Patents

Literature

87results about How to "Guaranteed impact performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

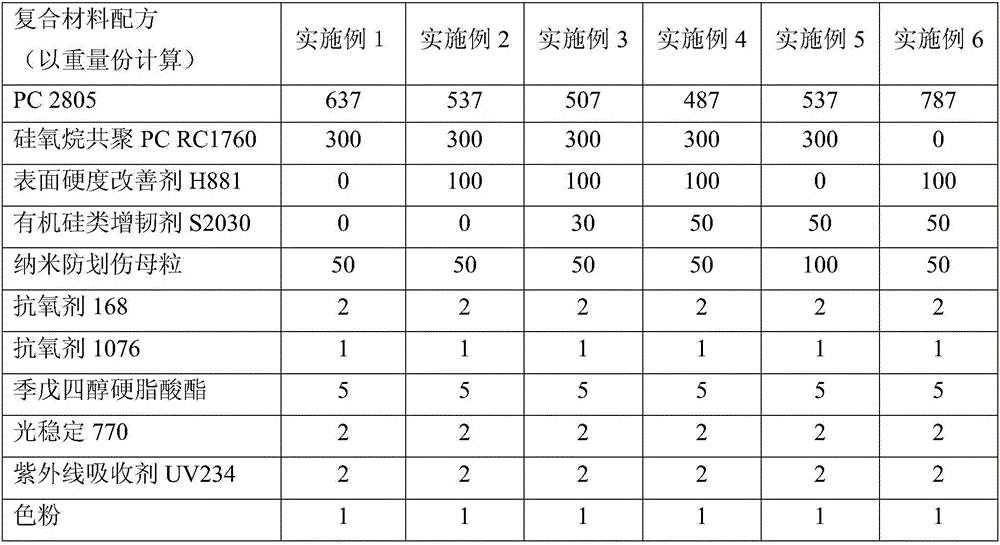

Transparent low-temperature-resistant scuffing-resistant polycarbonate composite material

The invention relates to the field of polymer composite materials, in particular to a transparent low-temperature-resistant scuffing-resistant polycarbonate composite material. The polycarbonate composite material is prepared from, by weight, 300-800 parts of bisphenol A polycarbonate resin, 100-500 parts of siloxane copolymerized PC resin, 10-50 parts of organosilicone flexibilizer, 50-200 parts of surface hardness improving agent, 10-100 parts of nanometer scuffing-resistant master batch and 5-15 parts of additive. The siloxane copolymerized PC, the surface hardness improving agent and the nanometer scuffing-resistant master batch are composited for use, on the basis that the luminousness and the basic mechanical properties of PC are uninfluenced, the surface hardness and the low-temperature properties of the material are improved, the surface hardness can be increased to 2 H, the abrasion resistance of the surface of a product is obviously improved, and the surface glossiness and the weather resistance are also improved. Moreover, the surface tension of the product can be increased, and the product is easier to clean; the composite material is good in mechanical property, high temperature impact property and low temperature impact property.

Owner:SHANGHAI CHANGWEI JINCI ENG PLASTIC

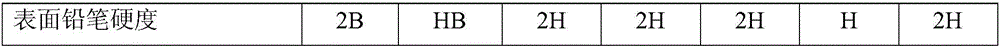

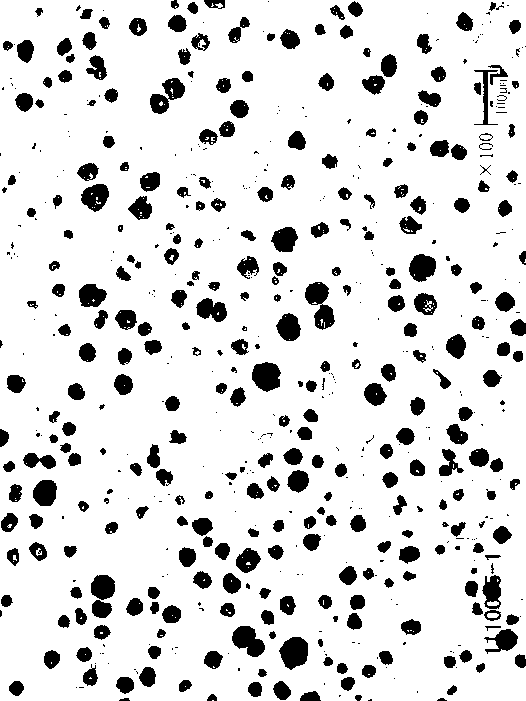

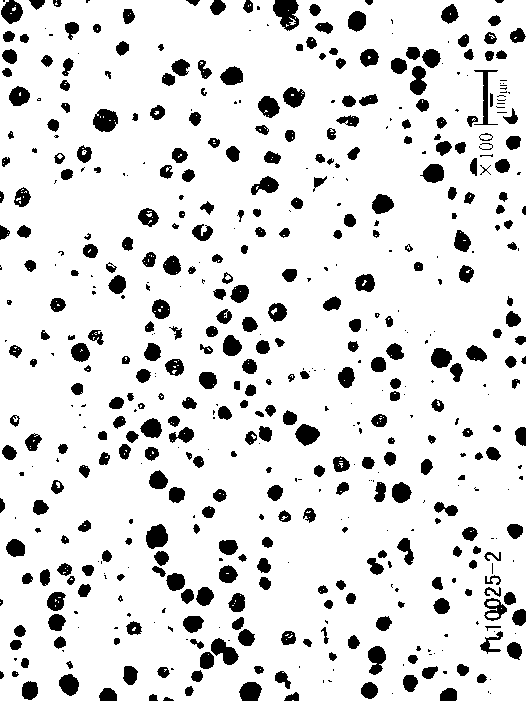

High-strength high-toughness low-temperature-resistant ferritic nodular cast iron

InactiveCN102703802AIncreased toughness-brittle transition temperatureReduce shockImpact toughnessDuctile iron

The invention discloses high-strength high-toughness low-temperature-resistant ferritic nodular cast iron. The high-strength high-toughness low-temperature-resistant ferritic nodular cast iron comprises the following components in percentage by weight: 3.62 to 3.80 percent of C, 1.90 to 2.35 percent of Si, less than 0.20 percent of Mn, 0.007 to 0.018 percent of RE, 0.043 to 0.060 percent of Mg, less than 0.035 percent of P, less than or equal to 0.020 percent of S, and the balance of iron and other impurity elements, wherein in the impurity elements, Mo is controlled to be less than 0.010 percent, and Ti is controlled to be less than 0.025 percent; and the ratio of the Si to the C is 0.50-0.63. Through a lot of test and research, the Si-C ratio is reasonably controlled, low-temperature nodular cast iron can obtain relatively high tensile strength and yield strength, and the low-temperature impact toughness of -40 DEG C can also be ensured; and the ideal low-temperature impact toughness is obtained while the function of a silicon reinforced metallic matrix is exerted, so that the performance requirements are met, and the cost is also greatly reduced.

Owner:上海宏钢电站设备铸锻有限公司

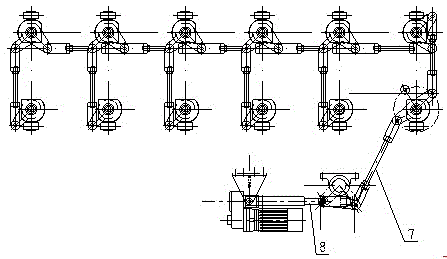

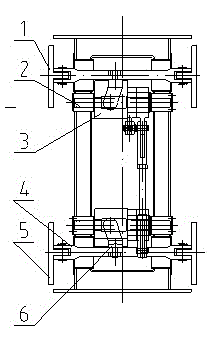

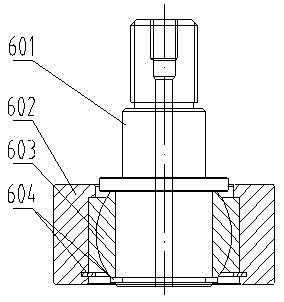

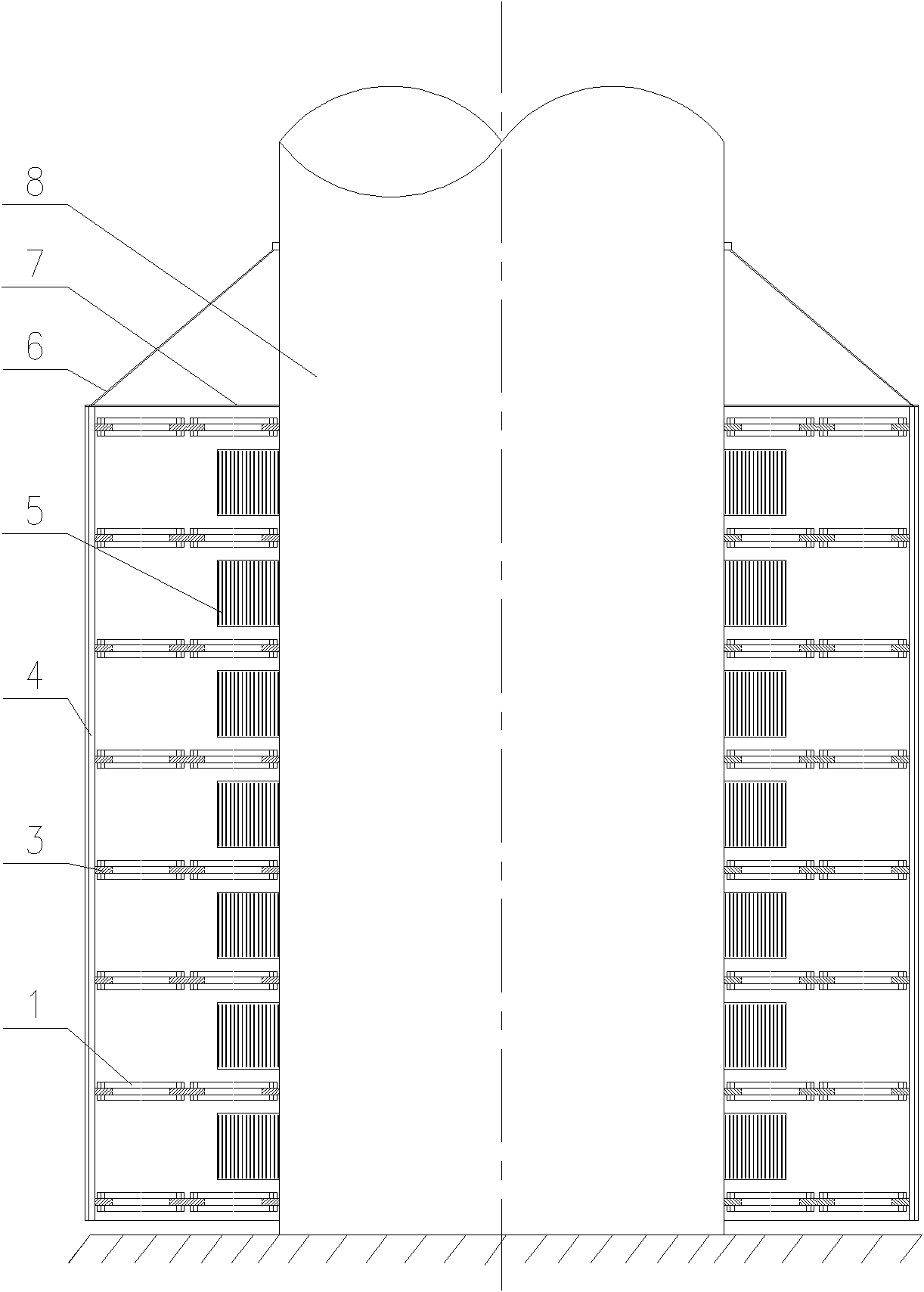

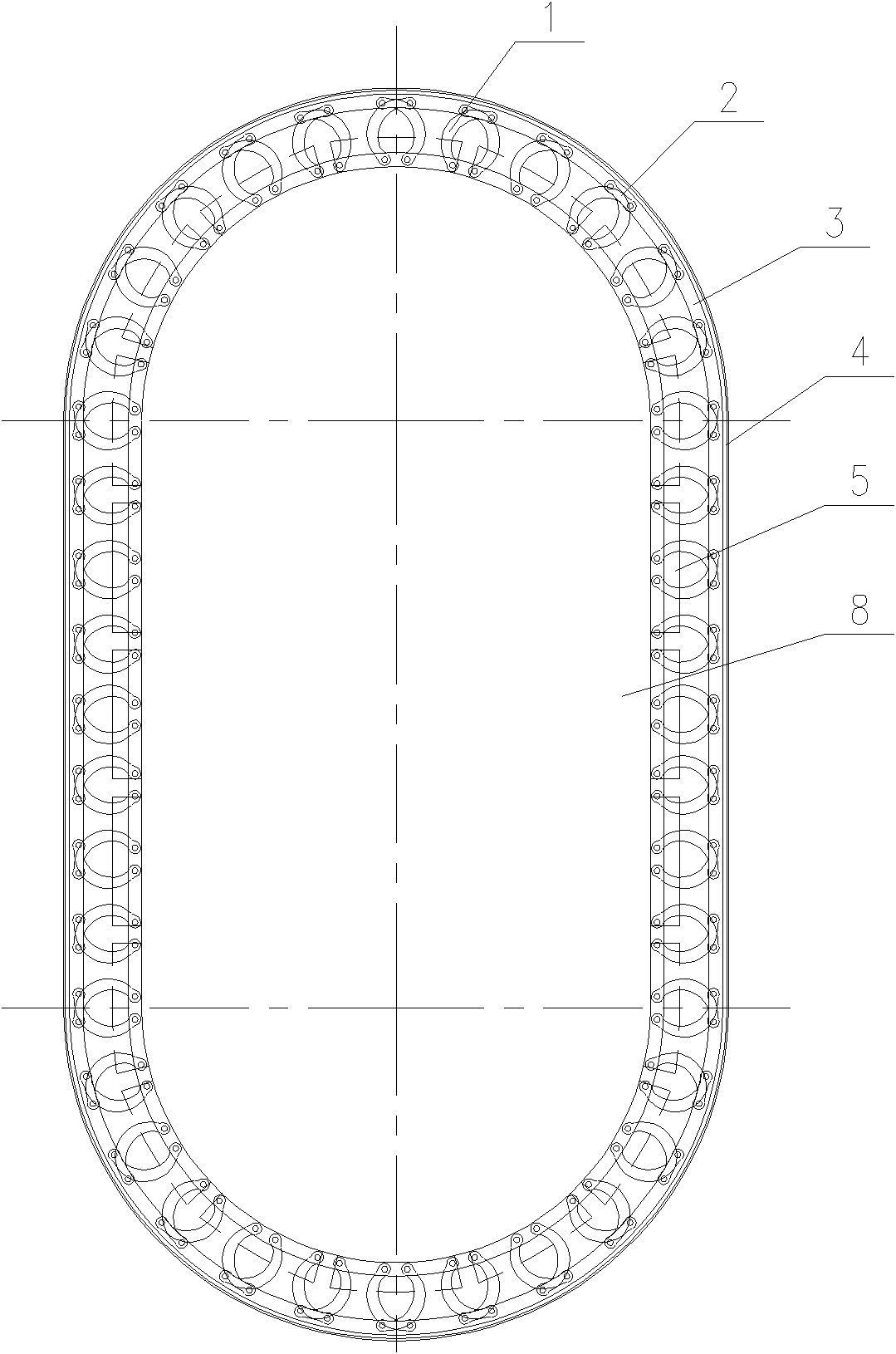

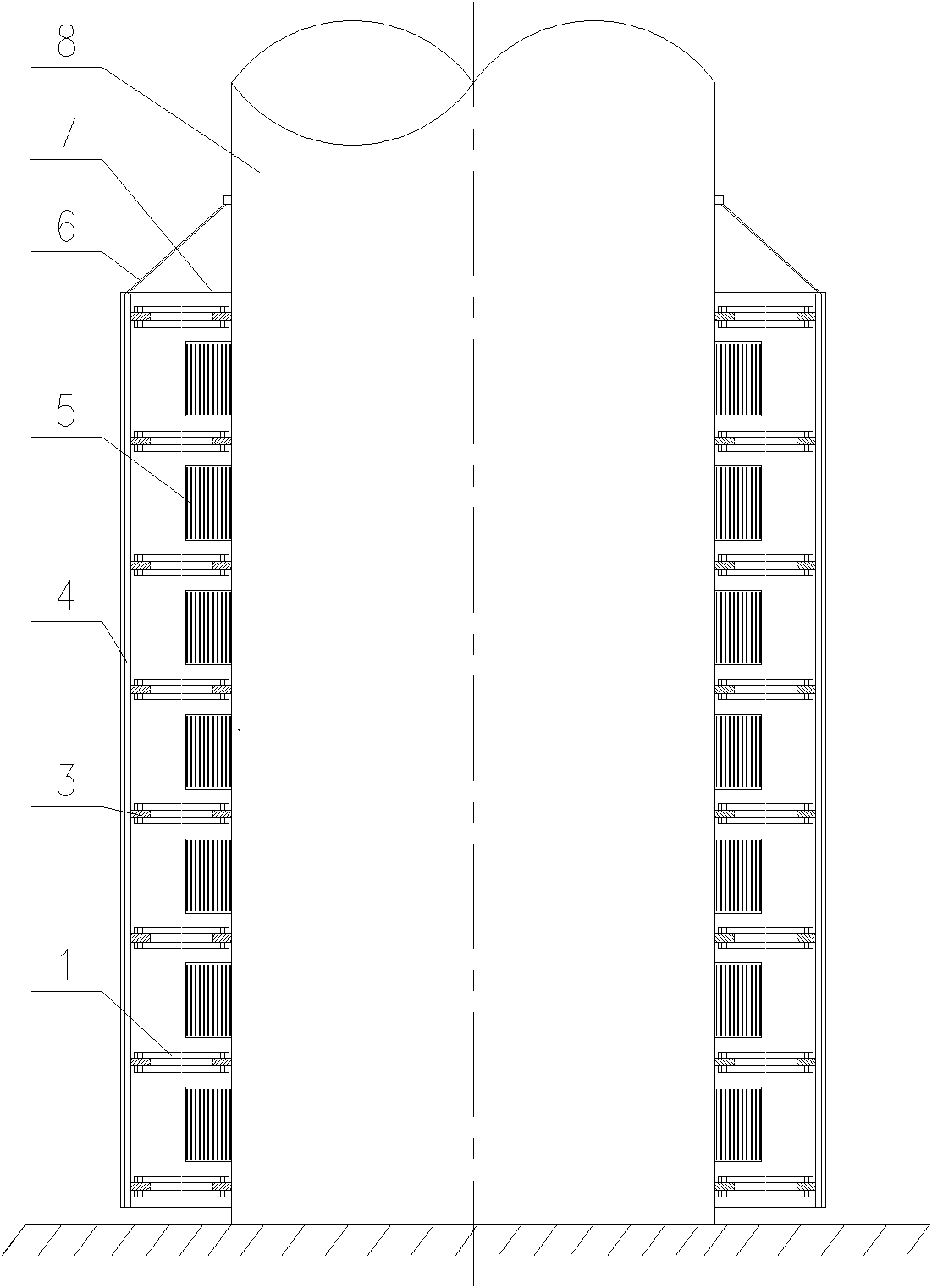

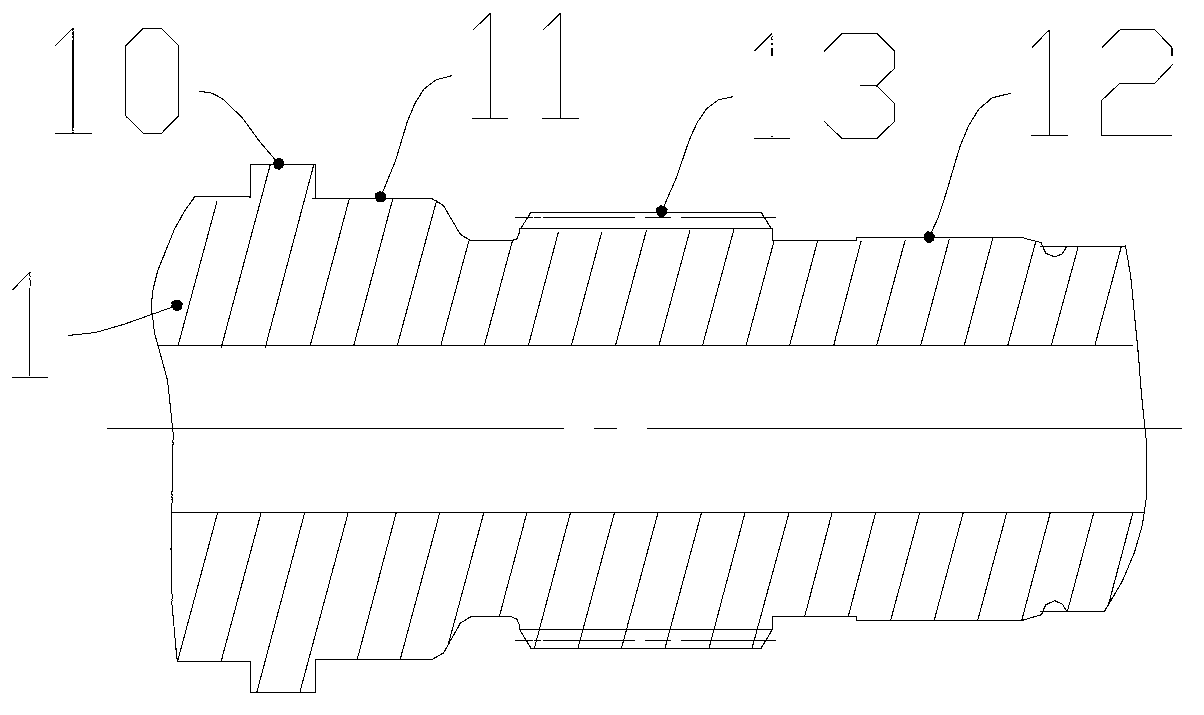

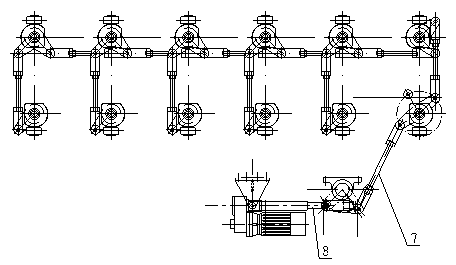

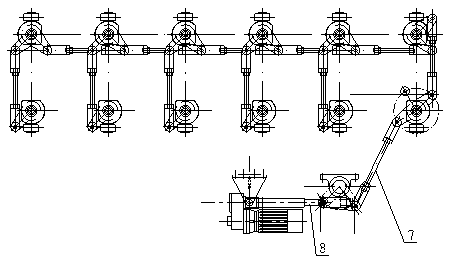

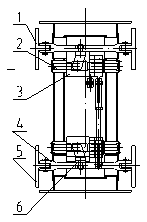

Bending device of joint flexible turnout

The invention relates to a bending device of a special rail transfer joint flexible turnout for straddle type monorail traffic line. The bending device comprises guide panels, stabilization panels, mount supports, cam support shafts, axial cams, double-plug connecting rods, roller assemblies, a connecting rod pair and an electric push rod, and adopts a cam and pull rod series connection driving form to realize synchronous bending of a guide surface and a stabilization surface; the guide panels and the stabilization panels are connected with the two ends of the double-fork-head pull rods by reamed holes; the double-fork-head pull rods are connected with driven components; the driven components are contacted and connected with cylindrical cam mechanisms; the above two adjacent cylindrical cam mechanisms and the two vertically corresponding cylindrical cam mechanisms are connected by connecting rods; when the electric push rod starts to push and pull, the pull rod drives the guide panels to move transversely and synchronously, and therefore, the transverse bending of the guide panels is accomplished.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

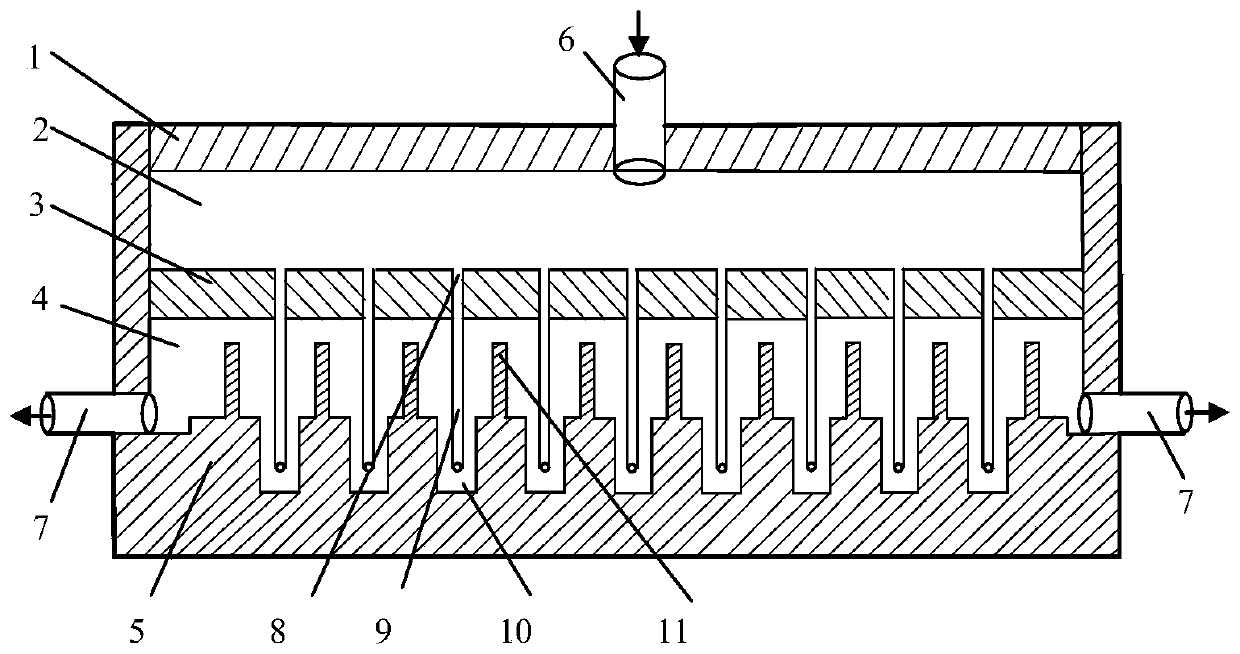

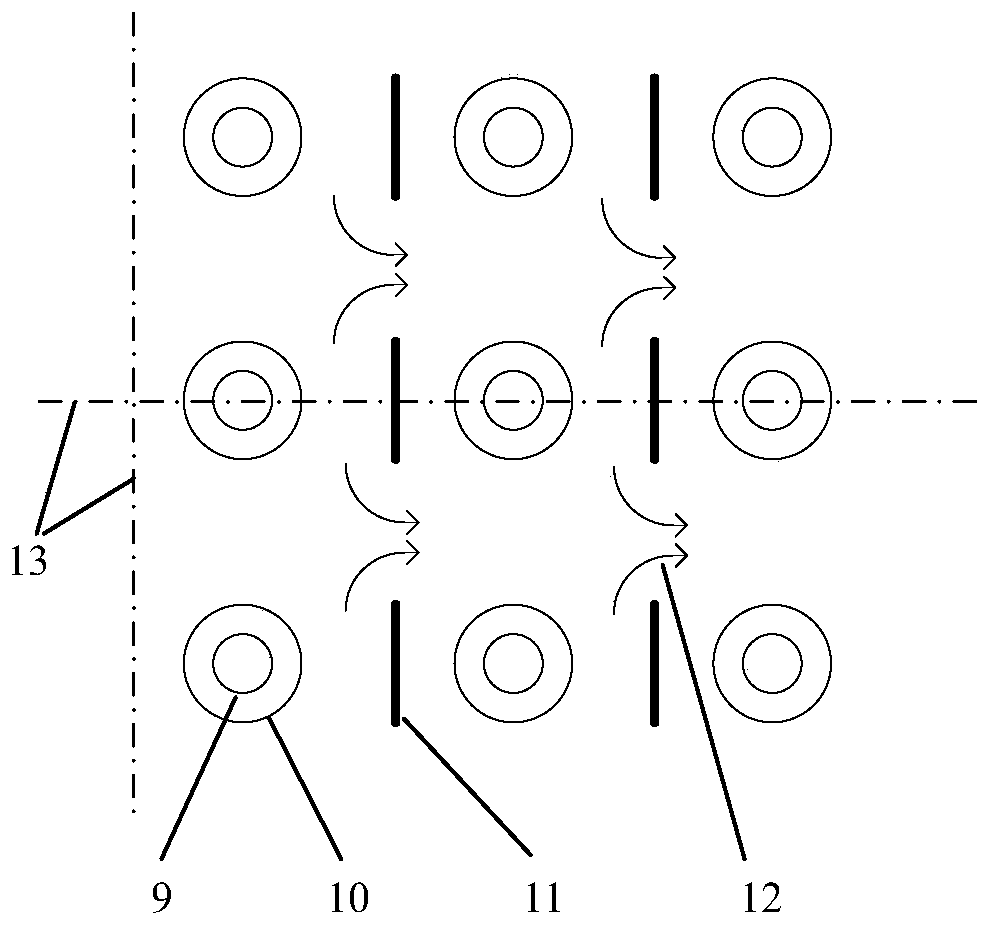

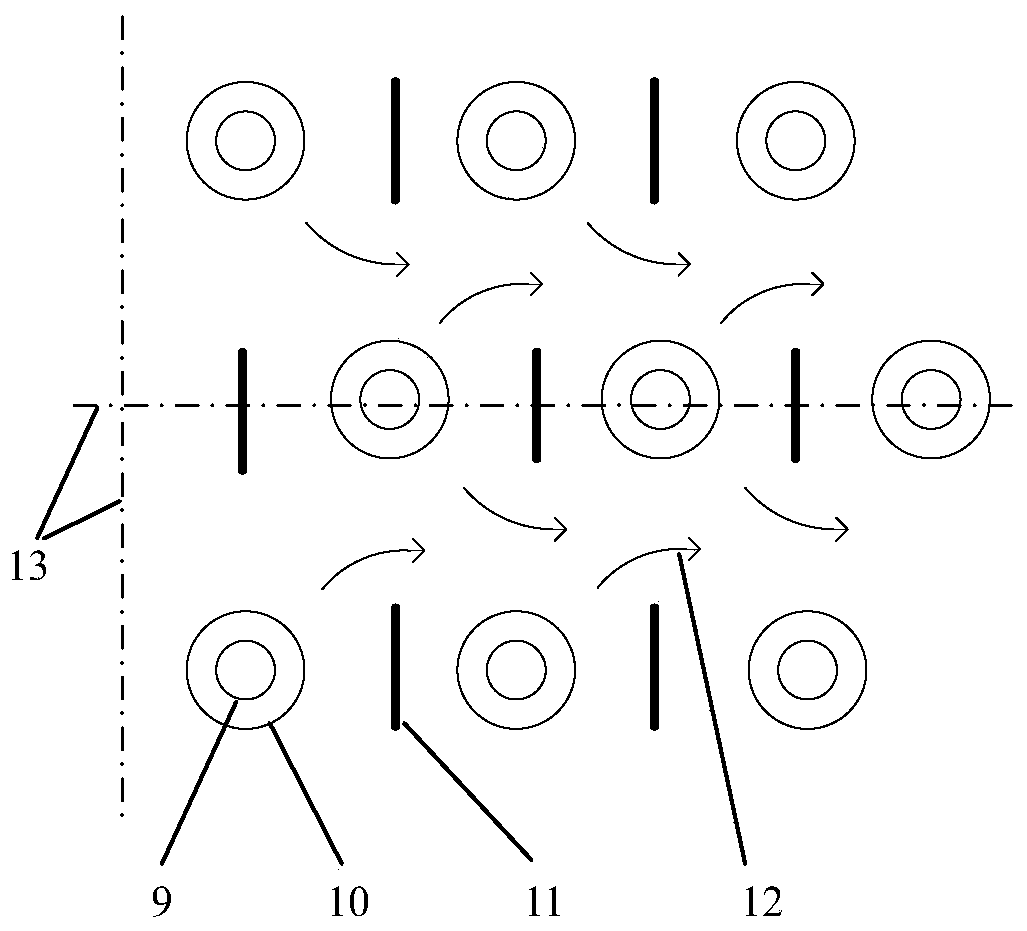

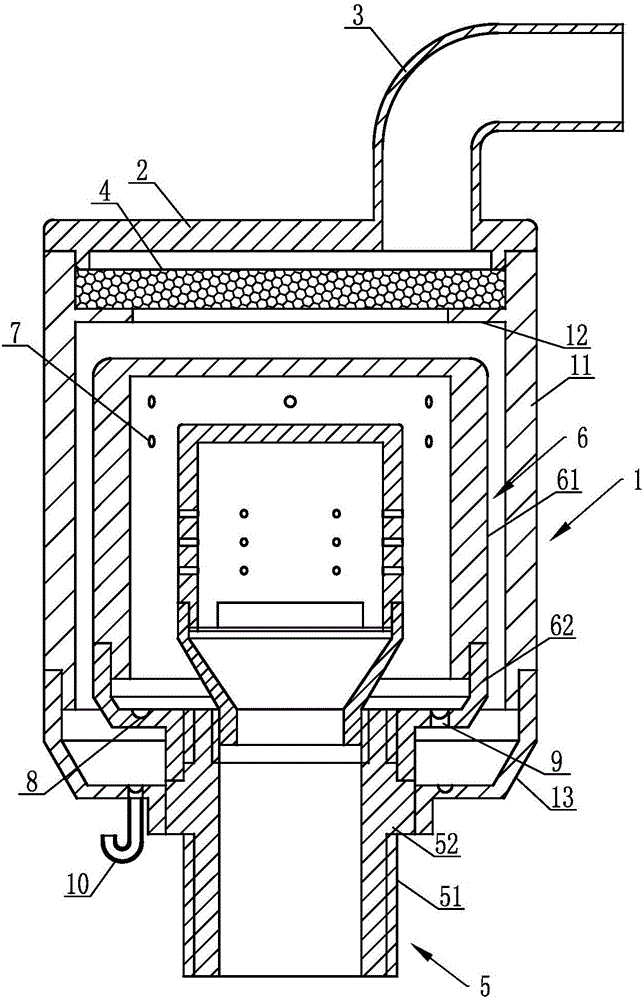

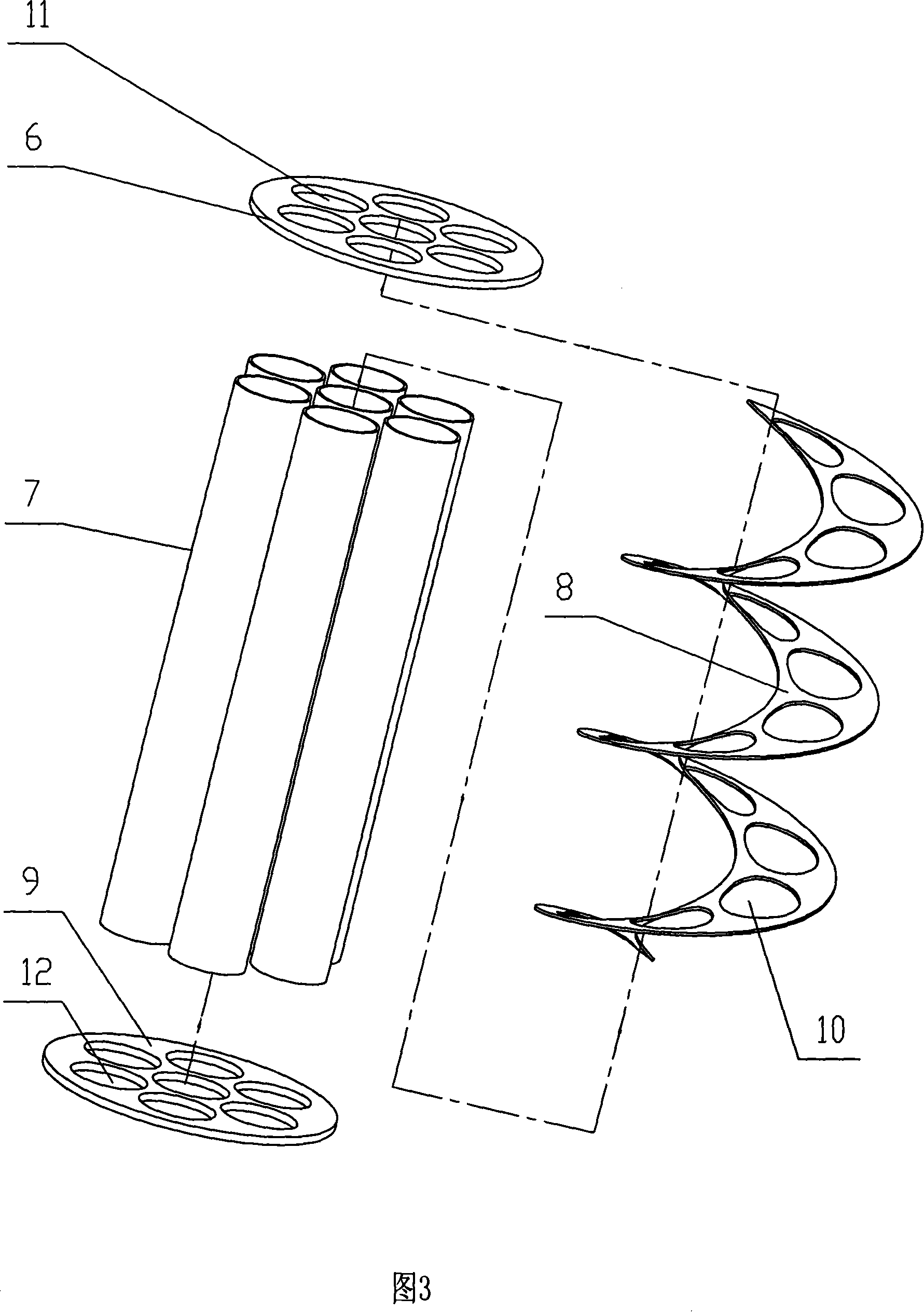

Micro-channel jet radiator

ActiveCN109755199AGuaranteed impact performanceGuaranteed cooling effectSemiconductor/solid-state device detailsSolid-state devicesSputteringEngineering

The invention discloses a micro-channel jet radiator. A cover plate is arranged on a heat conduction substrate to form a box-shaped body with an inner cavity; a partition plate is horizontally arranged in the inner cavity, and the inner cavity is divided into an upper liquid inlet cavity and a lower liquid outlet cavity; jet holes are distributed in the partition plate; pits are distributed in thelower liquid outlet cavity and located in the surface of the heat conduction substrate, and the pits are in one-to-one correspondence with jet holes in the partition plate; jet pipes are arranged inthe jet holes, and the lower ends of the jet pipes are suspended in the pits, so that the impact sputtering of the jet stream introduced by the jet pipes on the bottom surface of the pits is limited in the pits; in the lower liquid outlet cavity, rib sheets are distributed on the surface of the heat conduction substrate, and the rib sheets are arranged between the two adjacent pits in the workingmedium outflow direction, so that the working medium on the surface of the heat conduction substrate in the lower liquid outlet cavity is blocked from flowing through the downstream pits by virtue ofthe rib sheets. According to the radiator, the jet beam is not affected by the peripheral jet, and the sputtering jet is converted into positive disturbance to the heat conduction substrate, so that the heat exchange effect is enhanced.

Owner:黄山市开发投资集团有限公司

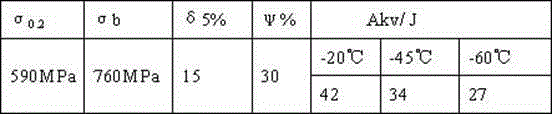

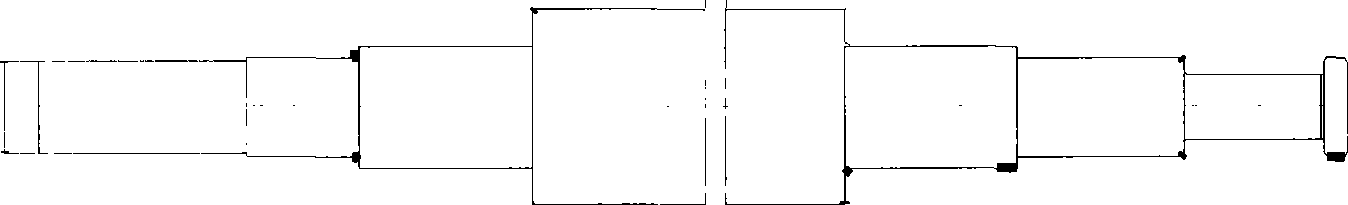

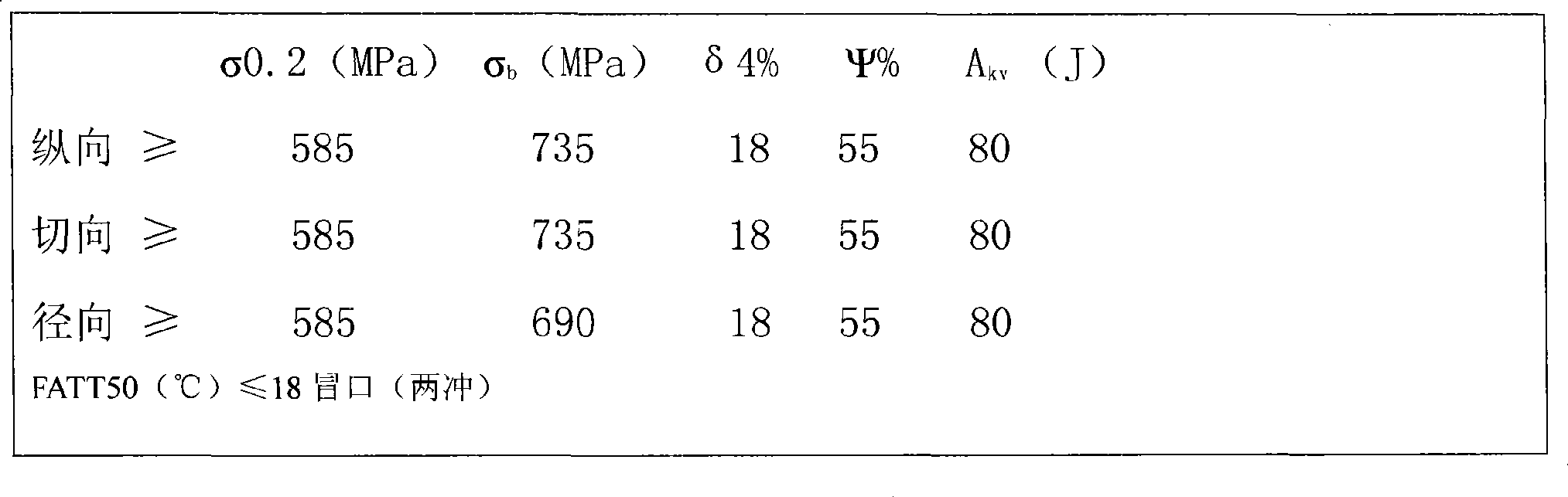

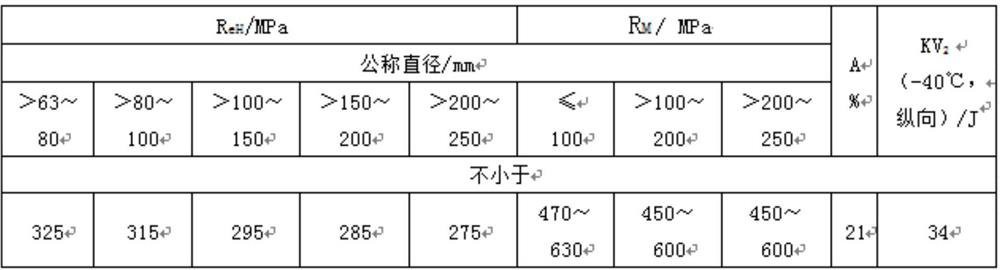

Manufacture technique of tap shells for polar drill rigs

The invention discloses a manufacture technique of tap shells for polar drill rigs. The manufacture technique incudes: (1) for forging, performing forging via upsetting, punching, broaching and forming to guarantee a forging fiber flow line under the conditions that heating temperature is 1270-1310 DEG C, initial forging temperature is 1100-1250 DEG C and terminal temperature is not lower than 850 DEG C, performing annealing after forging under the condition that the heating temperature is 880+ / -20 DEG C, and performing furnace cooling to enable tapping temperature not higher than 300 DEG C; (2) for heat treatment, normalizing at temperature of 880-900 DEG C prior to air cooling, quenching at temperature of 840-860 DEG C prior to oil cooling or cooling with a PAG quenching medium, tempering at temperature of 580+ / -40 DEG C prior to air cooling, performing subcritical quenching at temperature of 790+ / -10 DEG C prior to oil cooling or cooling with the PAG quenching medium, and tempering at temperature of 520-600 DEG C prior to air cooling; (3) for non-destructive inspection, finishing prior to machining a product according to size, and performing ultrasonic inspection and magnetic particle inspection, wherein the qualified level conforms to API Specification 8C standards. Compared with the prior art, the manufacture technique has the advantages that the tap shells manufactured with the technique have high strength to guarantee enough safety factor, adapt to polar regions (at the temperature of minus 60 DEG C) and meet the requirement on enough low temperature impact toughness so as to resist to the low-temperature environment of the polar regions.

Owner:RG PETRO MACHINERY GROUP

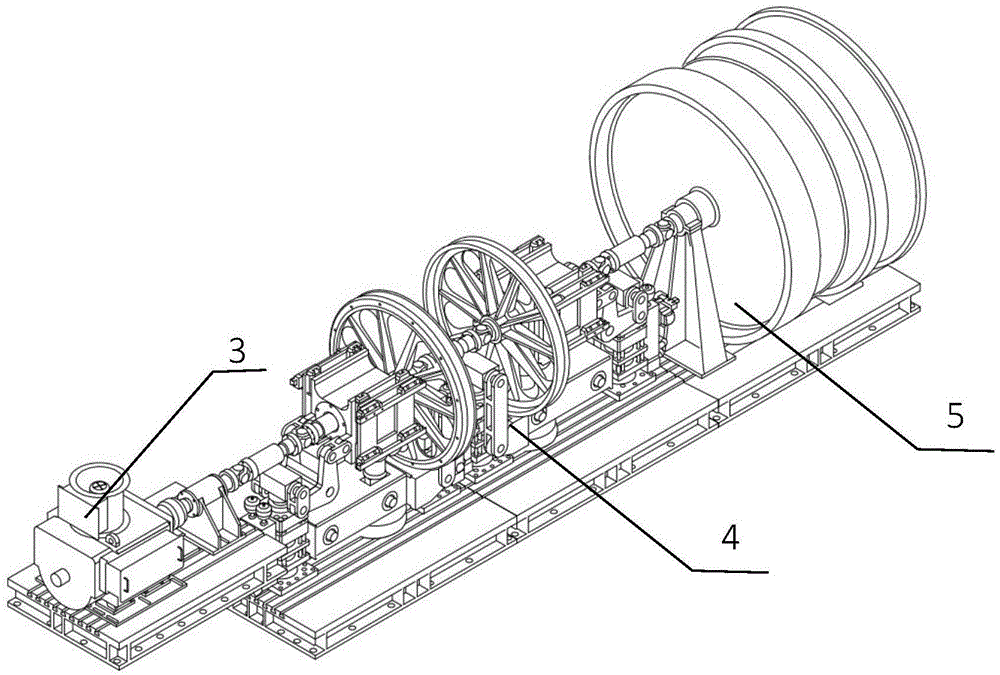

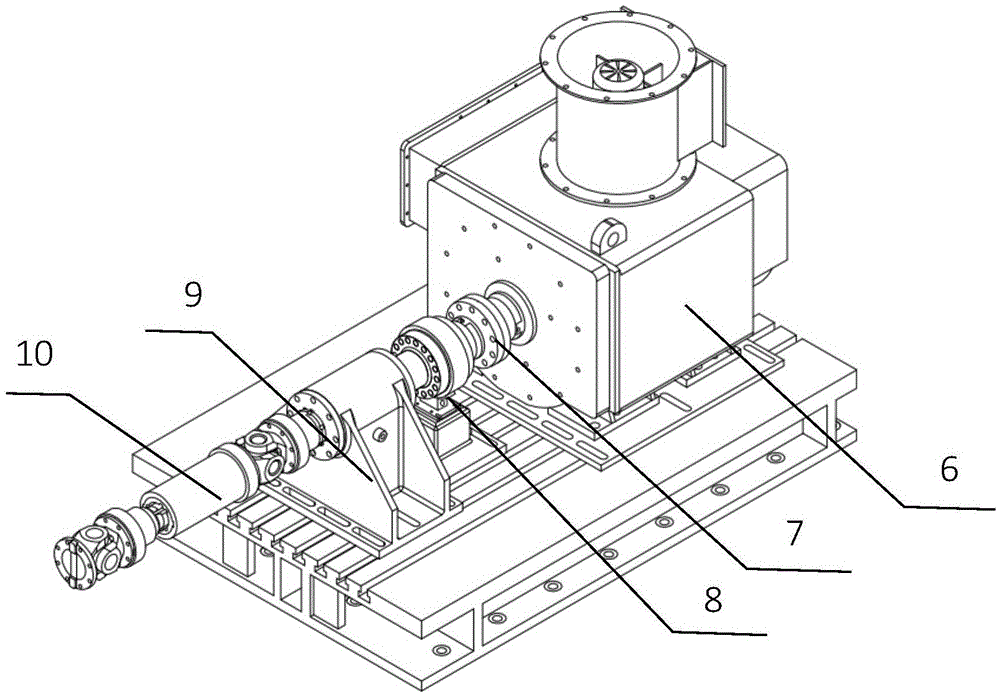

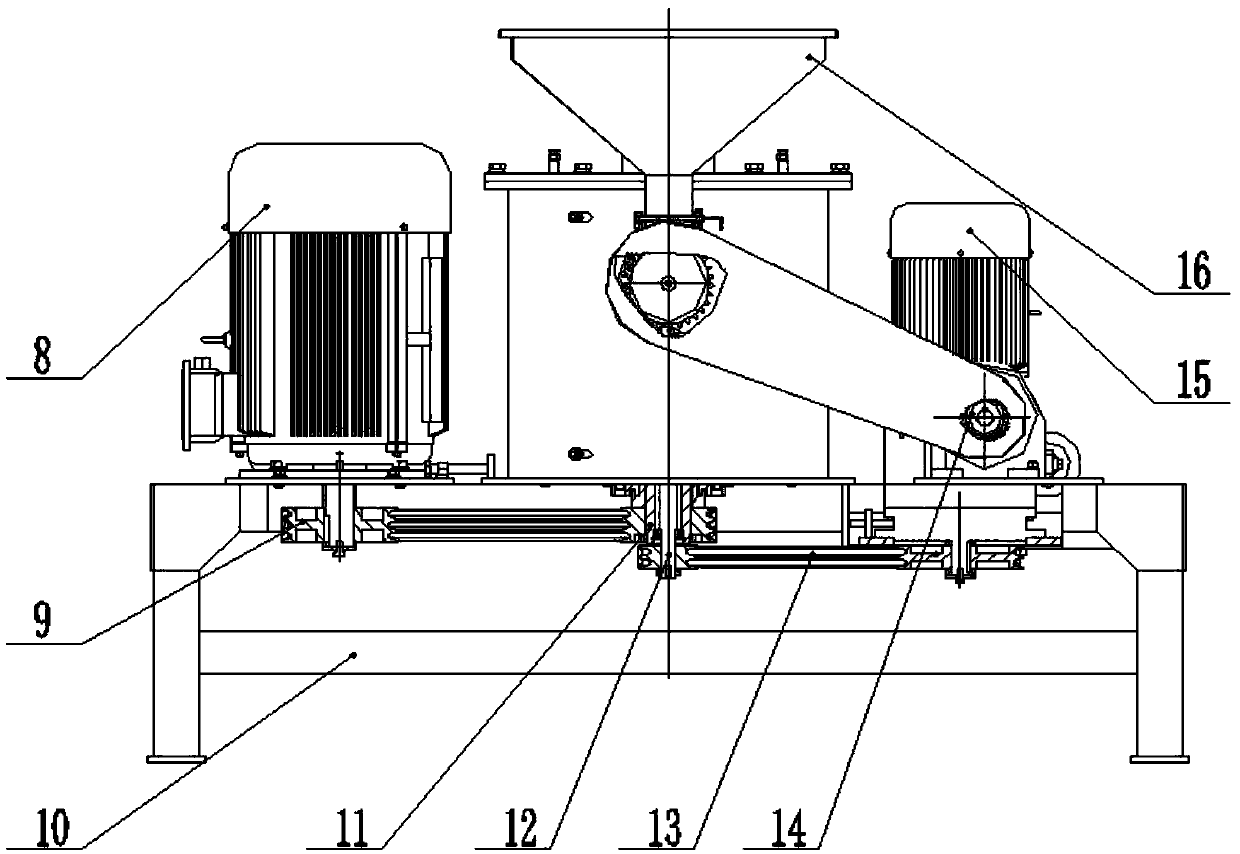

High-speed wheel-rail relation reliability test bed

InactiveCN105628410AMake up for deficienciesHigh simulationRailway vehicle testingTruckPower steering

The present invention relates to a high-speed wheel-rail relation reliability test bed. The high-speed wheel-rail relation reliability test bed comprises a rail wheel motion device and a power truck simulation loading framework, wherein two unilateral shafts of the rail wheel are respectively connected with number 1 roller linkage transmission shaft assembly body and a number 3 roller linkage transmission shaft assembly body; the power truck simulation loading framework includes a counter-force square tube beam frame vibration excitation device, a bearing frame-type support assembly body, a number 1 counter-force base fixed device and a number 2 counter-force base fixed device; the counter-force square tube beam frame vibration excitation device, the number 1 counter-force base fixed device and the number 2 counter-force base fixed device are respectively fixedly connected with globe joint bearing block assembly bodies of the numbers 1-3, the loading framework side beams of the side beam clamping plate assembly bodies of the numbers 1-2; and the outer sides of a number 5 spherical guide strip and a number 6 spherical guide strip are fixedly connected at the inner side of the number 1 bearding frame-type support. According to the invention, the problem is solved that a train is difficult to perform the wheel rail relation reliability test in the process of actual operation in the prior art, and the requirement of the reliability parameter detection of a rail vehicle wheel in a plurality of operation conditions is satisfied.

Owner:JILIN UNIV

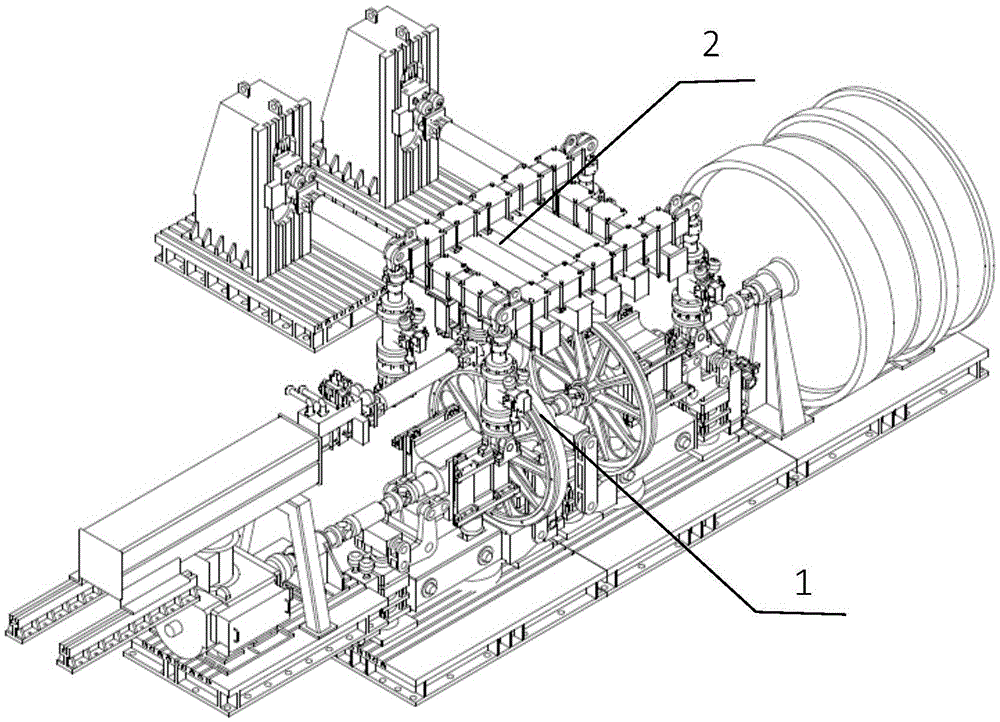

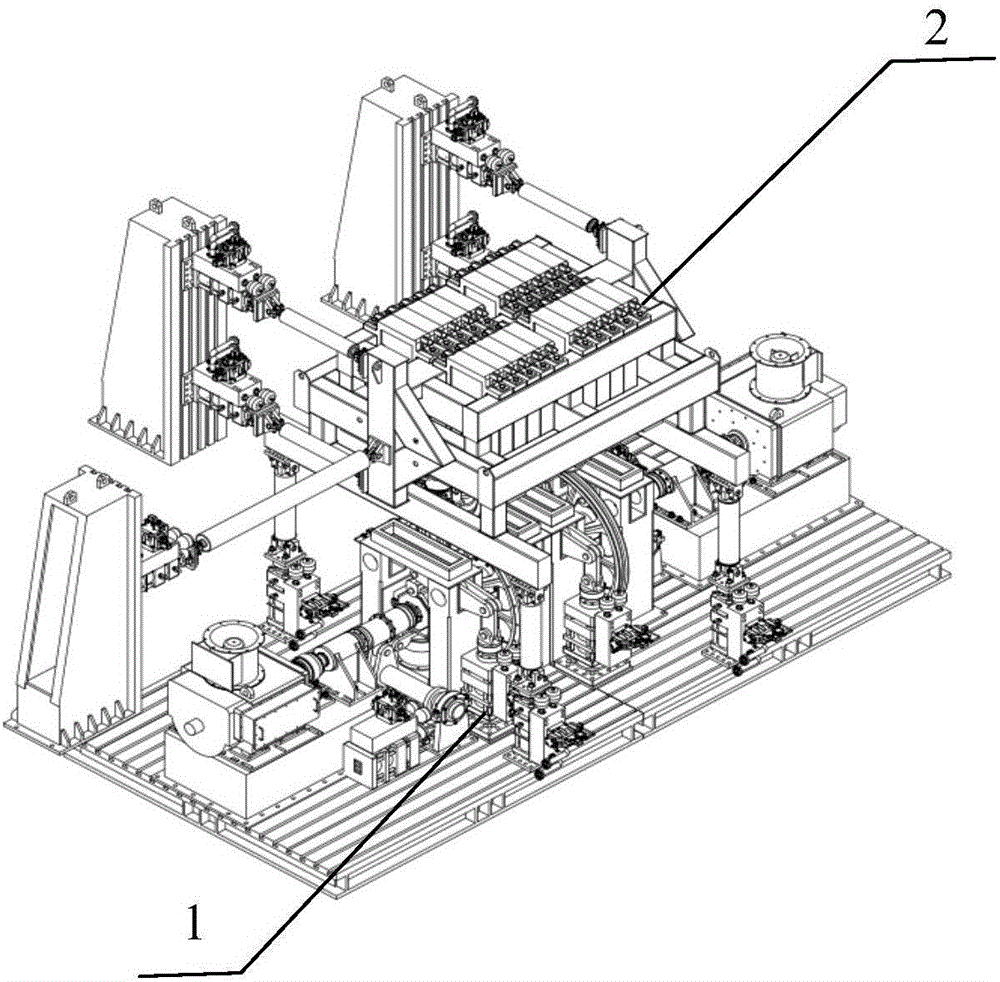

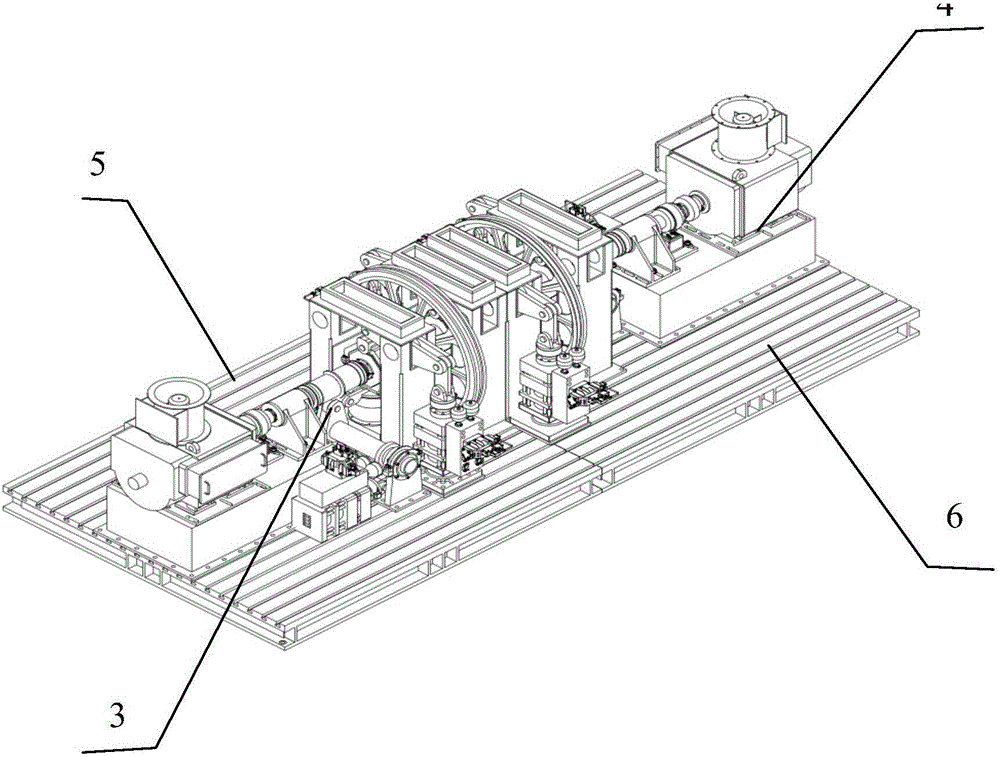

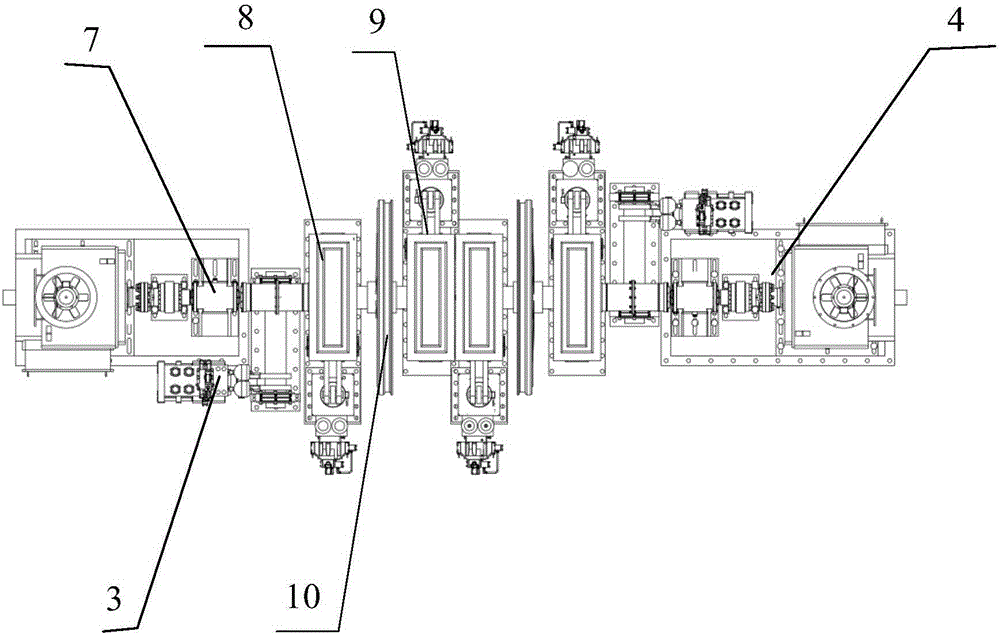

Three-degree-of-freedom wheel rail relation test stand for high-speed track

PendingCN106840718ARealize irregularitiesGuaranteed accuracyRailway vehicle testingVibration testingControl systemThree degrees of freedom

The invention relates to a three-degree-of-freedom wheel rail relation test stand for a high-speed track. The test stand comprises dual three-degree-of-freedom track wheel system devices (1) and a weight vehicle and six-degree-of-freedom pose control system device (2); the weight vehicle and six-degree-of-freedom pose control system device (2) is mounted on a No. 1 T-shaped groove platform (5) and a No. 2 T-shaped groove platform (6) through 2 No. 1 vertical actuator and connecting rod assemblies and 2 No. 2 vertical actuator and connecting rod assemblies. The test stand can be used to accurately simulate the vibration of opposite wheel sets on the track when a high-speed bullet train runs on an actual track; two track wheels are not directly connected and achieve three-degree-of-freedom movement respectively through six actuators, namely transverse movement, vertical movement and rotational movement around a longitudinal axis; and the simulation of unsmooth phenomenon on the high-speed train track can be realized. Therefore, the problem that wheeltrack reliability tests cannot be directly conducted in an actually running train is solved.

Owner:JILIN UNIV

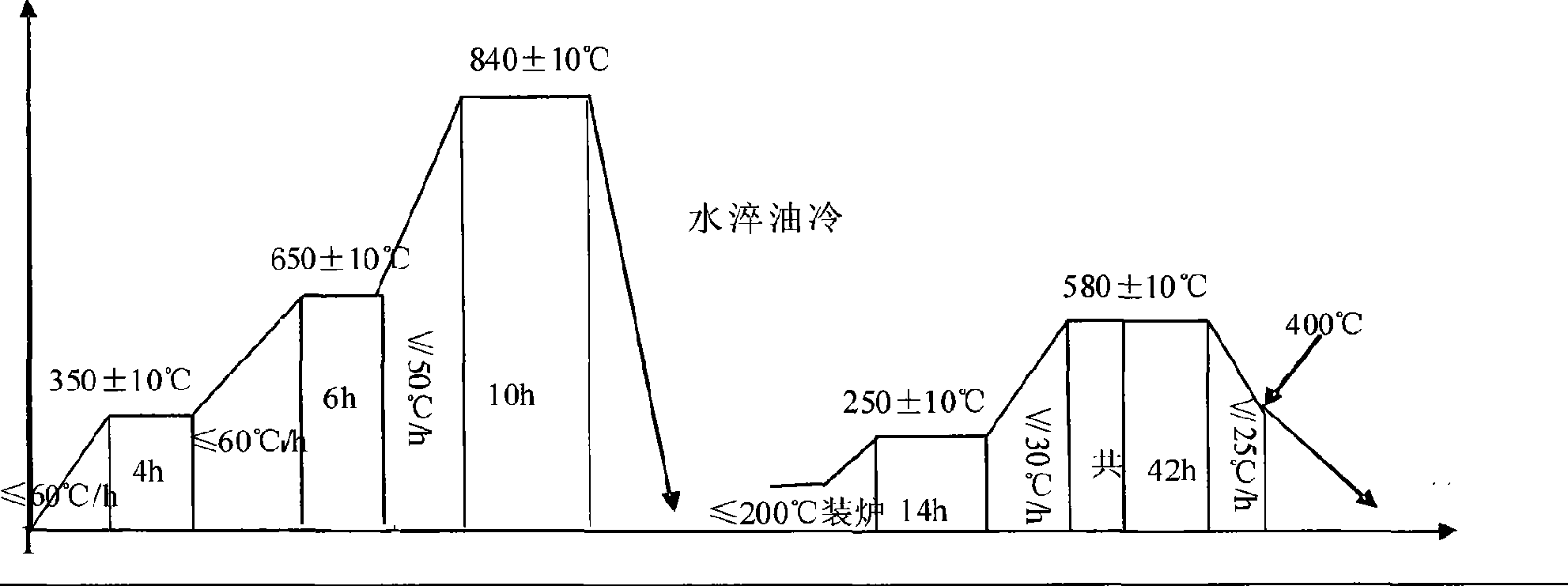

Heat treatment process for 200MW or lower large size rotor

InactiveCN101505081AIncrease the lengthWeight increaseManufacturing dynamo-electric machinesCooling speedOil cooling

The invention provides a process for the heat treatment of a 200 MW or below large-scale rotor, which adopts a cooling mode of water quenching and oil cooling, controls quenching temperature and tempering temperature and strictly controls the oil entry temperature of effluent. A, a rotor is suspended in a furnace, and the temperature is raised to be 350 DEG C and kept constant for 4 hours and then raised to be 650 DEG C and kept constant for 6 hours; B, heat-preservation quenching is performed according to 1h / 100mm, during quenching, and the rotor is first cooled in water according to 8 to 12 min / 100mm, then enters oil to be cooled according to 15 to 18 min / 100mm and finally is taken out from oil; C, after quenching, the rotor is cooled to be below 200 DEG C, and placed back into the furnace for tempering; and D, during tempering cooling, cooling speed is controlled to be less than or equal to 25 DEG C / h, and the highest temperature of the hearth is reduced to be less than or equal to 150 DEG C. The large-scale rotor processed by the process has extremely high strength and excellent plasticity, toughness, and high thermal resistance. The process solves the problem of low rotor performance, avoids cracking risks and guarantees the performance, strength index and impact resistance value of the rotor.

Owner:CITIC HEAVY INDUSTRIES CO LTD

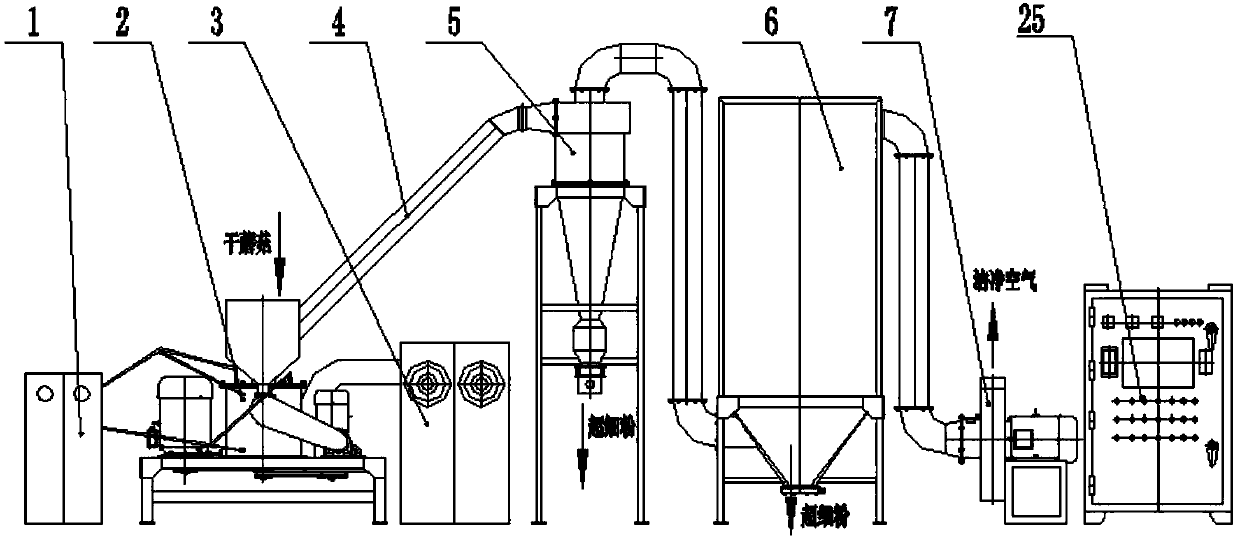

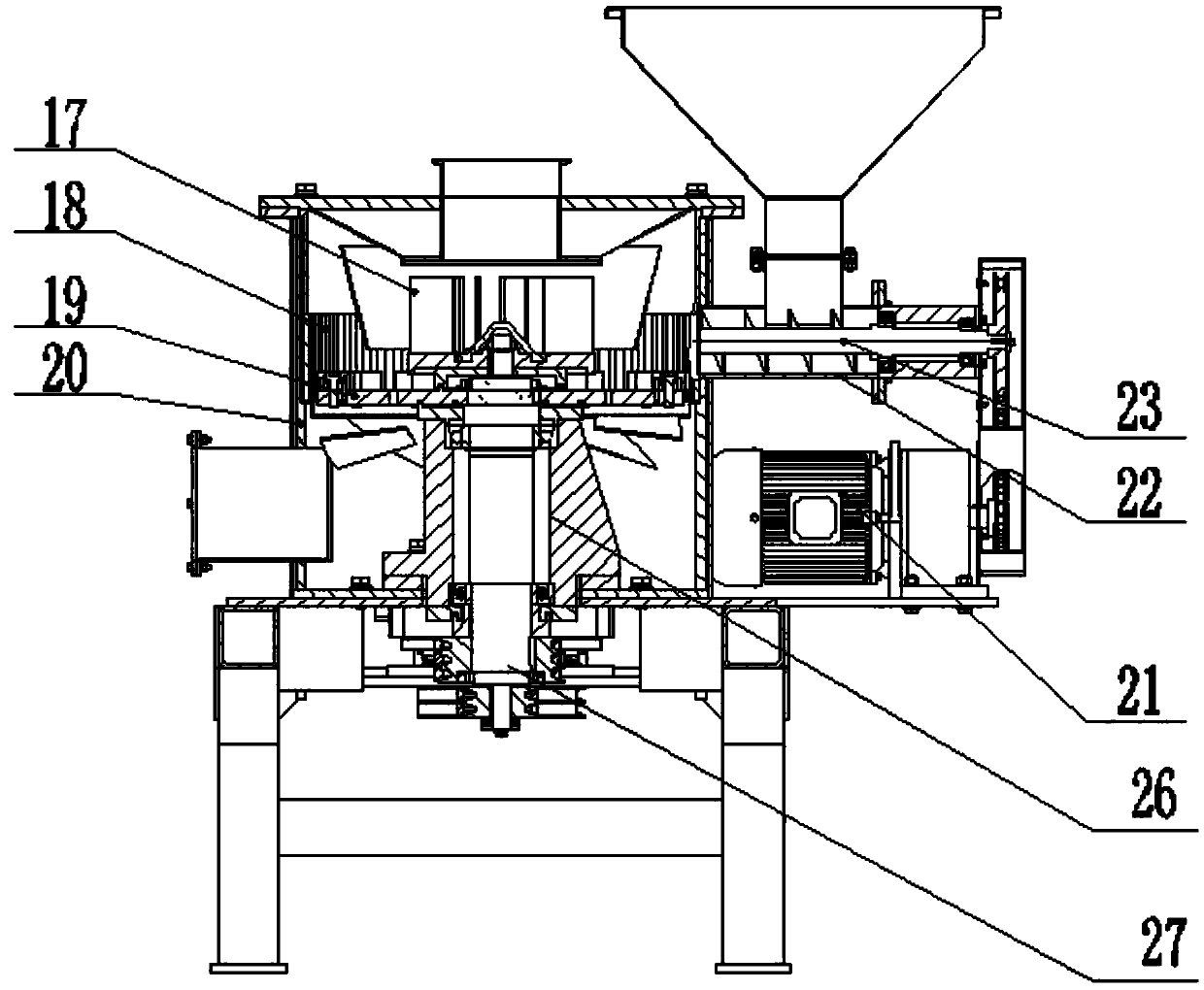

Direct feeding dried mushroom low-temperature ultrafine crusher and operation method

PendingCN107790267AIncrease productivitySave spaceDirt cleaningGrain treatmentsMushroomEnvironmental geology

The invention discloses a direct feeding dried mushroom low-temperature ultrafine crusher and an operation method, solves the problems of difficulty in direct feeding in deep processing of dried mushrooms, incapability of continuously producing, large particle size and nonuniform particle size in the prior art, and achieves the effects of capability of realizing direct feeding of the dried mushrooms without crudely crushing, prevention of aluminous degeneration through low-temperature crushing and small and uniform particle sizes of finished products. The direct feeding dried mushroom low-temperature ultrafine crusher comprises a mechanical ultrafine crusher head, a low-temperature heat balance device and an ultrafine powder collecting device; the low-temperature heat balance device comprises a water cooler and an air cooler; the ultrafine powder collecting device comprises a cyclone collector, a pulse dust remover and an induced draft fan; the low-temperature heat balance device usesthe water cooler and the air cooler for low-temperature protection of the mechanical ultrafine crusher head during crushing; crushed ultrafine powder is collected by the cyclone collector through a mixing conveying pipe under a negative-pressure effect generated by induced draft fan; and dust generated in the operating process is collected by the pulse dust remover.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

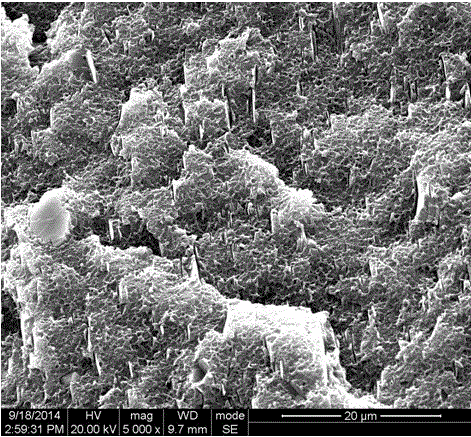

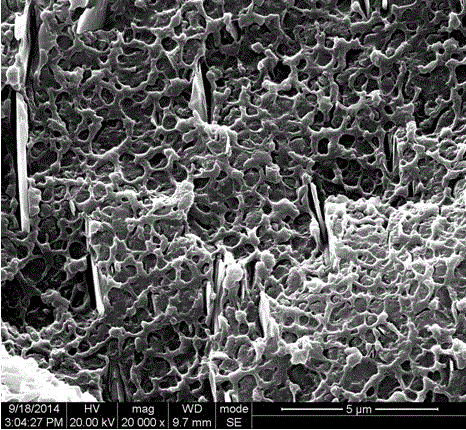

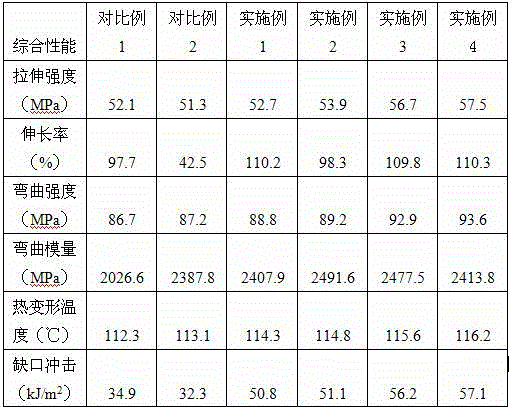

High-performance mineral-filled PC/ABS alloy material and preparation method thereof

The invention relates to the technical field of a macromolecular material, and particularly relates to a high-performance mineral-filled PC / ABS alloy material and a preparation method thereof. The high-performance mineral-filled PC / ABS alloy material is prepared from the following raw materials in parts by weight: 60-80 parts of bisphenol A type PC, 20-40 parts of master batch, 1-4 parts of a compatible flexibilizer, 0.1-0.2 part of an antioxidant, 0.2-0.3 part of a lubricating agent and 0.4-0.8 part of a silane coupling agent, wherein the master batch is a mixture consisting of talcum powder, a coupling agent and ABS according to amass ratio of (45-55) to (1-3) to (45-55). The high-performance mineral-filled PC / ABS alloy material disclosed by the invention is good in impact toughness and therefore the comprehensive performances of the material is comprehensively guaranteed. By adopting a secondary commixing technique, the preparation method of the high-performance mineral-filled PC / ABS alloy material has the advantages that inorganic fillers can be uniformly orientated and distributed inside a base body, so that the modulus, strength and heat resistance of the alloy material are improved.

Owner:SUZHOU SILVER AGE TECH CO LTD

Elastic-plastic steel-structured safety protection device

ActiveCN101949138AExtended impact timeDissipate impact energyRoadway safety arrangementsElastic plasticEngineering

Owner:CCCC CIVIL ENG SCI & TECH

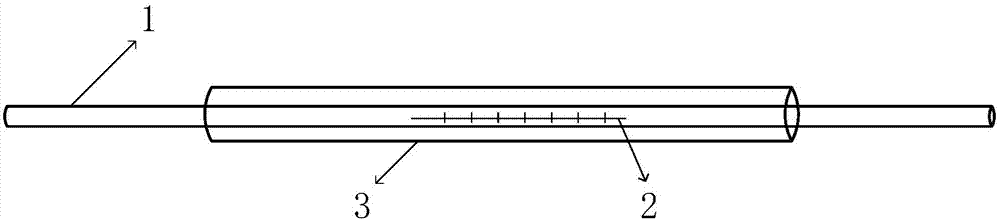

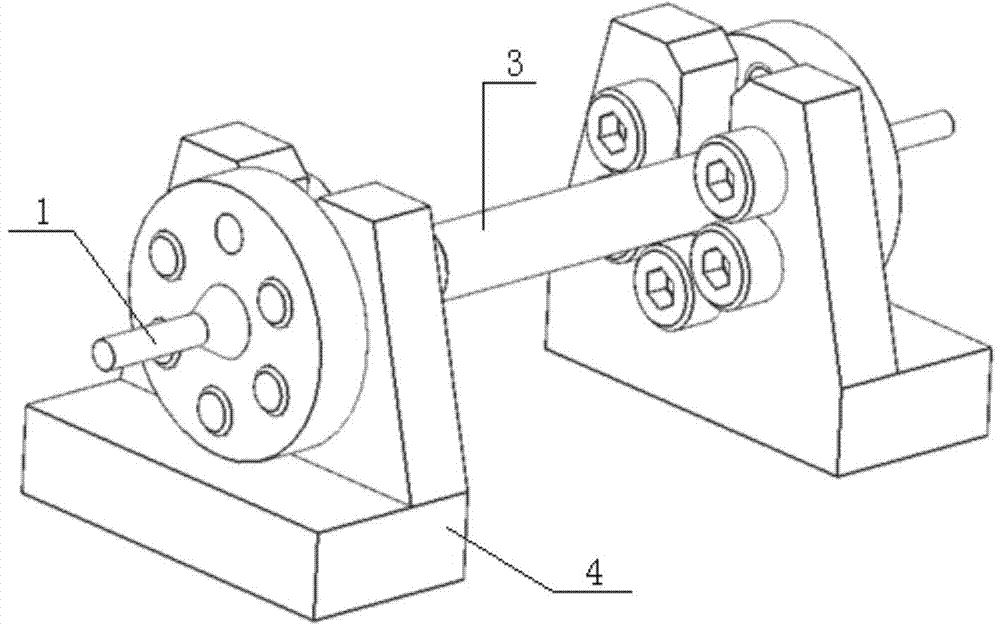

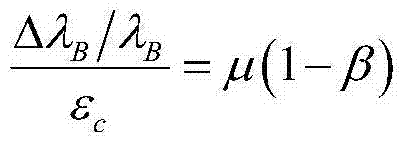

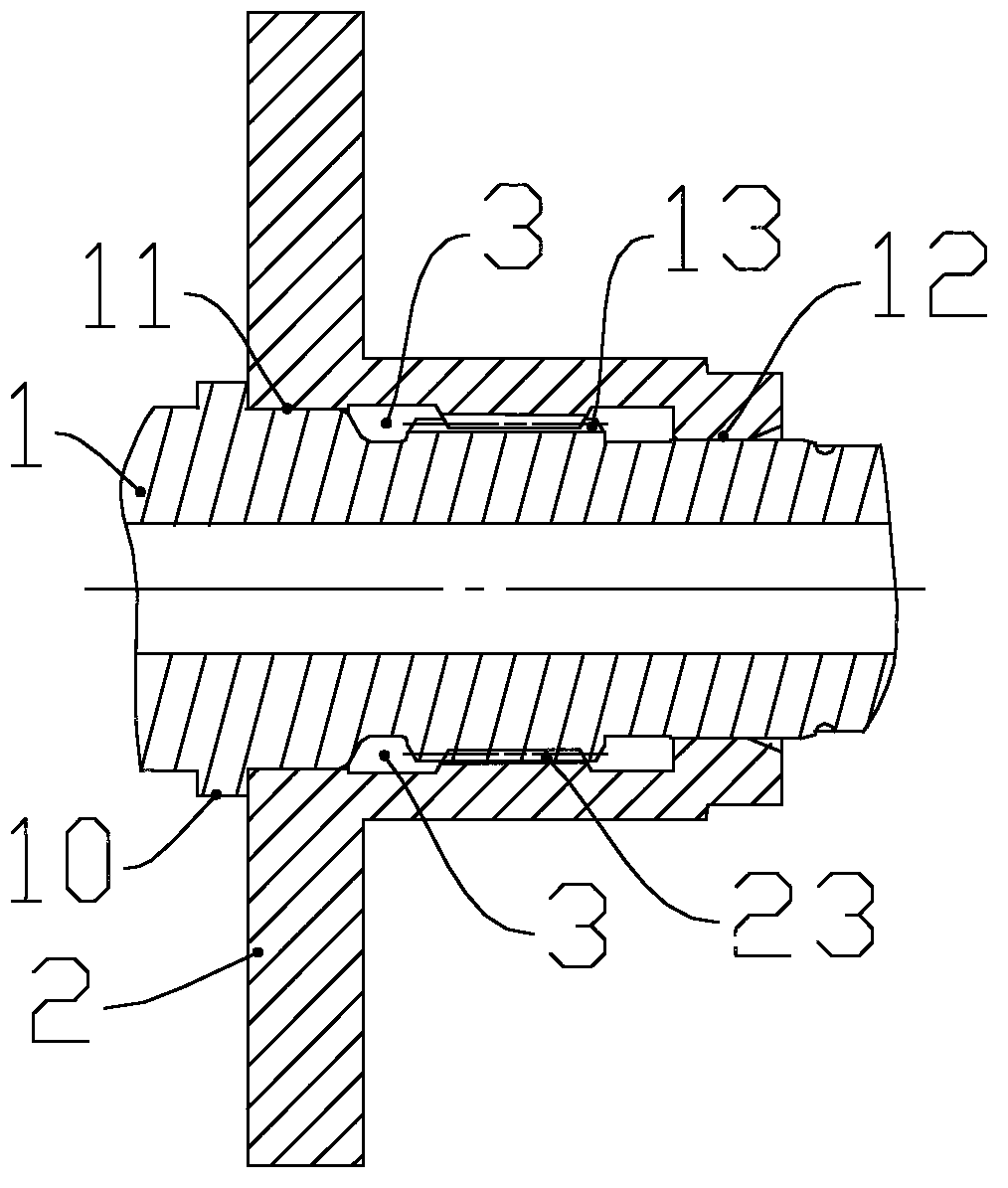

Split type optic fiber strain sensor assembly

InactiveCN104279974AEasy installation and layoutEasy to reuseUsing optical meansGratingUltrasonic welding

The invention provides a split type optic fiber strain sensor assembly. Under the premise that fiber bragg grating prestressed encapsulation is not influenced, an encapsulation mode and an assembling mode are decoupled, and the problem that a sensor cannot be used again after being mounted once is solved through separation of a metal encapsulation protection piece and an assembling base. The split type optic fiber strain sensor assembly comprises a sensing element, the encapsulation protection piece and the assembling base. The sensing element is a fiber bragg grating, and the encapsulation protection piece is a metal tube. After the fiber bragg grating penetrates through the mental tube, the clearance between the fiber bragg grating and the metal tube is welded and fastened in an ultrasonic welding mode. Optical fibers are led out from the two ends of the metal tube. The two ends of the metal tube are banded tightly through flange plates. The metal tube with the encapsulated sensing element is supported by the assembling base, and the flange plates at the two ends of the metal tube are connected with the assembling base.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

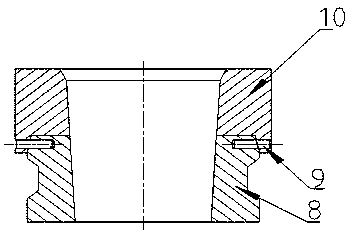

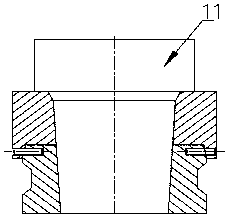

High-speed rotor positioning link structure

ActiveCN103307124AGuaranteed radial positioningGuaranteed reliabilityPortable liftingCouplings for rigid shaftsInterference fitHigh heat

The invention provides a high-speed rotor positioning link structure which comprises a rotor spindle and a rotor, wherein the rotor spindle is sleeved with the rotor on the periphery of the rotor spindle; the external diameter of the rotor spindle comprises a first end and a second end arranged in a position opposite to that of the first end; the external diameter of the rotor spindle is in interference fit connection with the internal diameter of the rotor at the first end and the second end; external gears are arranged on the external diameter of the rotor spindle; internal gears are arranged on the internal diameter of the rotor in an opposite manner; the external gears are in internal gearing with the internal gears. The high-speed rotor positioning link structure has the following benefits: a combined structure formed by the interference fit connection and the internal gearing of the gears can better ensure the radial positioning of the rotor spindle and the rotor, and the reliability and capability of bearing impulse load of the rotor spindle and the rotor during a high-speed high-temperature high-load operating process.

Owner:CHINA AVIATION POWER MACHINE INST

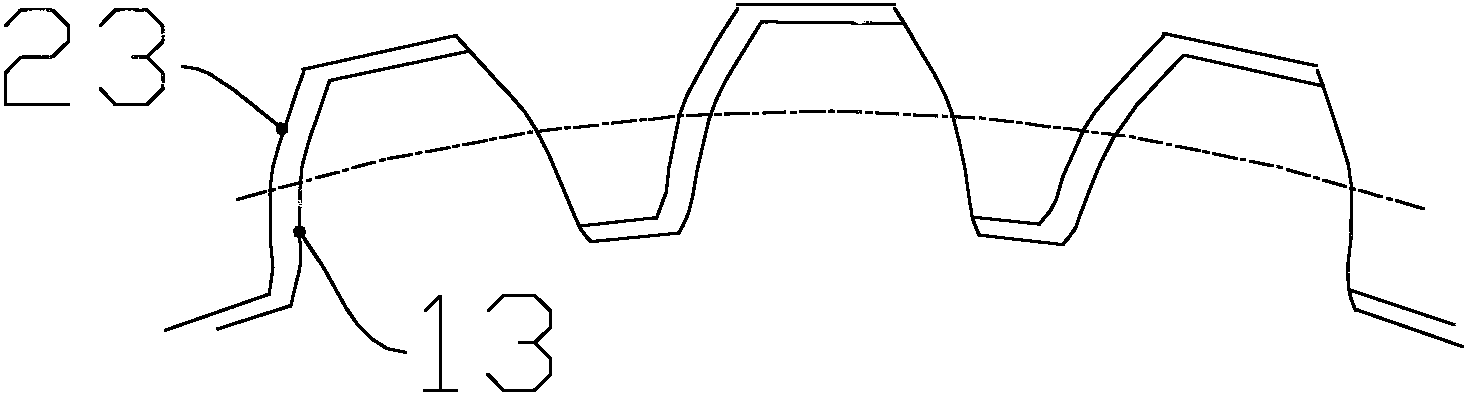

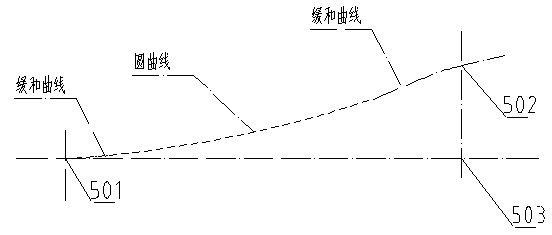

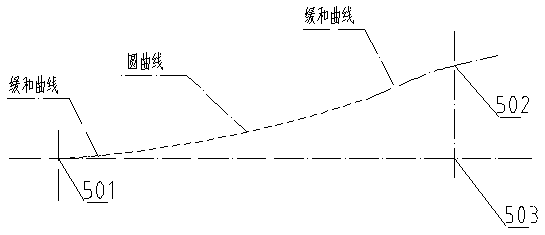

Turnout line shape of joint flexible type turnout bending device

ActiveCN103132404AImprove comfortExtend your lifeRailway tracksMechanical devices for scotch-blocksSacroiliac jointEngineering

The invention relates to a turnout line shape of a joint flexible type turnout bending device. The turnout line shape is used for special track conversion in straddle type single track traffic. The turnout line shape comprises a turnout fixed end, a movable end lateral line position and a movable end straight line position. A buffer curve is arranged between the turnout fixed end and the circular curve, and a buffer curve is arranged between the circular curve and the movable end lateral line position. The turnout line shape has the advantages of adopting combination of a rotating line, a round curve and a rotation curve, ensures that impact changes slowly when cars passe through the line, cannot cause the existing product hard impact, is favorable for improving passenger comfort, and prolongs service life of a vehicle bogie and a turnout.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

Pulse crusher

InactiveCN101574676AImprove work efficiencyIncrease the sieving speedGrain treatmentsEngineeringCrusher

The invention discloses a pulse crusher in the field of material crushing devices, which comprises a shell, wherein the upper part of the shell is provided with a feed opening, a rotor is arranged in the shell, a sieving plate is arranged on the periphery of the rotor in a half surrounded mode to form a crushing room, and the upper part of the sieving plate is connected with the lower side of the feed opening transitionally; and the upper side of the extended periphery of the sieving plate in the feed opening is provided with a plurality of nozzles blowing towards a circulation layer directly. When the pulse crusher works, pulse airflow can generate instant impact force to impact large particles directly so that the large particles get into a beating area of the rotor, and small particle materials have more sifting opportunities; and the pulse airflow can improve the sifting speed of the materials, and the pulse air flow is ensured to have excellent impact effect. The pulse crusher breaks through the inherent prejudice in the prior art and breaks the circulation layer in the feed opening, and the breaking effect is more direct and efficient, thus the pulse crusher can promote the sifting of the small particle materials and the re-striking and the re-crushing of the large particle materials, and improve the working efficiency of the crusher.

Owner:JIANGSU MUYANG GRP CO LTD

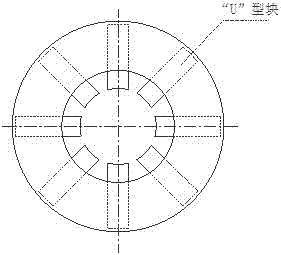

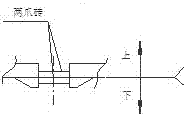

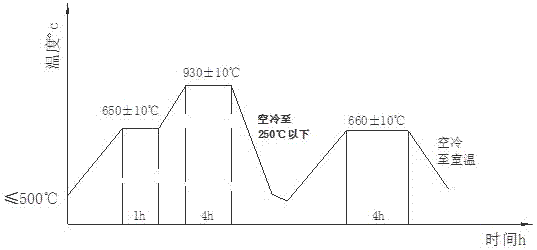

High-speed bullet train brake disc body and casting method and heat treatment method thereof

InactiveCN107354384AImprove mechanical propertiesImprove thermal conductivityBraking discsFoundry mouldsUltimate tensile strengthHeat treated

The invention discloses a high-speed bullet train brake disc body and a casting method and heat treatment method thereof. The brake disc body is obtained through casting and heat treatment, an upper disc surface and a lower disc surface of the disc body are parallel to each other, and the upper disc surface and the lower disc surface of the disc body are connected through a plurality of U-shaped blocks which are uniformly distributed. According to the physical design of the disc body, a good balance degree of the disc body during high-speed rotation is guaranteed, and the amplitude during high-speed braking of the brake disc is greatly reduced; according to the design of the casting technique of the disc body, the quality of the disc body is greatly improved, and a high safety coefficient and a long service life of the disc body in long-time continuous braking are guaranteed; and according to the design of the heat treatment technology, the strength and the impact to be borne by the disc body during high-speed braking under the extremely-cold environment are reduced, and the thermal warping deformation generated in the continuous braking process is also reduced.

Owner:JIANGSU JINSHI CASTING & FORGING

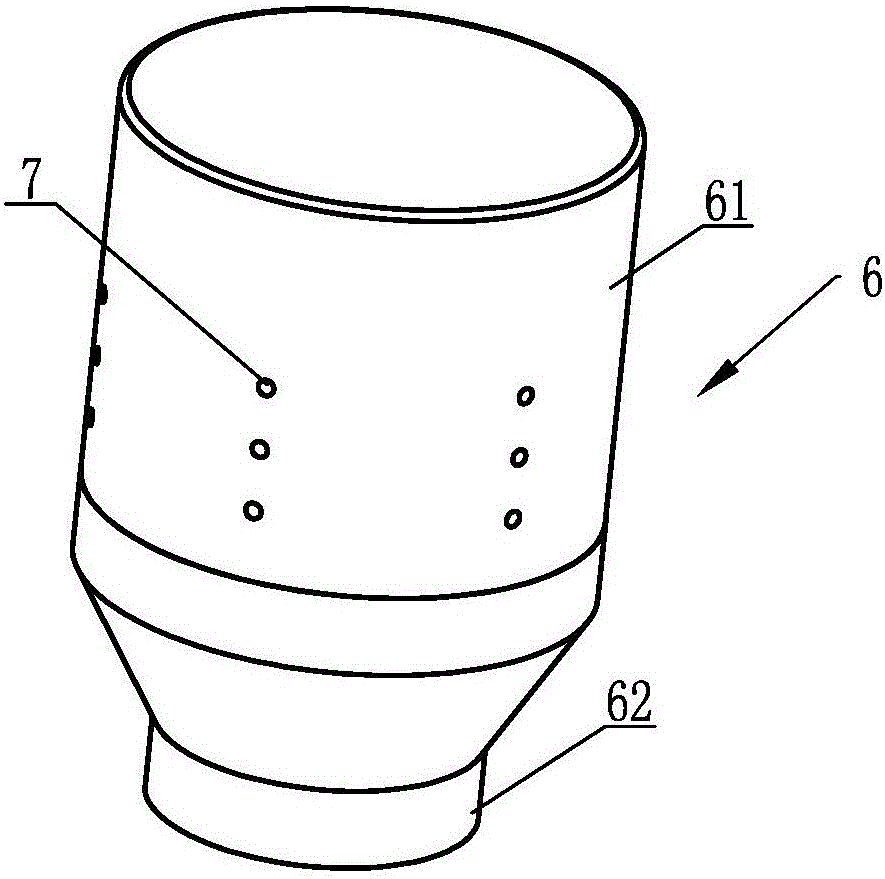

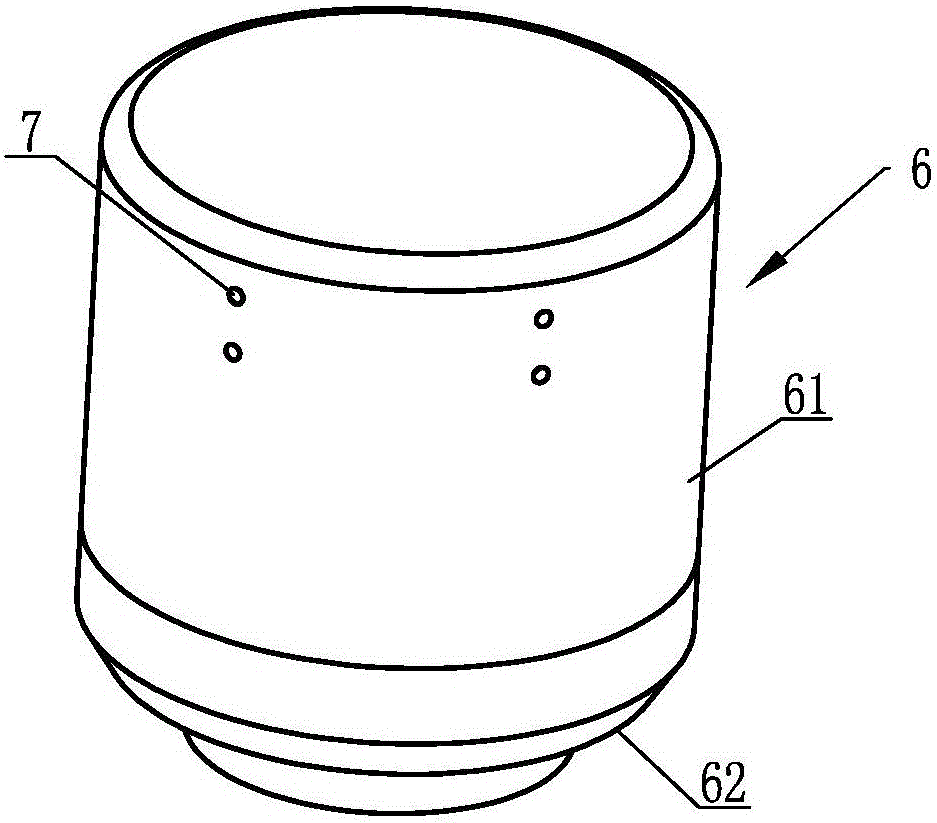

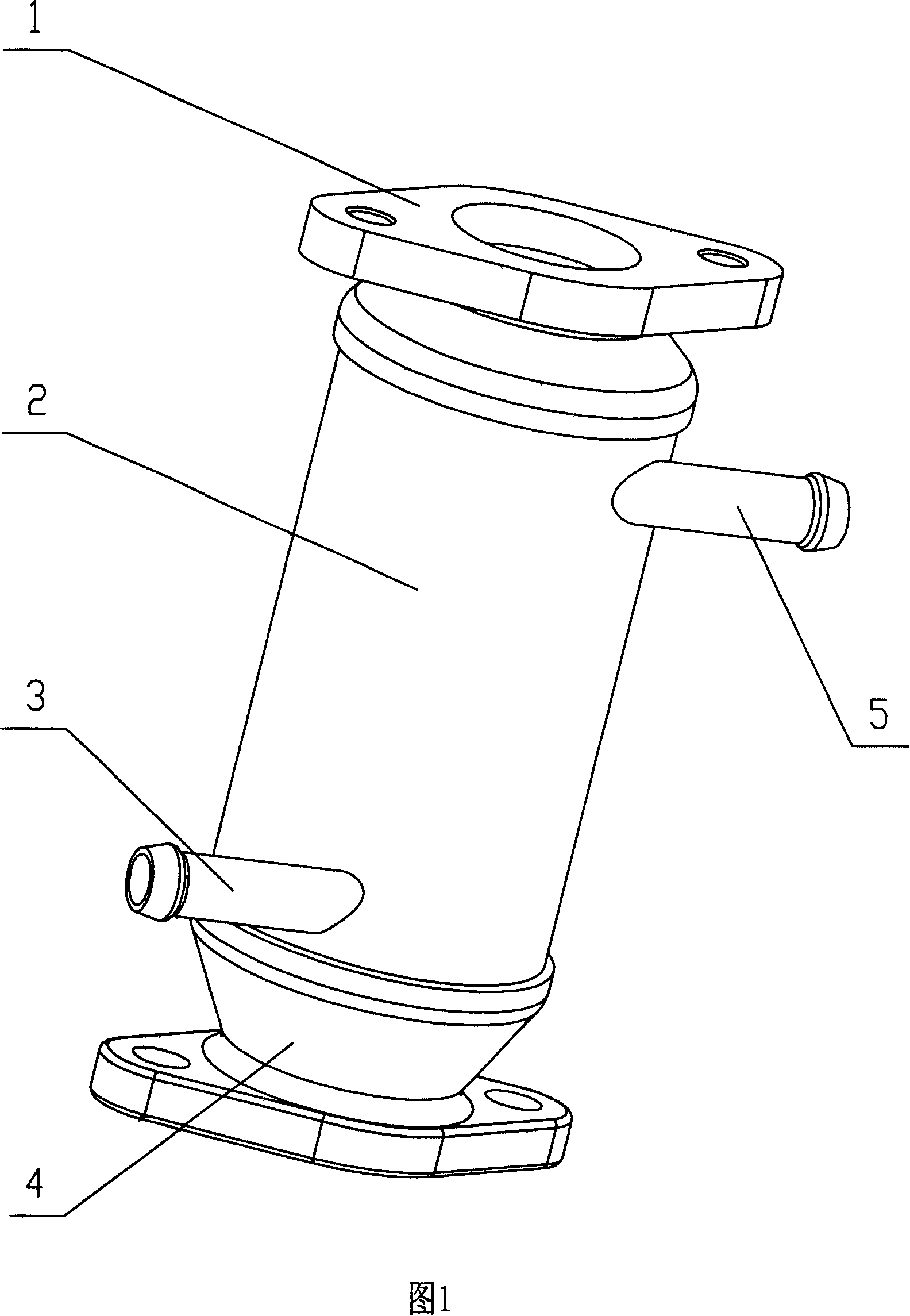

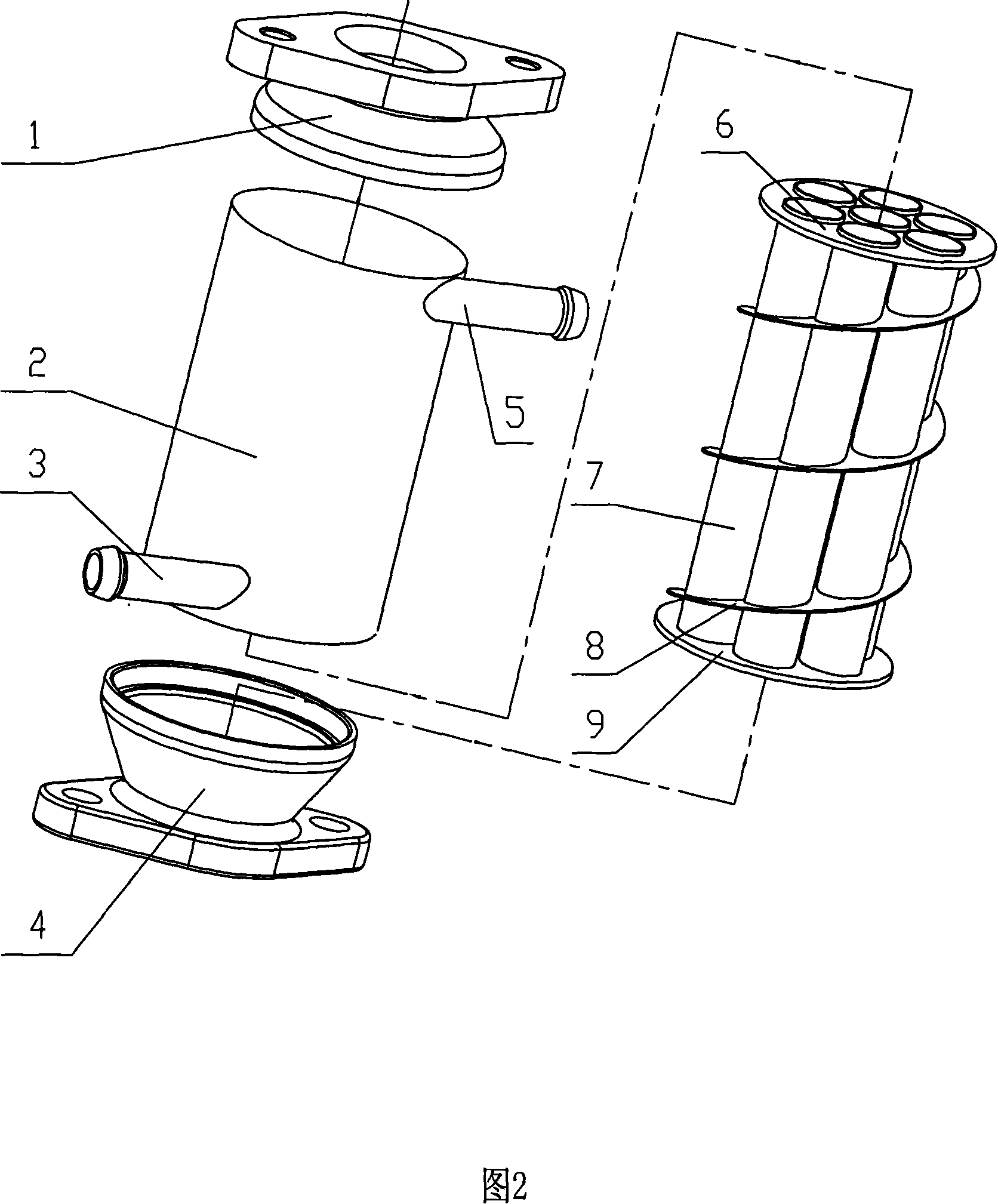

Colliding condensation type oil-gas separator for natural gas engine

ActiveCN105673137AImproved impact separationImprove separation efficiencyMachines/enginesCrankcase ventillationExhaust pipePetroleum engineering

The invention discloses a colliding condensation type oil-gas separator for a natural gas engine. The colliding condensation type oil-gas separator comprises an outer release sleeve, a sleeve end cover, an exhaust pipe, a filter element and an air inlet supporting pipe, wherein at least two layers of inner release sleeves which are separately connected with the air inlet supporting pipe sequentially are sleeved with the outer release sleeve; oil-gas jetting holes are formed in the circumferential walls of the inner release sleeves; oil accumulating circular grooves are separately formed in the lower ends of all the inner release sleeves positioned outside the innermost layer of inner release sleeve and the lower end of the outer release sleeve; oil guiding holes are separately formed in the corresponding oil accumulating circular grooves in a penetrating way; an oil accumulating choke tube communicates with the oil guiding hole positioned in the outer release sleeve; an oil-gas mixture can form a colliding condensation phenomenon by using all the oil-gas jetting holes; in addition, by using a separating action of a filter element, the oil-gas mixture is filtered and separated for multiple times; the sleeve end cover can be opened for facilitating cleaning and maintenance at fixed period; accumulated oil is exported outwards layer by layer for collecting by using the oil accumulating circular grooves and the oil guiding holes; and by using the oil accumulating choke tube, the reflow of the mixed oil and gas can be avoided, thereby guaranteeing the colliding condensation effect and improving the separating rate of oil and gas.

Owner:WEICHAI XIGANG NEW ENERGY POWER

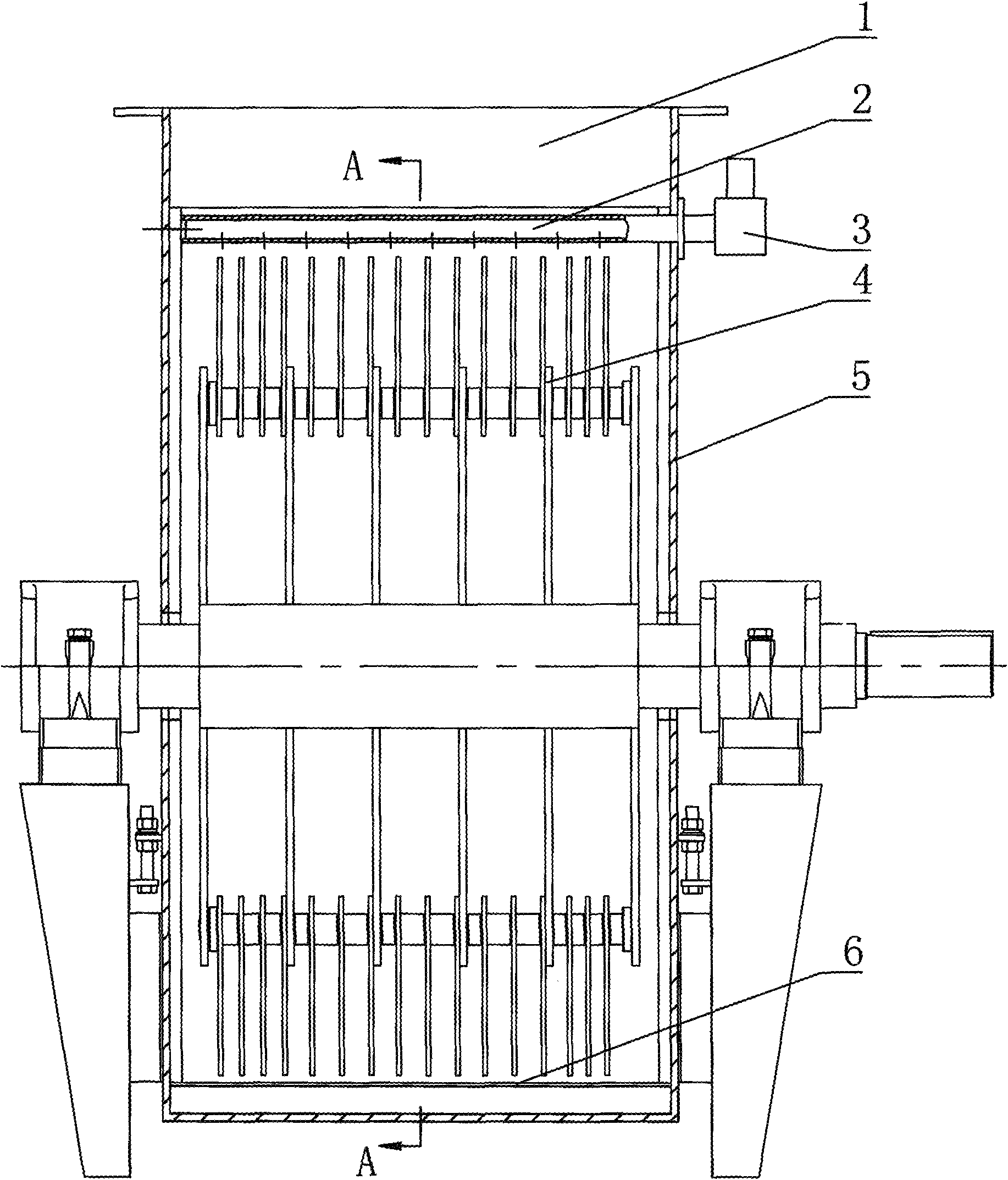

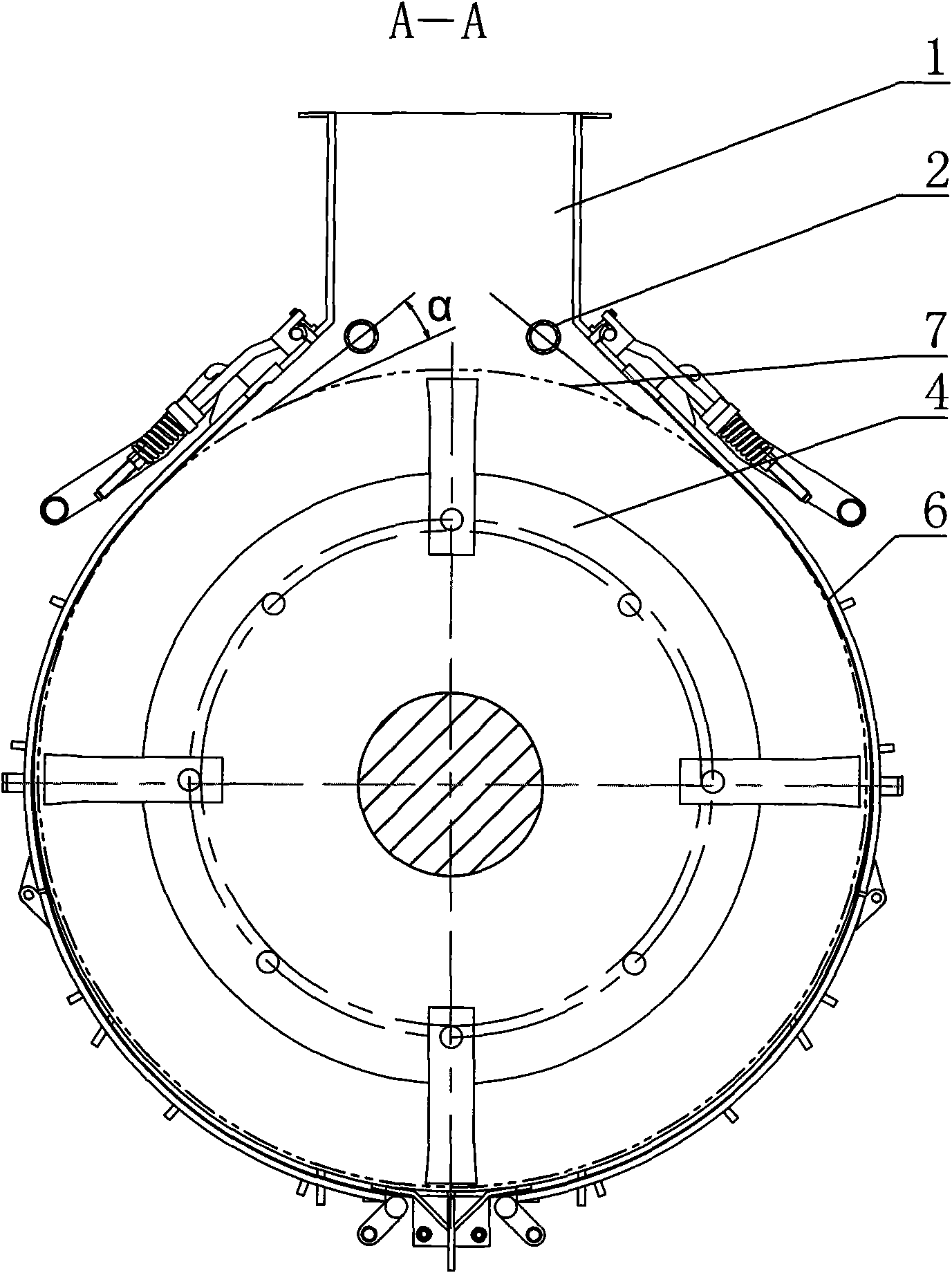

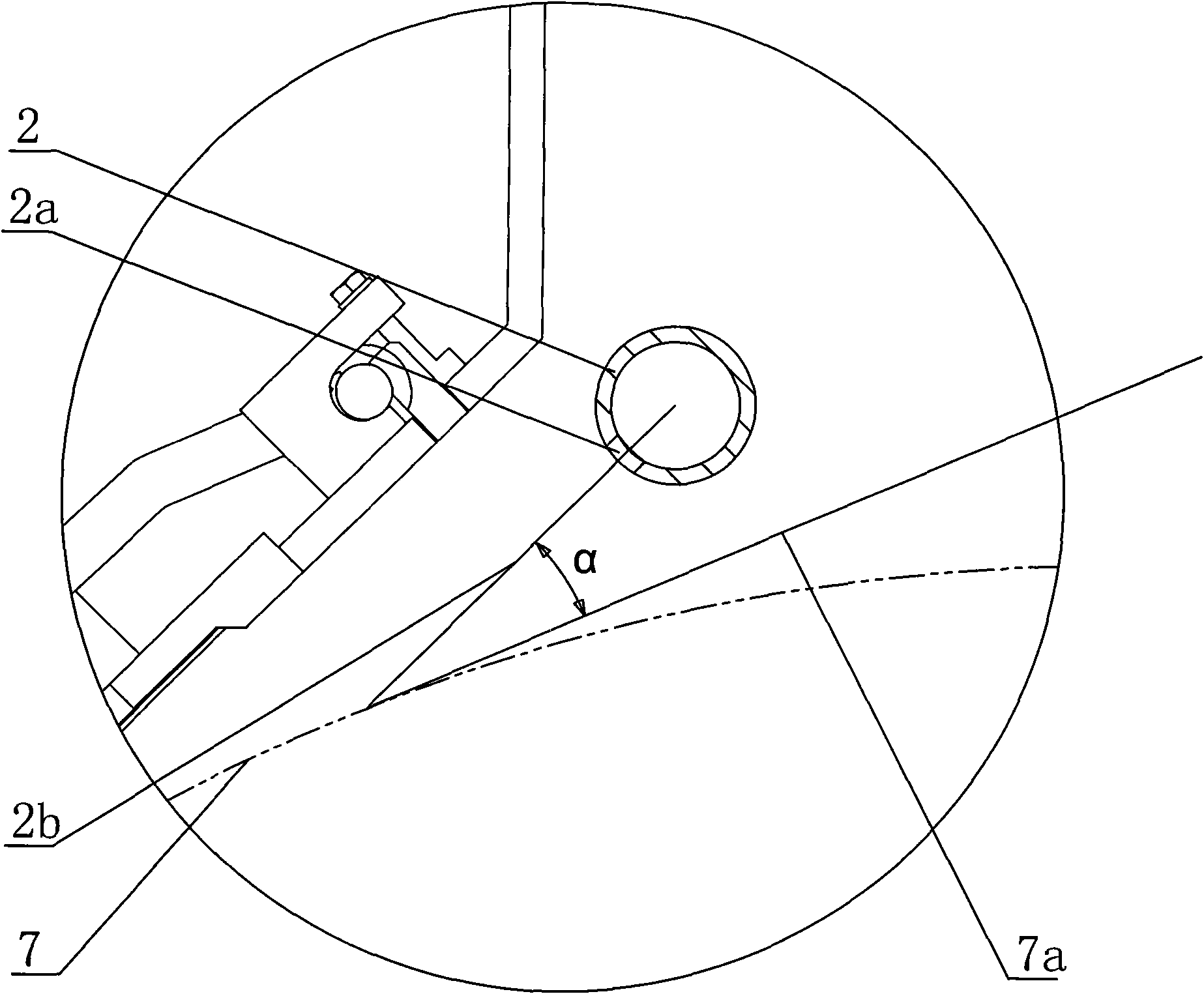

Pipe shell type heat exchanger and baffle

InactiveCN101055159AGuaranteed impact performanceImprove heat transfer effectHeat exchanger casingsStationary tubular conduit assembliesShell and tube heat exchangerEngineering

The invention discloses a tubular-shell type heat exchanger and deflector thereof. The deflector is of spiral-shape structure, and tube-beam in shell penetrates in the same. The shell and the spiral deflector form a spiral channel, cooling medium of shell side flows along the channel, always keeping a fixed included angle to the tube-beam, to effectively crash the tube-beam, so that heat exchange effect is good. The advantages of the invention includes: (1) the medium of the shell side always keeps a fixed included angle to the tube-beam in flowing, so that the invention has good crash heat exchange effect; (2) flowing distance of the medium of the shell side is relative longer; (3) dead angle does not exist during the flowing procedure of the medium of the shell side, so that flowing resistance is relatively small; (4) angle between cold medium inlet tube and cold medium outlet tube is optimized, so the cold medium can smoothly go in and out the shell side channel formed by spiral deflector for the small resistance; (5) spiral channel is easy to discharge the shell side gas at initial use thereby enhancing heat exchange efficiency.

Owner:ZHEJIANG YINLUN MACHINERY

Device and method for shocking and strengthening thin wall part edges through lasers

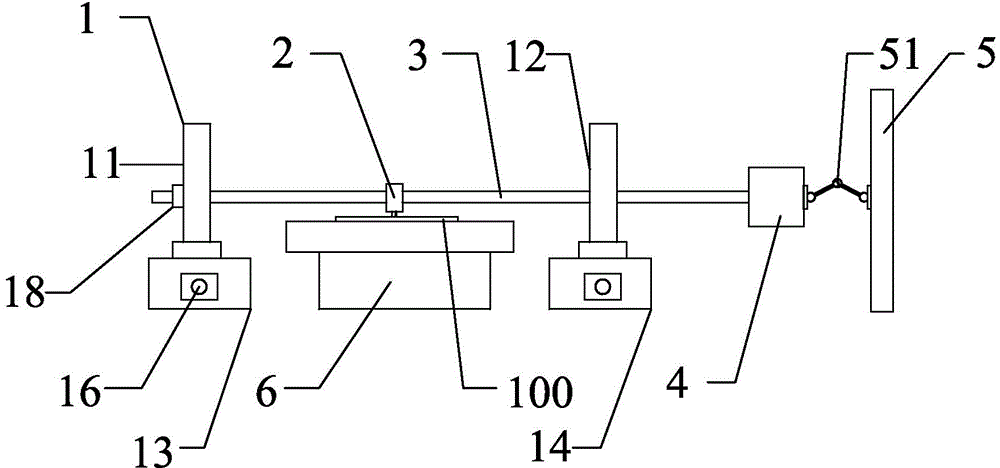

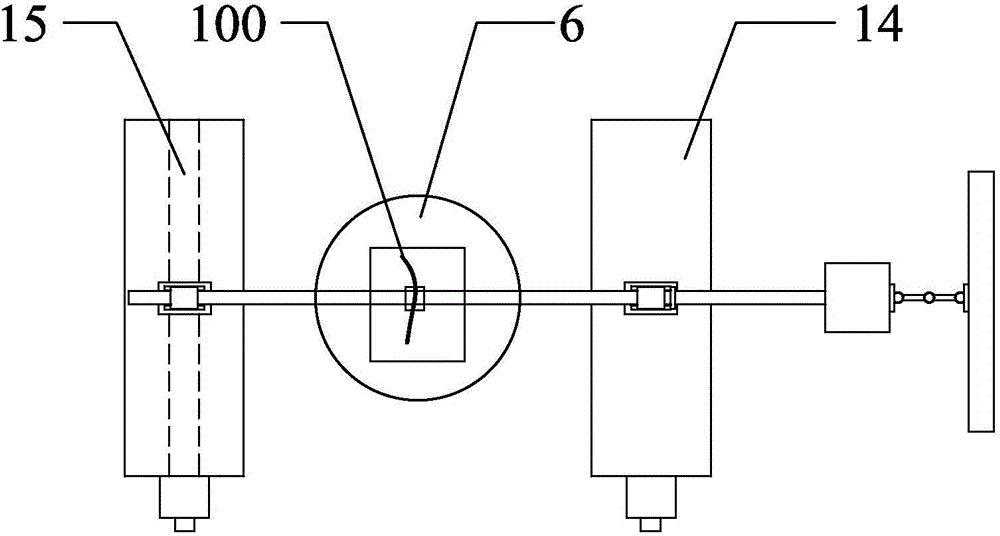

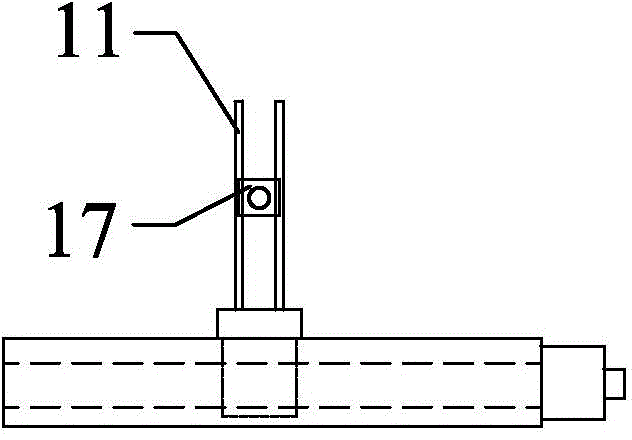

InactiveCN104148809ASave man hoursGuaranteed impact performanceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWorkbench

The invention discloses a device and method for shocking and strengthening thin wall part edges through lasers. The device comprises a surface path copy system and a laser shock system. The surface path copy system comprises a longitudinal support, an abutting device, a control rod, a control box, a fixing support and a workbench. The laser shock system comprises a pathway support, a motor set, a laser head and a shock workbench for placing parts to be shocked. According to the device and method for shocking and strengthening the thin wall part edges through the lasers, a theory of similar figures is mainly utilized, the surfaces of the parts to be shocked are tightly attached to the abutting device, the surface path copy system transmits the movement loci of attached blocks in the abutting device to the laser shock system, the movement loci of laser spots are kept pace with the closed blocks by adjusting movement of the laser head, and thus the purpose that laser shock and strengthening are conducted on the thin wall part edges is achieved. The device and method have the advantages of being low in cost, easy to operate and the like, and laser vertical incidence can be guaranteed.

Owner:DALIAN UNIV OF TECH +1

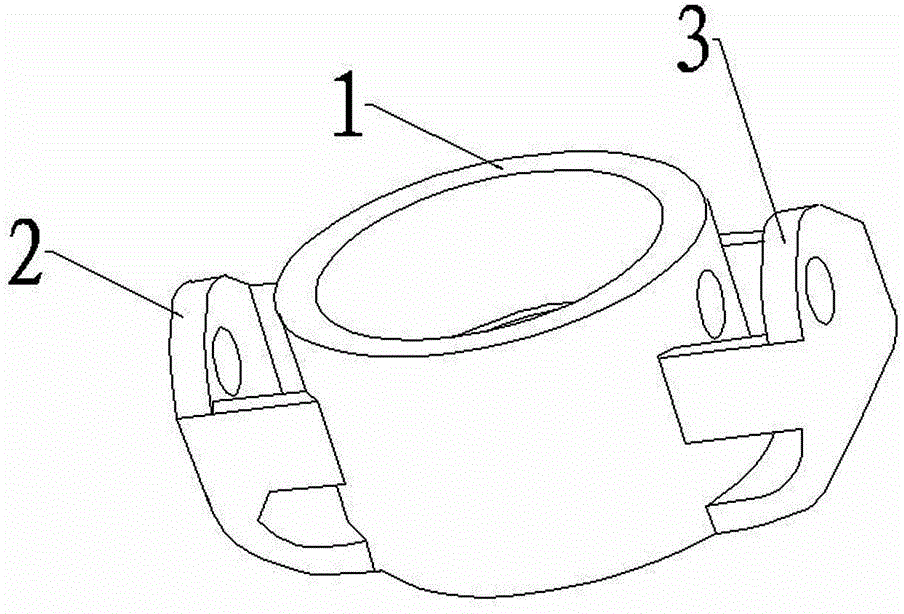

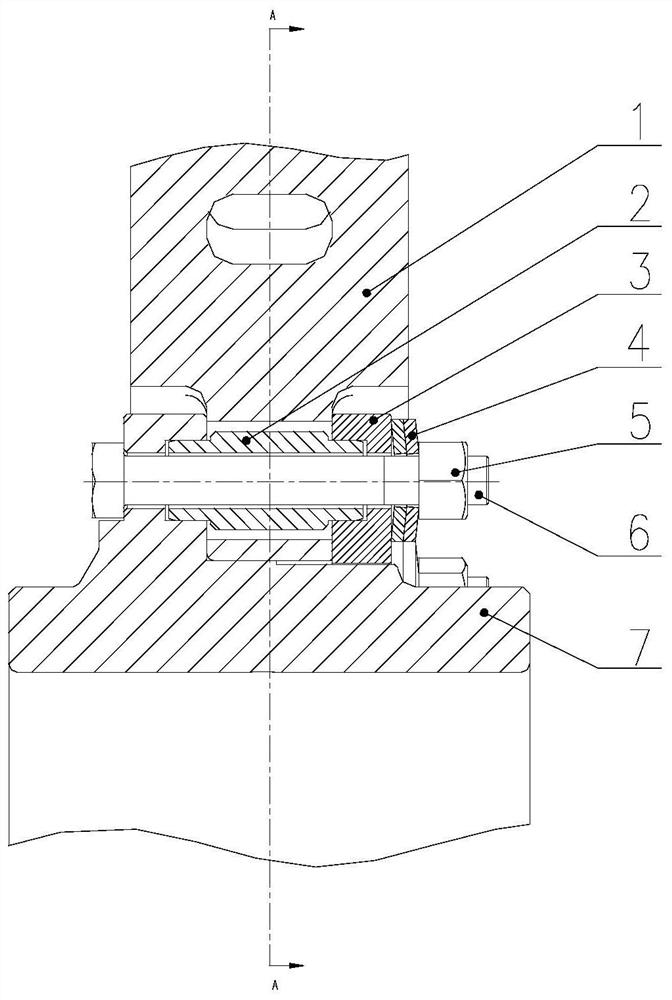

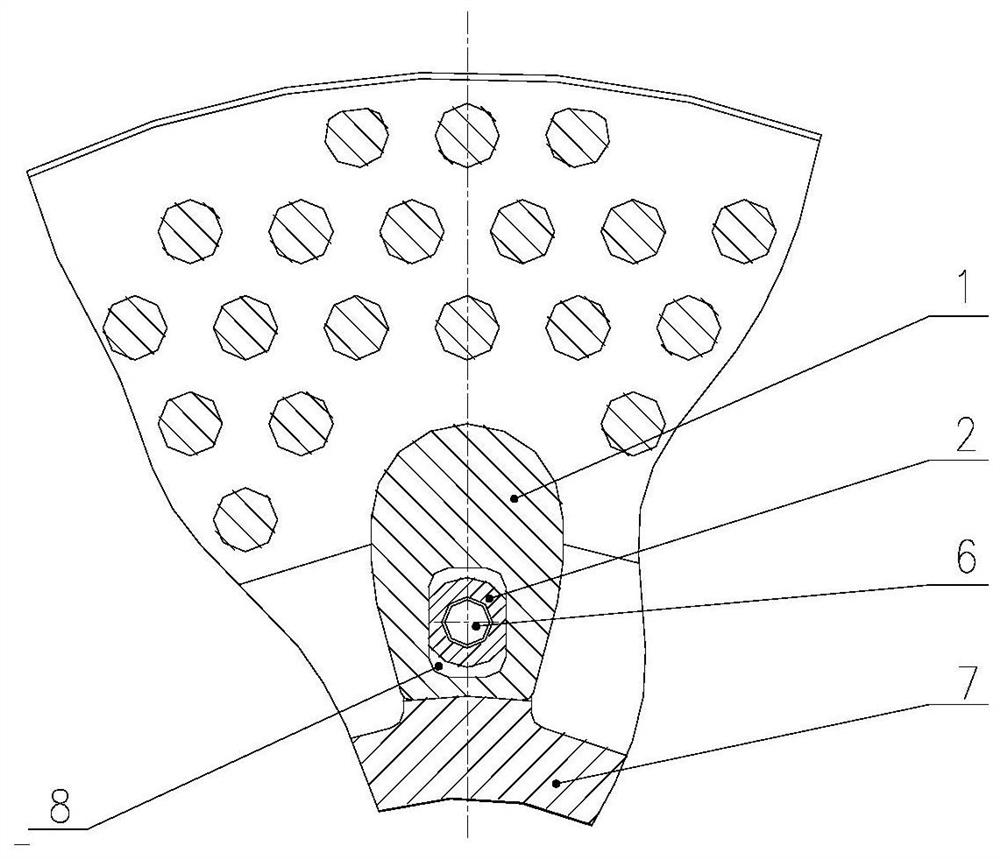

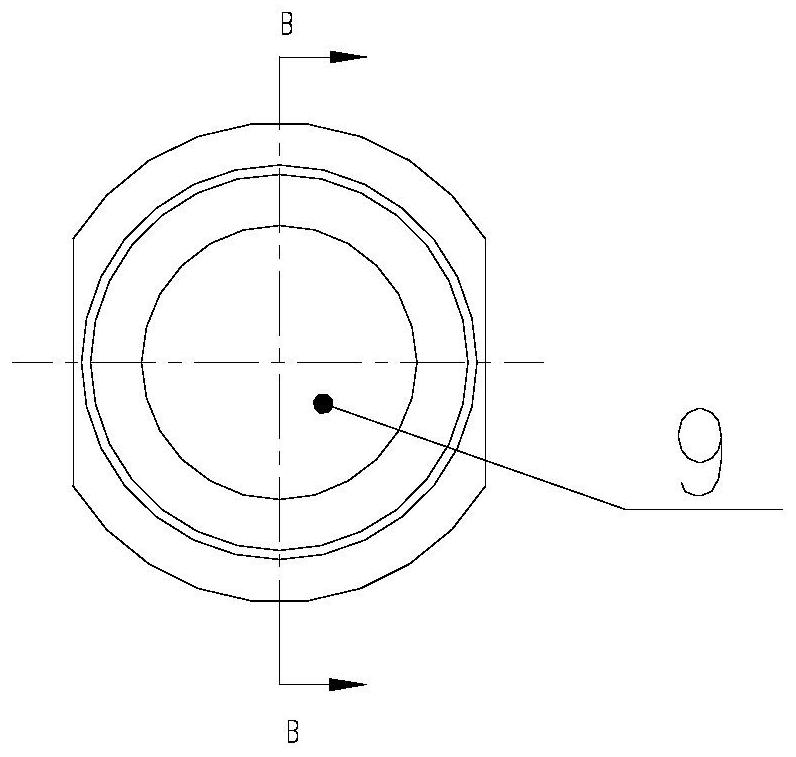

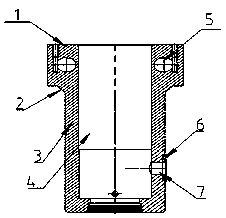

Shaft-mounted brake disc connecting device and vehicle adopting same

PendingCN112460170AGuaranteed normal expansionGuaranteed cutBraking discsEngineeringStructural engineering

The invention provides a shaft-mounted brake disc connecting device. A disc body and a disc hub are both provided with connecting parts which are the same in number and distributed in the same circumference; the connecting parts are provided with mounting holes; pressing plate connecting parts are provided with pressing plate mounting holes which are consistent with the mounting holes in the connecting parts of the disc body and disc hub in position and distributed in the same circumference; the mounting holes of the connecting parts of the disc body and the disc hub are correspondingly coincided; hollow pin connecting parts are inserted into the mounting holes; the pressing plate connecting parts are attached to the outer sides of the connecting parts of the disc body; the pressing platemounting holes of the hollow pin connecting parts are connected onto end columnar structures of the hollow pin connecting parts in a sleeving mode; and the connecting parts of the disc body are fixedonto the connecting parts of the disc hub through locking nut connecting parts. According to the shaft-mounted brake disc connecting device provided by the invention, by additionally arranging hollowpins with special structures, in the application process of a brake disc, circumferential rotation and dislocation do not occur among the disc body, a pressing plate and the disc hub, and meanwhile, when the disc body, the pressing plate and the disc hub are deformed or displaced in the radial direction due to temperature increase or accidental impact during braking of the brake disc, the risk ofdriving safety accidents caused by bolt breakage is reduced.

Owner:CRRC CHANGZHOU TECH MARK IND CO LTD +1

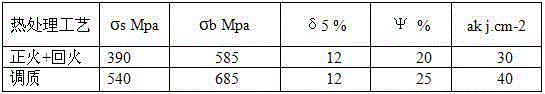

Manufacturing method of integral forging hook cylinder of hook bock assembly for minus 60 DEG C polar region drilling rig

InactiveCN108655665ASimple processGuaranteed StrengthDrilling rodsDrilling casingsPunchingCircular cone

The invention provides an integral forging hook cylinder of a hook bock assembly for a minus 60 DEG C polar region drilling rig and a manufacturing method of the integral forging hook cylinder. The forging hook cylinder is characterized in that the upper part is a square body, pin holes are formed in the square body, the lower part is a cylinder, the cylinder is provided with a base plate and pinholes, the middle part is in circular cone transition, and the interior is provided with a stepped through hole. The manufacturing method comprises the following steps that (1) forging is carried out,wherein upsetting and drawing are carried out on a blank in advance, then upsetting and punching are carried out in a die, a core penetrating shaft is drawn in a V-shaped anvil, the square body is formed by forging on a flat anvil, and finally correcting and forming are carried out in the die; and (2) heat treatment is carried out, wherein normalizing is carried out after forging, normal tempering is carried out after rough machining, and then sub-temperature quenching and high-temperature tempering are carried out. Compared with the prior art, the hook cylinder manufactured by the method isfewer in defect, good in low-temperature toughness, high in nondestructive inspection qualification rate, small in size and high in production efficiency is high; and meanwhile, the hook cylinder hasthe interchangeability with an original casting structure, the quality grade is in accordance with the PSL2 of Spec 8C of the American Petroleum Institute (API), and the use requirements of the minus60 DEG C polar environment are met.

Owner:RG PETRO MACHINERY GROUP

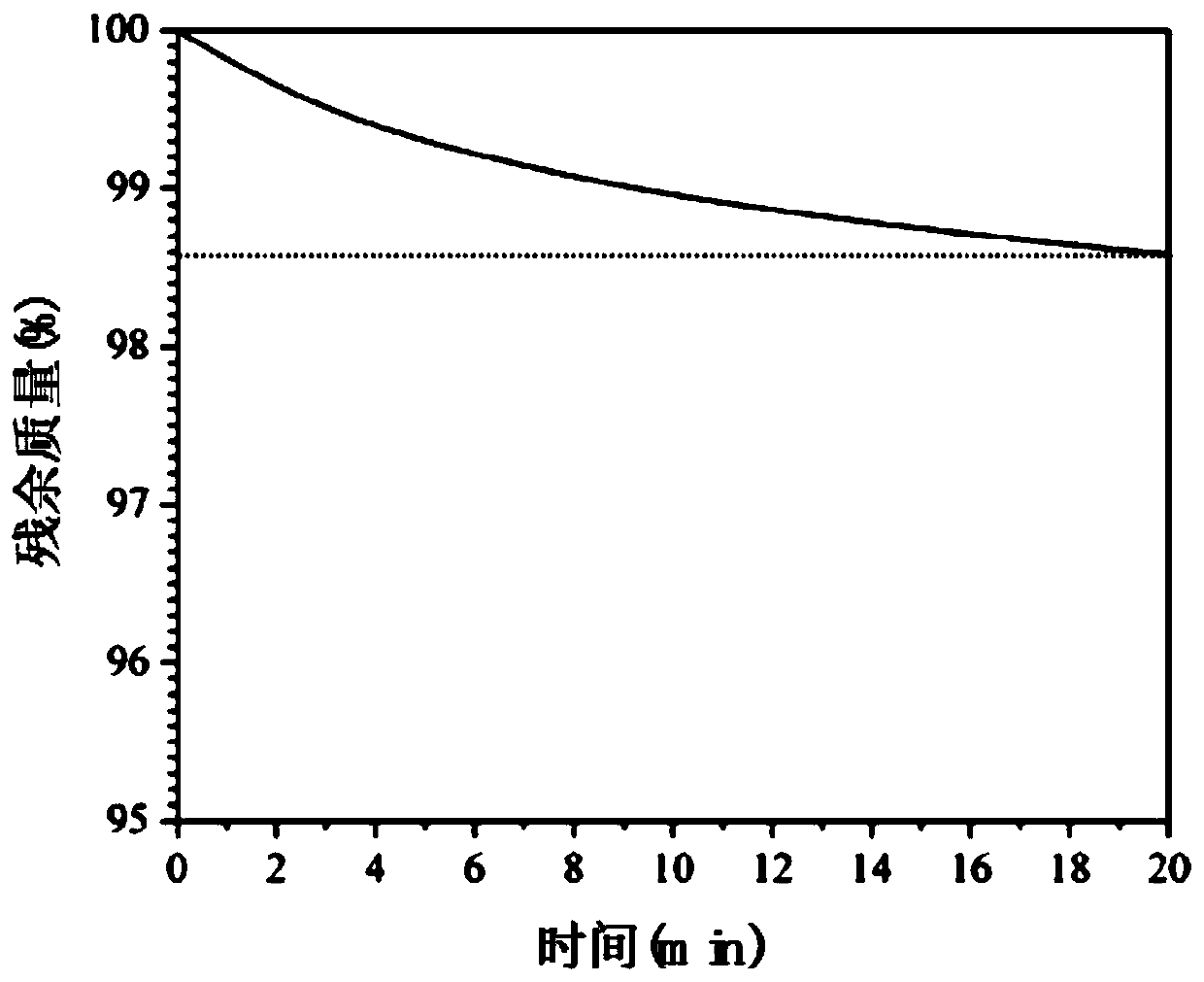

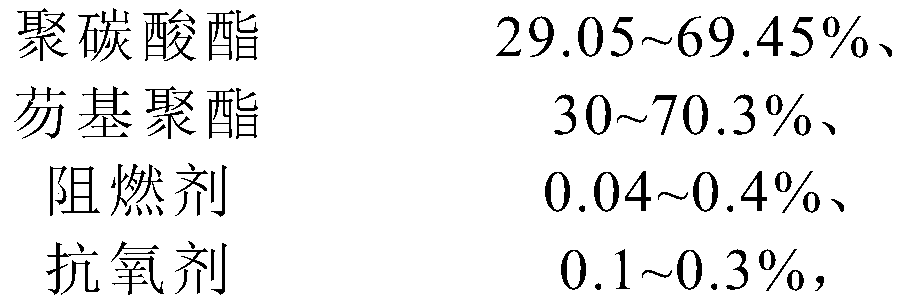

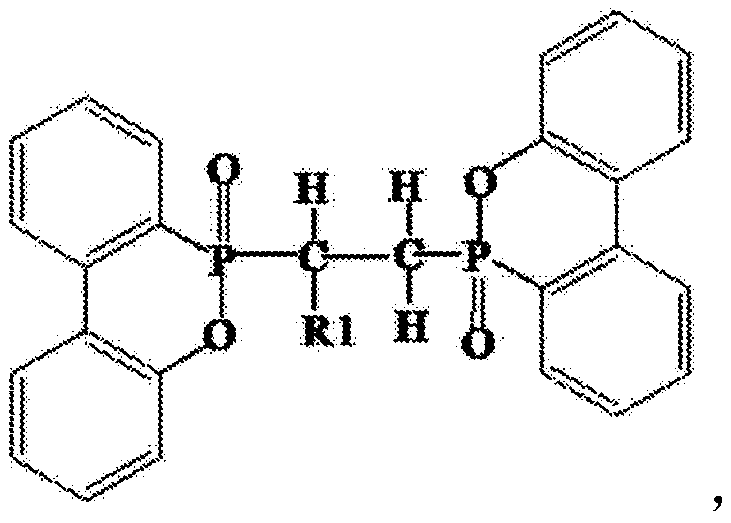

Low-temperature-impact-resistant high-transmittance flame-retardant polycarbonate composite material and preparation method thereof

The invention relates to a low-temperature-impact-resistant high-transmittance flame-retardant polycarbonate composite material and a preparation method thereof, and belongs to the technical field ofhigh polymer materials. The composite material comprises the following components in percentage by weight: 29.05-69.45% of polycarbonate, 30-70.3% of fluorenyl polyester, 0.04-0.4% of flame retardantand 0.1-0.3% of antioxidant, wherein the fluorenyl polyester is aromatic polyester resin with a main chain containing at least one fluorenyl group; the polycarbonate composite material disclosed by the invention is resistant to low-temperature impact, high in transparency, good in flame-retardant effect and low in birefringence.

Owner:宁波坚锋新材料有限公司

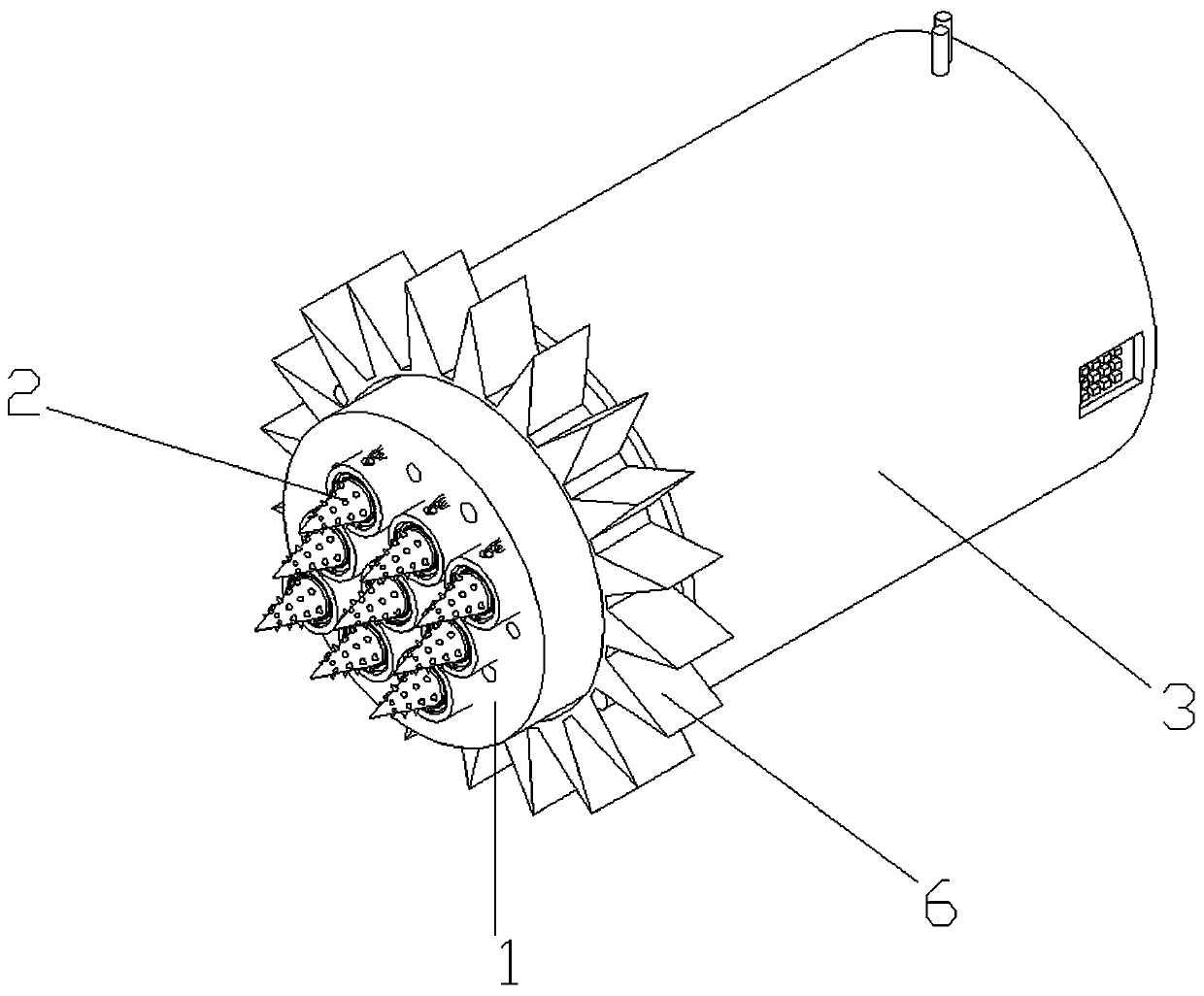

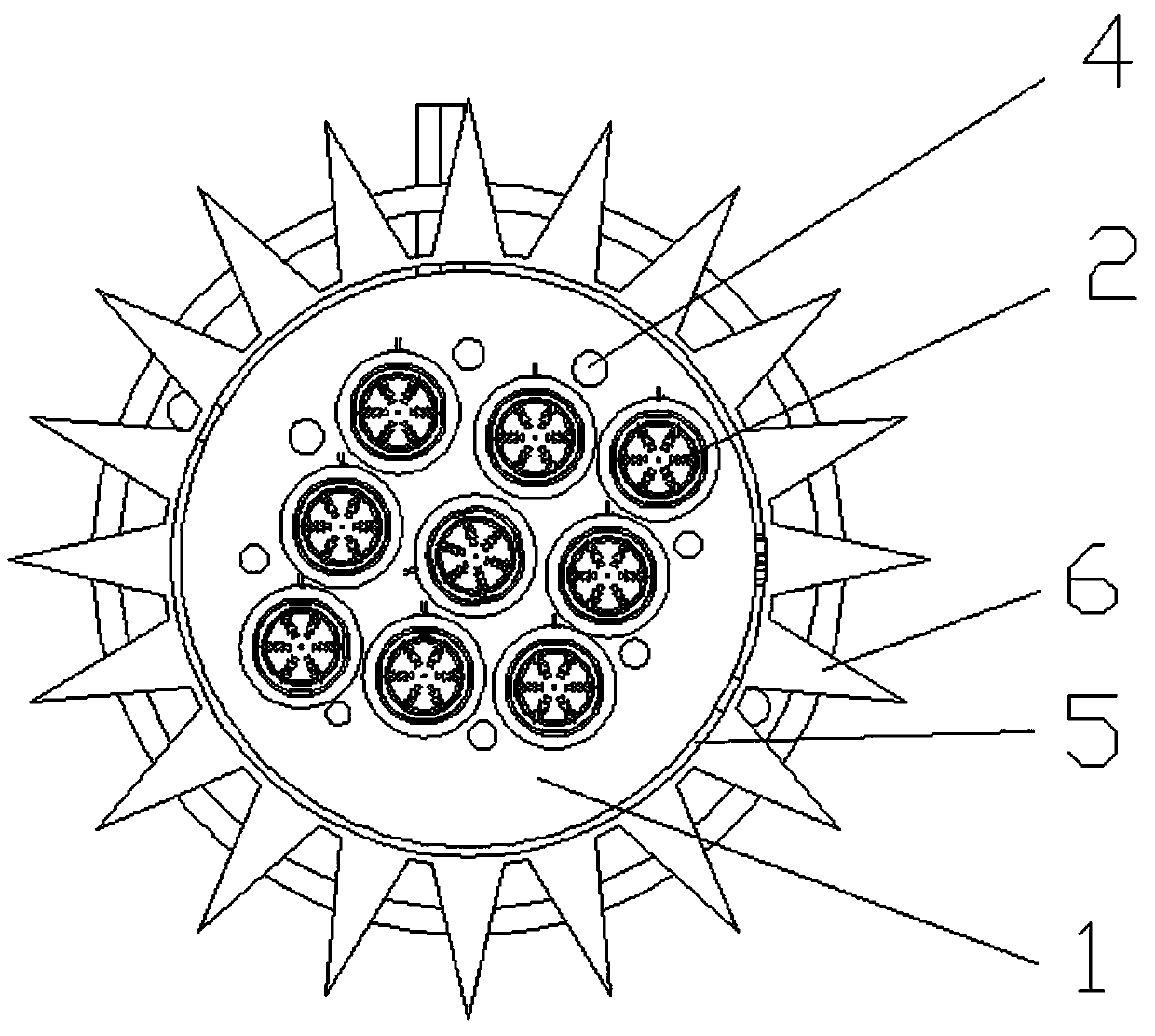

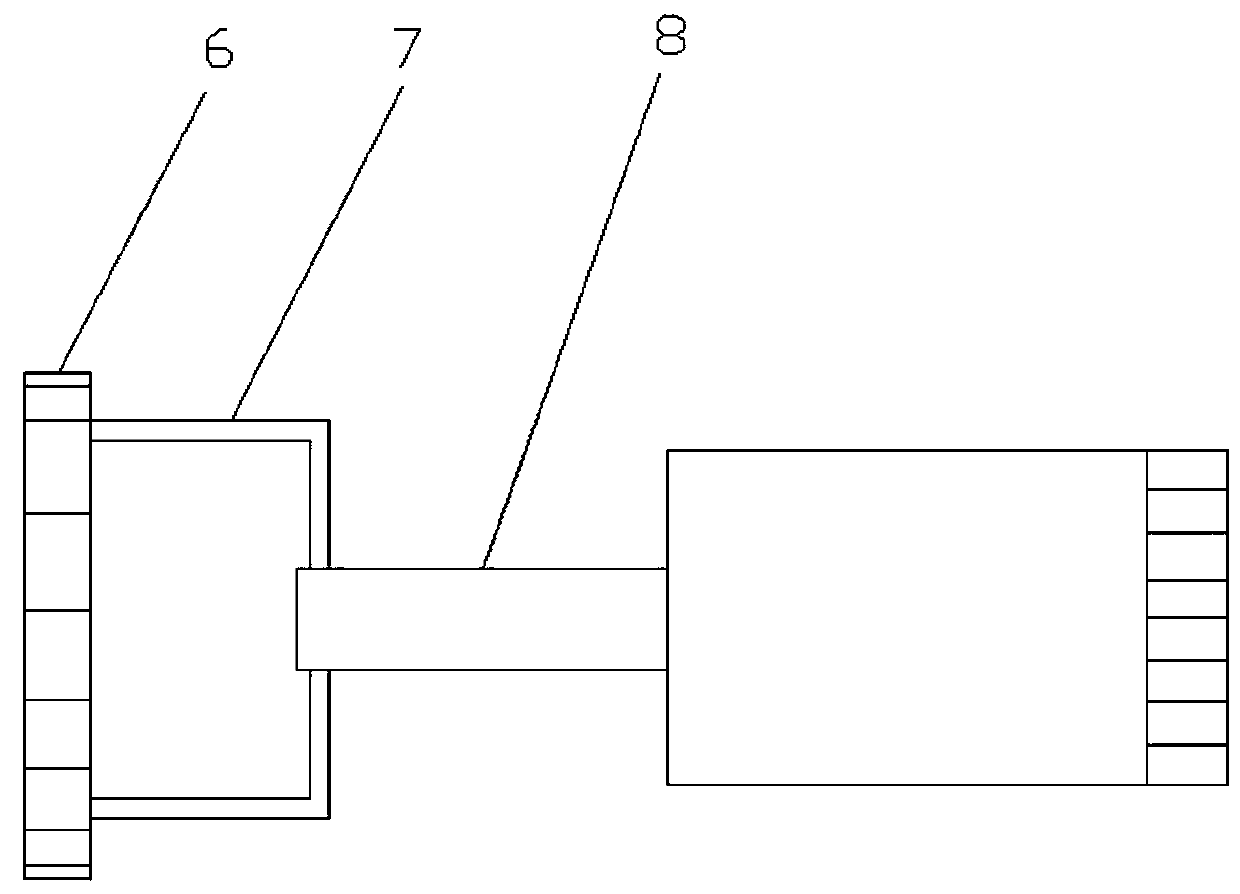

Electromagnetic impulsive rock breaking and drilling device and application method

The invention discloses an electromagnetic impulsive rock breaking and drilling device and an application method. The device comprises a mounting disc. A plurality of drill bit mechanisms are arrangedon one side of the mounting disc, the other side of the mounting disc is fixedly connected to the end part of a shield, and each drill bit mechanism comprises a mounting barrel fixedly arranged in the mounting disc, and a self-rotating drill bit capable of moving front and back is arranged in the mounting barrel. In addition, the invention discloses the application method corresponding to the device. The device solves the problem that an existing rock breaking technique is insufficient in safety, pollutes the environment and is low in efficiency, and meanwhile, achieves impulsive rock breaking and rotary drilling functions.

Owner:CHINA THREE GORGES UNIV

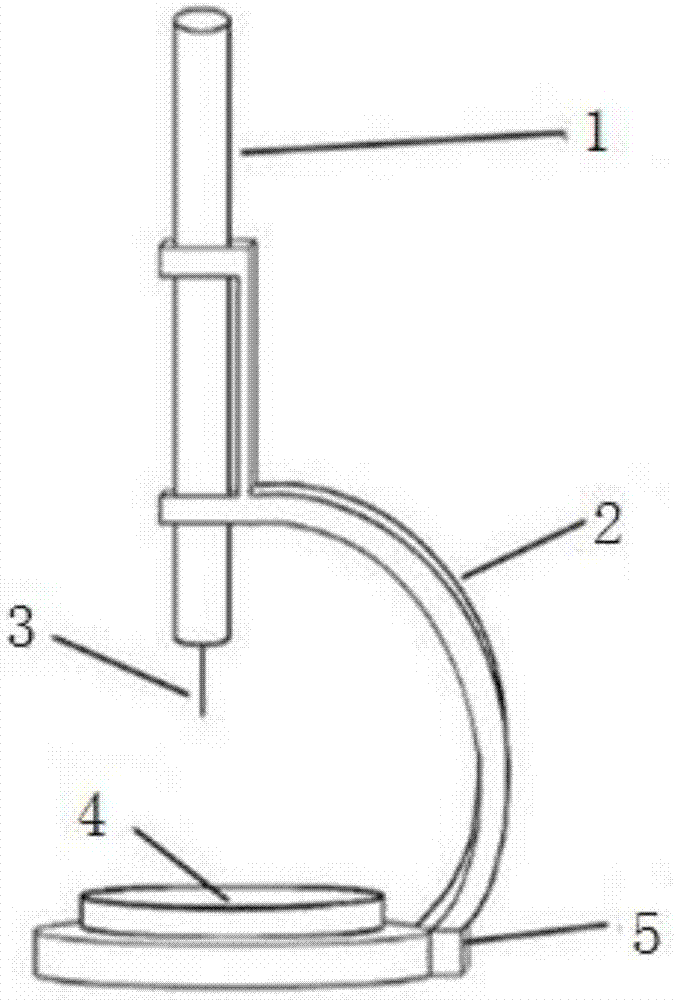

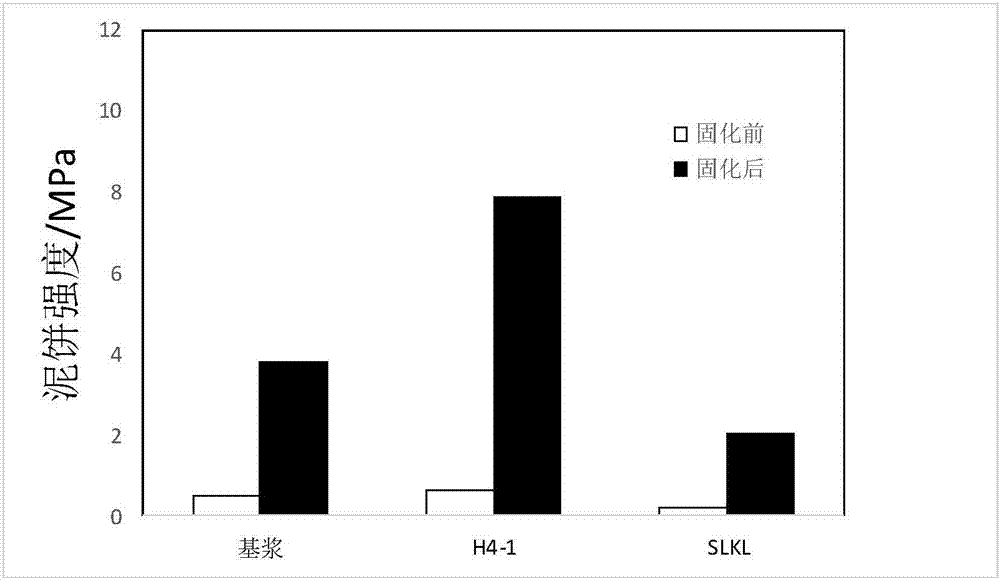

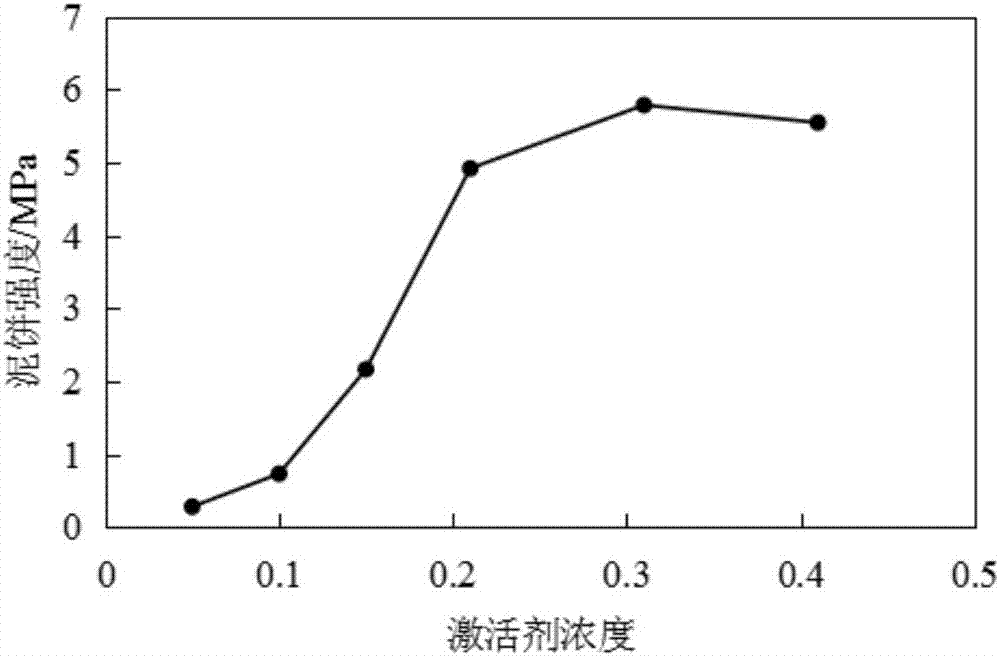

Mud cake solidification intensity evaluating method and mud cake solidification intensity detecting device

ActiveCN107035359AAccurate evaluationConducive to cementing operationsConstructionsSpecial data processing applicationsActivation functionMeasurement device

The invention discloses a mud cake solidification intensity evaluating method and a mud cake solidification intensity detecting device. The mud cake solidification intensity evaluating method includes the steps that a drilling fluid mud cake is made through a dehydration cylinder, and the mud cake has certain intensity through the activation function; the prepared and activated mud cake is placed on a pressure sensor of the mud cake solidification intensity detecting device, a metal rod is manually operated to act on the mud cake downwards, and force when a steel needle punctures the mud cake is tested; ABAQUS software is used for setting up a model of the mud cake, and the elasticity modulus and Poisson ratio of the mud cake are obtained through an ultrasonic measurement device, and stress analysis is carried out on the mud cake to obtain the intensity of the mud cake. The solidification degree of the mud cake can be presented in a quantified mode through the mud cake solidification intensity detecting method, and a foundation is laid for research of the mud cake solidification technology.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Q355NE hot-rolled round steel for high-speed rail bogie and production process

The invention provides Q355NE hot-rolled round steel for a high-speed rail bogie and a production process. The steel comprises the following chemical components in percentage by weight: 0.14%-0.18% of C, 0.17%-0.40% of Si, 1.41%-1.49% of Mn, 0.05%-0.18% of Cr, 0.02%-0.05% of V, less than or equal to 0.05% of Ni, less than or equal to 0.05% of Cu, less than or equal to 0.05% of Mo, 0.015%-0.040% of Als, less than or equal to 0.012% of P, less than or equal to 0.010% of S, less than or equal to 15 ppm of oxygen and the balance of iron and inevitable impurities. In order to reduce the normalizing cost, alloy addition is developed to replace normalizing treatment, the final structure and performance of a steel product can be improved through solid solution and precipitation of added alloy elements in the hot working process, the normalizing production procedures are reduced, and the production cost is reduced.

Owner:BENGANG STEEL PLATES

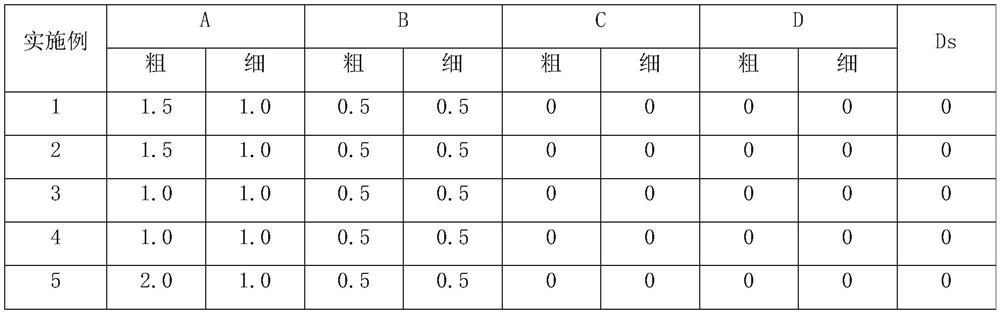

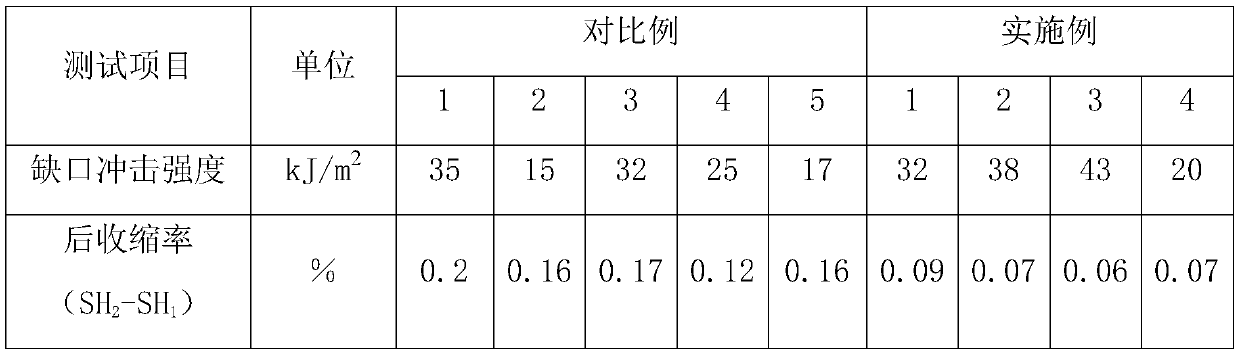

Low-after-shrinkage polypropylene composite material for vehicles and preparation method thereof

The invention provides a low-after-shrinkage polypropylene composite material for vehicles and a preparation method thereof. A polypropylene composition is prepared from raw materials in parts by weight: 50 to 65 parts of polypropylene, 5 to 15 parts of an impact modifier polyolefin elastomer, 15 to 25 parts of talcum powder, 5 to 10 parts of ultrahigh molecular weight polyethylene, 5 to 10 partsof a nano glass body and 0.1 to 0.5 part of an antioxidant; the nano glass body is a nano glass body subjected to organic matter surface treatment and spatial three-dimensional flat structural treatment, and the organic matter is a styrene-glycidyl methacrylate random copolymer. According to the invention, the ultrahigh molecular weight polyethylene and the nano glass body are added into the polypropylene at the same time, so that the post-shrinkage rate can be synergistically improved, and the compatibility of the ultrahigh molecular weight polyethylene and a PP matrix can be improved, and thus the impact property of the material is maintained.

Owner:重庆会通科技有限公司

Excavator bucket teeth and production method thereof

InactiveCN107587025AGuaranteed toughnessGuaranteed corrosion resistanceSoil-shifting machines/dredgersExcavatorMaterials science

The invention discloses excavator bucket teeth including tooth tips and a tooth holder; the tooth tips are prepared from the following raw materials in parts by weight: 1-2 parts of C, 4-6 parts of Si, 45-65 parts of Mn, 0.01-0.02 part of P, 0.02-0.08 part of S, 40-45 parts of Cr, 10-15 parts of Ni, 10-15 parts of Cu, 0.02-0.05 part of Fe, and 0.12-0.15 part of Al; the tooth holder is prepared from the following raw materials in parts by weight: 3-5 parts of C, 75-85 parts of Si, 65-70 parts of Mn, 0.02-0.05 part of P, 0.05-0.10 part of S, 60-65 parts of Cr, 20-25 parts of Ni, 20-25 parts of Cu, 0.05-0.10 part of Fe, and 0.2-0.5 part of Al. The invention also discloses a production method of the excavator bucket teeth.

Owner:太湖县众瑞精密铸造有限公司

Preparation method of clay quartz crucible for high-temperature alloy casting

The invention provides a preparation method of a clay quartz crucible for high-temperature alloy casting. The preparation method comprises the following steps: preparing pug, refining the pug, molding, drying and sintering. The pug comprises a basic material and water, and the basic material comprises the following components in percentage by mass: 25-30% of ball clay powder; 40-50% of quartz glass powder; 20-25% of white corundum powder; and 1%-5% of mullite powder. According to the clay quartz crucible, the raw material variety, the adding proportion and the raw material granularity are reasonably controlled; the adverse effect of clay on the thermal stability of the crucible is avoided, the problem that a pure quartz crucible cannot be plastically formed is solved, the requirements of high-temperature alloy on the use temperature and thermal shock resistance of the crucible are met, meanwhile, the sintering temperature of the crucible is 500 DEG C lower than that of a traditional magnesium crucible, and the sintering condition is easier to meet.

Owner:LIAONING SILICATE RES INST +1

Alignment of joint-flexible turnouts

ActiveCN103132404BGuaranteed impact performanceImprove comfortRailway tracksMechanical devices for scotch-blocksBogieEngineering

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

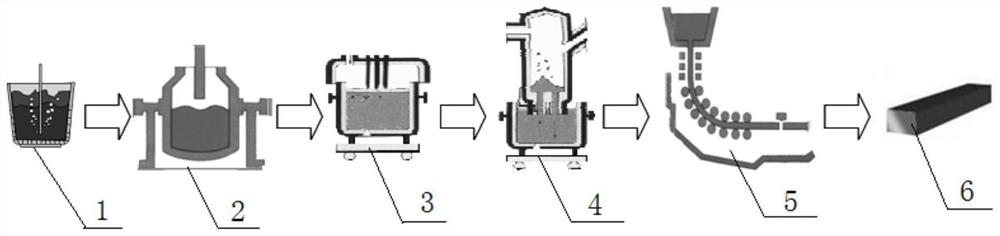

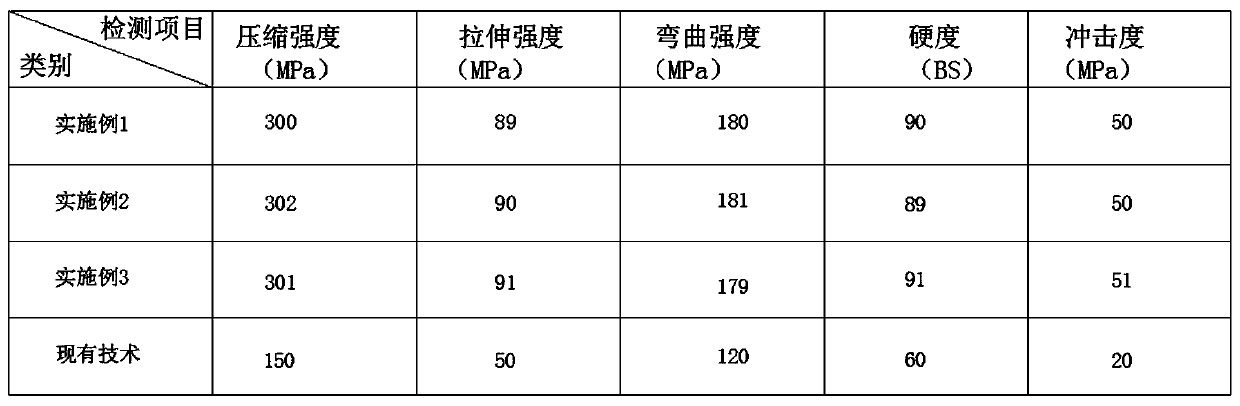

Fast-degradation plant fiber material and preparation method thereof

InactiveCN110819130AGuaranteed compressive strengthGuaranteed tensile strengthPolyvinyl alcoholPlant fibre

The invention discloses a fast-degradation plant fiber material. The fast-degradation plant fiber material comprises, by mass, 60-80% of plant fibers, 30-60% of natural starch, 6-10% of polypropylene,8-12% of polyvinyl chloride, 10-14% of polyvinyl alcohol, 5-9% of a reactive assistant, 10-20% of a plasticizer, 11-17% of talcum powder, 11-17% of paper pulp, 6-12% of an adhesive, 8-10% of a fillerand 2-4% of a cross-linking agent. The plant fiber material can be fast degraded, and still can ensure the compression strength, the tensile strength, the bending strength, the hardness and the impact degree.

Owner:浙江新亚伦纸业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com