Patents

Literature

402results about How to "Narrow size distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Monodisperse core/shell and other complex structured nanocrystals and methods of preparing the same

ActiveUS20050129947A1Narrow size distributionQuality improvementMaterial nanotechnologyFrom normal temperature solutionsChemistrySemiconductor nanostructures

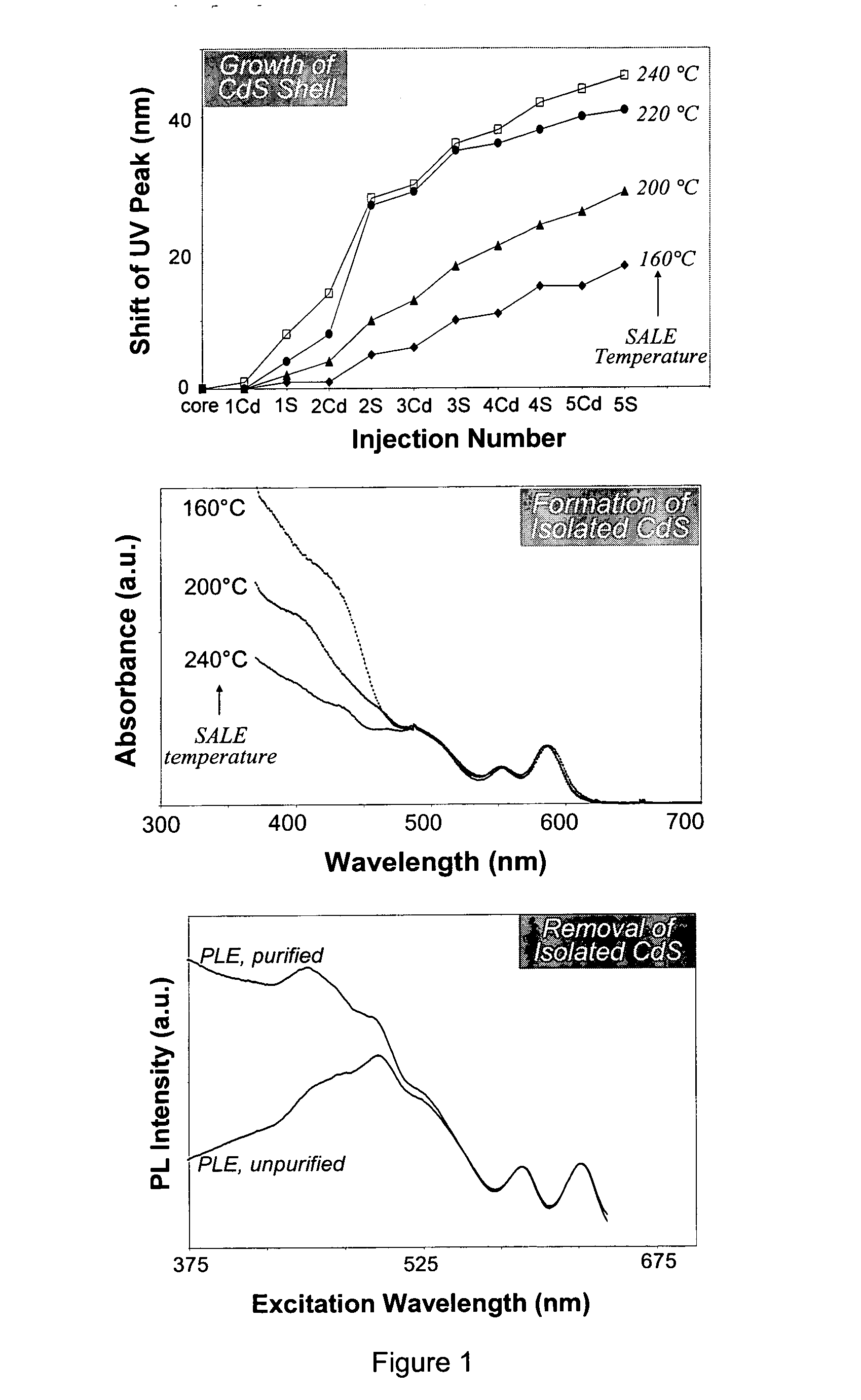

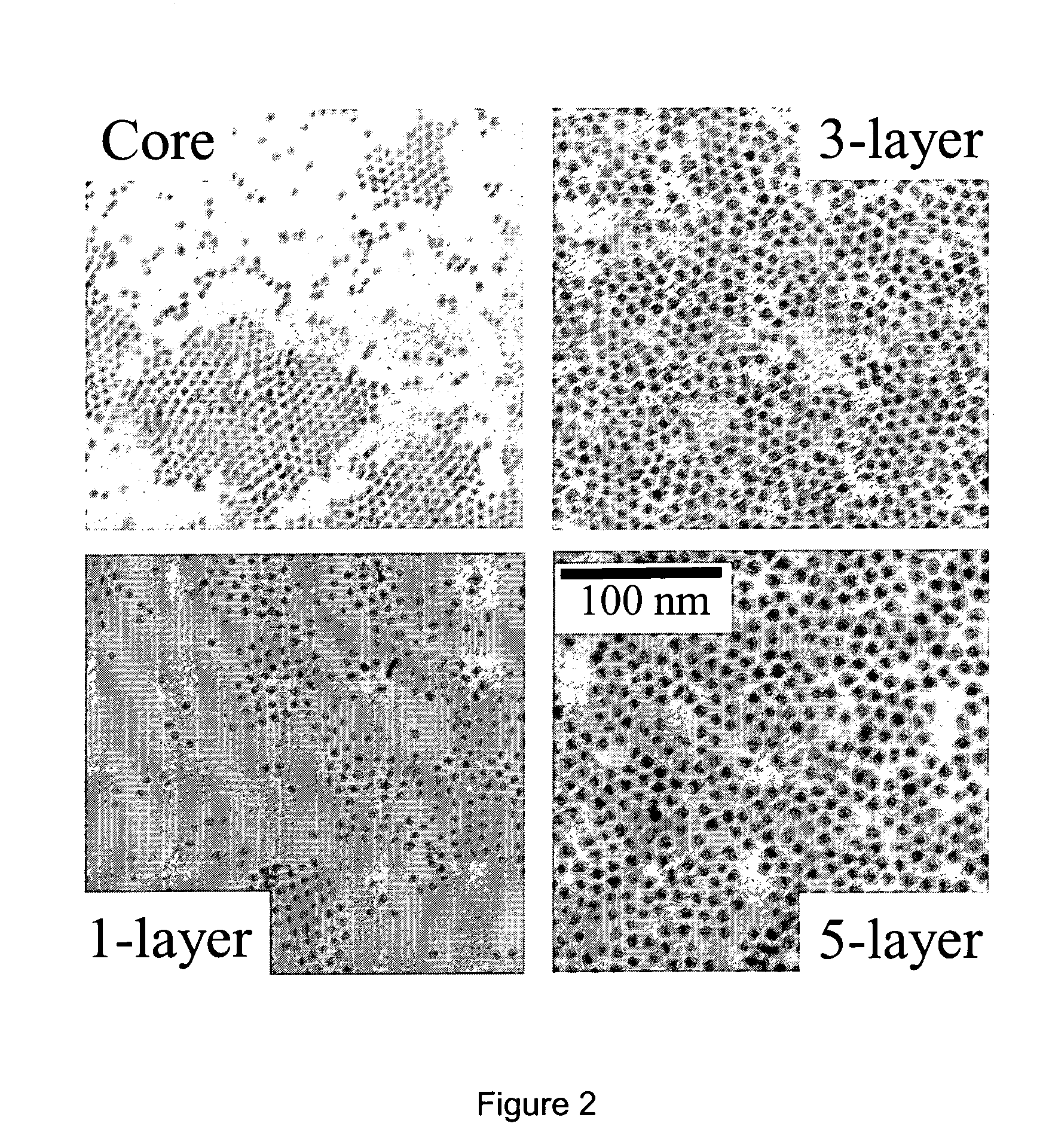

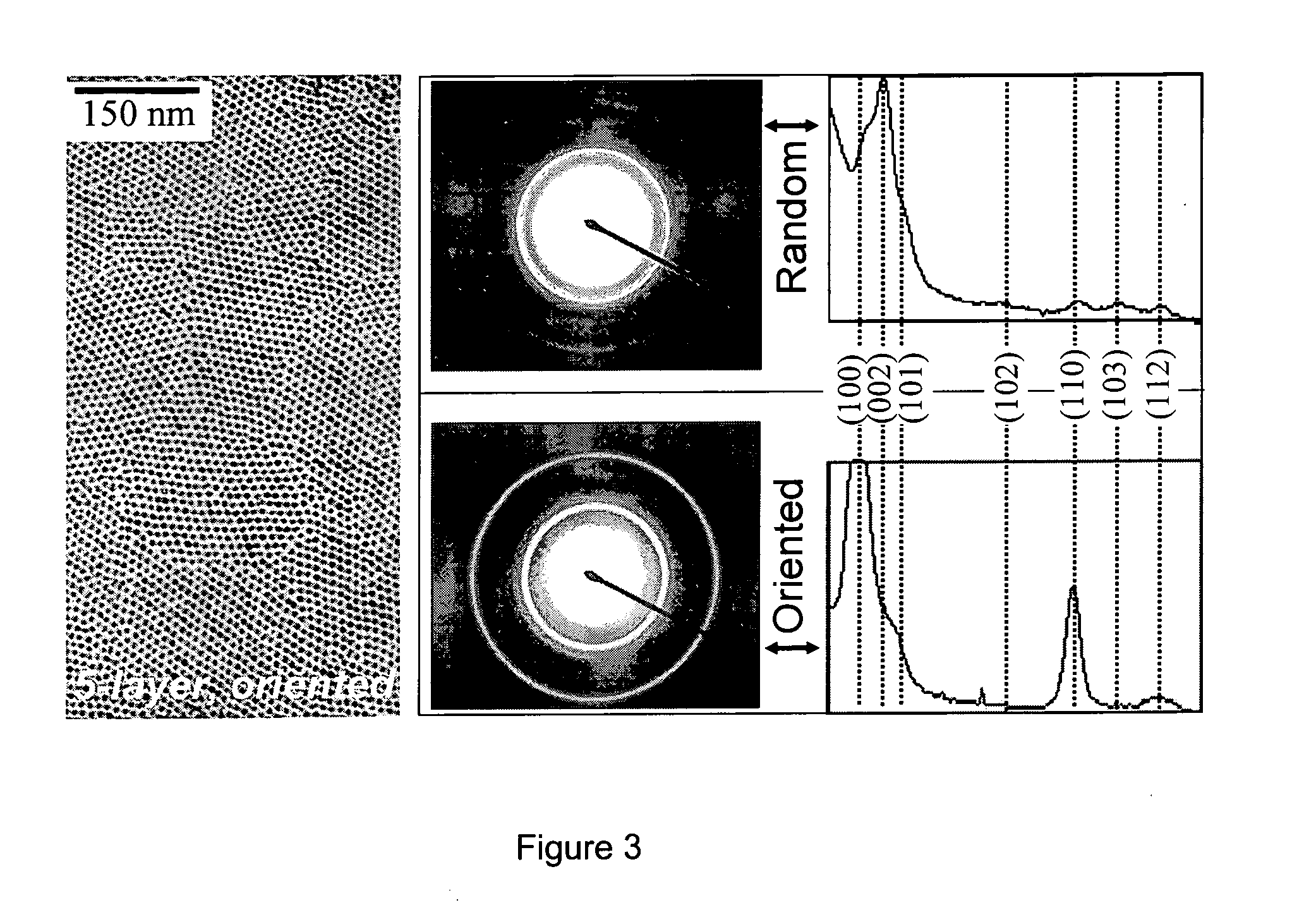

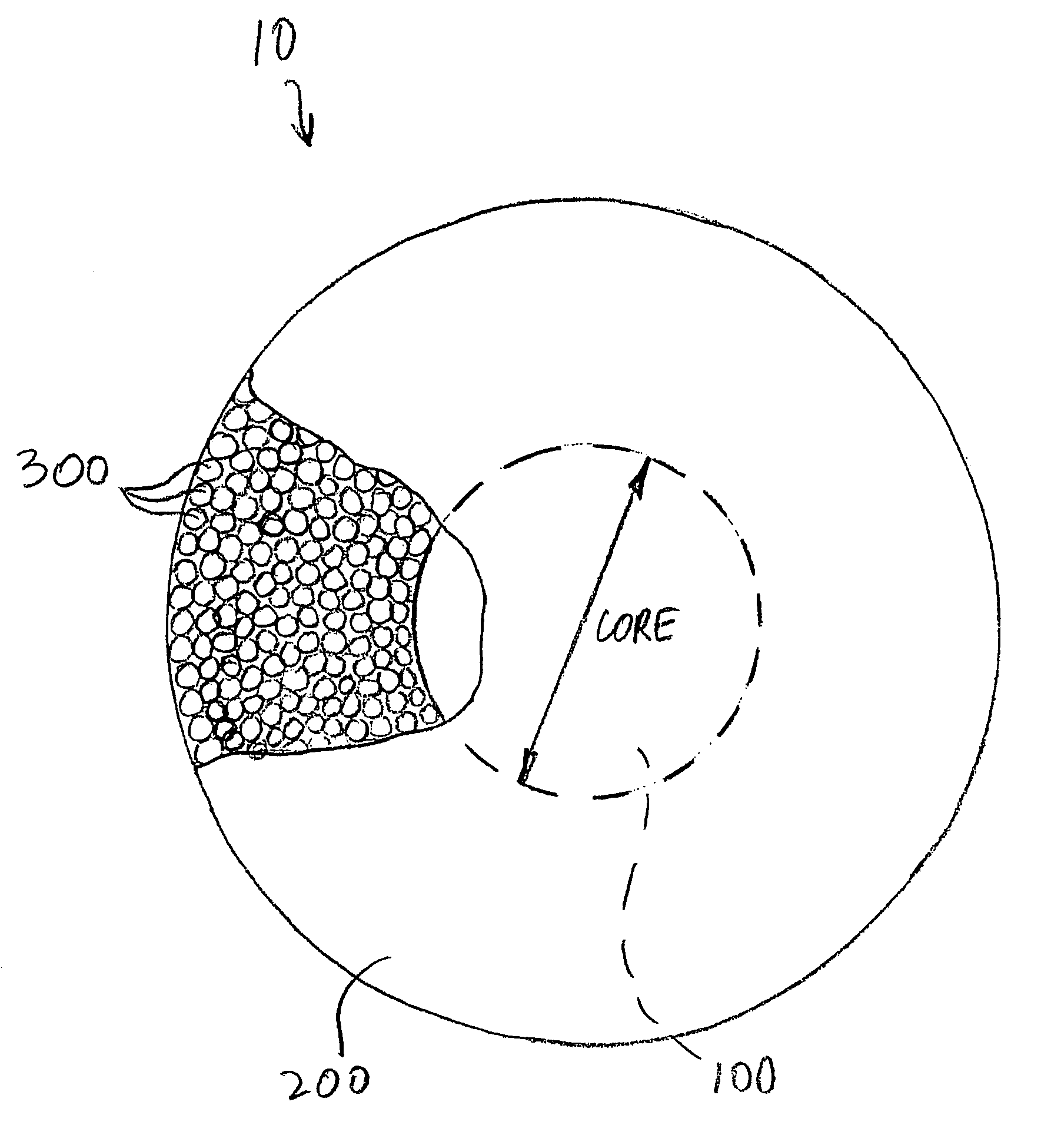

The present invention provides new compositions containing naearly monodisperse colloidal core / shell semiconductor nanocrystals with high photoluminescence quantum yields (PL QY), as well as other complex structured semiconductor nanocrystals. This invention also provides new synthetic methods for preparing these nanocrystals, and new devices comprising these compositions. In addition to core / shell semiconductor nanocrystals, this patent application also provides complex semiconductor nanostructures, quantum shells, quantum wells, doped nanocrystals, and other multiple-shelled semiconductor nanocrystals.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

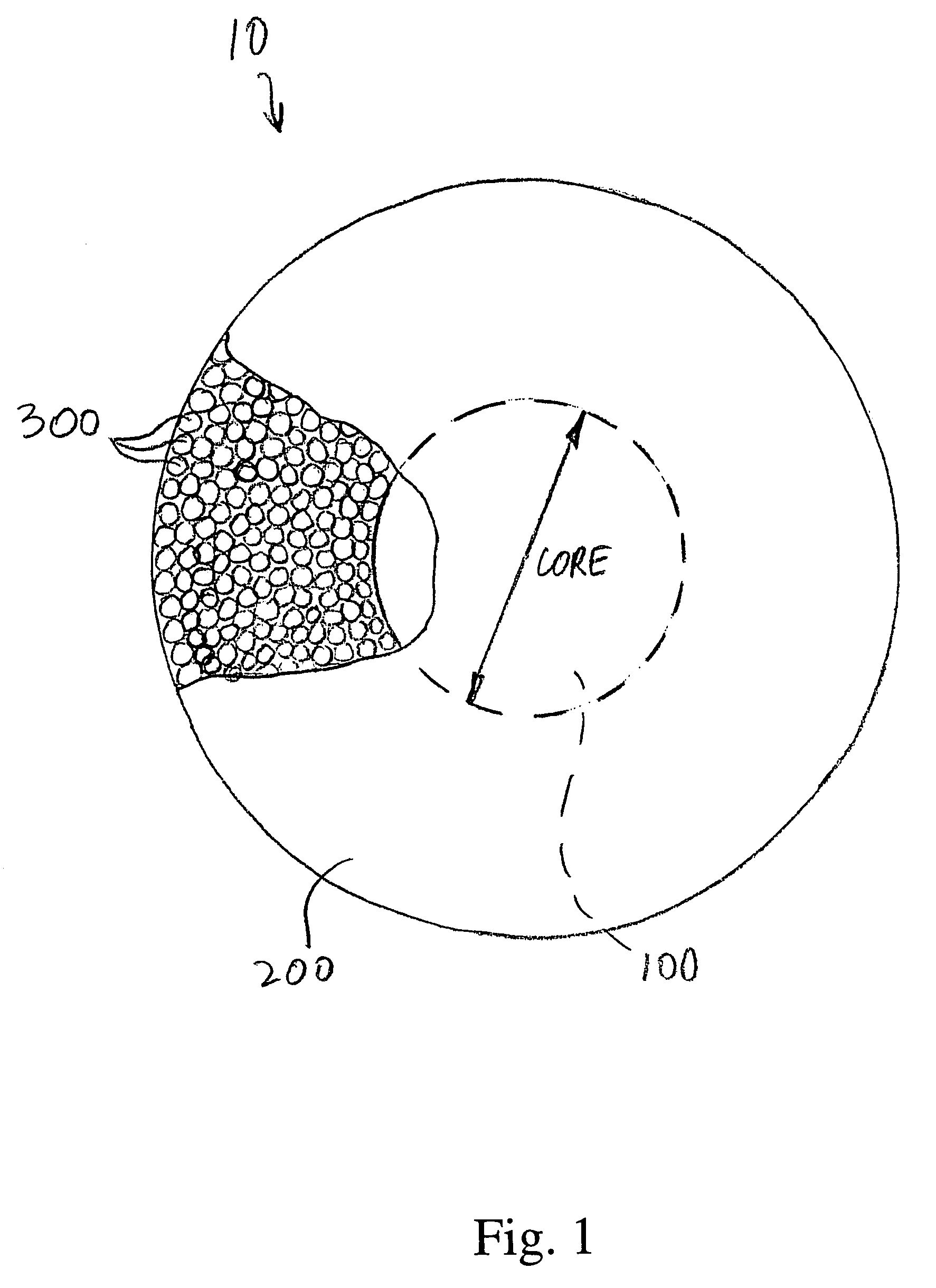

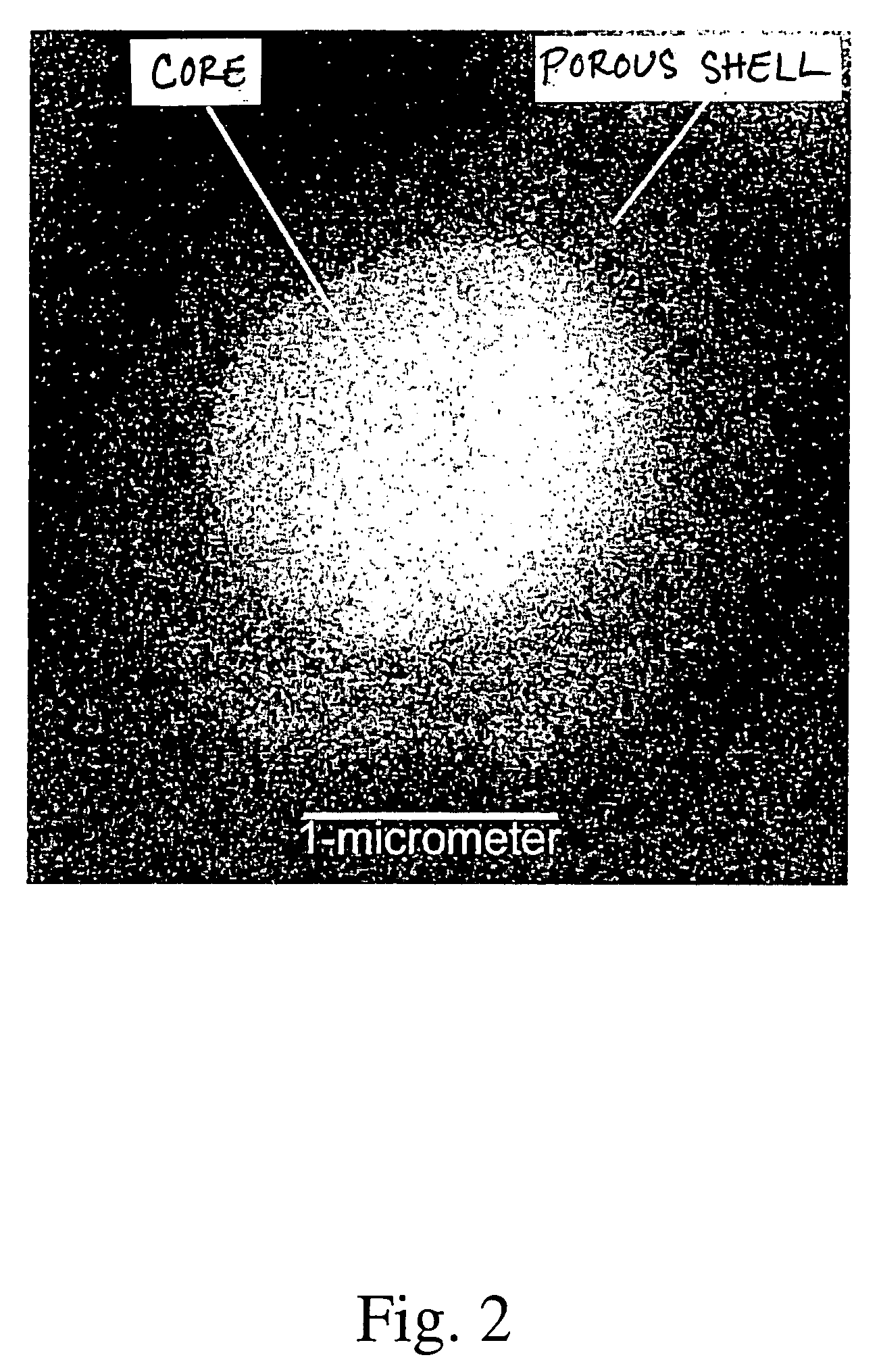

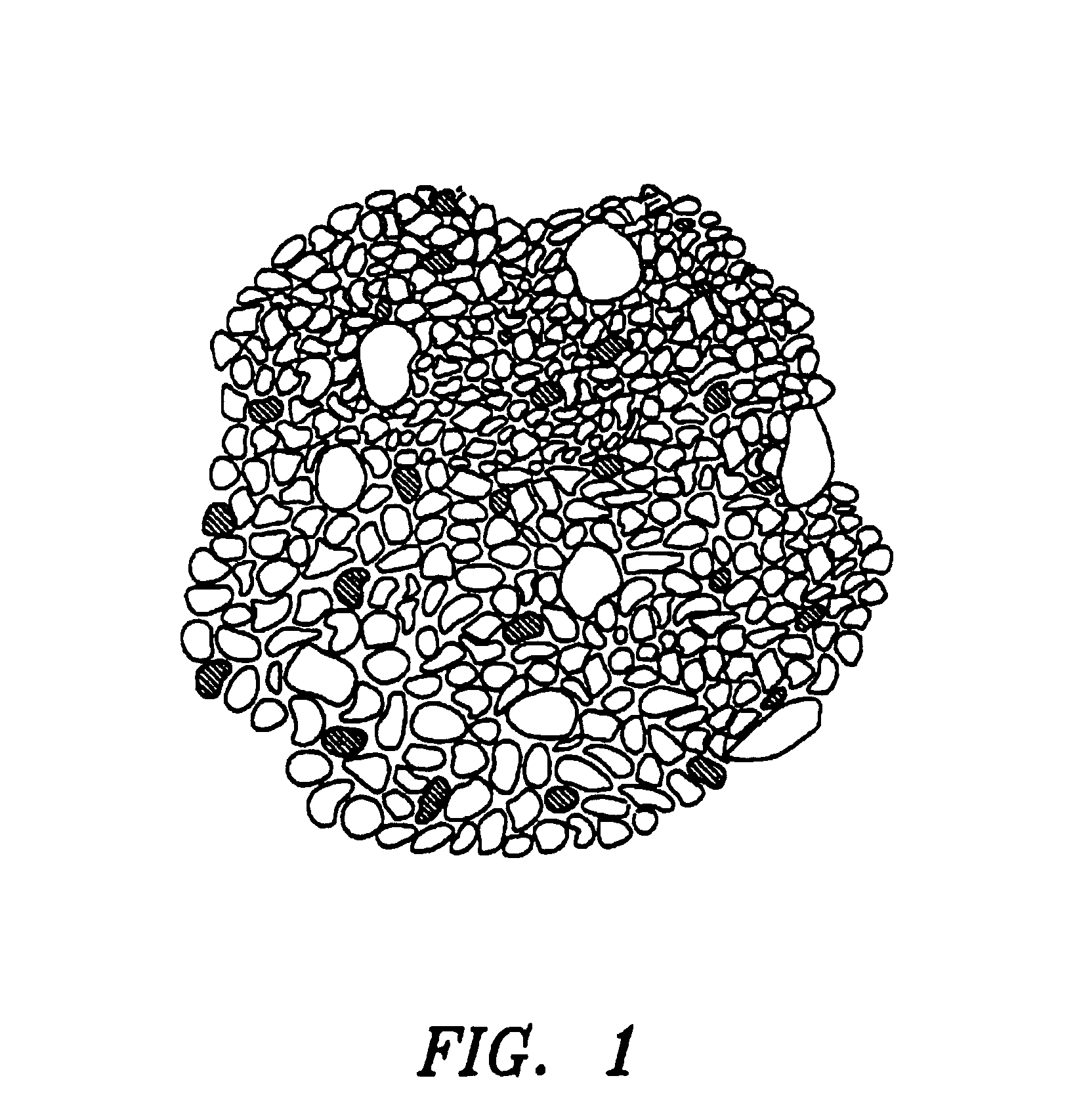

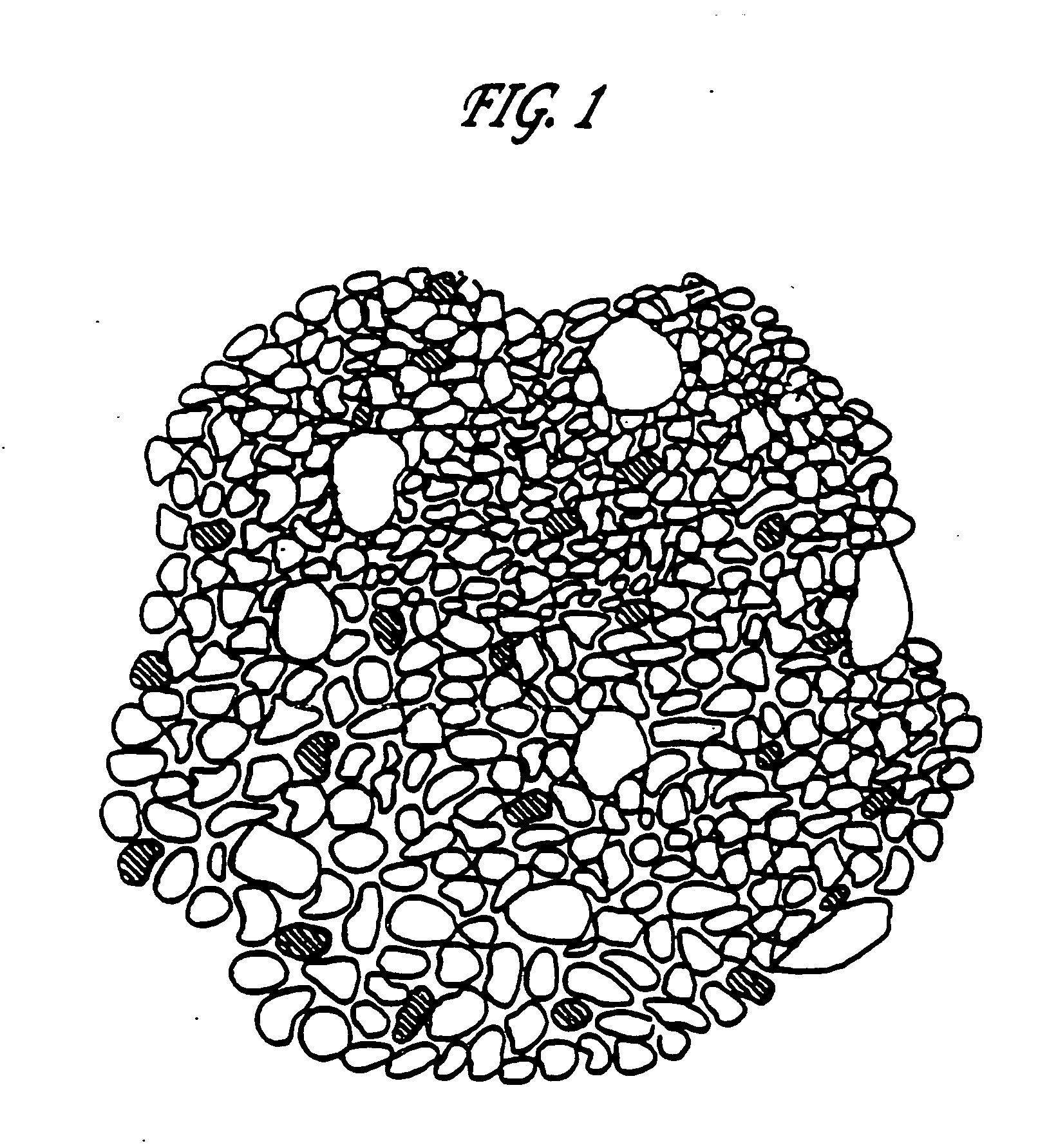

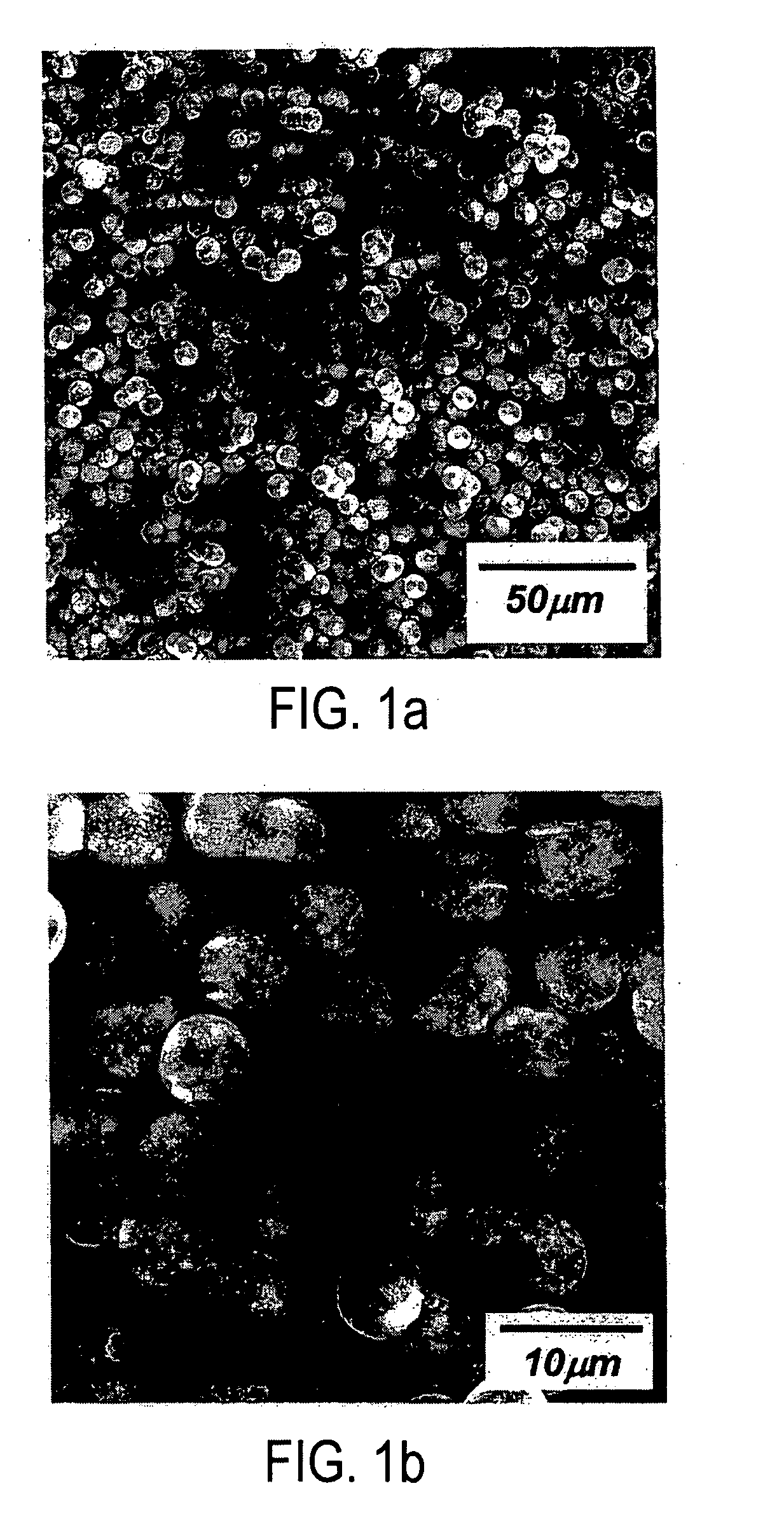

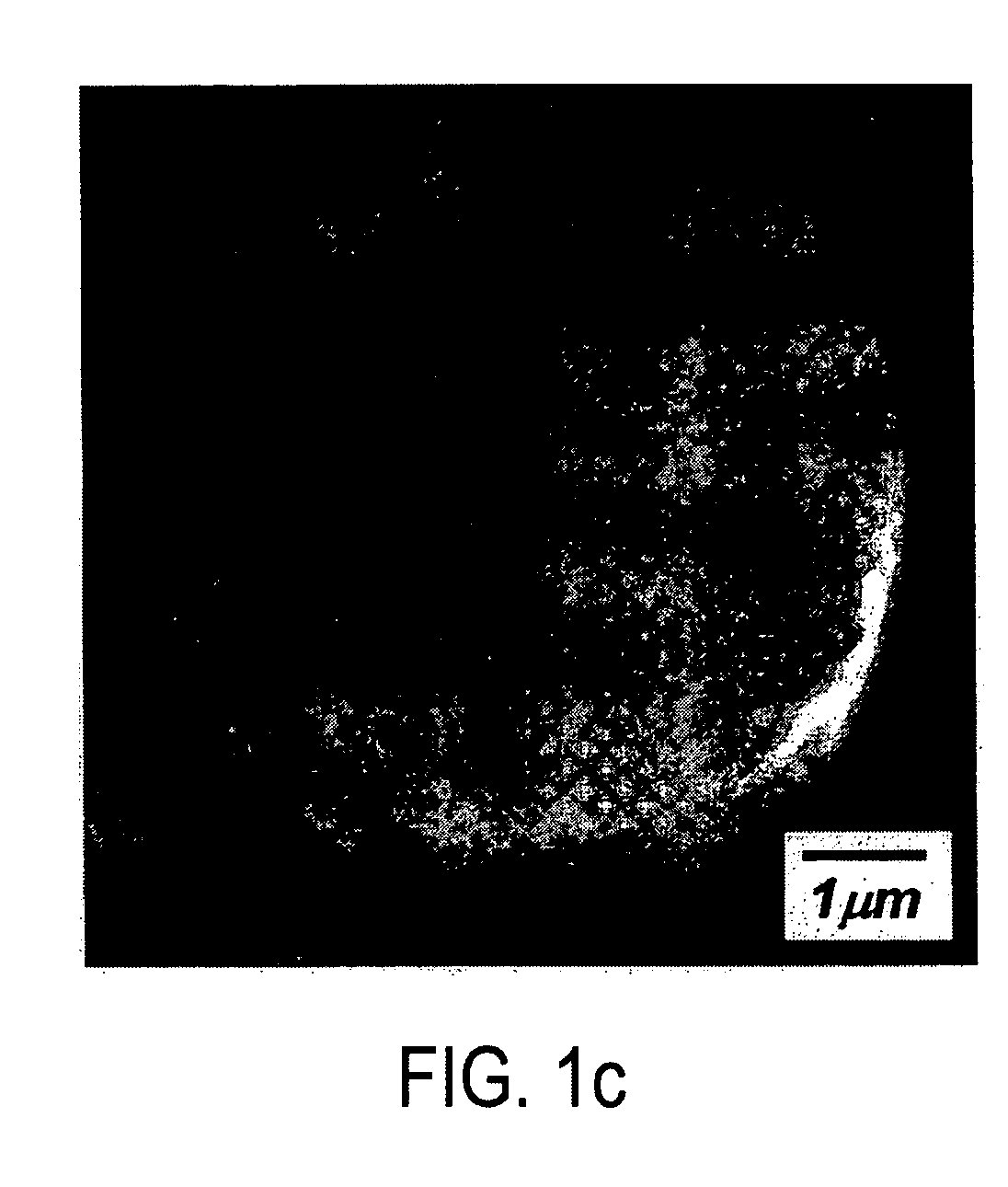

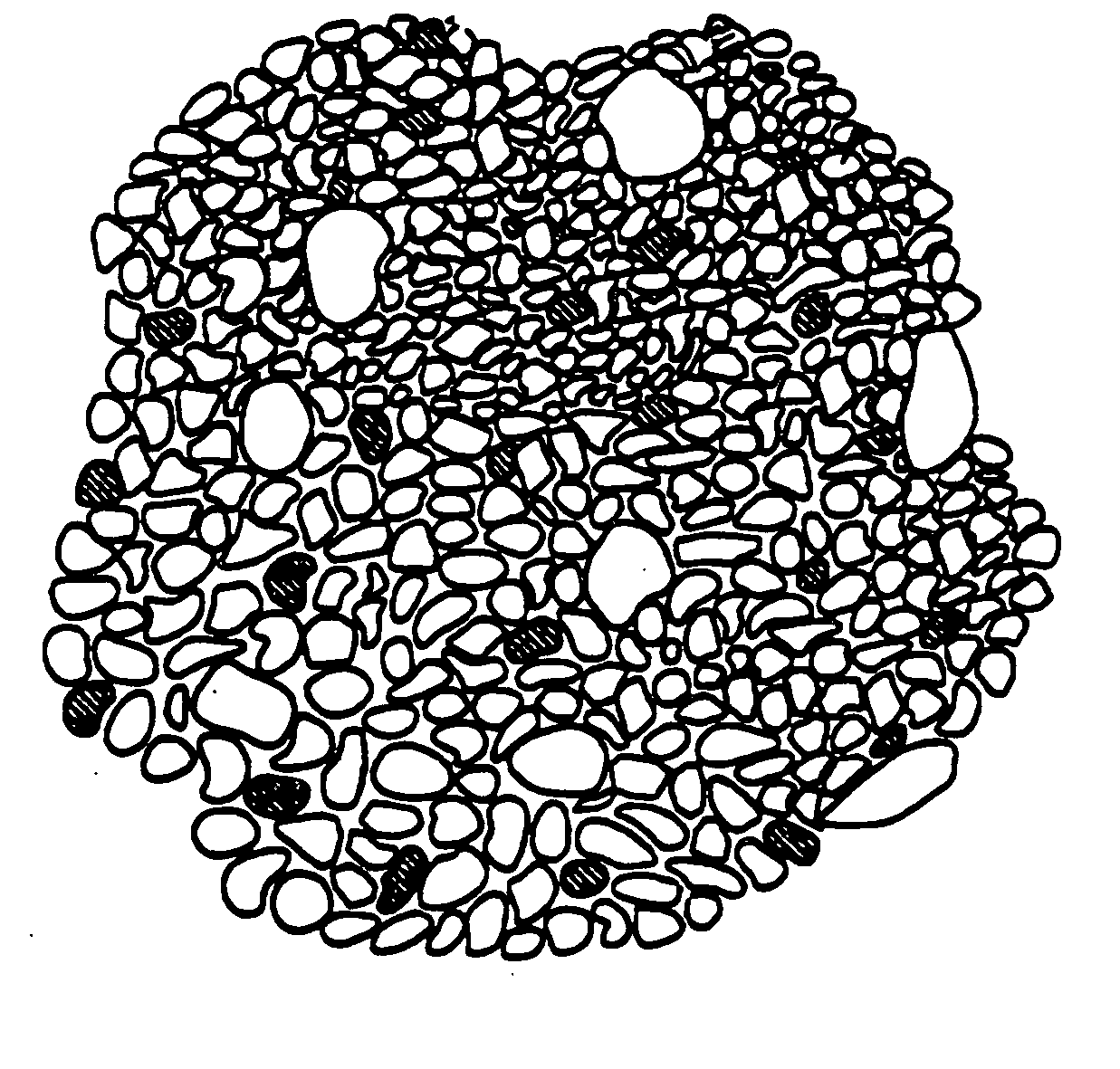

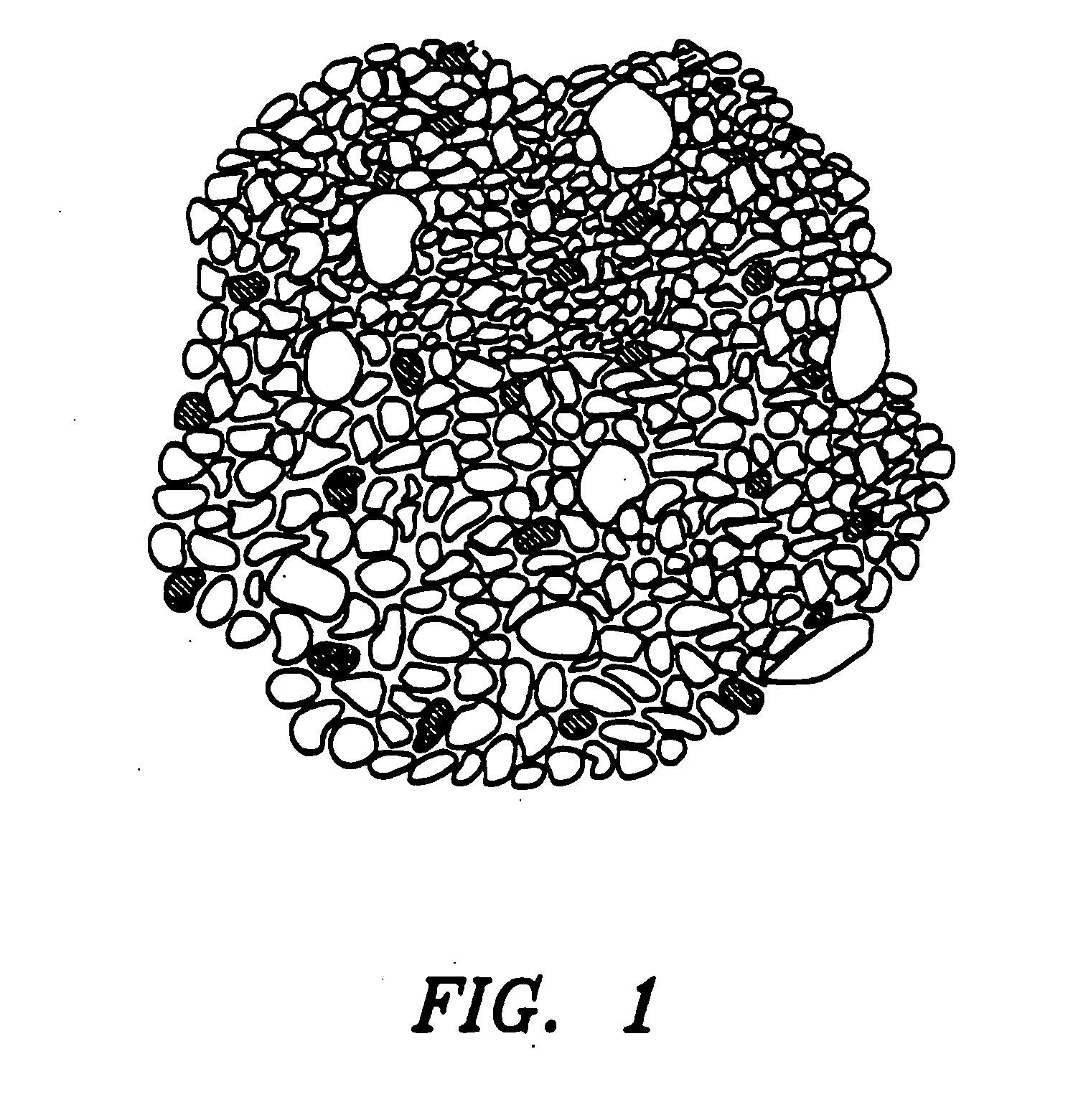

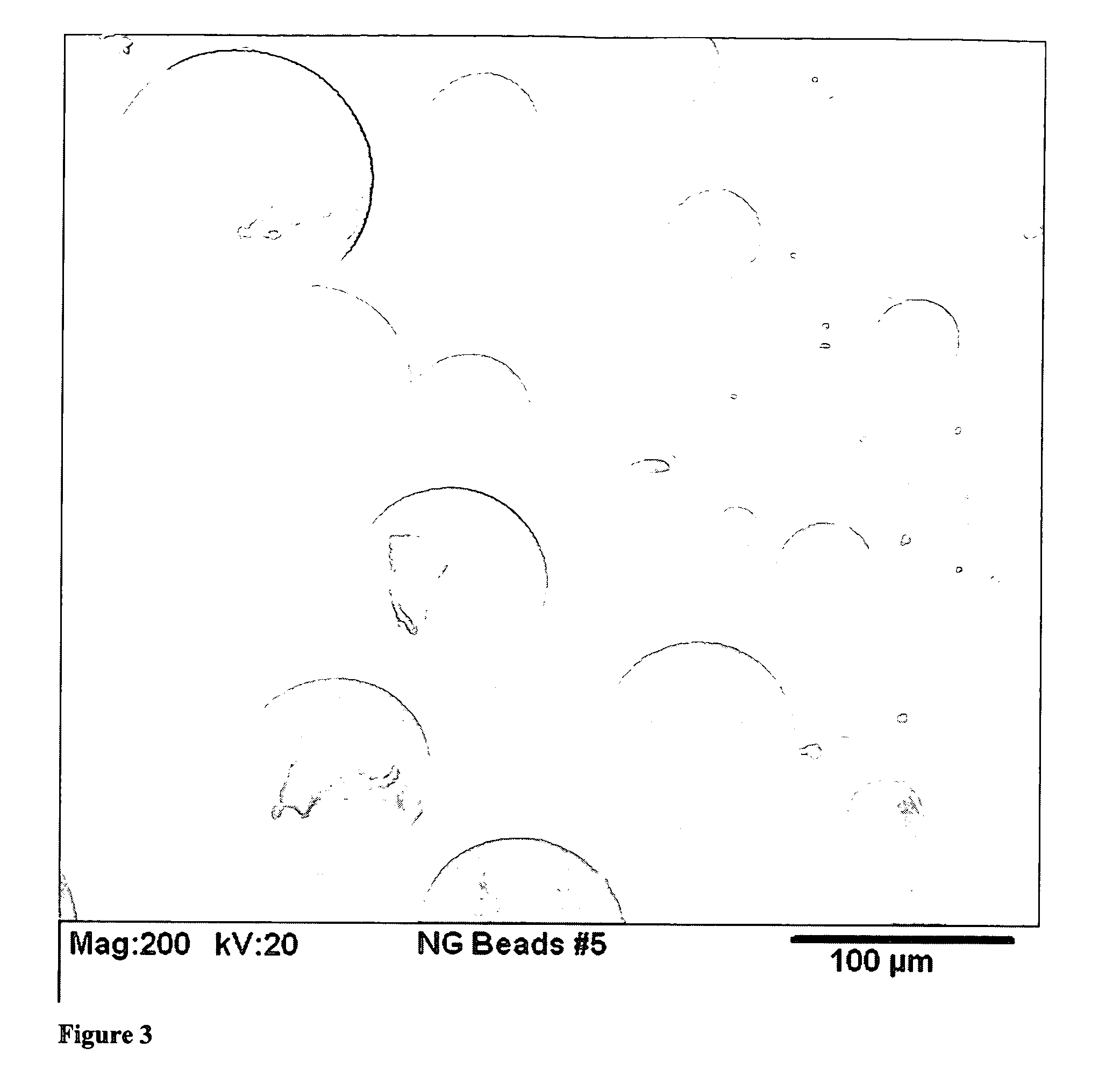

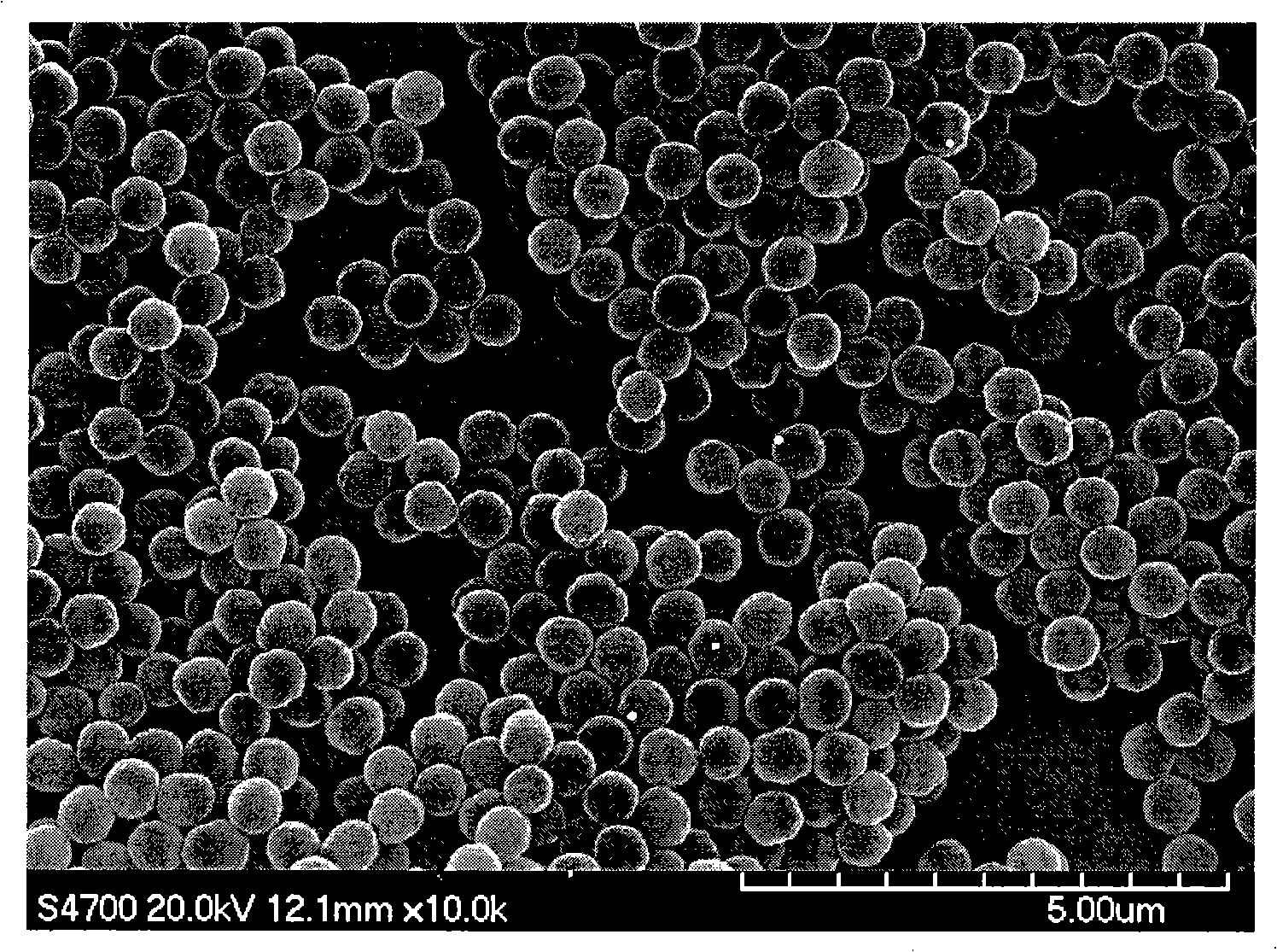

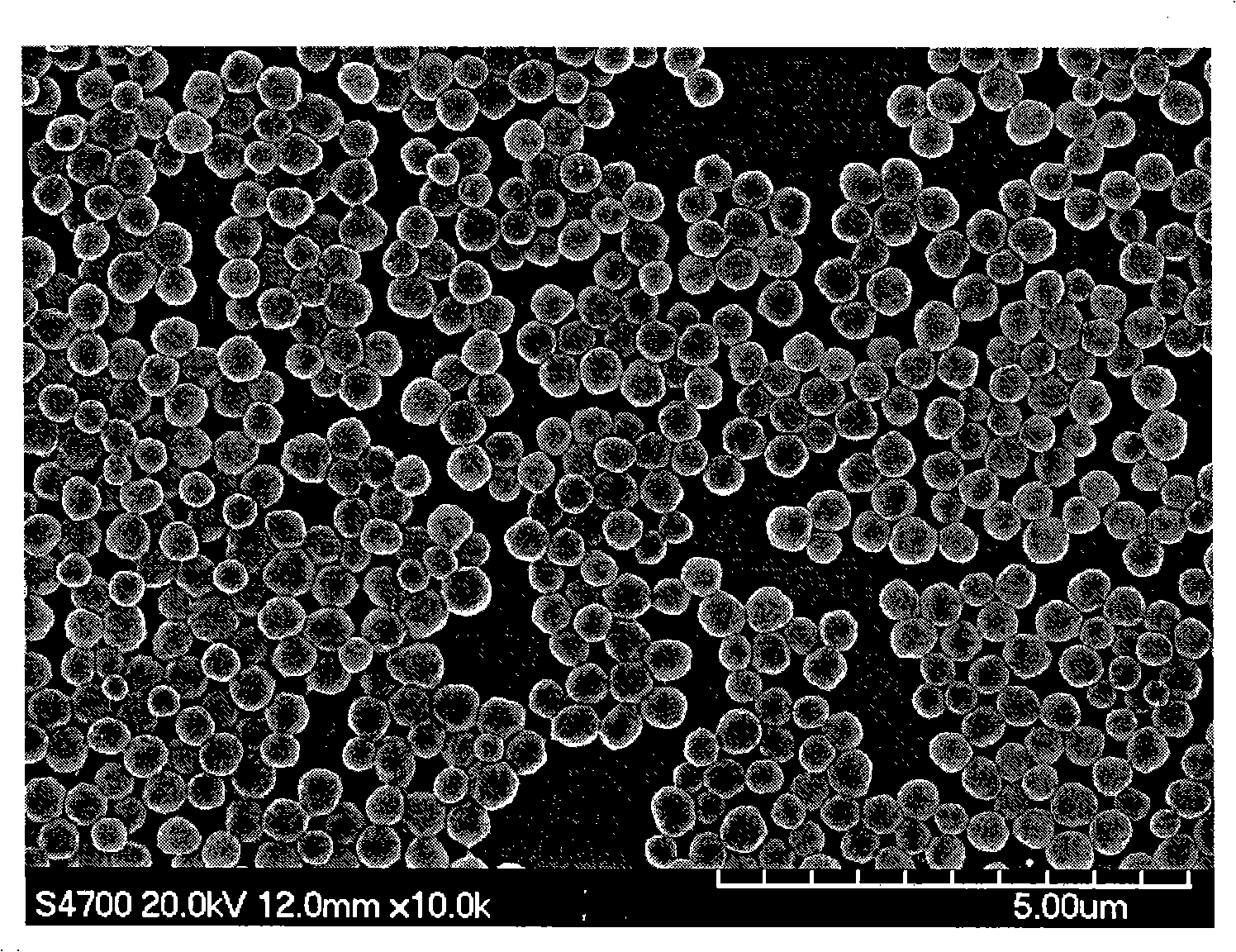

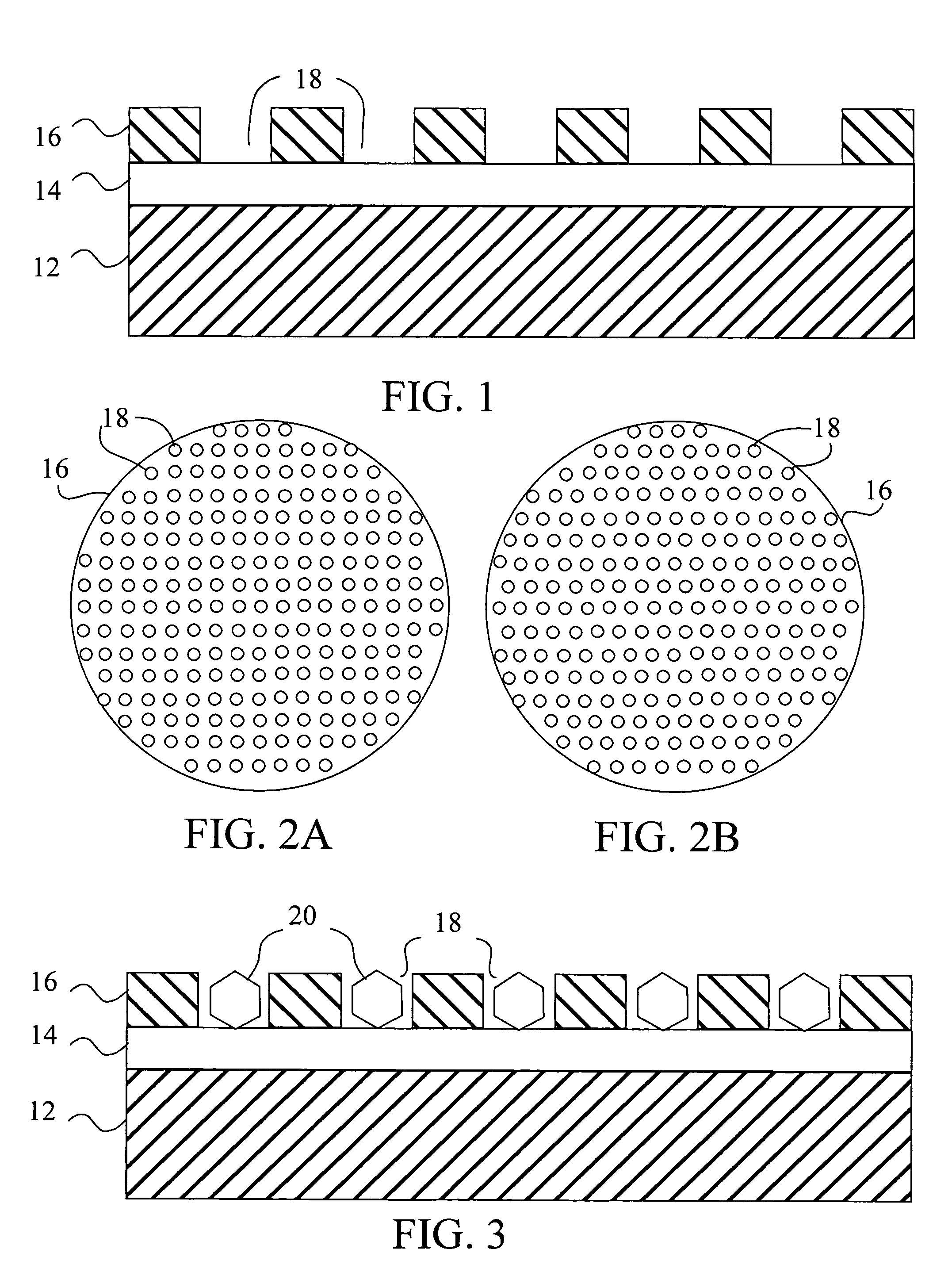

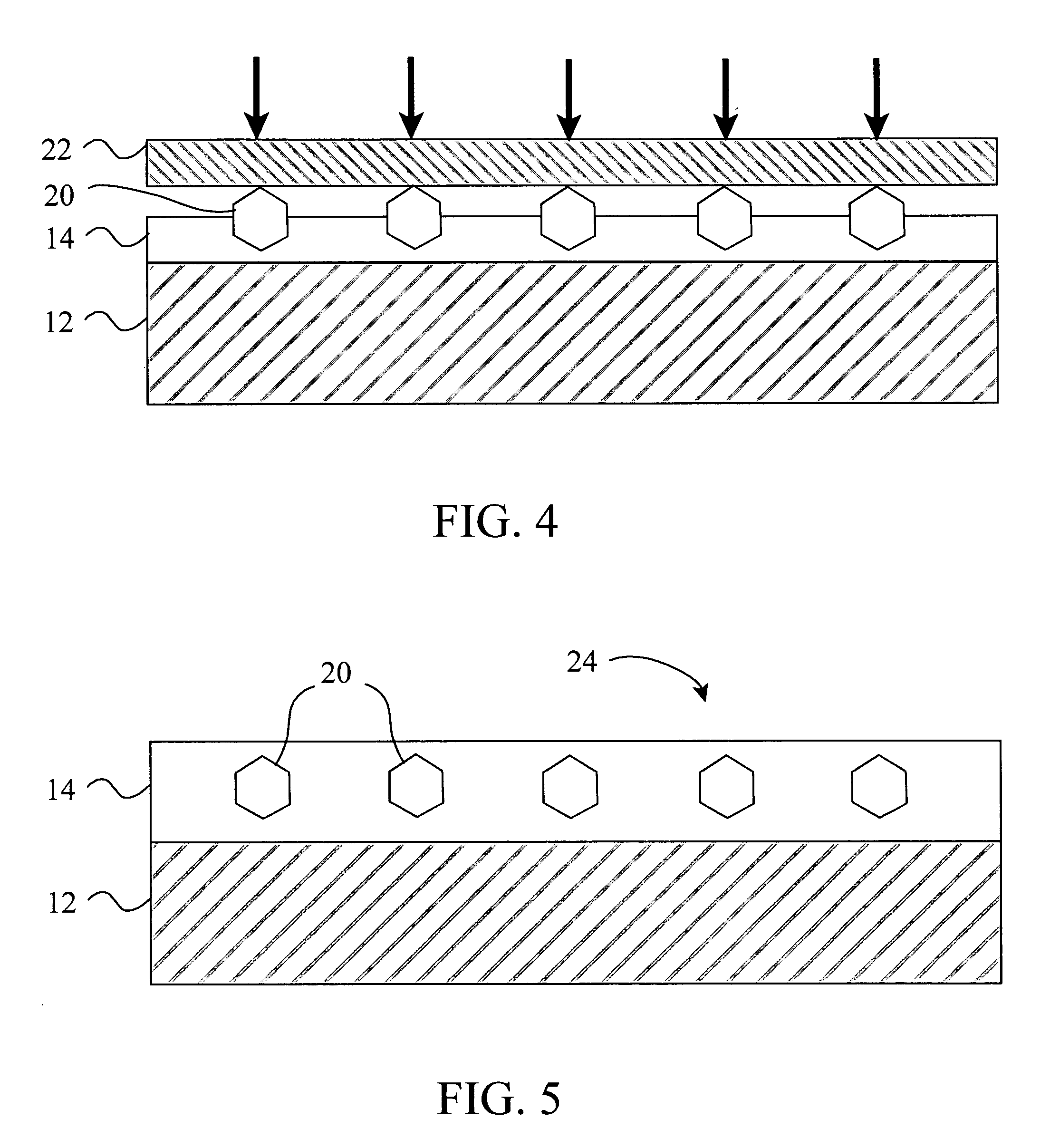

Porous microparticles with solid cores

InactiveUS20070189944A1Narrow size distributionHighly ruggedIon-exchange process apparatusMaterial nanotechnologyChromatography columnNanometre

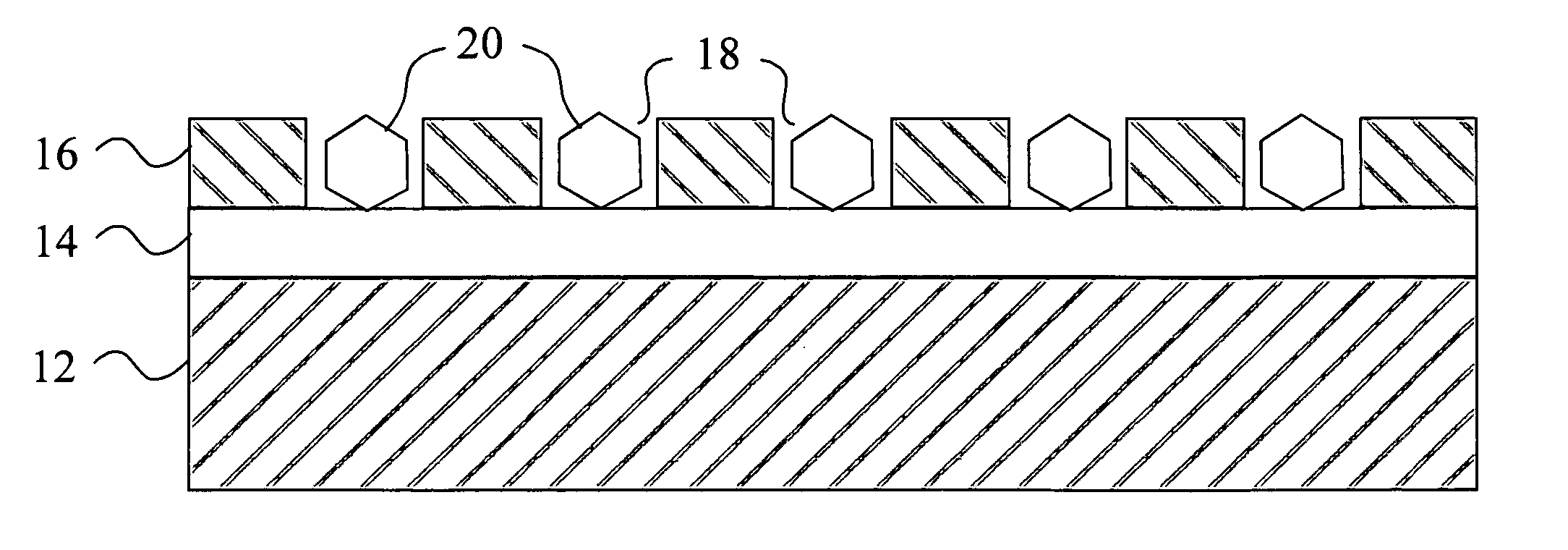

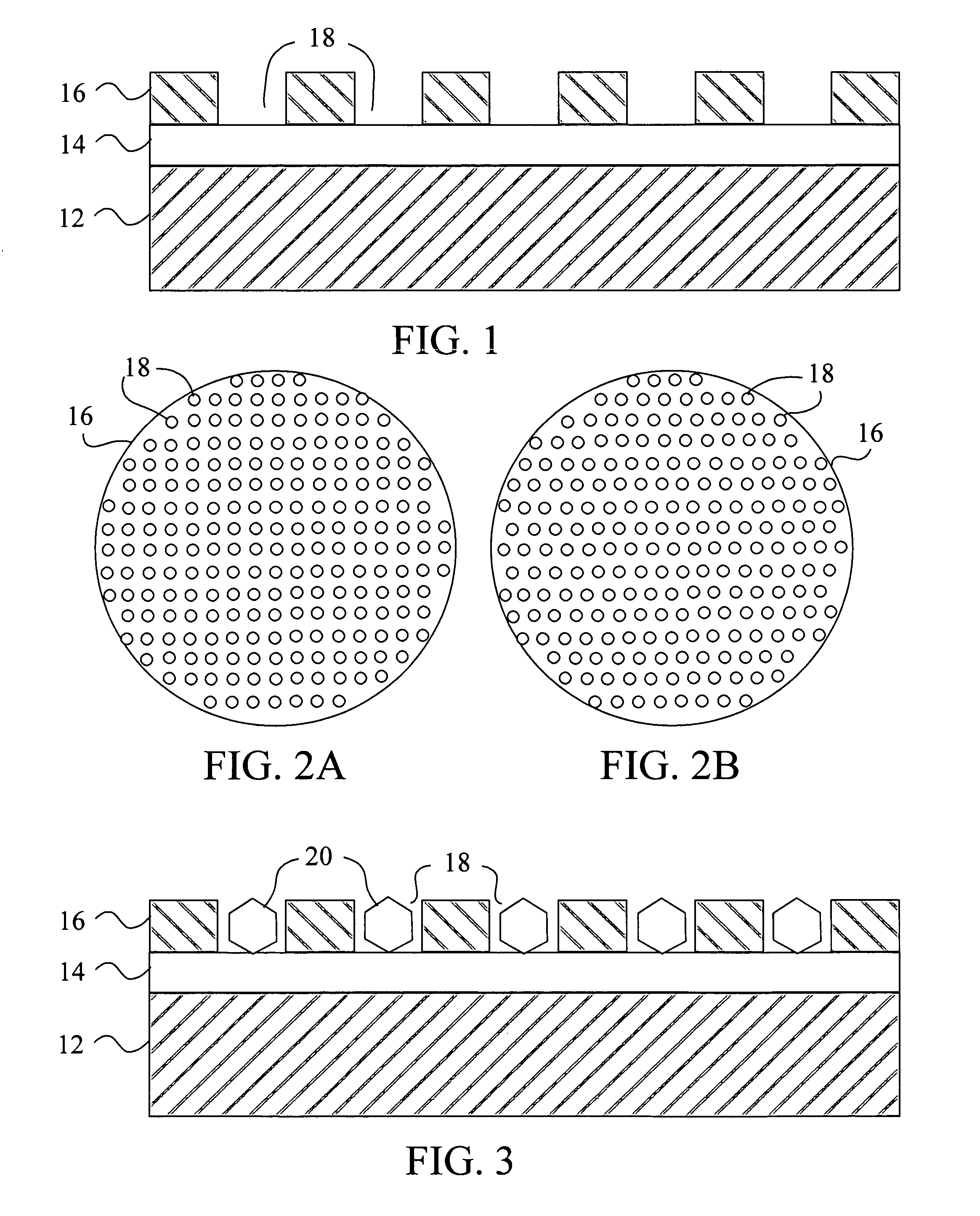

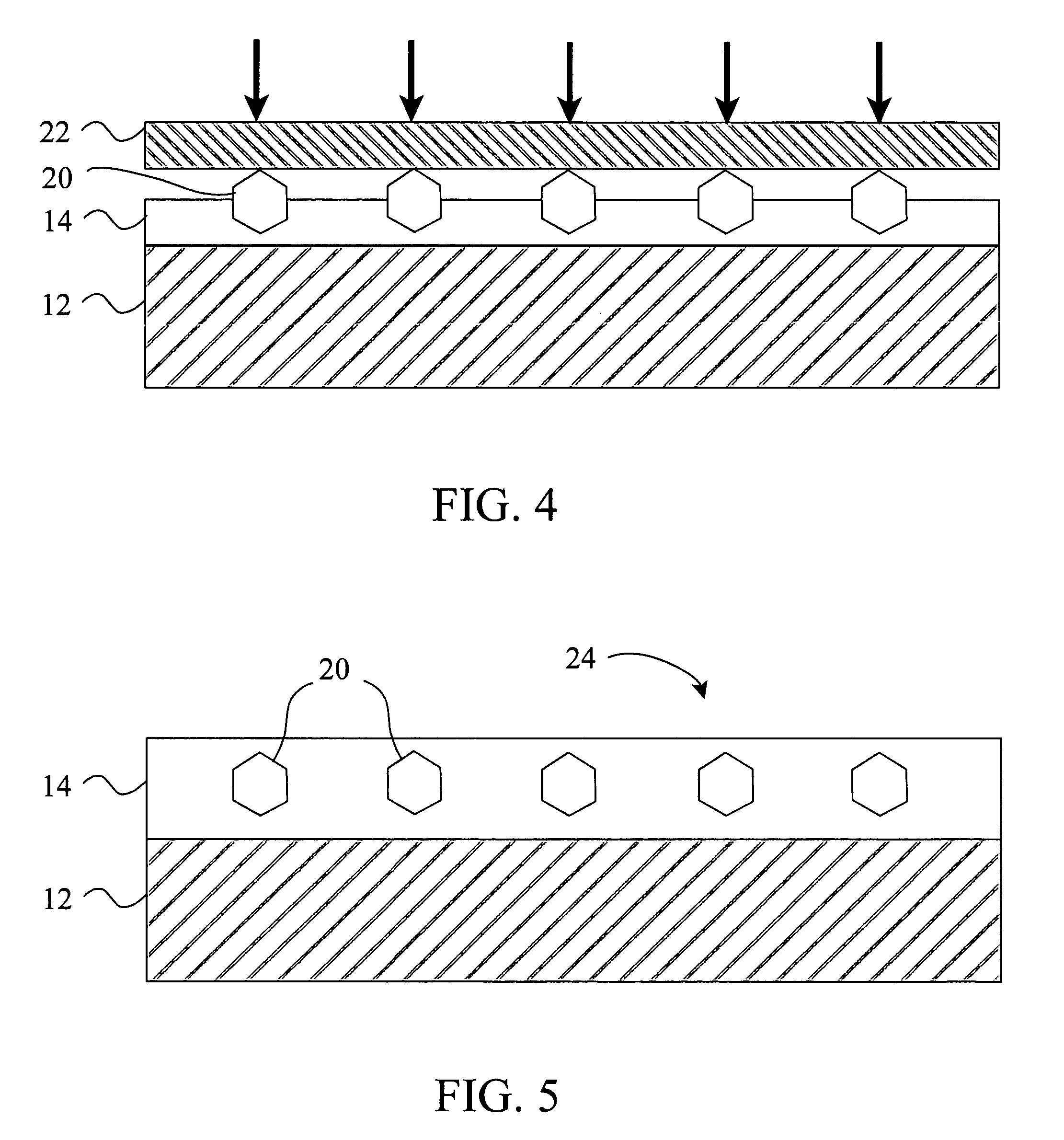

The present invention relates to microparticles, particularly spherical silica microparticles, which may be useful in liquid chromatography. Specifically, the microparticles include a solid core and an outer porous shell surrounding and irreversibly joined to the core. The shell is composed of a plurality of colloidal nanoparticles, which are applied using an electrostatic multi-multilayering method. The resulting microparticles have a small particle diameter, such as about 1 μm to 3.5 μm, a high particle density, such as about 1.2 g / cc to 1.9 g / cc, and a high surface area, such as about 50 m2 / g to 165 m2 / g. These microparticles can be used to form packed beds and liquid chromatographic columns, which are more efficient and rugged than conventional liquid chromatographic columns.

Owner:ADVANCED MATERIALS TECHNOLOGIES

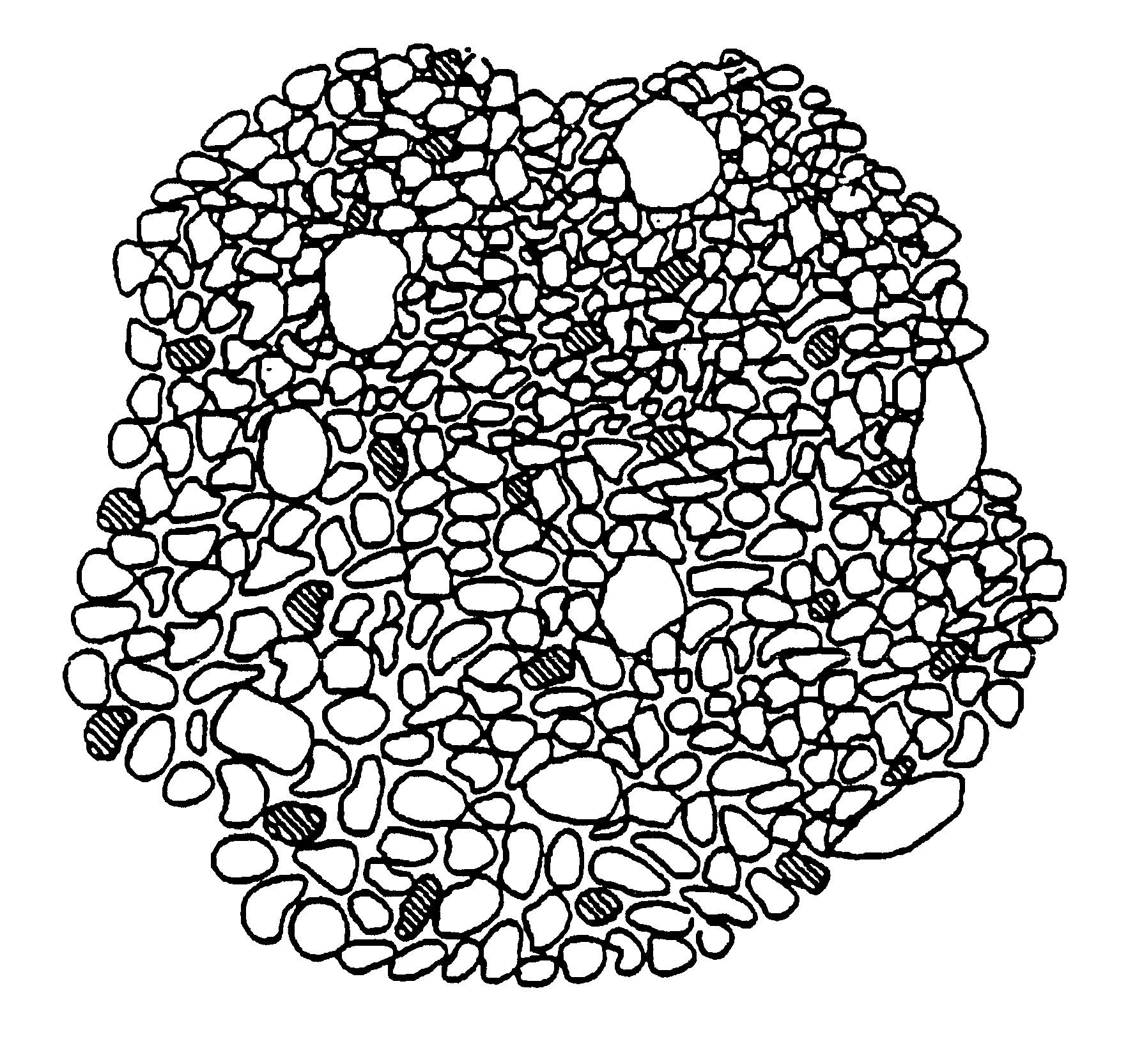

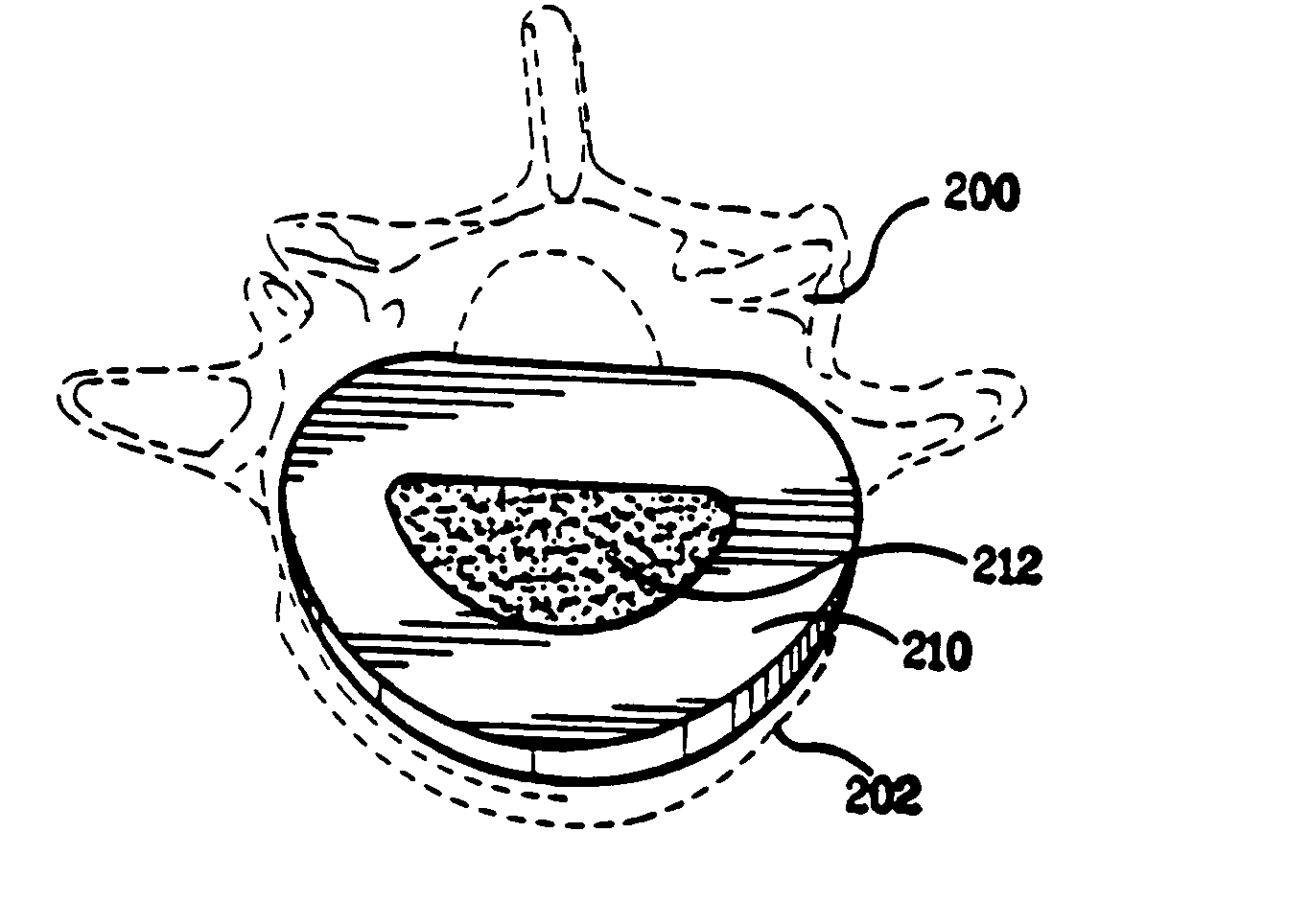

Composite shaped bodies and methods for their production and use

InactiveUS6863899B2Overcome the lack of robustnessNovel featuresCosmetic preparationsDental implantsCalcium biphosphatePlastic surgery

Shaped, composite bodies are provided. One portion of the shaped bodies comprises an RPR-derived porous inorganic material, preferably a calcium phosphate. Another portion of the composite bodies is a different solid material, preferably metal, glass, ceramic or polymeric. The shaped bodies are especially suitable for orthopaedic and other surgical use.

Owner:ORTHOVITA INC

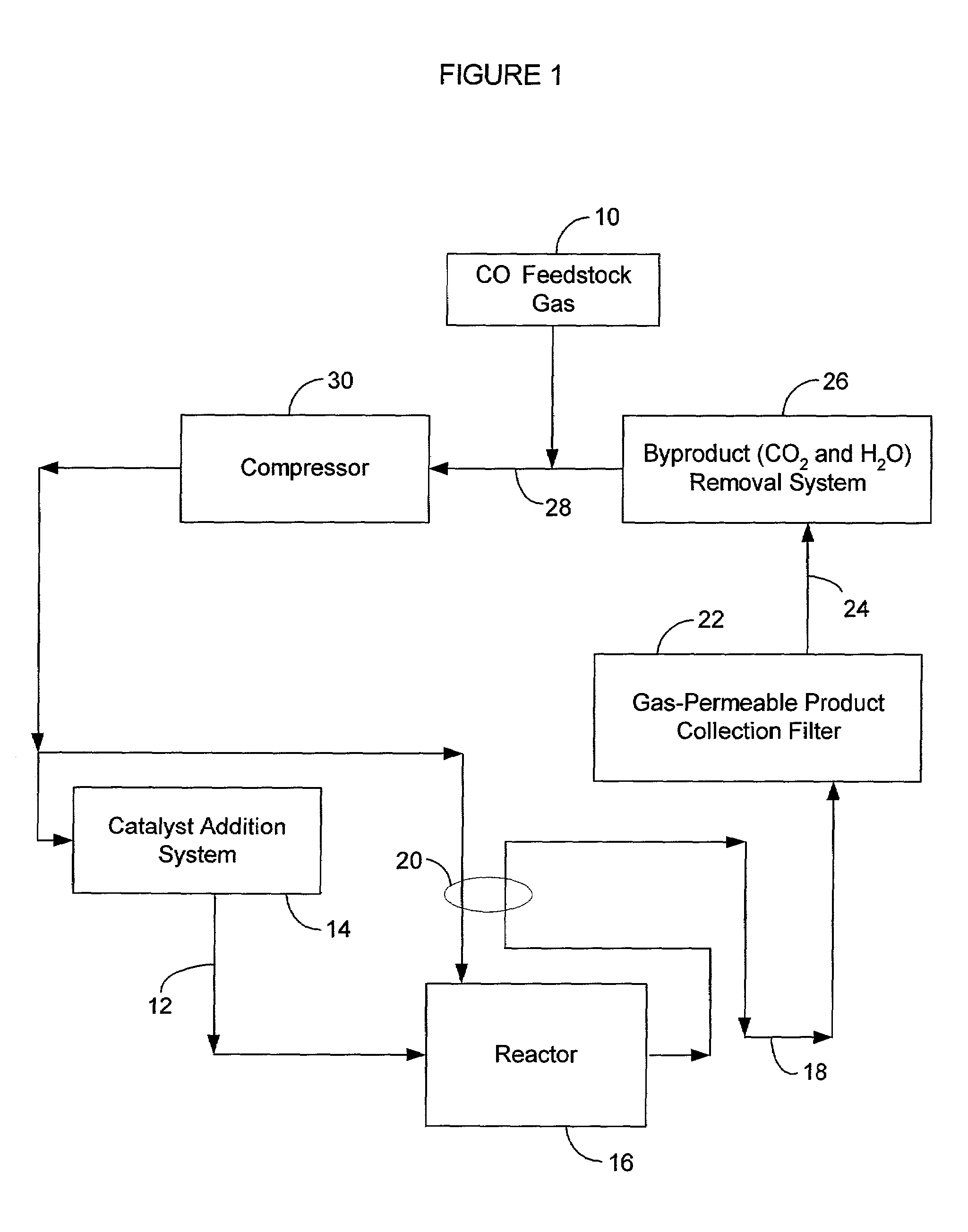

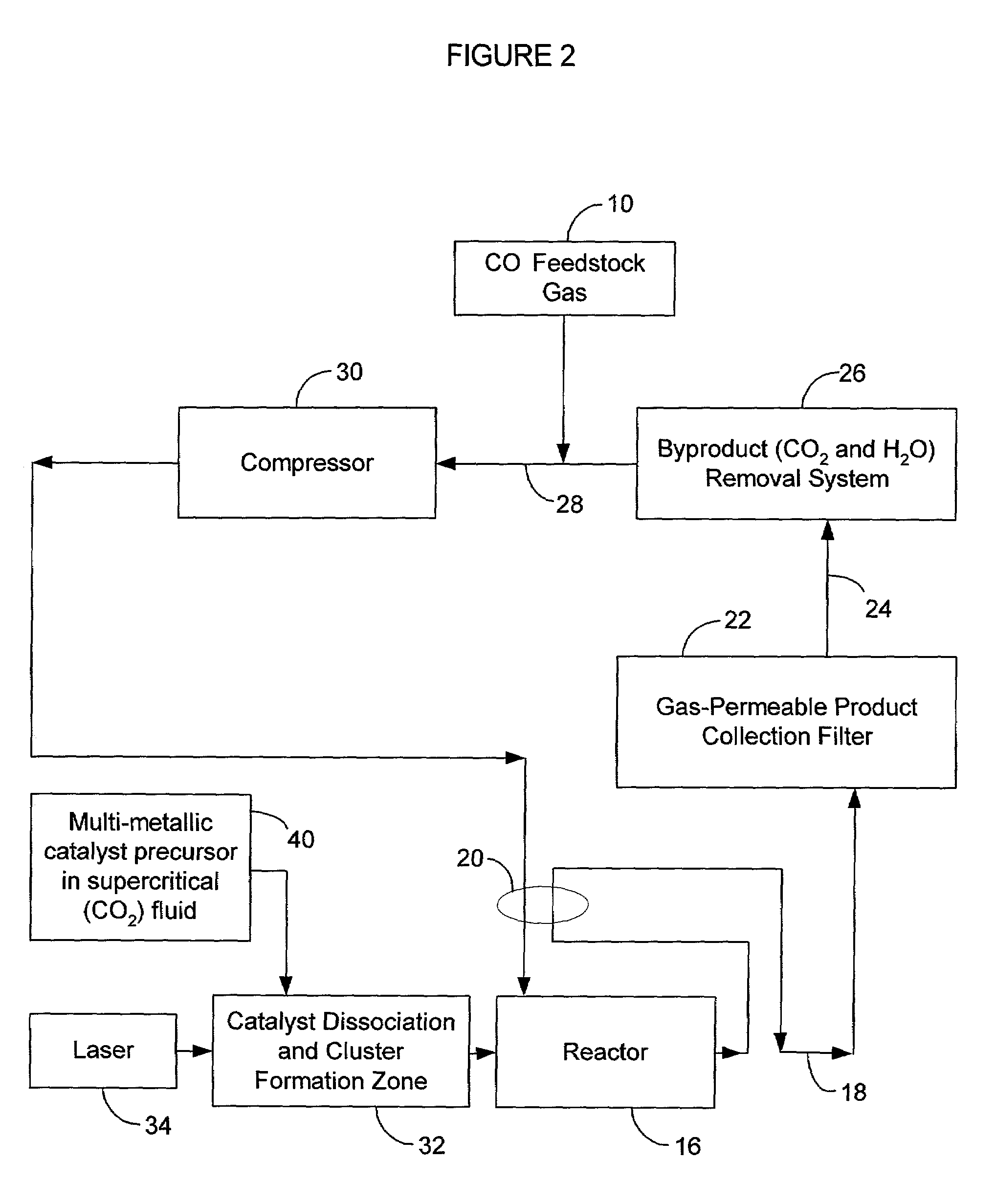

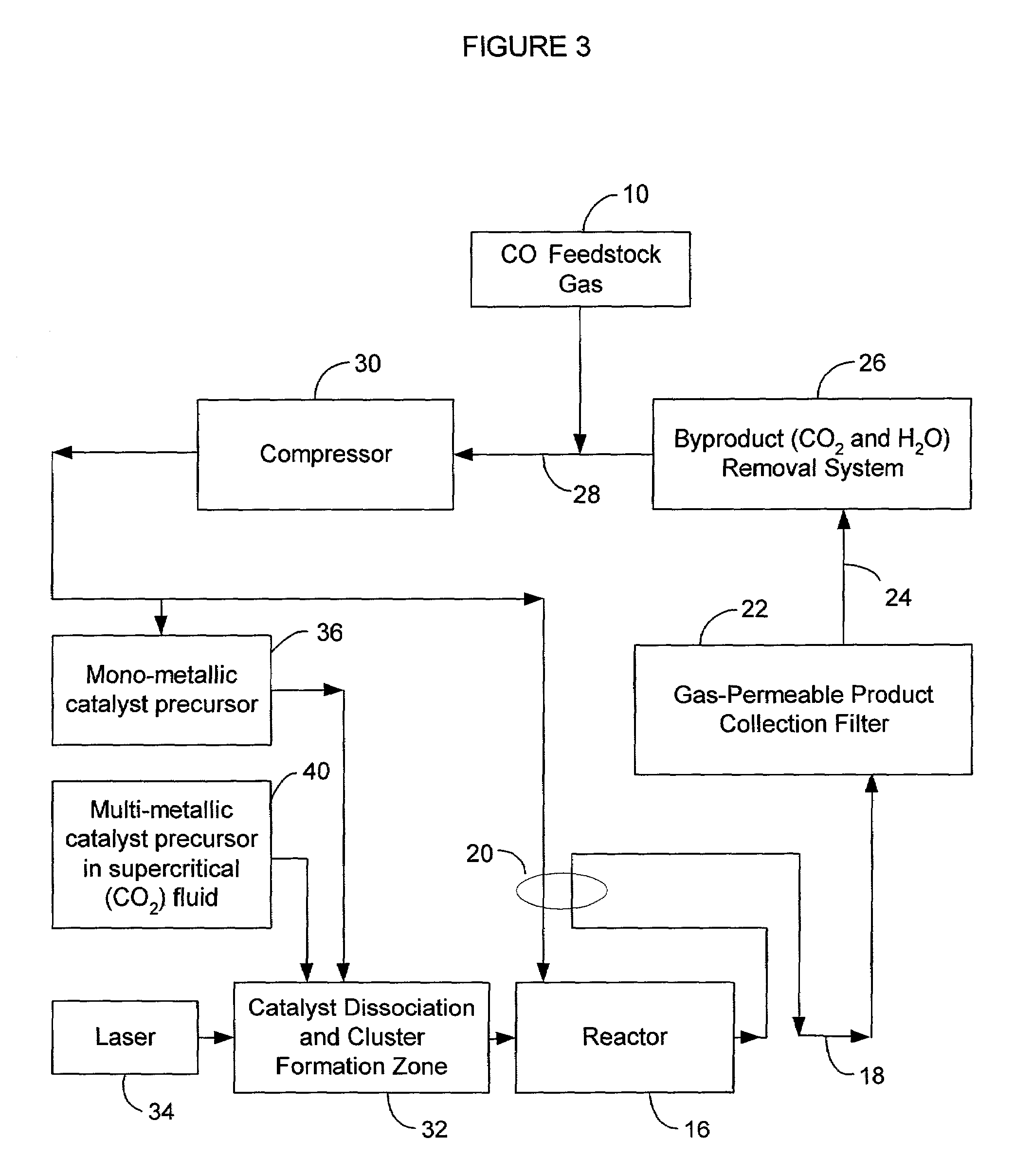

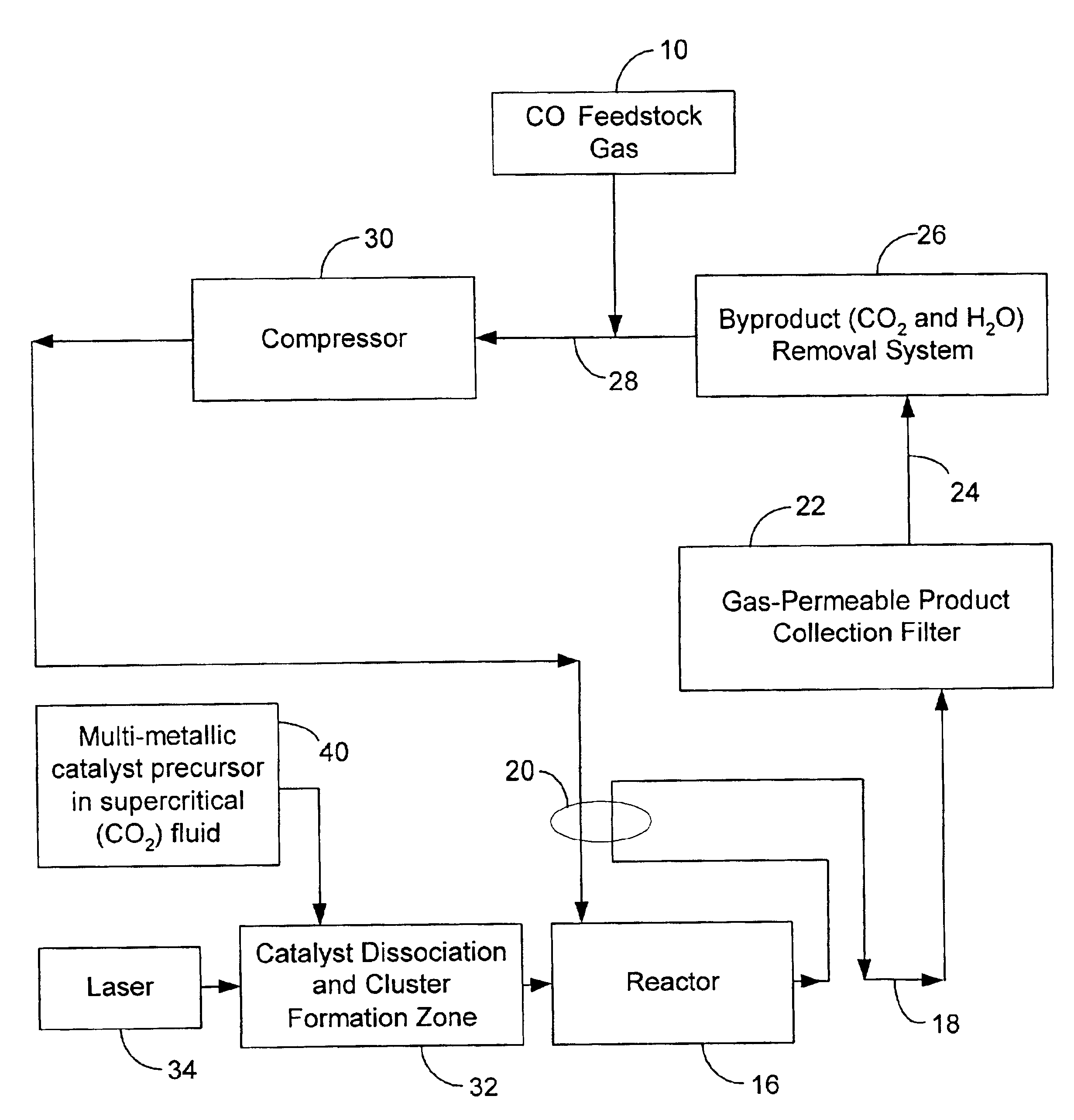

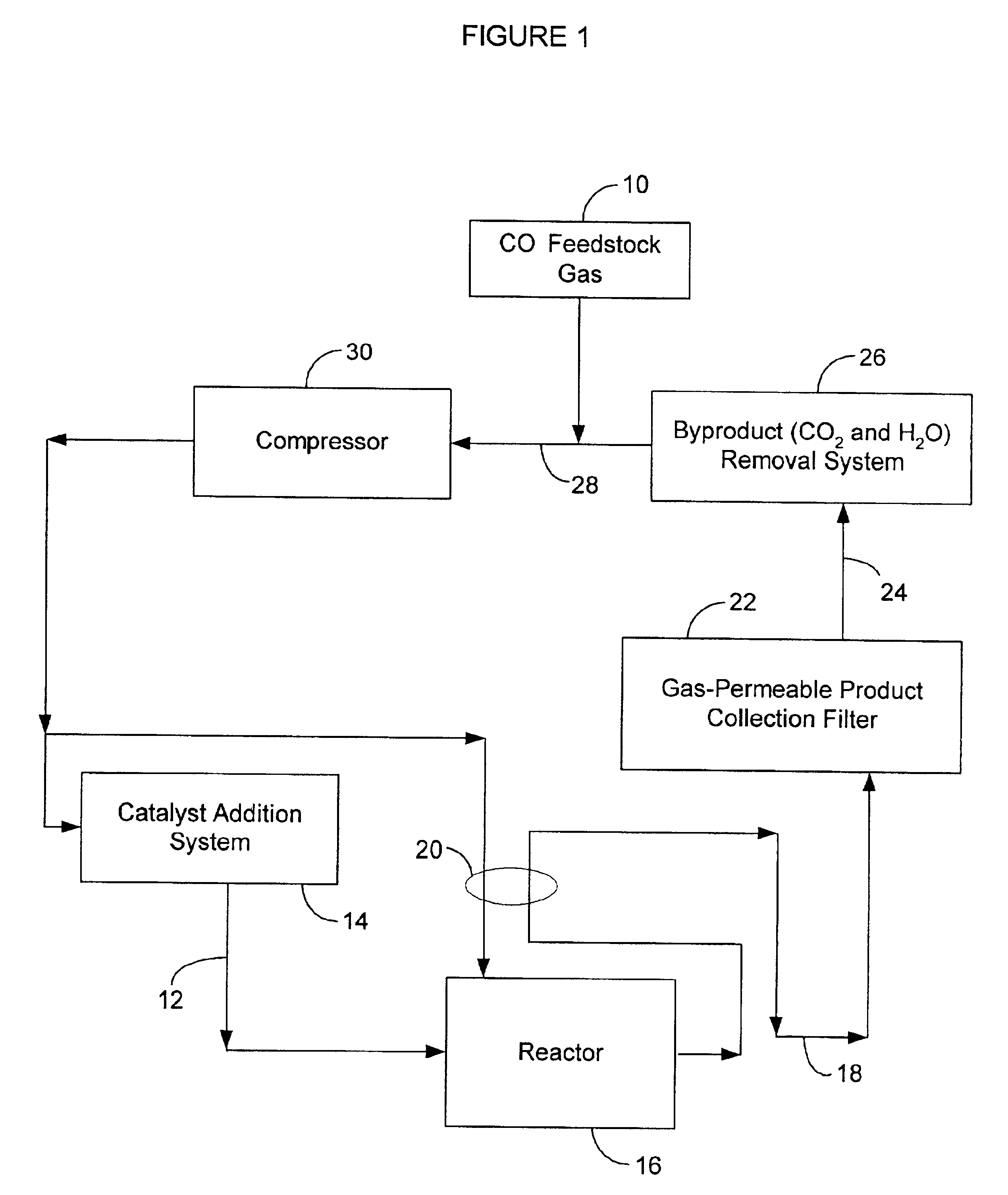

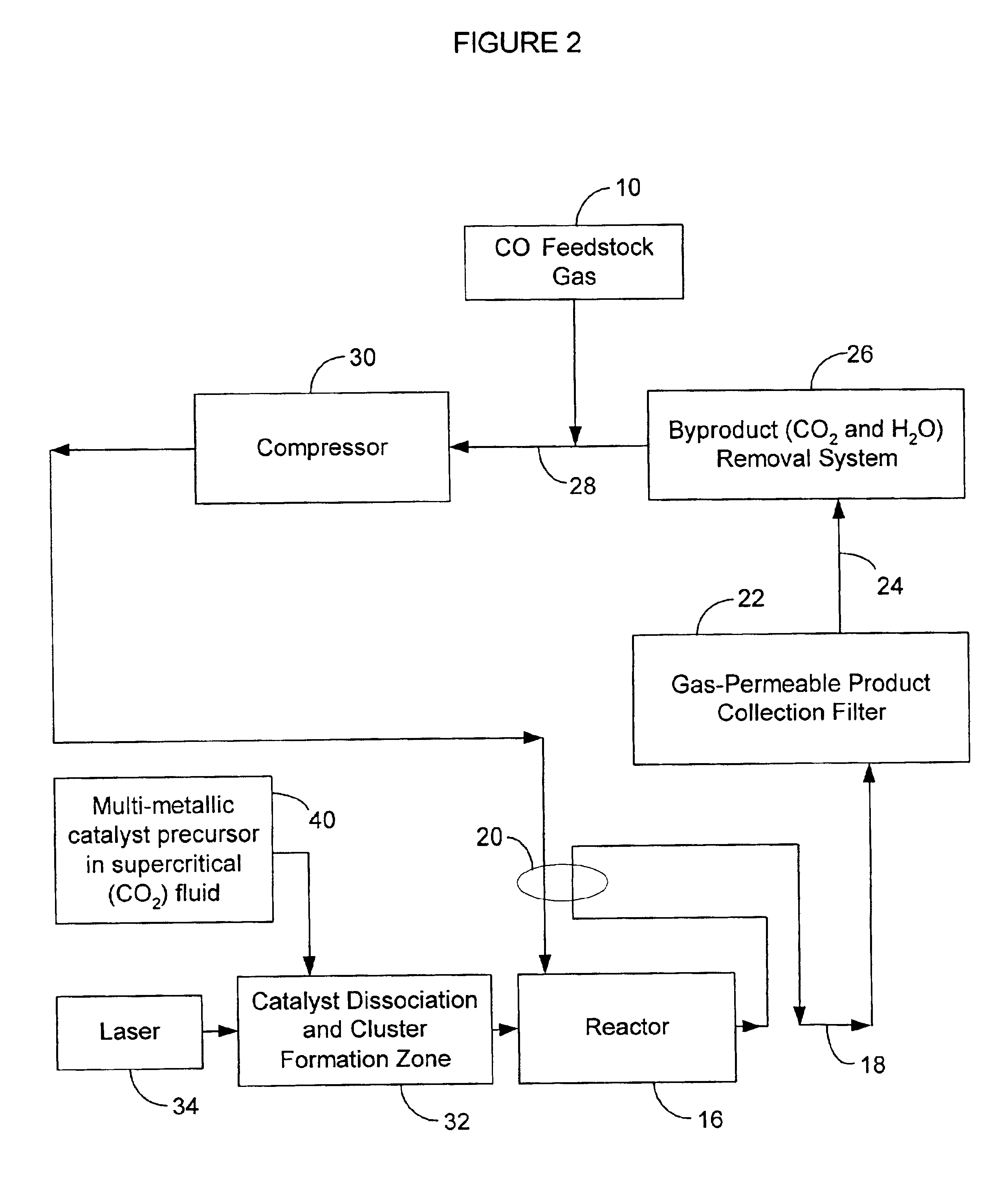

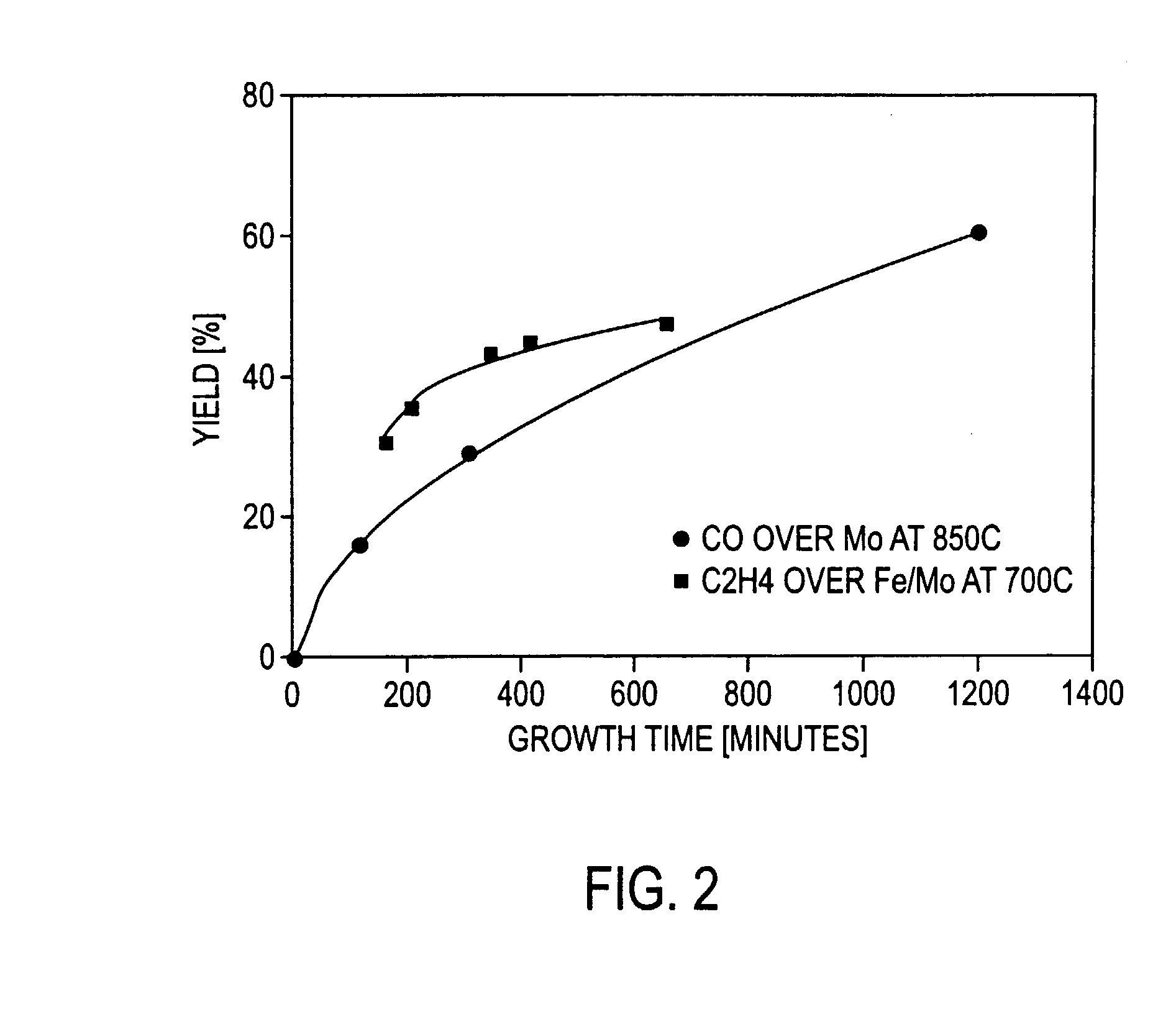

Process utilizing seeds for making single-wall carbon nanotubes

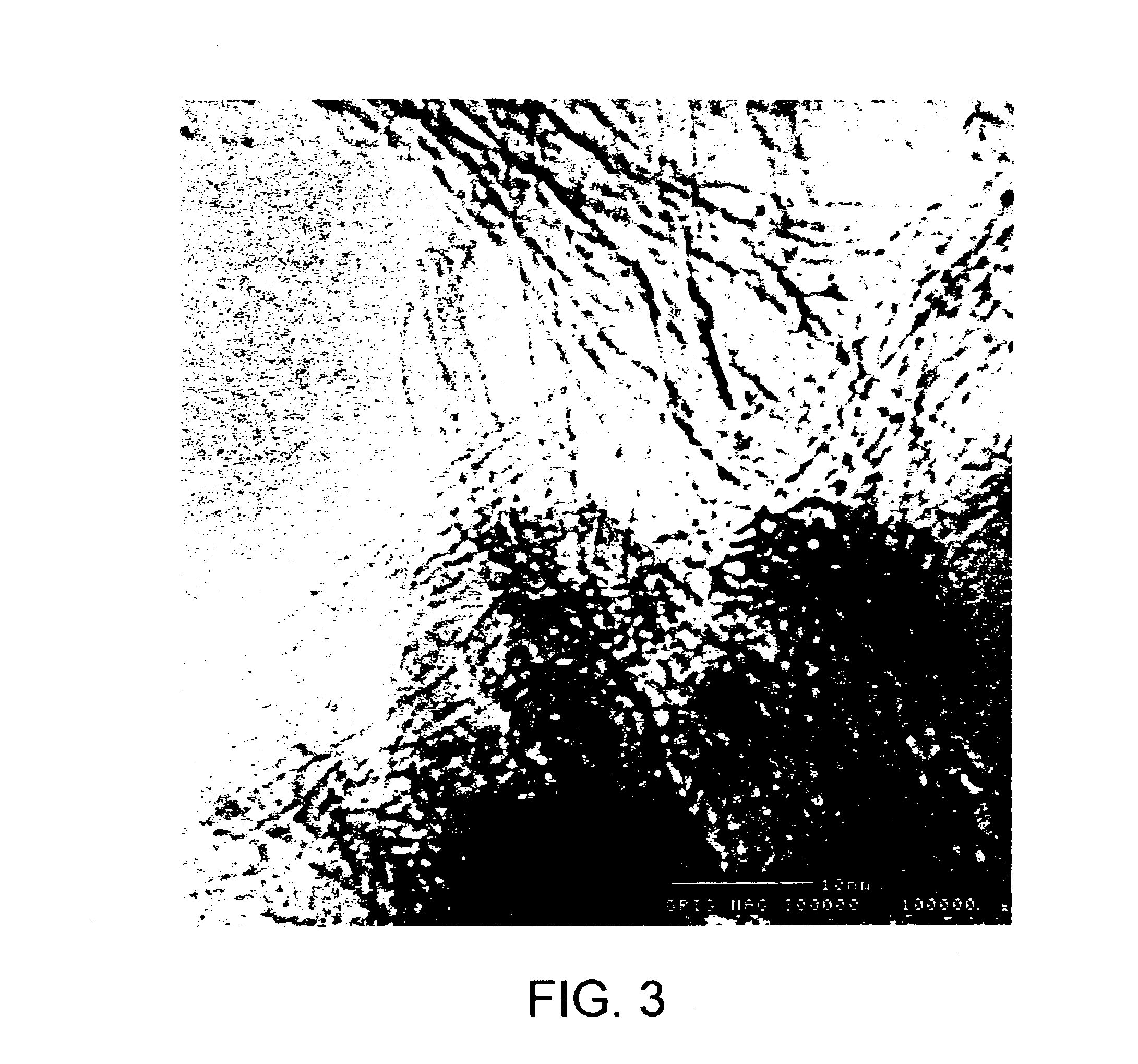

InactiveUS7052668B2Facilitates nucleation phaseFaster and more reproducible and stable clusteringMaterial nanotechnologyFullerenesMetal catalystGas phase

A gas-phase method for producing high yields of single-wall carbon nanotubes with high purity and homogeneity is disclosed. The method involves using preformed metal catalyst clusters to initiate and grow single-wall carbon nanotubes. In one embodiment, multi-metallic catalyst precursors are used to facilitate the metal catalyst cluster formation. The catalyst clusters are grown to the desired size before mixing with a carbon-containing feedstock at a temperature and pressure sufficient to initiate and form single-wall carbon nanotubes. The method also involves using small fullerenes and preformed sections of single-wall carbon nanotubes, either derivatized or underivatized, as seed molecules for expediting the growth and increasing the yield of single-wall carbon nanotubes. The multi-metallic catalyst precursors and the seed molecules may be introduced into the reactor by means of a supercritical fluid. In addition the seed molecules may be introduced into the reactor via an aerosol or smoke.

Owner:RICE UNIV

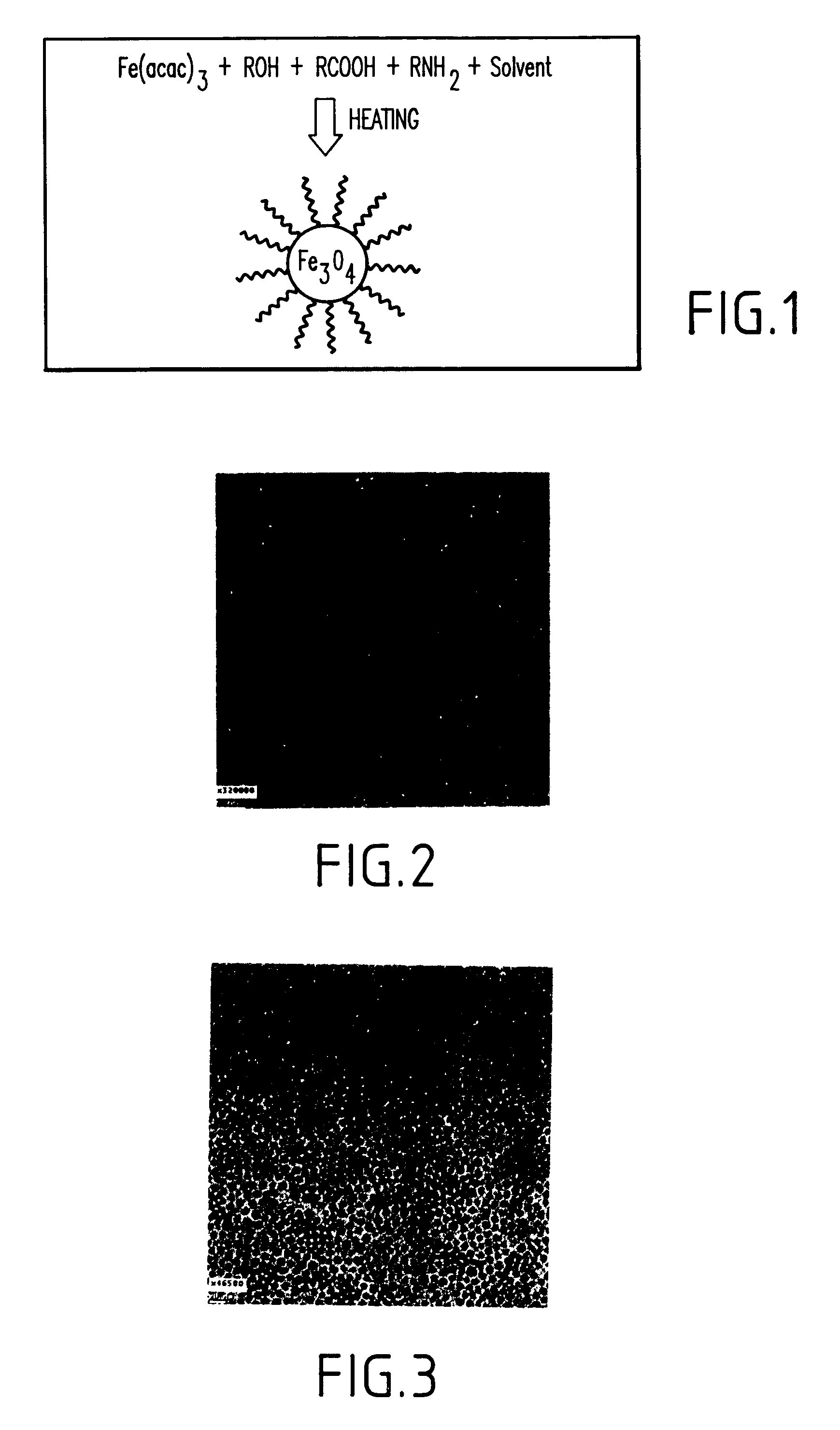

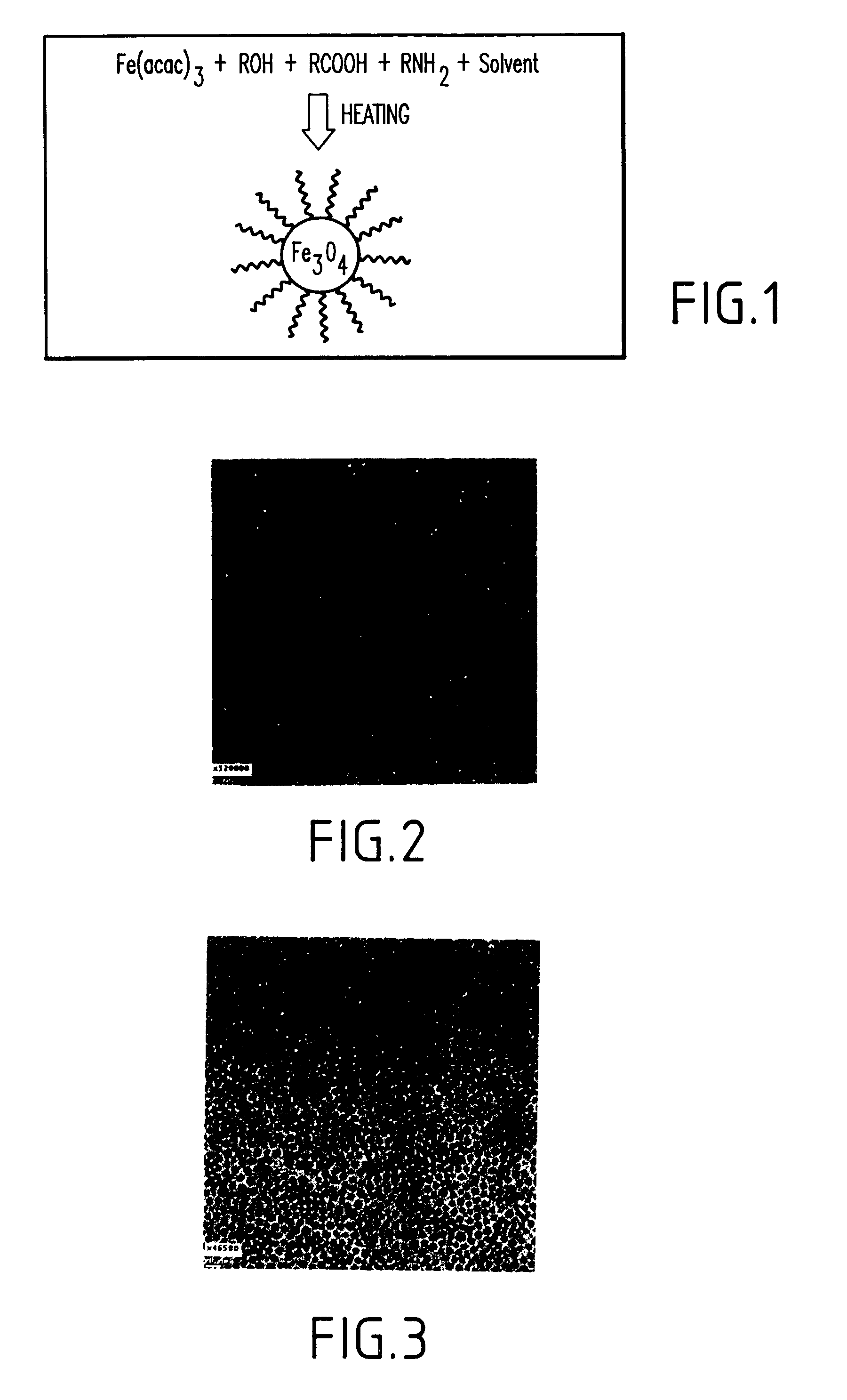

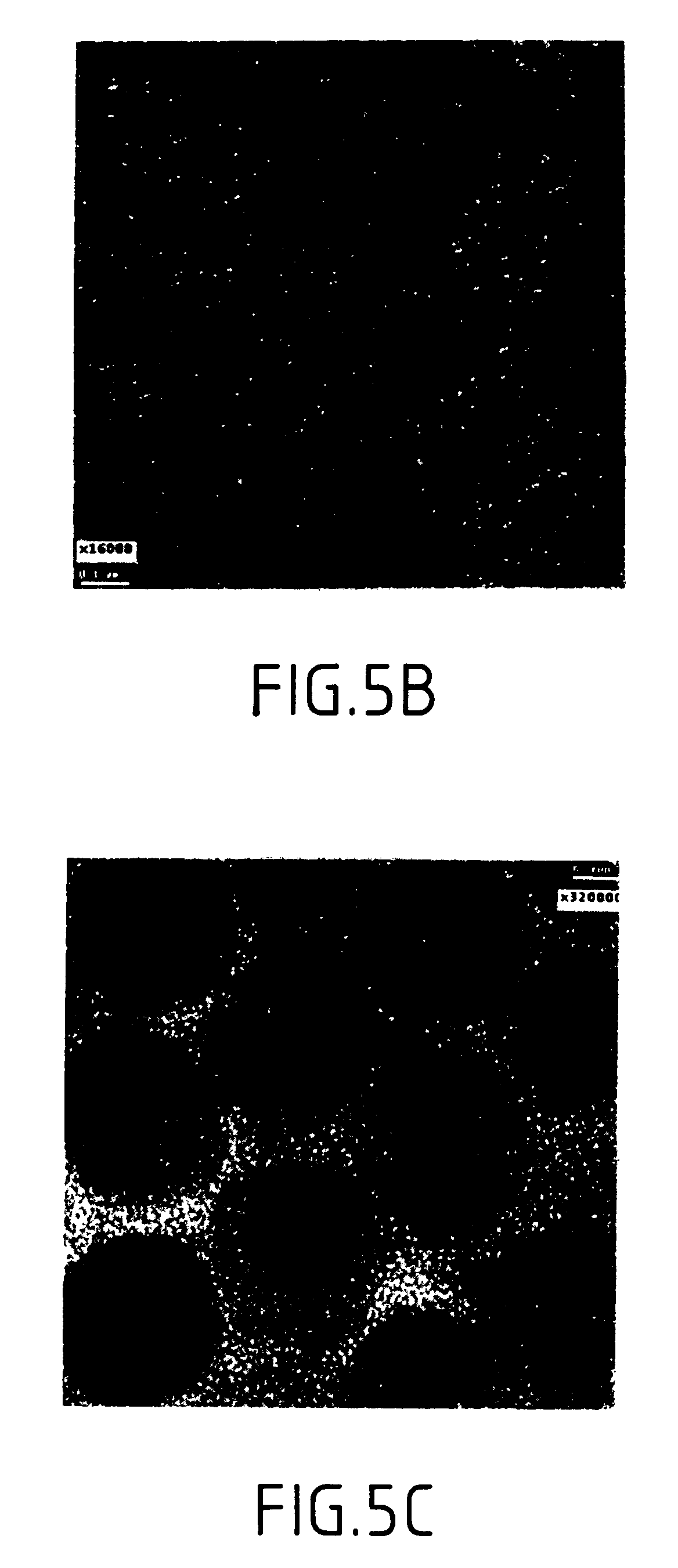

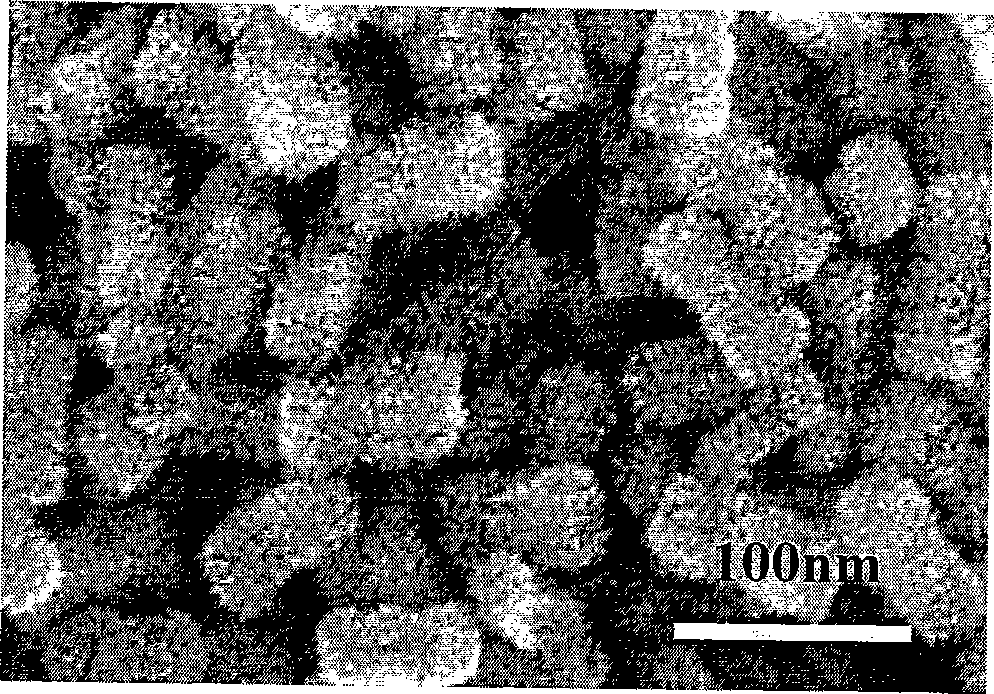

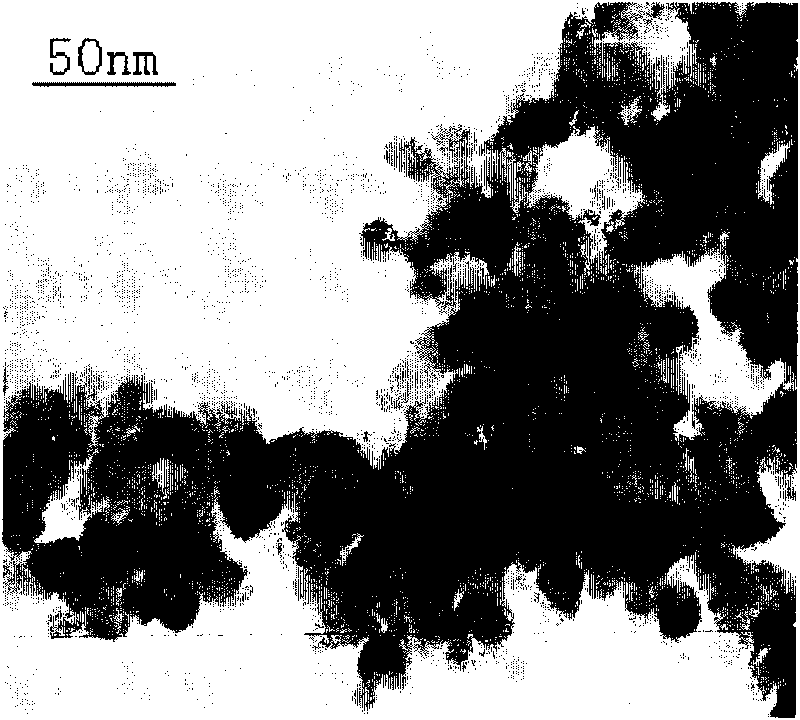

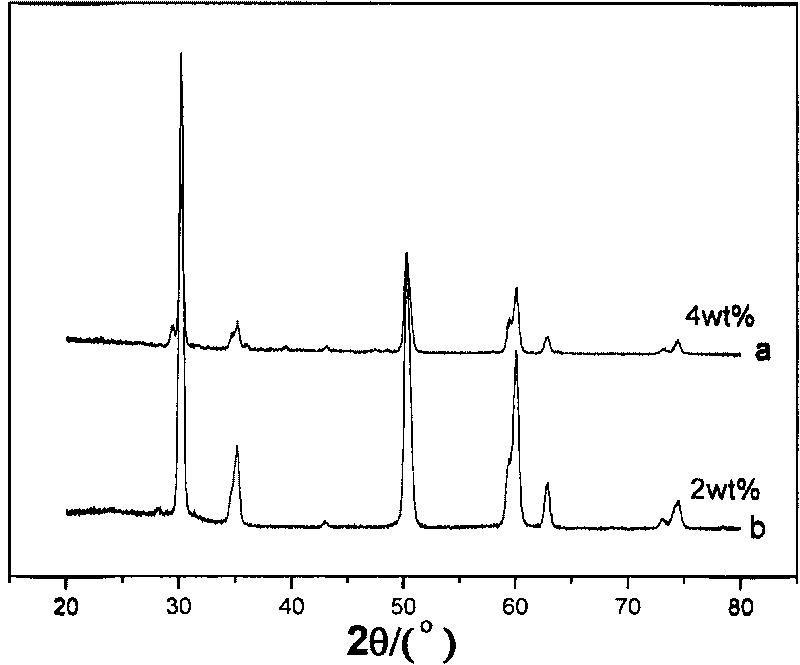

Synthesis of magnetite nanoparticles and the process of forming Fe-based nanomaterials

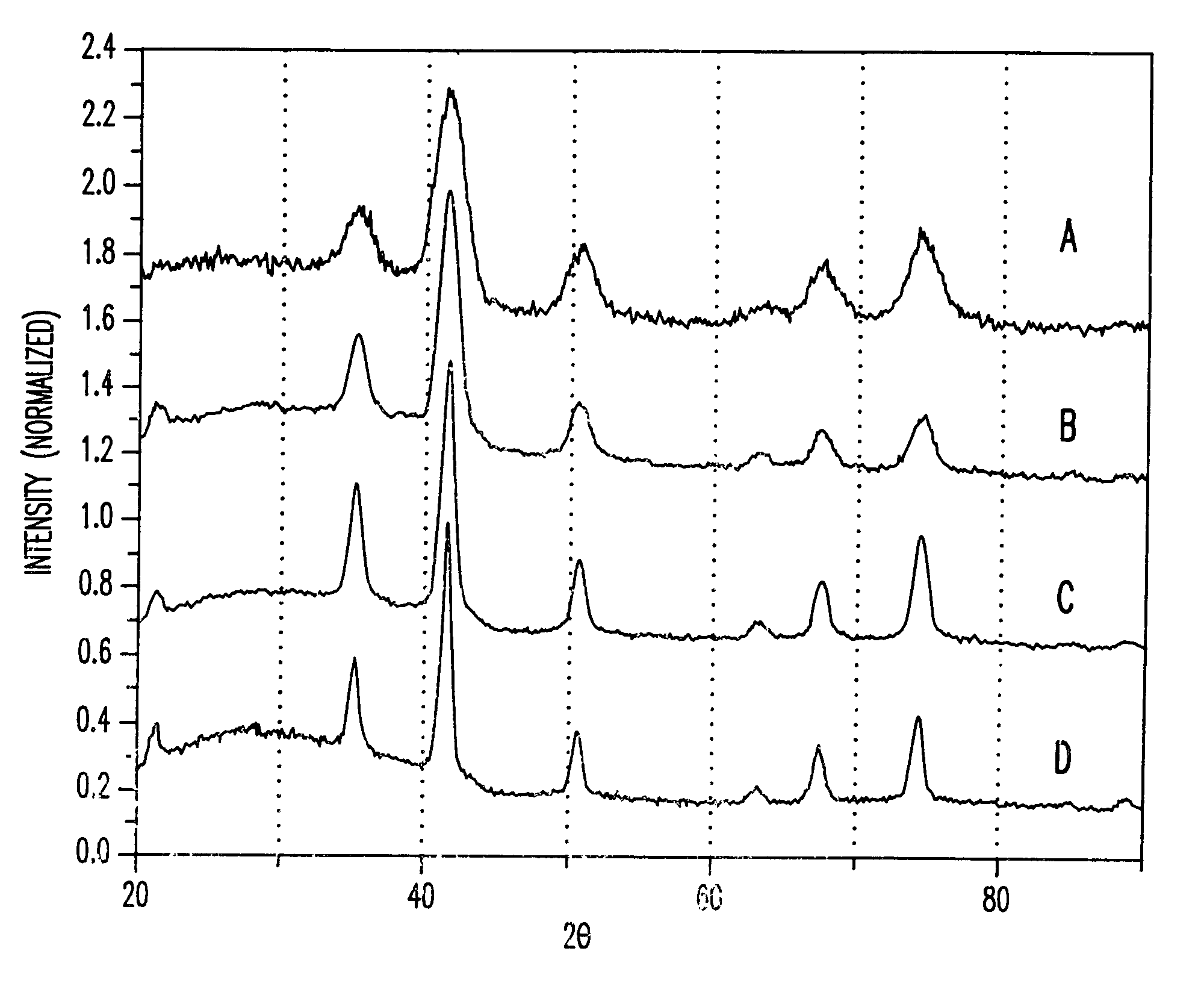

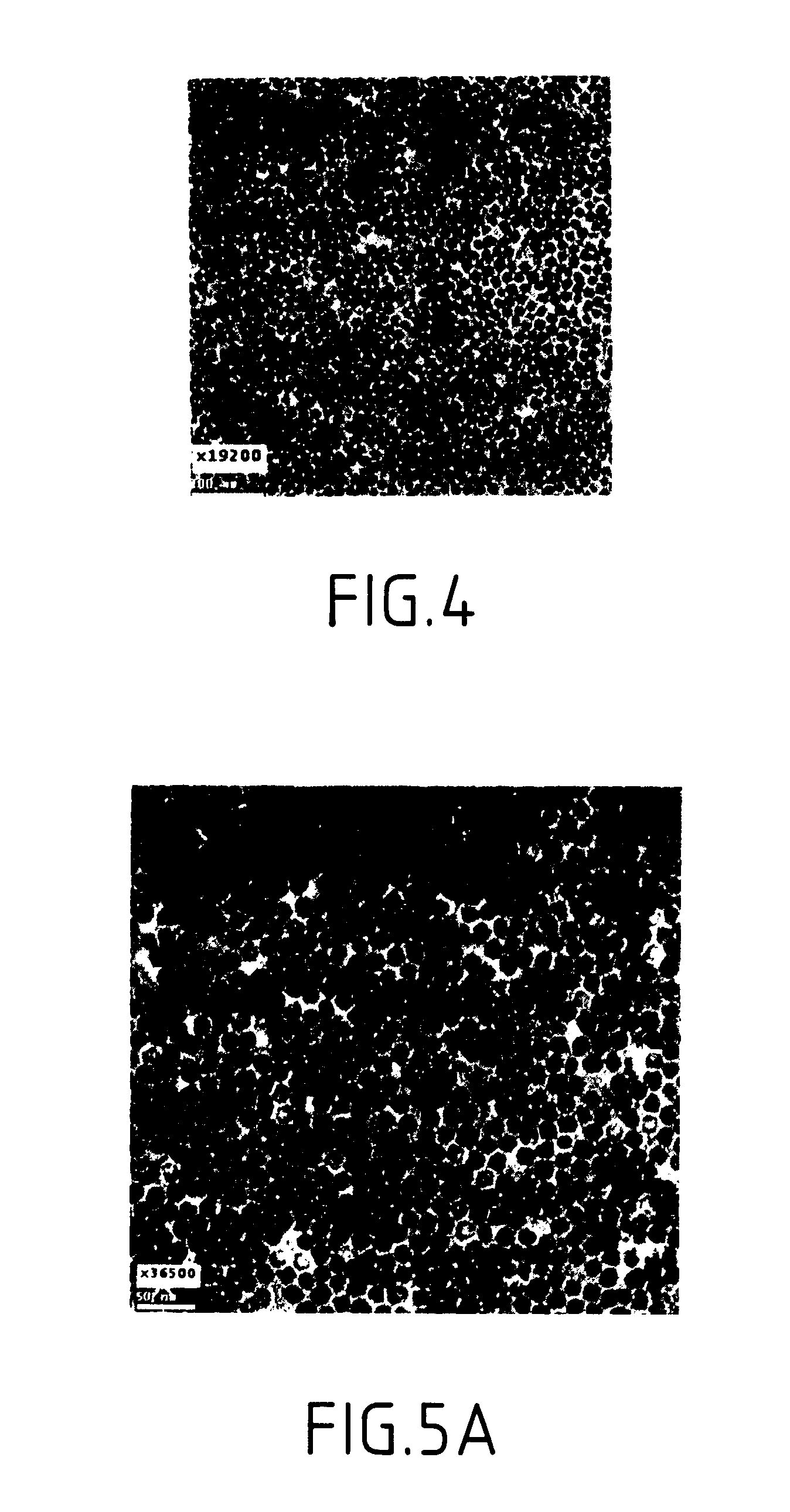

InactiveUS6962685B2Small sizeNarrow size distributionMaterial nanotechnologyNanomagnetismIron saltsMagnetite Nanoparticles

A method and structure for making magnetite nanoparticle materials by mixing iron salt with alcohol, carboxylic acid and amine in an organic solvent and heating the mixture to 200–360 C is described. The size of the particles can be controlled either by changing the iron salt to acid / amine ratio or by coating small nanoparticles with more iron oxide. Magnetite nanoparticles in the size ranging from 2 nm to 20 nm with a narrow size distribution are obtained with the invention. The invention can be readily extended to other iron oxide based nanoparticle materials, including M Fe2O4 (M=Co, Ni, Cu, Zn, Cr, Ti, Ba, Mg) nanomaterials, and iron oxide coated nanoparticle materials. The invention also leads to the synthesis of iron sulfide based nanoparticle materials by replacing alcohol with thiol in the reaction mixture. The magnetite nanoparticles can be oxidized to γ-Fe2O3, or α-Fe2O3, or can be reduced to bcc-Fe nanoparticles, while iron oxide based materials can be used to make binary iron based metallic nanoparticles, such as CoFe, NiFe, and FeCoSmx nanoparticles.

Owner:INT BUSINESS MASCH CORP

Inorganic shaped bodies and methods for their production and use

InactiveUS6991803B2Overcome the lack of robustnessNovel featuresPowder deliveryDental implantsPorosityCellulose

Shaped, preferably porous, inorganic bodies are provided which are prepared from a reactive blend. In accordance with one preferred embodiment, the solution is absorbed into a porous sacrificial substrate such as a cellulose sponge. The solution-saturated substrate is heated and an oxidation-reduction reaction occurs thereby forming an inorganic solid. A shaped, inorganic body is formed in situ. Optional, but preferred additional thermal treatment of the shaped, inorganic body removes the organic substrate, leaving an inorganic body that faithfully mimics the porosity, shape, and other physical characteristics of the organic substrate. Inorganic substrates may also be used to good effect. Large varieties of shaped bodies can be prepared in accordance with other embodiments of the invention and such shapes find wide use in surgery, laboratory and industrial processes and otherwise. The invention also provides chemically and morphologically uniform powders, including those having uniformly small sizes.

Owner:ORTHOVITA INC

Process utilizing pre-formed cluster catalysts for making single-wall carbon nanotubes

InactiveUS6913789B2Facilitates nucleation phaseFaster and more reproducible and stable clusteringMaterial nanotechnologyFibre chemical featuresGas phaseMetal catalyst

A gas-phase method for producing high yields of single-wall carbon nanotubes with high purity and homogeneity is disclosed. The method involves using preformed metal catalyst clusters to initiate and grow single-wall carbon nanotubes. In one embodiment, multi-metallic catalyst precursors are used to facilitate the metal catalyst cluster formation. The catalyst clusters are grown to the desired size before mixing with a carbon-containing feedstock at a temperature and pressure sufficient to initiate and form single-wall carbon nanotubes. The method also involves using small fullerenes and preformed sections of single-wall carbon nanotubes, either derivatized or underivatized, as seed molecules for expediting the growth and increasing the yield of single-wall carbon nanotubes. The multi-metallic catalyst precursors and the seed molecules may be introduced into the reactor by means of a supercritical fluid. In addition the seed molecules may be introduced into the reactor via an aerosol or smoke.

Owner:RICE UNIV

Composite shaped bodies and methods for their production and use

InactiveUS20050042288A1Increase productionLow process temperatureDental implantsPowder deliveryCalcium biphosphatePlastic surgery

Shaped, composite bodies are provided. One portion of the shaped bodies comprises an RPR-derived porous inorganic material, preferably a calcium phosphate. Another portion of the composite bodies is a different solid material, preferably metal, glass, ceramic or polymeric. The shaped bodies are especially suitable for orthopaedic and other surgical use.

Owner:ORTHOVITA INC

Method and apparatus for preparation of spherical metal carbonates and lithium metal oxides for lithium rechargeable batteries

ActiveUS20050058588A1Improve impedance characteristicsImprove stabilityConductive materialOxide conductorsDopantLithium metal

A number of materials with the composition Li1+xNiαMnβCoγM′δO2−zFz (M′=Mg,Zn,Al,Ga,B,Zr,Ti) for use with rechargeable batteries, wherein x is between about 0 and 0.3, α is between about 0.2 and 0.6, β is between about 0.2 and 0.6, γ is between about 0 and 0.3, δ is between about 0 and 0.15, and z is between about 0 and 0.2. Adding the above metal and fluorine dopants affects capacity, impedance, and stability of the layered oxide structure during electrochemical cycling. Another aspect of the invention includes materials with the composition Li1+xNiαCoβMnγM′δOyFz (M′=Mg,Zn,Al,Ga,B,Zr,Ti), where the x is between 0 and 0.2, the α between 0 and 1, the β between 0 and 1, the γ between 0 and 2, the δ between about 0 and about 0.2, the y is between 2 and 4, and the z is between 0 and 0.5.

Owner:UCHICAGO ARGONNE LLC

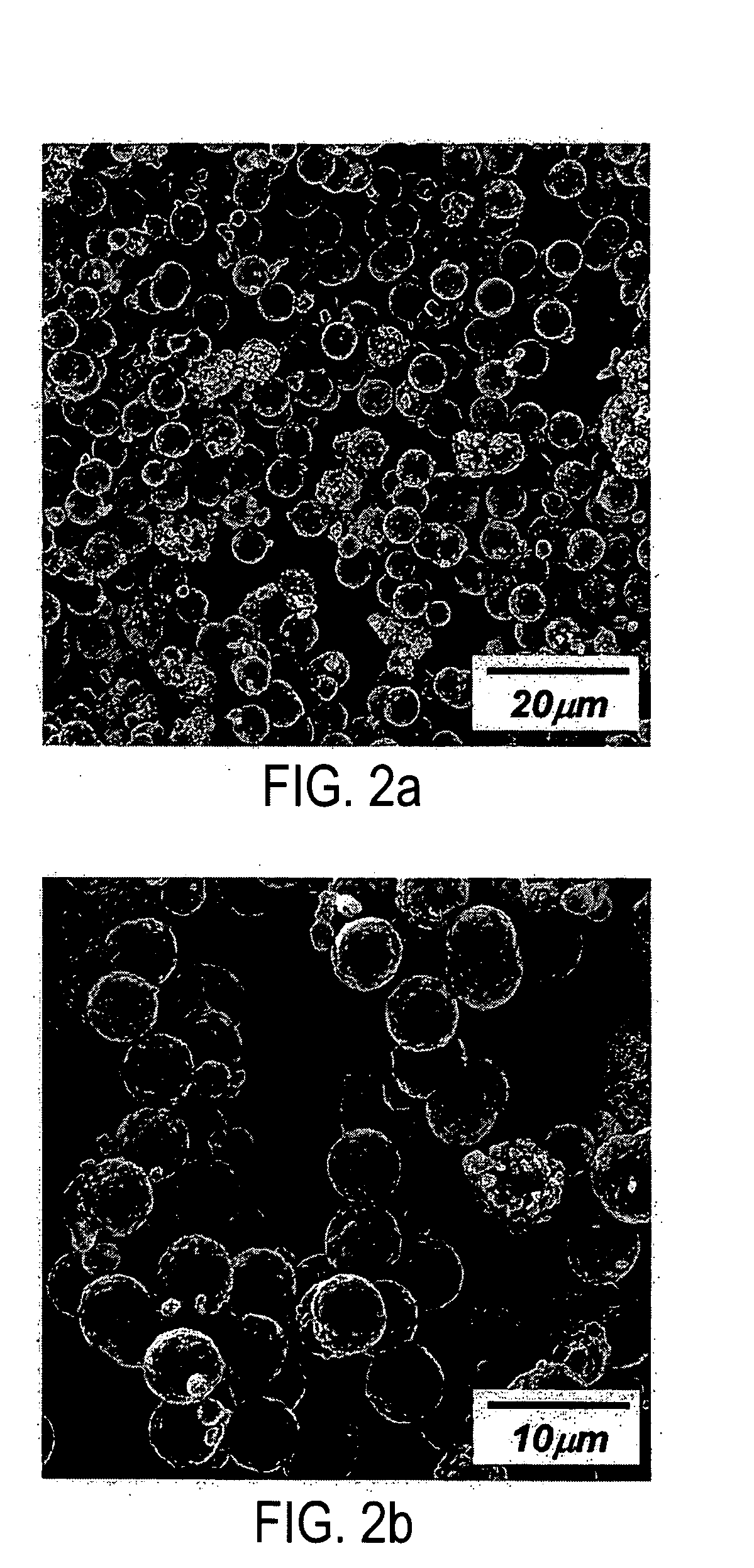

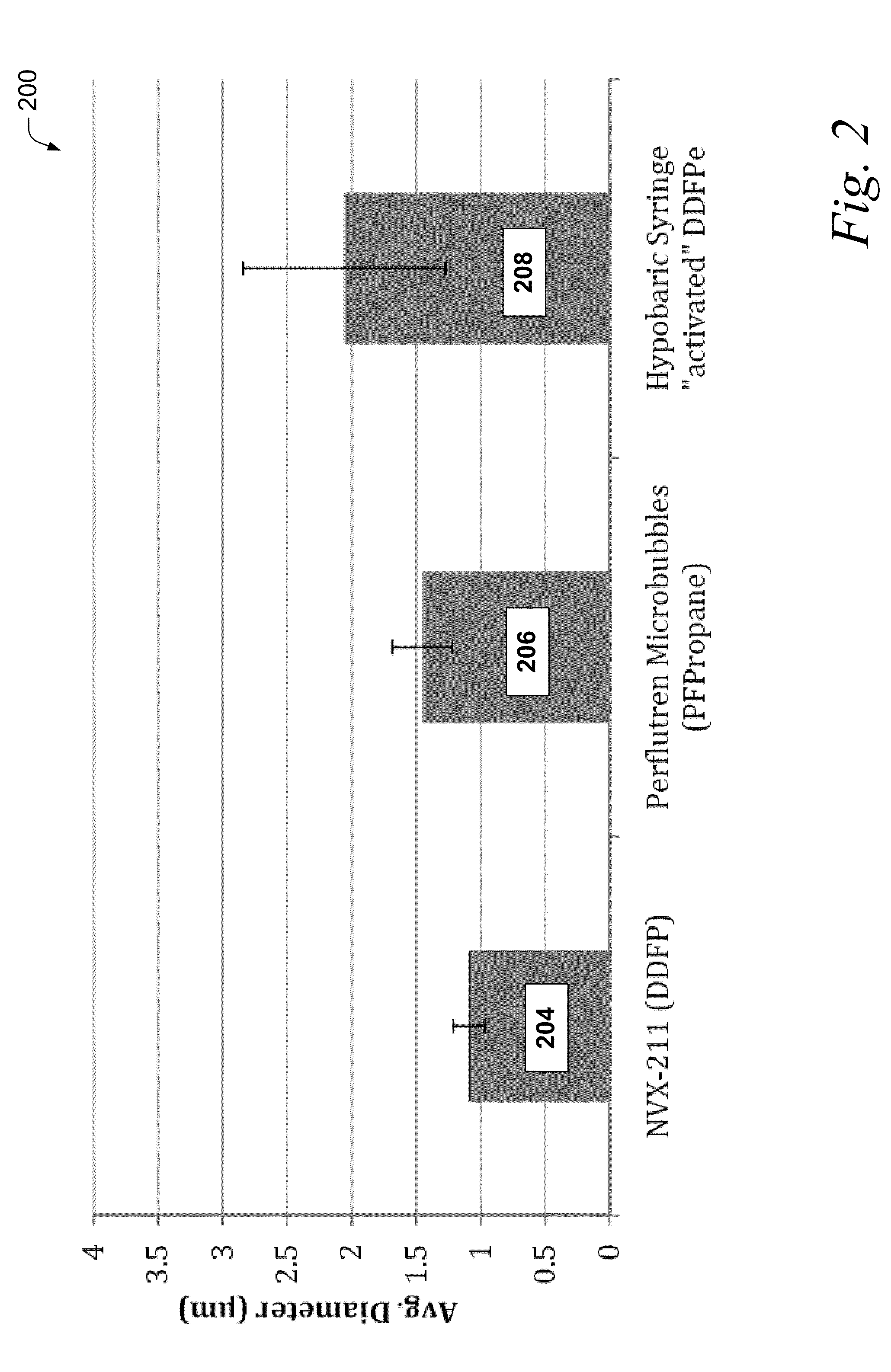

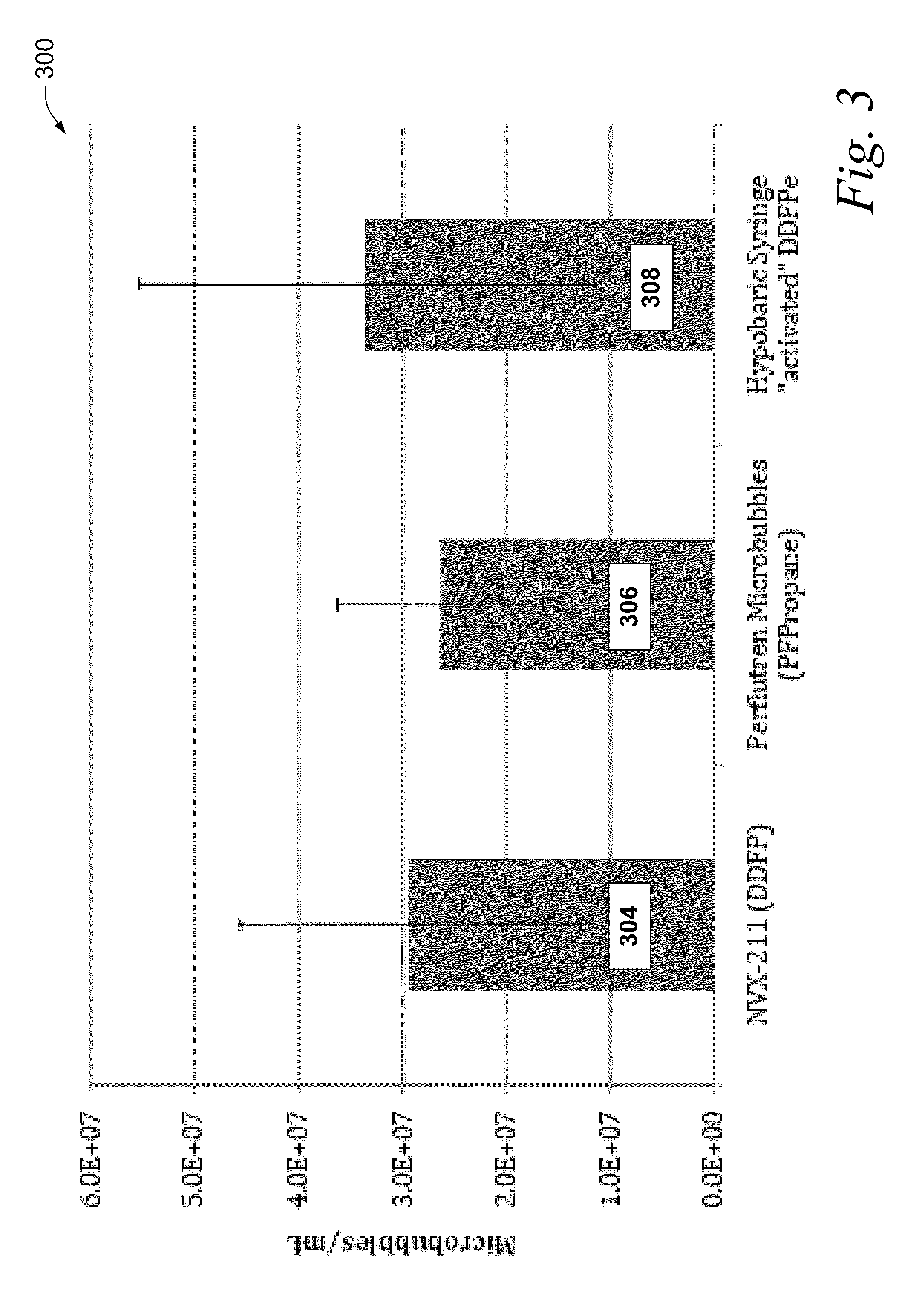

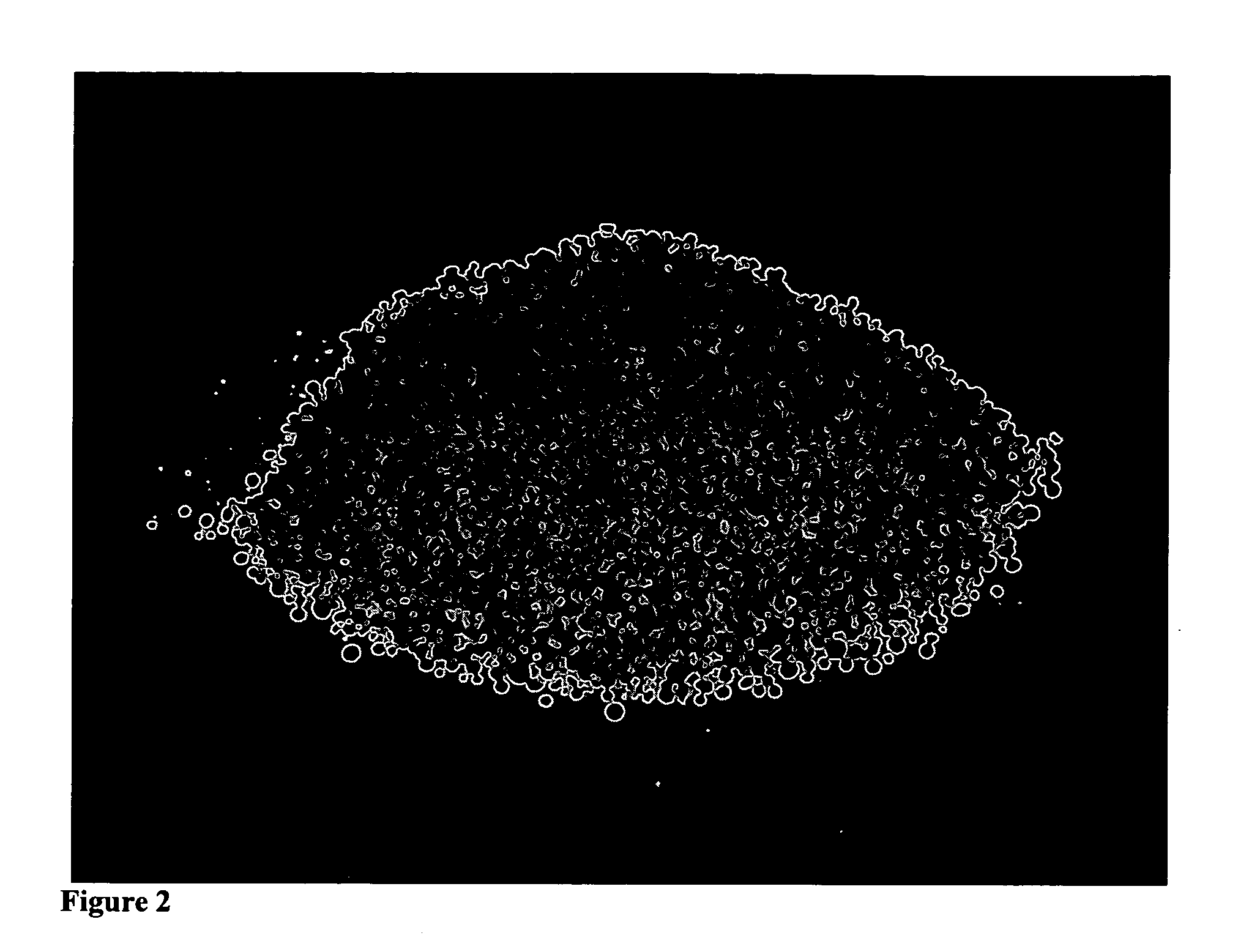

Microbubble Compositions, Method of Making Same, and Method Using Same

ActiveUS20130022550A1Extended shelf lifeNarrow size distributionUltrasonic/sonic/infrasonic diagnosticsEchographic/ultrasound-imaging preparationsMicrobubblesAmbient pressure

A method of forming a plurality of microbubbles, wherein the method disposes in a sealed container comprising a first volume at ambient pressure, a second volume of a mixture comprising one or more microbubble stabilizing materials. The first volume is greater than said second volume. The method further comprises sealing said container, introducing a gas into said sealed container, and shaking the container to form said plurality of microbubbles.

Owner:MICROVASCULAR THERAPEUTICS LLC

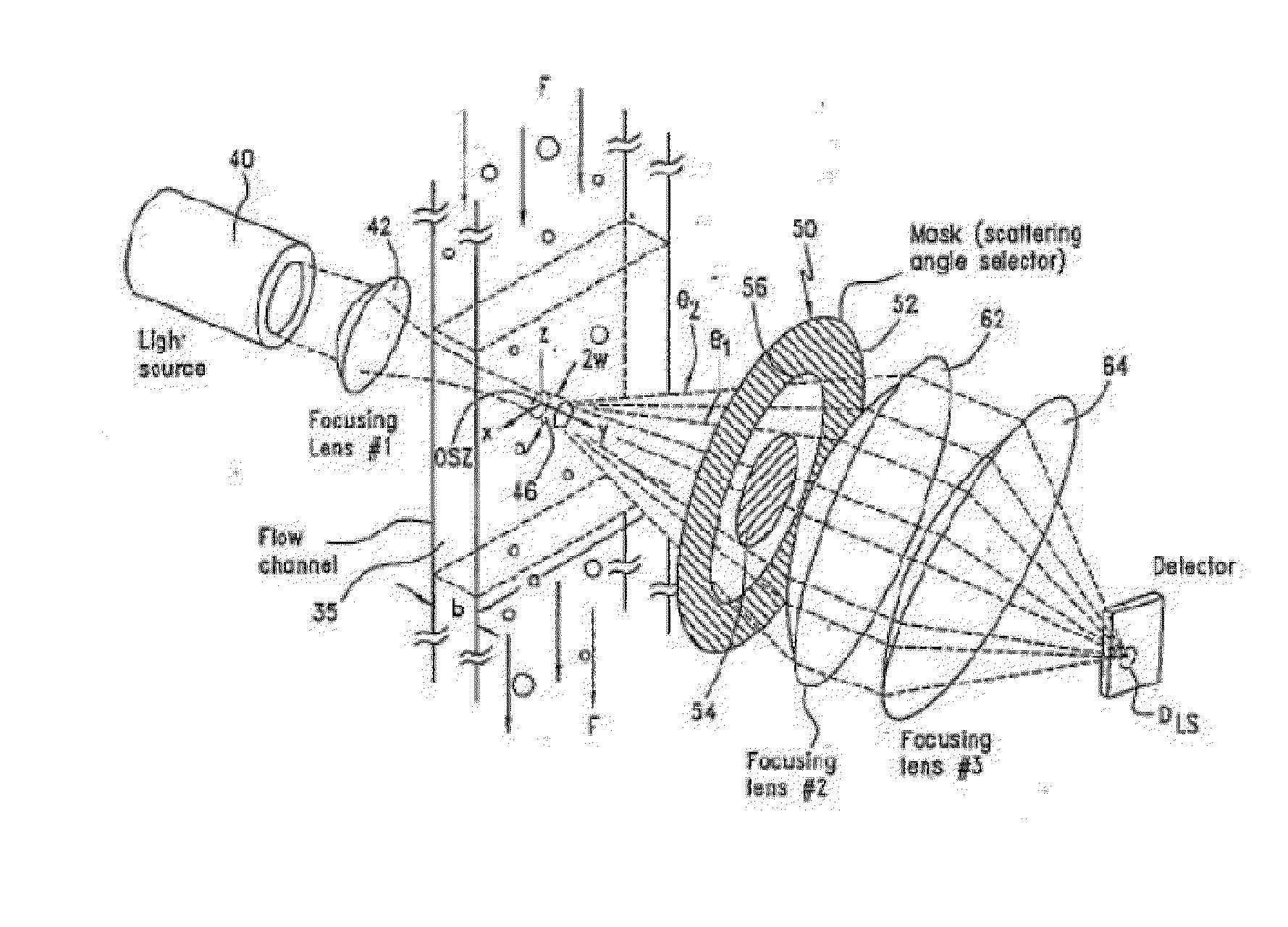

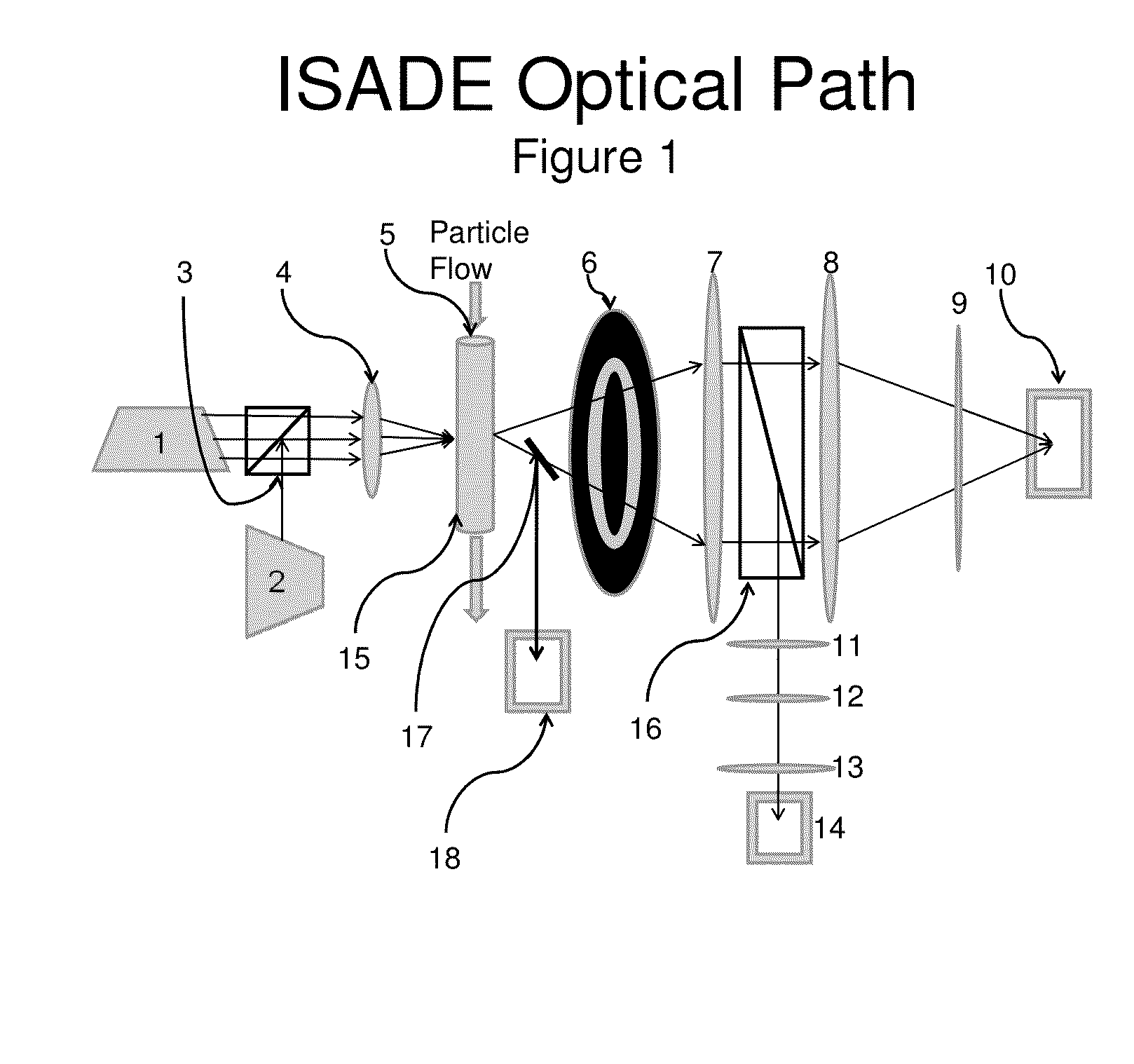

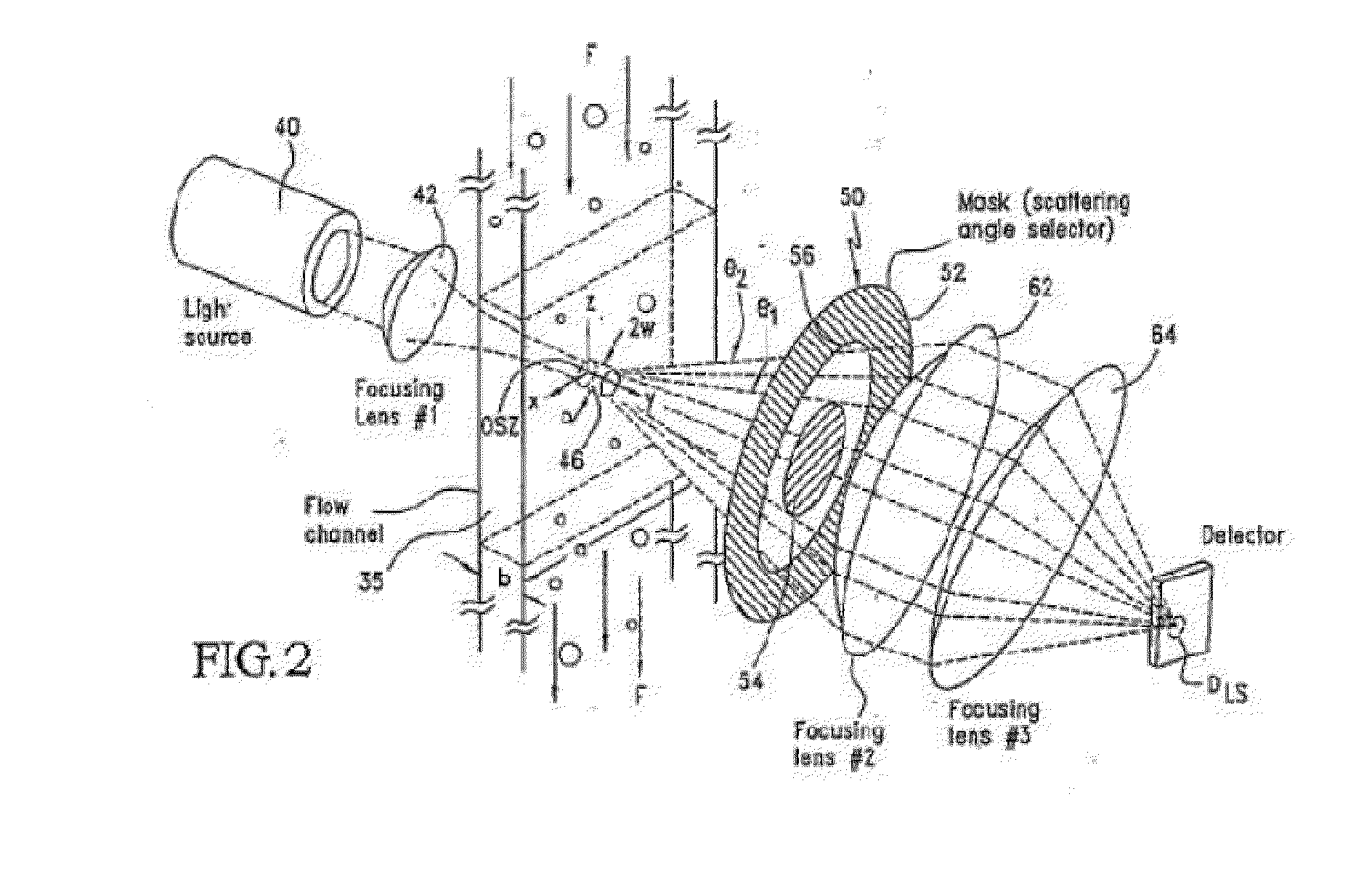

Instrument and method for optical particle sensing

ActiveUS20140234865A1Narrow size distributionConsistent amountCompound screeningApoptosis detectionFlow cellFluorescence

Devices for detecting particle sizes and distributions using focused light scattering techniques, by passing a sample through a focused beam of light, are disclosed. In one embodiment, the devices include one or more lasers, whose light is focused into a narrow beam and into a flow cell, and dispersions are passed through the flow cell using hydrodynamic sample injection. In another embodiment, a plurality of lasers is used, optionally with hydrodynamic sample injection. Particles pass through and scatter the light. The scattered light is then detected using scatter and extinction detectors, and, optionally, fluorescence detectors, and the number and size of the particles is determined. Particles in the size range of 0.1 to 10 μm can be measured. Using the device, significantly smaller particles can be detected than if techniques such as EQELS, flow cytometry, and other conventional devices for measuring biological particles.

Owner:INVITROX

Inorganic shaped bodies and methods for their production and use

InactiveUS20060039951A1Overcome the lack of robustnessNovel featuresDental implantsCosmetic preparationsCellulosePorosity

Owner:ORTHOVITA INC

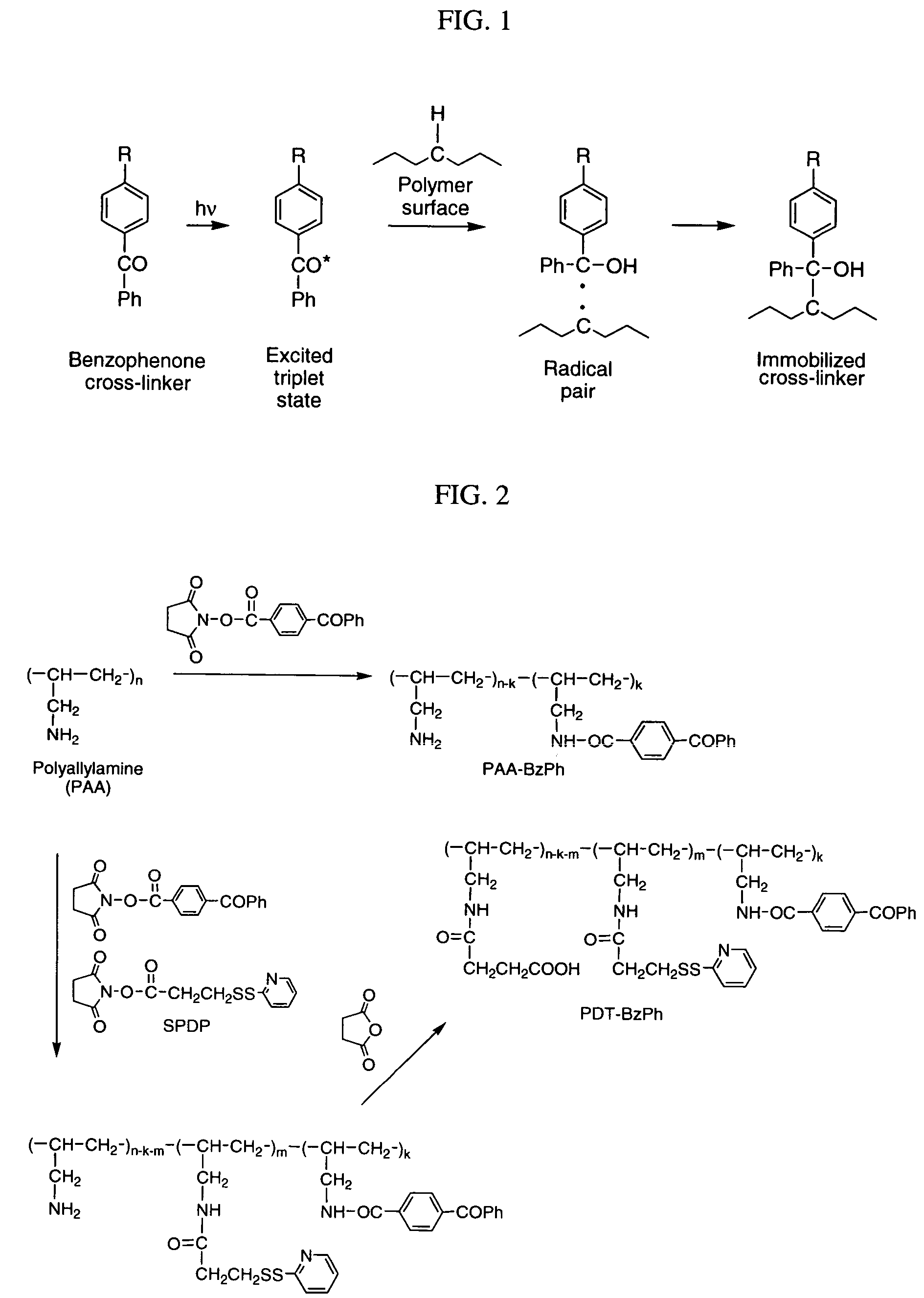

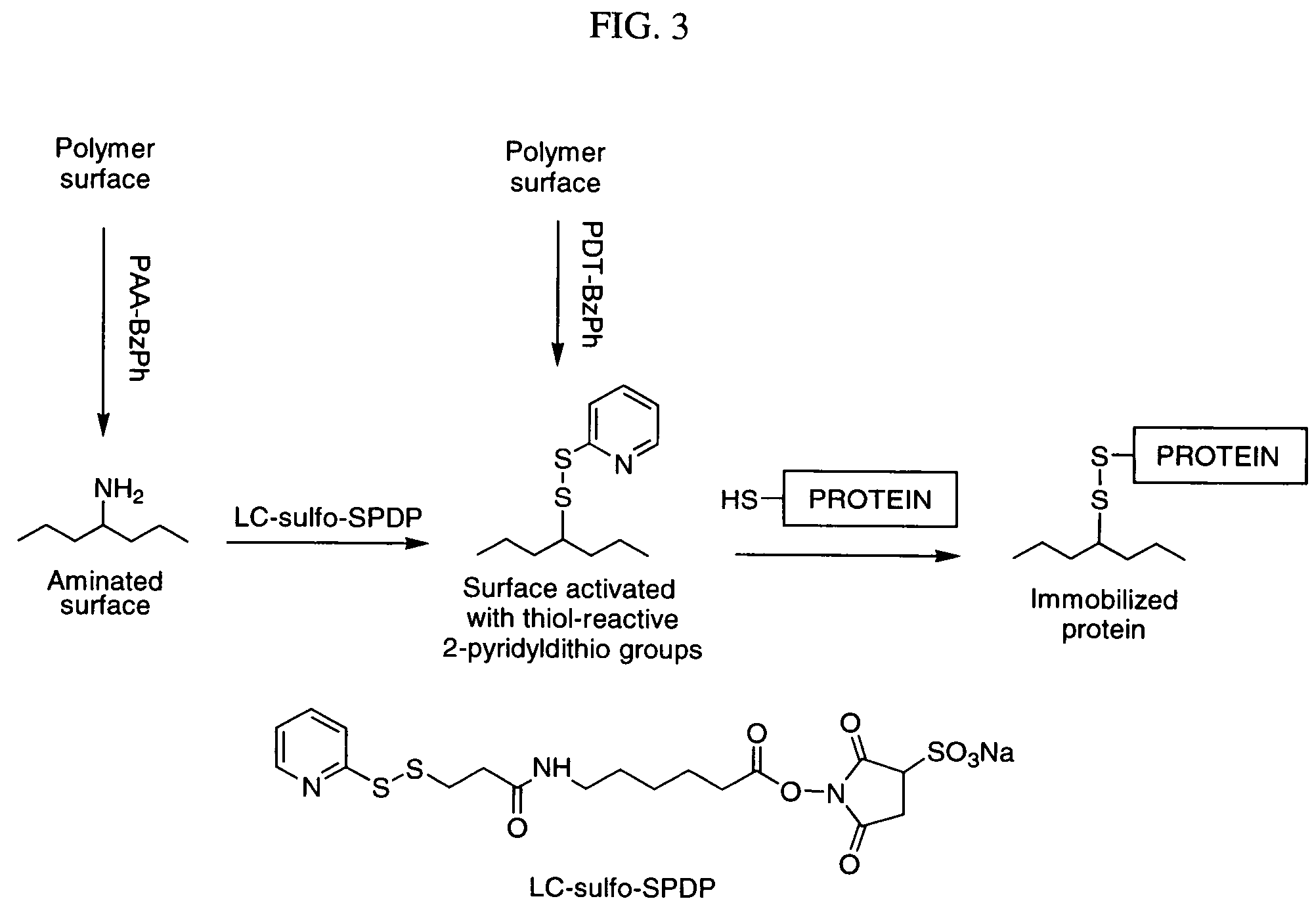

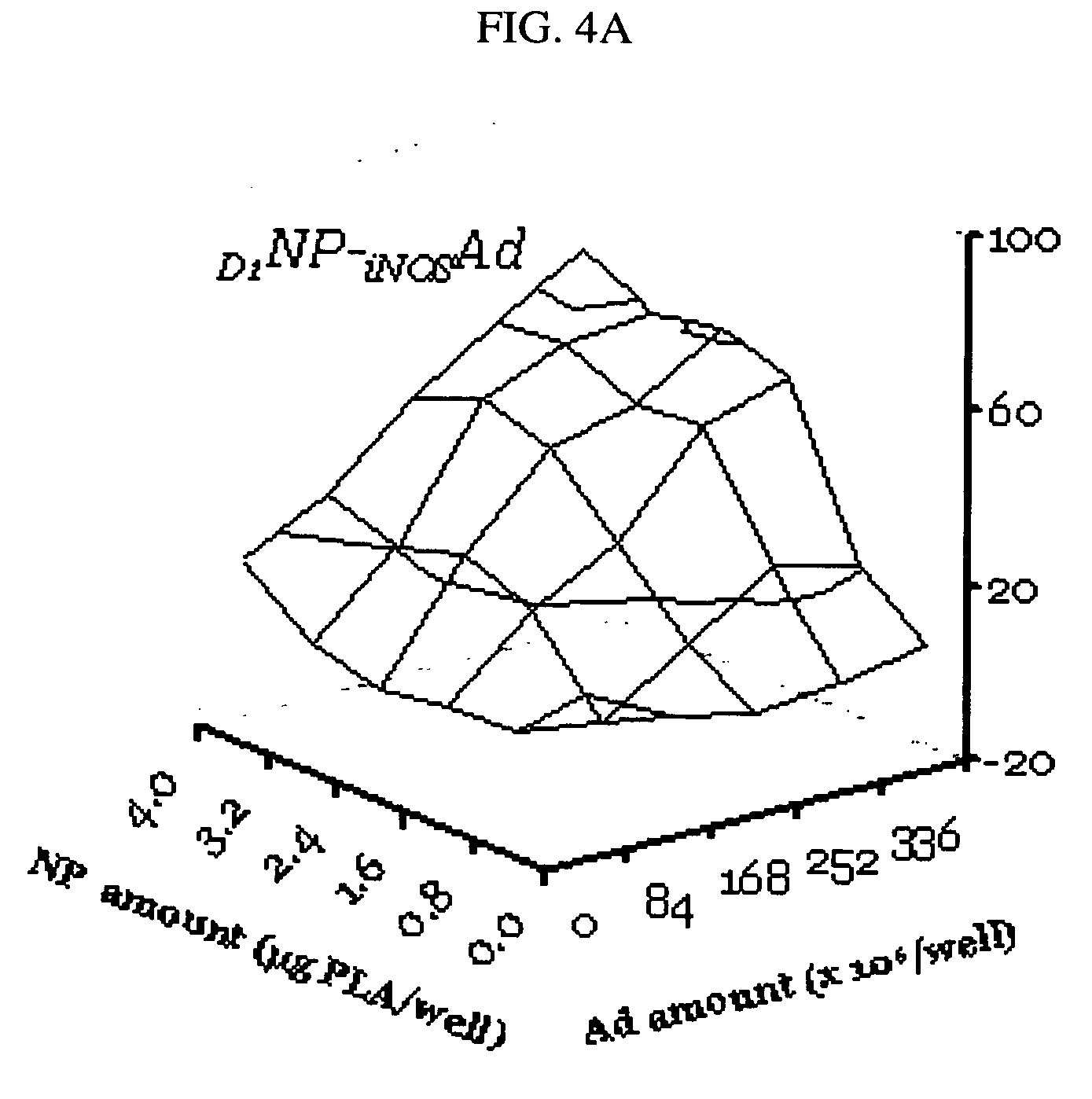

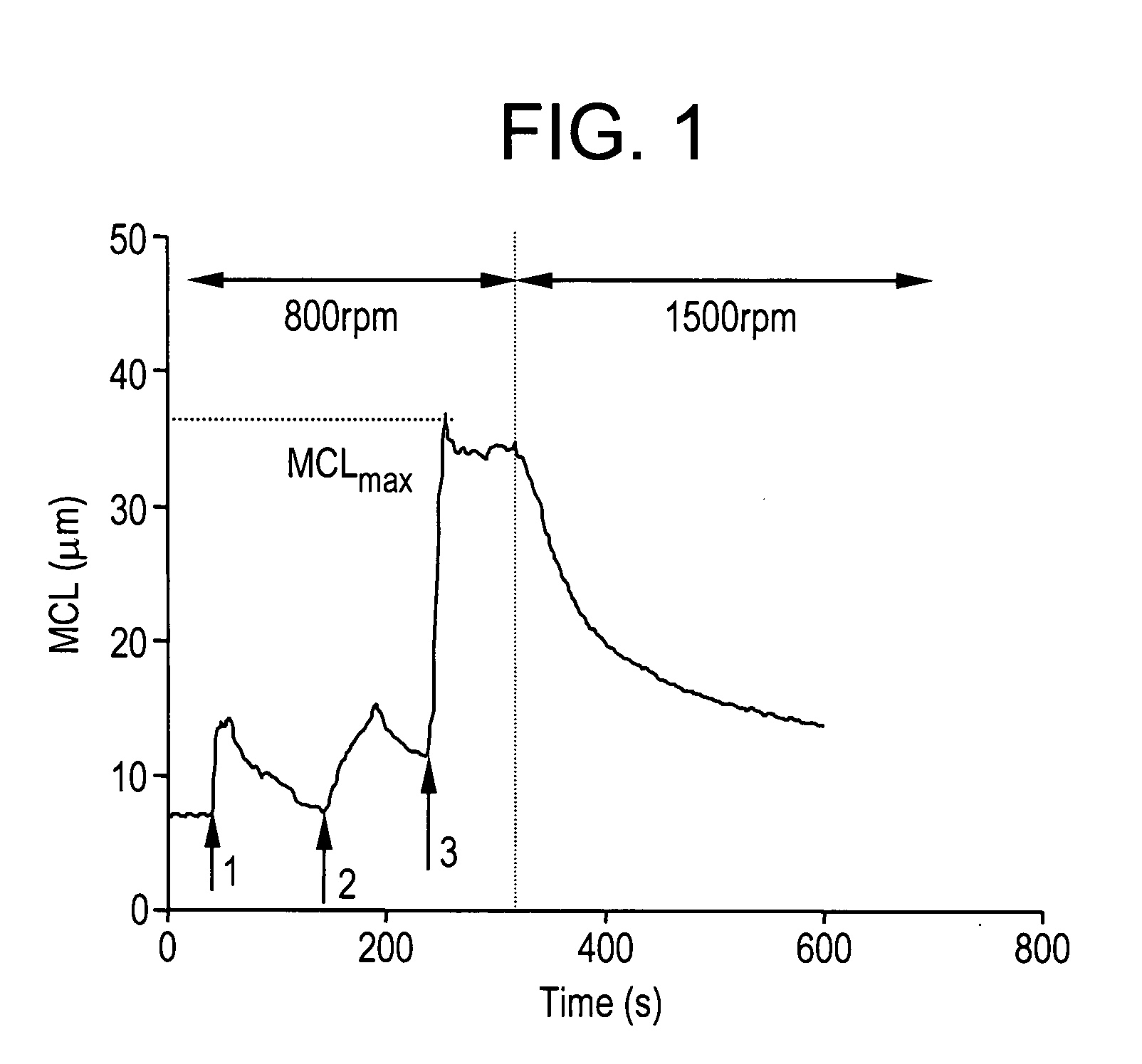

Photochemical activation of surfaces for attaching biomaterial

ActiveUS20060147413A1Efficient mechanismLow efficacyPharmaceutical delivery mechanismPharmaceutical non-active ingredientsPolymer chemistryPhotochemistry

A water-soluble photo-activatable polymer including: a photo-activatable group adapted to be activated by an irradiation source and to form a covalent bond between the water-soluble photo-activatable polymer and a matrix having at least one carbon; a reactive group adapted to covalently react with a biomaterial for subsequent delivery of the biomaterial to a cell; a hydrophilic group; and a polymer precursor. A composition including a monomolecular layer of the water-soluble photo-activatable polymer and a matrix having at least one carbon, wherein the monomolecular layer is covalently attached to the matrix by a covalent bond between the photo-activatable group and the at least one carbon. The composition further includes a biomaterial having a plurality of active groups, wherein the biomaterial is covalently attached to the monomolecular layer by covalent bonding between the active groups and reactive groups. Also provided is a method for delivery of a biomaterial to a cell.

Owner:THE CHILDRENS HOSPITAL OF PHILADELPHIA

Controllable filler prefloculation using a dual polymer system

ActiveUS20090065162A1Reduce molecular weightNarrow floe size distributionPigmenting treatmentNatural cellulose pulp/paperPolymer scienceAqueous dispersion

A method of preparing a stable dispersion of flocculated filler particles for use in papermaking processes comprises sequential addition of high and low molecular weight flocculating agents to an aqueous dispersion of filler particles followed by shearing of the resultant filler flocs to the desired particle size resulting in shear resistant filler flocs with a defined and controllable size distribution.

Owner:ECOLAB USA INC

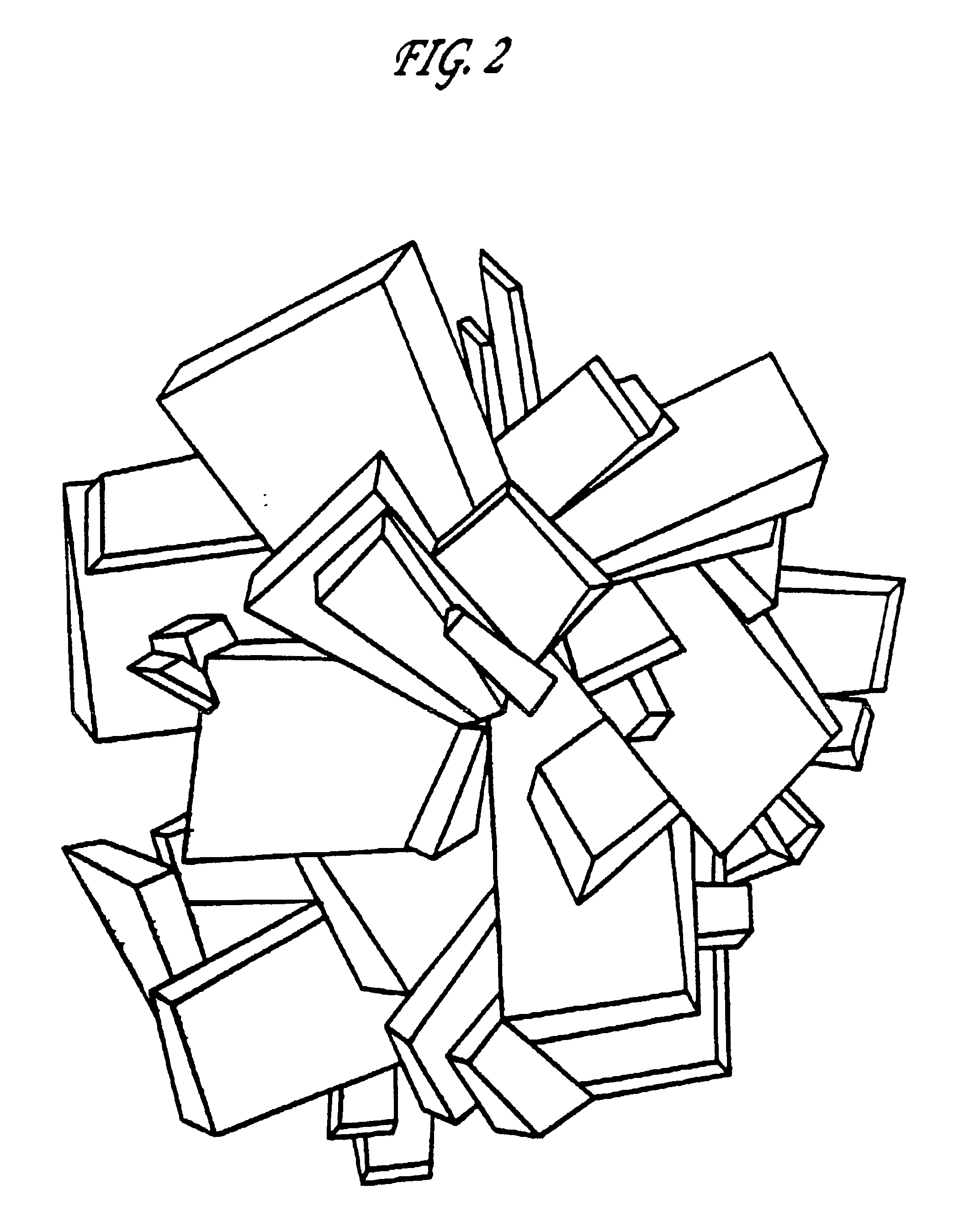

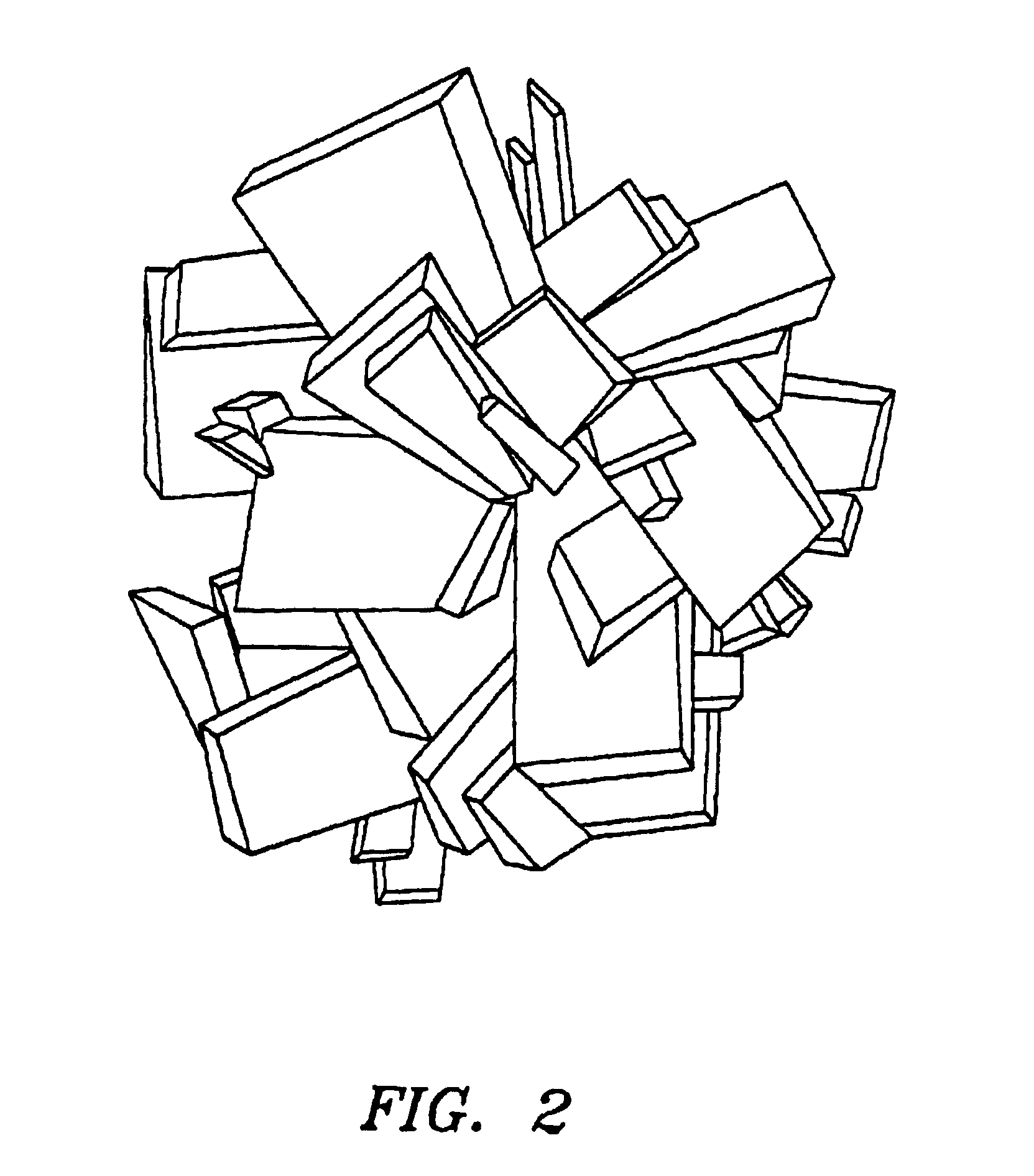

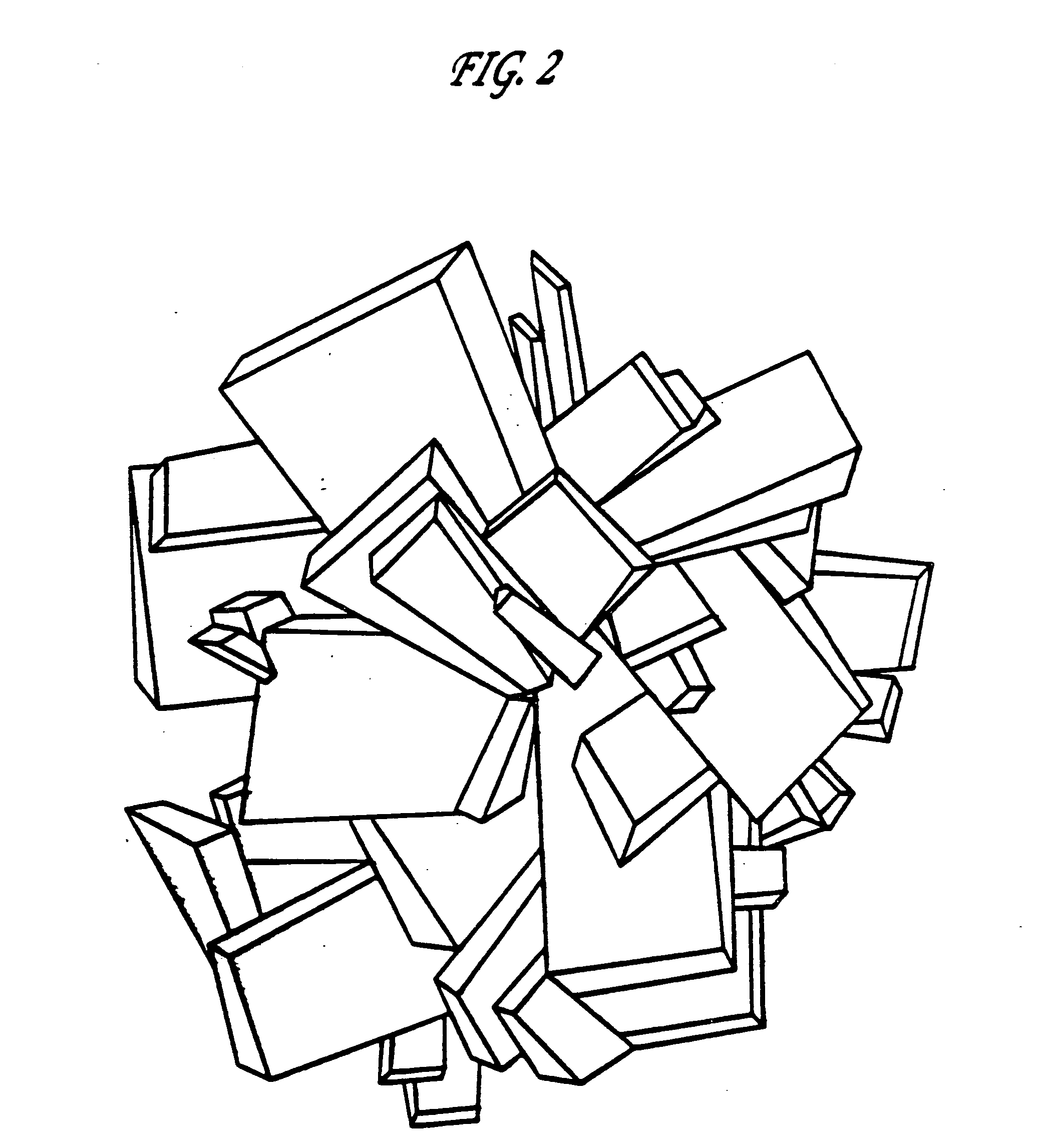

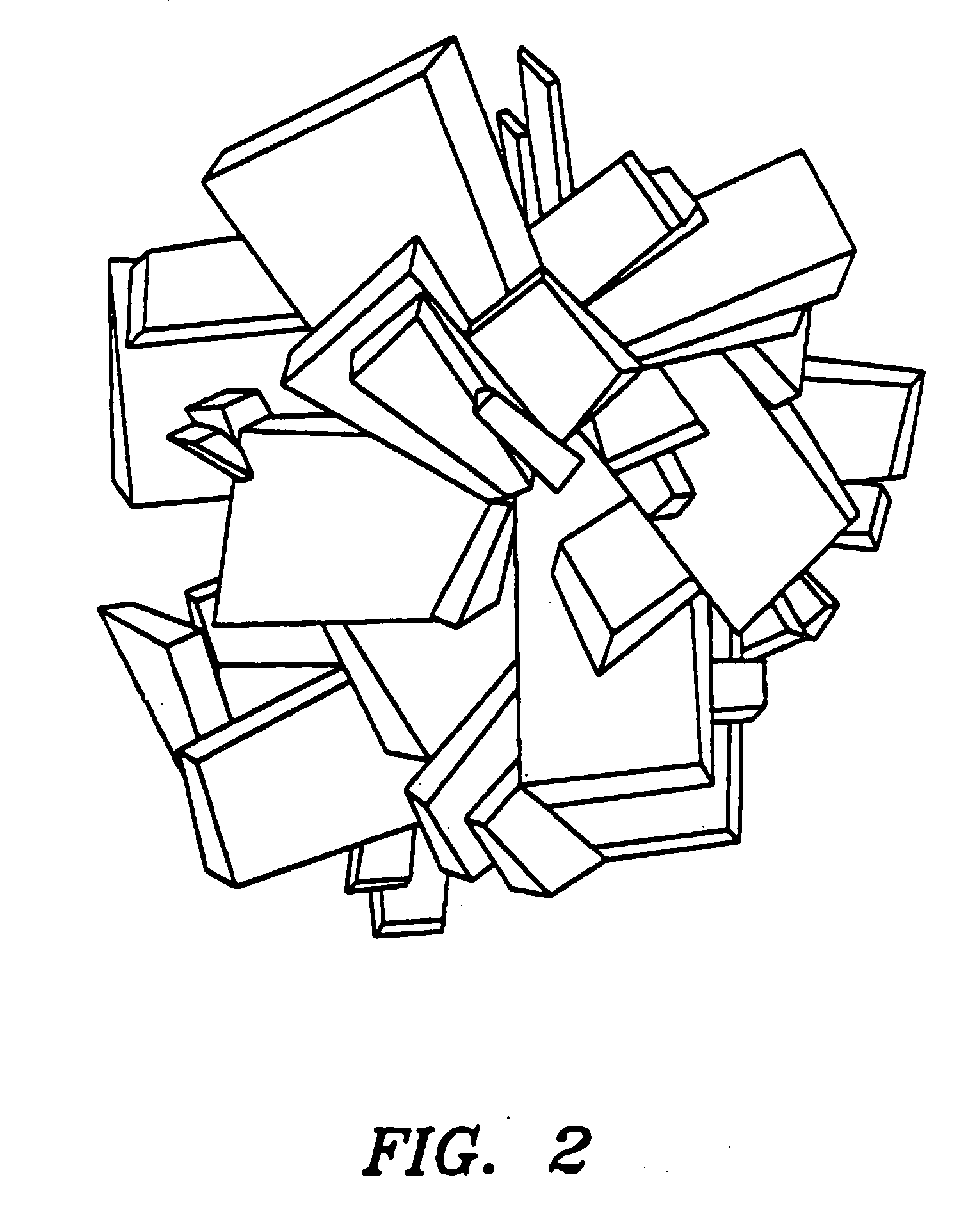

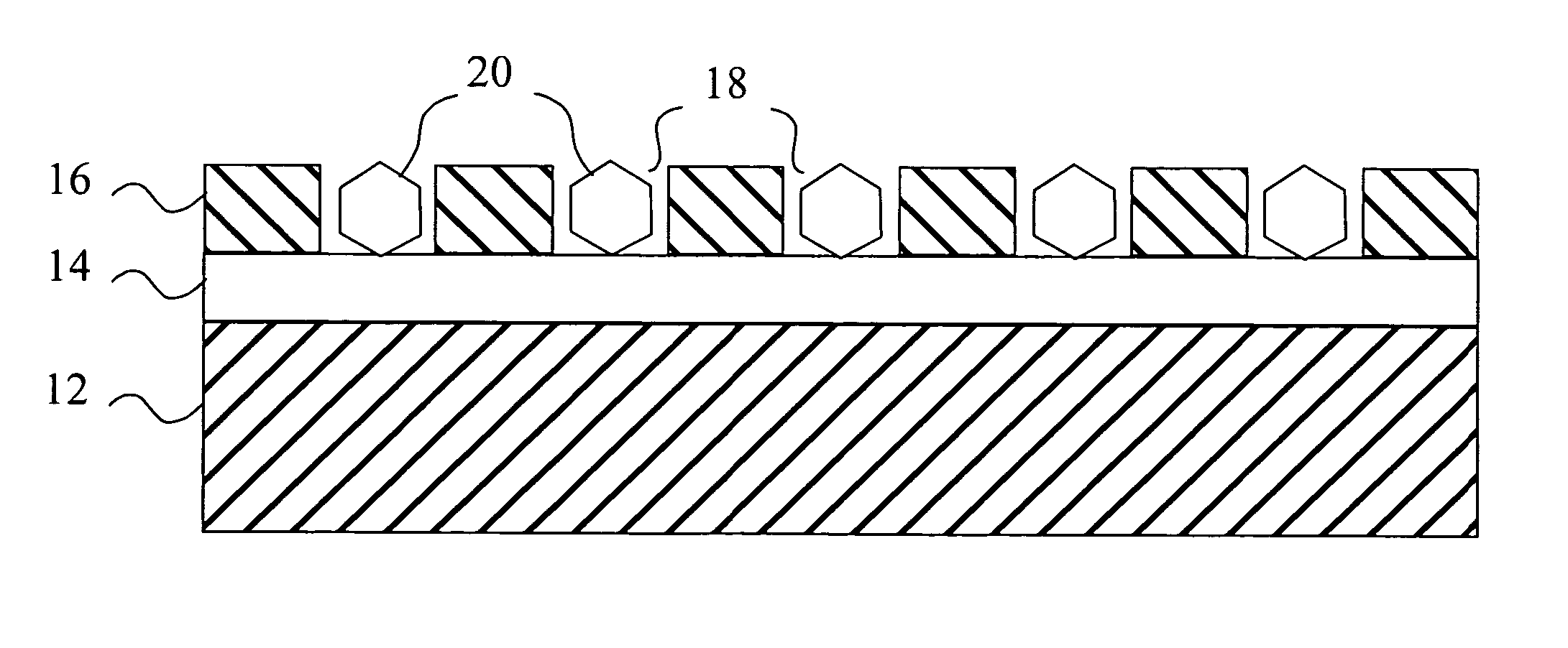

Superabrasive particle synthesis with controlled placement of crystalline seeds

InactiveUS20050136667A1Narrow size distributionQuality improvementDrill bitsOther chemical processesOctahedronSynthesis methods

An improved method for synthesizing superabrasive particles provides high quality industrial superabrasive I-,articles with high yield and a narrow size distribution. The synthesis method includes forming a substantially homogeneous mixture of raw material and catalyst material or layers of raw material and metal catalyst. A plurality of crystalline seeds is placed in a predetermined pattern in the mixture or one of the layers to form a growth precursor. The growth precursor is maintained at a temperature and pressure at which the superabrasive crystal is thermodynamically stable for a time sufficient for a desired degree of growth. Advantageously, the patterned placement of crystalline seeds and disclosed processes allow for production of synthetic octahedral diamonds and improved growth conditions generally. As a result, the grown superabrasive particles typically have a high yield of high quality particles and a narrow distribution of particle sizes.

Owner:SUNG CHIEN MIN

Controllable filler prefloculation using a dual polymer system

ActiveUS8172983B2Reduce molecular weightLess viscousNatural cellulose pulp/paperSpecial paperPolymer scienceAqueous dispersion

A method of preparing a stable dispersion of flocculated filler particles for use in papermaking processes comprises sequential addition of high and low molecular weight flocculating agents to an aqueous dispersion of filler particles followed by shearing of the resultant filler flocs to the desired particle size resulting in shear resistant filler flocs with a defined and controllable size distribution.

Owner:ECOLAB USA INC

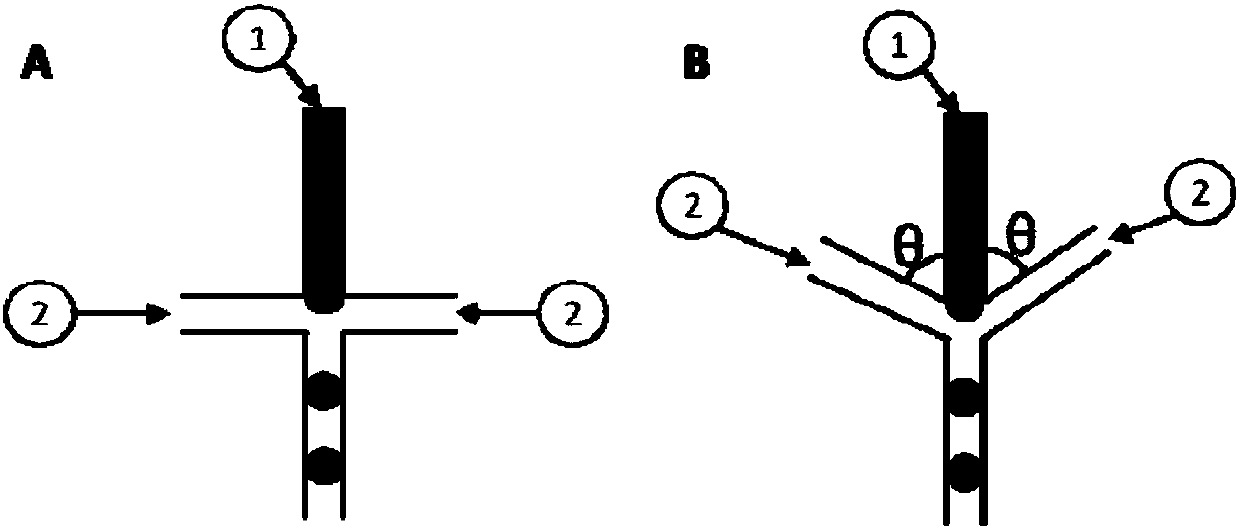

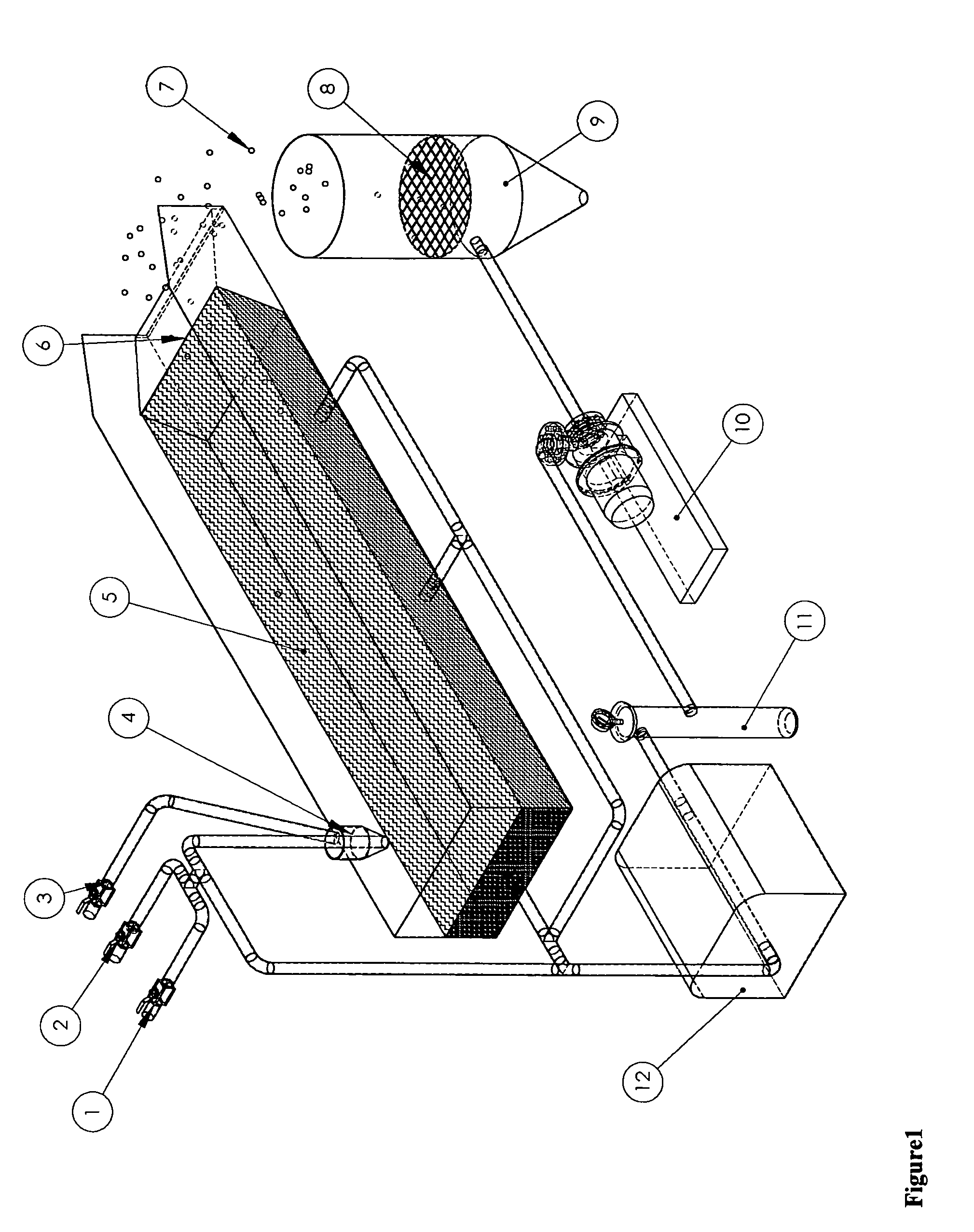

Microfluidic technology for one-step continuous preparation of calcium alginate microgel

ActiveCN107930542AFast shippingMaintain biological activityLaboratory glasswaresGel preparationOil phaseWater in oil emulsion

The invention relates to a microflow droplet technology-based method for one-step continuous preparation of multi-chamber calcium alginate microgel for immobilization of bioactive substances. The method realizes high-throughput continuous production of a microgel material. The method comprises forming a parallel and stable flow field through different hydrogel prepolymer solutions in a microfluidic channel, pouring the hydrogel prepolymer solutions for forming different chambers of the microgel into a microfluidic chip to form water phase solutions of multiple phase parallel fluids, mixing thewater phase solutions and an immiscible fluid (oil phase) through a T-shaped channel or a fluid focusing design to obtain water-in-oil emulsion drops and then alginic acid in the drops is linked immediately so that multi-chamber microgel is prepared, and cleaning the emulsion drops on the microfluidic chip so that the microgel is fast conveyed into a water phase. The method realizes one-step preparation of the calcium alginate microgel immobilized with bioactive substances and is suitable for industrial application.

Owner:SHENZHEN HUA NOVA BIOTECH LTD

Rubber powder compositions and process for the production thereof

InactiveUS6433064B1Easy to processNarrow size distributionFibre treatmentSpecial tyresPolymer scienceVulcanization

Finely divided, pulverulent rubbers containing filler which contain further processing and vulcanization auxiliaries necessary for the production of vulcanizable rubber mixtures, which rubbers are pourable even after exposure to mechanical action, and to a process for the production thereof. The rubber powder is obtained within two precipitation steps. These rubber powders are used for the production of vulcanizable rubber mixtures. The fillers used, which comprise not only precipitated silicas but also carbon blacks known in the rubber industry, are optionally surface modified with organosilicon compounds.

Owner:PKU PULVERKAUTSCHUK UNION GMBH

Methods for manufacture of aerogels

InactiveUS20060084707A1Capacity of equipmentShort gel timeOxide/hydroxide preparationSilicaEngineeringAerogel

Embodiments of the present invention describe a method for producing gel beads comprising: depositing catalyzed sol droplets comprising a gel precursor into a moving dispensing medium, said medium being immiscible with the sol, and allowing gelation of the sol to occur in the moving dispensing medium thereby producing gel beads. This system utilizes a horizontally flowing dispensing medium where the catalyzed sol droplet is fully formed before deposited therein.

Owner:ASPEN AEROGELS INC

Synthesis of magnetite nanoparticles and the process of forming fe-based nanomaterials

InactiveUS20050191231A1Small sizeNarrow size distributionMaterial nanotechnologyNanostructure manufactureIron saltsMagnetite Nanoparticles

A method and structure for making magnetite nanoparticle materials by mixing iron salt with alcohol, carboxylic acid and amine in an organic solvent and heating the mixture to 200-360 C. is described. The size of the particles can be controlled either by changing the iron salt to acid / amine ratio or by coating small nanoparticles with more iron oxide. Magnetite nanoparticles in the size ranging from 2 nm to 20 nm with a narrow size distribution are obtained with the invention. The invention can be readily extended to other iron oxide based nanoparticle materials, including MFe2O4 (M=Co, Ni, Cu, Zn, Cr, Ti, Ba, Mg) nanomaterials, and iron oxide coated nanoparticle materials. The invention also leads to the synthesis of iron sulfide based nanoparticle materials by replacing alcohol with thiol in the reaction mixture. The magnetite nanoparticles can be oxidized to γ-Fe2O3, or α-Fe2O3, or can be reduced to bcc-Fe nanoparticles, while iron oxide based materials can be used to make binary iron based metallic nanoparticles, such as CoFe, NiFe, and FeCoSmx nanoparticles.

Owner:IBM CORP

Process for preparing cross-linking maleic anhydride-styrene copolymer

A cross linking maleic anhydride-vinyl acetate copolymer preparation method belongs to the field of copolymers. At present, the research on maleic anhydride-vinyl acetate copolymers mostly focuses on the polymerization research of linear polymers. The invention introduces a monomer, cross linking agents and initiators into medium to dissolve under the condition of nitrogen protection, and reacts for 2 to 24 hours under the temperature of 60 DEG C to 90 DEG C; the monomer is maleic anhydride Man and styrene St, the mol ratio is 1:1, and the mass concentration in the polymerization system is 5 percent to 45 percent; the initiators are organic peroxides or azo compounds, and are 0.05 percent to 1 percent of the total mass of the monomers; the cross linking agents are polyfunctionality alkene organic compounds, and are 0.08 percent to 8.8 percent of the total mass of the reactions system, and the rest is the alkyl ester of medium organic acid. The invention does not use surface active agents or stabilizers, can realize the adjustment and control of crosslinking polymer particle size, appearance and chemical physical properties through the adjustment of the addition amount of the cross linking agents.

Owner:BEIJING UNIV OF CHEM TECH

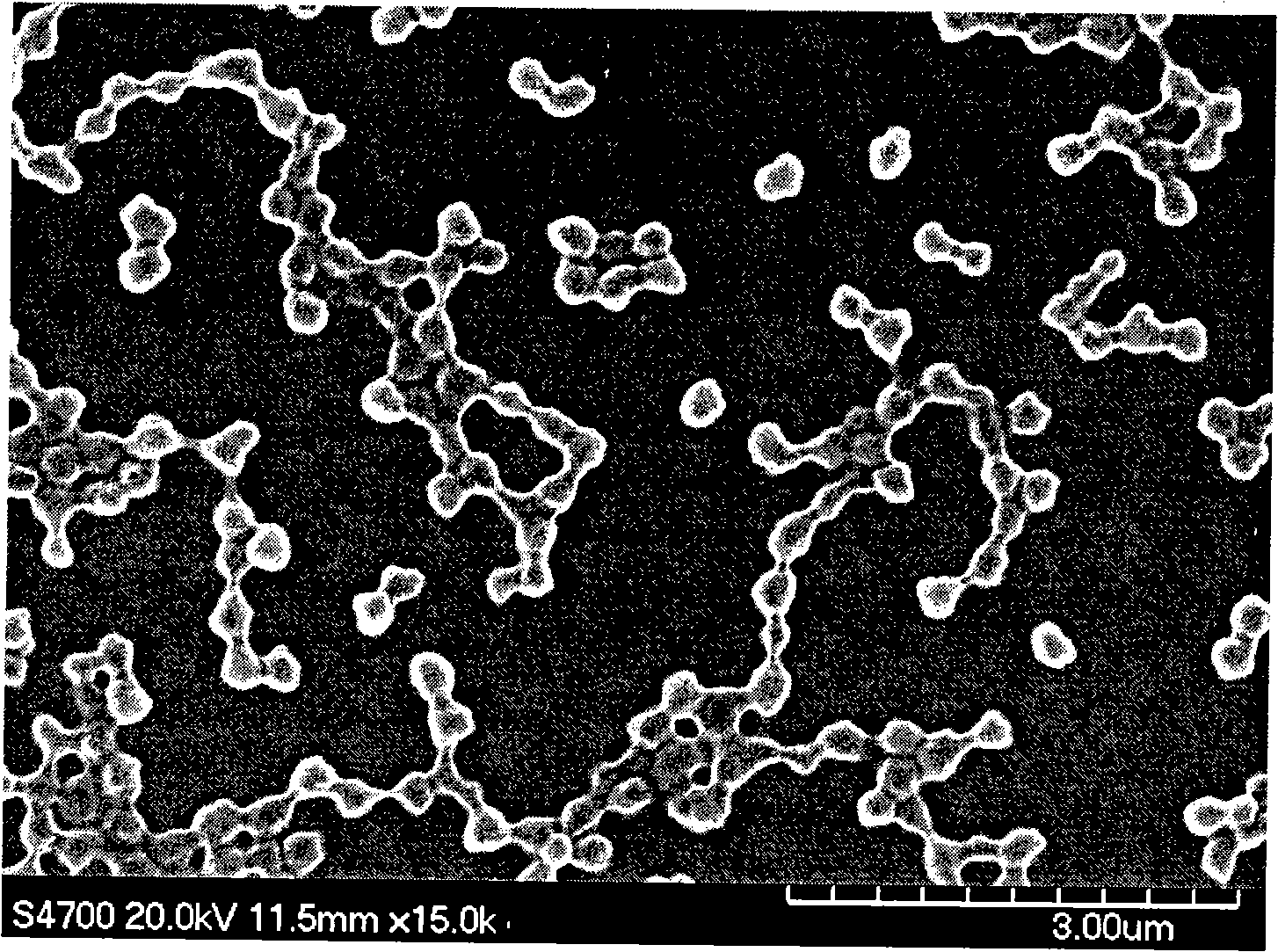

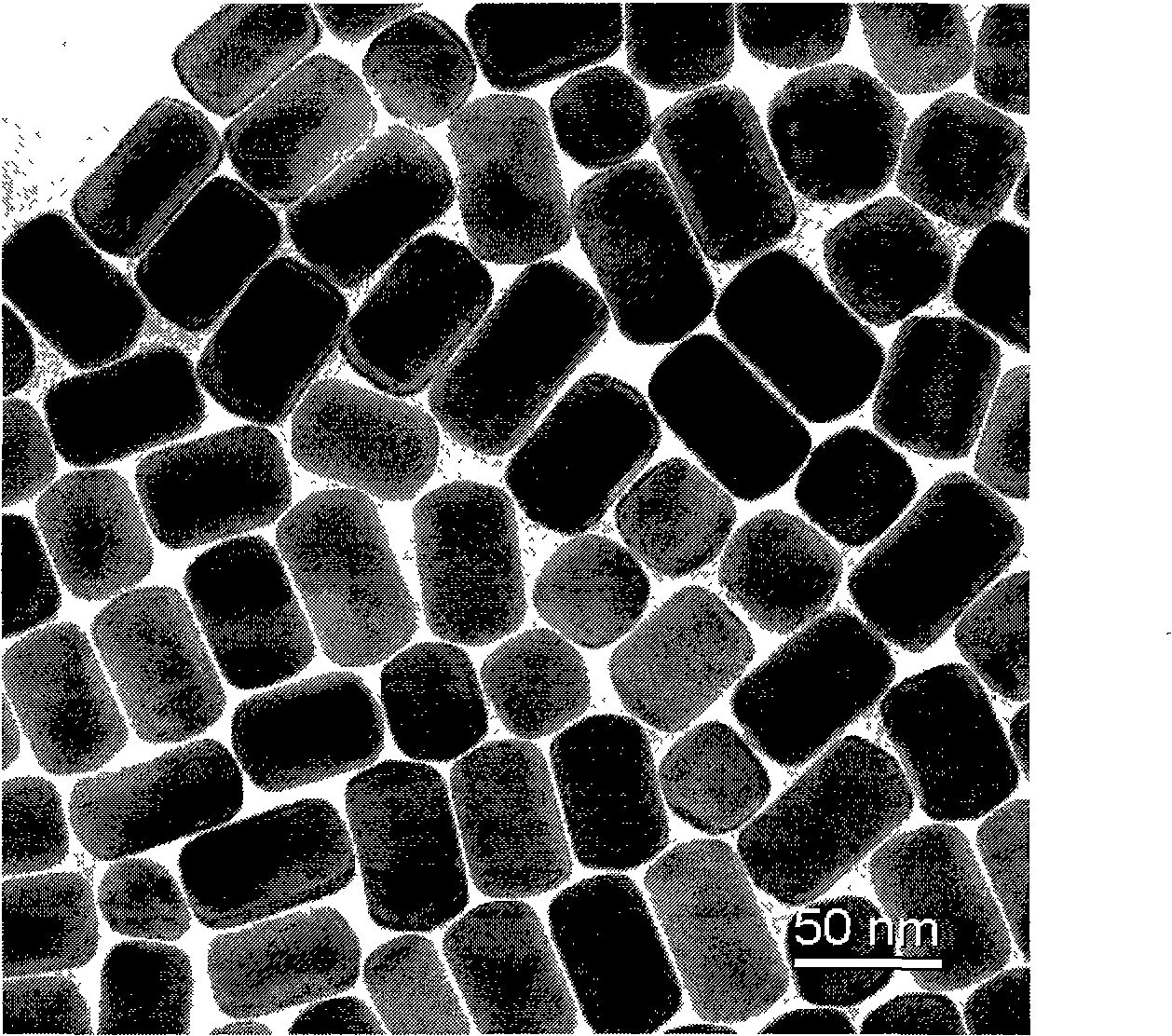

Bimetal nano rod of branched gold core/platinum shell structure and preparation method thereof

InactiveCN101450380AImprovement of poisoningLarge specific surface areaCoatingsPlatinumOptical property

The invention provides a dendritic gold-core / platinum-shell bimetal nanometer rod and a preparation method thereof. The dendritic gold-core / platinum-shell bimetal nanometer rod comprises a cylindrical gold nanometer-rod core and a porous platinum-shell layer covering the outer surface of the cylindrical gold nanometer-rod core; the diameter of the cylindrical gold nanometer-rod core is 10 to 15 nanometers; the length of the cylindrical gold nanometer-rod core is 55 to 60 nanometers; the thickness of the porous platinum-shell layer is 0.4 to 8 nanometers; and the length of platinum grains covering the outside of a nanometer rod is 2 to 4 nanometers. The preparation method provided by the invention has the advantages of simplicity, flexibility, environmental protection, green chemistry and low energy consumption. In addition, the obtained bimetal nanometer rod with a gold-core / platinum-shell structure has the characteristics of high yield, narrow size distribution, stable structure and adjustable optical properties.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

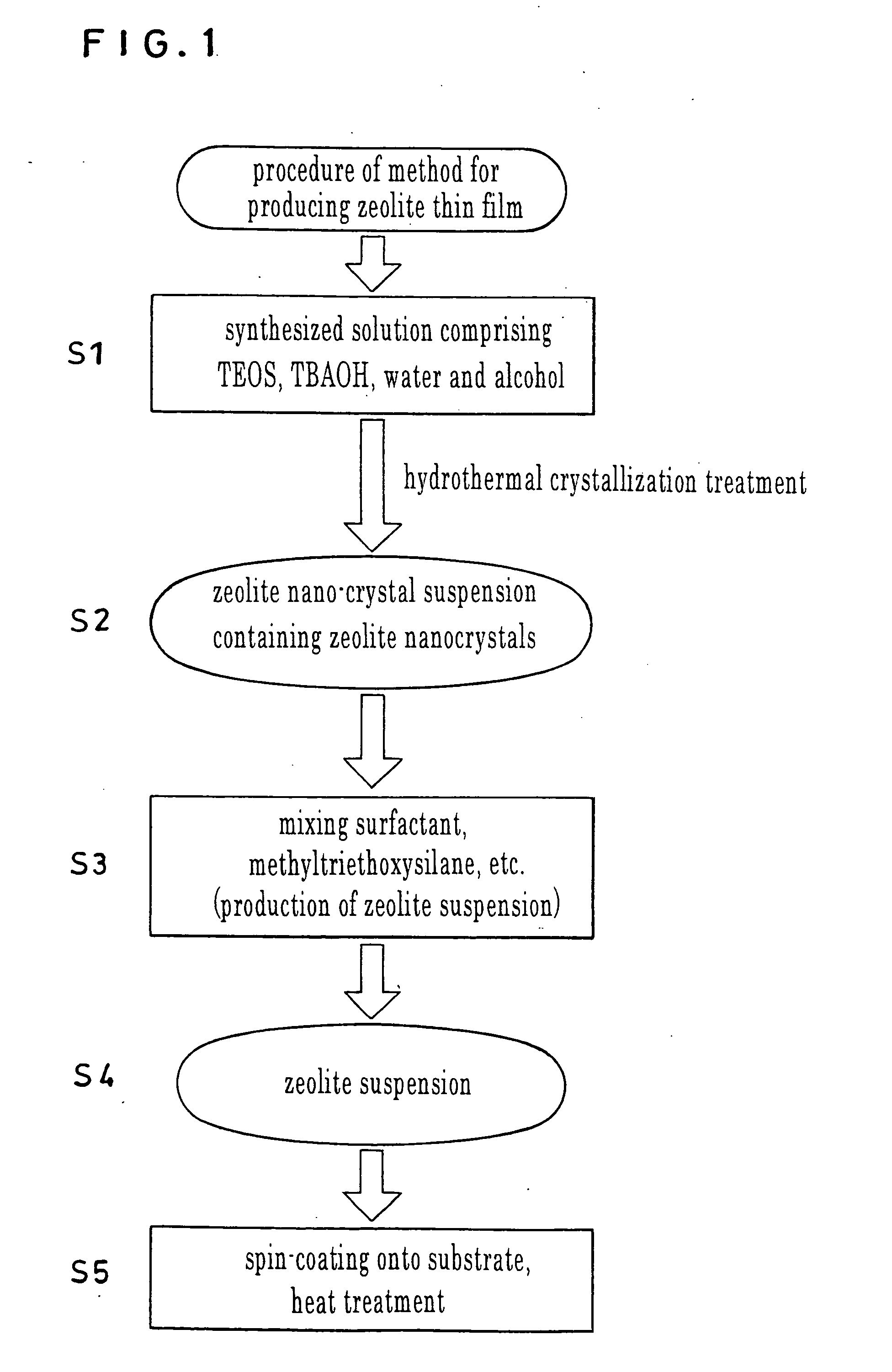

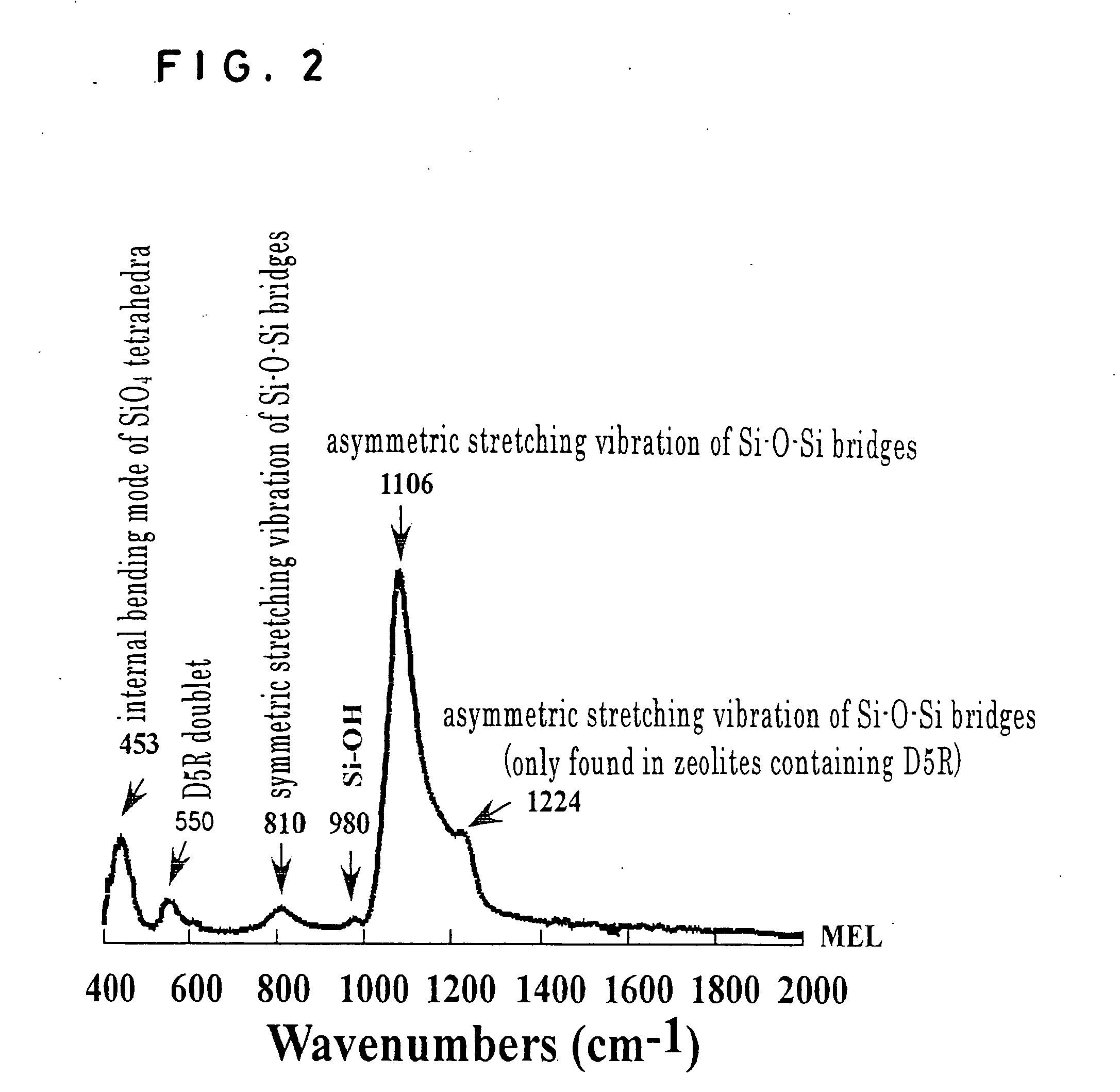

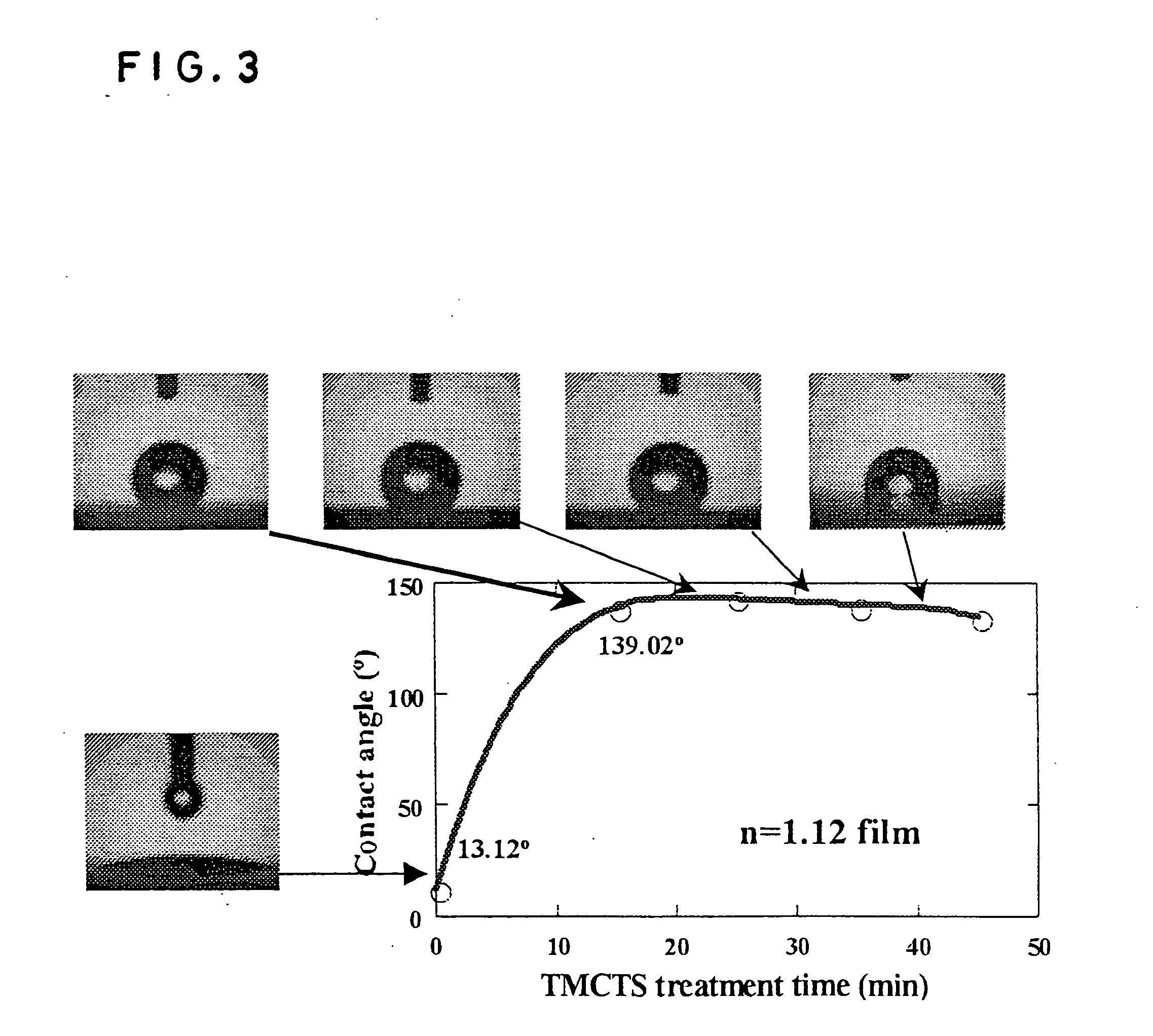

Zeolite nano-crystal suspension, zeolite nano-crystal production method, zeolite nano-crystal suspension production method, and zeolite thin film

InactiveUS20060063662A1High strengthHigh mechanical strengthAluminium compoundsMolecular sieve catalystsOrganic solventAlcohol

A zeolite suspension contains MEL-type zeolite nanocrystals as a principal component. A method for the production of MEL-type zeolite nanocrystals includes the steps of aging a synthesized solution comprising TEOS, TBAOH, water and alcohol and subjecting the aged solution to hydrothermal crystallization treatment at a predetermined temperature. A method for the production of a zeolite suspension includes the steps of aging a synthesized solution comprising TEOS, TBAOH, water and alcohol, subjecting the aged solution to hydrothermal crystallization treatment to produce MEL-type zeolite nanocrystals and mixing a composition having a surfactant dissolved in at least one organic solvent or a mixed solvent of alcohol-based organic solvents, amide-based organic solvents and ketone-based organic solvents with a zeolite nano-crystal suspension containing the MEL-type zeolite nanocrystals to produce a zeolite suspension.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

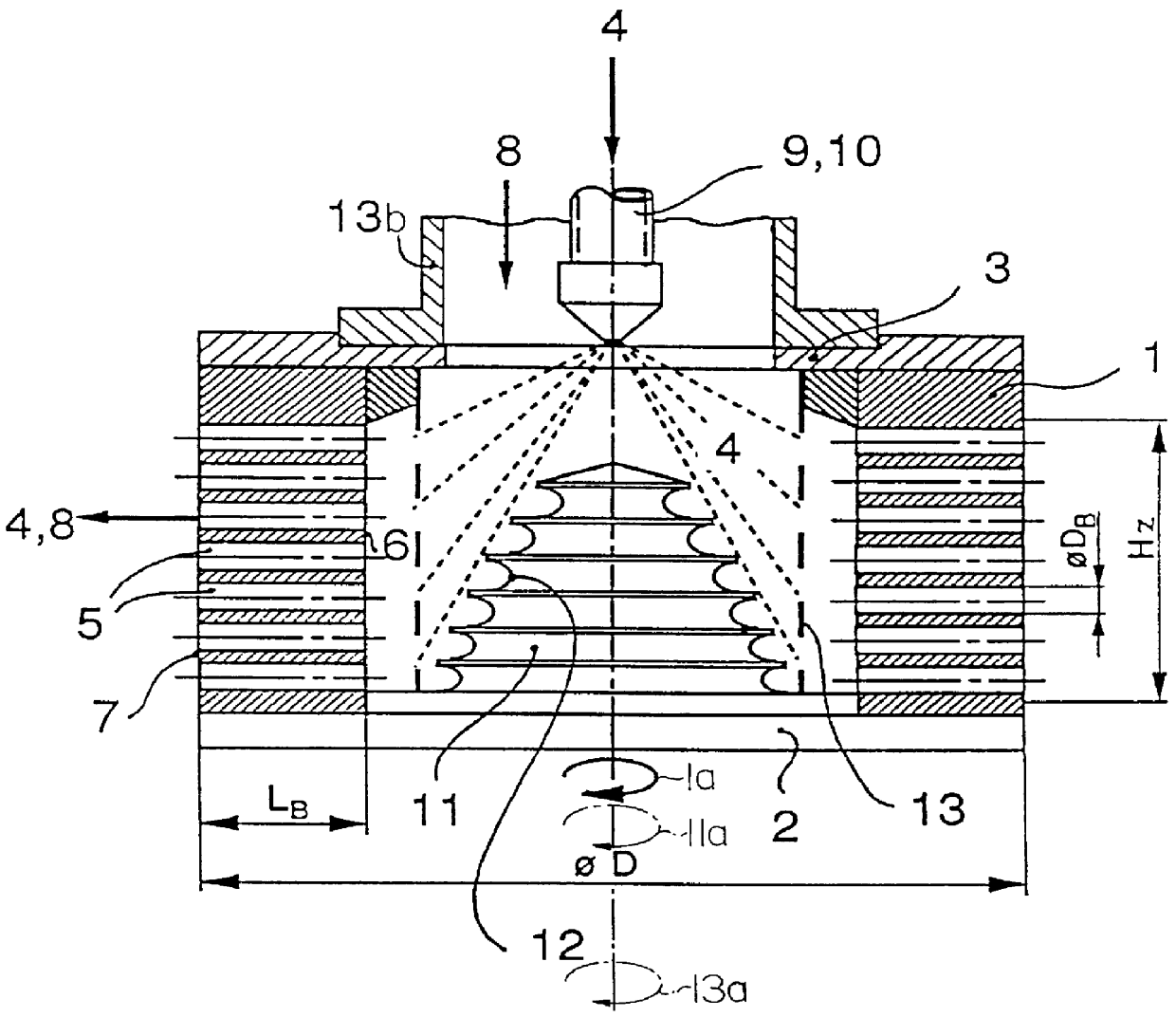

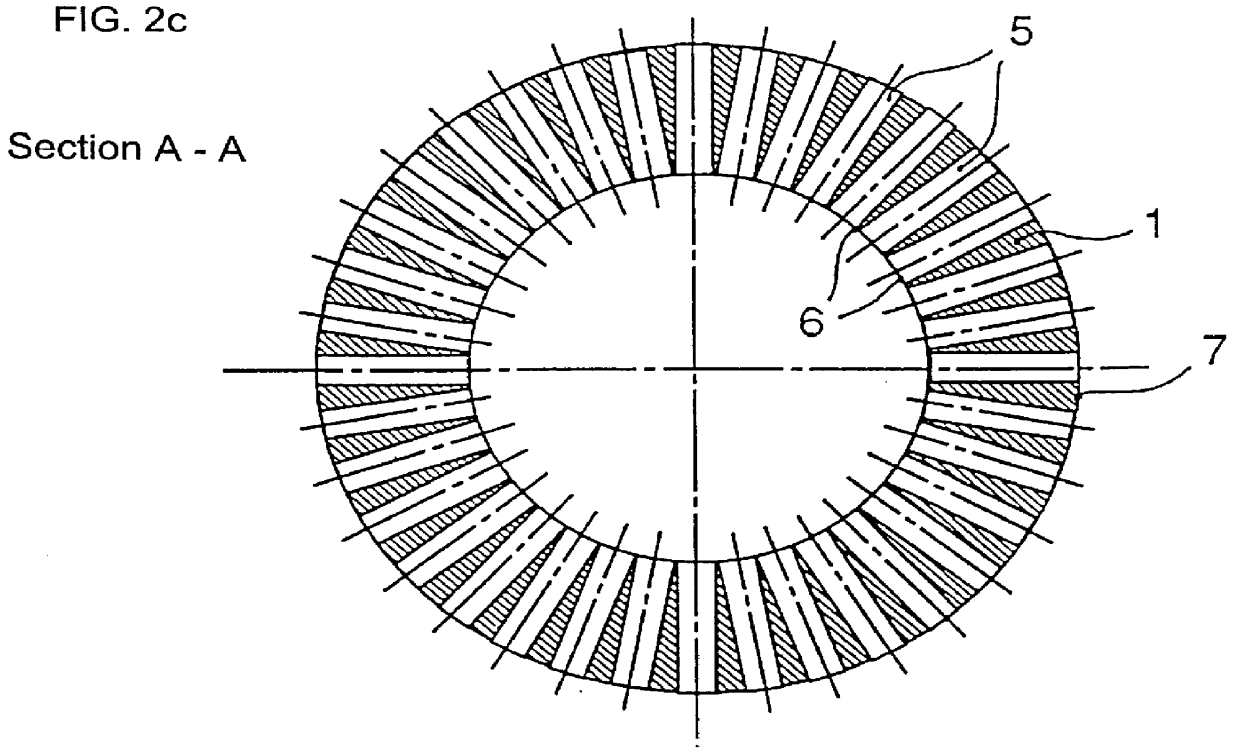

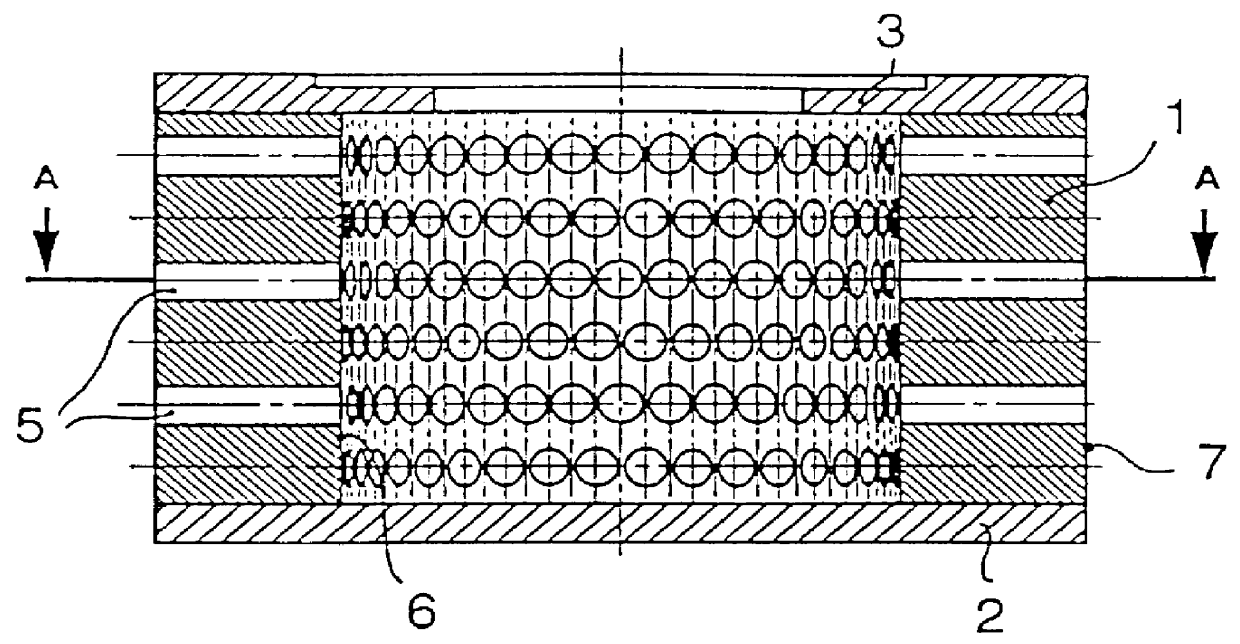

Process and a device for atomizing liquids

InactiveUS6098895ALarge caliberAvoid easy cloggingBurnersMovable spraying apparatusDecompositionEngineering

The liquid to be atomized is uniformly sprayed on the inner surface of a hollow rotating cylinder, for example by means of one- or two-fluid-nozzles and is thus distributed on bores provided in the cylinder wall. The rotation of the cylinder causes the liquid to flow outwards through the bores. Droplets are generated when the liquid flows out of the bores by laminary decomposition of the jet. The flow rate in each bore lies in the range 1.0<+E,dot V+EE B (a3 rho 5 / sigma 5)0.25<16 to prevent the droplets from becoming too large and to satisfy the condition of an adequate flow laminarity, i.e. for the value of the Reynolds number for the continuous liquid flow in the boress not to exceed Re delta 400. +E,dot V+EE B represents the flow rate of the liquid in each bore, a represents the centrifugal acceleration at the outer surface of the cylinder, rho represents the density of the liquid and delta indicates the surface tension of the liquid. The large number N>200 of bores having the diameter DB in the cylinder wall causes the flow rate of liquid through each bore to be relatively low, so that a continuous laminary flow in each bore is ensured even at low viscosities and technically useful total flow rates. Preferably cylindrical bores with a minimum length at least three times larger than the bore diameter are provided in the cylinder wall, with a narrow spacing in the range defined by 1.1<t / DB<5, so that a number of bores as large as possible may be arranged in the wall of the cylinder.

Owner:NIRO

Method for preparing black zirconia ceramics at low temperature

The invention relates to a method for preparing black zirconia ceramics at the low temperature and belongs to the technical field of the preparation of high-temperature structural material. The method respectively uses a homogeneous precipitation method for synthesizing a nanometer coloring agent, and a coprecipitation method for synthesizing nanometer zirconia powder, and adopts Fe-Co-Ni-Mn as a coloring agent. The zirconia powder is not added with any sintering additive, only added with small amount of coloring agent and sintered at the temperature of 1150-1350 DEG C, thus obtaining the black zirconia ceramics with excellent performance and bright color. As the homogeneous precipitation method is adopted for synthesizing coloring agent powder, the monodisperse nanometer particles with uniform powder granules, narrow size distribution and high purity are obtained so that the coloring agent easily colors the particles. As the coprecipitation method is used for synthesizing zirconia powder, nanometer particles with small granularity, big superficial area and high activity are obtained, and can reduce the temperature of the solid-phase reaction, greatly reduce the sintering temperature and solve the problem that the black coloring agent oxide decomposes and volatiles at the high temperature. Simultaneously the method adopts the Fe-Co-Ni-Mn as the coloring agent, thus avoiding the poisonous function of Cr on the human body.

Owner:TSINGHUA UNIV

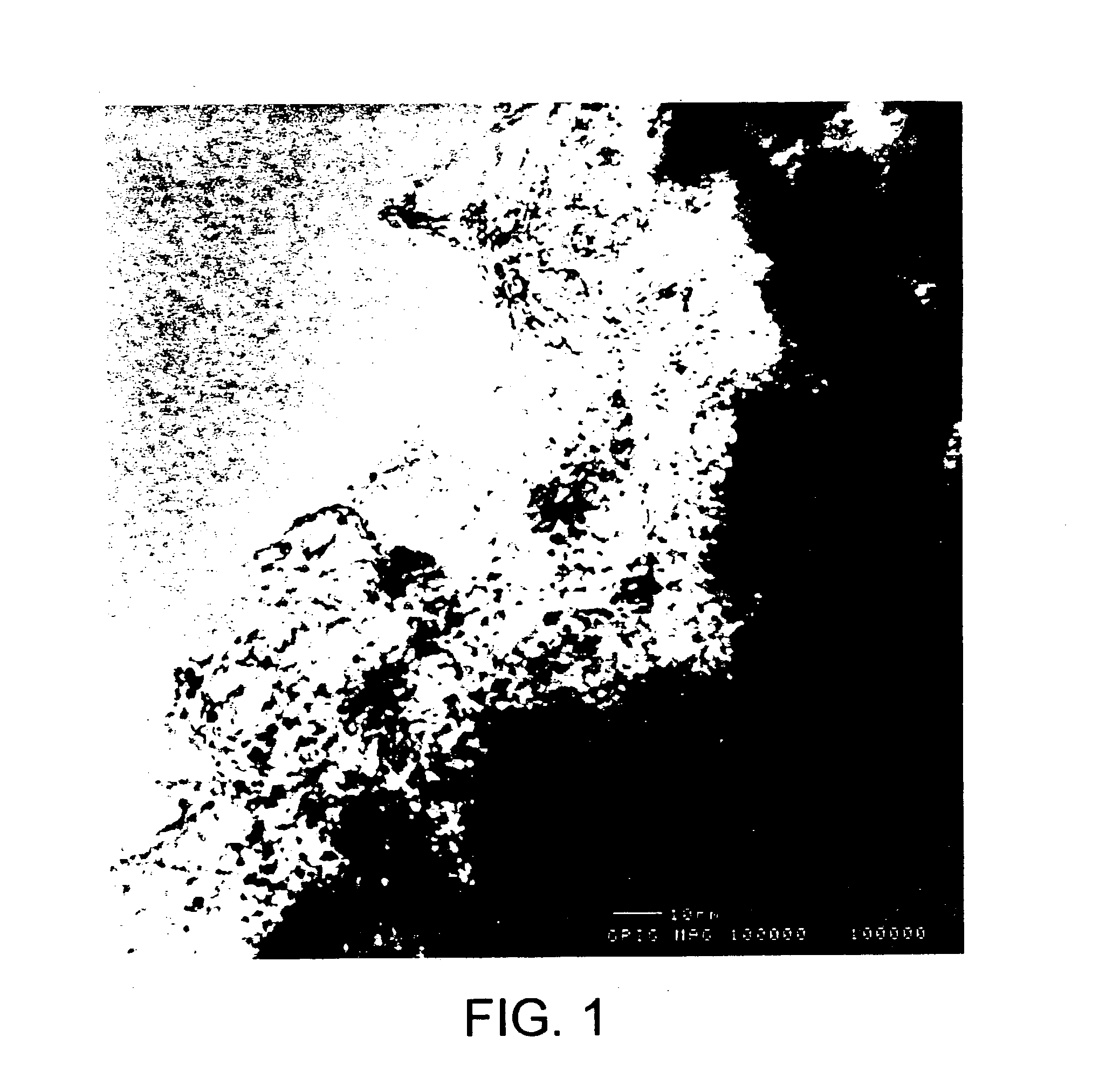

Catalytic growth of single-wall carbon nanotubes from metal particles

InactiveUS20030175200A1Less pollutionNarrow size distributionMaterial nanotechnologyFibre chemical featuresMetal catalystCatalytic decomposition

Single-walled carbon nanotubes have been synthesized by the catalytic decomposition of both carbon monoxide and ethylene over a supported metal catalyst known to produce larger multi-walled nanotubes. Under certain conditions, there is no termination of nanotube growth, and production appears to be limited only by the diffusion of reactant gas through the product nanotube mat that covers the catalyst The present invention concerns a catalyst-substrate system which promotes the growth of nanotubes that are predominantly single-walled tubes in a specific size range, rather than the large irregular-sized multi-walled carbon fibrils that are known to grow from supported catalysts. With development of the supported catalyst system to provide an effective means for production of single-wall nanotubes, and further development of the catalyst geometry to overcome the diffusion limitation, the present invention will allow bulk catalytic production of predominantly single-wall carbon nanotubes from metal catalysts located on a catalyst supporting surface.

Owner:RICE UNIV

Superabrasive particle synthesis with controlled placement of crystalline seeds

InactiveUS20060016127A1Narrow size distributionQuality improvementDrill bitsConstructionsOctahedronSynthesis methods

An improved method for synthesizing superabrasive particles provides high quality industrial superabrasive particles with high yield and a narrow size distribution. The synthesis method can include forming a growth precursor of a substantially homogeneous mixture of raw material and catalyst material or layers of raw material and metal catalyst. The growth precursor can have a layer of adhesive over at least a portion thereof. A plurality of crystalline seeds can be placed in a predetermined pattern on the layer of adhesive. The growth precursor can be maintained at a temperature and pressure at which the superabrasive crystal is thermodynamically stable for a time sufficient for a desired degree of growth. Advantageously, the patterned placement of crystalline seeds and disclosed processes allow for production of various morphologies of synthetic diamonds, including octahedral and cubic diamonds, and improved growth conditions generally. As a result, the grown superabrasive particles typically have a high yield of high quality particles and a narrow distribution of particle sizes.

Owner:SUNG CHIEN MIN

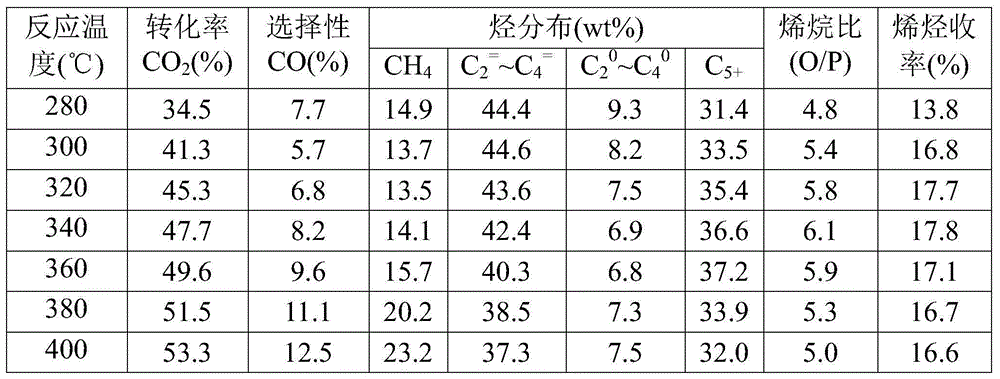

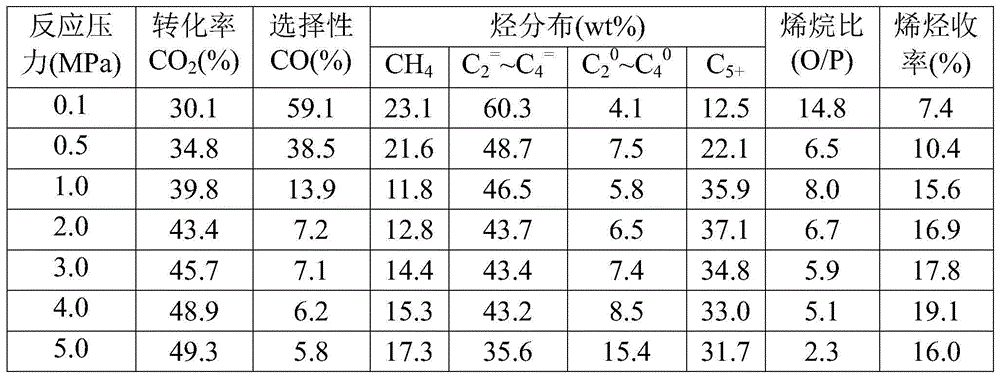

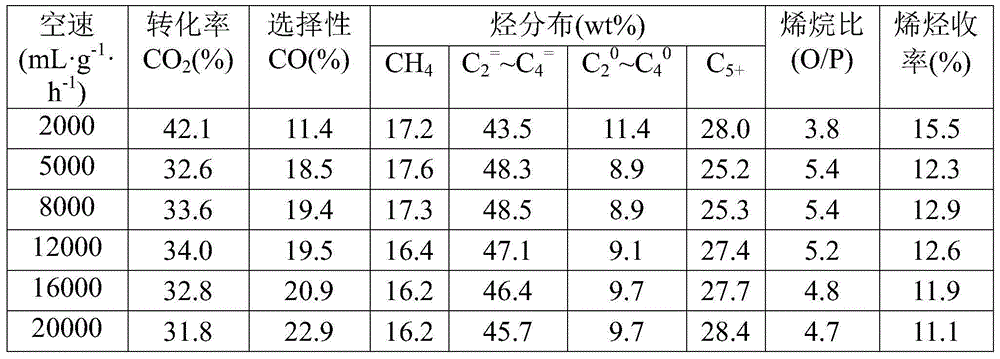

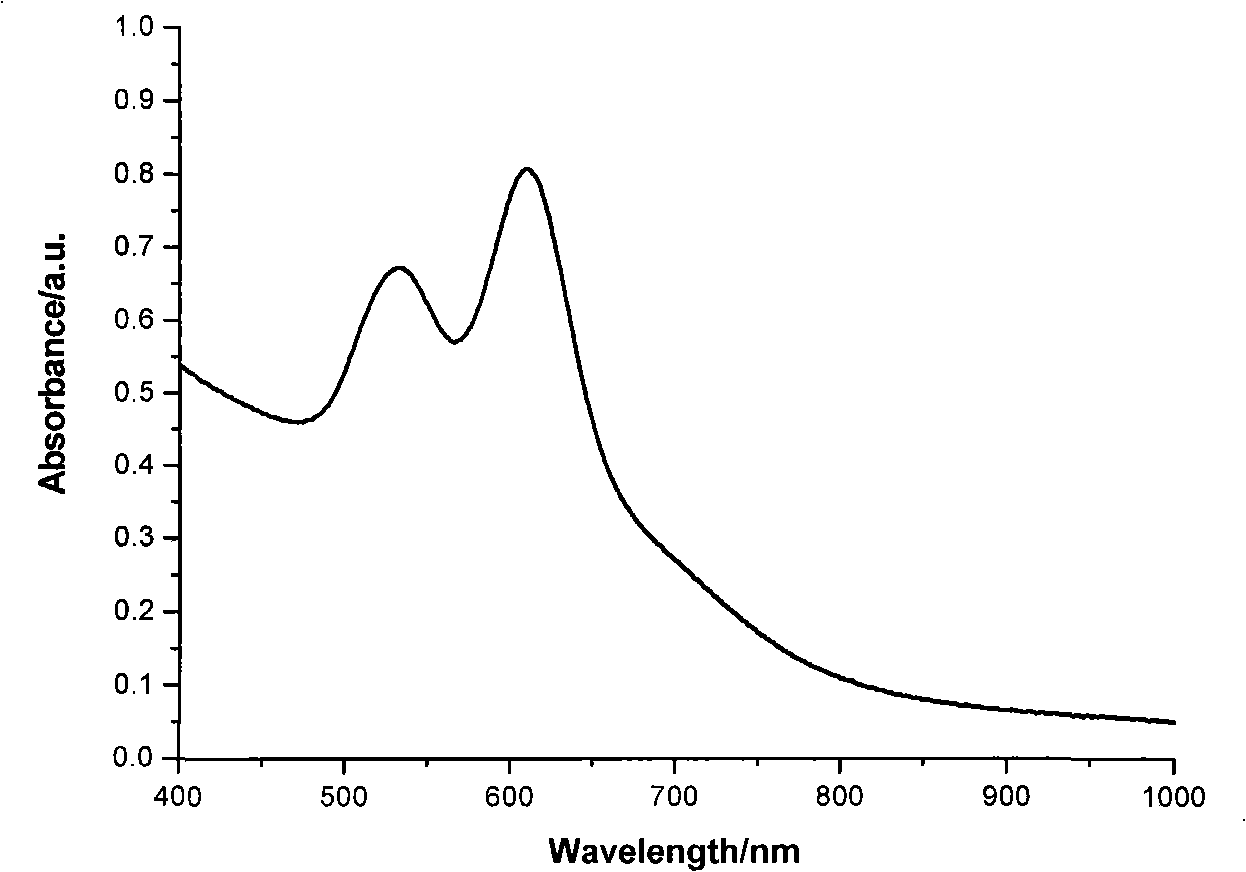

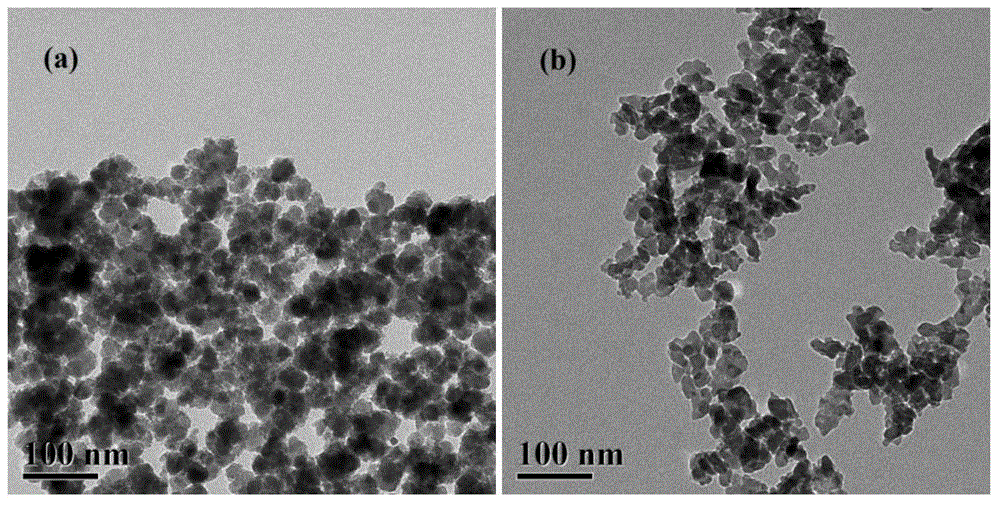

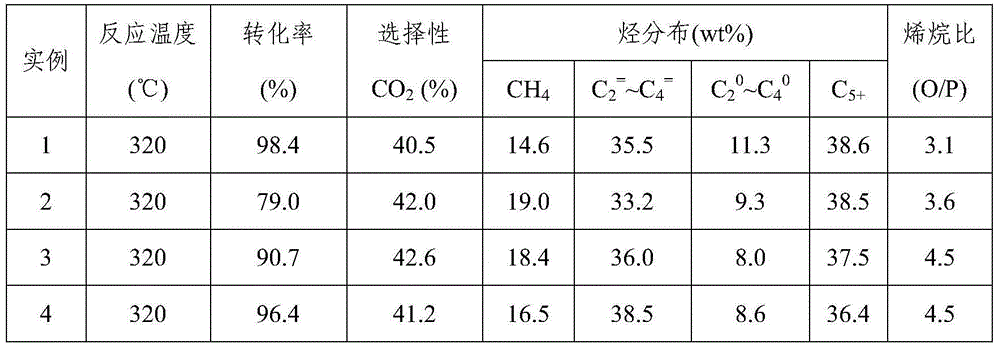

Iron-based catalyst for low-carbon olefin production through CO2 hydrogenation, and preparation and applications thereof

ActiveCN106031871AEasy to prepareLower catalyst costsHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsOxideFixed bed

The present invention provides an iron-based catalyst for low-carbon olefin production through CO2 hydrogenation, wherein the main active component of the catalyst is Fe3O4, the auxiliary agent is added or is not added, and is an oxide, the content of the auxiliary agent accounts for 0-30% of the total mass of the catalyst, and the auxiliary agent is one or more than two selected from the oxide of Si, Al, Mn, K, Cu, Na, Zr, V, Zn and Ce. The present invention further provides a preparation method and applications of the catalyst. According to the present invention, the catalyst has the following beneficial effects that 1) the particles have characteristics of regular spherical shape, uniform spatial distribution, and narrow size distribution; 2) the raw materials are inexpensive and easy to obtain, and the preparation method has characteristics of simpleness and low cost, and is suitable for industrial production; 3) the catalyst has characteristics of high mechanical strength, good wear resistance and compression resistance, and is suitable for the fixed bed, the fluidized bed and the slurry bed; 4) the CO2 hydrogenation activity and the low-carbon olefin selectivity are high, the single-pass conversion rate can achieve more than 40%, the methane selectivity in the hydrocarbon product is lower than 15%, the low-carbon olefin selectivity is higher than 40%, the alkene / alkane ratio (O / P) is 2-12, and the yield of the low-carbon olefin can achieve 10-60 g / m<3> (CO2+H2).

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

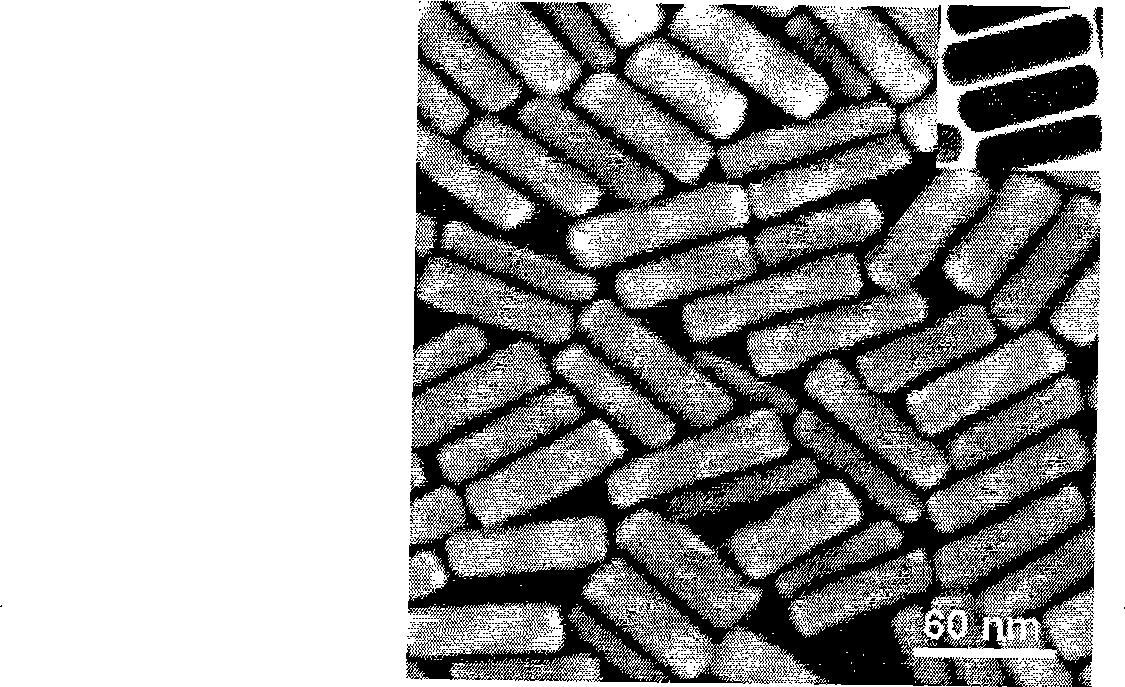

Process for producing golden nano stick with short length-diameter ratio

InactiveCN101343778ASolve the problem of hydrophobizationSolving Biomodification ProblemsPolycrystalline material growthFrom normal temperature solutionsDiameter ratioChloride

The invention discloses a short length-diameter ratio gold nanometer rod preparation method. A strong reducing agent of sodium borohydride is added in a hexadecyl trimethyl ammonium bromide surface modifying agent solution to reduce gold acid chloride and obtain a gold seed solution; a mixed fluid of didodecyl dimethyl ammonium bromide, gold acid chloride and silver nitrate is prepared, and an ascorbic acid solution is added thereto for obtaining a growth solution; the seed solution of a certain amount is filled into the growth solution to react for 5 to 12 hours, so as to obtain the short length-diameter ratio gold nanometer rod. The operation of the method is simple, the gold nanometer rod production rat is high, and the size distribution is narrow.

Owner:BEIHANG UNIV

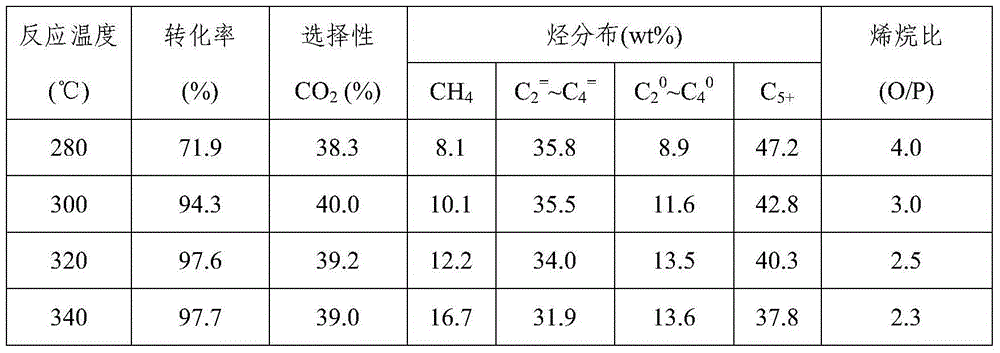

Iron-based catalyst for preparation of low carbon olefin from synthetic gas, and preparation method and application thereof

InactiveCN104801304AEvenly spacedNarrow size distributionMaterial nanotechnologyHydrocarbon from carbon oxidesFixed bedSlurry

The invention provides an iron-based catalyst for preparation of low carbon olefin from synthetic gas. The catalyst contains Fe3O4 as a main active component, and also contains one or two or above assistant M for modification, and M is selected from Si, Al, Mn, K, Cu, Na, Zr, V and Zn. The content of oxide of the assistant in the catalyst is 0-30wt%. The catalyst has the following advantages: 1, particles of the catalyst have regular spherical morphology, uniform space distribution, narrow dimension distribution, and average particle size of 30nm; 2, the catalyst has the characteristics of cheap and easily available raw materials, simple preparation method, low cost, and suitableness for industrial production; 3, the catalyst has good mechanical strength, wear resistance and compression resistance, and is suitable for being applied in fixed beds, fluidized beds and slurry beds; and 4, the catalyst has high Fischer-Tropsch synthesis activity and high low-carbon olefin selectivity, the single-pass conversion rate can reach above 95%, the methane selectivity is lower than 15%, the olefin / paraffin ratio (O / P) is 2-6, and the low-carbon olefin yield can reach 40-100g / m<3>(CO+H2).

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com