Patents

Literature

145 results about "Cross-linkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

• CROSS-LINKAGE (noun) The noun CROSS-LINKAGE has 1 sense: 1. a side bond that links two adjacent chains of atoms in a complex molecule. Familiarity information: CROSS-LINKAGE used as a noun is very rare.

Specific core-shell polymer additive for ink-jet inks to improve durability

InactiveUS6858301B2Improve propertiesGood shear stabilityPhotosensitive materialsDuplicating/marking methodsHydrophilic monomerVitrification

Polymer particles are provided having (1) a core with a glass transition temperature within a range of −50° to +110° C. and (2) a shell surrounding the core. The core comprises at least one layer, with the layer(s) comprising at least one polymerized hydrophobic monomer and, optionally, a first cross-linker. The shell comprises a copolymerized mixture of least one hydrophobic monomer and at least one hydrophilic monomer and a second cross-linker for increasing thermal shear stability by forming cross-linkages. Use of these polymer particles in aqueous-based ink-jet inks provide laser print quality without any secondary treatment.

Owner:HEWLETT PACKARD DEV CO LP

Method for preparing temperature-resistant and anti-salt type polyacrylamide

This invention relates to a preparation method for temperature-proof and anti-salt PAA, which adds PAA monomer solution with 18-30% weight density, hyhrolyst, composite initiator and aids in a polymerizing kettle, then penetrates N2 to remove O2 for heat isolation polymerization to be hydrolyzed, sized, baked and crushed to get the final product characterizing that during the process, salt-proof monomers, drain monomers, anion monomers, inorganic compounds, micro-cross-linkage are added to carry out heat-insulation copolymerization.

Owner:大连广汇化学有限公司

Vitamin powder and preparation method thereof

ActiveCN102716087AHigh mechanical strengthGood dispersionPowder deliveryHydroxy compound active ingredientsEmbedding rateAntioxidant

The invention mainly discloses vitamin powder and a preparation method of the vitamin powder. The vitamin comprises the following components in mass percentage: 5-60% of fat soluble vitamin, 30-70% of wall material, 5-30% of assistant wall material, 0.5-2% of emulsifier, 0.1-2% of antioxidant and 0.1-3% of cross linking agent. The invention further relates to a preparation method of the vitamin powder. By using a microencapsulation technique, the fat soluble vitamin oil (e.g. vitamin A, vitamin D3, vitamin E and vitamin K) is embedded to a micro-capsule, the wall material used in the embeeding process is starch sodium octenylsuccinate, the vitamin oil is embeeded in the wall and then the micro-capsule is subjected to cross linkage, mist spraying and drying are carried out to form the vitamin powder, and the embedding rate of the vitamin is more than 95.3%. According to the invention, the process is simple, the cost is low, the obtained vitamin powder is not soluble in water, high in oil loading amount and good in flowability, and can be used in the fields such as foods, daily-used industrial chemicals and medicines.

Owner:ZHEJIANG ZHONGTONG TECH

Specific core-shell polymer additive for ink-jet inks to improve durability

InactiveUS20040131855A1Improve propertiesGood shear stabilityPhotosensitive materialsDuplicating/marking methodsHydrophilic monomerVitrification

Polymer particles are provided having (1) a core with a glass transition temperature within a range of -50 to +110° C. and (2) a shell surrounding the core. The core comprises at least one layer, with the layer(s) comprising at least one polymerized hydrophobic monomer and, optionally, a first cross-linker. The shell comprises a copolymerized mixture of least one hydrophobic monomer and at least one hydrophilic monomer and a second cross-linker for increasing thermal shear stability by forming cross-linkages. Use of these polymer particles in aqueous-based ink-jet inks provide laser print quality without any secondary treatment.

Owner:HEWLETT PACKARD DEV CO LP

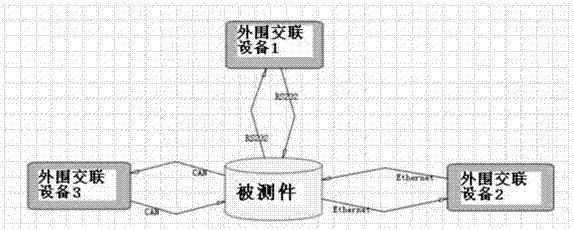

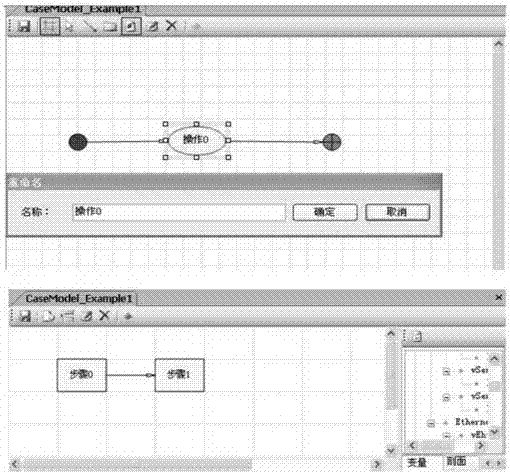

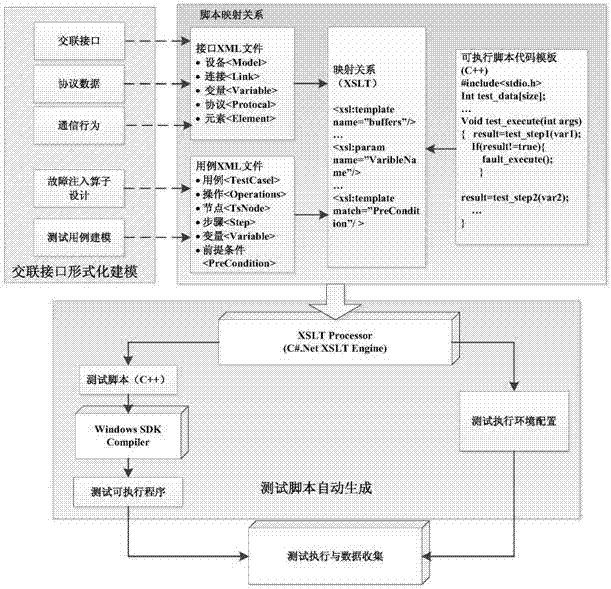

Interface-oriented automatic test method for software fault injection

InactiveCN107368408ALower requirementImprove versatilitySoftware testing/debuggingTest scriptData modeling

The invention provides an interface-oriented automatic test method for software fault injection, and aims at realizing the automatic test of interface fault injection. The method comprises the following steps of: firstly carrying out cross-linkage interface modeling, communication behavior modeling and protocol data modeling; designing a fault injection operator and carrying out test case modeling; automatically generating an XML-format test case on the basis of the model; and finally automatically generating the test case into a test script of C++ language on the basis of XSLT, calling windows SDK to automatically generate a test program and automatically executing the test program, realizing result collection through a Windows pipeline technology, and evaluating the test result so as to complete the fault injection test of the whole cross-linkage interface. According to the method, universality and usability realized by an interface fault injection test tool are effectively improved, the interface test efficiency is improved and the test cost is reduced.

Owner:中国船舶工业综合技术经济研究院

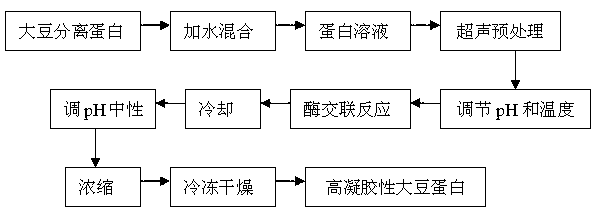

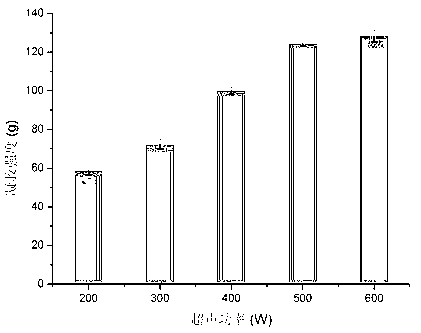

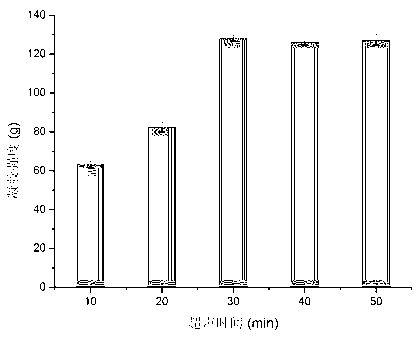

Preparation method of high-gelation soybean protein

InactiveCN102934731AReduce dosageImprove gel performanceVegetable proteins working-upProtein solutionFreeze-drying

The invention relates to a preparation method of a high-gelation soybean protein, and belongs to the technical field of soybean protein processing. The method comprises the following steps: (1) mixing soybean protein isolate and water to obtain a protein solution, and performing ultrasound preprocessing on the protein solution; and (2) adjusting the pH and temperature of the protein solution subjected to ultrasound preprocessing in the step (1), adding transglutaminase for cross linking reaction, cooling the product after cross linkage to room temperature, and then concentrating and freeze drying to obtain the high-gelation soybean protein. The method has the beneficial effects that the needed equipment is simple and safe to operate; the enzyme needed in production is small in amount, short in enzymolysis time, low in cost and environmentally-friendly; the obtained soybean protein is high in gel strength, and meanwhile the gel stability is good; and the application range of the soybean protein in foodstuff is expanded.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

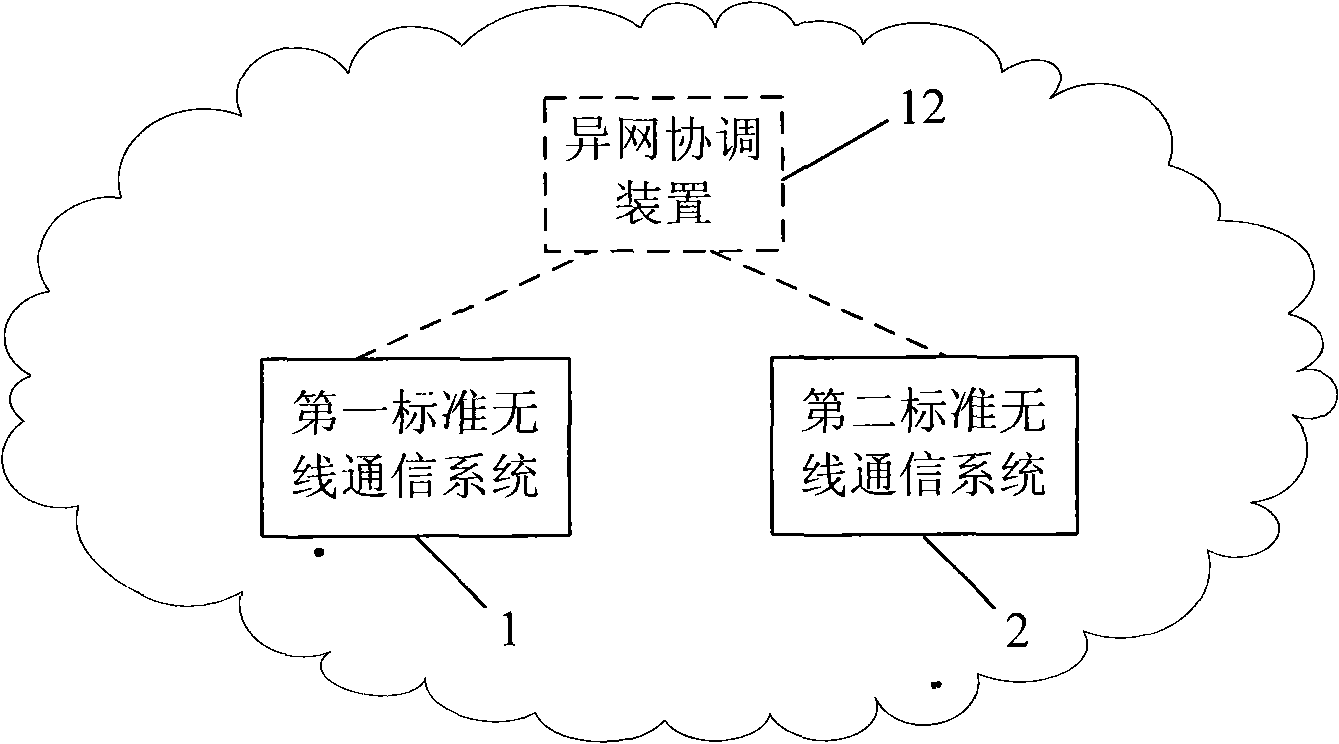

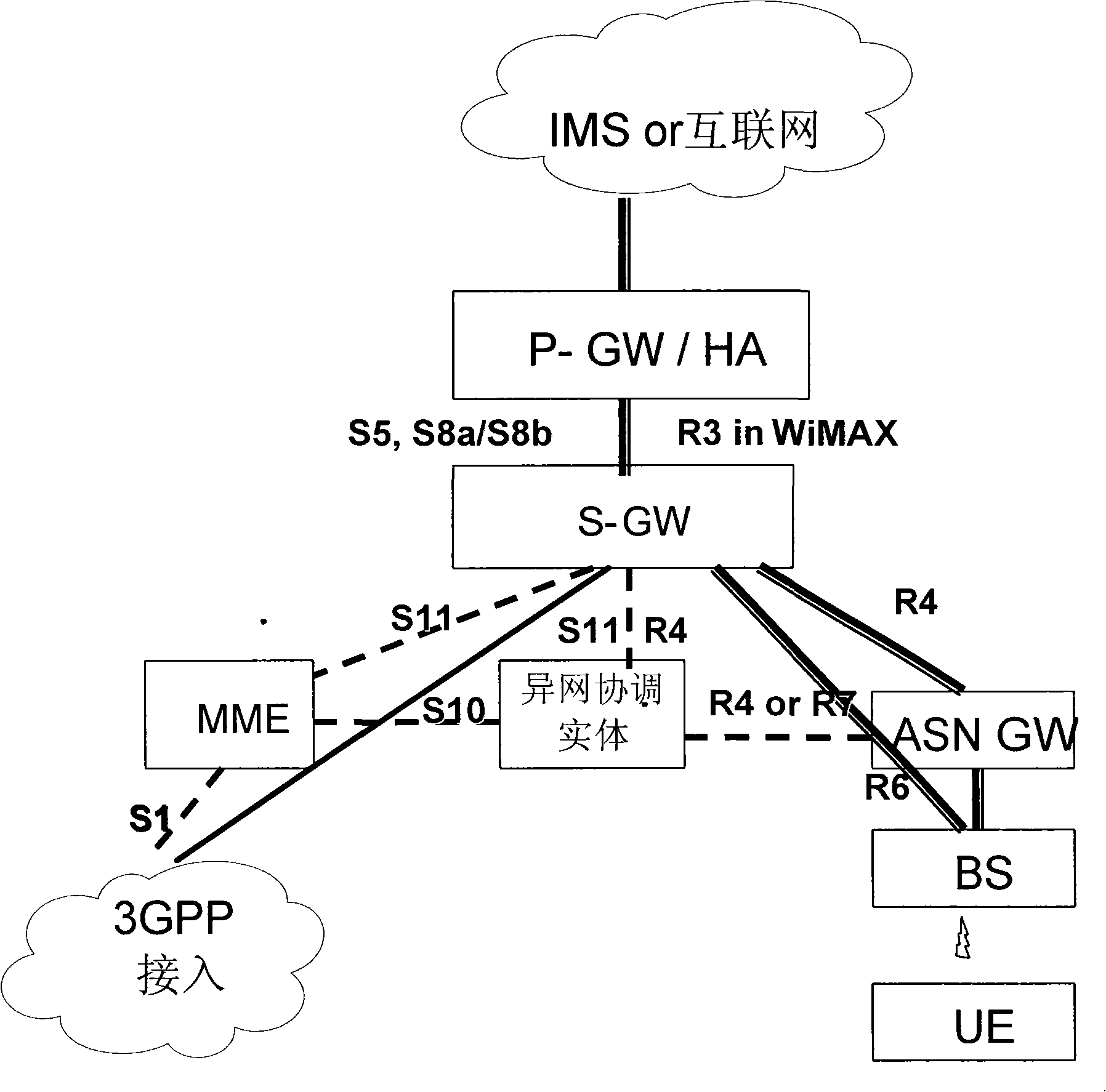

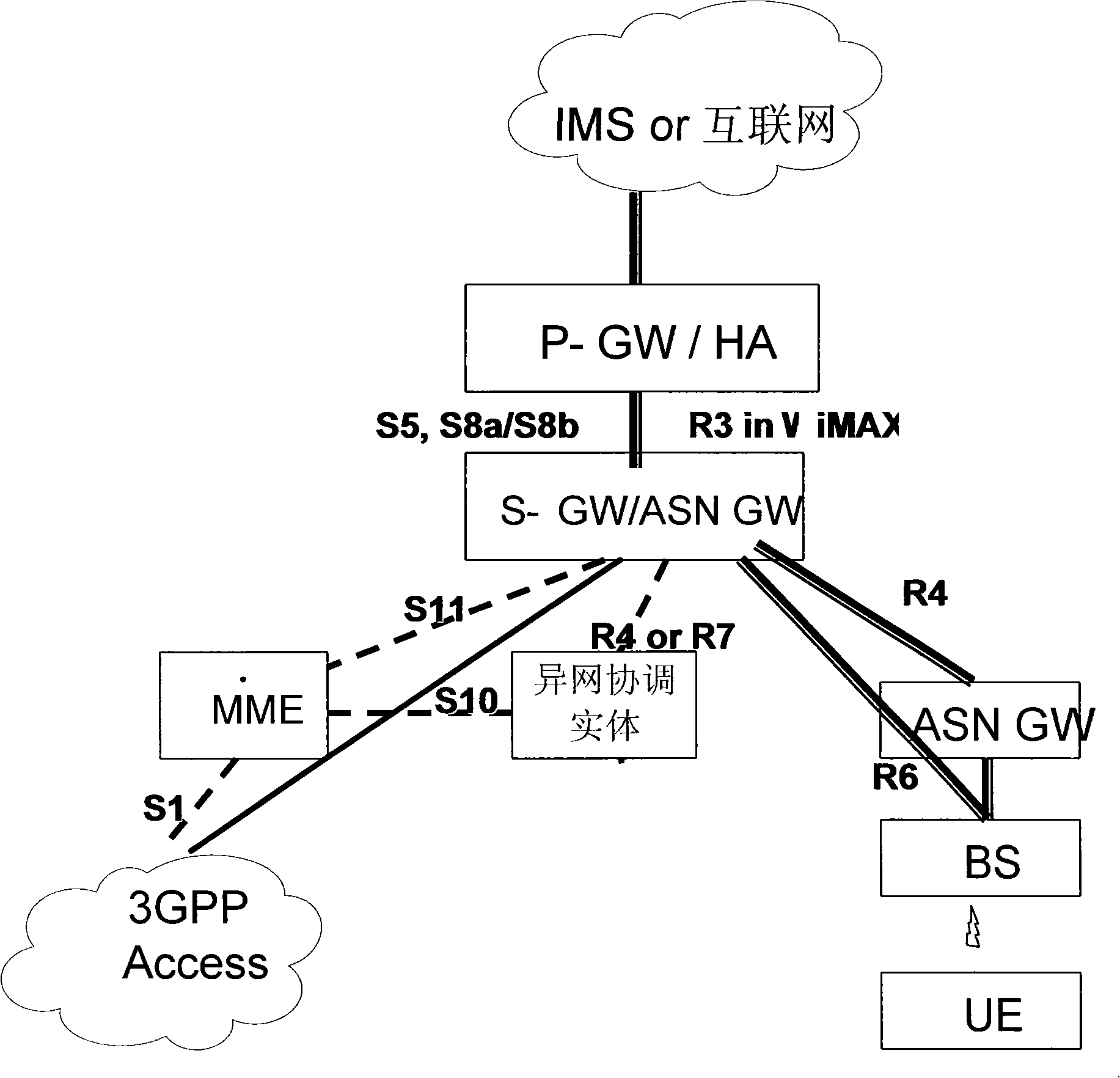

Apparatus for coordinating guiding network, wireless network as well as method for switching and attaching user equipment

InactiveCN101330713ASolve the problem of being unable to know each other frequently attached to the networkMinor changesRadio/inductive link selection arrangementsWireless communicationCommunications systemUser equipment

The invention discloses a wireless network, which comprises wireless communication systems of different standards. In addition, the wireless network comprises a different network coordinating device which is used for the coordination and switching between wireless communication systems of different standards or the coordination and process of a plurality of attachments to user equipment. The invention further discloses a corresponding user equipment switching and attachment method, which can provide convenient intersystem intercommunication, attachment, and optimized switch performance on the premise of keeping the access system standards developing independently and reducing the cross linkage.

Owner:HUAWEI TECH CO LTD

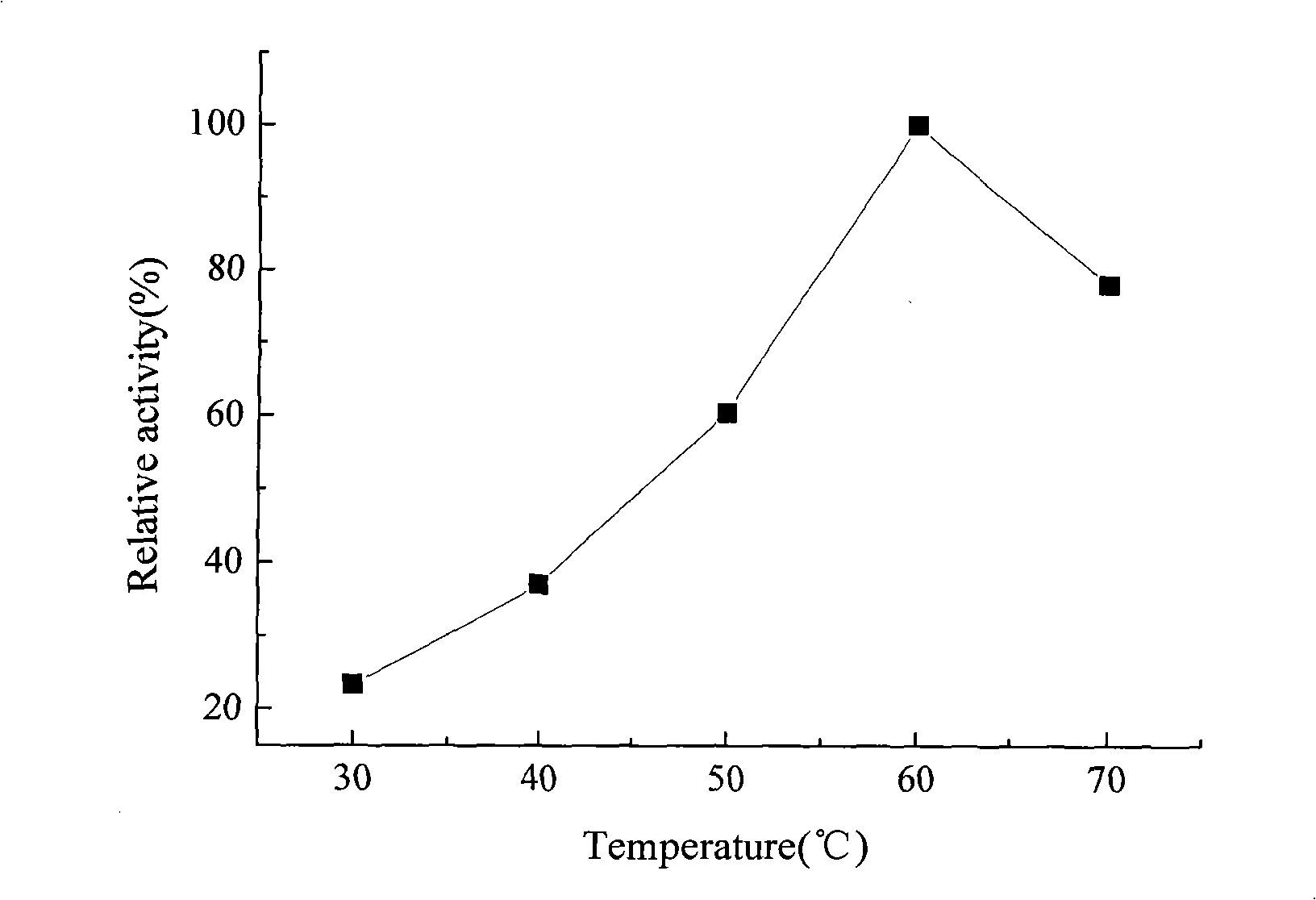

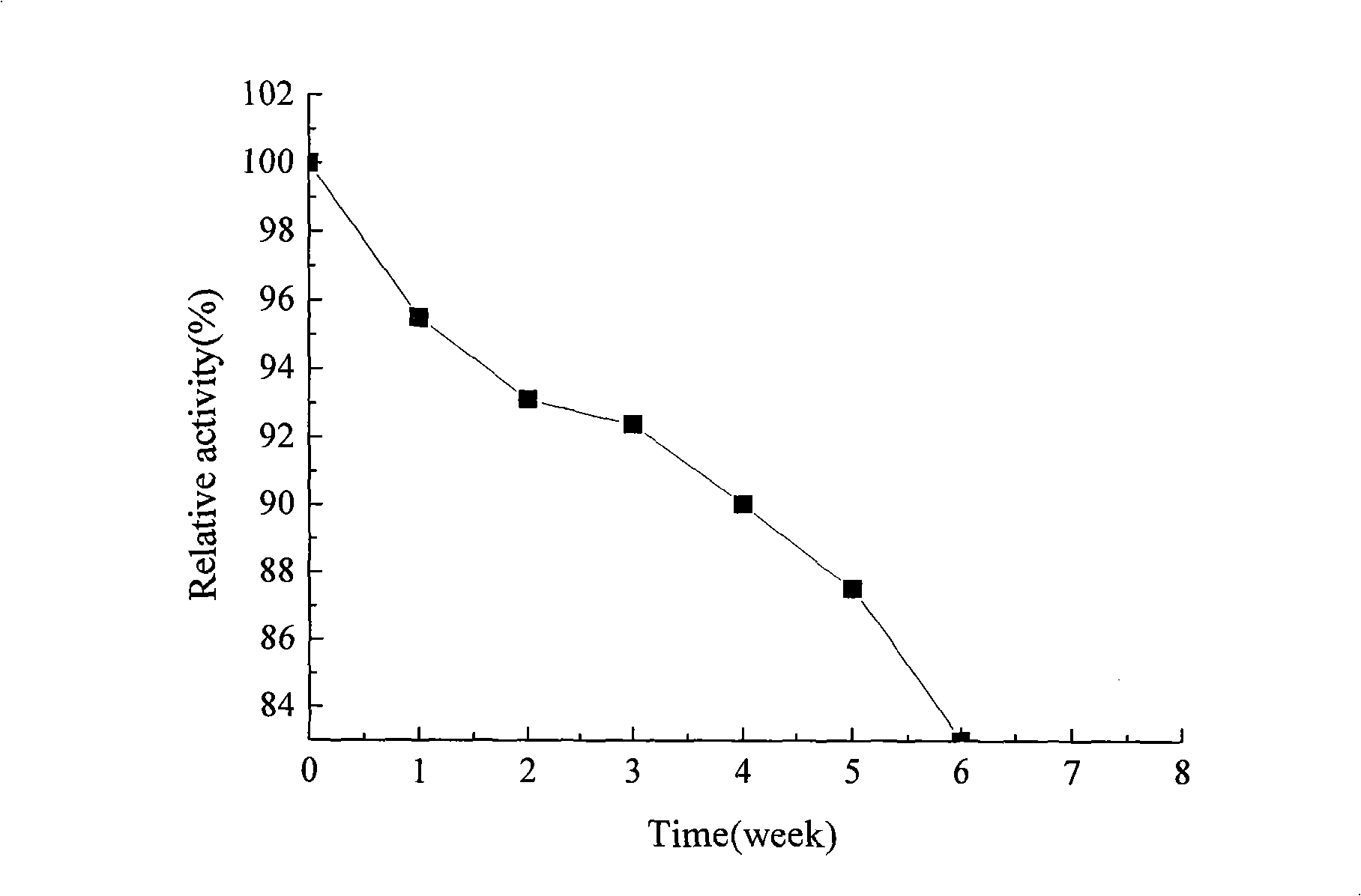

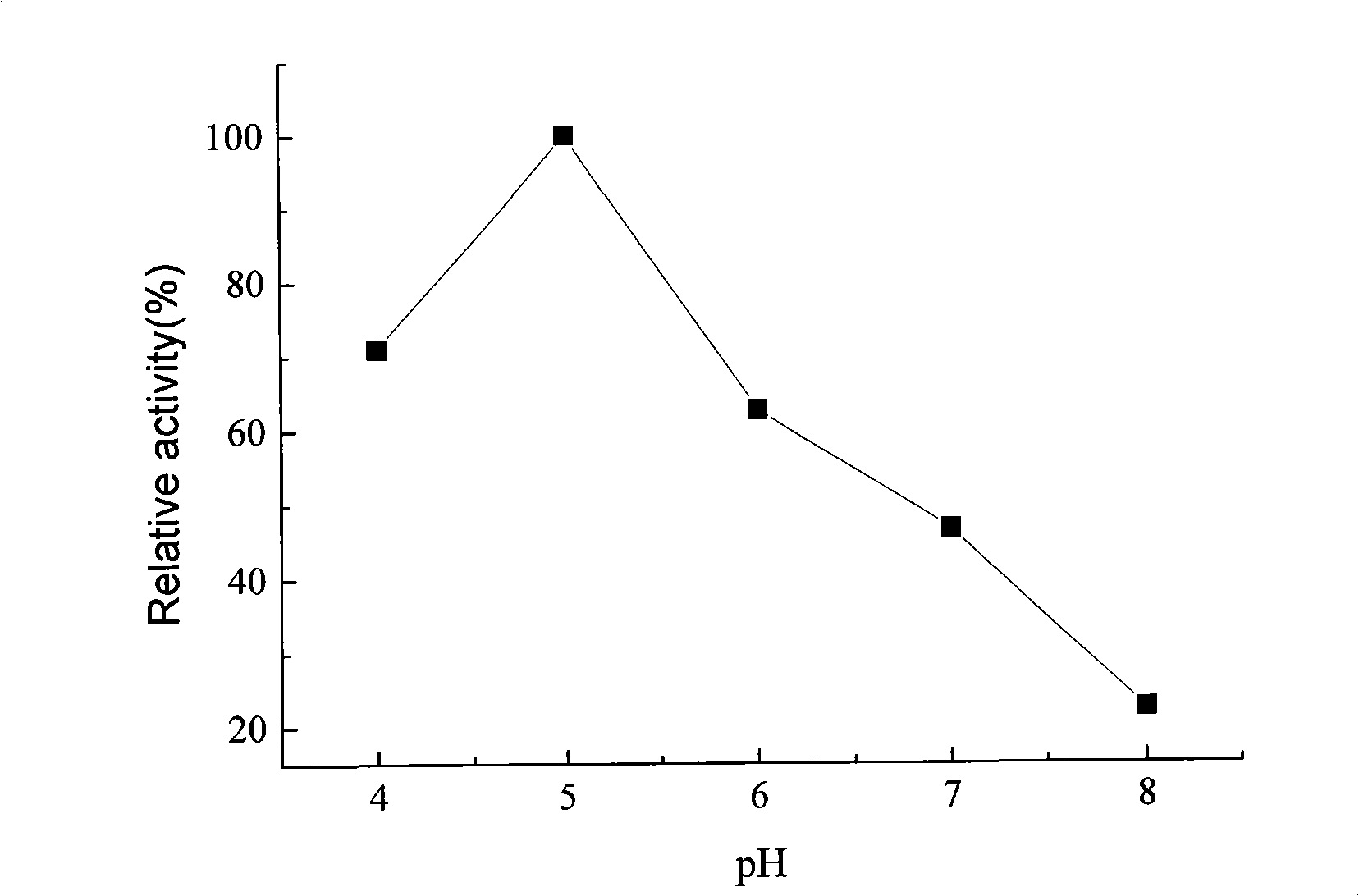

Method for preparing beta-glucosidase fixed with magnetic nano-particle

InactiveCN101270352AEasy to operateLow costOn/in organic carrierBeta-glucosidaseMagnetite Nanoparticles

The invention relates to a preparation method for magnetic nanoparticle fixed Beta-glucosaccharase, which comprises the steps that (1) precipitation reaction occurs between chloride solution of Fe<2+> and Fe<3+> and NaOH solution to prepare Fe3O4 particles; (2) chitosan is dissolved in acetum to form homogeneous transparent colloidal solution, and Fe3O4 particles are mixed with the homogeneous transparent colloidal solution, and the mixture is beaten, thus getting magnetic nanoparticles; (3) the magnetic nanoparticles are added to Beta-glucosaccharase solution, thus getting chitosan magnetic nanoparticle immobilized enzyme through absorption and cross linkage of glutaric dialdehyde solution; (4) citric acid buffer solution is added to immobilized Beta-glucosaccharase and free Beta-glucosaccharase solution, respectively, and reaction occurs after the temperature is adjusted; and the enzyme activity is examined. The method is quick, simple, convenient and is low in cost. The product got has the characteristics of uniform shape, large specific area, high coefficient of recovery of enzyme activity and so on.

Owner:DONGHUA UNIV

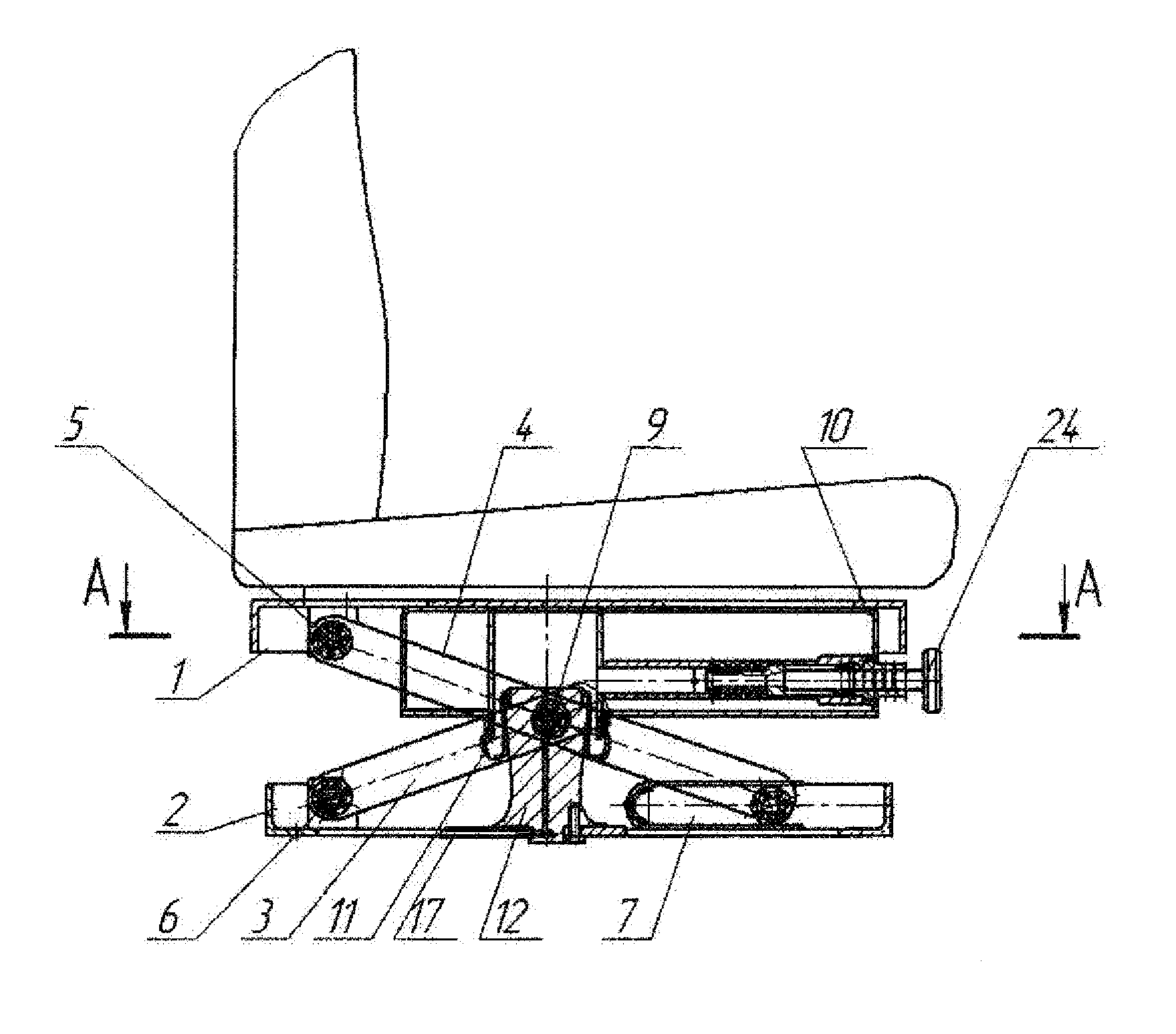

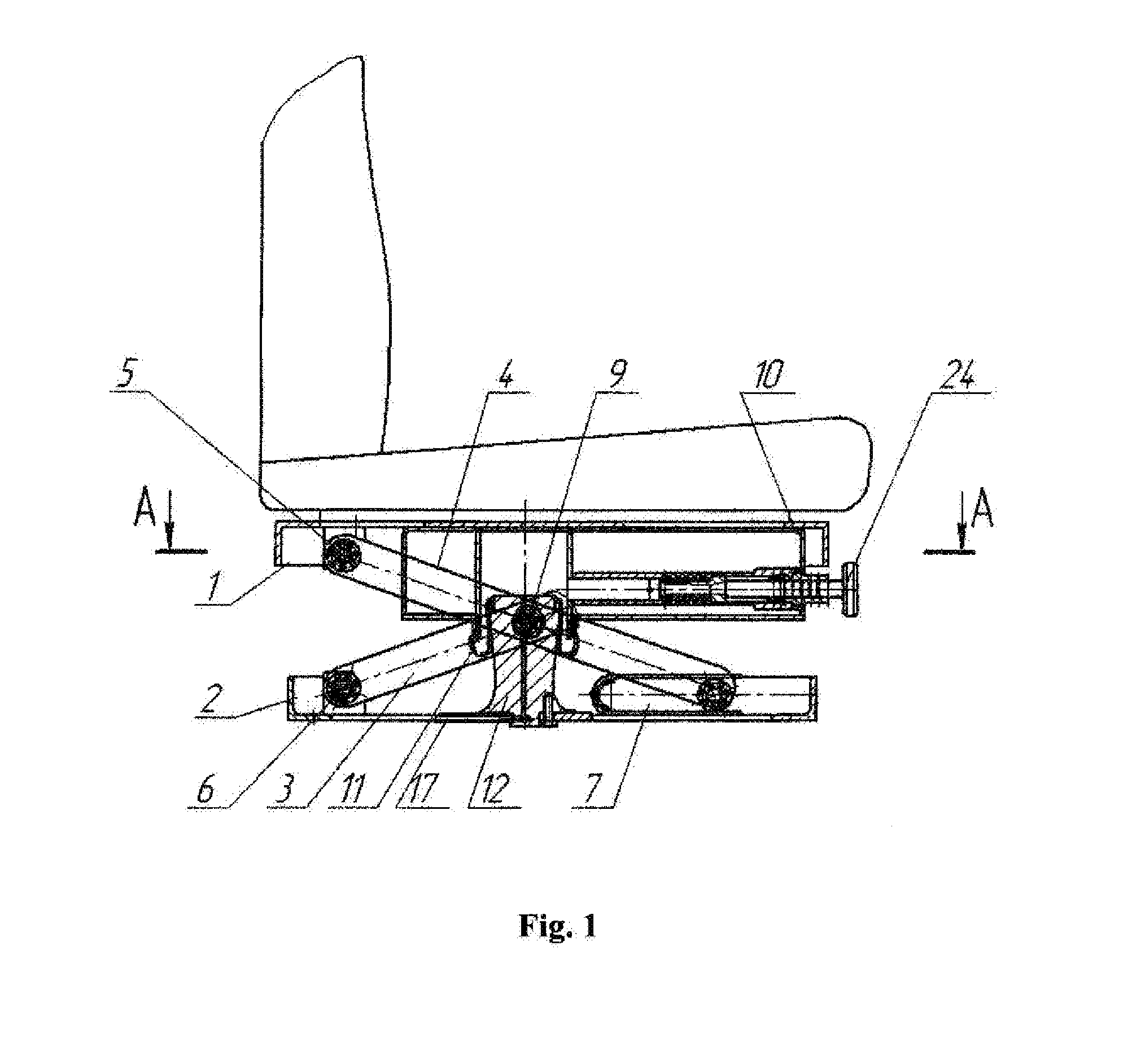

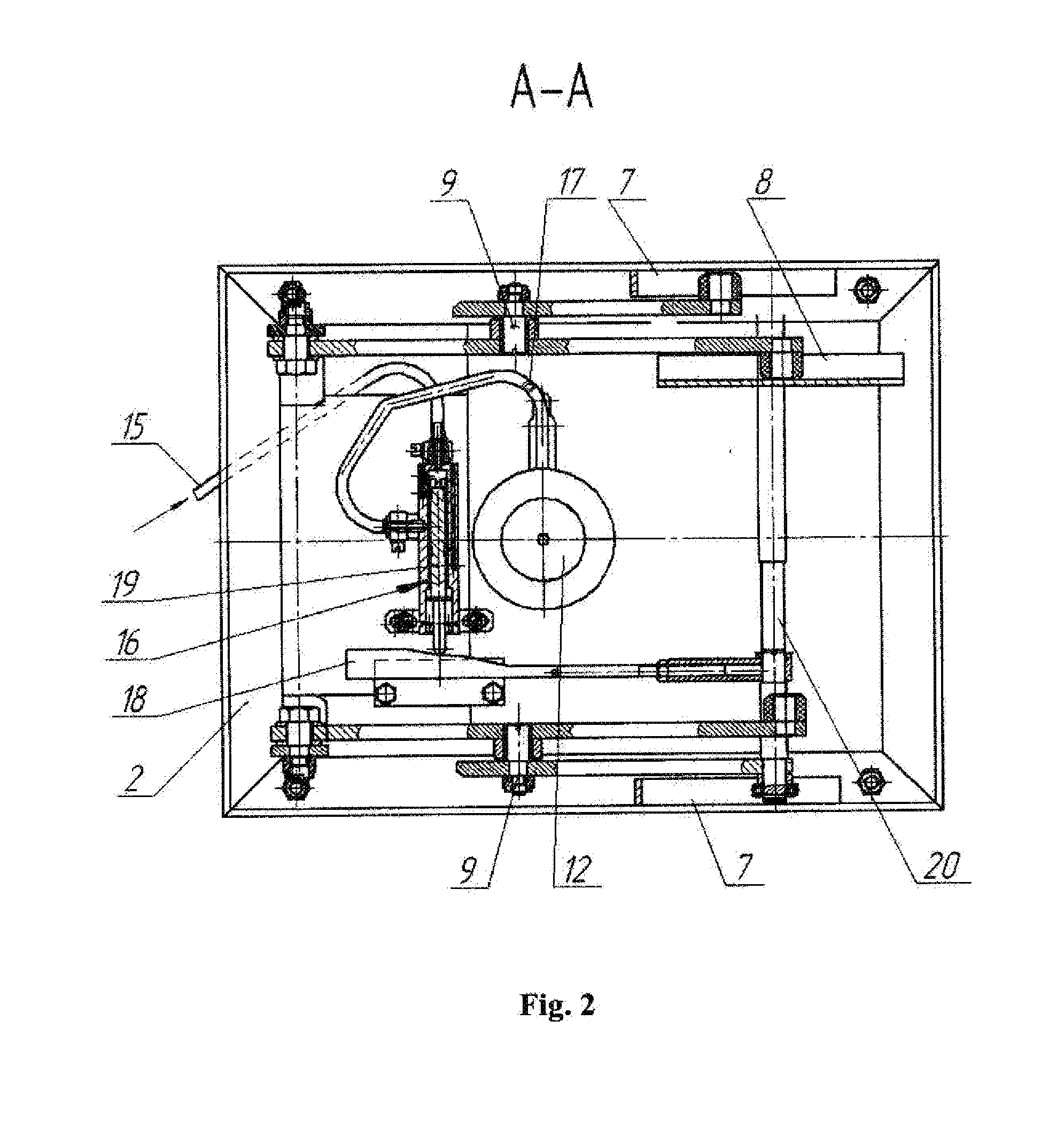

Vehicle seat suspension

InactiveUS20150158404A1Improve damping performanceDrawback can be obviatedStands/trestlesKitchen equipmentEngineeringMechanical engineering

Owner:INST OF TECHN MECHANICS OF THE NAS OF UKRAINE & NKA OF UKRAINE

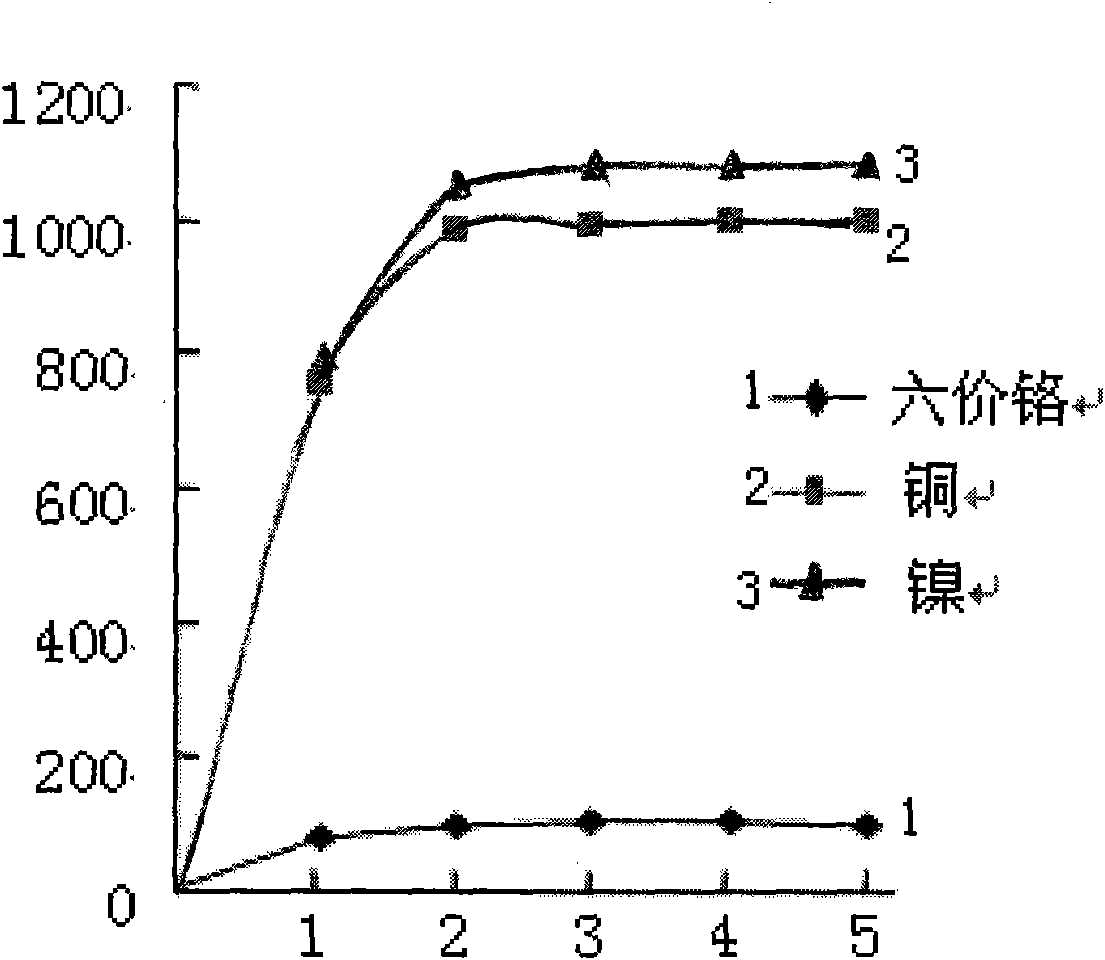

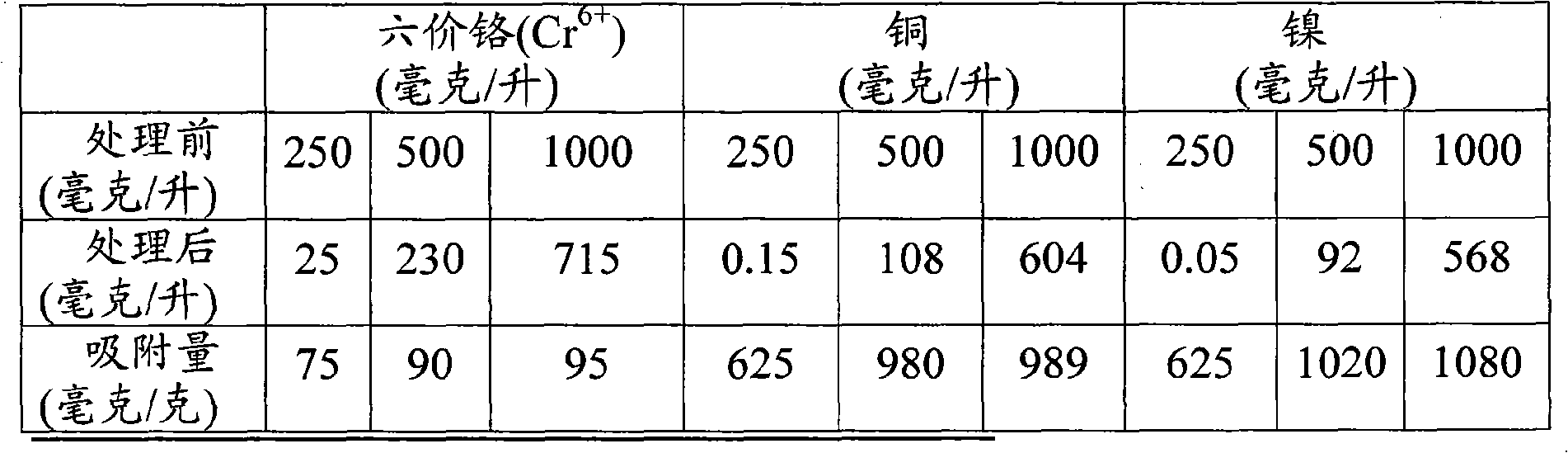

Processing method of waste water containing heavy metal and dye

InactiveCN101570377AImprove adsorption capacityEasy to handleMultistage water/sewage treatmentWaste water treatment from plant processingSorbentHydroquinone Compound

The invention discloses a processing method of waste water containing heavy metal and dye. In the method, a sorbent is utilized to process the waste water containing heavy metal and dye, and the sorbent contains ferroferric oxide micro-magnetic particles and laccase. The laccase is hydroquinone dioxygen oxidoreductase containing copper, and the class number is EC 1.10.3.2. The ferroferric oxide micro-magnetic particles and the lasscase are in cross-linkage combination through assistance of a cross linkage agent. Heavy metal and dye in the waste water can be fast adsorbed and recovered with high efficiency by the ferroferric oxide micro-magnetic particles and the laccase, thereby the waste water containing heavy metal and dye is effectively processed, and the environment is protected.

Owner:GUANGZHOU LANTAO WATER TREATMENT CO LTD

Vinyl esters with high cross-linkage density

InactiveUS6515166B1Improve temperature stabilityGood chemical resistanceOrganic compound preparationCarboxylic acid esters preparationVinyl esterCross-linkage

A vinyl ester produced by reacting at least one epoxide compound with at least on carboxylic anhydride, containing ethylenically unsaturated groups, the epoxide groups being substantially substituted by two vinyl ester groups.

Owner:MOMENTIVE SPECIALTY CHEMICALS

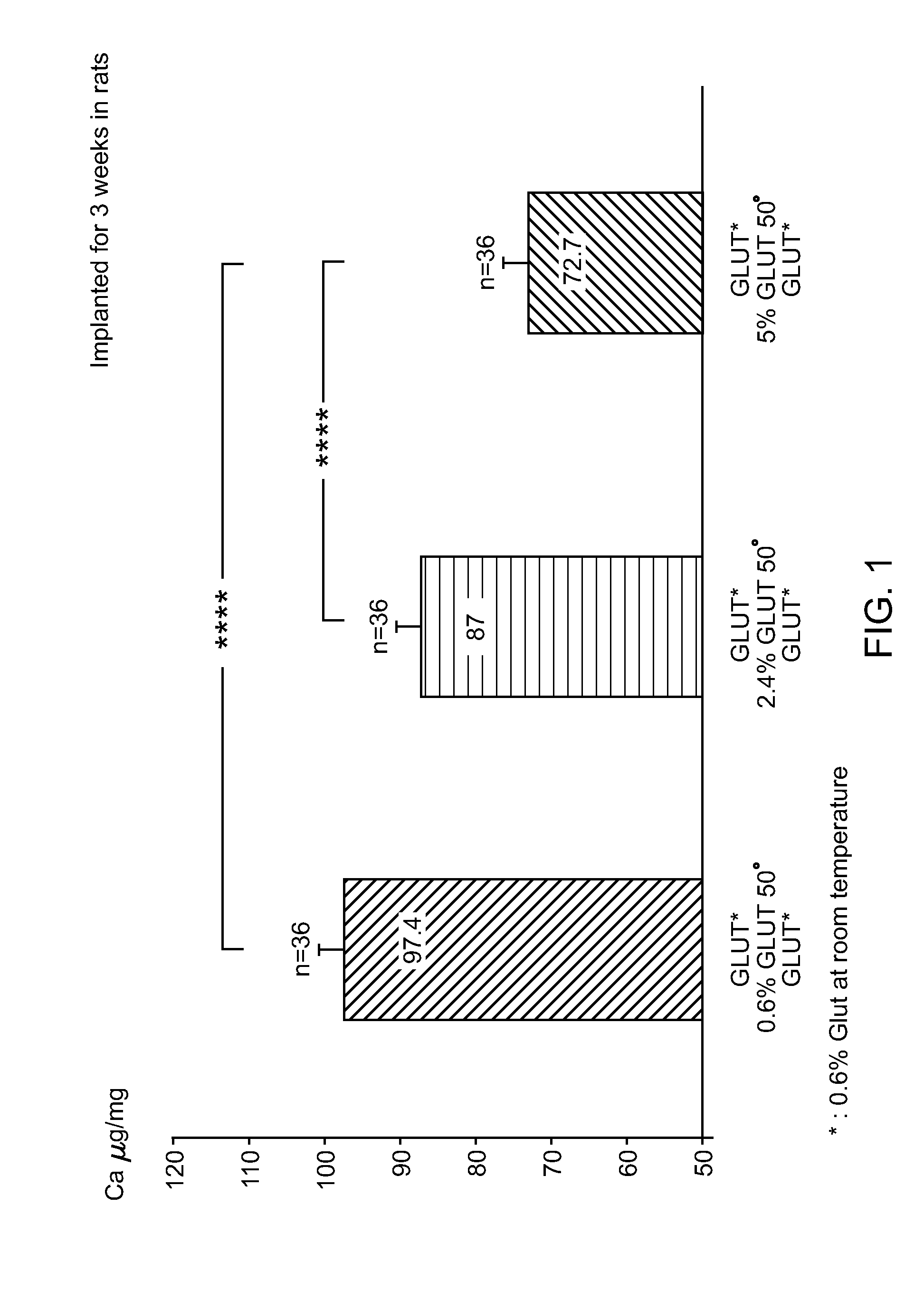

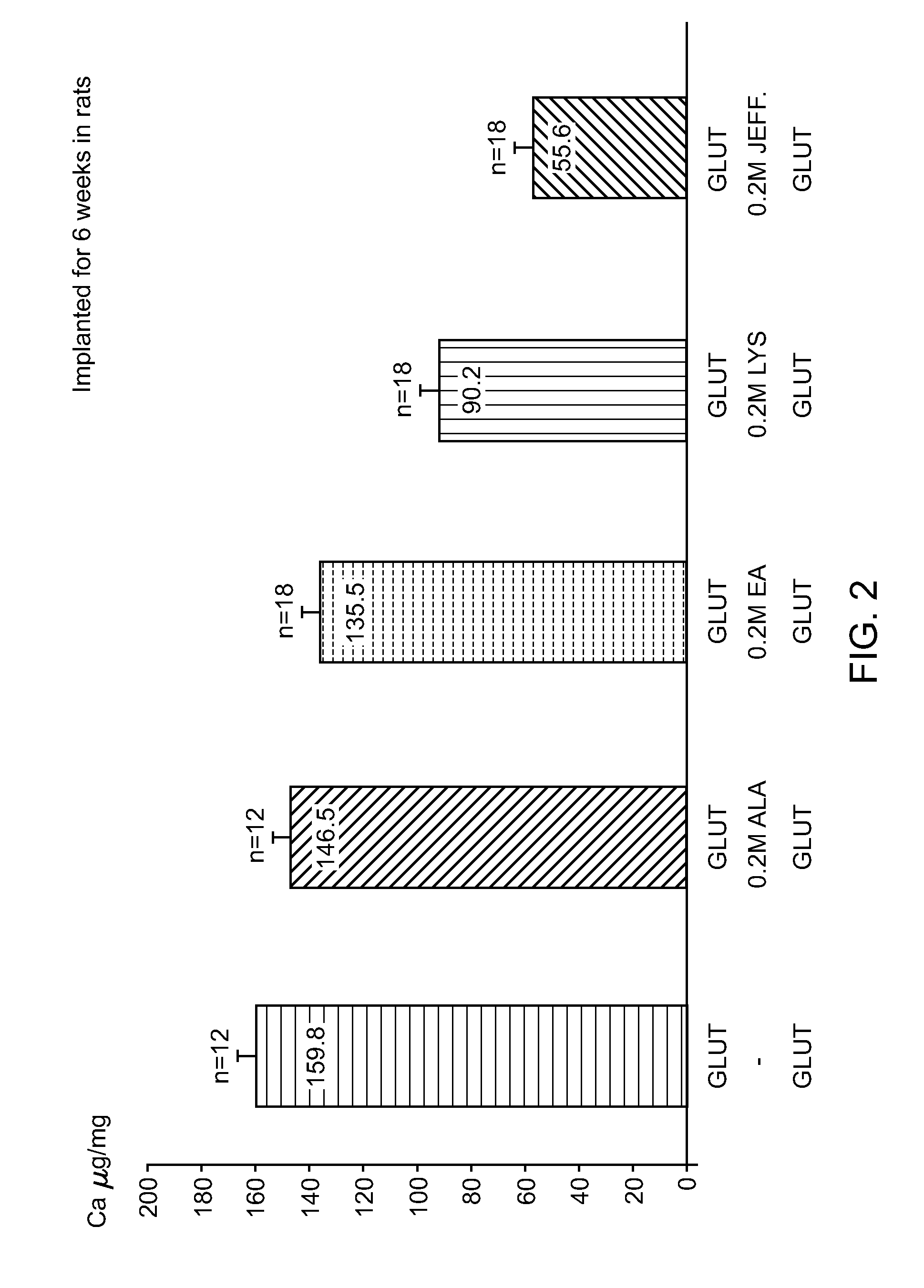

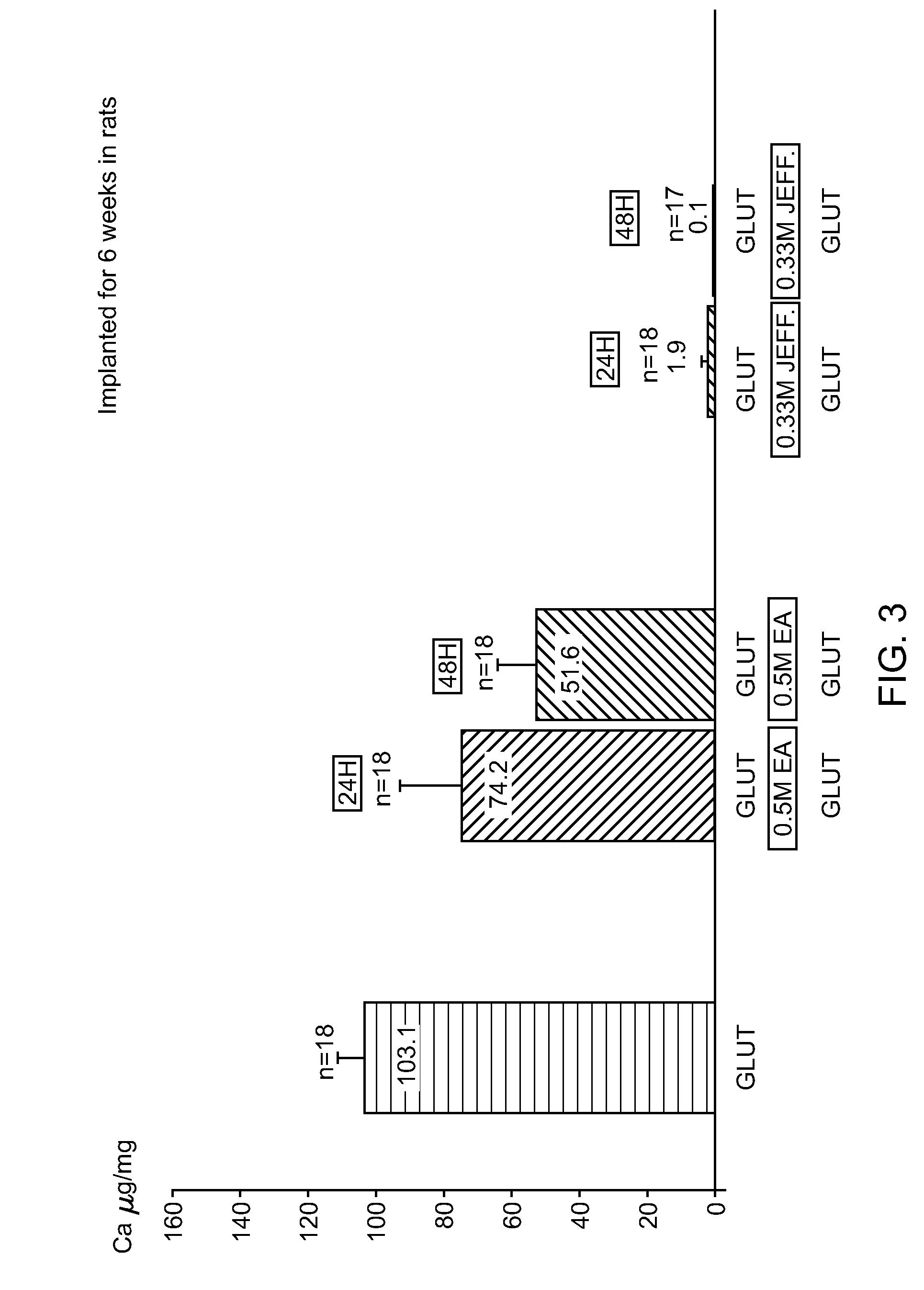

Double cross-linkage process to enhance post-implantation bioprosthetic tissue durability

ActiveUS20120123557A1Eliminating phospholipidHeart valvesPharmaceutical containersProsthesisPost implantation

Bioprosthetic tissues and methods for making same, comprising fixing bioprosthetic implant tissue by treatment with 0.1 to 10 wt. % glutaraldehyde at elevated temperature, capping said fixed tissue by treatment with a diamine crosslinking agent, and treating said capped tissue with about 0.6 wt. % glutaraldehyde.

Owner:EDWARDS LIFESCIENCES CORP

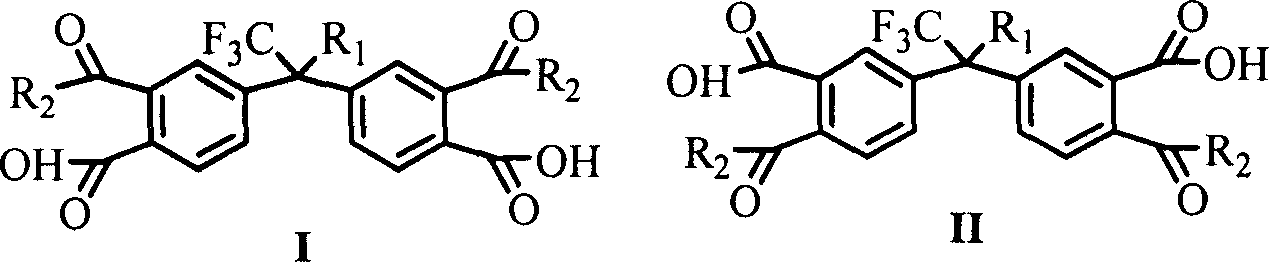

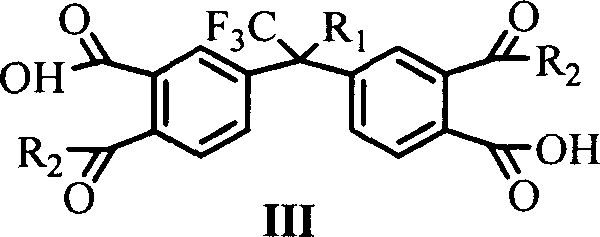

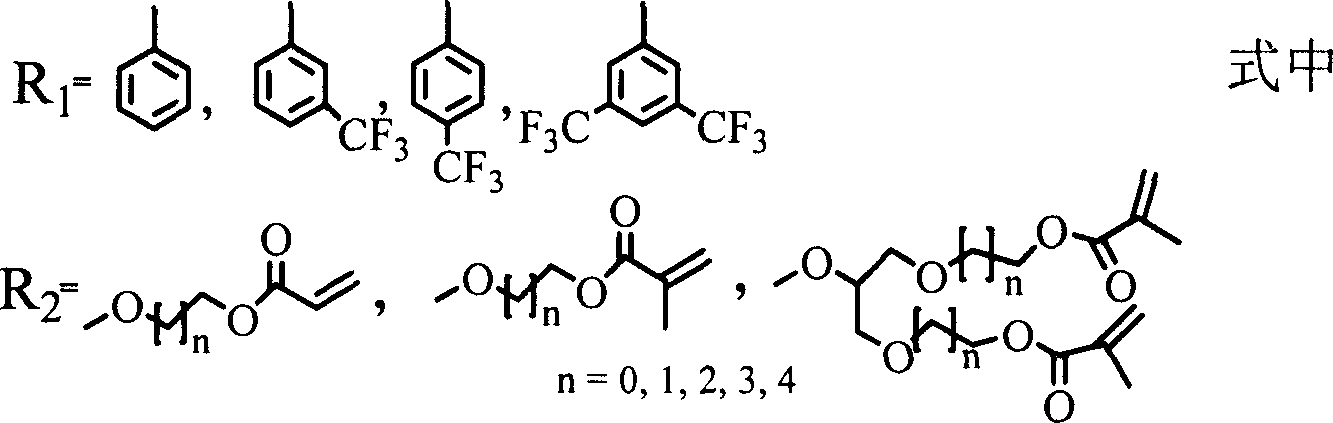

Photo-sensistive polyimide resin and composition and preparing method

InactiveCN1978529APhotosensitive materials for photomechanical apparatusUltravioletMechanical property

The invention relates to a kind of light-sensitive polyimide resin and its combination as well as their preparation methods. The said resin combination contains 10-70 portions of light-sensitive polyimide resin, 0.1-50 portions of light-sensitive assistant, 0-100 portions of cross linkage assistant and 0-50 portions viscous assistant by weight. The said light-sensitive polyimide resin is prepared by mixture of fluoric aromatic methacrylate ester, aromatic diamine monomer and compound with the molecular weight conditioner. Exposed to ultraviolet rays (the i and g line), The said resin then generates solidified cross linkage actions; figures with high-resolution can be obtained by dissolving the non-exposed part in water or aqueous solvent. The polyimide film has low dielectric and hygroscopic absorption coefficient, fine thermal stability, mechanical and optical property. It can be applied to passivate and protective film on chips and interlaminar dielectric film of the multi-layer circuit interconnection.

Owner:北京永晶科技有限公司

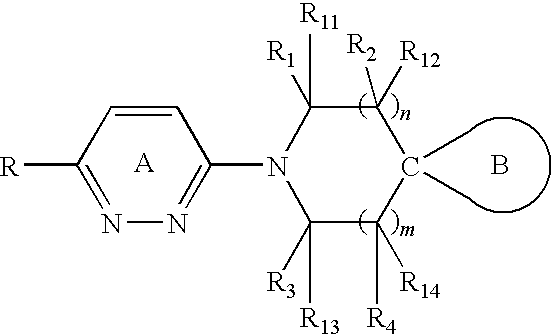

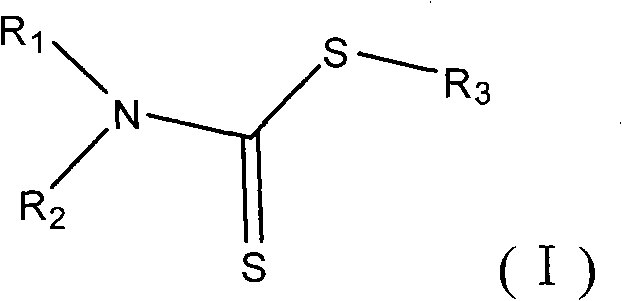

Spiro compound and use thereof

ActiveUS20100069351A1Suppression of body weight gainImprove energy consumptionBiocideOrganic chemistryHydrogen atomCross-linkage

The present invention aims to provide a novel SCD inhibitor.The present invention relate to SCD inhibitor comprising A compound represented by the formula (I)whereinR is an optionally substituted cyclic group or an optionally substituted carbamoyl group, provided that R is not an optionally substituted 7-pyrido[2,3-d]pyrimidyl group;ring A is an optionally further substituted pyridazine ring;R1, R2, R3, R4, R11, R12, R13 and R14 are each independently a hydrogen atom or a substituent, or R1 and R11 in combination, R2 and R12 in combination, R3 and R13 in combination, or R4 and R14 in combination optionally form an oxo group, or R2 and R4 in combination optionally form a bond or an alkylene cross-linkage;m and n are each independently an integer of 0 to 2;ring B is an optionally substituted ring, provided that the two atoms constituting ring B, which are adjacent to the spiro carbon atom, are not oxygen atoms at the same time, or a salt thereof, or a prodrug thereof.

Owner:TAKEDA PHARMA CO LTD

Preparation method of pervaporation film with preferential penetration of dimethyl carbonate

The invention relates to a preparation method of a pervaporation film with the preferential penetration of dimethyl carbonate. Film casting liquid containing vinyl polydimethylsiloxane (Vi-PDMS), hydrogen-containing polydimethylsiloxane (H-PDMS), hydrophobic nano SiO2, a catalyst and a solvent is adopted, a film is coated on an upper layer of a porous ultrafiltration film supported by a polyester non-woven fabric, is aired at room temperature and is also heated, and the cross linkage of the film is finished. An additive type polydimethylsiloxane compound film filled with the hydrophobic nano SiO2, which is obtained by the preparation method of the pervaporation film with the preferential penetration of the dimethyl carbonate, has a simple film preparation process, adopts the materials with low price, strong swelling resistance in dimethyl carbonate / methanol azeotropic liquid, and excellent performance of preferential penetration of the dimethyl carbonate. When the filling mass proportion of the hydrophobic nano SiO2 is 15 percent, the separation factor alpha of the pervaporation film is equal to 3.97, and the penetration flux J is equal to 0.707kg / m2h ([DMC]=30wt%, 40 DEG C).

Owner:TSINGHUA UNIV

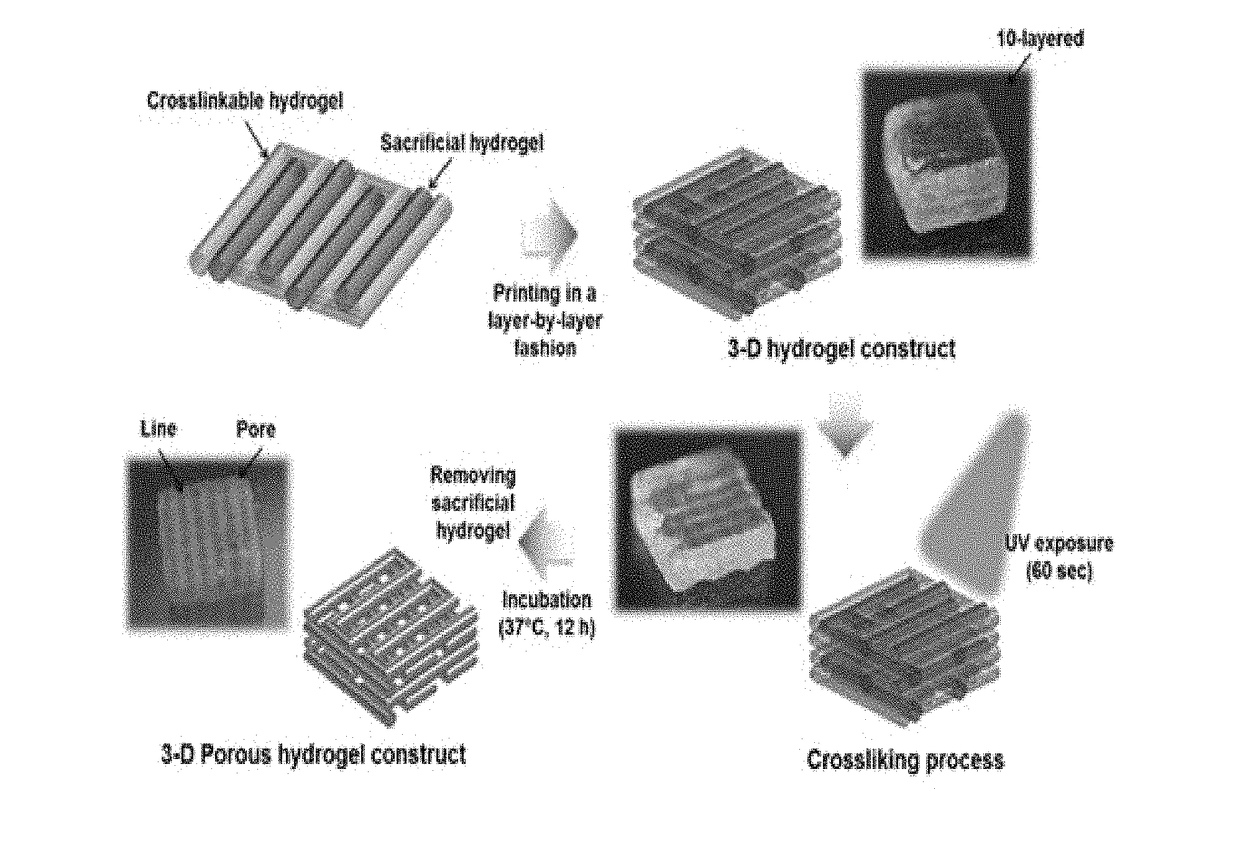

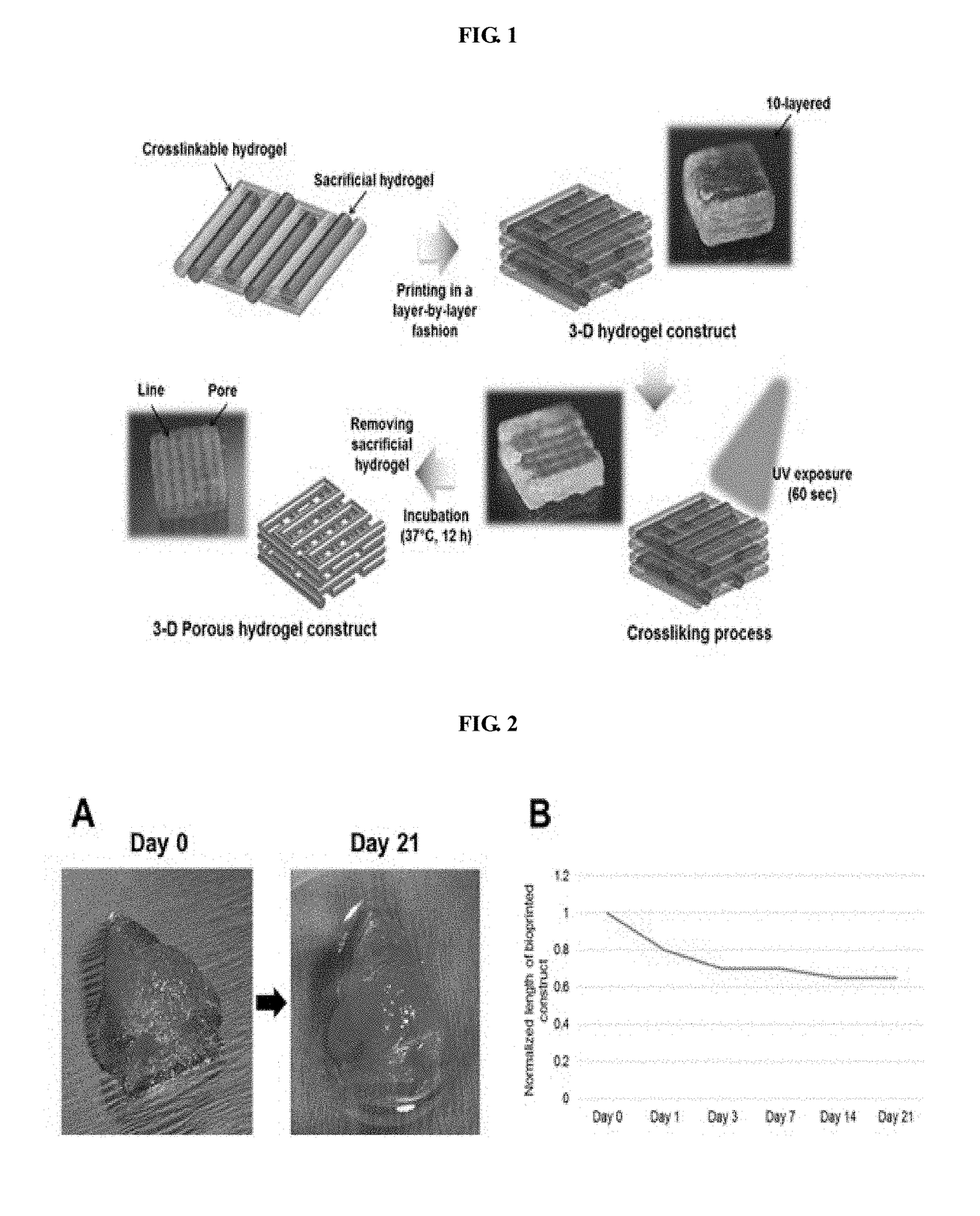

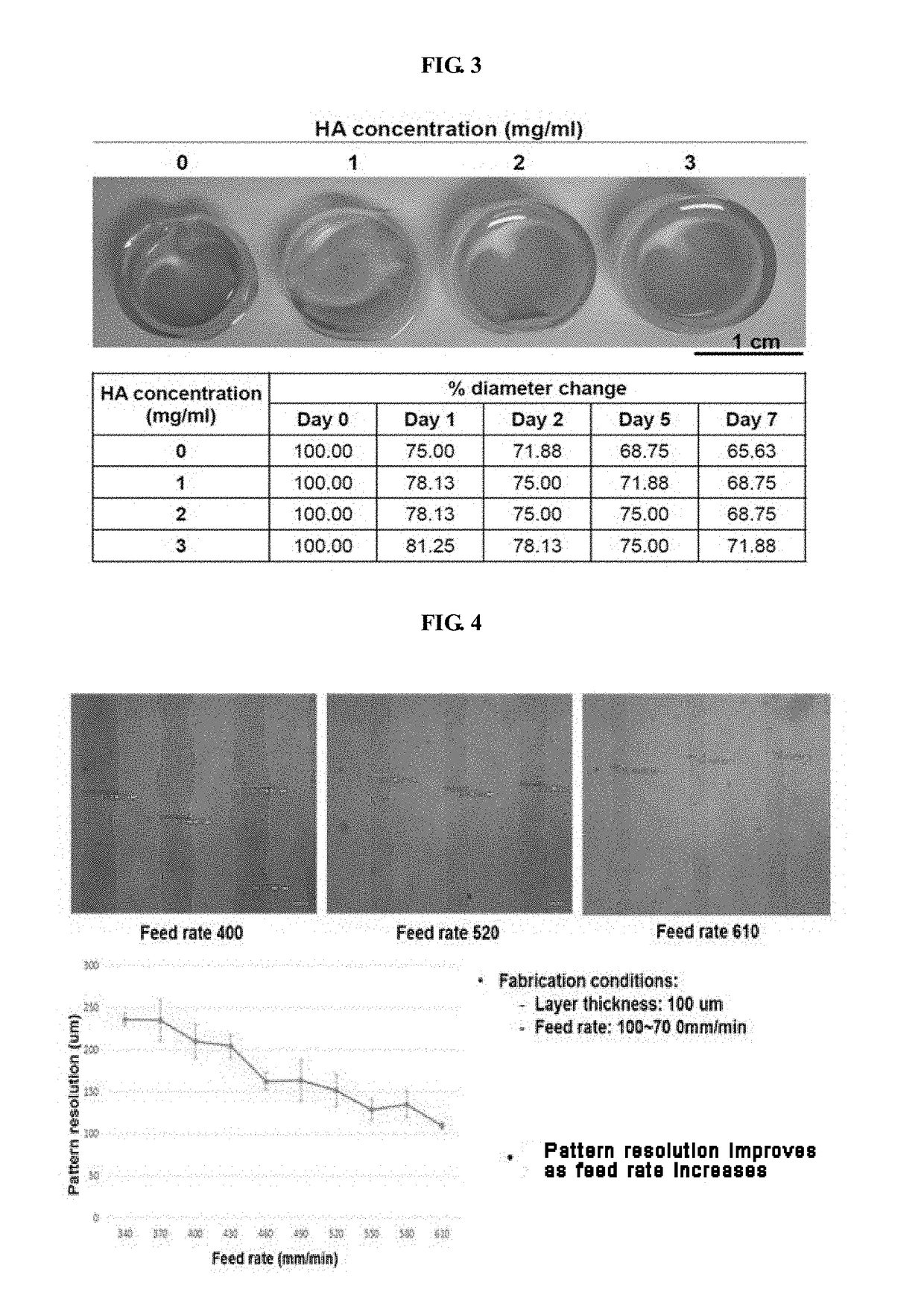

Bio-ink composition having improved physical and biological properties

InactiveUS20180280578A1High viscosityStrong shear-thinning tendencyAdditive manufacturing apparatusPharmaceutical delivery mechanismBiological propertyBiology

The present invention relates to a bio-link composition having improved physical and biological properties and, more specifically to a bio-link composition, which exhibits, through a combination of specific contents of components, high viscosity, strong shear-thinning tendencies, formations of fast cross linkages, and appropriate mechanical properties after printing. The bio-ink composition of the present invention is capable of being used very usefully in the preparation of three-dimensional bio-printed tissue-like organs and internal transplantable tissue structures.

Owner:BIOINKSOLUTION INC

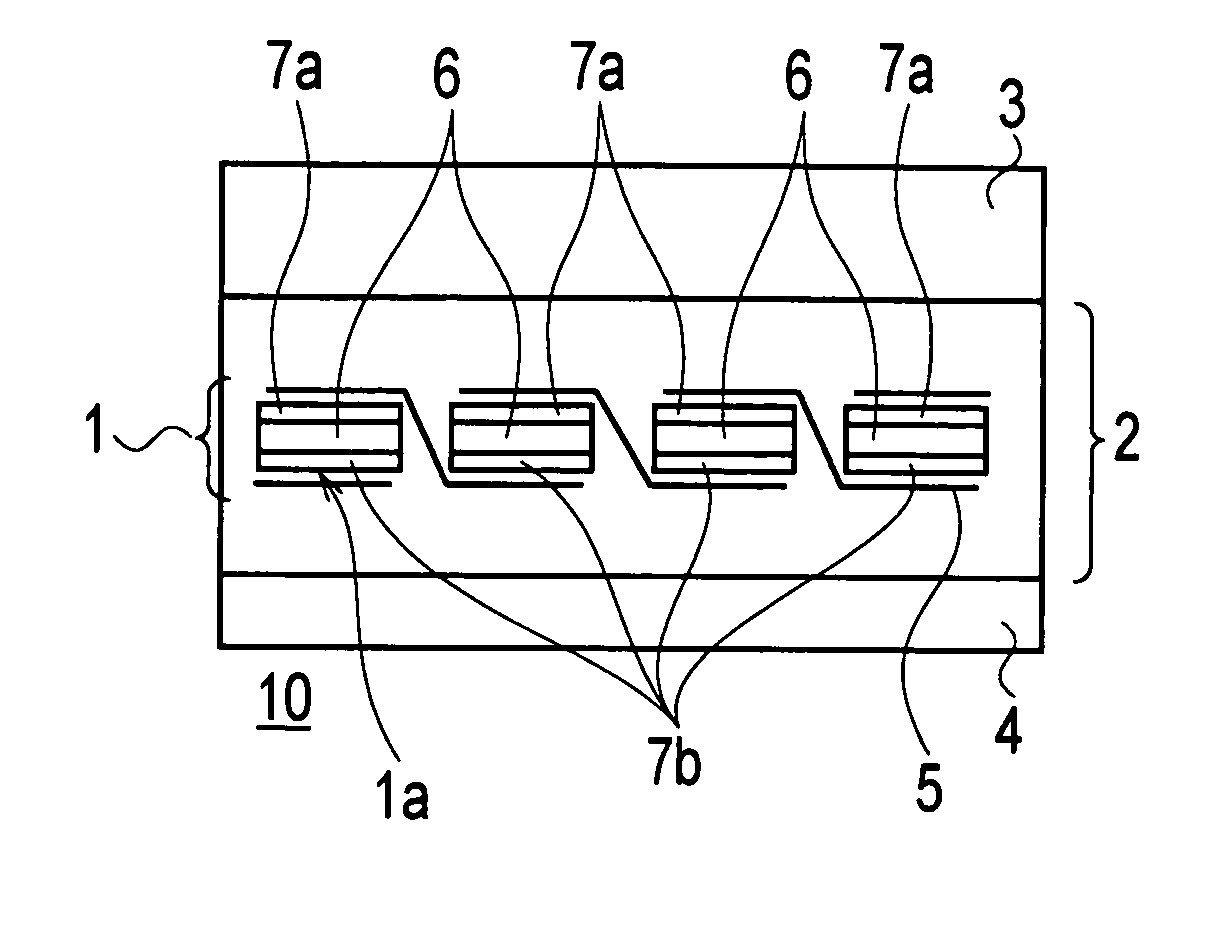

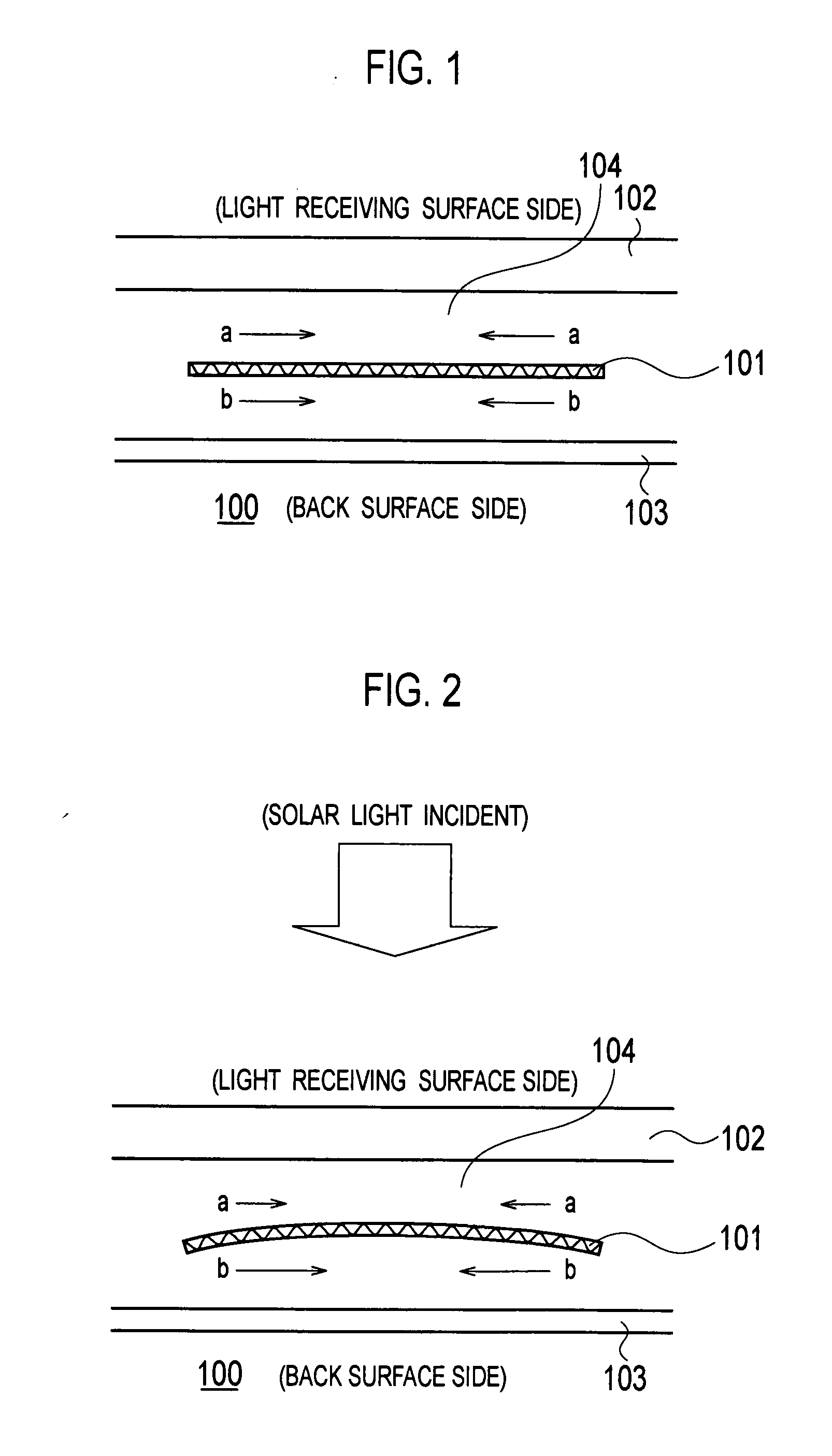

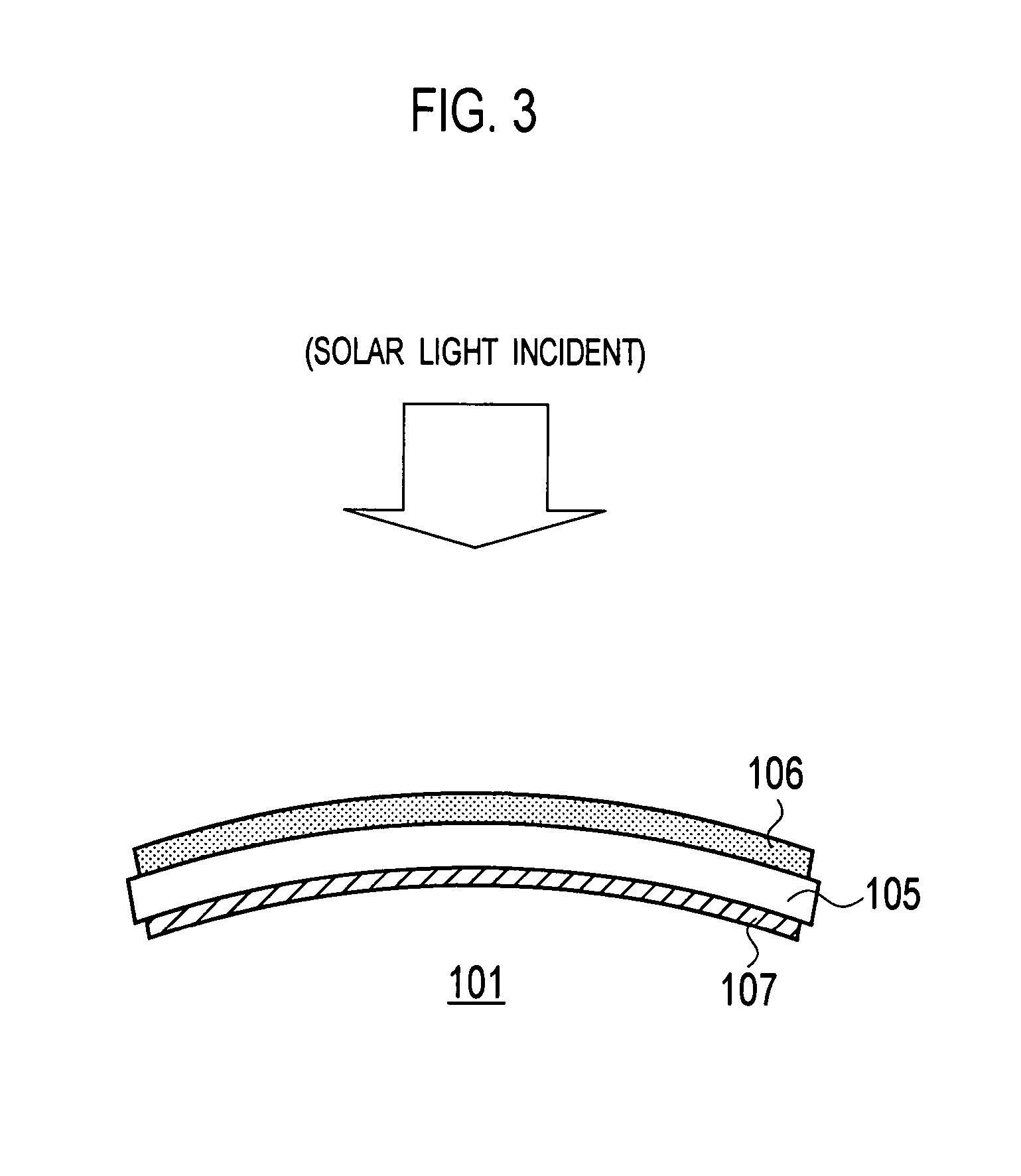

Photovoltaic module and method for manufacturing photovoltaic module

ActiveUS20070227584A1Improve reliabilityAvoid damagePV power plantsSemiconductor/solid-state device manufacturingCross-linkageEngineering

An object of the present invention is to provide a photovoltaic module that achieves a reduction in adverse influence of damage accumulated in a collector electrode provided on the light receiving surface side, and a method for manufacturing the photovoltaic module. To this end, in a photovoltaic module of the present invention, the degree of cross-linkage of the second region of the sealing material that is in contact with the back surface of the solar cell is smaller than that of the first region of the sealing material that is in contact with the light receiving surface of the solar cell.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

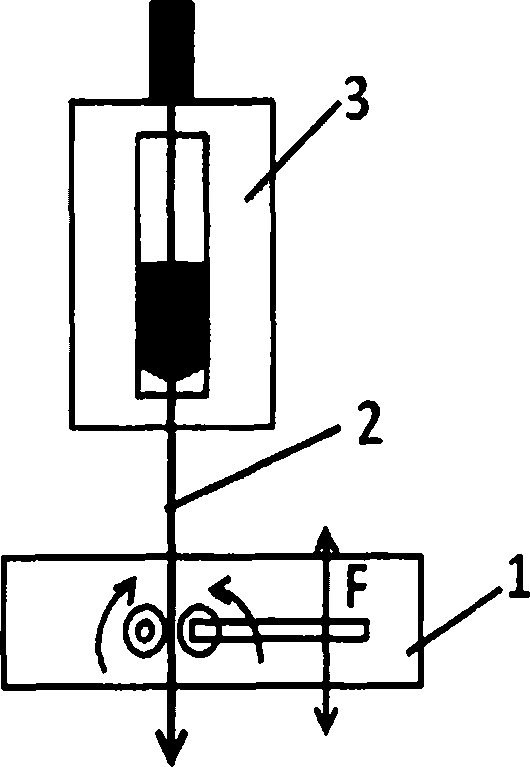

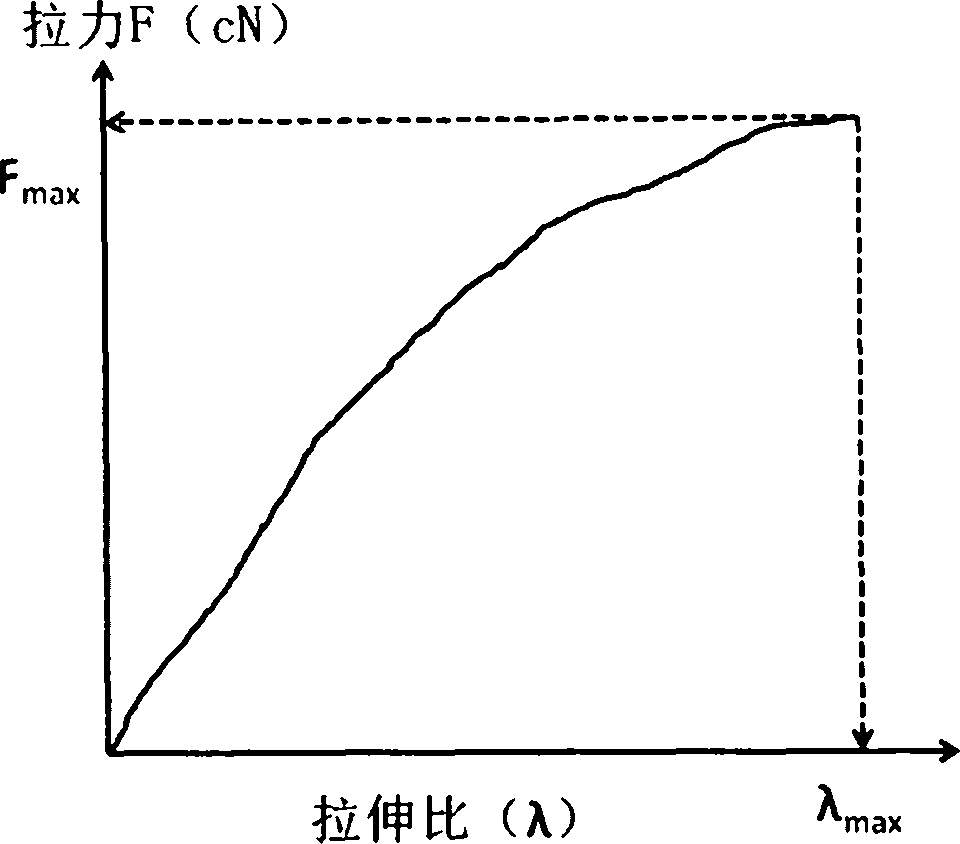

Method for preparing polypropylene melt with high melt strength

The embodiment of the invention discloses a method for preparing polypropylene melt with high melt strength, which uses alkadiene as a modified monomer, thus improving the tensile property of the polypropylene melt with high melt strength due to good compatibility of the alkadiene and polypropylene resin. In addition, the alkadiene monomers can perform grafting reaction with the polypropylene melt, and the alkadiene monomer has lower activity, thus inhibiting cross-linkage reaction so as to expedite the grafting reaction in a certain degree and ensure polypropylene to have higher melt strength. Therefore, the polypropylene melt with high melt strength prepared by the method provided by the invention not only has higher melt strength, but also has larger draw ratio and excellent melt ductility.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

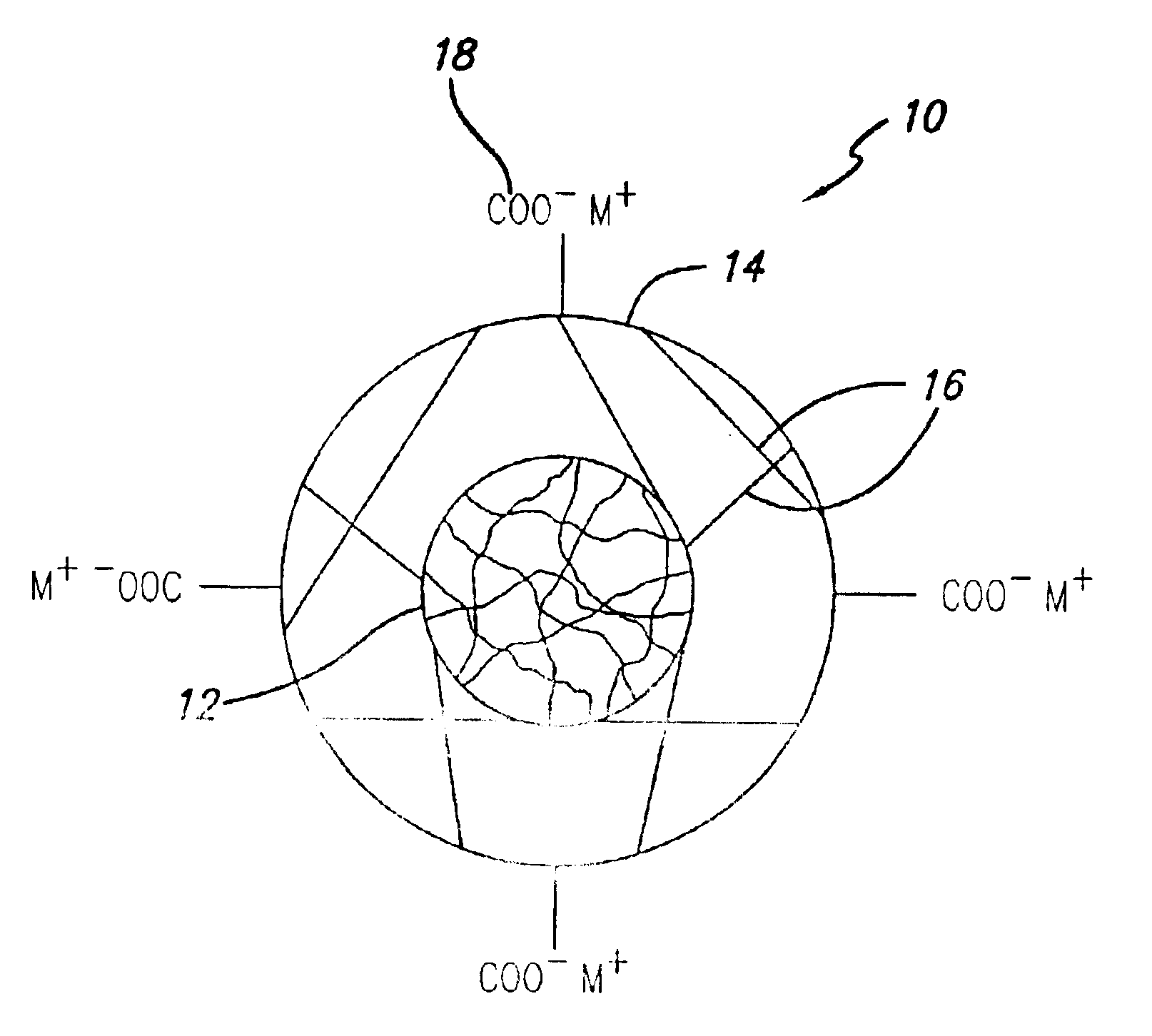

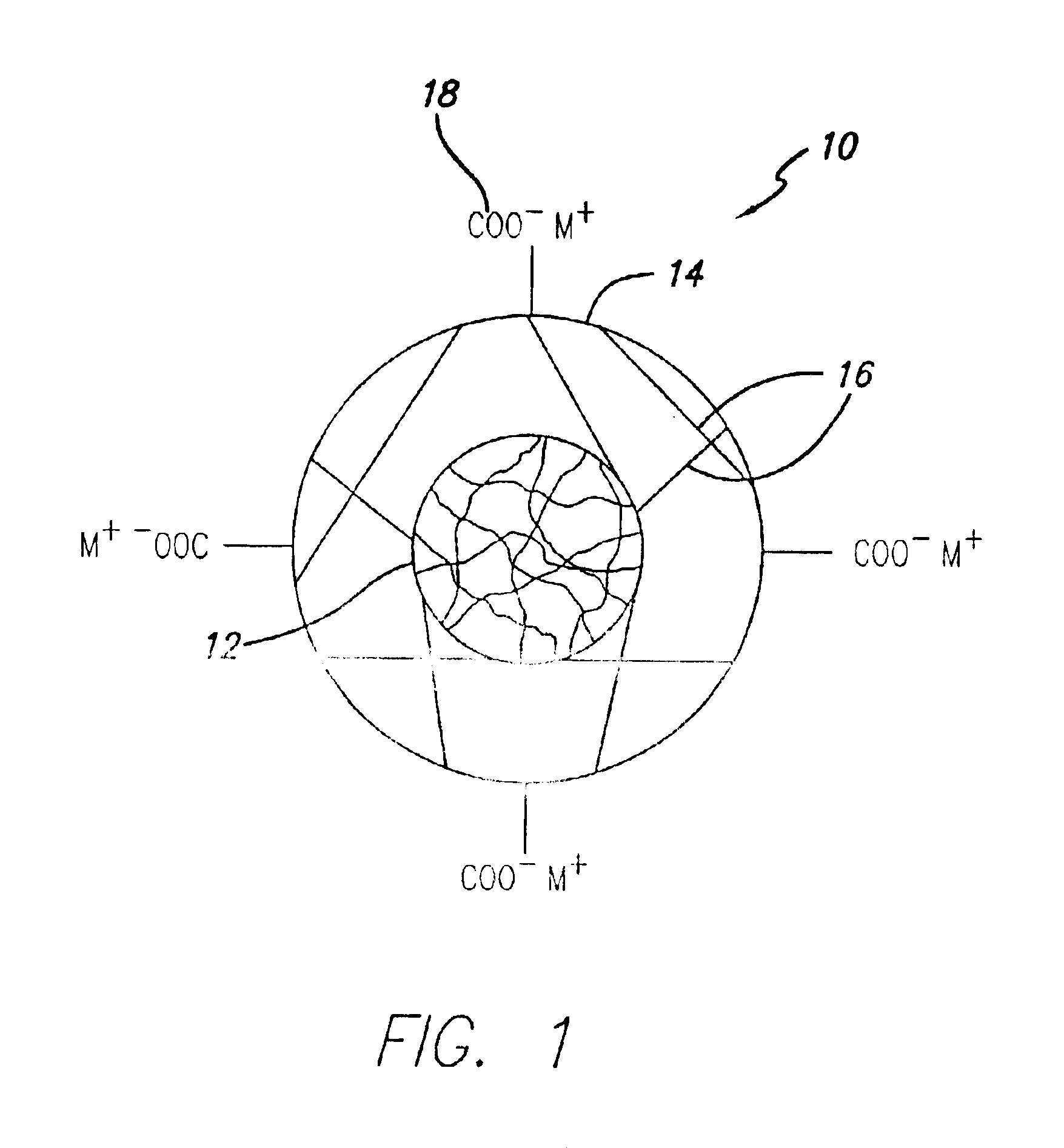

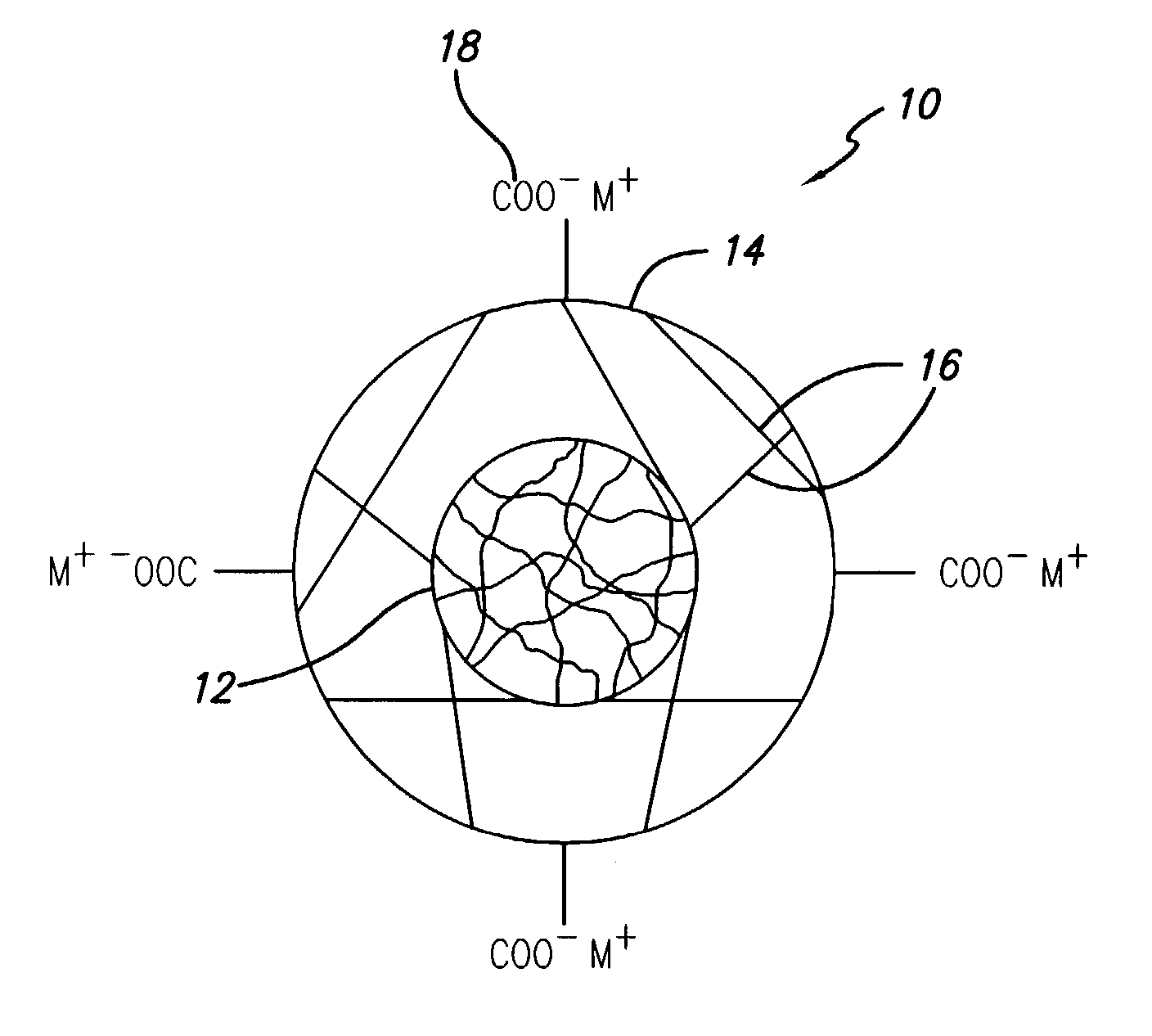

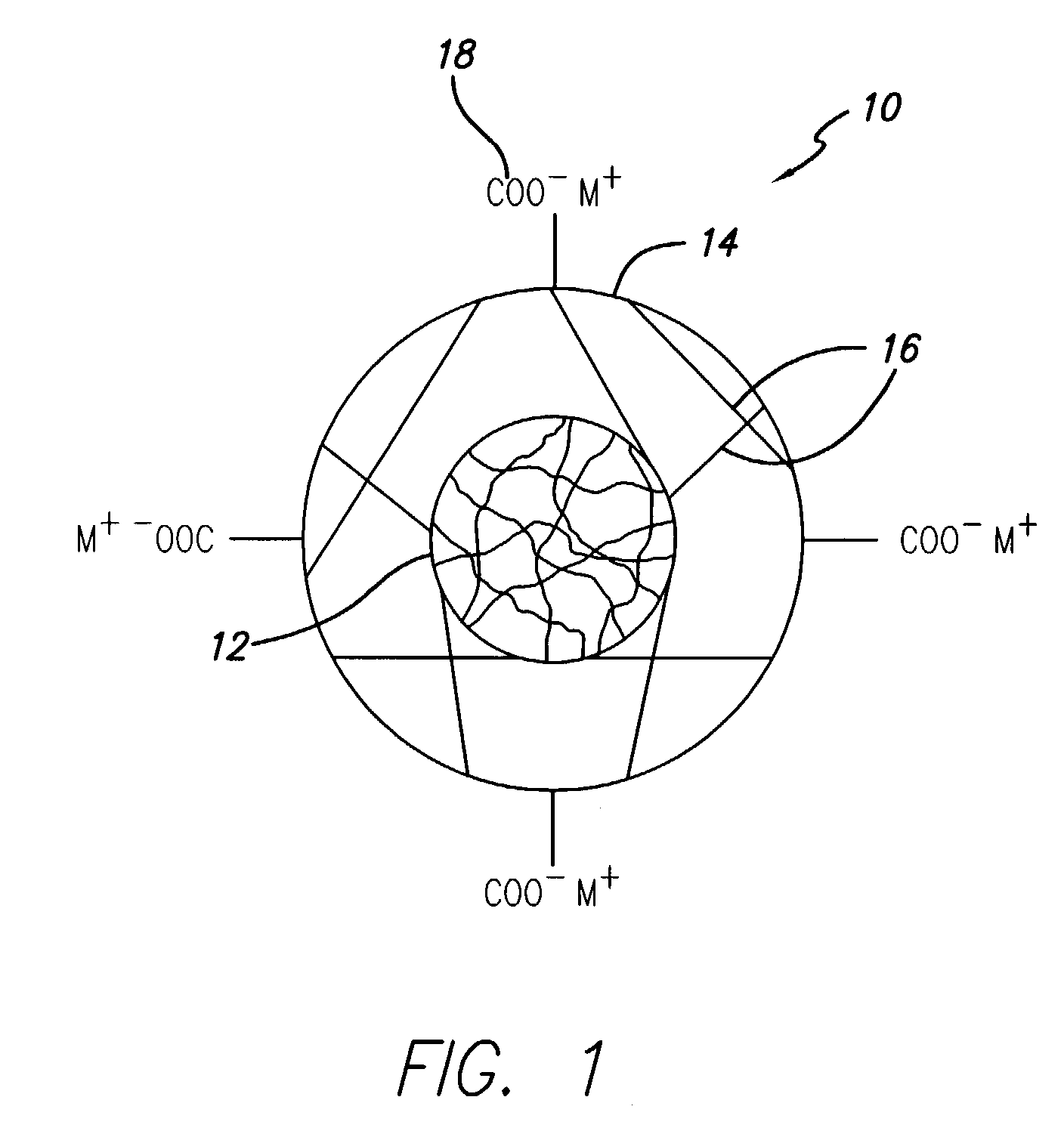

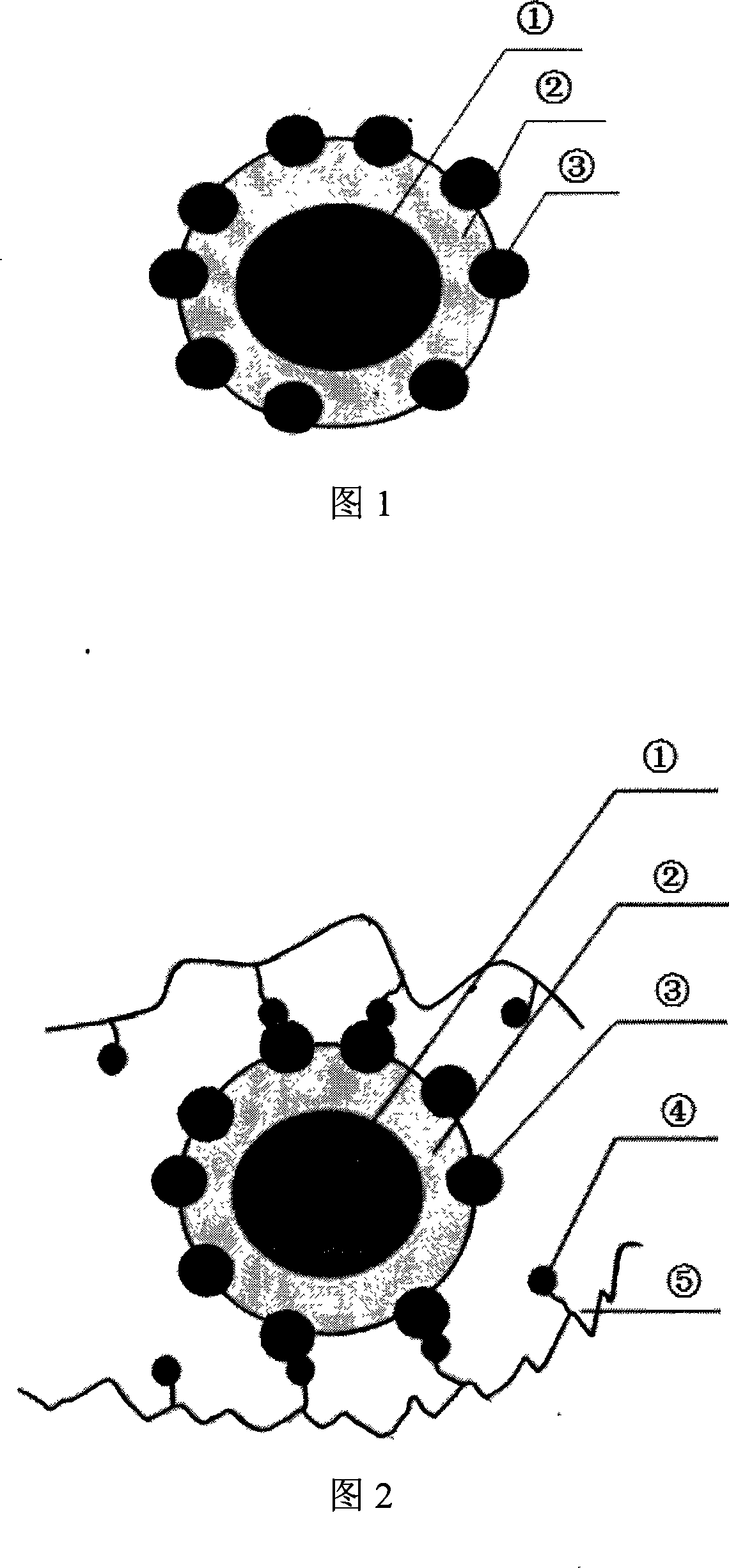

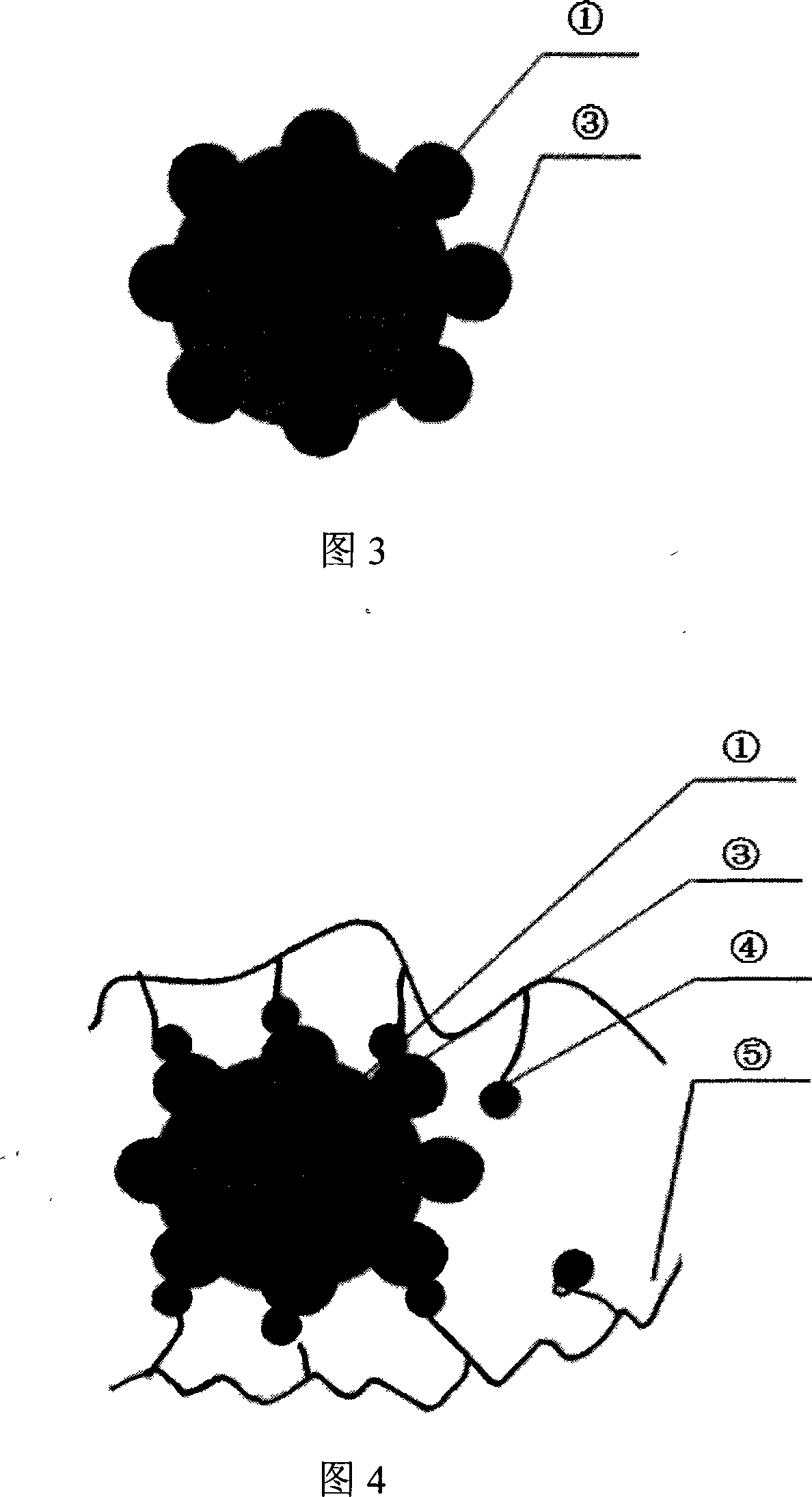

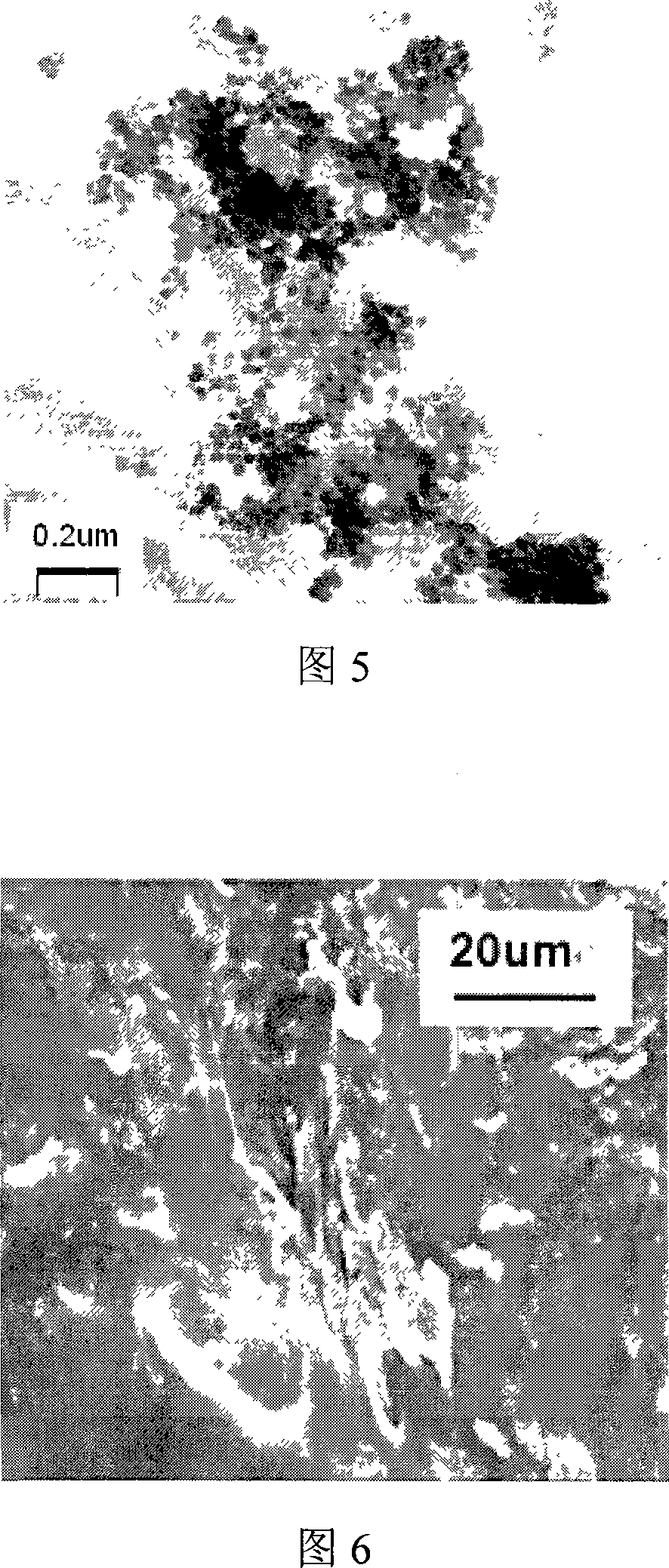

Nucleocapsid type rubber coordination crosslinking agent

The invention discloses a ligand cross-linking agent used in rubber, which is a cladding structure that a shell layer surrounds a core which consists of inorganic particles; the shell layer consists of organic high molecular polymer; a ligand center used for providing ligands is arranged on the organic high molecular polymer; the core is connected with the organic high molecular polymer by a covalent bond. The ligand center is transition metal ions and the inorganic particles are inorganic micron powder or inorganic nanoparticles. The core-shell ligand cross-linking agent can realize ligand cross linkage of nitrile rubber during hot-pressing process, which promotes the rigidity of the rubber as well as keeps good tenacity, thus substituting traditional sulfur carbon black reinforcing rubber cross linking system and obtaining rubber material that is not only reinforced but also rubbery.

Owner:ZHEJIANG UNIV OF TECH

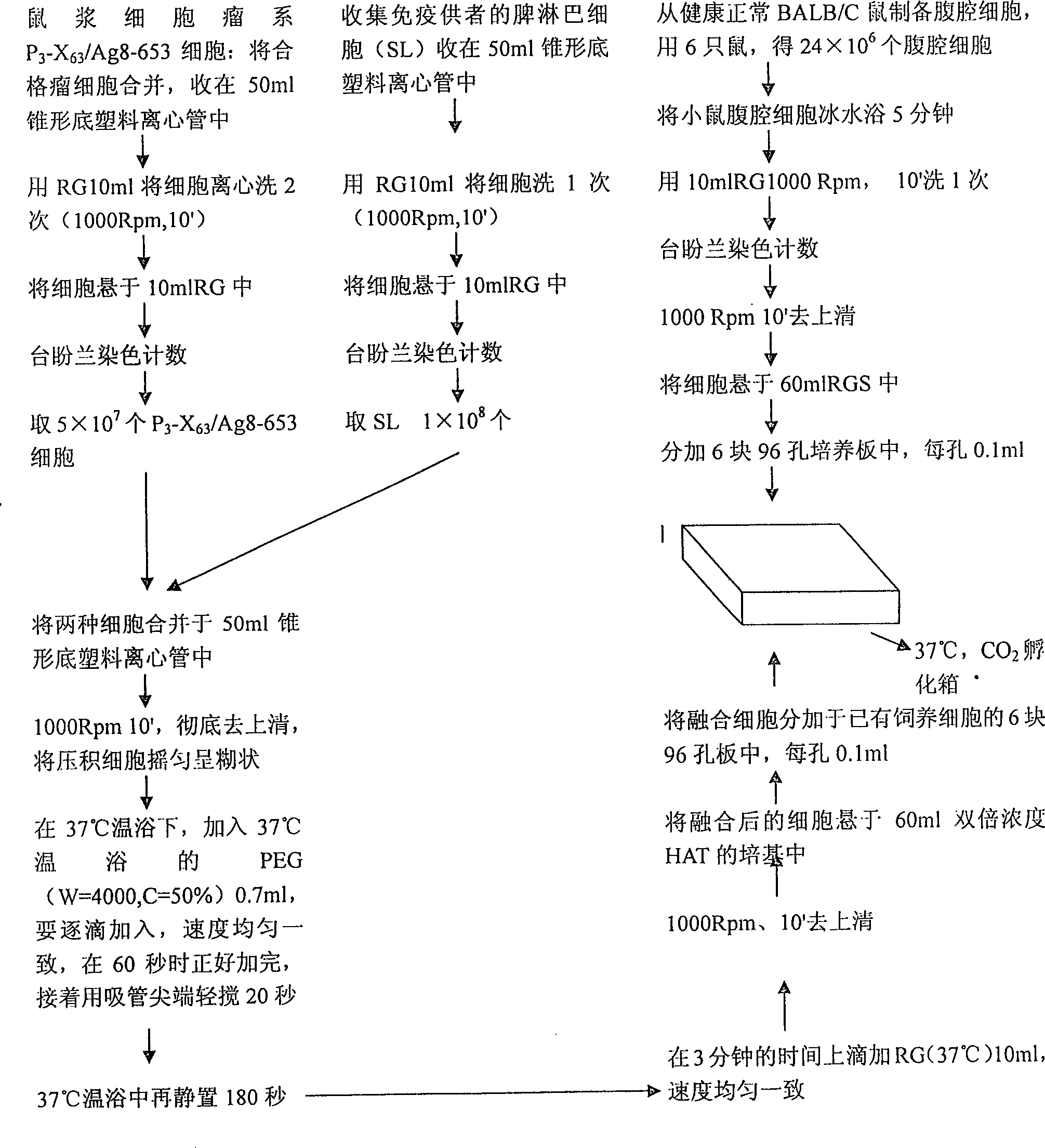

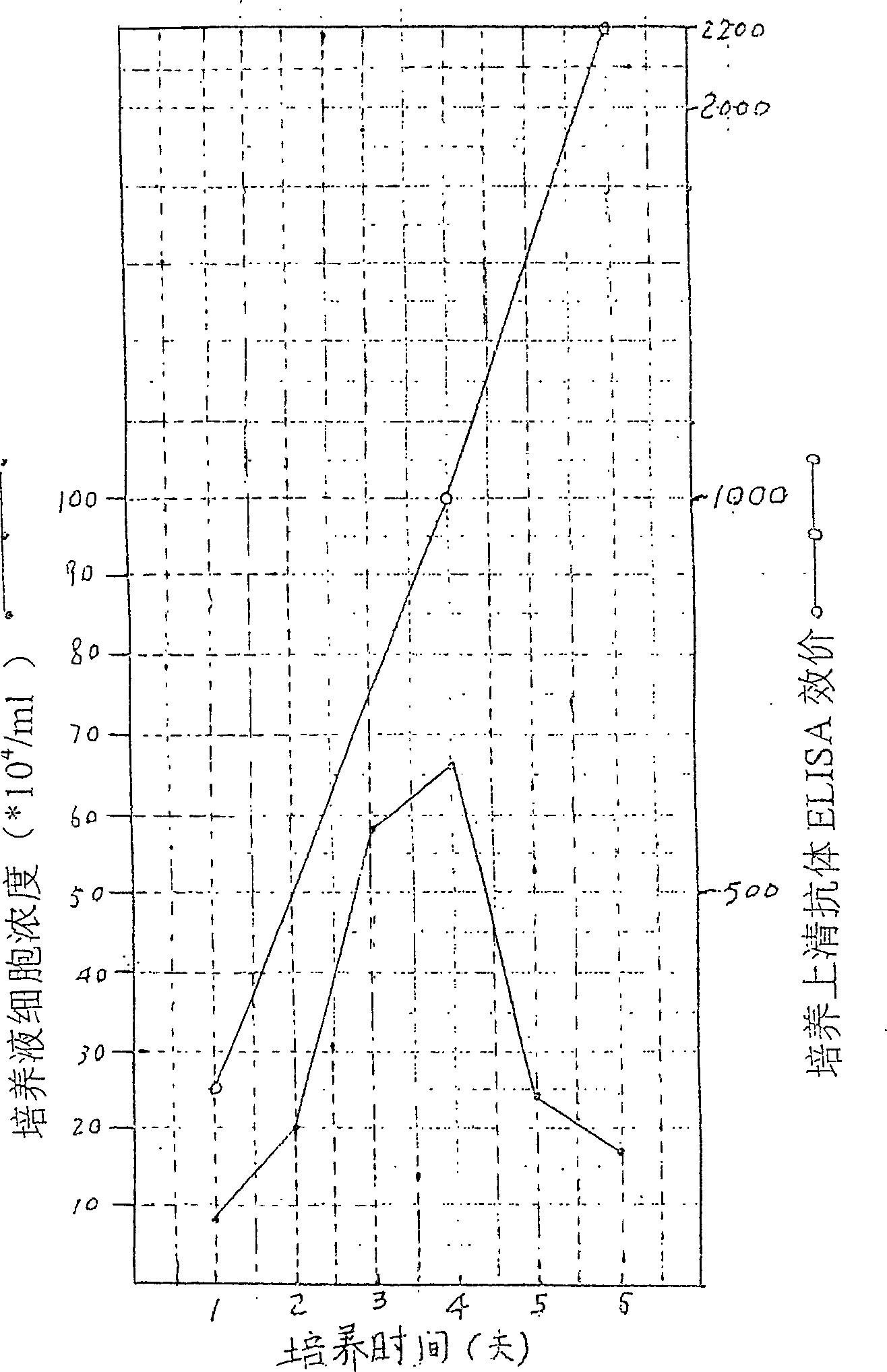

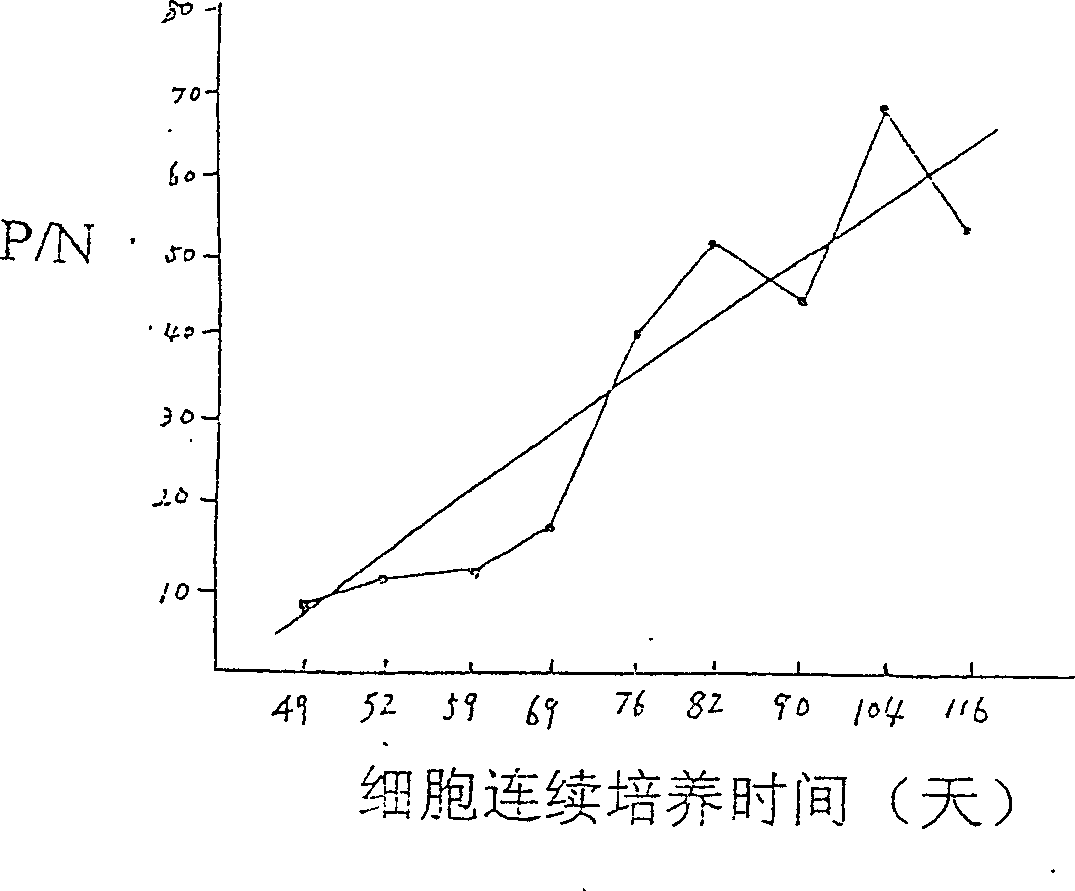

Method for constructing hybridoma cell line of heterogeneity of seereting human monoclonal antibody for anti hepatitis B

This invention provides a method for establishing hetero-hybrid tumor engineering cell sequence for producing human monoclonal antibody for anti-hepatitis B virus. The anti-HBs positive human splenic lymph cell (SL) is fused with mouse plasmacytoma sequence P3-X63 / Ag8-653 cell. Limiting dilution method is used for cloning the positive antibody poro-hybrid-tumor cell to obtain hetero hybrid tumor engineering cell sequence which produces human monoclonal antibody for anti-hepatitis B virus, with stable and high product, rate. Said monoclonal antibody is proceeded with purification and cross-linkage with interferon to produce target prepn. of anti-hepatitis B virus human monoclonal antibody crosslinking with itnerferon, and passive immune prepn. for hepatitis B, and testing agent for hepatitis B.

Owner:SHAANXI JIUZHOU BIOTECH

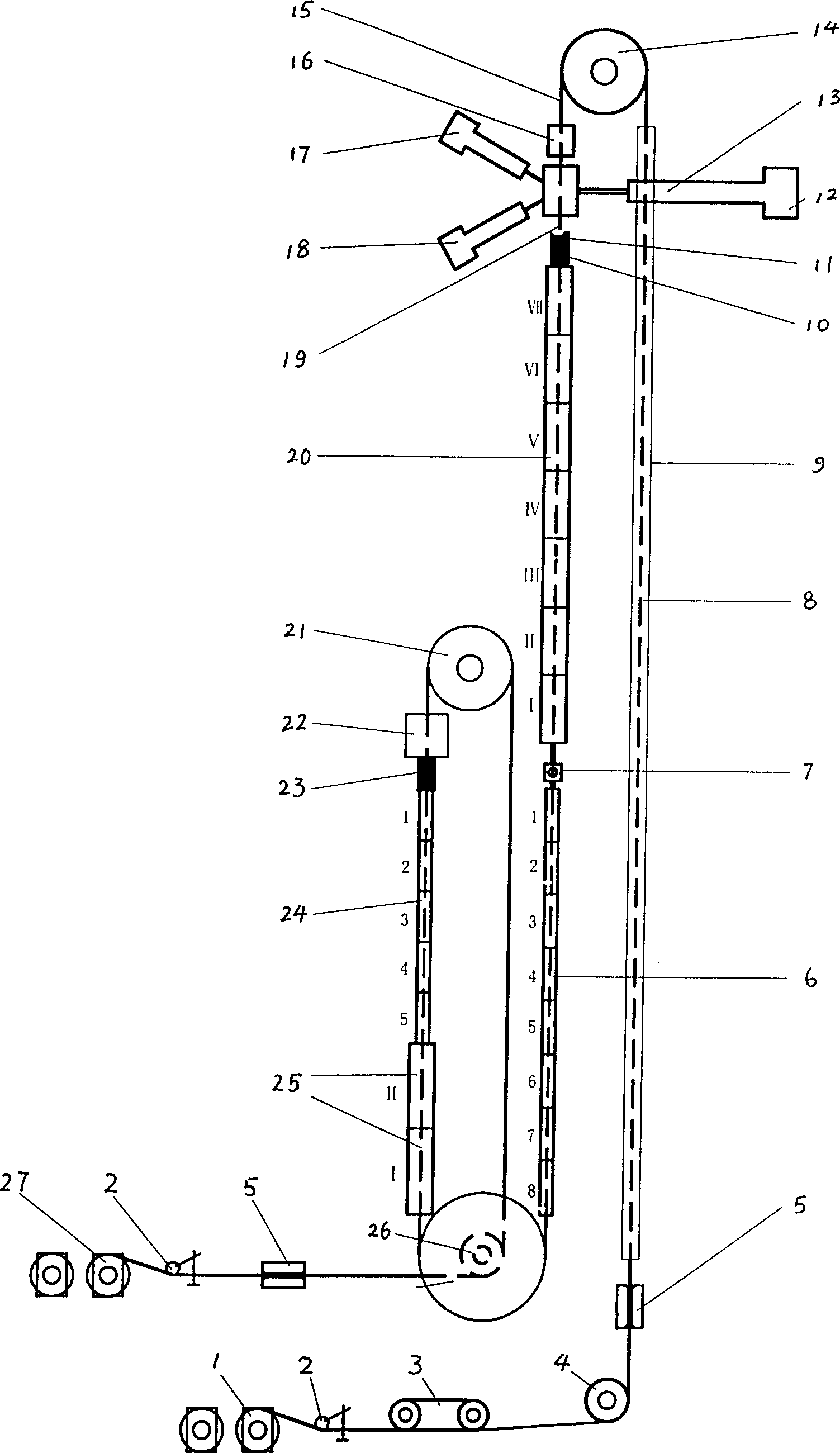

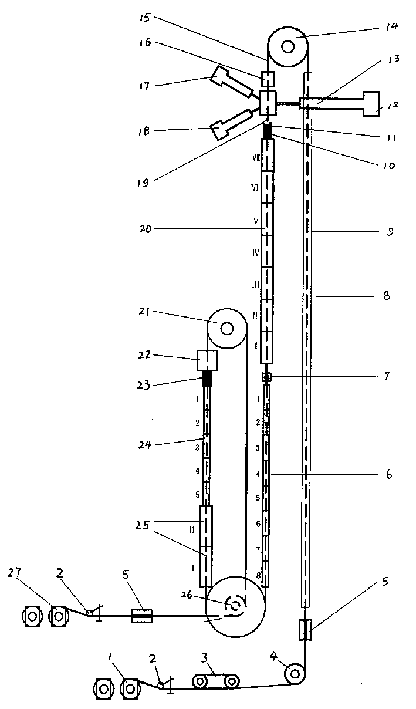

VCV vertical U type cross-linking polyethylene insulation cable production line

InactiveCN1419249AImproved heat shrinkageEliminate internal stressCable/conductor manufactureProduction lineElectrical conductor

The present invention discloses a VCV vertical cross-linkage polyethylene insulating cable production line having a U-shape layout, which includes metal conductor insualting cable core, take-up device, extruding device, tracting wheel, conductor-preheated equipment, low-temperature sulfuratino device, deflecting roller and stress relaxation device. The U-shape layout in the present invention can provide a rather large in-line stress relaxation space for insulating because of the longer cooling zone and eliminate all stresses after the insualtor passes through the stress relaxation device, which can guarantee the insualting quality reaching 750KV voltage grade and is resistant to insulation distortion.

Owner:河北宝丰线缆有限公司

II type collagen sponge bracket and uses thereof

Owner:广州市红十字会医院

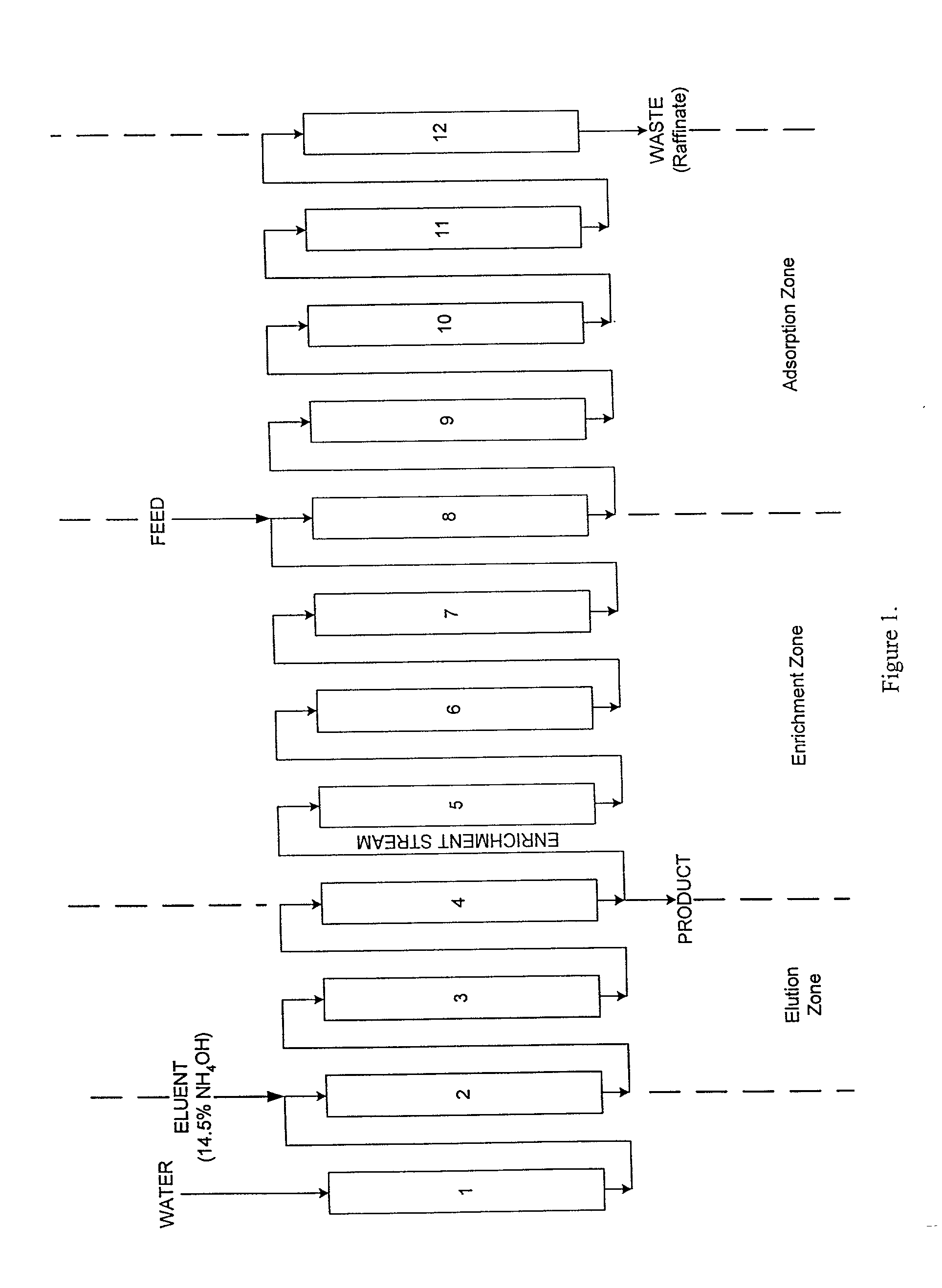

Method for separating a basic amino acid from fermentation broth

InactiveUS20020035269A1Low degreeMaintain good propertiesOrganic compound preparationAnimal feeding stuffStrong acidsIon-exchange resin

This invention relates to a method for separating basic amino acids from fermentation broth comprising contacting the broth with strong acid cation exchange resins that have a low degree of cross-linkage and eluting the amino acid. The method described herein results in higher yield and higher purity of lysine, in addition to higher throughput, as compared to conventional processes of purification of lysine from fermentation broth.

Owner:ARCHER DANIELS MIDLAND CO

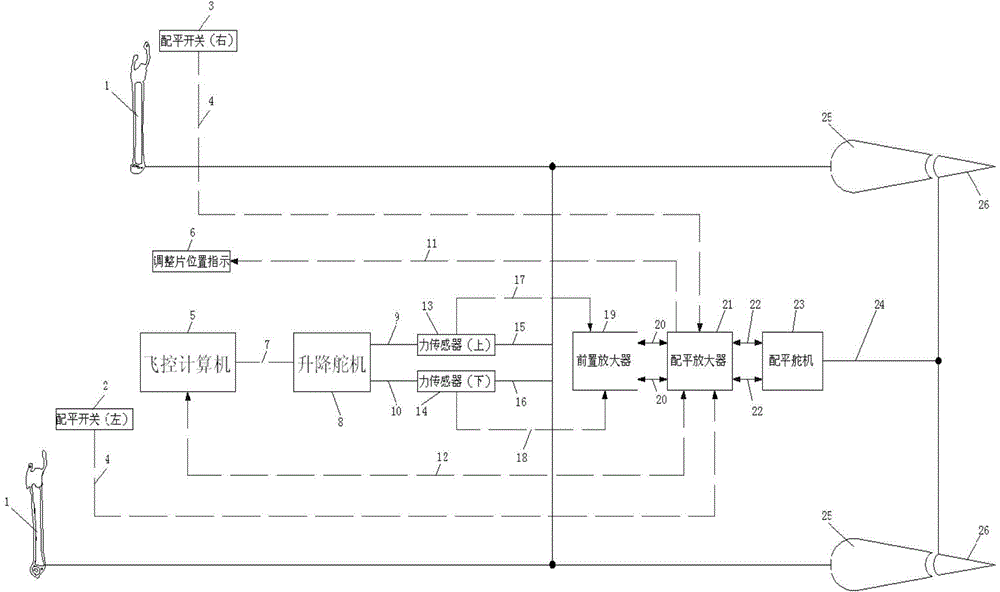

Steering column trimming system of aircraft

ActiveCN106184715AReduce physical exertionPrevent overloadHinged surface balancingElectricitySteering column

The invention discloses a steering column trimming system of an aircraft. The steering column trimming system comprises trimming switches, force sensors, a preamplifier, a trimming amplifier, a trimming steering engine and the like. The steering column trimming system has the advantages that the traditional mechanically transmitted instructions are replaced by telex signals, and the steering column trimming system is in cross-linkage with an automatic pilot system and has an automatic trimming function and an additional function of displaying trimming angles for pilots; the steering column trimming system is simple and reliable and is convenient to operate.

Owner:SHAANXI AIRCRAFT CORPORATION

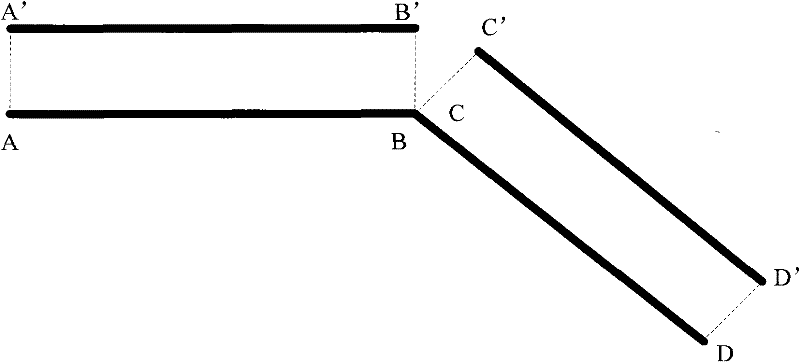

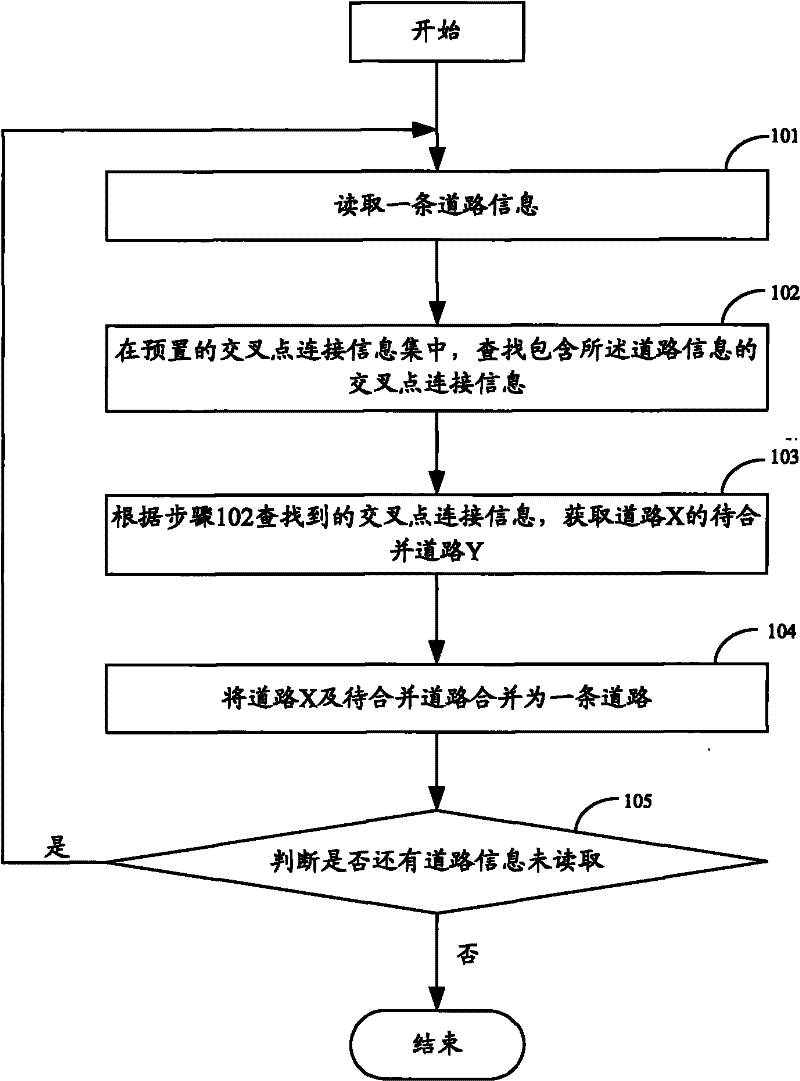

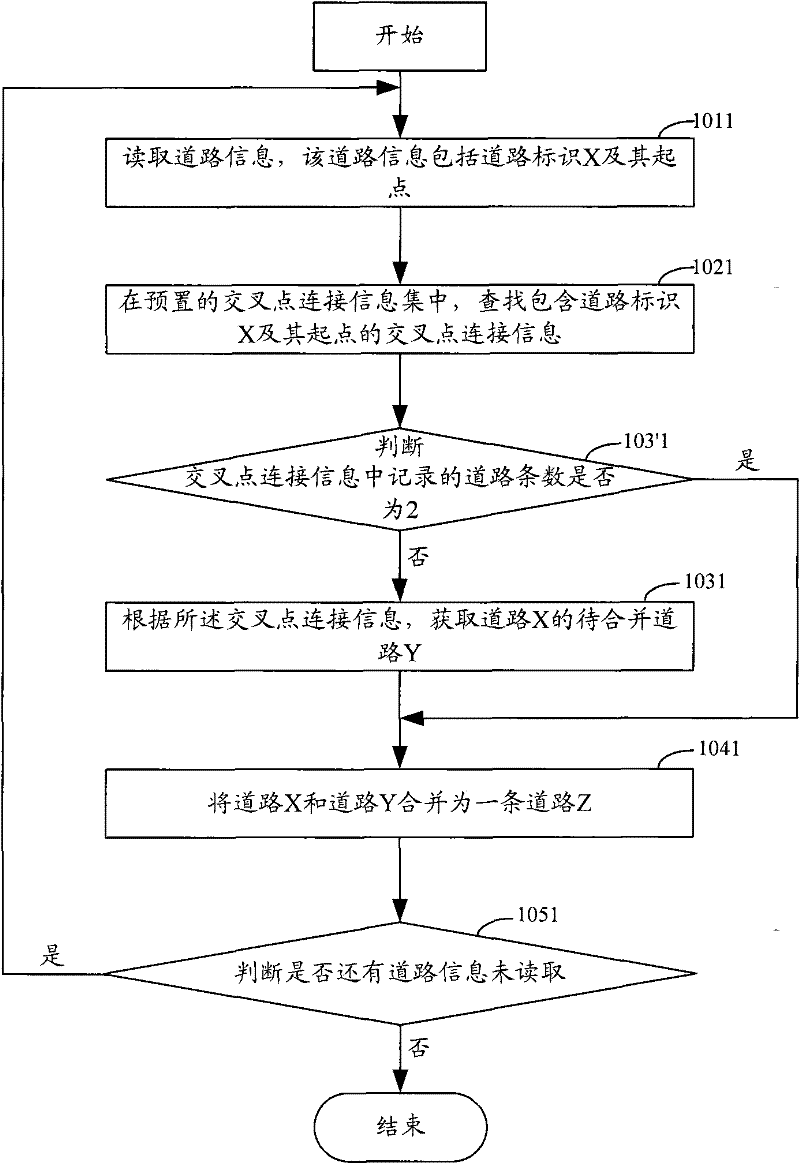

Road merging method and road merging device

ActiveCN102194312ASmooth connectionThere will no longer be intermittent issues with real-time traffic status displayDetection of traffic movementSpecial data processing applicationsComputer scienceCross-linkage

Owner:ALIBABA (CHINA) CO LTD

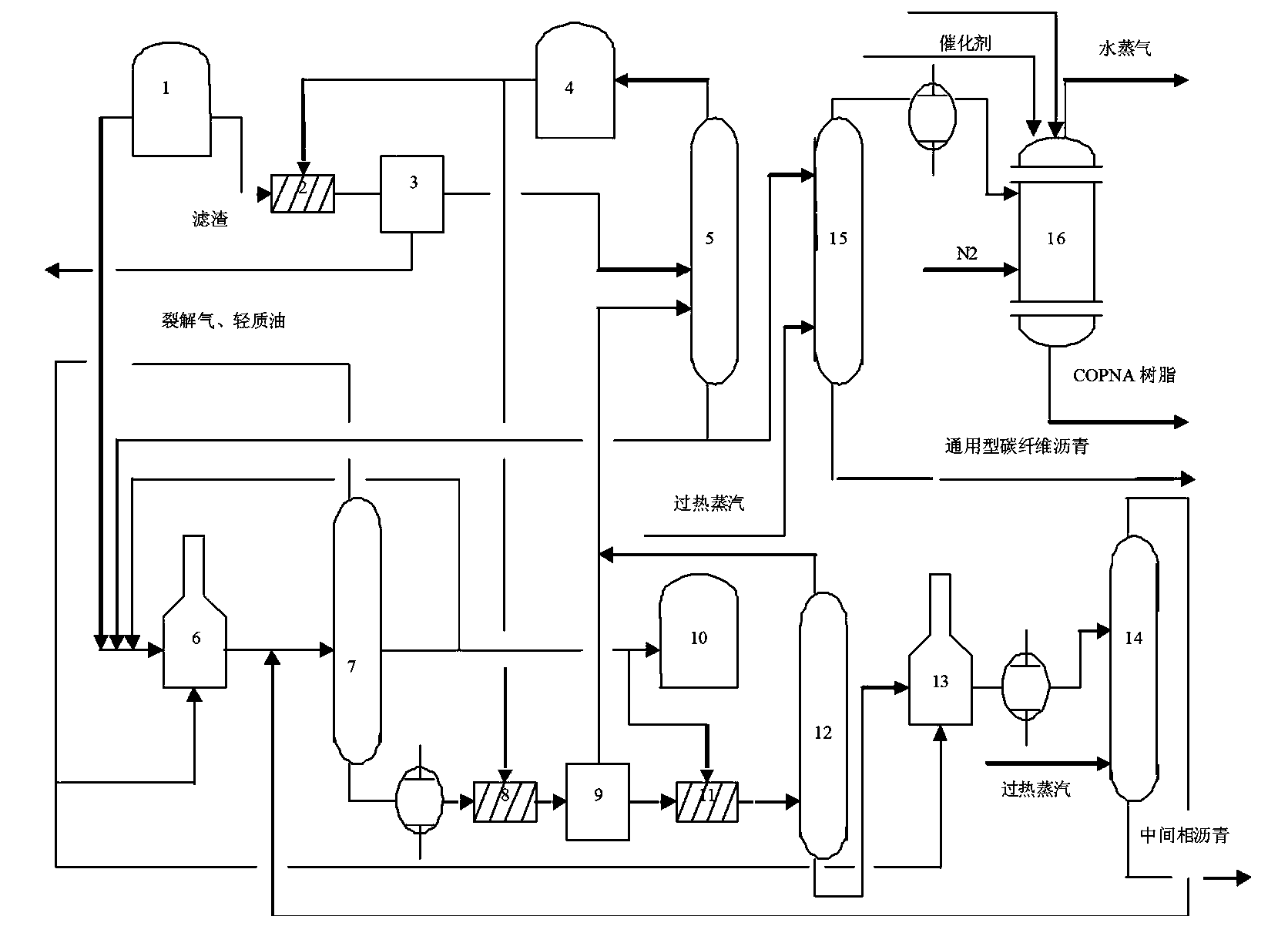

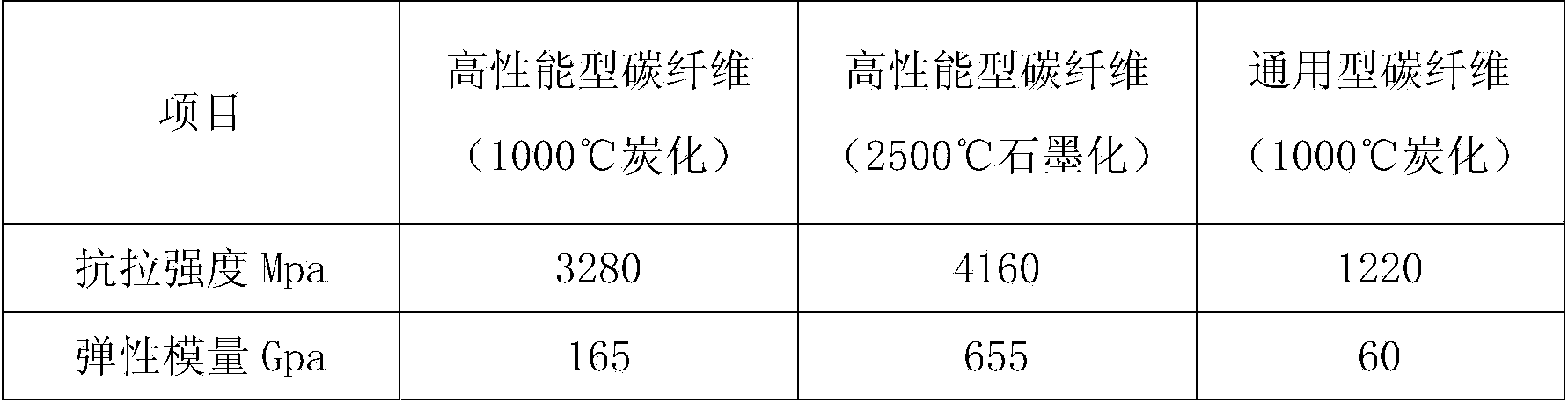

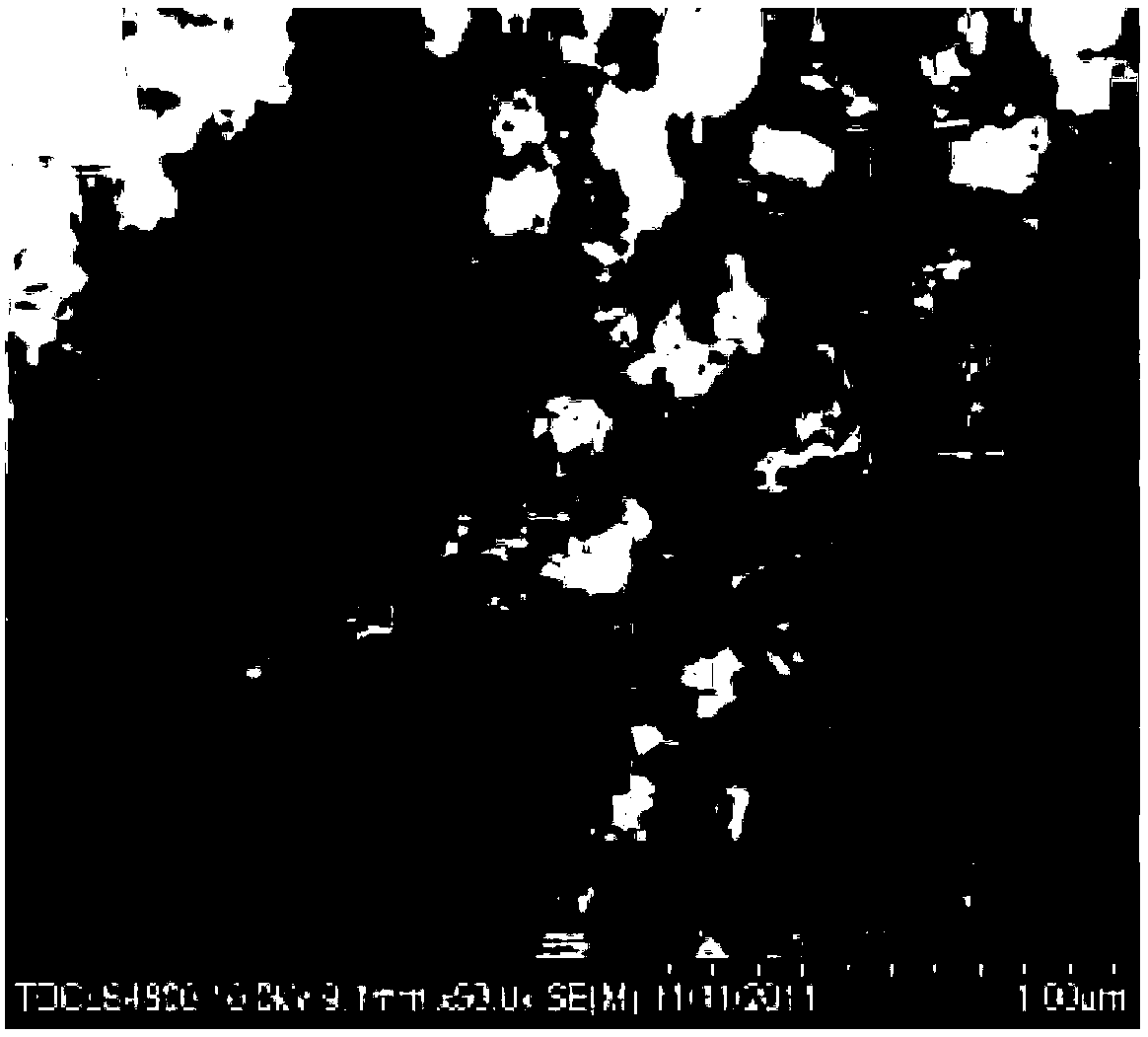

Method for preparing carbon material by use of heavy oil

InactiveCN103865558AImprove uniformityHigh content of mesophaseWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansCondensation processSolvent

The invention discloses a method for preparing a carbon material by use of heavy oil. The method adopts the heavy oil as a raw material to produce intermediate-phase spun asphalt, isotropic spun asphalt and COPNA resin through the following steps: 1, pretreating the heavy oil, and removing free carbon granules and dimethyl benzene insoluble substances from the heavy oil to obtain refined heavy oil; 2, treating the refined heavy oil through a proper thermal poly-condensation process to obtain pyrolysis heavy oil; 3, dissolving, washing and separating the pyrolysis heavy oil by use of dimethyl benzene to obtain a dimethyl benzene soluble component and a dimethyl benzene insoluble component; 4, dissolving the dimethyl benzene insoluble component by use of a hydrogenated heavy solvent and performing a hydrogenation and co-carbonization reaction to obtain hydrogenated asphalt; 5, thermally treating the hydrogenated asphalt to obtain intermediate-phase asphalt; 6, separating the solvent from the dimethyl benzene soluble component obtained in the step 3 and removing the dimethyl benzene solvent to obtain the soluble component; 7, recycling a part of the soluble component in the step 2 and making the part have thermal poly-condensation with the refined heavy oil, and thermally treating the other part to obtain the isotropic spun asphalt; and 8, letting distillate oil which is at a temperature lower than 350 DEG C and obtained by separation during the thermal treatment in the step 7 have a cross-linkage reaction with a cross-linking agent to obtain the CNPNA resin.

Owner:广州万熹龙新材料科技有限公司

Fish noodle and producing method thereof

InactiveCN101243845AIncrease the joining ratioGreat tasteDough treatmentFood preparationFlavorGlutaminase

The invention relates to fish noodle and the production method, belonging to technical field of food processing, which is prepared through mixing the following raw material according to weight percentage: pelletizing fish starch 40 to 50 %, flour 40 to 46%, table salt 1 to 3%, starch 1 to 5%, egg white 0.5 to 5%, rotary drumvacuum 0.5 to 1%. Glutamate in fish meat and glutamate in flour can be produced into a net shaped gluten structure by the rotary drumvacuum added into the invention through common frame and cross-linkage, thereby closely binding flour and fish meat and enabling flour elastic with strong binding force; thus adding proportion of fish meat can be improved to enhance the flavor and the texture of fish noodle; egg white added into the fish noodle can enable noodle to have lofty flavor, thereby furthermore improving flavor of fish noodle.

Owner:WUHAN XINZHOU ZHANGDIAN FISH NOODLES

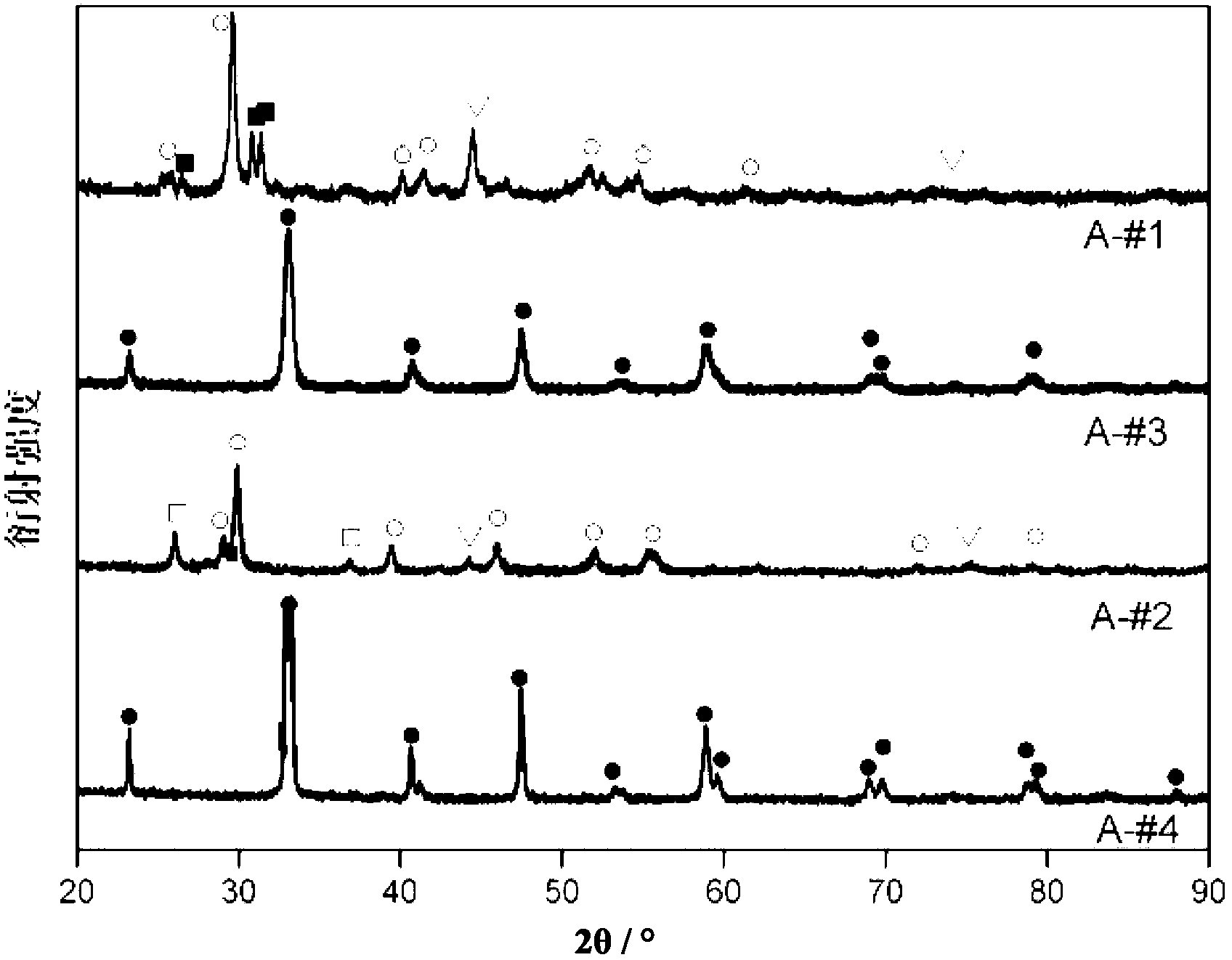

SiOC porous ceramics-loaded La0.9Sr0.1CoO3 nano particle catalyst prepared by fibre template method

InactiveCN102836732AHigh catalytic activityImprove catalytic performancePhysical/chemical process catalystsDispersed particle separationFiberDiesel engine

The invention discloses an SiOC porous ceramics-loaded La0.9Sr0.1CoO3 nano particle catalyst prepared by a fibre template method, which is prepared by the following steps of: firstly, preparing La0.9Sr0.1CoO3 gel by utilizing a gum gelling method, carrying out electrostatic spinning on the prepared sol gel, then placing the prepared gel fibre in SiOC precursor sol so as to obtain a precursor of the catalyst, and finally, carrying out thermal decomposition so as to obtain the SiOC porous ceramics-loaded La0.9Sr0.1CoO3 nano particle catalyst prepared by the fibre template method. According to the SiOC porous ceramics-loaded La0.9Sr0.1CoO3 nano particle catalyst prepared by the fibre template method, the defect of a coating process of a traditional catalyst is overcome, and a catalyst and a carrier are compounded, i.e. oxide gel fibre with ordered arrangement is used as a template construction passage so as to obtain a catalyst-loaded carrier with a porous structure by cross linkage, thermal decomposition and in-situ preparation. The catalyst has favorable performance of removing NOx and is suitable for the after-treatment of the tail gas of a diesel engine. The process of a preparation method of the SiOC porous ceramics-loaded La0.9Sr0.1CoO3 nano particle catalyst prepared by the fibre template method is simple.

Owner:TIANJIN UNIV

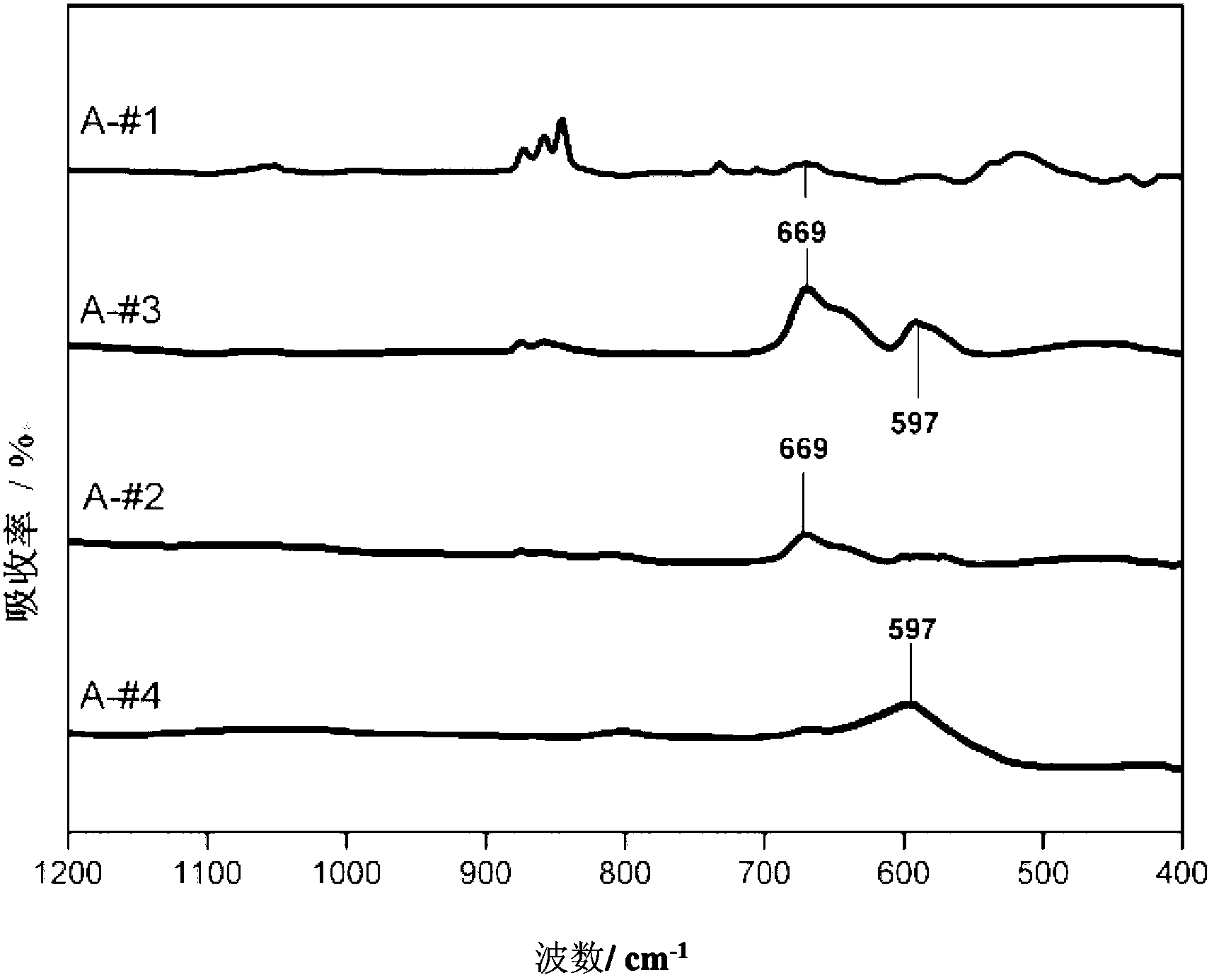

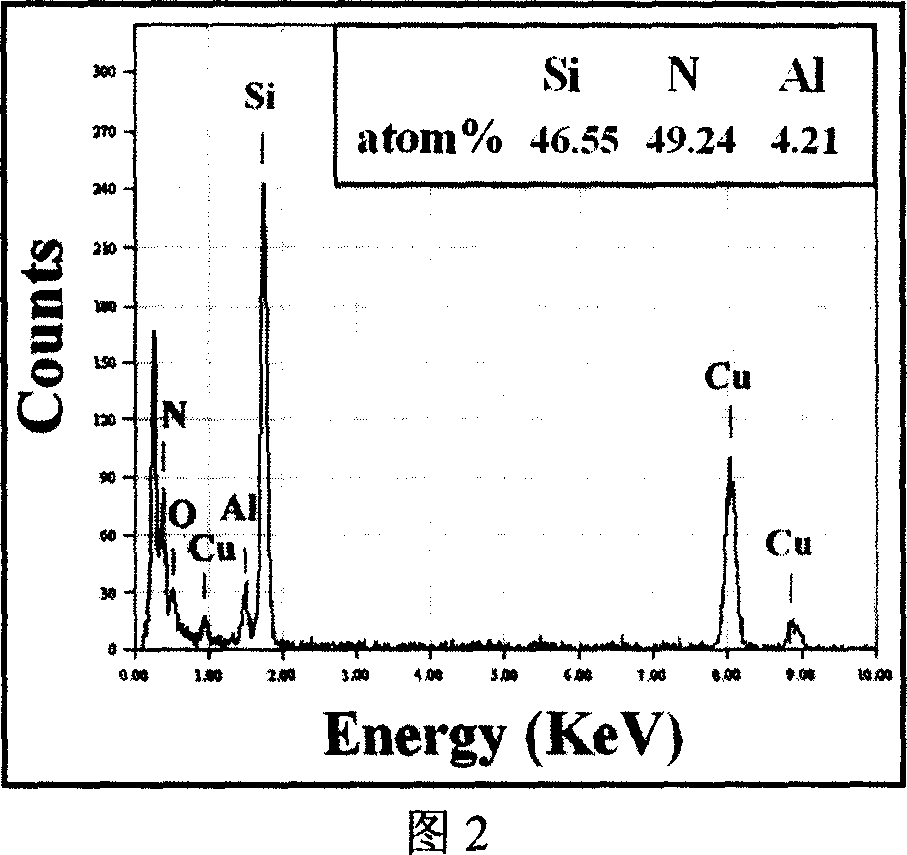

Controllable doping method for Si3N4 single-crystal low-dimension nano material

InactiveCN101054730AUniform and controllable dopingLow costPolycrystalline material growthDiffusion/dopingHigh energyPolysilazane

A novel process for realizing uniform and controllable doping of Si3N4 single crystal dimension nano materials by organic precursor co-pyrogenation comprises the following concrete steps: (1) ball milling mixing: ball milling and mixing homogeneously two organic precursors (polysilazane and aluminium isopropoxide ) according to different proportions; (2) low temperature cross linkage solidification: cross linkage solidifying after mixing homogeneously to get non-crystalline solids; (4) high-energy ball milling pulverizing: filled the non-crystalline solids to a nylon resin milling tank, introducing a catalyzer therein, and dry method ball milling pulverizing them in a high-energy globe mill; (4) high temperature thermal decomposition: after the high-energy ball milling, thermal decompositing the mixture. Different the traditional doping process, said novel process can realize the regulation and design of uniform doping of Si3N4 single crystal dimension nano material in molecular level by simply regulating the proportionality of two organic precursors, and then realize the regulation of performances such as actinoelectricity of Si3N4 single crystal dimension nano materials. Said process is hopeful to become a general process for realizing controllable doping of single crystal low dimension nano materials.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY +2

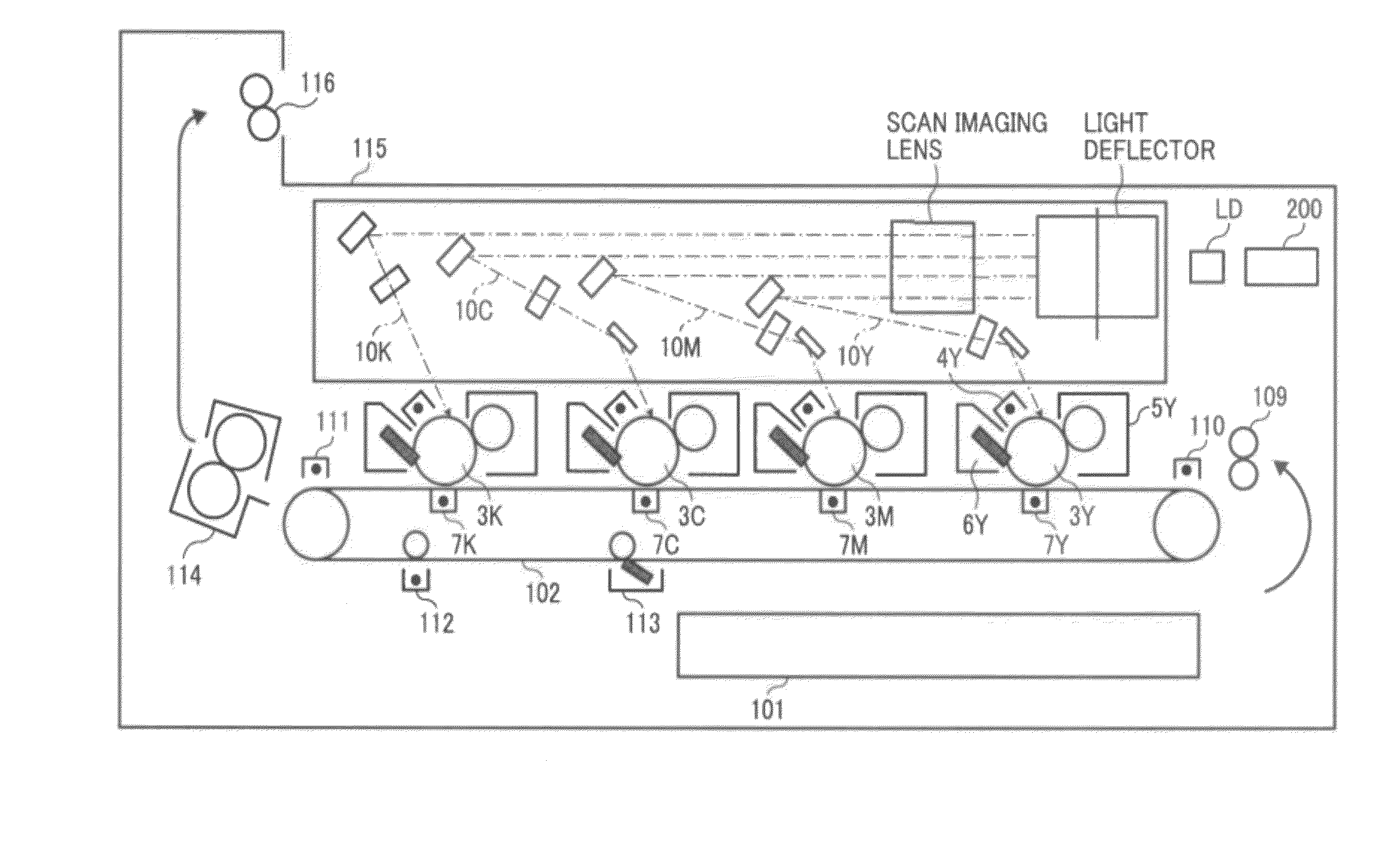

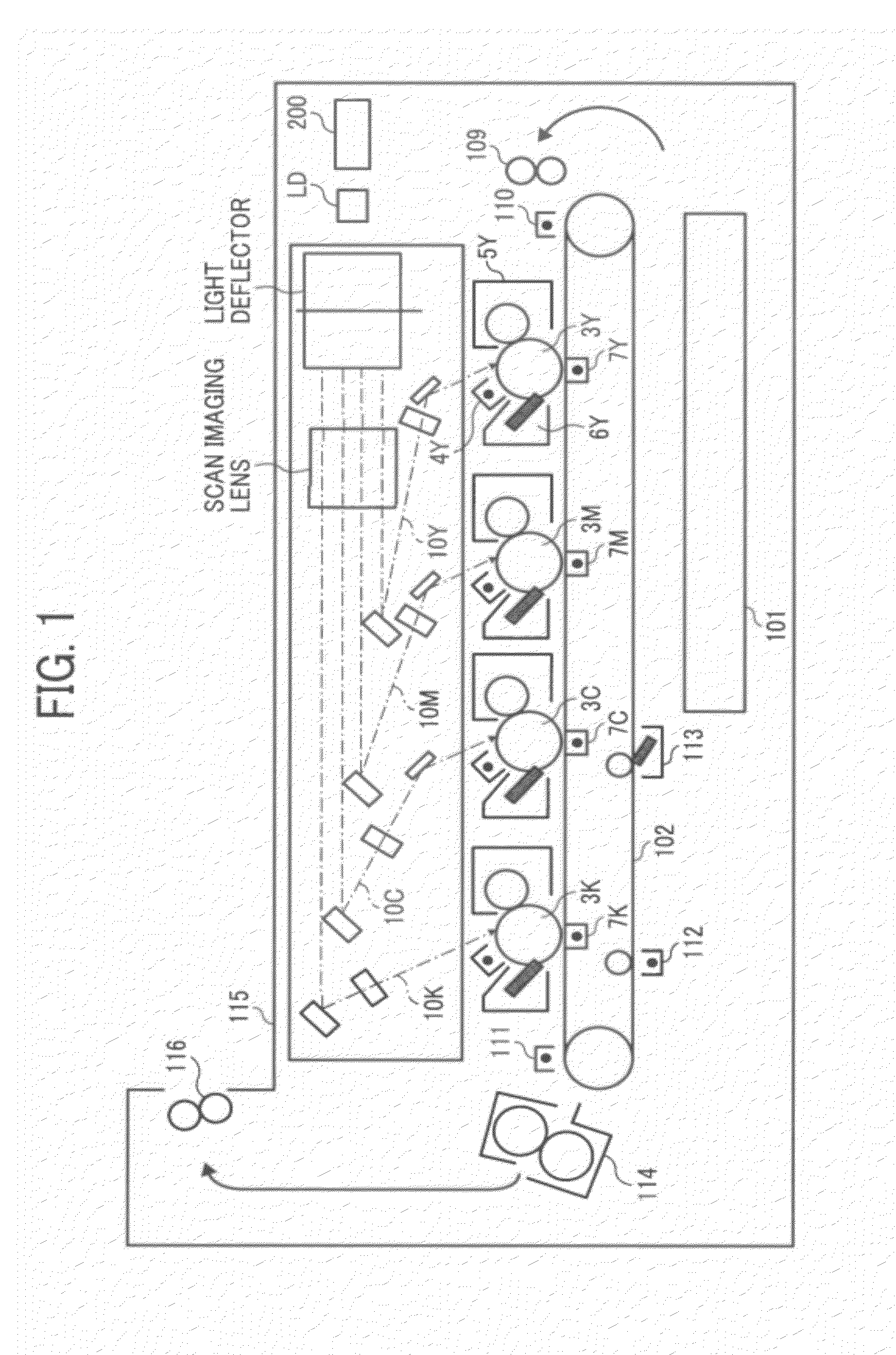

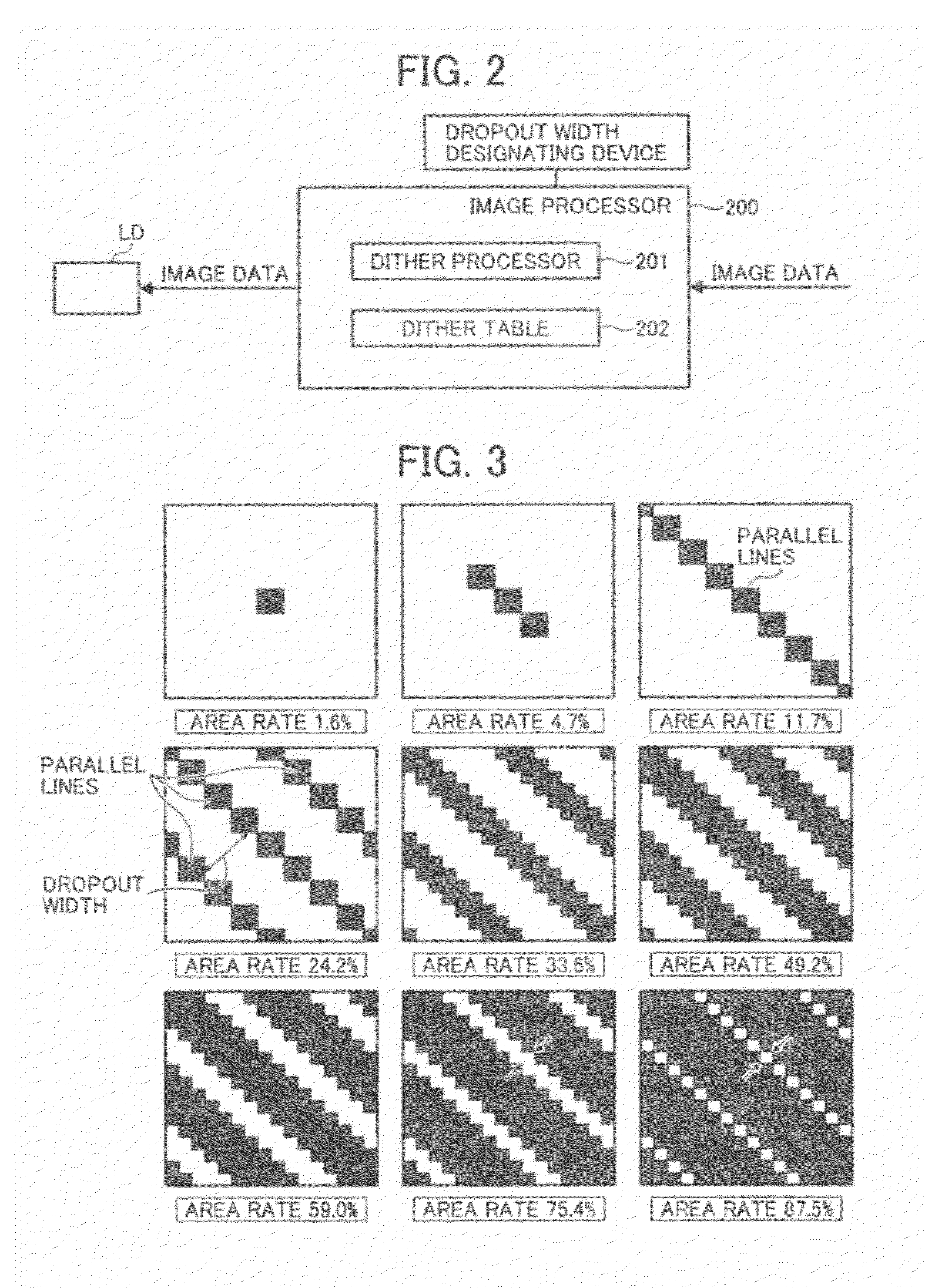

Image processing apparatus, control method, and computer program product capable of minimizing cross-linkage between line screens

InactiveUS20120120454A1Avoid crosslinkingReduce in quantityVisual presentationElectrographic process apparatusPattern recognitionImaging processing

An image processing apparatus comprises a dither processing device that applies dither processing to input image data to express halftone using line screens by increasing an area rate of the input image data and a controller that decreases the number of line screens and maintains a prescribed dropout width between the neighboring line screens when the area rate of the input image data increases and the dropout width falls below a prescribed level.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com