Soybean milk machine with small-space crushing cover

A crushing cover and small space technology, which is applied in beverage preparation devices, home appliances, applications, etc., can solve the problems of difficulty in ensuring the consistency of crushing effect and fluctuations in crushing effect, achieve a simplified structure, ensure long-term stable work, and produce liquid smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

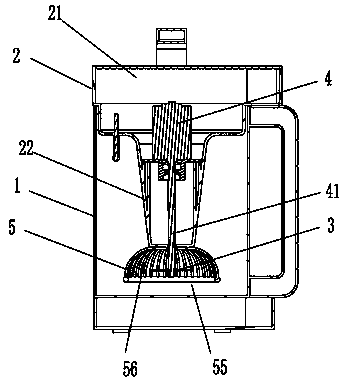

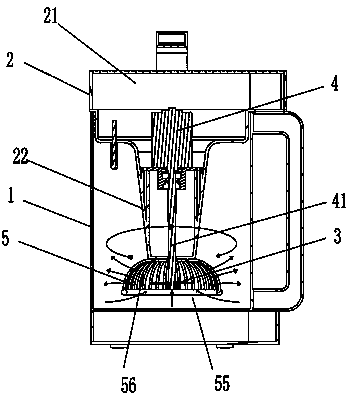

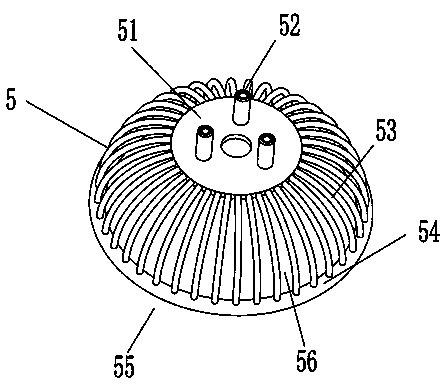

[0056] In addition to the small-space crushing cover, the cutter body is also an important component of the present invention, because to realize the present invention, the small-space centralized crushing is carried out first and then the circular crushing is carried out. When the cutter body is rotating, the water in the cup body 1 must be directed toward the Airtight small space smashes cover 5 motions. In order to achieve the above purpose, the present invention is realized by providing a pumping part on the cutter body, but there is not only one way to realize the pumping part, and it is not limited to one embodiment. The structure of the cutter body will be described in detail below.

[0057] In the present invention, the clockwise rotation of the cutter body is used for illustration, see Figure 11 , in this embodiment, the cutter body 3 with four blade wings is adopted, and the blade 31 on the cutter body 3 is provided with a blade 32 towards the side of the machine he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com