Patents

Literature

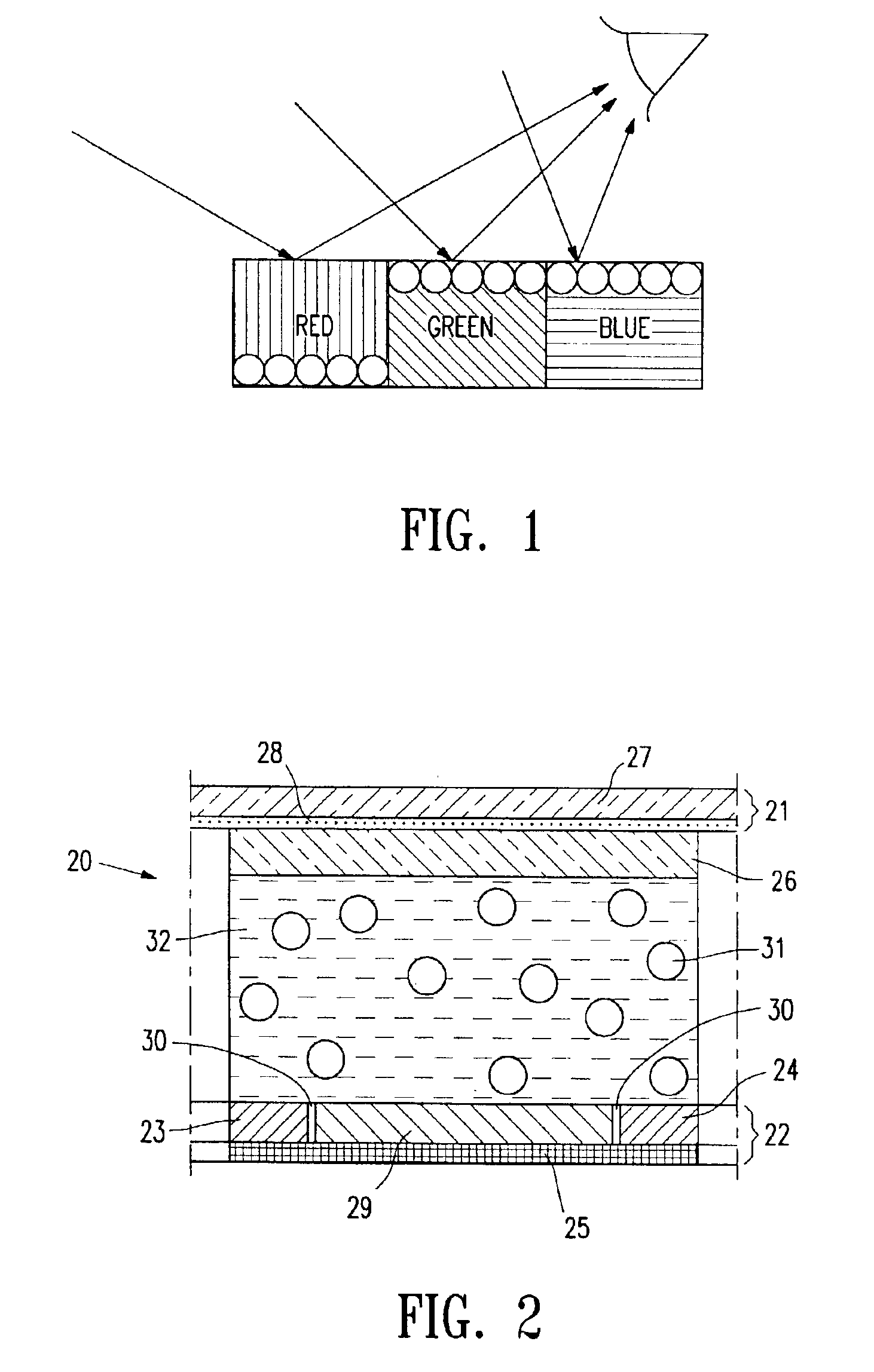

470 results about "Continuous manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous analyte sensors and methods of making same

InactiveUS20110024043A1Low production costMinimize changesHot-dipping/immersion processesPretreated surfacesAnalyteSolvent

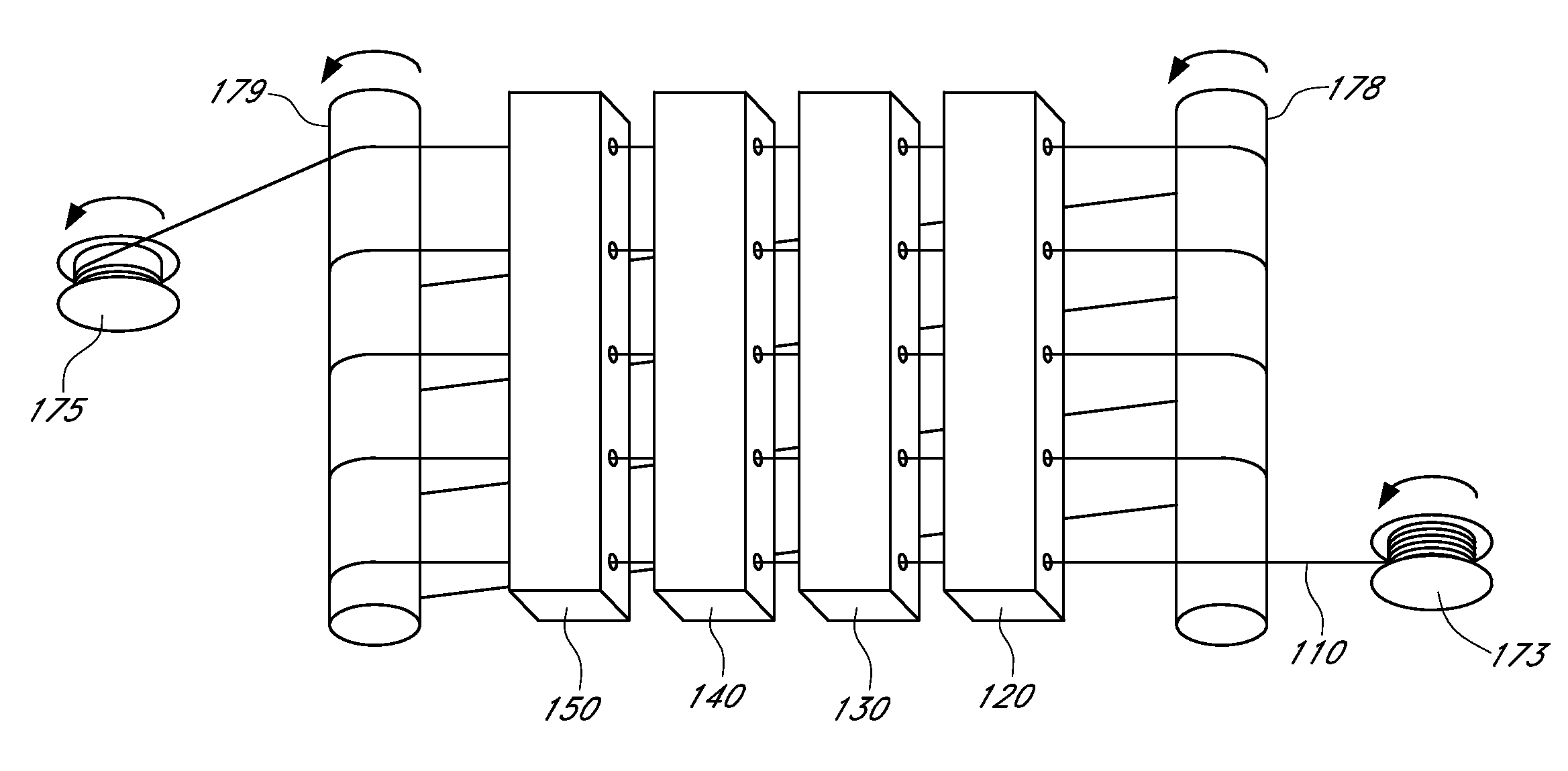

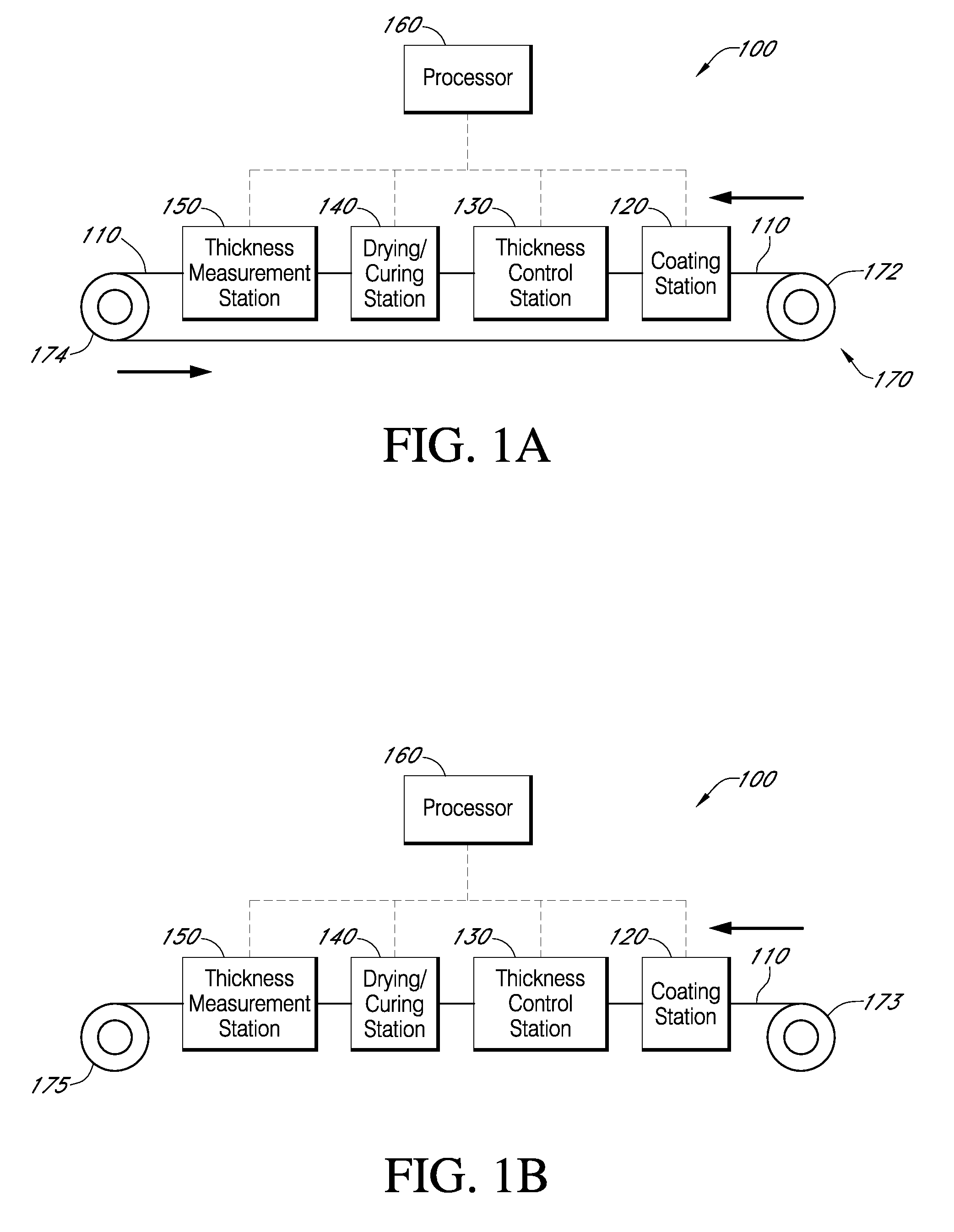

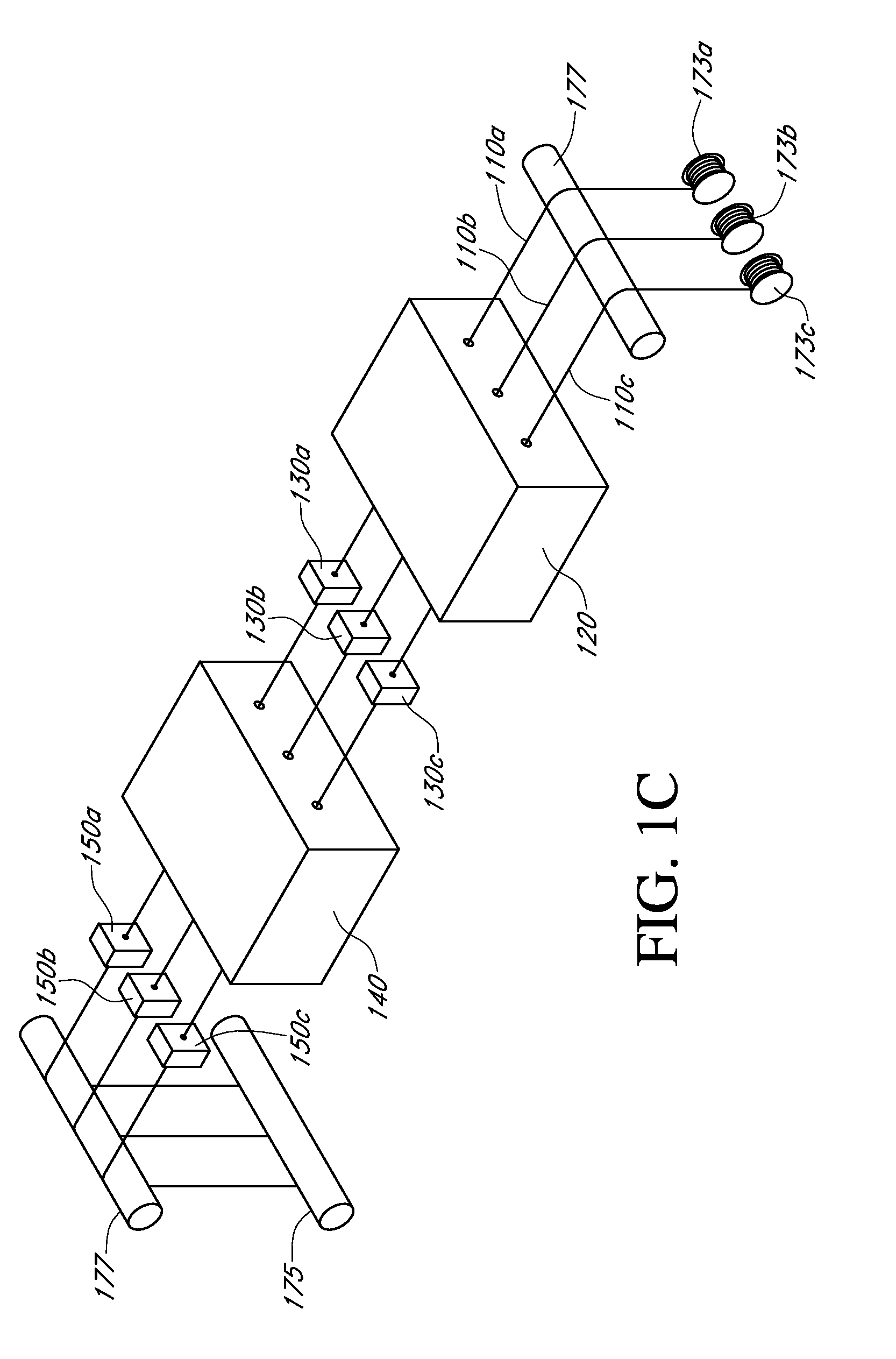

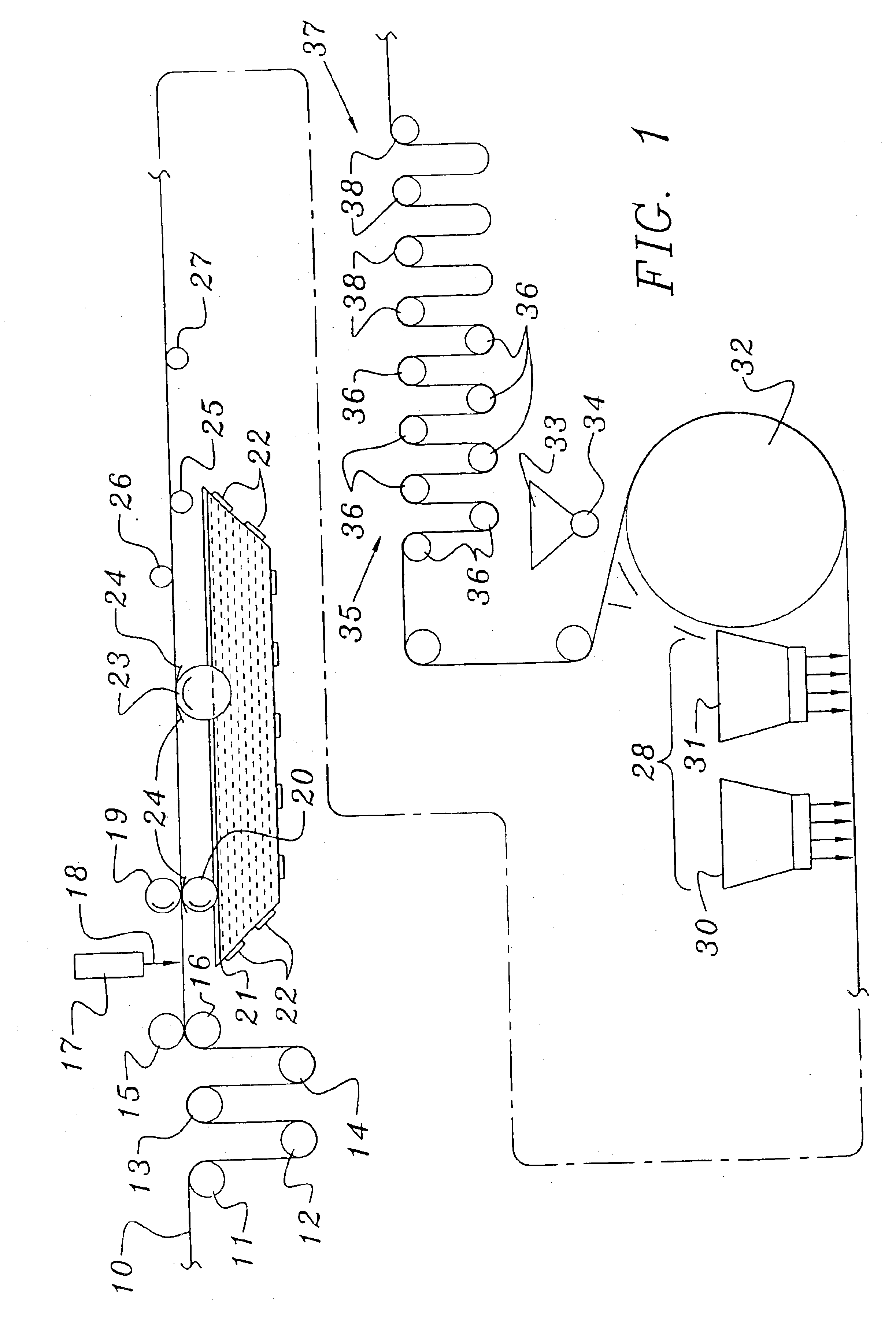

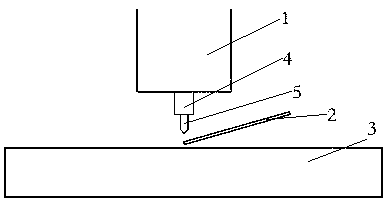

Described here are embodiments of processes and systems for the continuous manufacturing of implantable continuous analyte sensors. In some embodiments, a method is provided for sequentially advancing an elongated conductive body through a plurality of stations, each configured to treat the elongated conductive body. In some of these embodiments, one or more of the stations is configured to coat the elongated conductive body using a meniscus coating process, whereby a solution formed of a polymer and a solvent is prepared, the solution is continuously circulated to provide a meniscus on a top portion of a vessel holding the solution, and the elongated conductive body is advanced through the meniscus. The method may also comprise the step of removing excess coating material from the elongated conductive body by advancing the elongated conductive body through a die orifice. For example, a provided elongated conductive body 510 is advanced through a pre-coating treatment station 520, through a coating station 530, through a thickness control station 540, through a drying or curing station 550, through a thickness measurement station 560, and through a post-coating treatment station 570.

Owner:DEXCOM

Insulating sheathing with tough three-ply facers

InactiveUS6093481AImprove insulation performanceHighly controllableSynthetic resin layered productsHeat proofingPuncture resistanceHardness

A method for continuously manufacturing an insulation board by facing a foam-forming composition with one or two facing sheets to form a singly or doubly faced composite, at least one sheet comprising either a tough polymeric layer or a laminate of a tough polymeric layer with at least one other facing material, the tough polymeric layer of at least one sheet facing to the outside of the composite, and foaming and curing the faced foam-forming mixture to produce an insulation board having an exceptional hardness and puncture resistance.

Owner:THE DOW CHEM CO

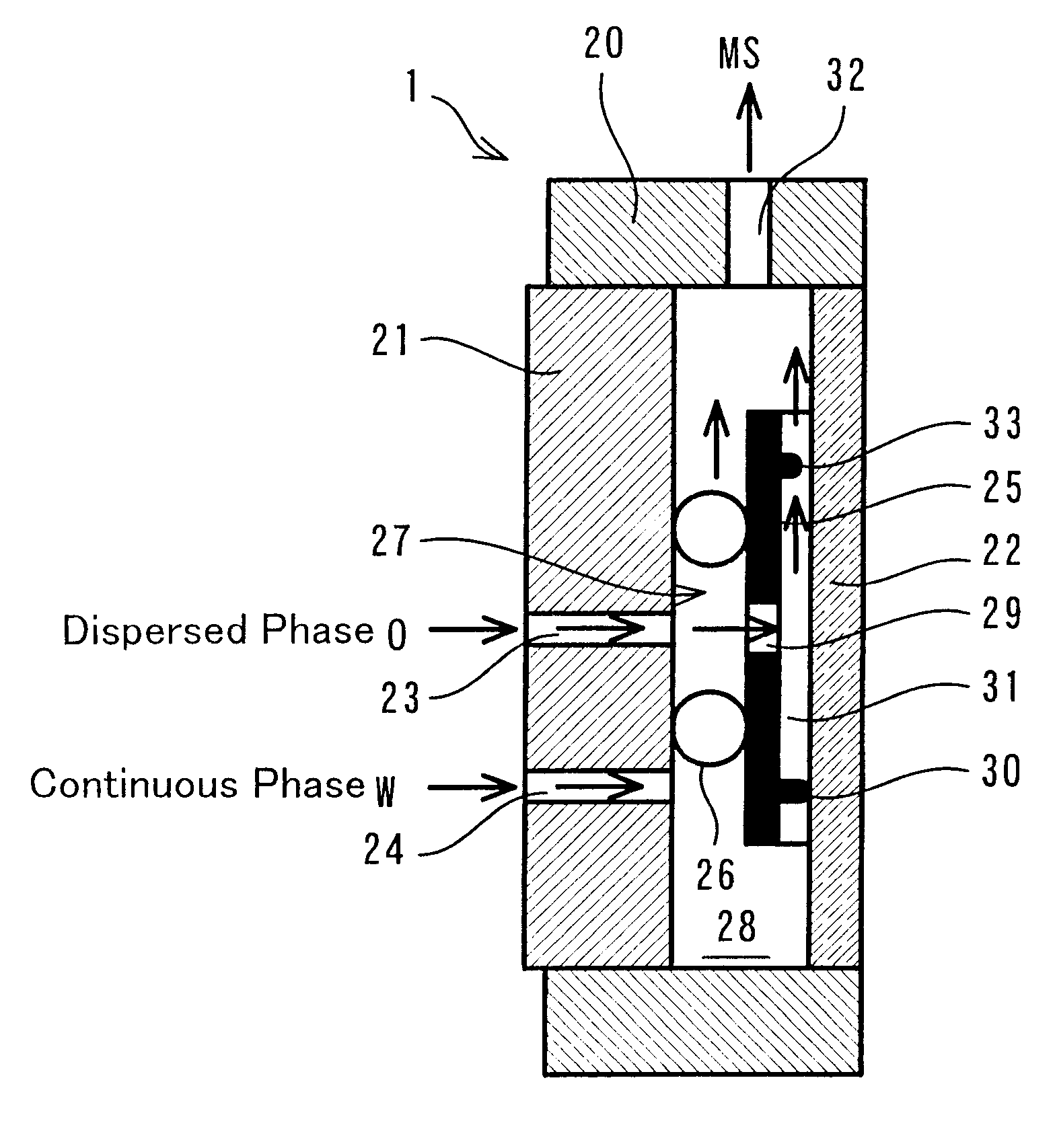

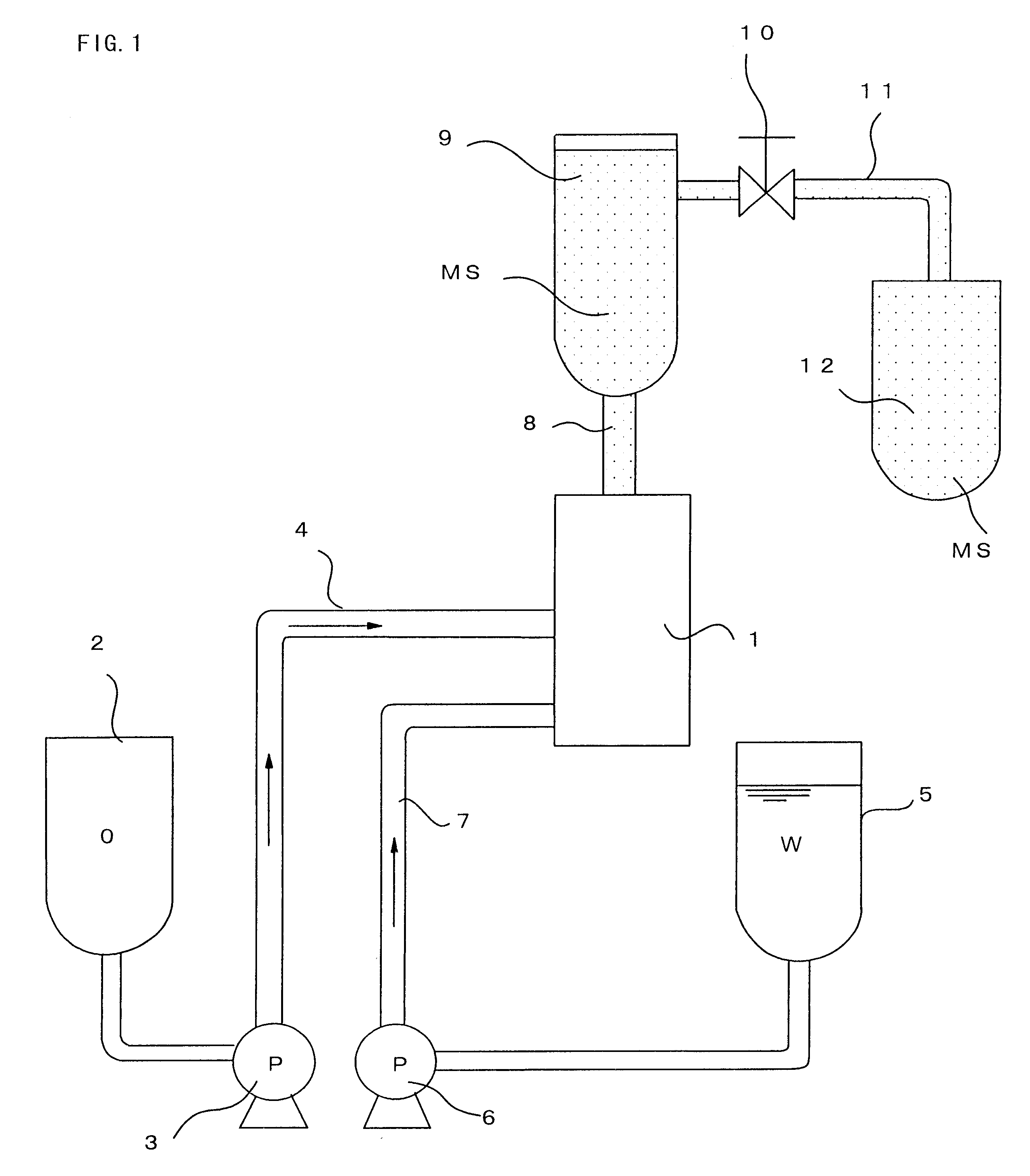

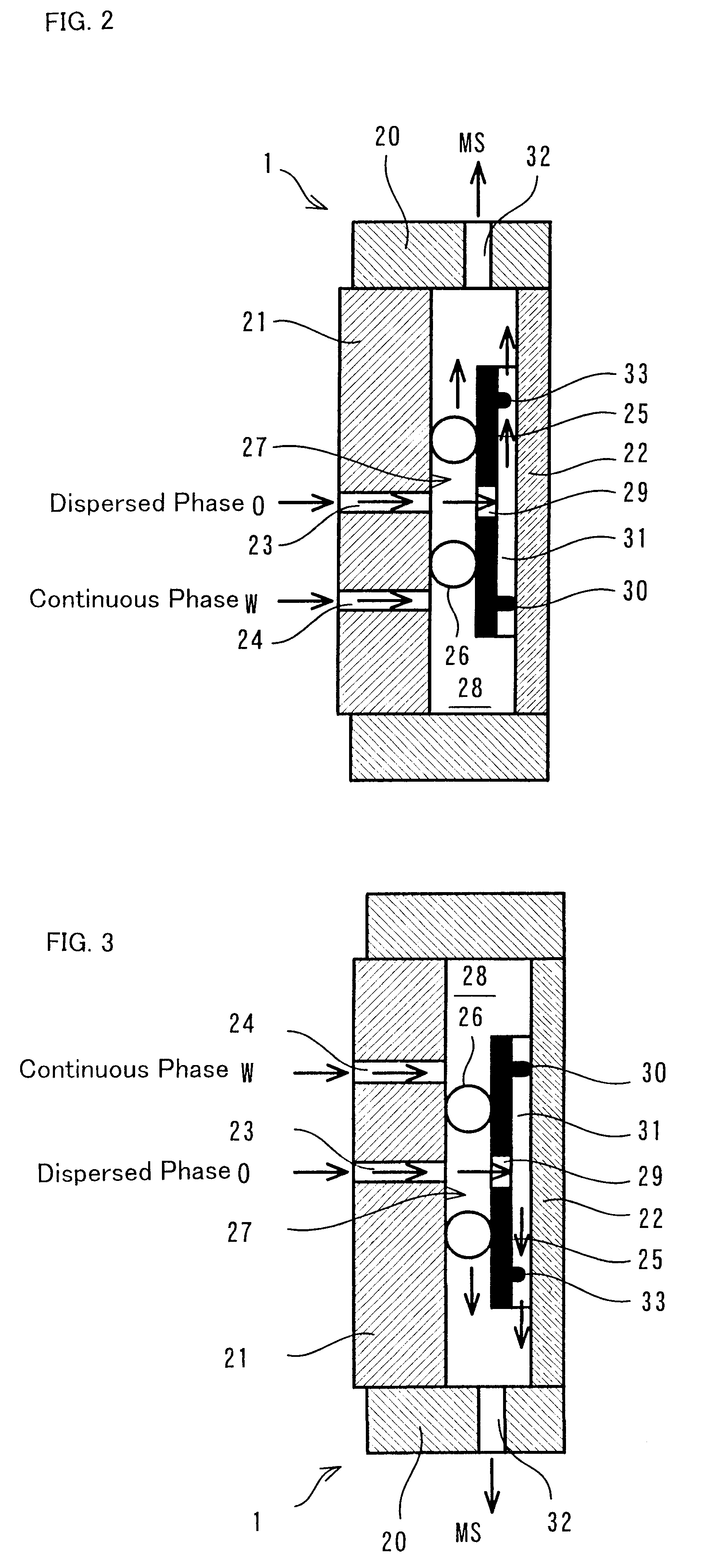

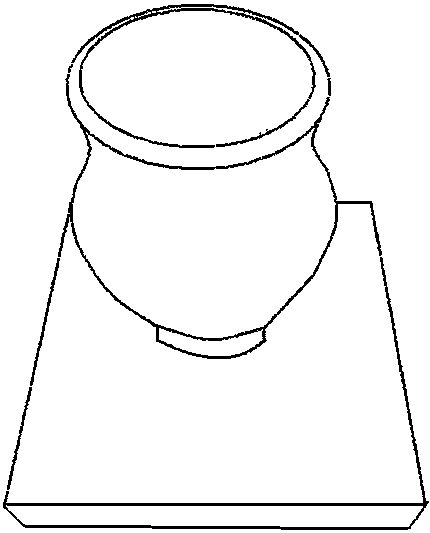

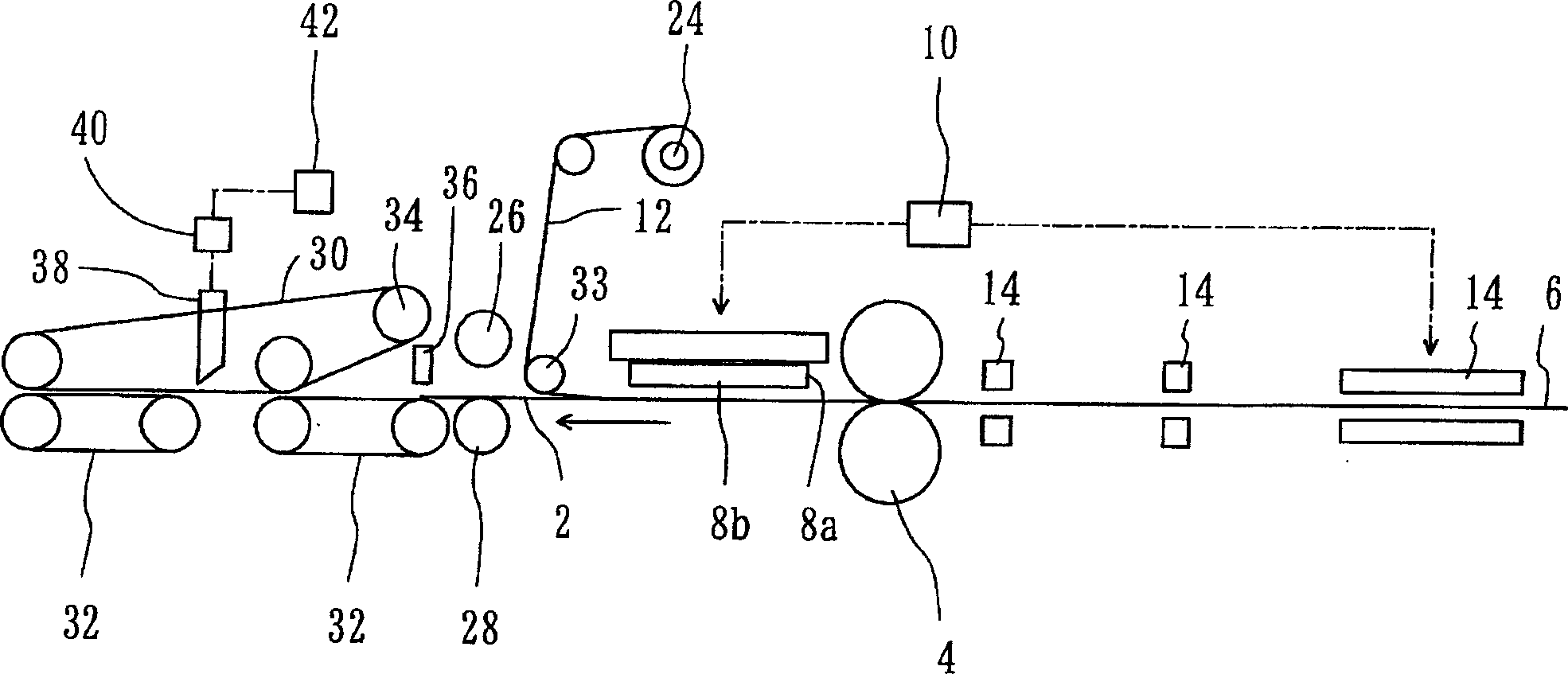

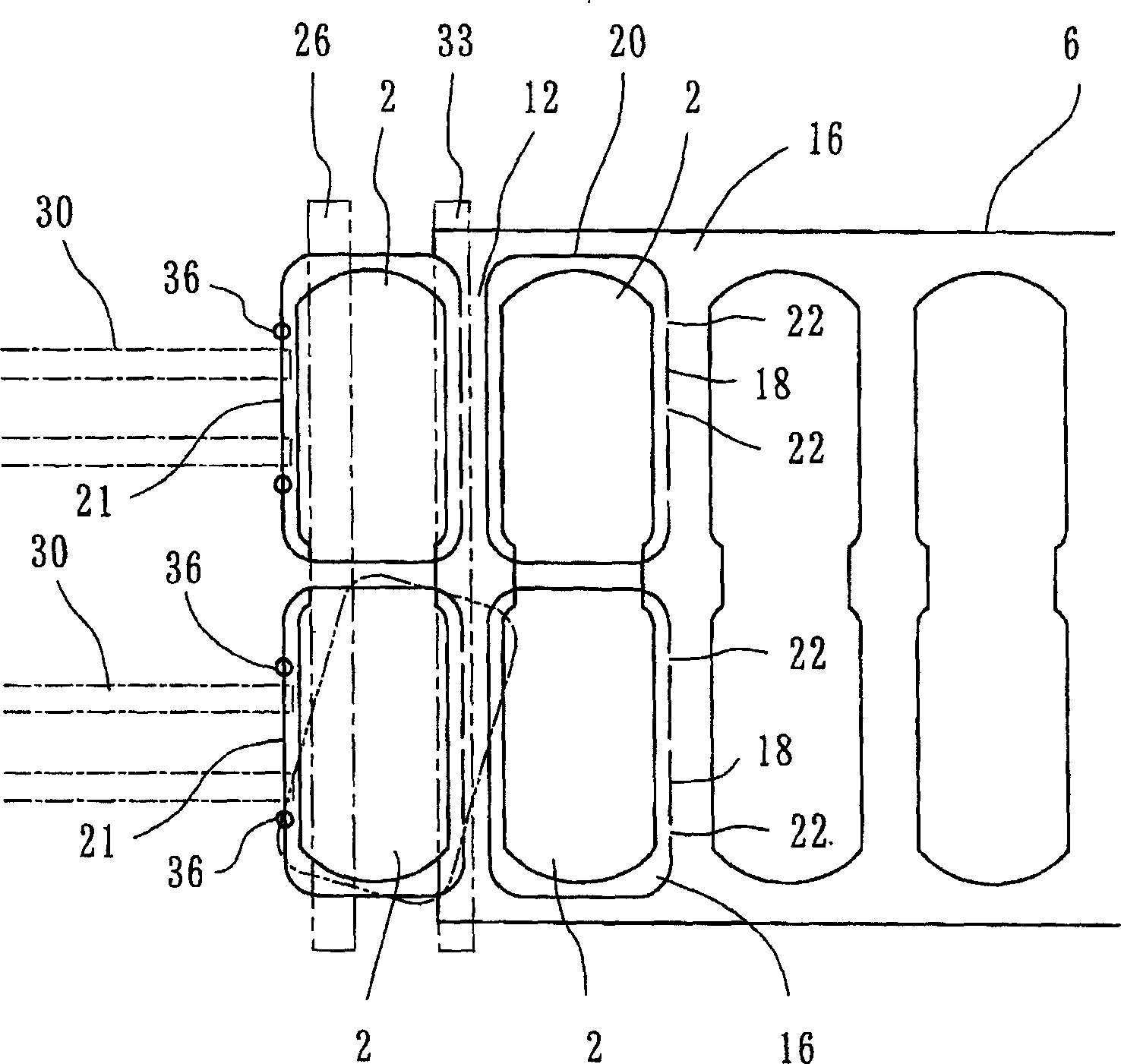

Continuous manufacturing method for microspheres and apparatus therefor

In an apparatus for continuously manufacturing microspheres, a dispersed phase (O) is supplied to a chamber 27 for the dispersed phase inside of a bulkhead member 26 via a supply port 23. Thereafter, the dispersed phase enters into a gap 31 between a plate 22 via a supply port 29 in a base 25. The dispersed phase which enters into the gap 31 grows microspheres (particles) having a certain diameter while passing through a microchannel 33 by pressure applied by, for example, a pump, and is mixed with a continuous phase (W), so that microspheres are produced. The thus-produced microspheres float or are suspended in the continuous phase without needing any particular external force in response to their specific gravity, allowing the microspheres to be generated and withdrawn from a withdrawal port 32 at a significantly reduced pressure in comparison to conventional methods and apparatus.

Owner:NAT FOOD RES INST +1

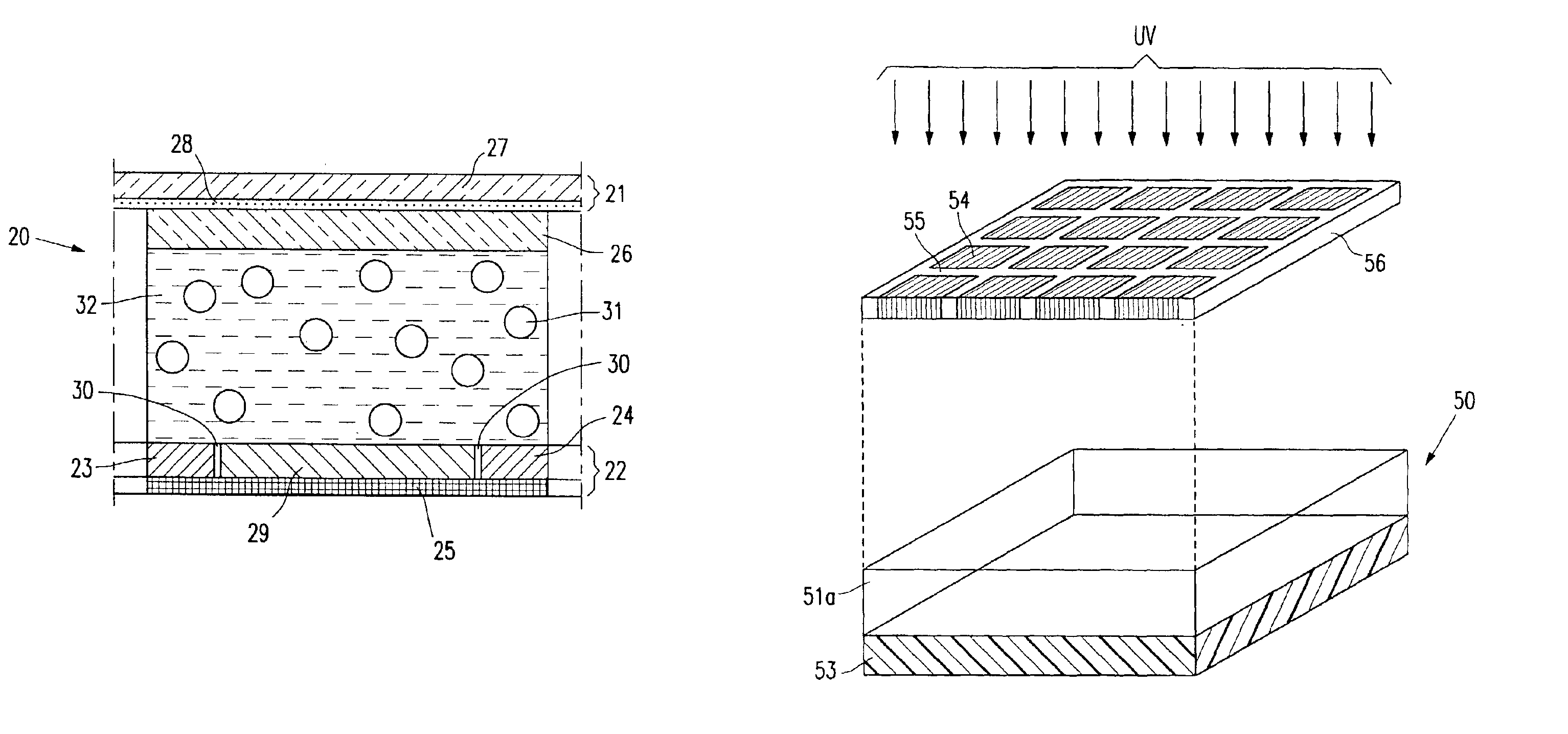

Electrophoretic display with in-plane switching

InactiveUS6885495B2Raise the ratioHigh saturationStatic indicating devicesNon-linear opticsElectrophoresisDisplay device

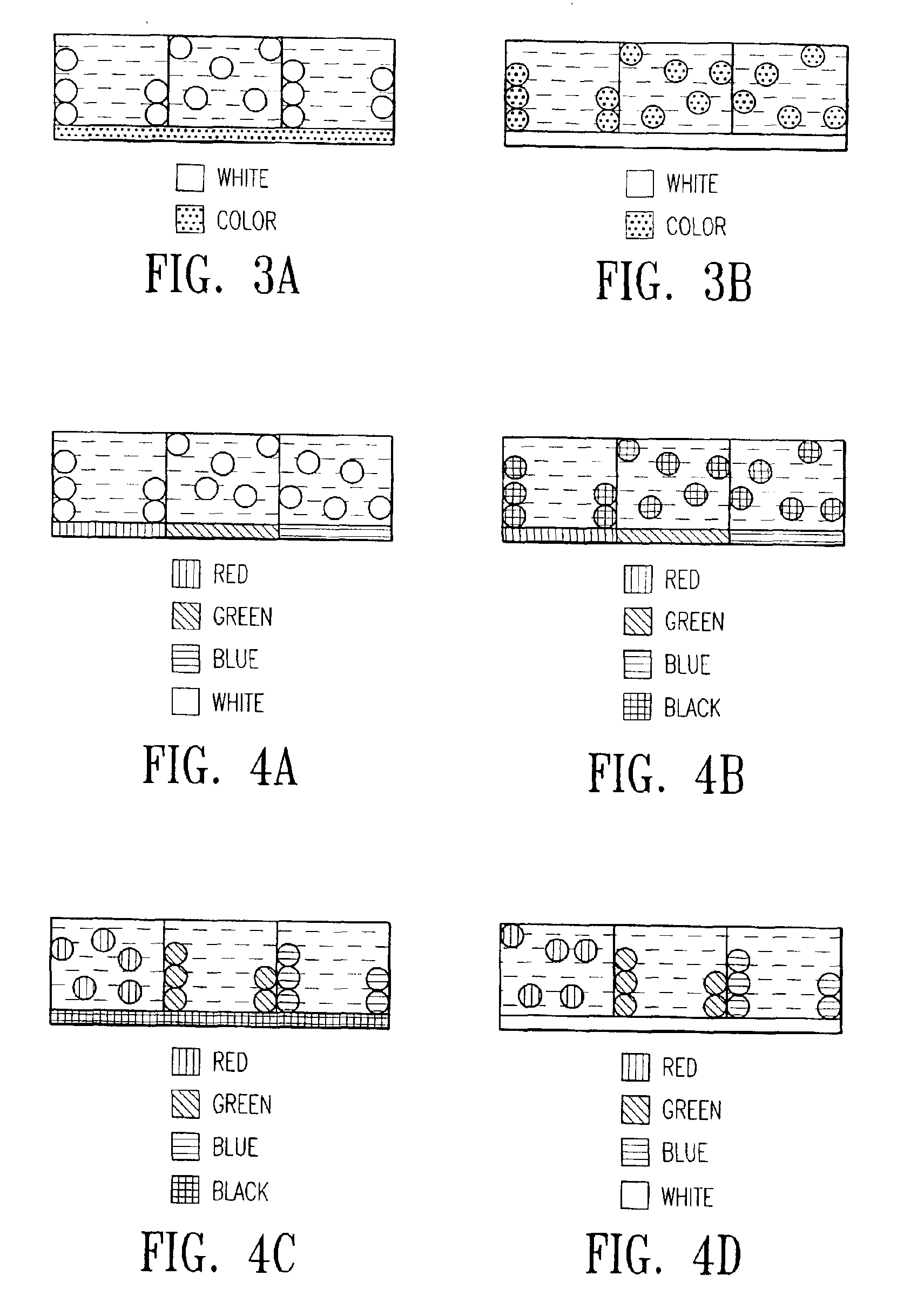

The present invention relates to an improved EPD which comprises the in plane switching mode. More specifically, the EPD of the present invention comprises isolated cells formed from microcups of well defined size, shape and aspect ratio and the movement of the particles in the cells is controlled by the in-plane switching mode. The EPD of the present invention may be produced in a continuous manufacturing process, and the display gives improved color saturation.

Owner:E INK CALIFORNIA

Continuous manufacture of superabsorbent/ion exchange sheet material

InactiveUS20020007166A1Increase in sizeNon-fibrous pulp additionWood working apparatusPapermakingIon exchange

A continuous sheet having a combination of acidic and basic water-absorbing resin particles that are essentially not neutralized and can be continuously manufactured on conventional papermaking apparatus, using a wet, dry, or wet-dry process to manufacture a water-absorbent sheet-like substrate containing 50%-100% by weight of the combination of acidic and basic water-absorbent particles. The acidic and basic essentially unneutralized resins can be contained in the sheet material articles of the present invention as separate acidic and basic resin particles, or as multicomponent particles containing both the acidic and basic resins. The sheet materials can be manufactured having new and unexpected structural integrity, with little or no shakeout or loss of superabsorbent particles during or after manufacture while exhibiting exceptional water absorption and retention properties. The sheet materials have an ability to absorb liquids quickly, demonstrate good fluid permeability and conductivity into and through the resin particles, and have a high gel strength such that the hydrogel formed from the SAP particles resists deformation under an applied stress or pressure, when used alone or in a mixture with other water-absorbing resins.

Owner:BASF AG

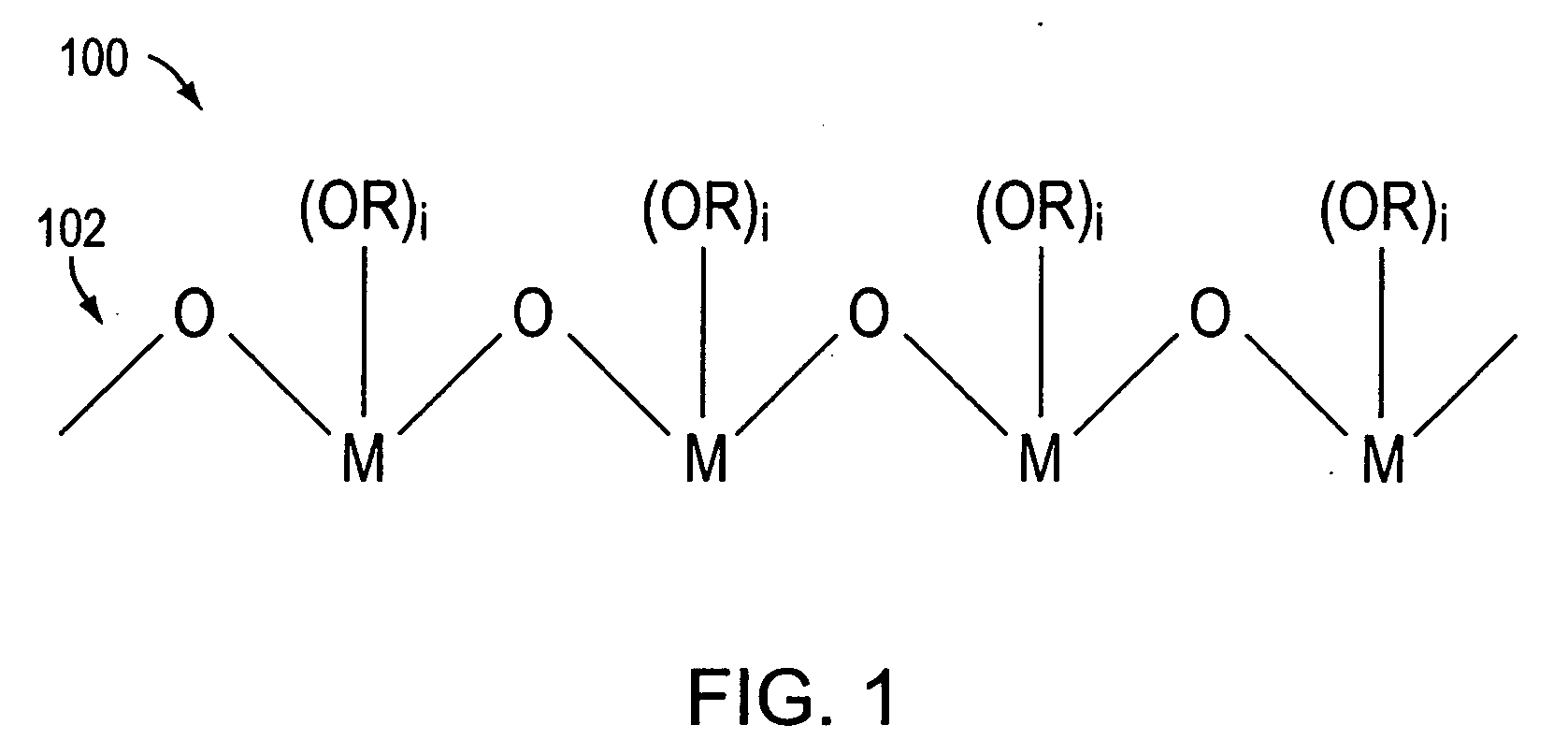

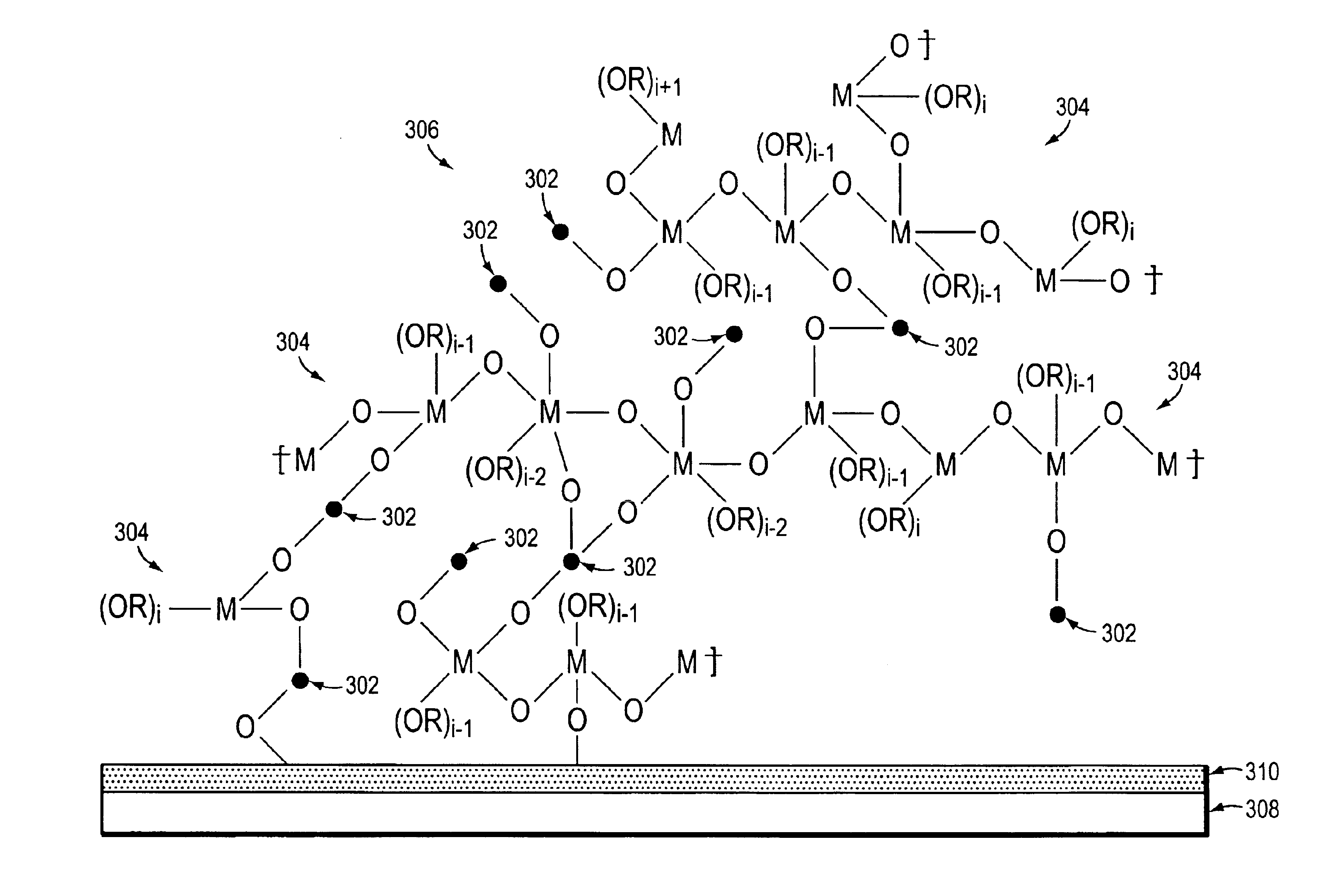

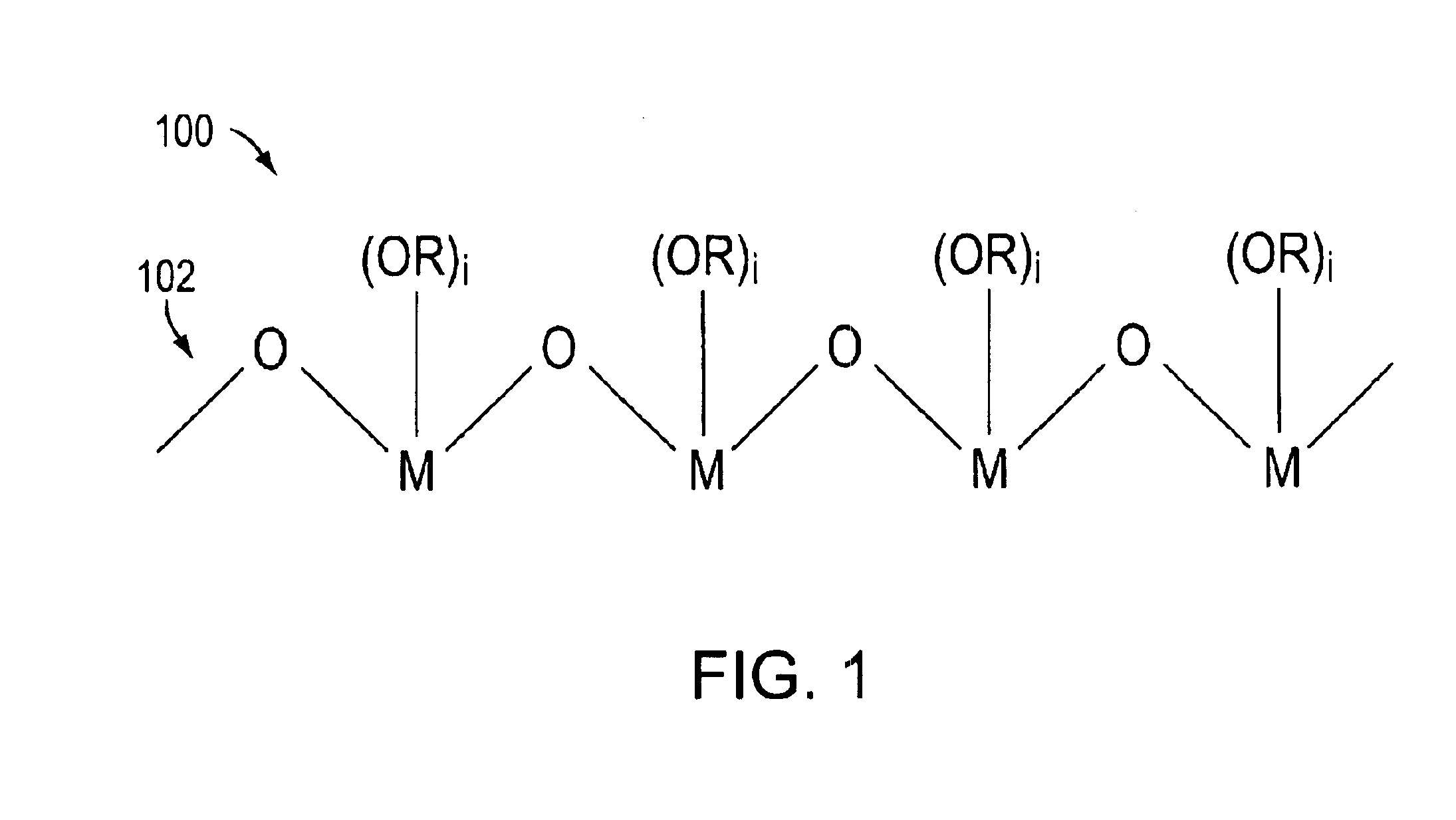

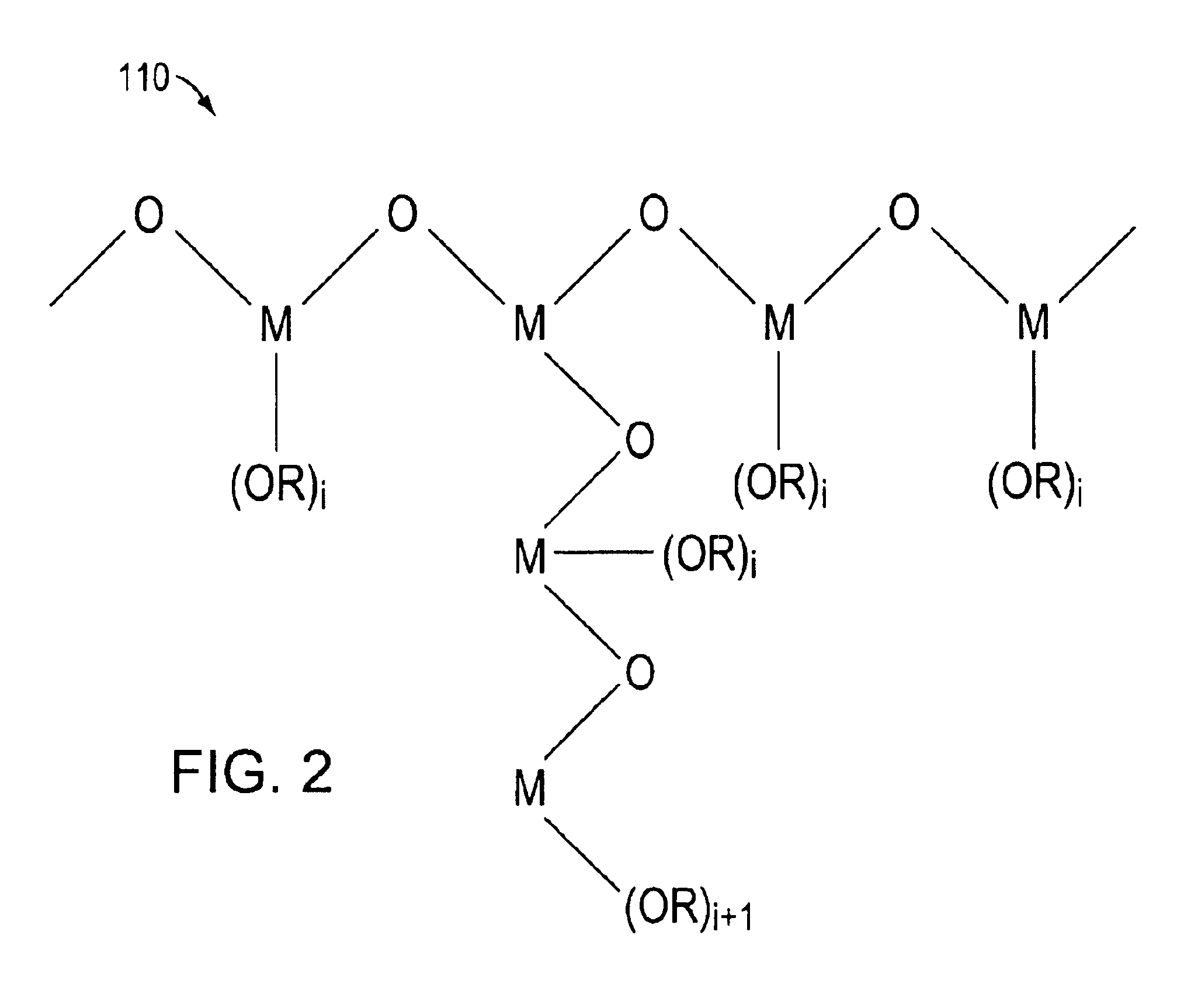

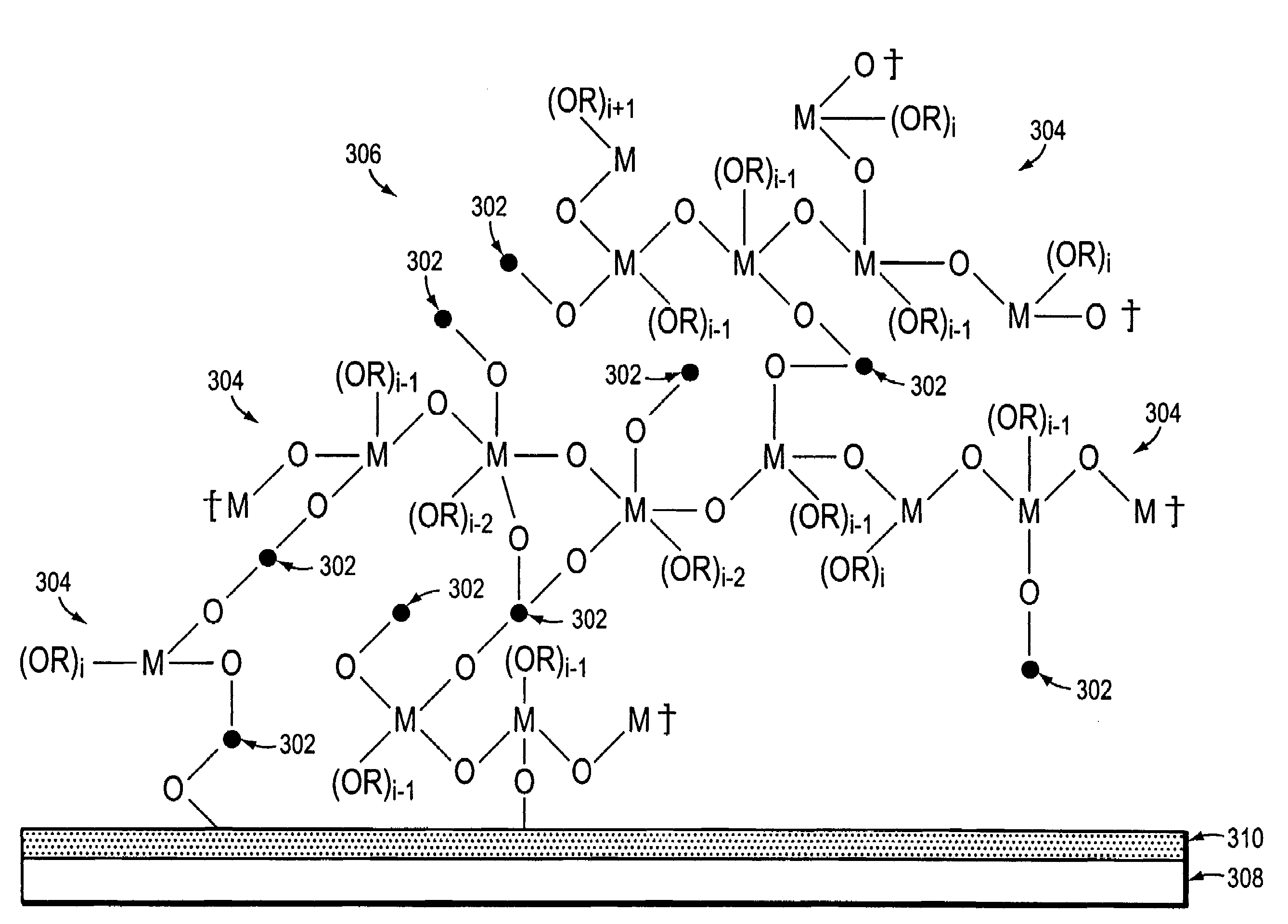

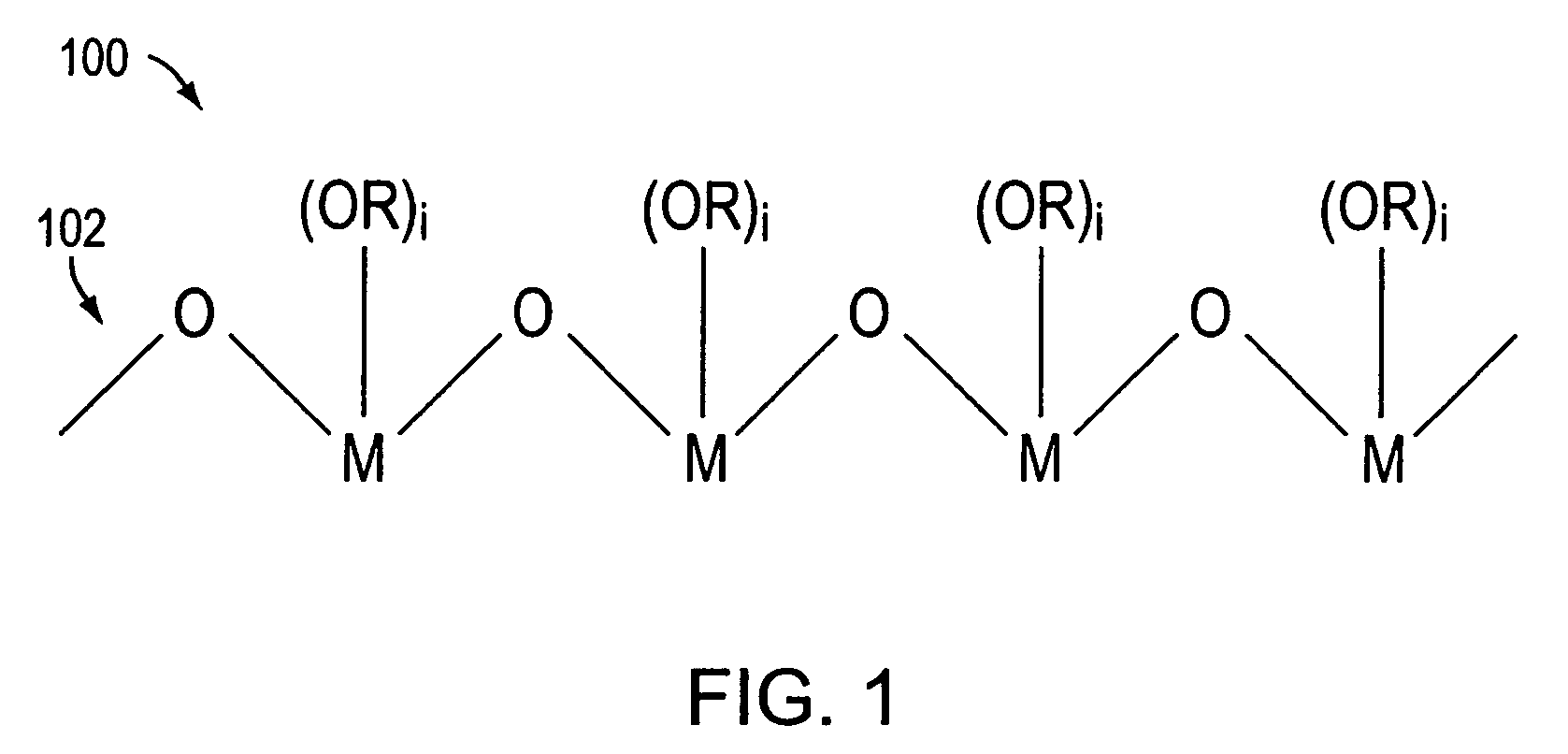

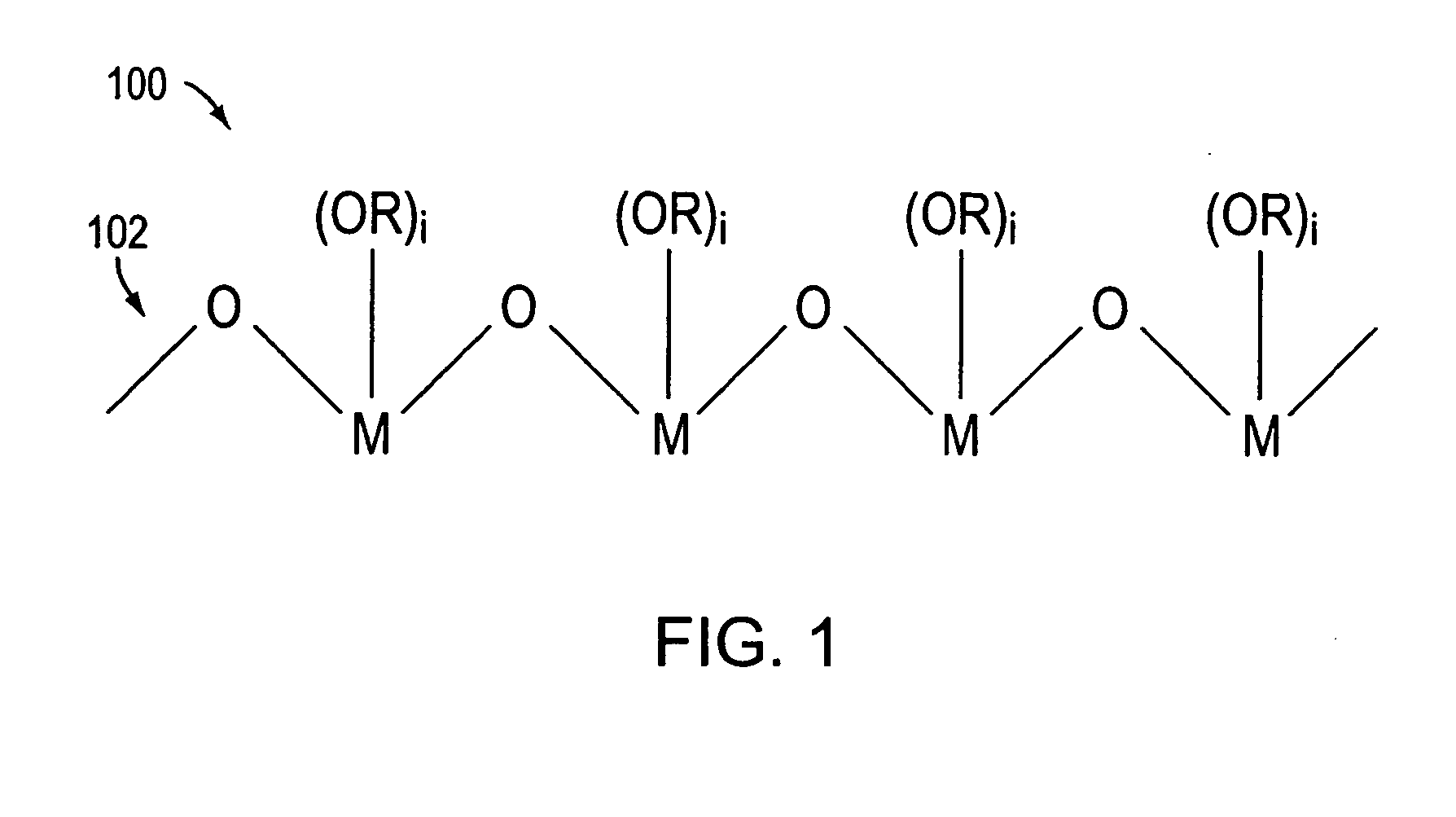

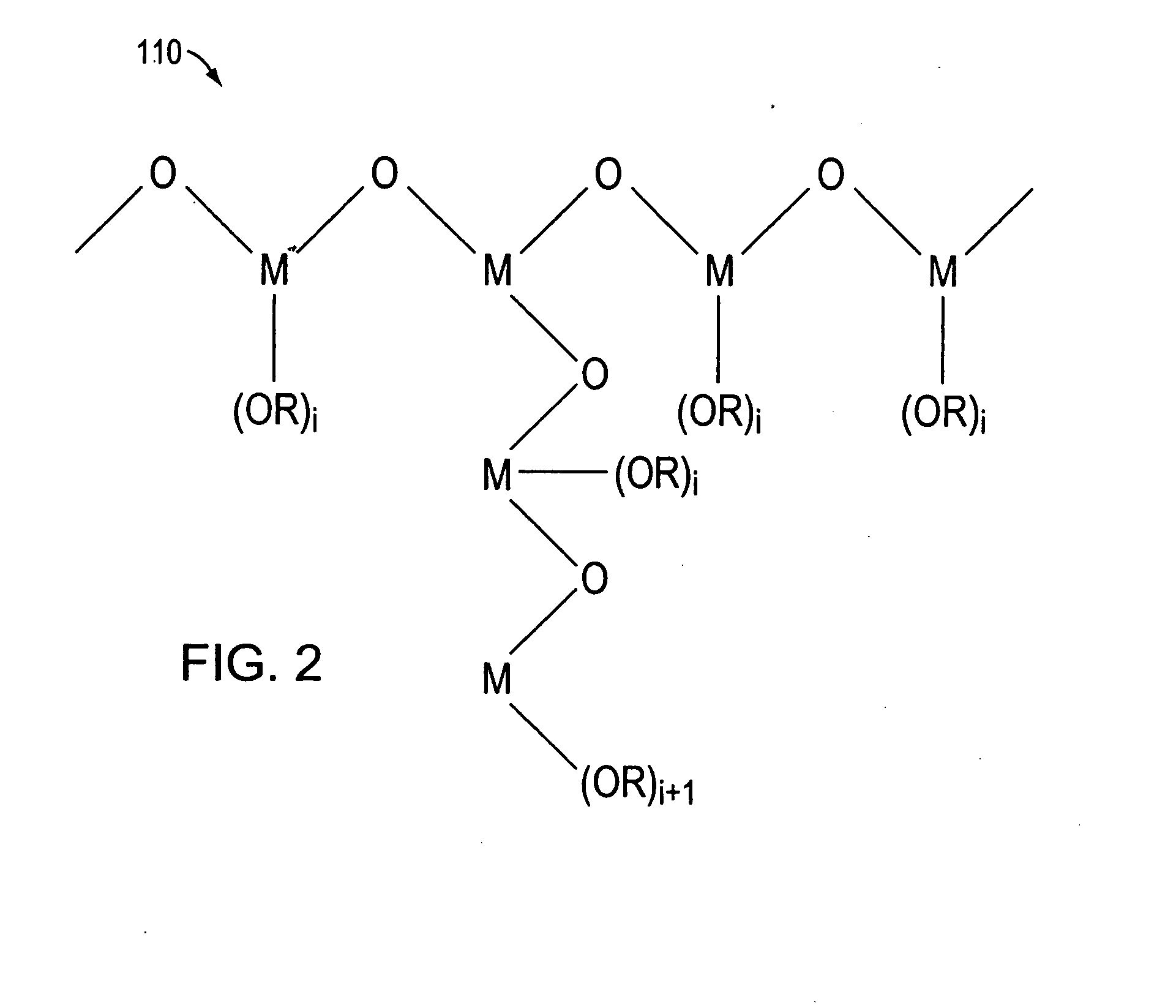

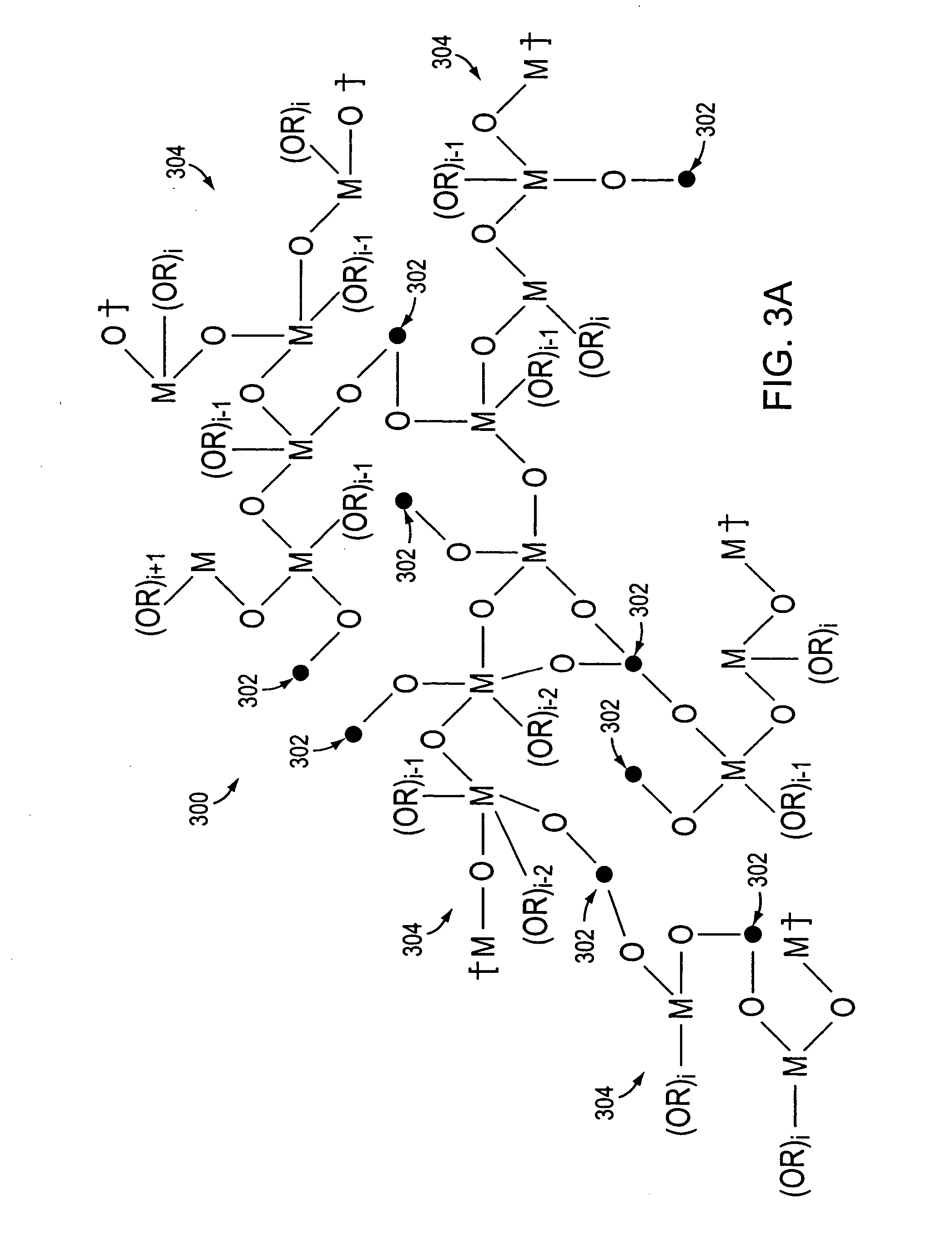

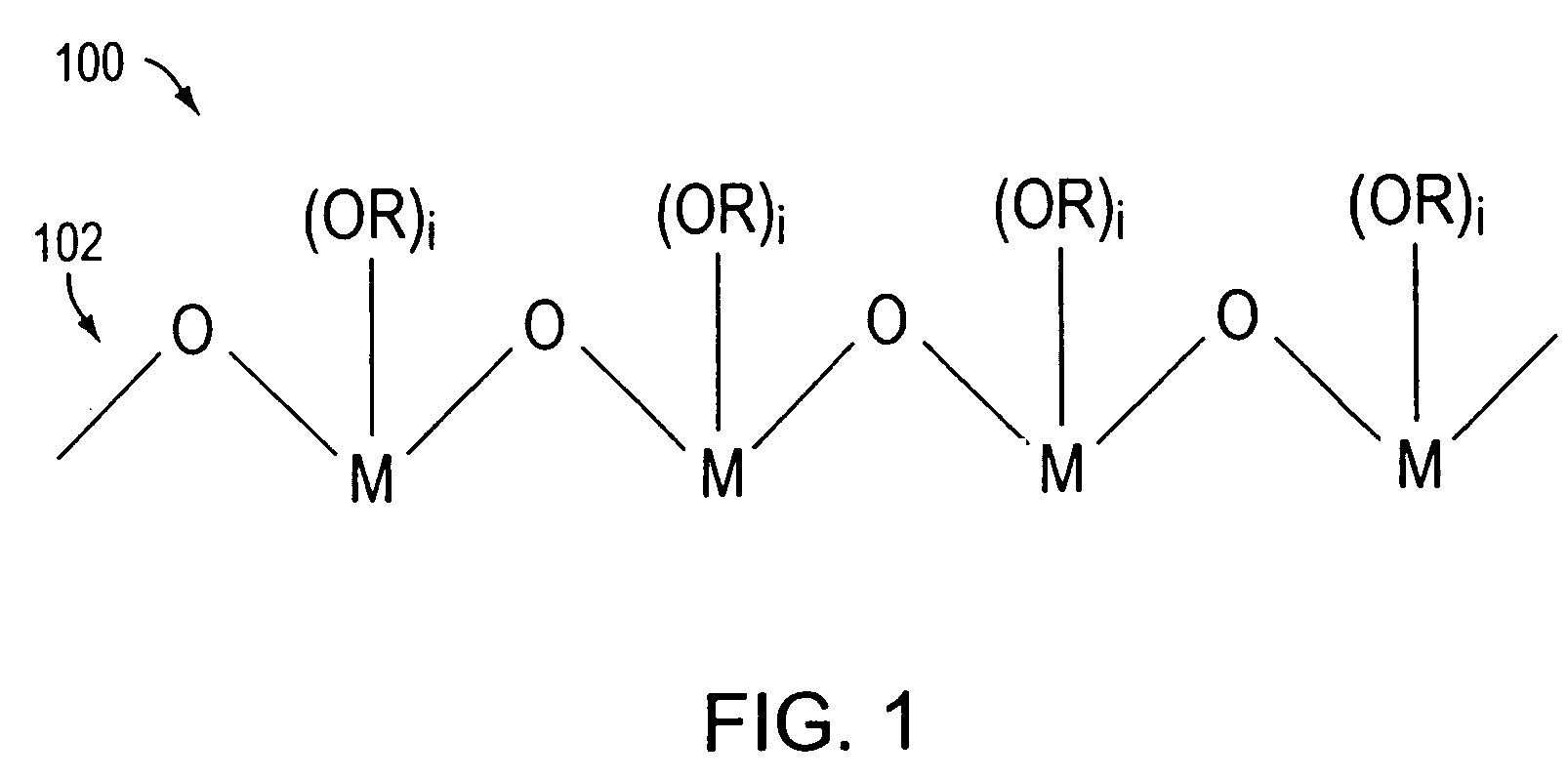

Low temperature interconnection of nanoparticles

A polymeric linking agent enables the manufacture of photovoltaic cells on flexible substrates, including, for example, polymeric substrates. Photovoltaic cells may be fabricated by a relatively simple continuous manufacturing process, for example, a roll-to-roll process, instead of a batch process.

Owner:MERCK PATENT GMBH

Low temperature interconnection of nanoparticles

InactiveUS20050011550A1From normal temperature solutionsLight-sensitive devicesNanoparticleEngineering

A polymeric linking agent enables the manufacture of photovoltaic cells on flexible substrates, including, for example, polymeric substrates. Photovoltaic cells may be fabricated by a relatively simple continuous manufacturing process, for example, a roll-to-roll process, instead of a batch process.

Owner:MERCK PATENT GMBH

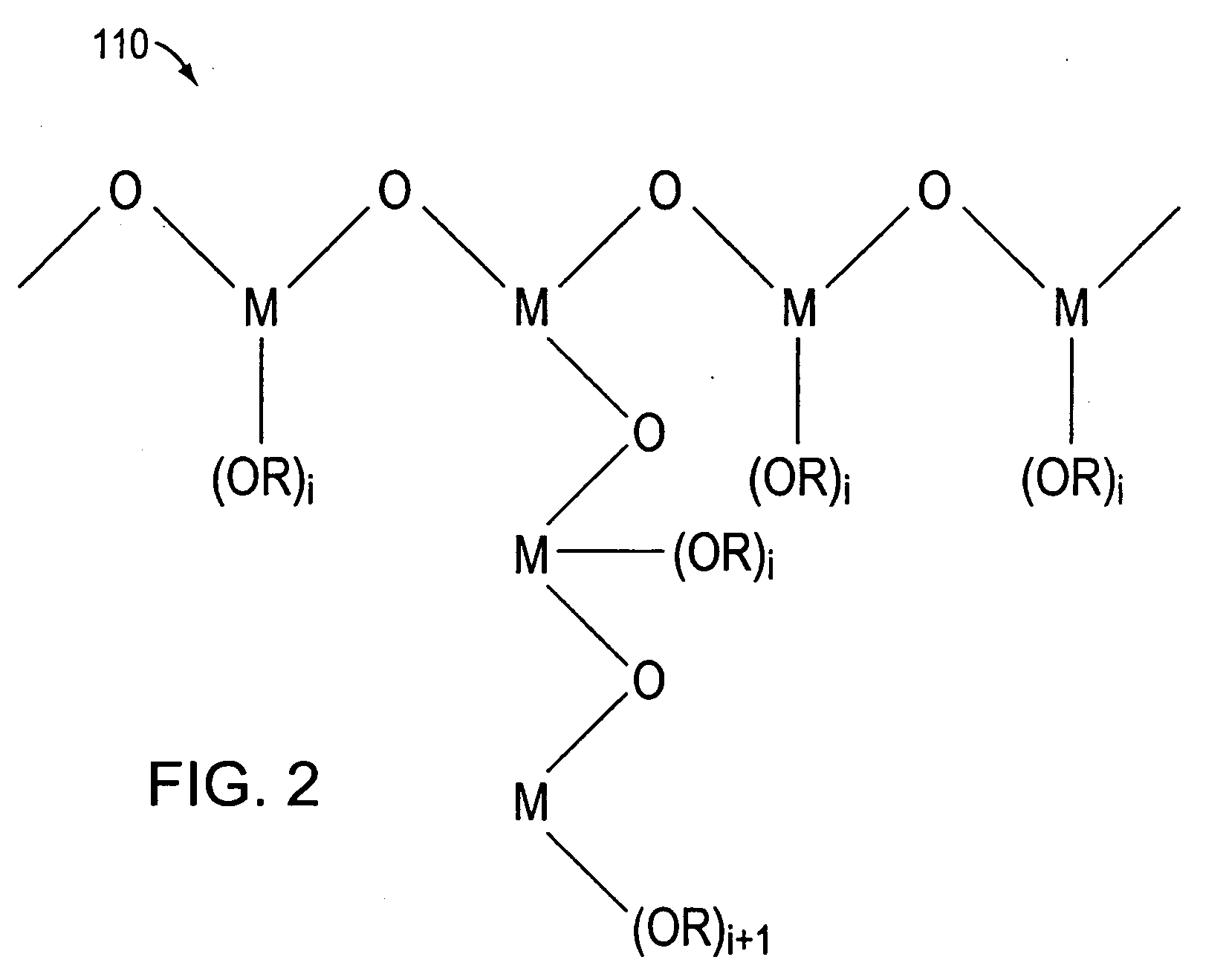

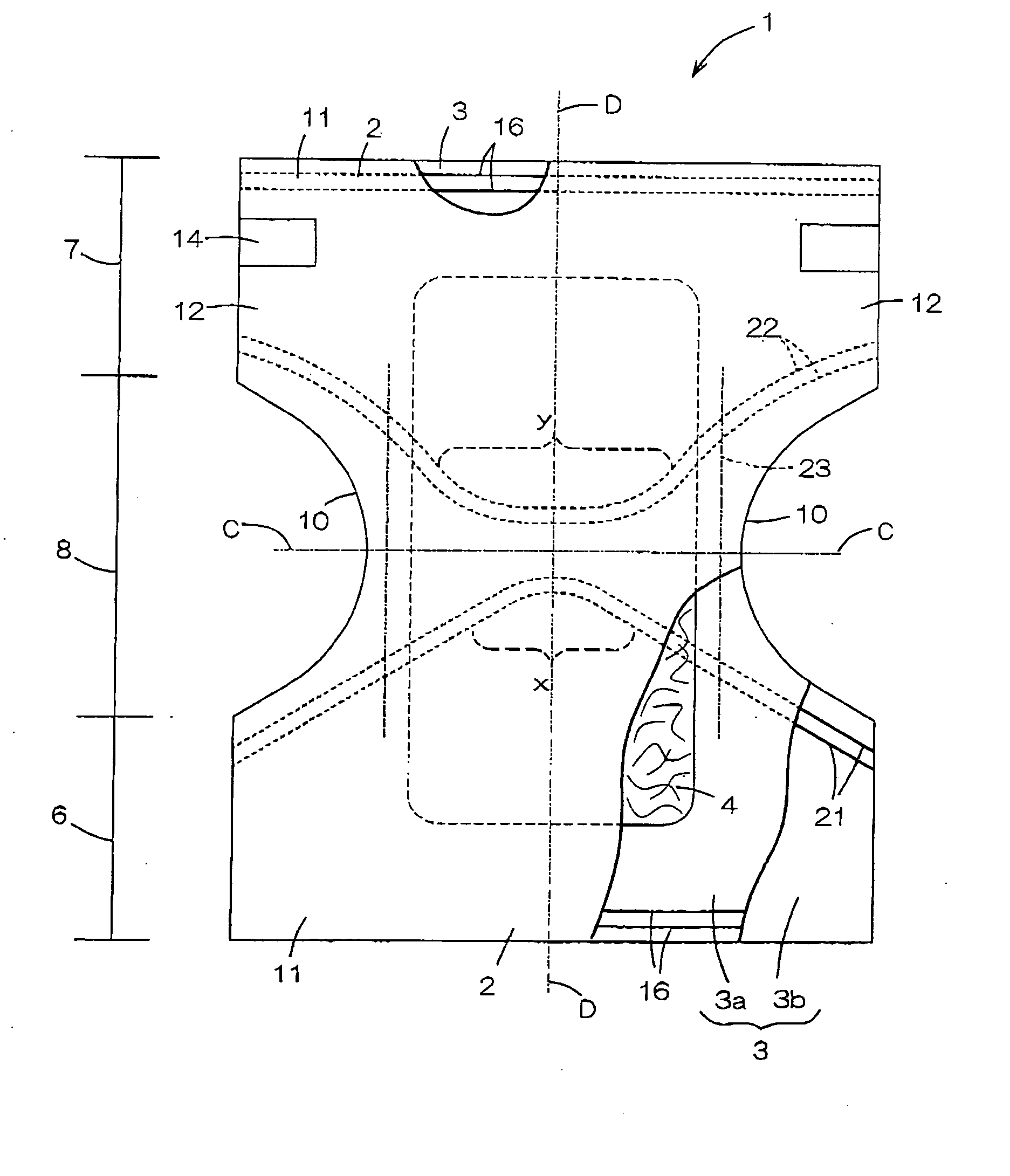

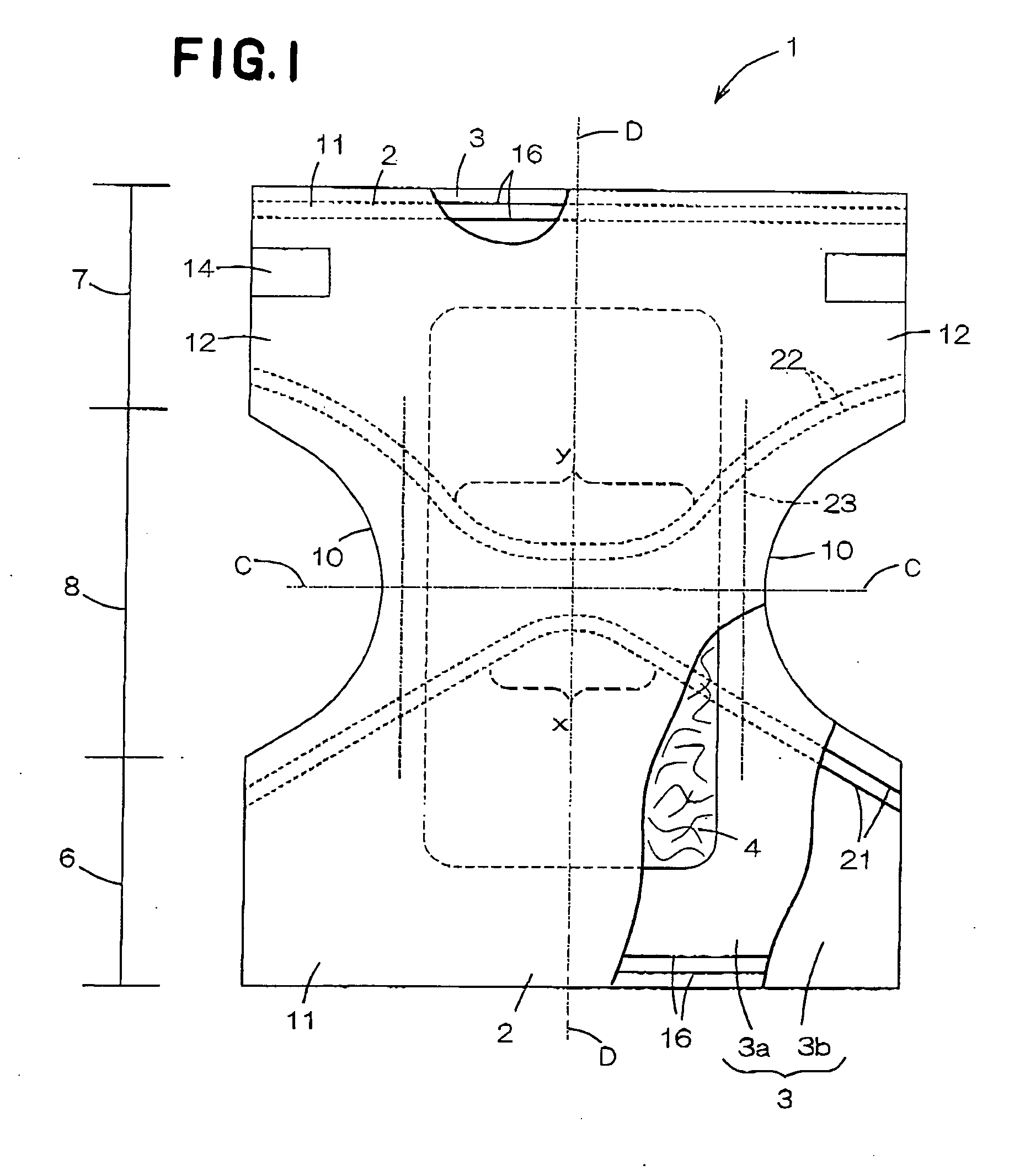

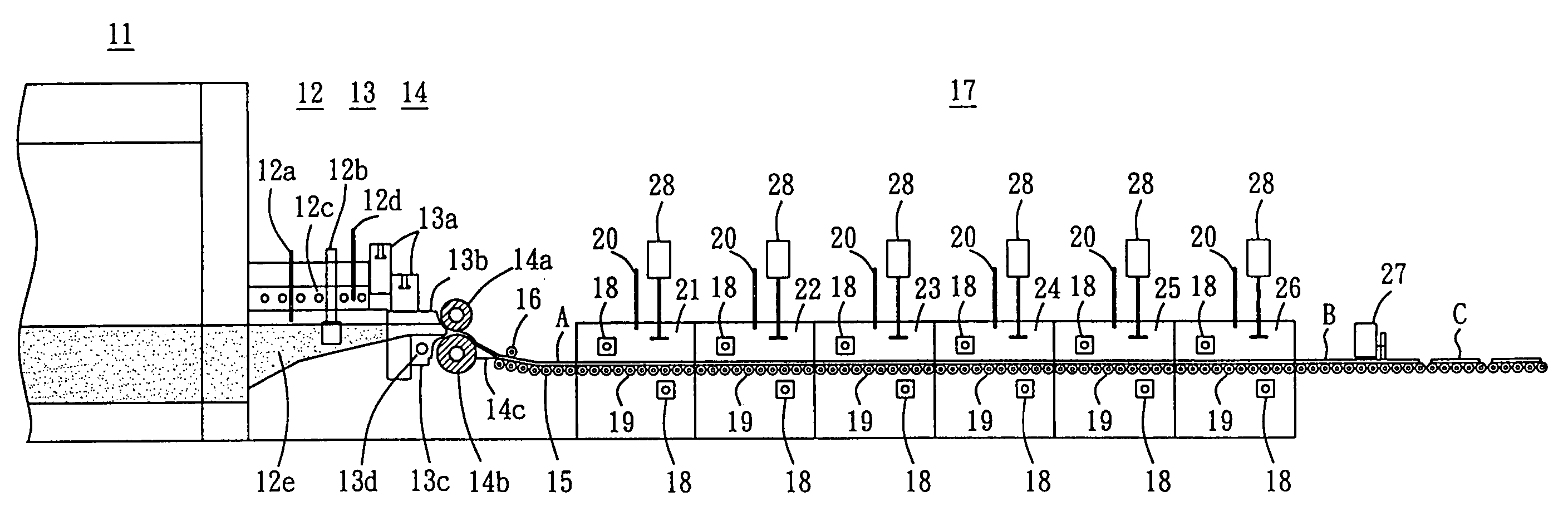

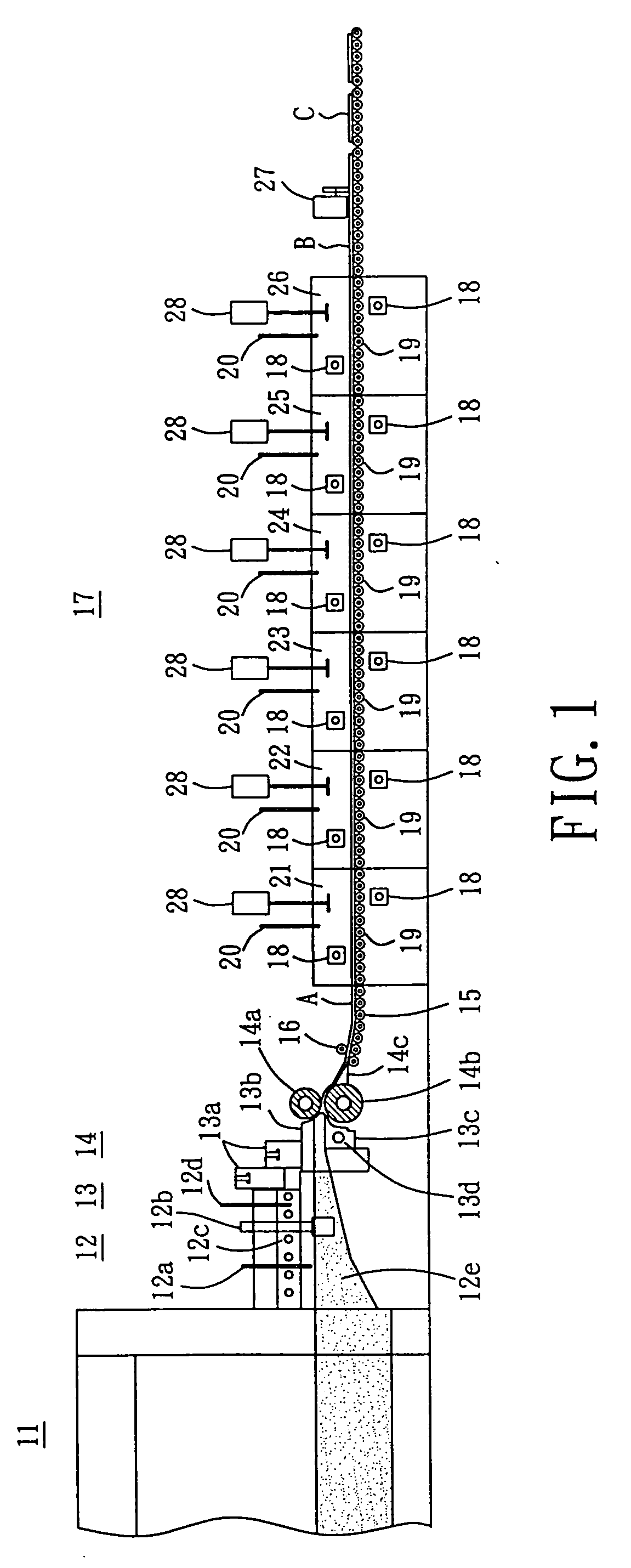

Process and apparatus to attach elastic members to disposable wearing article being continuously manufactured

ActiveUS20060185135A1Efficient use ofEasy to manufactureLaminationLamination apparatusEngineeringServomotor

First continuous web as a component of disposable wearing article to be continuously manufactured is fed in a machine direction and first continuous elastic members are fed via guide means adapted to oscillate the elastic members in a cross direction crossing the machine direction and attached thereto. Each of the guide means comprises a first servomotor having a rotary shaft adapted to repeat reversal of its rotational direction, a first arm connected directly with the rotary shaft and extending in a direction crossing the rotary shaft so that the first arm swings around the rotary shaft as the rotary shaft rotates and a first feed member adapted to direct the first continuous elastic members toward guide means formed on the first arm.

Owner:UNI CHARM CORP

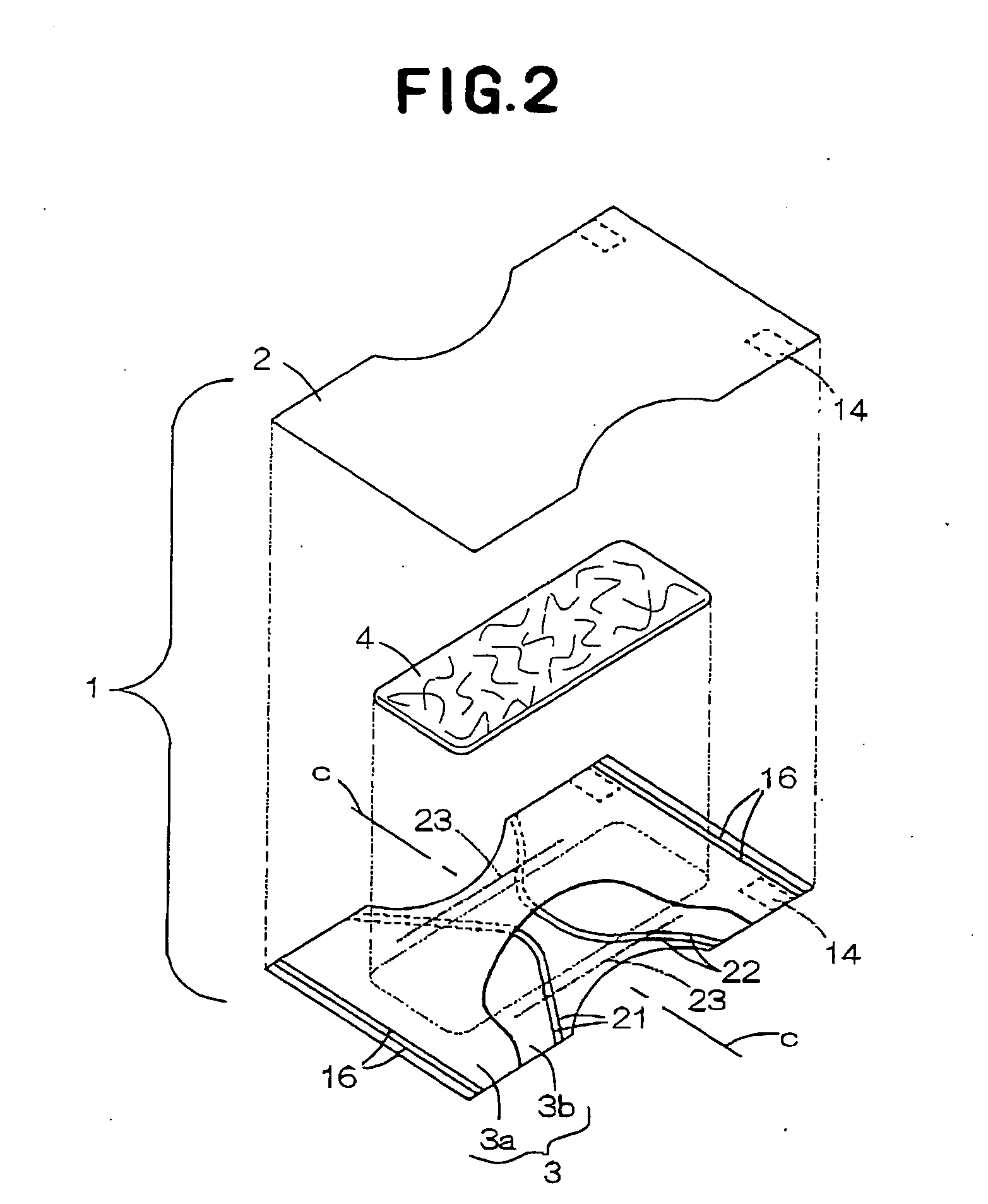

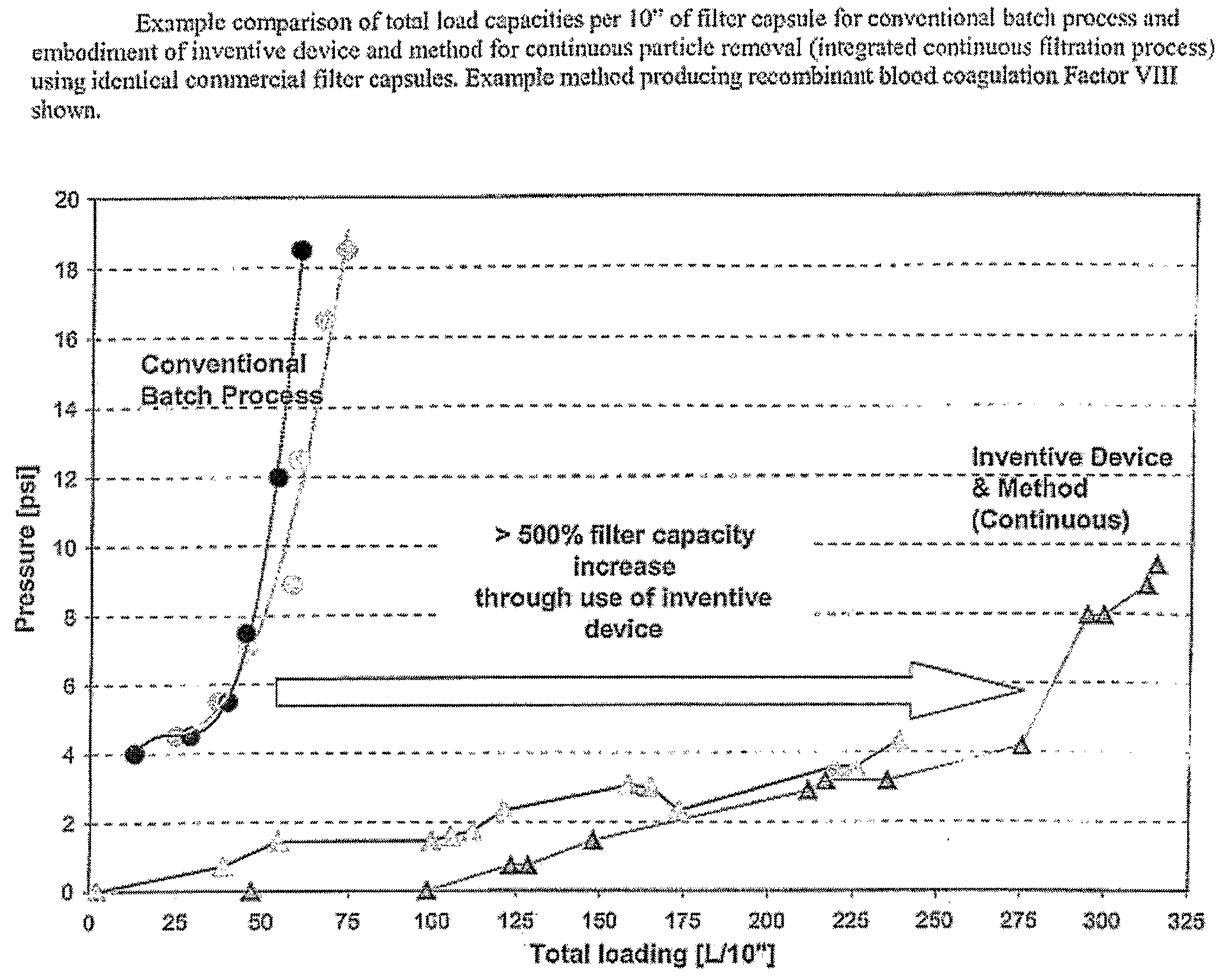

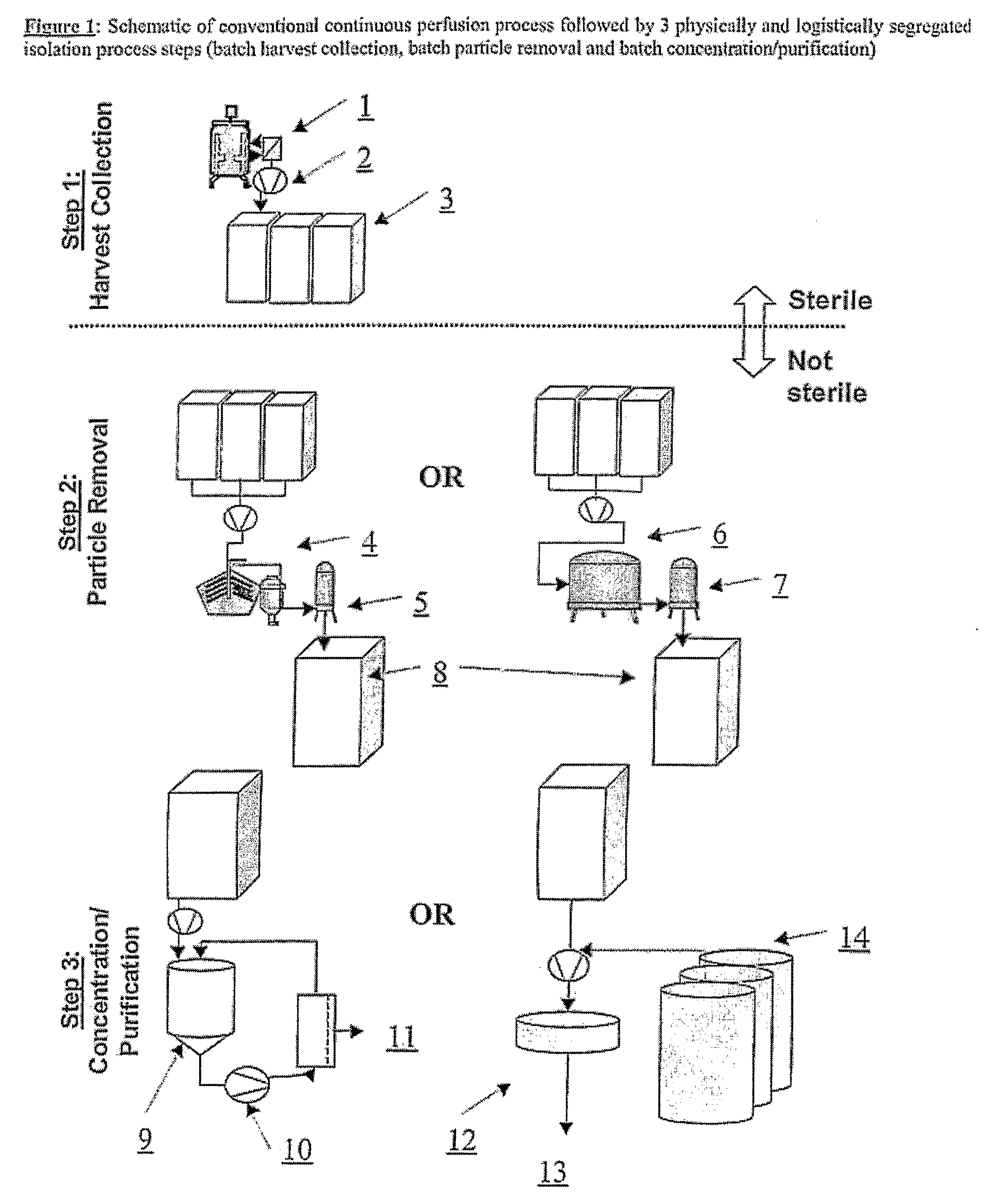

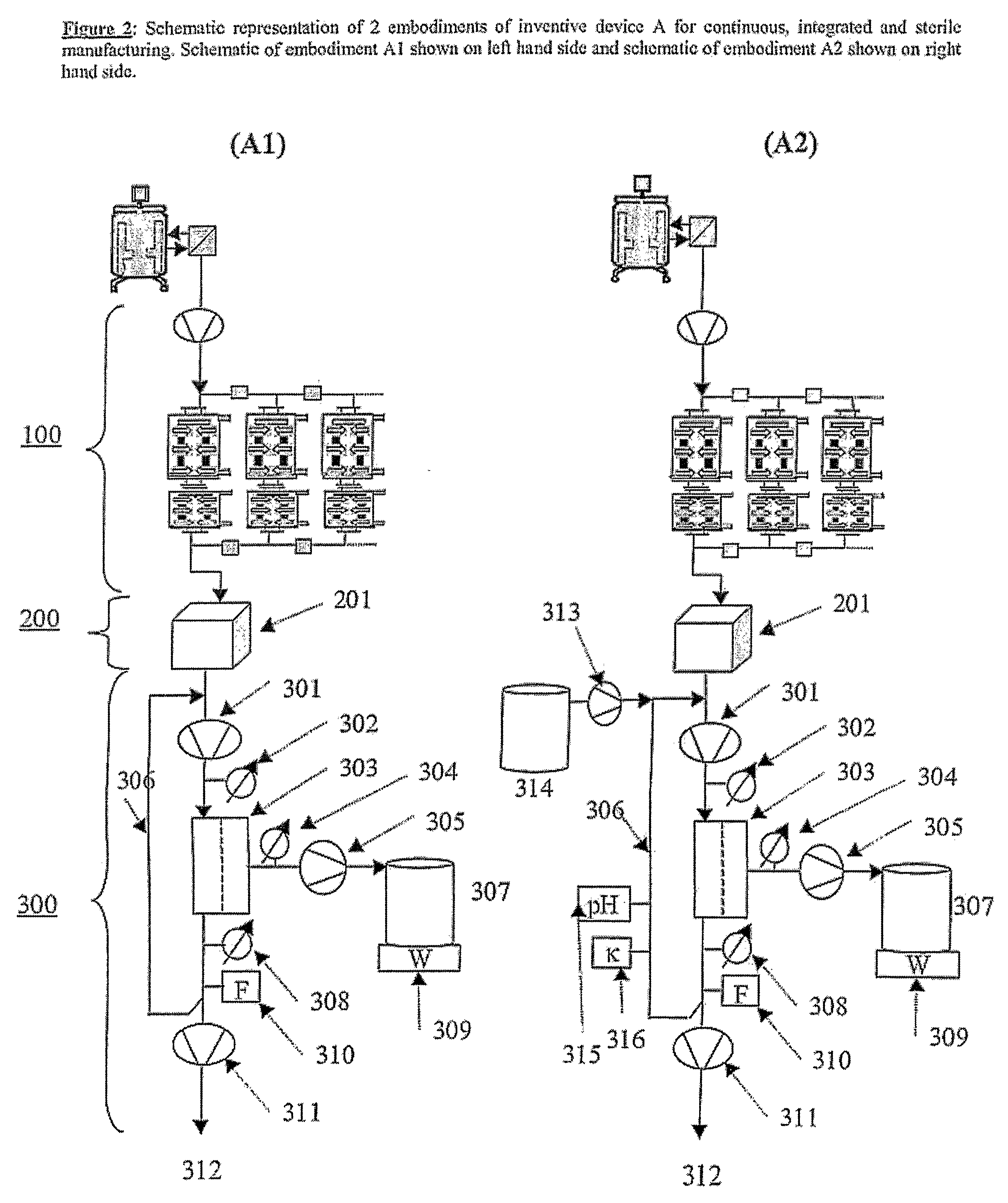

Devices and Methods for Integrated Continuous Manufacturing of Biological Molecules

ActiveUS20080269468A1Bioreactor/fermenter combinationsFactor VIIContinuous perfusionChemical physics

The present invention relates to a process and apparatus for purifying a molecule of interest from a heterogeneous clarified fluid mixture. The apparatus of the invention generally comprises a continuous perfusion fermentation system, a continuous particle removal system integrated with the perfusion fermentation system; and a continuous purification system integrated with the particle removal system, which is maintained under sterile conditions. The process comprises filtering a heterogeneous clarified fluid mixture by continuous ultrafiltration at a specific flow rate below the transition point of the molecule of interest in the pressure-dependent region of the flux versus TMP curve, wherein the specific flow rate is maintained substantially constant throughout the continuous ultrafiltration.

Owner:BAYER HEALTHCARE LLC

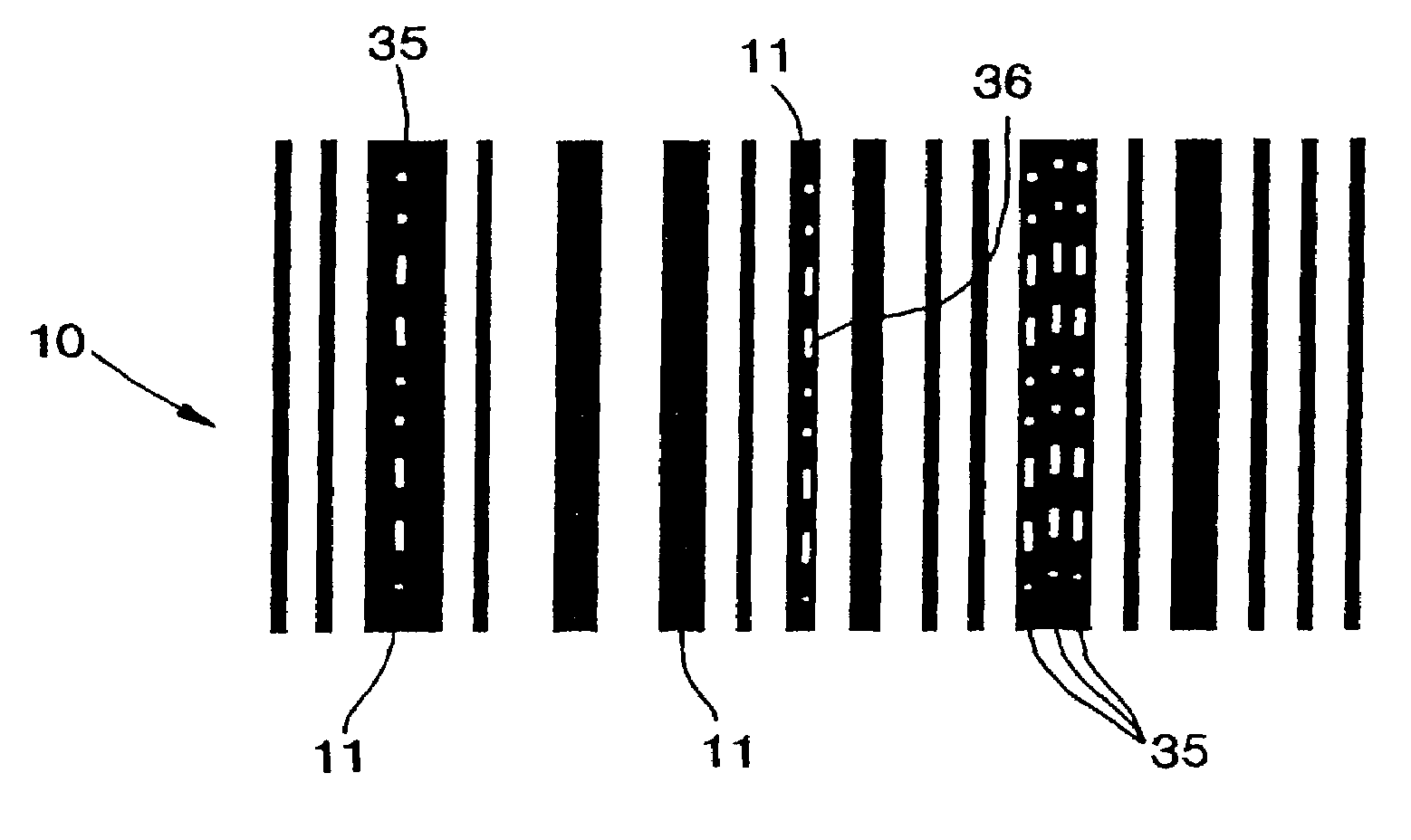

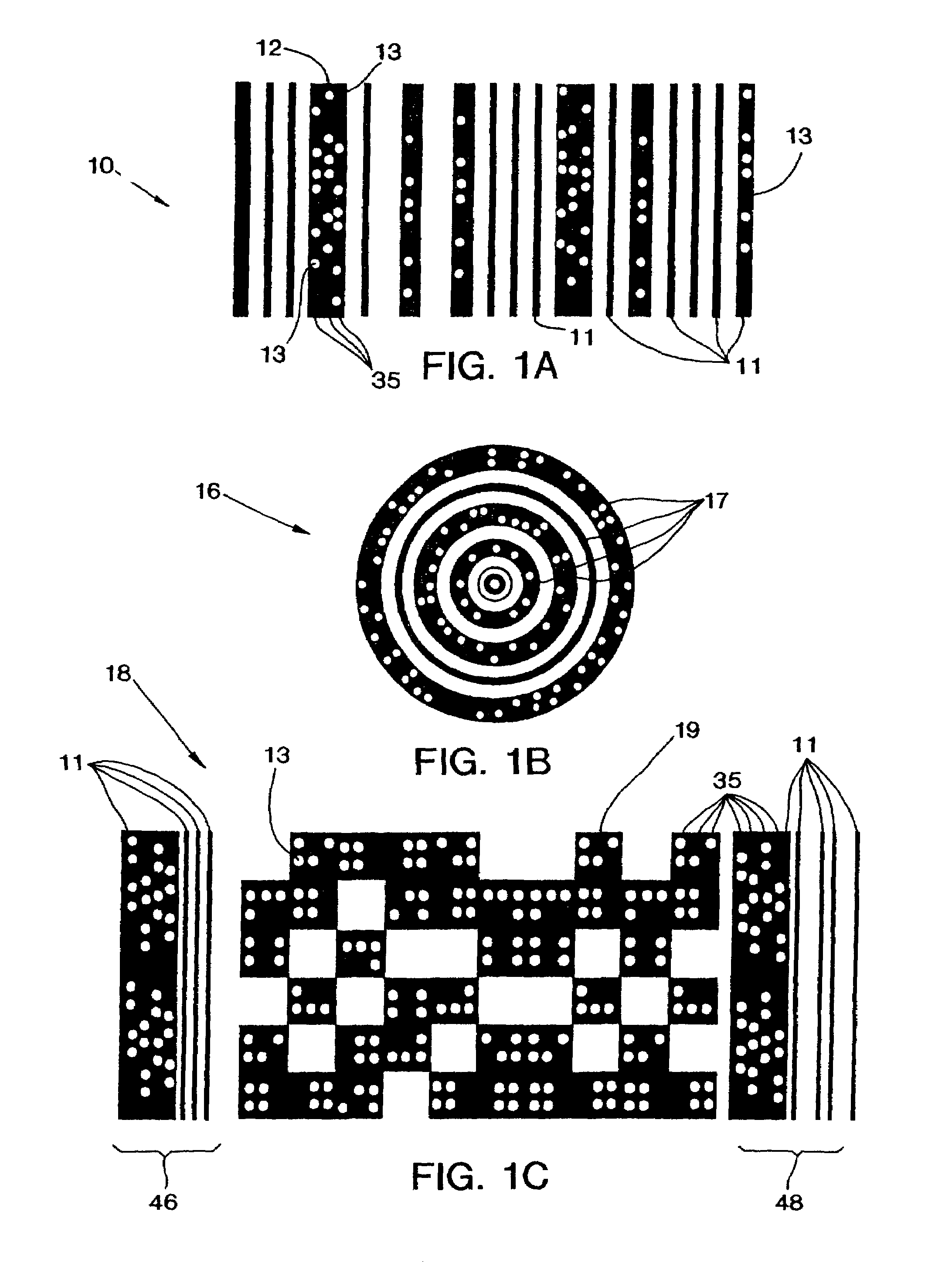

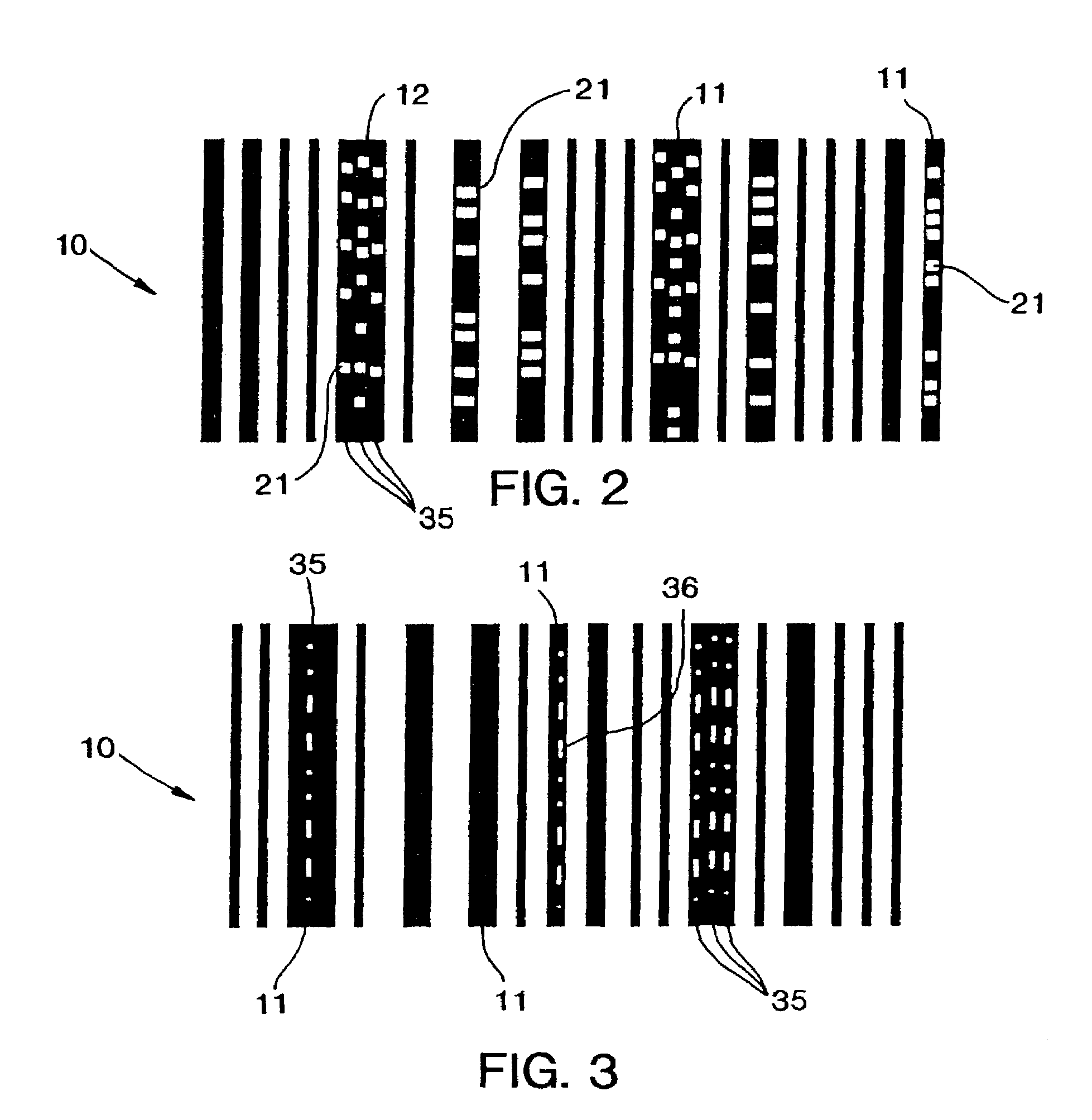

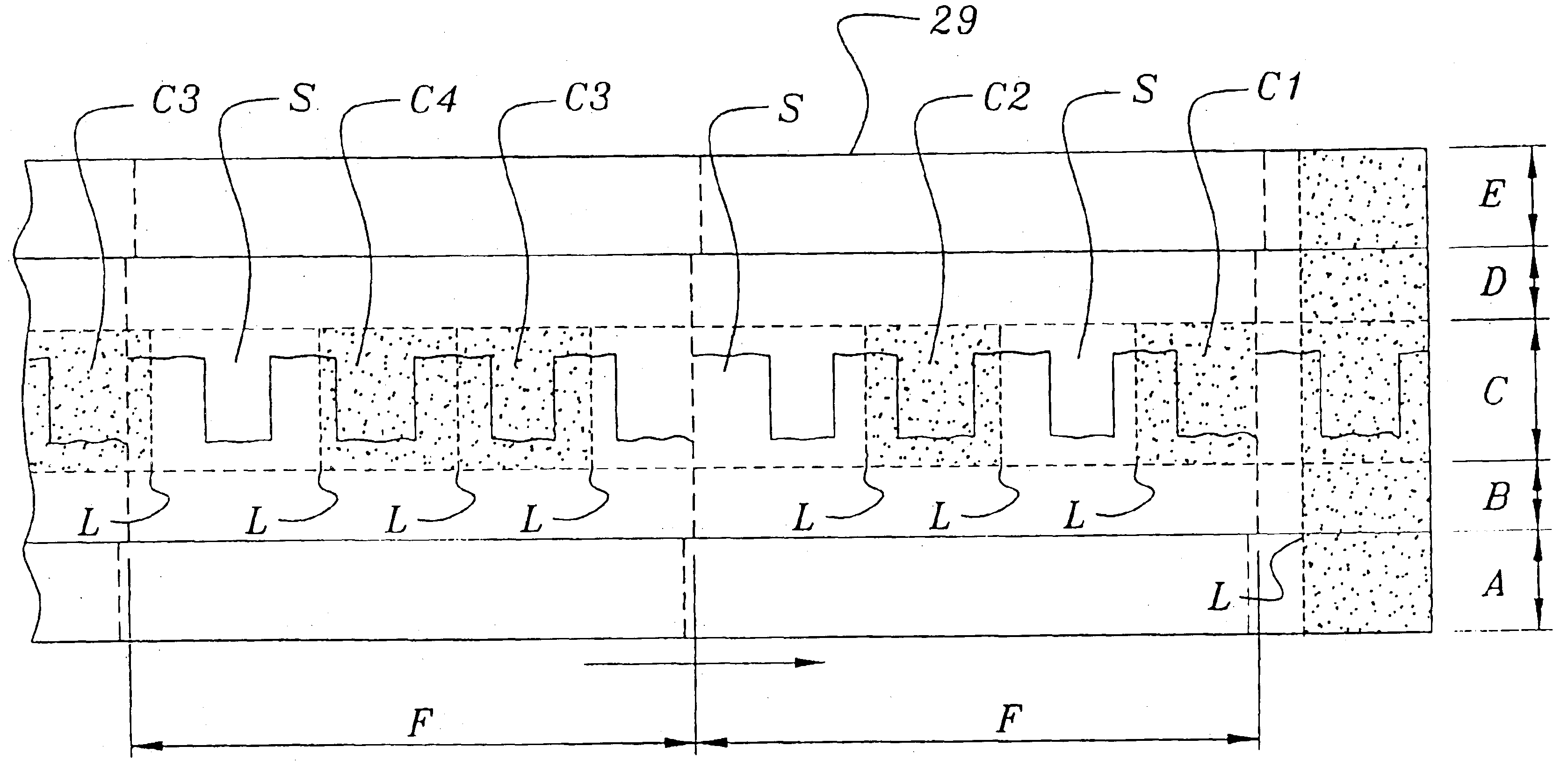

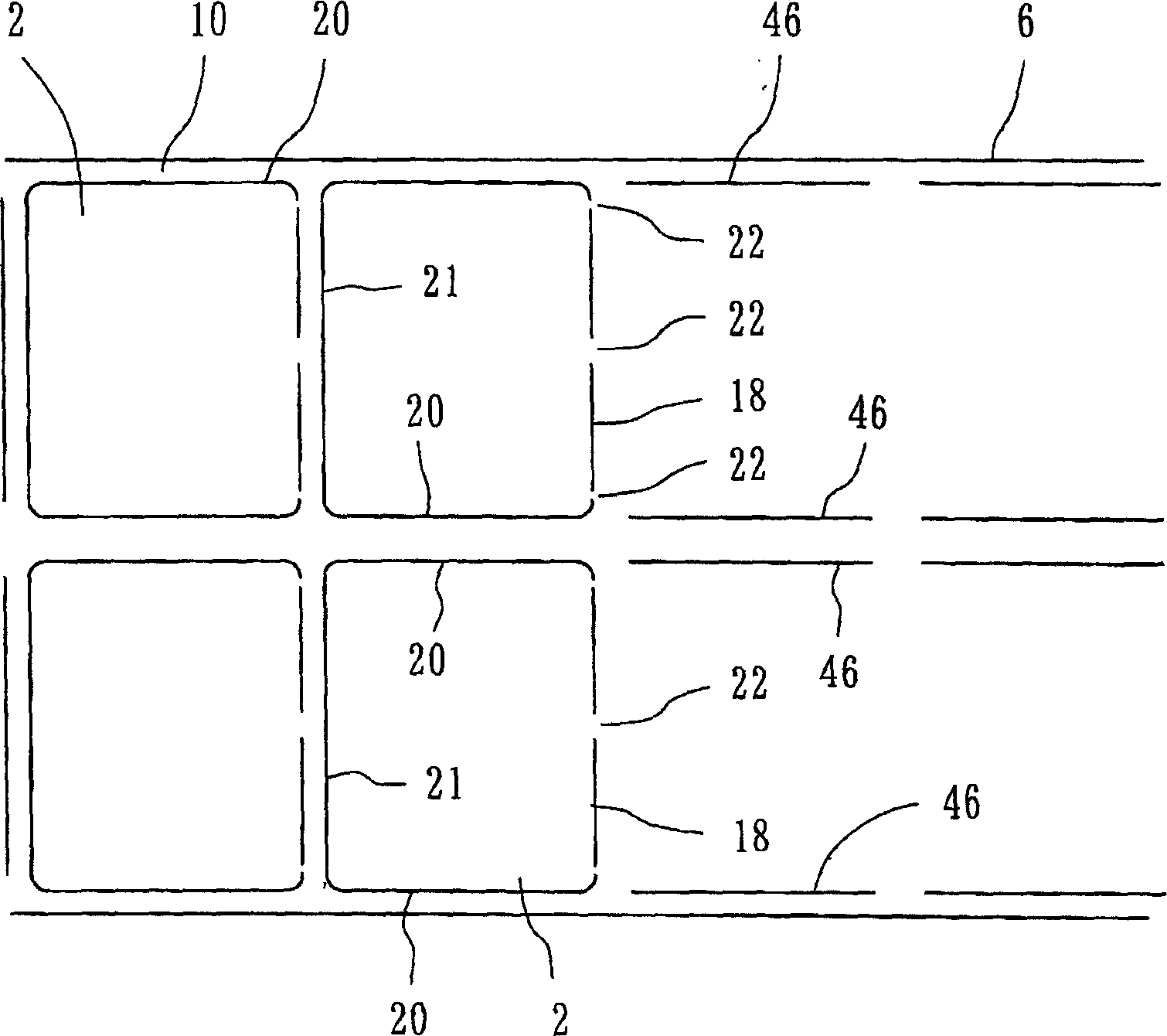

Method and apparatus for encoding and decoding bar codes with primary and secondary information and method of using such bar codes

InactiveUS6991164B2Character and pattern recognitionRecord carriers used with machinesScannerIn plane

A bar code (10) has primary information (46, 48, 50, 51) encoded in one direction (e.g., horizontally) and secondary information (13, 21, 36) encoded in another direction (e.g., vertically) in single (11) or multiple tracks (35) in selected ones of the vertical bars (11) of a bar code (10). Using a non-linear, variable amplitude scanner, all of the bars are scanned in the one direction to obtain all of the primary information and all of those vertical bars having secondary information are scanned in the other direction to obtain all of the secondary information. The one direction which is perpendicular to the vertical bars (11), is determined by first rotating the scan path axis (86, 87) until both start (46) and end (48) code bars are read thereby placing the scan path entirely within the total bar code, and, then, further rotating the scan path (88, 89) to determine the direction of the minimum crossing width (Lsc 80) of the total bar code (10). Secondary information is scanned in planes orthogonal to the one direction after those vertical bars (11) having such information are first identified and selected. In a preferred embodiment, the decoded secondary information may be used to control selected station process operations for selected products in a continuous manufacturing assembly line.

Owner:LEMELSON MEDICAL EDUCATION & RES FOUND PARTNERSHIP

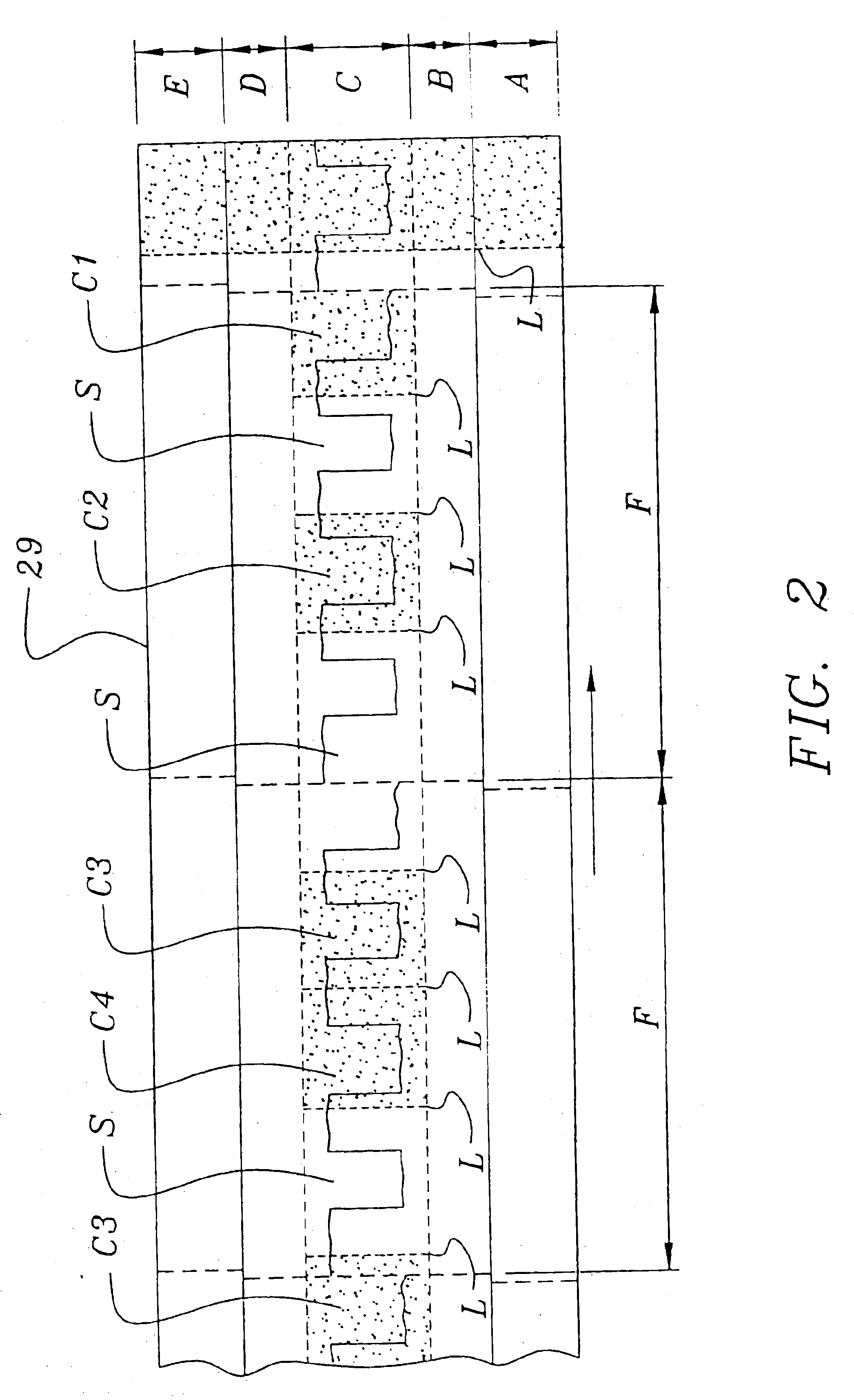

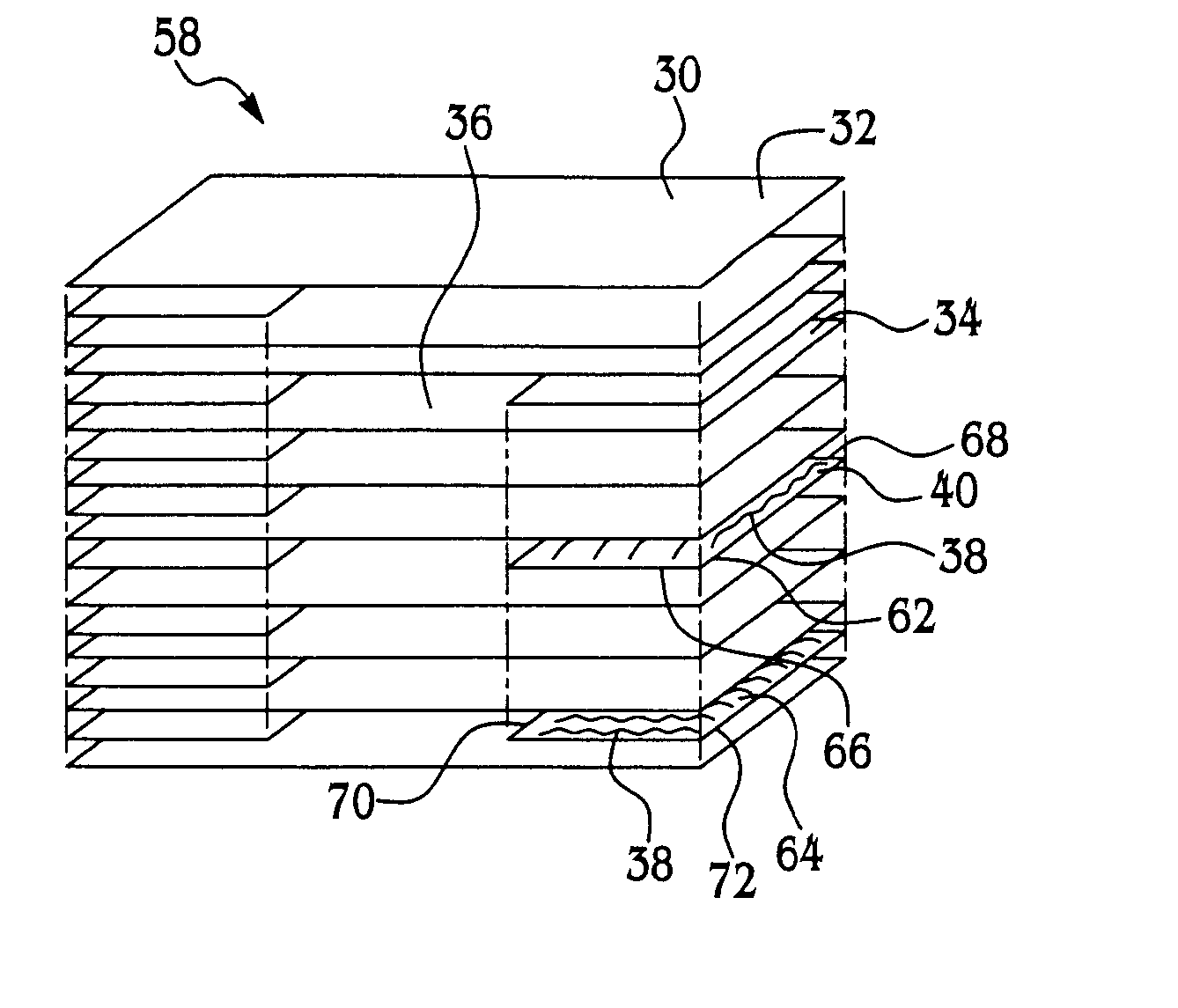

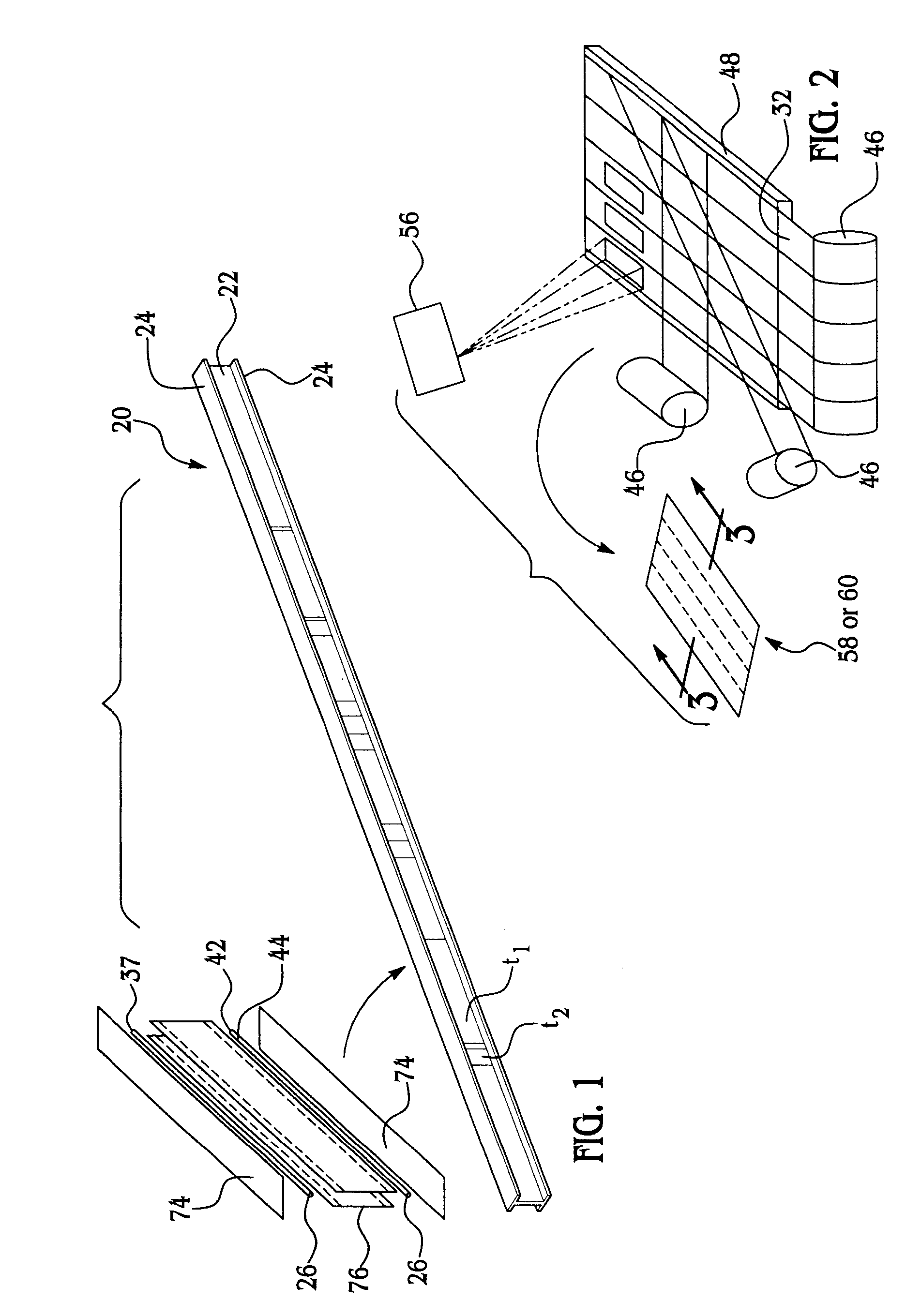

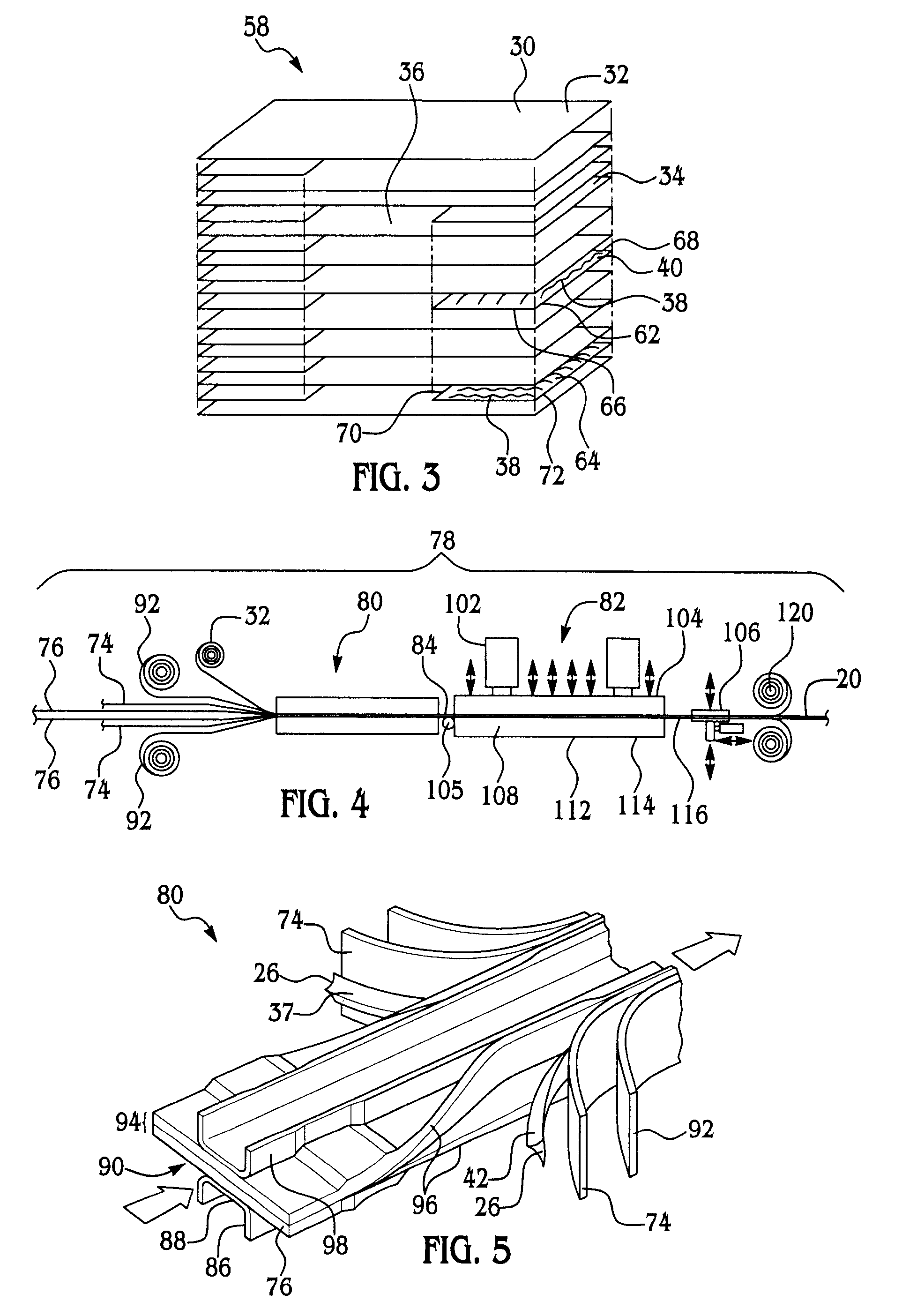

Multi-layered shingle and method of making same

InactiveUS6920730B2Good lookingSimple and efficient and economicalRoof covering using tiles/slatesLamination ancillary operationsEngineeringLaminated composites

A multi-layered shingle adapted to be positioned with other similar shingles in an overlapping arrangement on a roof to yield a simulated wooden shake roof covering comprising a headlap portion and a butt portion. The butt portion comprises a series of multi-layered tabs. All the tabs have the same number of layers and each multi-layered tab (a) is separated from the next adjacent multi-layered tab or tabs by a space or spaces, respectively, and (b) comprises an uppermost layer and at least two layers underlying the uppermost layer. Each underlying layer is laminated to the layer above it to form a multi-layered laminated composite. The laminated composite is integral with the headlap portion and the top surface of the uppermost layer of each tab is coplanar with the top surface of the headlap portion. The invention also includes an apparatus and a process for the continuous manufacture of the shingles of the invention.

Owner:CERTAINTEED CORP

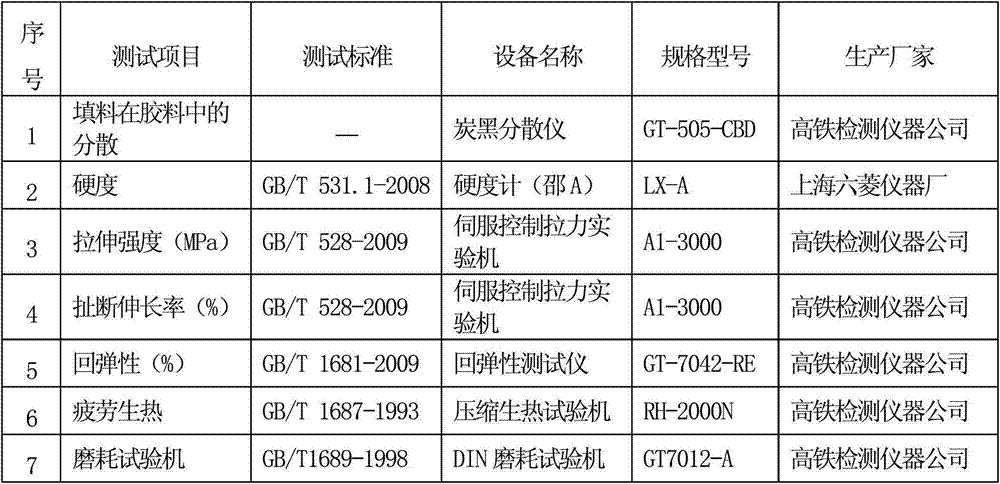

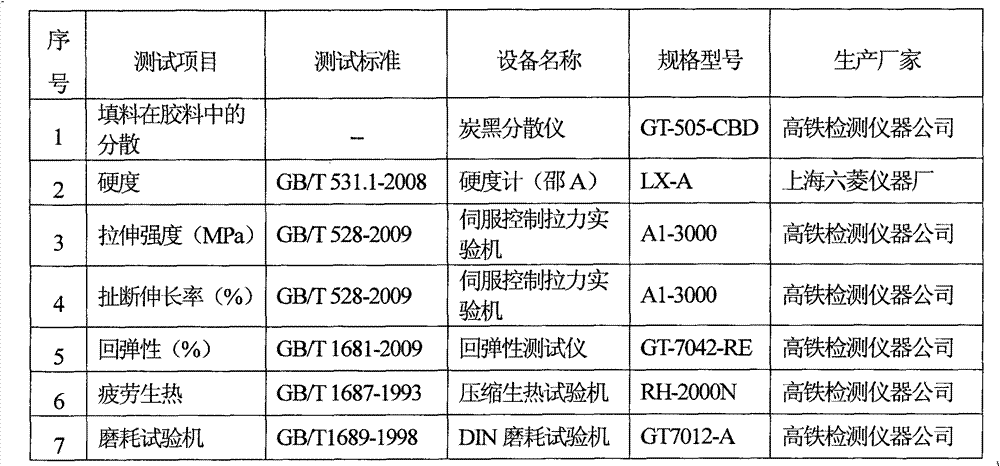

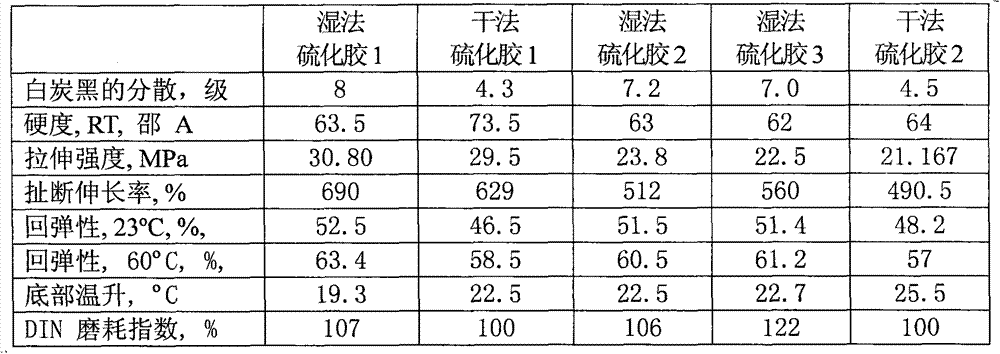

Continuous manufacturing method of rubber masterbatch and rubber masterbatch prepared by same

ActiveCN103113597AGood physical and mechanical propertiesQuality improvementMasterbatchPolymer science

The invention relates to a continuous manufacturing method of rubber masterbatch and rubber masterbatch prepared by the continuous manufacturing method. The invention discloses the continuous manufacturing method of rubber masterbatch. The continuous manufacturing method of rubber masterbatch comprises the following steps of: 1) adding stuffing into rubber liquor, and stirring to form a rubber / stuffing / solvent mixture; 2) feeding the rubber / stuffing / solvent mixture in step 1) to a flocculator, wherein the rubber / stuffing / solvent mixture is contacted and mixed with one or more of nitrogen, steam, stuffing aqueous slurry and oil, and flocculating to obtain a mixture of a rubber / stuffing compound and the solvent; and 3) removing the solvent and drying the mixture to obtain rubber / stuffing masterbatch. The invention further relates to masterbatch prepared by the method and a rubber product prepared by the masterbatch. Compared with the flocculating technology in current wet-method mixing, as no special requirements are posed to rubber and stuffing, the application range is wider. In addition, the manufacturing method is continuous in production process, efficient, low in energy consumption and less in labor, so that the cost is lower. Meanwhile, masterbatch prepared by the method is quite excellent in processability, physical and mechanical properties and product quality.

Owner:EVE RUBBER RES INST

Gel electrolytes for dye sensitized solar cells

Replacing liquid electrolytes with solid or quasi-solid electrolytes facilitates the production of photovoltaic cells using continuous manufacturing processes, such as roll-to-roll or web processes, thus creating inexpensive, lightweight photovoltaic cells using flexible plastic substrates.

Owner:MERCK PATENT GMBH

Continuous Fabrication of Parts Using In-Feed Spools of Fiber Reinforced Thermoplastic

ActiveUS20070175572A1Automate processingNeed can be reduced eliminatedWood veneer joiningBaby linensEngineeringVarying thickness

Thermoplastic composite laminate parts with tailored and varying thickness and / or curved sections are manufactured in a continuous process. Automated equipment or hand lay-up is used to collate parts or components into a multi-layer stack. Each stack contains all plies, including ply build-up areas, tacked in the proper location to maintain orientation and location. Some or all of the plies may be continuously fed from spools of single or multiply ply material. Ply consolidation tooling contains all necessary part features and is coordinated to the customized multiple ply stacks to form a single integrated thermoplastic composite laminate potentially having areas of differing thickness from the multiple ply stacks.

Owner:THE BOEING CO

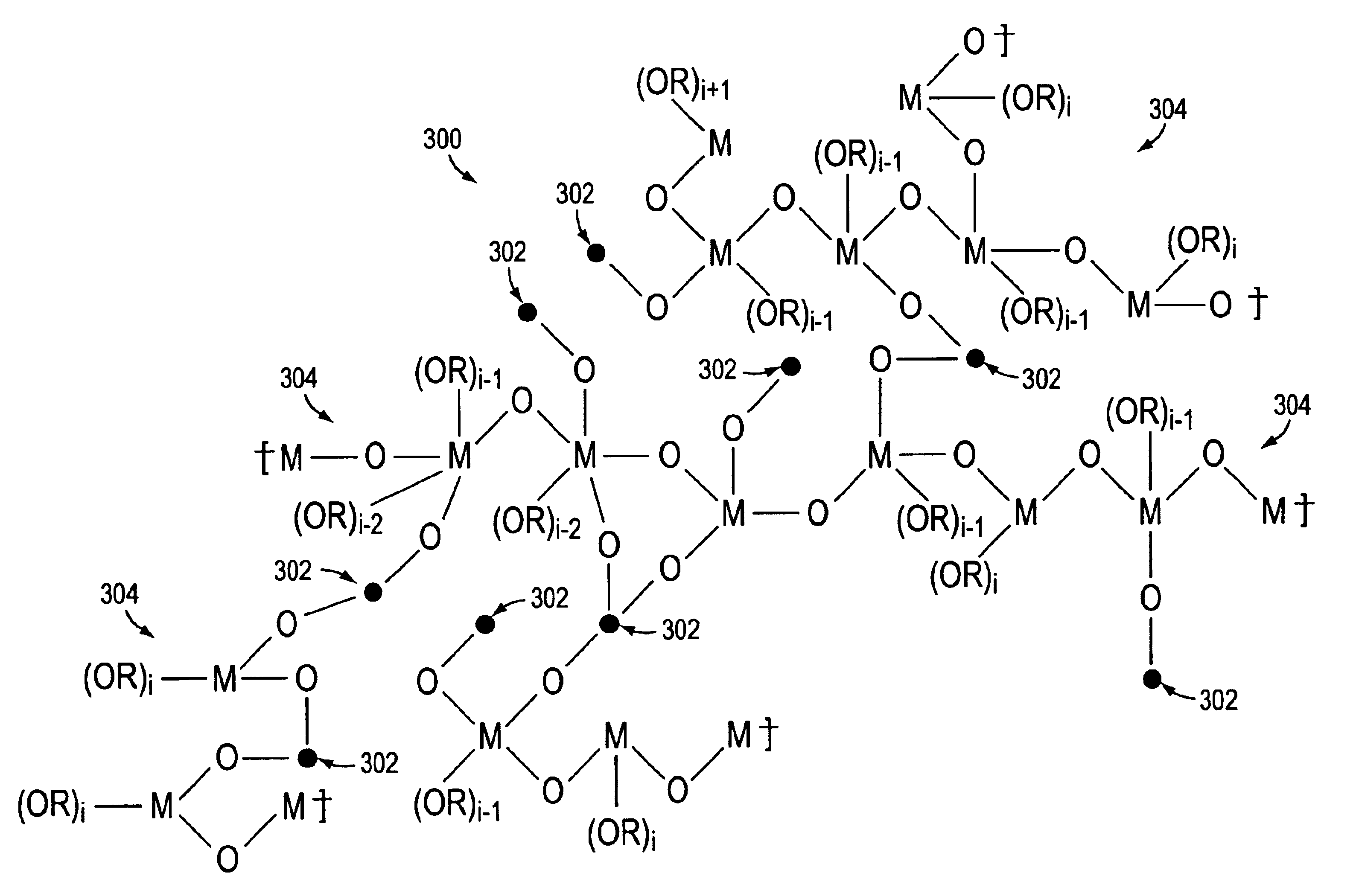

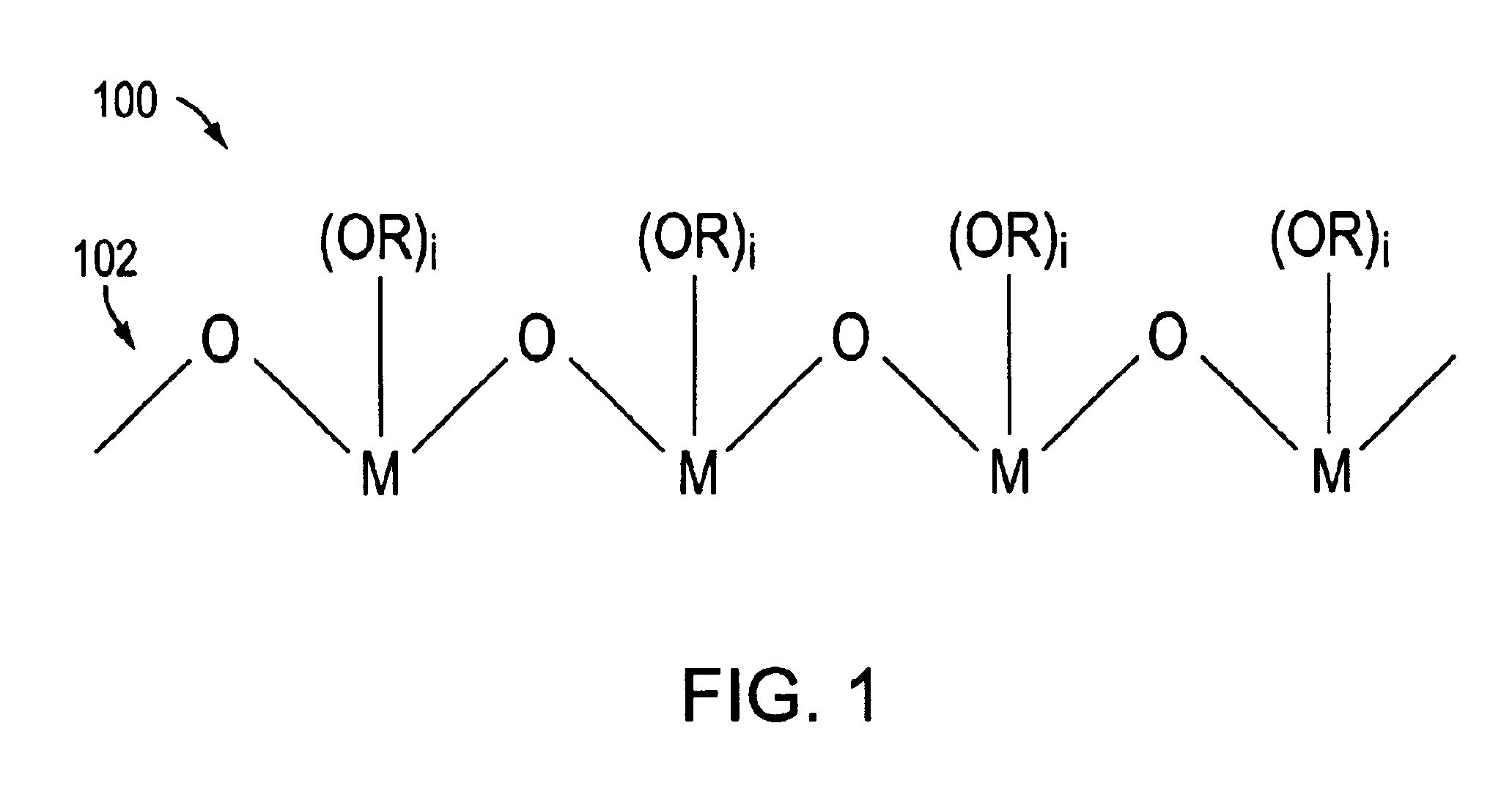

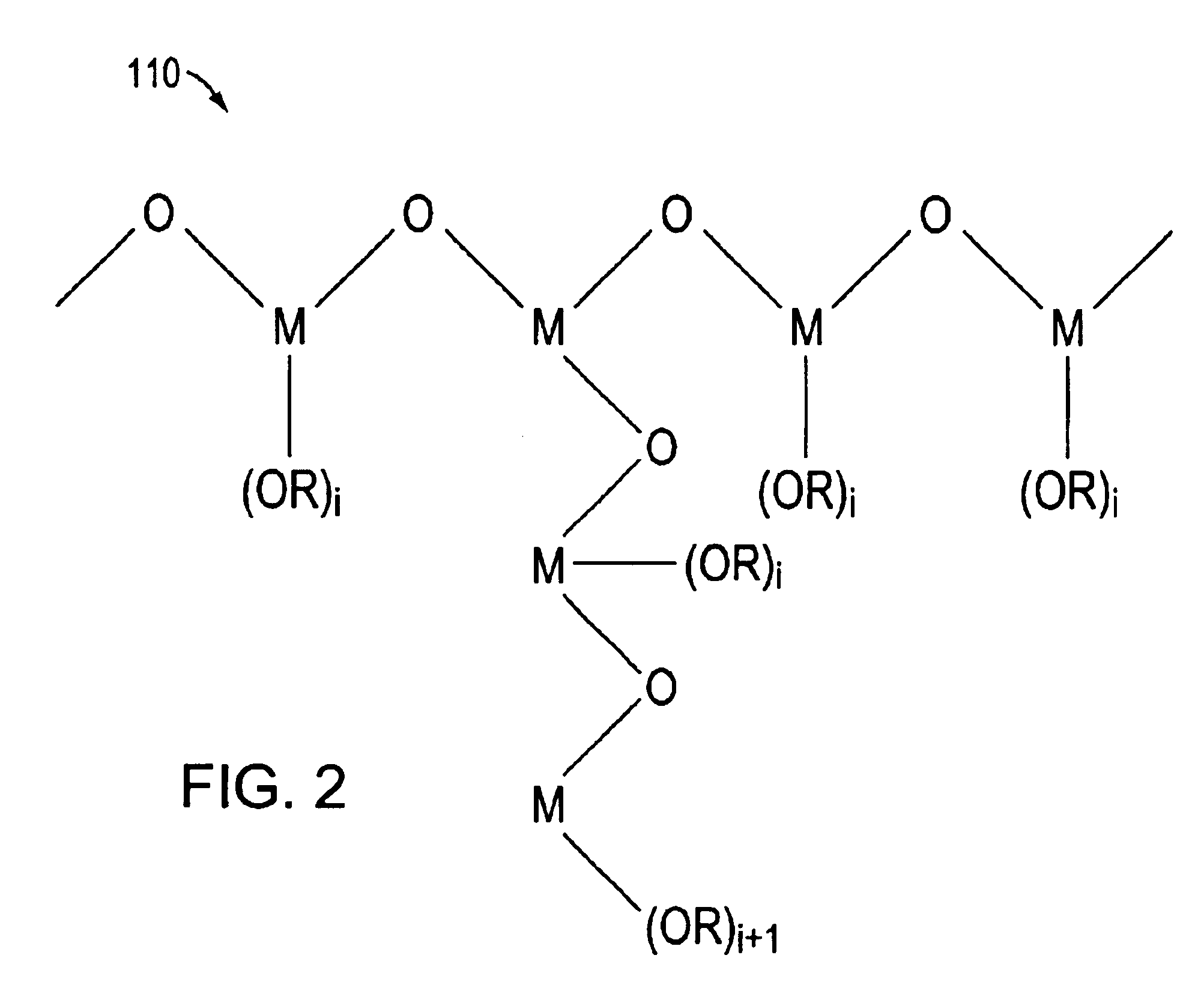

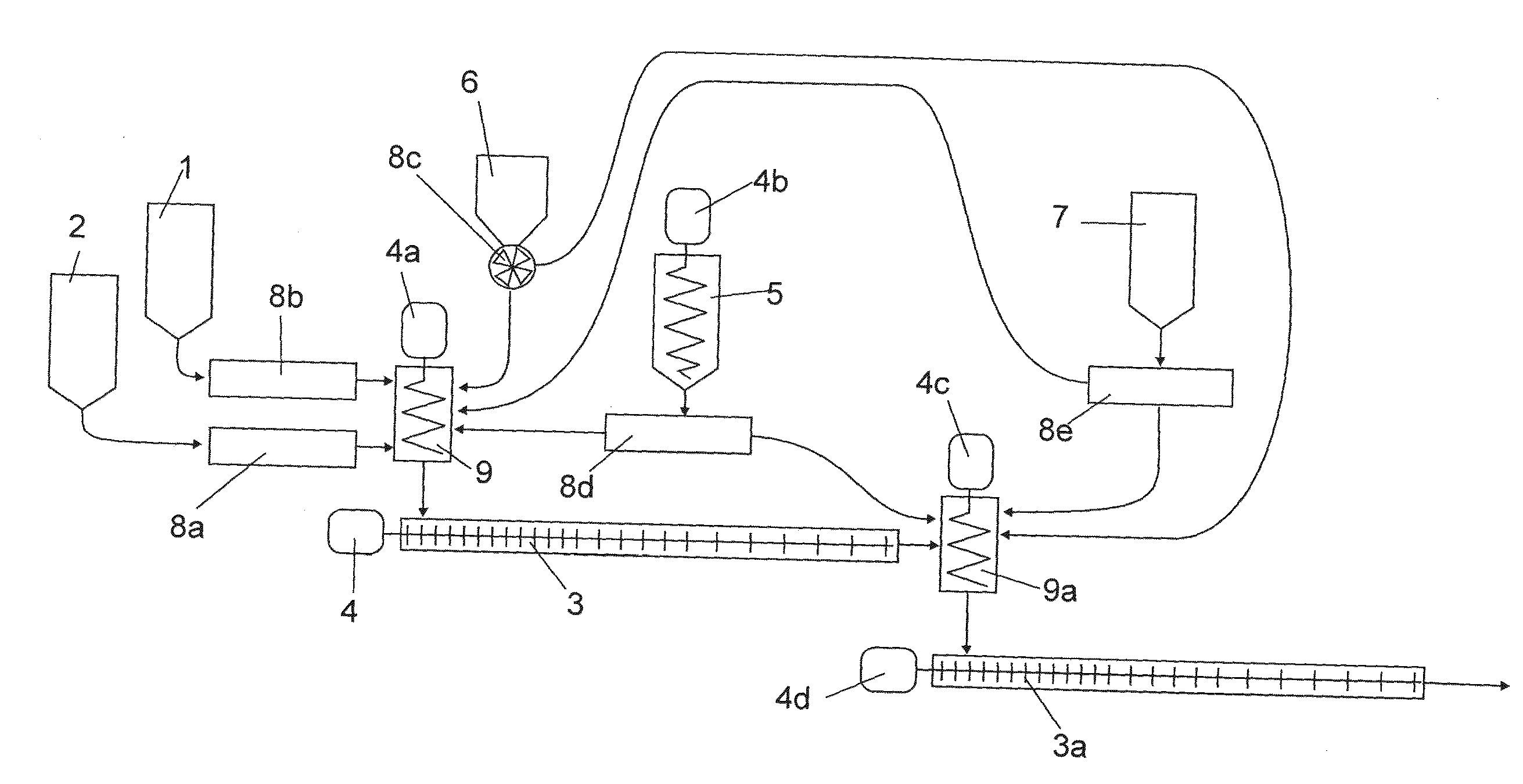

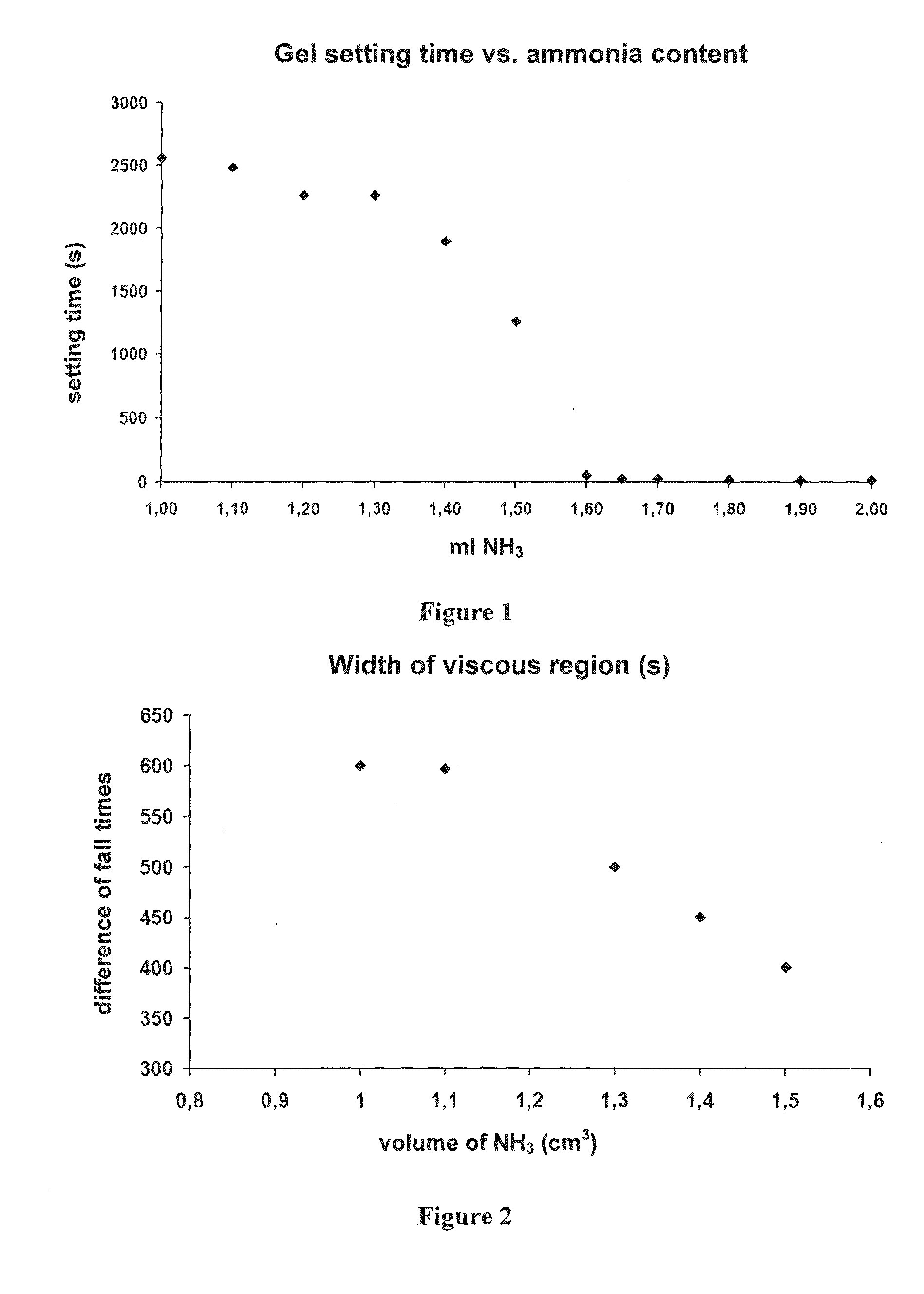

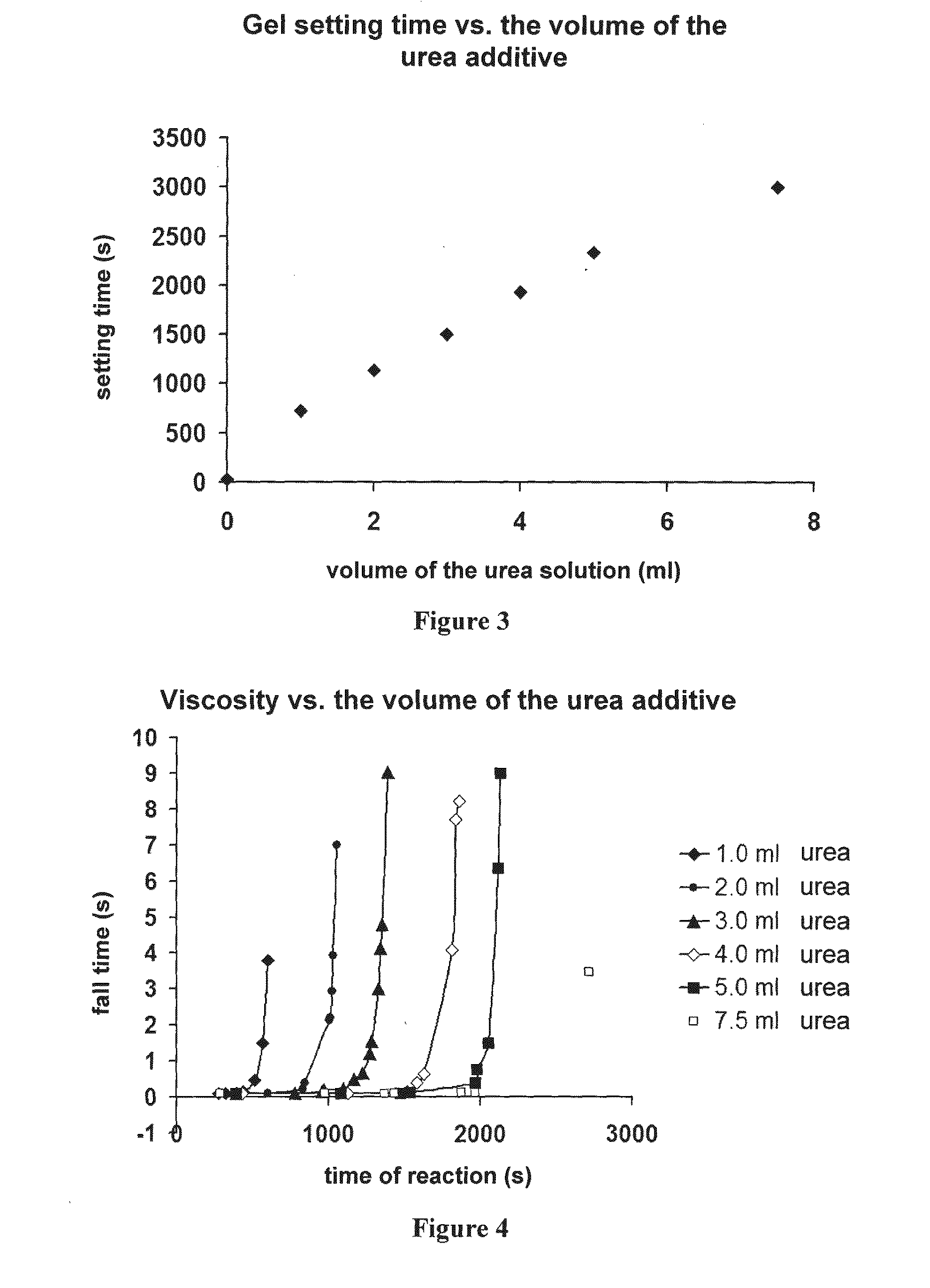

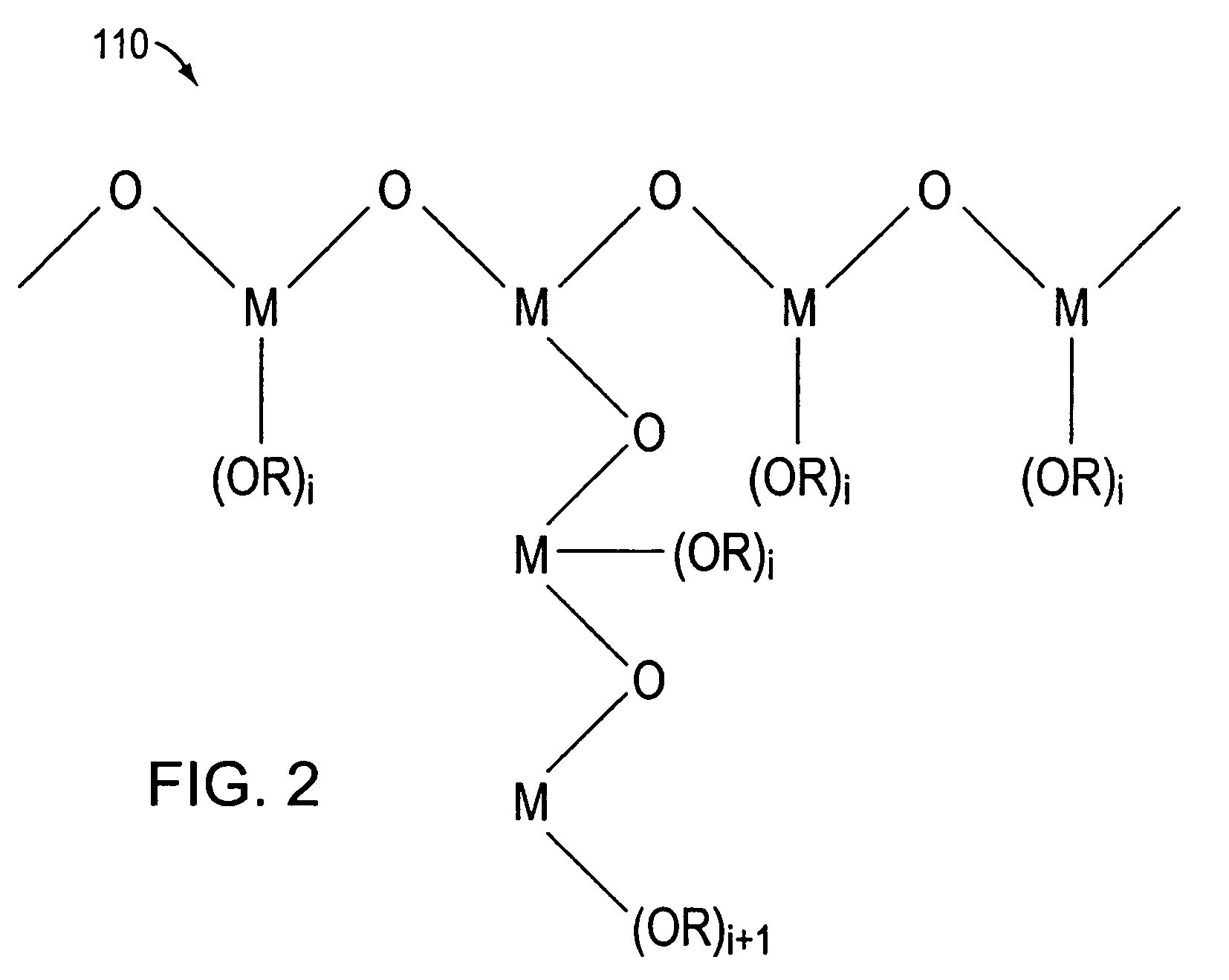

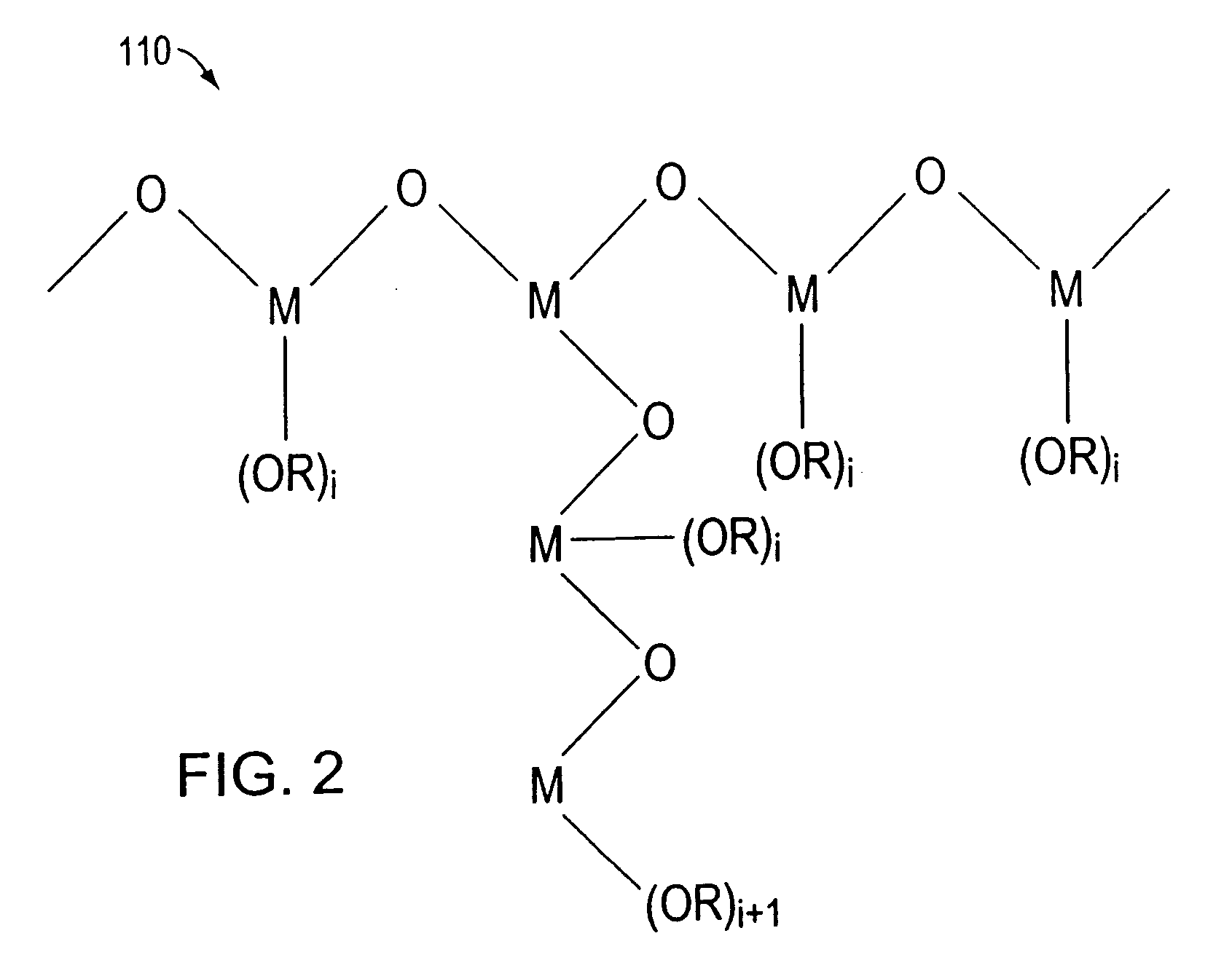

Method for the preparation of composite silica alcogels, aerogels and xerogels, apparatus for carrying out the method continuously, and novel composite silica alcogels, aerogels and xerogels

The invention relates to a method for the preparation of composite silica alcogels, aerogels and xerogels, comprisingi) providing a reaction mixture comprising at least the following:silane reagent,base catalyst,gelation retarding additive,aqueous / organic solvent mixture,guest particle,ii) agitating the reaction mixture as necessary and sufficient until achieving the viscosity where the spontaneous movement of the guest particles does not occur anymore; andiii) shaping the material obtained to a desired shape during or after step ii); theniv) drying, if desiredThe method according to the invention is also useful in continuous manufacturing technology, and the invention provides an apparatus for applying the method.The invention further provides novel composite silica alcogels, aerogels or xerogels obtainable by the method according to the invention.

Owner:DEBRECEN UNIV OF

Continuous manufacturing method for rubber masterbatch, rubber masterbatch prepared by using continuous manufacturing method and rubber product

The invention relates to a continuous manufacturing method for rubber masterbatch, the rubber masterbatch prepared by using the continuous manufacturing method and a rubber product. The manufacturing method comprises the following steps: 1) adding a filling material into a rubber solution, carrying out stirring so as to form a rubber / filling material / solvent mixture and subjecting the rubber / filling material / solvent mixture to further fine dispersion and refined dispersion so as to improve the dispersion degree of the filling material in the rubber solution; 2) subjecting rubber and the filling material in the rubber / filling material / solvent mixture having undergone refined dispersion in step 1) to hetero-coagulation so as to obtain a mixture of a rubber / filling material compound and a solvent; and 3) removing the solvent and drying the mixture so as to obtain the rubber / filling material masterbatch. The invention further provides the masterbatch prepared by using the manufacturing method and the rubber product prepared from the masterbatch. Compared with a conventional wet rubber compounding technology, the invention has the following advantages: there are no special requirements on rubber and the filling material, the prepared masterbatch has a wide application scope, and dispersity of the filling material in a rubber compound is accordingly improved.

Owner:EVE RUBBER RES INST

Low temperature interconnection of nanoparticles

InactiveUS7094441B2Light-sensitive devicesFrom normal temperature solutionsNanoparticleInterconnection

A polymeric linking agent enables the manufacture of photovoltaic cells on flexible substrates, including, for example, polymeric substrates. Photovoltaic cells may be fabricated by a relatively simple continuous manufacturing process, for example, a roll-to-roll process, instead of a batch process.

Owner:MERCK PATENT GMBH

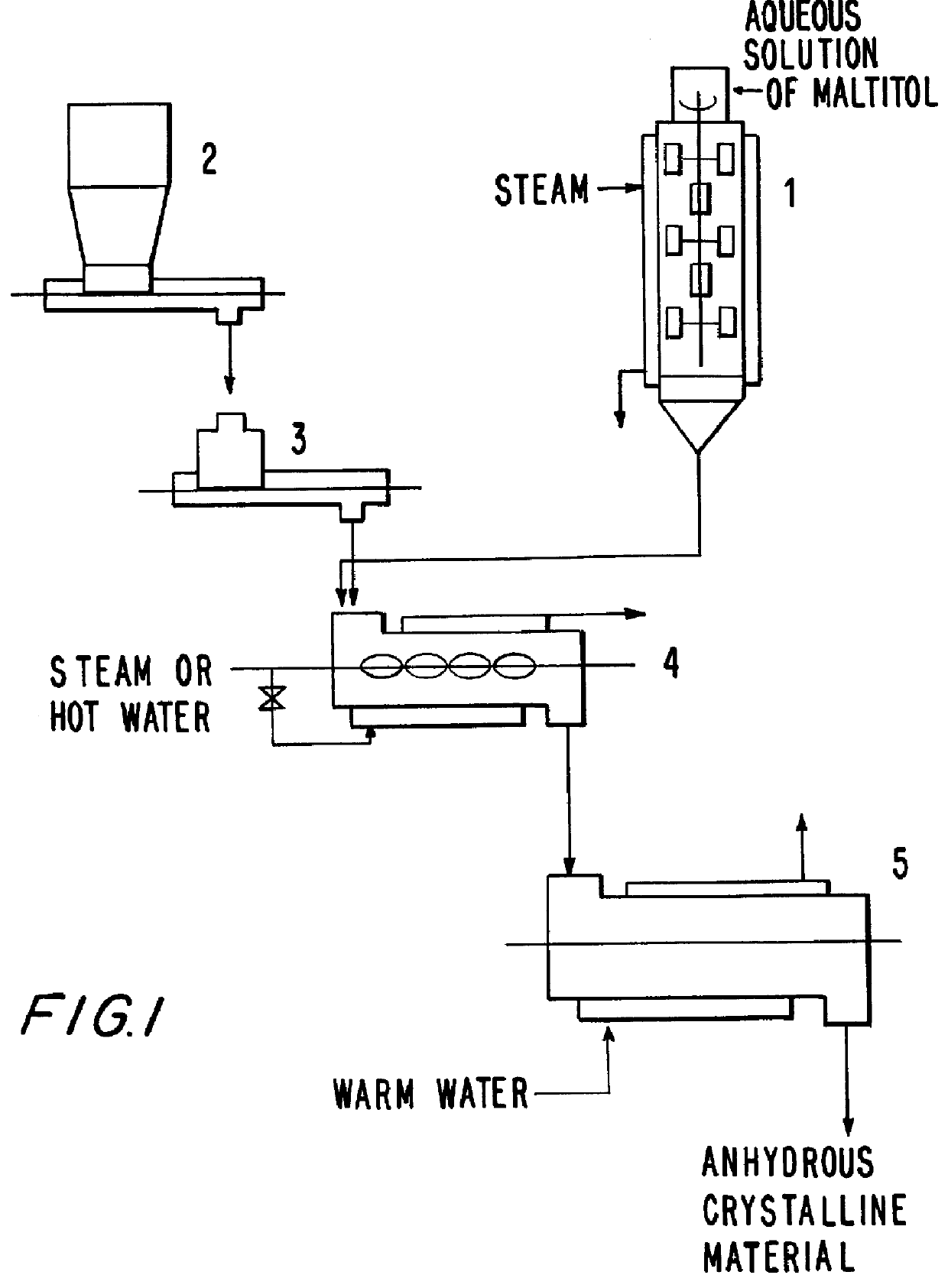

Method for the continuous manufacture of anhydrous crystalline maltitol and a manufacturing apparatus therefor

InactiveUS6120612ALow production costLabor expenseSugar derivativesSugar crystallisationHigh concentrationPolymer science

Disclosed herein is a continuous manufacturing method for anhydrous crystalline maltitol comprising the following steps: (i) a heating and concentrating step where an aqueous solution containing maltitol in which maltitol is a main ingredient is continuously heated and concentrated to give a concentrated solution having a high concentration; (ii) a seed crystal adding and mixing step where the seed crystals are added to and mixed with the above concentrated solution with heating to give a massceuite containing the seed crystals; and (iii) a crystal aging step where the massceuite is subjected to disintegration, mixing, stirring and transfer in an atmosphere in which temperature and moisture are adjusted to proceed the crystallization.

Owner:HAYASHIBARA BIOCHEMICAL LAB INC +1

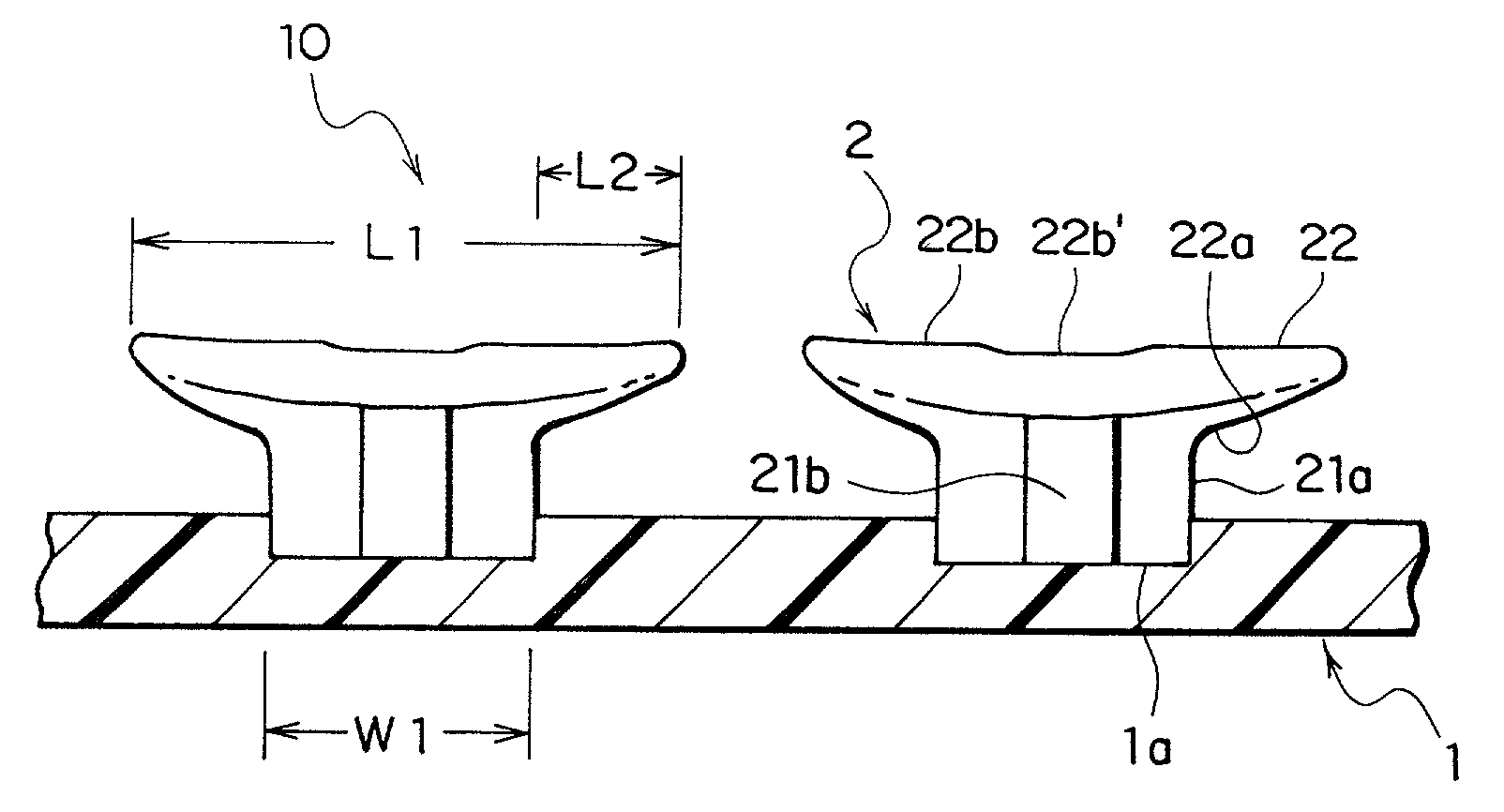

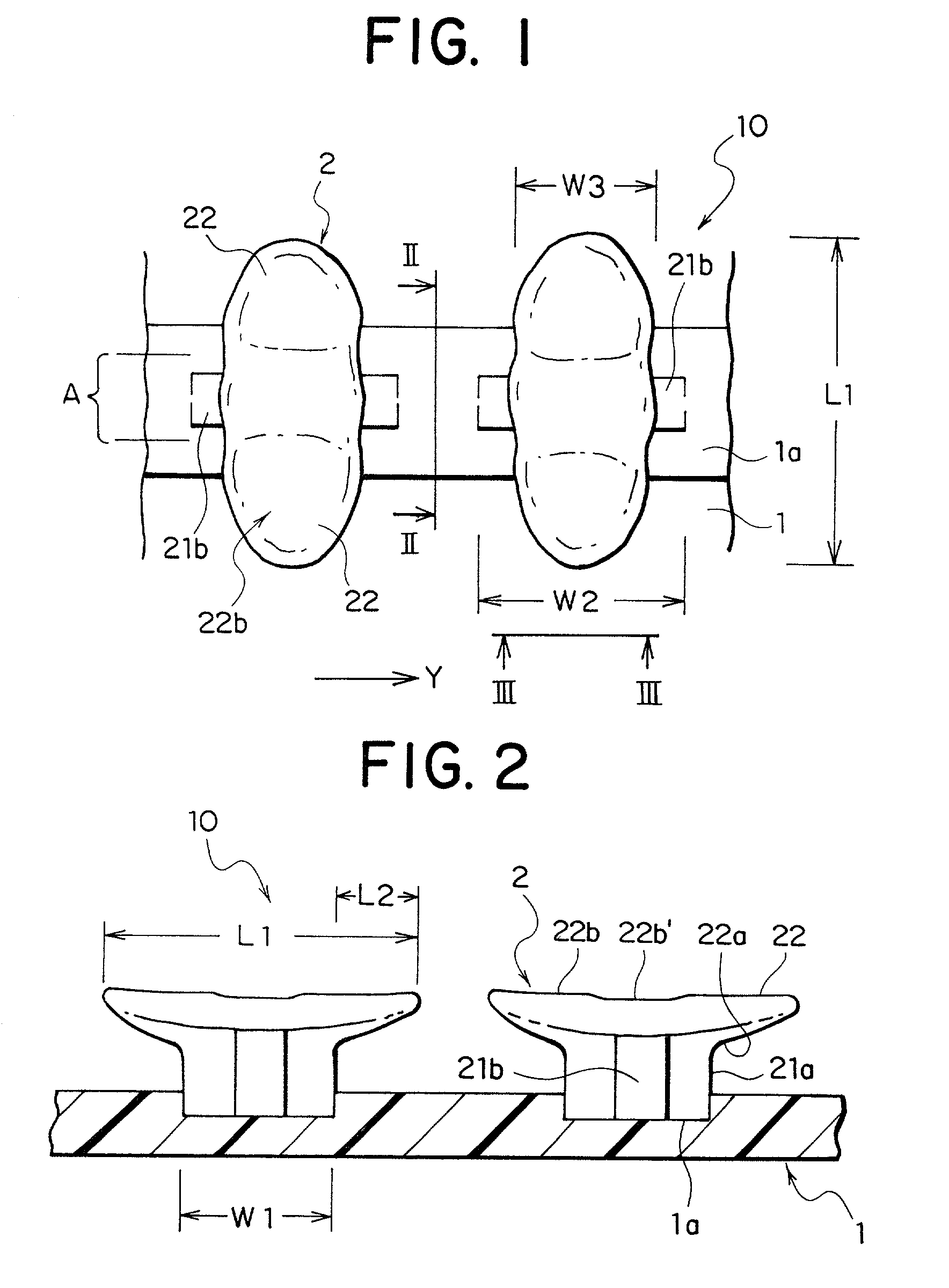

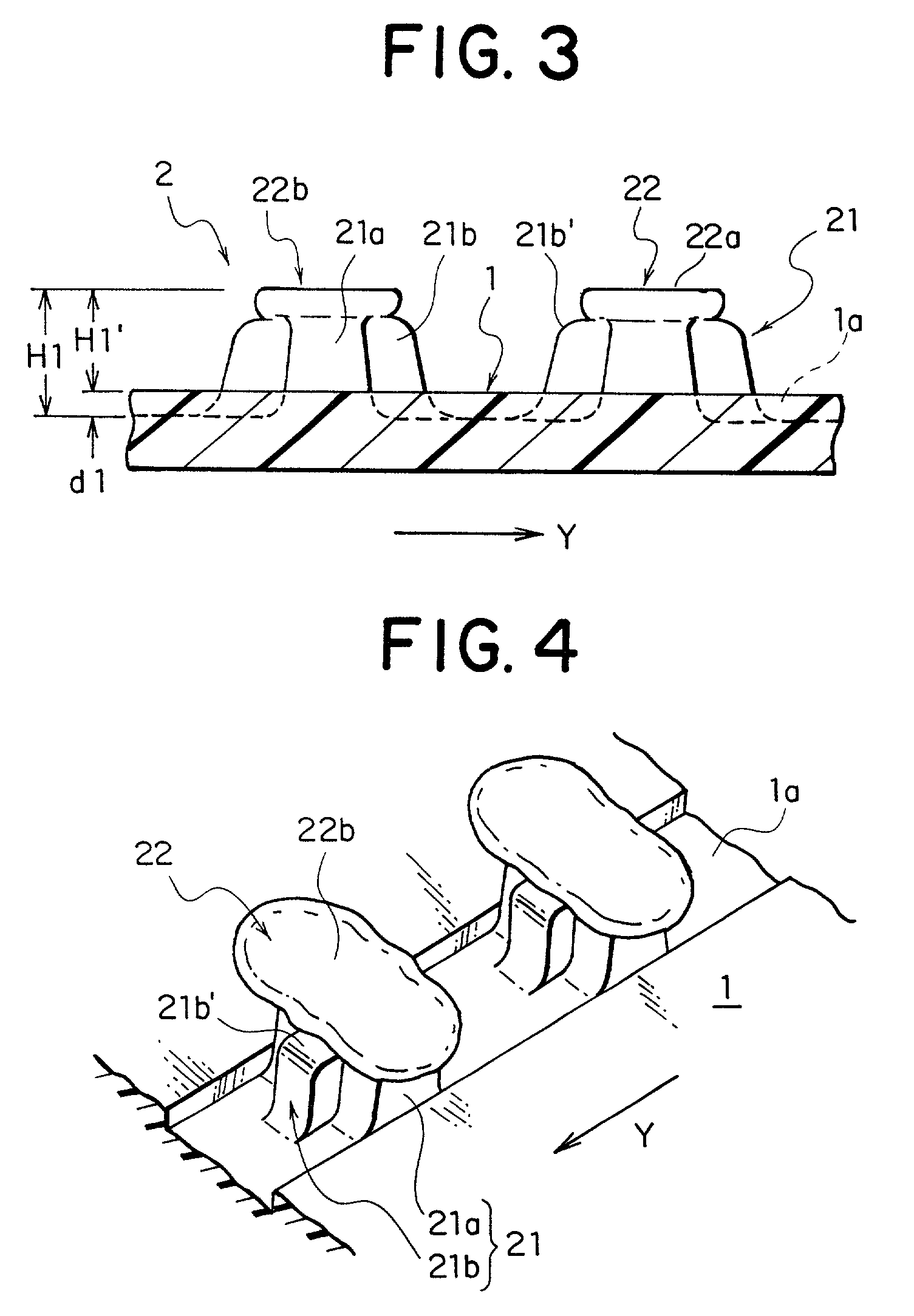

Integral molded surface fastener, and continuous manufacturing method and continuous manufacturing apparatus therefor

InactiveUS20020124359A1Increase participation rateSatisfactory durabilitySnap fastenersLayered productsFiberEngineering

An integral molded surface fastener having minute and peculiar engaging elements, which engage with minute, thickly wooded fiber piles securely while each engaging element secures appropriate engagement strength, shearing strength and separation strength is provided. Further, texture of a surface of the surface fastener is improved and a height of the engaging elements protruded from a surface of a substrate is lower than a conventional type, thereby preventing the engaging elements from being fallen down by a pressing strength. At the same time, a high engaging ratio with a mating pile piece is secured and a durability required for this kind of fastener is satisfied. Preferably, a desired plasticity and tearing strength of the flat substrate are secured. More specifically, a molded surface fastener having minute engaging elements of thermoplastic resin formed together with a substrate by continuous molding is provided, the engaging elements being hook-type engaging elements each comprised of a single column portion having a substantially cross-shaped section provided by intersection of a first column portion and a second column portion and rectangular thin plate-like engaging heads extended in the shape of wings in opposite directions along the width direction of the first column portion intersecting the second column portion around a top end of the column portion, and having substantially the same width dimension as the width dimension of a top end of the second column portion.

Owner:YKK CORP

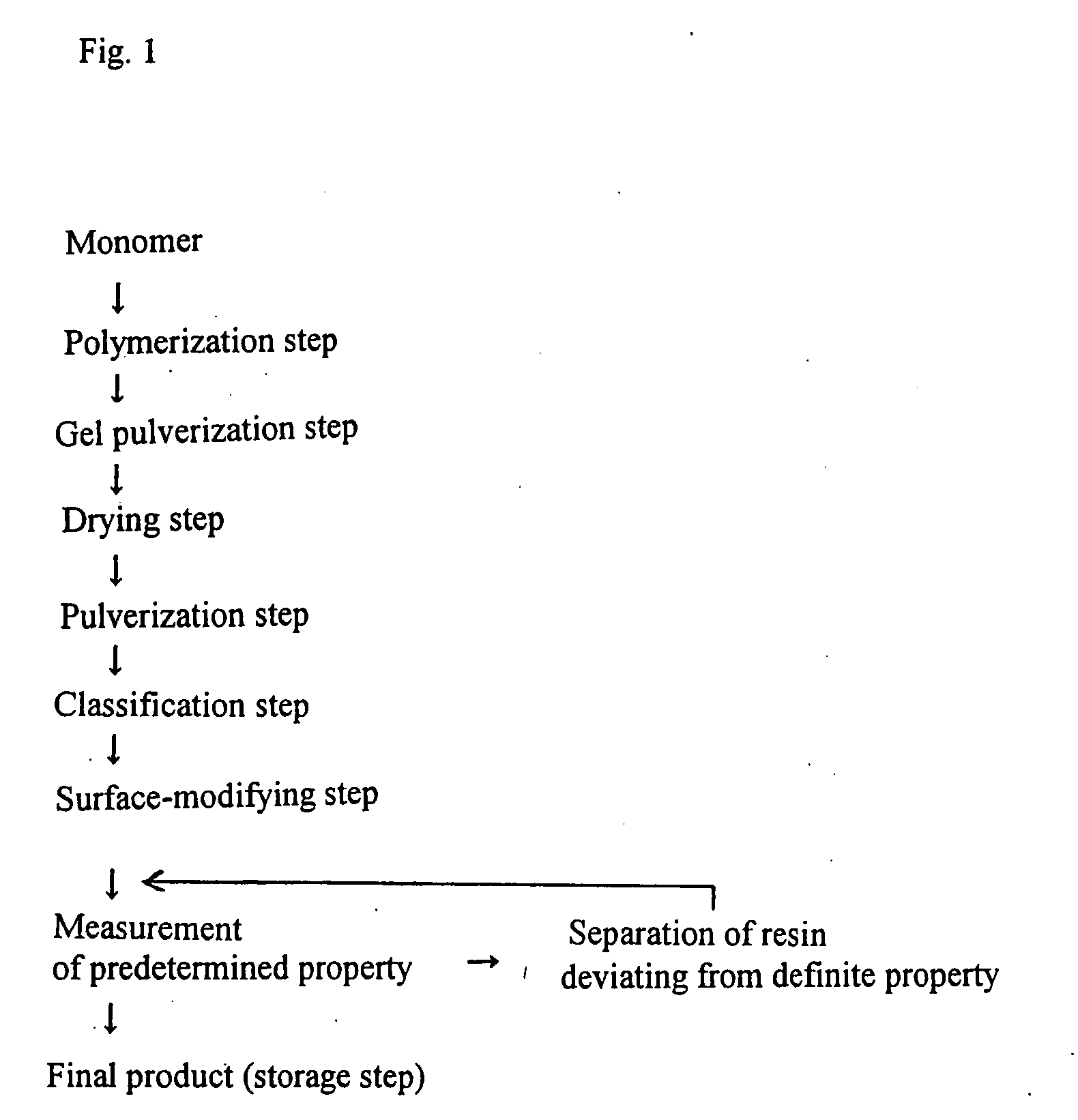

Process for continuous production of water-absorbent resin product

ActiveUS20070149691A1Quality improvementHigh propertyAbsorbent padsUsing optical meansProduction linePolymer science

There is disclosed a process for continuous production of a water-absorbent resin product by which the water-absorbent resin product having high properties can continuously be produced easily and inexpensively with stable constant quality. In addition, there is disclosed a water-absorbent resin product having high properties and being stable in quality. The process comprises the following steps of: (A) measuring a water-absorbent resin by its predetermined property and / or its predetermined component content, wherein the water-absorbent resin comes being continuously produced via a classification step and / or a surface-modifying step; (B) separating a predetermined amount of water-absorbent resin (a) from the water-absorbent resin that comes being continuously produced, wherein the water-absorbent resin (a) is a water-absorbent resin which displays not less than a definite value and / or a water-absorbent resin which displays not more than a definite value as to the predetermined property and / or the predetermined component content in accordance with results of the aforementioned measurement; and (C) mixing at least a portion of the aforementioned separated predetermined amount of water-absorbent resin (a) into a water-absorbent resin that comes being continuously produced via a classification step and / or a surface-modifying step on the same or another production line.

Owner:NIPPON SHOKUBAI CO LTD

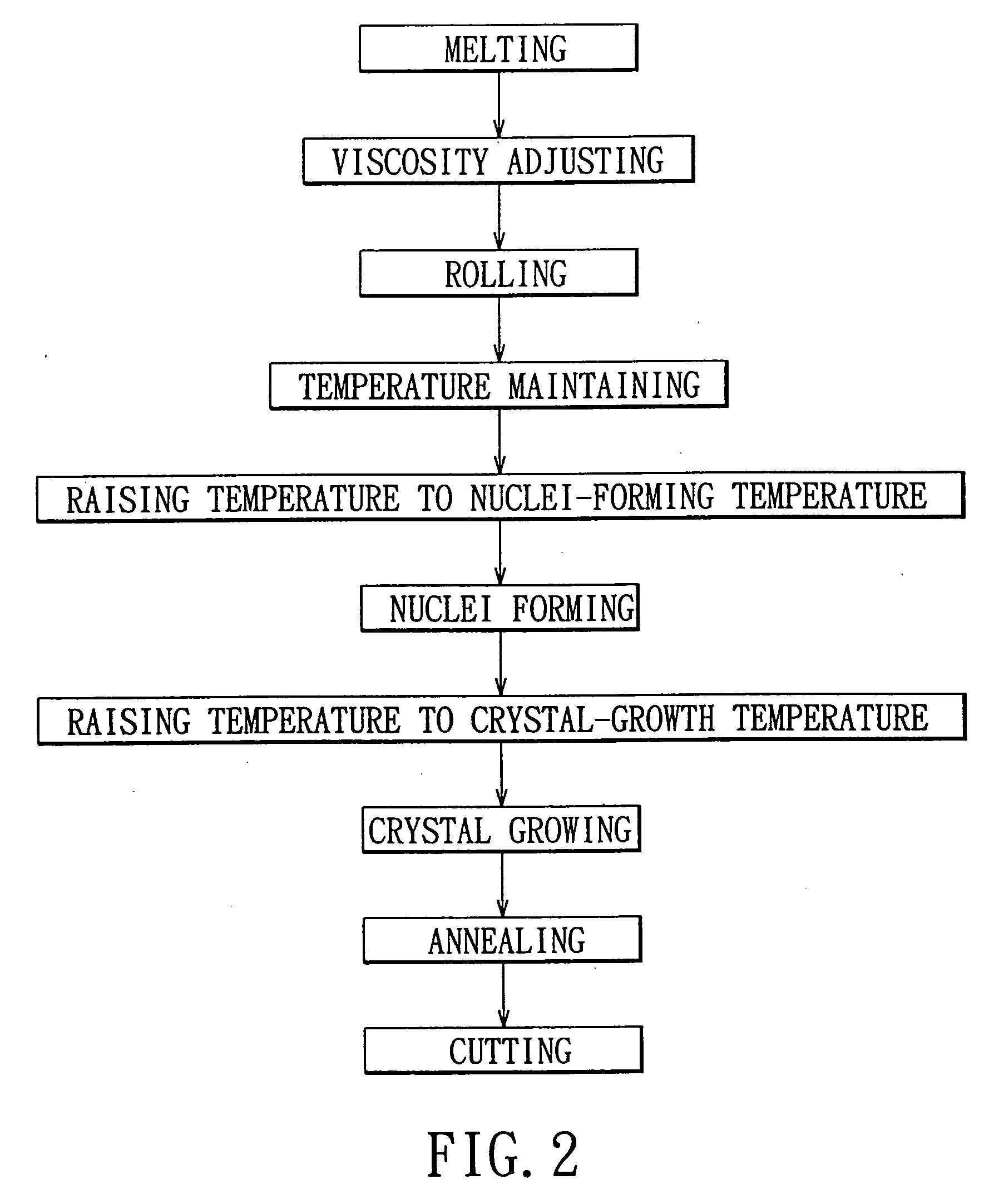

Continuous method and system for manufacturing a crystallized glass plate

InactiveUS20050016214A1Relieve pressureReduce stressRibbon machinesGlass furnace apparatusGlass sheetViscosity

A continuous method for manufacturing crystallized glass plates includes the steps of melting a raw crystallizable glass material to form molten glass, adjusting the molten glass to have a predetermined viscosity, rolling the molten glass to form a belt of crystallizable glass, and passing the belt of crystallizable glass through a crystallization tunnel so as to form a belt of crystallized glass.

Owner:TA HSIANG CONTAINERS IND +1

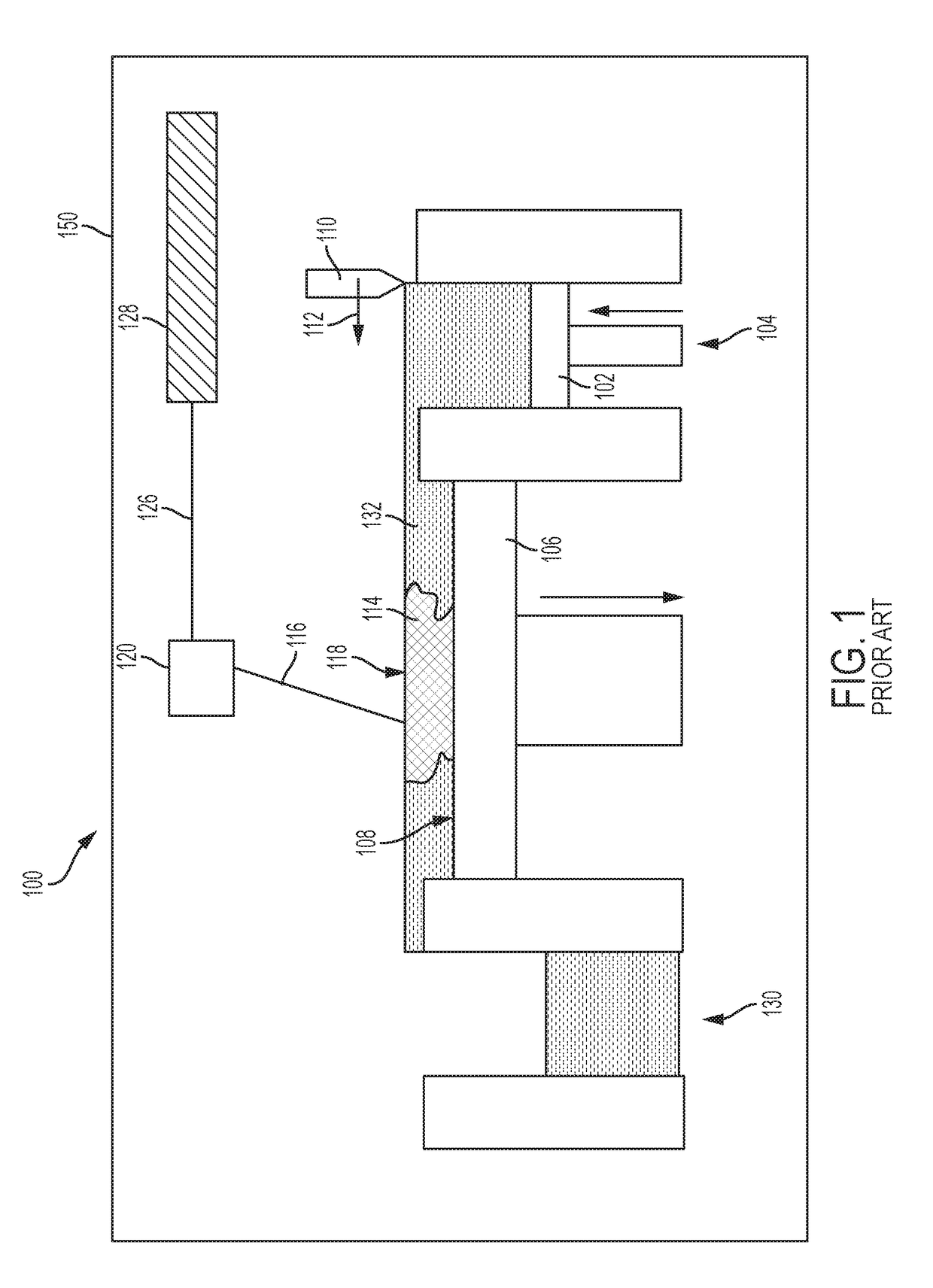

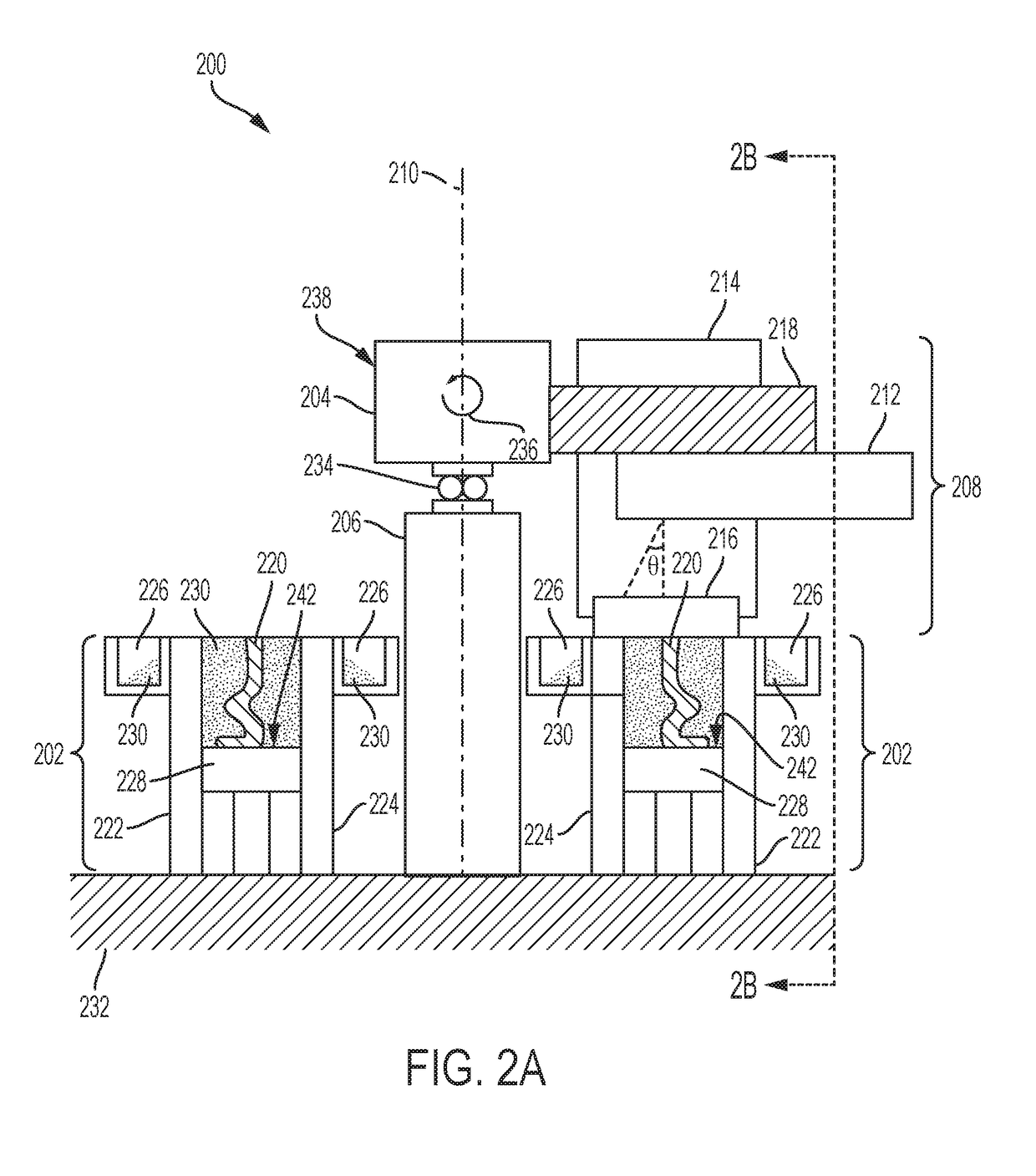

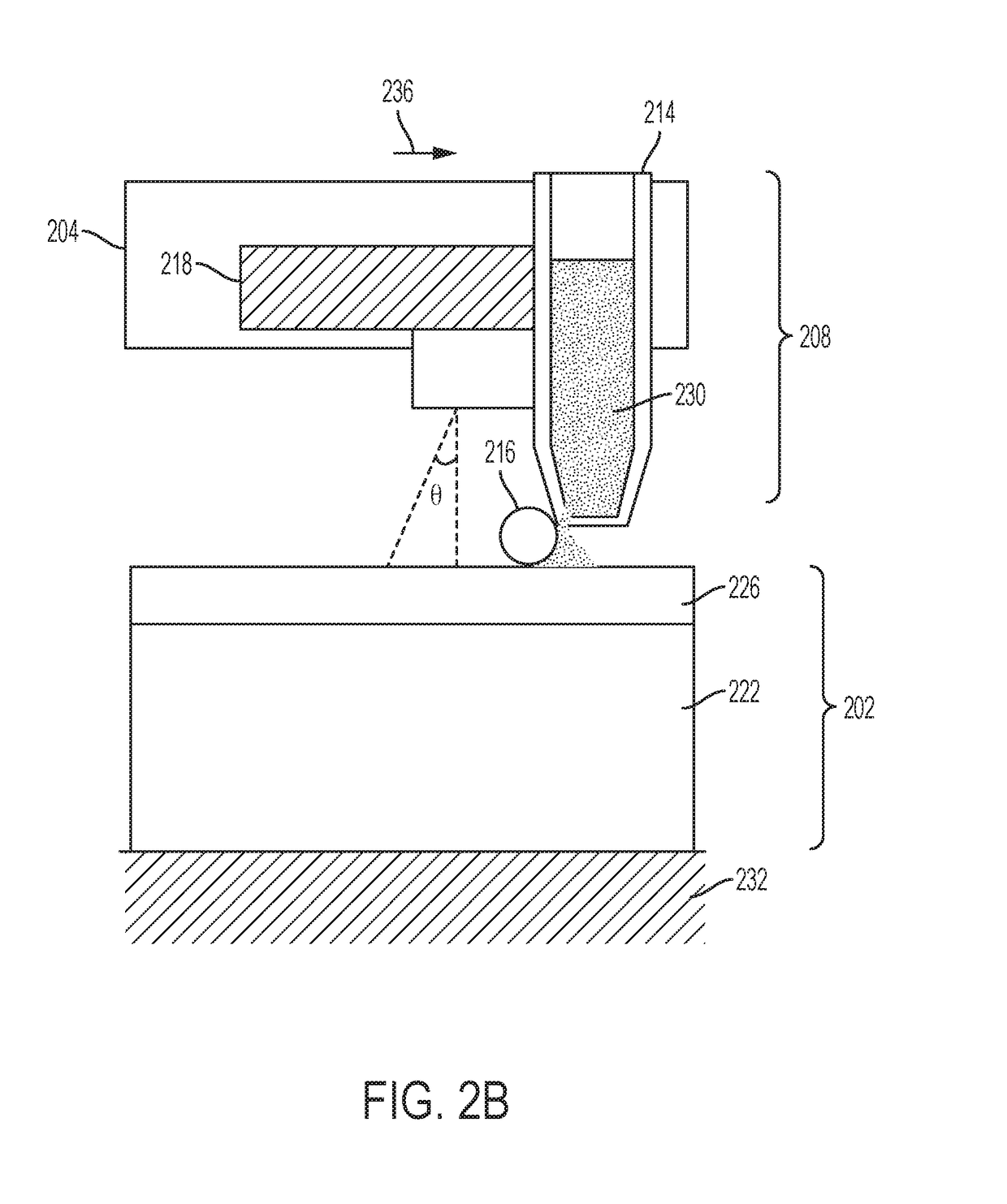

Apparatus and method for continuous additive manufacturing

ActiveUS20180345369A1Additive manufacturing apparatusIncreasing energy efficiencyPowder bedEngineering

An apparatus for continuous powder-based additive manufacturing of a large annular object or multiple smaller objects simultaneously is described. The build unit(s) of the apparatus includes a powder delivery mechanism, a powder recoating mechanism and an irradiation beam directing mechanism. The build unit(s) is attached to a rotating mechanism such that the build unit(s) rotates around and above the annular powder bed during production. The rotating mechanism is supported onto a central tower, and both the rotating mechanism and the tower are concentric with the non-rotating annular powder bed. An additive manufacturing method using the apparatus involves repetitive and continuous cycles of at least simultaneously rotating the build unit(s) to deposit powder onto the powder bed and irradiating the powder to form a fused additive layer. The continuous additive manufacturing process may be further aided with a helical configuration of the powder bed build surface.

Owner:GENERAL ELECTRIC CO

Electric arc additive manufacturing method

InactiveCN108723549AReduce mistakesNo crackElectrode holder supportersWelding accessoriesLoop controlSource type

The invention discloses an electric arc additive manufacturing method which comprises the following steps of (1) selecting a corresponding heat source type, a forming wire material, and a material type of a base plate according to the material requirement of a forming target part; (2) building a computer-aided design (CAD) geometric model of the forming target part, extracting a standard templatelibrary (STL) model, slicing the STL model, generating a G code file required for printing, and transmitting the G code to a printer; (3) setting printing parameters, starting the printer, and printing metal thin layers according to a planned route layer by layer; and (4) after finishing printing all layer sheets through the printer, carrying out arc failure through a welding gun, and obtaining the forming target part. An additive piece printed through the method provided by the invention is less in error and flawless, has the advantage of good surface quality, and is stable in process, high in dimensional accuracy and surface quality, short in processing period, and low in cost at the same time; the printing process is in closed-loop control, so that the automation degree is high, and thelabor intensity of operating personnel can be reduced; and continuous manufacturing can be realized, and the manufacturing efficiency is high.

Owner:HOHAI UNIV CHANGZHOU

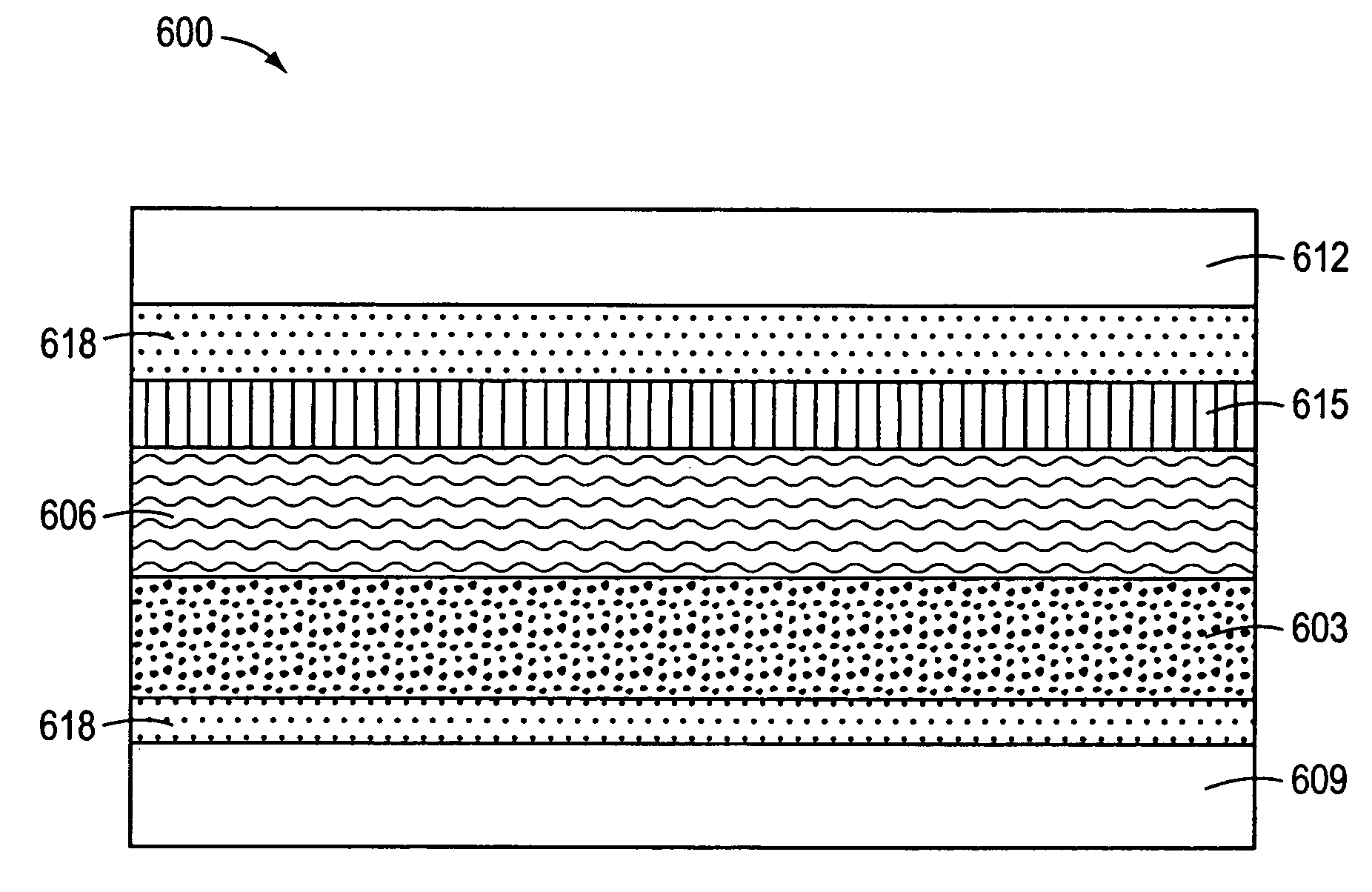

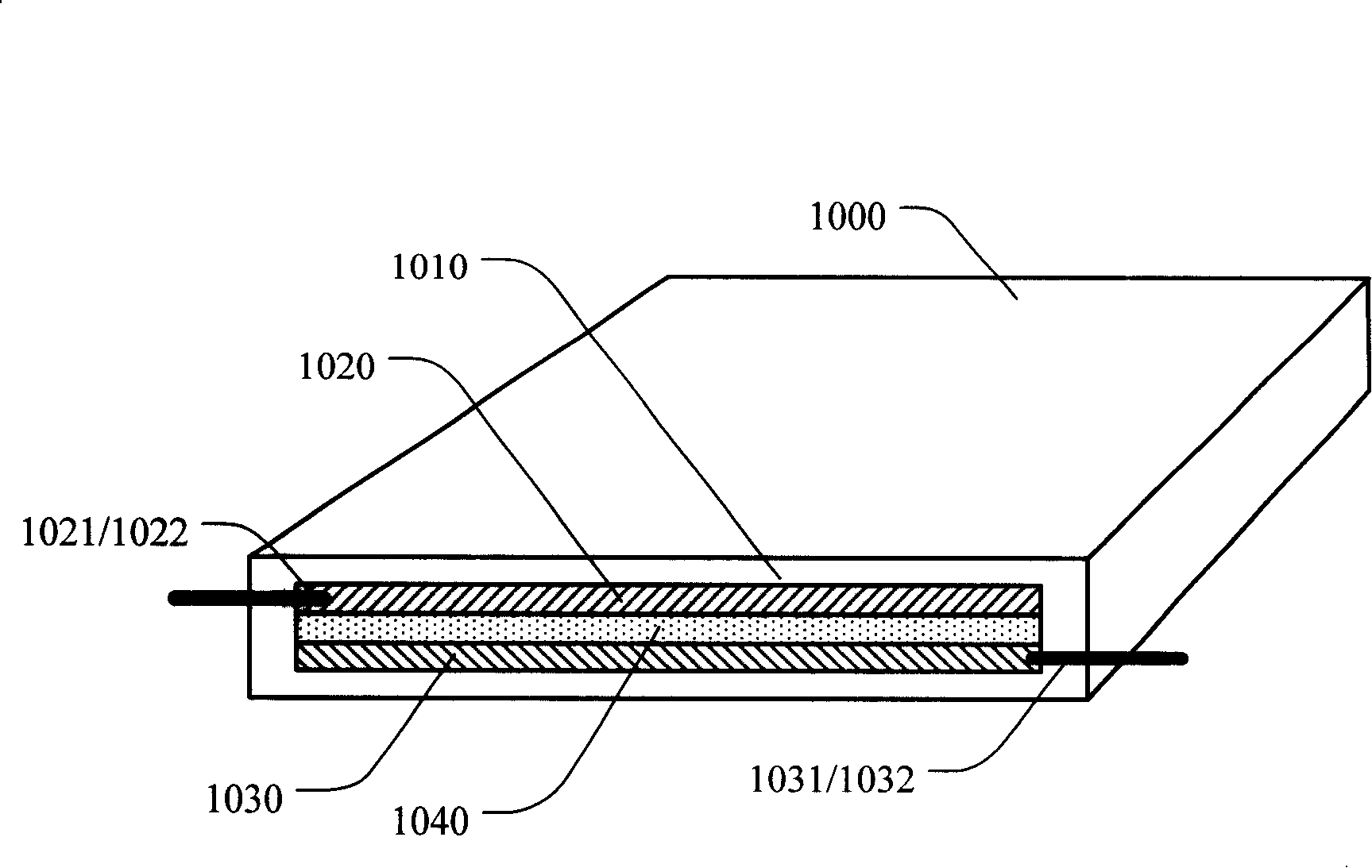

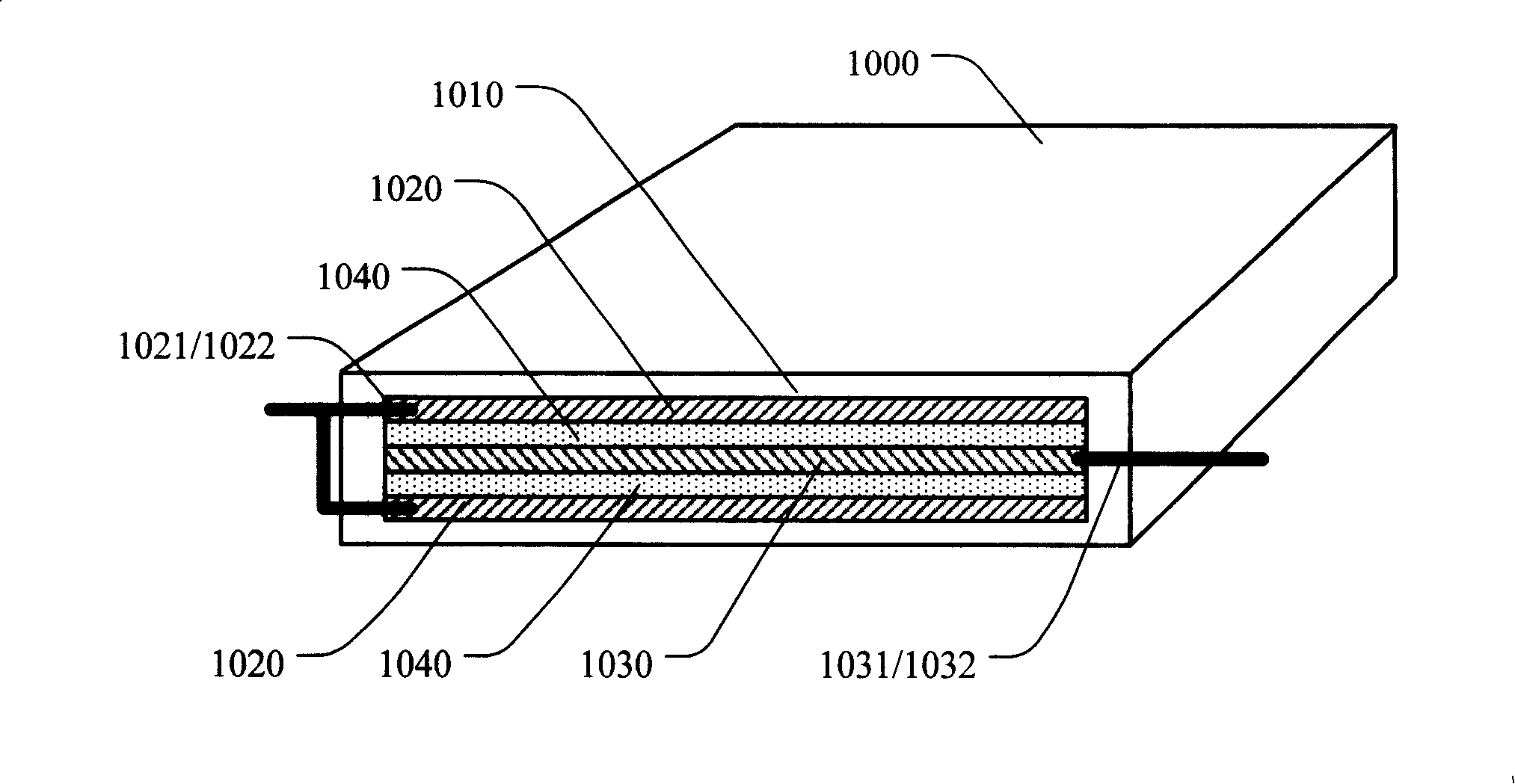

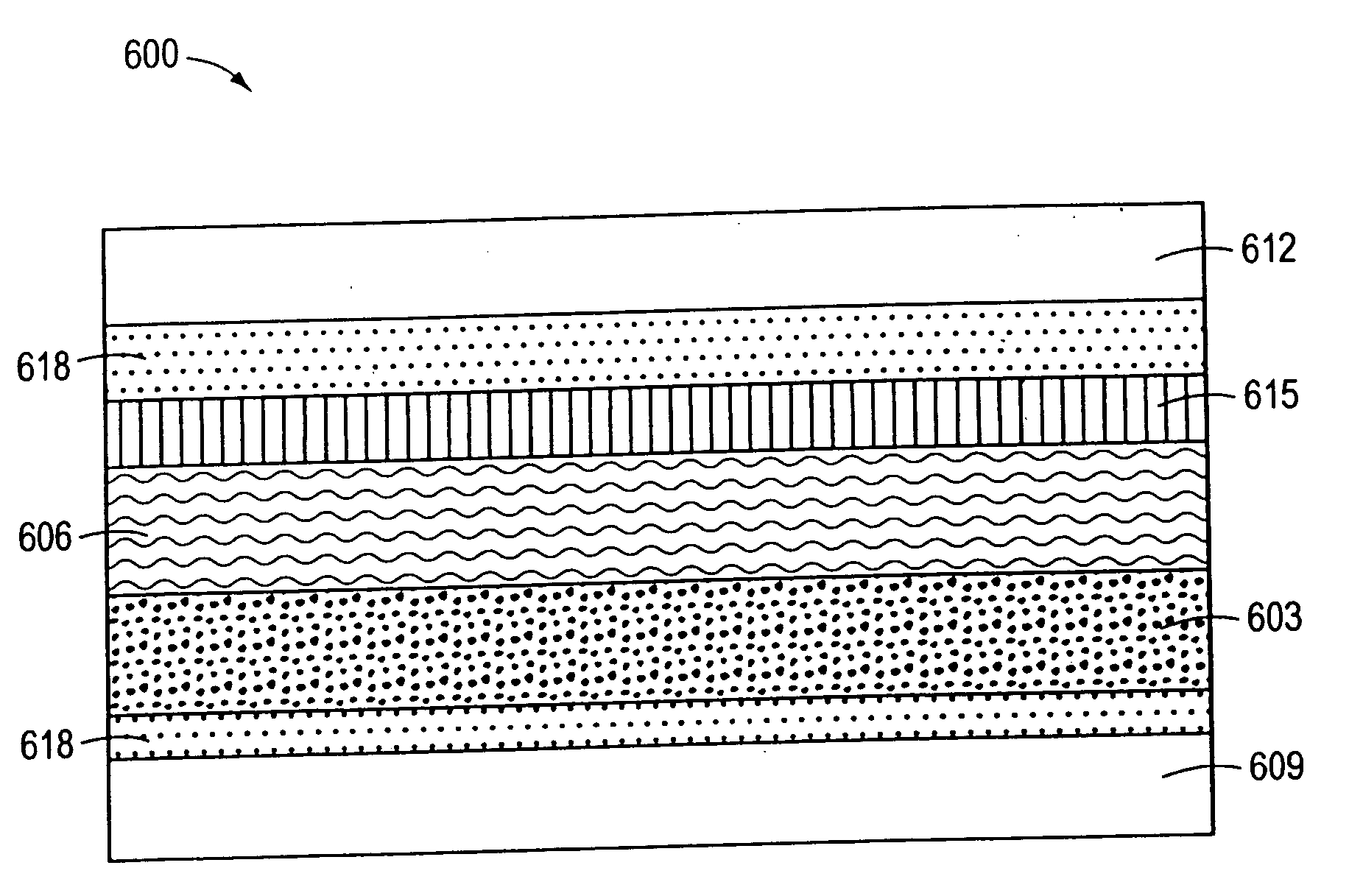

Flexible photovoltaic battery and method of manufacturing the same

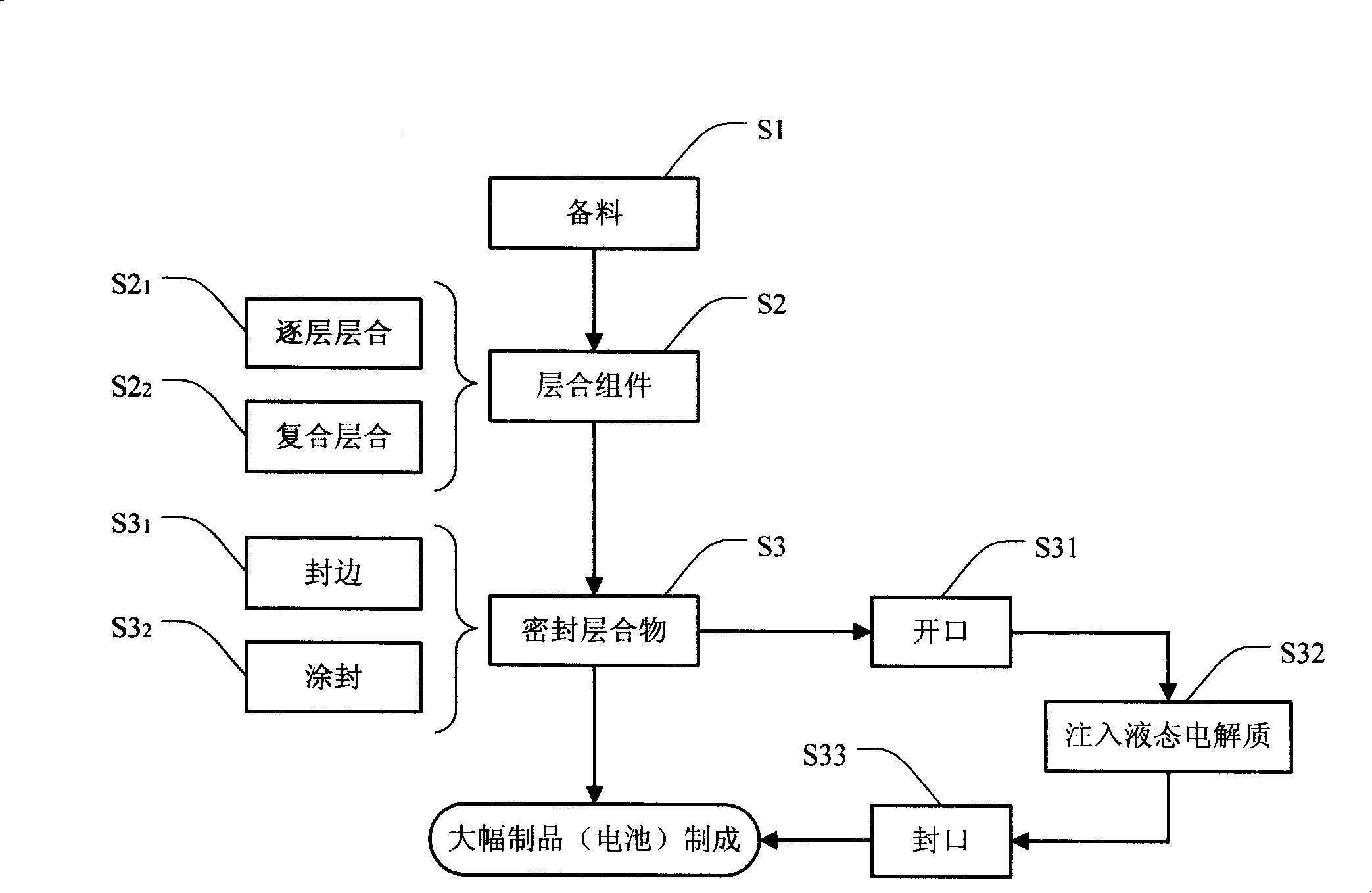

InactiveCN101207160AImprove photoelectric conversion rateConducive to large-area continuous manufacturingLight-sensitive devicesFinal product manufactureDielectricEngineering

The invention belongs to the photovoltaic cell technology field, in particular provides a flexible photovoltaic cell and the manufacturing method thereof. The flexible photovoltaic cell comprises an euphotic outer sealing layer, at least one flaky flexible electrode layer and one flaky flexible counter electrode layer which are arranged in an inner cavity of the outer layer, and dielectric which is arranged between the electrode and the counter electrode; wherein, one surface of each electrode layeris bordered upon or is attached with the inner wall of the outer layer, the place where the outer sealing layer and the electrode is bordered upon or is attached with is euphotic , and simultaneously the electrode outlet lines of each electrode layer are connected parallelly; one surface of the counter electrode is adjacent to the electrode, the other surface is adjacent to the inner wall of the outer sealing layer, or one surface is adjacent to one of the electrode layers, and the other surface is adjacent to the other electrode layer. The flaky flexible electrode which is adopted by the flexible photovoltaic cell can improve the electrical conductivity of the electrode and the photoelectric transformation rate of the cell, and is suitable for continuous manufacturing of the cell in a large area to reduce the production cost .

Owner:THE HONG KONG POLYTECHNIC UNIV

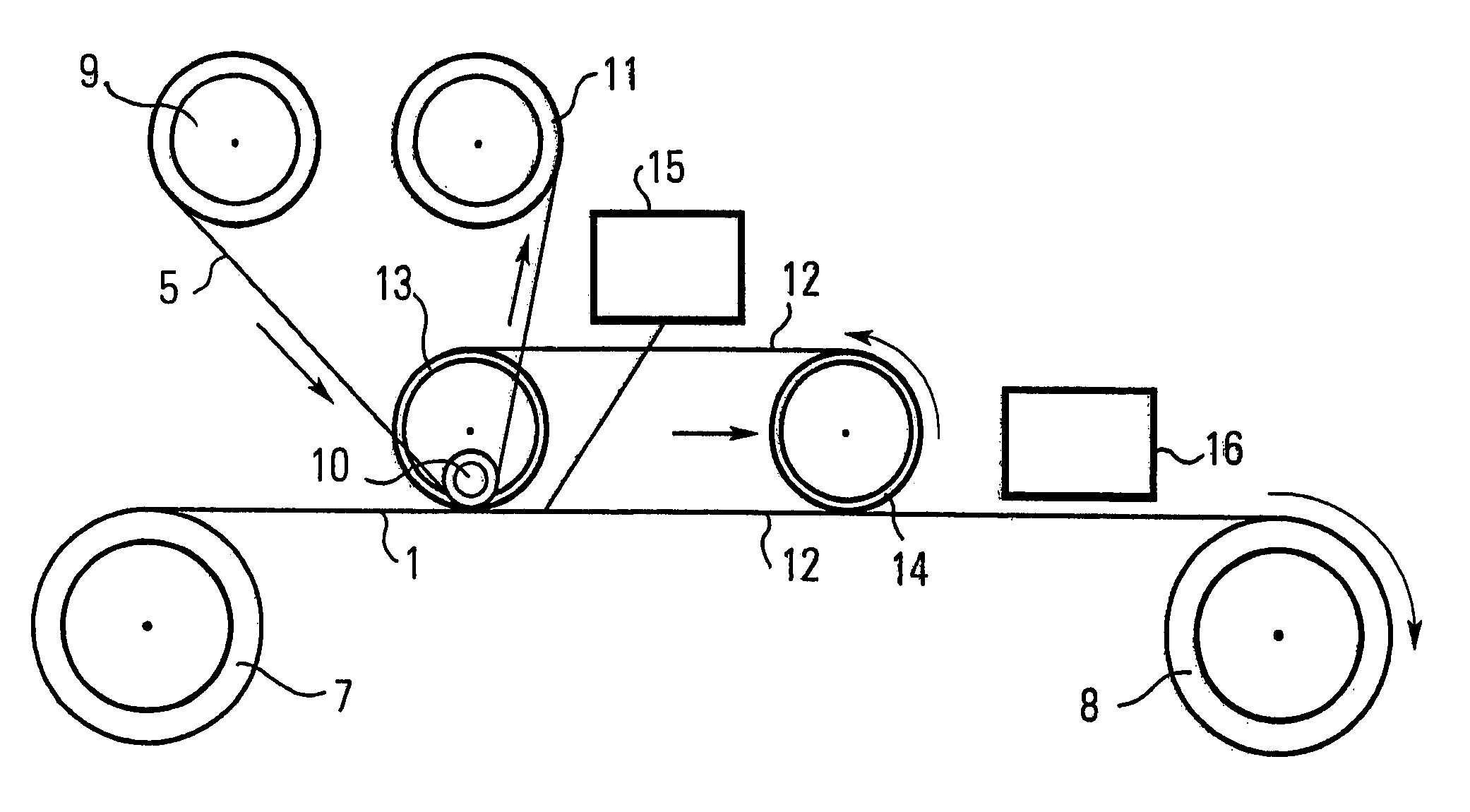

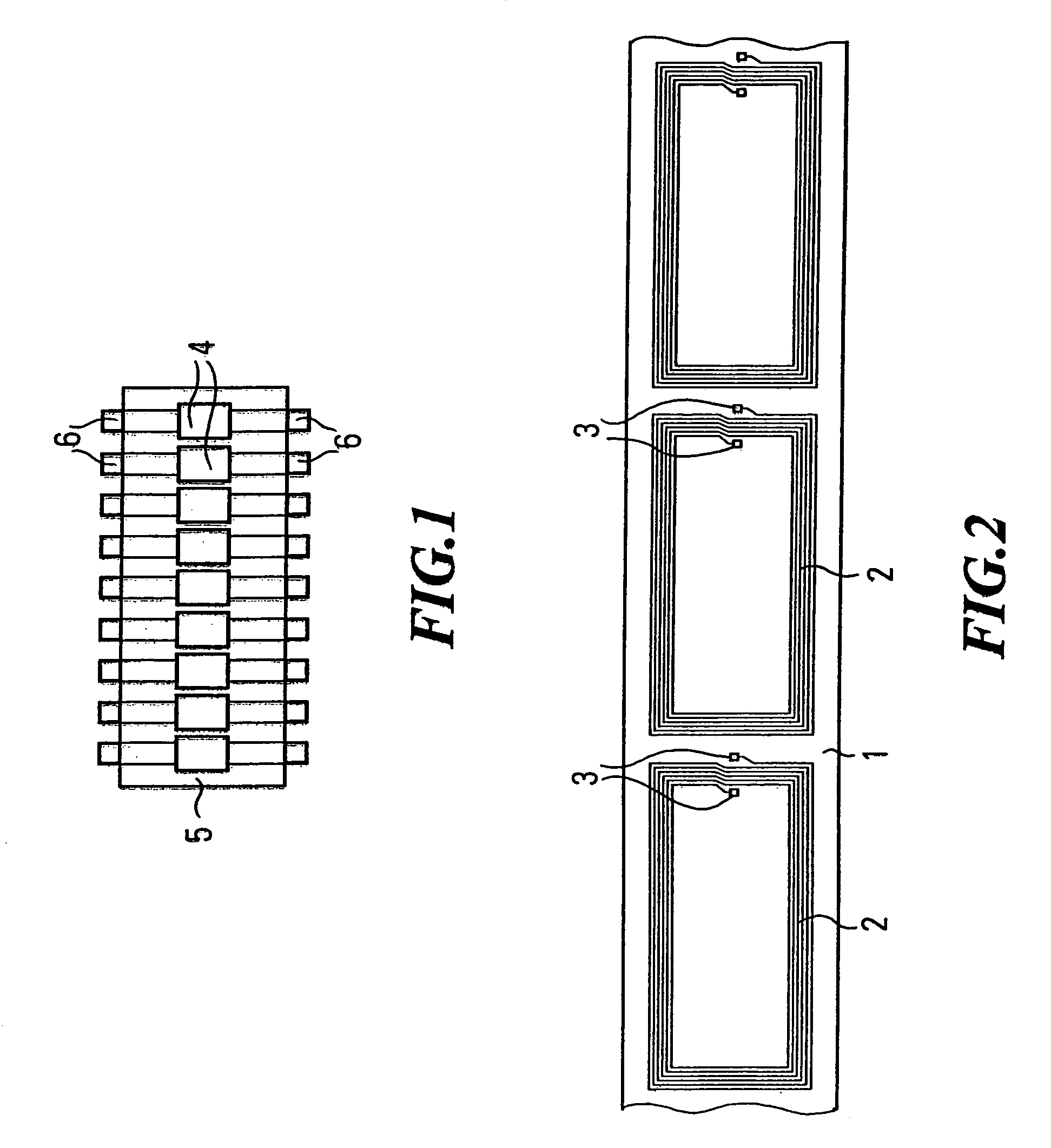

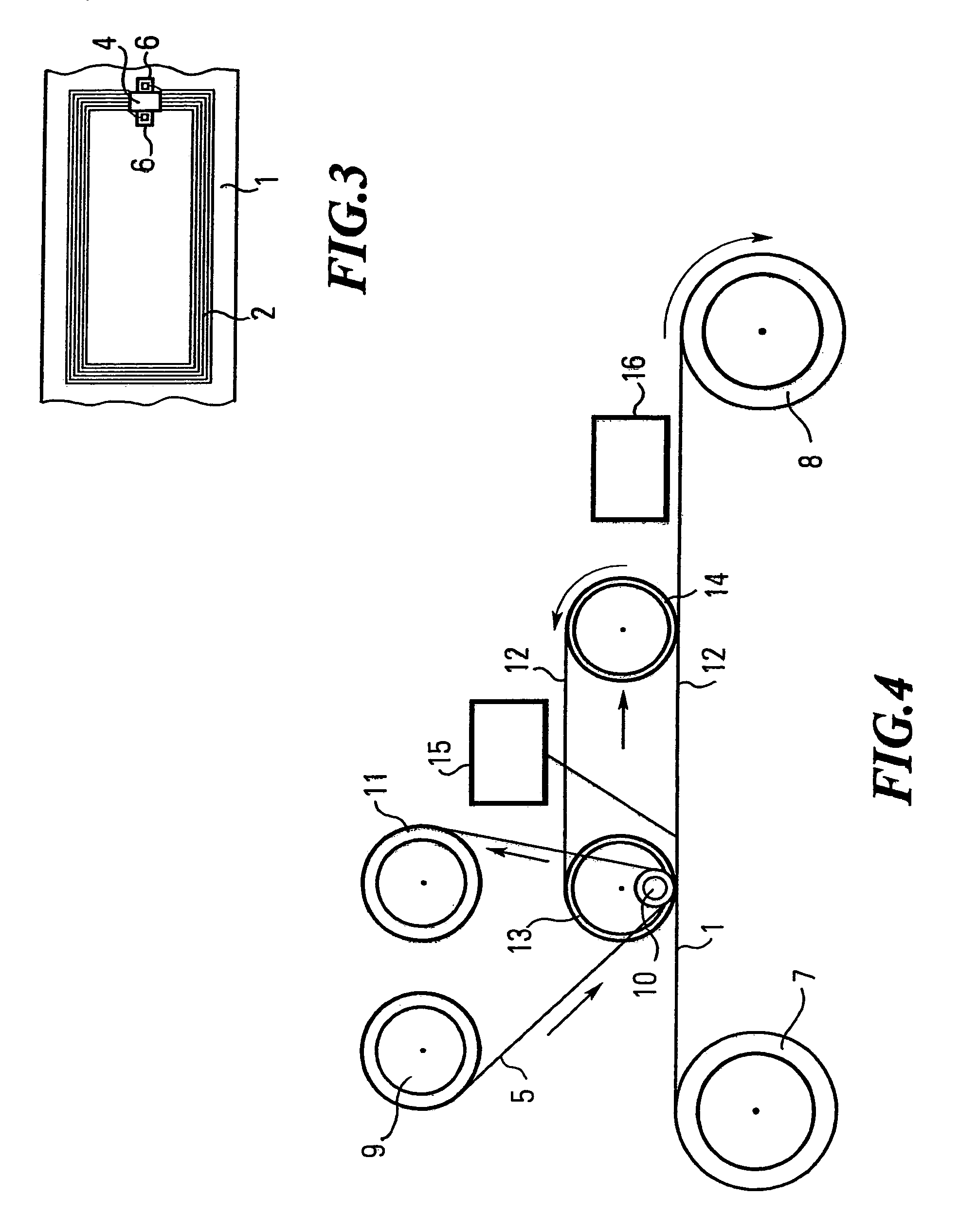

Method for connecting microchips to an antenna arranged on a support strip for producing a transponder

InactiveUS6972394B2Easy to makeEasy to implementDecorative surface effectsSoldering apparatusComputer moduleBonding process

The invention relates to a method of connecting micro-chip modules to antennas arranged on a first carrier tape for the manufacture of transponders. The method is characterised in that the micro-chips are packaged in a preceding bonding process to form a chip module with electrical terminals and are applied to a second carrier tape. The two carrier tapes are wound off a reel and brought one above the other, whereby the chip modules are removed from the second carrier tape and placed at a predetermined point on the first carrier tape. This method facilitates a continuous manufacturing process which is particularly economical and particularly fast.

Owner:MUEHLBAUEHR AG

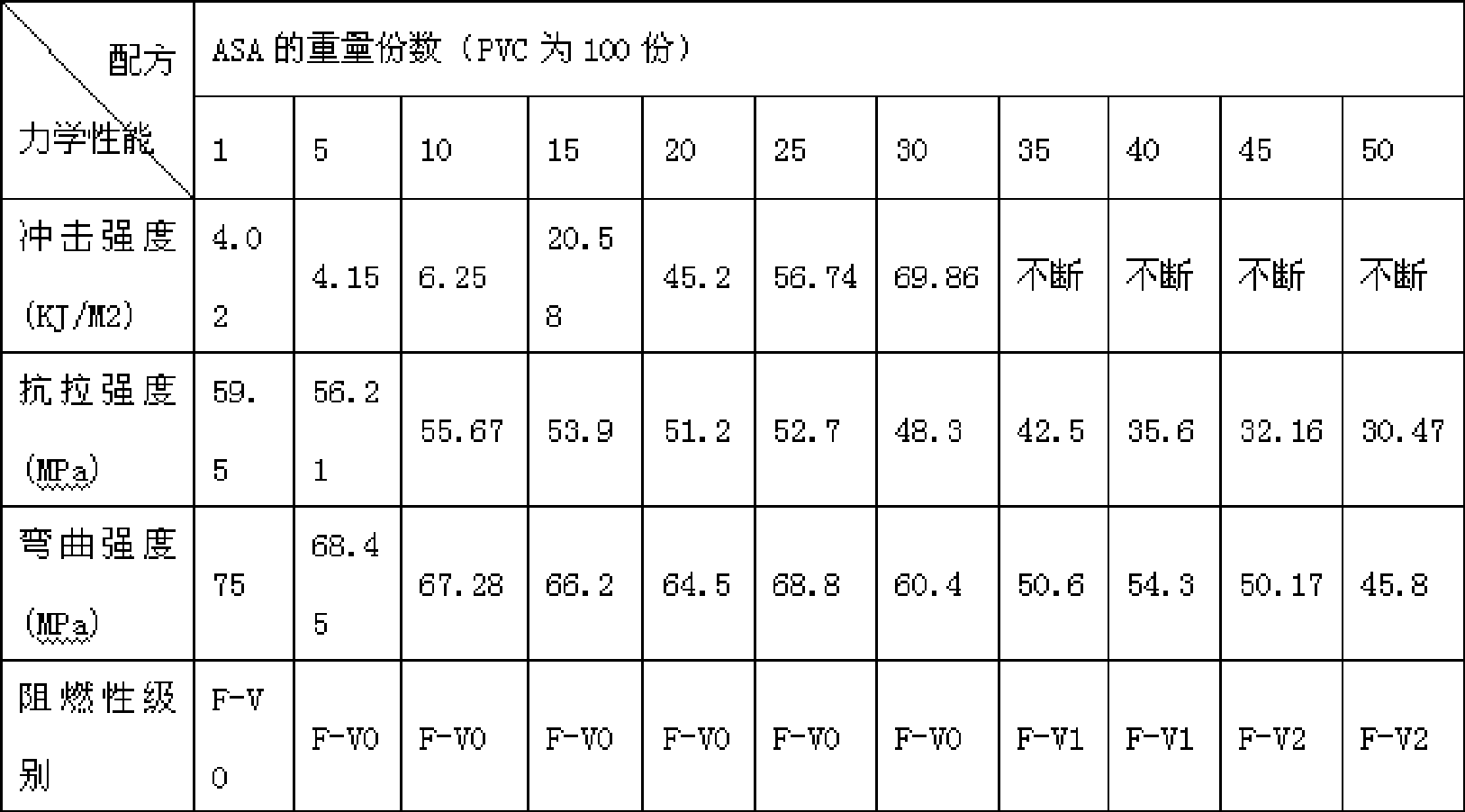

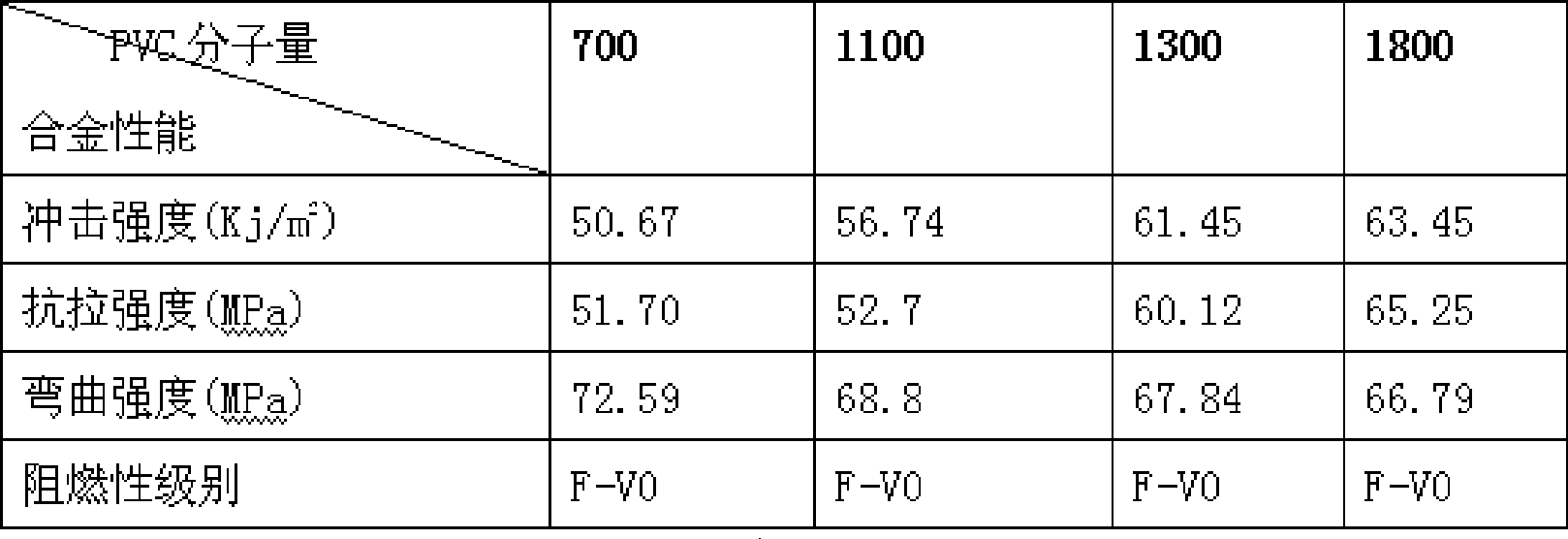

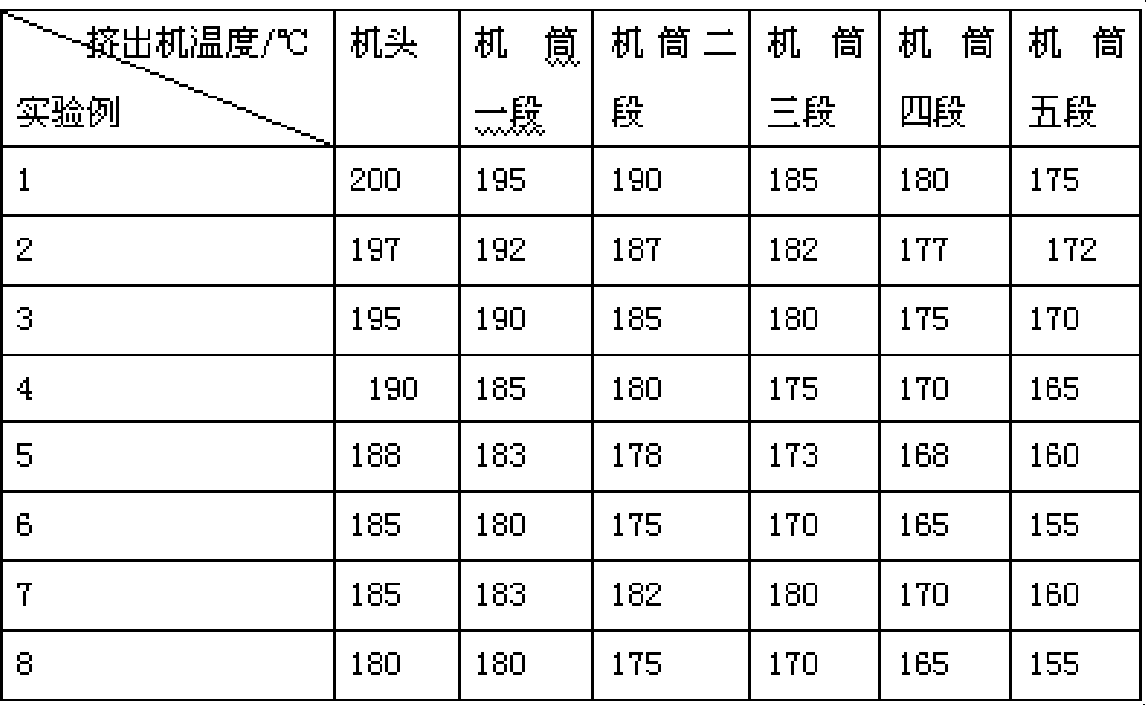

A polyvinyl chloride/ASA alloy

The invention discloses a polyvinyl chloride (PVC) / ASA alloy, which is prepared by polyvinyl chloride resin, ASA resin and right amount of processing aids. The preparation method includes: mixing uniformly the polyvinyl chloride resin and processing material at 60-120 DEG C, adding ASA resin powders, mixing evenly, dropping the temperature to 43 DEG C, to obtain the mixture; extruding the mixture through a screw extruder to obtain the alloy, wherein, the temperature of the extruder head is 165 DEG C - 185 DEG C, and the revolution speed is 120-160 r / min. Compared with the existing technology, the PVC / ASA alloy prepared by the invention has high impact resistance, weather resistance, fire-retardant, superior synthesized dynamic performance, good processing performance, stable preparation process, non three wastes pollution. The alloy can be formulated into various colors according to requirements, can be produced by screw rod extruding continuous manufacturing method, and can also be produced by extrusion molding and injection molding according to manufacturing requirements of products.

Owner:国家复合改性聚合物材料工程技术研究中心

Low temperature interconnection of nanoparticles

InactiveUS20050019414A1Improve performanceEasy to manufacturePowder deliveryHeavy metal active ingredientsNanoparticleOptoelectronics

A polymeric linking agent enables the manufacture of photovoltaic cells on flexible substrates, including, for example, polymeric substrates. Photovoltaic cells may be fabricated by a relatively simple continuous manufacturing process, for example, a roll-to-roll process, instead of a batch process.

Owner:CHITTIBABU KETHINNI +1

Gel electrolytes for dye sensitized solar cells

Replacing liquid electrolytes with solid or quasi-solid electrolytes facilitates the production of photovoltaic cells using continuous manufacturing processes, such as roll-to-roll or web processes, thus creating inexpensive, lightweight photovoltaic cells using flexible plastic substrates.

Owner:MERCK PATENT GMBH

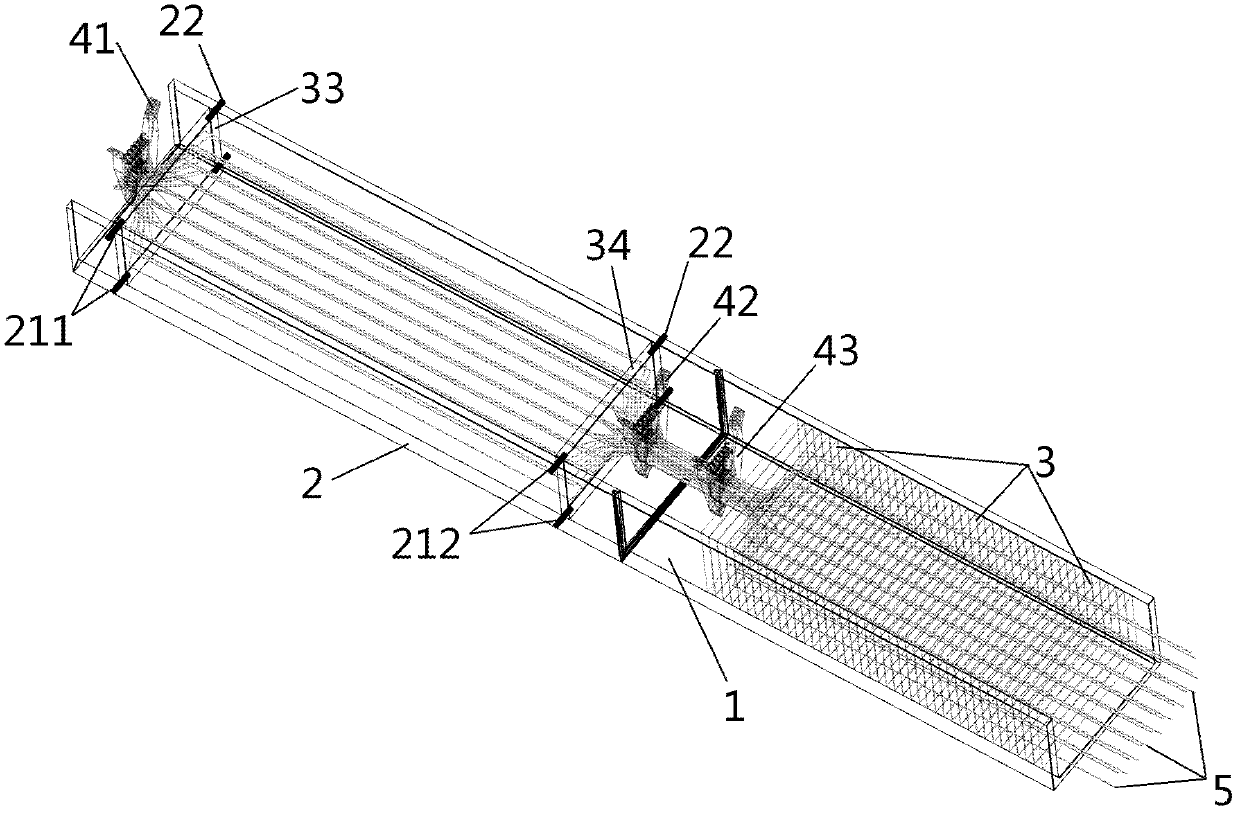

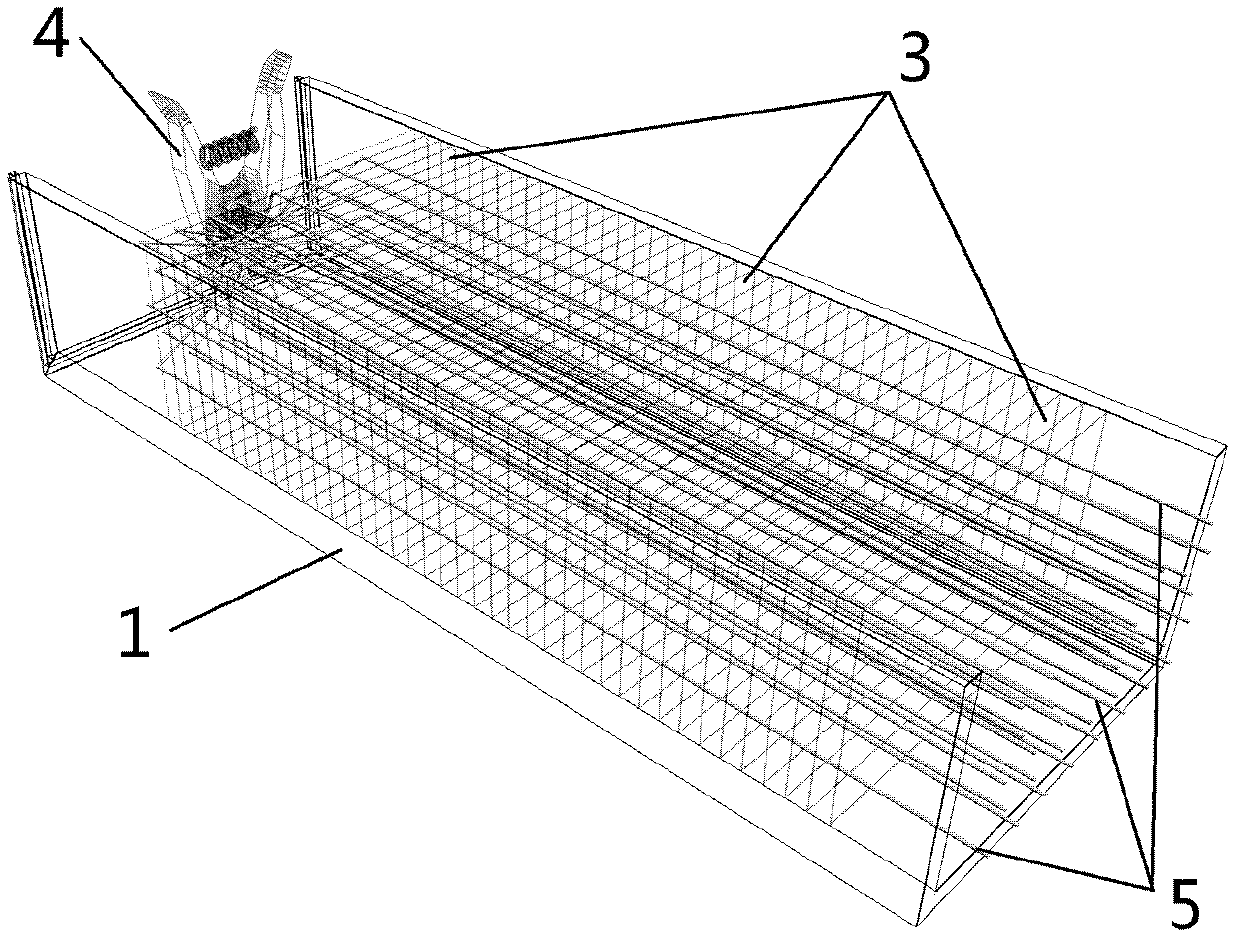

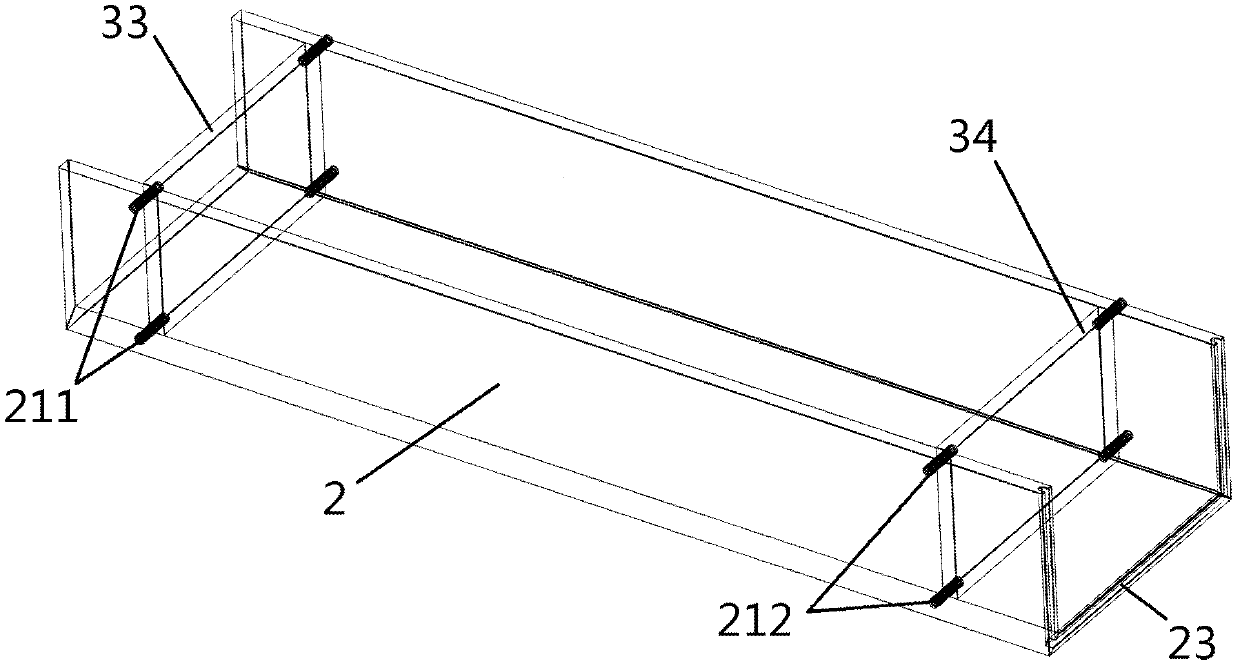

Manufacturing method and manufacturing device of light-transmitting concrete block

ActiveCN102601845AOptimize layoutIncrease profitConstruction materialFibre light guidesStructural engineeringMechanical engineering

The invention belongs to the technical field of building materials and particularly relates to a manufacturing method and a manufacturing device of a light-transmitting concrete block. The manufacturing method of the light-transmitting concrete block is characterized by comprising the following steps: (1), preparing the manufacturing device of the light-transmitting concrete block; (2), arranging optical fibers; (3) moulding concrete through casting: separating a moulding groove and a preparing groove; and then pouring concrete slurry in the moulding groove to perform vibration moulding; and (4) performing demoulding and cutting on concrete: demoluding hardened concrete from the moulding groove, cutting the concrete to the assigned thickness along the arrangement direction of the optical fibers so as to obtain the light-transmitting concrete block. The characteristics in the invention are that the optical fibers can be arranged fast and conveniently, the light-transmitting concrete block can be manufactured fast and can adopt a continuous manufacturing mode, and the utilization rate of the optical fibers is high, therefore, the industrialized production of the light-transmitting concrete block can be performed.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

Plastic bag producing apparatus

InactiveCN1509863AEnvelopes/bags making machineryBag making operationsPlastic filmContinuous manufacturing

Owner:TOTANI GIKEN KOGYO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com