Process for preparing high-performance composite concrete from mineral powder, machine-made sand and waste concrete

A technology for waste concrete and machine-made sand, which is applied in solid waste management, climate sustainability, sustainable waste treatment, etc. It can solve the problem of not formulating technical standards for recycled aggregates, improve resource utilization, and reduce emissions and storage. , the effect of reducing carbon dioxide emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

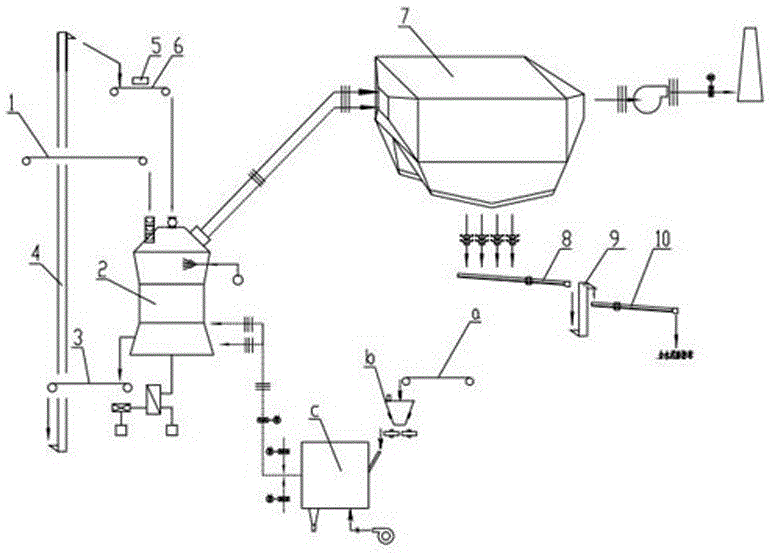

[0022] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

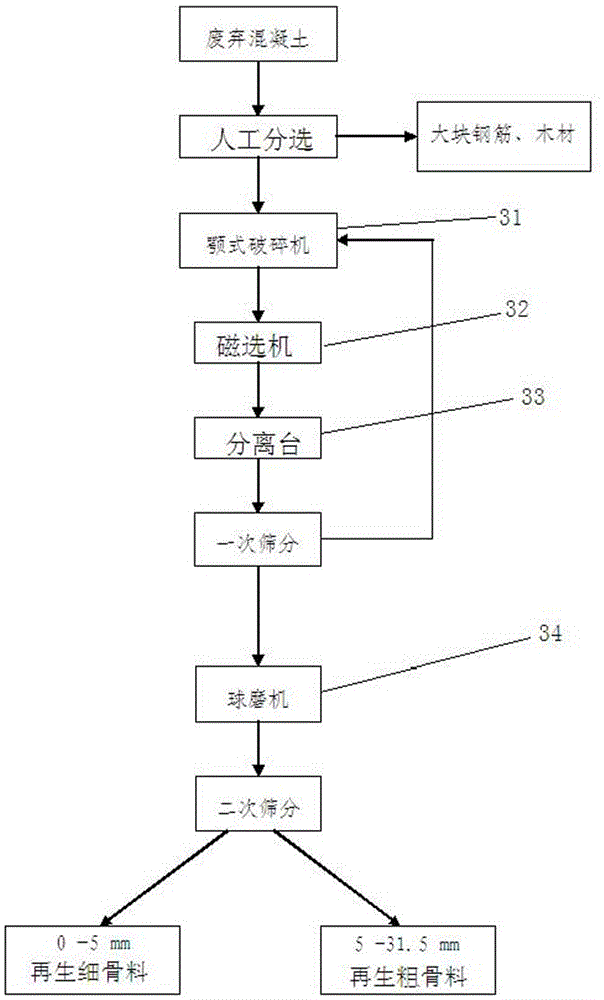

[0023] Such as figure 1 , figure 2 , image 3 As shown, a process for preparing composite concrete from mineral powder, machine-made sand and waste concrete includes the following steps, a. Preparation of mineral powder, drying and grinding of mineral powder by using a vertical mill; The output is 90 tons / hour.

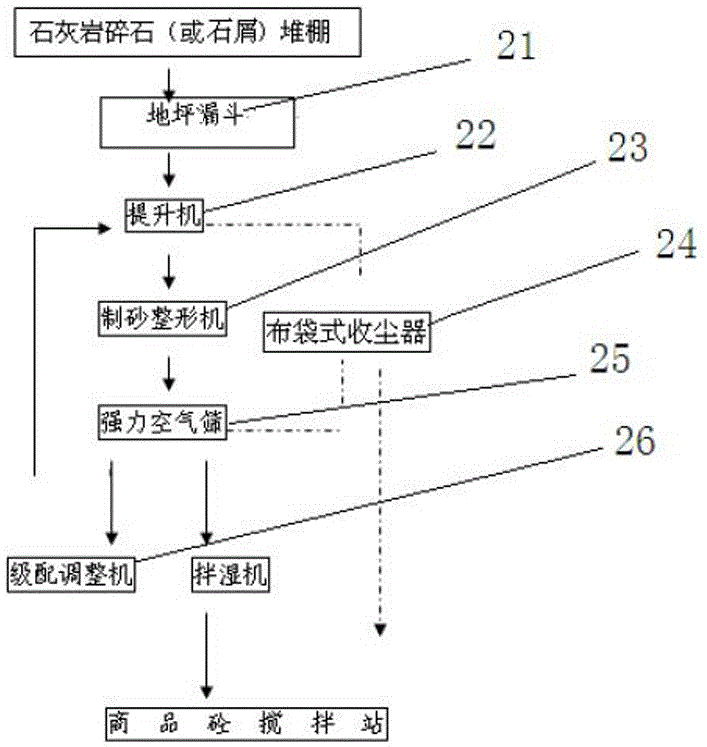

[0024] b. For the preparation of machine-made sand, the main raw material gravel or stone chips of ≤40mm entering the factory are stored in the shed and dried naturally; the main raw materials are naturally air-dried and then sent to the discharge floor funnel 21, fed through the discharge valve, and passed through the belt Conveyor and bucket elevator ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com