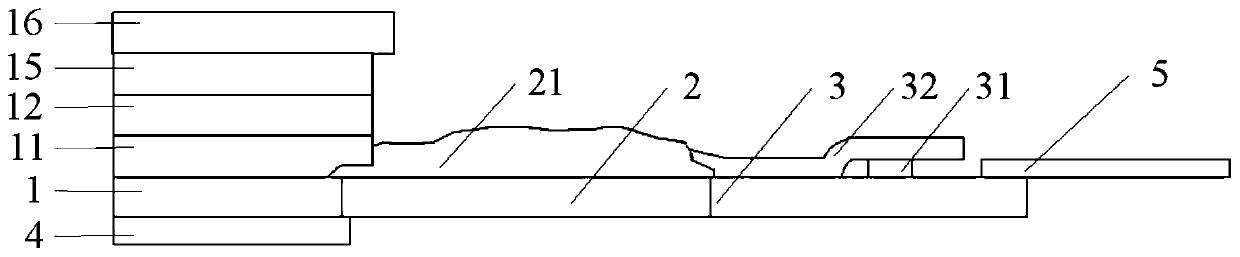

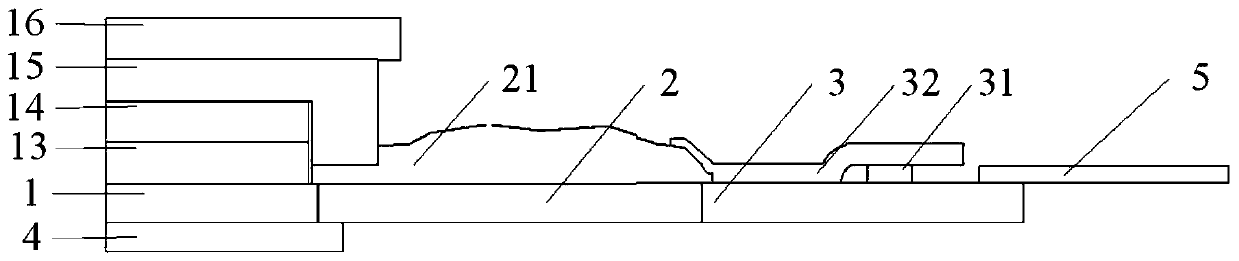

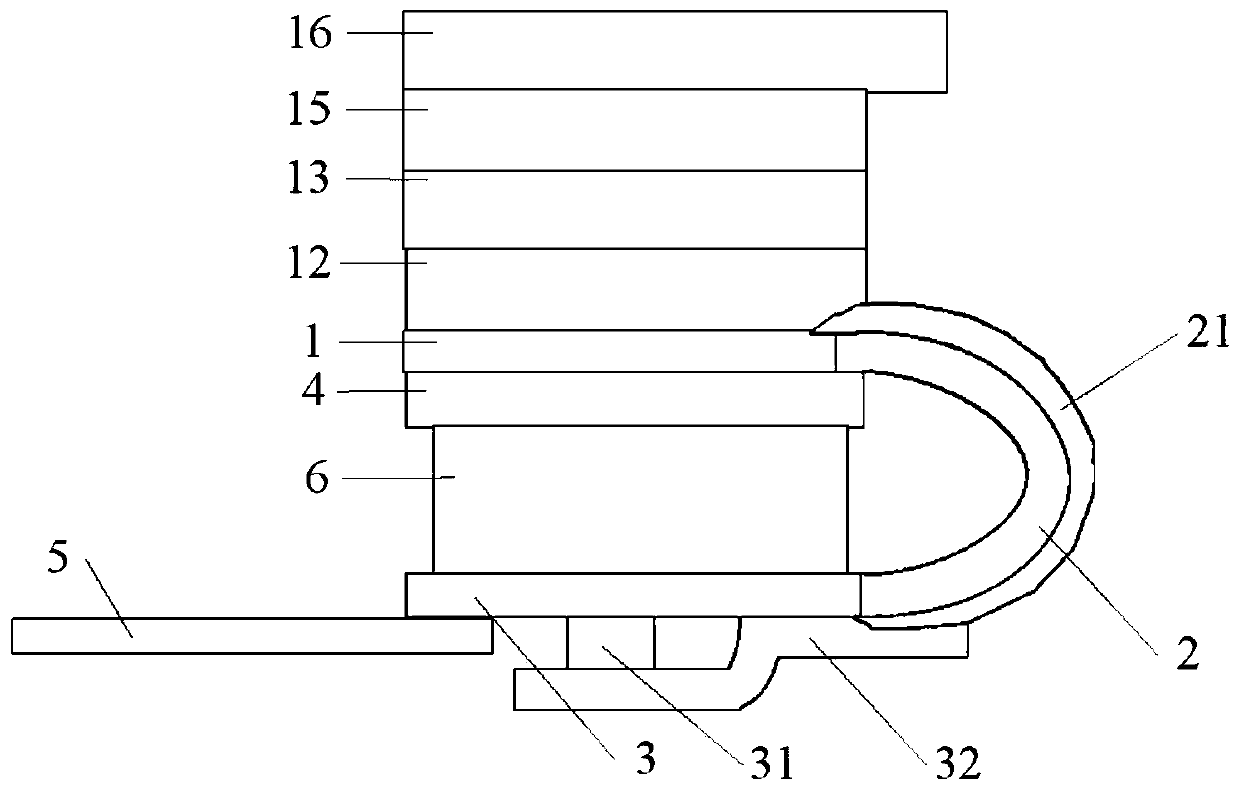

Display module and display device

ActiveCN110224081AHigh strengthGuaranteed bending yieldDigital data processing detailsSolid-state devicesAdhesiveDisplay device

The invention discloses a display module and a display device, relates to the technical field of display and achieves the purpose of improving the bending yield of the display module. The main technical solution of the present invention comprises that the display module comprises a display panel, and the display panel comprises an effective display area, a bending area and a pad area arranged in sequence, wherein an adhesive layer and a fixed layer are sequentially laminated on the effective display area, and the bending area is coated with a protective adhesive layer. The pad area is providedwith an electronic chip, and the electronic chip is covered with a chip protective film, and the adhesive layer extends to the protective adhesive layer and covers the edge of a first side of the protective adhesive layer, and the edge of the adhesive layer is placed in the coverage area of the fixed layer, the chip protective film extends to the protective adhesive layer and covers the edge of asecond side of the protective adhesive layer, wherein the first side and the second side are opposite sides of the protective adhesive layer, the first side is adjacent to the effective display areaand the second side is adjacent to the pad area.

Owner:BOE TECH GRP CO LTD +1

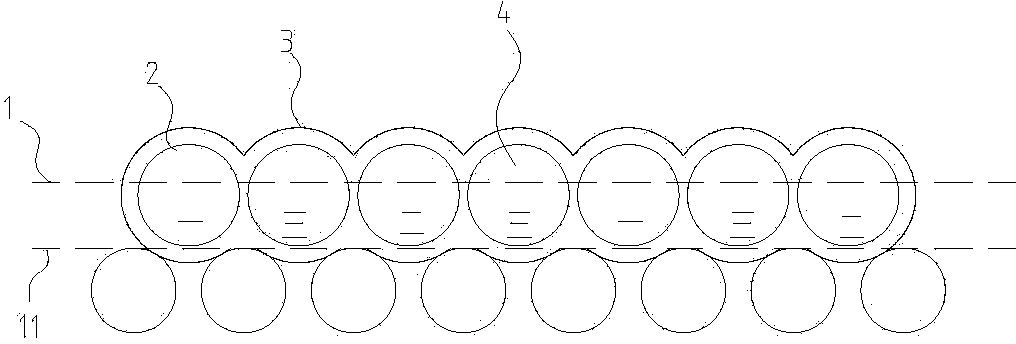

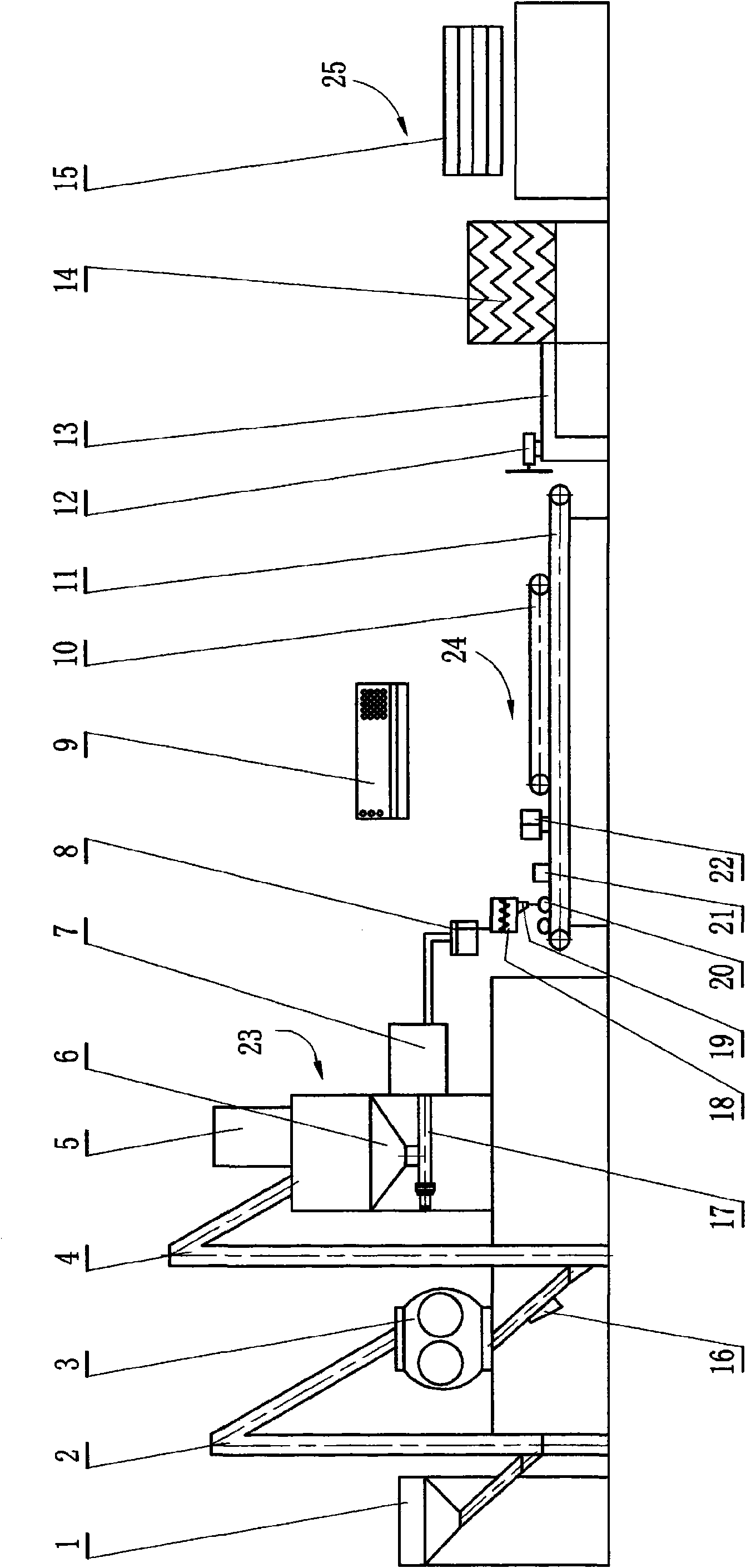

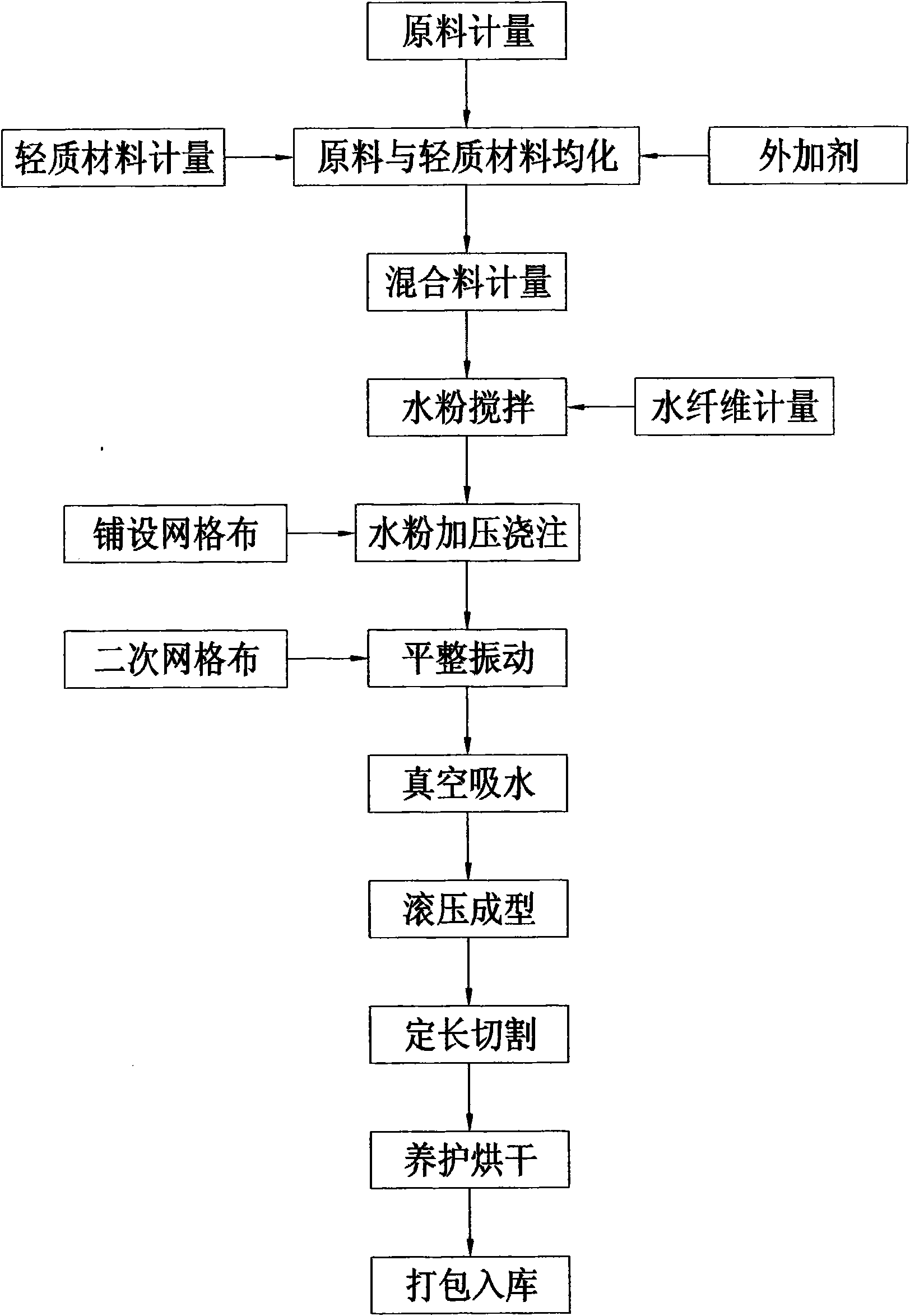

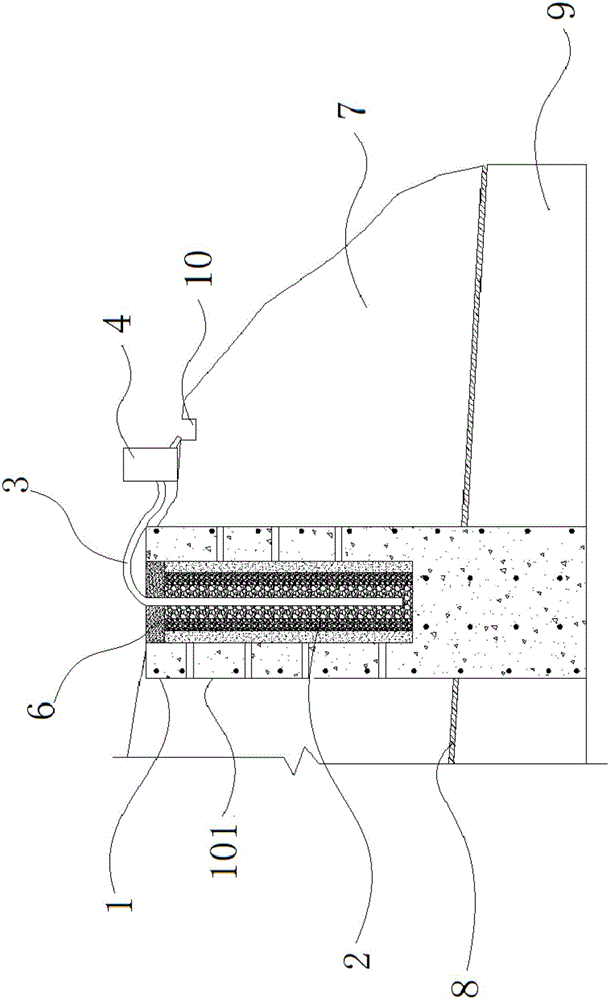

Preparation process of fiber cement slab or fiber gypsum board as well as production line

InactiveCN101670612AImprove stress resistanceStrong bending resistanceCeramic shaping apparatusProduction lineDistributor

The invention discloses a preparation process of a fiber cement slab or a fiber gypsum board as well as a production line, as shown in drawings, comprising an integrated console (9), a feeder (23), acast-molding device (24), a cutter (12) and a post-maintaining and drying conveyer (25). The feeder (23) is provided with a material storage bin (1), an initial lifter (2), a dry powder blender (3), an iron remover (16), a secondary lifter (4), a mixture bin (6) and an arch-breaking device (17); the cast-molding device (24) is provided with a metering conveyor (7), a water and fiber synthesizer (8), a water and powder blender (18), a distributor (19), a grid frame (20), a vibrator (21), a vacuum water pumping device (22), a compression belt (10) and a molding frame (11); and the post-maintaining and drying conveyer (25) is provided with a conveying line (13), a maintaining and drying furnace (14) and an automatic conveying table (15). The production line meters and feeds the materials andcontinuously works, the fiber cement slab or the fiber gypsum board prepared by the process of the invention has largely improved pressure resistance, bending resistance and toughness.

Owner:罗国军

Formula of concrete creak self-repair material and preparation technology

The invention relates to a formula for a concrete crack self-repairing material and a process for preparing the concrete crack self-repairing material. The material comprises the following components in weight percentage: 62 to 77 percent of Portland cement, 0.2 to 1.0 percent of sodium citrate, 3.0 to 8.0 percent of bilinurine, 1 to 4 percent of sodium silicate, 1.0 to 3.0 percent of calcium oxide and 22 to 35 percent of quartz sand with the grain diameter of between 80 and 120 meshes; the preparation process comprises the following steps: the 62 to 77 percent of Portland cement and the 22 to 35 percent of quartz sand with a grain diameter of between 80 and 120 meshes are mixed in a mixer, during which, the 0.2 to 1.0 percent of sodium citrate, the 3.0 to 8.0 percent of bilinurine, the 1 to 4 percent of sodium silicate and the 1.0 to 3.0 percent of calcium oxide are added and mixed for 3 to 5 minutes, and the mixture is subjected to material discharging and sealing storage. The material has the functions of compactness, penetration resistance, freeze resistance and chemical corrosion resistance, and can resist the strong water pressure and the invasion of harmful matters for a long time and has the same service life as the concrete; moreover, the material is not swelled to damage the concrete, and is non-toxic, harmless and environment friendly.

Owner:王可良

EL film sheet and its making method, and mobile phone keyboard with this film sheet

InactiveCN101193472AReduce EL sheet thicknessImprove the flexibility of EL sheetsElectrical apparatusElectroluminescent light sourcesPoly ethyleneEngineering

The invention discloses an inorganic electroluminescence (EL) diaphragm, a manufacture method and a mobile phone keyboard formed thereof. The diaphragm consists of a transparent substrate, a transparent conducting layer, a bus bar, an emitting layer, a dielectric layer, a back electrode layer and an insulating layer. By adopting the method for screen-printing the polymeric transparent conducting layer on the transparent and flexible diaphragm substrate, a novel transparent electrode is formed to replace a traditional conductive film of poly ethylene terephthalate / indium tin oxide (PET / ITO). The method reduces the thickness of the EL diaphragm and significantly improves the flexibility of the EL diaphragm. As for the mobile phone keyboard made of the EL diaphragm, a whole piece of the EL diaphragm adheres to a circuit board with an arched metal shrapnel. As the ultra-thin and flexible EL diaphragm hardly affects feeling of key, openwork process is not required on the metal shrapnel. Therefore, the invention provides backlight for the mobile phone keyboard with a good feeling of key, thin thickness and even luminescence.

Owner:海宁市盐官工业投资有限公司

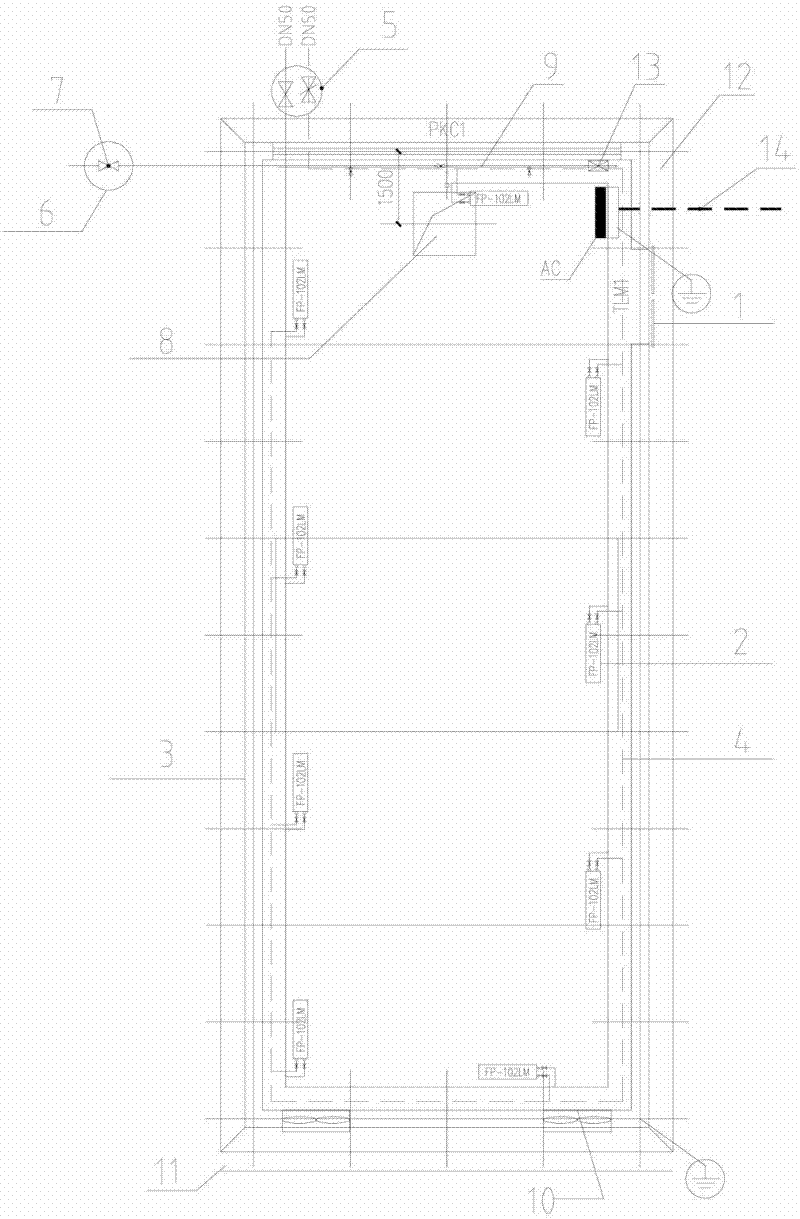

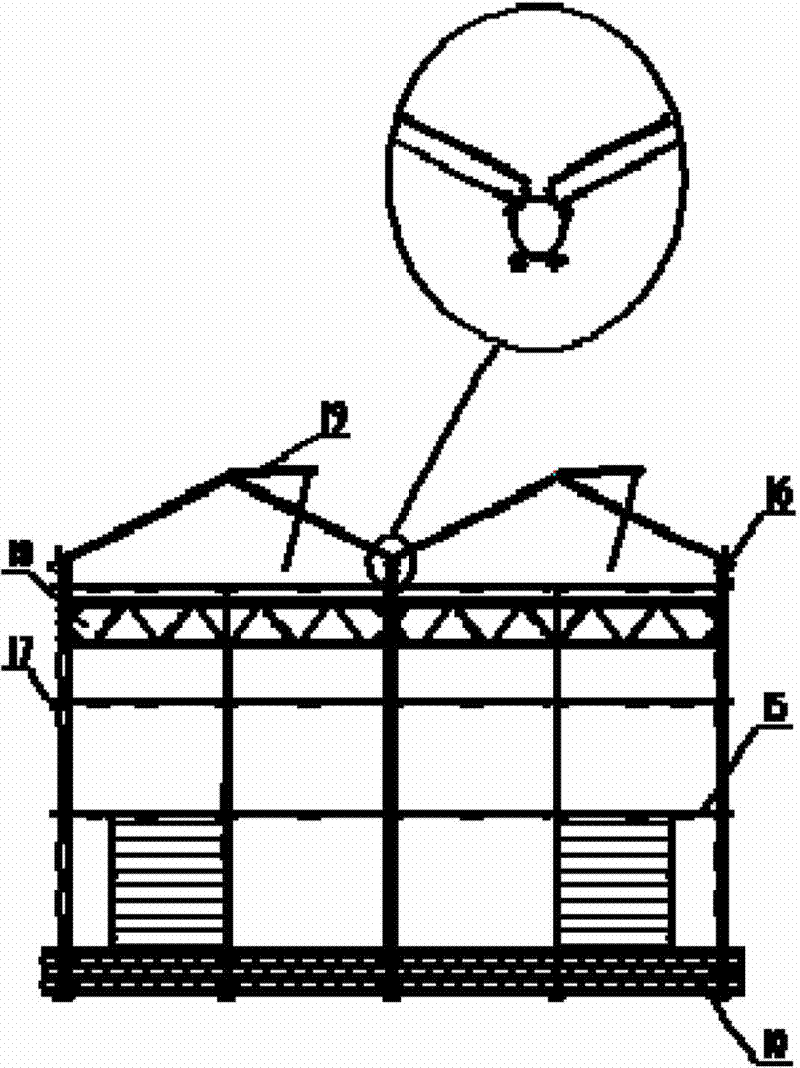

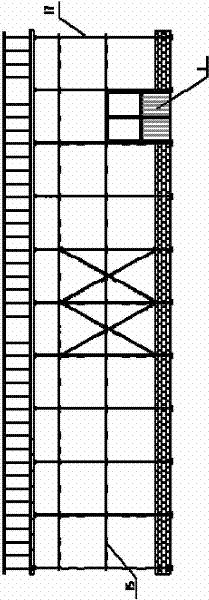

Double-layer aluminum gutter greenhouse

InactiveCN102550332AStrong bending resistanceReduce section sizeClimate change adaptationGreenhouse cultivationAutomatic controlEngineering

The invention discloses a double-layer aluminum gutter greenhouse, which is composed of a main body structure, a cover material and an ancillary facility, wherein the main body structure comprises upright columns, composite beams, water troughs and wall beams; the ancillary facility comprises a ventilation system, a heating system, a power distribution system and an automatic control system; the water trough adopt aluminum gutters, and the aluminum gutters are aluminum structure devices which have the functions of rainwater collection, condensate collection and drainage. According to the double-layer aluminum gutter greenhouse, the anti-bending performance is strong, the sectional dimension is smaller than that of a steel gutter, the shading area is small, and the problem of condensate collection in the greenhouse is solved; a middle cavity is used for separating air inside and outside the greenhouse, so that the heat loss of the steel gutter is reduced; and besides, the double-layer aluminum gutter greenhouse has the properties of dew collection and heat insulation and provides a good growing environment for seedling breeding.

Owner:BEIJING KINGPENG INT HI TECH CORP

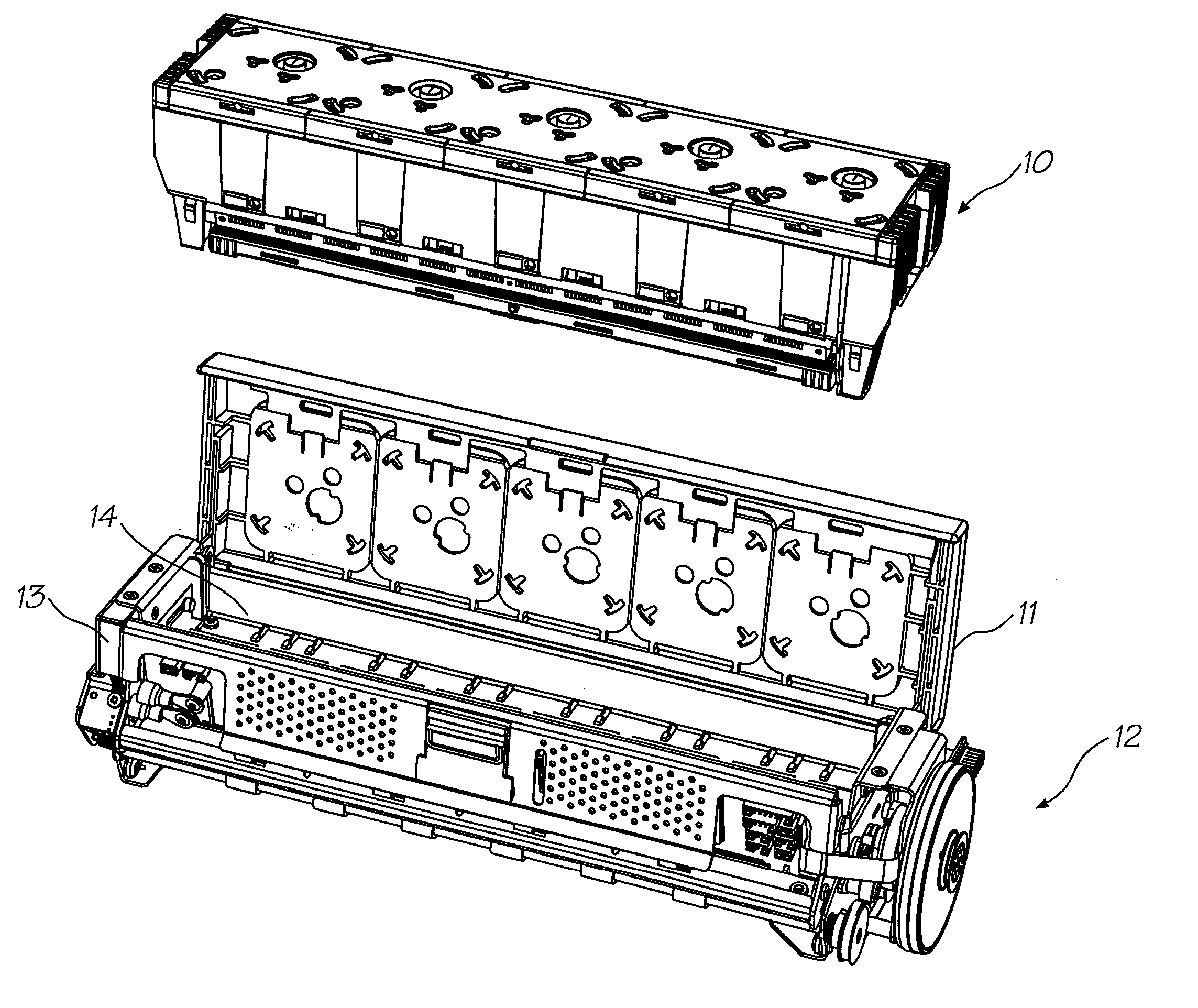

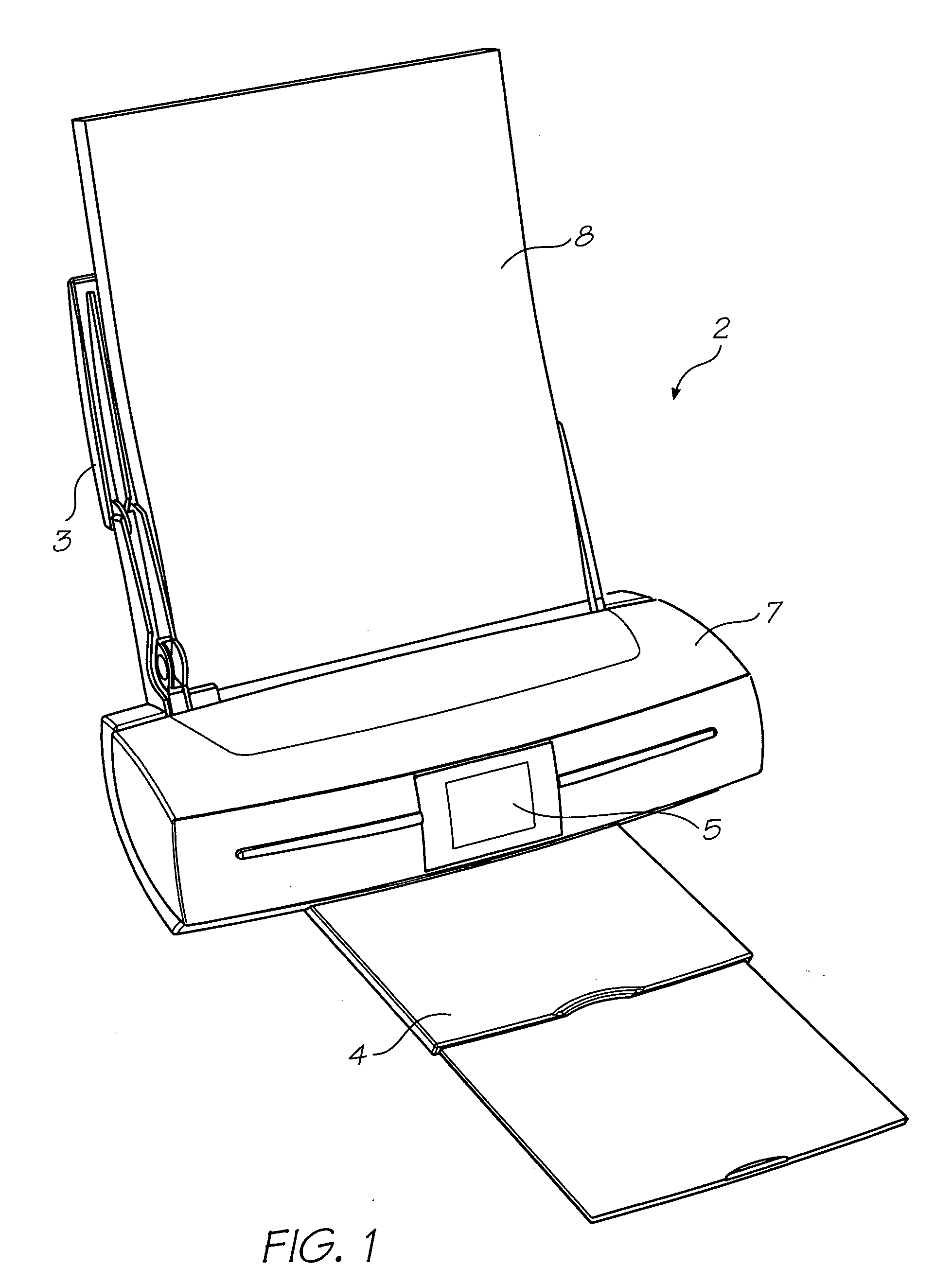

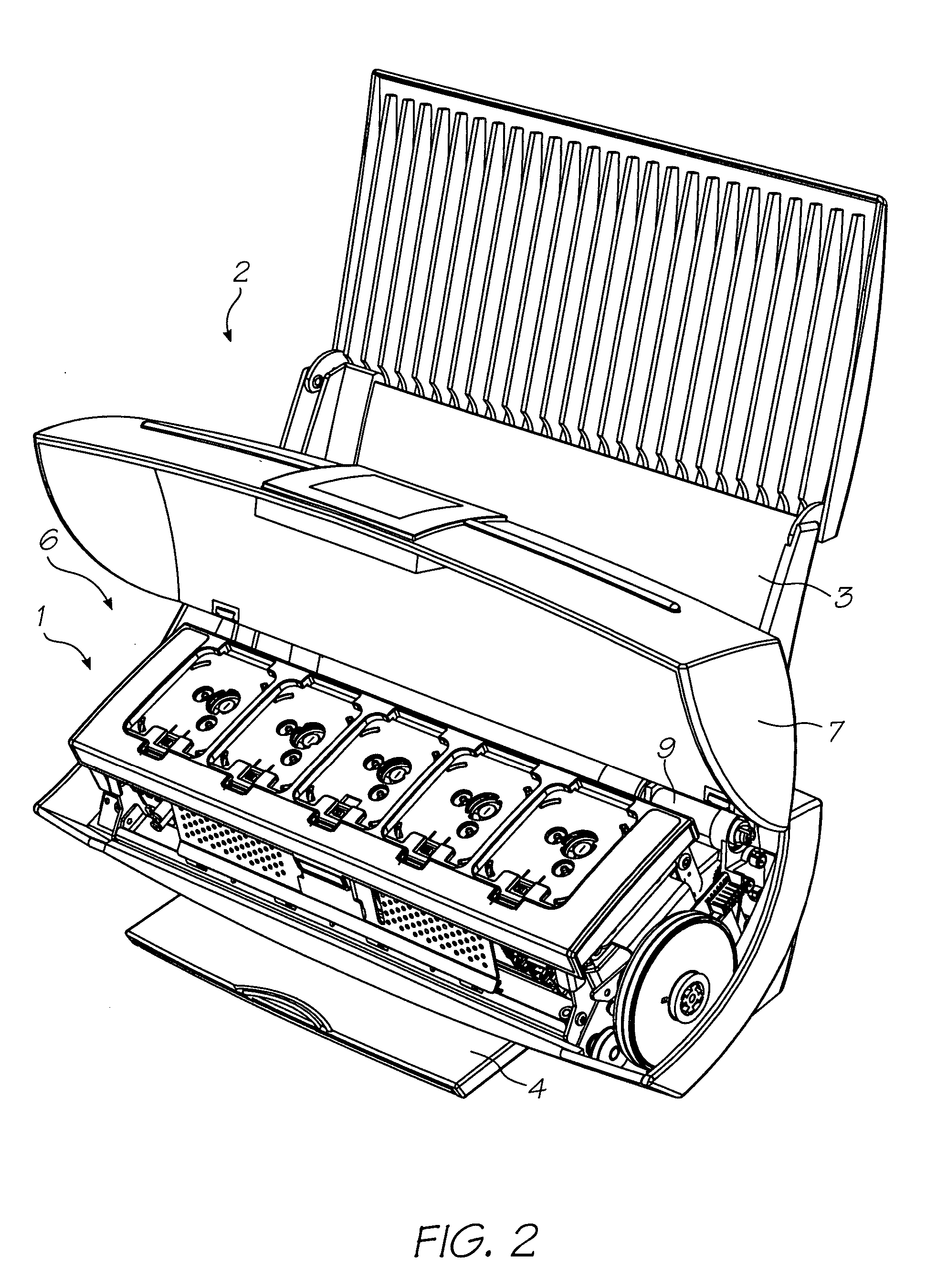

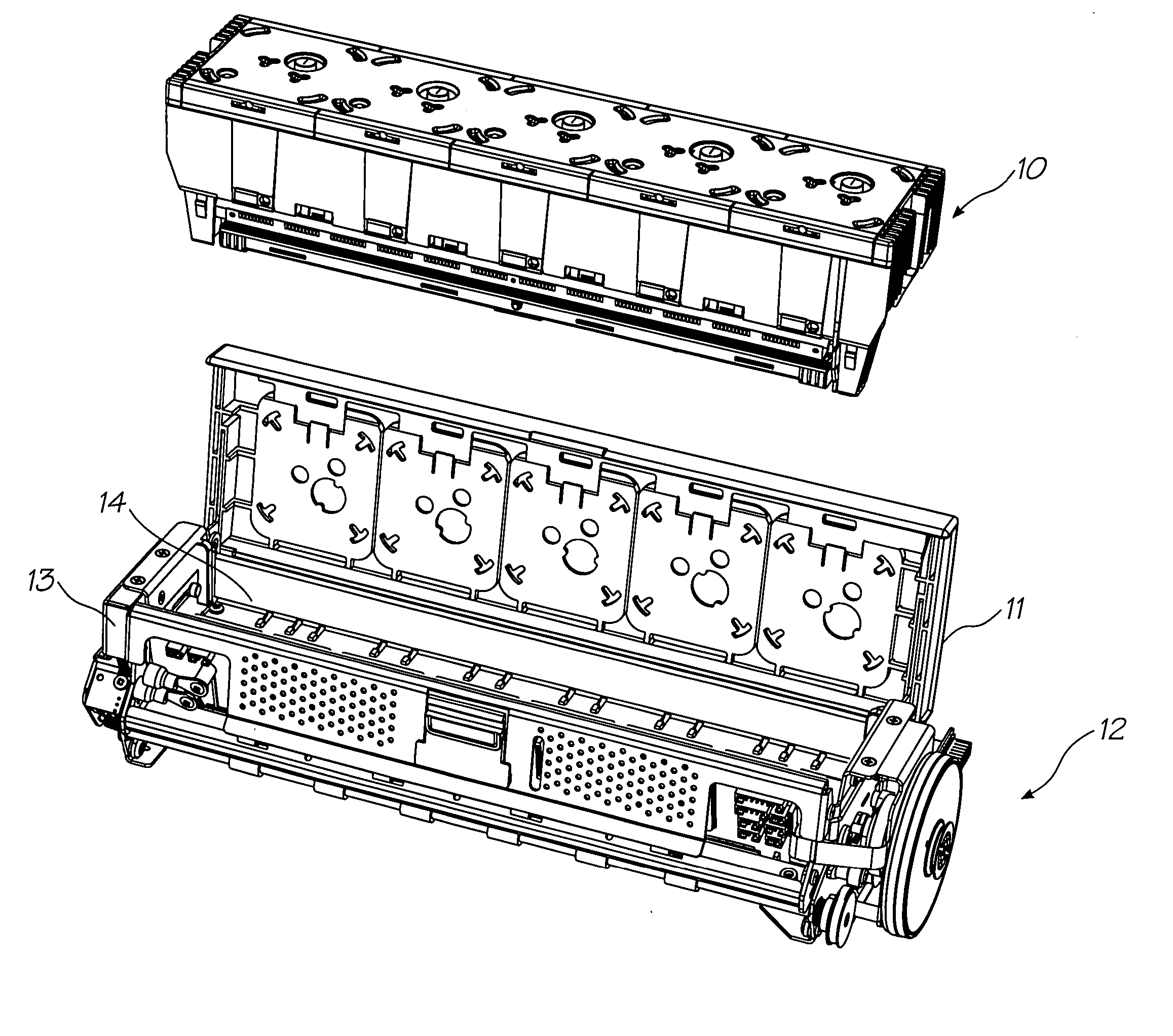

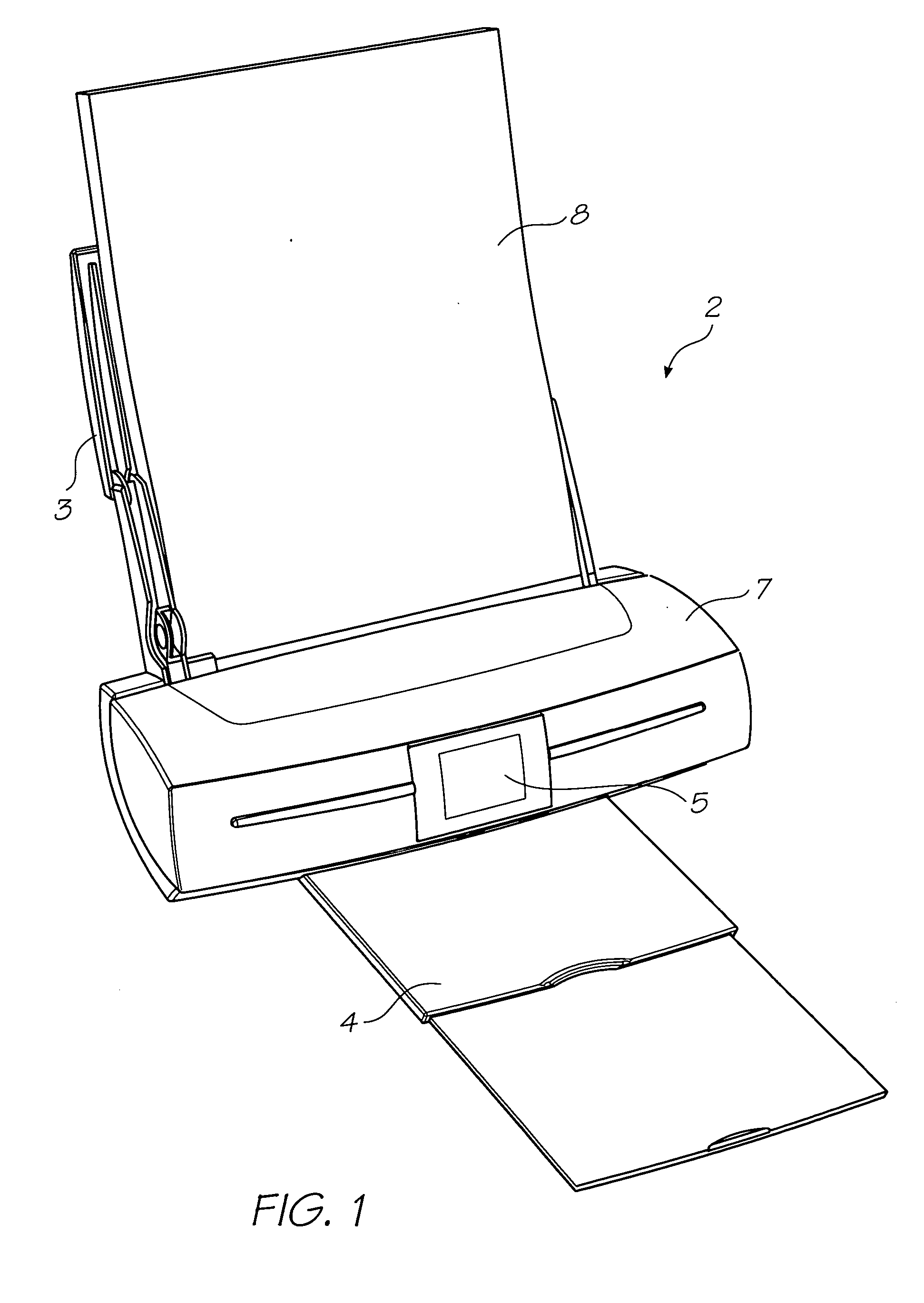

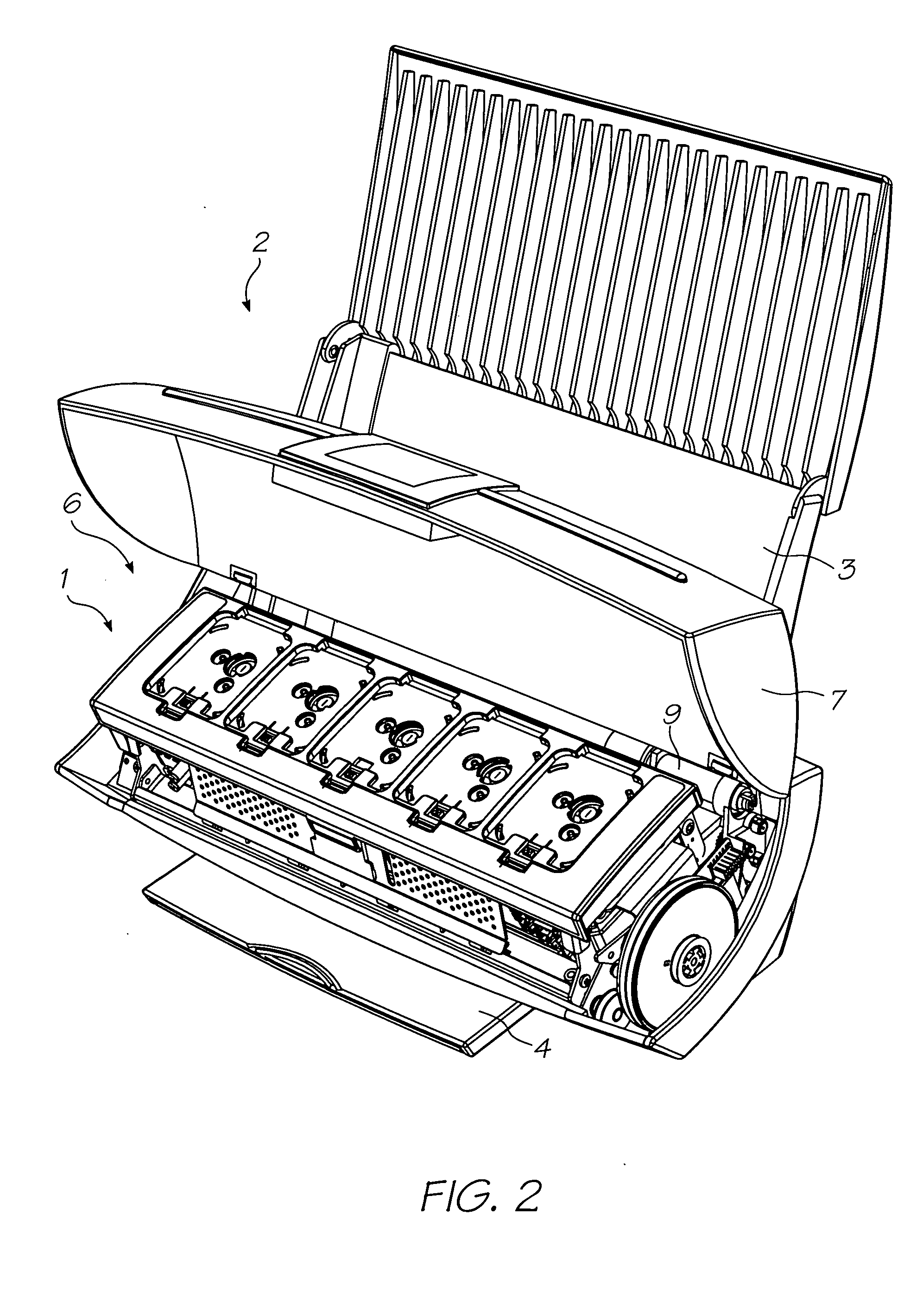

Refill unit for engaging with, and closing the outlet valve from an ink storage compartment

ActiveUS20050157016A1High riskRaise the possibilityInking apparatusPower drive mechanismsValve actuatorEngineering

A refill unit 155 contains a body of ink for refilling a negatively pressurized ink storage compartment 46 that in thurn supplies ink to a printhead assembly 22. The ink storage compartment supplies the printhead 22 via a normally open outlet valve 16. When refill unit 155 releasably engages the ink storage compartment 46, an outlet valve actuator 159 closes the outlet valve 16 as the refill unit 155 engages the ink storage compartment 46. The ink storage compartment is maintained at a negative pressure to avoid ink leakage from the printhead. However, during an ink refill process, the negative pressure is removed when the ink storage volume is filled to capacity. Without the negative pressure in the ink storage compartment, there is a high risk of ink leakage. It is possible to re-establish the negative pressure by slightly increasing the compartments capacity immediately after refilling, but until the negative pressure is re-established, there is a high likelihood of leakage. By designing the refill unit to shut the outlet valve as it engages the storage compartment, ink leakage is prevented until the negative pressure is re-established.

Owner:SILVERBROOK RES PTY LTD +1

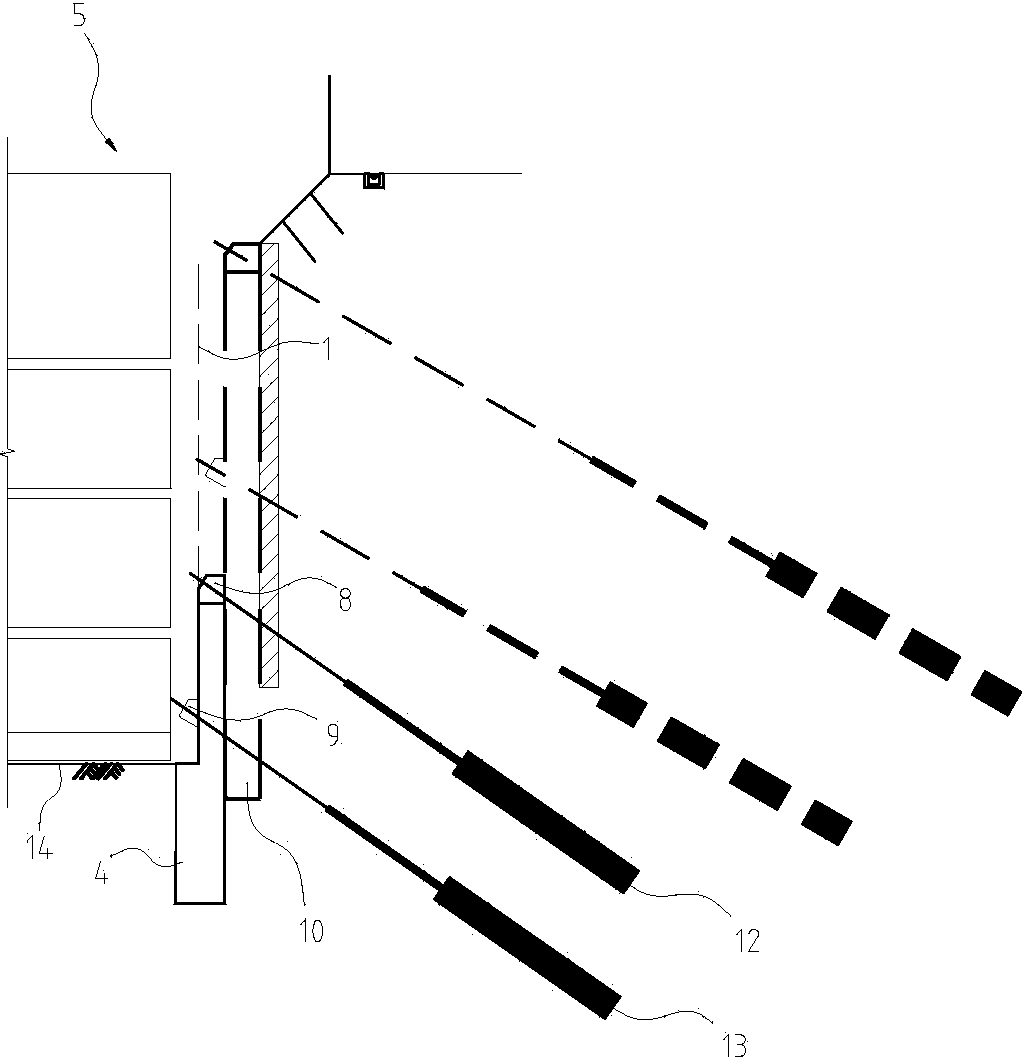

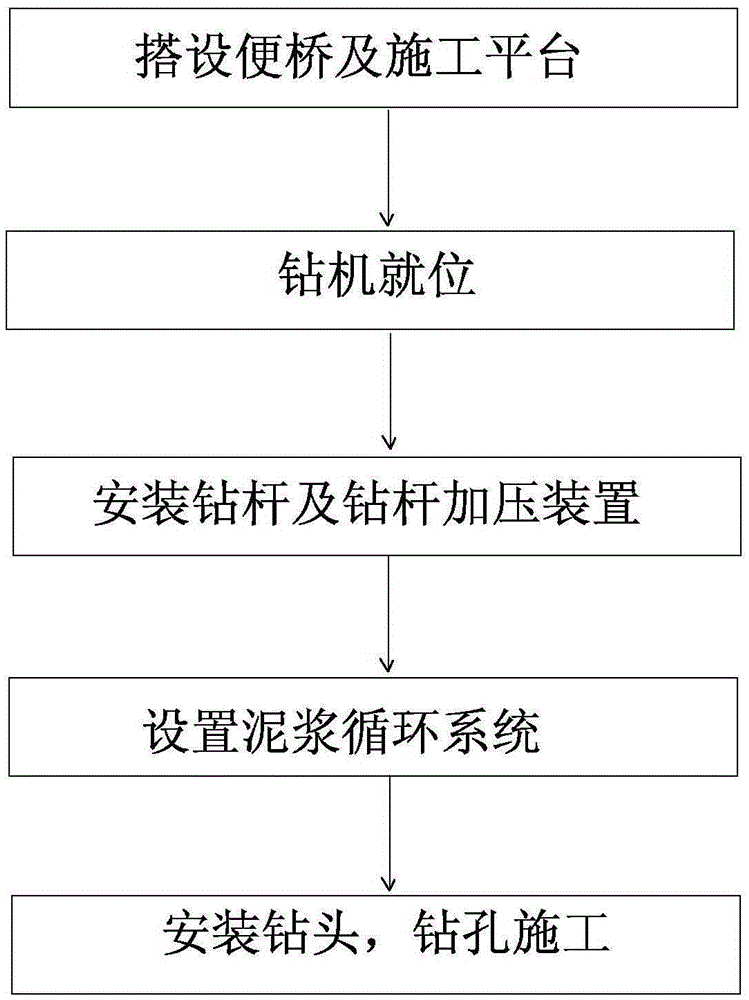

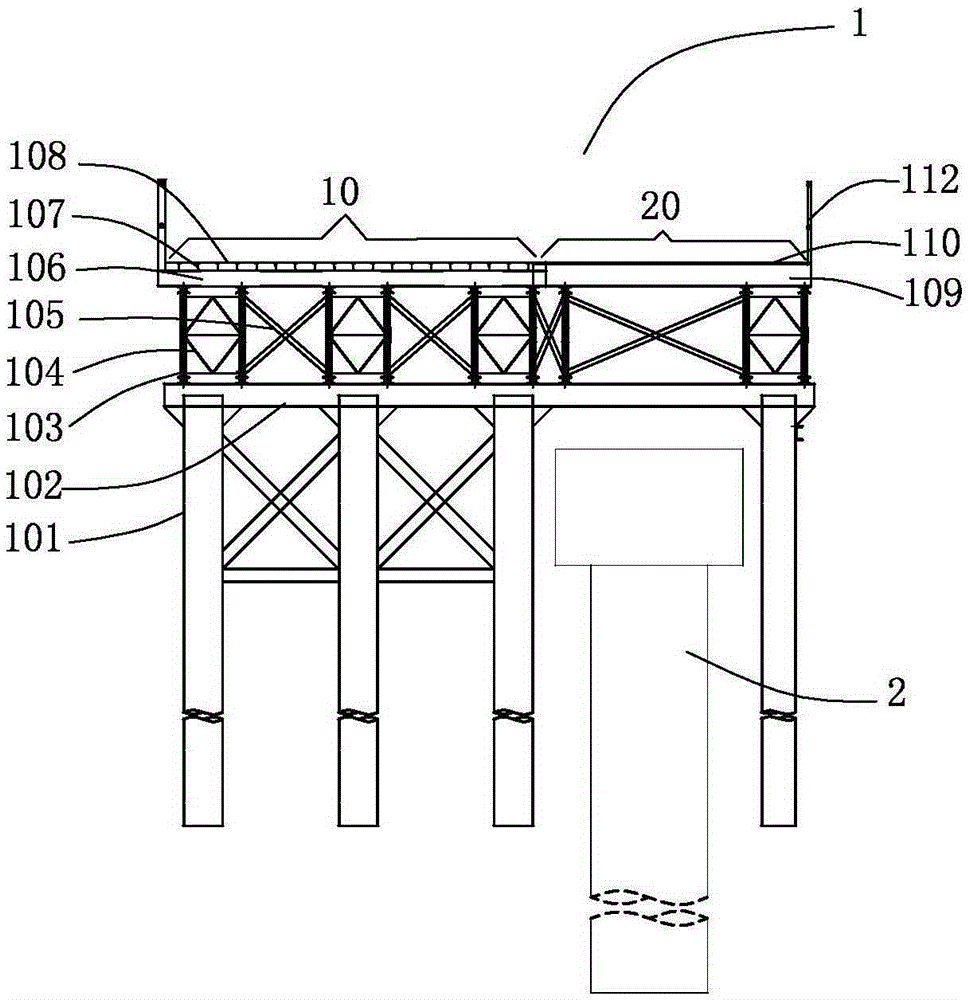

Method for performing in-water pile foundation hole drilling by large-diameter reverse circulation roller cone drilling

ActiveCN105257215ADrilling speed is fastStrong bending resistanceConstructionsDerricks/mastsSpecific gravityRiver water

The invention relates to a method for performing in-water pile foundation hole drilling by large-diameter reverse circulation roller cone drilling. The method comprises the following steps of (1) building a temporary bridge and an on-water construction platform; (2) putting a drilling machine in place; (3) installing a drill pipe; (4) setting a slurry circulation system; and (5) performing hole drilling construction. A construction platform can bear a large-size great-self-weight large-diameter reverse circulation roller cone drilling machine; the unique drill pipe is used; good anti-folding anti-twisting and pressure-bearing performance is realized; different roller cone drill bits can be replaced when different hard rock layers are met; a drill pipe pressurizing device is used, so that when the drilling is too slow, the drill pipe can be pressurized through the drill pipe pressurizing device, and the extrusion crushing and rock cutting capability is improved; the requirement on the specific gravity of the slurry is low, river water can be used for direct water supplementation; and the drill lifting is performed before the pile pouring, and the construction step of hole cleaning can be reduced.

Owner:CCCC FOURTH HIGHWAY ENG

Processing, formation and manufacturing method of piston rod using 38CrMoAlA steel as materials

InactiveCN102534392AReduce contentHigh purityProcess efficiency improvementPiston rodsHardnessHigh pressure

The invention discloses a processing, formation and manufacturing method of a piston rod using 38CrMoAlA steel as a material, which belongs to the technical field of powder metallurgy. A gear is realized through the following work procedures of baiting, powder metallurgical blank manufacture, annealing, tongs center emptying, rough turning, tempering, fine turning, center hole accurate grinding, hexagon milling and nitriding treatment. The piston rod manufactured by the manufacture method does not deform at high temperature and high pressure, the surface hardness is high, the abrasion performance is good, the bending resistance capability is high, the fatigue strength is high, in addition, the center roughness is good, the service life is long, the work reliability is high, and because blanks are manufactured by the powder metallurgy, the high-temperature resistance is good.

Owner:无锡市万邦机械制造厂

Waterable fingerpaint pigment and production method thereof

InactiveCN101469146ANo stratificationGood lookingStarch dervative coatingsArtist's paintsFlexural strengthSlurry

The invention discloses a finger painting pigment and a method for producing the same. The finger painting pigment consists of pigment base slurry and coloring matters; the compositions of the pigment base slurry comprise glycerin, modified starch and casson; a product has no phenomenon of delamination, has excellent appearance effect; simultaneously, in the painting process, the pigment is quite fluent and has no granular sensation, bright and beautiful color and strong flexural strength, also has obvious advantages in adhesion fastness and color saturation, is safe and innoxious and is easy to elute when stuck on clothes.

Owner:云之彩文创集团有限公司

Composite telegraph pole/street lamp pole and manufacturing method of street lamp pole

ActiveCN103711354AReduce weightEasy to installSynthetic resin layered productsLaminationGlass fiberFiber

A composite telegraph pole / street lamp pole is in a conical tubular shape and comprises a metal layer, a resin soaked cloth layer and an outer layer from inside to outside in sequence, wherein the resin soaked cloth layer is glass fiber reinforced plastic cloth or carbon fiber cloth or glass fabric or non-woven fabric socked with resin, and the resin socked cloth layer tightly winds the periphery of the metal layer after being melted. The composite telegraph pole / street lamp pole is light in weight and easy to transport and mount, the glass fiber reinforced plastic cloth or the carbon fiber cloth or the glass fabric or the non-woven fabric socked with the resin is adopted in tightly wind the metal layer after being melted, overall bending resistance is improved greatly, corrosion resistance and insulation performance are good, the inner metal layer can be directly connected with a lighting rod, mounting of the lighting rod is simplified, the metal layer is directly connected to a mould in a sleeved mode, and demoulding of products can also be easy. Meanwhile, an advertisement display position can be arranged in the outer layer, the advertisement display position can be an electronic display frame and can also be a billboard frame, and the frame is simply reserved when the outer layer is manufactured.

Owner:广东海志鸿宇科技有限公司

Thermoplastic elastomer and its production process

InactiveCN1441003ASmall compression deformationStrong bending resistancePlasticizerThermoplastic elastomer

The thermoplastic elastomer is used in environment-protecting cable sheath. It consists of at least thermoplastic polyurethane elastomer, styrene-butadidne-methyl methacrylate copolymer, modifier, plasticizer and stuffing. It is acid resistant, alkali resistant, low temperature resistant and light and the cable and wire produced with the said elastomer has less compression deformation, high flex resistance, high oil resistance and high resilience. The elastomer may be also used in sealing stripe for automobile, tractor, door and window, various hose and other mechanical parts.

Owner:阎俊龙

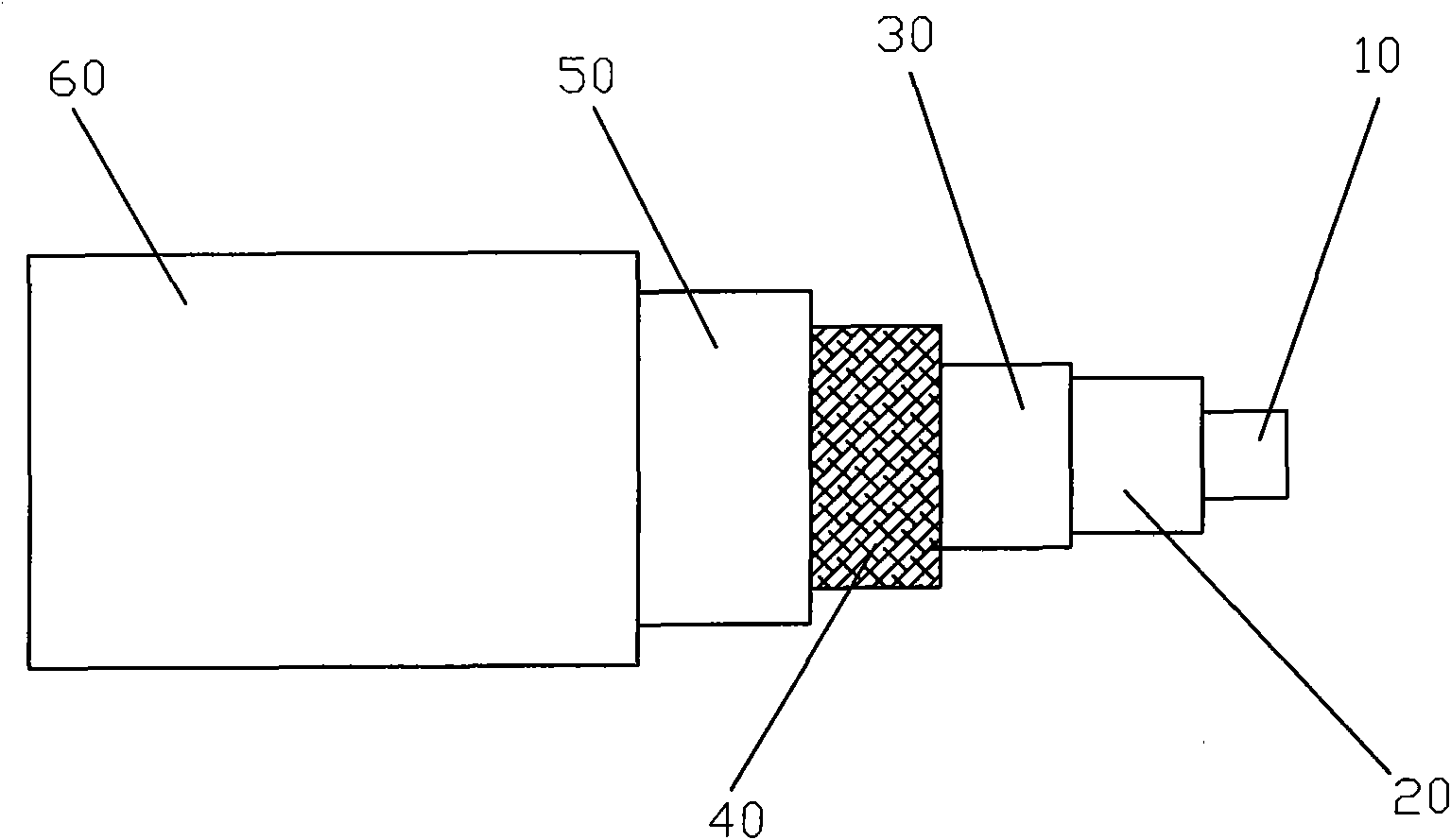

Semiconductive EVA plastic shielded flexible cable and manufacturing method thereof

ActiveCN101887771AImprove machinabilityReduce weightNon-insulated conductorsPlastic/resin/waxes insulatorsElectrical conductorPolyvinyl chloride

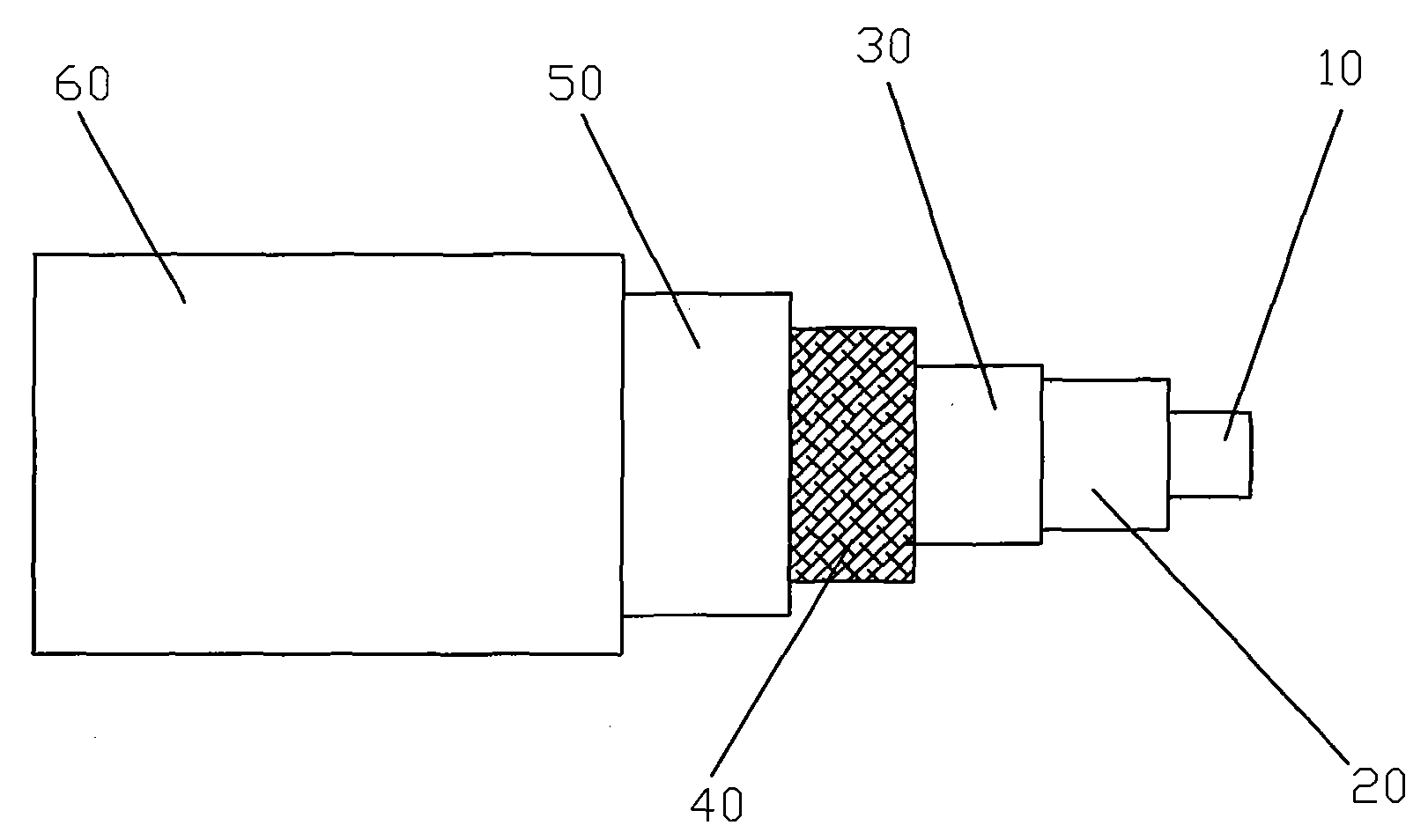

The invention relates to a flexible cable, in particular a semiconductive EVA plastic shielded flexible cable and a manufacturing method thereof. The cable comprises a copper core conductor (10), and is characterized in that the outer layer of the copper core conductor (10) is successively coated with a polrvinyl chloride insulating layer (20), an aluminium foil nylar (30), a fibrage layer (40), an EVA plastic shielding layer (50) and a polrvinyl chloride outer sheath (60), wherein the six parts are coated from inside to outside layer by layer. The invention adopts a new formula, and coordinates with the related process and manufacturing method to provide a new semiconductive EVA plastic shielded flexible cable which has good machining property, light weight, rounding and compact structure, excellent bending resistance, high strength of extension, excellent shielding property and long service life.

Owner:ANHUI LIANJIAXIANG SPECIAL CABLE

Metal wire and flexible display panel

InactiveCN106684115AImproves Strength and ToughnessStrong bending resistanceSolid-state devicesSemiconductor devicesSurface plateMetallurgy

The invention provides a metal wire. The problem of easy breaking of the metal wire is solved while the technical problems of complex preparation process, high production cost and the like in the prior art are also avoided. The invention also provides a flexible display panel; at least one metal layer is formed by the metal wire; the technical problems of instable display performance, low reliability, short service life and the like of the display panel are solved; the metal wire provided by the invention comprises sub wires and stress barrier materials which are arranged in a stacked manner alternatively; the sub wires and stress barrier materials are the same in extension directions, wherein the number of the sub wires is at least two; the flexible display panel provided by the invention comprises a substrate; an insulating layer and a metal layer are alternately arranged on the flexible substrate; and at least one metal layer is formed by the metal wire.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

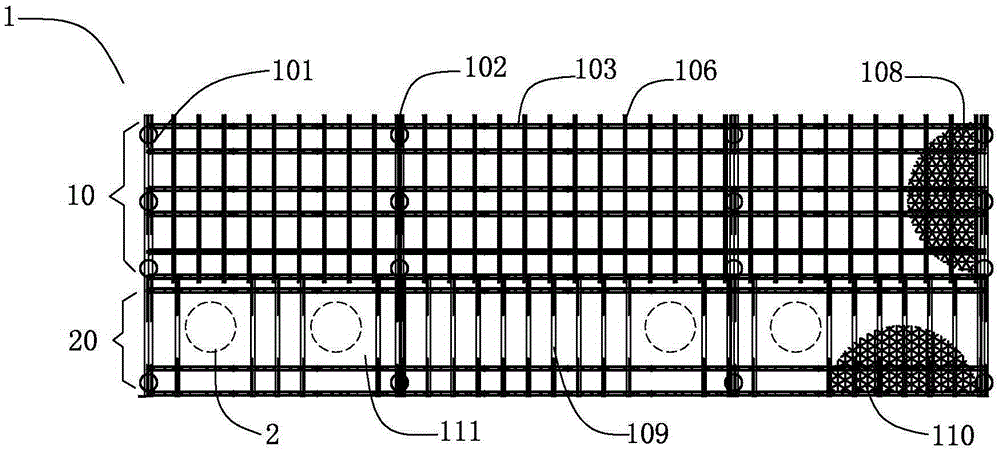

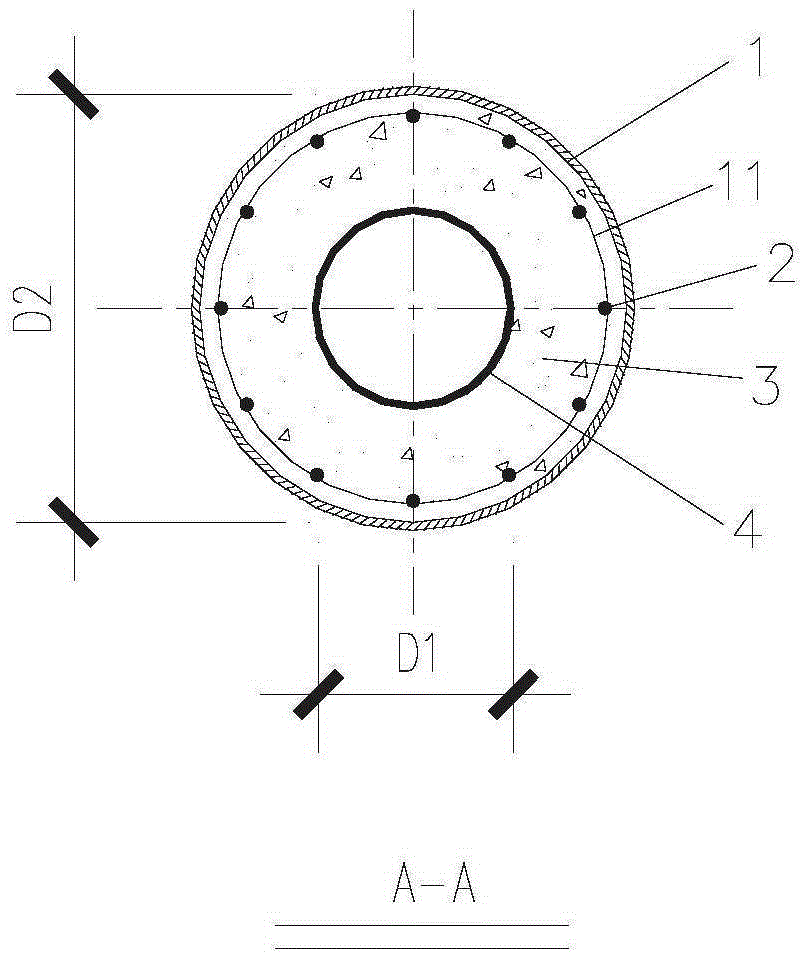

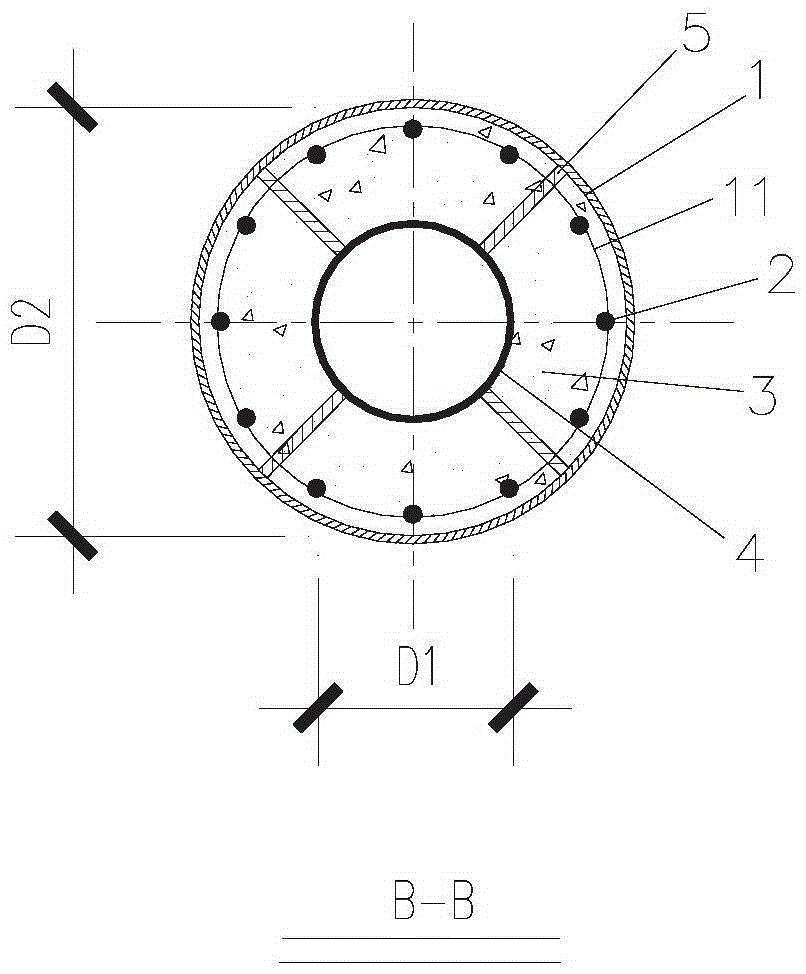

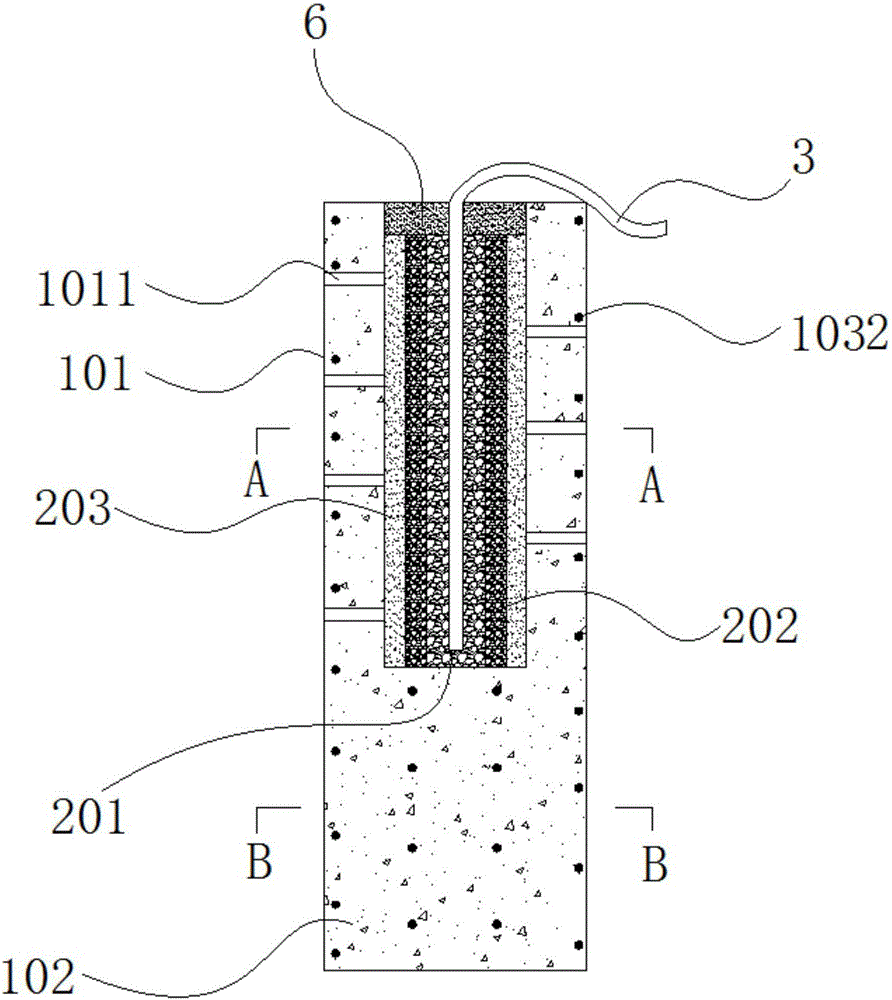

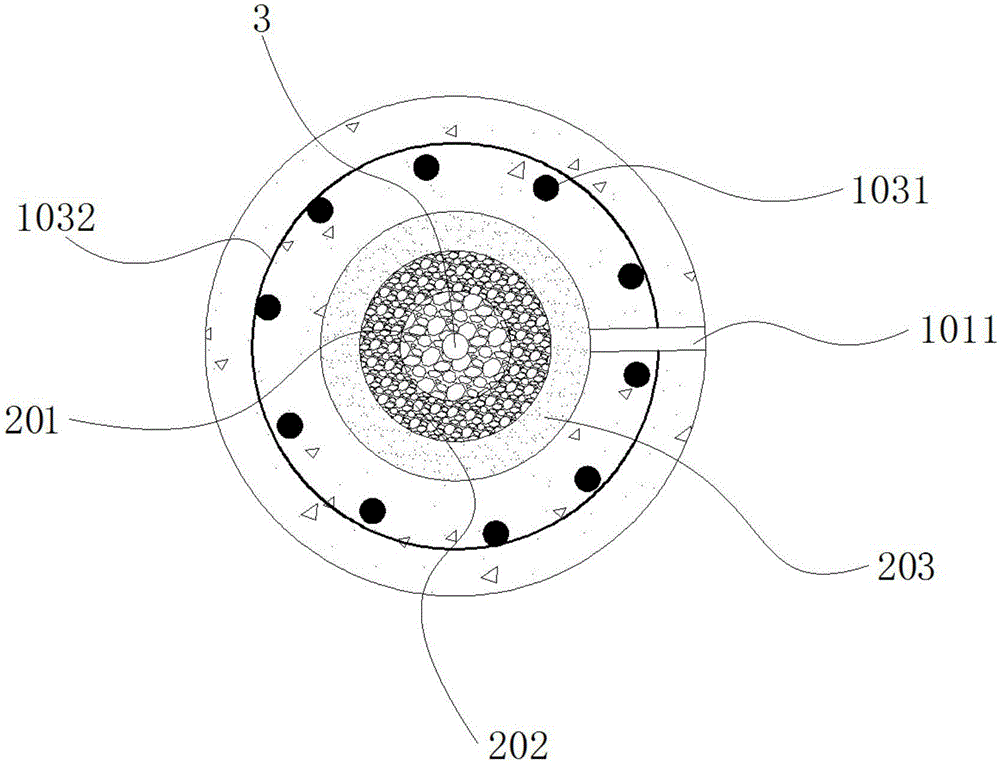

FRP pipe and thick-wall steel pipe compounding hollow recycled concrete pile

InactiveCN105386443AStop erosionInhibit deteriorationBulkheads/pilesThick wallFoundation engineering

The invention discloses an FRP pipe and thick-wall steel pipe compounding hollow recycled concrete pile which is mainly formed by an FRP pipe, a round reinforcement cage framework, a thick-wall steel pipe and recycled concrete. The round reinforcement cage framework and the thick-wall steel pipe are arranged in the FRP pipe, and the round reinforcement cage framework, the thick-wall steel pipe and the FRP pipe are arranged concentrically. The recycled concrete is poured in annular space between the FRP pipe and the thick-wall steel pipe. The bearing capacity and deformation resisting capacity of the single pile can be greatly improved through the built-in thick-wall steel pipe. The wrapping FRP pipe can effectively prevent a pile body from being corroded, and the durability of the pile body is improved. Meanwhile, the FRP pipe and spiral stirrups are combined to restrain the inner recycled concrete, and the bearing force of the compounding pile is further improved. Waste concrete is fully utilized as recycled aggregate, and application and popularization of the recycled concrete in building foundation engineering are facilitated. In a word, the compounding hollow recycled concrete pile has the advantages of being good in pile forming quality, high in bearing force, good in deformation resisting capacity and durability, small in influence on the environment, high in construction speed and the like.

Owner:GUANGXI UNIV

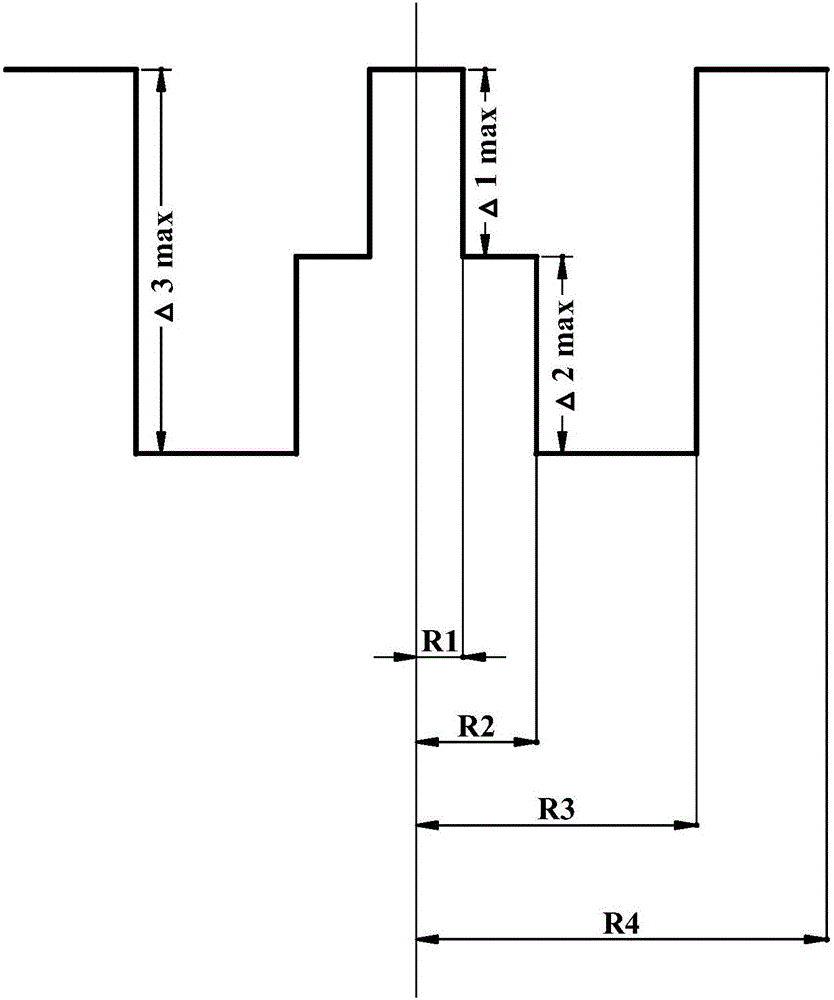

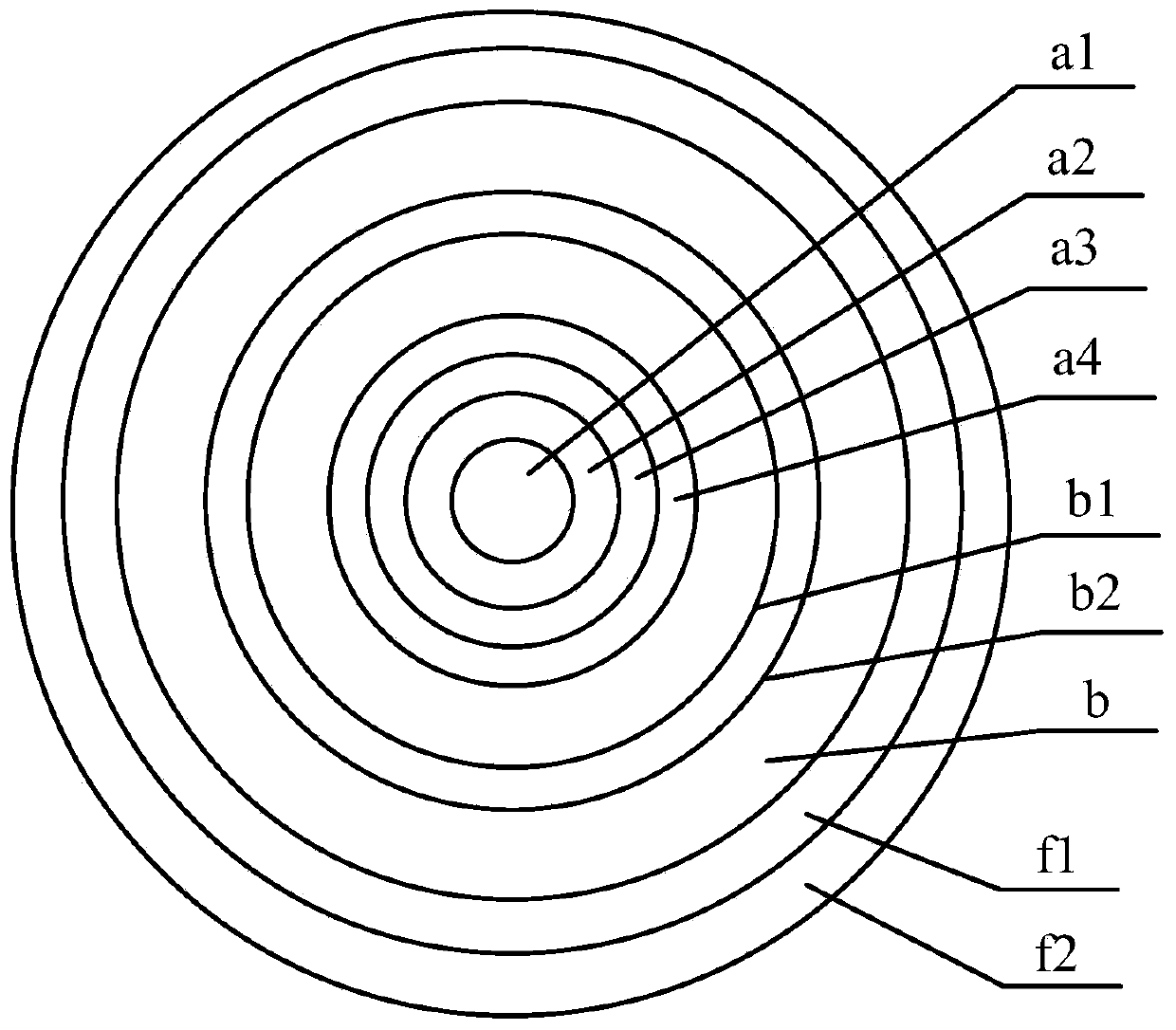

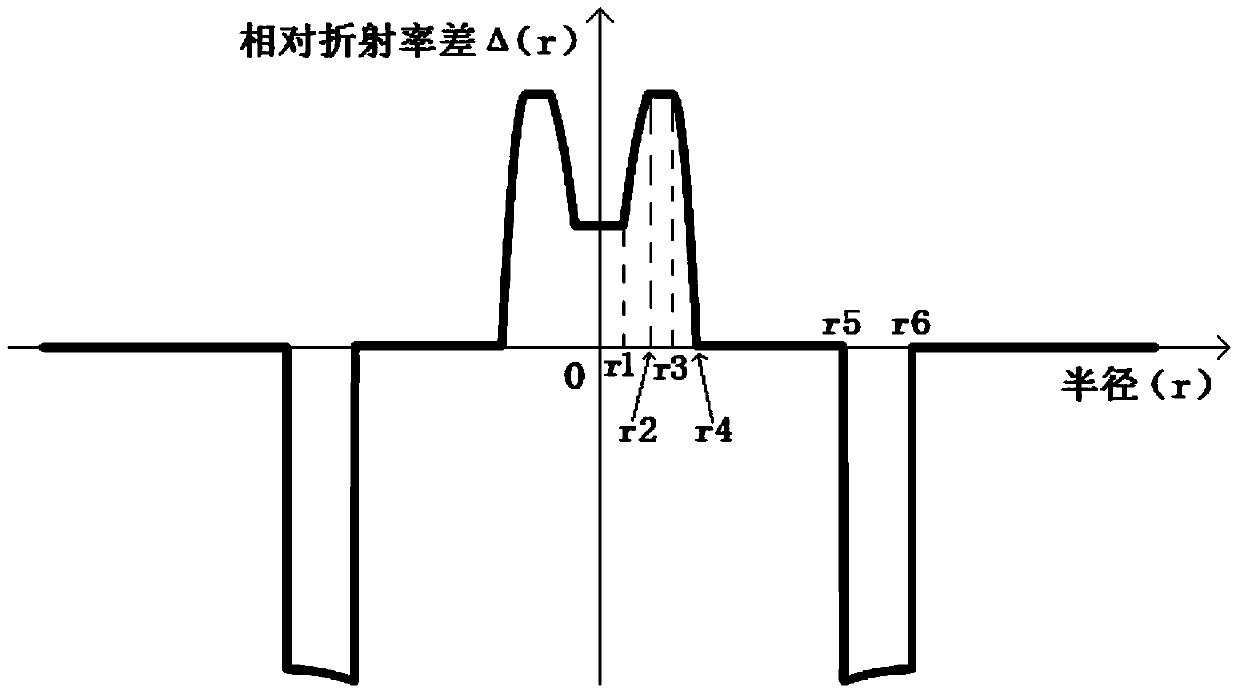

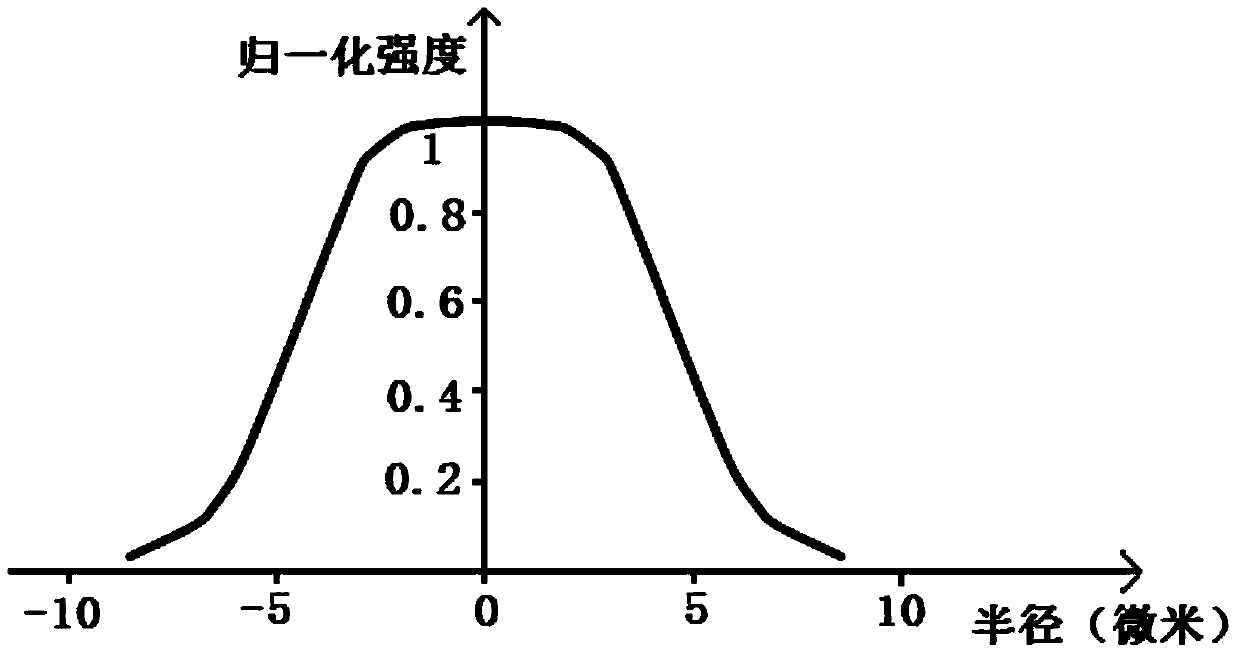

Low-loss large-effective area single mode fiber and manufacturing method thereof

ActiveCN103472525AIncrease the effective areaReduce optical power densityGlass making apparatusOptical fibre with graded refractive index core/claddingRefractive indexScattering loss

The invention discloses a low-loss large-effective area single mode fiber and a manufacturing method of the low-loss large-effective area single mode fiber, and relates to the field of optical fibers. The low-loss large-effective area single mode fiber comprises a quartz glass cladding, an internal coating and an external coating, wherein the quartz glass cladding, the internal coating and the external coating are arranged in sequence from inside to outside; the inside of the quartz glass cladding comprises a first fiber core area, a second fiber core area, a third fiber core area, a fourth fiber core area and a refractive index concave cladding, wherein the first fiber core area, the second fiber core area, the third fiber core area, the fourth fiber core area and the refractive index concave cladding are arranged in sequence from inside to outside; the refractive index concave cladding is subjected to deposition through a PCVD process; the quartz glass cladding is manufactured through an OVD process or a sleeving process. According to the low-loss large-effective area single mode fiber and the manufacturing method of the low-loss large-effective area single mode fiber, the scattering loss of the low-loss large-effective area single mode fiber and the additional loss of the low-loss large-effective area single mode fiber in a bent state can be reduced; due to the fact that the spire distribution of fiber core basic mode electromagnetic field power is adjusted into flattop distribution, optical power density is reduced, the effective area of the low-loss large-effective area single mode fiber is enlarged, the nonlinearity of the low-loss large-effective area single mode fiber is reduced, the incident power of an optical fiber communication system is increased by 0.4-2.6 dB, and the low-loss large-effective area single mode fiber is suitable for mass production.

Owner:FENGHUO COMM SCI & TECH CO LTD +1

Flexible transparent electronic circuit and preparation method thereof

InactiveCN102118918AImprove conductivityStrong bending resistanceConductive pattern formationMetallic pattern materialsEpoxySilver paste

The invention discloses a preparation method for a flexible transparent electronic circuit, which enables a circuit to be printed on a flexible circuit board and keeps the flexibility and transparency of the circuit. The method comprises the following steps: nanometer silver wires with diameter of 30 nm and with length-diameter ratio greater than 200 are prepared by a chemical reduction method, then the nanometer silver wires, epoxy resin and polyethylene glycol are mixed according to a certain proportion for preparing conductive silver paste, and then a circuit with thickness of 0.1 mm is printed on a flexible circuit board with the conductive silver paste by using the screen printing technology. The electronic circuit prepared by the method has the characteristics of high bending resistance, high electric conductivity, transparency and the like, and is a key component for a novel flexible transparent electronic device.

Owner:CHINA JILIANG UNIV

Deep sea culture platform and manufacturing method thereof

InactiveCN103798160ASimple preparation processImprove wind and wave resistanceClimate change adaptationPisciculture and aquariaClosed platformMarine engineering

A deep sea culture platform comprises a closed platform frame floating on the water. A large net is arranged inside the platform frame. The platform frame comprises bamboo or wood fixed inside the platform frame in a multi-layer and parallel mode at the interval of 5-50 centimeters, wherein rot prevention and moth prevention treatment is carried out on the bamboo or the wood. The deep sea culture platform further comprises mixed light-weight aggregate concrete poured inside the platform frame, and the density of the mixed light-weight aggregate concrete is 400-970 kilograms per cubic meter. The mixed light-weight aggregate concrete is formed by mixing rice shells, woven bag filaments or polypropylene fibers, building glue, early strength agents, polystyrene foam particles, water and cement. The platform frame serves as the foundation of the culture platform so that the culture depth and the culture area of the culture platform can be increased greatly. Various auxiliary culture facilities can be constructed on the platform frame so that the culture benefit can be increased. According to the rule of the tides, the manufacturing difficulty and the manufacturing cost are lowered greatly through a manufacturing method of the deep sea culture platform.

Owner:黄崇展

Refill unit for simultaneously engaging with, and opening inlet valve to, an ink cartridge

ActiveUS20050157015A1Improve performanceIncreased operating lifeInking apparatusPower drive mechanismsInlet valveActuator

A refill unit 155 for refilling a ink storage compartment 46 that supplies ink to a printhead 22. The ink storage compartment 46 having an interface 61 for receiving the refill unit 155. The interface 61 having an inlet valve 18 biased to its closed configuration. The refill unit 155 has an inlet valve actuator 152 for opening the inlet valve 18 as the refill unit 155 engages the ink interface 61 so that the ink in the body is in fluid communication with the ink storage compartment 46. By configuring the refill unit so that it opens the inlet valve on the ink cartridge at the same time that it docks with the cartridge, the risk of dust or other contaminants getting into the cartridge is reduced. This improves the performance and operational life of the printhead nozzles.

Owner:SILVERBROOK RES PTY LTD +1

Semi-hollow pile having drainage and skid resistance effects and construction method of semi-hollow pile

ActiveCN106759274AIncreased shear strengthMeet anti-slip design requirementsBulkheads/pilesSoil preservationSiphonReinforced concrete

The invention provides a semi-hollow pile having drainage and skid resistance effects and a construction method of the semi-hollow pile. The semi-hollow pile comprises a prefabricated reinforced concrete semi-hollow pile body, an in-pile filling core, a siphon and an external siphon device; the upper part of the prefabricated reinforced concrete semi-hollow pile body is hollow, and the lower part is solid; the lower solid pile body penetrates through a sliding surface and is embedded in a stable bed rock; multiple water collecting holes are formed in the upper hollow pile body along the pipe diameter; the hollow pile body is filled with the core; and the siphon is arranged in the middle of the hollow pile body and is connected with the external siphon device. The construction method of the semi-hollow pile comprises the steps as follows: the reinforced concrete semi-hollow pile body is prefabricated, a pile hole is excavated, the pile body is placed in the pile hole, the siphon is placed in, the pile is filled with the in-pile filling core in a layered manner, a clay layer is laid, and the like. Comprehensive consideration is performed in two aspects including drainage and skid resistance, and the effective supporting and stopping structure and the construction method are provided for prevention and control on landslide hazards induced by rainfall.

Owner:CHONGQING UNIV

High performance fireproof magnesite board and manufacturing process thereof

InactiveCN102731058AStrong bending resistanceStrong shear resistanceWater-setting substance layered productFire proofingShock resistanceFire prevention

The invention relates to a high performance fireproof magnesite board which comprises magnesium oxide, magnesium chloride, sawdust, vermiculite, glass fiber sieve cloth, talcum powder, pearlite and water. The manufacturing process of the high performance fireproof magnesite board comprises the steps of agitating, pouring, rolling and forming, maintaining and curing, edge cutting, sanding, and inspecting and packaging. The specific process of agitating comprises 1) preparing raw materials by weight percentage; 2) setting the agitating time; and 3) adding magnesium chloride, vermiculite, glass fiber sieve cloth, talcum powder, magnesium oxide, sawdust and glue into purified water; adding pearlite at 2 minutes of countdown and discharging. The invention has the beneficial effects that the high performance fireproof magnesite board has the advantages of strong resistance to deflection, shear-resistance, shock resistance, fire prevention, no smoke spreading, no deformation after being dipped into water, moth-prevention, and mildew prevention.

Owner:台山先驱建材有限公司

Open type aluminum plate curtain wall

The invention discloses an open type aluminum plate curtain wall, which is characterized in that: the open type aluminum plate curtain wall comprises vertical columns, horizontal beams, aluminum single plates and aluminum alloy secondary frames; the horizontal beams are fixed to the vertical columns by bolts running through the vertical columns; the aluminum alloy secondary frames comprise secondary frame main parts with hook grooves in the middle, and hook plates hooked in the hook grooves; one ends of the secondary frame main parts are fixedly connected with the vertical columns by the bolts, while the other ends of the secondary frame main parts are parallel to one ends of the hook plates far away from the hook grooves; one ends of the secondary frame main parts parallel to each other and one ends of the hook plates are fixedly connected with two adjacent aluminum single plates by the bolts respectively; and one ends of the secondary frame main parts parallel to each other and one ends of the hook plates are formed with open type space. The open type installation method meets needs of seeking different effects, so that the open type aluminum plate curtain wall is more beautiful; in addition, the non rigid connection method is more favorable for expansion and contraction among the plates, so that the open type aluminum plate curtain wall is improved in structural stability.

Owner:无锡金城幕墙装饰工程有限公司

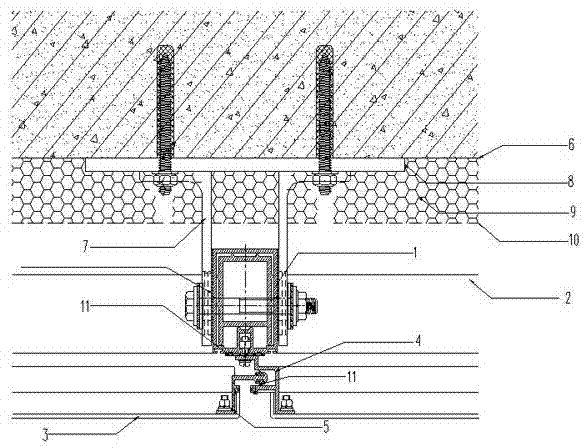

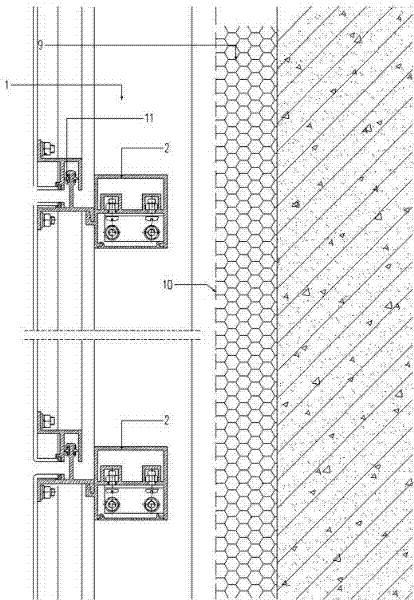

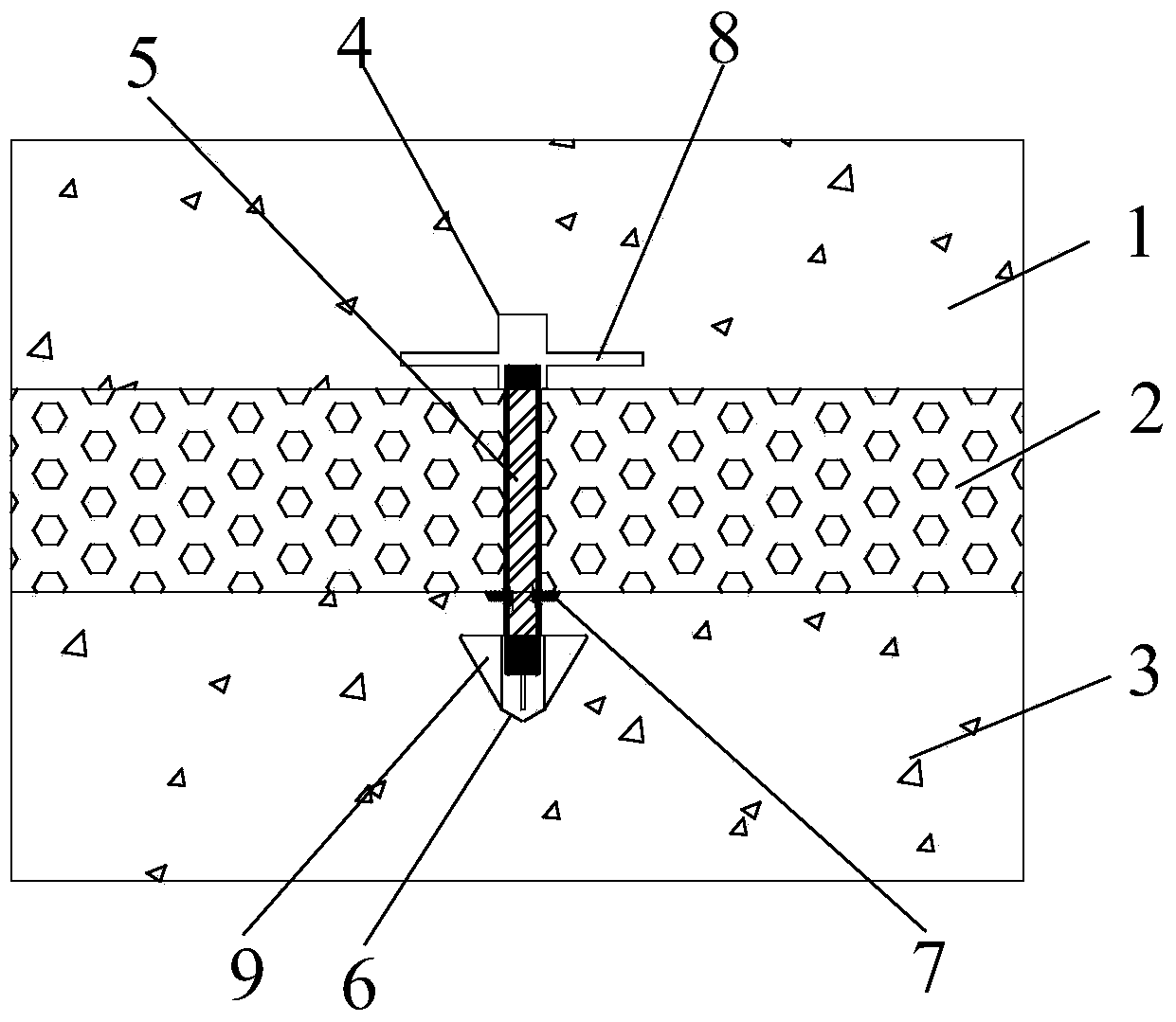

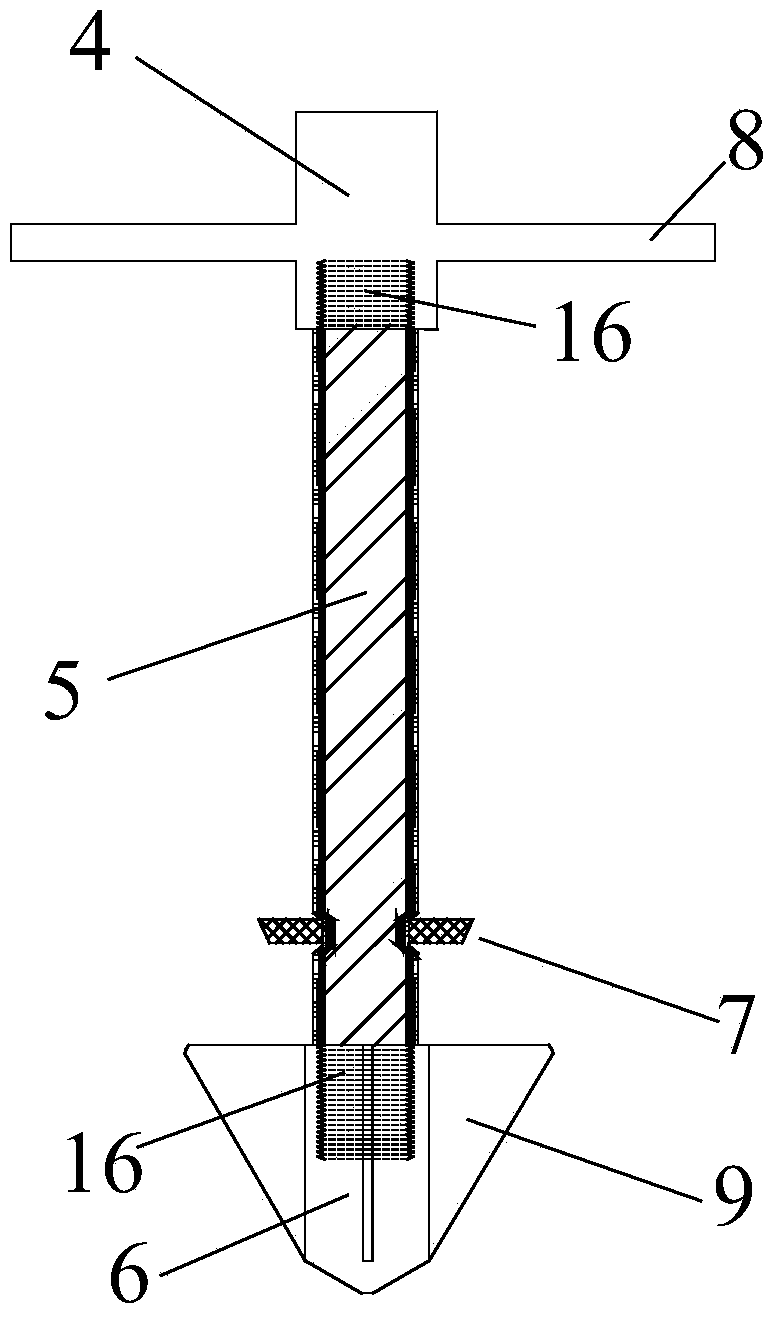

Steel-fiber plastic combined connector, prefabricated sandwich thermal insulation wall and manufacturing method

ActiveCN103967162AStrong bending resistanceStrong shear resistanceWallsBuilding material handlingFiberThermal insulation

The invention discloses a steel-fiber plastic combined connector, a prefabricated sandwich thermal insulation wall and a manufacturing method. The connector comprises a columnar connecting body, a connecting base and a connecting cap, and the connecting base and the connecting ca are fixedly connected to the two ends of the columnar connecting body respectively. The columnar connecting body comprises a metal column, fiber cloth wrapping the outer side of the metal column and a fiber bunch axially wound on the fiber cloth along the metal column. The connecting base comprises a metal base body and a plurality of metal rib angles, and the metal rib angles are distributed on the lateral surface of the metal base body at intervals. The connecting cap comprises a metal cap body, metal inserting ribs and a plastic cap sleeve. The metal inserting ribs transversely penetrate through the metal cap body, and the plastic cap sleeve wraps the exposed part of the metal cap body and the exposed parts of the metal inserting ribs. The connector has the advantages of being high in anti-shear strength, low in processing cost, high in fire resistance, low in heat conduction coefficient, convenient and fast to install and the like. The prefabricated sandwich thermal insulation wall has the advantages of being high in anti-bending performance and anti-shear performance, good in thermal insulation effect, low in manufacturing cost, long in service life and the like.

Owner:SHANGHAI CONSTRUCTION GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com