Patents

Literature

169results about How to "Avoid lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

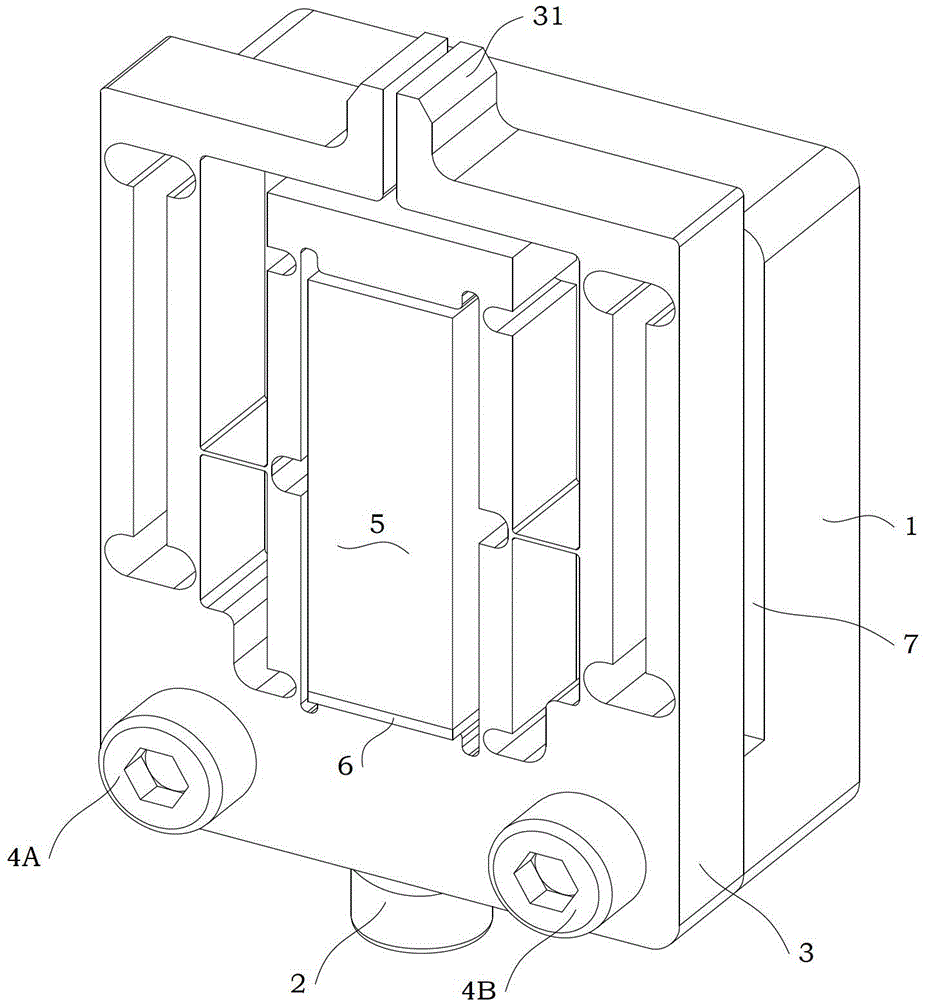

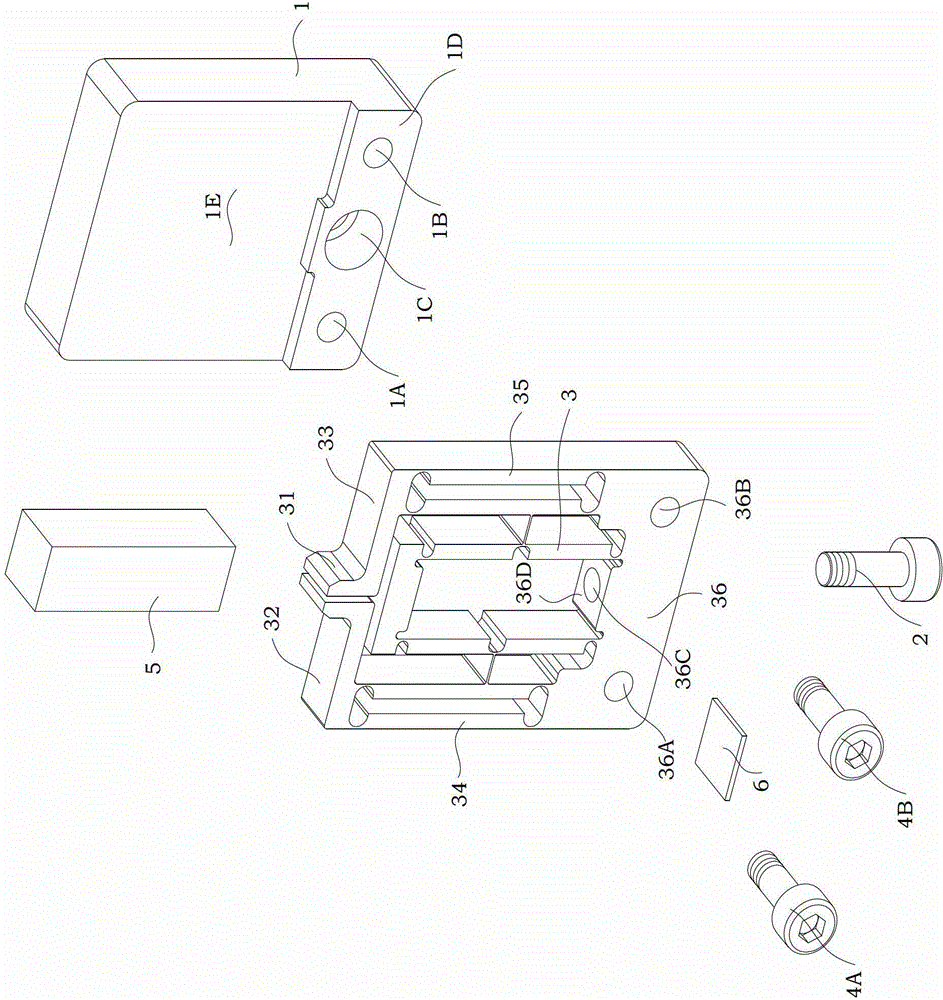

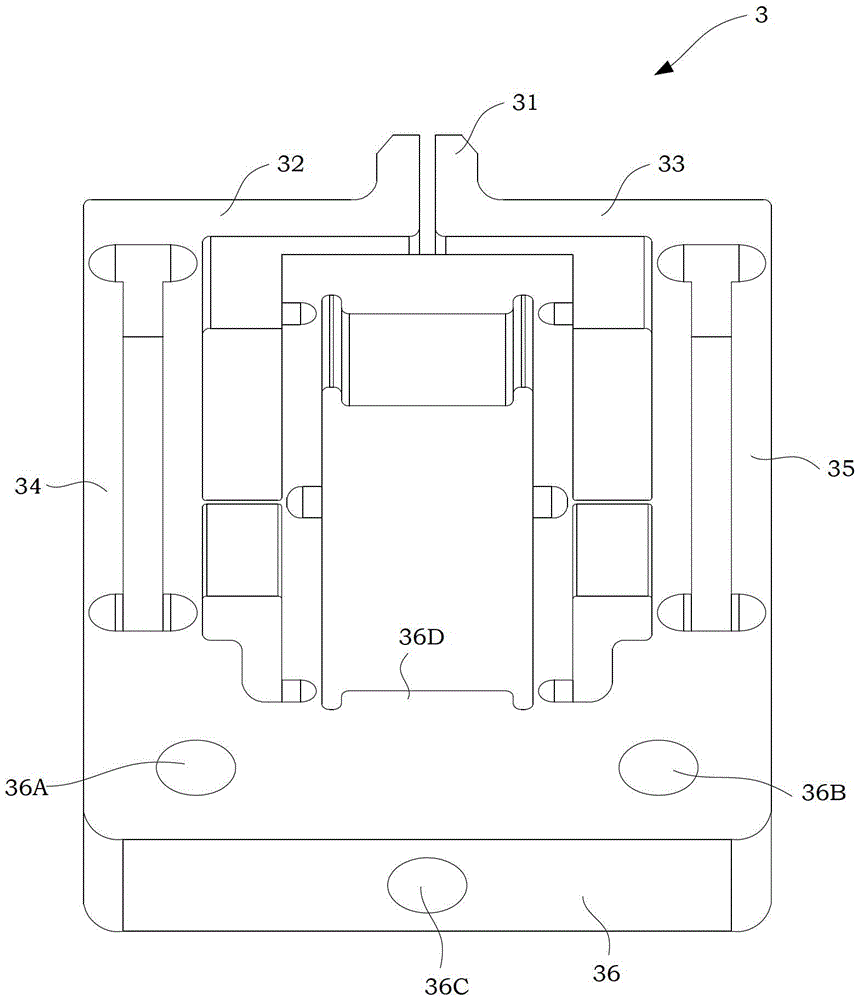

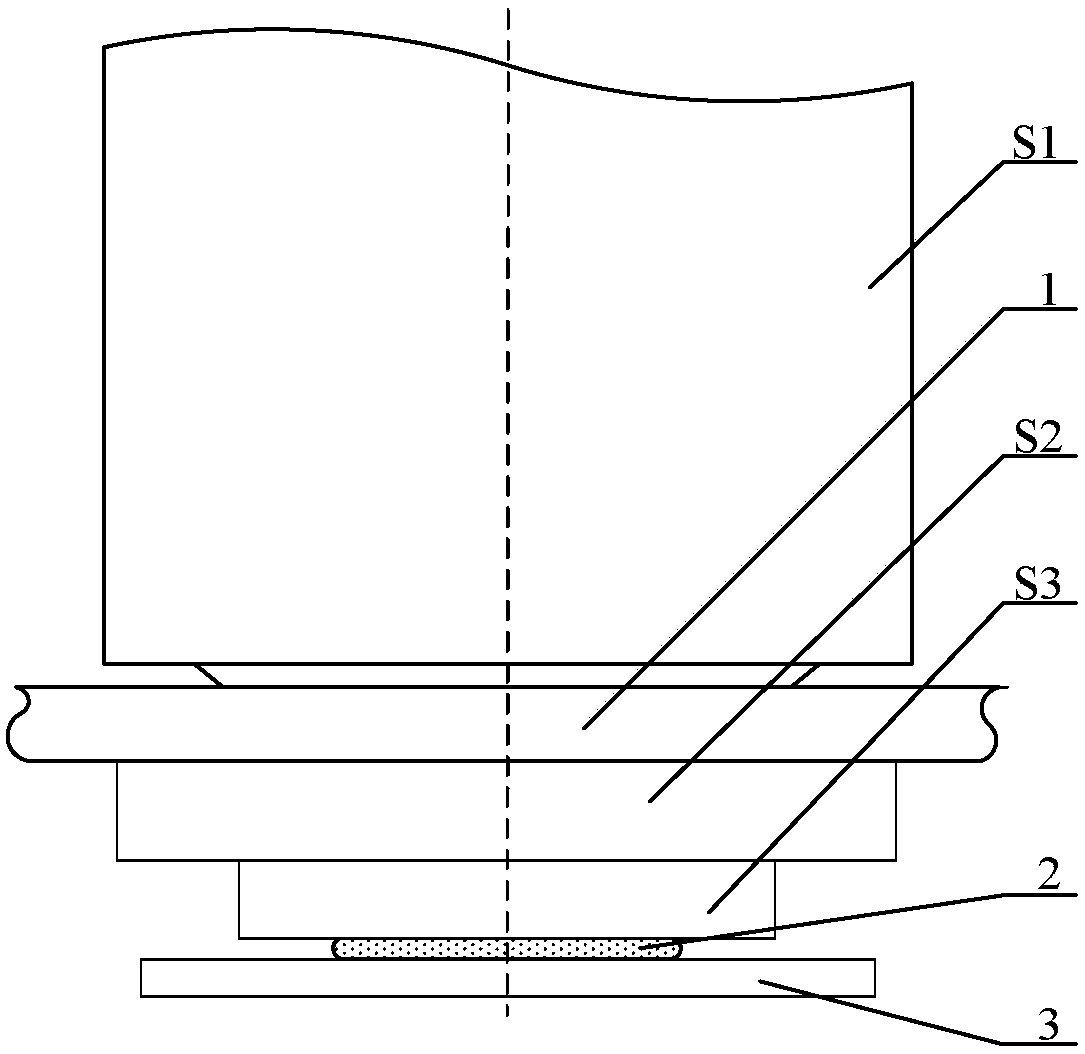

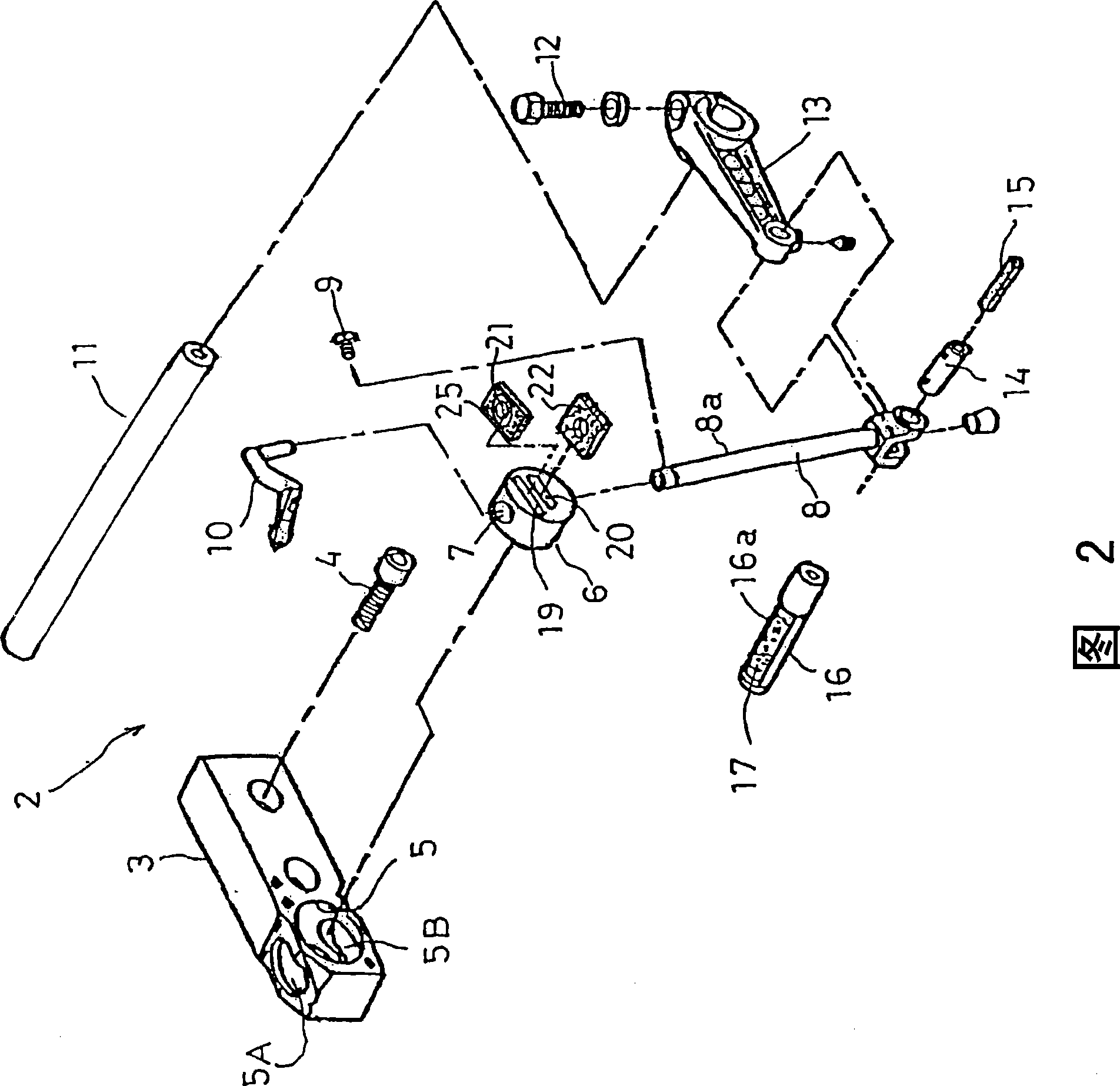

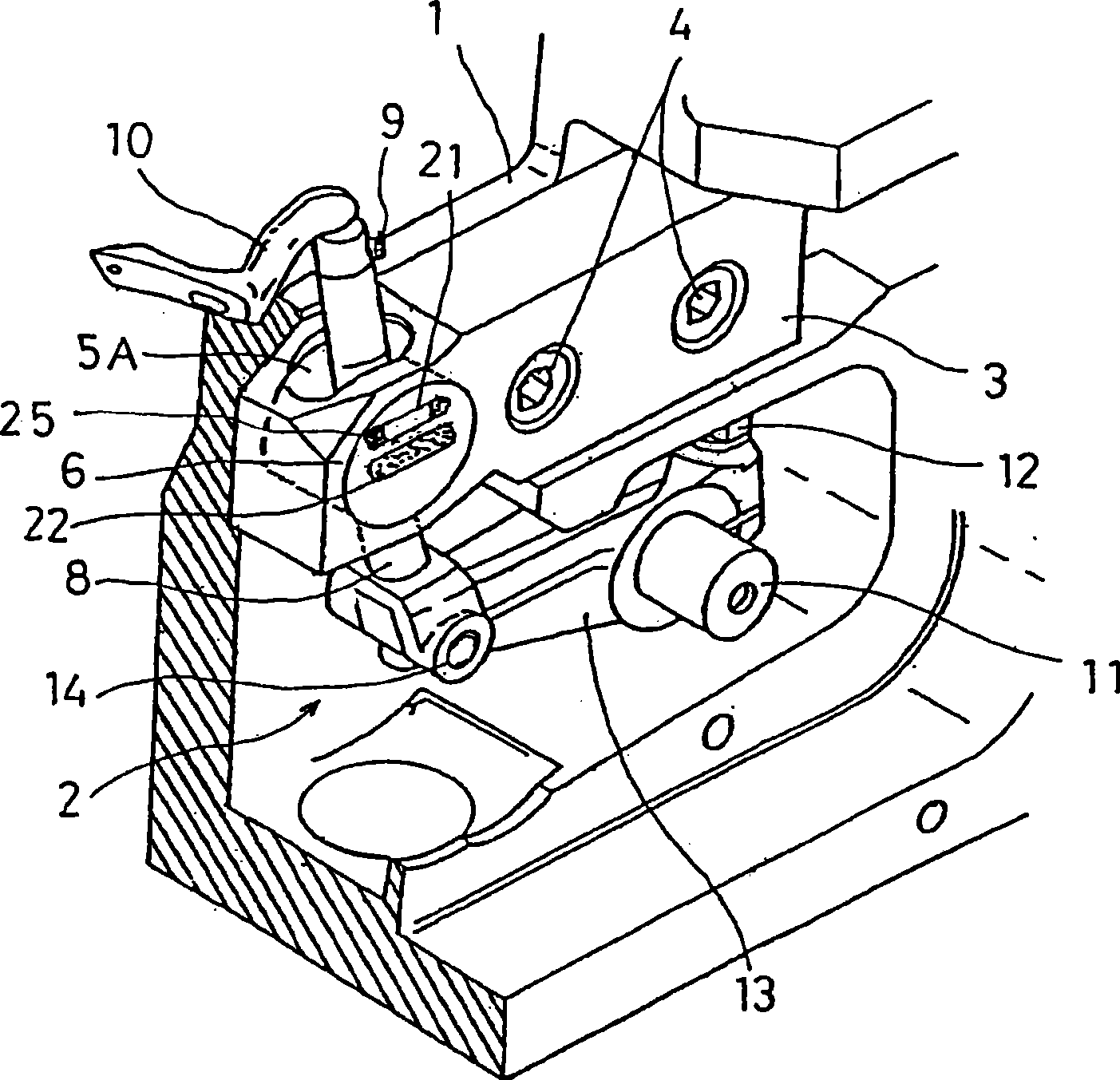

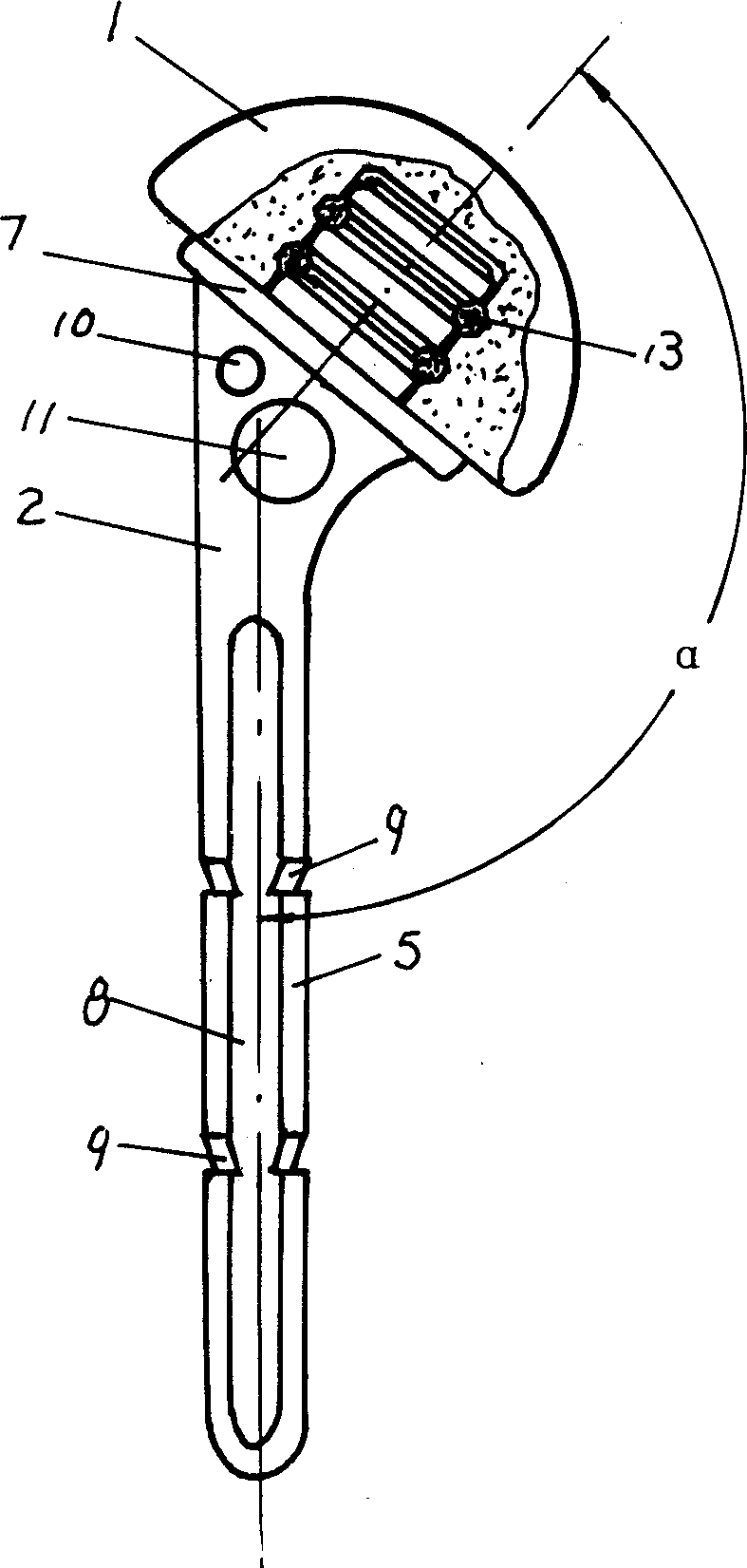

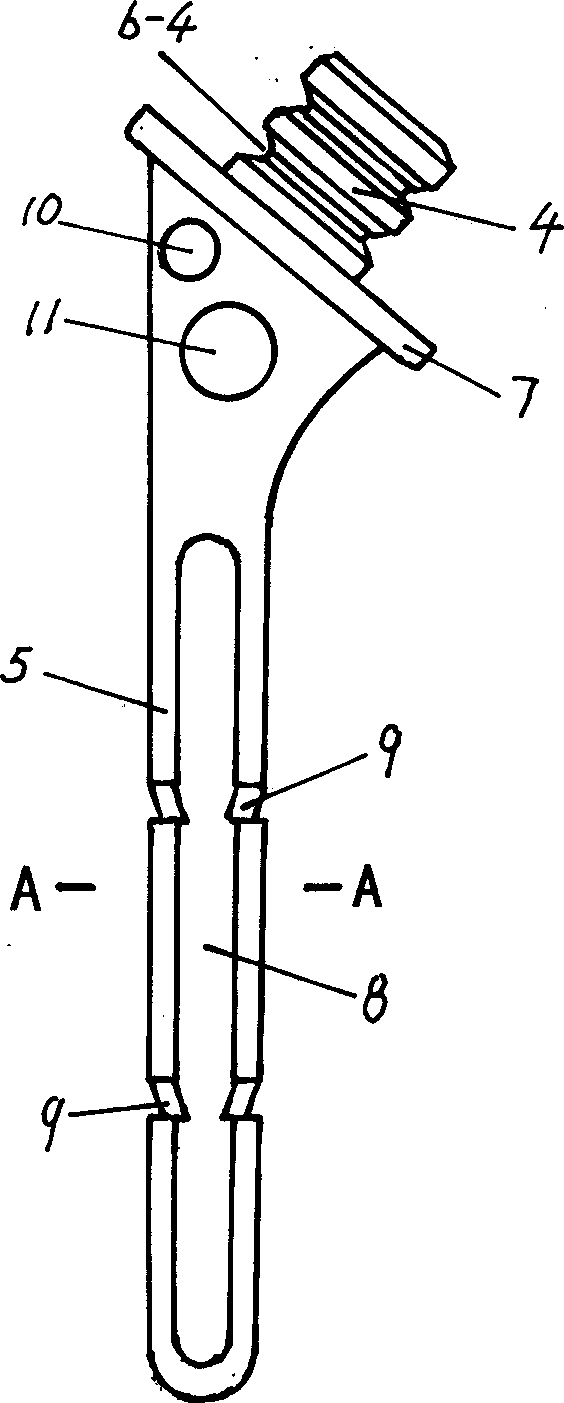

Miniaturized flexible micro clamp based on piezoelectric driving

InactiveCN103331748AImprove grasping accuracyEfficient crawlingMicromanipulatorGripping headsElectricityMiniaturization

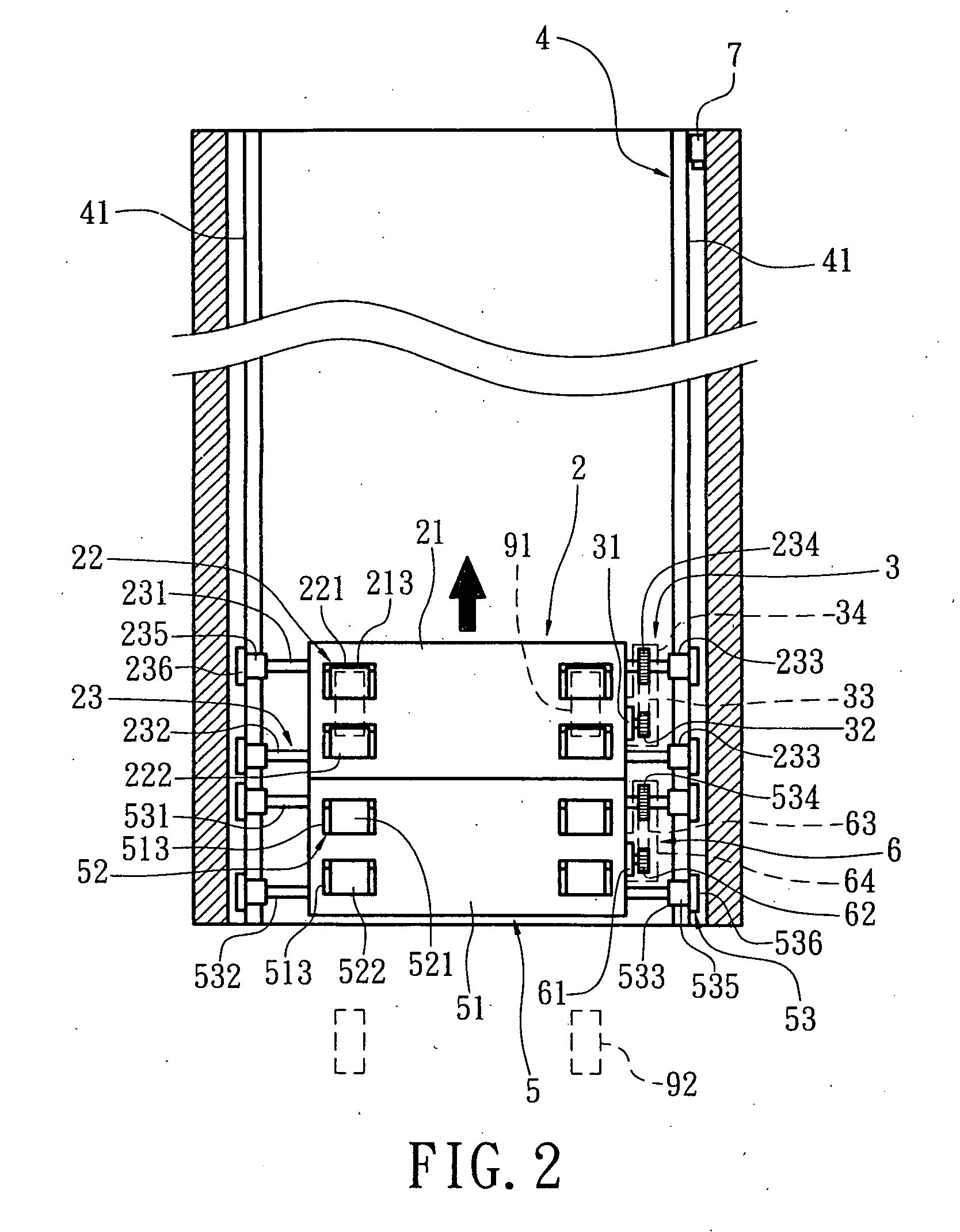

The invention discloses a miniaturized flexible micro clamp based on piezoelectric driving. The micro clamp comprises a base, a pretension screw, a motion transmission mechanism, a first fastening screw, a second fastening screw, a piezoceramic driver and a spacer, wherein the base and the motion transmission mechanism are fixedly mounted through the first fastening screw and the second fastening screw; the pretension bolt is arranged at the rear end of the motion transmission mechanism; the piezoceramic driver and the spacer are arranged in a first cutting slot of the motion transmission mechanism. According to the design of the invention, through a two-stage amplification mechanism in the amplification mechanism, the parallel grabbing of the closed-type micro clamp can be realized.

Owner:BEIHANG UNIV

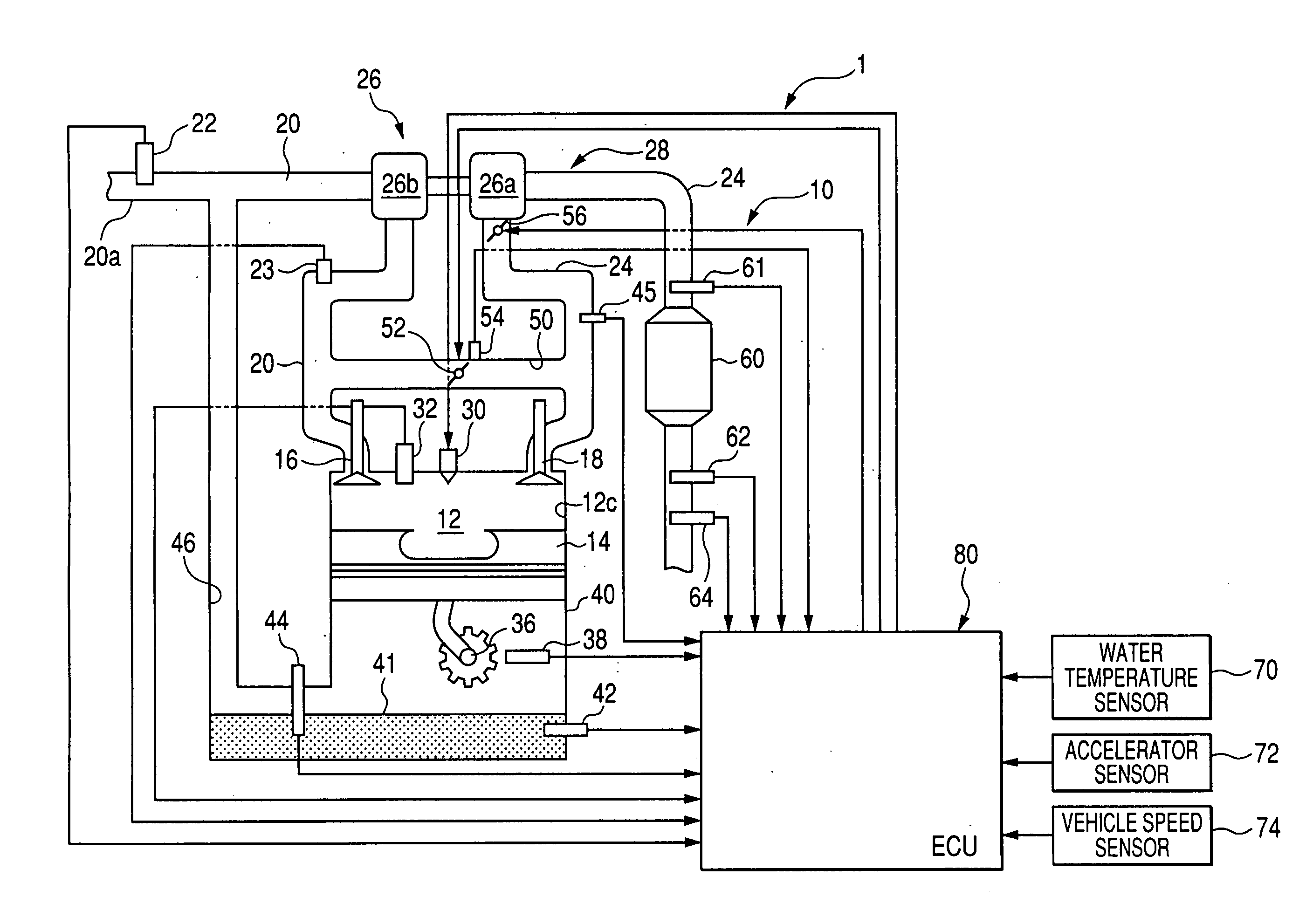

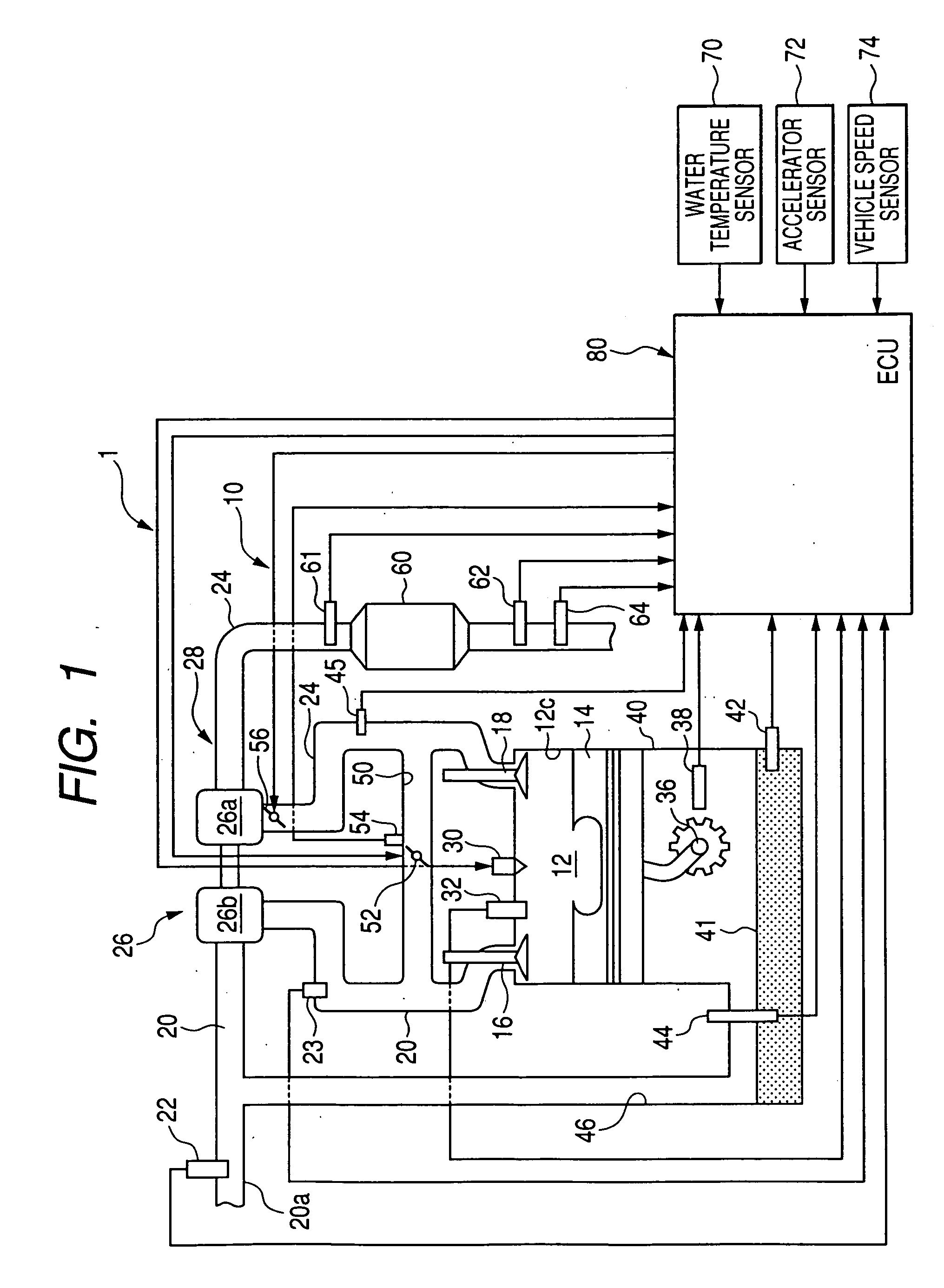

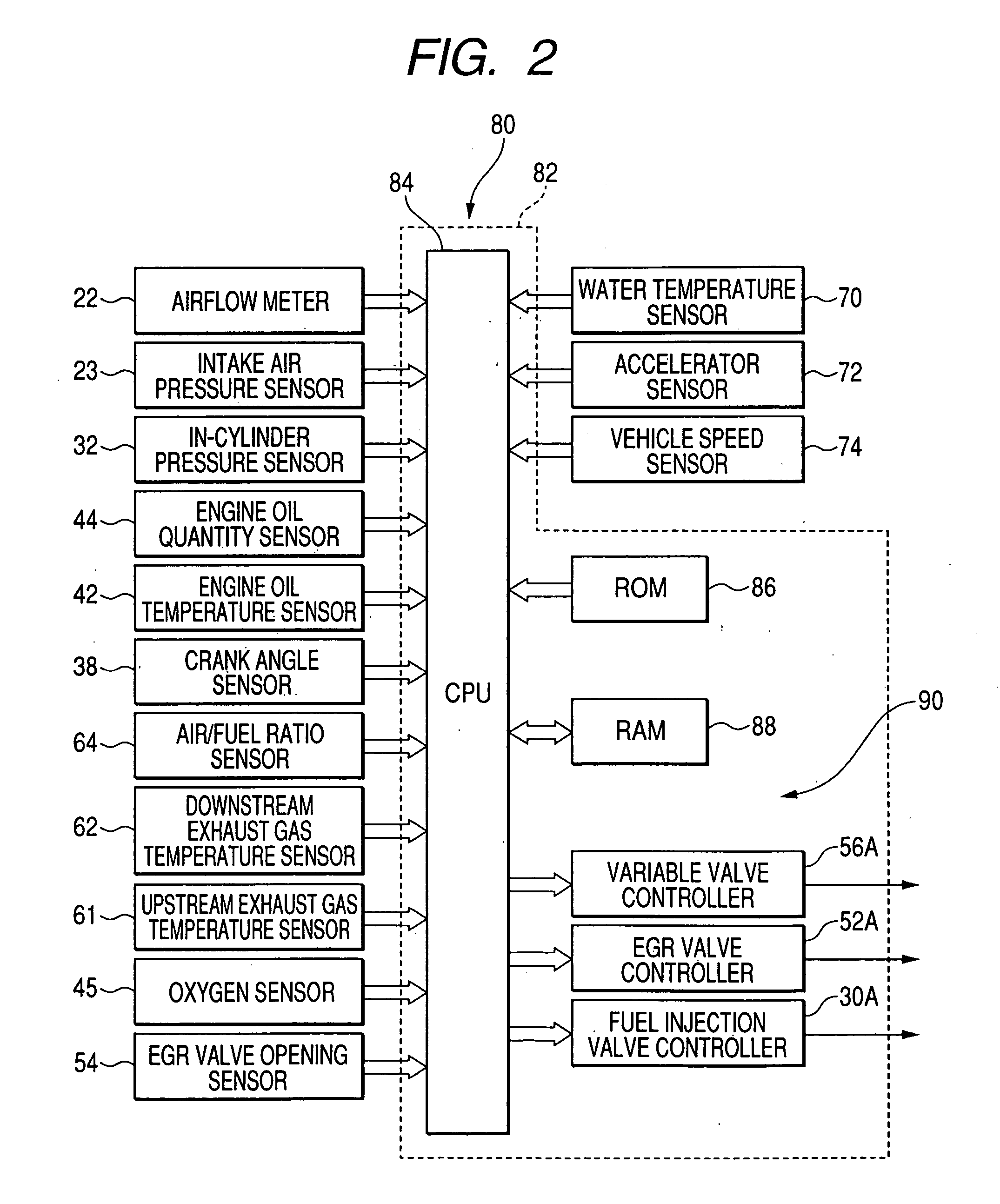

Engine control system and engine control method

InactiveUS20070156322A1Avoid lubricationSimple wayAnalogue computers for vehiclesElectrical controlControl systemEngineering

An engine control system and an engine control method are disclosed wherein a combustible component quantity of intake air, reflecting combustible components in a crankcase of an engine, is calculated on the basis of a deviation between basic injection quantity for a target rotational speed to be attained and an actual injection quantity during operation to perform idling stabilizing control. A ratio of the combustible components mixed to engine oil is calculated on the basis of the combustible component quantity of intake air and a temperature of engine oil. During a status of the engine with a given temperature of engine oil and the mixing ratio of the combustible components in engine oil, a fuel injection affect eliminating operation is executed.

Owner:DENSO CORP

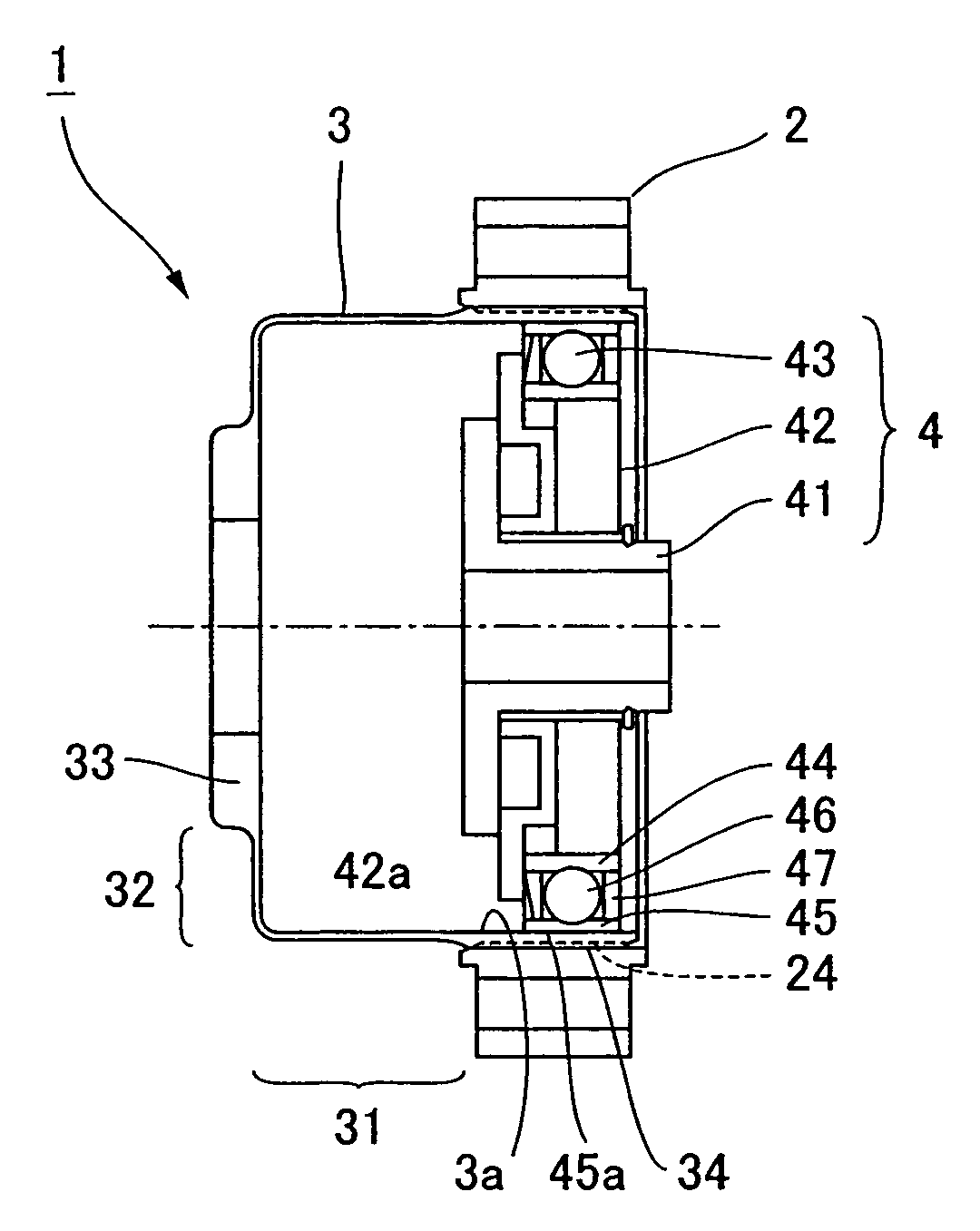

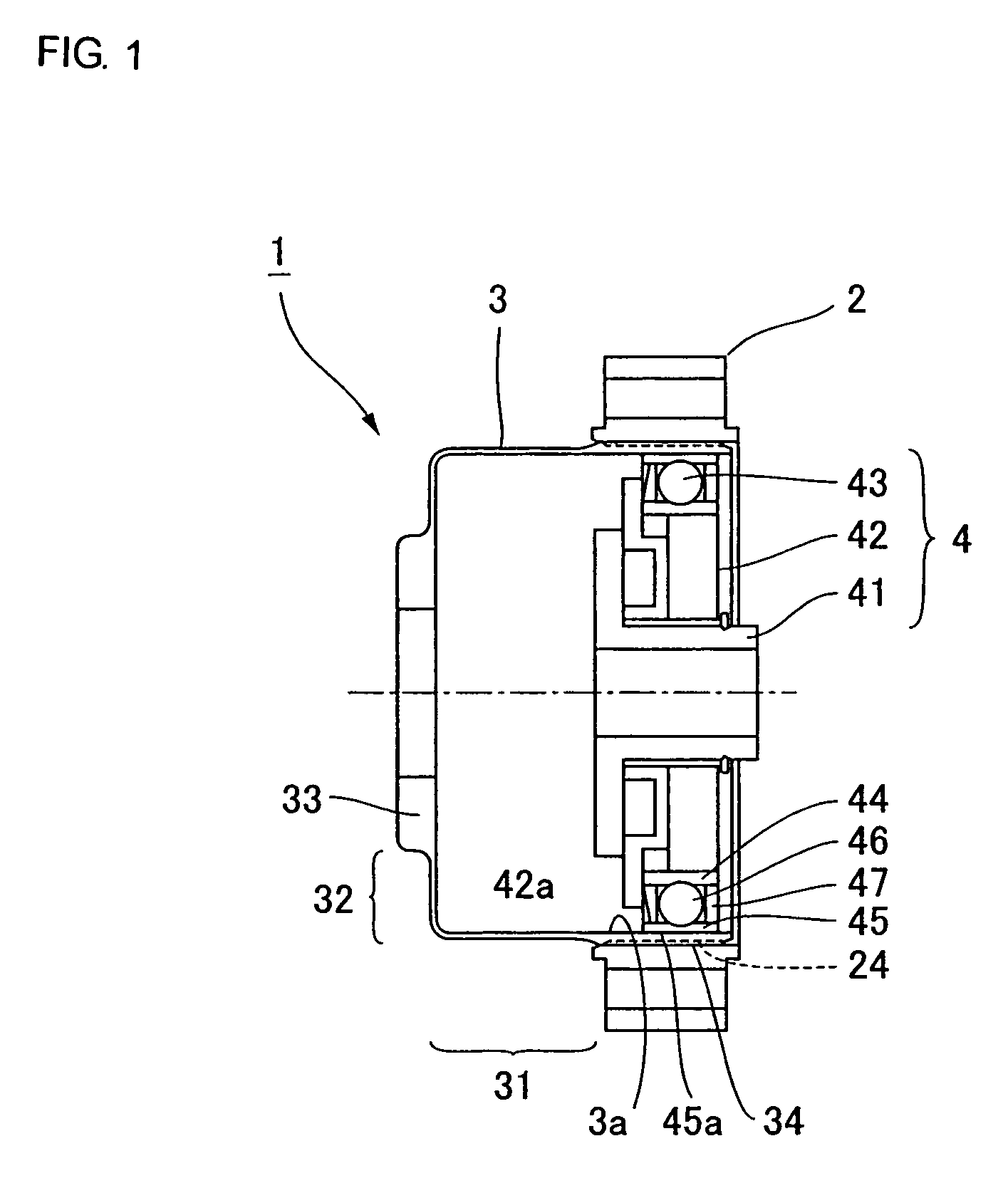

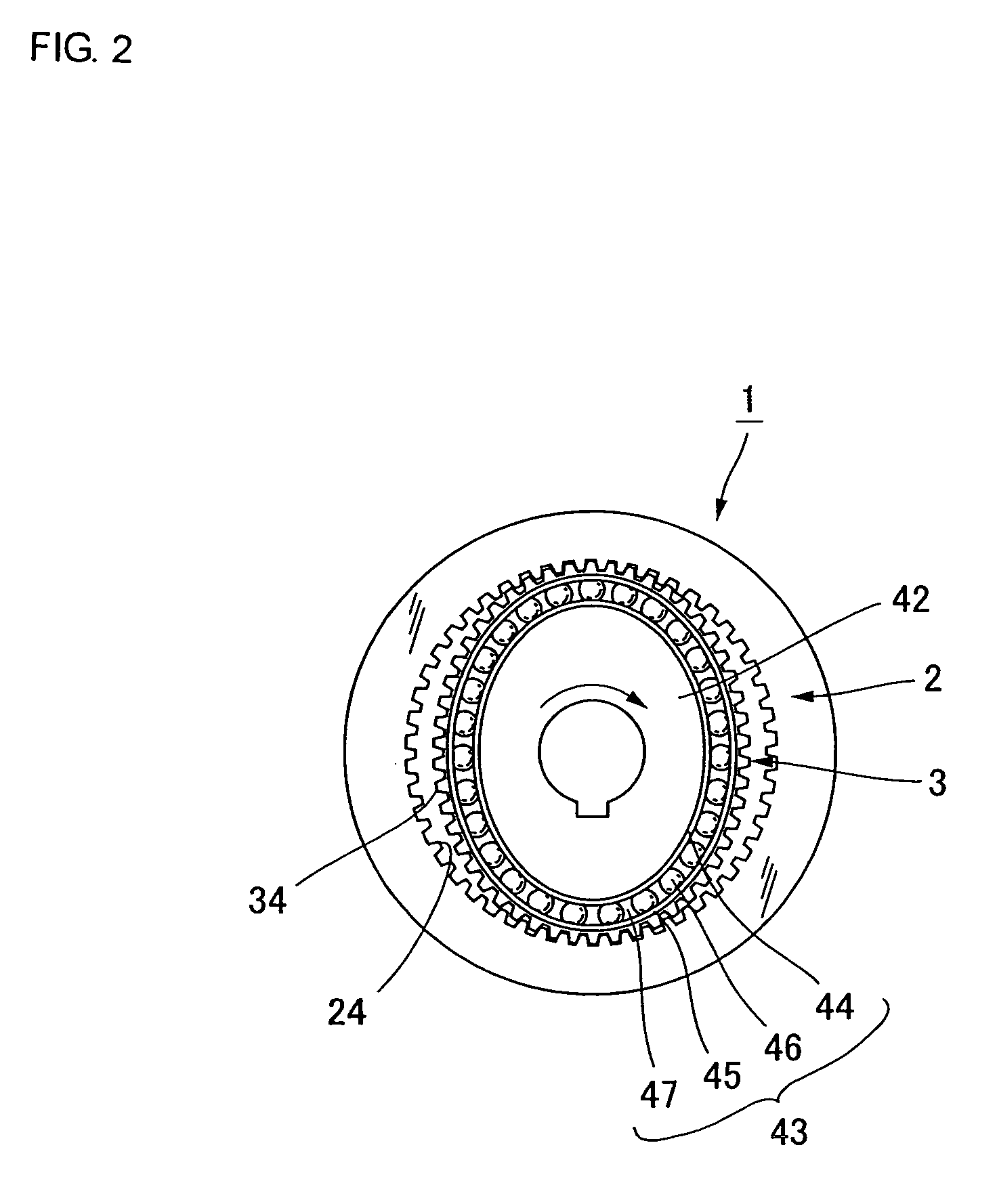

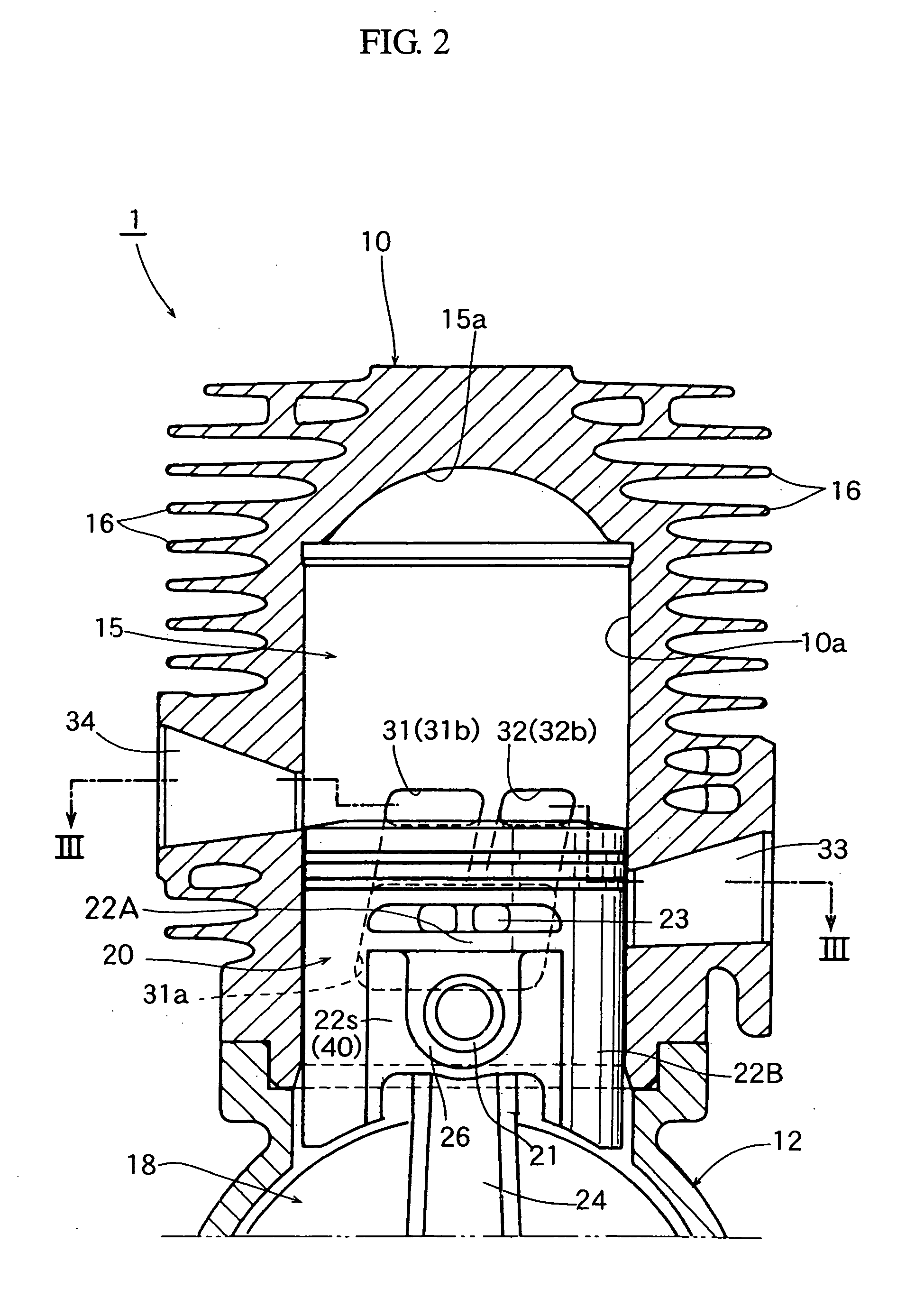

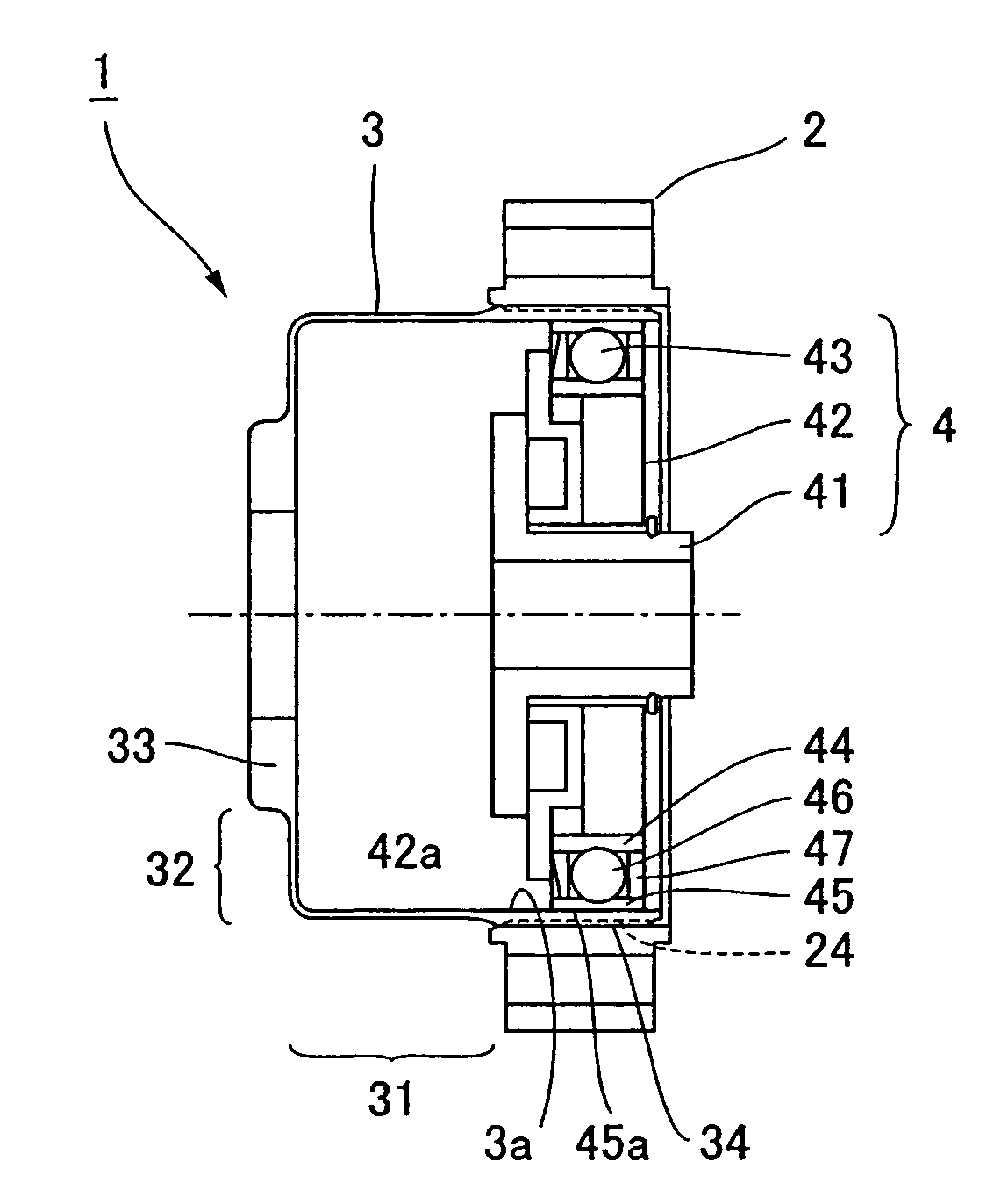

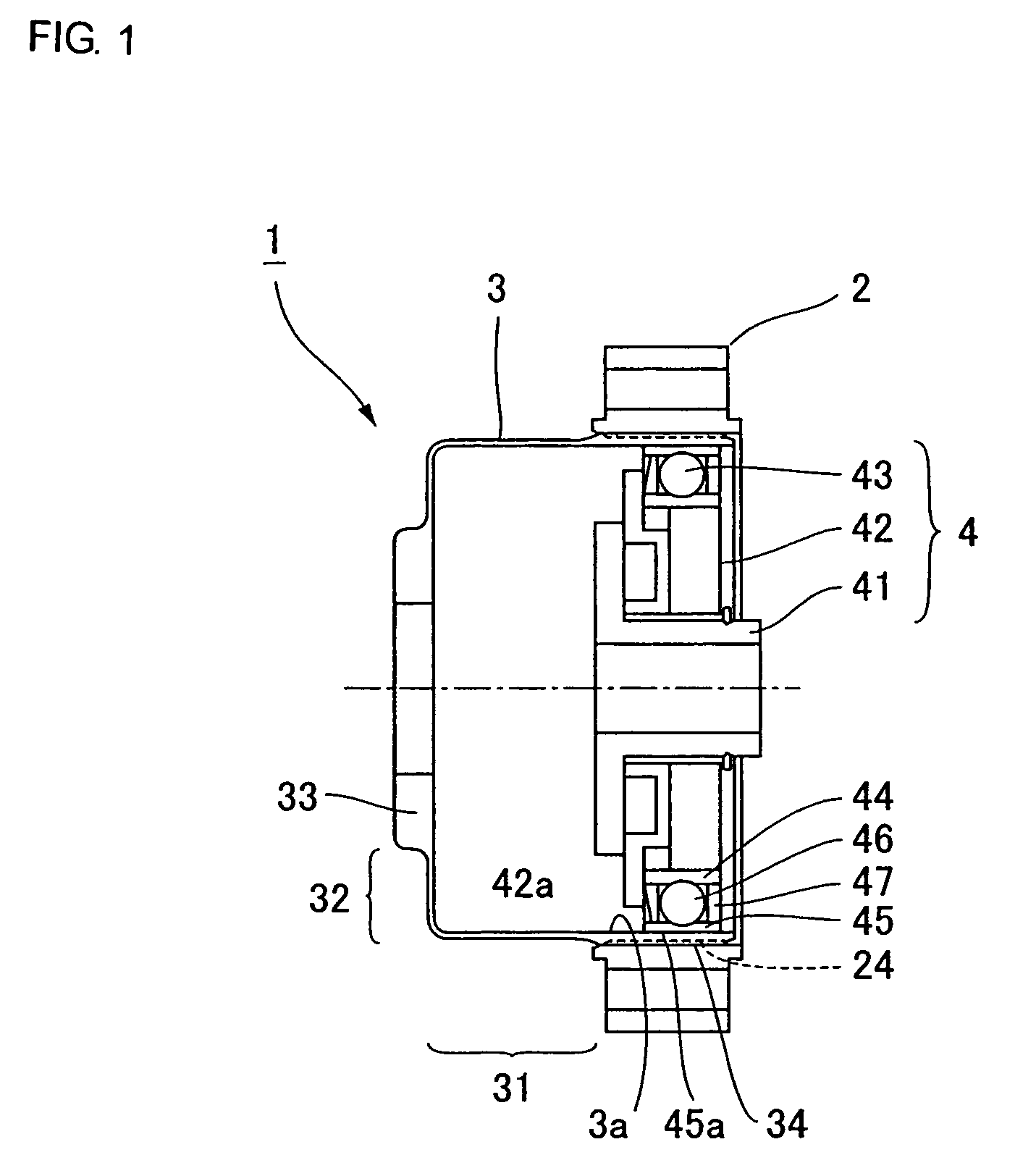

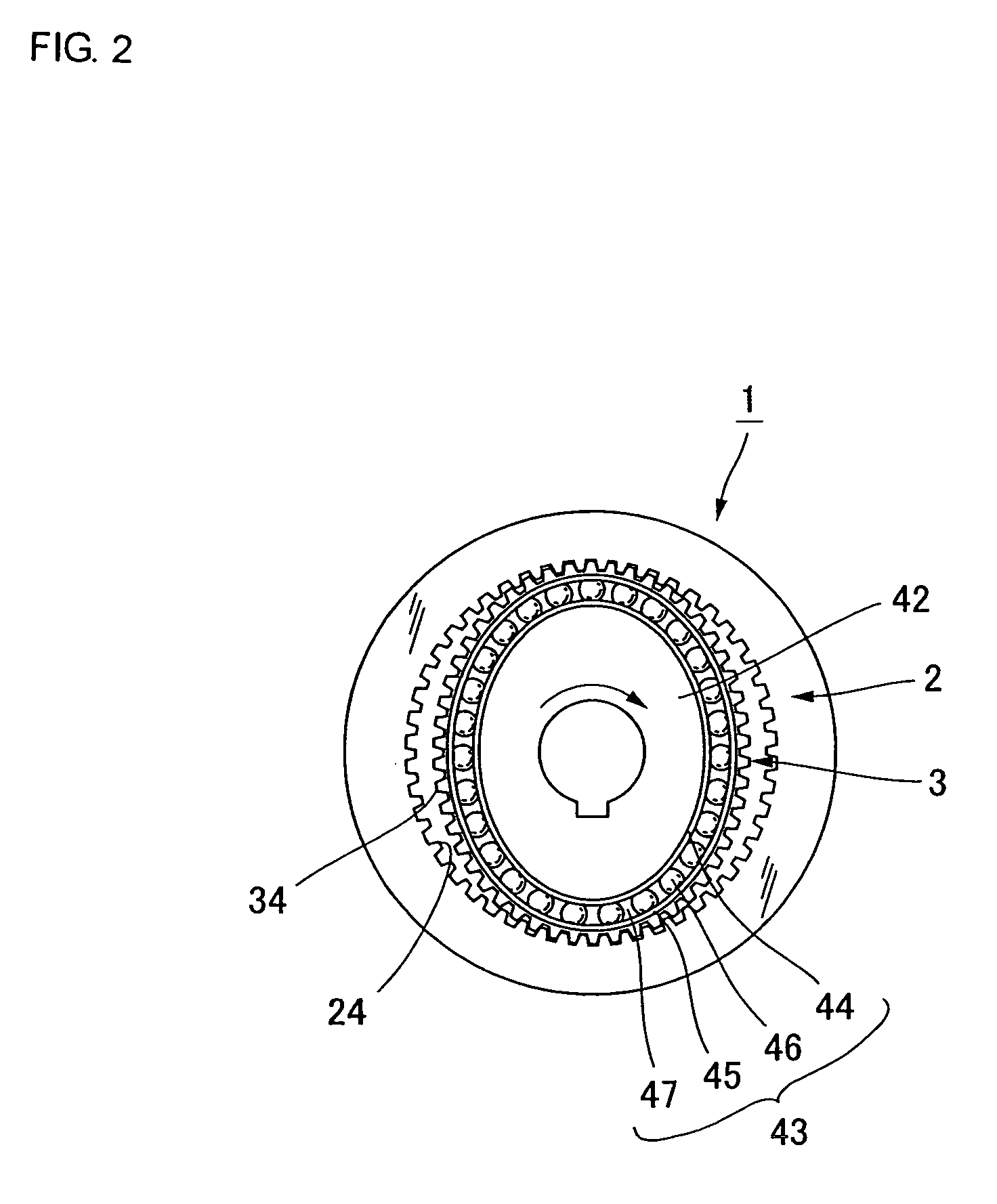

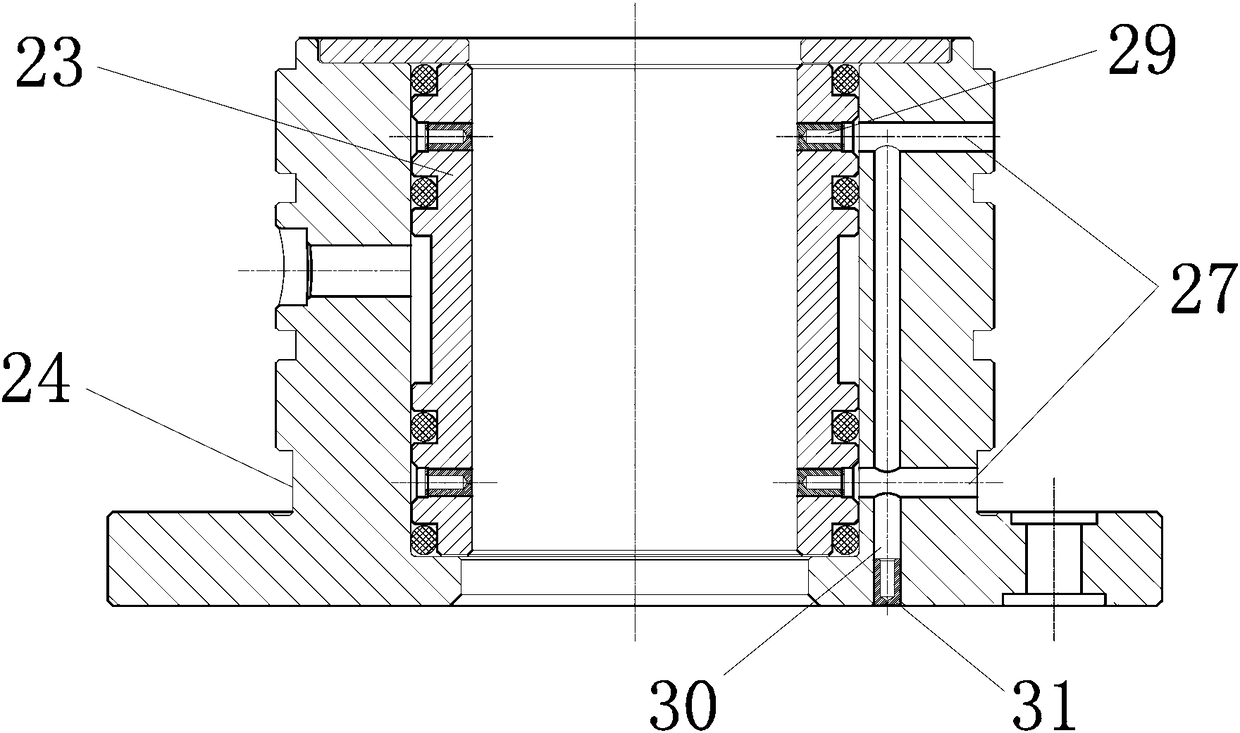

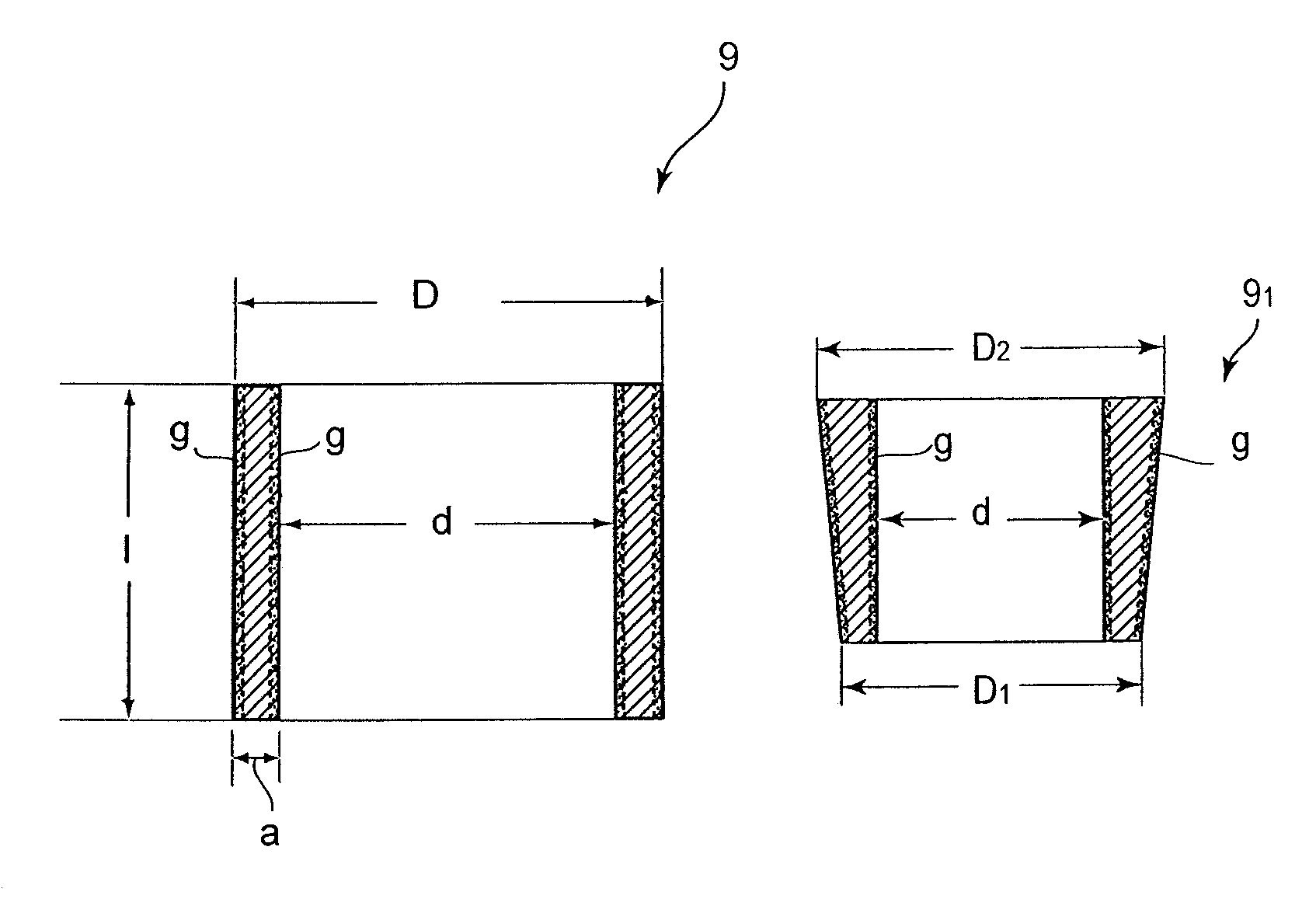

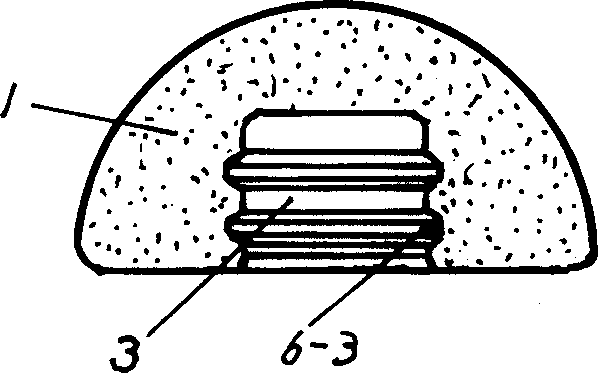

Wave gear device

ActiveUS20070157760A1Inadequate lubrication be preventReduce lifeRotary combination bearingsRolling contact bearingsEngineeringOil film

A wave gear device (1), wherein when a wave generator (4) is in a low speed rotating state, a rolling bearing state is formed by a wave bearing (43) and the wave generator (4) and a flexible external gear (3) are held in a relatively rotatable state and when the wave generator (4) is in a high speed rotating state, partition pieces (7) and split side plate pieces (8) forming the retainer (47) of the web bearing (43) are displaced to the outside to stop the rotation of balls (46) in their axes and the revolution thereof. Accordingly, a sliding bearing state is formed by lubricating oil film (9) formed between the wave generator (4) and the flexible external gear (3) and the wave generator and the flexible external gear are held in a relatively rotatable state. When the wave generator (4) returns to the low speed state, the constraint of the wave bearing (43) is released by the elastic return force of the elastic ring (5) of the retainer (47) and the wave bearing (43) returns to the rolling bearing state. Since a rolling fatigue does not occur on the wave bearing (43) in high speed rotation, the wave gear device allowing the input of the high speed rotation therein can be realized.

Owner:HARMONIC DRIVE SYST IND CO LTD

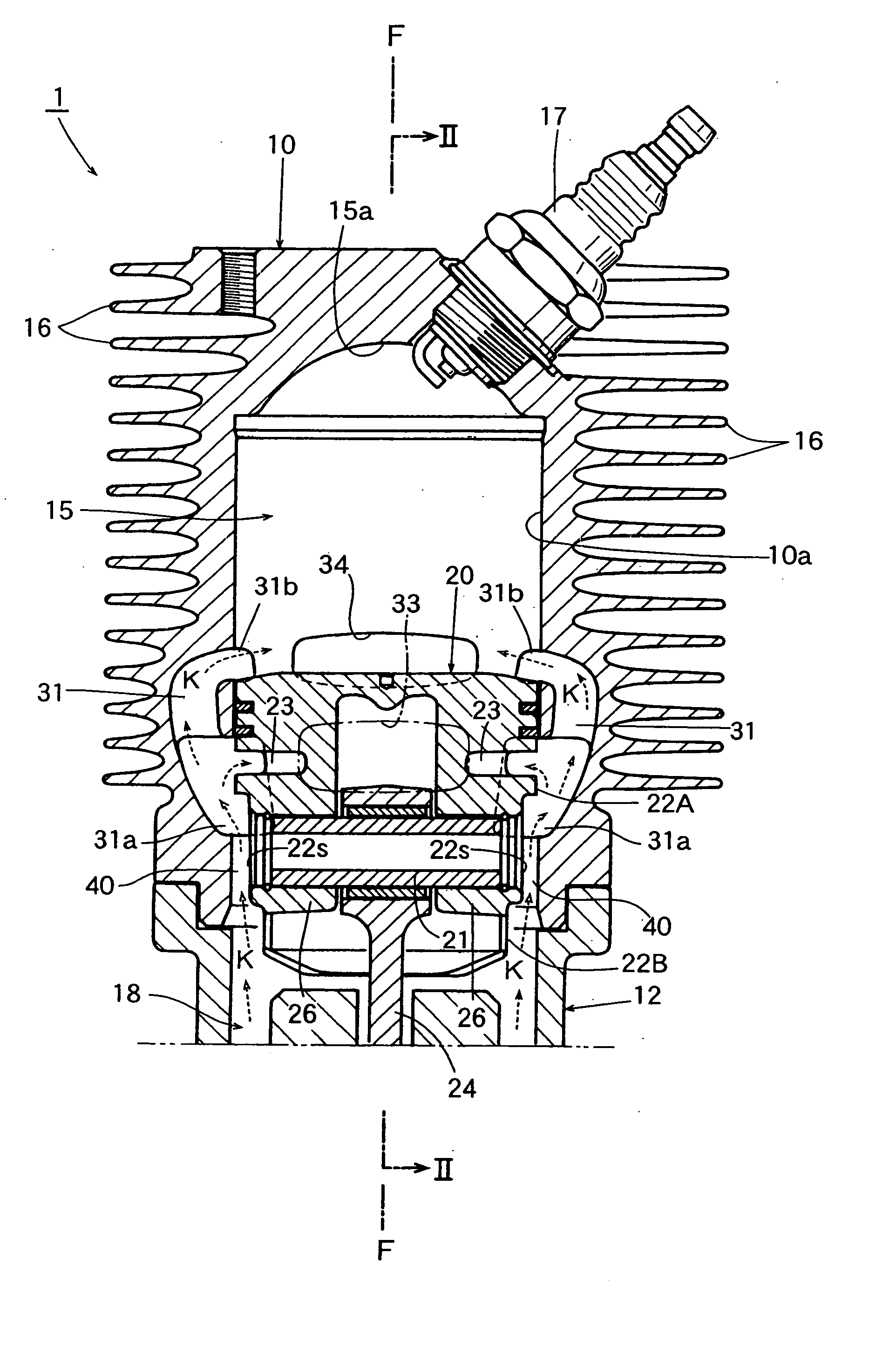

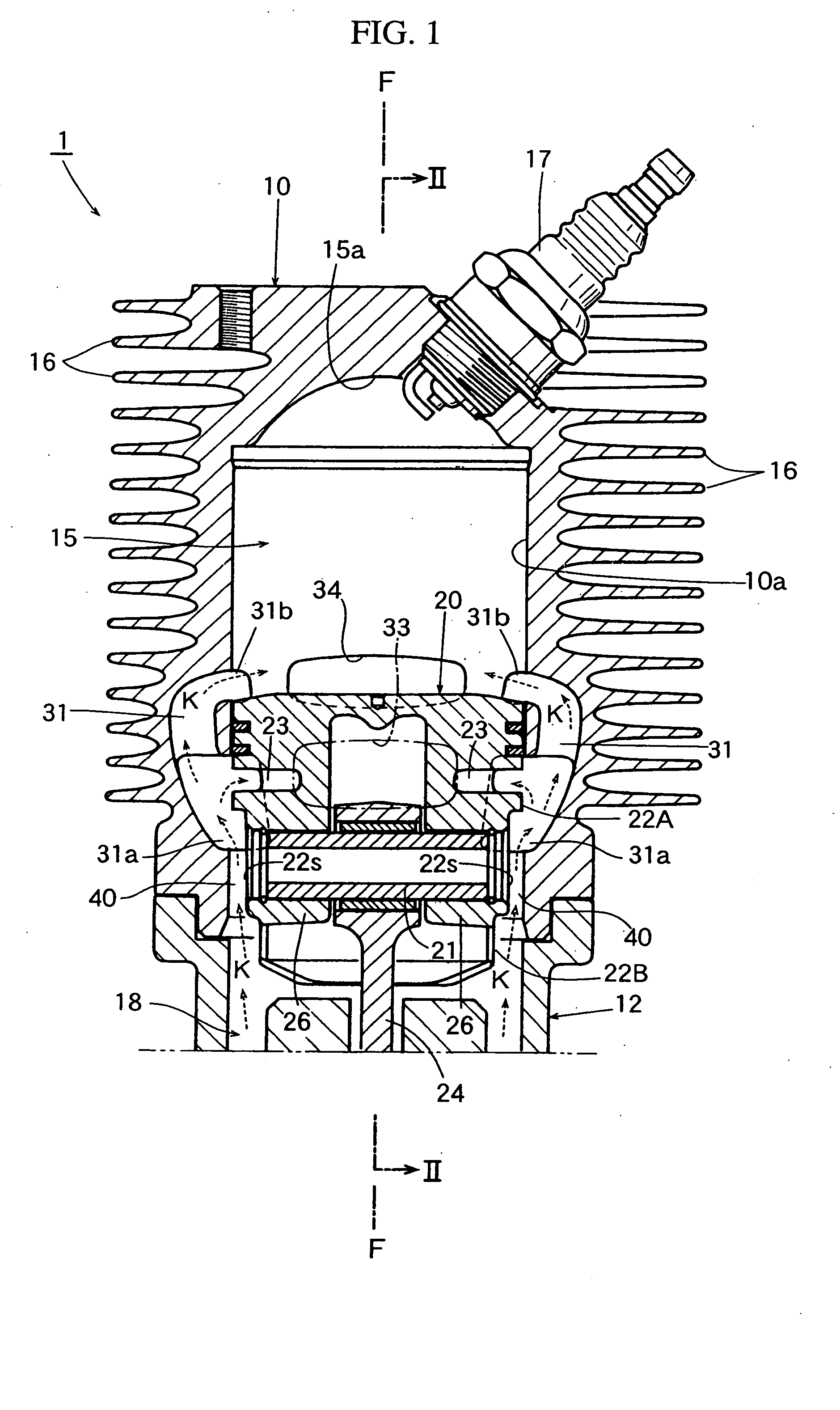

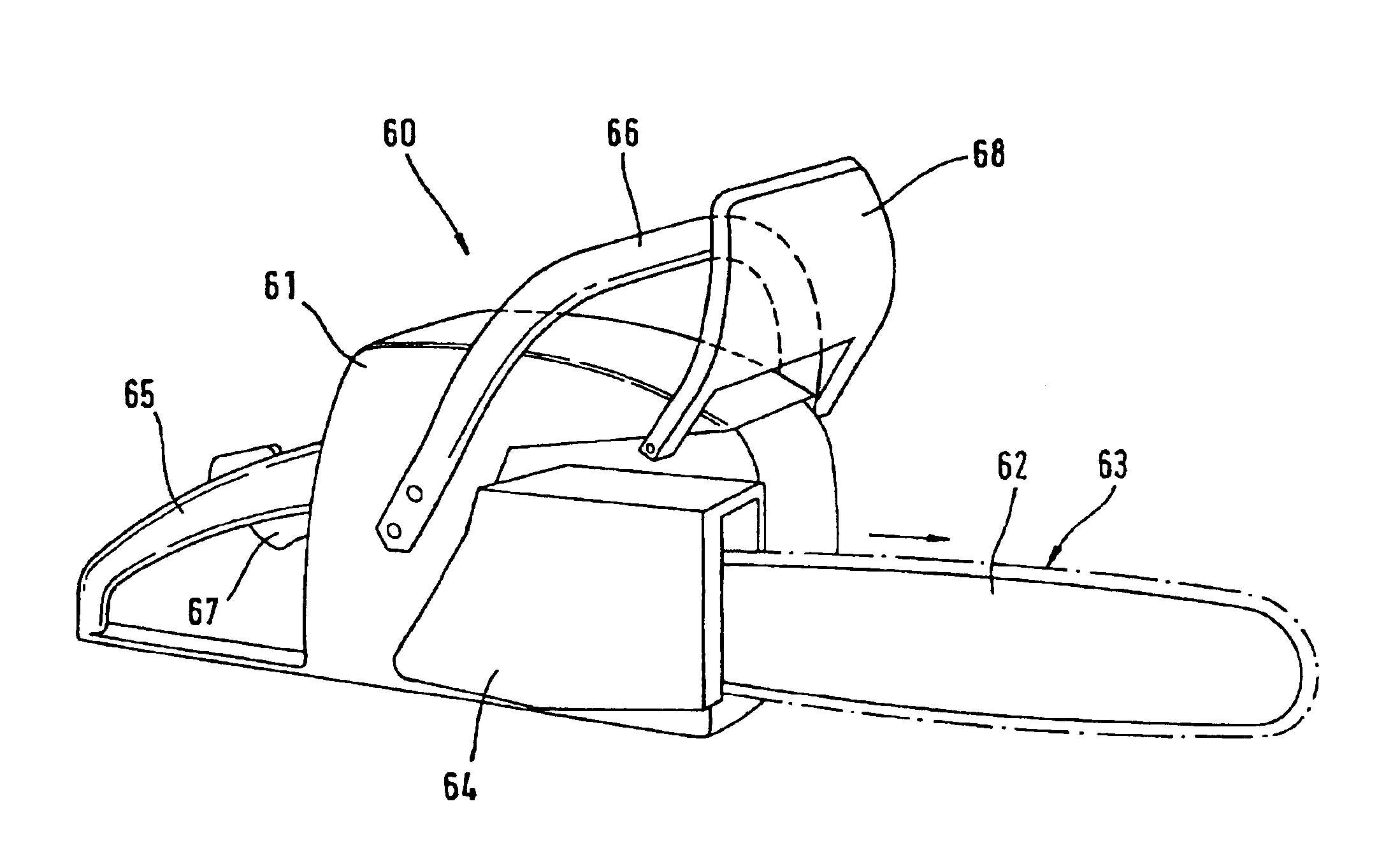

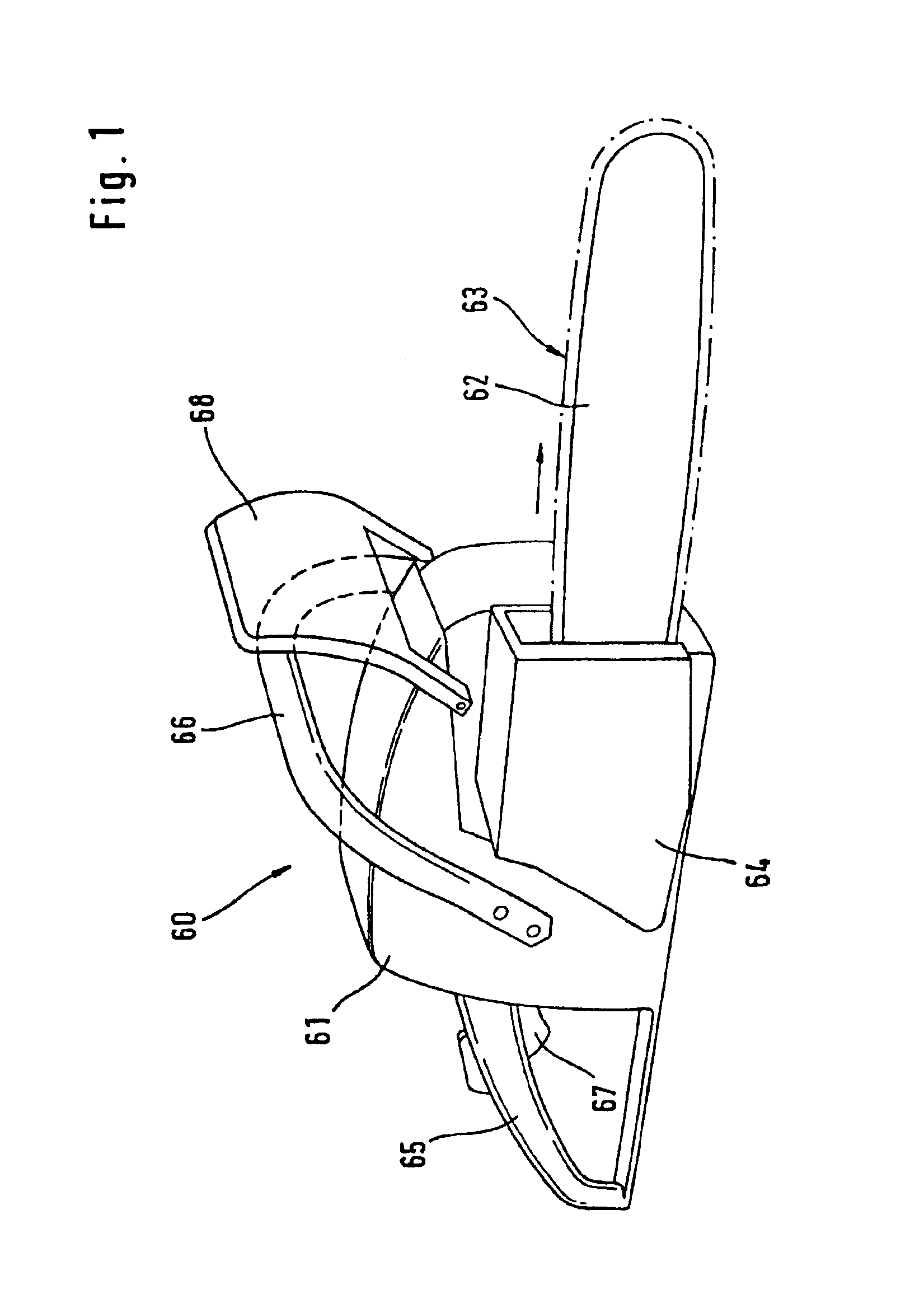

Two-stroke internal combustion engine

InactiveUS20050022757A1Improve atomization effectImprove removal efficiencyCylinder headsCombustion enginesEngineeringInternal combustion engine

A two-stroke internal combustion engine (1) is provided with one pair or plural pairs of C-shaped scavenging passageways (31, 32) of a reverse flow system where scavenging inlet ports (31a) as well as scavenging outlet ports (31b, 32b) are both opened to a cylinder bore (10a), wherein a scavenging introducing passageway (40) for introducing an air-fuel mixture (K) from a crank chamber (18) into the scavenging inlet ports (31a) is provided between the cylinder bore and the piston adapted to reciprocatively move up and down in the cylinder bore (10a), and an effective opening area of the scavenging inlet ports (31a) is gradually decreased due to the piston (20) in the course of descending stroke of the piston (20).

Owner:KIORITZ

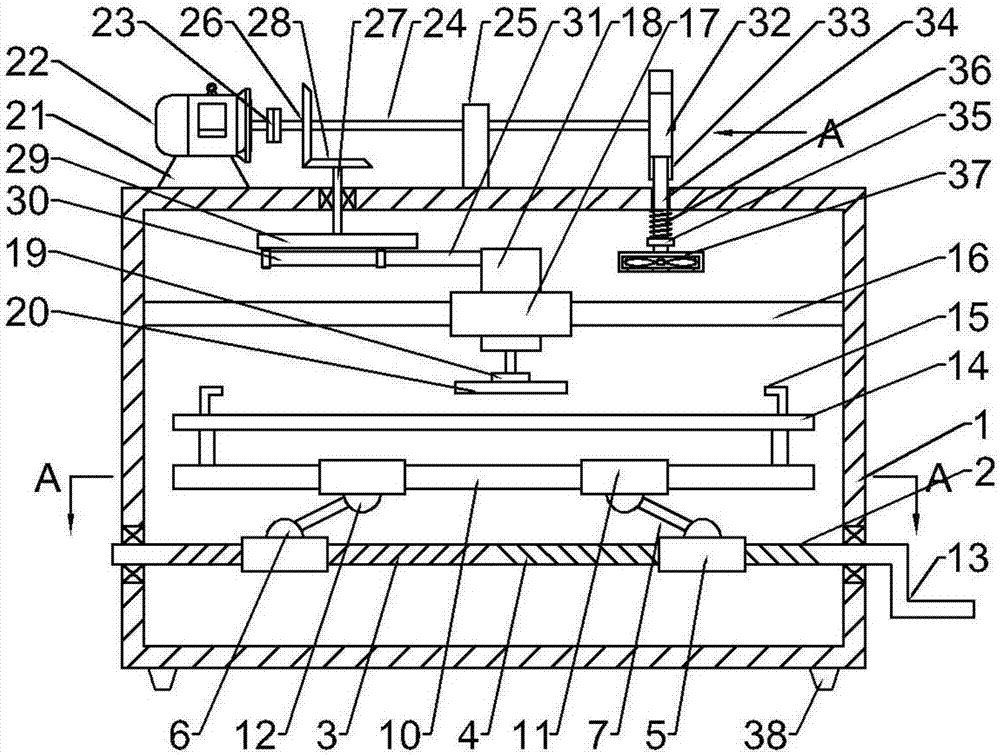

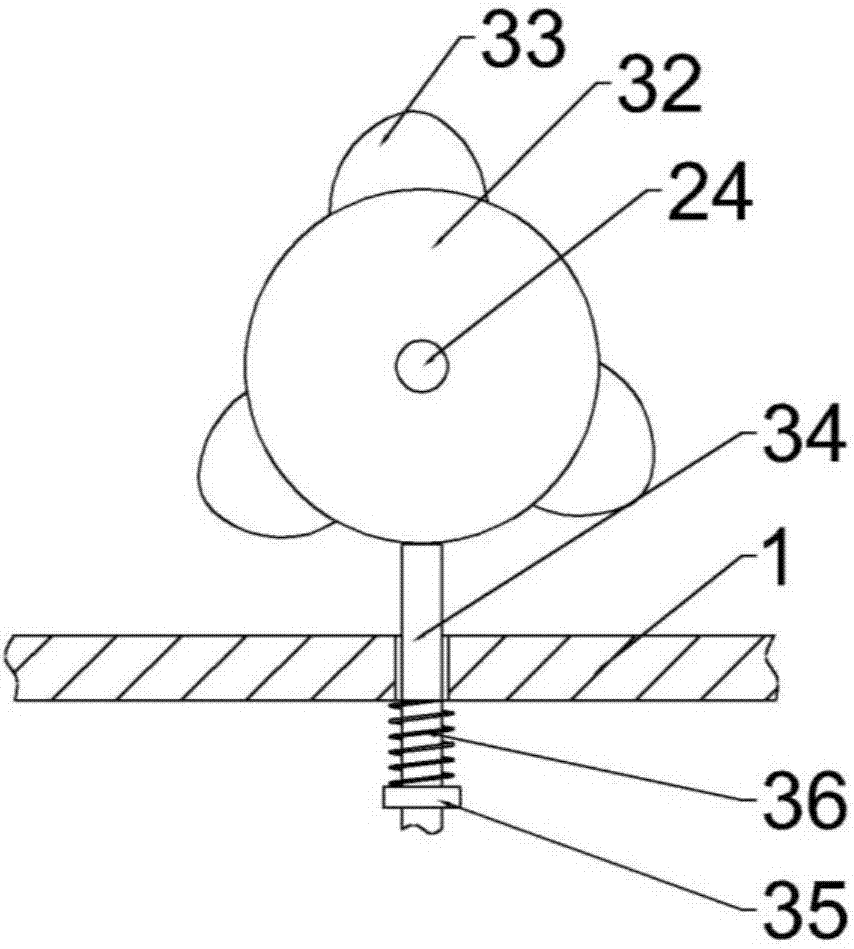

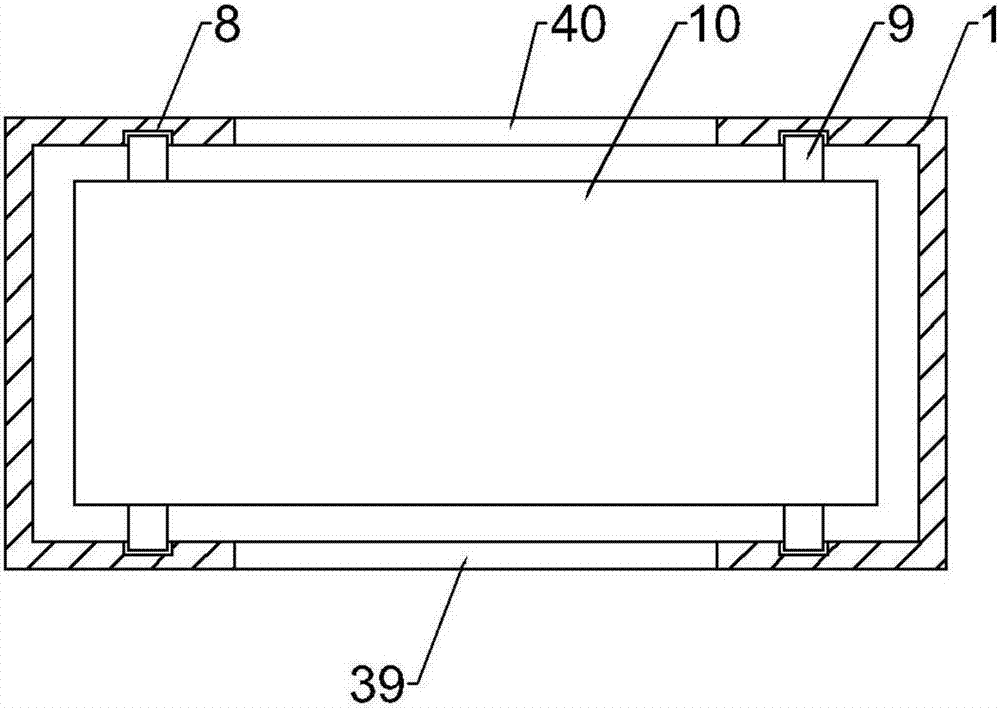

Stone polishing device with periodical ash removal function for building

InactiveCN107116428AImprove processing efficiencyAvoid lubricationGrinding carriagesGrinding drivesDielectricArchitectural engineering

The invention discloses a building stone grinding device with periodic dust cleaning function, which comprises a frame, the bottom of the frame is connected with an adjustment shaft through a bearing in rotation, and the outside of the left end of the adjustment shaft is fixedly connected with a right thread, and the adjustment shaft The outside of the right end is fixedly connected with a left thread, the outside of the left thread and the right thread are all threaded with an adjustment sleeve, the top of the adjustment sleeve is fixedly connected with a lower rotating hinge, and the top of the lower rotating hinge is fixedly connected with a tilting connecting rod. Compared with the prior art, the beneficial effects of the present invention are: the present invention is simple in structure, easy to use, and is used for stone processing in construction, and the stone processing efficiency is higher by reciprocating grinding of stone during processing. In addition, the device During grinding, the blasting fan is pushed down periodically to blow away the ground stone powder, so as to prevent the stone powder from being interposed between the grinding plate and the stone and acting as a lubricant, thereby reducing the effect of grinding.

Owner:苏昭缄

Wave gear device

ActiveUS7484436B2Avoid lubricationRotary combination bearingsRolling contact bearingsLow speedGear wheel

Owner:HARMONIC DRIVE SYST IND CO LTD

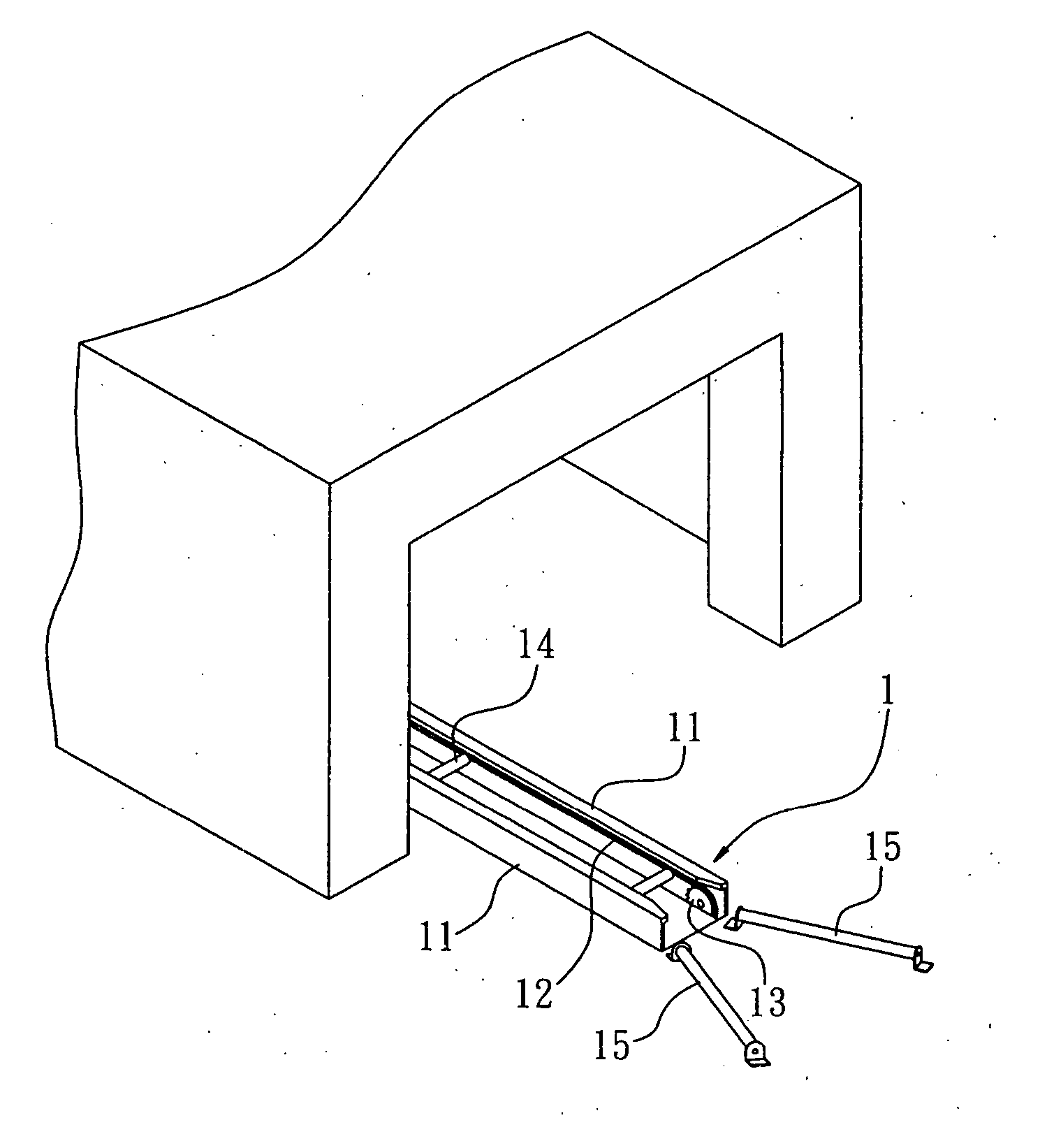

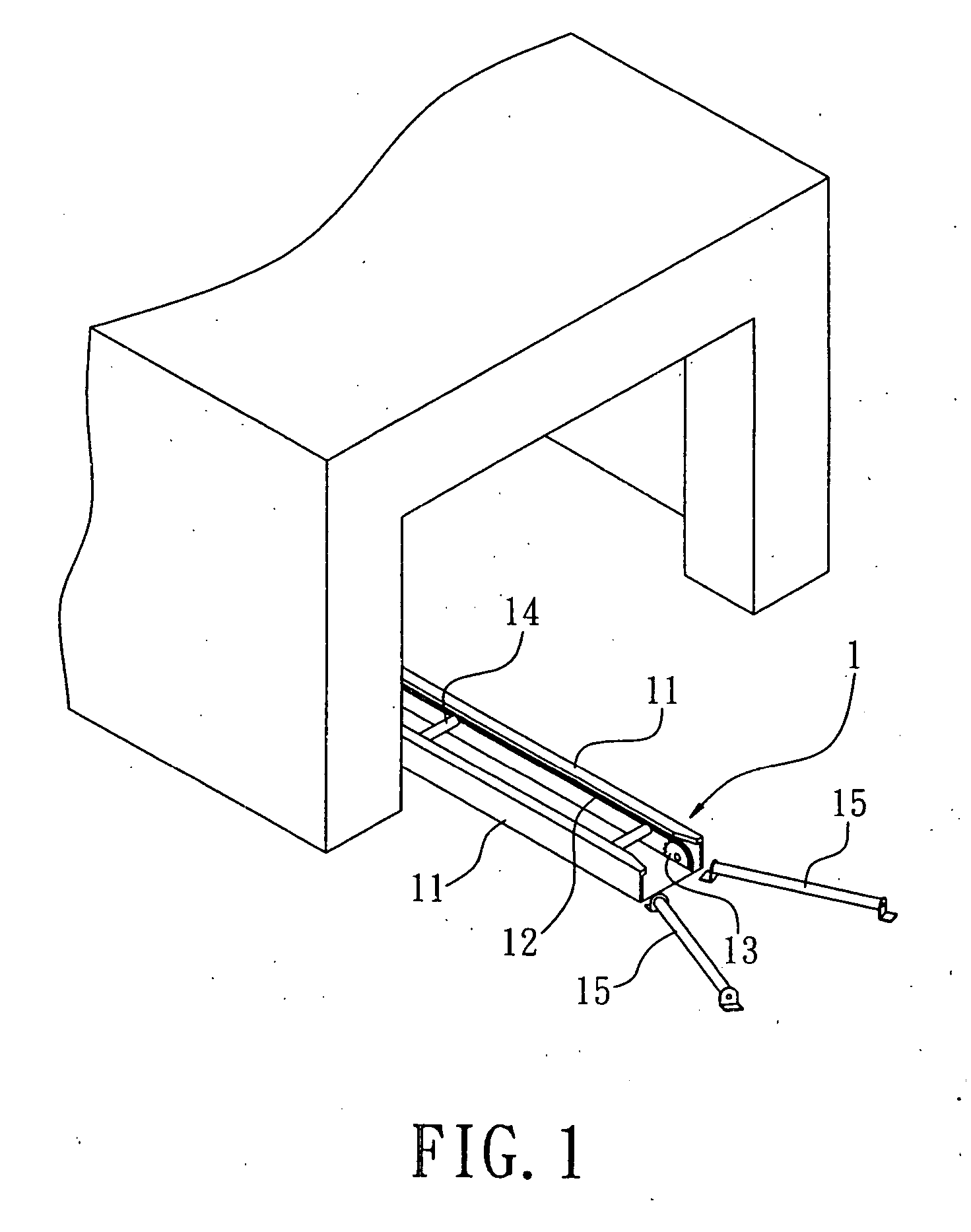

Conveying apparatus of a vehicle washing machine

InactiveUS20070028796A1Avoid wear and tearAvoid lubricationCleaning apparatus with conveyorsTrain hauling devicesMechanical engineeringEngineering

A conveying apparatus of a vehicle washing machine includes a first carrying mechanism, a first driving mechanism and a guiding mechanism. The first carrying mechanism has a base, at least one positioning device, which is disposed on the base and can position a wheel of a to-be-washed vehicle, and a moving device disposed on the base. The first driving mechanism has a driving unit for driving the moving device of the first carrying mechanism. The guiding mechanism guides the moving device to move in a moving direction. The wheel of the vehicle is positioned on the base of the first carrying mechanism, and the base is driven by the driving unit to move the vehicle forward.

Owner:TSAI JUNG HSIN

Compressor and compressor oil temperature control method and device

ActiveCN106286227ASolve the problem of low oil temperatureAvoid damagePositive displacement pump componentsPositive-displacement liquid enginesEngineeringOil temperature

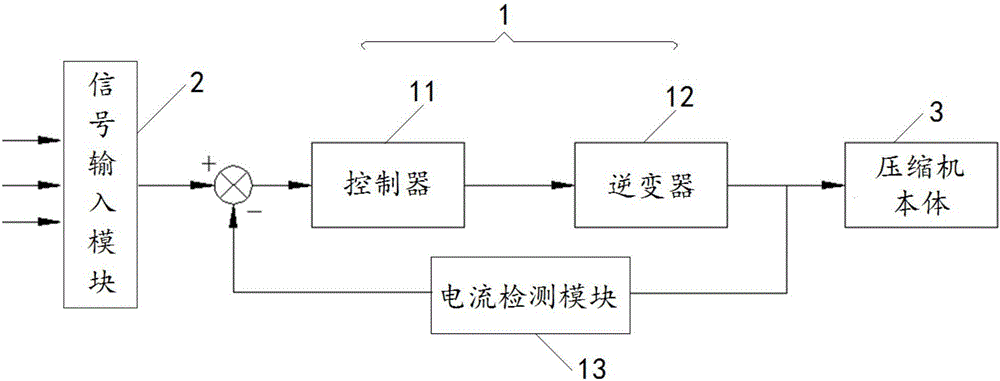

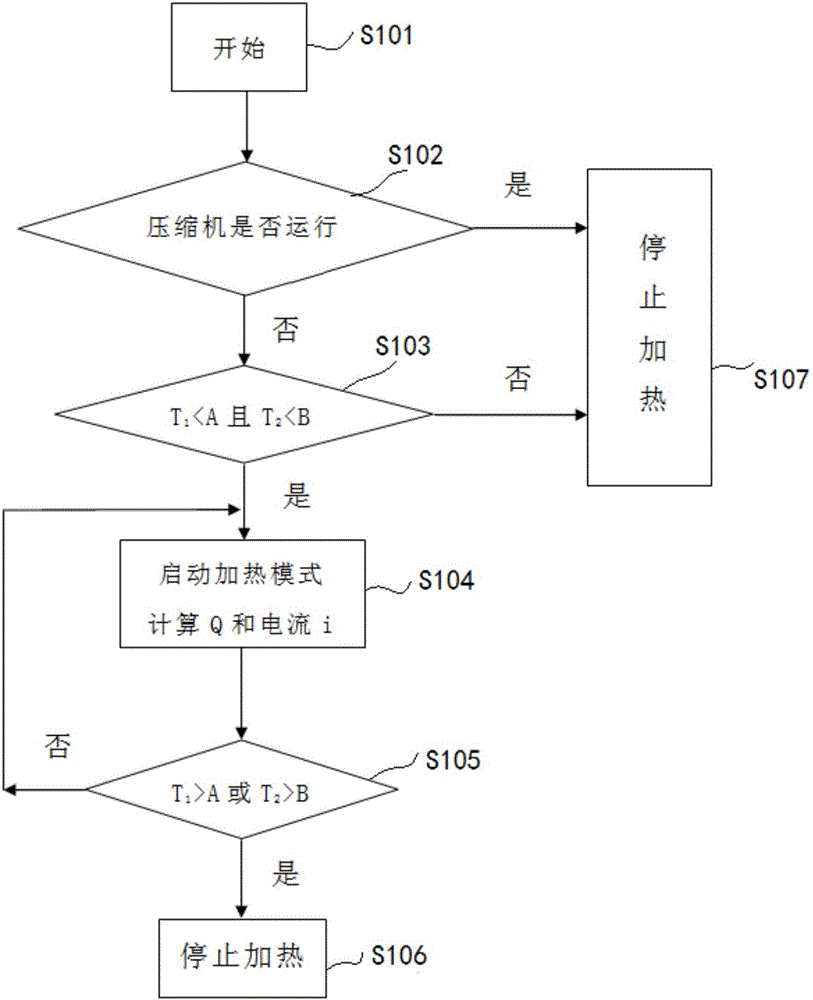

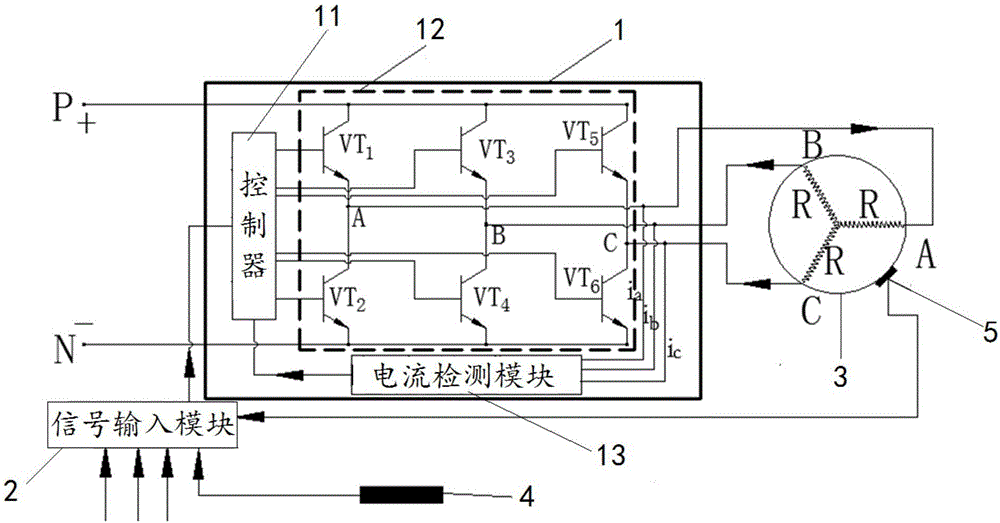

The invention discloses a compressor oil temperature control method. The compressor oil temperature control method comprises the steps that 1, whether a compressor is in a shutdown state or not is judged, and if yes, the step 2 is conducted; 2, whether the environment temperature T1 is lower than a preset value A or not and whether the temperature T2 of a shell of the compressor is lower than a second preset value B or not are detected, and if both yes, the step 3 is conducted; 3, a coil of the compressor is heated. The invention further discloses a compressor oil temperature control device and the compressor with the same. According to the compressor oil temperature control method, the problem that the oil temperature of the compressor which does not run at low environment temperature is too low can be solved, and the problems of poor lubrication, a restart failure and the like which are caused by the fact that the compressor oil temperature is too low are prevented.

Owner:GUANGDONG CHIGO HEATING & VENTILATION EQUIP CO LTD

Wear-resisting heat-conducting polyurethane bearing as well as preparation method and application thereof

The invention belongs to the field of light-weight wear-resisting materials and discloses a wear-resisting heat-conducting polyurethane bearing as well as an preparation method and an application thereof. The preparation method of the wear-resisting heat-conducting polyurethane bearing comprises the following steps of: soaking a fiber into a copolymer, dispersing ultrasonically, adding a polyurethane prepolymer, a curing agent and a heat-conducting filler, mixing the materials, degassing in vacuum, pouring the degassed mixture into a preheating mold, heating to cure, cooling, and demolding to obtain the wear-resisting heat-conducting polyurethane bearing. The wear-resisting heat-conducting polyurethane bearing prepared by adopting the preparation method has the advantages of light weight, wear resistance (relative volume wear loss of 150mm<3>), good heat conductivity of 4W / m*K, high strength (high modulus of compression of 520Mpa, and notched impact strength of 120J / m), low cost, long service life and the like, is simple in forming process, is suitable for industrial production and can be widely applied to clean-energy power generation equipment.

Owner:JINAN UNIVERSITY

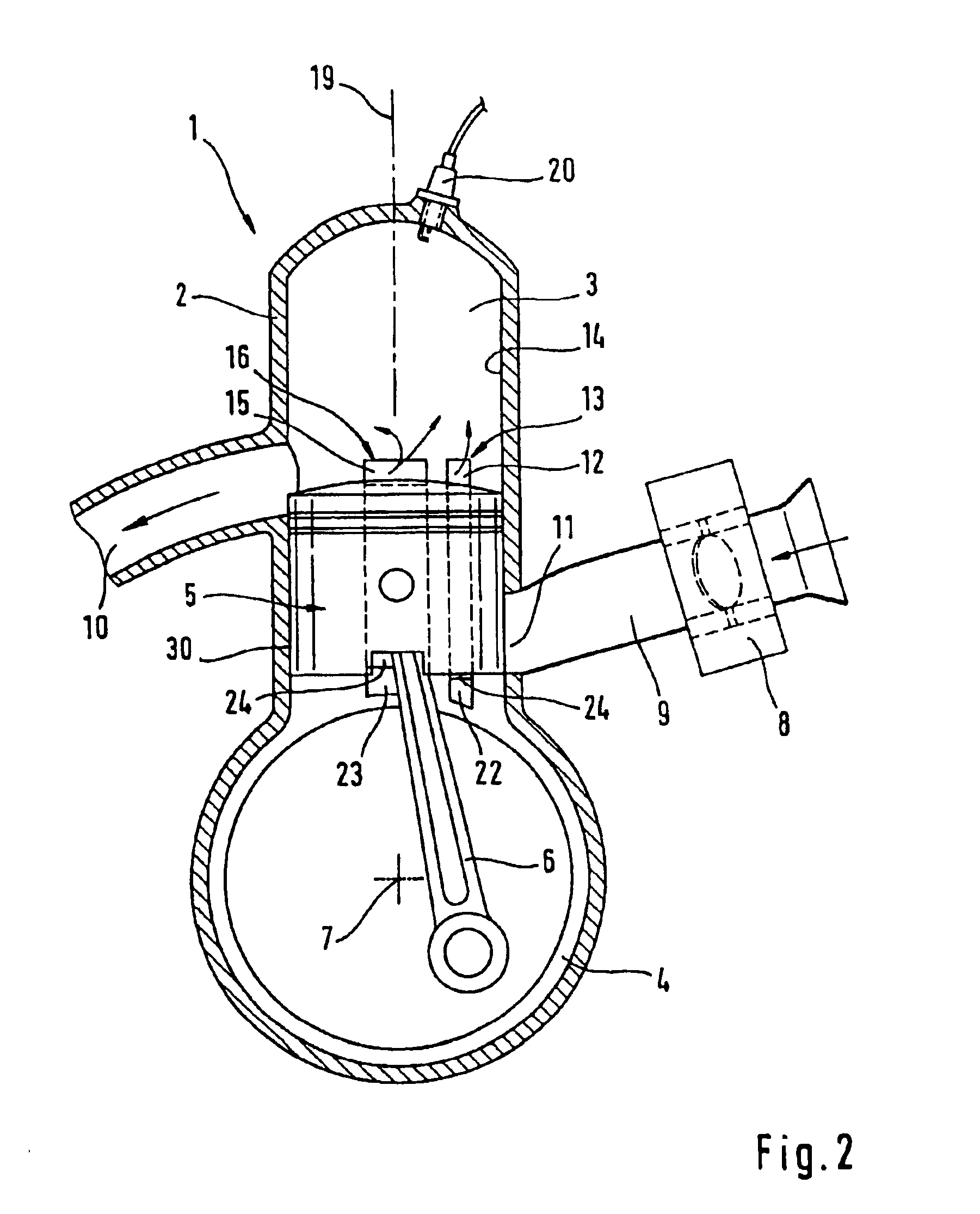

Method for operating a two-stroke engine having mixture induction

ActiveUS6912979B2Easy to adjustImprove the lubrication effectCombustion enginesExhaust gasAutomotive engineering

The invention relates to a method for operating a two-stroke engine having scavenging-advance storage. The combustion chamber (3) which in configured in the cylinder (2) is supplied with an air / fuel mixture via a transfer channel (12, 15). This air / fuel mixture is drawn by induction through an inlet into the crankcase (4) during the intake phase. During the intake phase, a fuel-free fluid such as pure air is inducted via a fluid channel (17) and stored in the transfer channel. To obtain good exhaust-gas values while also having reduced fuel consumption and reliable lubrication, lambda (λ) of the air / fuel mixture, which is stored in the crankcase (4), is adjusted in a range of approximately 0.2 to 0.6 in the part-load and full-load ranges of the two-stroke engine (1).

Owner:ANDREAS STIHL AG & CO KG

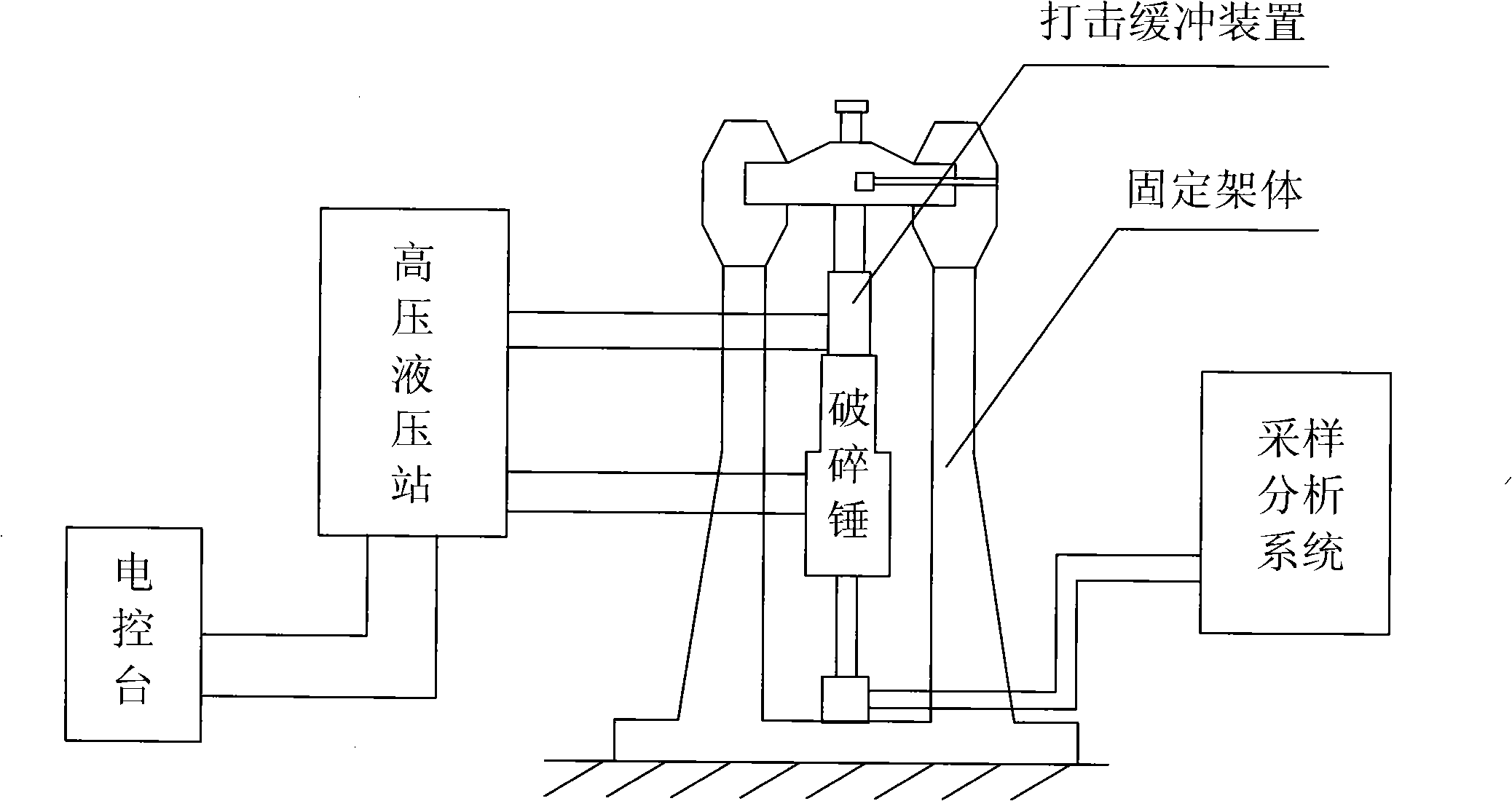

Hydraulic breaking hammer performance measurement system

InactiveCN101339098AAvoid the phenomenon of strainSolve the problem that is not easy to mountStructural/machines measurementData acquisitionEngineering

The invention discloses a performance test system used in a hydraulic breaking hammer. The performance test system comprises a hydraulic breaking hammer fixing frame, a striking buffer device which is connected with the frame, a high-pressure hydraulic oil station which is connected with the detected hydraulic breaking hammer, an electric controlling table which is connected with the high-pressure hydraulic oil station, and a sampling and analyzing system which is used for collecting and processing the data of the detected hydraulic breaking hammer. A vertical testing device is used for testing the performance of the hydraulic breaking hammer, and simulating the working condition of the hydraulic breaking hammer, so as to acquire accurate testing results. The performance test system also prevents the cylinder of the testing device from poor lubrication as a result of excessively high pressure which is caused by the gravity of the piston, protects the piston and the cylinder from being pulled, and saves the space. In addition, the use of the pressure sensor to measure the impact of the hydraulic breaking hammer improves the accuracy of measurement. The data acquisition card and the work controlling table can be used for direct and clear on-line measurement, display and calculation of the impact of the hydraulic breaking hammer.

Owner:NANYANG KAITIAN ENG MACHINERY +1

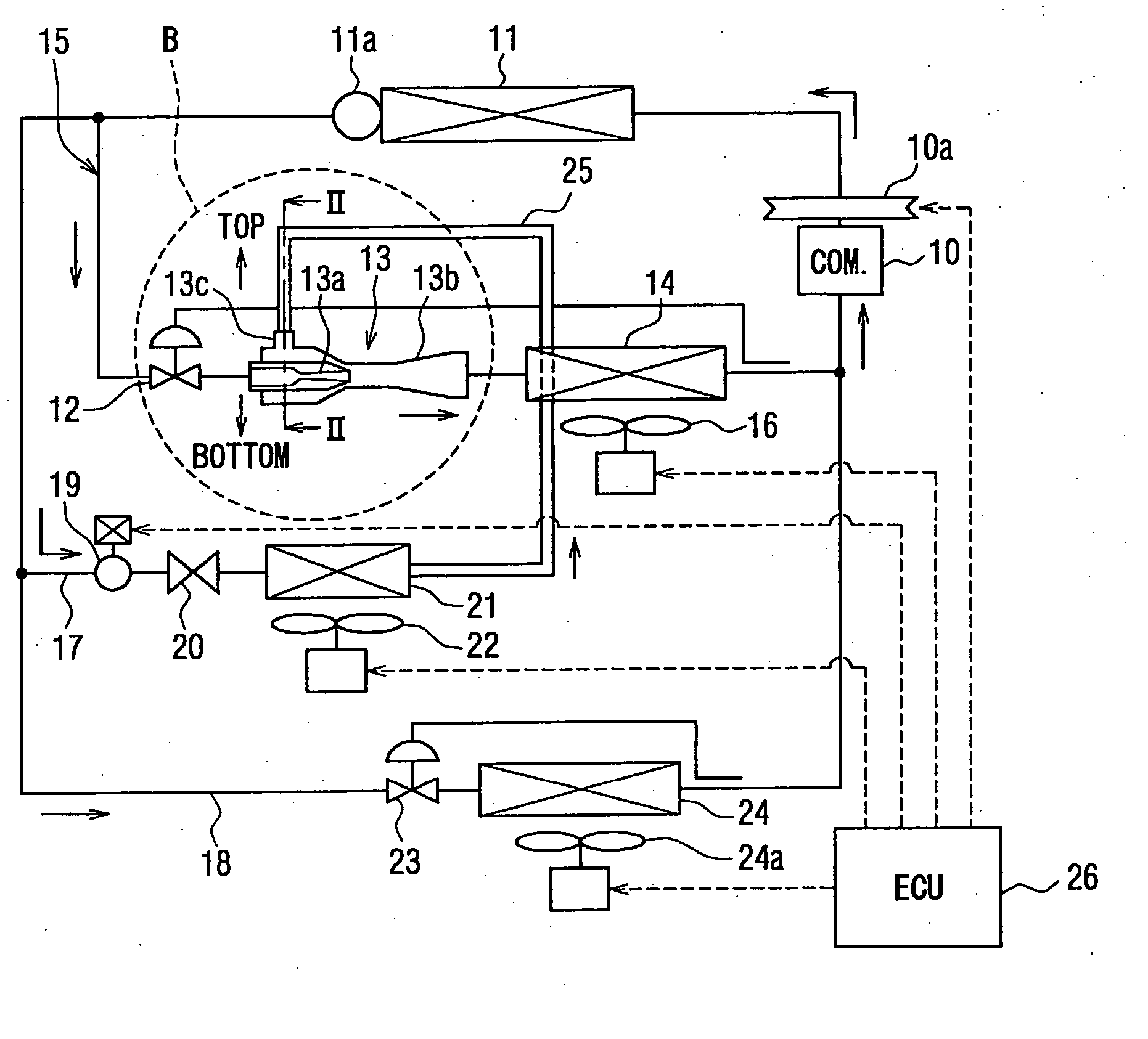

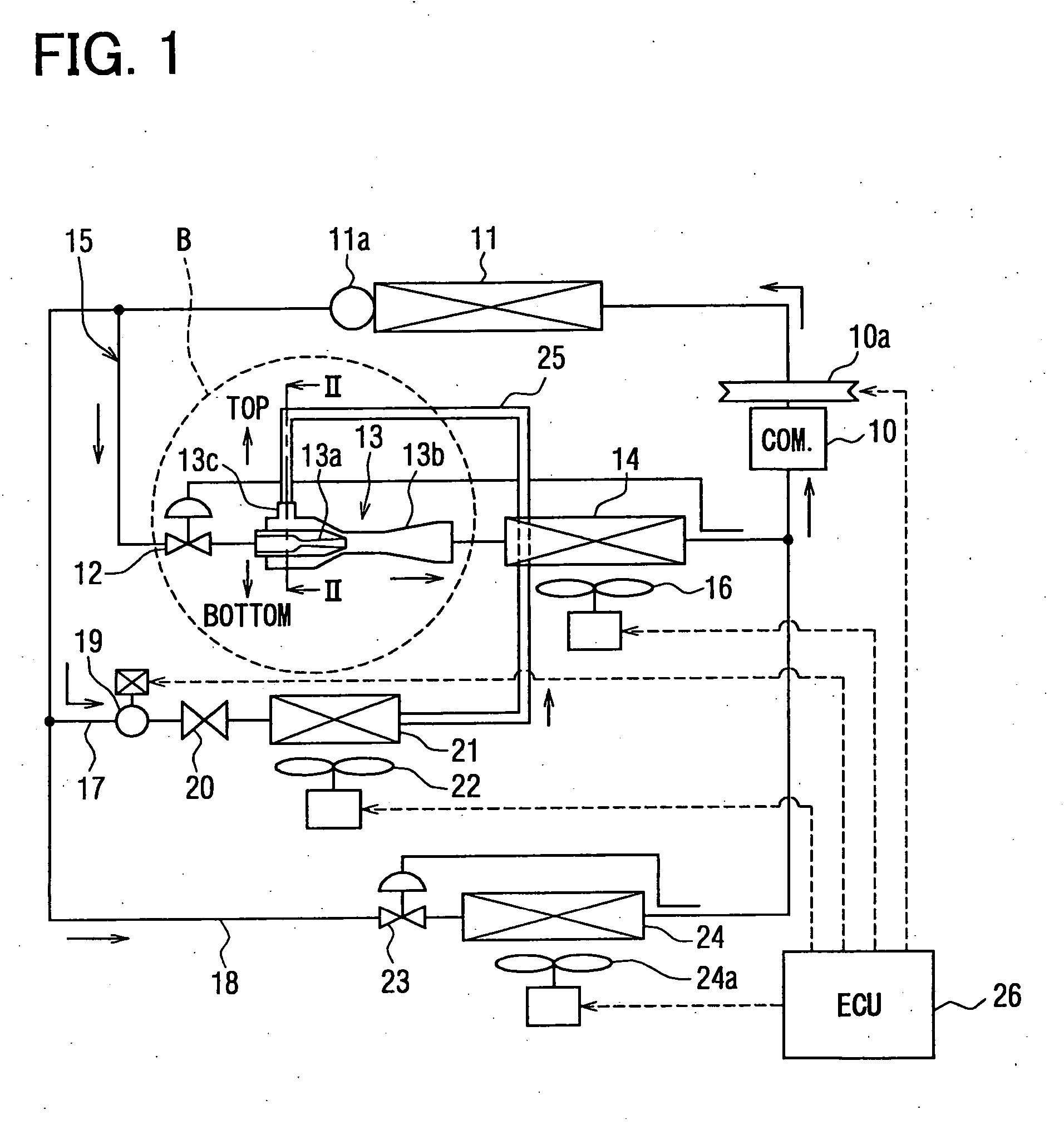

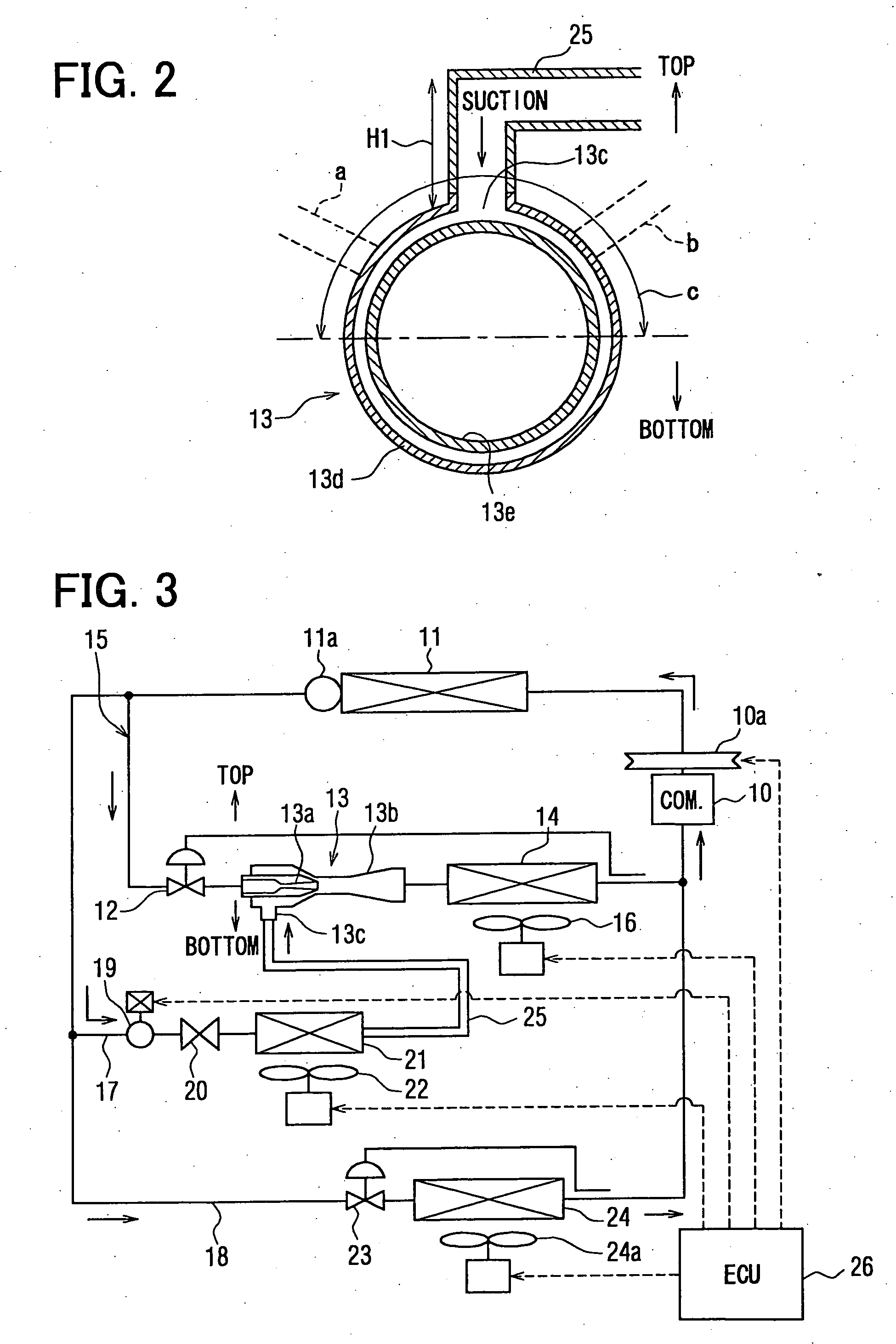

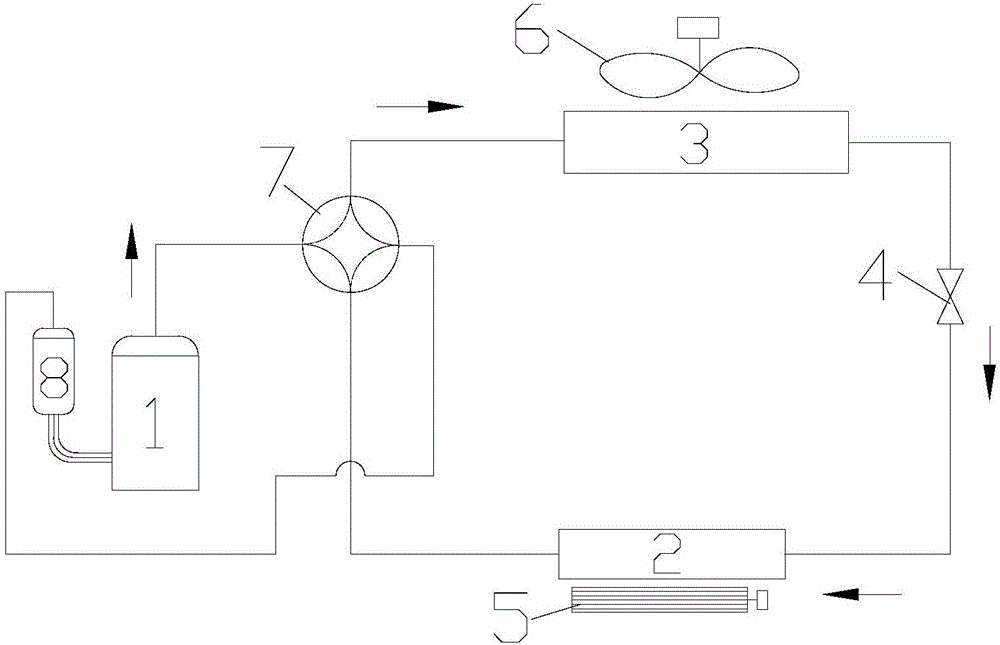

Vapor-compression refrigerant cycle system with ejector

ActiveUS20060065011A1Avoid flowAvoid stayingCompressorCompression machines with non-reversible cycleEngineeringVapor-compression refrigeration

A vapor-compression refrigerant cycle system having an ejector includes a first evaporator for evaporating refrigerant from a pressure-increasing portion of the ejector, and a second evaporator for evaporating refrigerant to be drawn into a refrigerant suction port of the ejector. Furthermore, a valve member for opening and closing a refrigerant passage of the second evaporator is arranged in serious with the second evaporator in a refrigerant flow, and refrigerant flowing out of the second evaporator flows into the refrigerant suction port through a refrigerant suction pipe. The system is provided to restrict lubrication oil contained in refrigerant from being introduced from the ejector into and staying in the refrigerant suction pipe when the valve member is closed. For example, the refrigerant suction port is provided at an upper side of the ejector.

Owner:DENSO CORP

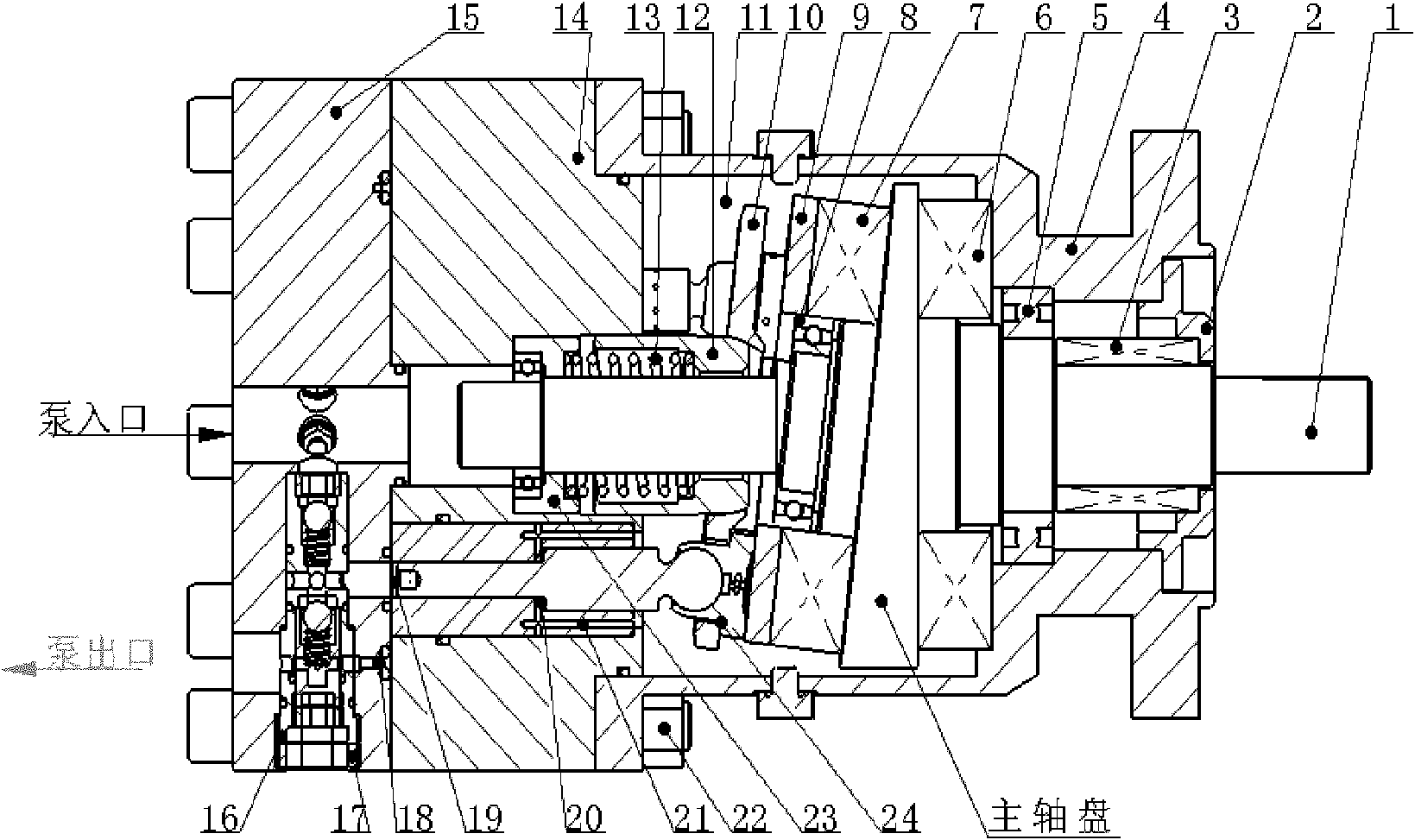

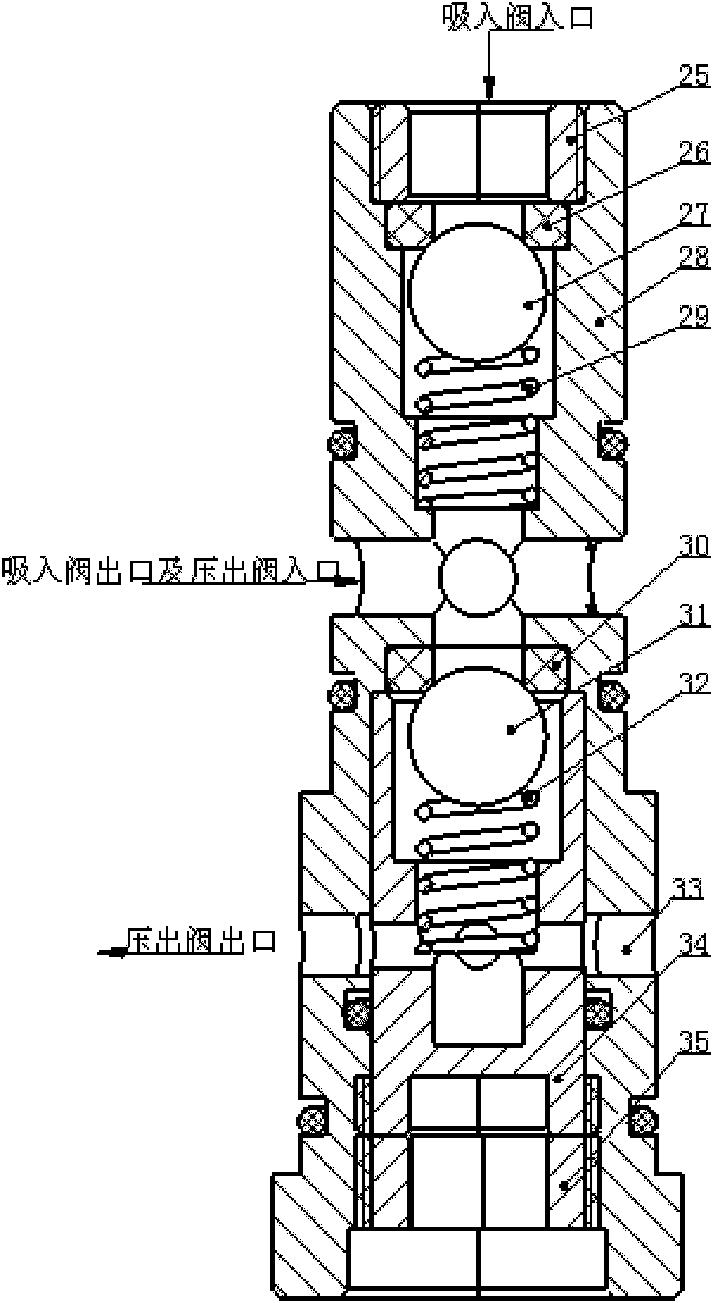

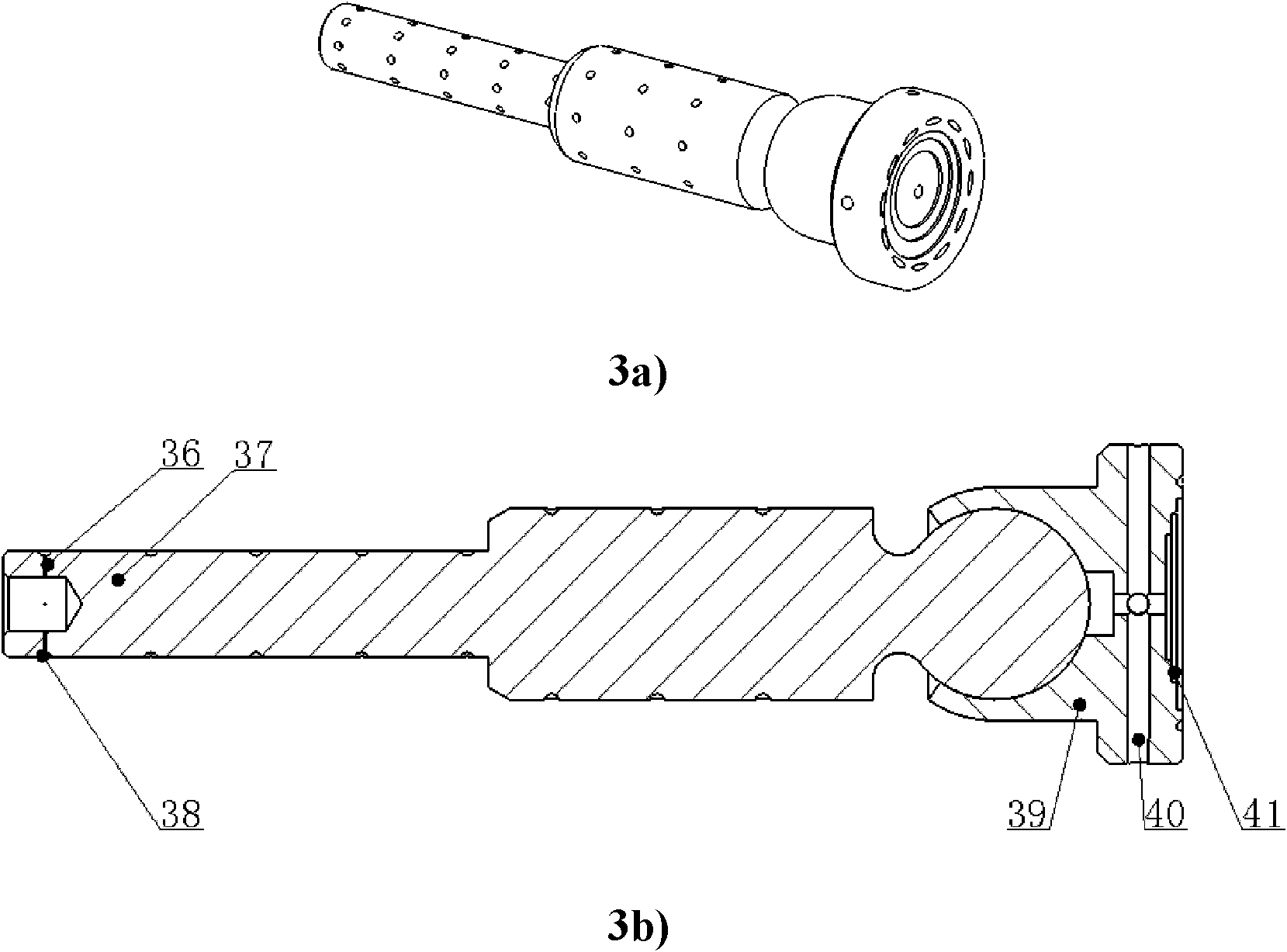

Fully water-lubricated super-pressure plunger water pump

InactiveCN101956685AReduce contact stressSolve friction and wear problemsPositive displacement pump componentsPositive-displacement liquid enginesReciprocating motionEngineering

The invention provides a fully water-lubricated super-pressure plunger water pump, mainly comprising a cavity, a live spindle and a plunger flow-distribution unit; the plunger flow-distribution unit comprises a flat valve assembly and a plunger slipper assembly; the plunger slipper assembly is used for dividing the cavity into a pressure cavity and a lubricating cavity which are independent from each other; the plunger slipper assembly carries out reciprocating motion by the driving of the live spindle so that the flat valve assembly sucks in water and discharges water through a water pump inlet and a water pump outlet, and water is simultaneously conveyed to the lubricating cavity through the water pump inlet so as to provide fluid to the rotating unit for lubricating and realizing full water lubrication. The flat valve assembly is designed integrally, and the assembly can be replaced quickly when maintenance so as to shorten maintenance time; the plunger is a stepped structure, the cylindrical surface thereof is provided with recesses, and the bottom of the slipper is provided with a stepped support cavity, thereby solving the wearing and friction problem of the plunger / plunger sleeve pair and slipper / sloping cam plate pair under high-speed heavy-duty condition, and prolonging the service life of the water pump.

Owner:HUAZHONG UNIV OF SCI & TECH

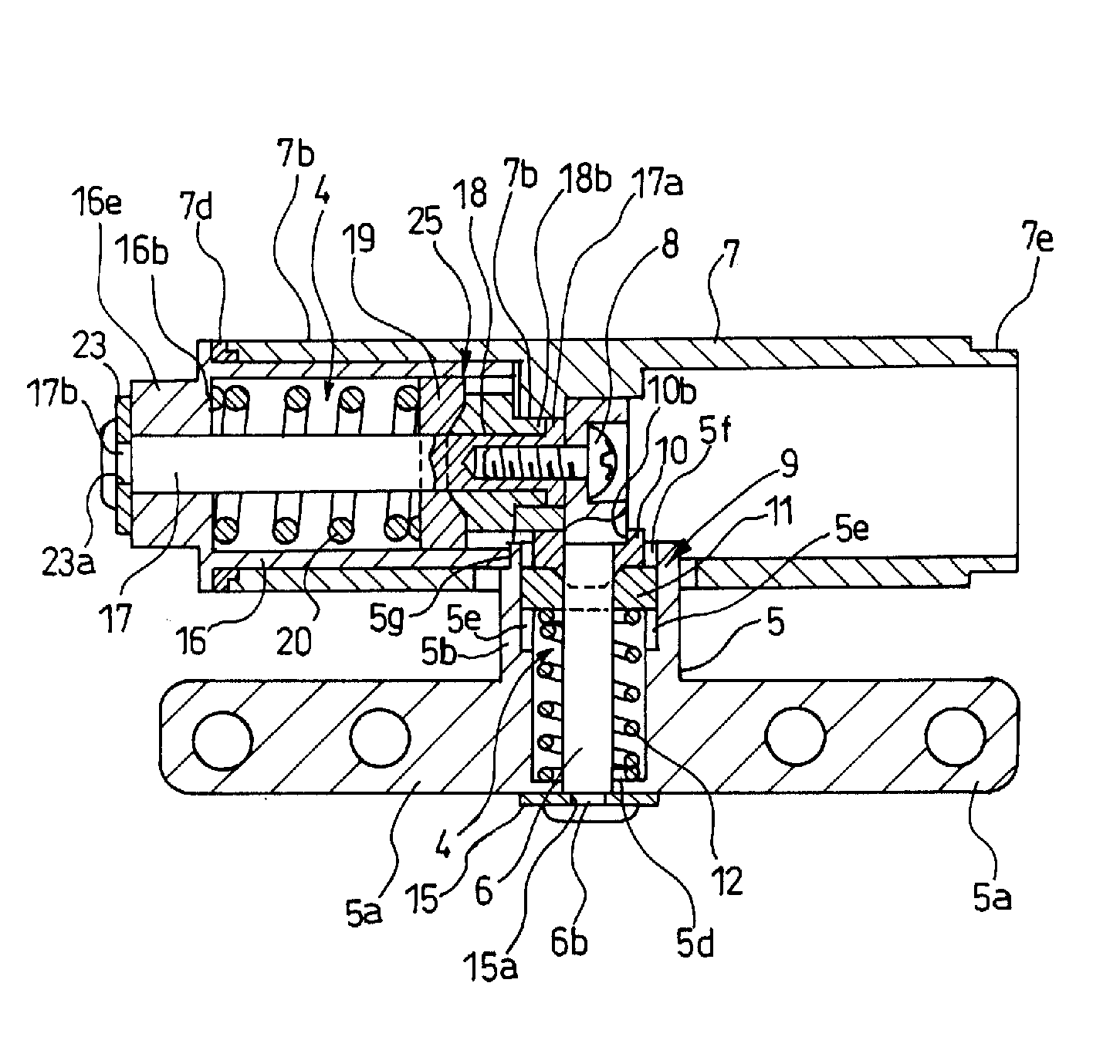

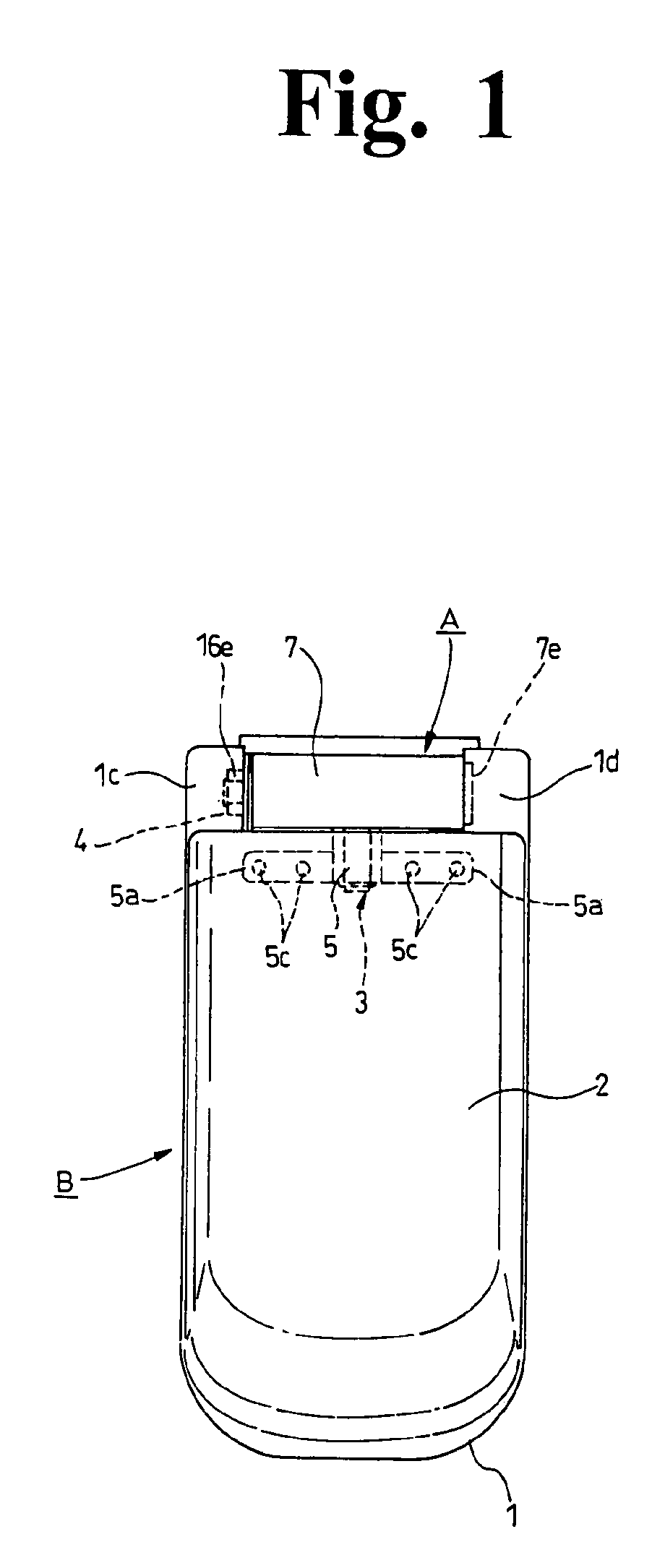

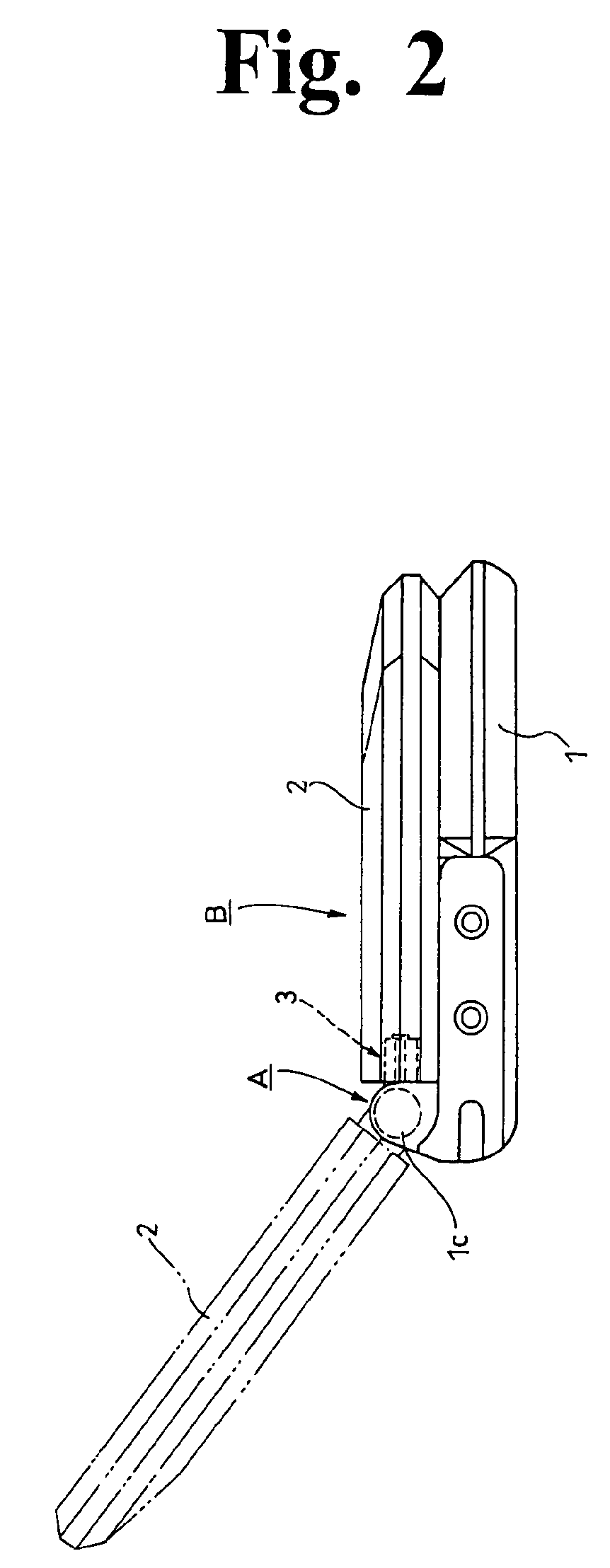

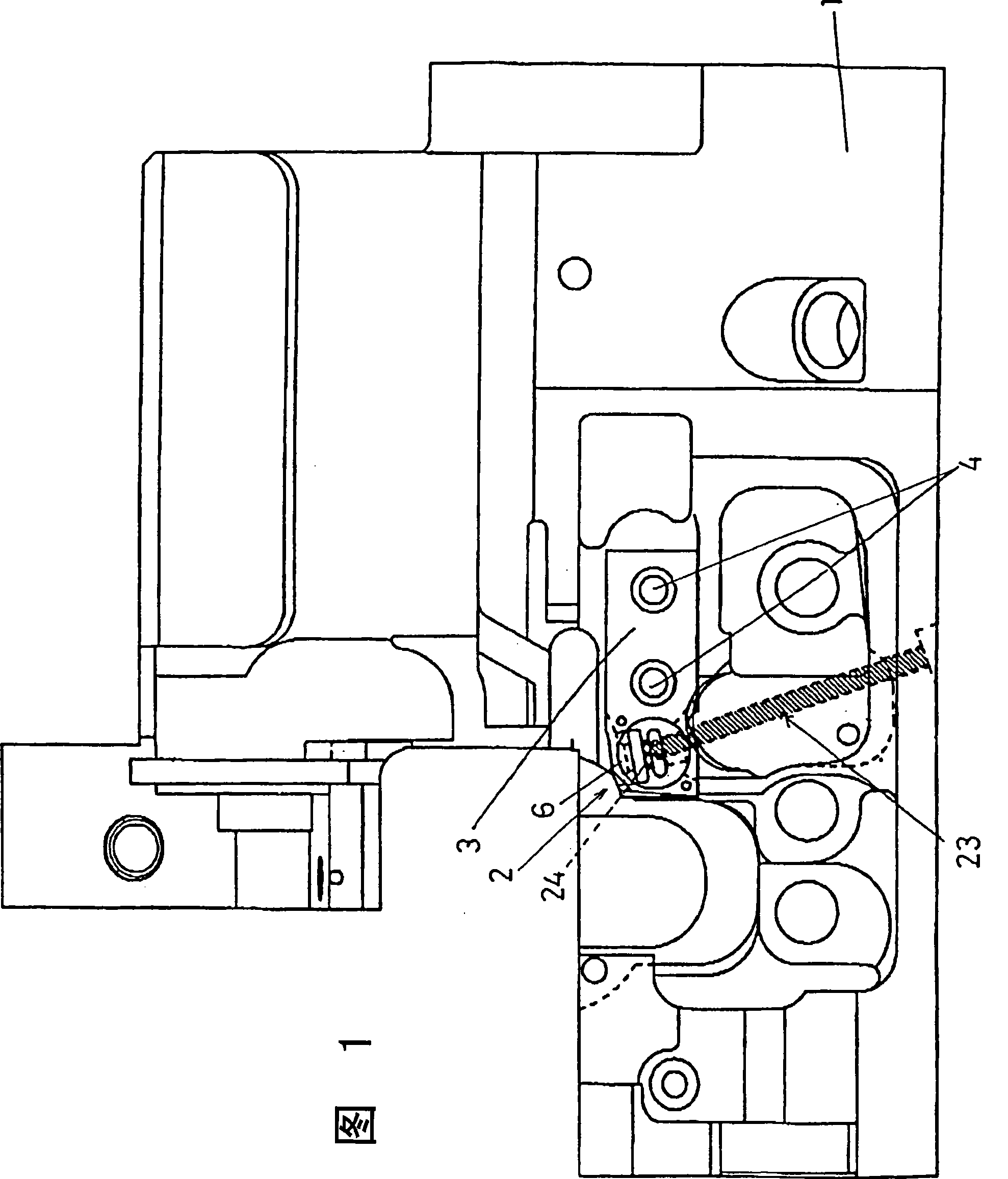

Hinge for portable terminal

InactiveUS7150074B2Avoid lubricationWing accessoriesDetails for portable computersClose relativesComputer terminal

A hinge for portable terminal that not only has both functions of allowing a second casing to open / close relative to a first casing and allowing the second casing to turn relative to the first casing in a direction right angle to the opening / closing direction, but also is capable of preventing external leakage of a lubricating oil and is formed to be as compact as possible. The hinge includes: a rotary hinge module; and an opening / closing hinge module wherein: the rotary hinge module has a fixed member attached to the first casing and a cylindrical rotary member attached to the fixed member with a turn thereof being controlled via a first cam mechanism; the opening / closing hinge module is provided in the cylindrical rotary member and has an opening / closing member which is rotatably mounted with a rotation thereof being controlled to be in a right angle direction to a direction of the turn of the rotary hinge module via a second cam mechanism and to which an end portion of the second casing is coupled; and the rotary hinge module operates from an instant when the opening / closing hinge module reaches a predetermined angle.

Owner:KATOH ELECTRIC MACHINERY

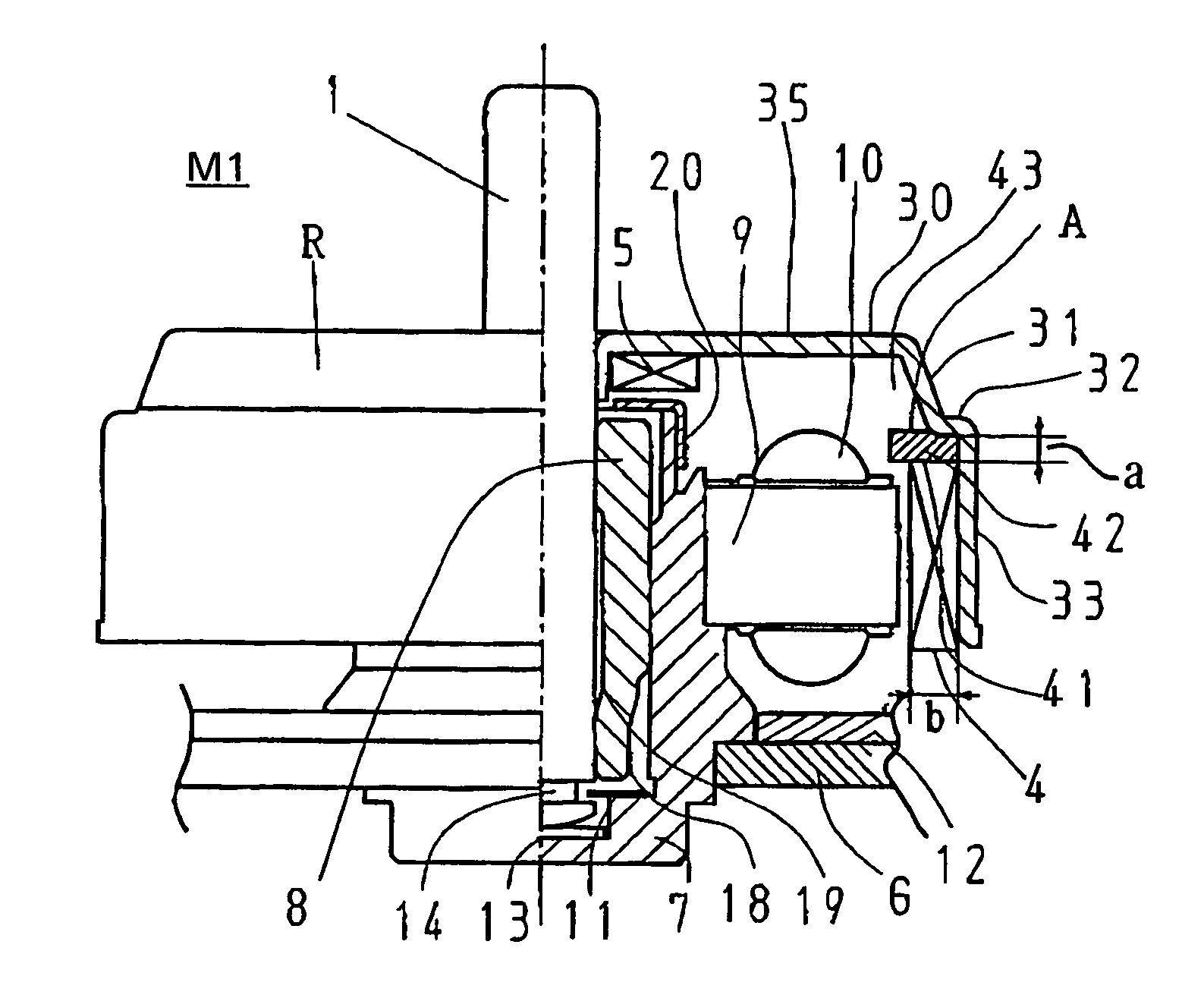

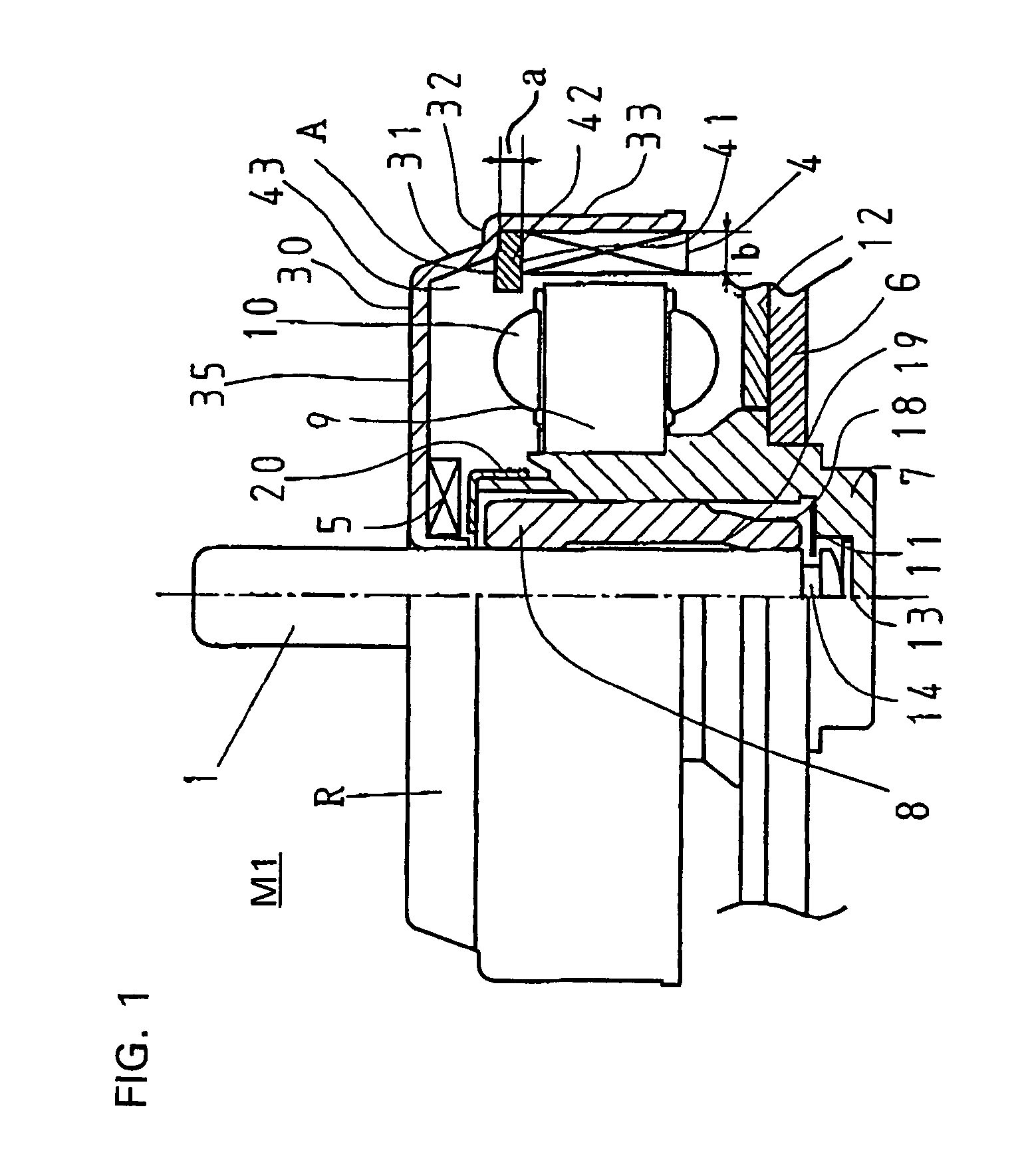

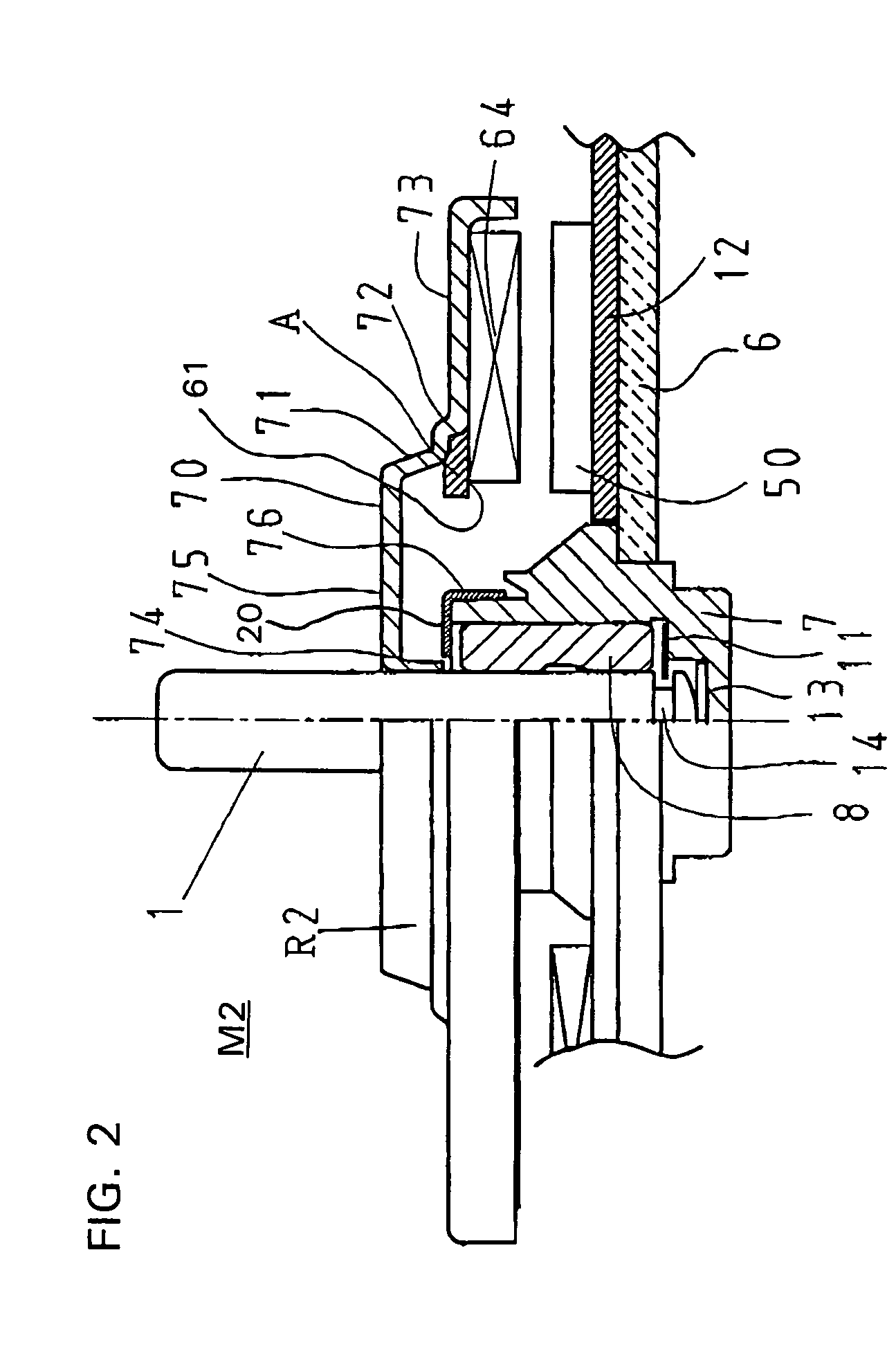

Brushless motor

InactiveUS7002272B2Simplified suppressionSimple and inexpensive productionMagnetic circuit rotating partsLubrication elementsBrushless motorsMagnet

A lubricating oil scattering prevention arrangement provided near a bearing whereby the outward scattering of lubricating oil that leaked from between a stator and rotor due to tilting, impact or the like is prevented. A plate-shaped rotor case 30 is provided with a descending portion 31, a step portion 32 and an outer peripheral portion 33. A magnet 4 is provided on the inner side of the outer peripheral portion 33 and a lubricating oil absorption member is provided between the magnet 4 and the step portion 32. Because an outer peripheral portion of the lubricating oil absorption member is compressed by the magnet 4 upper surface portion and the step portion 32 and thus attached, the lubricating oil absorption member absorbs lubricating oil leaked from the bearing part and the compressed portion prevents the lubricating oil from leaking outwardly.

Owner:TOKYO PARTS IND CO LTD

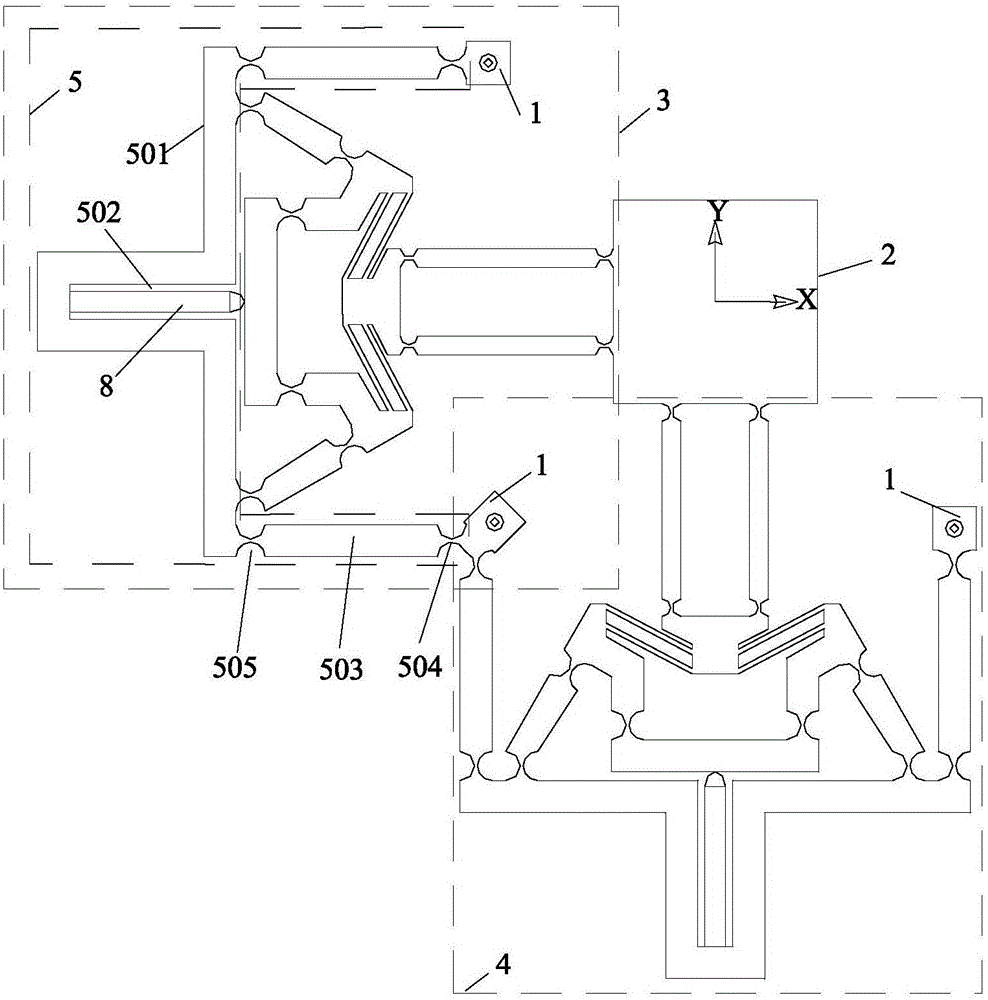

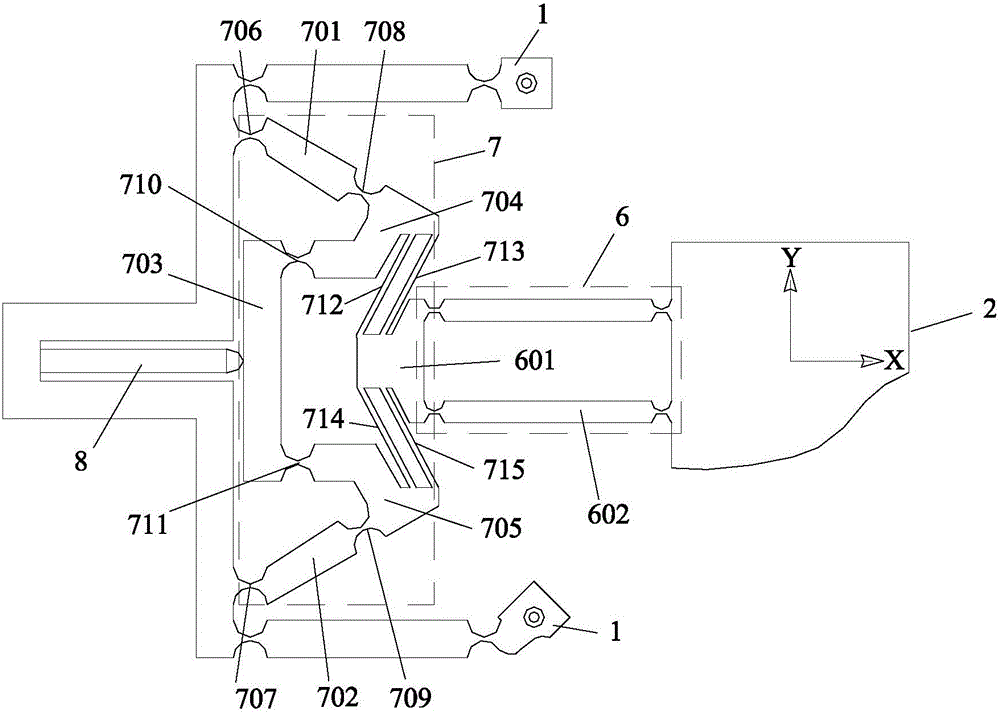

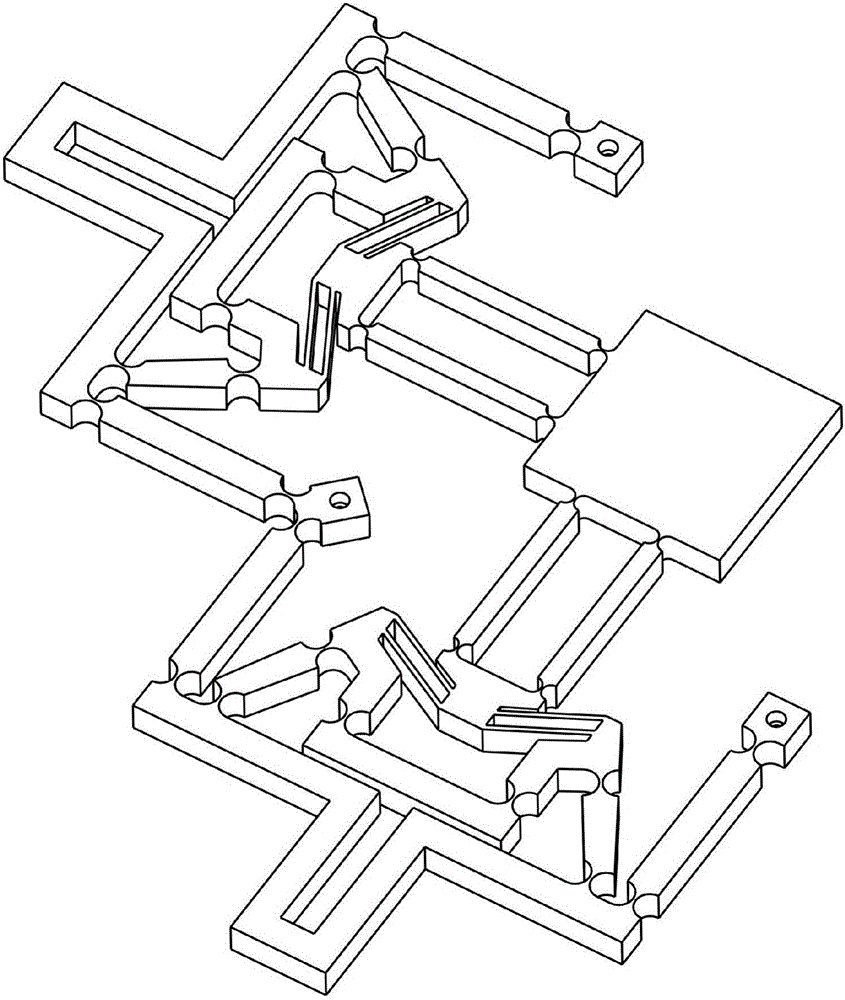

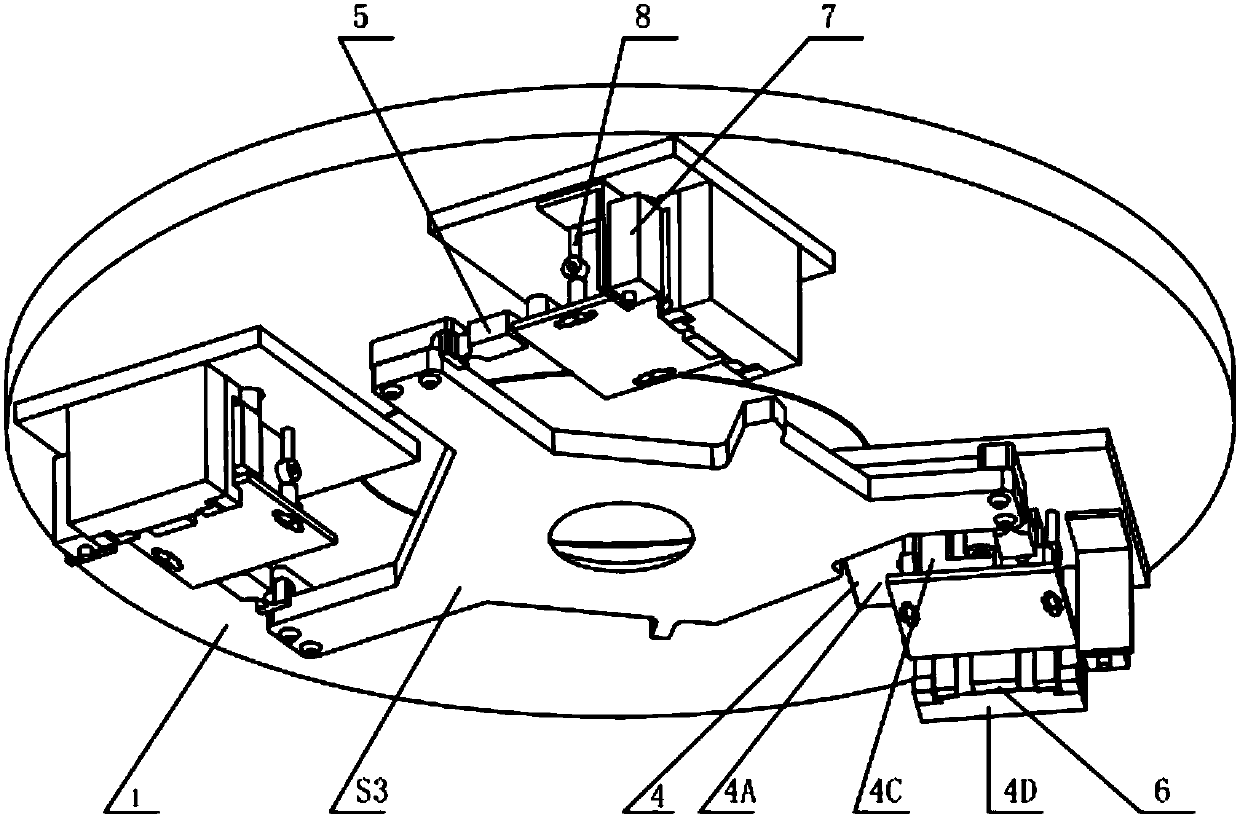

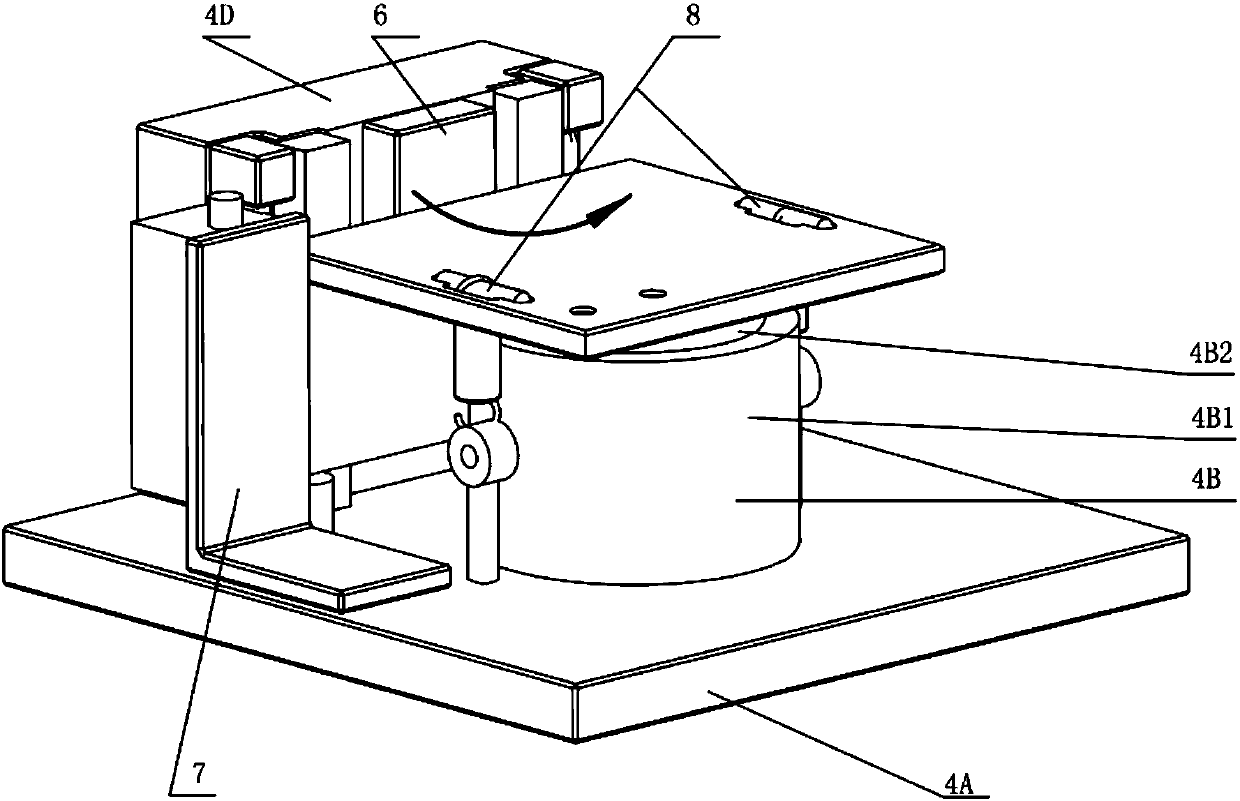

Two-degree-of-freedom flexible parallel mechanism for motion decoupling

ActiveCN105904443AIncrease stiffnessHigh precisionProgramme-controlled manipulatorEngineeringMechanical engineering

The invention discloses a two-degree-of-freedom flexible parallel mechanism for motion decoupling. The two-degree-of-freedom flexible parallel mechanism comprises a base, a movable platform, an X-axis branch and a Y-axis branch. The base and the movable platform are connected through the X-axis branch and the Y-axis branch. The X-axis branch and the Y-axis branch are distributed in an orthogonal mode and are of the same structure. The X-axis branch and the Y-axis branch each comprise a first parallel four-rod guiding mechanism, a second parallel four-rod guiding mechanism and a displacement amplification mechanism; the first parallel four-rod guiding mechanism is connected with the base; the second parallel four-rod guiding mechanism is connected with the movable platform; and the displacement amplification mechanism is connected between the first parallel four-rod guiding mechanism and the second parallel four-rod guiding mechanism. According to the two-degree-of-freedom flexible parallel mechanism, the parallel structure is adopted, and the structure is compact; each branch comprises two parallel four-rod guiding mechanisms and one displacement amplification mechanism, the input displacement of a piezoelectric ceramic driver can be amplified, and a large operating stroke is achieved; and meanwhile coupling between X-axis movement and Y-axis movement is avoided.

Owner:SOUTH CHINA UNIV OF TECH

Double flexible pair-based three-degree-of-freedom precision adjustment parallel mechanism

ActiveCN107942622ANo pollution in the processNo pollutionPhotomechanical exposure apparatusMicrolithography exposure apparatusLinear motionModular design

The invention relates to a double flexible pair-based three-degree-of-freedom precision adjustment parallel mechanism, comprising three groups of motion branch chains which are connected in parallel and have the same structure, wherein the three groups of motion branch chains are in uneven circumference distribution at three extending ends of an immersion unit by taking a center hole of the immersion unit as a center; each group of motion branch chain comprises a linear motion assembly, a double flexible pair connecting rod assembly, a mechanical anti-collision assembly, a Z-direction displacement measuring assembly and a gravity compensation assembly. The double flexible pair-based three-degree-of-freedom precision adjustment parallel mechanism is used for realizing installation, fixationand space position adjustment of the immersion unit of an immersion type photoetching machine and realizing micron-level positioning of the immersion unit; double flexible pairs are adopted, the structure is simple and compact, and the advantages of no friction and no need of lubrication are achieved; the wholly mechanism adopts a parallel mechanism, the rigidity is high, the response is quick, the adjustment range is large, modular design and assembly are adopted, and the mechanism can be used for three-degree-of-freedom precision adjustment in other occasions except the immersion type photoetching machine.

Owner:ZHEJIANG CHEER TECH CO LTD

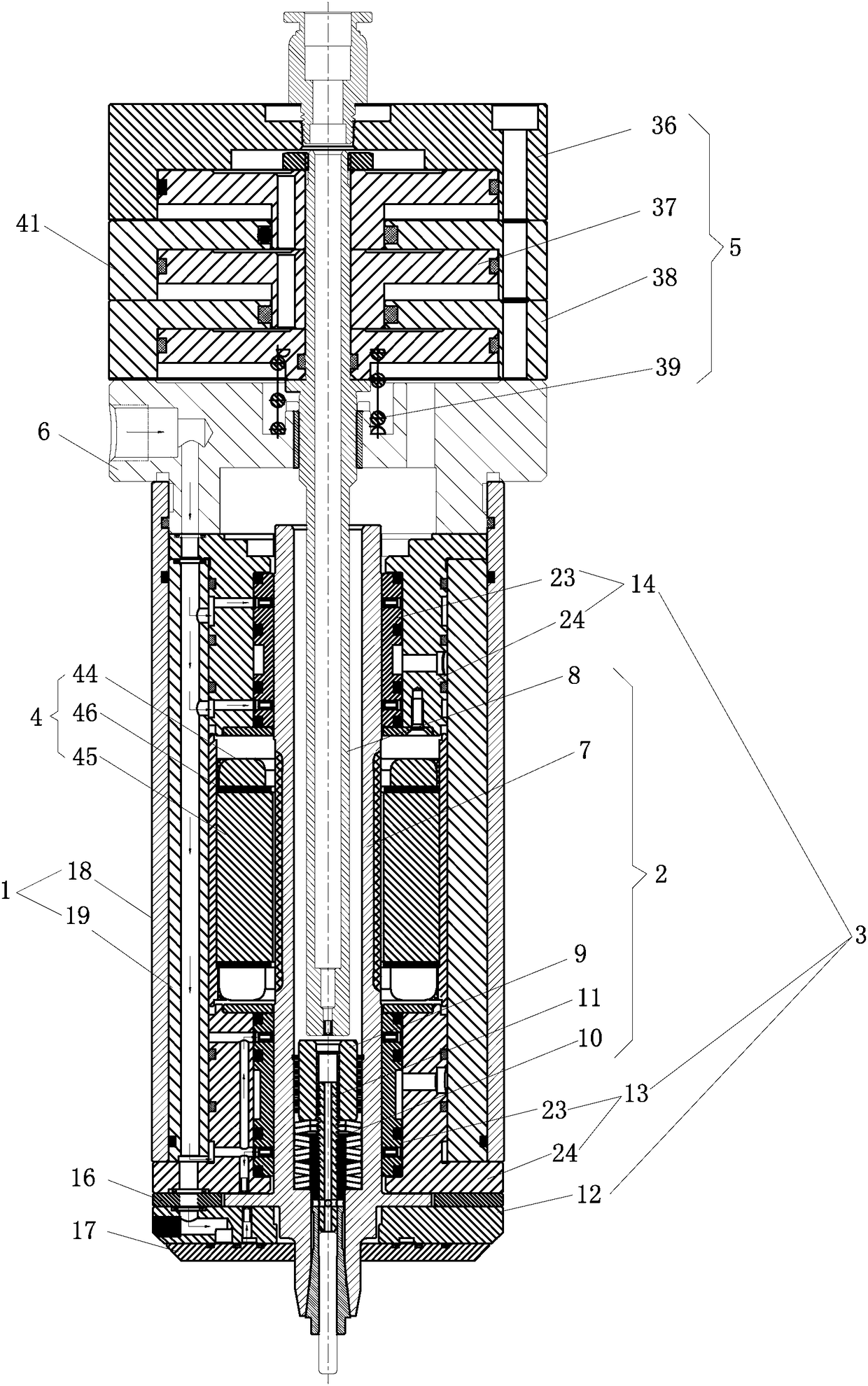

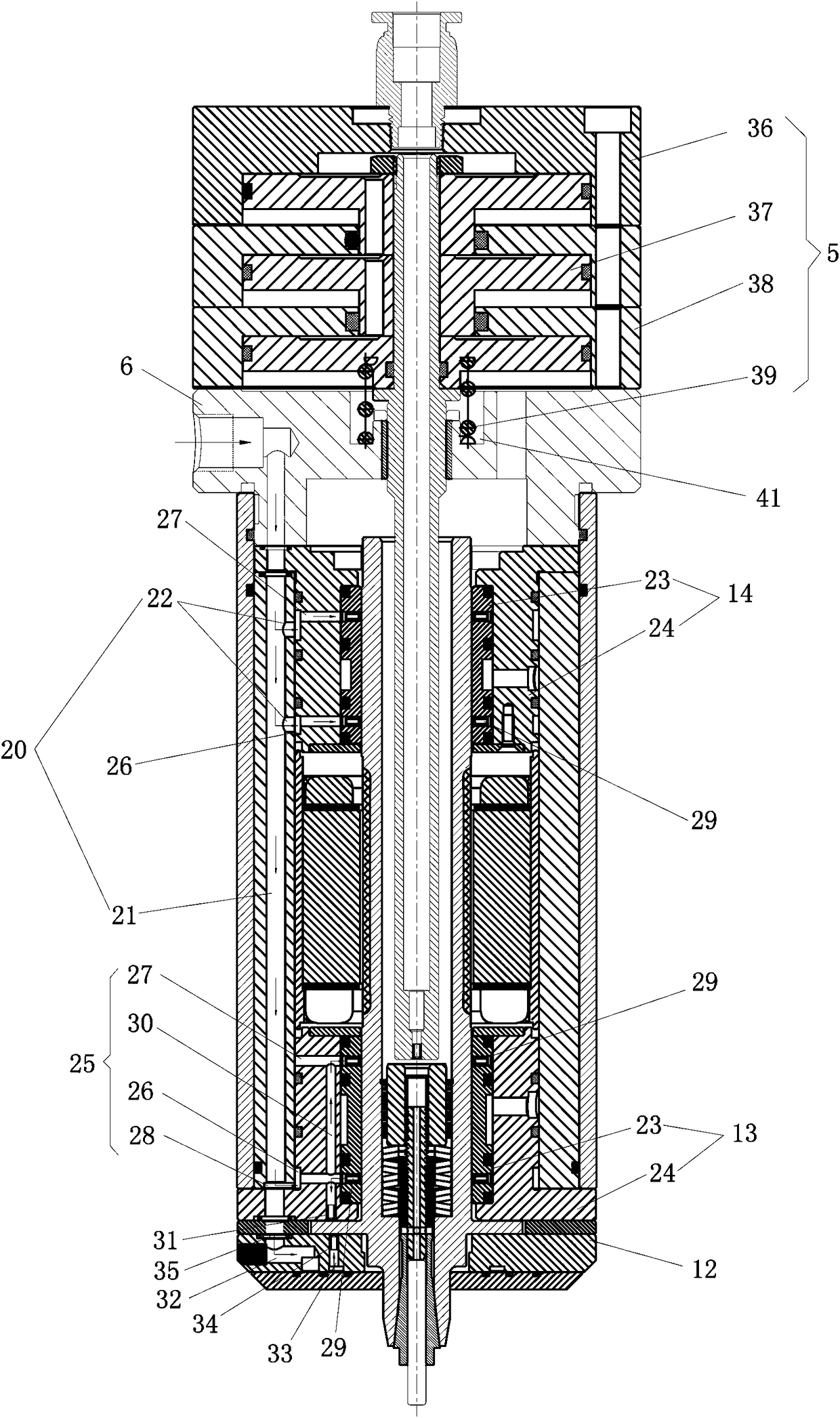

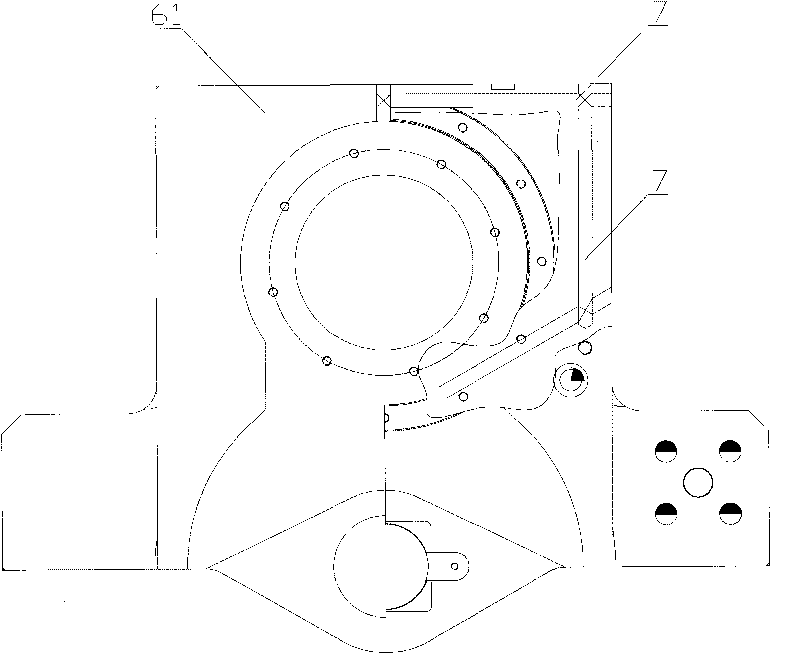

High-precision and low-energy-consumption high-speed air floating type electric spindle

PendingCN108817421AImprove machining accuracyHigh precisionLarge fixed membersGrip forceElectric machinery

The invention relates to a high-precision and low-energy-consumption high-speed air floating type electric spindle. The high-precision and low-energy-consumption high-speed air floating type electricspindle comprises a body mechanism, a rotor mechanism, a bearing mechanism, a stator mechanism, an air cylinder mechanism and a rear base mechanism. The rotor mechanism comprises a shaft core, an ejector rod, a pull rod, a spring assembly and a chuck. The chuck is connected with the pull rod through a screw. The bearing mechanism comprises a thrust bearing, a front bearing assembly and a rear bearing assembly. The shaft core is provided with an extension part connected with the thrust bearing. A thrust clearance ring is arranged between the thrust bearing and the front bearing assembly. The thrust bearing is provided with a dustproof mechanism. The high-precision and low-energy-consumption high-speed air floating type electric spindle has the beneficial effects that a composite bearing inner sleeve is embedded in an air hydrostatic bearing of the air floating spindle, abrasion resistance is good, self-lubricating and self-centering can be conducted, and friction with the shaft core iseffectively avoided; an efficient circulation water cooling channel is adopted, and higher CPK precision and rotation speed are achieved; a reasonable damping plug is embedded in the bearing, air consumption is greatly reduced, and cost is saved; and the excellent motor torque and tool gripping force are achieved, and high adaptability and practicability are achieved.

Owner:岳阳市显隆电机有限公司

Anti-oil leakage device of top bend needle mechanism

InactiveCN101381933ALong-term and smooth maintenance of lifting motion effectSmoothly maintain the effect of lifting movementLubrication/cooling devicesLubrication elementsFree rotationEngineering

The invention relates to an oil leak preventing device for an upwards curved needle mechanism. A columned upwards curved needle guiding body capable of being freely and rotationally inserted and kept on a circular hole formed on an upwards curved needle guiding component is formed with an upper communicating slotted hole and a lower communicating slotted hole orthogonal with a communicating hole for sliding and lifting of an upwards curved needle table, an oil seal ring elastically and glidingly contacting the outer peripheral face of the upwards curved needle table and provided with a labial part for scraping lubricating oil is inserted in the upper communicating slotted hole, and an oil suction ring capable of sucking and keeping the scraped residual lubricating oil is inserted in the lower communicating slotted hole, therefore, the oil leak preventing device can reliably and favorably exert scraping function of the residual lubricating oil, can reliably prevent the scraped residual lubricating oil from being attached to the outer peripheral face of the upwards curved needle table again to disperse upwards, and can stably maintain the oil link preventing function for a long term.

Owner:YAMATO SEWING MASCH MFG CO LTD

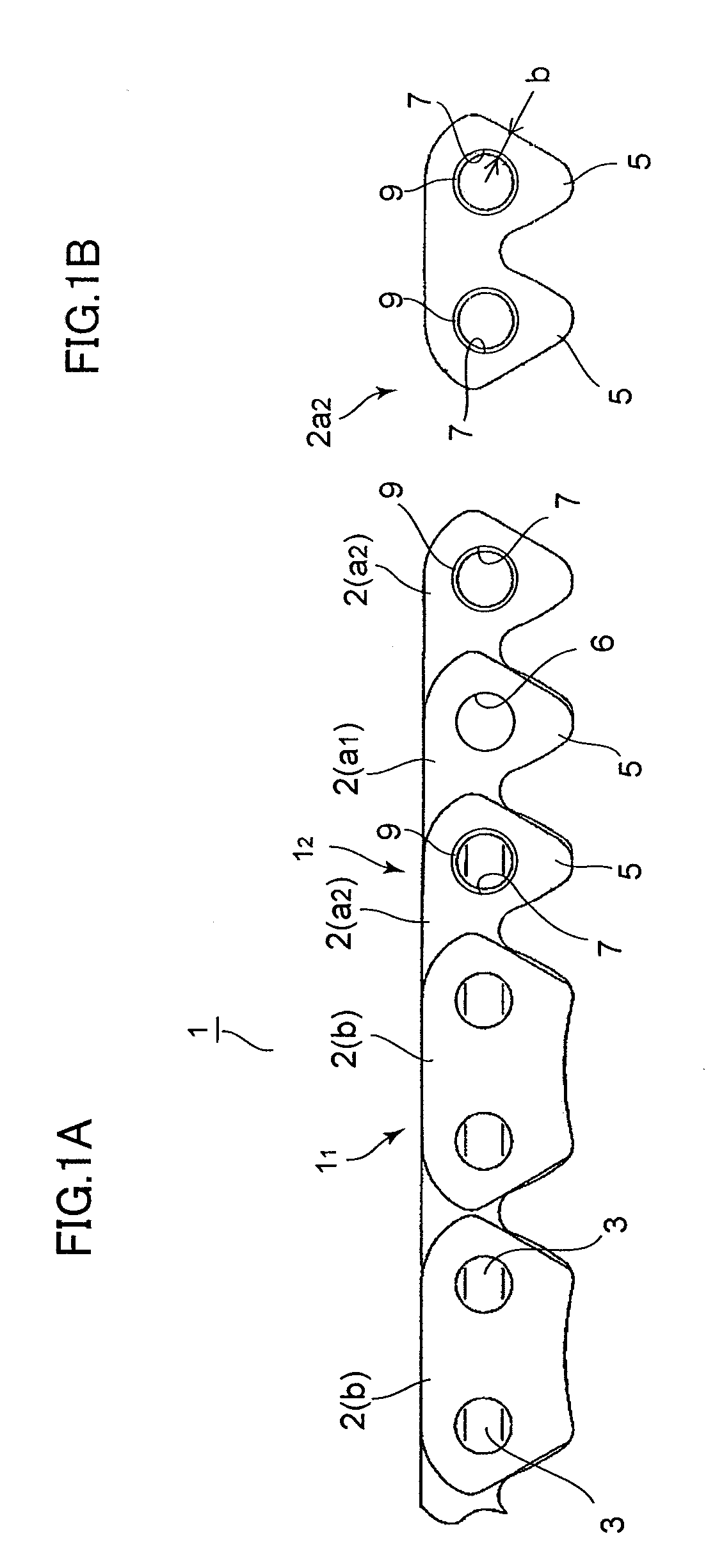

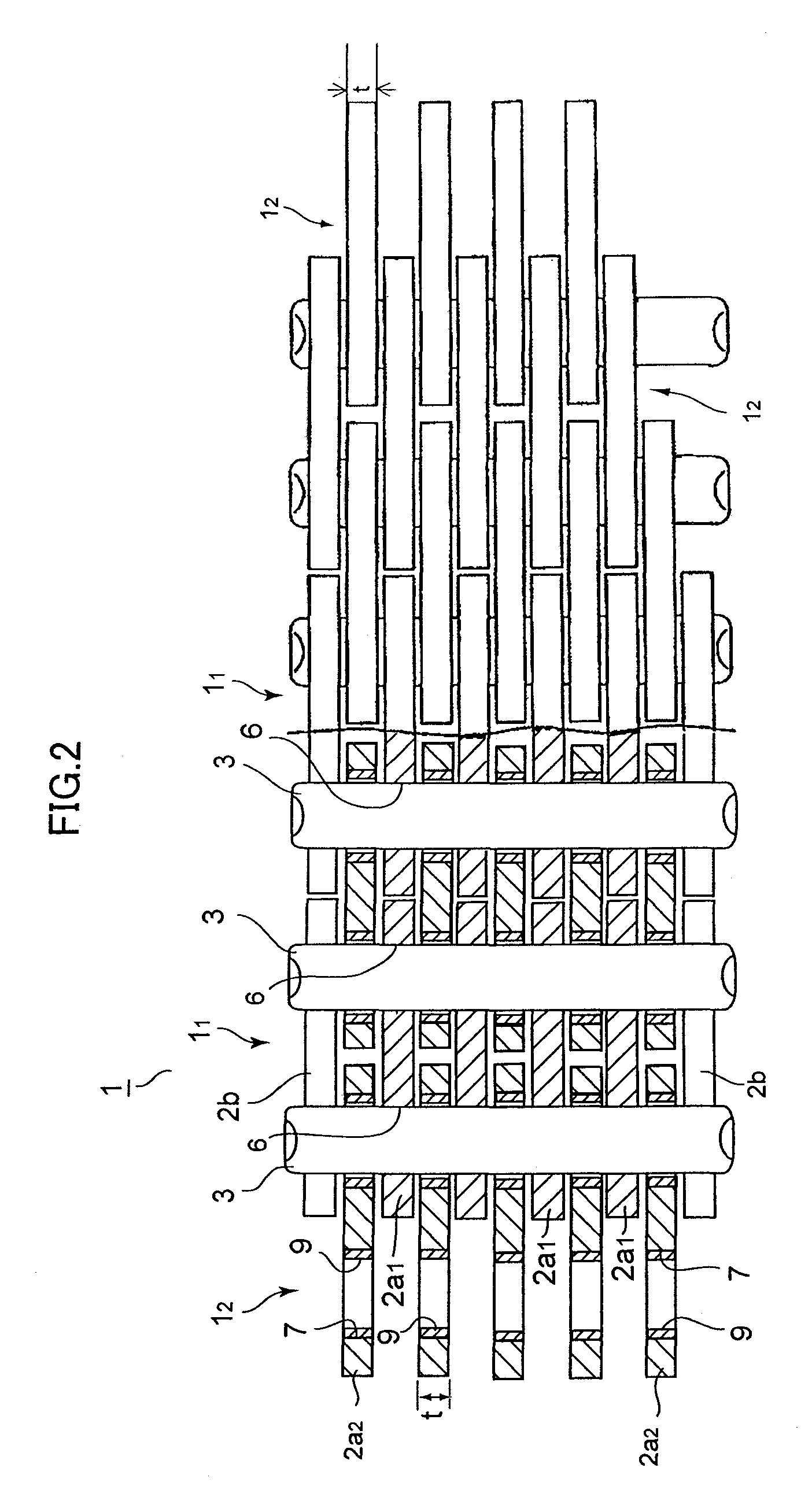

Link chain

A bush is pressed into a link plate in a turning link rank that turns relatively with a pin. The bush is molded into a seamless cylindrical shape by cold-forging and is coated with a metal carbide layer formed by cementation of chrome, vanadium and other metals and having Vickers hardness of 1300 Hv or more similarly to the pin. Afterwards, the bush is treated by a quenching, tempering or isothermal transformation process. Thereby, wear resistance of the pins and the link plates of a silent (link) chain is improved, productivity is improved and associated costs are reduced.

Owner:DAIDO KOGYO CO LTD

Composition for cleaning residue in bore of artillery

InactiveCN1483796APrevent rustAvoid lubricationOrganic non-surface-active detergent compositionsAdditivesCleansers skinOrganic solvent

The present invention relates to a kind of abrasive cleanser composition for removing gunpower residue from bore of gun and other scale deposit. The lubricating base oil of said composition organic solvent, viscosity index improving agent and oil-soluble anti-corrsive agent, in which their contents are respectively 5-30%, 3-10% and 5-20%. Besides, said composition also has the functions of preventing rust and lubricating bore of the gun.

Owner:ORDNANCE TECH RES INST OF THE GENERAL ARMAMENT DEPT PLA

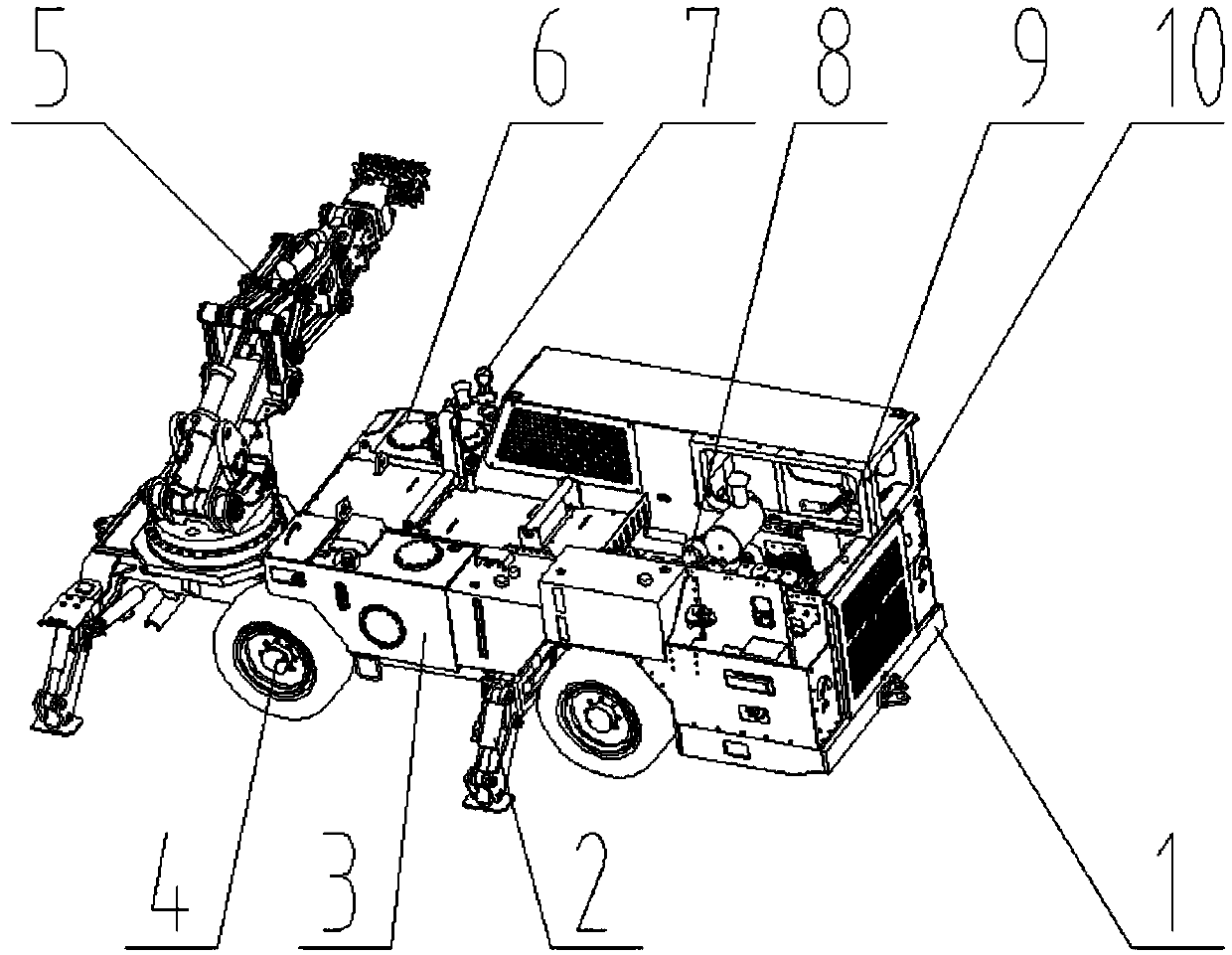

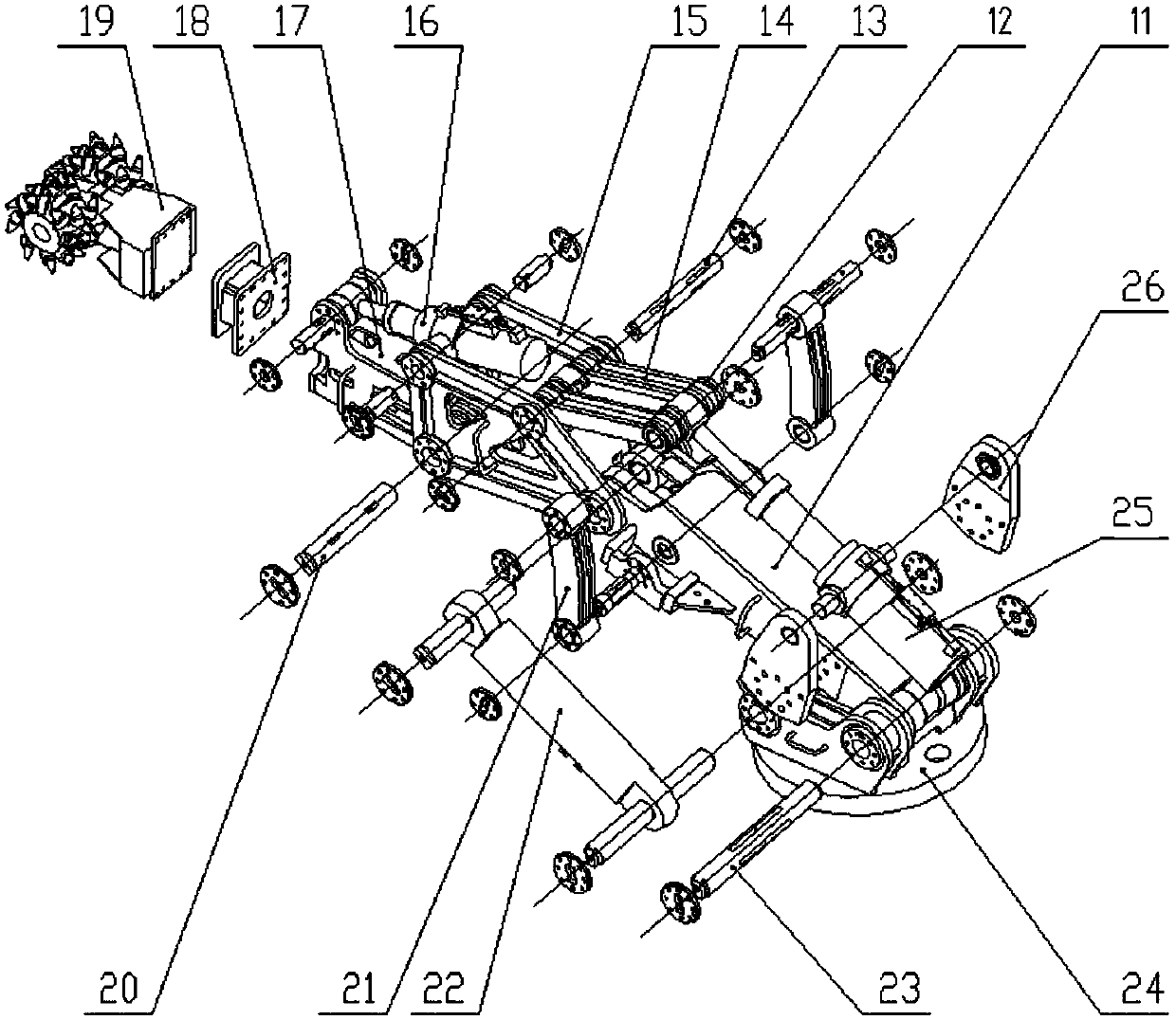

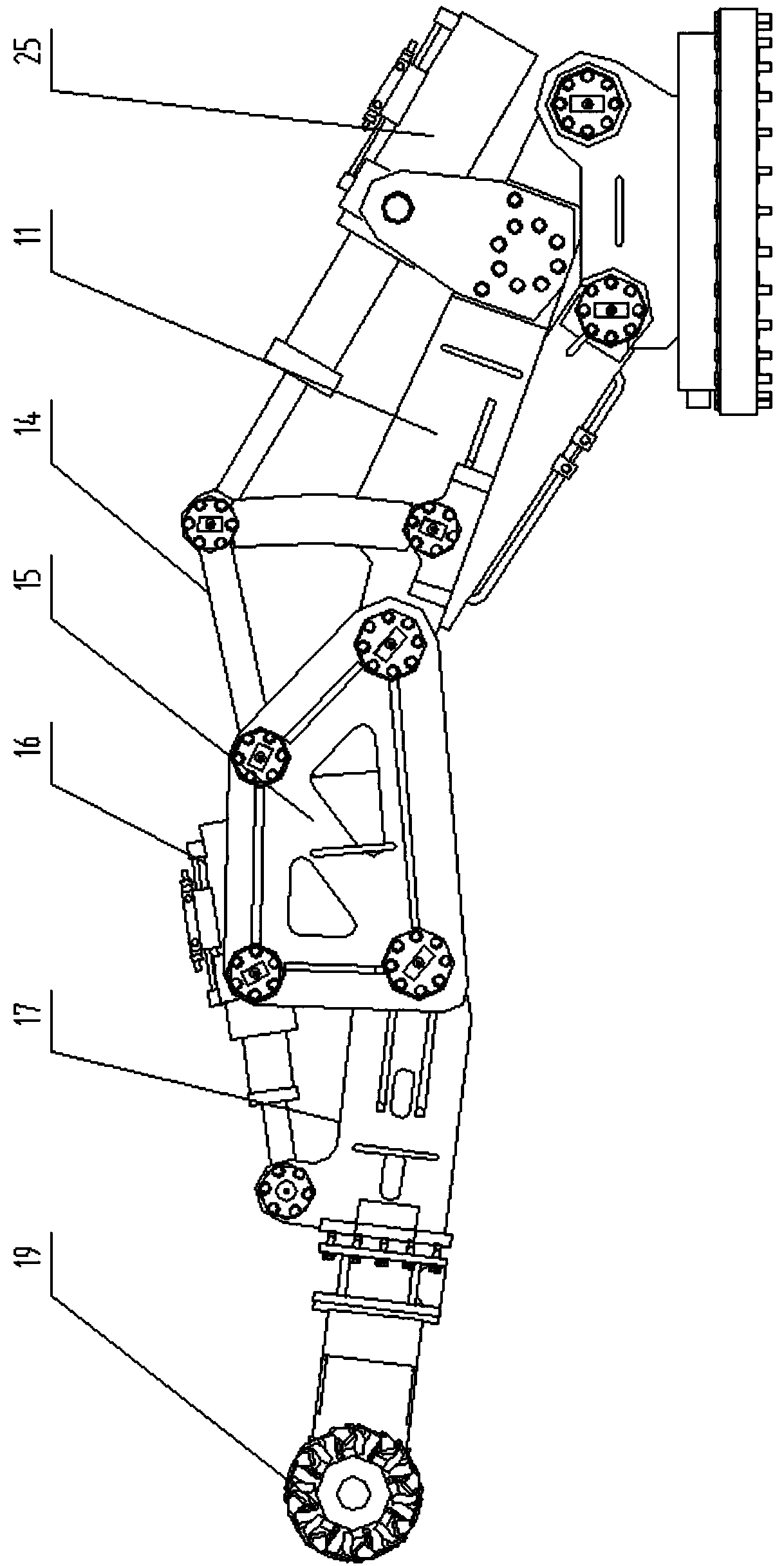

Coal mine underground grooving machine

PendingCN107559003ASolve the problem of difficult slotting operationsEasy to cutDriving meansPropulsionVehicle frameMining engineering

The invention discloses a coal mine underground grooving machine, which comprises a carriage, wherein the carriage is provided with a traveling mechanism, a hydraulic oil tank, a cab assembly, a hydraulic system, an electrical system, a pneumatic system, a dust removal system, a power device and a grooving device; the grooving device is arranged on the rear end of the carriage. According to the coal mine underground grooving machine disclosed by the invention, the problem that an existing coal mine underground tunnel is difficult in grooving operation is thoroughly solved, mechanical operationis realized, a driving working condition and a grooving operation working condition can be simultaneously met, the coal mine underground grooving machine has the characteristics of high driving speed, high operation efficiency, convenience, flexibility, convenience in operation, safety and reliability and the like, the efficiency of the type of operation is improved, an underground construction mechanization rate is improved, and labor cost is lowered.

Owner:LIANYUNGANG TIANMING EQUIP

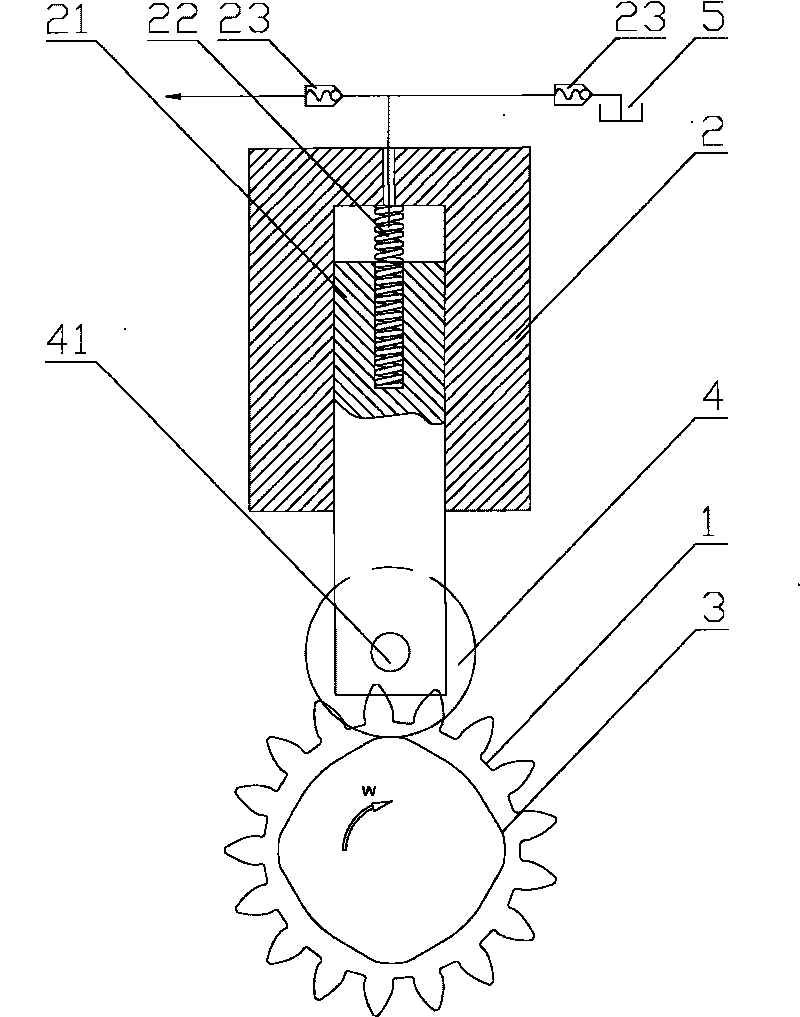

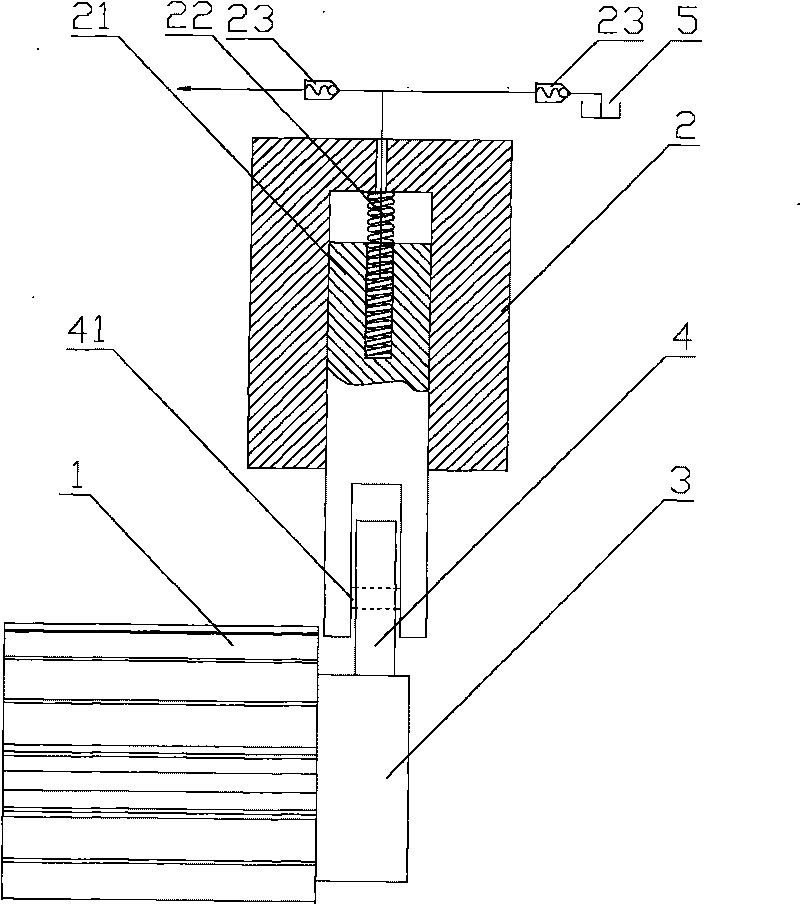

Engineering machinery and lubricating device thereof

InactiveCN101705992AReduce design difficultySimple structureGear lubrication/coolingCutting machinesEngineeringLubrication

The invention discloses a lubricating device for lubricating a gear mechanism and an engineering machinery provided with the same. The lubricating device comprises a lubricant pump (2) driven by the gear mechanism (1), and the outlet of the lubricant pump (2) corresponds to the lubricating position of the gear mechanism (1) such that lubricant in the lubricant pump (2) can lubricate the gear mechanism (1). The gear mechanism (1) can automatically lubricate in working so as to efficiently avoid the condition of no lubricating while the gear mechanism (1) works; in addition, the lubricating device has smaller dependency on operators and can be less influenced by operator responsibility or personal factor, thus the reliability of the lubrication of the gear mechanism (1) can be remarkably improved, the service life of the gear mechanism (1) is prolonged, and the economical efficiency of the construction machinery provided with the gear mechanism (1) is improved.

Owner:SANY HEAVY EQUIP

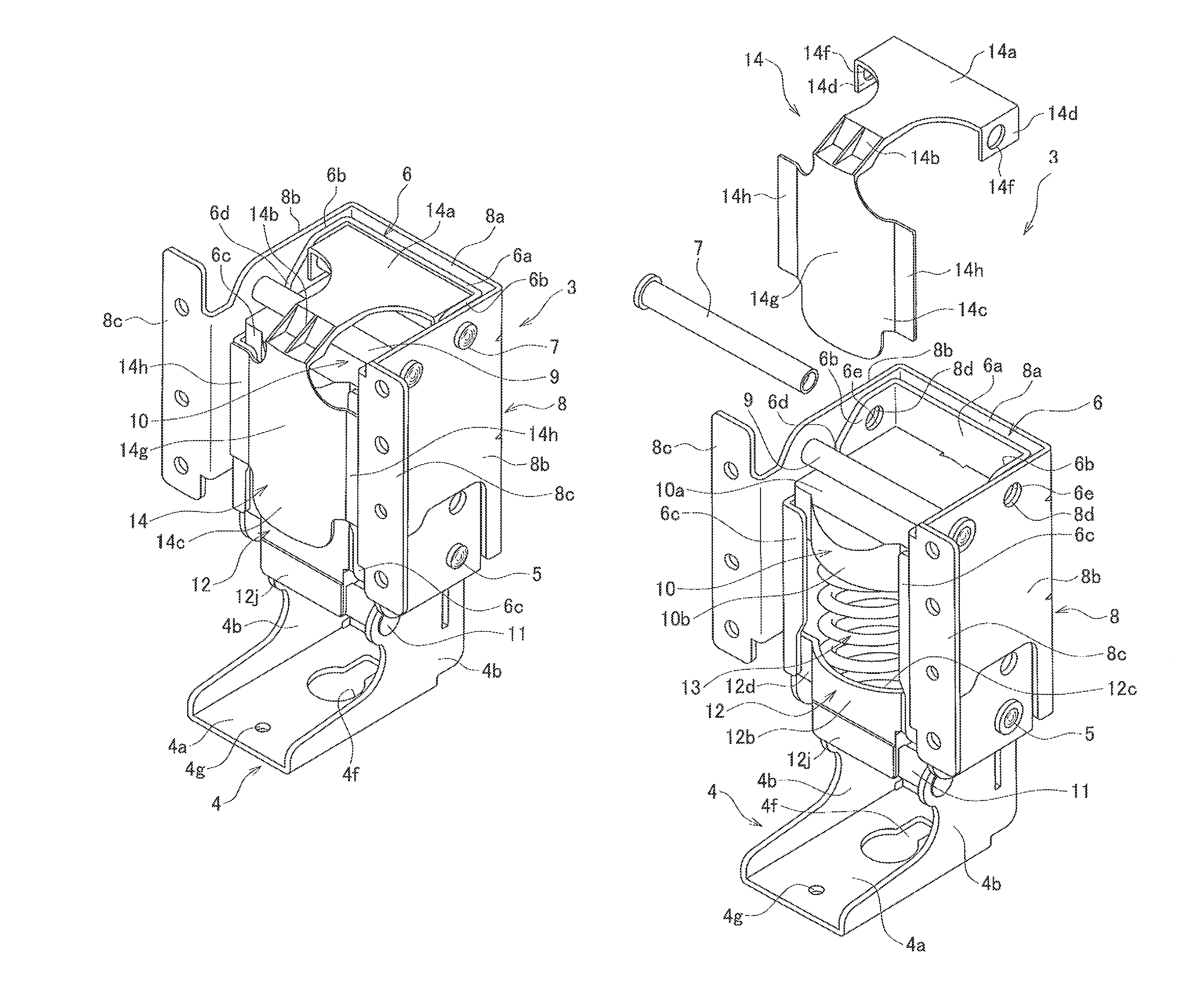

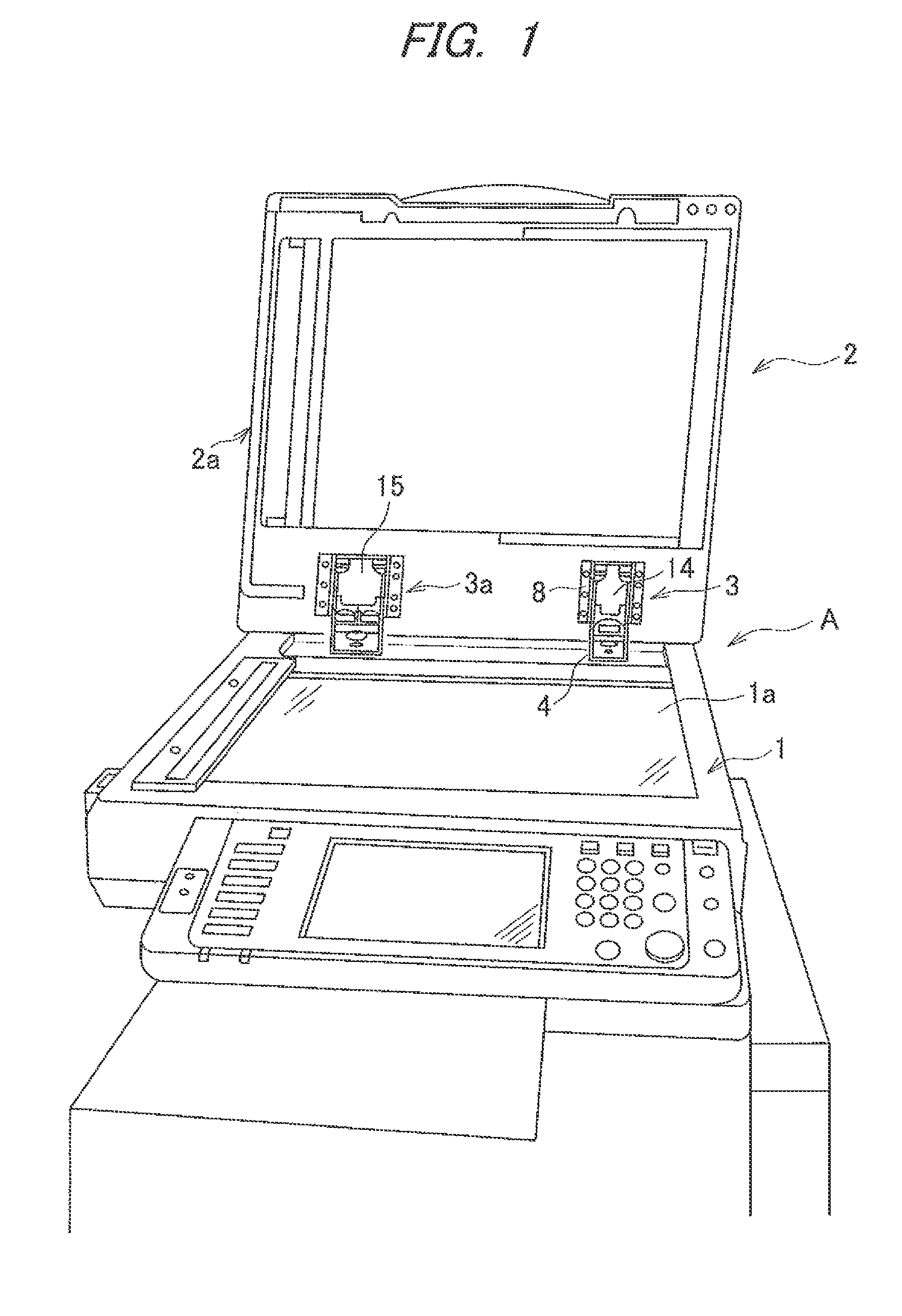

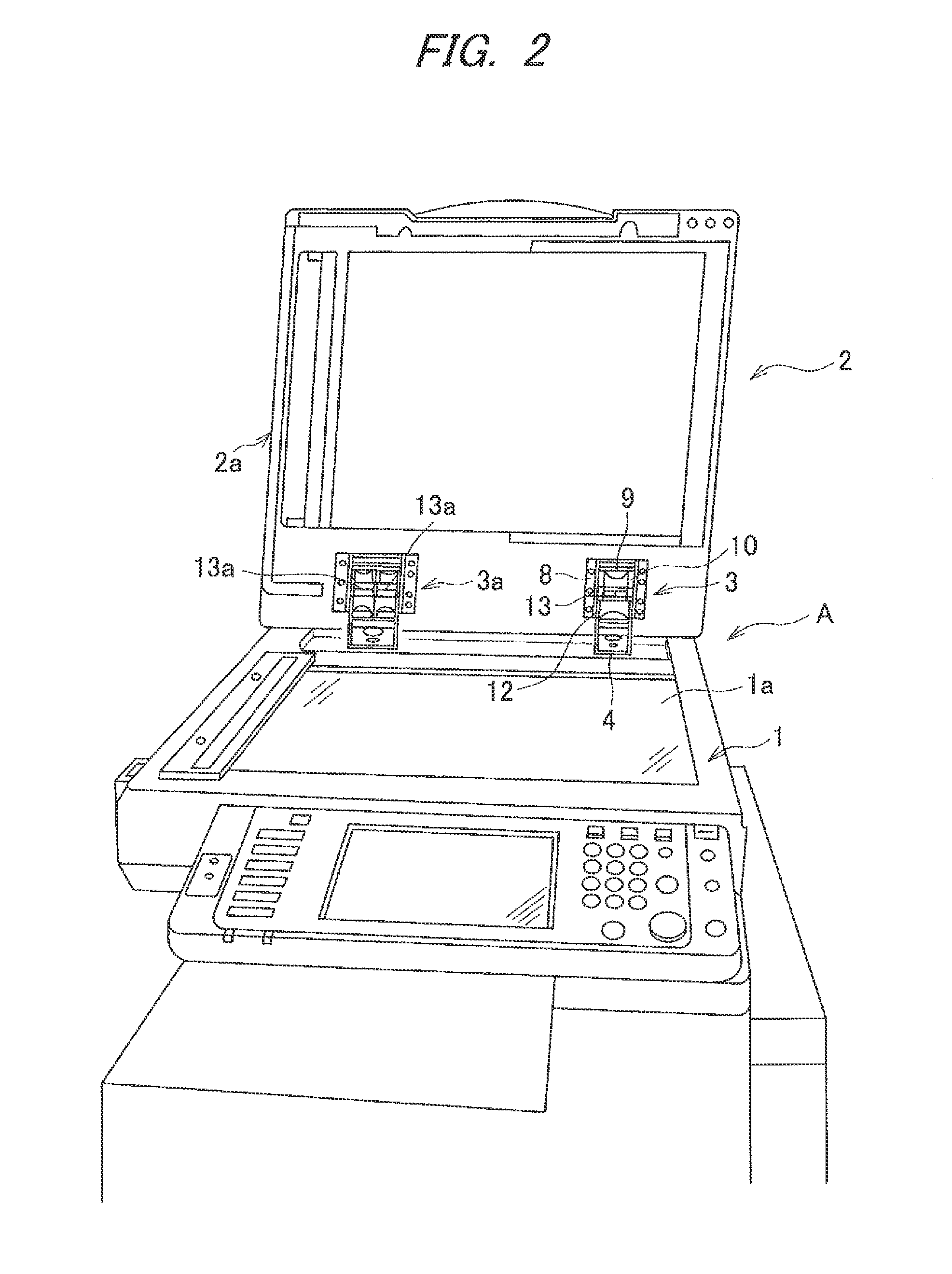

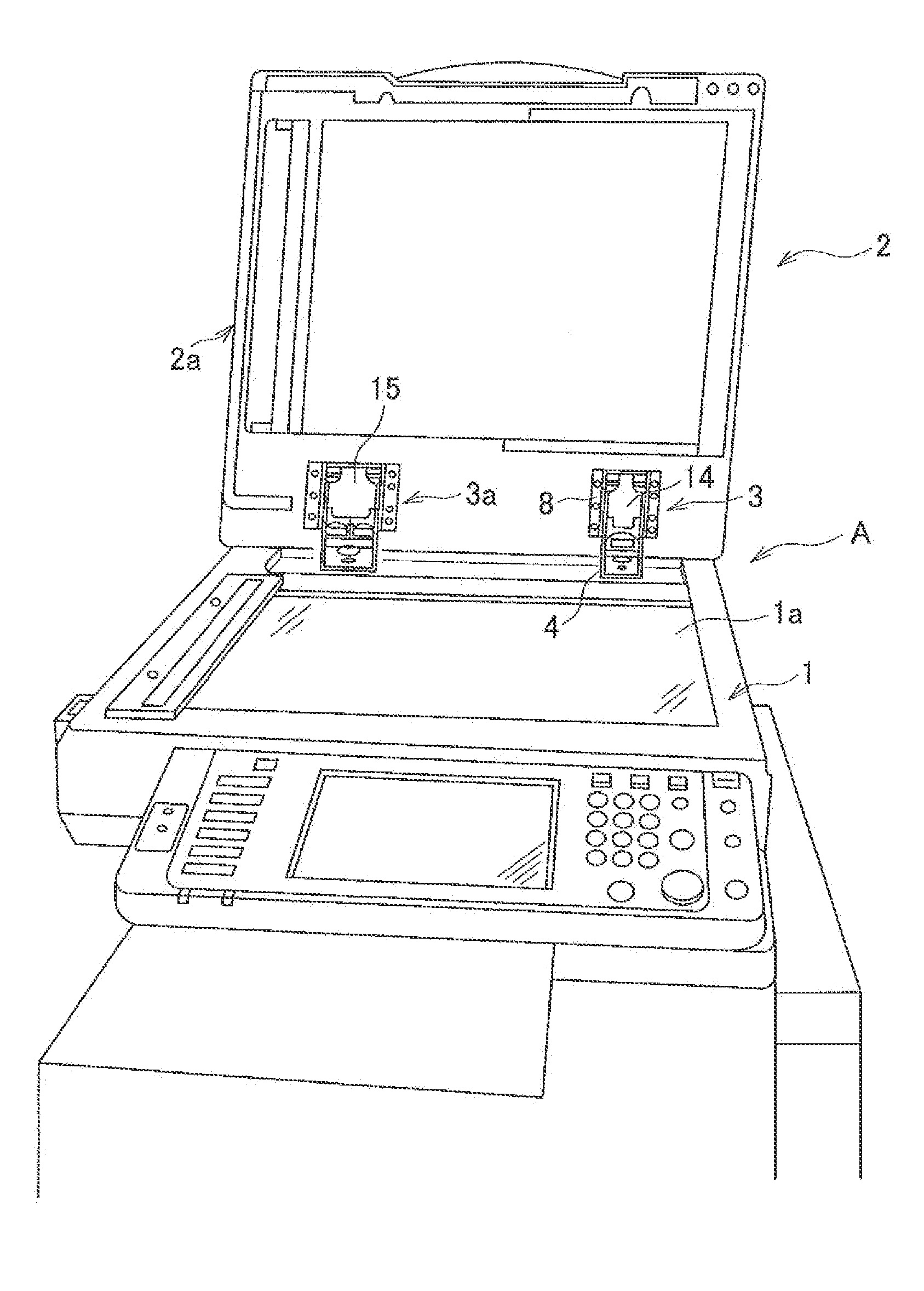

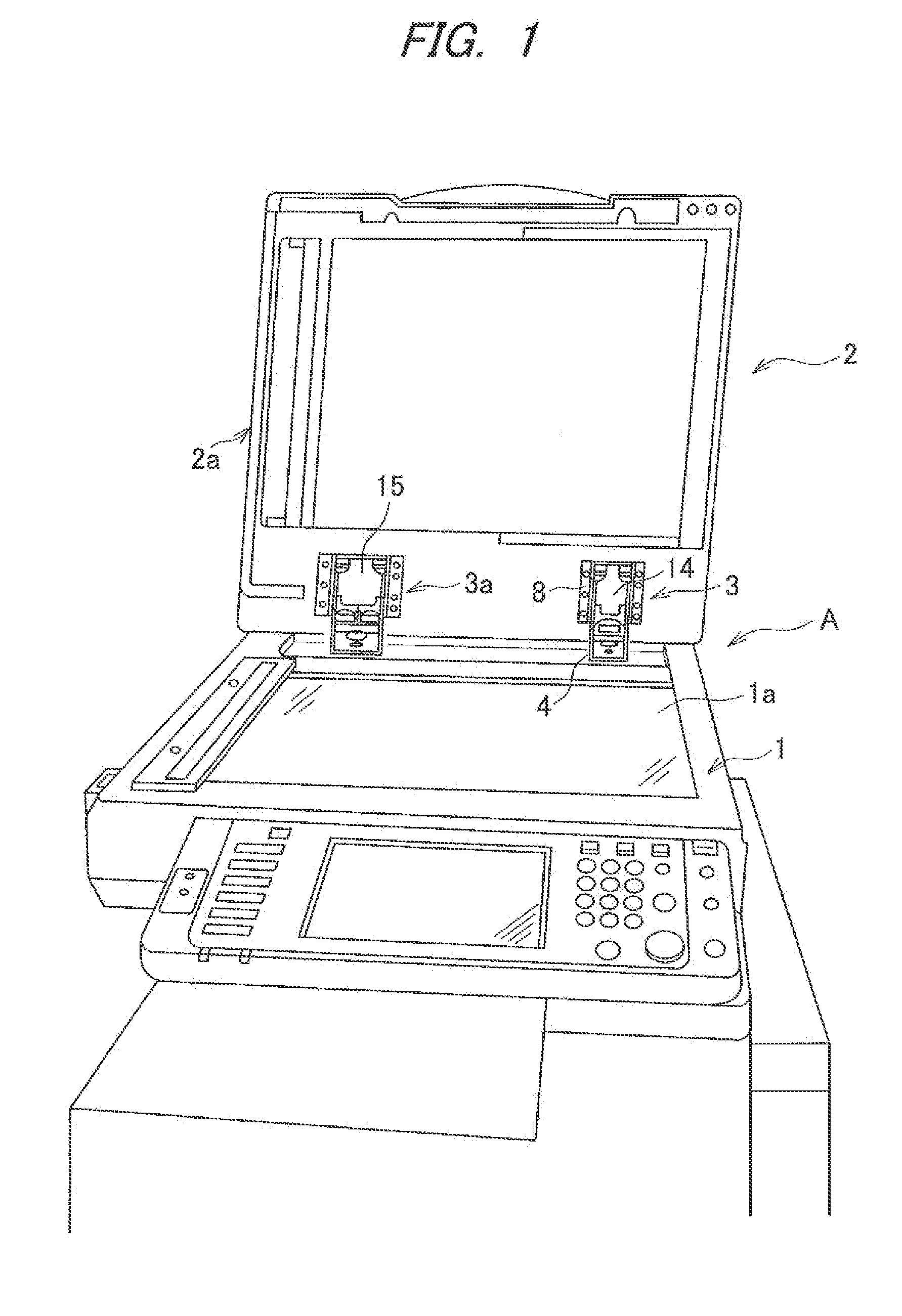

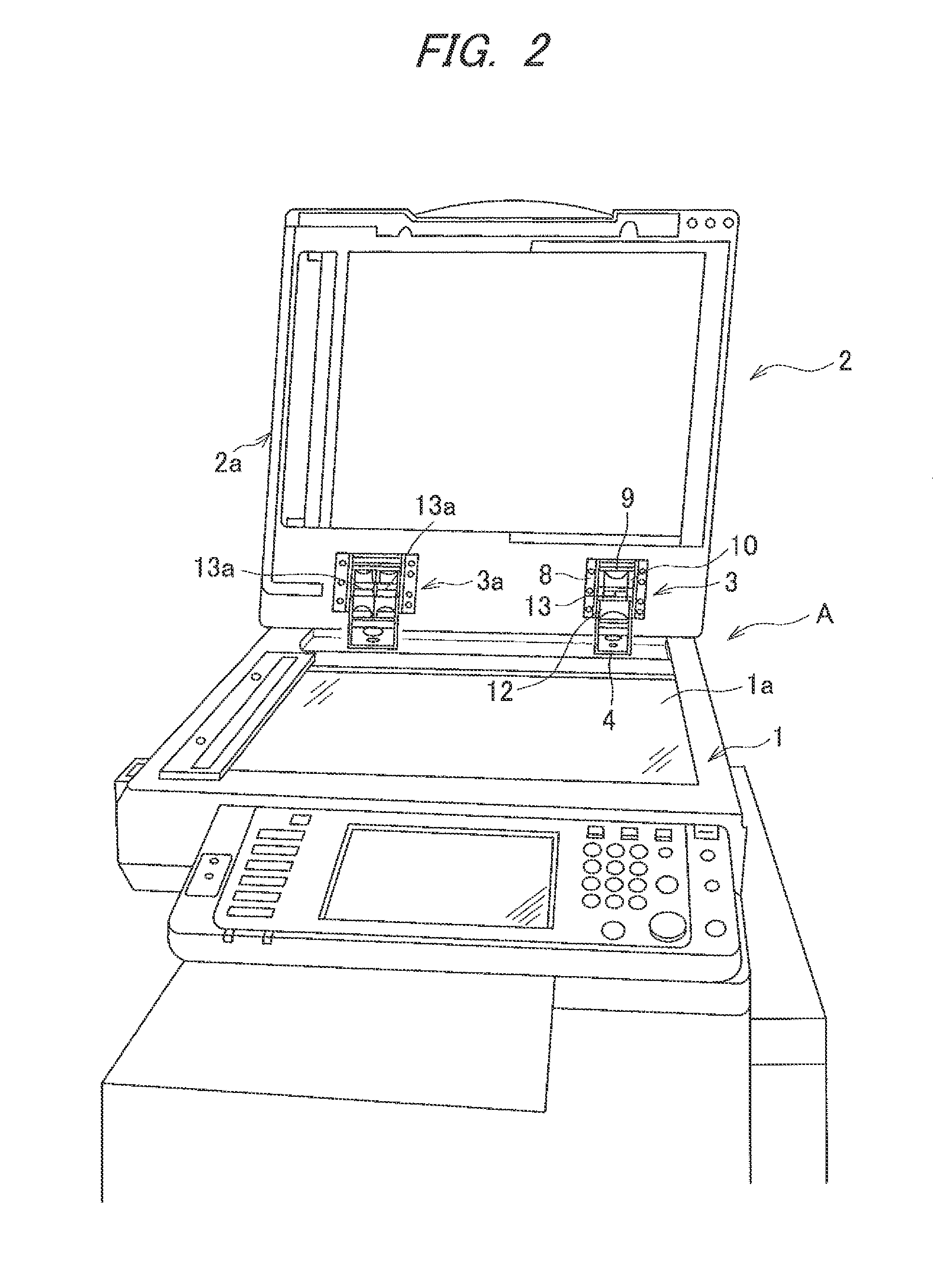

Original cover closer and office equipment having the same

To provide an original cover closer which prevents inner components from exposure to the outside, when the original cover is opened, and from smears of grease on the end of the original lying on the contact glass, the original cover closer comprises the attaching member, the supporting member assembled by rotatably coupling its own both side plates to the both side plates of the attaching member, the lifting member assembled by rotatably coupling its own both side plates to the both side plates of the supporting member, the pressure bearing member provided between the both side plates of the attaching member, a second slider in contact with the pressure bearing member, and slidably housed between the both side plates of the supporting member; an actuating member attached to the side on which the both side plates of the attaching member rotate via said second hinge pin; a first slider in contact with the actuating member, held by the holding pieces and slidably housed between the both side plates of said supporting member, and a compression coil spring resiliently provided between the first slider and the second slider, wherein a cover member is fixed to the supporting member, for covering at least in part areas of components such as the actuating member, the first slider and the second slider which are exposed to the outside.

Owner:KEM HONGKONG

Carbonaceous artificial head of humerus prosthesis

InactiveCN1481765APrevent dislocationPrevent rotationBone implantJoint implantsHumerus HeadBiocompatibility Testing

The artificial carbon humeral prosthesis consists of carbon humeral ball and carbon humeral handle, the humeral ball has fixing slot in its bottom and the humeral handle comprises fixing column and humeral handle rod. The fixing column is embedded into the fixing slot, and the axis of the humeral ball joint surface and the axis of the humeral handle rod form one angle of 135-145 deg. The humeral carbon ball of the present invention has high mechanical strength and high chemical stability, no cell toxicity, no irritability, no genetic toxicity, good biocompatibility, elastic modulus near that of bone, osteoplastic activity and lubricating property. The humeral handle has high mechanical strength, high corrosion resistance and good biocompatibility. The present invention is suitable for use in case of replacing humerus.

Owner:JILIN CENT HOSPITAL

Zinc series phosphating solution for aluminum alloys

ActiveCN104404489ALower working temperatureLess sedimentMetallic material coating processesAlloy substrateZinc

The invention relates to a zinc series phosphating solution for aluminum alloys. The zinc series phosphating solution comprises the following components: Zn<2+> 15-18 g / l, PO4<3-> 15-20 g / l, Cu<2+> 0.001-0.003 g / l,Fe<2+> 1-2.5 g / l, F<-> l-2.5 g / l, Ni<2+> 0.5-1.5 g / l. The components are mixed with deionized water so as to prepare the zinc series phosphating solution. The phosphating solution provided by the invention doesn't employ chromium so as to avoid the problem of chromium poison to environment and people, works at a low temperature (35-45 DEG C) so as to save energy, produces few sediments during working, can form a uniform and compact phosphating film with favorable corrosion resistance and the effects such as antifriction and lubrication at a high speed, and increases the bonding strength of a synthetic coating and an aluminum alloy substrate. Besides, the components of the phosphating solution are simple, and the raw materials are easy to purchase.

Owner:CHONGQING YUEJIN MACHINERY

Original cover closer and office equipment having the same

ActiveUS20140201946A1Prevent grease and oilAvoid contactPin hingesWing openersCoil springEngineering

To provide an original cover closer which prevents inner components from exposure to the outside, when the original cover is opened, and from smears of grease on the end of the original lying on the contact glass, the original cover closer comprises the attaching member, the supporting member assembled by rotatably coupling its own both side plates to the both side plates of the attaching member, the lifting member assembled by rotatably coupling its own both side plates to the both side plates of the supporting member, the pressure bearing member provided between the both side plates of the attaching member, a second slider in contact with the pressure bearing member, and slidably housed between the both side plates of the supporting member; an actuating member attached to the side on which the both side plates of the attaching member rotate via said second hinge pin; a first slider in contact with the actuating member, held by the holding pieces and slidably housed between the both side plates of said supporting member, and a compression coil spring resiliently provided between the first slider and the second slider, wherein a cover member is fixed to the supporting member, for covering at least in part areas of components such as the actuating member, the first slider and the second slider which are exposed to the outside.

Owner:KEM HONGKONG

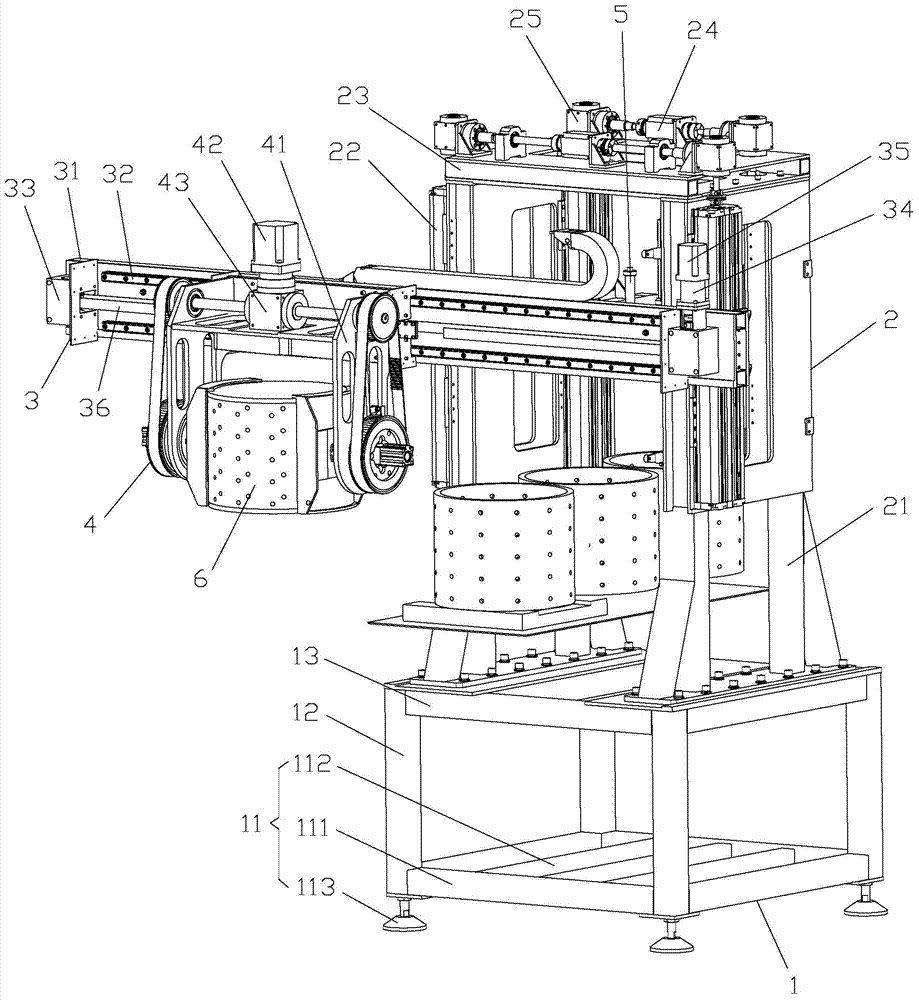

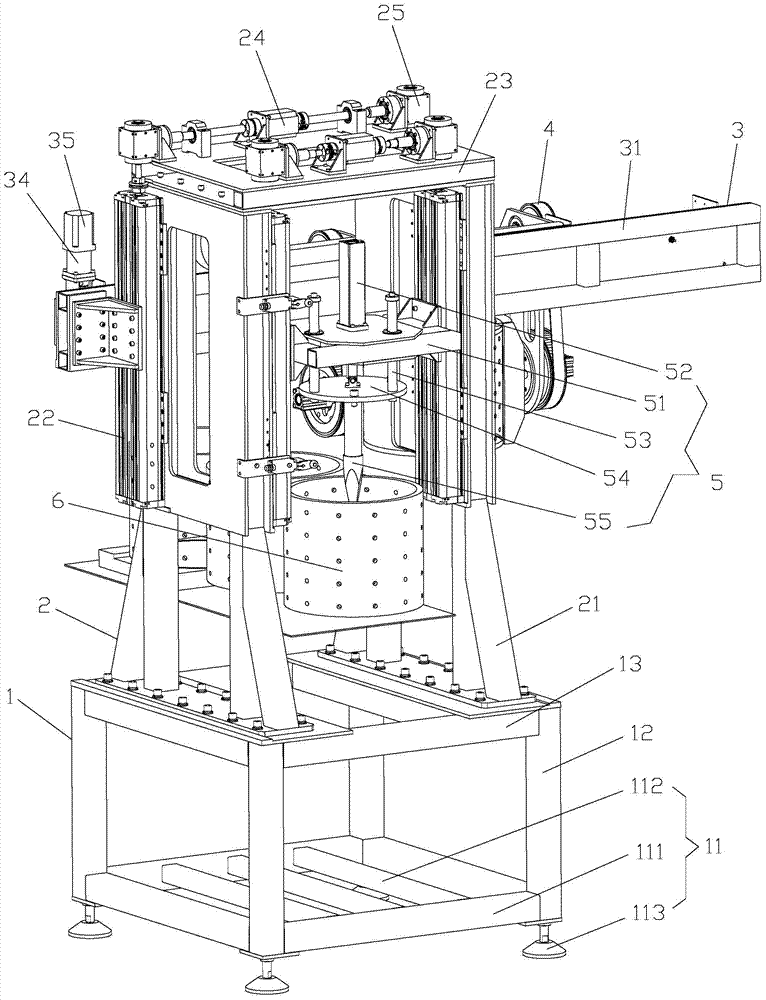

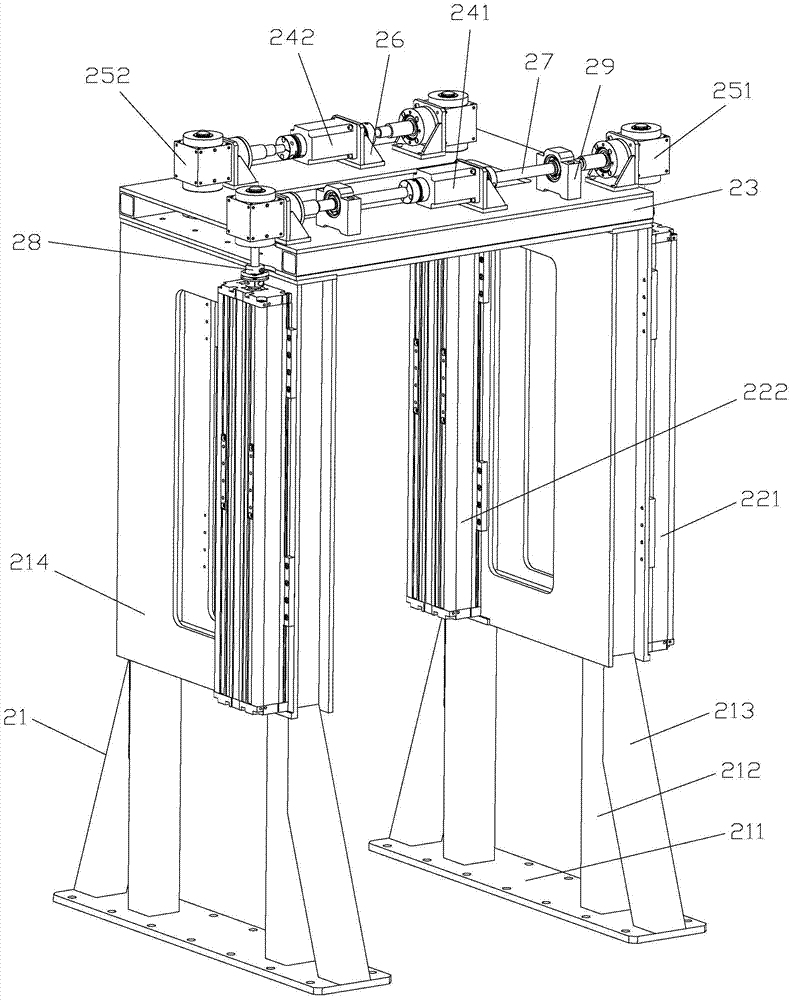

Full-automatic vanadium-nitrogen alloy discharging device

InactiveCN104326275AGuaranteed stabilityReduce noiseBottle emptyingLoading/unloadingElectricityDischarge efficiency

The invention relates to a full-automatic vanadium-nitrogen alloy discharging device. The device comprises a base, a Z-axis moving mechanism, a Y-axis moving mechanism, a turnover mechanism, a scattering mechanism and an electric control system, wherein the Z-axis moving mechanism, the Y-axis moving mechanism, the turnover mechanism and the scattering mechanism are electrically connected with the electric control system and are controlled to act by the electric control system; the Z-axis moving mechanism is arranged on the base, and comprises a Z-axis support, a Z-axis linear module, a Z-axis head piece, a Z-axis step motor and a Z-axis reducer; the Y-axis moving mechanism is arranged on the Z-axis linear module and comprises a Y-axis frame, a guide rail, a Y-axis bearing block, a Y-axis reducer, a Y-axis motor and a synchronous belt; the turnover mechanism is arranged on one side of the Y-axis moving mechanism; one end of the turnover mechanism is connected with the synchronous belt, and a graphite crucible is clamped to the other end of the turnover mechanism; the scattering mechanism is arranged on the Z-axis linear module. The full-automatic vanadium-nitrogen alloy discharging device is reasonable and compact in structural design, works stably and reliably, and is high in discharging efficiency, and the labor intensity of workers and dust harm on the workers can be effectively reduced.

Owner:CHENGDU UNIV OF INFORMATION TECH

Preparation method of trapezoidal carbon brush for seat motor

ActiveCN106299969AImprove the lubrication effectReduce noiseRotary current collectorBrushes manufactureCopperProduct processing

The invention provides a preparation method of an trapezoidal carbon brush for a seat motor. The method comprises that electrolytic copper powder, natural graphite and phenolic resins powder are mixed uniformly to prepare a high conducting layer mixture; electrolytic copper powder, natural graphite, phenolic resins powder and a lubricant with urotropine are mixed uniformly to prepare a high lubricating layer mixture; the high conducting layer mixture and the high lubricating layer mixture are added successively into a die whose cross section is trapezoidal for compaction, and a pressed compact of the carbon brush is prepared; and sintering and finished product processing are carried out on the pressed compact of the carbon brush to prepare the carbon brush whose cross section is trapezoidal. The carbon brush for the seat motor is formed by combining the high conducting layer mixture with the high lubricating layer mixture and is of a special shape, the side, close to a commutator, is a bending cambered surface, it can be ensured that the front end of the high lubricating layer mixture is protruded and makes contact with the commutator always, and thus, the prepared carbon brush is high in conductive performance, resistant to friction and low in noise.

Owner:湖北东南佳新材料有限公司

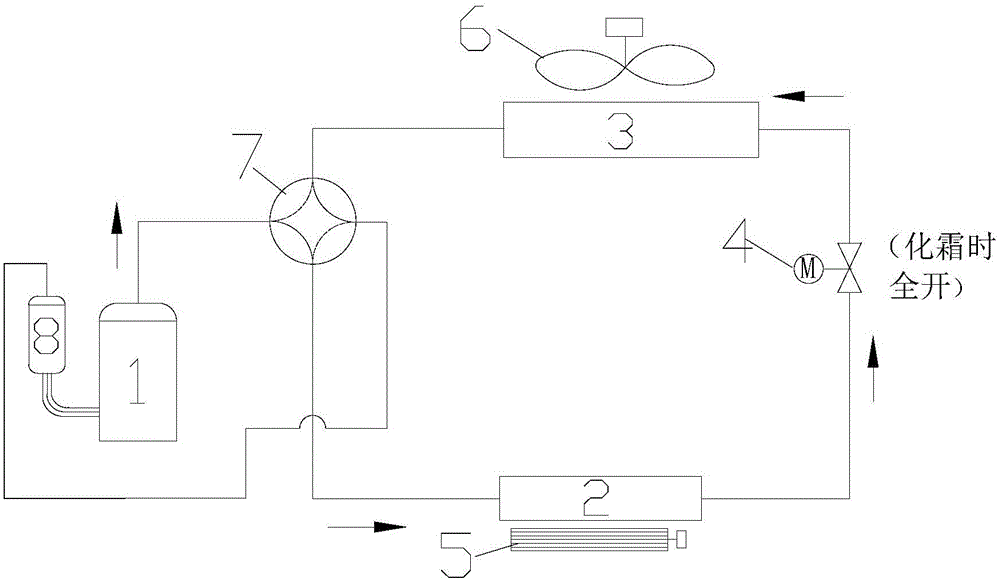

Defrosting control device and defrosting control method for air conditioning system, and air conditioning system

InactiveCN106247533APrevent evaporation and heat absorptionReduce ambient temperatureMechanical apparatusSpace heating and ventilation safety systemsFour-way valveEvaporation

The present invention provides a defrosting control device, control method and air-conditioning system for an air-conditioning system, wherein the air-conditioning system includes a compressor (1), an indoor heat exchanger (2), an outdoor heat exchanger (3) and a throttling device ( 4), wherein, the control device includes: a judging unit for judging whether the outdoor heat exchanger (3) has reached the level where defrosting is required; an execution unit for controlling the throttling device according to the judgment result of the judging unit Action to defrost when needed. The present invention uses the executive unit to adjust the throttling device to control the defrosting, cancels the original control through the four-way valve reversing, and can effectively prevent the indoor heat exchanger from evaporating and absorbing heat during defrosting, causing indoor The ambient temperature is lowered, which increases the indoor ambient temperature, avoids slow temperature rise, reduces energy loss, reduces noise and abnormal noise, reduces power consumption, improves operational reliability, and prevents problems such as compressor oil shortage and poor lubrication.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com