Patents

Literature

1386 results about "Bucket elevator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A bucket elevator, also called a grain leg, is a mechanism for hauling flowable bulk materials (most often grain or fertilizer) vertically.

Mobile dry material storage

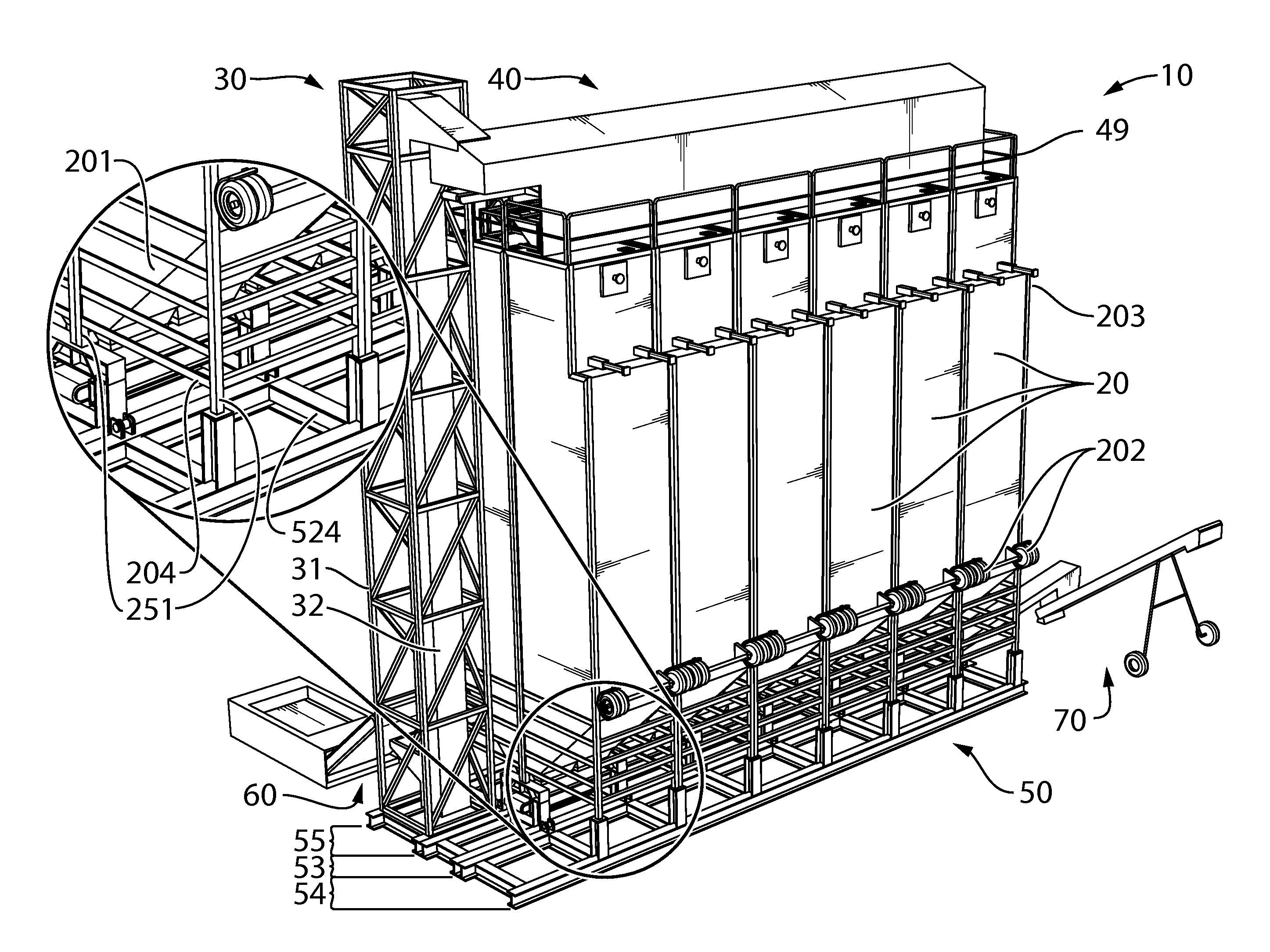

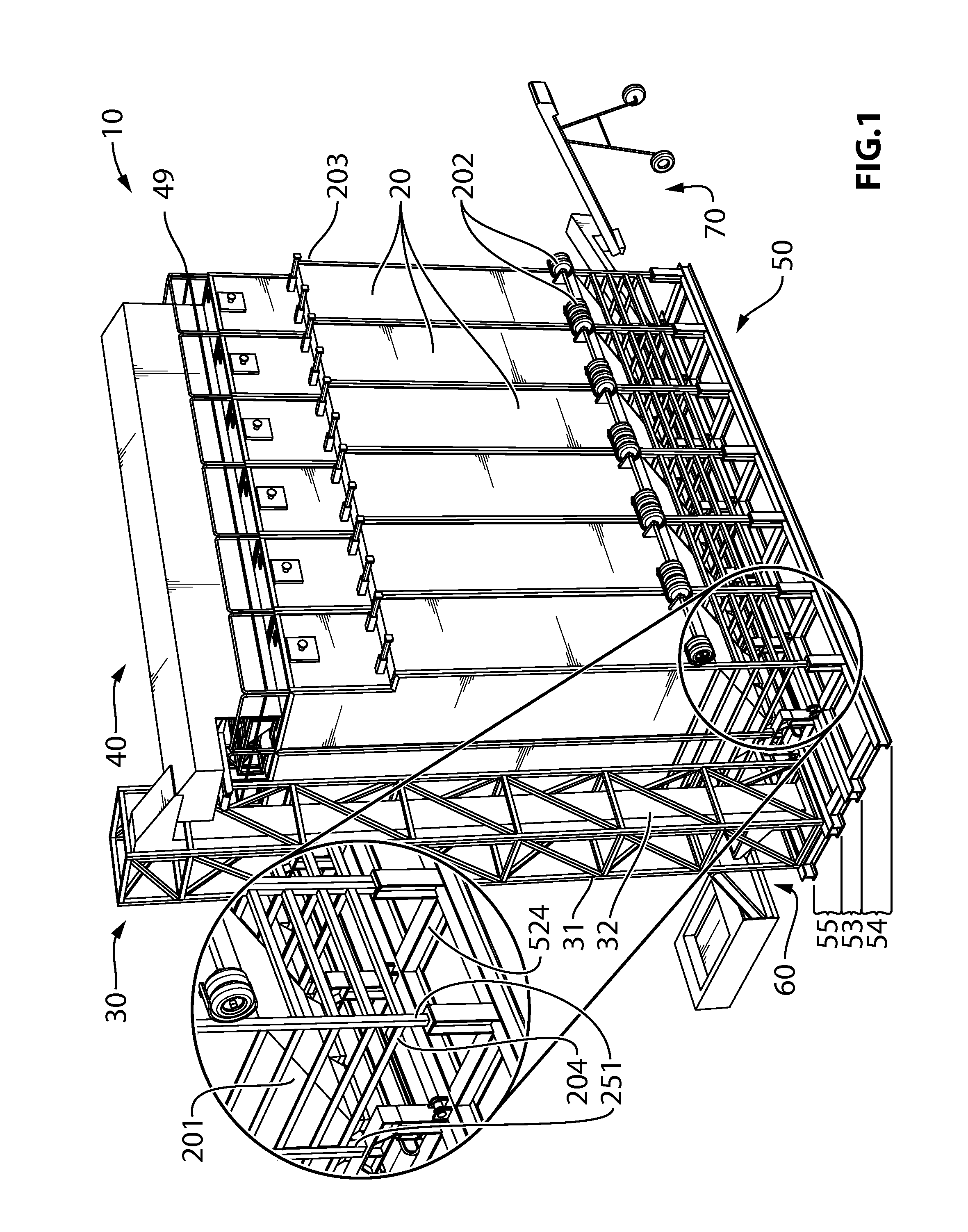

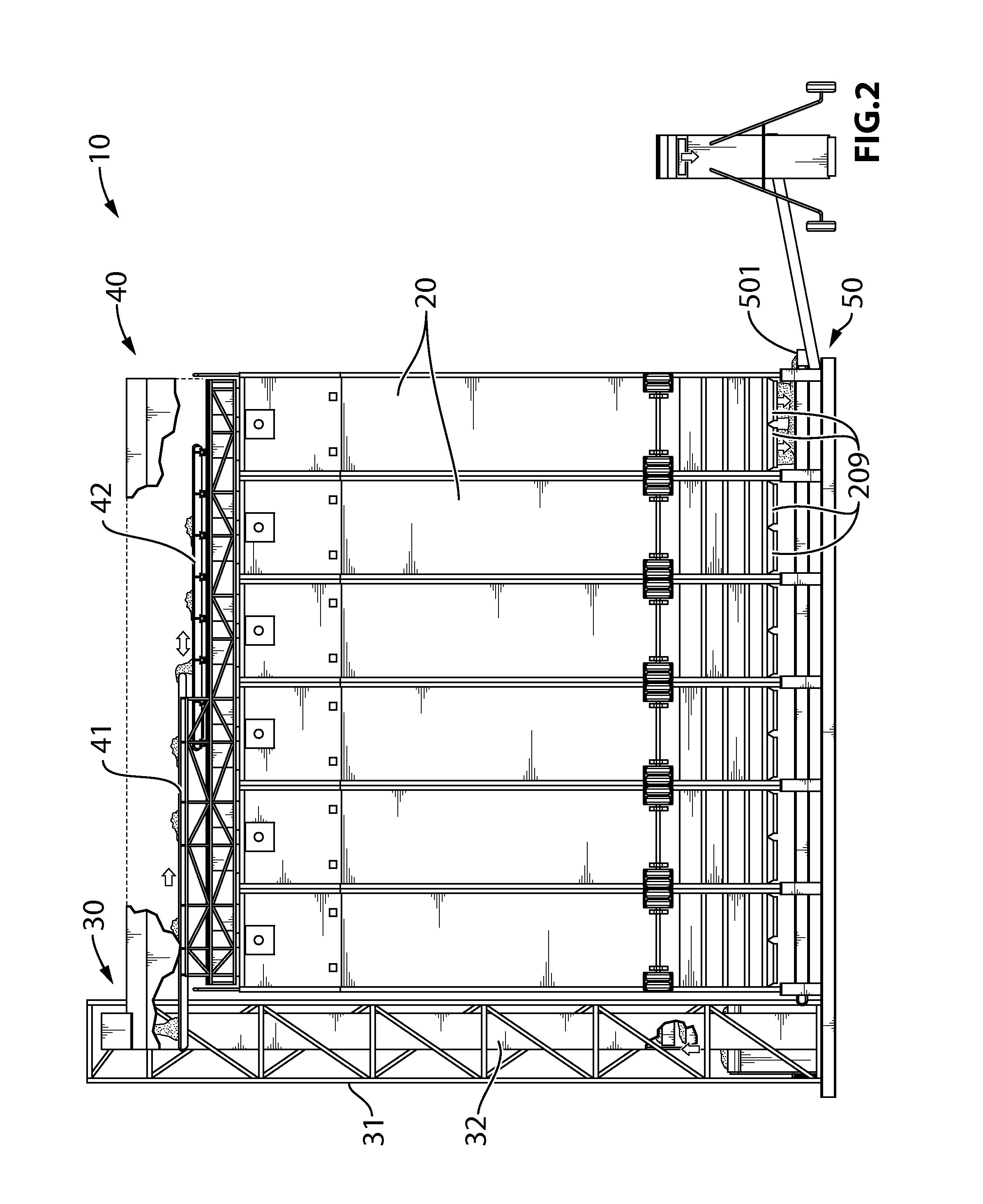

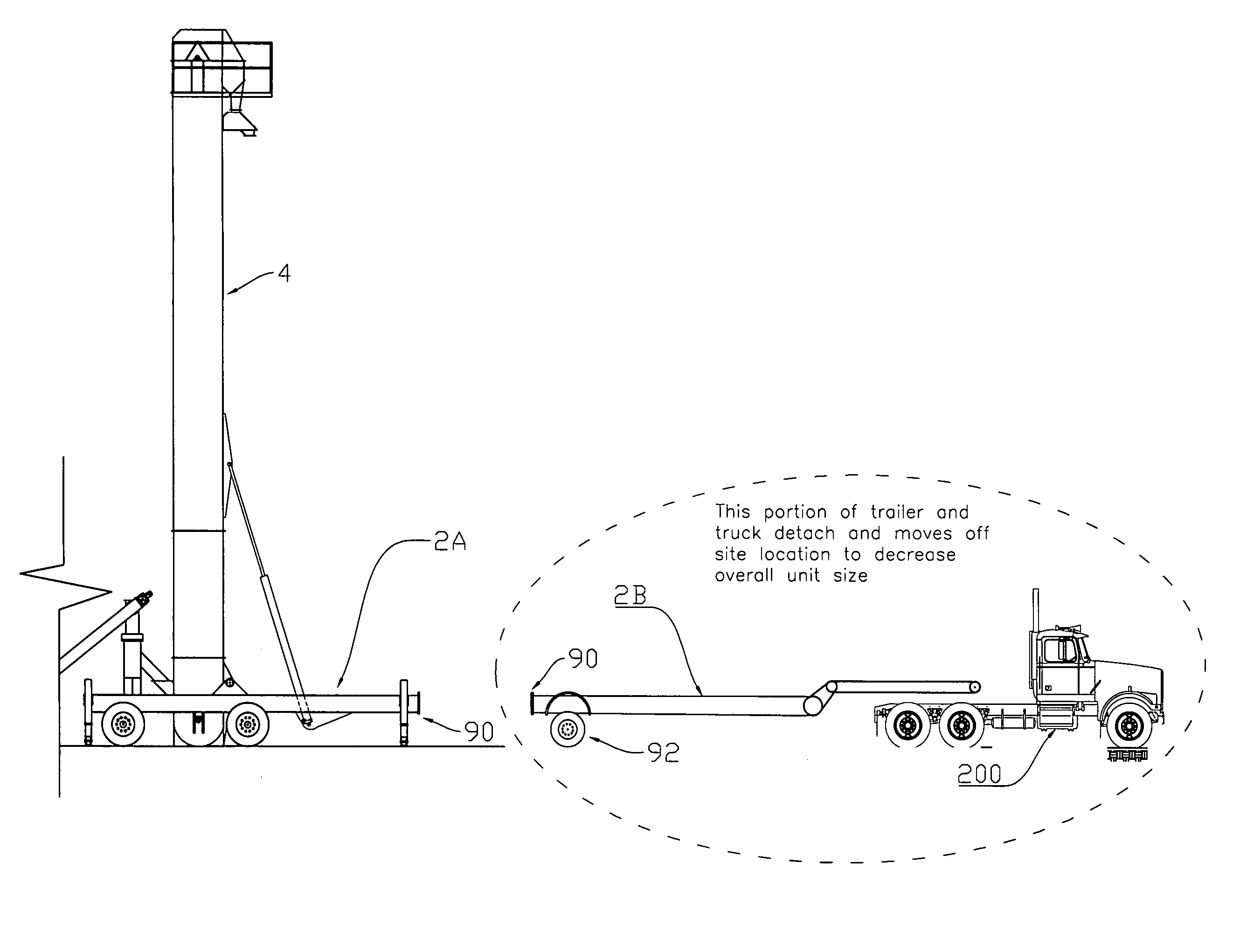

ActiveUS20140377042A1Avoid accidental damageIncrease volumeTractor-trailer combinationsKitchen equipmentWell drillingBucket elevator

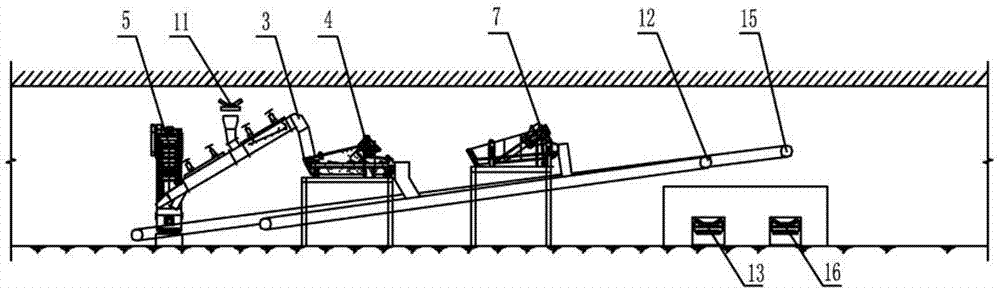

A system that can be assembled at a well drilling or other site for storing bulk material such as sand includes a plurality of storage bins configured as trailers, a skid that includes a lower conveyor, a bucket elevator and a top conveyor system. At the site, the bins and the elevator are vertically oriented and stood on the skid, resulting in discharge outlets on the bins becoming positioned over the lower conveyor. The top conveyor is installed on top of the bins. In operation, the elevator lifts the material and discharges it onto the top conveyor system. The top conveyor system discharges the material into the bins for storage. The stored material is controllably discharged from the discharge outlets of the bins onto the lower conveyor from which the material is conveyed to one end of the skid for transport to a new location or directly into a blender.

Owner:SOURCE LOGISTICS LTD O A AMMOS FIELD SOLUTIONS +1

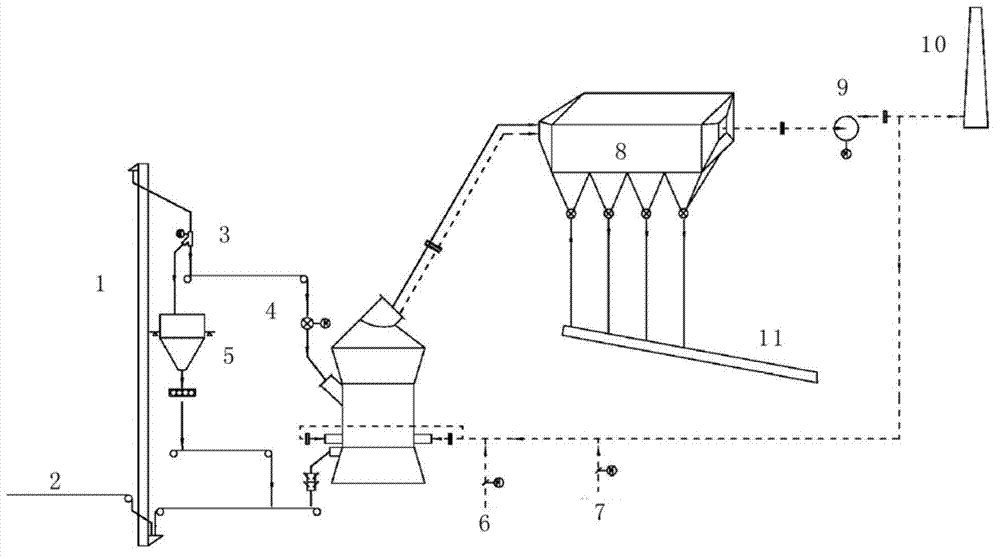

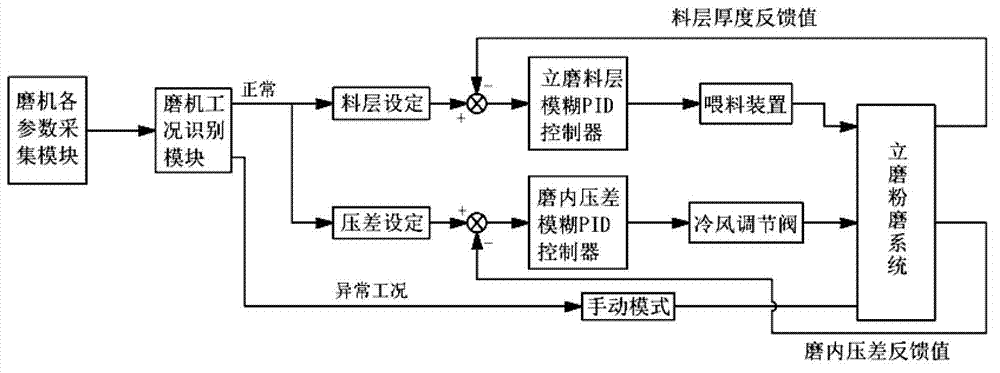

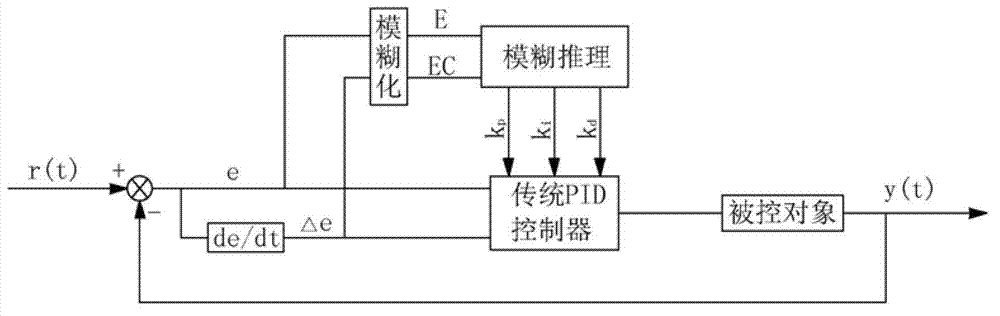

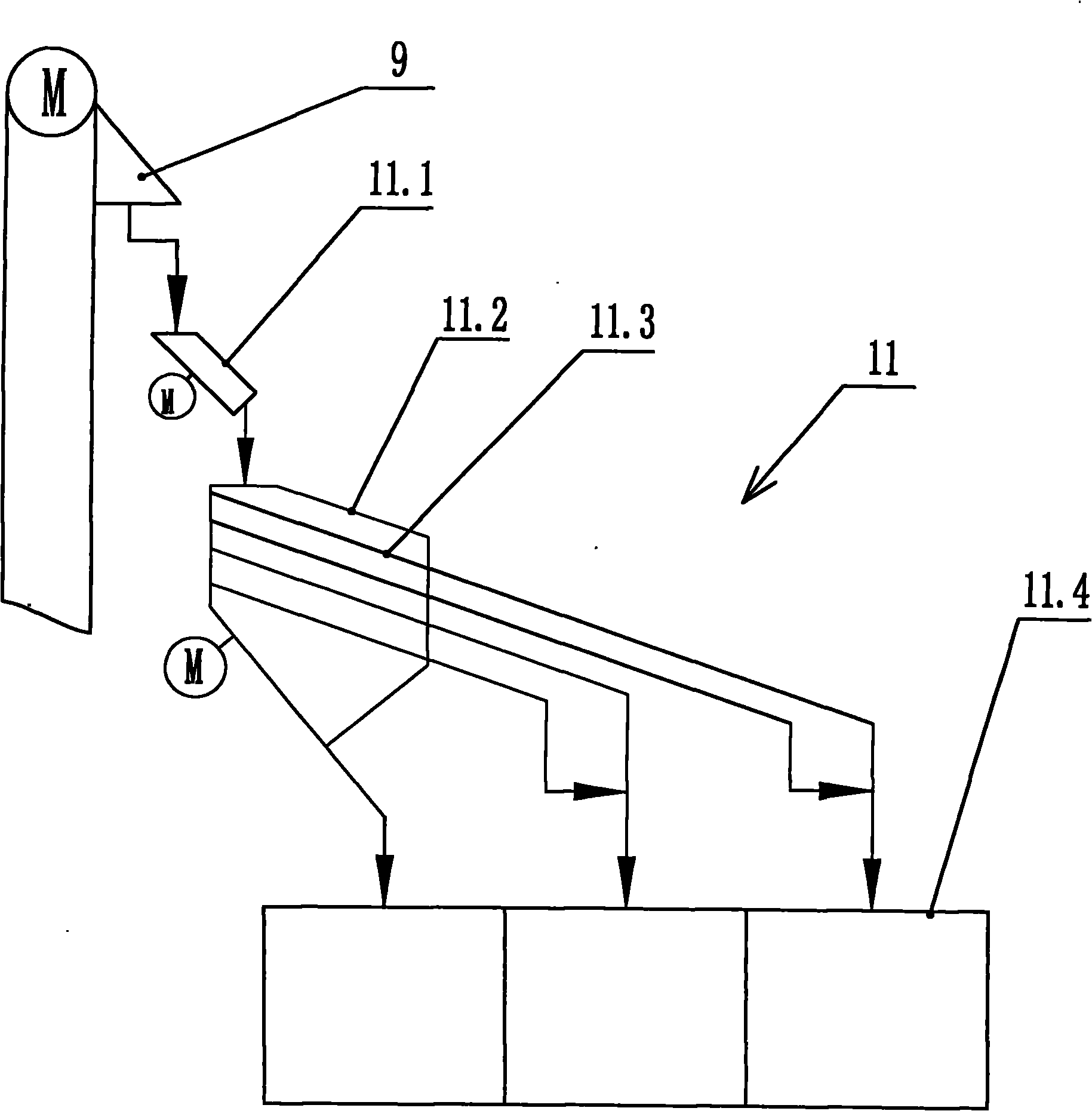

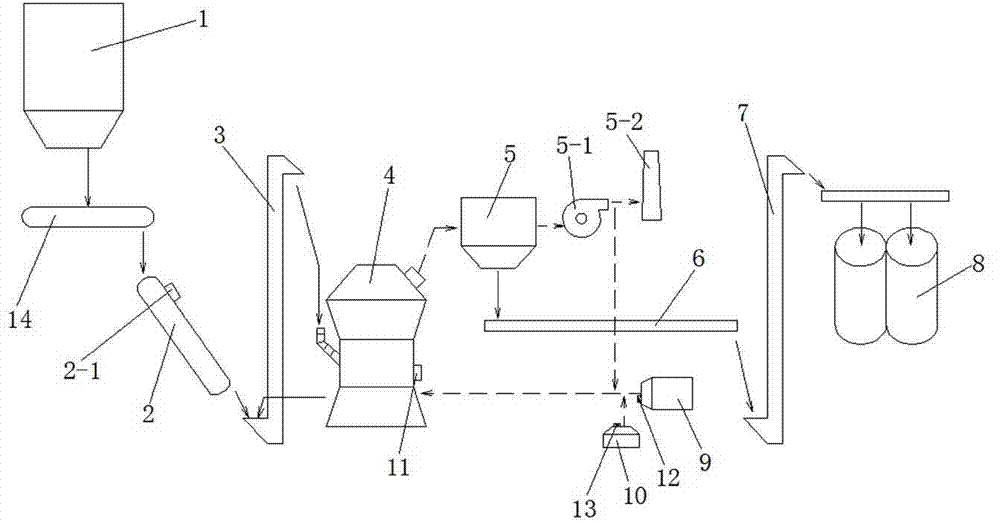

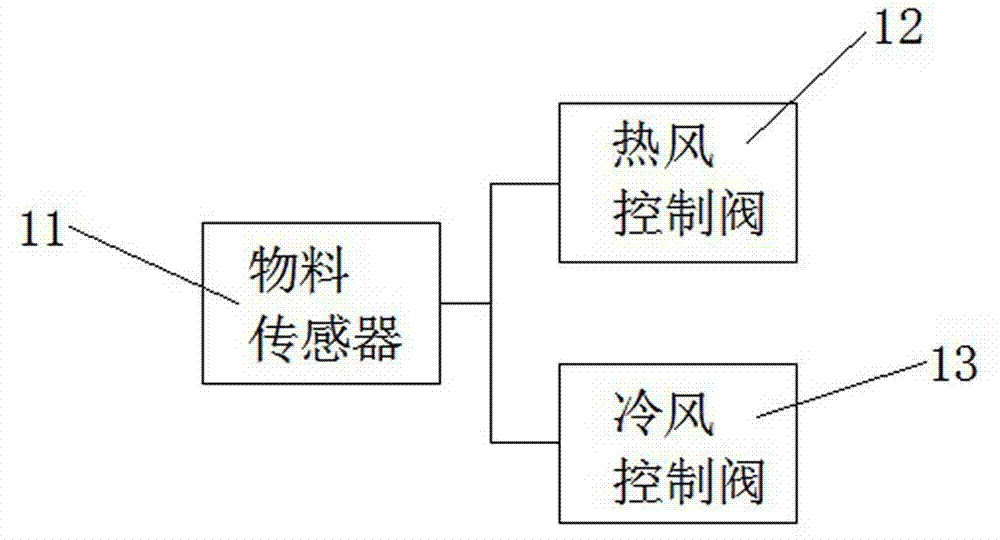

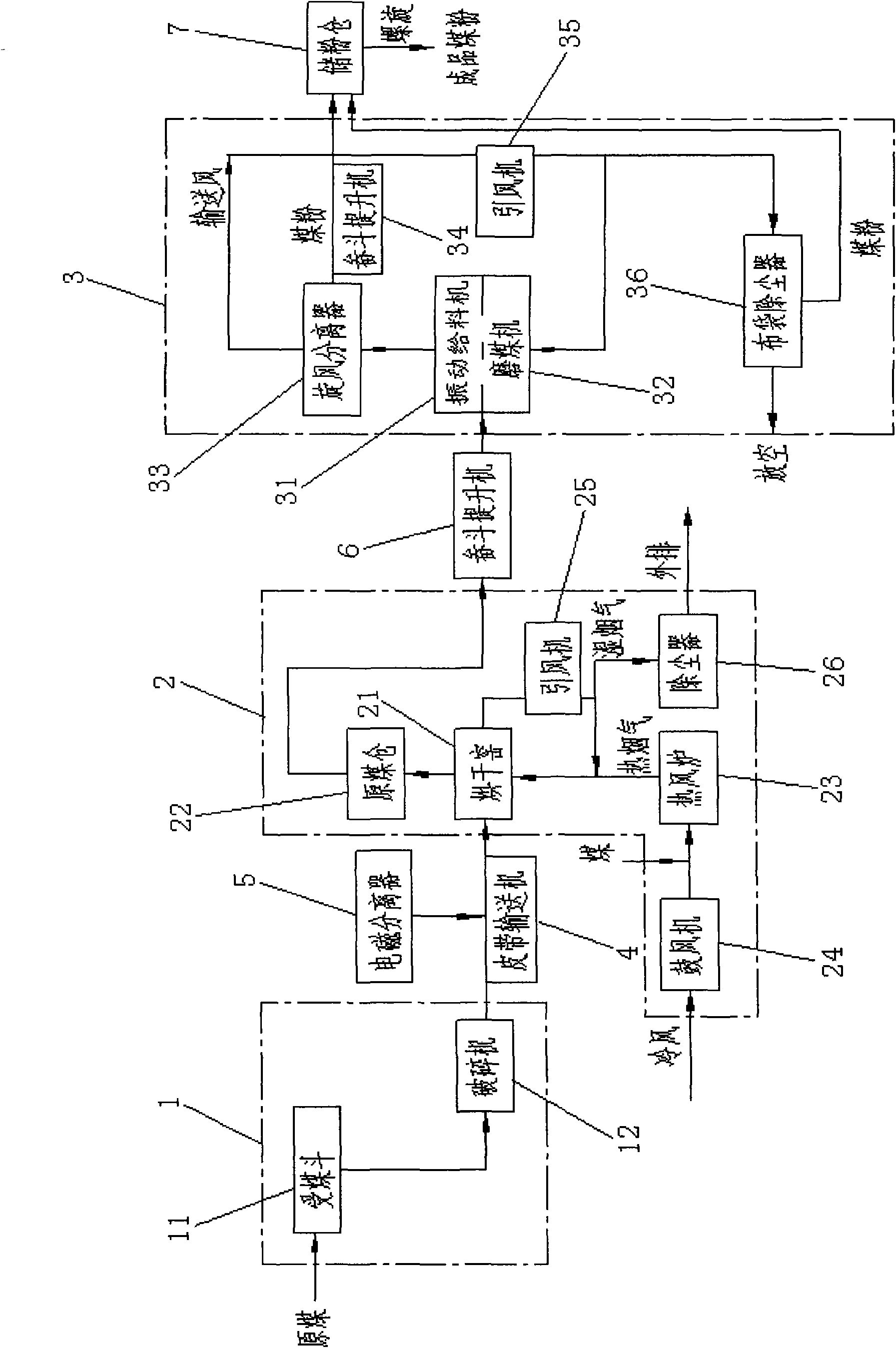

Intelligent control system for vertical mill based on fuzzy PID (proportion integration differentiation) algorithm

ActiveCN103028480AStable thicknessStable mill internal pressure differenceGrain treatmentsAdaptive controlCold airProportion integration differentiation

The invention relates to the technical field of control on production equipment, and particularly relates to an intelligent control system for a vertical mill based on a fuzzy PID (proportion integration differentiation) algorithm. The intelligent control system comprises the vertical mill, a dust remover and a feeding device, wherein the feeding device comprises an unloader, a bucket elevator and a storage bin; and the intelligent control system is characterized in that an air inlet in the bottom of the vertical mill is connected with a fan via a pipeline, a cold-air device and a hot-air stove are arranged on the pipeline between the air inlet and the fan, a cold-air adjusting valve and a hot-air adjusting valve are respectively arranged on the cold-air device and the hot-air stove, a vertical mill material layer PID controller is arranged on the feeding device, and an in-mill pressure difference fuzzy PID controller is arranged on the cold-air adjusting valve. According to the intelligent control system disclosed by the invention, mathematical models of the change of the vertical mill material layer thickness and an in-mill pressure difference along with parameters of a feeding amount, a mill inlet hot-air temperature and the like can be established only by inputting and outputting data without analyzing the complex grinding process of the vertical mill; and the intelligent control system is simple in process, high in adaptability, fast in the dynamic response time of a controller algorithm, high in robustness, high in control accuracy, and good in market prospect.

Owner:SHANGHAI TRIUMPH ENERGY CONSERVATION ENG TECH CO LTD

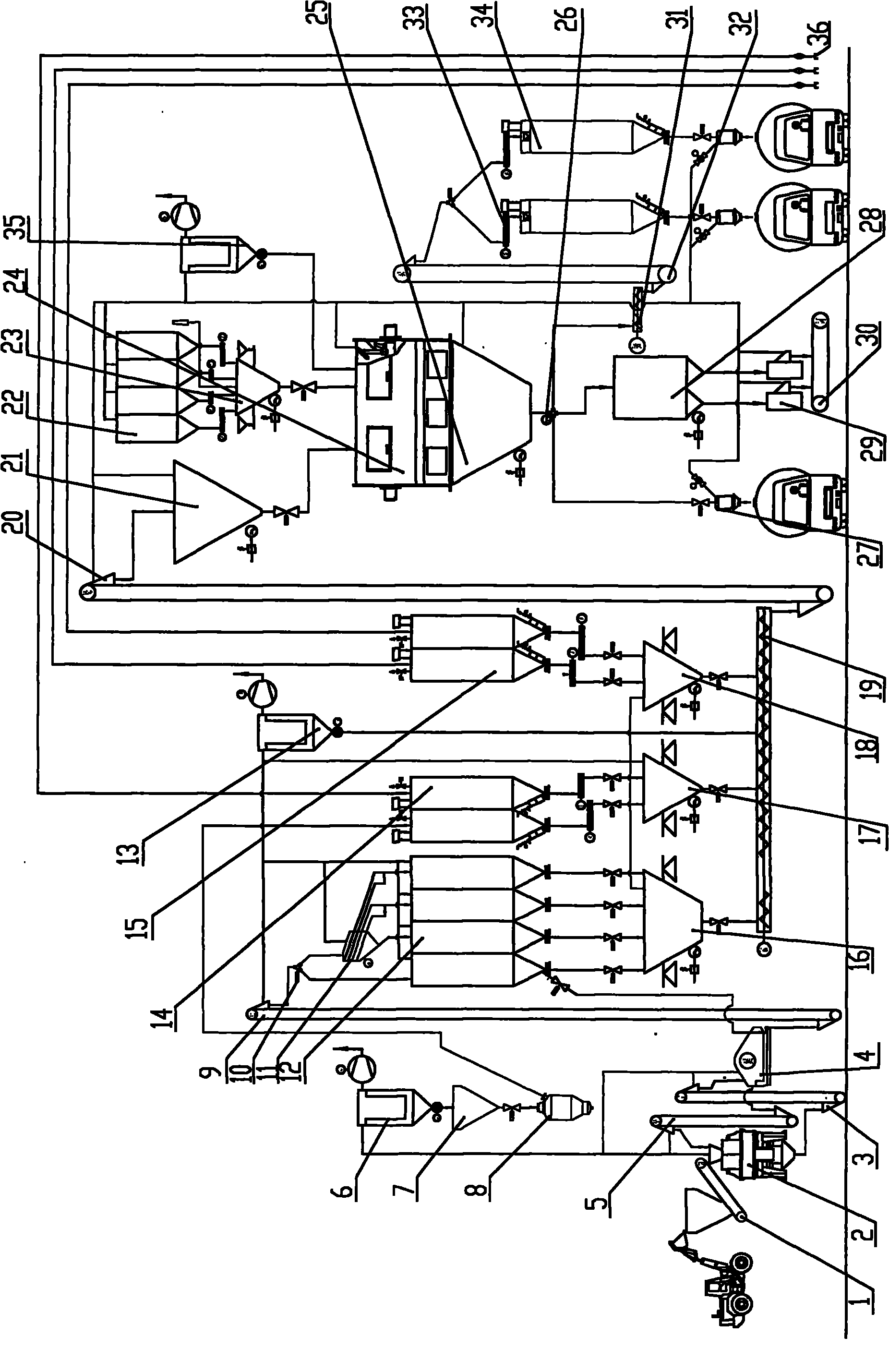

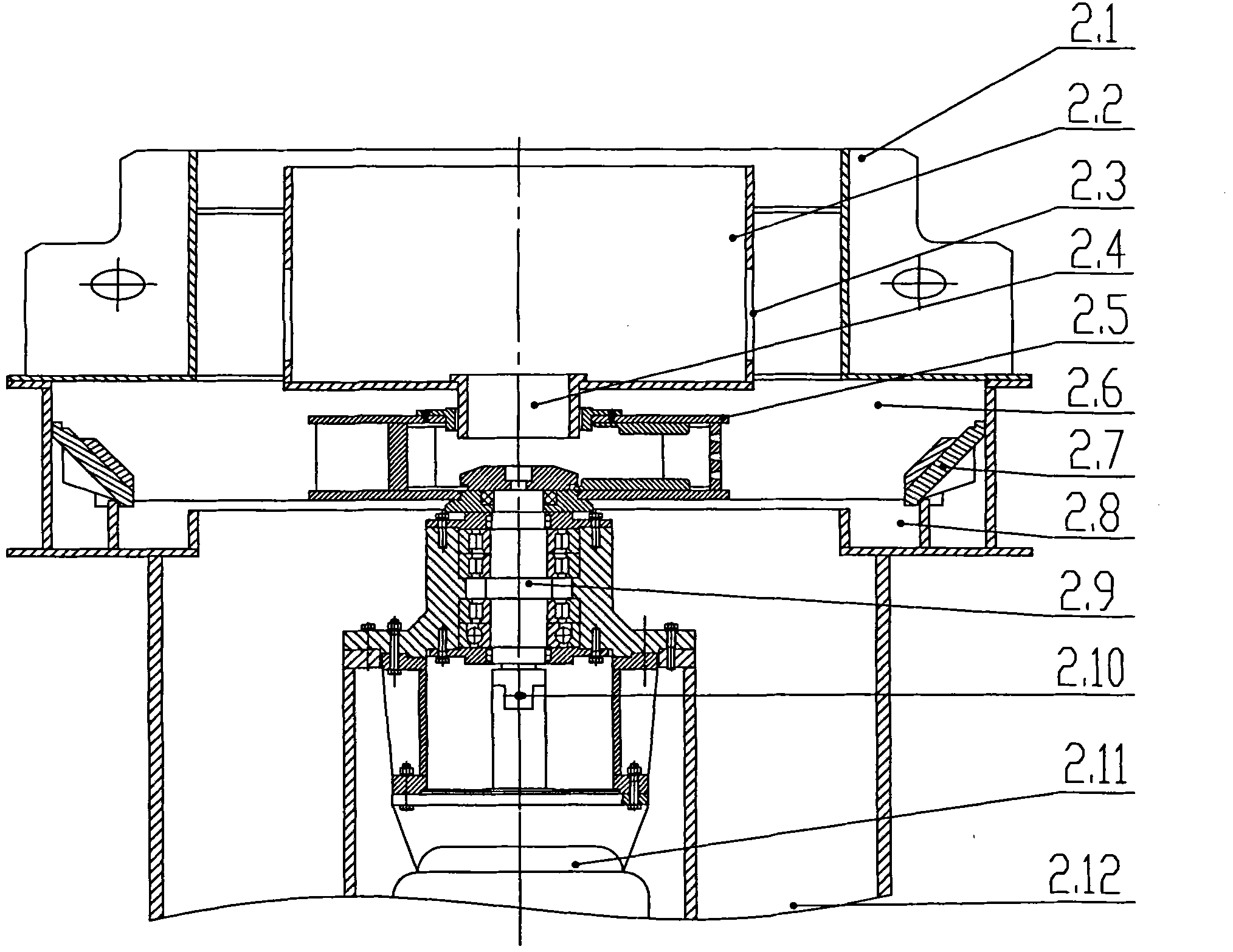

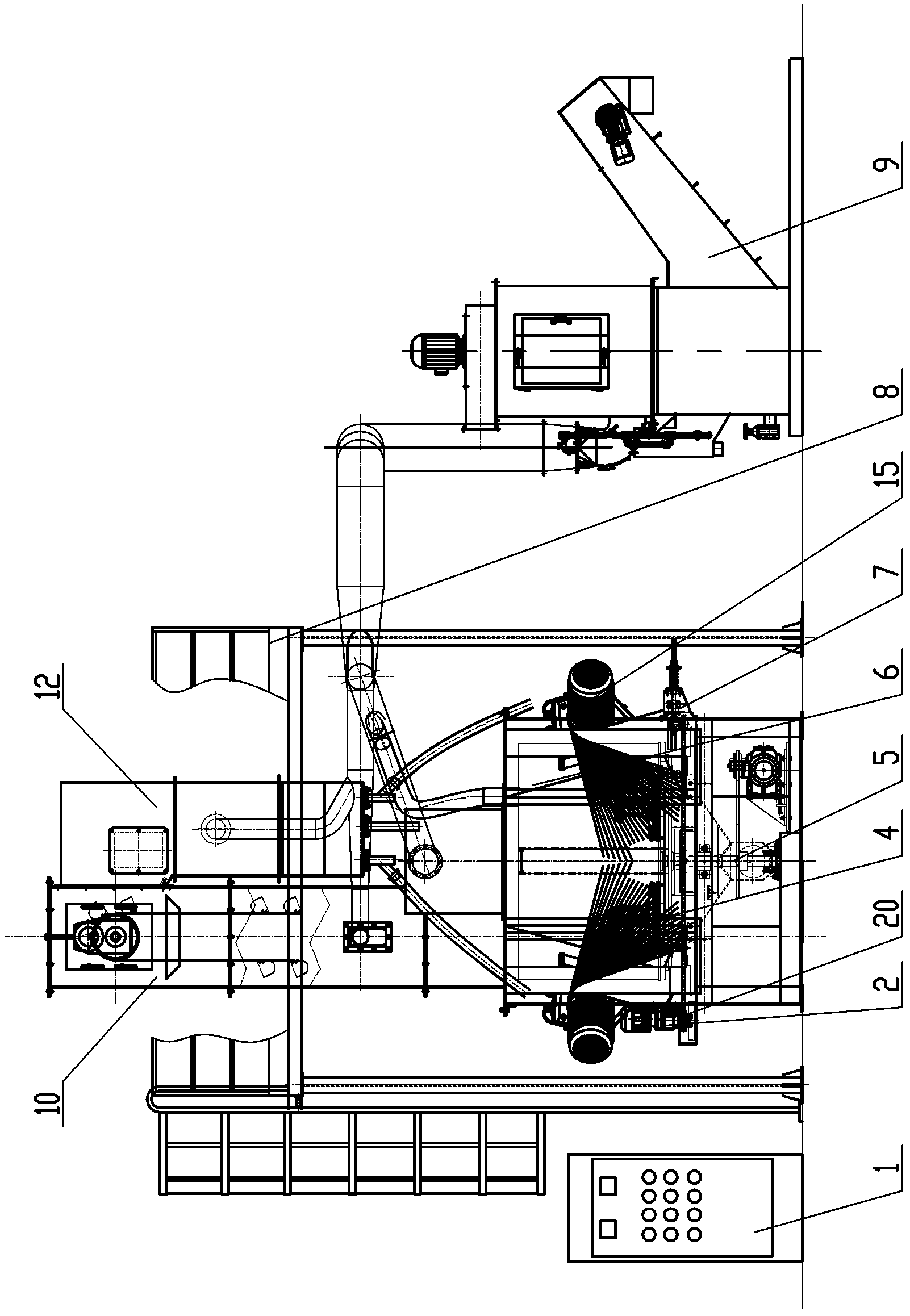

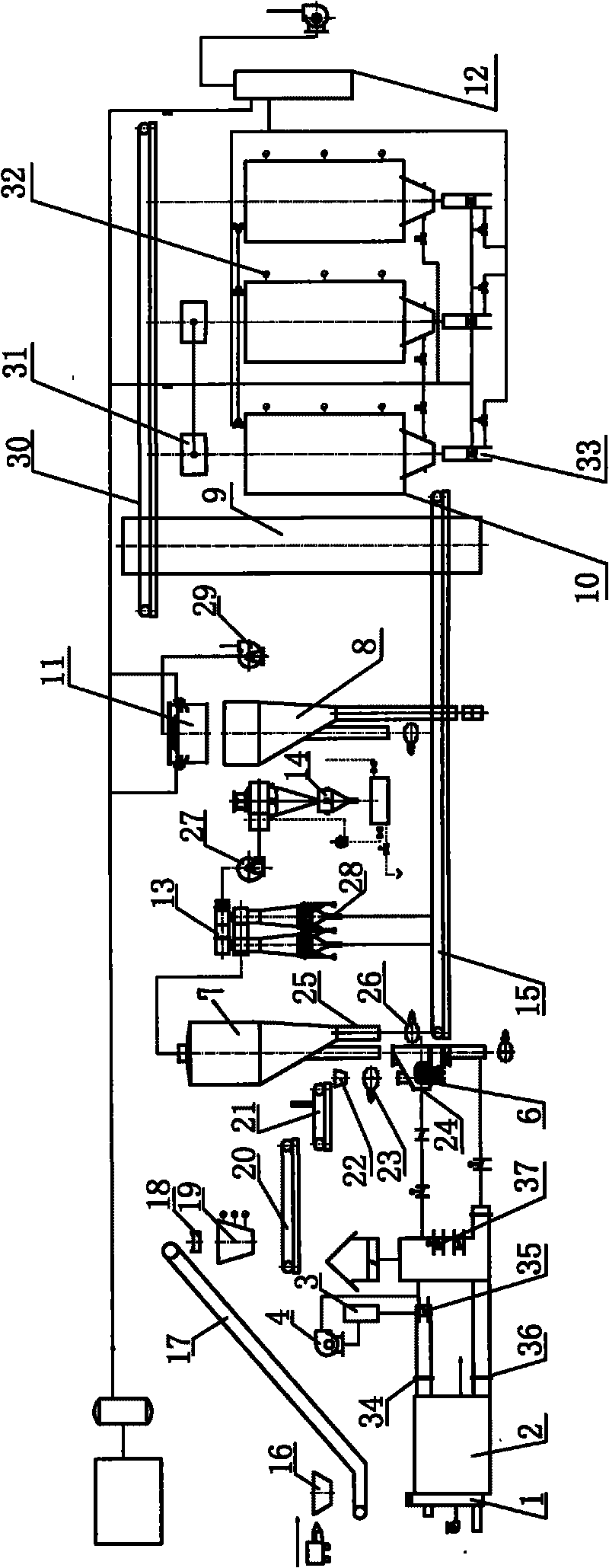

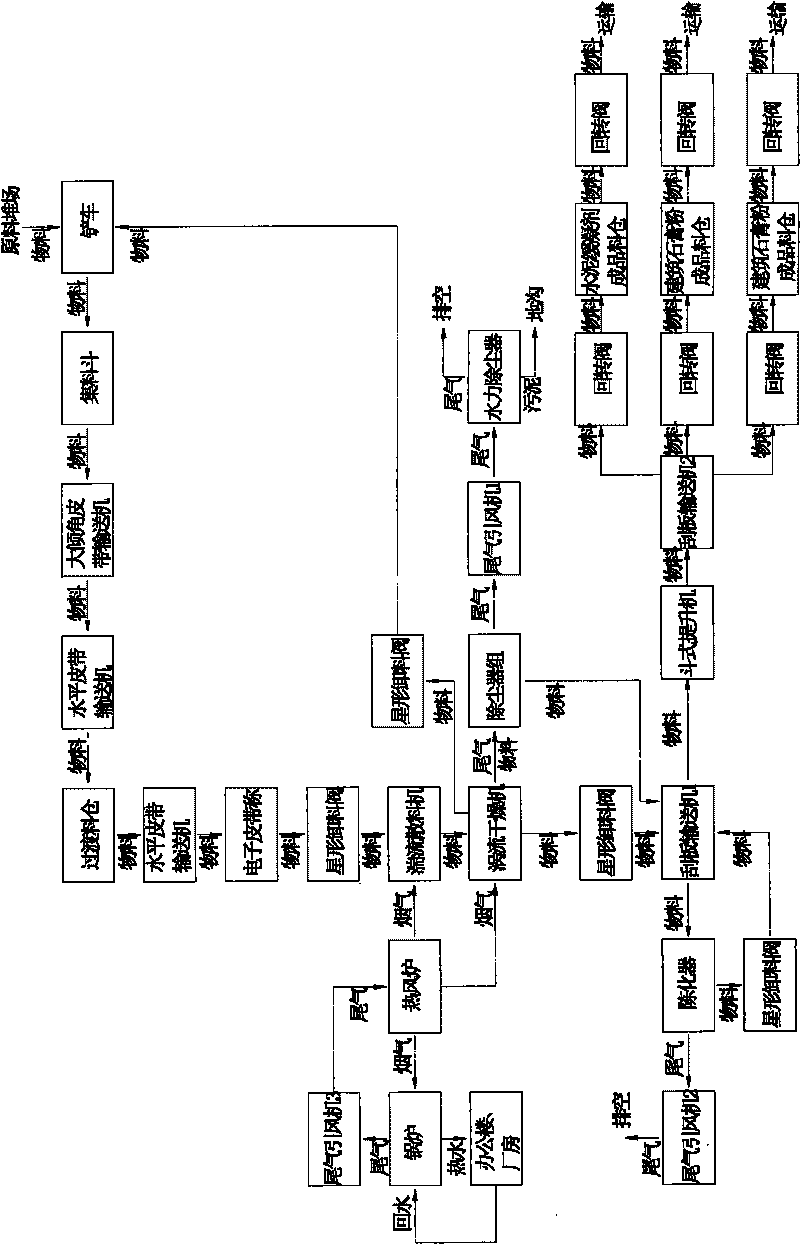

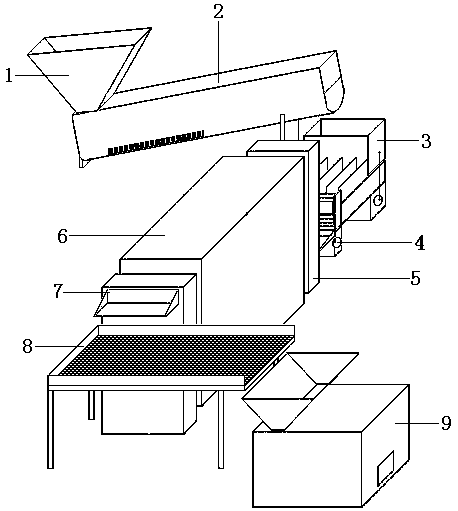

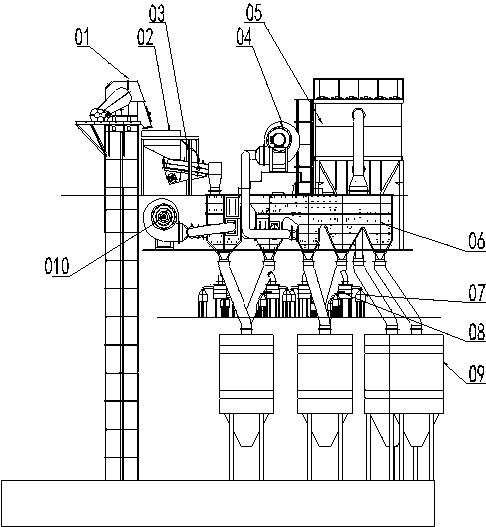

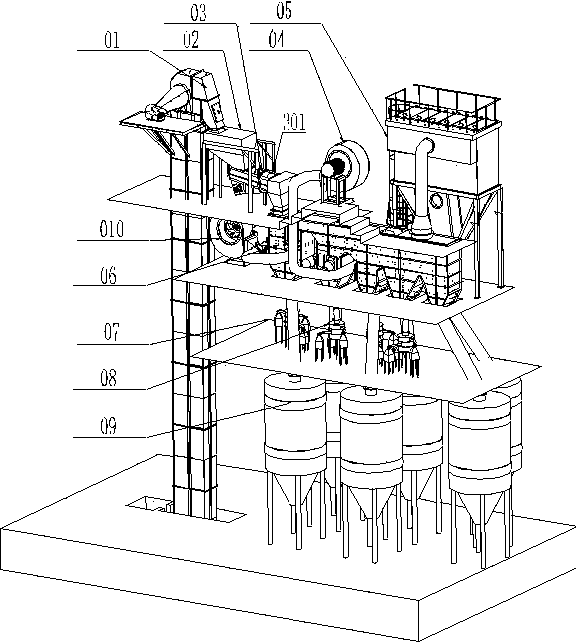

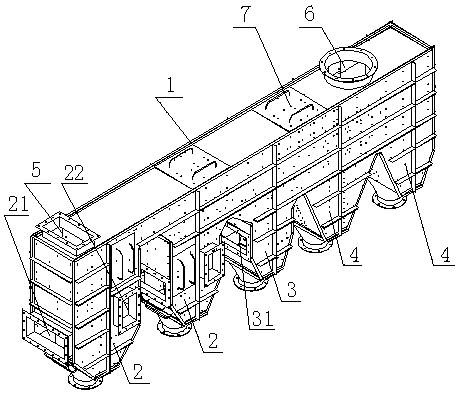

Drying-free dry-mixed mortar complete equipment

The invention relates to drying-free dry-mixed mortar complete equipment, comprising a charging belt conveyor (1), a crusher sand making machine (2), a discharging bucket elevator (3), a circulating vibration screen (4), a screening bucket elevator (9), a vibrating screen classifier (11), a classified sand warehouse (12), a return bucket elevator (5), a stone powder dust collector (6), a stone powder temporary storage bin (12), a stone powder delivery tank (8), a stone powder additive bin (14), a cement bin (15), a sand dispensing and metering device (16), an additive dispensing and metering device (17), a cement dispensing and metering device (18), a metering material spiral conveyer (19), a metering material bucket elevator (20), a metering material intermediate transition bin (21), an additive storage silo (22), an accurate dispensing and metering device (23), a mixer (24), a finished product material transition bin (25), a bulk head (27), a wrapping finished product bin (28), a sack filler (29), a package belt conveyer (30), a finished product material storage spiral conveyer (31), a finished product material storage bucket elevator (32), a dissociation-proof transport unloading device (33) and a finished product material bulk storage silo (34). The invention can omit drying and realizes drying-free effect.

Owner:WUXI JIANGJIA CONSTR MACHINERY

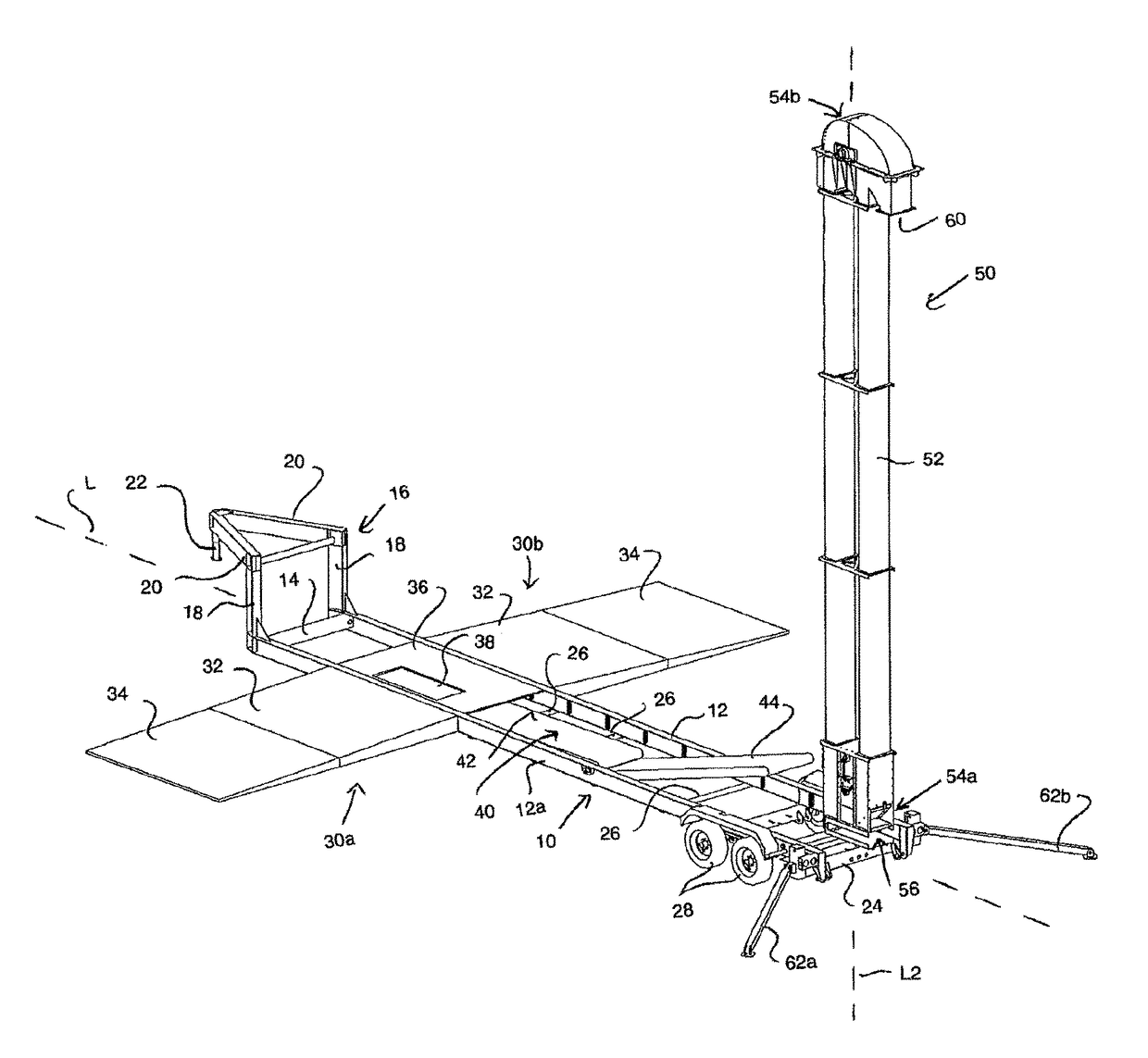

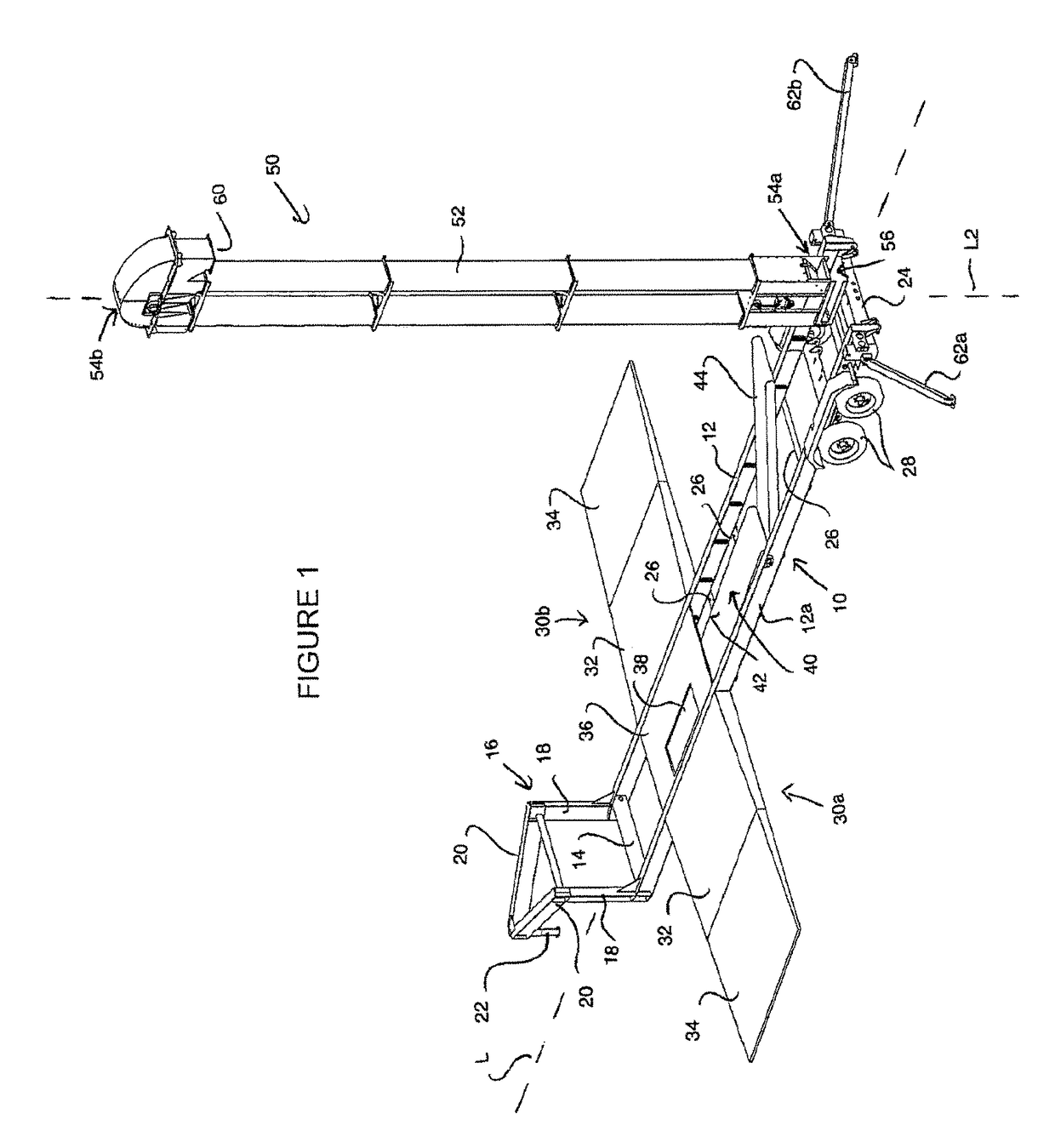

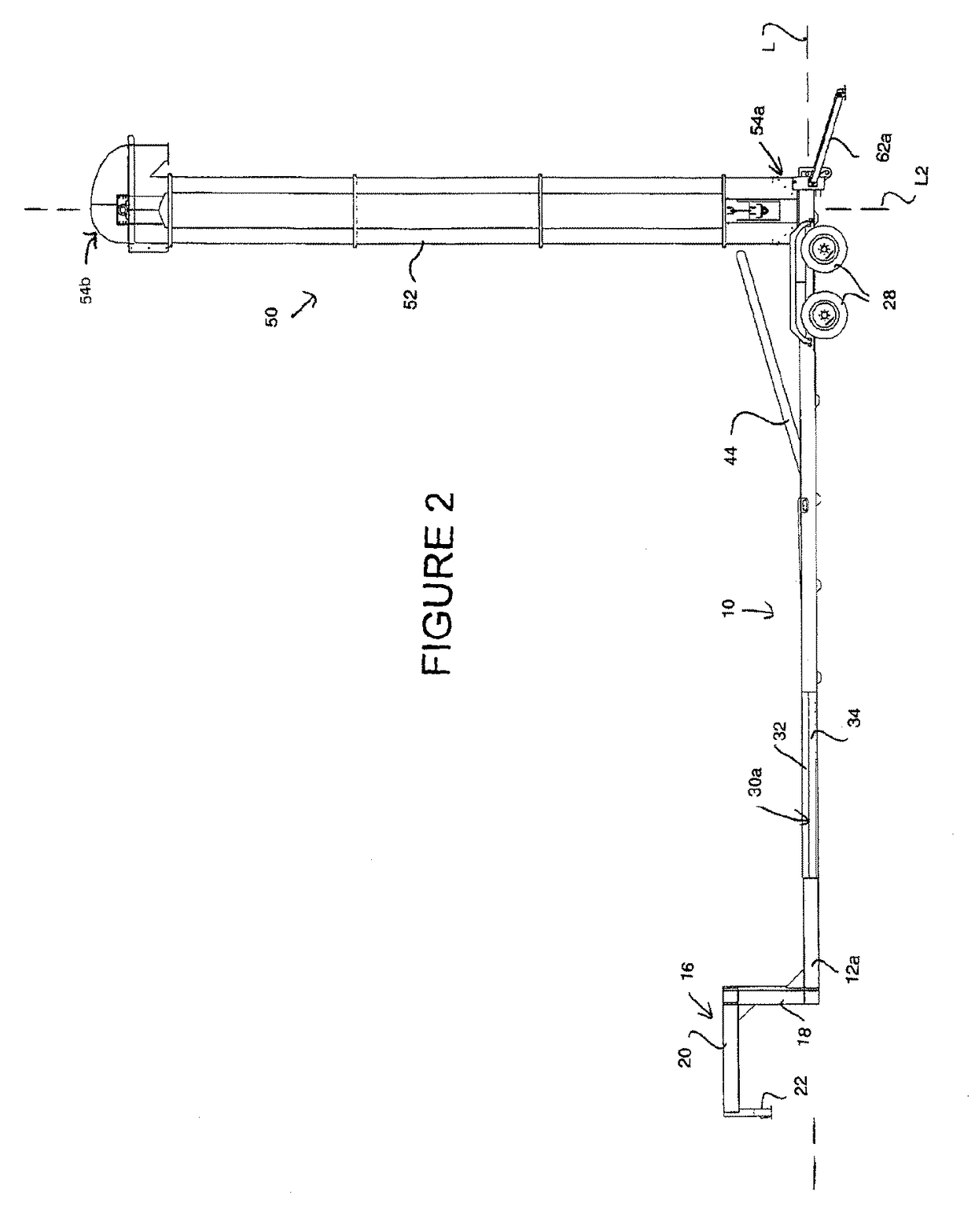

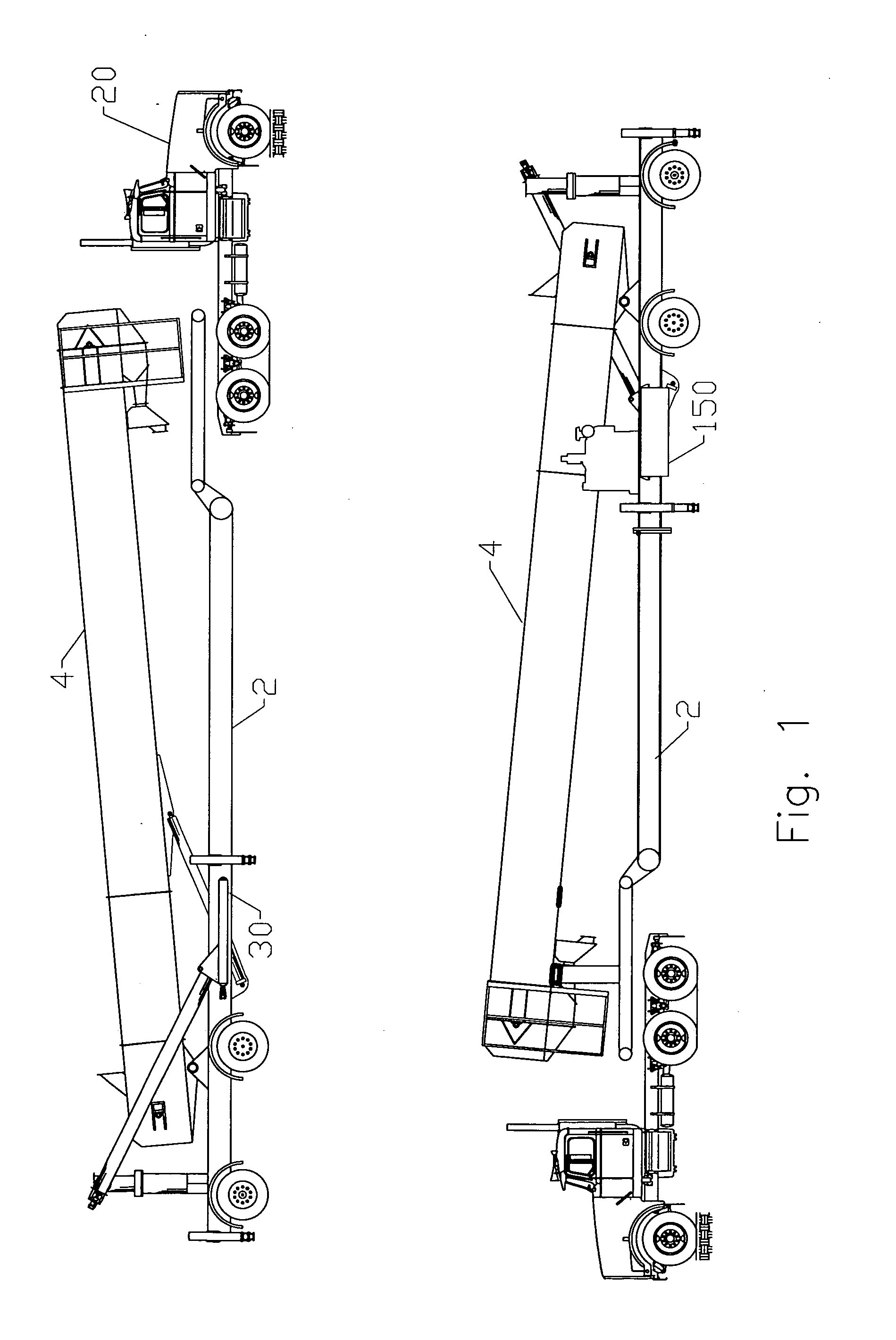

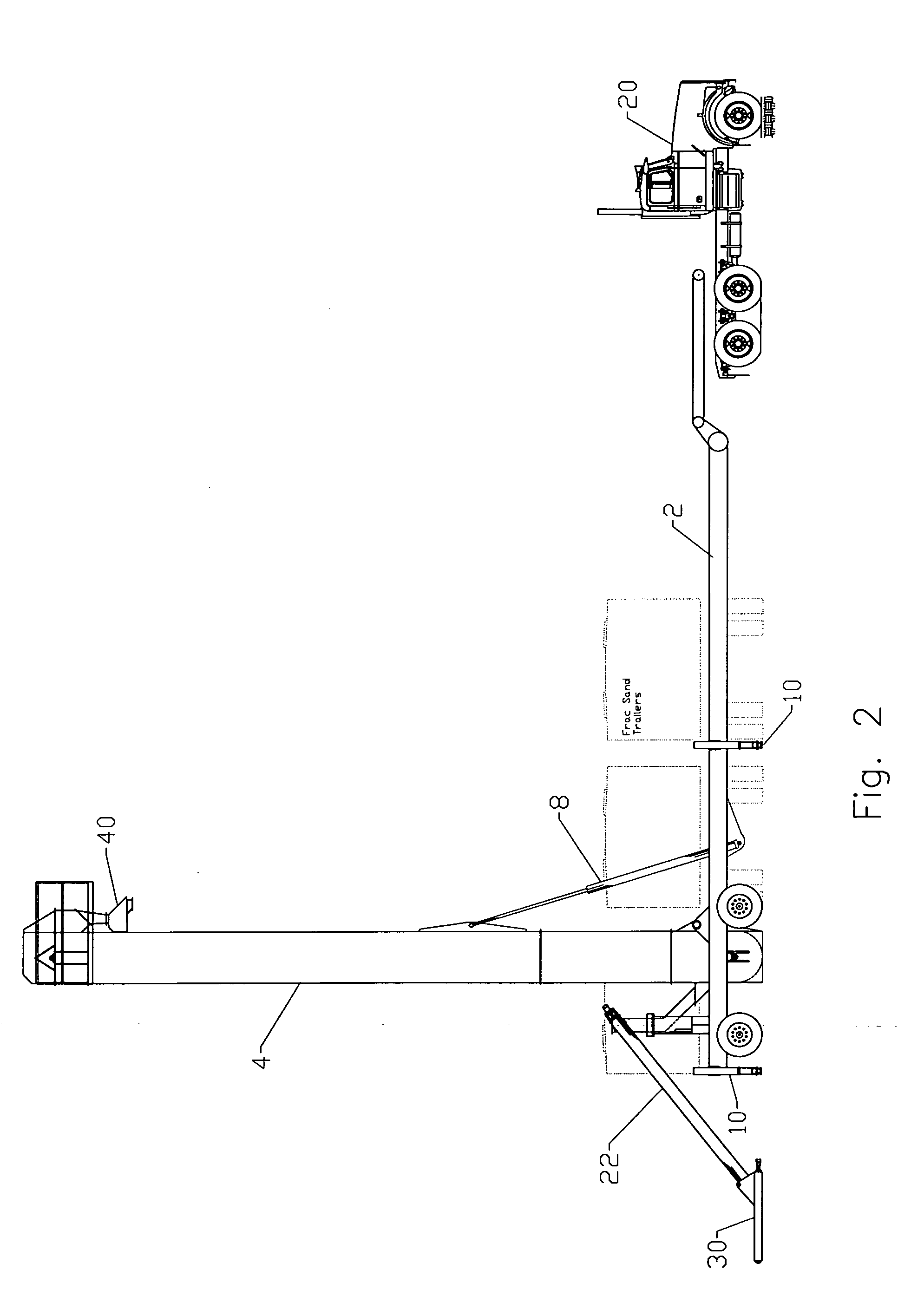

Portable conveyor system with drive-over unloading ramp and a longitudinal conveyor feeding a bucket elevator

A portable conveyor system for receiving particulate material from a transport vehicle and conveying the particulate material to an elevated location. A main conveyor features a bucket elevator carried on a wheeled transportable frame and movable between an operational position standing upright from the transportable frame and a storage position laid down along the transportable frame. A feeder conveyor connected to the transportable frame is operable to convey material from into an inlet of the bucket elevator that is situated adjacent a lower end the elevator's upright operational position. A drive-over assembly enables loading of the feeder conveyor from a bottom unload transport vehicle. The feeder conveyor and the drive-over assembly may be carried on a movable framework for movement of the feeder conveyor between a stowed position on the transportable frame, and a use position extending laterally outward to position the drive-over assembly beside the transportable frame.

Owner:NORSTAR IND

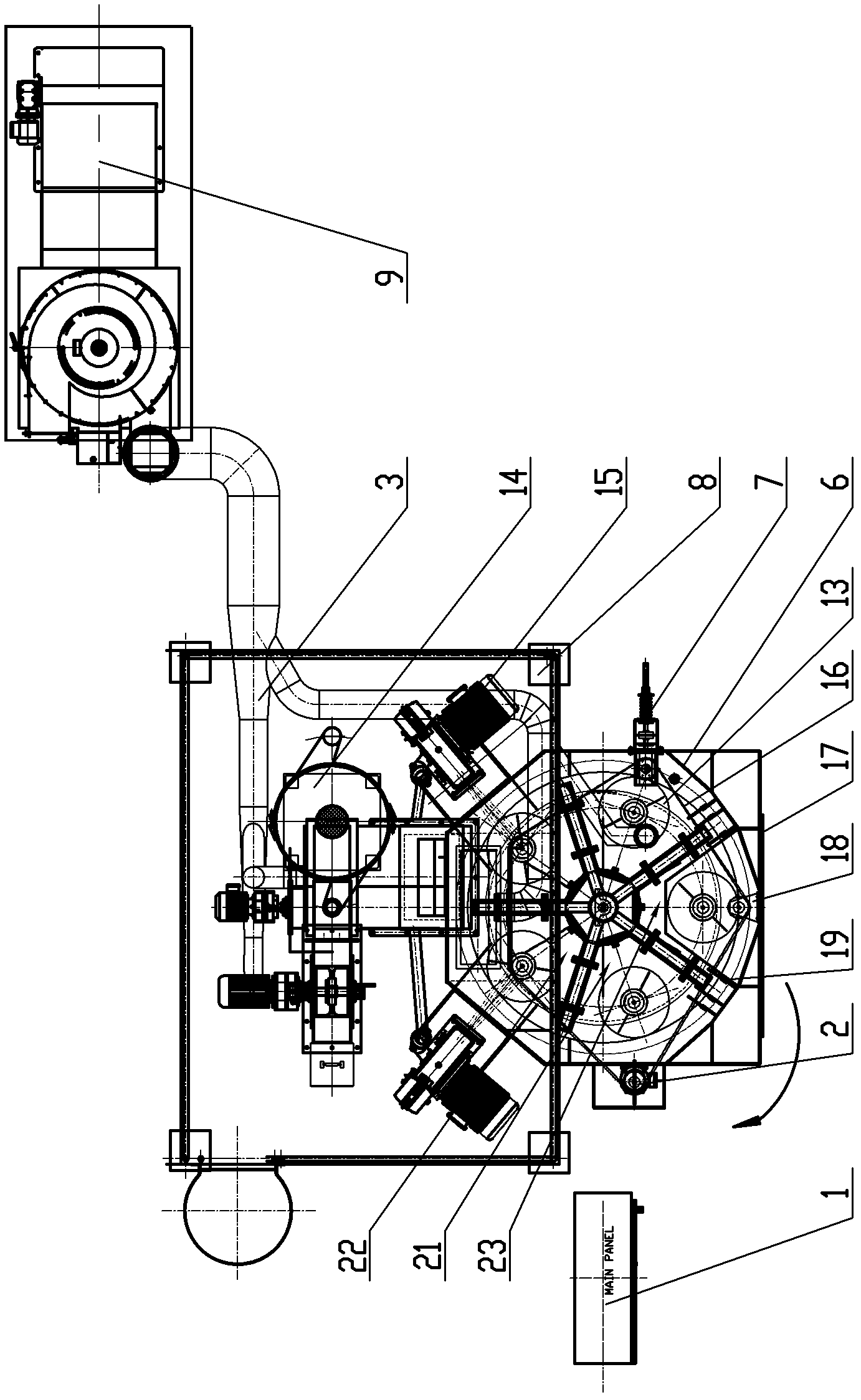

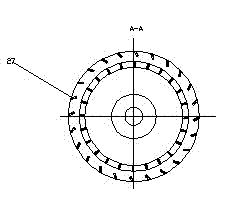

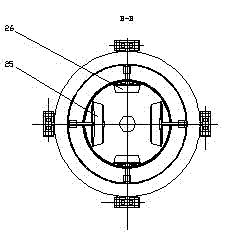

Reinforced shot blast machine for multi-position turntable

InactiveCN102248493APrevent flying outPrevent splashAbrasive blasting machinesEngineeringLoading unloading

The invention relates to a reinforced shot blast machine for a multi-position turntable. A main rotary worktable is mounted in a shot blast cleaning room, a shot blast machine is arranged out of the shot blast cleaning room, a steel shot selector is fixed above the shot blast cleaning room, a helical conveying device is fixed below the shot blast cleaning room, a hopper-type lifter is arranged behind the shot blast cleaning room, a feeding port and a discharging port of the hopper-type lifter are respectively connected with the helical conveying device and the steel shot selector, a discharging port of a steel shot separator is connected with the shot blast machine; the main rotary worktable is fixed with a partition wall assembly for partitioning the table-board of the main rotary worktable into five stations which are respectively two shot blast stations, two isolation stations and a loading-unloading station, and each station is rotatably equipped with a planetary worktable. The main rotary worktable is partitioned into the shot blast stations, the isolation stations and the loading-unloading station, the isolation stations are arranged between the loading-unloading station andthe shot blast stations with the effect of sealing; therefore, the shot can be prevented from flying out from the shot blast station, and the security is good.

Owner:无锡国达机械设备有限公司

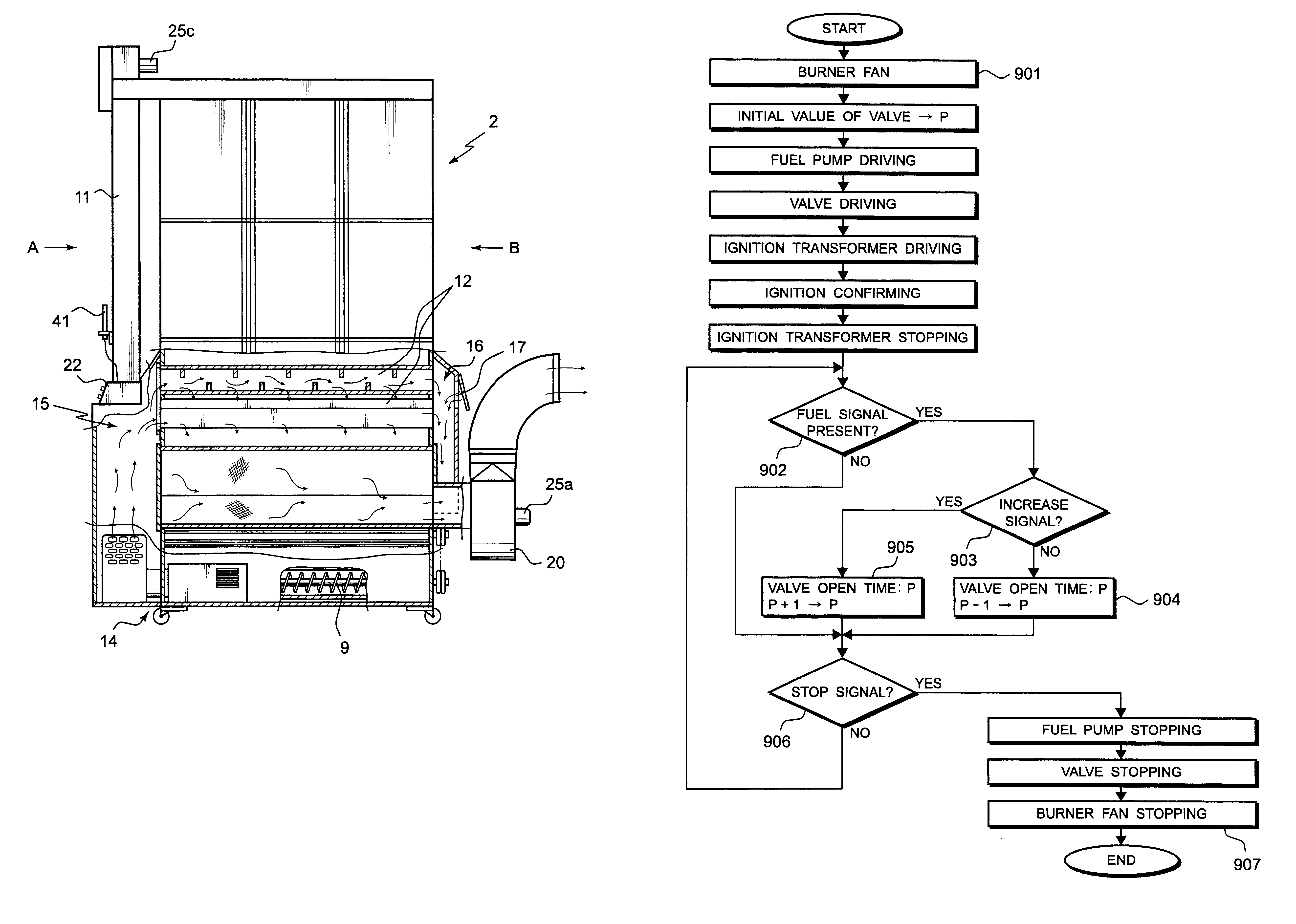

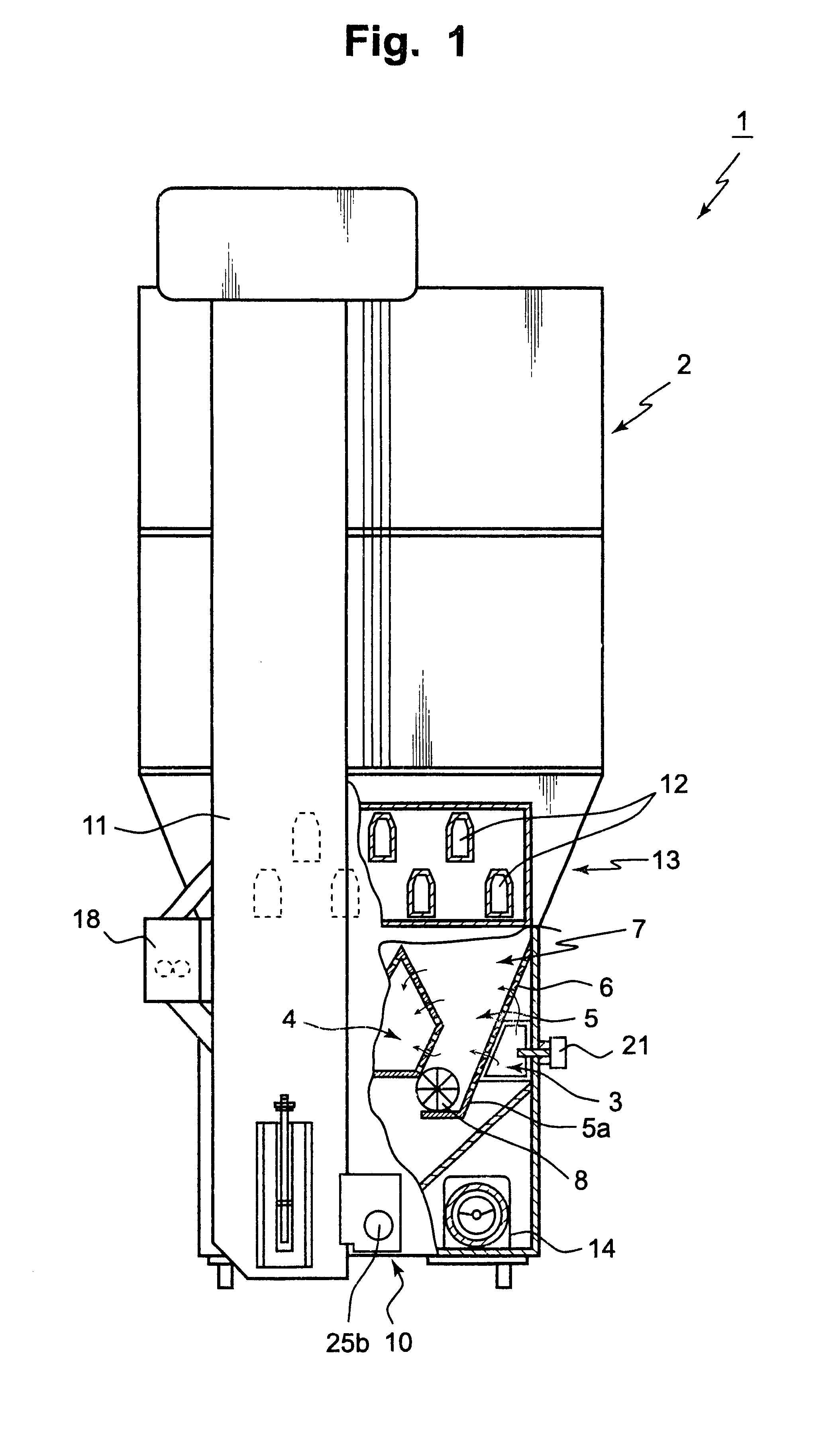

Apparatus for drying granular objects involving pre-heating process

InactiveUS6223451B1Reduce harmMoreDrying solid materials with heatDrying gas arrangementsProcess engineeringBucket elevator

An apparatus for drying granular objects comprises, from the top of the apparatus, a holding section; a heating section for heating the granular objects flowing down from the holding section, the heating section being provided beneath the holding section and having a plurality of air ducts to which heated air is introduced; a drying air producing section connected to the air ducts, in which the heated air from the air ducts is mixed with air taken-in from the outside of the apparatus to produce a drying air; and a drying section for drying the granular objects by directly exposing the granular objects to the drying air. The dried granular objects are taken out from a taking-out section and returned to the holding section through a bucket elevator. The apparatus further comprises a detector for detecting the temperature of the drying air. Based on the detected temperature, a control device controls the temperature of the heated air so as to keep the temperature of the drying air to a predetermined temperature. The temperature of the drying air can be set to a desirable temperature while the heated air for the heating is kept at a high temperature. The drying operation is performed speedily and safely.

Owner:SATAKE CORP

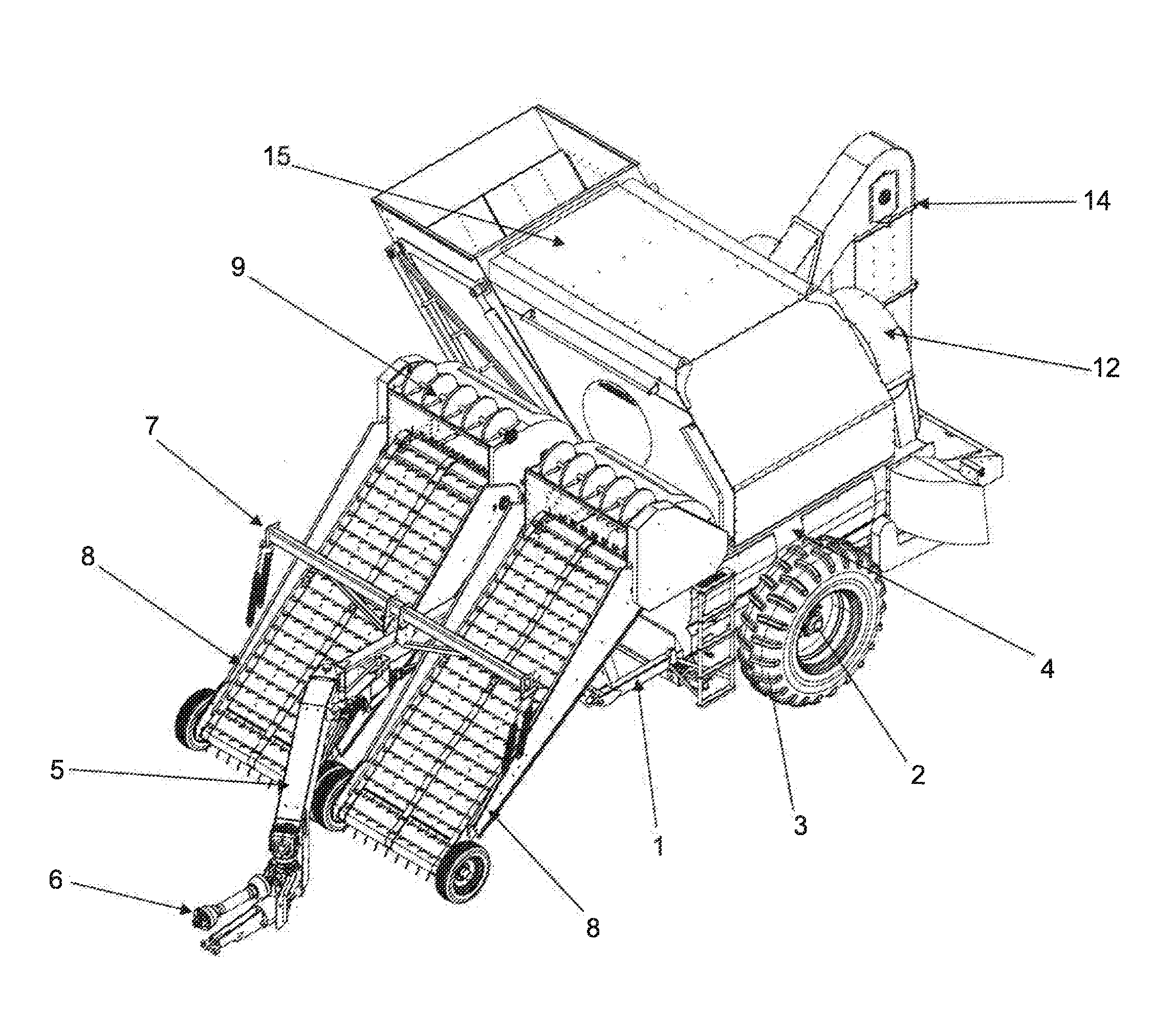

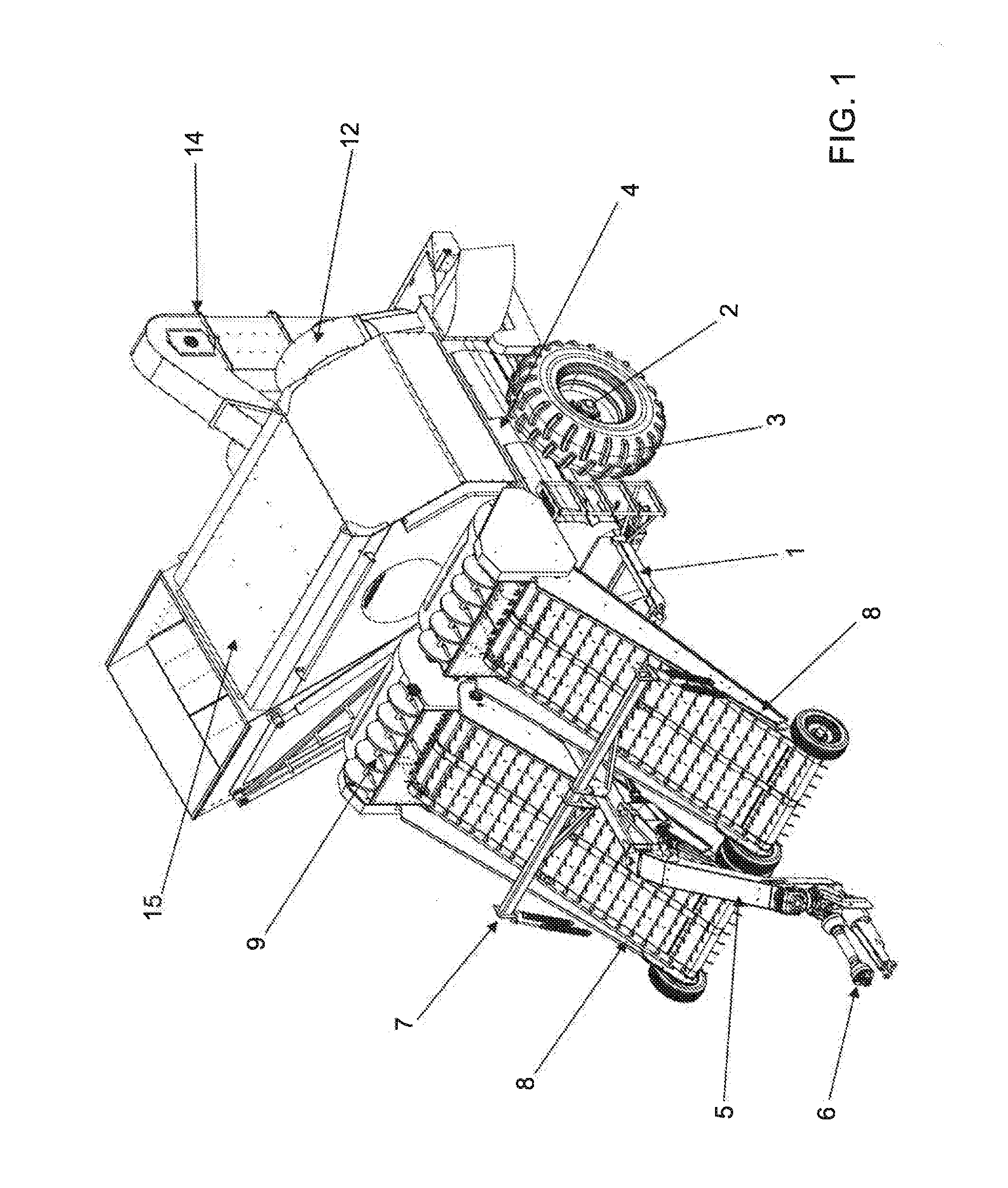

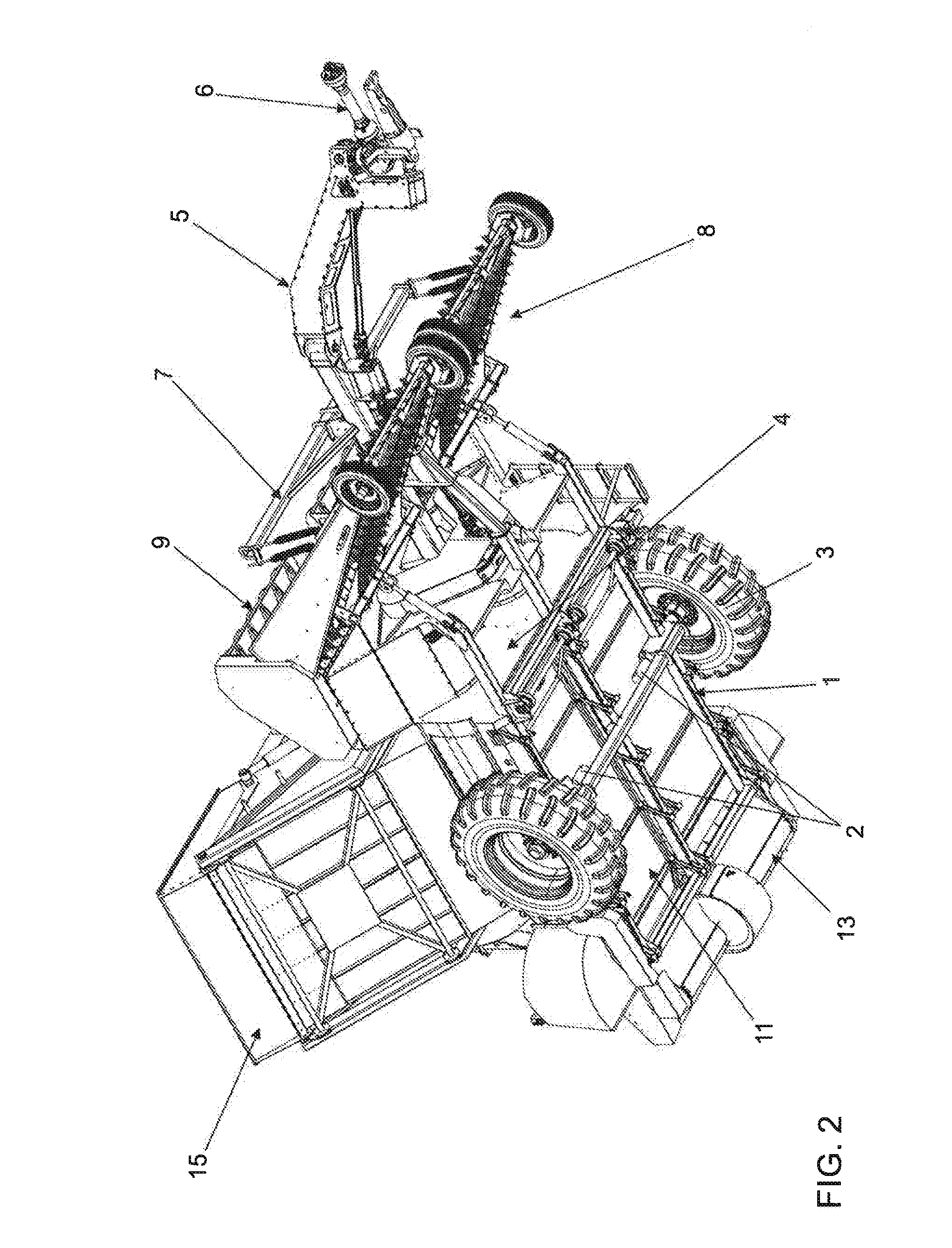

Harvester and processor for peanuts

ActiveUS20160316626A1Uniform transitionSpeed up the flowLoadersDigger harvestersAnti jammingEngineering

A harvester and processor for peanuts that comprises a drag type machine to be towed and actuated by a conventional tractor, which has various double assemblies to harvest lined up peanuts and process them through various steps of cleaning, up to the separation of the cleaned grains that are stored in an embedded tipper bucket, and to perform all this, said machine contains a chassis (1), that on its bottom side is supported by wheels (3), while on its top side is integrated with a plate body (4) forming a mono block structure for the assembling of all the embedded assemblies, starting with the frontal hitch pole (5) integrated with the transmission assembly (6) which is responsible for the actuation of various parts of the machine, specially two harvesting conveyor belts (8), anti-jamming receptive boxes (9), threshing cylinders (10), and in these cylinders starts the cleaning process together with the vibrating sieves (11) and the ventilation assembly (12), being that the cleaned fruits are delivered to a receptive chute (13), where they are collected by a bucket elevator (14) and dropped inside of a tipper bucket (15).

Owner:IND REUNIDAS COLOMBO LTD

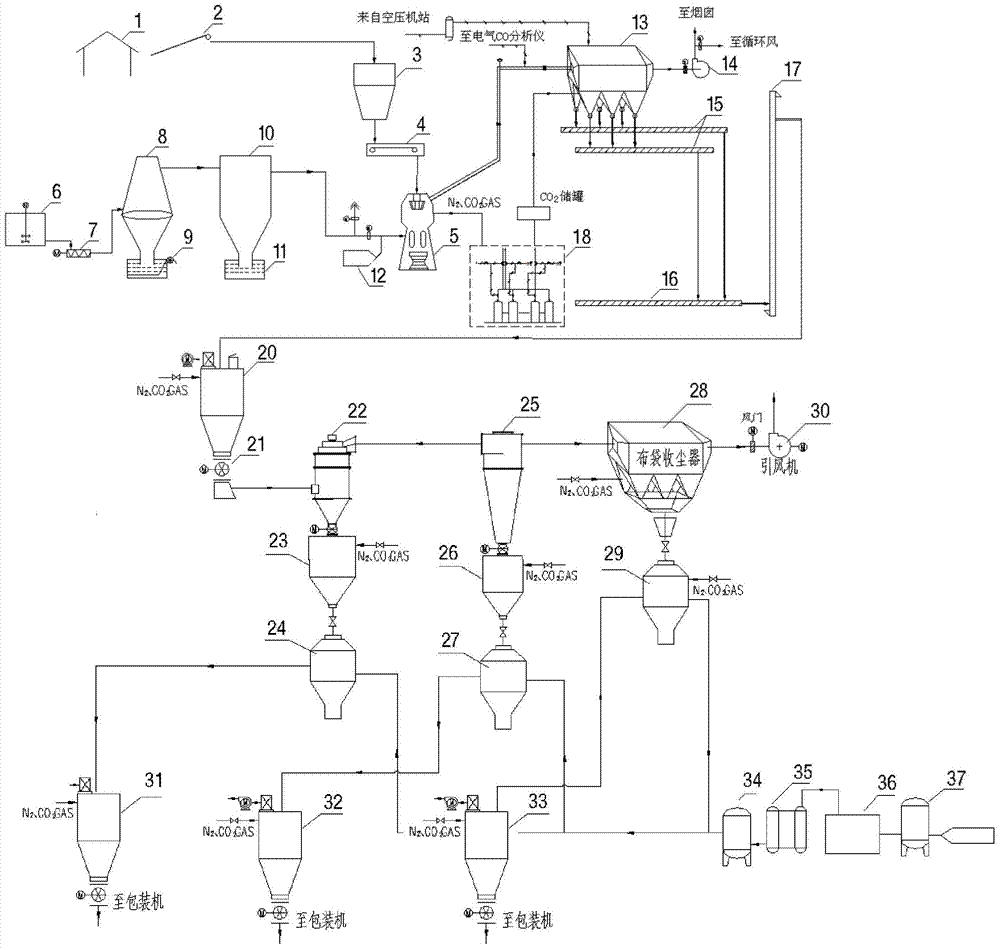

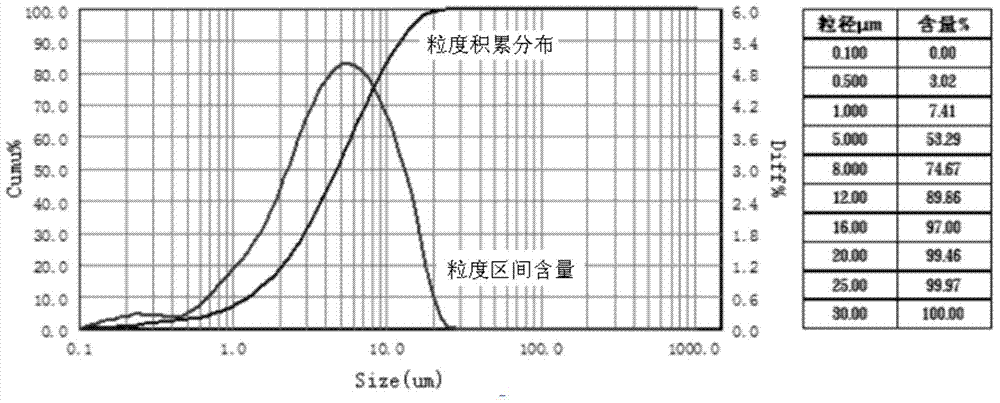

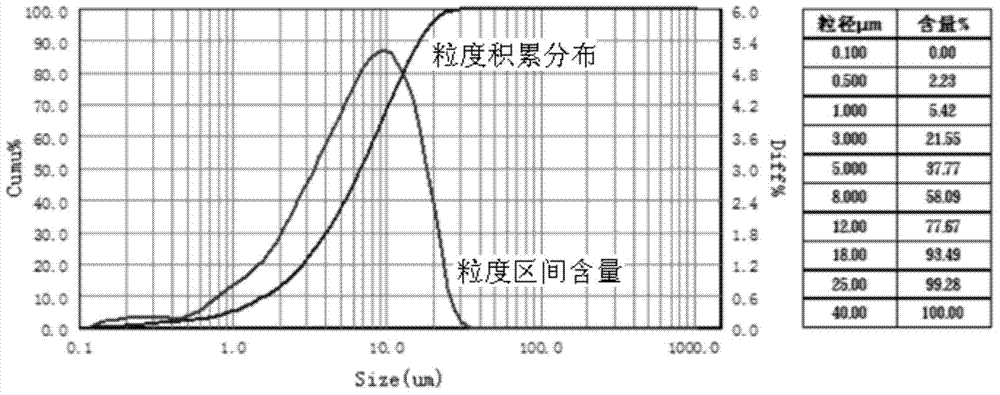

System and method for preparing ultrafine pulverized coal

InactiveCN103537355AIncrease productionReduce electricity consumption costsCombination devicesGrain treatmentsCoal waterProcess engineering

The invention discloses a system and a method for preparing ultrafine pulverized coal. The system comprises a fine pulverized coal preparation system and an ultrafine pulverized coal separation system. The fine pulverized coal preparation system comprises a vertical-type grinding machine. The vertical-type grinding machine is communicated with a bucket elevator. The bucket elevator is communicated with the ultrafine pulverized coal separation system. The ultrafine pulverized coal separation system comprises a pulverized coal surge bin. The pulverized coal surge bin is communicated with a grading machine. The grading machine is communicated with a cyclone separator. The cyclone separator is communicated with a pulse bag-type dust collector. The grading machine is communicated with a fine pulverized coal finished-product bin. The cyclone separator is communicated with an ultrafine pulverized coal finished-product bin 1#. The pulse bag-type dust collector is communicated with an ultrafine pulverized coal finished-product bin 2#. The method comprises fine pulverized coal preparation and ultrafine pulverized coal separation extraction. Through three-grade separation extraction adopting the grading machine, the cyclone separator and the pulse bag-type dust collector, the ultrafine pulverized coal is divided into different grades of ultrafine pulverized coal. The ultrafine pulverized coal obtained by the system and the method has a low cost and does not burn easily. The graded ultrafine pulverized coal can satisfy requirements on particle size graduation of coal water slurry master batch. The system and the method can realize industrial production.

Owner:SHENMU ZHANGJIAMAO COAL MINING CO LTD OF SHAANXI COAL & CHEM IND GRP

Novel mineral slag grinding system

The invention relates to the technical field of a mineral slag grinding system, and in particular relates to a novel mineral slag grinding system, wherein a discharge hole of a feeding bin is connected with a feeding hole of a first bucket elevator by a belt conveyor; a discharge hole of the first bucket elevator is connected with a feeding hole of a vertical mill machine; a discharge hole of the vertical mill machine is connected with a feeding hole of a bag type dust collector; a discharge hole of the bag type dust collector is connected with a feeding hole of a second bucket elevator by an air chute. According to the system, a raw material discharged from the feeding bin is conveyed into the first bucket elevator by the belt conveyor and is conveyed into the vertical mill machine by the first bucket elevator so as to be ground; a ground material is collected by the bag type dust collector, and is conveyed into a finished product storage sequentially by the air chute and the second bucket elevator; in the grinding process, the ground material is blown by high-speed airflow by a gas hot air furnace and an air cooler, thus being conveniently collected; the novel mineral slag grinding system is reasonable in design, high in productivity and high in production safety.

Owner:NANTONG LIYUANHENG MACHINERY

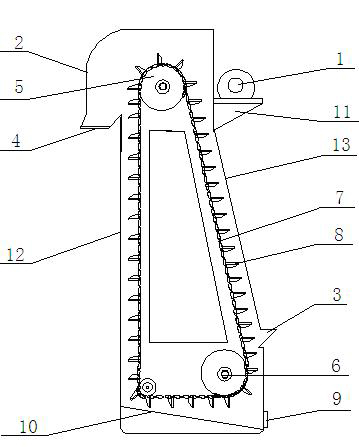

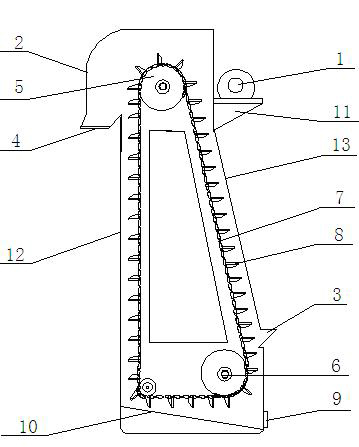

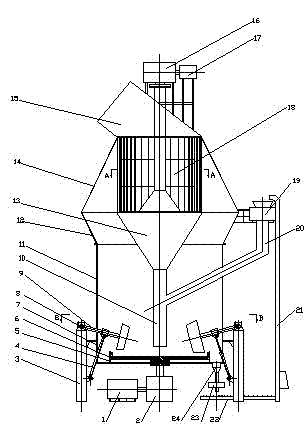

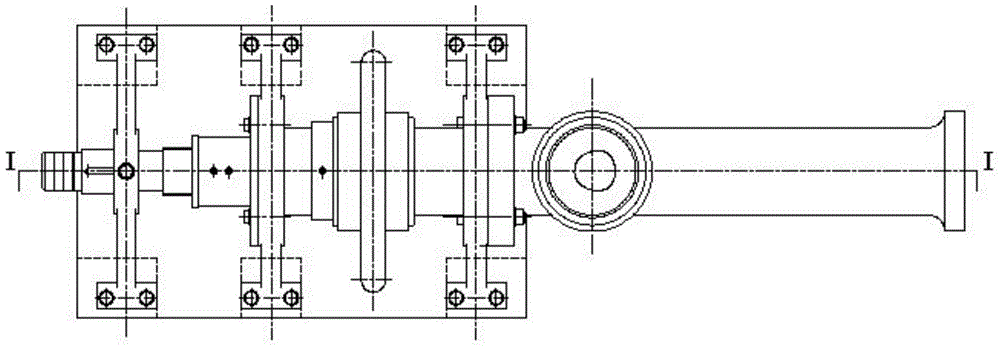

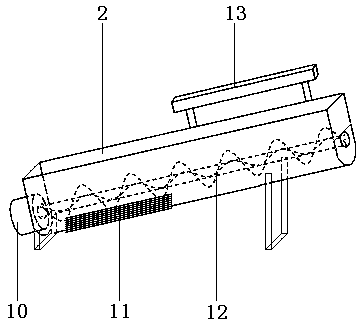

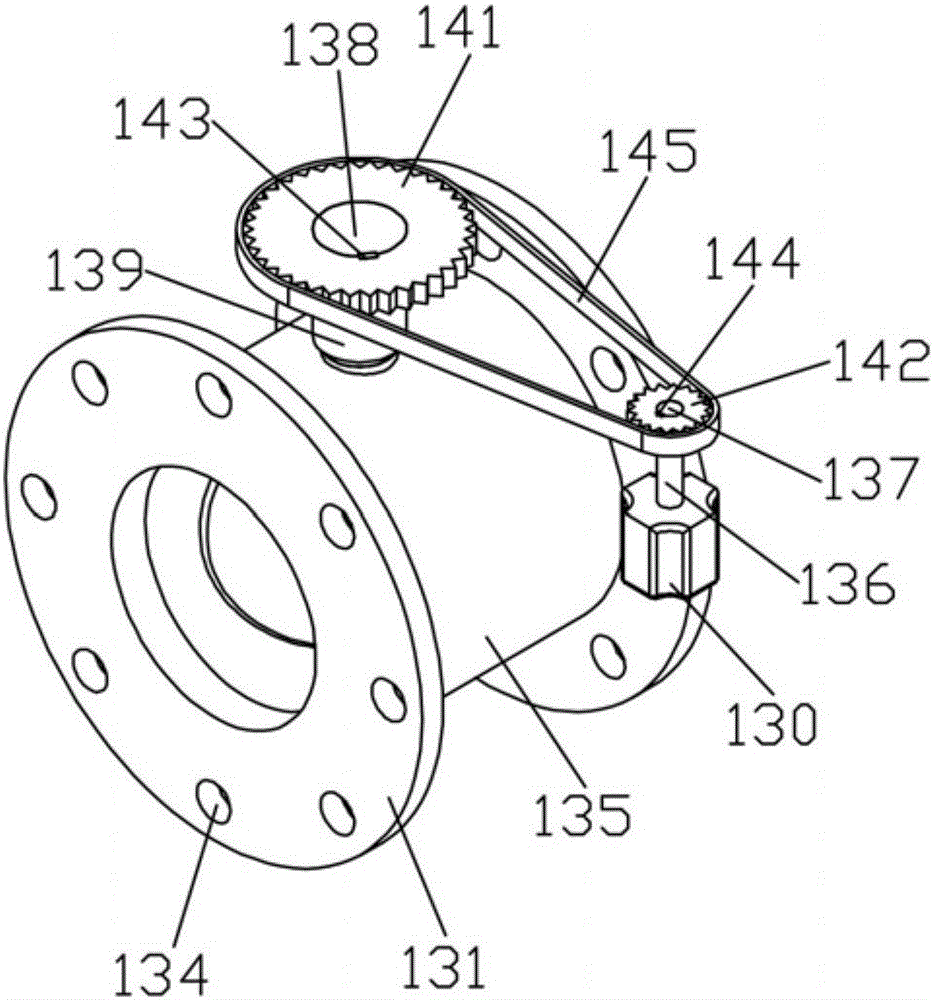

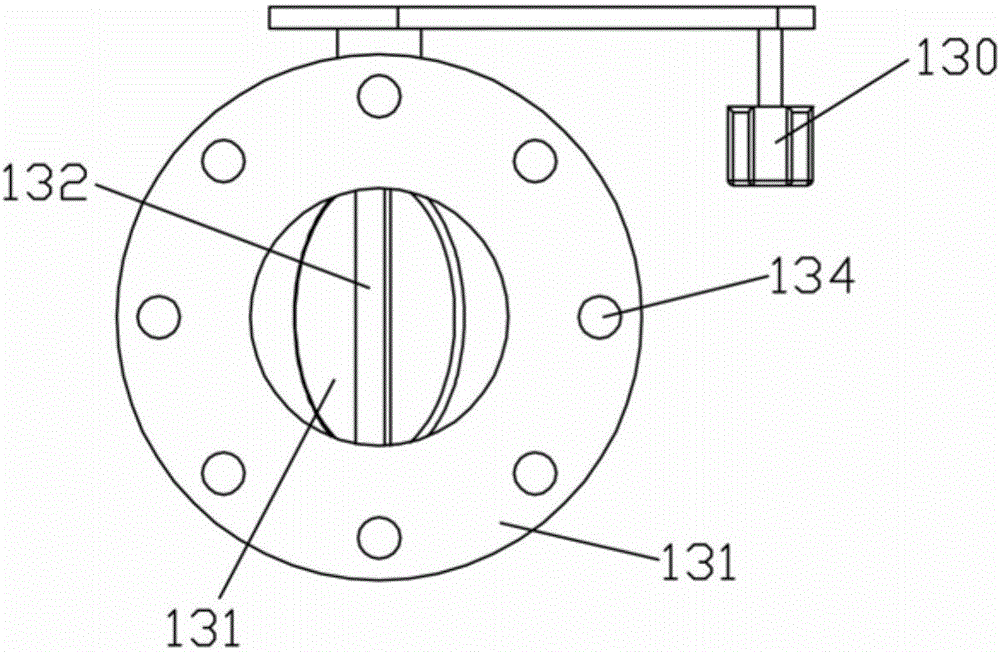

Bucket type elevator

The invention provides a bucket type elevator which comprises a motor, an enclosure, a feeding port and a discharging port, wherein the feeding port is formed at the bottom of the enclosure; the discharging port is formed at the top of the enclosure; a maintenance port is formed at the bottom of the enclosure; the top part of the enclosure is connected with a triangular bracket; the motor is arranged on the triangular bracket; the inside bottom surface of the enclosure is a slope; an upper chain wheel and two abreast-arranged lower chain wheels are arranged inside the enclosure; the upper chain wheel is connected with the motor; a ring-shaped chain is meshed on the peripheries of the upper chain wheel and the lower chain wheels; and chain buckets are uniformly arranged on the ring-shaped chain. The bucket type elevator has the beneficial effects that the inside bottom surface of the enclosure is the slope, materials at the bottom of the elevator can be centralized together, the rotating resistance of a hopper at the bottom of the elevator can be reduced, the accumulation of the materials at the bottom of the elevator is reduced, the materials at the bottom of the elevator can be conveniently cleaned through the maintenance port, and the maintenance and the production of the elevator are facilitated.

Owner:JIANGSU XINLEI MALT

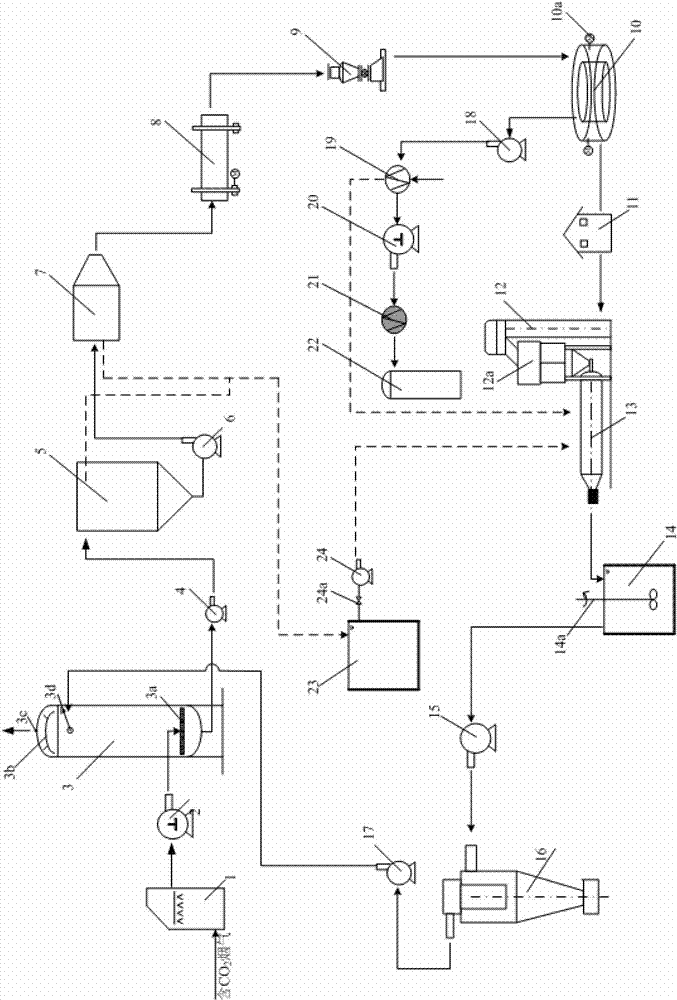

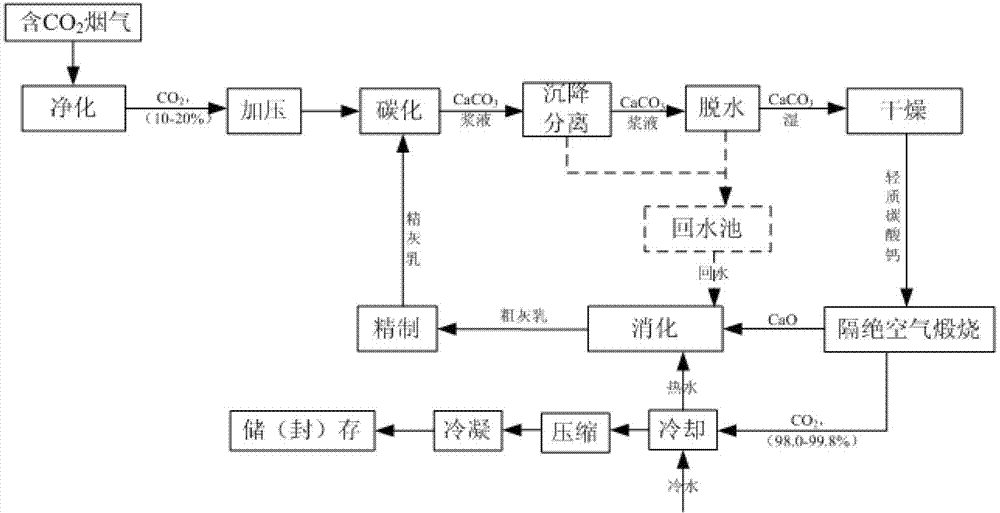

Device and process for cyclic capture of carbon dioxide by taking CaO as carrier

InactiveCN102773006ALow costImprove absorption rateCalcium/strontium/barium carbonatesProductsDesorptionDigestion

The invention discloses a process for cyclic capture of carbon dioxide in smoke gas by taking CaO as a carrier. The process comprises the following steps of: step A) performing purification treatment on tail gas; step B) carbonizing; step C) performing CaCO3 treatment on a carbonized product; step D) performing CO2 desorption; step E) performing CaO digestion; step F) performing lime milk refining; step G) recycling lime milk; and step H) storing (sealing) high-purity CO2. Correspondingly, the invention further discloses a device for cyclic capture of the carbon dioxide in the smoke gas by taking the CaO as the carrier, and the device comprises a purifying device, a carbonizing tower, a settling separation machine, a centrifuge, a drying machine, a metering device, an annular calcining furnace, a material storage bin, a bucket type elevator, a slaking machine, a coarse pulp pool and a hydrocyclone separator, which are connected through a pipeline and a material conveying system. The process has the advantages of mature conditions, simple steps and high capture efficiency of the CO2, and the device for implementing the process has the advantages of compact structure, low investment operation strength and good industrial application prospects.

Owner:西安华茂众鑫建设工程有限公司

External-circulation slag vertical roller mill

InactiveCN102847587AGranularity is easy to adjustSmall size rangeGrain treatmentsSlagBucket elevator

The invention relates to an external-circulation slag vertical roller mill. The vertical roller mill comprises a mill body; a powder selecting mechanism comprising a stator and a rotor is arranged on the upper part of the mill body; the powder selecting mechanism is connected with a discharge port; the side of the mill body is provided with a feeding pipe at the lower part of the powder selecting mechanism; the lower part of the mill body is provided with a discharge pipe corresponding to the powder selecting mechanism; the lower part of the discharge pipe is provided with a roller mechanism corresponding to the feeding pipe; and the roller mechanism is provided with a blowing device; a discharge pipe is arranged at the bottom of the mill body; and the discharge pipe is connected to the feeding pipe through a buckettype elevator. The external-circulation slag vertical roller mill provided by the invention is simple and convenient for installation and repair, and has greatly improved grinding efficiency, service life and operation rate.

Owner:扬州中材机器制造有限公司

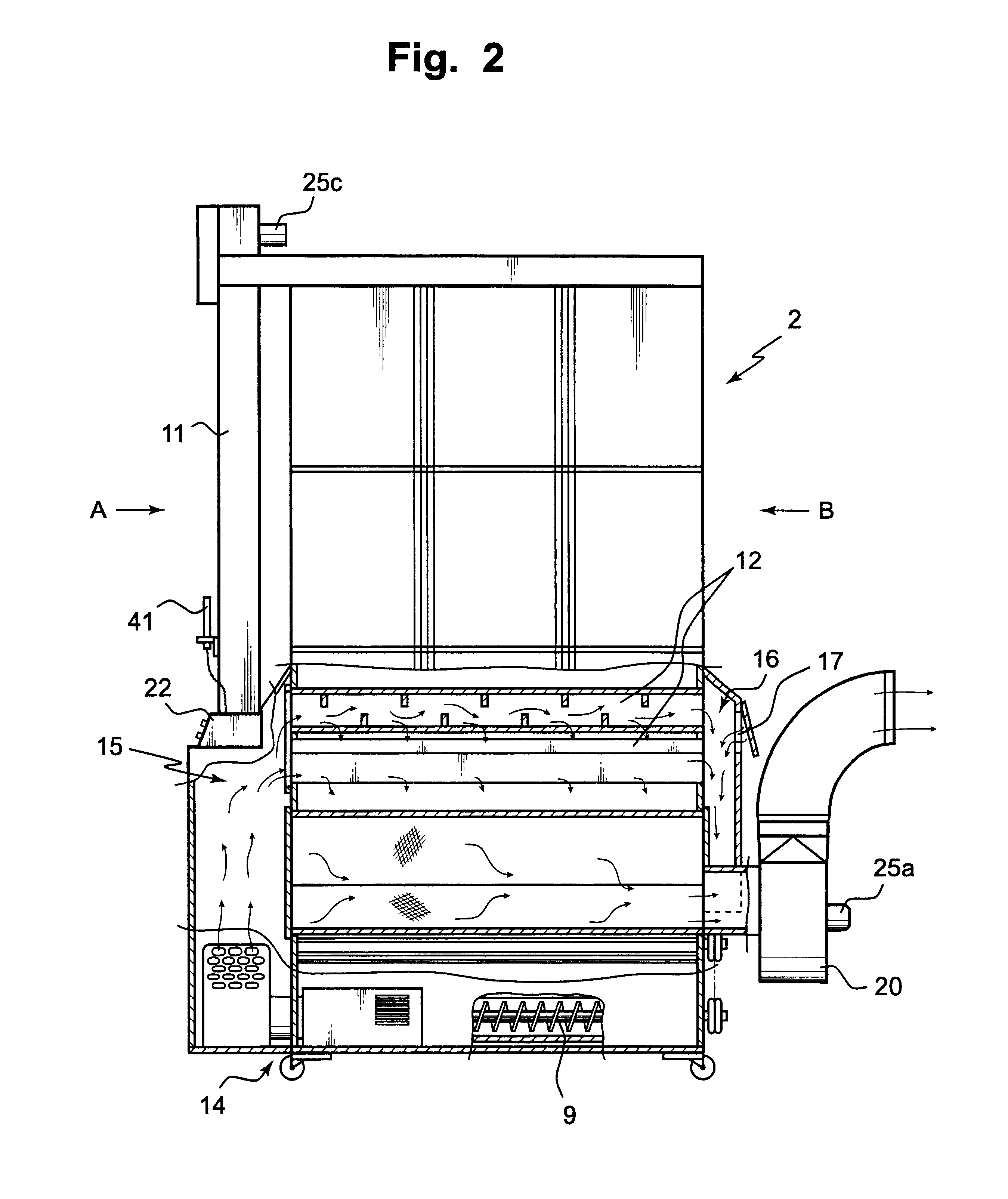

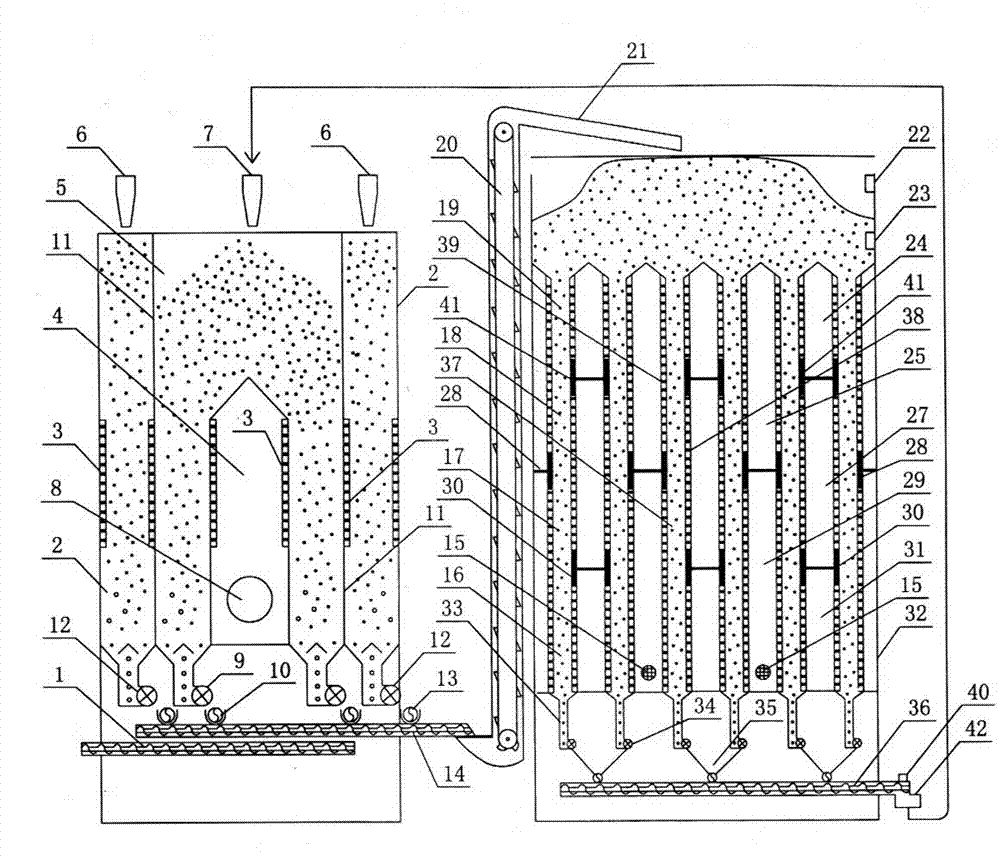

Quality-guaranteeing and energy-saving drying machine for grains

The invention discloses a quality-guaranteeing and energy-saving drying machine for grains. The drying machine comprises two wet grain preheating bins, a hot grain cooling bin and a drying bin, wherein the two wet grain preheating bins are arranged on the left side and the right side of the hot grain cooling bin respectively and are spaced from the hot grain cooling bin through baffles; a ventilating net plate is arranged between the baffles; a cold air chamber is formed in the middle of the hot grain cooling bin; a cold air inlet is formed in the bottom end of the cold air chamber; wet grain outlets are formed in the bottom sides of the wet grain preheating bins; a dry grain outlet is formed in the bottom side of the hot grain cooling bin; a hot grain shifting wheel is arranged on the right side of the dry grain outlet; a dry grain helical collector is arranged on the bottom side of the dry grain shifting wheel; a dry grain helical conveyer is arranged on the bottom side of the dry grain helical collector; the drying bin is arranged on the right sides of the wet grain preheating bins; 2-30 groups of grain distribution channels are formed in the middle of the drying bin; ventilating net plates are arranged on the left and right sides of each grain distribution channel; a hopper type lifting machine is arranged on the left side of the drying bin. The drying machine is reasonable in structure, unique in design and good in using effect.

Owner:HUNAN NONGYOU SHENGTAI AGRI TECH

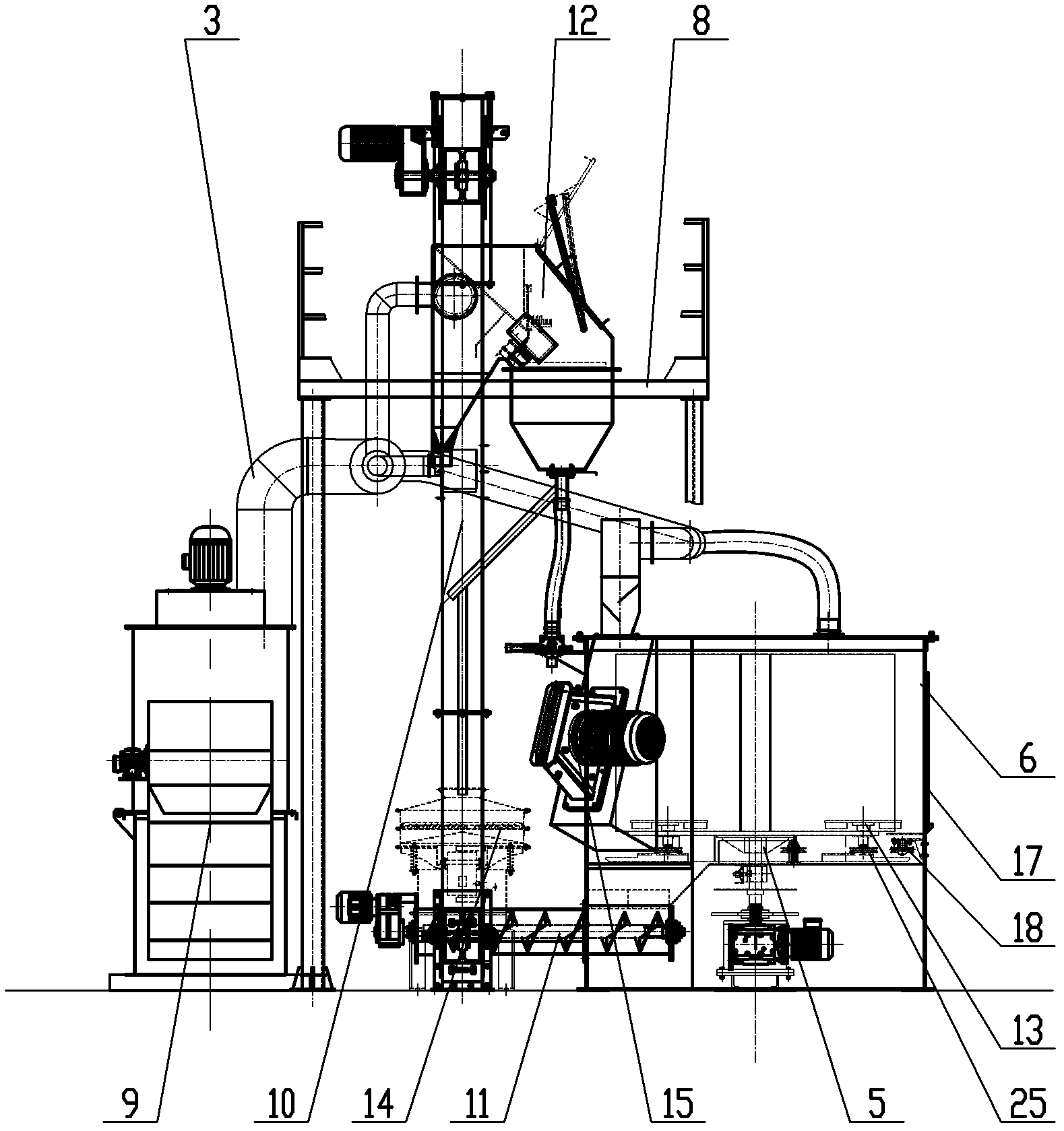

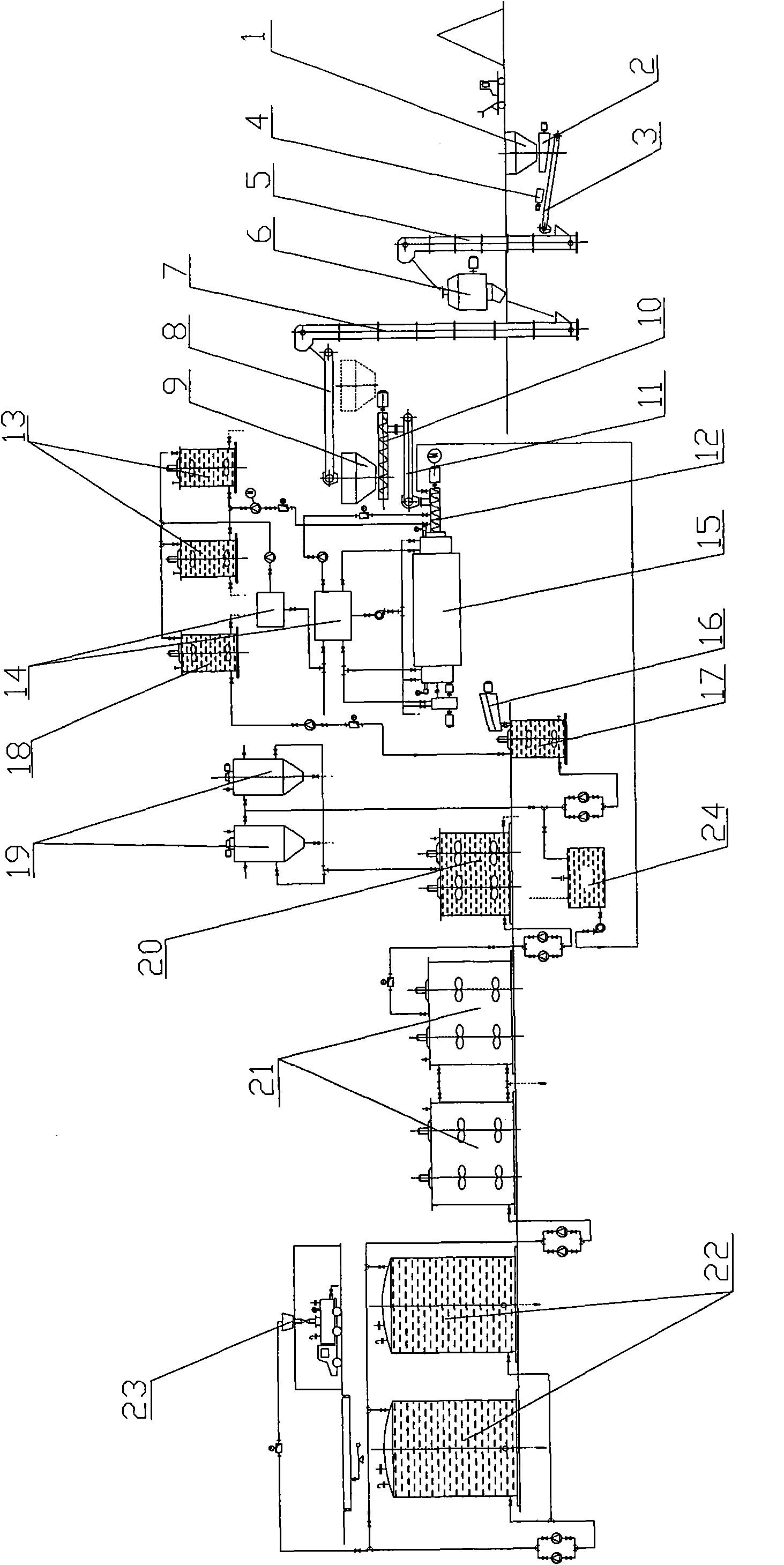

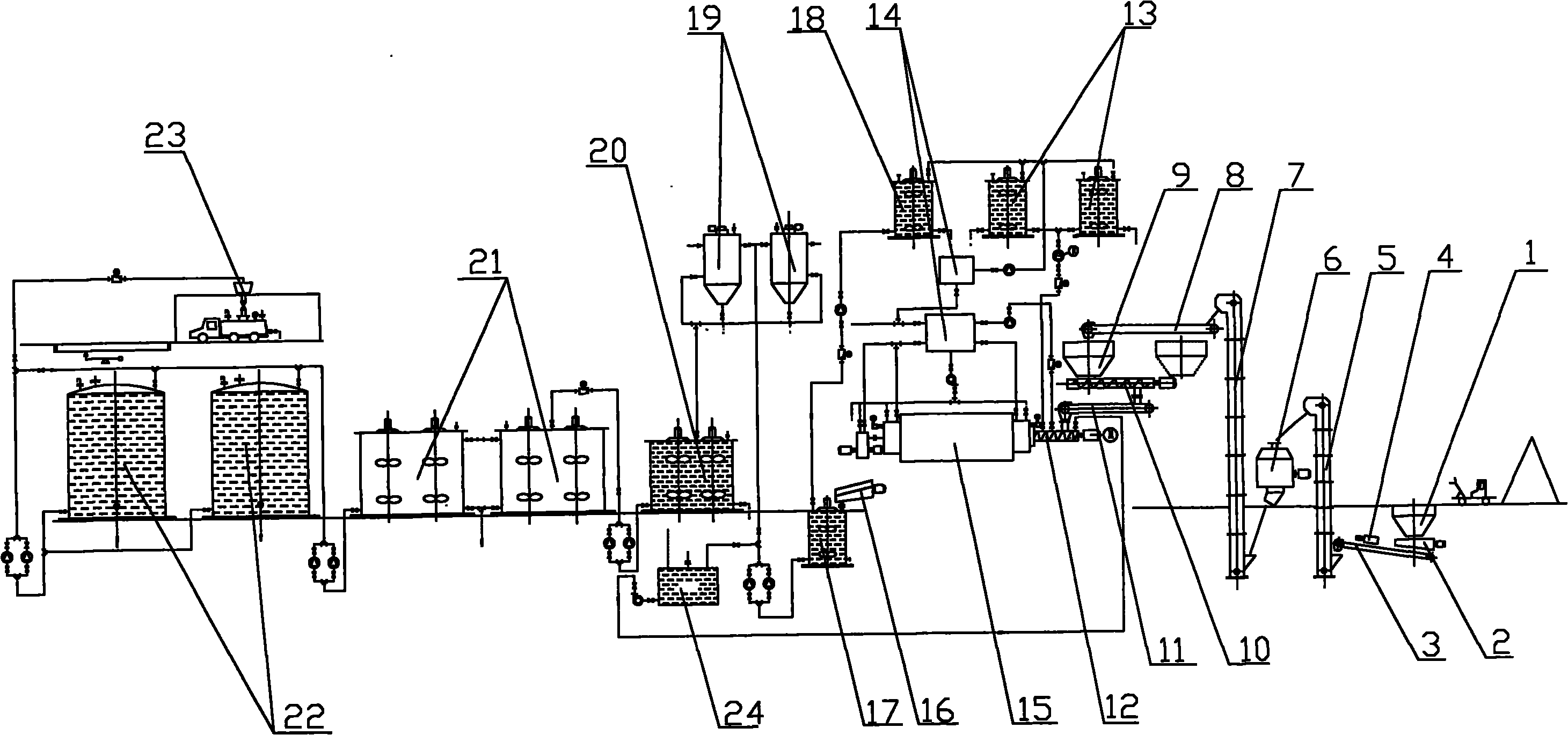

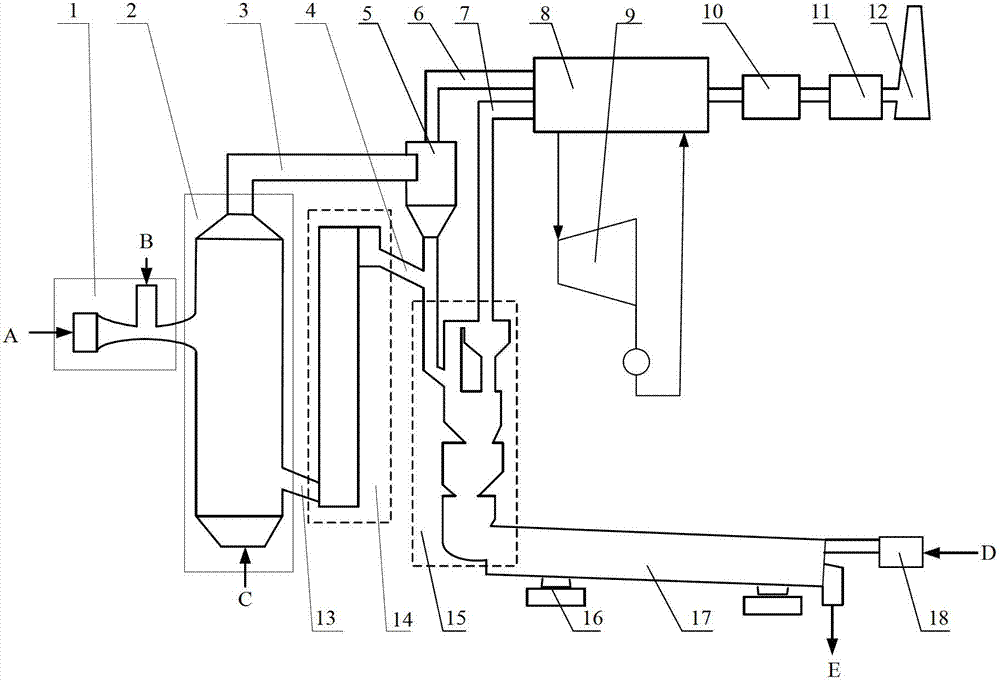

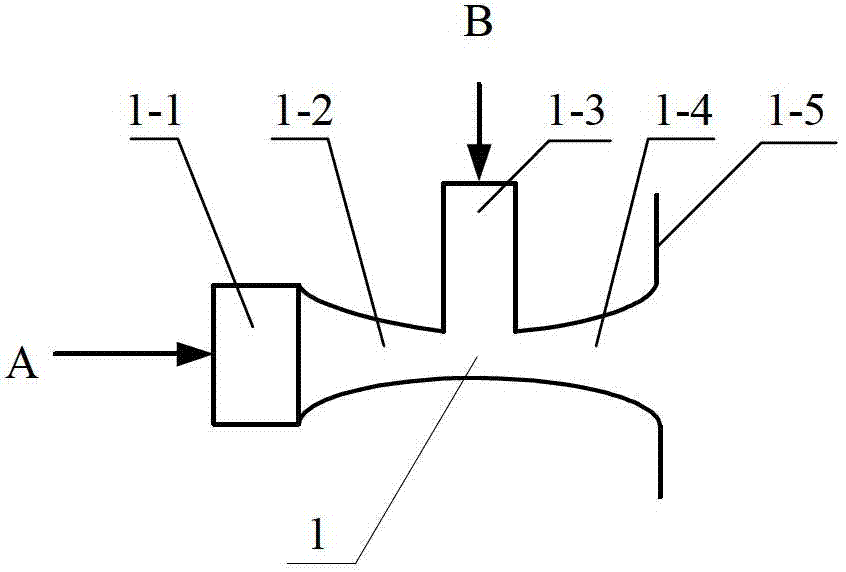

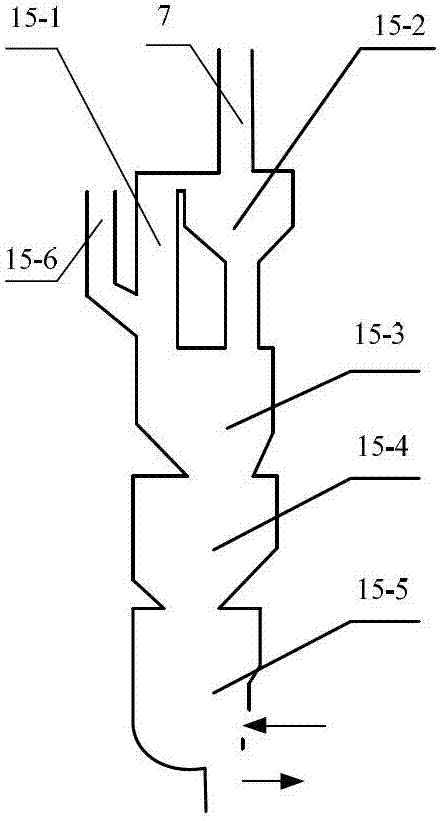

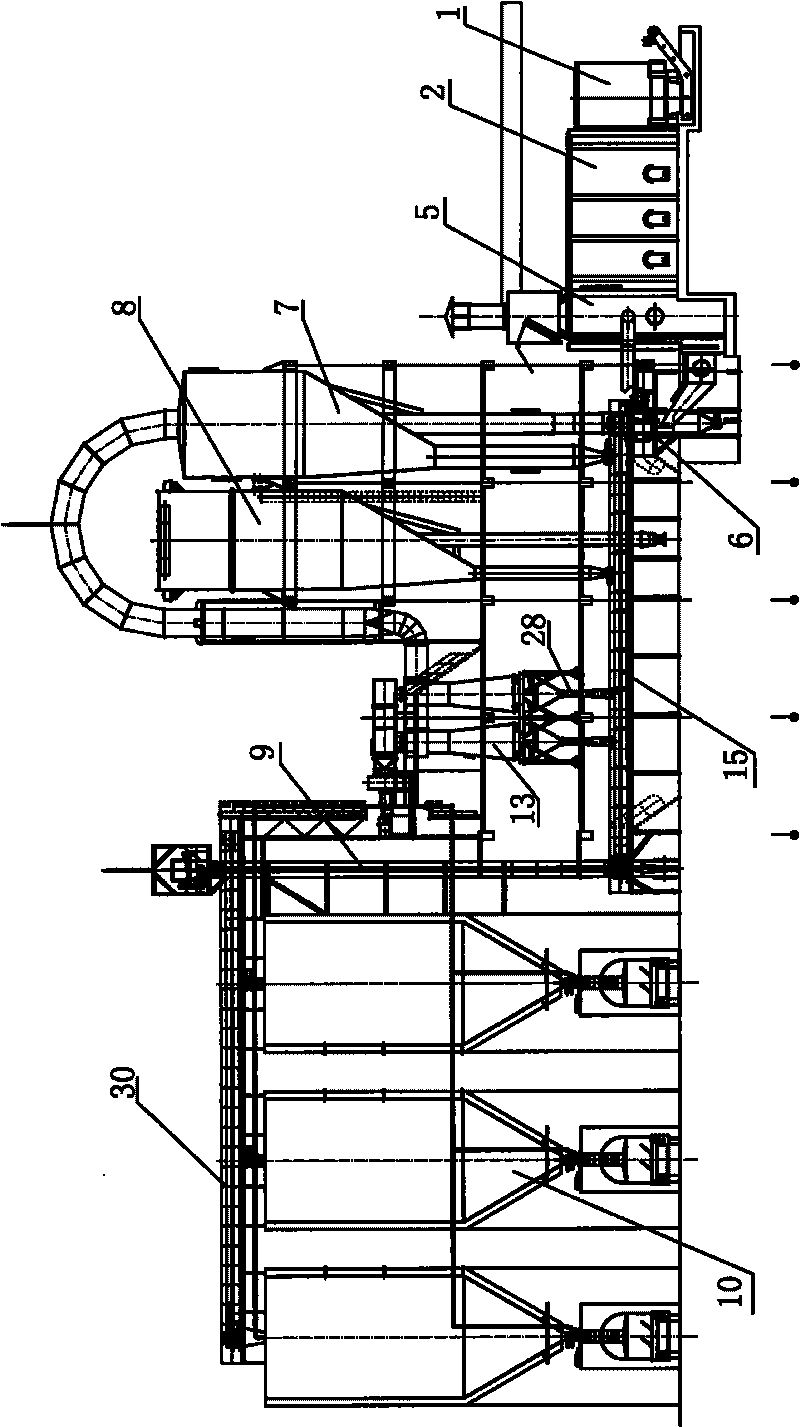

Coal-water slurry slurrying system and method for coal chemical industry

ActiveCN101899338AGuaranteed operational safetySmall footprintLiquid carbonaceous fuelsChemical industrySmall footprint

The invention relates to a coal-water slurry slurrying system and a method for a coal chemical industry. The system comprises a raw material bin (1), a vibrator feeder (2), a belt conveyor I (3), a magnetic separator (4), a bucket elevator I (5), a crusher (6), a bucket elevator II (7), a belt conveyor II (8), an intermediate bin (9), a screw conveyor (10), a belt weigher (11), a coal-water slurry screw feeder (12), a dispersing agent thinning tank (13), a water tank (14), a special coal-water slurry mill (15), a vibration sieve (16), a coal-water slurry buffer tank (17), a stabilizing agent thinning tank (18), a coal-water slurry filter (19), a bucket (20) for adjusting and treating stability, a homogeneous maturation tank (21), a slurry-storage tank (22), a slurry station (23) and a waste reservoir (24). The coal-water slurry slurrying system and the method for coal chemical industry in the invention have wide adaptability of coal varieties, small occupied area, long service life and high slurry-producing stability.

Owner:江阴市中立机械工业有限公司

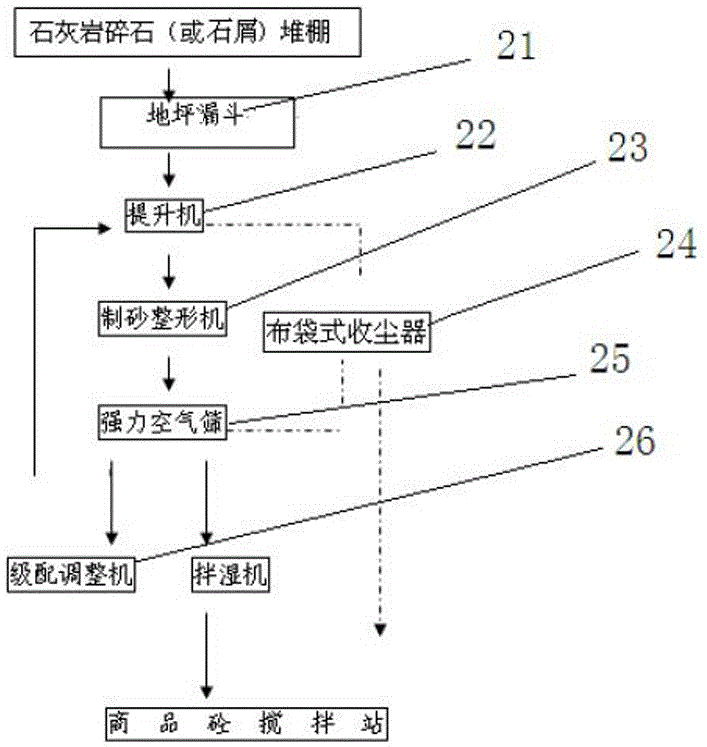

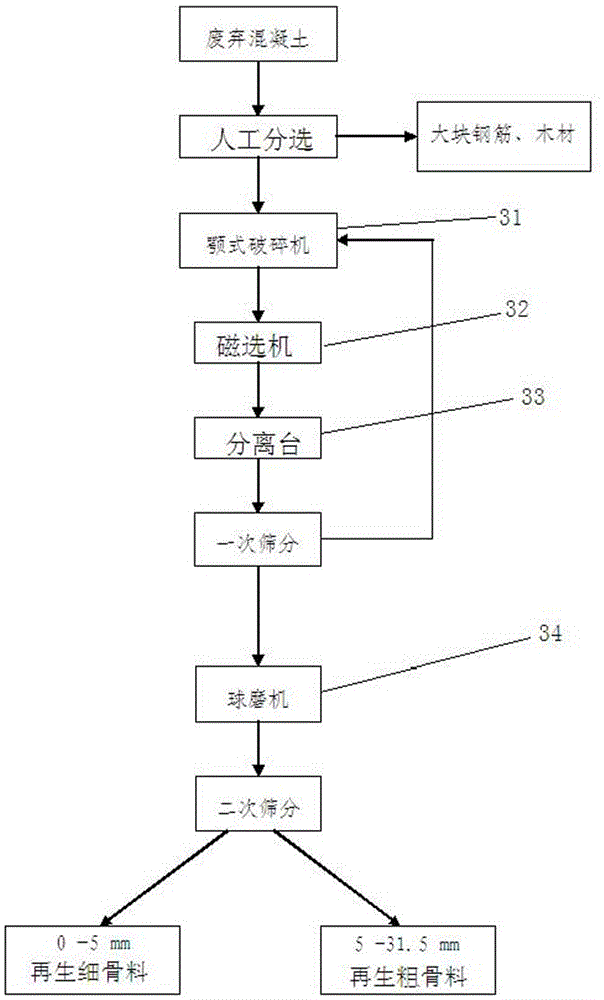

Process for preparing high-performance composite concrete from mineral powder, machine-made sand and waste concrete

The invention discloses a process for preparing high-performance composite concrete from mineral powder, machine-made sand and waste concrete. The process comprises the following steps of 1, the process of preparing the mineral powder, wherein the mineral powder is dried and pulverized through a vertical mill; 2, preparation of the machine-made sand, wherein incoming main raw materials broken stone or stone chips with the particle size smaller than or equal to 40 mm are placed in a piling shed for natural air drying, then sent to a feeding grade-level funnel, fed through a feeding valve and elevated through a belt conveyor and a belt-bucket elevator to enter a sand-making tower, the broken stone or stone chips pass through a sand-making shaping machine, a powerful air sieve and a graduation adjusting machine from top to bottom, a centralized pulse cloth bag type dust collector is adopted, discharging is conducted, so that a finished product, namely the machine-made sand, is obtained, and remaining aggregate returns to the belt-bucket elevator for re-circulation treatment; 3, the process of preparing regenerated aggregate from the waste concrete, wherein the waste concrete is subjected to artificial sorting, simple crushing, separation, sieving and reinforcing, so that the regenerated aggregate is obtained. The process has the advantages that discharging and piling of waste are reduced, and the treatment site is saved.

Owner:GUANGXI YUFENG CONCRETE CO LTD

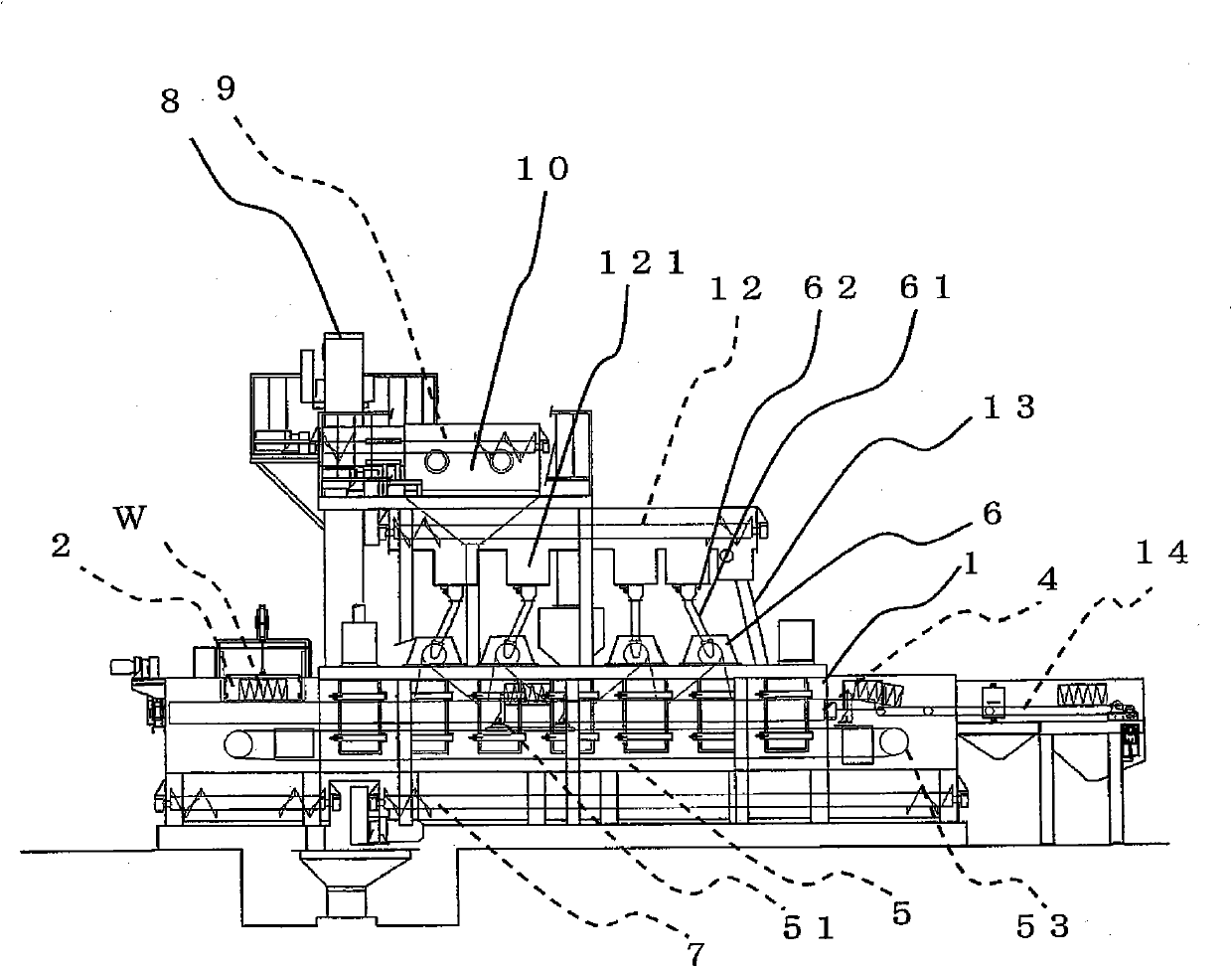

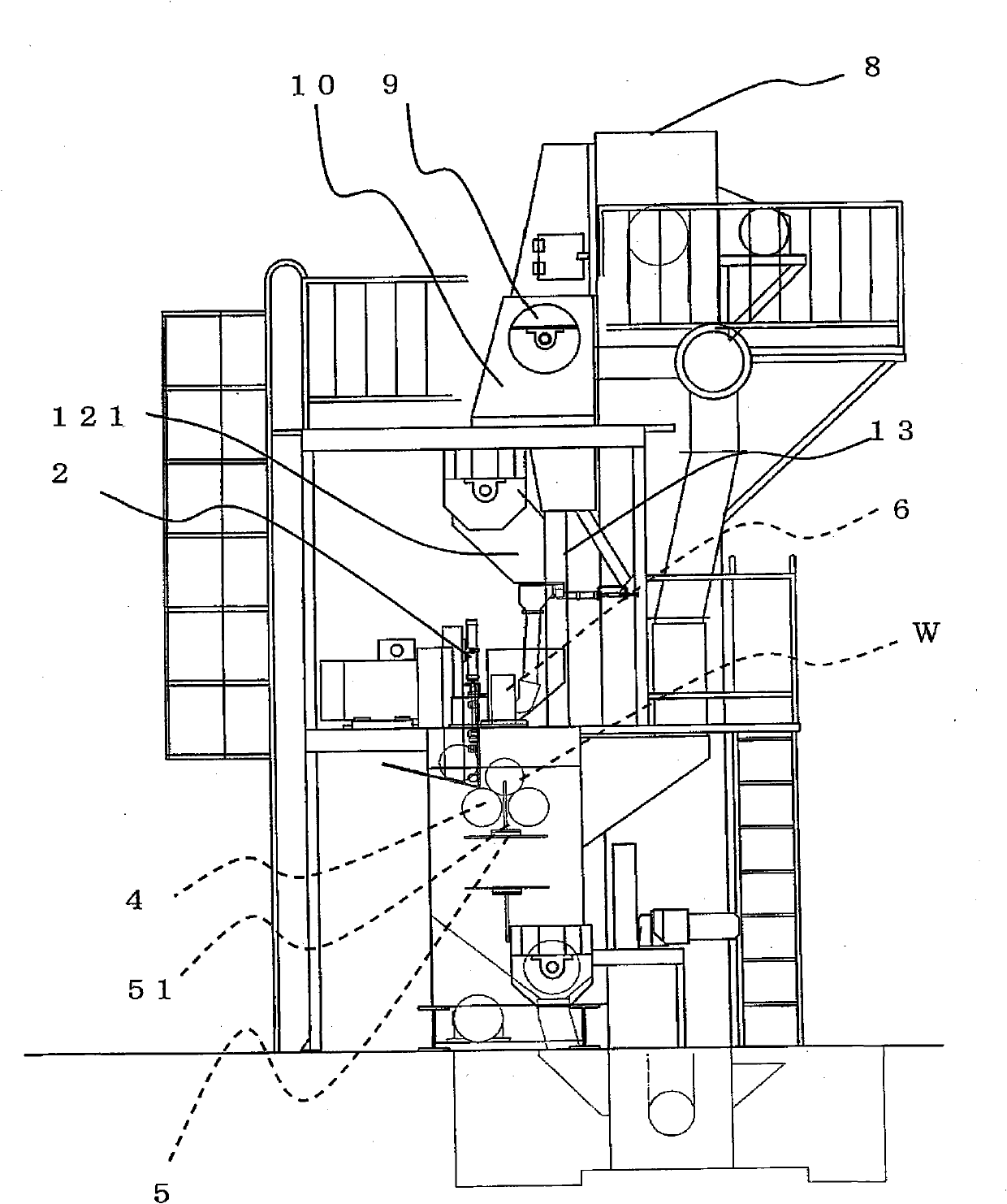

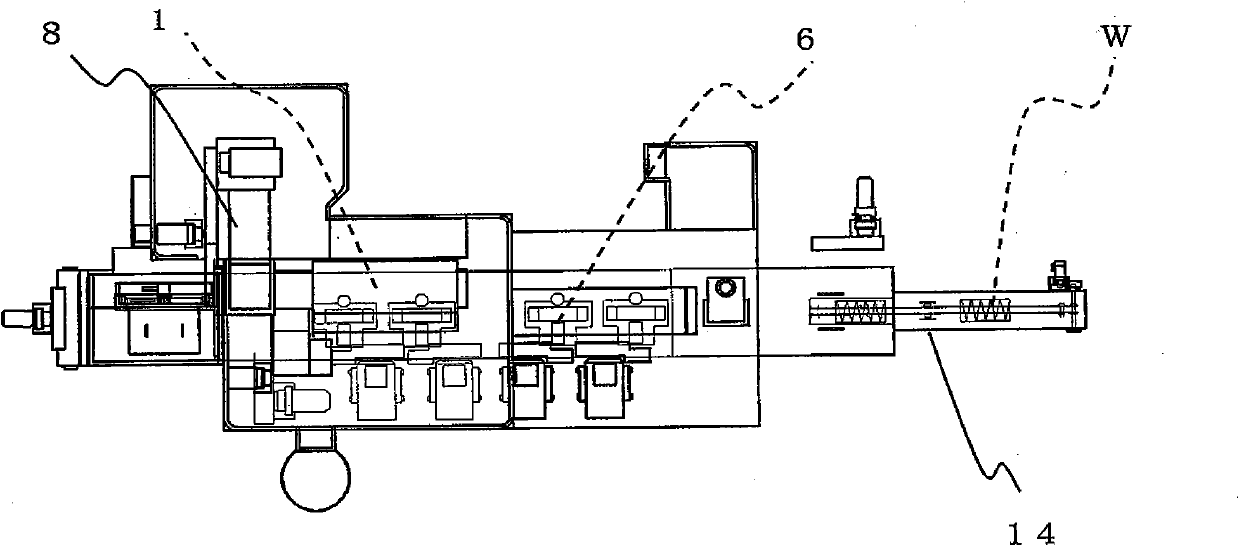

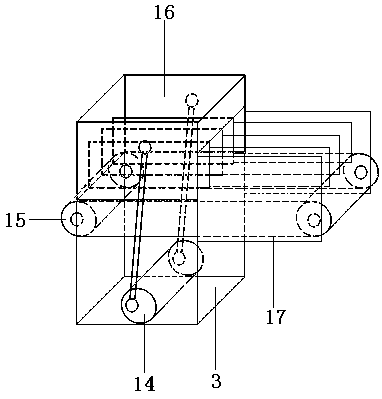

Continuous conveyor type peen vulcanizing device and method

The present invention provides a continuous conveyor type peen vulcanizing device and method, capable of keeping postures of cylindrical metal products such as screw spring and implementing stable peen vulcanization treatment. Inside a cavity (1) having a feed strobe (2), a chain conveyor (5) having an accessory (51) for pressing ends (W1) of a product (W) to be processed is provided, two rotating rollers (4) having drive sources are arranged on two sides of the chain conveyor in parallel, the rotating rollers (4) are formed in cylinder shapes capable of rotating along an identical direction, such that the product (W) to be processed is rotated and simultaneously is conveyed. A centrifugal type projection device (6) is arranged on the upper side of the cavity (1), so as to perform peen vulcanization to a whole surface of the product (W) to be processed without leakage. Projection material is recovered by a lower spiral conveyer (7), and is conveyed to the upper side of the cavity by a bucket elevator (8) to reuse.

Owner:SINTOKOGIO LTD

Device and method for carrying out granulation treatment and residual heat utilization on liquid-state furnace slag

The invention discloses a device and a method for carrying out granulation treatment and residual heat utilization on liquid-state furnace slag. The liquid-state furnace slag is chilled and granulated in a granulation assembly through introduced high-pressure air or high-pressure water; granulated grains enter a slag storing pot; slag grains are lifted into a gas-solid separation cooling chamber through a bucket elevator; granulating rough tail gas at an outlet of the upper end of the slag storing pot passes through a tail gas cyclone separator and the separated solid grains are conveyed into the gas-solid separation cooling chamber; the granulating tail gas is conveyed into a residual heat boiler; the gas-solid separation cooling chamber is connected with a converter and the air enters from an air inlet of the converter and sequentially passes through the converter and the gas-solid separation cooling chamber, so that the solid slag grains are further cooled; the gas absorbing the residual heat of the furnace slag is discharged from the upper end of the gas-solid separation cooling chamber and enters the residual heat boiler; finally, the cooled furnace slag is discharged from a grain outlet of the converter; and steam generated by the residual heat boiler enters a steam turbine to generate power.

Owner:江苏东能环保能源科技有限公司

Production method of semi-hydrated gypsum powder

The invention relates to a production method of semi-hydrated gypsum powder. The production method has the technical points that gypsum materials are conveyed to an electronic belt scale through a gypsum conveyer system and then enter a turbulence breaking drier through a hopper; meanwhile, high-temperature hot wind generated by a hot wind furnace directly enters the turbulence breaking drier to quickly dry the gypsum materials, and drying and sintering are finished in the drier in one step; generated high-concentration powder materials are wrapped and held by hot wind and directly enter a vortex sedimentation drier arranged above the turbulence breaking drier, and after carrying out drying and gas-liquid separation through the vortex sedimentation drier, dry materials are discharged from a discharge outlet of the vortex sedimentation drier and fall on a first scraper conveyer; the dried and sintered gypsum powder are conveyed to a feed inlet of an aging device by the first scraper conveyer; meanwhile, a second draught fan is started to suck the materials into the aging device, and the materials are discharged on the first scraper conveyer through a discharge outlet of the aging device after aging and conveyed to a feed inlet of a bucket type lifter through the horizontal scraper conveyer; and then the materials are conveyed to a second scraper conveyer through the bucket type lifter and fall in a tempering storage silo through a rotary valve. The production method can improve the product quality, reduce the energy consumption and reduce occupation area.

Owner:沈阳康环脱硫石膏综合利用有限公司

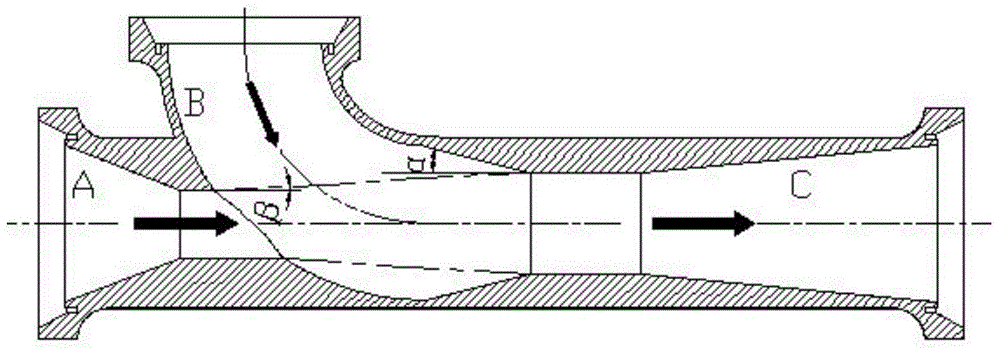

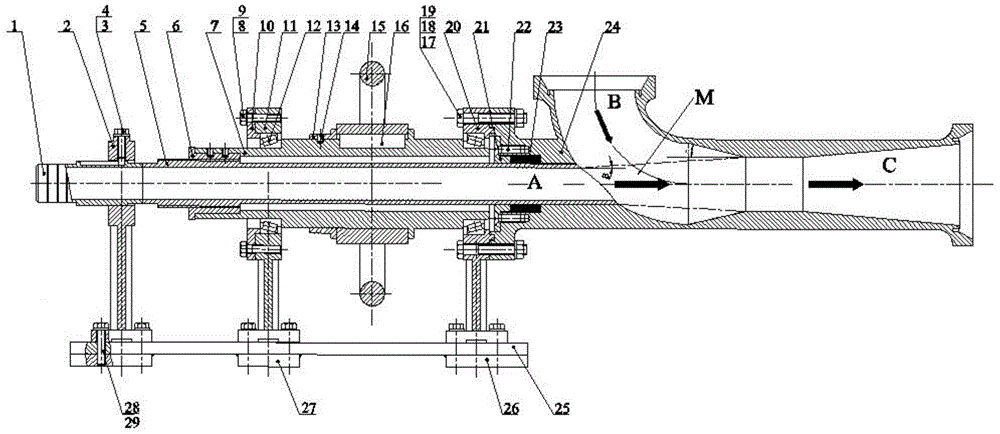

High-efficiency jet nozzle capable of continuously regulating position of jet pipe

InactiveCN104437157AStrong process adaptabilityBest Jet EfficiencyFlow mixersSpray nozzleEngineering

The invention relates to a high-efficiency jet nozzle capable of continuously regulating the position of a jet pipe. An auxiliary device capable of continuously regulating the position of the jet pipe is fixedly mounted on the jet pipe of the jet nozzle and comprises a fixing plate, a rotating hollow shaft, a rotating wheel, the jet pipe and an external pipe, wherein the rotating hollow shaft is horizontally mounted on the fixing plate by a rotating bearing; one rotating driving device is coaxially mounted on the outer wall of the middle part of the rotating hollow shaft; the jet pip horizontally and coaxially penetrates into the rotating hollow shaft; a push nut is coaxially and hermetically mounted between the left end of the rotating hollow shaft and the jet pipe; the push nut and the rotating hollow shaft are coaxially and fixedly mounted; the external pipe is coaxially and fixedly mounted at the left end of the jet pipe. The high-efficiency jet nozzle disclosed by the invention is optimal in efficiency, minimized in equipment size, minimized in horizontal area, minimized in operational maintenance and equipment maintenance, minimized in equipment installation cost, low in investment cost and capable of replacing a bucket elevator to convey solid powder, being economical and environmentally friendly, and having wide application prospects.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

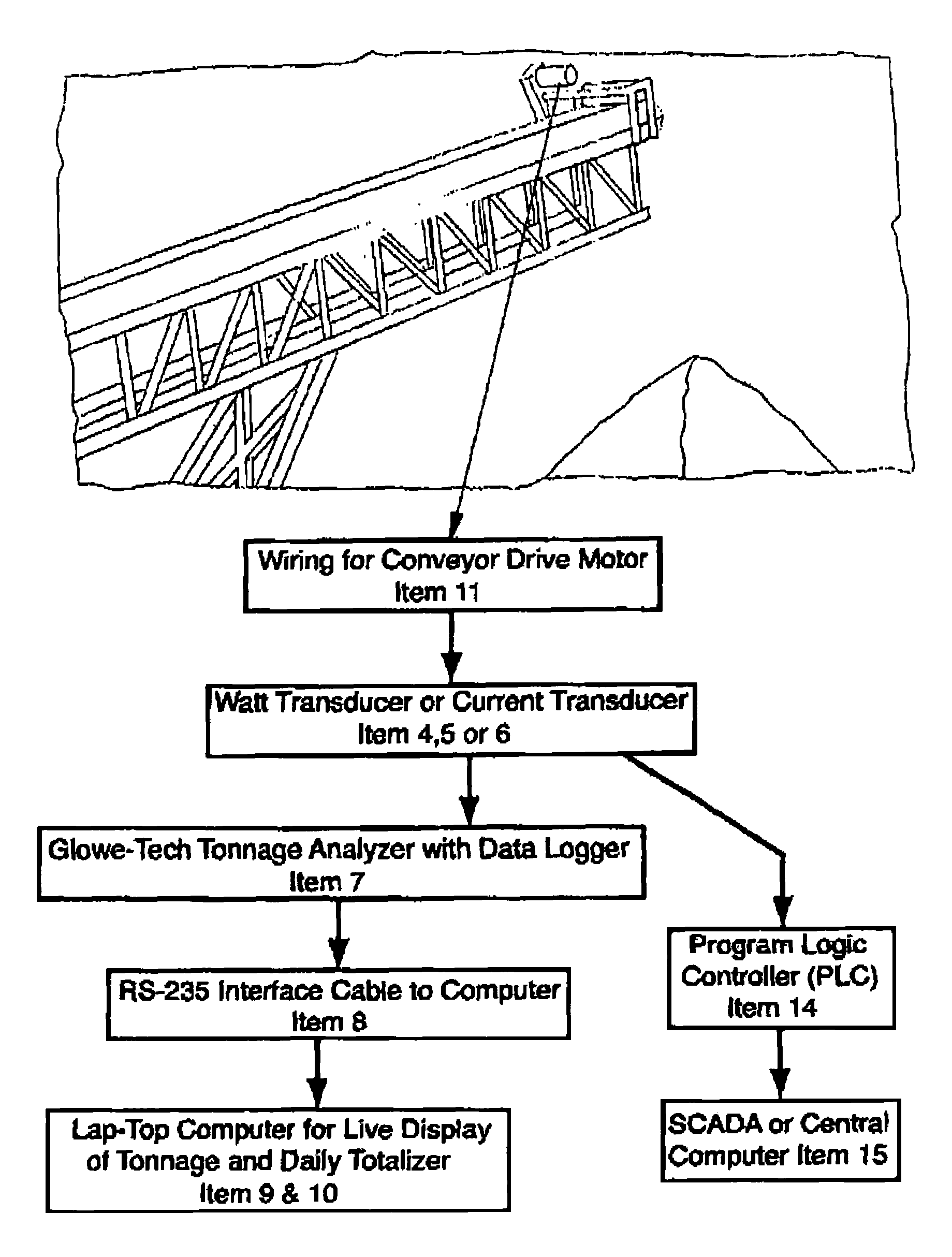

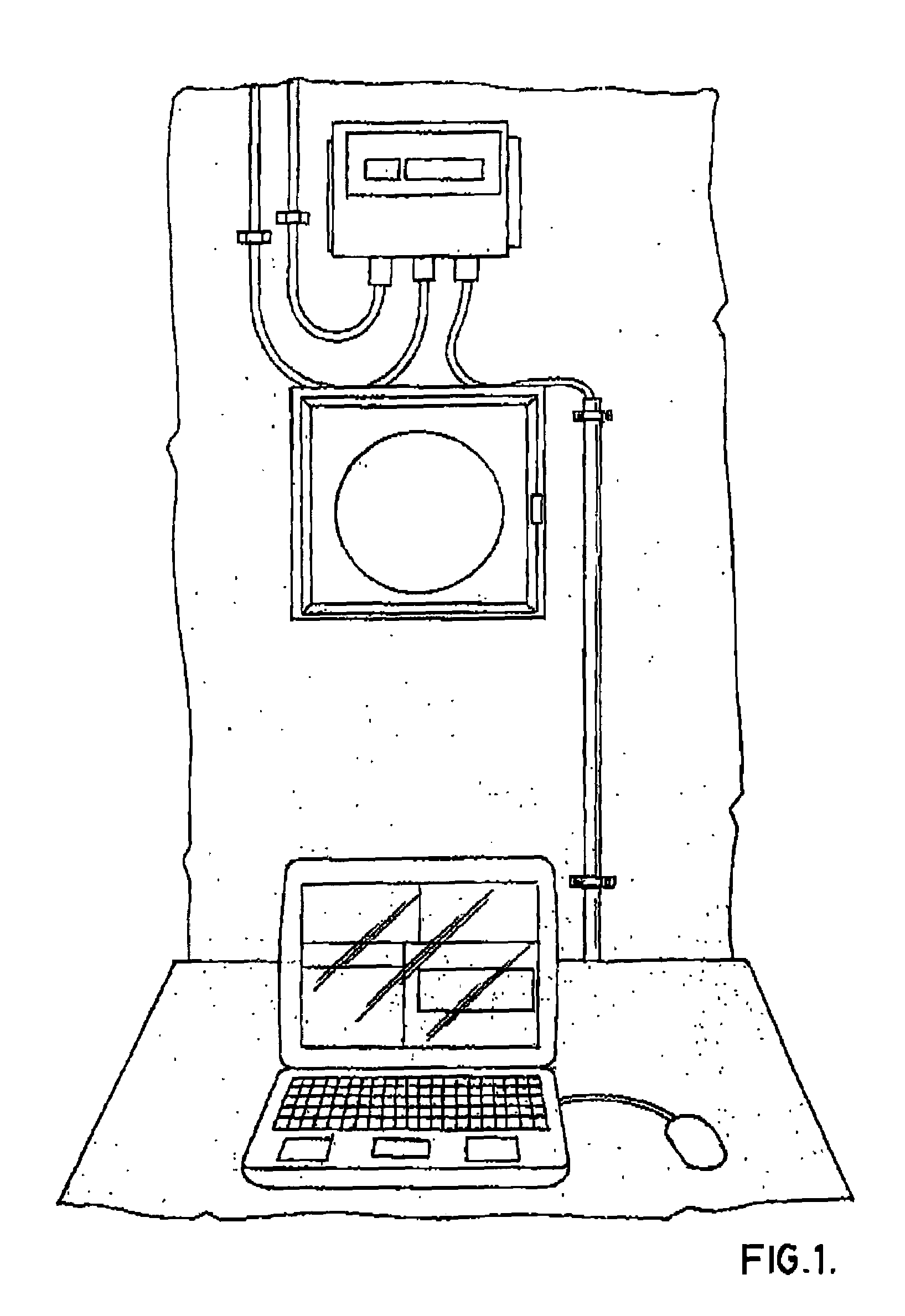

Method for assessing the operation of a conveying apparatus

ActiveUS7193162B2Mass flow measurement devicesDigital computer detailsEngineeringProcess engineering

The present invention is directed to an apparatus and method for measuring the weight of material such as rock, earth, wood, pulp, grain, gravel, sand, ore, cement etc. being processed or moved by an apparatus such as a conveyor, apron conveyor or bucket elevator driven by an electrical motor. The apparatus measures the electrical energy consumed by the motor powering the apparatus during operation of the apparatus and uses a calibration formula derived from an average of no-load readings plus up to 2.0 standard deviations for converting the power consumption of the motor to tonnage per hour of raw material processed by the apparatus. A continual record is kept of all “No-load” and “start-up load” time during the recording process and these figures are totalized along with tonnage for the recording period.

Owner:GLOWE CONSULTING SERVICES

Mobile material elevating system

InactiveUS20160244268A1Negates needQuickly lineConveyorsControl devices for conveyorsEngineeringHydraulic fracturing

Apparatus for elevating materials that is particularly useful in limited spaces and / or where flexibility in positioning is desirable. Fully self-contained, the apparatus is trailer mounted and provided with a hydraulic system for positioning and powering the individual components as needed to feed material from supply trucks to the apparatus and then to vertically elevate the material for distribution to desired locations as needed for such purposes as, for instance, delivering proppant to site storage for hydraulic fracturing of oil wells. The individual components, including a material-receiving feeder pan, inclined auger, rotatable tower mount, and bucket elevator are preferably trailer-mounted and the bucket elevator is selectively positionable from a first, position for operating and elevating materials to a second position for over-the-road transport.

Owner:VITA INT

System and process for coal powder preparation

The invention relates to a system and a process for coal powder preparation, which is characterized in that the system for coal powder preparation comprises a crushing system, a drying system and a grinding system; the crushing system comprises a coal receiving hopper and a crushing machine connected with the coal receiving hopper; the drying system comprises a drying kiln, and the drying kiln is communicated with the crushing machine through a belt conveyer; the drying kiln is connected with a raw coal silo; an air inlet opening at the charging side of the drying kiln is connected with a hot blast furnace and the hot blast furnace is connected with an air blower; an air outlet opening at the top of the drying kiln is connected with a first induced draft fan and an air outlet opening of the first induced draft fan is respectively connected with a hot air pipeline and a dust collector between the drying kiln and the hot blast furnace; the grinding system comprises a vibration feeder and a coal grinding mill connected with the vibration feeder, wherein the vibration feeder is communicated with the raw coal silo through a first bucket elevator; the coal grinding mill is connected with a cyclone separator, an ascension pipe of the cyclone separator is connected to the storage silo through a second bucket elevator; and the cyclone separator is connected with a second induced draft fan and connected to the coal grinding mill. The invention not only can be applied to establish the independent coal powder preparation plant, but also can be applied in front of an industrial coal powder boiler as the stokehole powder-making unit.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

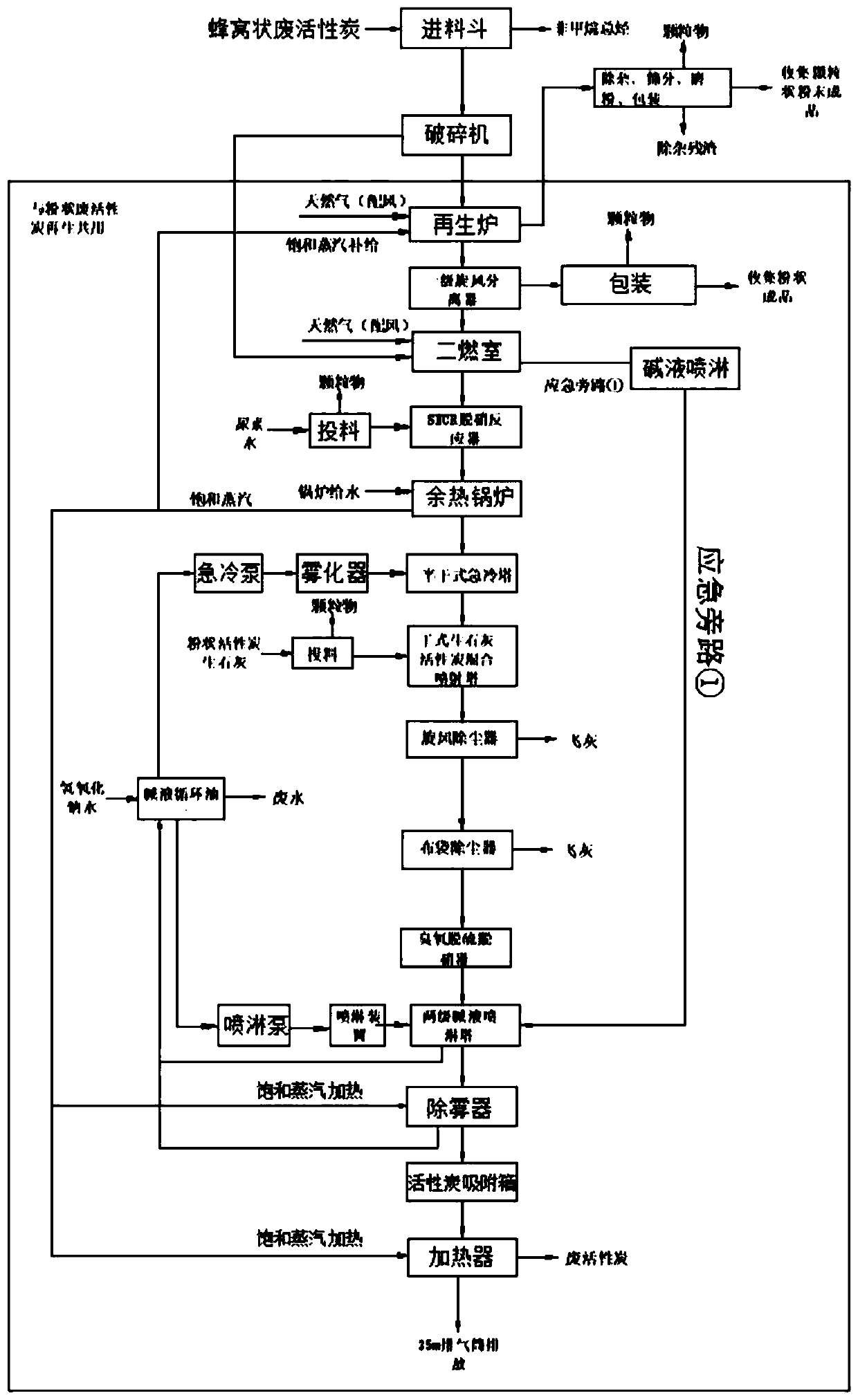

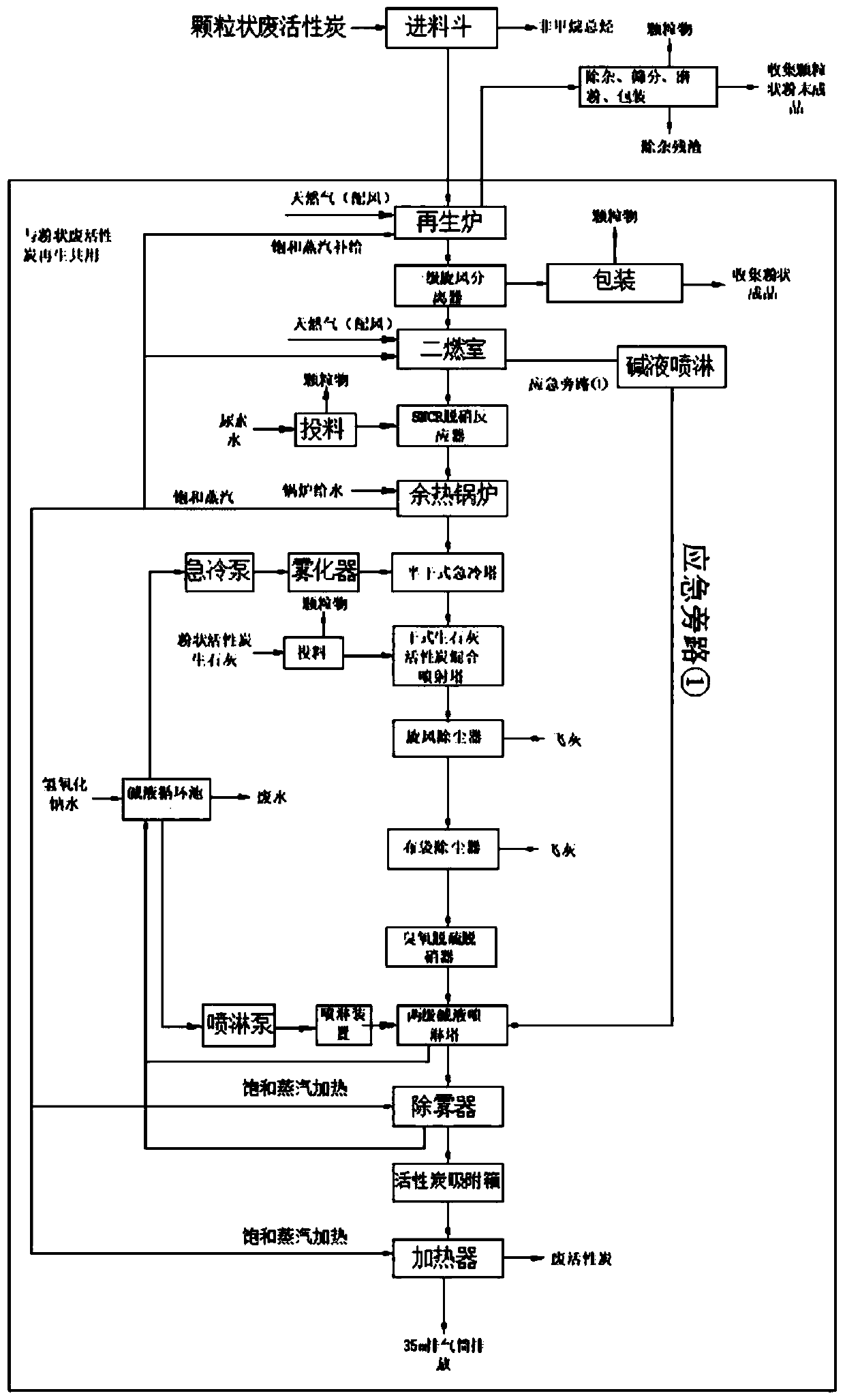

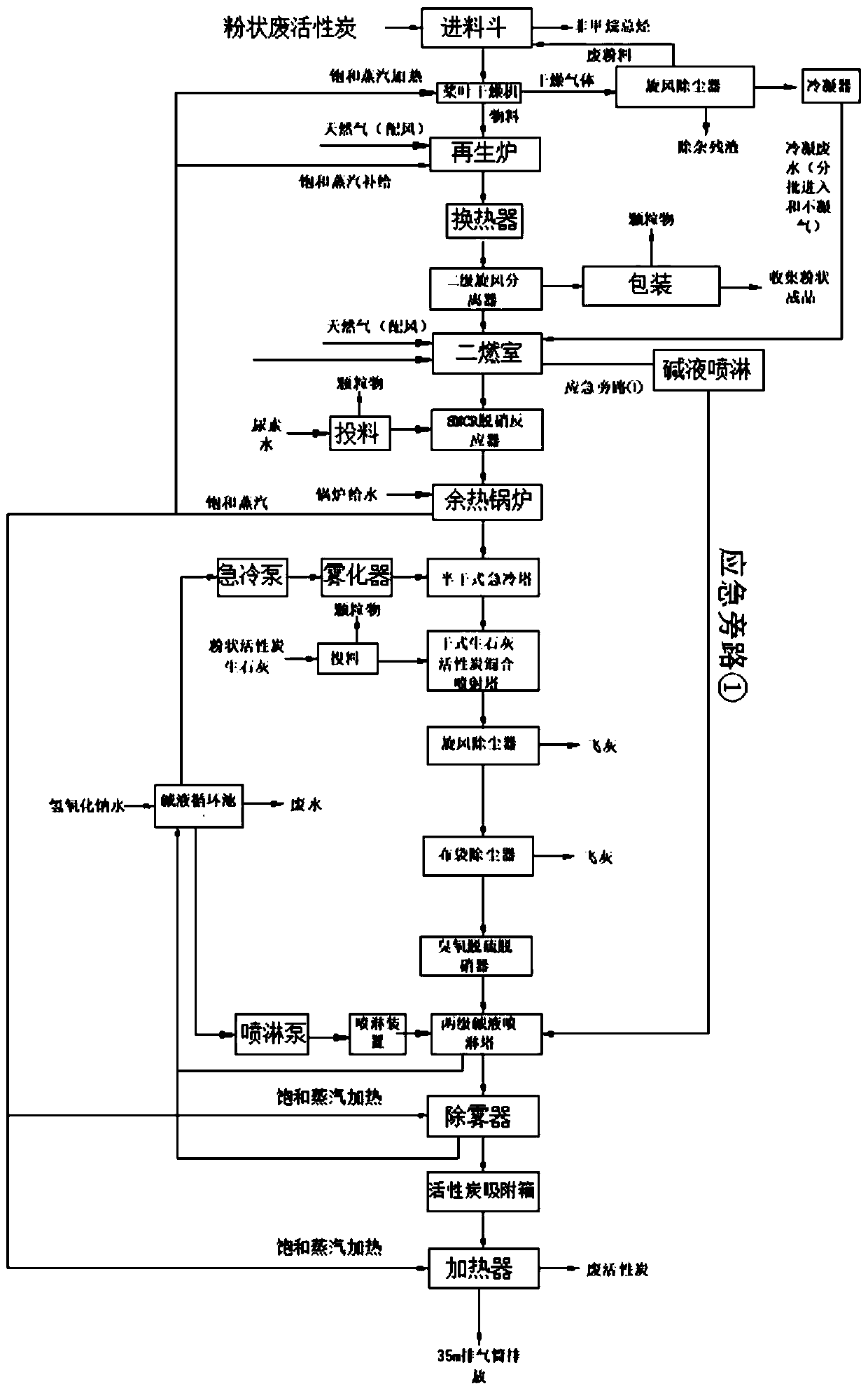

Efficient, energy-saving and environmentally-friendly waste activated carbon regeneration method

InactiveCN110560019ATargetedIncrease profitOther chemical processesCombustible gas purificationWater vaporOxygen

The invention discloses an efficient, energy-saving and environmentally-friendly waste activated carbon regeneration method. A system for implementing the method comprises a feeding system, a regeneration system, a discharging system, a combustion system, a flue gas purification system and a waste heat recovery system. A to-be-regenerated material is put into a feeding hopper, and is fed into a closed stock bin through a bucket elevator and a scraper; the material in the closed stock bin enters a regeneration furnace through a screw feeder, and is regenerated, small amounts of air and water vapor are introduced, and exhaust gas adsorbed by waste activated carbon is desorbed at a high temperature, and reacts with oxygen to generate water vapor and carbon dioxide gas. Compared with the priorart, the efficient, energy-saving and environmentally-friendly waste activated carbon regeneration method of the invention has the characteristics of flexibility, convenience, high utilization rate,high pertinence for the regeneration process of saturated activated carbon with different properties and forms, high efficiency, energy saving and environmental friendliness.

Owner:常州碧之源再生资源利用有限公司

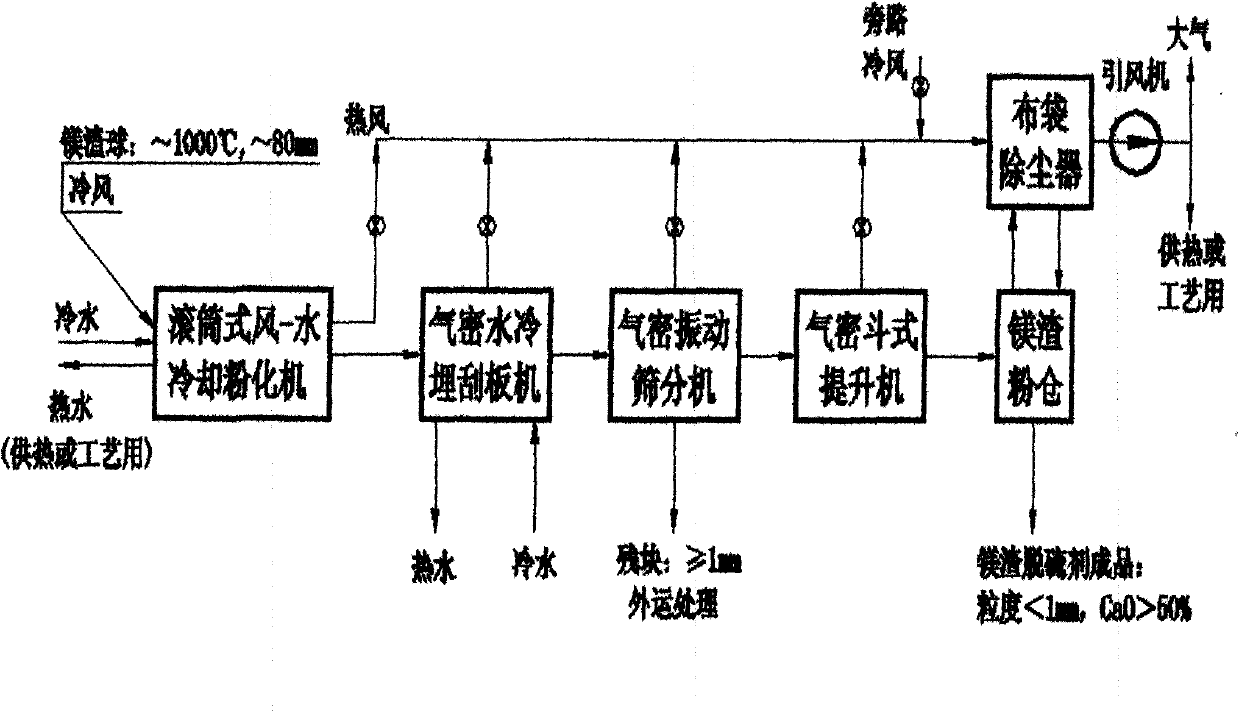

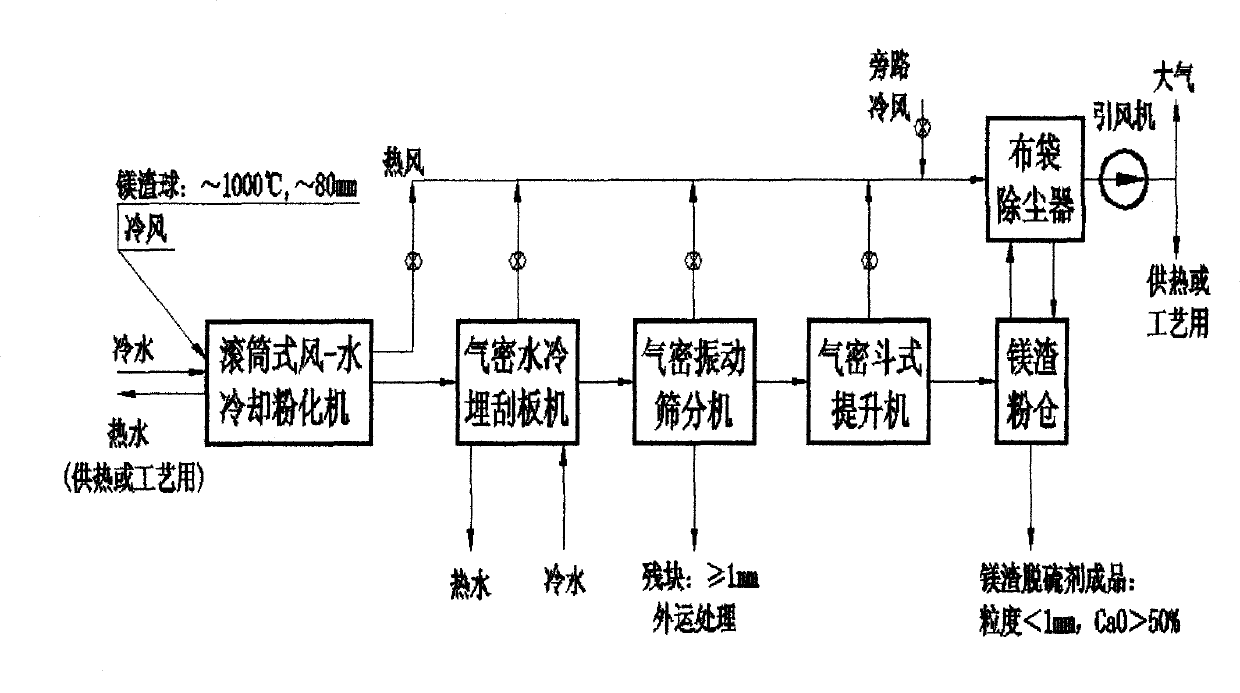

Process method for converting metal magnesium slag into desulphurizer of boiler

InactiveCN101791622AImprove cooling efficiencyEasy to handleSolid waste disposalDispersed particle separationSlagBucket elevator

Owner:山西猗顿生态环保股份有限公司

Calcium carbide sensible heat recovery equipment and method for calcium carbide furnace

InactiveCN103776270AReduce pollutionLow costIncreasing energy efficiencyWaste heat treatmentCycloneTunnel kiln

The invention discloses calcium carbide sensible heat recovery equipment and method for a calcium carbide furnace. The equipment comprises a calcium carbide furnace and a calcium carbide chute arranged on the calcium carbide furnace, wherein the lower part of the calcium carbide furnace is erected on an annular track through a calcium carbide furnace trolley; the upper part of the calcium carbide furnace is connected with an air blower, and the calcium carbide furnace is communicated with a hot air tunnel kiln through the calcium carbide chute and a smoke exhaust hood; a furnace top smoke pipeline is communicated with a high-temperature cyclone dust collector which is communicated with a waste heat boiler, and the waste heat boiler is communicated with a user and a bag type dust collector respectively; the calcium carbide furnace erected on the annular track is connected to a jaw crusher through an upending device, connects a bucket elevator to a storage hopper through the jaw crusher, then is connected to a chain scraper conveyor through an articulated chute, and is connected to a storehouse through the chain scraper conveyor; and the equipment further comprises a PLC (programmable logic controller) console which is connected to the storehouse through an industrial machine. With the adoption of the calcium carbide sensible heat recovery equipment for the calcium carbide furnace, a large amount of dissipated heat in calcium carbide production is utilized reasonably, effectively and sufficiently, the comprehensive effects of energy saving, consumption and pollution reduction, environment improvement and cost reduction are achieved, and the economic benefit is increased.

Owner:XIAN UNIV OF SCI & TECH

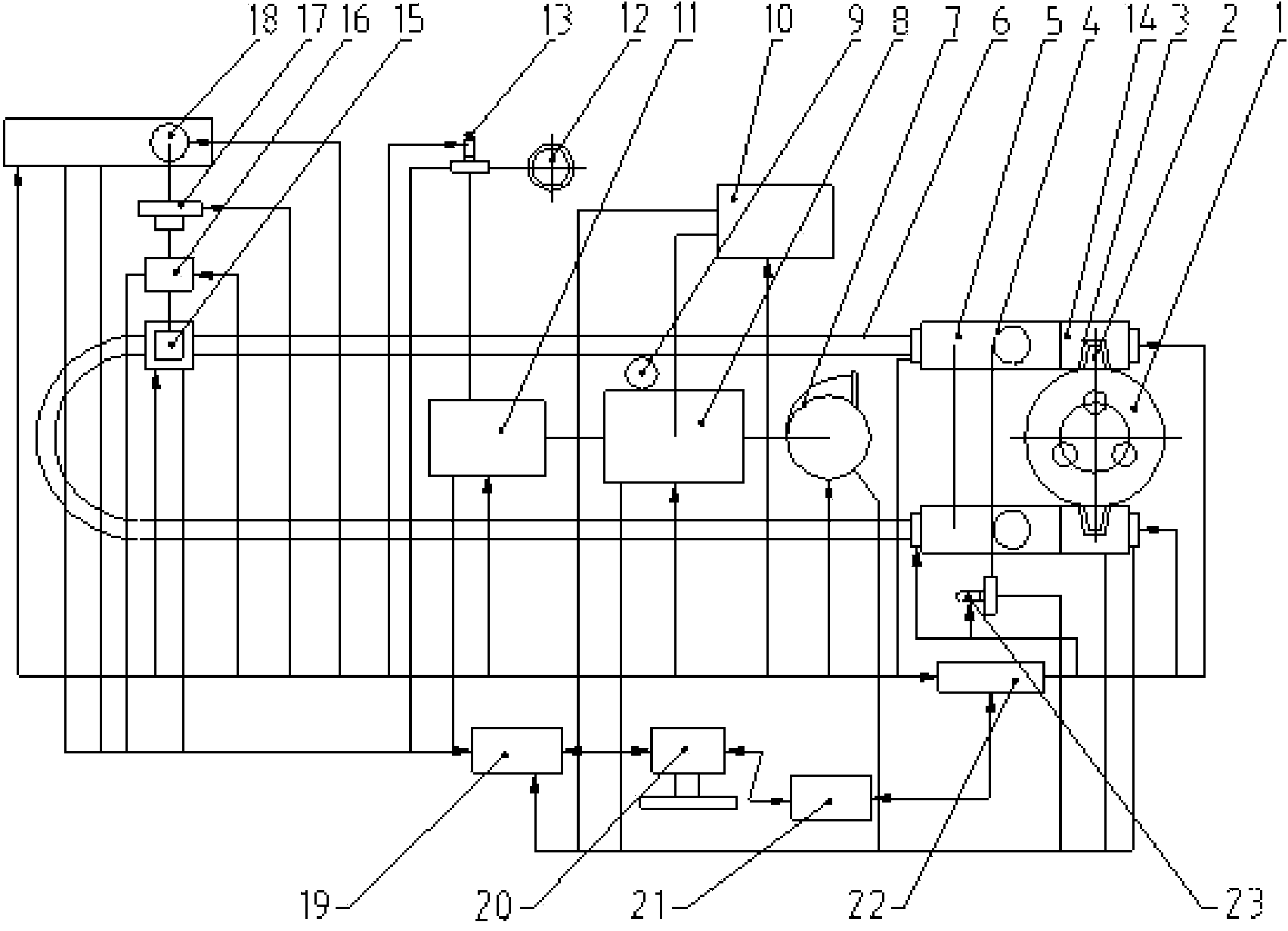

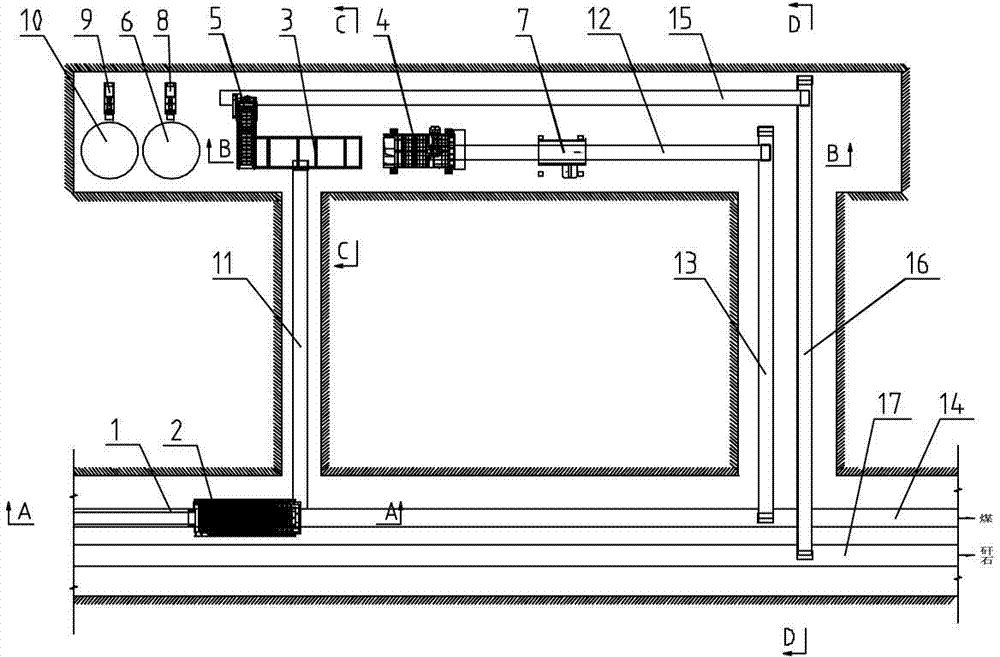

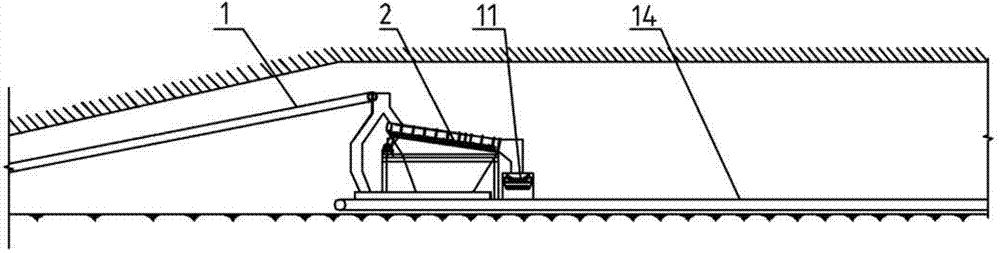

Flowing current separation process coal mine underground gangue dumping system

ActiveCN103480482AIncrease production capacityImprove efficiencyWet separationEngineeringBucket elevator

The invention relates to a flowing current separation process coal mine underground gangue dumping system. The technical scheme includes that a run-of-mine coal conveyor is mounted on one side of a feeding end of a roller screen, two ends of an on-screen selected raw material coal conveyor are connected with a front-screen chute of the roller screen and a feeding port of a flowing current separation machine respectively, a block coal of the flowing current separation machine is connected with a dewatering screen, an oversize material discharging end of the dewatering screen is sequentially connected with a block coal conveyor, a block coal transferring conveyor and a pulverized coal conveyor, a high frequency screen is mounted in the middle of the block coal conveyor, under-screen water of the dewatering screen is connected with a concentration tank through a pipeline, the concentration tank is connected with the high frequency screen, a gangue outlet of the flowing current separation machine is connected with a bucket elevator, a discharging end of the bucket elevator is sequentially connected with a gangue conveyor, a gangue transferring conveyor and a gangue warehousing conveyor, under-screen water of the high frequency screen and overflow of the concentration tank are connected with a circulating water tank through pipelines respectively, and the circulating water tank is connected with a water inlet of the flowing current separation machine through a circulating water pump and a pipeline. The flowing current separation process coal mine underground gangue dumping system is simple in process, good in separation effect, low in power consumption and low in operating cost.

Owner:沈阳科迪通达工程技术有限公司

Using method of full-automatic production line of slices

InactiveCN108687818ARealize automatic assembly line productionSievingScreeningProduction lineBiochemical engineering

The invention provides a using method of a full-automatic production line of slices, and belongs to the field of decoction pieces processing devices. The using method comprises the following steps ofcleaning by using an ultrasonic cleaner, shaping by using a root stock shaping machine, slicing by using a reciprocating slicer, elevating and feeding by using a bucket elevator, drying by using a hotair dryer, separating by using a rail-mounted reciprocating separating screen, and storing by using a moistureproof storage tank. Traditional Chinese medicine decoction pieces prepared from the rootstocks of bupleurum chinense realizes automatic assembly line production.

Owner:FANGXIAN COUNTY ZHONGYI EQUIP

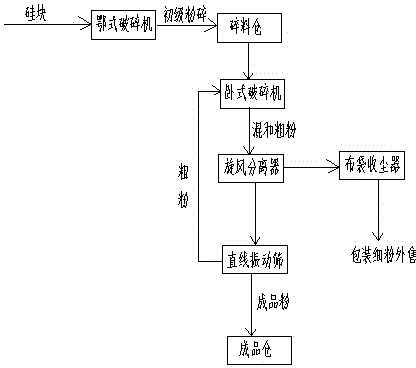

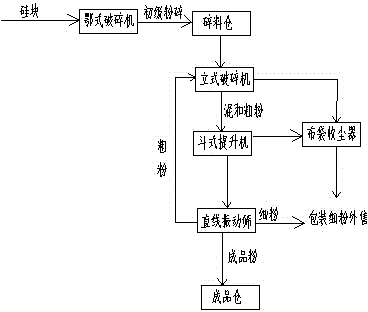

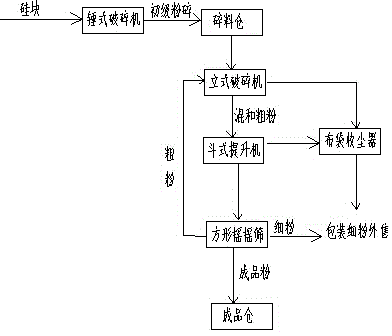

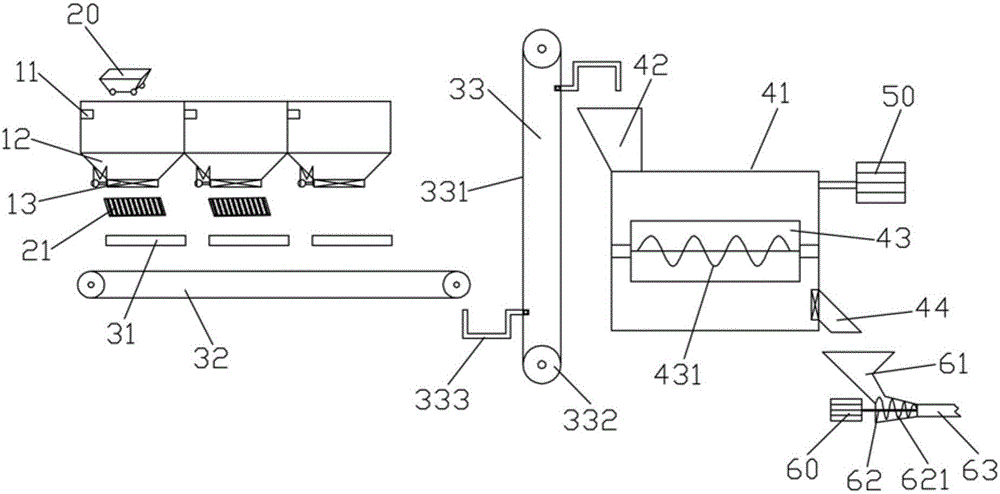

Metal silicon powder production process and device

ActiveCN104923370AReduce feed particle sizeImprove first-time yieldSievingScreeningCrusherBucket elevator

The invention relates to a metal silicon powder production process. The metal silicon powder production process includes: silicon blocks are primarily crushed by a hammer type crusher, the crushed silicon blocks enter a crushed material bin through a first bucket type elevator, and the crushed silicon blocks are pulverized in a vertical type pulverizer into pulverized materials; the mixed coarse powder of the pulverized materials is fed into a square swing screen through a second bucket type elevator and screened, the finished powder screened to the lower portion of the square swing screen is stored in a finished product bin, and the coarse powder remained on the square swing screen is returned to the vertical type pulverizer through a third bucket type elevator for secondary pulverizing; the fine powder of the pulverized materials are collected by a cloth bag dust collector to enter a fine powder bin, and fine powder is packed for sale. A metal silicon powder production device comprises the hammer type crusher, the first bucket type elevator, the vertical type pulverizer, a second bucket elevator, the cloth bag dust collector, the third bucket type elevator and the square swing screen.

Owner:HOSHINE SILICON IND CO LTD

Automatic proportioning system of concrete mixing station

ActiveCN105690568AAccurate weighingPrecise deliveryDischarging apparatusMixing operation control apparatusControl systemBucket elevator

The invention discloses an automatic proportioning system of a concrete mixing station. The automatic proportioning system comprises a raw material storage system, a raw material weighing system, a mixer system, a raw material conveying system and a control system, wherein the raw material storage system comprises three silos which are arranged side by side; the raw material conveying system is composed of a belt conveyor and a bucket elevator; and the raw material weighing system comprises three belt weighers which are positioned above the belt conveyor, and are positioned below the openings of the silos. The automatic proportioning system can meet a large-scale concrete manufacturing process, can be used for precisely weighing and conveying various raw materials, and further can realize precise control and efficient management on a concrete proportioning process while the product quality is guaranteed, so that the problems such as a complex and out-of-order procedure in a convention producing and proportioning process, confused record management in a proportioning process, severe proportioning resource waste and the like are obviously avoided.

Owner:陕西恒盛混凝土有限公司

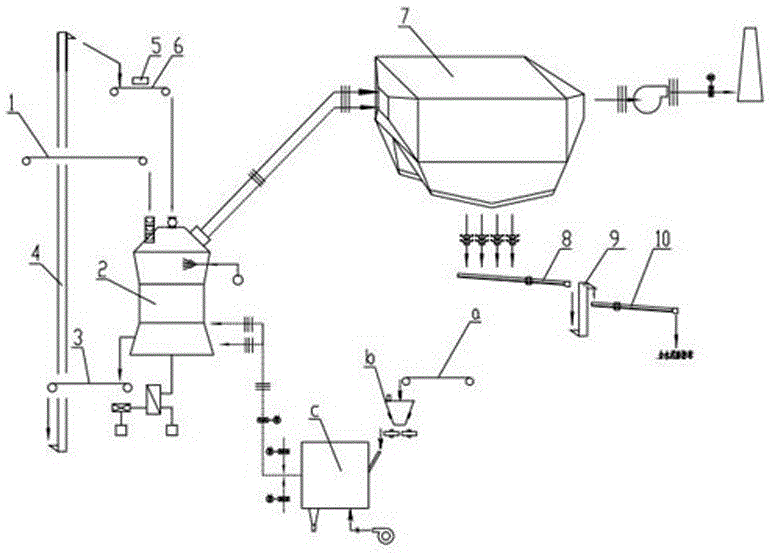

Machine-made sand wind power winnowing system and winnowing method

ActiveCN103357577ATo achieve the purpose of dust-freeTo achieve the purpose of winnowingGas current separationProgrammable logic controllerEngineering

The invention relates to a machine-made sand wind power winnowing system and a winnowing method, which not only can adopt wind power to realize selection of machine-made sand with different particle sizes, but also realizes dustlessness. The machine-made sand wind power winnowing system comprises a PLC (Programmable Logic Controller), wherein a discharge opening of a mixing finished product bucket elevator directly faces to the inlet of a buffer stock bin; a discharge opening of a buffer stock bin directly faces to the inlet of a feeding machine; the outlet of the feeding machine is communicated with a feed opening of a machine-made sand wind power air separator cabin; multiple stage discharge openings of the machine-made sand wind power air separator cabin are communicated with respective material storage cylinders in each stage through material conveying tubes; the air outlet of a main air blower is communicated with a main wind opening of the machine-made sand wind power air separator cabin; the air outlet of an assistant blower is communicated with assistant wind openings in the machine-made sand wind power air separator cabin; a dedusting opening in the machine-made sand wind power air separator cabin is communicated with the inlet of a dust remover.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com