Preparation method of high-gelation soybean protein

A soybean protein and soybean protein isolate technology, which is applied in the field of soybean protein processing, can solve the problems of low modification degree, large enzyme dosage, and long enzymatic hydrolysis time, and achieve low production cost, low enzyme dosage, and short enzymatic hydrolysis time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

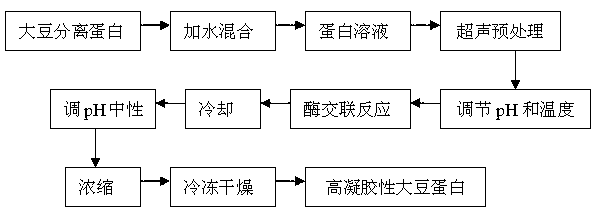

[0024] A method for preparing high-gelling soybean protein, the method comprising the following steps:

[0025] (1) Soybean protein isolate was mixed with water to make a protein solution with a volume concentration of 5%, and the protein solution was ultrasonically pretreated;

[0026] (2) Adjust the pH and temperature of the protein solution pretreated by ultrasound in step (1) to perform enzyme cross-linking reaction, cool the cross-linked product to room temperature, adjust the pH to 7-7.5, and then concentrate and freeze After drying, high-gelling soybean protein is obtained.

[0027] The ultrasonic power of the step (1) is 200-600W, and the ultrasonic time is 10-50min.

[0028] The ultrasonic power of the step (1) is 500W, and the ultrasonic time is 30min.

[0029] The cross-linking reaction enzyme in the step (2) is transglutaminase.

[0030] The enzymatic crosslinking reaction time of the step (2) is 0.5-2.5h, the amount of enzyme added is 20-60 U / g of the weight of...

Embodiment 1

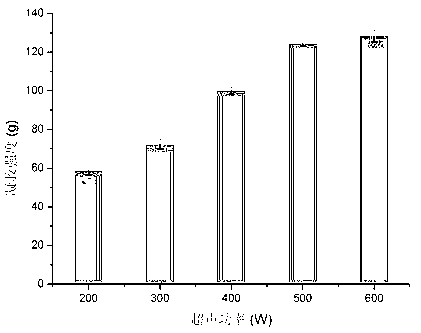

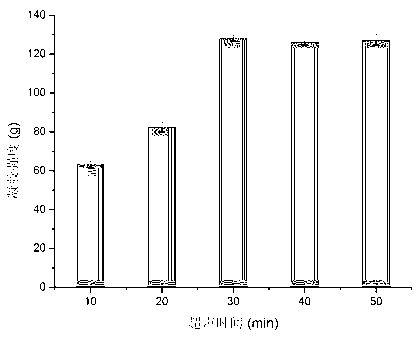

[0032] Embodiment 1: the screening experiment of ultrasonic pretreatment optimal parameter

[0033] 1 Materials and methods

[0034] 1.1 Materials and reagents

[0035] Isolated Soy Protein Hargaoke transglutaminase Danish novo company

[0036] 1.2 Main instruments and equipment

[0037] pHS-25 acidity meter Shanghai Weiye Instrument Factory electronic analytical balance Merlot-Toledo Instruments (Shanghai) Co., Ltd. centrifuge Beijing Medical Centrifuge Factory Precision electric mixer Ronghua Instrument Manufacturing Co., Ltd., Jintan City, Jiangsu Province Electric constant temperature water bath Yuyao Dongfang Electrical Instrument Factory F2102 plant sample pulverizer Tianjin Test Instrument Co., Ltd. Ultrasound Shanghai Boxun Industrial Co., Ltd. Medical Equipment Factory Constant temperature incubator Beijing Yongguangming Medical Instrument Factory

[0038] 1.3 Test method

[003...

Embodiment 2

[0049] Embodiment 2: the screening test of optimal parameter of enzyme cross-linking reaction

[0050] Based on the optimal process parameters of the ultrasonic pretreatment determined in Example 1, a single-factor enzyme cross-linking reaction test was carried out to determine the range of the enzyme cross-linking reaction process parameters. Taking the gel strength as the index, a response surface design experiment with 4 factors and 5 levels was carried out.

[0051] 1 Materials and methods

[0052] 1.1 Materials and reagents

[0053] Isolated Soy Protein Hargaoke transglutaminase Danish novo company

[0054] 1.2 Main instruments and equipment

[0055] pHS-25 acidity meter Shanghai Weiye Instrument Factory electronic analytical balance Merlot-Toledo Instruments (Shanghai) Co., Ltd. centrifuge Beijing Medical Centrifuge Factory Precision electric mixer Ronghua Instrument Manufacturing Co., Ltd., Jintan City, Jiangsu Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com