Patents

Literature

597results about "Fullerenes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano carbon materials for enhancing thermal transfer in fluids

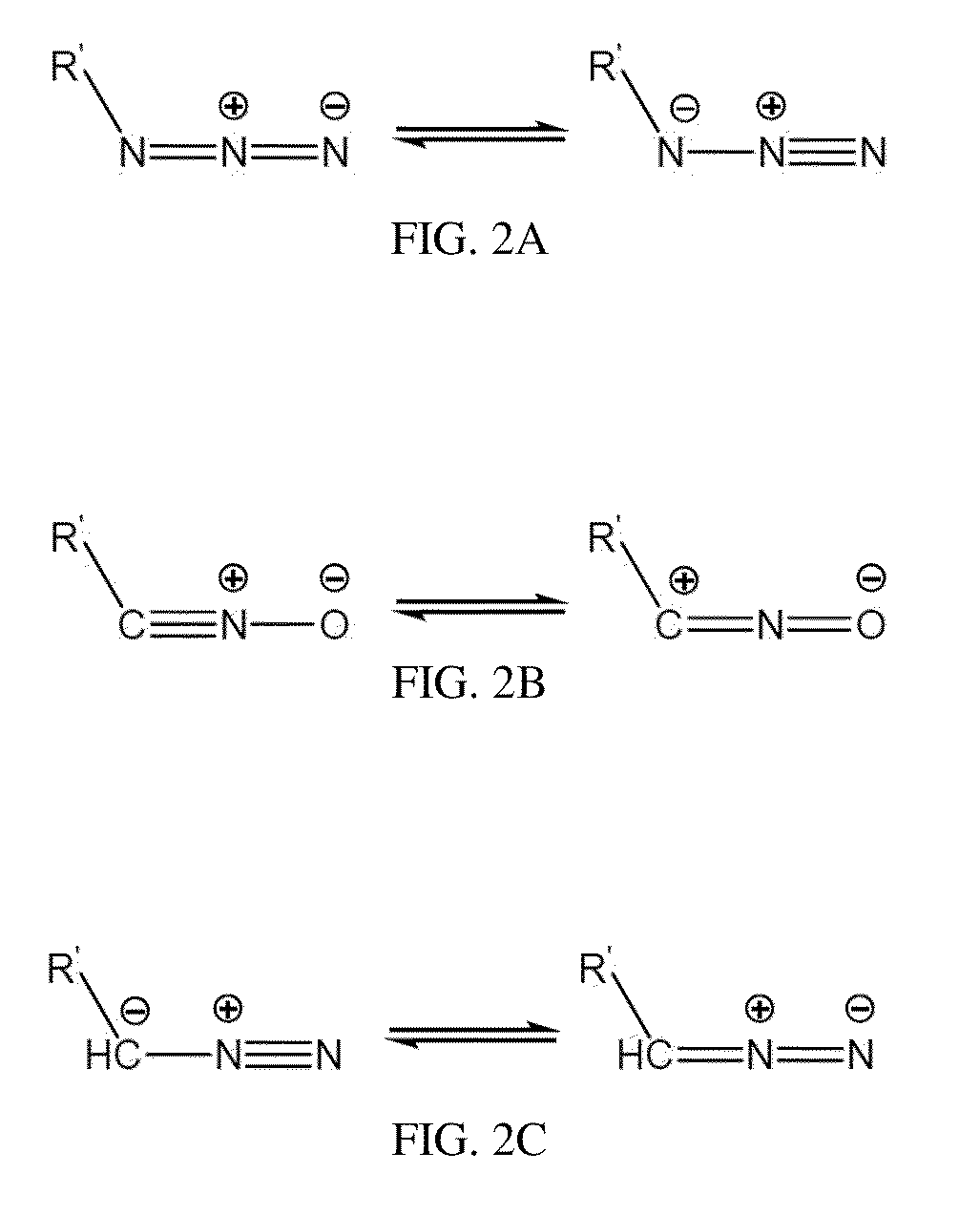

InactiveUS6695974B2Improve thermal conductivityImprove heat transfer performanceMaterial nanotechnologyNanostructure manufactureOrganic groupElectrical polarity

A novel fluid heat transfer agent suitable for use in a closed heat transfer system, for example, wherein energy is transferred between an evaporator and a condenser in heat exchange relationship with the heat transfer agent that is caused to flow from one to the other. The novel heat transfer agent is a complex comprising a body of heat transfer fluid, for example, ethylene glycol or water, having suspended therein carbon nanoparticles in a quantity sufficient to enhance the thermal conductivity of the body of heat transfers fluid, per se. The carbon nanoparticles are selected from carbon in the form of sp<2 >type and sp<3 >type bonding and preferably comprise nanotubes or fullerenes and may have a coupling agent bonded thereto or enclosed therein when the nanotube or fullerene forms a hollow capsule. The coupling agent may be a polar organic group covalently bonded to the carbon nanoparticles and miscible in the fluid medium.

Owner:MATERIALS & ELECTROCHEM RES

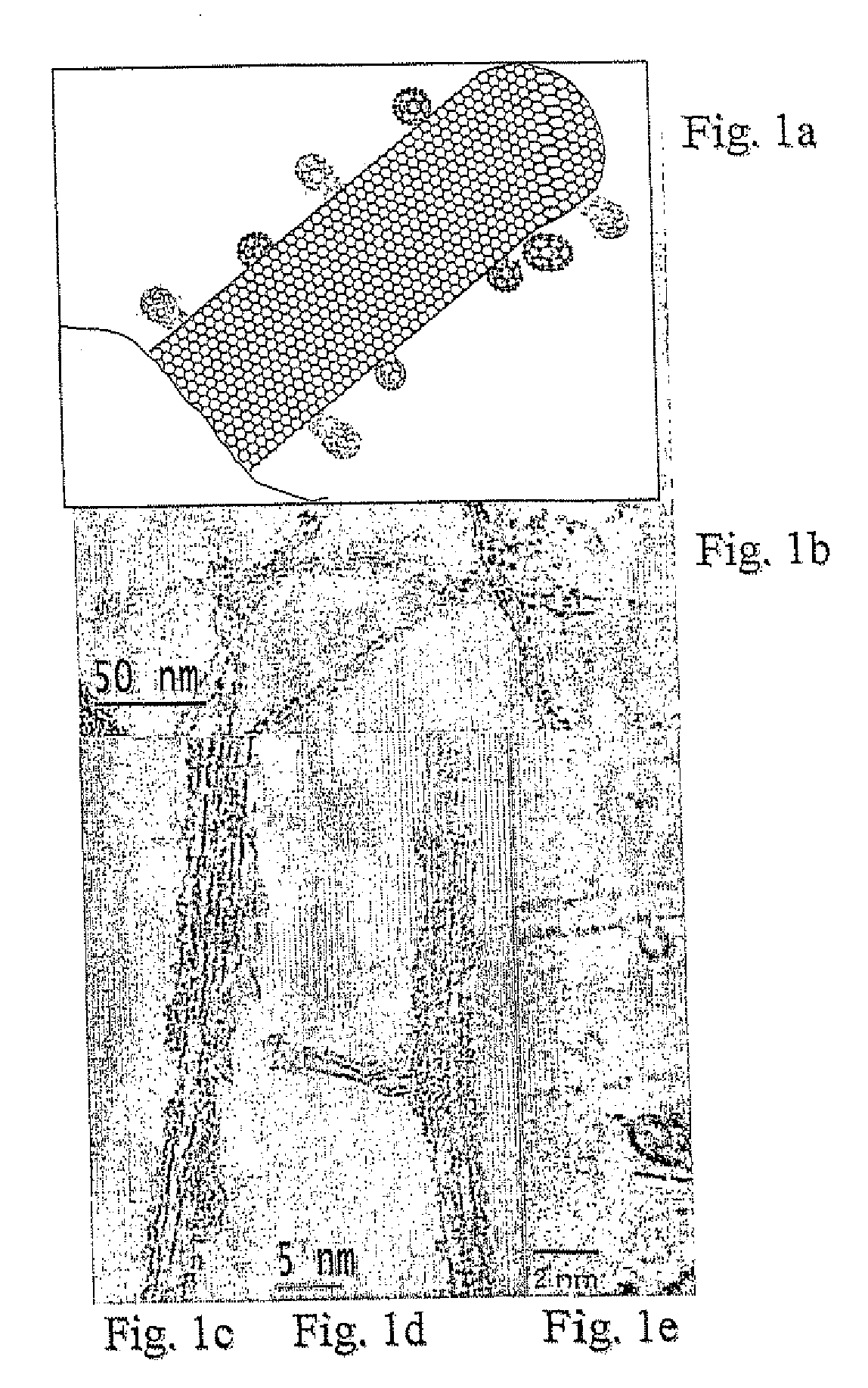

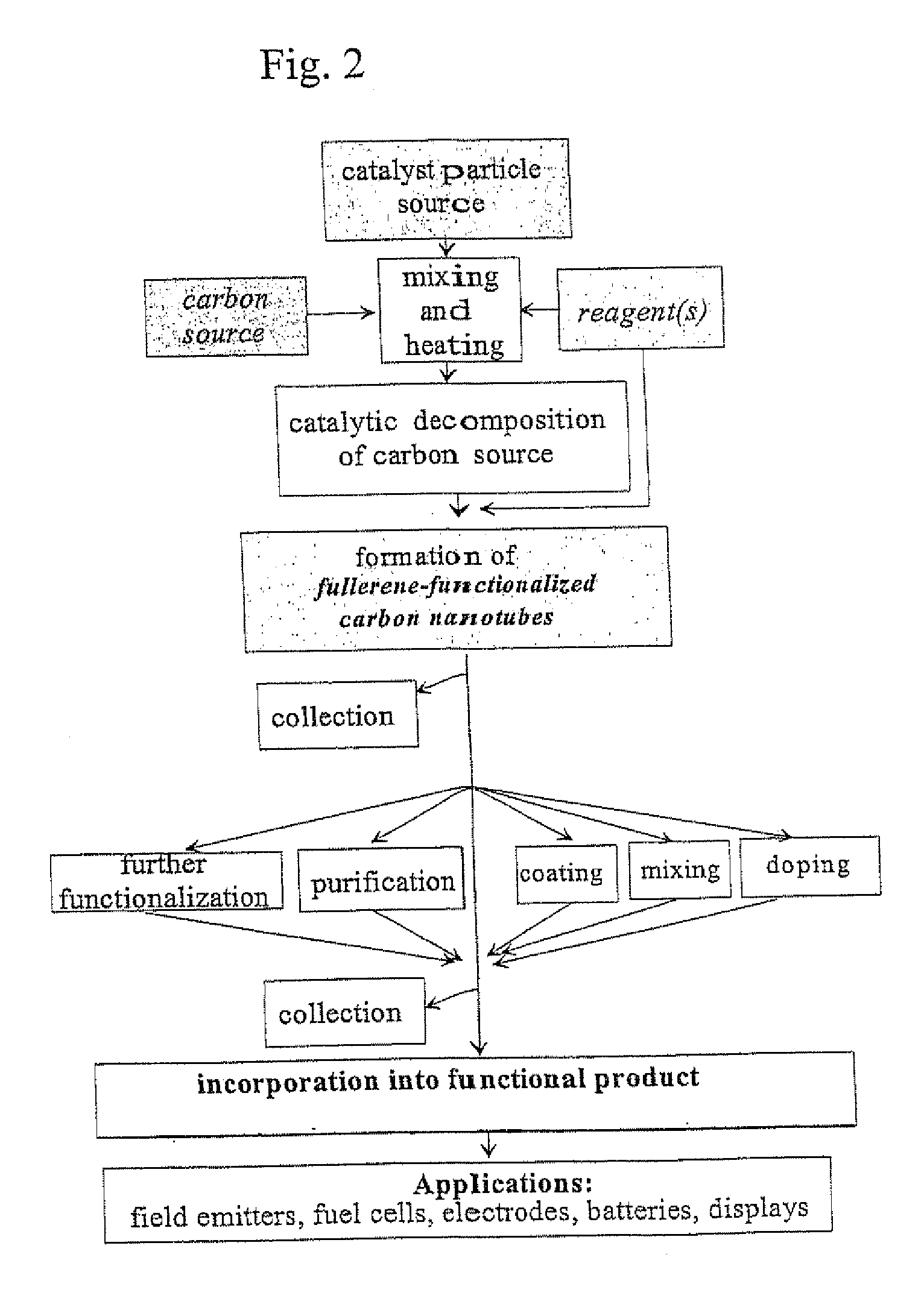

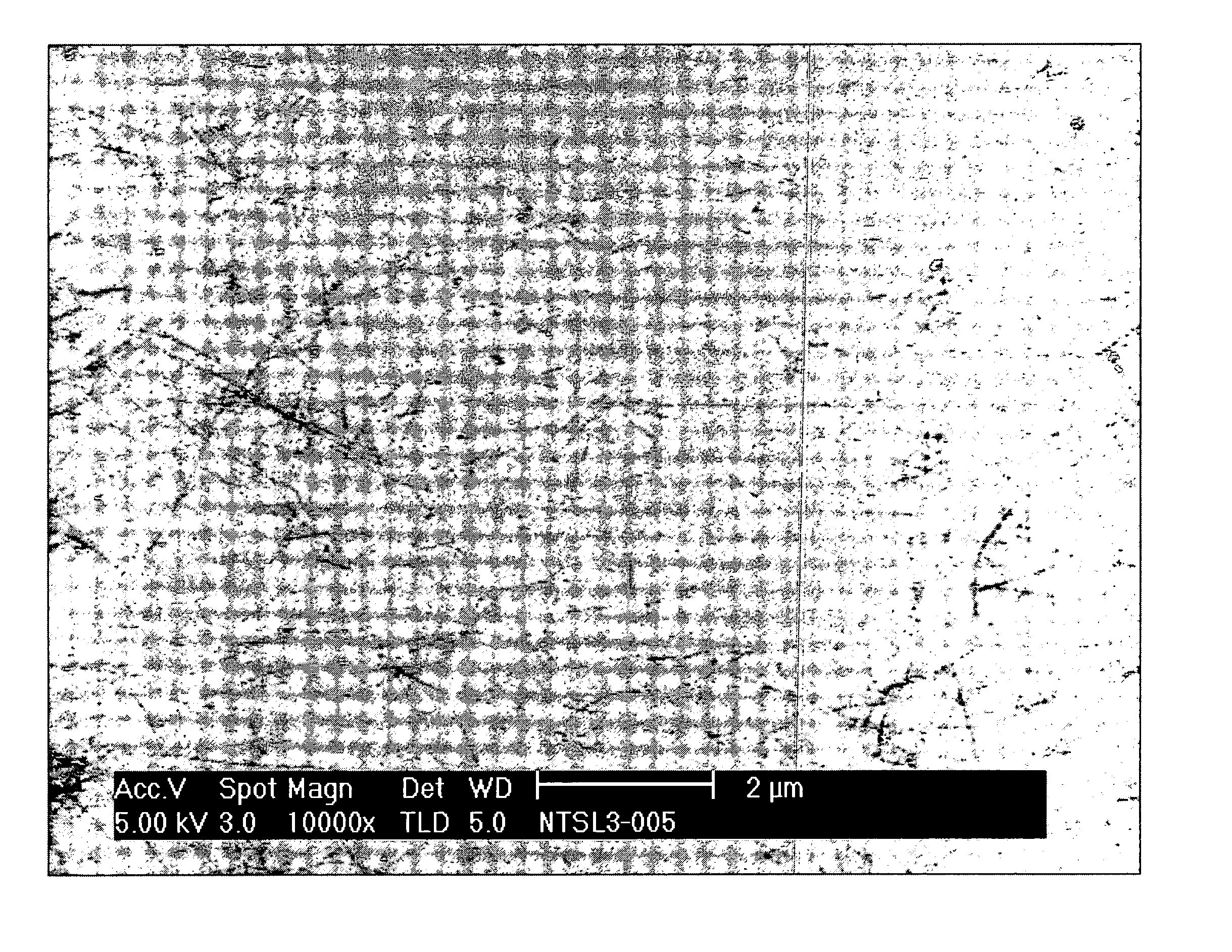

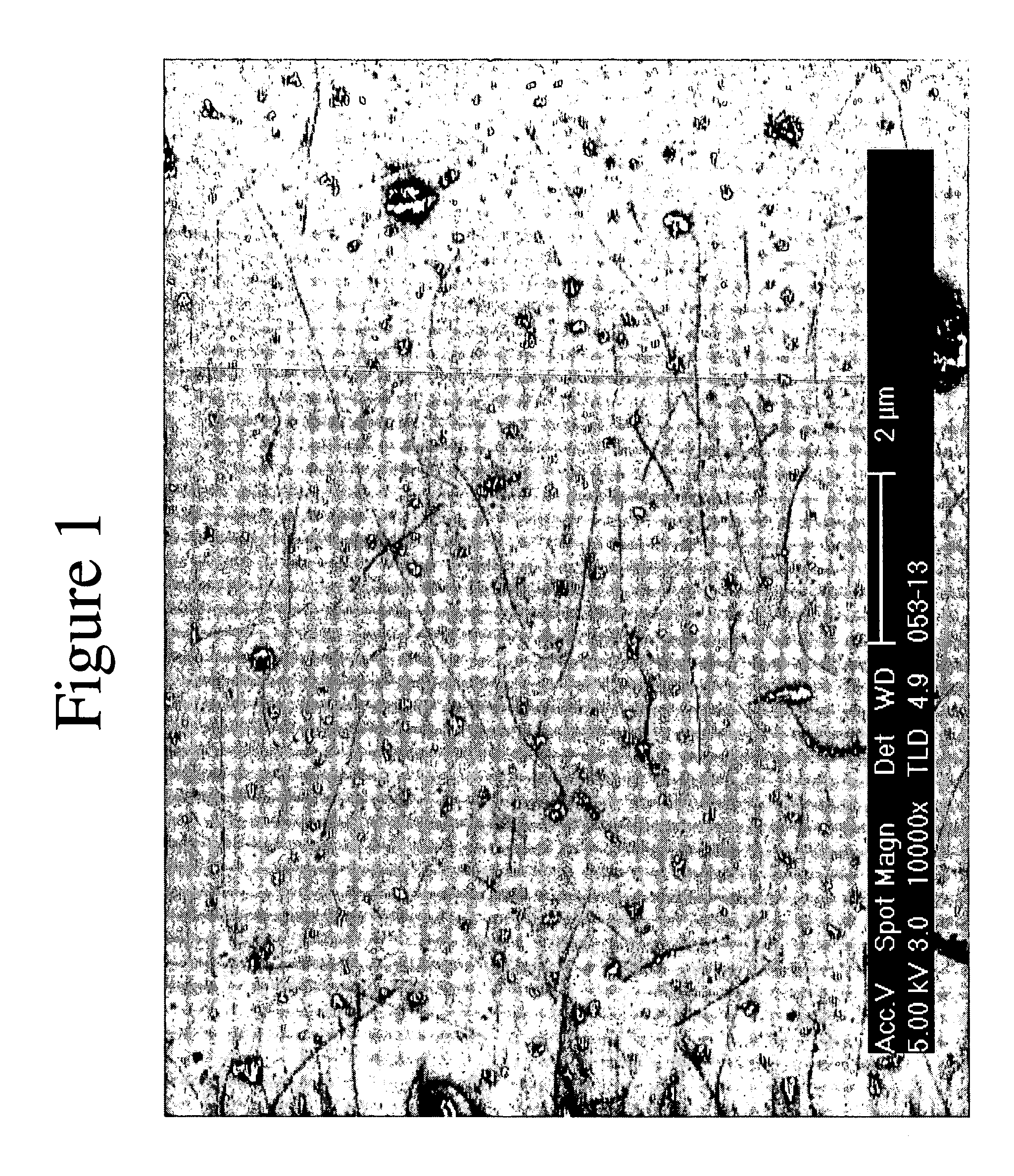

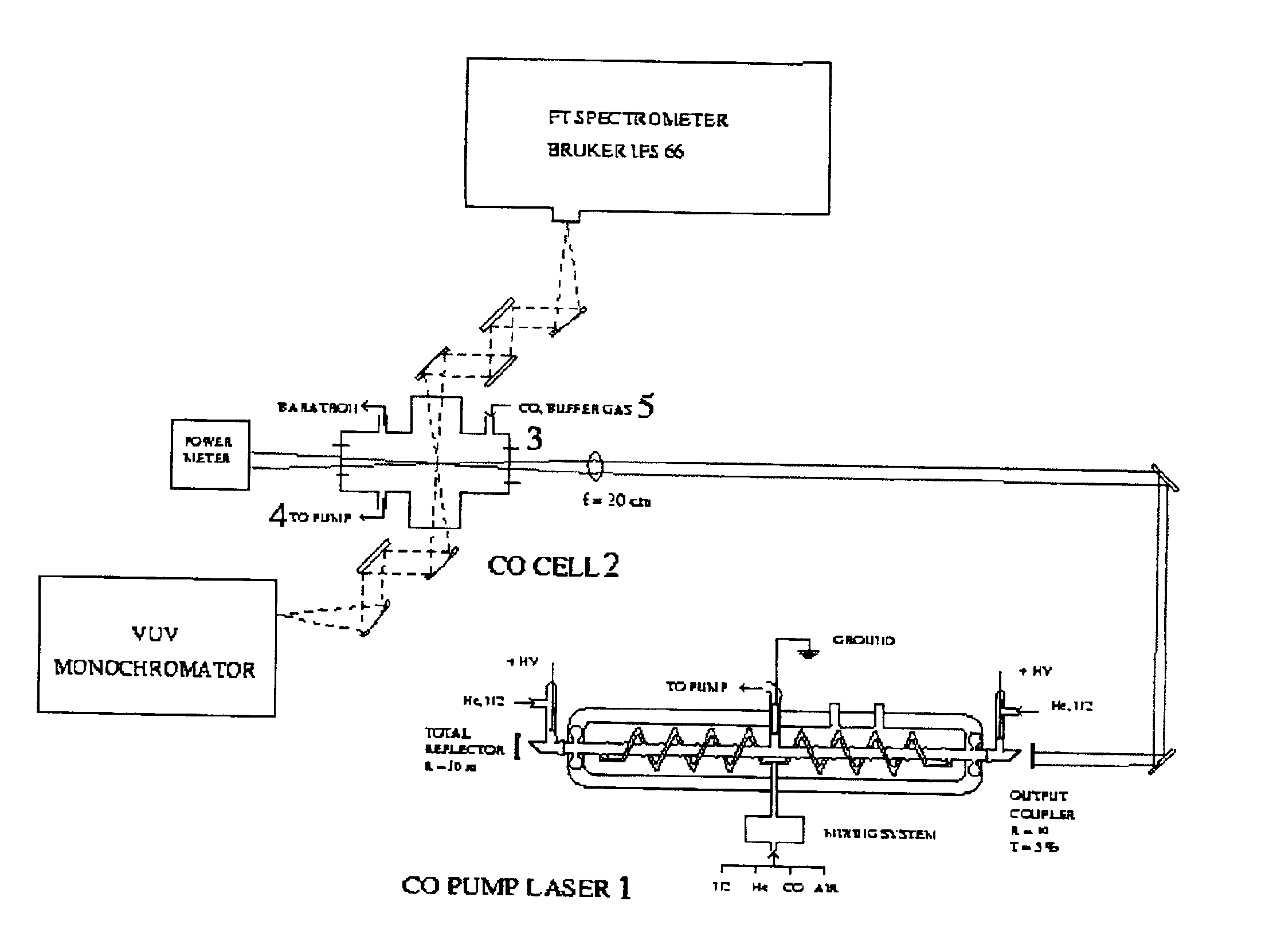

Carbon nanotubes functionalized with fullerenes

InactiveUS20090226704A1Enhancement in cold electron field emissionImprove mechanical propertiesSpecific nanostructure formationMaterial nanotechnologyC60 fullereneNanotube

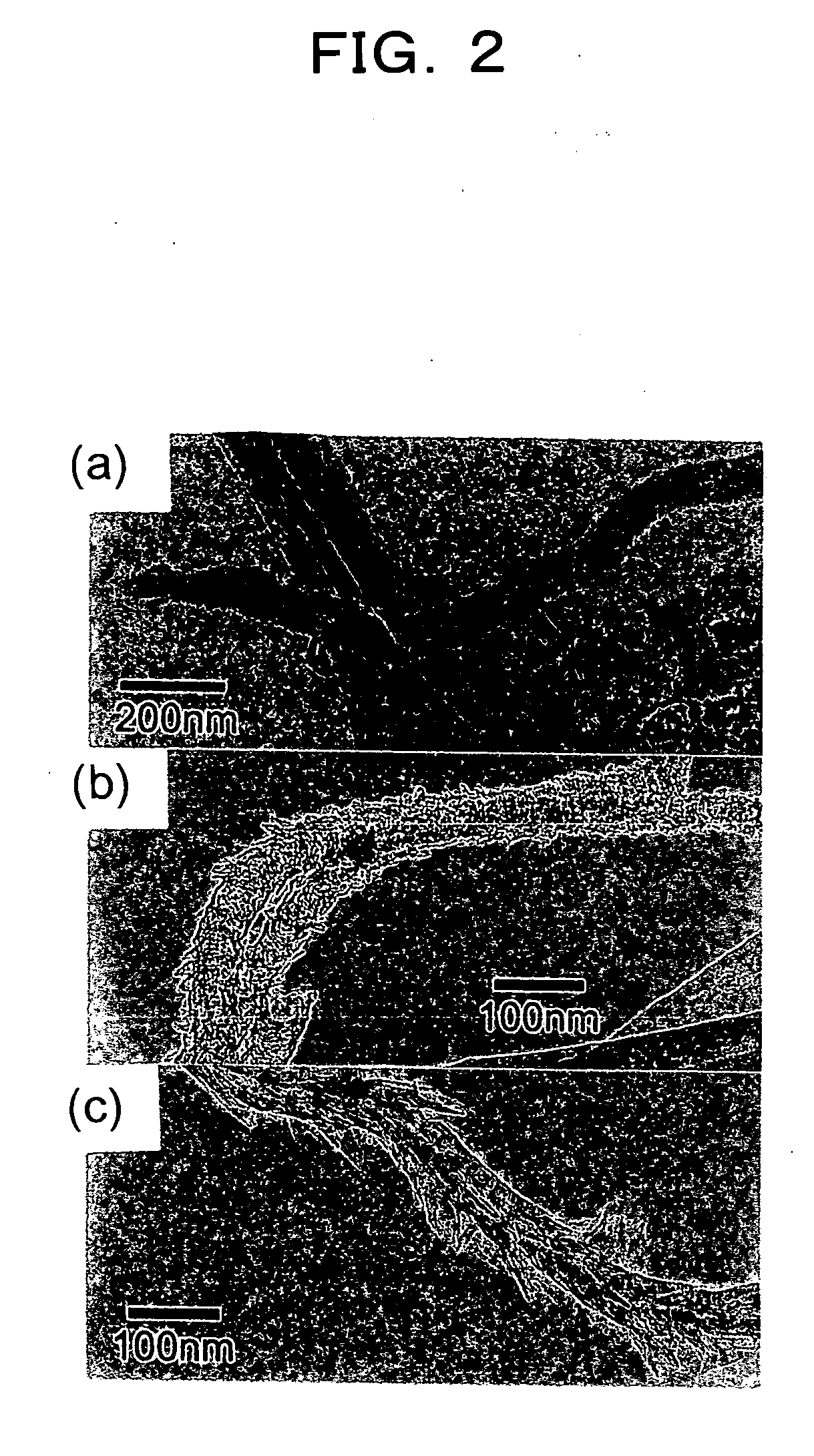

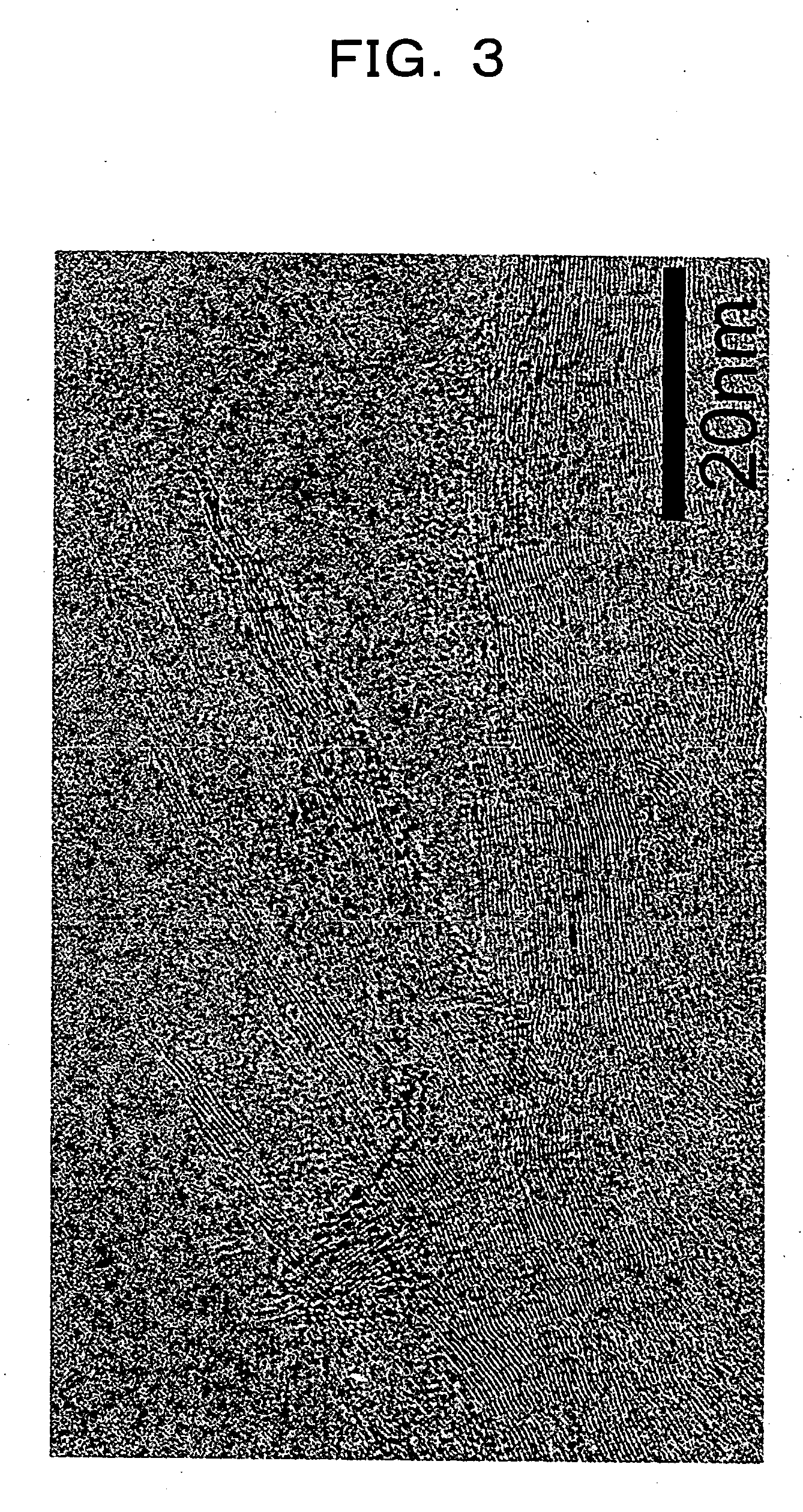

The present invention relates to covalently bonded fullerene-functionalized carbon nanotubes (CBFFCNTs), a method and an apparatus for their production and to their end products. CBFFCNTs are carbon nanotubes with one or more fullerenes or fullerene based molecules covalently bonded to the nanotube surface. They are obtained by bringing one or more catalyst particles, carbon sources and reagents together in a reactor.

Owner:CANATU OY

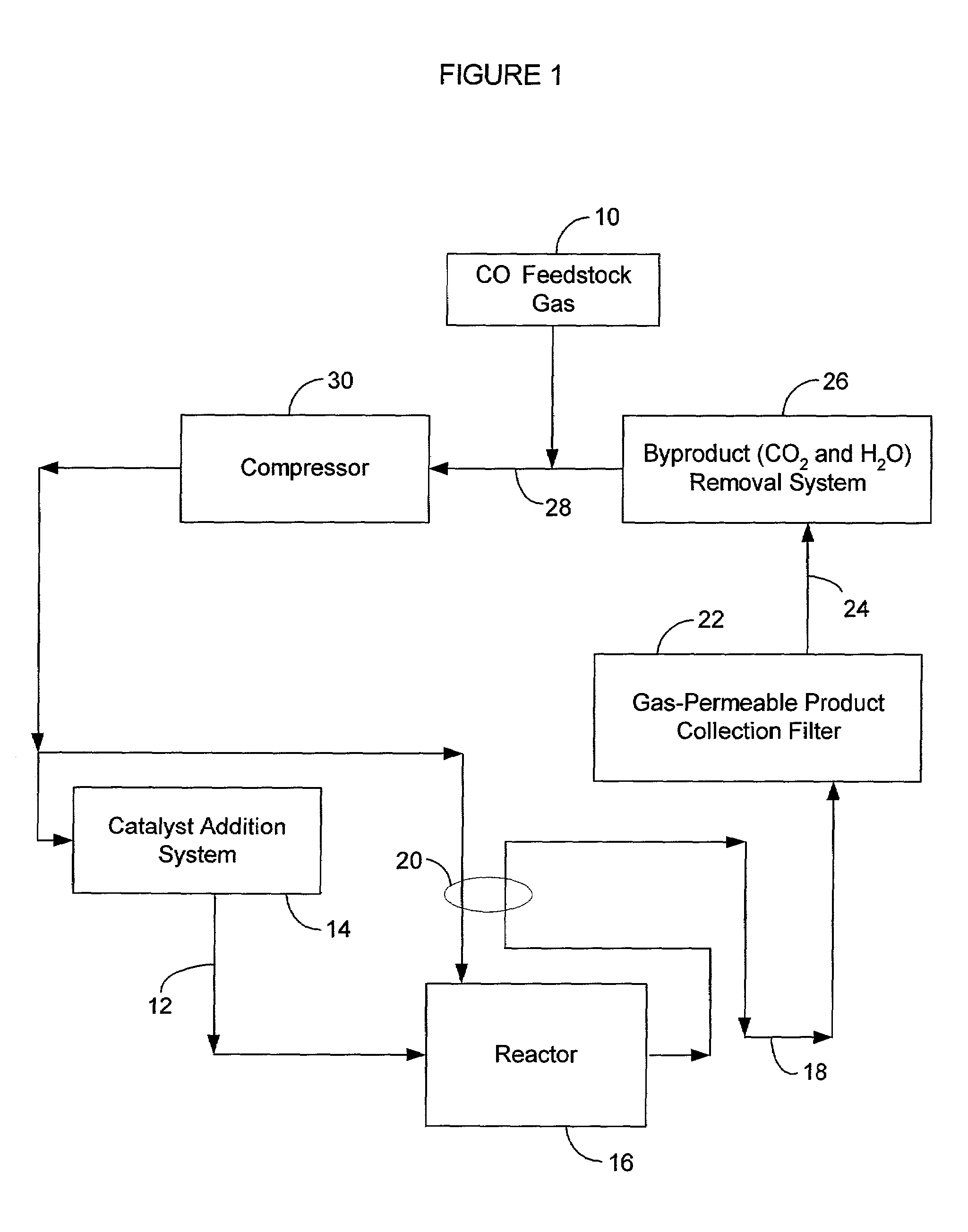

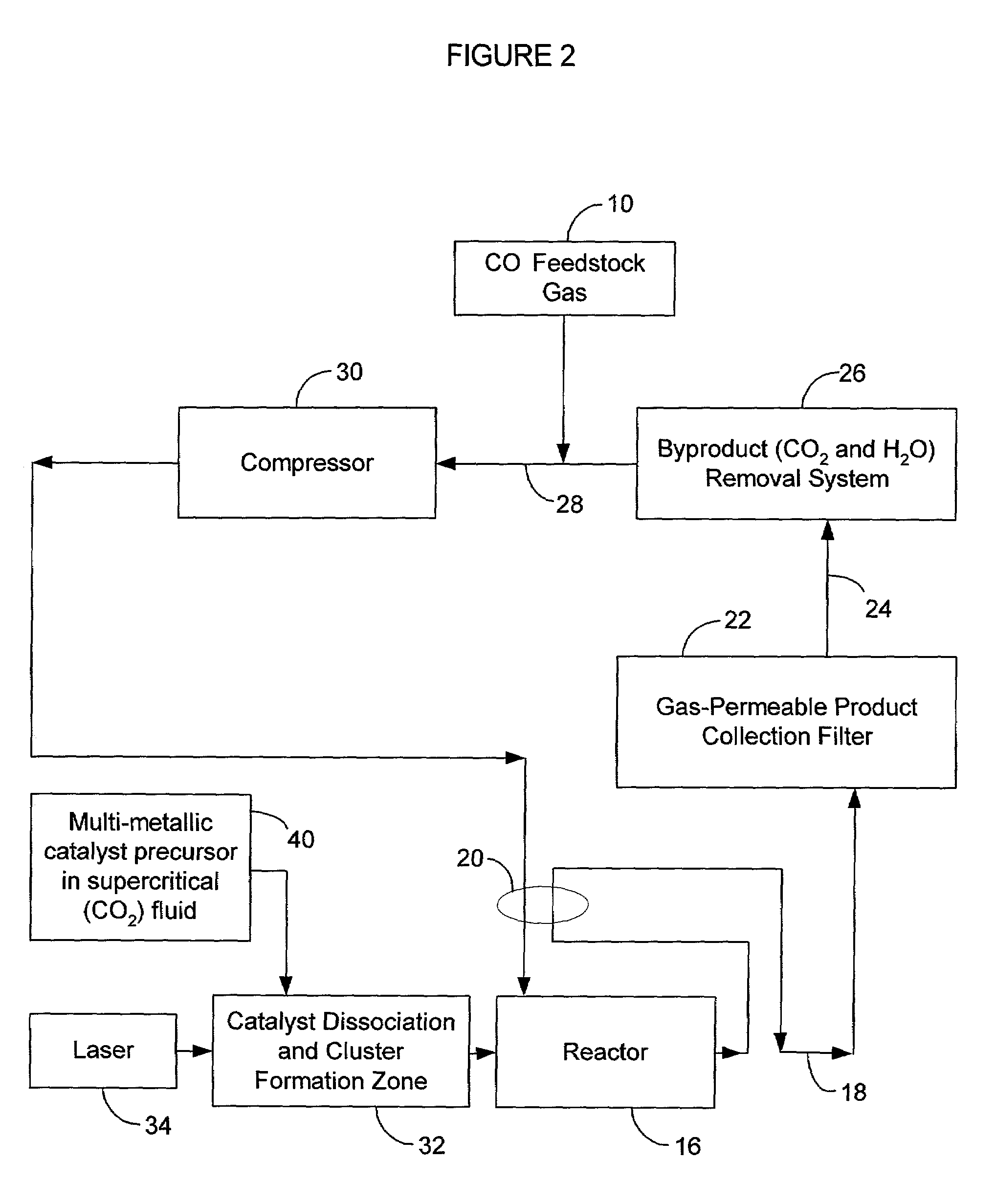

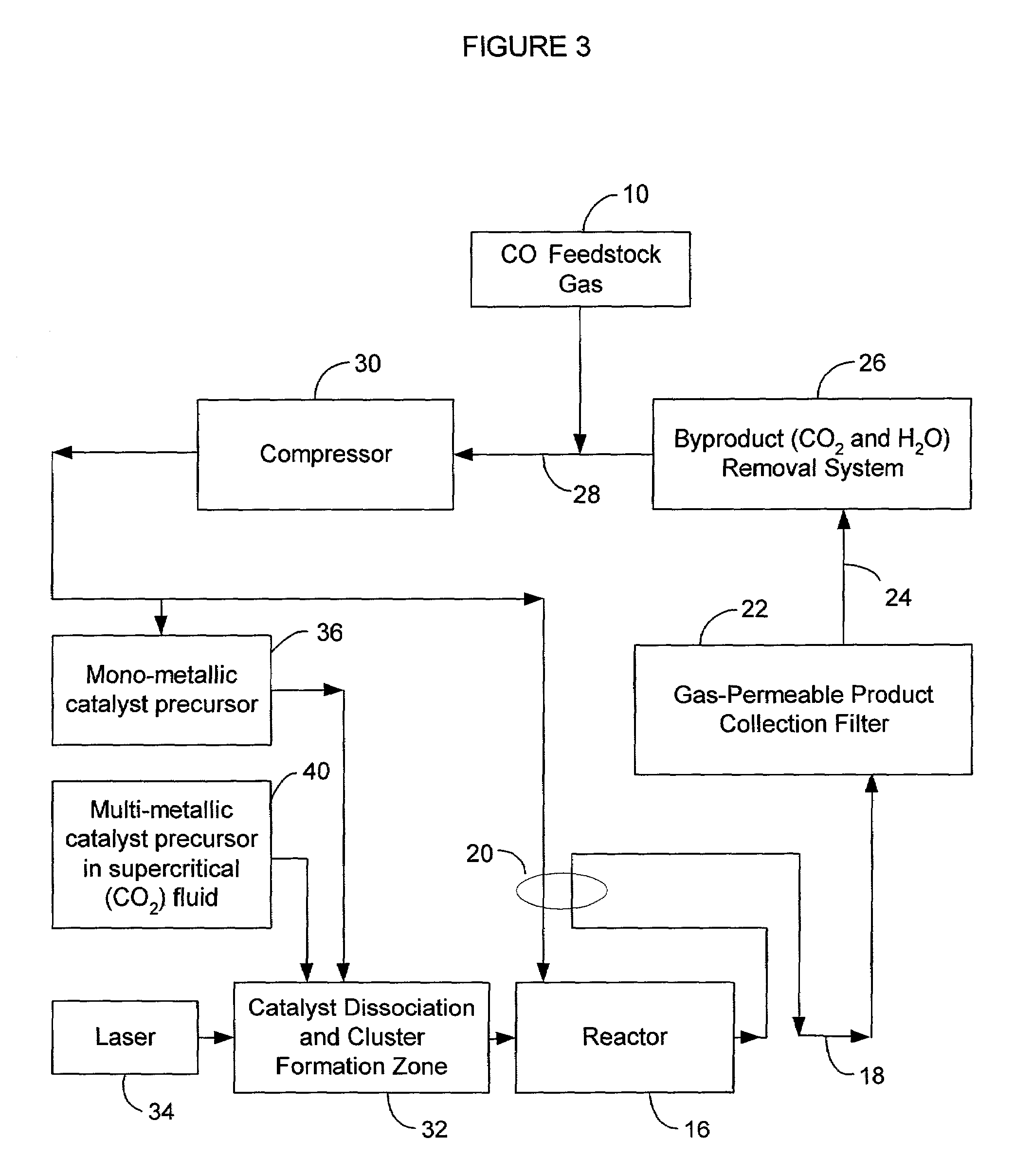

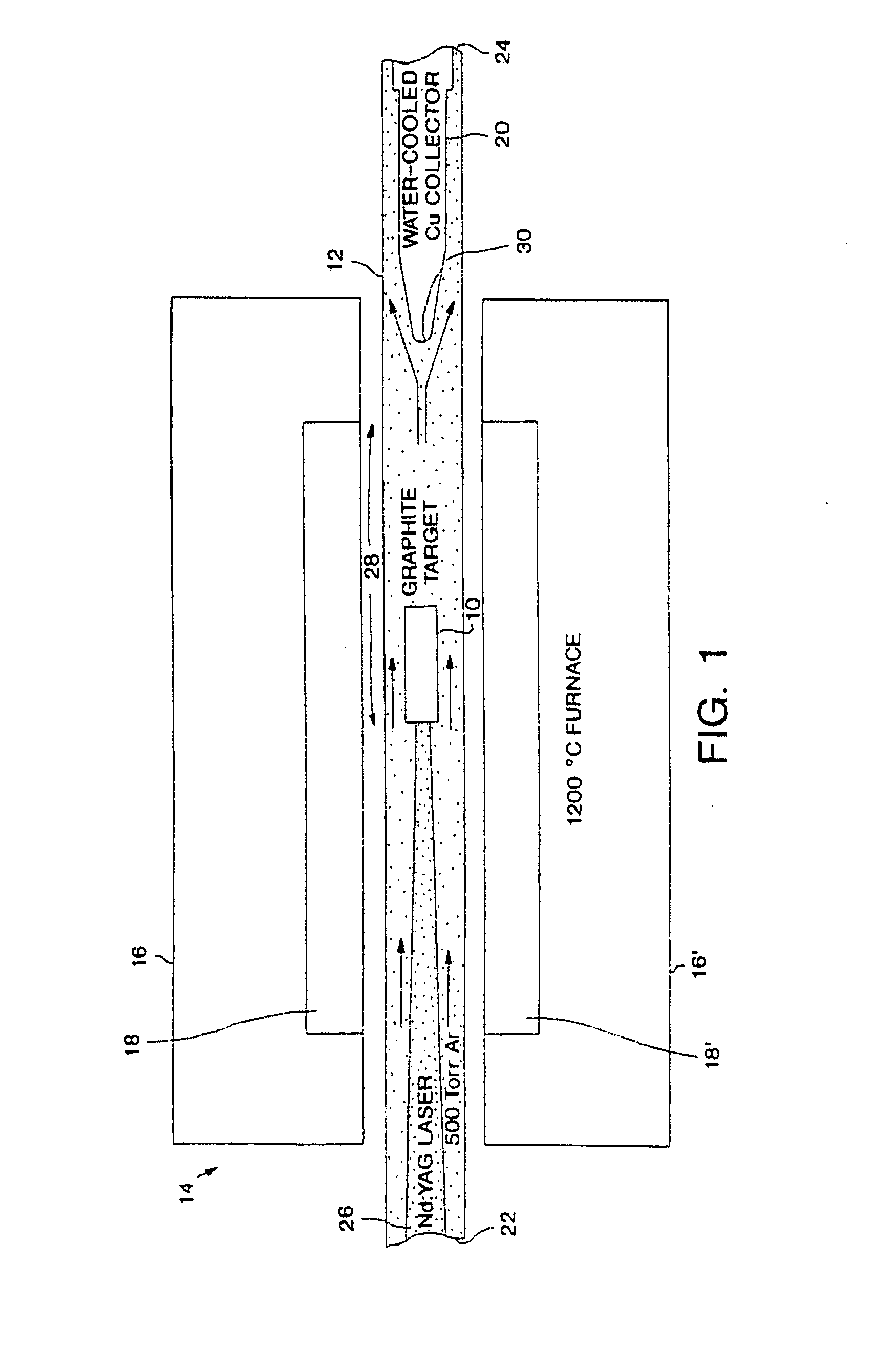

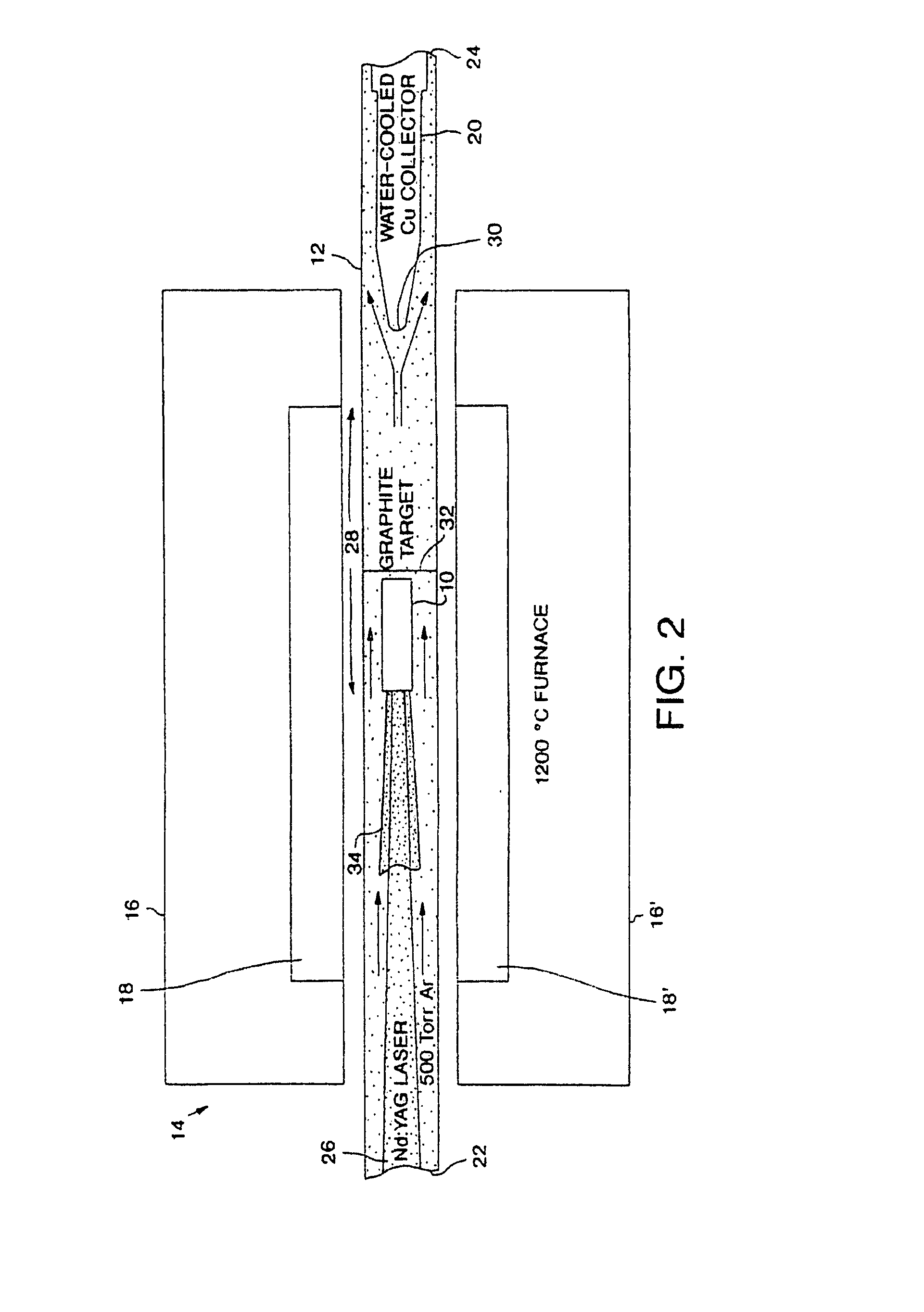

Process utilizing seeds for making single-wall carbon nanotubes

InactiveUS7052668B2Facilitates nucleation phaseFaster and more reproducible and stable clusteringMaterial nanotechnologyFullerenesMetal catalystGas phase

A gas-phase method for producing high yields of single-wall carbon nanotubes with high purity and homogeneity is disclosed. The method involves using preformed metal catalyst clusters to initiate and grow single-wall carbon nanotubes. In one embodiment, multi-metallic catalyst precursors are used to facilitate the metal catalyst cluster formation. The catalyst clusters are grown to the desired size before mixing with a carbon-containing feedstock at a temperature and pressure sufficient to initiate and form single-wall carbon nanotubes. The method also involves using small fullerenes and preformed sections of single-wall carbon nanotubes, either derivatized or underivatized, as seed molecules for expediting the growth and increasing the yield of single-wall carbon nanotubes. The multi-metallic catalyst precursors and the seed molecules may be introduced into the reactor by means of a supercritical fluid. In addition the seed molecules may be introduced into the reactor via an aerosol or smoke.

Owner:RICE UNIV

Fullerene nanotube compositions

InactiveUS20080063585A1High yieldModerate temperatureMaterial nanotechnologyFullerenesFullereneNanotube

This invention relates generally to a fullerene nanotube composition. The fullerene nanotubes may be in the form of a felt, such as a bucky paper. Optionally, the fullerene nanotubes may be derivatized with one or more functional groups. Devices employing the fullerene nanotubes of this invention are also disclosed.

Owner:RICE UNIV

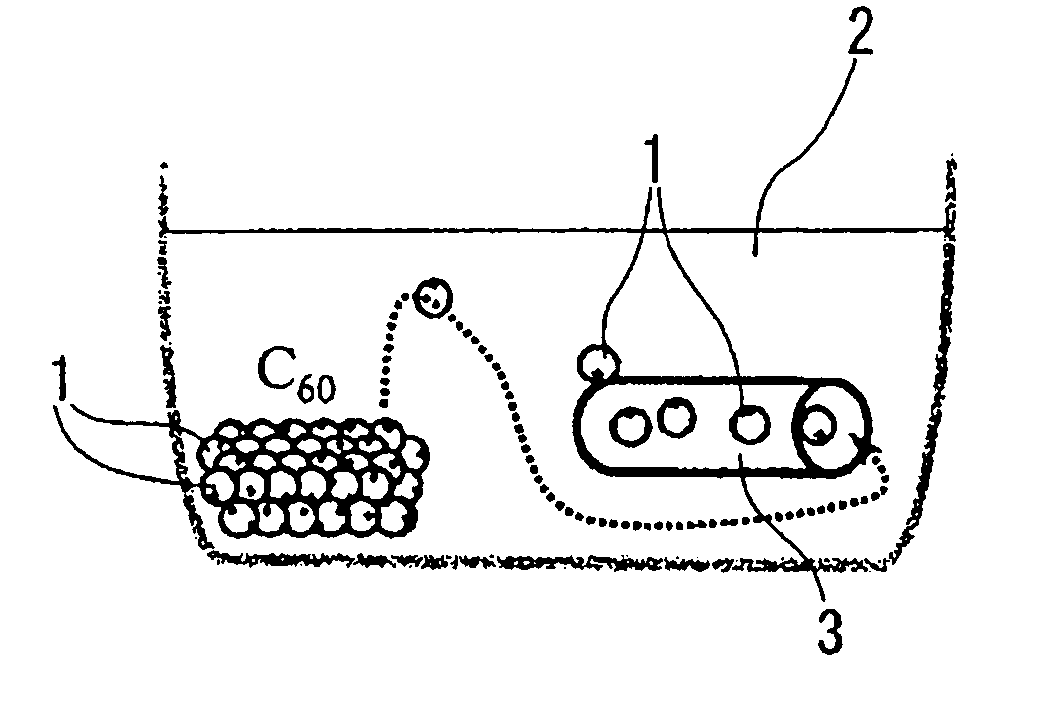

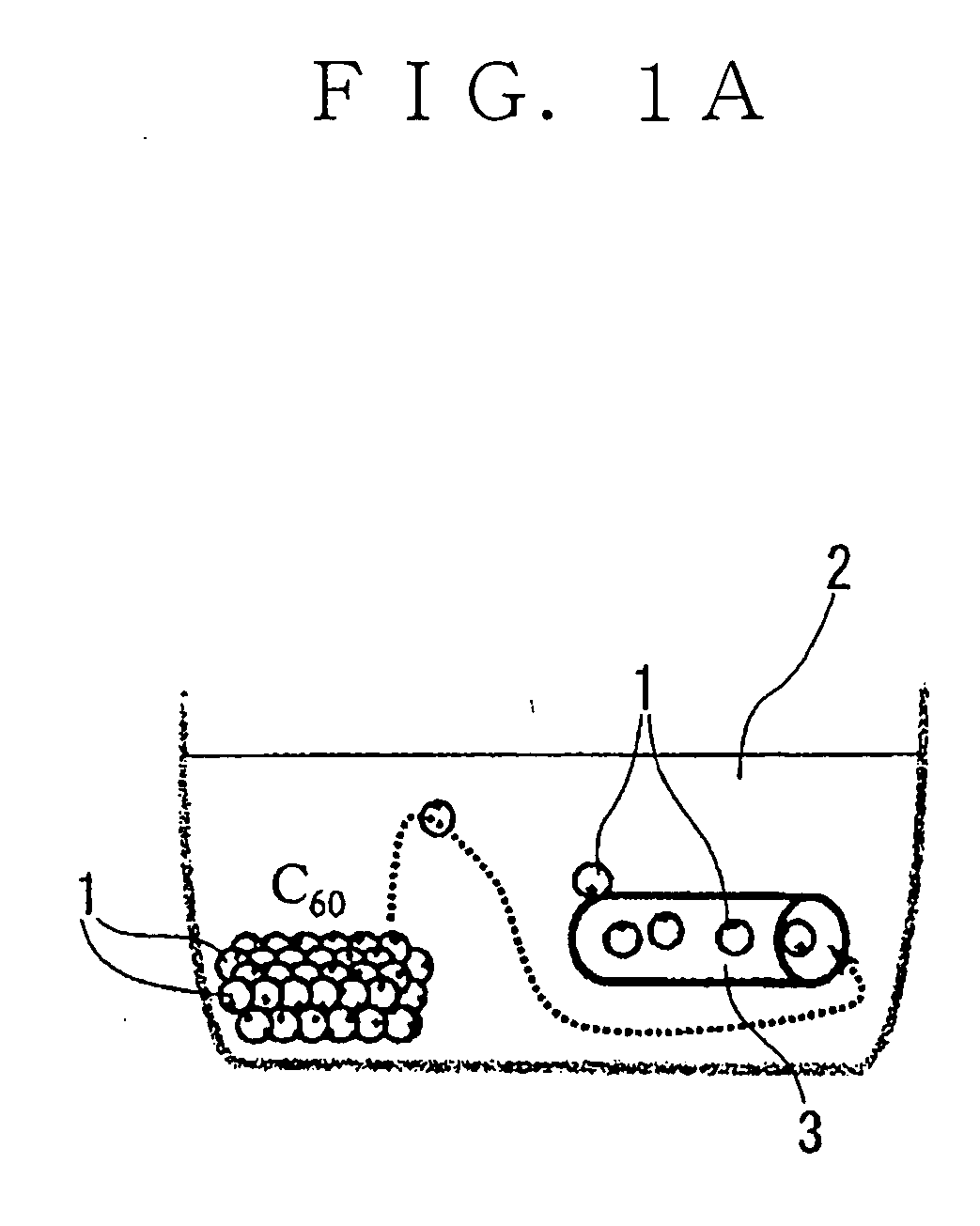

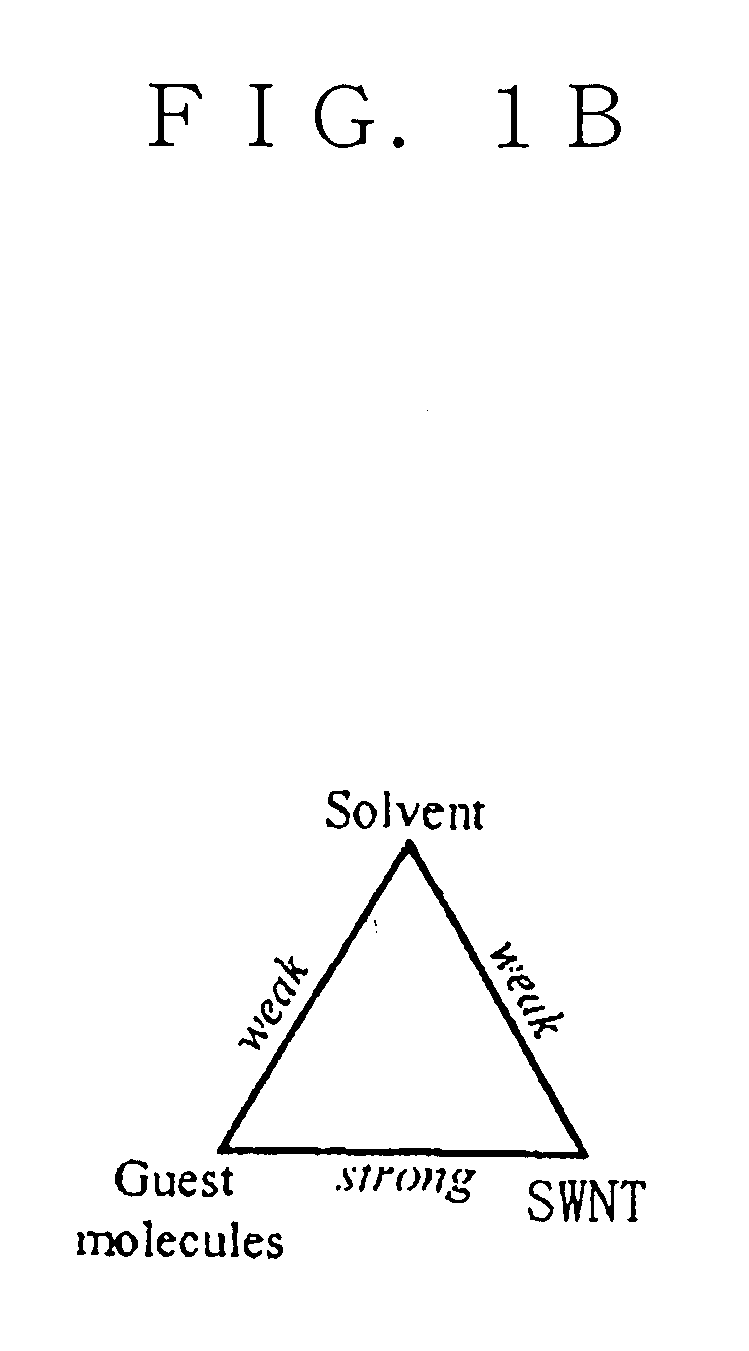

Nano-extraction method and nano-condensation methods for guest molecules incorporation into single-wall carbon nanotube

The objects of this patent application are to provide a new nano-extraction method for guest molecules to be incorporated into single-wall carbon nanotube (SWNT) comprising: putting guest molecules in solvent, wherein the guest molecules have a poor affinity to the solvent and a strong affinity to single-wall carbon nanotube (SWNT) and the attractive force between the guest molecules and SWNT is greater than that between the guest molecules and solvent molecules and that between the solvent molecules and SWNT, ultrasonicating the solution including the solvent and quest molecules, adding single-wall carbon nanotube (SWNT) or single-wall carbon nanotubes (SWNTs) with opened tips and wall-holes in the solution, and leaving the SWNT-guest molecules-solvent mixture until becoming stable with the guest molecules incorporated into SWNT at room temperature, and a nano-condensation method for guest molecules to be incorporated into single-wall carbon nanotube (SWNT) comprising: dropping saturated solution including solvent and guest molecules having a strong affinity to the solvent and a strong affinity to single-wall carbon nanotube (SWNT) onto SWNT or SWNTs placed on a grid disk laid on filtration paper for sucking up the excess solution as quickly as possible.

Owner:NEC CORP

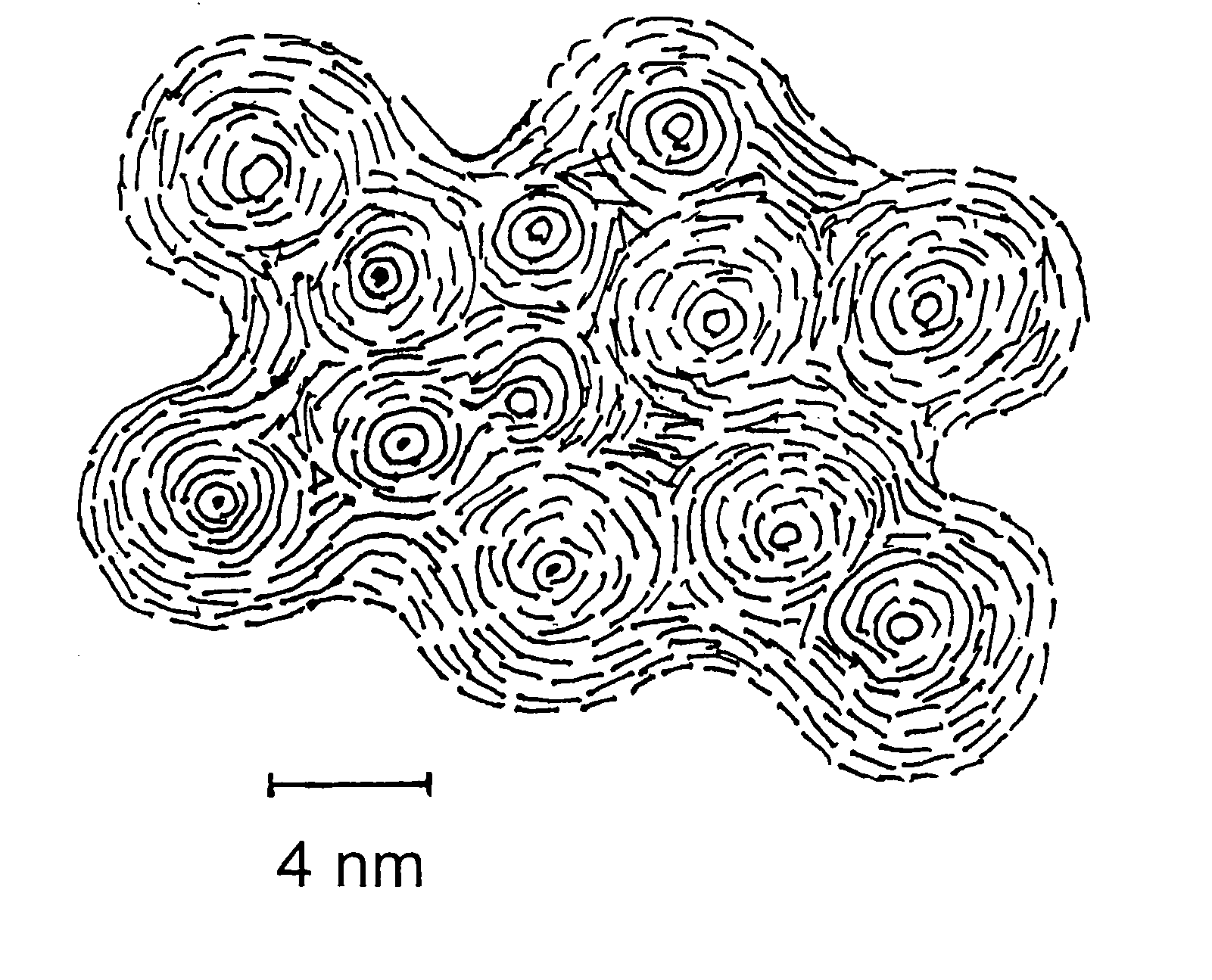

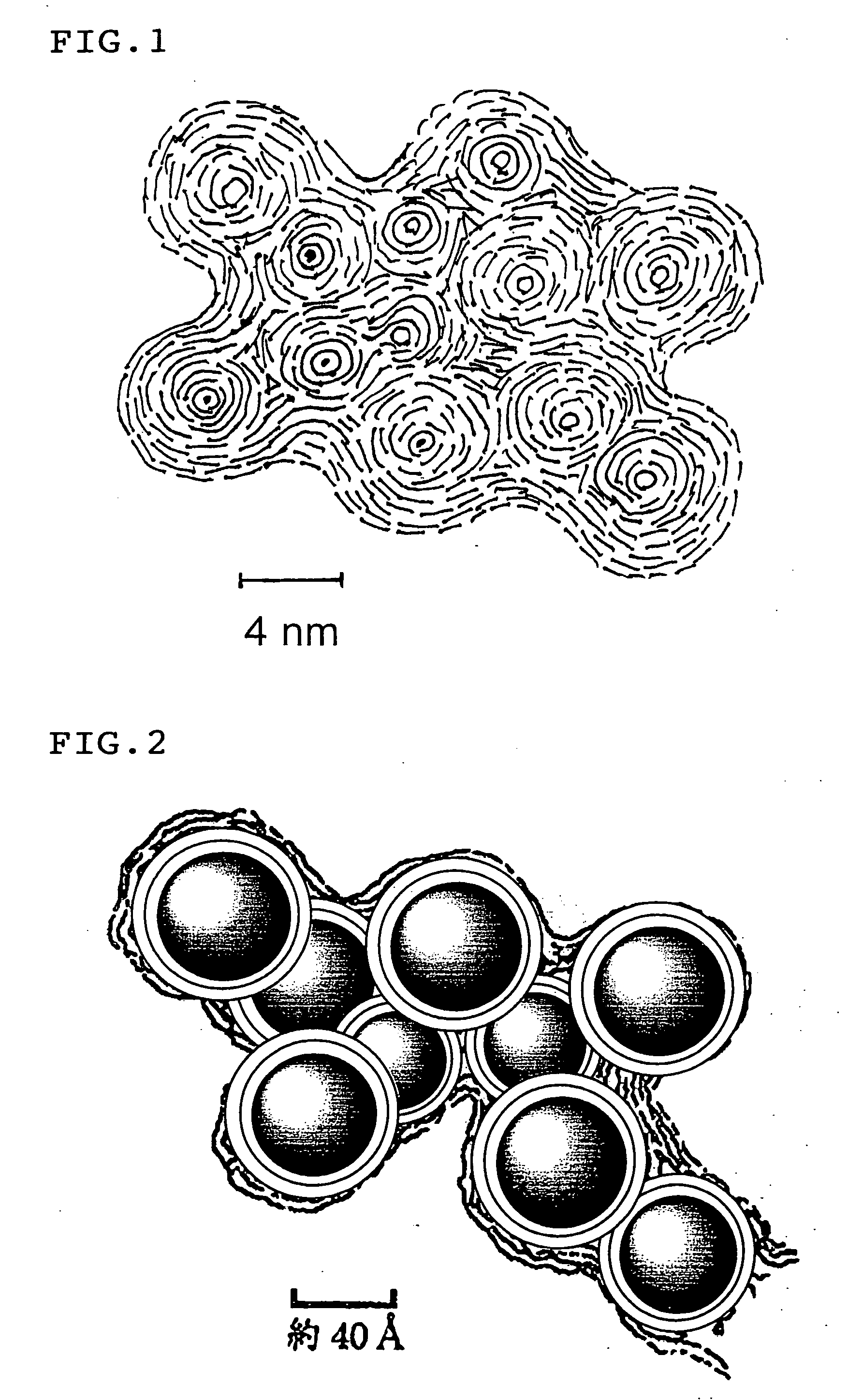

Ultra-dispersed nanocarbon and method for preparing the same

InactiveUS20050008560A1Avoid reorganizationMaterial nanotechnologyPigmenting treatmentDispersed mediaHigh energy

Ultradispersed ones of primary particles of nanometer-sized carbon are obtained by applying a wet-type milling method and / or a wet dispersion method to an aggregate structure of the primary particles to overcome van der Waals forces, by which forces the primary particles are held together to form the aggregate structure, whereby the ultradispersed primary particles are obtained in a colloidal dispersion on a large-scale basis at low cost without using any additive. In a method of manufacturing the ultradispersed primary particles, the wet-type milling method is carried out in a ball mill, preferably in combination with a high-energy ultrasonic-wave process carried out in a dispersing medium such as pure water, whereby a colloidal solution or slurry with a low-concentration of the primary particles ultradispersed in the dispersing medium is obtained.

Owner:FUTABA CORPORATION +2

Carbon nanostructures and process for the production of carbon-based nanotubes, nanofibres and nanostructures

InactiveUS20070183959A1Enhanced interactionImprove mechanical propertiesMaterial nanotechnologyFullerenesThermal insulationNanostructure

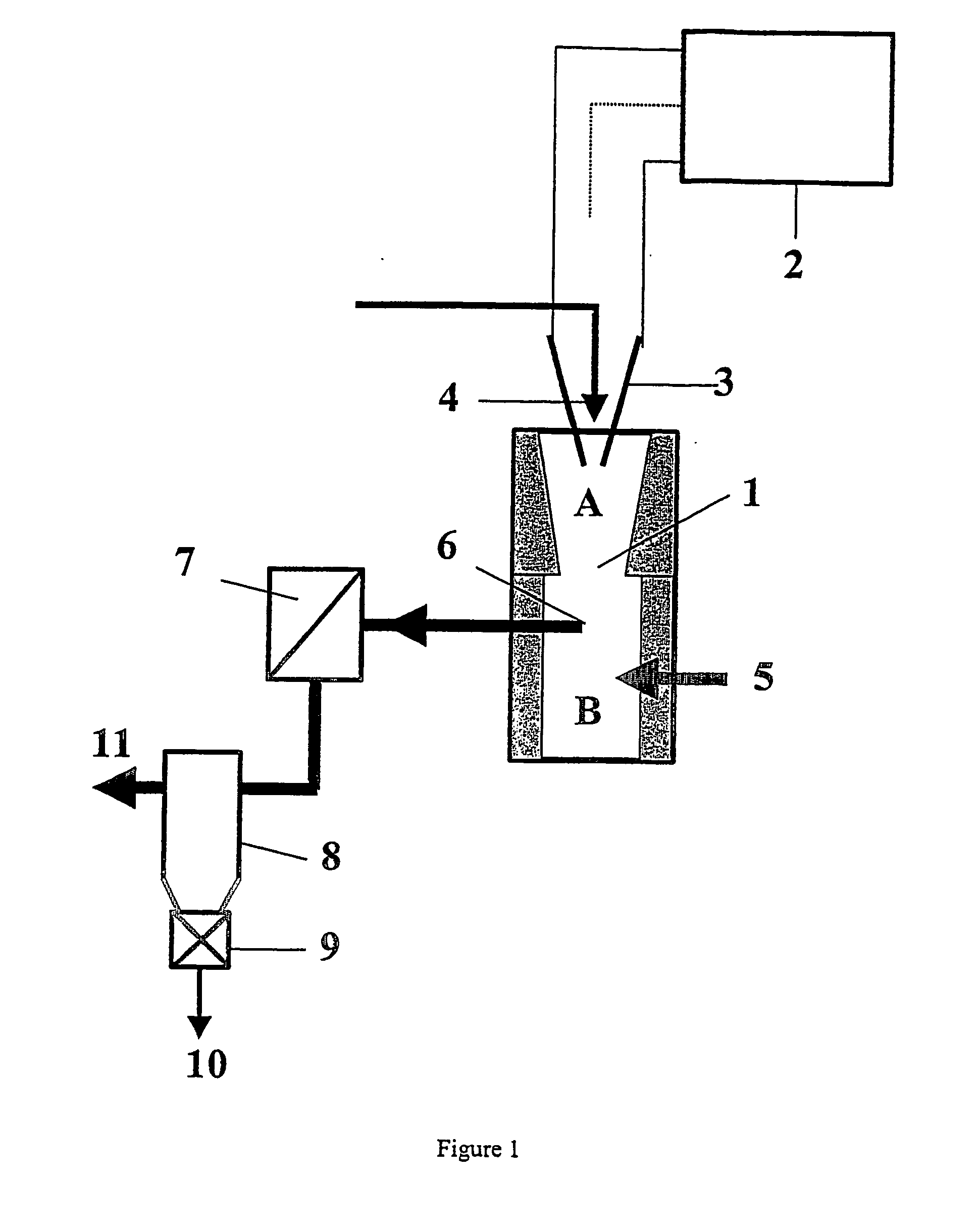

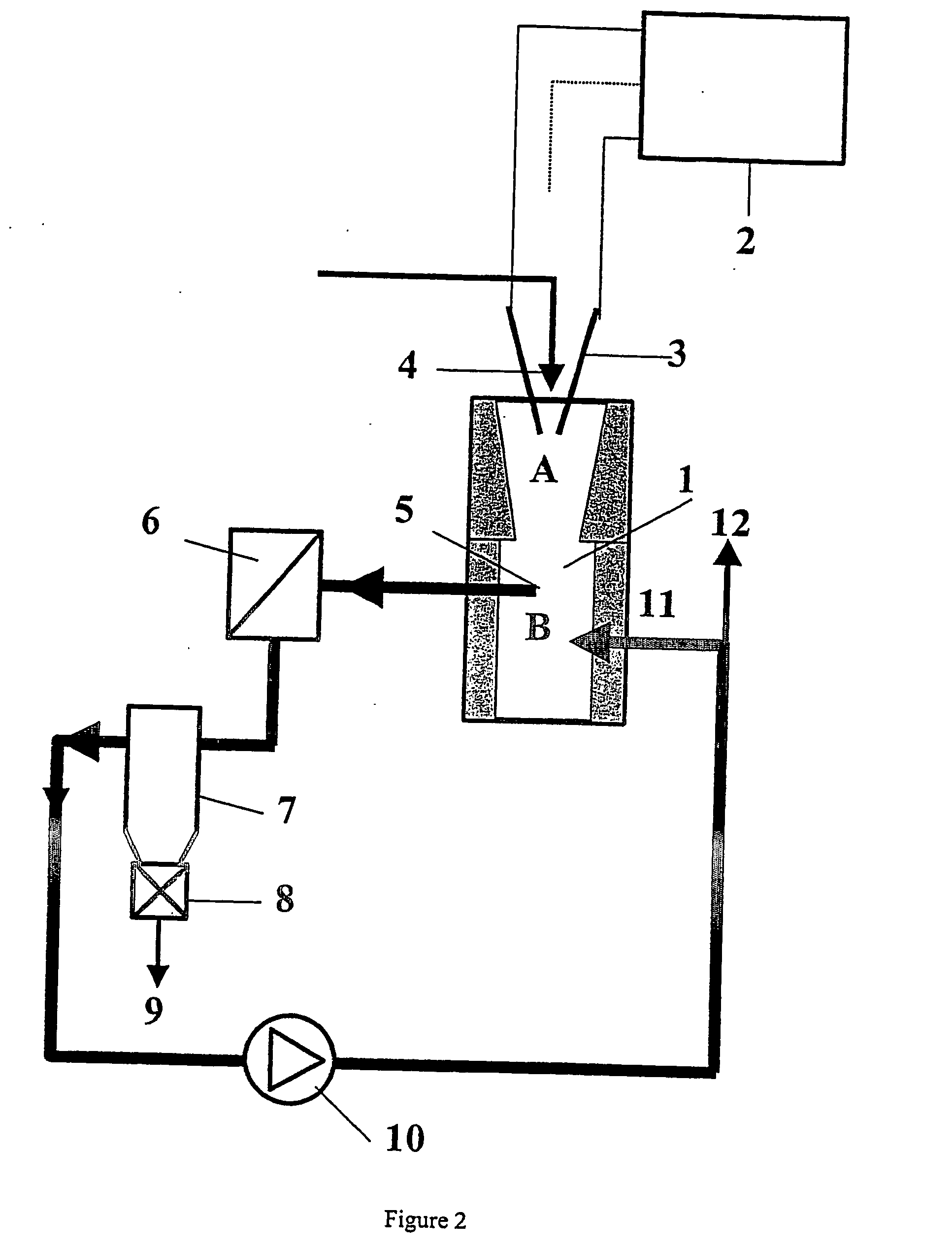

Continuous process for the production of carbon-based nanotubes, nanofibres and nanostructures, comprising the following steps: generating a plasma with electrical energy, introducing a carbon precursor and / or one or more catalysers and / or carrier plasma gas in a reaction zone of an airtight high temperature resistant vessel optionally having a thermal insulation lining, vaporizing the carbon precursor in the reaction zone at a very high temperature, preferably 4000° C. and higher, guiding the carrier plasma gas, the carbon precursor vaporized and the catalyser through a nozzle, whose diameter is narrowing in the direction of the plasma gas flow, guiding the carrier plasma gas, the carbon precursor vaporized and the catalyses into a quenching zone for nucleation, growing and quenching operating with flow conditions generated by aerodynamic and electromagnetic forces, so that no significant recirculation of feedstocks or products from the quenching zone into the reaction zone occurs, controlling the gas temperature in the quenching zone between about 4000° C. in the upper part of this zone and about 50° C. in the lower part of this zone and controlling the quenching velocity between 103 K / s and 106 K / s quenching and extracting carbon-based nanotubes, nanofibres and other nanostructures from the quenching zone, separating carbon-based nanotubes, nanofibres and nanostructures from other reaction products.

Owner:ТІМКАЛ SА +1

Spin-coatable liquid for formation of high purity nanotube films

ActiveUS20050058590A1Lower Level RequirementsPigmenting treatmentMaterial nanotechnologyLiquid mediumSpins

Certain spin-coatable liquids and application techniques are described, which can be used to form nanotube films or fabrics of controlled properties. A spin-coatable liquid for formation of a nanotube film includes a liquid medium containing a controlled concentration of purified nanotubes, wherein the controlled concentration is sufficient to form a nanotube fabric or film of preselected density and uniformity, and wherein the spin-coatable liquid comprises less than 1×1018 atoms / cm3 of metal impurities. The spin-coatable liquid is substantially free of particle impurities having a diameter of greater than about 500 nm.

Owner:ZEON CORP

Nano carbon materials for enhancing thermal transfer in fluids

InactiveUS20020100578A1Improve thermal conductivityImprove heat transfer performanceMaterial nanotechnologyNanostructure manufactureElectrical polarityOrganic group

A novel fluid heat transfer agent suitable for use in a closed heat transfer system, for example, wherein energy is transferred between an evaporator and a condenser in heat exchange relationship with the heat transfer agent that is caused to flow from one to the other. The novel heat transfer agent is a complex comprising a body of heat transfer fluid, for example, ethylene glycol or water, having suspended therein carbon nanoparticles in a quantity sufficient to enhance the thermal conductivity of the body of heat transfers fluid, per se. The carbon nanoparticles are selected from carbon in the form of sp2 type and sp3 type bonding and preferably comprise nanotubes or fullerenes and may have a coupling agent bonded thereto or enclosed therein when the nanotube or fullerene forms a hollow capsule. The coupling agent may be a polar organic group covalently bonded to the carbon nanoparticles and miscible in the fluid medium.

Owner:MATERIALS & ELECTROCHEM RES

Coated fullerenes, composites and dielectrics made therefrom

InactiveUS20050089684A1Rate of formation is fasterFaster ratePigmenting treatmentMaterial nanotechnologyDielectricFullerene

The present invention relates to coated fullerenes comprising a layer of at least one inorganic material covering at least a portion of at least one surface of a fullerene and methods for making. The present invention further relates to composites comprising the coated fullerenes of the present invention and further comprising polymers, ceramics and / or inorganic oxides. A coated fullerene interconnect device wherein at least two fullerenes are contacting each other to form a spontaneous interconnect is also disclosed as well as methods of making. In addition, dielectric films comprising the coated fullerenes of the present invention and methods of making are further disclosed.

Owner:RICE UNIV +1

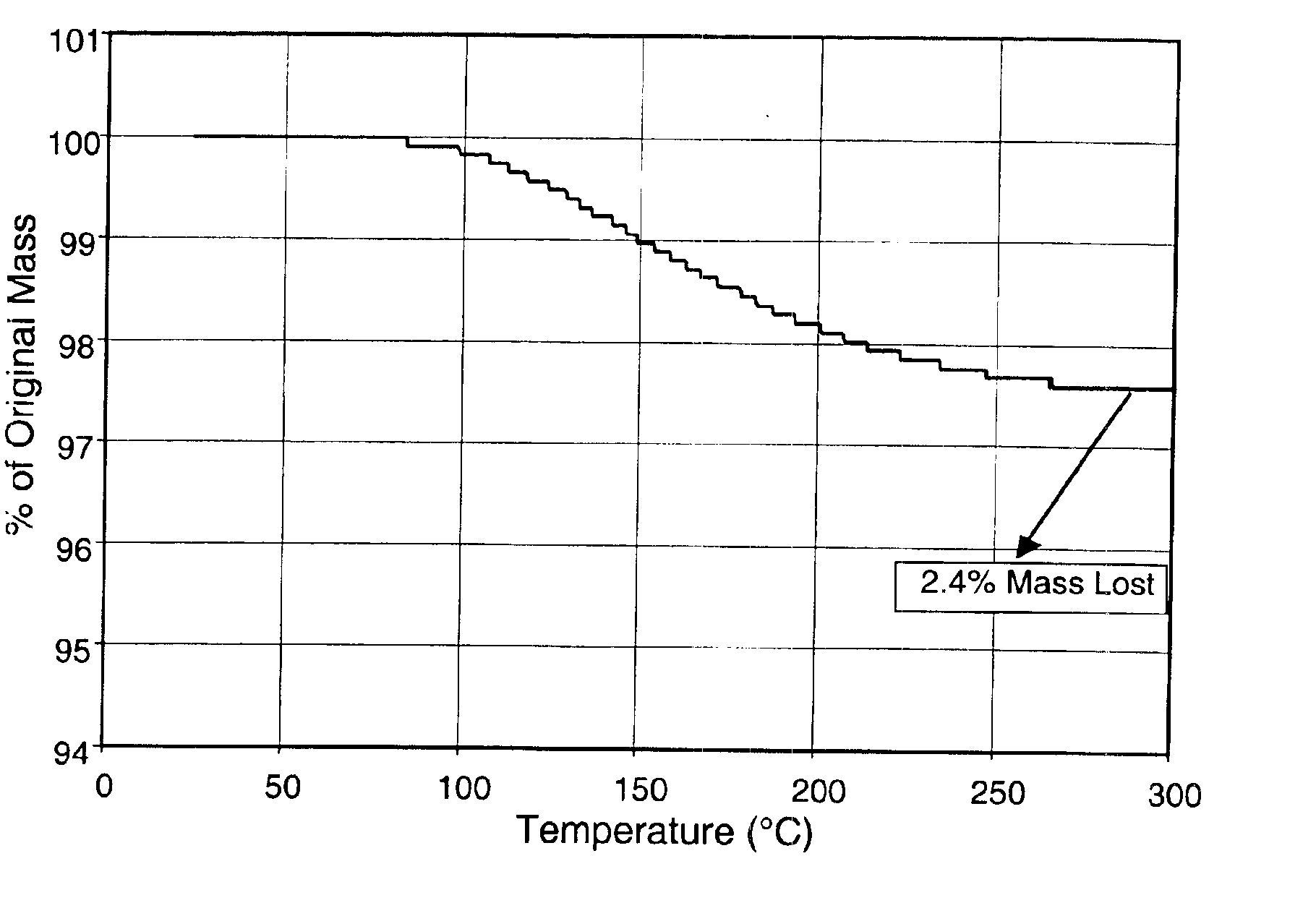

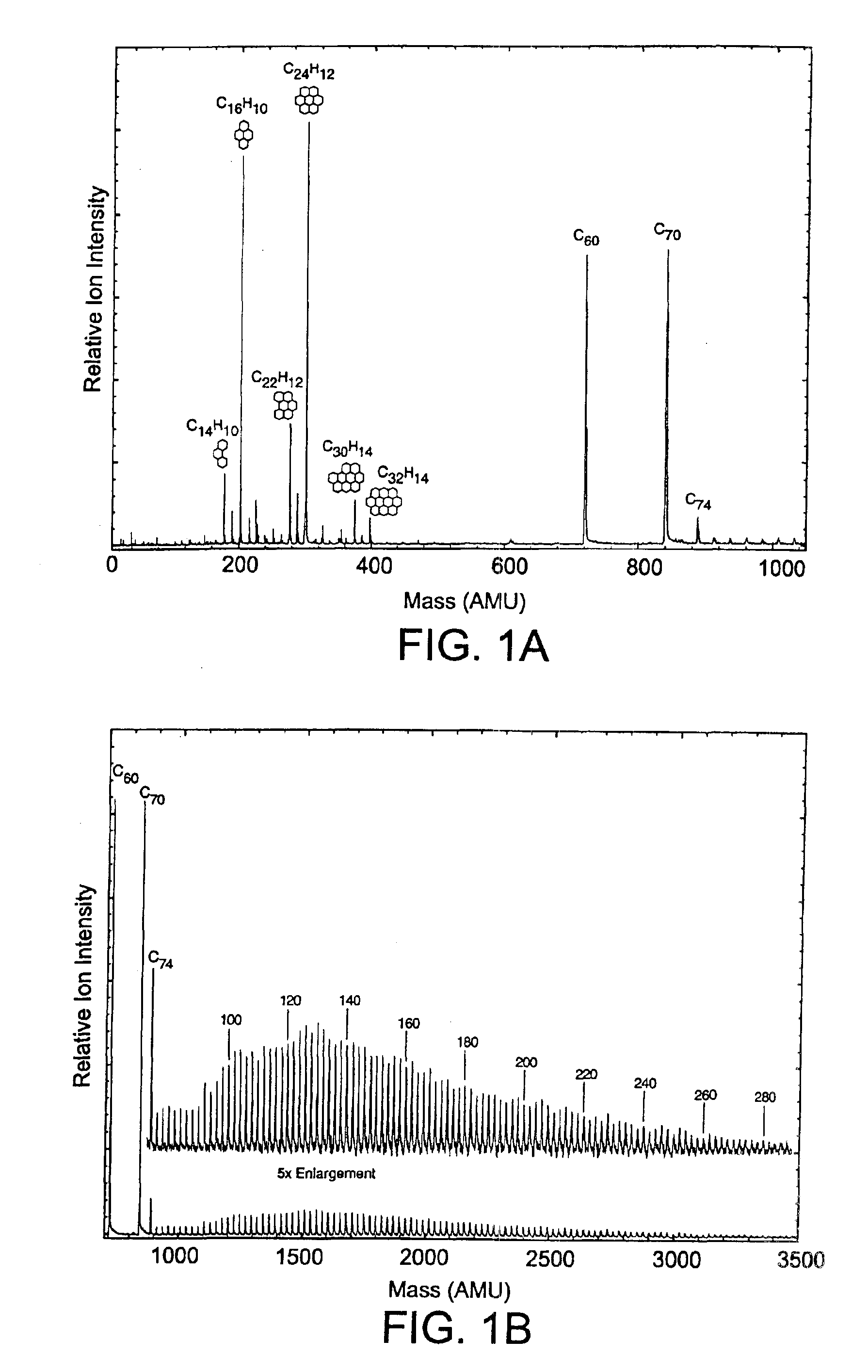

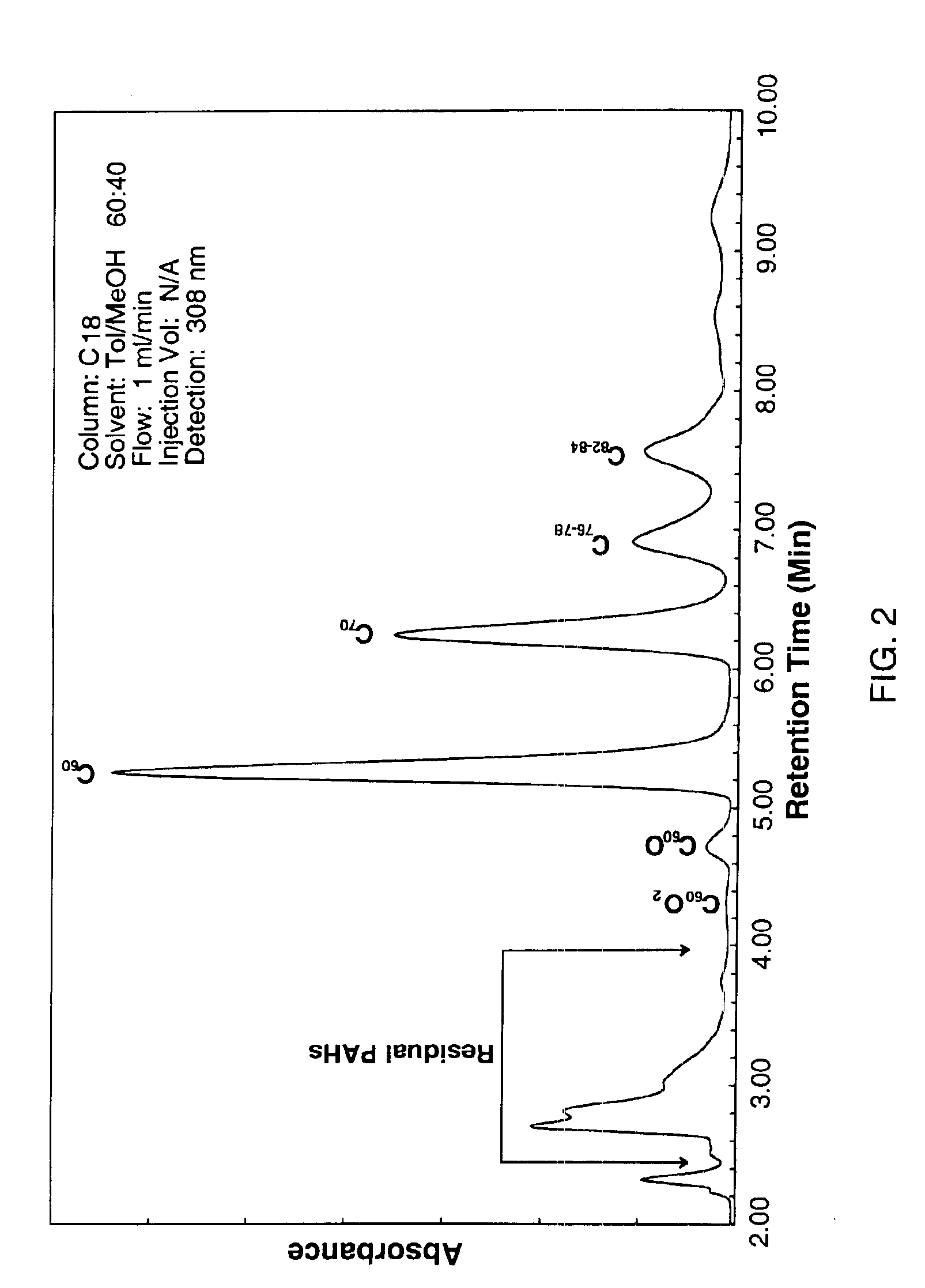

Process for the removal of impurities from combustion fullerenes

InactiveUS6923915B2Without incurring undo costEfficient removalMaterial nanotechnologyFullerenesO-XylenePurification methods

The invention generally relates to purification of carbon nanomaterials, particularly fullerenes, by removal of PAHs and other hydrocarbon impurities. The inventive process involves extracting a sample containing carbon nanomaterials with a solvent in which the PAHs are substantially soluble but in which the carbon nanomaterials are not substantially soluble. The sample can be repeatedly or continuously extracted with one or more solvents to remove a greater amount of impurities. Preferred solvents include ethanol, diethyl ether, and acetone. The invention also provides a process for efficiently separating solvent extractable fullerenes from samples containing fullerenes and PAHs wherein the sample is extracted with a solvent in which both fullerenes and PAHs are substantially soluble and the sample extract then undergoes selective extraction to remove PAHs. Suitable solvents in which both fullerenes and PAHs are soluble include o-xylene, toluene, and o-dichlorobenzene. The purification process is capable of treating quantities of combustion soot in excess of one kilogram and can produce fullerenes or fullerenic soot of suitable purity for many applications.

Owner:FRONTIER CARBON CORP

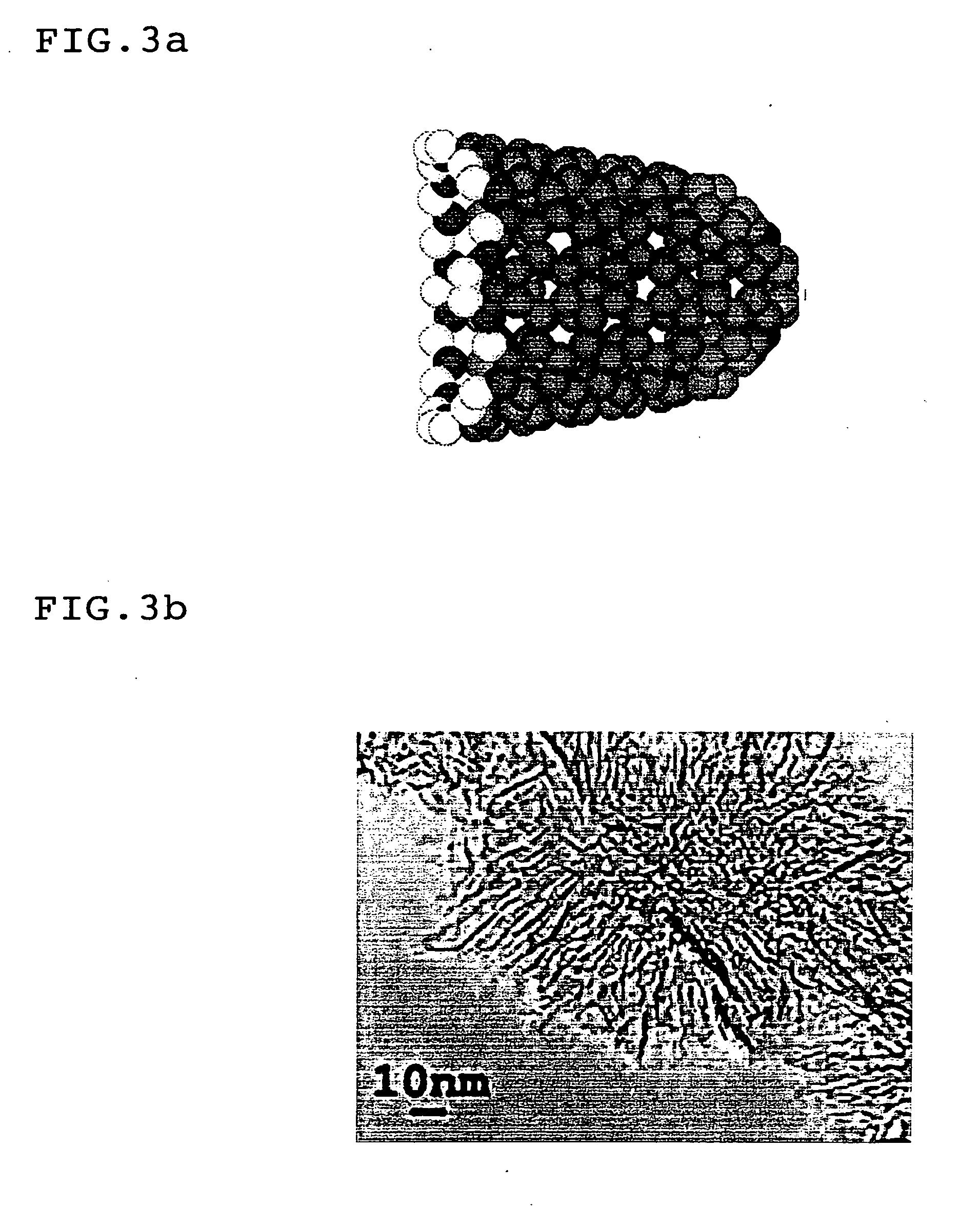

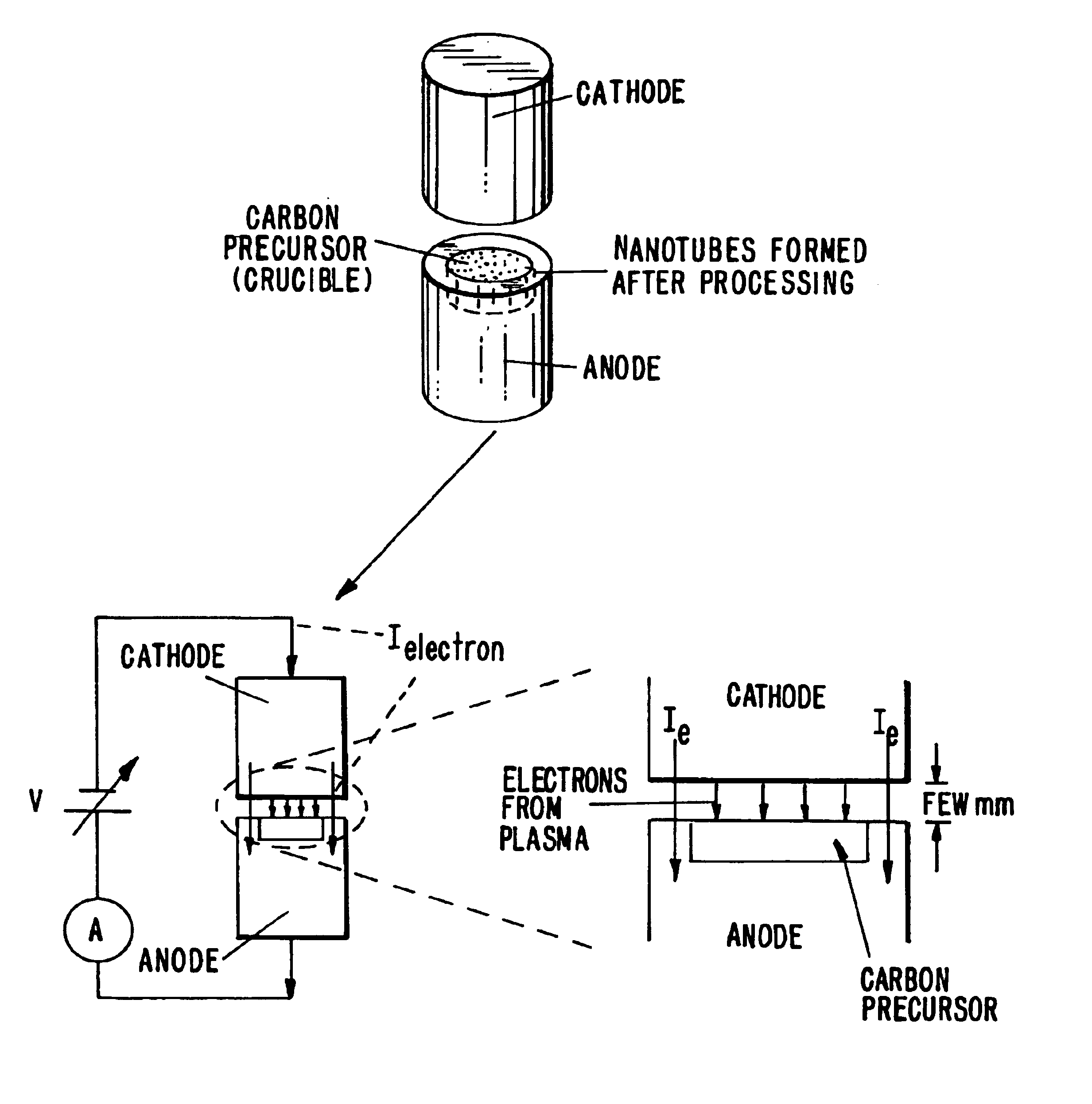

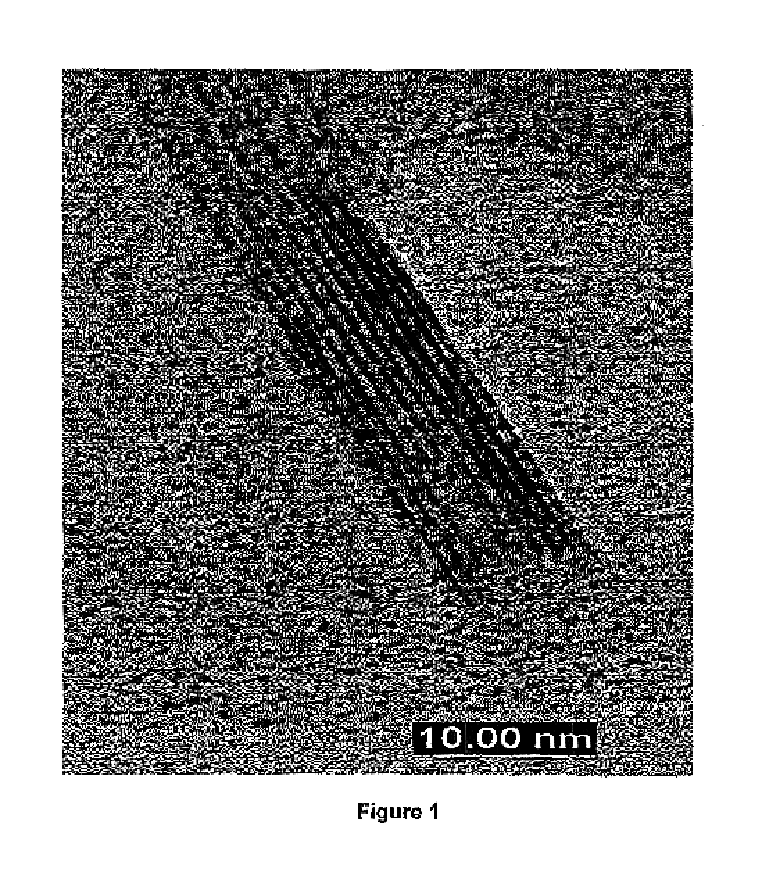

Carbon nanostructures and methods of preparation

InactiveUS6765949B2Enhanced and superior structural and mechanical propertyImprove processing efficiencyMaterial nanotechnologyElectric discharge heatingSufficient timeElectric arc furnace

An electric arc furnace and method for forming tubular carbon nanostructures comprising a first electrode (cathode) and an a second electrode (anode) opposite the first electrode, sources of voltage (V) and current (A) to create charged particles (Ie) and produce an arch between the electrodes, a source of a gas to surround the arc, and a source of carbon precursor positioned adjacent the anode and within the arc, wherein the arc is maintained at a pressure and high temperature for a time sufficient to heat the carbon precursor to form carbon nonotubes upon the anode.

Owner:CHANG ROBERT P H

Composite materials containing carbon nanoparticles

InactiveUS20060155376A1Adversely affecting the physical and chemical stabilityMaterial nanotechnologyPigmenting treatmentCarbon NanoparticlesOrganic polymer

The present invention relates to a process of producing composite materials by a sol / gel-process, comprising carbon nanoparticles and organic polymer material. The invention further relates to composite materials, which are manufactured with the use of said sol / gel technology.

Owner:CINVENTION AG

Spin-coatable liquid for formation of high purity nanotube films

ActiveUS7375369B2Lower Level RequirementsPigmenting treatmentMaterial nanotechnologyLiquid mediumMetal impurities

Certain spin-coatable liquids and application techniques are described, which can be used to form nanotube films or fabrics of controlled properties. A spin-coatable liquid for formation of a nanotube film includes a liquid medium containing a controlled concentration of purified nanotubes, wherein the controlled concentration is sufficient to form a nanotube fabric or film of preselected density and uniformity, and wherein the spin-coatable liquid includes less than 1×1018 atoms / cm3 of metal impurities. The spin-coatable liquid is substantially free of particle impurities having a diameter of greater than about 500 nm.

Owner:ZEON CORP

Carbon material and method for producing same

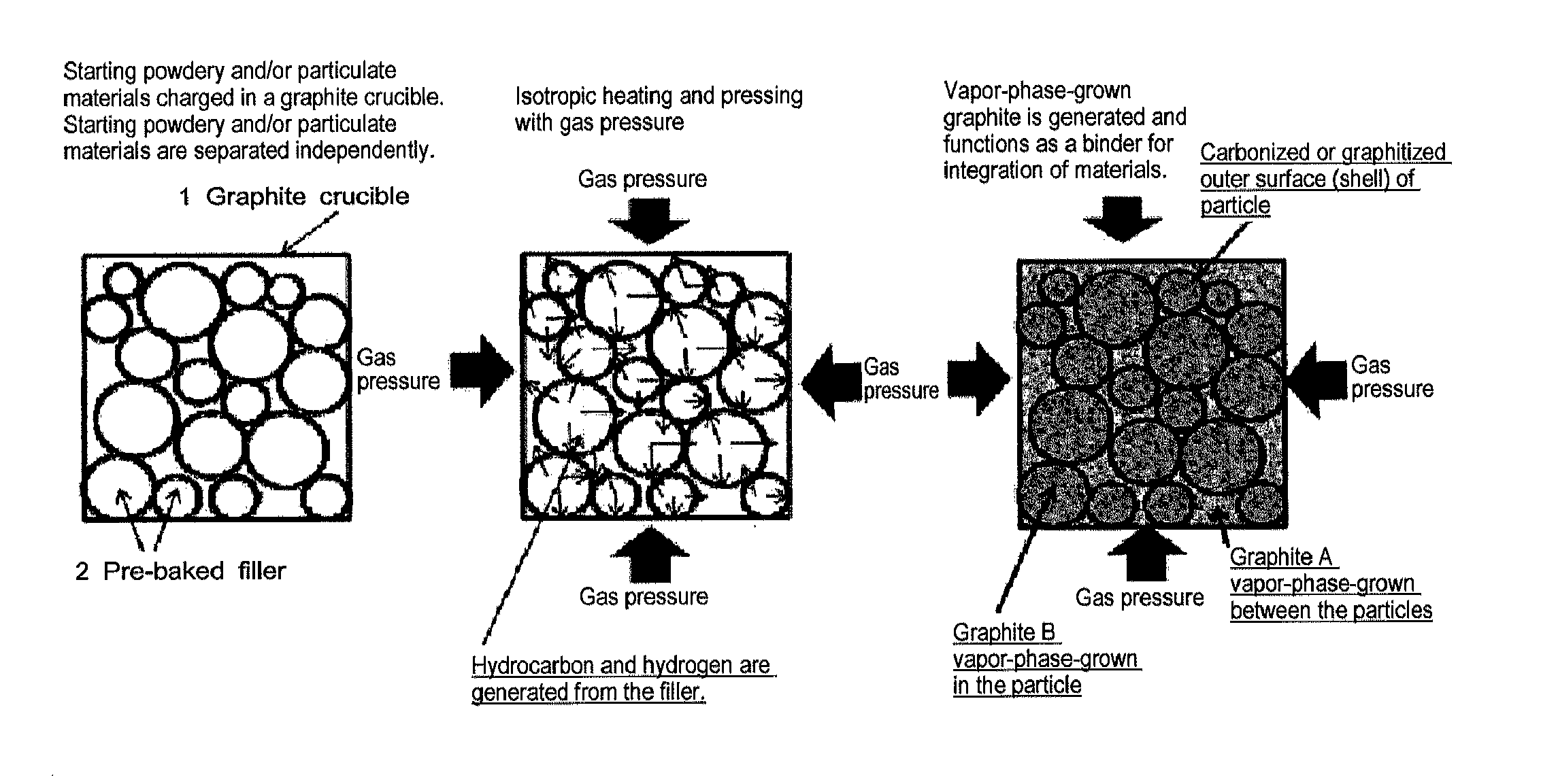

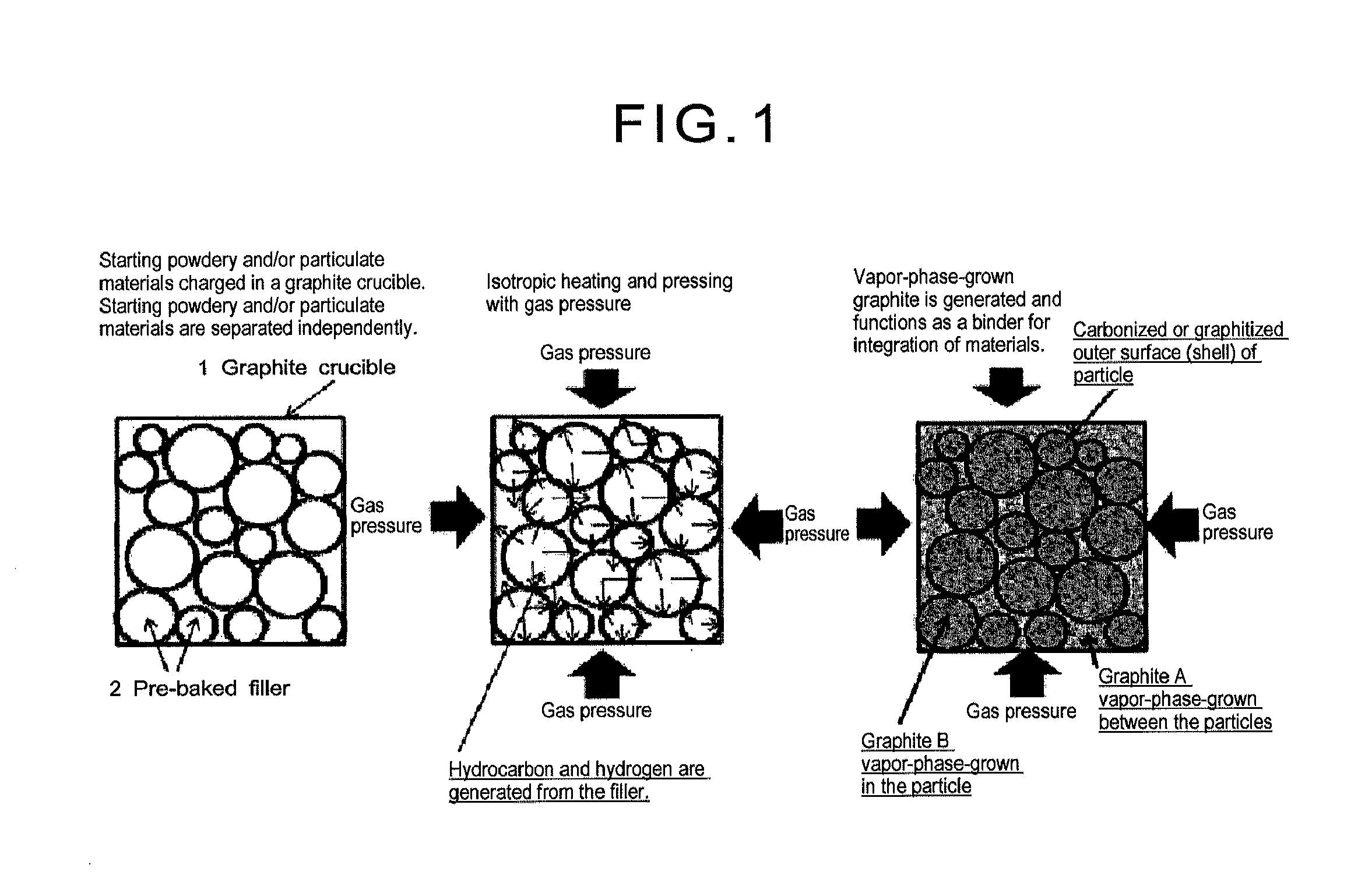

ActiveUS20120077020A1Simple processLow costMaterial nanotechnologyFullerenesGas phaseSource material

(Problem)In conventional method for producing artificial graphite, in order to obtain a product having excellent crystallinity, it was necessary to mold a filler and a binder and then repeat impregnation, carbonization and graphitization, and since carbonization and graphitization proceeded by a solid phase reaction, a period of time of as long as 2 to 3 months was required for the production and cost was high and further, a large size structure in the shape of column and cylinder could not be produced. In addition, nanocarbon materials such as carbon nanotube, carbon nanofiber and carbon nanohorn could not be produced.(Means to Solve)A properly pre-baked filler is sealed in a graphite vessel and is subsequently subjected to hot isostatic pressing (HIP) treatment, thereby allowing gases such as hydrocarbon and hydrogen to be generated from the filler and precipitating vapor-phase-grown graphite around and inside the filler using the generated gases as a source material, and thereby, an integrated structure of carbide of the filler and the vapor-phase-grown graphite is produced. In addition, nanocarbon materials are produced selectively and efficiently by adding a catalyst or adjusting the HIP treating temperature.

Owner:INCUBATION ALLIANCE

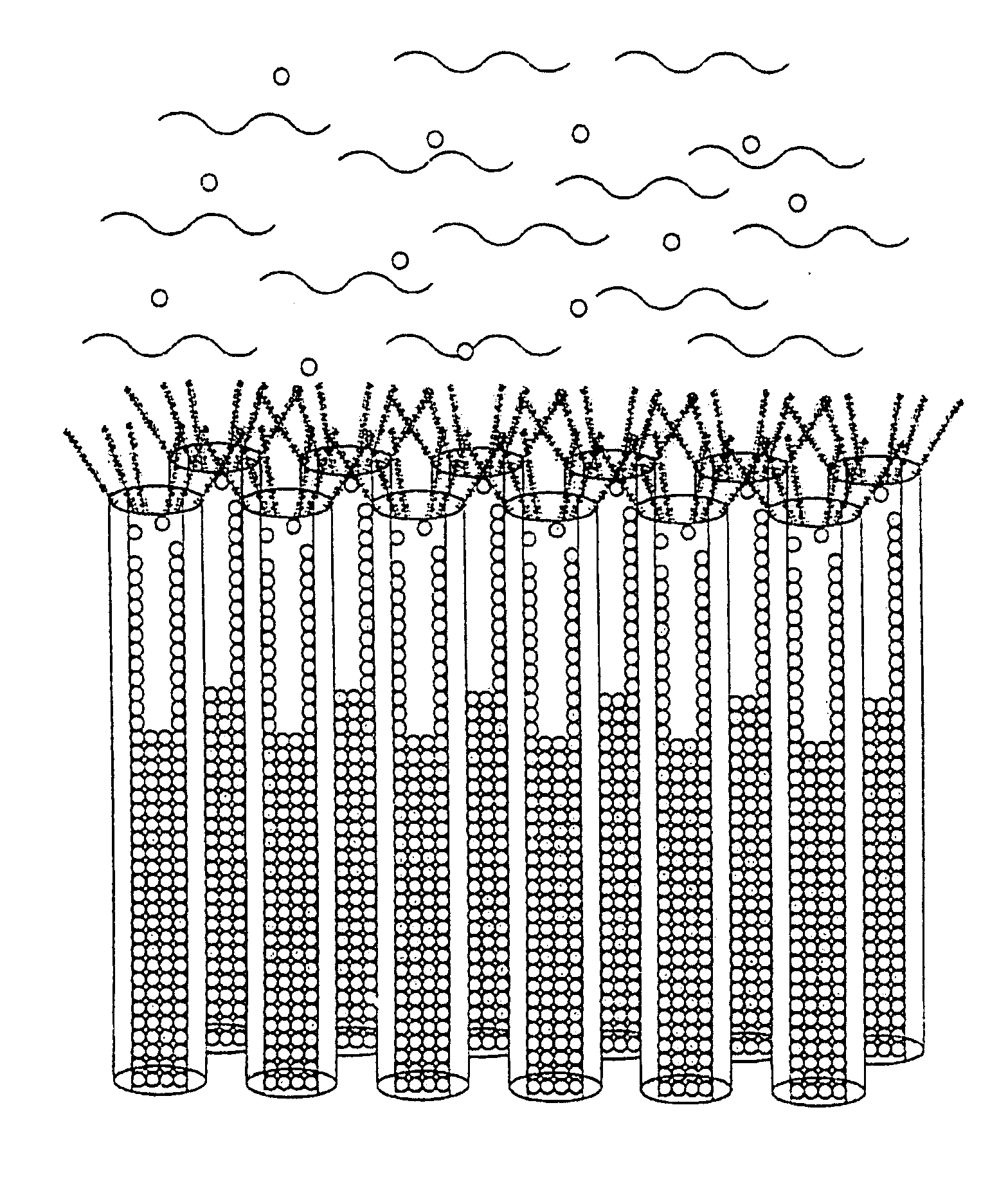

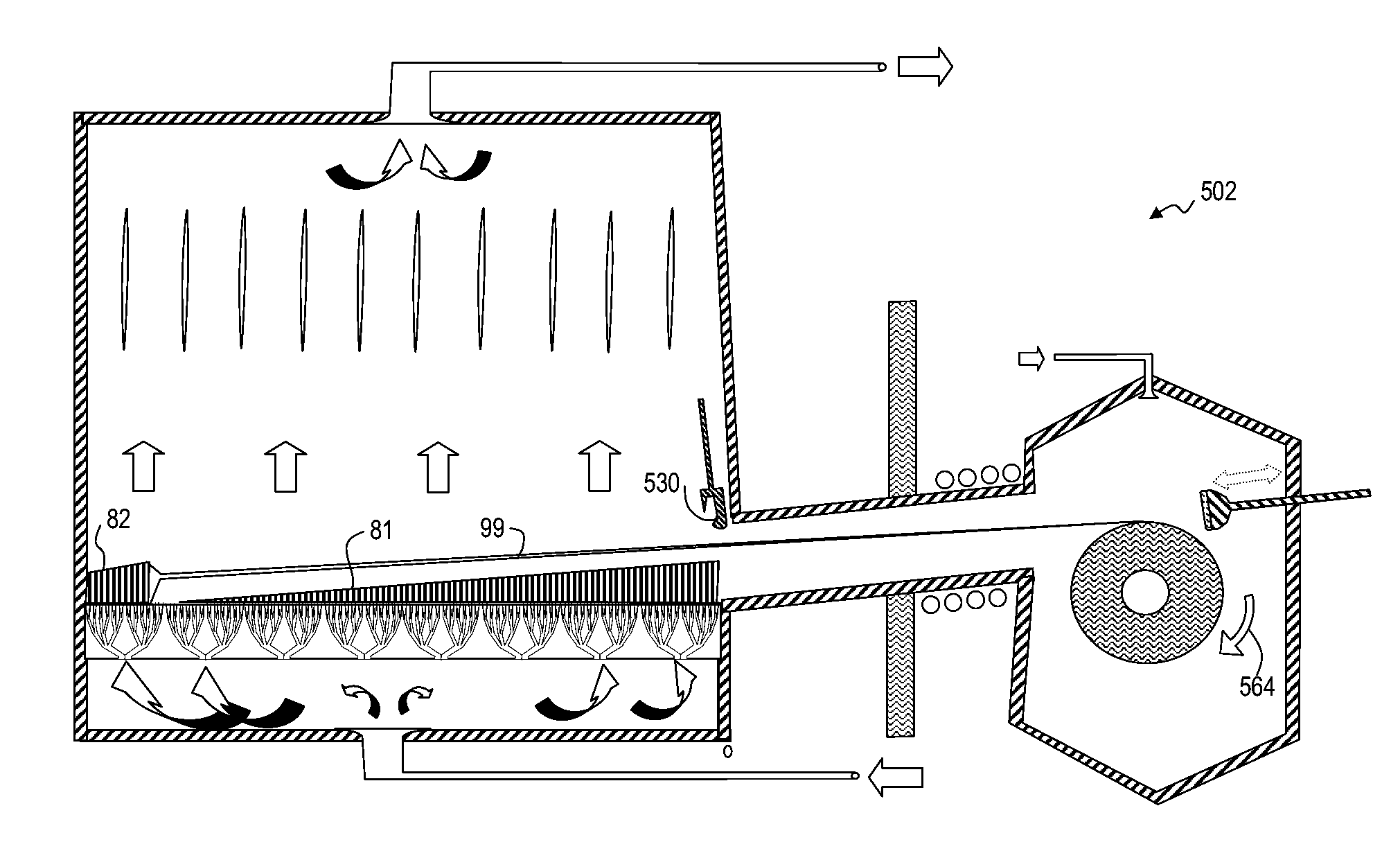

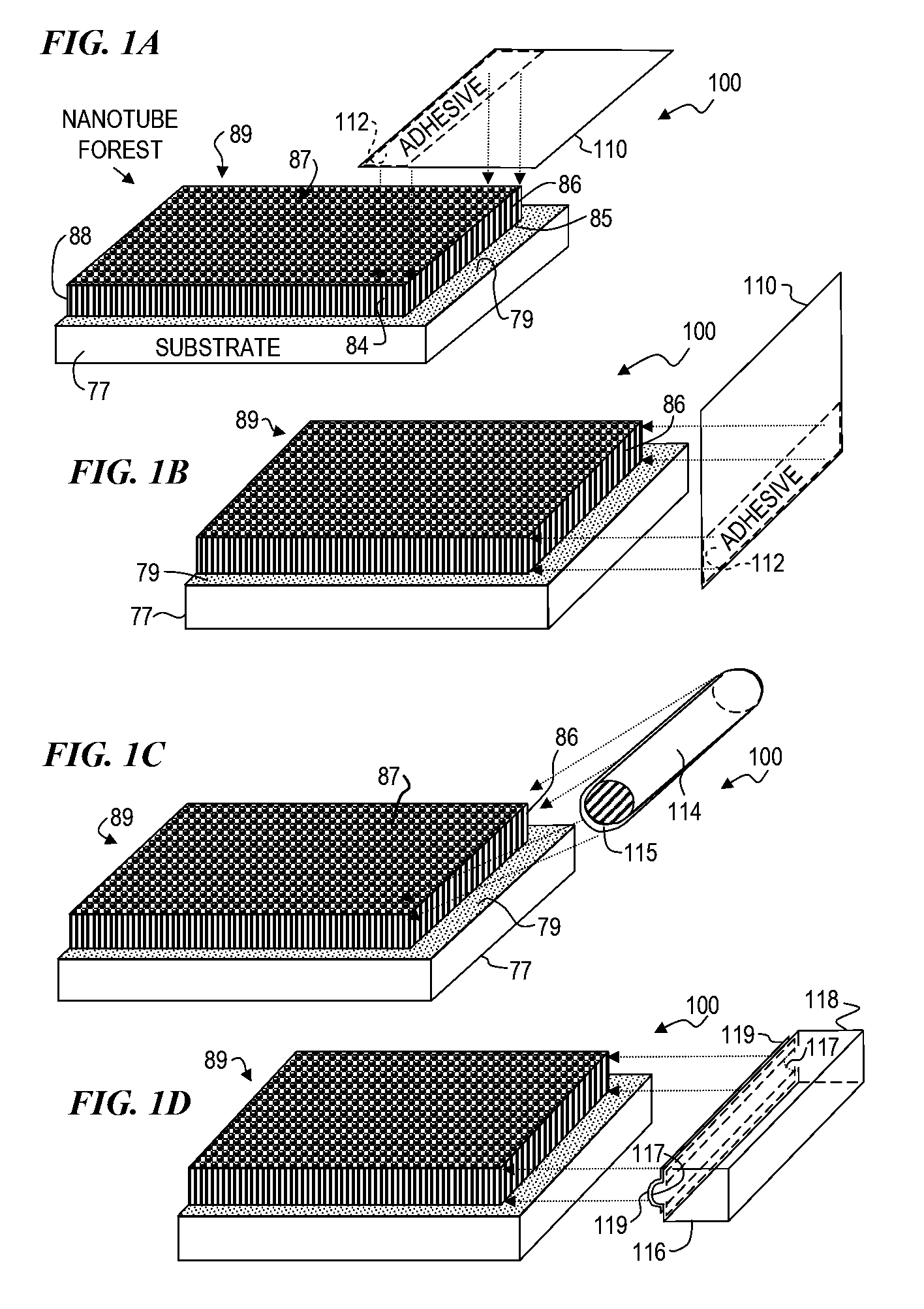

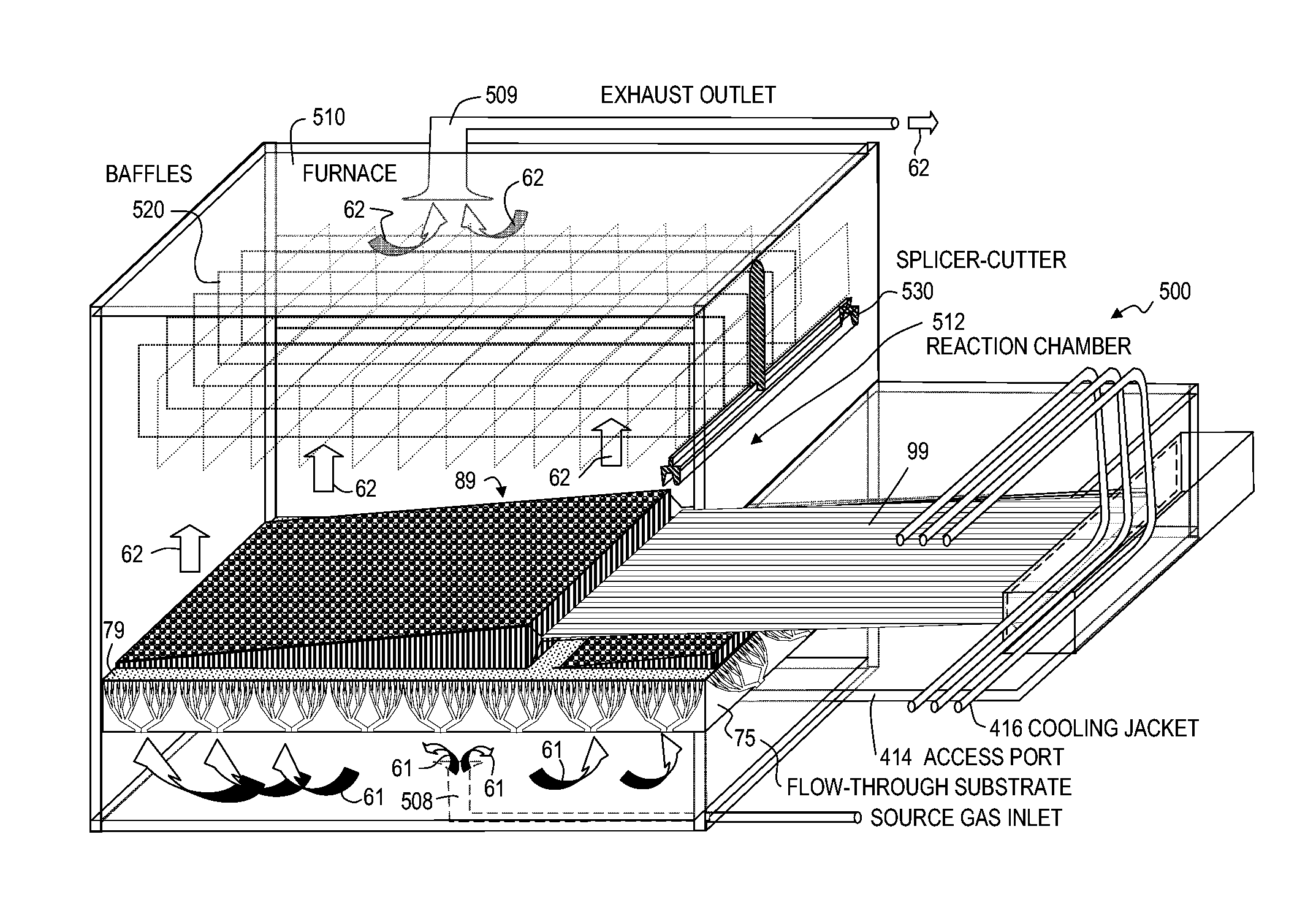

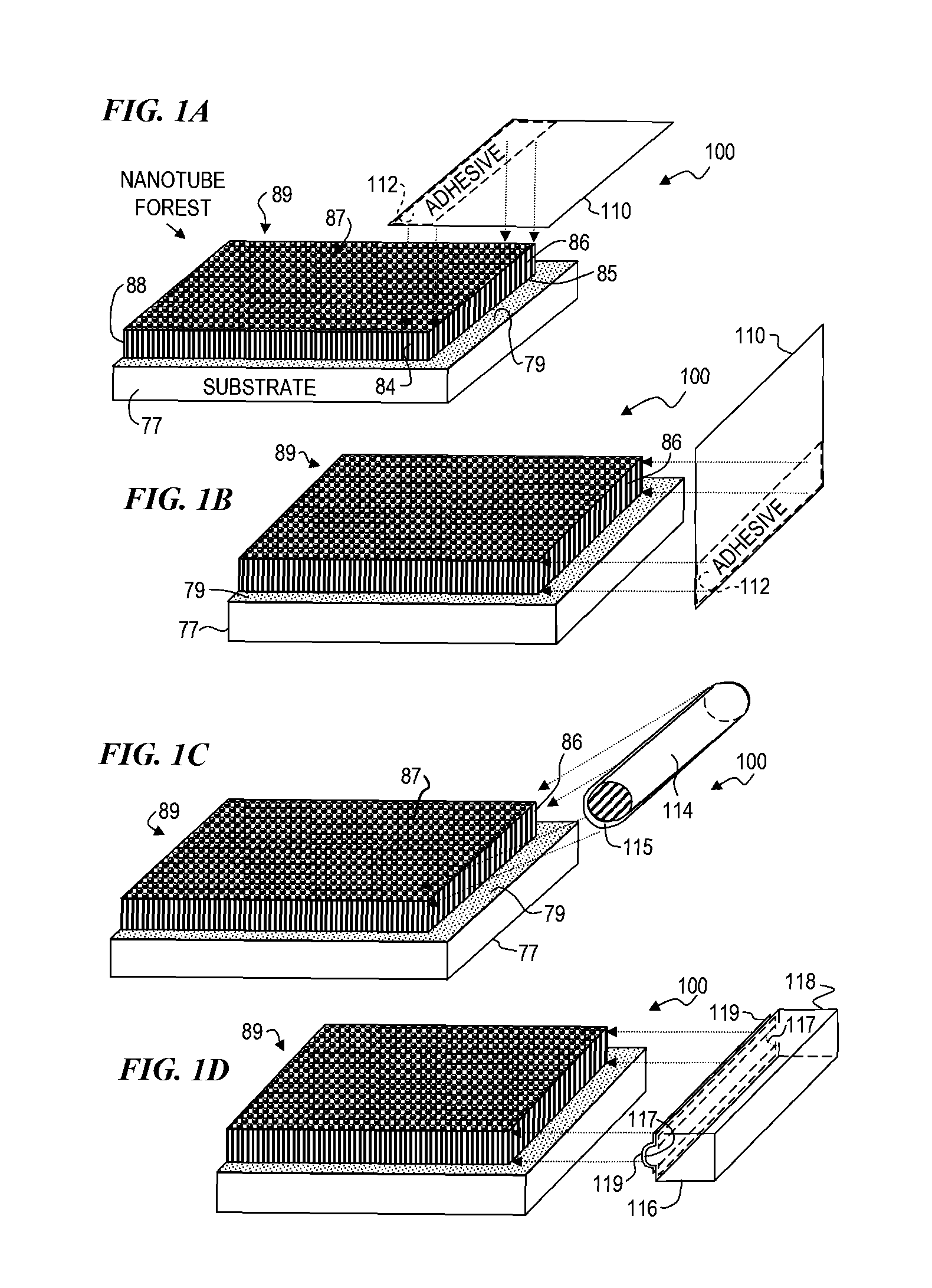

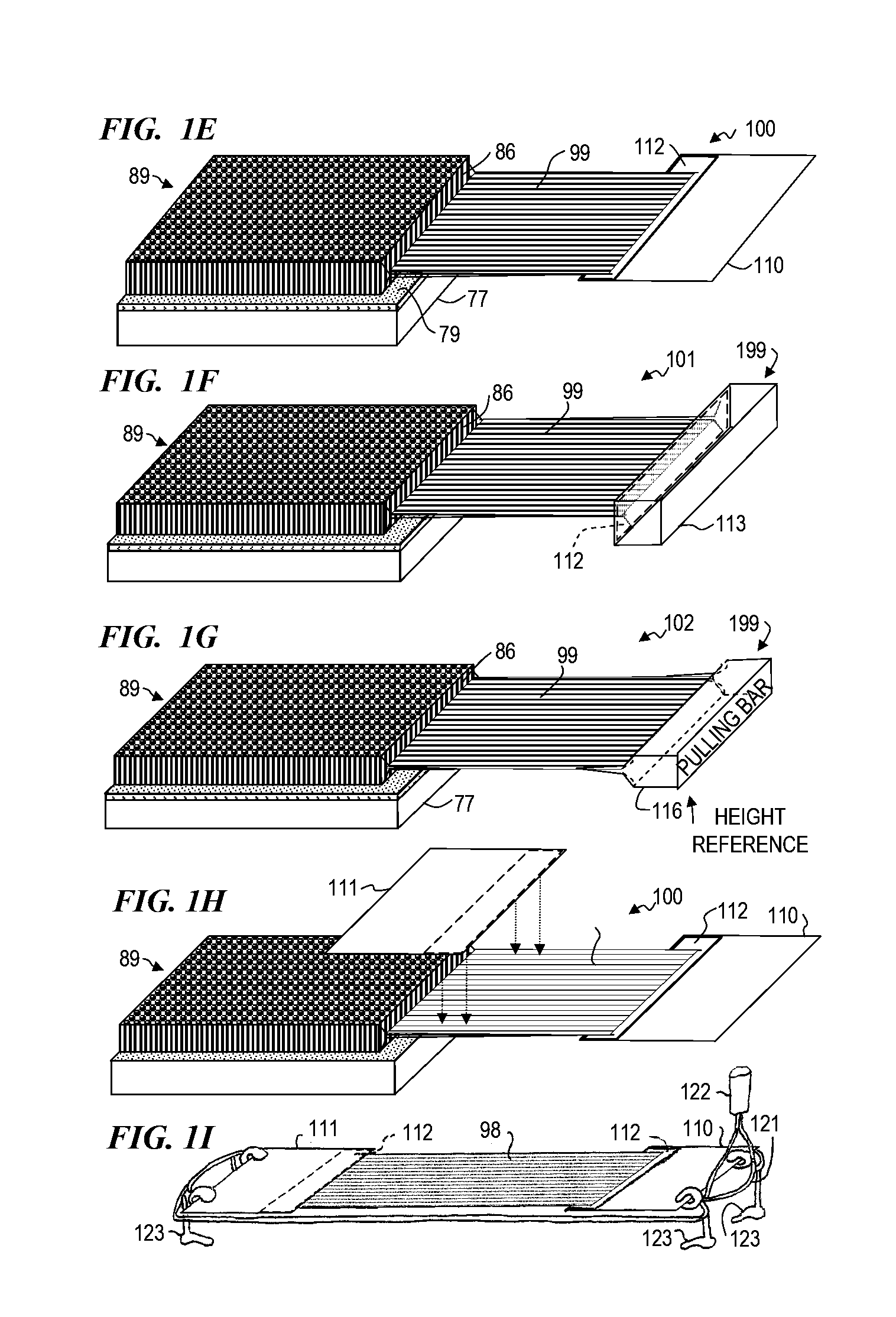

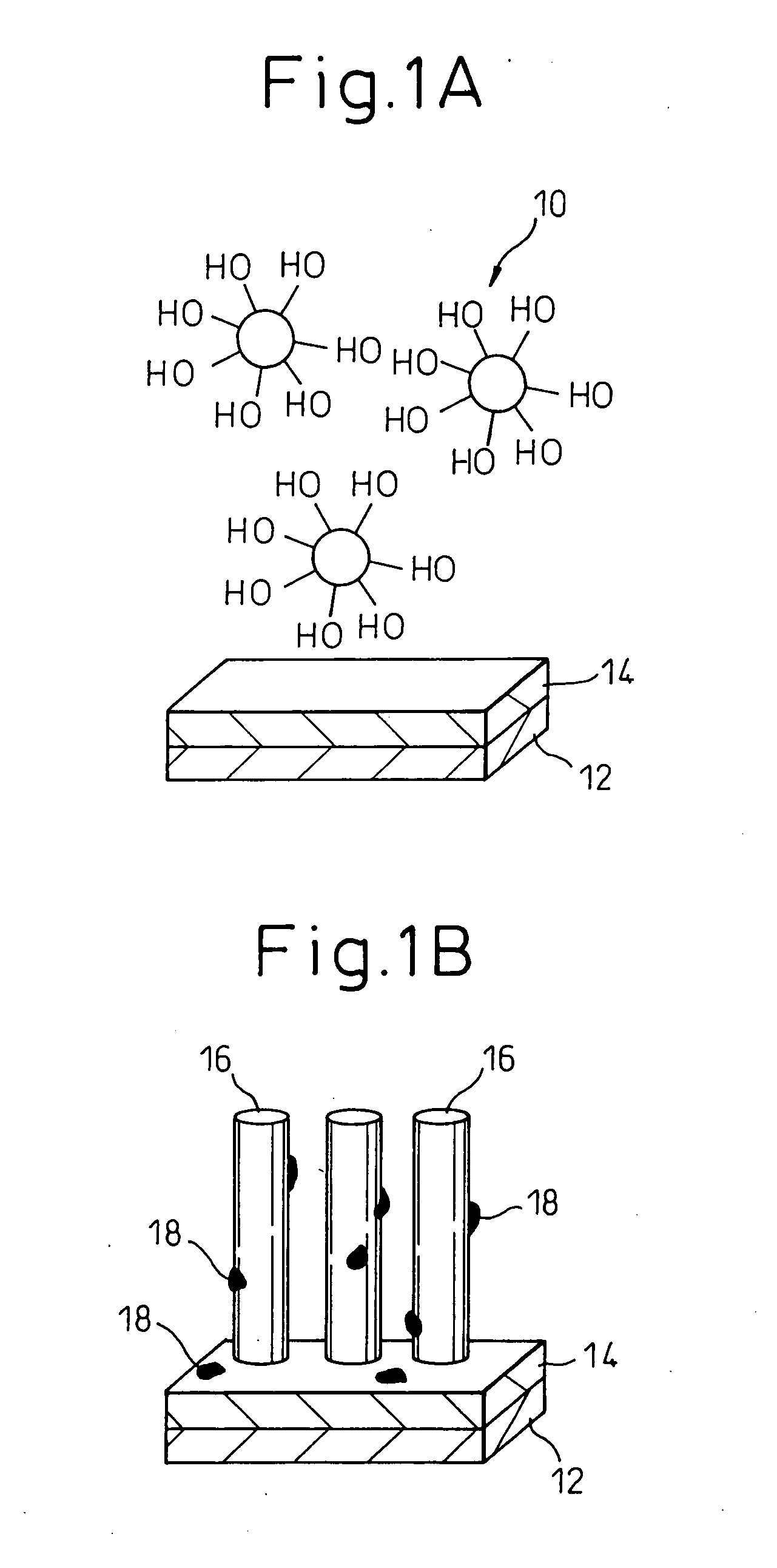

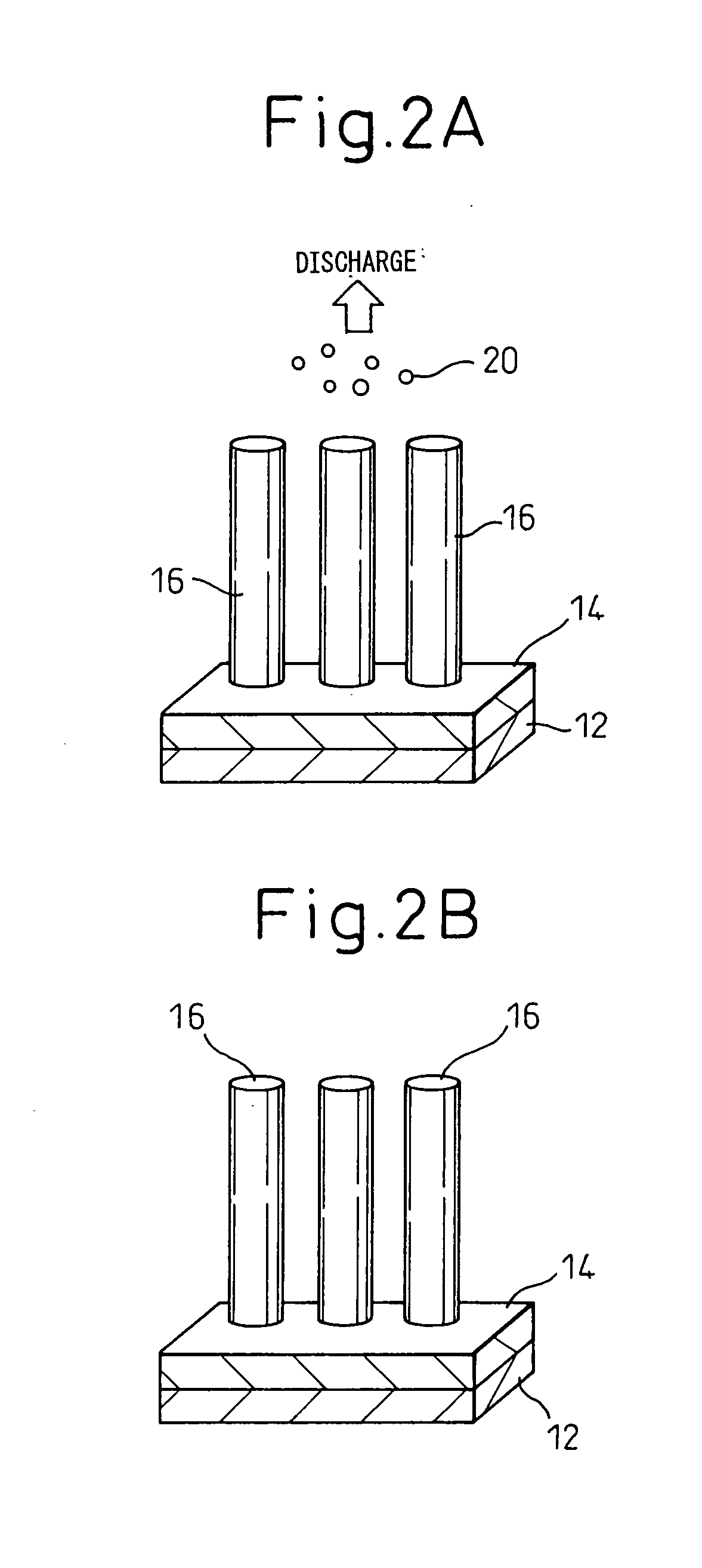

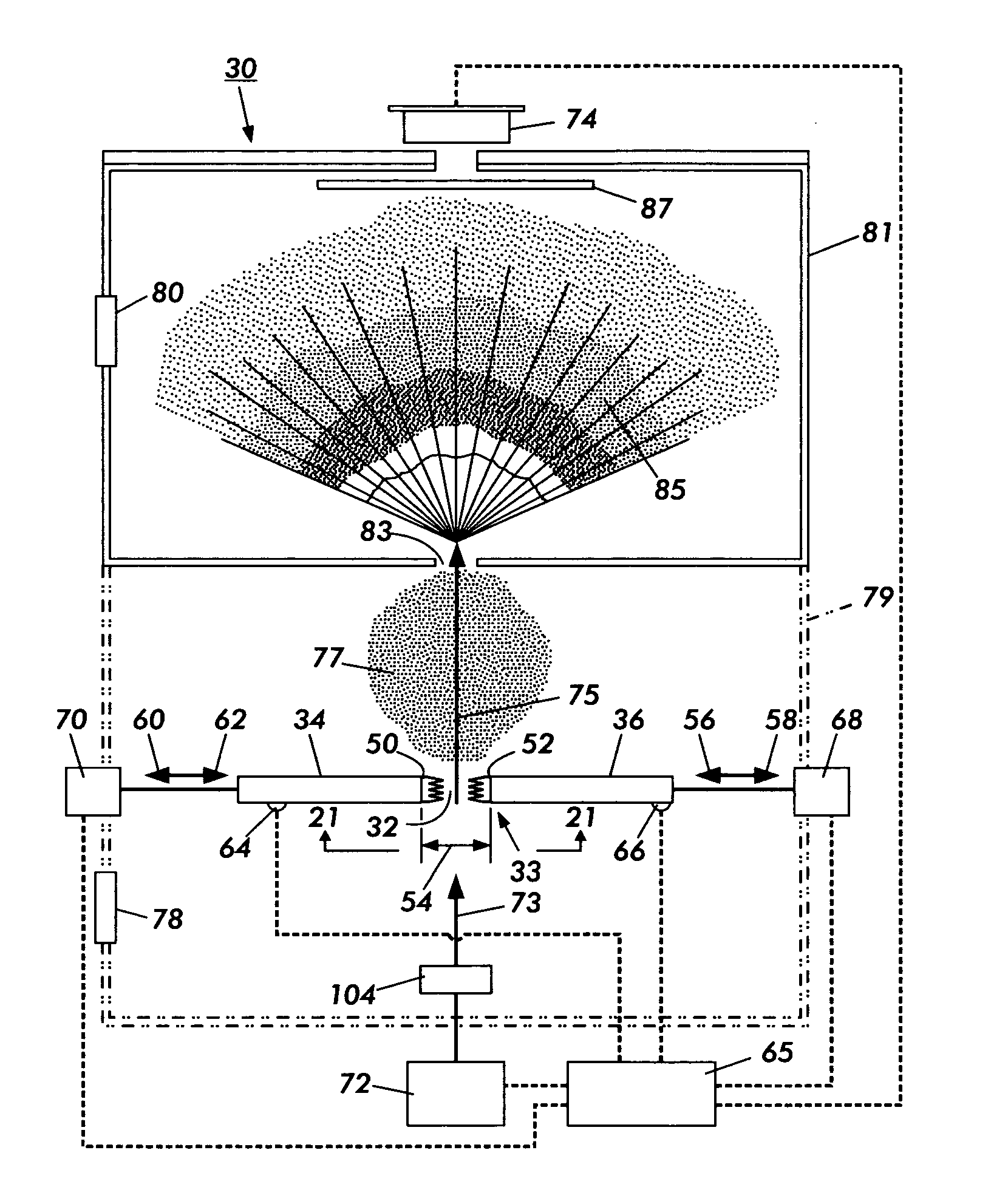

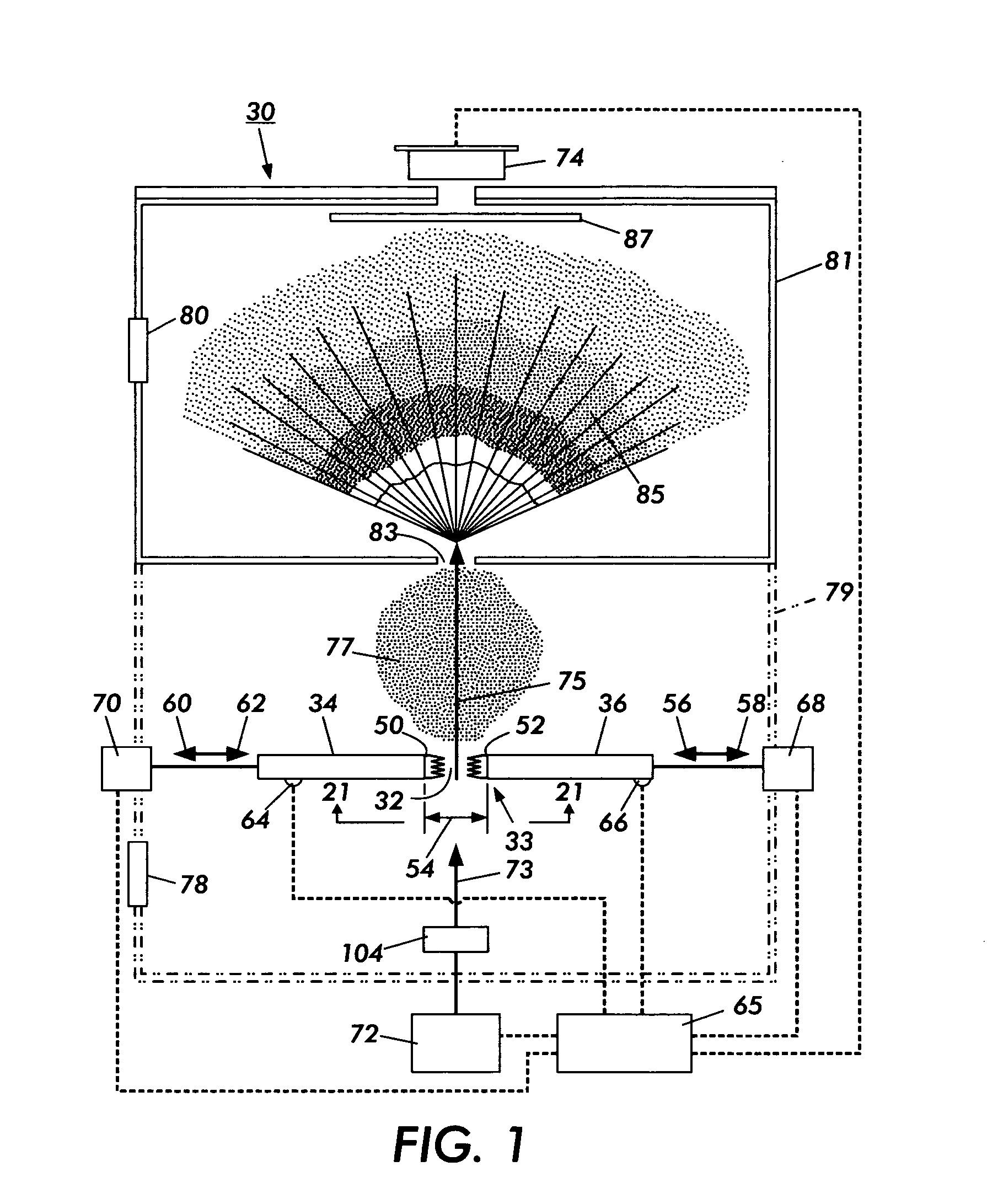

Apparatus and method for growing fullerene nanotube forests, and forming nanotube films, threads and composite structures therefrom

The present invention provides apparatus and methods for growing fullerene nanotube forests, and forming nanotube films, threads and composite structures therefrom. In some embodiments, an interior-flow substrate includes a porous surface and one or more interior passages that provide reactant gas to an interior portion of a densely packed nanotube forest as it is growing. In some embodiments, a continuous-growth furnace is provided that includes an access port for removing nanotube forests without cooling the furnace substantially. In other embodiments, a nanotube film can be pulled from the nanotube forest without removing the forest from the furnace. A nanotube film loom is described. An apparatus for building layers of nanotube films on a continuous web is described.

Owner:GRANDNANO

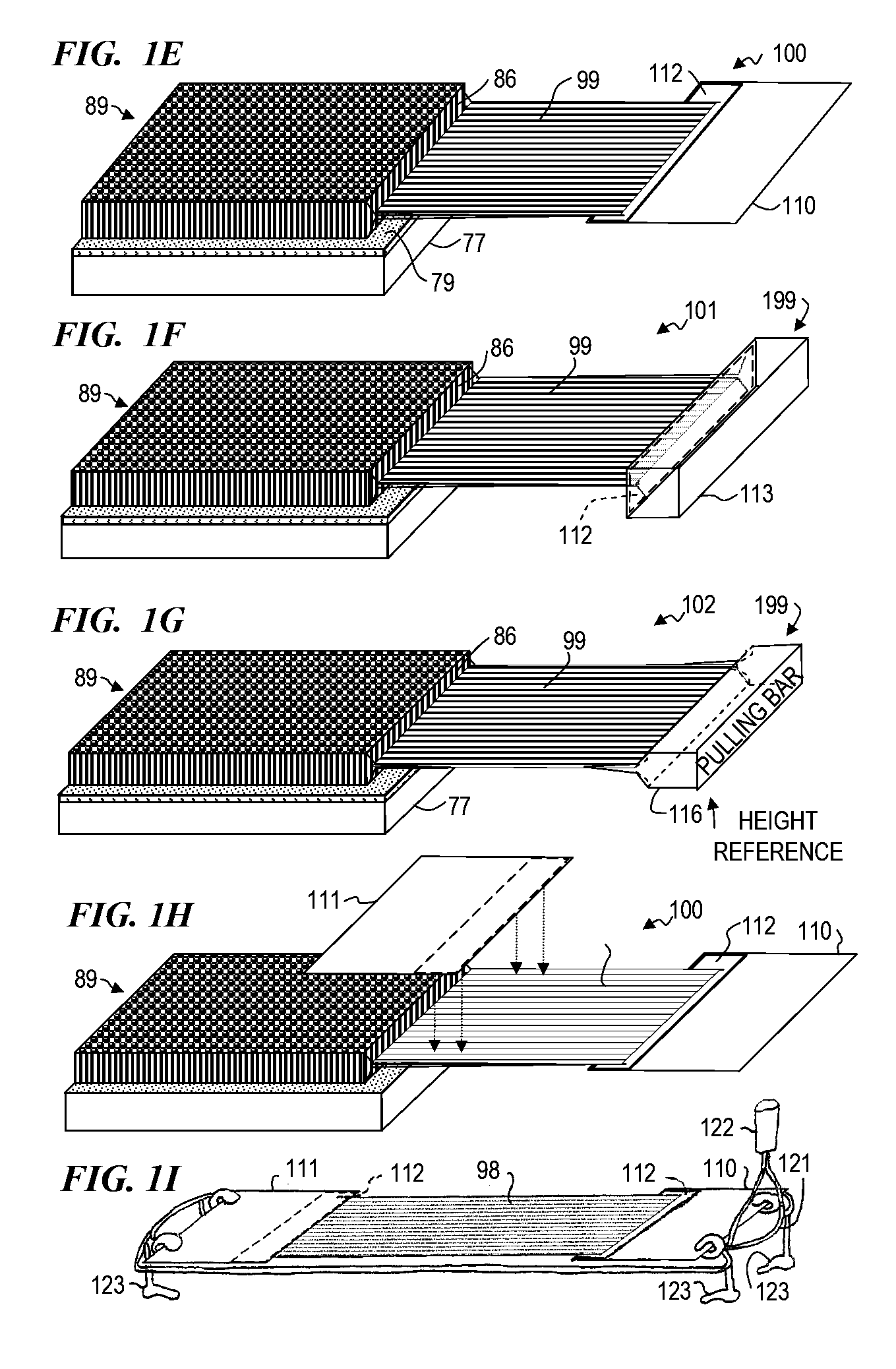

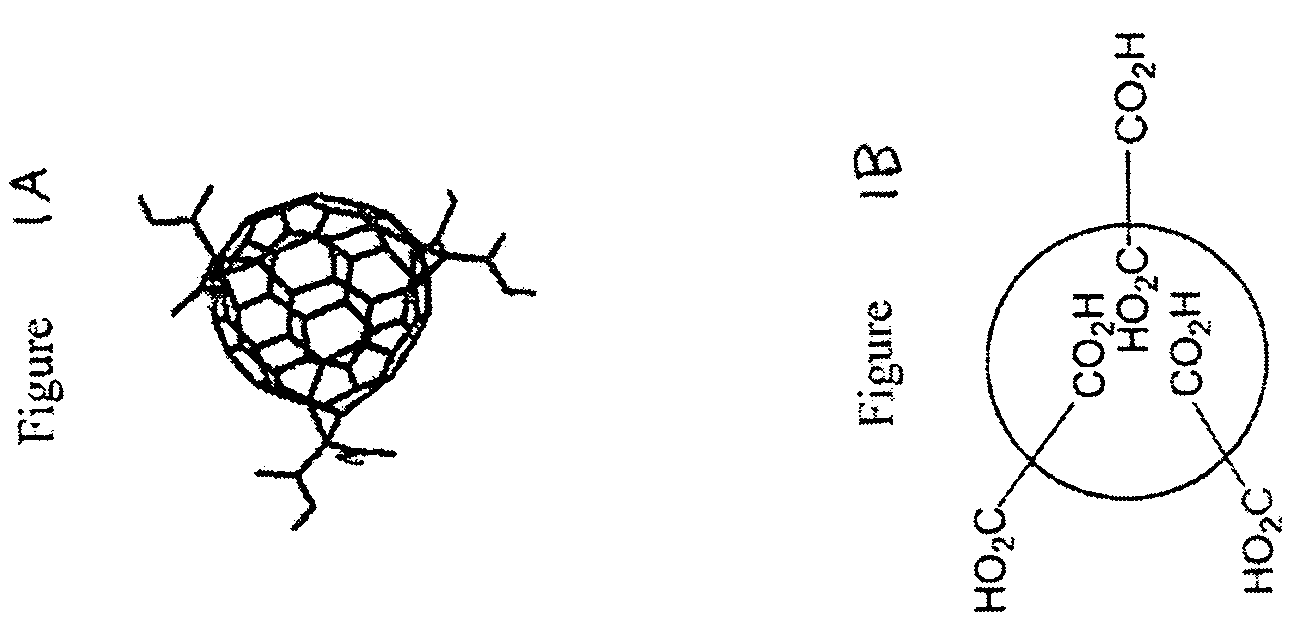

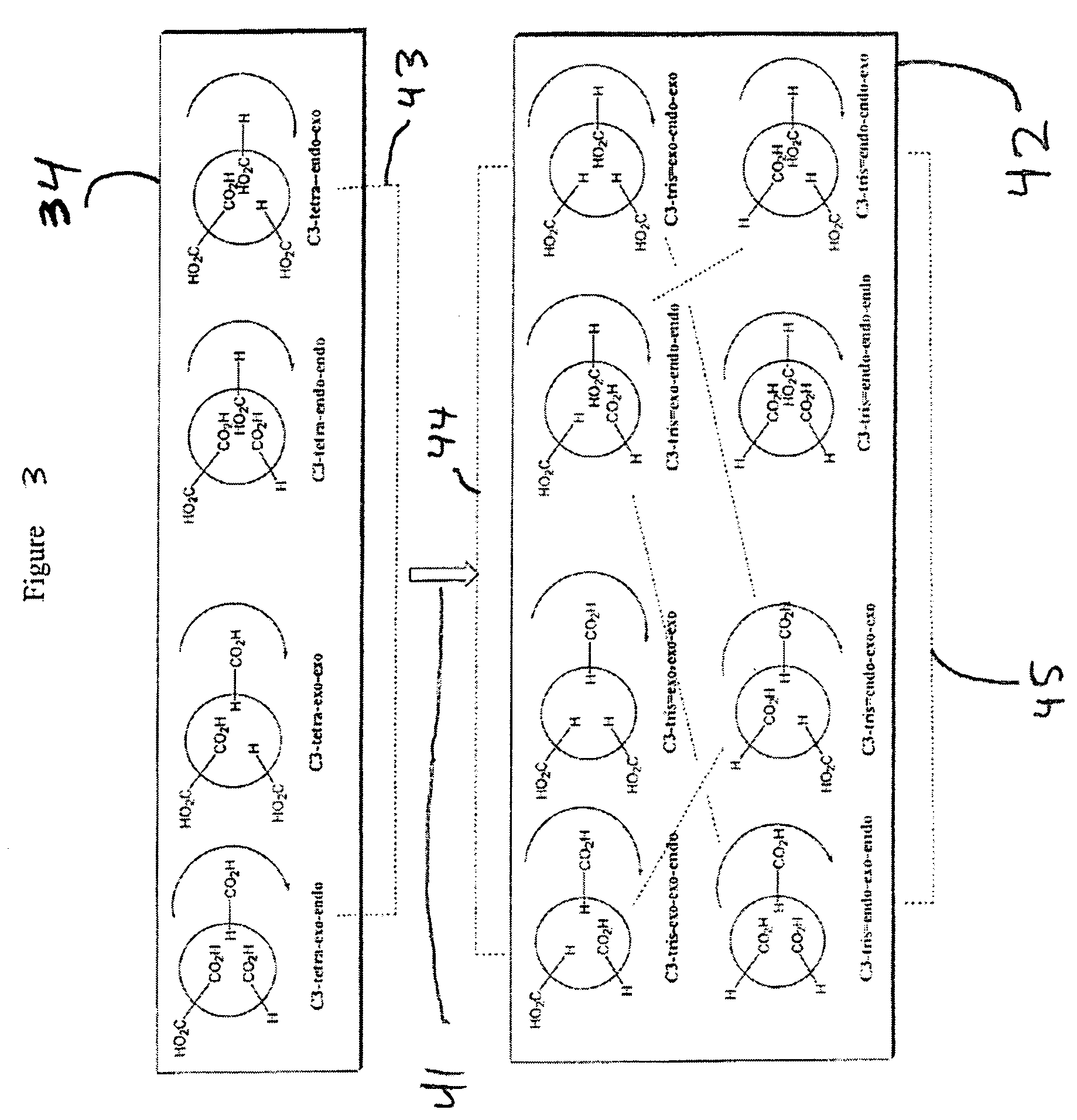

Substituted fullerene compositions and their use as antioxidants

InactiveUS7163956B2Ameliorating damage to tissues for transplantationAmeliorating spoilage of foodMaterial nanotechnologyBiocideAntioxidantFullerene

This patent discloses a substituted fullerenes, compositions comprising the same, and their use as antioxidants. The substituted fullerenes comprise a fullerene core (Cn) and at least one of: (i) from 1 to 6 (>CX1X2) groups bonded to the fullerene core; (ii) from 1 to 18 —X3 groups bonded to the fullerene core; (iii) from 1 to 6 —X4— groups bonded to the fullerene core; or (iv) from 1 to 6 dendrons bonded to the fullerene core.

Owner:LUNA INNOVATIONS

Apparatus and method for growing fullerene nanotube forests, and forming nanotube films, threads and composite structures therefrom

The present invention provides apparatus and methods for growing fullerene nanotube forests, and forming nanotube films, threads and composite structures therefrom. In some embodiments, an interior-flow substrate includes a porous surface and one or more interior passages that provide reactant gas to an interior portion of a densely packed nanotube forest as it is growing. In some embodiments, a continuous-growth furnace is provided that includes an access port for removing nanotube forests without cooling the furnace substantially. In other embodiments, a nanotube film can be pulled from the nanotube forest without removing the forest from the furnace. A nanotube film loom is described. An apparatus for building layers of nanotube films on a continuous web is described.

Owner:GRANDNANO

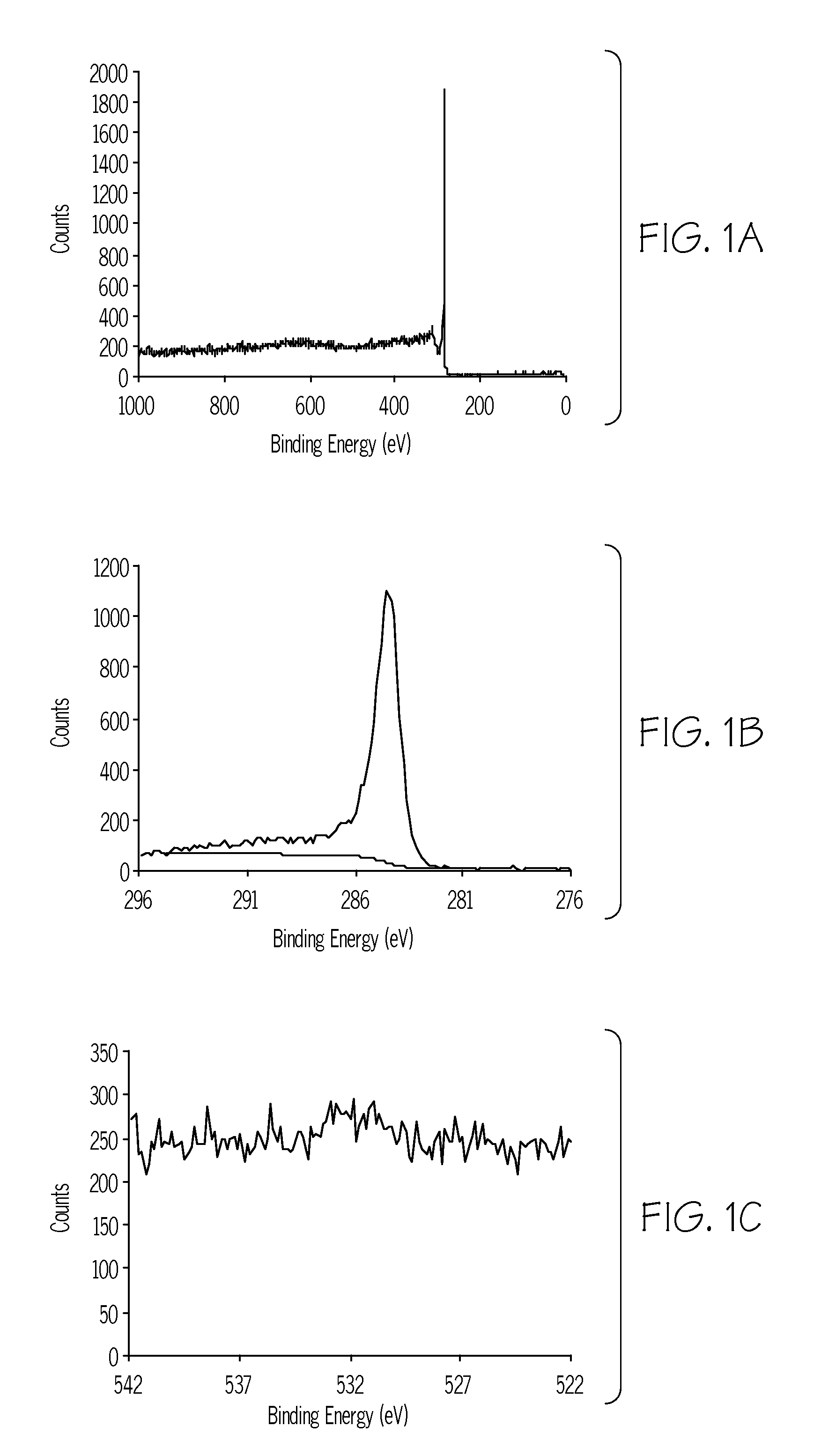

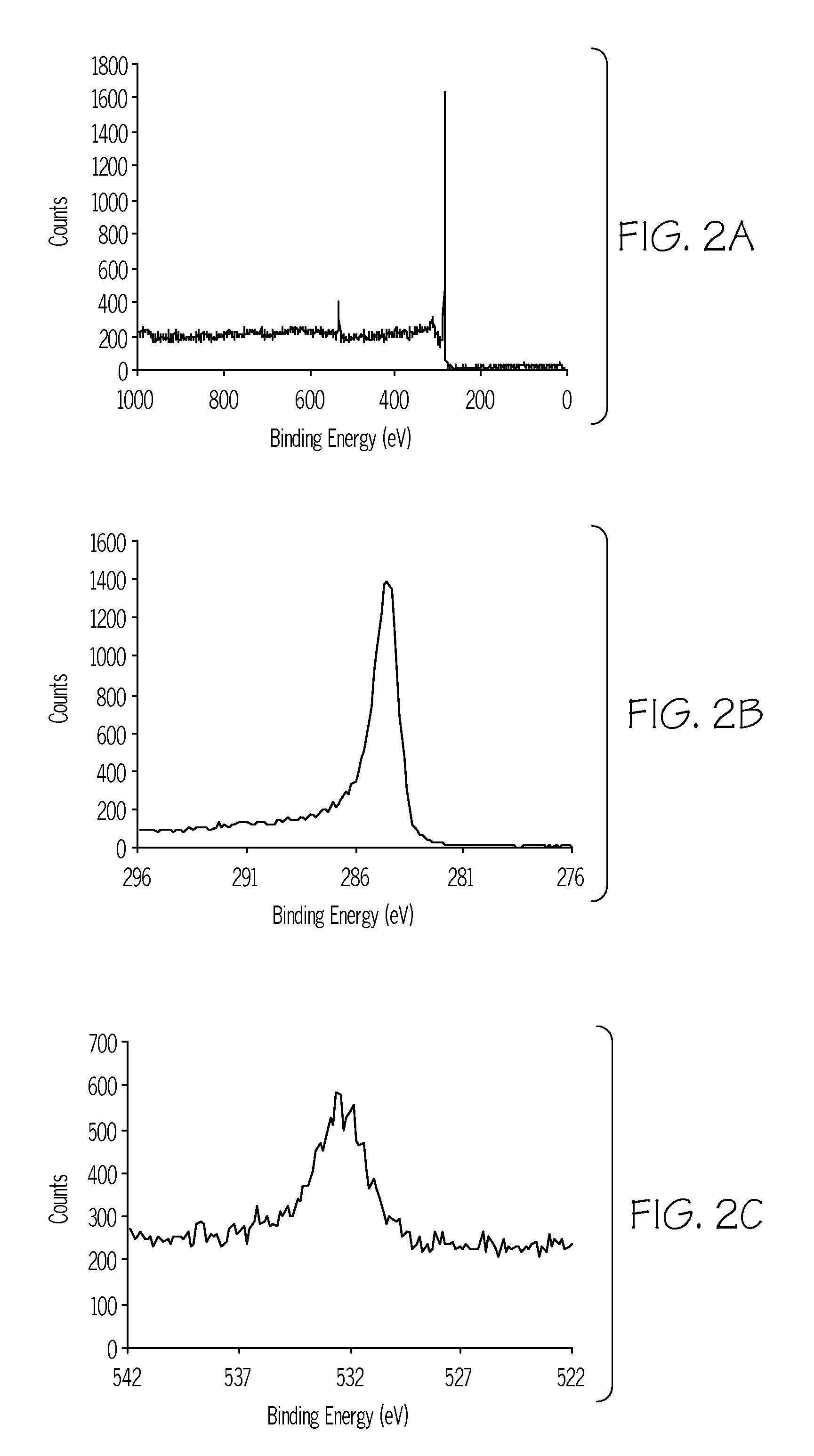

Microwave induced functionalization of single wall carbon nanotubes and composites prepared therefrom

InactiveUS20060210466A1Rapid funtionalizationHigh purityMaterial nanotechnologyGroup 1/11 element organic compoundsCarbon nanotubeMicrowave electromagnetic radiation

The invention is directed to a method of forming, producing or manufacturing functionalized nanomaterials, and, specifically, soluble functionalized nanomaterials. The presently described invention also relates to nanomaterial-based composites consisting of a target material, which can include ceramic, polymer, or metallic matrices incorporated into or grown on nanomaterials, as well as a method or synthesis technique for the formation, production, or manufacture of nanomaterial-based composites through microwave-induced reaction.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

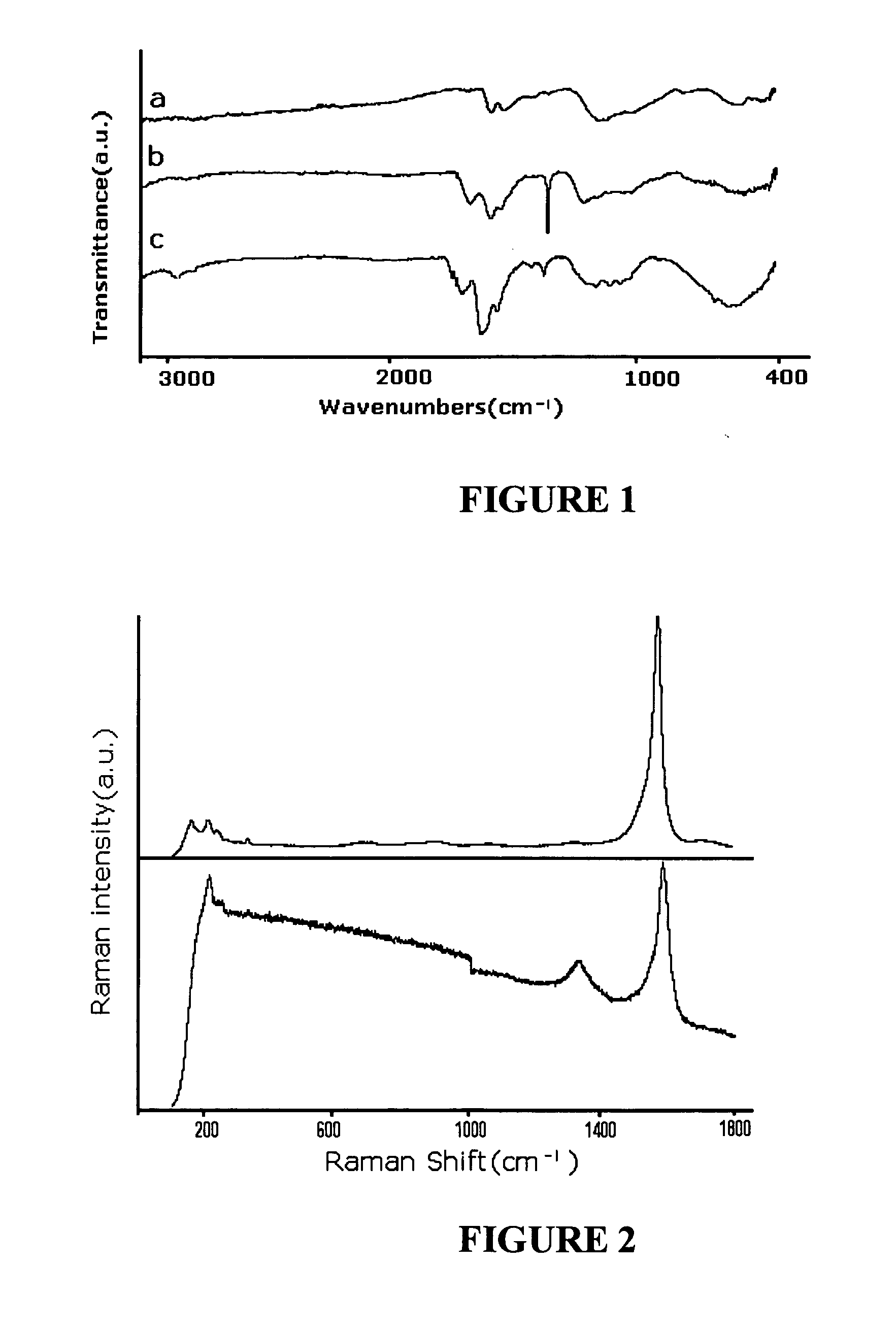

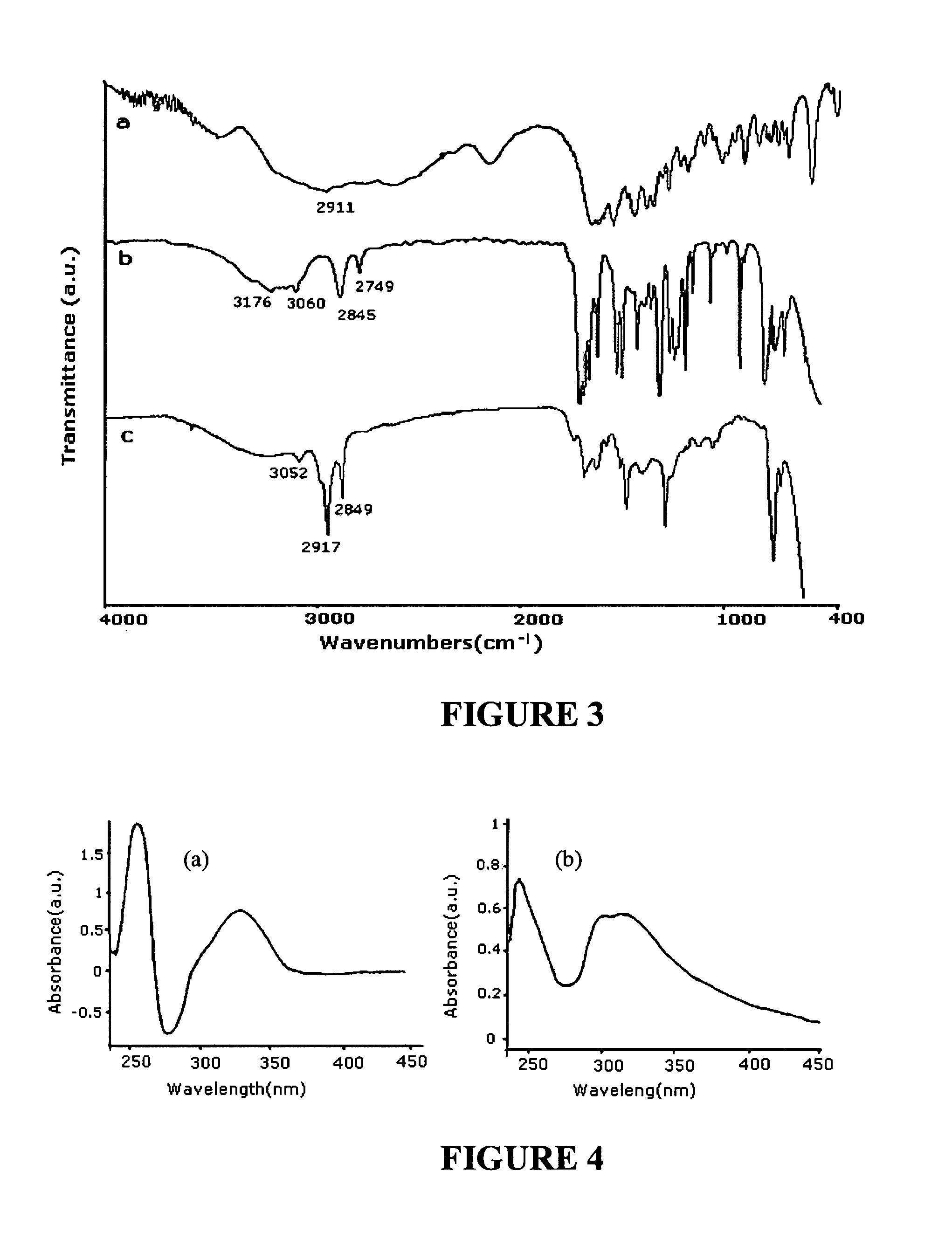

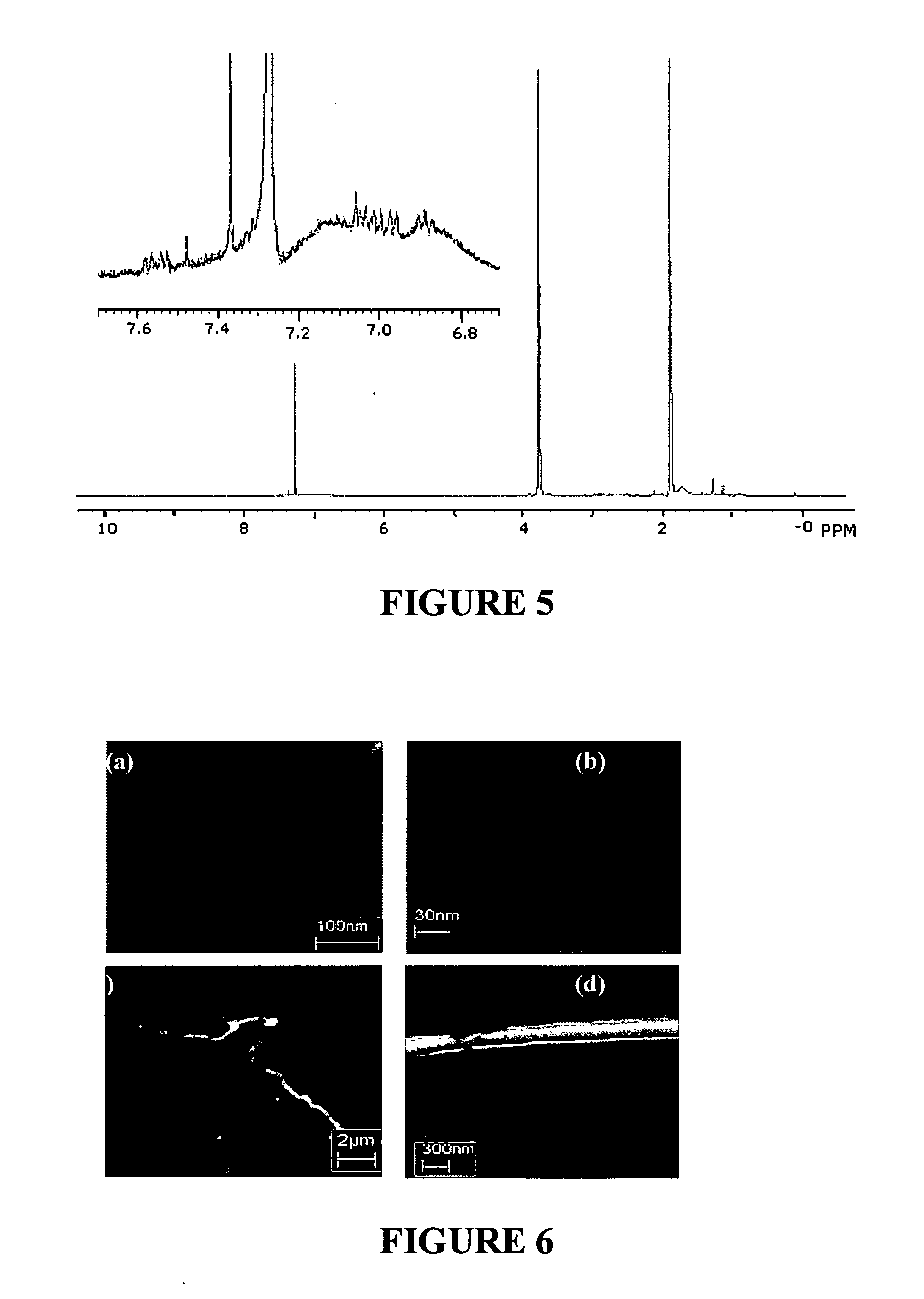

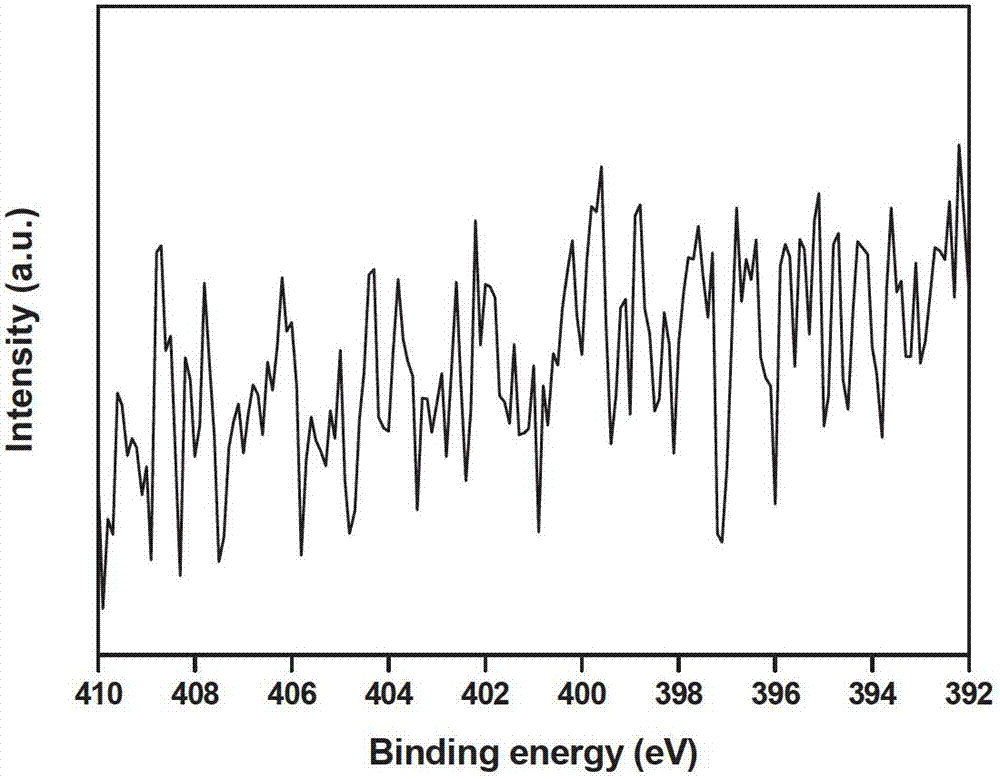

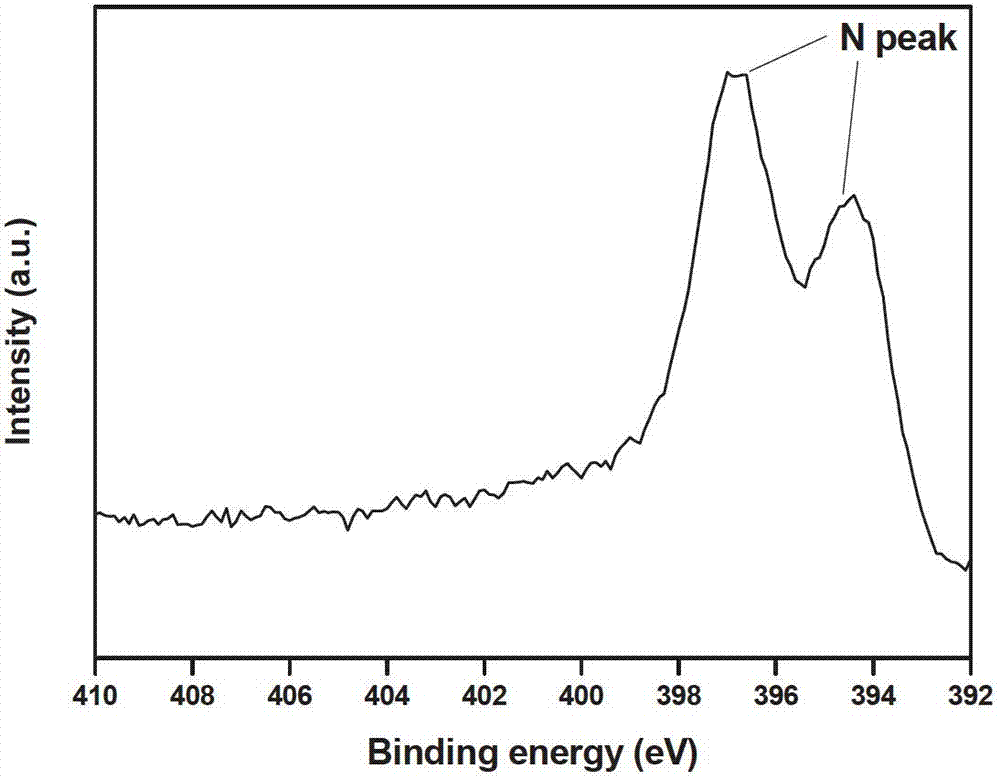

Method for preparing nitrogen-doped carbonaceous material by modifying polymer

InactiveCN102826538AHigh specific capacityWide applicabilityFullerenesSimple Organic CompoundsPolymer modified

The invention discloses a method for preparing a nitrogen-doped carbonaceous material by modifying polymer, which can be used for preparing the nitrogen-doped carbonaceous material with the nitrogen doping amount of 5 to 26 at%. The method disclosed by the invention is characterized by comprising the following steps of: selecting a nitrogen-containing organic compound as a nitrogen precursor and utilizing the nitrogen-containing organic compound to perform polymerization reaction on a carbonaceous material to form a compound of the nitrogen-containing polymer and carbonaceous material; and then carrying out heat treatment on the polymer / carbonaceous material compound in the inert atmosphere to carbonize nitrogen-containing polymer in the compound so as to implement the nitrogen doping on the carbonaceous material and prepare the nitrogen-doped carbonaceous material. According to the invention, when the carbonaceous material is subjected to effective nitrogen doping, the original intrinsic structure of the carbonaceous material can be ensured; moreover, the nitrogen-doped carbonaceous material with the nitrogen content of 5 to 26 at% can be prepared; the specific capacity of using a carbon material as an electrode material of a supercapacitor is obviously improved; and the method has the characteristics of simple technical process and wide applicability.

Owner:UNIV OF SCI & TECH LIAONING

Synthesis method for producing carbon clusters and structured carbon clusters produced thereby

InactiveUS6855301B1Increase ratingsOptimizationMaterial nanotechnologyElectrolysis componentsSynthesis methodsMolecular cluster

The present invention includes carbon synthesis devices and systems. The invention also includes machines and instruments using those aspects of the invention. The present invention also includes methods of carbon synthesis. The present invention includes an array of carbon nanotubes, each nanotube having a longitudinal axis. The nanotubes are placed into an array such that the longitudinal axes of all nanotubes in the array are substantially parallel. The array may be a two-dimensional array or a three-dimensional array. The present invention also includes methods of preparing such carbon molecular clusters and arrays thereof.

Owner:THE OHIO STATES UNIV

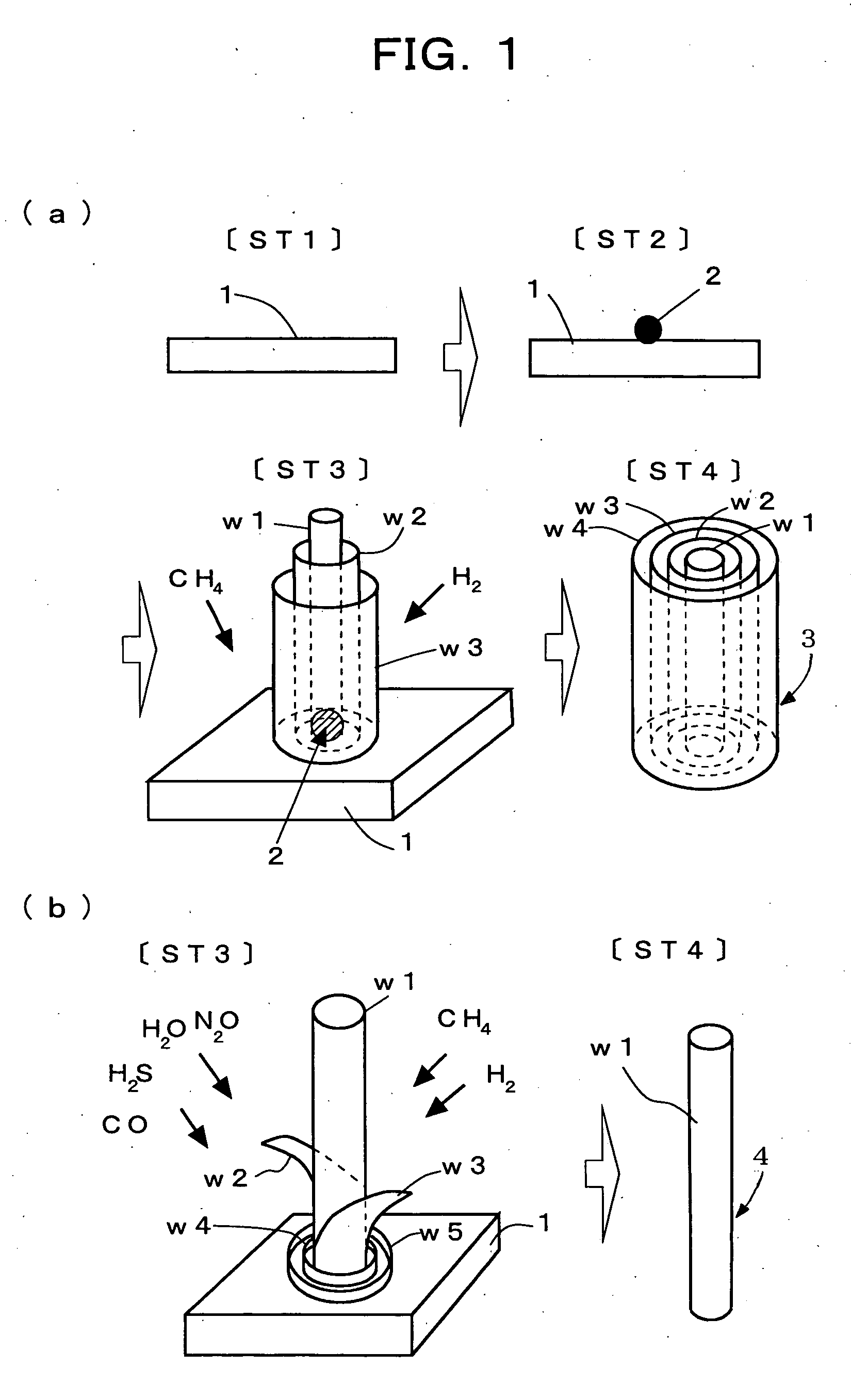

Method of manufacturing carbon nanotubes

A method of manufacturing carbon nanotubes that is capable of growing carbon nanotubes on a substrate by a CVD method without giving rise to residual carbon impurities is provided. The method of manufacturing carbon nanotubes according to the present invention is a method in which carbon nanotubes are grown on a substrate by a chemical vapor deposition (CVD) process using a reaction gas containing a compound for the carbon source, wherein a compound having a carbon skeleton and a functional group which is effective for removing carbon impurities that deposit during the growth of carbon nanotubes is used as the compound for the carbon source.

Owner:FUJITSU LTD

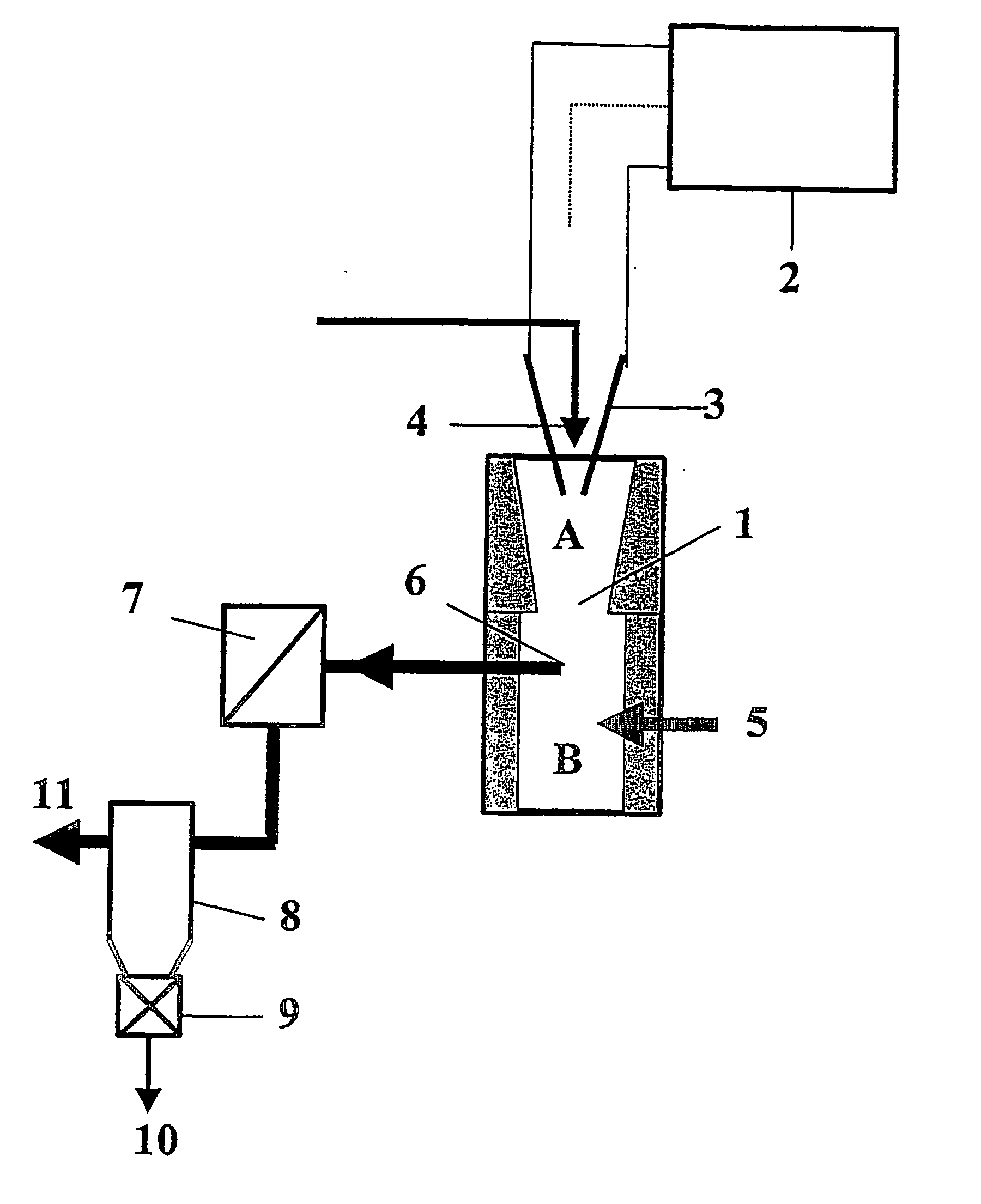

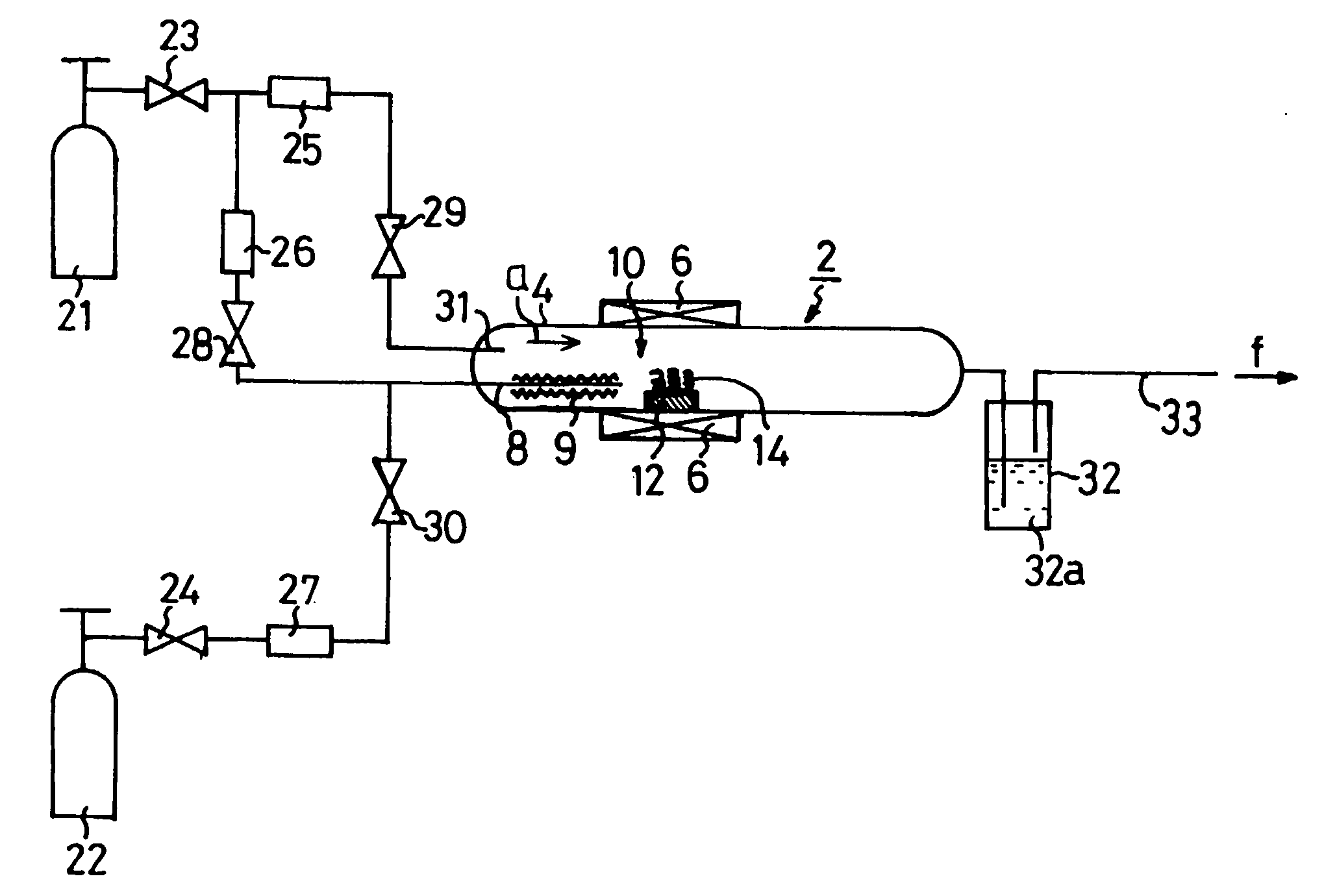

Highly Efficient Material Spraying Type Carbon Nanostructure Synthesizing Method and Apparatus

InactiveUS20070253890A1Reduce generationImprove efficiencyMaterial nanotechnologyFullerenesSynthesis methodsTar

Developed are a synthesizing method for carbon nanostructures where the generation of tar-like byproducts is reduced and carbon nanostructures are generated highly efficiently, and a unit therefor. A highly efficient material spraying type carbon nanostructure synthesizing apparatus according to the present invention is formed of a catalyst body that is placed inside a reaction tube, a heating unit that is provided in order to heat the vicinity of this catalyst body to the temperature range where carbon nanostructures are generated, a material gas supplying pipe for introducing a material gas into reaction tube which is provided in such a manner that an end of this supplying pipe is placed in proximity to catalyst body, and a preheating unit for preheating the material gas supplying pipe to a temperature range where no tar-like products are generated from a material gas. No tar-like substance is generated in the material gas supplying pipe, and the material gas is directly sprayed against the catalyst body, skipping the middle temperature range. Therefore, the probability of reaction occurring is high, and the yield in the generation of carbon nanostructures is high. Most of the material gas is consumed; thus, no tar-like substance is generated inside reaction tube.

Owner:JAPAN SCI & TECH CORP +3

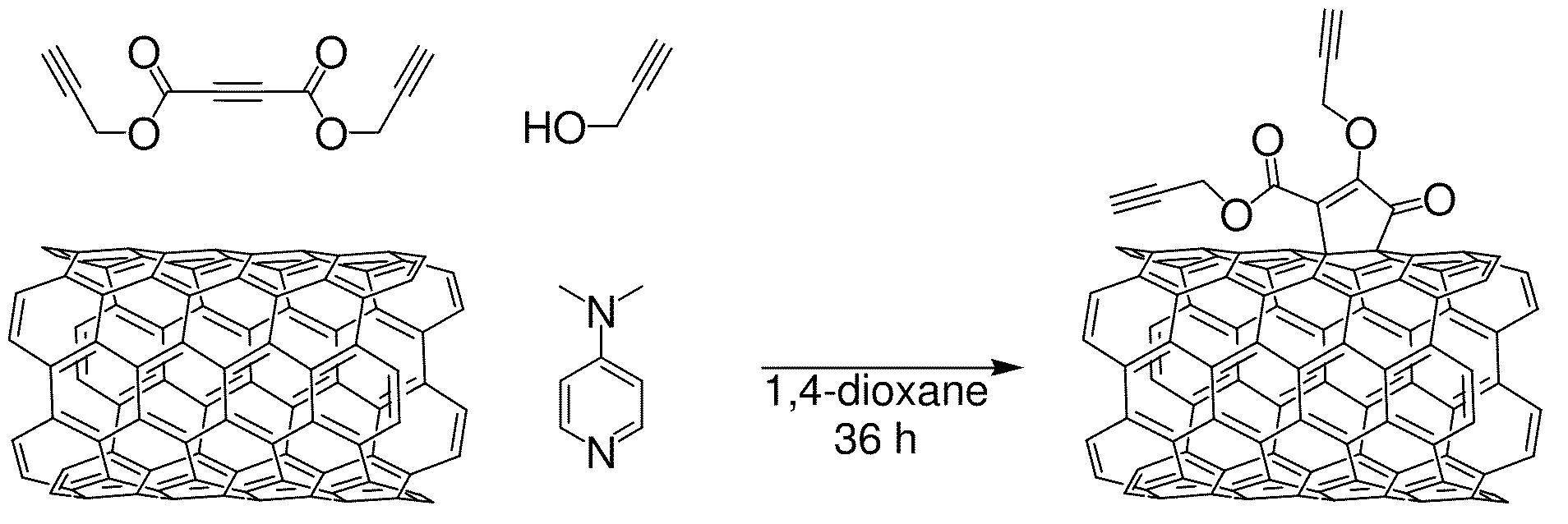

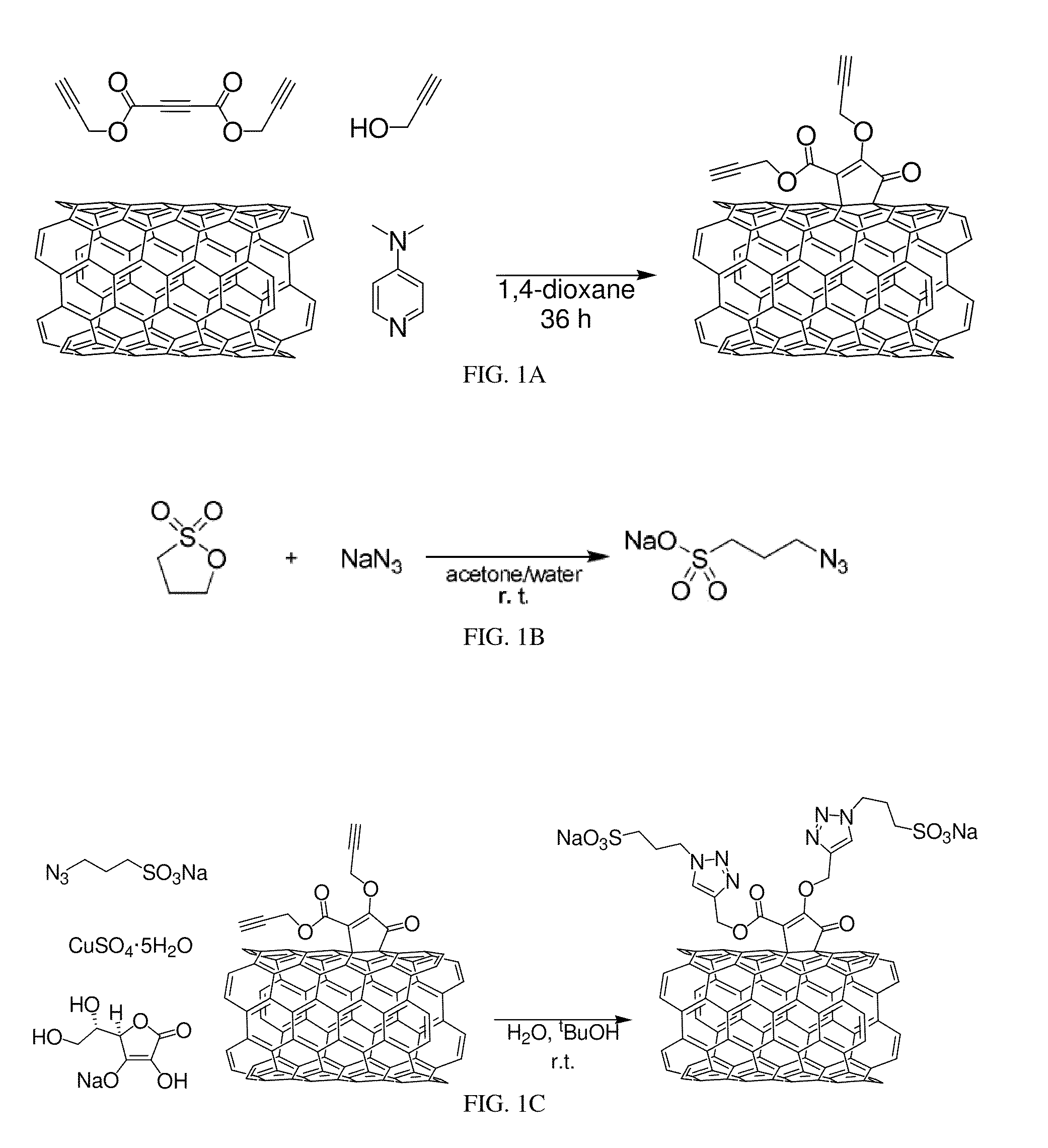

High charge density structures, including carbon-based nanostructures and applications thereof

The present invention generally provides compositions including carbon-based nanostructures, catalyst materials and systems, and related methods. In some cases, the present invention relates to carbon-based nanostructures comprising a high density of charged moieties. Methods of the invention may provide the ability to introduce a wide range of charged moieties to carbon-based nanostructures. The present invention may provide a facile and modular approach to synthesizing molecules that may be useful in various applications including sensors, catalysts, and electrodes.

Owner:MASSACHUSETTS INST OF TECH

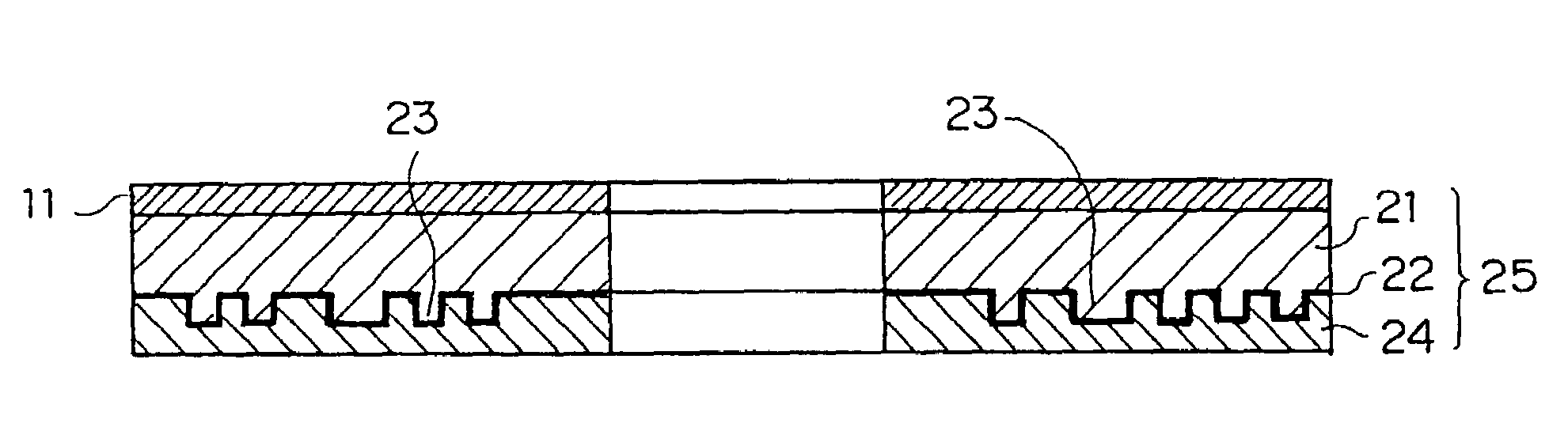

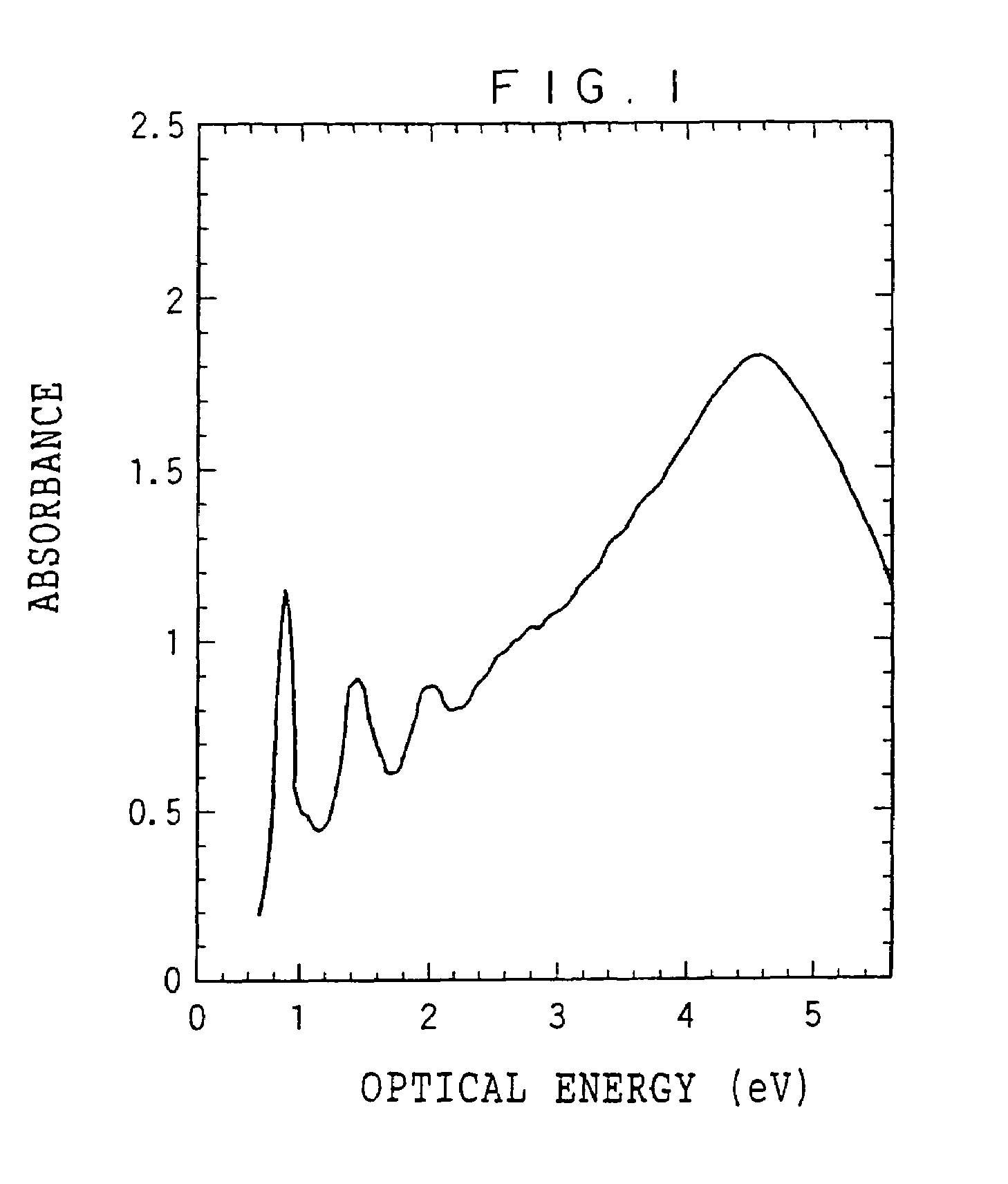

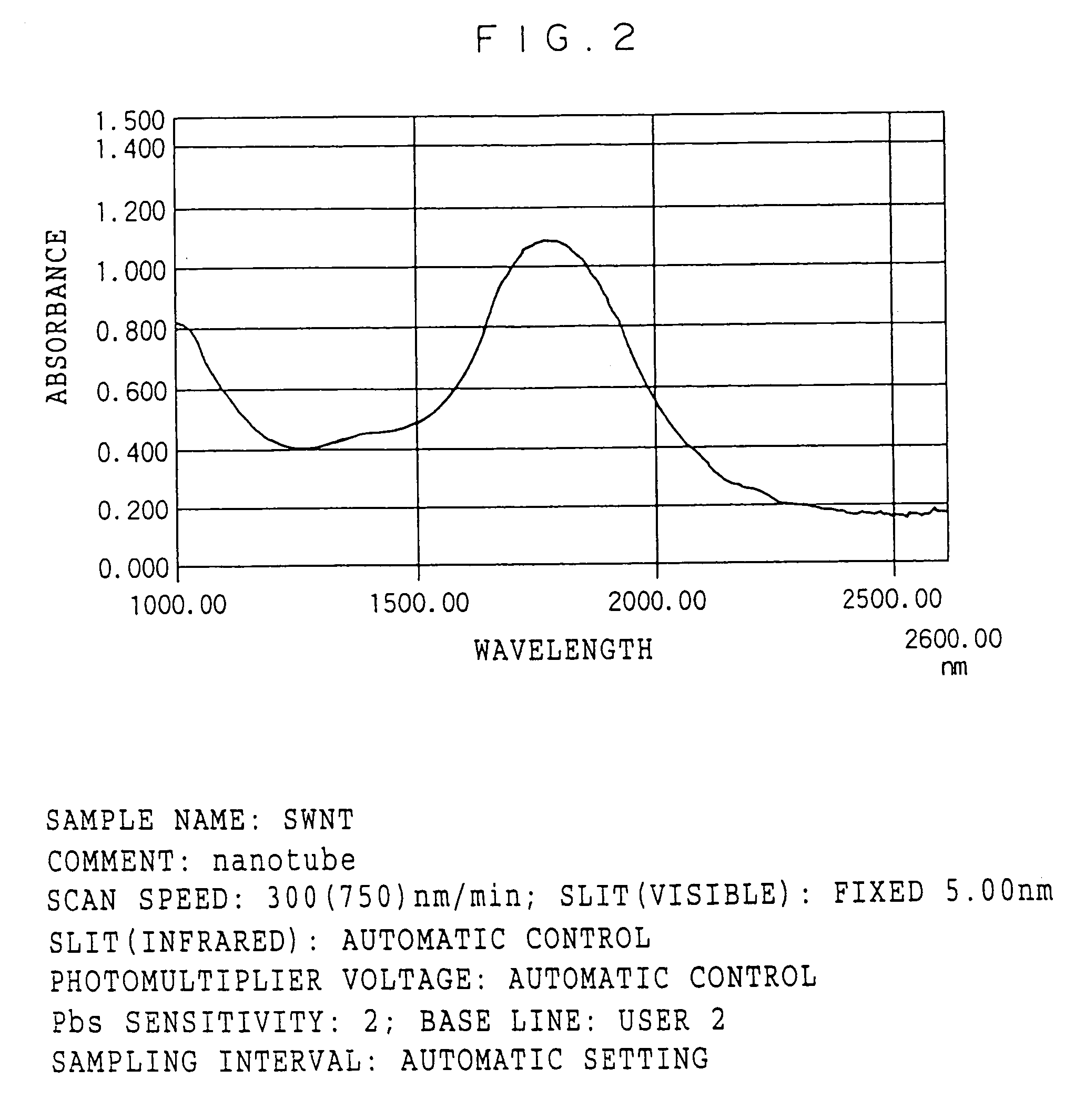

Optical element, and manufacturing method thereof

An optical element according to the present invention has a thin film, in which single-wall carbon nanotubes are laminated, and utilizes a saturable absorption function of the single-wall carbon nanotubes. Further, in a method for producing the optical element according to the present invention, the thin film is formed by spraying, to a body to be coated, a dispersion liquid prepared by dispersing the single-wall carbon nanotubes in a dispersion medium. Accordingly, a nonlinear optical element, which can operate in an optical communication wavelength region and which is extremely inexpensive and efficient, and a method for producing the optical element can be provided.

Owner:NAT INST OF ADVANCED IND SCI & TECH

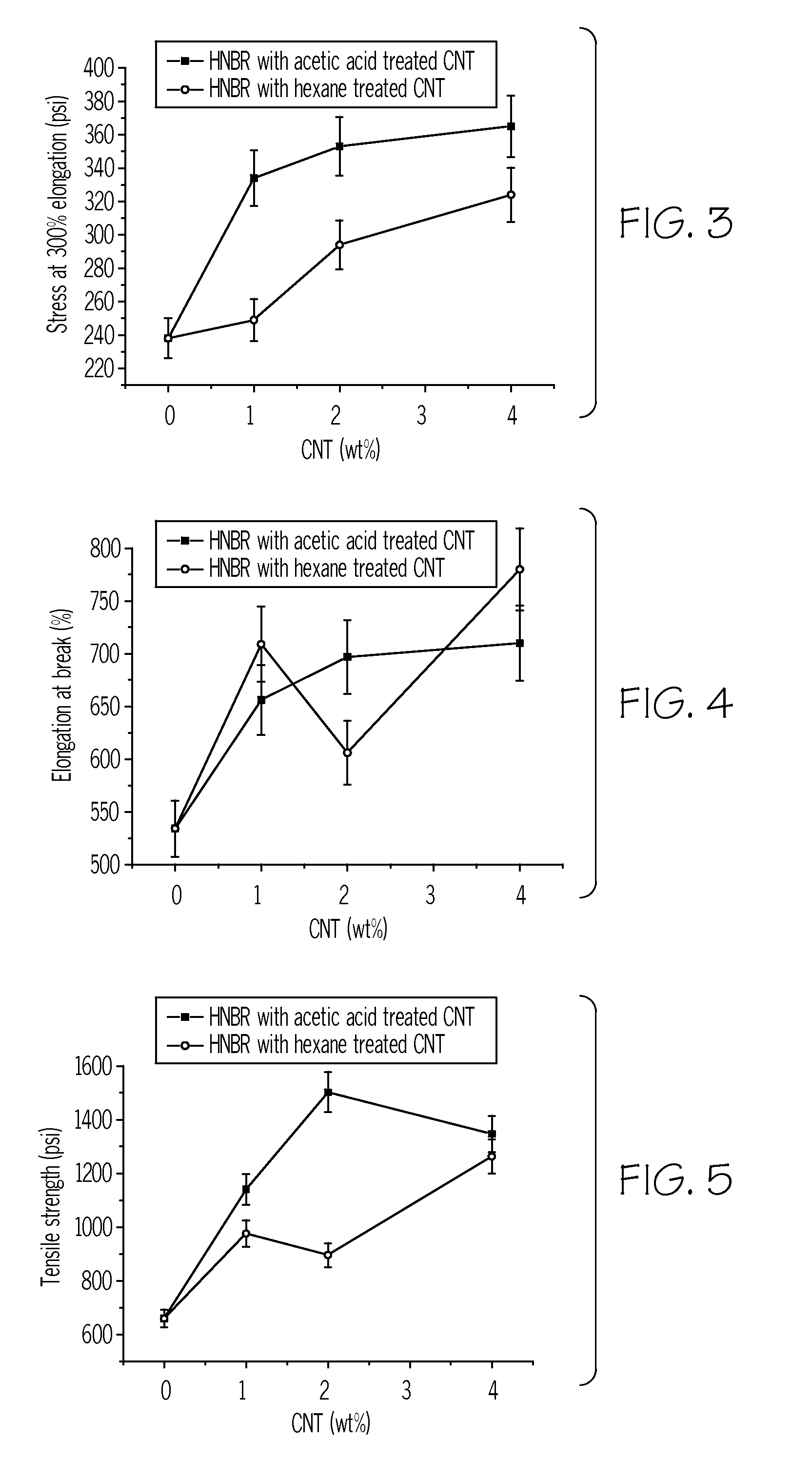

Method of modifying carbon nanomaterials, composites incorporating modified carbon nanomaterials and method of producing the composites

A polymer-carbon nanomaterial composite. The composite includes a polymer matrix; and plasma-modified carbon nanomaterials having surface functional groups attached thereto, wherein the carbon nanomaterial is selected from carbon nanotubes, carbon nanofibers, carbon nanoparticles, carbon black, nanodiamond, fullerenes, or combinations thereof. The invention also involves a method of making a polymer-carbon nanomaterial composite, and a method of modifying carbon nanomaterials.

Owner:UNIV OF DAYTON

Method for preparing functional nanomaterials utilizing endothermic reaction

InactiveUS20050002849A1High yieldIncrease productionMaterial nanotechnologyNanostructure manufactureGas phaseSilicon carbide nanotubes

A method is disclosed whereby a functional nanomaterial such as a monolayer carbon nanotube, a monolayer boron nitride nanotube, a monolayer silicon carbide nanotube, a multilayer carbon nanotube with the number of layers controlled, a multilayer boron nitride nanotube with the number of layers controlled, a multilayer silicon carbide nanotube with the number of layers controlled, a metal containing fullerene, and a metal containing fullerene with the number of layers controlled is produced at a high yield. According to the method, when a multilayer carbon nanotube (3) is formed by a chemical vapor deposition or a liquid phase growth process, an endothermic reaction aid (H2S) is introduced in addition to a primary reactant (CH4, H2) in the process to form a monolayer carbon nanotube (4).

Owner:JAPAN SCI & TECH CORP

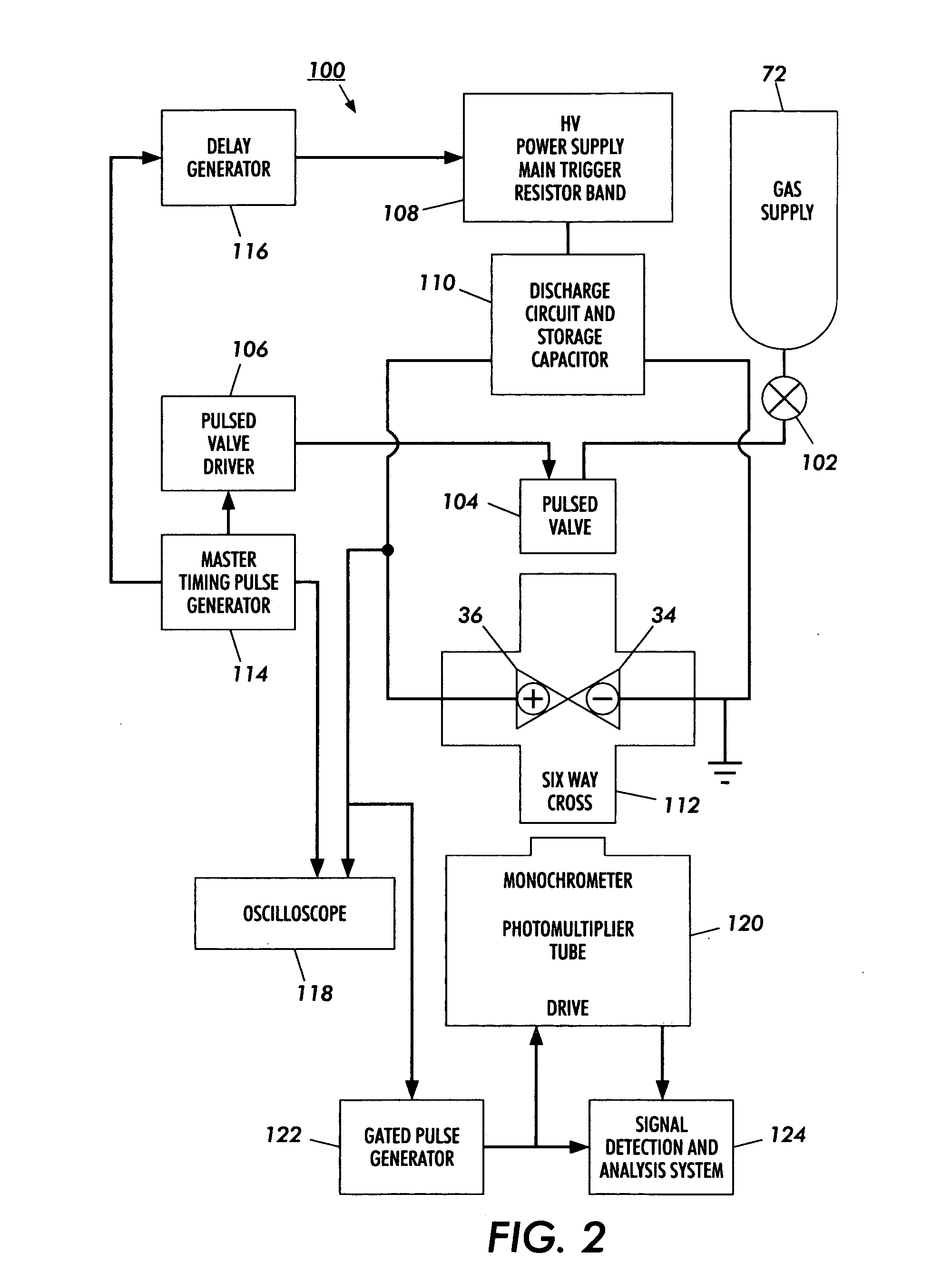

Multi-component substances and apparatus for preparation thereof

An apparatus for the synthesis of multi-component substances, comprising entities of at least two elements, molecules, grains, crystals, structural units, or phases of matter, in which the scale of the distribution of the elements, molecules, or phases of matter may range from on the order of nanometers or less, to about one millimeter, depending upon the specific materials and process conditions that are chosen. The apparatus of the present invention comprises a vacuum chamber, a target assembly, an energy source for generating a plasma containing materials ablated from the target assembly, and a reagent gas supply for directing gas into the vacuum chamber toward the plasma.

Owner:GARVEY JAMES F +3

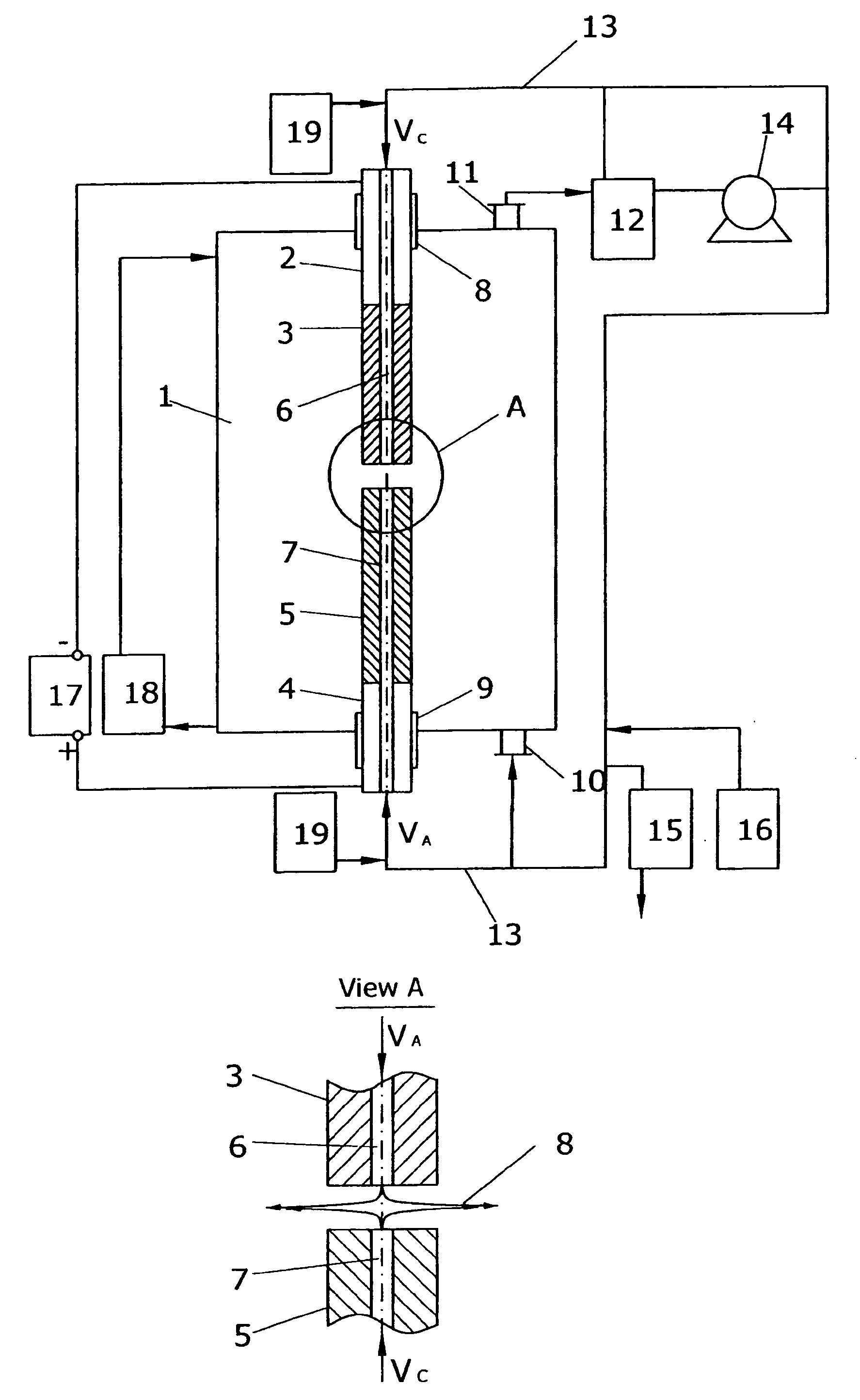

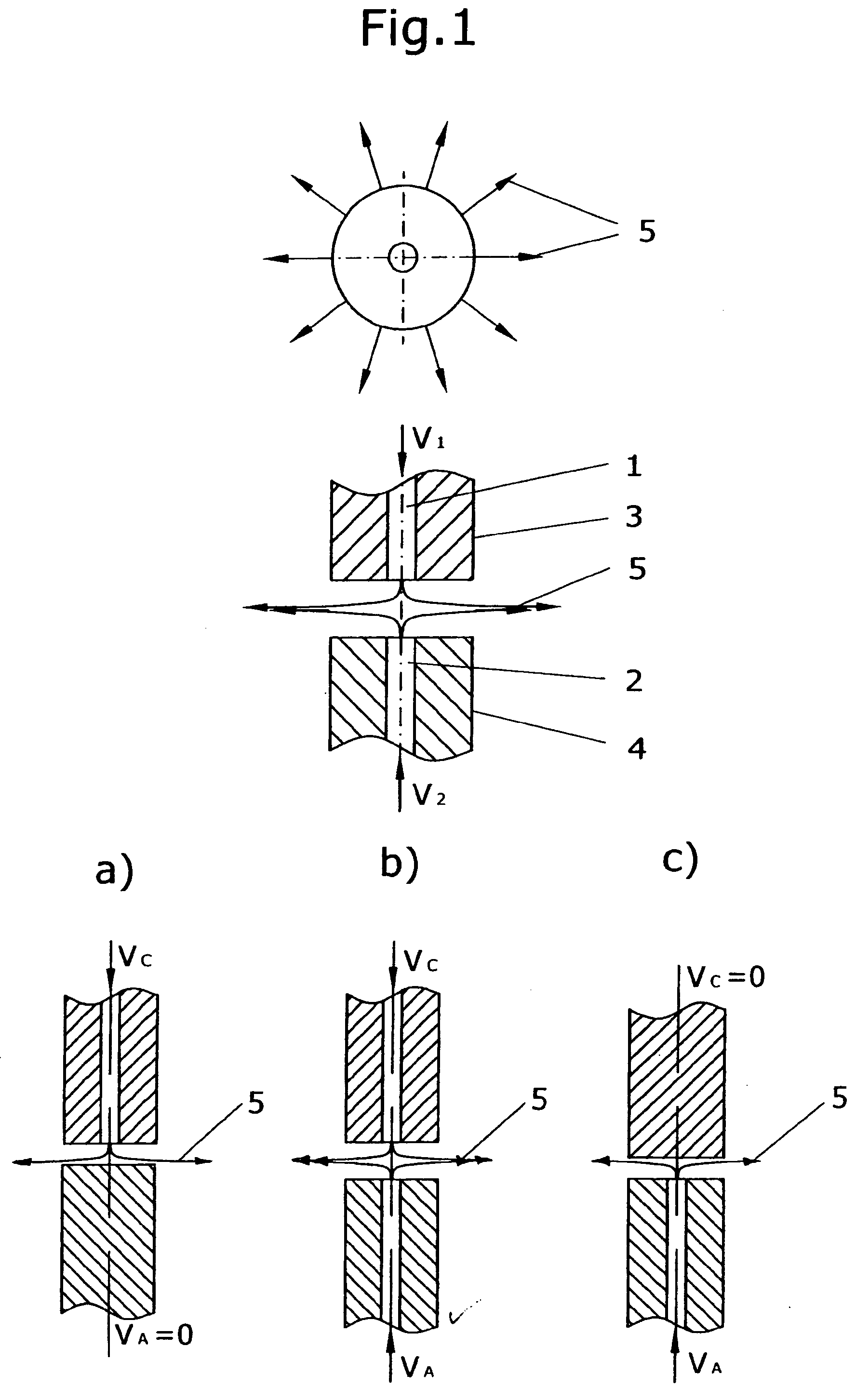

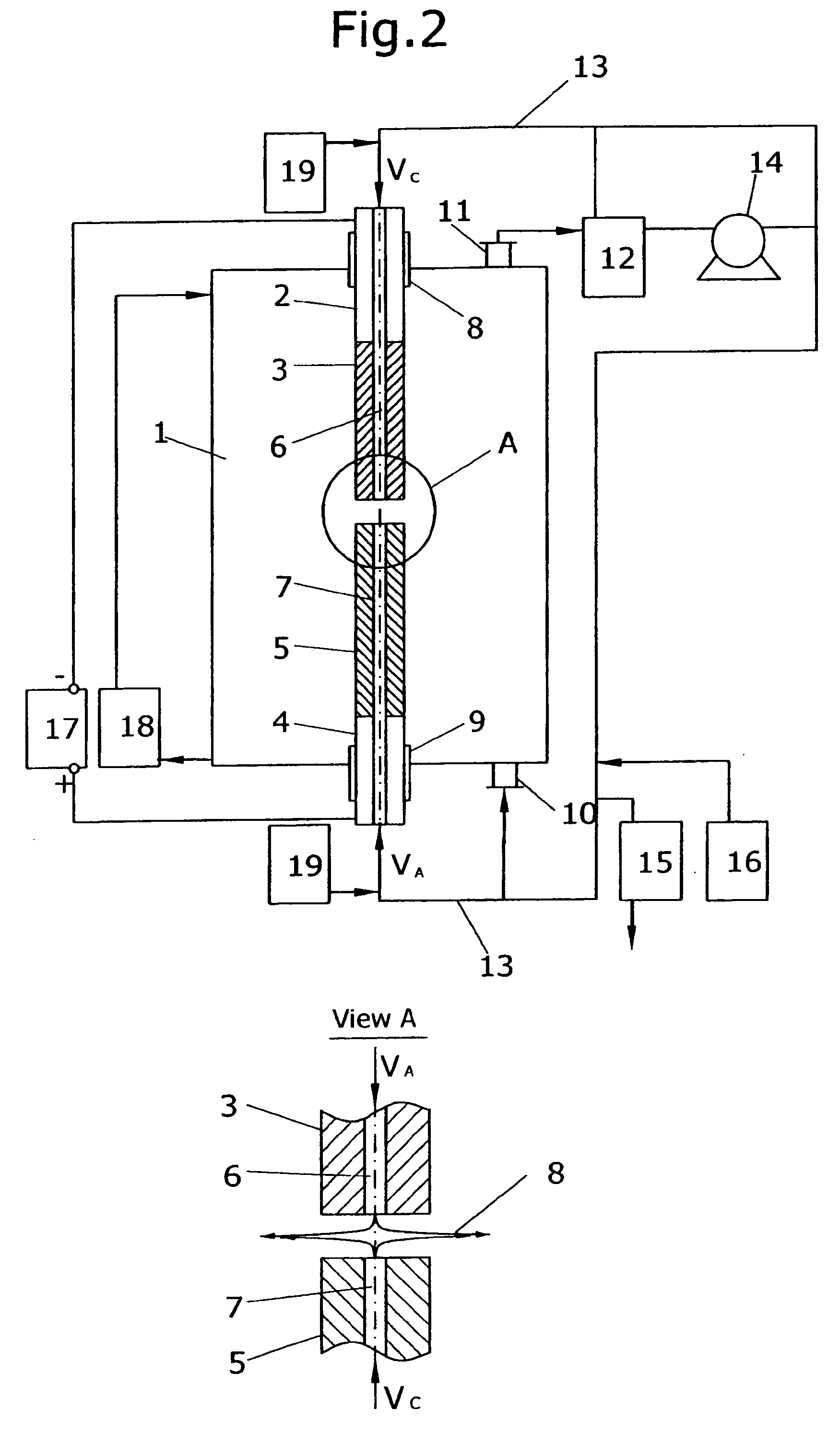

Method and apparatus for carbon allotropes synthesis

InactiveUS20050230240A1Easy and inexpensiveEliminate the problemMaterial nanotechnologyFullerenesOxygenCarbon allotrope

A method and apparatus for synthesis of fullerenes and nanotubes in large quantities at an economical cost from graphite in electric arc plasma process are presented. Different embodiments of channeled graphite electrodes for both direct current (DC) and alternative current (AC) processes are disclosed. High productivity of the carbon allotropes is achieved by feeding consumable graphitic electrode into hot plasma zone, injecting of feedstock, catalyst and buffer gas flow through the longitudinal inner channel electrodes into the hot plasma zone and creating the radial gas outflow in the gap between electrodes, and following removal of produced carbon and catalytic vapors from the hot plasma zone into an oxygen deprived reaction vessel for quenching and condensing. Deposited after condensation soot containing carbon allotropes is collected and carbon allotropes are recovered by known techniques. The final products of recovering are fullerenes C60, C70 and higher fullerenes or nanotubes.

Owner:DUBROVSKY ROMAN +1

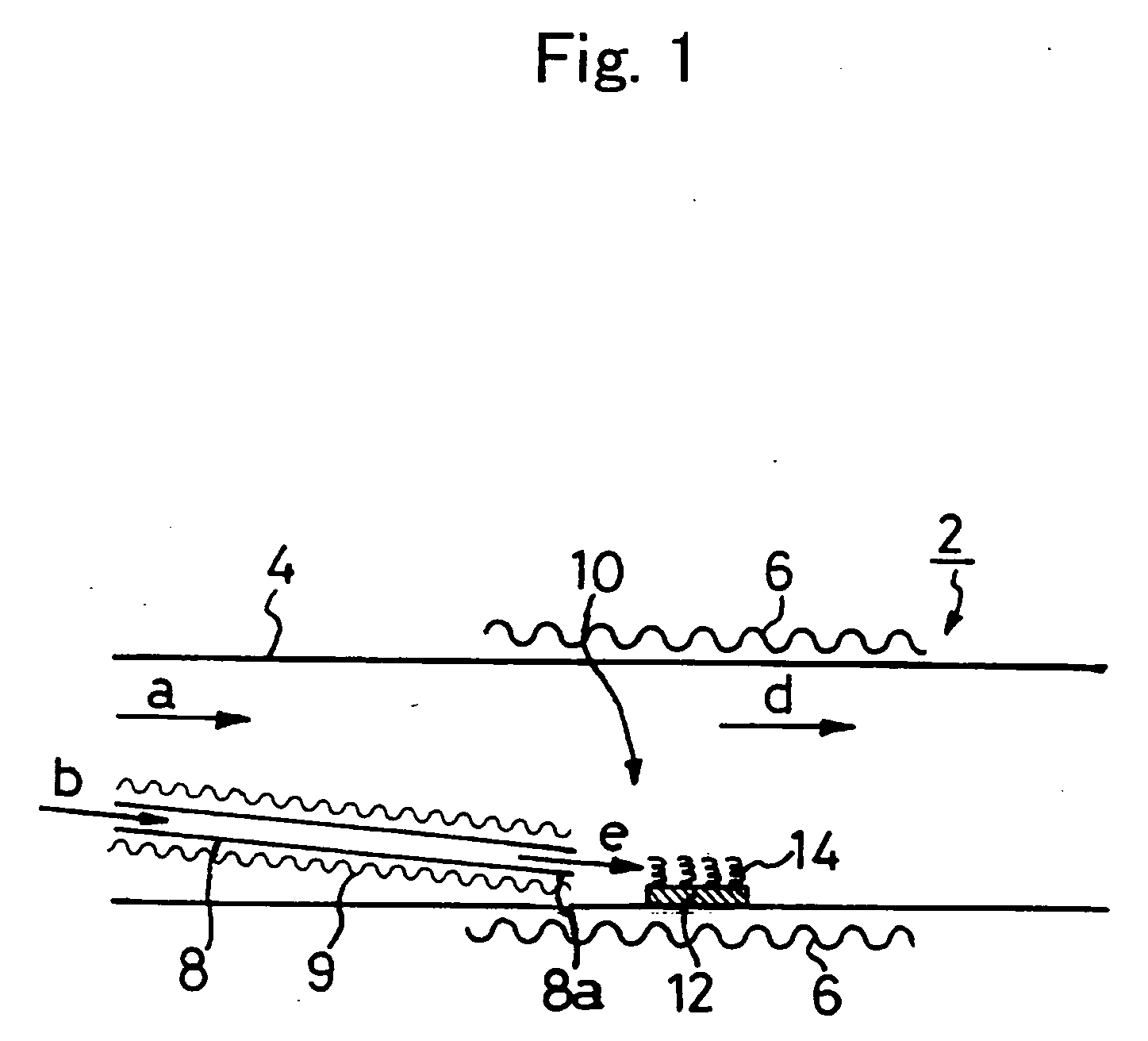

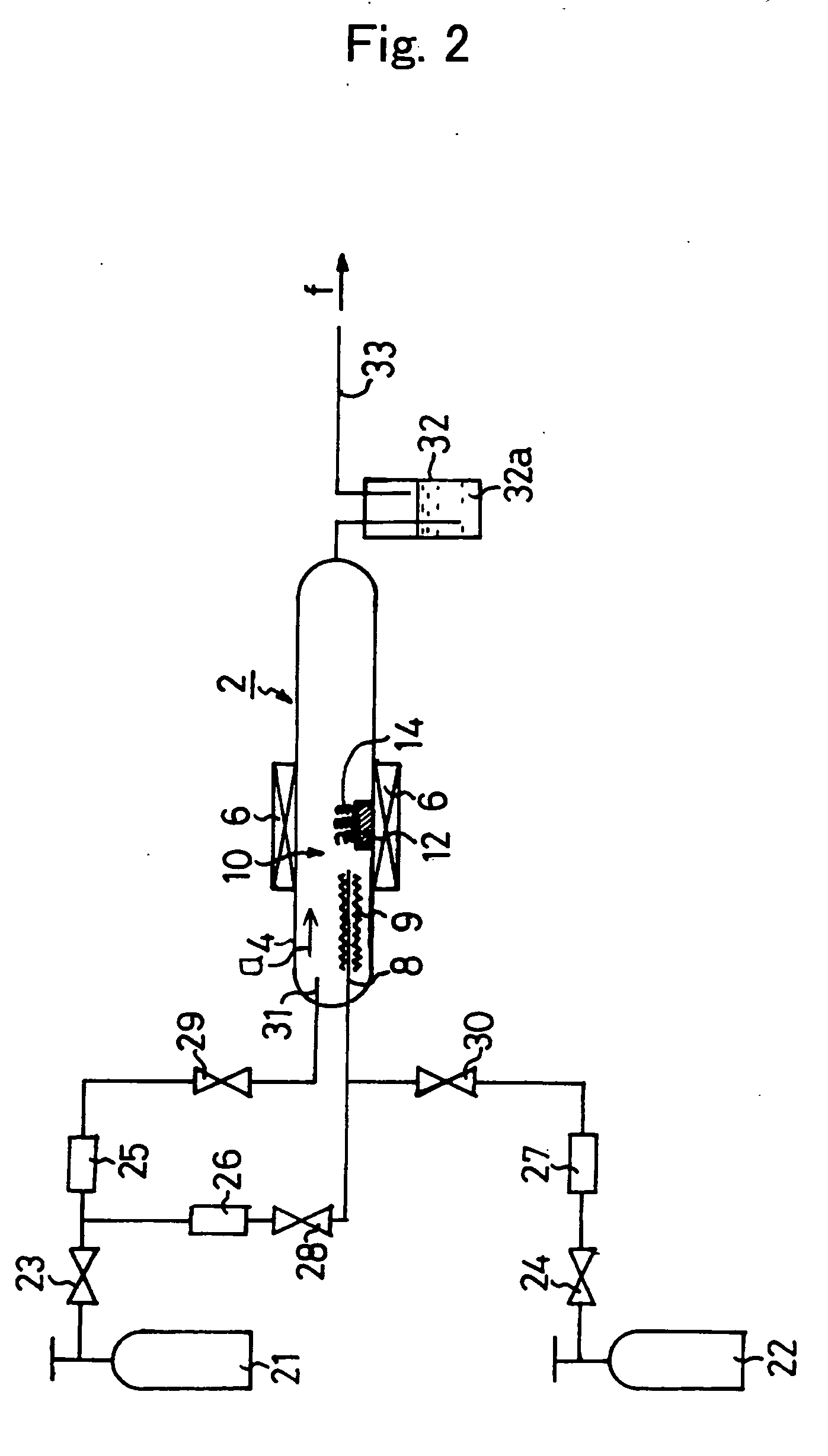

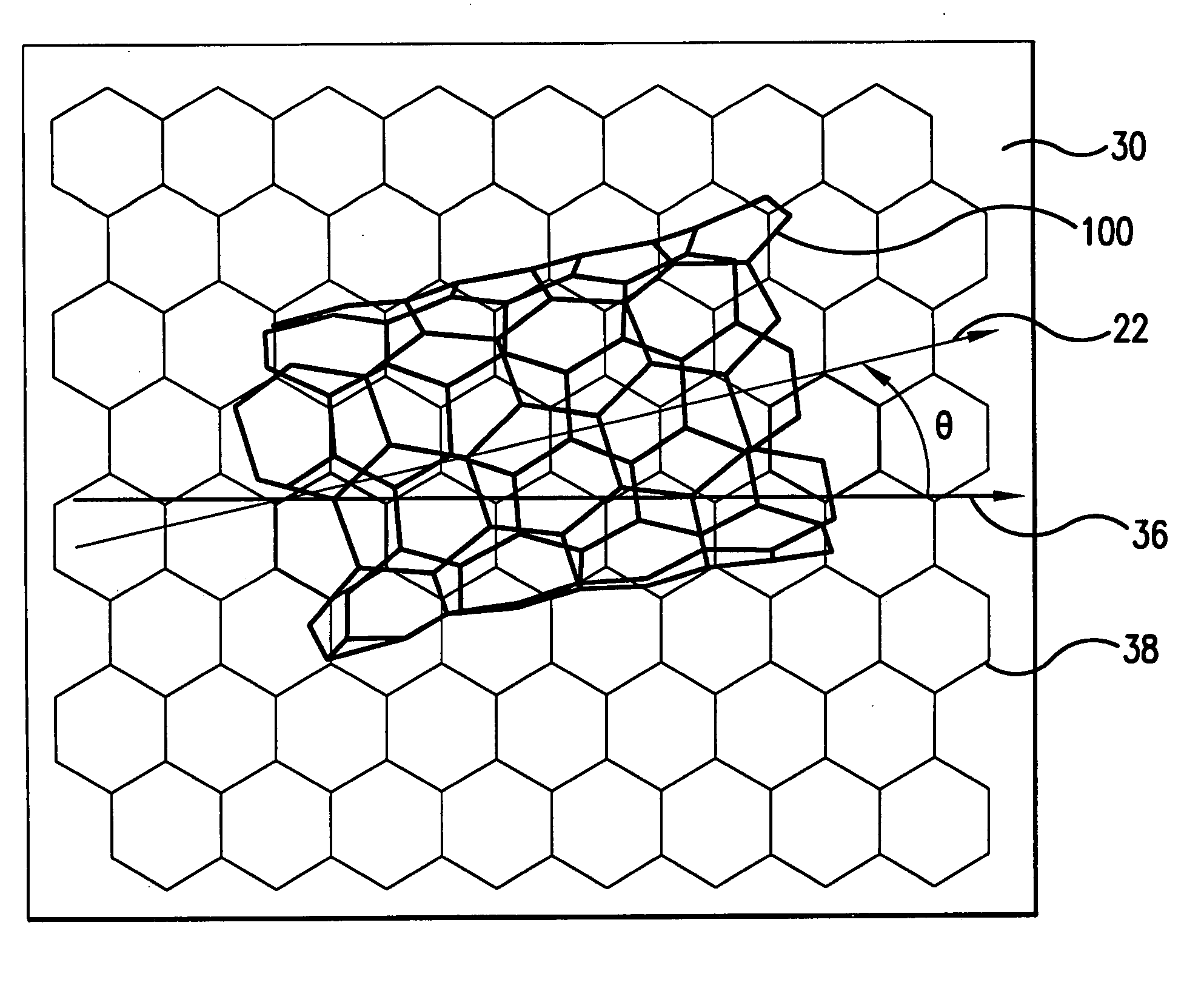

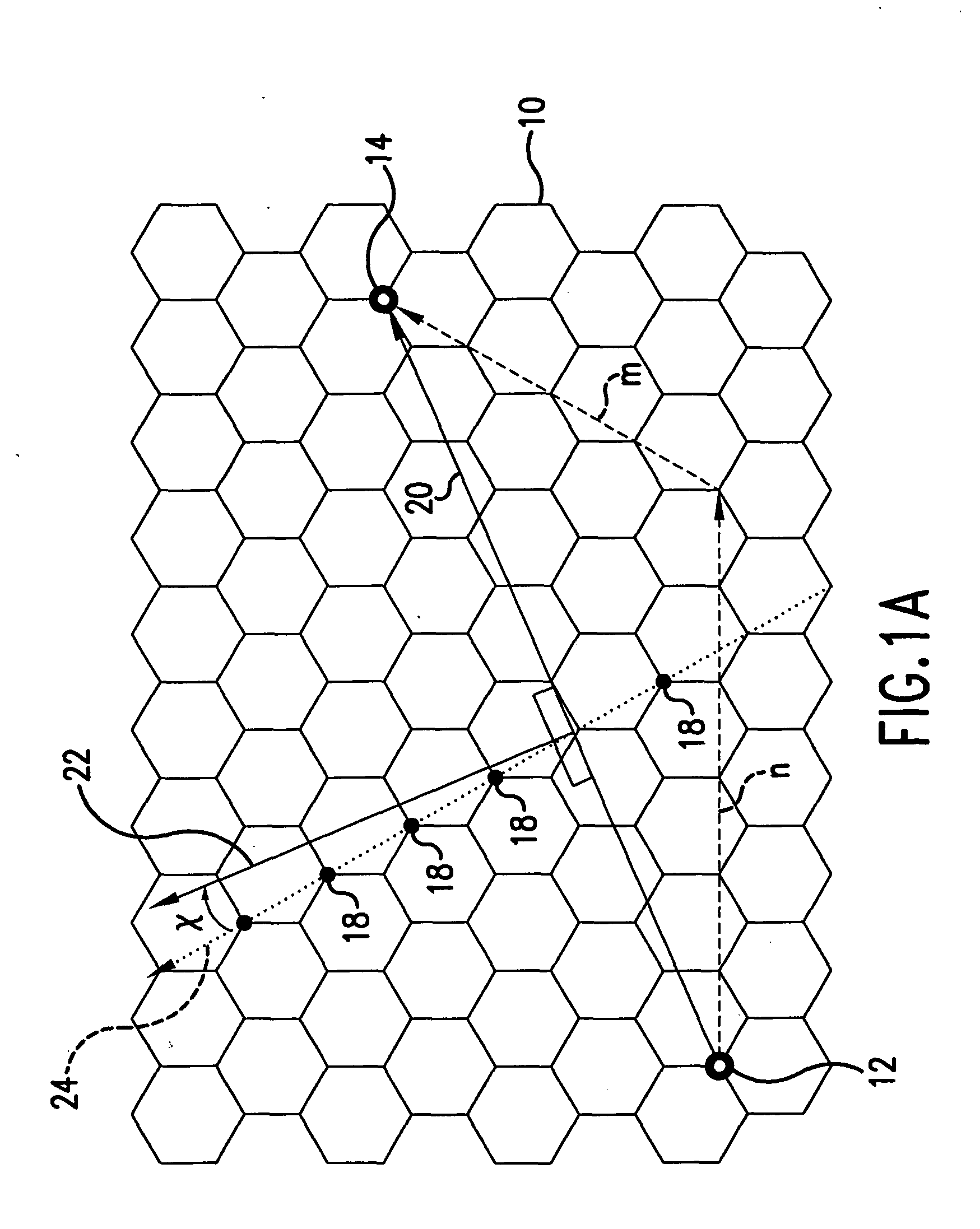

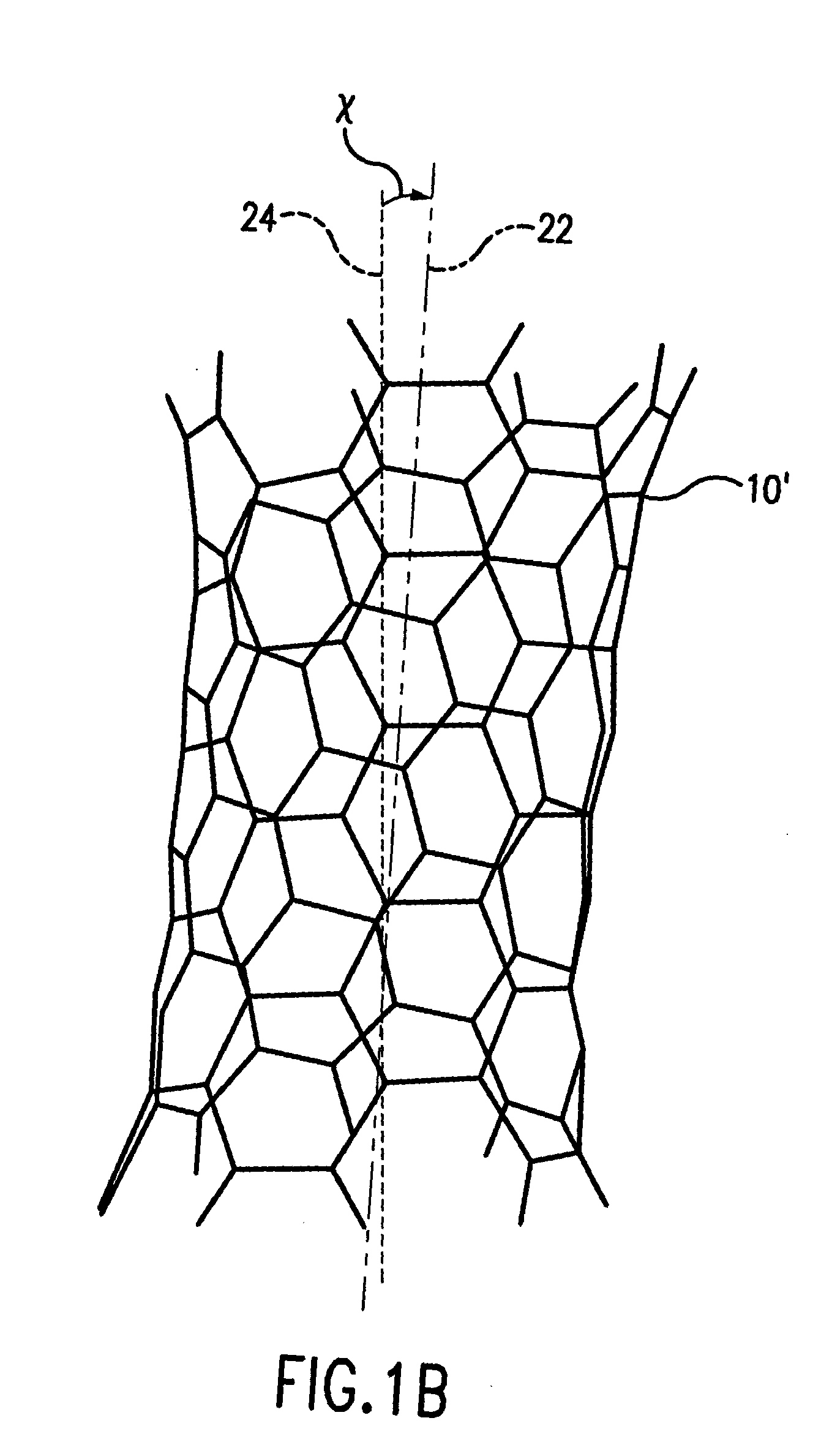

Directed flow method and system for bulk separation of single-walled tubular fullerenes based on helicity

A method for bulk separation of single-walled tubular fullerenes (100) based on helicity is provided wherein a solution or suspension of the single-walled tubular fullerenes (100) is flowed onto a crystalline or highly oriented substrate (30). The single-walled tubular fullerenes (100) that flow onto the substrate (30) have a respective longitudinal axis that is aligned with the flow direction (105). The direction of flow (105) is oriented at a predetermined angle with respect to a lattice axis (24) of the substrate (30) for energetically favoring adsorption of a respective plurality of single-walled fullerenes (100) having a tubular contour and a selected helicity. Subsequently, the adsorbed single-walled tubular fullerenes (100) of the selected chirality are removed from the substrate (30).

Owner:ETHICON INC +2

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com