Patents

Literature

4276results about How to "Large particle size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

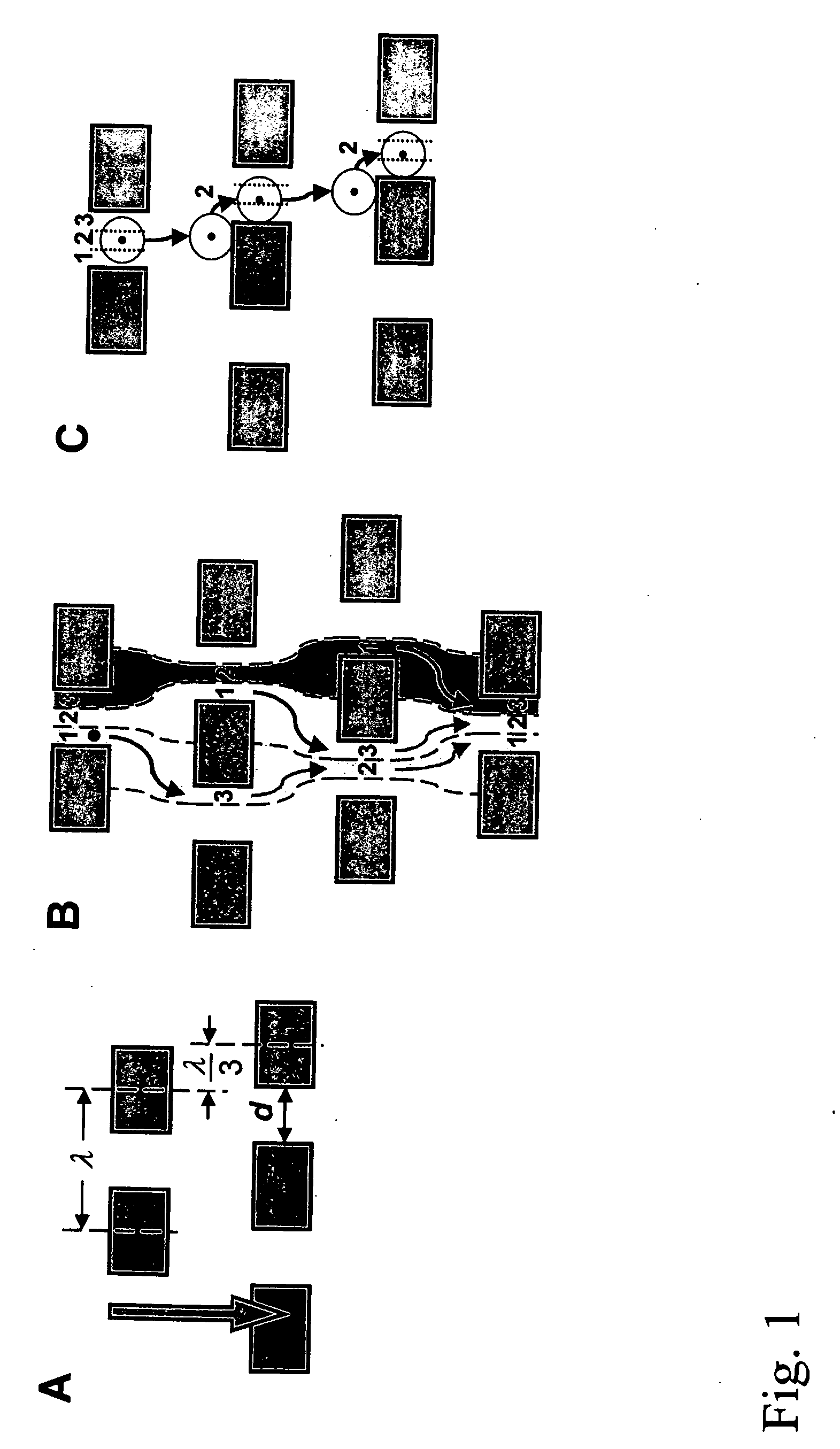

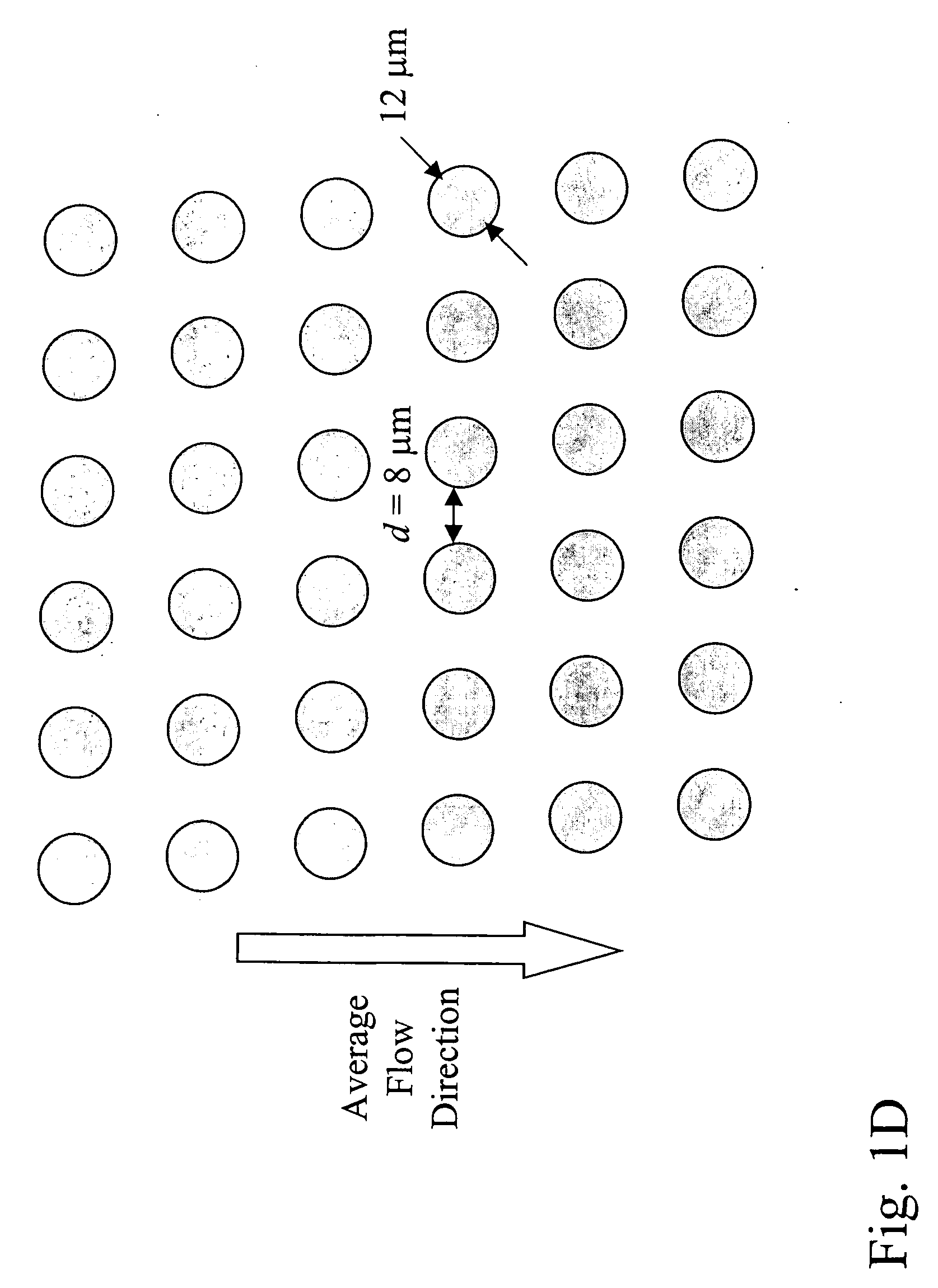

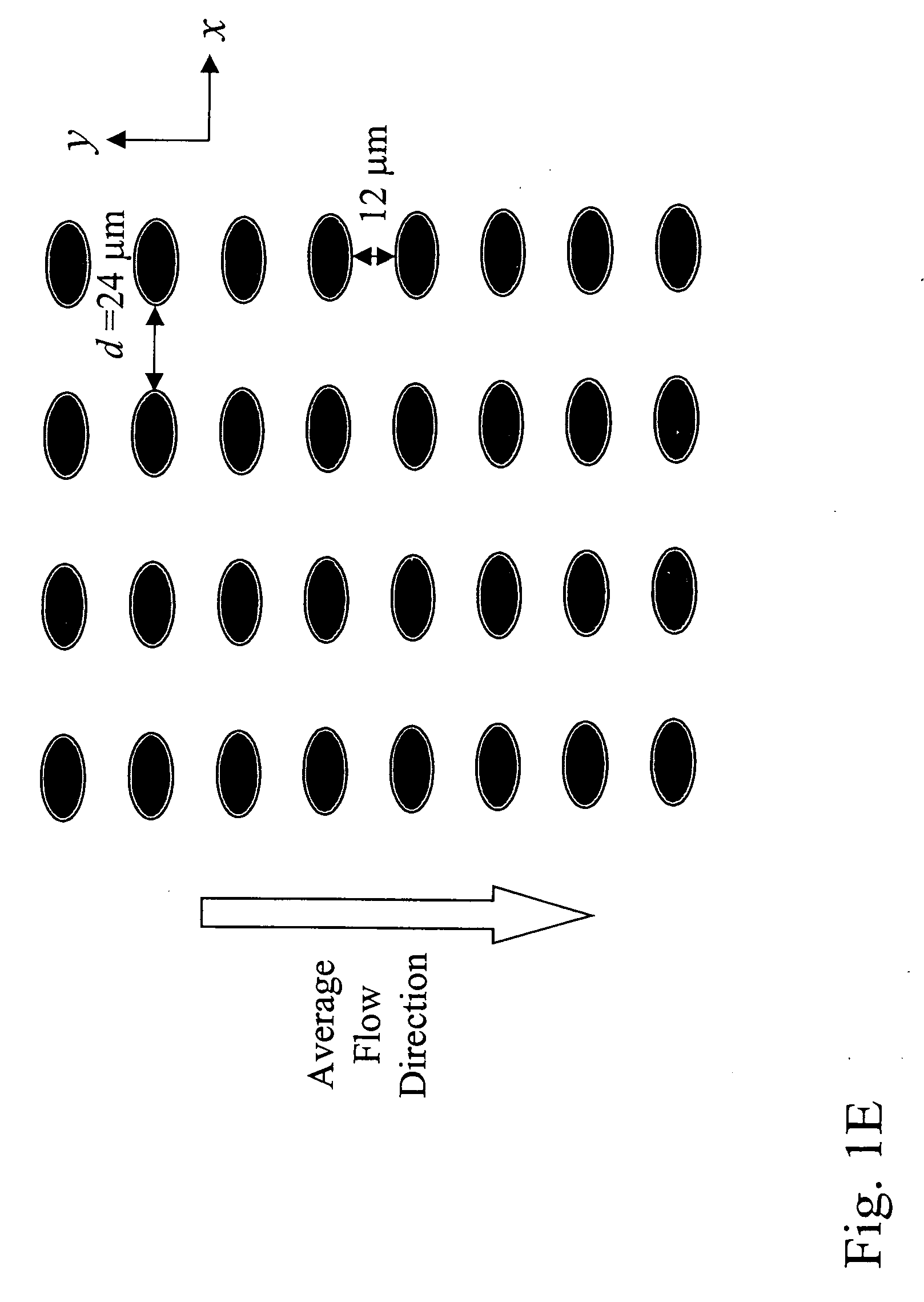

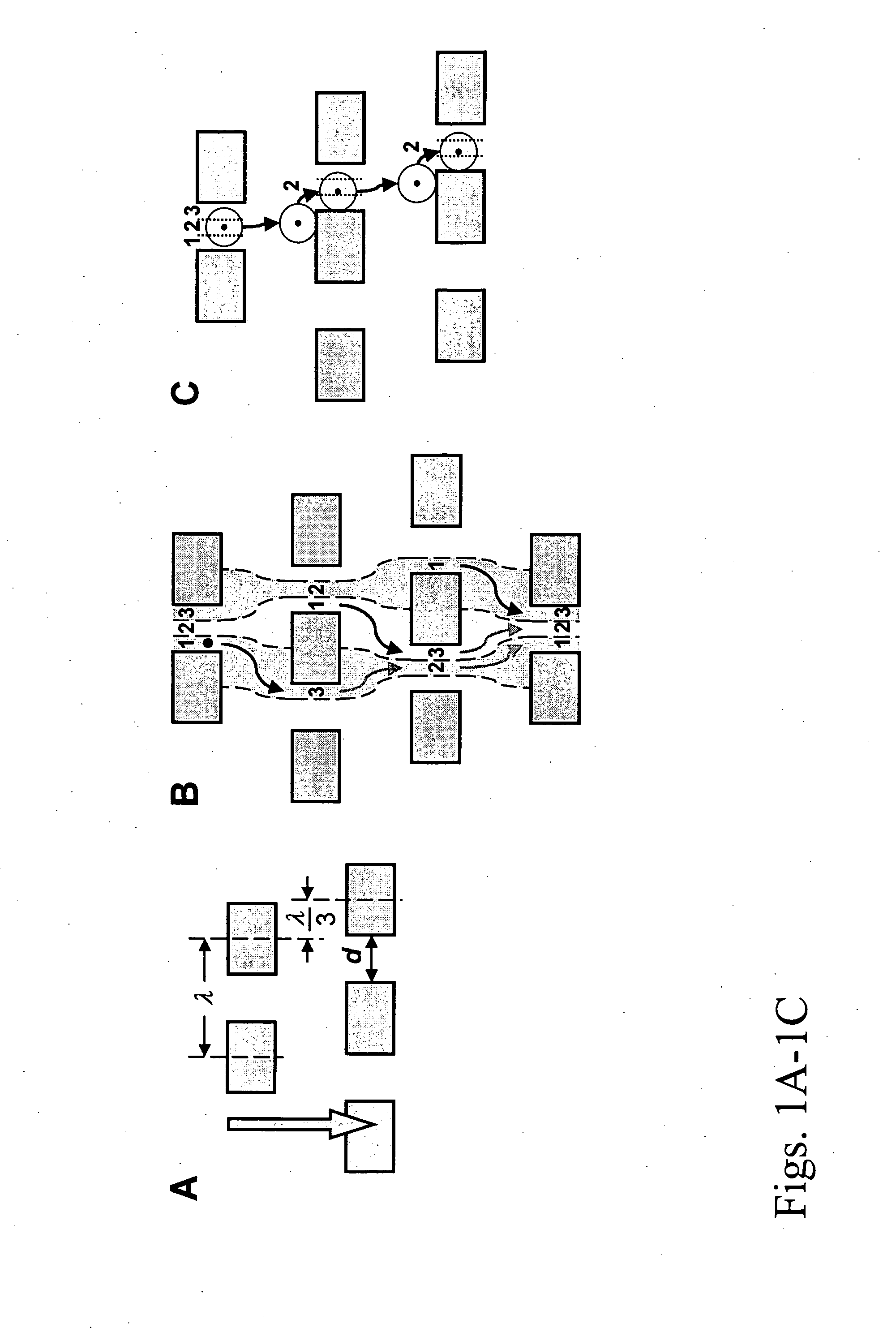

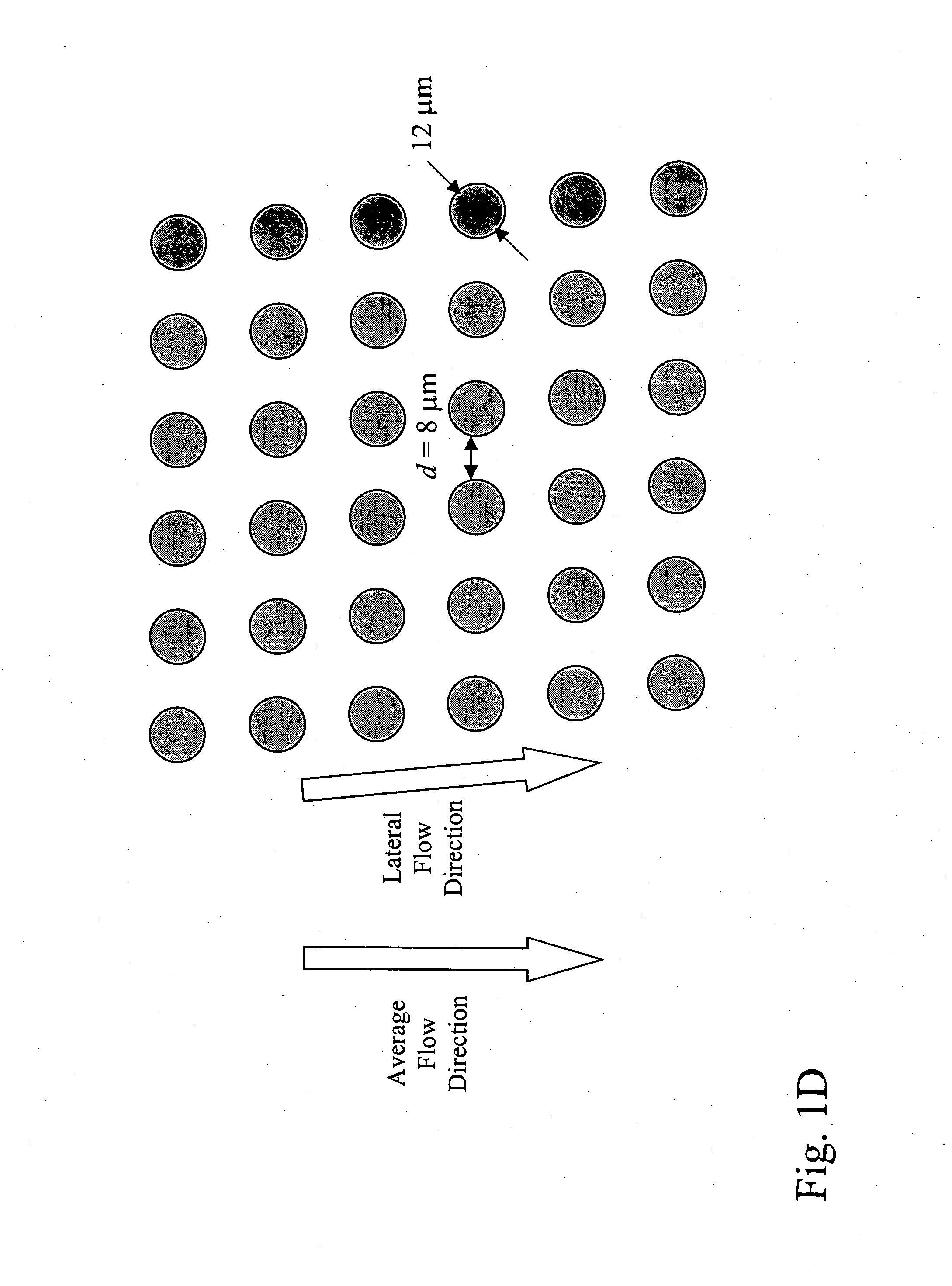

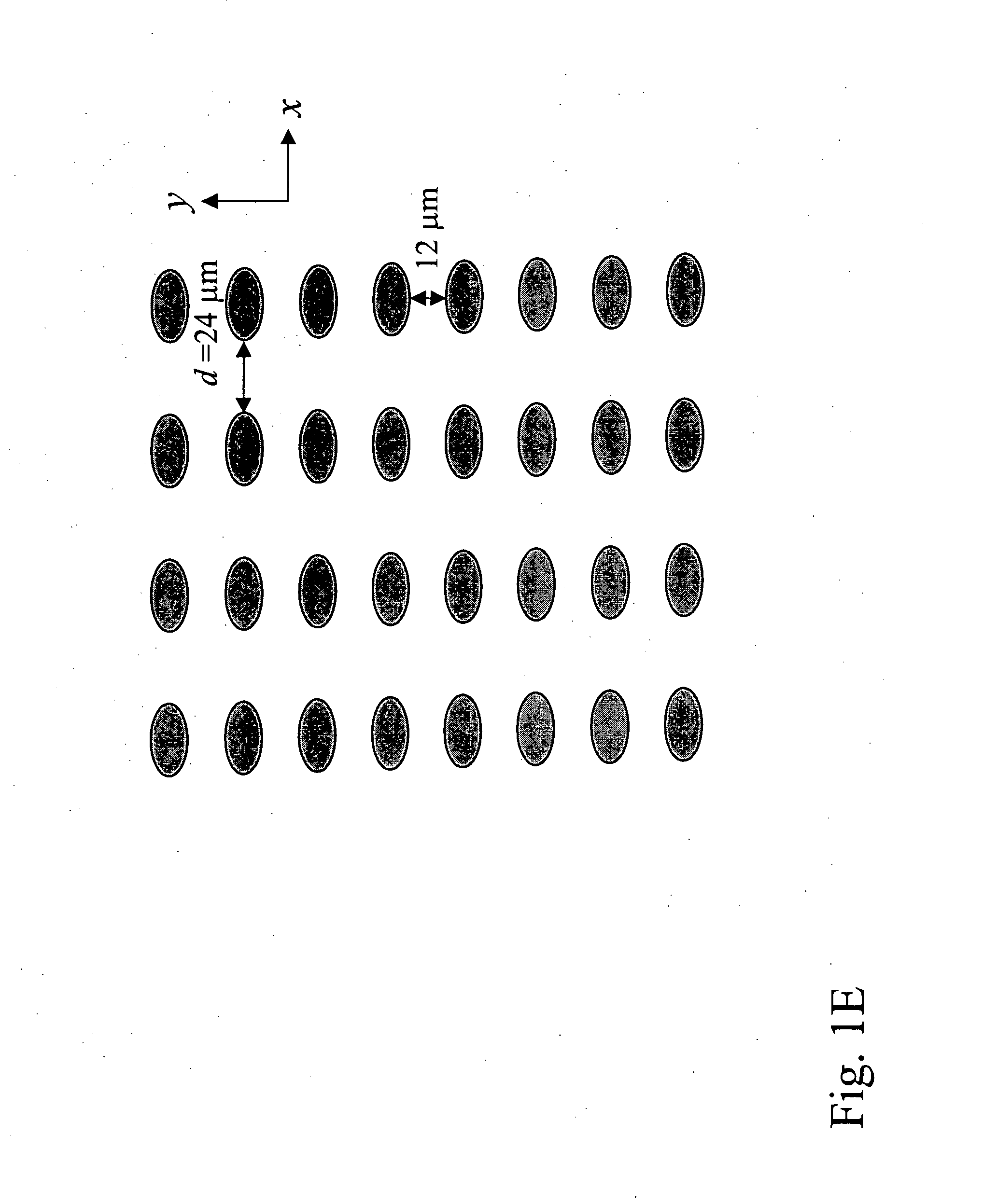

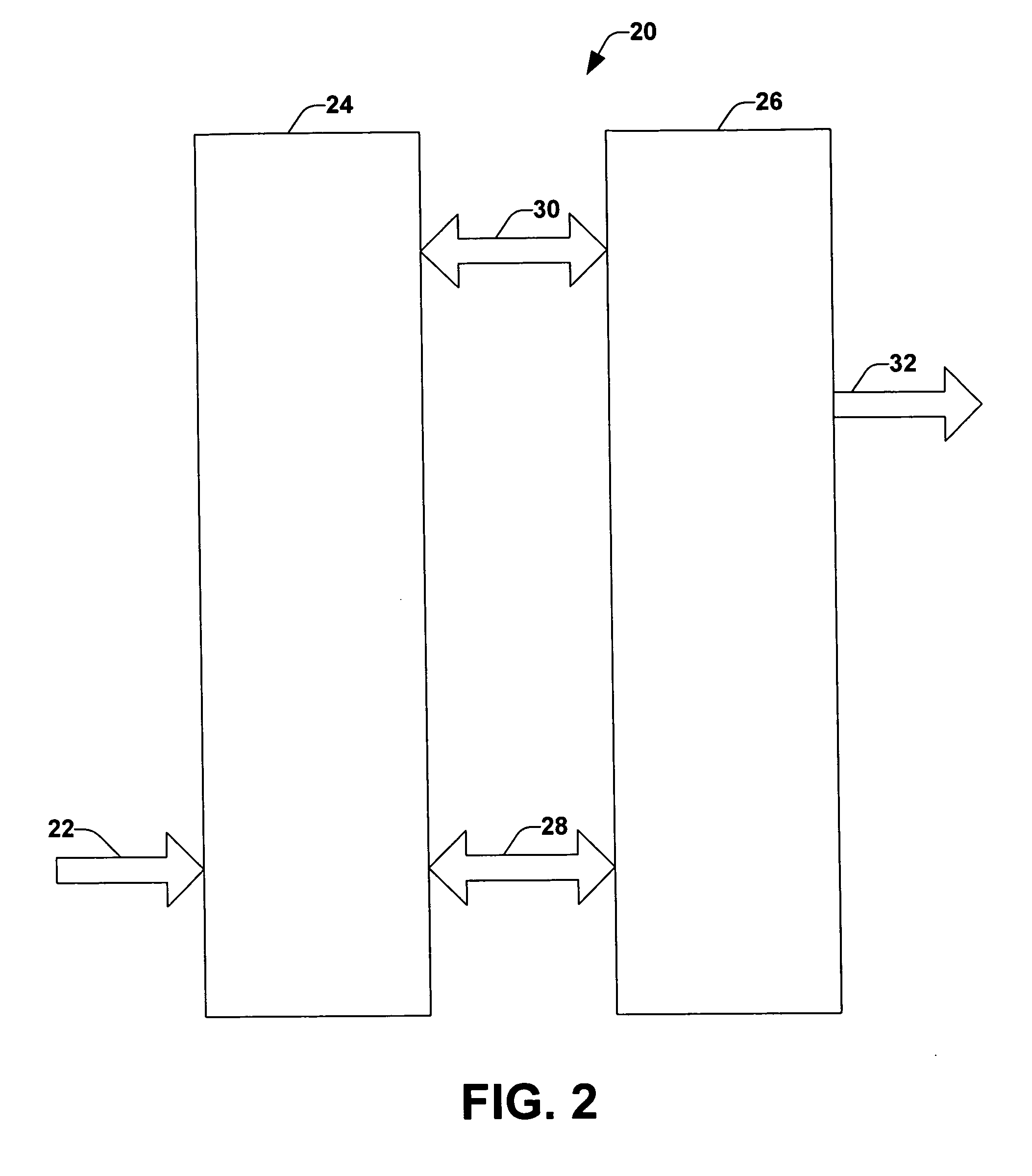

Devices and methods for magnetic enrichment of cells and other particles

InactiveUS20060223178A1Small particle sizeLower the volumeArtificial cell constructsLaboratory glasswaresAnalyteMedicine

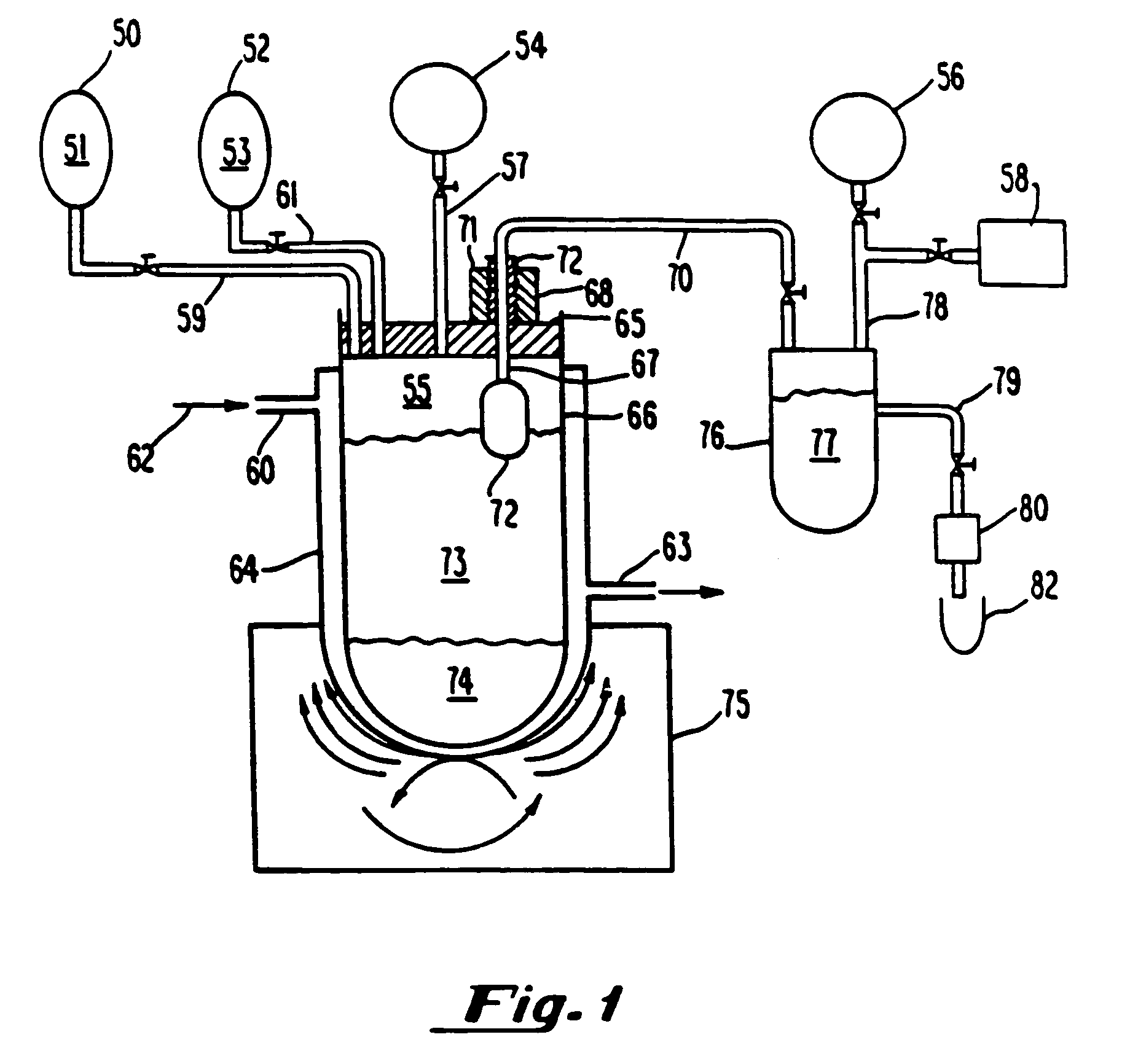

The invention features devices and methods for the enrichment of cells and other desired analytes by employing a magnetic field, alone or in conjunction with size-based separation. The devices and methods may be advantageously employed to enrich for rare cells, e.g., fetal cells or epithelial cells, present in a sample, e.g., maternal blood.

Owner:THE GENERAL HOSPITAL CORP +1

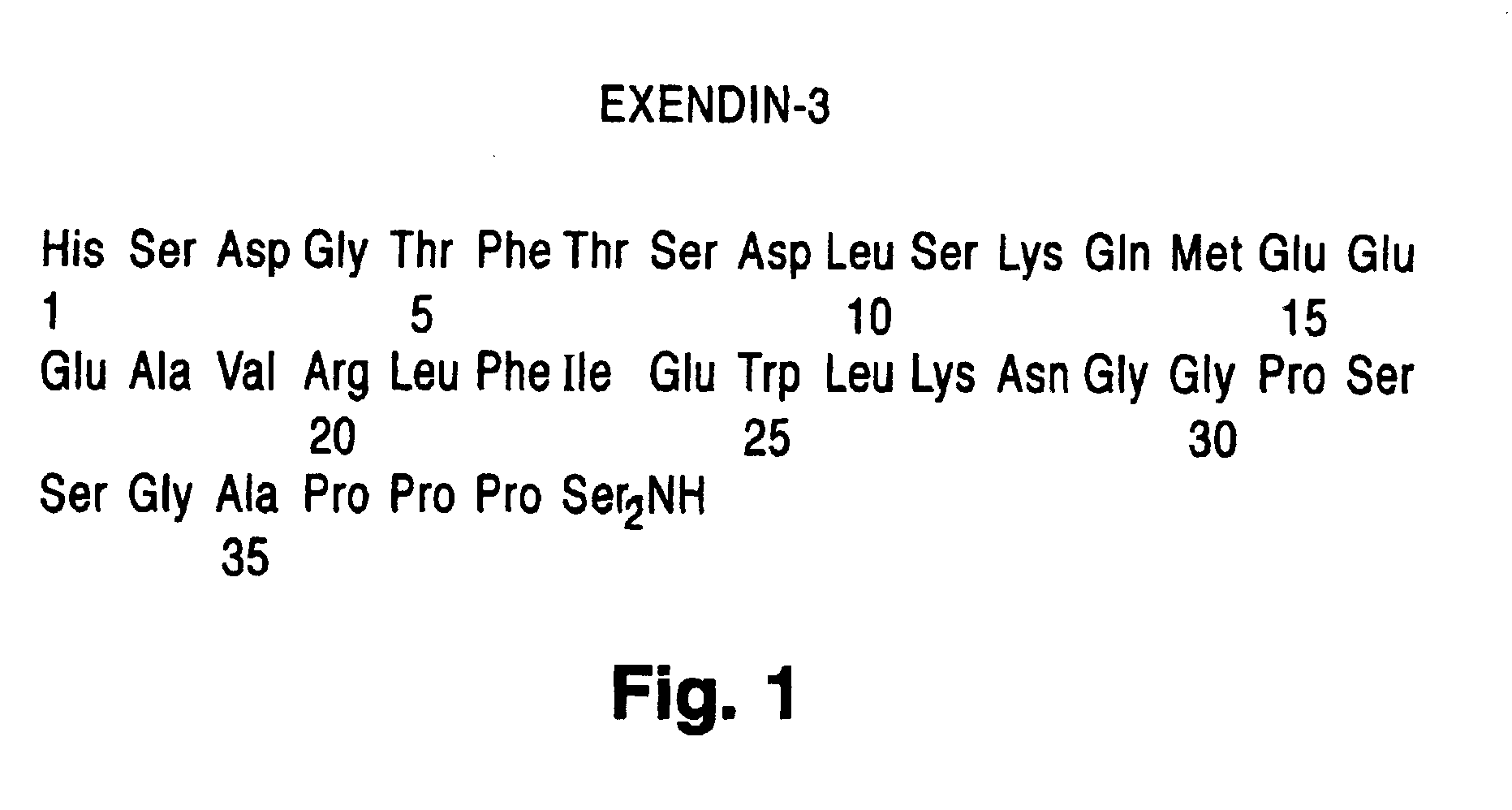

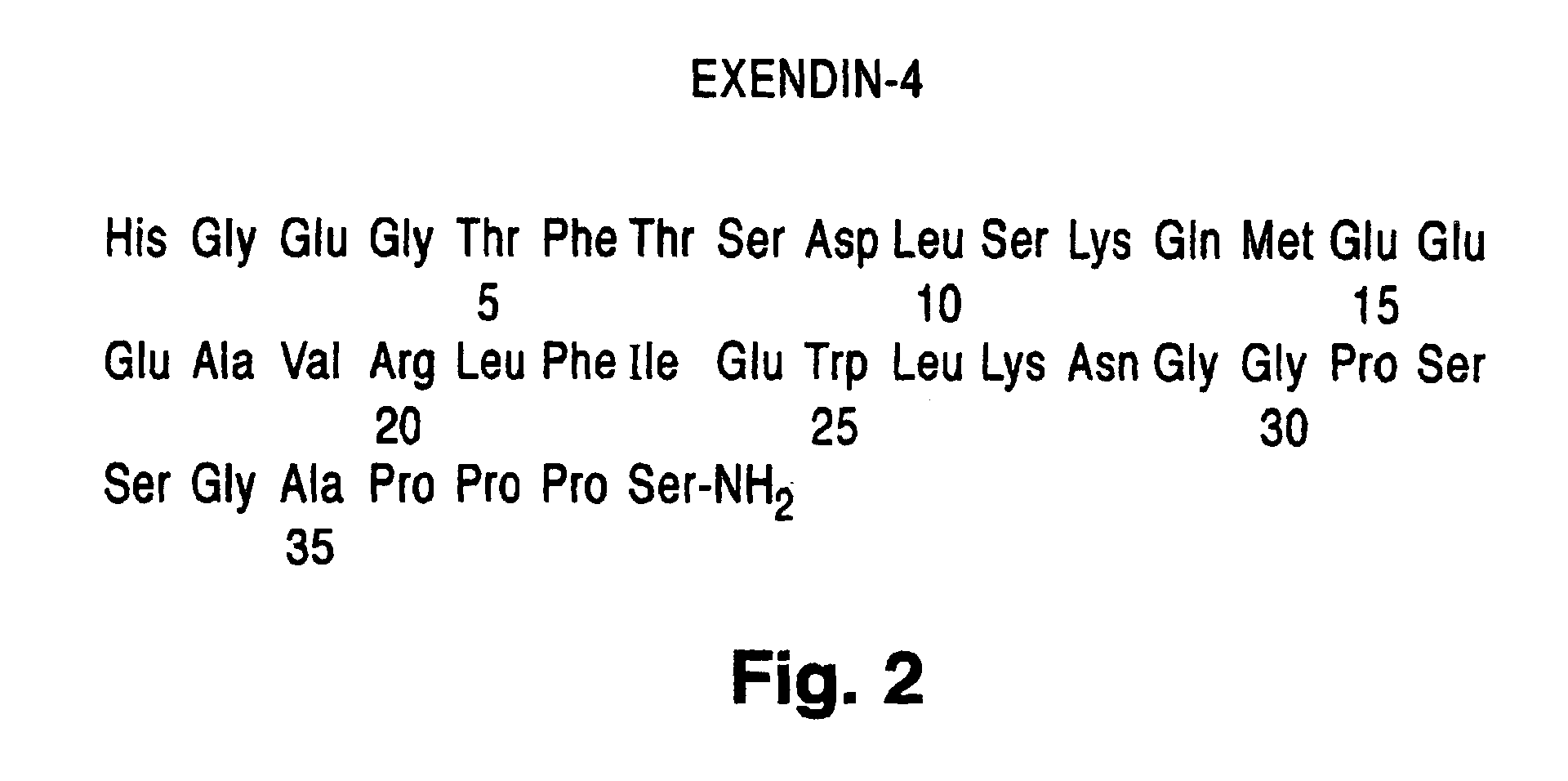

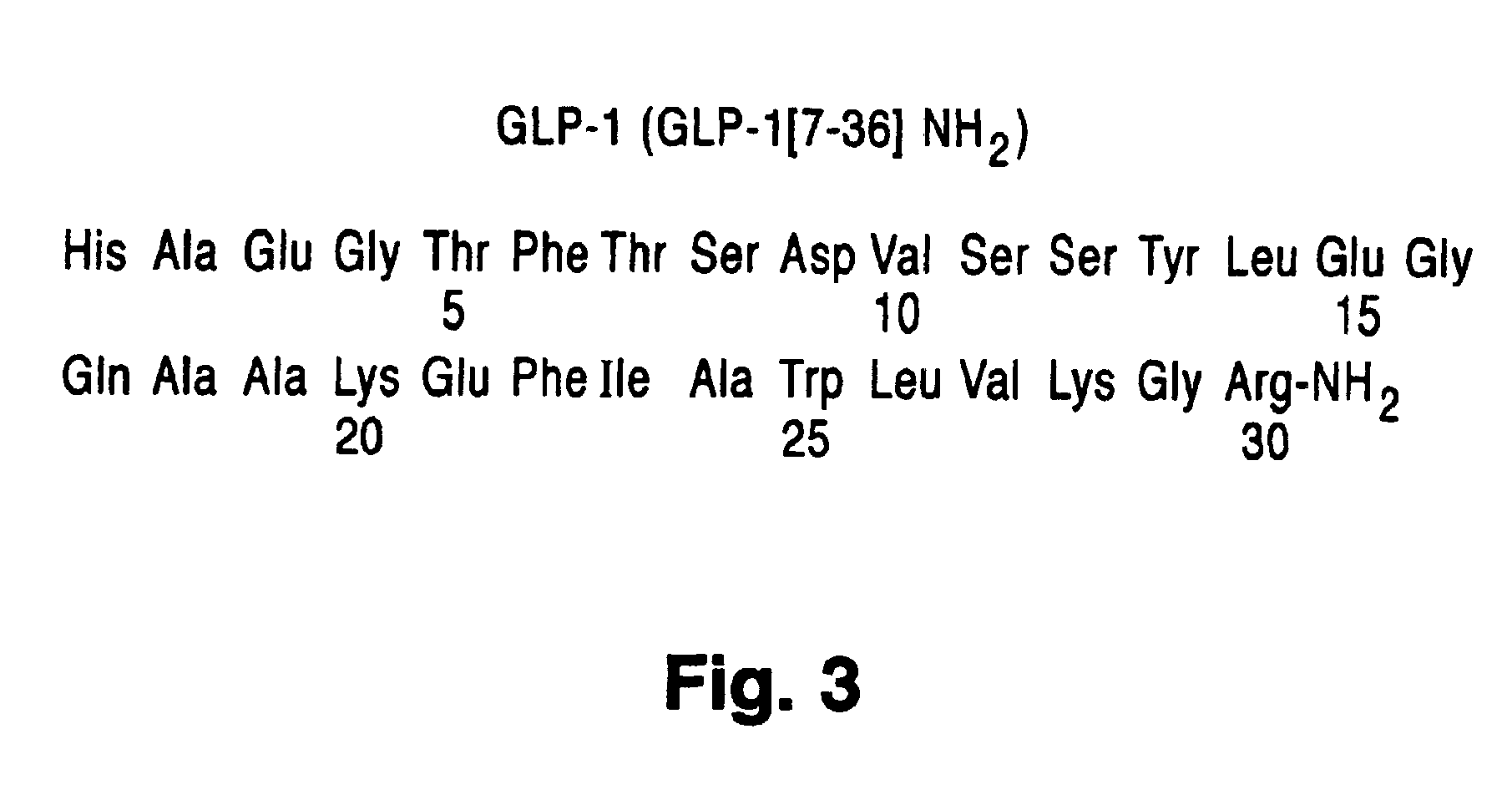

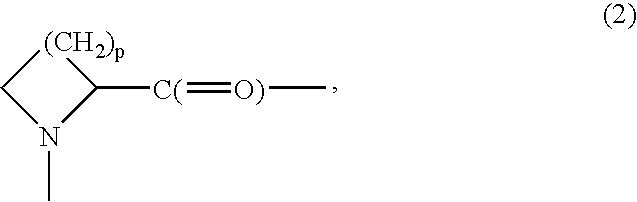

Exendin agonist formulations and methods of administration thereof

InactiveUS6902744B1Slow gastric emptyingLowering plasma glucose levelPowder deliveryPeptide/protein ingredientsGastric emptyingPlasma glucose

Novel exendin and exendin agonist compound formulations and dosages and methods of administration thereof are provided. These compositions and methods are useful in treating diabetes and conditions that would be benefited by lowering plasma glucose or delaying and / or slowing gastric emptying or inhibiting food intake.

Owner:ASTRAZENECA PHARMA LP

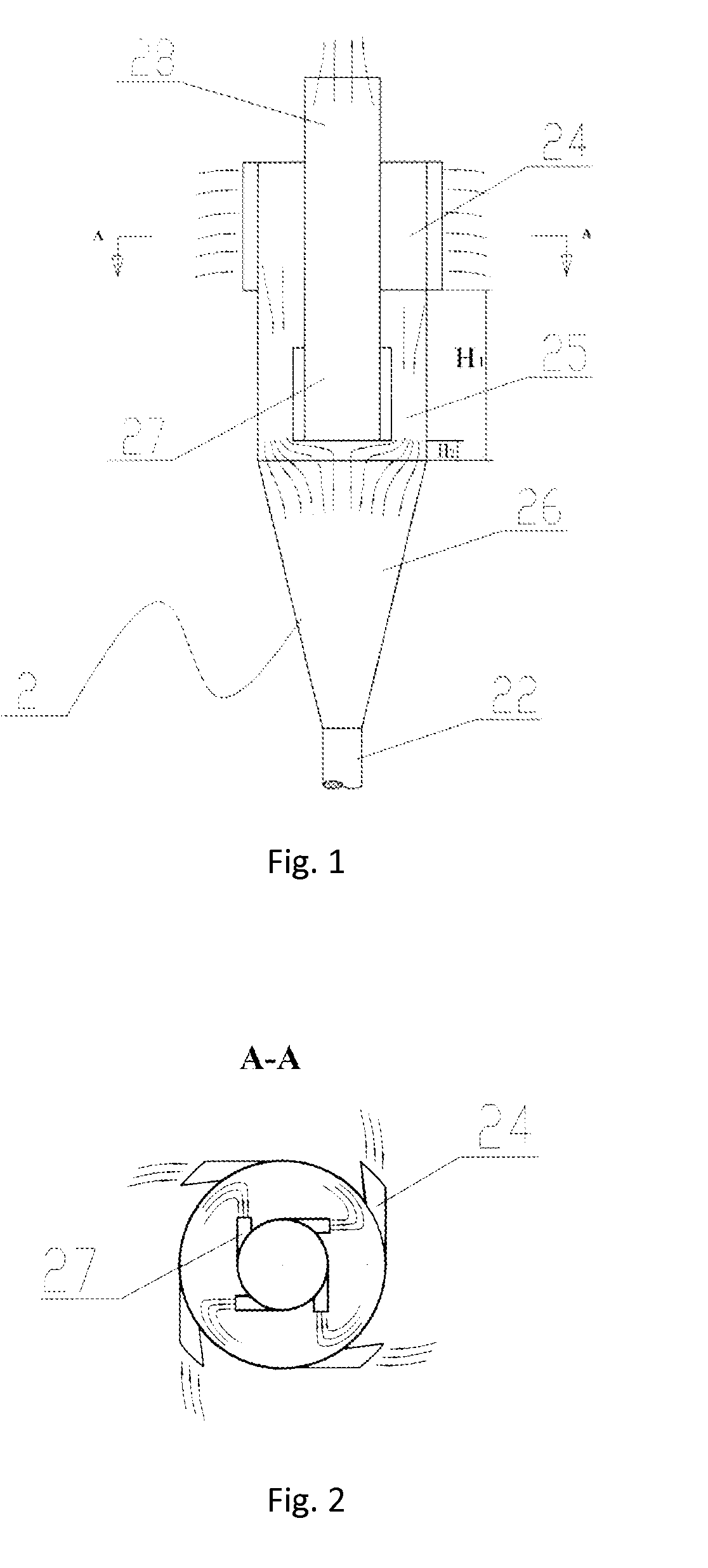

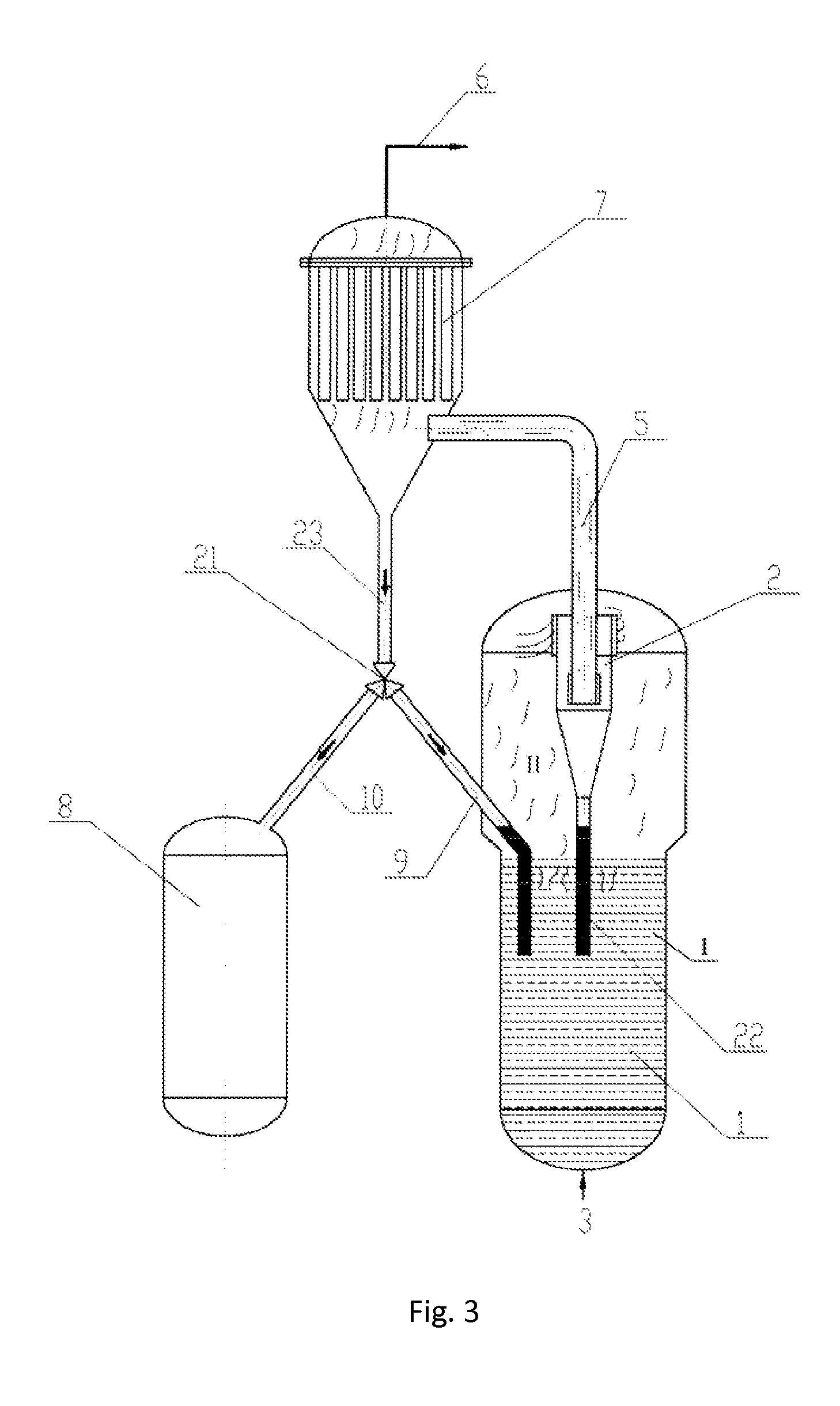

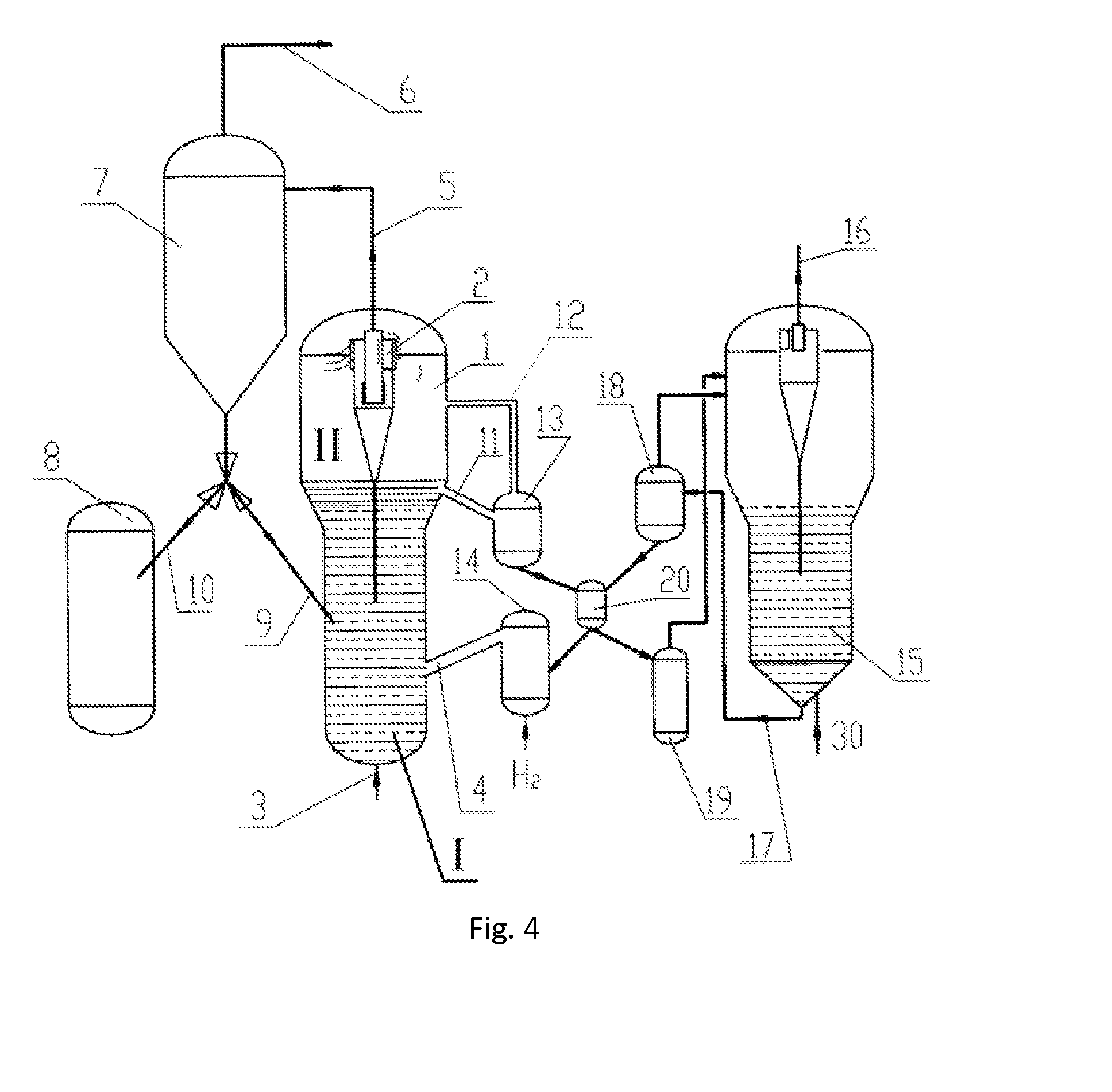

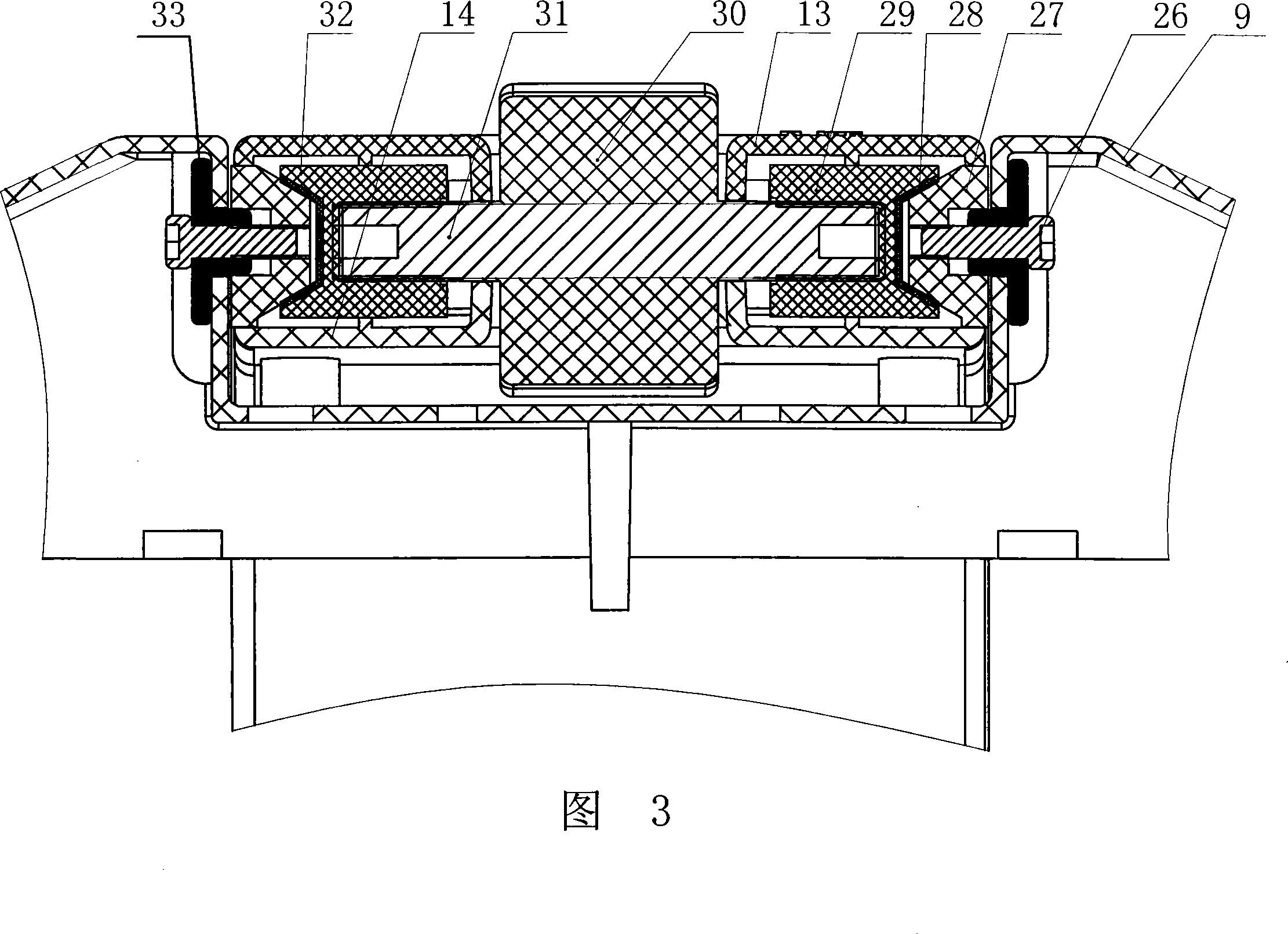

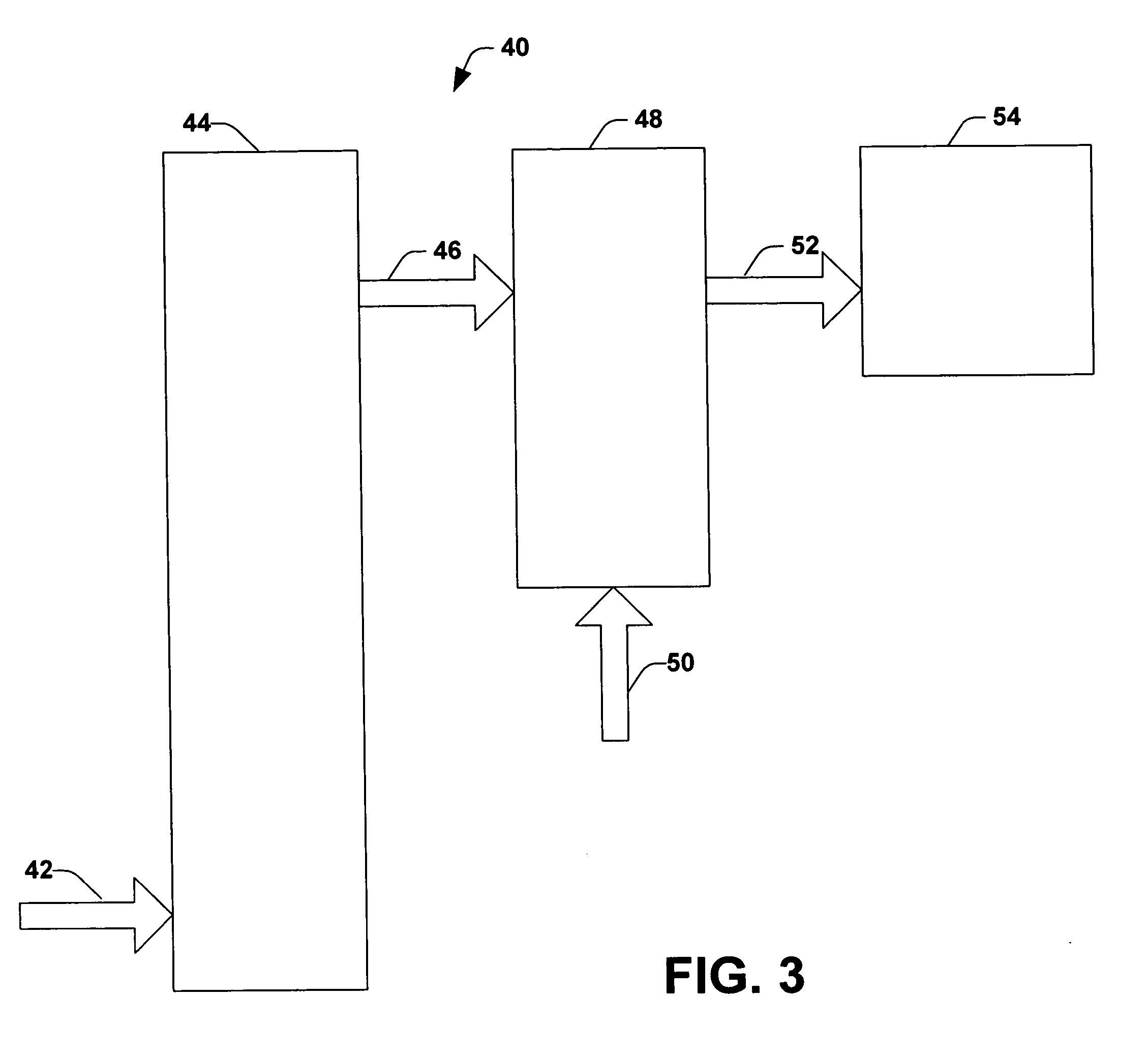

Adsorption Desulfurization Process for Hydrocarbons and a Reaction Apparatus Therefor

ActiveUS20140121438A1Efficient removalReduce flow rateReversed direction vortexHydrocarbonsFluidized bedStraight tube

The present invention relates to an airflow particle sorter, comprising: a top-sealed sorter main body, a discharge port, an outtake tube and at least one directing-intake port; the inner space of the sorter main body, from the above to the bottom, includes, a straight tube zone and a cone zone, the conical bottom of the cone zone is connected to the straight tube zone; the discharge port is located at the bottom of the cone zone; the directing-intake port is installed in the upper part of the straight tube zone in a tangential direction of the straight tube zone, and is communicated with the inner space of the sorter main body; the outtake tube is hermetically inserted into the top of the sorter main body, and extends downwardly to the lower part of the straight tube zone, and the outtake tube has a sealed bottom end; the lower part of the outtake tube is installed with at least one directing-outtake port, which communicates the outtake tube with the inner space of the sorter main body, the directing-outtake port is installed in a tangential direction of the outtake tube. The present invention further relates to a fluidized bed reactor and an adsorption desulfurization reaction apparatus as well as an adsorption desulfurization process.

Owner:CHINA PETROCHEMICAL CORP +1

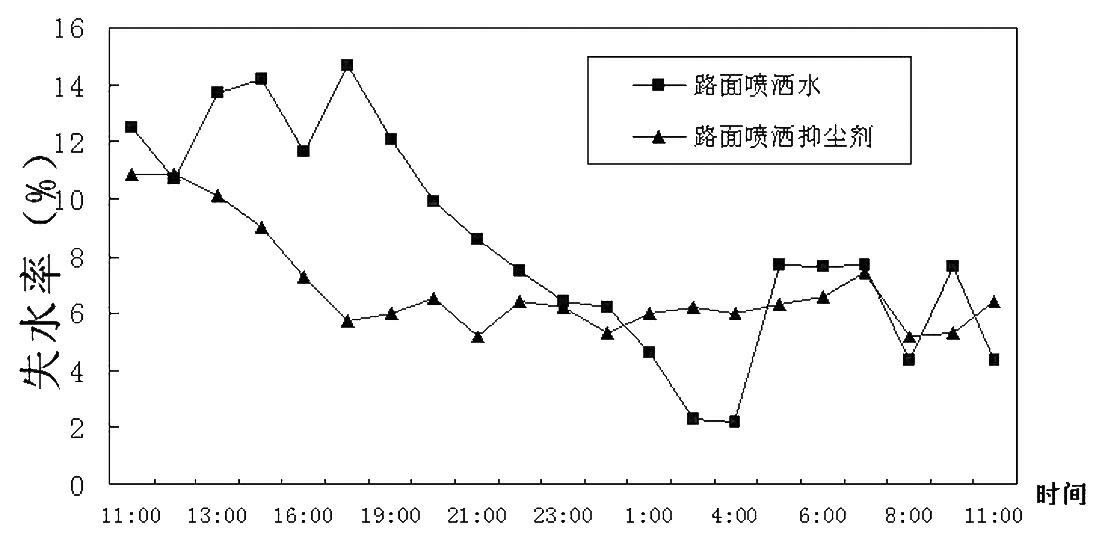

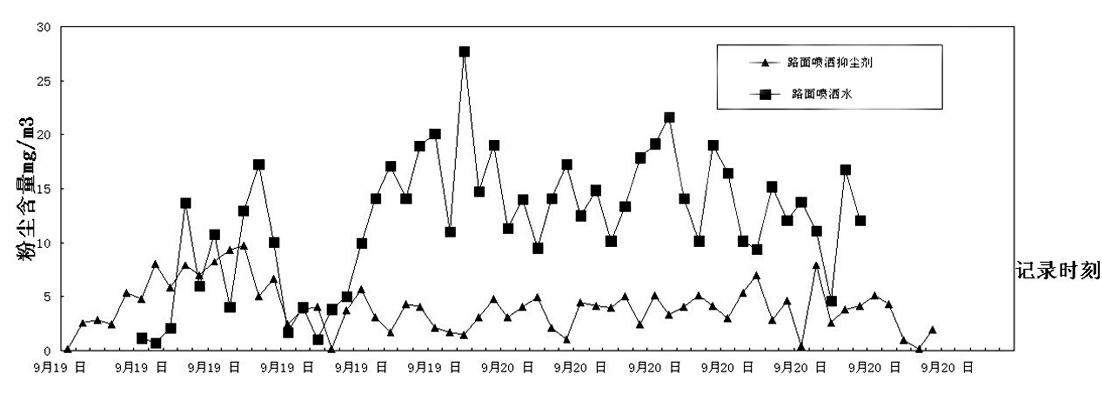

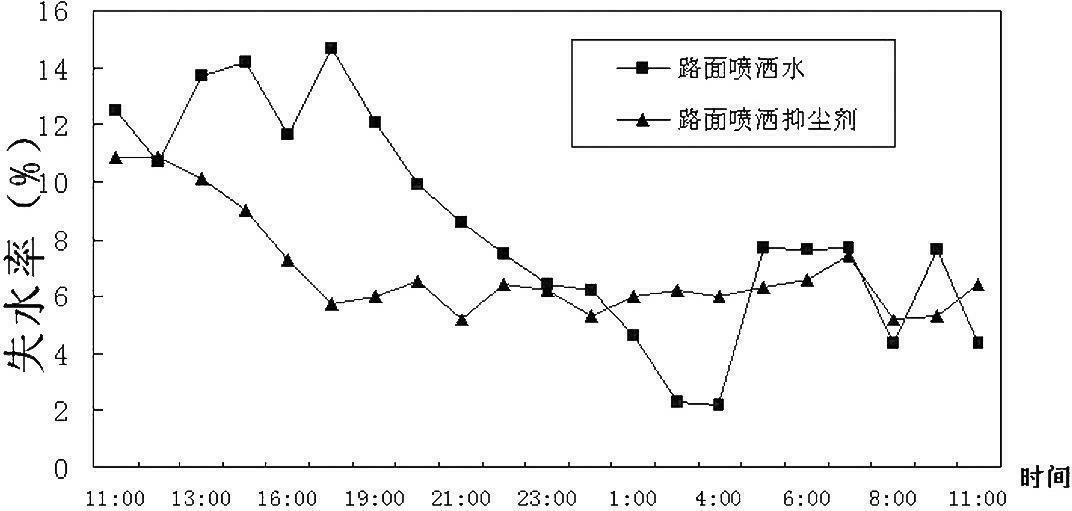

Road dust suppressant

ActiveCN102660227AStrong anti-pressure functionLarge particle sizeOther chemical processesLiquid productEvaporation

The invention discloses a road dust suppressant, which is prepared by mixing and blending 0.1-2.0% of water-soluble high molecular polymer, 20-50% of moisture absorption humectant, 1.0-5.0% of preservative, 0.5-5.0% of penetrating agent and the balance water. The road dust suppressant is a dynamic dust-proof and dust-suppressing liquid product which combines functions of wetting, bonding, permeating, adsorbing moisture and the like into a whole and has extremely strong pressurization-resistant function. The road dust suppressant has the advantages of obvious anti-evaporation performance and good water retention hygroscopicity, and dust on the road surface can be coagulated and is unlikely to fly. The road dust suppressant disclosed by the invention not only can be applied to road dust suppressing but also can be simultaneously used for the aspects, such as the mine exploration and transportation environment, storage yards of coal ash, coal and other ores, and the treatments of municipal construction earthwork dust raise.

Owner:山西兴源盛科技有限公司

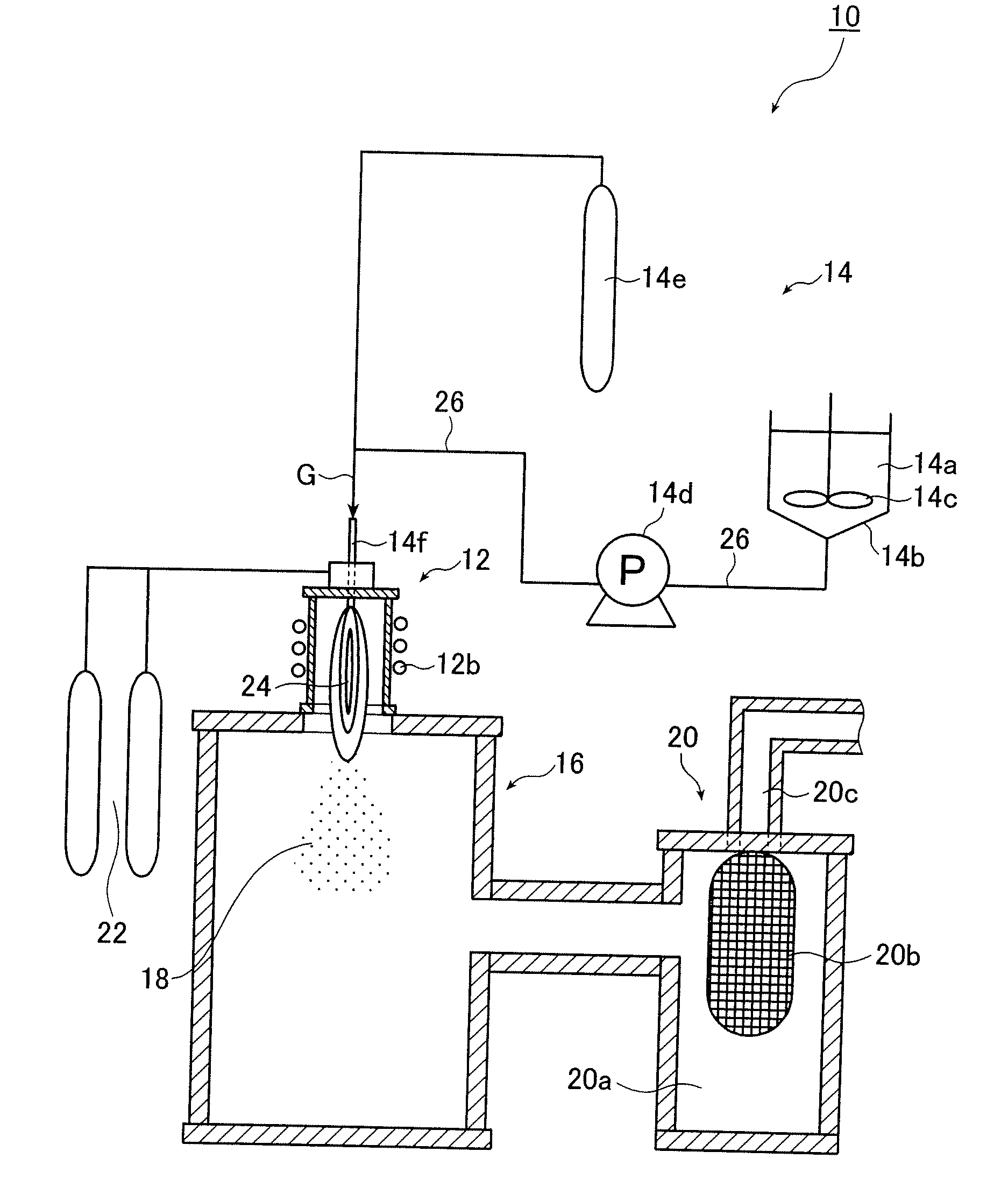

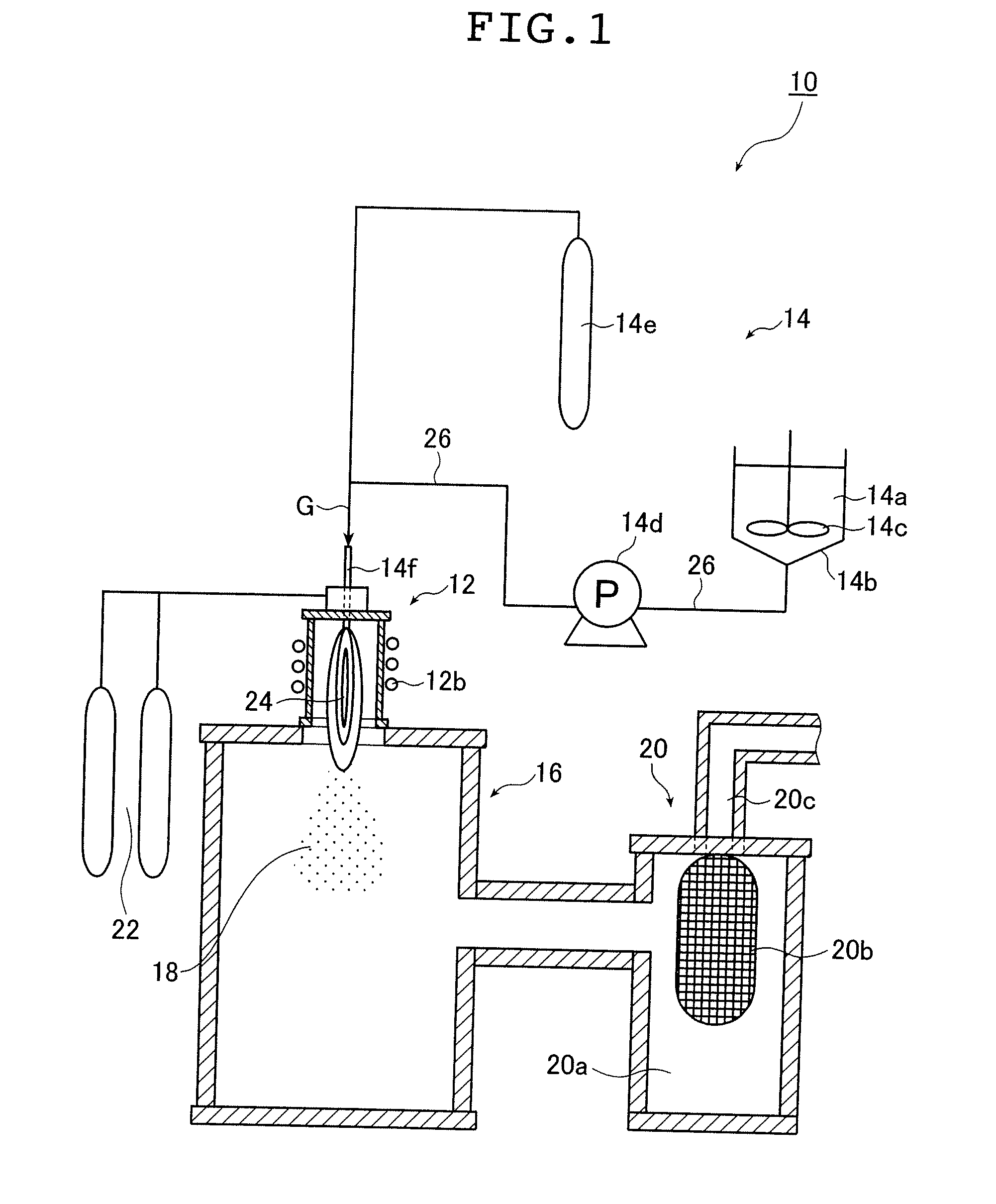

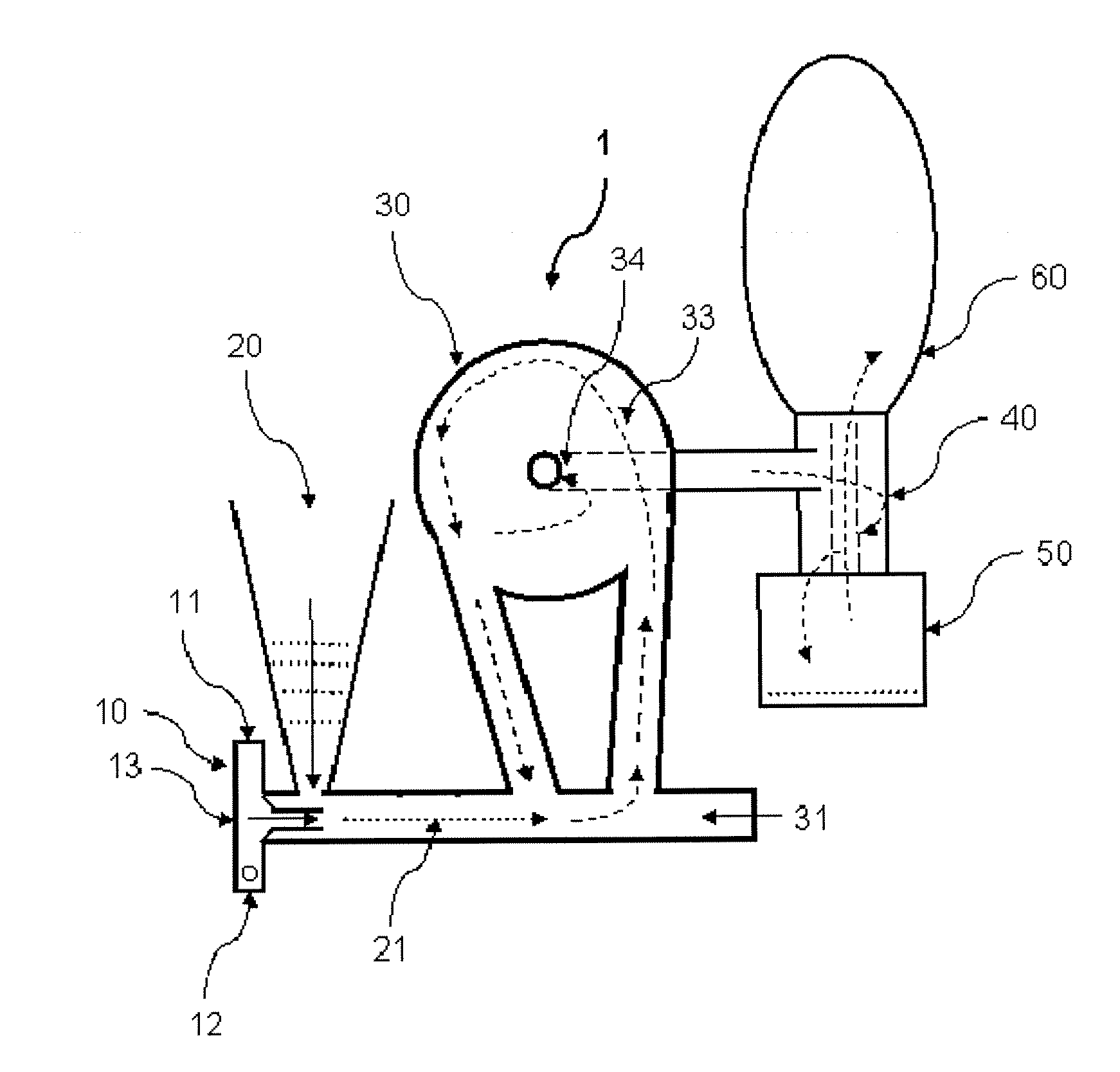

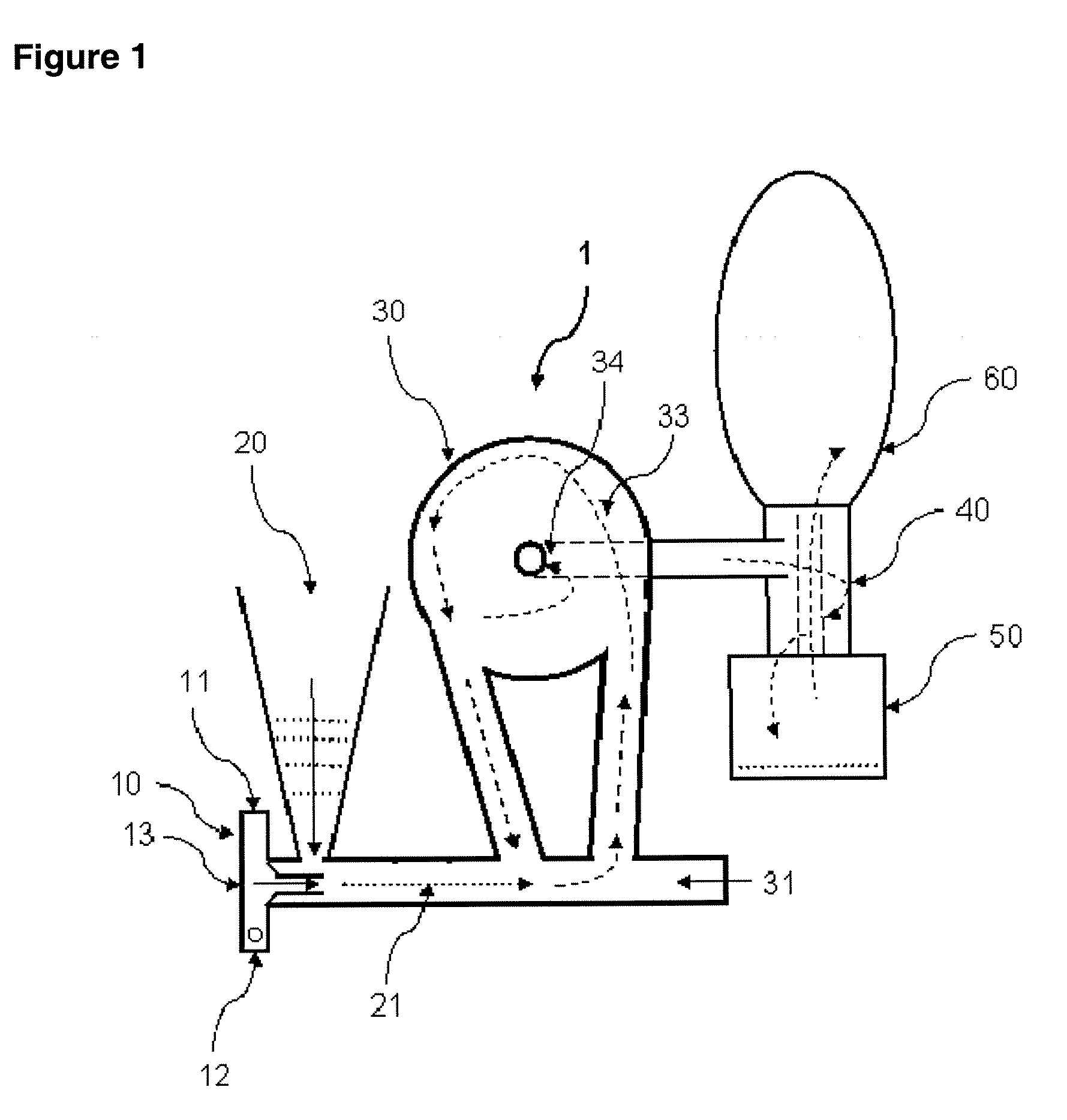

Process and Apparatus for Producing Fine Particles

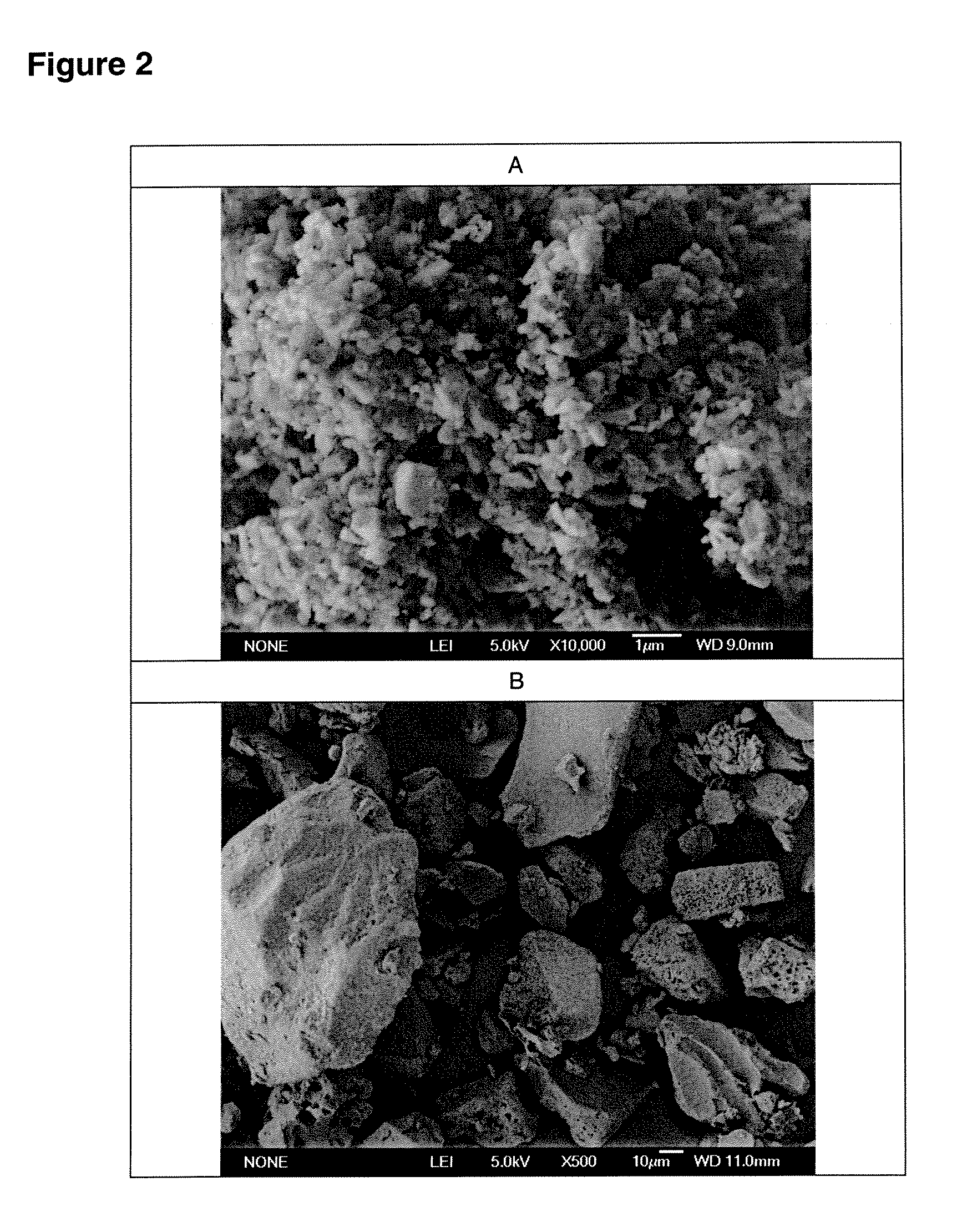

ActiveUS20080006954A1Improve productivityFunction increaseAlkaline earth titanatesMaterial nanotechnologyGas phaseSlurry

A fine particle producing process introduces a material for producing fine particles into a thermal plasma flame to make a vapor-phase mixture and quenches the vapor-phase mixture to form the fine particles. In the process, the material for producing the fine particles is dispersed or dissolved in a dispersion medium or solvent, preferably containing a combustible material to prepare a dispersion such as a slurry, a colloidal solution or a dissolution solution, the dispersion is made into a form of droplets, or the material for producing the fine particles is dispersed with a carrier gas and a combustible material and the dispersion in a droplet form or the dispersed material is introduced into the thermal plasma flame. In the fine particle producing process and apparatus, a gas of an amount sufficient to quench the vapor-phase mixture is supplied toward a tail of the thermal plasma flame. In the process and apparatus, primary fine particles are introduced into a cyclone to be subjected to cooling and classification and secondary fine particles having a particle size of 100 nm or less which are left upon removal of coarse particles are recovered.

Owner:NISSHIN SEIFUN GRP INC +1

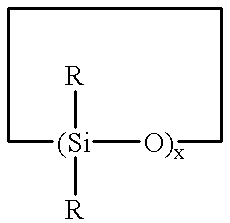

Method for making polysiloxane emulsions

A method for making oil free polysiloxane standard, fine and microemulsions using emulsion polymerization is disclosed. The method comprises reacting a cyclicsiloxane in the presence of a catalyst, ionic surfactant and nonionic surfactant within a certain operating window. Emulsions containing silicone copolymers can also be produced using the method of the instant invention.

Owner:DOW SILICONES CORP

Process for producing shrinkage-matched ceramic composites

InactiveUS6576182B1Large particle sizeHigh sintering activitySemi-permeable membranesOther chemical processesCeramic matrix compositeMetallurgy

A process for producing a composite, containing at least one shrinkage-matched ceramic layer, wherein a starting material for the ceramic layer(s) has shrinkage behavior on sintering which is matched to remaining layer(s), and which is selected such that the ceramic-forming constituent of the same contains at least one ceramic powder of a specific size, and which process entails joining the layers of the composite by sintering.

Owner:NASS RUEDIGER

Devices and methods for enrichment and alteration of circulating tumor cells and other particles

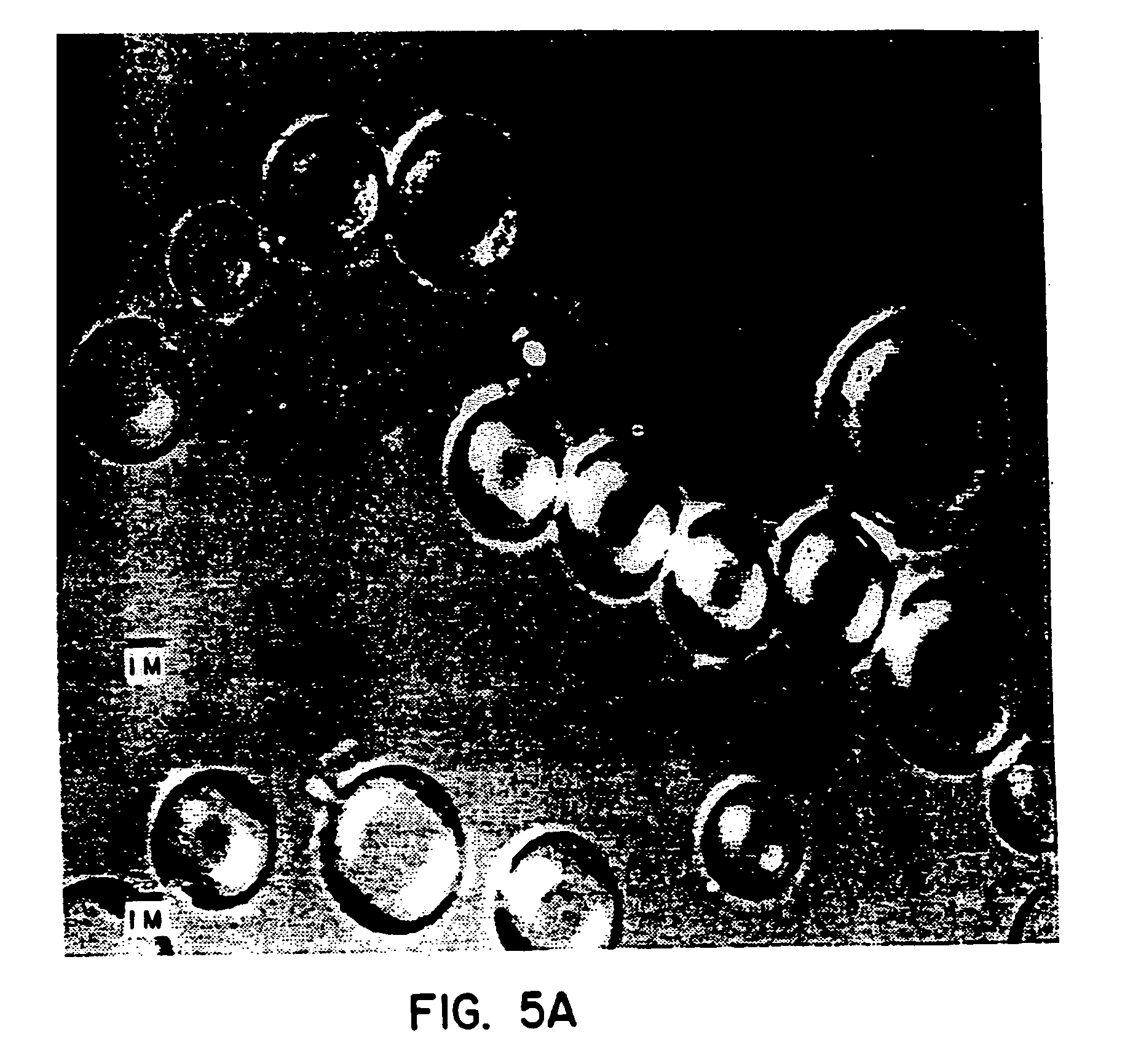

InactiveUS20070026414A1Small particle sizeLower the volumeBioreactor/fermenter combinationsBiological substance pretreatmentsCirculating cancer cellTumor cells

The invention features devices and methods for detecting, enriching, and analyzing circulating tumor cells and other particles. The invention further features methods of diagnosing a condition, e.g., cancer, in a subject by analyzing a cellular sample from the subject.

Owner:THE GENERAL HOSPITAL CORP +2

Method of soft tissue augmentation

InactiveUS20050226936A1Prevents and diminishes migrationPrevents and diminishes migration and displacementPowder deliveryDrug compositionsSalt solutionBiomedical engineering

Particles according to the invention are made of a viscoelastic medium, are injectable gel particles, and have a size, when subjected to a physiological salt solution, in the range of from 1 to 5 mm. The particles are useful in a soft tissue augmentation implant. The implant comprises particles of a viscoelastic medium, wherein a major volume of the particles are injectable gel particles according to the invention. The implant is useful in a method of soft tissue augmentation in a mammal, including man, comprising subepidermal administration at a site in said mammal where soft tissue augmentation is desirable, of an implant according to the invention.

Owner:Q MED AB

Ultrasound imaging and treatment

InactiveUS7078015B2Low costSuitable for useUltrasonic/sonic/infrasonic diagnosticsCosmetic preparationsSound energyUltrasonic imaging

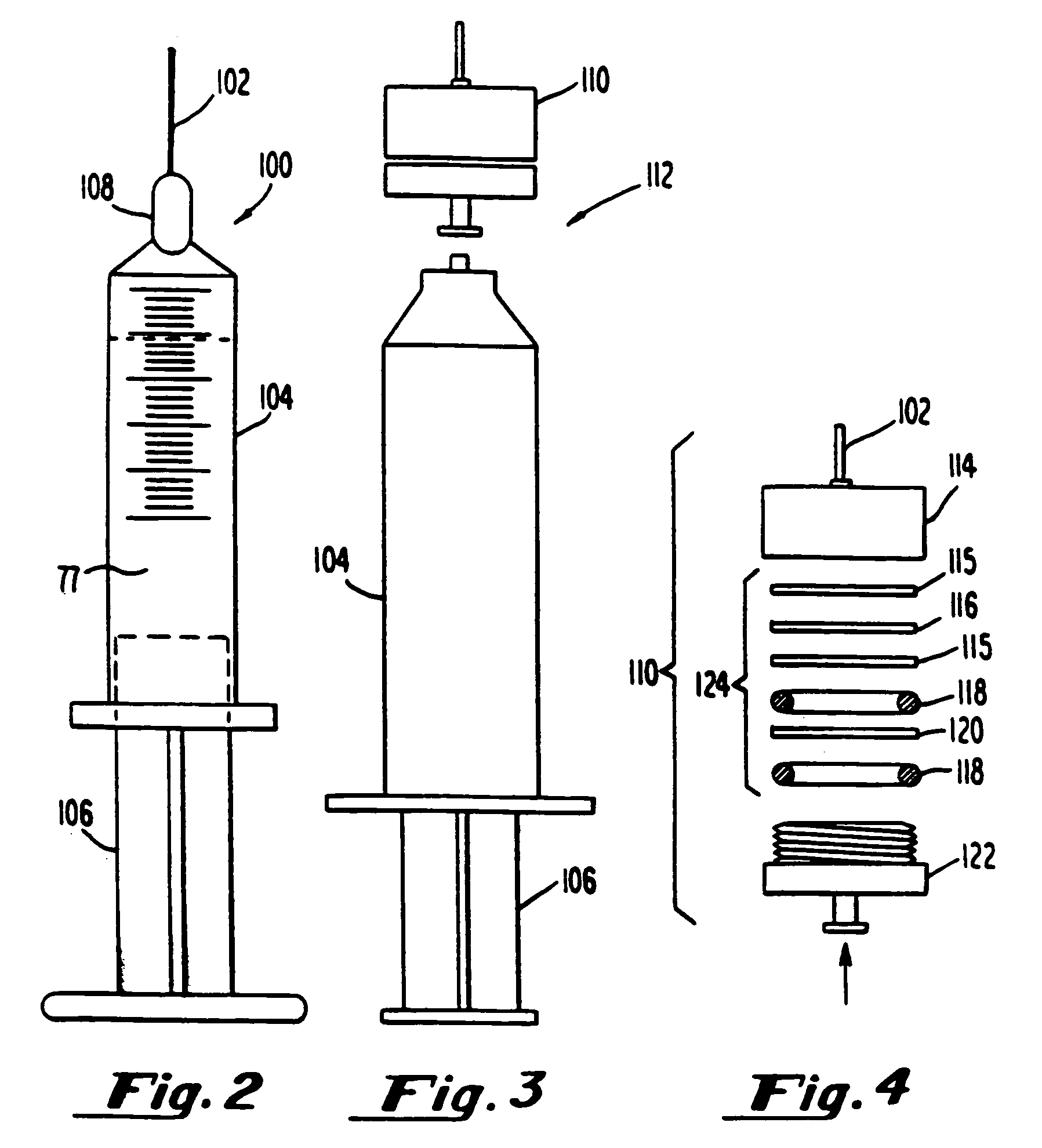

Methods of and apparatus for preparing temperature activated gaseous precursor-filled liposomes are described. Gaseous precursor-filled liposomes prepared by these methods are particularly usefull for example, in ultrasonic imaging applications and in therapeutic drug delivery systems.Gas, gaseous precursors and perfluorocarbons are presented as novel potentiators for ultrasonic hyper-thermia. The gas, gaseous precursors and perfluorocarbons which may be administered into the vasculature, interstitially or into any body cavity are designed to accumulate in cancerous and diseased tissues. When therapeutic ultrasonic energy is applied to the diseased region heating is increased because of the greater effectiveness of sound energy absorption caused by these agents.

Owner:IMARX THERAPEUTICS

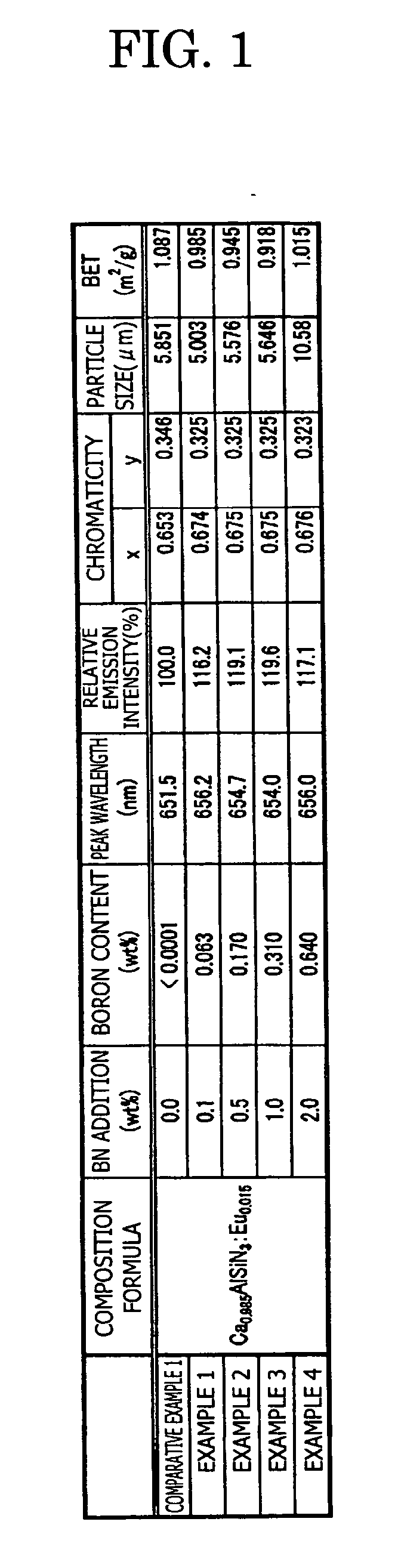

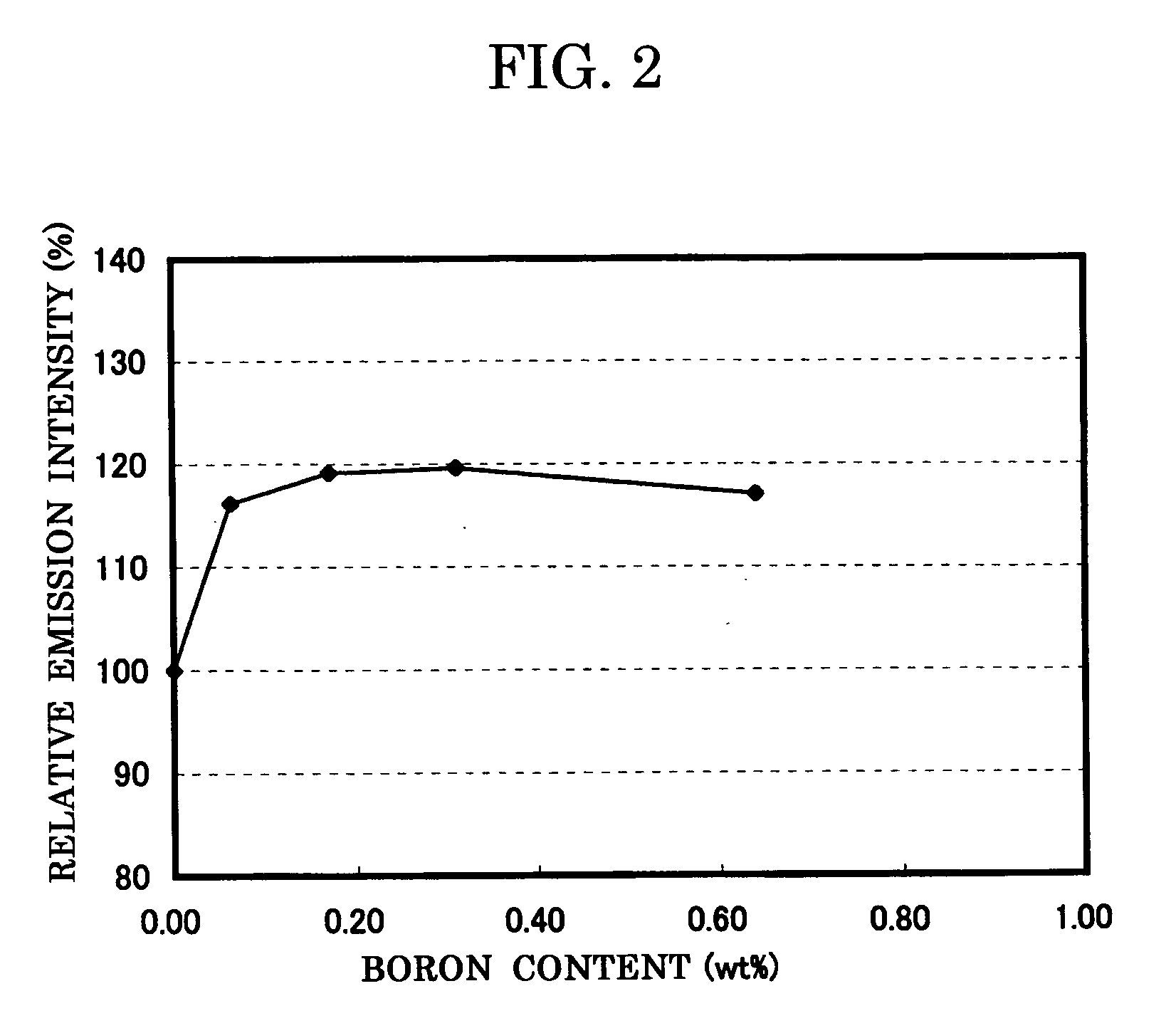

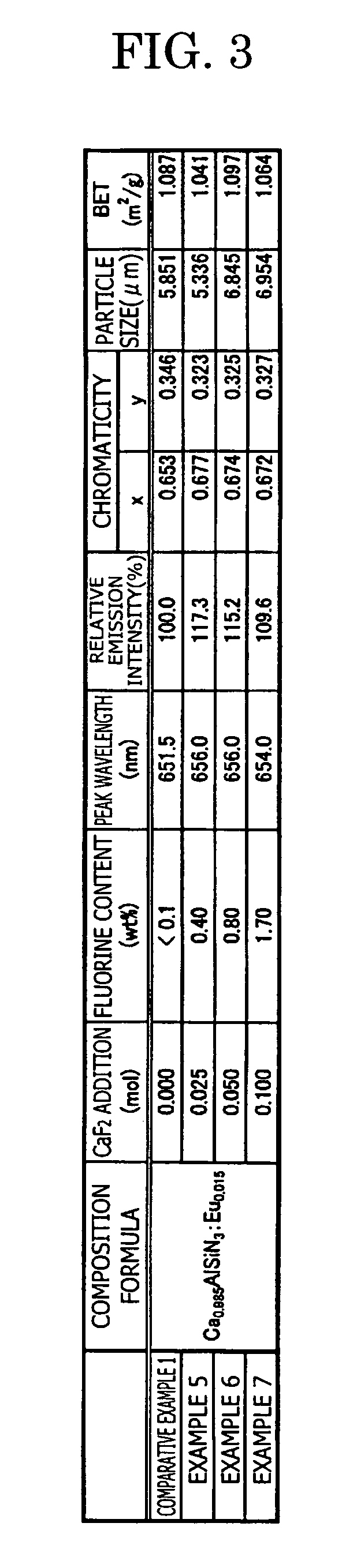

Phosphor and manufacturing method for the same, and light source

ActiveUS20060065878A1Improve emission efficiencyImprove efficiencySynthetic resin layered productsCellulosic plastic layered productsRare-earth elementUltraviolet

To provide a phosphor having an emission spectrum with a broad peak in a range from yellow color to red color (580 nm to 680 nm) and an excellent excitation band on the longer wavelength side from near ultraviolet / ultraviolet of excitation light to visible light (250 nm to 550 nm), and having an improved emission intensity. The phosphor is provided, which is given by a general composition formula expressed by MmAaBbOoNn:Z, (wherein element M is more than one kind of element having bivalent valency, element A is more than one kind of element having tervalent valency selected from the group consisting of Al, Ga, In, Tl, Y, Sc, P, As, Sb, and Bi, element B is more than one kind of element having tetravalent valency, O is oxygen, N is nitrogen, and element Z is more than one kind of element selected from rare earth elements or transitional metal elements, satisfying m>0, a>0, b>0 o≧0, and n=2 / 3m+a+4 / 3b−2 / 3o), and further containing boron and / or fluorine.

Owner:CITIZEN ELECTRONICS CO LTD +1

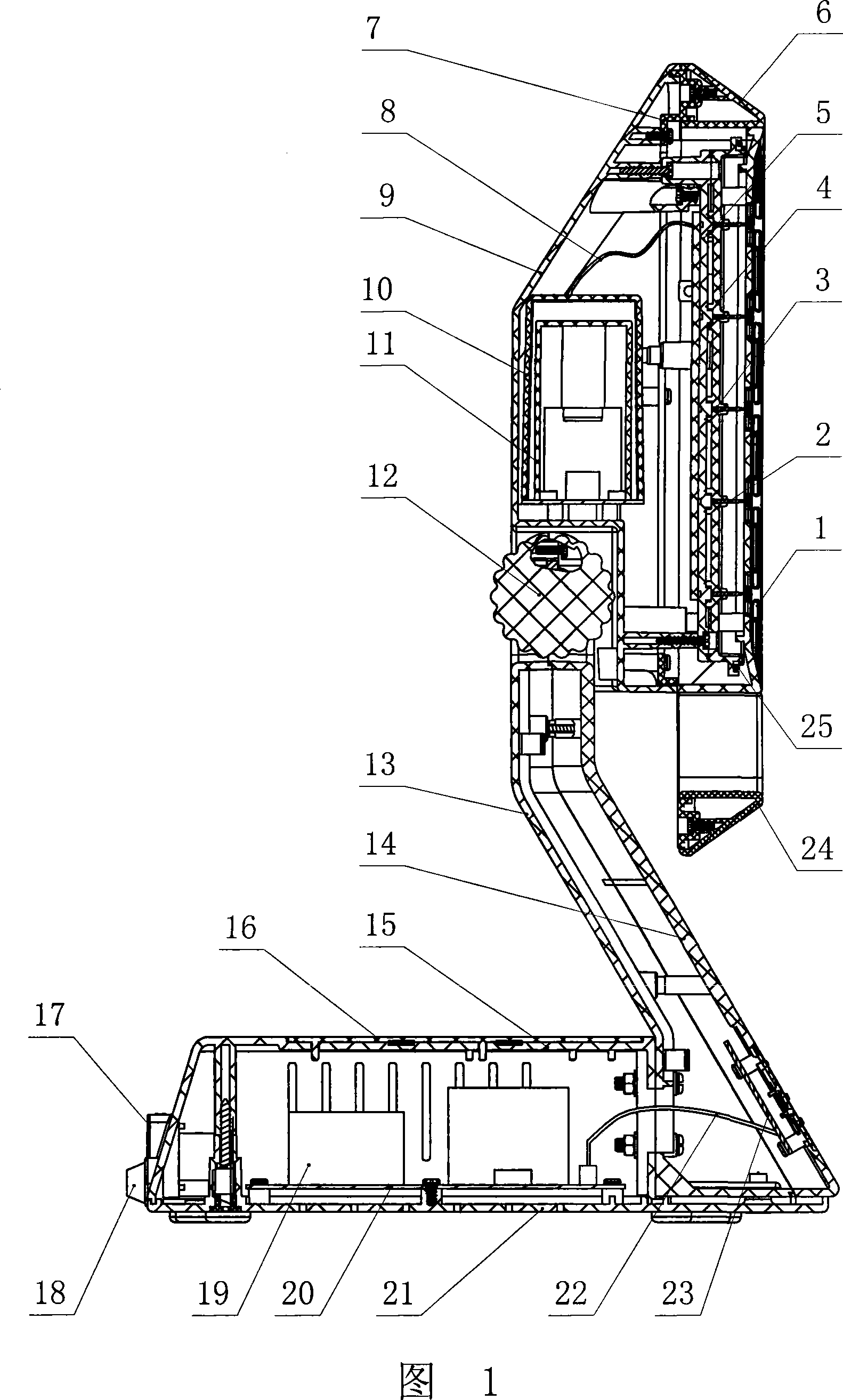

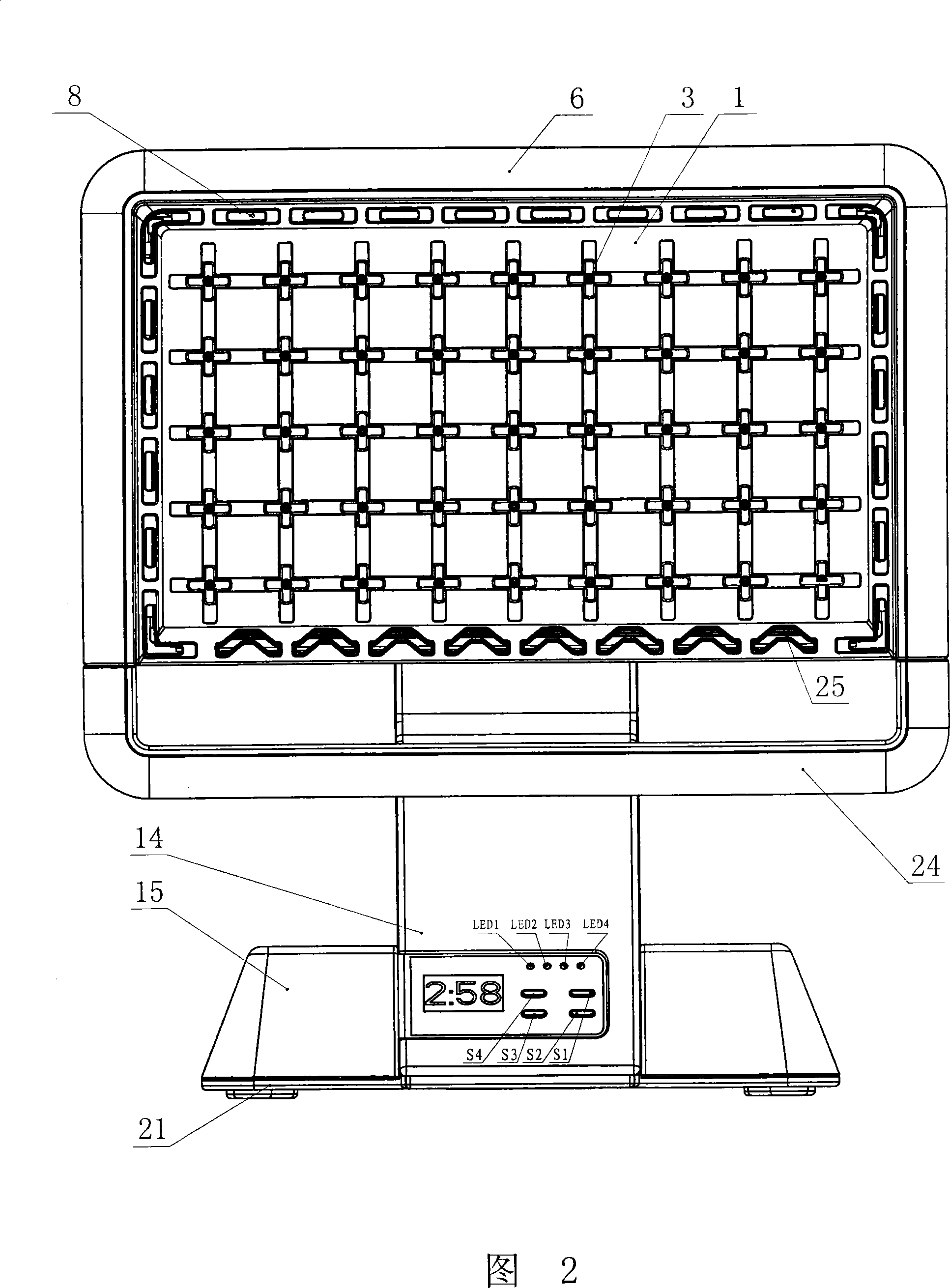

Negative ion generating device

ActiveCN101214390AQuality improvementLarge particle sizeDeodrantsCorona dischargeFiberHigh concentration

An anion generator includes a base and a shell assembled on the base, needle stripes of homopolar spray points vertically lined with equal spacing fixed between a partition plate and a window grating, and a control circuit. The technical proposal is that the shell consists of a rear shell and a front shell; the window grating is moveably connected with the rear shell; the homopolar tungsten alloy spray points vertically lined with equal spacing are fixed between the needle stripes and press plates through the one-off sealing and packaging technique; the carbide fibre fixed on the needle stripes is communicated with the small high voltage blocks; a closed carbide fibre ring is arranged in a circular slot on the circumference of the needle stripes; the high voltage block assembly components fixed in the shell are sealed and packaged in a shield screen; the base and the shell are hinged together by a rotary positioning device. The invention has the advantages of reasonable structure design, convenience in adjustment and positioning, good transmission direction of the anion, high concentration and small grain size of the generated anion, large output quantity within unit time and obvious improvement of the air quality, thus obviously improving the curative effect of diseases and the air purification efficiency, and obviously extending the service life.

Owner:柏学红

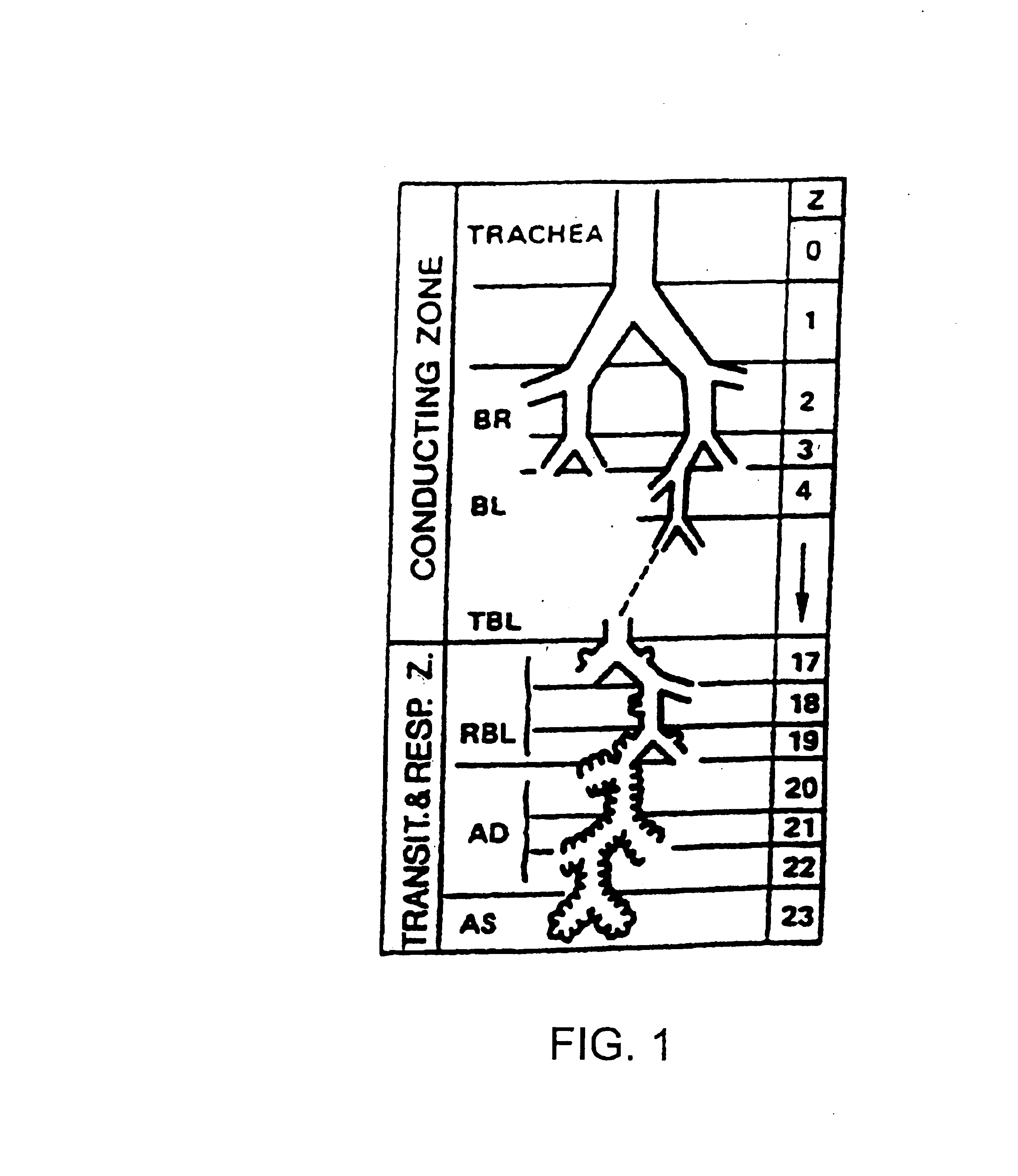

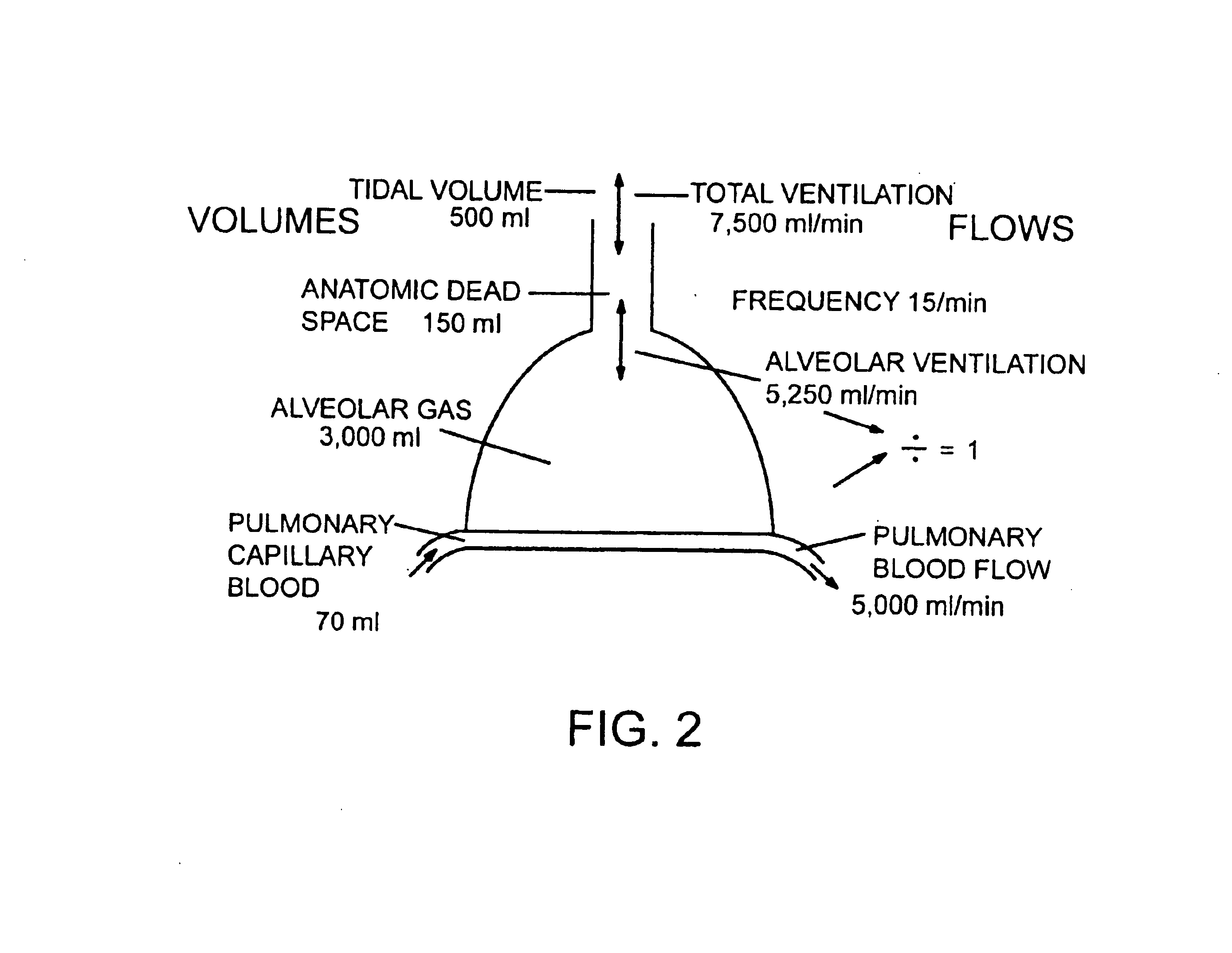

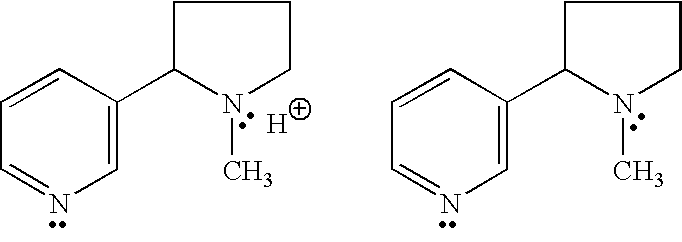

System for effecting smoking cessation

InactiveUS6874507B2Improve the level ofLarge particle sizeRespiratorsMedical devicesHigh concentrationSmoking cessation

A system is disclosed which makes it possible for a patient to be delivered gradually reduced amounts of nicotine over time thereby allowing the patient to be gradually weaned off of dependence on nicotine and quit smoking. The system is comprised of a means for aerosolizing a formulation and containers of formulation. The formulation is comprised of nicotine in a pharmaceutically acceptable carrier. Preferably, a plurality of containers are produced wherein the concentration of nicotine in the different containers or different groups of containers is reduced. The patient uses containers with the highest concentration initially and gradually moves towards using containers with lower and lower concentrations of nicotine until the patient's dependence on nicotine is eliminated.

Owner:ARADIGM

Spherical catalyst for olefin polymerization

InactiveUS7135531B2Large particle sizeOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyolefinPolymer science

Disclosed are catalyst systems and methods of making the catalyst systems / supports for the polymerization of an olefin containing a solid titanium catalyst component having a substantially spherical shape and containing an internal electron donor, a support made from a magnesium compound, an alcohol, an ether, a surfactant, and an alkyl silicate. The catalyst system may further contain an organoaluminum compound and an organosilicon compound. Also disclosed are methods of making an impact copolymer involving polymerizing an olefin to provide a polyolefin matrix and polymerizing a polyolefin rubber using a catalyst component containing a support made from a magnesium compound, an alcohol, an ether, a surfactant, and an alkyl silicate.

Owner:ENGELHARD CORP

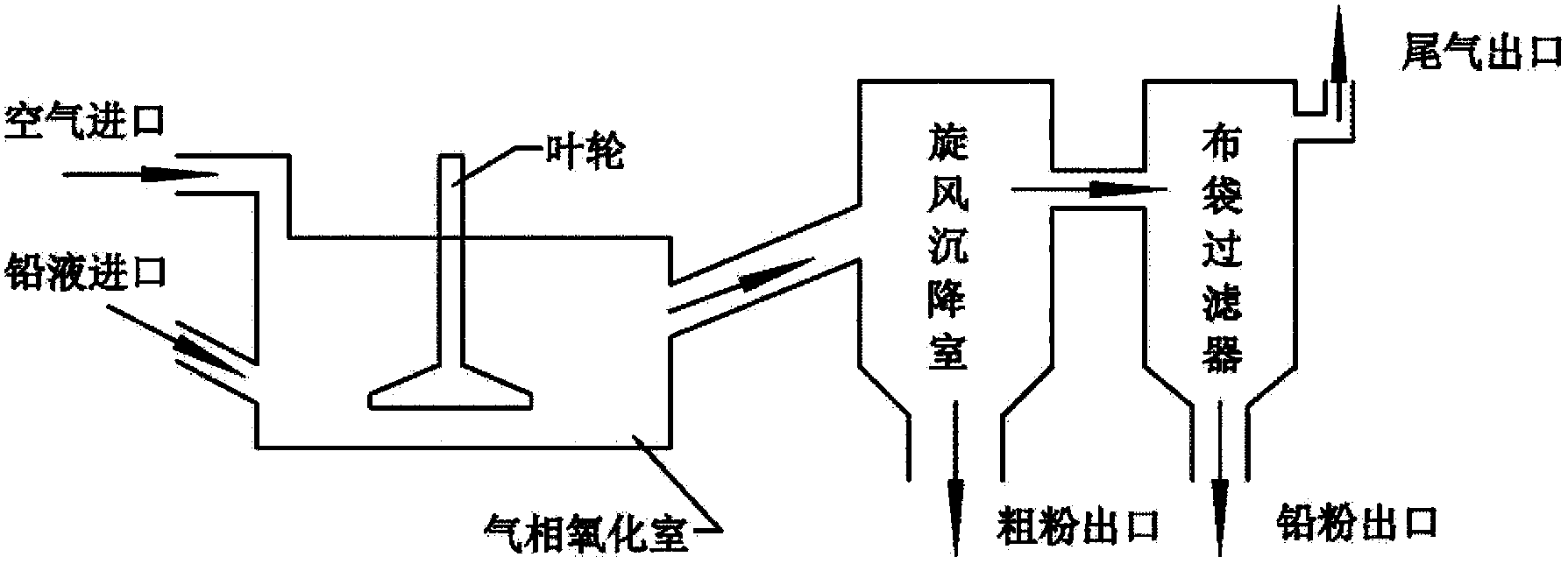

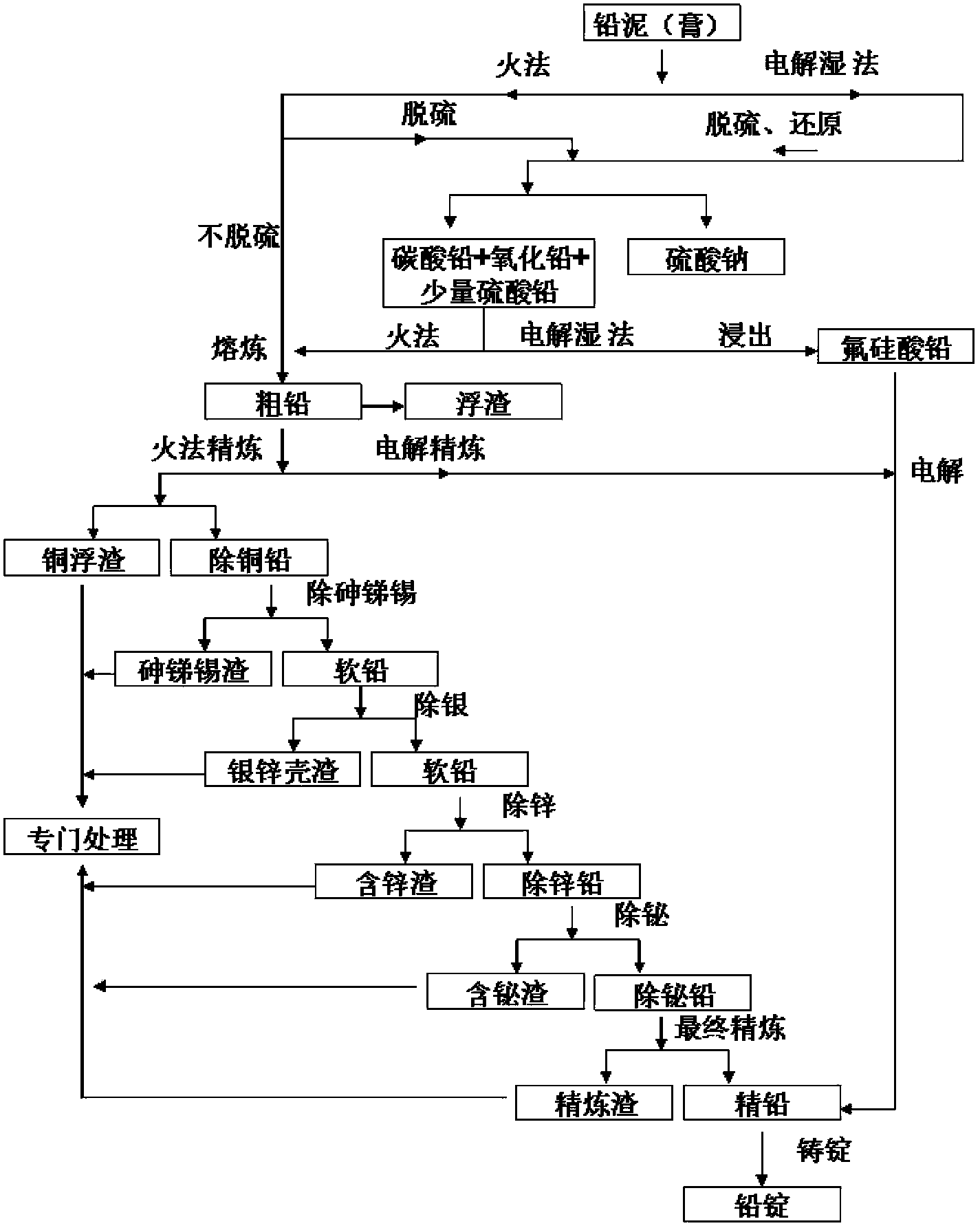

Methods and equipment for recovering waste diachylon by wet method and manufacturing electrode active material of high performance lead acid battery by wet method

ActiveCN103509949AIncrease profitLarge particle sizeWaste accumulators reclaimingProcess efficiency improvementElectrical batteryEngineering

The invention discloses methods and equipment for recovering waste diachylon by a wet method and manufacturing an electrode active substance material of a high performance lead acid battery by the wet method. The equipment comprises device required for a technology process by a chemical method, a chemical machinery method or an electrochemical machinery method. The active substance material provided by the invention can substantially raises an utilization rate of the active substance of the lead acid battery, specific energy of the battery and charging capability of the battery, simultaneously avoids generation and discharge of harmful substances such as lead gas, lead smoke, lead dust and SO2, raises a lead utilization rate in a production process, is beneficial for treating and recycling lead compounds and lead-containing liquid generated in a lead gas recovering process in a plate casting or welding technology, and reduces cost.

Owner:杨春晓

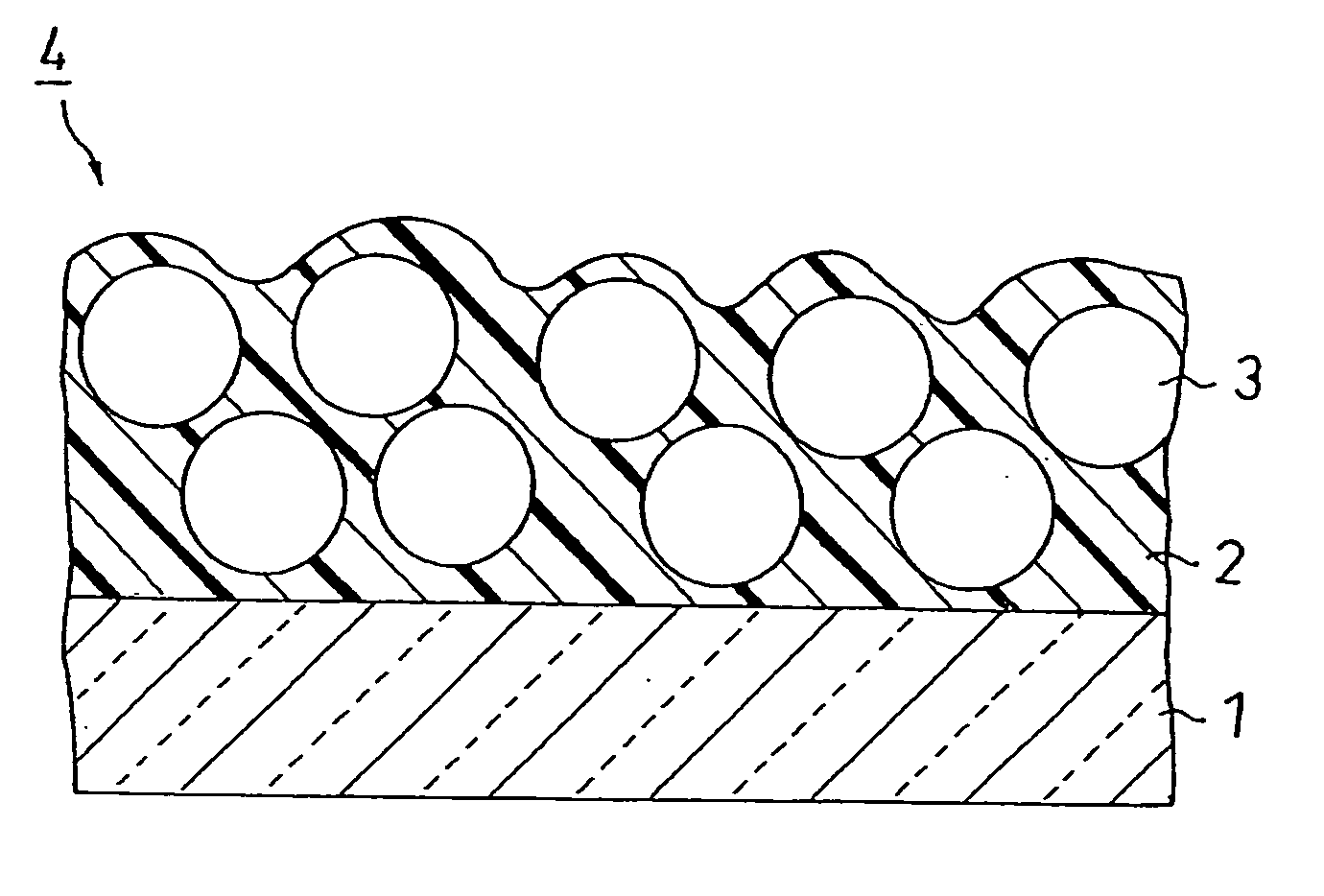

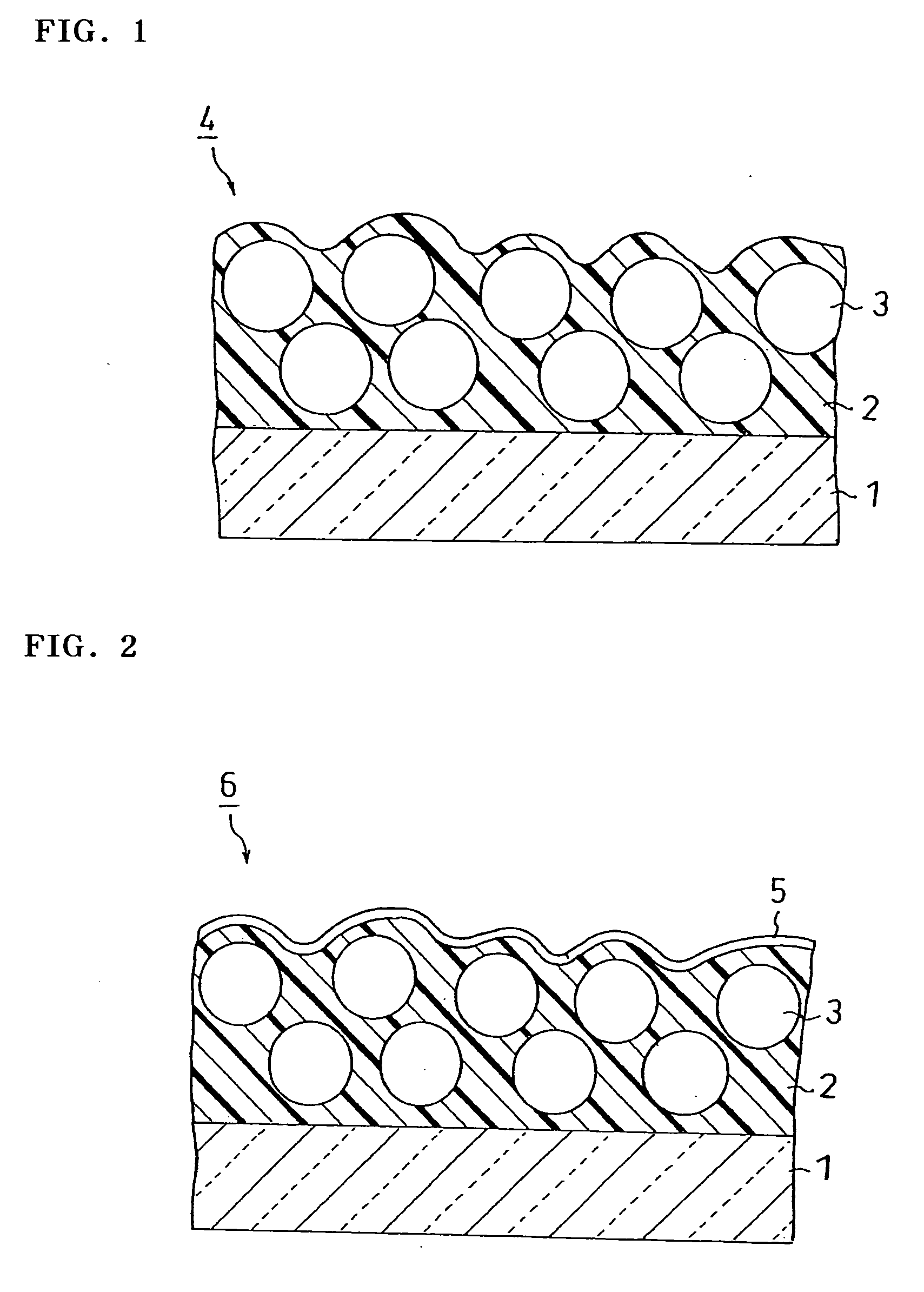

Hard-coated antiglare film and method of manufacturing the same

InactiveUS20060132922A1High hardnessGood anti-glare effectPolarising elementsCoatingsDisplay deviceHardness

There are provided a hard-coated antiglare film with high hardness, high scratch resistance and good antiglare properties, a method of manufacturing the film, an optical element using the film, and an image display including the film or the optical element. The hard-coated antiglare film of the invention includes a transparent film substrate and a hard-coating layer that contains fine particles and is formed on at least one side of the transparent film substrate, wherein the hard-coating layer has a thickness of 15 μm to 30 μm, the fine particles have an average particle size of 30% to 75% of the thickness of the hard-coating layer, and the fine particles form unevenness with a θa value of 0.4° to 1.5° according to JIS B 0601.

Owner:NITTO DENKO CORP

Method and apparatus for forming nano-particles

ActiveUS7282167B2Reduce flow turbulenceLarge particle sizeMaterial nanotechnologyTransportation and packagingMetallurgyCooling fluid

Nano-scale particles of materials can be produced by vaporizing the material and allowing the material to flow in a non-violently turbulent manner into thermal communication with a cooling fluid, thereby forming small particles of the material that can be in the nano-scale size range.

Owner:VIVAKOR INC +1

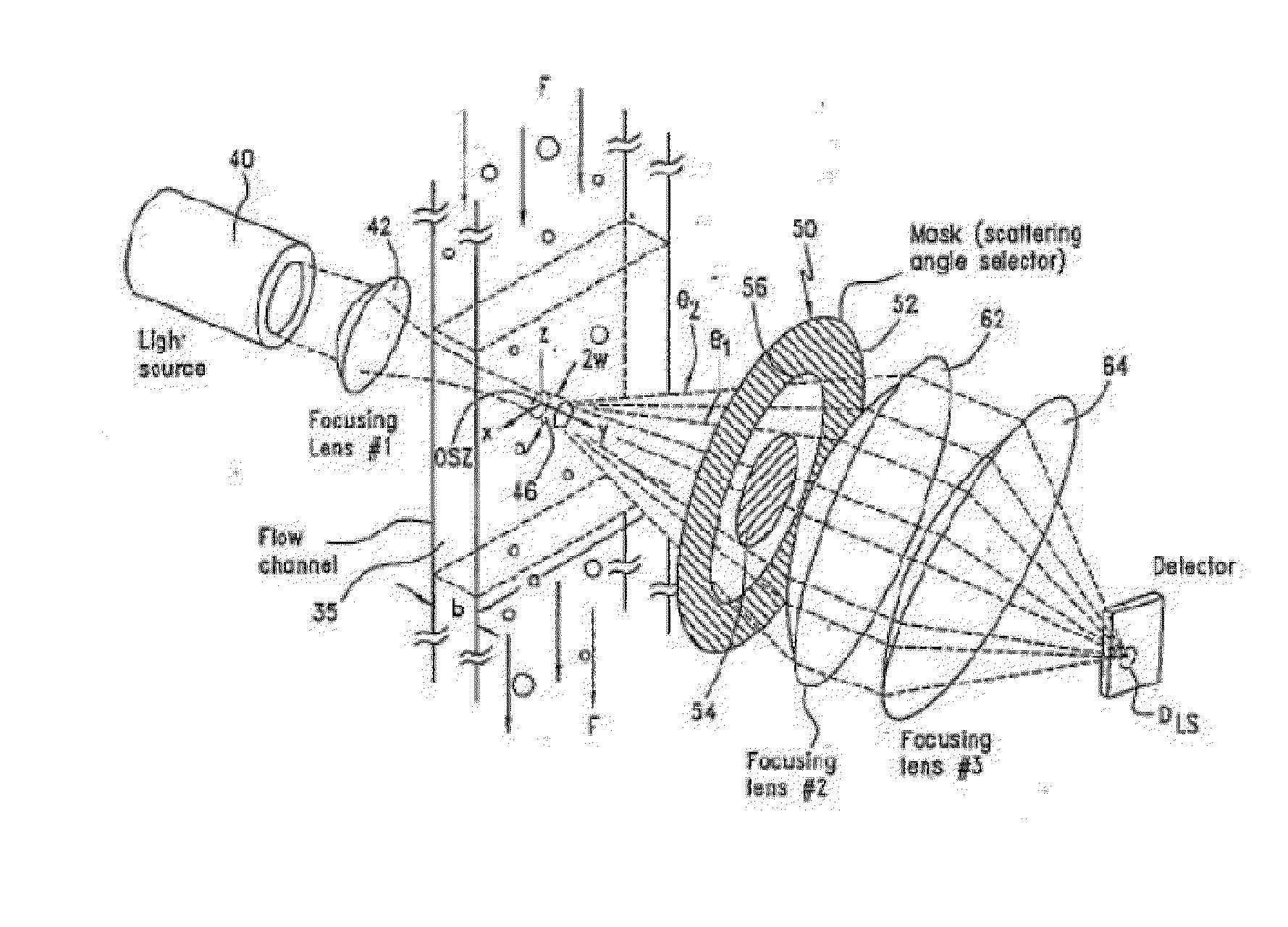

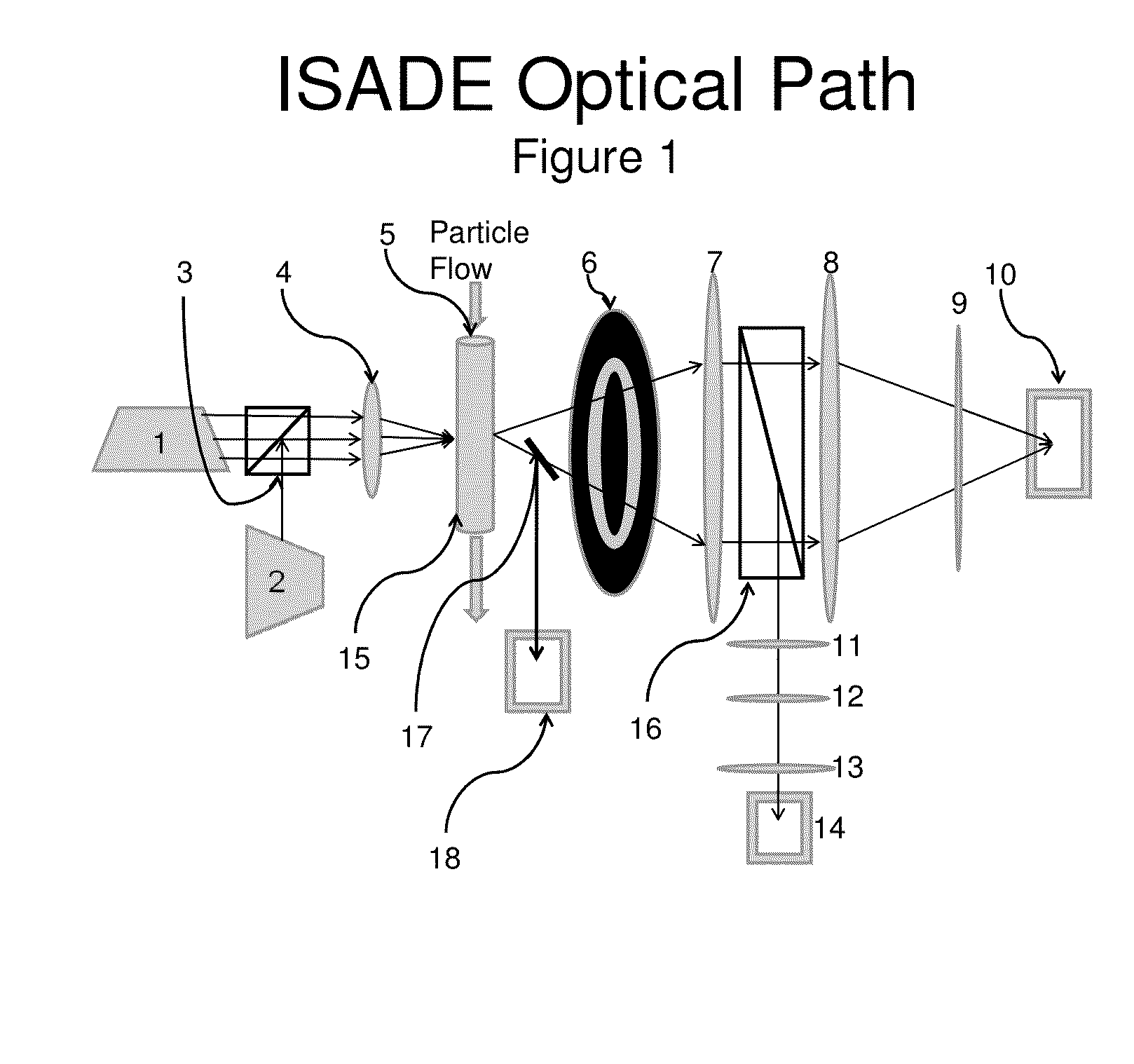

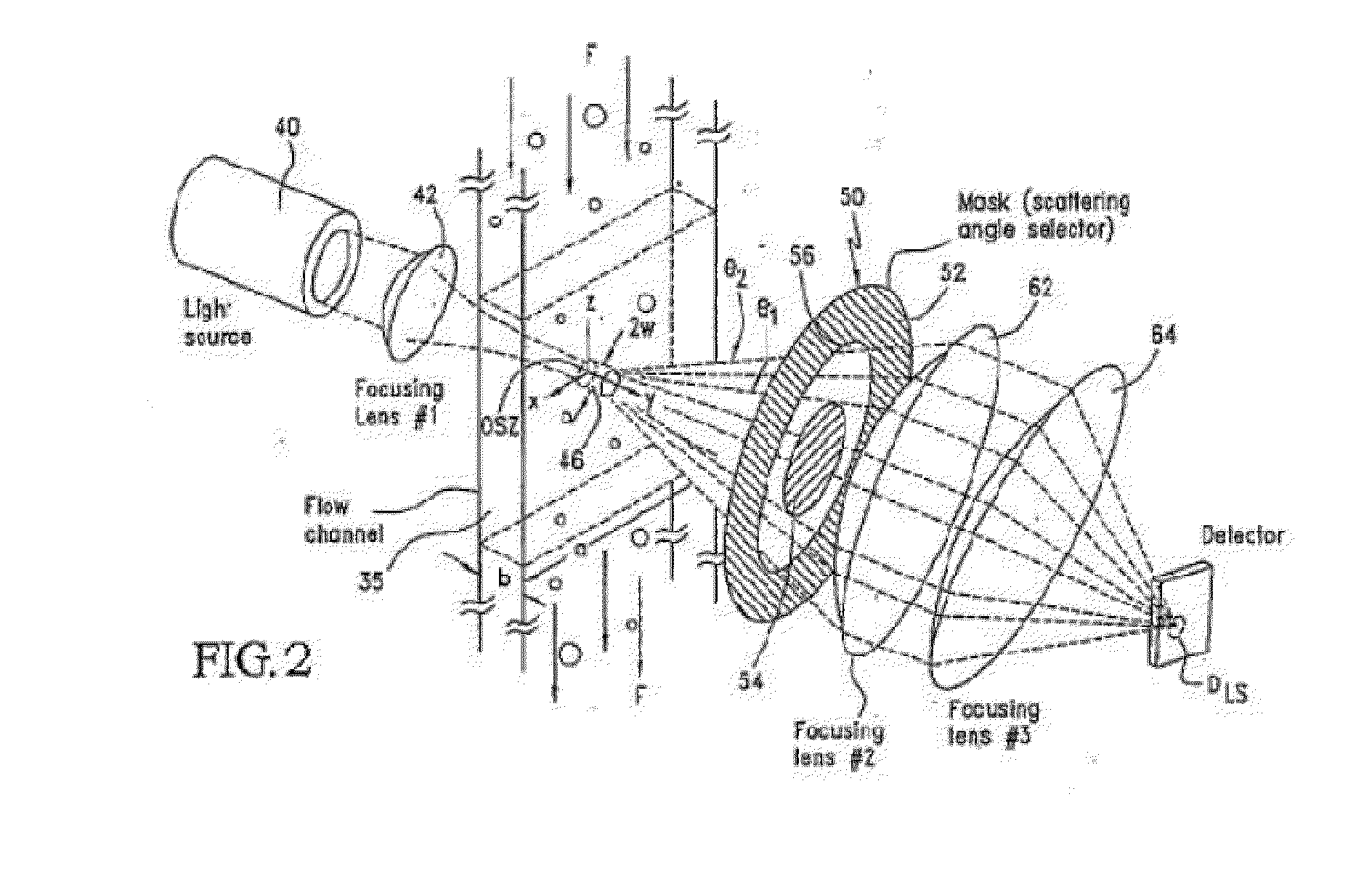

Instrument and method for optical particle sensing

ActiveUS20140234865A1Narrow size distributionConsistent amountCompound screeningApoptosis detectionFlow cellFluorescence

Devices for detecting particle sizes and distributions using focused light scattering techniques, by passing a sample through a focused beam of light, are disclosed. In one embodiment, the devices include one or more lasers, whose light is focused into a narrow beam and into a flow cell, and dispersions are passed through the flow cell using hydrodynamic sample injection. In another embodiment, a plurality of lasers is used, optionally with hydrodynamic sample injection. Particles pass through and scatter the light. The scattered light is then detected using scatter and extinction detectors, and, optionally, fluorescence detectors, and the number and size of the particles is determined. Particles in the size range of 0.1 to 10 μm can be measured. Using the device, significantly smaller particles can be detected than if techniques such as EQELS, flow cytometry, and other conventional devices for measuring biological particles.

Owner:INVITROX

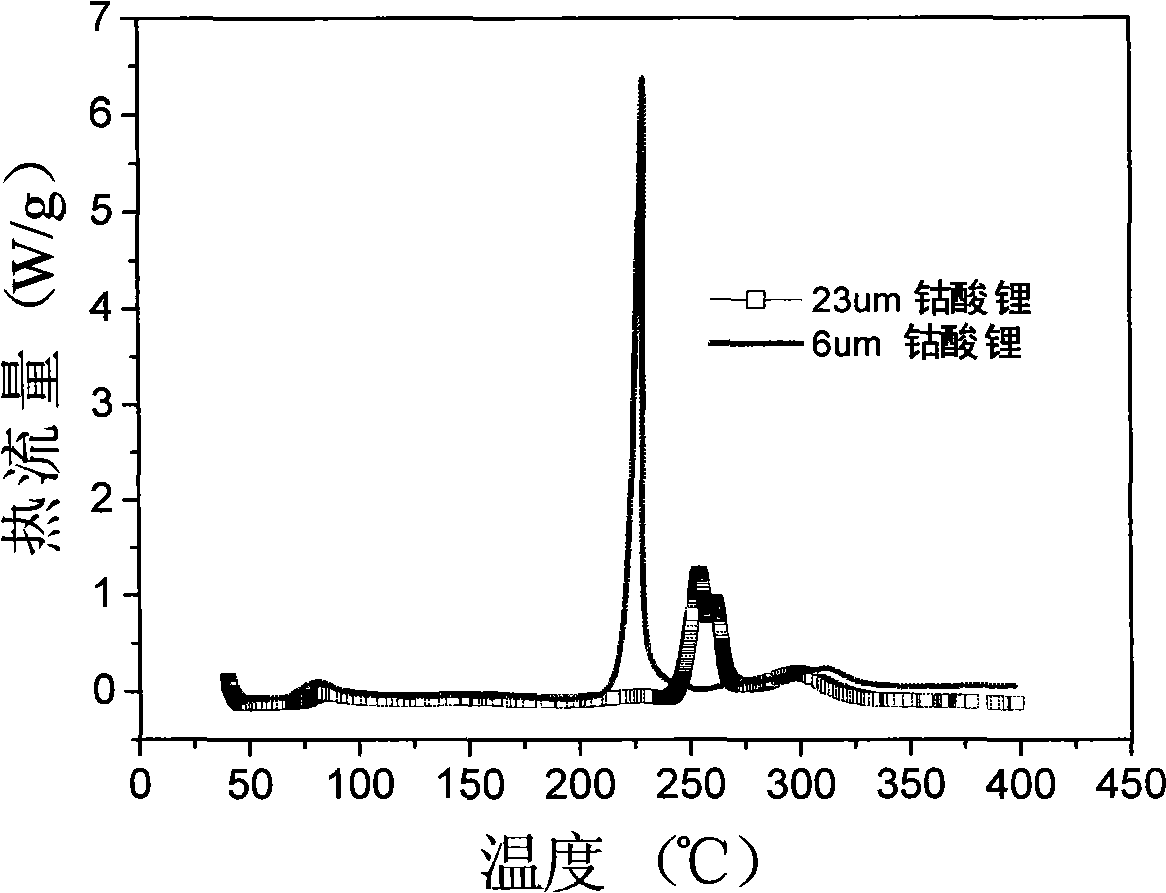

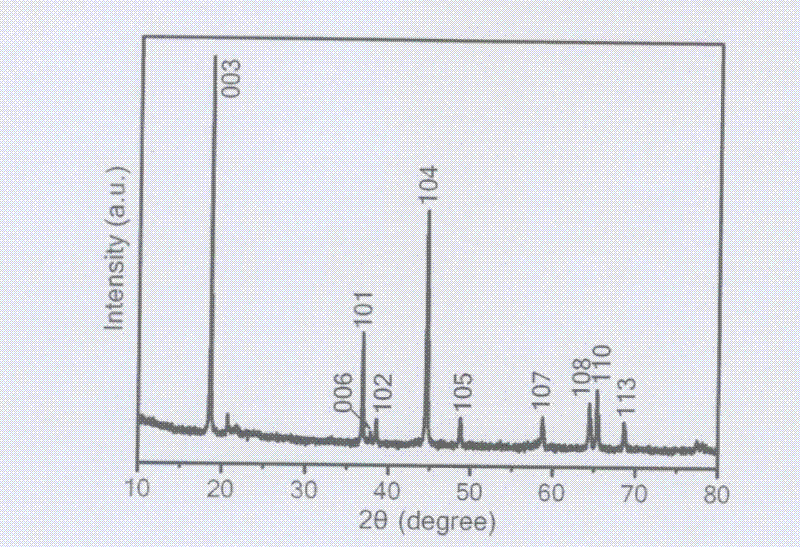

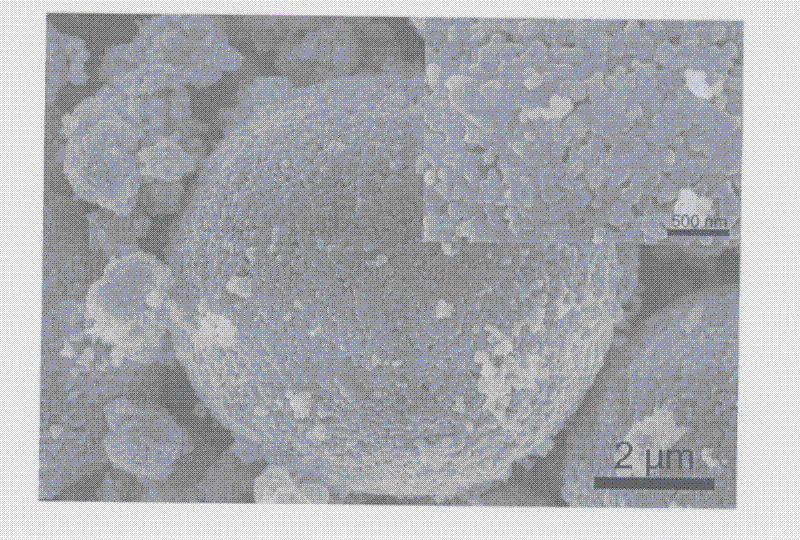

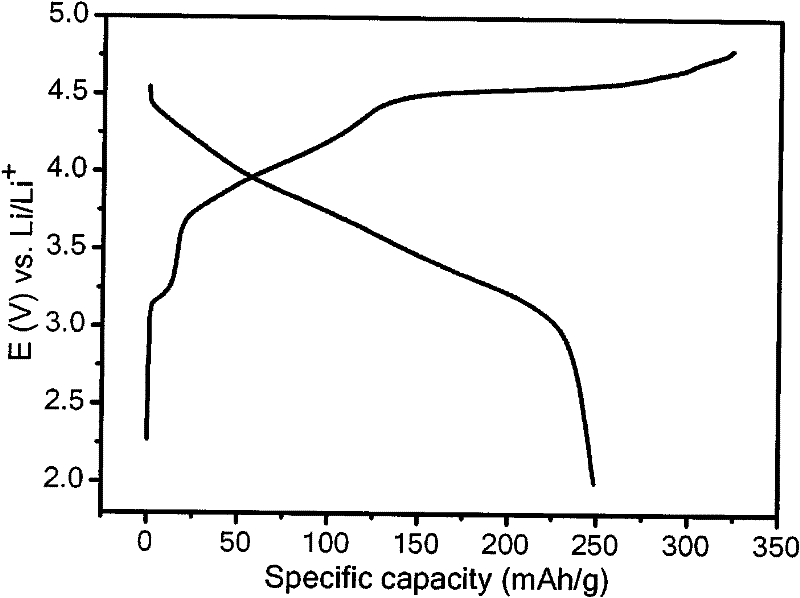

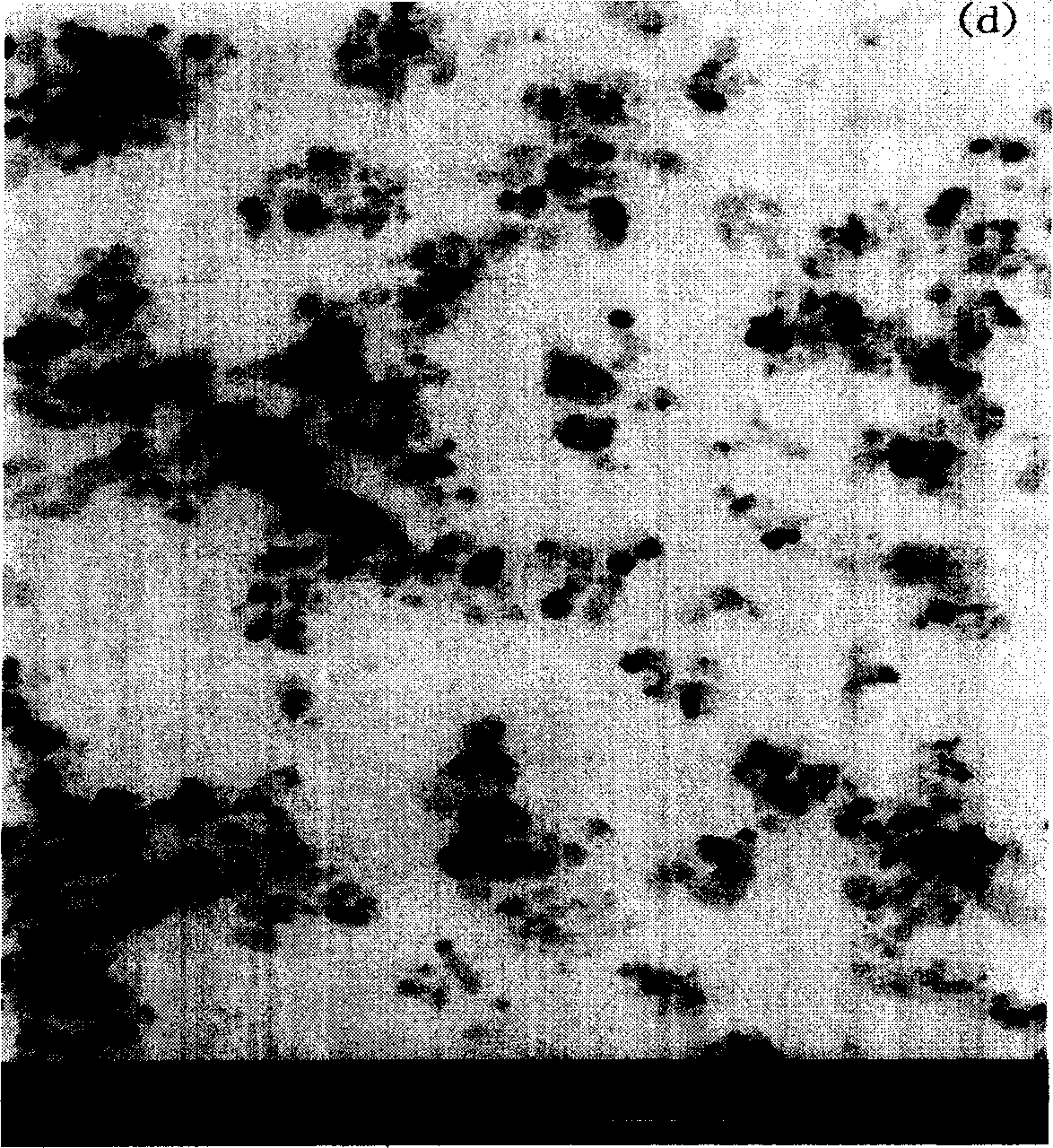

Super-size and high-density lithium cobalt oxide and method for preparing the same

ActiveCN101284681ALarge particle sizeHigh tap densityCell electrodesLithium compoundsHigh densityThermal impact

The invention relates to a high-density lithium cobalt oxide power material with a super-large grain diameter. The method comprises the steps of mixing a cobalt compound, a lithium compound or meanwhile a small amount of doping element compounds; sintering for 3 to 30 hours at the high temperature of 950 to 1,100 DEG C to form a block sintered product; crushing and grading the product to obtain the lithium cobalt oxide power material (molecular formula is LiaCo1-bMbO2), wherein, when b is not equal to 0, the middle diameter of the lithium cobalt oxide containing the doping elements is larger than or equal to 15 Mum, and the tap density is higher than or equal to 2.5g / cm<3>; when b is equal to 0, the middle diameter of the lithium cobalt oxide without the doping elements is larger than 20 Mum, and the tap density is higher than or equal to 2.6g / cm<3>. the 3.6V platform capacity rate of the material as the anode active substance for a lithium battery is higher than or equal to 75%; in the thermal impact test in a 150 DEG C thermotank, the lithium battery with the material is free from leakage and does not catch fire or explode for 60 minutes; the 1C5A specific capacity of the material in the battery is larger than or equal to 135mAh / g.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

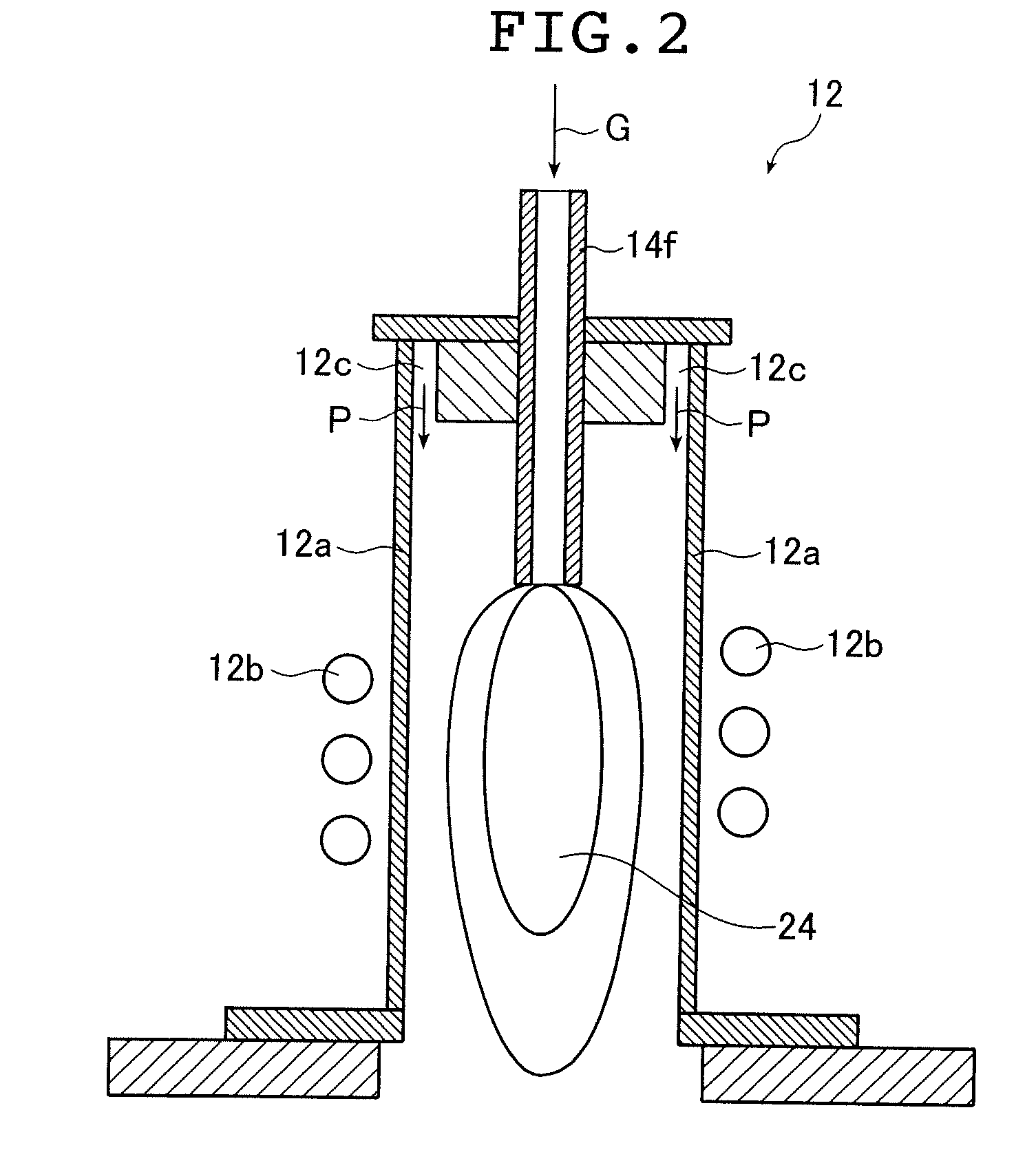

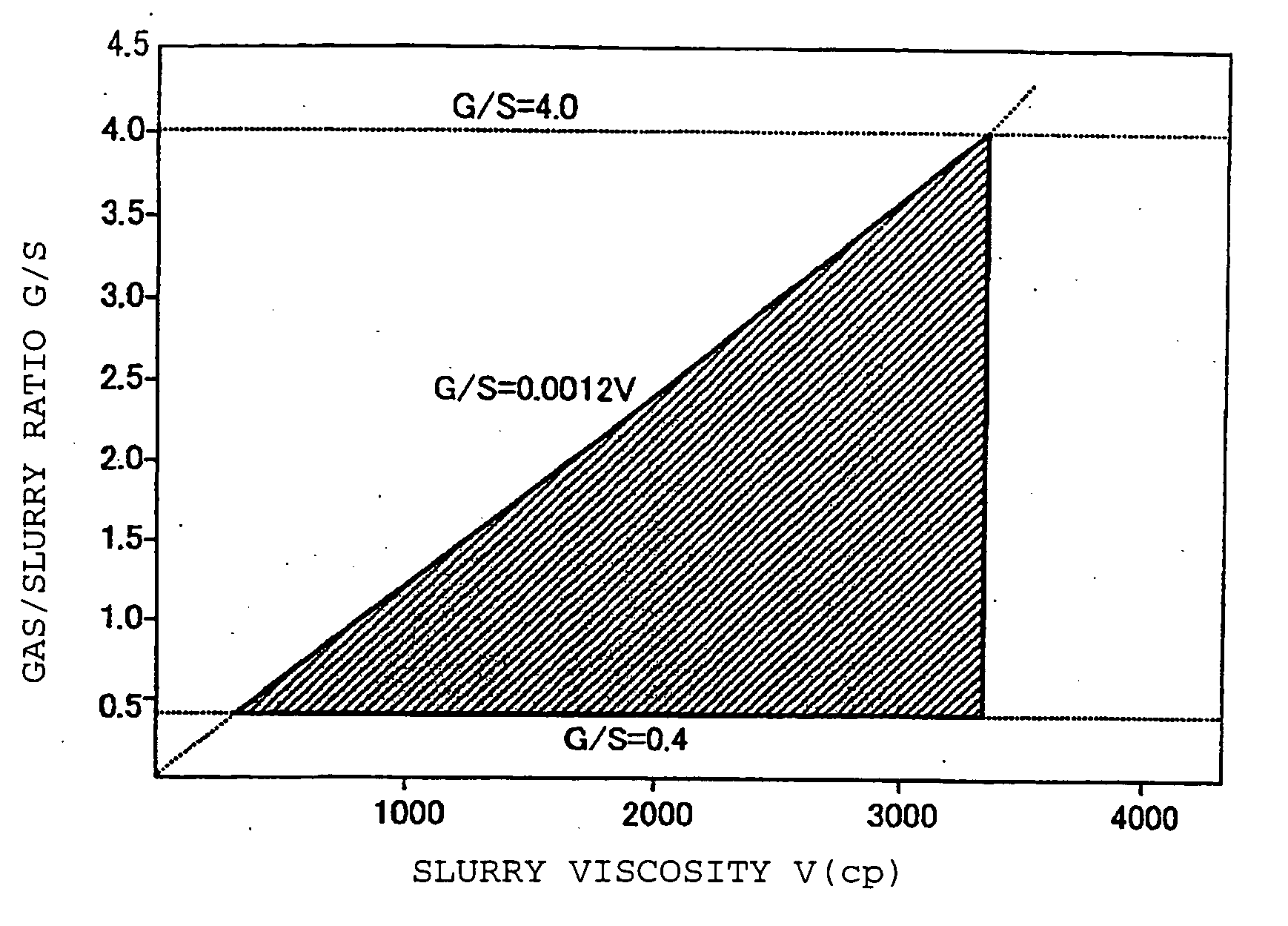

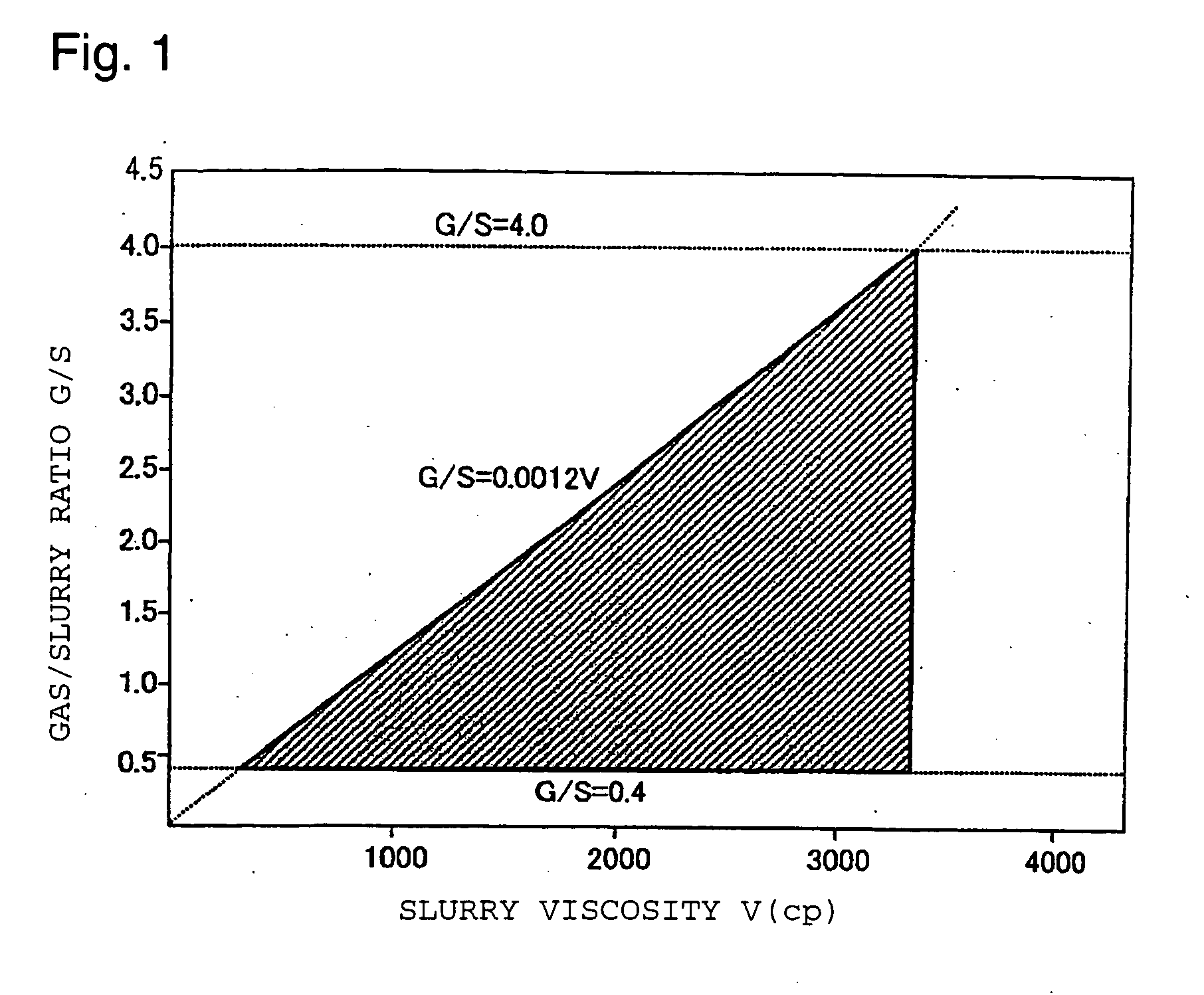

Layered lithium-nickel-based compound oxide powder and its production process

ActiveUS20050158546A1High bulk densityGood rate characteristicsElectrode thermal treatmentSolid electrolyte cellsLiquid mediumNickel compounds

A layered lithium-nickel-based compound oxide powder for a positive electrode material for a high density lithium secondary cell, capable of providing a lithium secondary cell having a high capacity and excellent in the rate characteristics also, is provided. A layered lithium-nickel-based compound oxide powder for a positive electrode material for a lithium secondary cell, characterized in that the bulk density is at least 2.0 g / cc, the average primary particle size B is from 0.1 to 1 μm, the median diameter A of the secondary particles is from 9 to 20 μm, and the ratio A / B of the median diameter A of the secondary particles to the average primary particle size B, is within a range of from 10 to 200. In production of a layered lithium-nickel-based compound oxide powder, which comprises spray drying a slurry having a nickel compound and a transition metal element compound capable of substituting lithium other than nickel, dispersed in a liquid medium, followed by mixing with a lithium compound, and firing the mixture, the spray drying is carried out under conditions of 0.4≦G / S≦4 and G / S≦0.0012 V, when the slurry viscosity at the time of the spray drying is represented by V (cp), the slurry supply amount is represented by S (g / min) and the gas supply amount is represented by G (L / min).

Owner:MITSUBISHI CHEM CORP

Spherical catalyst for olefin polymerization

InactiveUS20050176900A1Large particle sizeOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationOrganosiliconMagnesium

Disclosed are catalyst systems and methods of making the catalyst systems / supports for the polymerization of an olefin containing a solid titanium catalyst component having a substantially spherical shape and containing an internal electron donor, a support made from a magnesium compound, an alcohol, an ether, a surfactant, and an alkyl silicate. The catalyst system may further contain an organoaluminum compound and an organosilicon compound. Also disclosed are methods of making an impact copolymer involving polymerizing an olefin to provide a polyolefin matrix and polymerizing a polyolefin rubber using a catalyst component containing a support made from a magnesium compound, an alcohol, an ether, a surfactant, and an alkyl silicate.

Owner:ENGELHARD CORP

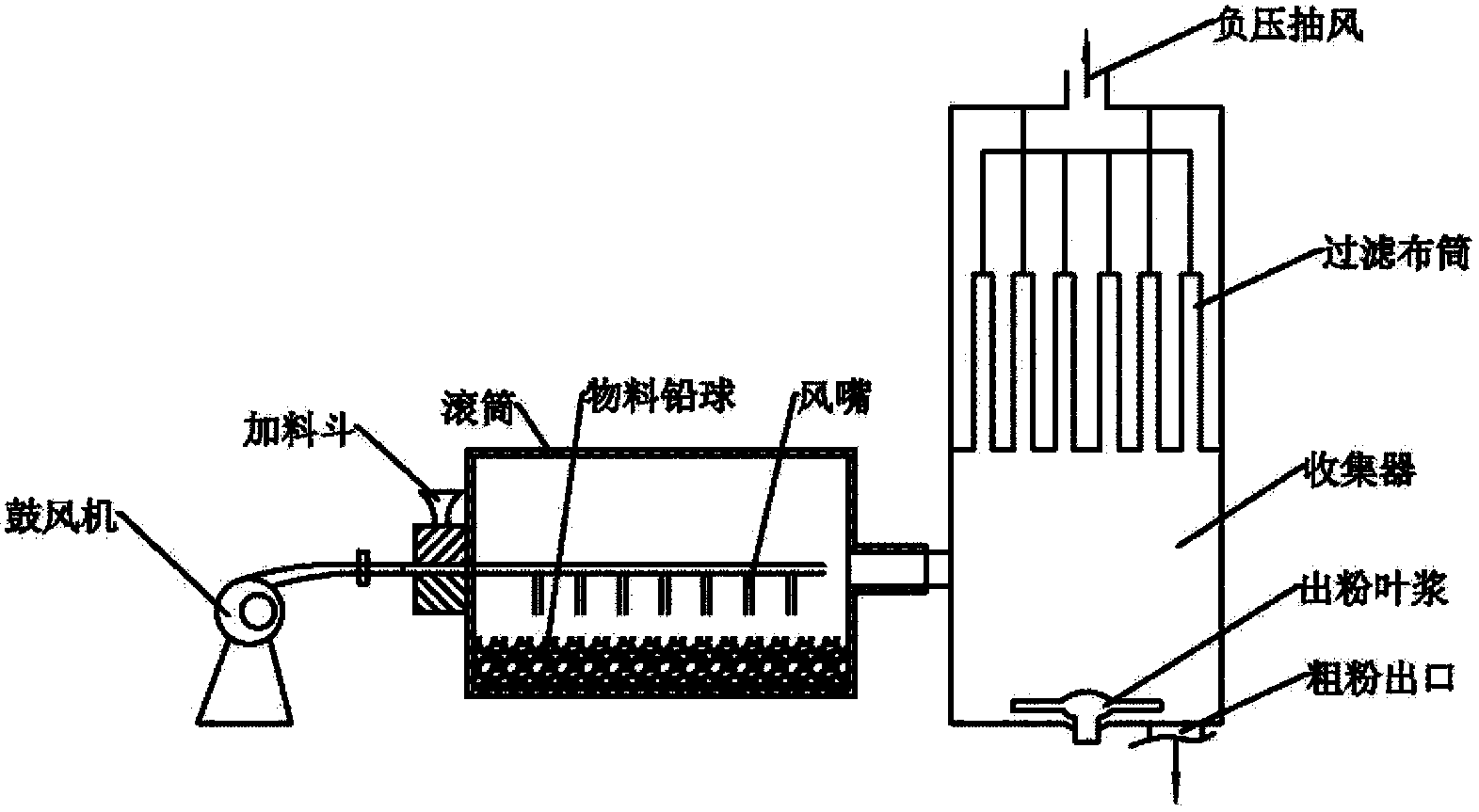

Process for milling and preparing powders and compositions produced thereby

ActiveUS20080029625A1Low costImprovement in particle size reduction efficiencyPowder deliveryGrain treatmentsDrug carrierProduct gas

A method of milling a powder comprising introducing a gas stream containing a cryogenic liquid and a drug carrier gas into a jet mill, and milling a powder with the jet mill in one or more milling passes. A product produced by the method. A milling apparatus comprising a cryogenic gas input system, a powder feeder, a main jet-mill, and at least one output port for collecting the powder.

Owner:NANOSHIFT LLC

Exendin analog formulations

InactiveUS20060069029A1Slow gastric emptyingLowering plasma glucose levelPowder deliveryPeptide/protein ingredientsAgonistPharmacology

Owner:ASTRAZENECA PHARMA LP

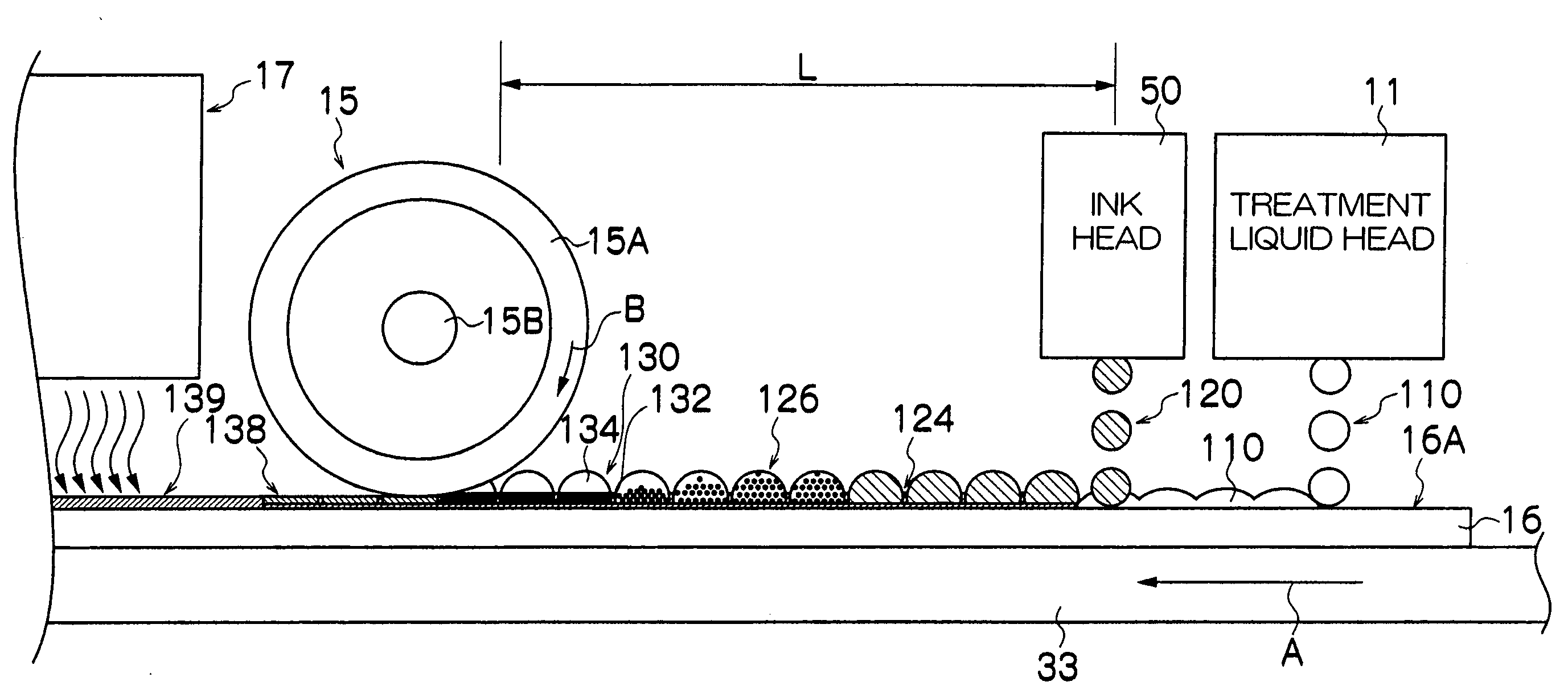

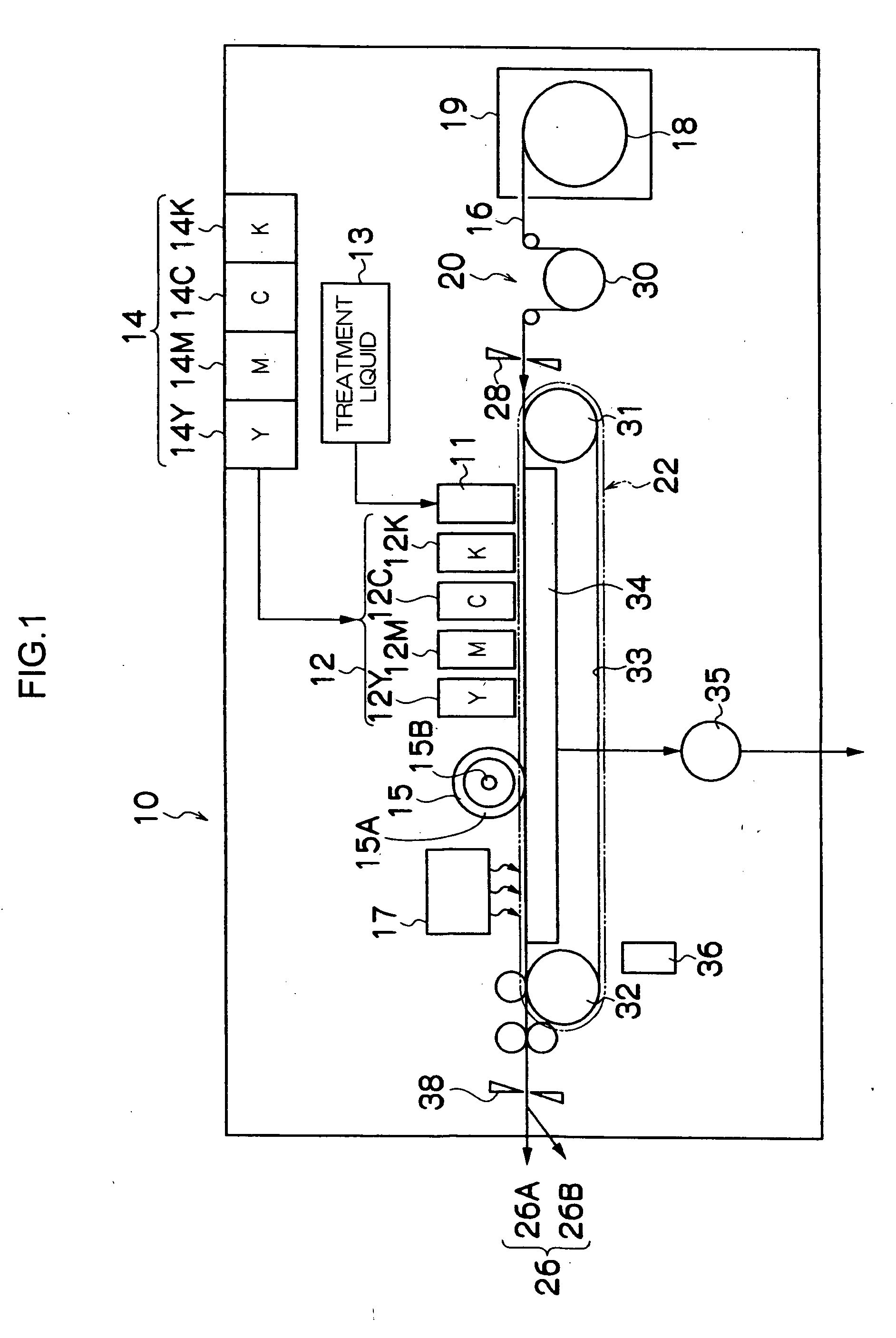

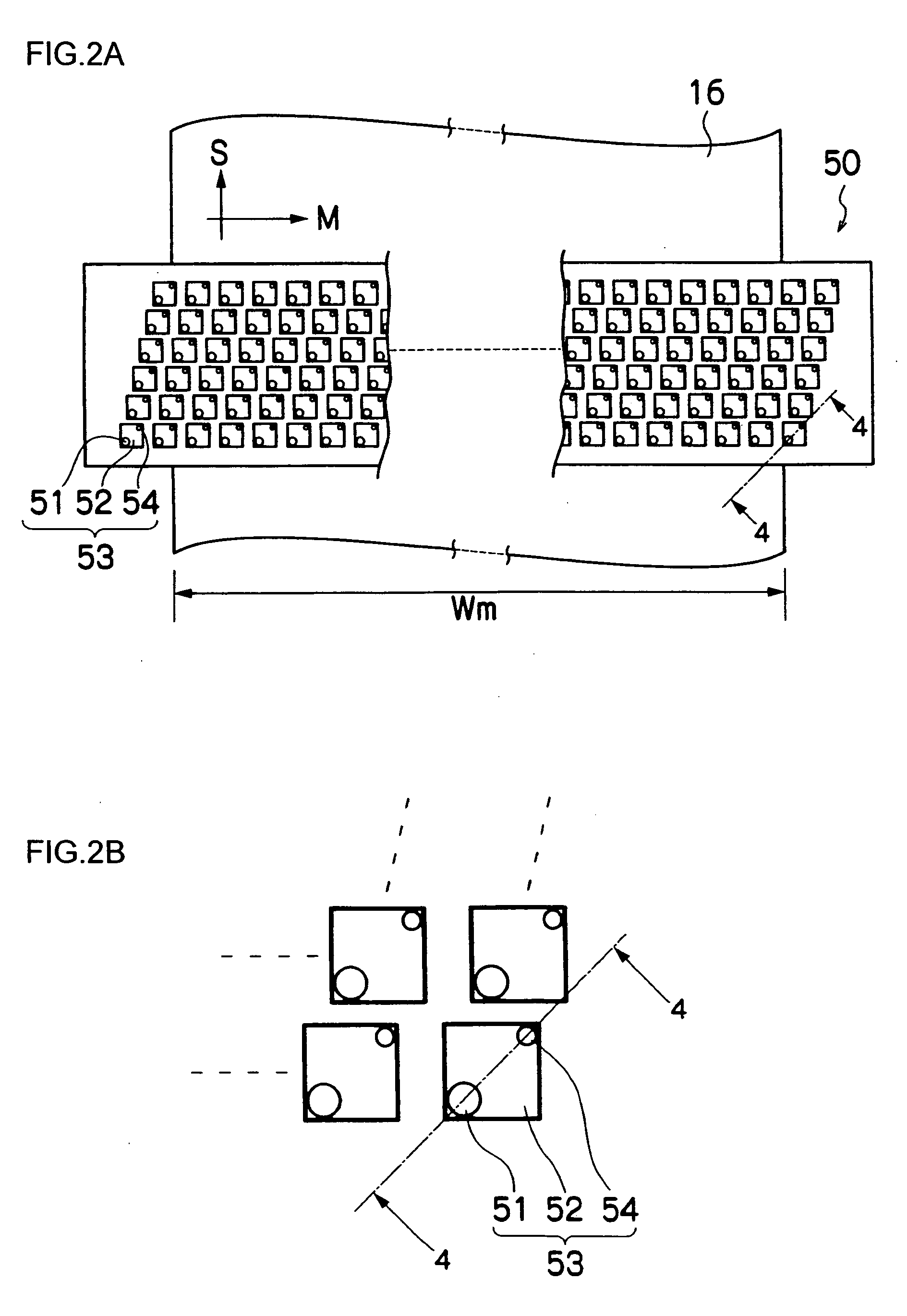

Ink set for inkjet recording, and image recording method and image recording apparatus

ActiveUS20070229577A1Improve featuresEnsuring optical densityMeasurement apparatus componentsDuplicating/marking methodsImage recordingWater soluble

The ink set for inkjet recording includes: a first liquid which contains at least a water-soluble solvent, water, and pigment particles dispersed and retained in a medium including the water-soluble solvent and the water; and a second liquid which does not contain coloring material but contains at least a water-soluble solvent, water, and a liquid composition which enhances printing characteristics, wherein: an image is formed by making the first liquid and the second liquid come into contact with each other on a recording medium; and a ratio of pigment particles having a particle diameter of not less than 150 nm is not greater than 2 volume percent with respect to a whole of the pigment particles contained in the first liquid.

Owner:FUJIFILM CORP

Titanium silicon molecular sieve catalyst as well as preparation method and use thereof

ActiveCN101371989ALarge particle sizeHigh mechanical strengthOrganic chemistryMolecular sieve catalystsMolecular sieveNano al2o3

The invention relates to a titanium silicate molecular sieve catalyst and the preparation method and the application thereof. The catalyst comprises 25-65 percent of titanium silicate molecular sieve and 20-65 percent of nanometer alumina. The mechanical strength is 20-30N / cm<2>. Prepared by an extruded moulding method, the catalyst has the characteristics of high mechanical strength, high catalytic activity and selectivity, and the like, and is especially applied to catalyzing 3-chloropropene oxidation reaction to prepare epichlorohydrin.

Owner:CHINA PETROLEUM & CHEM CORP +1

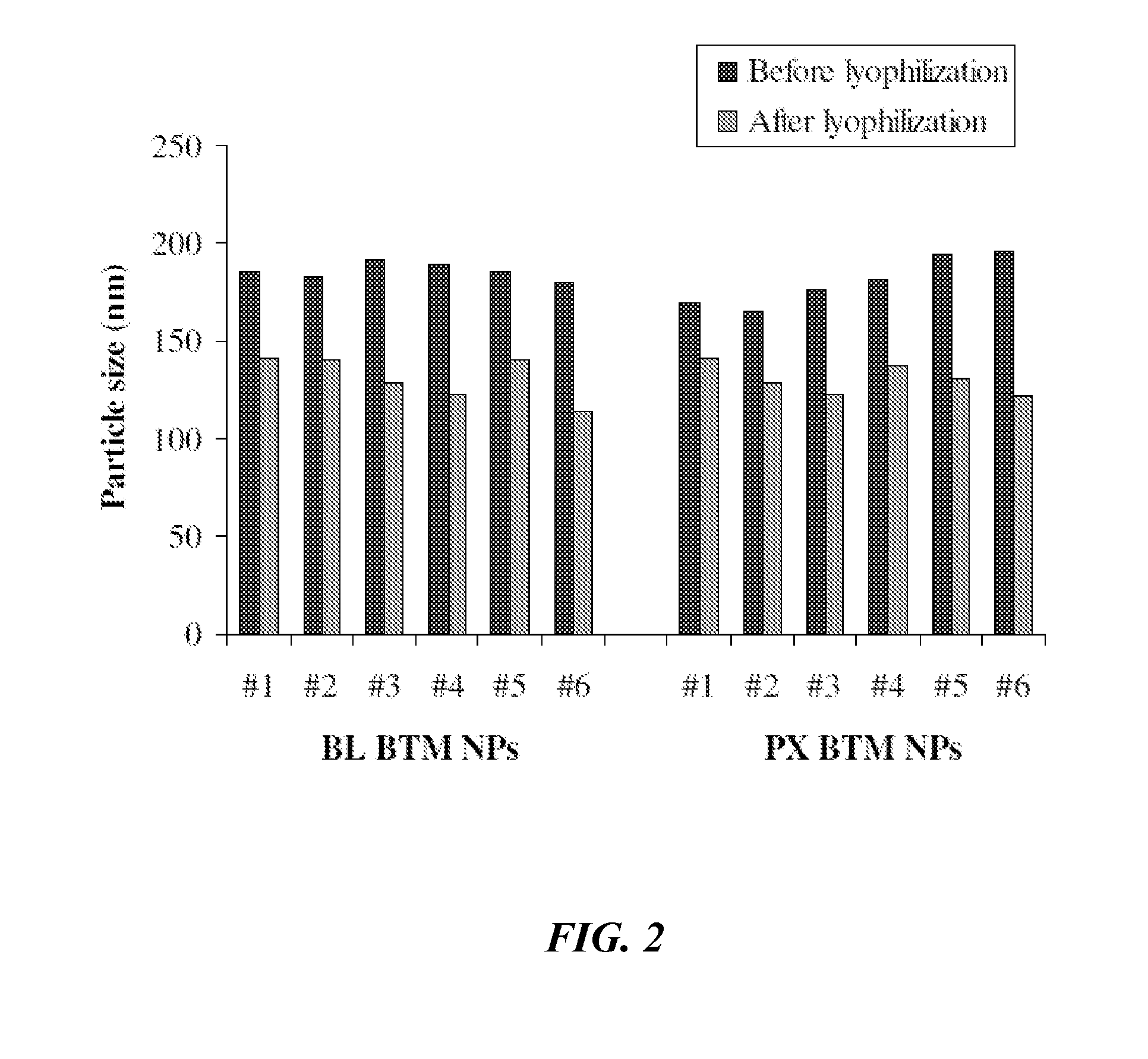

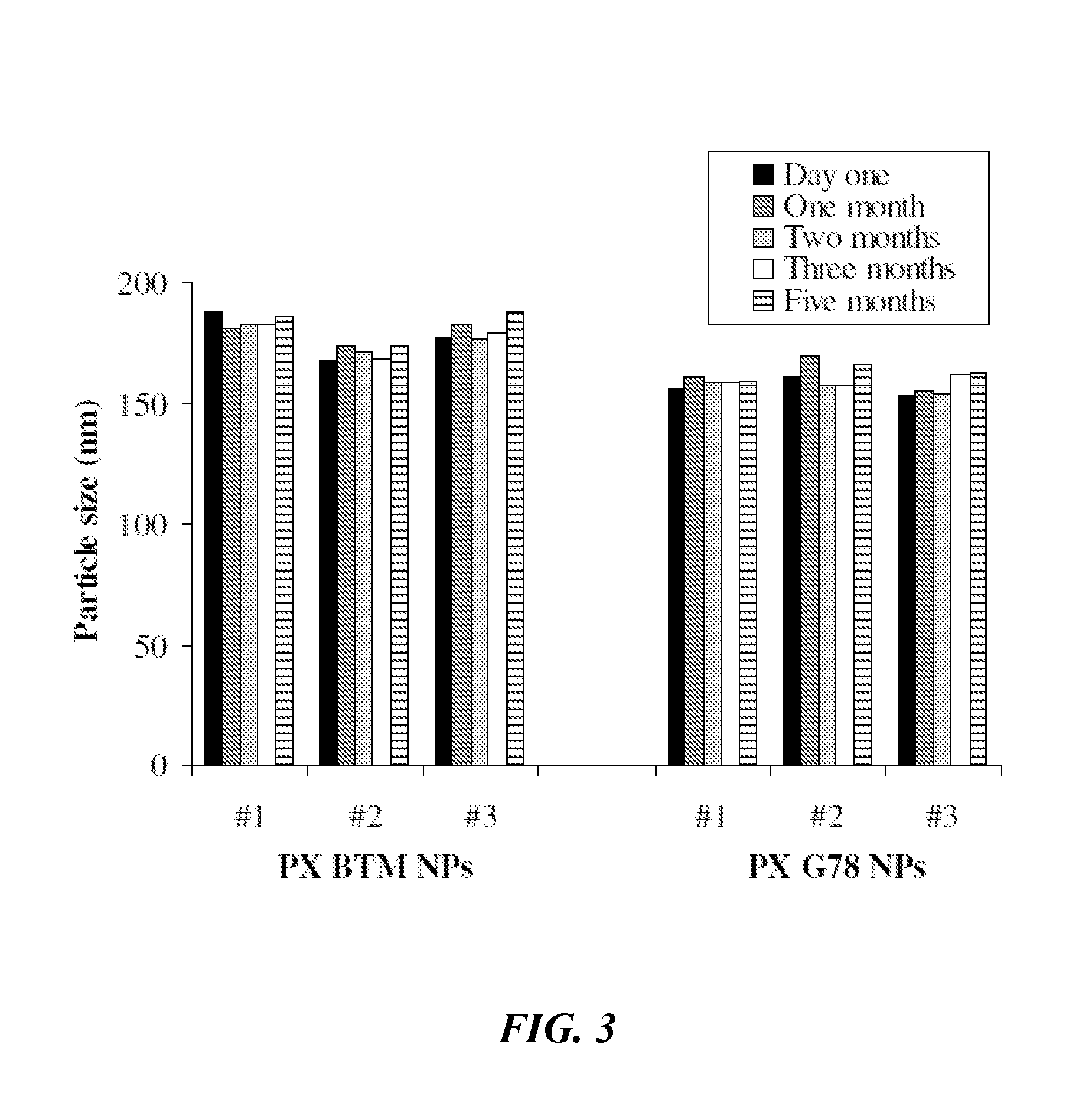

Nanoparticle compositions comprising liquid oil cores

InactiveUS20110195030A1Improved physical characteristic and stabilityWithout adversely size and functionOrganic active ingredientsBiocideParticle compositionIsopropylene glycol

Nanocapsule and nanoemulsion particle compositions having improved physical and pharmacological properties are provided. The nanocapsule or nanoemulsion particle composition can comprise a pharmaceutically acceptable liquid oil phase, a surfactant, and optionally a co-surfactant. The liquid oil phase can comprise a monoglyceride, a diglyceride, a triglyceride, a propylene glycol ester, or a propylene glycol diester. In certain embodiments, the nanocapsule or nanoemulsion particle composition can be lyophilized and subsequently re-hydrated without increasing the mean particle size and / or adversely affecting the potency or efficacy of a therapeutic agent (e.g., paclitaxel) present in the nanocapsules or nanoemulsion particles.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL +1

Preparation method of layered lithium-rich manganese base oxide of positive material of lithium ion battery

InactiveCN102683645AImprove electrochemical performanceReduce energy consumptionCell electrodesManganeseSodium-ion battery

The invention discloses a preparation method of a layered lithium-rich manganese base oxide of a positive material of a lithium ion battery. The preparation method comprises the following steps of: slowly adding transition metal brine solution, alkali liquor and ammonia water which conform to a stoichiometric ratio into a stirring reactor respectively; stirring and heating; aging, filtering, washing and drying the obtained precipitate to obtain a nickel cobalt and manganese composite precursor; proportioning and mixing with a lithium source according to the stoichiometric ratio; adding a fluxing agent of a certain proportion and uniformly mixing in a mechanical mode; placing mixed powder in a furnace for sintering; cooling to room temperature; fully washing with water; and removing remaining fluxing agent to obtain the layered lithium-rich manganese base oxide Li1+xNialphaCobetaMngammaO2 (wherein x is greater than 0 and is less than or equal to 0.33, alpha is greater than or equal to 0 and is less than 1, beta is greater than or equal to 1 and is less than 1, gamma is greater than 0 and is less than 1, and alpha and beta are not zero simultaneously.). According to the preparation method, the heating efficiency is greatly increased, the energy consumption is reduced, and meanwhile, the electrochemical performance of the material is improved; the prepared spherical layered lithium-rich manganese base oxide has no doped phase; and a product has a uniform average particle diameter and superior circulation performance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Nano alumina and its preparation method

ActiveCN1865147AAvoid particle size increaseNarrow particle size distributionAluminium oxide/hydroxide preparationActive agentAluminium salts

Owner:CHINA PETROLEUM & CHEM CORP +1

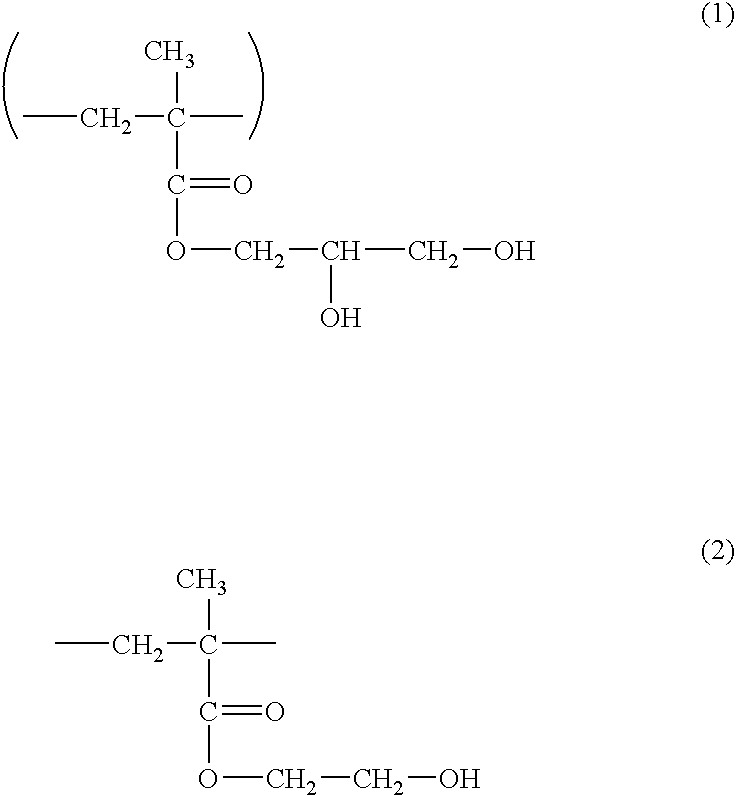

Graft copolymer particles and thermoplastic resin compositions

PCT No. PCT / JP98 / 03304 Sec. 371 Date Mar. 25, 1999 Sec. 102(e) Date Mar. 25, 1999 PCT Filed Jul. 24, 1998 PCT Pub. No. WO99 / 06457 PCT Pub. Date Feb. 11, 1999There is provided graft copolymer particles prepared by graft-polymerizing a vinyl monomer to a coagglomerated rubber, wherein said rubber is prepared by coagglomerating rubber particles of mixed latexes obtained by mixing (A) a silicone rubber latex with (B) an acrylic rubber latex and / or a conjugated diene rubber latex in such an amount as a silicone content is from 1 to 90% by weight based on the total rubber component. A physical property of a thermoplastic resin is improved using the graft copolymer particles. The thermoplastic resin composition using the graft copolymer particles is excellent in impact resistance, weather resistance, processability, thermal discoloration resistance and appearance of molded products.

Owner:KANEKA CORP

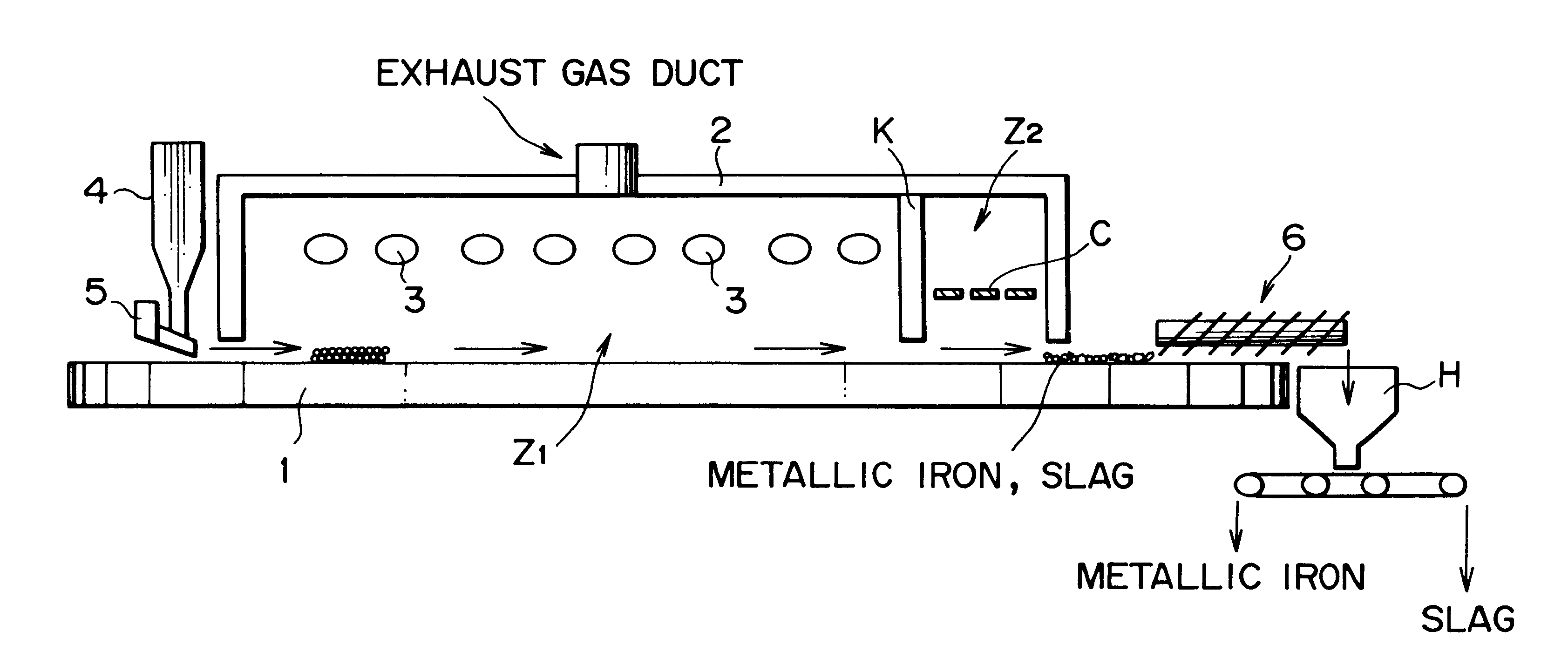

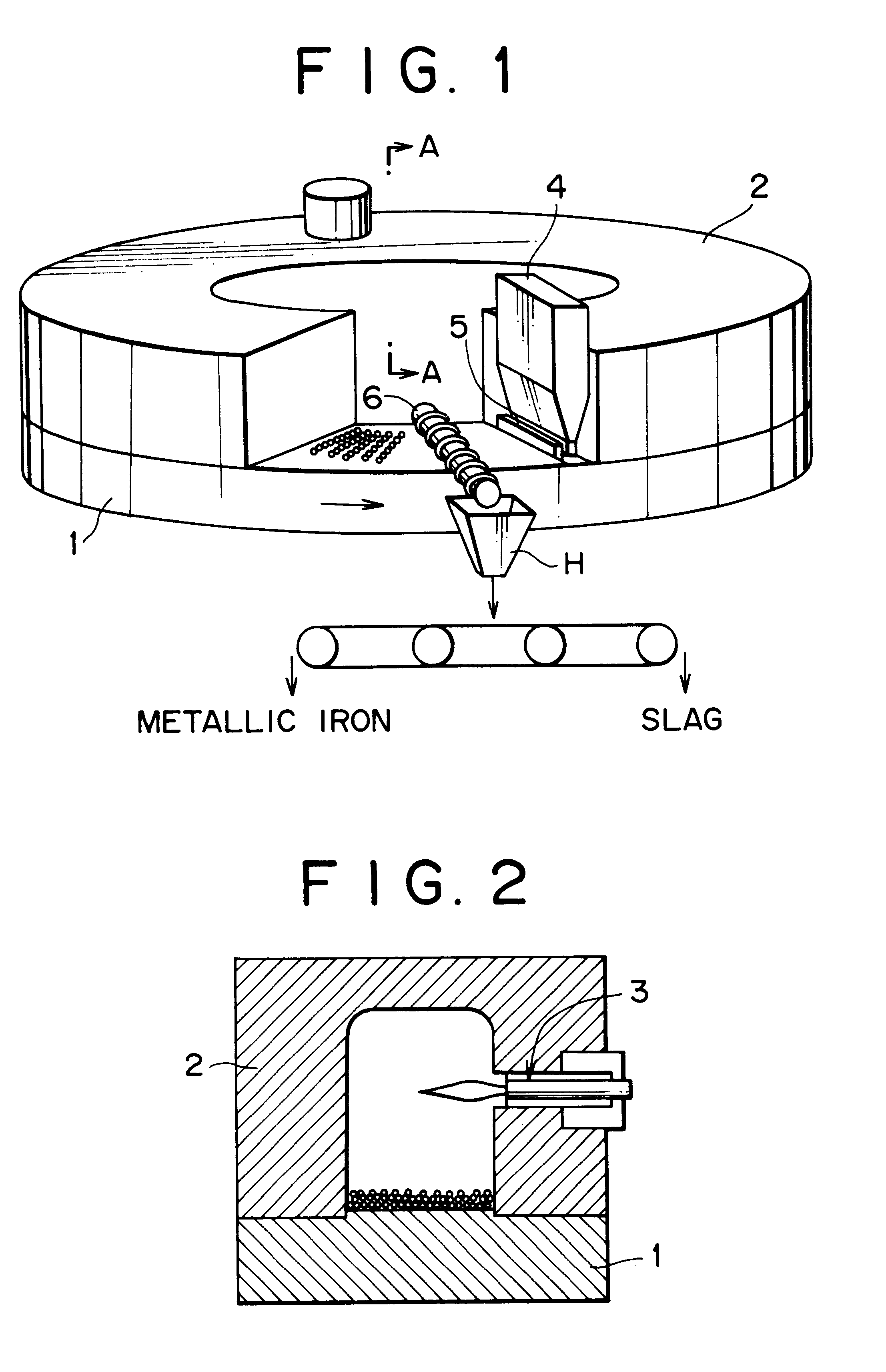

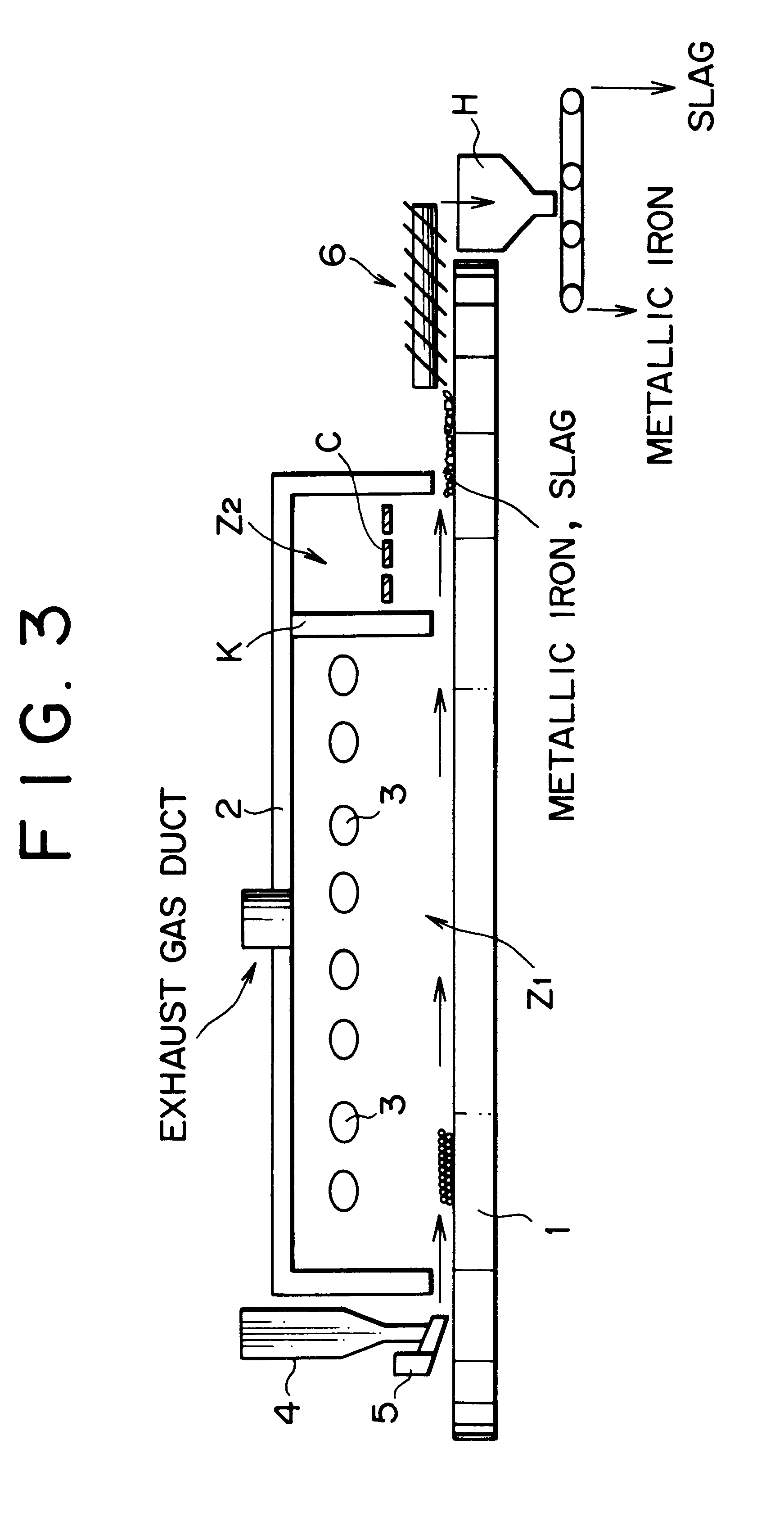

Method of producing iron nuggets

InactiveUS6592649B2Avoid smallImprove productivityProcess efficiency improvementGas emission reductionProduction rateSlag

The present invention provides a method of producing metallic iron nuggets with a high yield and good productivity, and more particularly a method which can produce metallic iron nuggets which have a high Fe purity and are excellent in transporting and handling due to a large grain diameter with a high yield and good productivity, when they are produced by reducing and melting raw material containing iron oxide such as iron ore and carbonaceous reducing agent such as coke. The method of producing metallic iron nuggets comprises steps of: heating raw material containing carbonaceous reducing agent and iron oxide-containing material in a reducing / melting furnace, reducing iron oxide in the raw material, and then heating and melting the metallic iron produced by the reduction and simultaneously making it coalesce while separating the metallic iron nuggets from slag components characterized in that the fixed carbon content ratio as the carbonaceous reducing agent is at least 73% and the volatile matter content in the raw material is not more than 3.9% are used, and the mixing content of carbonaceous reducing agent is restrained to be not more than 45% in relation to the iron oxide components, which is contained in the iron oxide-containing material of the raw material.

Owner:IDREX INT BV ROTTERDAM ZURICH BRANCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com