Manufacture technique of tap shells for polar drill rigs

A faucet shell and manufacturing process technology, which is applied to the driving device for drilling in the borehole, earthwork drilling and production, drilling equipment, etc., can solve the problems of low pass rate, high reject rate, small operating space, etc., and achieve economical and simple. Effect of high strength and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

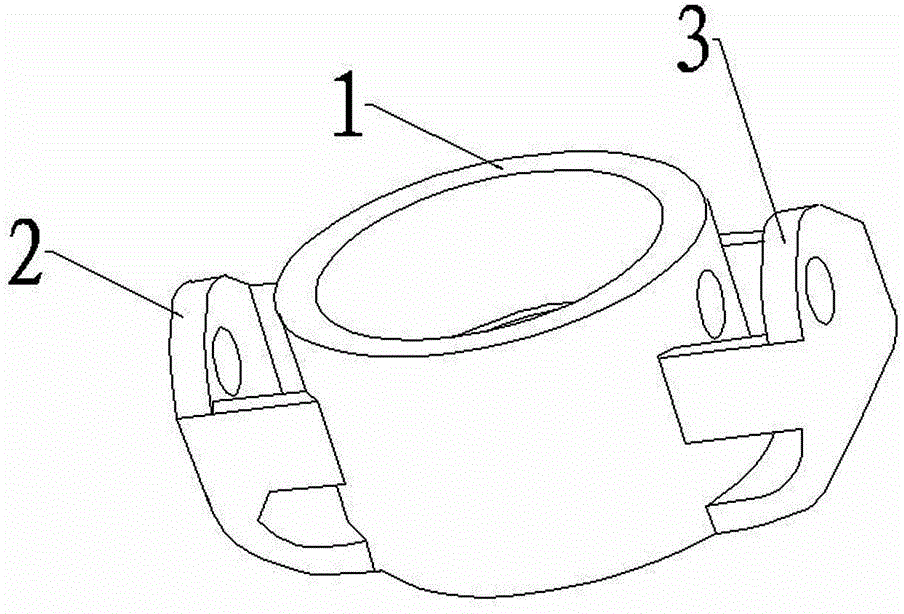

[0043] Example 1: Design and manufacturing process of the faucet shell for the ZJ15 polar drilling rig.

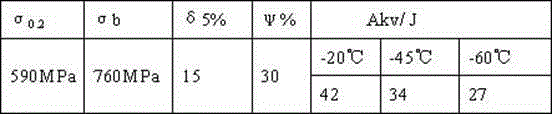

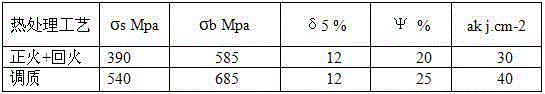

[0044] 1) Design description: use the engineering machinery design software solidworks to carry out the molding process design of the faucet shell, and determine the process dimensions of the shell body and the ear plate; specifically, the rated load is 1100KN, and the minimum service temperature is -60 ℃, calculated by design, see the shape figure 1 , outer diameter 404mm, inner diameter 326mm, housing pin hole inner diameter 70mm, safety factor 3.20, material 35CrMoA, mechanical performance requirements: σ0.2≥590MPa, σb≥780MPa, δ5≥15%, ψ≥30%, Akv (-20 ℃) ≥ 42J, Akv (-60 ℃) ≥ 27J, according to GB / T19190 and API Spec Specification 8C for magnetic particle testing and ultrasonic testing.

[0045] 2) Cutting material: Ф250х649mm round steel; cutting according to the principle that the size ratio is not less than 3, the material block I corresponding to the main body of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com