Patents

Literature

1010 results about "Skin effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

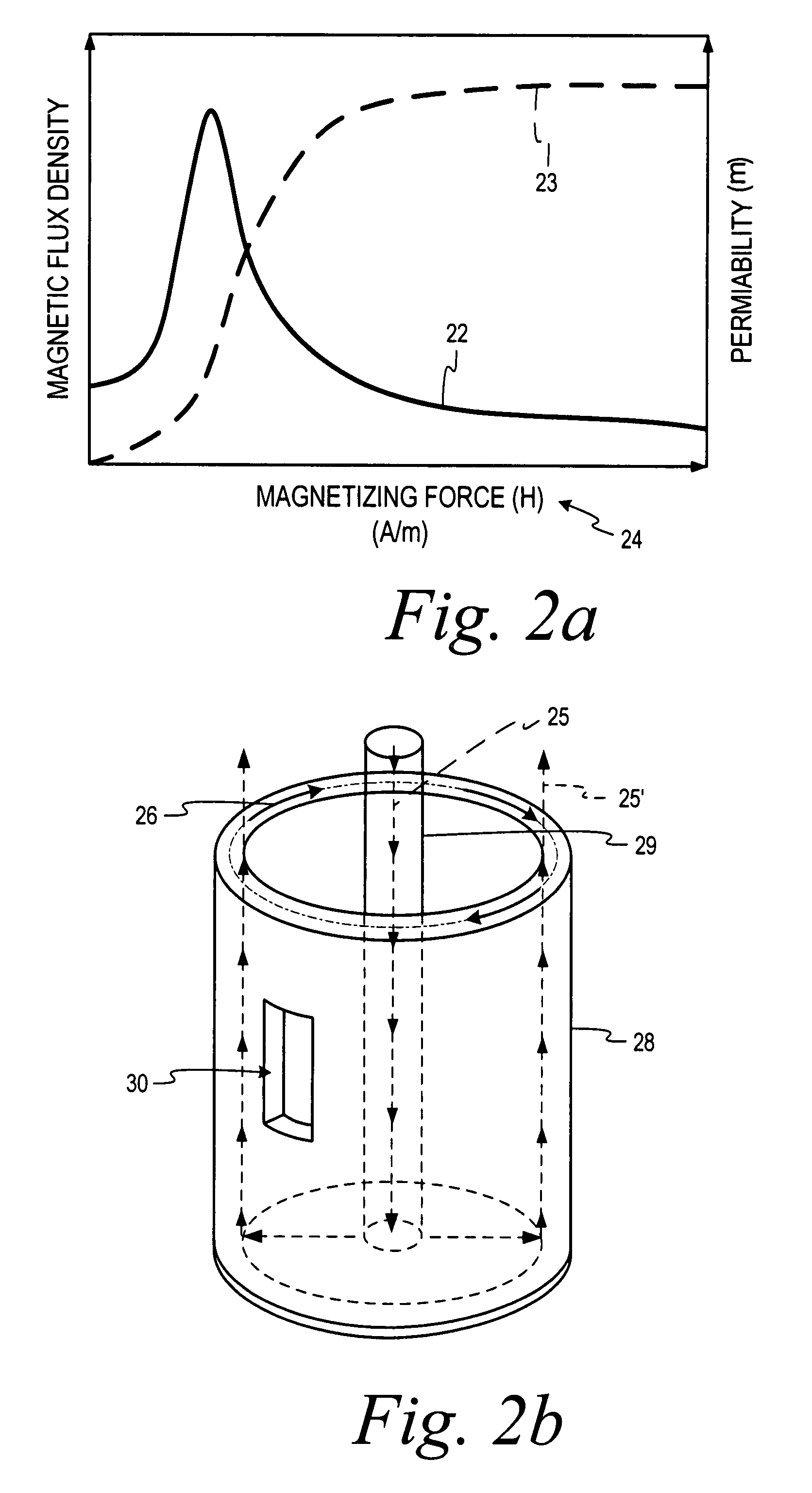

Skin effect is the tendency of an alternating electric current (AC) to become distributed within a conductor such that the current density is largest near the surface of the conductor, and decreases with greater depths in the conductor. The electric current flows mainly at the "skin" of the conductor, between the outer surface and a level called the skin depth. The skin effect causes the effective resistance of the conductor to increase at higher frequencies where the skin depth is smaller, thus reducing the effective cross-section of the conductor. The skin effect is due to opposing eddy currents induced by the changing magnetic field resulting from the alternating current. At 60 Hz in copper, the skin depth is about 8.5 mm. At high frequencies the skin depth becomes much smaller. Increased AC resistance due to the skin effect can be mitigated by using specially woven litz wire. Because the interior of a large conductor carries so little of the current, tubular conductors such as pipe can be used to save weight and cost.

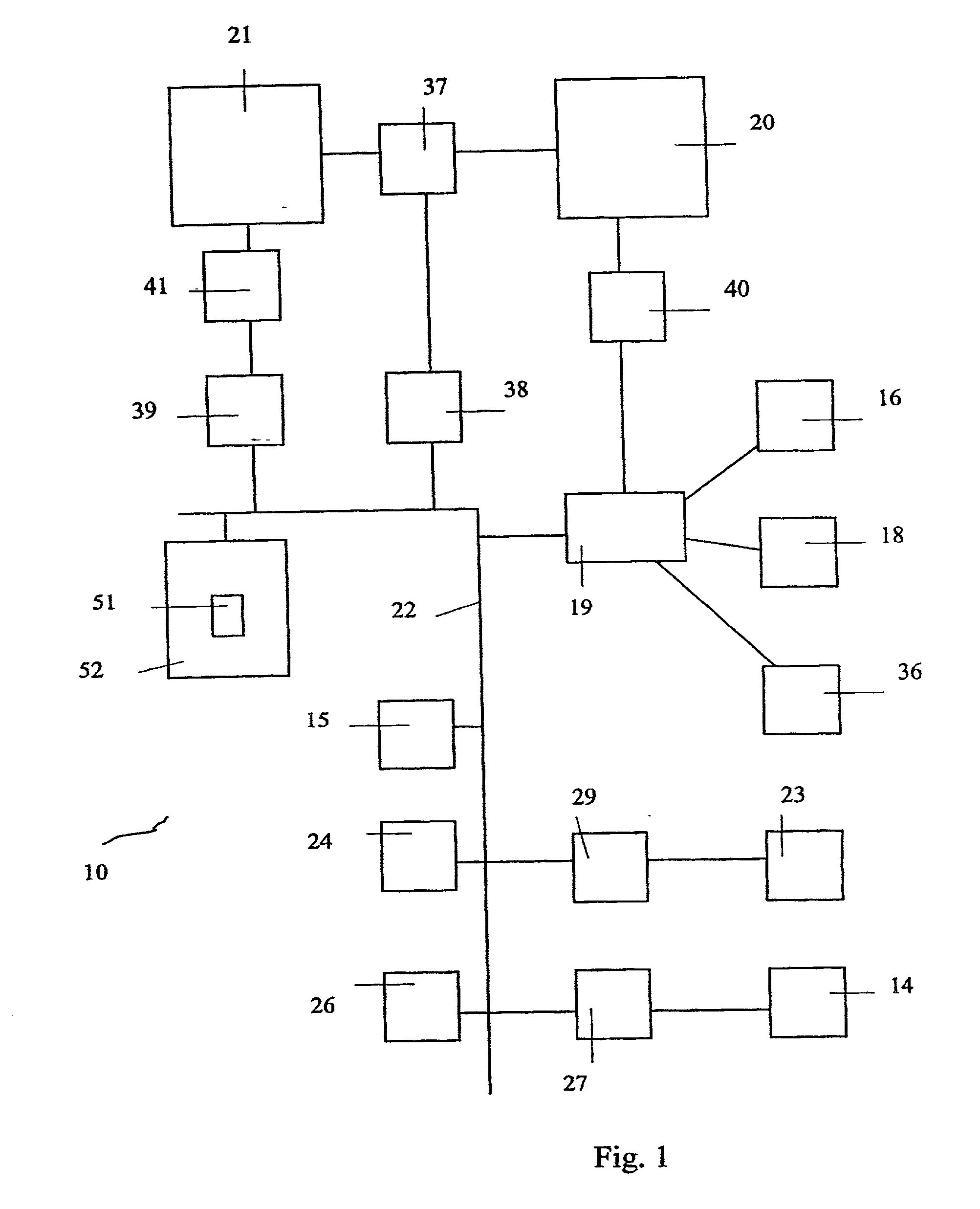

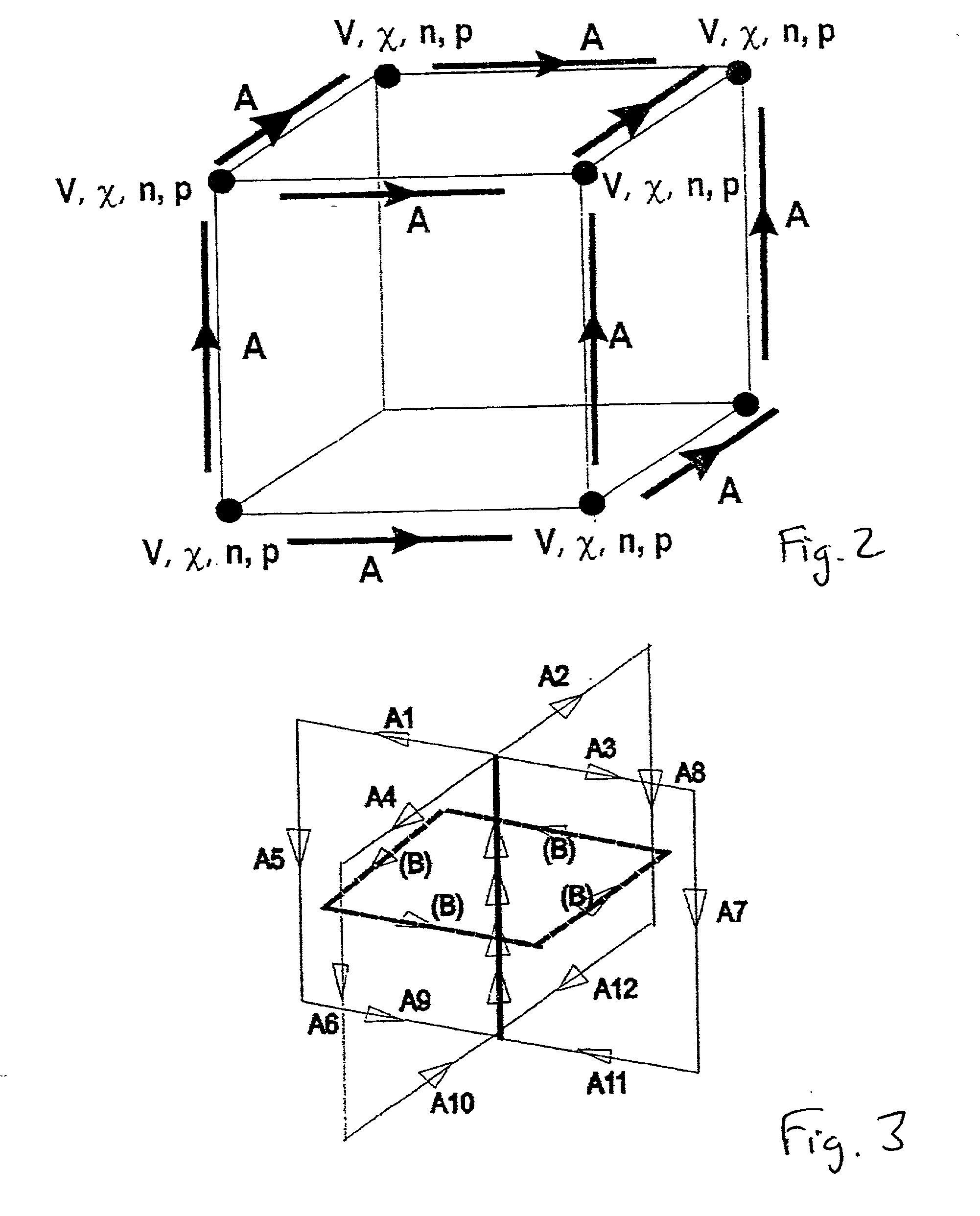

Method and apparatus for simulating physical fields

InactiveUS6665849B2Less storage spaceAvoid excessive intensityDetecting faulty computer hardwareAnalogue computers for chemical processesPhysical fieldEngineering

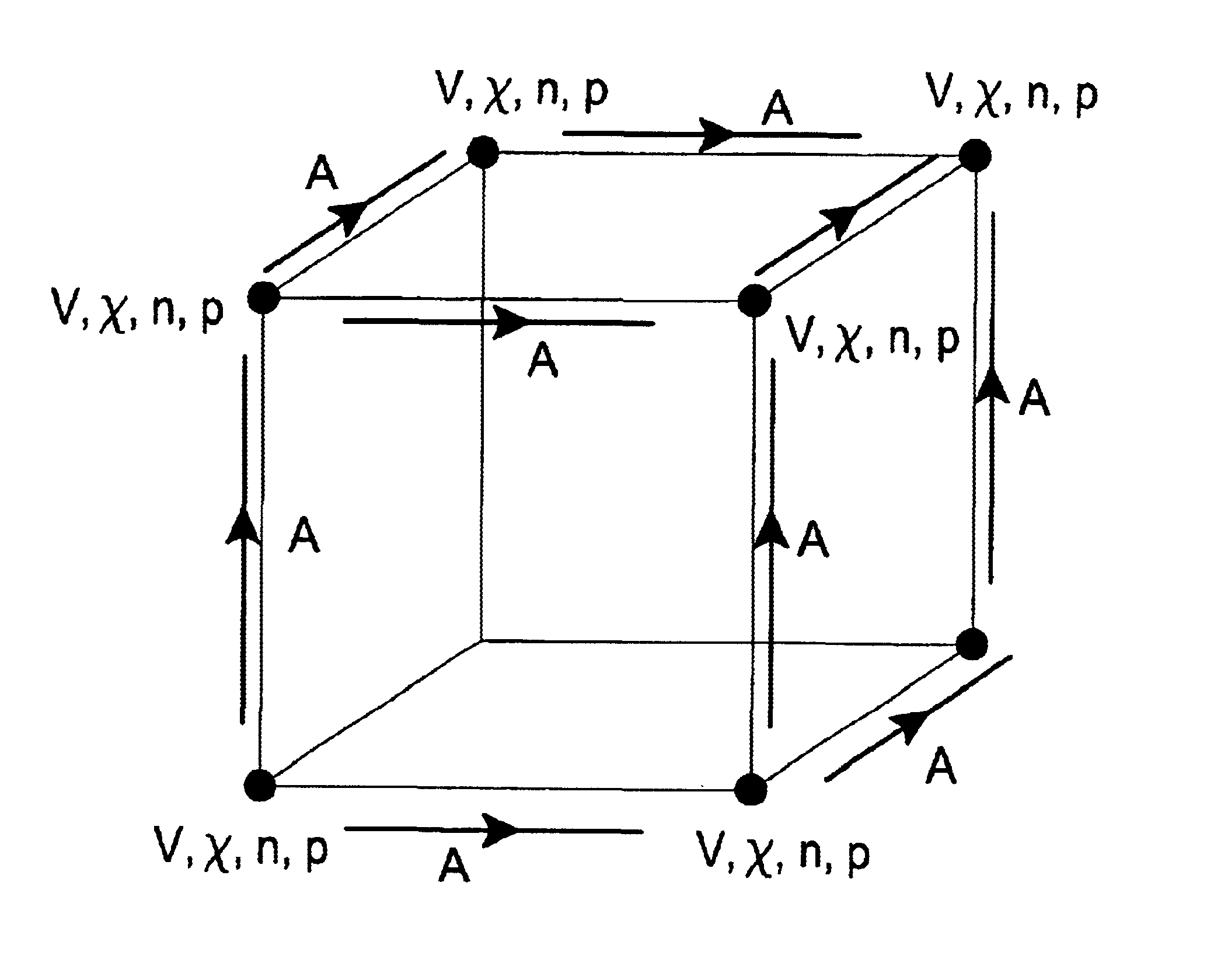

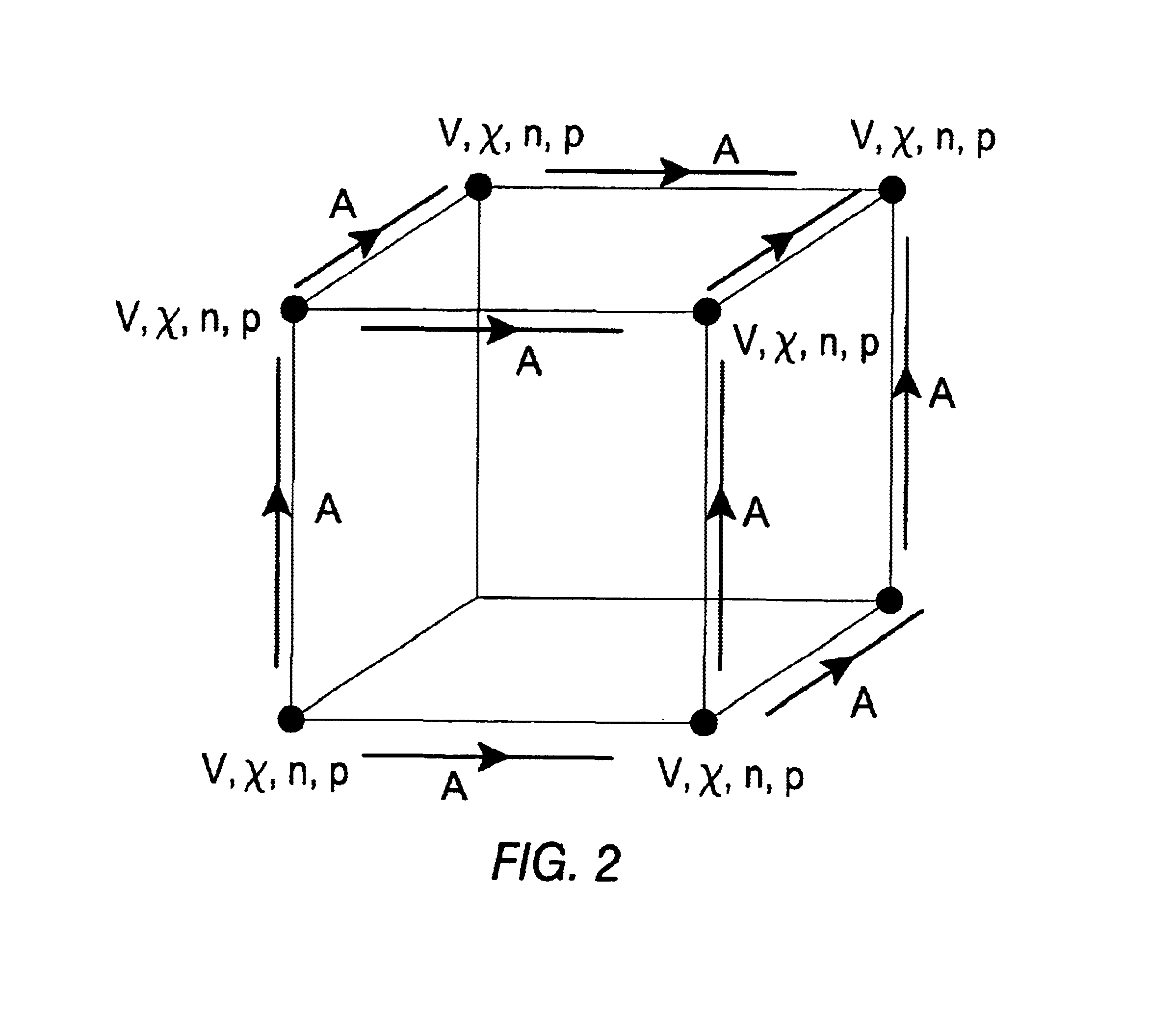

In order to design on-chip interconnect structures in a flexible way, a CAD approach is advocated in three dimensions, describing high frequency effects such as current redistribution due to the skin-effect or eddy currents and the occurrence of slow-wave modes. The electromagnetic environment is described by a scalar electric potential and a magnetic vector potential. These potentials are not uniquely defined, and in order to obtain a consistent discretization scheme, a gauge-transformation field is introduced. The displacement current is taken into account to describe current redistribution and a small-signal analysis solution scheme is proposed based upon existing techniques for static fields in semiconductors. In addition methods and apparatus for refining the mesh used for numerical analysis is described.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

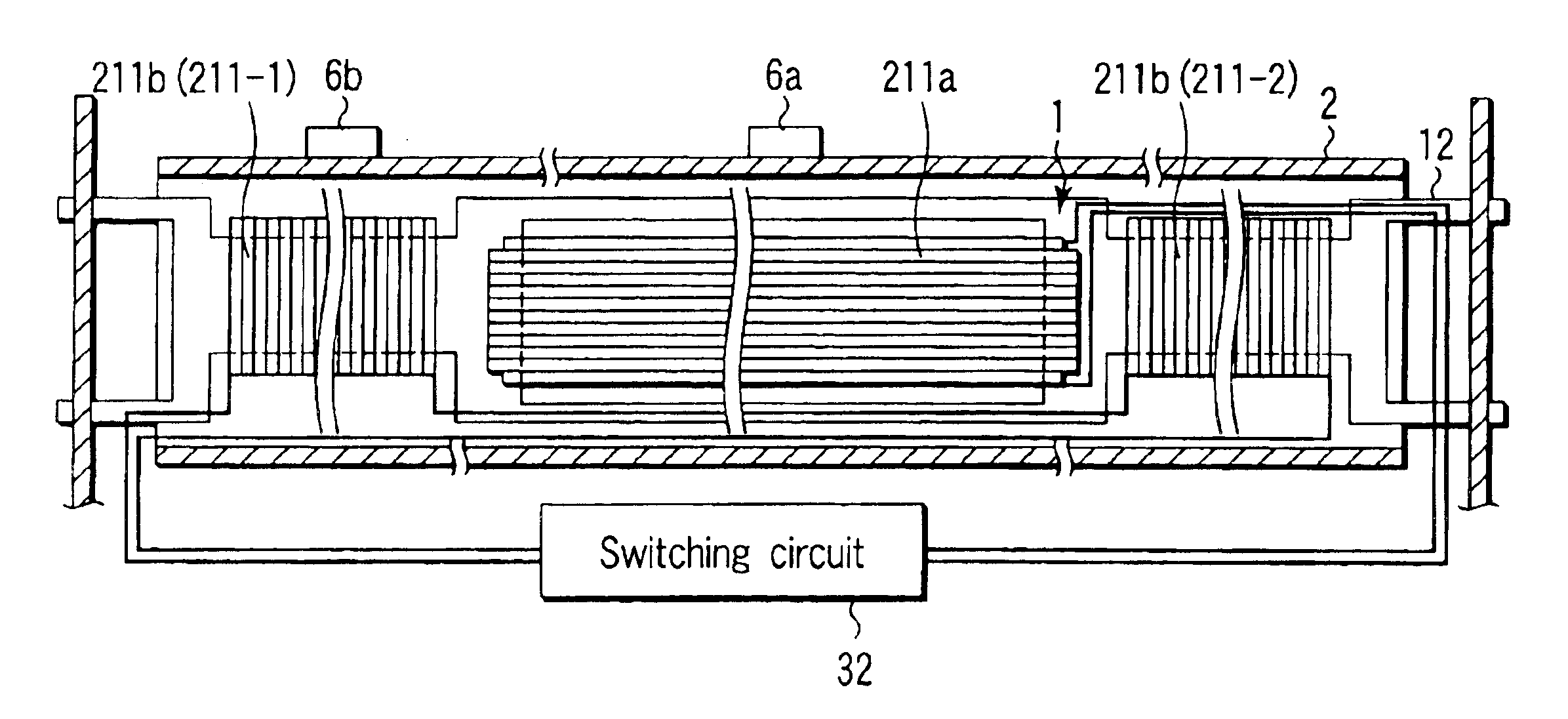

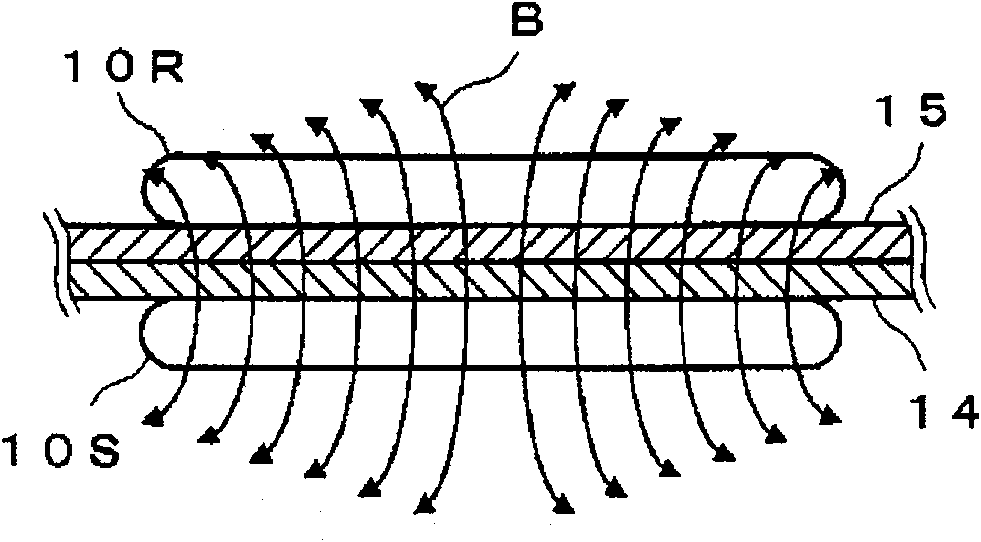

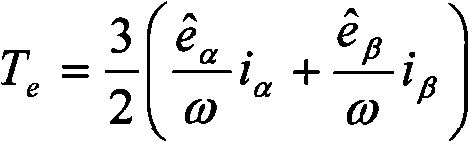

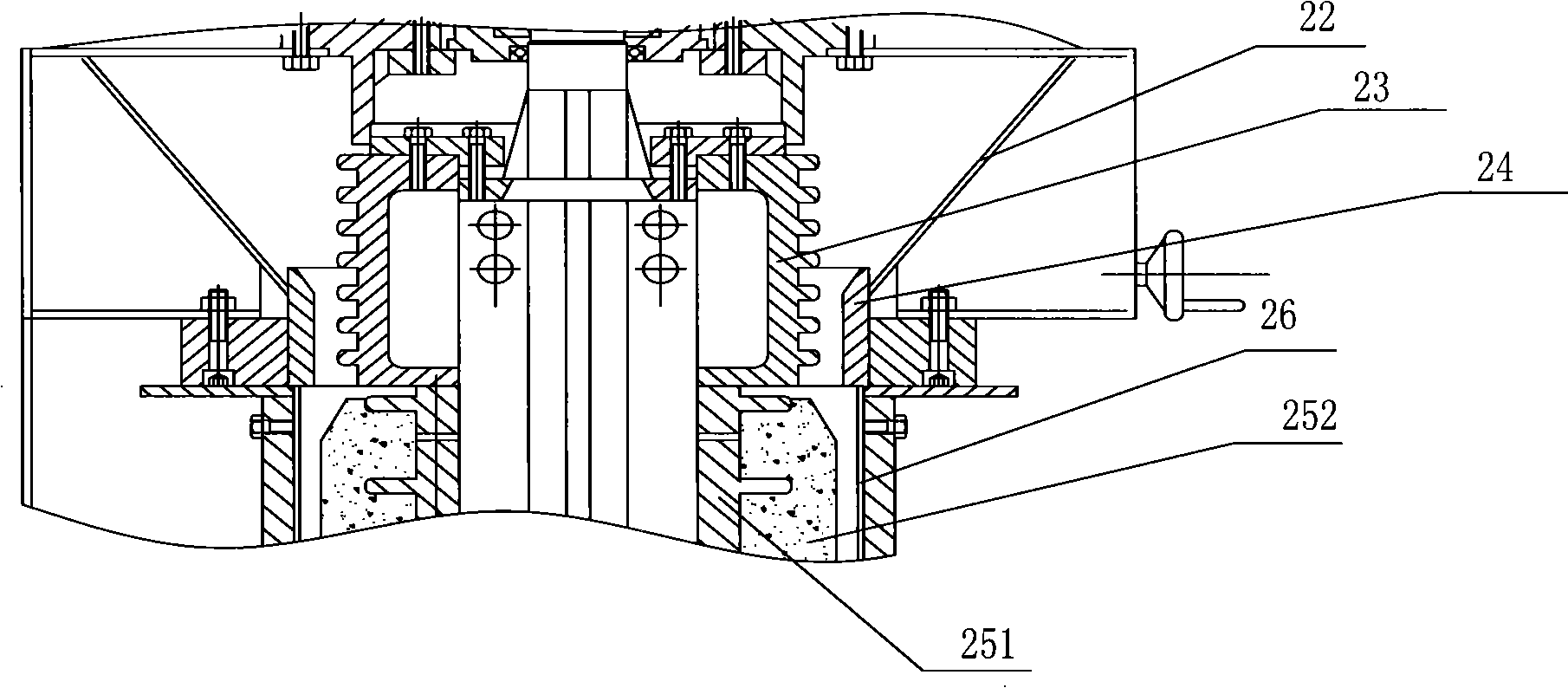

Transformer

InactiveUS6879235B2Improve coupling conditionsCopper loss is reducedTransformers/reacts mounting/support/suspensionTransformers/inductances coils/windings/connectionsElectromagnetic couplingTransformer

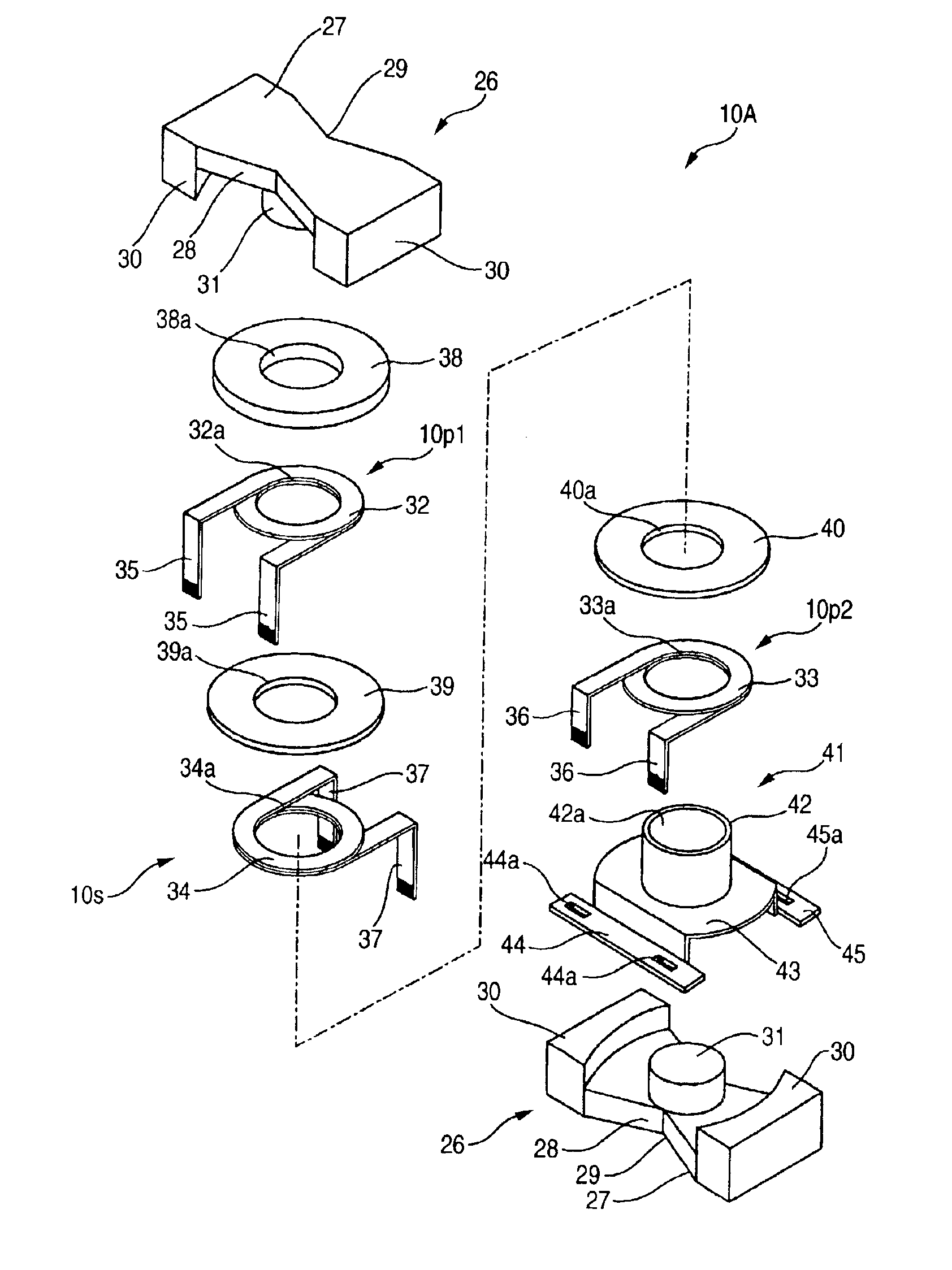

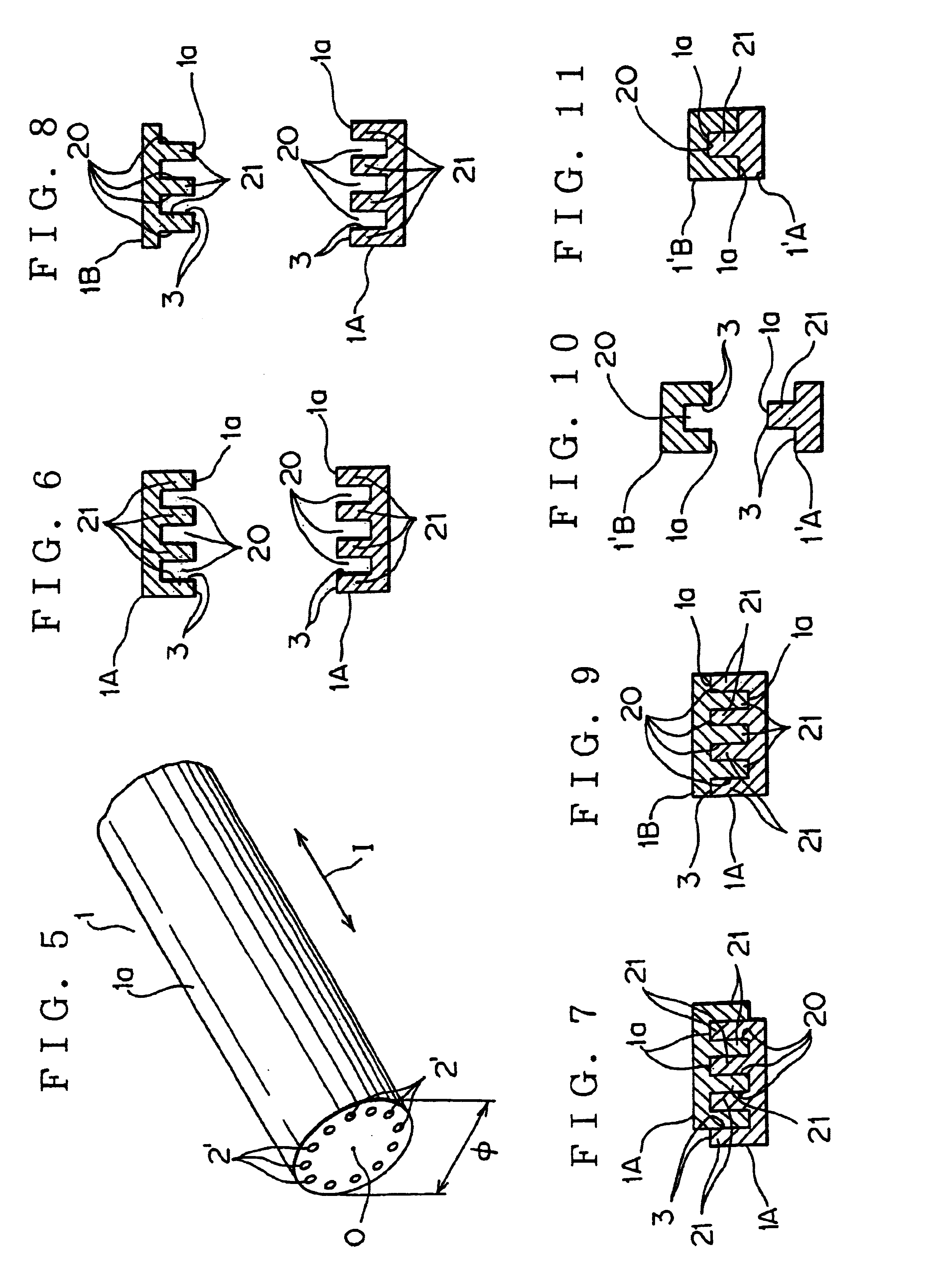

A transformer is provided with a coil portion containing primary windings and a secondary winding. Cores sandwich the coil portion. Each of these windings includes a toroidal-shaped portion that is formed by winding flat type wires in a toroidal shape and by overlapping these flat type wires. Edge portions of this flat type wire are derived from the toroidal-shaped portion respectively. A plurality of windings and the cores are arranged along an overlapping direction of the flat type wires. employed, By this structure, a copper loss caused by the skin effect can be reduced and the electromagnetic coupling conditions between the windings can be improved.

Owner:KOITO MFG CO LTD

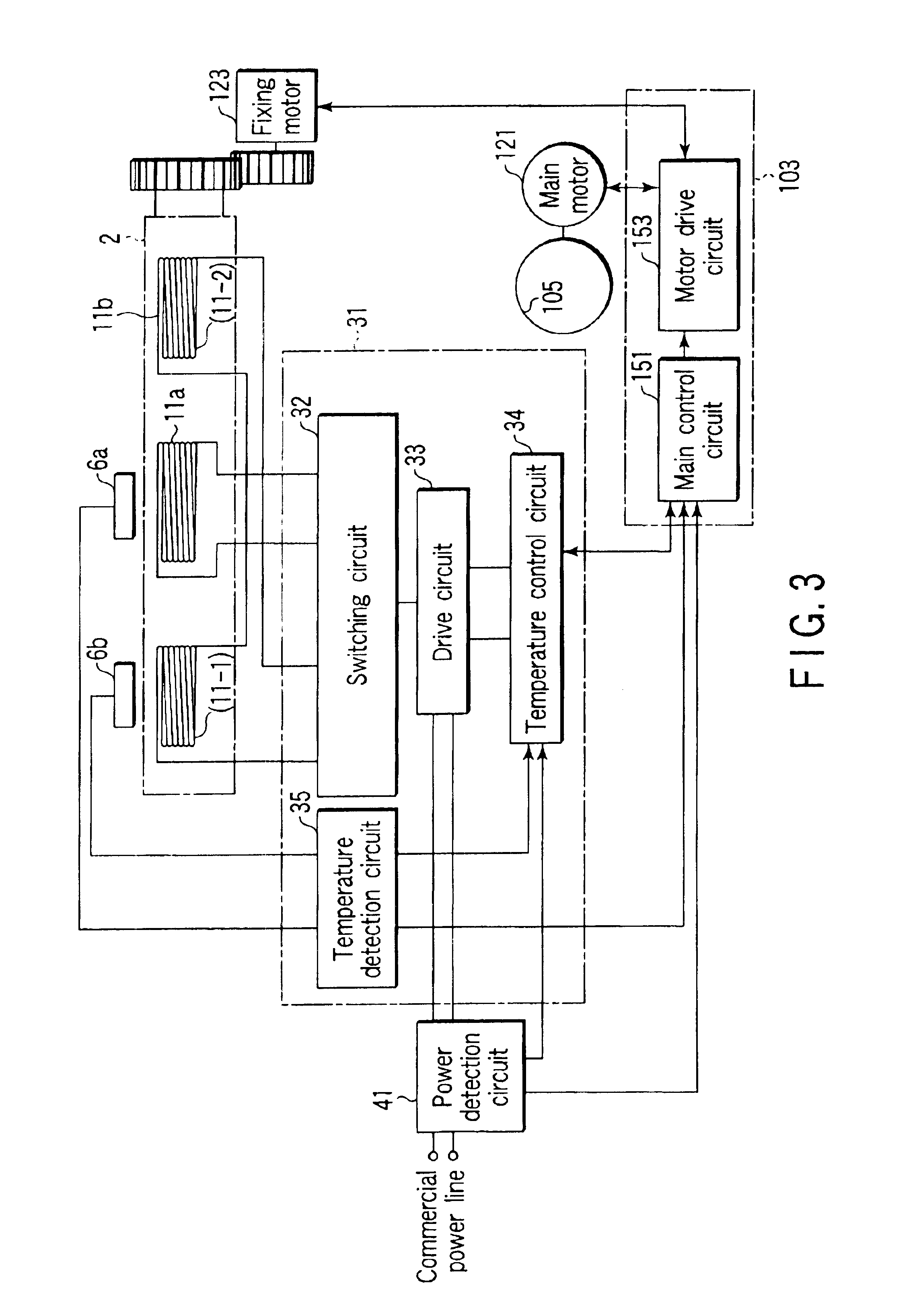

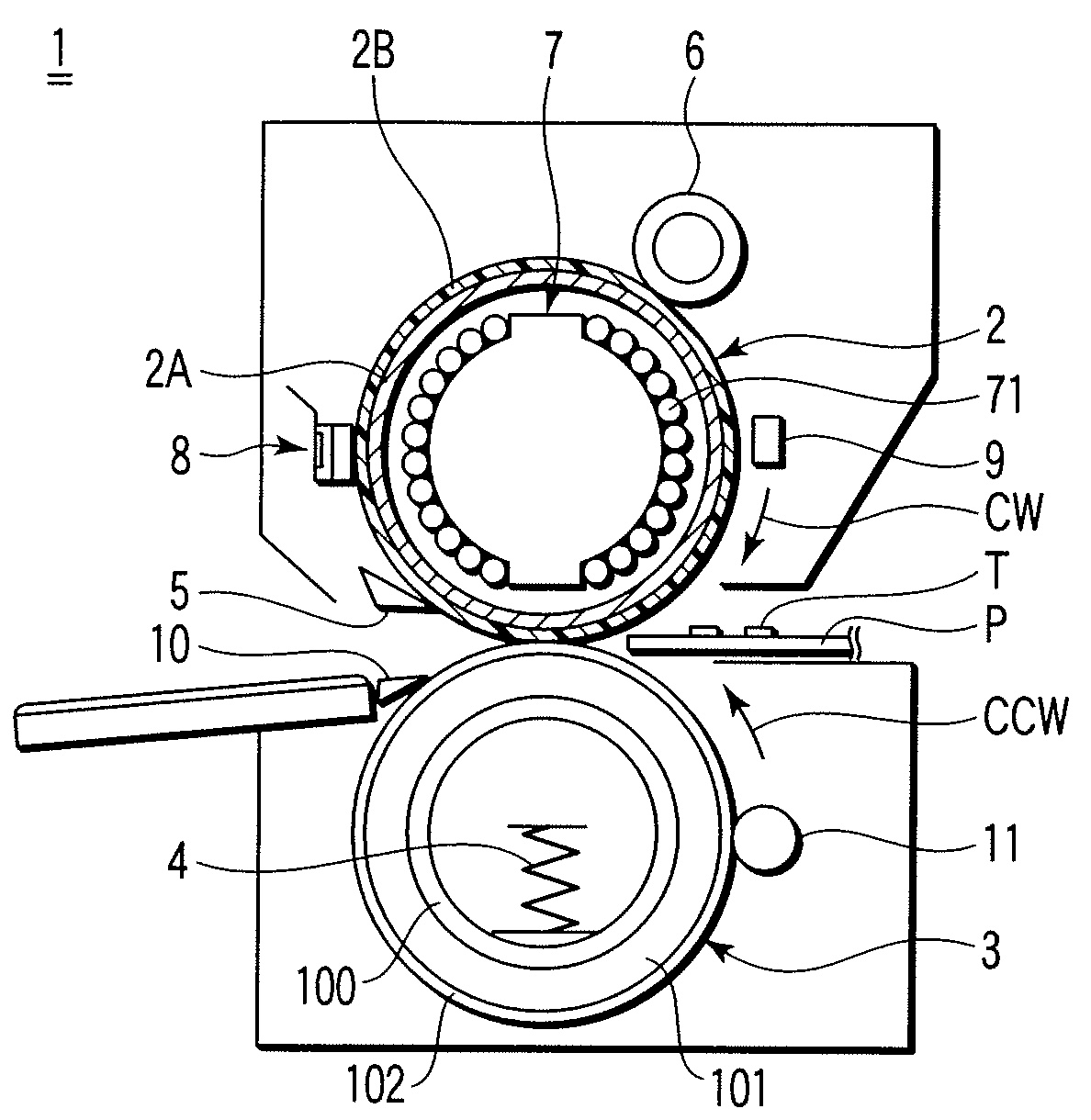

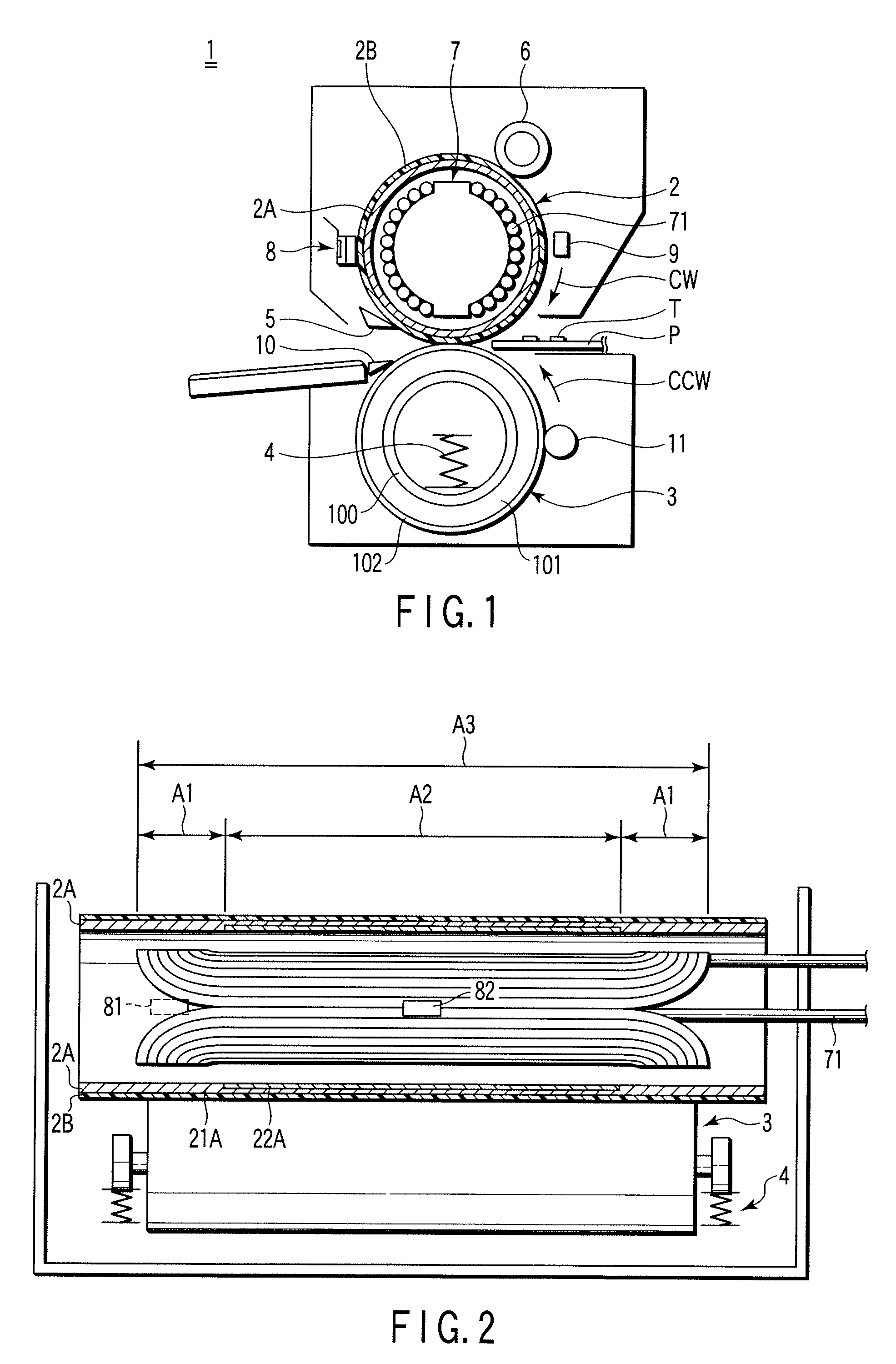

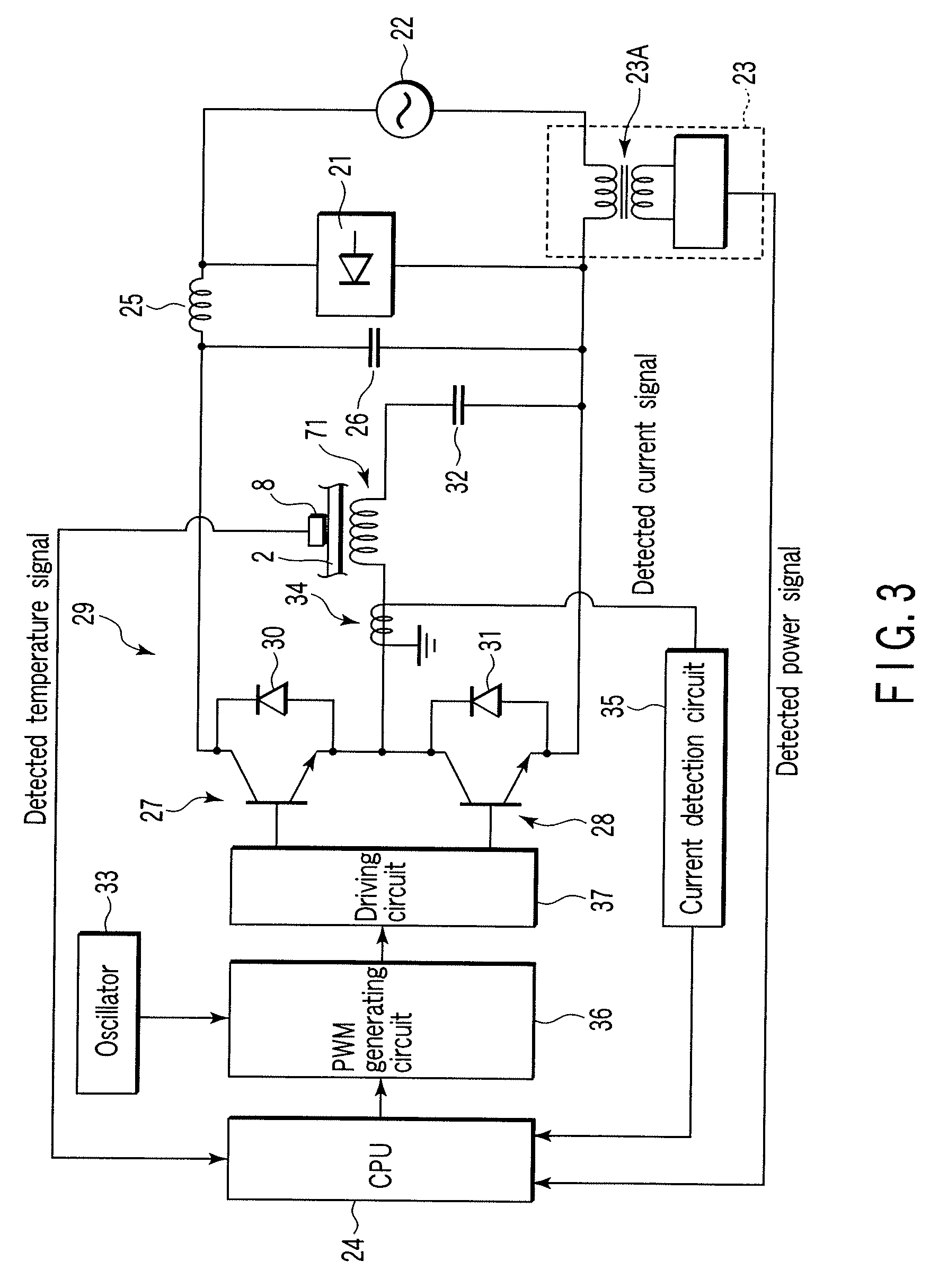

Fixing apparatus

InactiveUS6900419B2Avoid changeReduced dimensionCoil arrangementsElectrographic process apparatusSkin effectElectromagnetic induction

A fixing apparatus an aspect of the present invention includes, a heating object which generates the heat by a magnetic flux produced from a coil which generates a predetermined magnetic flux by electromagnetic induction in accordance with a frequency of an input current, and a pressurization mechanism which can provide a predetermined pressure to the heating object, and a coil of the heating object is formed of a litz wire obtained by twisting the number of conductors having a small cross section which are not affected by the skin effect caused due to the frequency of the input current, the number of which allows passage of a quantity of current to be inputted.

Owner:KK TOSHIBA +1

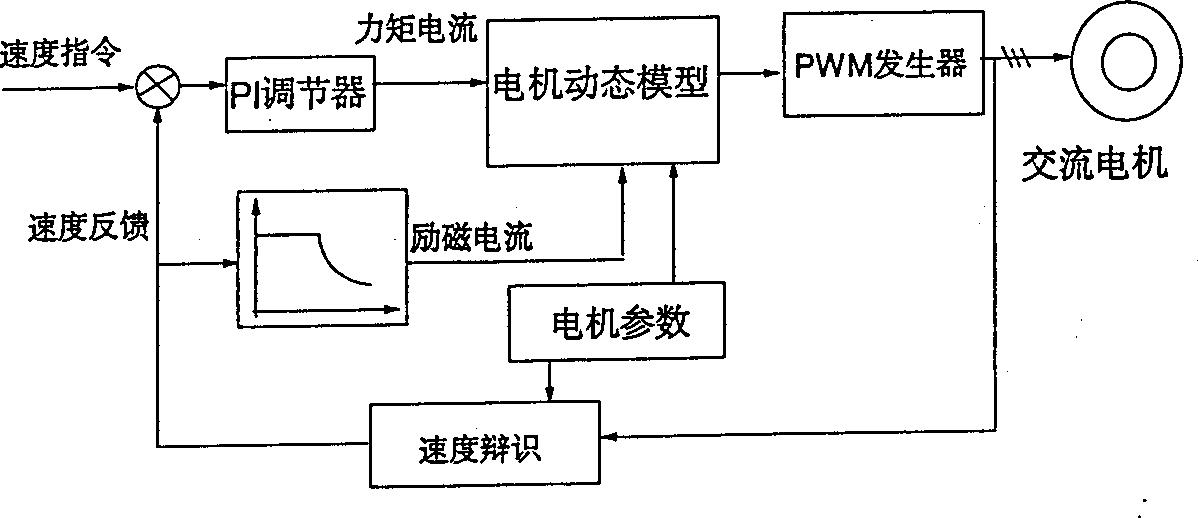

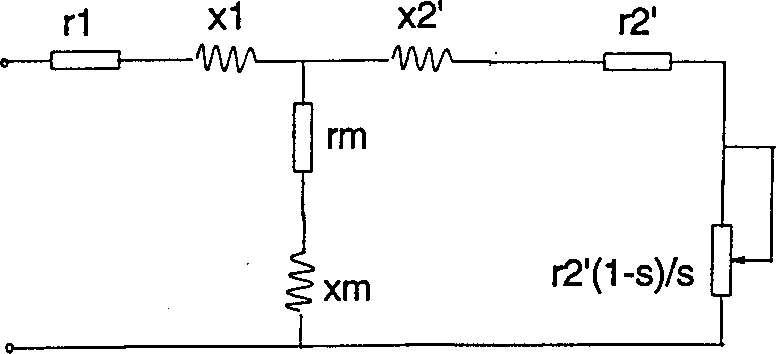

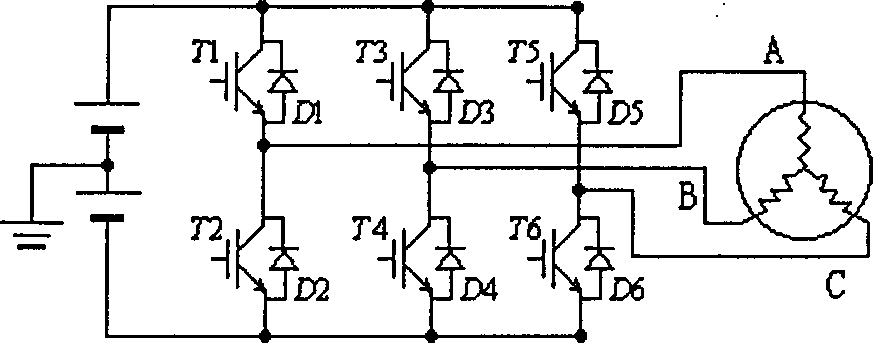

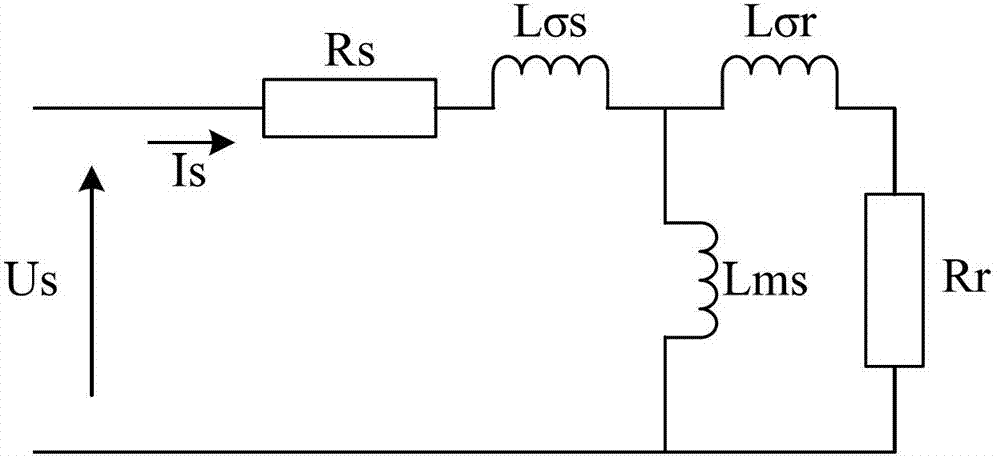

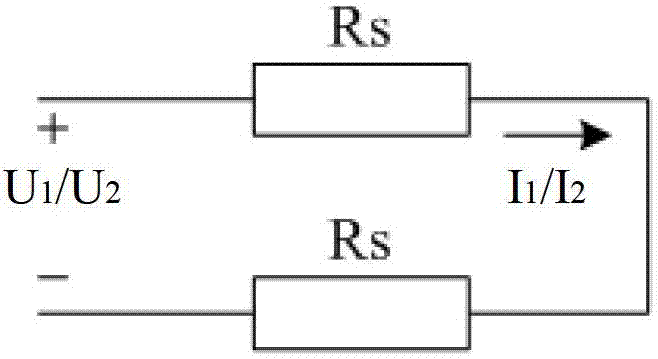

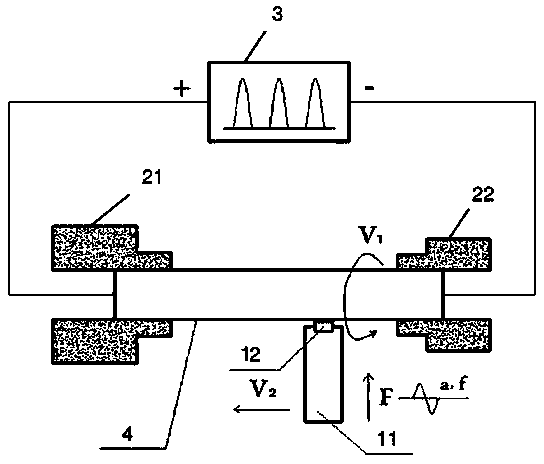

Non-synchronous motor parameter identification method

InactiveCN1354557AHigh precisionImprove stabilityElectronic commutation motor controlDC motor speed/torque controlDead timeSynchronous motor

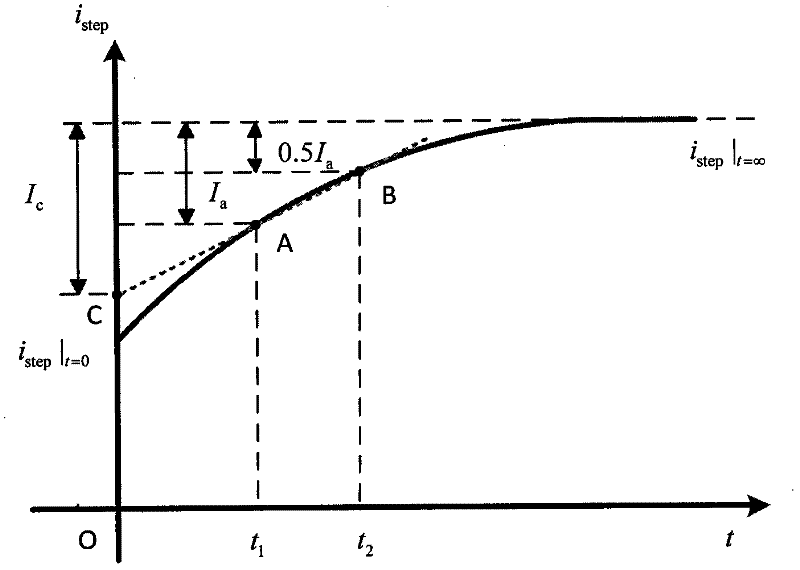

The invention relates to a method for recognizing parameters of asynchronous motor. The stator resistance of motor is measured by a method of DC volt-ampere. The rotor resistances as well as leakage inductance of stator and rotor of motor is obtained by short circuit test. Mutual inductance of stator and rotor of motor can be taken from method of no-load test. Compensating voltage drop in on state, switch time delay and dead time raises the accuracy and stability of recognized parameter. The resistance values of rotor at frequency of rating sliding difference are calculated by method of two points through test of locked rotor at two frequencies. Since skin effect is overcome, the resistance values of rotor are accurate enough so as to meet the requirement of vector control system completely.

Owner:SOMER LEROY ELECTRO TECH FUZHOU CO LTD

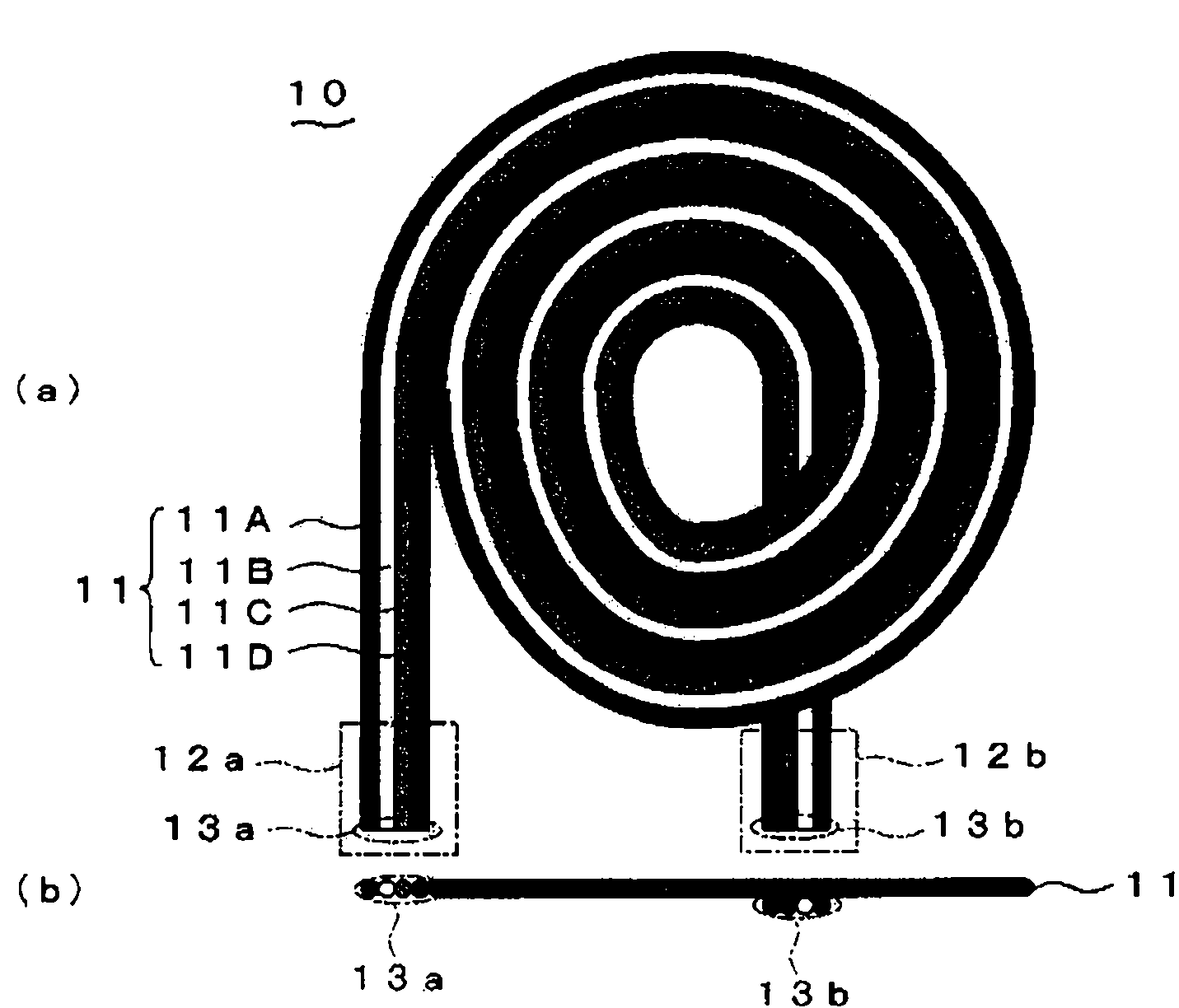

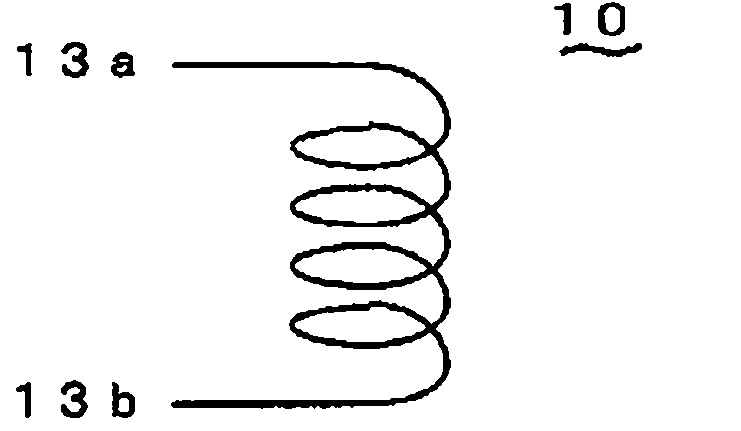

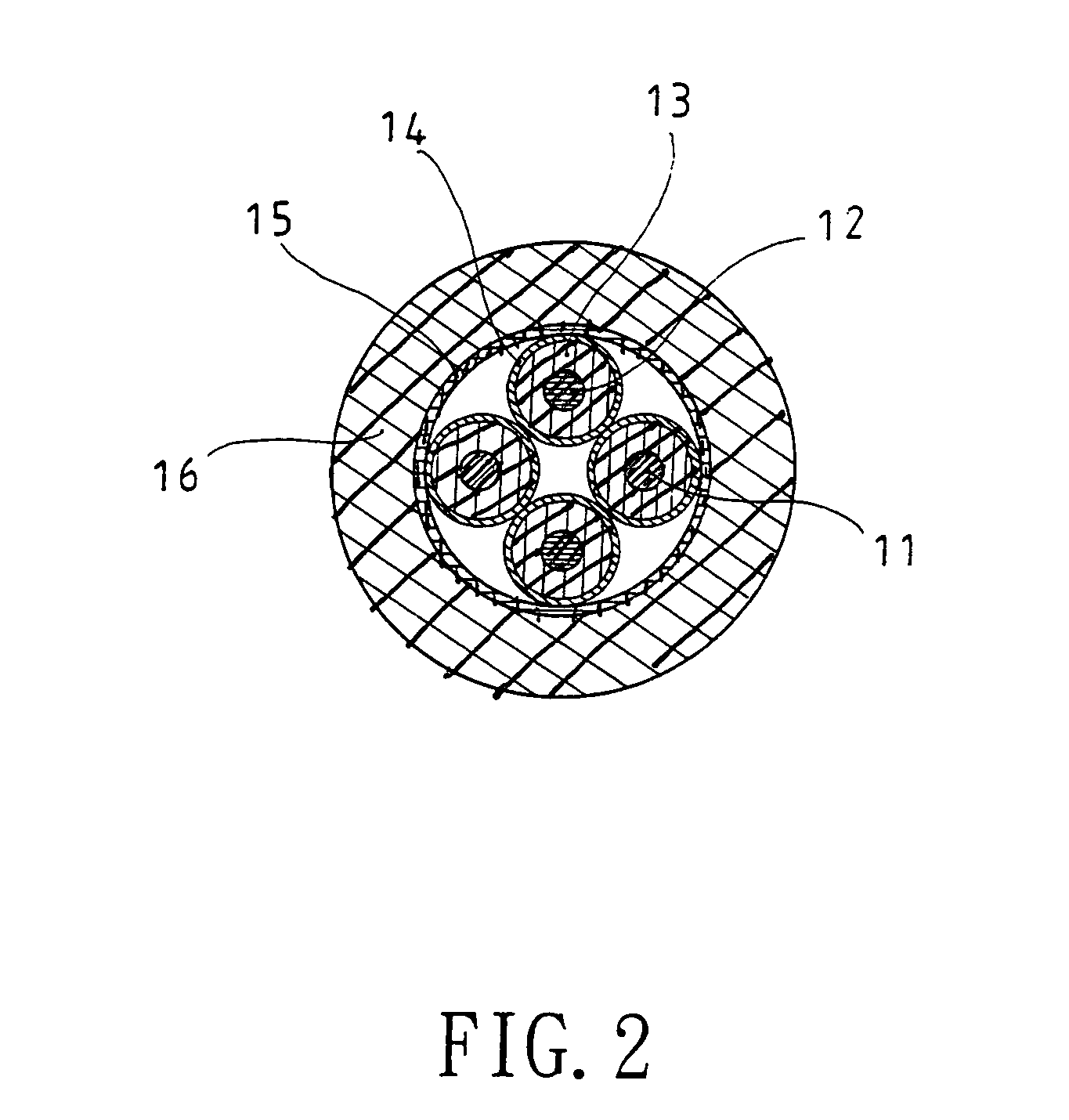

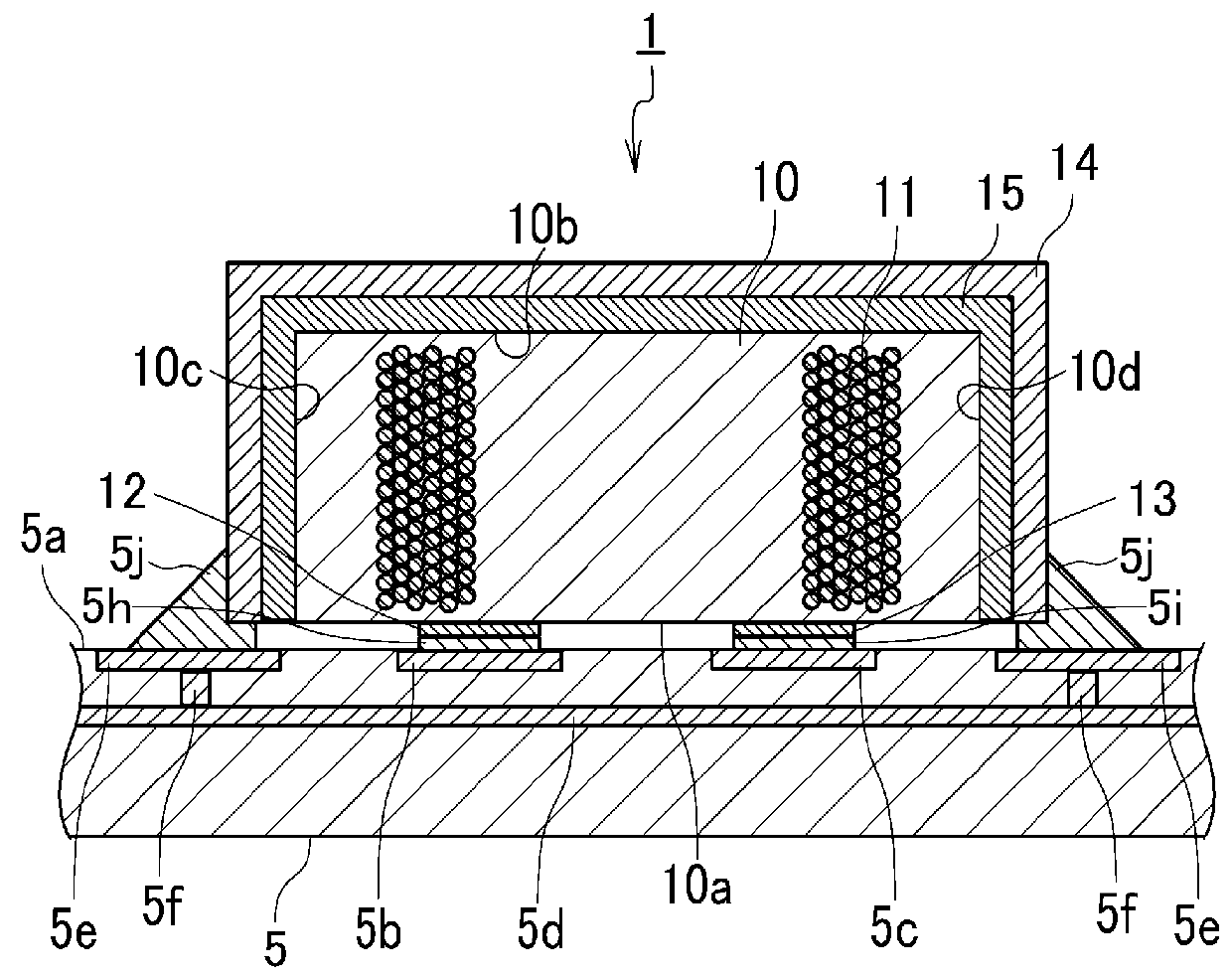

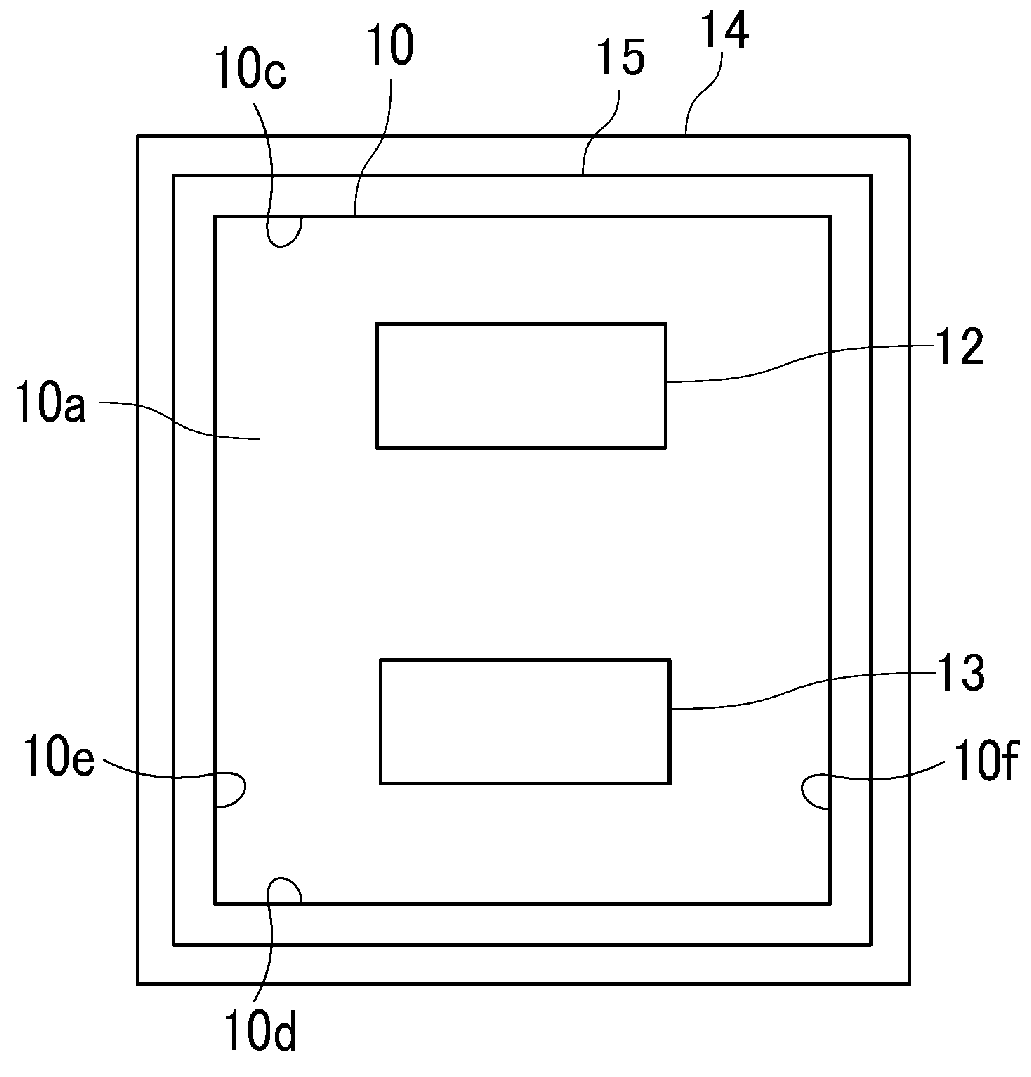

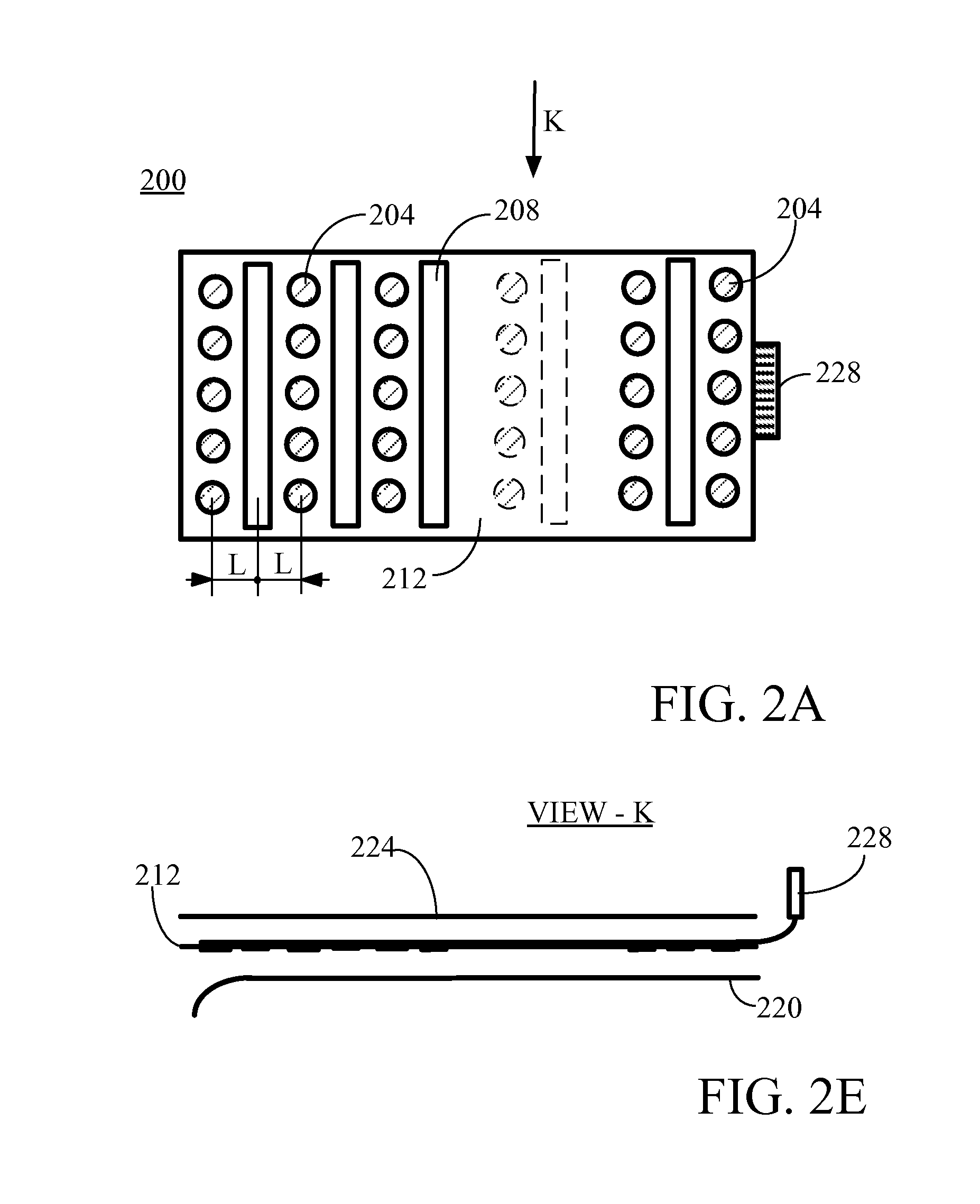

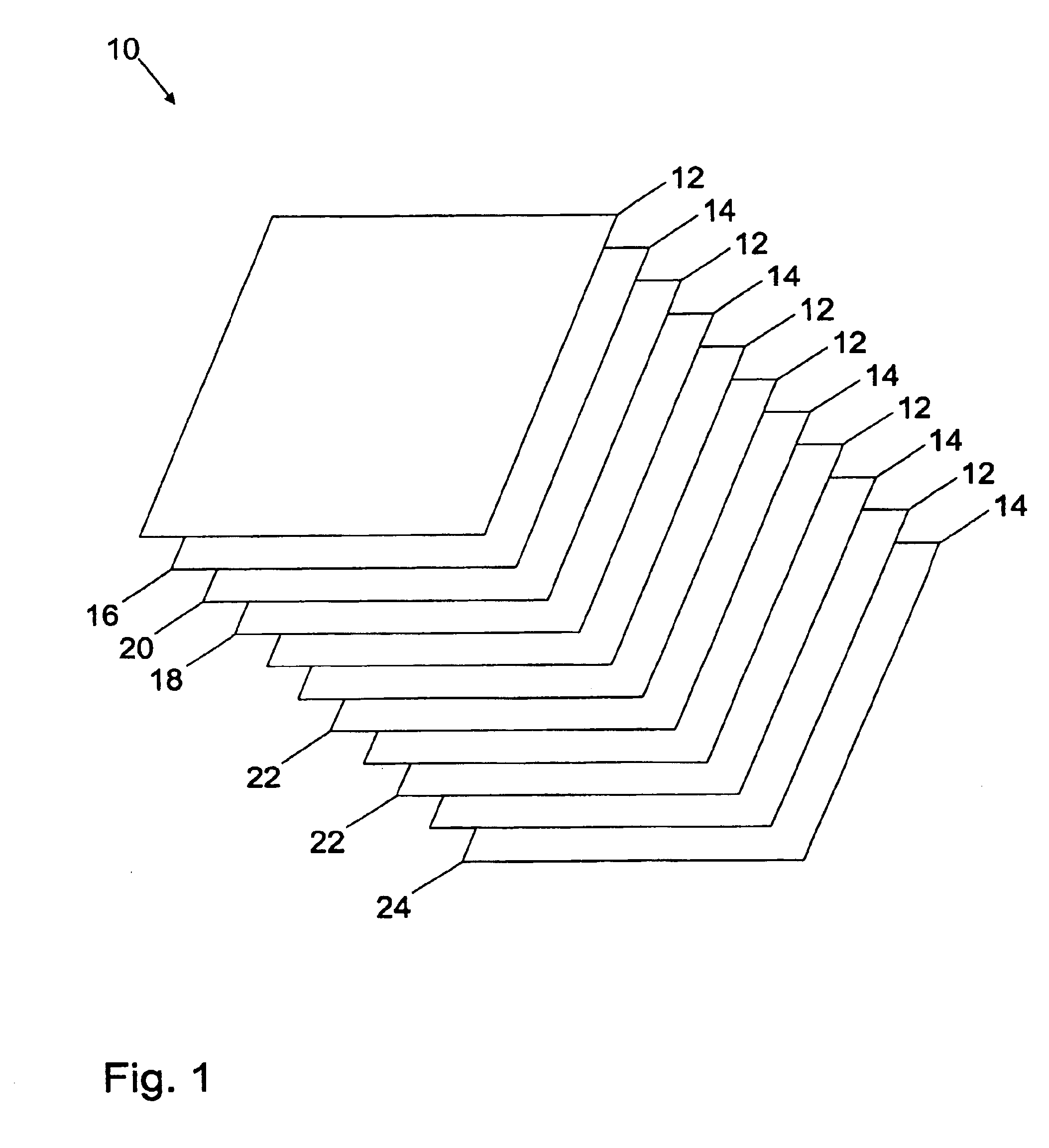

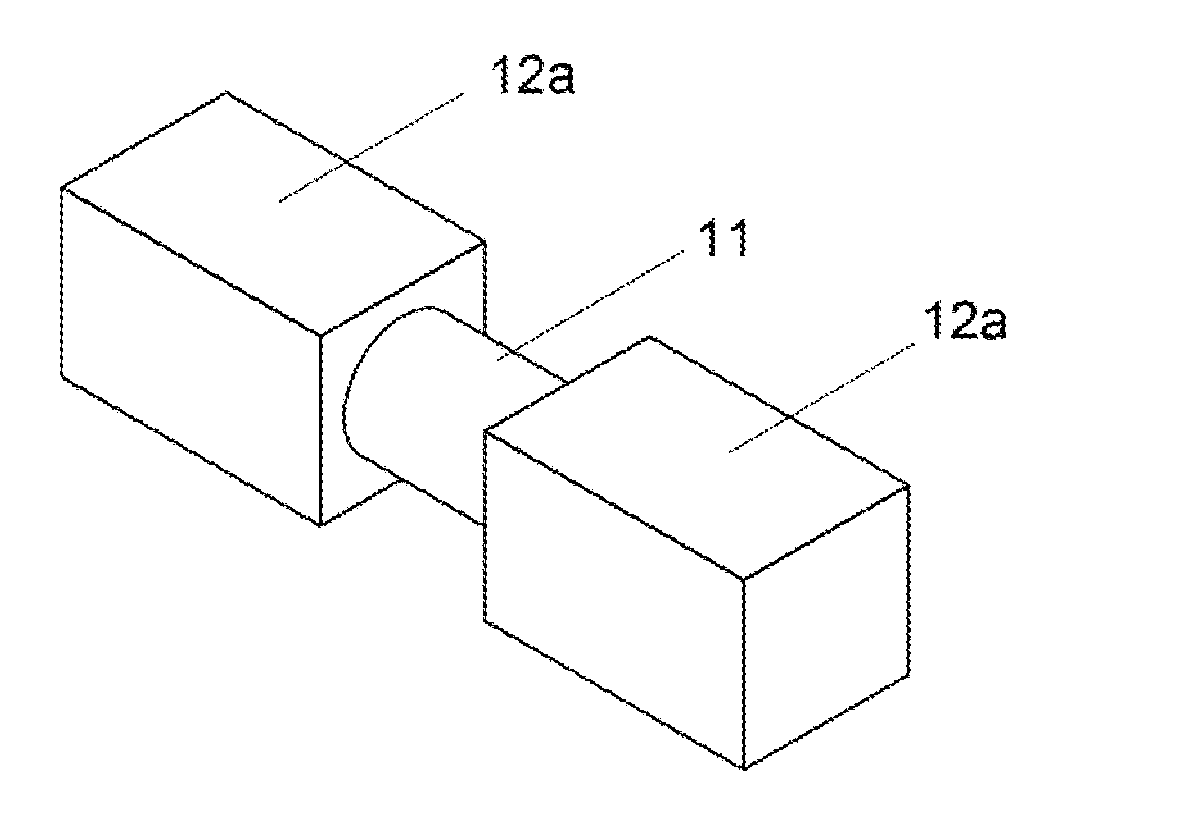

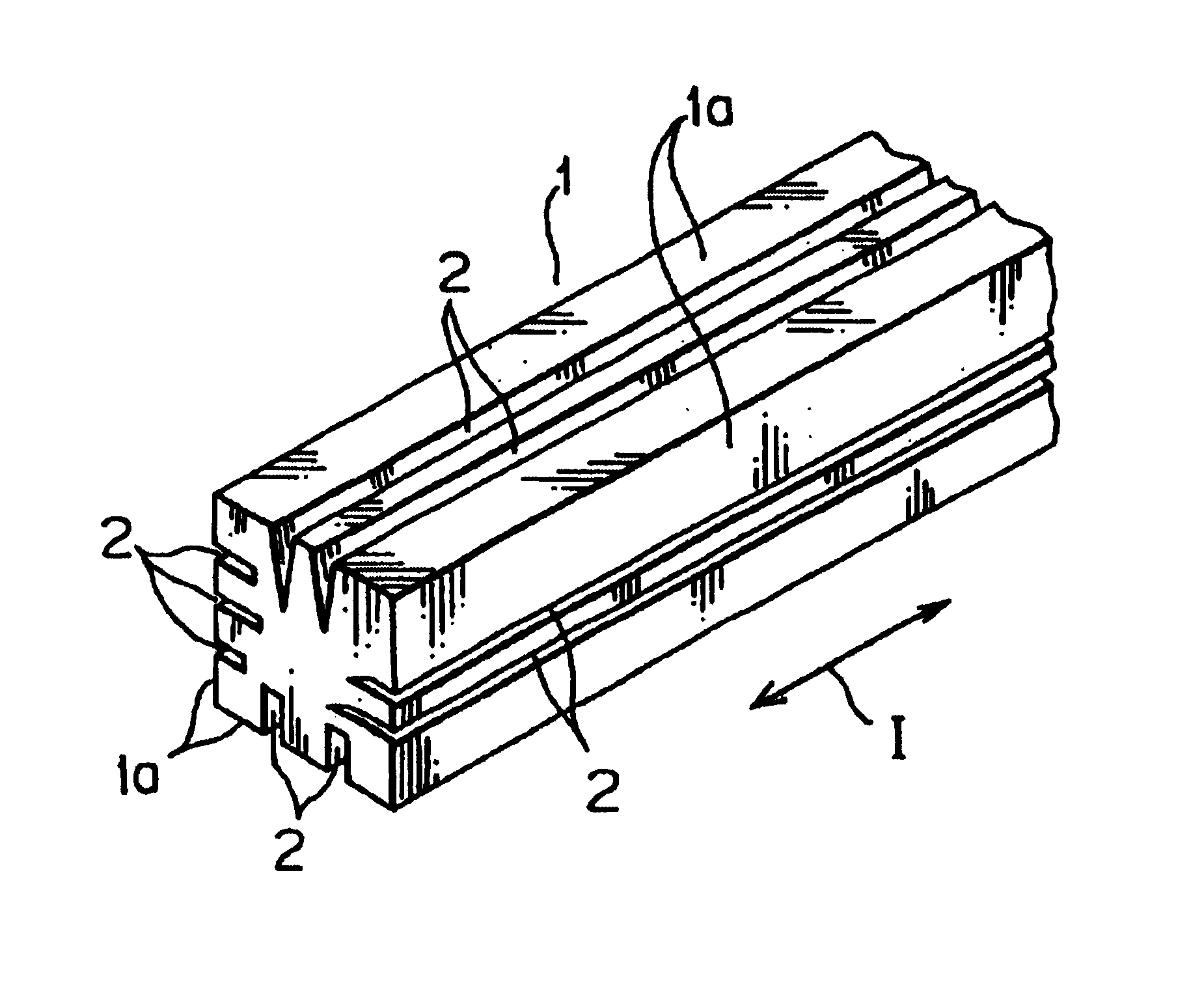

Plane coil

InactiveCN102084440AElectromagnetic wave systemTransformersElectricityElectrical resistance and conductance

Disclosed is a plane coil which is made thin while an increase in effective resistance in the high frequency region is minimized. A plane coil (10) is configured such that a plurality of electrically conductive wires (11) arranged in parallel with each other are wound spirally while being arranged planarly, and are connected in parallel because the ends (13a) of the respective electrically conductive wires (11) are connected electrically with each other at a coil lead-out portion (12a) and the ends (13b) thereof are also connected with each other at a coil lead-out portion (12b). Since the electrically conductive wires (11) of the plane coil (10) are arranged substantially planarly, coil thickness does not increase and the plane coil (10) is made thin. Furthermore, an increase in effective resistance due to skin effect is minimized in the high frequency region because the plurality of electrically conductive wires (11) are connected in parallel.

Owner:PANASONIC CORP

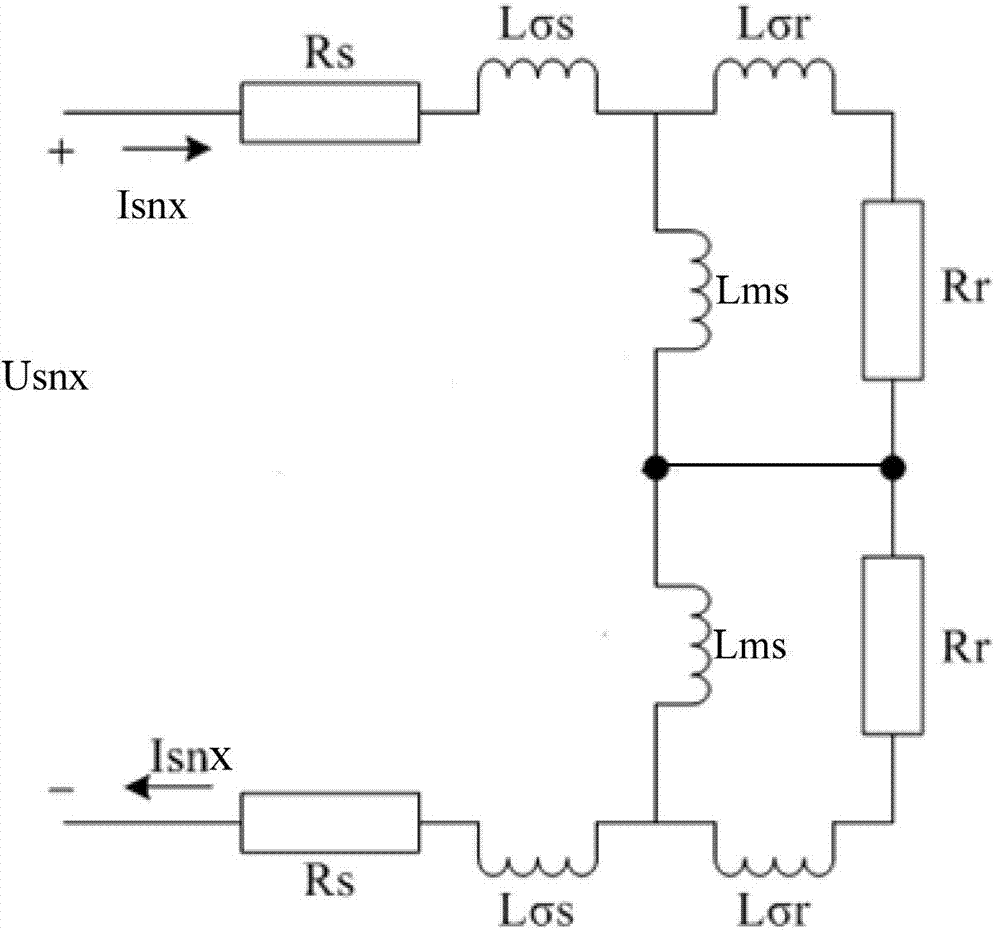

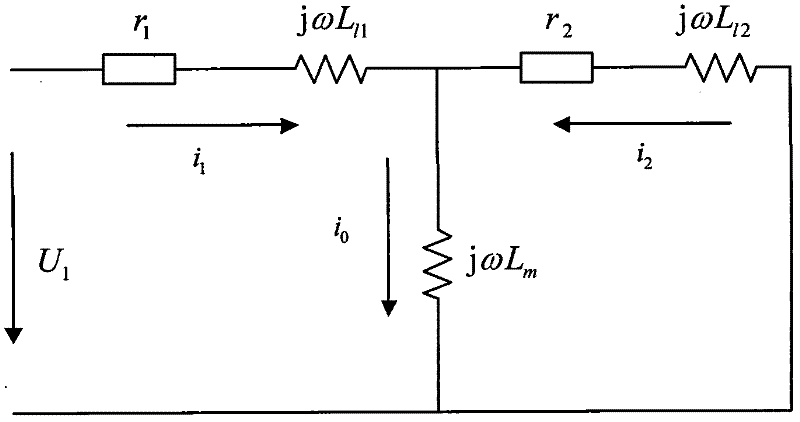

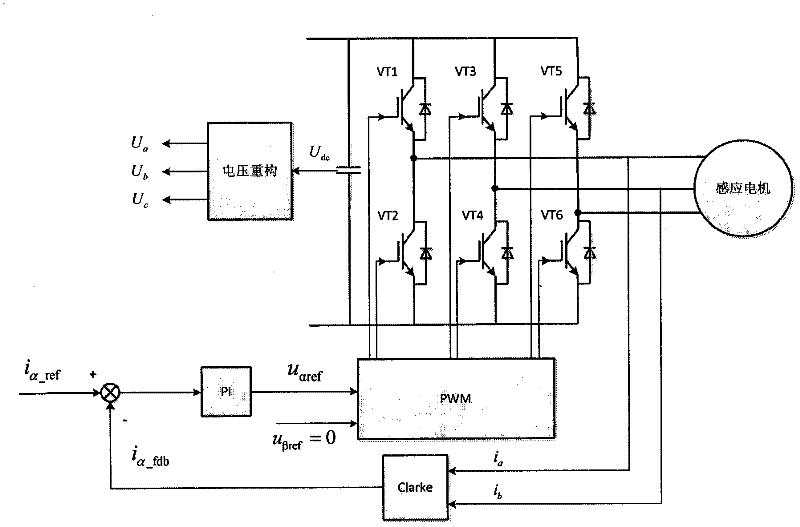

Method for identifying asynchronous motor parameters offline under stationary state

ActiveCN103208965AImprove accuracyPracticalMotor parameters estimation/adaptationVoltage referenceAlternate current

The invention provides a method for identifying asynchronous motor parameters offline under a stationary state. The method comprises the steps of firstly, identifying a stator resistance value of a motor by using a direct current voltammetry; and then taking a single-phase rated-frequency alternating voltage and a single-phase low-frequency alternating voltage as an excitation source respectively to perform a single-phase alternating current test, obtaining steady-state response currents of the motor through detection, and obtaining a motor stator leakage inductance, a rotor inductance, a rotor resistance and a stator-rotor mutual inductance value through calculation. According to the method, calculation is performed in strict accordance with a motor classic equivalent circuit model, the accuracy is high, additionally, the condition that a reference voltage output by a motor controller is not accordant with the actual voltage and effects of the skin effect are further considered, corresponding compensation measures are taken, and the parameter identifying accuracy is further improved.

Owner:三垦力达电气(江阴)有限公司

Motor parameter detection method and motor parameter detection device

The invention discloses a motor parameter detection method and a motor parameter detection device. The motor parameter detection method comprises the following steps: opening the circuit of one of phase windings of a motor; detecting stator leakage inductance and rotor leakage inductance; applying rated voltage with higher frequency than rated power between the other two phases of the motor; and detecting the stator leakage inductance and the rotor leakage inductance according to the computational formula of the stator leakage inductance and the rotor leakage inductance. The invention provides the off-line motor parameter detection method and the motor parameter detection device under the static condition of the rotor of an induction motor, which achieve high accuracy of motor parameter detection through reducing the influences of voltage errors and a skin effect as long as current or voltage with different frequencies is applied between the two phases of the motor in sequence.

Owner:BEIJING A&E TECH

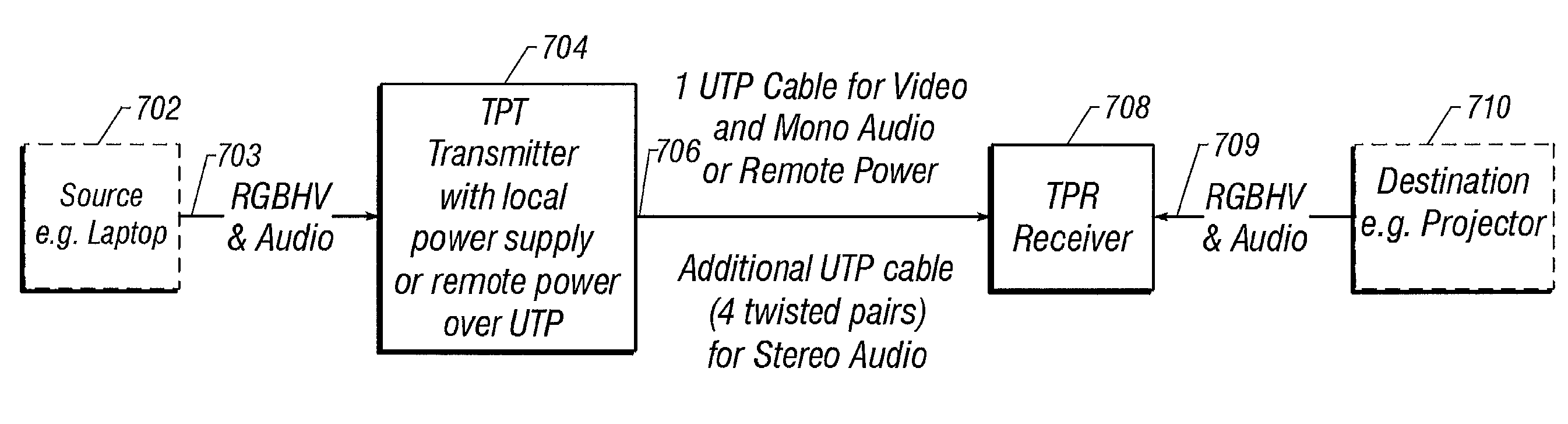

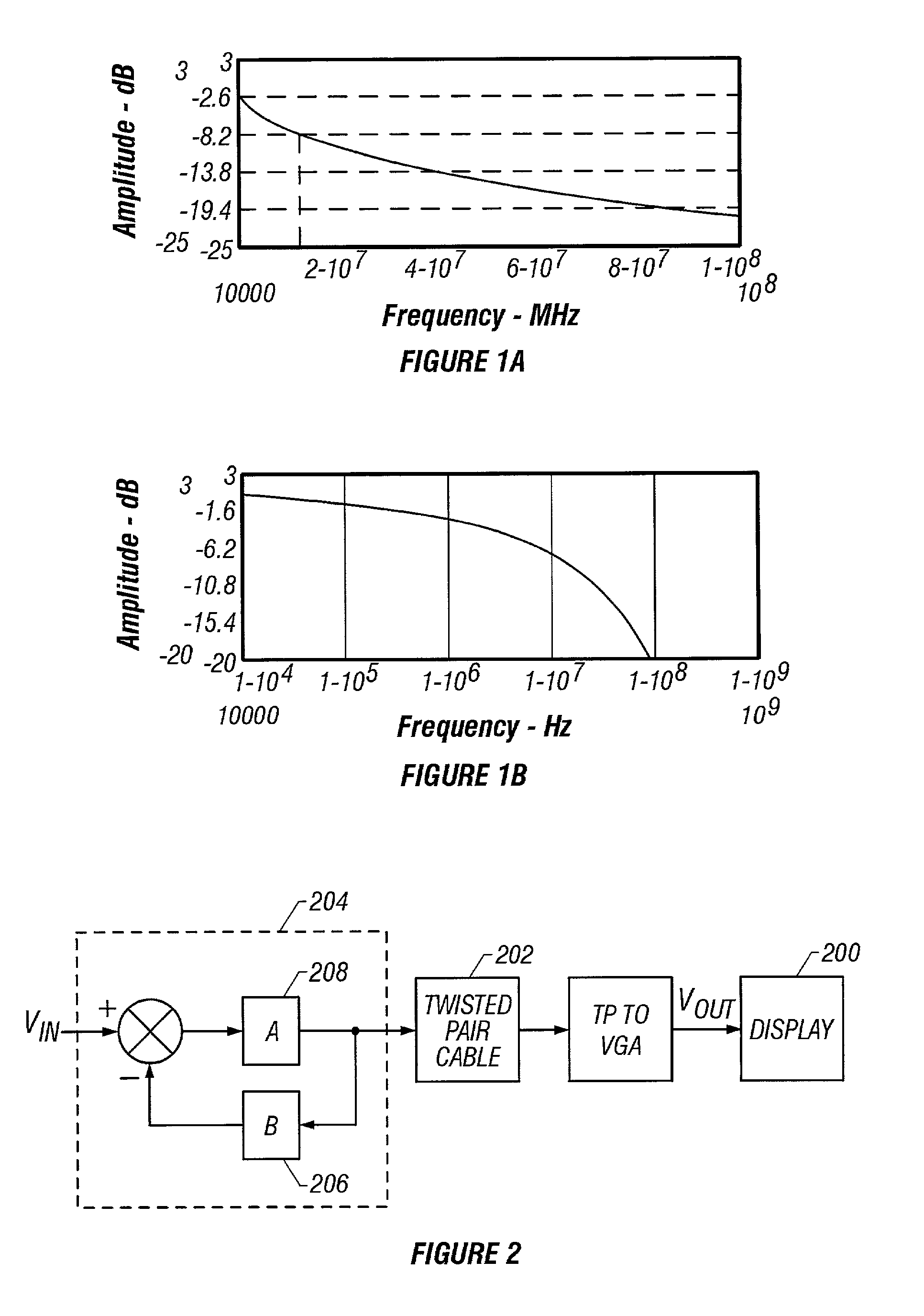

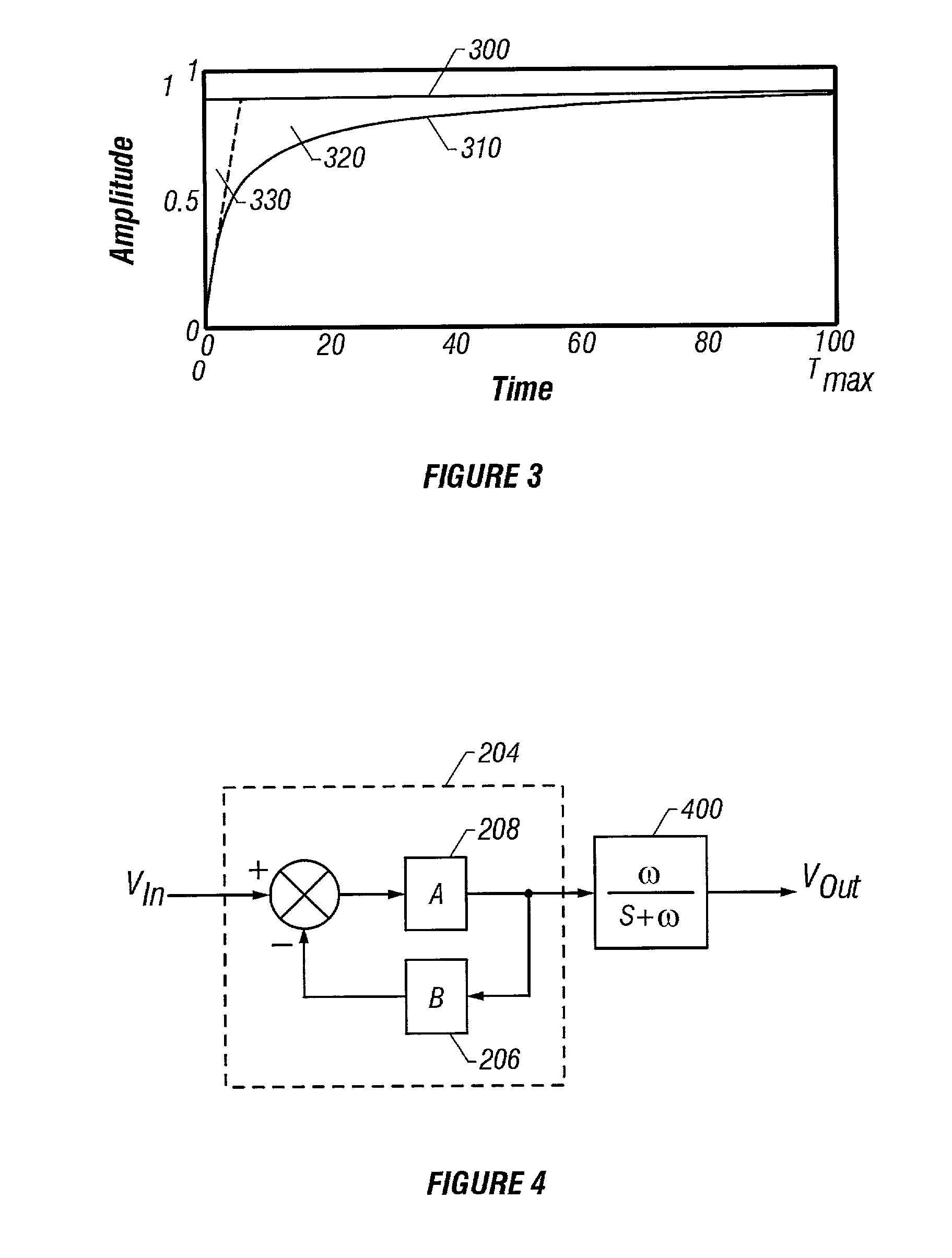

Method and apparatus for equalizing video transmitted over twisted pair cable

ActiveUS7047556B2Enhancing and improving quality of high-resolutionGood cost advantageTelevision system detailsTransmission control/equlisationBrute forceTwisted pair

A apparatus and apparatus for compensating for video insertion loss due to transmission over long twisted pair cable lines is presented. Transmission of video over twisted pair cable is advantageous because of its superior cost advantage over coaxial cable. However, twisted pair cables have significant loss characteristics at the higher frequencies (i.e., broadband) compared to coaxial cables. At a transmitter station, the video signal is amplified in the high frequency region for possible skin effect losses thereby brute forcing the high frequency components to the receiving station. At the receiver station, the video signal is further compensated for diffusion line and skin effect losses. The total skin effect compensation applied in both the transmitter and receiver stations is such that the square root of frequency characteristics of skin effect losses is compensated for. Thus, at the receiving station, the high frequency compensation added at the transmitter to brute force the high frequency components to the receiving station may be removed if found excessive. Additionally, compensation is included to adjust for skew that may occur because of irregularities between the various twisted pairs used to transmit the individual video components. Non-minimum phase type filters are used to inject delay into the faster arriving signals so that they may coincide in phase with later arriving signals resulting in a true reproduction of the video.

Owner:RGB SYST INC

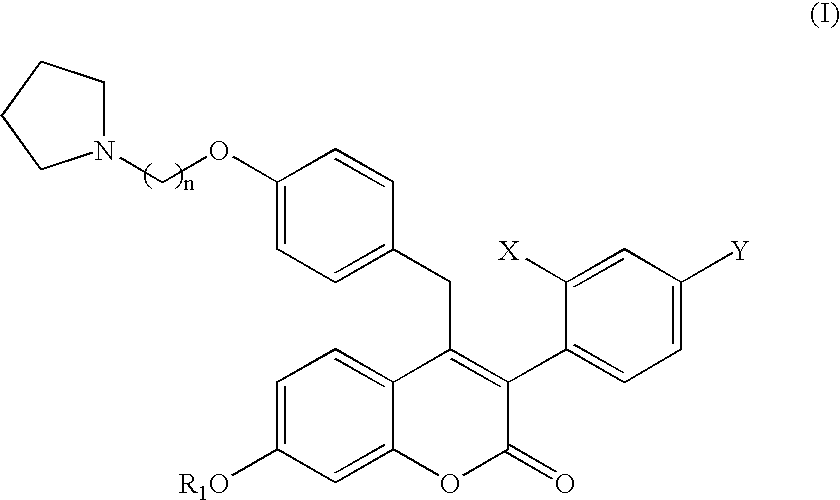

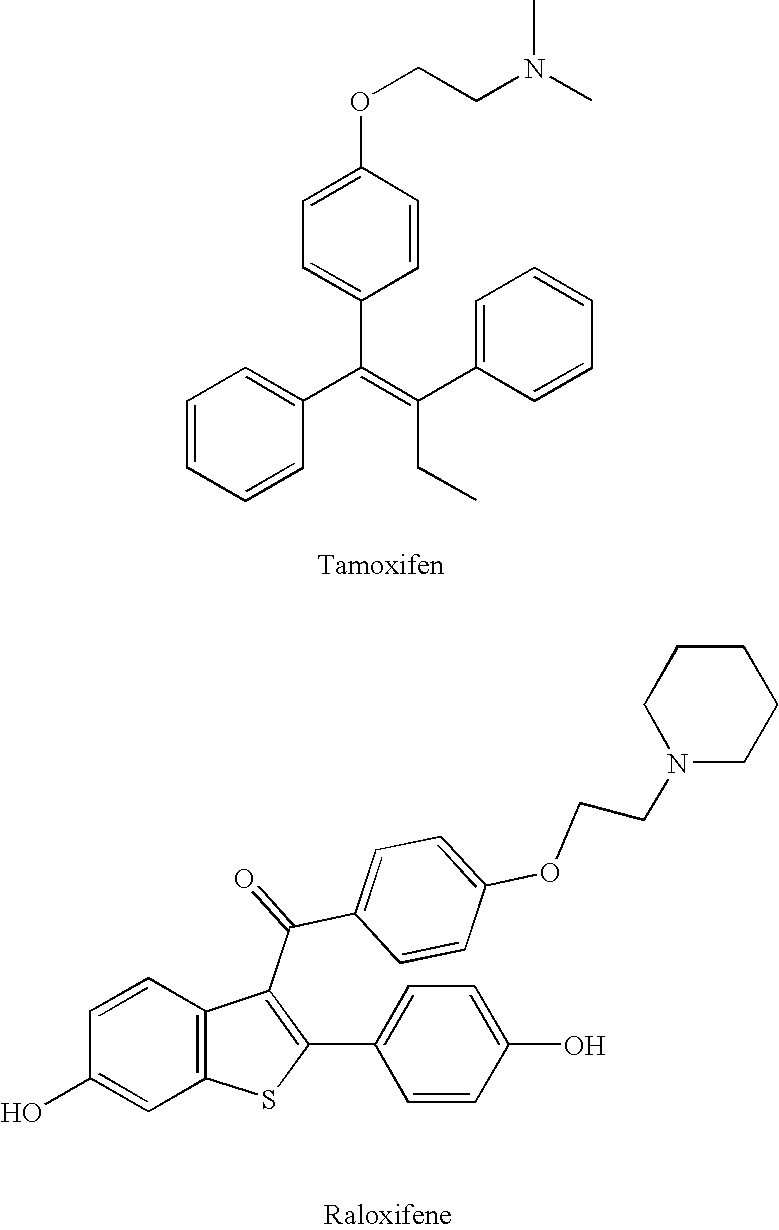

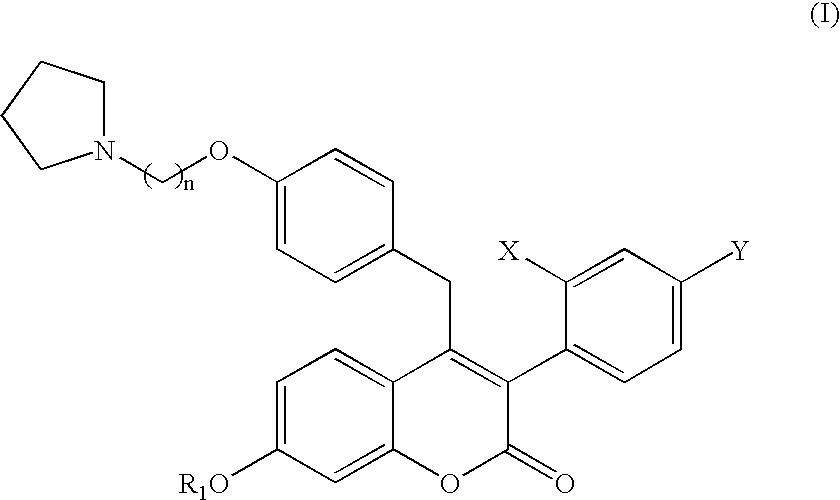

Benzopyranone compounds, compositions thereof, and methods of treatment therewith

Benzopyranone compounds having the following structure: wherein R1, X, Y and n are as defined here, are disclosed. The compounds of formula (I), wherein R1 is H, can be prepared by demethylation of the corresponding phenolic methyl ether. The compounds are useful for treating a bone-resorbing disease, cancer, arthritis or an estrogen-related condition such as breast cancer, osteoporosis, endometriosis, cardiovascular disease, hypercholesterolemia, prostatic hypertrophy, prostatic carcinomas, obesity, hot flashes, skin effects, mood swings, memory loss, and adverse reproductive effects associated with exposure to environmental chemicals or natural hormonal imbalances.

Owner:SIGNAL PHARMA LLC +1

Method and apparatus for simulating physical fields

InactiveUS20020042698A1Simple structureLess storage spaceDetecting faulty computer hardwareAnalogue computers for chemical processesPhysical fieldEngineering

In order to design on-chip interconnect structures in a flexible way, a CAD approach is advocated in three dimensions, describing high frequency effects such as current redistribution due to the skin-effect or eddy currents and the occurrence of slow-wave modes. The electromagnetic environment is described by a scalar electric potential and a magnetic vector potential. These potentials are not uniquely defined, and in order to obtain a consistent discretization scheme, a gauge-transformation field is introduced. The displacement current is taken into account to describe current redistribution and a small-signal analysis solution scheme is proposed based upon existing techniques for static fields in semiconductors. In addition methods and apparatus for refining the mesh used for numerical analysis is described.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

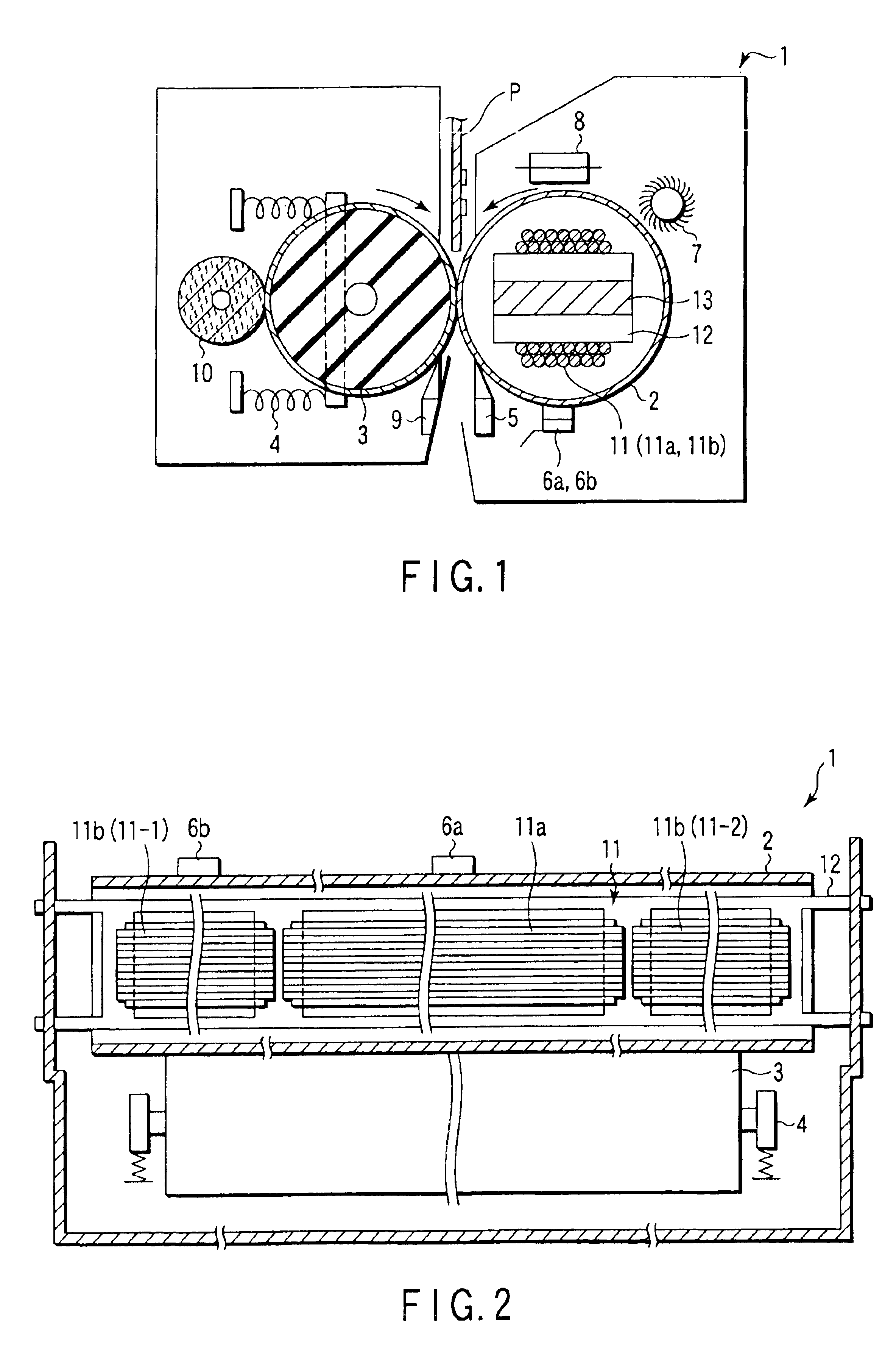

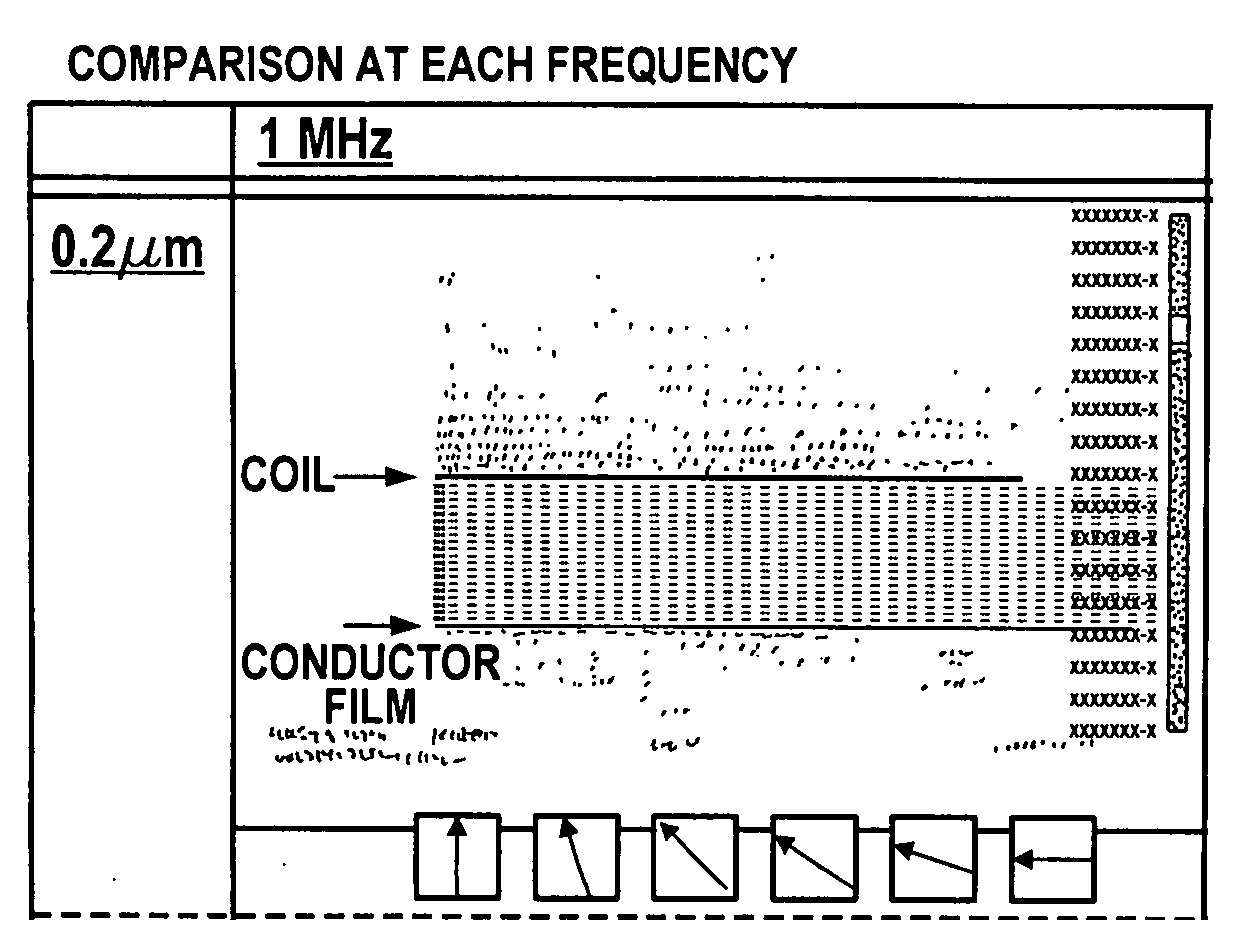

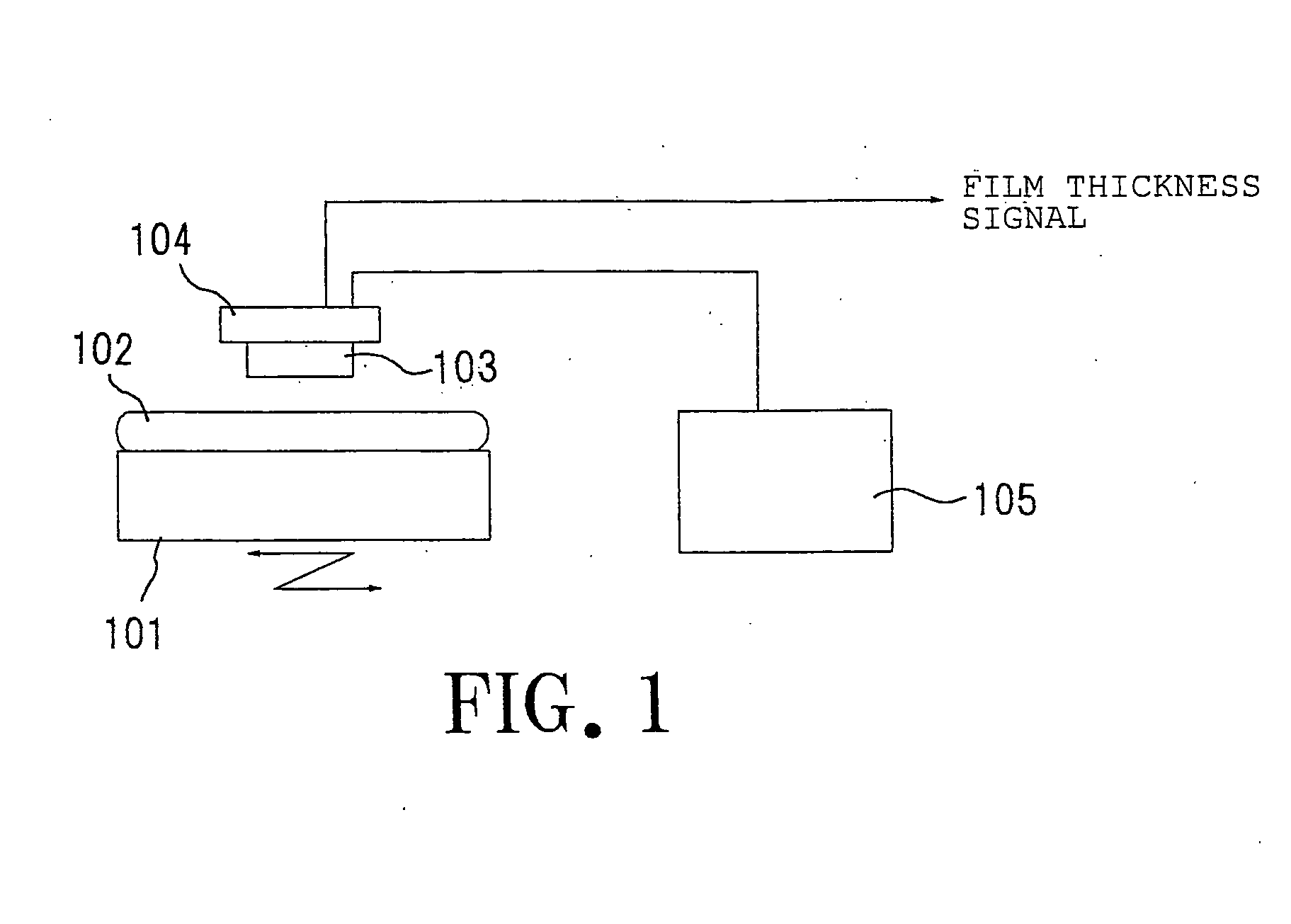

Film thickness measuring apparatus and film thickness measuring method

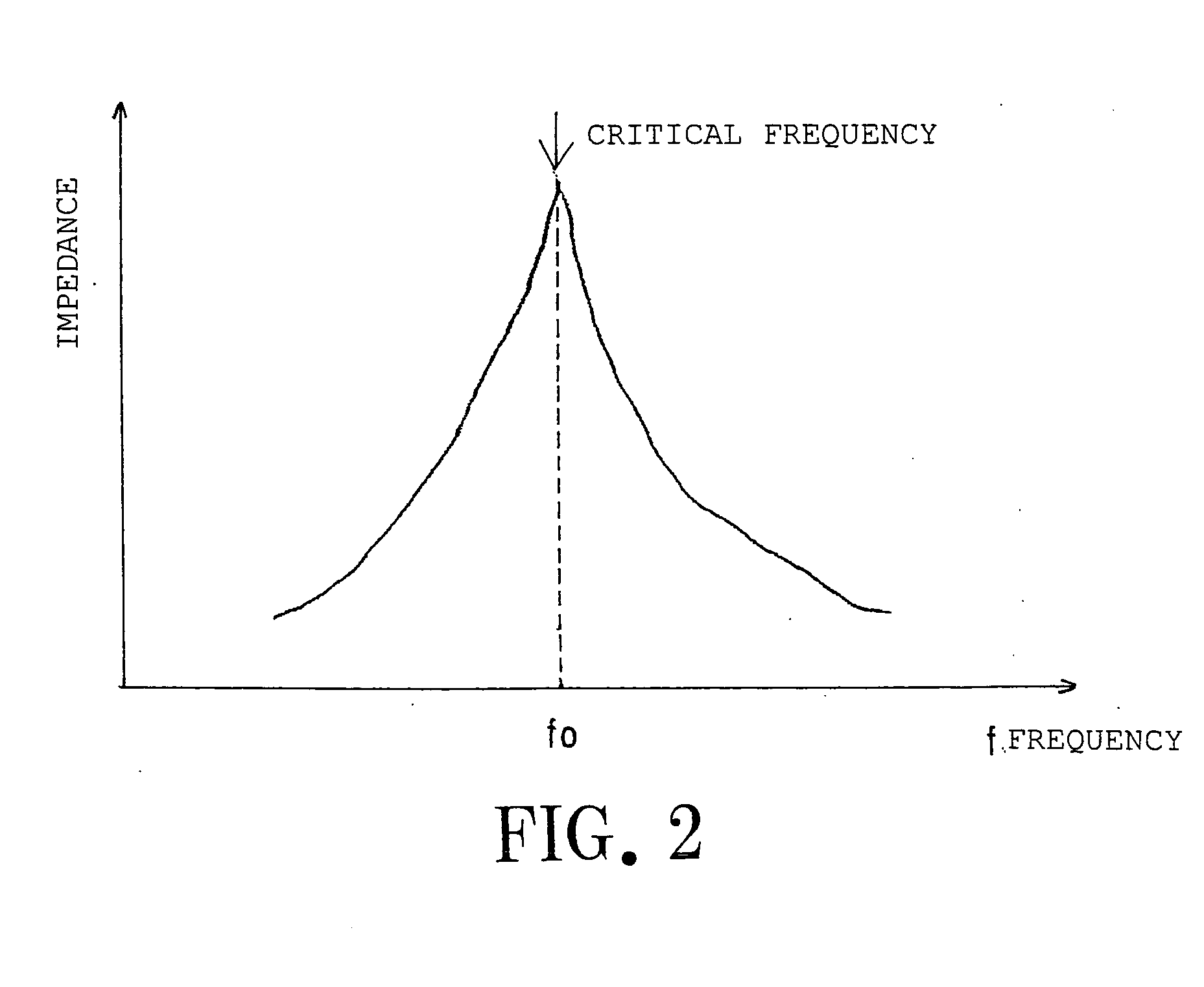

InactiveUS20090256558A1Eliminating infiltration of the magnetic fieldImprove conductivityMagnetic property measurementsUsing electrical meansSkin effectEddy current

Coil is made to be disposed with gap opposed to the surface of wafer, and wafer stage is made to move in X and Y direction and R and θ direction. When supplying an alternating current to coil with the frequency swept by impedance analyzer, the magnetic field made to be induced in coil will operate on the conductive film of wafer. By changing a parameter (a frequency or an angle) influencing the skin effect of the conductive film and giving the parameter to coil, the state where a magnetic field is not made to penetrate relatively the film of wafer and the state where the magnetic field is made to penetrate relatively the film can be formed. From the variation of various values corresponding to the eddy current induced based on the change of state influenced by the skin effect of the conductive film, the film thickness of wafer can be measured with sufficient accuracy.

Owner:TOKYO SEIMITSU

A production method for copper-coated aluminum material

InactiveCN101123129AAvoid high temperature oxidationAvoid lubricationCable/conductor manufactureCelsius DegreeMaterials science

Owner:丹阳市中信化工电器设备有限公司

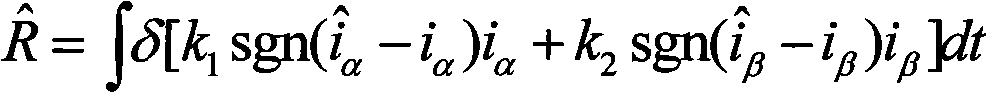

Brushless direct current motor electromagnetic torque observation method based on self-adapting slipform observer

InactiveCN101951211AAccurate torque feedback valueSimple procedureSingle motor speed/torque controlPhase currentsLoop control

The invention discloses a brushless direct current motor electromagnetic torque observation method based on a self-adapting slip-form observer, belonging to the control field of permanent magnet motors. The observation method comprises the following steps of: constructing a state space equation of a brushless direct current motor in an alpha-beta coordinate system based on easily-observing signals, such as motor rotating speed, each phase current of a stator, each ground voltage of the stator, rotor position, and the like; observing a counter emf (Electromotive Force) of the brushless direct current motor in the alpha-beta coordinate system in real time by using the slip-form observer; meanwhile online identifying a stator resistance parameter of the brushless direct current motor to eliminate the influence of a resistance parameter error on counter emf observation; and finally calculating the electromagnetic torque of the brushless direct current motor in real time according to the counter emf, the current and the rotating speed. In the invention, when the stator resistance parameter is unknown or a stator resistance changes due to the influences of temperature and skin effect, the counter emf and the electromagnetic torque of the brushless direct current motor can be accurately observed, the problem of the traditional method influenced by the resistance parameter is solved, and an accurate torque feedback value can be provided for the torque close loop control of the brushless direct current motor.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

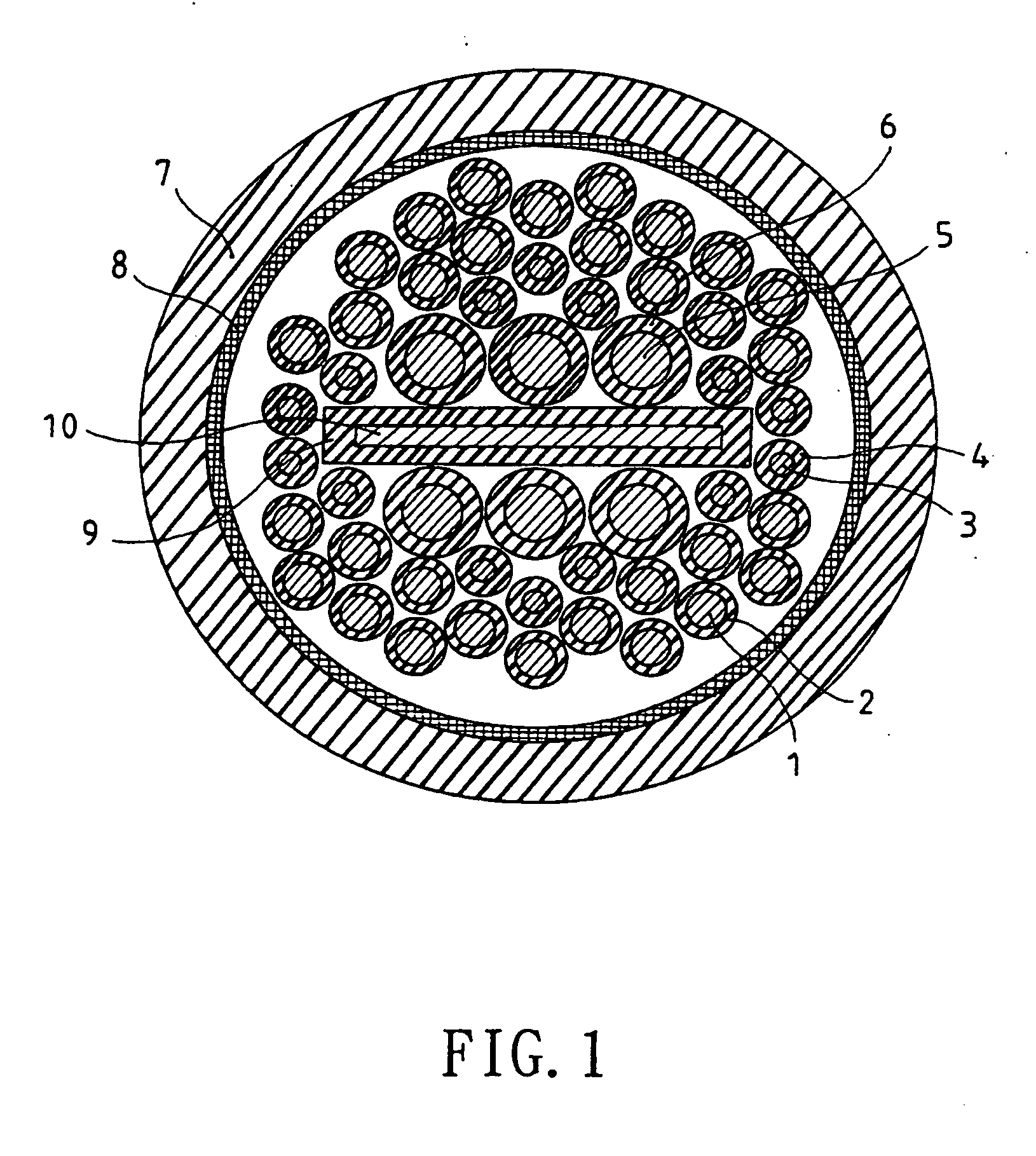

Audio and video signal cable

InactiveUS20050121222A1Avoid it happening againImprove high-frequency phase characteristicInsulated cablesDetails of conductive coresFiberElectrical conductor

An audio and video signal cable consisting of solid conductors of different cross-sectional areas that are parallel arrayed, and after each conductor is insulated, all are surrounded in an insulation, wherein the conductor structure is composed of numerous wires of unequal cross-sectional areas that are furthermore individually insulated. Tinsel, enamel covered wire, or 100% fiber covered copper are utilized for conductors of smaller cross-sectional area, which not only reduces cable outer diameter and increases tensile strength, but also effectively benefits skin effect and enhances high frequency transmission, while larger cross-sectional area conductors facilitate rapid low frequency passage. As such, the present invention is capable of high- and low-frequency band phase synchronicity as well as optimal balance across all frequencies.

Owner:RICH ELECTRIC WIRE & CABLE

Method for preparing special-shaped composite contact tape

ActiveCN101259583AImprove your own performanceGood dimensional stabilityWork treatment devicesMetal rolling arrangementsHydrogenNitrogen

The invention discloses a preparation method of a special composite contact belt, wherein, two or more clean strips with matched properties are heated rapidly in protective atmosphere according to a certain speed by a brushing mechanism and a high frequency induction heater, continuously rolled and compounded according to a certain processing rate under the condition of atmosphere protection such as hydrogen, nitrogen, argon, etc. after a die is precisely located, and formed a long strip with two or more layers. After the long strip carries out heat treatment, the long strip is rolled to the regulated thickness and divided into a plurality of micro sized strips on a precise stripping device. The micro sized strips are prepared into special composite contact strips after being shaped, rolled and molded by a precise die. The preparation method of the invention has the advantages that close combination can be formed and at the same time performance of material is protected by making use of skin effect of the high frequency induction heating; no large rolling equipment is needed; strength of interlayer combination is high and stable; longer strips can be continuously compounded; production efficiency is high by combination of precise stripping technology, thus being suitable for production in large amount.

Owner:兰溪市金铎金属材料科技有限公司

Inductor and dc-dc converter

ActiveUS20180166211A1Inhibition effectSmall sizeTransformers/inductances coolingTransformers/inductances coils/windings/connectionsDc dc converterSkin effect

An inductor includes a core made from a metallic magnetic material, a wire wound around the core, a pair of outer electrodes coupled to respective end portions of the wire, a shielding member arranged so as to cover a top face and three or more side faces of the core, and an insulating member arranged between the core and the shielding member and having thermal conductivity. The thickness of the shielding member is set by applying the electric resistivity and permeability of the shielding member and the frequency of noise desired to be shielded to an expression for determining the depth of a skin of skin effect. The thickness of the insulating member is set according to the breakdown voltage of the insulating member and the voltage with which insulation is desired to be ensured under a use environment of the inductor.

Owner:MURATA MFG CO LTD

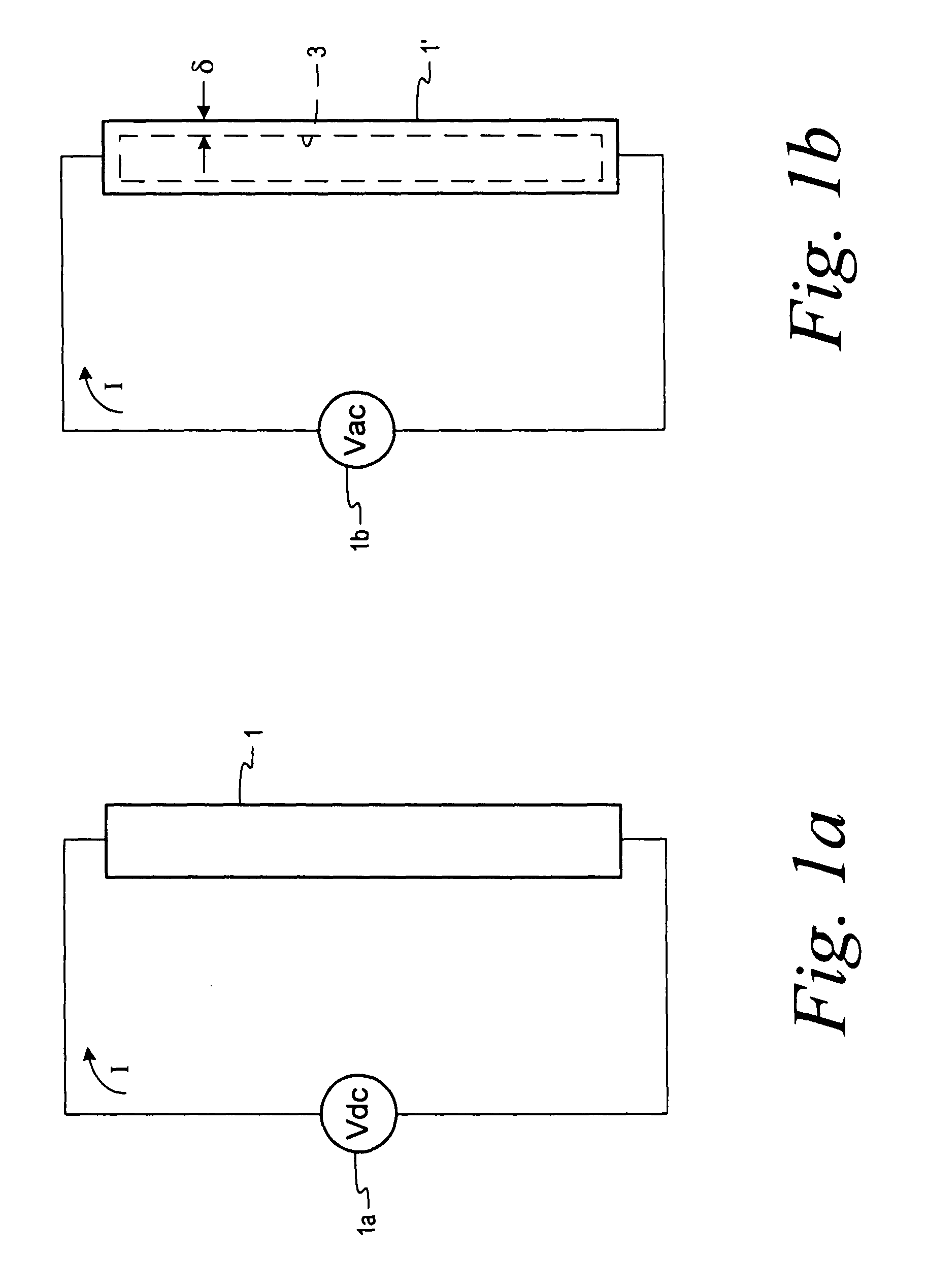

Disposable patch for personal aesthetic skin treatment

An apparatus for personal aesthetic skin treatment by RF voltage. The apparatus includes an RF voltage supply and a disposable patch with an assembly of individual electrodes operative to contact segments of the skin and deliver to each contact RF voltage. The RF voltage may be supplied to each of the electrodes according to a predetermined experimentally established skin treatment protocol. The treatment RF current generated by the applied RF voltage heats the skin and is applied intermittently to different electrodes being in contact with the skin in an order and duration sufficient to cause the desired skin effect and enable proper cooling of earlier treated skin segments. The selected protocol ensures safe non-ablative skin treatment parameters.

Owner:SYNERON MEDICAL LTD

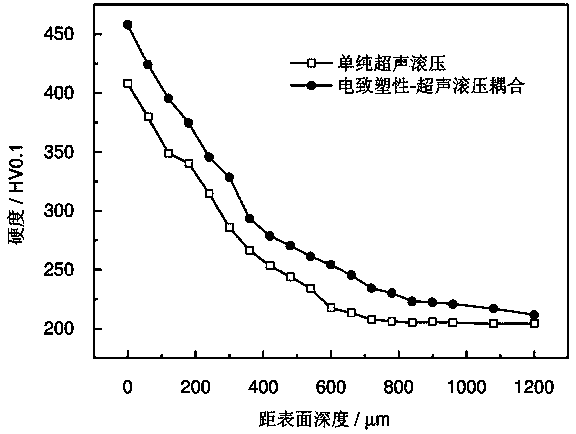

Surface strengthening treatment method for metal material through coupling electroplastic effect and ultrasonic rolling

ActiveCN104195322AHigh hardnessImprove wear resistanceHeat treatment process controlSurface layerMetallic materials

The invention relates to a surface strengthening treatment method for a metal material through coupling an electroplastic effect and ultrasonic rolling. The surface strengthening treatment method comprises the steps of (1) clamping a metal workpiece on a supporting device; and (2) applying a pulse current to a processing region of the metal workpiece, and properly reducing the plastic transformation resistance of the surface layer of the processing region by virtue of an electroplastic effect, a skin effect and a thermal effect of the pulse current; and meanwhile driving the metal workpiece to rotate by the supporting device, and carrying out ultrasonic impact rolling on the surface layer of the processing region by using an ultrasonic rolling device moving along the axial direction of the metal workpiece to ensure that the surface layer of the processing region generates violent plastic deformation to increase the dislocation density and refine grains to further form a strengthened layer. According to the method, the strengthening treatment on the surface of the metal material is realized by combining the electroplastic effect, ultrasonic impact and a rolling effect; and compared with a single ultrasonic rolling method, the method has the advantages that the acting thickness of the strengthened layer is further increased, and the extreme surface hardness of the workpiece is further improved. When the method is used for surface strengthening treatment on intractable metal materials with high hardness or seriously-hardened intractable metal materials, the quality of the strengthened layer can be remarkably improved, the processing efficiency can be greatly increased, and the production cost can be reduced.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

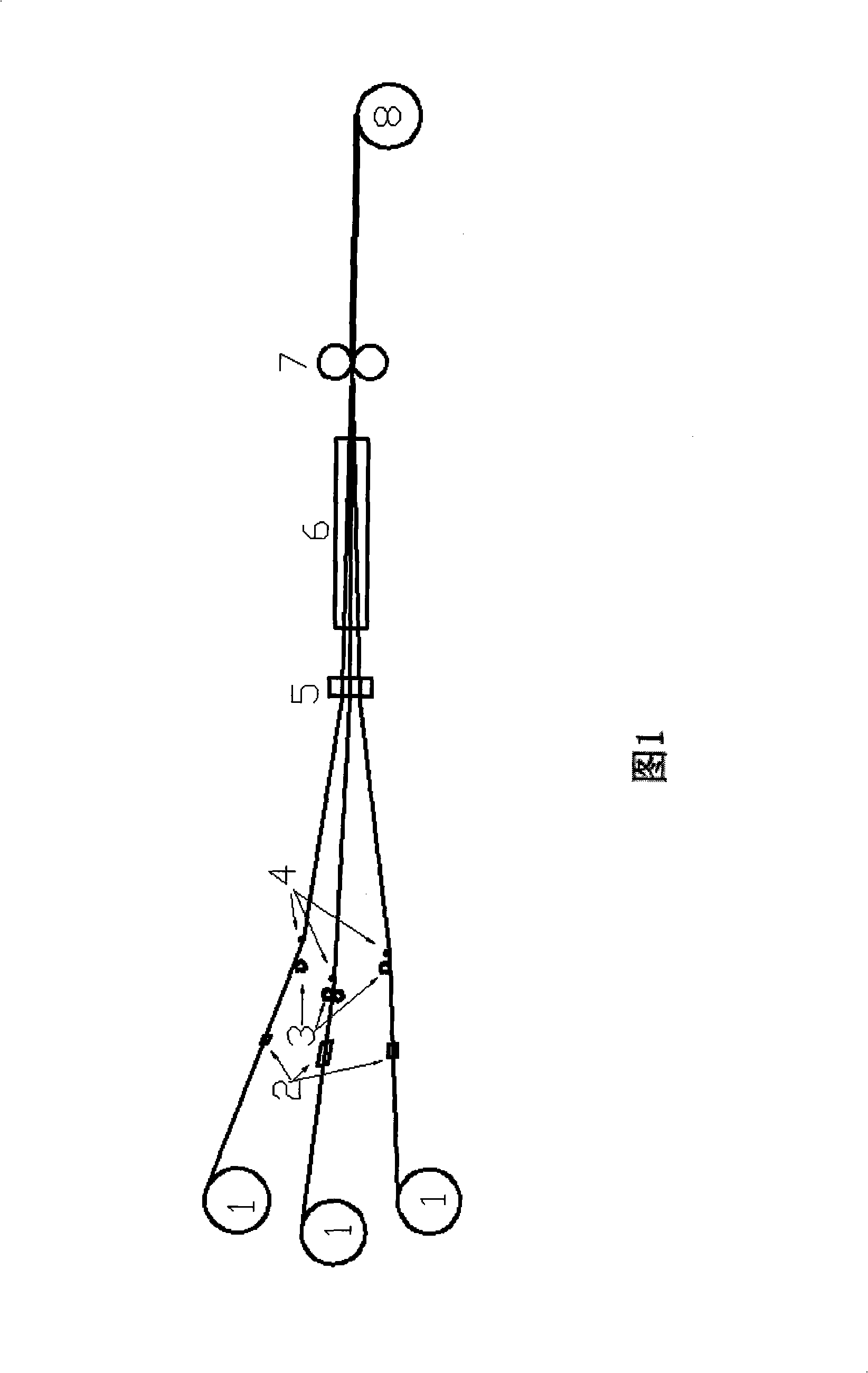

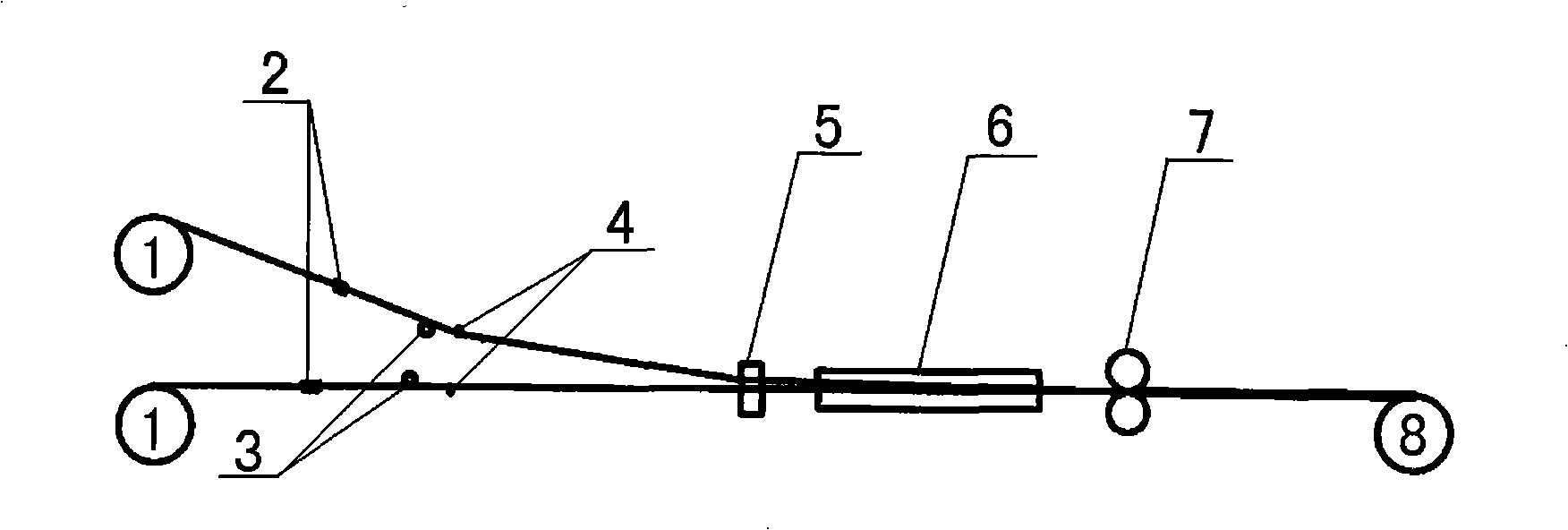

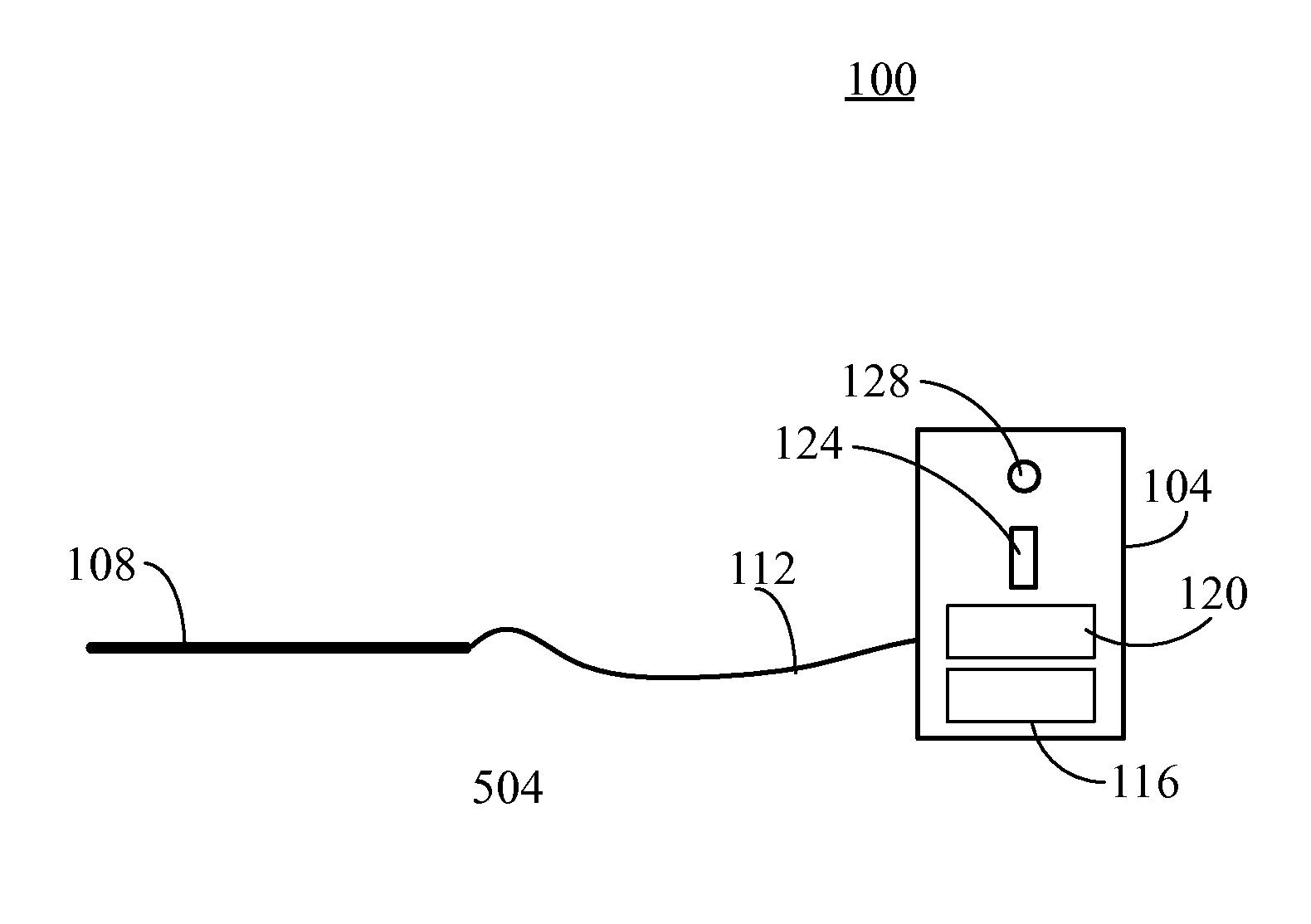

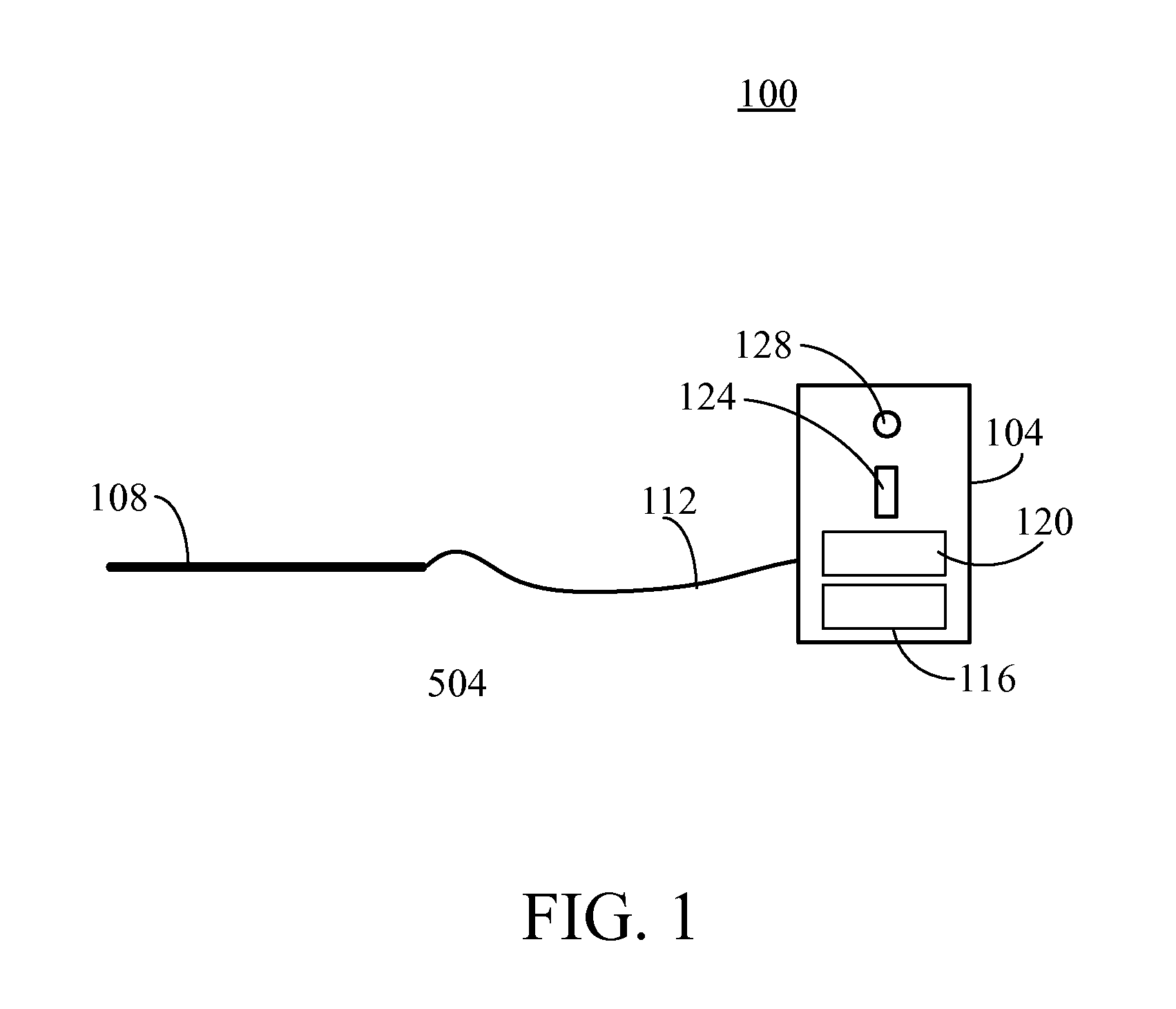

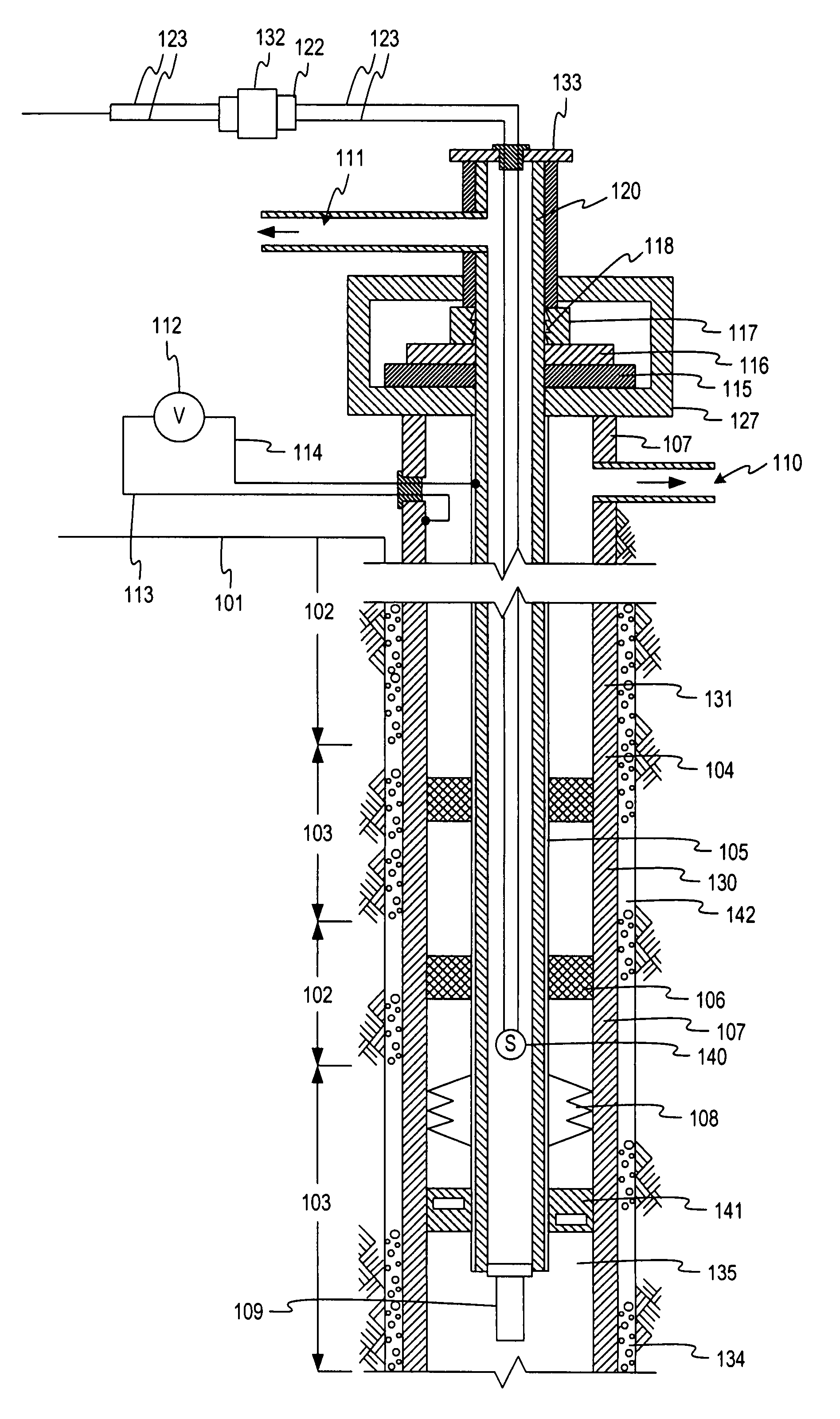

Radio frequency technology heater for unconventional resources

ActiveUS8210256B2Easy to installPromote recoveryInsulationFluid removalElectricityElectrical conductor

Owner:PYROPHASE INC

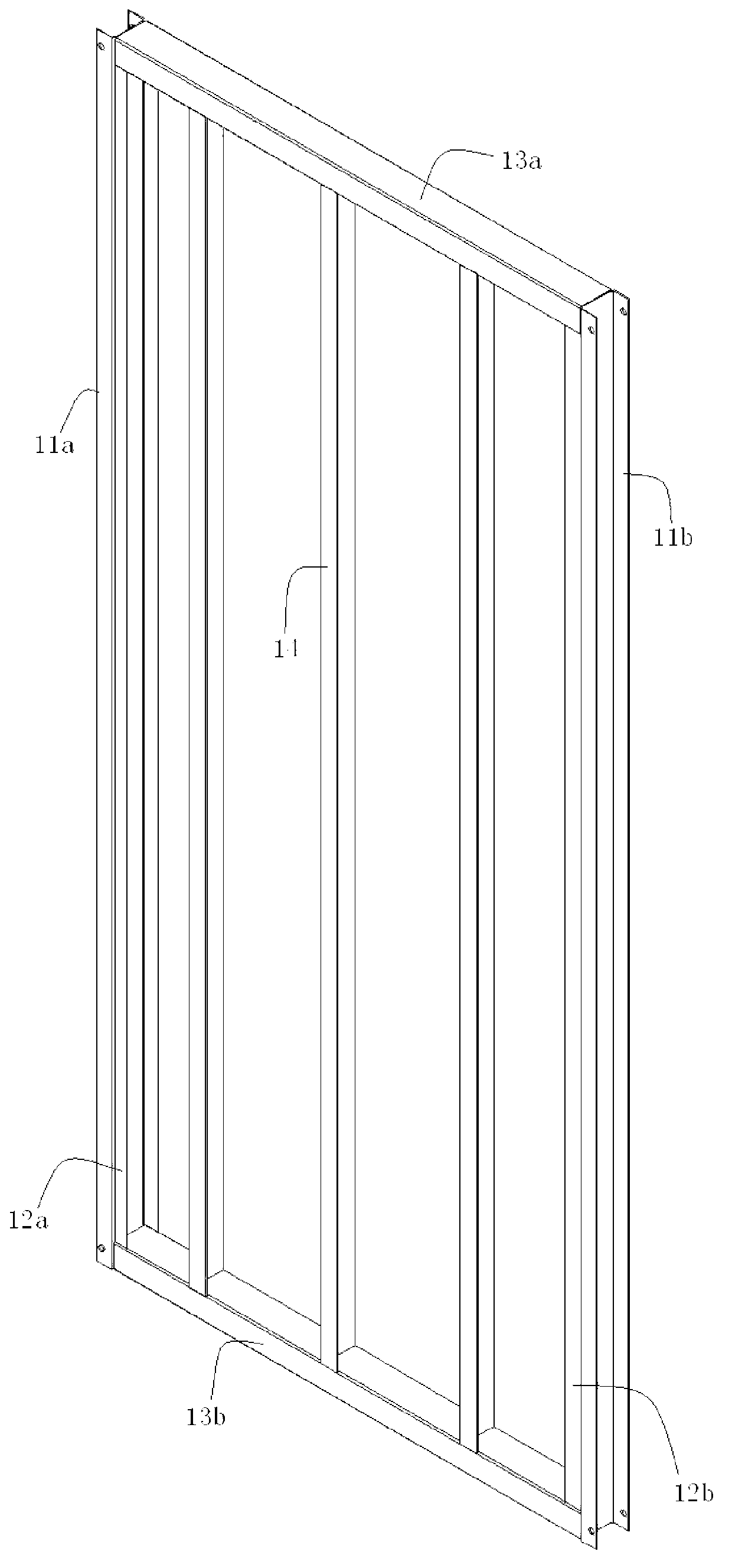

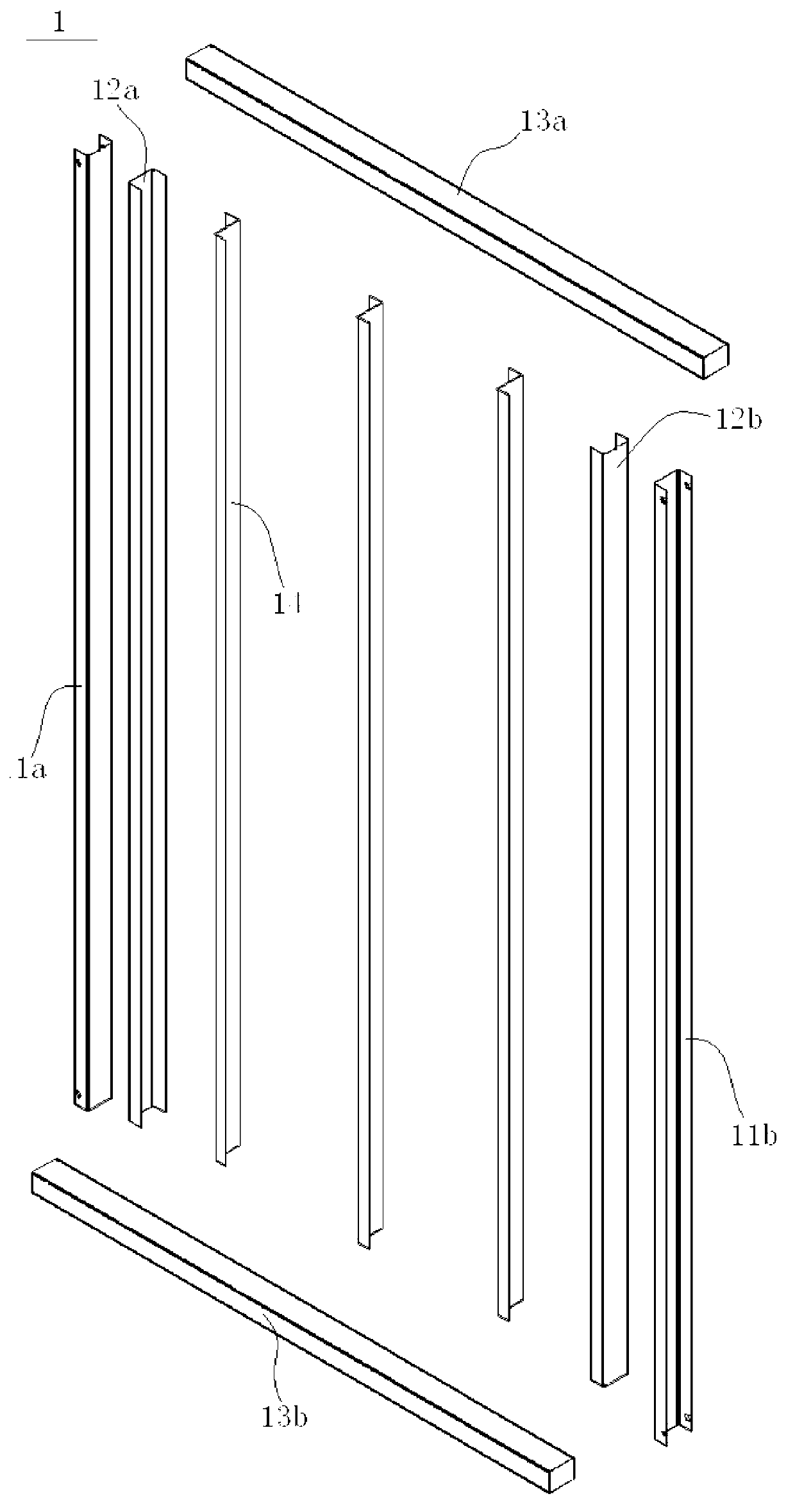

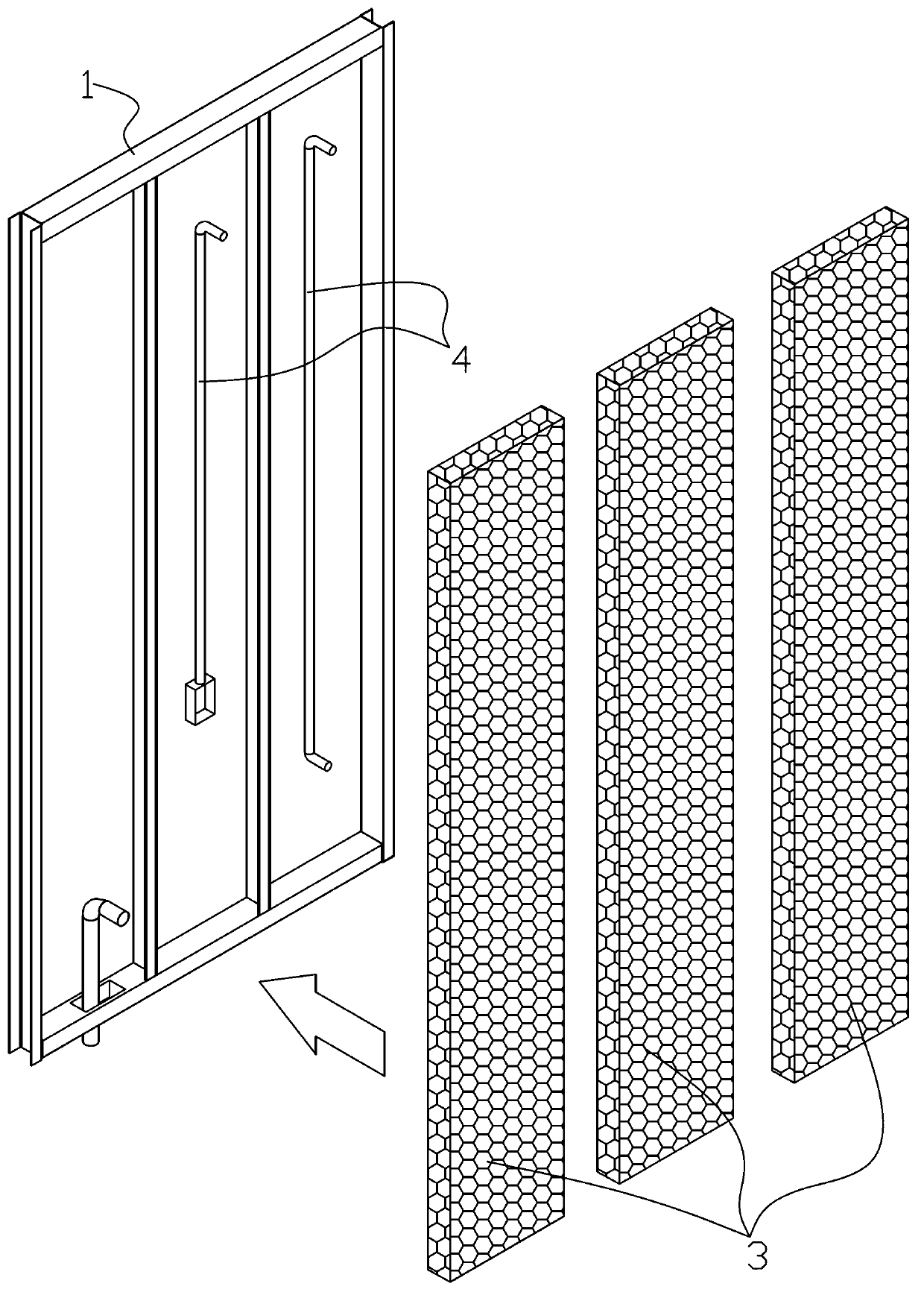

Prefabricated slab and fixed mounting structure thereof

The invention discloses a prefabricated slab and a fixed mounting structure thereof. The prefabricated slab comprises a light steel frame, a front board and a rear board, wherein the light steel frame comprises a left border, a right border, an upper border, and a lower border, which are enclosed together to form a square frame; U-shaped notches of the left border and the right border are respectively arranged towards the left and the right, so that the prefabricated slab can be inserted together with a structure member through the U-shaped notches; mounting holes through which bolts penetrate to fix the prefabricated slab on the structure member are arranged on front and rear connecting arms of the left and right borders; the front board and the rear board are respectively paved on the light steel frame as front and rear panels of the light steel frame; and the top surfaces and the bottom surfaces of the upper and lower borders are exposed outside. The light steel frame is internally built into the prefabricated slab; the light board is paved outside a skeleton by a 'stressed-skin effect' technology; the performance stronger than that of a single material is developed; and the light steel skeleton internally arranged inside the prefabricated slab is exposed at the periphery of the prefabricated slab, so that the prefabricated slab can be conveniently and effectively connected with a steel structure by the existing steel structure connecting technology.

Owner:广州市澳居科技有限公司

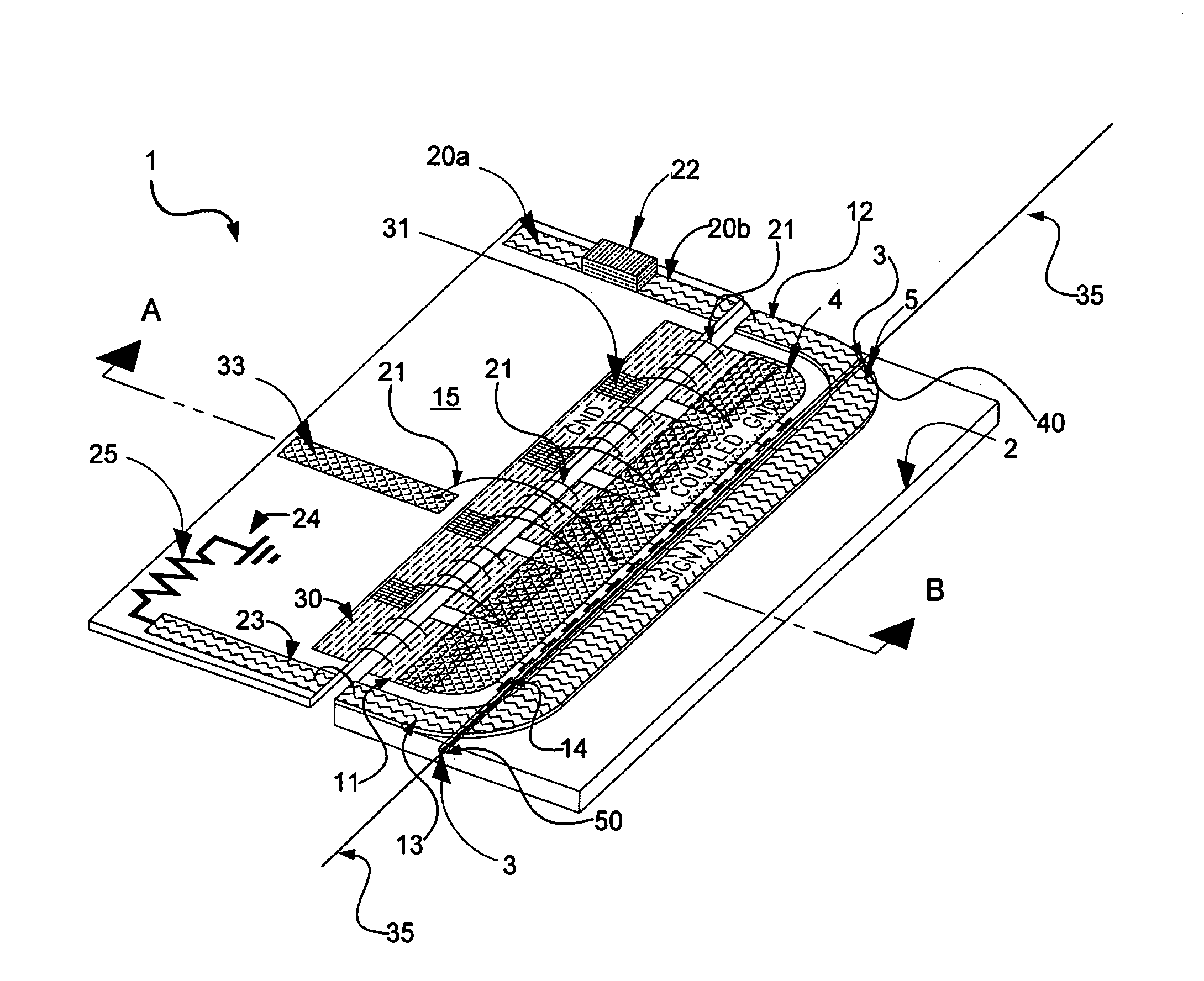

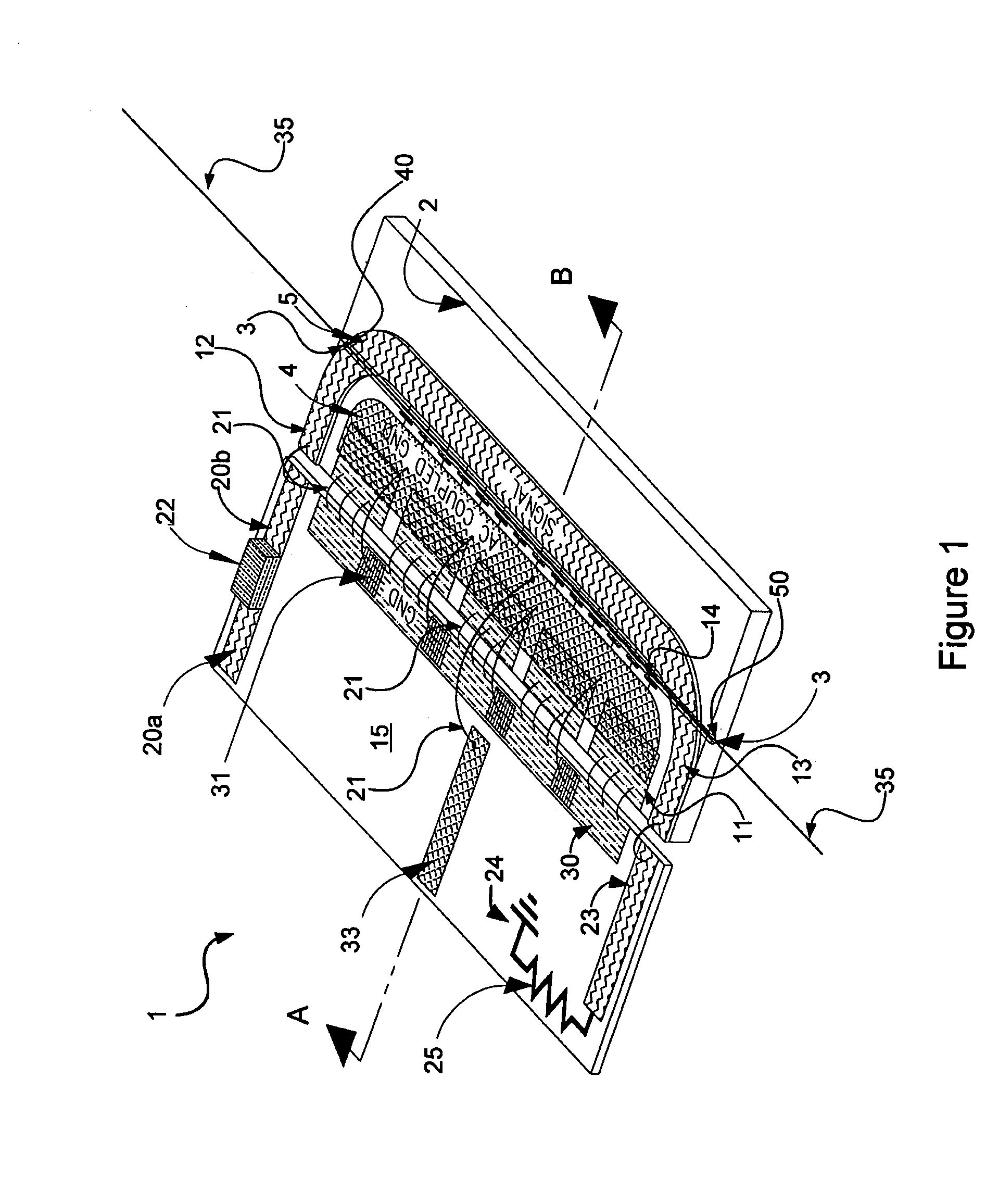

Method and apparatus for improving frequency response in mode converters

A semiconductor based electro-optic modulator comprising a capacitively coupled ground allowing for DC biasing of the modulator and a pre-distortion circuit for alleviating RF skin effect and for increasing bandwidth of modulator. Electrical components and functions of modulator partly located on an alumina pane. Reduction of thermally-induced stresses by connecting modulator ground to package ground via alumina pane is also disclosed.

Owner:OPTELIAN ACCESS NETWORKS

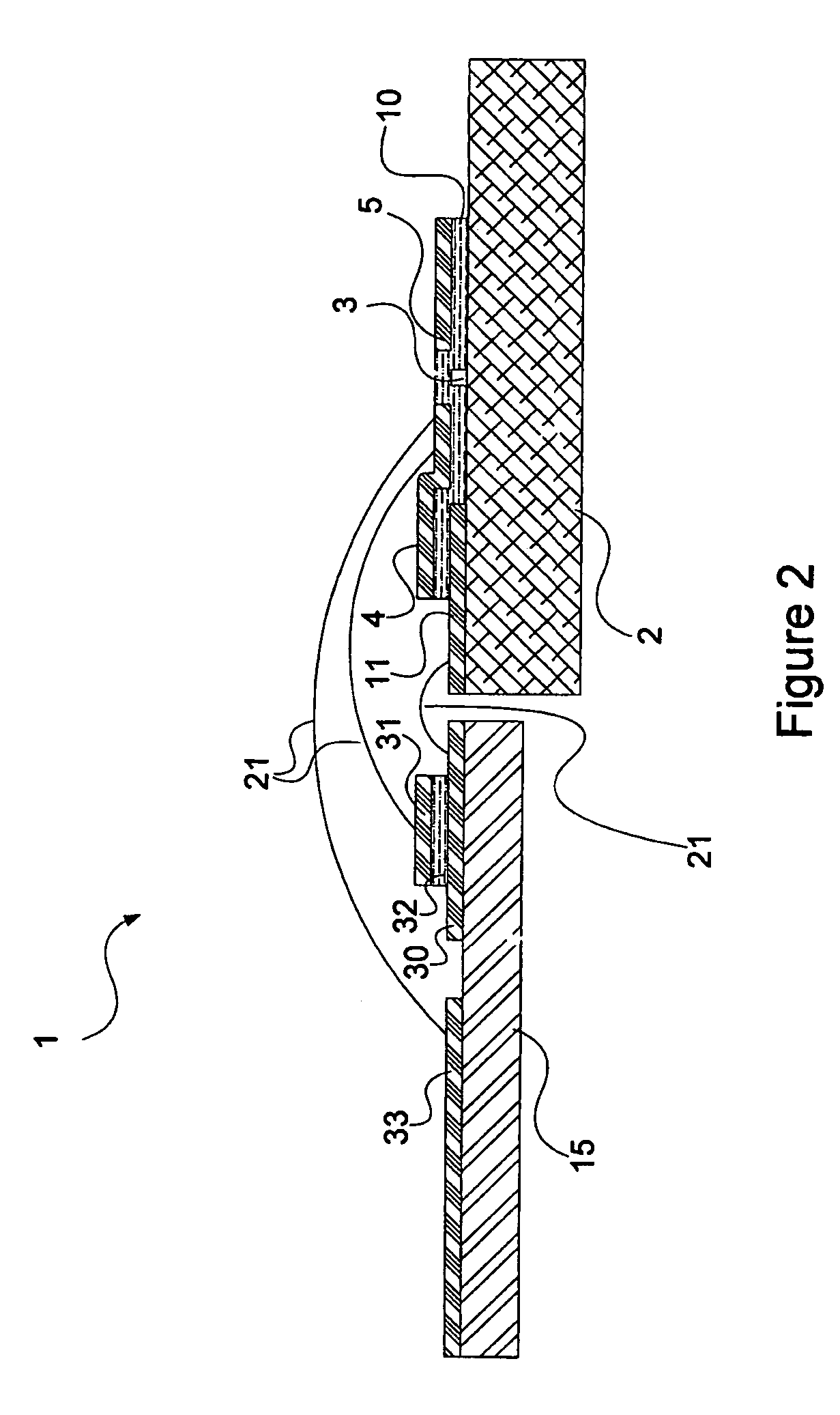

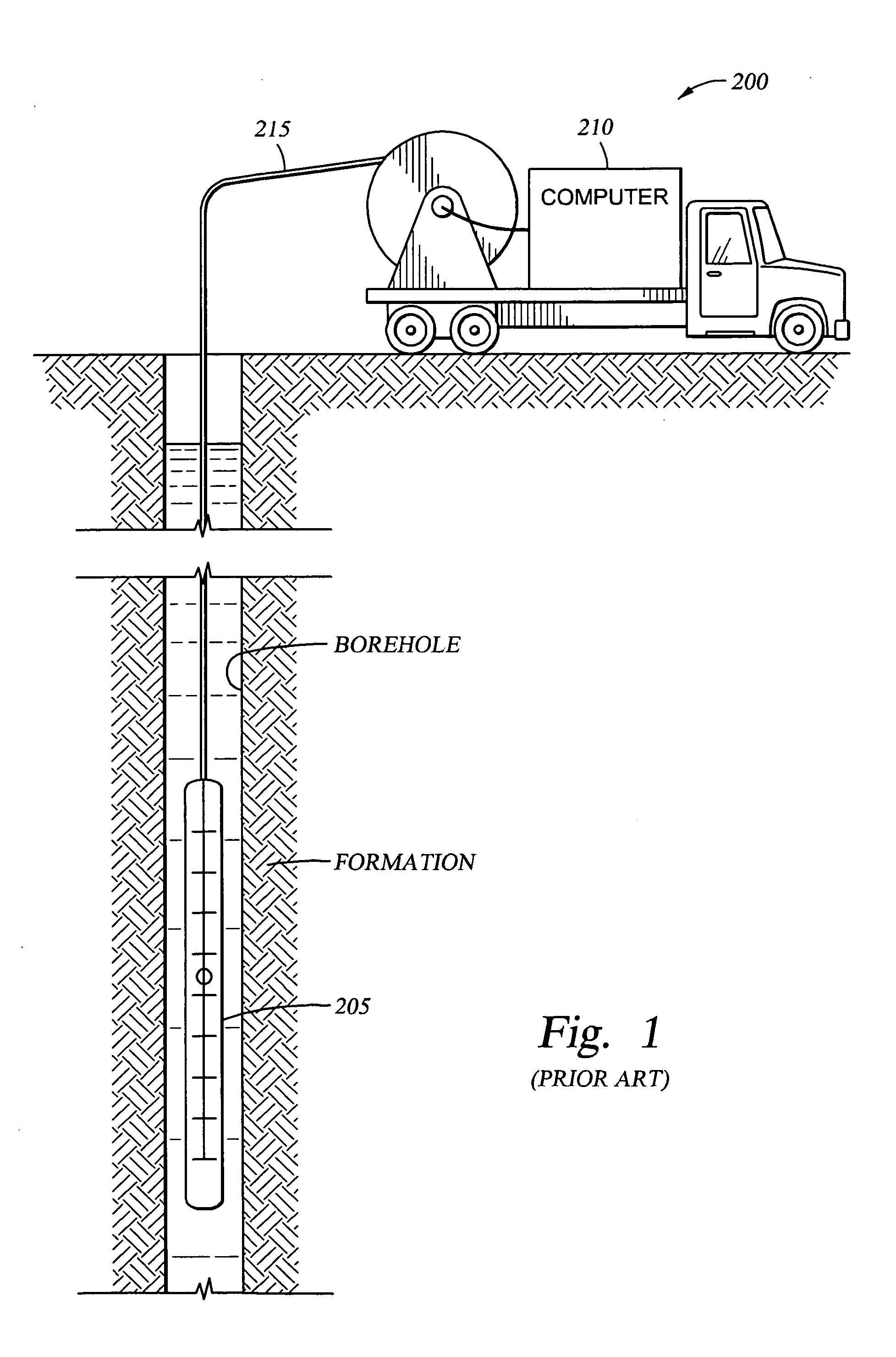

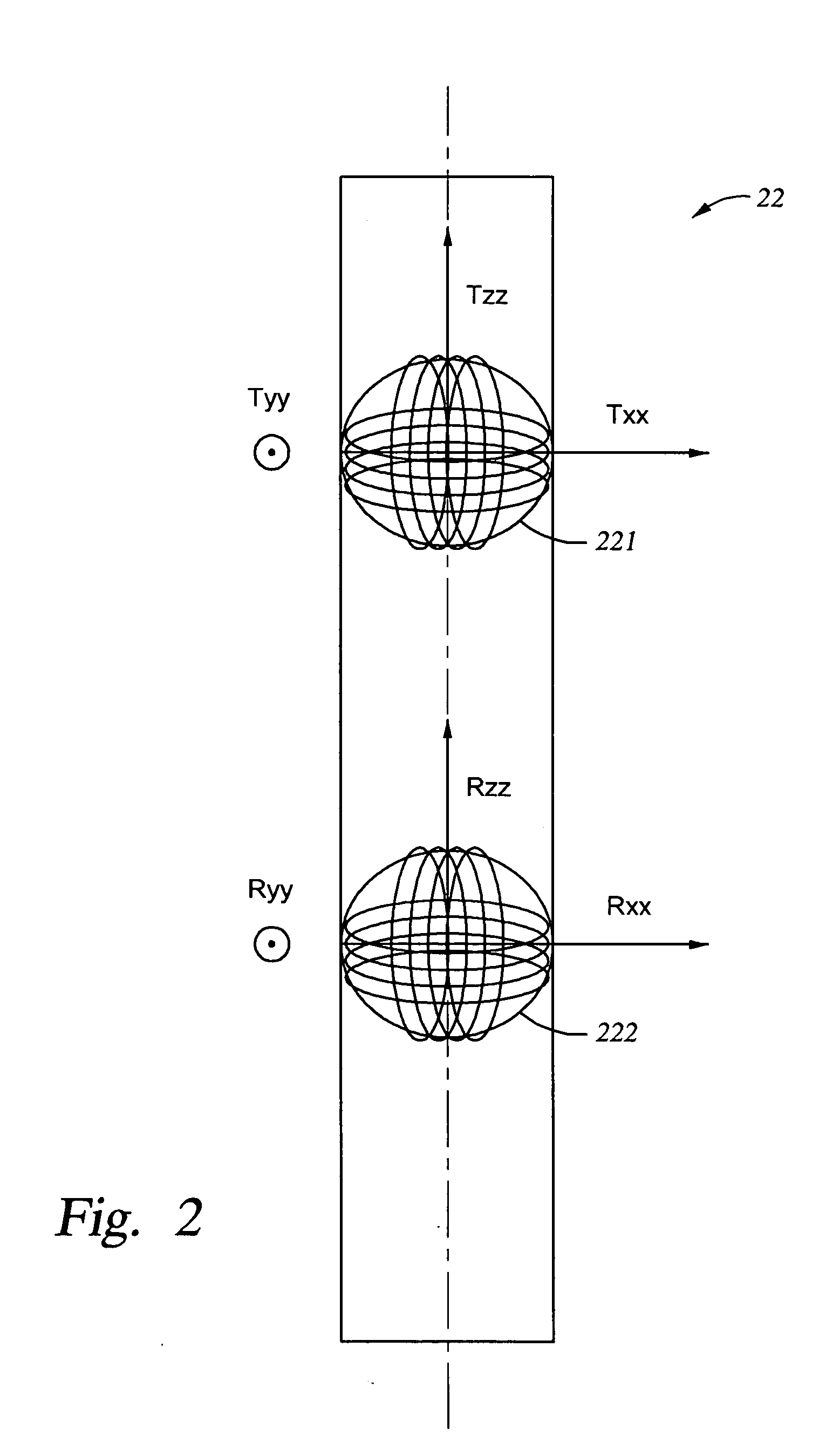

Methods and systems for estimating formation resistivity that are less sensitive to skin effects, shoulder-bed effects and formation dips

InactiveUS20050083061A1Electric/magnetic detection for well-loggingAcoustic wave reradiationElectricitySkin effect

A method for determining an electrical property of a formation includes acquiring a first resistivity measurement by energizing a first transmitter and receiving a first signal in a first receiver, wherein the first transmitter and the first receiver are disposed on the logging tool in a first orientation substantially parallel to a longitudinal axis of the logging tool; acquiring a second resistivity measurement by energizing a second transmitter and receiving a second signal in a second receiver, wherein the second transmitter and the second receiver are disposed on the logging tool in a second orientation that is substantially orthogonal to the first orientation; and deriving the electrical property of the formation from a difference measurement that is derived from the first resistivity measurement and the second resistivity measurement.

Owner:SCHLUMBERGER TECH CORP

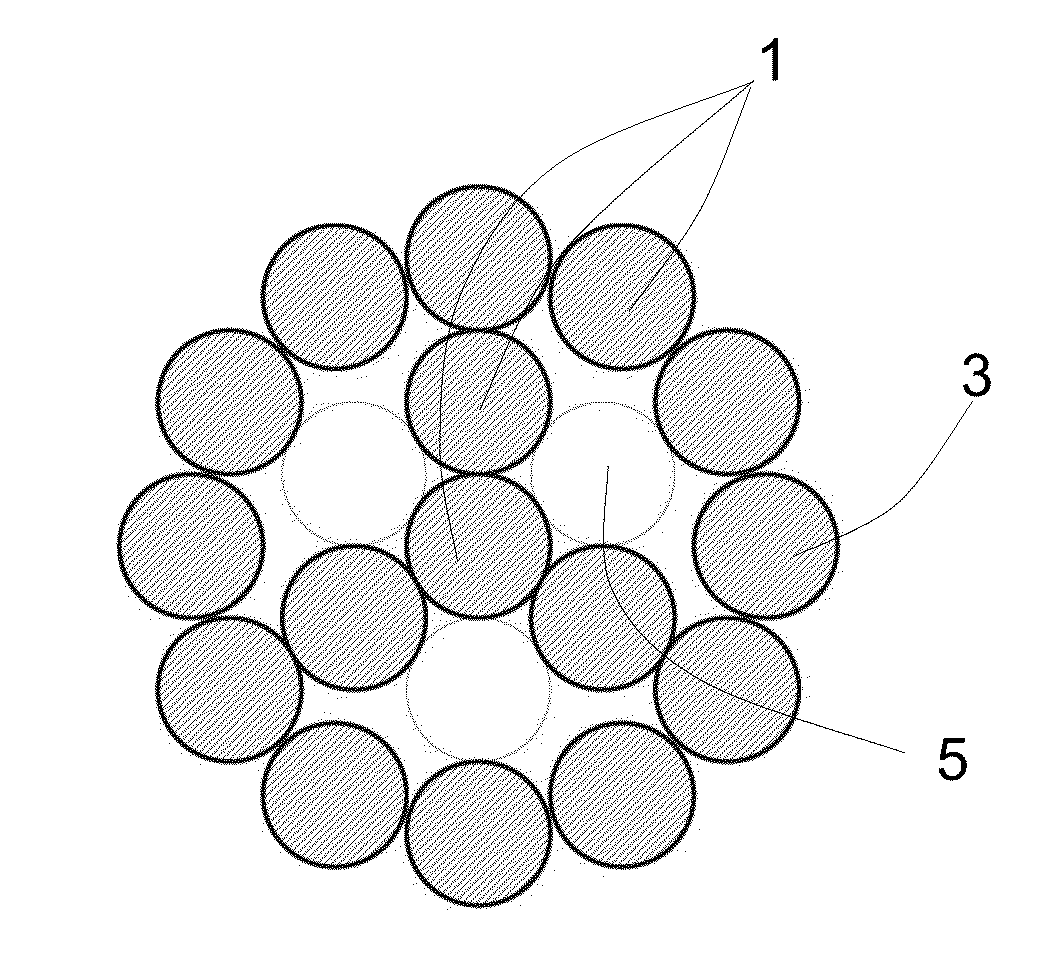

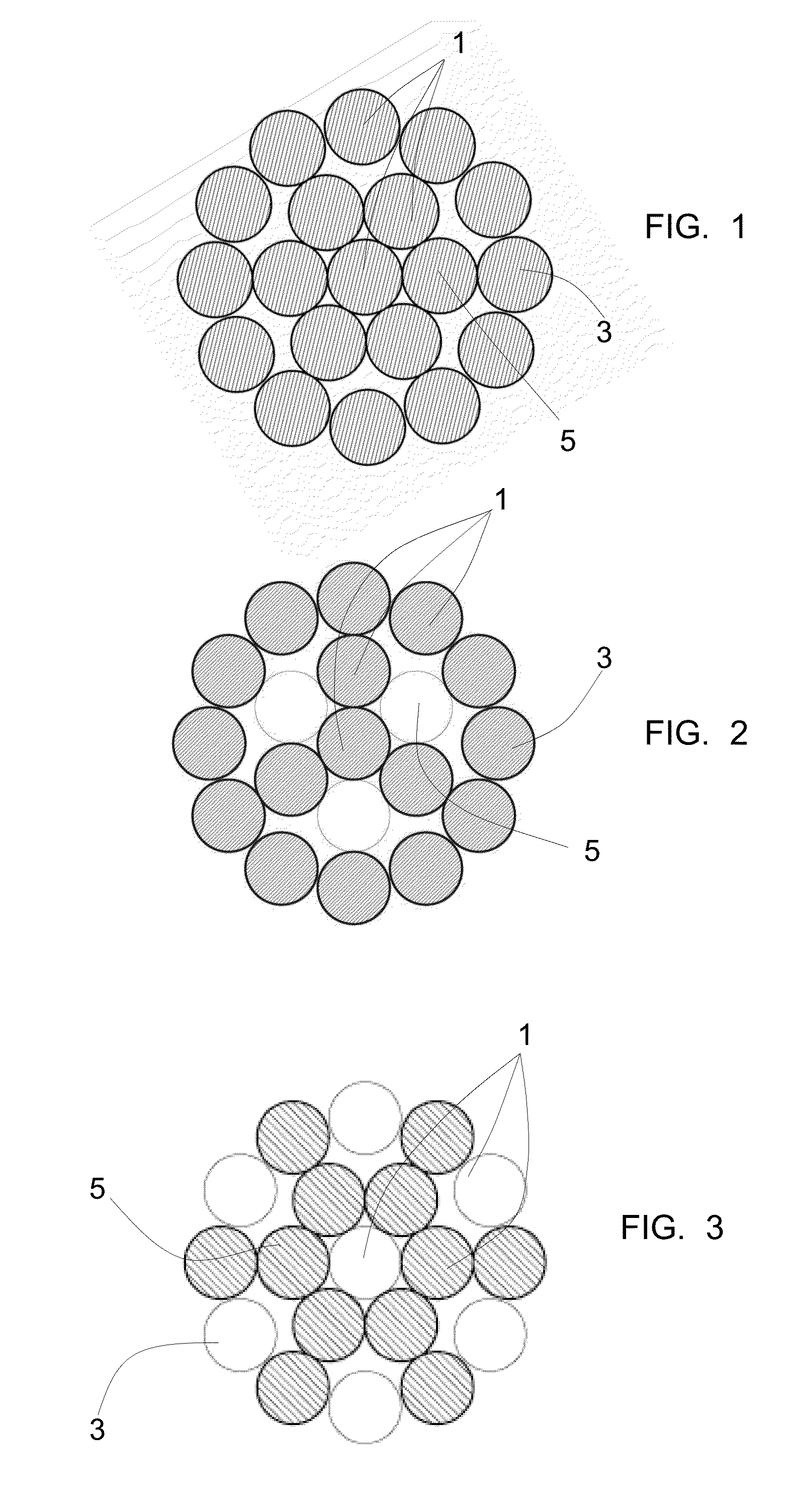

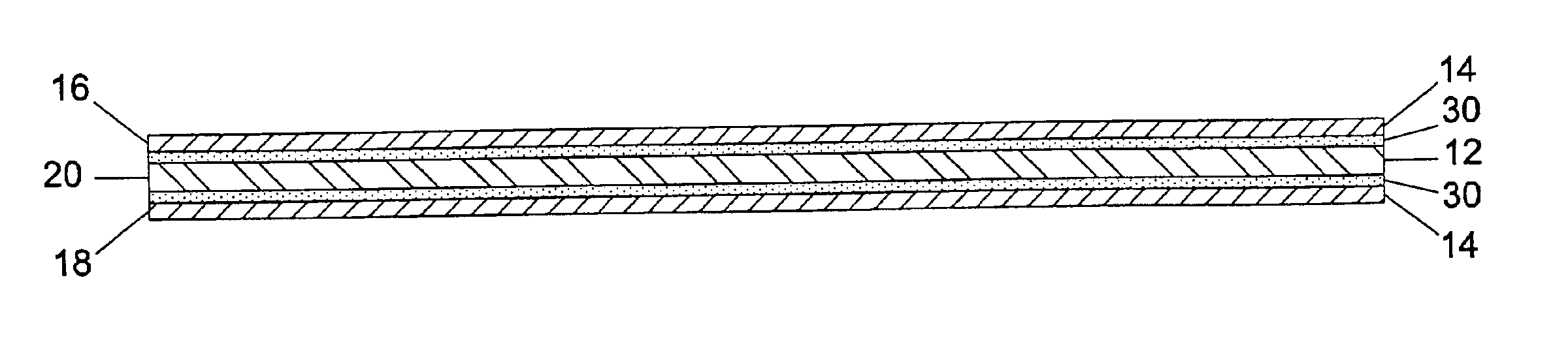

Electrical Conductor for Transporting Electrical Energy and Corresponding Production Method

InactiveUS20130264093A1Small catenary sagImprove electrical performanceNon-insulated conductorsConductive materialElectrical conductorSkin effect

An electrical conductor for transmission of electrical power, having a total cross-section equal to or above 10 mm2 and comprising a plurality of stranded filamentary members, where at least one of the filamentary members is made from microalloyed copper or microalloyed aluminium having annealing temperatures higher than 250° C., and has the side surface thereof totally coated with a fluorinated polymer. The conductor has a better behavior relative to the skin effect and allows operation at high temperatures. Furthermore, if the electrical conductor is suspended, it has a smaller sag and prevents or reduces the accumulation of ice and / or snow.

Owner:LA FARGA LACAMBRA

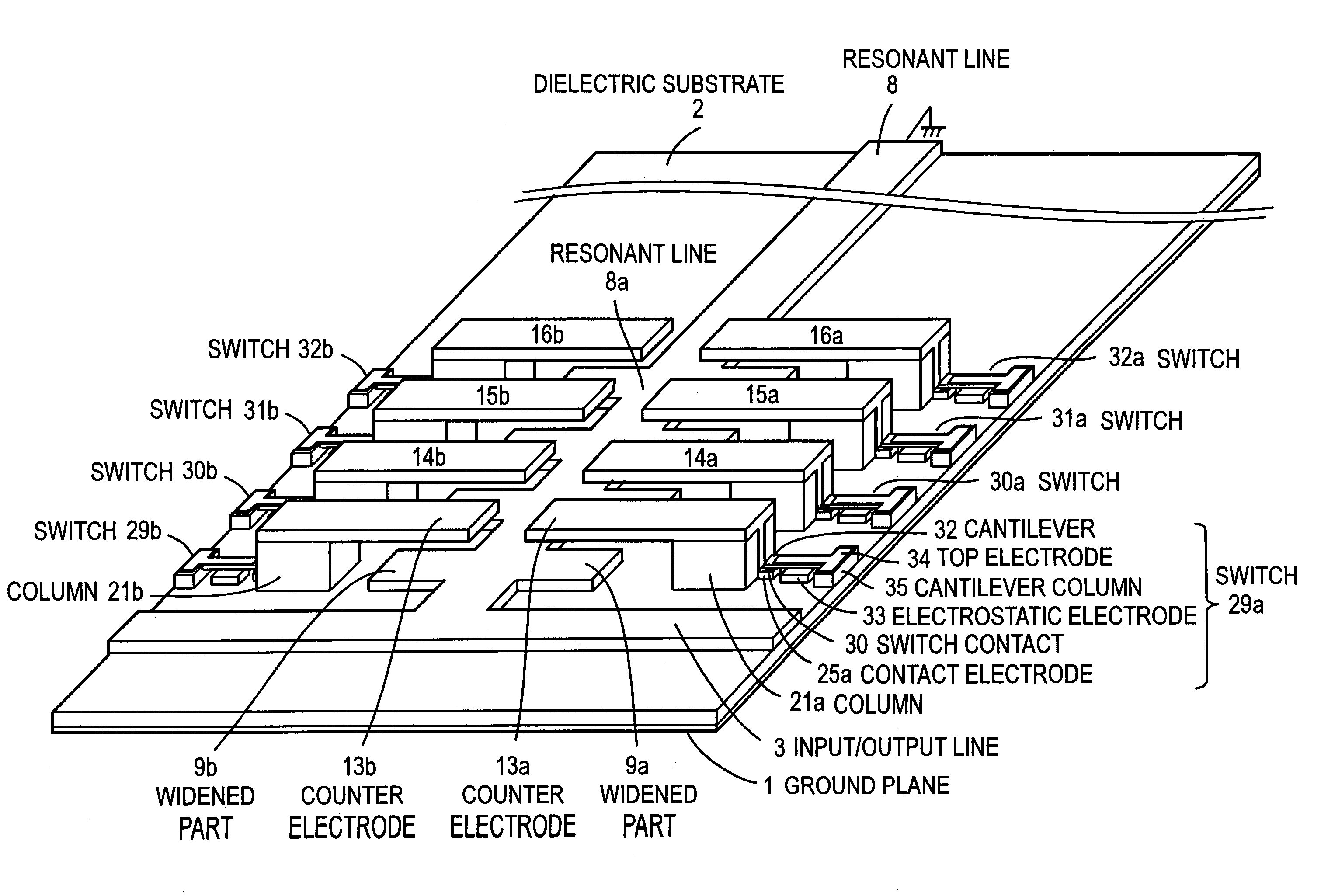

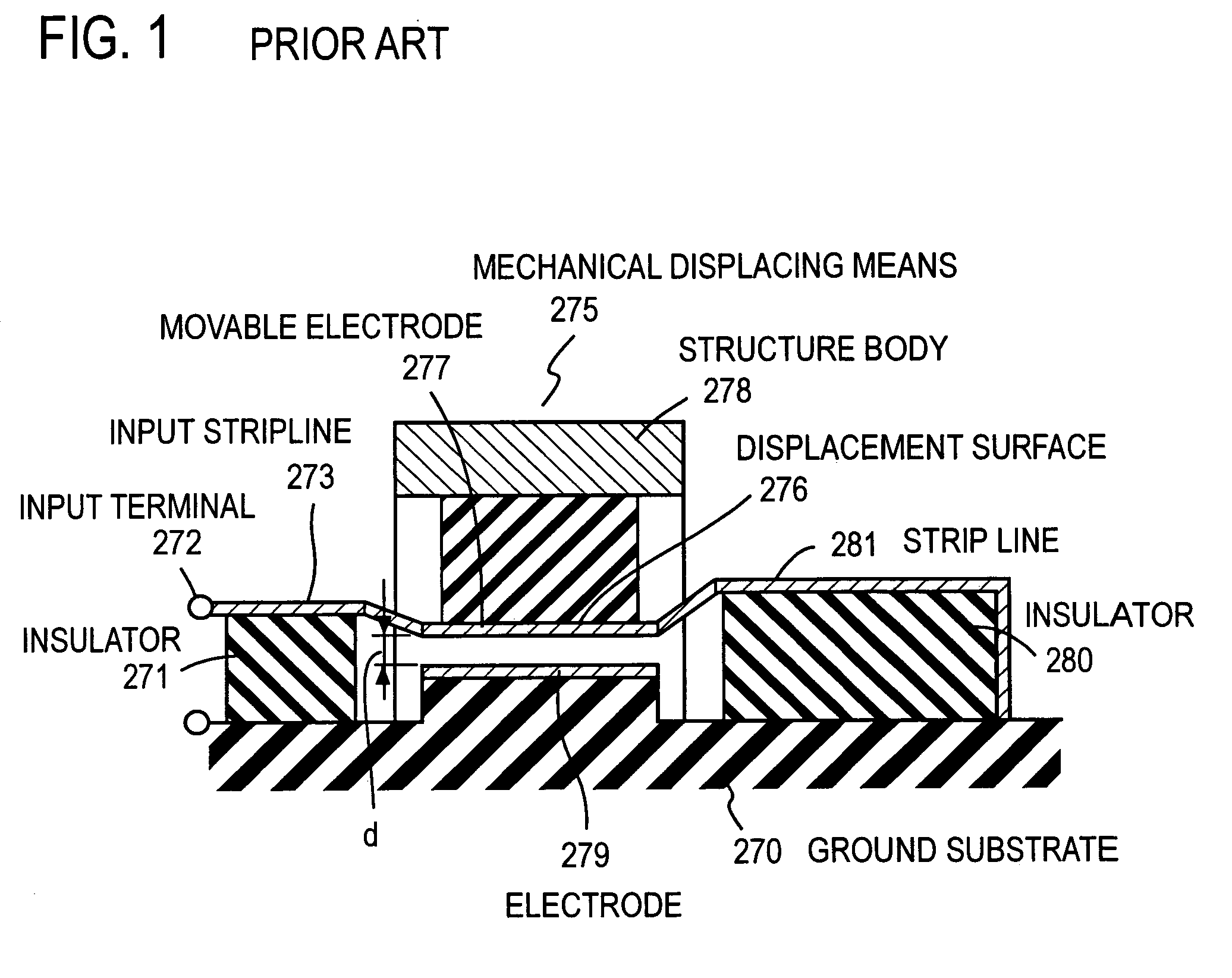

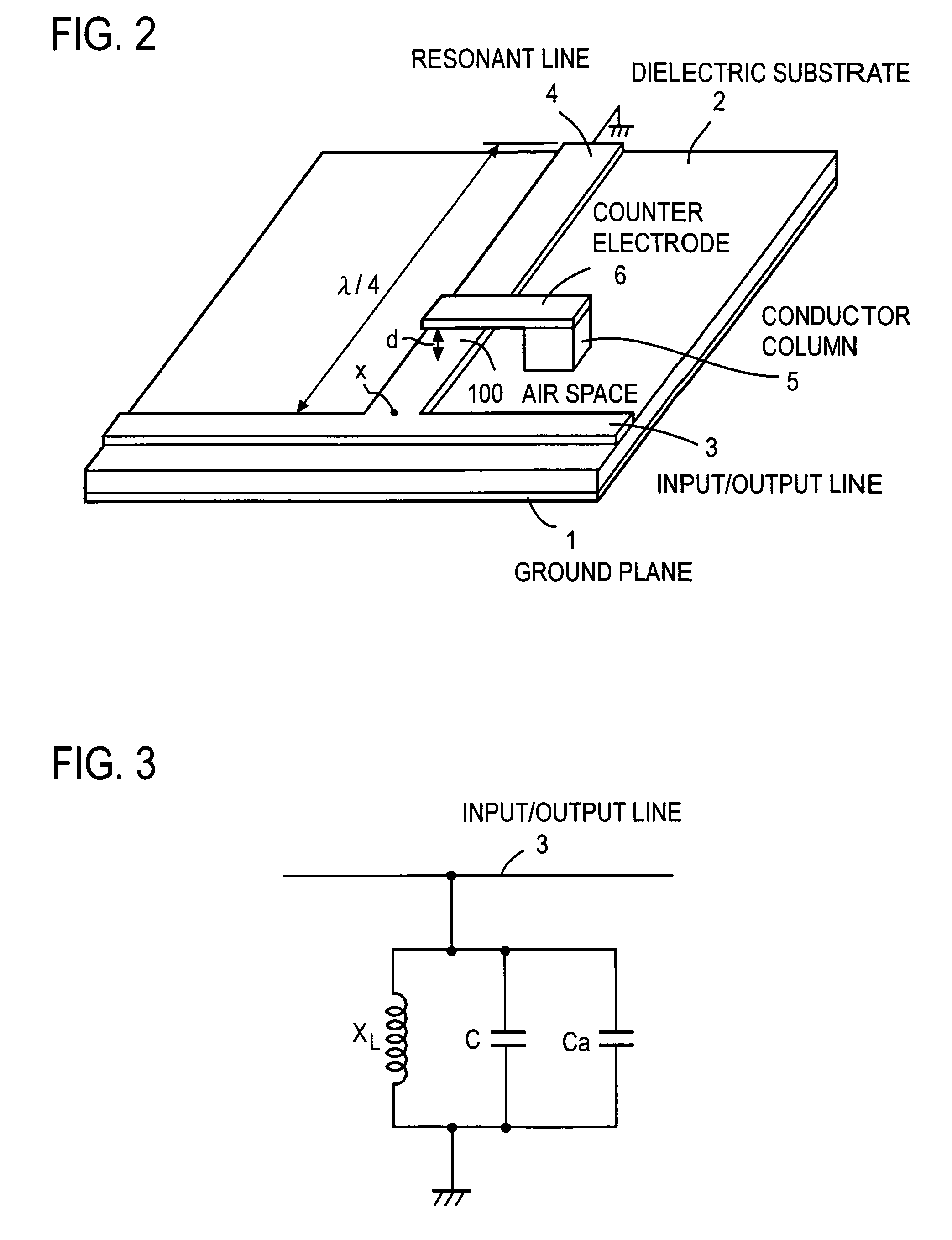

Resonator

InactiveUS7583168B2Small sizeImprove batch productivityMultiple-port networksResonatorsCapacitanceResonance

Owner:NTT DOCOMO INC

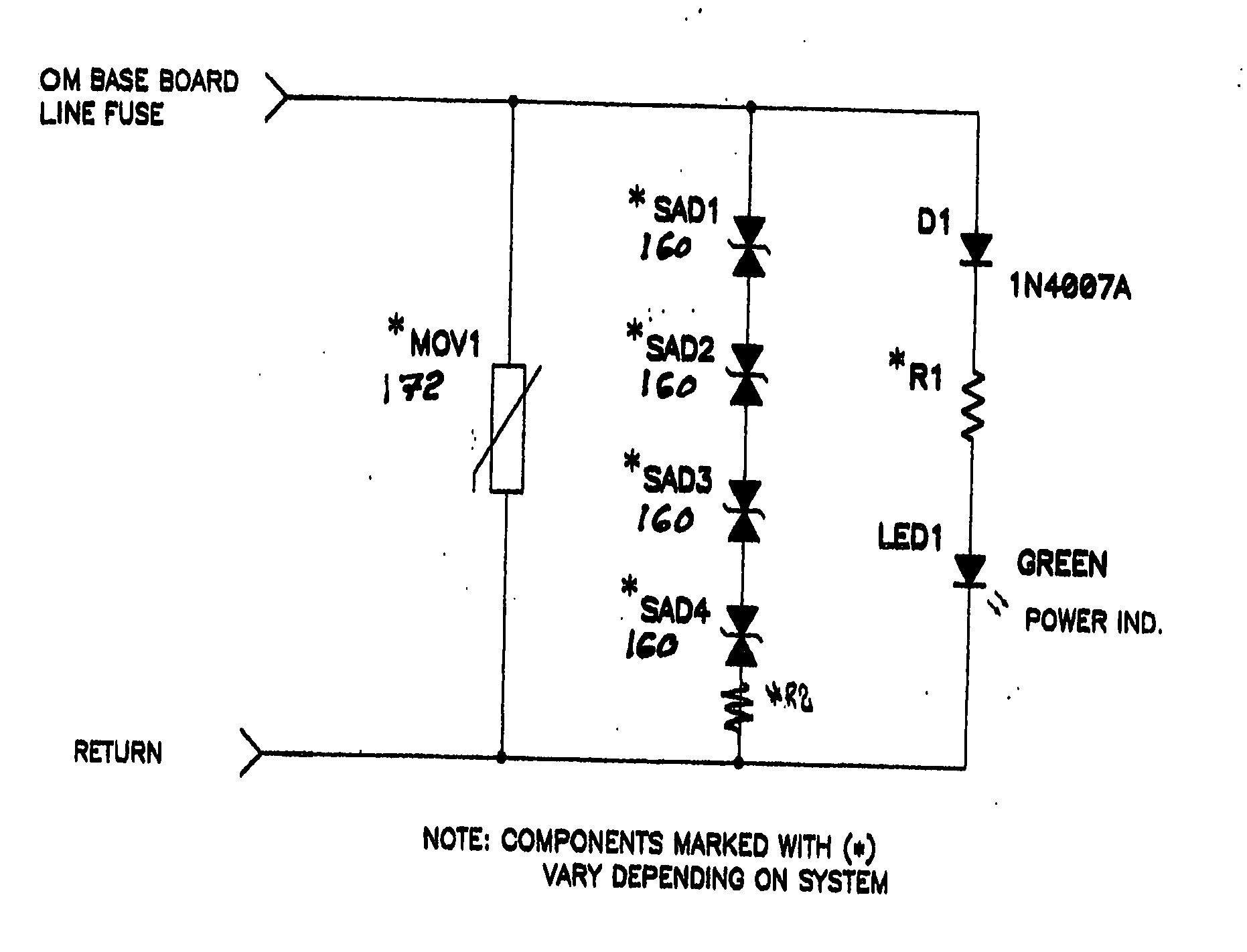

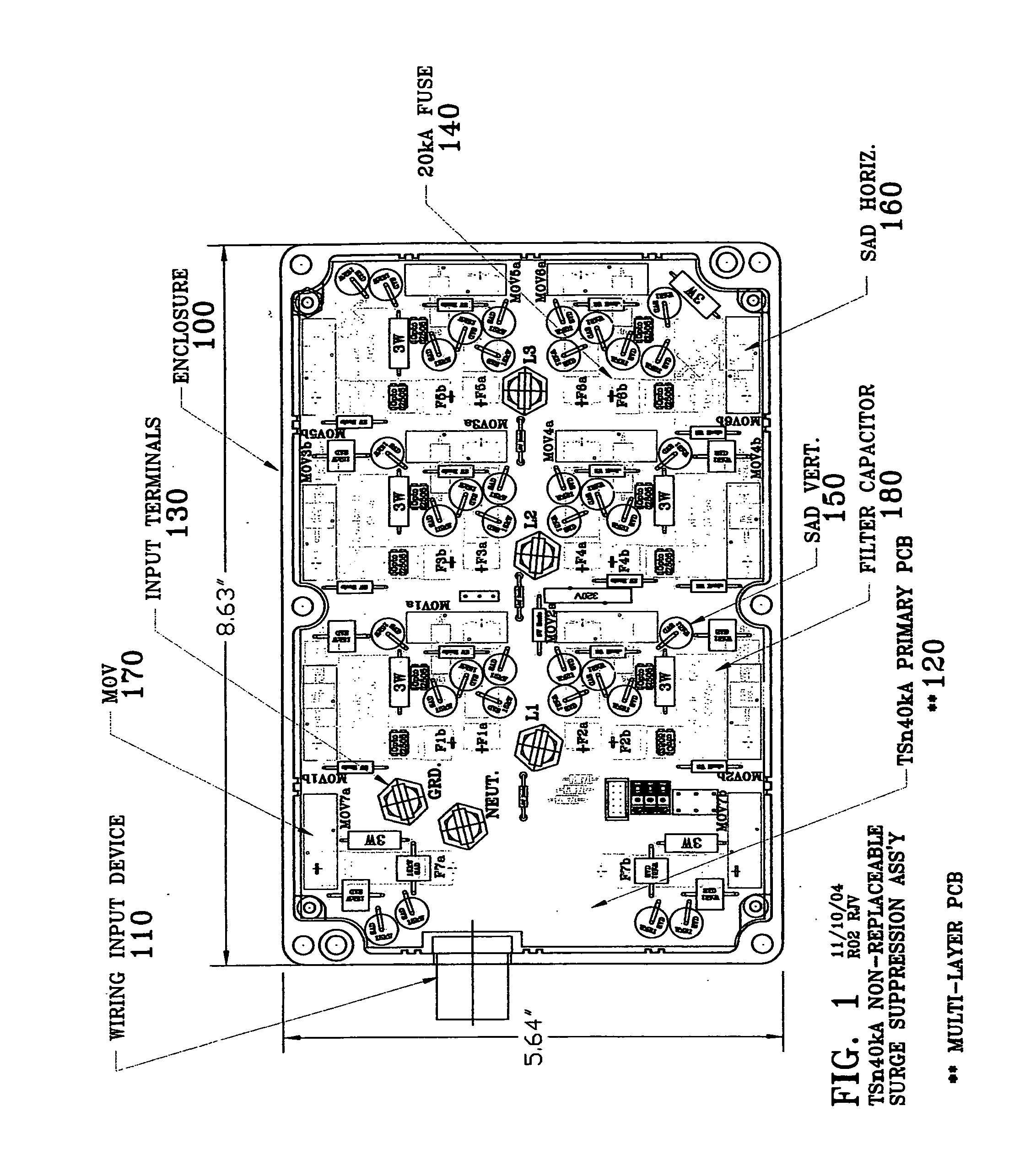

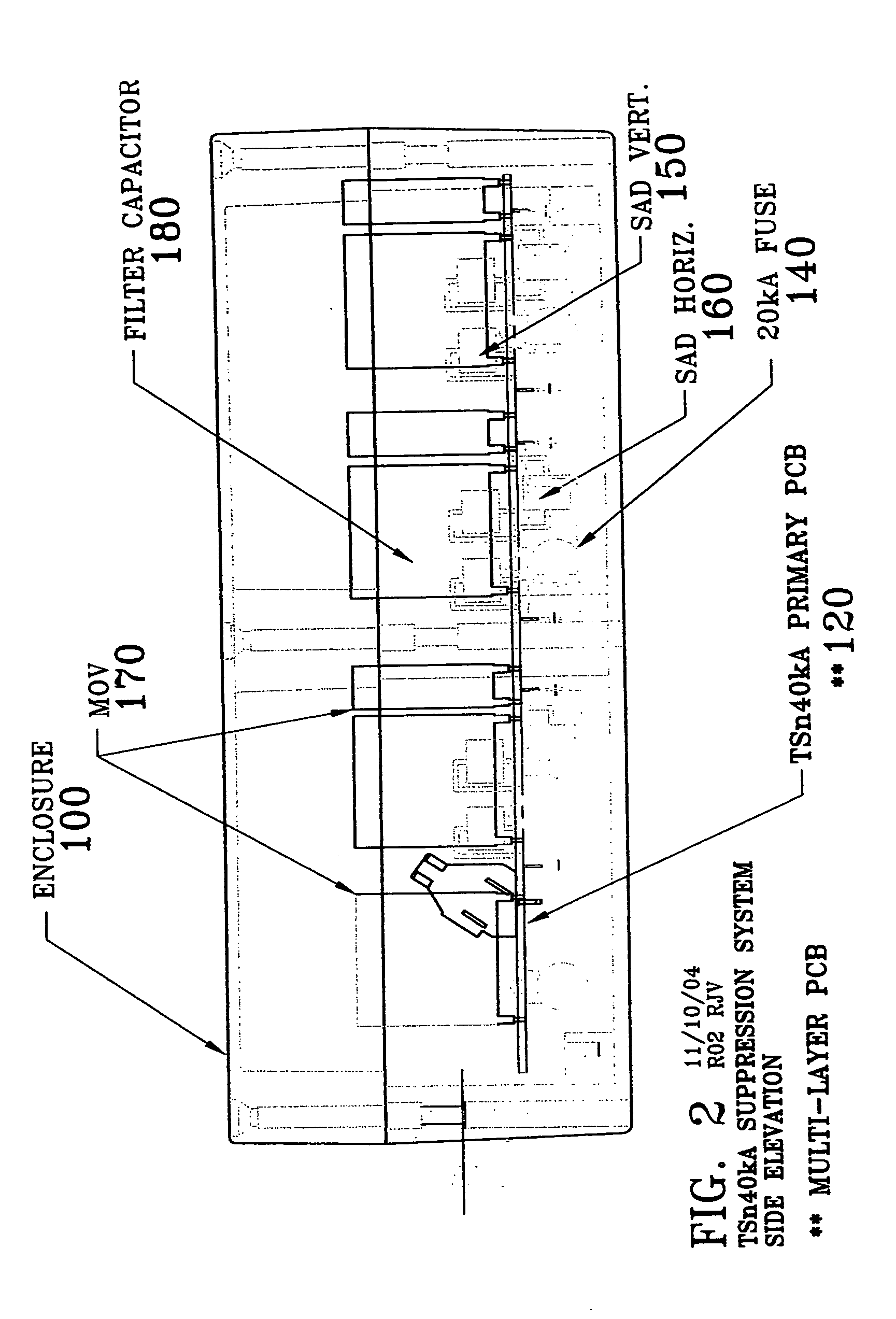

Transient voltage surge suppression systems

InactiveUS20060120005A1Intensifying skin-effect conditionIncrease surface areaCross-talk/noise/interference reductionPrinted circuit aspectsElectrical conductorEngineering

A surge-suppression system utilizing a hybrid design comprised of metal oxide varistors, silicon avalanche diodes, a fuse element, filter capacitor and multiple surge planes and surge paths to dissipate and divert transient over-voltages away from sensitive electronic equipment. These multiple surge conduction paths provide redundant parallel planes which optimize the skin-effect phenomena, which is the flow of electrical current at the conductor surface. This design provides a very low impedance which produces a high performance surge-suppression system.

Owner:VAN SICKLE ROBERT JACKSON

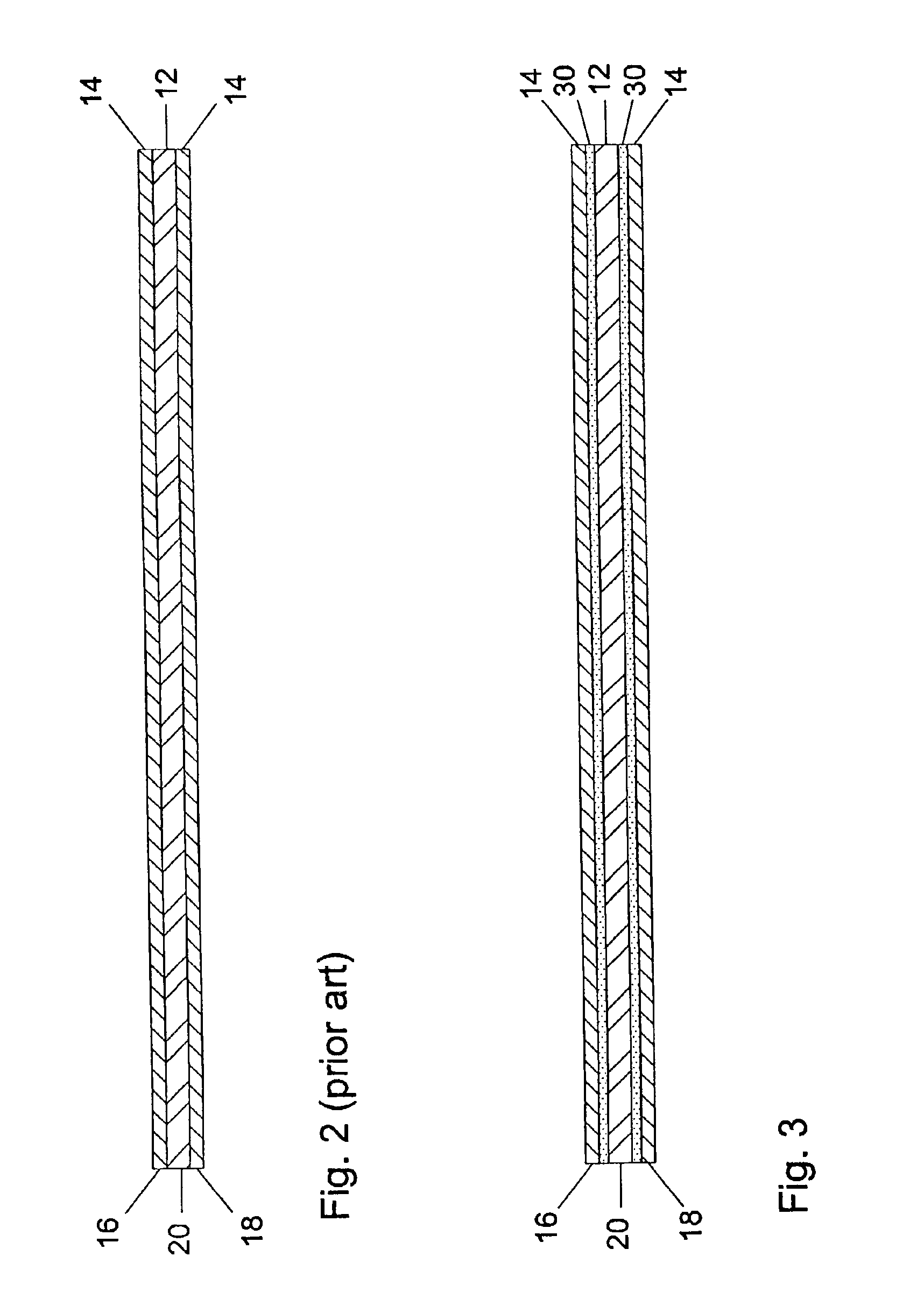

Printed circuit board noise attenuation using lossy conductors

InactiveUS6873219B2Multiple-port networksMagnetic/electric field screeningElectrical conductorSkin effect

A method and related configuration for attenuating high-frequency noise that may appear on power planes in printed circuit boards. In one embodiment, the noise attenuation means of the present invention involves applying a lower conductivity material between the conductive and dielectric layers within a printed circuit board. High-frequency noise is then attenuated by the skin effect. In another embodiment, the low conductivity material is applied between the power plane and dielectric layer within the printed circuit board. The low conductivity material may be a material, such as nickel or lead, having an electrical conductivity ranging between about 1×104 mhos / m and 5.8×107 mhos / m for layers having a thickness of about 2 mils.

Owner:HEWLETT PACKARD DEV CO LP

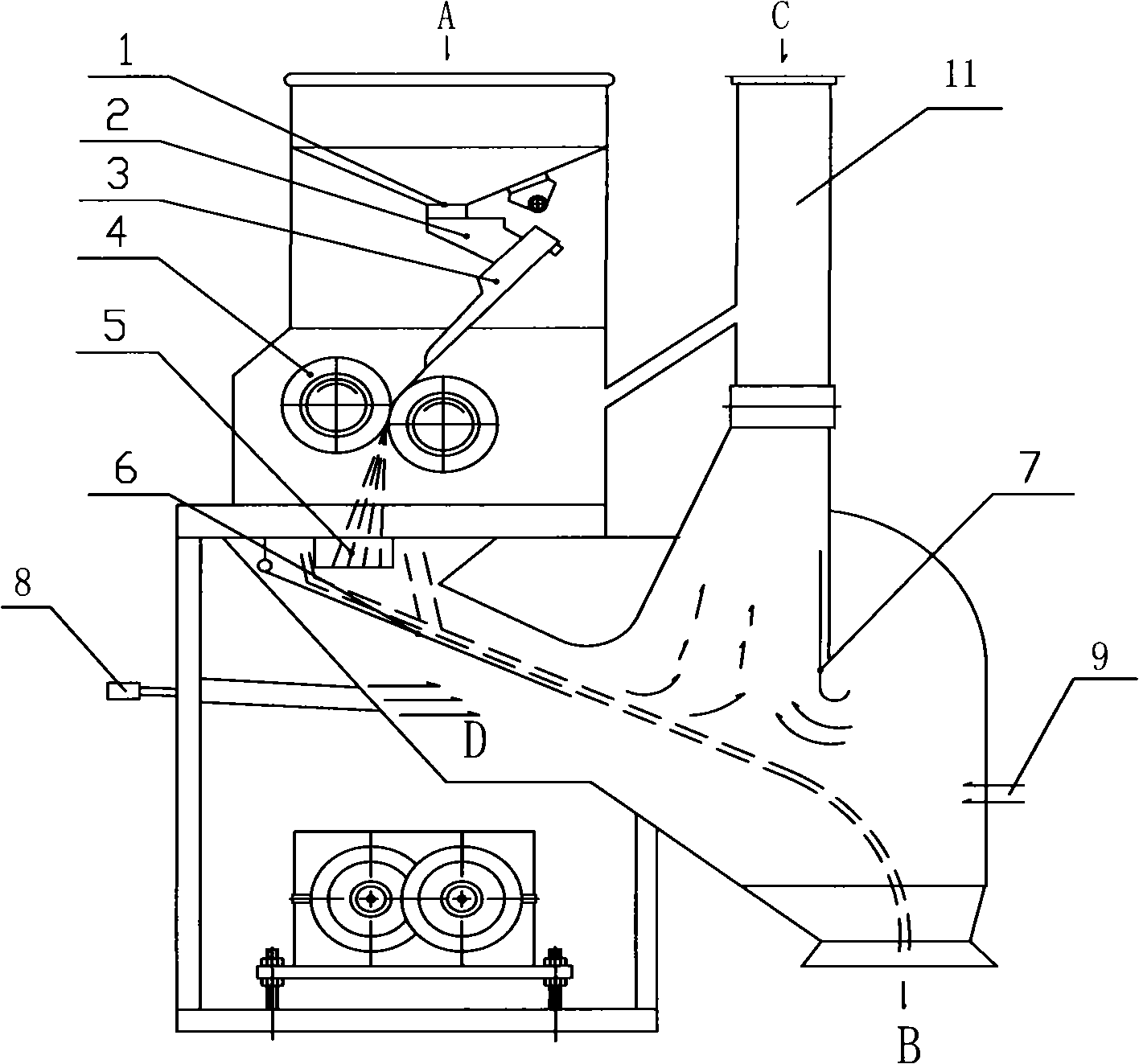

Oat barking equipment and barking method

ActiveCN101264459AShort preparation timeFragrant smellGrain huskingGrain polishingNutritive valuesSkin effect

The invention discloses an oat pelt puller and the skinning method. The pelt puller comprises a frame, a feeding assembly, a propeller, a sand drum assembly and a power unit; which is characterized in that: the whole components are arranged on the frame; the propeller is arranged in the feeding assembly, the propeller is connected with the momentum output terminal of the power unit, the lower end of the propeller passes through the exit end of the feeding assembly and is connected with the sand drum assembly, a sand plate is correspondingly arranged on the periphery of the sand drum assembly, a skinning chamber forms between the sand plate and the sand drum assembly, the distance between the sand plate and the sand drum assembly is 1 to 10mm, the lower end of the skinning chamber is a discharge opening. The pelt puller has the advantages of simple combination, high efficiency, good skinning effect, and no damage to oat grain, the obtained oat without peel has the advantages of ability to be used for cooked congee, rice steaming, short process time, ability to direct edible, moderate mouthfeel, fragrant odor, high nutritive value, suitability for traditional food habits of Asian, satisfaction for the diversification requirements for oats food edible mood.

Owner:SANZHULIANG ZAOZHUANG FOOD BEVERAGE CO LTD

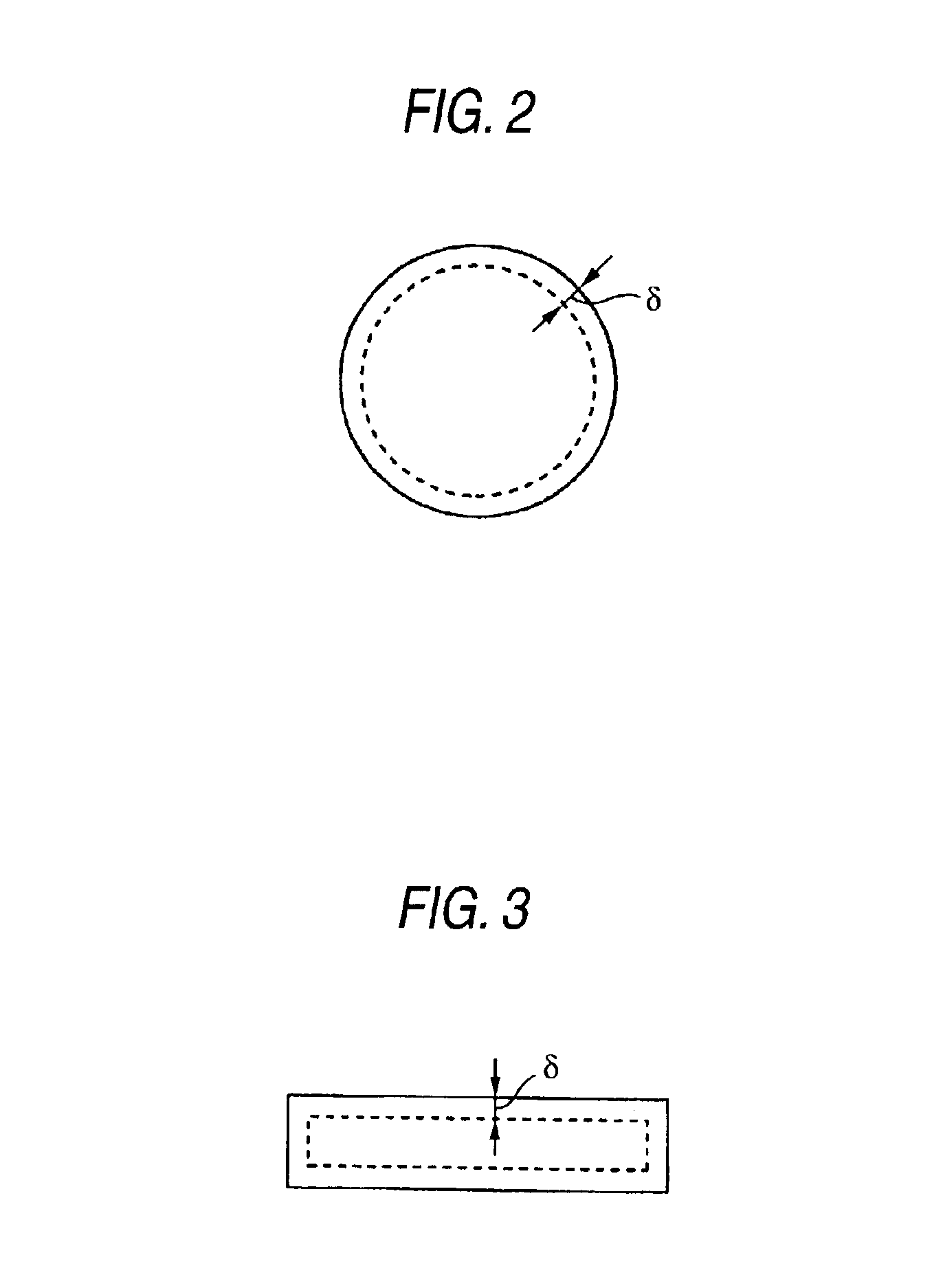

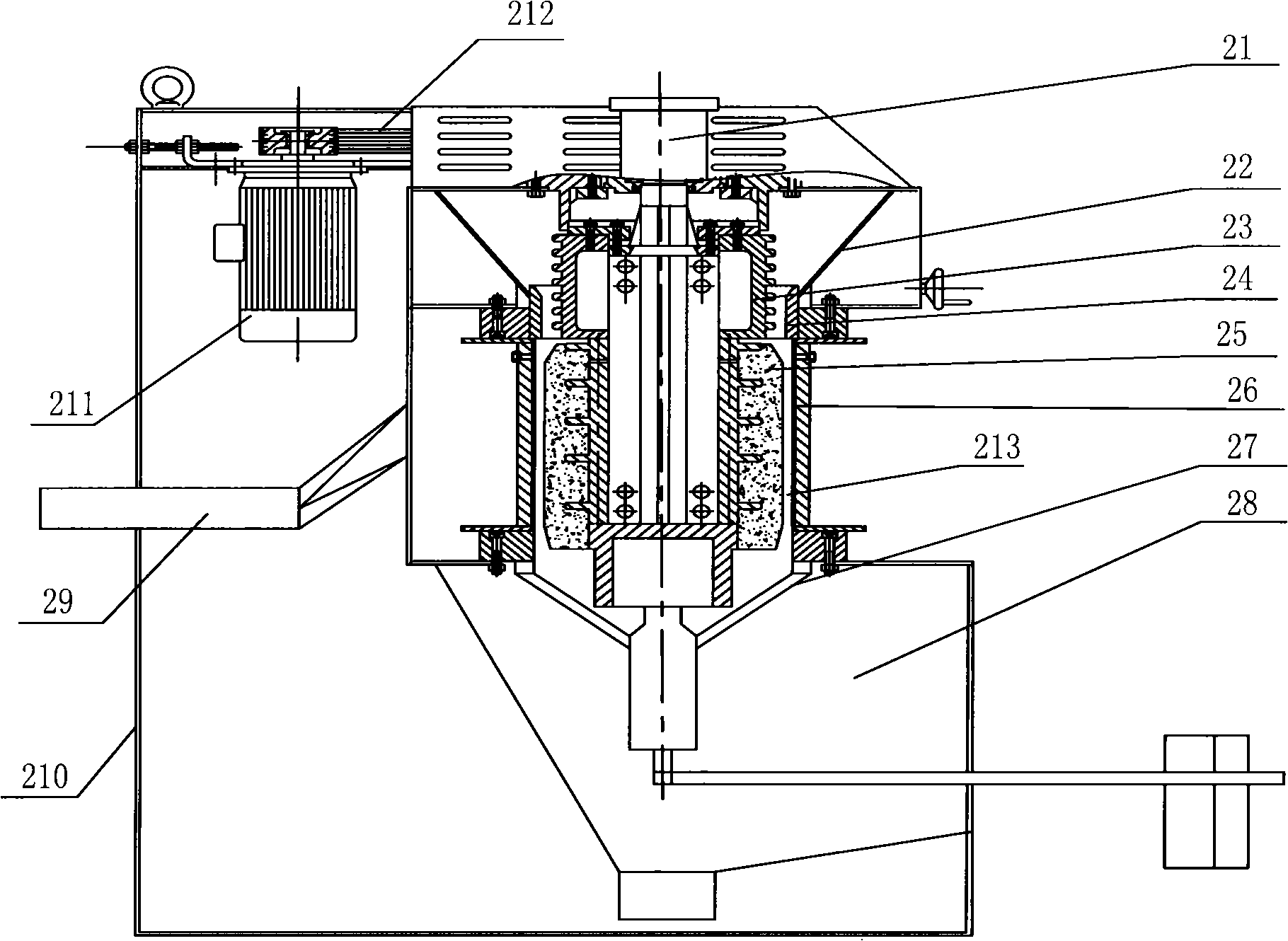

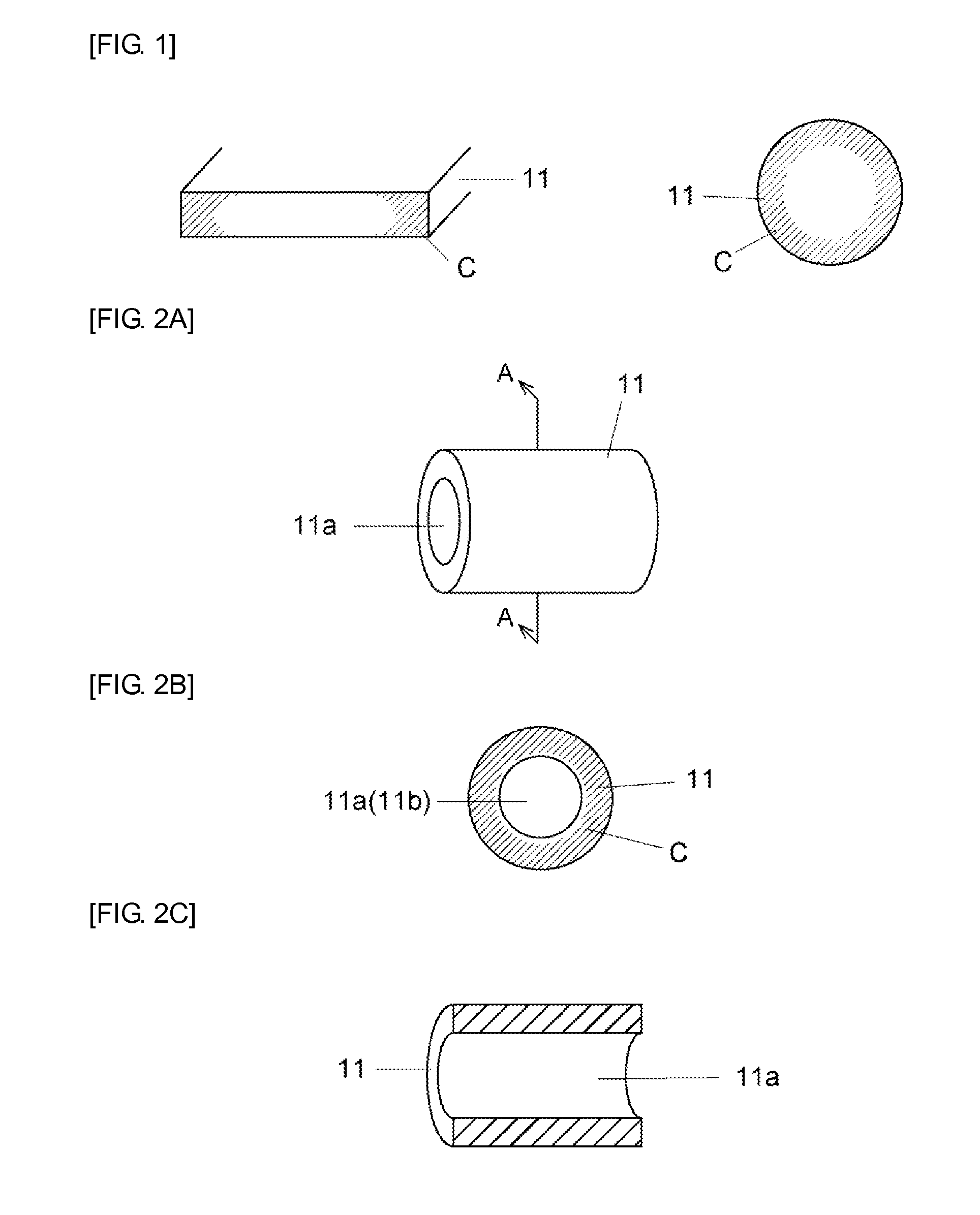

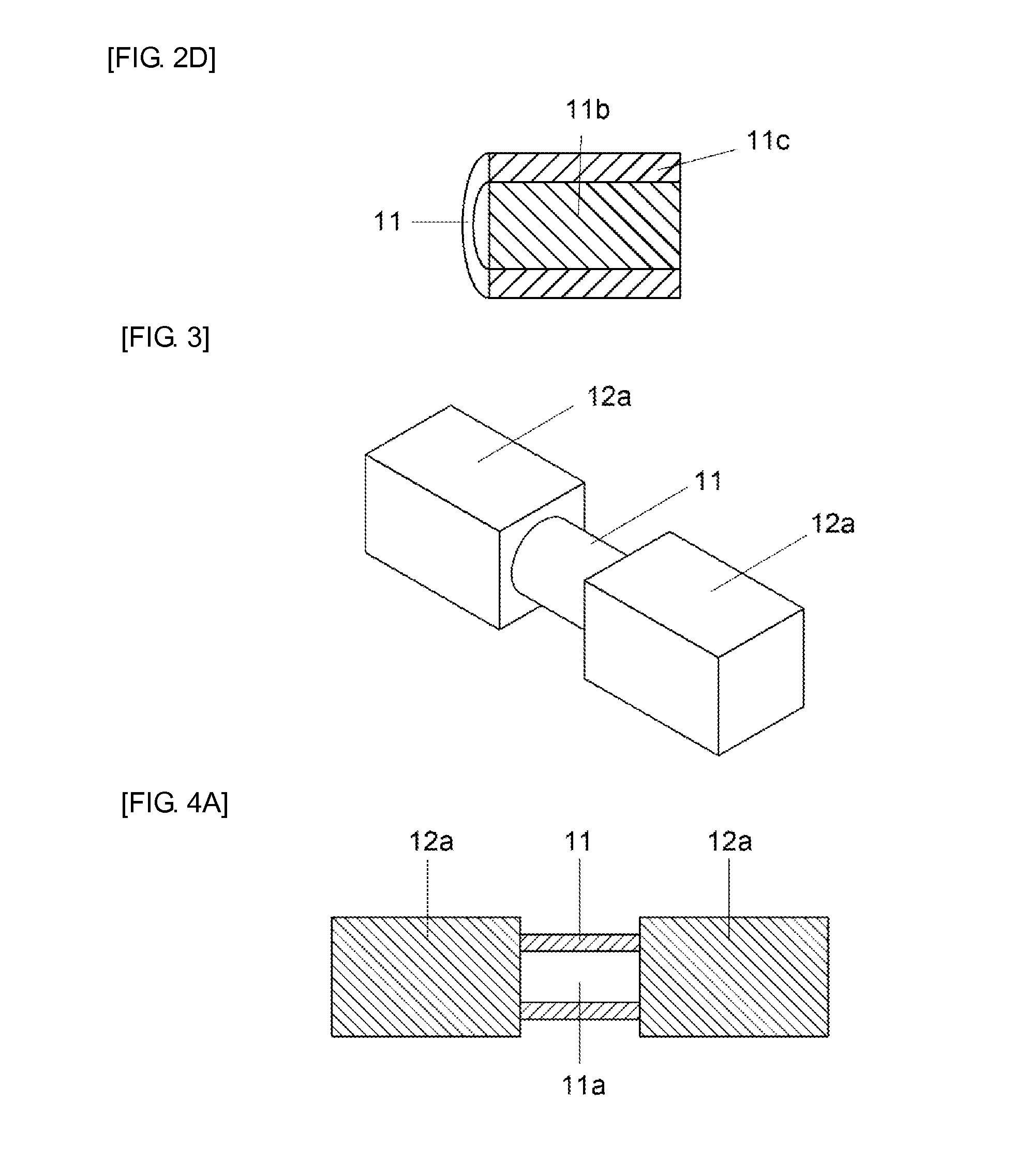

Shunt resistor and method for manufacturing the same

ActiveUS20140097933A1Fluctuation band can be reducedLower resistance value changesResistors adapted for applying terminalsResistor detailsElectrical resistance and conductanceSkin effect

Provided is a shunt resistor, which controls an influence of skin effect by high frequency current. The shunt resistor has a rod-shaped resistance body (11), and a pair of main electrode (12), of another material from the resistance body, wherein end faces of the resistance body and the main electrode are bonded. The resistance body (11) has a hole (11a) going through in direction where main electrodes are disposed, or a high resistance part (11b) going through at its axis portion that is highly resistive than outer part, and low resistance part (11c) that is formed in outer of the high resistance part. It is preferable that outer circumference of the resistance body is circle-shaped. Since, current doesn't flow fundamentally in the through hole or the high resistance part, fluctuation band in the current pathway can be reduced. Therefore, change of resistance value by skin effect by high-frequency current can be reduced.

Owner:KOA CORP

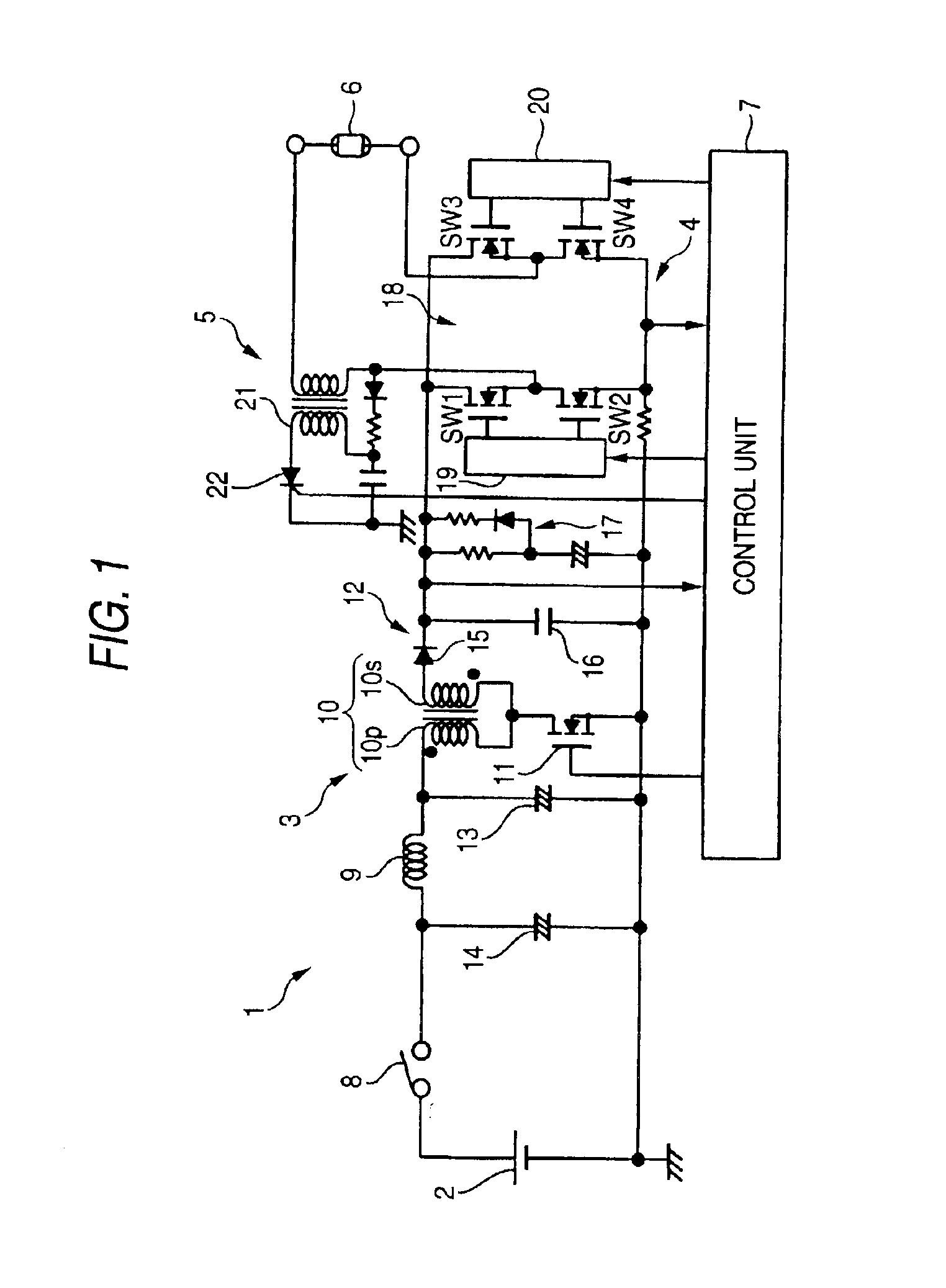

Heating apparatus and induction heating control method

InactiveUS20090238593A1Ohmic-resistance heatingElectrographic process apparatusDriving currentElectrical resistance and conductance

A fixing device of an image forming apparatus of the present invention enables induction heating coils for a 100 V power source to set a ratio of inductance L to load resistance R of a heat roller to L / R<35×10−6 (H / Ω) and coil impedance ZΩ to Z<10Ω and supplies a drive current at a high frequency of 40 to 70 kHz. By doing this, an eddy current generated in the heat roller is concentrated upon a metallic conductive layer by the skin effect and the heat generation efficiency of the heat roller is improved.

Owner:KK TOSHIBA +1

Electric wire

InactiveUS6967289B2Increase currentIncrease surface areaSingle bars/rods/wires/strips conductorsBus-bar installationTransmittanceSkin effect

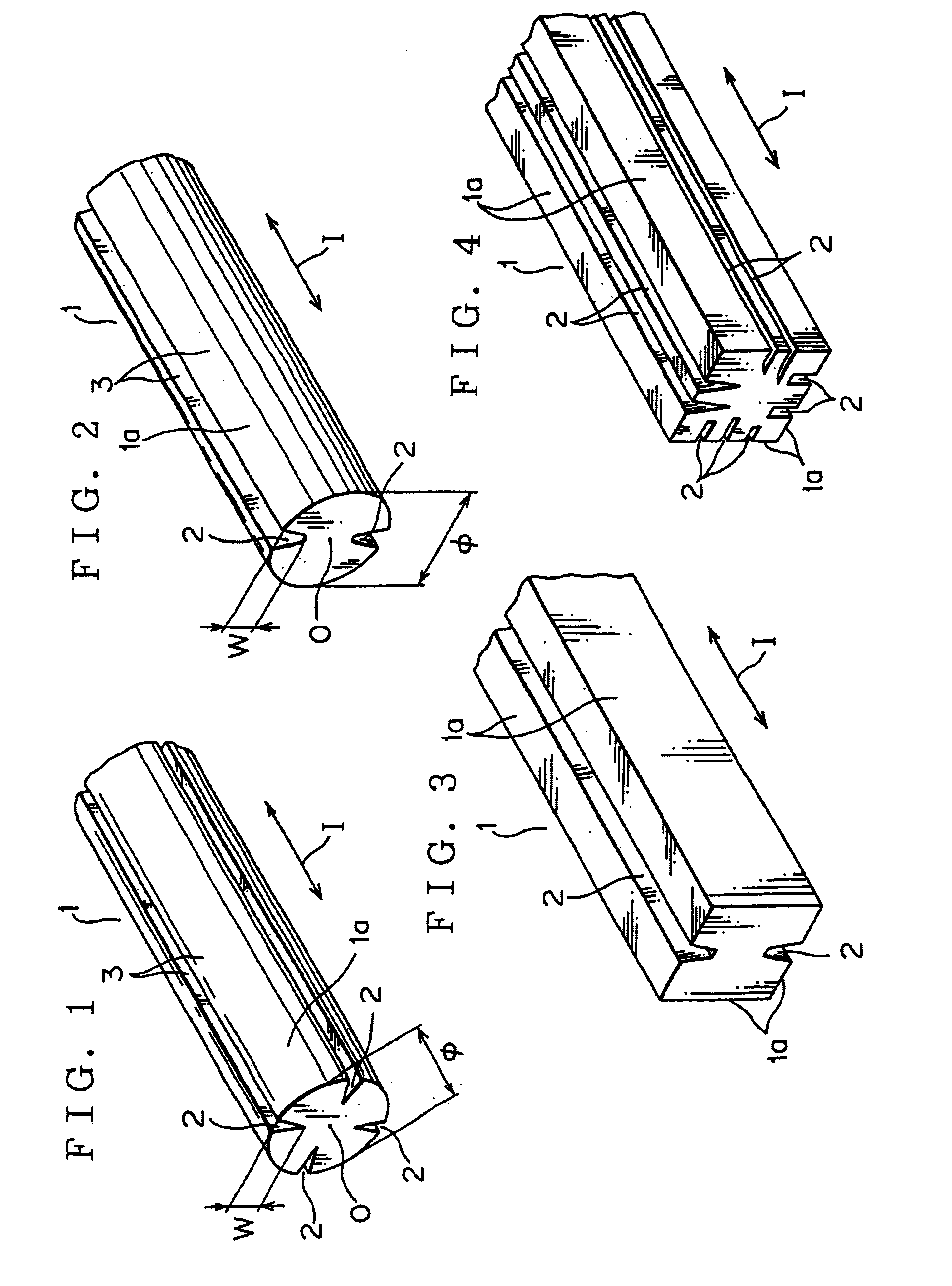

An electric wire having a conductive portion with grooves on the surface thereof to increase a surface area of the conductive portion for enlarging the skin effect in high frequency current and enhancing the transmissibility and the space factor in high frequency current is provided. The conductive portion 1a being made of an electric conductive material is formed on the surface 1a with a convexo-concave surface 3 to provide predetermined amount of grooves 2 or concave portions 20 having a predetermined section with a predetermined depth W extending in a direction of thickness or toward a center of the conductive portion on the surface of the conductive portion along lengthwise the conductive portion

Owner:GOTO DENISH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com