Fully water-lubricated super-pressure plunger water pump

A water-lubricated, plunger-type technology, applied in the direction of variable-capacity pump components, pumps, pump components, etc., to simplify the structure, reduce the impact sound, and solve the problem of friction and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

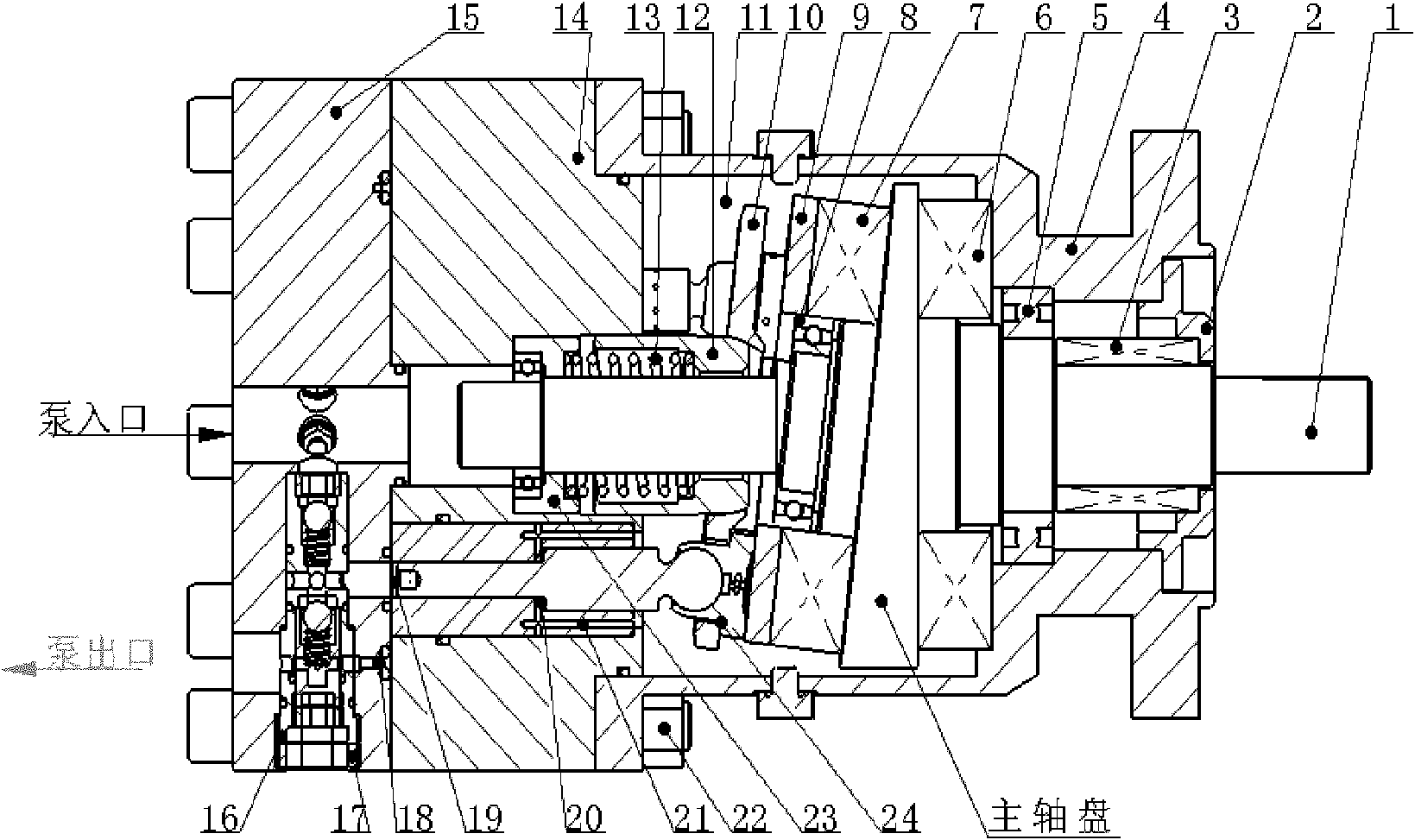

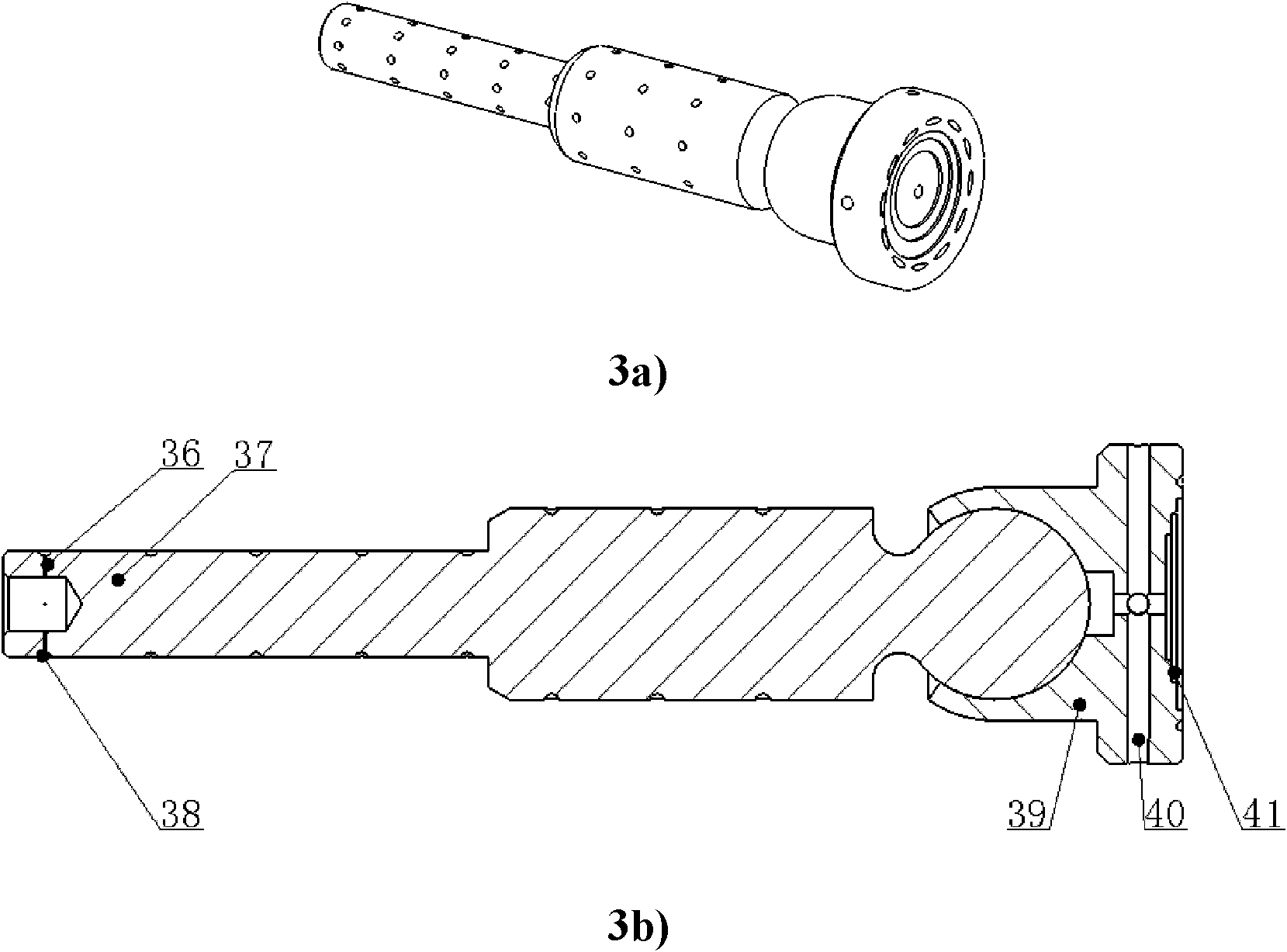

[0028] figure 1 The shown valve distribution full water lubricated axial plunger high-pressure sea / fresh water pump includes a water pump cavity, which is composed of a front end cover 2, a rear end cover 15, a cylinder body 14 and a casing 4 connected in sequence, and the rotating main shaft 1 It is connected with the housing 4 and the cylinder body 14 through ceramic bearings 5, 6, 23.

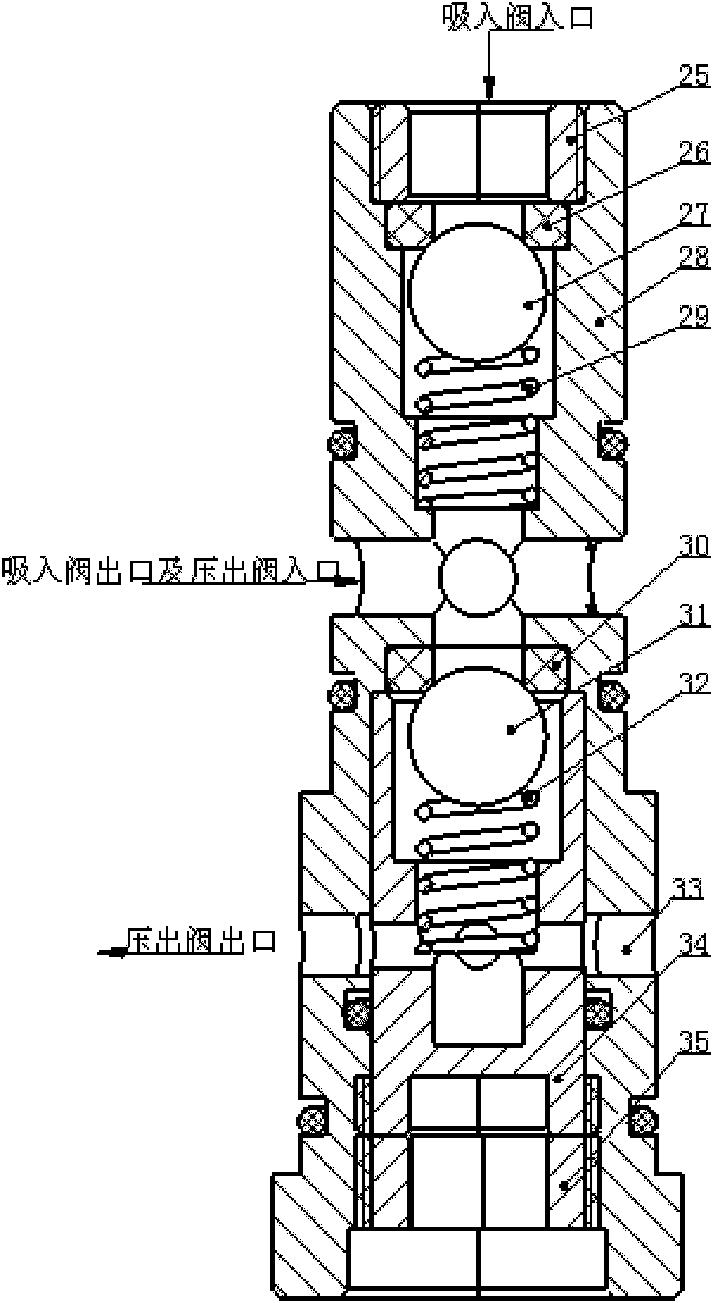

[0029] The left end face of the rear end cover 15 is machined with two holes along the axial direction, which are the inlet and the outlet of the water pump respectively, and an annular flow groove 18 is uniformly processed along the axial direction on the other end face. There are stepped holes equal to the number of plungers evenly distributed in the radial direction of the rear end cover, and threads are processed on the outside of the stepped holes for the instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com