Patents

Literature

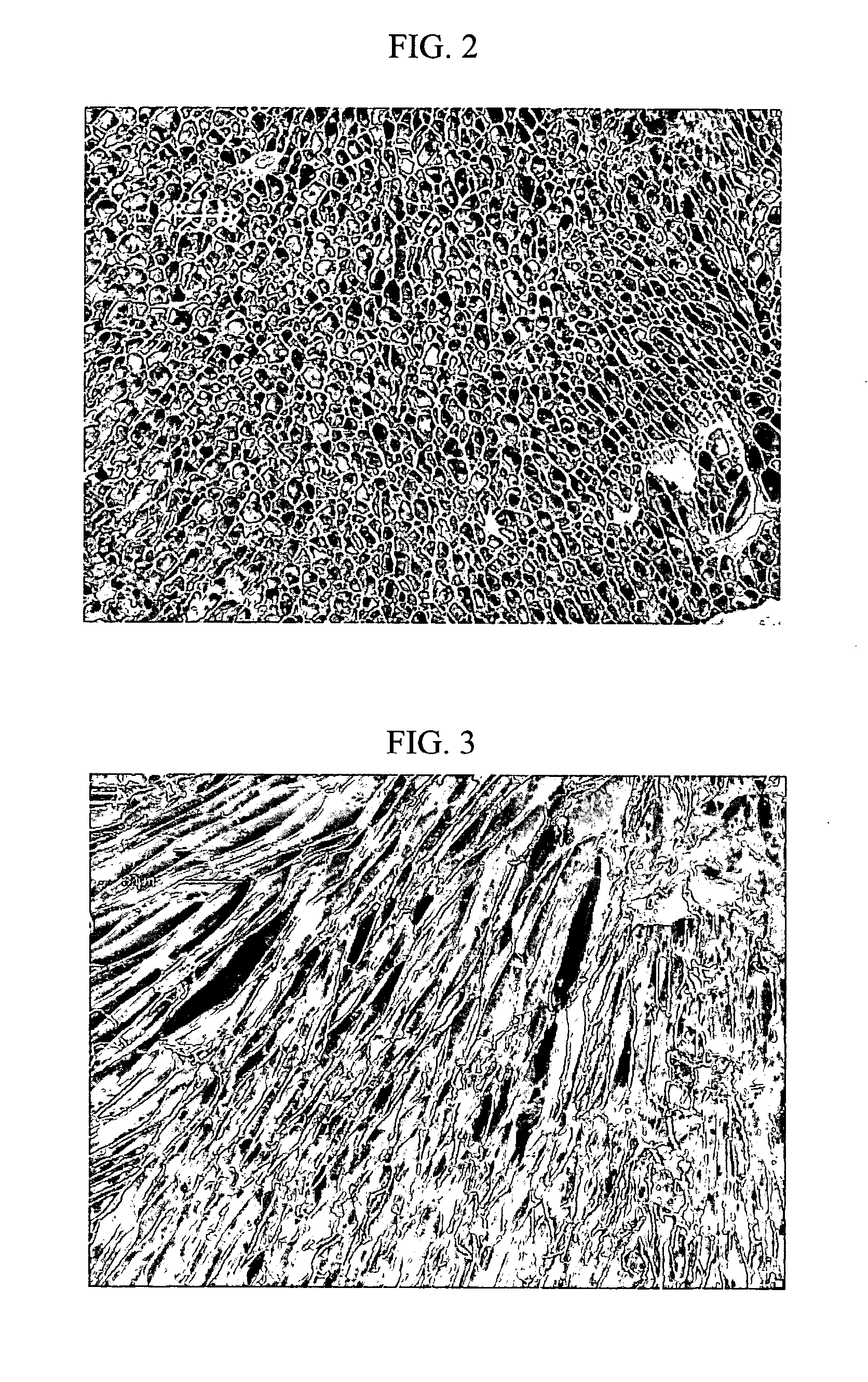

851 results about "Gel strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

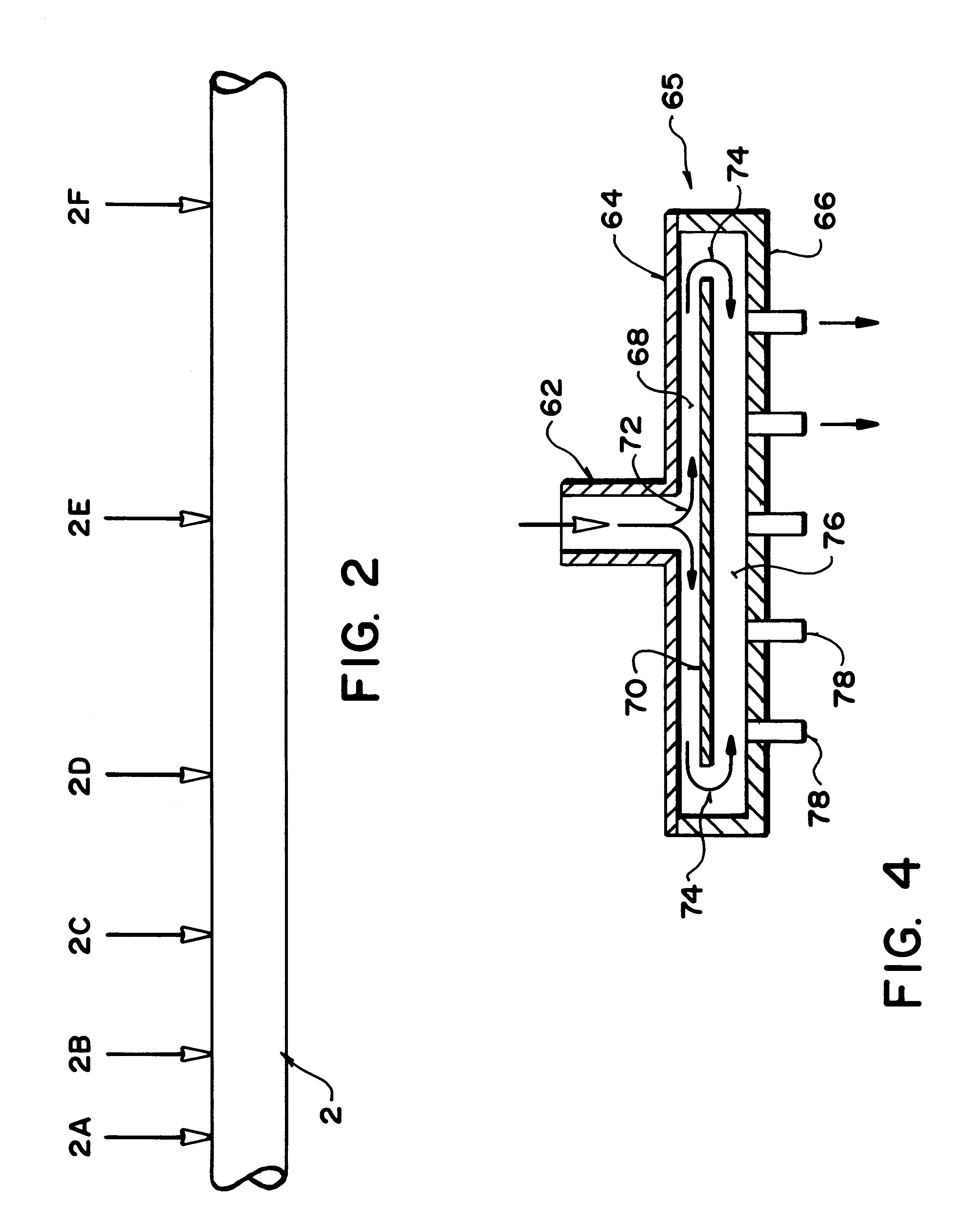

Continuous manufacture of superabsorbent/ion exchange sheet material

InactiveUS20020007166A1Increase in sizeNon-fibrous pulp additionWood working apparatusPapermakingIon exchange

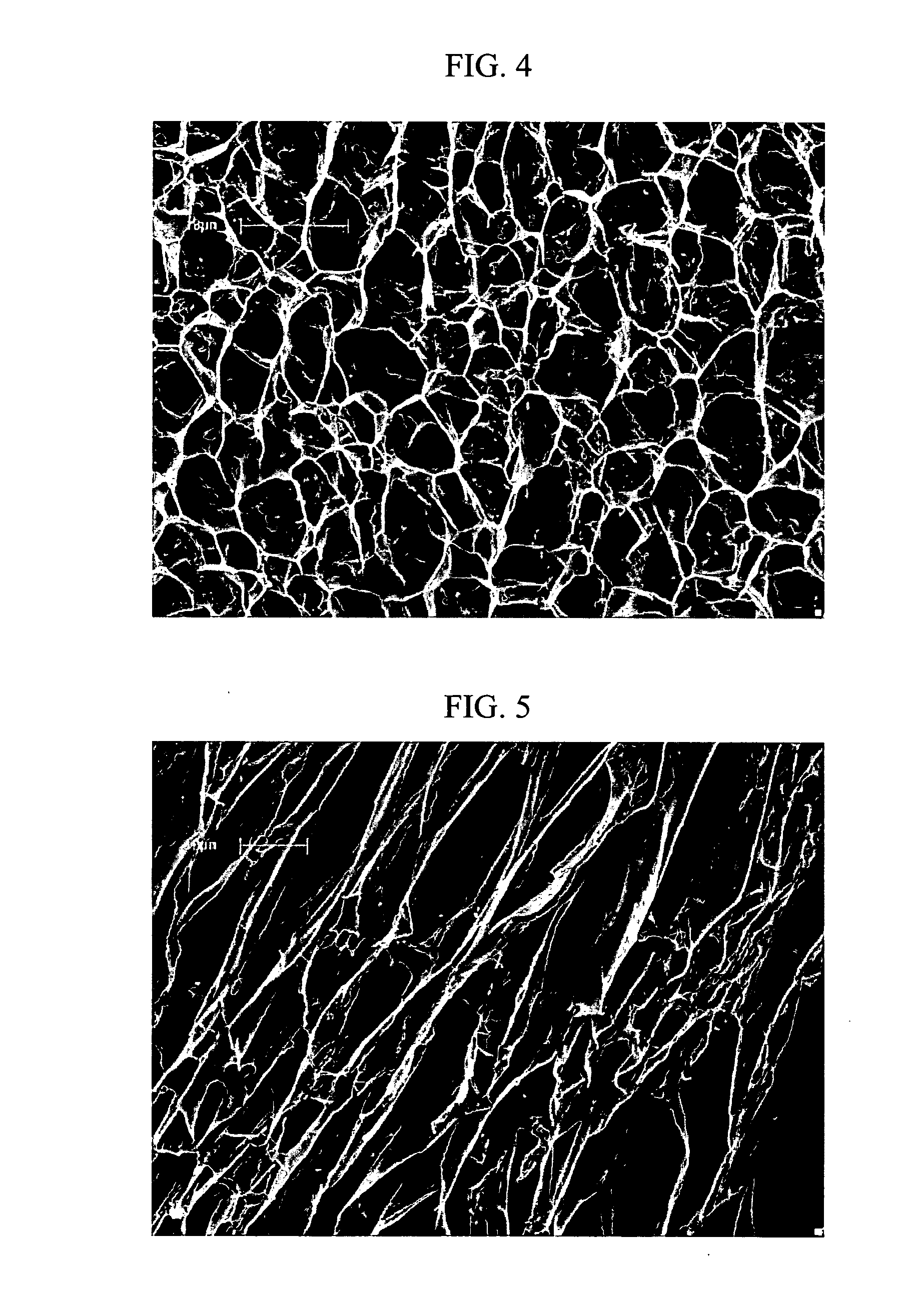

A continuous sheet having a combination of acidic and basic water-absorbing resin particles that are essentially not neutralized and can be continuously manufactured on conventional papermaking apparatus, using a wet, dry, or wet-dry process to manufacture a water-absorbent sheet-like substrate containing 50%-100% by weight of the combination of acidic and basic water-absorbent particles. The acidic and basic essentially unneutralized resins can be contained in the sheet material articles of the present invention as separate acidic and basic resin particles, or as multicomponent particles containing both the acidic and basic resins. The sheet materials can be manufactured having new and unexpected structural integrity, with little or no shakeout or loss of superabsorbent particles during or after manufacture while exhibiting exceptional water absorption and retention properties. The sheet materials have an ability to absorb liquids quickly, demonstrate good fluid permeability and conductivity into and through the resin particles, and have a high gel strength such that the hydrogel formed from the SAP particles resists deformation under an applied stress or pressure, when used alone or in a mixture with other water-absorbing resins.

Owner:BASF AG

Sustained release heterodisperse hydrogel systems-amorphous drugs

Sustained release oral solid dosage forms comprising agglomerated particles of a therapeutically active medicament in amorphous form, a gelling agent, an ionizable gel strength enhancing agent and an inert diluent, as well as processes for preparing and using the same are disclosed. The sustained release oral solid dosage forms are useful in the treatment of hypertension in human patients.

Owner:PENWEST PHARMA CO

Transparent gel and contact lense from the same

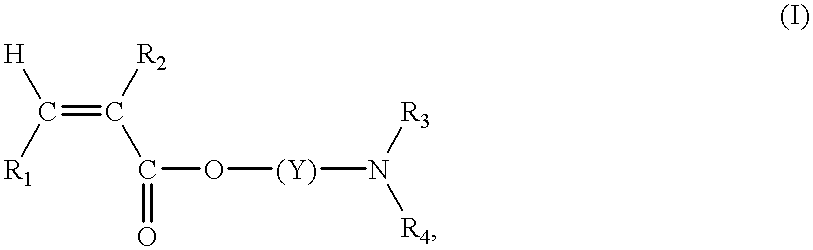

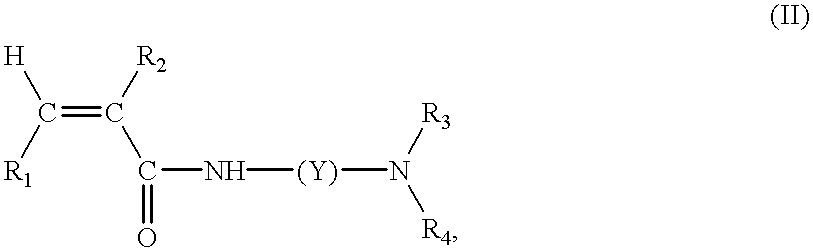

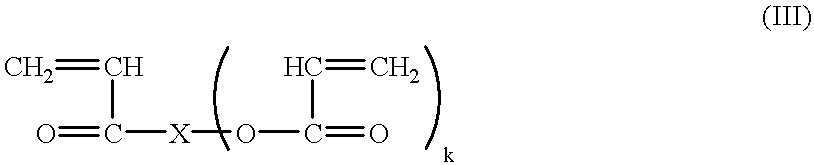

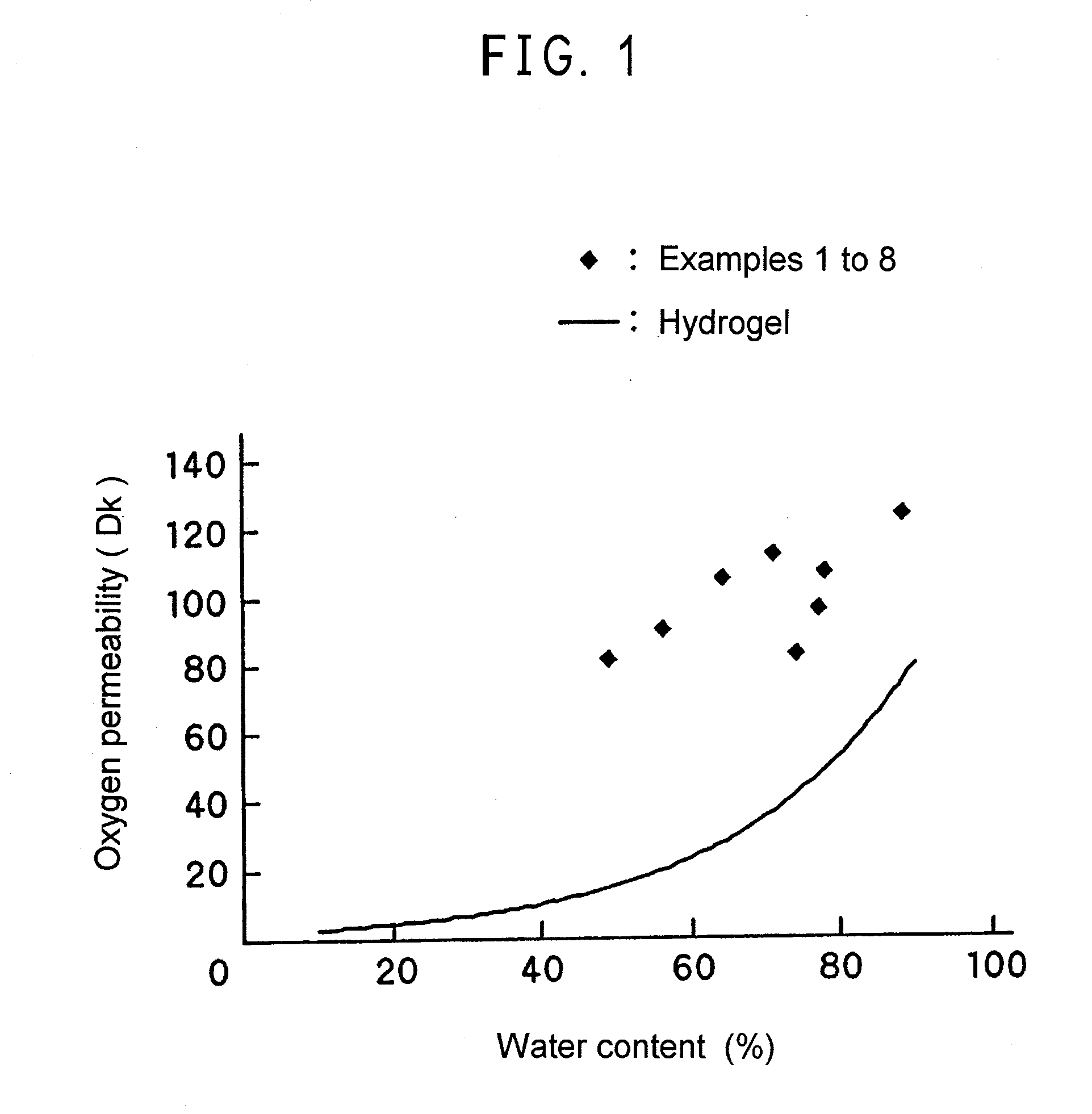

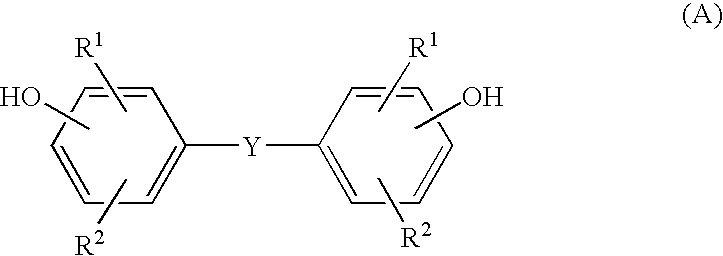

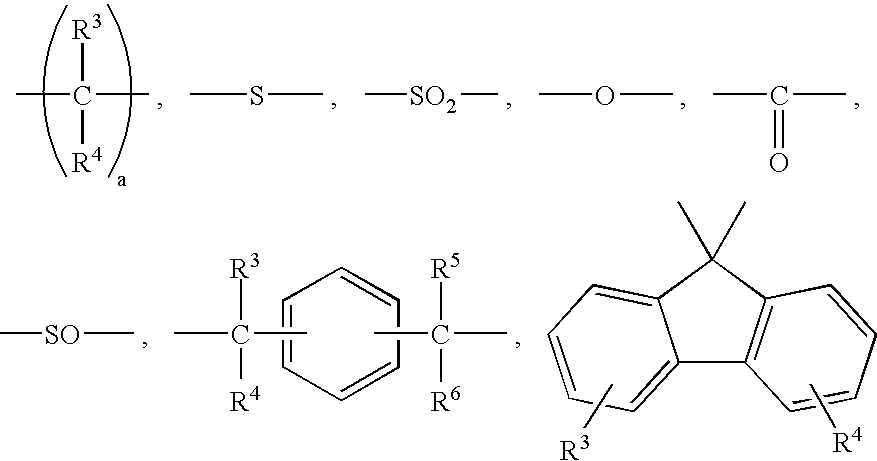

InactiveUS20090012205A1Easily purifiableEasily synthesizableOptical articlesOptical elementsHydrophilic monomerPolymer science

A transparent gel is disclosed which has an interpenetrating polymer network of a copolymer containing a polysiloxane structure and a polycarbonate structure and a hydrophilic polymer obtained by polymerizing a hydrophilic monomer. The transparent gel is useful as a cultivation substrate, a container for storage and an ophthalmic material, comprising an easily synthesizable and purifiable silicon-containing resin, wherein a gel strength, transparency, oxygen permeability, birefringence and other characteristics are excellent.

Owner:MITSUBISHI GAS CHEM CO INC +1

Well Treatment with Ionic Polymer Gels

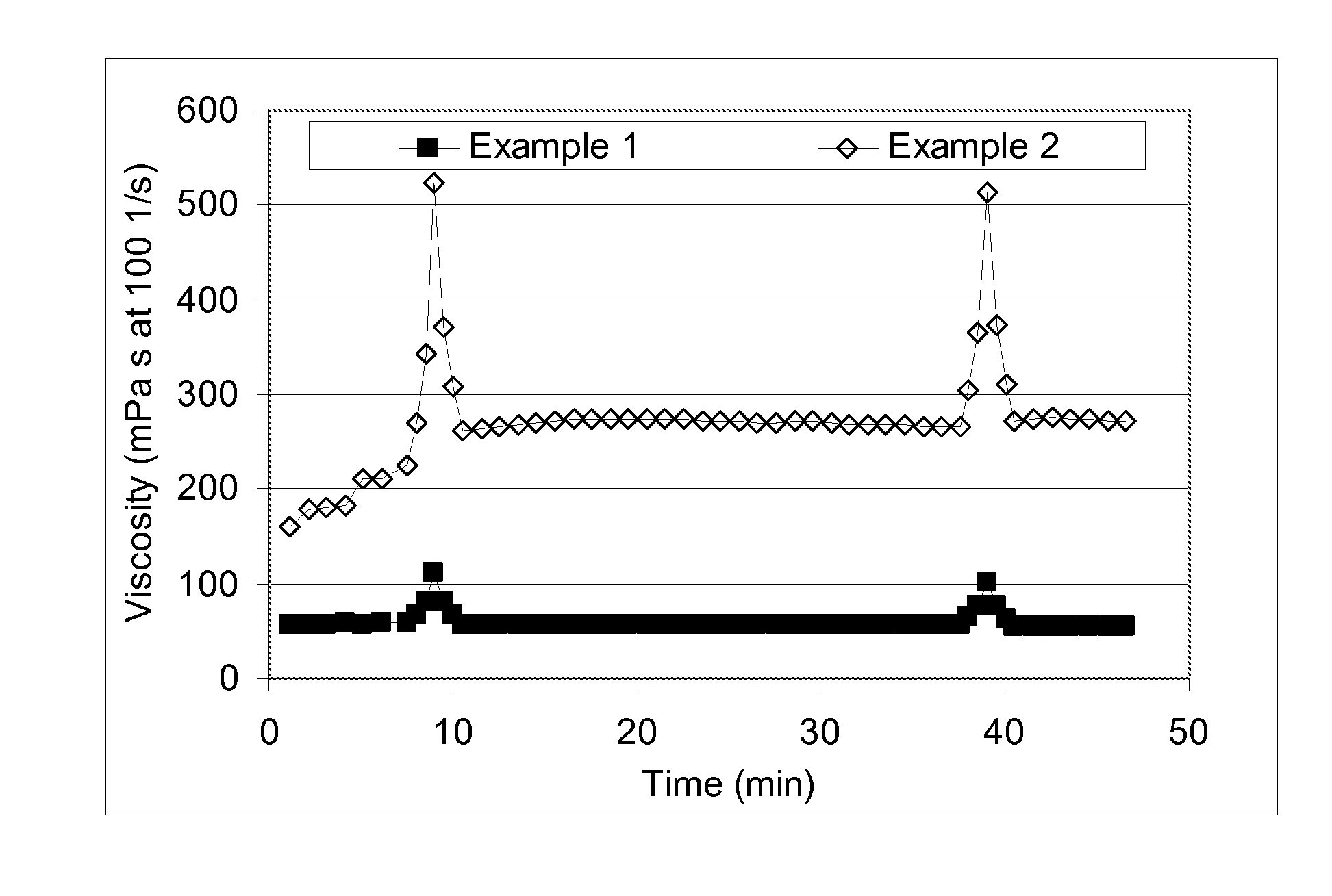

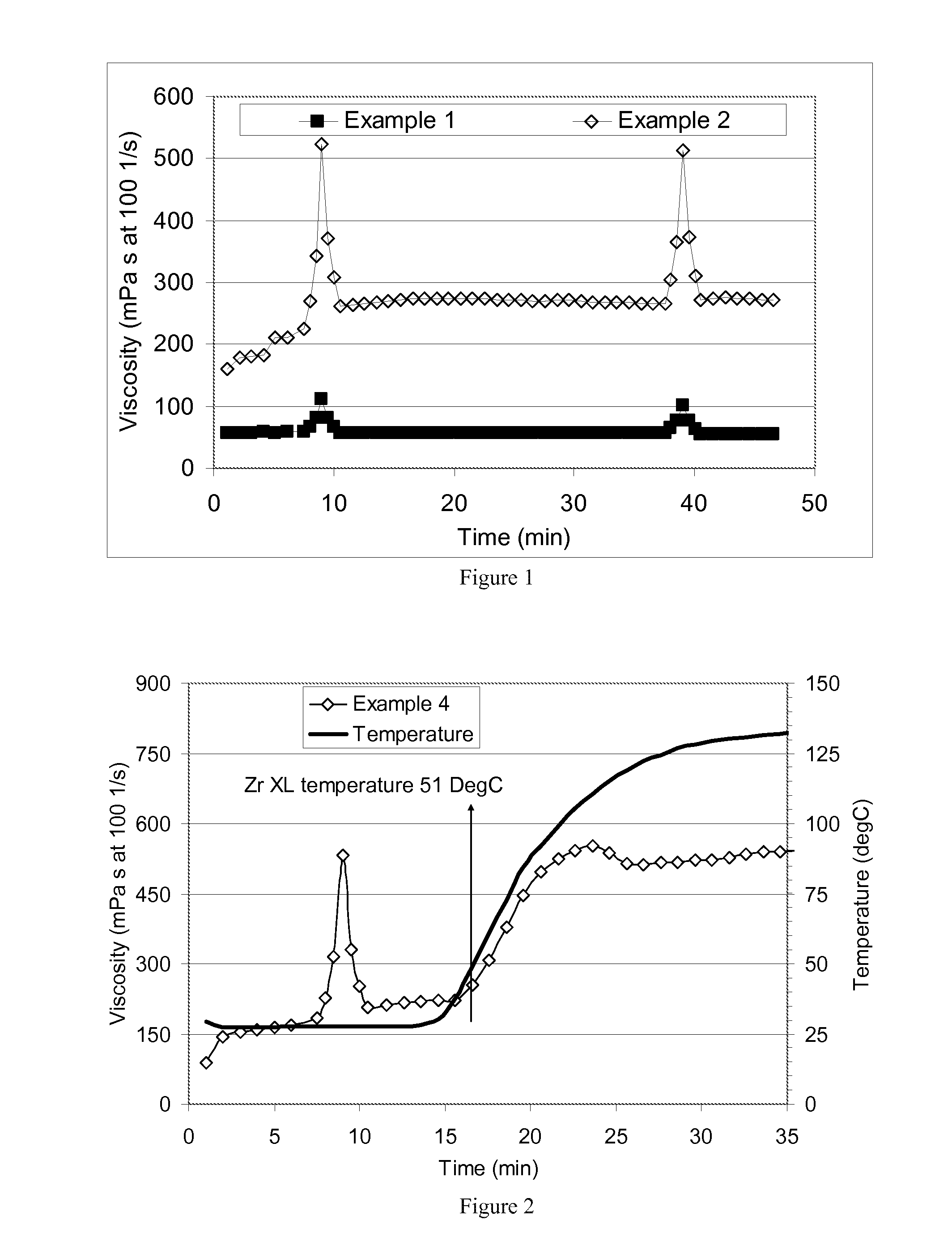

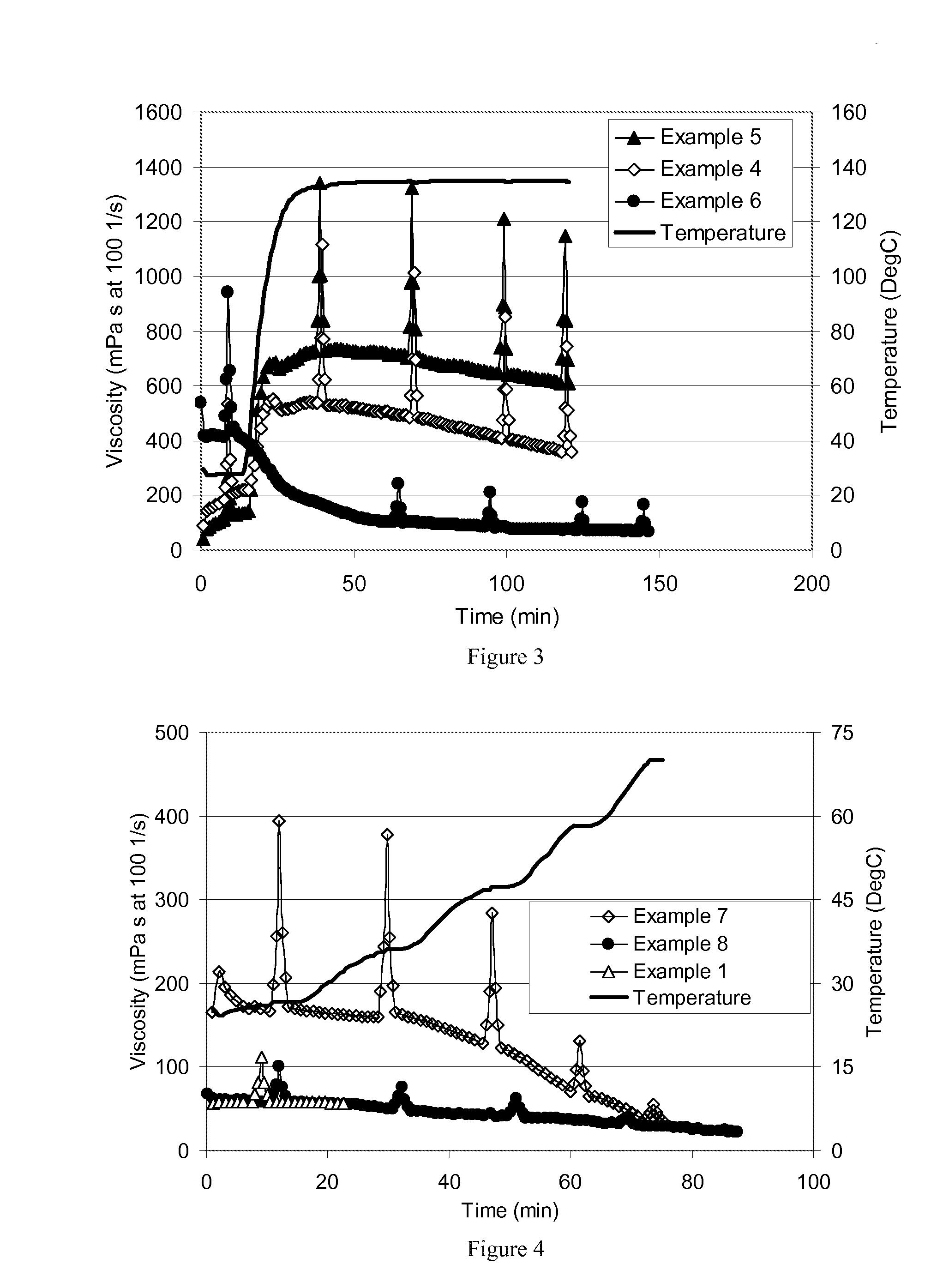

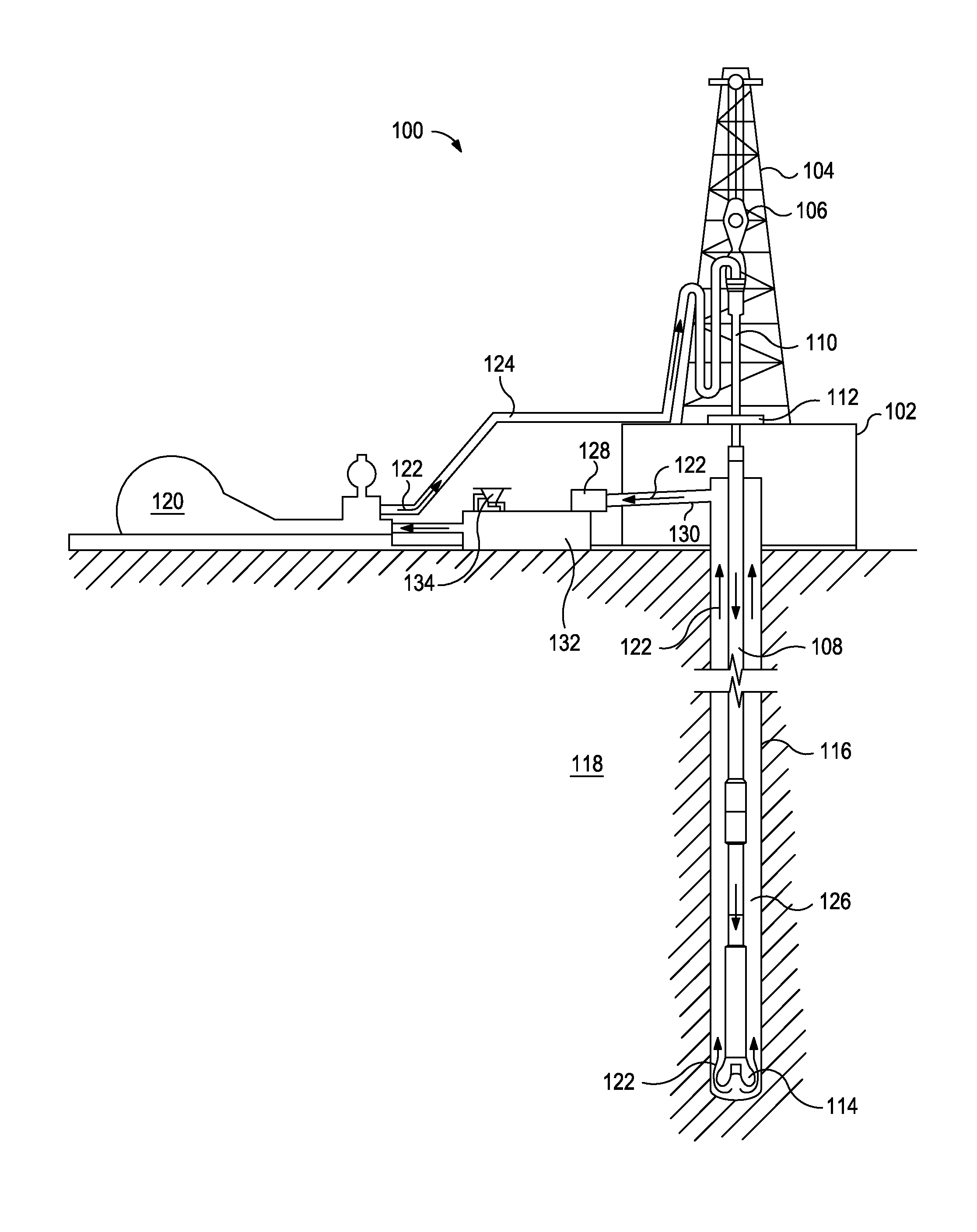

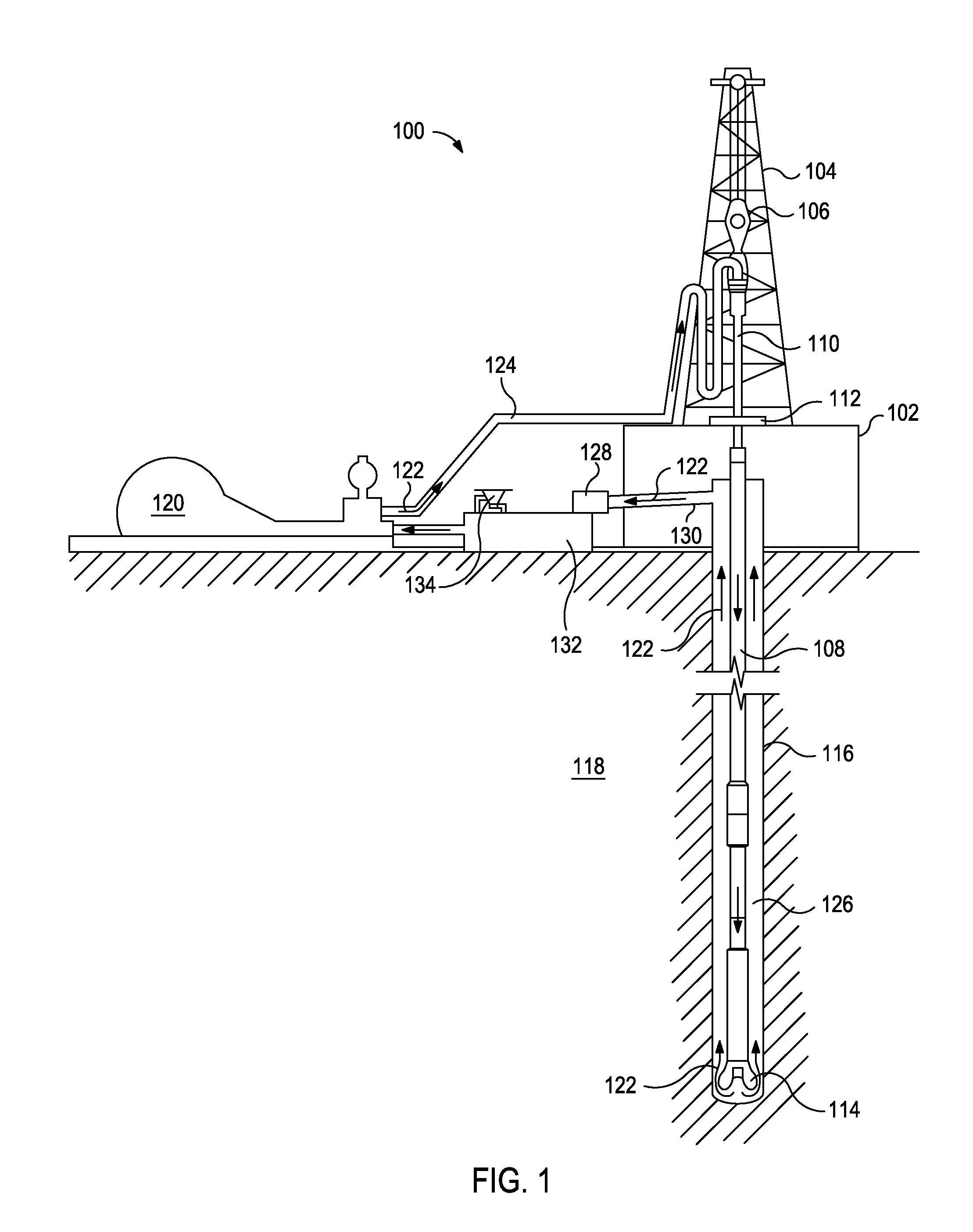

Methods comprising preparing an aqueous mixture of an anionic polymer, a charge screening surfactant, and a borate crosslinker, wherein the mixture has a conductivity less than 10 mS / cm, injecting the mixture down a wellbore, and gelling the mixture. An embodiment of the aqueous mixture can also include tetramethylammonium chloride as a clay stabilizer and a metal crosslinker such as a complex of zirconium and an amino acid ligand system. An embodiment can effectively provide borate crosslinking of an anionic polymer in a low-ionic-strength fluid system, without sacrificing ultimate gel strength or thermal persistence of the metal crosslinked polymer.

Owner:SCHLUMBERGER TECH CORP

Invert Emulsion Drilling Fluids for Flat Rheology Drilling

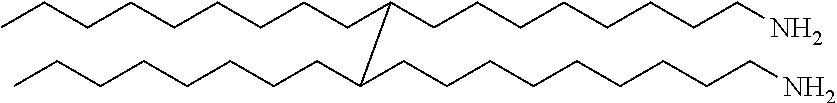

An invert emulsion drilling fluid, and a method of drilling with such fluid, having substantially flat or relatively controlled rheology, as demonstrated by the drilling fluid exhibiting little change in its yield point and gel strength across a temperature range of from about 40° F. to about 180° F., and effected with addition of a fatty dimer diamine additive together with an acid and without the addition of organophilic clays or lignites.

Owner:HALLIBURTON ENERGY SERVICES INC

Water absorbent and producing method of same

ActiveUS20070123658A1Improve gel performanceMaintain good propertiesOther chemical processesAbsorbent padsCross-linkPolymer science

An object of the present invention is to provide a water absorbent having excellent gel properties and showing excellent properties when used in a water-absorbing material of a sanitary / hygienic material such as paper diaper. Moreover, another object of the present invention is to provide a water absorbent which is safe and excellent in liquid permeability, and in which an amount of liquid permeability improver for improving the liquid permeability is reduced. The water absorbent is made from a water-absorbing resin prepared by a specific polymerization method and having a high degree of cross-linking, a high liquid holding property and a high gel strength (its swelling pressure of gel layer of is 35 kdyne / cm2 or more). This water absorbent is further processed to have a particular particle size distribution (95 wt % or more of its particles are less than 850ƒÊm but not less than 106ƒÊm, and logarithmic standard deviation (ƒĐƒÄ) is in a range of 0.25 to 0.45) and then surface cross-linked. After that, a liquid permeability improver is added therein.

Owner:NIPPON SHOKUBAI CO LTD

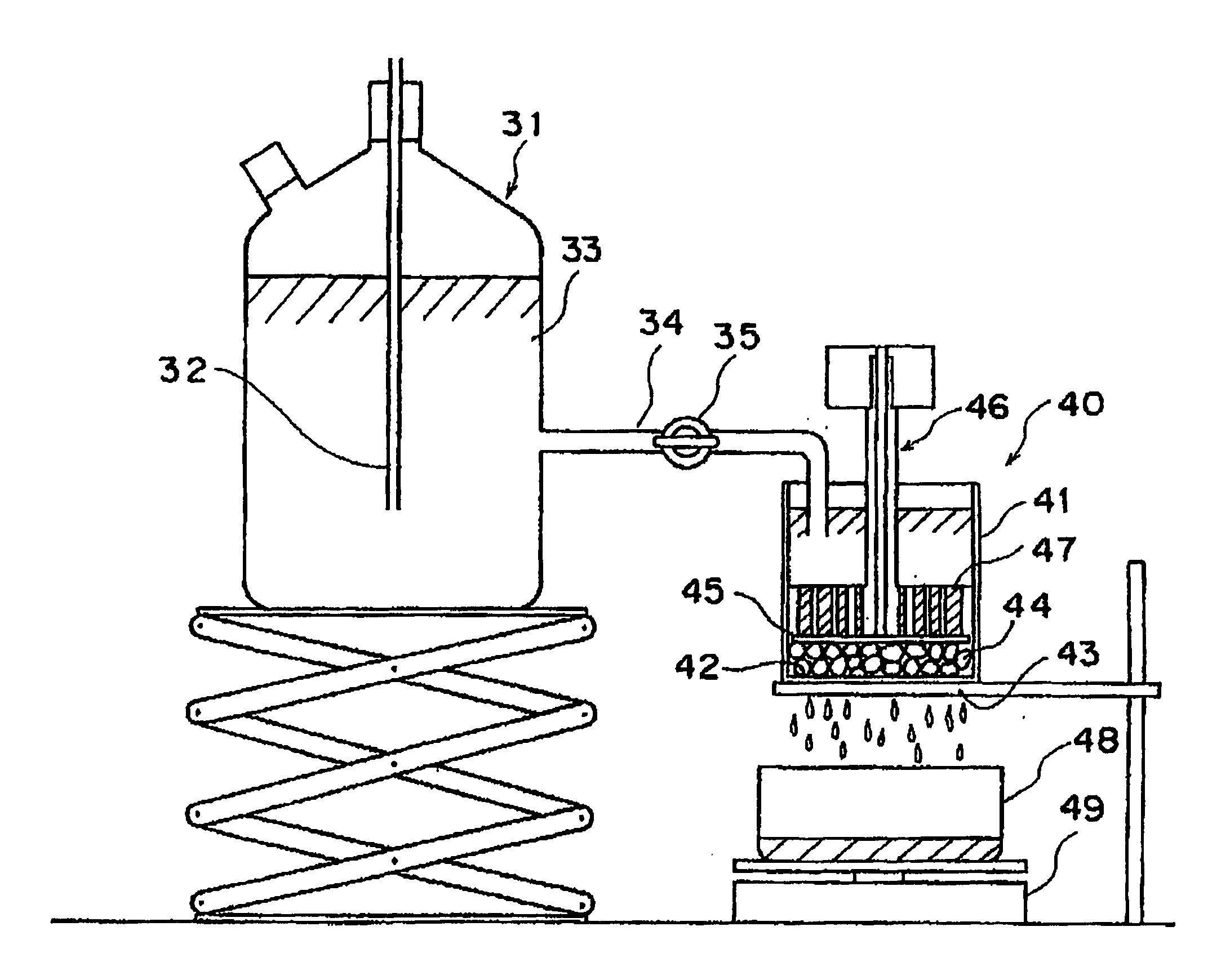

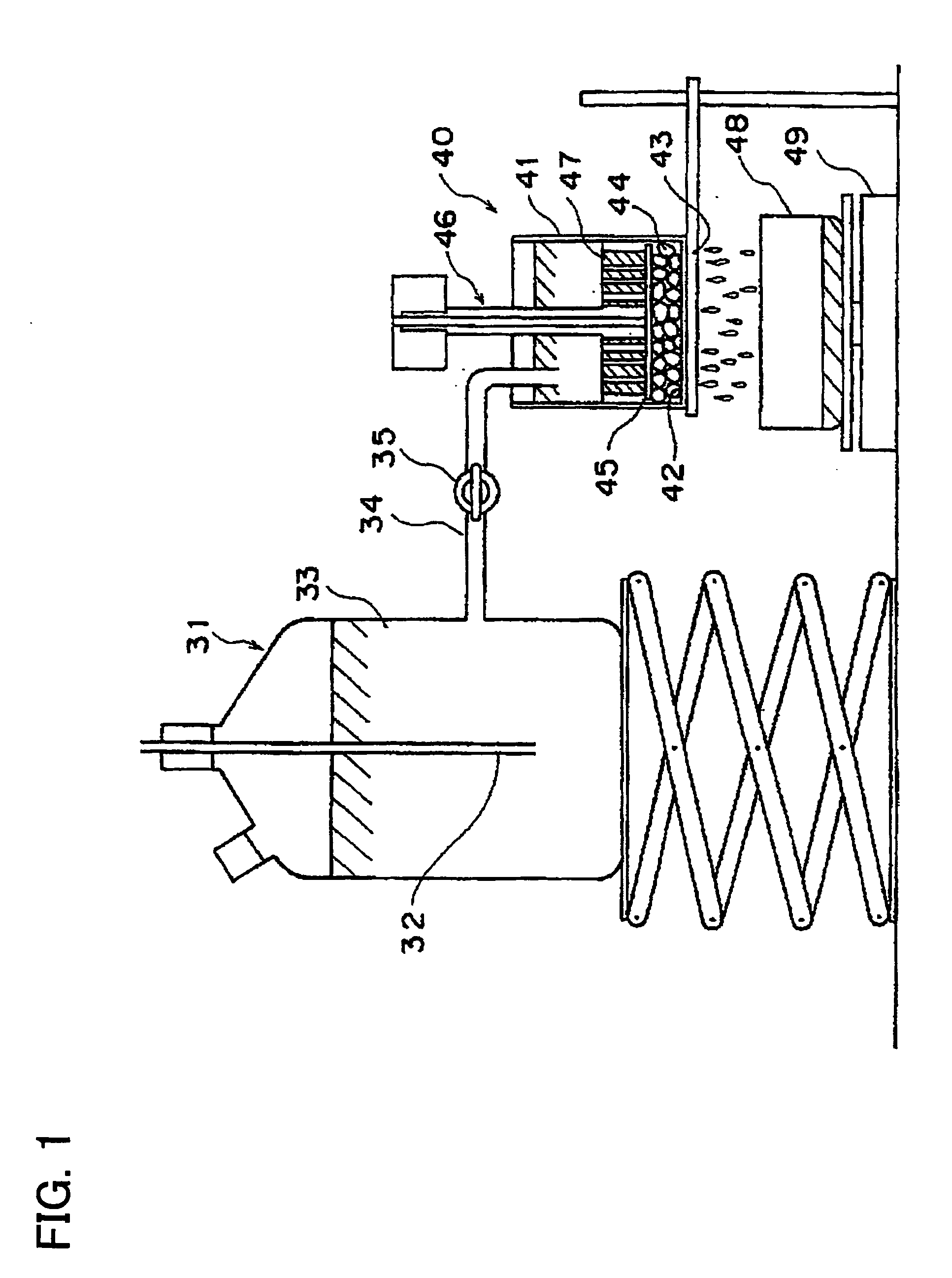

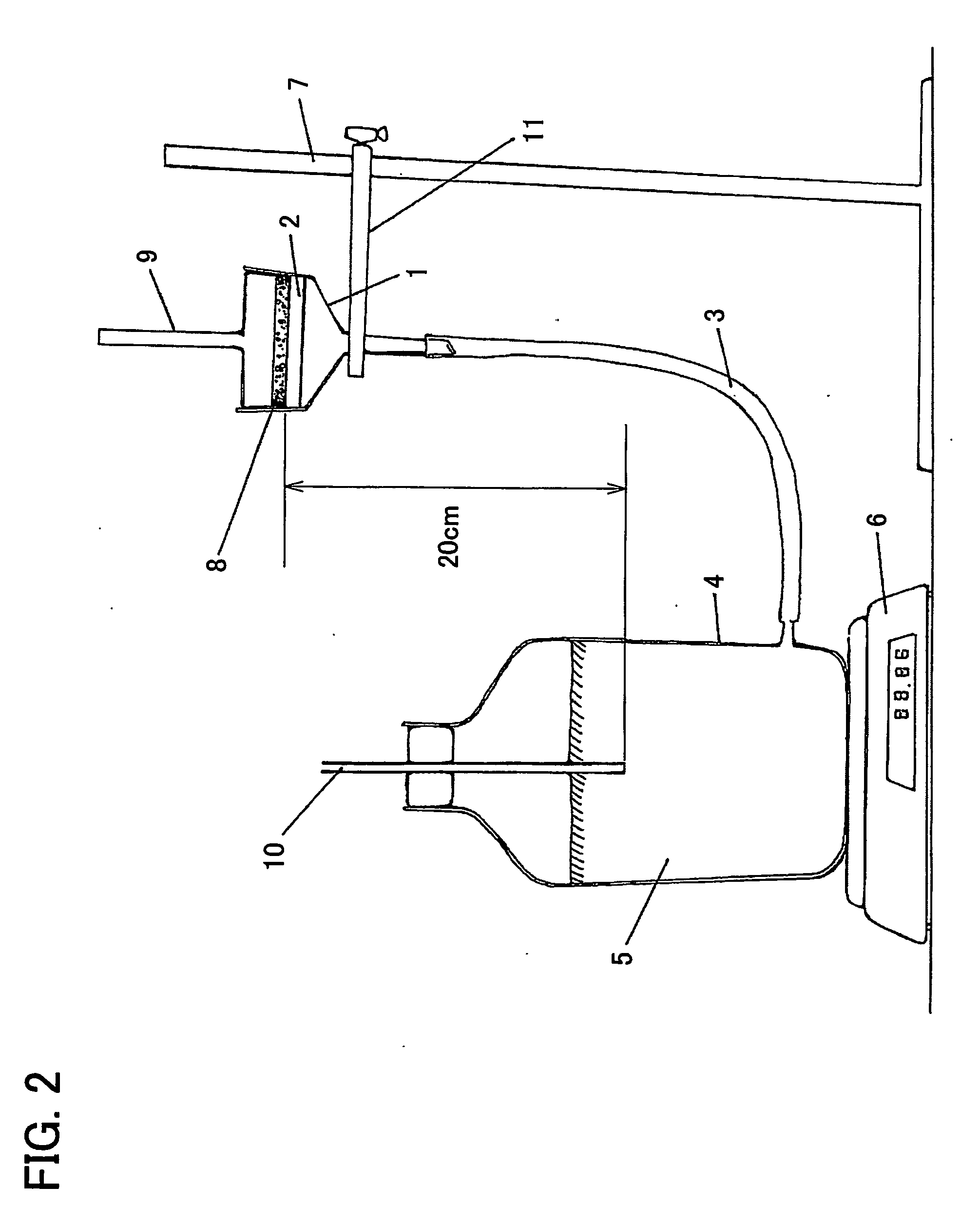

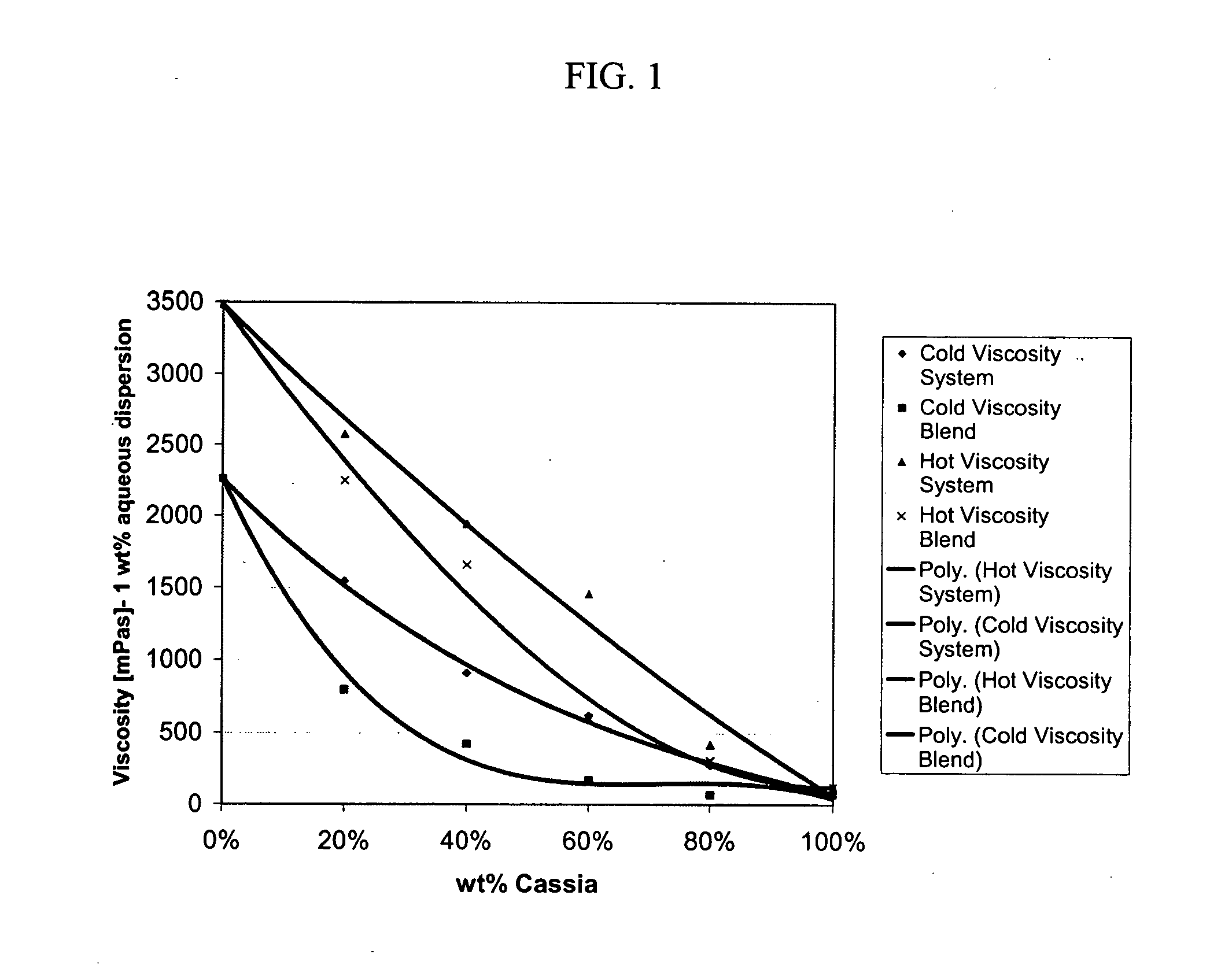

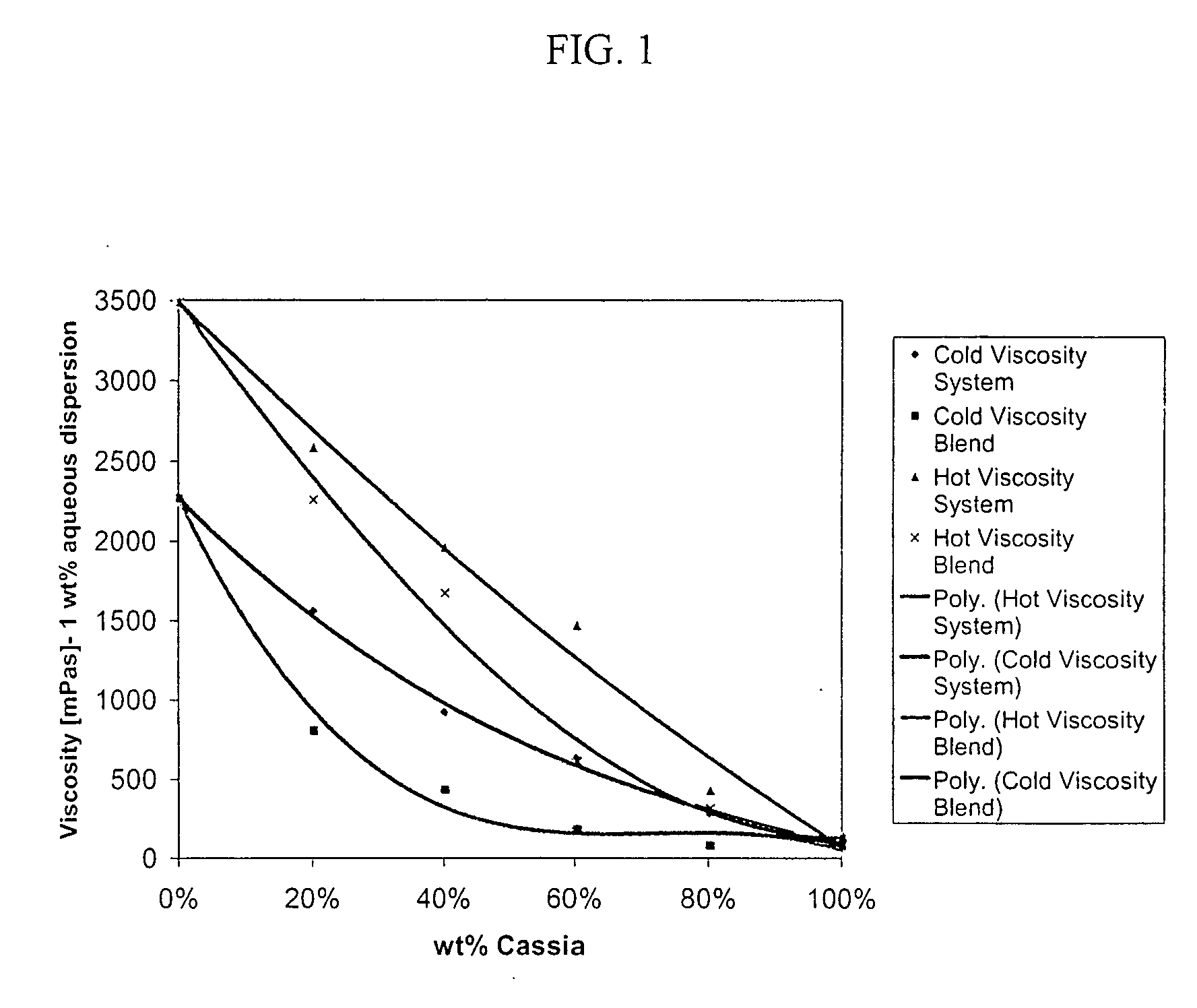

Hydrocolloids and process therefor

The present invention relates to substantially pure hydrocolloids and derivatives thereof, a novel method of making said hydrocolloids, compositions comprising said hydrocolloids, and using said hydrocolloids as a gelling and thickening agent for aqueous systems, for instance, in the area of food, fodder, cosmetic and pharmaceutical compositions. Typical hydrocolloids are selected from tamarid, fenugreek, cassia, locust bean, tara and guar. The hydrocolloids obtainable by the method of the invention are colorless, odorless and tasteless and they exhibit improved performance properties such as viscosity properties as well as gel strength and break strength.

Owner:LUBRIZOL ADVANCED MATERIALS INC

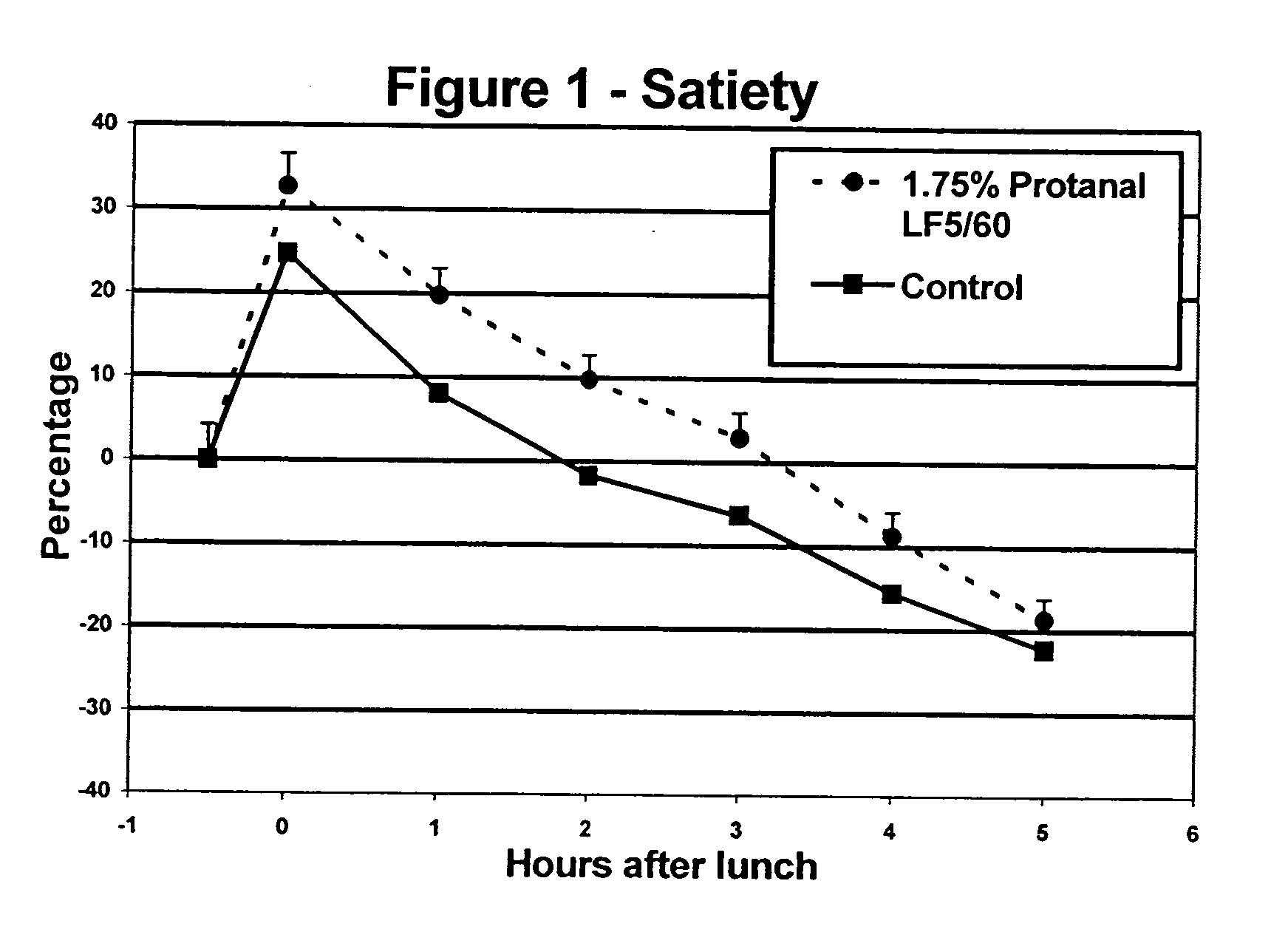

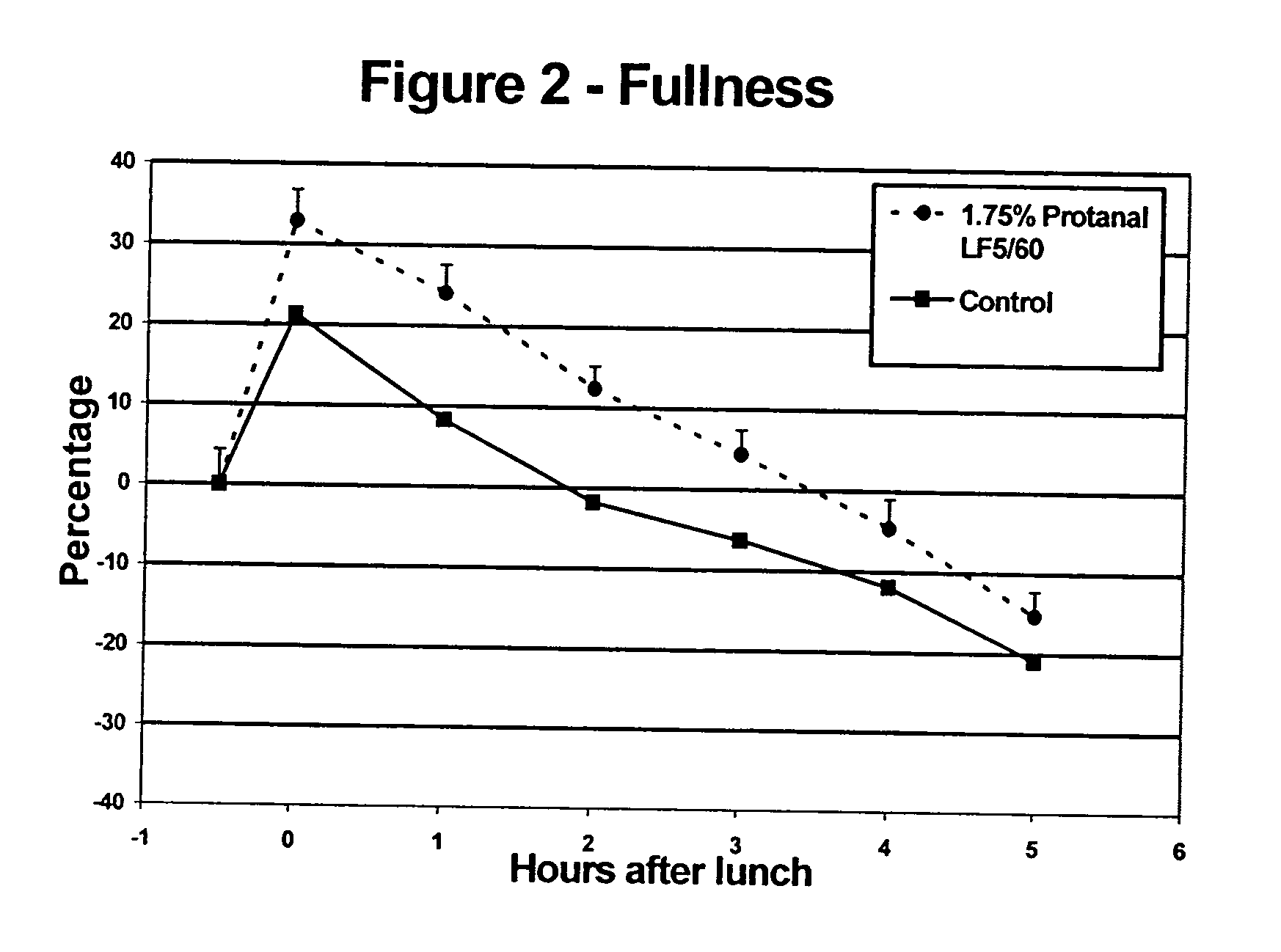

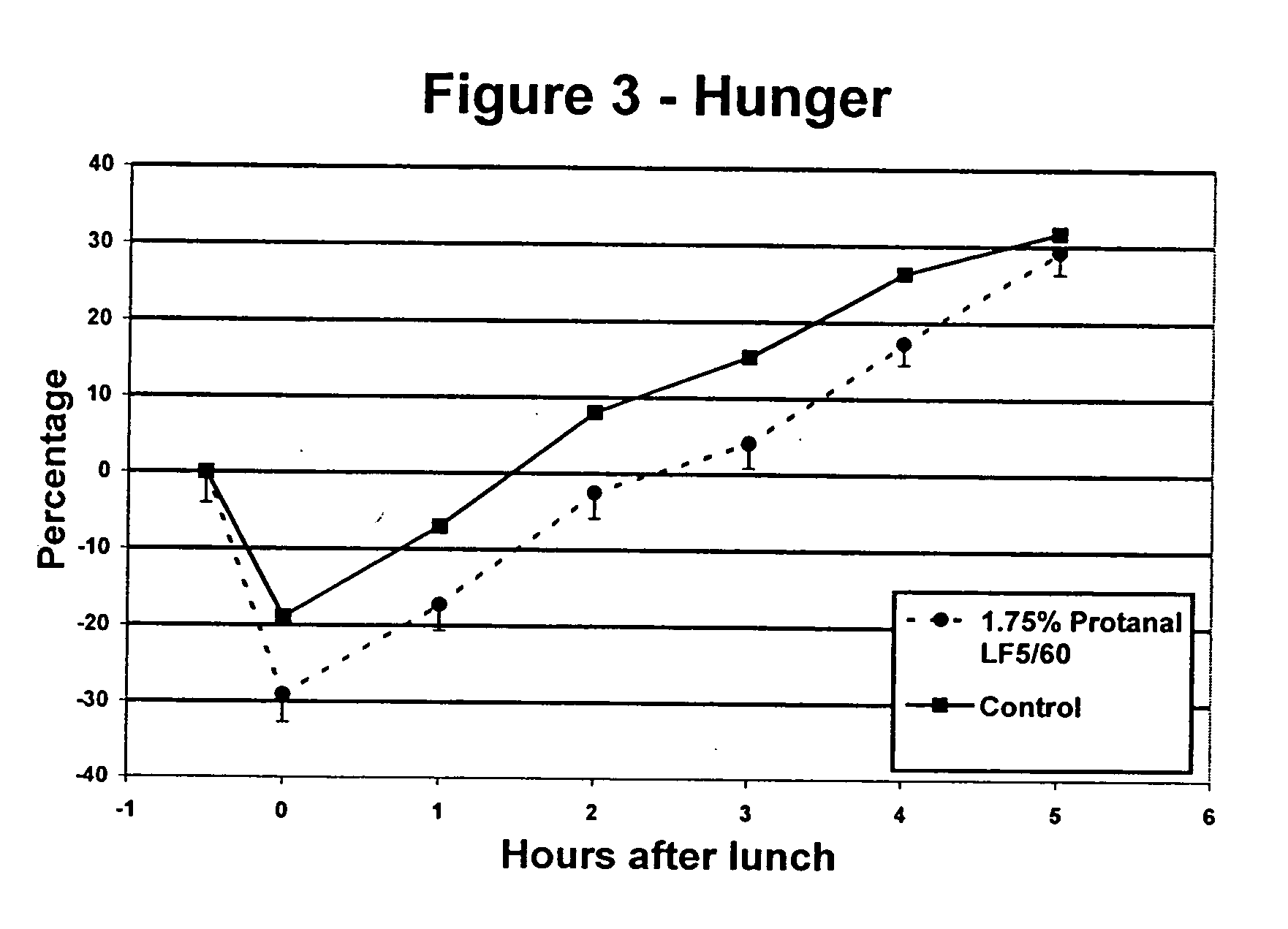

Satiety enhancing food compositions

InactiveUS20050084592A1Low production costPromote effectiveMetabolism disorderFood ingredientsFood componentsGel strength

The present invention provides an aqueous liquid or spoonable edible composition comprising at least 1% wt protein and from 0.1 to 5% wt of a biopolymer thickening agent which is not denatured or hydrolysed between pH 2 and 4, and wherein the composition has a gel strength at 37° C. and pH 2 of at least 10 KPa. The compositions of the invention have good satiety effects and are beneficial for use in weight control plans.

Owner:SLIM FAST FOODS

Microcapsule for retarding oil gas well working fluid additive release and preparation method thereof

InactiveCN101144011AReduce releaseImprove stress resistanceDrilling compositionWorking fluidFracturing fluid

The invention provides a microcapsule for delaying the release of working fluid additives in oil and gas well and a method for preparing the same, which belongs to oilfield chemical field. The invented microcapsule is formed by 3.5-25 percent of working fluid additive in oil and gas well, 70-94 percent of aluminosilicate beads, 2-5 percent of polymer membrane, wherein the working fluid additive in oil and gas well is one of oil well cement early strength accelerator, gel strength accelerator, retarder or fracturing fluid crosslinking agent, gel breaker, the aluminosilicate beads are waste catalysts with 10-250 um particle size and 0.20-0.60cm3 / g pore volume 0.20-0.60cm3 / g, the polymer membrane is non water-soluble polymer with 0.02-03 million relative molecular mass. The prepared microcapsules have good effect of delaying release, pressure resistance, temperature resistance, and wide application range. The main raw material of aluminosilicate beads for preparing microcapsules belongs to waste reutilization, which is economical and environment-friendly. Furthermore, the microcapsule preparation technology of the invention is simple and the production cost is low, which is beneficial for industrial production.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

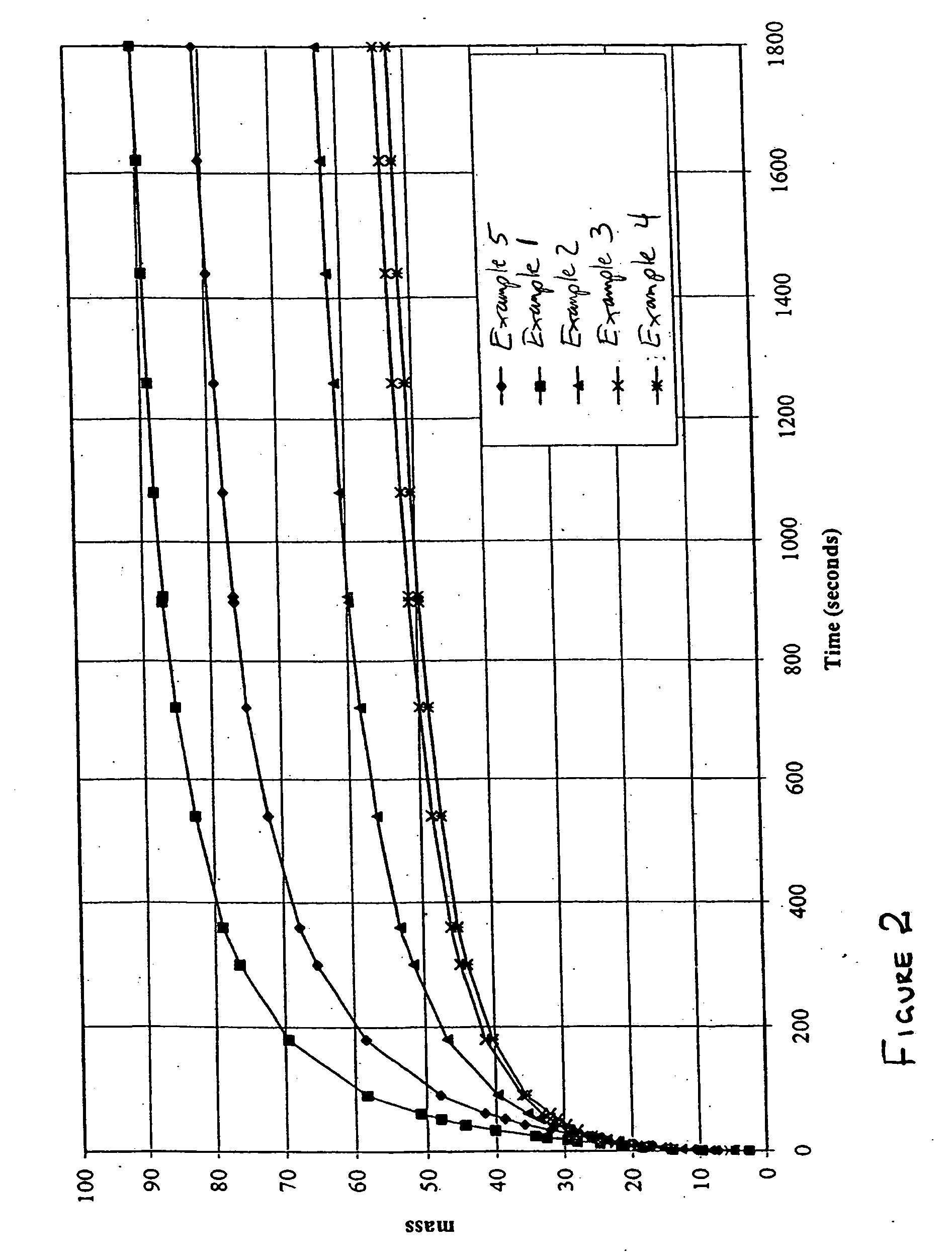

Process for preparing high water absorption resin

The preparation process of high water absorption resin includes following steps: neutralizing acrylic acid monomer with alkali solution to 60-90 % neutralizing degree, adding functional monomer in 0.5-50 % of total monomer weight, water soluble initiator or oxidation-reduction system in 0.05-0.5 % and water soluble cross-linking agent in 0.005-0.2 %; feeding the said mixed liquid into reactor, adding non-polar organic solvent in 2-10 times the volume of the mixed liquid and containing non-ionic surfactant, stirring to form inverse suspended polymerizing system; heating to 35-80 deg.c for free radical cross-linking copolymerization while adding oil soluble cross-linking agent in 0.005-0.3 % total monomer weight; dewatering after finishing polymerization, separation and drying to obtain the high water absorption resin. The obtained polyacrylate resin has the advantages of powerful water absorption, high salt tolerance, high gel strength and fast water absorption speed.

Owner:ZHEJIANG UNIV

Method for preparing quick temperature response semi-interpenetration network hydrogel

InactiveCN1586706AGood pH responsivenessImprove performanceMicroballoon preparationMicrocapsule preparationCross-linkTemperature response

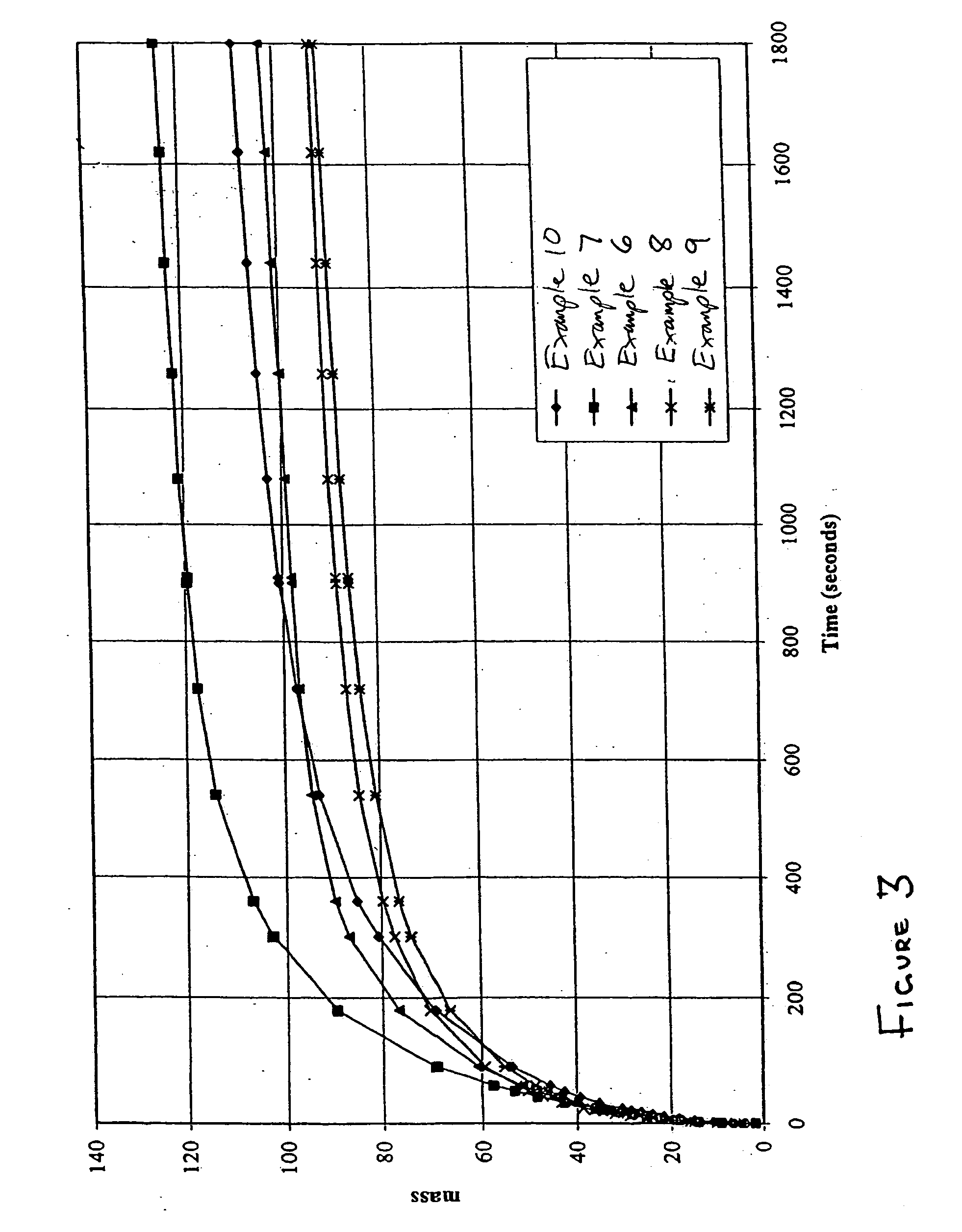

The preparation process of semi-interpenetration network hydrogel with quick temperature response includes the following steps: dissolving the monomer and cross-linking agent in deionized water; adding polyeleectrolyte, electrolyte and initiator through stirring under inertial atmosphere for 5-10 min, reaction at 0-30 deg.c for 2-48 hr, and collecting semi-interpenetration network hydrogel with quick temperature response. The hydrogel has not only quick temperature response, but also great gel strength, and its response speed may be regulated via altering the consumption and molecular weight of the polyeleectrolyte and salt concentration in the reaction liquid. The hydrogel has 90 sec dehydration rate over 95 % at the temperature over its phase conversion point, can reach dehydration balance in 2 min, and has good pH response and thus expanded application range, especially in biological and medicine fields.

Owner:DONGHUA UNIV

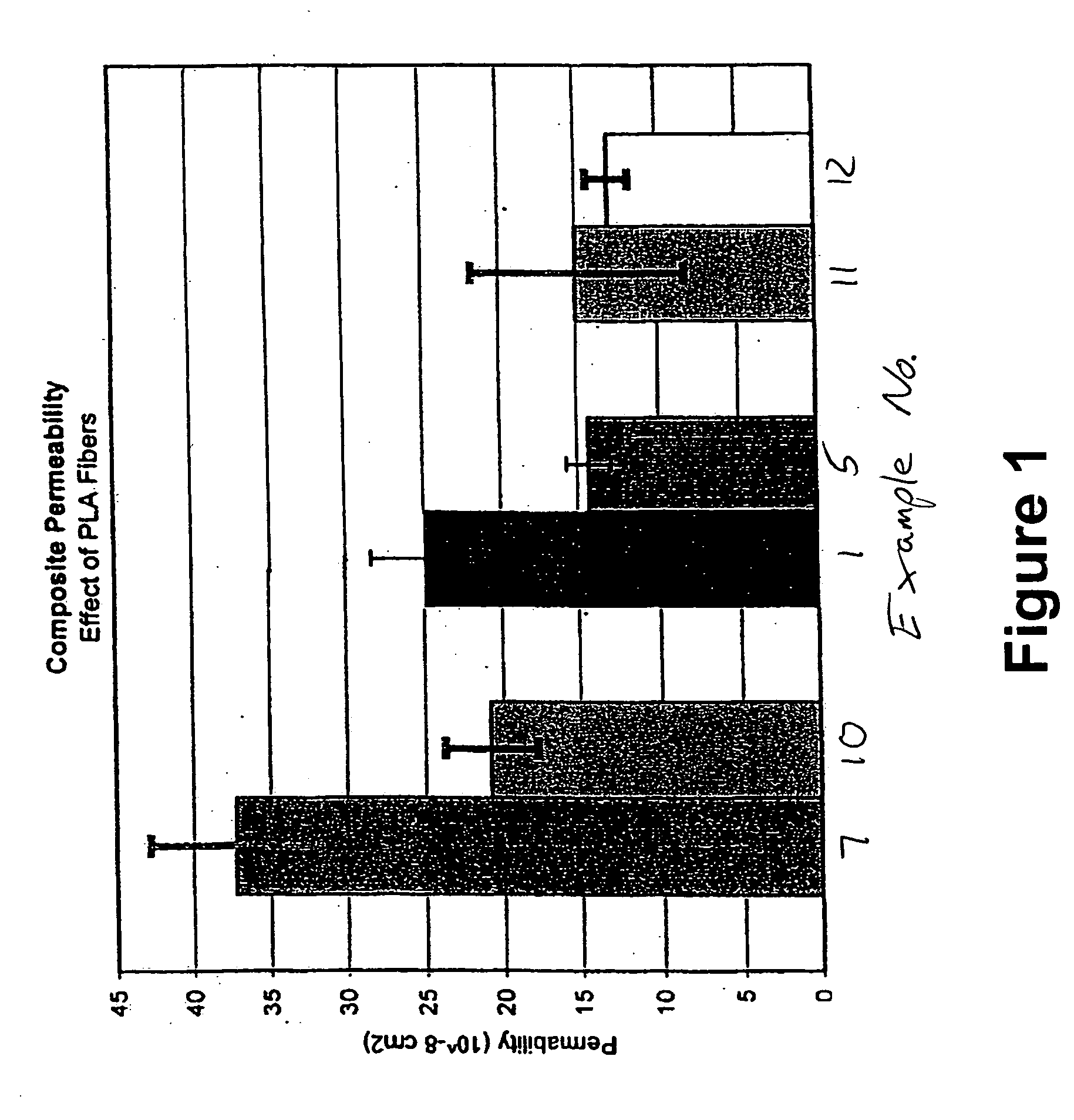

Absorbent composites containing biodegradable reinforcing fibers

An absorbent composite contains a superabsorbent material and thermoplastic biodegradable reinforcing fibers, and may also contain pulp fibers. The superabsorbent material may be biodegradable, providing a biodegradable absorbent composite. The superabsorbent material may have a gel strength from about 500 dynes / cm2 to about 80,000 dynes / cm2. The biodegradable reinforcing fibers may contain fibers of a polyester such as poly(lactic acid). The biodegradable reinforcing fibers may be wettable, reducing or eliminating the need for treating the surface of the fibers with a wetting agent such as a surfactant, and may provide desirable performance without being bonded to the other components.

Owner:KIMBERLY-CLARK WORLDWIDE INC

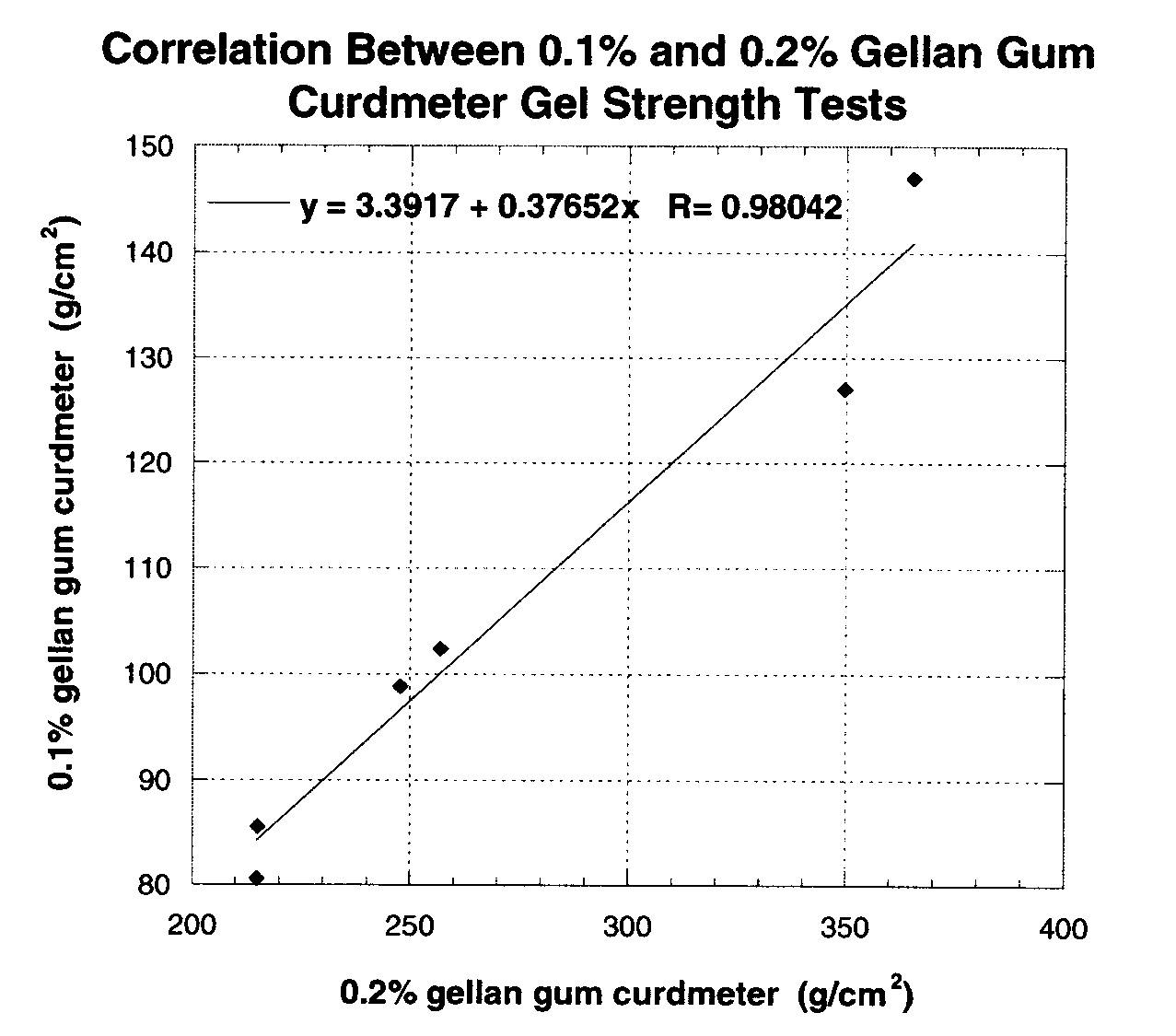

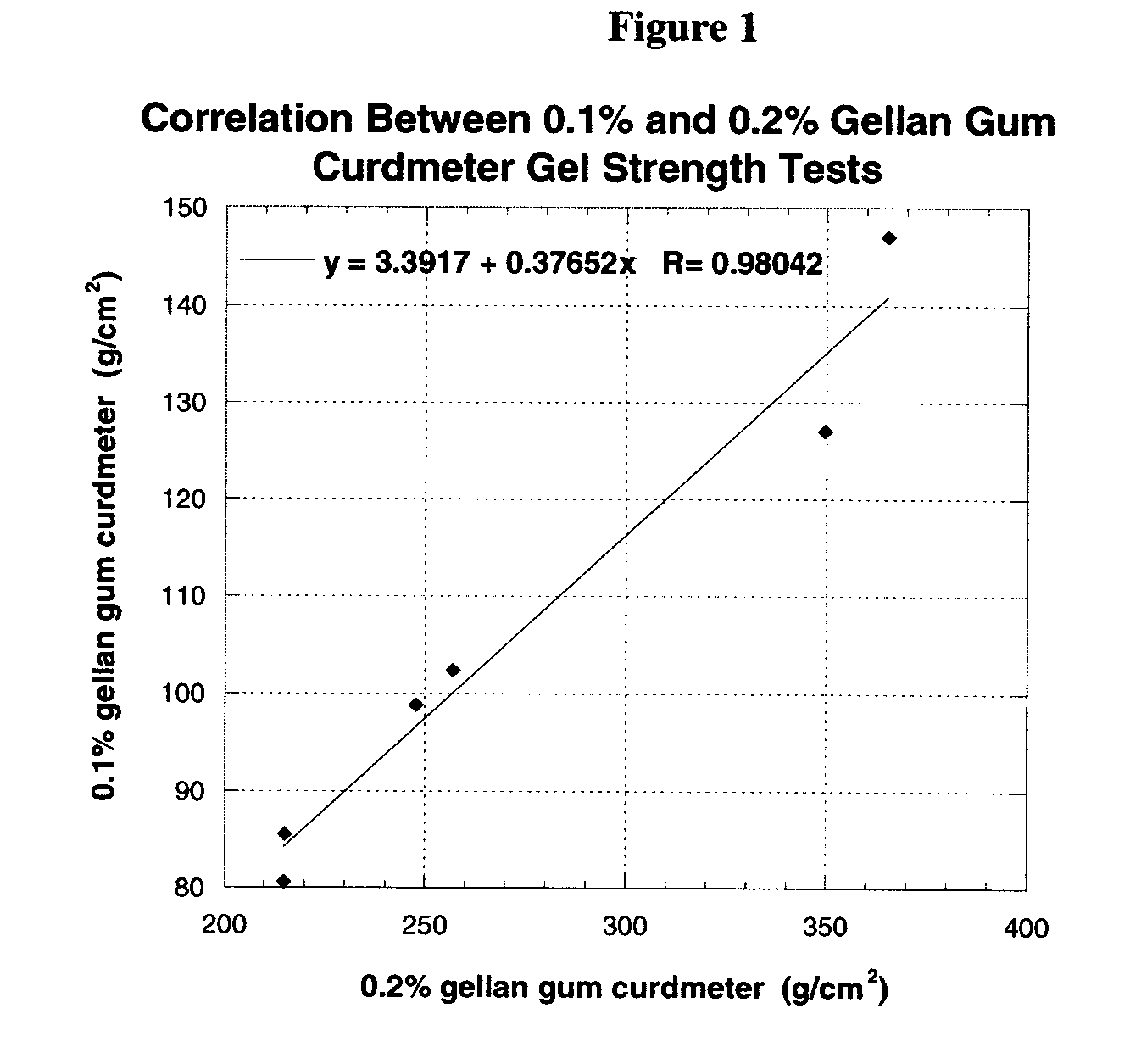

High Performance Gellan Gums and Methods for Production Thereof

The invention relates to high performance gellan gum compositions having a 0.1% curdmeter gel strength of at least about 117 g / cm2, i.e. from about 117 g / cm2 to about 400 g / cm2. The high performance gellan gums have a low acyl content but an increased molecular weight. One embodiment of the invention also relates to processes for producing high performance gellan gums having high clarity. The invention further relates to food and non-food industrial products comprising high performance gellan gums.

Owner:CP KELCO U S INC

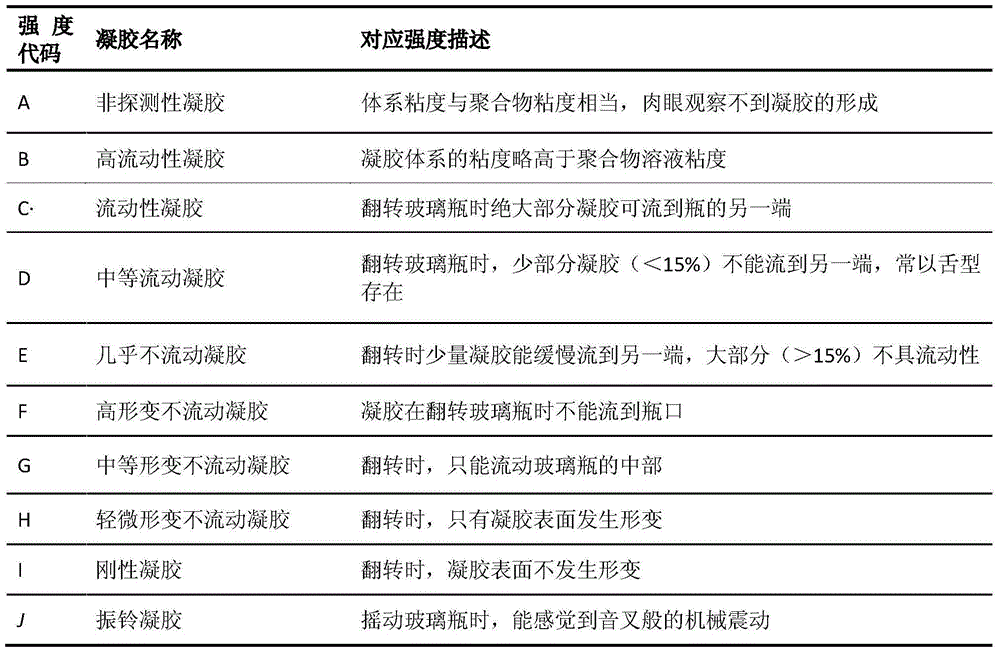

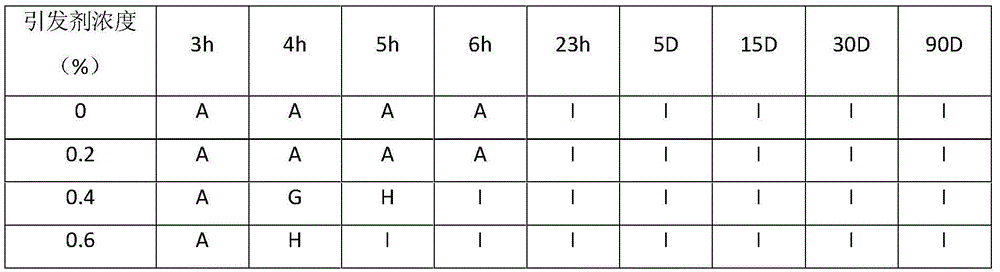

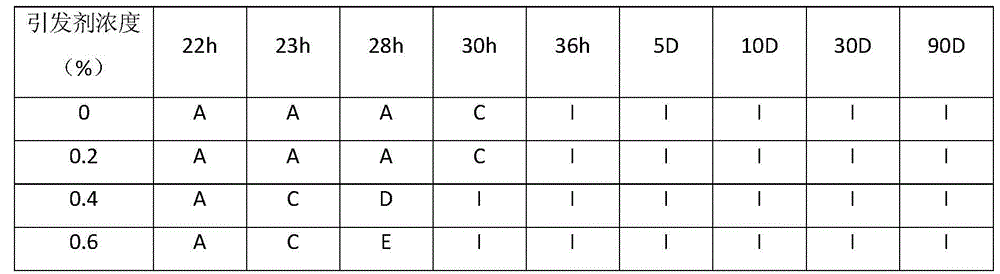

Temperature-resisting salt-tolerant high-temperature self-cross-linking onsite polymerization water plugging gel

The invention discloses temperature-resisting salt-tolerant high-temperature self-cross-linking onsite polymerization water plugging gel which mainly consists of, by mass, main agent 4%-6%, cross-linking agent 1%-2% and the balance saline water. The main agent consists of a monomer A and a monomer B, wherein the monomer A is acrylamide, and the monomer B is ester matter. The cross-linking agent is one of or a mixture of two or more formaldehyde, phenolic resin, resorcinol, hexamethylene tetramine, paraformaldehyde and polyethyleneimine. The temperature-resisting salt-tolerant high-temperature self-cross-linking onsite polymerization water plugging gel spontaneously produces cross-linking polymerization under the condition of high temperature, an initiator is not added, the gelling time can be controlled to be 2 hours to 28 hours at the temperature of 120 DEG C, the water plugging gel can be directly prepared by high-salinity water, the gelling strength can be up to the visual inspection code level I, and synaeresis does not occur after 90 days. The temperature-resisting salt-tolerant high-temperature self-cross-linking onsite polymerization water plugging gel is low in initial viscosity, has the advantages of being few in components, good in instant solubility and pumping injection performance, high plugging strength, good in thermohaline stability, low in cost and the like and has wide application prospect on the aspect of high-temperature high-salinity oil reservoir profile control water plugging.

Owner:成都西南石大石油工程技术有限公司

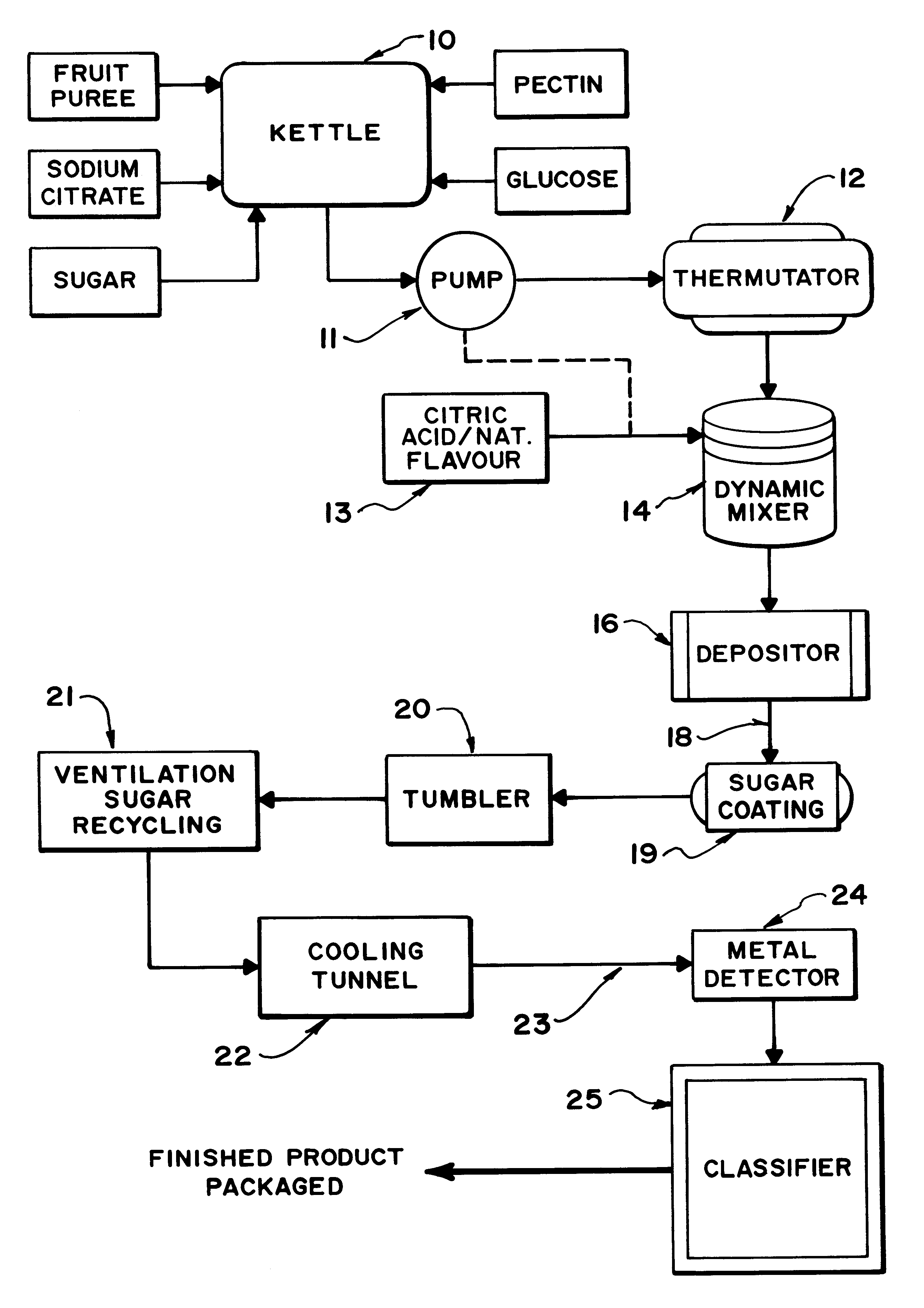

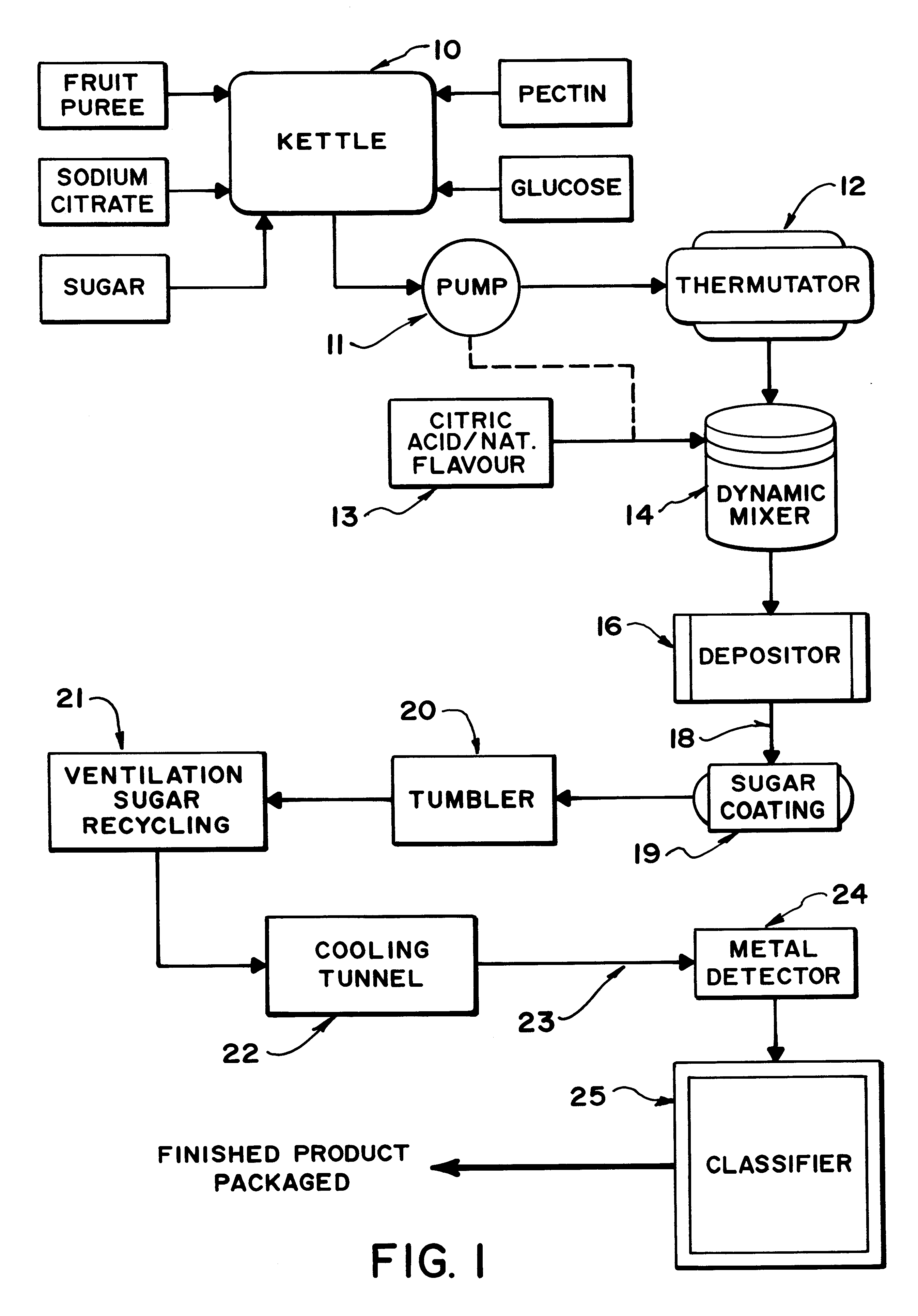

Particulate natural fruit product and method of making same

InactiveUS6251466B1Conveniently formedNatural flavorMilk treatmentCheese manufactureParticulatesNatural product

The present invention relates to a novel method of making a non-liquid fruit product (fruit chip) which has a natural fruit flavor and which can be formed in desired individual or discrete configurations and sizes. A method of making a dry particulate natural fruit chip product comprising: (a) adding a fruit ingredient and water to a heated kettle; (b) adding buffer, sugar and pectin to the fruit ingredient and water; (c) boiling the buffer, sugar and pectin fruit ingredient and water mixture to hydrate the pectin; (d) adding liquid sugar to the mixture and continuing to boil the mixture until excess water is boiled away; (e) adding sugar to the mixture in the kettle to reduce the temperature of the mixture and increase solids concentration; (i) transporting the mixture from the kettle through a heat exchanger to raise the temperature of the mixture; (g) adding acid and flavoring mix to the mixture and mixing the acid / flavour into the mixture; (h) passing the mixture into a heated depositor and dispensing the mixture onto a surface in the form of discrete fruit chips; (i) retaining the fruit chips on the surface until they lose heat and form a stable gel; (j) transporting the gelled fruit chips through a zone to remove excess moisture and enhance gel strength of the fruit chips; and (k) transporting the fruit chips through a cooling zone so that the fruit chips lose further heat and reach ambient temperature.

Owner:BROOKSIDE FOODS

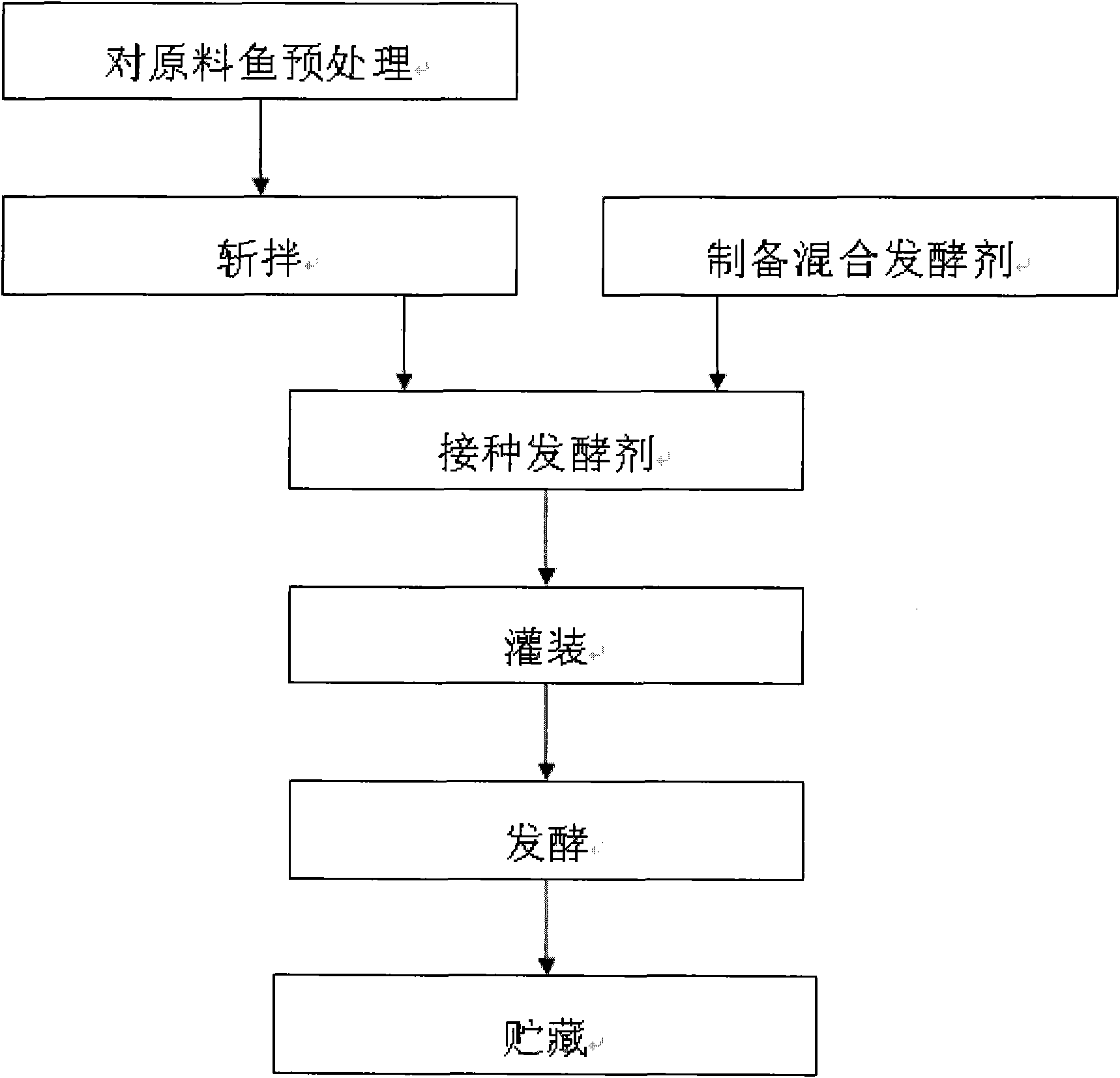

Method for making fermented surimi by utilizing lactic acid bacteria starter

The invention discloses a method for making fermented surimi by utilizing a lactic acid bacteria starter, and the method is characterized by adopting fresh or frozen fish as the raw material and comprising the steps of preprocessing, chopping, inoculating the starter, filling, fermenting and storing, thus obtaining the surimi. The product processed in the method has fresh taste, good gel property, intense fermentation flavor, high nutritive value and good safety and can solve the problems that protein of freshwater fish is easy to modify when being frozen and has poor gel strength and heavy fishy smell, and the method has simple process, greatly enhances the yield rate and the gel strength of the product and improves the flavor of surimi products.

Owner:SUZHOU DUORUNDUO AGRI TECH +1

Hydrocolloids and process therefor

The present invention relates to substantially pure hydrocolloids and derivatives thereof, a novel method of making said hydrocolloids, compositions comprising said hydrocolloids, and using said hydrocolloids as a gelling and thickening agent for aqueous systems, for instance, in the area of food, fodder, cosmetic and pharmaceutical compositions. Typical hydrocolloids are selected from tamarid, fenugreek, cassia, locust bean, tara, and algal hydrocolloids such as carrageenan and alginates. The hydrocolloids obtainable by the method of the invention are colorless, odorless and tasteless and they exhibit improved performance properties such as viscosity properties as well as gel strength and break strength.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Processed food composition containing dextrin

InactiveUS20110008502A1Lower calorie valueCalorie valueDough treatmentFrozen sweetsEmulsionDistilled water

The present invention relates to a processed food or beverage composition containing a dextrin having the following characteristics (a) to (d): (a) the dextrin has a blue value within the range of 0.4 to 1.2, (b) having a gel strength of 4 N / cm2 or more as measured after being dissolved in distilled water at 80° C. to prepare a 30 wt % aqueous solution of the dextrin, and then being allowed to stand at 5° C. for 24 hours, (c) having a viscosity of 100 mPa·s or less as measured after being dissolved in distilled water at 25° C. to prepare a 30 wt % aqueous solution of the dextrin, and then being allowed to stand at 25° C. for five minutes; and (d) the ratio (A / B) of the following gel strengths A and B being 2 or less: A: a gel strength (N / cm2) as measured after being dissolved in distilled water at 80° C. to prepare a 30 wt % aqueous solution of the dextrin, and then being allowed to stand at 5° C. for 24 hours, and B: a gel strength (N / cm2) as measured after being dissolved in distilled water at 25° C. to prepare a 30 wt % aqueous solution of the dextrin, and then being allowed to stand at 5° C. for 24 hours. Examples of the processed food or beverage composition to which the present invention is directed include: fatty tissue substitutes; processed meat foods prepared using the fatty tissue substitutes in place of fat tissue; emulsion-like foods; emulsion foods; cheese-like foods; processed foods which are prepared using the cheese-like foods in place of cheeses; sugar confectioneries; and beverages.

Owner:SAN EI GEN F F I

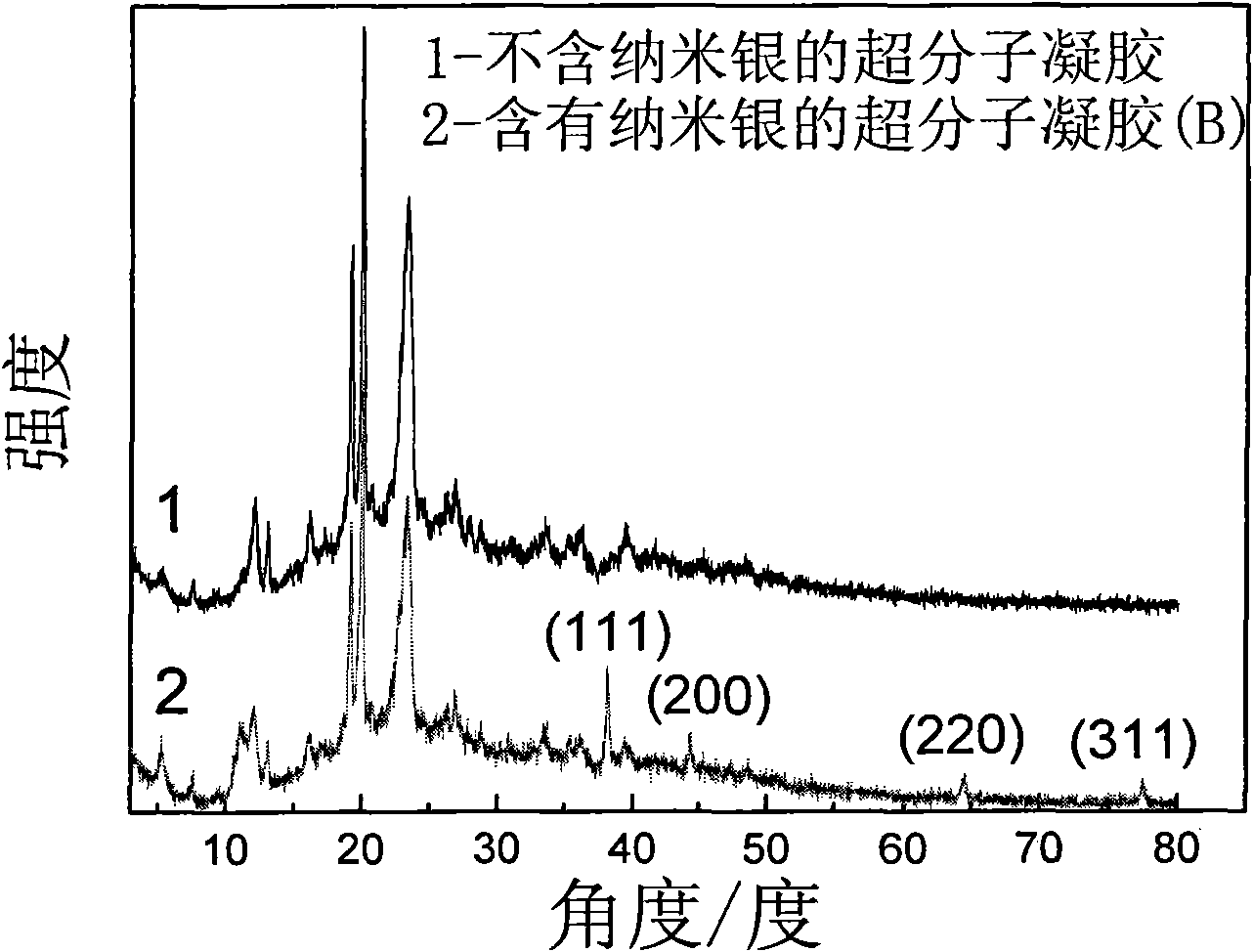

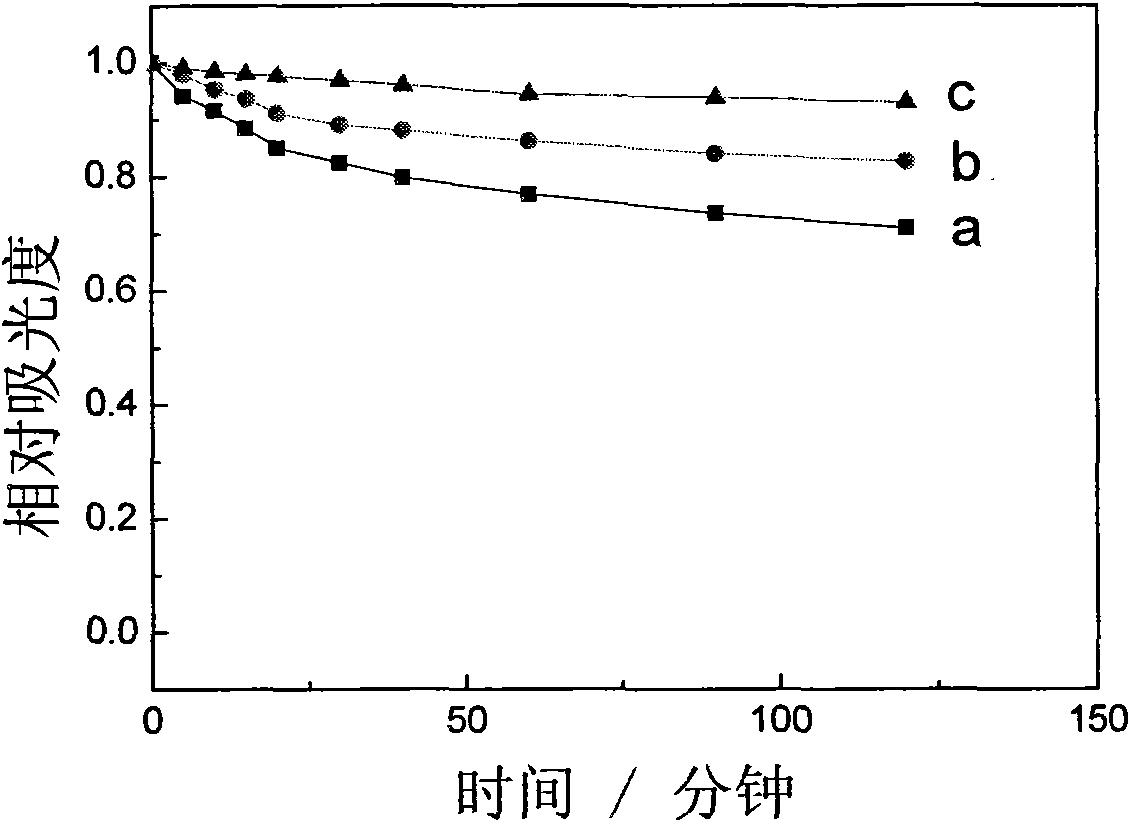

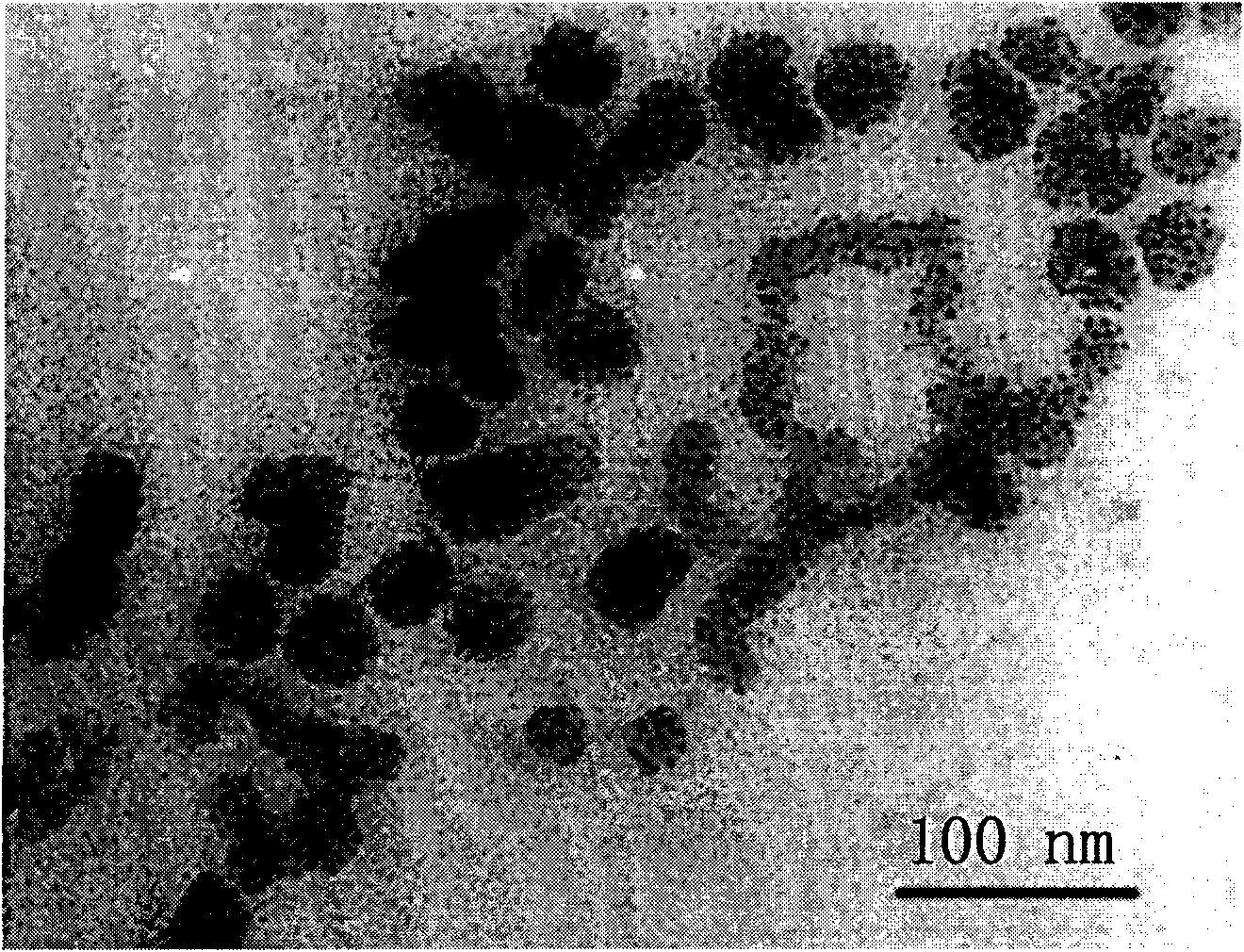

Antibacterial supermolecule aquogel and preparation method and application thereof

InactiveCN101564400AEasy to prepareEasy to operateAntibacterial agentsInorganic active ingredientsBiocompatibility TestingSILVER NITRATE CRYSTALS

The invention discloses a method for in-situ preparing antibacterial supermolecule aquogel. The method comprises the following operation steps: silver nitrate crystal and polyethyleneglycol-polypropylene glycol-polyethyleneglycol triblock copolymer solution are mixed and stirred to obtain mixed solution; the steps of stirring the mixed solution for 15 minutes and ultrasonically dispersing the mixed solution for 5 minutes are alternatively carried out for 2-4 hours to obtain nano silver sol; and the nano silver sol and Alpha-cyclodextrin solution are mixed, stirred and stands at the room temperature to obtain hydrogel. The hydrogel can be used for preparing injectable drug carriers. The invention has the advantages of simple operation, adjustable gel strength and the gelation time, room temperature forming, no involvement of chemical cross linking reaction and the usage of organic solvent, favorable biocompatibility and antibacterial property of obtained gel, and the like and is prospective to be widely applied in the field of biomedical engineering materials.

Owner:SUN YAT SEN UNIV

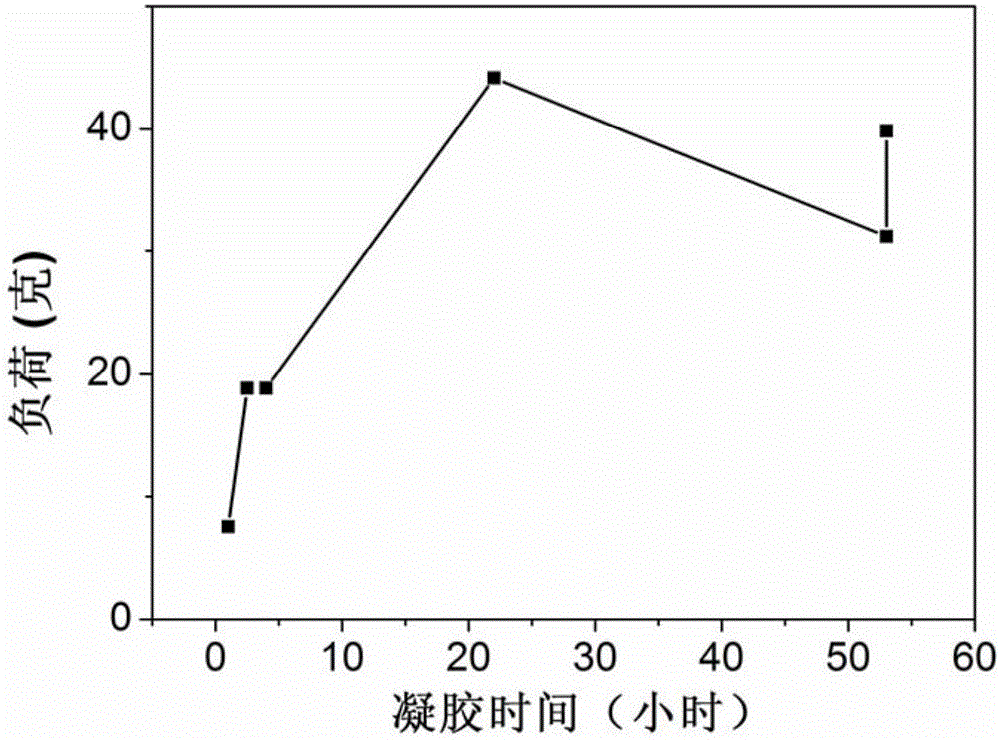

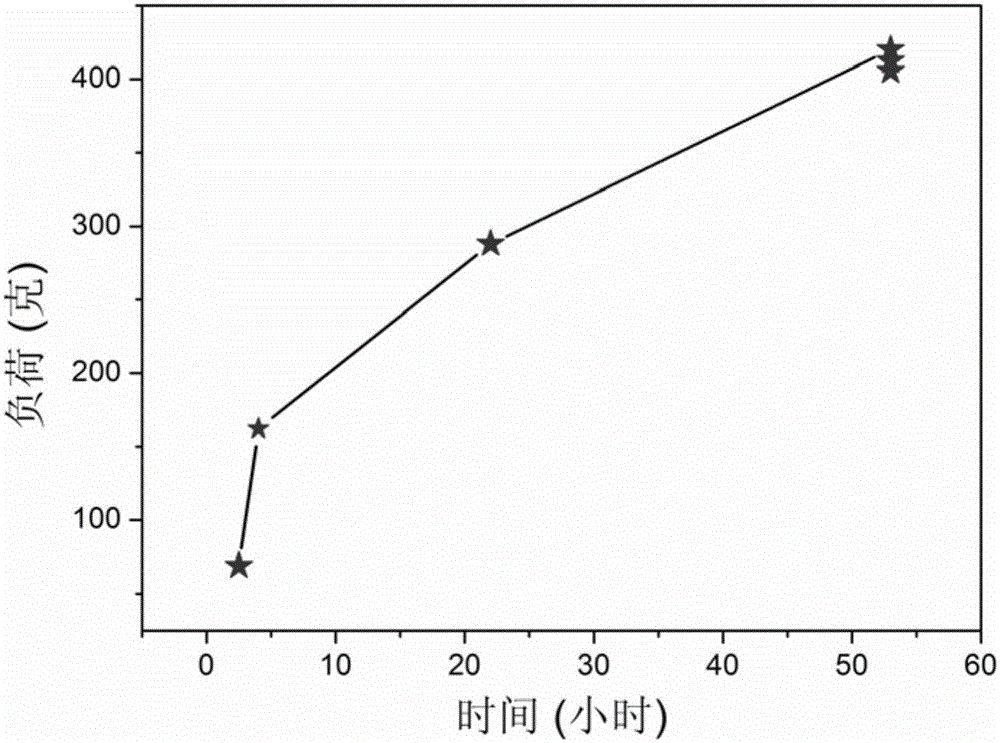

Preparation method of fishskin gelatin

InactiveCN101735464AImprove the status quo of high pollutionReduce lossesHigh concentrationCentrifugation

The invention discloses a preparation method of fishskin gelatin, which comprises the following steps: drying fishskin, cleaning to remove impurities, degreasing, removing impurities, cleaning, treating with superhigh pressure, pulping, extracting gelatin, centrifugating and drying to obtain finished gelatin. The invention produces the high-quality fishskin gelatin by the superhigh pressure technique for auxiliary treatment in combination with thermal extraction. The invention does not use high-concentration acid or alkali, thereby fundamentally improving the present status of high pollution in gelatin industry. The method reduces the steps of cleaning and neutralization, thereby reducing the loss of collagen, and the product yield reaches more than 80% (calculated by the content of collagen). Compared with the present status that the features of the fishskin gelatin product are inferior to those of pig and ox gelatin in the traditional technique, the gel strength, viscosity, transparency and other indices of the fishskin gelatin product produced by the method meet the grade A standard for edible gelatin (GB6783-94), and thus, the fishskin gelatin can be an effective substitute for pig and ox gelatin.

Owner:SOUTHWEST UNIVERSITY

Stabilizer composition of co-attrited microcrystalline cellulose and carboxymethylcellulose, method for making, and uses

Methods of making a high gel strength, water-dispersible, stabilizing colloidal microcrystalline cellulose composition are disclosed. This stabilizer composition is useful in many food and non-food applications.

Owner:DUPONT NUTRITION USA INC

Sustained release heterodisperse hydrogel systems-amorphous drugs

InactiveUS6048548AHigh total specific surfaceMacromolecular non-active ingredientsCoatingsDiluentHuman patient

Sustained release oral solid dosage forms comprising agglomerated particles of a therapeutically active medicament in amorphous form, a gelling agent, an ionizable gel strength enhancing agent and an inert diluent, as well as processes for preparing and using the same are disclosed. The sustained release oral solid dosage forms are useful in the treatment of hypertension in human patients.

Owner:PENWEST PHARMA CO

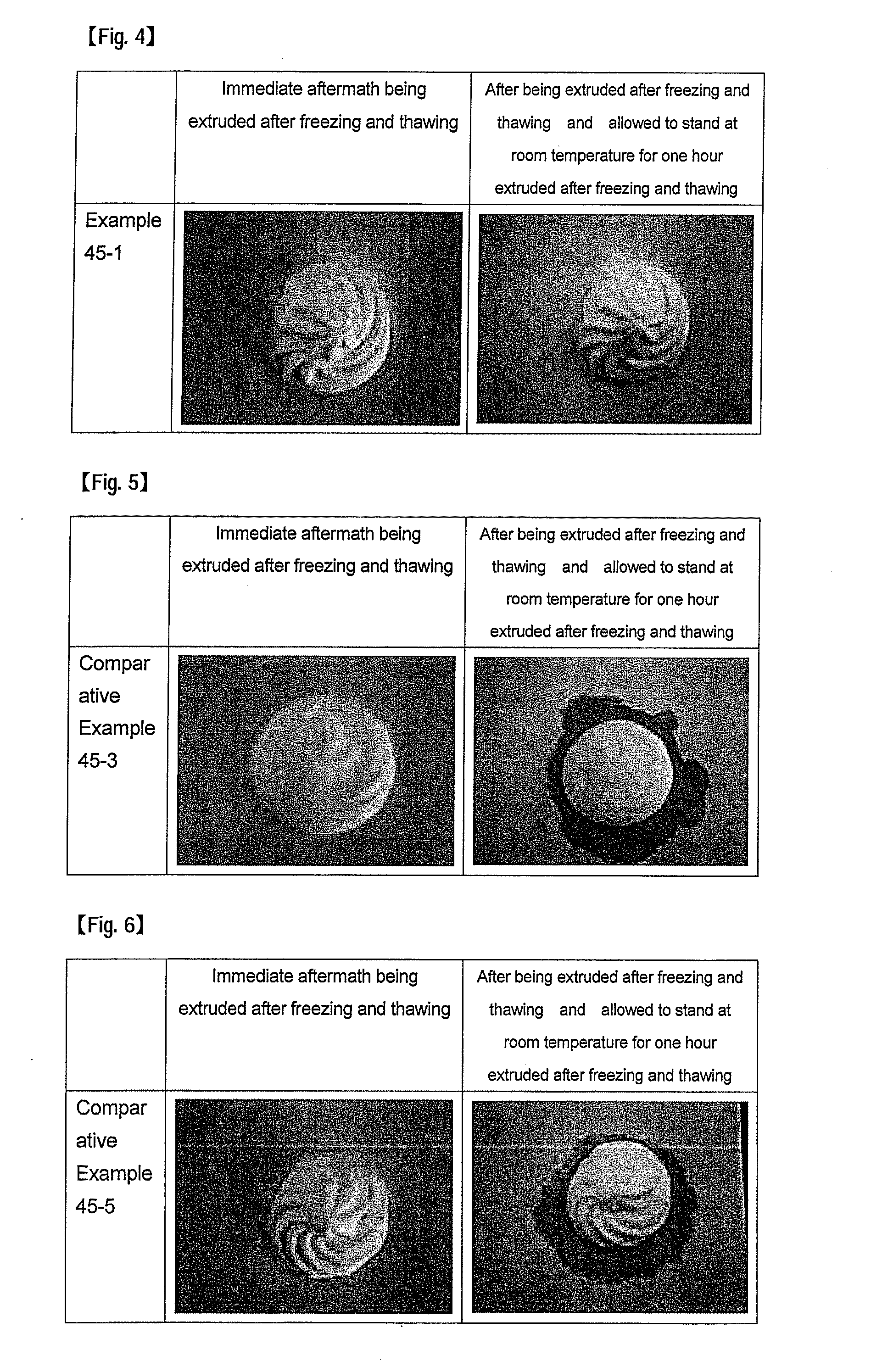

Method for processing frozen minced fillets of java tilapia

InactiveCN101627828AMeat/fish preservation by freezing/coolingFood preparationIce waterPre treatment

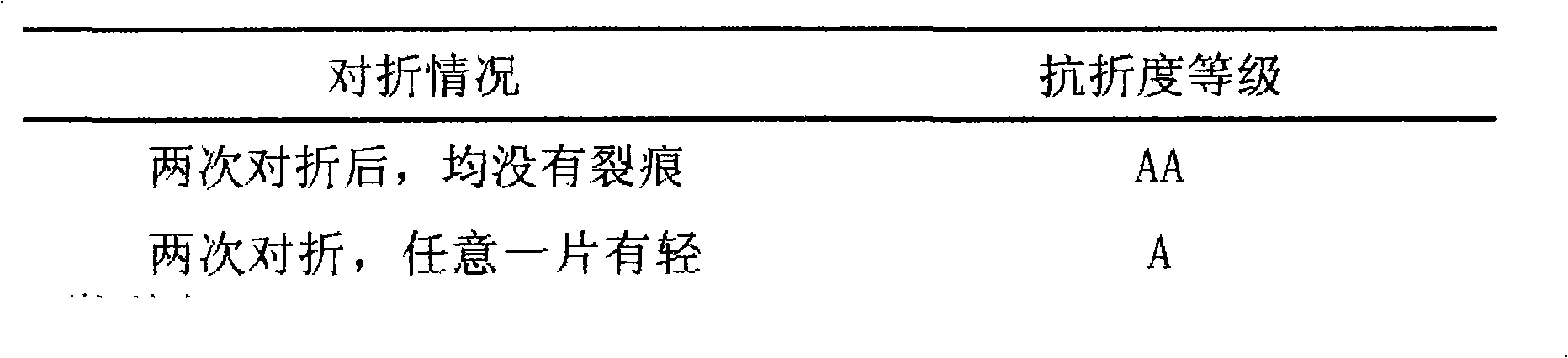

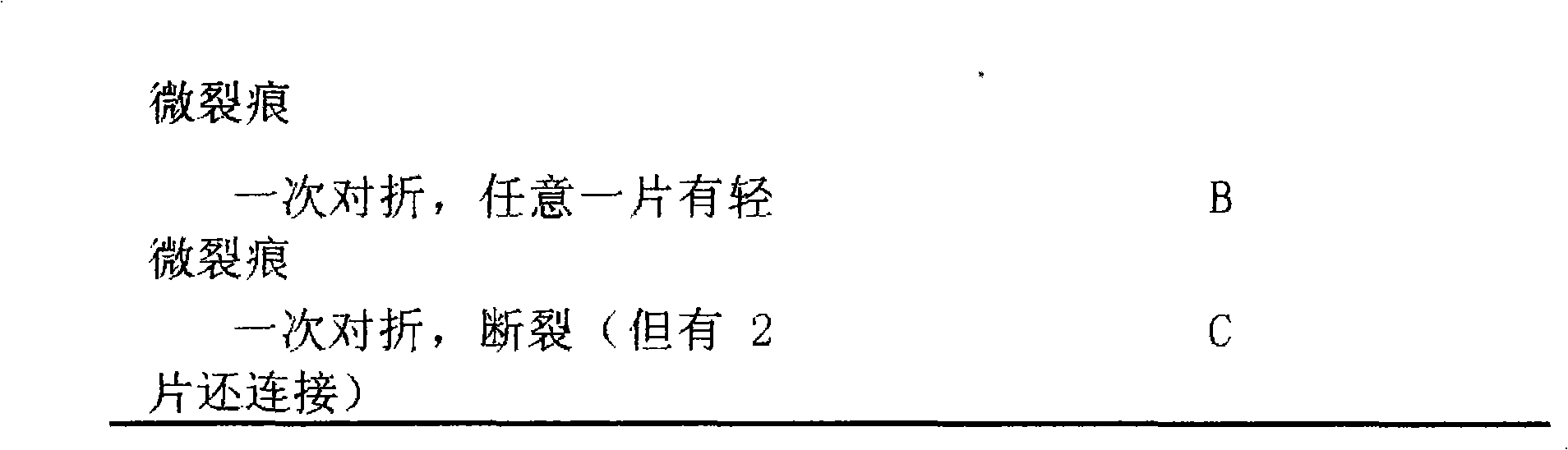

The invention relates to the technical field of foods, in particular to a method for processing the frozen minced fillets of java tilapia. The method comprises the following steps: the fish head, the fish scales and the viscera of java tilapia are removed by preprocessing, the java tilapia is washed cleanly and made into minced fish, then the minced fish is dewatered and finely filtered after ice water with the weight of 2-3 times of the weight of the minced fish and 0.15-0.2% of NaCl solution are sequentially used for rinsing the minced fish fully, a compound antifreeze with the weight of 7-9% of the weight of the minced fish is added, and minced fillets are obtained by fully mixing evenly, subpackaged at the temperature of -40 DEG C to -80 DEG C for quick freezing and put for freezing preservation at -18 DEG C; the moisture content of the minced fillets is smaller than 79%, and the gel strength and the folding resistance degree are used as indexes for judging the quality of the minced fillets. In the frozen minced fillets made and obtained according to the method, the gel strength of the minced fillets before freezing storage exceeds 800 (g.cm) by the detection of the gel strength and the folding resistance degree, the gel strength of the minced fillets after the freezing storage for 2 months still reaches more than 600 (g.cm), and the folding resistance degree reaches an AA level. The quality of the frozen minced fillets is equivalent to that of the SA level minced fillets of marine products, such as nemipterus virgatus, red sea bream and the like.

Owner:GUANGDONG OCEAN UNIVERSITY

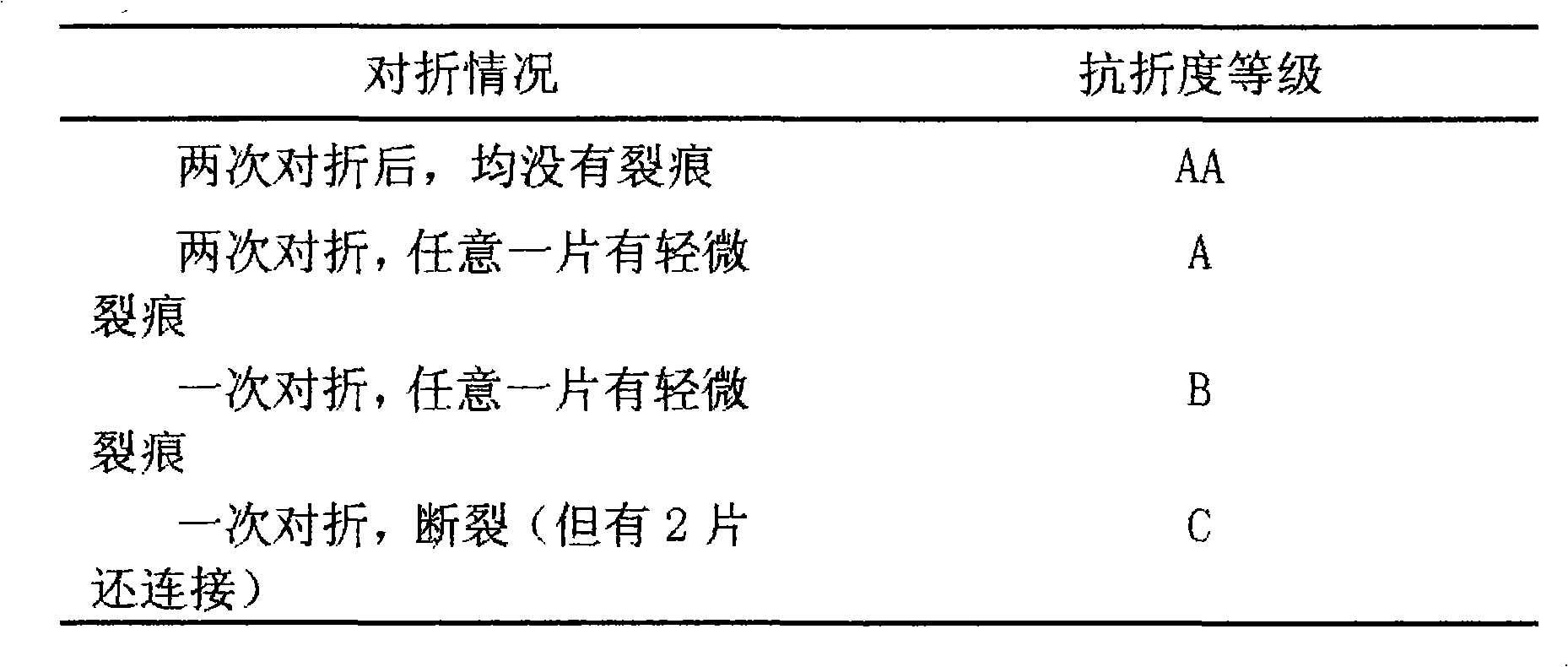

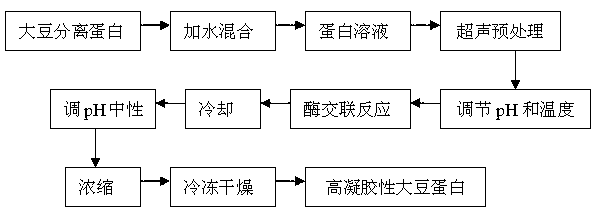

Preparation method of high-gelation soybean protein

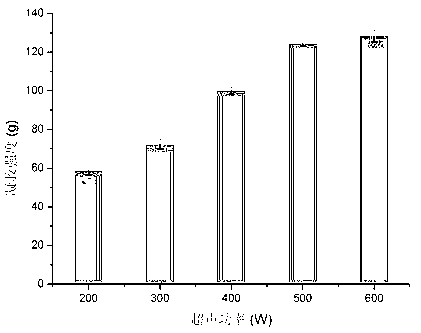

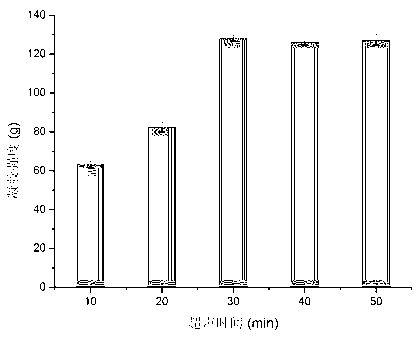

InactiveCN102934731AReduce dosageImprove gel performanceVegetable proteins working-upProtein solutionFreeze-drying

The invention relates to a preparation method of a high-gelation soybean protein, and belongs to the technical field of soybean protein processing. The method comprises the following steps: (1) mixing soybean protein isolate and water to obtain a protein solution, and performing ultrasound preprocessing on the protein solution; and (2) adjusting the pH and temperature of the protein solution subjected to ultrasound preprocessing in the step (1), adding transglutaminase for cross linking reaction, cooling the product after cross linkage to room temperature, and then concentrating and freeze drying to obtain the high-gelation soybean protein. The method has the beneficial effects that the needed equipment is simple and safe to operate; the enzyme needed in production is small in amount, short in enzymolysis time, low in cost and environmentally-friendly; the obtained soybean protein is high in gel strength, and meanwhile the gel stability is good; and the application range of the soybean protein in foodstuff is expanded.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

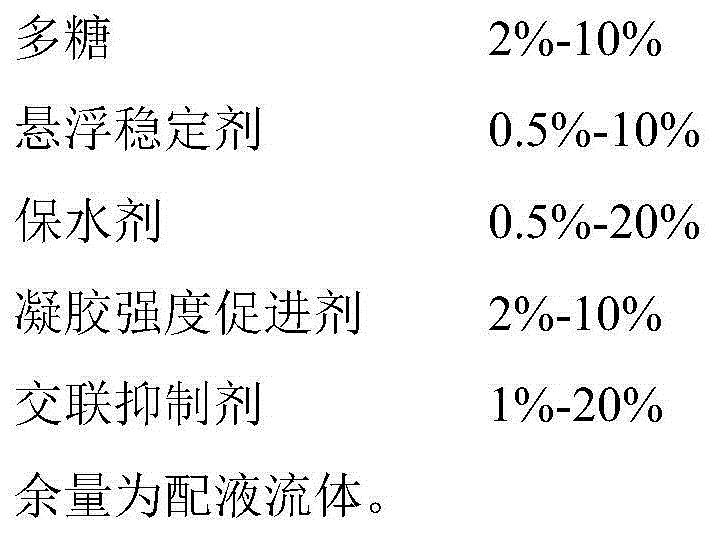

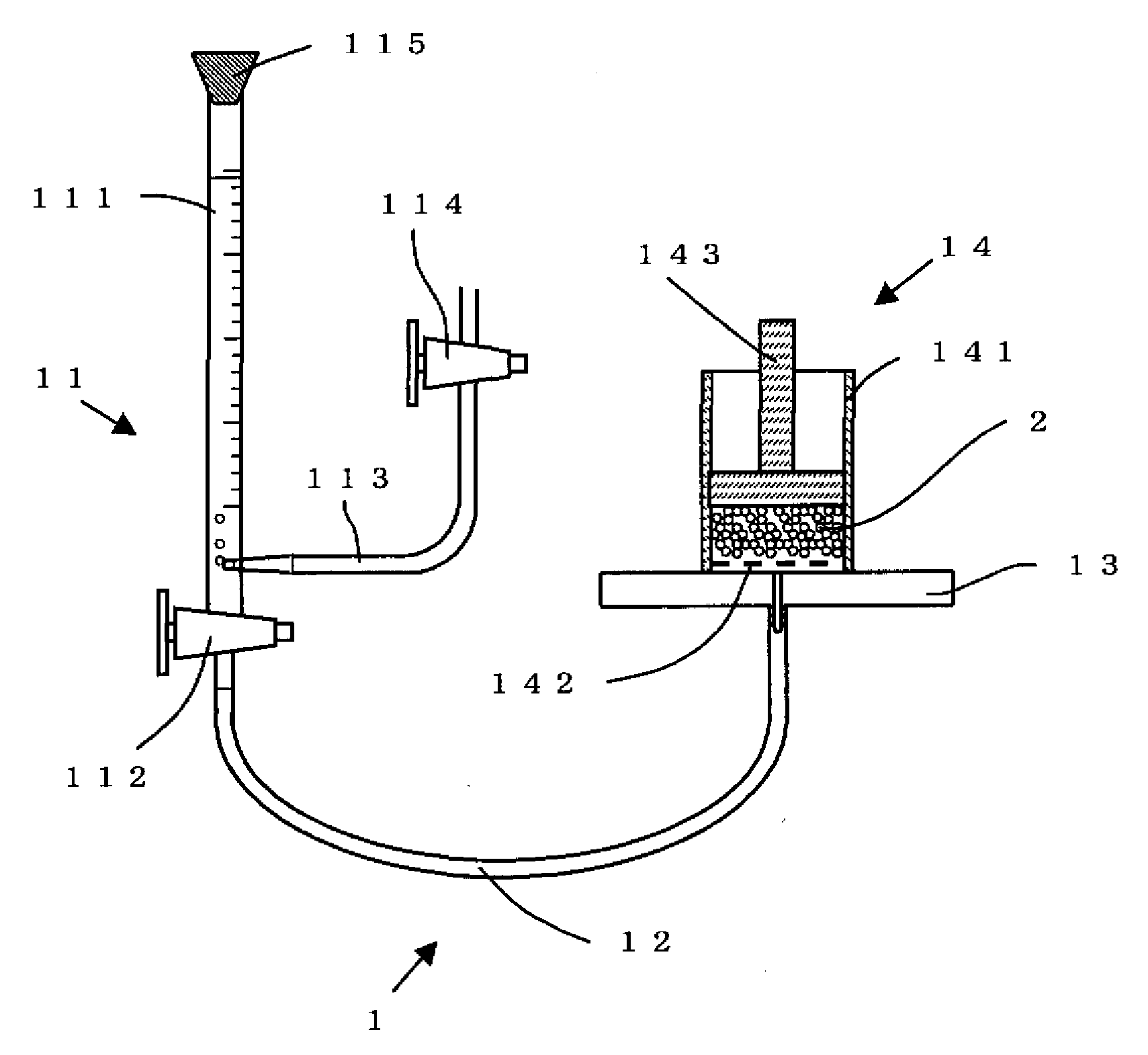

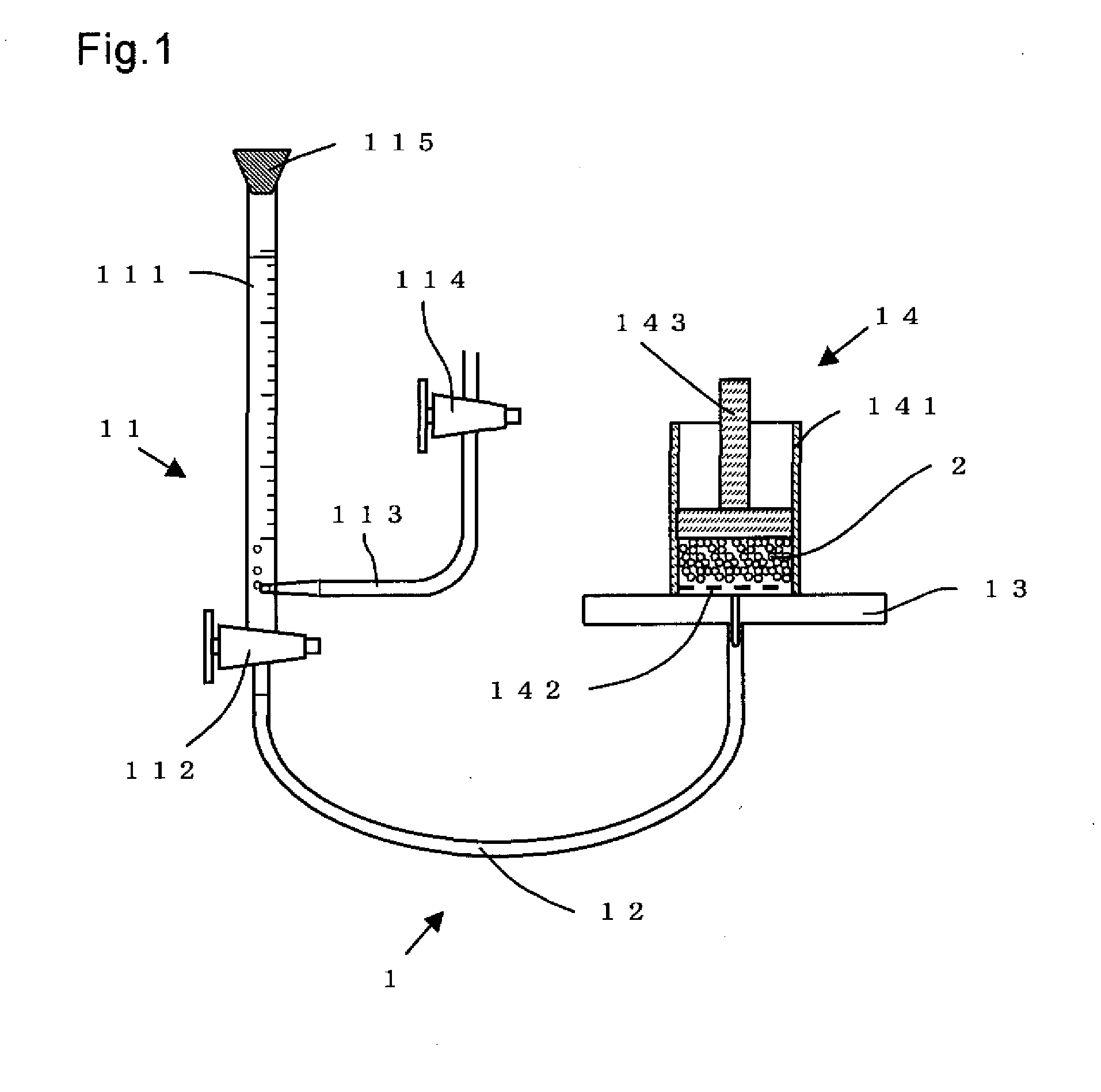

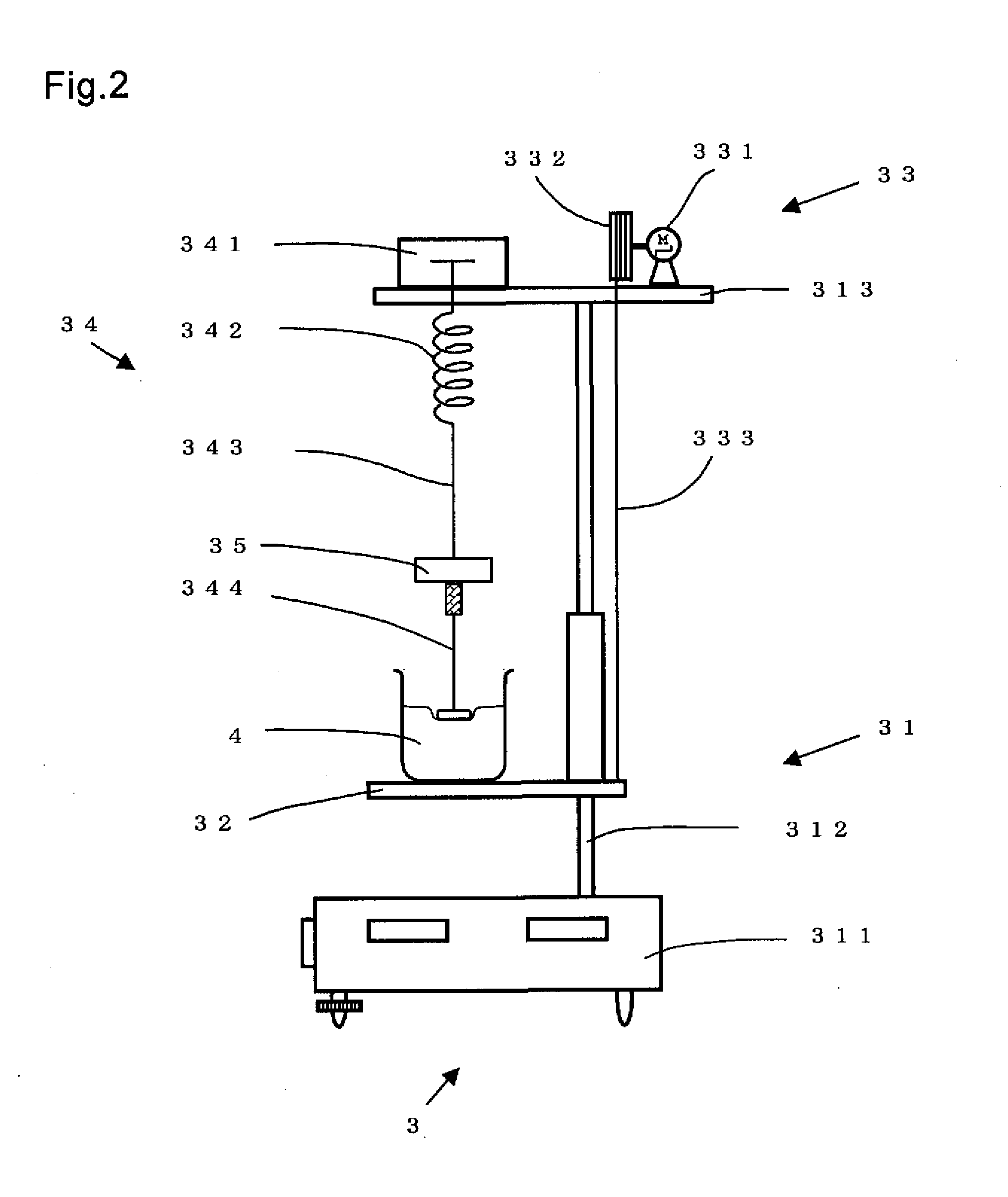

Profile modifying/water plugging agent and preparation method and application thereof

The invention relates to the technical field of oil field development, and in particular relates to a profile modifying / water plugging agent for oil well water plugging and profile modification. The water plugging agent is prepared from the following components in mass percent: 1-15% of polysaccharide, optimally 2-10% of the polysaccharide; 0.5-10% of a suspension stabilizer, optimally 1-6% of the suspension stabilizer; 0.5-20% of a gel strength accelerating agent, optimally 2-10% of the gel strength accelerating agent; and the balance of preparation fluid. The invention also provides a method for preparing the water plugging agent and application thereof.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for Producing Water-Absorbing Resin Particles, Water-Absorbing Resin Particles Made by the Process, and Absorbent Materials and Absorbent Articles Made by Using the Particles

ActiveUS20080280154A1Advantageously usableImprove water retentionSugar derivativesOther chemical processesPolymer scienceWater soluble

The present invention provides a process for producing water-absorbing resin particles which possess a high water retention capacity (absorbing capacity), a high water-absorbing capacity under pressure, and a high gel strength and a small amount of water-soluble substance and is favorably usable in sanitary materials; water-absorbing resin particles obtained by the process; and absorbent materials and absorbent articles made by using the particles. More specifically, the water-absorbing resin particles are produced by a process for producing water-absorbing resin particles, comprising a step of a post-crosslinking reaction by adding a post-crosslinking agent in at least two stages to a water-absorbing resin particle precursor obtained by polymerization of a water-soluble ethylenic unsaturated monomer to carry out the post-crosslinking reaction.

Owner:SUMITOMO SEIKA CHEM CO LTD

High-gel strength, salt resistant amphoteric ion type nano-composite hydrogel and preparing method

The invention relates to high-strength-gel and salt-resistant zwitterionic nano-composite hydrogel and a preparation method thereof. The hydrogel consists of a polymer matrix accounting for 60 to 100 weight percent of the gel and inorganic components accounting for 0 to 40 weight percent of the gel. The preparation method is that prepolymerization reaction solution is firstly prepared; the inorganic components are dispersed and stripped in deionized water to form even and stable colloidal dispersion; and then monomer is dissolved in the deionized water to prepare into monomer solution with 30 percent to 100 percent of mass concentration; when being stirred, the monomer solution is added into the colloidal dispersion, and then a crosslinking agent, an initiator and a catalyst are added in to prepare the prepolymerization reaction solution; under the nitrogen condition and 20 DEG C to 60 DEG C, the prepolymerization reaction solution is polymerized for 12 to 30 hours to obtain a polymerization product; and then the polymerization product is treated for 3 to 7 days under 40 DEG C to 60 DEG C; the mechanical strength of the gel after the obtained hydrogel absorbs water is up to 225mJ / g, and the salt absorbing magnification is up to 140g / g.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Preparation method of profile control agent for oil field deep temporary blocking

ActiveCN101531890AChange directionImprove adsorption capacityDrilling compositionAcetic acidOil field

The invention relates to a preparation method of a profile control agent for oil field deep temporary blocking, belonging to the technical field of petroleum exploration. Phenolic resin, organic chromium, glacial acetic acid, resorcinol and polyacrylamide are firstly weighed according to mass percentages, then the weighed polyacrylamide is slowly added in weighed water and stirred, and the weighted other retarding crosslinking agents are sequentially added and stirred. The profile control agent for the oil field deep temporary blocking prepared by the method has the advantages that the gelling time of the profile control agent is controllable during the use by adding different crosslinking agents, the gelling time is 8-48 hours; the gel strength is great, the gel is difficult to break, and the validity period is 1-2 years; the profile control agent can effectively change the water flow of injection water of a formation and have great absorption and blocking effects on the formation.

Owner:DALIAN TRICO CHEM

Water absorbent and producing method of same

ActiveUS20100308263A1Improve gel performanceMaintain good propertiesOther chemical processesAbsorbent padsCross-linkPolymer science

An object of the present invention is to provide a water absorbent having excellent gel properties and showing excellent properties when used in a water-absorbing material of a sanitary / hygienic material such as paper diaper. Moreover, another object of the present invention is to provide a water absorbent which is safe and excellent in liquid permeability, and in which an amount of liquid permeability improver for improving the liquid permeability is reduced. The water absorbent is made from a water-absorbing resin prepared by a specific polymerization method and having a high degree of cross-linking, a high liquid holding property and a high gel strength (its swelling pressure of gel layer of is 35 kdyne / cm2 or more). This water absorbent is further processed to have a particular particle size distribution (95 wt % or more of its particles are less than 850ƒÊm but not less than 106ƒÊm, and logarithmic standard deviation (ƒĐƒÄ) is in a range of 0.25 to 0.45) and then surface cross-linked. After that, a liquid permeability improver is added therein.

Owner:NIPPON SHOKUBAI CO LTD

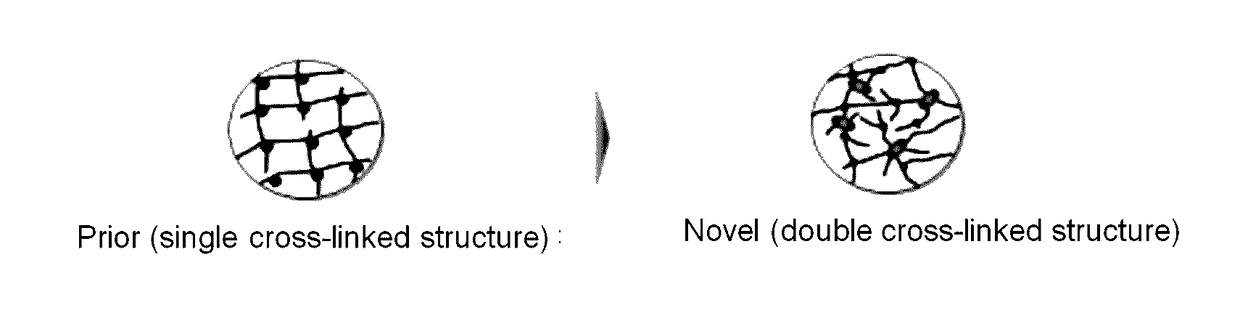

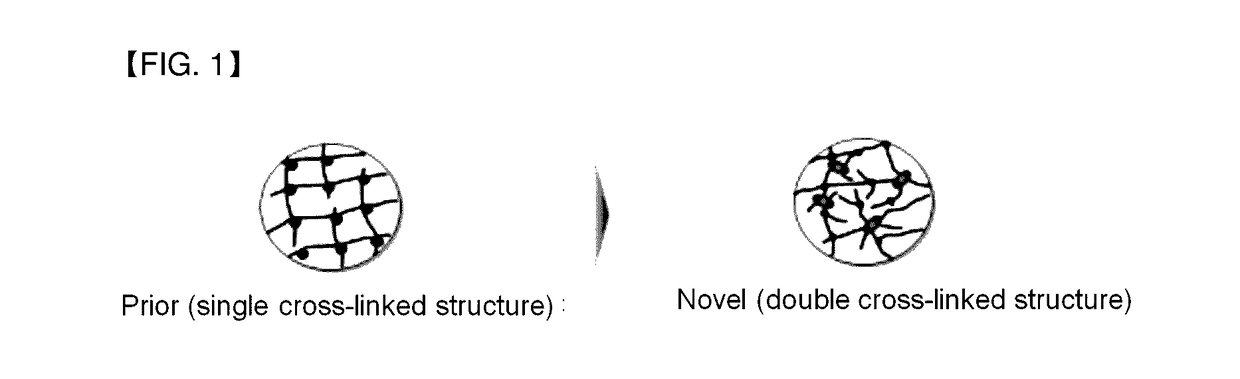

A superabsorbent polymer and a preparation method thereof

ActiveUS20170073478A1Improve featuresAbsorption under pressureOther chemical processesAbsorbent padsCross-linkSuperabsorbent polymer

The present invention relates to a superabsorbent polymer that has more improved gel strength and is improved in both water retention capacity (centrifuge retention capacity, CRC) and absorption ability under pressure (AUP) because of an optimized cross-linked structure of a base resin powder inside a cross-linked surface layer, and a preparation method thereof. The superabsorbent polymer includes a base resin powder including a 1st cross-linked polymer of a water-soluble ethylenic unsaturated monomer having acid groups of which at least a part is neutralized, and a cross-linked surface layer that includes a 2nd cross-linked polymer further cross-linked from the 1st cross-linked polymer and is formed on the base resin powder, wherein an inorganic particle is chemically bonded to the 1st cross-linked polymer by the medium of a cross-linking bond, an oxygen-containing bond (—O—), or a nitrogen-containing bond (—NR—, where R is hydrogen or a C1-C3 alkyl or an amide bond).

Owner:LG CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com