Production system and process of pigment carbon black with low impurity content

A pigmented carbon black and production system technology, applied in the direction of fibrous fillers, etc., can solve the problems of carbon black product quality and adverse effects of application, and achieve the effects of simple structure, increased quality, and prevention of coking on the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

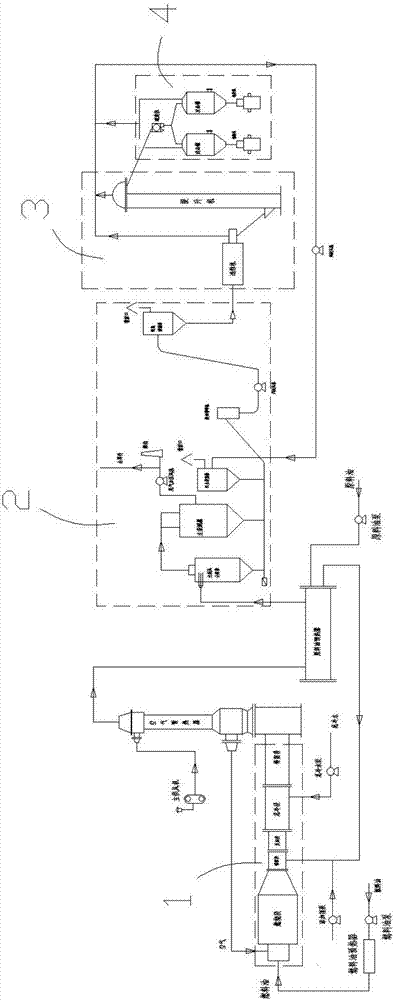

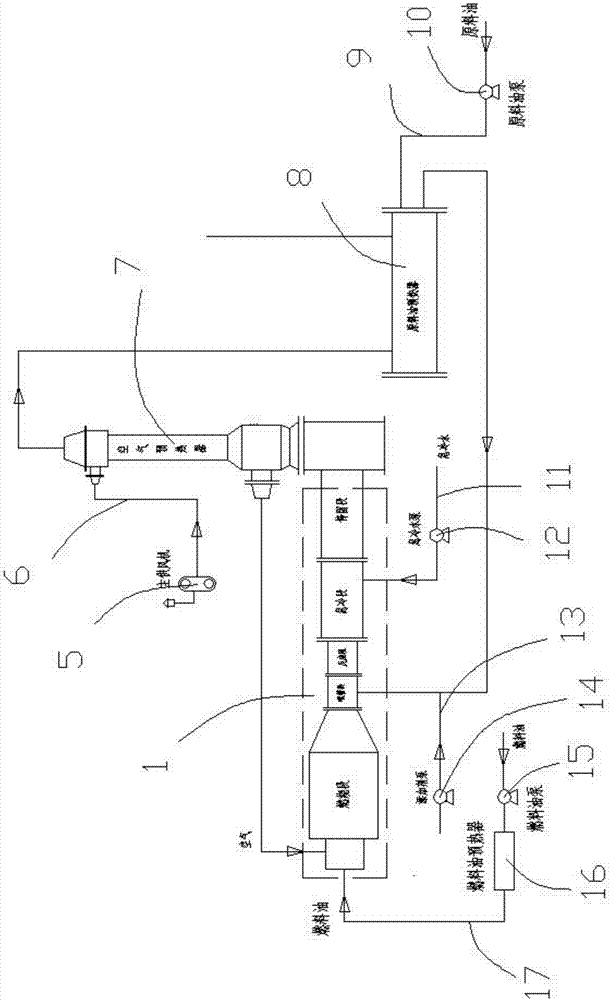

[0053] This embodiment provides a pigment carbon black production system with low impurity content, comprising a raw material supply device, a reaction device 1, a preheating device, a collection device 2, a granulation device 3 and a storage and packaging device 4, and the raw material supply device includes and Raw material oil pump 10, fuel oil pump 15, additive pump 14, quenching water pump 12, and main supply fan 5 matched with the reaction device;

[0054] The preheating device includes an air preheater 7, a raw oil preheater 8, and a fuel oil preheater 16;

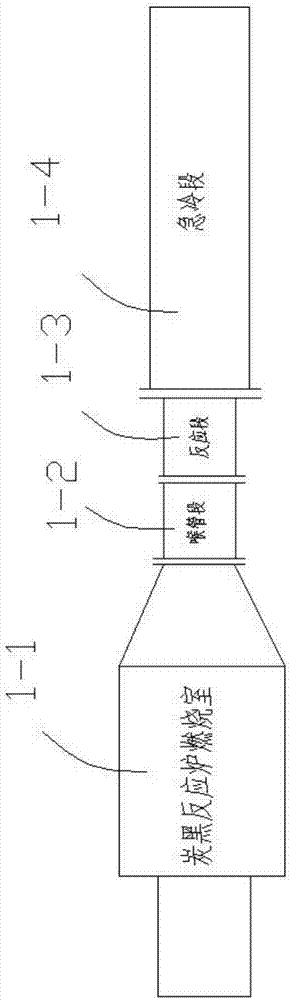

[0055] Reactor 1 comprises the carbon black reaction furnace combustion section 1-1, throat section 1-2, reaction section 1-3, rapid cooling section 1-4 and stay section 1-5 that are arranged in sequence; The outlet is connected to the air preheater 7 and the raw oil preheater 8 in turn, and the gas outlet of the raw oil preheater 8 is connected to the collecting device 2;

[0056] The collection device 2 includes ...

Embodiment 2

[0064] A production process of pigment carbon black with low impurity content, comprising the following steps:

[0065] Step 1): selection and purification of raw oil: the raw oil is unloaded from the oil tanker, transported to the oil tank, and then sent to the reaction device to set up 4 oil filtration devices. The content of aromatics in the raw oil is between 120 and 175, and the content of asphaltene ≤2%, require sodium content ≤20ppm, potassium content ≤2ppm, ash content ≤0.05%;

[0066] Step 2): The preheated air reaches about 750°C, and the preheated air and the preheated combustion oil are fully mixed, reacted and burned in the combustion chamber of the carbon black reaction furnace of the reaction device;

[0067] Step 3): After burning in step 2, a high-temperature combustion airflow with a temperature of about 1950°C is generated, and the high-temperature combustion airflow flows into the throat section;

[0068] Step 4): After the high-temperature combustion air ...

Embodiment 3

[0075] This embodiment is further optimized on the basis of embodiment 2, specifically:

[0076] The 4 oil filter devices include a first filter device, a second filter device, a third filter device, and a fourth filter device, and the first filter device is for the oil tanker to the oil tank inlet and outlet 5-mesh filter screen, the aperture of the filter screen is 4mm; the second filter device is two negative pressure 20-mesh oil filters connected in parallel at the inlet of the oil pump sent from the oil tank to the workshop process tank, the oil filter The pore size of the screen is 850 μm; the third filtering device is two negative pressure 35 mesh oil filters connected in parallel at the inlet of the process oil pump sent from the workshop process tank to the raw material oil preheater. The pore size of the screen of the device is 500 μm; the fourth filter device is two positive pressure 50 mesh oil filters connected in parallel from the outlet of the raw material oil p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com