Coal pore correction method based on mercury injection experiment

A correction method and pore technology, which is applied in the analysis of suspensions and porous materials, measuring devices, instruments, etc., can solve the problems of increased mercury injection, calculation errors, calculation models and actual pore errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

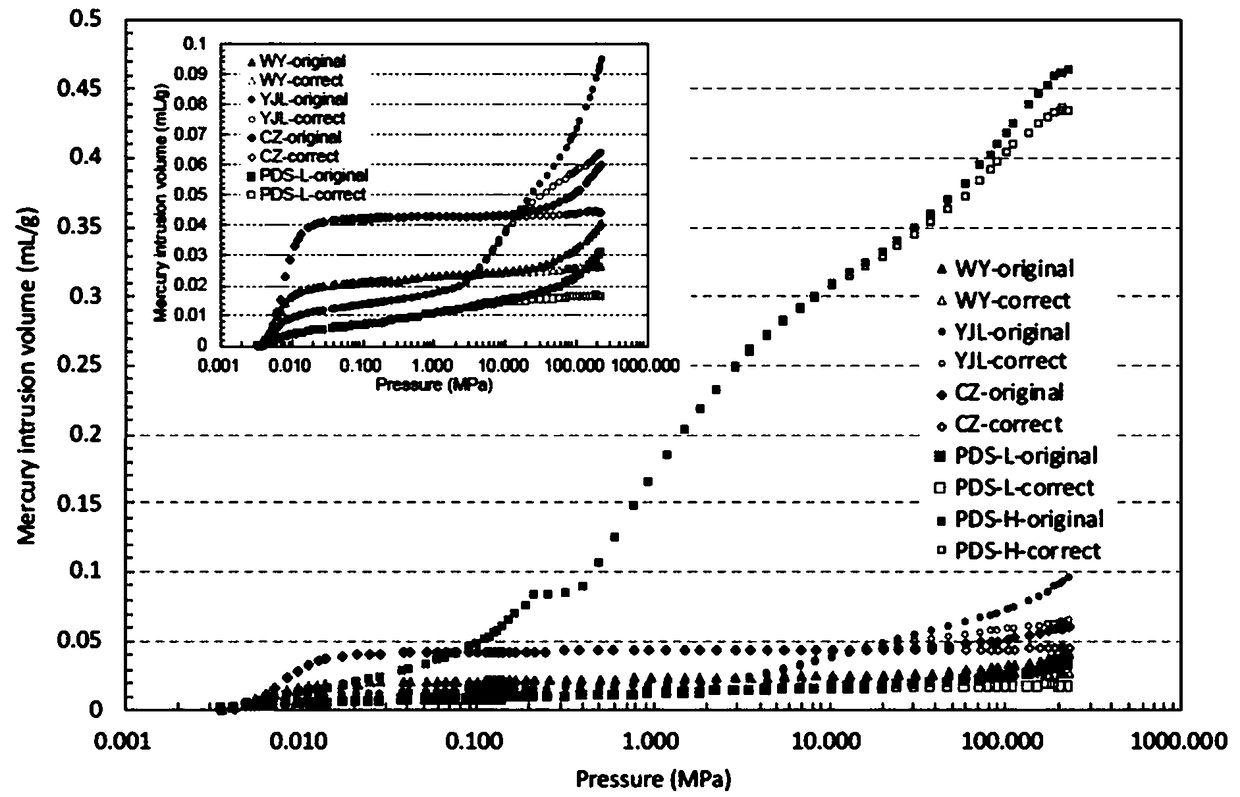

[0065] Embodiment 1. The correction of matrix compression effect is as follows:

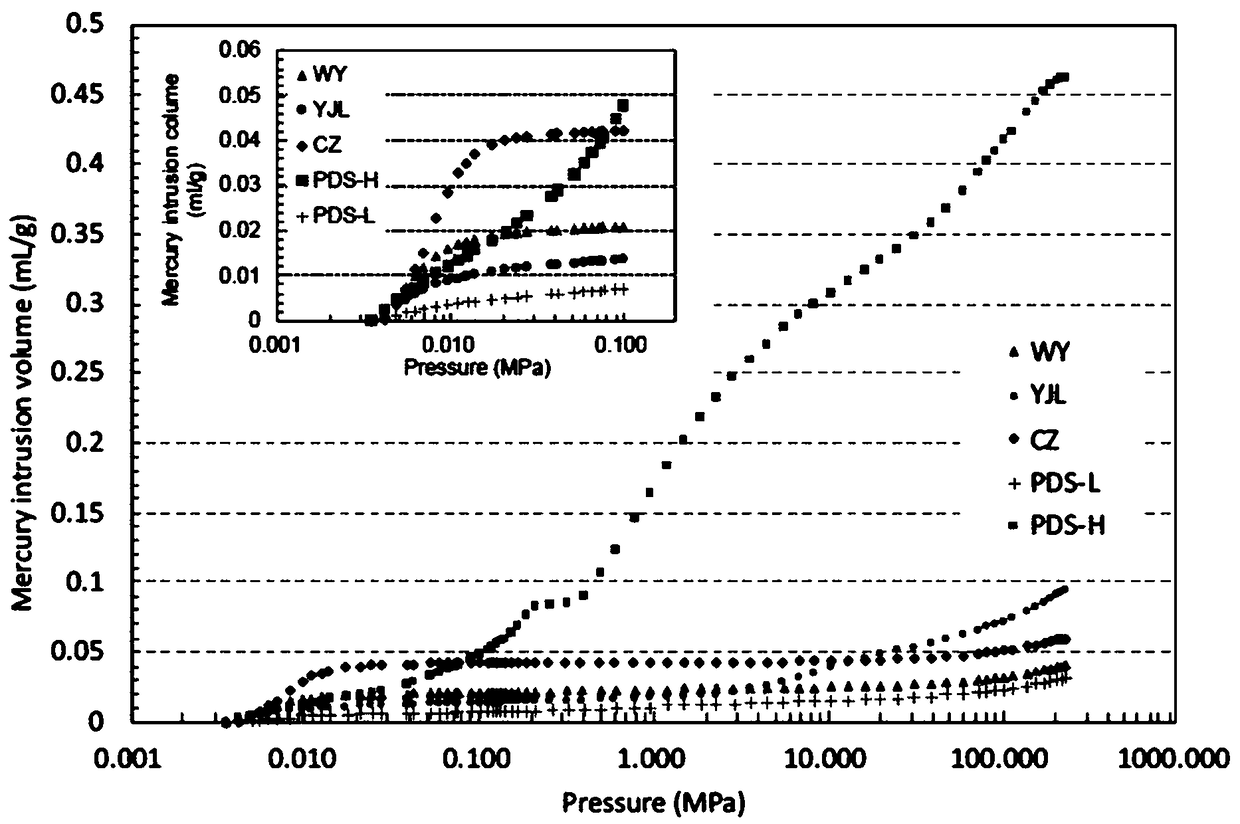

[0066] The amount of mercury injected during the mercury injection test is the sum of the amount of mercury filled in the pores, the amount of compression deformation of the matrix, and the amount of shrinkage deformation of pores not filled with mercury. As the mercury injection pressure increases, the amount of mercury-filled pores will gradually increase, and the pore deformation will also change accordingly. Therefore, in the process of mercury injection, the mercury injection amount under different mercury injection pressures is related to the number of pores in the coal and the compression of the coal matrix. The amount of deformation and the amount of shrinkage and deformation of coal pores is a dynamic process, and the relationship between the three is extremely complicated. It is difficult to accurately describe the continuous change of each variable and the relationship between them. Ho...

Embodiment 2

[0076] Embodiment 2, the intergranular pore effect and the hemp skin effect correction are as follows:

[0077] The mercury injection error in the low-pressure section is mainly due to the intergranular pore effect and the hemp skin effect. When the particle size of the test sample is small and the particles are randomly piled up, mercury can only enter the gaps between the particles under a certain pressure. The amount of mercury intrusion caused by the intergranular pores is called the intergranular pore effect. The surface of coal particles is uneven, with well-developed edges and corners. At the initial stage of mercury injection, it is difficult to be completely filled with mercury in the rough pits and corners. As the pressure gradually increases, the cavity gradually shrinks and disappears until it is completely filled with mercury. The amount is called the hemp effect. This is an important factor affecting the amount of mercury injected in the low-pressure section.

...

Embodiment 3

[0082] Embodiment 3, the correction of pore shape effect is as follows:

[0083] According to the provisions of ISO 15901-1:2005, the pores of porous materials are cylindrical, and the relationship between the calculated pressure and the pore diameter is calculated by the washburn equation to obtain the following formula:

[0084]

[0085] Among them, σ is the surface tension of mercury, which is 0.485N / m; d p is the pore diameter, in nm; p is the mercury injection pressure, in MPa; θ is the wetting angle of coal to mercury, in radians;

[0086] The relationship between pore diameter and pressure is also different for different pore shapes. The mercury injection pressure is related to the additional pressure Δp generated by the curved liquid surface in the pore fissure. According to the Young-Laplace equation, the relationship between Δp and the radius of curvature of the liquid surface in different shapes can be obtained for:

[0087]

[0088] Among them, σ is the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com