Patents

Literature

188 results about "Carbon impurities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The carbon adsorbs a wide range of impurities and contaminants, including chlorine, odors, and pigments. Other substances, like sodium, fluoride, and nitrates, are not as attracted to the carbon and are not filtered out.

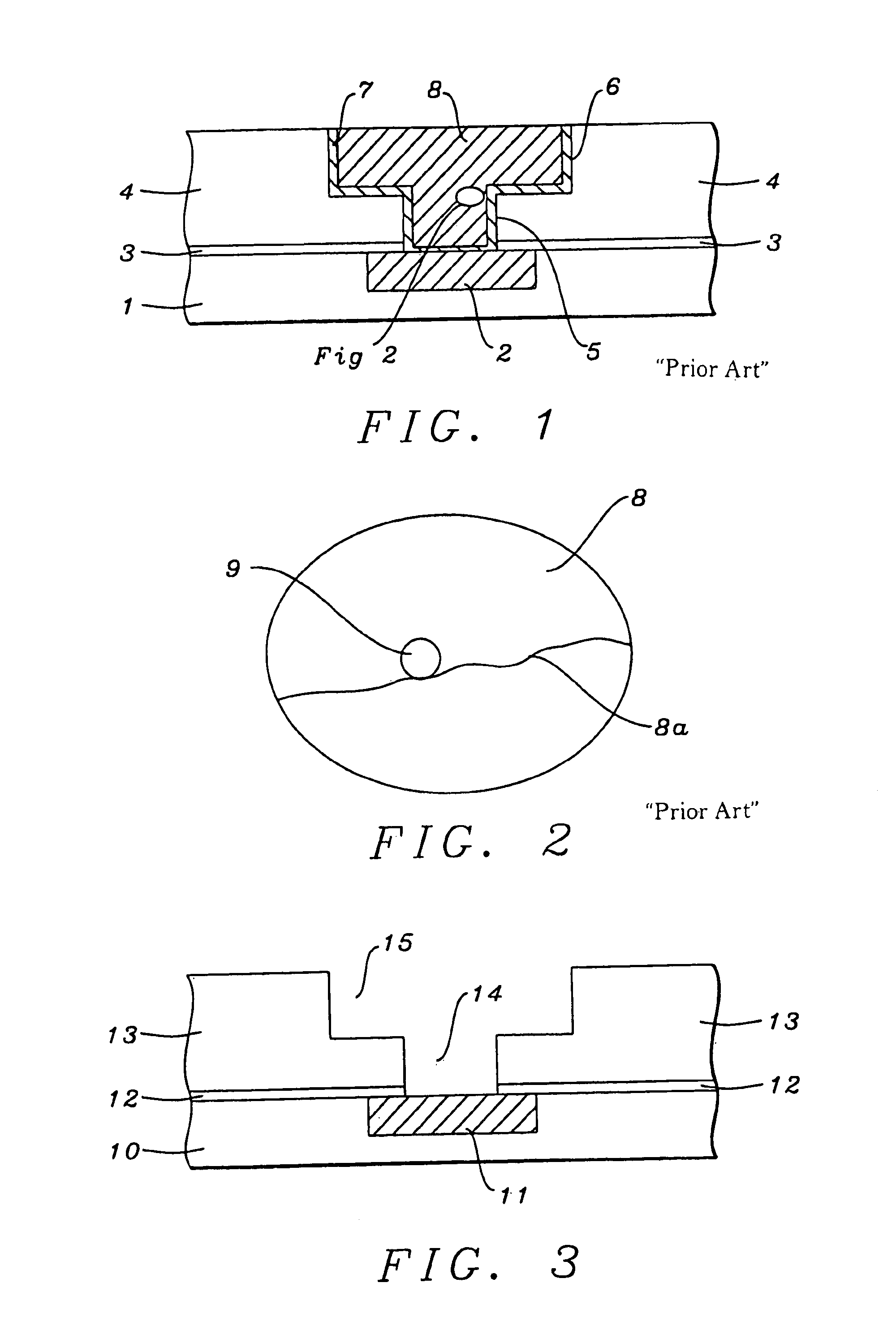

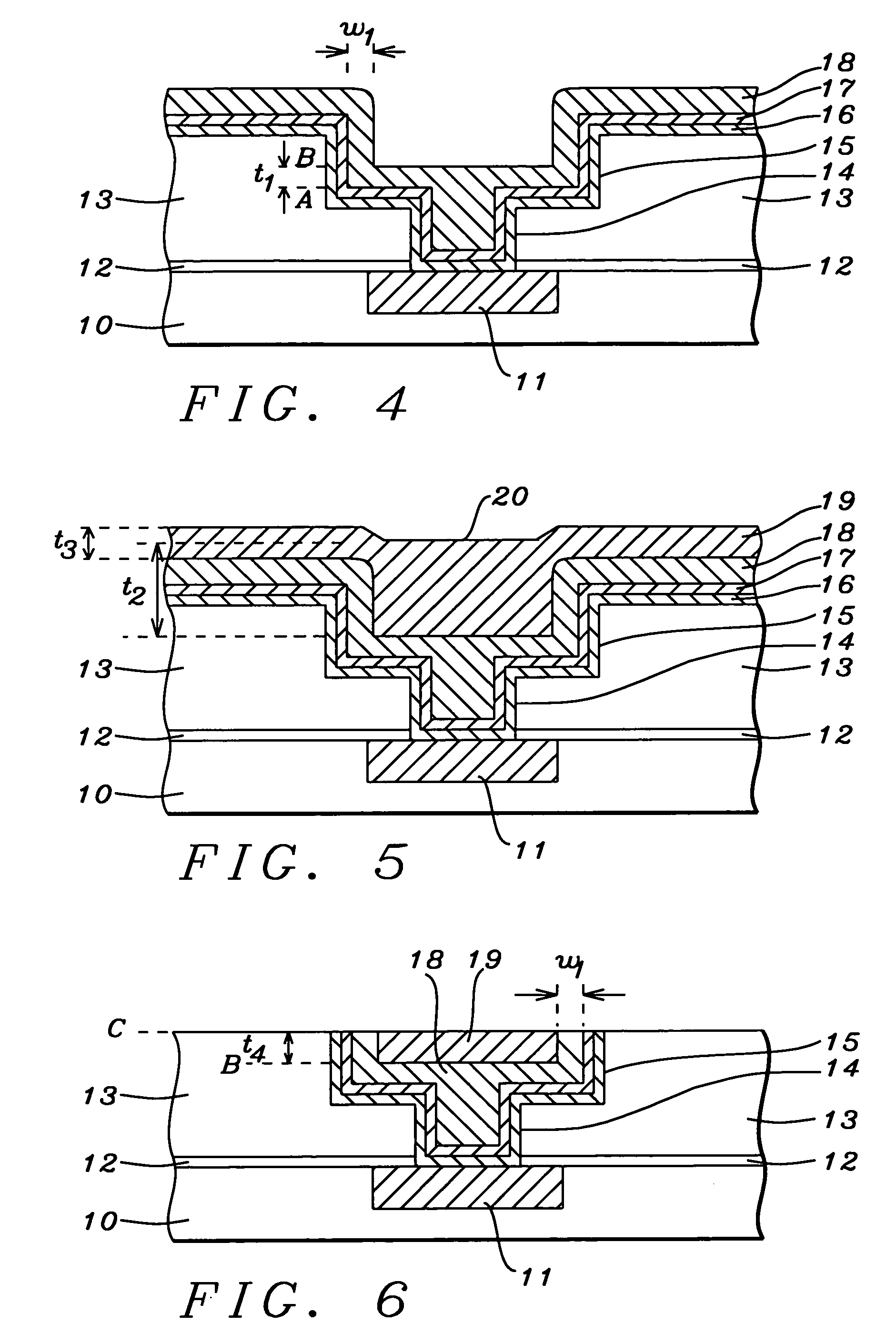

Post ECP multi-step anneal/H2 treatment to reduce film impurity

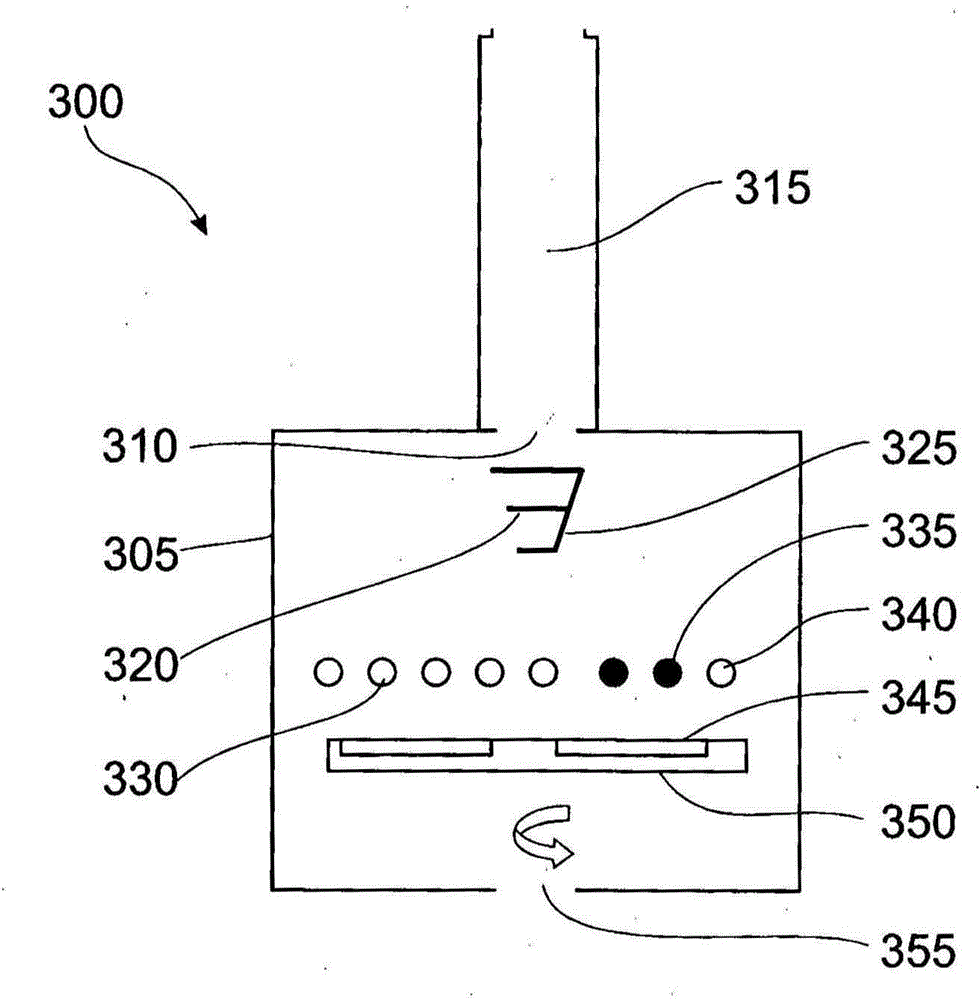

InactiveUS20050227479A1Improve reliabilityReduce defect densitySemiconductor/solid-state device manufacturingCopper interconnectCarbon impurities

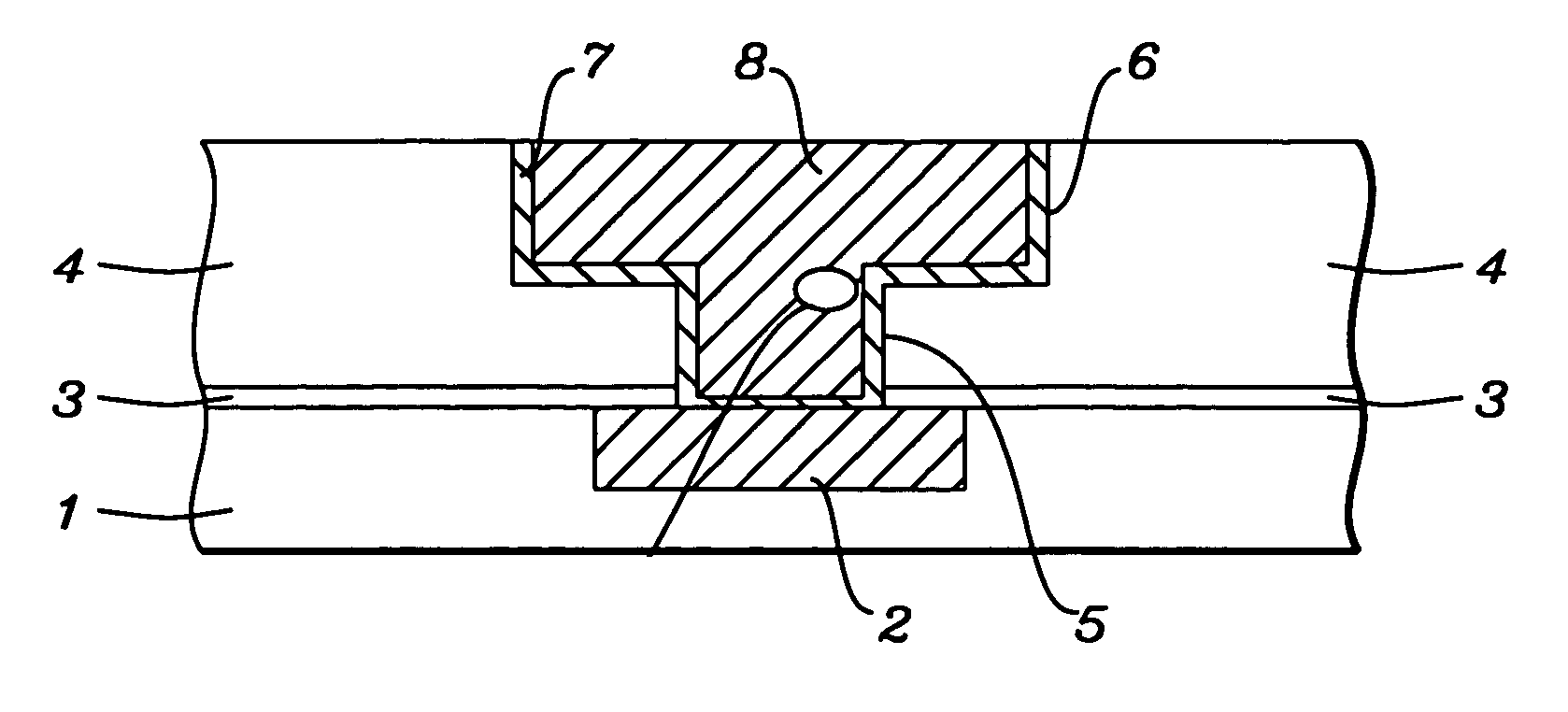

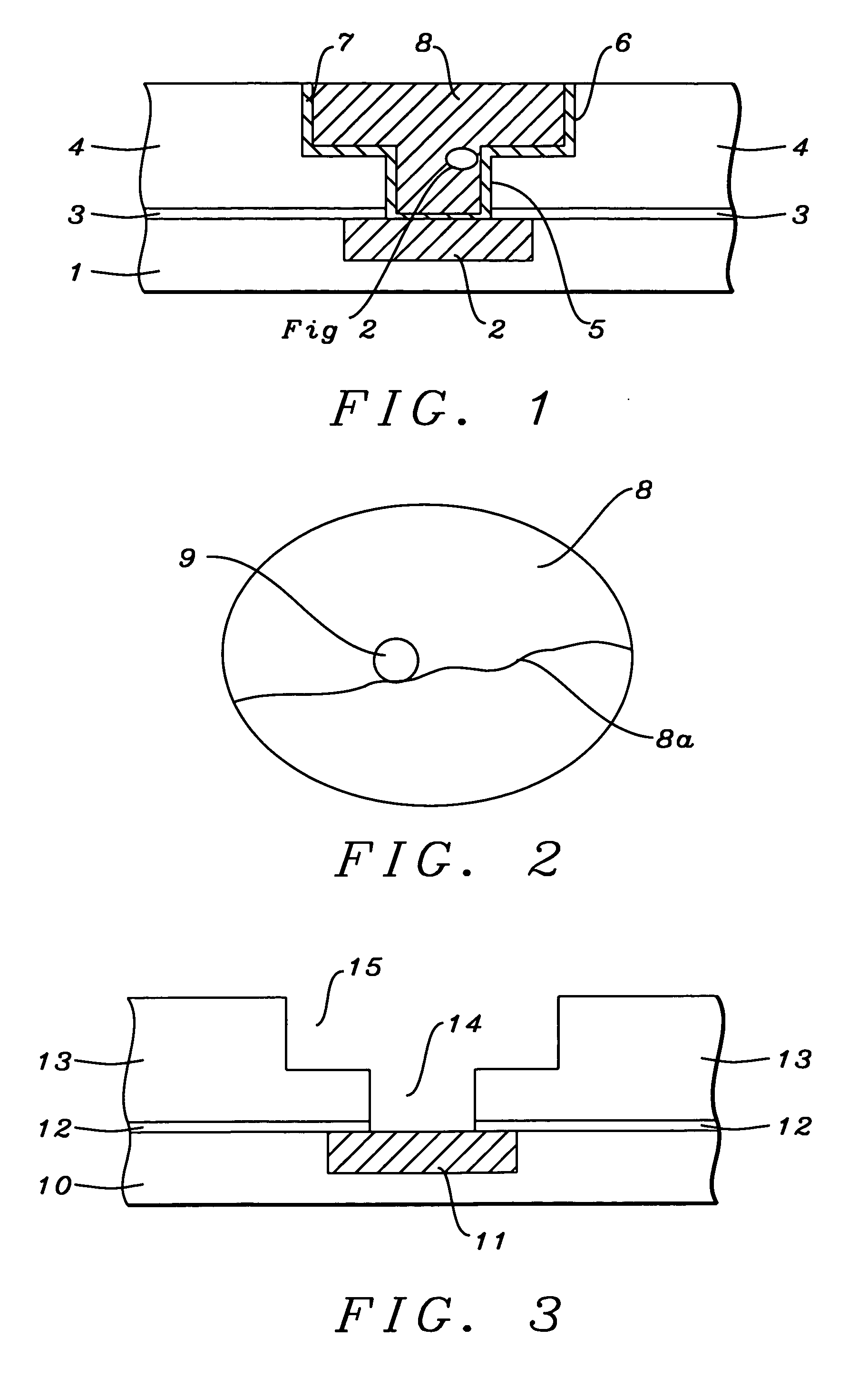

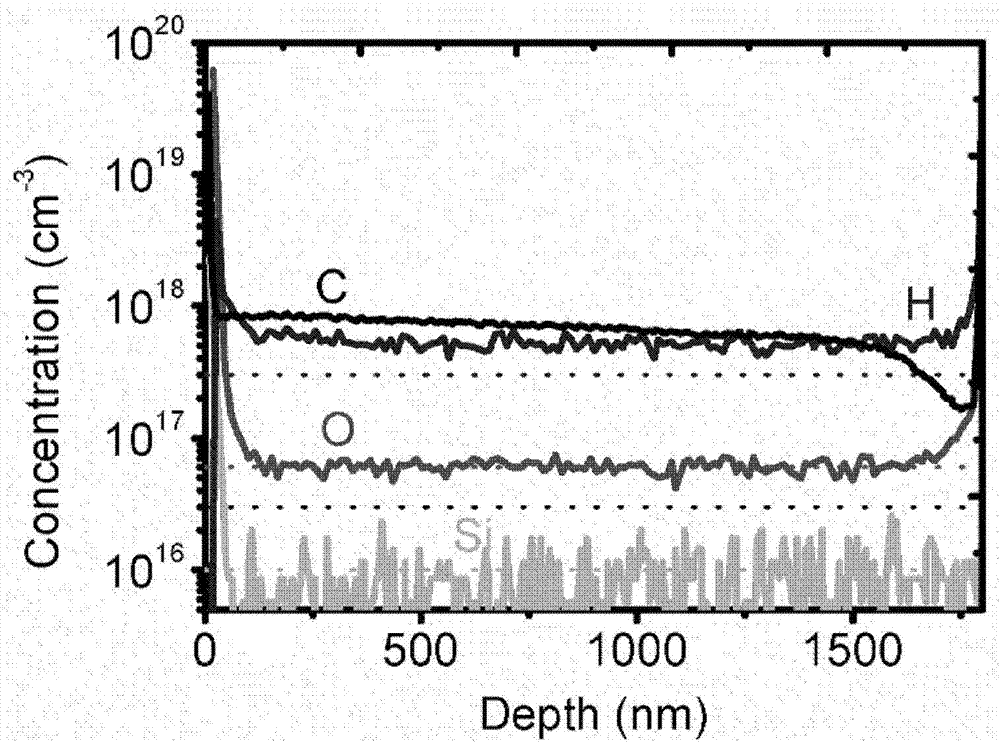

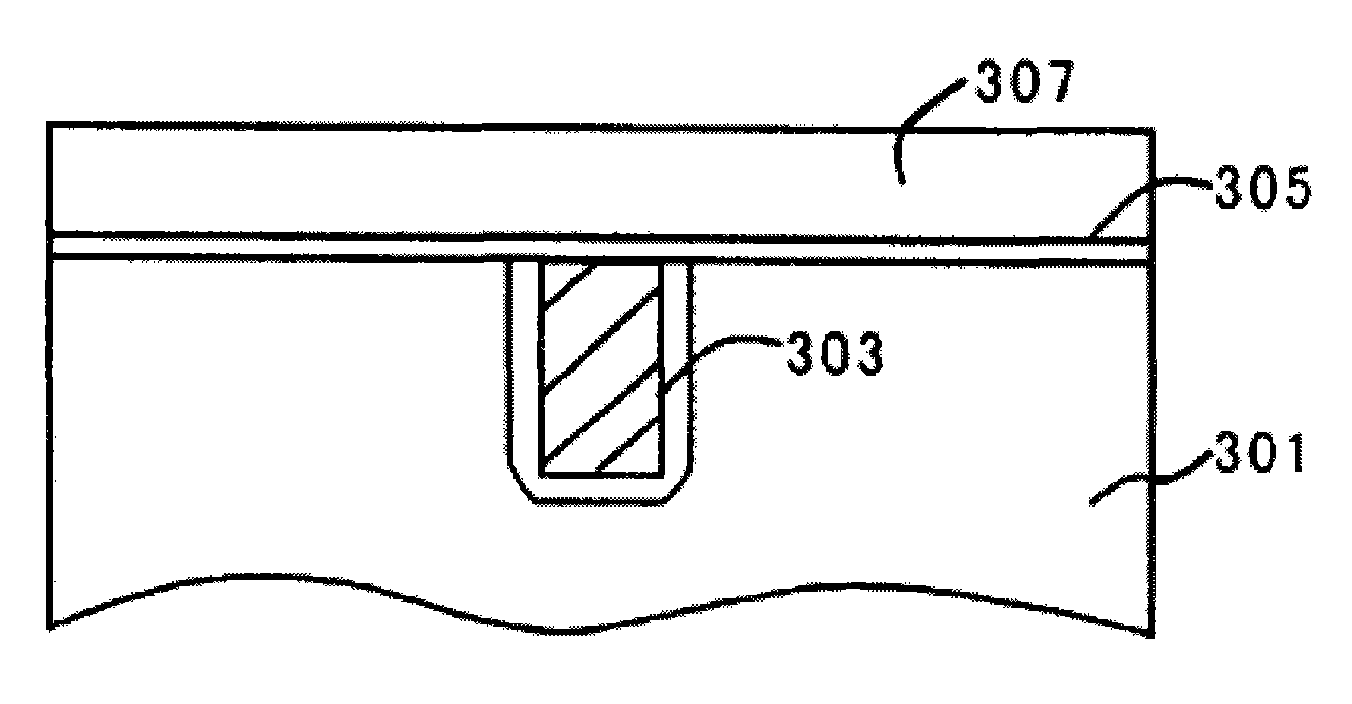

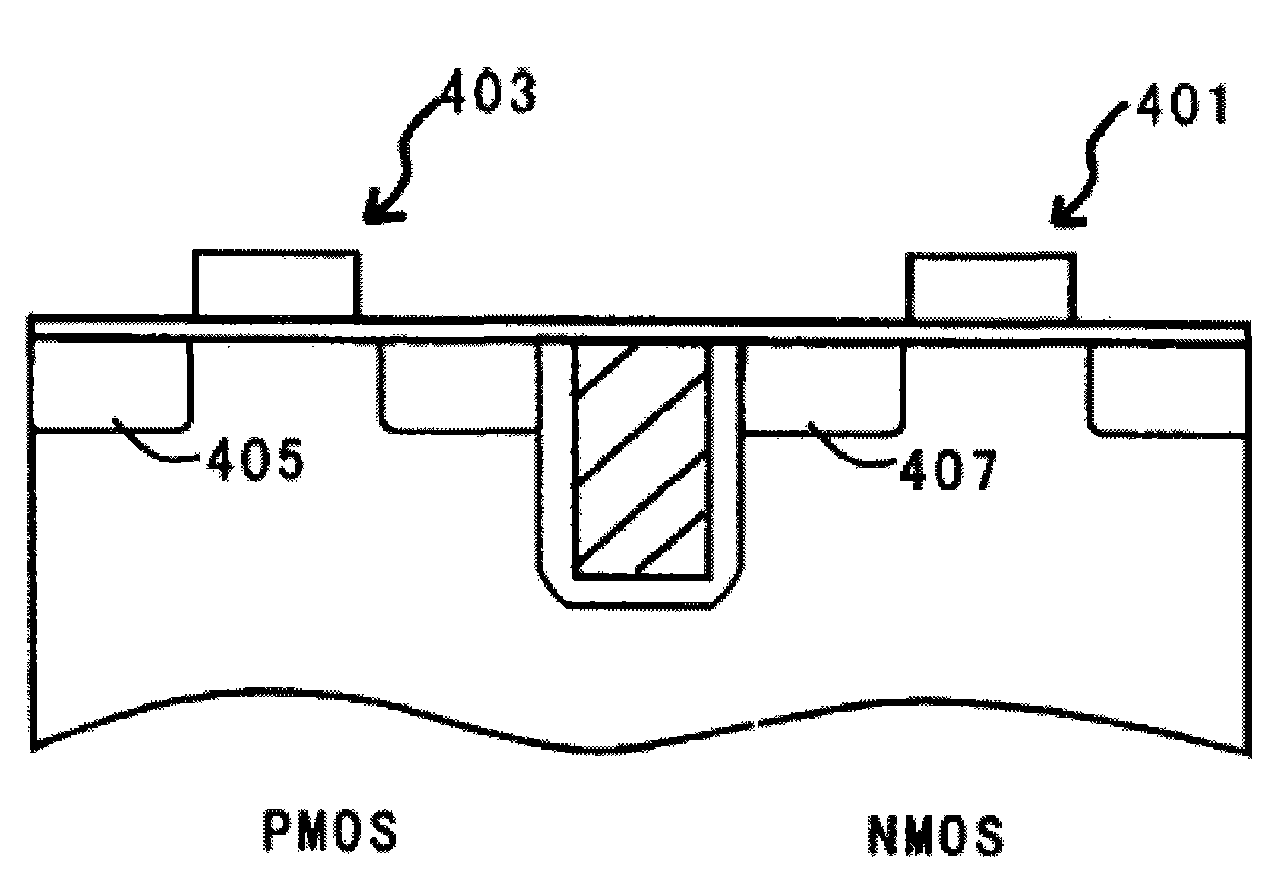

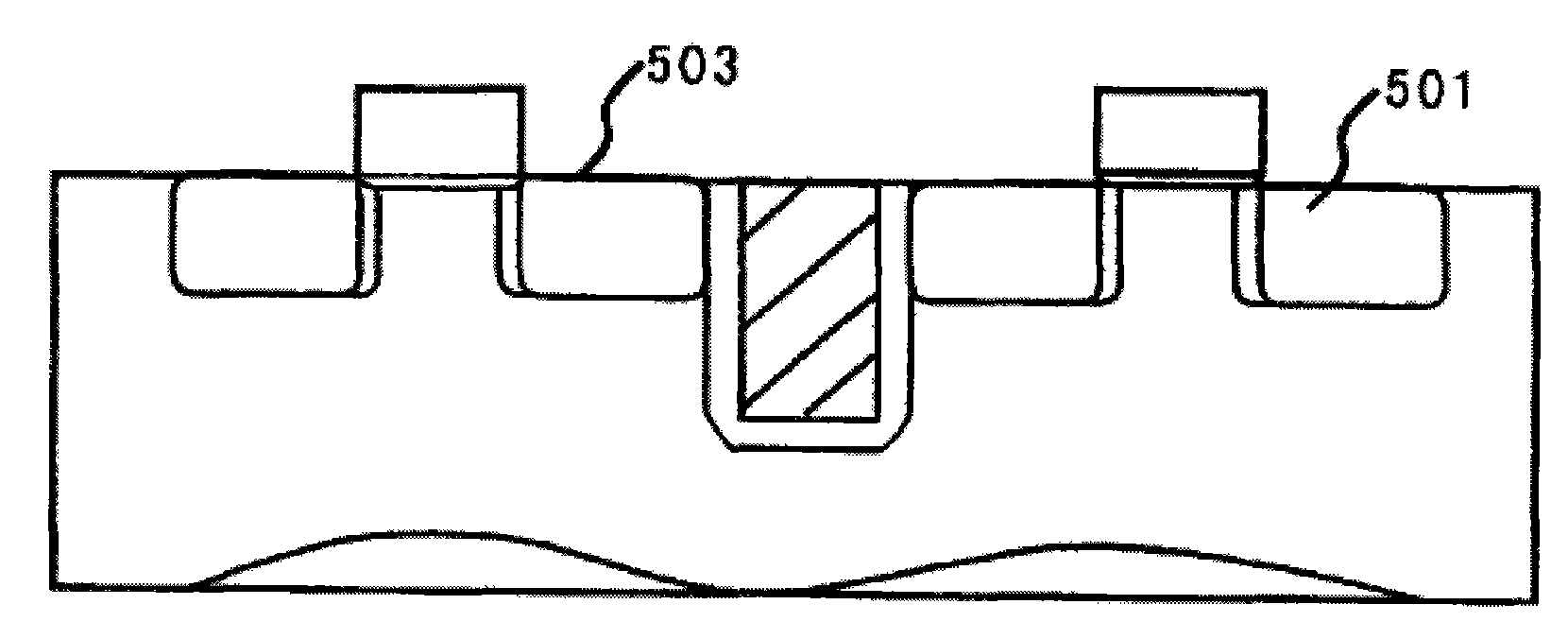

A method of forming a copper interconnect in a dual damascene scheme is described. After a diffusion barrier layer and seed layer are sequentially formed on the sidewalls and bottoms of a trench and via in a dielectric layer, a first copper layer is deposited by a first ECP process at a 10 mA / cm2 current density to fill the via and part of the trench. A first anneal step is performed to remove carbon impurities and optionally includes a H2 plasma treatment. A second ECP process with a first deposition step at a 40 mA / cm2 current density and second deposition step at a 60 mA / cm2 current density is used to deposit a second copper layer-that overfills the trench. After a second anneal step, a CMP process planarizes the copper layers. Fewer copper defects, reduced S, Cl, and C impurities, and improved Rc performance are achieved by this method.

Owner:TAIWAN SEMICON MFG CO LTD

Comprehensive recovery method of waste and old cathode charcoal block of aluminium electrolytic tank

ActiveCN106064813AReduce consumptionShorten the alkaline leaching timeAluminium fluoridesAluminium oxides/hydroxidesRecovery methodElectrolysis

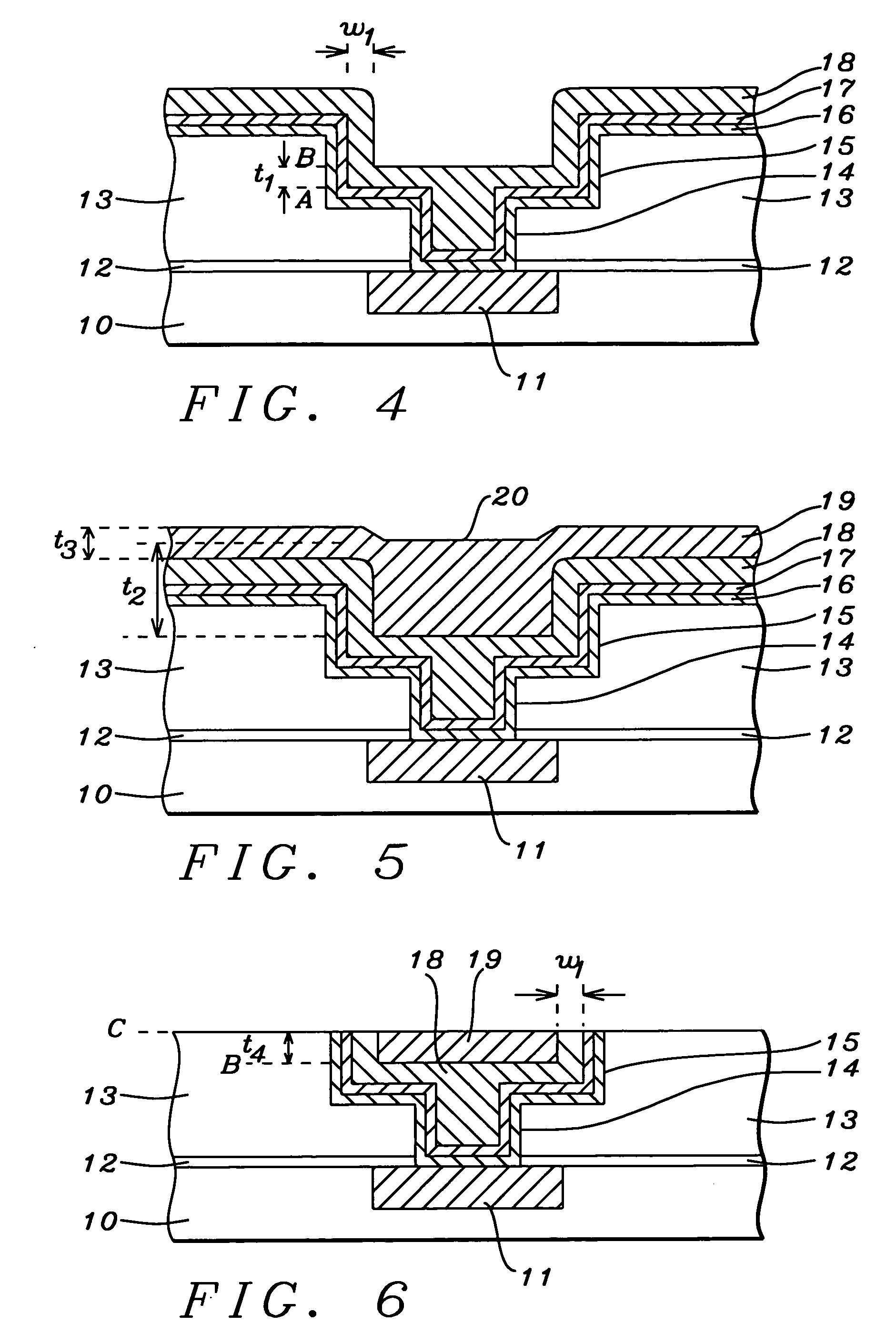

The invention relates to a comprehensive recovery method of waste and old cathode charcoal block of an aluminium electrolytic tank, and belongs to the technical field of comprehensive utilization of industrial solid waste resources. The method is as below: crushing and grinding waste and old cathode charcoal block of the aluminium electrolytic tank at 200-400 DEG C, insulating, removing cyanide, conducting flotation separation on the material with cyanide removed to obtain carbon slag and electrolyte slag, heating the electrolyte slag at 550-800 DEG C to remove carbon impurities, so as to obtain an electrolyte powder, removing to soluble substances in the electrolyte slag by alkali leaching to obtain a carbon powder with high purity, and precipitating a mixture of cryolite and aluminium hydroxide form the alkali leaching liquid by CO2. The invention has the advantages of reasonable process design, simple process, high treatment efficiency, high recovery rate and recycling rate of each material and no secondary pollution, and is applicable to large-scale industrial application.

Owner:CENT SOUTH UNIV

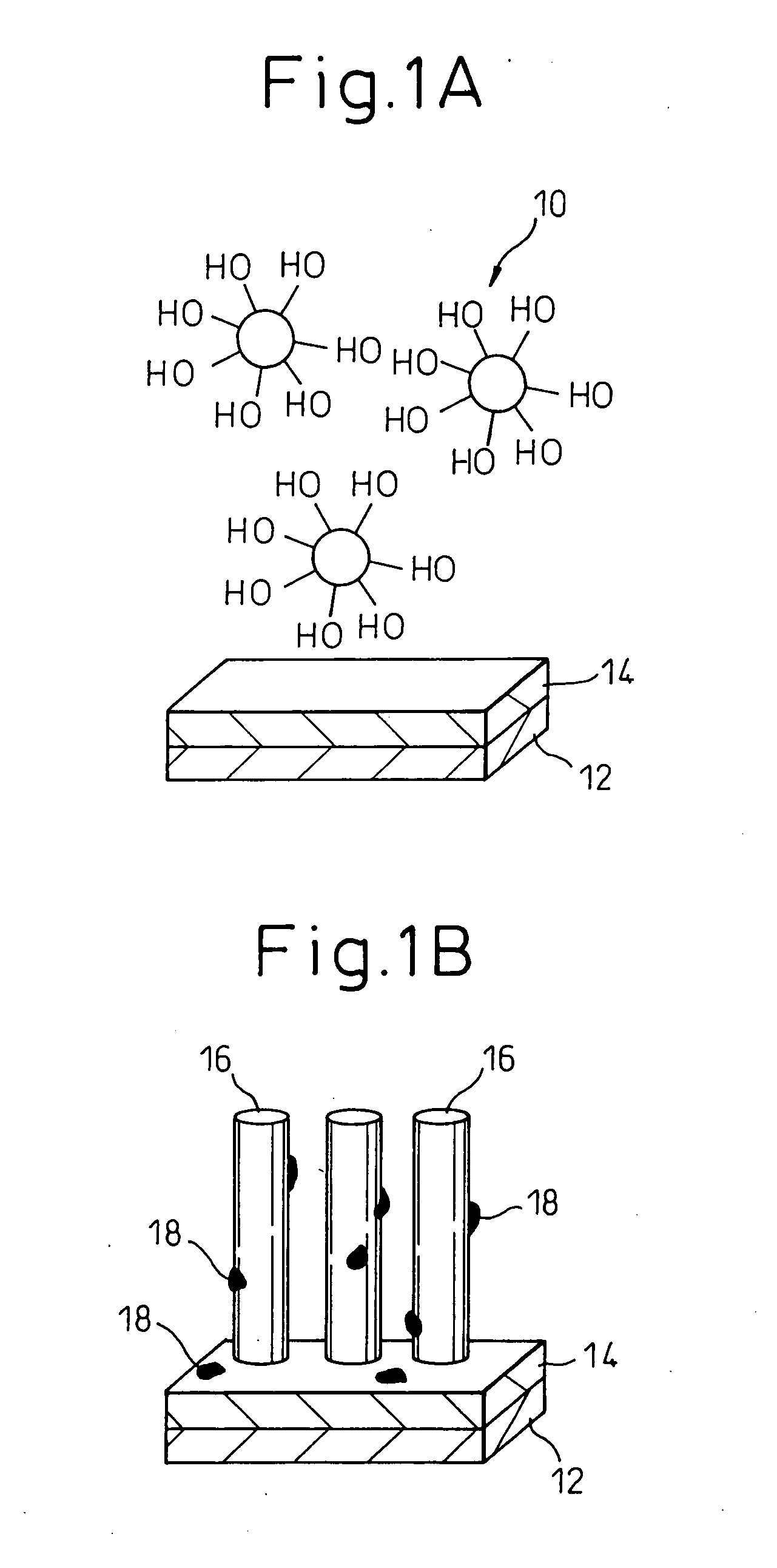

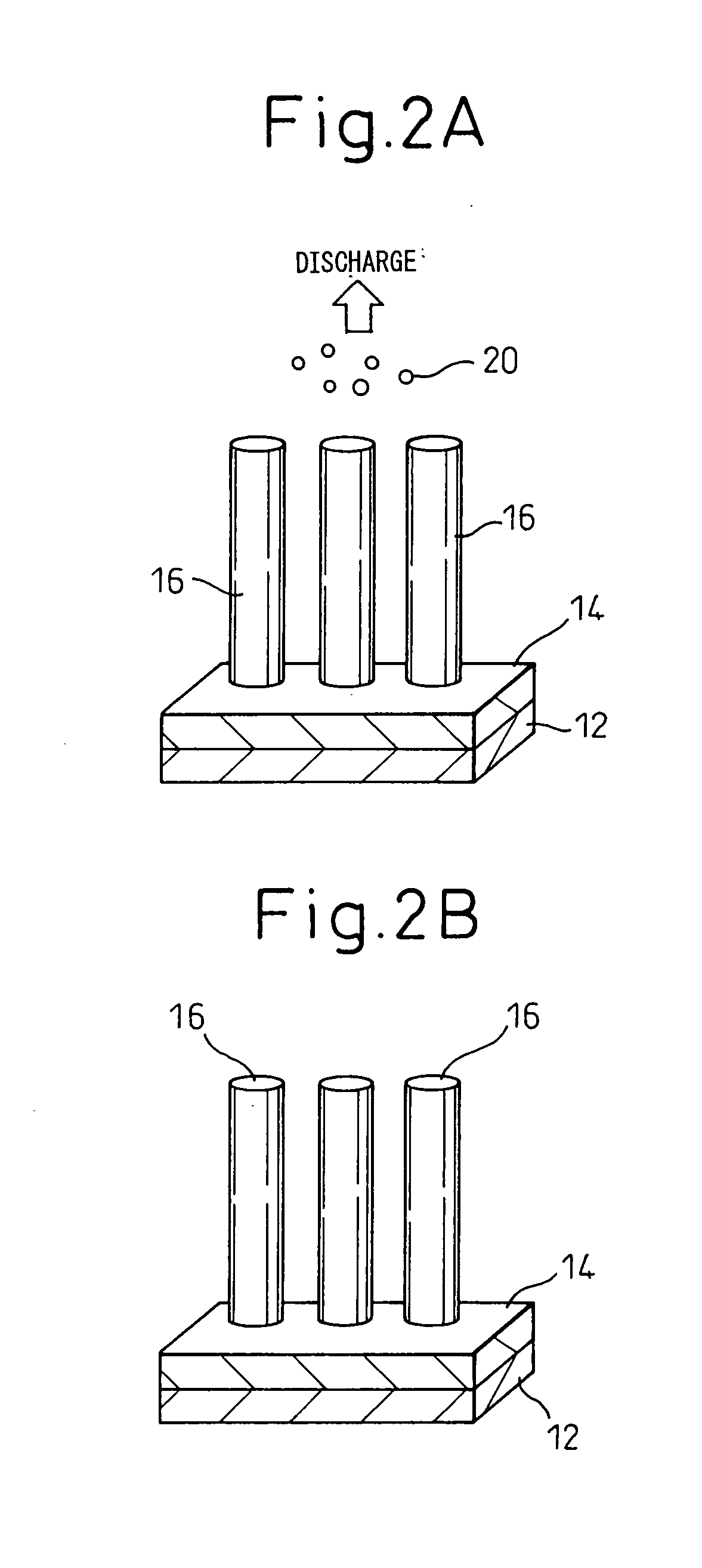

Method of manufacturing carbon nanotubes

A method of manufacturing carbon nanotubes that is capable of growing carbon nanotubes on a substrate by a CVD method without giving rise to residual carbon impurities is provided. The method of manufacturing carbon nanotubes according to the present invention is a method in which carbon nanotubes are grown on a substrate by a chemical vapor deposition (CVD) process using a reaction gas containing a compound for the carbon source, wherein a compound having a carbon skeleton and a functional group which is effective for removing carbon impurities that deposit during the growth of carbon nanotubes is used as the compound for the carbon source.

Owner:FUJITSU LTD

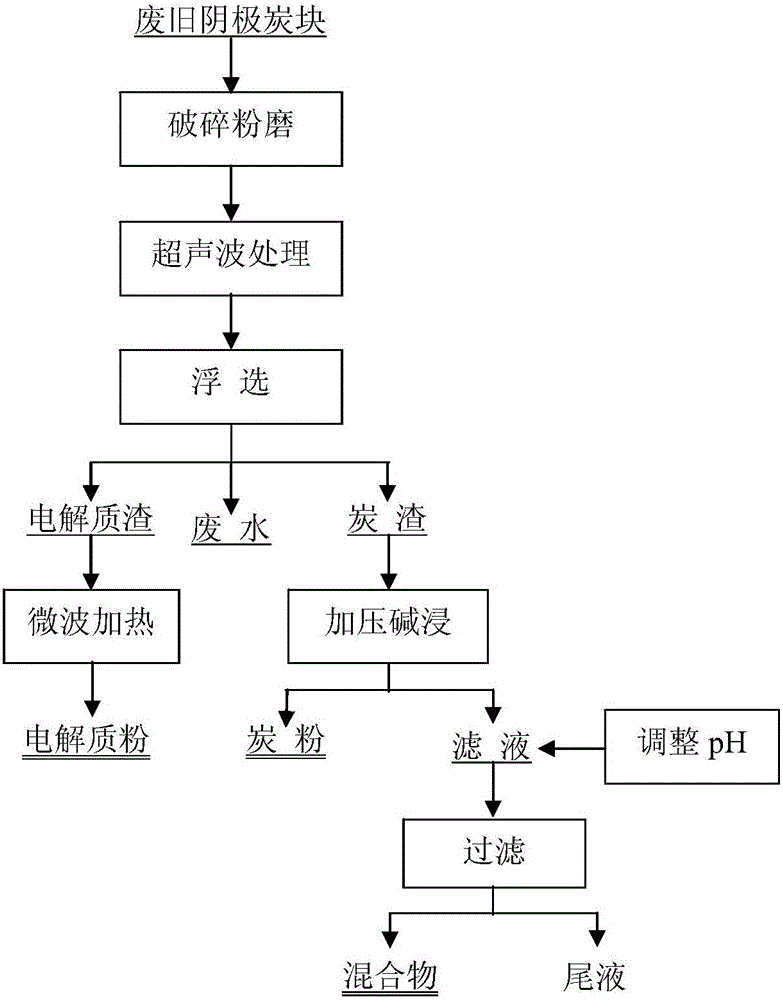

Method for comprehensively recovering aluminum electrolysis waste cathode carbon blocks through ultrasonic-assisted floatation and pressure alkali leaching

ActiveCN106077038AReduce consumptionShorten the alkaline leaching timeSolid waste disposalFiltrationMaterials science

The invention relates to a method for comprehensively recovering aluminum electrolysis waste cathode carbon blocks through ultrasonic-assisted floatation and pressure alkali leaching, and belongs to the technical field of comprehensive utilization of aluminum electrolysis solid waste resources. The method comprises the steps of carrying out ultrasonic pretreatment after crushing and grinding the aluminum electrolysis waste cathode carbon blocks, carrying out floatation on pretreated powder to obtain electrolyte residues and carbon residues, and reusing the wastewater of floatation; removing carbon impurities after the electrolyte residues are subjected to microwave heating to obtain electrolyte powder with high purity, and carrying out pressure alkali leaching on the carbon residues to remove solvend so as to obtain carbon powder with high purity; adjusting the pH of alkali leaching filter liquor to generate sediment, carrying out filtration to obtain electrolyte, and reusing the filter liquor. According to the method, through collaborative assistance action among the ultrasonic pretreatment technology, the microwave heating technology and the pressure alkali leaching technology, the high-efficiency comprehensive recycling of aluminum electrolysis waste cathodes is achieved. The method for comprehensively recovering aluminum electrolysis waste cathode carbon blocks through ultrasonic-assisted floatation and pressure alkali leaching is reasonable in technological design, high in recovery rate of valuable matter, purity of obtained products and processing speed, free of secondary pollutants and applicable to industrial large-scale application.

Owner:CENT SOUTH UNIV

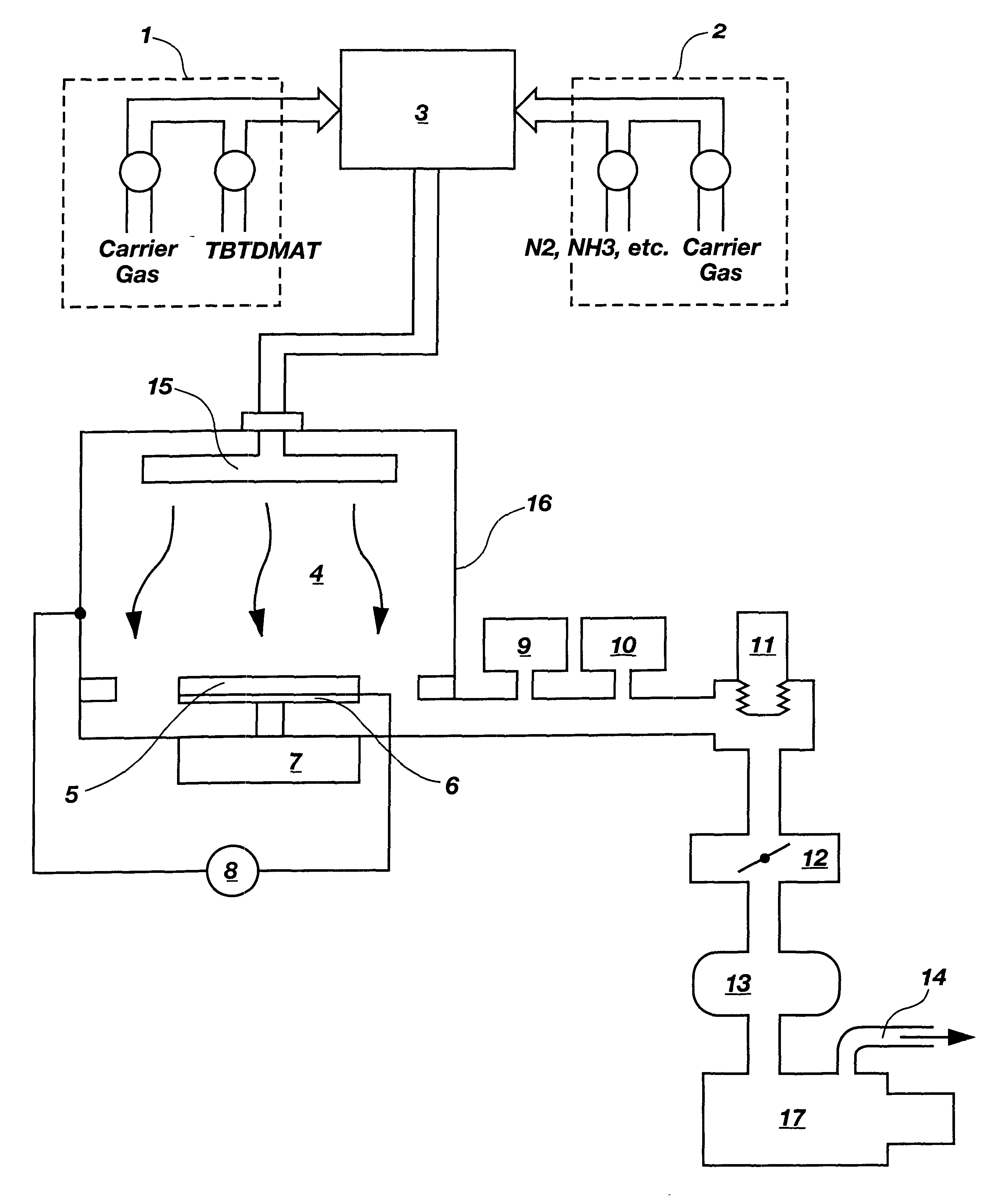

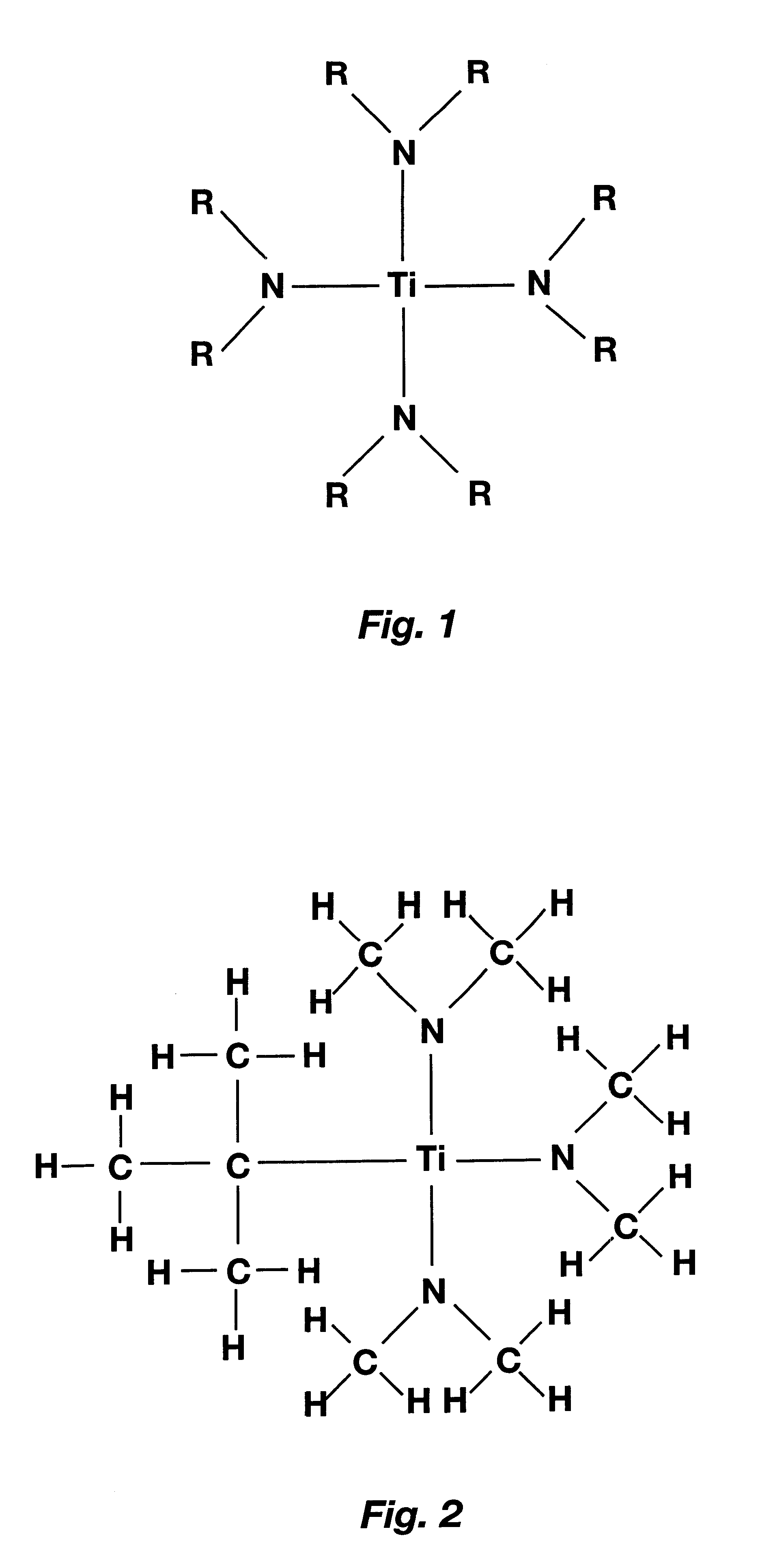

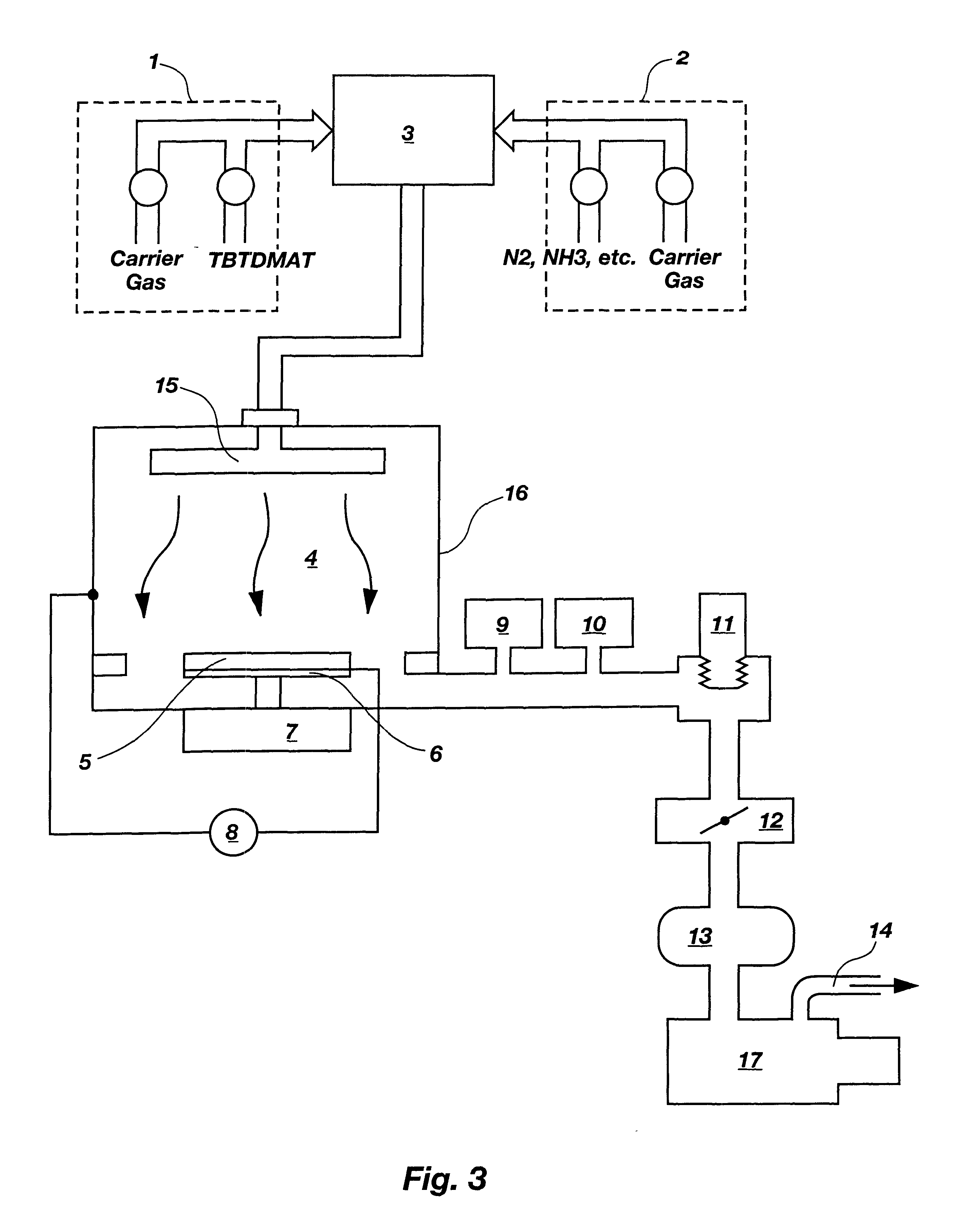

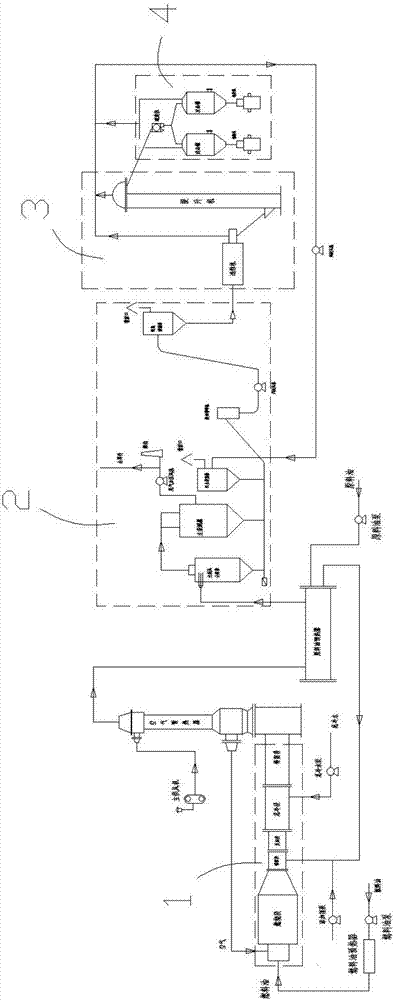

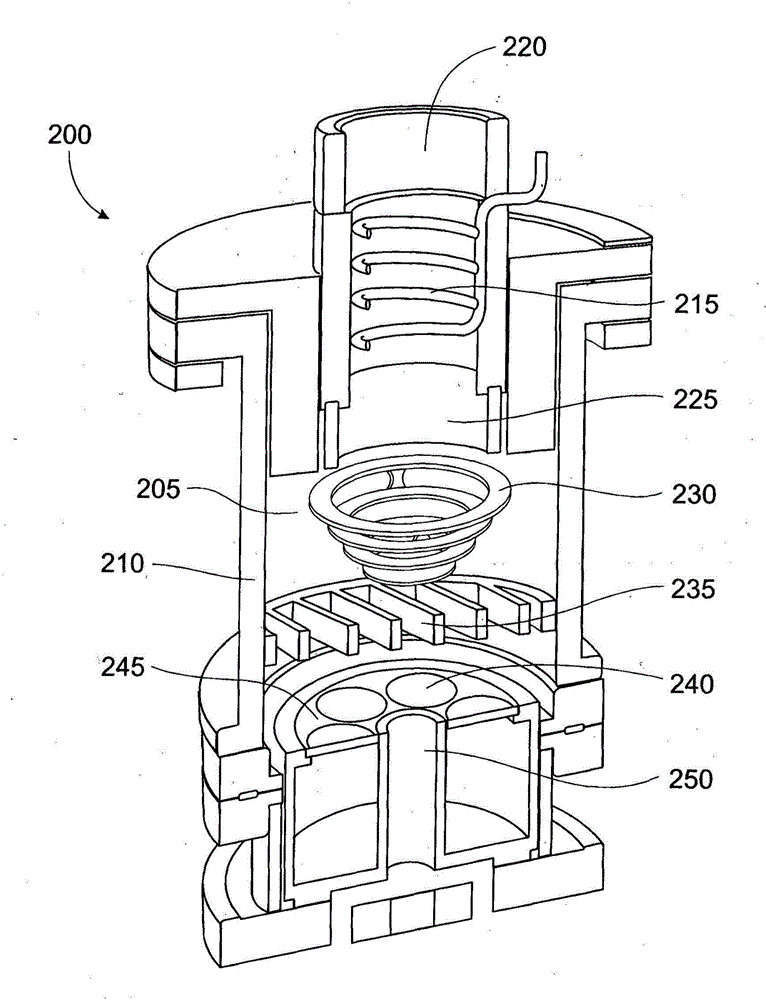

Chemical vapor deposition process for depositing titanium nitride films from an organometallic compound

InactiveUS6338880B1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseHydrazine compound

A process for depositing titanium nitride films containing less than 5% carbon impurities and less than 10% oxygen impurities by weight via chemical vapor deposition is disclosed. Sheet resistance of the deposited films is generally be within a range of about 1 to 10 ohms per square. The deposition process takes place in a deposition chamber that has been evacuated to less than atmospheric pressure and utilizes the organometallic compound tertiary-butyltris-dimethylamido-titanium and a nitrogen source as precursors. The deposition temperature, which is dependent on the nitrogen source, is within a range of 350° C. to 700° C. The low end of the temperature range utilizes nitrogen-containing gases such as diatomic nitrogen, ammonia, hydrazine, amides and amines which have been converted to a plasma. The higher end of the temperature range relies on thermal decomposition of the nitrogen source for the production of reaction-sustaining radicals. In such a case, the use of diatomic nitrogen gas is precluded because of its high dissociation temperature. Other materials may be simultaneously incorporated in the titanium nitride films during either embodiment of the deposition process as heretofore described. For example, a titanium nitride film incorporating aluminum and having the general formula TiAIN may be deposited by introducing aluminum-containing compounds. Additionally, a titanium nitride film incorporating tungsten and having the general formula TiNW may be deposited by introducing tungsten-containing compounds.

Owner:MICRON TECH INC

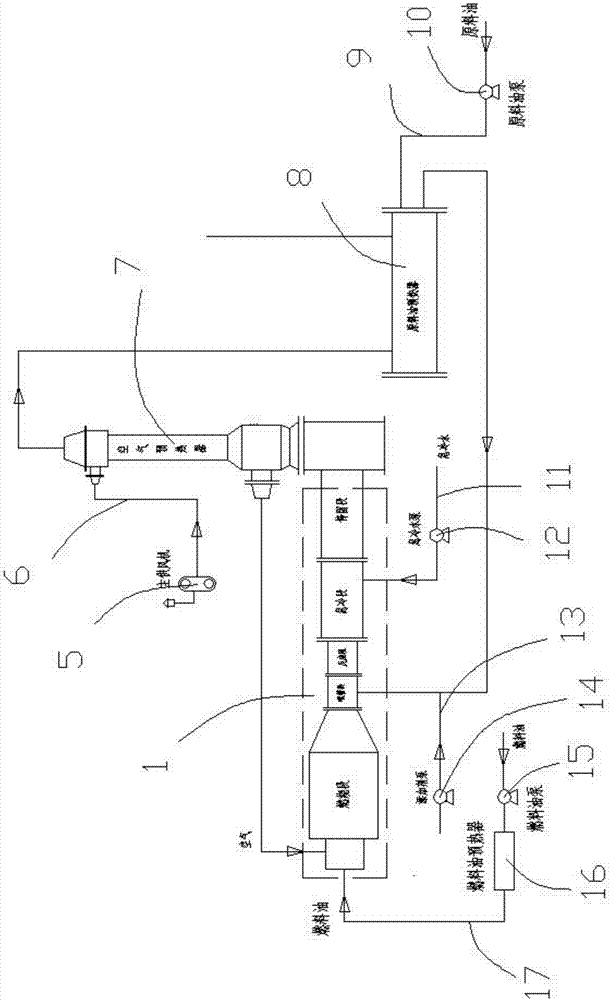

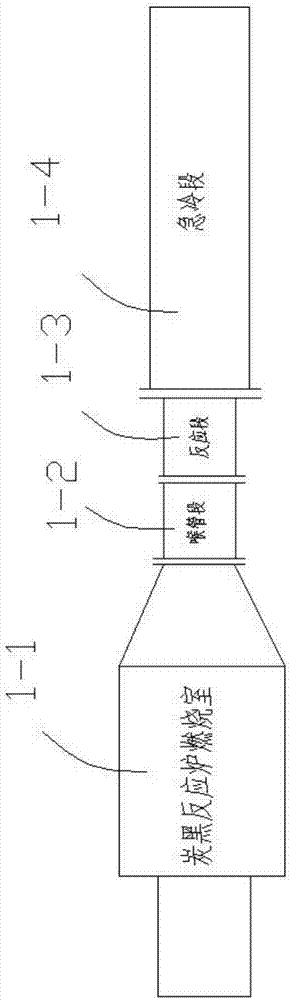

Production system and process of pigment carbon black with low impurity content

The invention discloses a production system and process of pigment carbon black with low impurity content and relates to the field of production of carbon black. The production system comprises a raw material supply device, a reaction device, pre-heating devices, a collection device, a granulation device and a storage and packaging device, wherein air, raw oil and fuel oil enter the reaction device from the respective pre-heating devices; carbon black flue gas passing through the reaction device is used for pre-heating the air and the raw oil and sequentially enters the collection device, the granulation device and the storage and packaging device to finish carbon black collection; in the production process, the raw oil passes through four paths of filtering devices in advance; before an additive is blended, the raw oil is pre-dissolved with water; quenched water needs to be purified; an ultrafine grinding device is arranged in the collection device; the content of non-carbon impurities in a production process is effectively reduced and the purity of the pigment carbon black is improved; advanced equipment and process technology are adopted so that the aim of reducing the content of the impurities in a carbon black finished product is realized.

Owner:四川博蓝科新材料有限公司

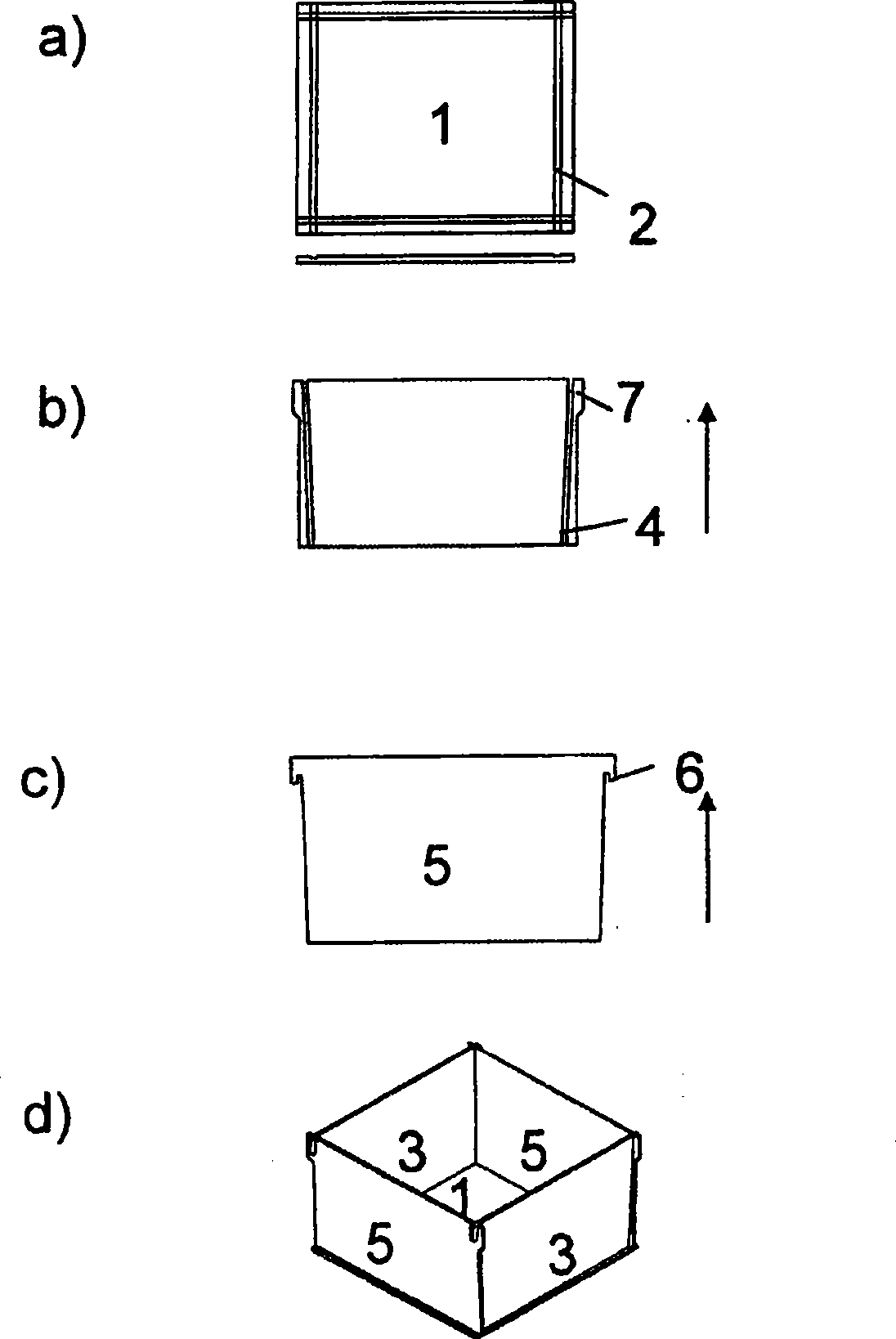

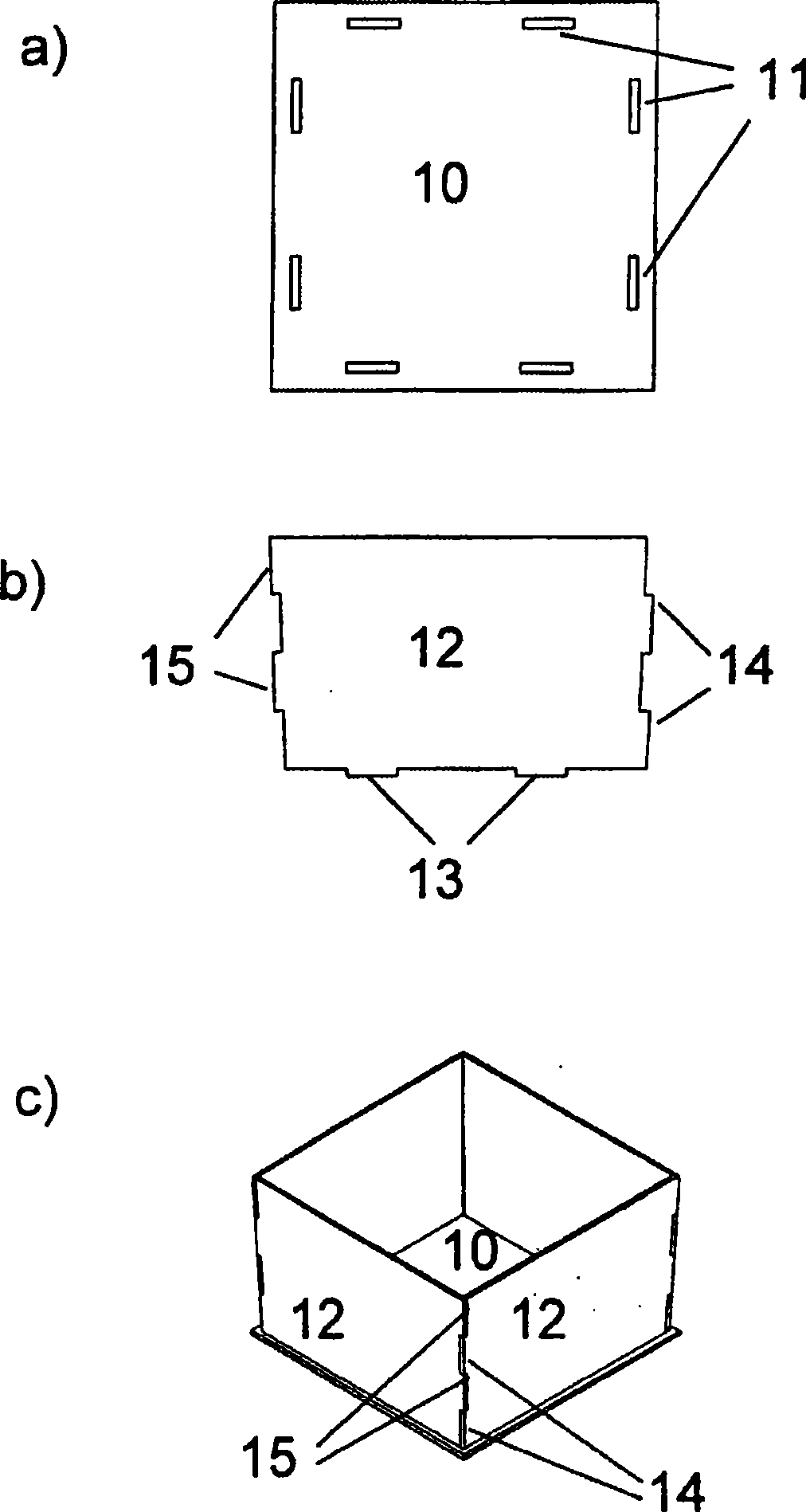

Method and crucible for direct solidification of semiconductor grade multi-crystalline silicon ingots

InactiveCN101479410AQuality improvementPolycrystalline material growthFrom frozen solutionsCarbon impuritiesCrucible

This invention relates to a method for direct solidification of semiconductor grade multi-crystalline silicon ingots allowing improved control with the solidification process and reduced levels of oxygen and carbon impurities in the ingot, by crystallizing the semiconductor grade silicon ingot, optionally also including the melting of the feed silicon material, in a crucible made of silicon nitride, or in a crucible made of a composite of silicon carbide and silicon nitride, and where the wall thickness of the bottom of the crucible is dimensioned such that the thermal resistance across the bottom is reduced to a level of at least the same order as thermal resistance across the support below carrying the crucible or lower. The invention also relates to crucibles which are made of silicon nitride, or of a composite of silicon carbide and silicon nitride, and where the wall thickness of the bottom of the crucible is dimensioned such that the thermal resistance across the bottom is reduced to a level of at least the same order as thermal resistance across the support below carrying the crucible or lower.

Owner:REC SCANWAFER

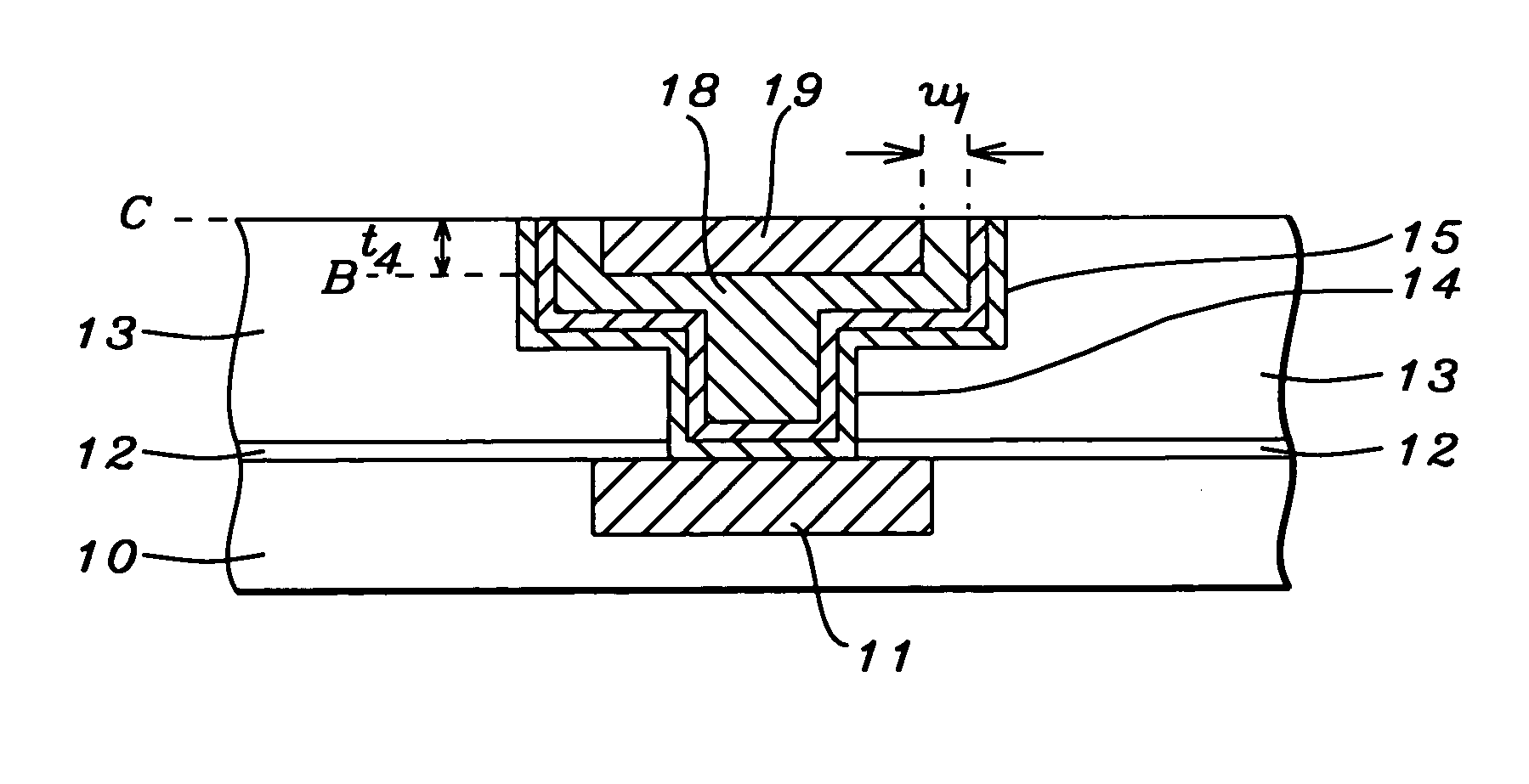

Post ECP multi-step anneal/H2 treatment to reduce film impurity

InactiveUS7030016B2Improve reliabilityReduce defect densitySemiconductor/solid-state device manufacturingCopper interconnectCarbon impurities

A method of forming a copper interconnect in a dual damascene scheme is described. After a diffusion barrier layer and seed layer are sequentially formed on the sidewalls and bottoms of a trench and via in a dielectric layer, a first copper layer is deposited by a first ECP process at a 10 mA / cm2 current density to fill the via and part of the trench. A first anneal step is performed to remove carbon impurities and optionally includes a H2 plasma treatment. A second ECP process with a first deposition step at a 40 mA / cm2 current density and second deposition step at a 60 mA / cm2 current density is used to deposit a second copper layer-that overfills the trench. After a second anneal step, a CMP process planarizes the copper layers. Fewer copper defects, reduced S, Cl, and C impurities, and improved Rc performance are achieved by this method.

Owner:TAIWAN SEMICON MFG CO LTD

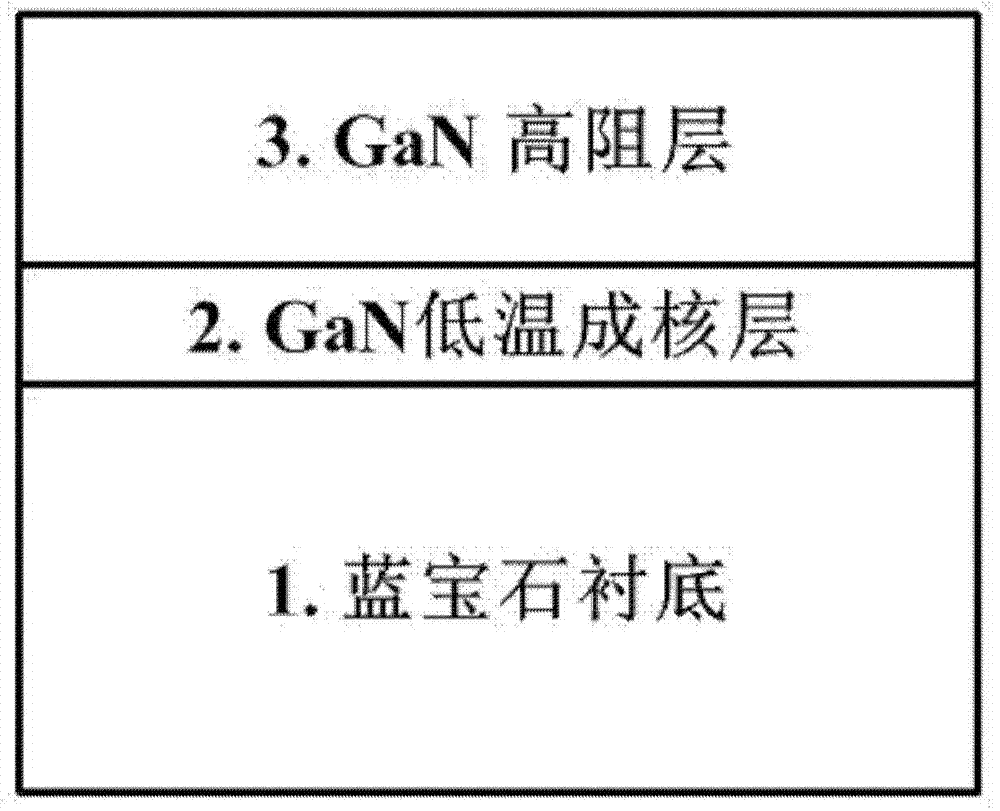

Method for manufacturing high-resistance GaN thin film

InactiveCN103578986AHigh resistivityQuality assuranceSemiconductor/solid-state device manufacturingSemiconductor devicesHigh resistanceMaterial growth

The invention discloses a high-resistance GaN thin film and a method for manufacturing the high-resistance GaN thin film. The high-resistance GaN thin film comprises a substrate, a GaN low-temperature nucleating layer and a GaN high-resistance layer, wherein the GaN low-temperature nucleating layer is manufactured on the substrate, and the GaN high-resistance layer is manufactured on the GaN low-temperature nucleating layer. The high-resistance GaN thin film grows through MOCVD equipment, with trimethyl gallium and ammonia gas used as a gallium source and a nitrogen source, and with hydrogen used as carrier gas; the growth temperature of the GaN low-temperature nucleating layer is 550 DEG C, the pressure of a reaction chamber for the GaN low-temperature nucleating layer is 200 Torr, and the thickness of the GaN low-temperature nucleating layer ranges from 0.2 micrometer to 0.3 micrometer; the growth temperature of the GaN high-resistance layer is 1040 DEG C, the pressure of a reaction chamber for the GaN high-resistance layer is 50 Torr, and the thickness of the GaN high-resistance layer is 2 micrometers. According to the high-resistance GaN thin film, by controlling the pressure of the reaction chambers in the material growth process and controlling merging of carbon atoms in reaction precursors TMGa, carbon impurities are imported to acquire acceptor levels under the condition that a carbon source is not independently added, and background carrier concentration is compensated for.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Stress NMOS device and manufacturing method of stress CMOS

ActiveCN101593701AImprove stabilityIncrease stressSemiconductor/solid-state device manufacturingDriving currentCMOS

A manufacturing method of a stress NMOS device comprises the followings: semiconductor substrates with grid structures are offered; a source electrode and a drain electrode are formed in the semiconductor substrates at two sides of the grid structures; wherein after the grid structures are formed and before the source electrode and the drain electrode are formed, or after the source electrode and the drain electrode are formed, the method further comprises the following steps: ions are implanted, and carbon impurities are doped in the semiconductor substrates at two side of the grid structures; solid phase epitaxy process is carried out to facilitate the carbon impurities react with silicon to form a strain silicon carbide layer. The invention also provides a manufacturing method of the stress CMOS device. Carbon in the strain silicon carbide layer in the stress MOS device formed by the invention has comparatively high content, the stress applied to an NMOS conducting channel by an epitaxial layer of a silicon carbide material is greatly increased; the mobility of carriers can be effectively improved, thus enlarging the drive current and improving the performance of the NMOS device.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

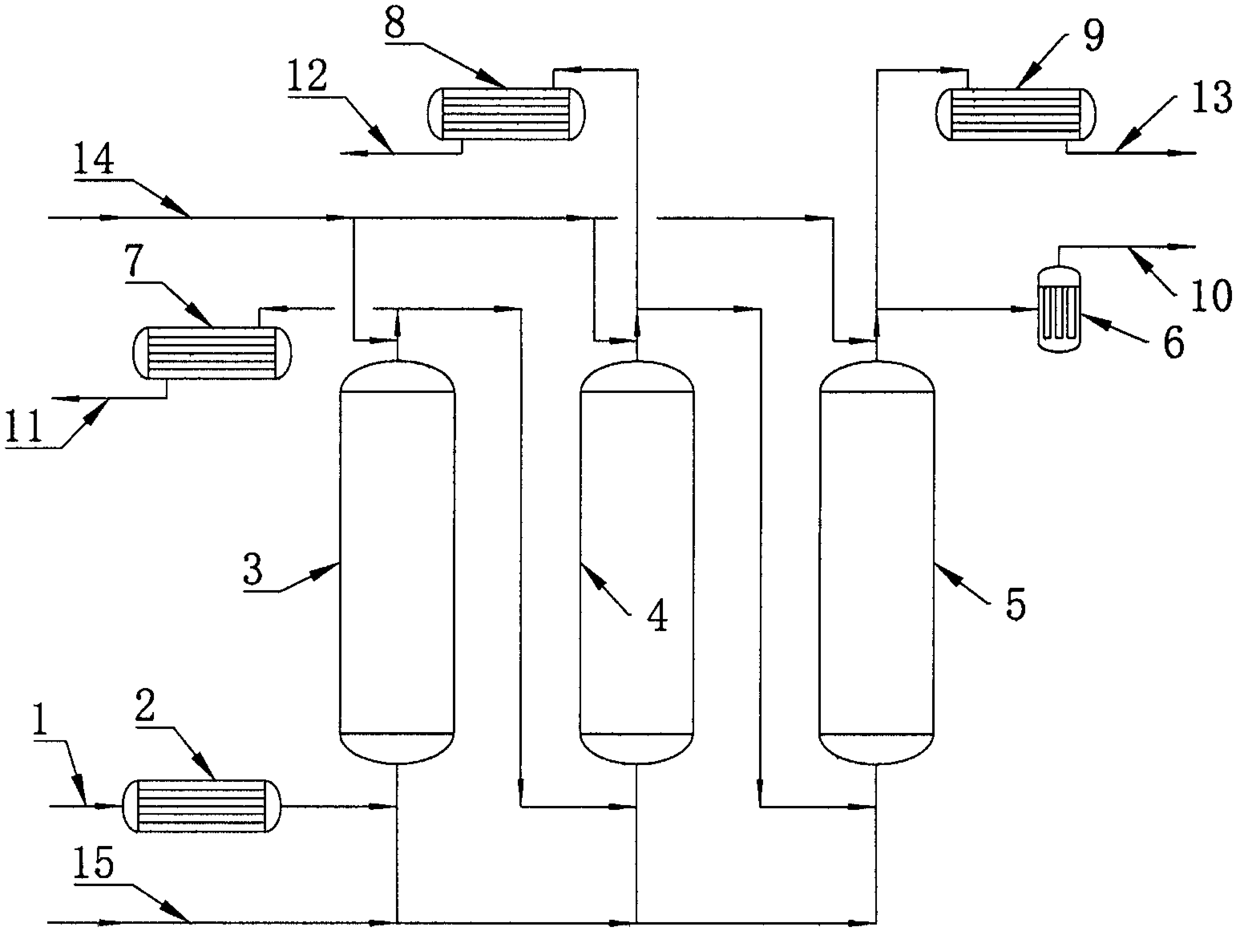

Device and method for adsorbing and removing methyl chlorosilane impurities to prepare high-purity trichlorosilane

InactiveCN109205627AImprove efficiencyExtend the life cycleHalogenated silanesSize differenceSorbent

The invention relates to a device and a method for adsorbing and removing methyl chlorosilane impurities to prepare high-purity trichlorosilane. According to molecule size difference of different methyl chlorosilane monomers, an adsorbent with an oriented adsorption function is prepared; three adsorption columns are respectively filled with a pretreatment adsorbent and the oriented adsorbent; trichlorosilane which is rectified and purified in a multilevel mode is utilized as a raw material, a designed multilevel adsorption device is utilized to perform oriented adsorption, the content of carbon impurities in the adsorbed trichlorosilane is greatly reduced, and electronic-grade polycrystalline silicon production can be realized. Meanwhile, as the adsorption columns are filled with the adsorbent which can perform oriented adsorption on the trichlorosilane, dimethyl chlorosilane and methyl dichlorosilane can be selectively adsorbed in an adsorption process; thus, the dimethyl chlorosilaneand the methyl dichlorosilane can be effectively separated, the dimethyl chlorosilane and the methyl dichlorosilane can be respectively utilized as organosilicone products to be directly recycled after being desorbed, aftertreatment technologies are reduced, energy consumption is saved, and economic benefits are improved.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

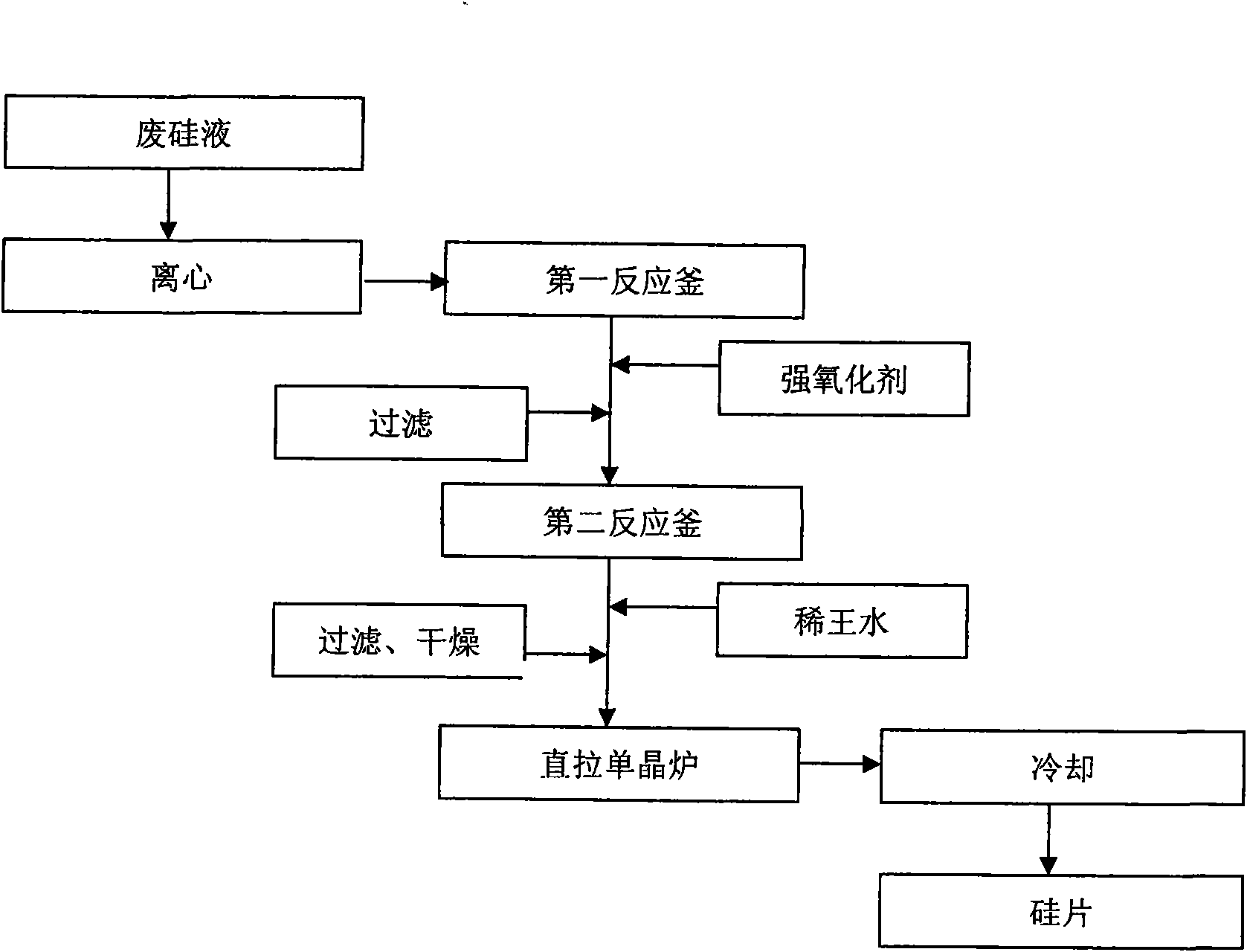

Method for recycling waste silicon solution

InactiveCN101683981AMeet the requirements of power generationMeet the indicator requirementsSiliconDownstream processingFiltration

The invention relates to a method for recycling a waste silicon solution, in particular to a method for recycling a waste silicon solution generated in cutting silicon chip sheets. The method is characterized by comprising the following steps: carrying out centrifugal separation on the waste silicon solution generated in cutting silicon bars by filter cloth with the pore diameter of 800-1,500 meshes, and then obtaining silicon powder; putting the silicon powder obtained after separation in a reaction kettle; adding a strong oxidizer to react, and then filtering the reaction solution so as to remove organic carbon impurities, wherein the strong oxidizer is one of concentrated sulfuric acid, hydrogen peroxide and nitric acid or a mixed solution prepared from concentrated sulfuric acid, hydrogen peroxide and nitric acid; putting the silicon powder obtained after secondary filtration in the reaction kettle; adding diluted aqua fortis to react, and then filtering and drying the reaction solution so as to remove metal and metal oxide impurities; and putting the silicon powder obtained after third filtration in a Czochralski single crystal furnace; sufficiently reacting in the single crystal furnace in vacuum at the temperature of 800-1,000 DEG C so as to remove surface impurities, then cooling, and finally obtaining solar-grade silicon sheets. Applying the method can recycle most silicon powder in the waste silicon solution, and the silicon powder can be used for manufacturing solar batteries by downstream processing, thereby not only saving resources, but also not generating environmental pollution.

Owner:ZHEJIANG YUHUI SOLAR ENERGY SOURCE

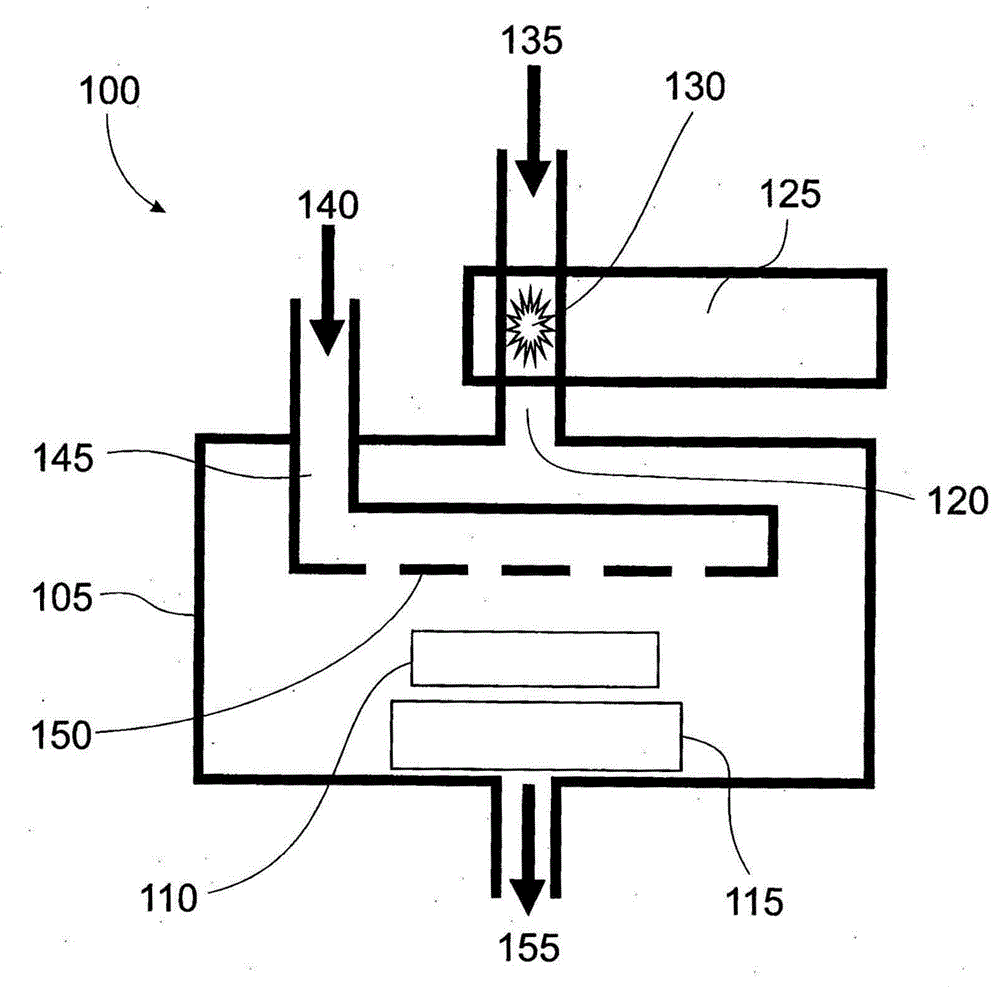

Apparatus and method for film formation

An apparatus and method for forming a thin film on a substrate by RPCVD which provides for very low levels of carbon and oxygen impurities and includes the steps of introducing a Group VA plasma into a first deposition zone of a growth chamber, introducing a Group IIIA reagent into a second deposition zone of the growth chamber which is separate from the first deposition zone and introducing an amount of an additional reagent selected from the group consisting of ammonia, hydrazine, di-methyl hydrazine and a hydrogen plasma through an additional reagent inlet into the second deposition zone such that the additional reagent and the Group IIIA reagent mix prior to deposition.

Owner:GALLIUM ENTERPRISES

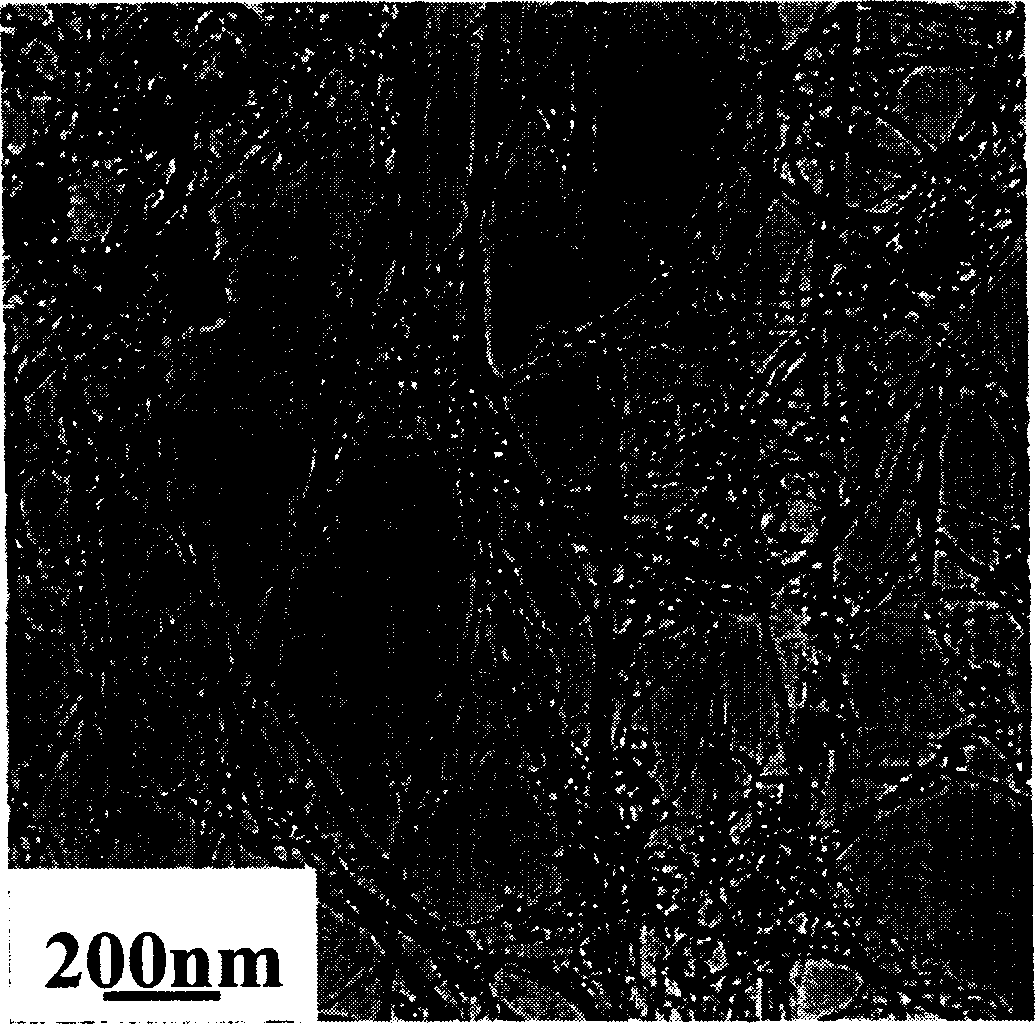

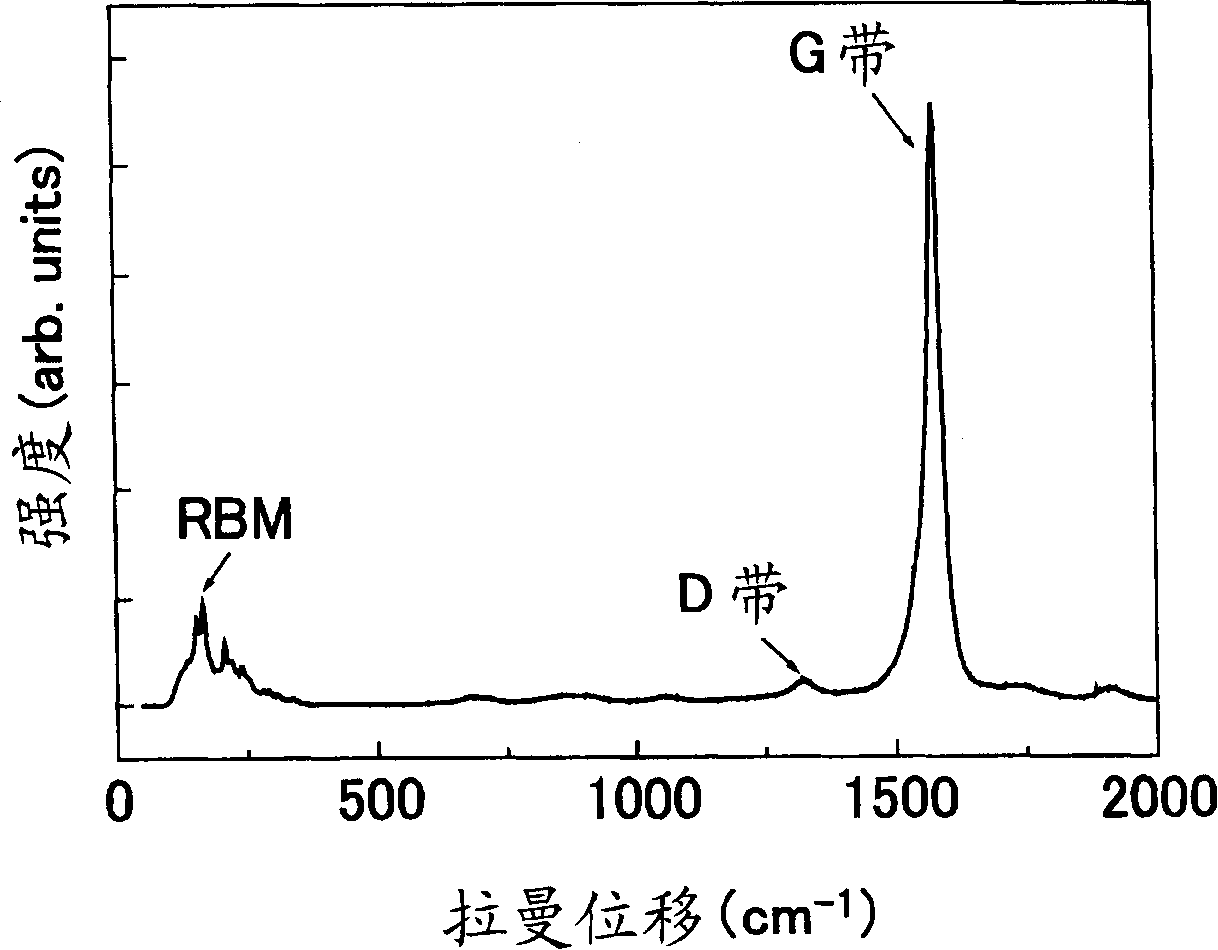

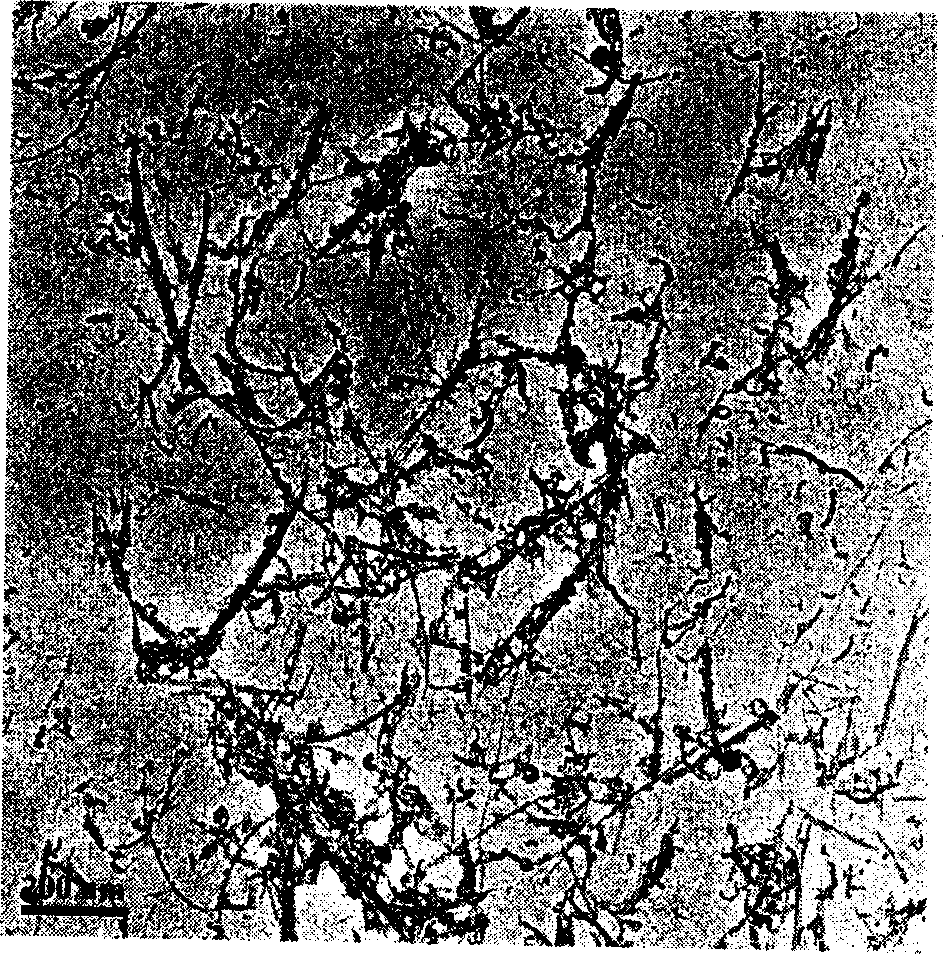

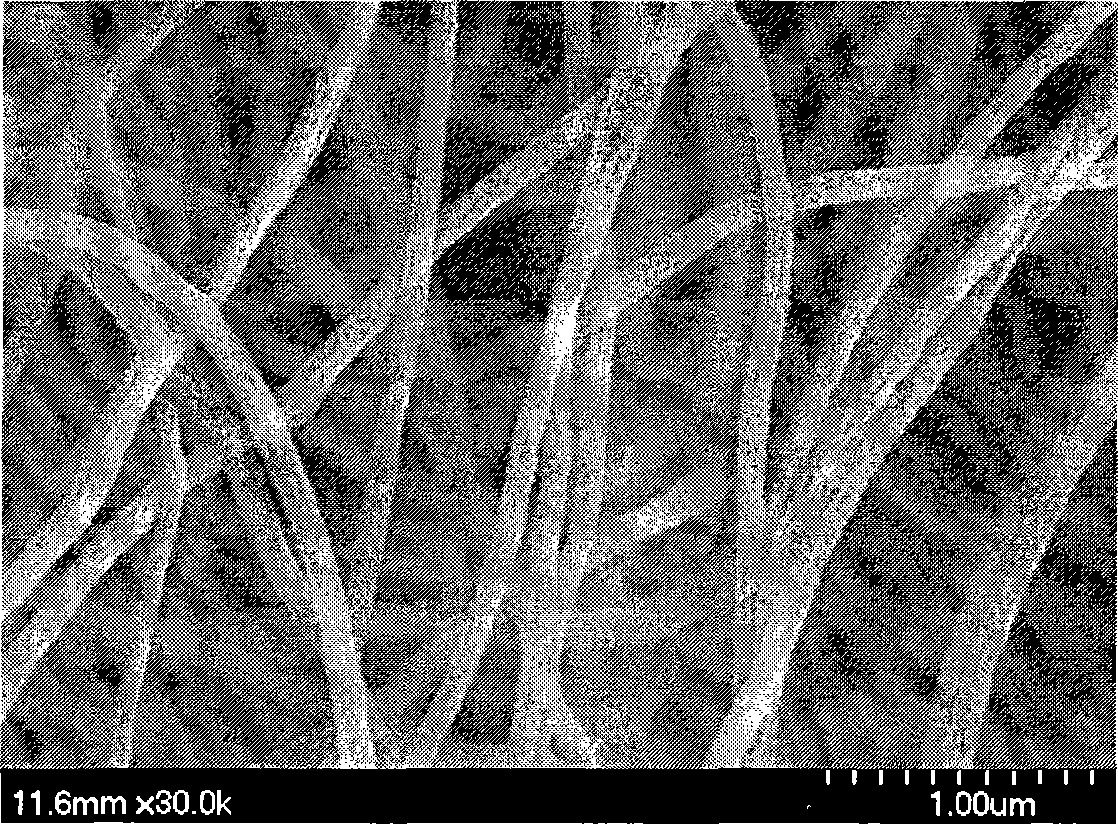

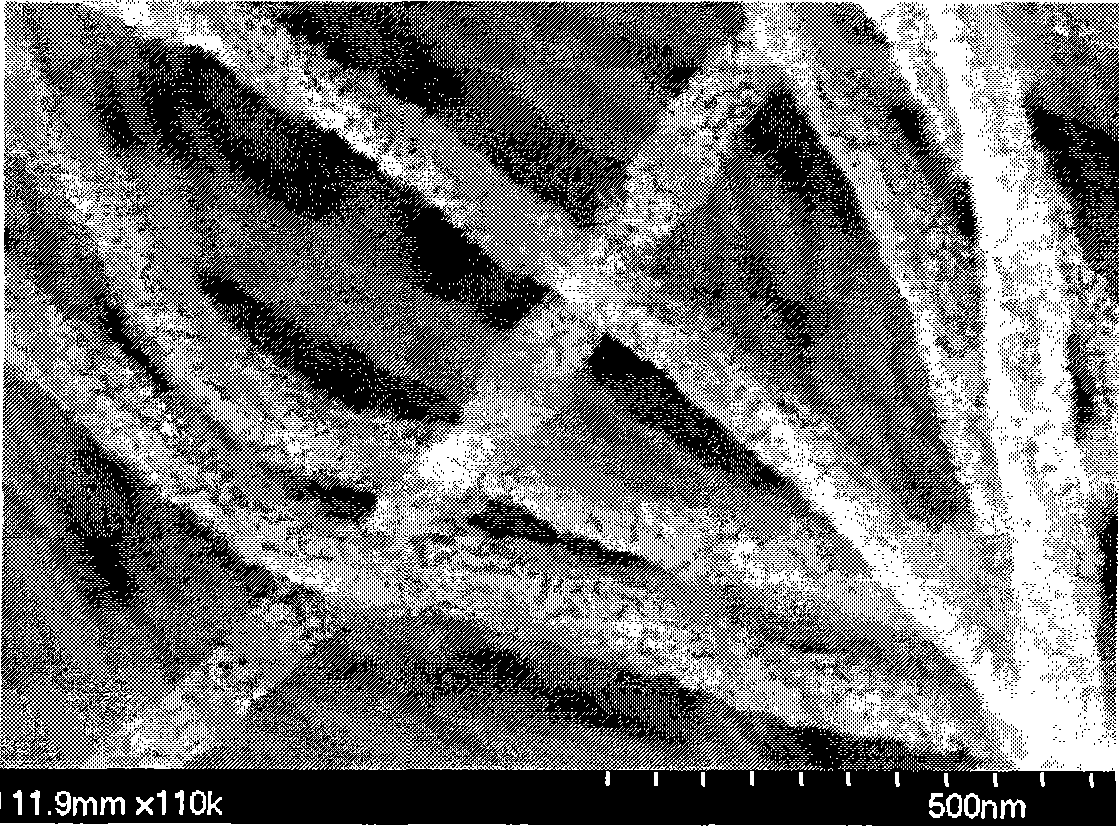

Method for removing carbon impurities in single-walled carbon nanotube

ActiveCN104310375AAvoid volume shrinkageReduce filterMaterial nanotechnologyMultiwalled carbonCarbon impurities

The invention discloses a method for removing carbon impurities in a single-walled carbon nanotube. The method comprises the following steps: mechanically grinding; carrying out high-temperature hydrogen or medium-temperature plasma hydrogen treatment; carrying out class screening on an air flow; and repeating the steps for two or three times. According to the method, the mass fraction of the carbon impurities in the single-walled carbon nanotube, namely onion carbon nanoparticles, a multiwalled carbon nanotube or amorphous carbon can be reduced from 50% to below 0.05%. Meanwhile, as the carbon impurities are fully treated by a dry method, the bulk structure of the single-walled carbon nanotube can be maintained, thereby providing a base for applications such as energy storage of a supercapacitor or transparent conductive display. The method has the advantages of being less in equipment, simple to operate, easy to repeat, easy for process amplification and low in cost.

Owner:TSINGHUA UNIV

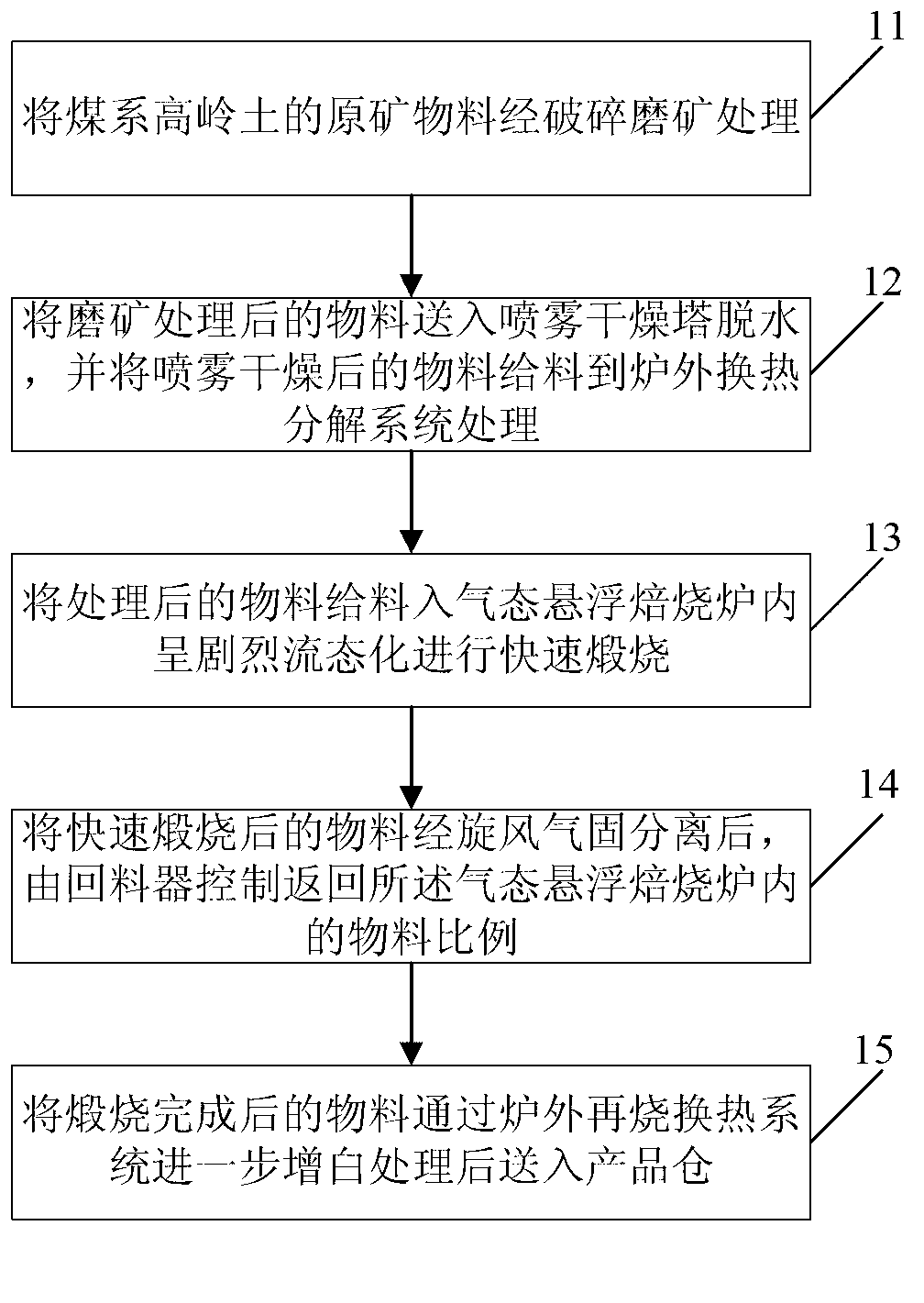

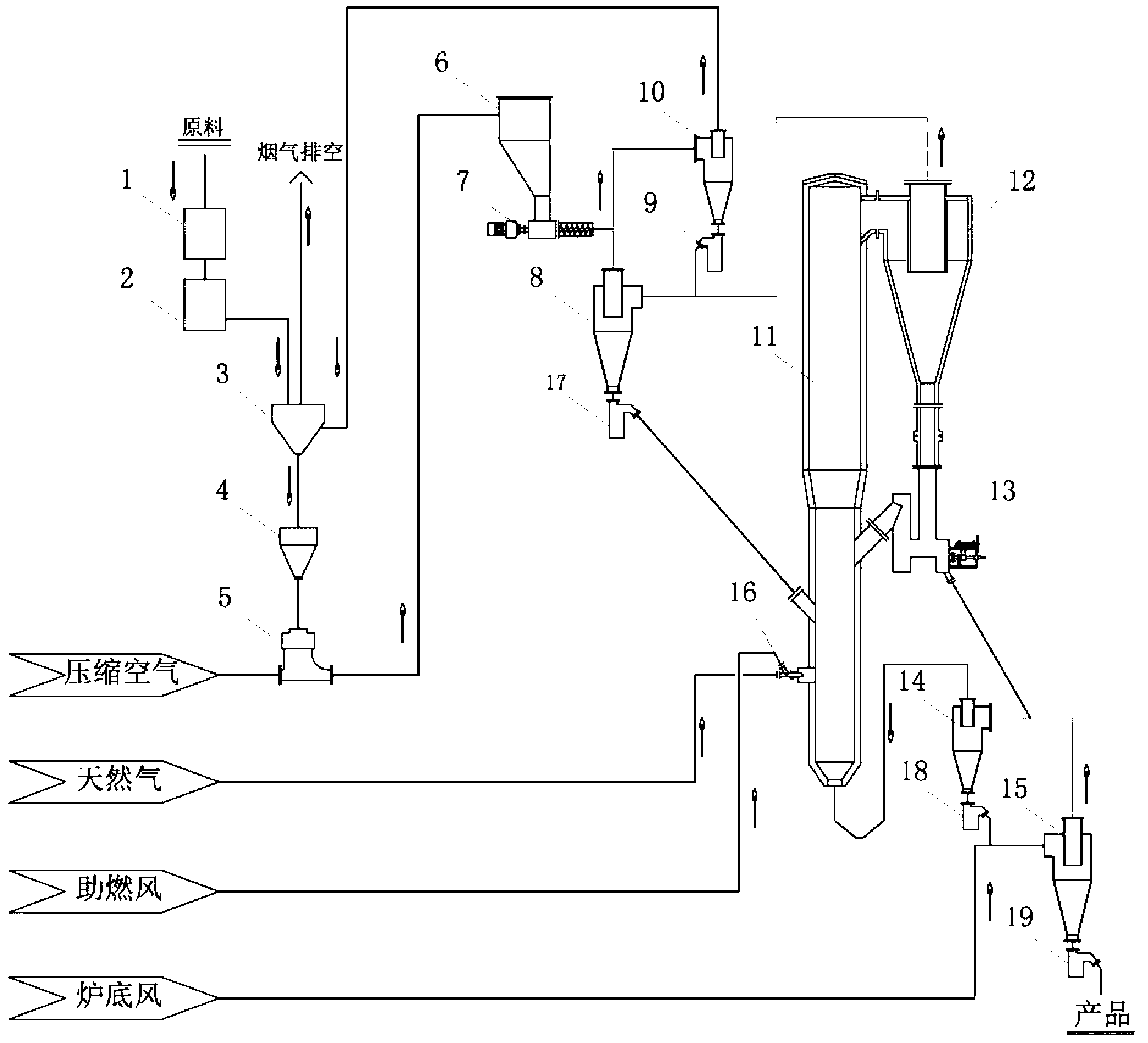

Coal-series kaolin gas suspension calcination method

InactiveCN102795633AEasy to removeImprove thermal efficiencyEnergy inputSilicon compoundsStructural waterDecomposition

The invention discloses a coal-series kaolin gas suspension calcination method comprising the following steps of: firstly, crushing and grinding mineral raw materials of coal-series kaolin, feeding the mineral raw materials into a spray drying tower for dehydration, and feeding the materials subjected to spray drying into a furnace external heat exchange decomposition system for treatment; feeding the treated materials into a gas suspension calciner for rapid calcination in an intensive fluidization condition, wherein the fluidizing velocity is 8-40m / s, and the calcination temperature is controlled within 600-1400 DEG C according to the requirements of products; carrying out gas-solid separation on the rapidly calcined materials under the action of whirlwind, then, controlling the proportions of materials returned to the gas suspension calciner through a loop seal, and adjusting the total standing time of the materials in the gas suspension calciner to control the calcination quality of a product; and further carrying out whitening treatment on the calcined materials through a furnace-external reburning heat exchange system, and then, feeding the materials into a product cabin. The method is simple in process, high in heat efficiency, good gas-solid heat and mass transfer and narrow in calcination temperature fluctuation range; and the product is stable and uniform in quality, smoke waste heat can be sufficiently utilized, high handling capacity is realized, and carbon impurities and structural water in the coal-series kaolin can be rapidly removed.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

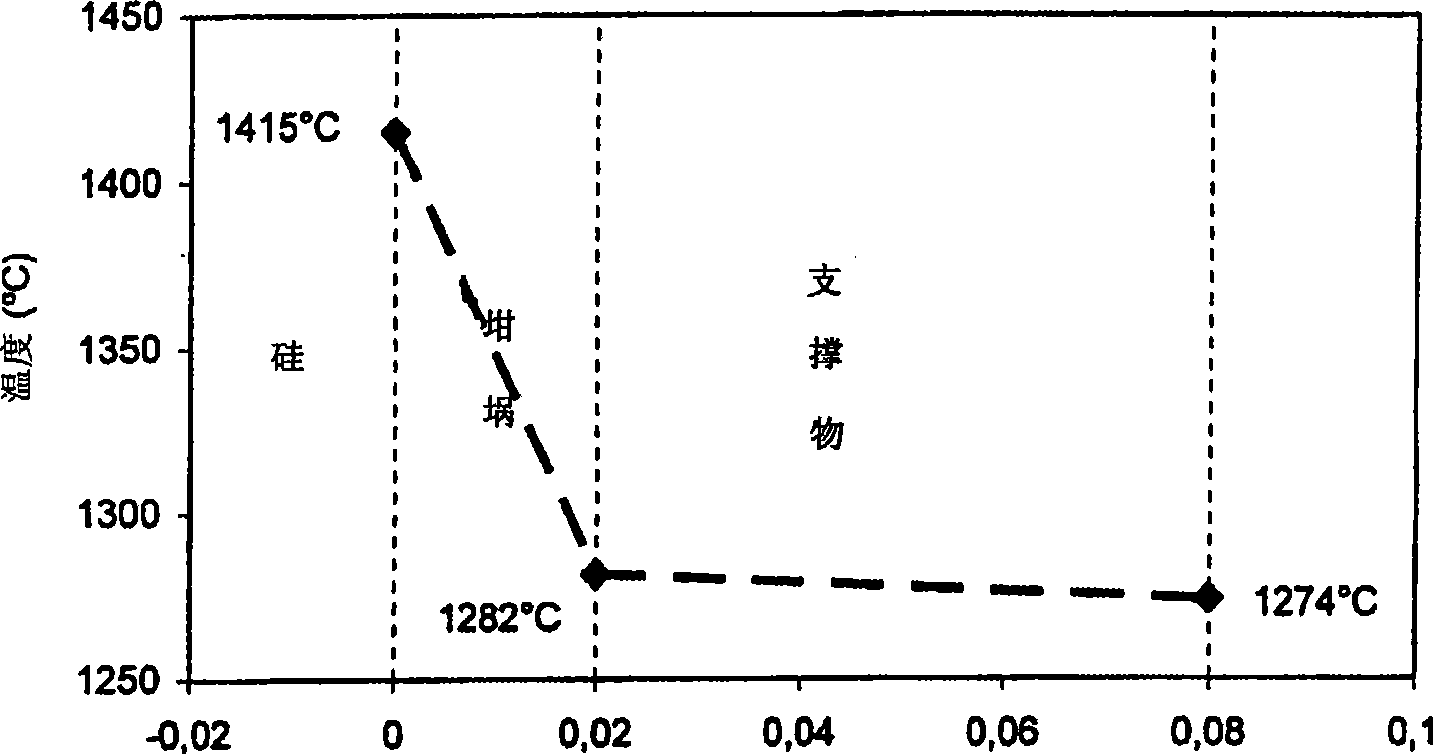

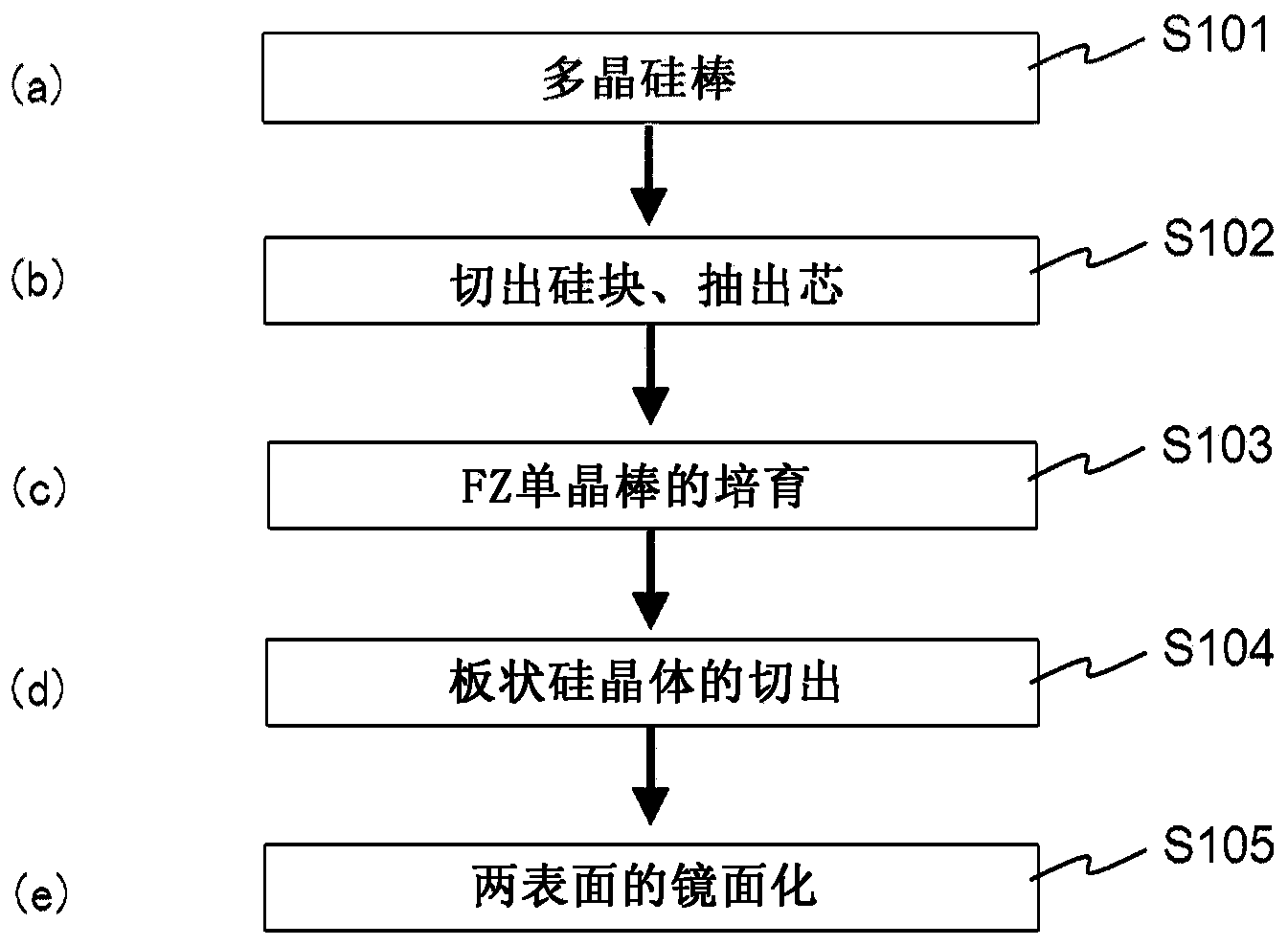

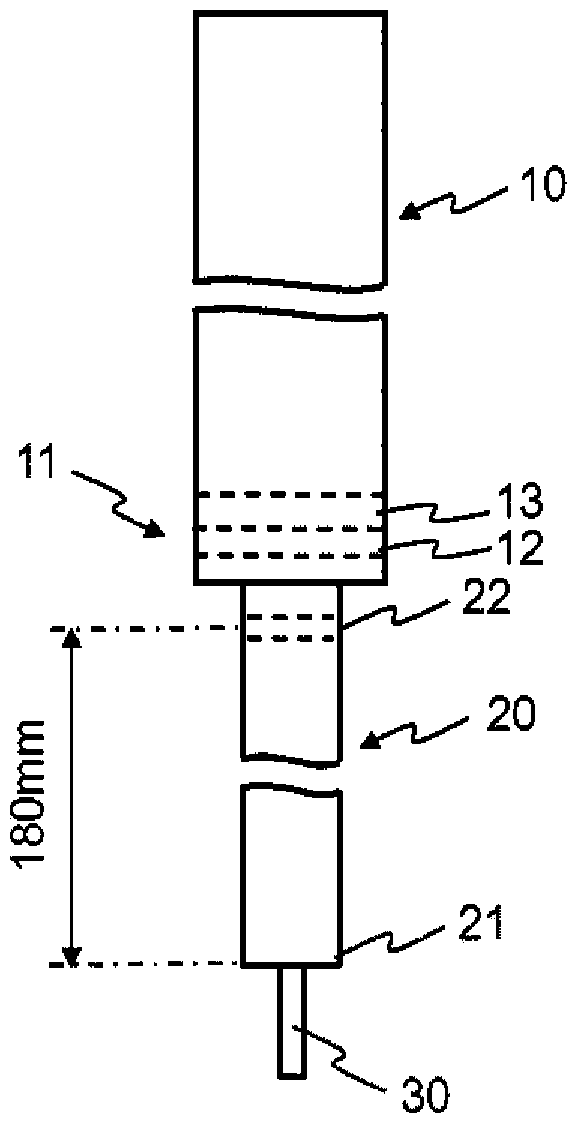

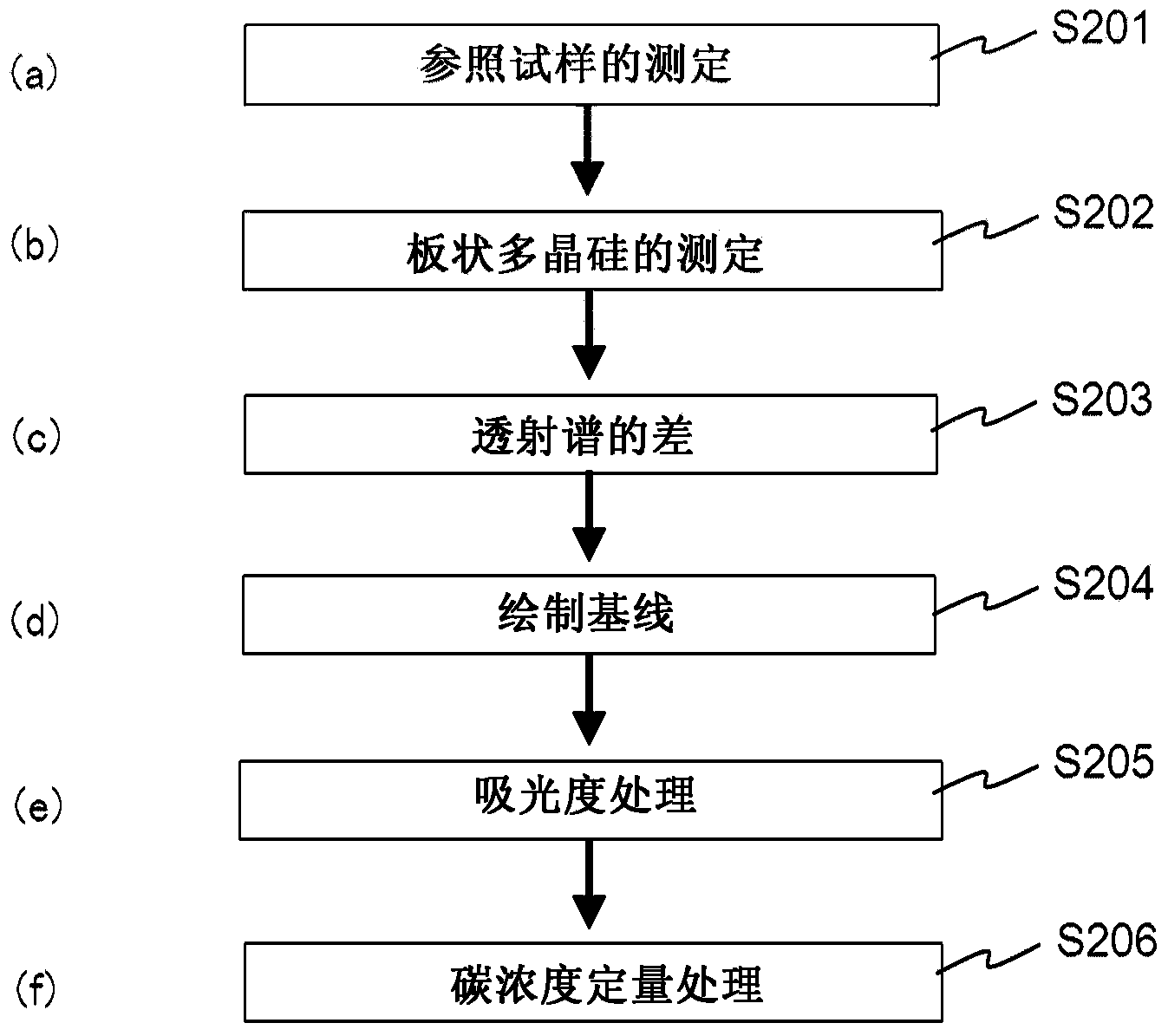

Method for measuring carbon concentration in polycrystalline silicon

InactiveCN103477207AEasy to measureAbsorption/flicker/reflection spectroscopyColor/spectral properties measurementsCarbon impuritiesCalibration curve

The present invention provides a method with which it is possible to measure the approximate concentration of substitutional carbon impurities easily and simply and at a desired location in a polycrystalline silicon rod. A polycrystalline silicon plate is cut out from a polycrystalline silicon rod. Both surfaces of the polycrystalline silicon plate are mirror-polished to a thickness of 2.12+-0.01 mm. A calibration curve is created in accordance with a standard measurement method through infrared absorption spectroscopy by employing a monocrystalline silicon standard sample having a known substitutional carbon concentration and a thickness of 2.00+-0.01 mm. An infrared absorption spectrum in the wave number range including the absorption band peak of substitutional carbons in the mirror-polished polycrystalline silicon plate is obtained under the same conditions as those employed at the time of creating the calibration curve, and the substitutional carbon concentration is found without performing thickness correction.

Owner:SHIN ETSU CHEM CO LTD

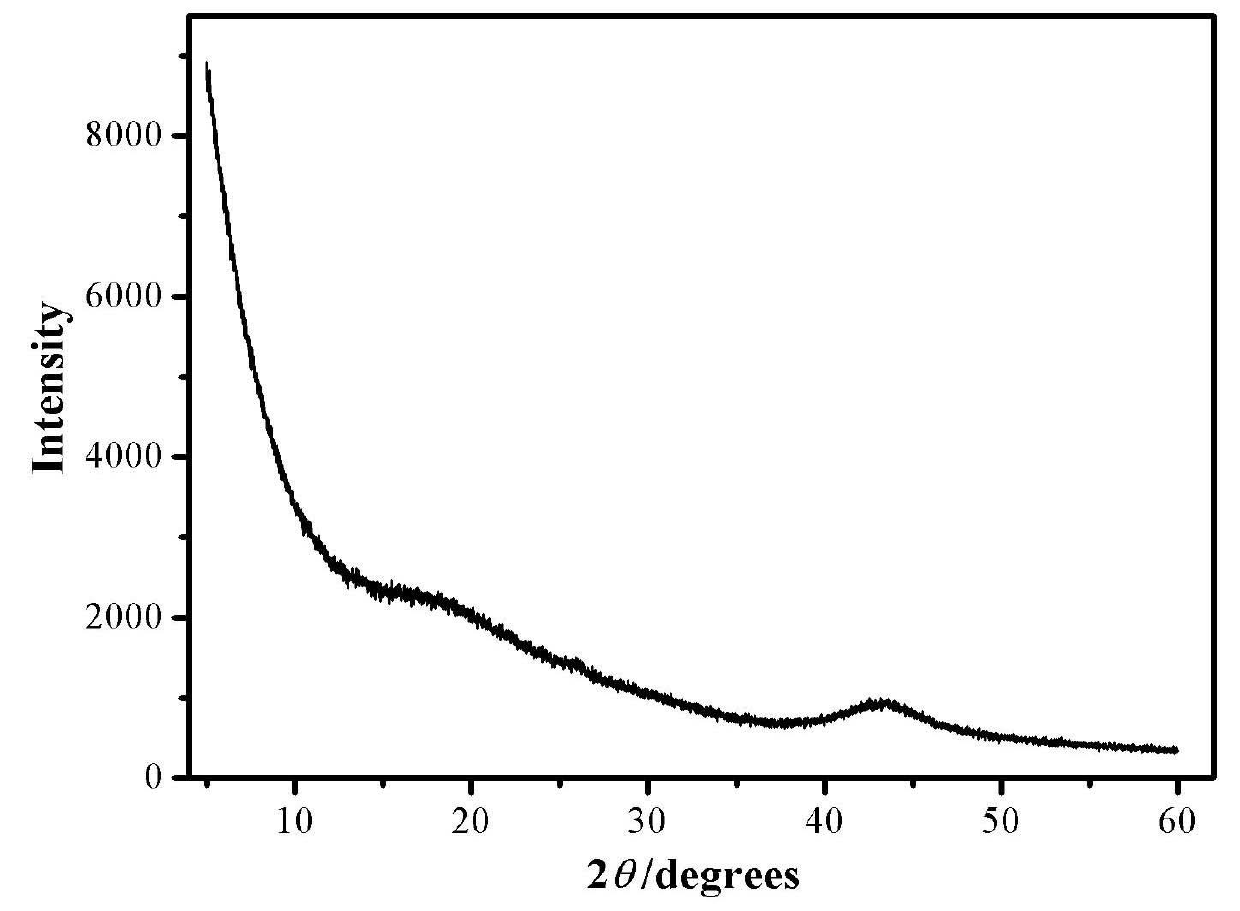

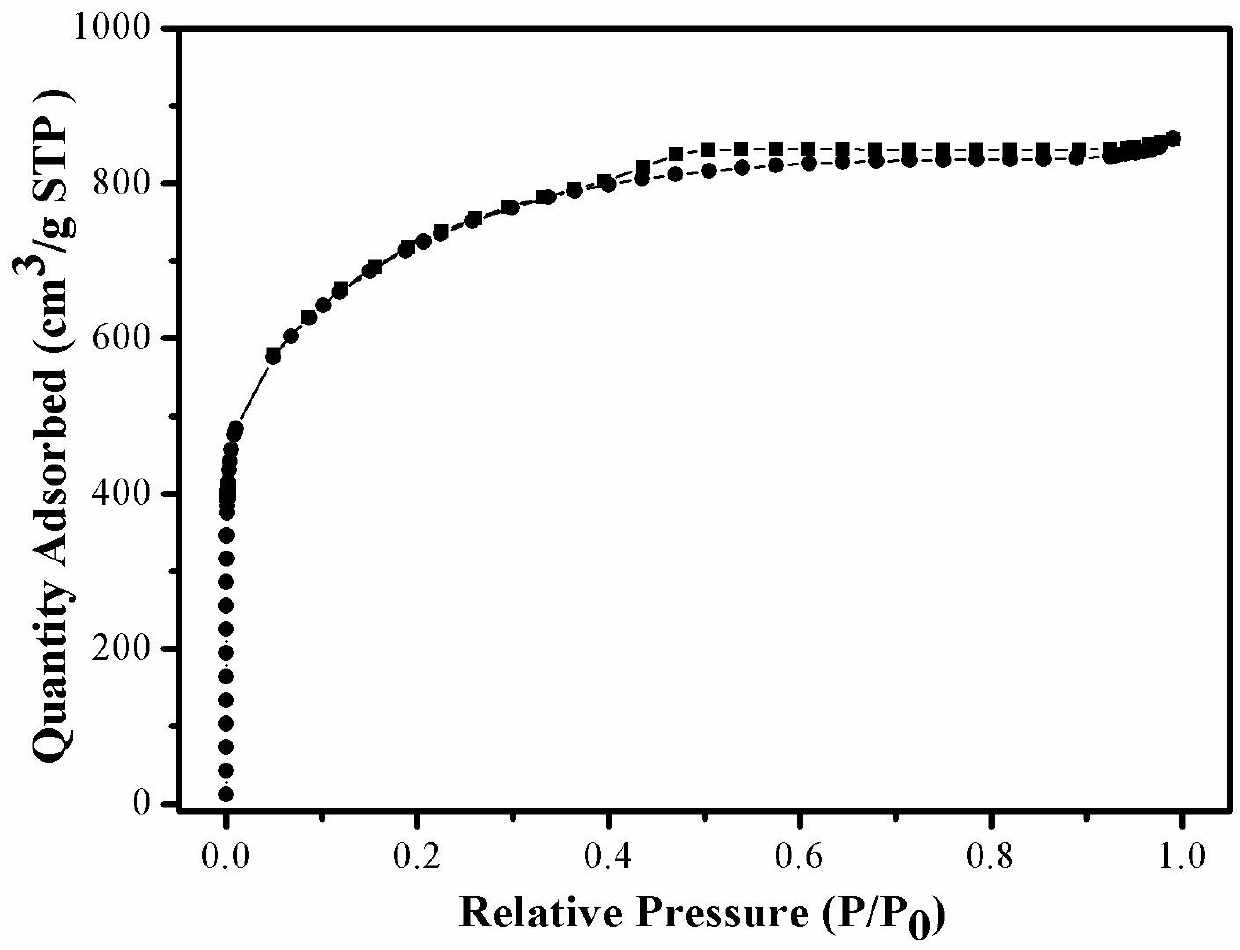

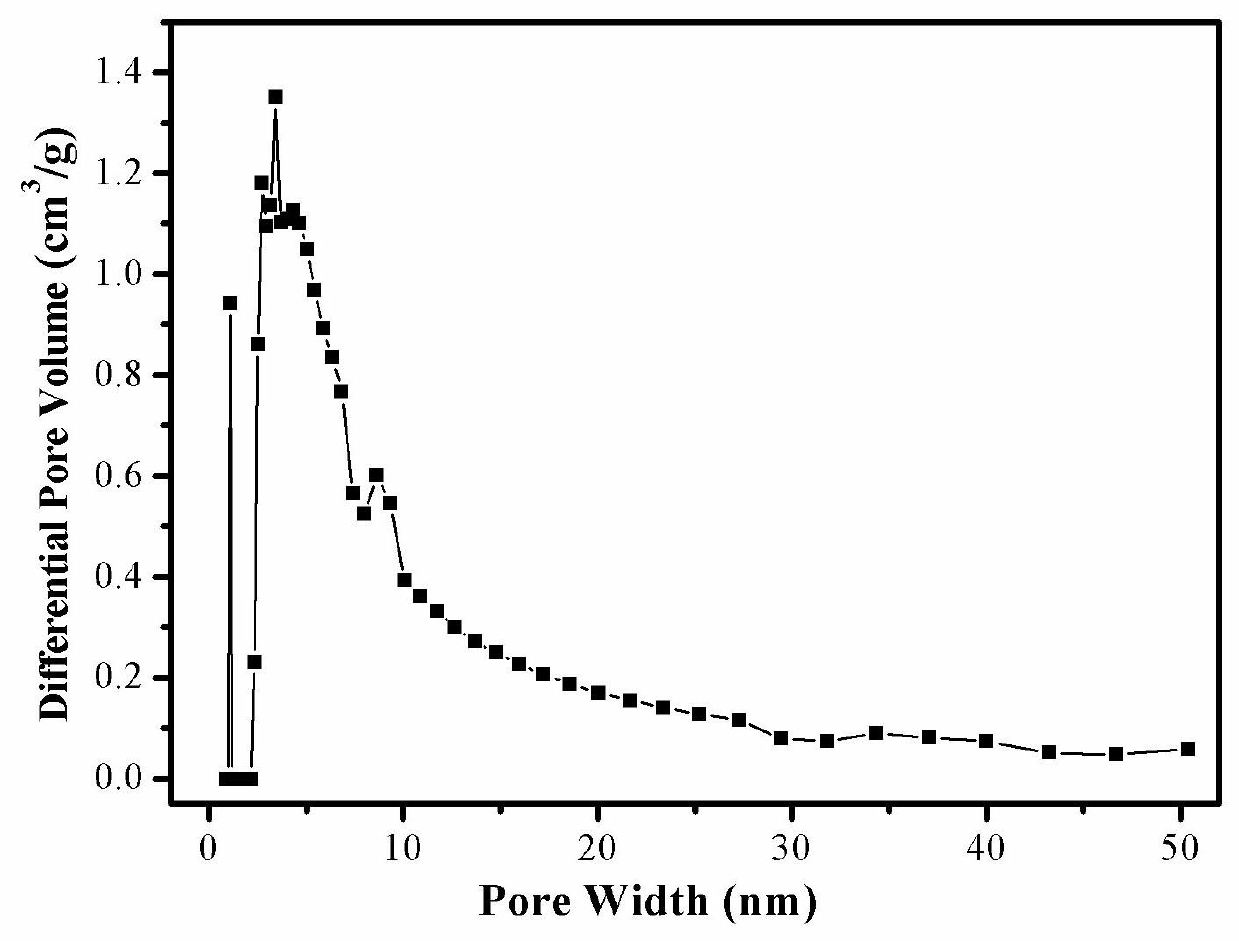

Process for preparing high-specific surface area composite pore structure coal-based activated carbon by using low dosage of KOH

InactiveCN102674346AImprove utilization efficiencyReduce consumptionCarbon compoundsActivated carbonCarbon impurities

The invention discloses a process for preparing high-specific surface area composite pore structure coal-based activated carbon by using coal. The process comprises steps of firstly, crushing the coal into 100 meshes per square inch to 200 meshes per square inch, then mixing coal powder and an alkali activator uniformly by grinding in inert atmosphere, performing multi-stage temperature controlling activation, washing and drying to obtain the high-ratio surface area activated carbon with a micro pore-meso pore composite pore structure. The prepared high-ratio surface area activated carbon is low in non carbon impurity content, high in specific surface area and good in adsorption performance and has the micro pore-meso pore composite pore structure. Compared with the prior art, consumption of the alkali activator is reduced greatly, therefore, the product has high cost performance.

Owner:XINJIANG UNIVERSITY

Method for manufacturing mono-layer carbon nano pipe

This invention provides a method for manufacturing the same length, high purity, single-layer carbon nanometer tubes with safety, high yield and controllable product length. The carbon series material, including single-layer carbon nanometer tubes, manufactured by various kinds of synthesis, is treated by nitric acid or the like, removing the metal impurities and forming defects on the wall of said nanometer tubes. Then, said carbon series material is treated by nitric acid, hydrogen peroxide, persulphates or this kinds of oxidants, cutting said single-layer nanometer tubes, finally the same is treated by reductive gas, such as ammonia, for removing the carbon impurity, and restoring from the defects for the single-layer carbon nanometer tubes.

Owner:SONY CORP

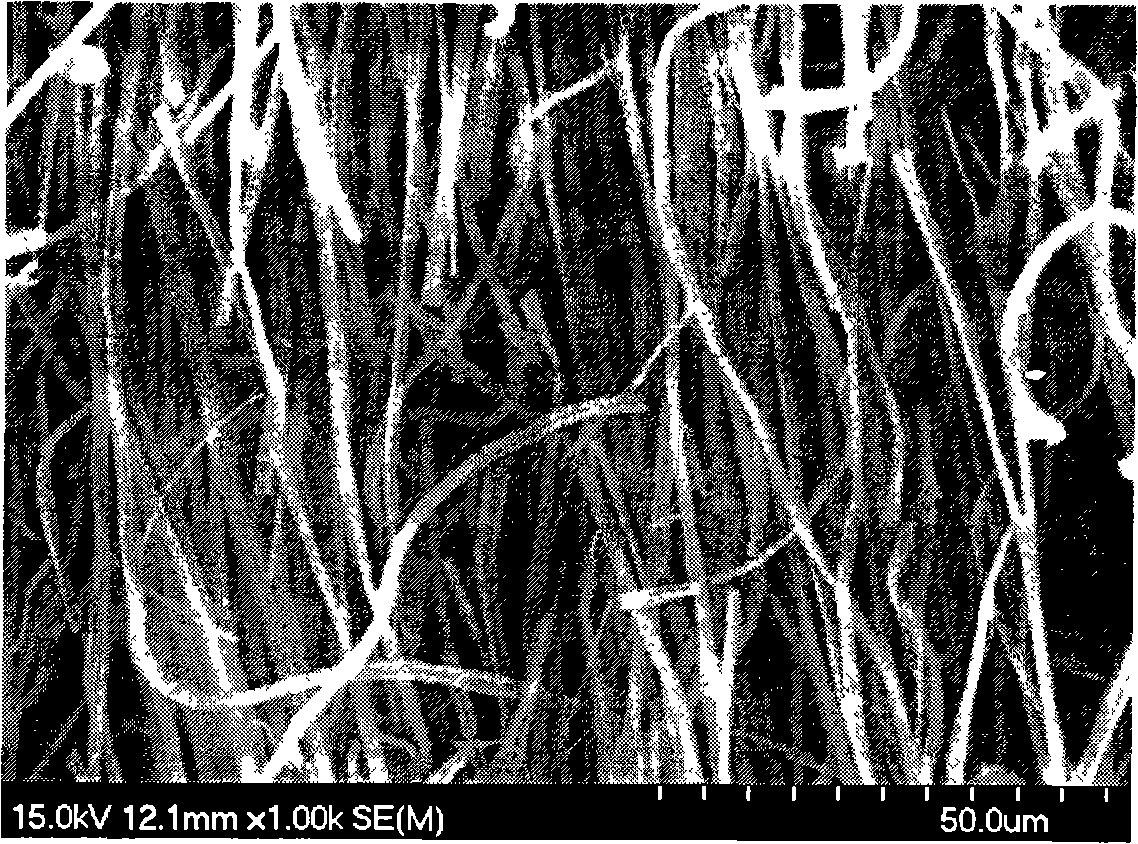

Preparation method of cup-stack carbon nano-tube

InactiveCN101585526AReduce concentrationReduce formationIndividual molecule manipulationOrganic compoundAccelerant

The invention relates to a preparation technique of carbon nano-tubes, in particular to a preparation method of a cup-stack carbon nano-tube, which is suitable to prepare a short cup-stack carbon nano-tube. The cup-stack carbon nano-tube can be produced by the following steps: an organic compound carbon source, catalyst, buffer gas and sulfur-containing growth promoter are adopted, an organic metal compound is used as both the carbon source and the catalyst precursor, and the organic compound catalyst is sublimated and is fully uniformly mixed with the carbon source and then is input into a reaction region, wherein the mol ratio of sulfur atoms and carbon atoms in the gas state compound of the reaction region is 1 / 10-1 / 500. The invention realizes the growth of the short cup-stack carbon nano-tube and reduces the formation of carbon impurities through decreasing the concentration of the carbon atoms in the reaction region.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

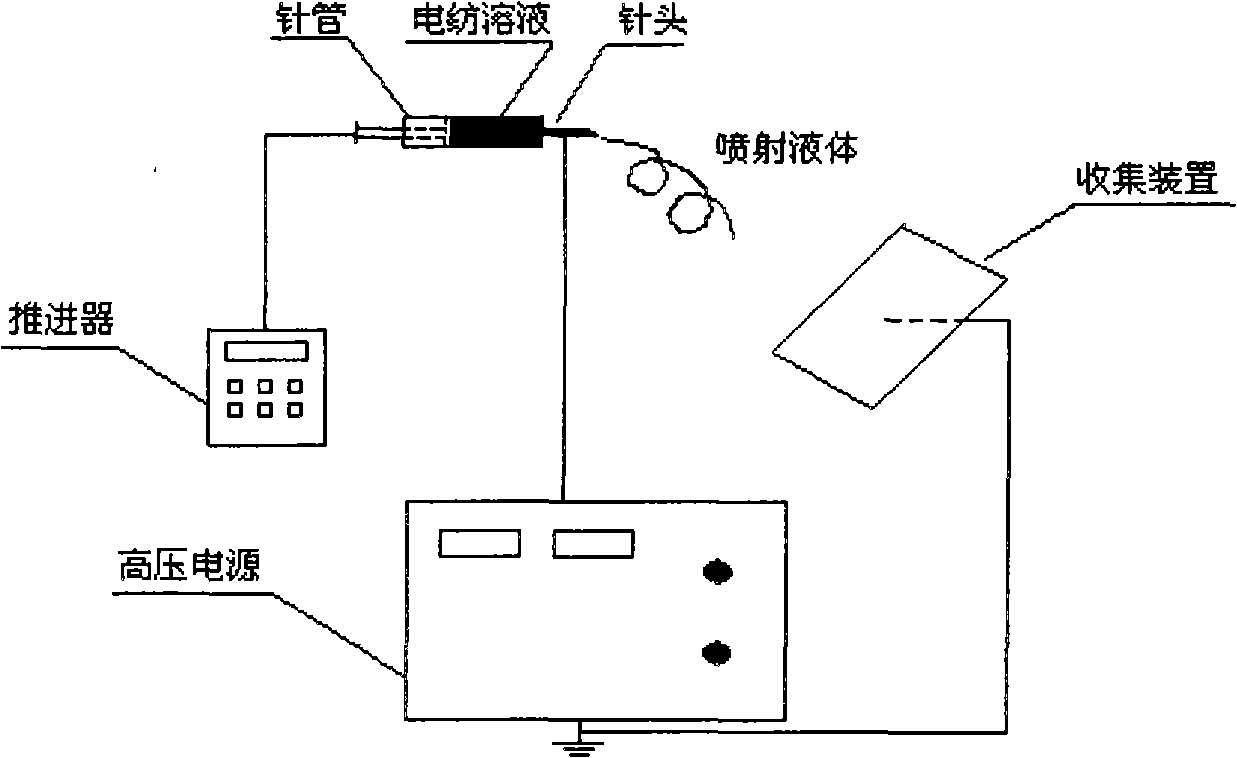

Process for producing ultra-fine boron nitride continuous nano-fibre

The invention relates to a method for preparing superfine kubonit continuous nanofiber, which is characterized in that the polymer fiber prepared by adopting the electrical spinning technique is taken as a template agent, then the surface of the template fiber is evenly coated with a boron source precursor by adopting a certain coating technique, and the superfine kubonit continuous nanofiber can be obtained after polymer template agent desorption and azotization treating processes. The appearance of the kubonit fiber product can be controlled through adjusting relative preparation parameters, the diameter of the fiber can be as thin as 50 nm, and no carbon impurity is contained in the kubonit fiber product, so that the purity can be above 98%. The method has the advantages of simple process and cheap raw material and equipment, and the obtained kubonit continuous nanofiber has the advantages of superfine diameter, controllability, high purity and the like, so that the invention has good industrialization prospect.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Method for preparing boron nitride continuous nano fibre

InactiveCN101254904AShape is easy to controlSimple processNitrogen compoundsCarbon impuritiesElectrospinning

The invention relates to a method for preparing boron nitride continuous nanofiber. The method is characterized in that solution electrostatic spinning technique is adopted to prepare the primary fiber; and polymer removal and nitrizing treatment are carried out to obtain the nitride continuous nanofiber. By adjusting the electrostatic spinning process parameter and the mixture ratio of raw materials, the morphology of boron nitride can be well controlled, and the fiber diameter is lower than 100nm. The boron nitride product contains no carbon impurity, and the purity thereof reaches more than 98%. The method has the advantage of simple process, low material and device cost, high quality of the obtained product and good industrialization prospect.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

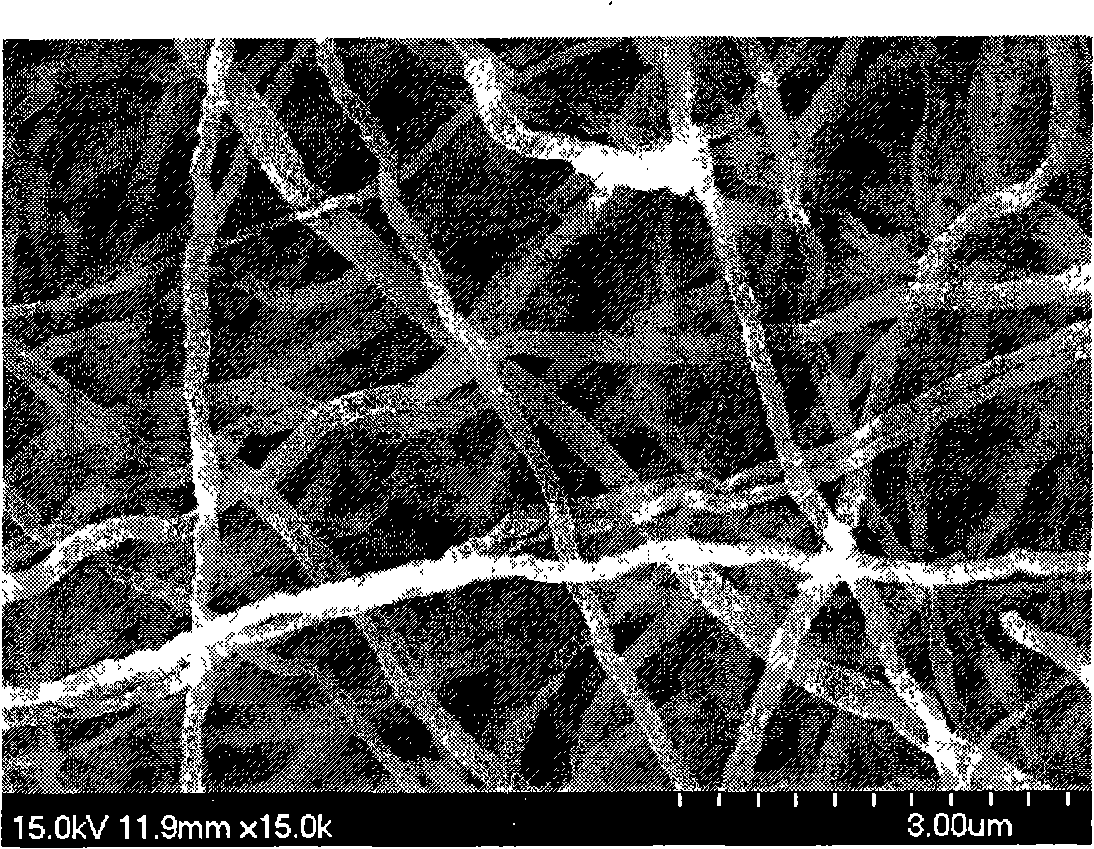

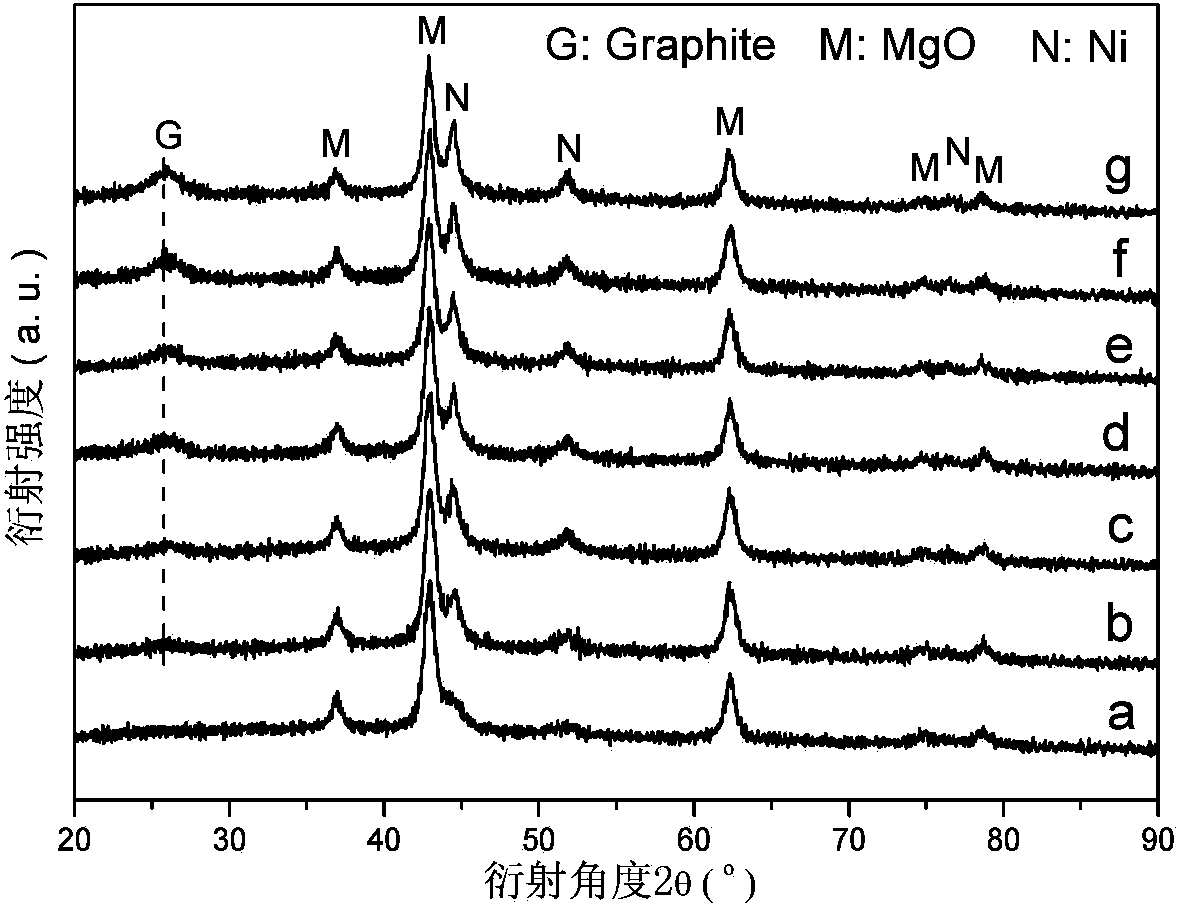

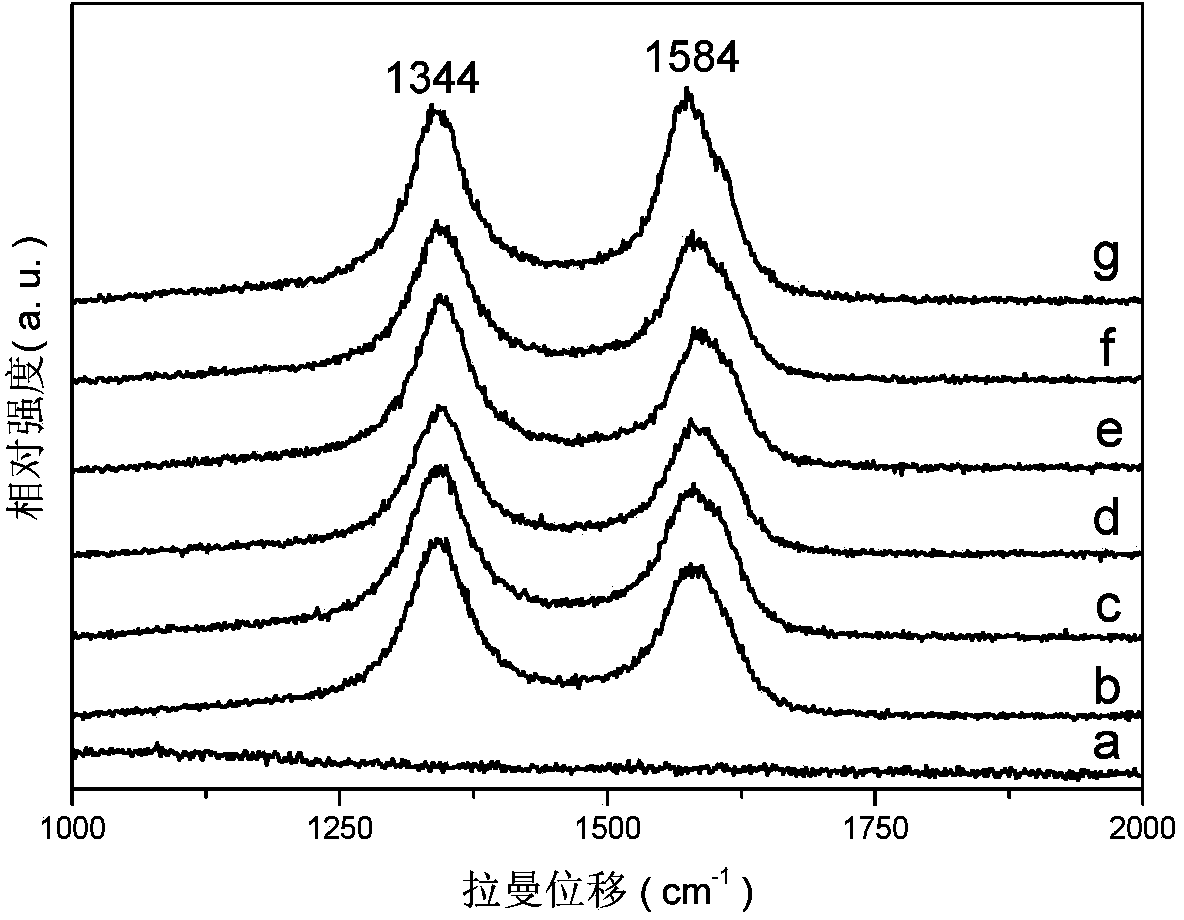

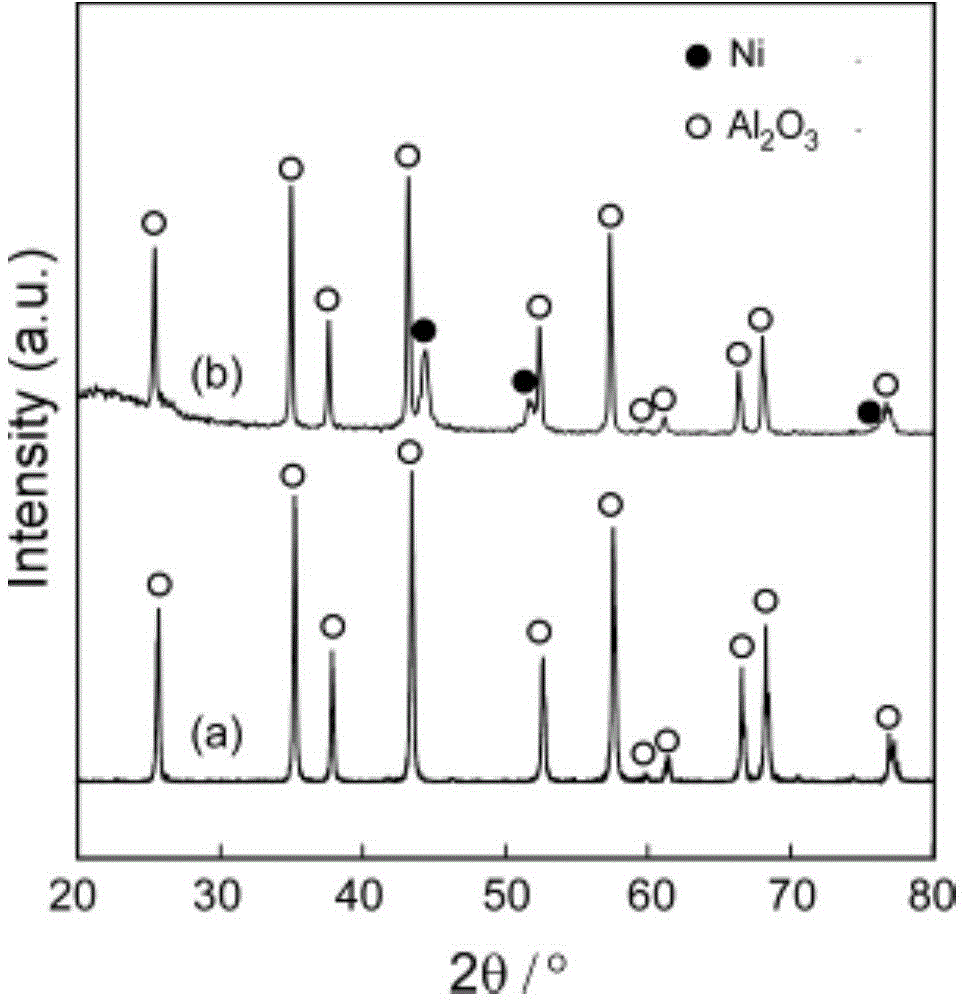

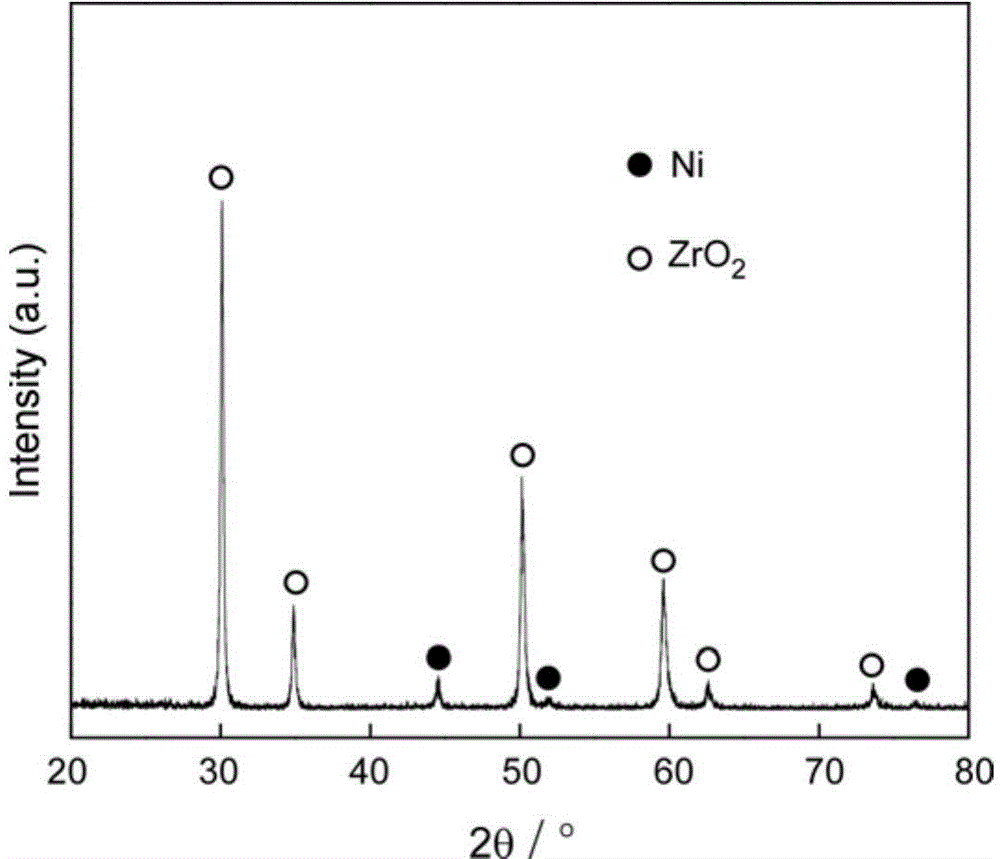

Nickel-based methanation catalyst promoted by in-situ grew carbon nano tube and preparation method for nickel-based methanation catalyst

InactiveCN103769106AHigh catalytic activityEasy to makeGaseous fuelsMetal/metal-oxides/metal-hydroxide catalystsCarbon impuritiesMethanation

The invention discloses a nickel-based methanation catalyst promoted by an in-situ grew carbon nano tube and a preparation method for the nickel-based methanation catalyst and relates to a methanation catalyst. The catalyst comprises a main component and a promoter, wherein the main component comprises Ni and Mg; the promoter is the carbon nano tube and is represented by Ni / MgO-CNTs. The preparation method comprises the steps of mixing Ni(NO3)2*6H2O and Mg(NO3)2*6H2O, and dissolving the mixture in water to prepare a solution A, dissolving NaOH and NaHCO3 in water to prepare a solution B; adding the solution A and the solution B into a reaction container for reaction, aging and filtering precipitation liquid, washing until the filtrate is neutralized, drying and roasting to obtain an Ni / MgO catalyst precursor, then performing tabletting and screening, performing mixed dilution through quartz sand, putting the precursor in a rector, heating to 873K, reducing the precursor to obtain an Ni / MgO catalyst in a reduced state, converting gas flow into CO gas reaction, growing the carbon nano tube in situ, cooling to 823K to remove carbon impurities, and cooling to 473K to obtain a product.

Owner:XIAMEN UNIV

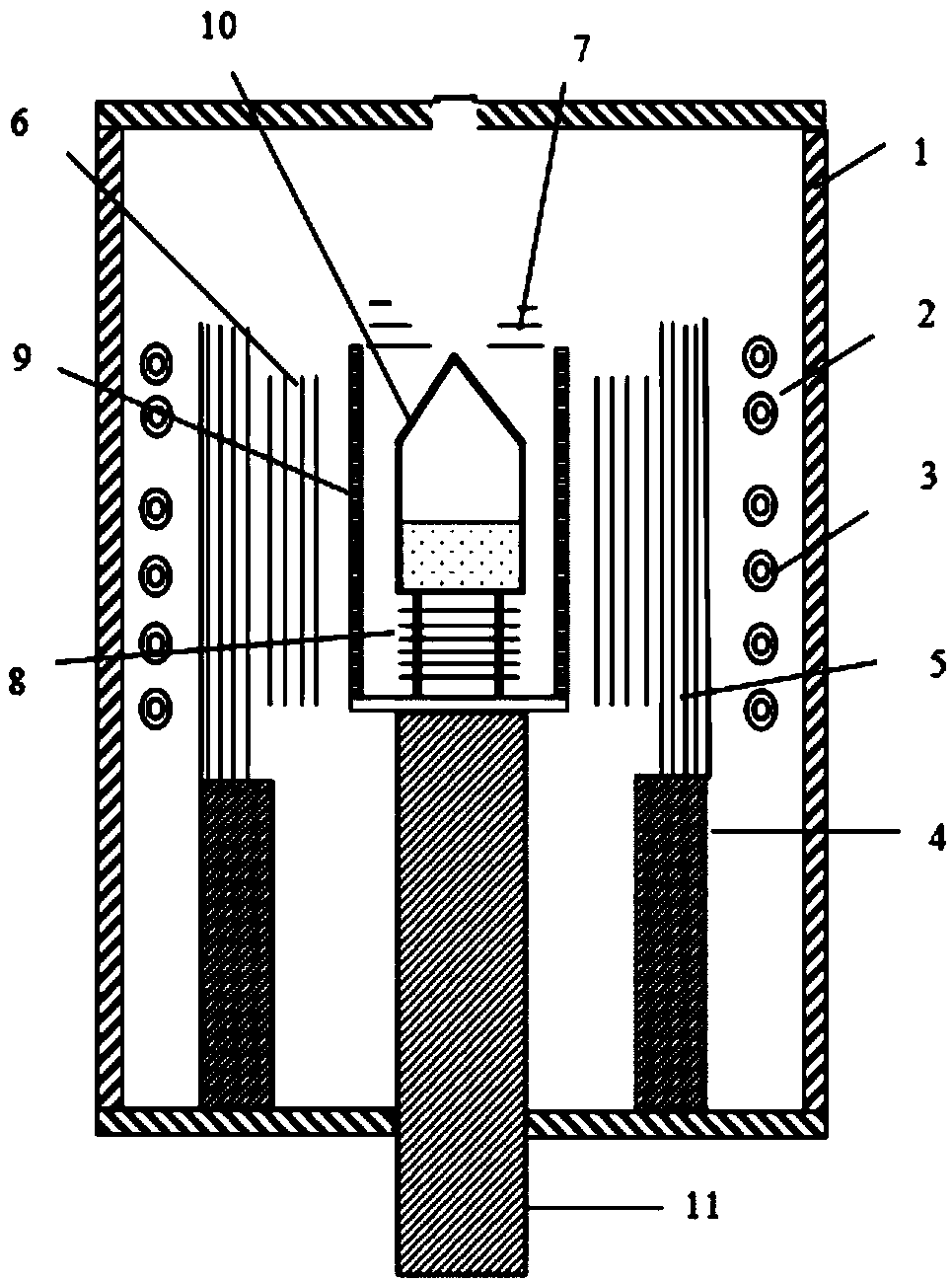

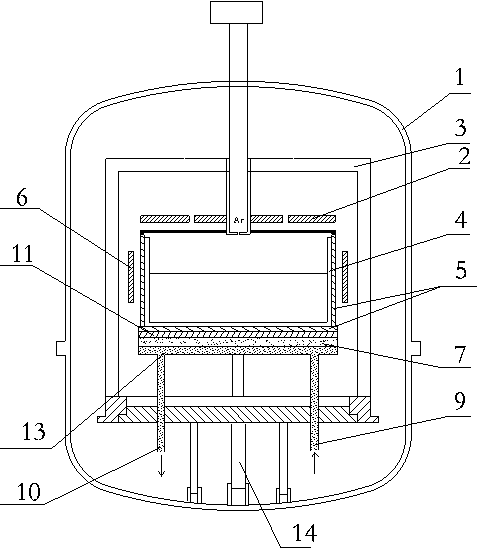

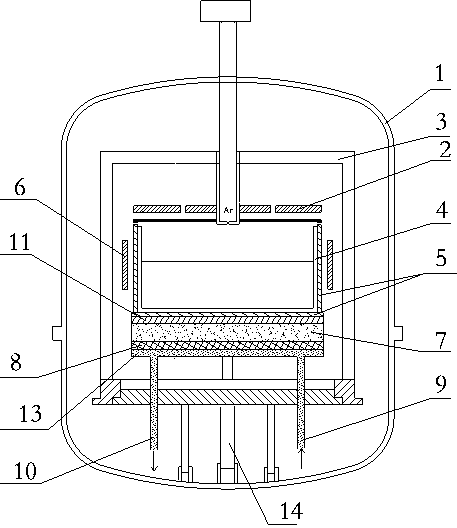

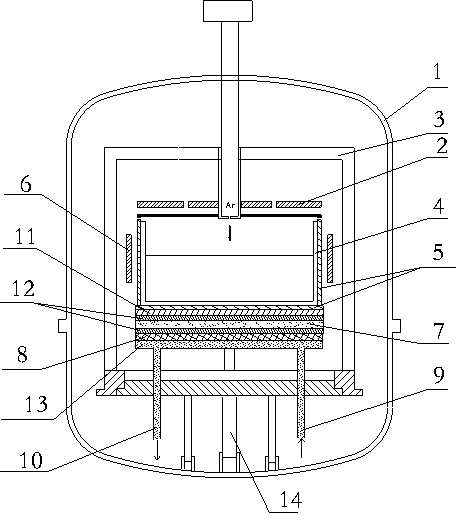

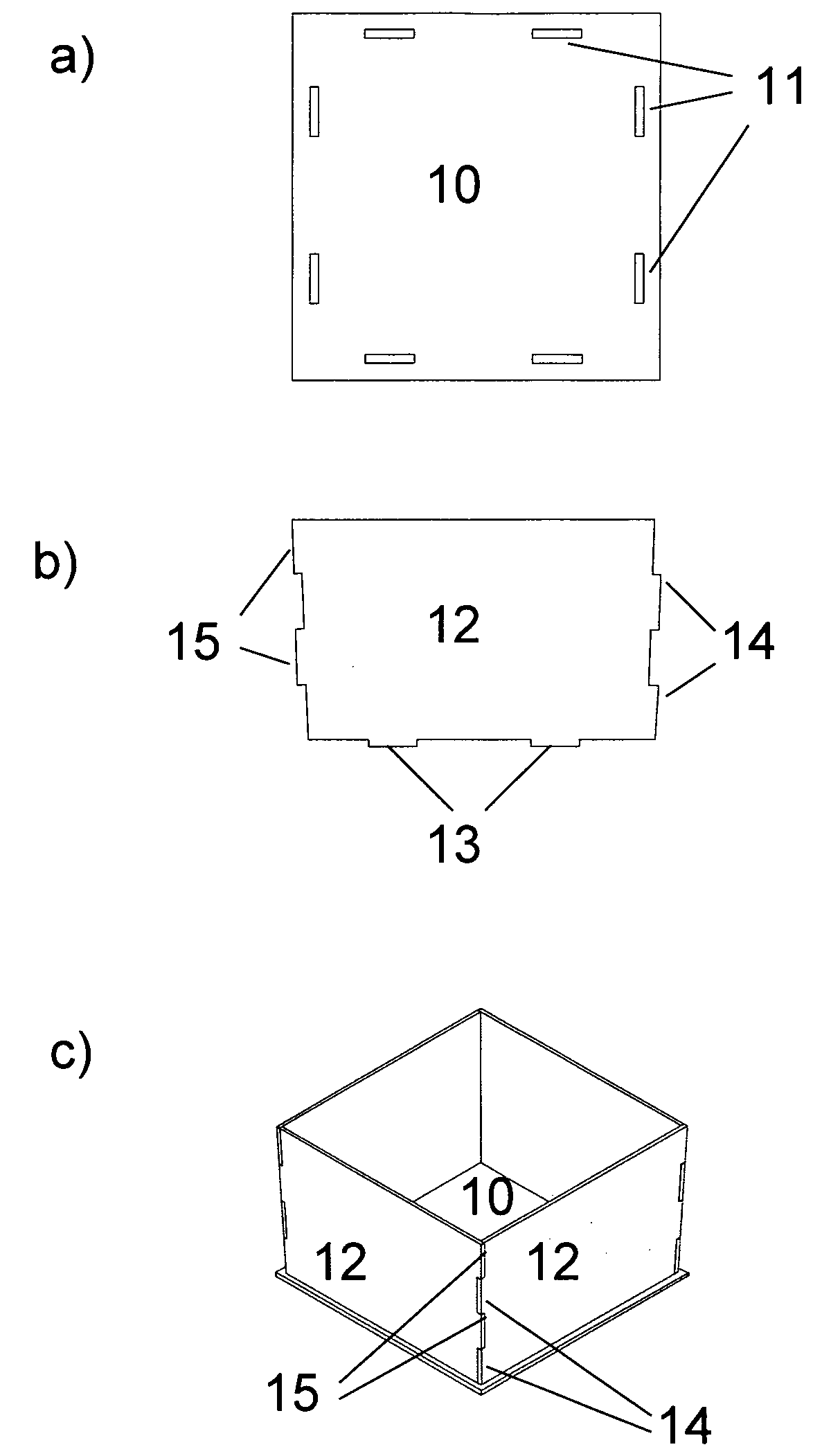

Thermal field for aluminum nitride crystal growth furnace

InactiveCN107916454AFlexible control of temperature gradientsFlexible temperature controlPolycrystalline material growthFrom condensed vaporsThermal insulationCarbon impurities

The invention discloses a thermal field for an aluminum nitride crystal growth furnace. The growth furnace comprises a furnace body and a support rod penetrating through the lower part of the furnacebody, the thermal field comprises a crucible arranged above the support rod, a thermal insulation mechanism as well as multistage heating mechanisms sequentially distributed in the vertical directionin the furnace body and used for heating the crucible, and the thermal insulation mechanism comprises a first thermal insulation screen, a second thermal insulation screen arranged between the crucible and the support rod, a third thermal insulation screen arranged on the outer side of the crucible in a surrounding manner as well as a fourth thermal insulating screen arranged between the third thermal insulation screen and the inner wall of the furnace body in a surrounding manner. The thermal field for the aluminum nitride crystal growth furnace is made of tungsten and boron nitride materials, so that impurity effects of oxygen and carbon impurities in the graphite thermal field on crystal growth are effectively prevented; the temperatures of the top end and the bottom end of the cruciblecan be flexibly regulated by the aid of the multistage heating mechanisms; by means of the movable support rod, the temperature gradient for crystal growth can be controlled conveniently, the crucible can be taken out conveniently, and thus, a furnace chamber can be cleaned.

Owner:SUZHOU AOQU OPTOELECTRONICS TECH CO LTD

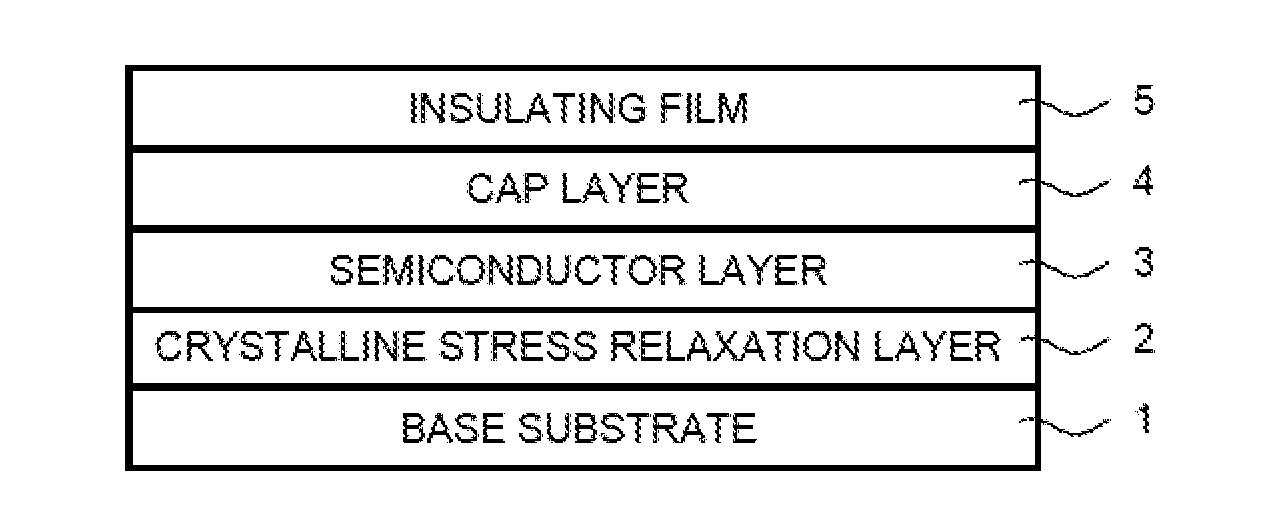

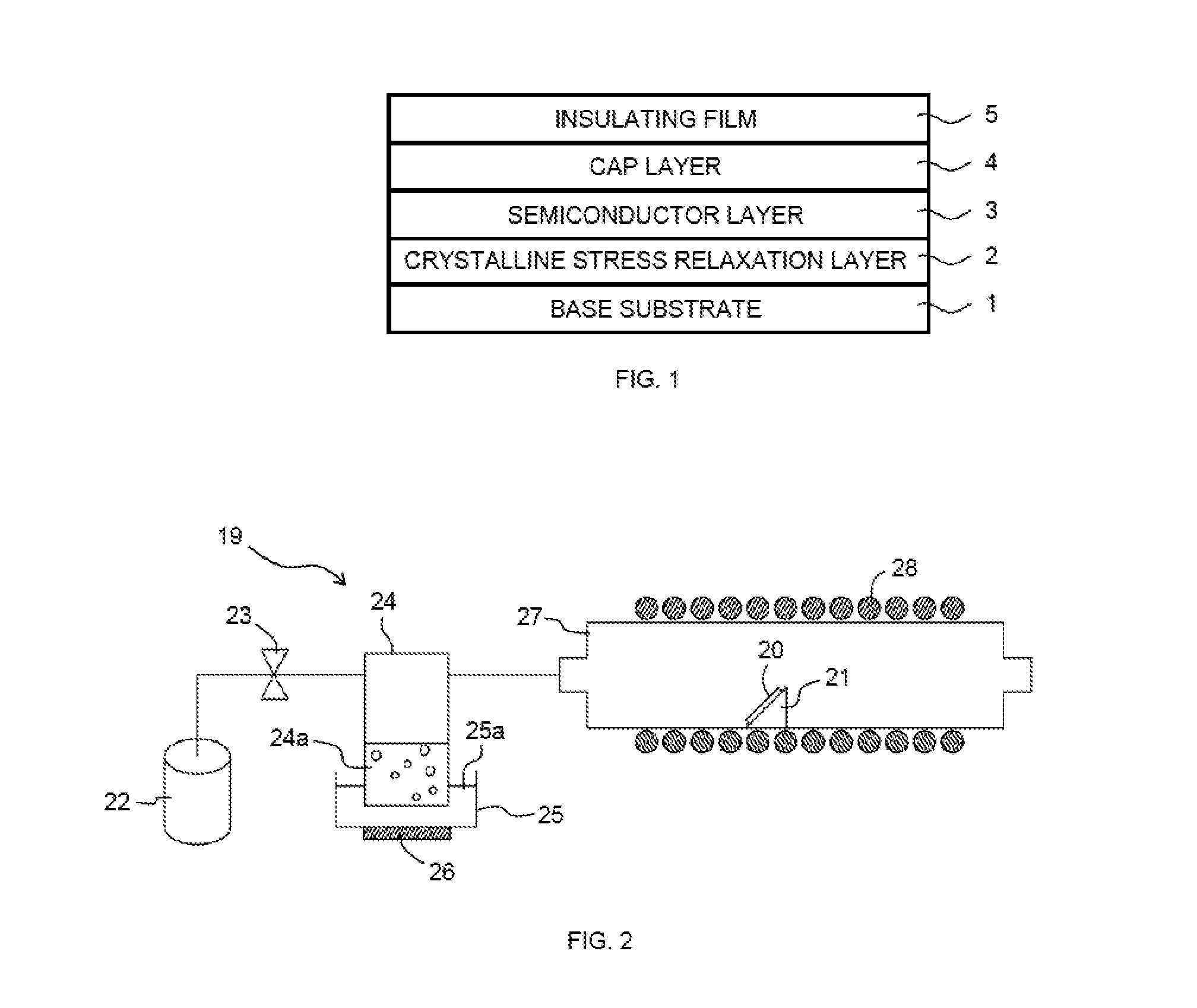

Method of manufacturing oxide crystal thin film

ActiveUS20150225843A1Reduce impurity concentrationFast film formationPolycrystalline material growthSuperconductors/hyperconductorsIodideCarbon impurities

There is provided a thin film manufacturing method which allows both a reduction in the carbon impurity concentration and a high film forming speed, as well as allows separate formation of stable crystal structures. There is provided a method for manufacturing an oxide crystal thin film. The method includes carrying raw material fine particles to a film forming chamber by means of a carrier gas, the raw material fine particles being formed from a raw material solution including water and at least one of a gallium compound and an indium compound, and forming an oxide crystal thin film on a sample on which films are to be formed, the sample being placed in the film forming chamber. At least one of the gallium compound and the indium compound is bromide or iodide.

Owner:FLOSFIA

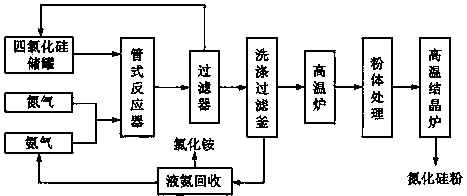

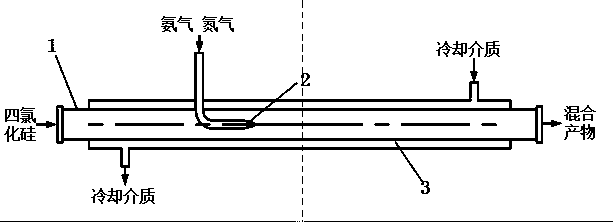

Method for producing silicon nitride powder

The invention discloses a method for producing silicon nitride powder. The method comprises the following steps: 1) reacting silicon tetrachloride and ammonia which are used as raw materials in order to synthesize a silicon nitride precursor Si(NH)2 solid, and obtaining pure Si(NH)2 powder; 2) transferring the Si(NH)2 into a high temperature furnace, and calcining the Si(NH)2 to obtain amorphous silicon nitride powder; and 3) refining and briquetting the obtained silicon nitride powder, transferring the briquetted powder into a high temperature crystallization furnace, and performing calcination to obtain crystalline silicon nitride powder. The method can continuously synthesize the silicon nitride precursor, and can flexibly control the particle size, the shape and the phase composition of the final product silicon nitride powder by adopting two calcination treatments which are low temperature decomposition of the Si(NH)2 and high-temperature crystallization of the amorphous silicon nitride powder; no organic solvents participate in the whole process, so carbon impurities in the silicon nitride powder are avoided; and the raw materials used for the product are produced in large scale in China, so low-cost production of high-purity sub-micron isometric silicon nitride powder is achieved.

Owner:JIANGSU ZHONGNENG POLYSILICON TECH DEV

Method for separating lead from carbon and copper in copper-lead-zinc mixed sulfide ore

The invention discloses a method for separating lead from carbon and copper in copper-lead-zinc mixed sulfide ore. The method comprises the steps of (1) carrying out rough concentration and grinding on the copper-lead-zinc mixed sulfide ore to obtain rough concentrate; (2) regrinding the rough concentrate to obtain ore pulp; (3) sequentially adding modified calcium lignosulphonate, water glass, zinc sulfate, sodium sulfite and sodium cyanide to ore pulp to separate lead from carbon-copper-zinc sulfide; (4) carrying out concentration on the floating product after separation in a concentration tank to obtain lead concentrate; (5) adding a foaming agent to the product in a tank after separation to float the floating product; and (6) adding copper sulfate to the product in the tank for activating, then adding a collector for floating the copper mineral, and carrying out concentration to obtain the copper concentrate. As the method is adopted, the lead grade of the obtained lead concentrate reaches more than 59%, the lead recovery rate reaches about 71-73%, the copper grade of the obtained copper concentrate reaches about 15%, the copper recovery rate reaches about 48-53%, the lead loss rate in carbon impurity is reduced to 1-2% from about 5-8%, and the separating effect is remarkable.

Owner:西安西北有色地质研究院有限公司

Water chilling ingot furnace and ingot casting process thereof

InactiveCN103451726AFacilitated releaseImprove yieldPolycrystalline material growthSingle crystal growth detailsCrucibleIngot casting

The invention discloses a water chilling ingot furnace and an ingot casting process thereof. A water cooling disc (13) is arranged at the lower end of a heat exchange table (11), located at the lower end of a bottom heater (7), internally provided with a flow cavity and provided with a water inlet (9) and a water outlet (10), wherein the water inlet (9) and the water outlet (10) are communicated through the flow cavity, and are respectively communicated with the outer end of a furnace body (1). The water chilling ingot furnace disclosed by the invention has the beneficial effects that the problem of influence on formation of columnar crystals due to transfer of heat of a crucible in a radial direction caused by lifting an insulating cage to dissipate heat from a side is solved by way of replacing the original mode of lifting the insulating cage to dissipate heat by water cooling; an insulating cage body in a lifting process is prevented from rubbing with the top of the insulating cage to generate carbon dust which is easy to enter the crucible to increase carbon impurity content of a silicon ingot so as to cause lattice deformation.

Owner:TIANWEI NEW ENERGY HLDG

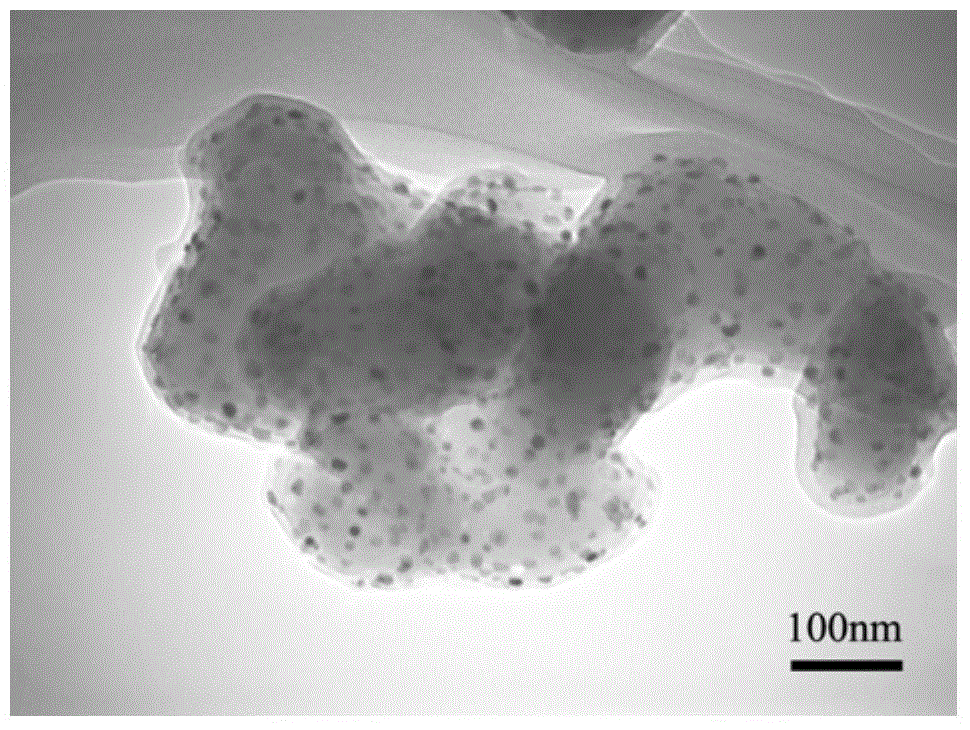

Method for coating surface of oxide ceramic powder with metal nanoparticles

The invention discloses a method for uniformly coating the surface of oxide ceramic powder with carbon impurity-free metal nanoparticles. The method comprises the following steps: grinding and mixing a metal organic raw material and the oxide ceramic powder, and putting the mixture into a rotary reaction chamber; under a rotary heating condition, introducing oxidizing gas to oxidize the metal organic raw material into a metal oxide; and introducing reductive gas to reduce the metal oxide into metal-state nanoparticles. Through adoption of the method, uniform coating of the metal-state nanoparticles is realized, and the problems of roughening and growing of the nanoparticles caused by a long-term coating reaction at a high temperature are solved. The method disclosed by the invention is simple, and is short in the preparation period. The prepared metal nanoparticles are dispersed uniformly, and the oxide ceramic powder coated by the metal nanoparticles have wide application prospects in a plurality of fields as a catalytic material, conductive ceramics and the like.

Owner:HOHAI UNIV

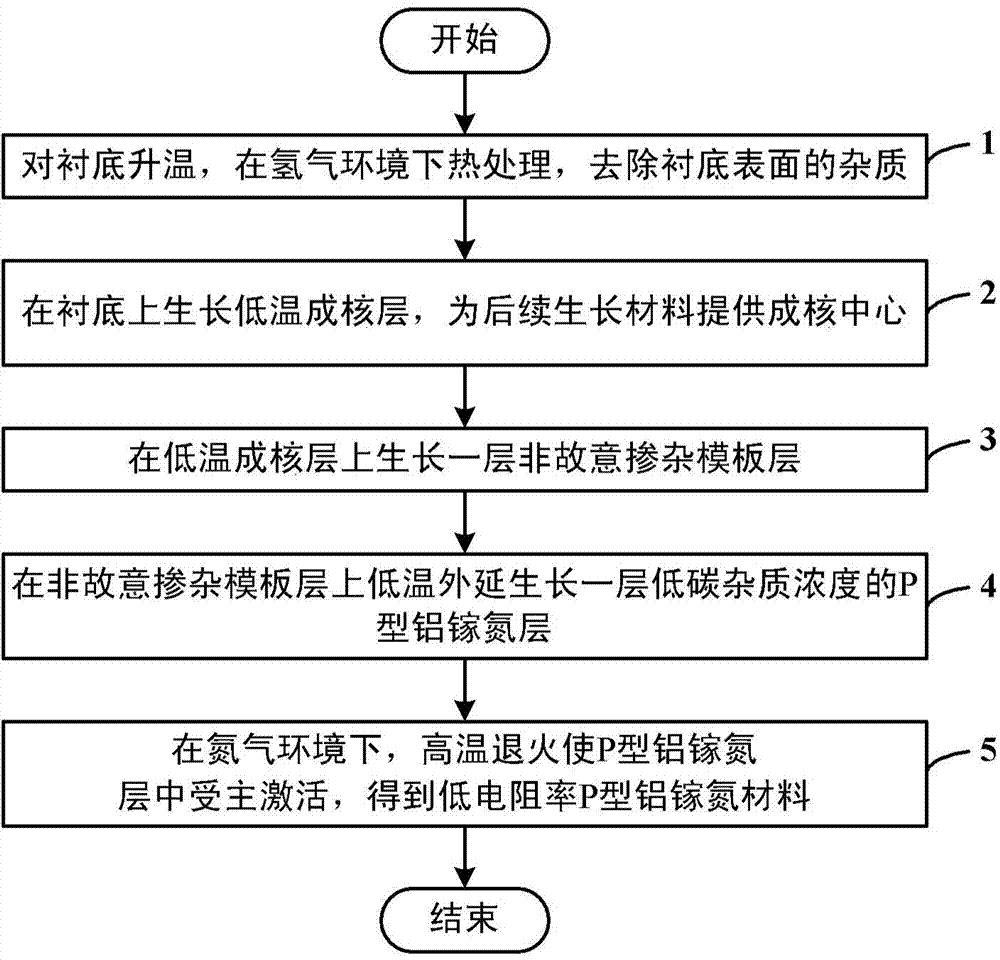

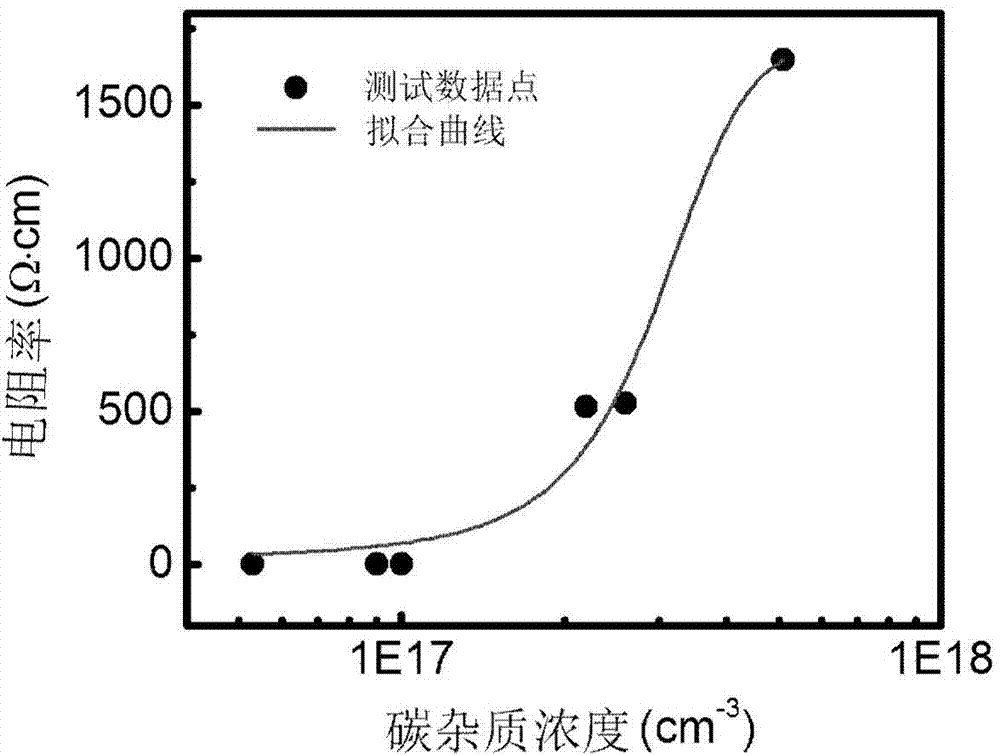

Low-electrical-resistivity p-type aluminum gallium nitrogen material and preparation method thereof

InactiveCN104332545ALow resistivityReduce concentrationLaser detailsSemiconductor lasersHydrogenCarbon impurities

The invention discloses a low-electrical-resistivity p-type aluminum gallium nitrogen material and a preparation method thereof. The preparation method includes the following steps: raising the temperature of a substrate and carrying out heat treatment under a hydrogen environment and removing impurities of the surface of the substrate; growing a low-temperature nucleating layer on the substrate and providing a nucleating center for follow-up growth materials; growing a layer of unintentionally doped template layer on the low-temperature nucleating layer; epitaxially growing a layer of low-carbon-impurity-concentration P-type aluminum gallium nitrogen layer on the unintentionally doped template layer in a low-temperature; and under a nitrogen environment, carrying out high-temperature annealing so as to make an acceptor in the P-type aluminum gallium nitrogen layer activated and thus the low-electrical-resistivity p-type aluminum gallium nitrogen material is obtained. When the preparation method is changed, through change of the growth conditions, the concentration of unintentionally doped carbon impurities in the low-temperature-growth P-type aluminum gallium nitrogen material is reduced so that the compensation action of the acceptor is reduced and an objective of reducing the electrical resistivity of the P-type aluminum gallium nitrogen material is achieved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

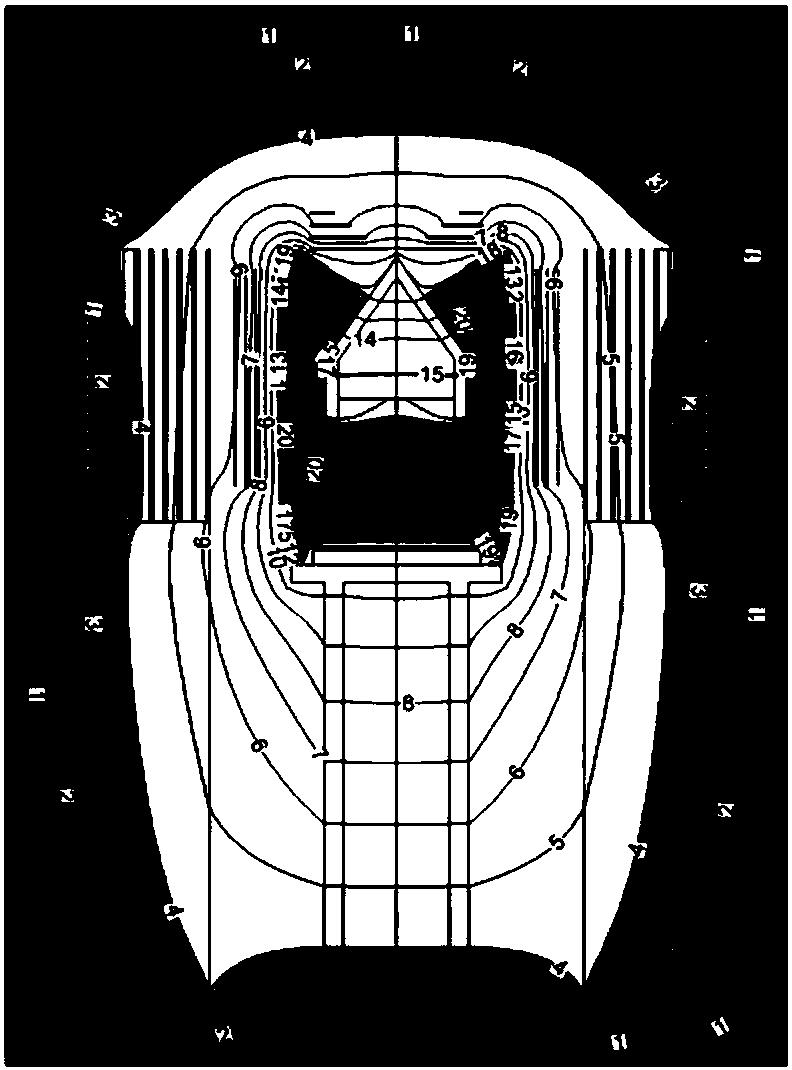

Method and crucible for direct solidification of semiconductor grade multi-crystalline silicon ingots

InactiveUS20090208400A1Reduce thermal resistanceIncrease the rate of crystallizationPolycrystalline material growthSiliconCrucibleCarbon impurities

This invention relates to a method for direct solidification of semiconductor grade multi-crystalline silicon ingots allowing improved control with the solidification process and reduced levels of oxygen and carbon impurities in the ingot, by crystallizing the semiconductor grade silicon ingot, optionally also including the melting of the feed silicon material, in a crucible made of silicon nitride, or in a crucible made of a composite of silicon carbide and silicon nitride, and where the wall thickness of the bottom of the crucible is dimensioned such that the thermal resistance across the bottom is reduced to a level of at least the same order as thermal resistance across the support below carrying the crucible or lower. The invention also relates to crucibles which are made of silicon nitride, or of a composite of silicon carbide and silicon nitride, and where the wall thickness of the bottom of the crucible is dimensioned such that the thermal resistance across the bottom is reduced to a level of at least the same order as thermal resistance across the support below carrying the crucible or lower.

Owner:REC SCANWAFER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com