Patents

Literature

148 results about "Injection test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

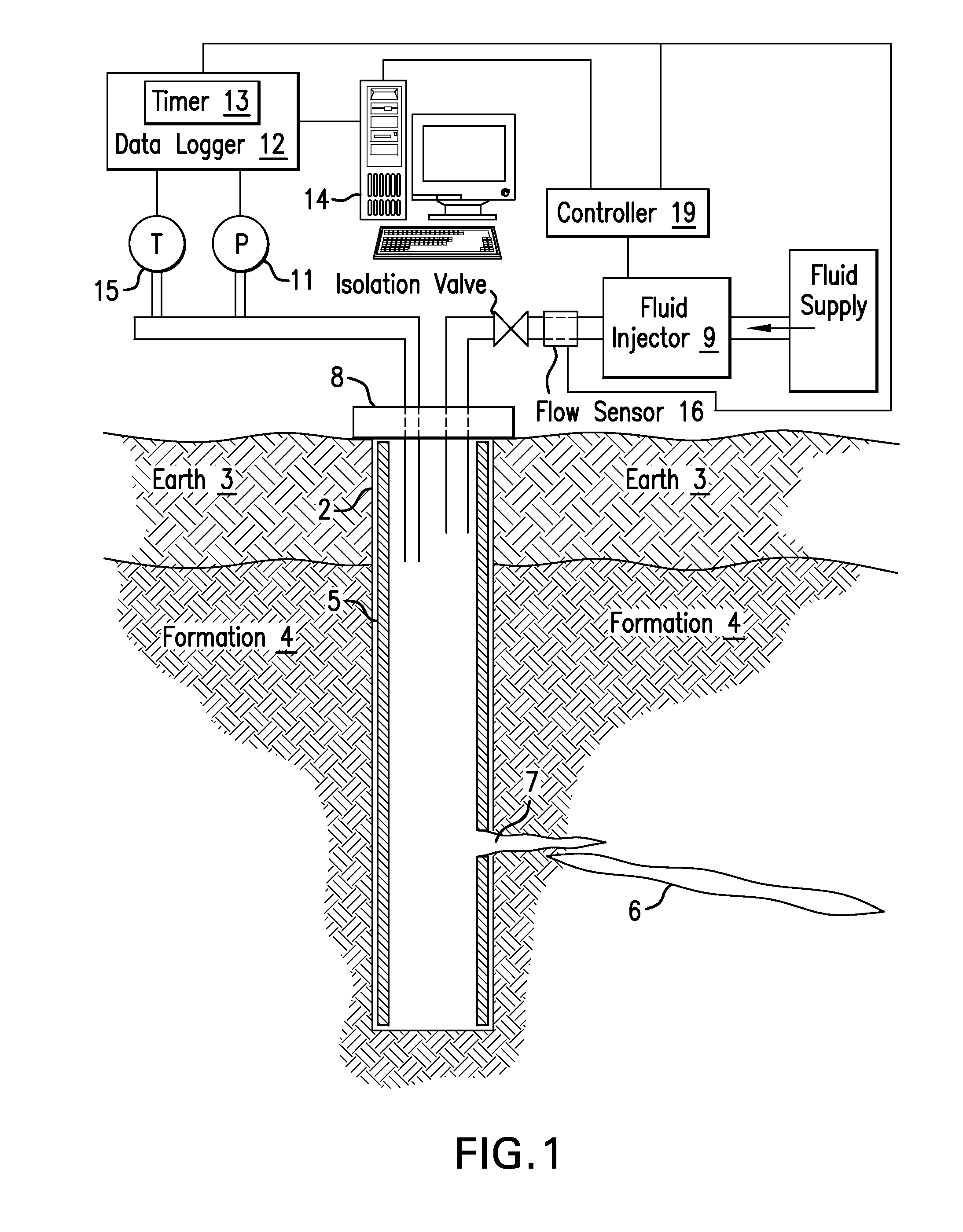

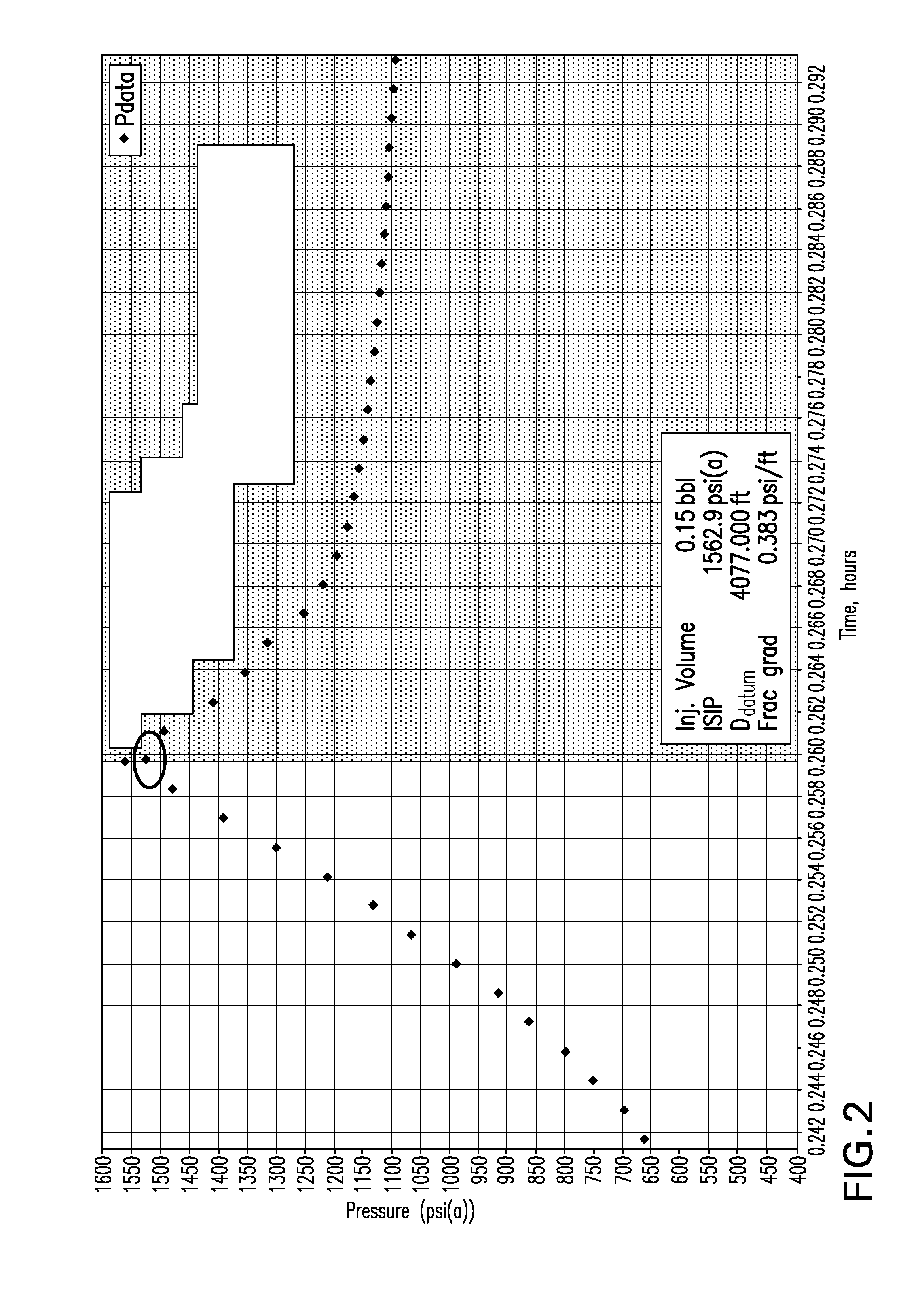

Method and an apparatus for detecting fracture with significant residual width from previous treatments

ActiveUS20050222852A1Rapid determinationElectric/magnetic detection for well-loggingSurveyDual unitMedicine

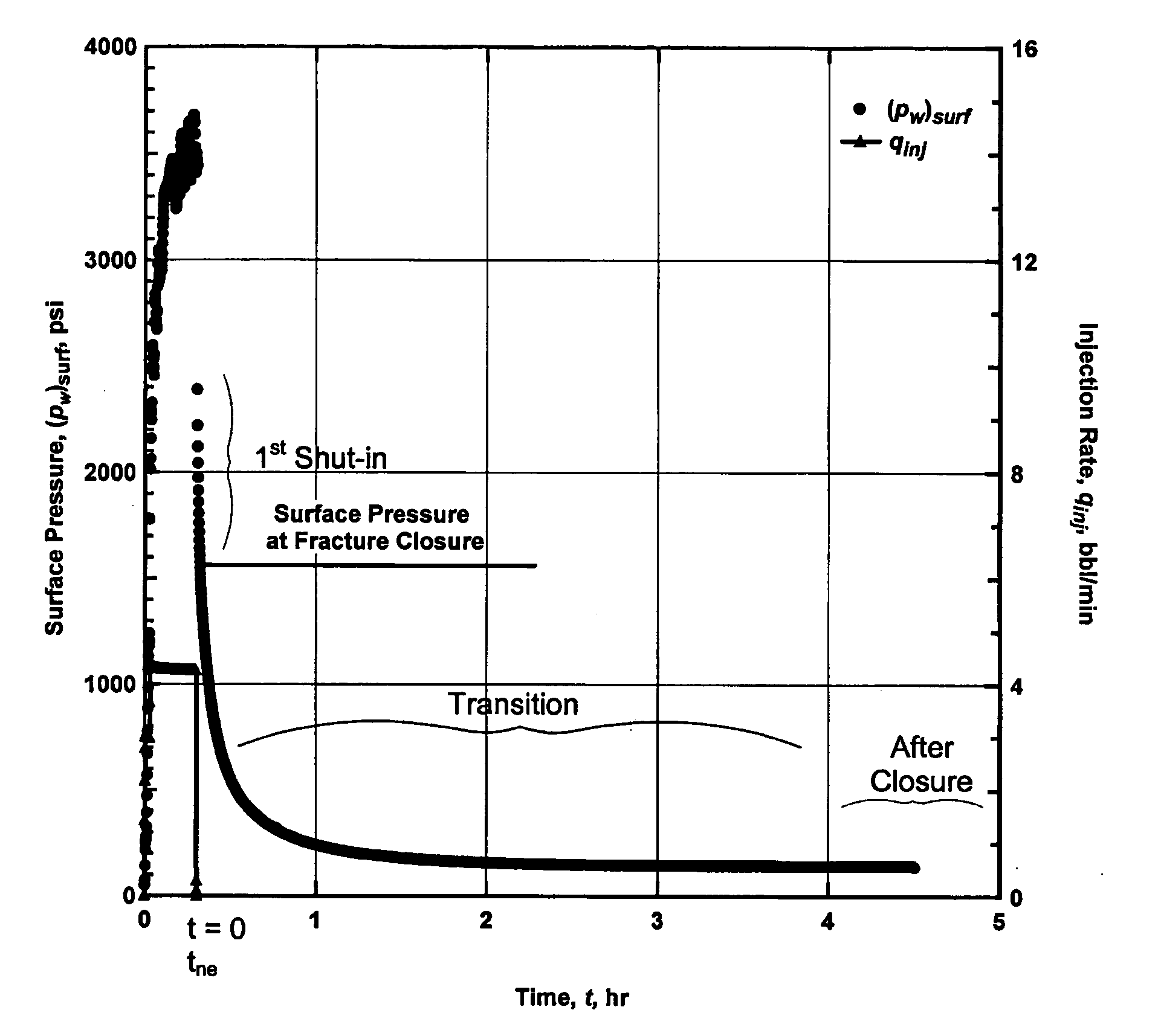

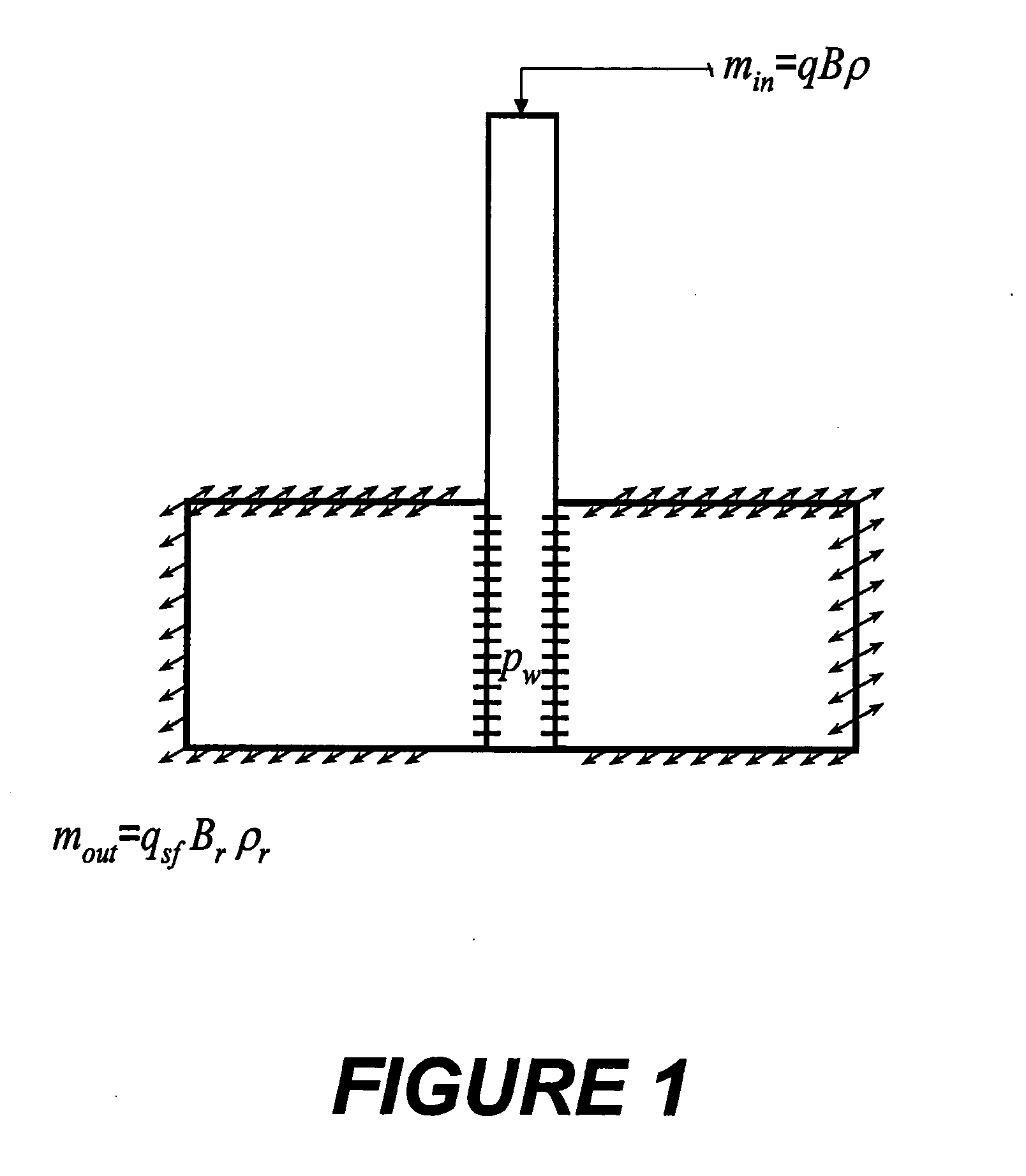

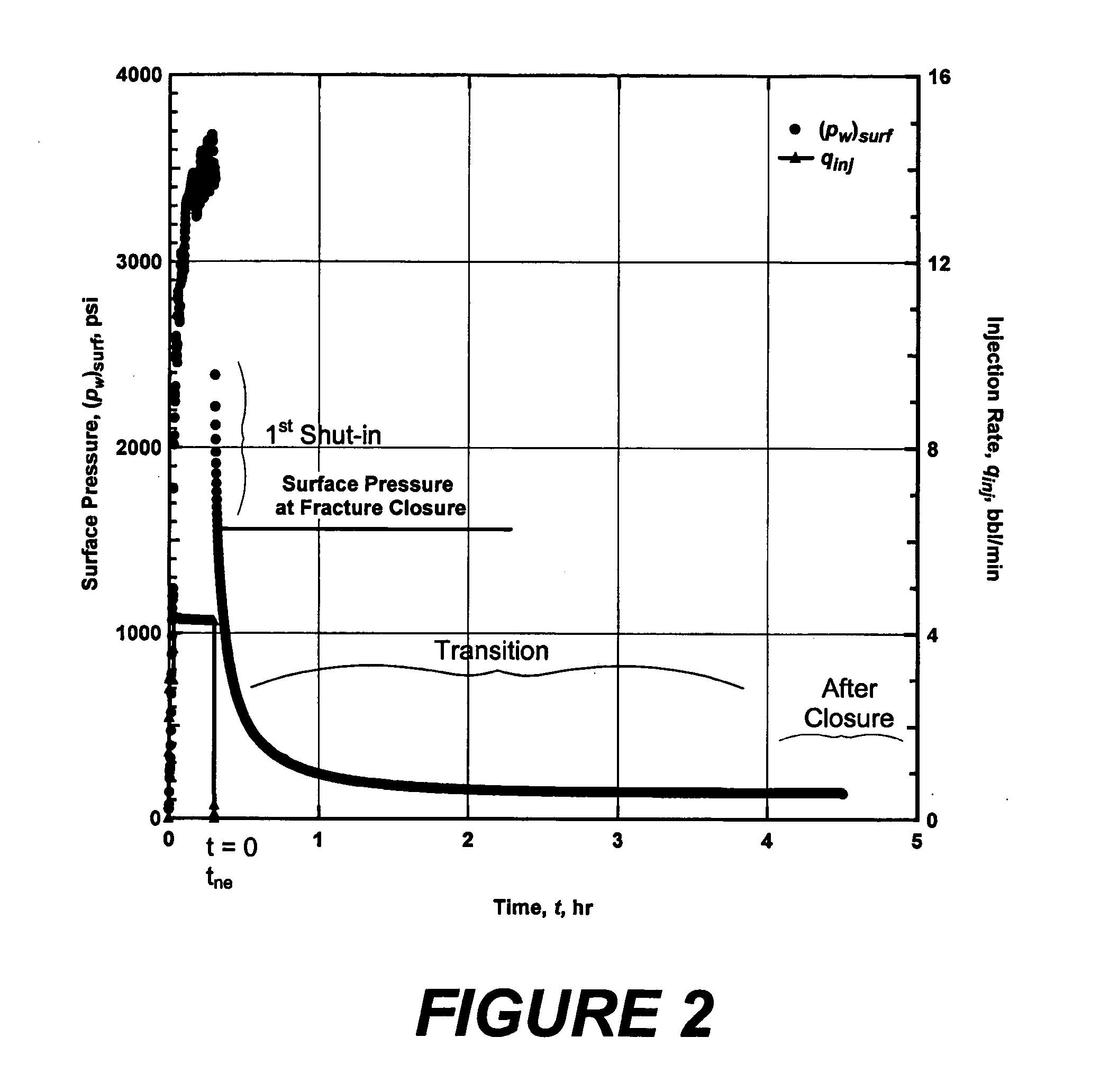

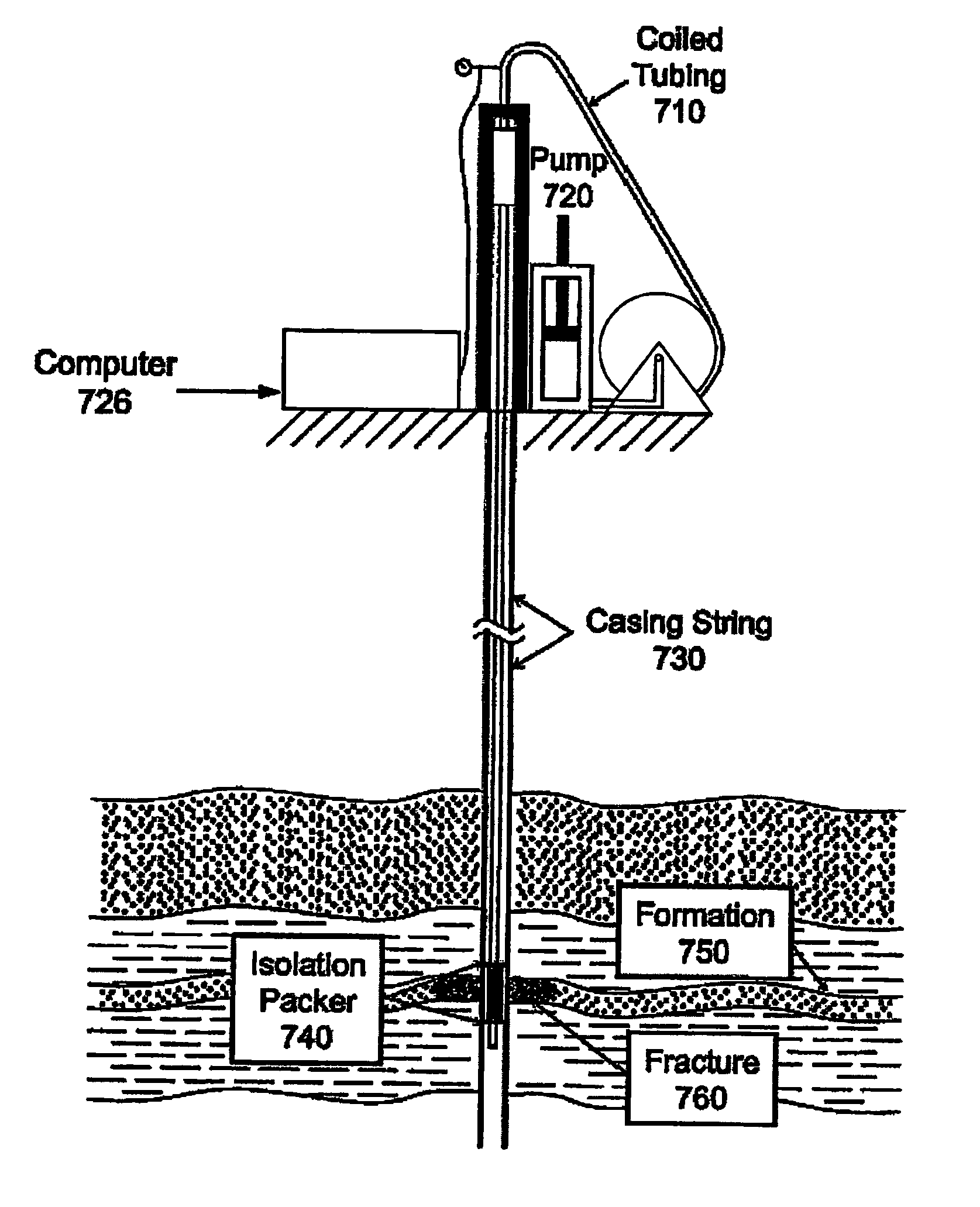

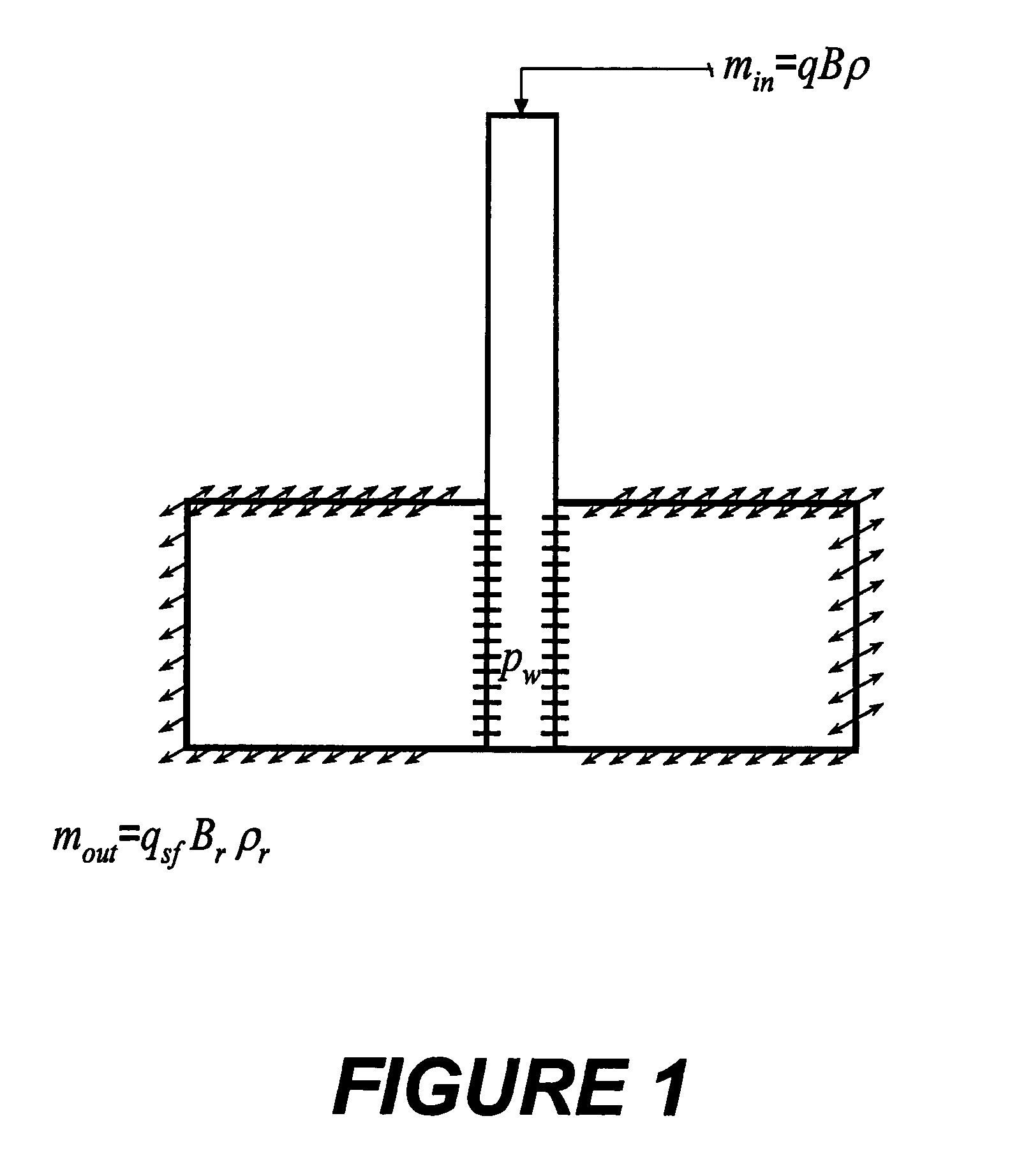

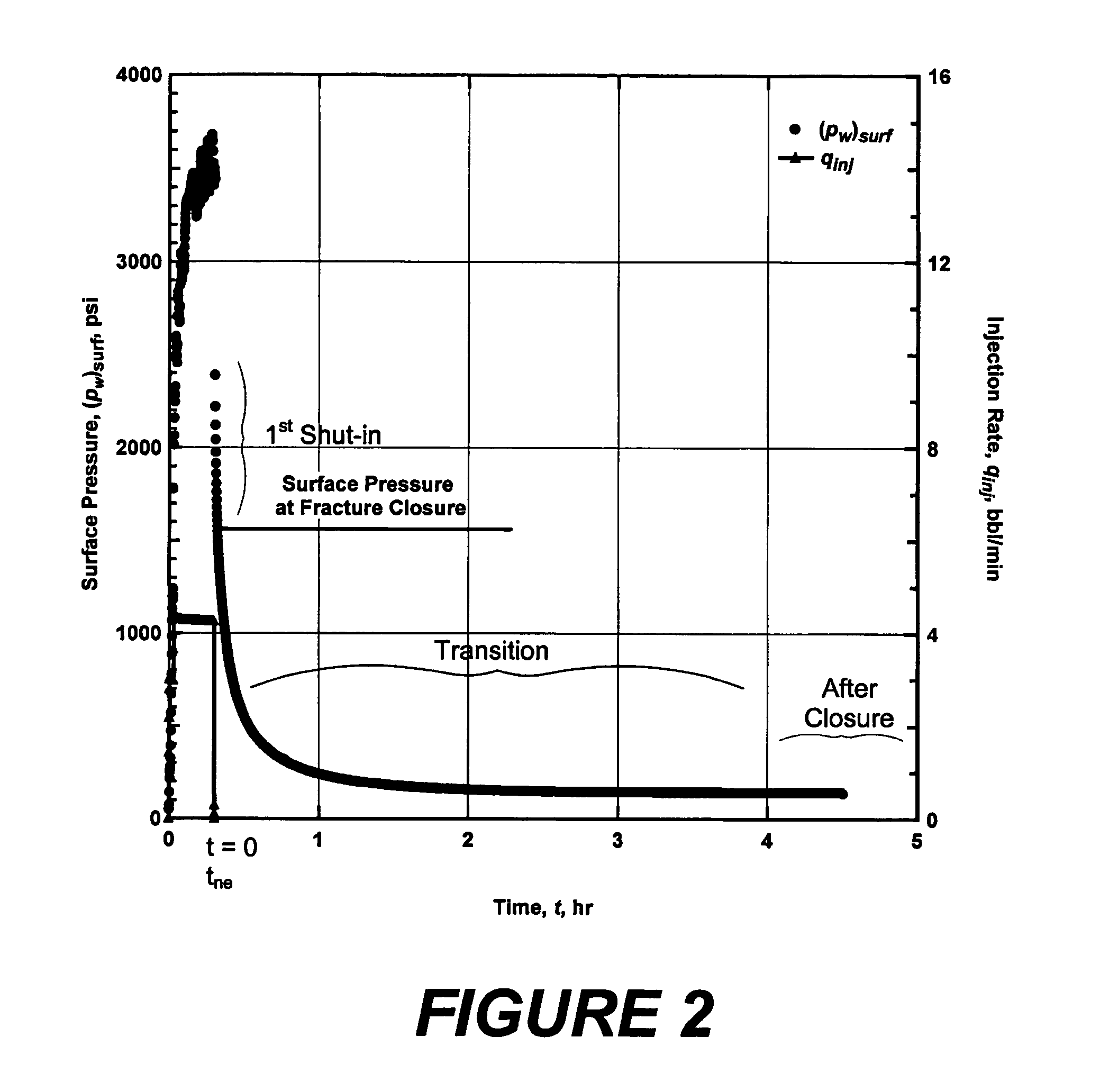

A refracture-candidate diagnostic test is an injection of compressible or slightly compressible fluid such as liquid, gas, or combination at pressures in excess of minimum in-situ stress and formation fracture pressure with pressure decline following injection test recorded to detect a fracture retaining residual width from previous stimulation treatments. The diagnostic consists of small volume injections with injection time being a small fraction of time required for compressible or slightly compressible reservoir fluid to exhibit pseudoradial flow. The fracture-injection portion of a test can be considered as occurring instantaneously, and the results obtained in an open infinite-conductivity hydraulic fracture with pressures above fracture closure stress during before-closure portion of pressure falloff and with pressures less than fracture closure stress during after-closure portion of pressure falloff. Data measurements are transformed into a constant rate equivalent pressure transformation to obtain adjusted pressures or adjusted pseudovariables which are analyzed to identify dual unit-slope before and after closure periods confirming a residual retaining width.

Owner:HALLIBURTON ENERGY SERVICES INC

Method for determining in situ injection repair diffusion radiuses of contaminated soil and underground water

ActiveCN105973759ASolve the problem of back slurryEasy to operateConstructionsContaminated soil reclamationHigh pressureInjection test

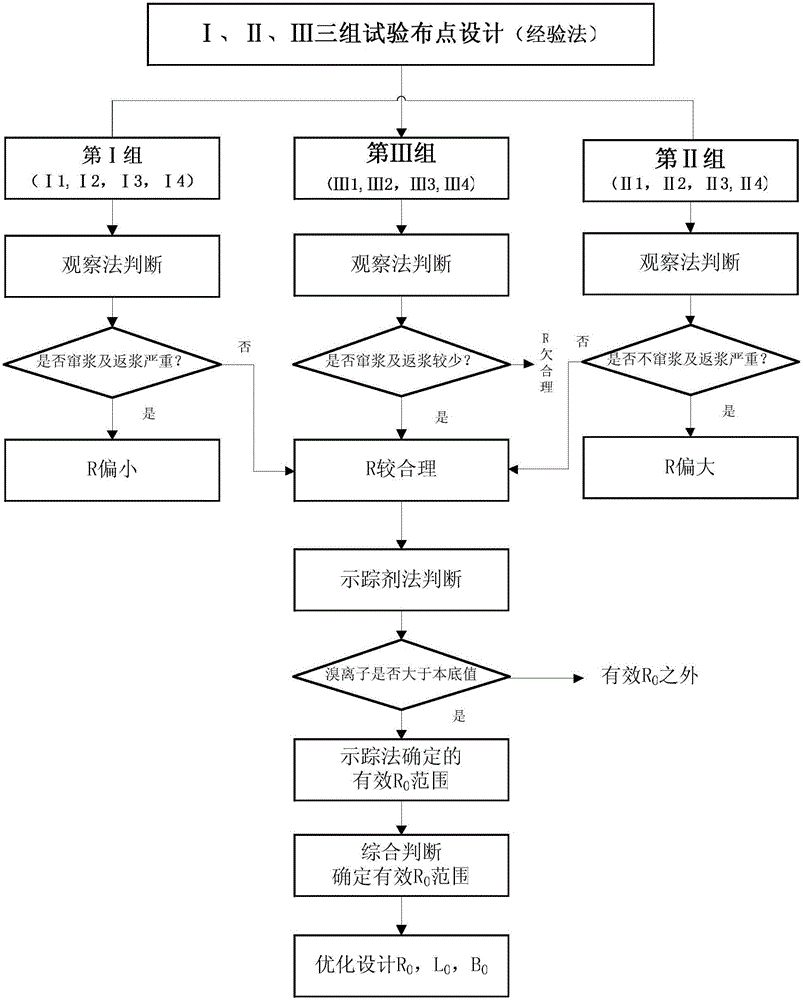

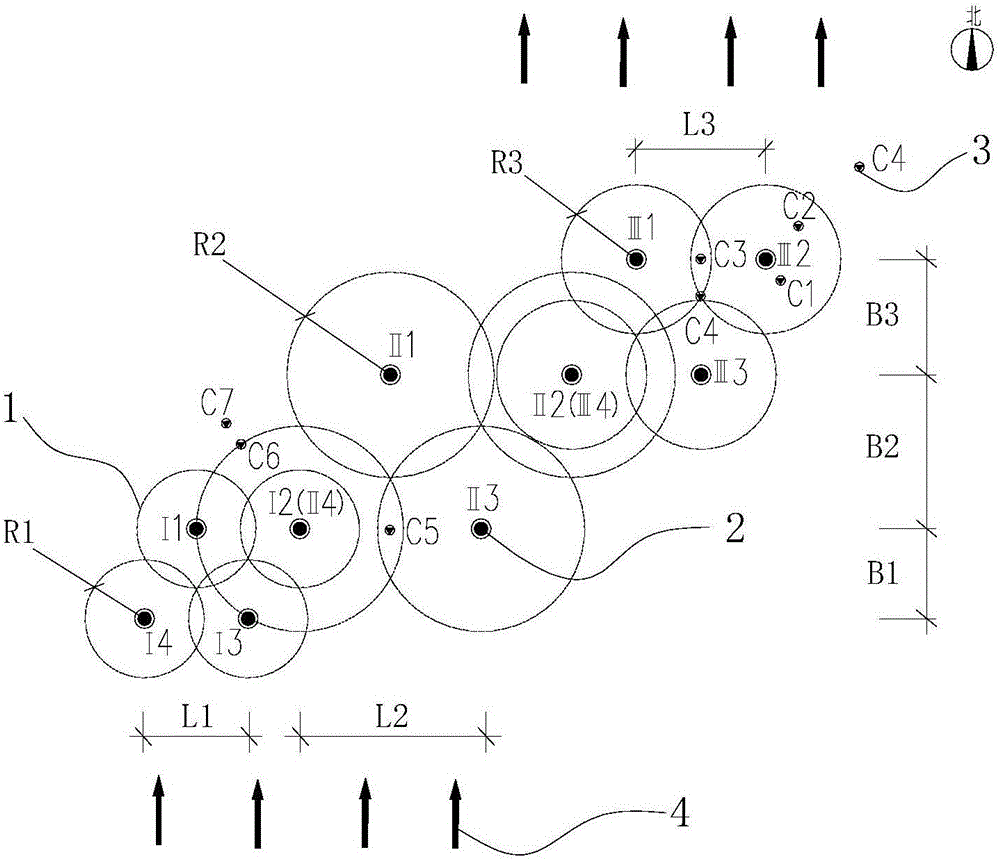

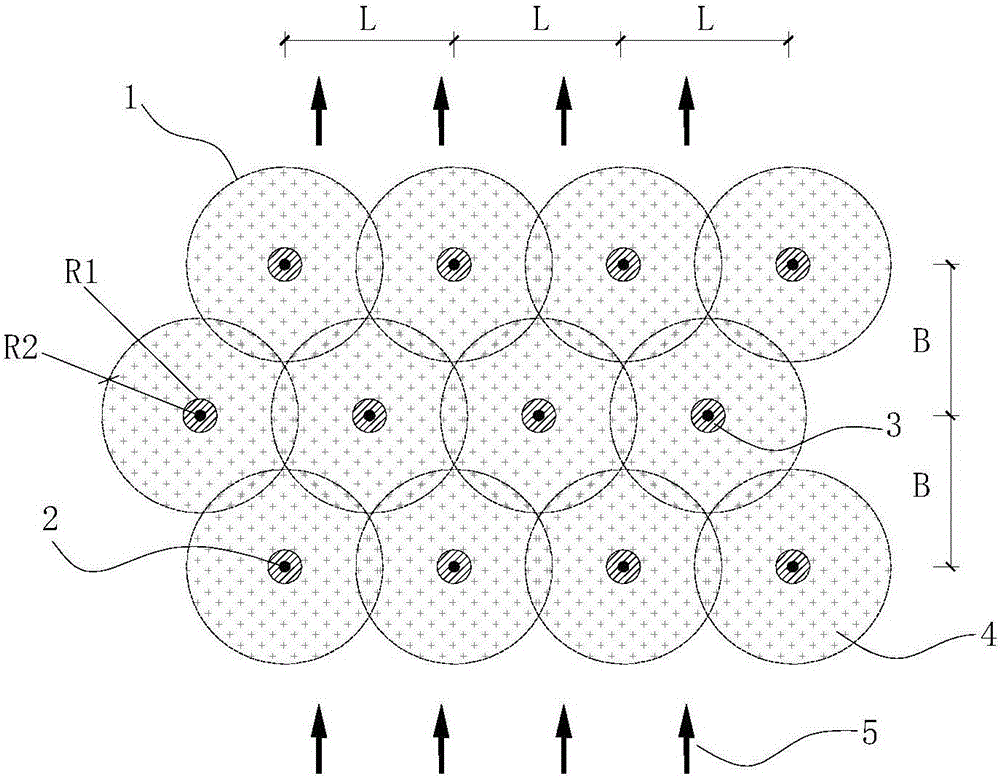

The invention discloses a method for determining in situ injection repair diffusion radiuses of contaminated soil and underground water. According to the method, points are distributed according to a triangle method, pitch-row is designed to be perpendicular to the flowing direction of the underground water, array pitch is in the flowing direction of the underground water, and the flow expansion of a repair reagent in the underground water within the reaction effective time is taken into account. The method comprises three steps: firstly, observation method: the repair reagent and a definite proportion of bromide ion serving as tracers are simultaneously injected into an aqueous stratum in the condition of high pressure whirl spraying injection. The diffusion of the reagent is judged by observing the phenomena of grout return and grout leaking between adjacent injection points; secondly, bromide ion tracer method: after the completion of injection, underground water depth setting rapid sampling is performed, the concentration of the tracers is rapidly detected in field, and the concentration of the bromide ion in the underground water is compared with a background value; thirdly, bromide ion tracer method and observation method: the optimum diffusion radiuses are determined through synthetic judgment. The method is applied to optimal design of diffusion radiuses and hole arrangement parameters and monitoring of injection effect in soil and underground water in situ injection tests and repair construction.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

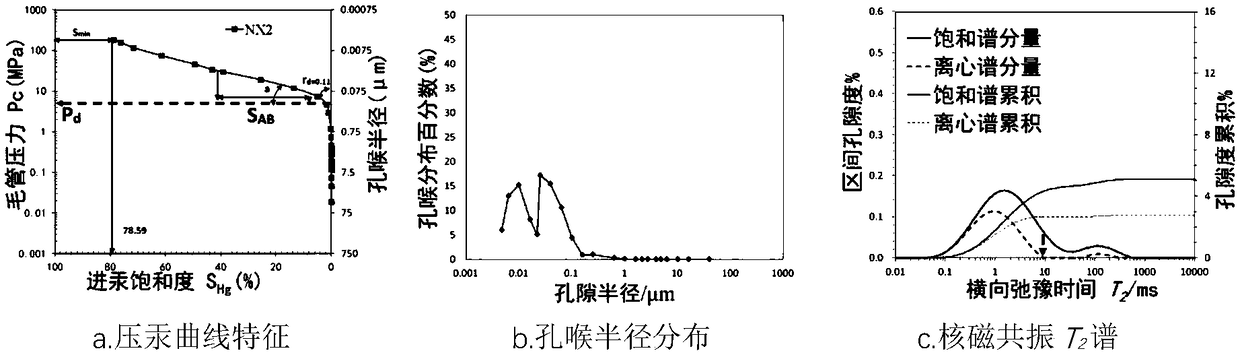

Blasting damaged rock sample preparation and micro-macro combined damage degree determination method

InactiveCN104949868AEasy to operateThe test data is reliableAnalysing solids using sonic/ultrasonic/infrasonic wavesPreparing sample for investigationDetonatorOsmotic coefficient

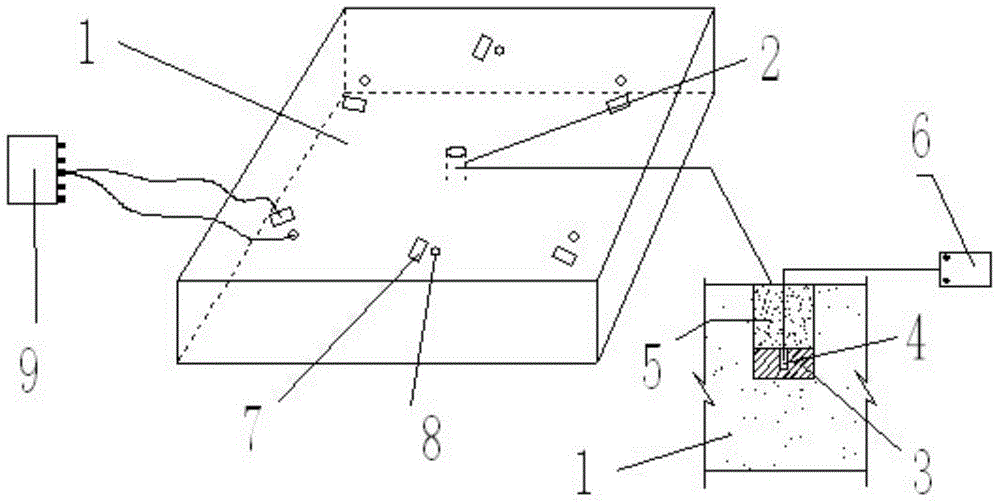

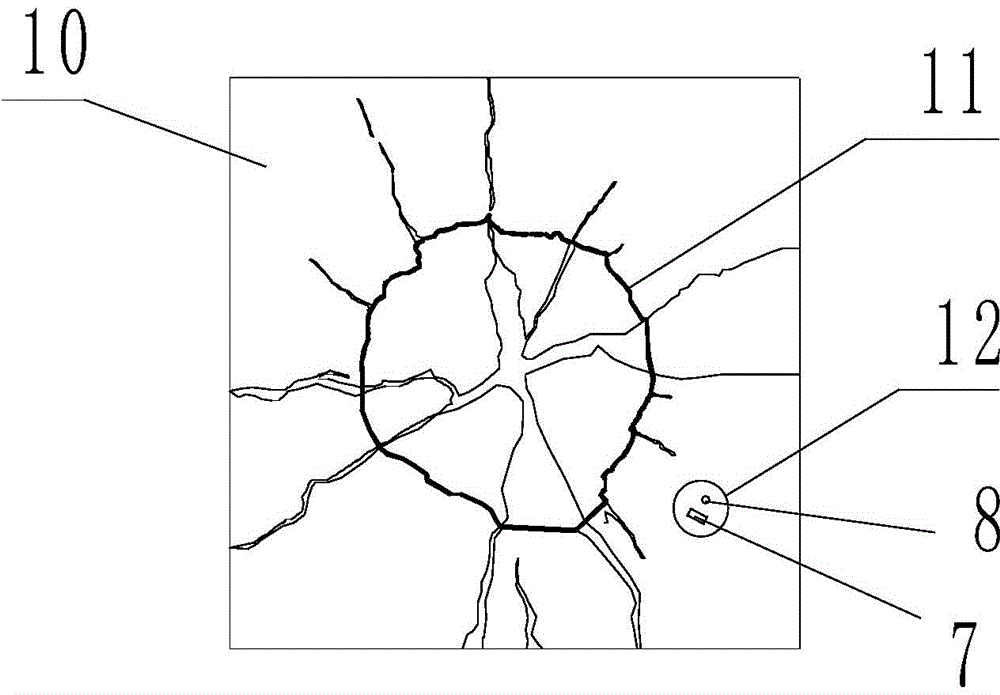

The invention discloses blasting damaged rock sample preparation and a micro-macro combined damage degree determination method, and belongs to a determination method for a damage degree of a damaged rock sample. The micro-macro combined damage degree determination method comprises the following steps: a, manufacturing a square rock with thickness of 105mm, putting an explosive and a detonator at the geometric center of the rock, adhering resistance strain gauges and acceleration sensors at key points of the rock, and connecting the resistance strain gauges and the acceleration sensors to a super dynamic data acquisition instrument; b, drilling the rock with large blasting fragment size with the key points as circle centers along the thickness direction, polishing standard rock samples, and collecting small irregular rocks; c, performing a mercury injection test on the irregular rocks, and performing CT, nuclear magnetic resonance, longitudinal wave velocity, osmotic coefficient, elasticity modulus and uniaxial compressive strength tests on the blasting damaged standard rock samples; e, performing identical micro-macro tests on homogeneous complete rock samples; and f, based on dynamic strains and acceleration waveforms, quantitatively determining the degree of damage, caused by blasting impact, to a rock material by synthesizing micro-macro test data. The determination method has the advantages of simplicity in operation and comprehensive and reliable test data.

Owner:CHINA UNIV OF MINING & TECH

Method and an apparatus for detecting fracture with significant residual width from previous treatments

ActiveUS7774140B2Rapid determinationElectric/magnetic detection for well-loggingSurveyDual unitReservoir fluid

Owner:HALLIBURTON ENERGY SERVICES INC

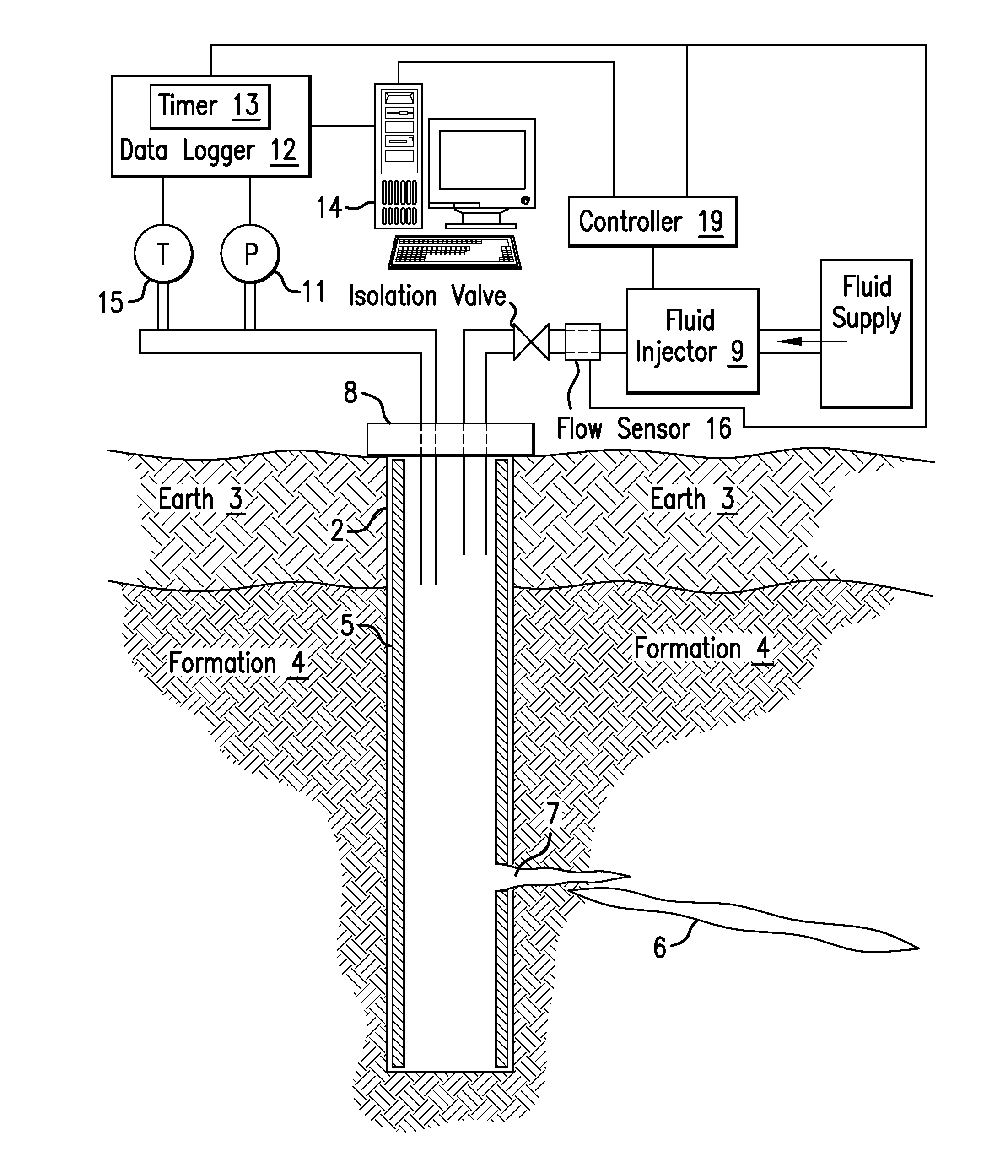

Natural fracture injection test

A method for estimating a property of an earth formation penetrated by a borehole includes: performing a borehole integrity test at a pressure less than a fracture gradient pressure of the formation to provide leakage data; injecting a fluid into the formation at a first pressure greater than the fracture gradient pressure during a first injection time interval using a fluid injector; measuring pressure versus time using a pressure sensor and a timer during a first test time interval to provide first pressure data; injecting a fluid into the formation at a second flow rate greater than the first flow rate during a second injection time interval using the fluid injector; measuring pressure versus time using the pressure sensor and the timer during a second test time interval to provide second pressure data; and estimating the property using the first pressure data, the second pressure data, and the leakage data.

Owner:BAKER HUGHES INC

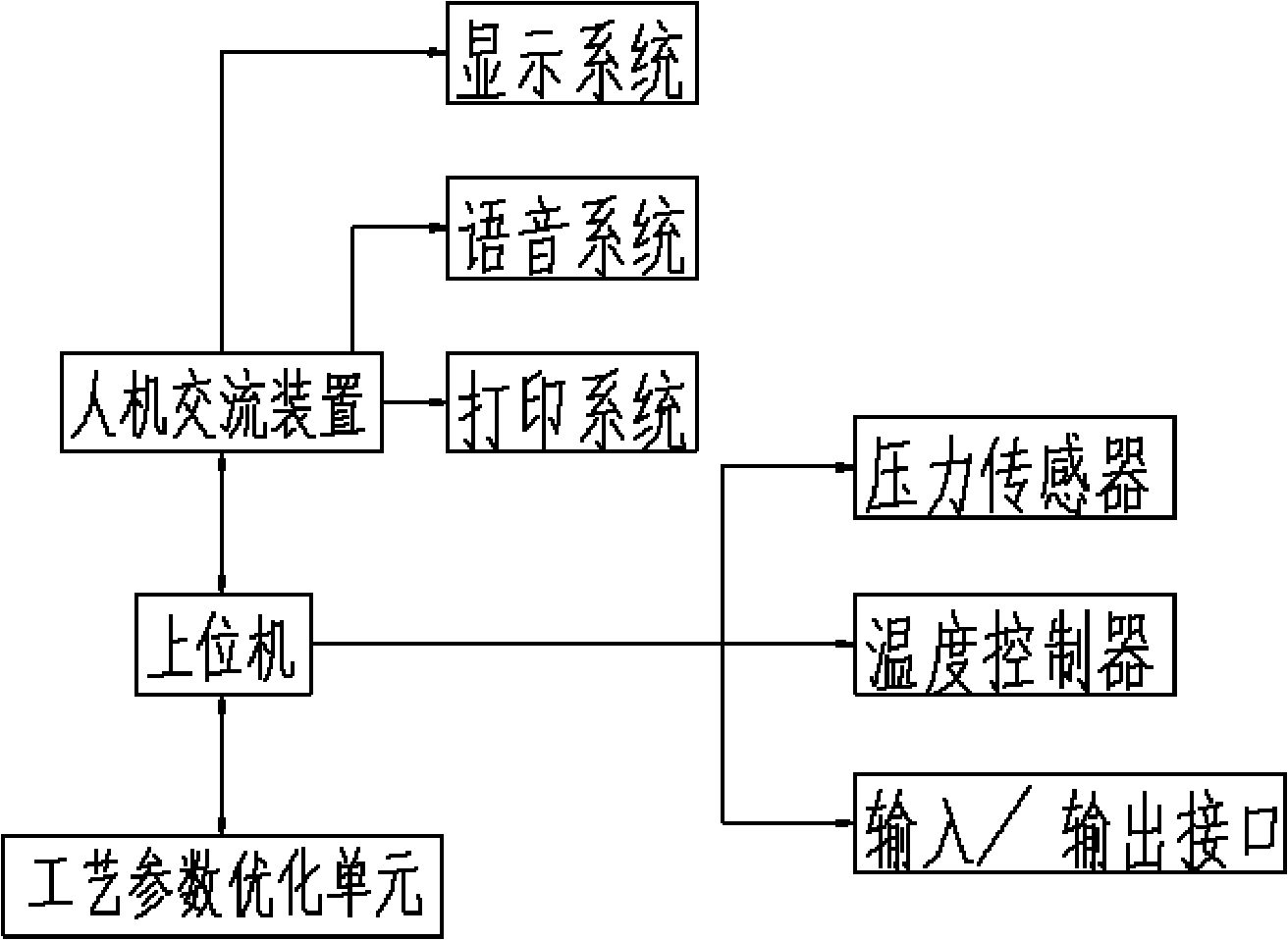

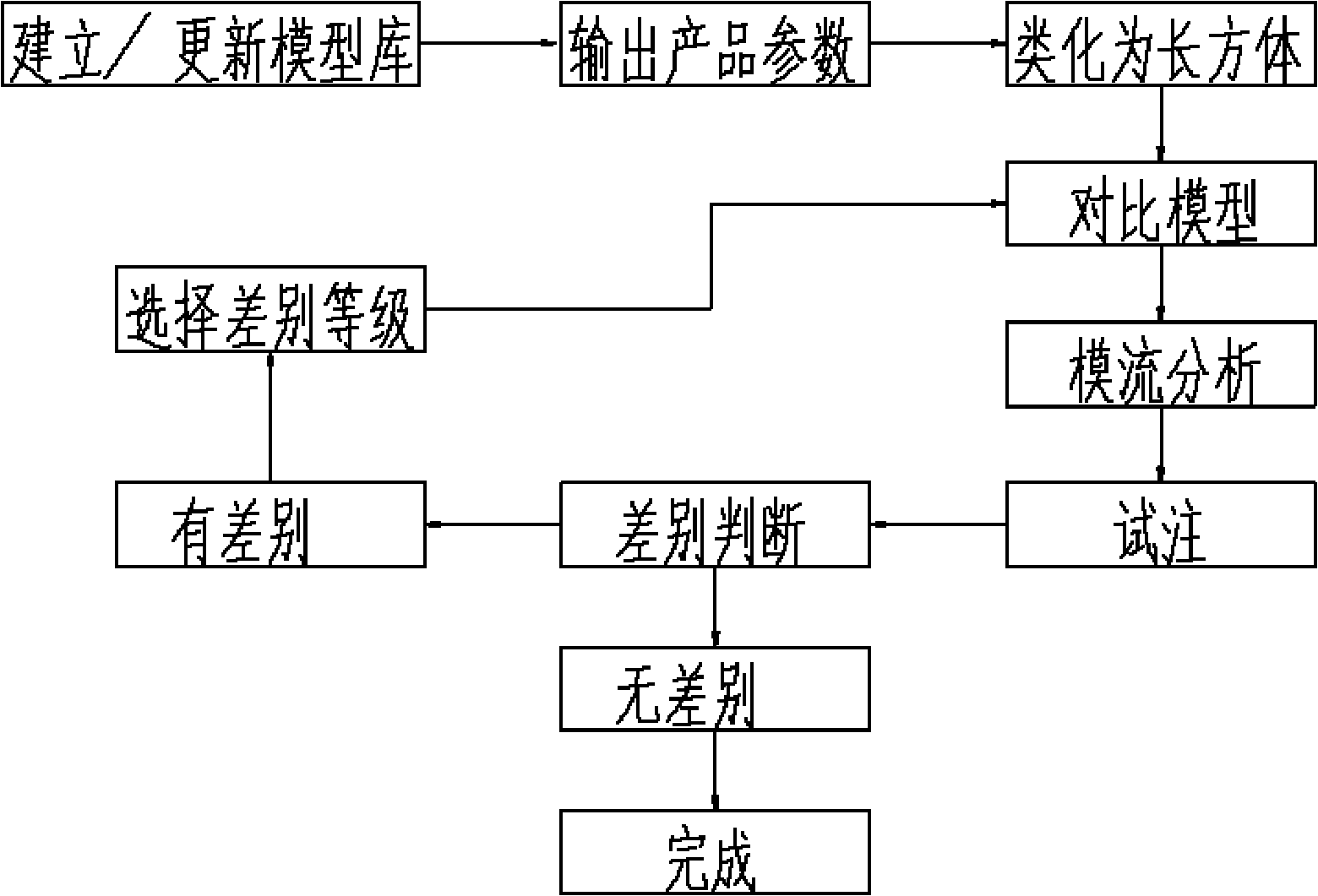

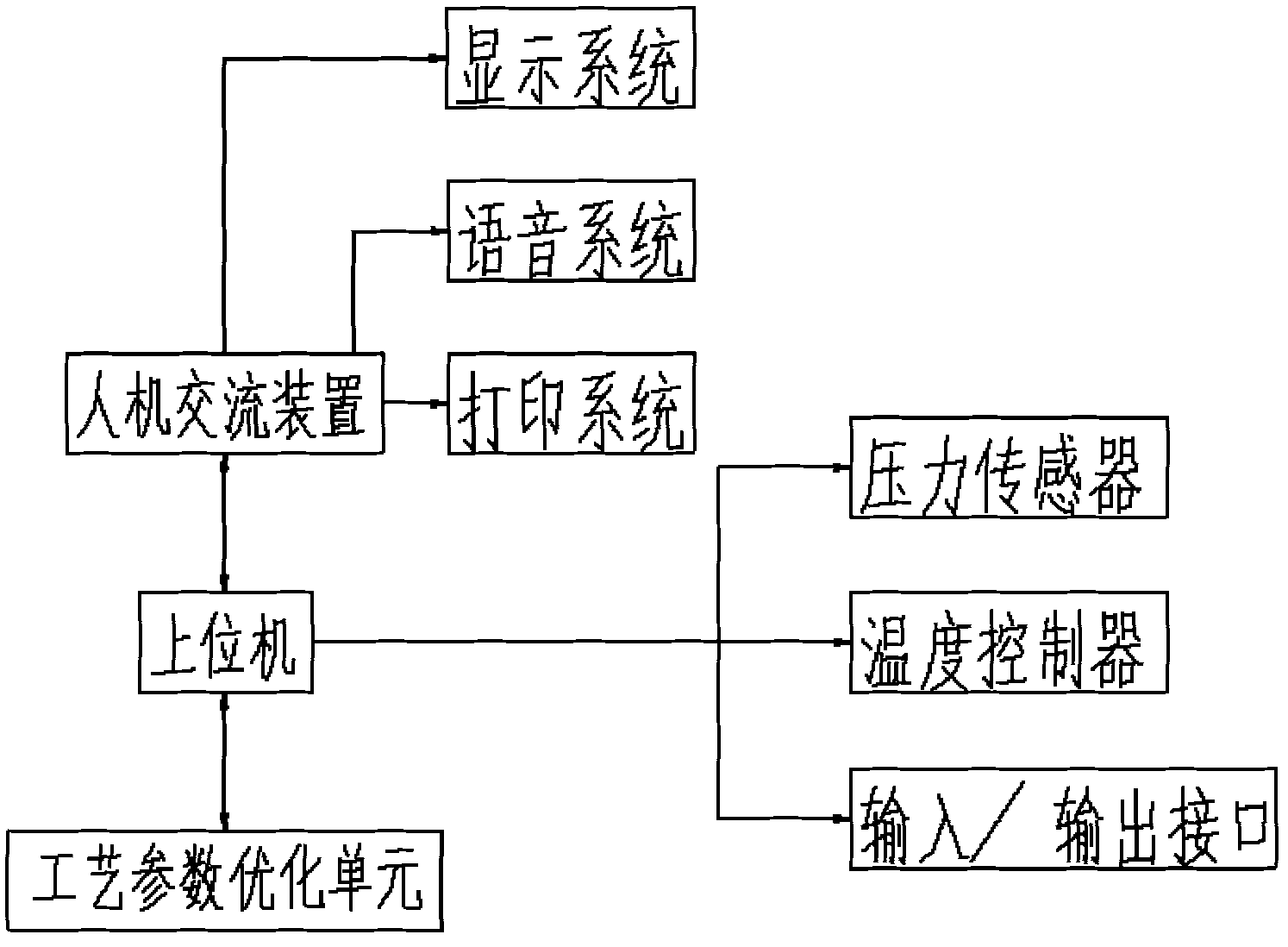

Automatic technological parameter-optimizing injection molding machine control system and control method thereof

The invention relates to an automatic technological parameter-optimizing injection molding machine control system and a control method thereof. The control system comprises an upper computer and a human-machine intercommunication device, and is characterized in that the upper computer is provided with a technological parameter optimization unit, a model library is arranged in the technological parameter optimization unit, and the upper computer is respectively connected with a pressure sensor, a temperature sensor and an input / output interface. The upper computer has data processing and storage functions, the human-machine intercommunication device can provide the functions and parameters of the system to an operator, and the operator can use the human-machine intercommunication device toinput a corresponding instruction. The function of the model library is to store the parameters of a large quantity of models in the form of data. By comparing the parameters of an actual product with the parameters of a model, processing data can be obtained, consequently, the technological parameters of an injection-molded product can be accurately and efficiently determined, and moreover, the frequency of injection test can be reduced.

Owner:NINGBO TECHMATION

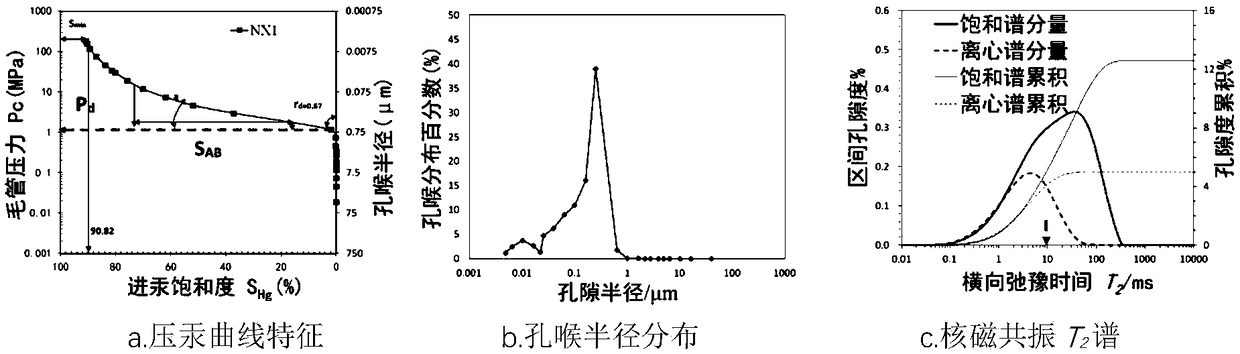

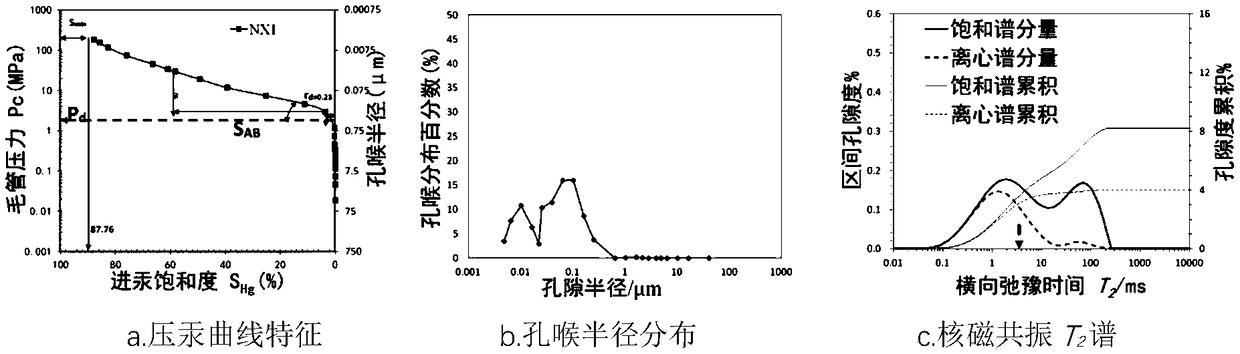

Pore structure classification and recognition method based on magnetic resonance imaging T2 spectrum sensitive parameters

ActiveCN109030311AObvious right-skewed spectrumPermeability/surface area analysisElectric/magnetic detectionNMR - Nuclear magnetic resonanceRock core

The invention discloses a pore structure classification and recognition method based on magnetic resonance imaging T2 spectrum sensitive parameters. The method comprises the following steps of S1, preparing a standard rock core sample; S2, separately performing a magnetic resonance imaging test, and physical property and high pressure mercury injection tests; and S3, dividing pore structure categories of laboratory rock samples and dividing magnetic resonance imaging T2 spectrum sensitive parameter standards of the underground reservoir pore structure categories. The method provided by the invention has the advantages that mercury injection, nuclear magnetism and physical property information are synthesized, rock core sample pore structure categories and features can be determined and represented, an underground reservoir pore structure type division plate is made by using the multiple magnetic resonance imaging T2 spectrum sensitive parameters, and the pore structure category and reservoir effectiveness assessment can be performed on the profile of a well.

Owner:SOUTHWEST PETROLEUM UNIV

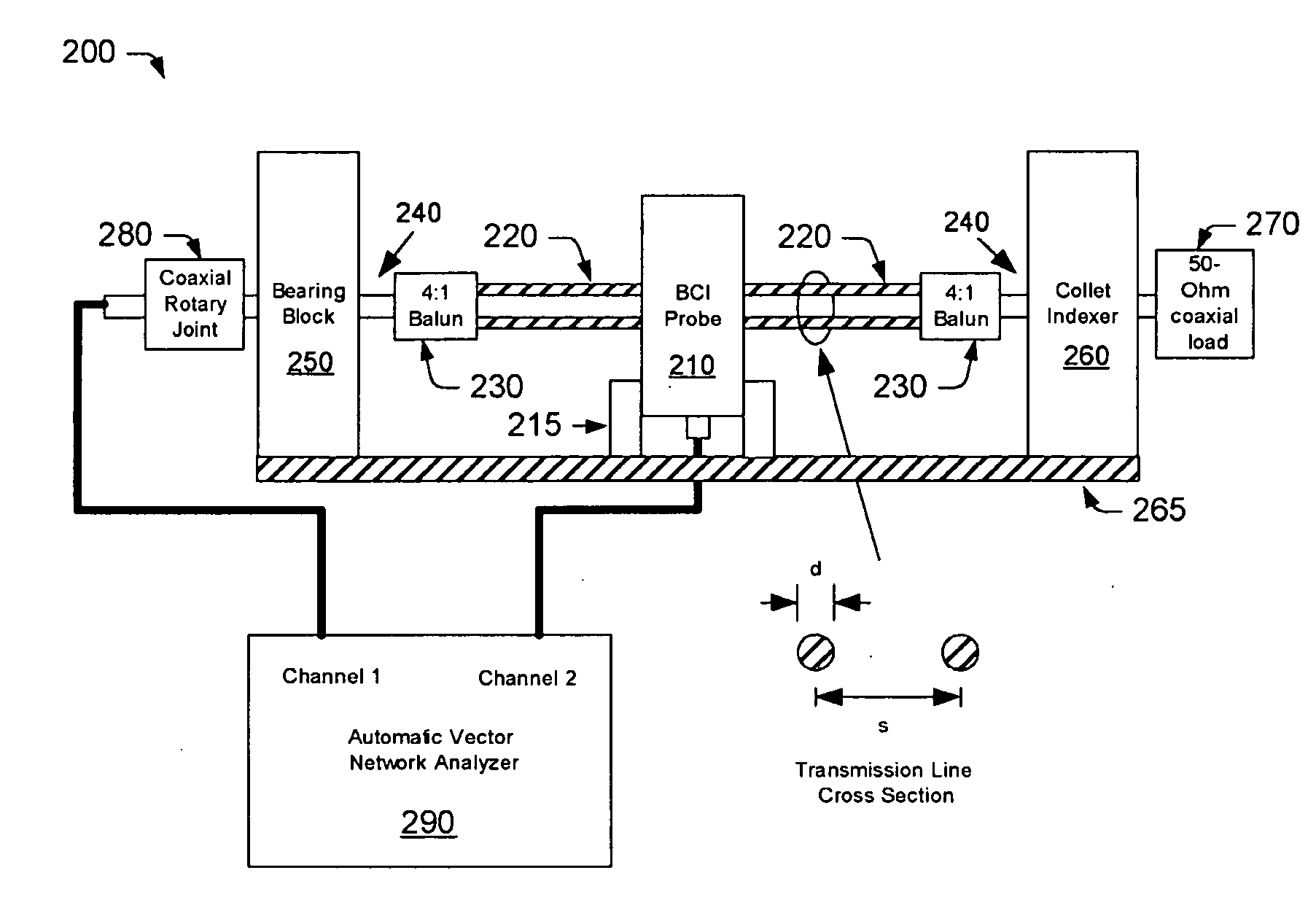

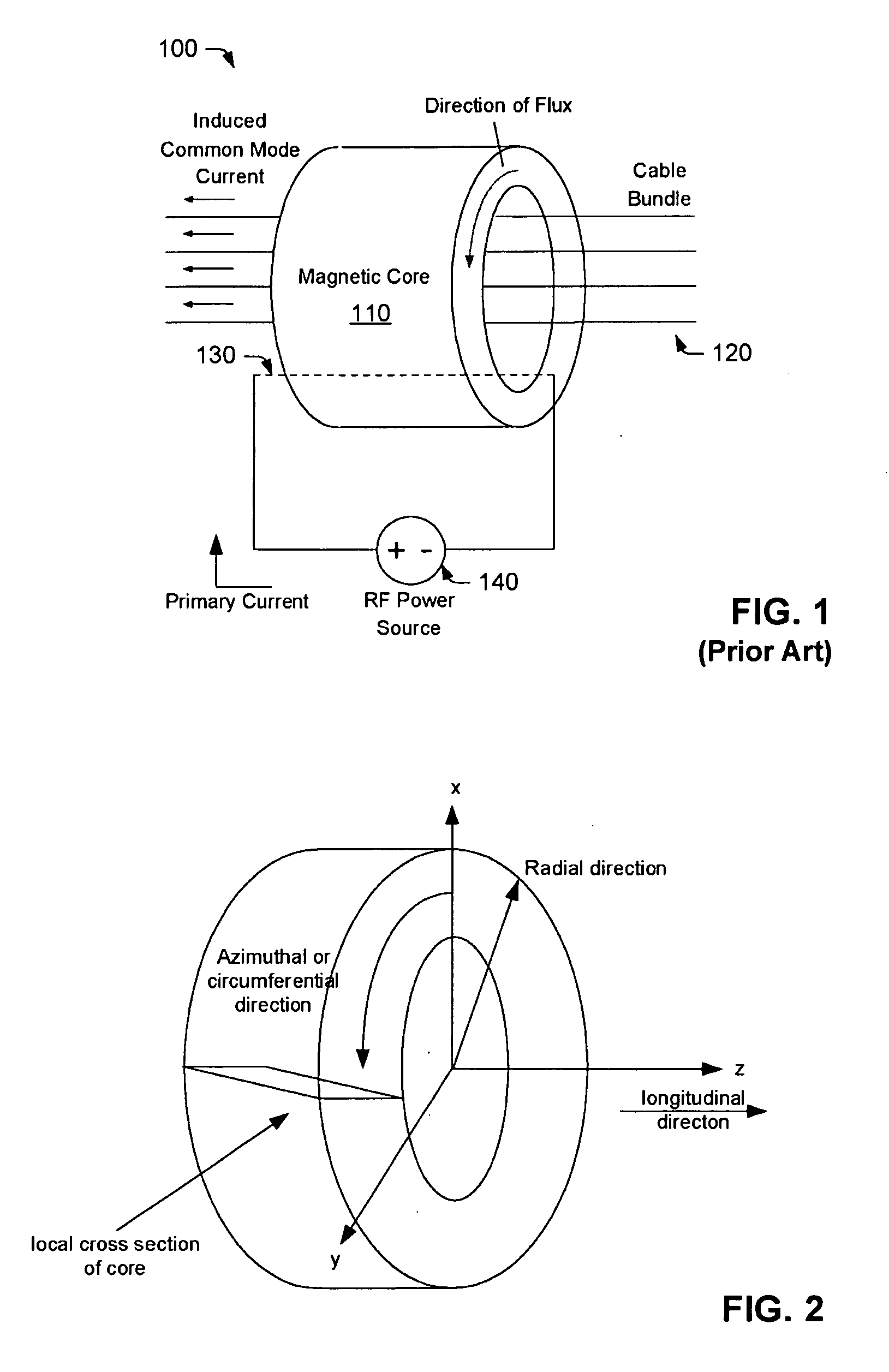

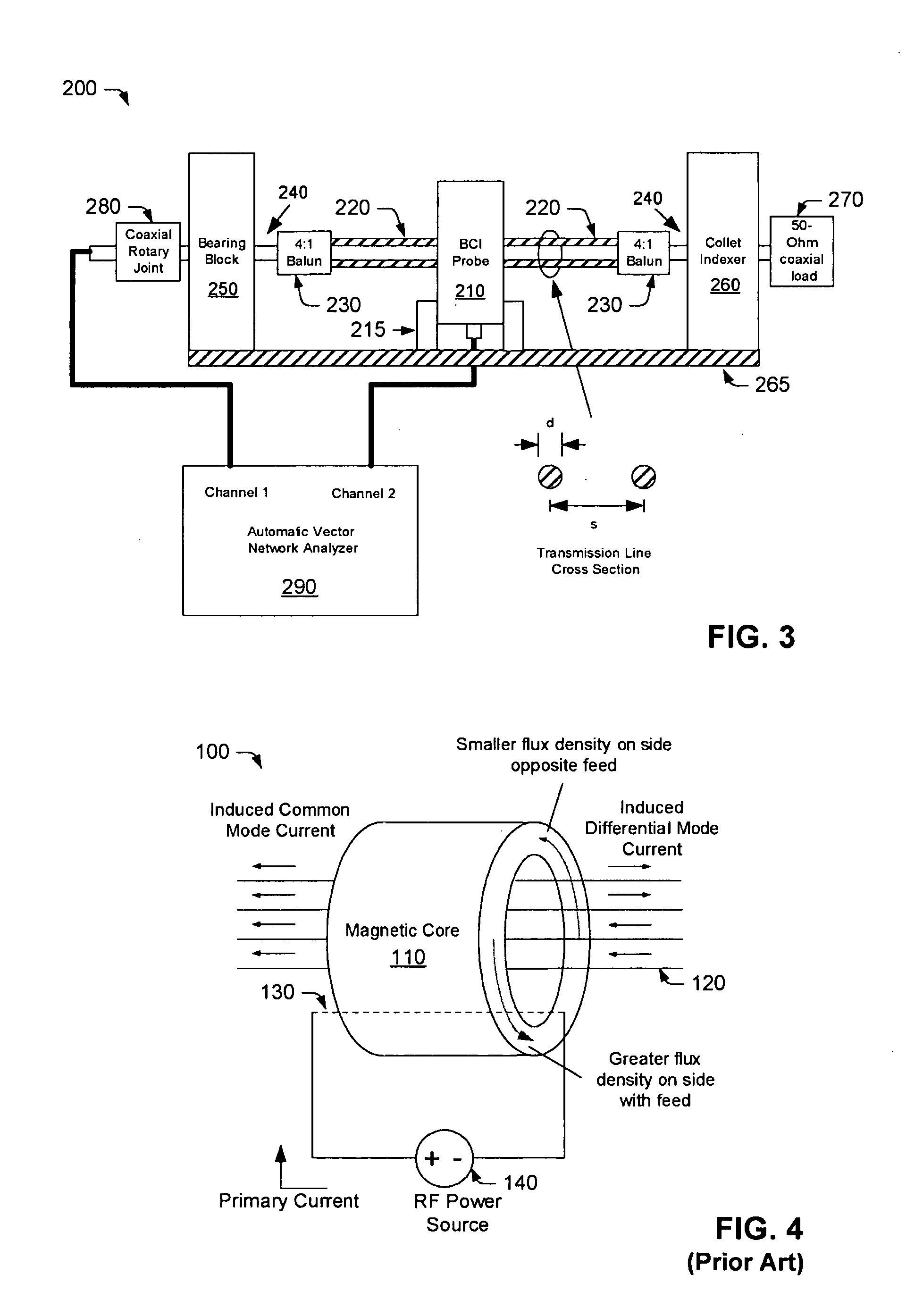

Bulk Current Injection (BCI) Probe with Multiple, Symmetrically Spaced Feeds

ActiveUS20100176817A1Uniform flux densityTransformersResistance/reactance/impedenceElectricityElectrical conductor

A Bulk Current Injection (BCI) transformer is provided herein with a magnetic core and a plurality of windings. The magnetic core is configured for encircling one or more electrical conductors under test. Each of the plurality of windings are wrapped, at least in part, around a longitudinal dimension of the magnetic core and spaced apart around an azimuthal dimension of the magnetic core. During injection tests, a power source may be coupled for supplying current to each of the windings at a respective “feed point.” Arranging multiple feed points around the magnetic core enables current flow through the windings to generate an azimuthally-uniform magnetic flux density in the magnetic core. The uniform magnetic flux density enables the BCI transformer to excite only common mode currents in the electrical conductors under test. BCI test methods, including injection tests and current sensing tests are also provided herein, along with a test setup for characterizing BCI transformers.

Owner:TDK CORPARATION

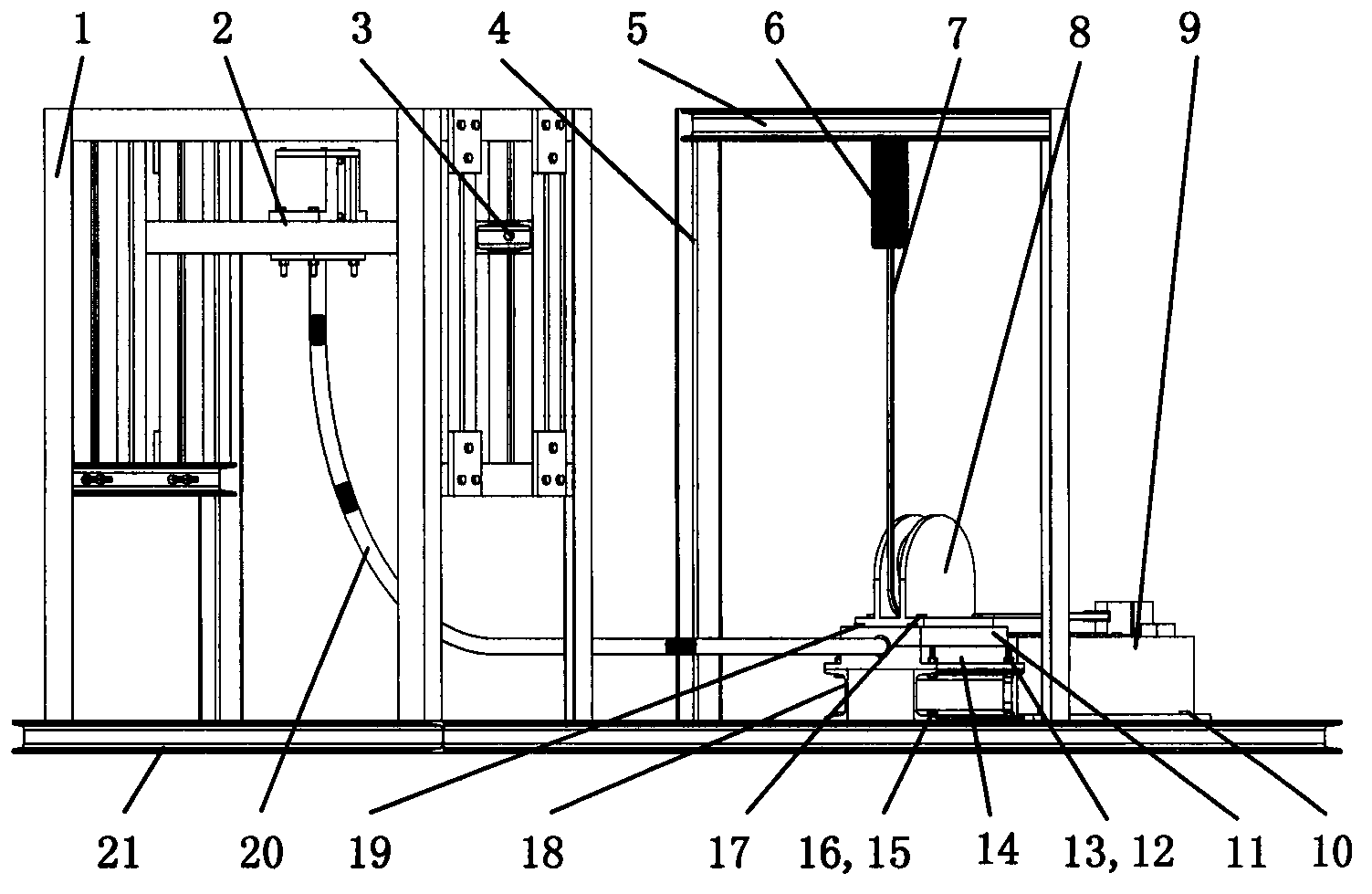

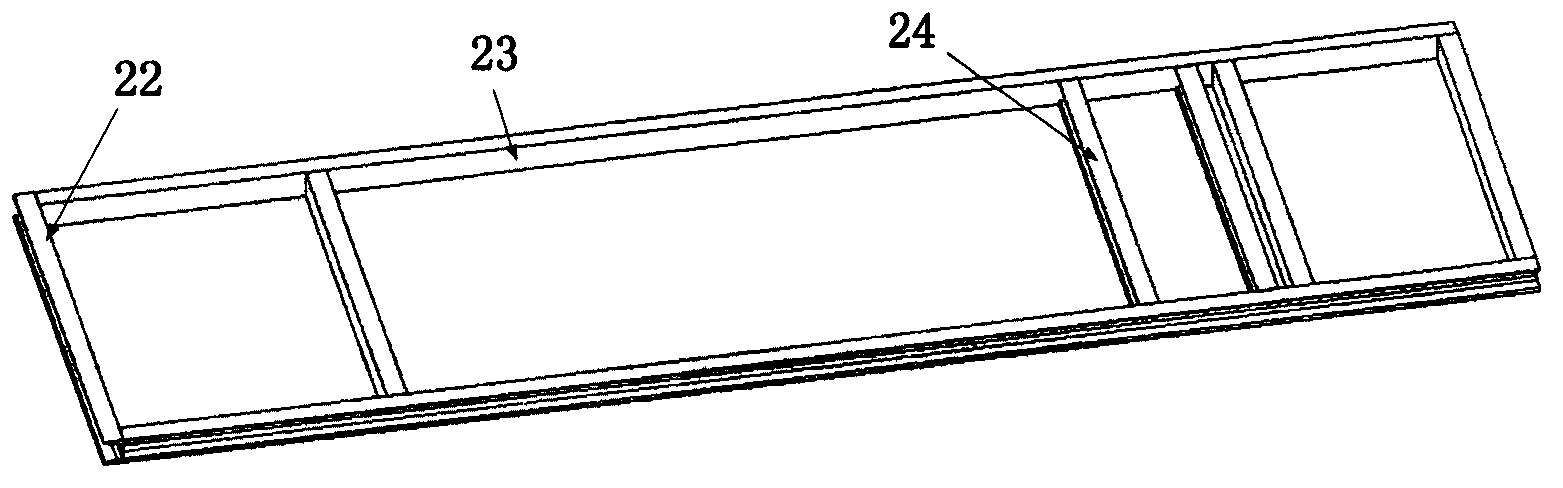

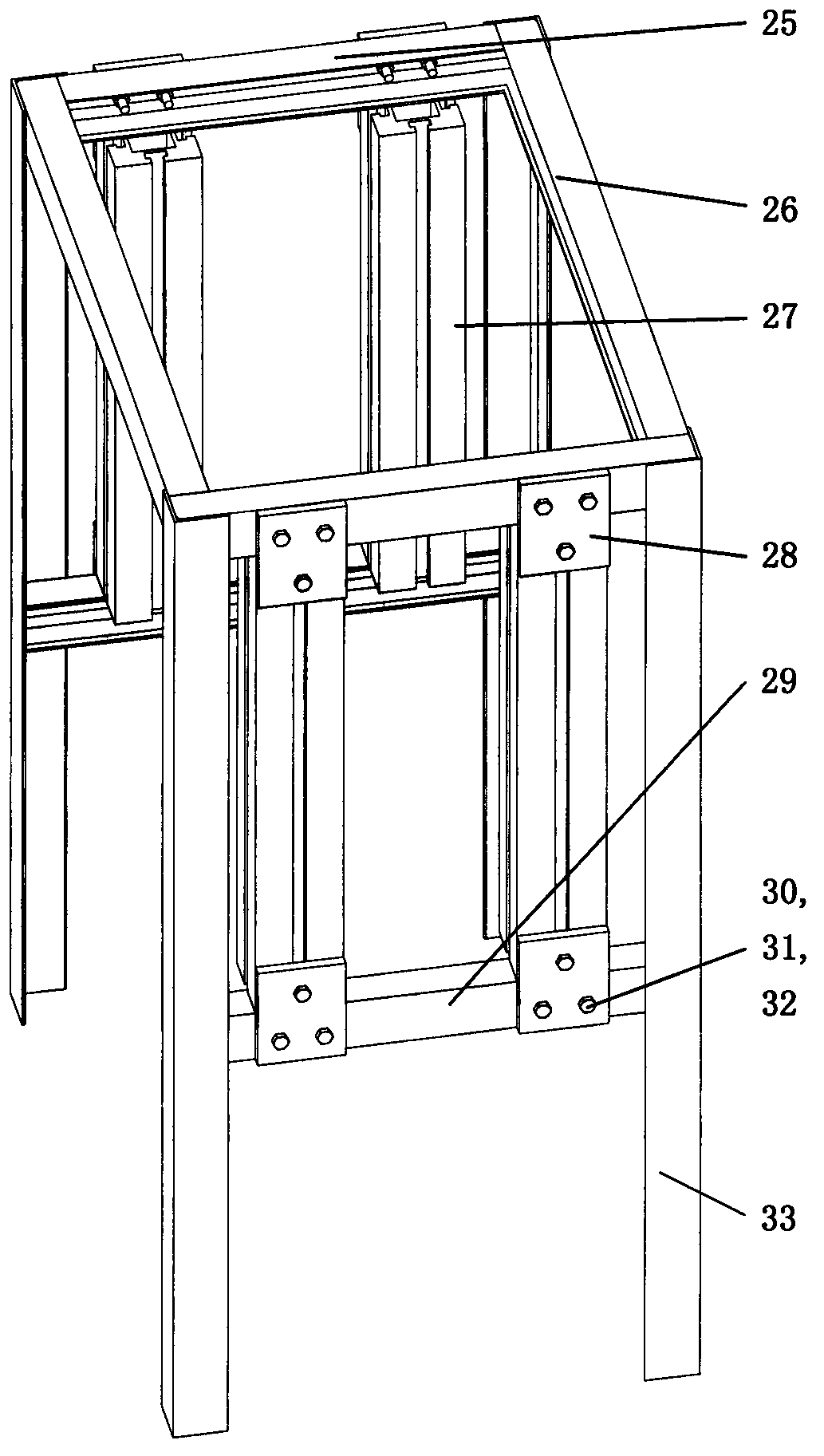

Deep-sea pipe-in-pipe mechanical transfer characteristic analysis experiment device

The invention relates to a deep-sea pipe-in-pipe mechanical transfer characteristic analysis experiment device, in particular to a device for analyzing mechanical transfer characteristics in the process of coiled tubing tripping into a deep-sea riser. When in experiment, a chain hoist 6 is opened, and an injection test assembly 9 clamps simulated coiled tubing to perform injection operation under the traction effect of a steel wire rope 7. The injection force of the simulated coiled tubing can be obtained by reading parameters of a tension compression sensor on the injection test assembly 9 in the injection process, the injection depth of the simulated coiled tubing can be obtained by reading parameters of a displacement sensor on the injection test assembly 9, the stress of the end of the simulated coiled tubing can be obtained by reading parameters of a pressure sensor inside a pipe end fixing test assembly 2, and the stress of a simulated riser can be obtained by reading parameters of a strain gauge on a pipe-in-pipe system 20. Finally obtained results can be used for analyzing mechanical characteristics of the coiled tubing tripping into the marine riser.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

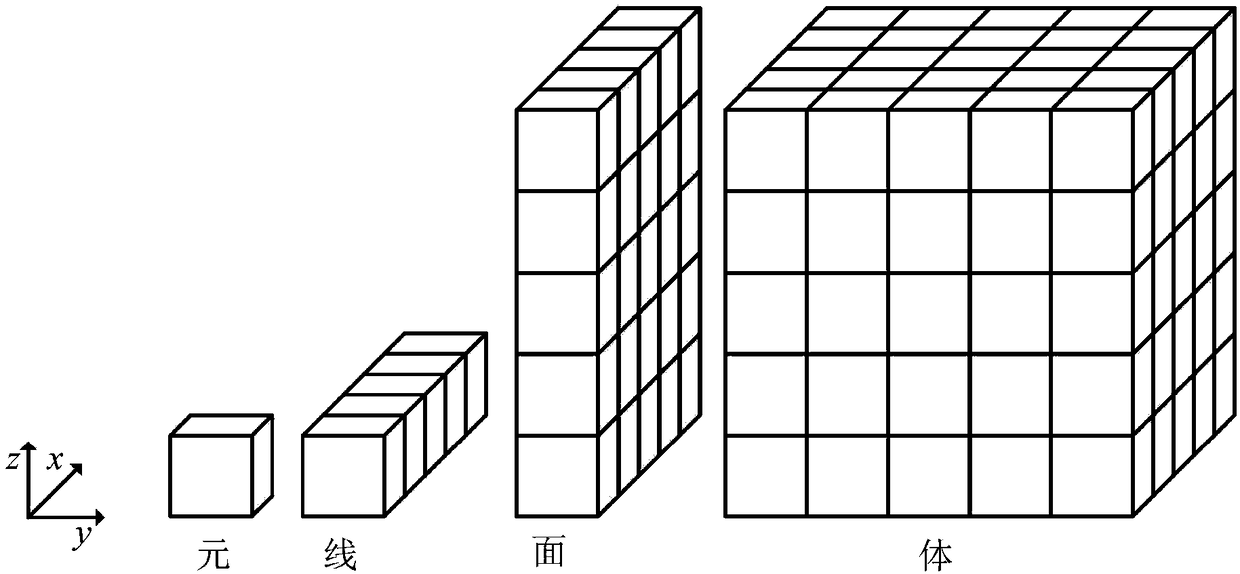

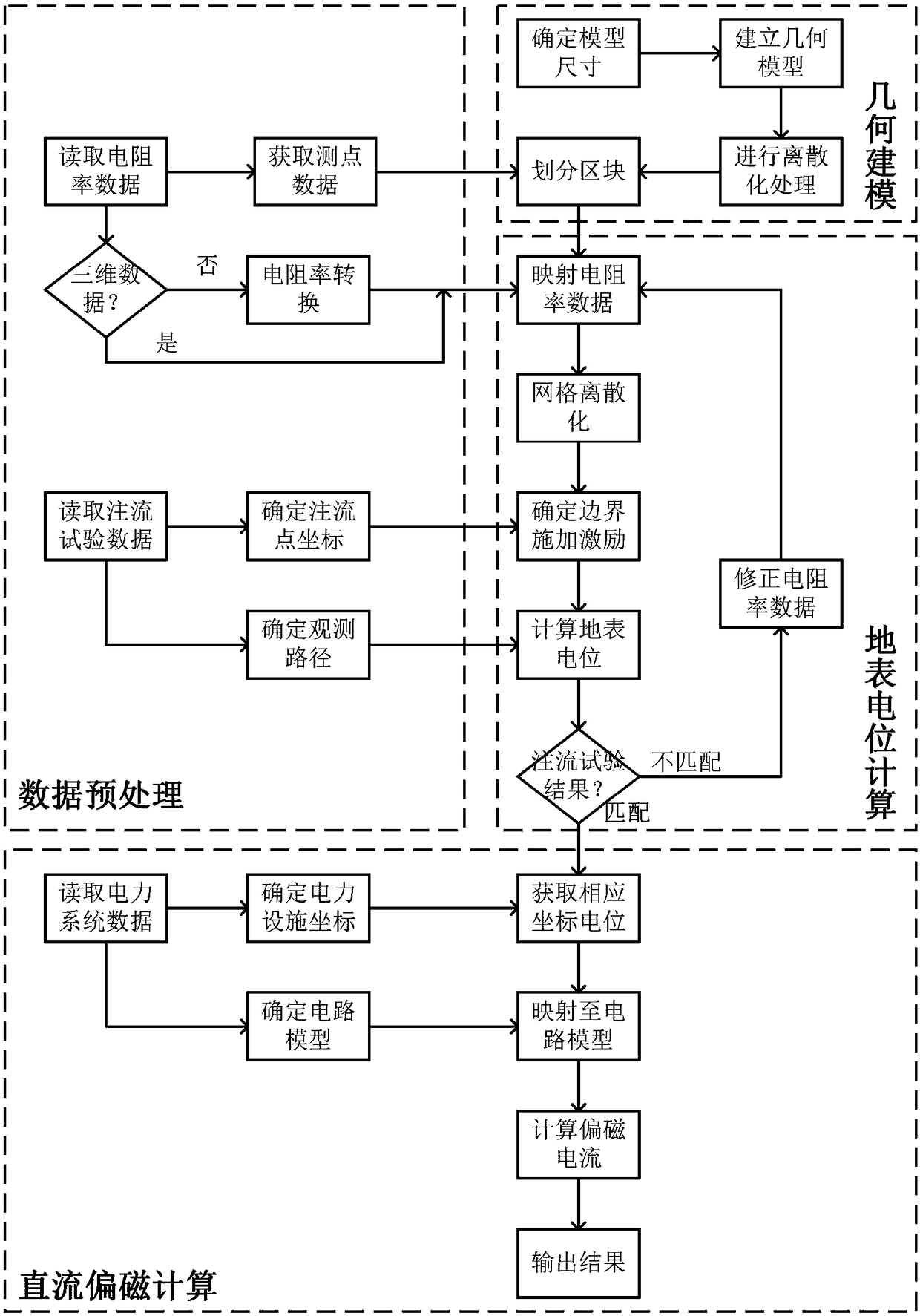

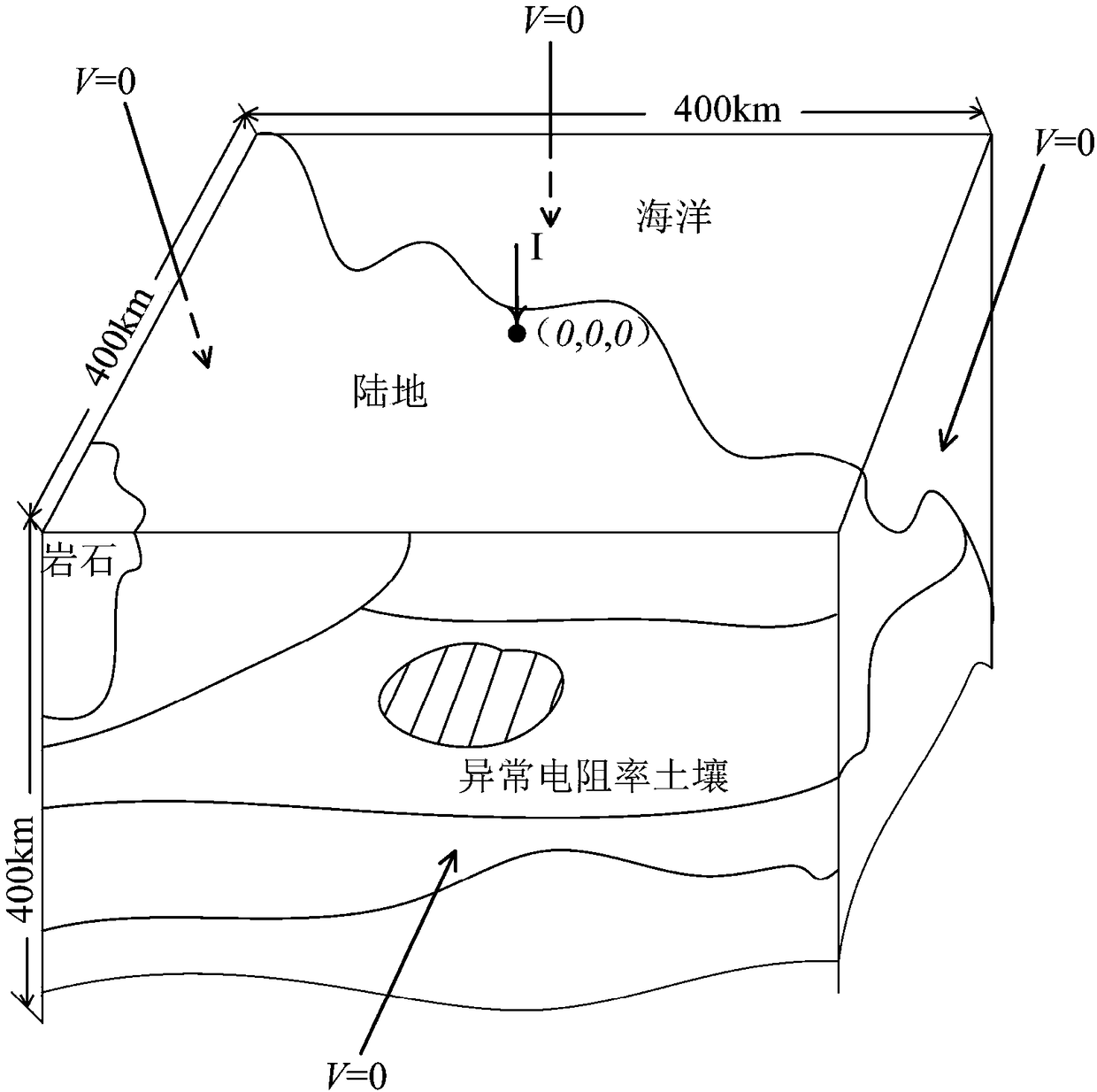

Field-circuit coupling-based direct current magnetic bias calculation method for soil model adopting three-dimensional asymmetric structure

ActiveCN108388707AReduce mistakesImprove evaluation accuracyDesign optimisation/simulationCAD numerical modellingNODALElectric power system

The invention discloses a field-circuit coupling-based direct current magnetic bias calculation method for a soil model adopting a three-dimensional asymmetric structure. The method comprises the steps of determining the size of the soil model through a direct current magnetic bias influence range needed to be considered, and discretizing the model into small cubes with side lengths of 2m; throughactual measurement point data, determining block division of the model; mapping inverted three-dimensional resistivity to blocks, and mapping non three-dimensional resistivity data after conversion;determining stream injection point coordinates through stream injection test data, applying stimulation, determining a boundary condition, dividing grids, and performing surface potential calculation;determining an observation path, performing comparison with a stream injection test result, and correcting the soil model; obtaining a peripheral power system wiring diagram of an earth electrode andparameters such as coordinates and the like, and building a direct current circuit model; and inputting node potentials to perform direct current magnetic bias calculation. Starting from an initial model, the direct current magnetic bias calculation precision is improved; the possibility of protection mal-operation or refusal operation is reduced after operation of a direct current project; and the stability of power system operation is improved.

Owner:CHINA THREE GORGES UNIV

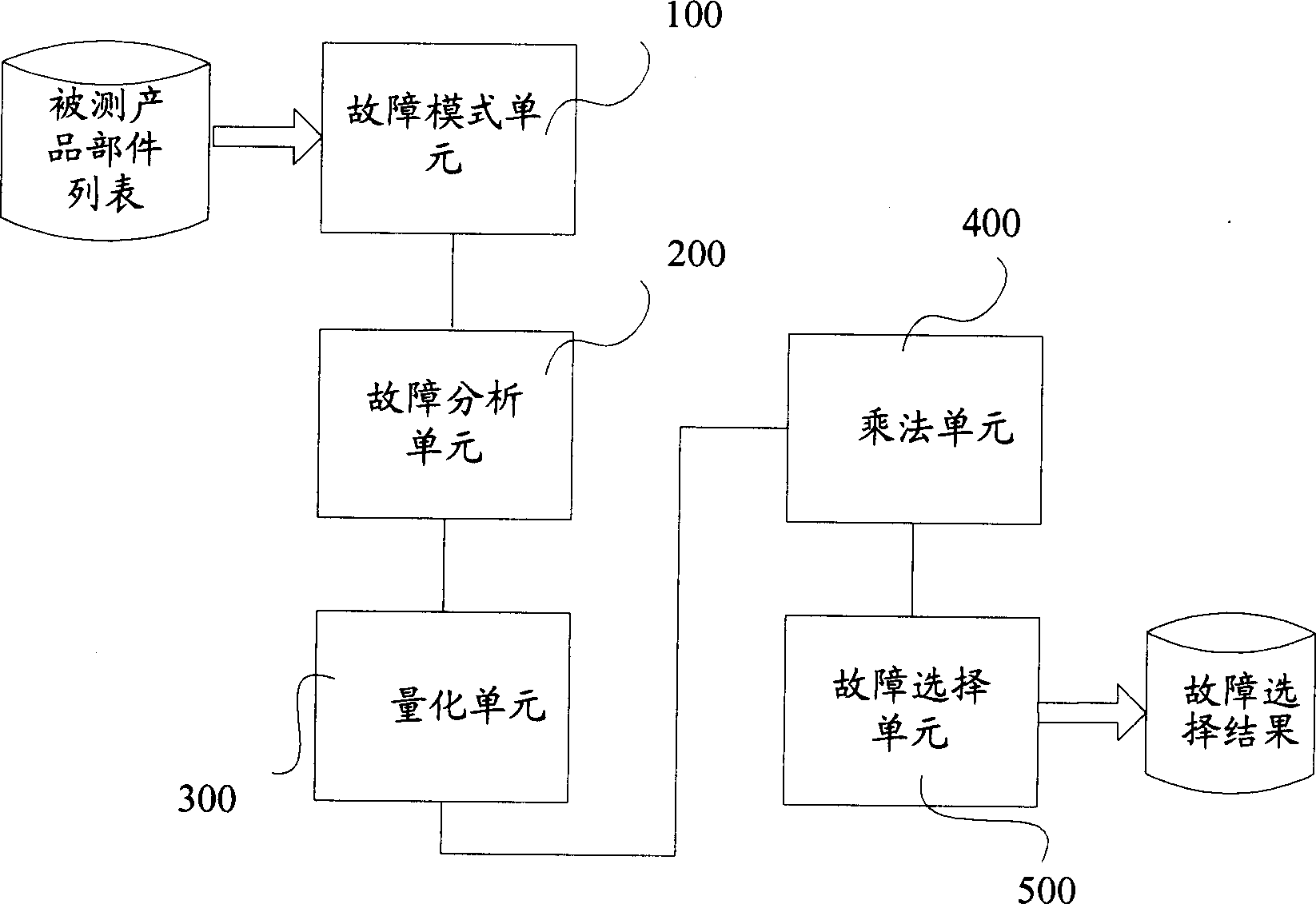

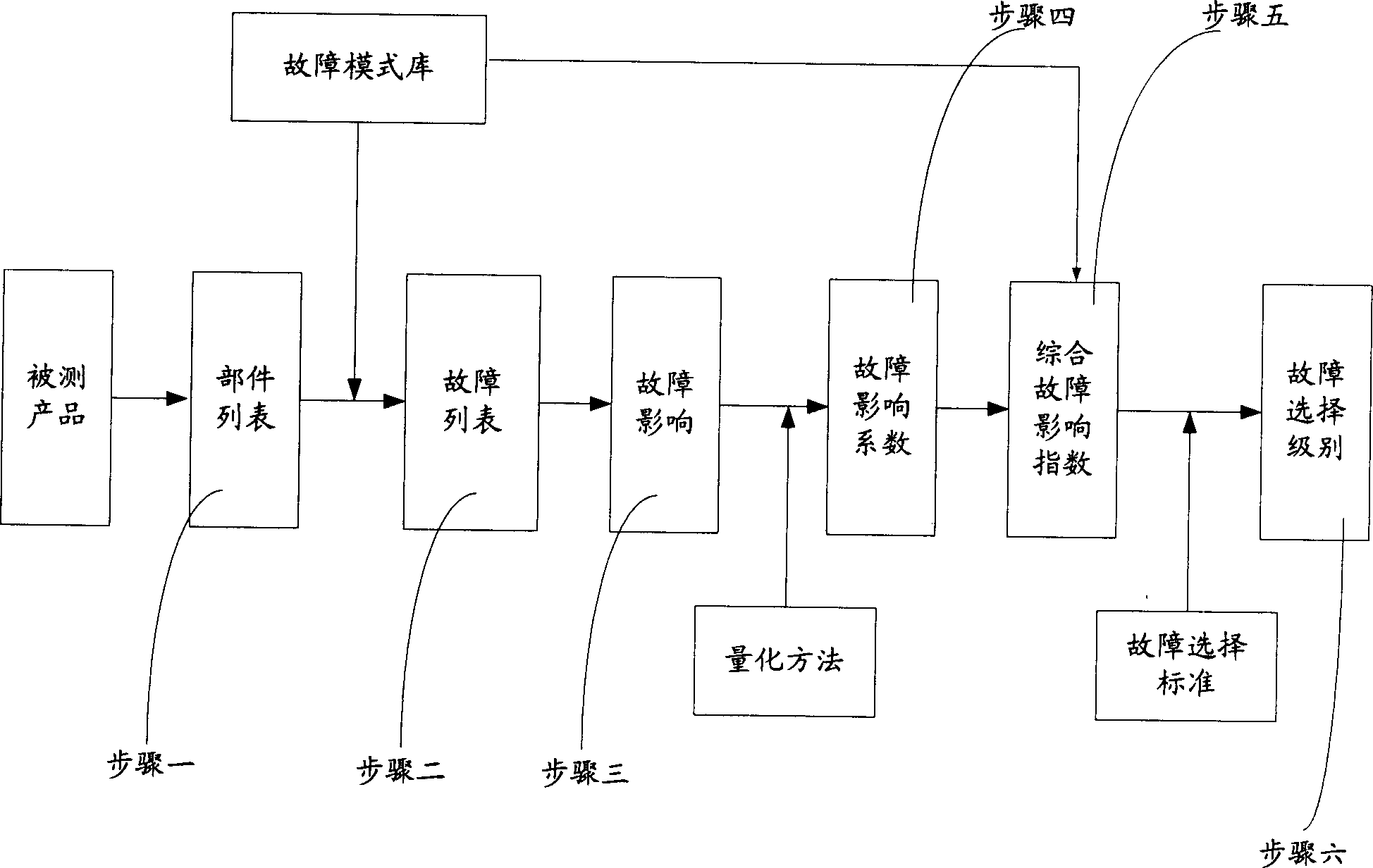

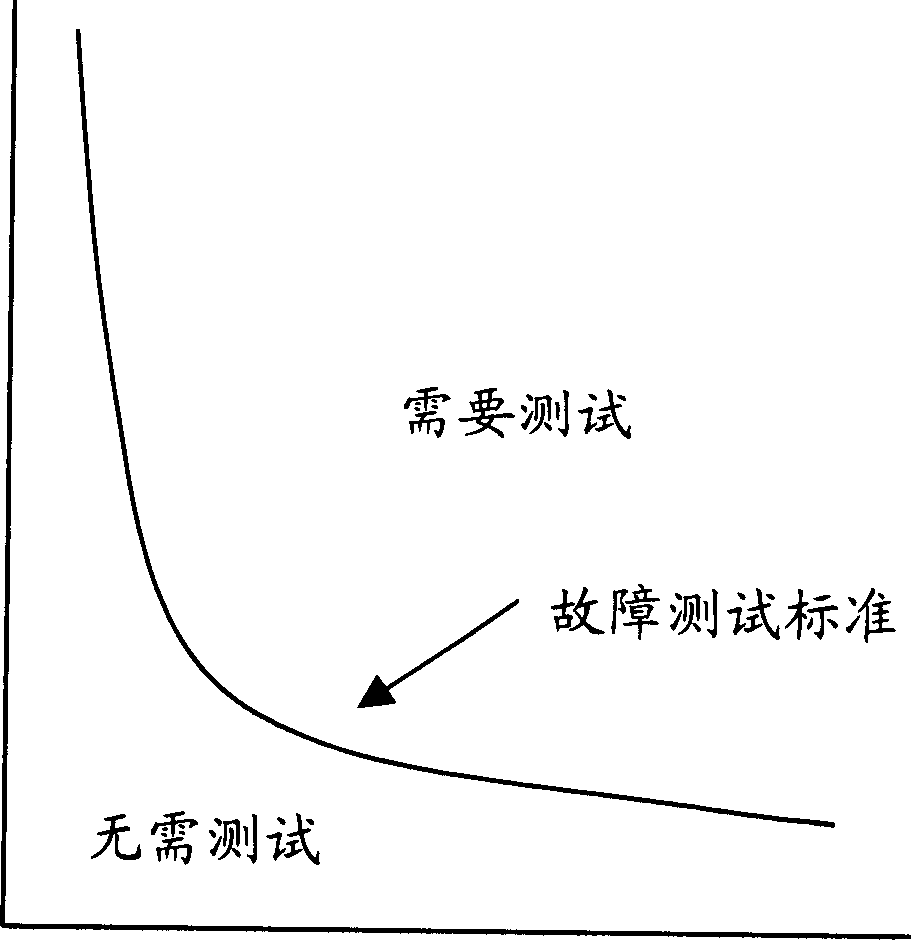

Fault selecting method and apparatus

InactiveCN1770117AImprove accuracyFault selection is reasonableFunctional testingComputer scienceInjection test

The invention discloses a method for accident selection for performing accident injection test on products which comprises: getting accident modes and accident probability of each component; verifying accident influence grade according to the accident mode and preset accident influence grades of each component; performing accident selection according to the accident influence grade and the accident probability. The invention also discloses a device for performing accident selection. The invention has the advantages of improving accident injection test accuracy.

Owner:HUAWEI TECH CO LTD

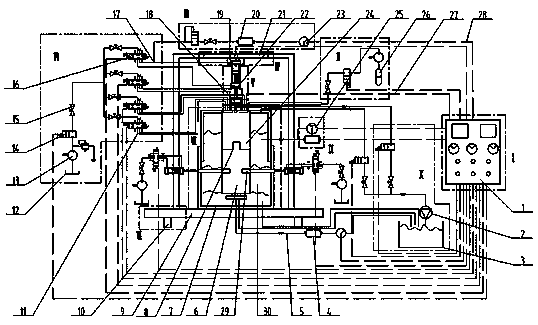

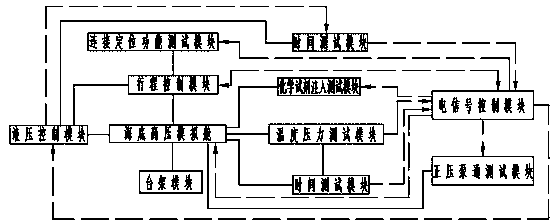

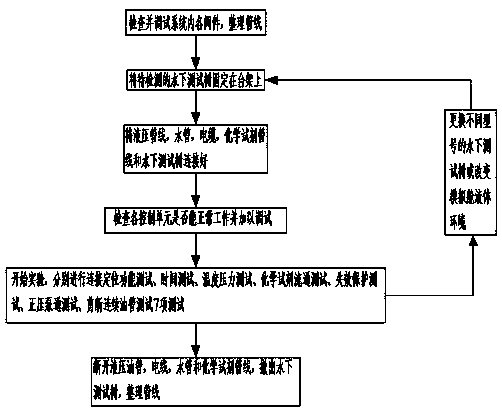

Underwater test tree test system for deepwater oil and gas test

ActiveCN109141956AGuaranteed feasibilityGuaranteed practicalityStructural/machines measurementOcean bottomPilot system

The invention discloses an underwater test tree test system for the deepwater oil and gas test. The test system includes a stroke control module, a subsea high pressure simulation cabin, a gantry module, an electrical signal control module, a hydraulic control module, a connection positioning function test module, a time test module, a temperature and pressure test module, a chemical reagent injection test module and a positive pressure pumping test module. The test system is advantaged in that the wellhead condition simulation of deepwater test operation is achieved, functions and characteristics of underwater test trees in different models and structures, such as release tie-back, positioning guide, failure protection, positive pressure pumping, shut-off time, chemical injection, steel wire and continuous pipe cutting and temperature and pressure monitoring are achieved, a test platform is provided for design and optimization of underwater test tree prototypes, practicality and feasibility of new products are guaranteed, overall research and development efficiency are improved, the test platform can be provided for maintenance and repair of the underwater test tree products, andthereby safety and reliability in the application process are better guaranteed.

Owner:SOUTHWEST PETROLEUM UNIV

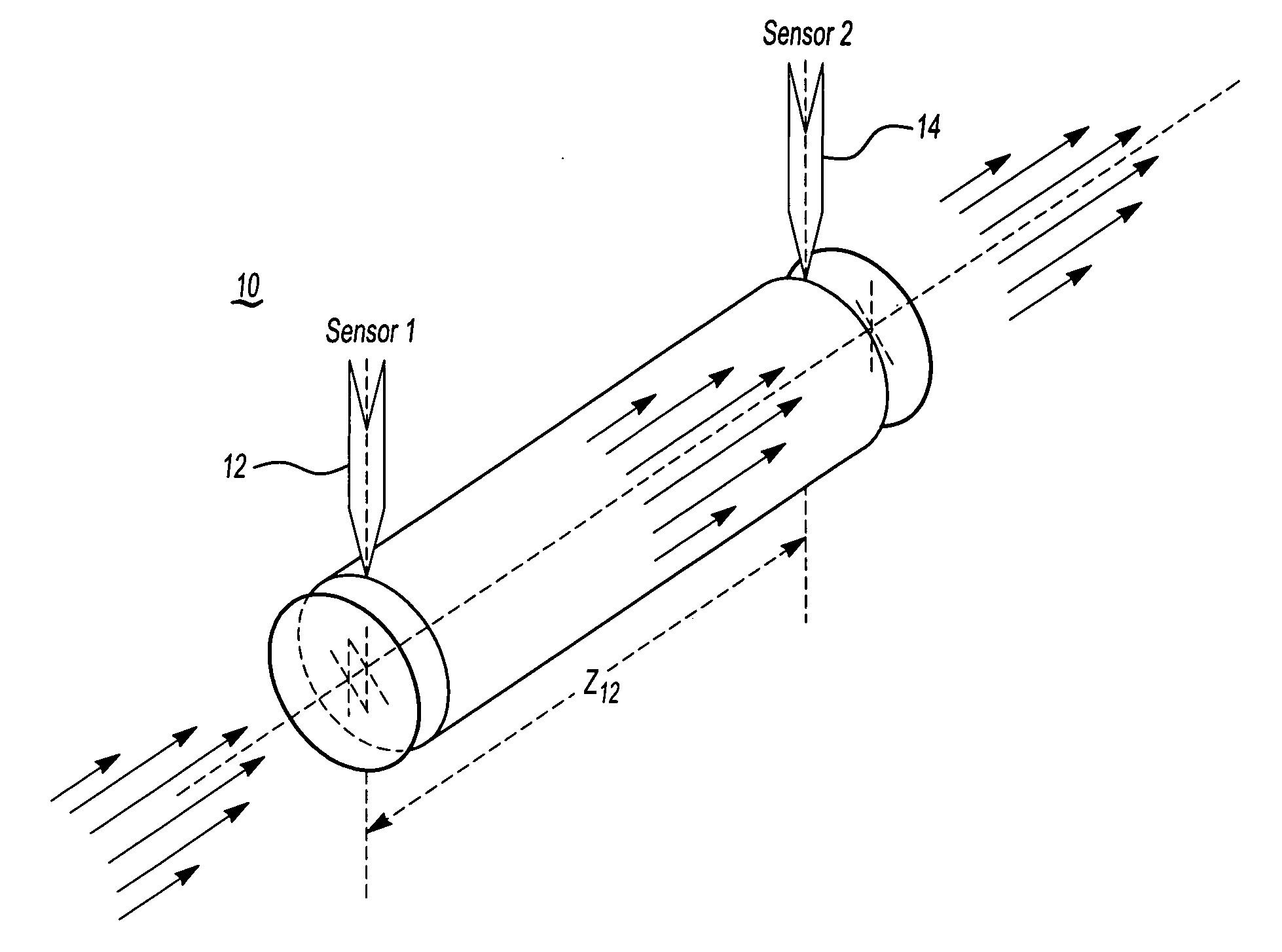

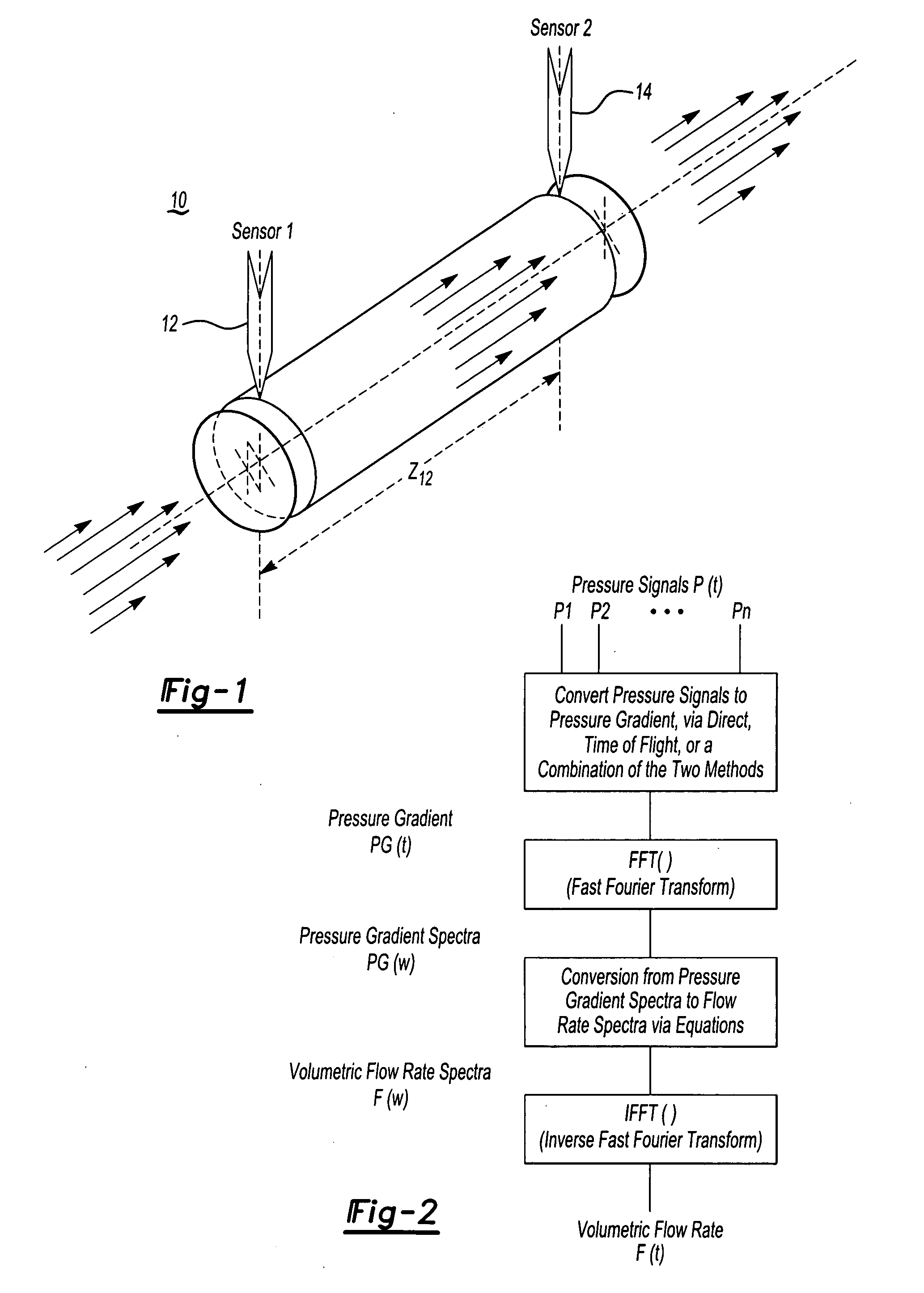

Flow meter and method

InactiveUS20070022826A1Accurate measurementAccurate dataVolume/mass flow by dynamic fluid flow effectVolume/mass flow by differential pressureMultiple injectionStream flow

The invention relates to a new method and a new apparatus to accurately measure flow rates in injection systems such as gasoline, direct injection gasoline and diesel downstream of the injector where the fuel (liquid in general) is discharged from a nozzle (e.g. an injector). More specifically, it measures the flow velocities and volumetric flow rates in highly transient flows discharged cyclically with injection duration within a few hundred microseconds. Moreover, it is able to resolve multiple injection shots produced within an engine cycle with high volumetric (0.01 mm3) and temporal (10 μs) sensitivities. The main uses of this instrument in automotive industry are manufactures of FIE, injection test machines and injection diagnostic systems. In other industries the uses maybe represented by measuring and controlling of highly transient flows with a need to accurately perform quantitative flow data in wide range of timing and dosing.

Owner:MICHIGAN CUSTOM MACHINES

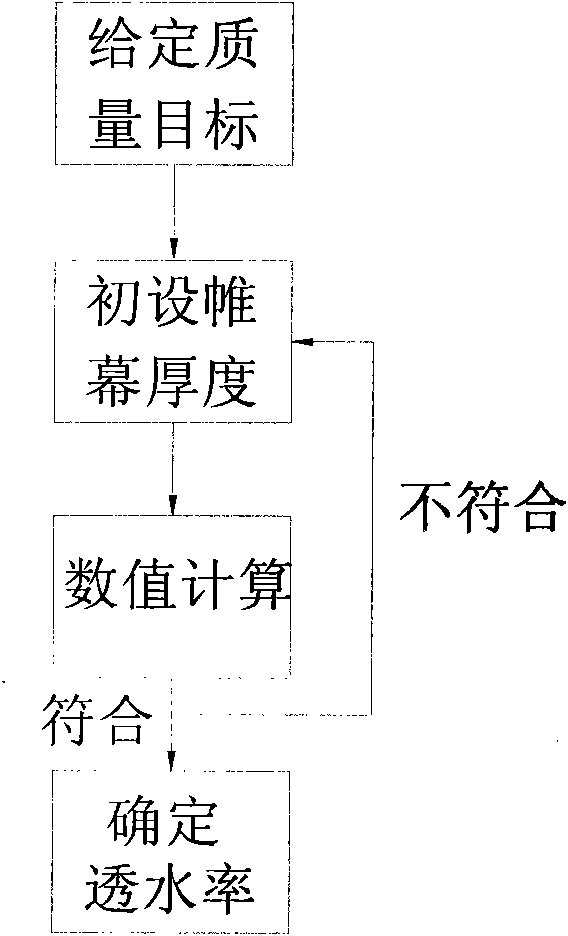

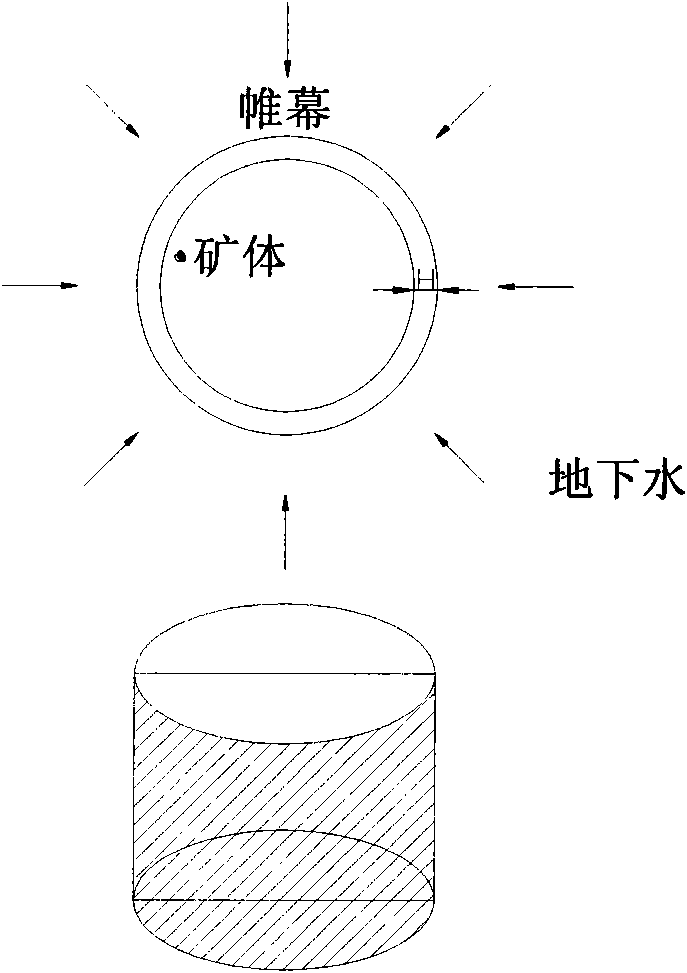

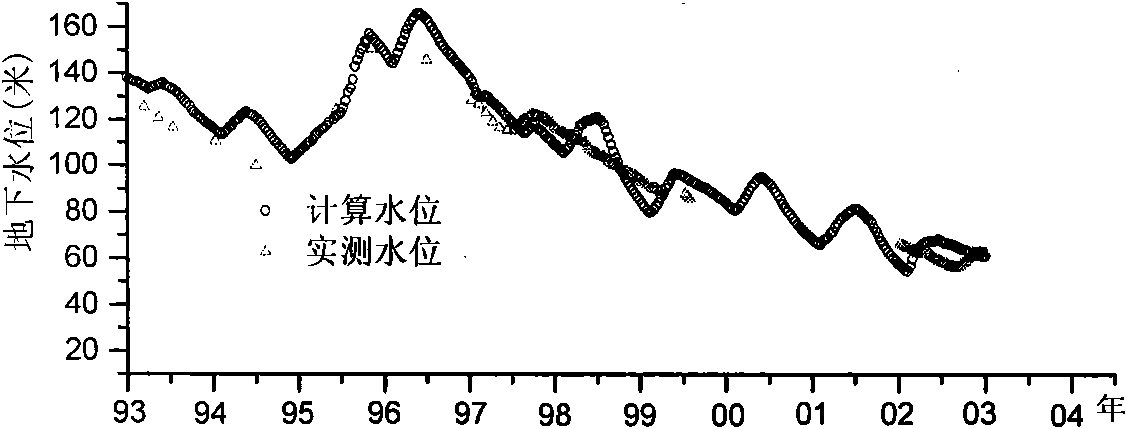

Determining method for water-plugging curtain permeability inversion analysis construction

The invention relates to a determining method for a water-plugging curtain permeability inversion analysis construction, in particular to the technical field of underground water management, which comprises the steps: a) a project quality target is put forward according to the project requirements, i.e. the water plugging ratio (%) and the anti-permeating standard (Lu) of a curtain body are inversely calculated by utilizing an inverse calculation method; b) the technical parameters of a curtain project are designed; c) a slurry injection test of the curtain is carried out, and the parameters are verified and perfected; d) the main body construction of the curtain is carried out according to the finally determined curtain project technical parameters, and the quality control is carried out according to the quality target determined in advance; and e) the water plugging effect of the curtain body is verified through construction check holes. The method has the advantages that the construction quality standards can be obtained in advance before the slurry injection construction of the curtain, i.e. the water plugging ratio and the anti-permeating standards of the curtain body; the method is scientific, reasonable, simple and convenient, has high accuracy and is beneficial to the guarantee of the construction quality of the construction; the efficiency is enhanced; and the method is especially suitable for the anti-permeating treatment of a dam foundation and can be widely applied to the construction of various projects of mine, water conservation and hydraulic power, railway, buildings and the like.

Owner:NORTH CHINA ENG INVESTIGATION INST

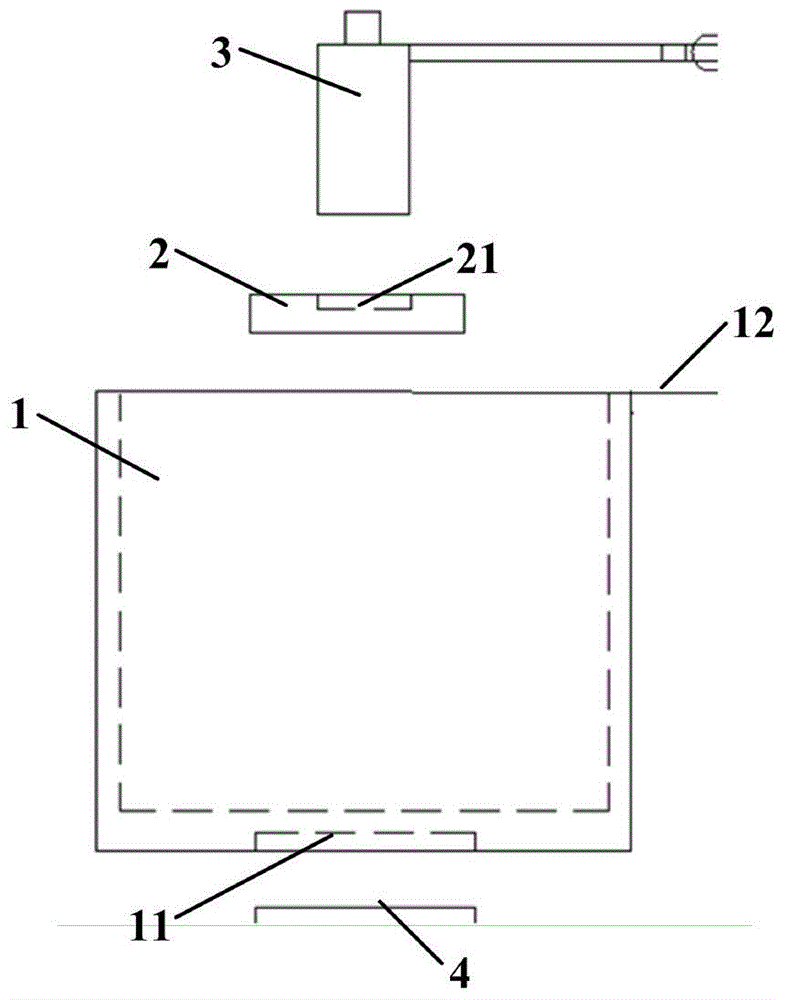

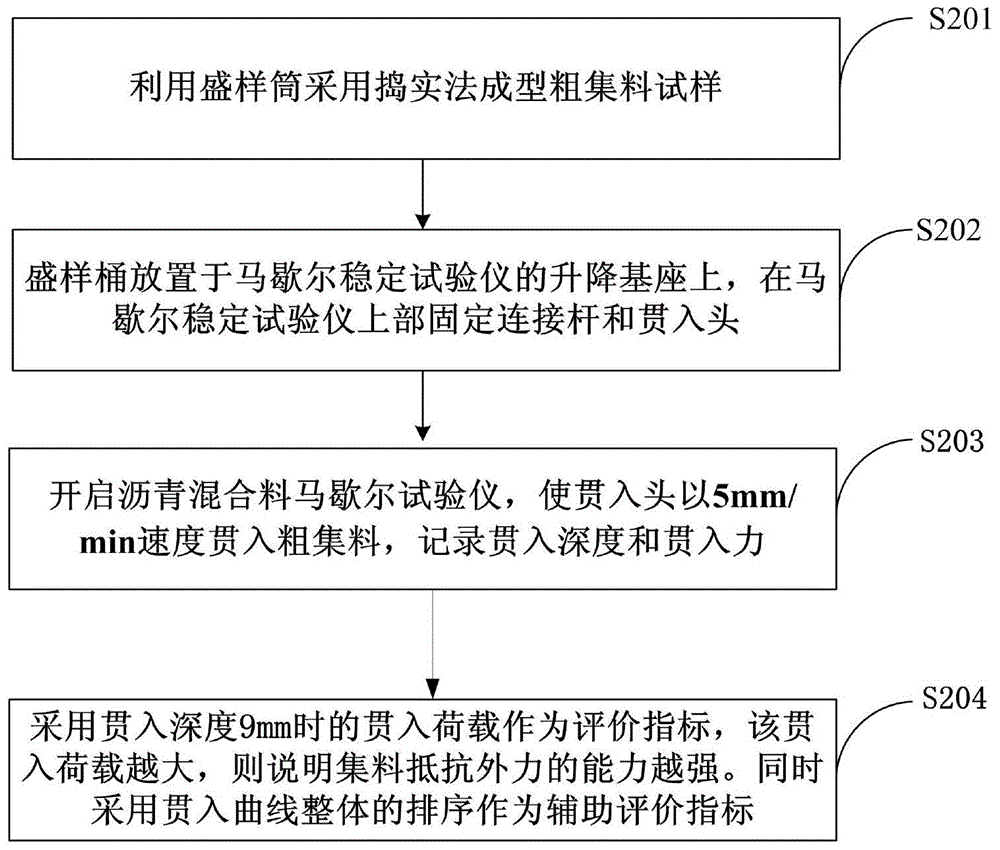

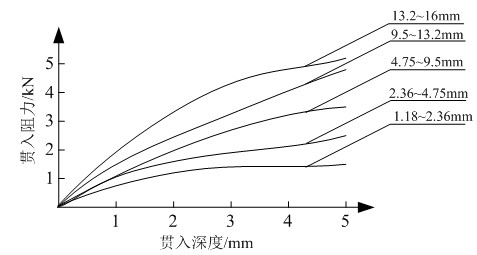

Coarse aggregate injection test device and coarse aggregate injection test method based on asphalt mixture tester

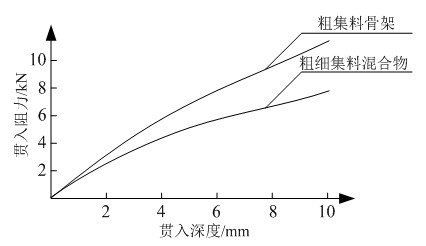

InactiveCN104090092AImproves rutting resistanceImprove effectivenessMaterial testing goodsUltimate tensile strengthAsphalt

The invention discloses a coarse aggregate injection test device and a coarse aggregate injection test method based on an asphalt mixture tester. A coarse aggregate sample is formed through a sample containing barrel by a tamping method; the sample containing barrel is arranged on a lifting base of an asphalt mixture Marshall tester; a connecting rod and an injection head are fixed on the upper part of the asphalt mixture Marshall tester; with a fixed displacement sensor and the turned-on asphalt mixture Marshall tester, the injection head injects aggregate at a speed of 5mm / min, the instrument automatically records the injection depth and injection force, and the injection load at the injection depth of 9mm is used as an evaluation index for the coarse aggregate skeleton strength. According to the device and the method disclosed by the invention, the bearing performance of coarse aggregate can be evaluated and a basis is provided for the optimal design of coarse aggregate grading, so that the high-temperature rutting resistance of the asphalt mixture can be estimated; moreover, the effectiveness of the mixture grading design can be improved while the rutting resistance of the asphalt mixture is enhanced; the device and the method have relatively high popularization and application values.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

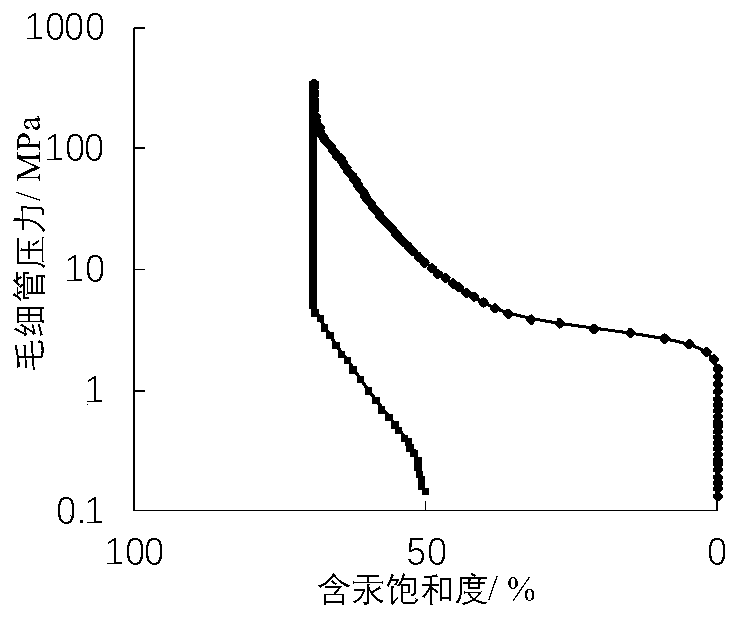

Coal pore correction method based on mercury injection experiment

The invention discloses a coal pore correction method based on a mercury injection experiment. The coal pore correction method comprises the following steps: 1) performing low pressure section and high pressure section mercury injection tests on a to-be-tested coal sample by utilizing a mercury injection instrument and obtaining mercury injection data; 2) performing pore structure correction including matrix compression effect correction, inter-granular pore effect and skin effect correction effect correction and pore shape effect correction; 3) performing quantitative characterization on a pore structure by utilizing corrected data. The invention provides a model for correcting coal pores by utilizing the mercury injection tests, which can be used for coal-bed methane reservoir evaluationand research on gas prevention and control and the like; a mercury injection test method in the national standard is referenced and utilized, mercury injection pressure and mercury injection amount data are obtained, and then related factors affecting the mercury injection test accuracy are corrected; correction results can accurately characterize the coal pores. Therefore, a strong technical support is provided for coal-bed methane exploitation and underground gas prevention and control.

Owner:HENAN POLYTECHNIC UNIV

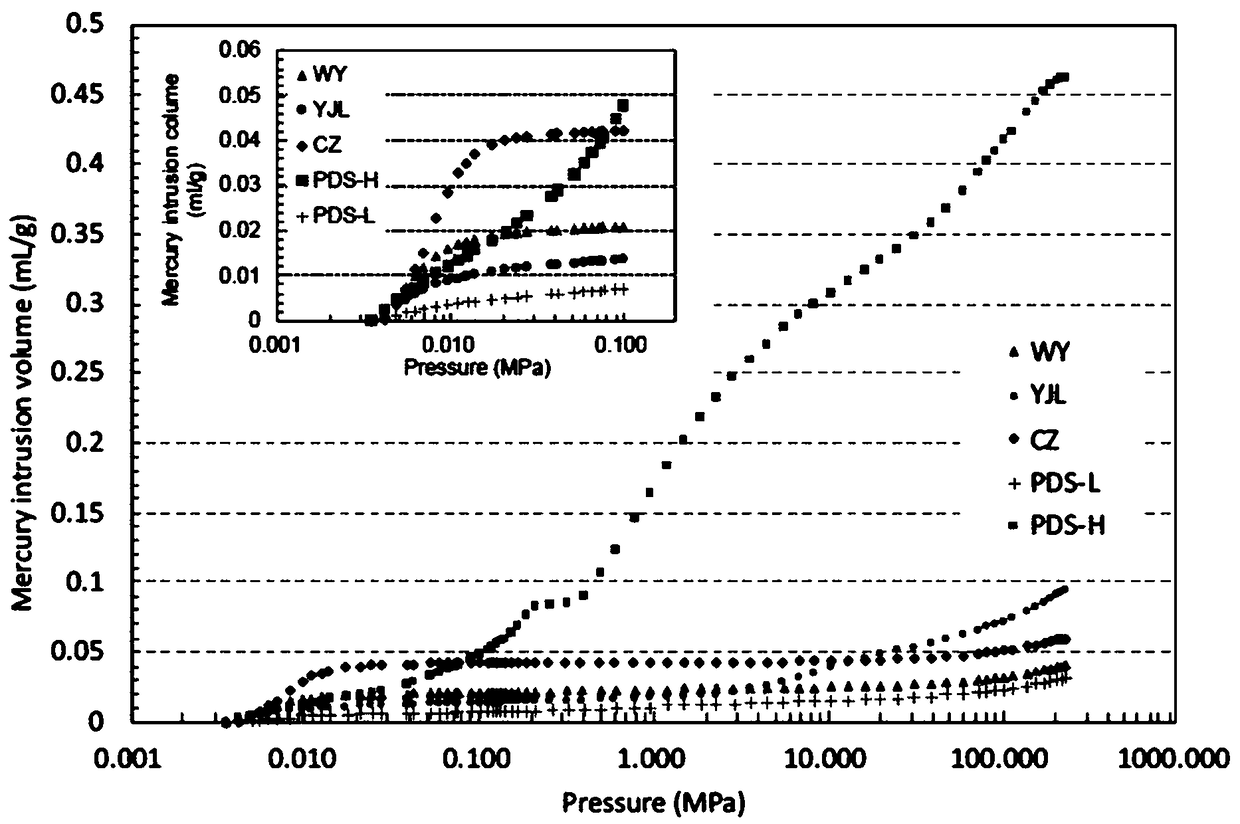

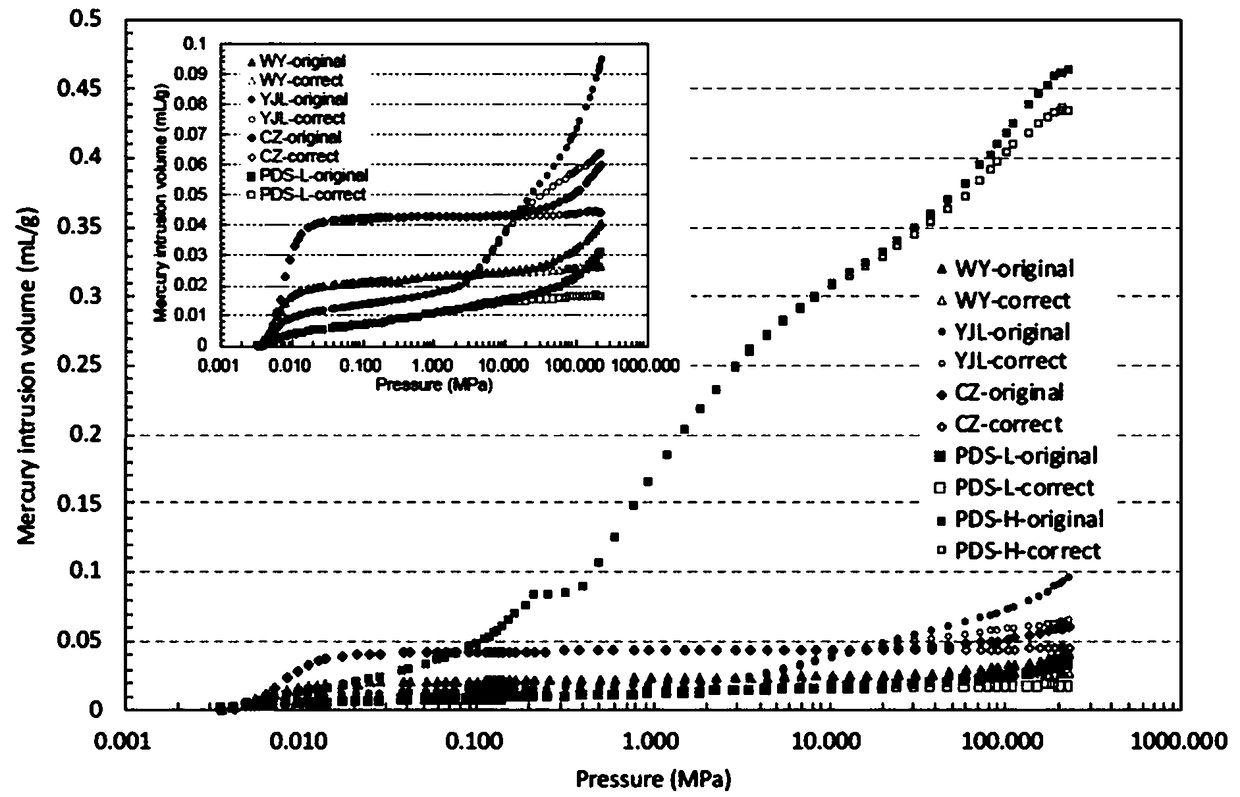

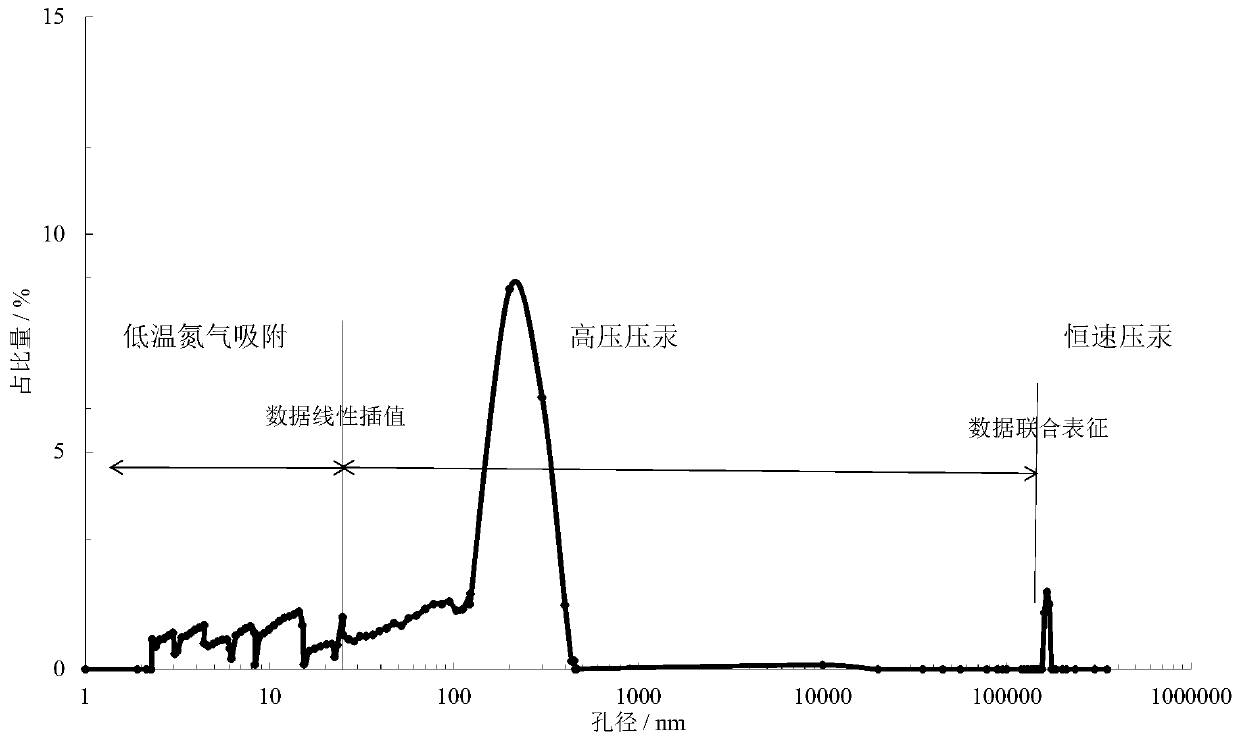

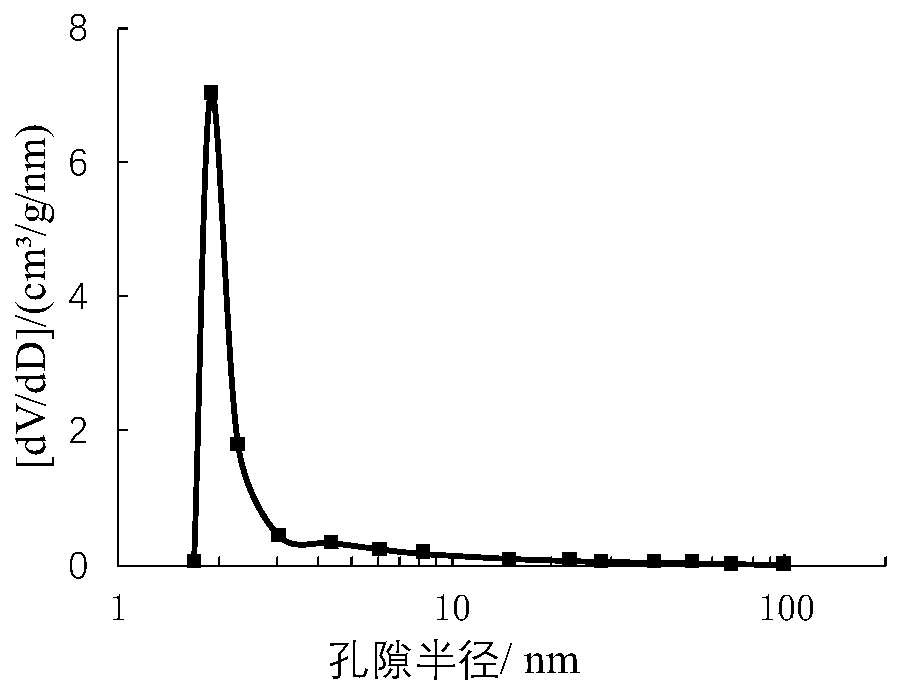

Method for full-scale characterization of pore throats of tight sandstone or shale oil reservoir

PendingCN111189758AReduce development costsImprove development efficiencyPermeability/surface area analysisTester deviceMeasurement precision

The invention provides a method for full-scale characterization of the pore throats of tight sandstone or shale oil reservoir. According to the method, microcosmic pore throat multi-scale distributioncharacteristics of tight sandstone / shale oil reservoir are quantitatively characterized in a mode combining the three pore throat radius testing methods including low-temperature nitrogen adsorption,high-pressure mercury injection and constant-speed mercury injection; according to the measurement precision ranges of different test instruments, pore throats with a radius of 2-25nm are characterized in a low-temperature nitrogen adsorption and high-pressure mercury injection test data linear interpolation mode; pore throats with a radius of greater than 25nm are jointly characterized by high-pressure mercury injection and constant-speed mercury injection test data, therefore, full-scale characterization is carried out on pore throat radius distribution of the tight sandstone / shale oil reservoir, a pore throat radius full-scale distribution atlas of the tight sandstone / shale oil reservoir is made according to the full-scale characterization, so that pore diameter full-scale distributioncharacteristics of the tight sandstone / shale oil reservoir are effectively characterized.

Owner:MINJIANG UNIV

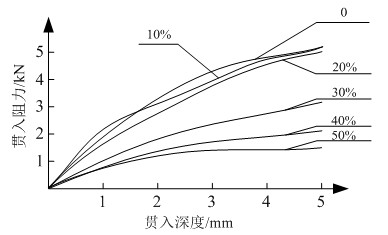

Method for judging bituminous mixture skeleton structure

InactiveCN102680391ASimple test methodSimple test stepsPreparing sample for investigationUsing mechanical meansRoad surfaceInjection test

The invention discloses a method for judging whether a bituminous mixture skeleton structure is formed or not. The technical problem that whether coarse aggregates form a skeleton structure or not cannot be judged in a skeleton type bituminous mixture designed process needs to be solved. As the coarse aggregates and fine aggregates have completely different injection features in an injection test, injection tests for measuring a coarse aggregate skeleton structure are proposed. The method comprises following steps: performing the injection test for coarse aggregate mixture and obtaining the relation curve of the injection resistance and the injection depth of the coarse aggregate mixture; and adding the fine aggregates in the coarse aggregate mixture, performing the injection test under the same test conditions, comparing the largest injection resistance with the largest injection resistance of the coarse aggregate mixture; and judging whether the coarse aggregates form the skeleton structure or not. The injection tests are used as evaluation means, and a stress state of bituminous mixture in a road surface structure is met. Compared with the prior art, the method can more scientifically judge whether the coarse aggregates in the bituminous mixture form the skeleton structure or not.

Owner:HOHAI UNIV

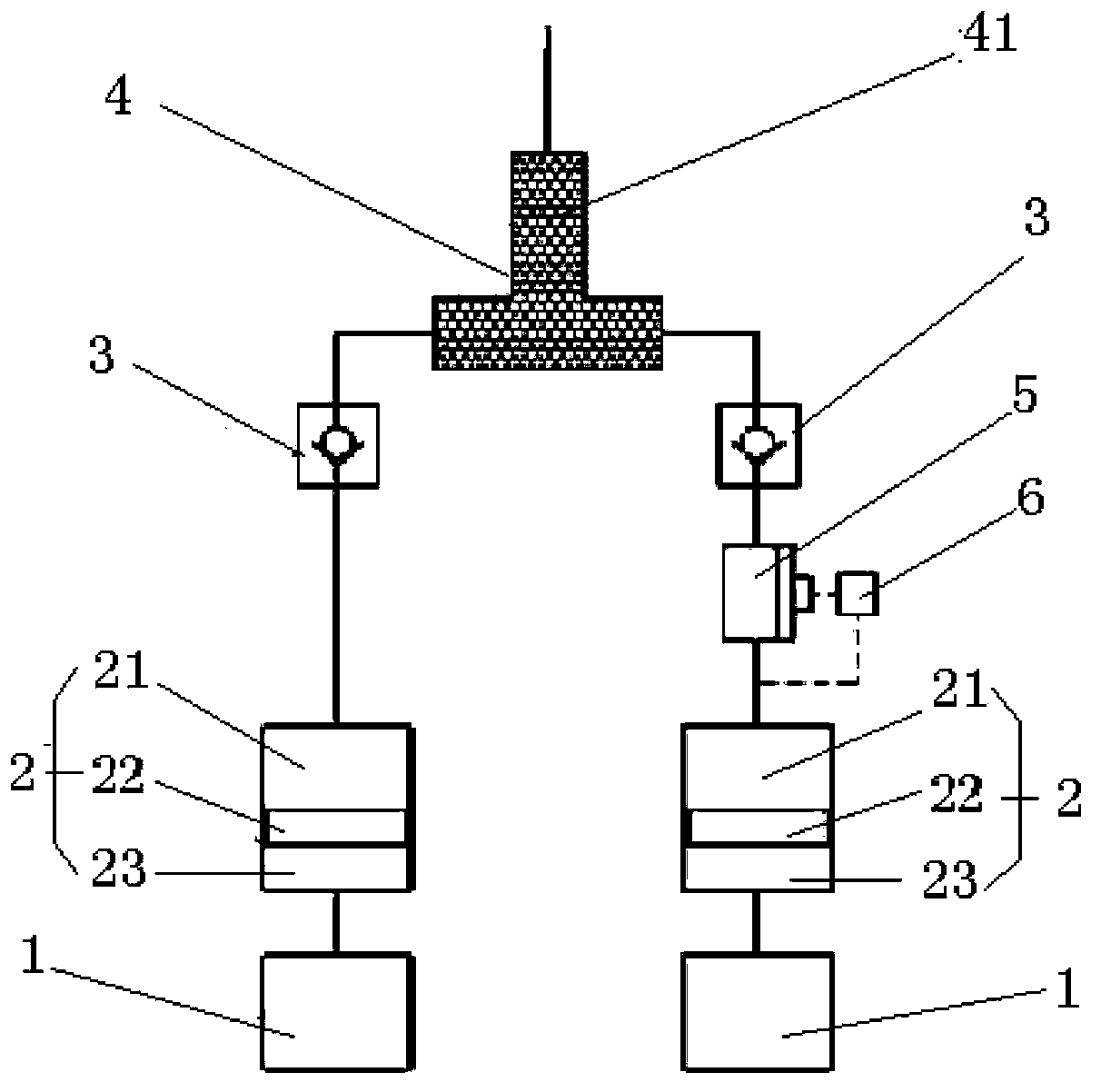

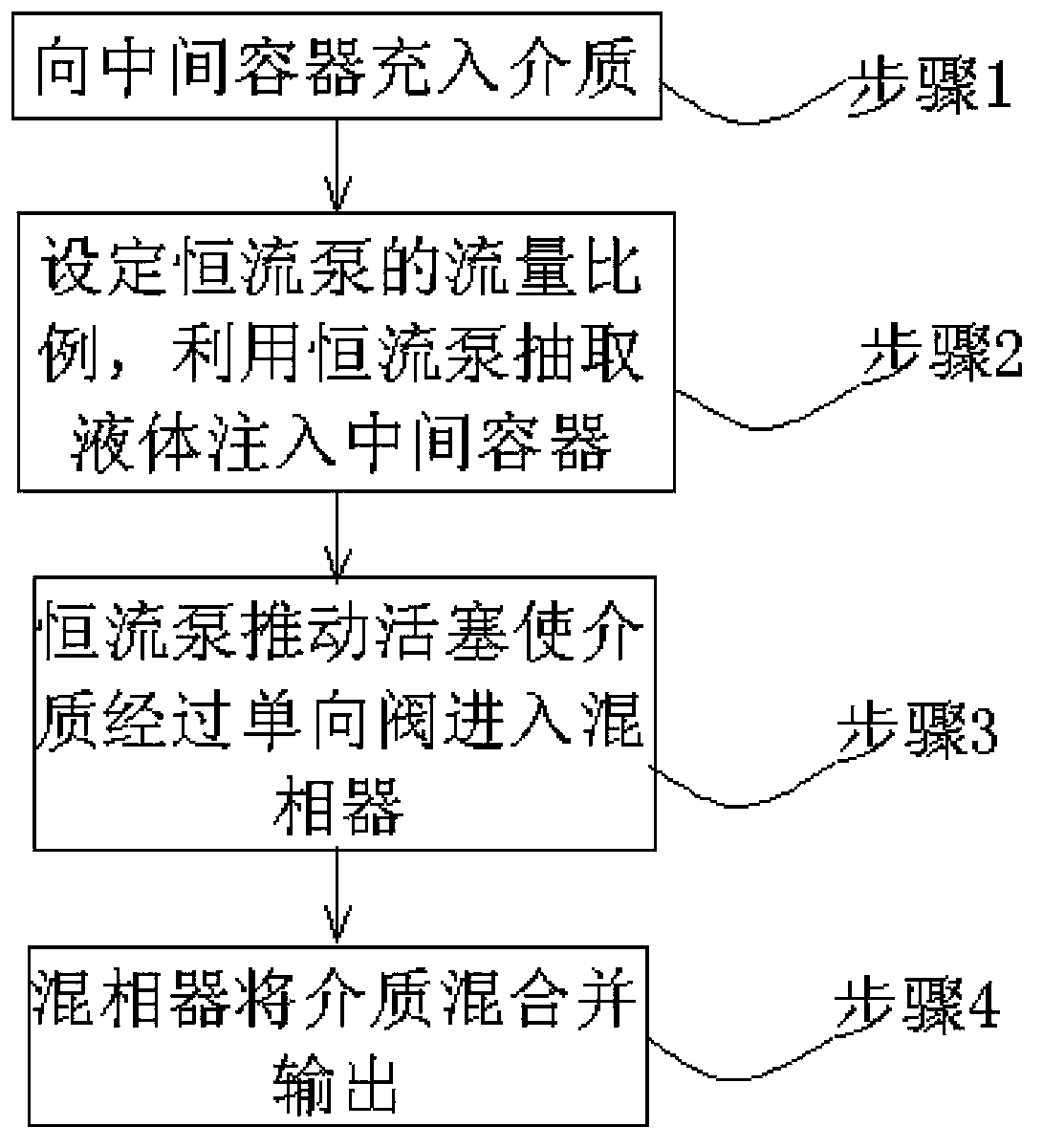

Medium mixing injection device and medium mixing injection process

InactiveCN103899303AHigh precision requirementsTroubleshoot flow control issuesFlow mixersMixer accessoriesMulti phaseInjection device

The invention discloses a medium mixing injection device and a medium mixing injection process. The medium mixing injection device comprises a phase mixer and at least two sets of injection components, the at least two sets of injection components are respectively communicated with the phase mixer, the phase mixer is used for enabling media injected by the at least two sets of injection components to be mixed, each set of injection component comprises a constant flow pump, an intermediate container and a one-way valve, the constant flow pumps, the intermediate containers and the one-way valves are connected in sequence, and the one-way valves are communicated with the phase mixer. In the work process, the media are injected into the intermediate containers, the constant flow pumps push the media in the intermediate containers to pass through the one-way valves, and the media are injected into the phase mixer. The flow of liquid pumped into the intermediate containers can be controlled by setting the flow proportion of the constant flow pumps of the injection components, therefore, the flow of the media injected into the phase mixer can be accurately controlled, and the flow control problem needing a quantitative injection test is solved. In addition, multi-medium multi-phase mixing injection can be directly carried out, the process of switching injection openings is eliminated, and the actual operation is extremely convenient and easy.

Owner:PETROCHINA CO LTD

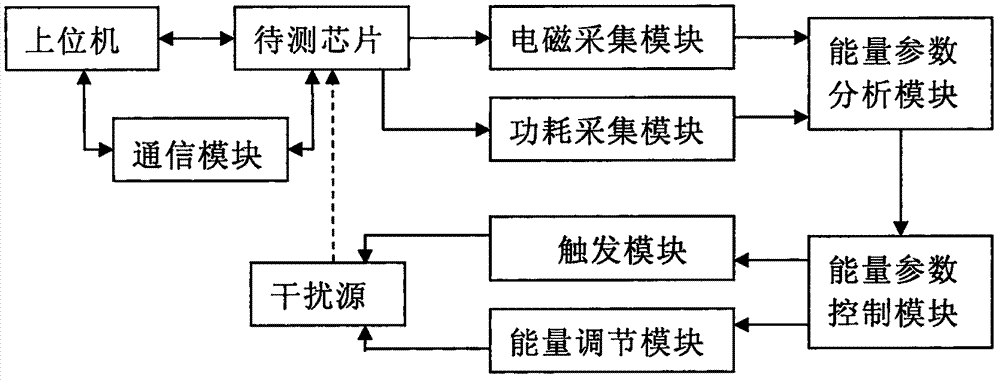

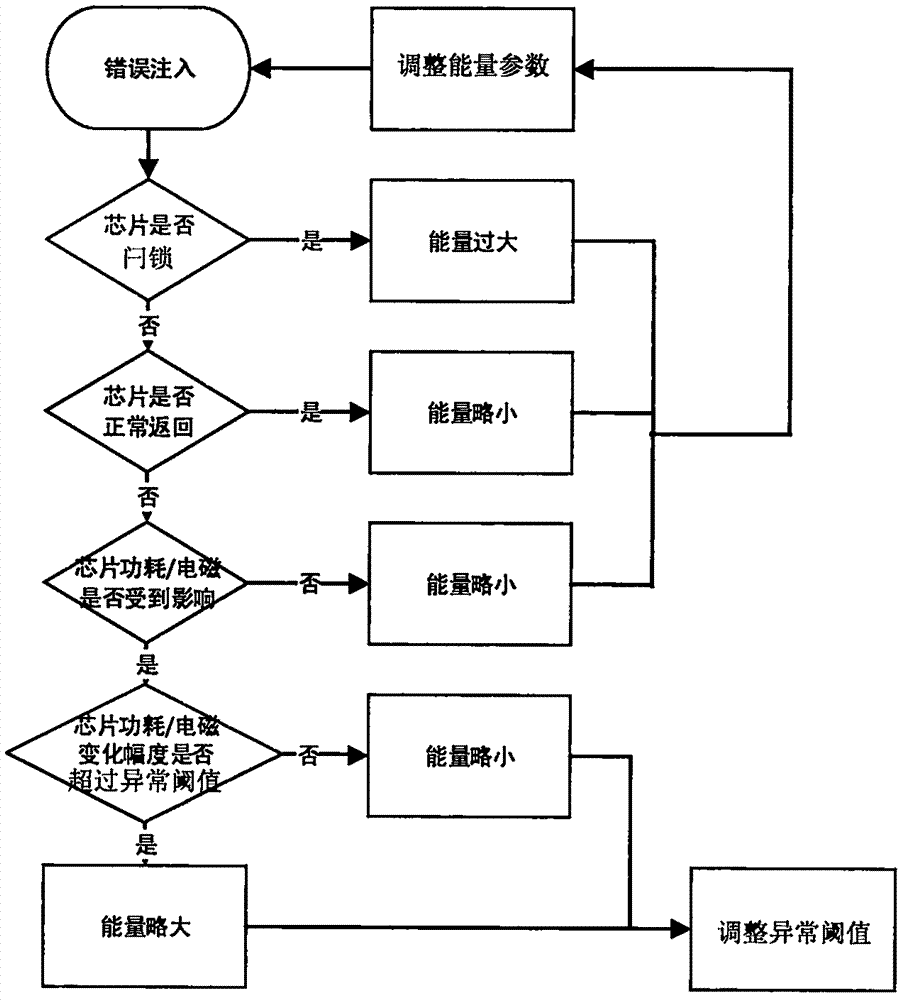

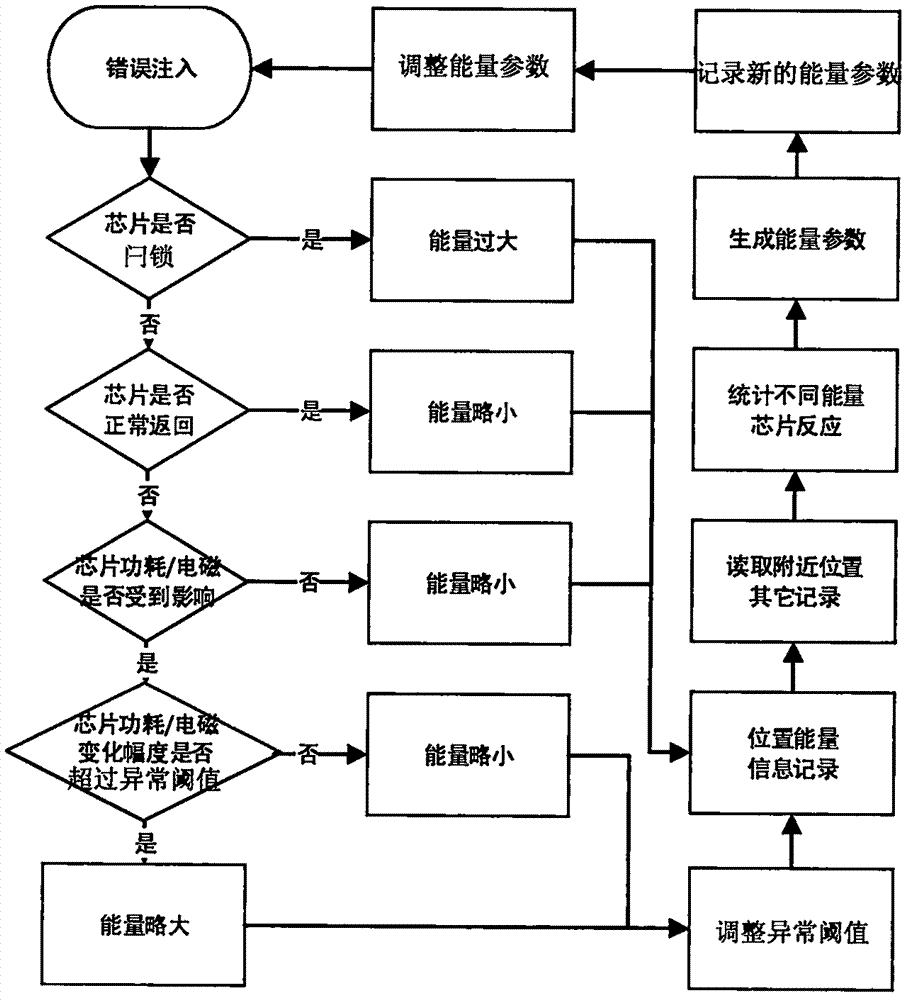

Energy parameter adjustment system and method in chip error injection test

ActiveCN107505560AAdjust Auto AdjustImprove test productivityElectronic circuit testingEngineeringInjection attacks

The invention discloses an energy parameter adjustment system and method in a chip error injection test, and the method comprises the steps: collecting a state signal, electromagnetic signal and power consumption signal of a to-be-tested chip in an error injection attack test process; judging and analyzing whether the injected energy is reasonable or not according to the state signal, the electromagnetic signal and the power consumption signal; dynamically adjusting the energy parameters of an interference source according to an analysis result, and controlling the output energy of the interference source according to the adjusted energy parameters; generating more reasonable energy parameter information in advance through the former test and adjustment process, carrying out the testing operation later according to the energy parameter information, and updating and optimizing the pre-generated energy parameter information in the test process. The system and method can achieve the automatic adjustment and optimization of parameters, greatly improve the testing efficiency, and guarantee the accuracy and effectiveness of a testing result.

Owner:北京银联金卡科技有限公司

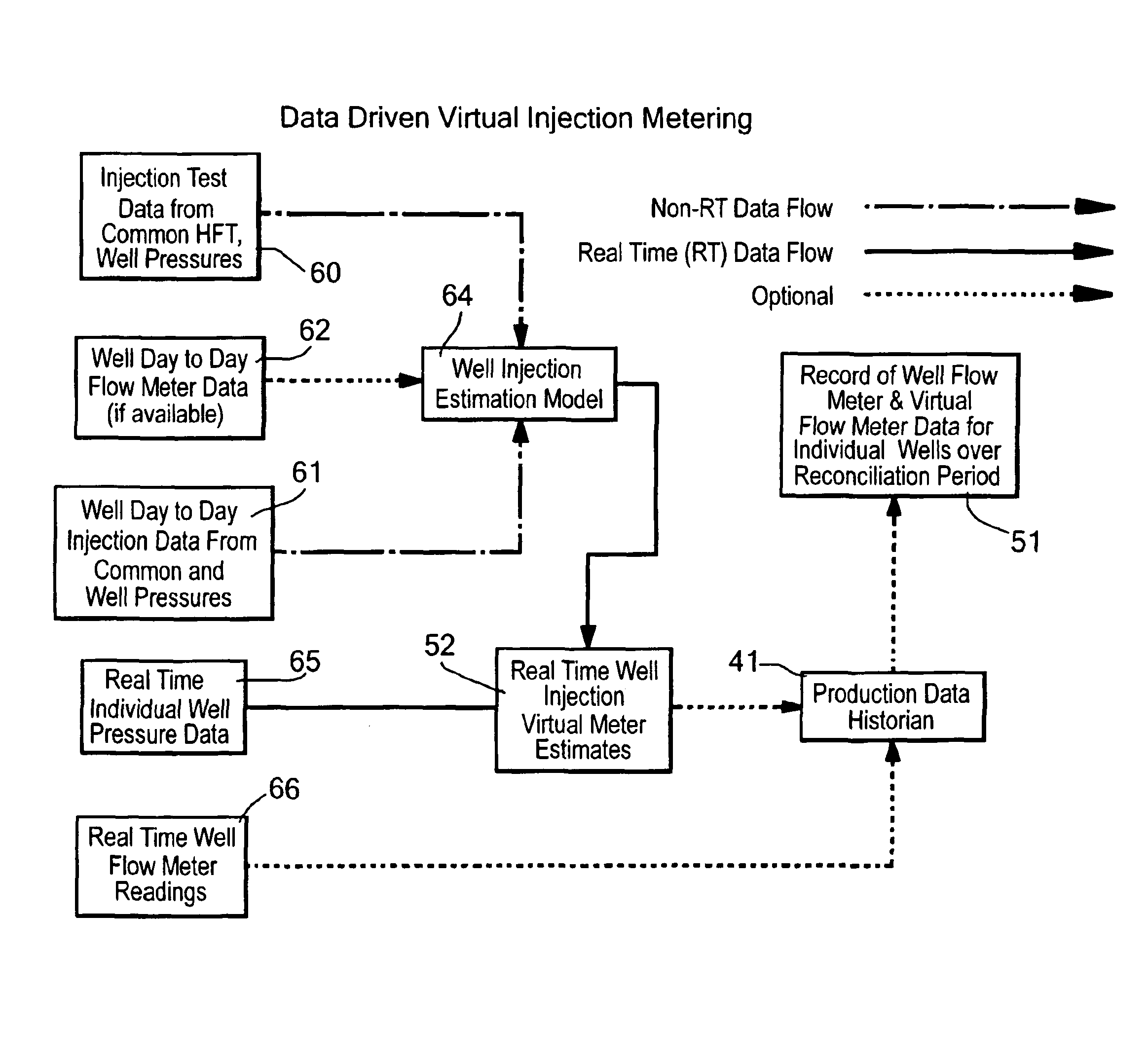

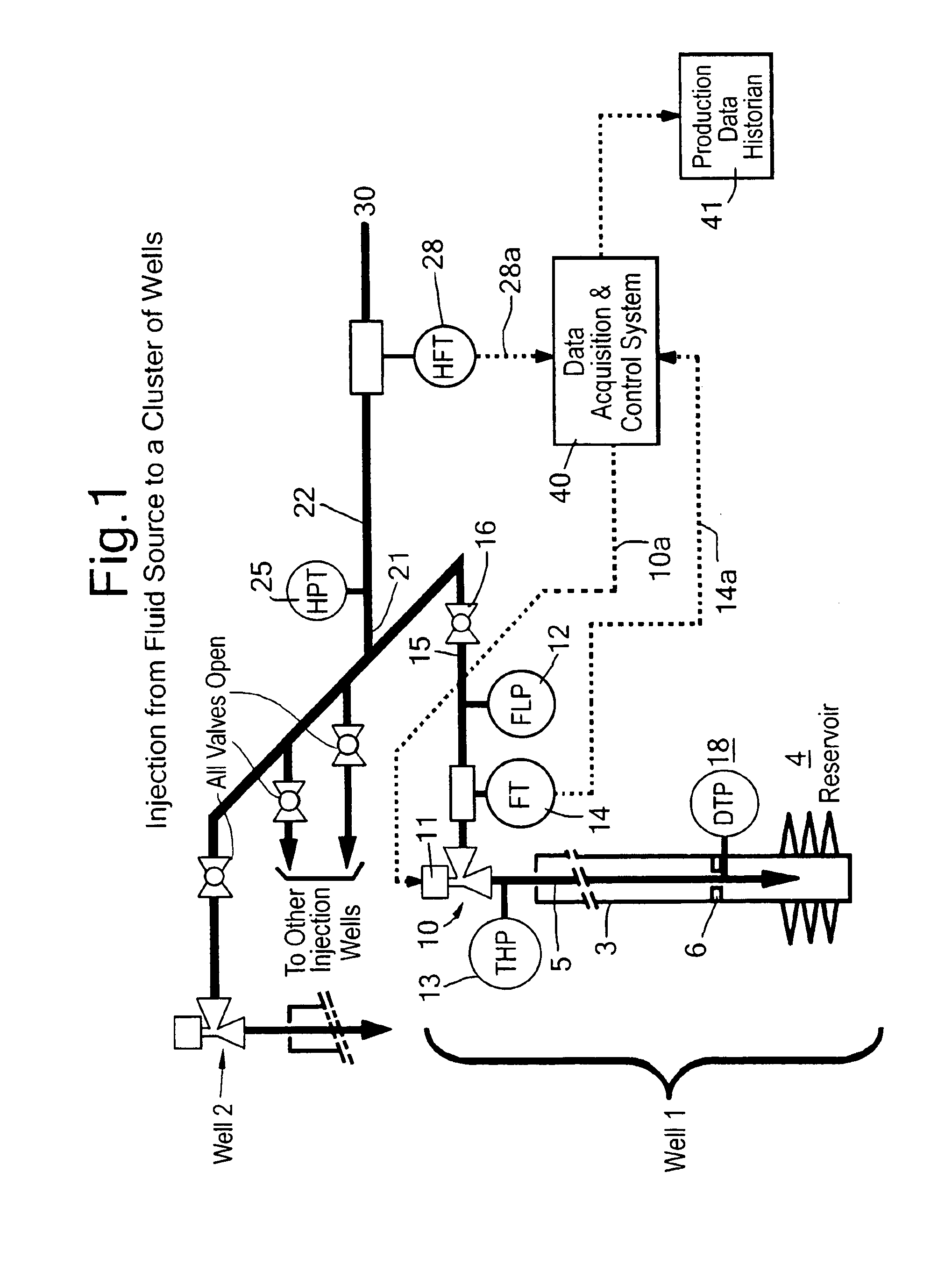

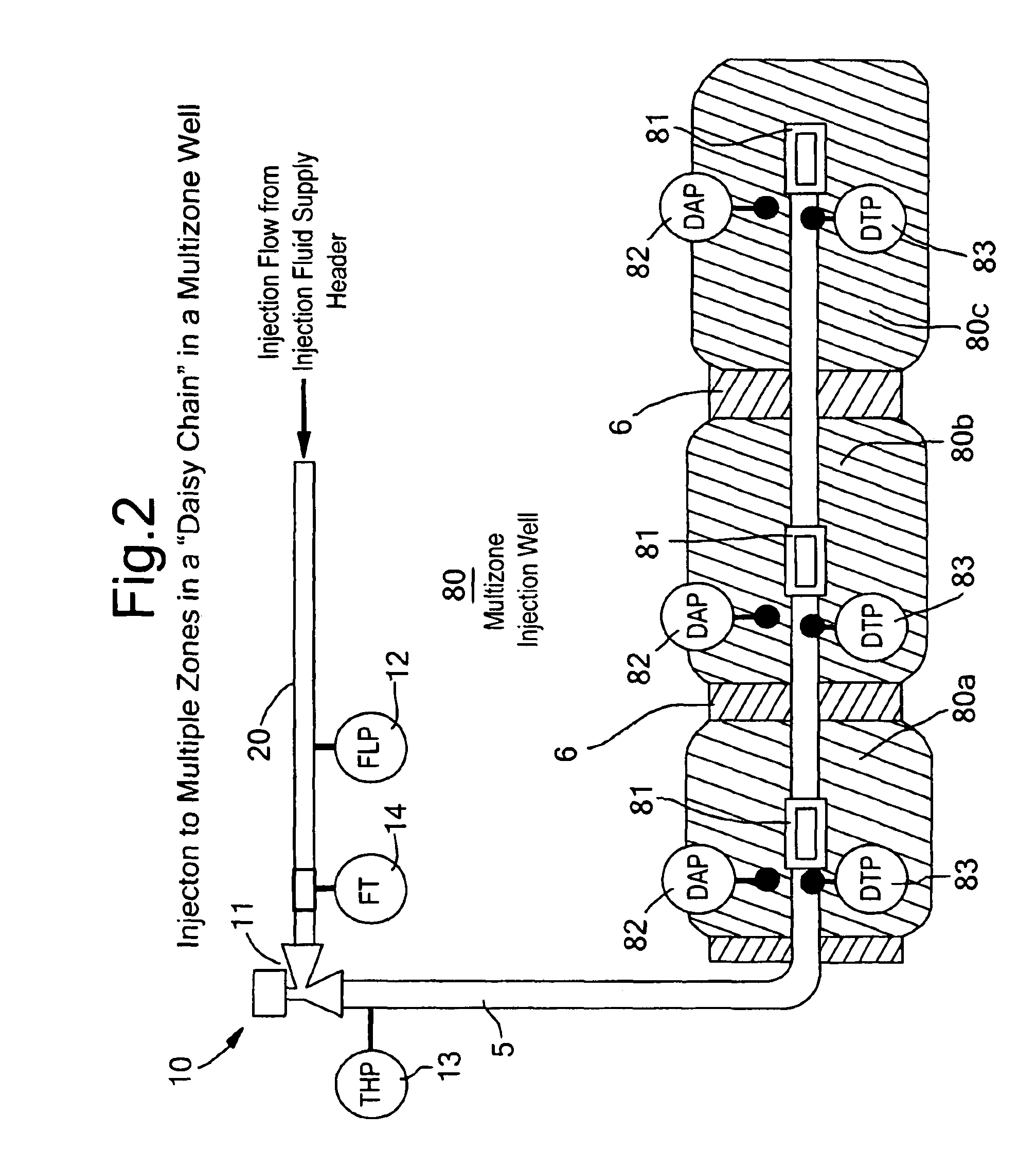

Method for virtual metering of injection wells and allocation and control of multi-zonal injection wells

ActiveUS8204693B2Electric/magnetic detection for well-loggingVolume/mass flow measurementEngineeringInjection well

A method for virtually metering flow rates in a cluster of injection wells comprises: closing each well in and performing a dynamically disturbed injection test (DDIT) on it, during which the injection rate to the well is varied while the flow rate in the header conduit assembly (HCA) and one or more injection well variables of the test well and the other wells are monitored, and the other wells are controlled so that their tubing head pressures or flow meter readings remain constant; for each tested well deriving a model providing a correlation between variations of the fluid flowrate attributable to the test well and variations of the well variables monitored during each DDIT; injecting fluid into each well while monitoring a flow pattern in the HCA and one or more well variables; calculating an estimated injection rate at each well basis on flow pattern, well variables and the model.

Owner:SHELL USA INC

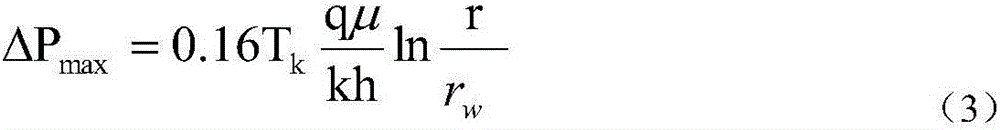

Method for determining increase range of conglomeratic oil pool polymer flooding injection pressure

ActiveCN106150463ASolve the problem of using differentiated injection parameters for different well groupsAddressing the use of differentiated injection parametersFluid removalInjection pressureOperability

The invention provides a method for determining an increase range of the conglomeratic oil pool polymer flooding injection pressure. The method comprises the following steps of a, collecting the reservoir thickness h, the injector producer distance r, the wellbore radius rw, the polymer injection viscosity mu and the injection speed q of a polymer injection well group; b, calculating the average permeability k which is an average value of the permeability ki of an injection well and a production well of the polymer injection well group; c, calculating an average heterogeneity coefficient of permeability Tk which is an average value of the heterogeneity coefficient of permeability of the injection well and the production well of the polymer injection well group according to the average permeability k obtained in the step a; d, calculating the increase range delta Pmax of the maximum injection pressure. The method for determining the increase range of the conglomeratic oil pool polymer flooding injection pressure is clear in principle, quantified, strong in operability and convenient to use, avoids determining injection parameters through in-site injection test in the present, solves the problem that different well groups of a conglomerate reservoir use different injection parameters, greatly improves efficiency and saves cost.

Owner:PETROCHINA CO LTD

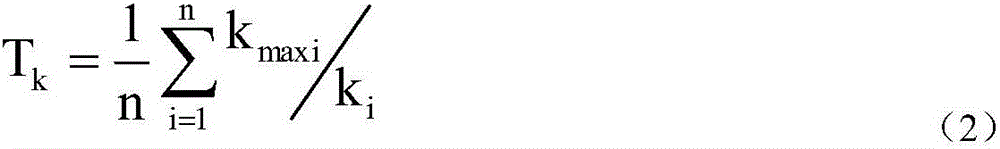

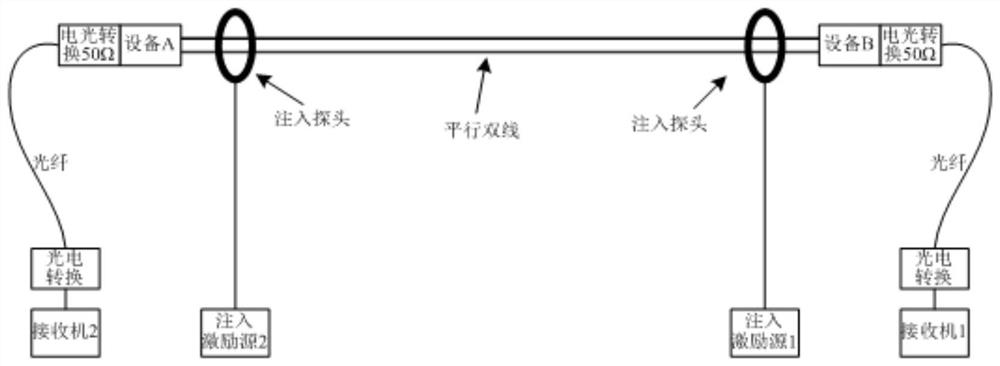

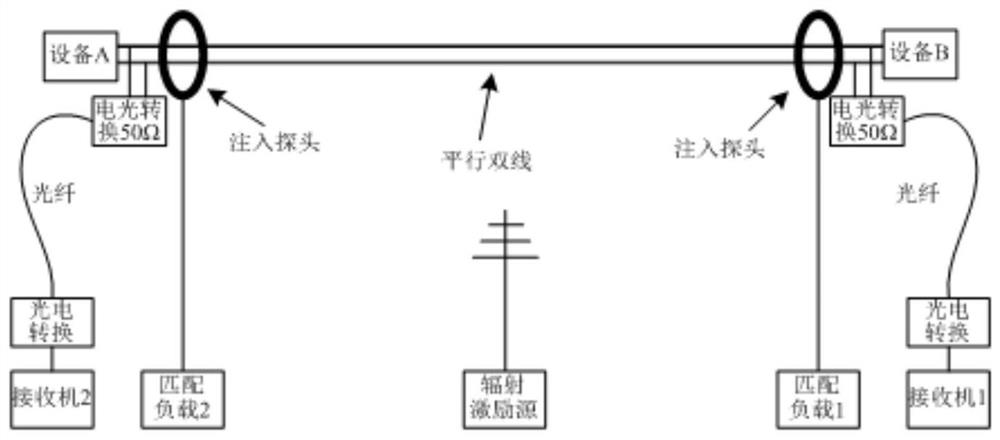

Double-line double-end bulk current injection equivalent strong-field continuous wave radiation effect test and system

ActiveCN112327060AOvercome limitationsElectromagentic field characteristicsMeasuring interference from external sourcesTerminal equipmentComputational physics

The invention discloses a double-line equivalent strong-field continuous wave radiation effect test. The method comprises the following steps: (1) monitoring equipment at two ends of a cable; (2) carrying out an injection pre-test; (3) carrying out a low-field-intensity electromagnetic radiation pre-test; (4) carrying out an equivalent injection test; and (5) acquiring an injection test result equivalent to that of a strong-field electromagnetic radiation test; the system corresponding to the method comprises a double-line radiation test and double-line injection test configuration module whenthe terminal equipment responds to a monitorable state, and a double-line low-field-intensity radiation test and double-line injection equivalent low-field-intensity radiation test configuration module when the terminal equipment responds to an unmonitorable state. The double-line double-end bulk current injection equivalent strong-field continuous wave radiation effect test and system are mainlyused for an interconnection system of which the interconnection cable is a parallel wire or a twisted pair, and the method has the advantage that the equivalent strong-field electromagnetic radiationtest can be carried out under the condition that the response of tested equipment is non-linear.

Owner:ARMY ENG UNIV OF PLA

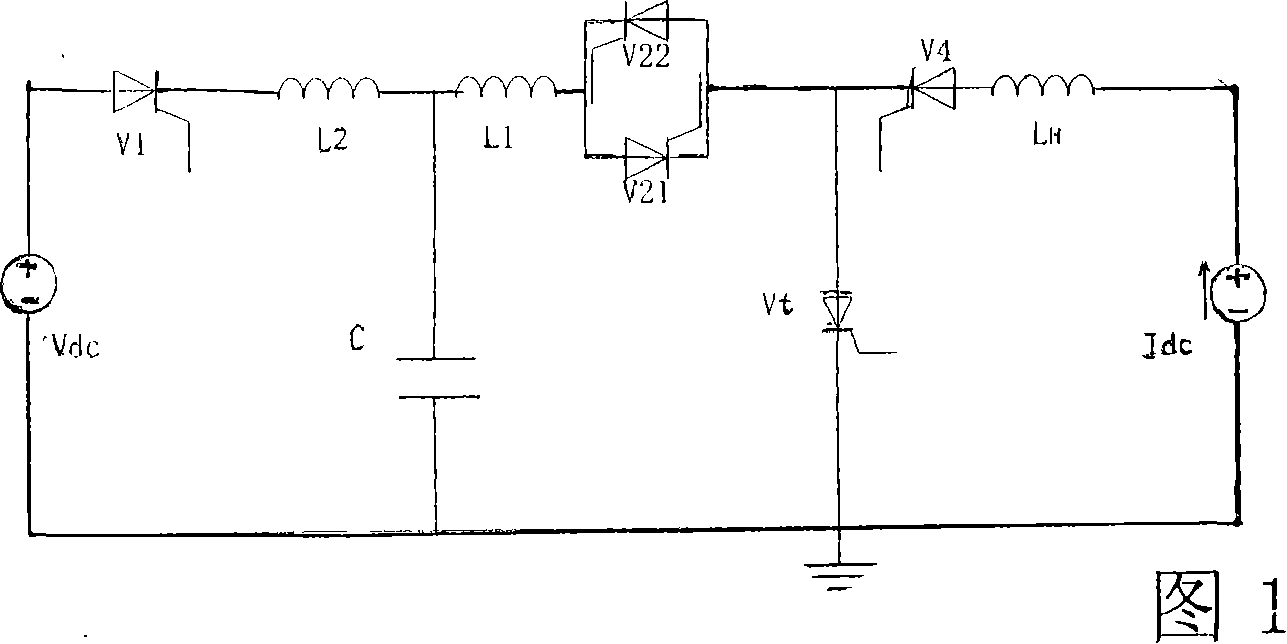

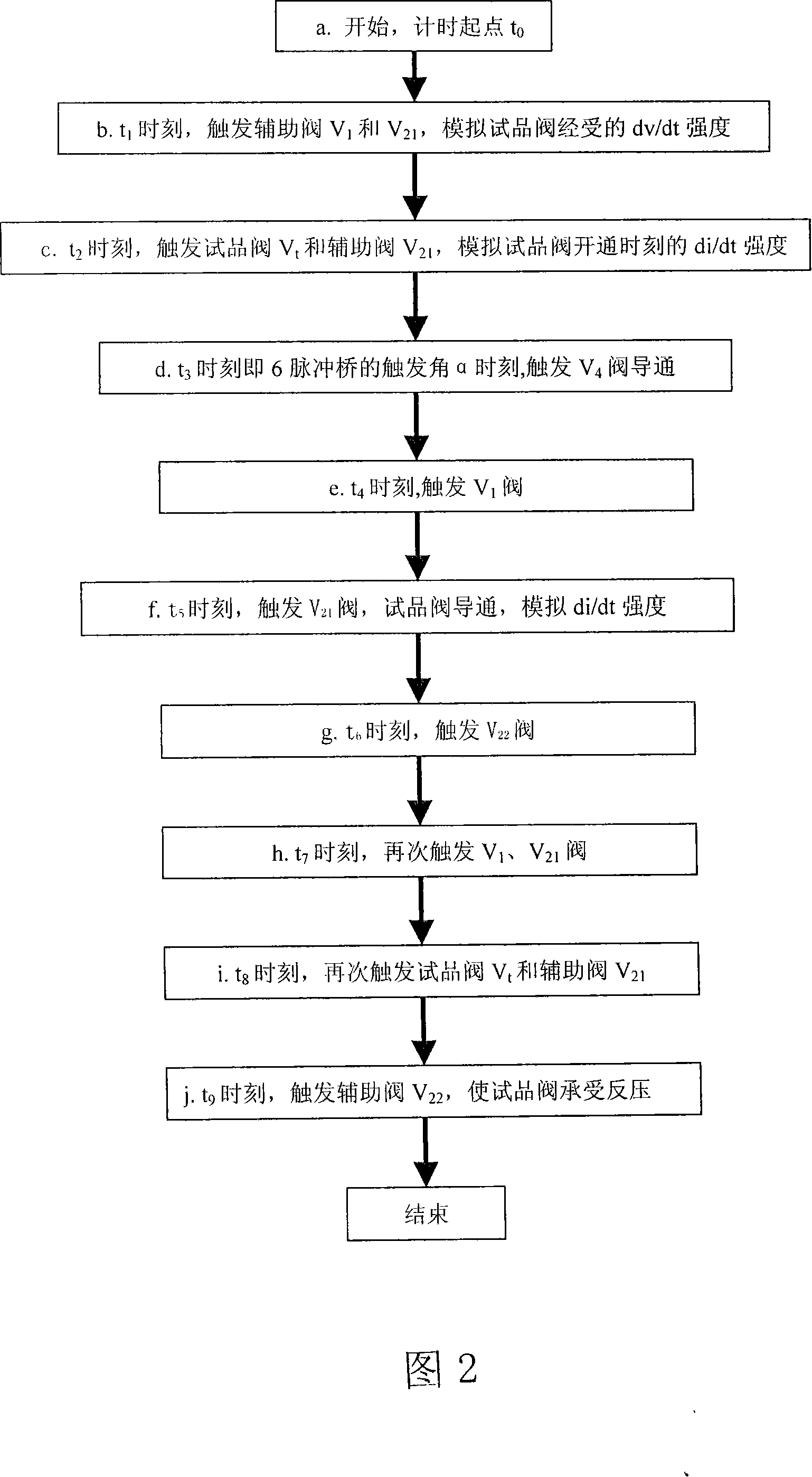

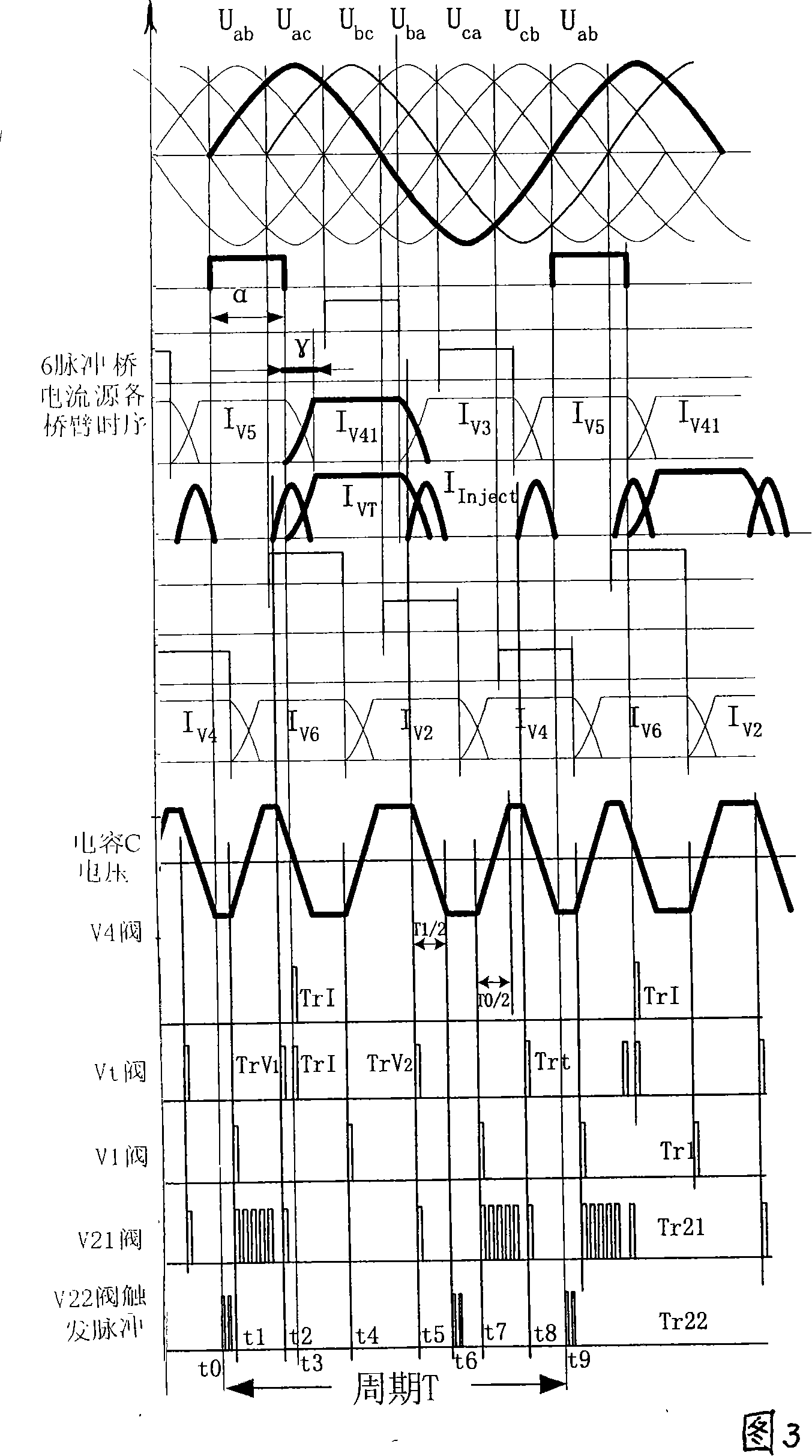

High voltage DC transmission converter valve three injection test methods

ActiveCN101162252AVersatilityConservation Strategies FavorableCircuit interrupters testingTransient stateElectricity

The invention discloses a method for a high voltage direct current valve three implantation test, belonging to the power electronic and power system field, wherein the synchronous voltage of the test is the input voltage of a big-current source; the working sequence of the test is determined by the synchronous signals; steps in a test cycle beginning at the time of t0 include: triggering service valves V1 and V21 to simulate the dv / dt intensity at the time of t1; triggering a test valve Vt and the service valve V21 to simulate the di / di intensity when the test valve is put into operation at the time of t2; triggering a valve V4 at the time of t3 which is also the time when a six-pulse bridge is at a triggering angle of alpha; triggering the service valve V1 at the time of t4; triggering the valve V21 and replenishing the test valve with pulse to conduct the test valve to simulate the di / dt intensity when the test valve is shut off at the time of t5; triggering a valve V22 at the time of t6; triggering the valves V1 and V22 again at the time of t7; triggering the test valve Vt and the service valve V21 again at the time of t8; and triggering the service valve V22 and applying counter pressure on the test valve at the time of t9. The adopted synchronous signals are commonly used; meanwhile, the method is easy to carry out with obvious results and meets the requirement of the operation of the high voltage direct current valve.

Owner:CHINA ELECTRIC POWER RES INST +1

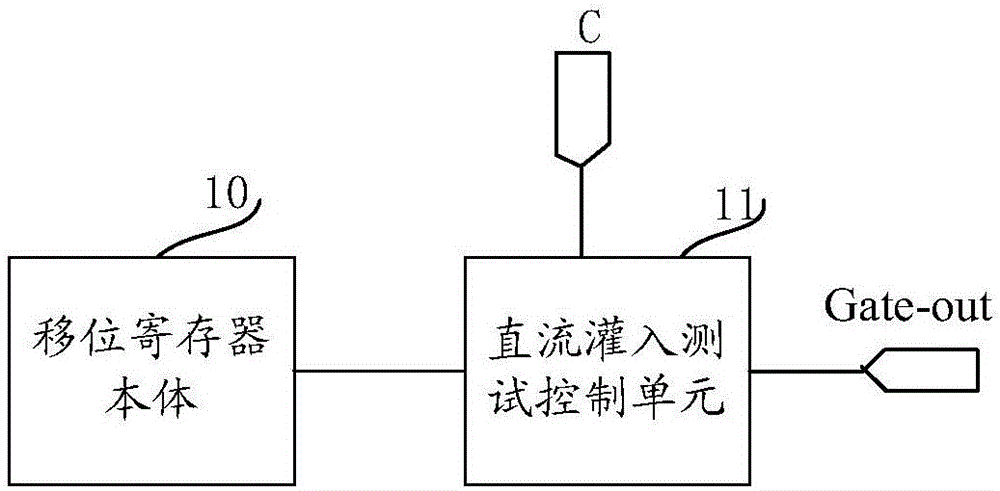

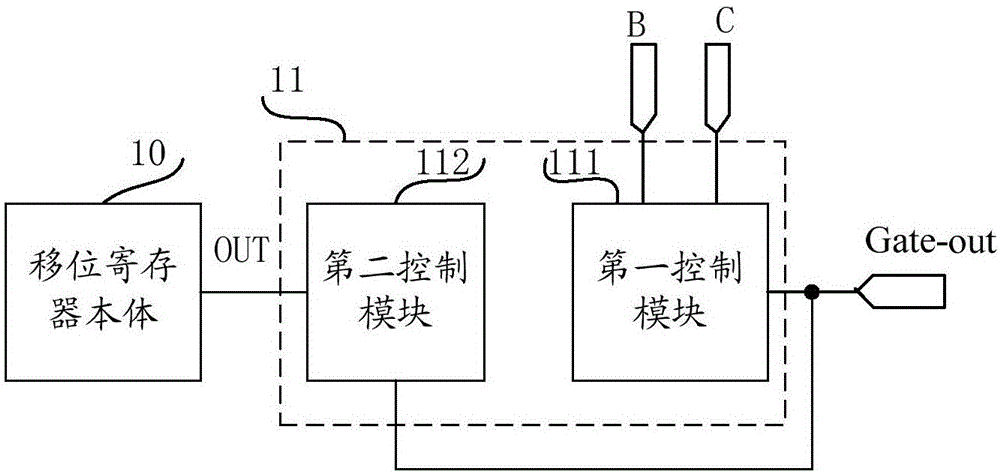

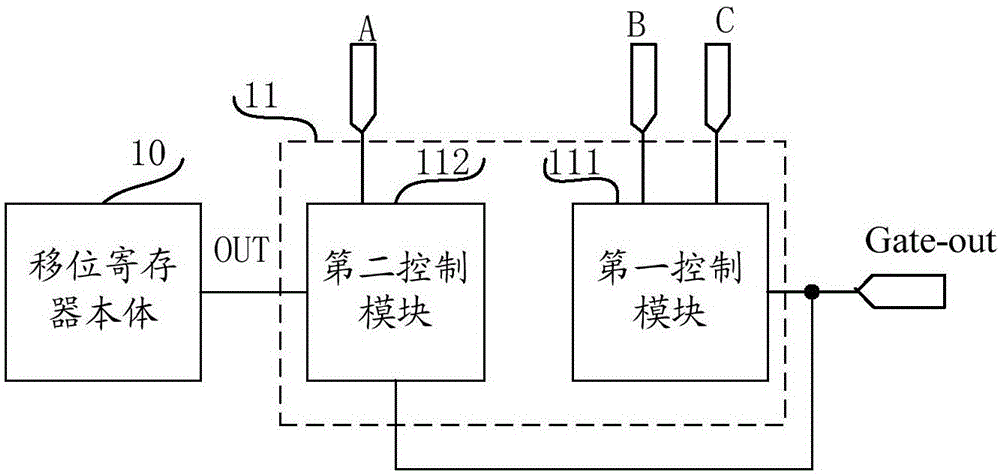

Shift register, driving method, GOA circuit and display device

ActiveCN106601174AEnables adjustable inputAvoid uncertaintyStatic indicating devicesDigital storageShift registerDisplay device

The invention provides a shift register, a driving method, a GOA circuit (a gate drive circuit manufactured on an array substrate) and a display device. The shift register comprises a shift register body, a gate driving signal output end, a direct current test signal writing end, and a direct current injection test control unit which is used for controlling the direct current test signal writing end to connect the gate driving signal output end in a direct current injection test period and controlling the direct current test voltage signal written by the direct current test signal writing end to be not coupled to the shift register body. According to the shift register, the driving method, the GOA circuit and the display device, the adjustable input of a gate direct current signal can be carried out in a direct current injection test period.

Owner:BOE TECH GRP CO LTD +1

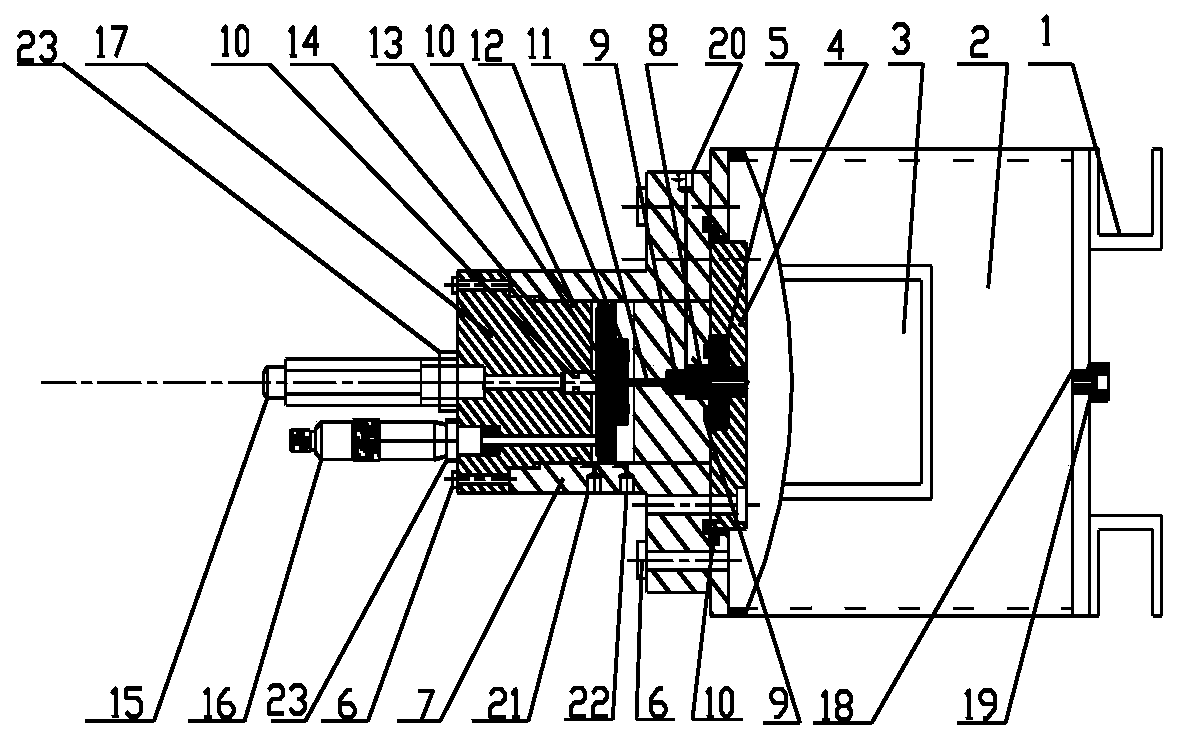

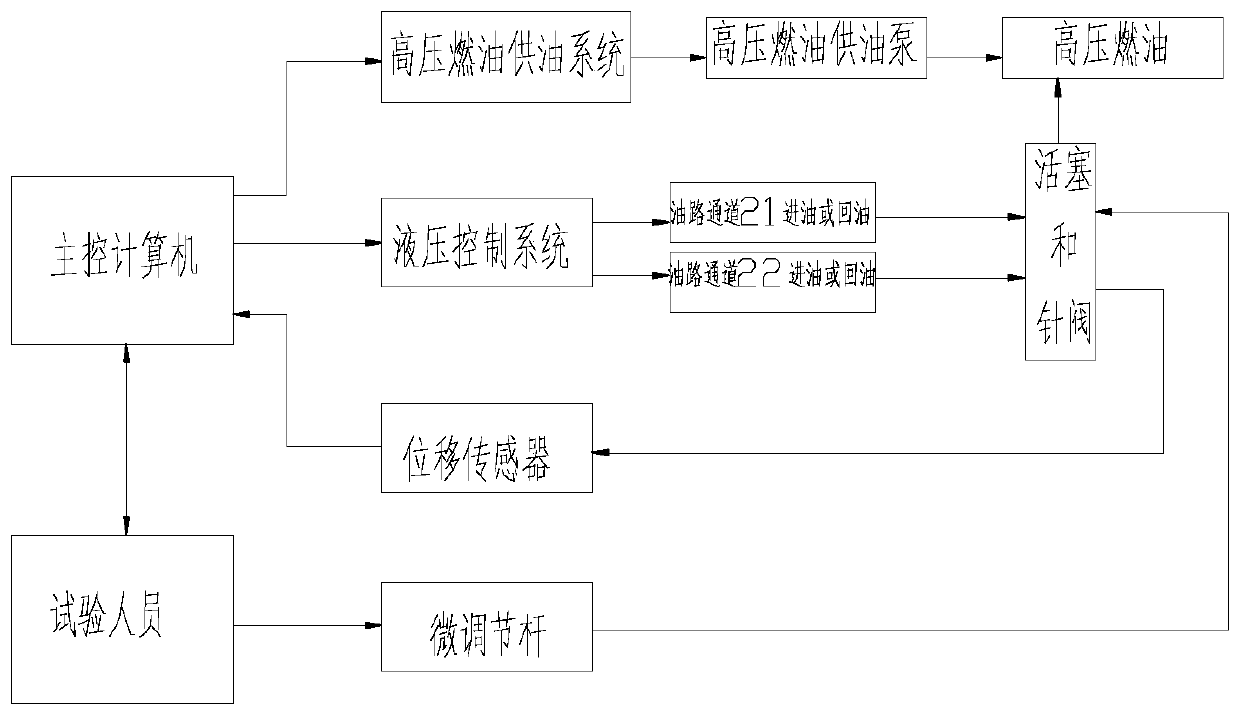

Injection test device with controllable needle valve movement speed and adjustable needle valve lift

ActiveCN110067685AControl movement speedAchieve movement speedEngine testingFuel injection apparatusControl systemFuel oil

The invention discloses an injection test device with a controllable needle valve movement speed and an adjustable needle valve lift. The injection test device with the controllable needle valve movement speed and the adjustable needle valve lift comprises a base device, a needle valve regulation injection device, a cavity device, a high-pressure fuel oil supply system and a hydraulic control system, wherein a fuel inlet and two fuel path channels are arranged on the cavity device; the needle valve regulation injection device is arranged in the cavity device; the cavity device is connected with the base device through an inner hexagonal screw; the fuel inlet is connected with the high-pressure fuel oil supply system; and the two fuel path channels are connected and provided with the hydraulic control system. The application of the injection test device is as follows that a experimental personnel through the hydraulic control system and a micro-adjusting rod, controls the movement speedof a needle valve, and the maximum stroke of the needle valve, to study the influence of the dynamic process of the needle valve on the fuel atomization; and meanwhile, a device for controlling a needle valve to ascend and descend or controlling the needle valve to ascend and descend by using a mechanical spring and fuel or an air cylinder is replaced, so that the speed of the needle valve and the displacement of the needle valve are adjusted with high precision.

Owner:SHANGHAI MARITIME UNIVERSITY

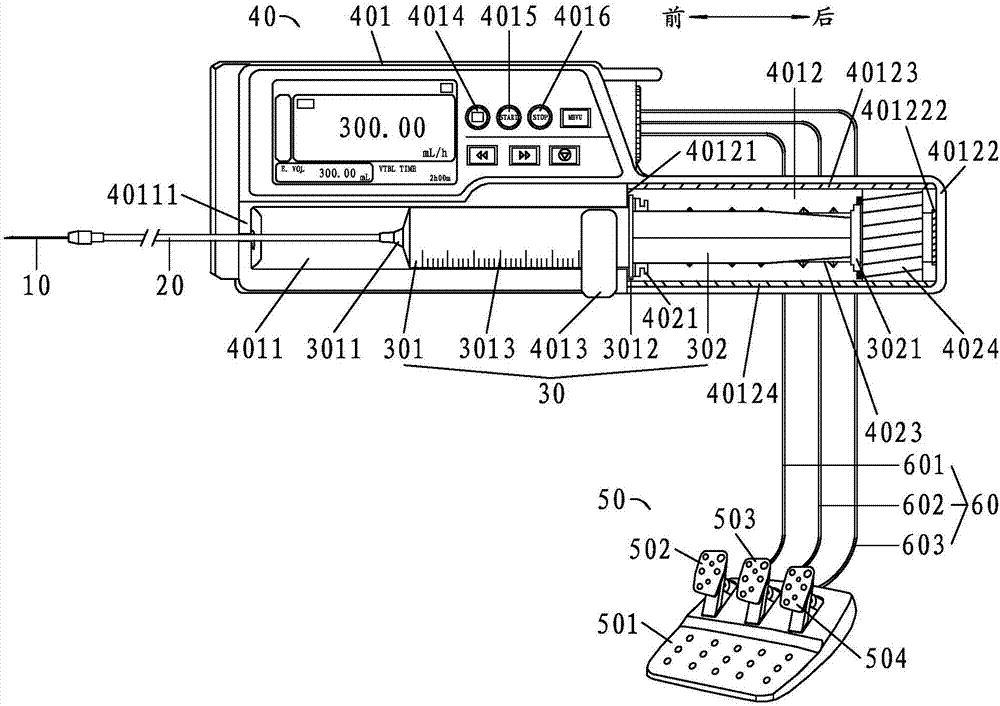

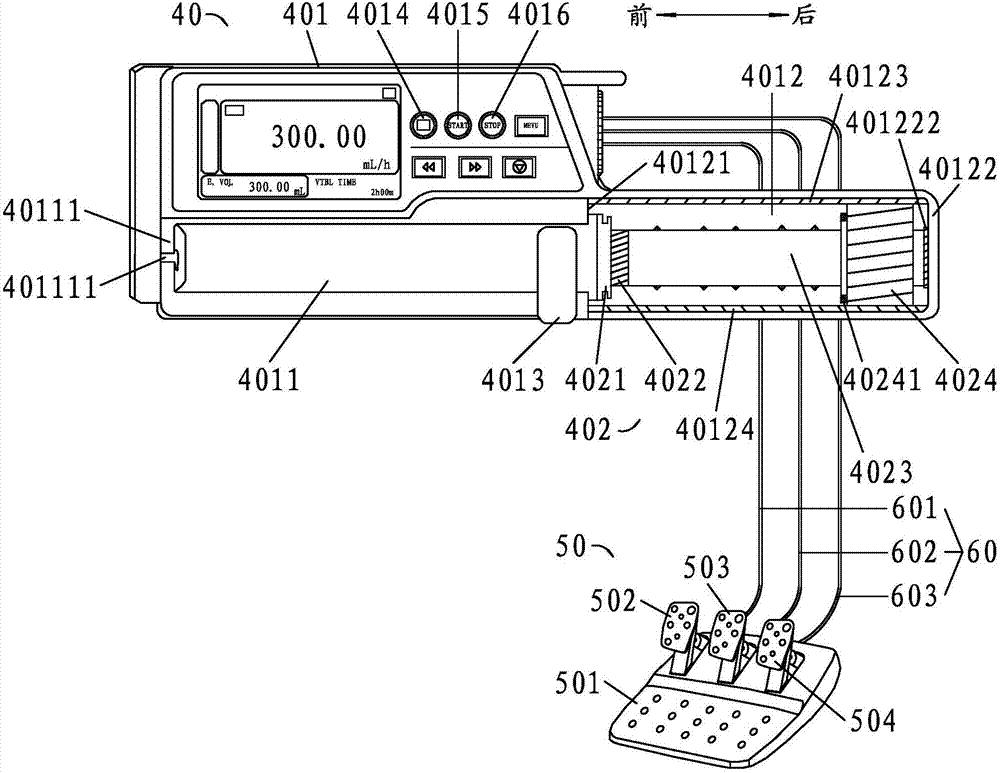

Nerve block injection test device

PendingCN107308522ASave human effortImprove work efficiencyAutomatic syringesMedical devicesPharmacy medicineNarcotic

The invention discloses a nerve block injection test device. The device comprises a nerve block puncture needle, a liquid injection catheter, an injector, an injection pump and a treadle type filling injector; the liquid inlet end of the nerve block puncture needle is connected with the liquid outlet end of the liquid injection catheter; the liquid inlet end of the liquid injection catheter is connected with the liquid outlet end of the injector; the injector is clamped on the injection pump; the treadle type filling injector is connected with the injection pump through signal conveying lines. The device has the advantages that when in implementation, a doctor holds an ultrasonic probe by one hand so that a part which needs anesthetization on a patient body can develop on a computer, the doctor holds the nerve block puncture needle by the other hand to conduct puncture on the corresponding part which needs anesthetization, and then the filling injection of narcotic liquid can be completed by stepping on the corresponding treadle type filling injector, so that the troubles can be omitted that the doctor talks to another doctor and guides another doctor to hold the injector and push the narcotic medicine to a narcotic part, then the injection test work can be completed only by one doctor, and thus the labor can be saved, and the working efficiency can be improved.

Owner:PEKING UNIV SHENZHEN HOSPITAL

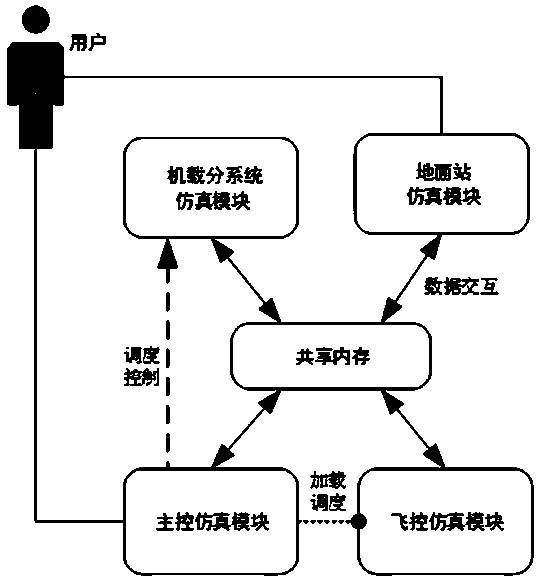

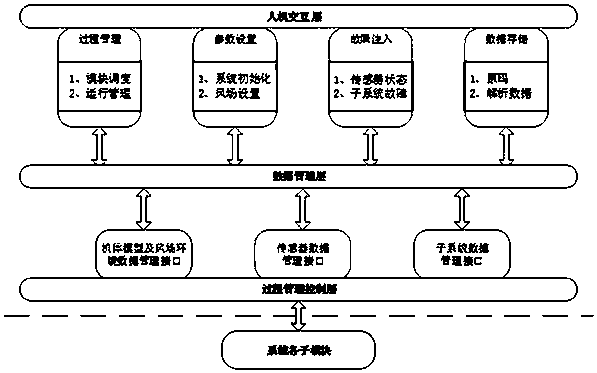

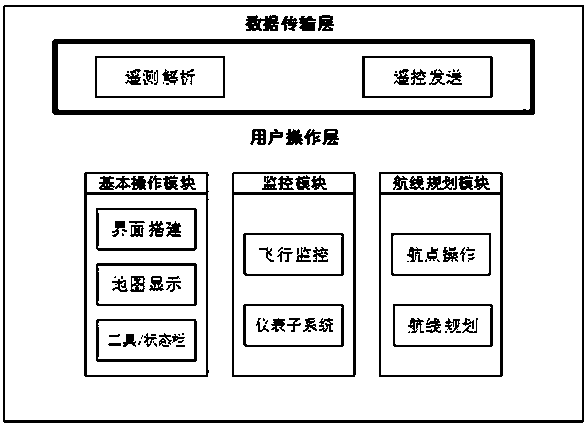

Unmanned plane portable simulation system

InactiveCN109283854AEasy to carryEasy to use and maintainSimulator controlFlight testSystems simulation

The invention discloses an unmanned plane portable simulation system comprising a flight control simulation module, an airborne subsystem simulation module, an earth station simulation module and a master control simulation module; the flight control simulation module, the airborne subsystem simulation module, the earth station simulation module and the master control simulation module are integrated on a PC machine; data communication among said parts can be realized via a shared memory mechanism, thus finishing an unmanned plane normal flight test, a fault injection test and a wind interference injection test; the shared memory mechanism forms a global data pool. The system can realize the unmanned plane task profile simulation flight that includes the normal flight test, the fault injection test and the wind interference injection test, thus ensuring the timeliness simulation requirements; in addition, scientific research personnel can easily take the system outside for field simulation tests, thus providing an excellent developing environment for research and development works of the scientific research personnel.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

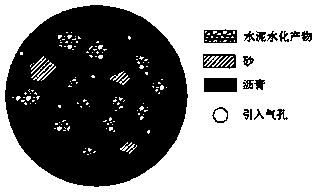

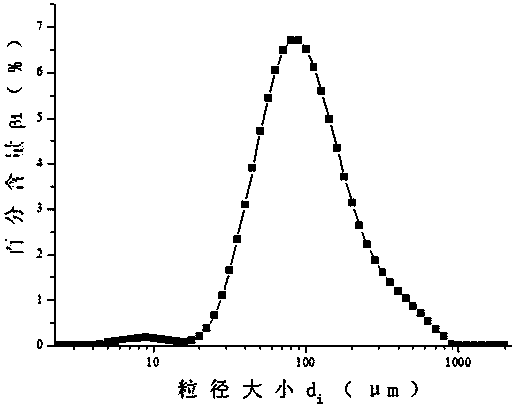

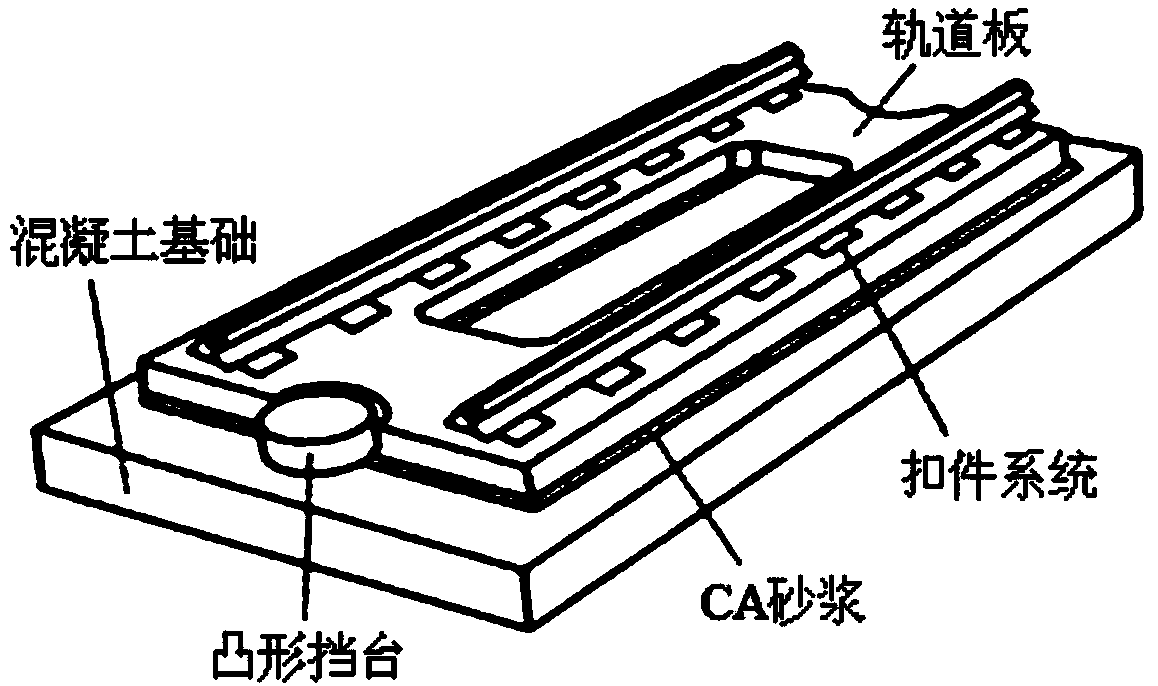

Test method for determining CRTSI type CA mortar asphalt film thickness

The invention discloses a test method for determining the CRTSI type CA mortar asphalt film thickness. The CRTSI type CA mortar asphalt film thickness is determined through combination between tests and theoretical calculation. The CA mortar solidified body comprises, by volume, asphalt, cement hydration particles, sand and pores. The asphalt film thickness is determined according to the volume composition relationship of the CA mortar solidified body, and the average particle diameter of the cement hydration product particles, the average particle diameter of the sand, and the size (average particle diameter) and porosity in the CA mortar solidified body are determined at first. The volume composition relationship of the CA mortar solidified body is sufficiently taken into consideration during calculation of the asphalt film thickness. The particle diameter composition of the sand is obtained through a screening test, the particle diameter composition of the cement hydration products is obtained through a laser particle diameter analysis test, and the composition of the pores in the CA mortar solidified body is obtained through a mercury injection test. On this basis, the CA mortar asphalt film thickness can be accurately calculated through the test method.

Owner:HARBIN INST OF TECH

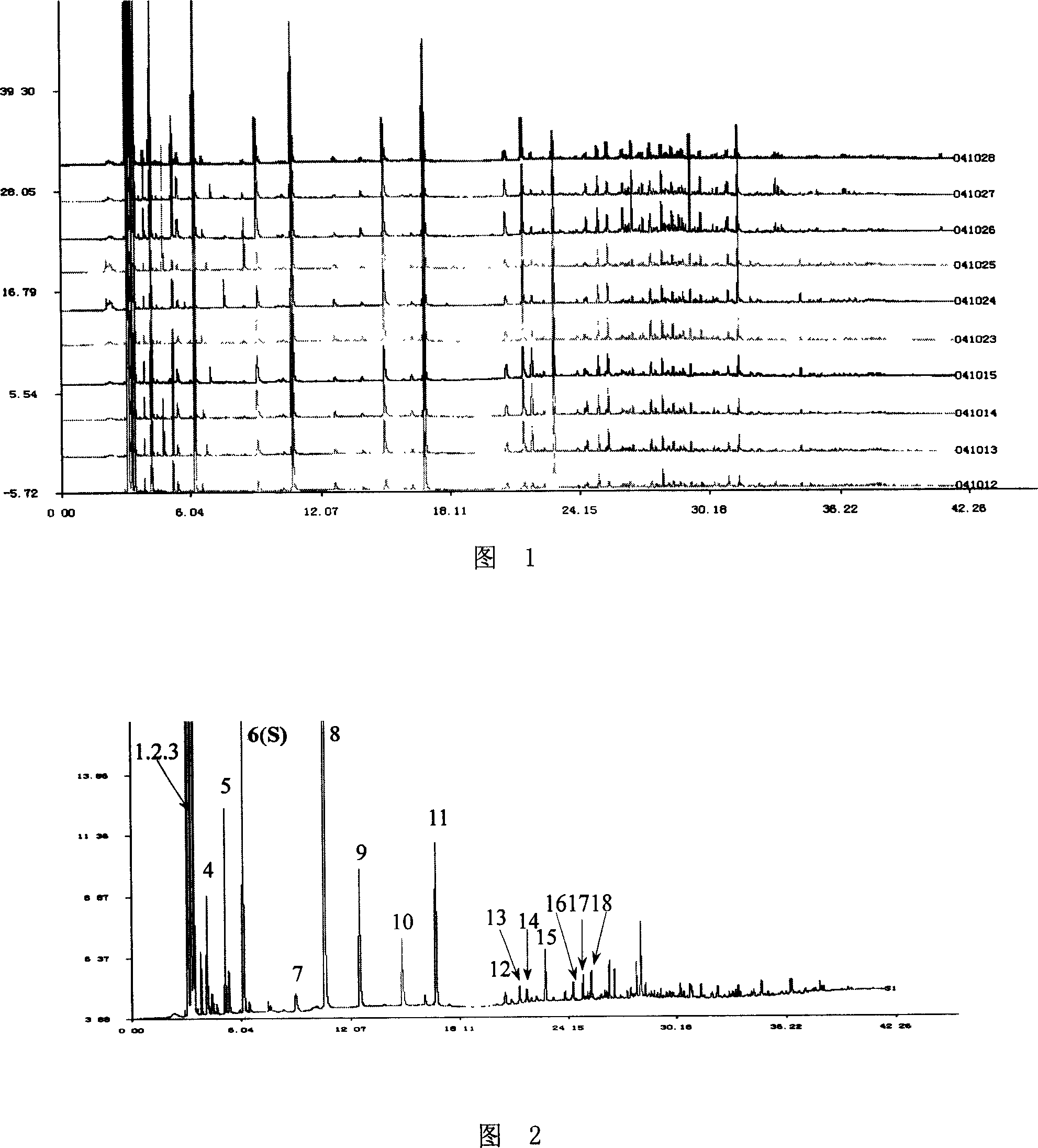

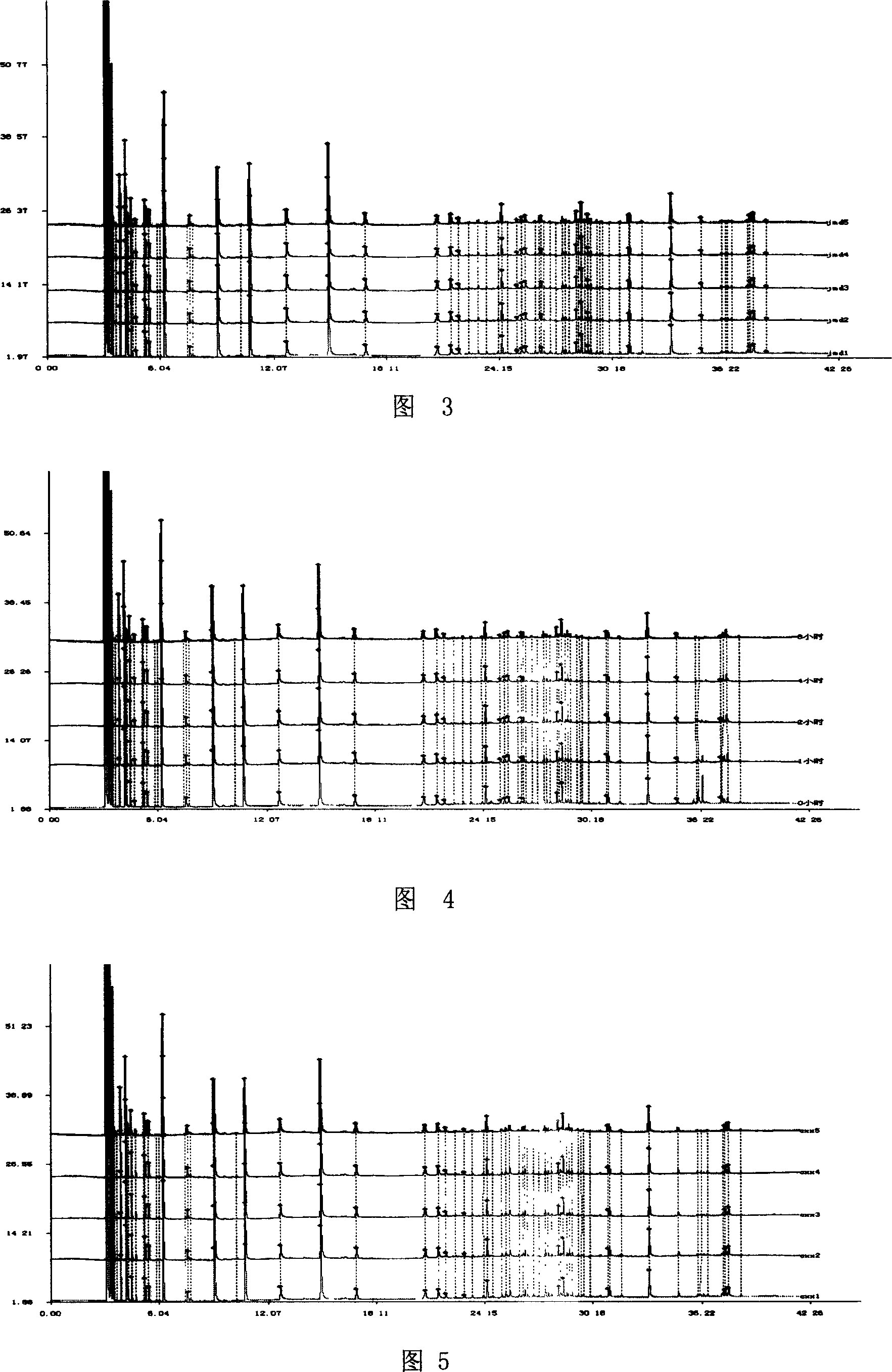

Quality controlling method of Bupleurum injection

InactiveCN101013110AEffective Quality MonitoringImprove stabilityComponent separationTesting medicinal preparationsClinical efficacyPattern detection

The invention discloses Bupleurum injection quality control method. Bupleurum injection quality control method of this invention includes the following steps: the first step, using gas chromatography to establish Bupleurum injection comparison fingerprint pattern: the second step, according to the first step, measuring Bupleurum injection testing saple fingerprint pattern; the third step, calculating similarity of Bupleurum injection testing sample fingerprint pattern and comparison fingerprint pattern, and screening the samples according with Bupleurum injection fingerprint pattern detection standard as qualified products. Through the establishment of Bupleurum injection fingerprint pattern, the invention uses fingerprint pattern to control the quality of Bupleurum injection, with advantages of good repeatability, higher stability, and so on, and it can effectively monitor the quality of Bupleurum injection, to ensure stable and consistent Bupleurum injection clinical effect, and it has important application value.

Owner:北京华医神农医药科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com