Patents

Literature

3425 results about "Air preheater" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An air preheater (APH) is any device designed to heat air before another process (for example, combustion in a boiler) with the primary objective of increasing the thermal efficiency of the process. They may be used alone or to replace a recuperative heat system or to replace a steam coil.

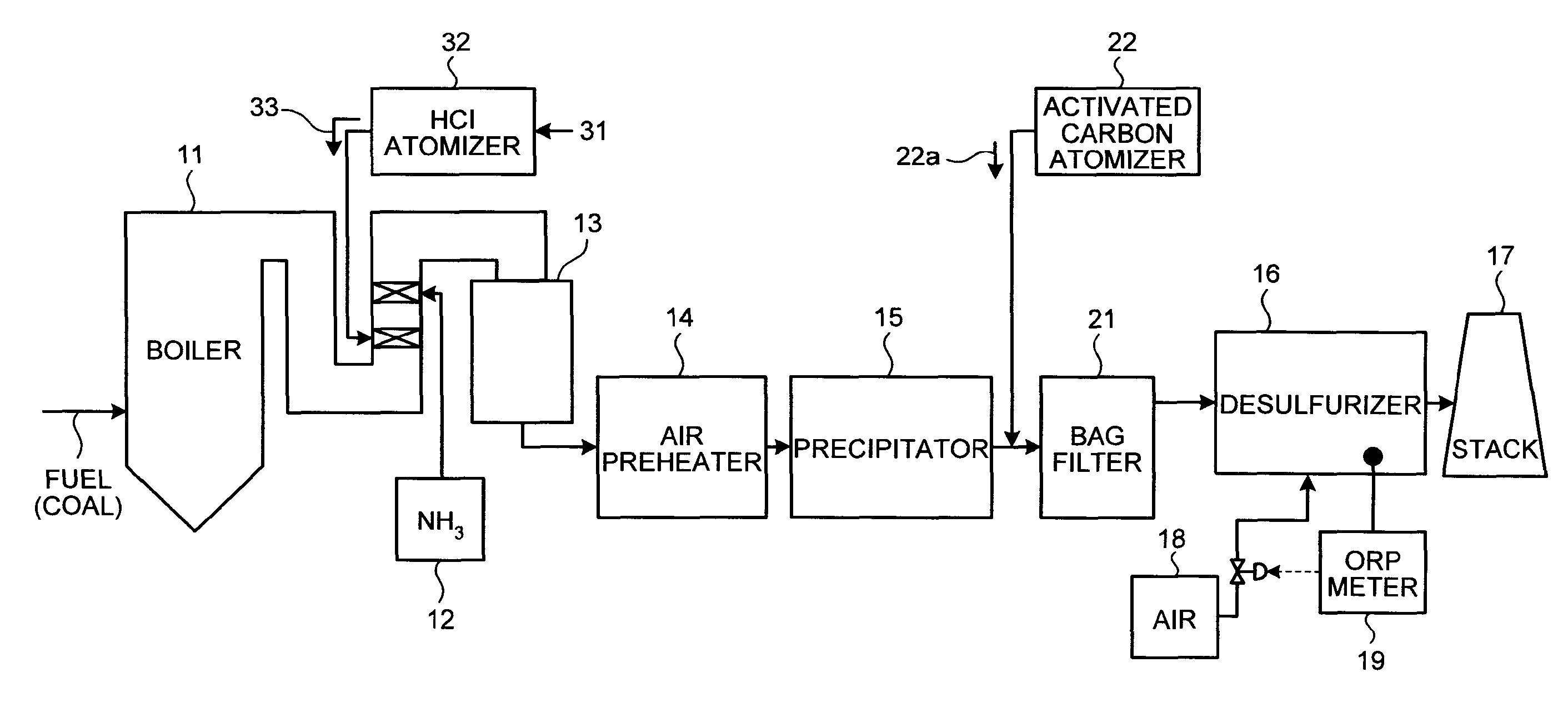

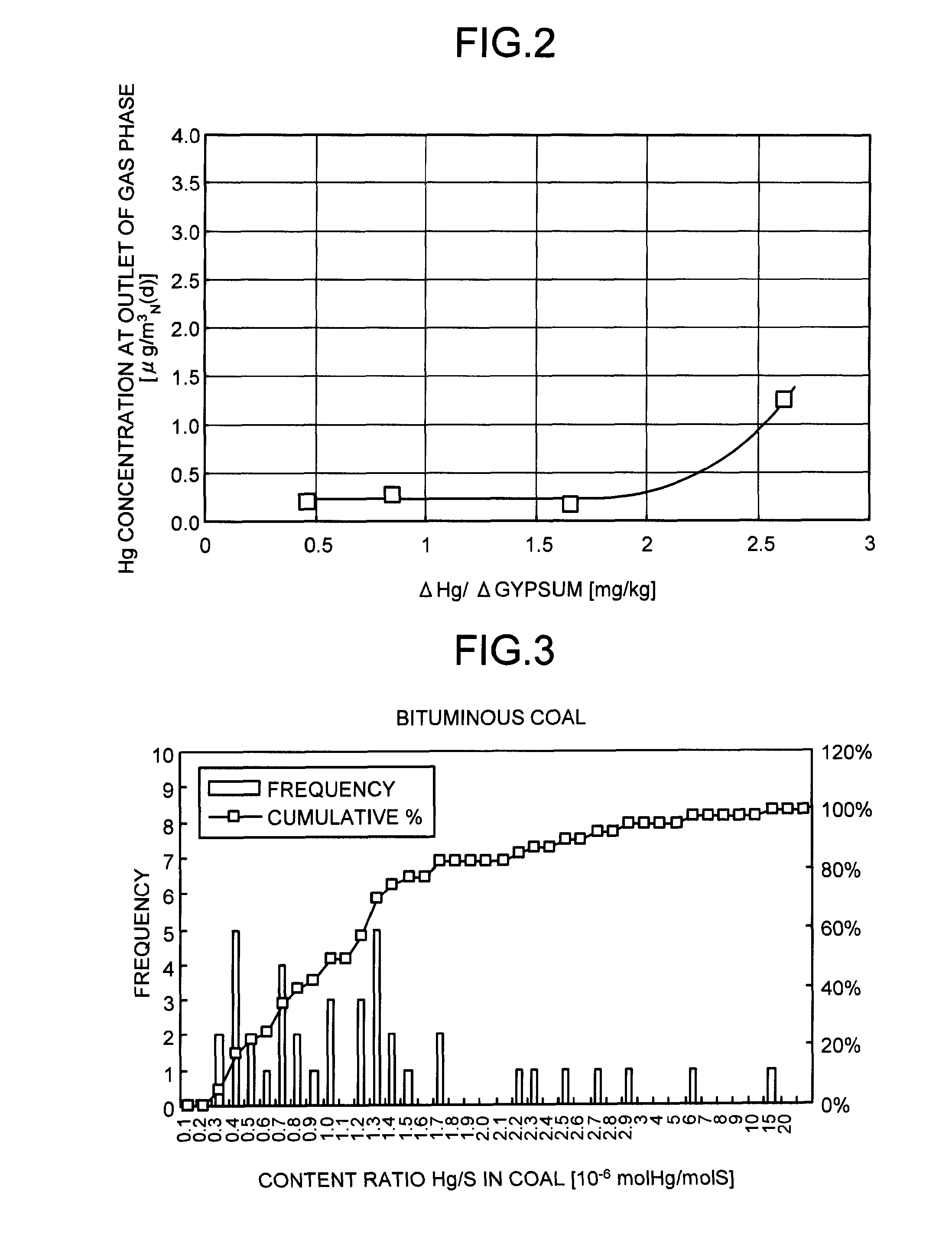

Flue gas control system of coal combustion boiler and operating method thereof

ActiveUS8071060B2Reduce operating costsCombination devicesNitrogen compoundsAir preheaterParticulates

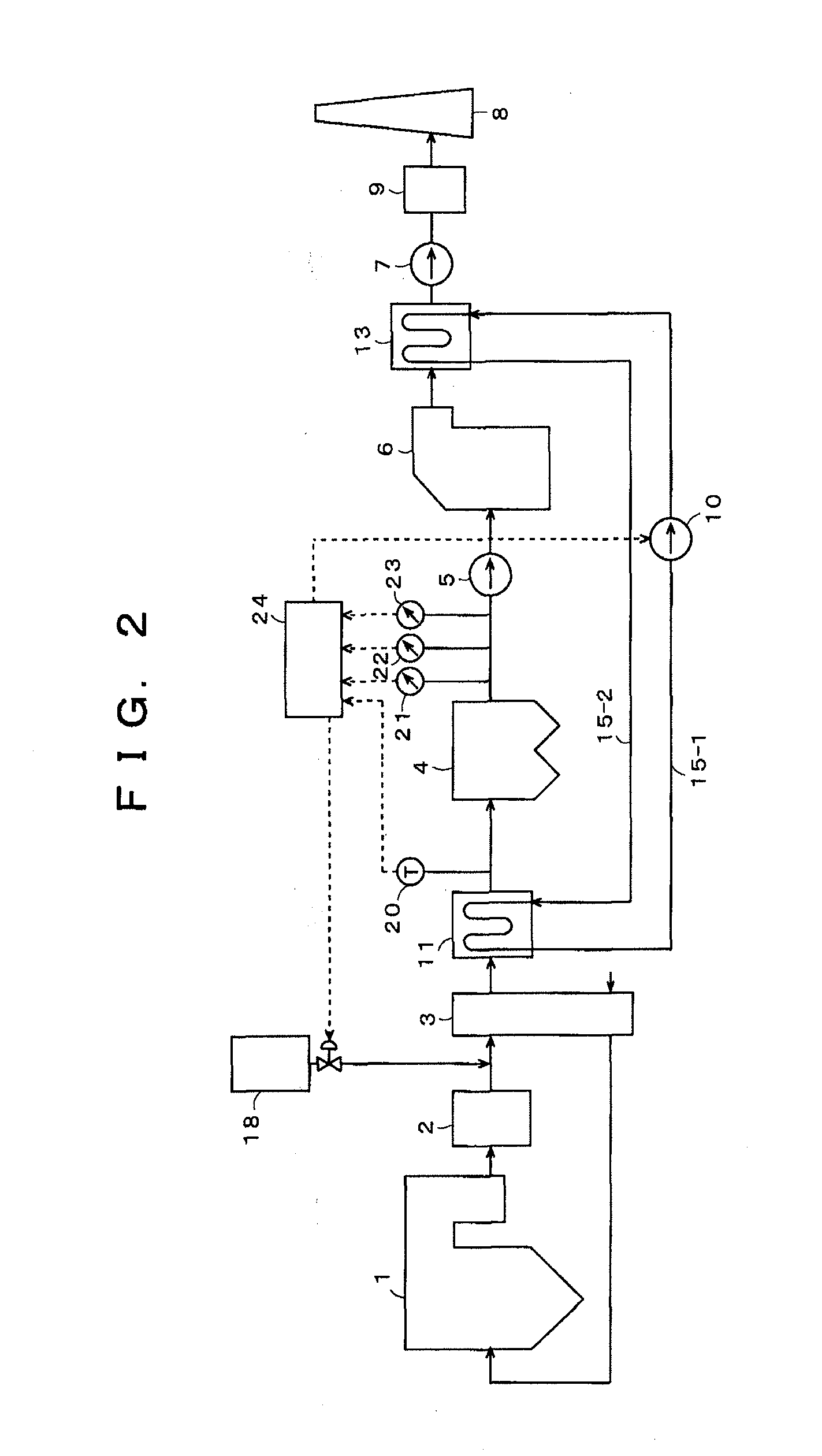

A flue gas control system of a coal combustion boiler comprises an HCl atomizer that sprays hydrogen chloride to flue gas from a coal combustion boiler that uses coal as a fuel; NOx removing apparatus that removes nitrogen oxides by ammonia denitration by adding ammonia to the flue gas after spraying hydrogen chloride and oxidizes mercury; an air preheater that recovers heat in the gas after removal of nitrogen oxides; a precipitator that removes particulates in the gas; an activated carbon atomizer that sprays activated carbon into the gas after particulate collection; a bag filter that collects activated carbon having adsorbed mercury; a desulfurizer that removes sulfur oxides in the flue gas after removal of activated carbon; a stack that discharges the gas which has undergone desulfurization to outside; and an ORP meter that measures an oxidation reduction potential for feeding air to a slurry absorbent in the desulfurizer.

Owner:MITSUBISHI HEAVY IND LTD

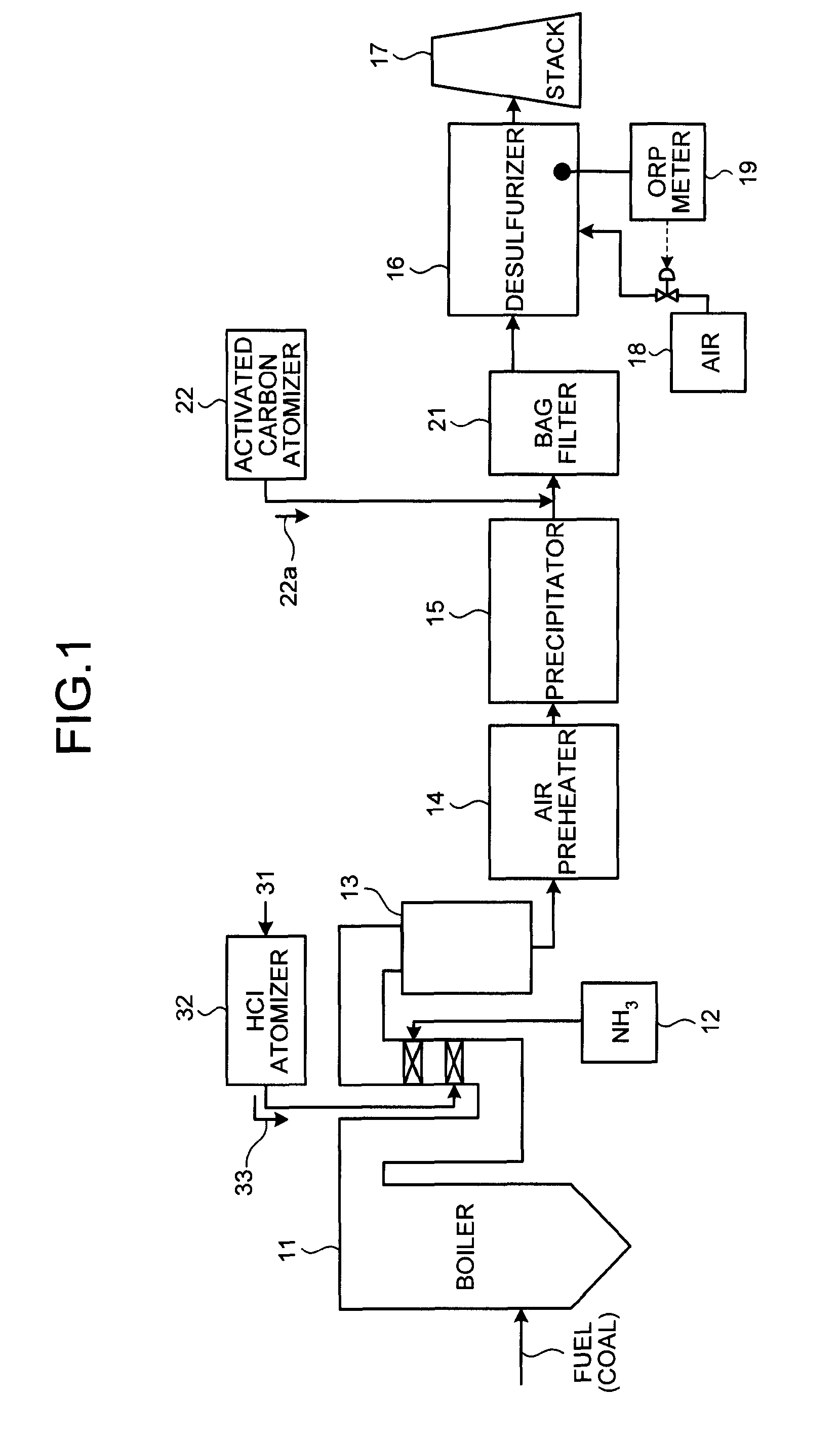

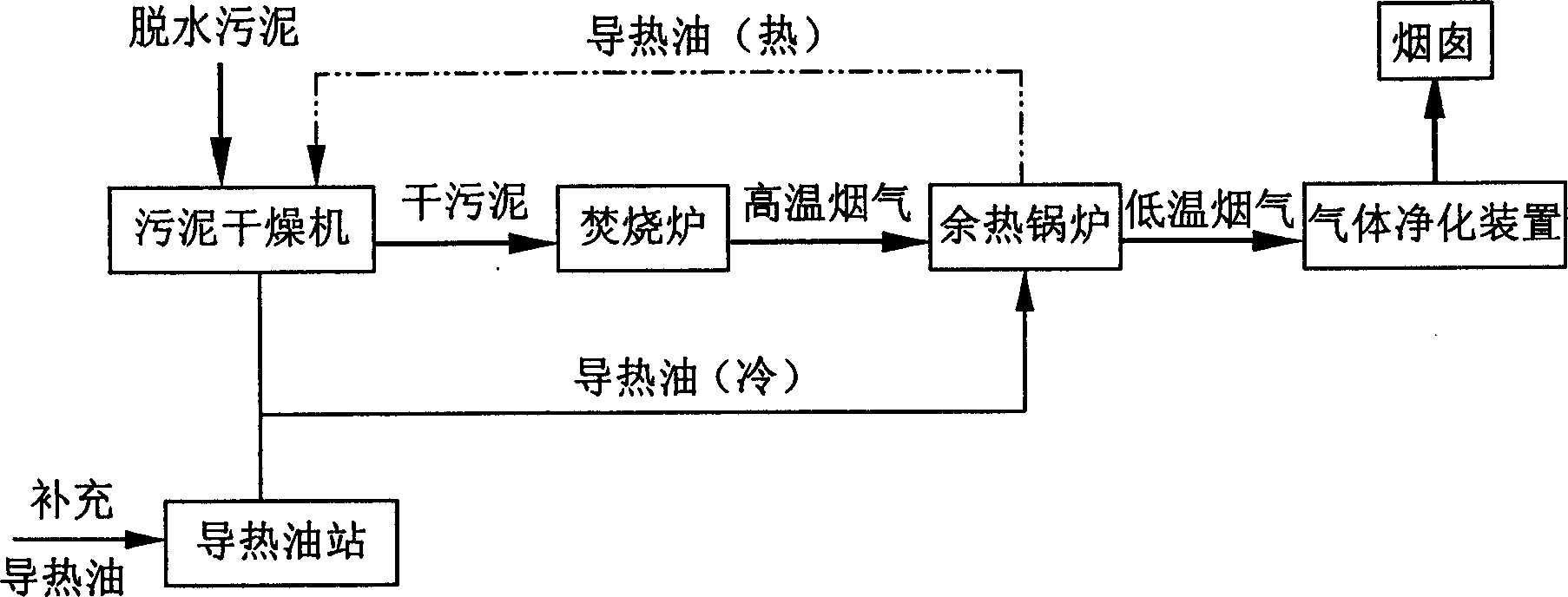

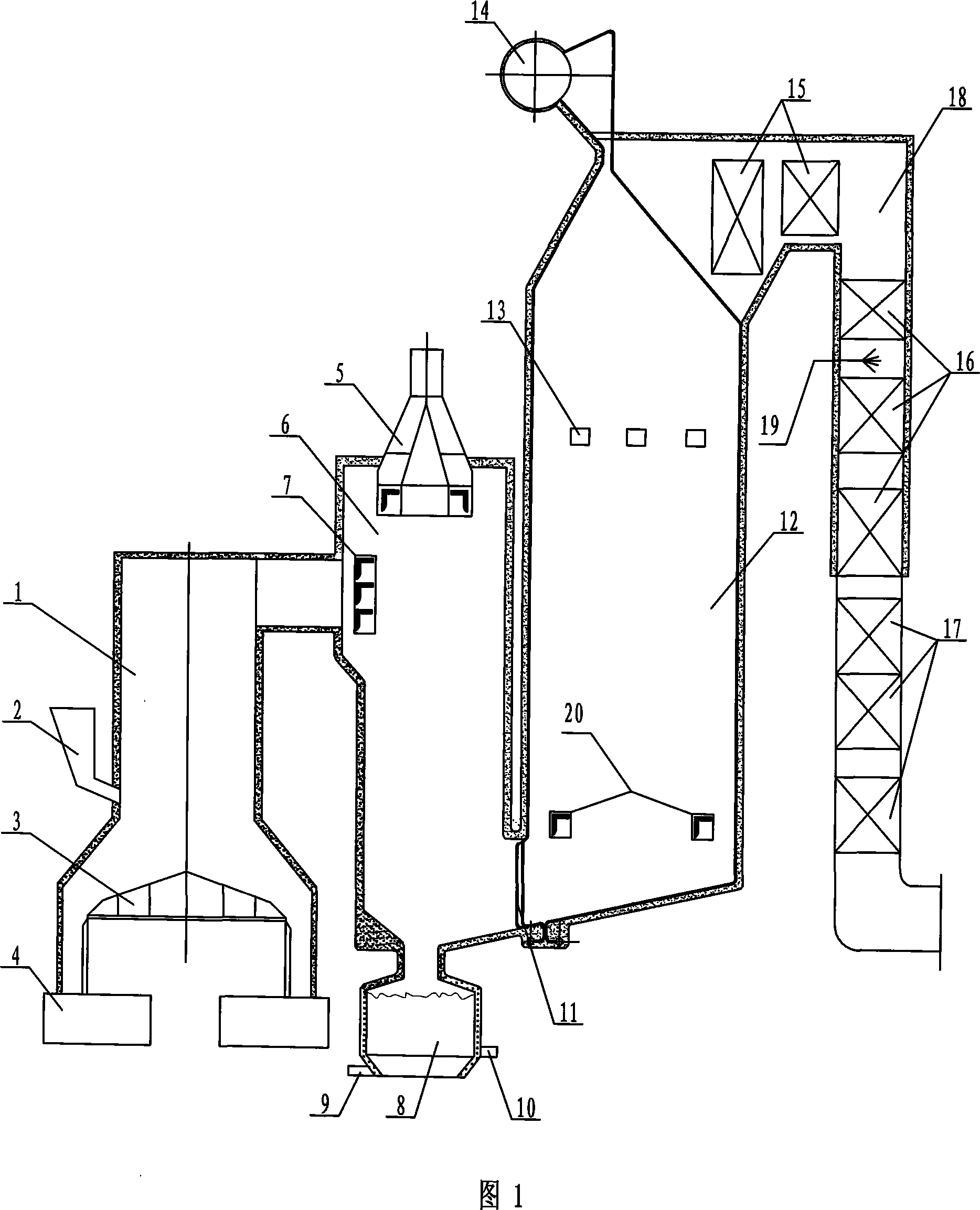

Sludge anhydration and burning process, and its systematic device

ActiveCN1800062ALow investment costLow running costSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationAir preheaterHeat conducting

The invention relates to a sludge drying and burning technique and its system devices, applying to the handling of active sludge in urban sewage treatment plants, its process flows through: wet sludge stock house, measuring bin, sludge mixer, sludge dryer, granular splitter, cooler, drying products storage bin, incinerator, smoke gas cleaning devices, which is characterized by: said incinerator is bubbling fluid bed incinerator with coal economizer, air heater fixed in its end part, high-heat smoke gas generated by burning is used to heat heat-conducting oil and cool air individually, and heat-conducting oil after being heated is transferred to sludge dryer through the circulating pump to dry wet-sludge. The invention is characterized by: take heat-conducting oil as heating medium, use the heat generated by burning dry sludge to heat heat-conducting oil and then dry wet-sludge to make full use of resources; the volume-reducing quantity after drying and burning could reach over 90%; the percentage of desulphurization in incinerator could reach 75% as a result of adopting two stage technology of sulfur removal, and the gross percentage of desulphurization meets national environmental legislation requirements. The invention accomplishes the resources, volume reduction, and innocence of sludge.

Owner:贵州筑信水务环境产业有限公司

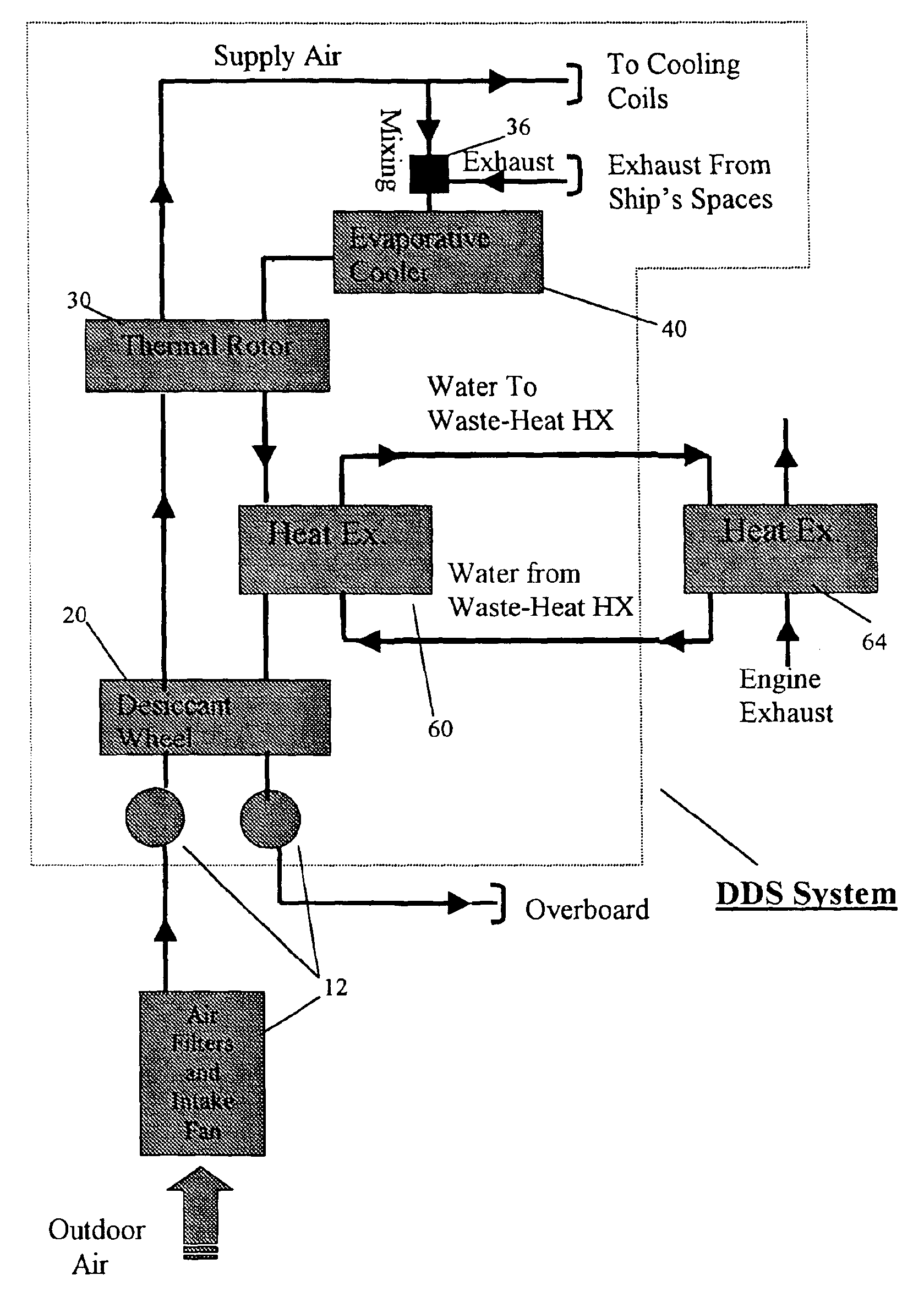

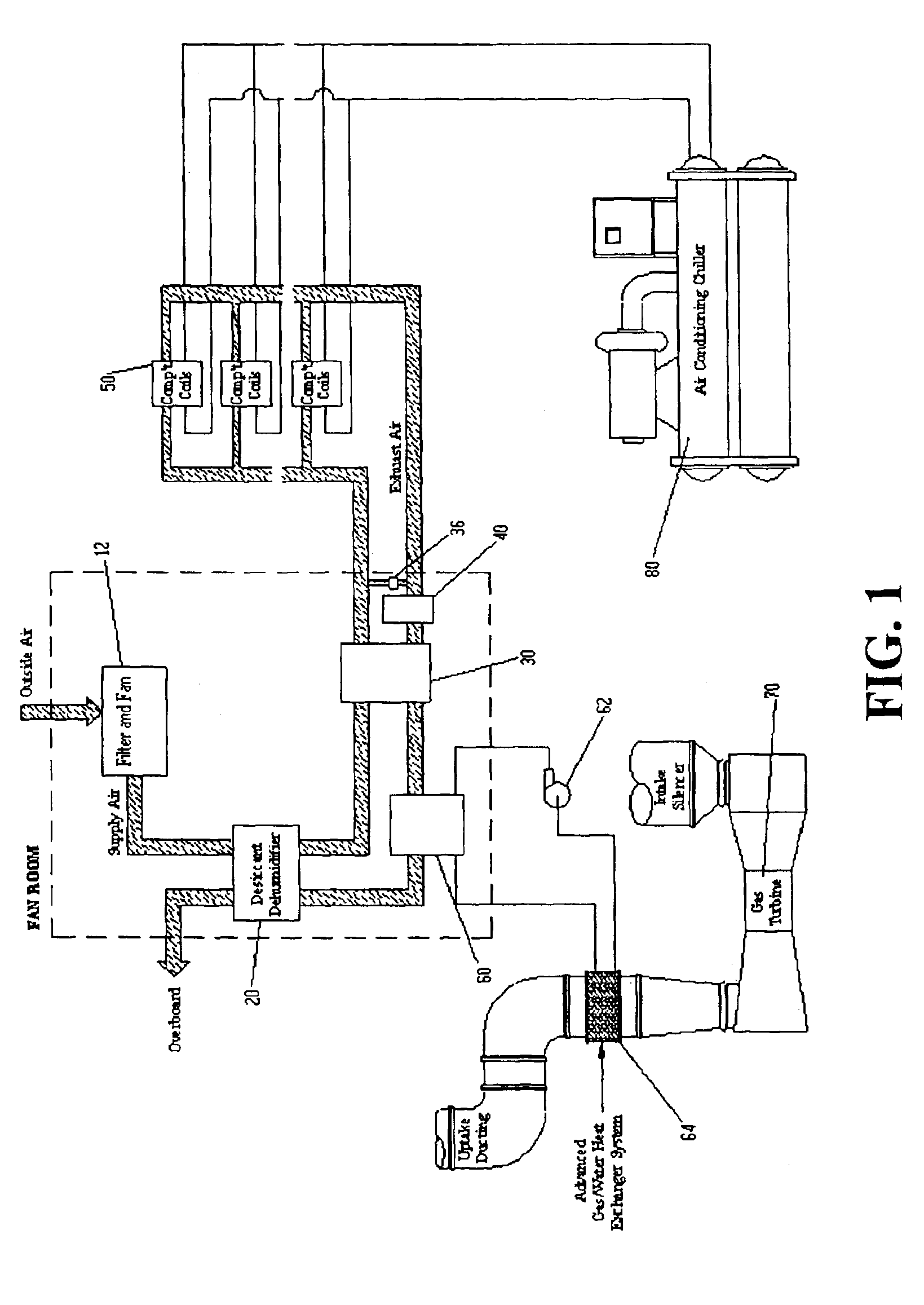

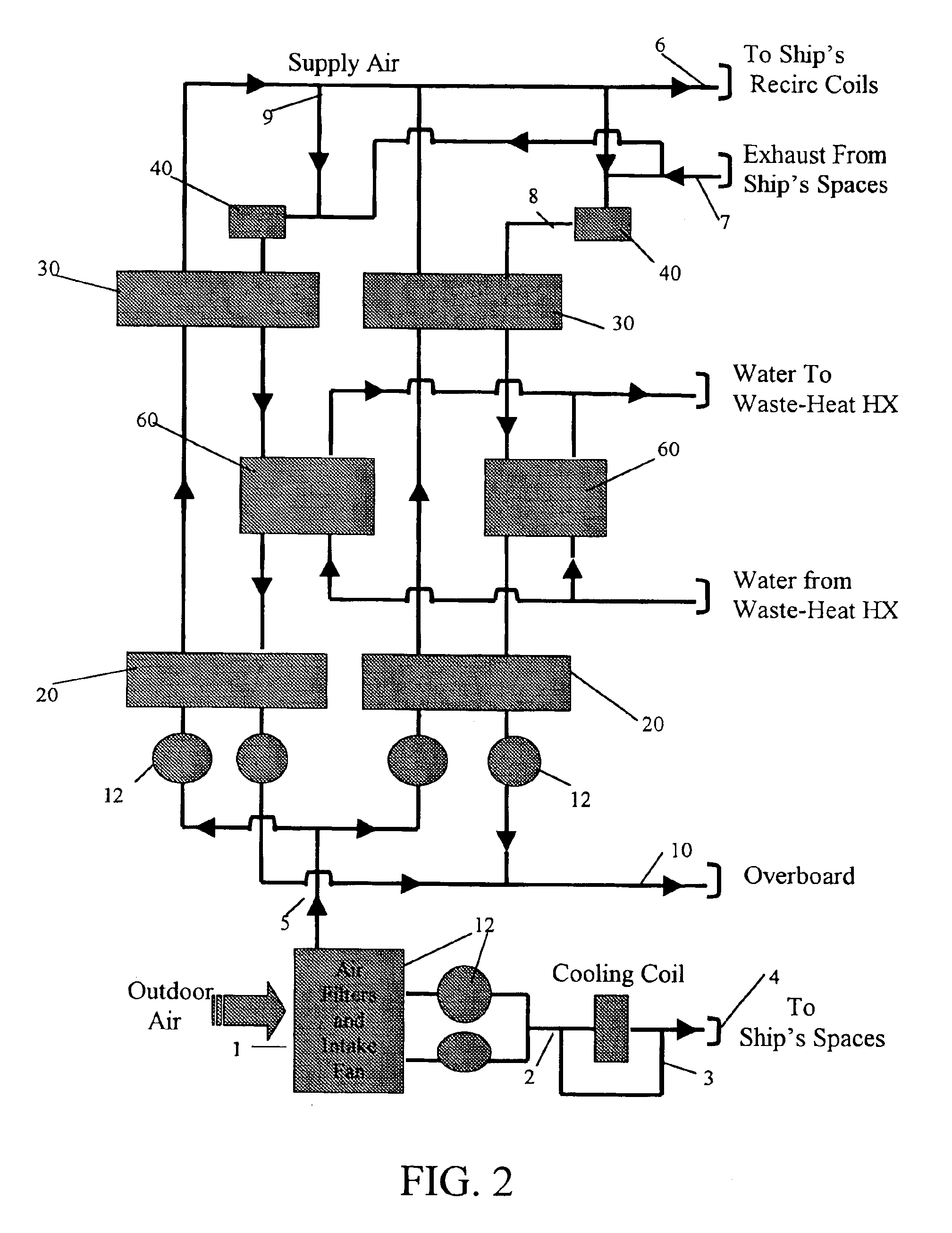

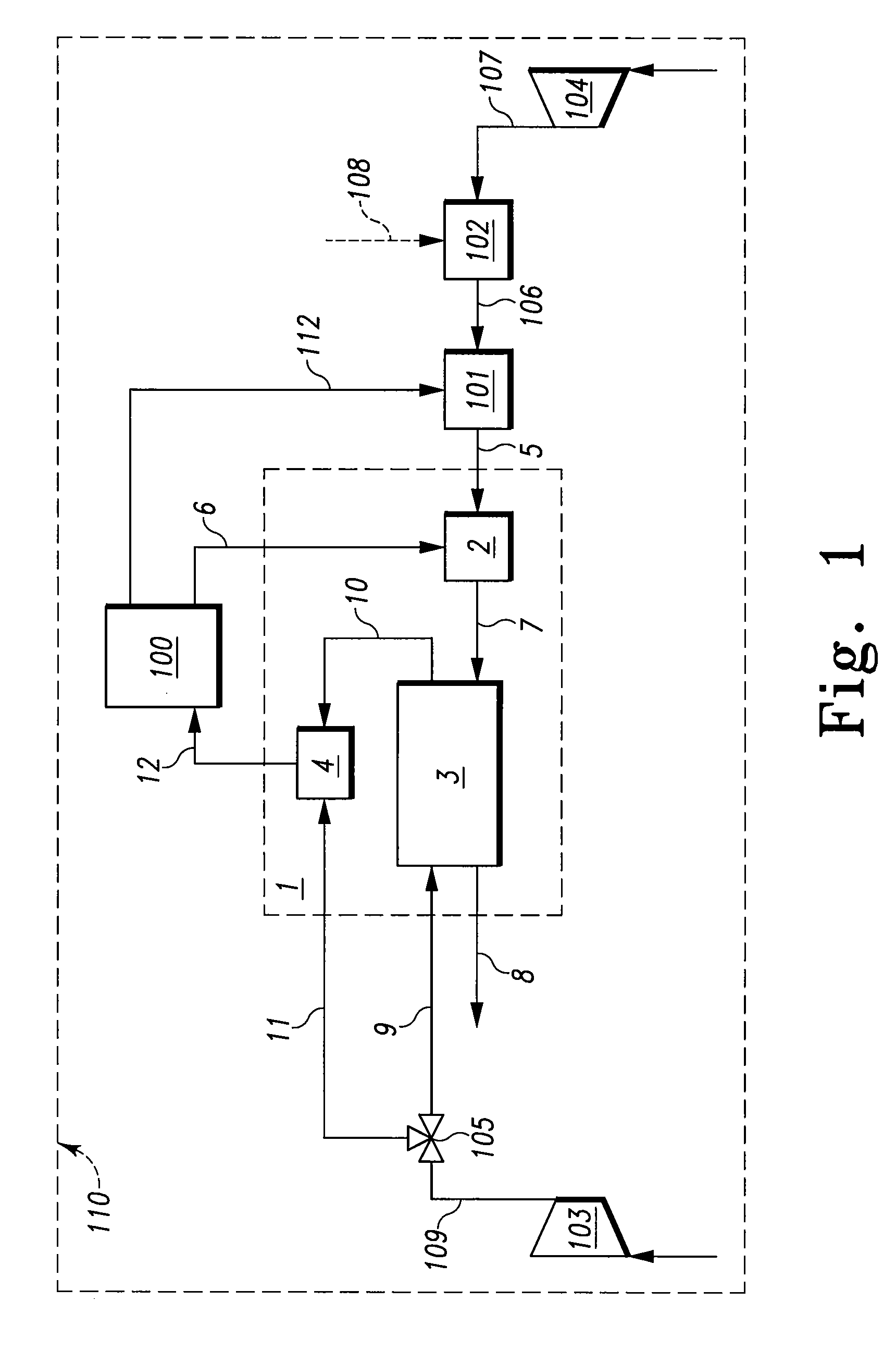

Dynamic desiccation cooling system for ships

InactiveUS6854279B1Air treatment detailsLighting and heating apparatusAir preheaterEvaporative cooler

The present invention describes methods and apparatus for controlling the humidity of air supplied to cooling coils on a gas turbine powered ship through a dynamic desiccation system. The system passes supply air through a desiccant wheel, which dries and concomitantly heats the supply air. This supply air stream is then passed through a rotatable thermal wheel, wherein heat is transferred from the dry supply air to an exhaust-air mixture, thereby conditioning the supply air for delivery and circulation to a plurality of cooling-coil units in a plurality of compartments. The exhaust air from the compartments is first mixed with some of the treated supply air to lower the absolute humidity to a value needed for effective regeneration of the desiccant wheel. An evaporative cooler then conditions the exhaust-air mixture for effective cooling of the supply air in the thermal rotor, which also serves as an air preheater for desiccant regeneration. The exhaust-air mixture is then heated to the desiccant regeneration temperature by passing the preheated exhaust air through a heat exchanger supplied with gas-turbine waste heat. After this heated exhaust-air mixture regenerates the desiccant wheel by fully drying out the desiccant on the wheel, it is expelled from the fan room.

Owner:CHIEF OF NAVAL RES OFFICE OF COUNSEL DEPT OF COUNSEL

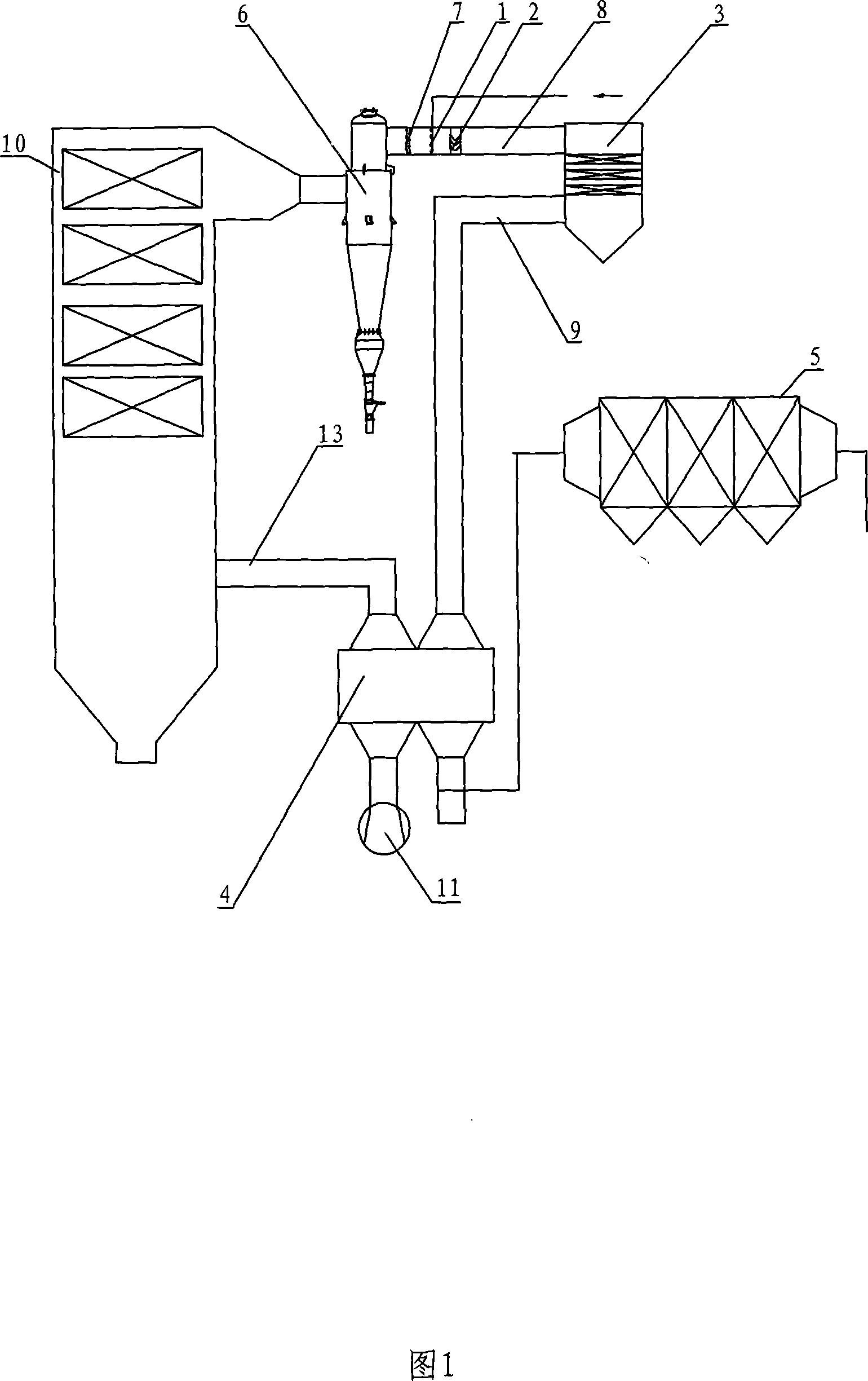

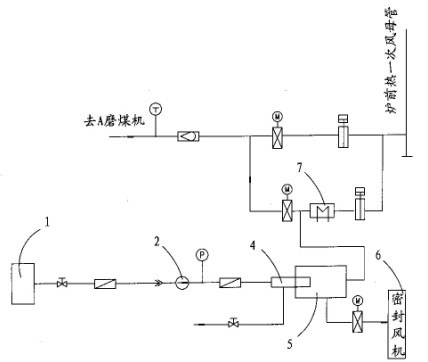

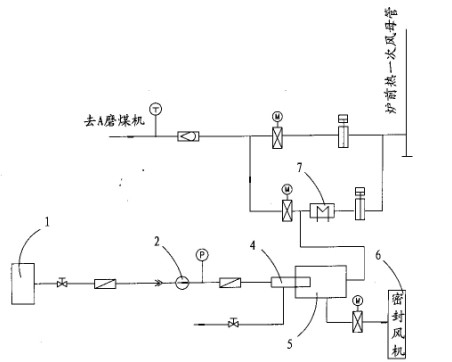

Low-temperature furnace smoke sucking exhaust gas and hot air drying composite powder feeding bituminous coal and meagre coal universal type powder preparing system

ActiveCN101761933ALow oxygenReduce the temperatureGrain treatmentsLump/pulverulent fuel feeder/distributionAir preheaterPowder mixture

The invention relates to a low-temperature furnace smoke sucking exhaust gas and hot air drying composite powder feeding bituminous coal and meagre coal universal type powder preparing system. A middle bin storage type steel ball coal mill hot air power feeding and meagre coal power preparation system is adopted as a prototype, and part of low-temperature furnace smoke is sucked from an outlet of a suction fan by a furnace smoke fan as an inert medium and part of drying mediums to be mixed with hot air taken from an outlet of an air preheater to enter a coal mill for drying and delivering coal powder; the oxygen content of the powder preparation system is reduced, and the explosion preventing requirement on grinding bituminous coal can be met. In addition, part of exhaust gas at an outlet of a power exhauster is led to an inlet of a heat primary fan by an exhaust gas transfer pipeline to be mixed with hot air to enter a primary bellows for delivering the coal powder; the temperature of a primary air and powder mixture and the oxygen concentration of the system are effectively reduced, and the combustion and explosion preventing requirement of bituminous coal delivery is met. Isolating doors are both installed on a furnace smoke system and an exhaust gas transfer system; by the switch control of the isolating doors, the switching of a typical hot air power feeding meagre coal system and a low-temperature furnace smoke exhaust gas and hot air drying composite powder feeding bituminous coal system is realized, and the invention is not only suitable for the meagre coal, but also suitable for the bituminous coal.

Owner:XIAN THERMAL POWER RES INST CO LTD

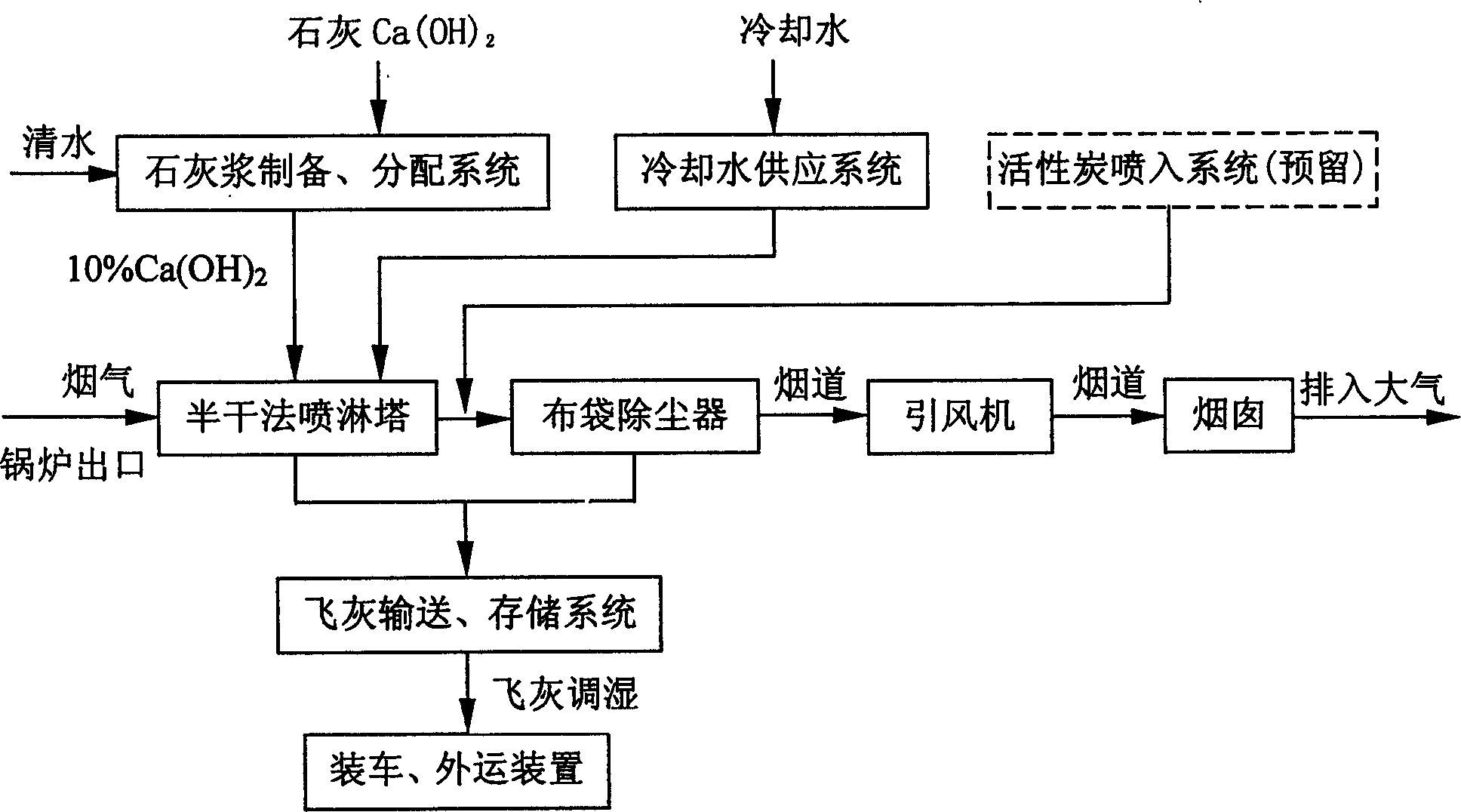

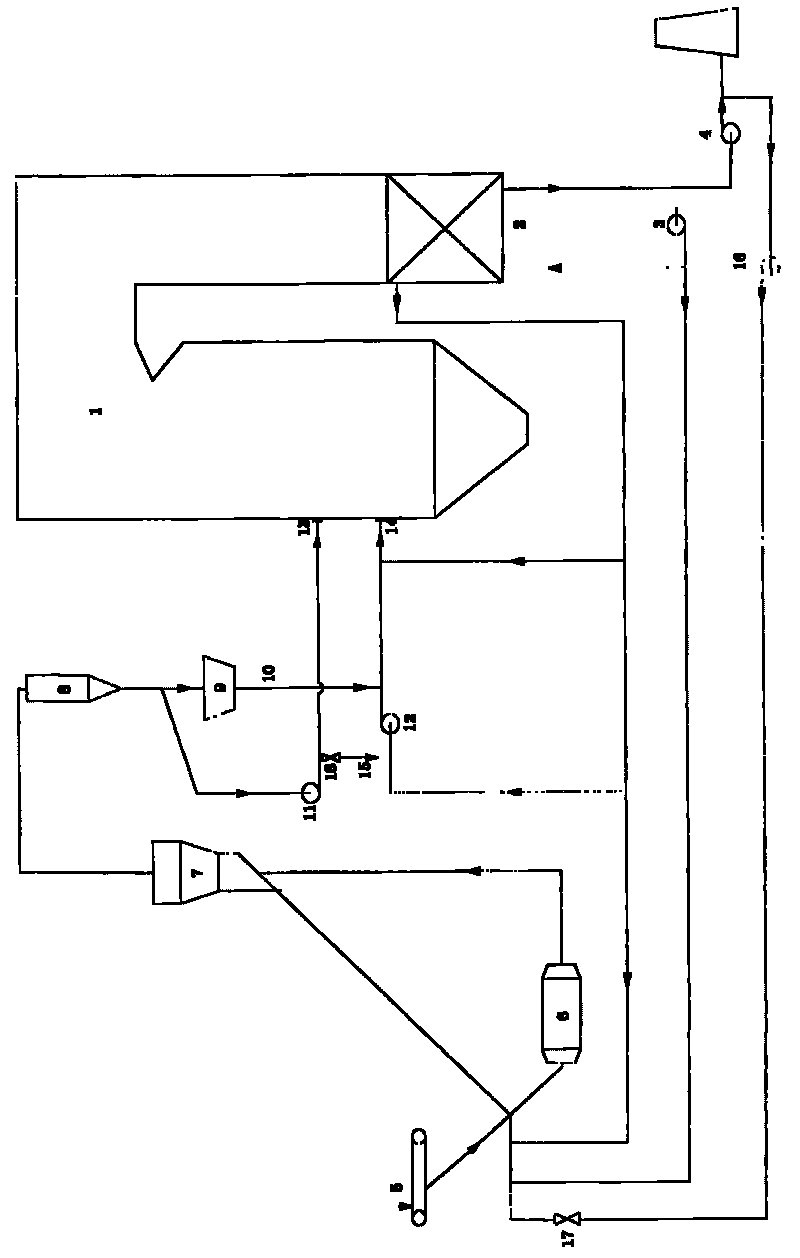

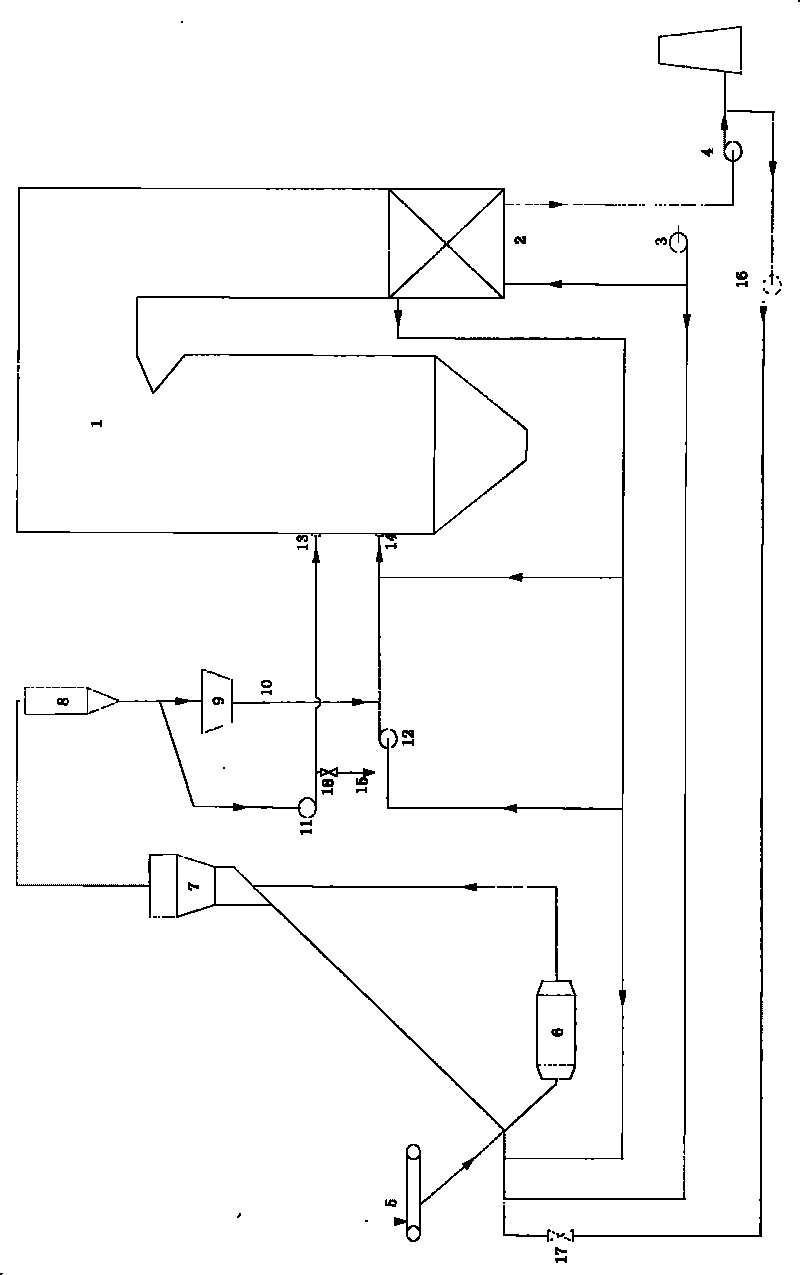

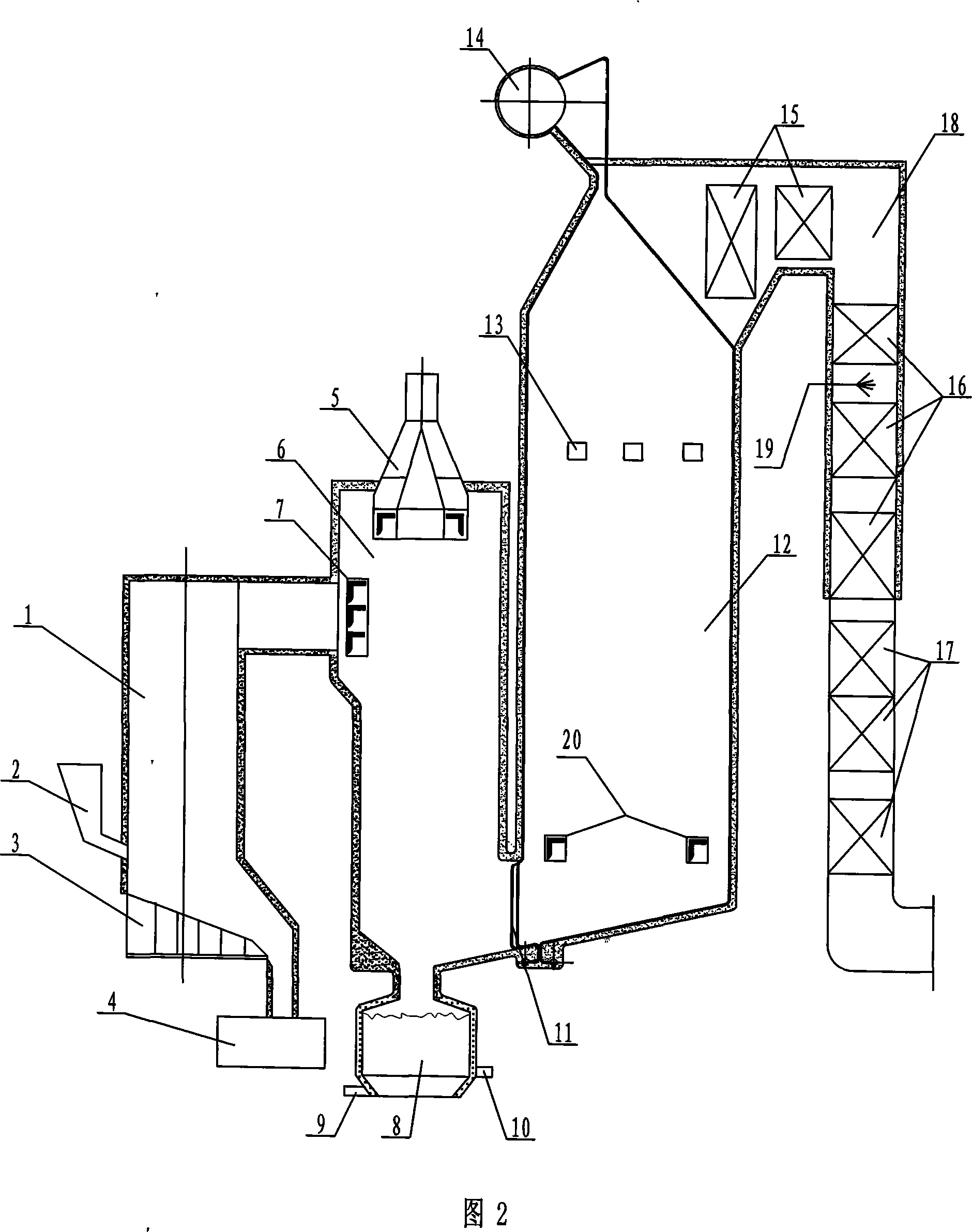

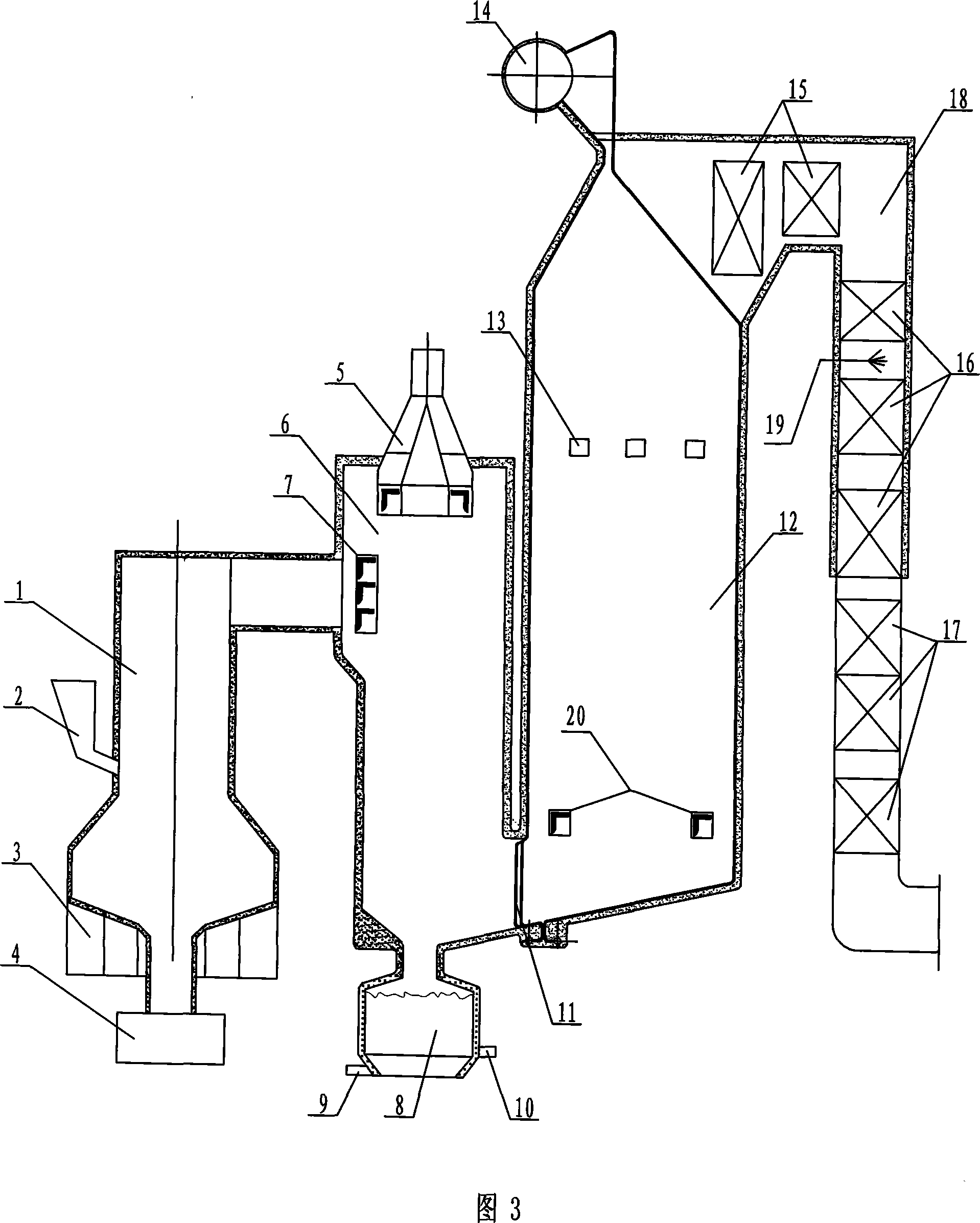

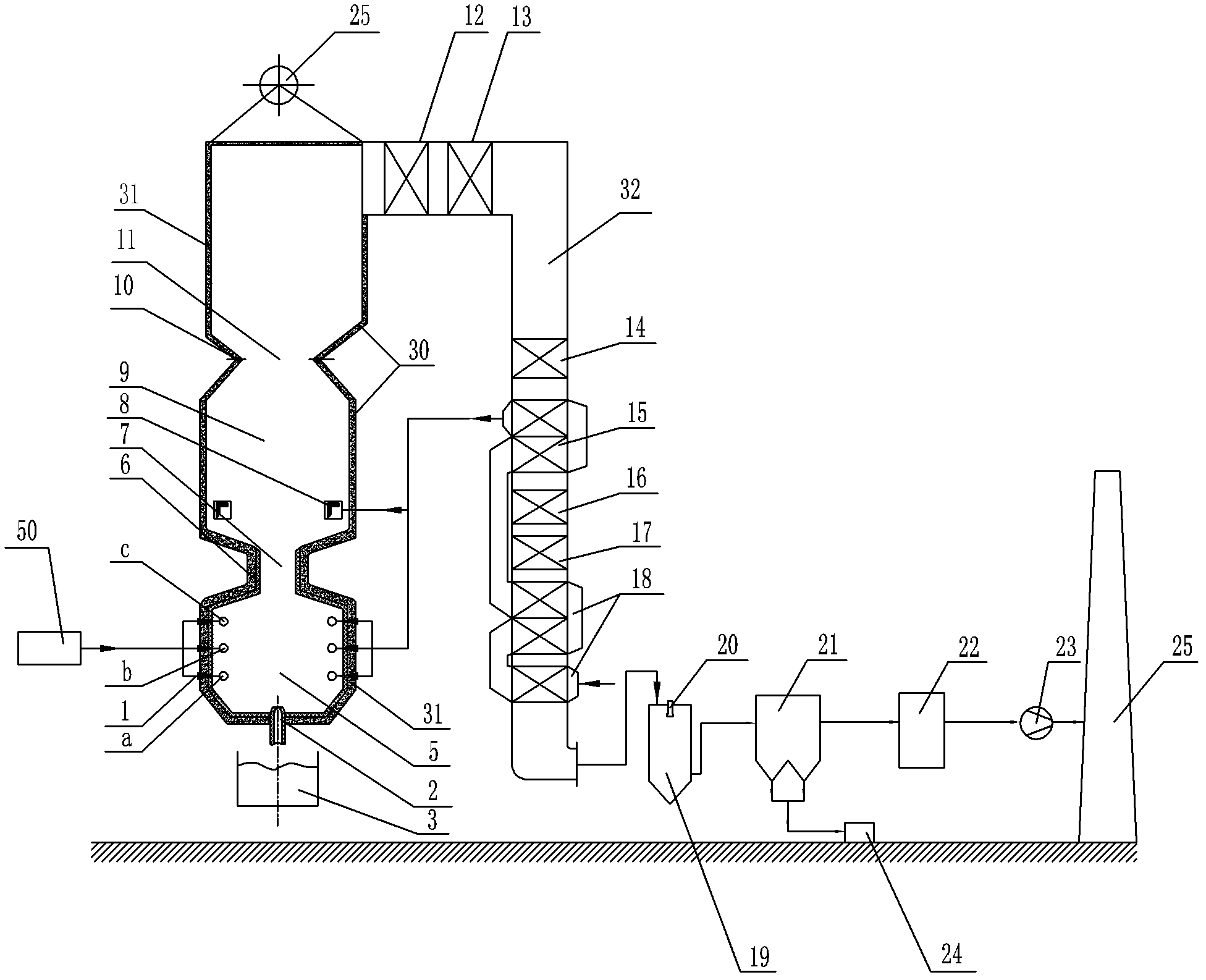

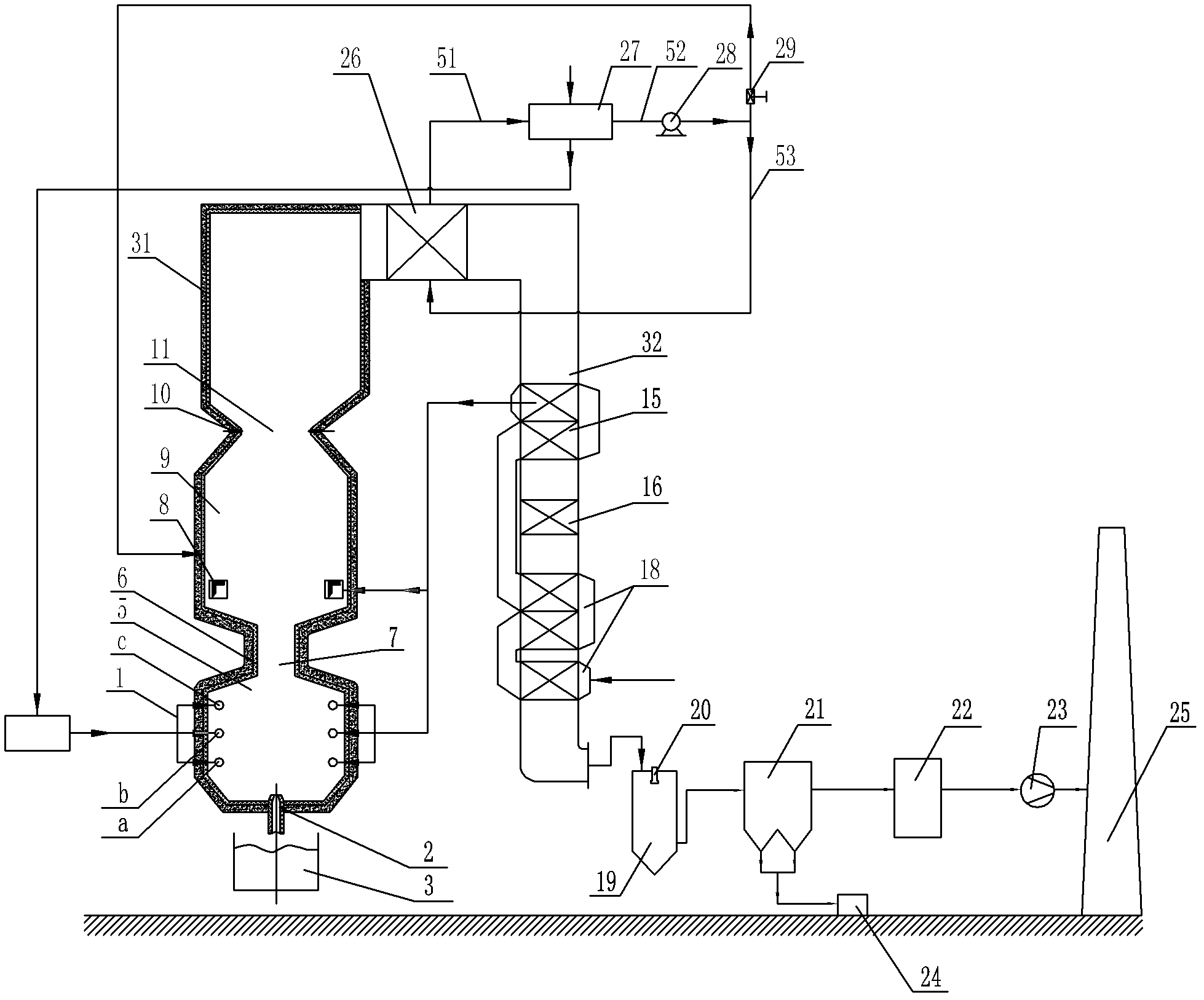

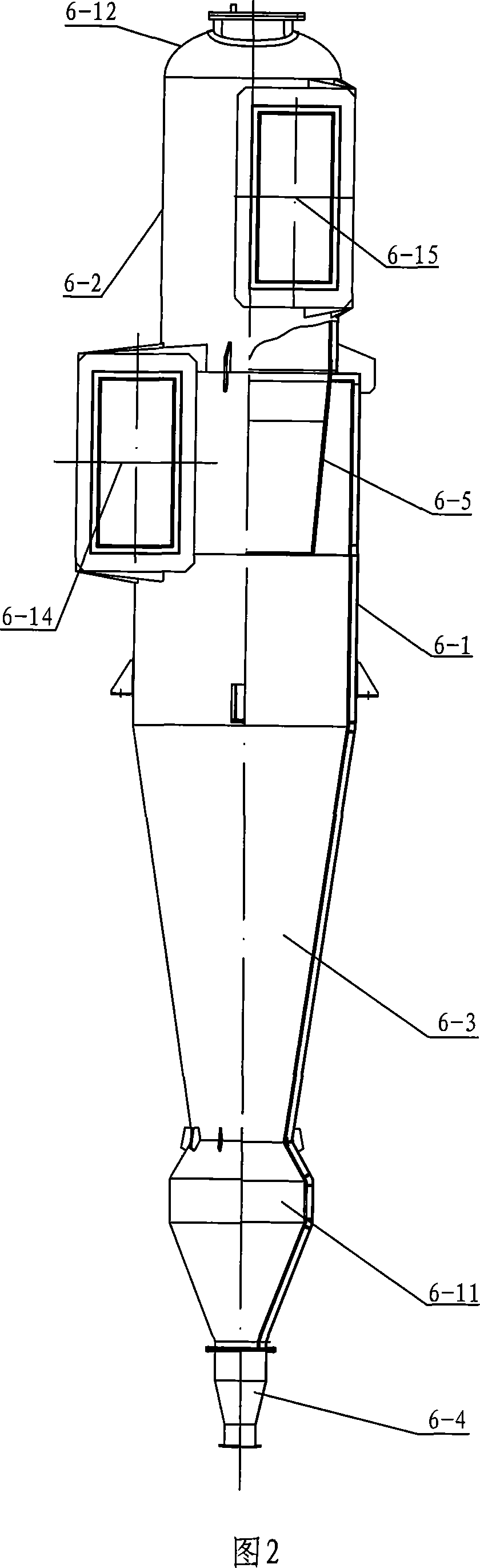

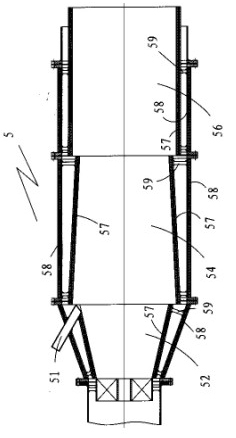

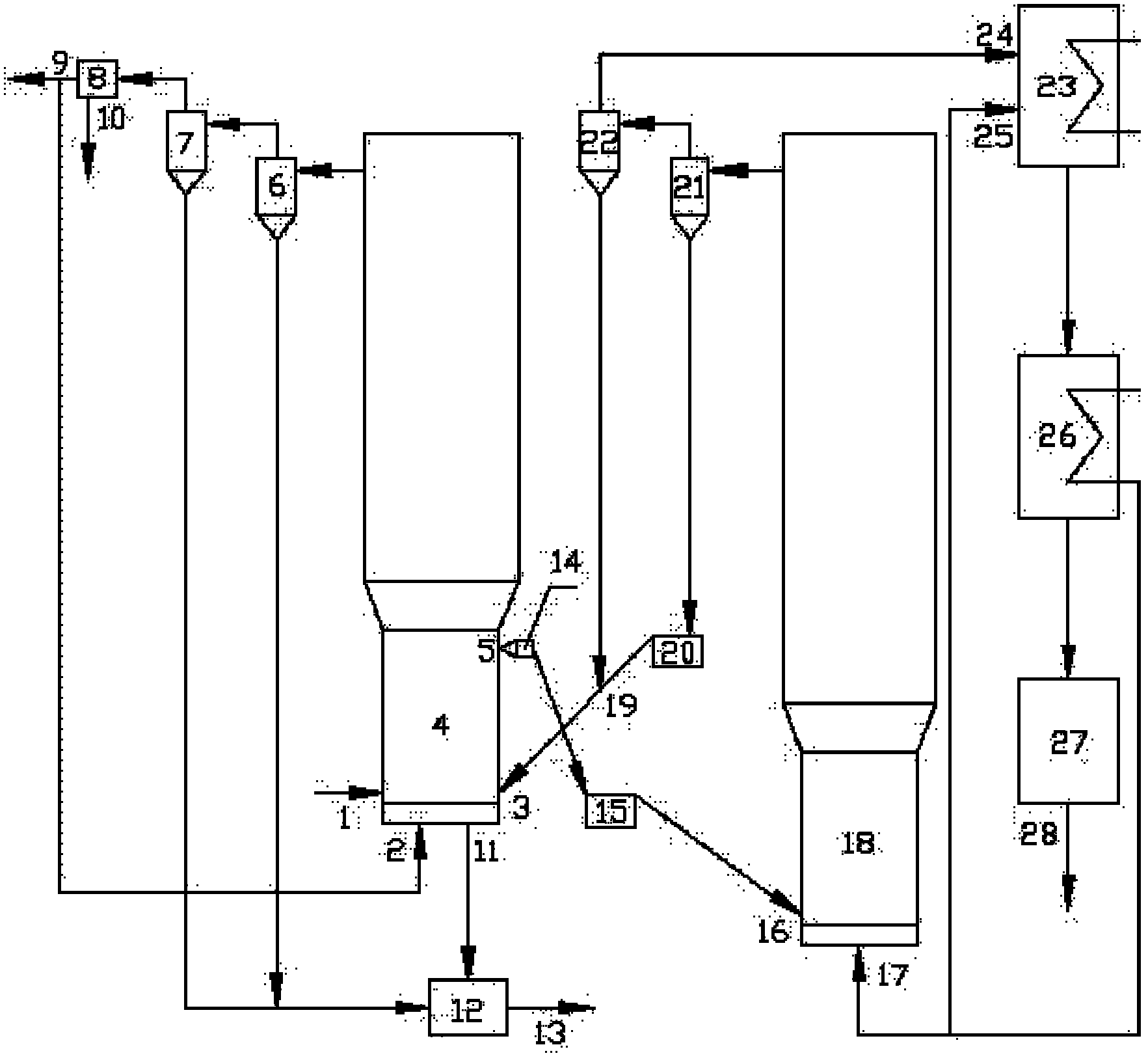

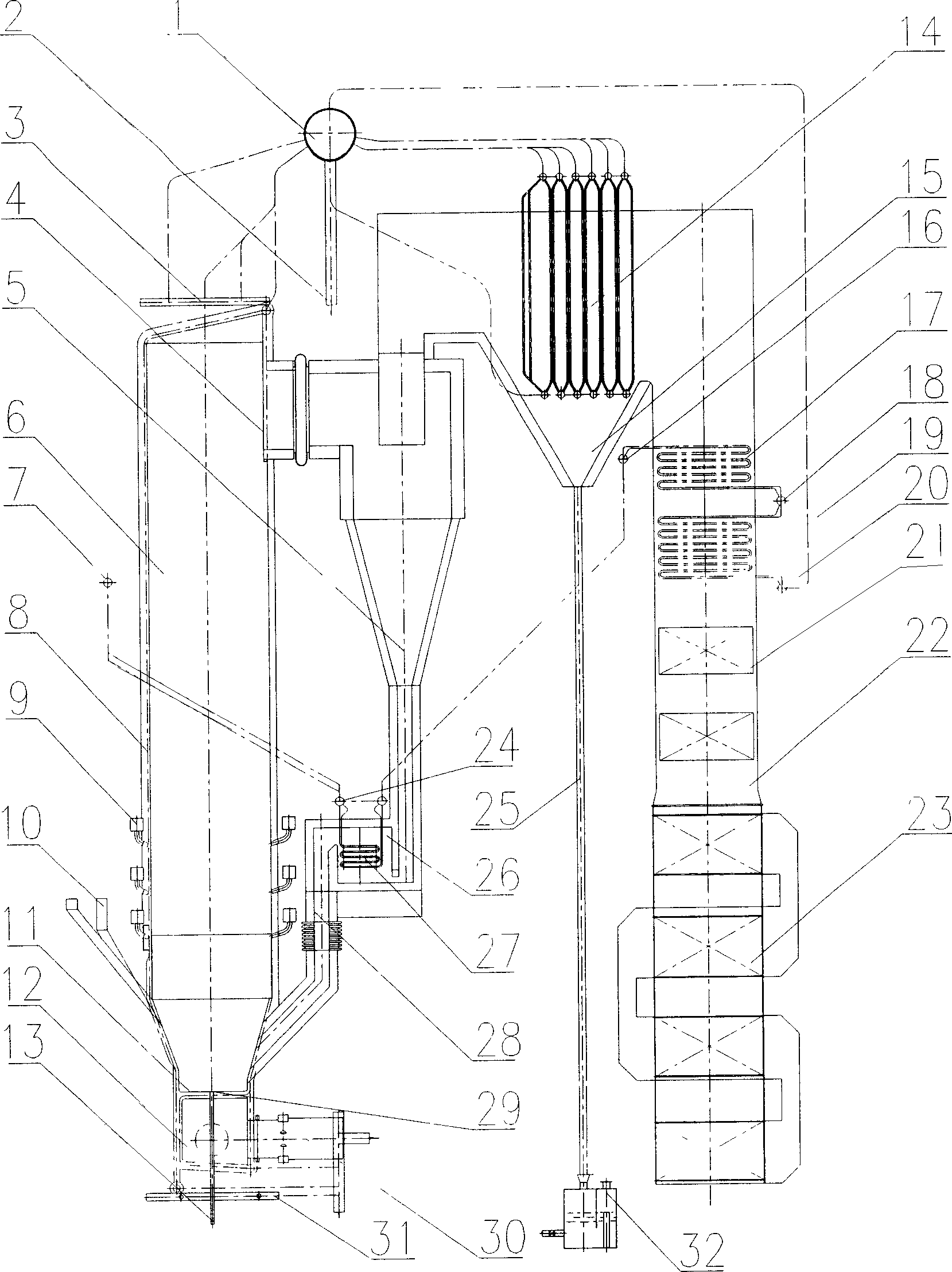

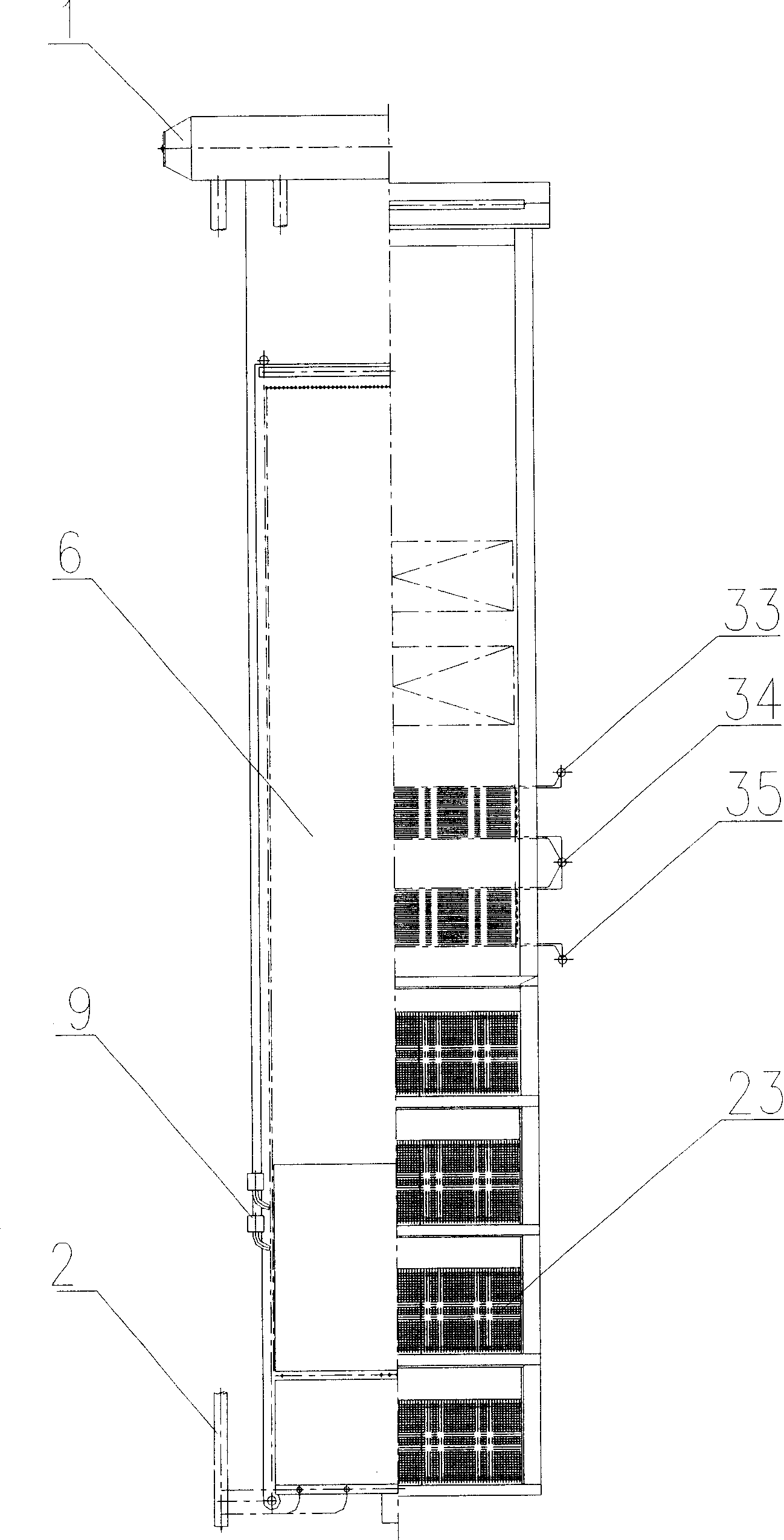

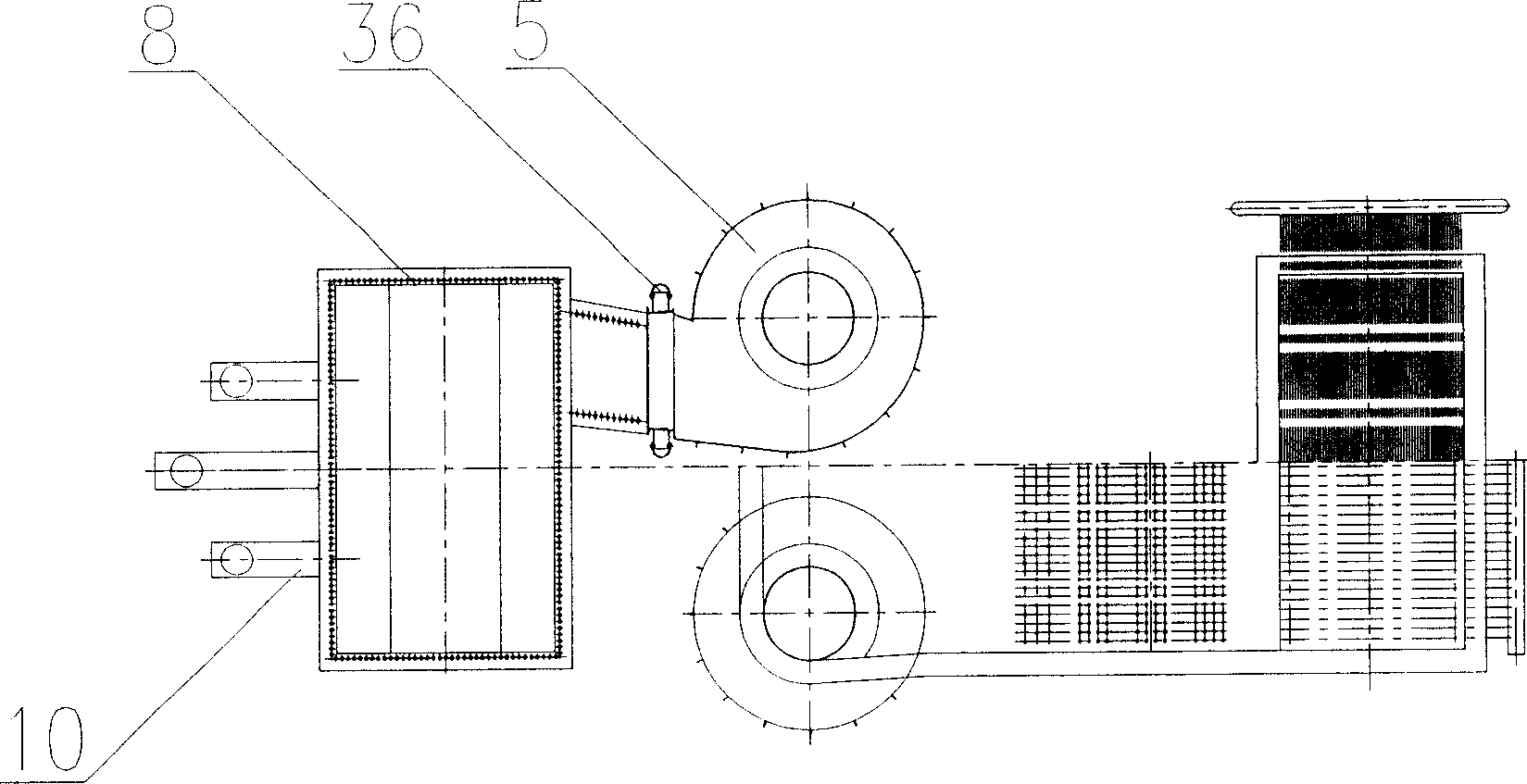

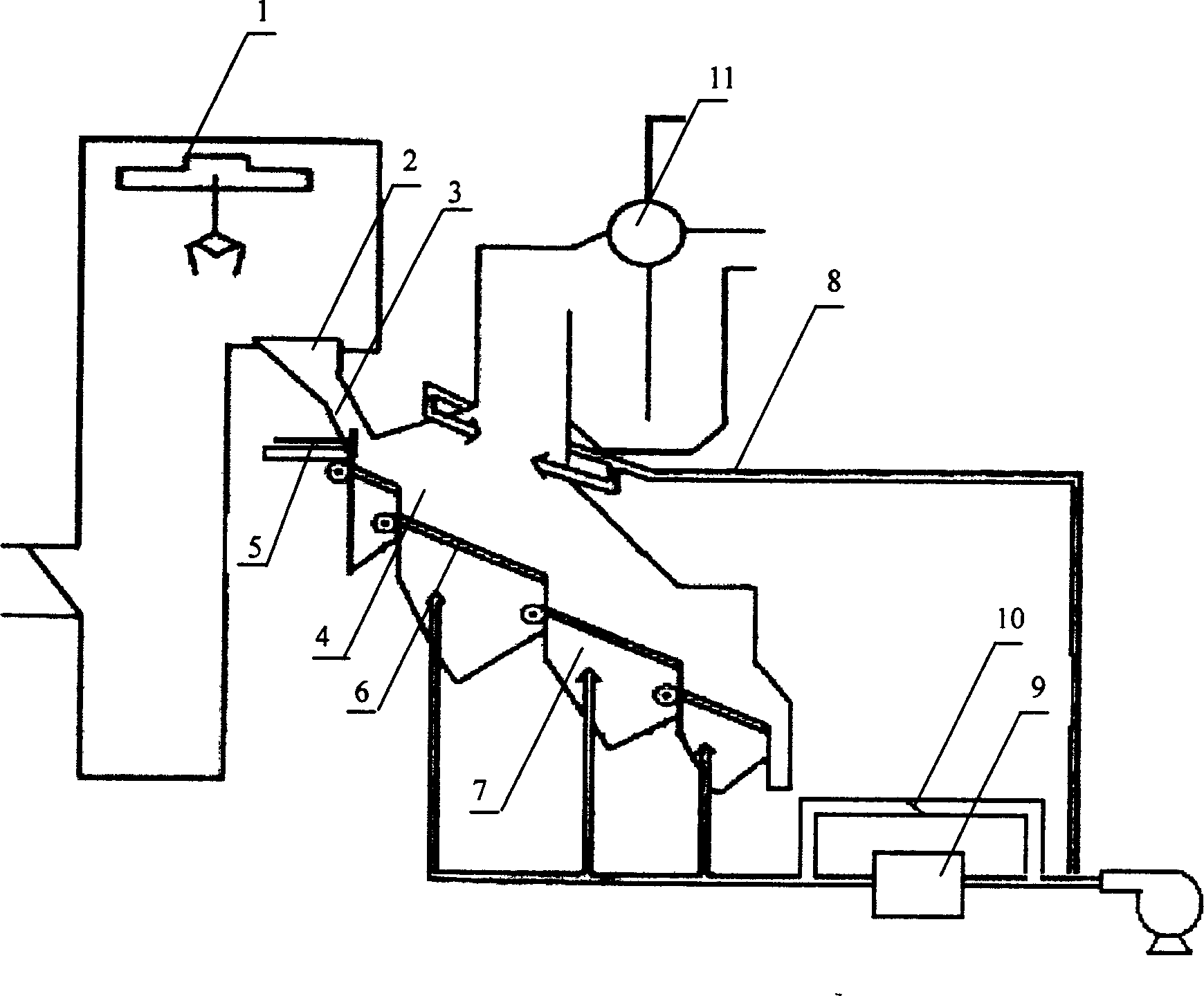

Apparatus and method for gasification of refuse and hyperthermia melt processing of flying ash

ActiveCN101201167AWith waste heat utilizationHigh heat intensity of combustionDamper arrangementIndirect carbon-dioxide mitigationAir preheaterEngineering

A device and method for garbage gasification and flying ash high temperature melting treatment relates to an integrated technology for garbage gasification and flying ash high temperature melting. The invention aims at solving the problem that the heavy metals and dioxins in the ash collected by a hop-pocket in an incinerator for garbage gasification exceeds the standard limits greatly. The device is formed in the way that a fluidized bed gasifier is communicated with a cyclone furnace; the cyclone furnace is communicated with a burnt chamber and the burnt chamber is communicated with a flue. The method includes that the smoke and gas generated by the gasification of the garbage in the fluidized bed gasifier enters the cyclone furnace and burns with the help of coal powder; the heavy metals in the flying ash are reduced to metals and recycled; the dioxins in the flying ash are decomposed; the exhaust smoke and gas enters a tail gas treatment device after entering the burnt chamber, a superheater, a coal saving device and an air preheater. The invention leads the smoke and gas generated by the gasification and burning of the garbage in the fluidized bed gasifier to enter the cyclone furnace for high temperature melting treatment so as to lead the dioxins in the tail gas collecting ash and in the tail gas to be respectively lower than 50ng-TEQ / kg, 0.1ng-TEQ / m{3}.

Owner:HARBIN INST OF TECH

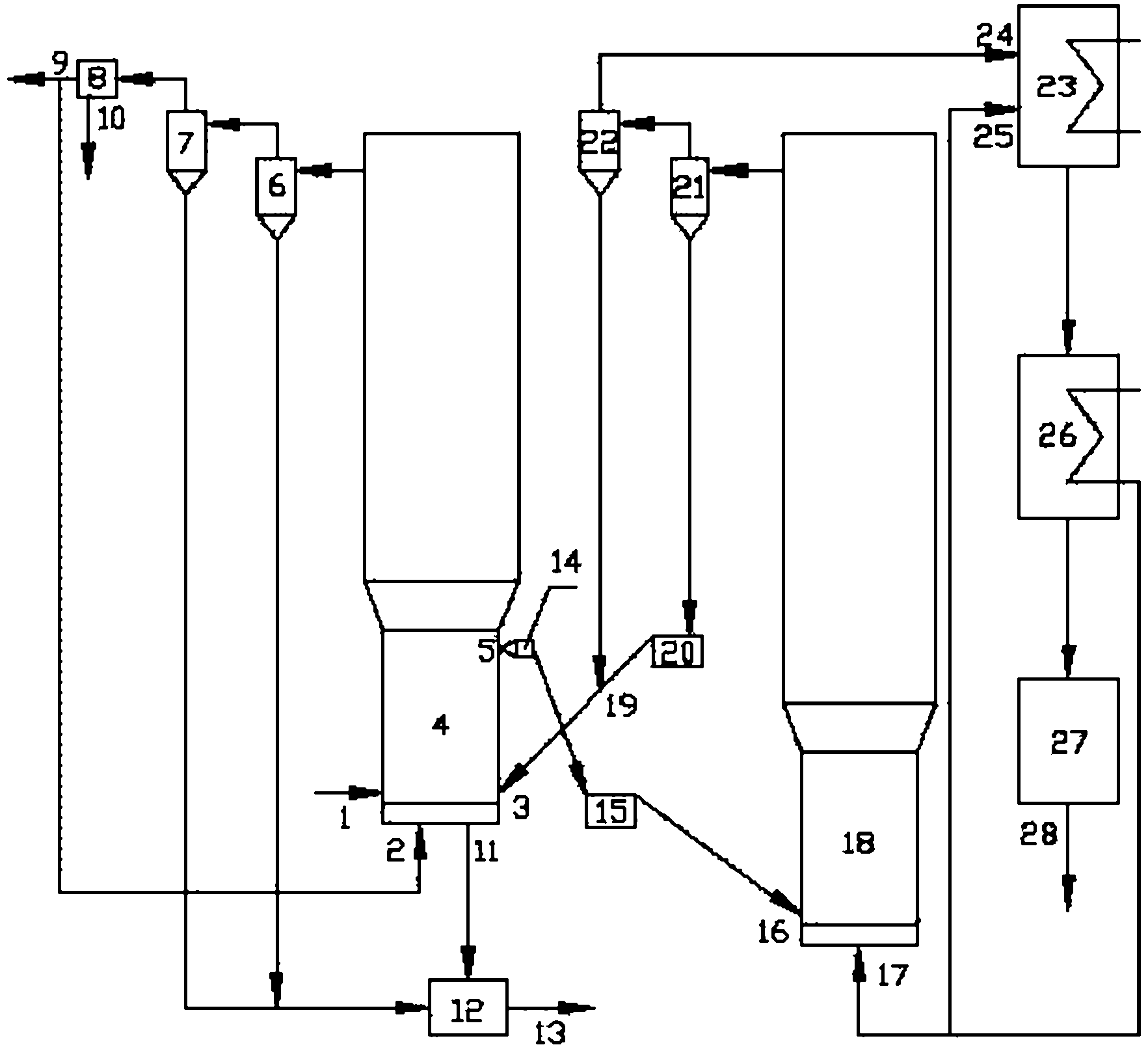

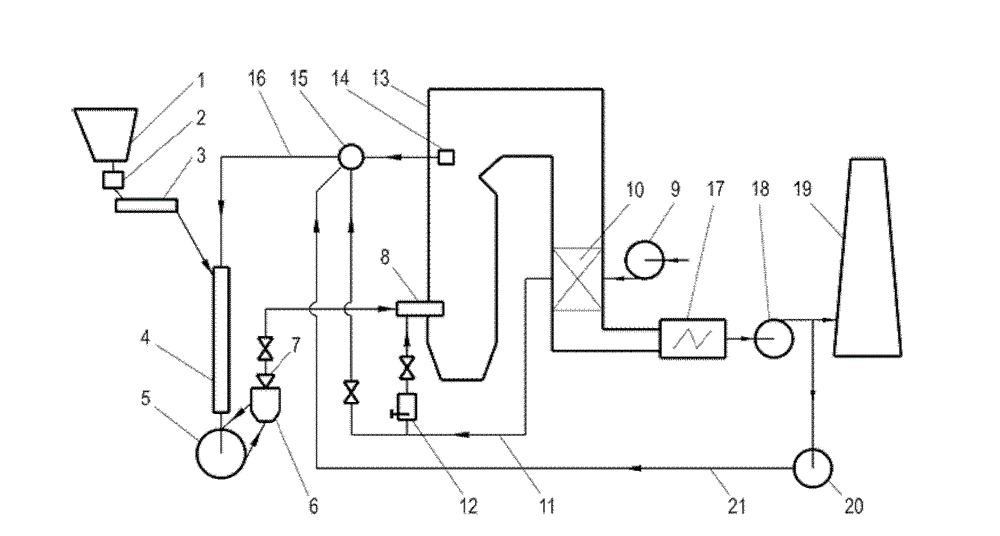

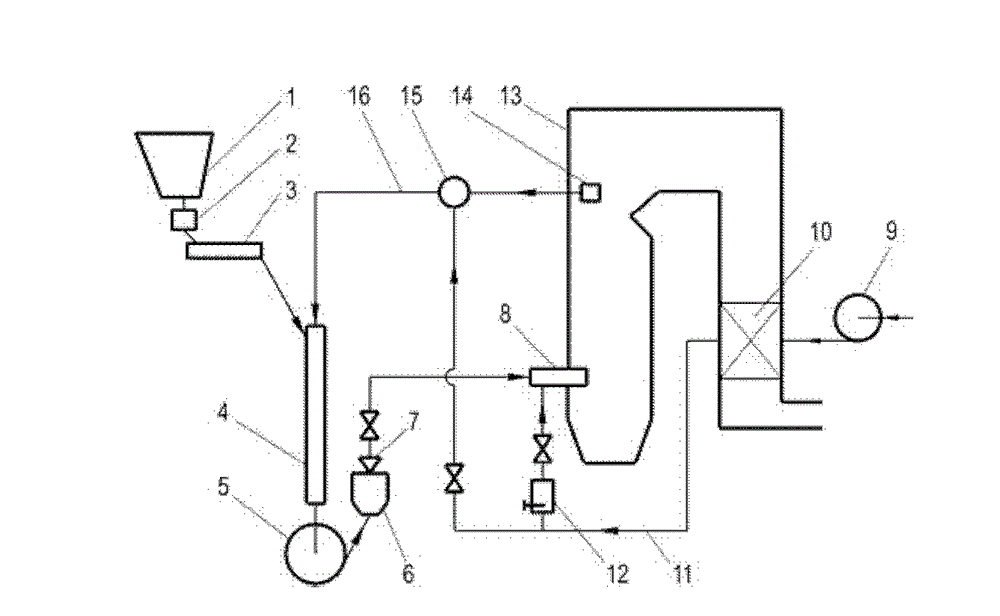

Method for cooperatively promoting agglomeration growth of PM (particulate matter) 2.5 and treating desulfuration wastewater in evaporation manner and device of method

InactiveCN102380278ALow running costConvenient sourceCombination devicesWater/sewage treatmentAir preheaterFlue gas

The invention discloses a method for cooperatively promoting agglomeration growth of PM (particulate matter) 2.5 and treating desulfuration wastewater in an evaporation manner and a device of the method. The method particularly includes steps that agglomeration liquor prepared by desulfuration wastewater, high polymer adhesive and wetting agent is sprayed into an inlet flue of an electric precipitator and is evaporated by the aid of heat of flue gas, in an evaporation process, the wetting agent promotes dust to enter drops of the agglomeration liquor, the high polymer adhesive is connected with PM2.5 via a polymer chain with polar groups, the grain diameter of the PM2.5 is prompted to be enlarged, so that the PM2.5 can be gathered by the follow-up electric precipitator, the desulfuration wastewater is evaporated completely, suspended matters and dissolvable pollutants in the wastewater are converted into solid to be dissolved out, and the suspended matters and the dissolvable pollutants in the wastewater, together with dust in the flue gas, are gathered by the electric precipitator. The device consists of a boiler, an air preheater, the electric precipitator, a desulfurizing tower, a hydraulic cyclone, a desulfuration wastewater clarification tank and an agglomeration liquor preparation tank, and a double-fluid atomizing nozzle is arranged in the flue between the air preheater and the electric precipitator.

Owner:SOUTHEAST UNIV

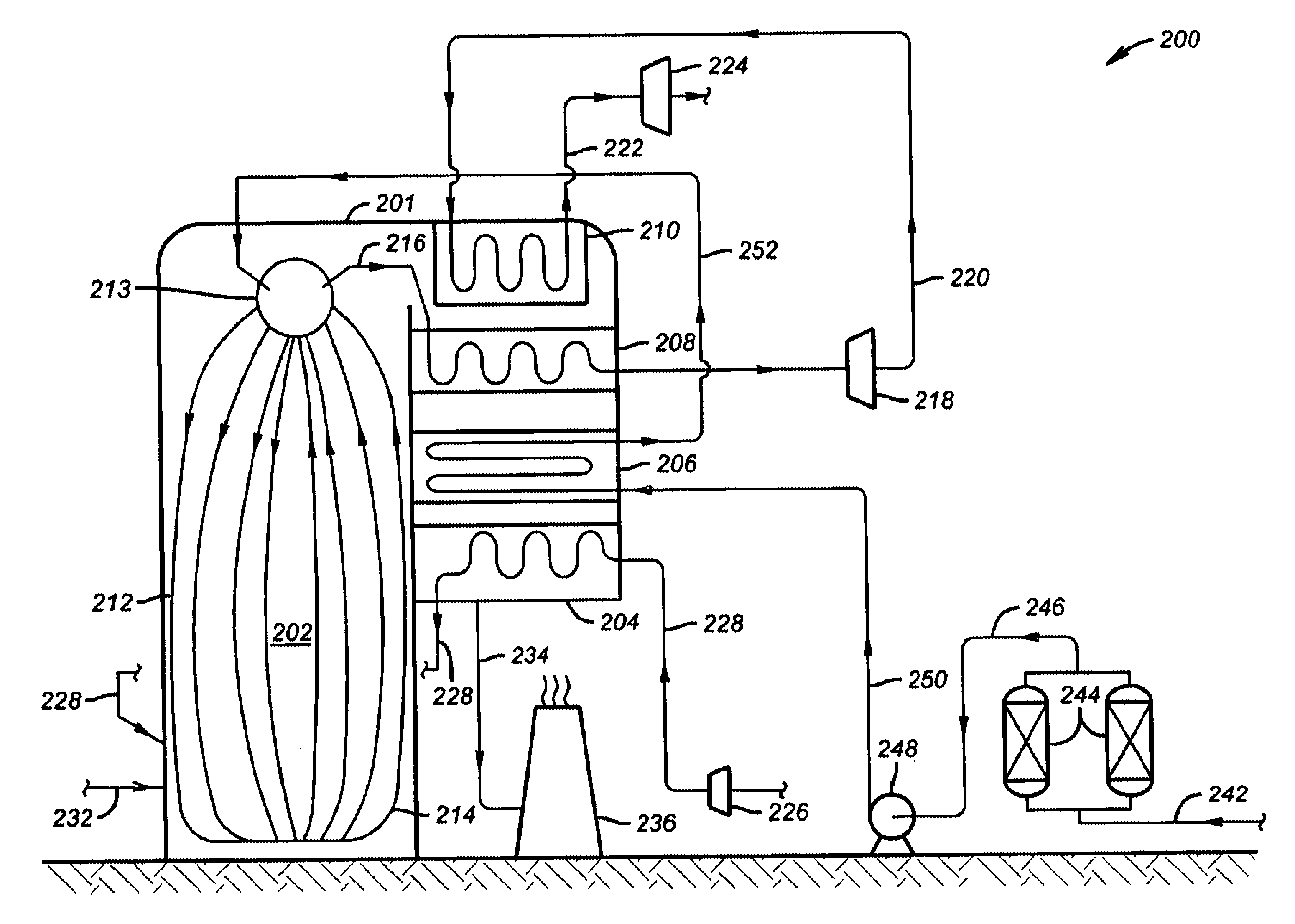

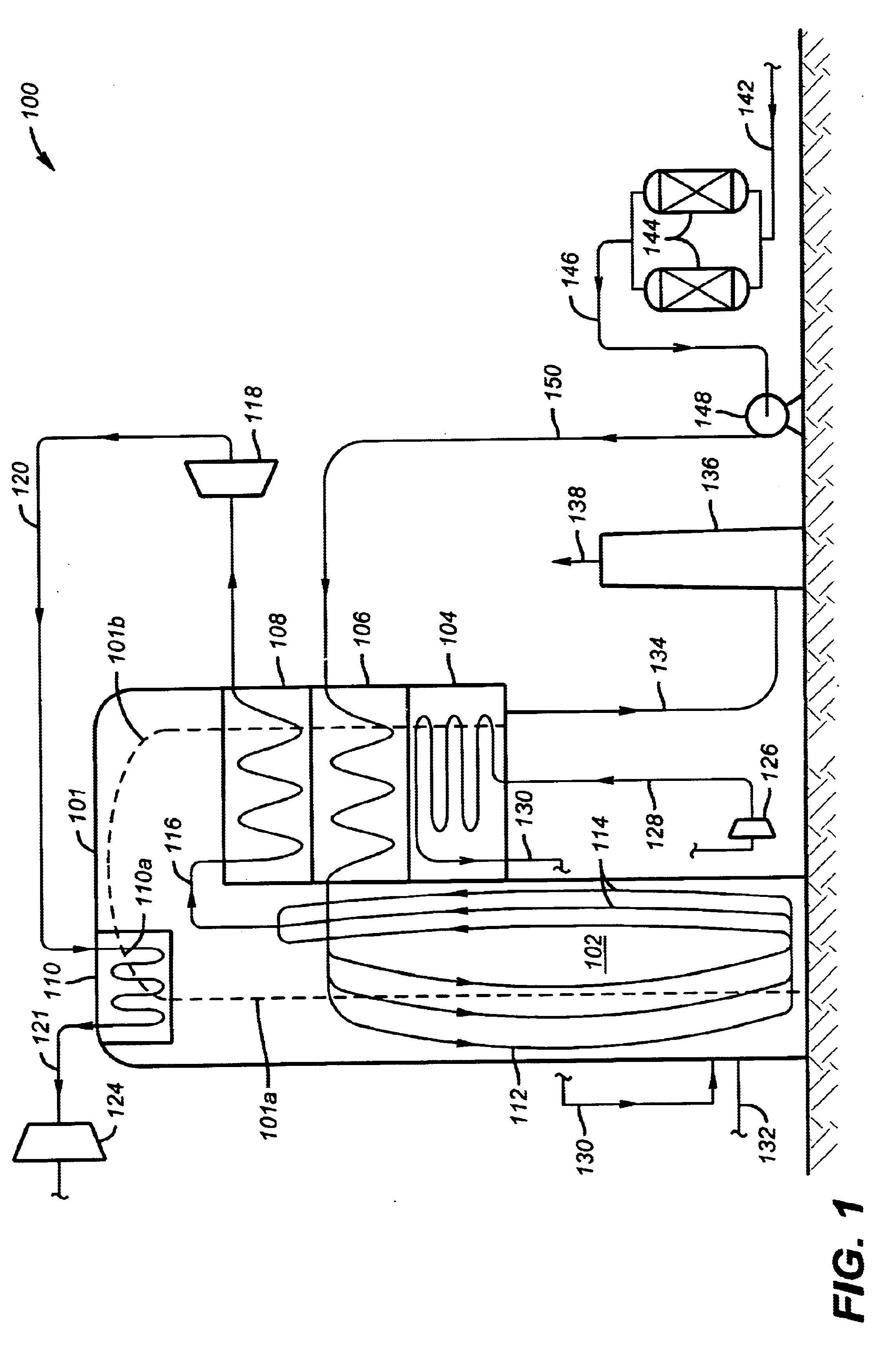

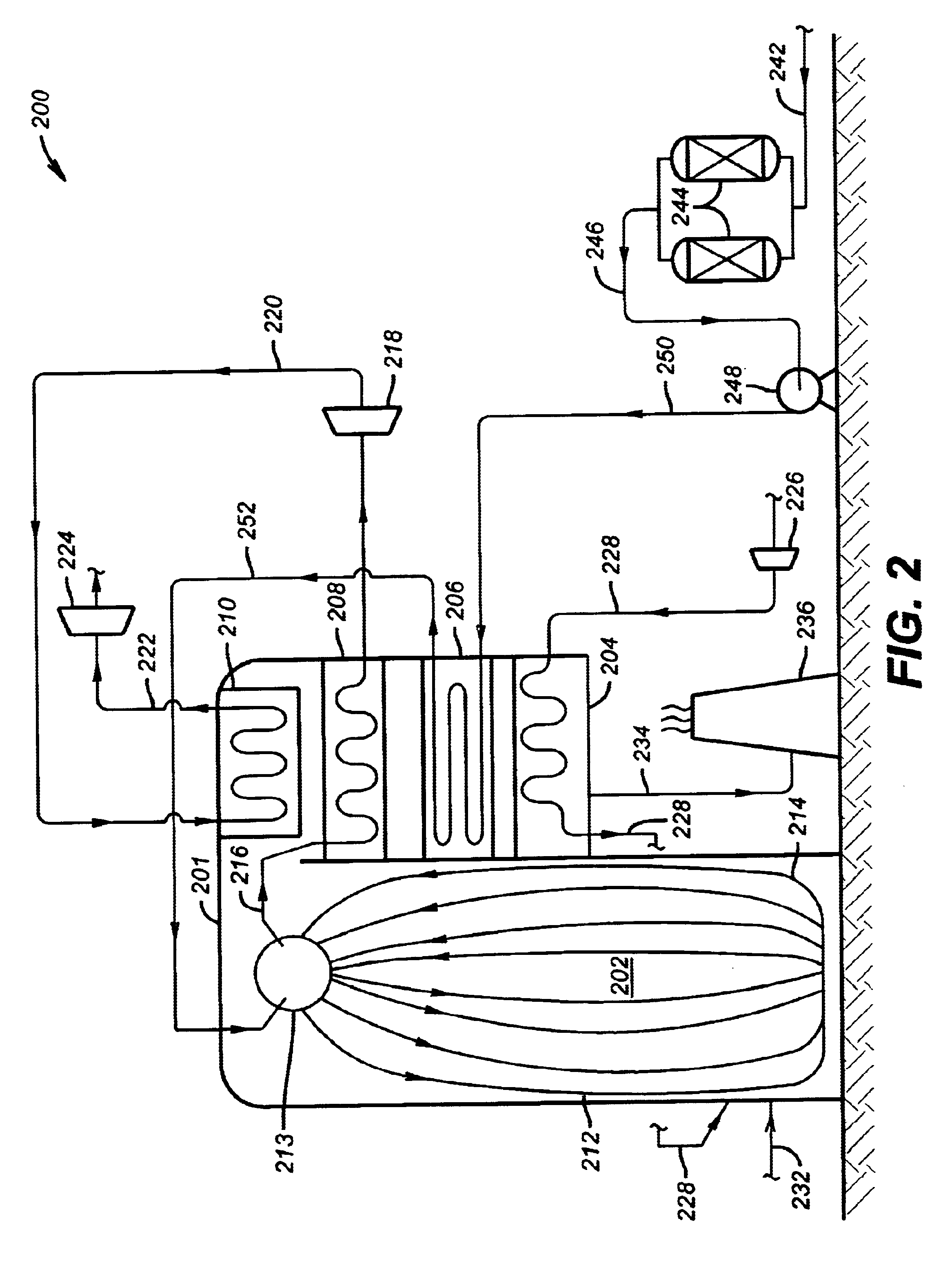

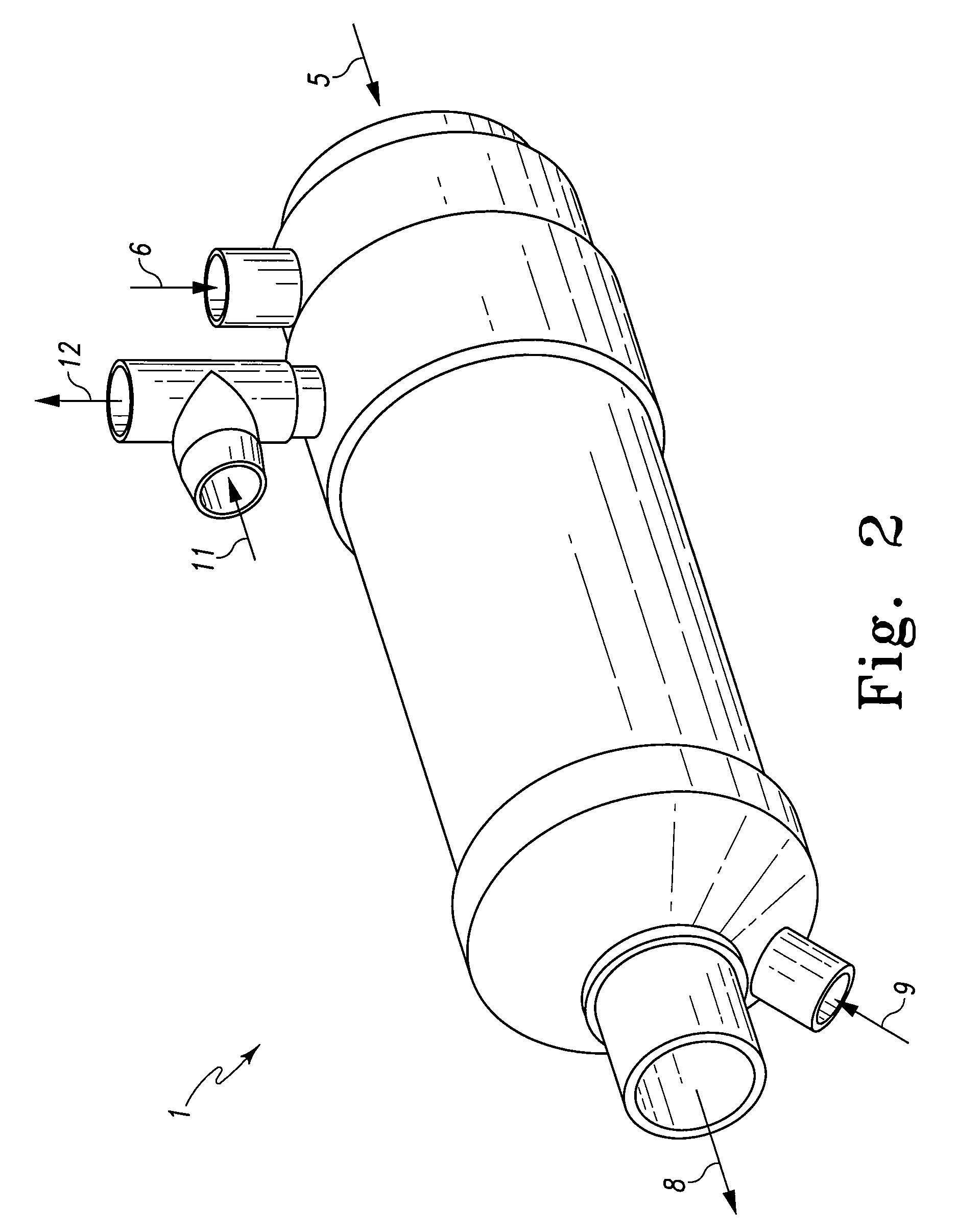

Steam generation apparatus and methods

Steam generation apparatus and methods are presented that are dedicated to oxygen-enriched air combustion of a fuel, wherein the oxygen concentration of the oxygen-enriched air may range from just above 21 percent to 100 percent. One apparatus comprises an oxygen-enriched air preheater through which oxygen-enriched air flows and exchanges heat indirectly with flue gas, creating a preheated oxygen-enriched air stream. The apparatus further comprises a boiler having a radiant section and a convection section, and other heat transfer units adapted to handle reduced flue gas flow rate and higher temperature flue gases than comparable air / fuel combustion boilers, thus allowing a smaller heat transfer surface area, a more compact design and a higher efficiency.

Owner:AIR LIQUIDE AMERICA INC +1

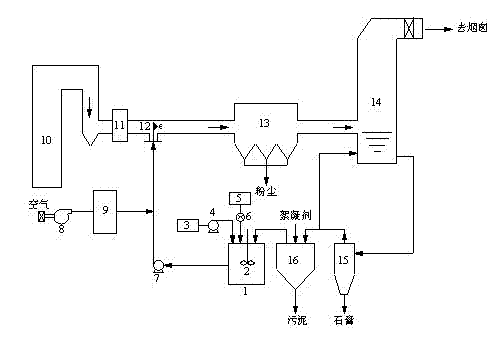

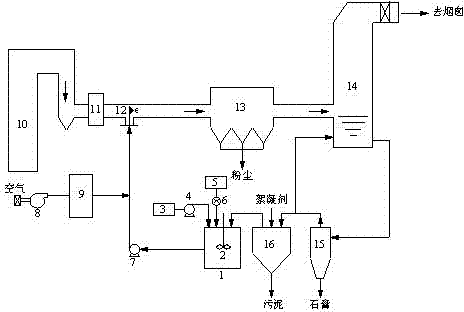

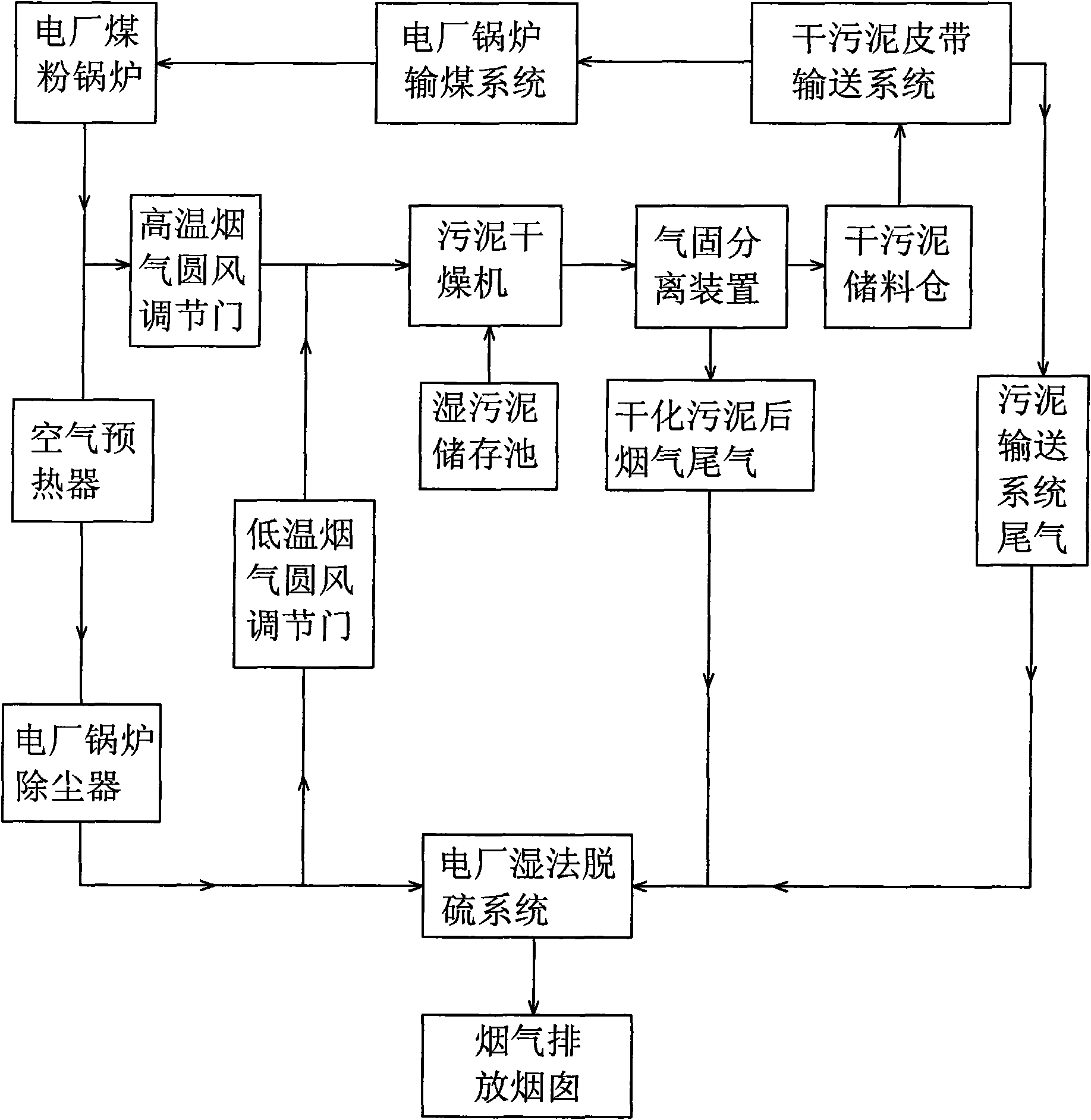

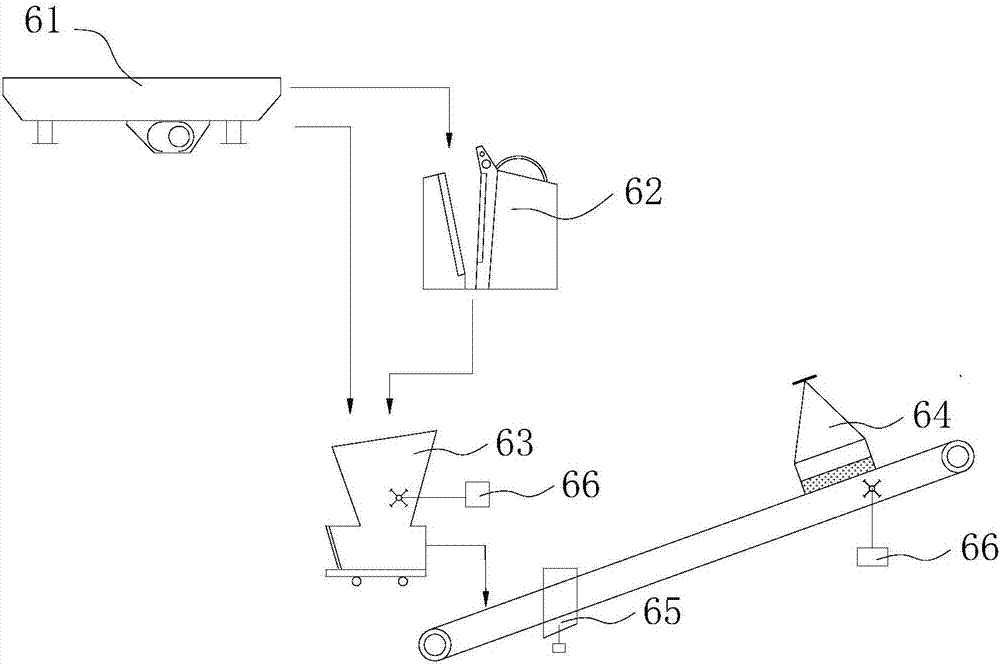

Harmless recycling treatment process for urban sludge

ActiveCN101570388ASimple processLess investmentSludge treatment by de-watering/drying/thickeningDispersed particle separationAir preheaterFlue gas

A harmless recycling treatment process for urban sludge carries out urban sludge treatment through the prior pulverized coal boiler and coal conveying and tail exhaust treatment systems in a power plant. In the treatment process, flue gas extracted from the front part of an air preheater of a power plant pulverized coal boiler is mixed with flue gas extracted from the back part of a power plant boiler dust remover into flue gas with the temperature ranging between 140 and 180 DEG C; the flue gas is conveyed to a sludge drier to carry out sludge drying; and the dried sludge is fed into a power plant coal conveying system, mixed with coal, and then fed into a furnace to carry out incineration for power generation so as to realize the recycling utilization of the sludge. The coal and dry sludge are burnt in a boiler and discharged flue gas is fed into the power plant boiler dust remover and a wet desulphurization system for treatment; and the flue gas after the drying and tail gas generated by storing and conveying the dry sludge are discharged into a power plant desulphurization system for treatment, so that the standard discharge of pollutants is realized and secondary environmental pollution is eliminated. The harmless recycling treatment process makes effective use of the prior power plant boiler and coal conveying, burning, dust removal and desulphurization facilities, and has the advantages of simple equipment, less investment, short construction cycle and low operating cost.

Owner:华电滕州新源热电有限公司

High-temperature melting treatment system and method for sludge

ActiveCN102537980ALow running costEmission reductionCombination devicesSludge treatment by pyrolysisAir preheaterCooling tower

The invention discloses a high-temperature melting treatment system and a method for sludge, and relates to a sludge treatment system and a sludge treatment method. The system and the method solve the problem that dioxine exists in sludge incineration methods in prior arts. A first device comprises a melting chamber with a furnace body integrally manufactured from a lower side to an upper side, a shrinking section smoke outlet and a secondary combustor, high temperature and low temperature superheaters arranged in a smoke duct, high temperature and low temperature coal economizers, high temperature and low temperature air preheaters, and an SCR (selective catalytic reduction) denitration system, wherein the smoke duct is communicated with a smoke fast cooling tower, the smoke fast cooling tower is communicated with a bag-type dust collector, and the bag-type dust collector is communicated with a chimney by a smoke wet desulphurization system and a draught fan. The first method comprises the steps of feeding dry sludge powder into the melting chamber for burning to a high-temperature melting state, recycling liquid-state slag and reusing, treating high-temperature smoke after entering the smoke duct, and discharging. The differences between a system in a second scheme and the first device are as follows: the high temperature and low temperature superheaters and the high temperature and low temperature coal economizers are not arranged, and a steam heat exchanger is additionally arranged. A difference between a system in the third scheme and the second scheme is as follows: a multistage sludge dryer is additionally arranged. The high-temperature melting treatment system and method for the sludge are used for high-temperature melting treatment of the sludge.

Owner:HARBIN INST OF TECH

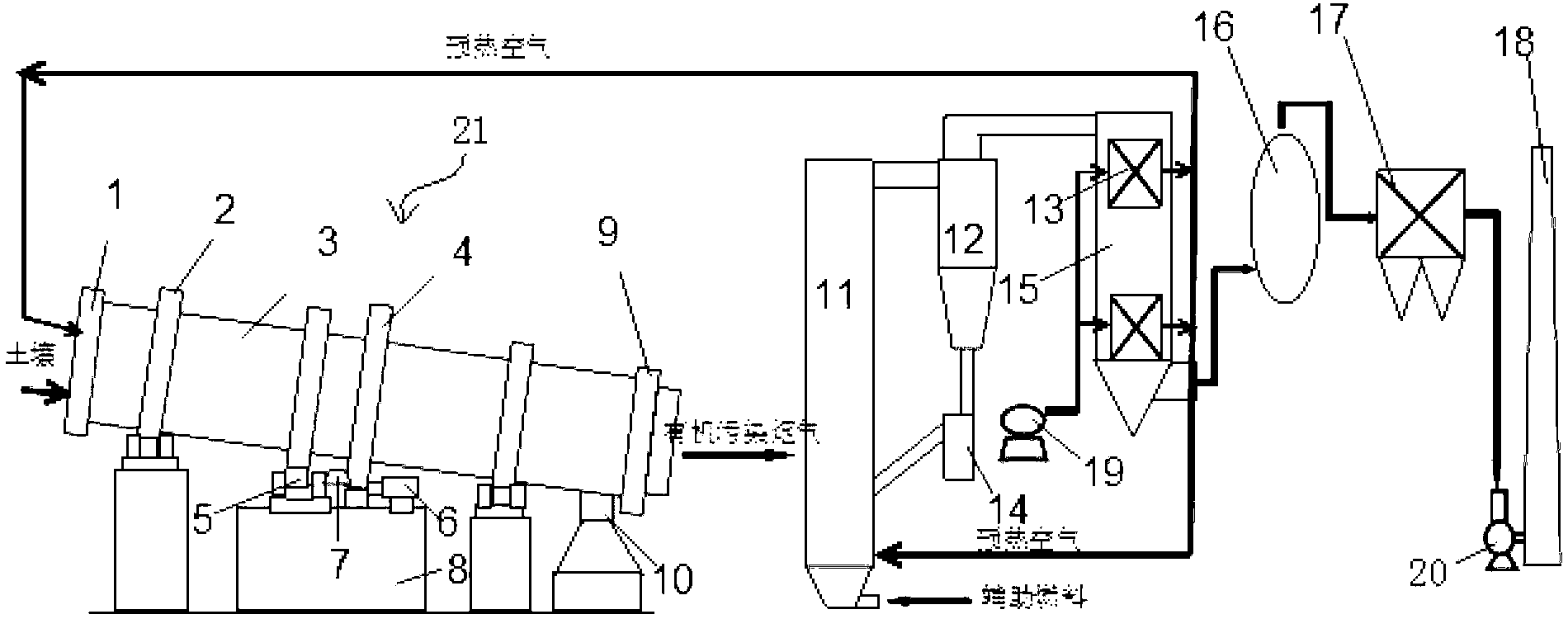

System and method for repairing organic material polluted soil

ActiveCN103008337AClear division of laborGive full play to the advantages of technologyContaminated soil reclamationAir preheaterEngineering

The invention discloses a system for repairing organic material polluted soil, which comprises a chimney and a rotary kiln reactor, wherein the smoke exhaust port of the rotary kiln reactor is connected with a furnace chamber; the furnace chamber is connected with a cyclone separator; one end of the cyclone separator is connected with a preheating passage; the other end of the cyclone separator is connected with a refeeder; the refeeder is connected with the furnace chamber; the preheating passage is connected with the chimney after passing through a flue gas desulfurization denitration purifier and a bag-type dust remover; an air preheating device is arranged in the preheating passage; one end of the air preheating device is connected with a first blower; the other end of the air preheating device is connected with the rotary kiln reactor and the furnace chamber respectively; and a rotary kiln repaired soil outlet is arranged on the rotary kiln reactor. The invention further discloses a method for repairing organic material polluted soil. According to the invention, the advantages of the thermal desorption technology in the organic material polluted soil repairing process are fully played; and organic material polluted soil, which is difficult to repair, can be repaired fast through the combination of new rotary kiln thermal desorption technology and the circulatory fluidized bed incineration technology.

Owner:HUAZHONG AGRI UNIV

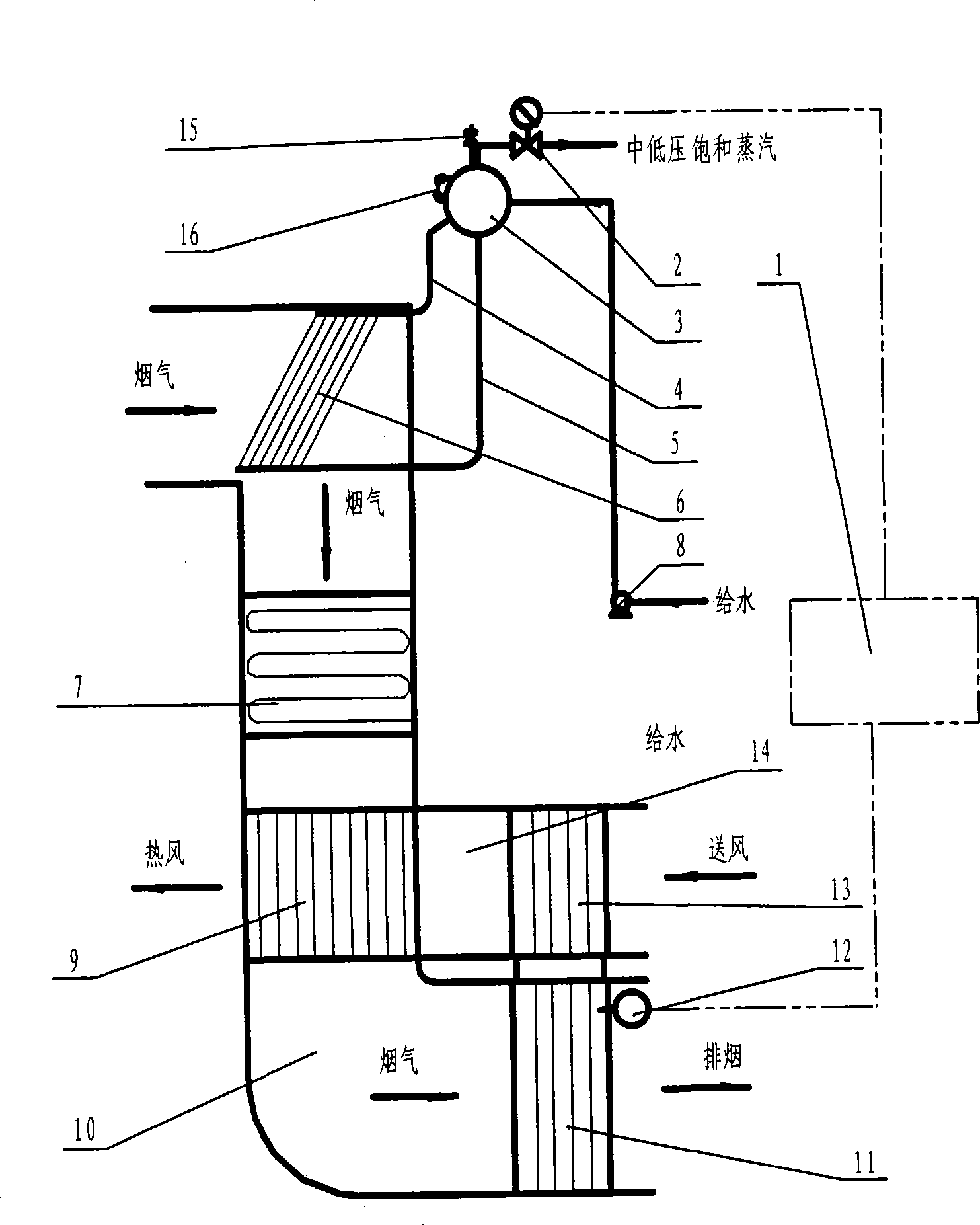

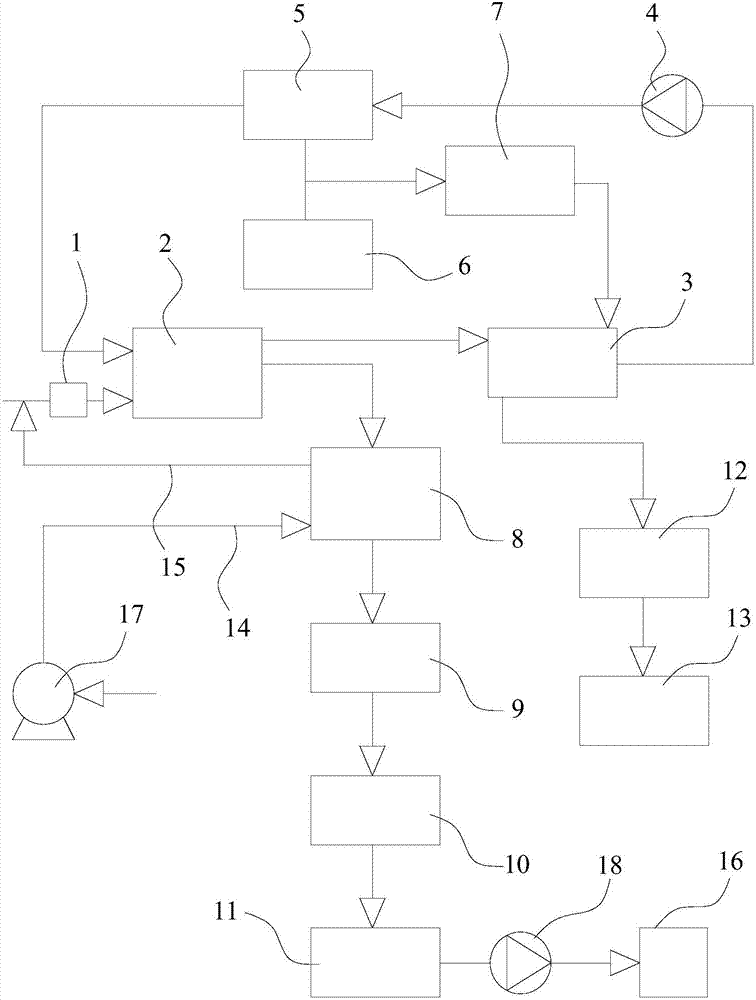

Flue gas denitrating technique with preposed whirlwind beforehand dust removal SCR

The invention discloses a preposing cyclone pre-dedusting SCR flue gas denitration technique. The flue gas extracted from a boiler economizer (12) primarily passes through a high temperature resistant cyclone separator (6), then passes through a flue gas current equalizer (7) and a static mixer (2) to unify the flow direction of the flue gas evenly; meanwhile, the flue gas after being mixed evenly with ammonia is preprocessed before reacting with a catalyst of an SCR reactor (3); finally, the flue gas is output after the temperature is reduced through an air preheater (4) and the flue gas is dedusted through an electrical precipitator (5). The invention reduces the volume of the catalyst and the SCR reactor, reduces the requirements of the support, eliminates an SCR bypass and greatly reduces engineering cost of the SCR; meanwhile, the invention also prolongs the service life of the catalyst and the cleaning period of the air preheater without installing a soot blower or prolonging the period of sootblowing.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG +1

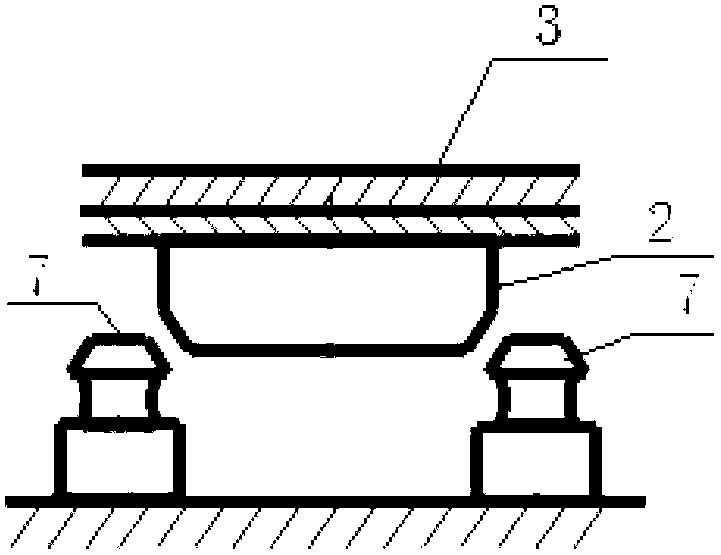

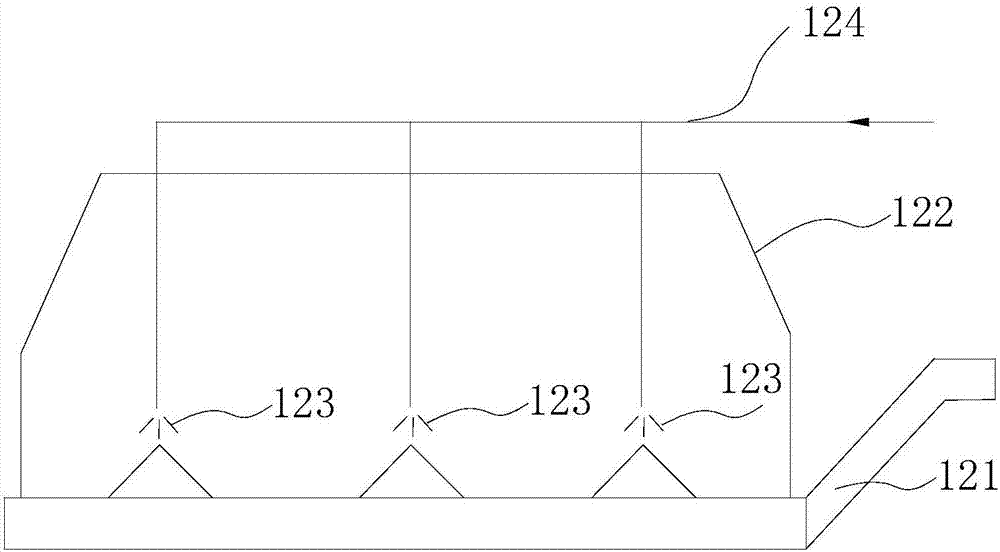

Composite phase change heat exchanger with medium and low pressure

InactiveCN101398265AAvoid condensationIndirect heat exchangersHeat exchange apparatusAir preheaterAutomatic control

The invention discloses a composite phase change heat exchanger with a medium-pressure and low-pressure evaporator, which comprises the medium-pressure and low-pressure evaporator and a steam header which are communicated by an ascending pipe and a descending pipe, a water feeding pipe and a steam outputting pipe are arranged on the steam header, an upper section of the composite phase change heat exchanger is positioned in a wind channel of an original air preheater, and a lower section of the composite phase change heat exchanger is positioned in a back flue channel of the air preheater; an automatic control device of the composite phase change heat exchanger adjusts and controls the heat exchange volume of the evaporator and the wall temperature of the lower section of the composite phase change heat exchanger. The composite phase change heat exchanger not only directly produces low-pressure or medium-pressure steam by using the recycled heat through a steam generating device and provides heat usage as a heat supply, but also controls the thermal equilibrium among the heat exchange volumes of the flue gas, the medium-pressure and low-pressure evaporator, a coal economizer and the wall of the air preheater by adjusting the steam flow of the steam outputting pipe of the steam header through the automatic control device, and consequently leads the flue gas temperature at the outlet to be higher than a flue gas acid dew point on the lower section wall surface of the composite phase change heat exchanger, avoids moisture condensation and achieves the purpose of utilizing waste heat of the flue gas to the utmost degree.

Owner:杨本洛 +1

Cold start oil auxiliary heating system of boiler and heat source-less independent starting method of generating set

InactiveCN102506407AAchieving a cold startReduce operating costsPilot flame ignitersBoiler controlAir preheaterEngineering

The invention discloses a cold start oil auxiliary heating system of a boiler and a heat source-less independent starting method of a generating set. The method includes the following steps that: mounting a set of small oil gun igniting system at an inlet air passage of a coal mill for preheating the cold air entering the coal mill and enabling the coal mill to satisfy the working conditions; communicating coal economizer ash conveying gas source of the boiler with a soot blowing steam pipeline of an air preheater through a shutoff valve for supplying soot blowing medium of the air preheater; starting a shaft seal steam valve on a main steam pipeline after the boiler is ignited for supplying steam for shaft seal of a turbine; and supplying steam to an auxiliary steam header of the generating set after the boiler is ignited and the combustion steam reaches a certain parameter, and then supplying steam by the auxiliary steam header for the rolling of a water thermal power deoxidizing and steam-driven feedwater pump. The invention has the advantages that as the cold start of the generating set can be realized through the ignition of the plasma installed in the combustor and the stable combustion technology under the conditions that no starting boiler room is independently established or the external heat source is insufficient, and the operating cost and the labor cost of the power plant are greatly reduced.

Owner:WENERGY HEFEI POWER GENERATION

Coal gas, tar, semi-coke and steam poly-generation method based on fluidized bed pyrolysis technology

ActiveCN102585913AImprove qualityEasy to controlEnergy inputSpecial form destructive distillationAir preheaterHeat carrier

The invention relates to a coal gas, tar, semi-coke and steam poly-generation method based on a fluidized bed pyrolysis technology. The method comprises the following steps of: mixing coal and high-temperature semi-coke serving as a heat carrier in a fluidized bed pyrolysis furnace, heating, precipitating volatiles, and cooling and separating the volatiles to obtain tar and pyrolysis coal gas; discharging one part of semi-coke to obtain a semi-coke product, feeding the other part of semi-coke into a fluidized bed semi-coke heating furnace, performing combustion reaction with a small amount of fed air, heating all the fed semi-coke by using heat released after a small amount of semi-coke is combusted, feeding the heated semi-coke into a cyclone separator along with flue gas, and feeding the separated high-temperature semi-coke serving as the heat carrier into the fluidized bed pyrolysis furnace; and feeding the flue gas subjected to gas-solid separation into a complementary combustion waste heat boiler, completely combusting a small number of combustible components in the flue gas, producing steam, feeding into an air preheater to heat air required by combustion, removing dust by using a dust remover, and emptying. The method has the advantages of realizing the fractional conversion of the coal and improving the utilization efficiency and benefit of the coal.

Owner:ZHEJIANG UNIV

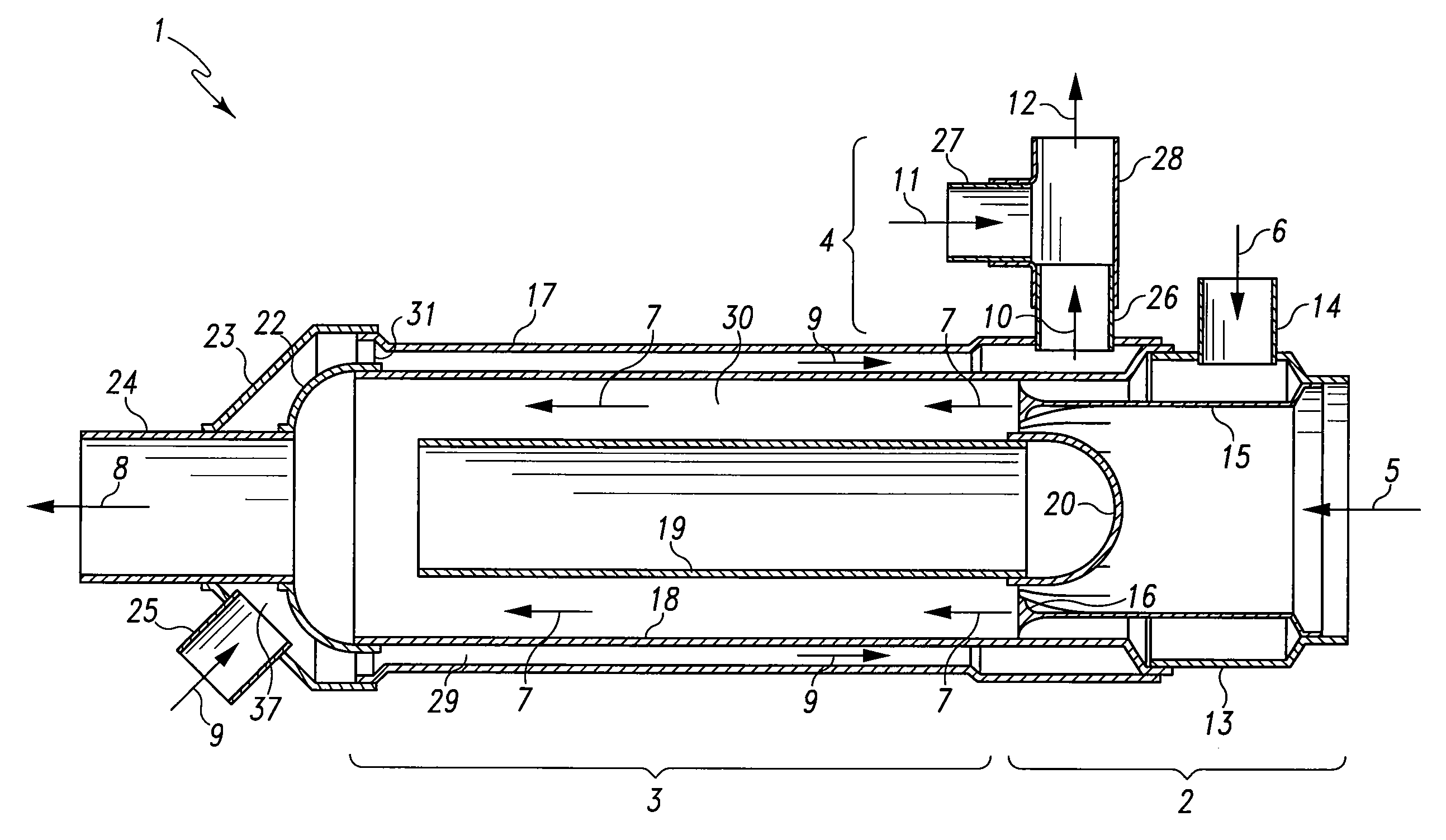

Compact air preheater for solid oxide fuel cell systems

InactiveUS20080020247A1Structural failureRemove heatFuel cells groupingRecuperative heat exchangersAir preheaterFuel cells

The present invention provides, among other things, a method of operating a solid oxide fuel cell system including a fuel cell stack. The method can include the acts of combining an exhaust flow from an anode side of the fuel cell stack and an exhaust flow from a cathode side of the fuel cell stack, transferring heat from the combined exhaust flow to a first air flow, and combining a second air flow and the heated first air flow upstream from the fuel cell stack to control a temperature of the combined air flow entering the cathode side of the solid oxide fuel cell.

Owner:MODINE MFG CO

Straw circulation fluidized-bed combustion boiler

InactiveCN1912461AGood load regulation performanceAvoid corrosionFluidized bed combustionCombined combustion mitigationAir preheaterCombustion chamber

A recirculation fluidized bed combustion boiler of straw is prepared as setting material feed mouth and residue extraction mouth on firepot, setting cooling device being connected to ignition combustion chamber and refeeder with secondary wind opening at bottom of firepot, using water cooling wall with top and bottom collection boxes as side wall of firepot, connecting outlet of firepot to separation device being connected to refeeder and two stages of thermo reduction devices separately, connecting one stage of thermo reduction device to a overheat unit with economizer and preheater as well as setting steam pocket and water supply pipe at top of firepot.

Owner:SHANDONG GUODIAN TECH CONSULTING +1

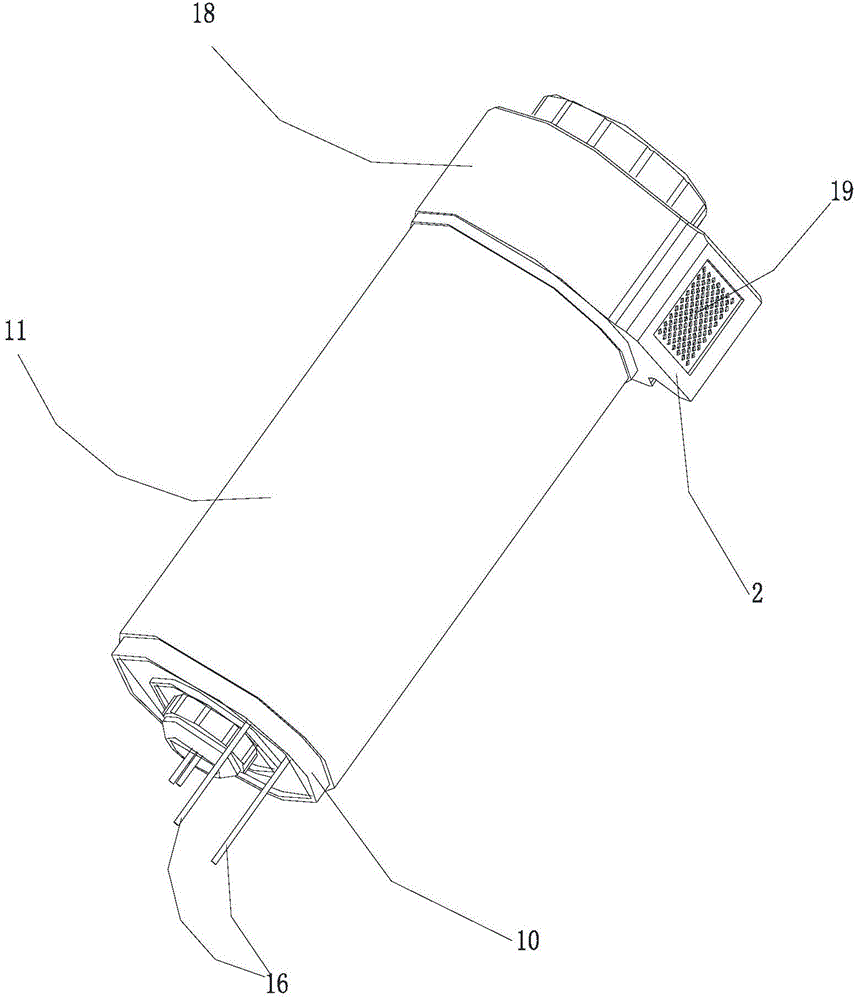

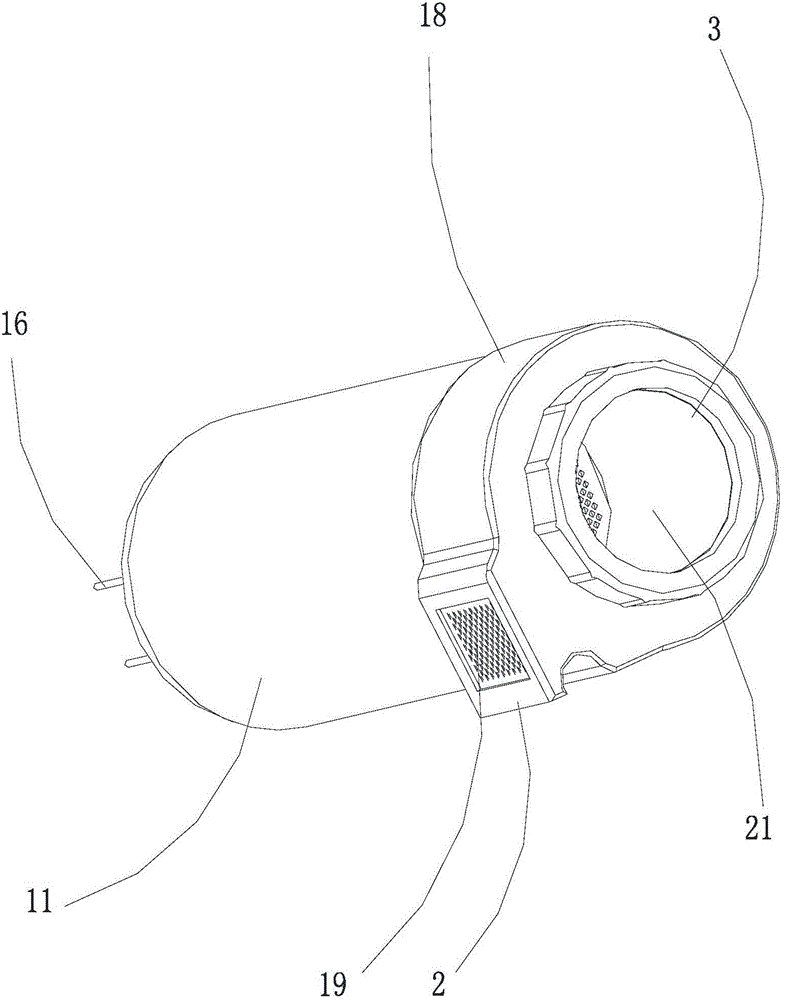

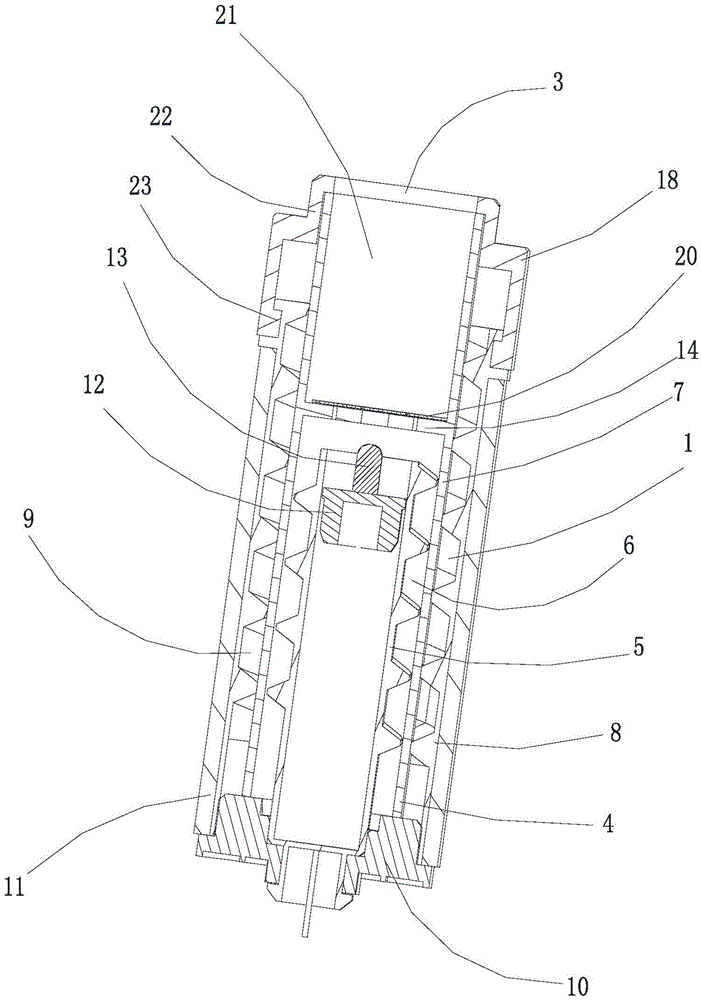

Air preheater

The invention discloses an air preheater, comprising an air passage. One end of the air passage is provided with an air inlet. The other end of the air passage is provided with an air outlet. A heater for heating the air flowing in the air passage is provided within the air passage. The use of the air passage and the heater allows full curing of tobacco shreds, reduction in harmful substances and improvement in taste.

Owner:SMISS TECH

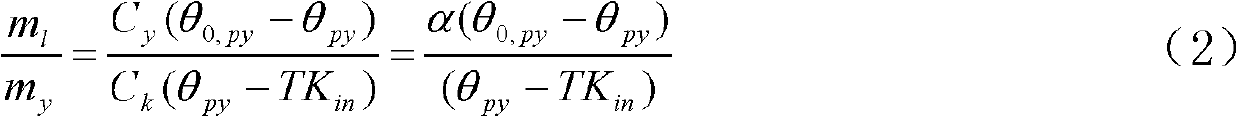

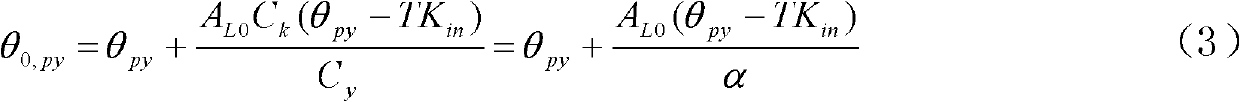

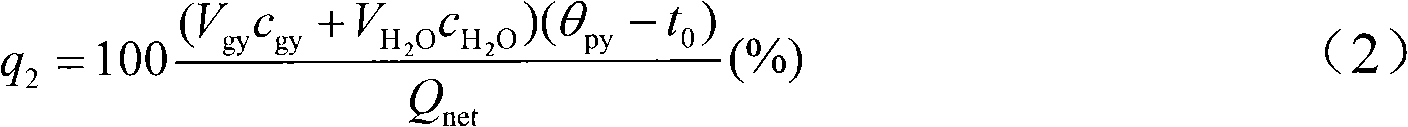

Method for testing air leak rate of air preheater

ActiveCN102213708AConvenient operation monitoringEasy to implementMaterial analysisAir preheaterEngineering

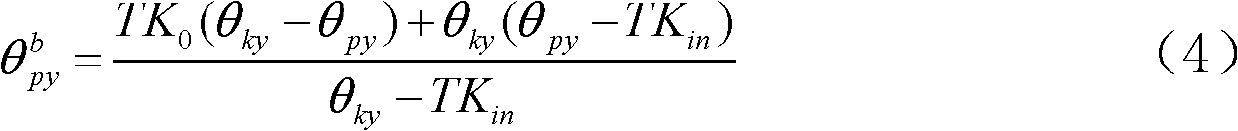

The invention relates to a method for testing the air leak rate of an air preheater, which is easy to implement, accurate and reliable and is suitable for analyzing and testing the air preheater. The accuracy of temperature measurement can reach 0.1 DEG C, the smoke venting temperature is within the range of between 100 and 200 DEG C approximately, and when a boiler runs stably, the smoke venting temperature is constant basically, so the relative accuracy of the temperature measurement is higher than the analytic accuracy of the oxygen content of smoke. Therefore the air leak rate, which is calculated according to the change of the smoke venting temperature, of the air preheater has the higher test accuracy. The method comprises the following steps of: 1) measuring the smoke venting temperature theta py of the air preheater and the temperature TKin of air entering the air preheater; and 2) utilizing a formula, namely when the change of the air leak rate is needed to be monitored due to the change of the air leak rate with the change of the running condition or equipment condition of the air preheater, measuring the air temperature TKin and the smoke venting temperature thetapy in the running state, which corresponds to the temperature thetapy, of the boiler, and calculating the air leak rate AL by the formula.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Efficient waste heat using organic contaminated soil displacement thermal desorption repairing system and method

ActiveCN107971330AReduce consumptionEmission reductionCombination devicesDispersed particle filtrationAir preheaterThermal desorption

The invention relates to an efficient waste heat using organic contaminated soil displacement thermal desorption repairing system and method. A burner is communicated with a high temperature oxidizingchamber, a high temperature smoke pipe of the high temperature oxidizing chamber is communicated with a rotary kiln heating processing system and an air heat exchanger, a high temperature air outletof the air heat exchanger is communicated with the burner, a smoke pipe of the air preheater is communicated with an inlet of a quench tower, an outlet of the quench tower is communicated with an inlet of a bag-type dust collector, an outlet of the bag-type dust collector is communicated with an inlet of a deacidification tower, an outlet of the deacidification tower is communicated with an air inlet of a second induced draft fan, and an outlet of the second induced draft fan is communicated with a chimney. A part of high temperature flue gas generated by the burner enters a rotary kiln thermal desorption reactor to achieve desorption of organic pollutant and soil drying pretreatment, organic matter enters the high temperature oxidizing chamber through a backflow pipe for burning treatment, and thorough oxidative degradation removal is achieved; and the other part of high temperature flue gas is used for increasing the temperature of combustion air through the air heat exchanger.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

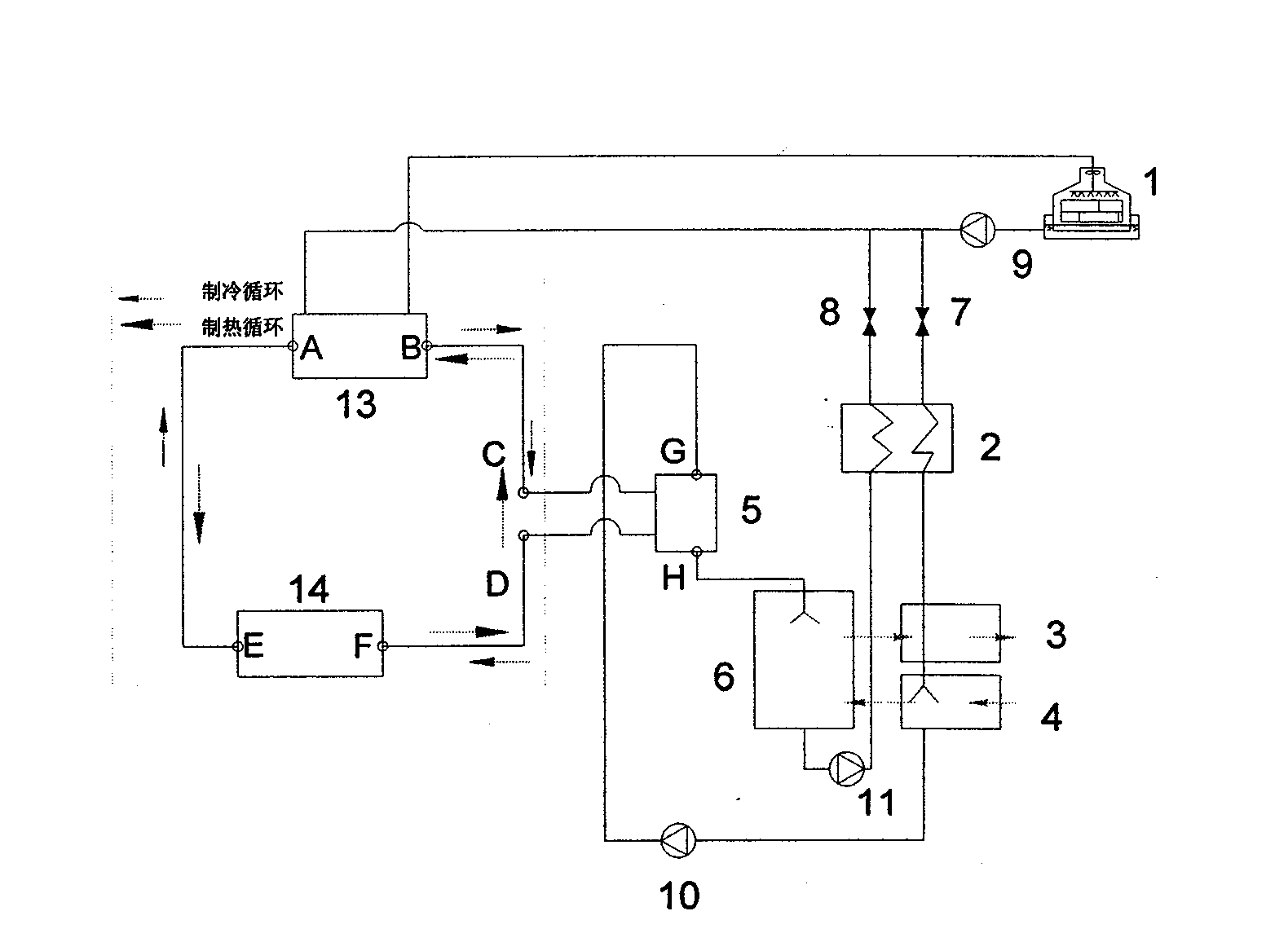

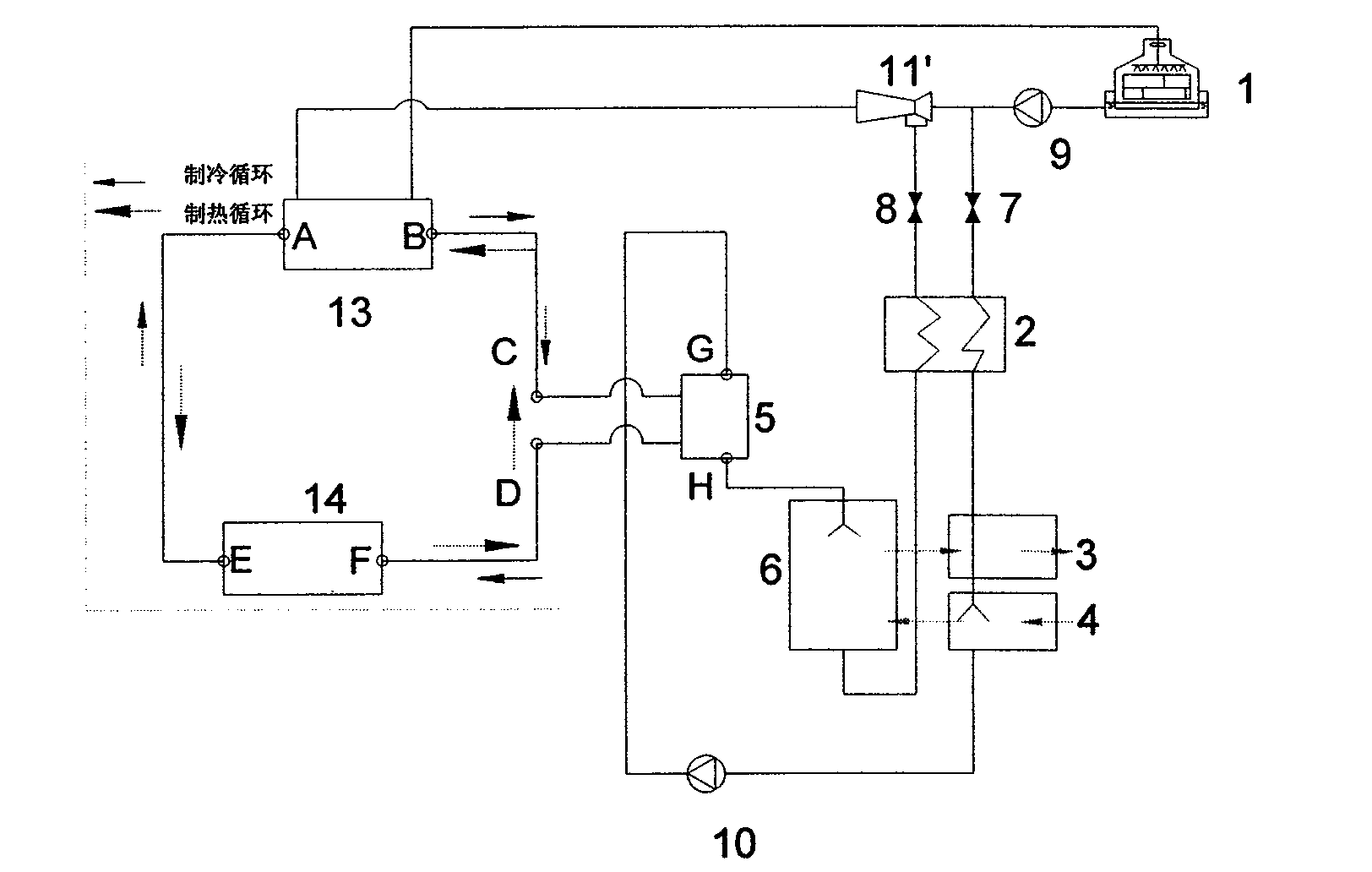

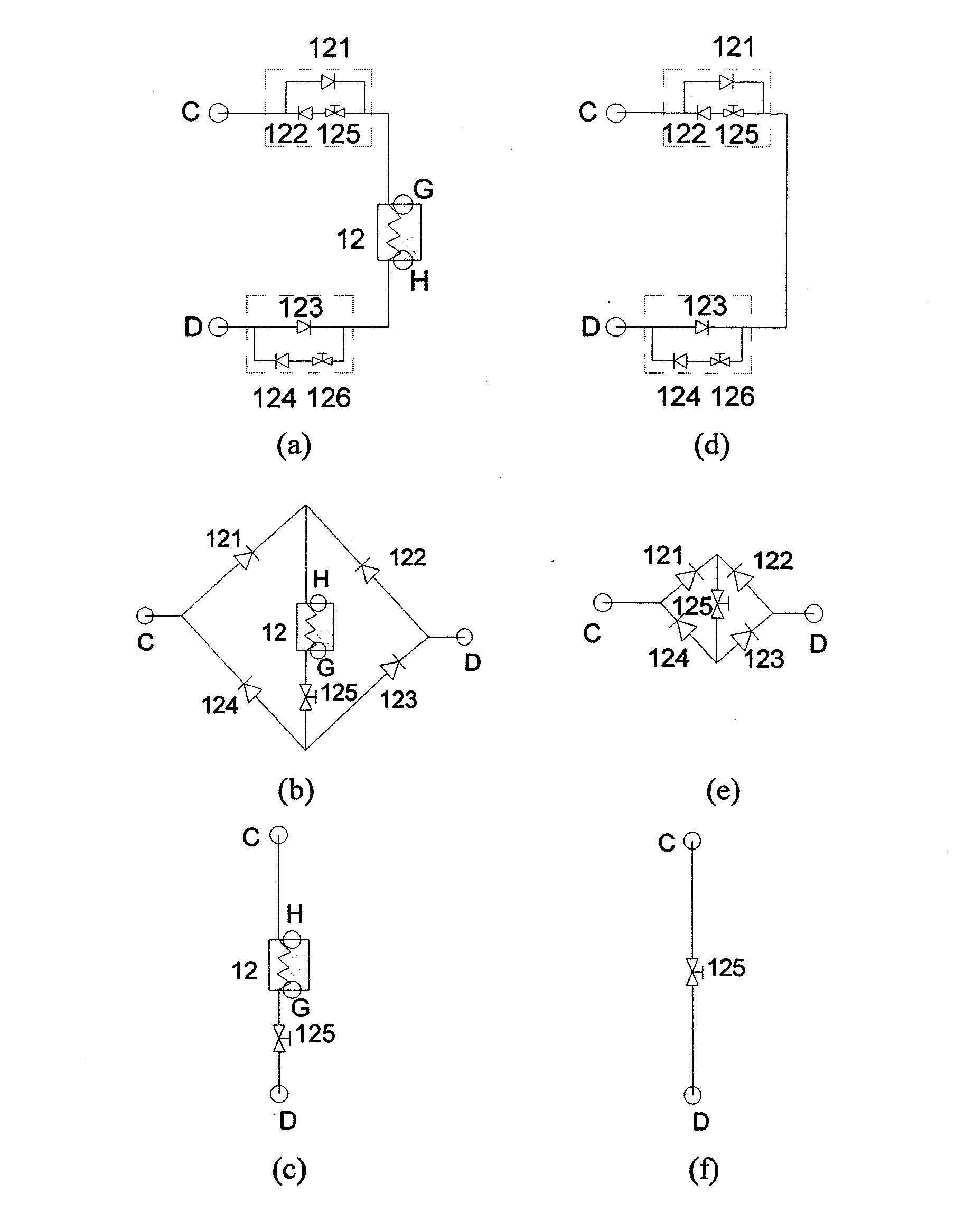

Frost-free type air source heat pump system

The invention discloses a frost-free type air source heat pump system. The system carries out heat pump circulation, can absorb heat from ambient air and can avoid a frosting phenomenon. The system utilizes the characteristic of the absorption / desorption of a similar salt solution, and the heat is absorbed from an ambient environment by a cooling tower. The system comprises a heat pump subcycle part, a solution heat-absorbing subcycle part and a solution regeneration subcycle part. The solution regeneration subcycle part comprises a solution heat regenerator, a solution / air preheater, a first regenerator, a second regenerator and a regenerated heat absorber. After being preheated by the first regenerator, the ambient air enters the second regenerator, and then flows out of the solution / air preheater after water in a regenerated solution is absorbed, and the effluent air is used for preheating part of a low-temperature dilute solution entering the solution / air preheater. The invention avoids the occurrence of the frosting condition of the traditional air source heat pump system; the utilization rate of equipment and energy resources is enhanced.

Owner:ZHEJIANG UNIV

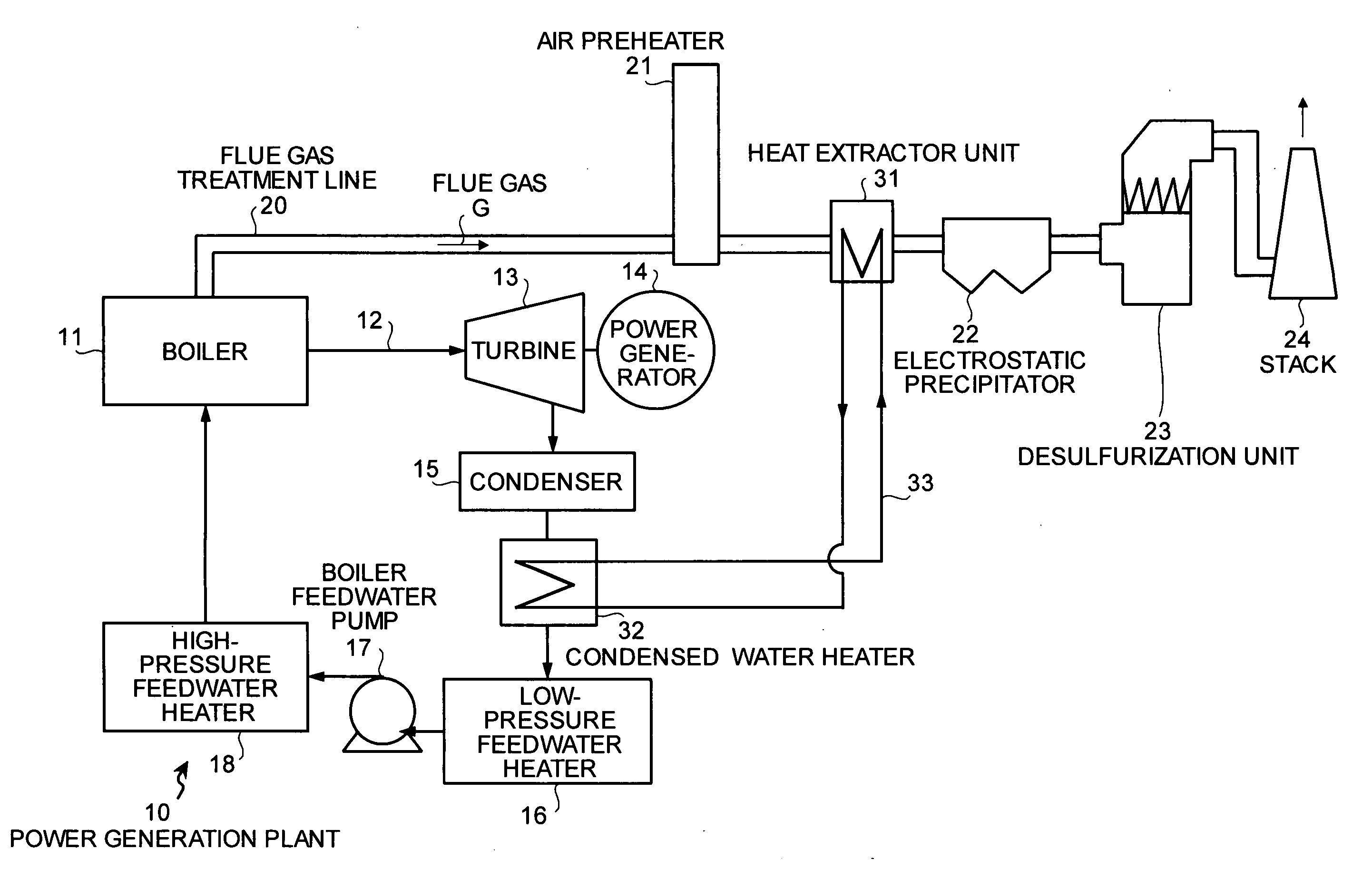

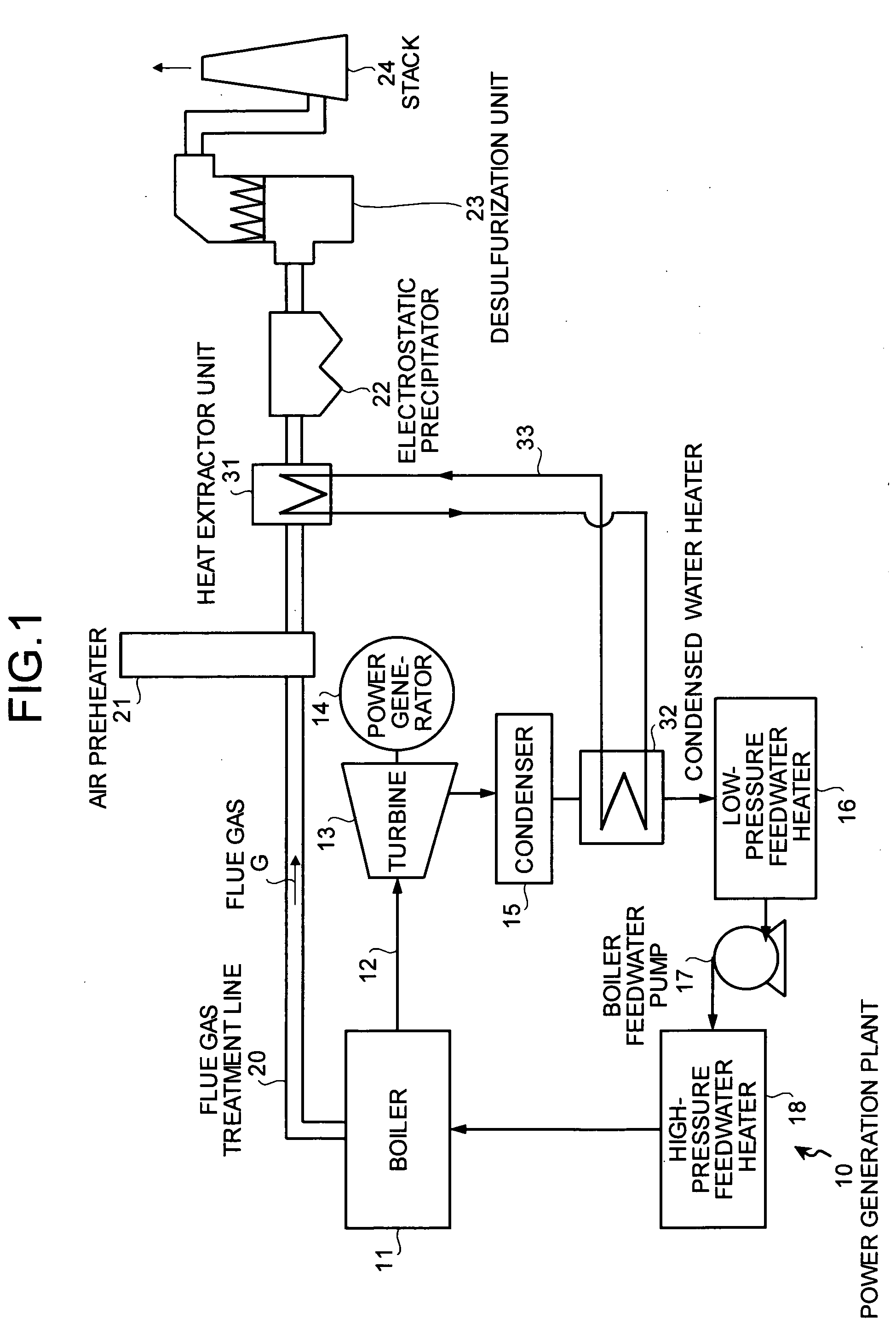

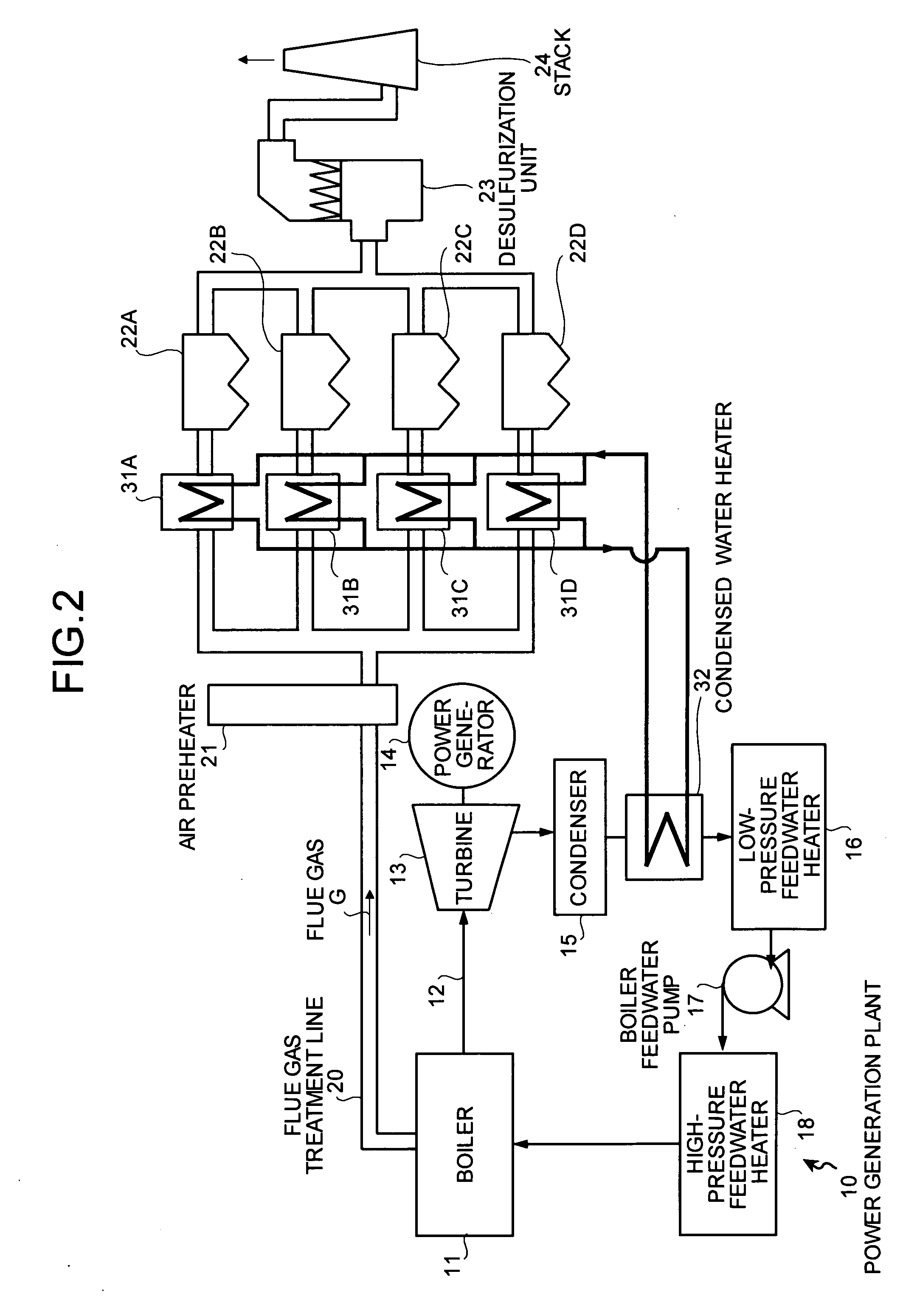

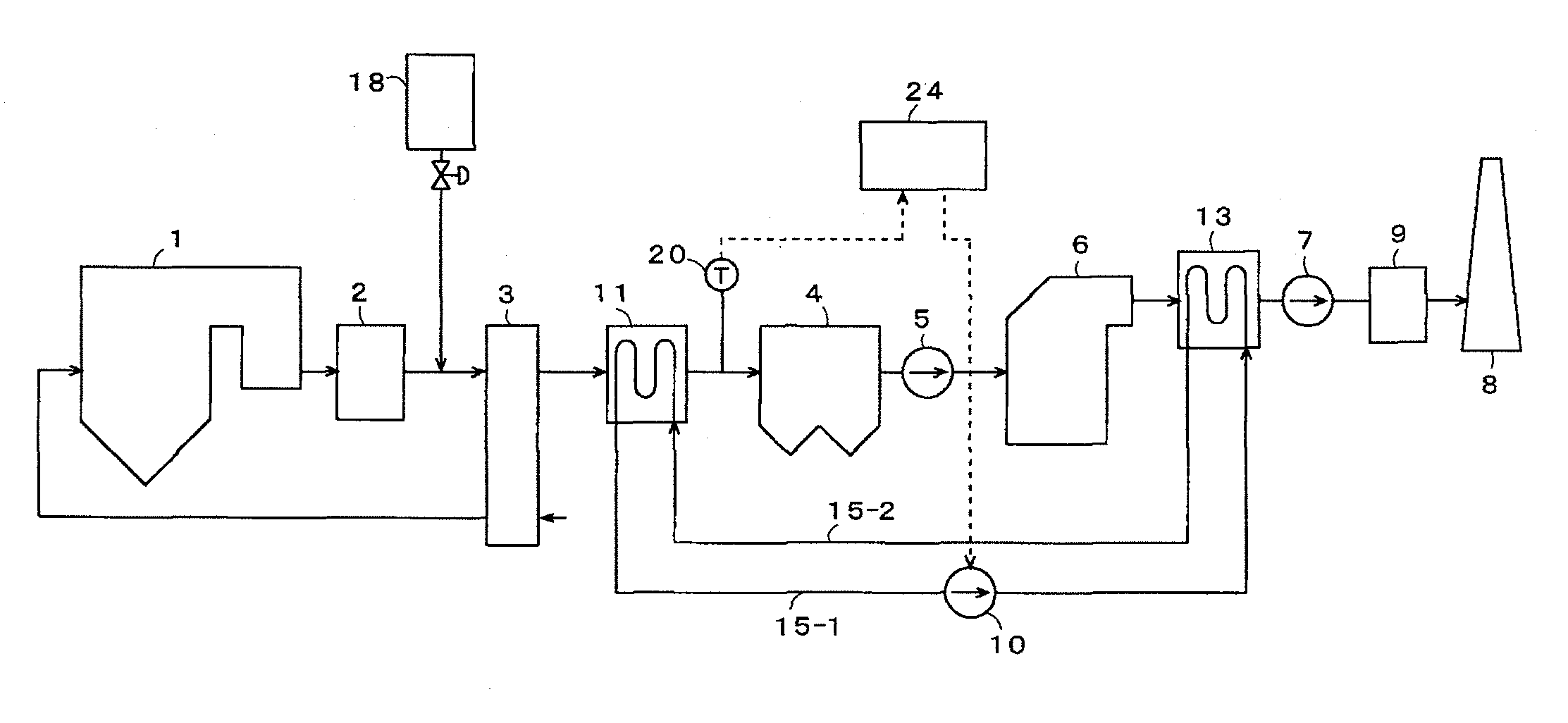

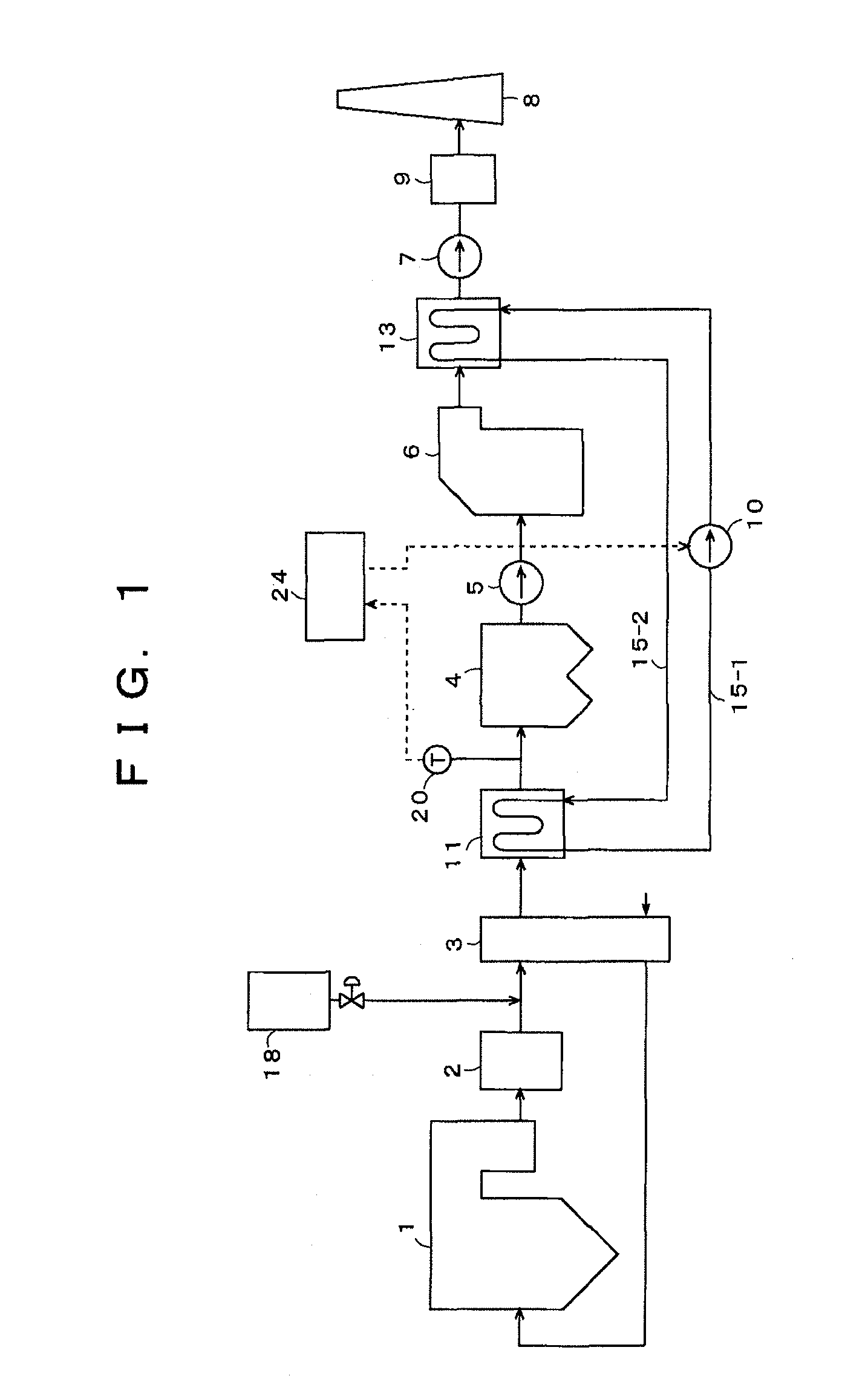

Heat recovery equipment

Heat recovery equipment recovers heat from flue gas. The heat recovery equipment includes a power generation plant that drives a steam turbine by superheated steam produced in a boiler, and an exhaust-gas treatment line that treats flue gas output from the boiler. The exhaust-gas treatment line includes a first air preheater, a heat extractor unit, and a dry electrostatic precipitator. The power generation plant includes a condensed water line. The condensed water line includes a condenser, a condensed water heater, and a low-pressure feedwater heater. The condensed water heater heats water condensed by the condenser with the heat recovered by the heat extractor unit.

Owner:MITSUBISHI POWER LTD

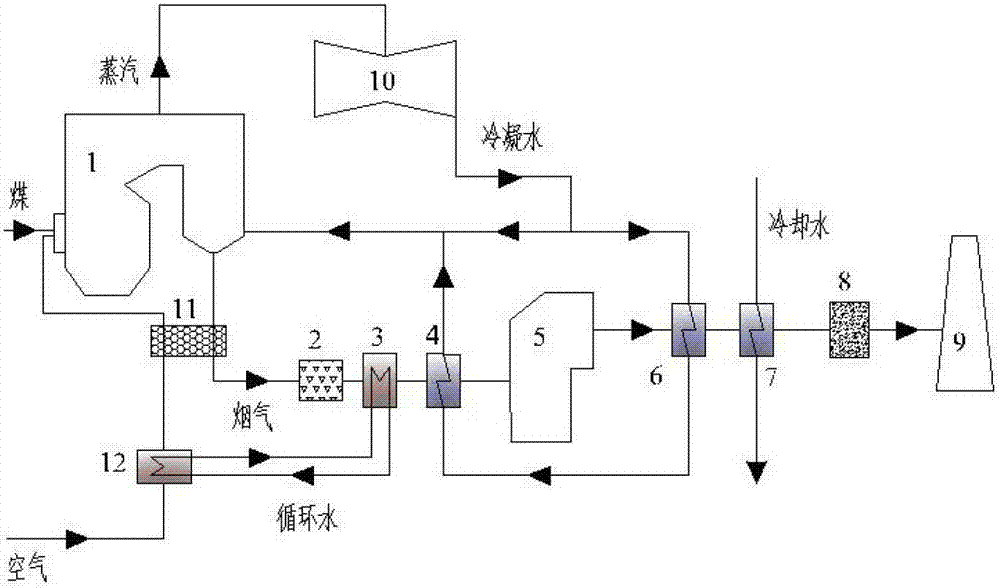

Smoke waste heat utilization system

ActiveCN102759096AIncrease profitReduce heat consumptionCombustion processIndirect carbon-dioxide mitigationAir preheaterPollutant emissions

The invention discloses a smoke waste heat utilization system, wherein two condensation heat exchangers are added between a desulfurizing tower and a CO2 catching system, so as to absorb smoke heat and lower exhaust smoke temperature; and the absorbed heat is used for condensation water heating and municipal heating respectively. Two smoke coolers are arranged between an electric precipitator and the desulfurizing tower, and the heat recovered from the smoke is used for boiler primary air heating and further condensation water heating respectively. An air heater is arranged between an air inlet and an air preheater, and the heat recovered from the smoke by the smoke coolers is used for boiler primary air heating. The smoke waste heat utilization system can facilitate energy conservation and efficiency improvement for a power plant, and is particularly important for a running power plant which is difficult to improve the back-heating efficiency through increasing a steam parameter. Through optimizing running parameters of a unit, increasing condensation water heating bypasses and raising the temperature of the boiler primary air entering the air preheater, the heat consumption of a whole heating device can be lowered, the pollutant emission is reduced, and the energy utilization is improved.

Owner:XI AN JIAOTONG UNIV

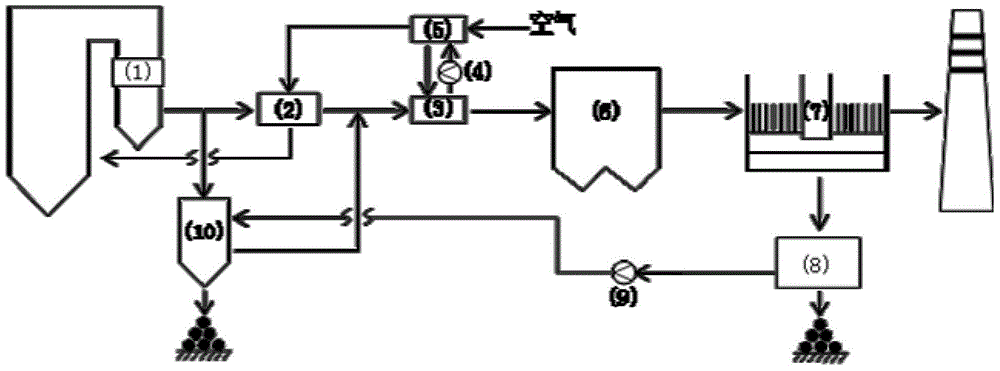

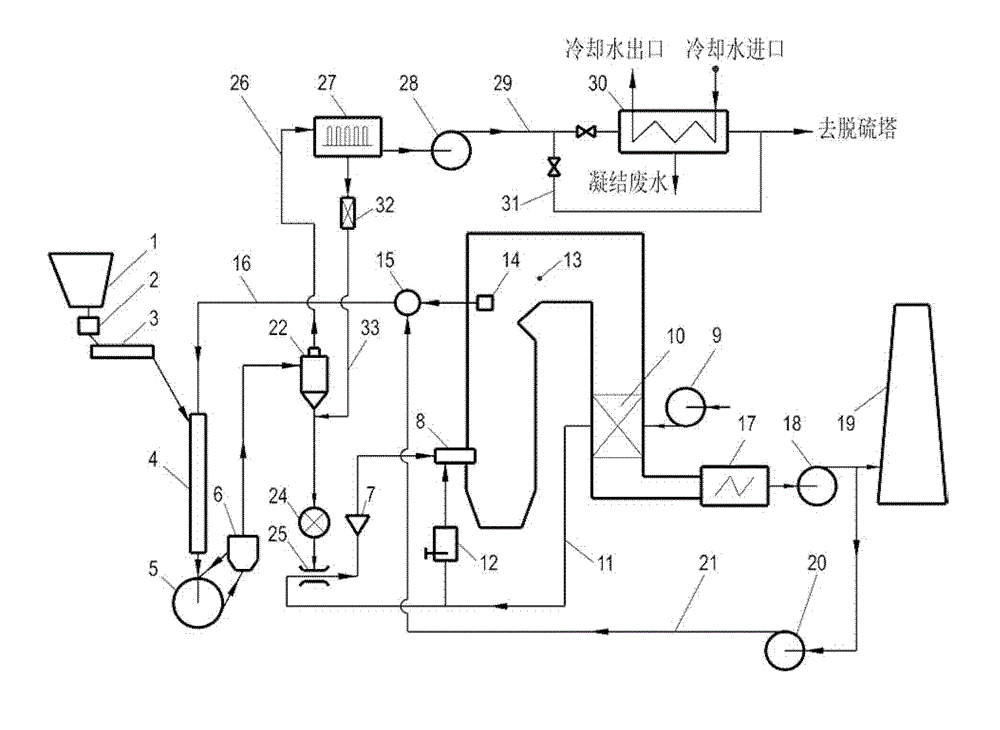

System and method for treating tail end waste water by using smoke waste heat

ActiveCN103982903AAchieve recyclingLower smoke temperatureLighting and heating apparatusWater/sewage treatmentAir preheaterCoal

The invention discloses a system and a method for treating tail end waste water by using smoke waste heat. The system comprises a coal economizer, an air preheater, a smoke cooler, an electric deduster, a desulfurization tower, a waste water preprocessor and a waste water spraying evaporator which are communicated in sequence; a waste water pump is arranged on the pipeline for communicating the waste water processor and the waste water spraying evaporator; the smoke inlet of the waste water spraying evaporator is communicated with the pipeline between the coal economizer and the air preheater; the hot water outlet of the smoke cooler is communicated with a waste heat air heater by a circulation pump; the hot air outlet of the waste heat air heater is communicated with the air preheater. The smoke outlet of the waste water spraying evaporator is communicated with the electric deduster by the smoke cooler. The invention provides the method for treating tail end waste water by using the smoke waste heat. The smoke tampering is performed and the smoke temperature is reduced while the tail end waste water is treated, so the dedusting efficiency is improved, the low-temperature dedusting is realized, the desulfurization water consumption is reduced, the method has benefits of three aspects of energy saving, water saving and environment friendliness, and the zero emission of the waste water from a power station is truly realized.

Owner:XIAN THERMAL POWER RES INST CO LTD

Method for monitoring thermal efficiency and coal quality data of pulverized coal fired boiler in real time

InactiveCN102012968AThe real-time monitoring method is scientific and reasonableAccurate real-time monitoringSpecial data processing applicationsAir preheaterAir volume

The invention relates to a method for monitoring thermal efficiency and coal quality data of a pulverized coal fired boiler in real time. A digital model for monitoring the thermal efficiency of a pulverized coal fired boiler system in real time is established to obtain an excess air coefficient, theoretical air volume of a fuel, theoretical nitrogen volume of a combustion product, flue gas carbon dioxide, carbon monoxide, sulfur dioxide, dry flue gas volume, volume difference between theoretical oxygen demand of full coal combustion and practical combustion oxygen consumption, mass percentage of coal as received basis machinery unburned carbon, mass percentage of coal generated carbon dioxide as received basis carbon, mass percentage of coal generated carbon monoxide as received basis carbon, mass percentage of coal as received basis; densities of carbon, hydrogen, oxygen, nitrogen, sulfur, ash, water and flue gas, flow speed of flue gas in air preheater, lower heating value of coal,heat loss due to exhaust smoke, heat loss due to chemical incomplete combustion, heat loss due to mechanical incomplete combustion, radiating heat loss, ash residue physic heat loss, boiler thermal efficiency, mass percentage of carbon in fly ash and coal combustion. The method has the characteristics that: the method is scientific and reasonable, monitors data correctly, and the like.

Owner:NORTHEAST DIANLI UNIVERSITY +1

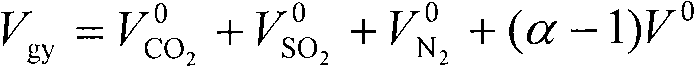

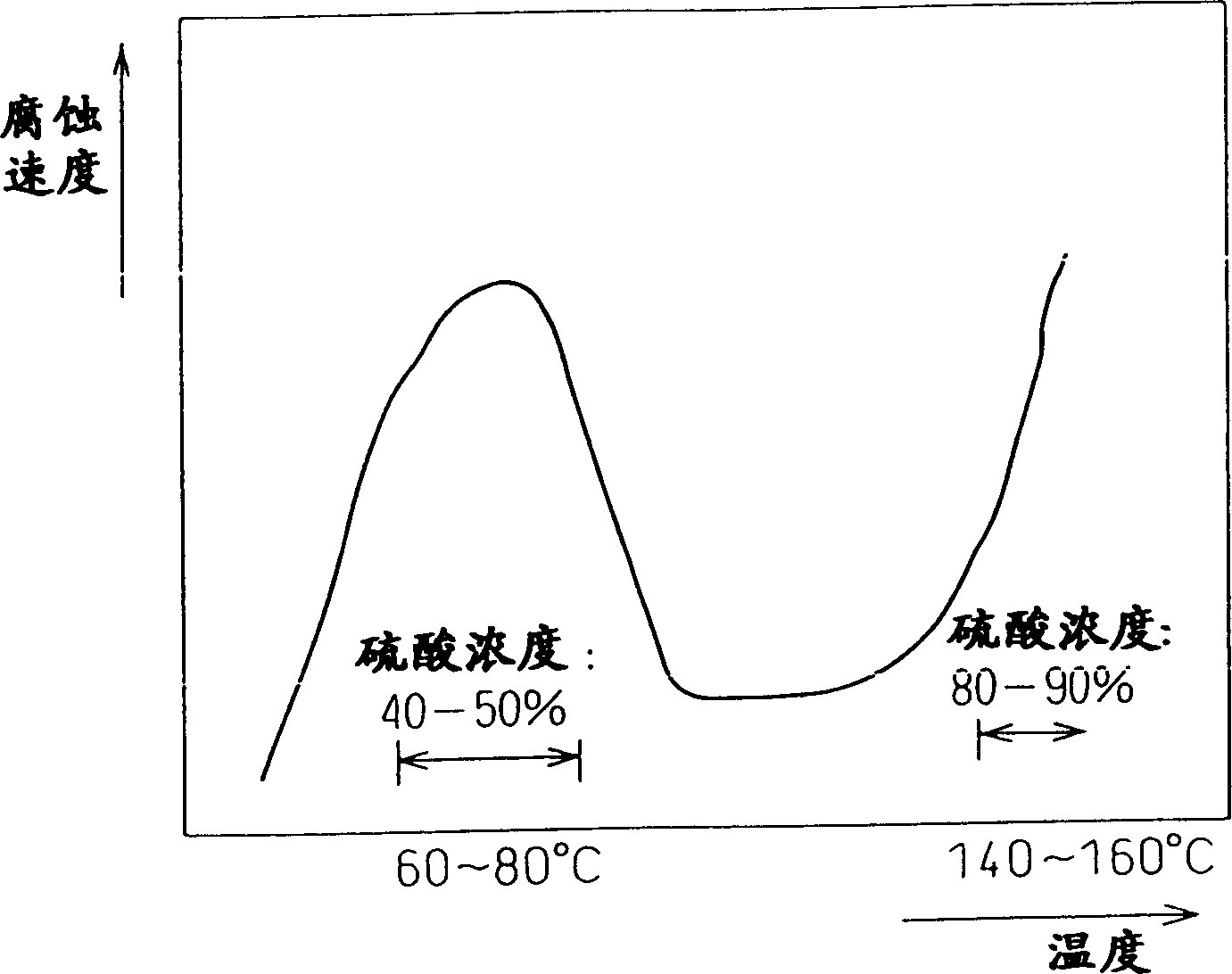

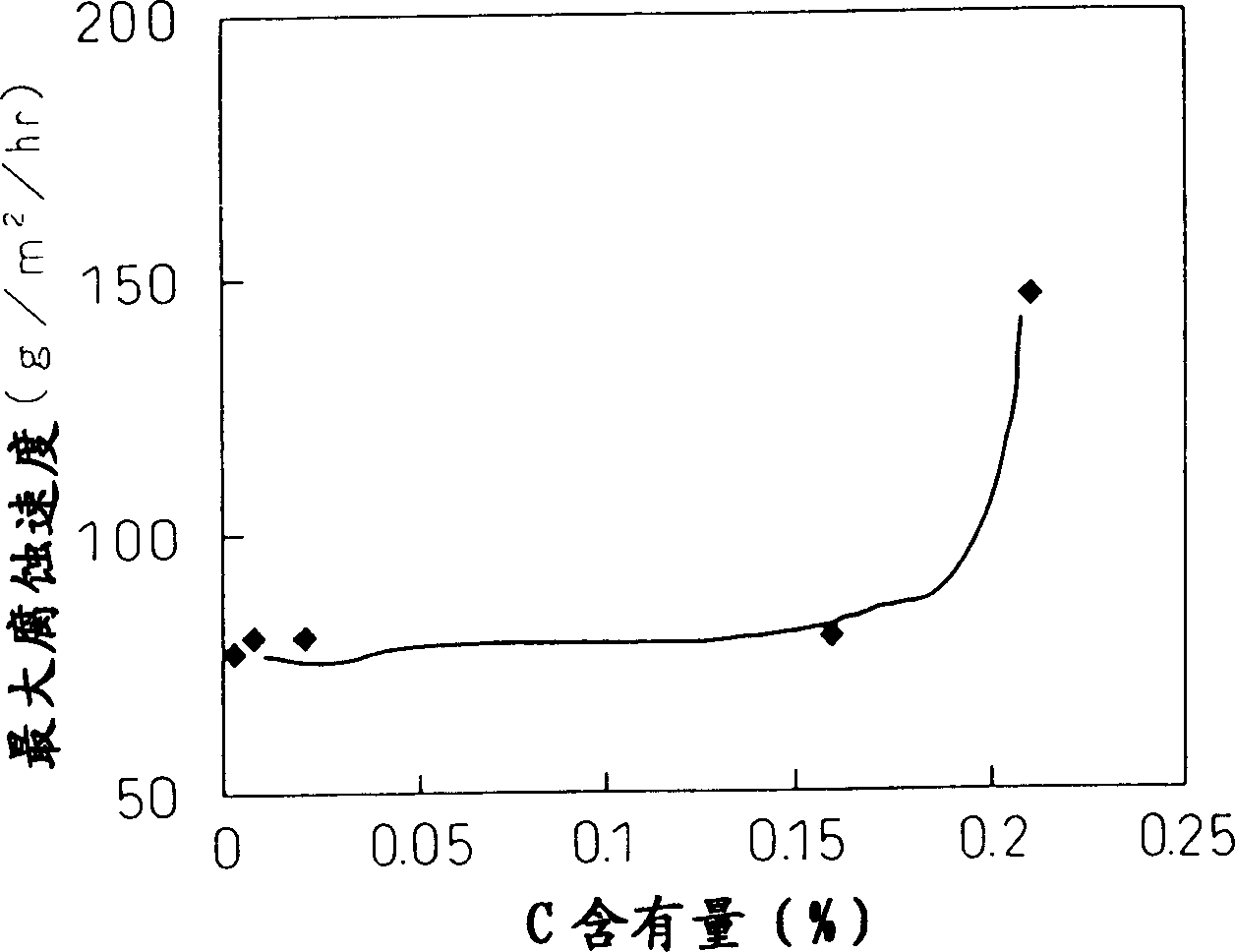

Steel excellent in resistance to sulfuric acid dew point corrosion and preheater for air

A steel excellent in the resistance to sulfuric acid dew point corrosion, which has a chemical composition, in mass %: C: C22C 38 / 00 3 8 0 2002 / 2 / 1 1455822 2003 / 11 / 12 1195883 2005 / 4 / 6 2005 / 4 / 6 2005 / 4 / 6 Nippon Steel Corporation Japan Sakamoto Shunji Mishimura Satoshi Uzo Jiaki duan chengen liu jinhui 11247 Japan 2001 / 2 / 2 27455 / 01 2002 / 9 / 29 PCT / JP2002 / 000856 2002 / 2 / 1 WO2002 / 063056 2002 / 8 / 15 Japanese

Owner:NIPPON STEEL CORP

Fan grinding hot blast powder feeding and pulverizing system utilizing flue gas drying and water recycling

ActiveCN102798133AImprove fuel consumption qualityReduce volumeLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationAir preheaterFlue gas

The invention relates to a fan grinding hot blast powder feeding and pulverizing system utilizing flue gas drying and water recycling. The system is further provided with a steam exhaust separator, a pulverized fuel feeder and a coal-dust mixer in sequence between a tailing separator and a coal-dust distributor; the upper part of the steam exhaust separator is provided with a steam exhaust outlet; the steam exhaust outlet is communicated with a steam exhaust filter; the coal outlet of the steam exhaust filter is communicated with the pulverized fuel feeder; the air outlet of the steam exhaust separator is communicated with a steam exhaust fan; the steam exhaust fan is then communicated with a desulfurizing tower; and an air preheater is further communicated with the coal dust mixer. The system has the advantages of improving the burn-up quality of brown coal and the thermal efficiency of fuel coal, and as drying, pulverizing, upgrading, water conservation and storage of the brown coal are combined, the coal consumption of power generation can be reduced, and a large amount of water in the brown coal can be recycled.

Owner:NORTHEAST ELECTRIC POWER DESIGN INST CO LTD OF CHINA POWER ENG CONSULTING GRP +1

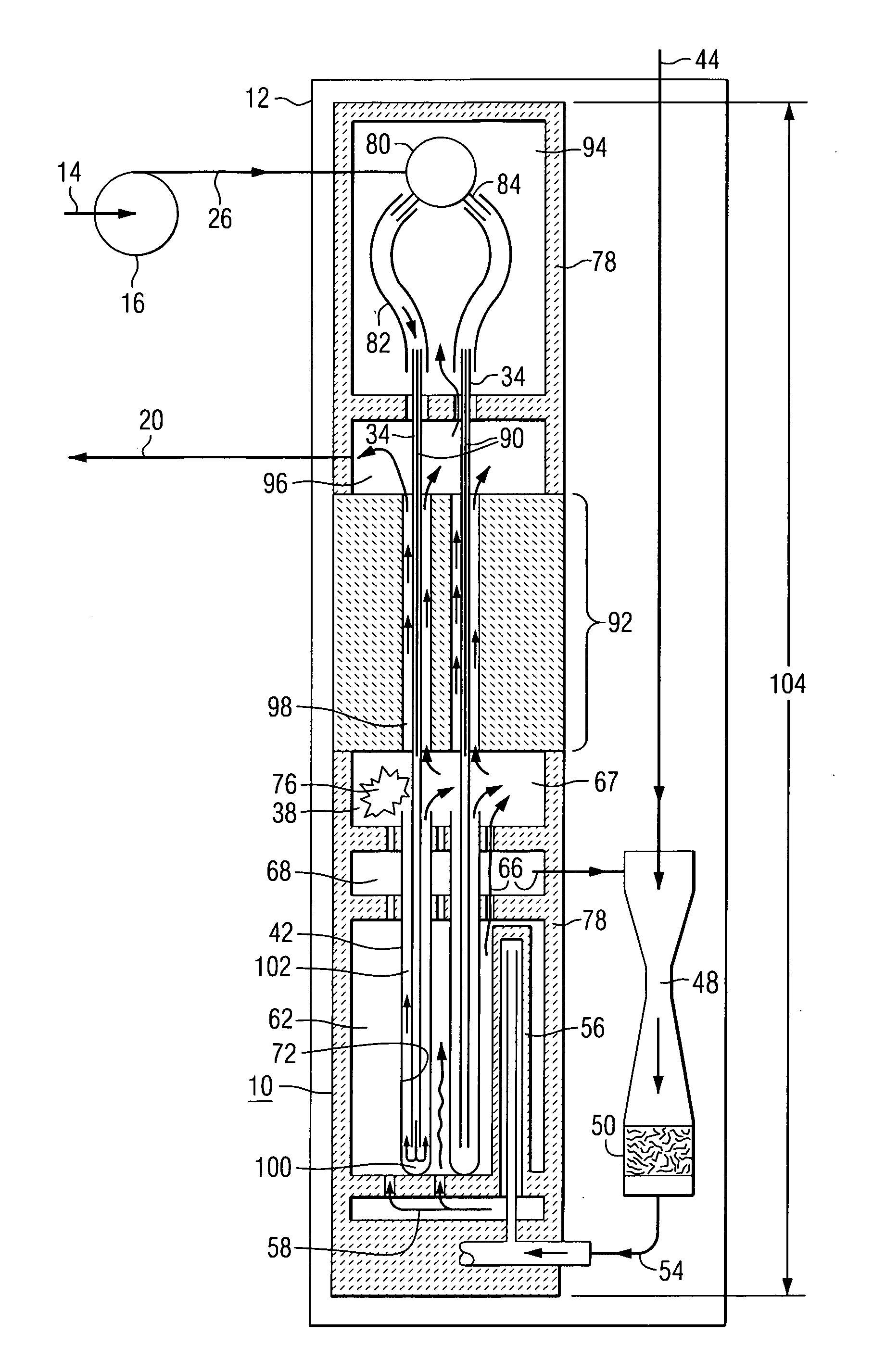

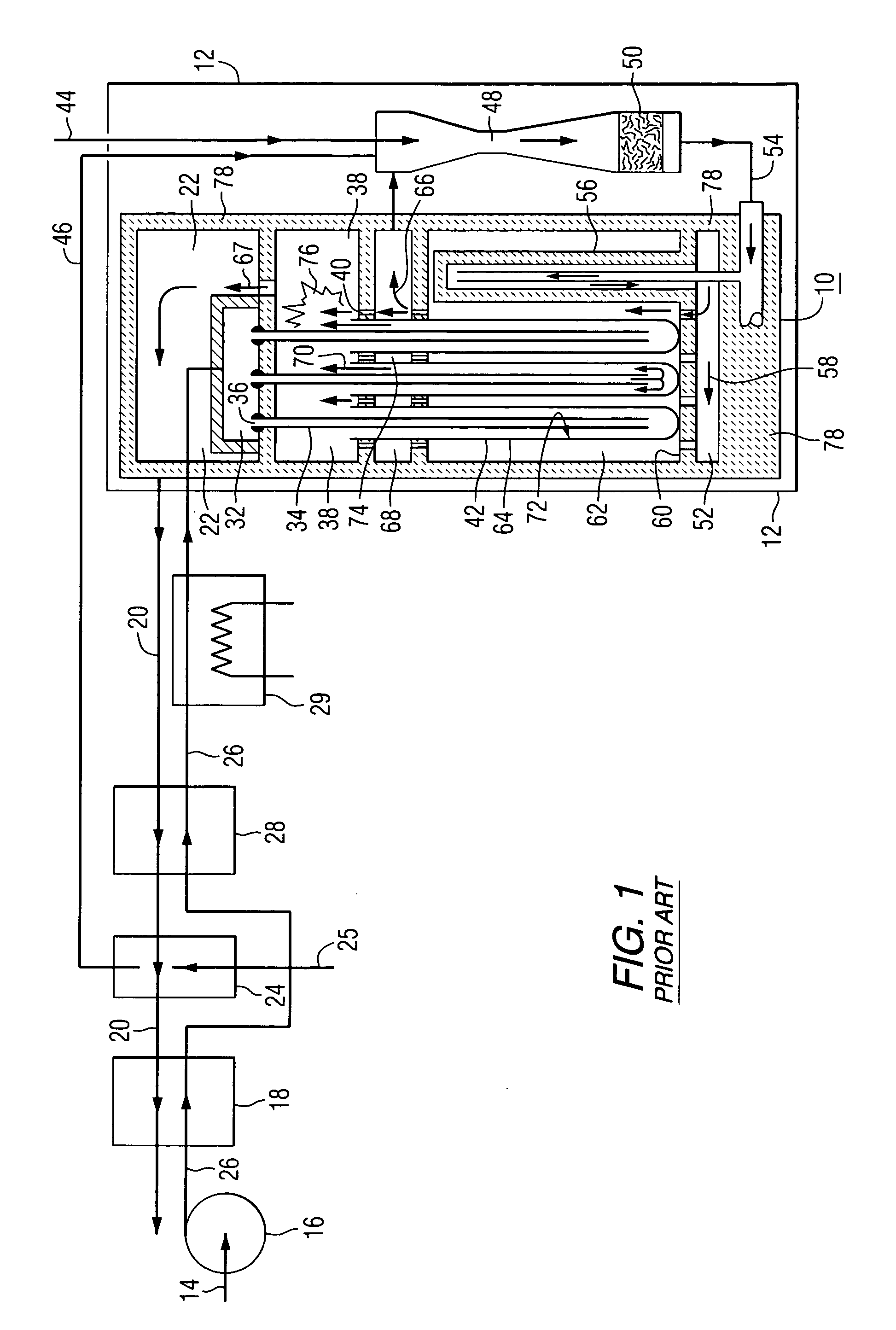

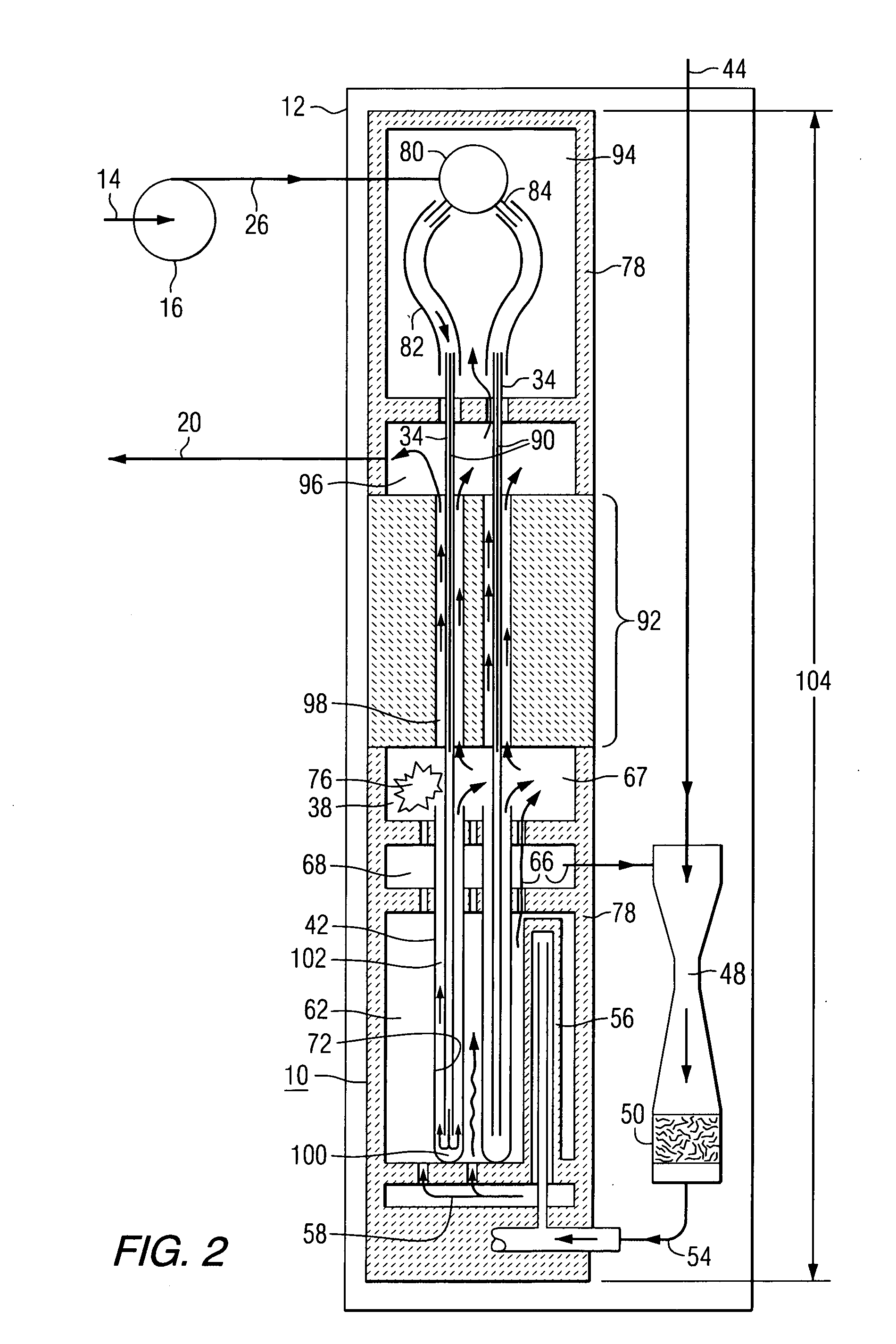

Integral air preheater and start-up heating means for solid oxide fuel cell power generators

InactiveUS20050123808A1The equipment is bulkySubstantial ducting savingReactant parameters controlFuel cells groupingAir preheaterFuel cells

A high temperature fuel cell generator (10) having a housing (12) containing a top air feed plenum (80), a bottom fuel inlet (54), a fuel reaction generator chamber (62) containing fuel cells (42) and a reacted fuel-reacted air combustion chamber (38) above the fuel reaction generator chamber (62), where inlet air (14) can be heated internally within the housing in at least one interior heat transfer zone / block (92) located between the reacted fuel-reacted air combustion chamber (38) and the air feed plenum (80).

Owner:SIEMENS AG

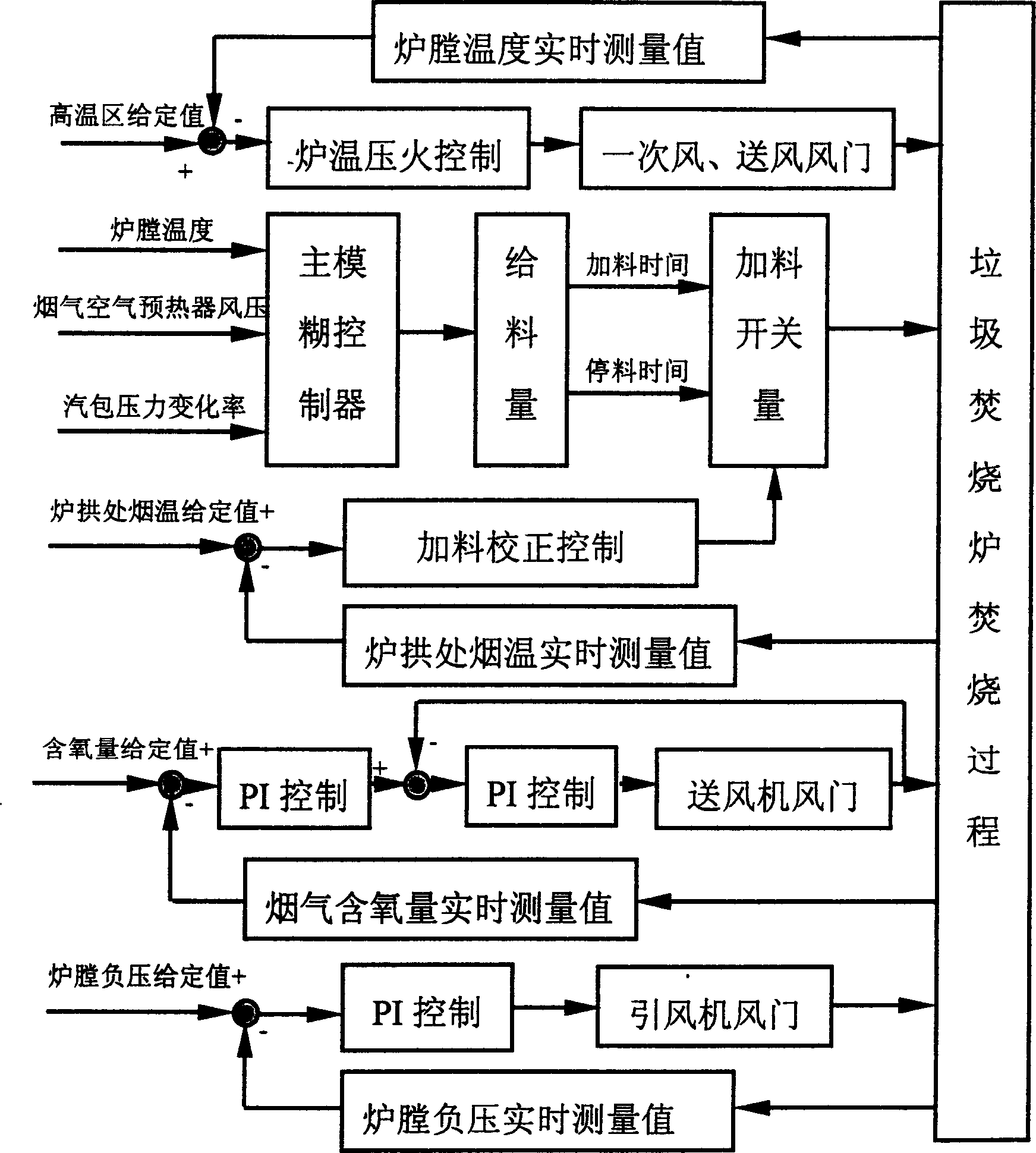

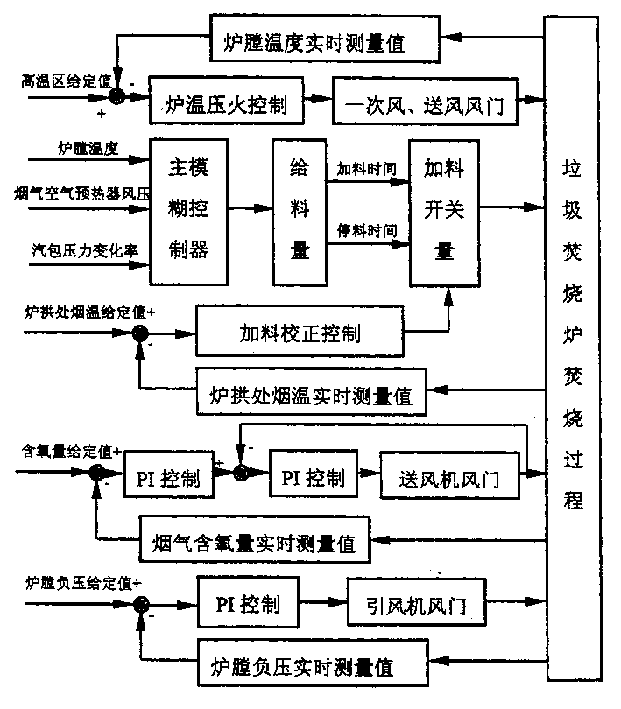

Control method of burning process of garbage incinerator

InactiveCN1479037AExclude too thickEliminate the disadvantages of low burnout rateIncinerator apparatusAir preheaterFuzzy control system

A method for controlling the incineration procedure of garbage incinerator includes such steps as measuring the real-time parameters of incinerator, creating the primary fuzzy controller, correcting the output of primary fuzzy controller, regulating the opening of the air gate of blower, regulating the fire power, and regulating the opening of air gate of exhauster. Its advantage is full combustion of garbage.

Owner:HUAZHONG UNIV OF SCI & TECH

Method and apparatus for treating discharge gas

ActiveUS20100074817A1Reduce concentrationImprove adsorption capacityCombination devicesNitrogen compoundsAir preheaterSorbent

The following devices are successively disposed in the following order from an upstream side to a downstream side in an exhaust gas duct of a combustion apparatus: an air preheater, preheating combustion air for use in an exhaust gas treating apparatus; a heat recovery unit, recovering exhaust gas heat at an exit of the air preheater; a precipitator, collecting soot / dust contained in an exhaust gas at an exit of the heat recovery unit; a wet flue gas desulfurizer, removing sulfur oxides contained in the exhaust gas at the exit of the precipitator; and a reheater, heating the exhaust gas at the exit of the wet flue gas desulfurizer. Each of the heat recovery unit and the reheater has a heat exchanger tube, and a circulation line is disposed to connect the heat exchanger tubes. A sulfur trioxide (SO3) removing agent is supplied to the upstream side of the heat recovery unit, and the temperature of the exhaust gas at the exit of the heat recovery unit is adjusted to not more than a dew point of sulfur trioxide. As the sulfur trioxide removing agent, use is preferably made of at least one among a sulfur trioxide adsorbent, a sulfur trioxide reducing agent, and a sulfur trioxide neutralizing agent. Thus, even when coal with a high sulfur content is used as fuel, heavy metals contained in the exhaust gas can be removed effectively from the exhaust gas.

Owner:MITSUBISHI POWER LTD

Method for producing superconducting carbon black with high specific surface area

ActiveCN102174277AHigh strengthReduce usagePigmenting treatmentChemical industryElectricityAir preheater

The invention relates to a method for producing superconducting carbon black with high specific surface area, and aims to make a production process simple and product performance stable. The method comprises the following steps of: completely combusting gas in a combustion section of a reaction furnace, mixing the gas, air and raw oil, adding into a throat pipe section of the reaction furnace, and making the temperature of a reaction section of the reaction furnace reach 1,300 to 1,600 DEG C under the action of a K2CO3 catalyst; performing thermal cracking and thermal polycondensation on the gas and the raw oil rapidly to generate the superconducting carbon black; continuously reacting the superconducting carbon black with a CO2 catalyst in a rapid cooling section of the reaction furnace,and performing catalytic activation on the superconducting carbon black to form a developed pore structure and improve the specific surface area of the superconducting carbon black; exchanging the flue gas of the superconducting carbon black with cold air by using an air preheater in a retention section of the reaction furnace to reduce the temperature to be lower than 600 DEG C; and when reaction for preparing a product from raw materials is finished, cooling the superconducting carbon black to 320-350 DEG C by using a tubular rapid cooling boiler, slowly cooling, adding into a bag filter, and collecting, wherein recycled heat is used for generating electricity.

Owner:山西永东化工股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com