Patents

Literature

50results about How to "The equipment is bulky" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plating apparatus and method

InactiveUS20020008036A1Strong Gap Filling CapabilityReduce stressCellsSemiconductor/solid-state device manufacturingElectrolyte leakageEngineering

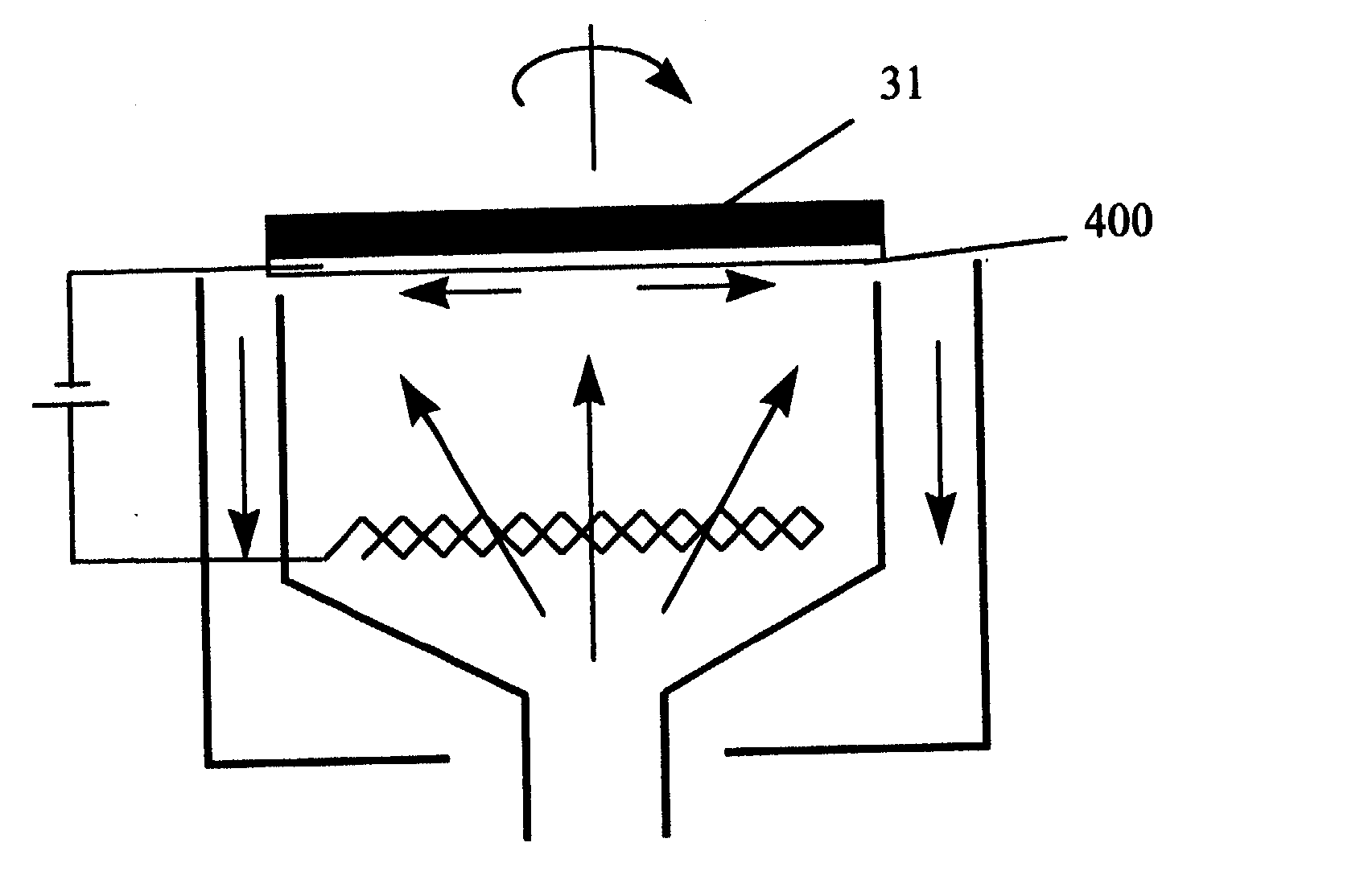

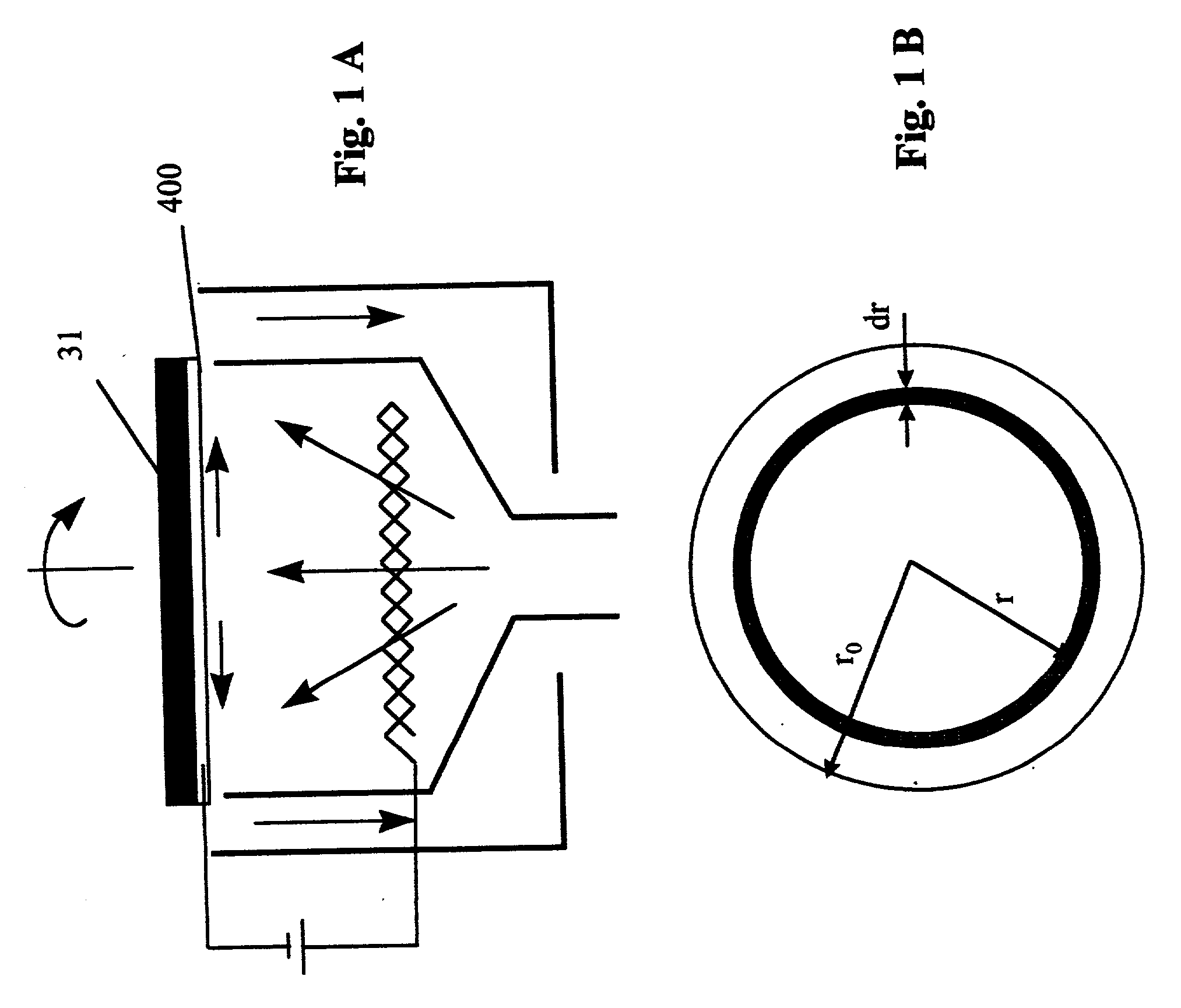

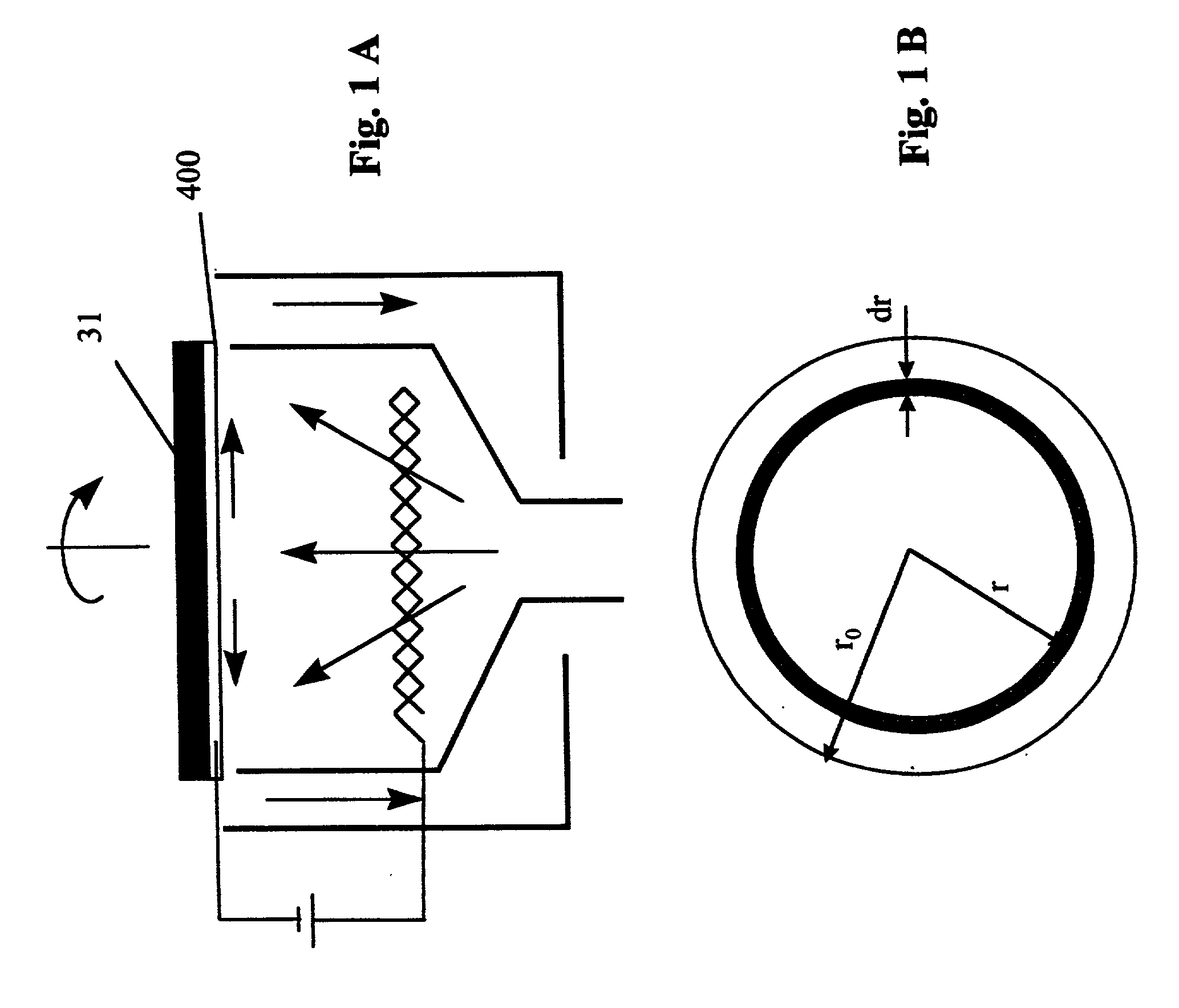

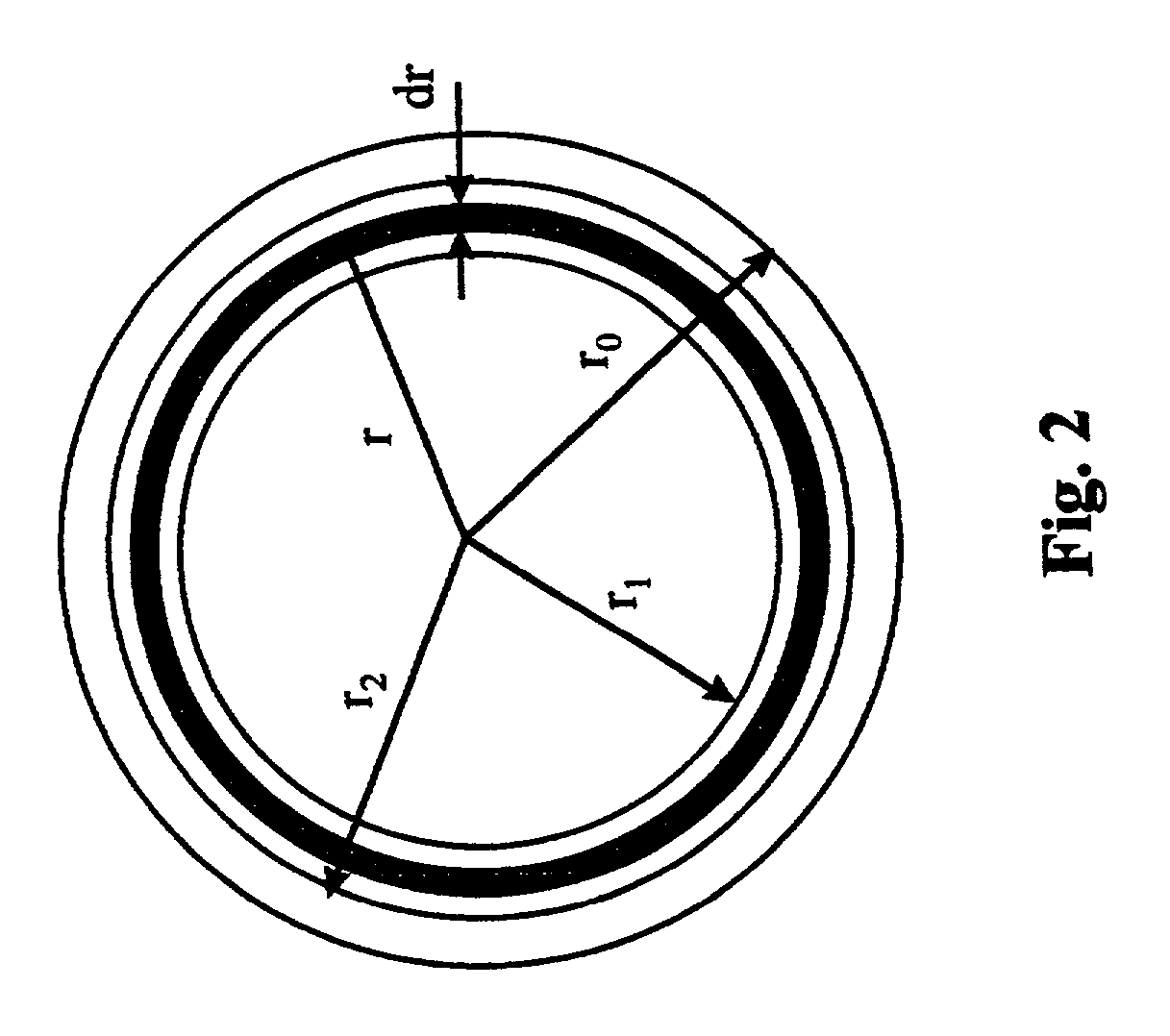

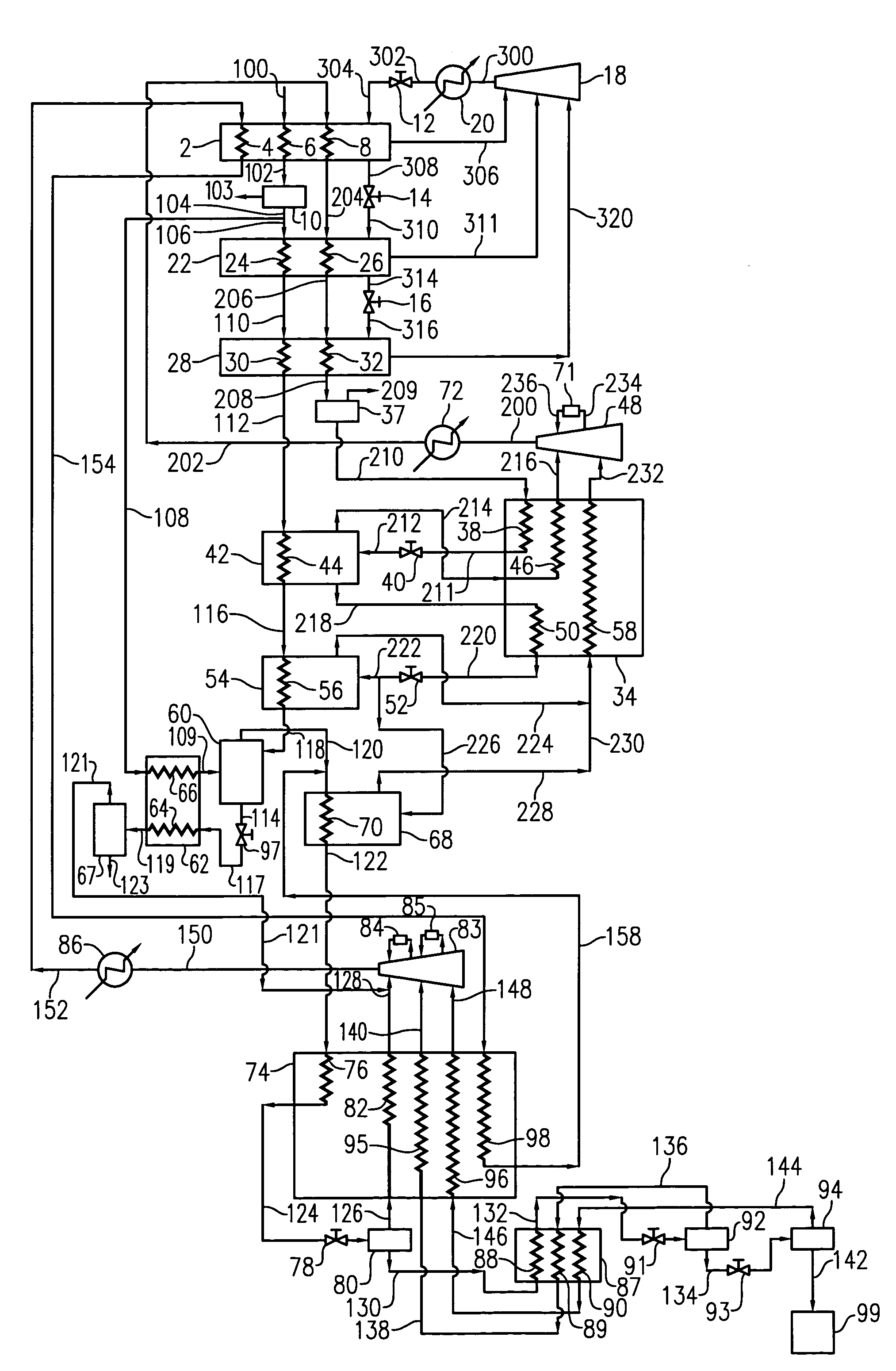

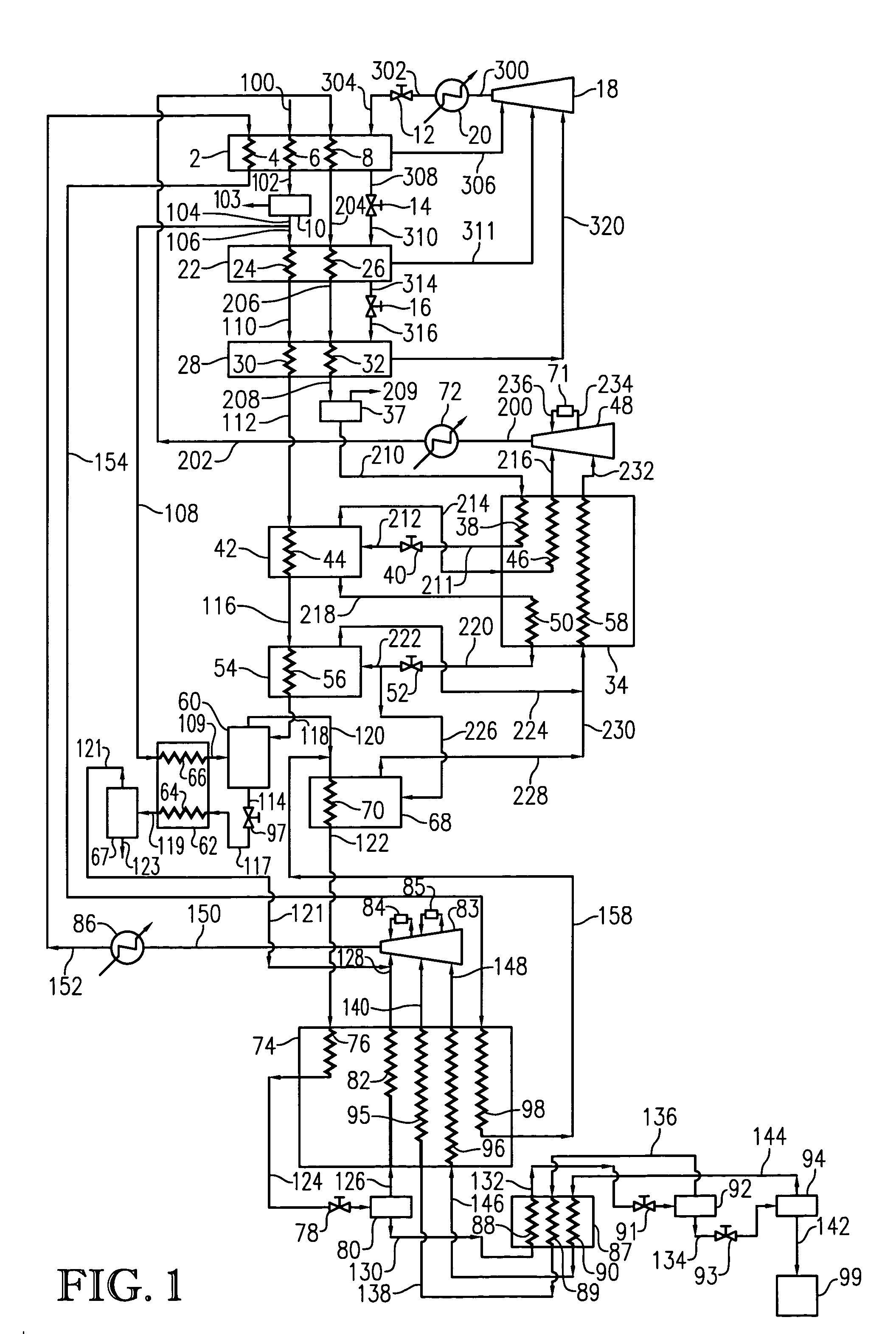

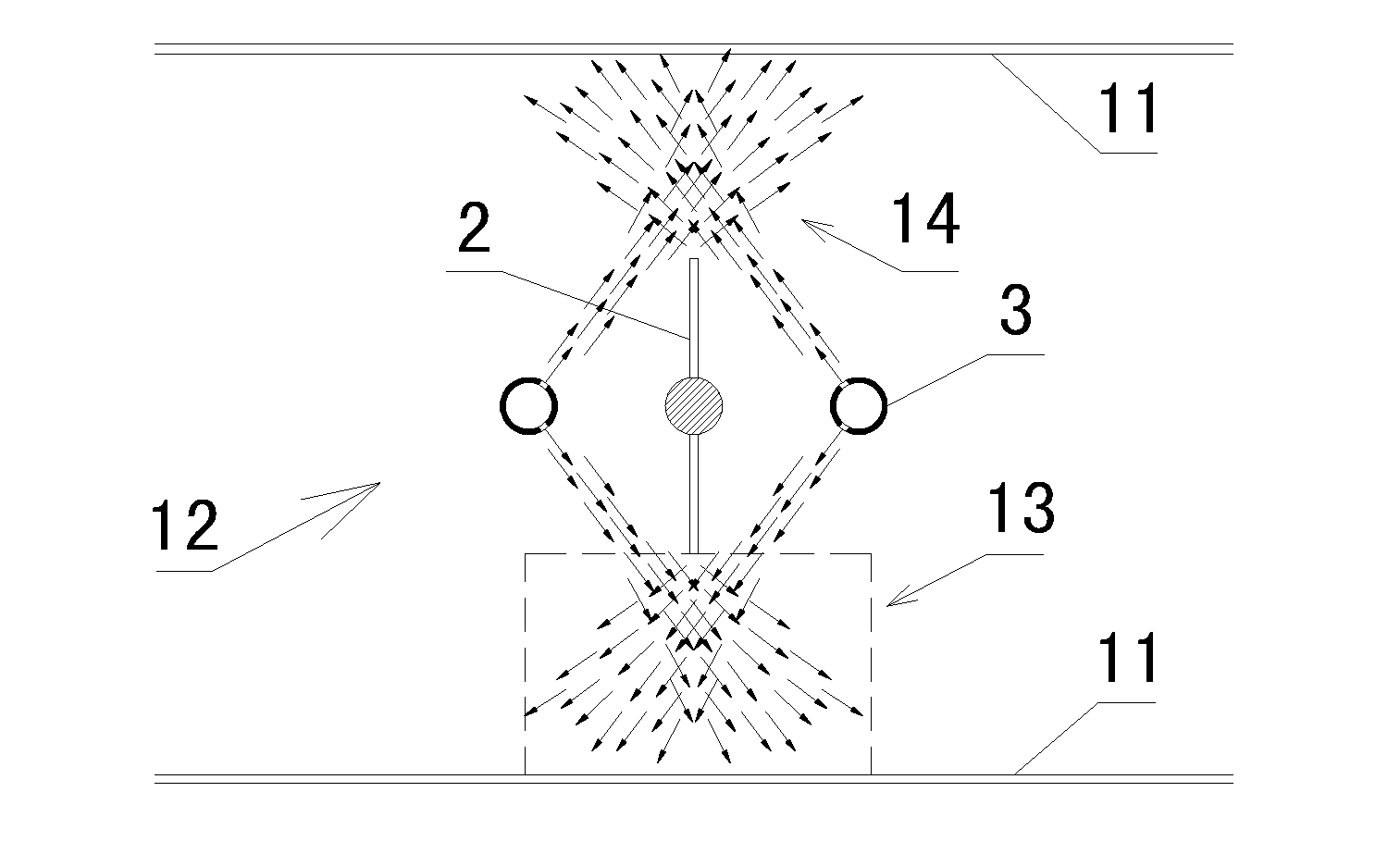

An apparatus for plating a conductive film directly on a substrate with a barrier layer on top includes anode rod (1) placed in tube (109), and anode rings (2), and (3) placed between cylindrical walls (107) and (105), (103) and (101), respectively. Anodes (1), (2), and (3) are powered by power supplies (13), (12), and (11), respectively. Electrolyte (34) is pumped by pump (33) to pass through filter (32) and reach inlets of liquid mass flow controllers (LMFCs) (21), (22), and (23). Then LMFCs (21), (22) and (23) deliver electrolyte at a set flow rate to sub-plating baths containing anodes (3), (2) and (1), respectively. After flowing through the gap between wafer (31) and the top of the cylindrical walls (101), (103), (105), (107) and (109), electrolyte flows back to tank (36) through spaces between cylindrical walls (100) and (101), (103) and (105), and (107) and (109), respectively. A pressure leak valve (38) is placed between the outlet of pump (33) and electrolyte tank (36) to leak electrolyte back to tank (36) when LMFCs (21), (22), (23) are closed. A wafer (31) held by wafer chuck (29) is connected to power supplies (11), (12) and (13). A drive mechanism (30) is used to rotate wafer (31) around the z axis, and oscillate the wafer in the x, y, and z directions shown. Filter (32) filters particles larger than 0.1 or 0.2 mum in order to obtain a low particle added plating process.

Owner:ACM RES

Plating apparatus and method

InactiveUS20010040100A1Uniform thicknessStrong Gap Filling CapabilityCellsSemiconductor/solid-state device manufacturingElectrolyte leakageEngineering

An apparatus for plating a conductive film directly on a substrate with a barrier layer on top includes anode rod (1) placed in tube (109), and anode rings (2), and (3) placed between cylindrical walls (107) and (105), (103) and (101), respectively. Anodes (1), (2), and (3) are powered by power supplies (13), (12), and (11), respectively. Electrolyte (34) is pumped by pump (33) to pass through filter (32) and reach inlets of liquid mass flow controllers (LMFCs) (21), (22), and (23). Then LMFCs (21), (22) and (23) deliver electrolyte at a set flow rate to sub-plating baths containing anodes (3), (2) and (1), respectively. After flowing through the gap between wafer (31) and the top of the cylindrical walls (101), (103), (105), (107) and (109), electrolyte flows back to tank (36) through spaces between cylindrical walls (100) and (101), (103) and (105), and (107) and (109), respectively. A pressure leak valve (38) is placed between the outlet of pump (33) and electrolyte tank (36) to leak electrolyte back to tank (36) when LMFCs (21), (22), (23) are closed. A wafer (31) held by wafer chuck (29) is connected to power supplies (11), (12) and (13). A drive mechanism (30) is used to rotate wafer (31) around the z axis, and oscillate the wafer in the x, y, and z directions shown. Filter (32) filters particles larger than 0.1 or 0.2 mum in order to obtain a low particle added plating process.

Owner:ACM RES

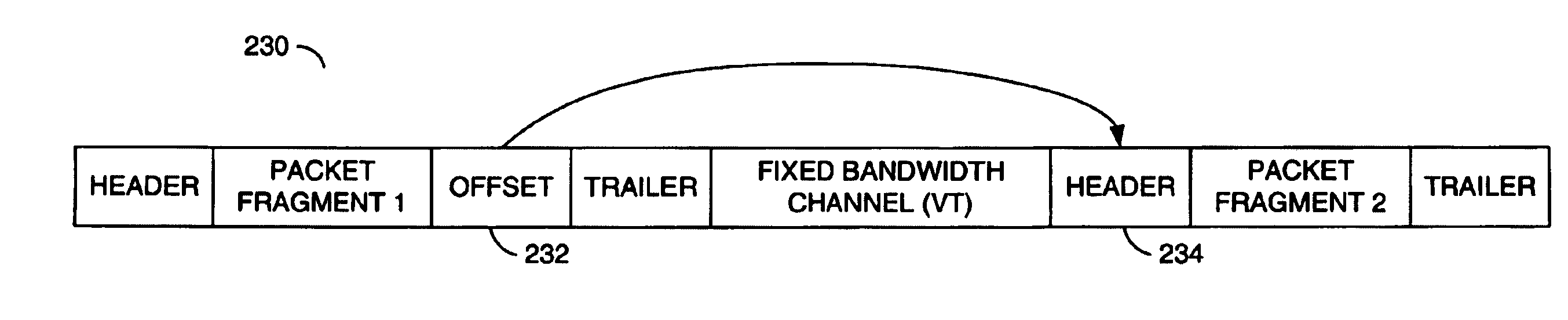

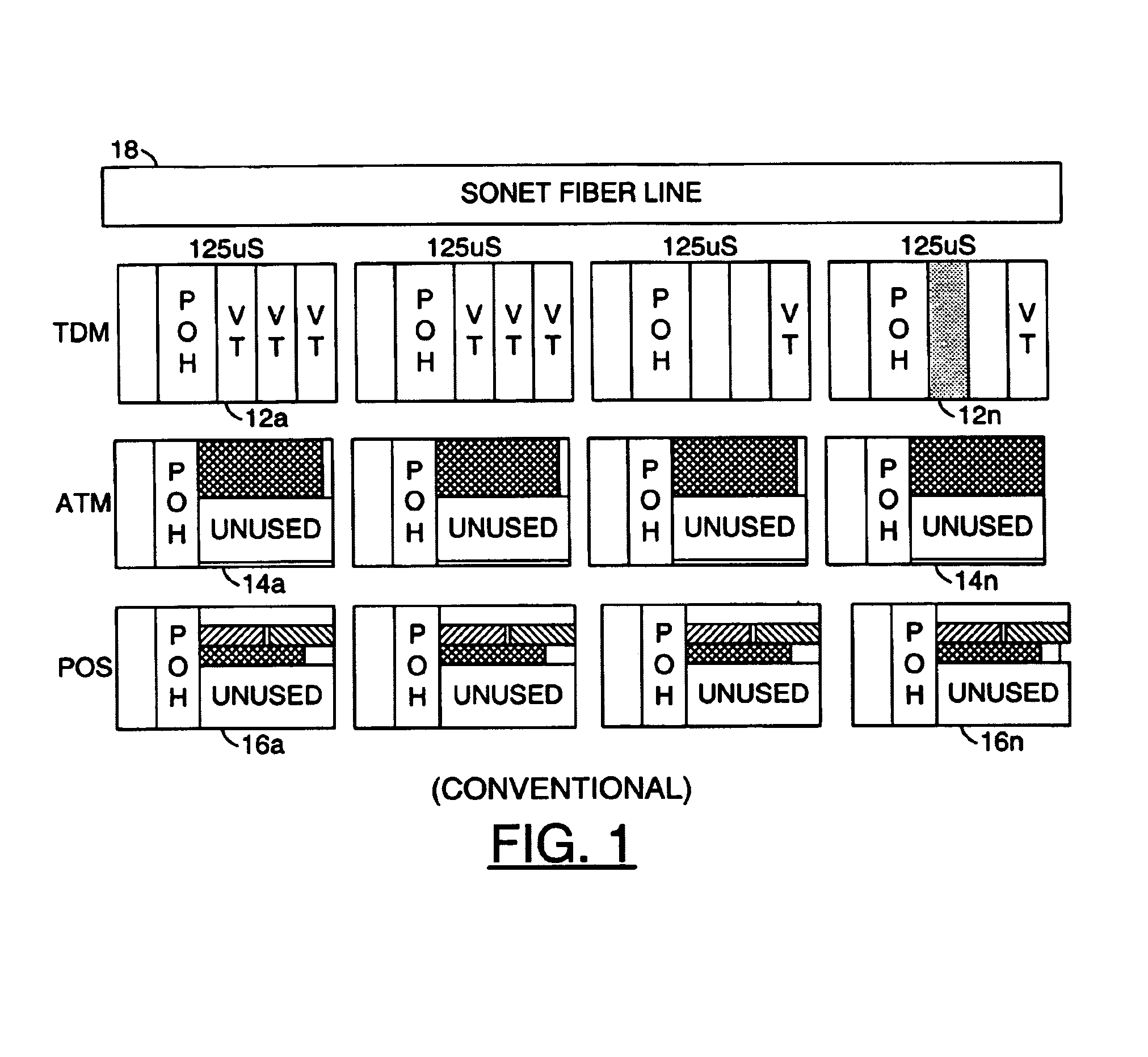

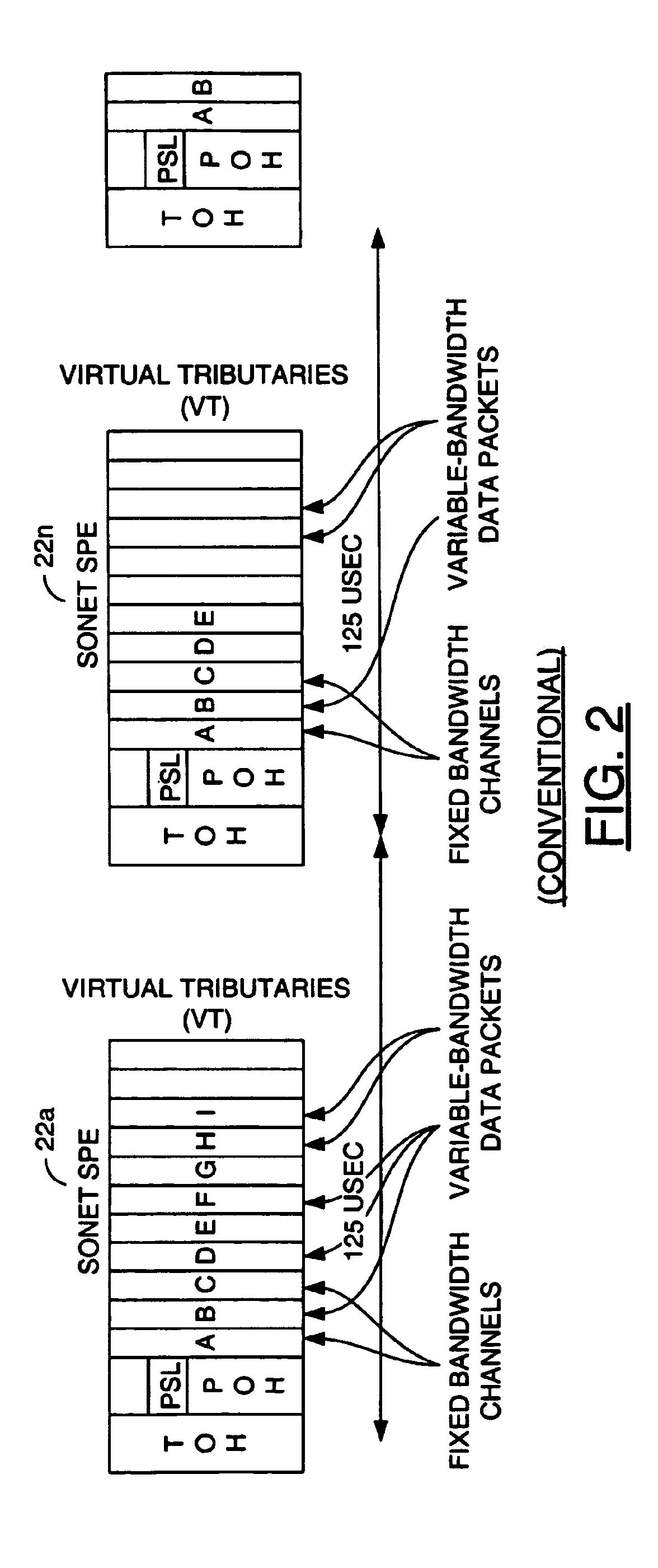

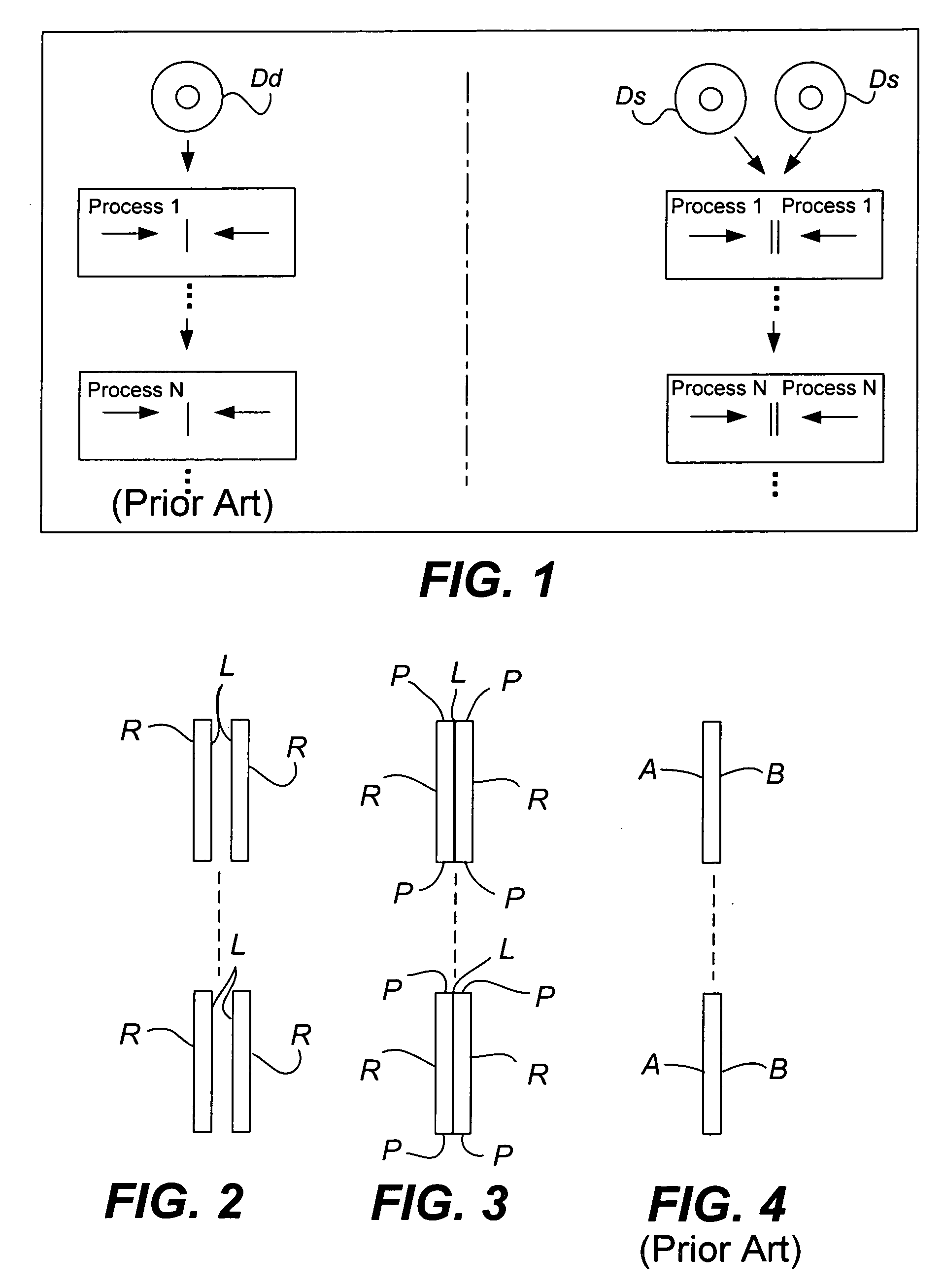

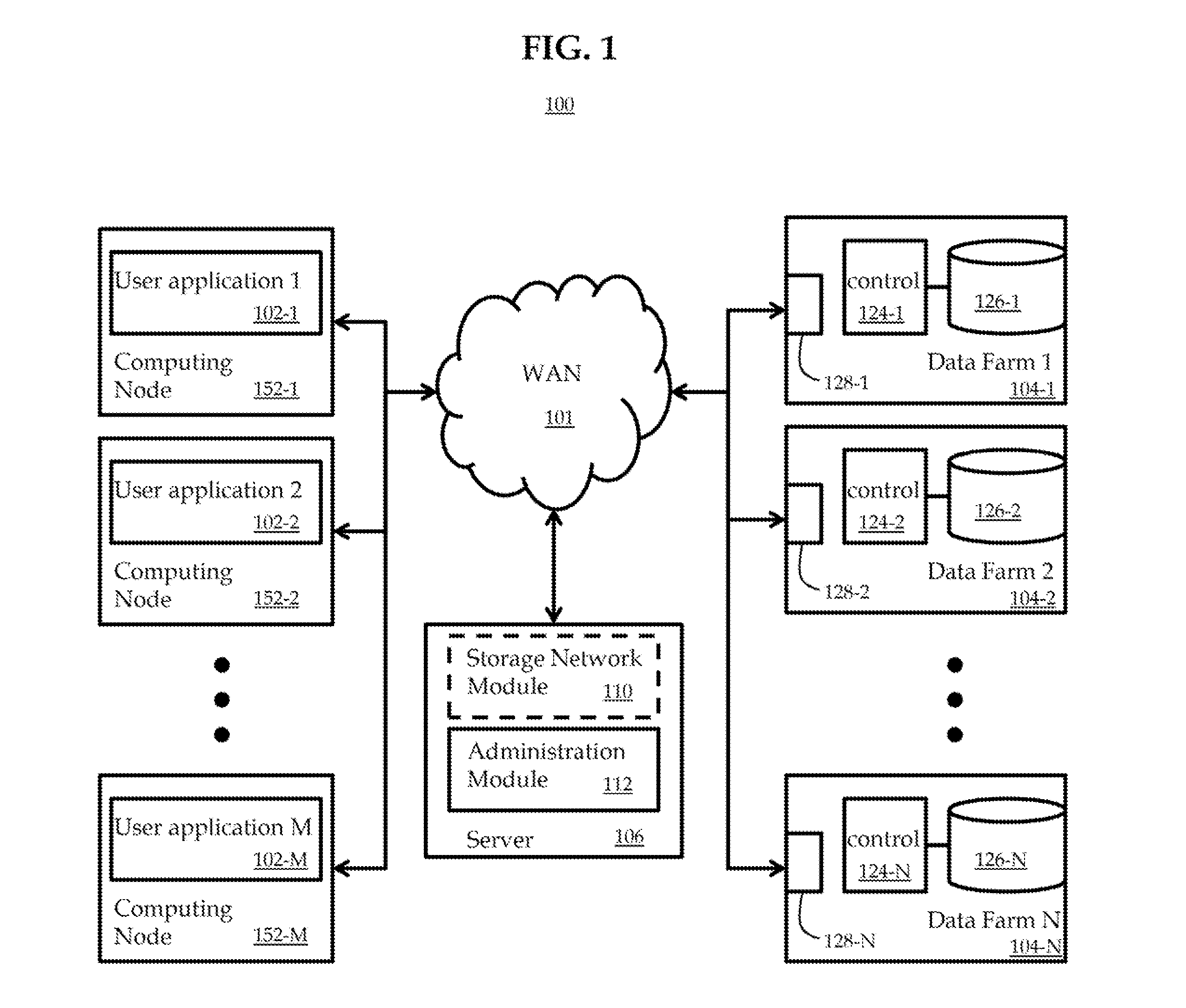

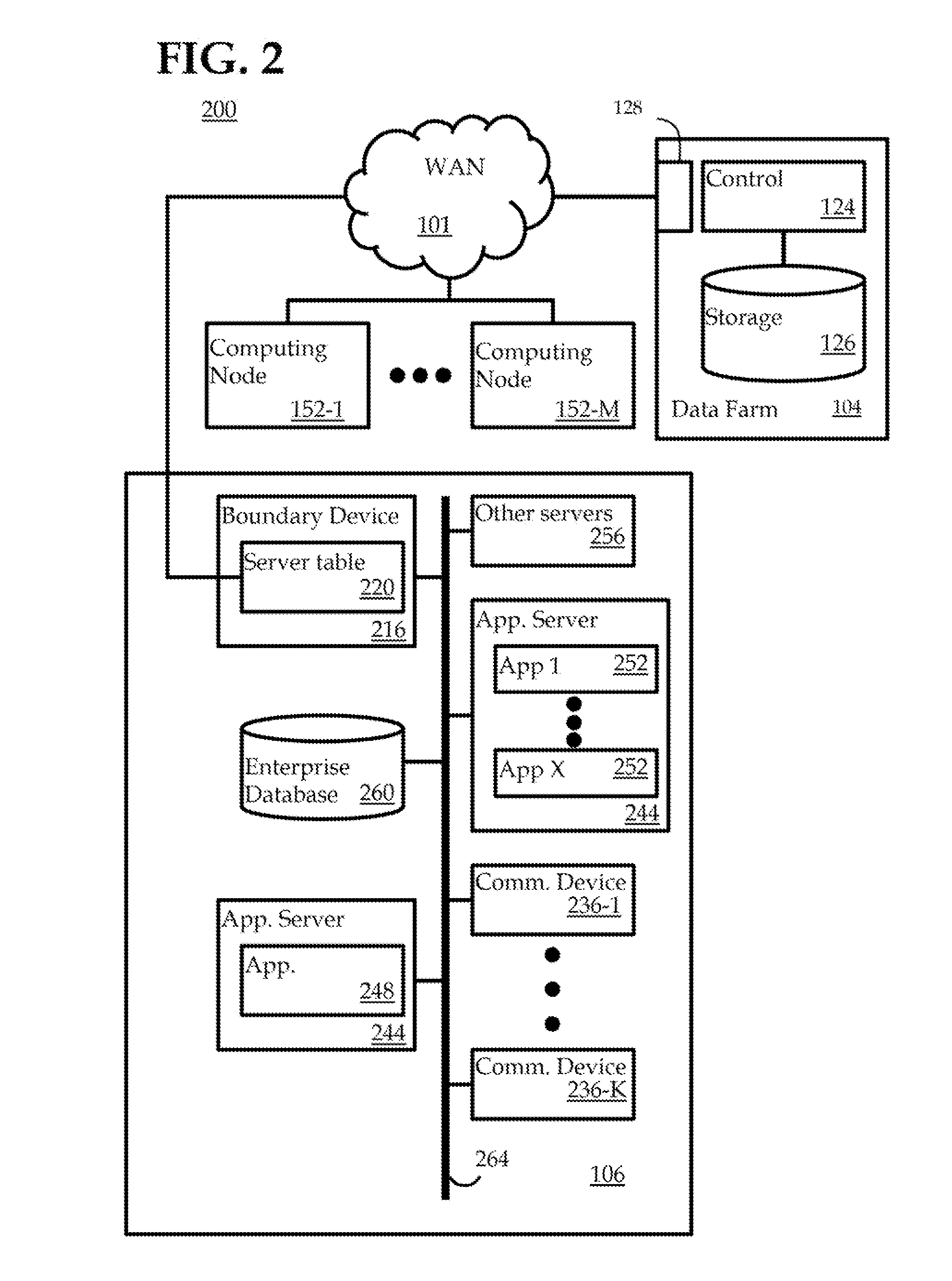

Hybrid data transport scheme over optical networks

InactiveUS7006525B1The equipment is bulkyEffectively boosting SONET bandwidthTime-division multiplexHybrid dataReal-time computing

Owner:TAMIRAS PER PTE LTD LLC

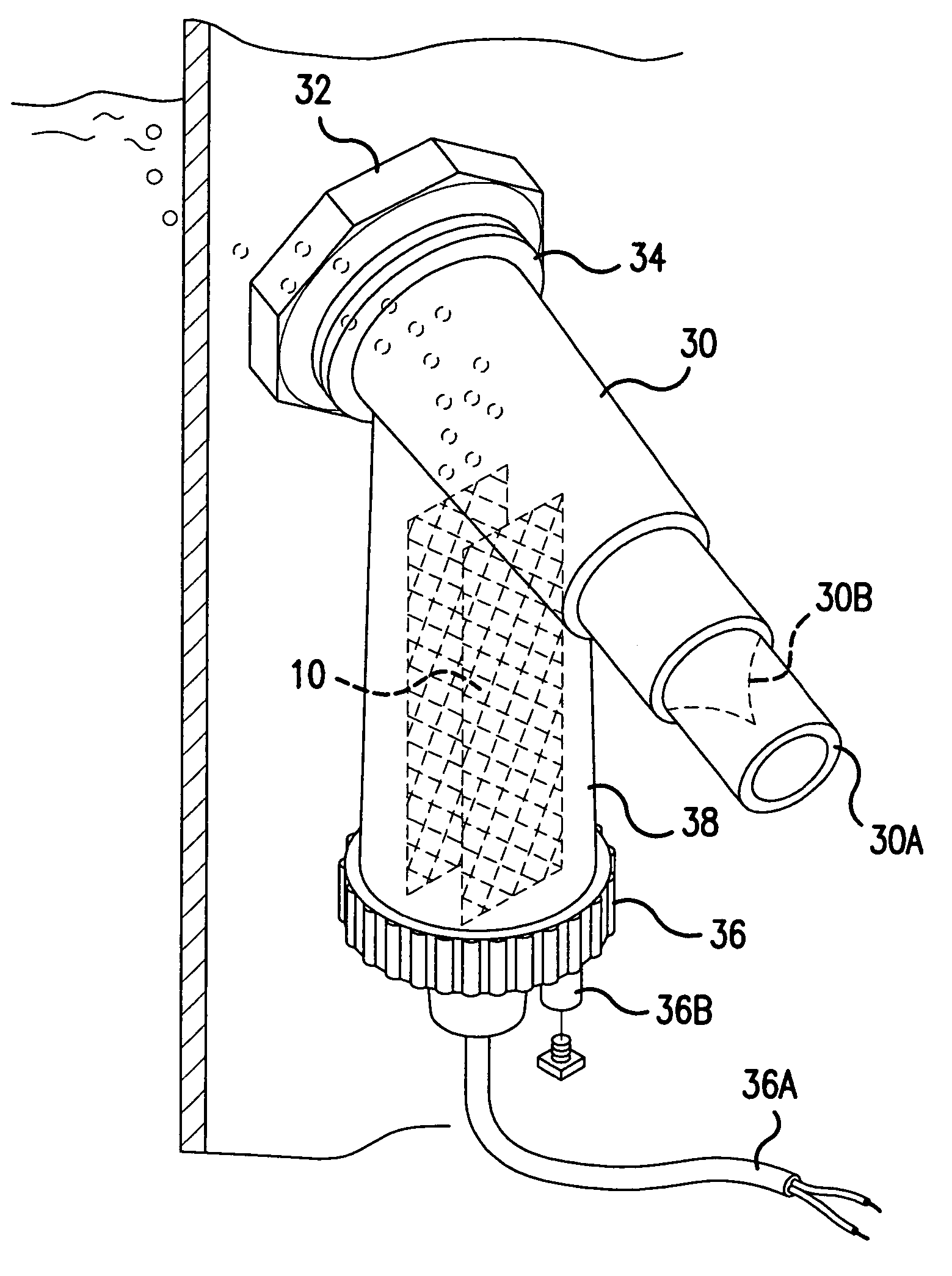

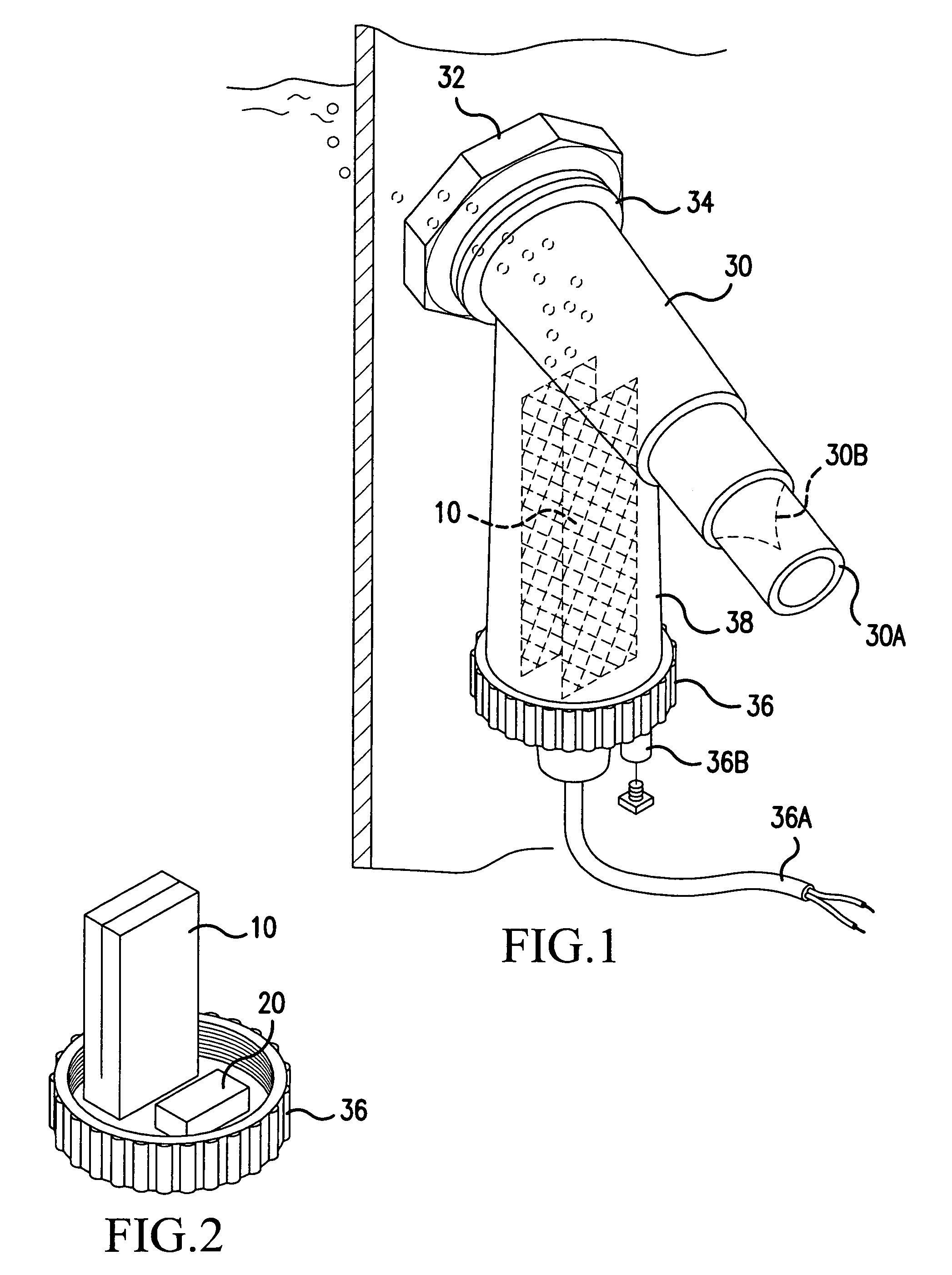

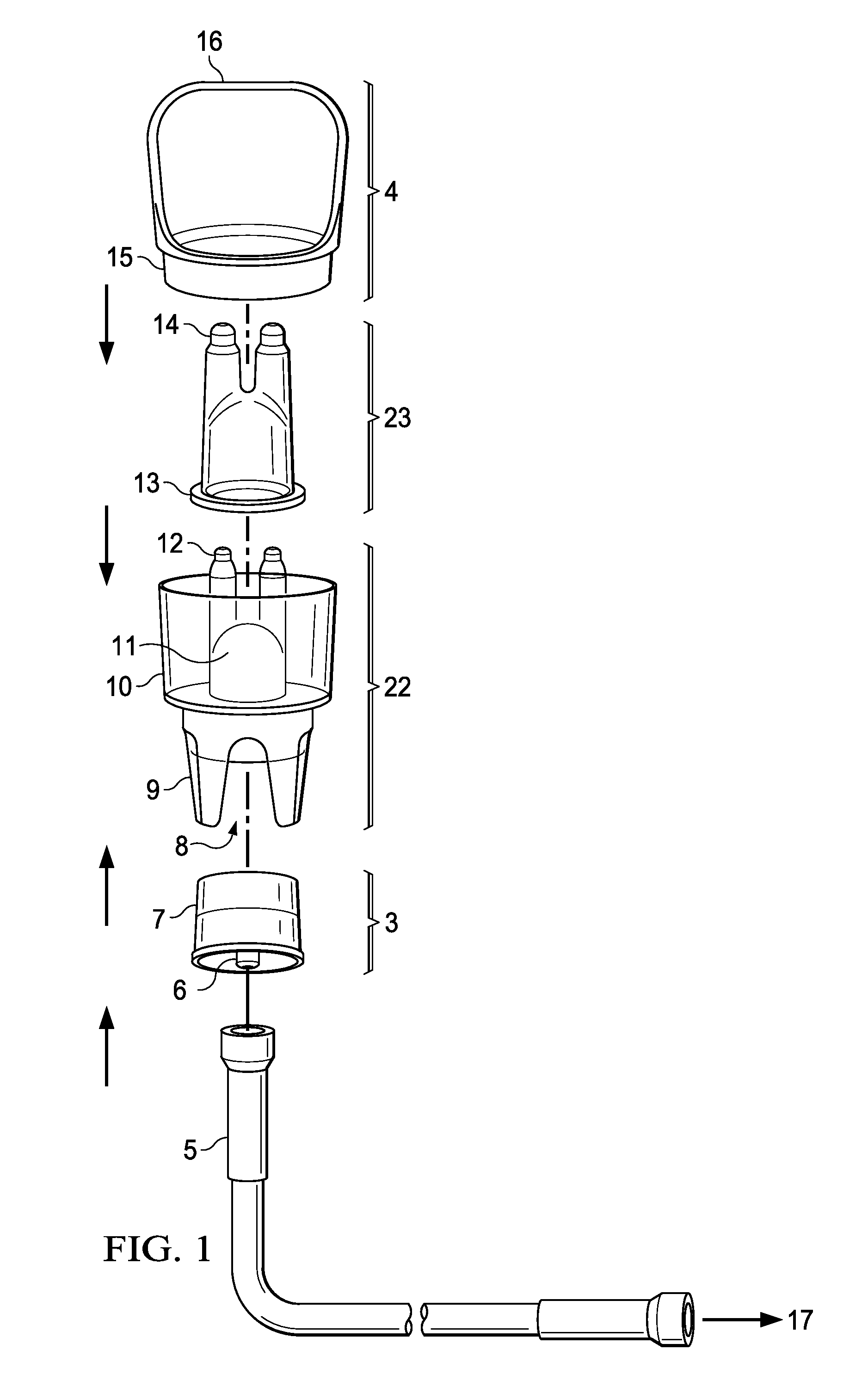

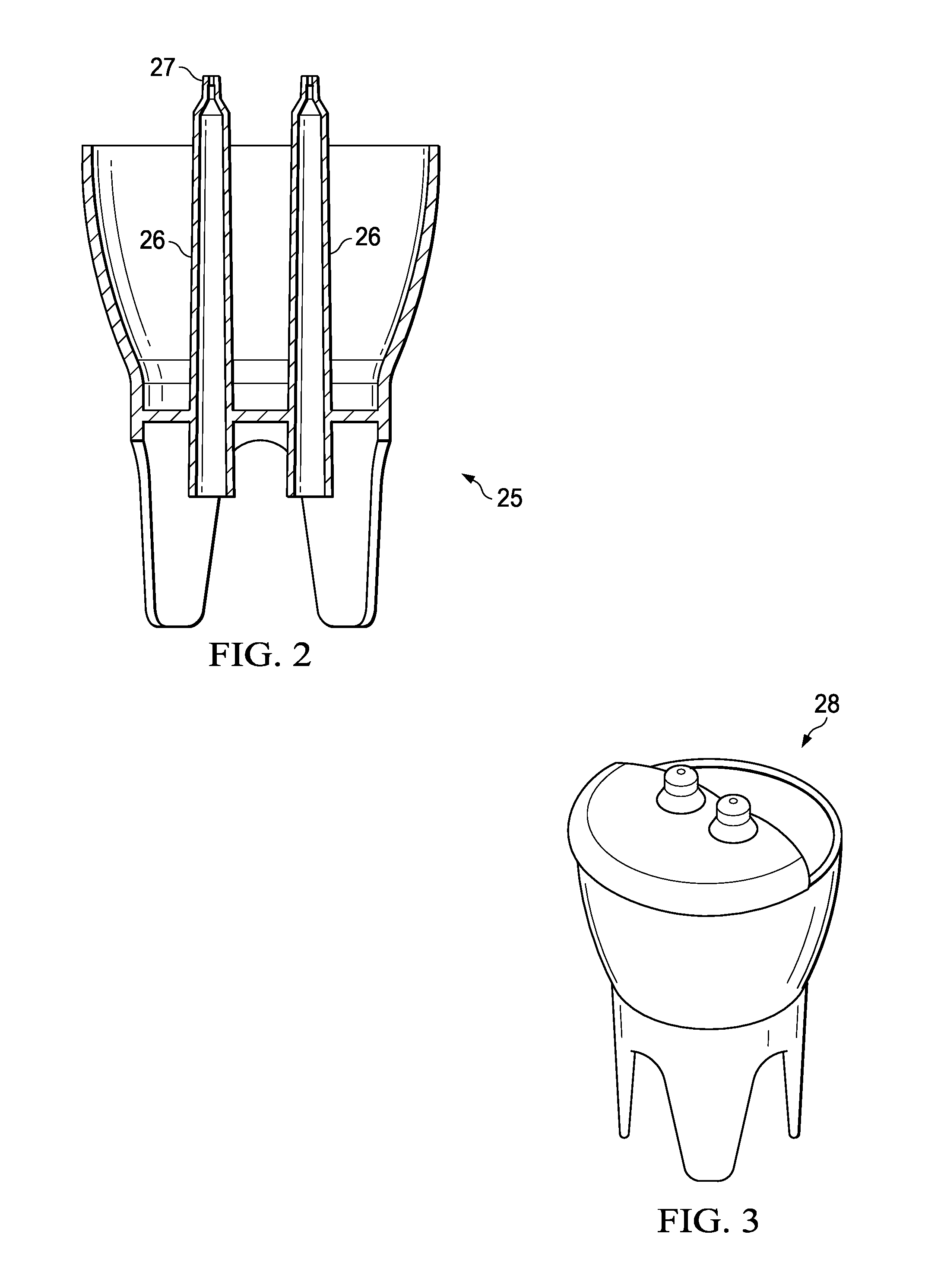

Salt chlorine generator

ActiveUS7014753B2Low costEasy to installSludge treatmentPhotography auxillary processesFiltrationEngineering

An electrolytic cell combined into a unitary structure with a liquid circulation fitting, which purifies water by electrode plates inside the cell when an aqueous solution is present. The unitary structure replaces the existing water return fitting. This integrated structure is well suited for use in pools, tubs, spas, fountains or similar large liquid containers. The production of halogen inside the structure is not required to coincide with the cycle of the existing pool filtration system. Rather, the electrodes receive a continuous supply of low level power and the halogen produced inside the structure is disbursed back into the body of water through the fitting using an integrated, dedicated circulation pump, special channels in the surface and a check valve to insure one directional flow from the pool pump and natural convection. Using fresh water drawn from the vessel, halogen is then disbursed back into the vessel with the water at a location different from where the fresh water was drawn. The level of halogen production may be regulated using a timing mechanism and / or sensors in the circuitry.

Owner:SMARTPOOL

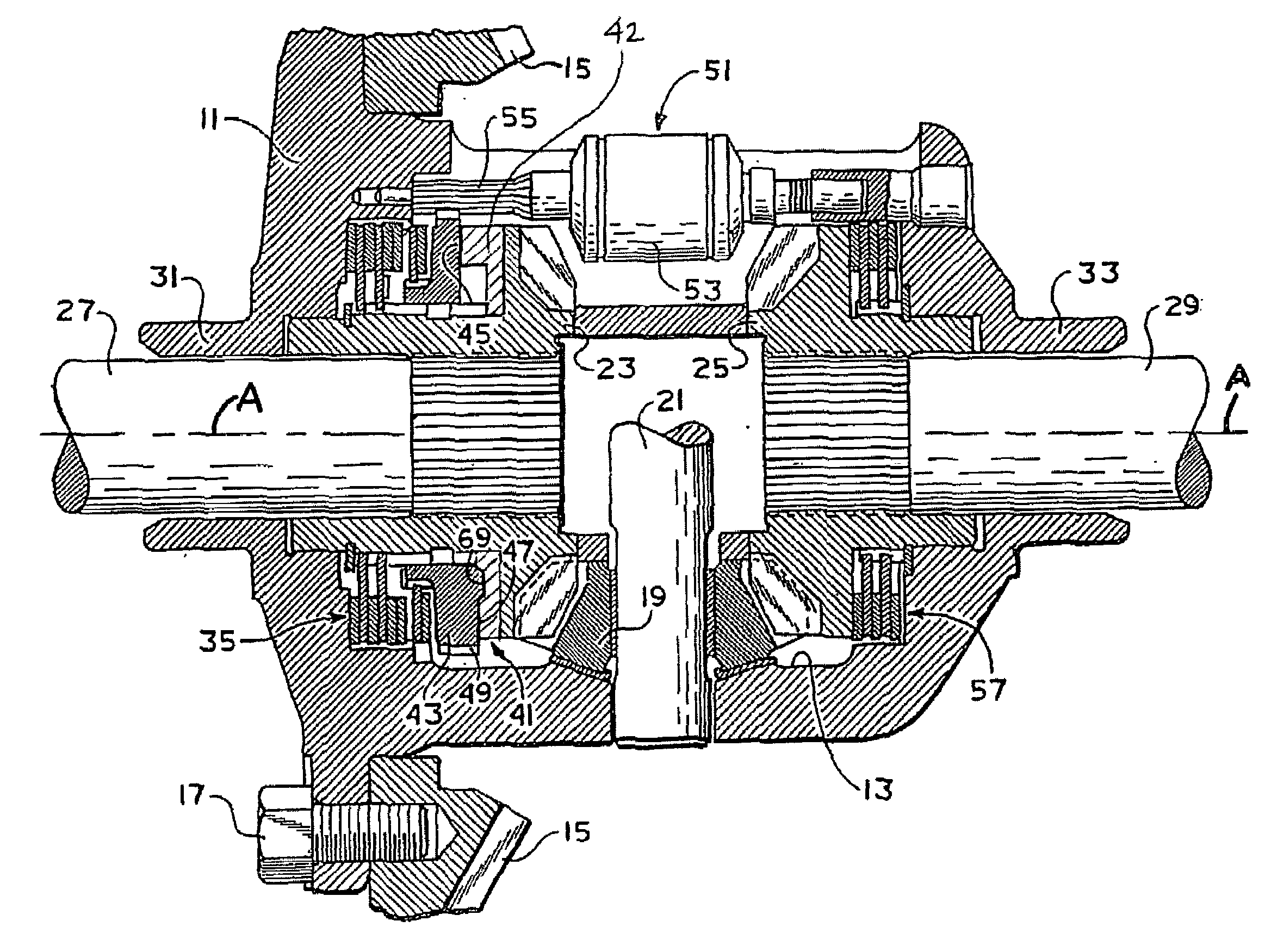

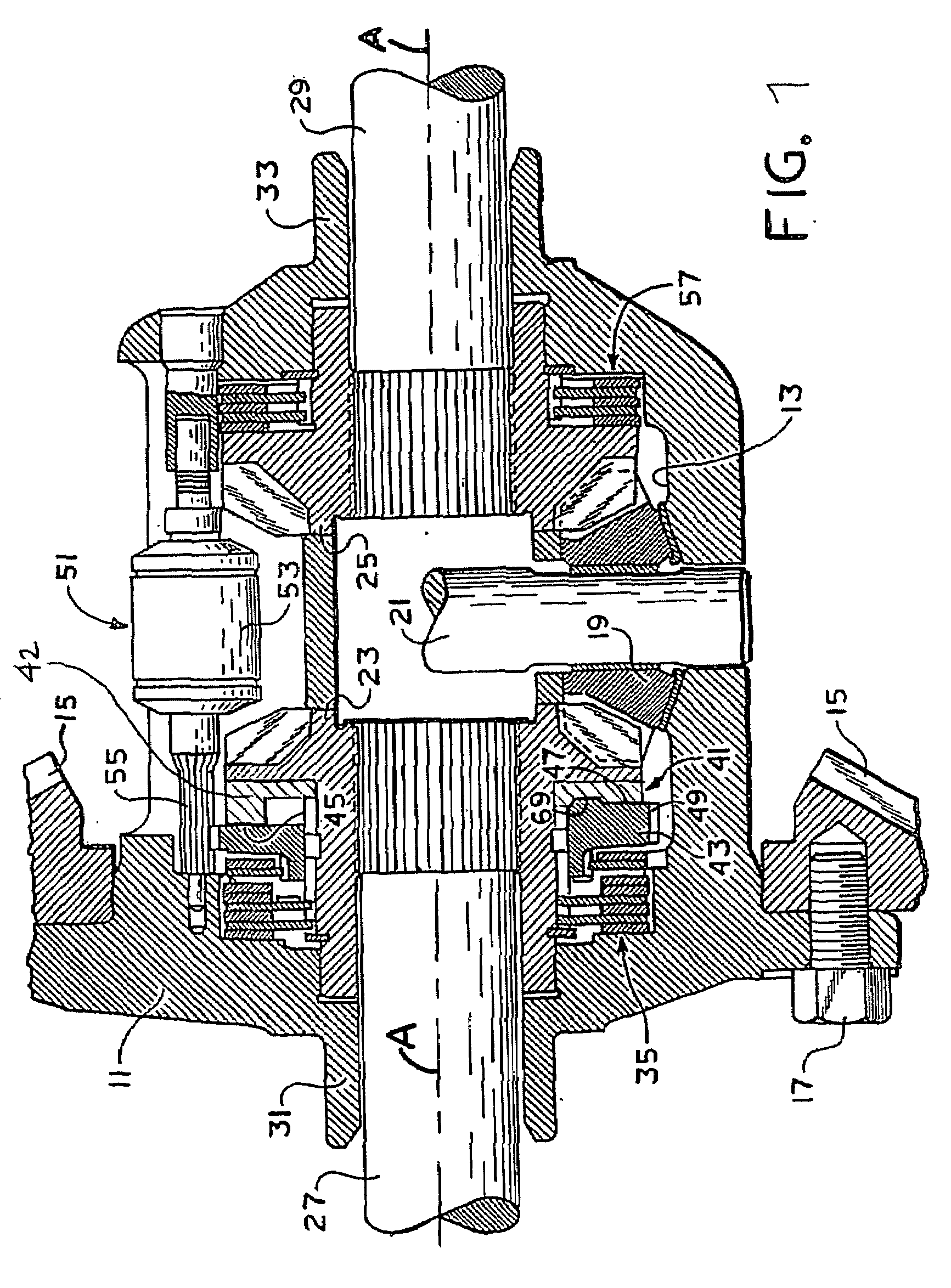

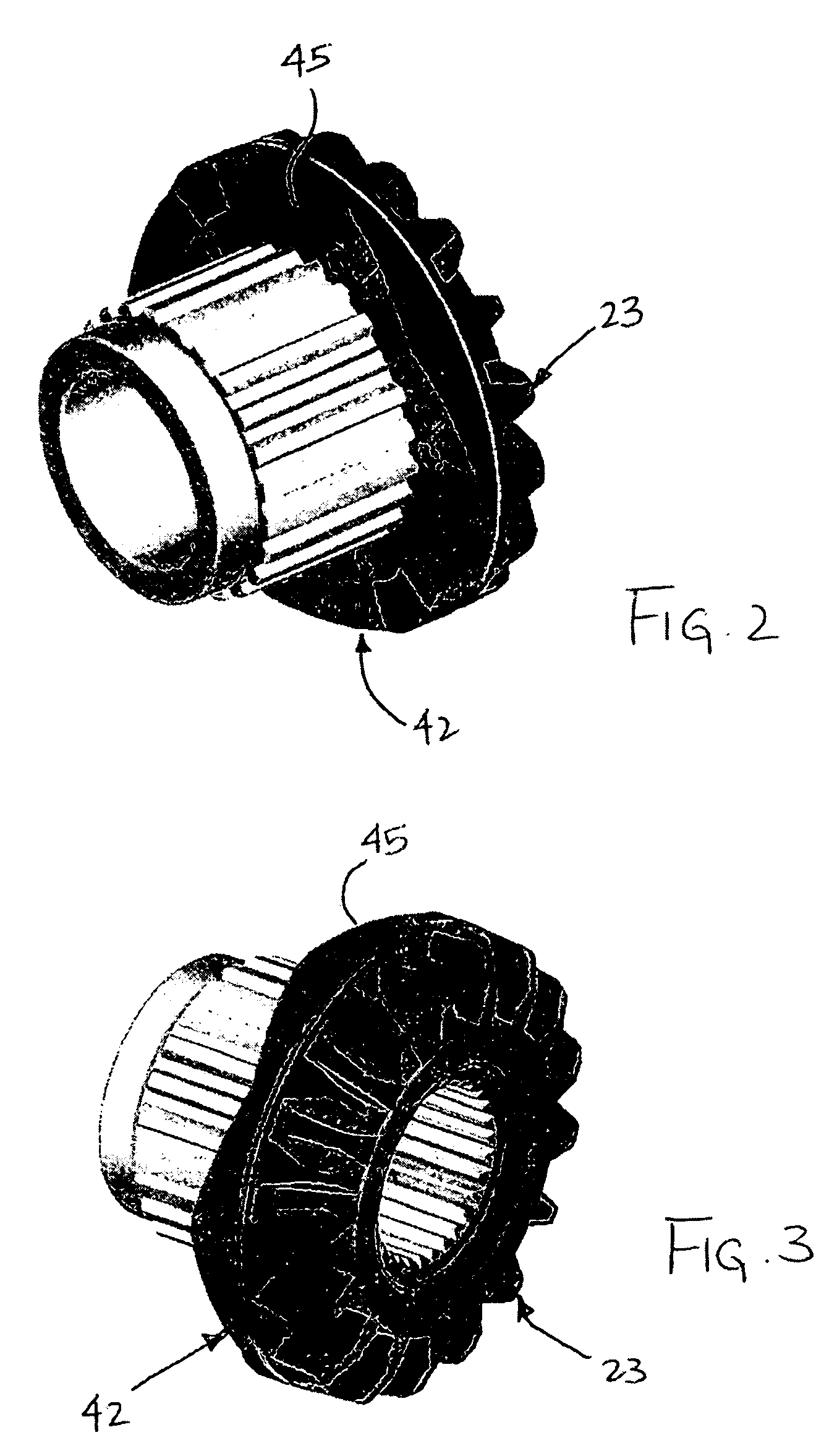

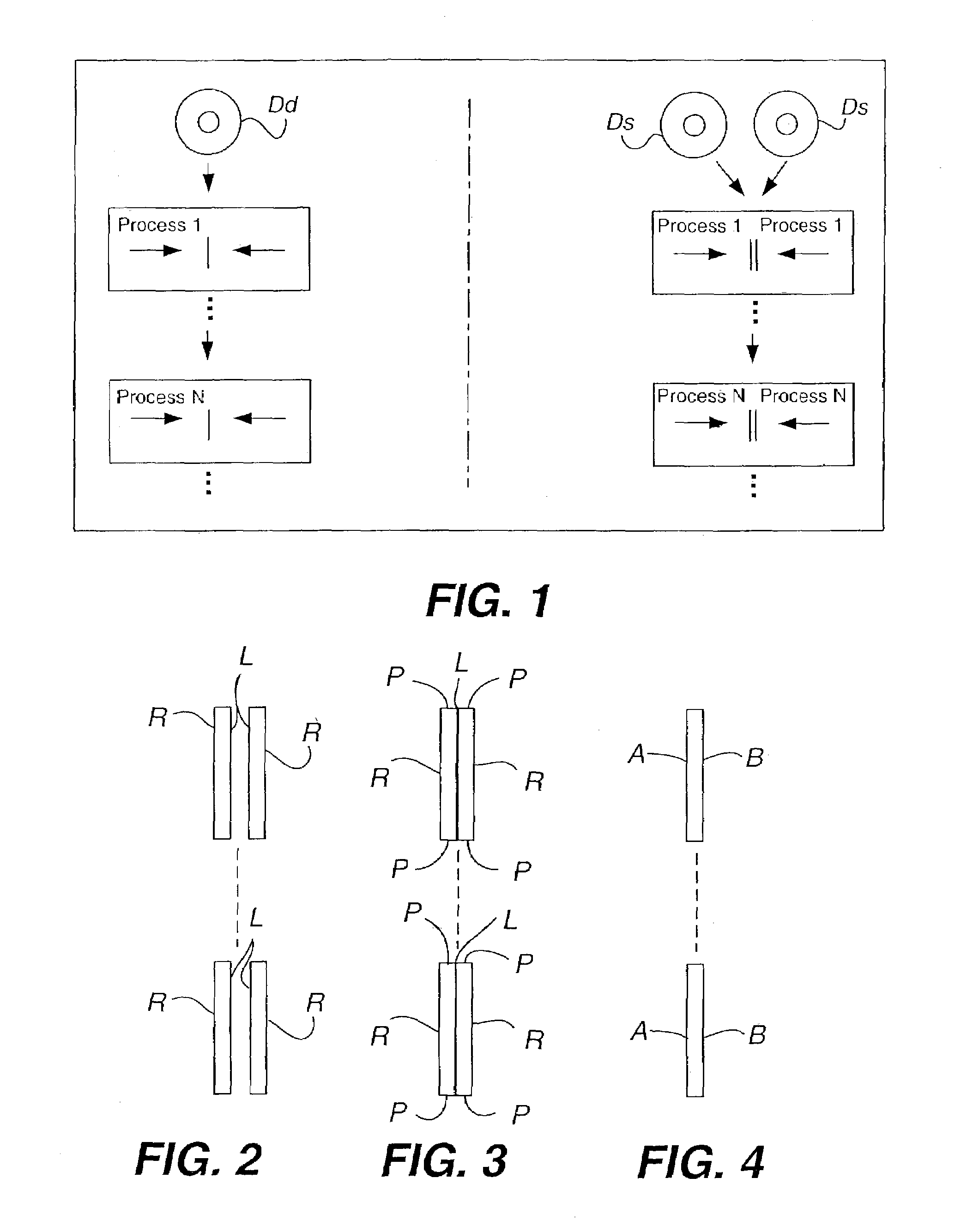

Cam gear for mechanical locking differential

InactiveUS20080058151A1EliminatesImproved mechanismDifferential gearingsControl devicesCamEngineering

An improved differential gear mechanism is characterized by a cam mechanism including a first cam member fixed to rotate with one of said output gears and a second cam member free to rotate relative to said first cam member and said output gear. The first cam member defines a first cam surface and the second cam member defines a second cam surface engagable with the first cam surface to impart movement of the second cam member along axis. The first cam member comprises a powdered metal component, which provides consistency in the cam surface profile and eliminates the substantial capital equipment needed to machine the cam surface.

Owner:EATON CORP

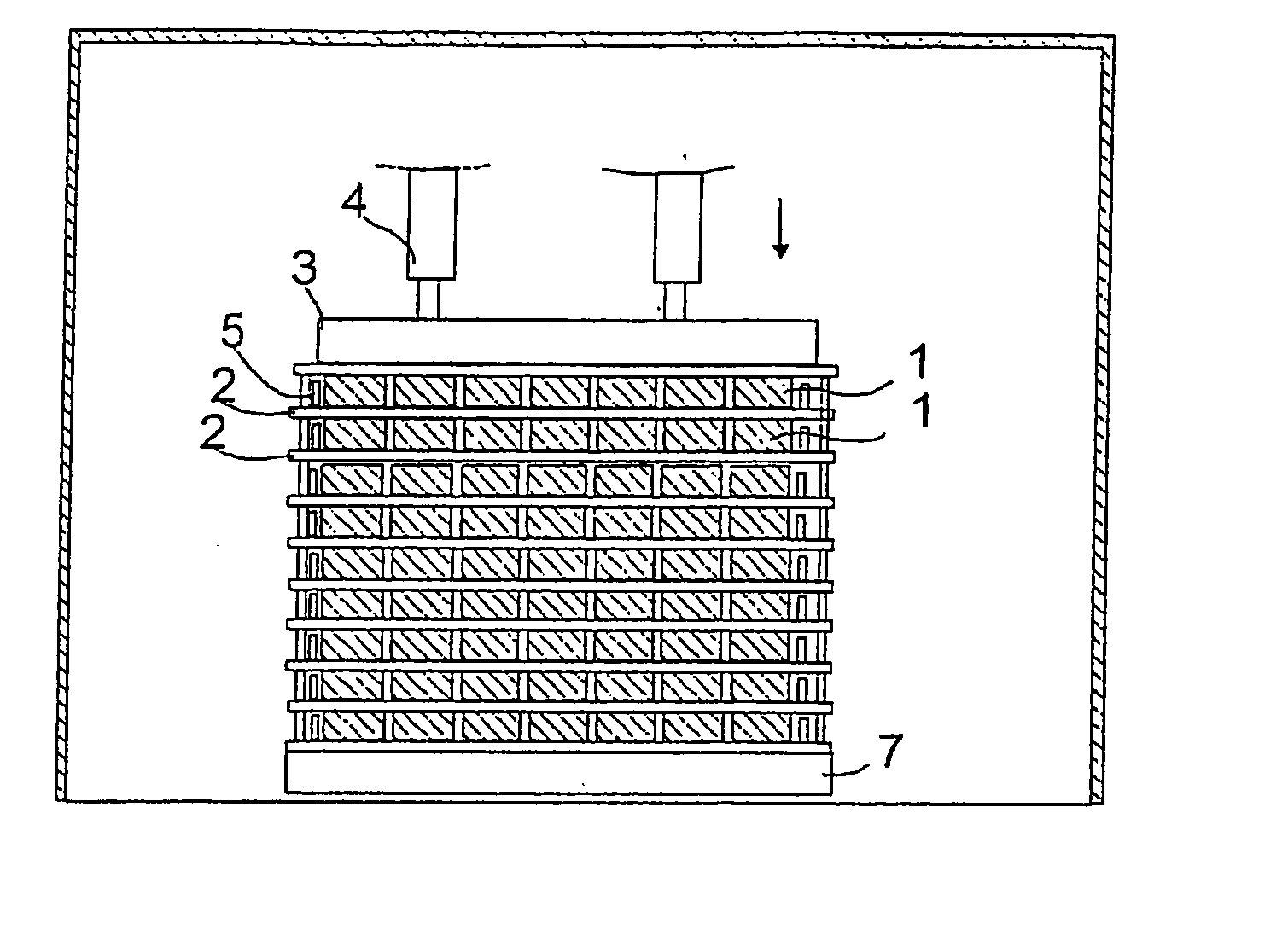

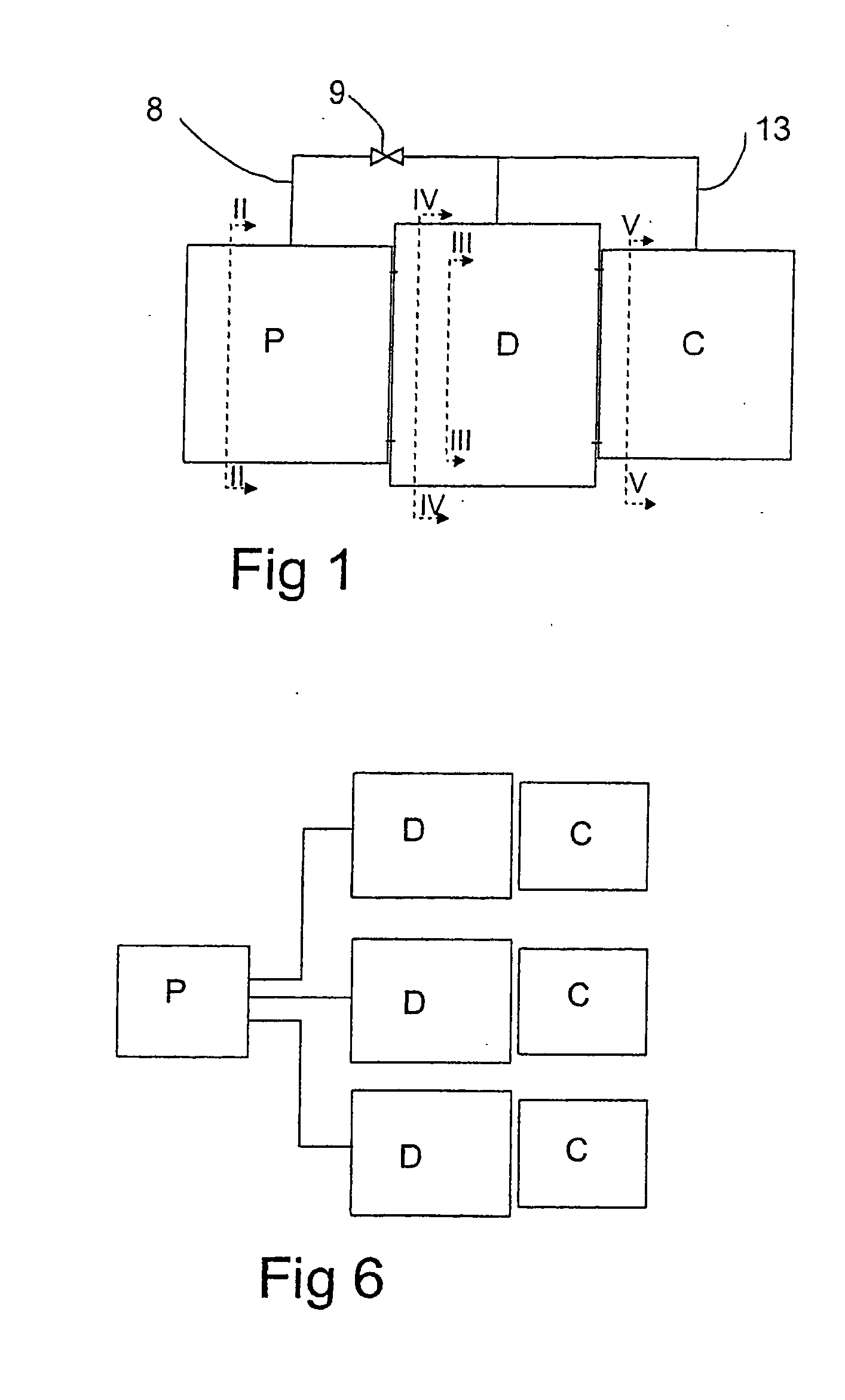

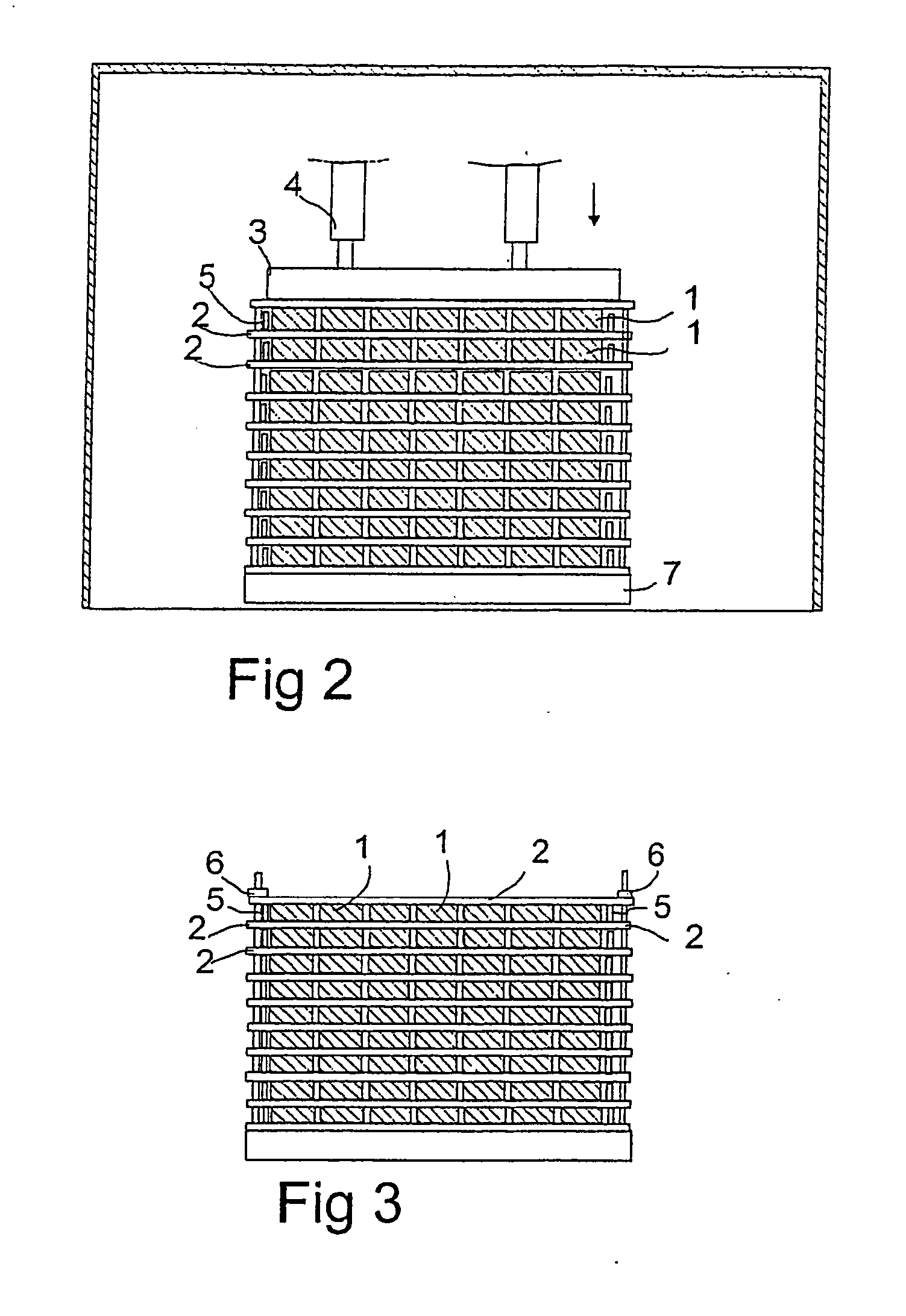

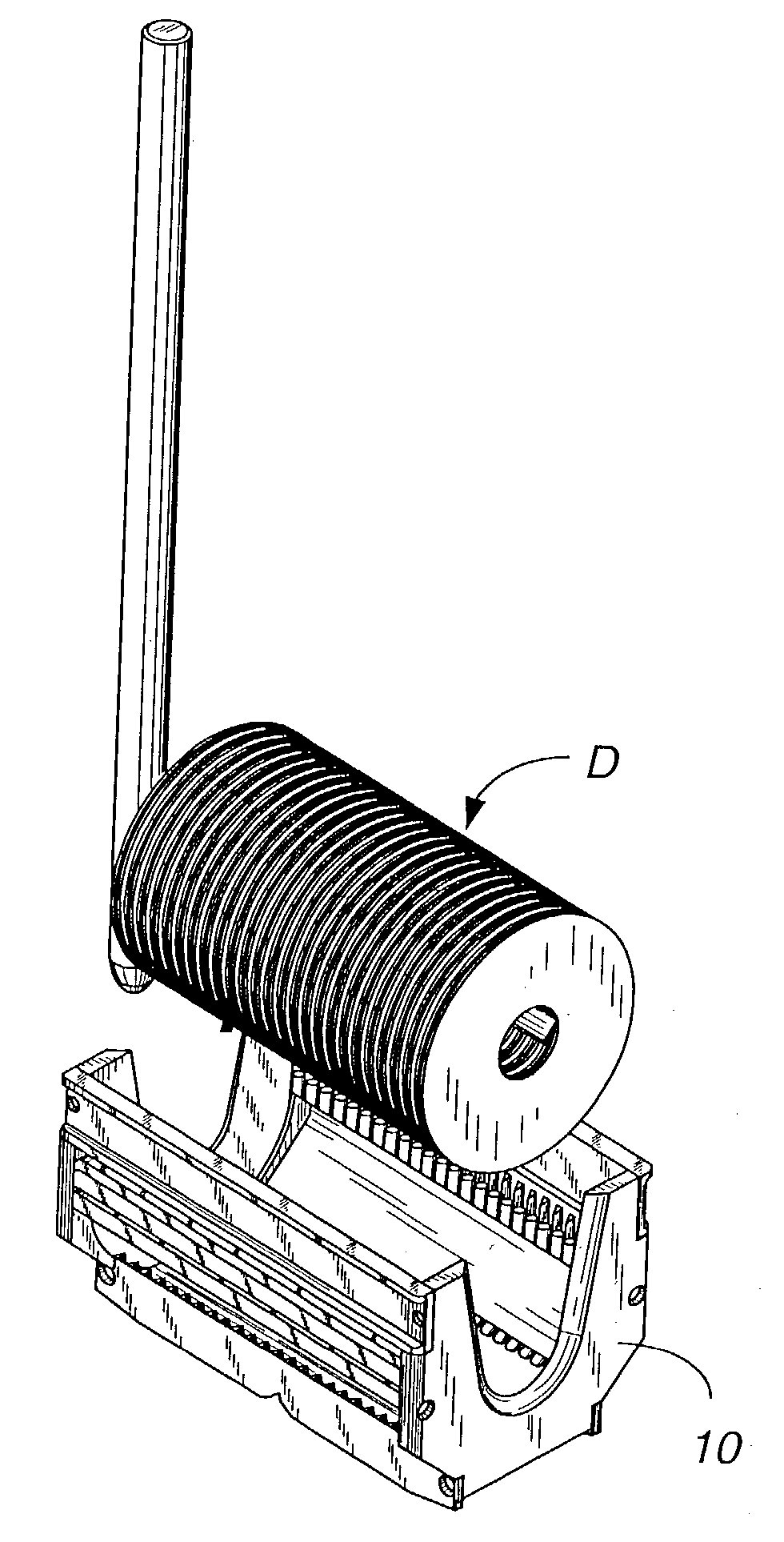

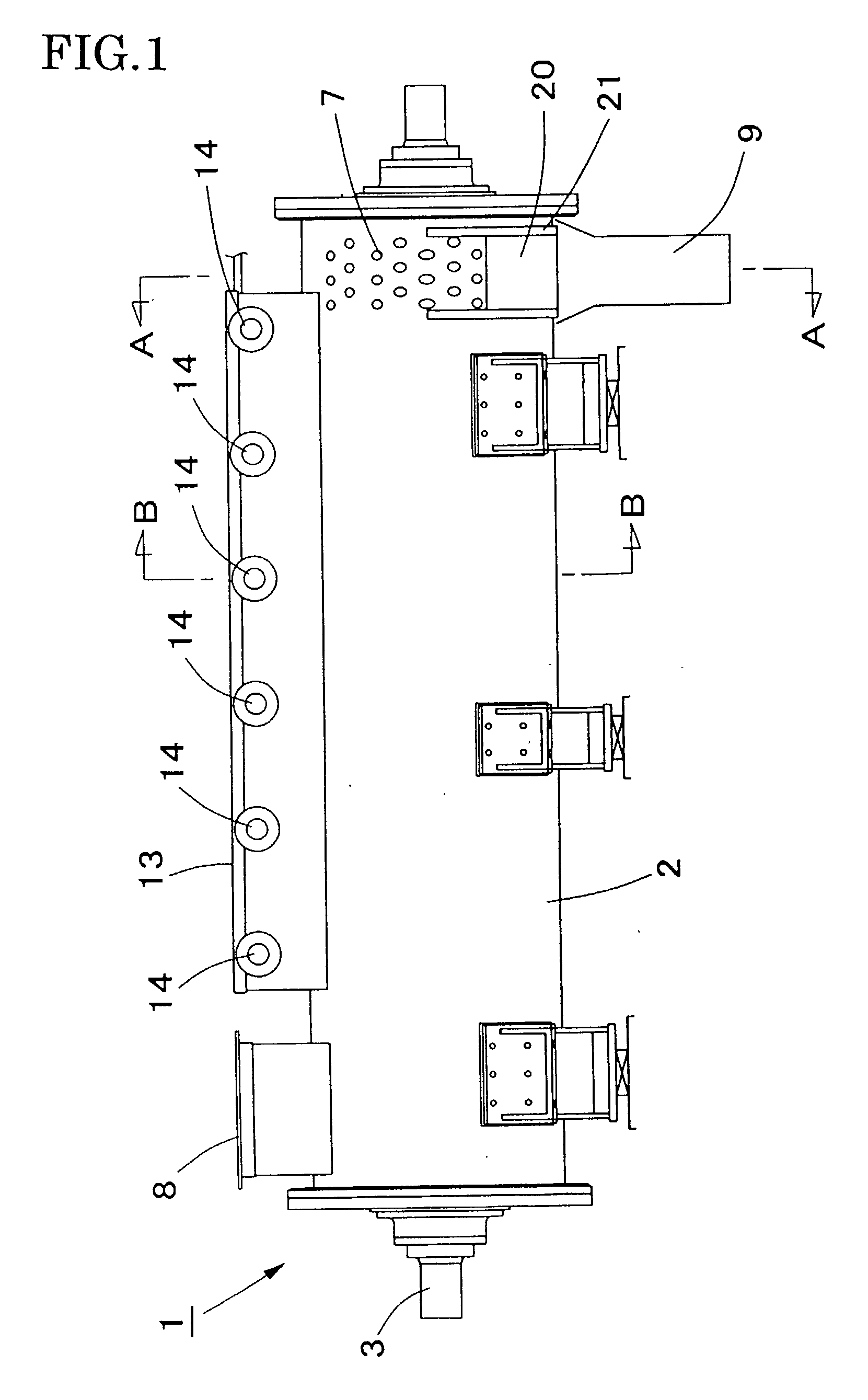

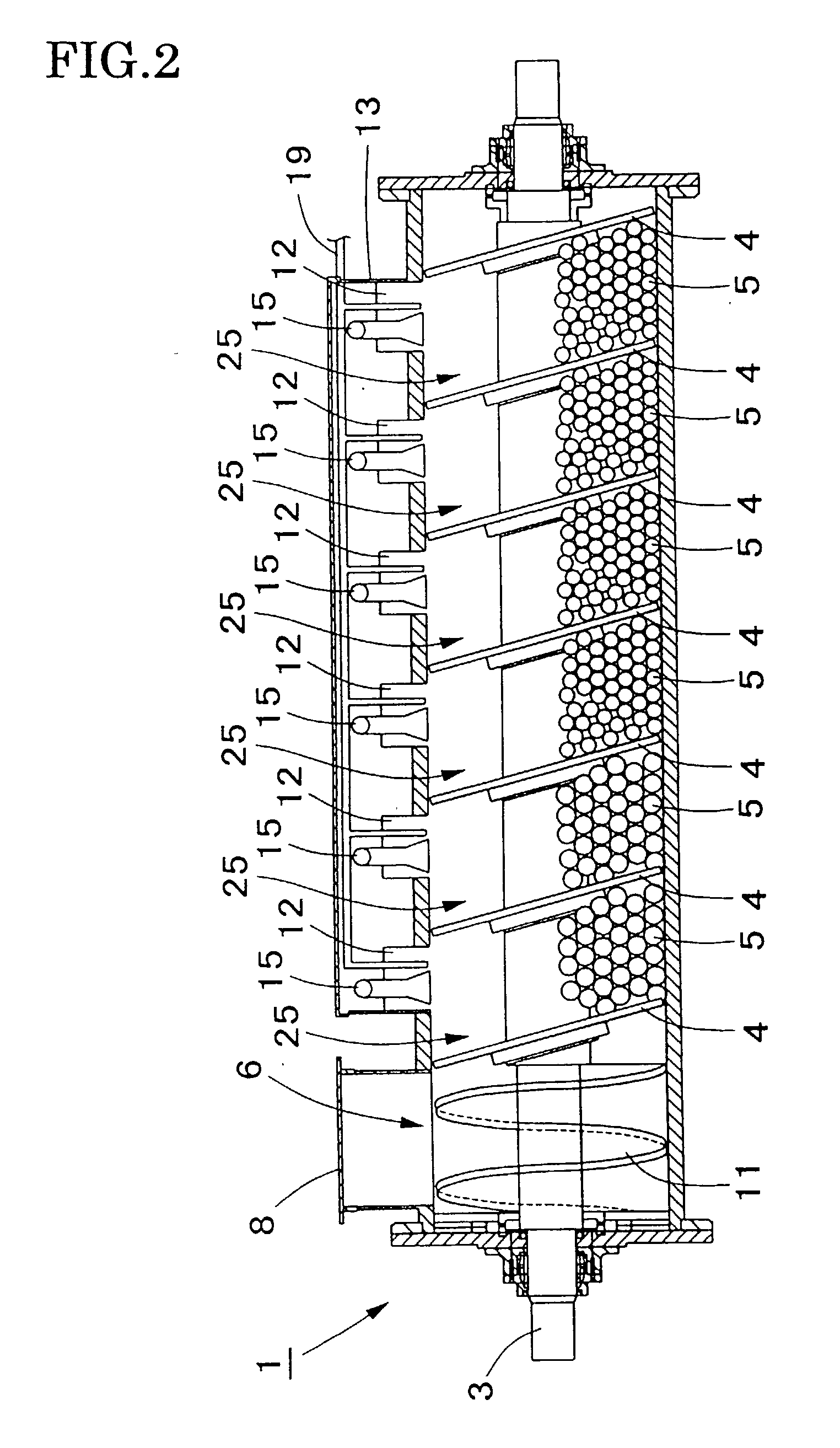

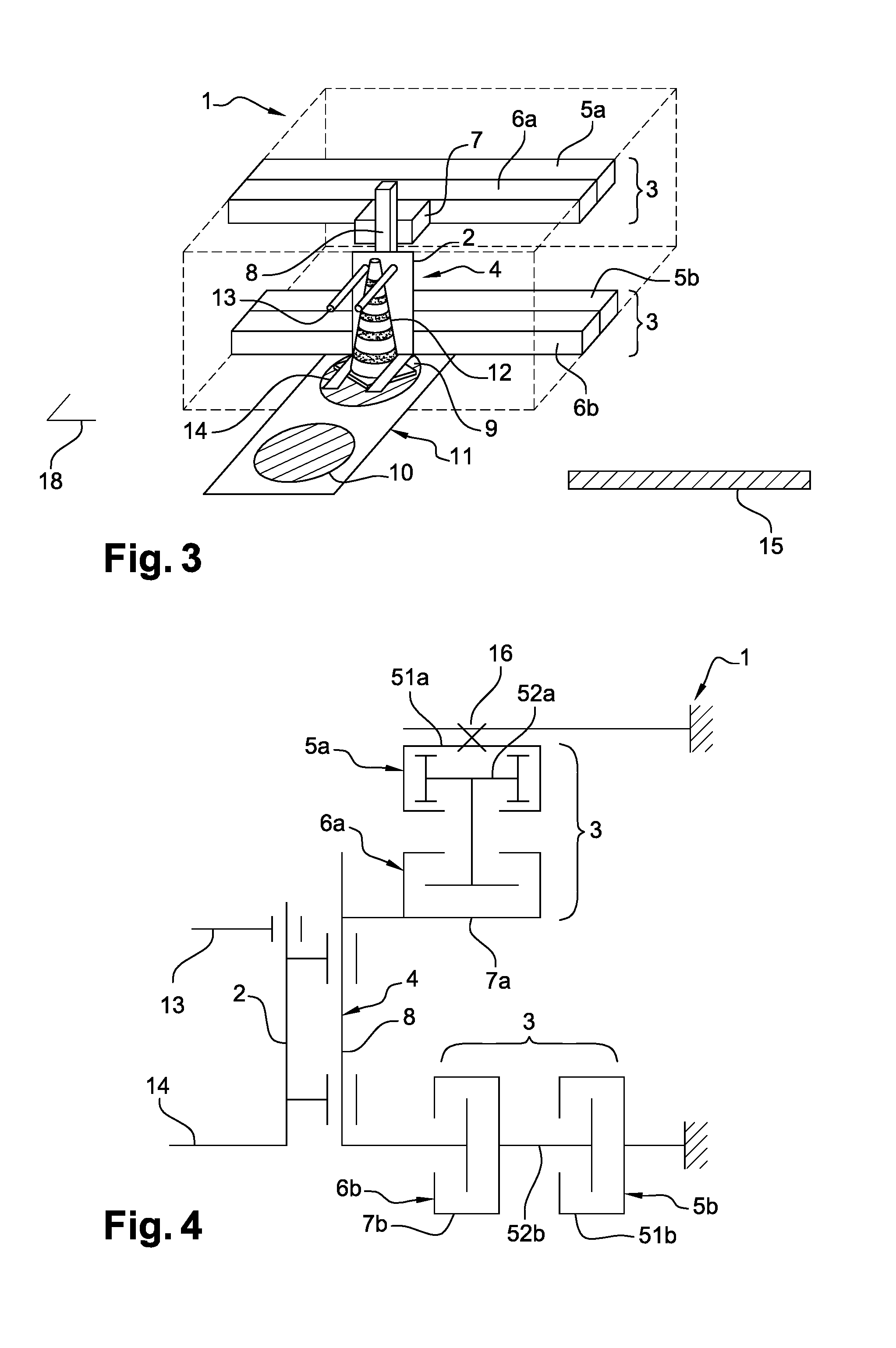

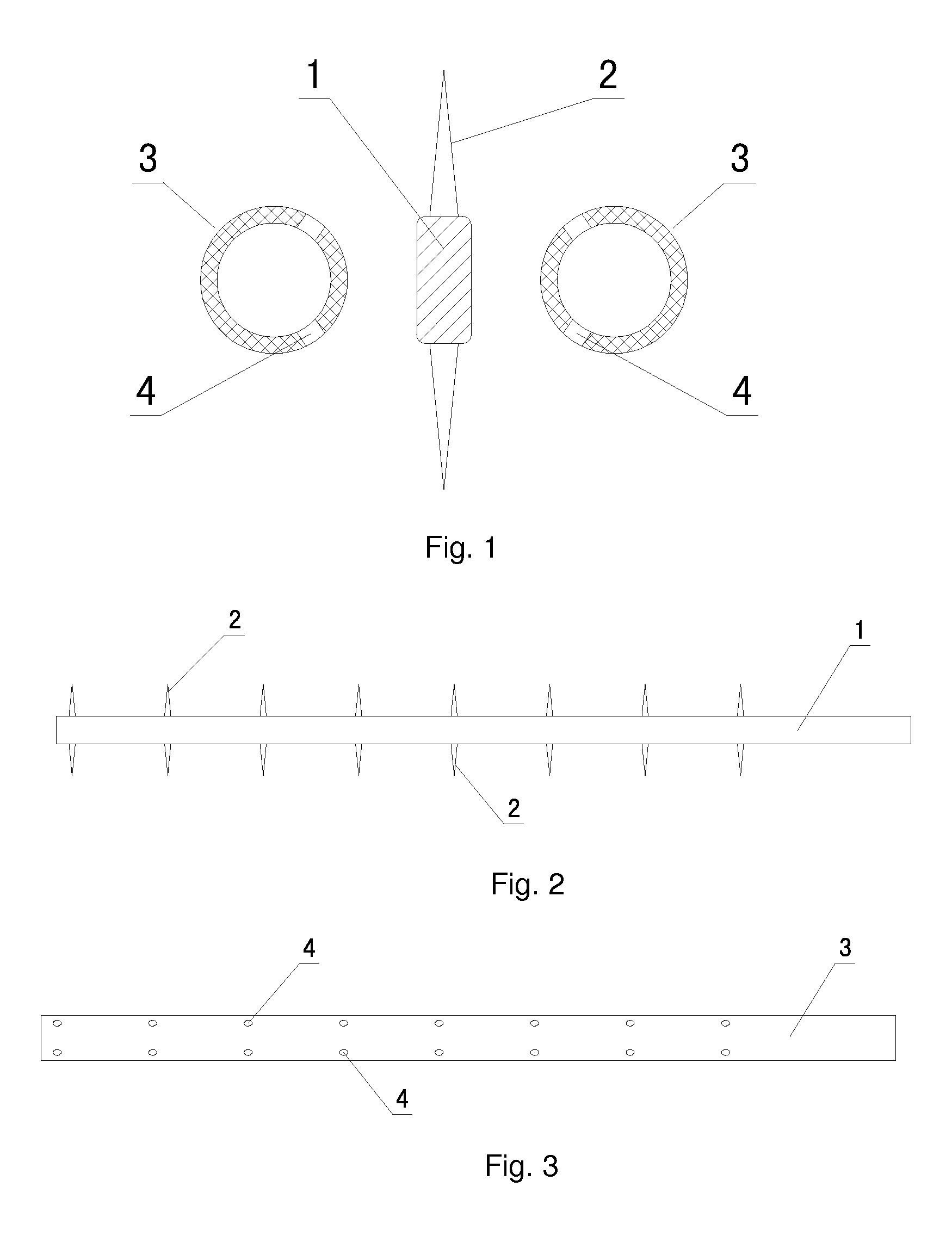

Method and apparatus for the treatment of wood or wood products

InactiveUS20060278336A1Avoid large amounts of heatSave energyDrying using combination processesPlywood pressesPulp and paper industryWood product

A method for the treatment of wood or wood products, in which method moist wood or wood products (1) are dried by first pressing and further by heating so that a desired degree of dryness is reached. In a first stage, the wood or wood products (1) arranged between treating elements (2) are pressed between the treating elements (2) so that a considerable amount of water is removed from the wood being treated, next the treating elements (2) are locked so that the wood or wood products (1) remain compressed between the treating elements (2), and the combination of treating elements (2) and wood or wood products (1) between them thus formed is moved into a drying chamber (D), where the wood or wood products are dried further by applying heat. The invention also relates to an apparatus.

Owner:TEKNOCOMP

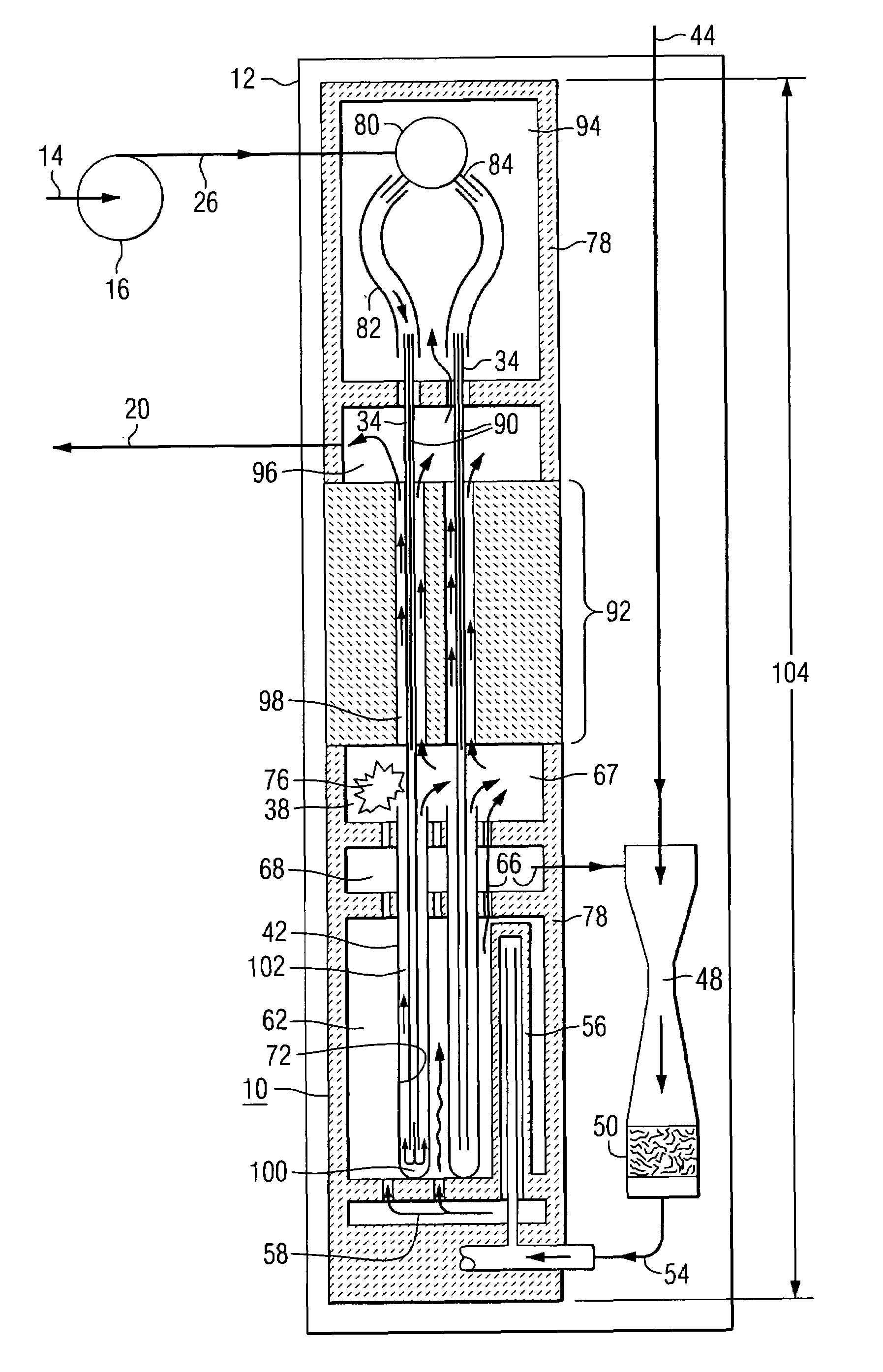

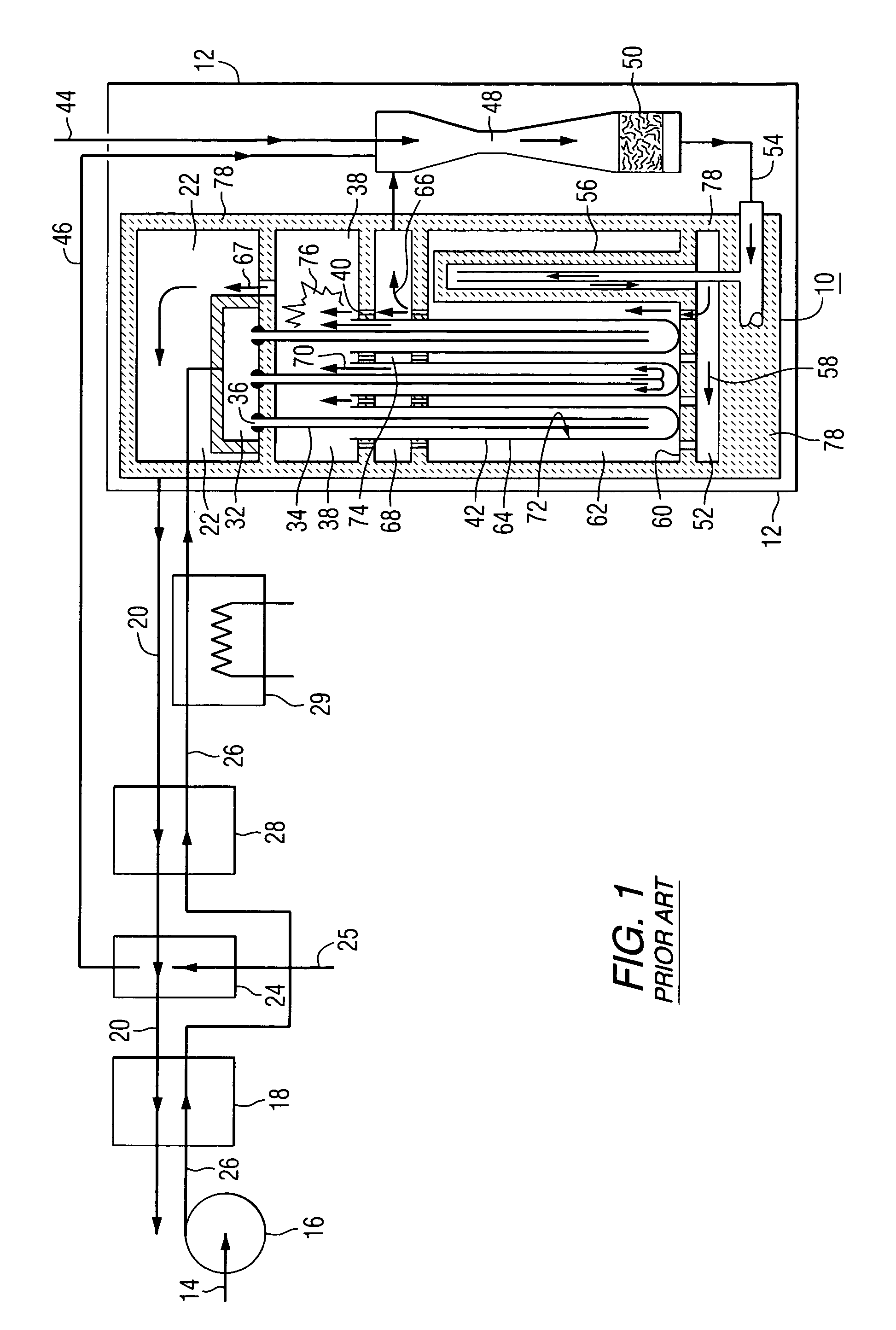

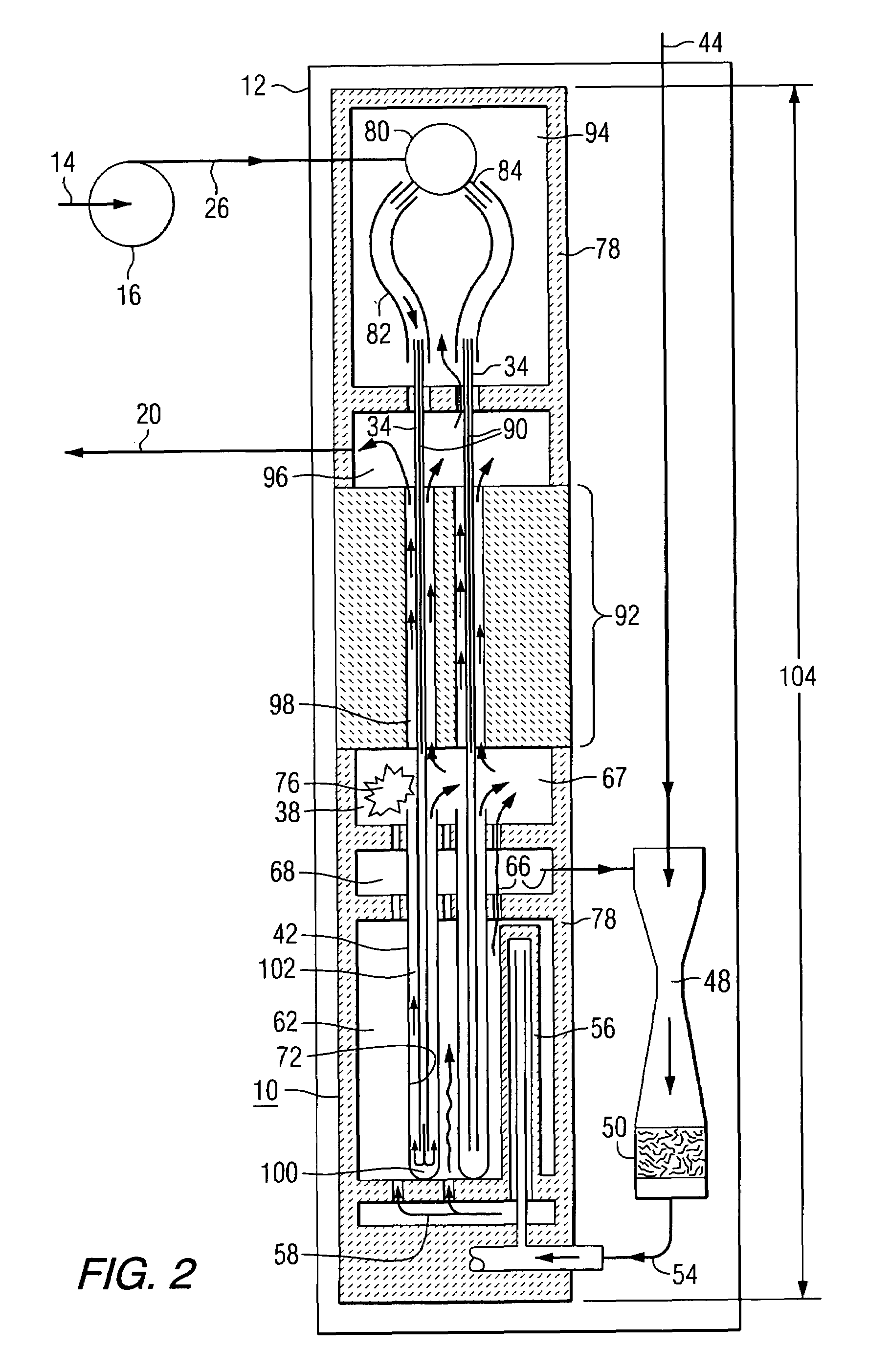

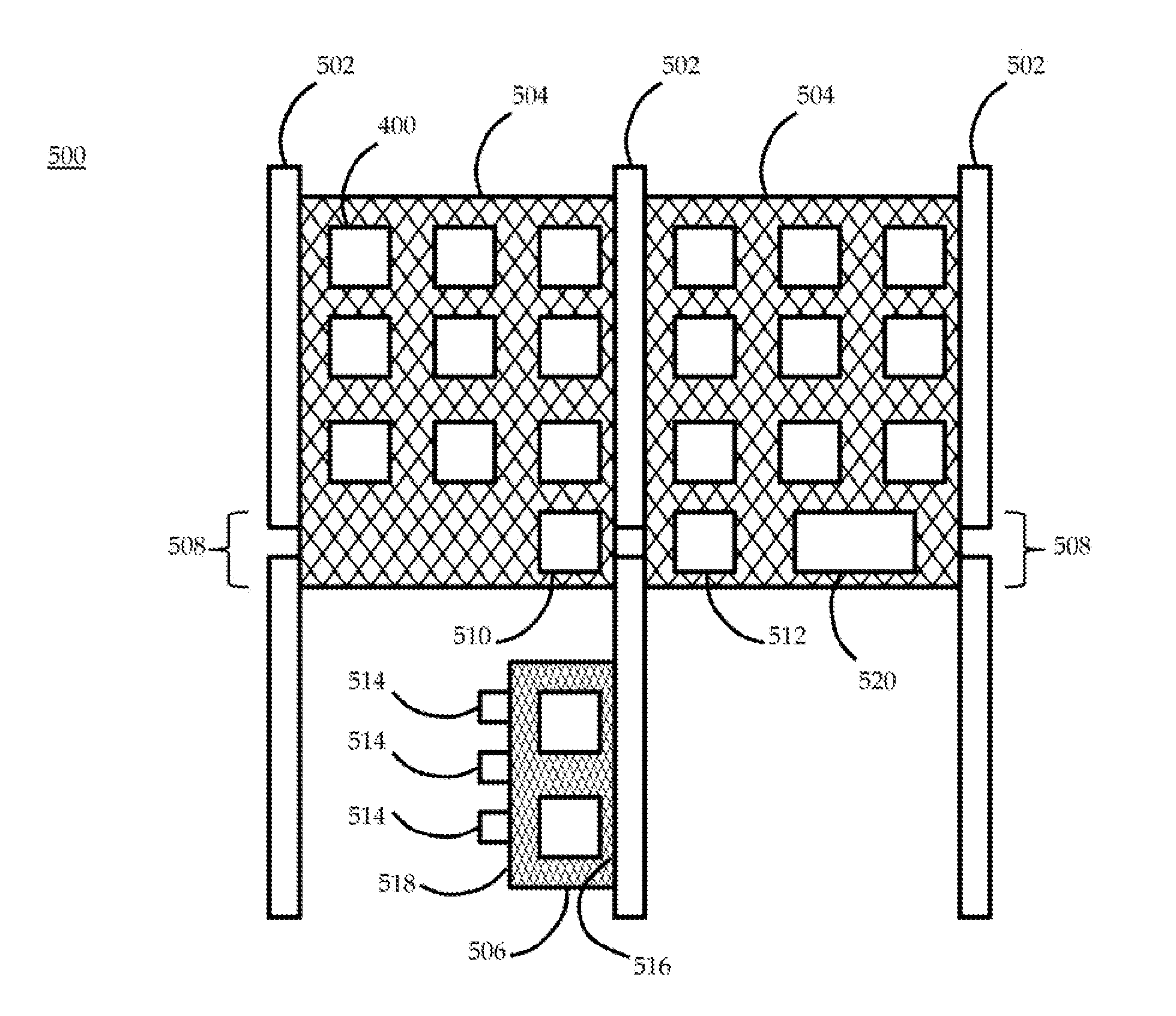

Integral air preheater and start-up heating means for solid oxide fuel cell power generators

InactiveUS7320836B2Simple designThe equipment is bulkyReactant parameters controlFuel cells groupingAir preheaterCombustion chamber

A high temperature fuel cell generator (10) having a housing (12) containing a top air feed plenum (80), a bottom fuel inlet (54), a fuel reaction generator chamber (62) containing fuel cells (42) and a reacted fuel-reacted air combustion chamber (38) above the fuel reaction generator chamber (62), where inlet air (14) can be heated internally within the housing in at least one interior heat transfer zone / block (92) located between the reacted fuel-reacted air combustion chamber (38) and the air feed plenum (80).

Owner:SIEMENS AG

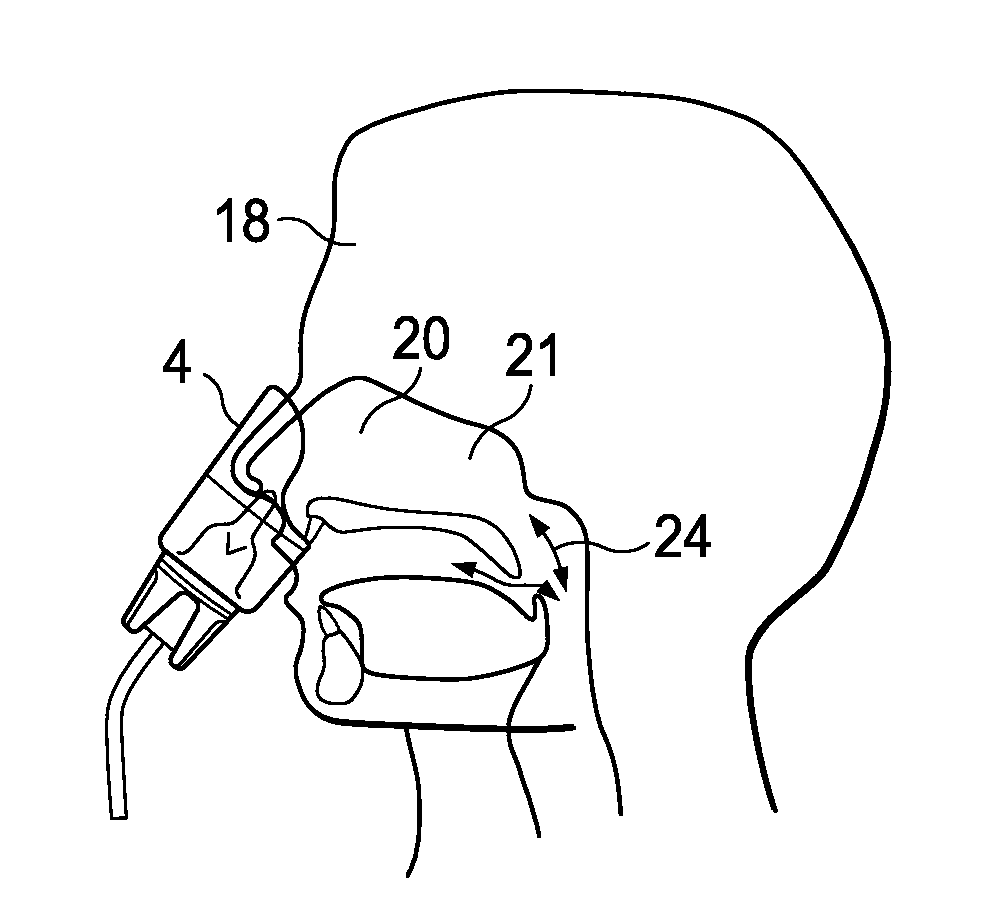

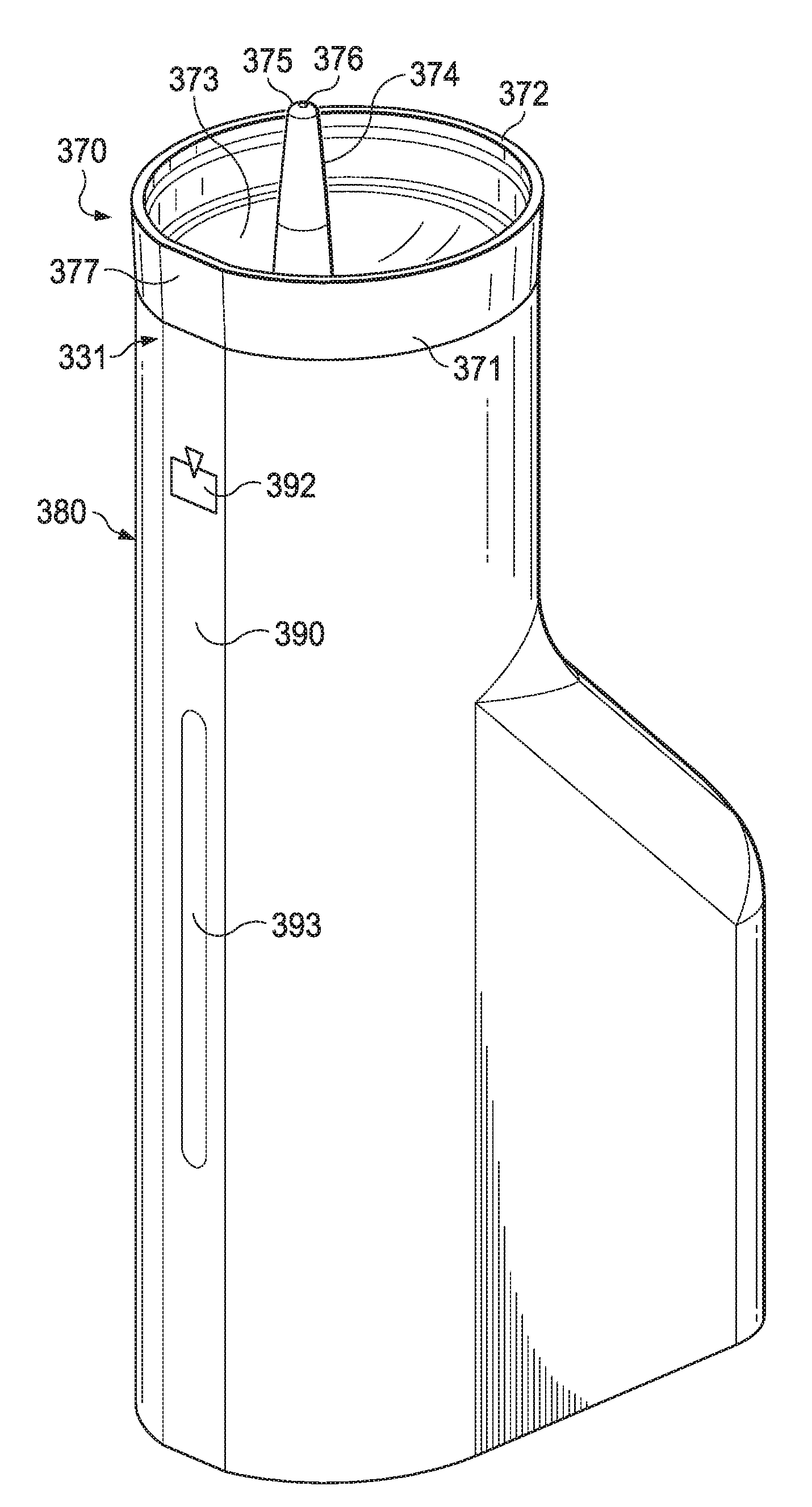

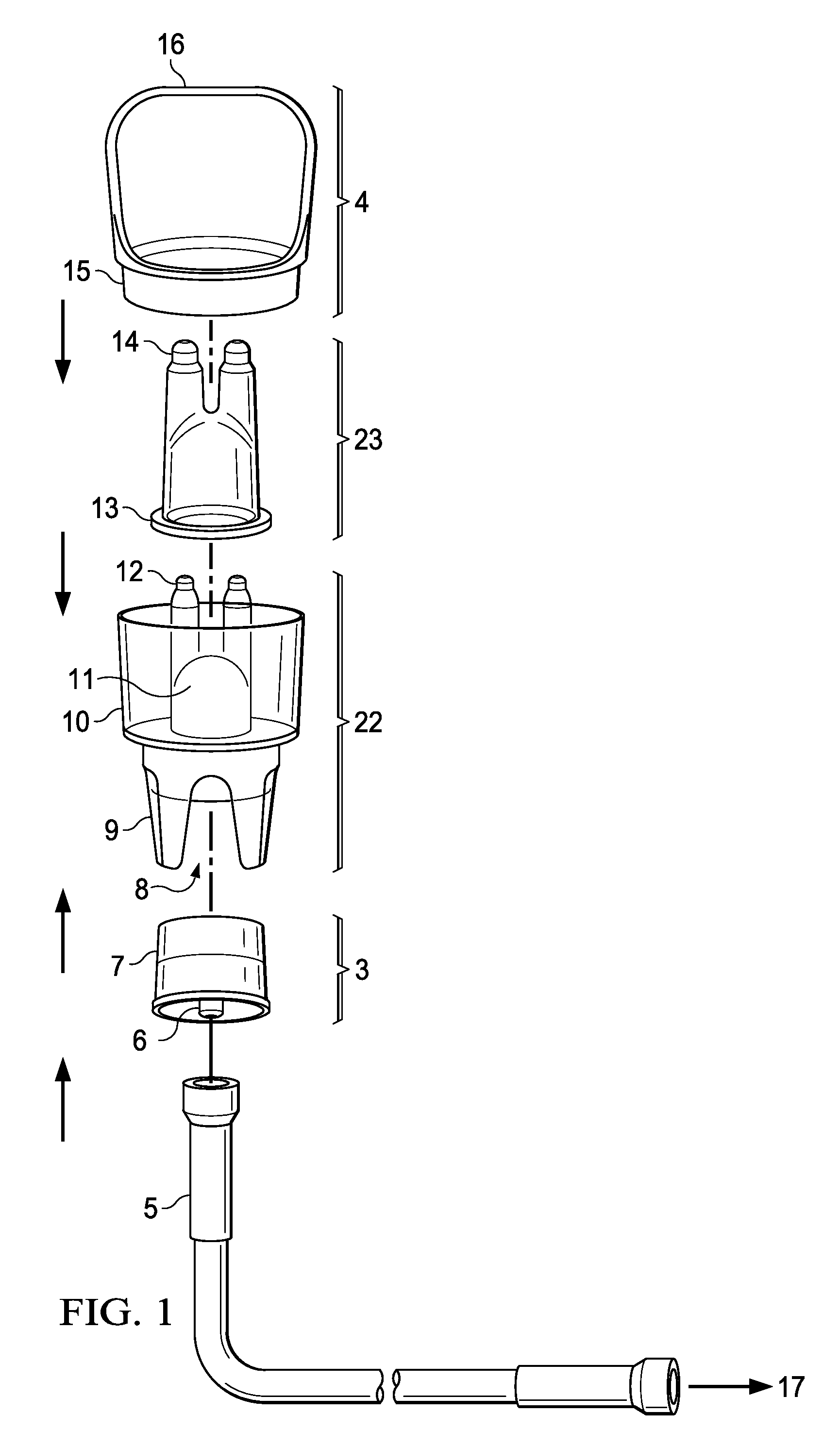

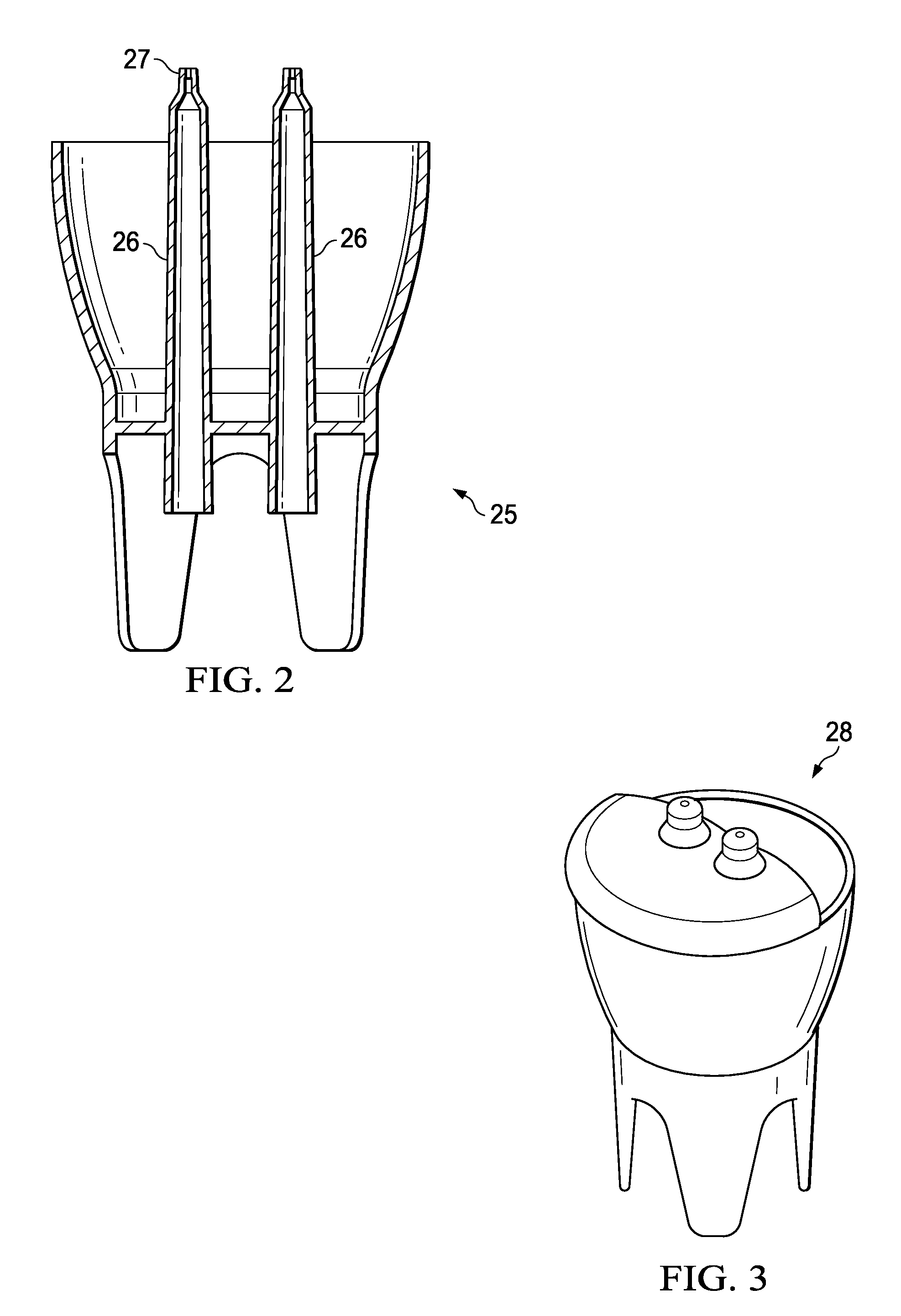

Portable Fluid Delivery System for the Nasal and Paranasal Sinus Cavities

A pressurized air supply source for a portable nasal irrigator houses an airflow regulating system, instead of external bulky, heavy components, to power the atomization of fluid for irrigation of nasal passages. The airflow regulating system is made up of a pump, a motor to drive the pump, a filter with an inlet air manifold connected to the pump to eliminate additional tubing within the pressurized air supply source, and an optionally rechargeable battery to drive the motor. An external AC / DC power supply may charge the battery or operate the device when the battery is in a discharged state. A canister for holding fluid attaches on top of the pressurized air supply source and an insert fits that over a fluid channel in the canister to create a venturi effect and draw the fluid out. The pressurized air supply source creates a clinically effective airflow despite its small size.

Owner:MONAGHAN MEDICAL

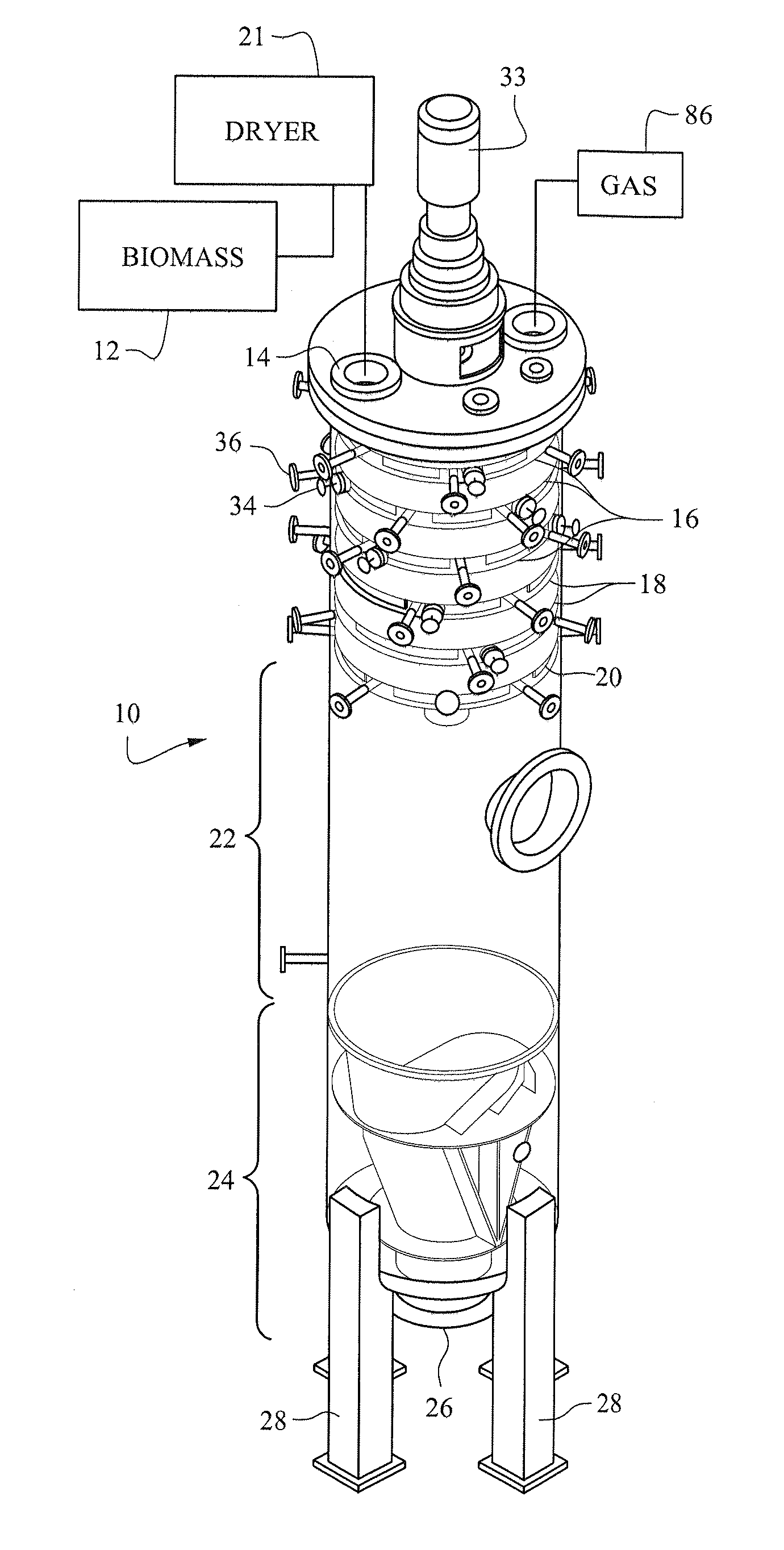

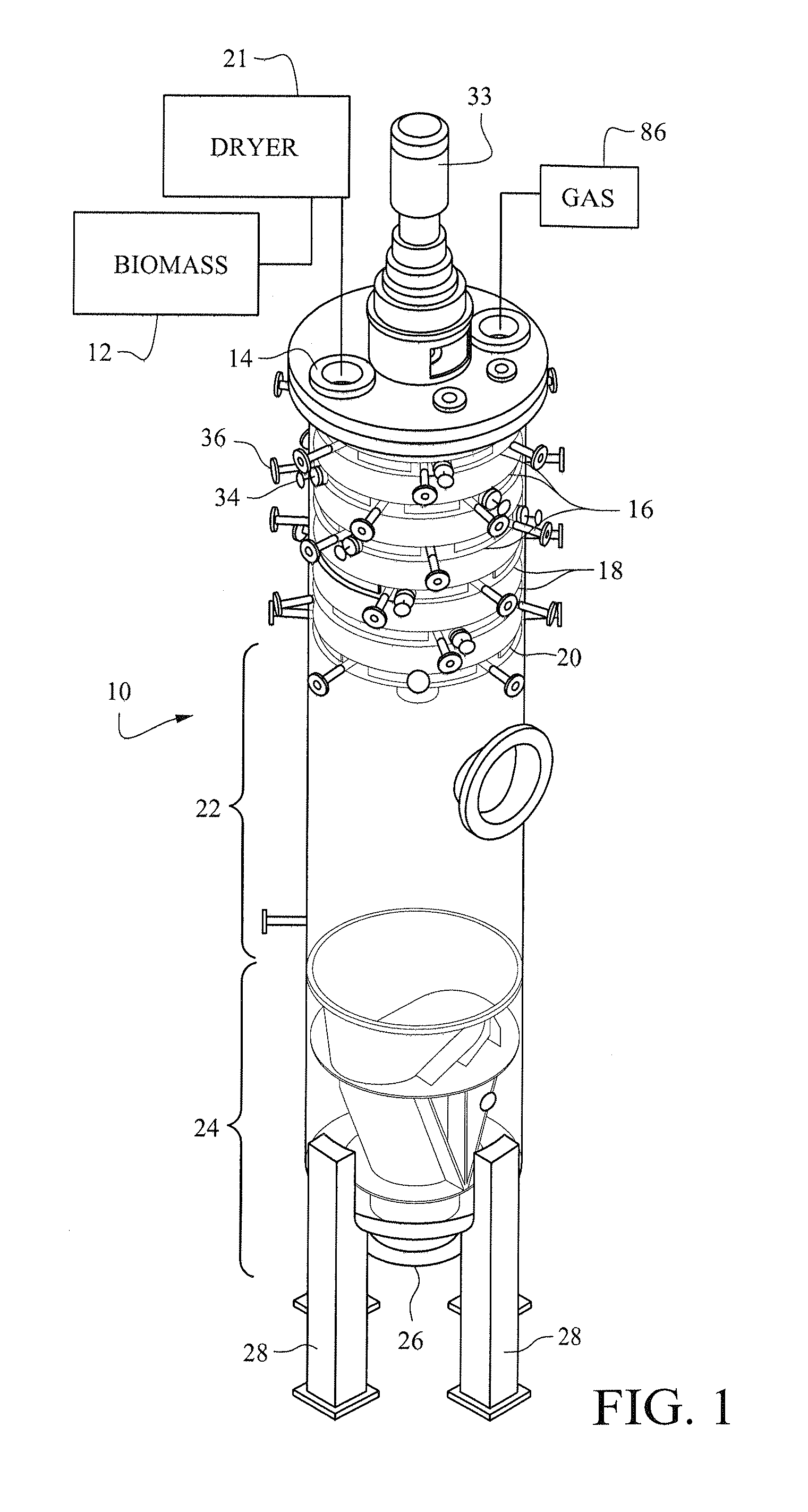

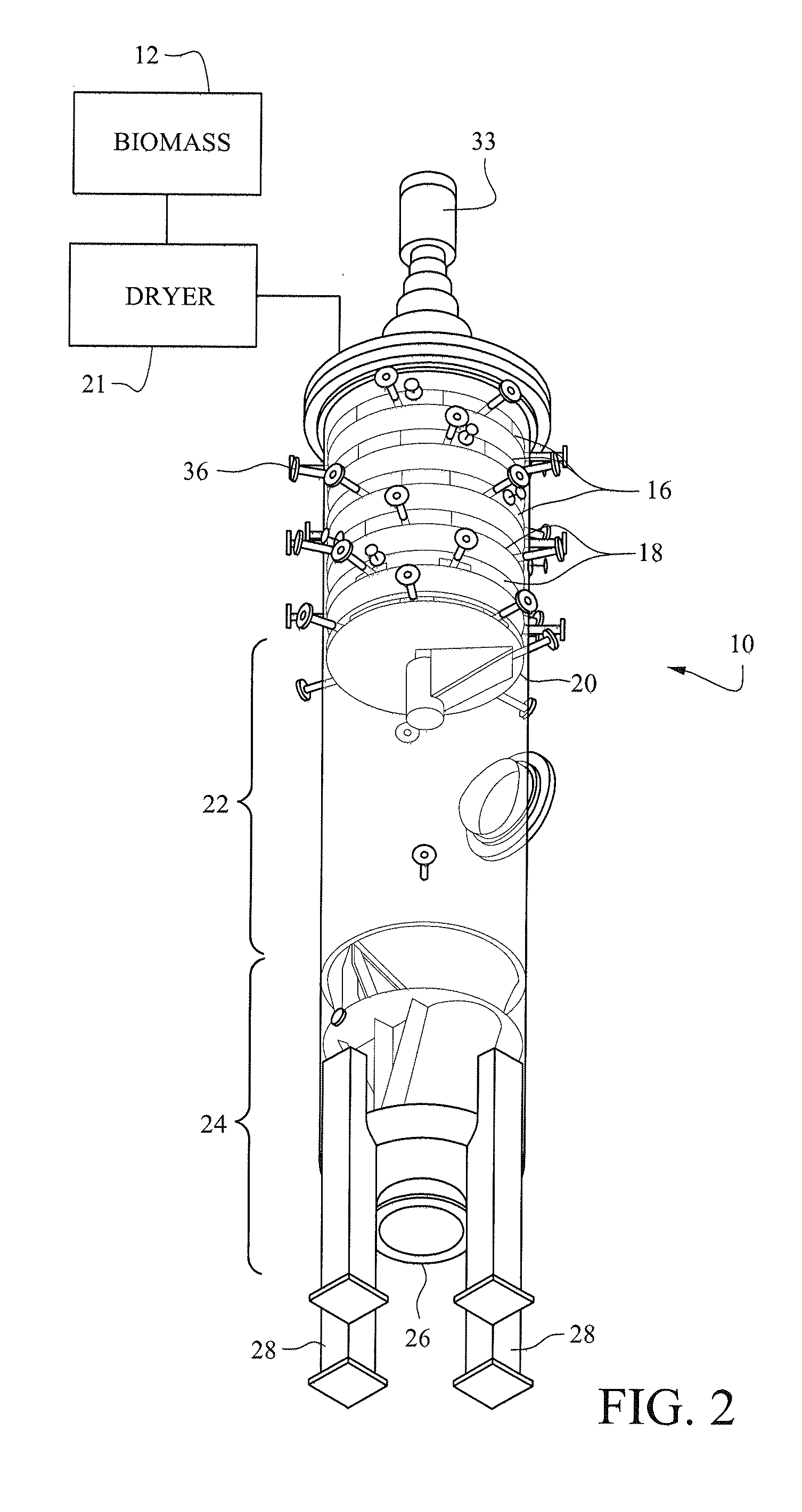

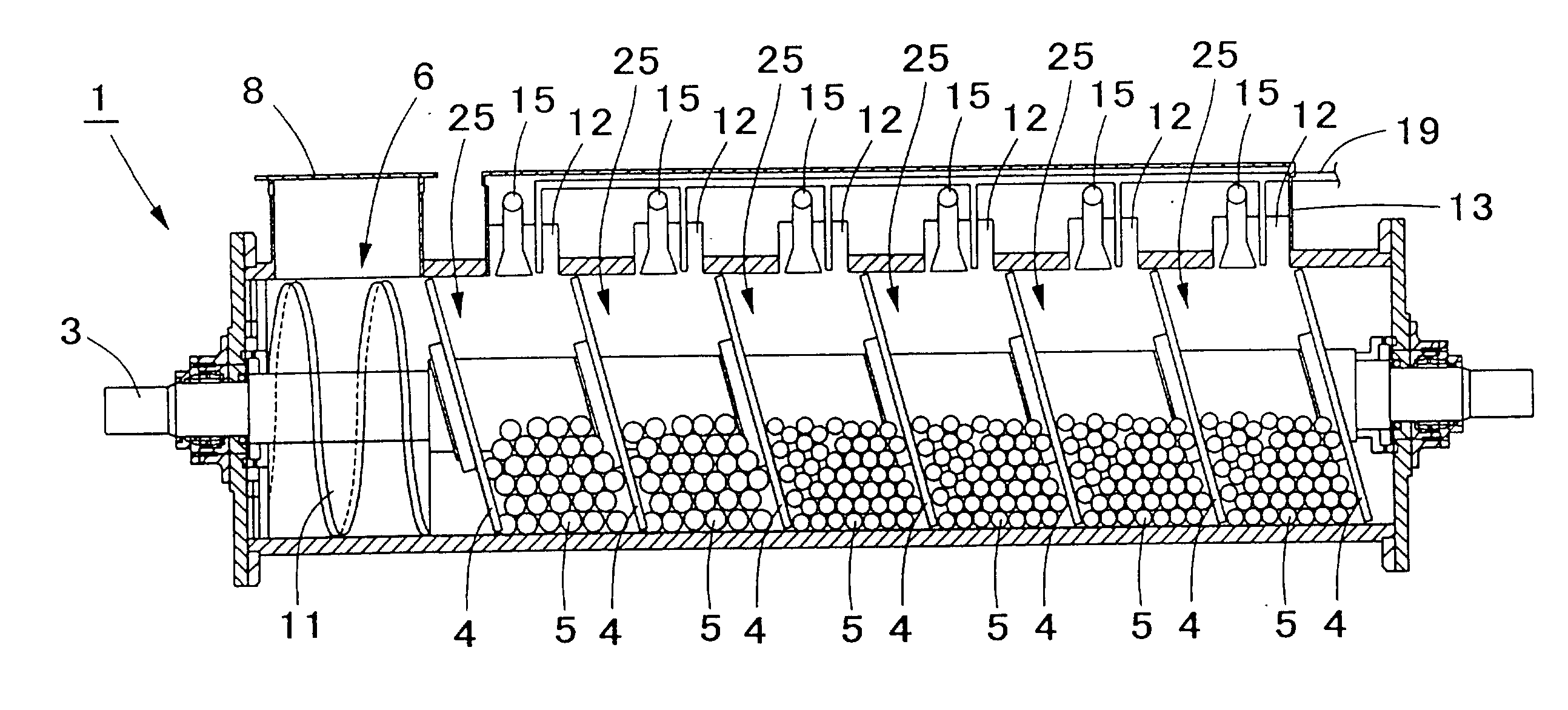

System for the torrefaction of lignocellulosic material

InactiveUS20130105295A1The equipment is bulkyHigh energy consumptionCombustible gas coke oven heatingDirect heating destructive distillationTorrefactionCellulose

A pressurized torrefaction reactor vessel including: a rotatable shaft extending vertically down from a top of the vessel; scraper devices each at a different elevation within the vessel and mounted to the shaft; a tray associated with each one of the scraper devices such that the scraper device is immediately above a tray of the tray assembly; wherein the tray is an open mesh and impermeable to passage of biomass through the tray; each tray includes a discharge opening to transfer biomass from the tray and down to a tray of a lower one of the tray assemblies, and wherein the discharge opening in the lowermost tray assembly transfers the biomass to a pile of the biomass in the vessel, and a bottom discharge port of the vessel through which the torrefied biomass is discharged.

Owner:ANDRITZ INC

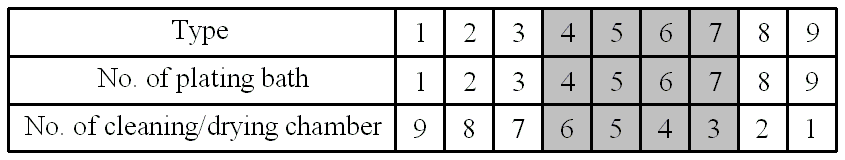

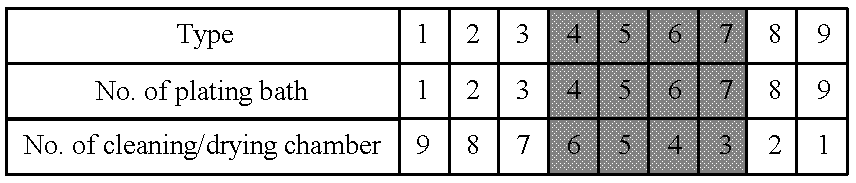

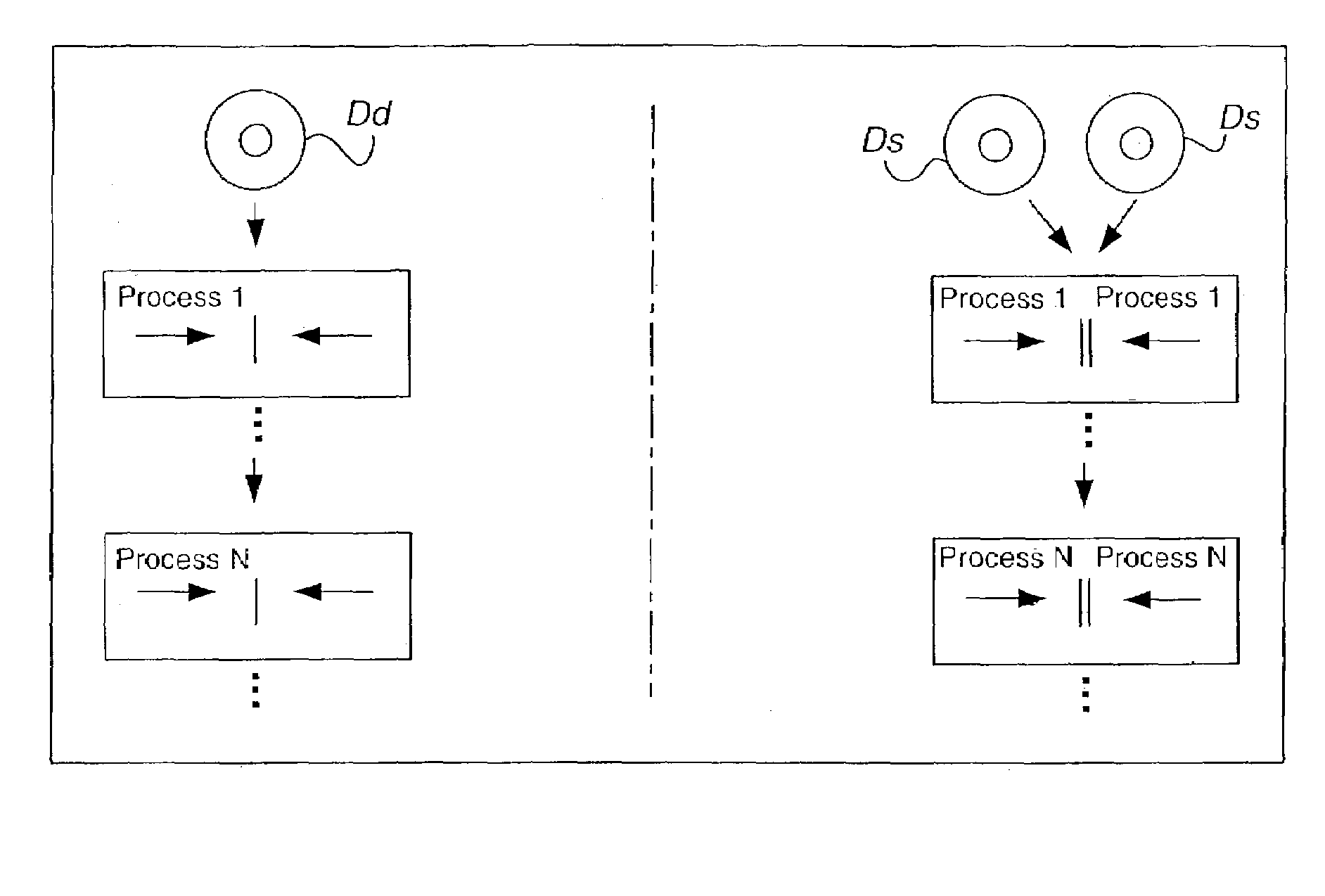

Method of lubricating multiple magnetic storage disks in close proximity

InactiveUS7052739B2Increase productionSubstantial capital equipment savingLiquid surface applicatorsReconditioning/cleaning record carriersMagnetic storageMechanical engineering

Owner:MAXTOR

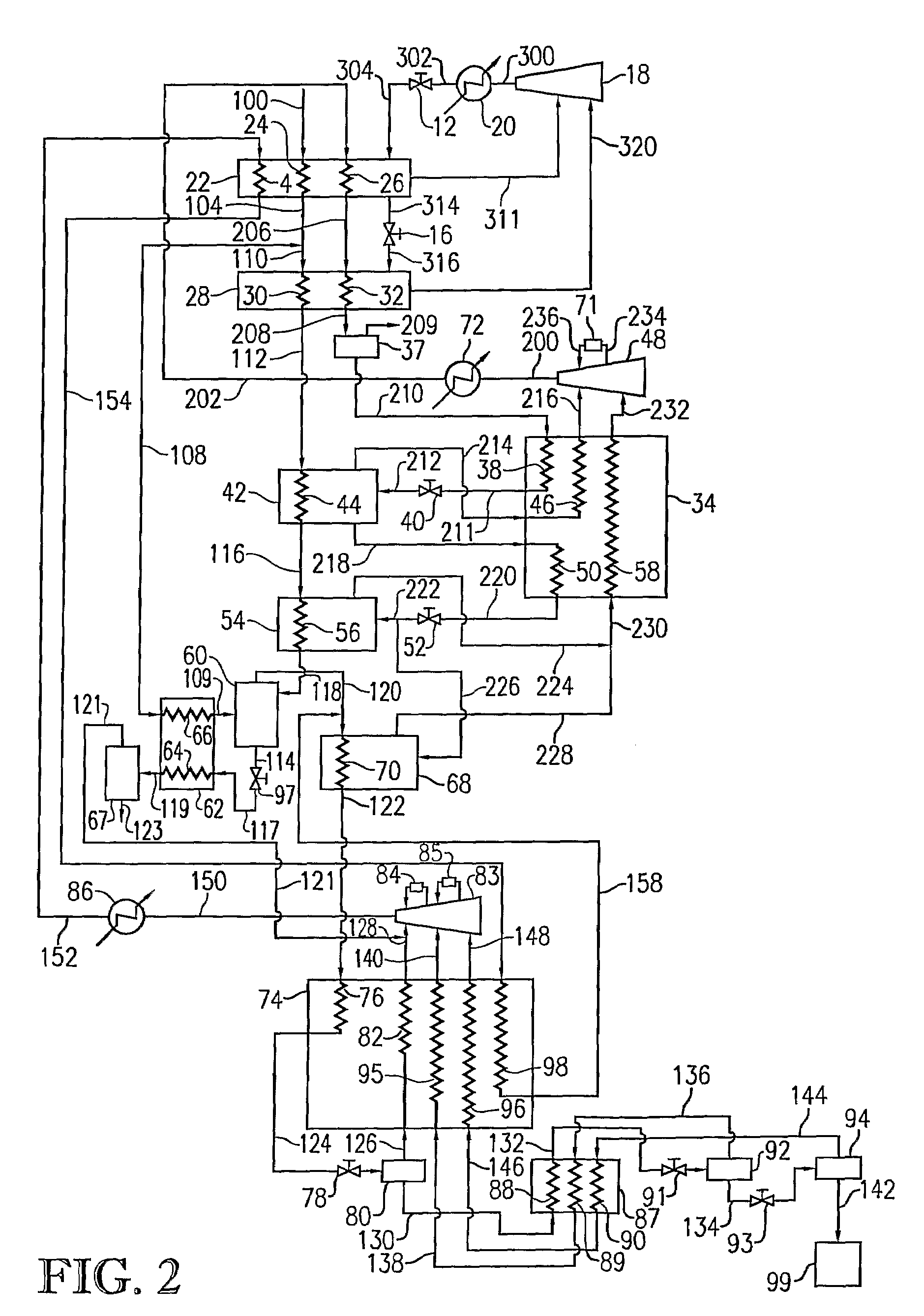

LNG system with enhanced pre-cooling cycle

InactiveUS20090249828A1Large capacityThe equipment is bulkySolidificationLiquefactionCold weatherEngineering

A natural gas liquefaction system employing a high pressure pre-cooling refrigeration cycle. The natural gas liquefaction system can be advantageously employed in cold weather regions and / or in regions that exhibit large variations in ambient temperature.

Owner:CONOCOPHILLIPS CO

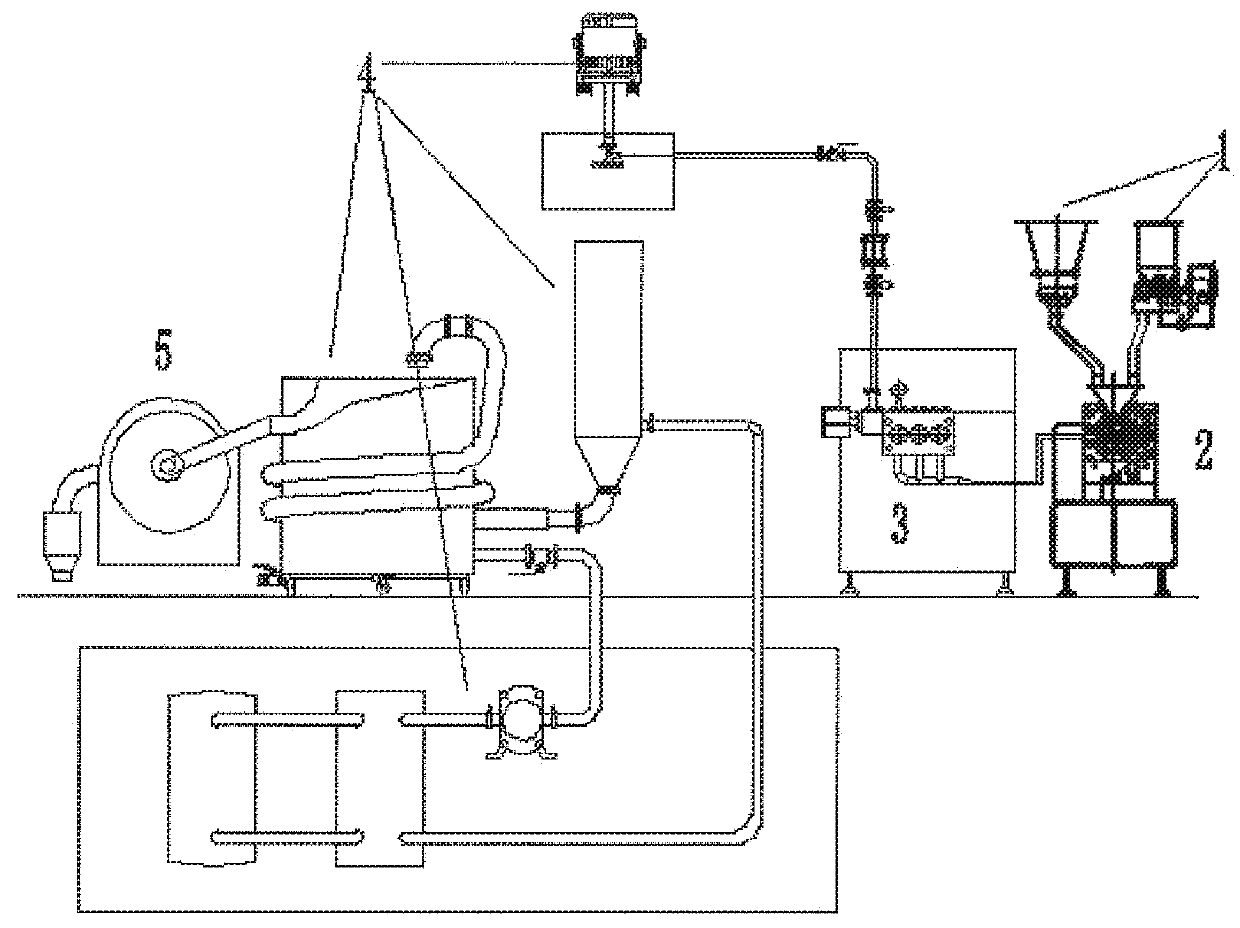

Fine powdered sand gathering system in dry condition

InactiveUS20030226920A1Efficiently and securely collect the fine powderThe equipment is bulkyGas current separationSortingCollection systemMachining process

The purpose is to provide a dry type fine powder collecting system which enables that, in the crusher and triturator which process materials under dried condition, the fine powder generated during processing is collected efficiently and certainly, and the same washing effect as in wet condition is acquired without needing a large amount of equipment cost, and the quality and processing efficiency of the product is improved, and the work environment is also improved. To achieve the purpose described as above, the present invention provides a fine powder collection system having a processing space which accommodates, crush or triturate materials, and the system is in the device where materials are crushed or triturated under dried condition in the said processing space. In addition, it is a dry type fine powder collection system wherein a blowing mean which floats the fine powder generated during crushing or triturating by blowing vapor into the processing space, and a suction mean which sucks the fine powder floated by the said blowing mean in the processing space are arranged in the said device.

Owner:YANASE SIGEO

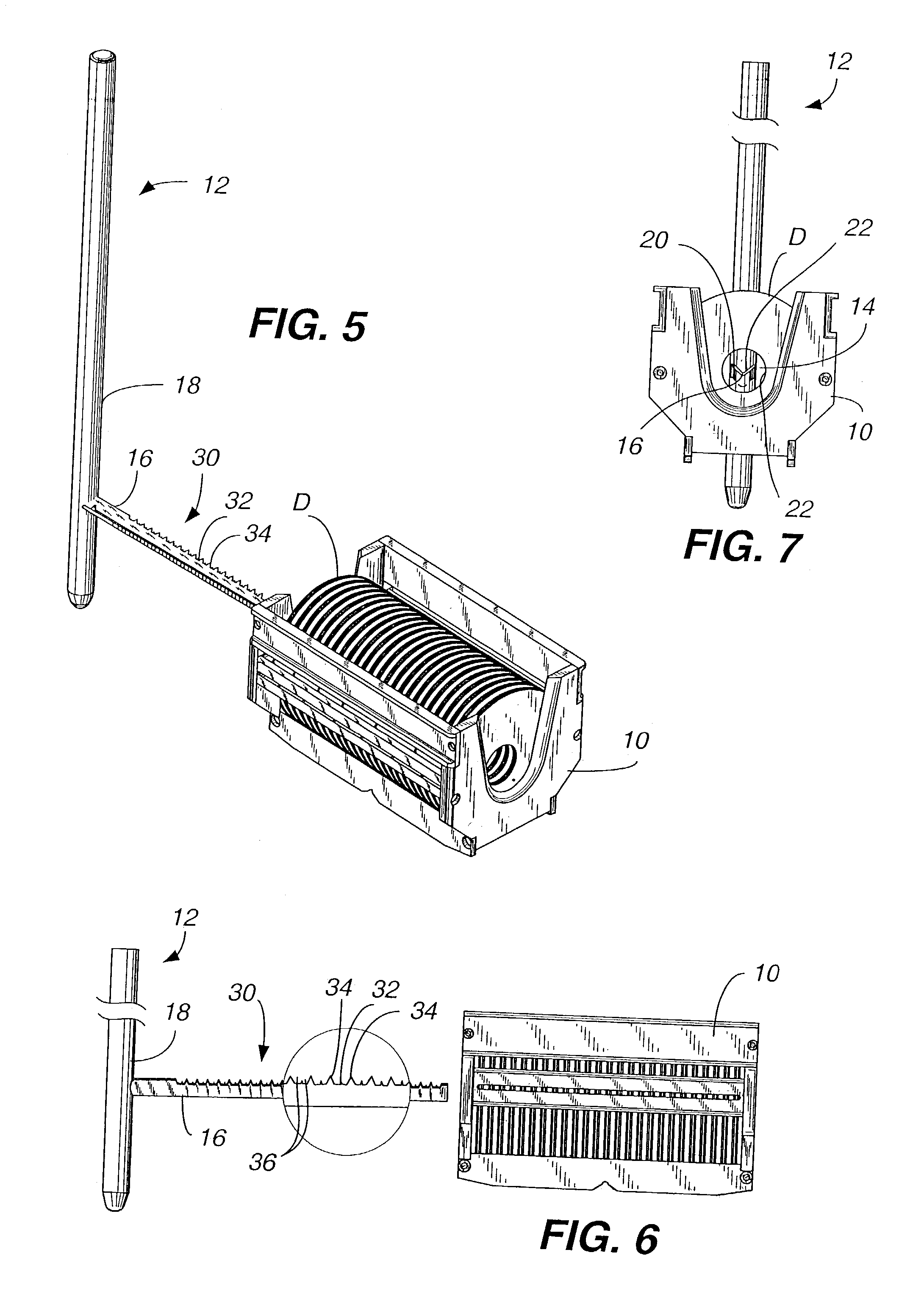

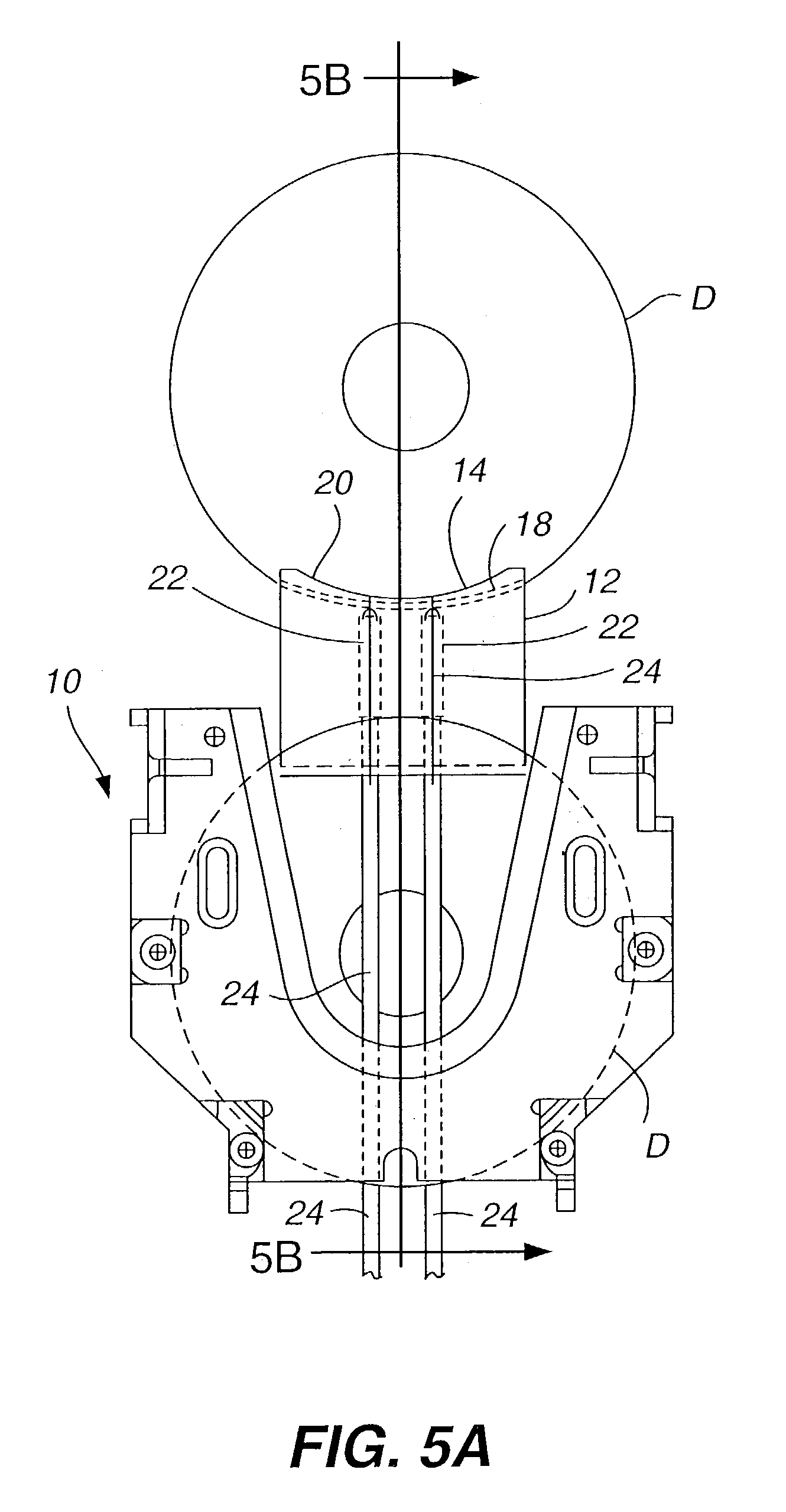

Tool and method for cleaning a drilled hole

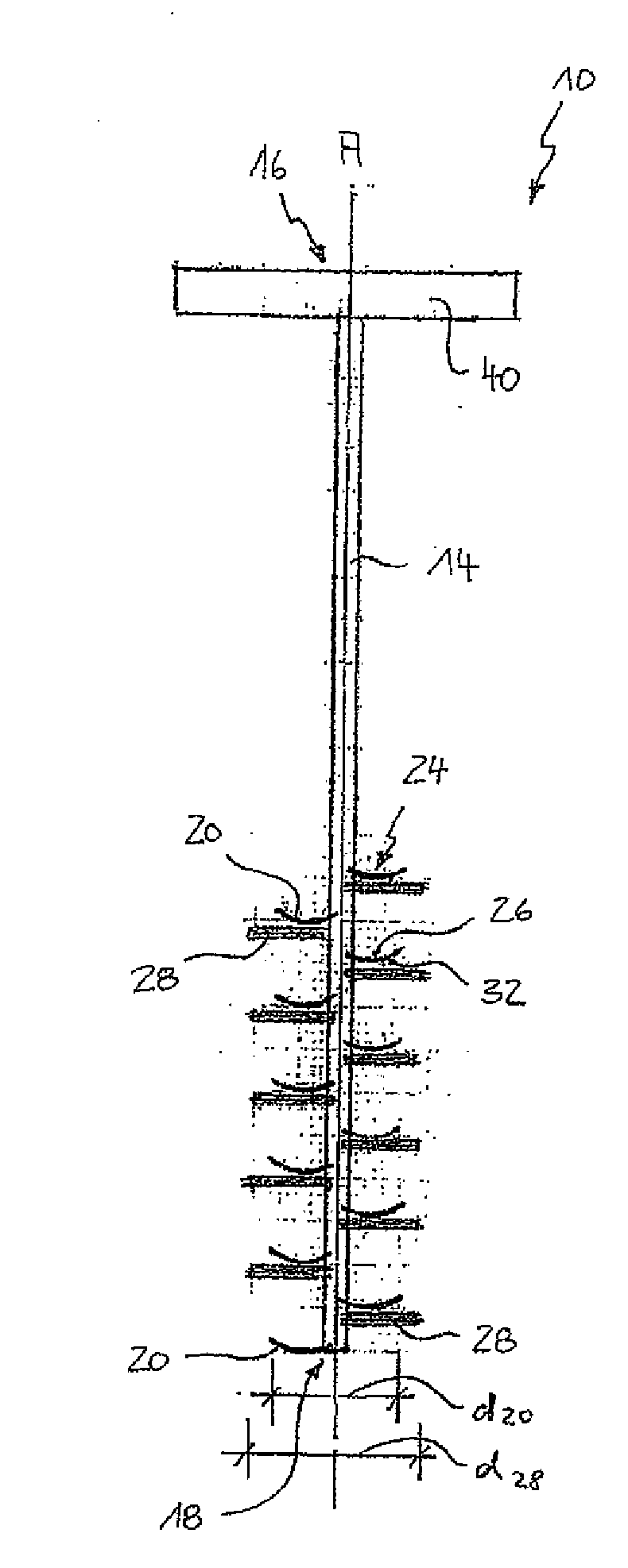

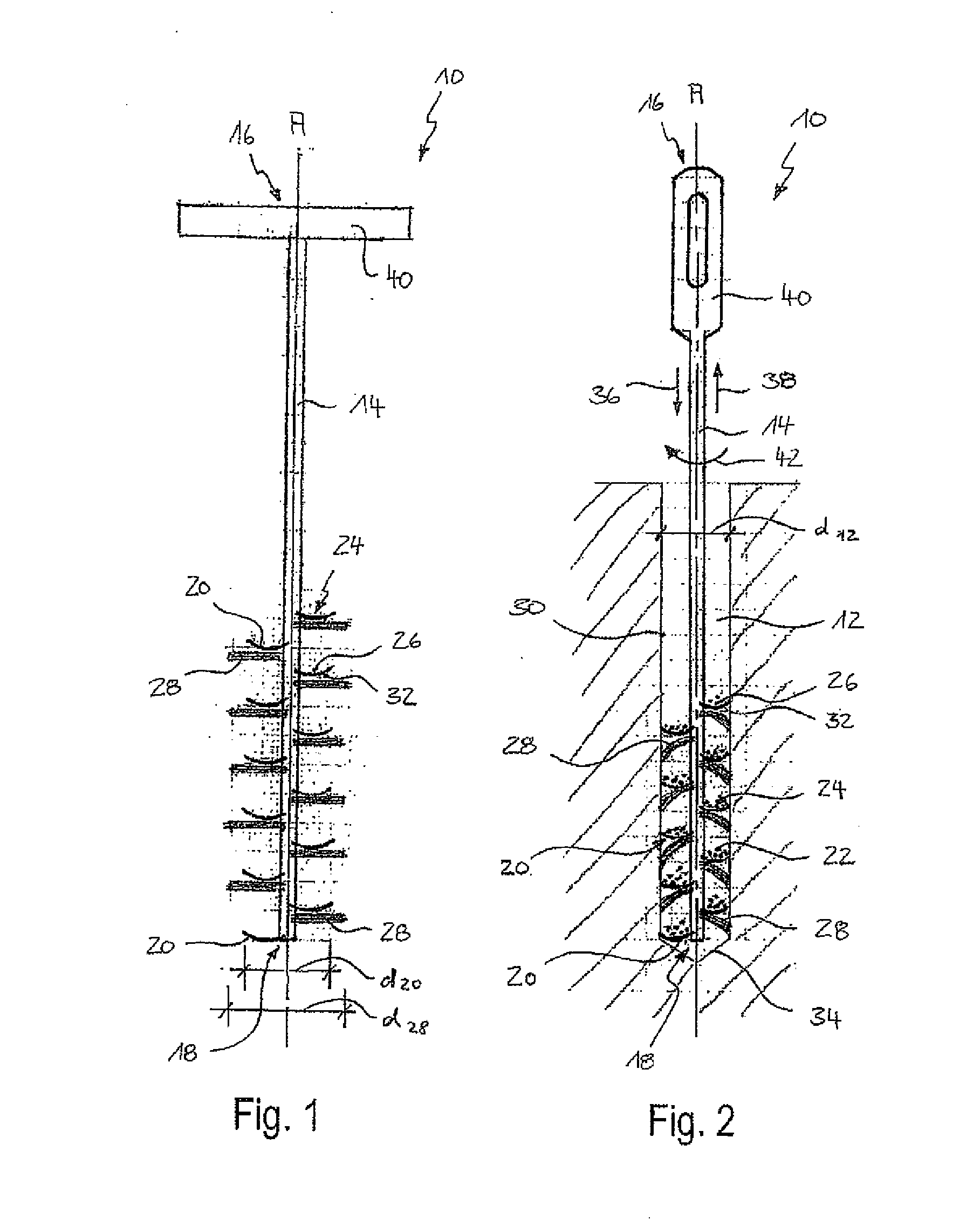

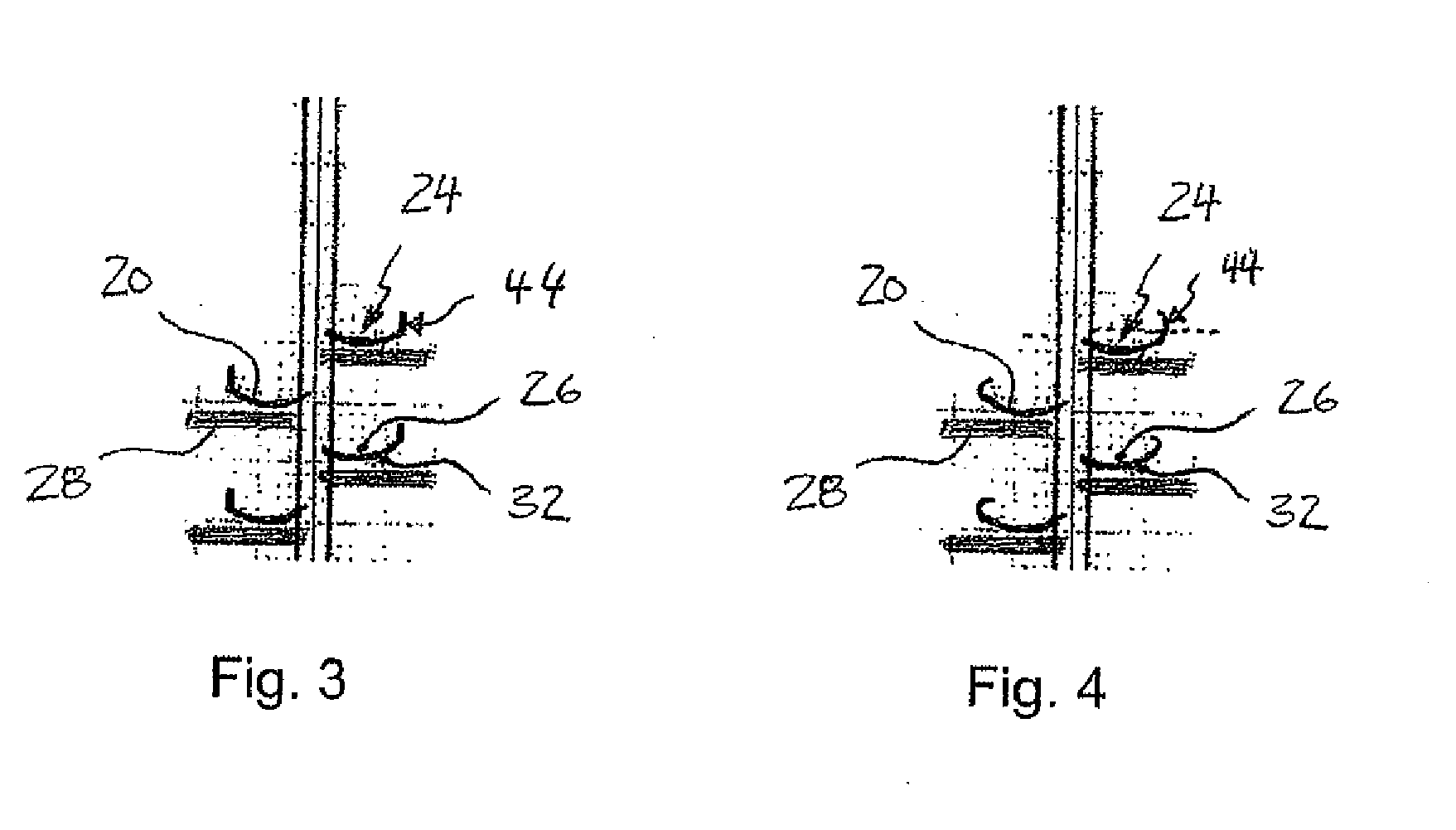

InactiveUS20130019896A1Without generating much dustSimple and quick procedureBrush bodiesHollow article cleaningEngineeringMechanical engineering

A tool (10) for cleaning a drilled hole (12), including a tool shank (14) that, relative to the shank axis (A), has an axial attachment end (16) and an opposite axial cleaning end (18), as well as at least one conveying element (20) for removing drilling dust (22) from the drilled hole (12). The conveying element (20) is attached to the tool shank (14) and arranged in the axial direction like a helix around the tool shank (14). The conveying element (20) is configured as a channel (24) that is open in the direction of the attachment end (16). A method for cleaning a drilled hole by such a tool (10) is also disclosed.

Owner:HILTI AG

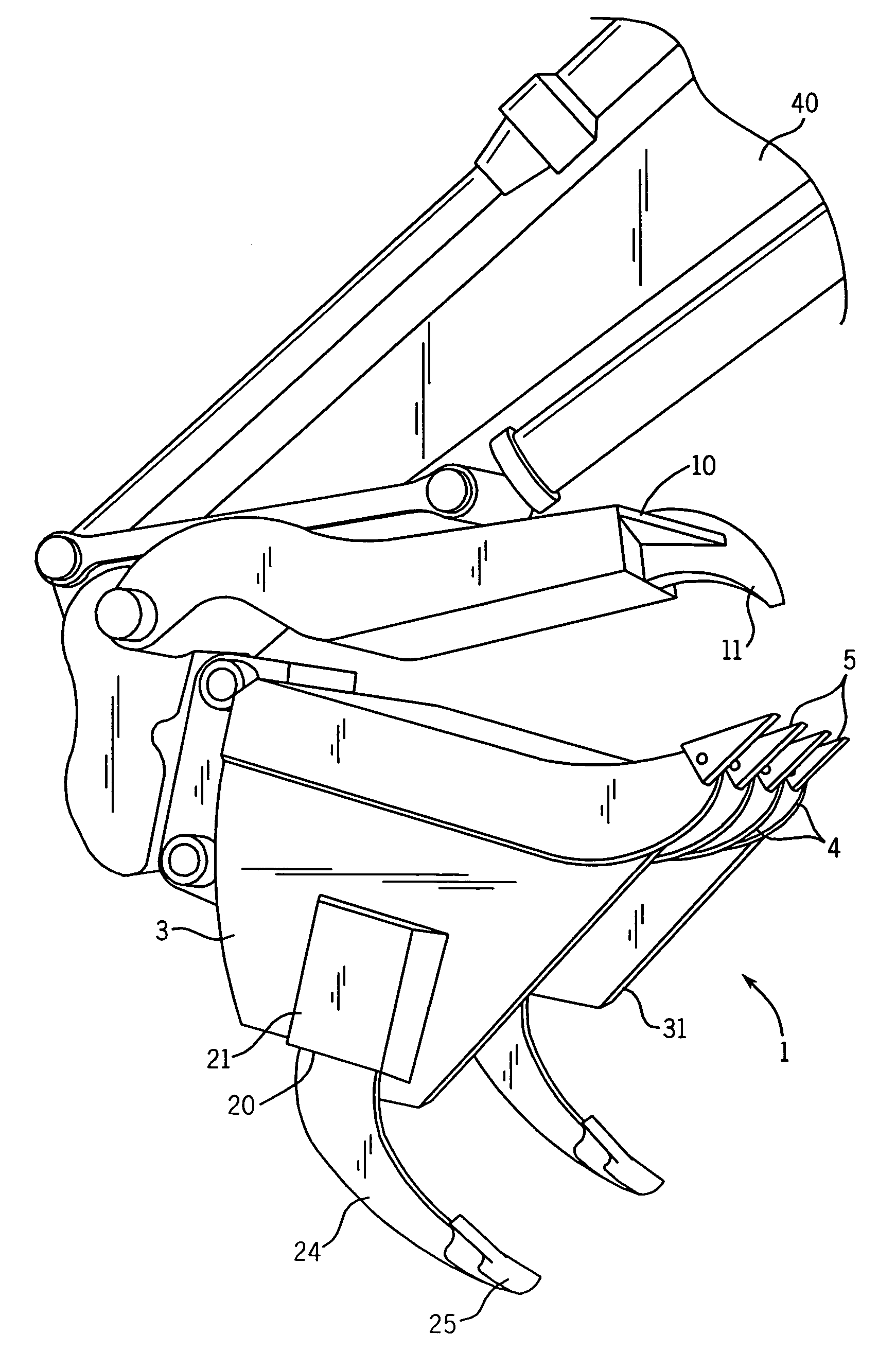

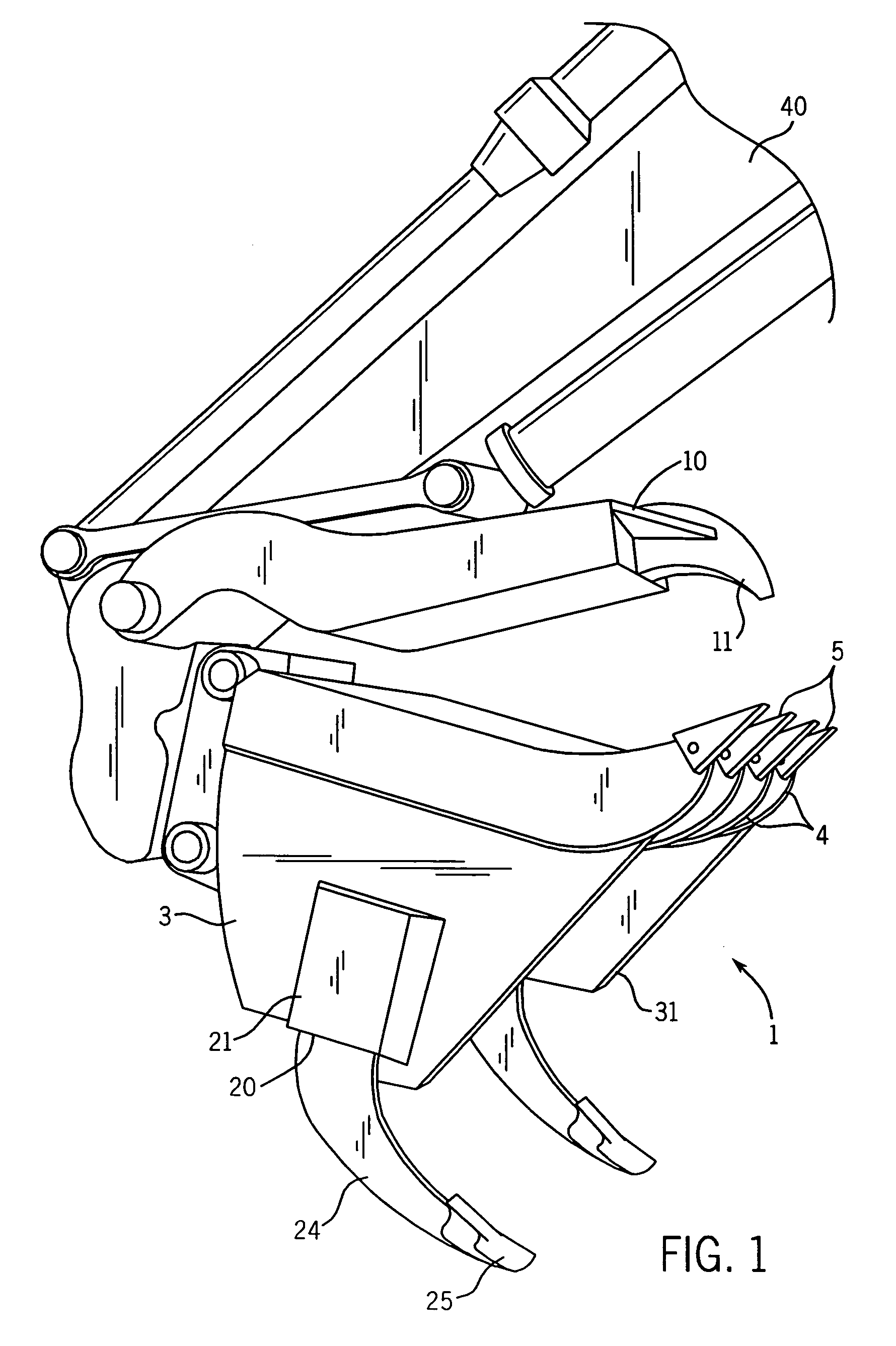

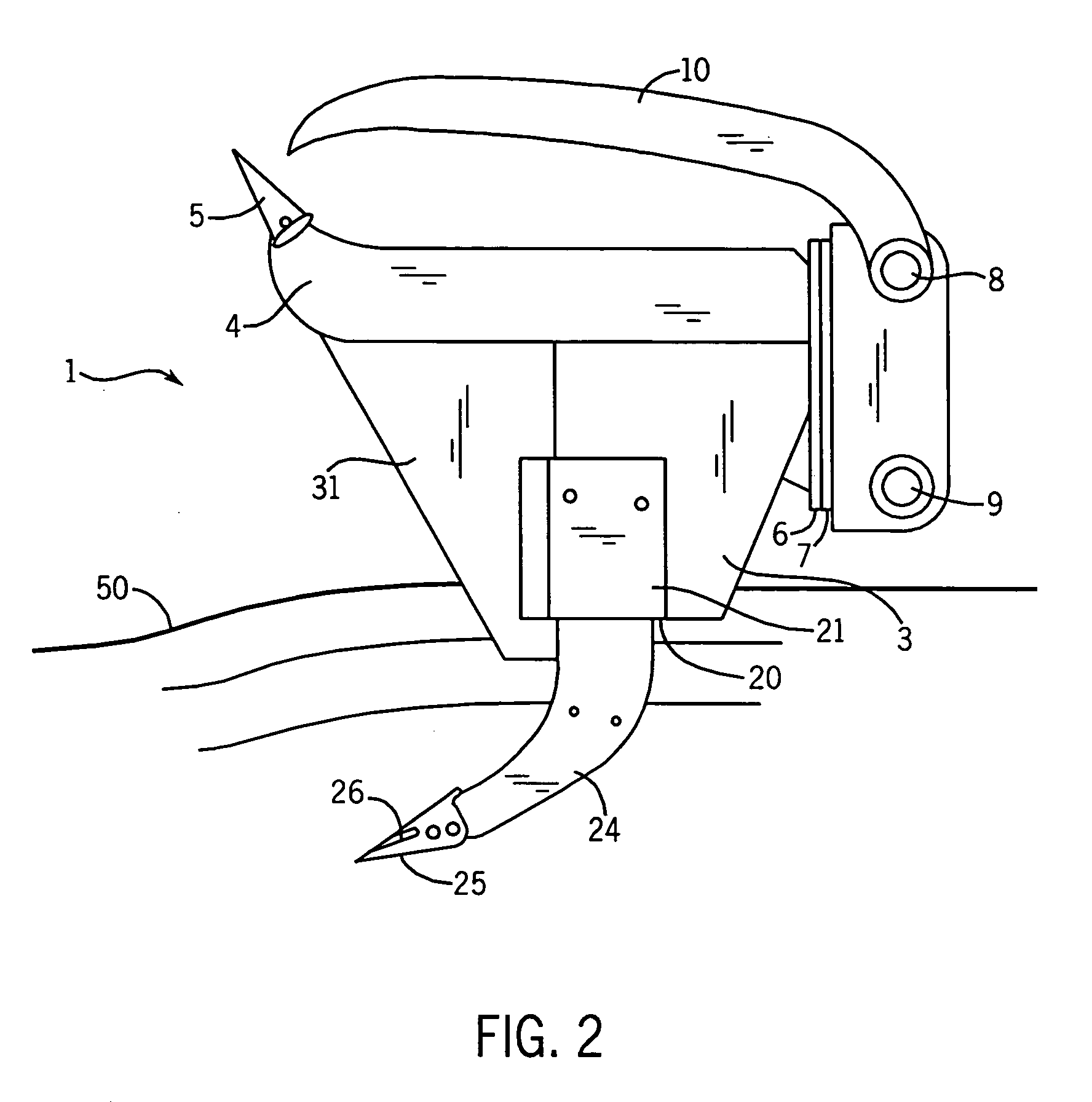

Subsoiling grapple rake

InactiveUS7086184B2Improve productivityReduce soil compactionMechanical machines/dredgersLifting devicesForest roadEngineering

A grapple rake adapted for receiving subsoiler shanks is useful for multiple post-timber harvest management activities. A pair of downwardly-depending, forward-oriented subsoiling shanks is mounted on the underside of the rake, allowing the implement to accomplish the tasks of (1) grapple piling to deal with post-timber harvest fuels reduction and (2) subsoiling to improve soil productivity by reducing soil compaction. The implement is optionally equipped with a coulter blade. This invention will be useful for decommissioning forest roads, skid trails, landings, and harvest units with new and / or legacy compaction without the need for multiple pieces of heavy equipment or for multiple entries into the treatment area.

Owner:US SEC AGRI

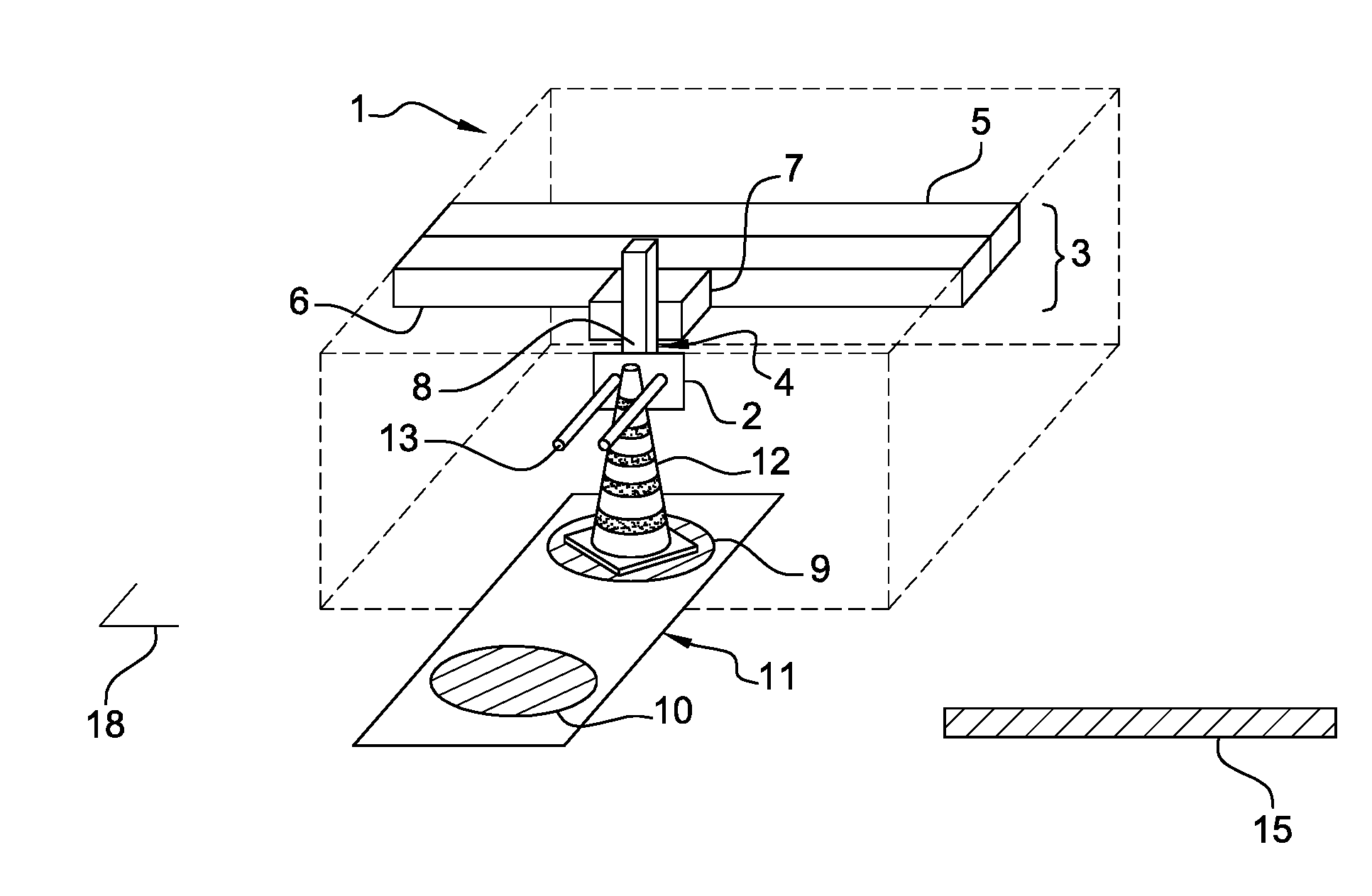

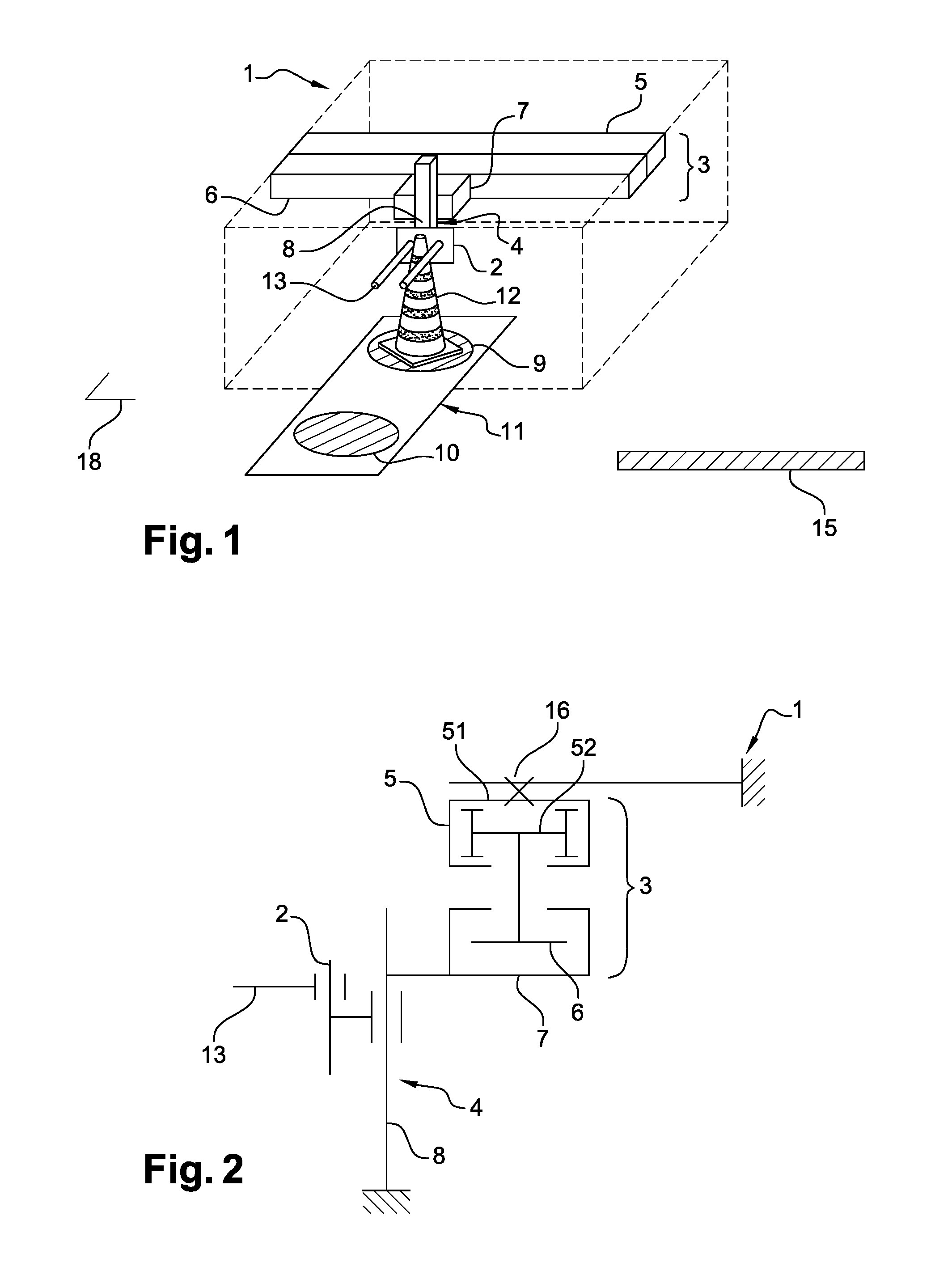

Accessory for positioning and recovering traffic cones

A device for handling traffic cones that may equip a vehicle, including a frame, a mechanism for transferring the cones from a provisioning unit to a handling station, a cone gripping unit, and mechanism for moving said gripping unit between the handling station and release points, wherein the moving mechanism include a lifting unit ensuring vertical movement for raising and lowering the gripping unit, a translation unit ensuring the transverse horizontal movement of said lifting unit and said gripping unit, said translation unit comprising at least one first slider that comprises a fixed part rigidly connected to the frame and a part that can move in translation, a second slider that comprises a part rigidly connected to the movable part of the first slider and a second part that can move in translation.

Owner:MATI IND & TECH

Building support with concealed electronic component for a structure

PendingUS20140230342A1Less electricityReduce power consumptionServersMetering/charging/biilling arrangementsTransceiverEngineering

Building support with a concealed electronic component for a structure, including: a rigid support member; a mounting attachment affixed to the rigid support member, the mounting attachment adapted to support an electronic component; and a transceiver coupled to the electronic component, the transceiver adapted to support an external communication link. Other embodiments provide a backing material to support an electronic component concealed within a building structural element, wherein the building structural element comprises one or more rigid building support members, the backing material including: a substrate; a structure attachment along at least one surface of the substrate, the attachment adapted to attach the substrate to a rigid building support member; and one or more electronic component attachments disposed on a major surface of the rigid substrate.

Owner:CFM GLOBAL

Continuously working magnetic stimulation device and method

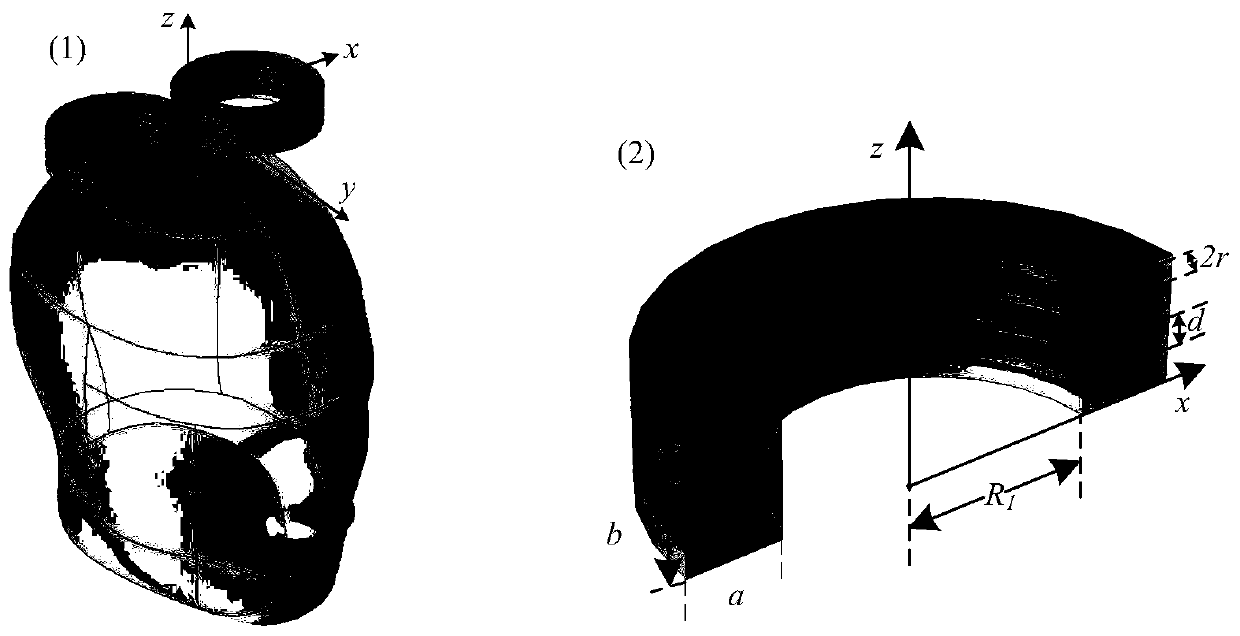

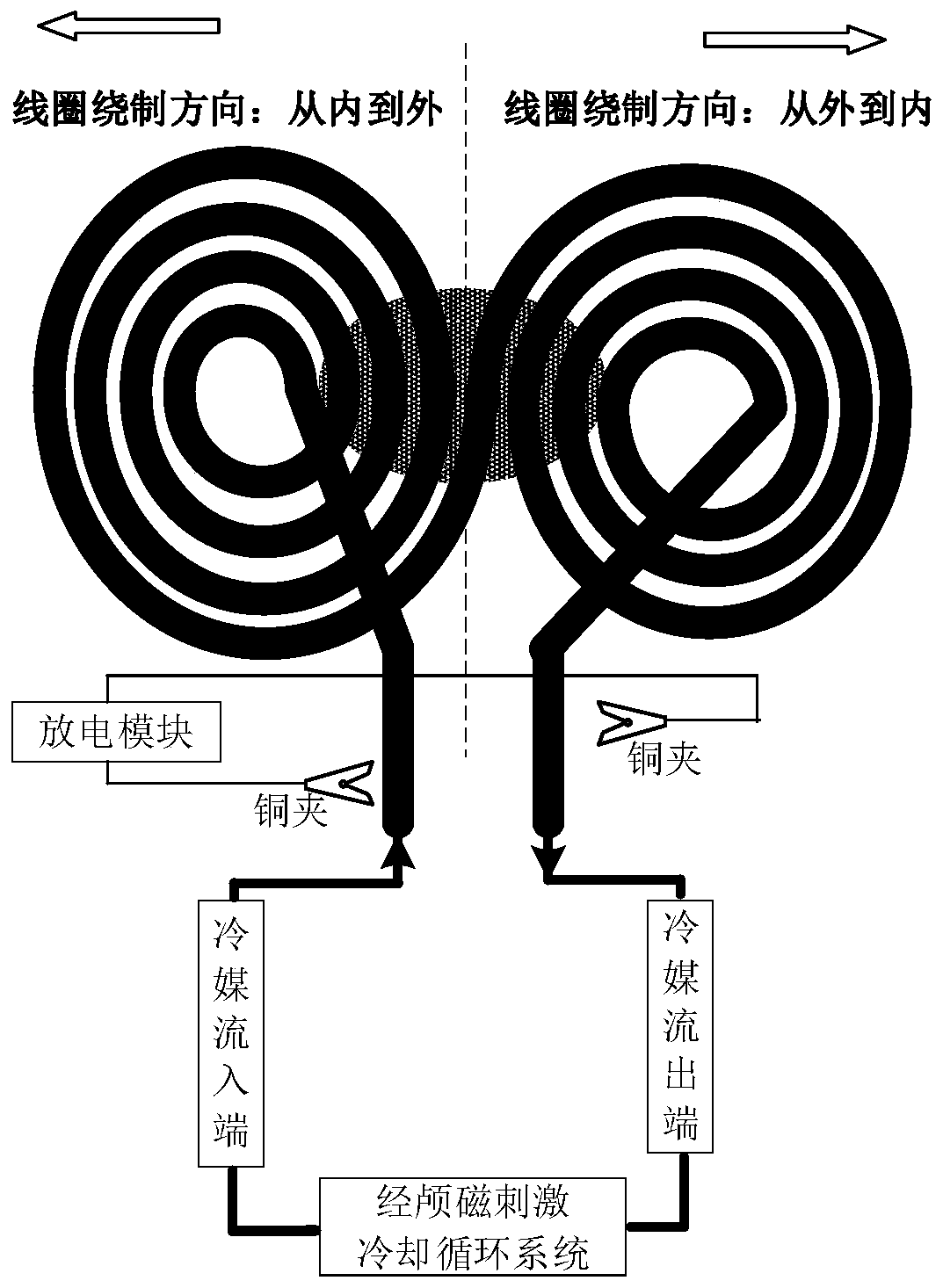

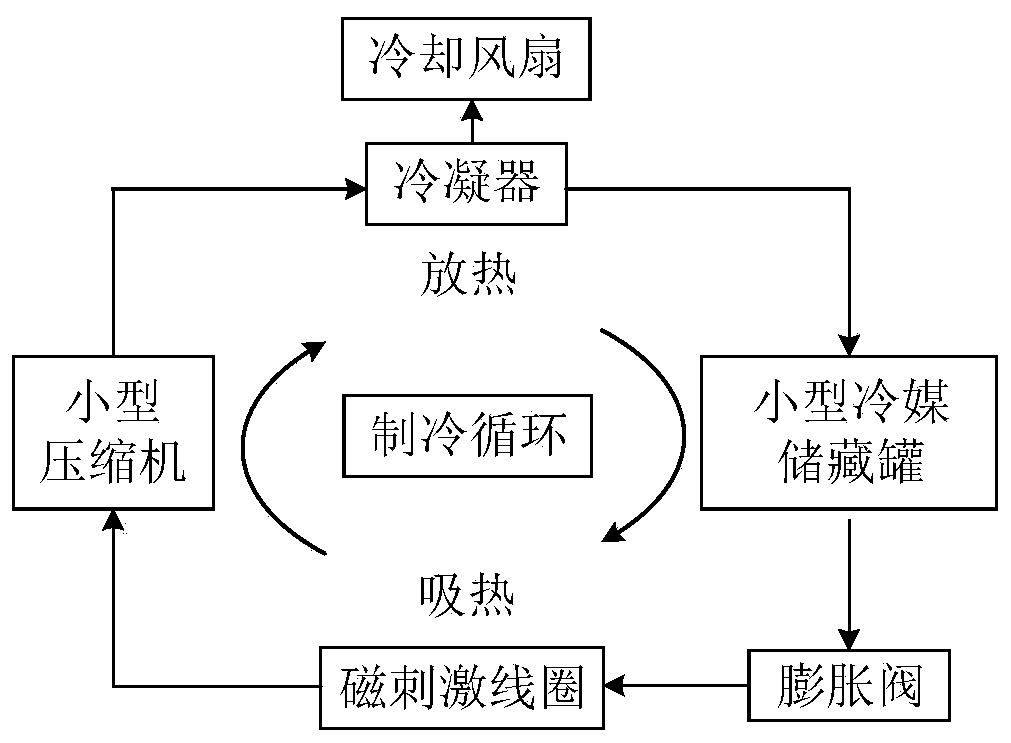

InactiveCN110975152ARealize equipment integrationThe equipment is bulkyMagnetotherapy using coils/electromagnetsPhysicsCopper wire

The invention discloses a continuously working magnetic stimulation device and method. The device comprises a magnetic stimulation coil formed by winding a hollow wire and a refrigerant circulation unit; a low-temperature refrigerant preparation flows at the hollow part of the wire, and the low-temperature refrigerant preparation flows in the hollow part of the wire to take away Joule heat generated during working of the magnetic stimulation coil; and the refrigerant circulation unit is used to circulate the low-temperature refrigerant preparation to absorb the Joule heat absorbed by the low-temperature refrigerant preparation from the magnetic stimulation coil, so that the Joule heat generated during the working of the magnetic stimulation coil is absorbed circularly to ensure that the magnetic stimulation coil can work continuously. The device realizes the integration of equipment, does not need to immerse the stimulation coil in cold oil, does not increase the volume of the equipment, and easily realizes flexible movement of the stimulation coil; and compared with a traditional air cooling method, the method provided by the invention has the following advantages: the refrigerantis in full contact with a heated copper wire from the interior, so that the method has a good cooling effect and no noise, and does not increase the discomfort of a stimulated object.

Owner:HUAZHONG UNIV OF SCI & TECH

LNG system with high pressure pre-cooling cycle

InactiveUS20070107464A1Large capacityThe equipment is bulkySolidificationLiquefactionProcess engineeringHigh pressure

Owner:CONOCOPHILLIPS CO

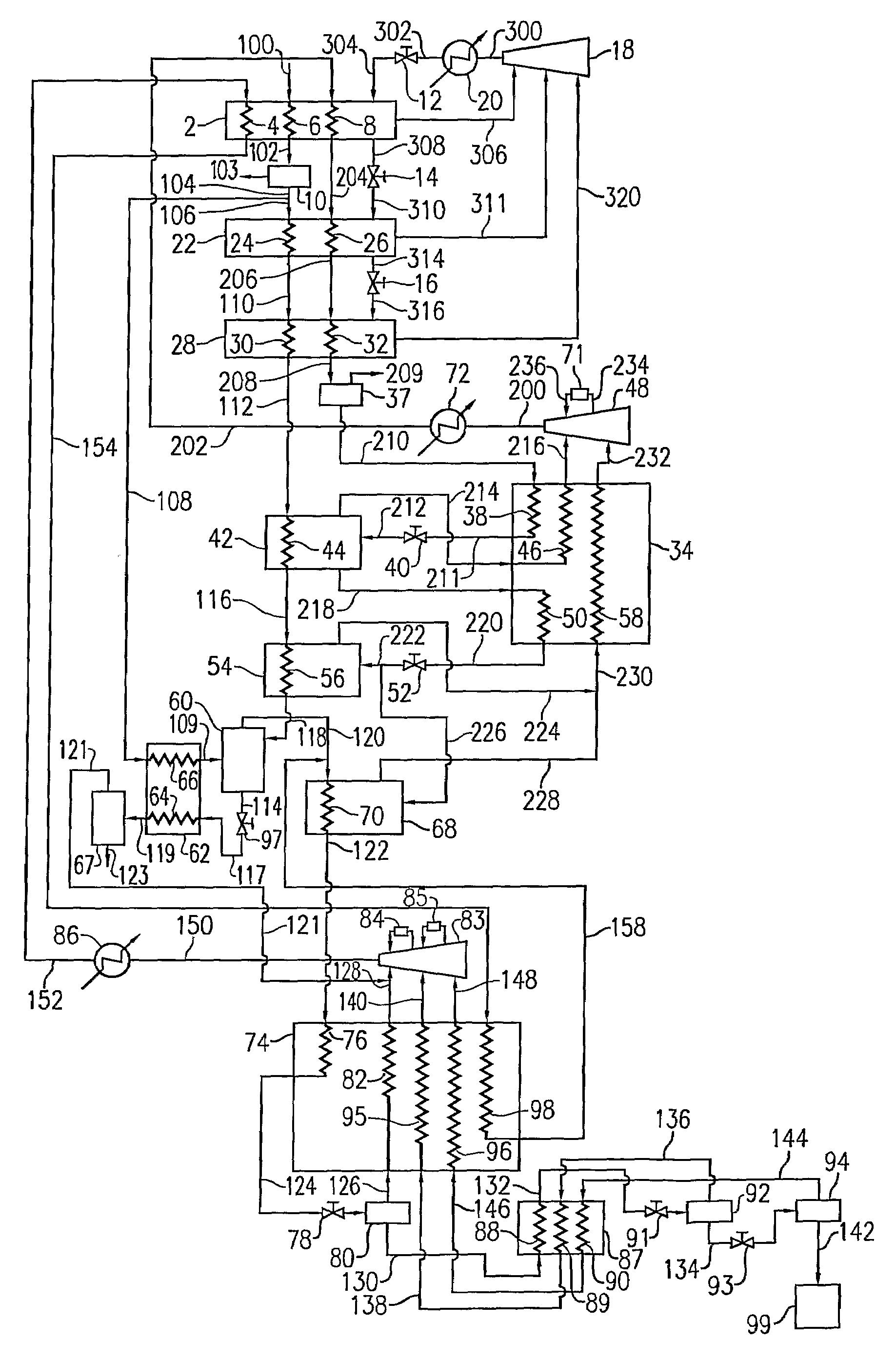

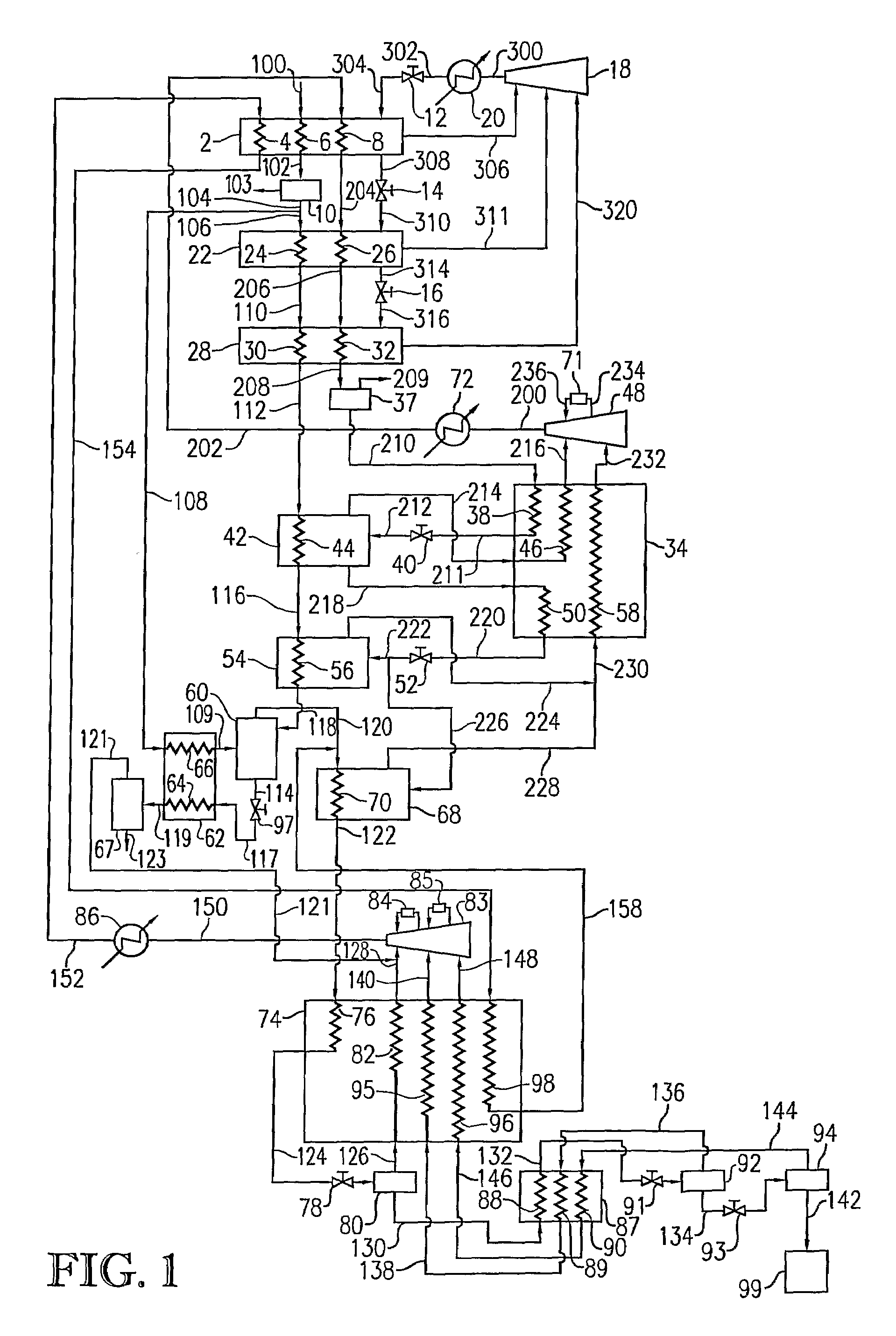

Combustion plant and a method of combusting a fuel

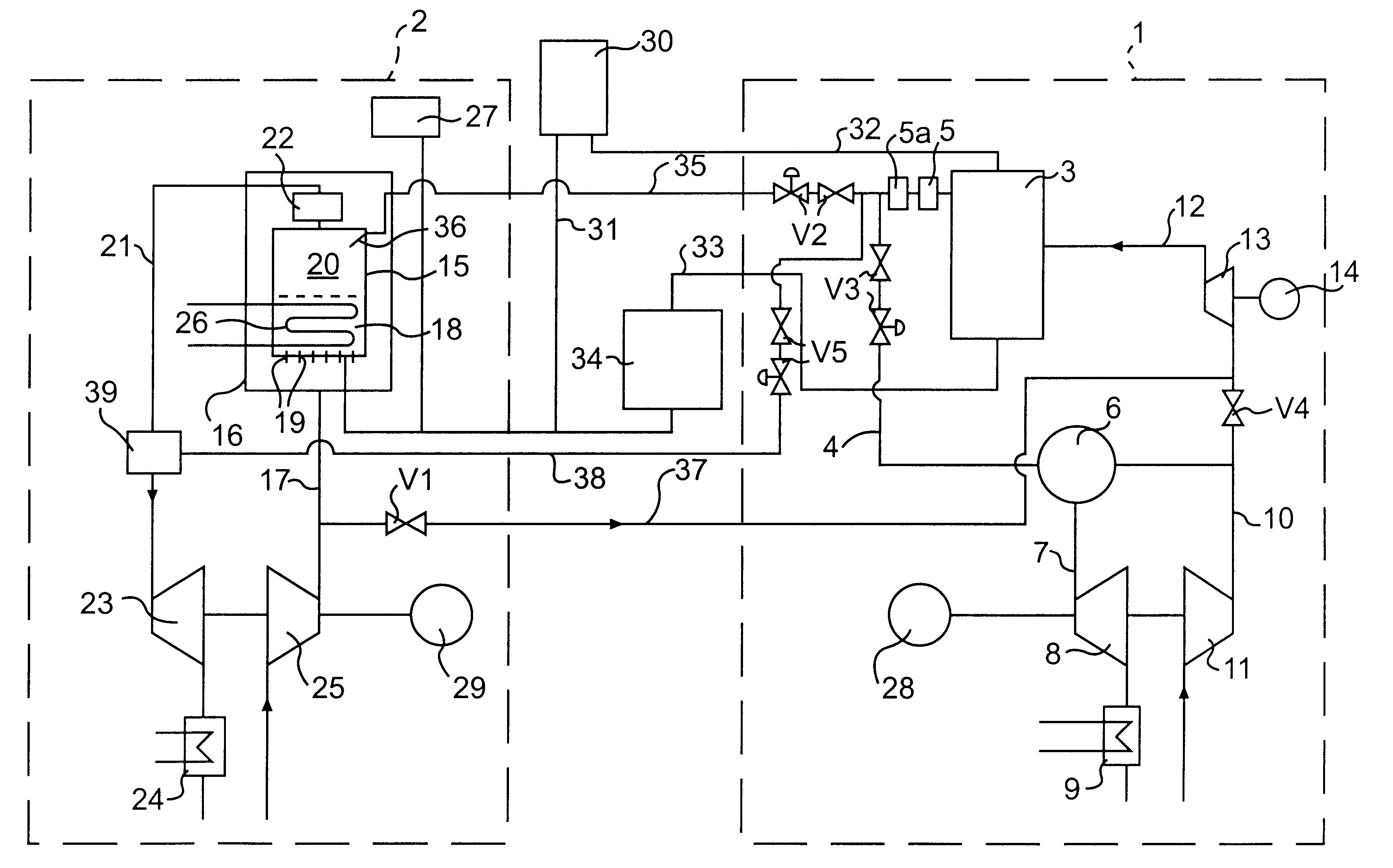

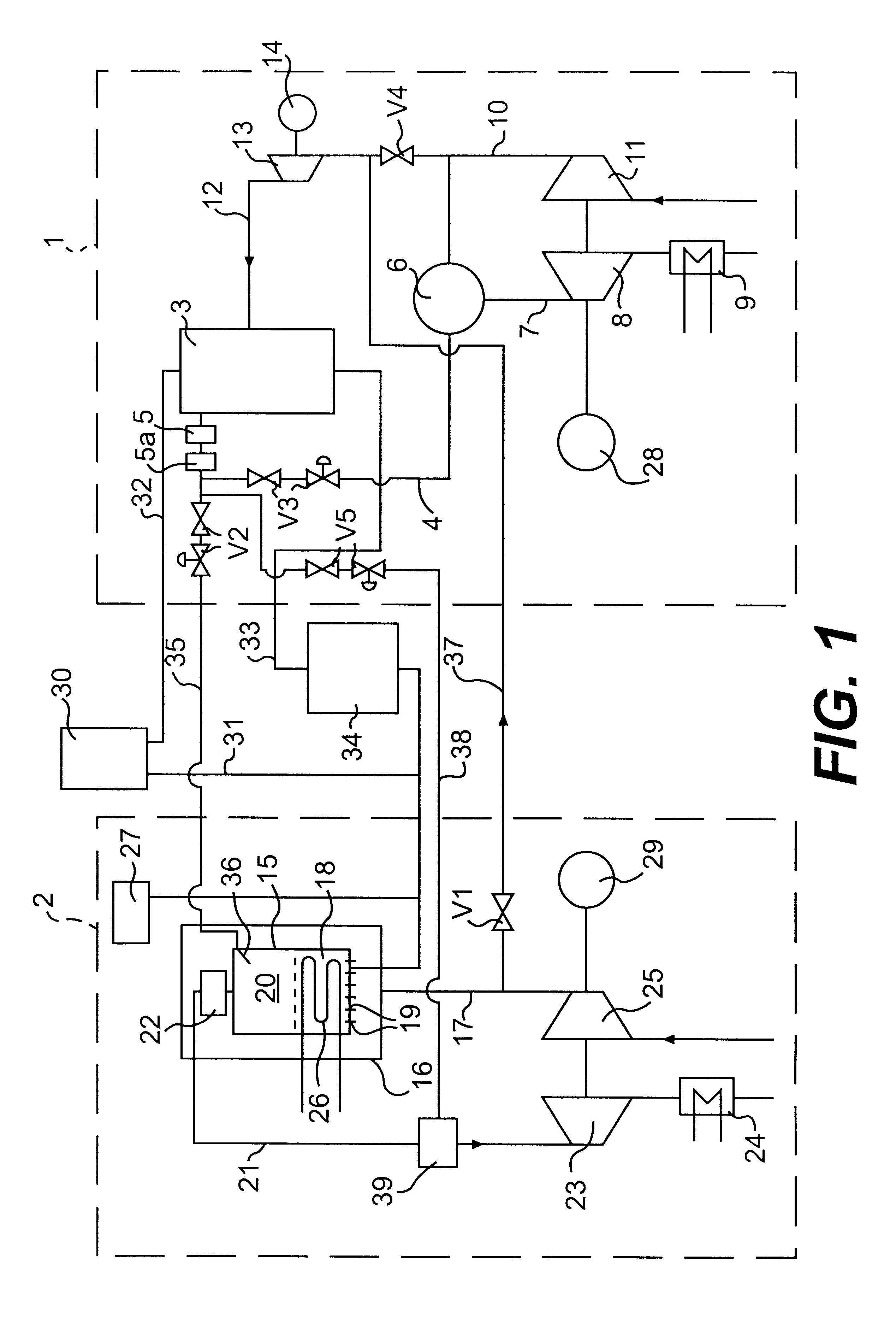

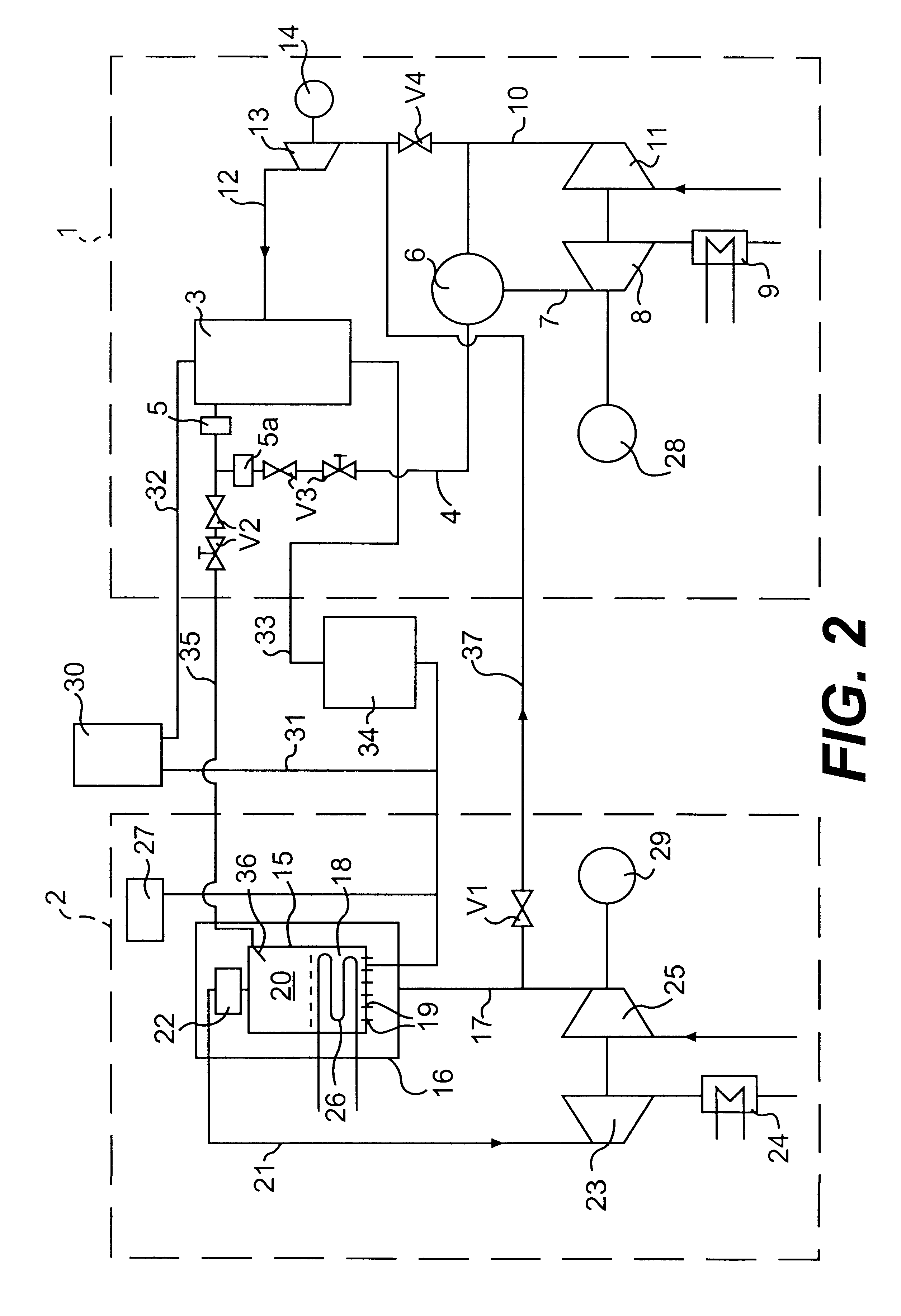

InactiveUS6260346B1Improve efficiencyLow investment costFluidized bed combustionCombustion enginesCombustion chamberCombustible gas

A method of combusting a fuel, and a combustion plant are proposed. The combustion plant comprises a first circuit (1) with a gasifying reactor (3) to produce a combustible gas and a degassed, combustible rest product from the fuel. The combustible gas is supplied to a first combustion chamber (6) and there it is combusted while forming combustion gases. First means (8, 9) are arranged to take advantage of the energy in these gases. The plant further comprises a second circuit (2) with a second combustion chamber (15) which is supplied with the combustible rest product from the gasifying reactor (3). The rest product is combusted in the second combustion chamber (15) while forming combustion gases. The second circuit (2) further comprises second means (23, 24) for taking advantage of the energy of the combustion gases produced in the second circuit (2).

Owner:GENERAL ELECTRIC TECH GMBH

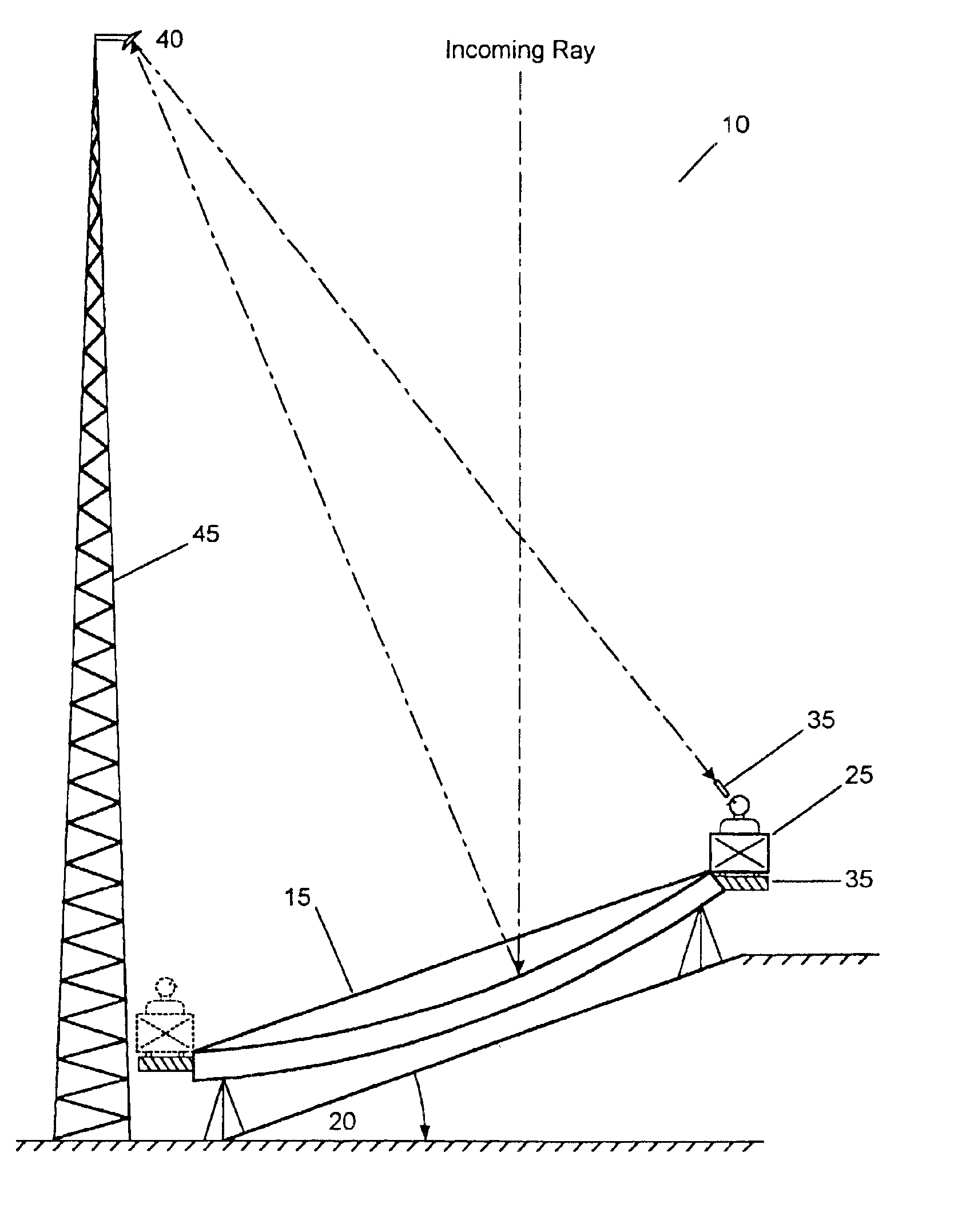

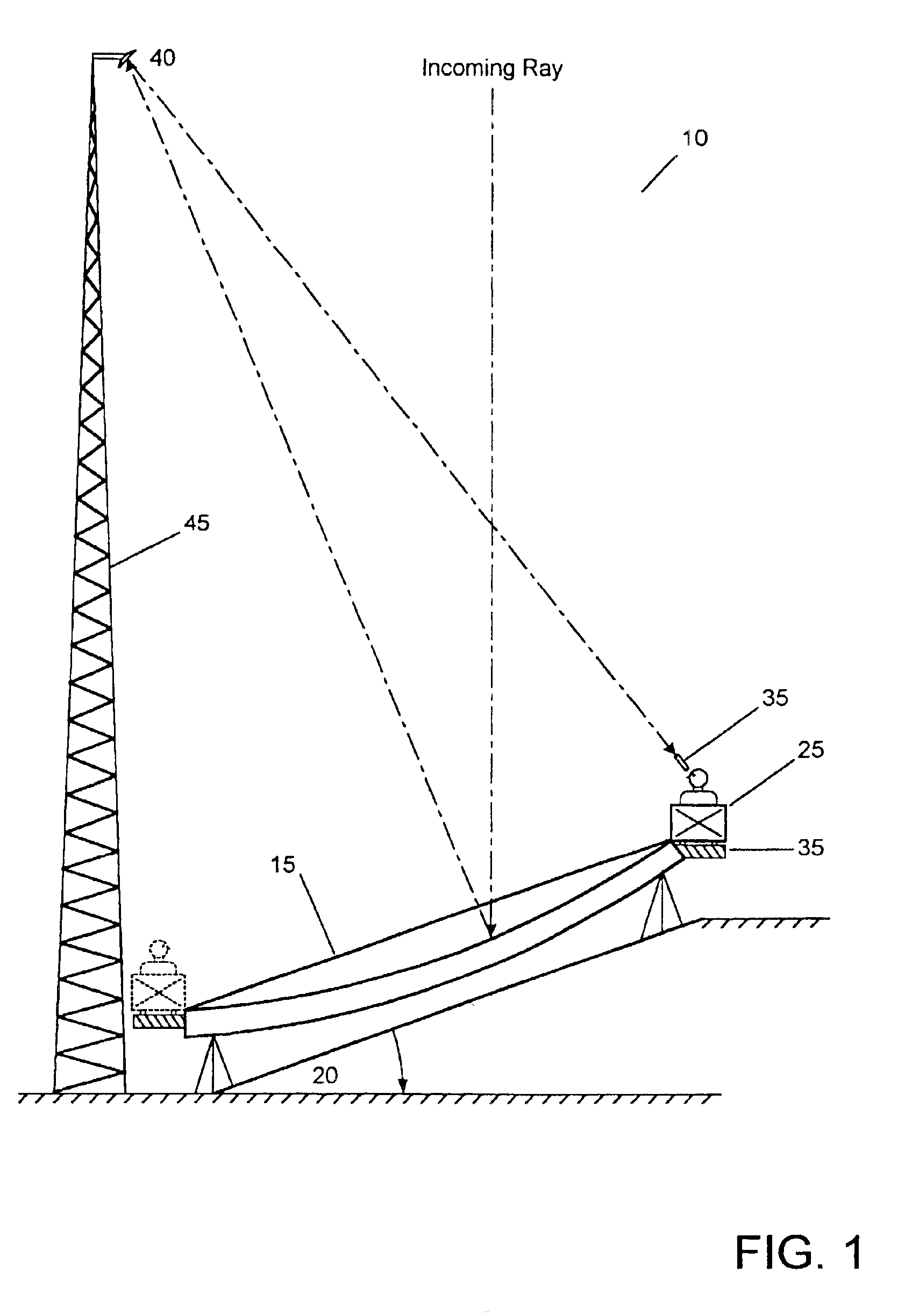

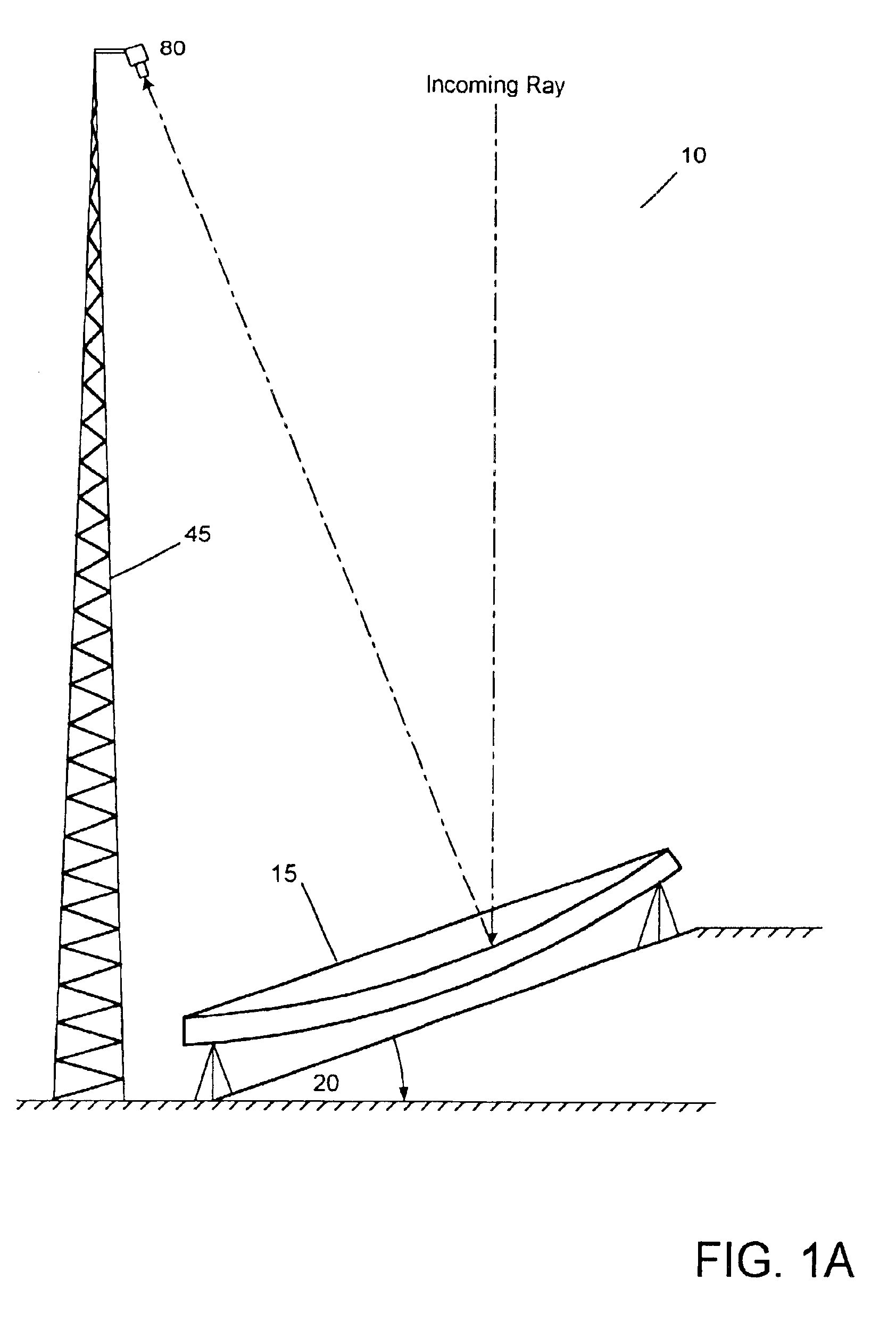

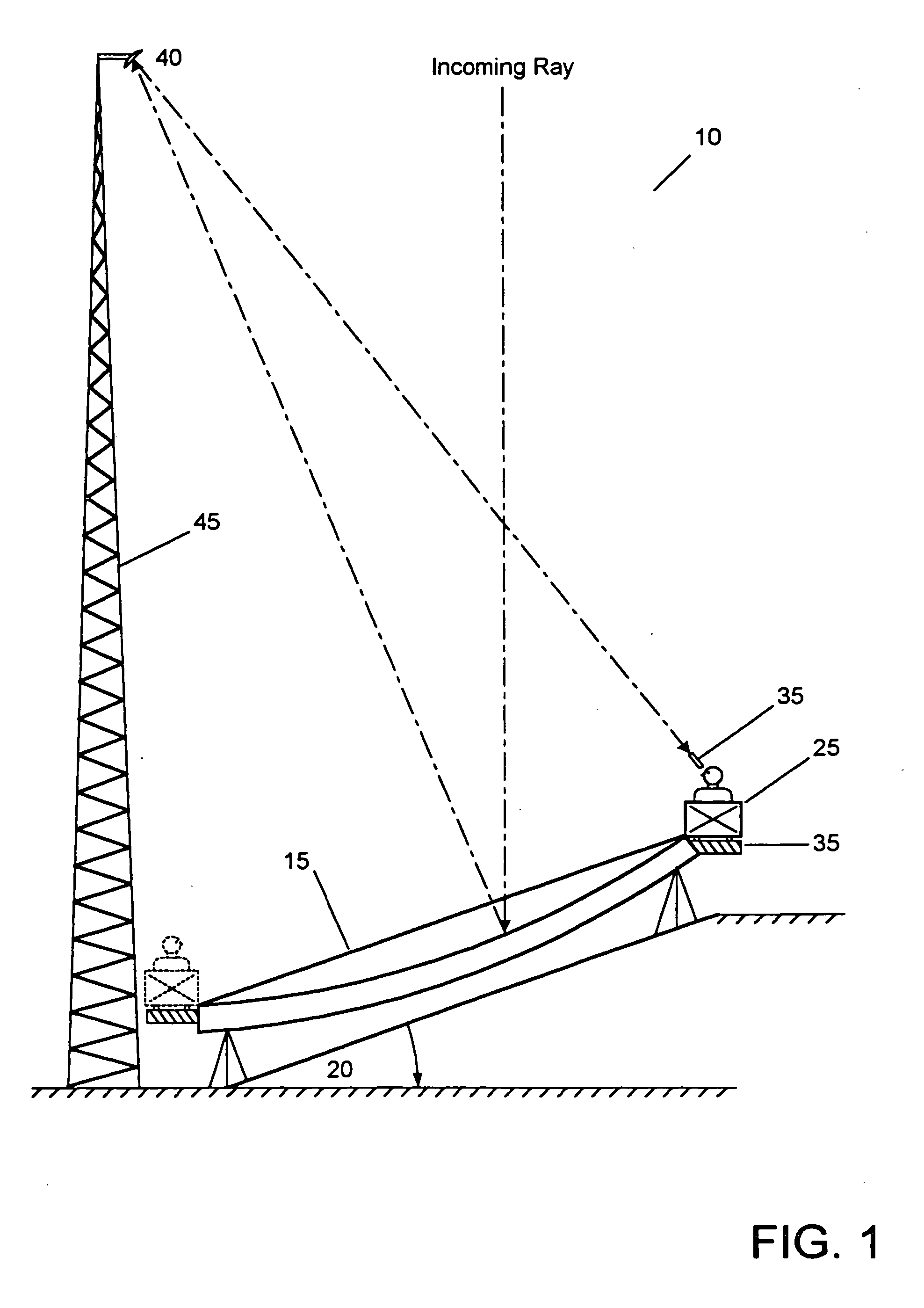

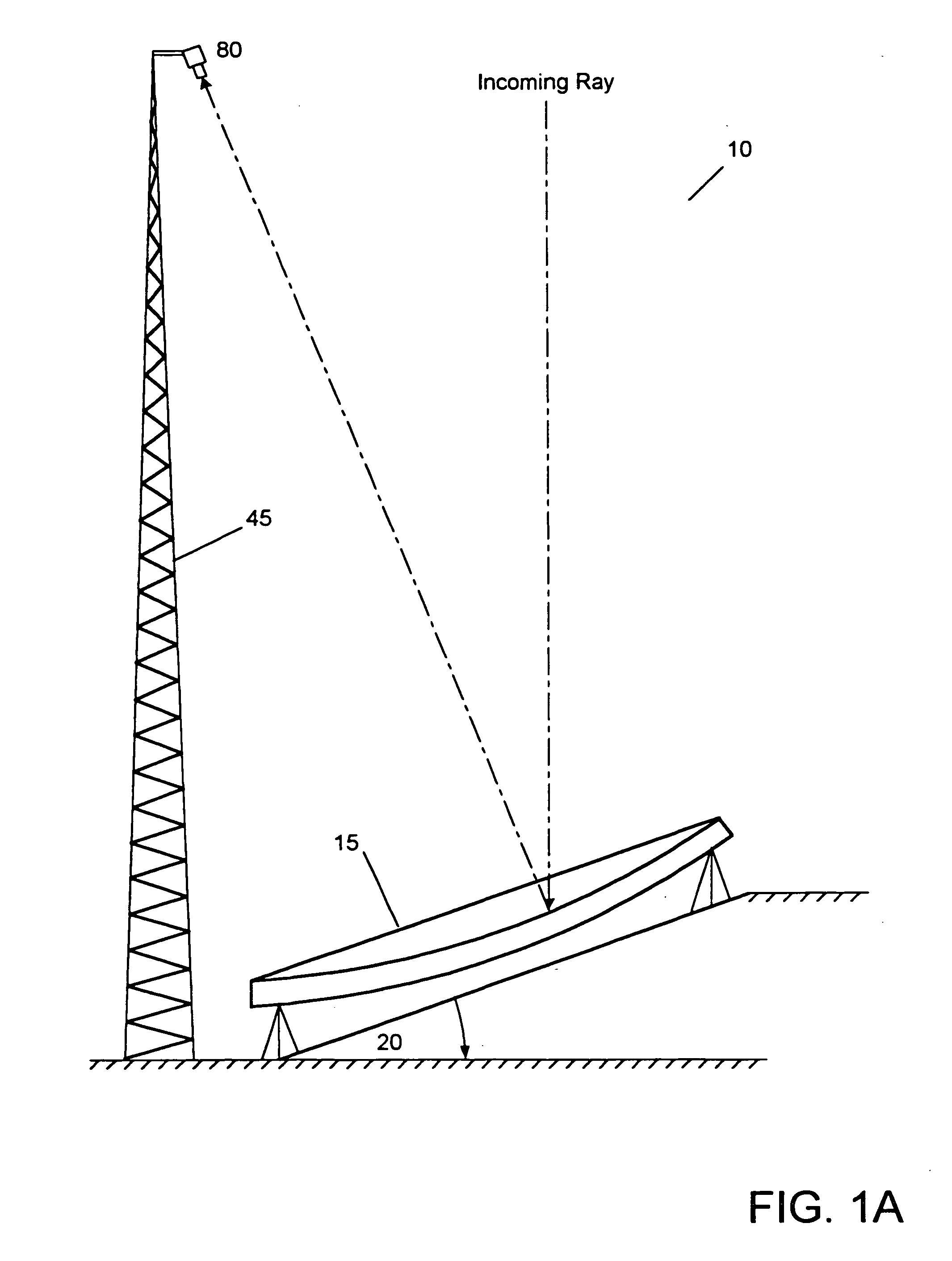

Compound telescope with a stationary primary objective mirror having movable collectors

The present invention relates to a novel land based reflecting telescope having a stationary, equatorially mounted, segmented mirror comprised of a plurality of movable mirrored collectors. These movable collectors are arranged in hexagonal groups to form a multiple mirrored reflector, which comprises the stationary compound telescope. A secondary mirror mounted atop a tower at the focal point directs the image toward the observation cart. Observers ride the periphery of the stationary mirror at a rate of one revolution per day. A retractable air supported hypalon cover protects the large primary mirror structure.

Owner:POPIL NICHOLAS B

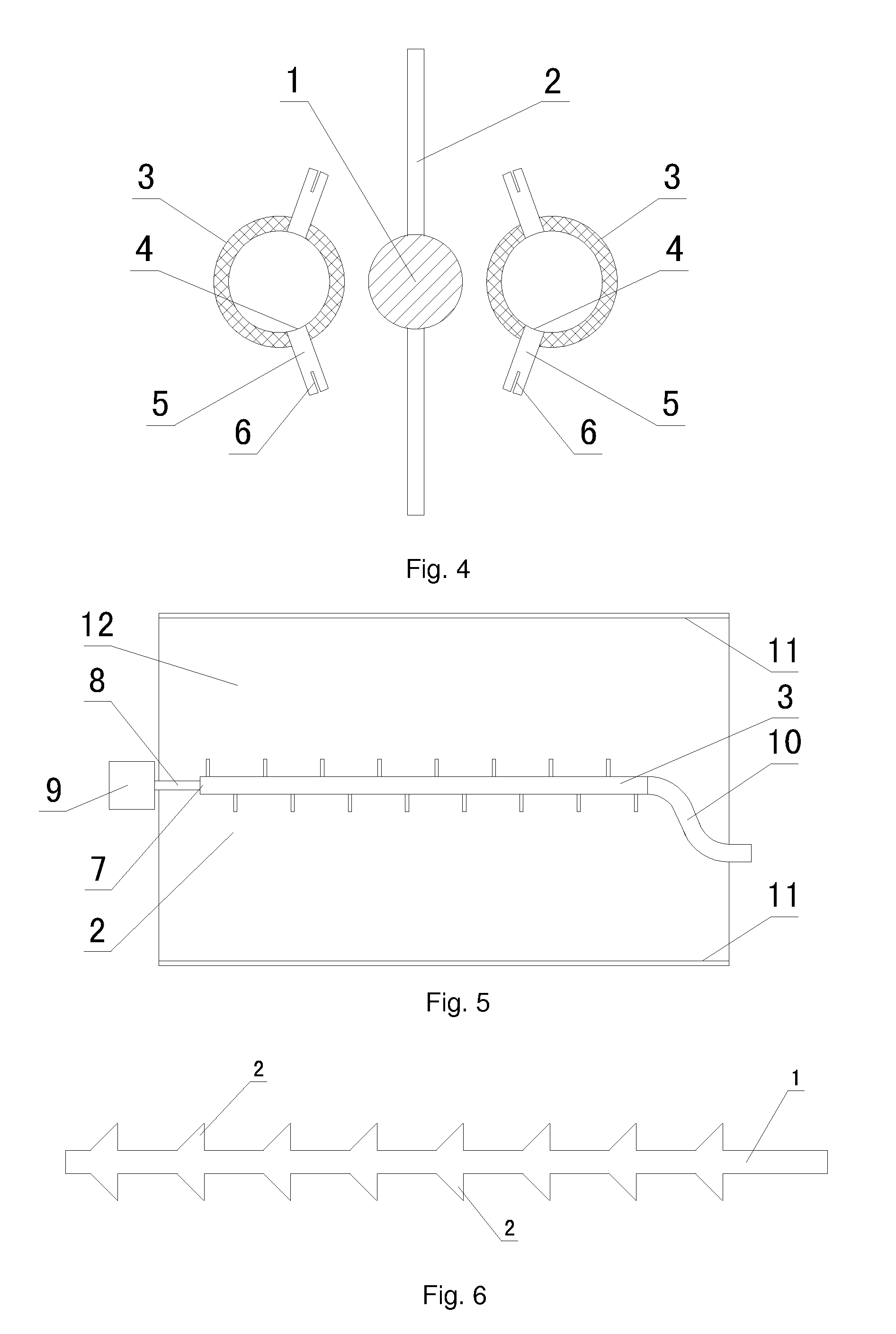

Free radical injection ionizer for flue gas treatment with corona discharge

InactiveUS20110296996A1Low costGood treatment effectGas treatmentChemical/physical/physico-chemical processesFlue gasCorona discharge

A free radical injection ionizer for flue gas treatment with corona discharge comprises an injection device for releasing free radical source substances and an electrode device for producing corona, wherein the injection device and the electrode device are arranged separately, wherein the electrode device comprises a conductive pole, and discharge tips arranged on the upper and lower sides of the conductive pole at equal intervals, and the injection device comprises nozzles symmetrically arranged on two sides of the electrode device, and two lines of holes axially arranged on the walls of the nozzles nearby the electrode device, the axial lines of the holes directing the discharge tips nearest the holes.

Owner:GAO XIANG +15

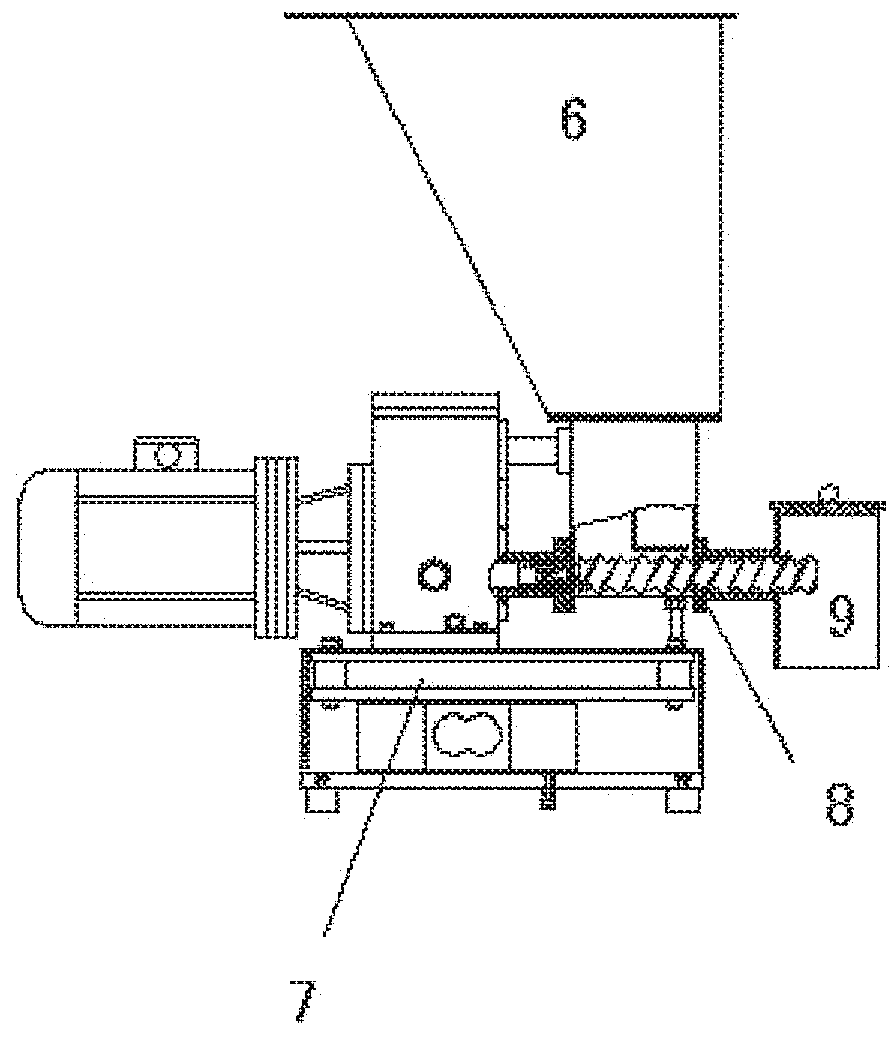

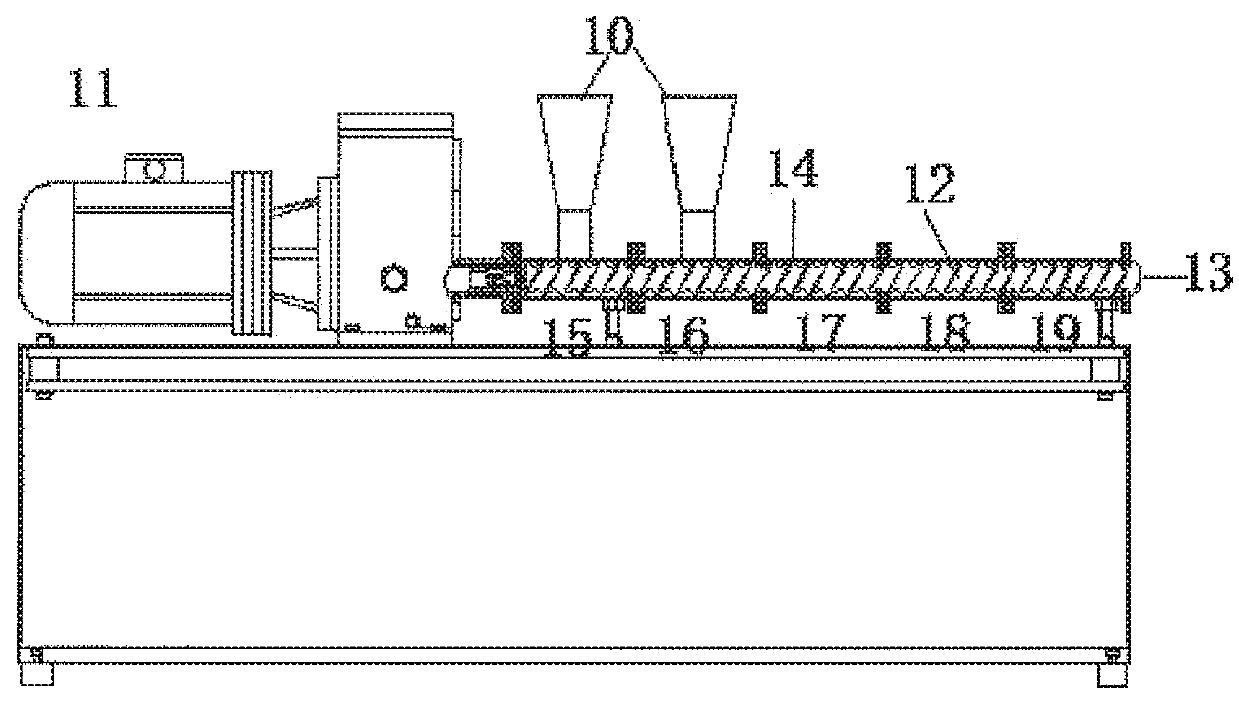

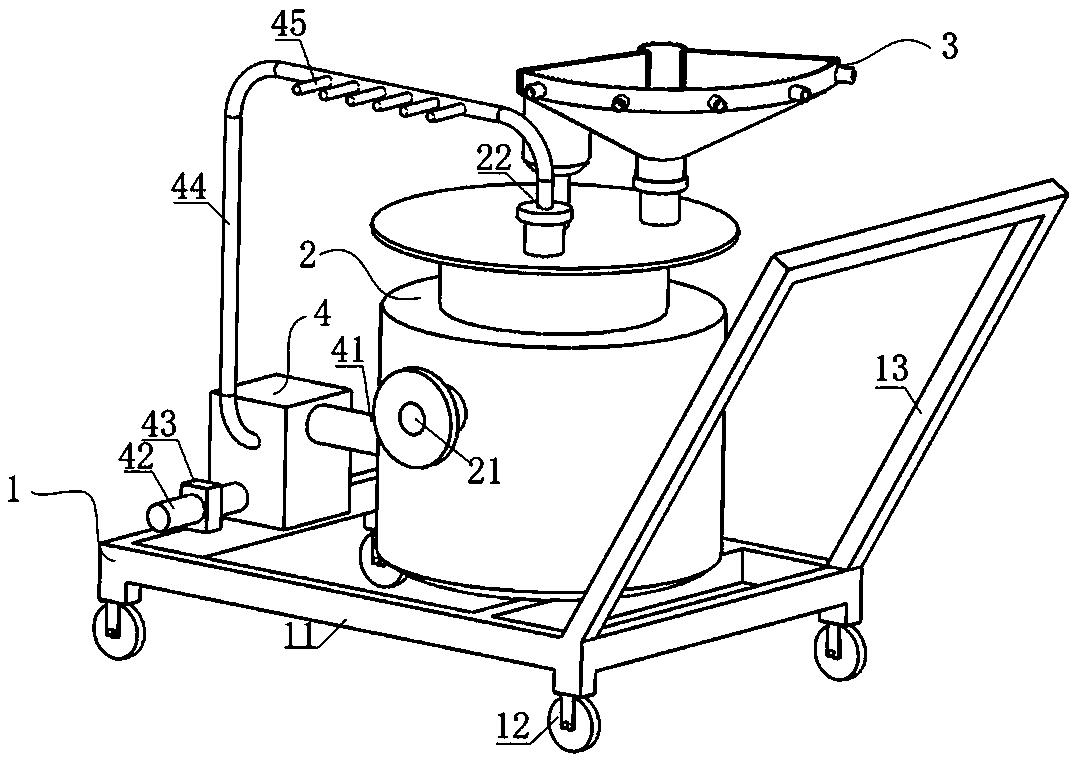

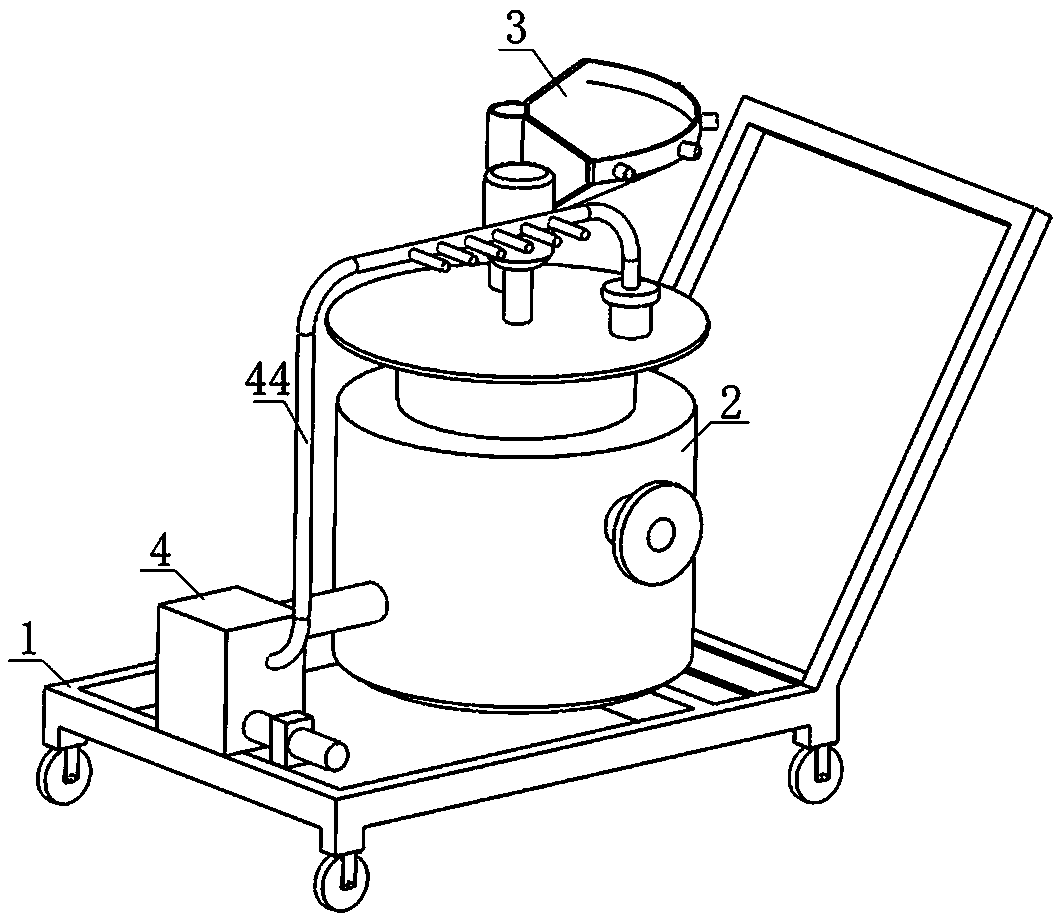

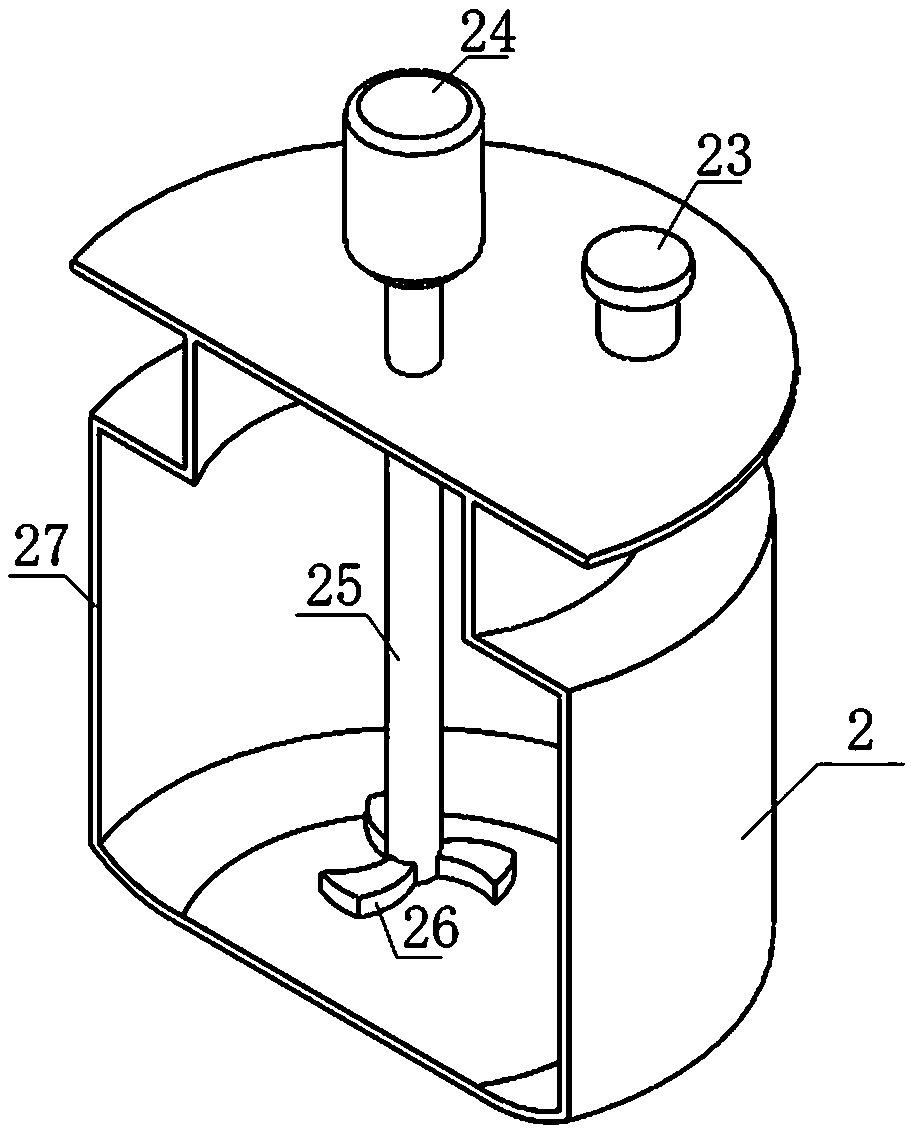

Intelligent dripping pill machine for continuous liquid solidification

ActiveUS20180263851A1Good oil-water separation effectSolve low manufacturing efficiencyTransportation and packagingPharmaceutical product form changeCentrifugationTransmission channel

An intelligent dripping pill machine for continuous liquid solidification comprises: a feeding device (1), a material combining device (2), a homogenizing device (3), a dripping device (4) and a de-oiling device (5) sequentially connected via a transmission channel. The intelligent dripping pill machine removes, via high-speed centrifugation, a cooling liquid attached to dripping pills, and each component device is connected compactly, thereby achieving a continuous manufacturing operation, and reducing an occupied space of the devices as a whole while ensuring the yield of the dripping pills.

Owner:TIANJIN TASLY PHARMA CO LTD

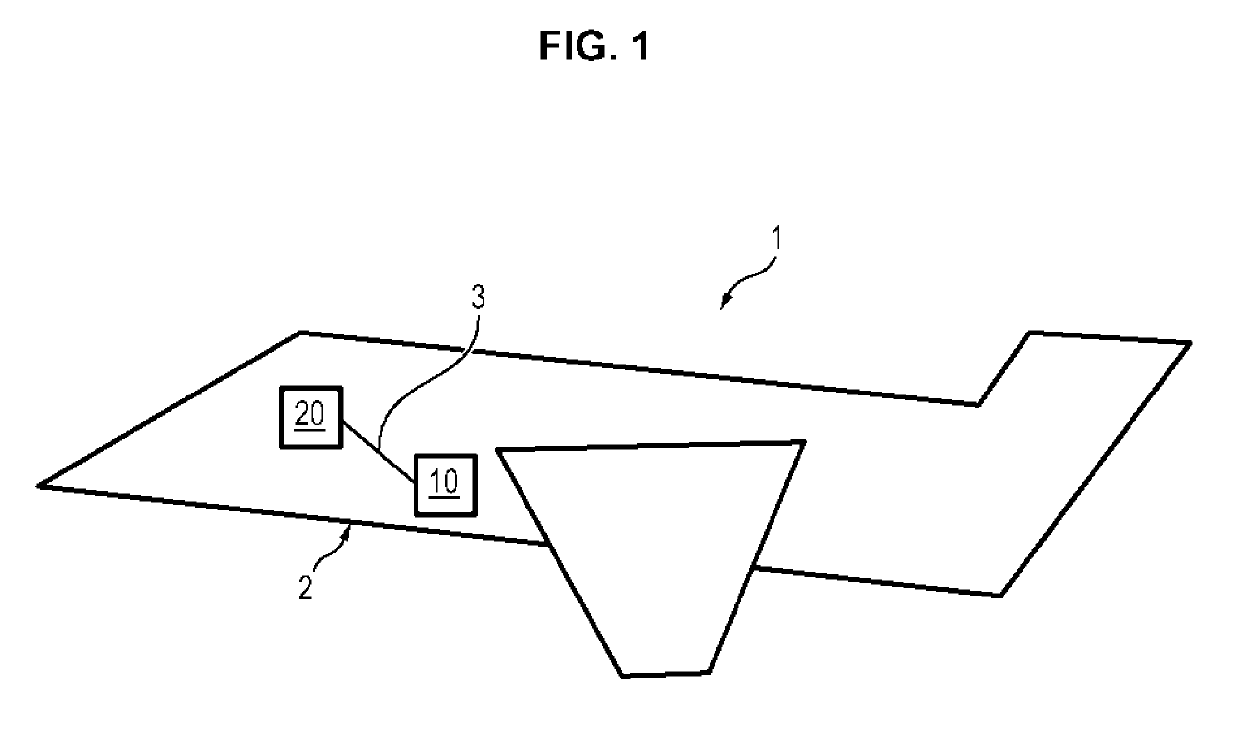

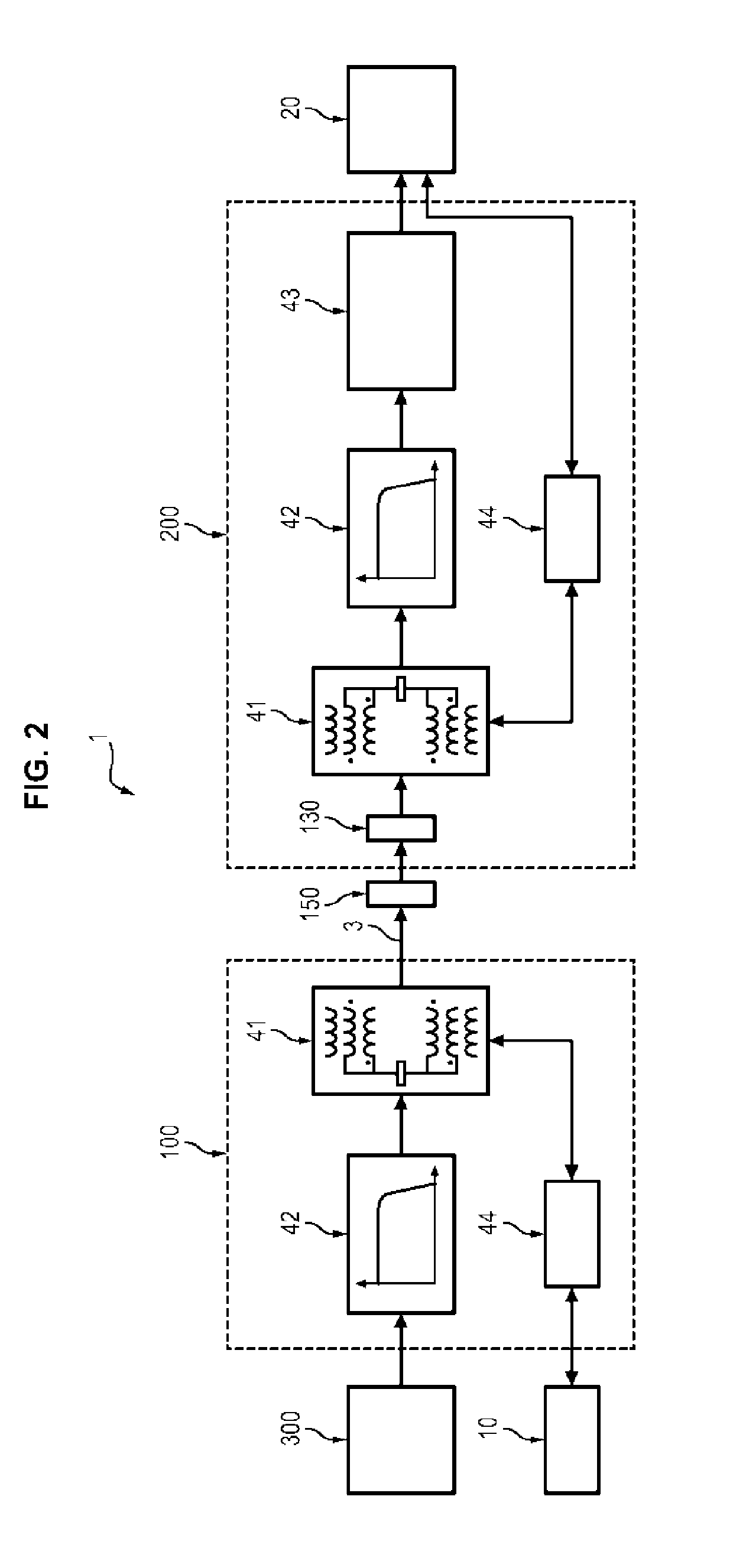

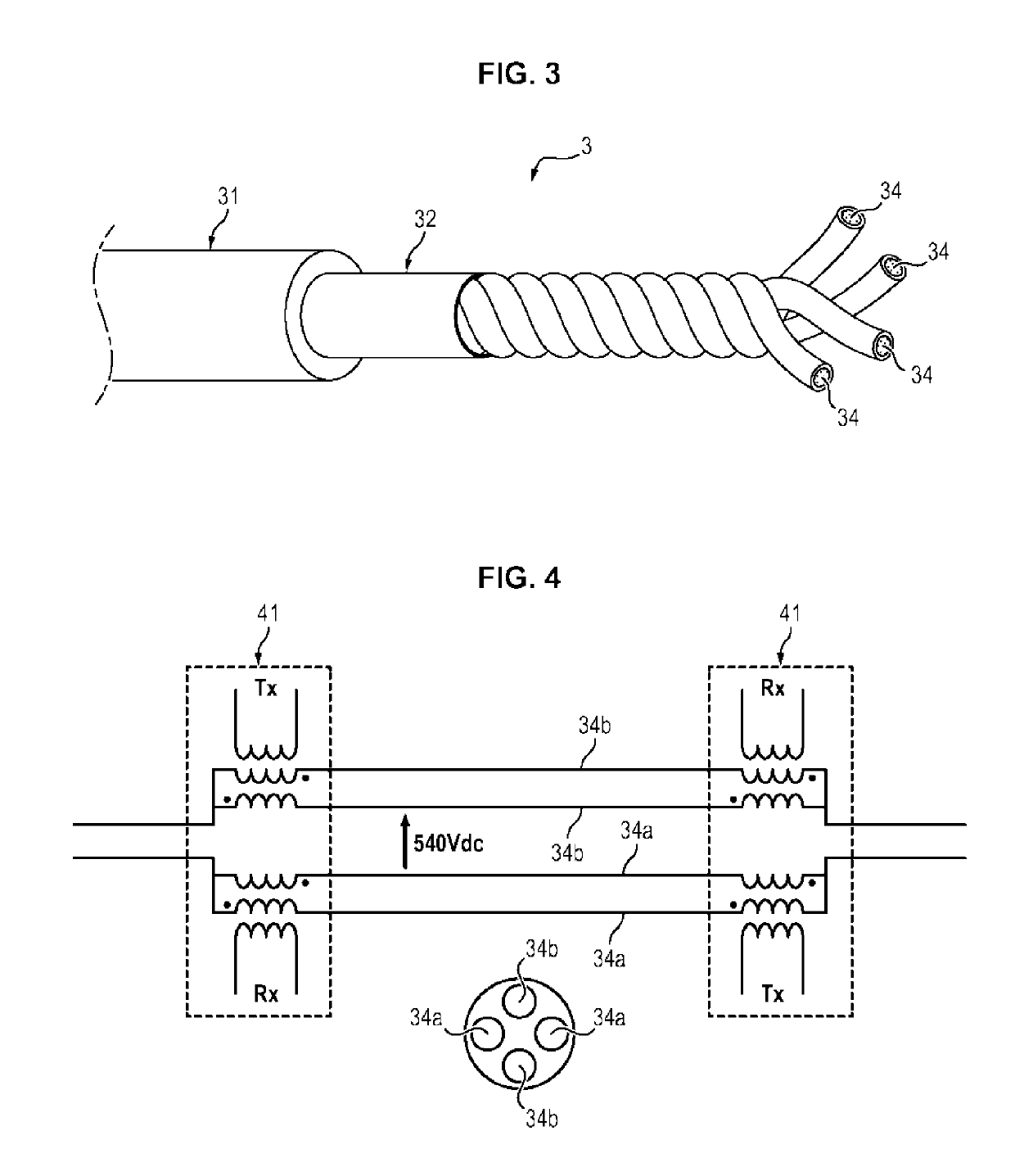

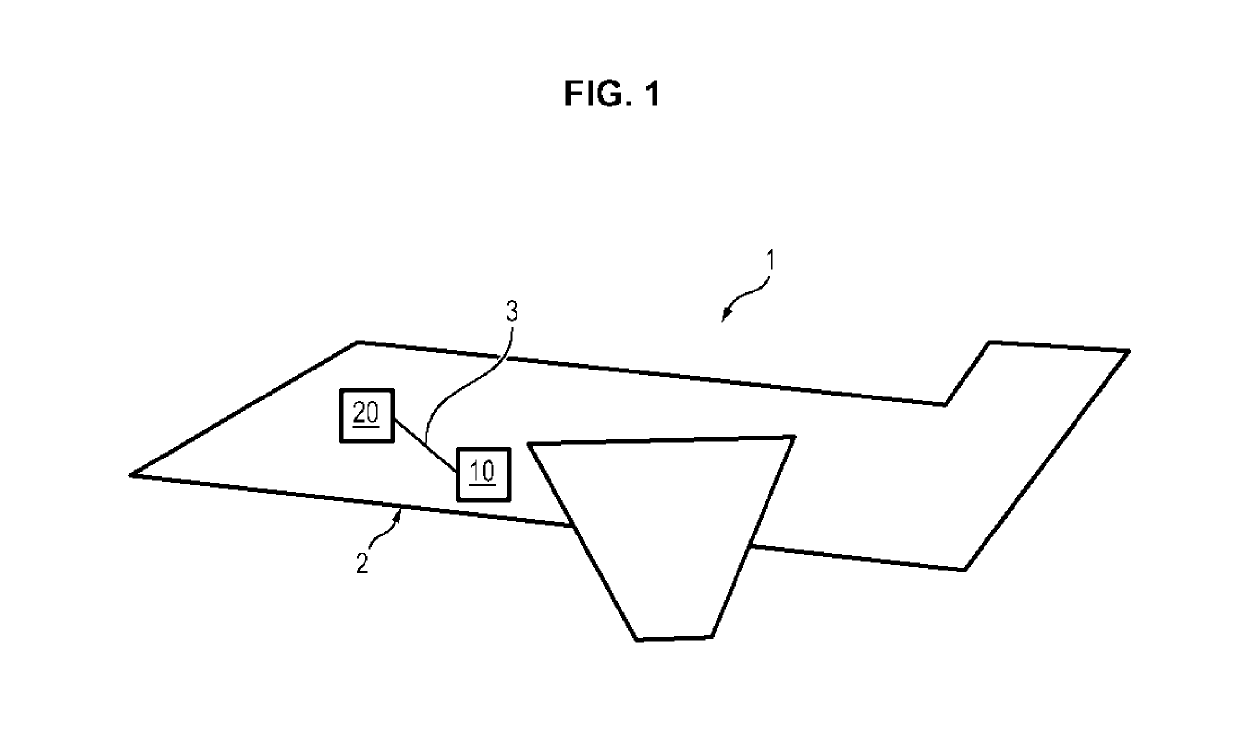

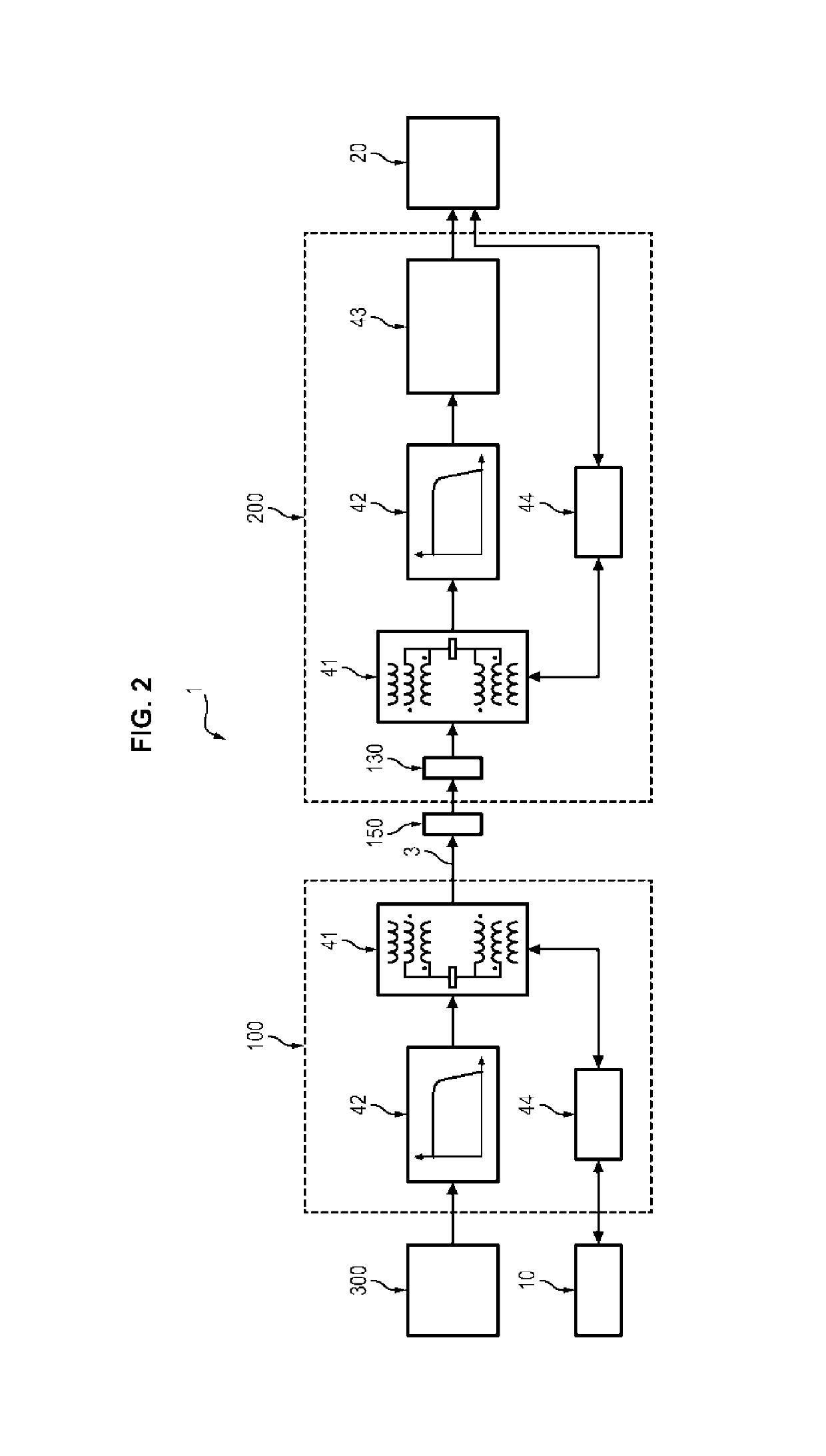

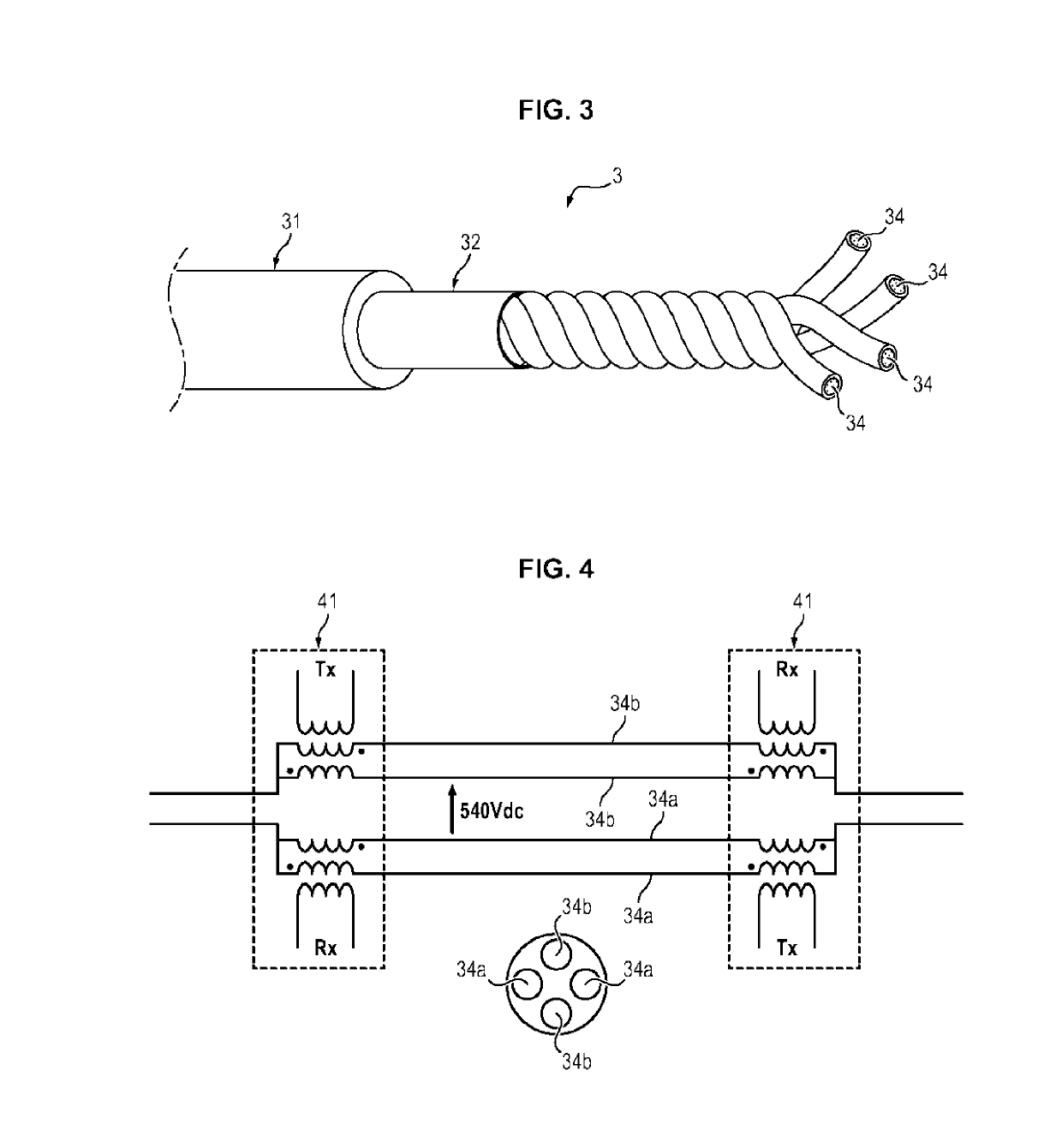

Device for transmission by power-line communication in an aircraft

ActiveUS20190132026A1Data is very largeReduce in quantityTransmission/receiving by adding signal to waveElectric power distributionOn boardCarrier signal

The present invention relates to a device for transmission by power-line communication (1) between two items of equipment (10, 20) on board an aircraft (1), comprising a transmission cable (3) configured to simultaneously transmit a power sup ply current and a data signal. This cable (3) comprises two twisted pairs of conductors (34, 34a, 34b). The device comprises a data sender (100) comprising a COFDM coupler (44) configured to modulate a signal by carrier modulation according to a COFDM mode, and a data receiver (200) comprising a COFDM coupler (44) configured to demodulate a signal modulated by carrier modulation according to a COFDM mode. The data sender (100) is configured to send a test signal by carrier modulation according to a COFDM mode, while the data receiver (200) is configured to detect signals corresponding to the test signals sent, and to analyse the carriers of the detected signal in regard to the signal sent and deduce therefrom the state of the transmission cable (3).

Owner:SAFRAN ELECTRONICS & DEFENSE

Device for transmission by power-line communication in an aircraft

ActiveUS10305543B2Reduce in quantityThe equipment is bulkyTransmission/receiving by adding signal to waveElectric power distributionPower flowOn board

The present invention relates to a device for transmission by power-line communication (1) between two items of equipment (10, 20) on board an aircraft (1), comprising a transmission cable (3) configured to simultaneously transmit a power supply current and a data signal. This cable (3) comprises two twisted pairs of conductors (34, 34a, 34b). The device comprises a data sender (100) comprising a COFDM coupler (44) configured to modulate a signal by carrier modulation according to a COFDM mode, and a data receiver (200) comprising a COFDM coupler (44) configured to demodulate a signal modulated by carrier modulation according to a COFDM mode. The data sender (100) is configured to send a test signal by carrier modulation according to a COFDM mode, while the data receiver (200) is configured to detect signals corresponding to the test signals sent, and to analyze the carriers of the detected signal in regard to the signal sent and deduce therefrom the state of the transmission cable (3).

Owner:SAFRAN ELECTRONICS & DEFENSE

Portable fluid delivery system for the nasal and paranasal sinus cavities

A pressurized air supply source for a portable nasal irrigator houses an airflow regulating system, instead of external bulky, heavy components, to power the atomization of fluid for irrigation of nasal passages. The airflow regulating system is made up of a pump, a motor to drive the pump, a filter with an inlet air manifold connected to the pump to eliminate additional tubing within the pressurized air supply source, and an optionally rechargeable battery to drive the motor. An external AC / DC power supply may charge the battery or operate the device when the battery is in a discharged state. A canister for holding fluid attaches on top of the pressurized air supply source and an insert fits that over a fluid channel in the canister to create a venturi effect and draw the fluid out. The pressurized air supply source creates a clinically effective airflow despite its small size.

Owner:MONAGHAN MEDICAL

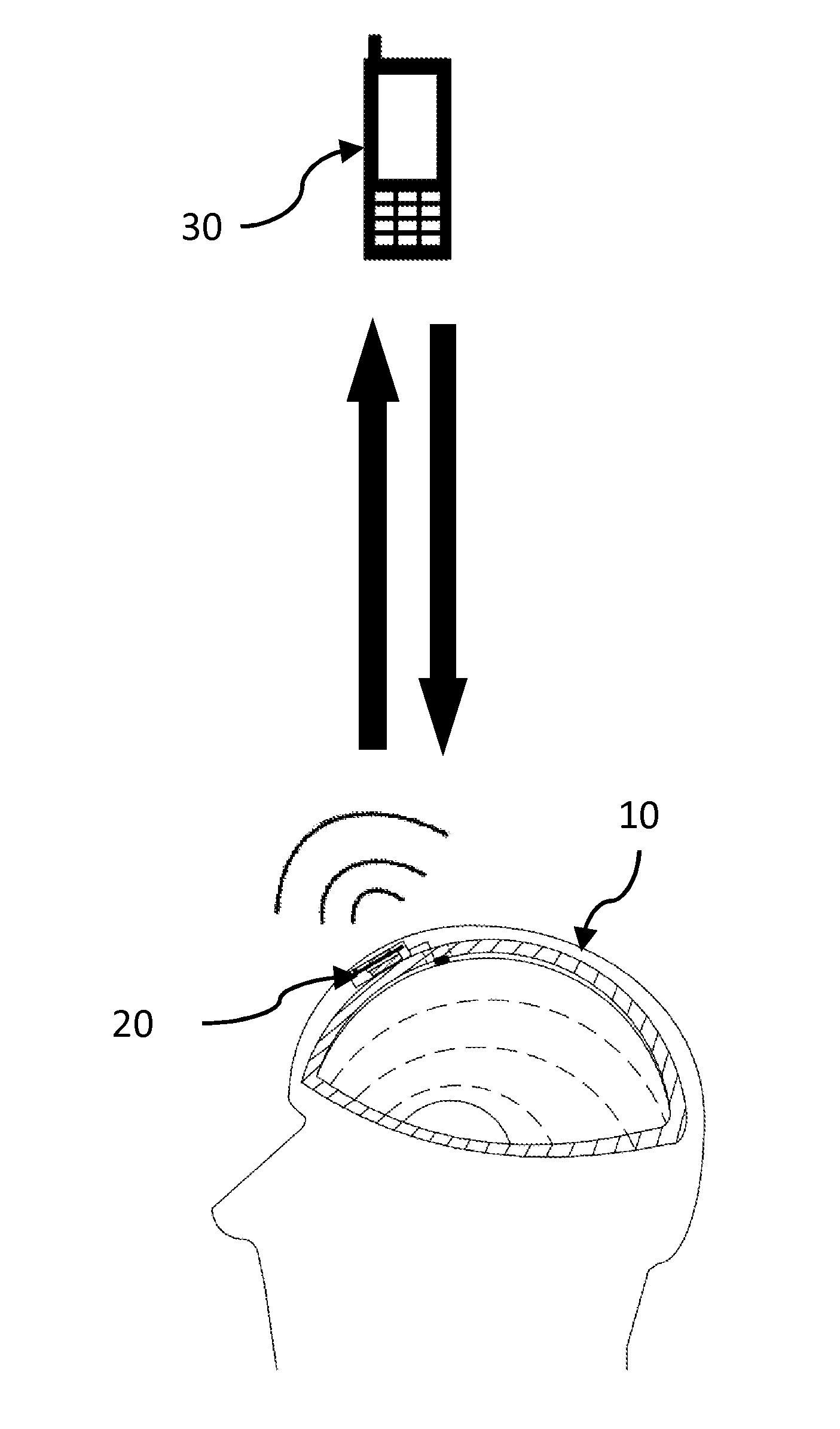

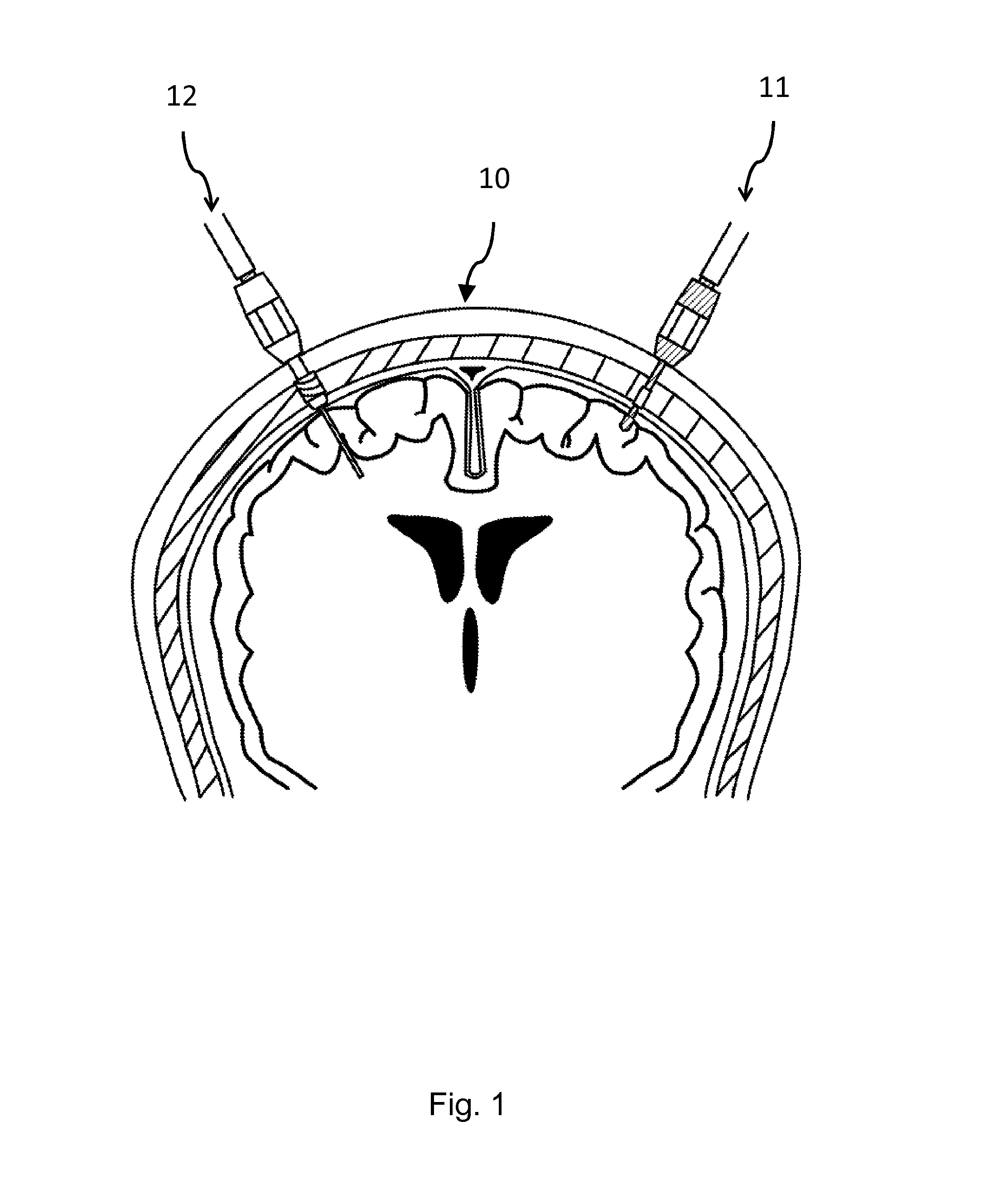

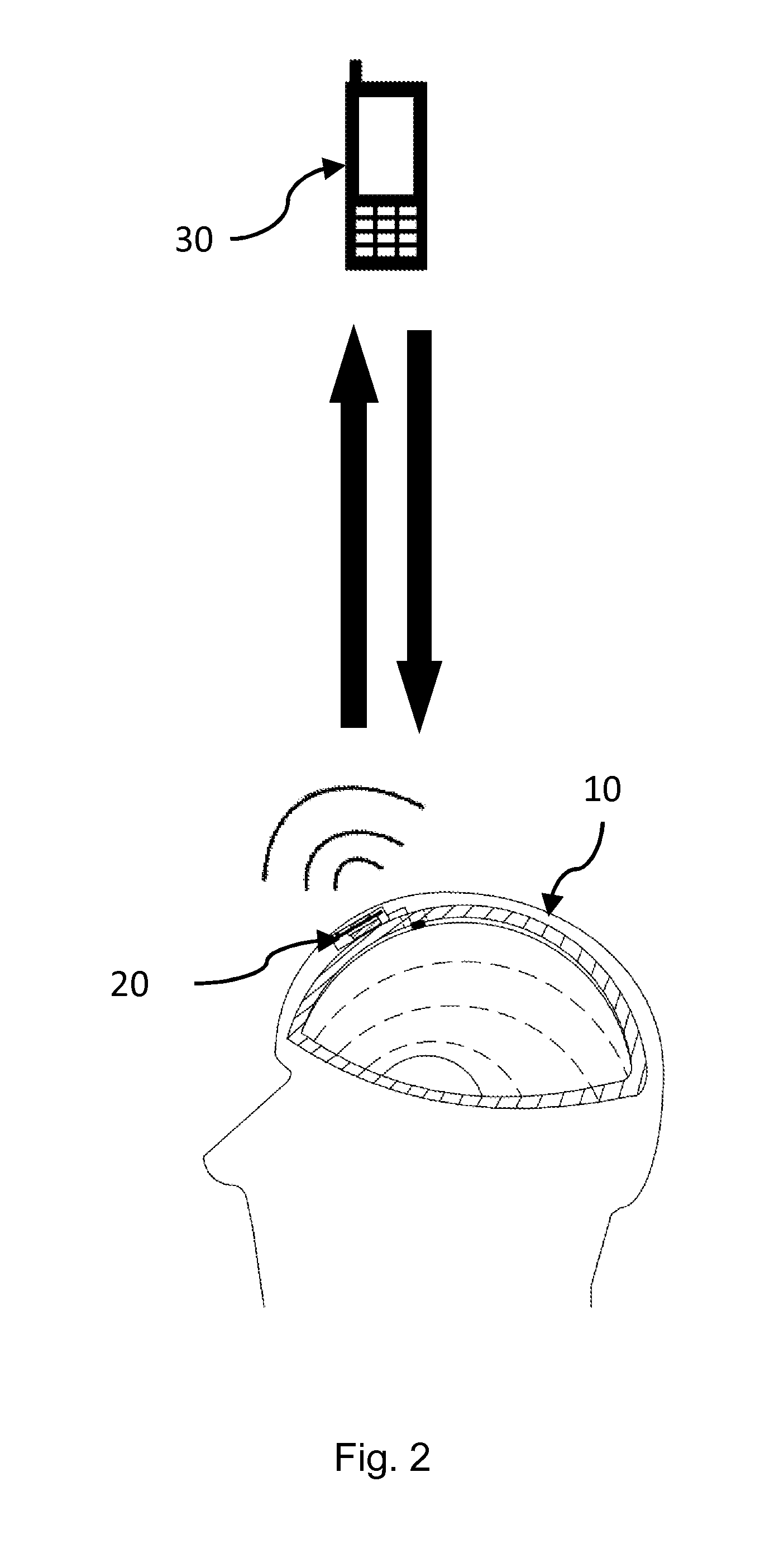

Wireless detection system of physiological signals and method thereof

InactiveUS20130317381A1Reduce health impactImprove securityIntracranial pressure measurementSensorsWireless transceiverTransceiver

A wireless detection system of physiological signals is provided for wirelessly transmitting variation values of physiological signals, and includes a wireless detecting notification device and a wireless transceiver display device. The wireless detecting notification device comprises at least one transplantable sensor, a connecting line, a printed circuit board, a wireless communication micro-processor chip, an antenna and a power integration module. The power integration module includes a power management chip, a wireless charging coil and a chargeable battery, for integrating a power supply of the wireless detecting notification device. Further, a wireless detection method of physiological signals is further provided to detect variation values of physiological signals in organs of an organism. After calculating and analyzing the variation values of physiological signals, identifying an analyzed result for determining to store the variation values or to wirelessly transmit an alarm signal to the wireless transceiver display device.

Owner:TAIPEI MEDICAL UNIV

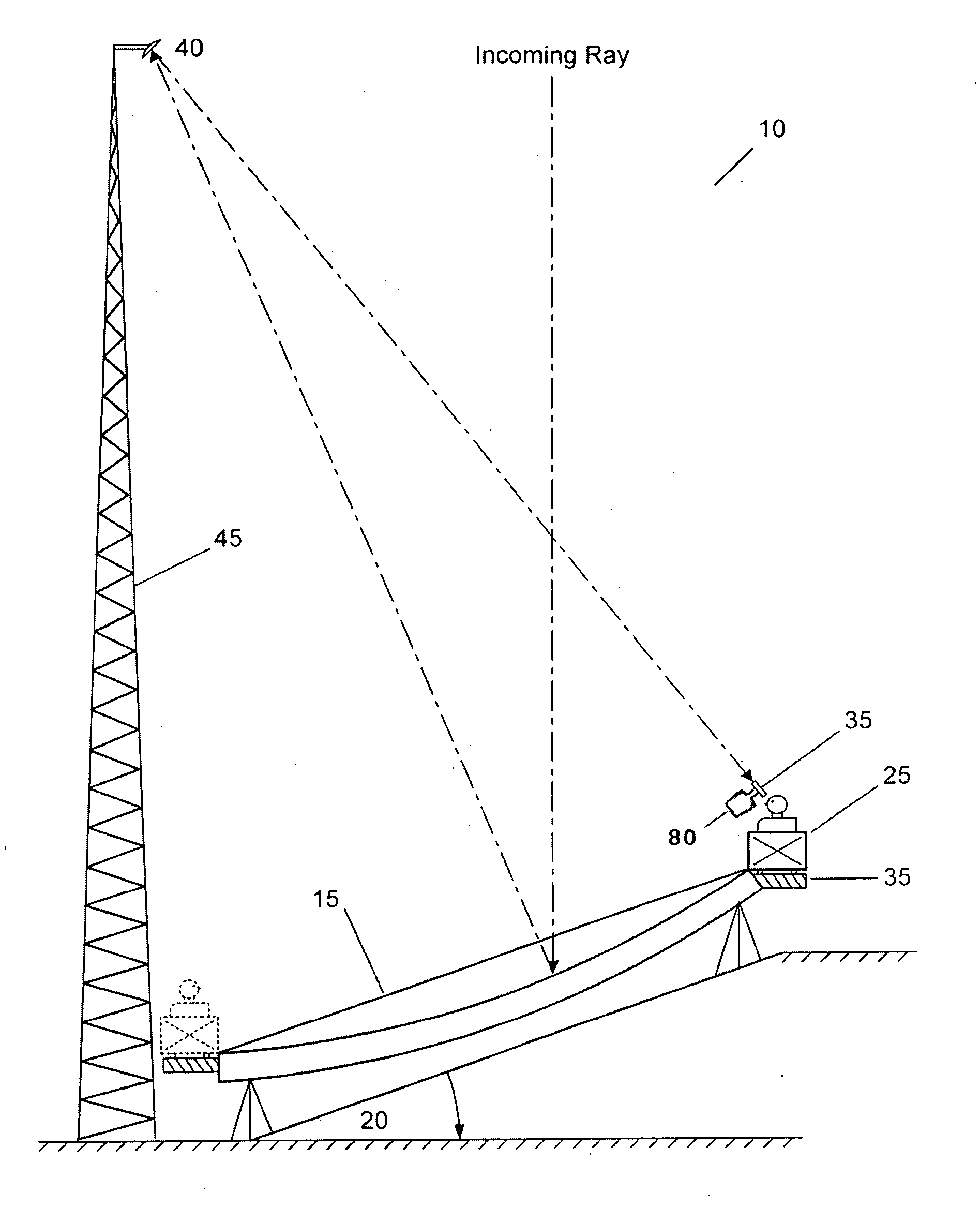

In-ground telescope with a stationary primary objective mirror having movable collectors

The present invention relates to a novel land based reflecting telescope having a stationary, equatorially mounted, segmented mirror comprised of a plurality of movable mirrored collectors. These movable collectors are arranged in hexagonal groups to form a multiple mirrored reflector, which comprises the stationary compound telescope. A secondary mirror mounted atop a tower at the focal point directs the image toward the observation cart. Observers ride the periphery of the stationary mirror at a rate of one revolution per day. A retractable air supported hypalon cover protects the large primary mirror structure.

Owner:POPIL NICHOLAS B

Method for simultaneous two-disk texturing

InactiveUS7083502B2Increase productionSubstantial capital equipment savingRecord carriersGrinding drivesComputer science

Owner:SEAGATE TECH LLC

Movable type impregnating agent supply circulating tank

The invention discloses a movable type impregnating agent supply circulating tank. The movable type impregnating agent supply circulating tank comprises a frame, a tank body, a stirring device, a diaphragm pump and a material reflowing box, wherein a top cover is arranged at the upper part of the tank body; the top cover is provided with a material reflowing opening and a circulating material returning opening; the tank body is provided with a steam inlet which is communicated with a hollow structure; a feeding opening of the diaphragm pump is communicated with the tank body through a feedingpipe; a discharging opening of the diaphragm pump is connected with a discharging pipe; the discharging pipe is provided with a discharging branch pipe; the discharging branch pipe is communicated with an impregnating agent feeding pipe of a glass fiber wiredrawing device; the end part of the discharging pipe is communicated with the circulating material returning opening; a gas inlet of the diaphragm pump is communicated with a gas inlet pipe of a gas inlet valve; the material reflowing box is provided with a material returning connector and a discharging opening; an impregnating agent discharging pipe is communicated with the material returning connector; and the discharging opening of the material reflowing box is communicated with the material reflowing opening. By adopting the movabletype impregnating agent supply circulating tank, a complicated layout of an impregnating agent pipeline in a plant area can be reduced; and furthermore, a relatively large equipment volume needed forarranging fixed impregnating agent supply equipment is also reduced.

Owner:重庆天泽新材料有限公司

Method of supporting the differentiation of corneocytes

InactiveUS20100111382A1Large in costThe equipment is bulkyCharacter and pattern recognitionBiological testingCorneocyteComputer science

On the methods of creating corneocyte specimen for providing useful information for appropriate selection of cosmetic products or assessment of the skin condition, it is intended to provide a method of indicating an unstained image of corneocytes or the like in an observable pseudocolor in a method of creating corneocyte specimen, without resorting to staining the corneocyte specimen. The state of corneocytes of skin is input into a computer as an enlarged image by using, for example, a digital microscope. Then, the RGB values of the individual pixels in the image are converted with the use of a conversion system such as a conversion formula, a conversion table or a conversion chart and an image is indicated in a pseudocolor by using the individual RGB values converted.

Owner:POLA CHEM INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com