Preparation process of fiber cement slab or fiber gypsum board as well as production line

A technology of fiber cement board and production process, which is applied in the field of construction machinery, can solve the problems of high cost, poor bending resistance and toughness, high pollution, etc., and achieve the effect of strong operability, reasonable structure and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

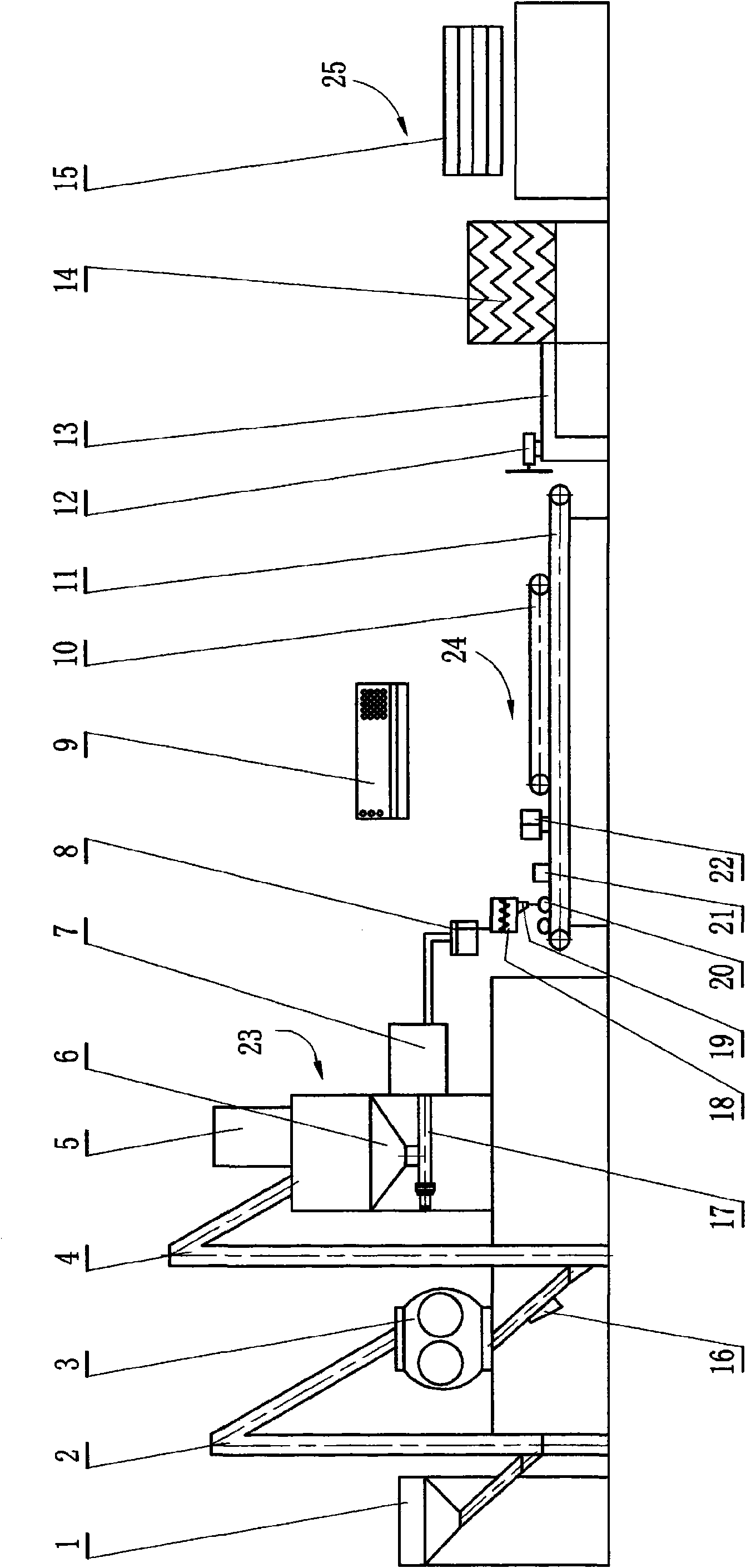

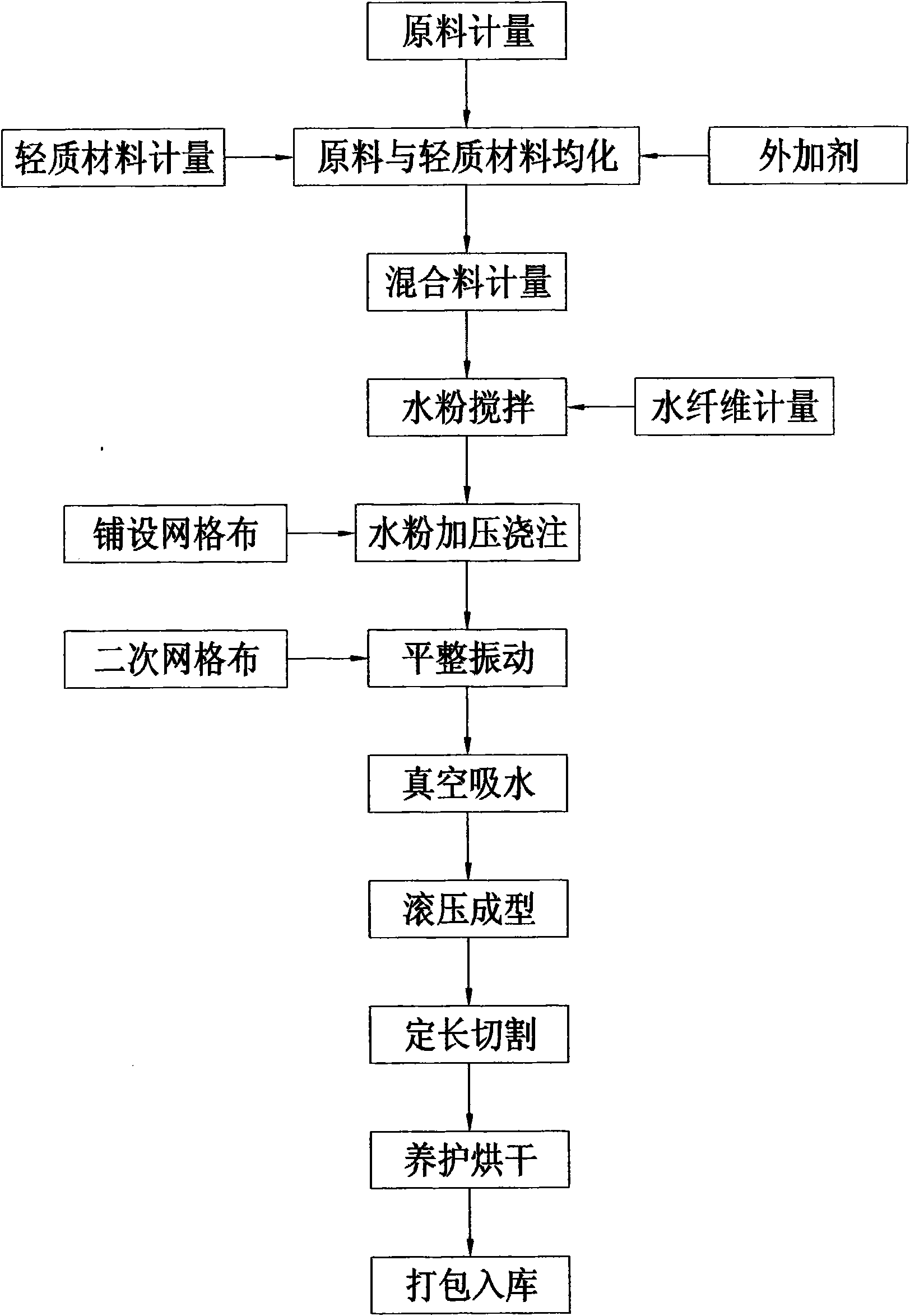

[0014] Referring to the accompanying drawings, this embodiment is a fiber cement board or fiber gypsum board production process and production line, which consists of a centralized console 9, a feeding device 23, a casting device 24, a cutting device 12, and a post-drying and conveying device 25.

[0015] The storage bin 1 and the mixing bin 6 of the feeding device 23 are made of stainless steel plate profiles, the dry powder mixer 3 is a domestic kettle type GY JIA-2 semi-dry powder mixer, and the hoists (2, 4) are made of Commercially available GYTS type bucket elevator conveyor; the output port of the dry powder mixer 3 is provided with an iron remover 16 , and a dust collector 5 is provided above the mixing bin 6 .

[0016] The conveying meter 7 connecting the output port of the mixing bin 6 and the input port of the water powder mixer 18 of the pouring molding device 24 adopts a ZBLX-2 type screw metering and feeding device, and the water powder mixer 18 adopts a ZBJB-1 ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com