Patents

Literature

3028results about How to "Simple mechanical structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inductive power supply

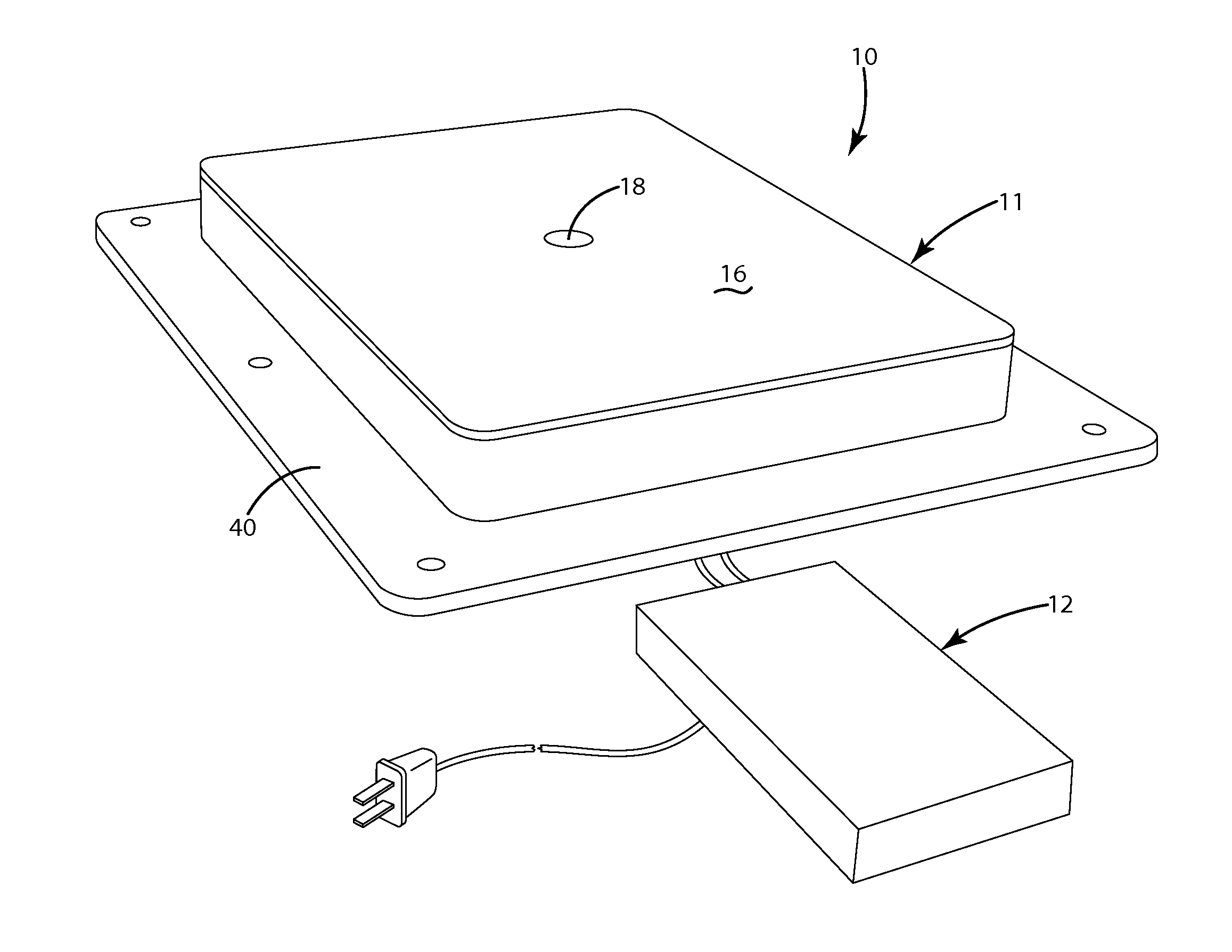

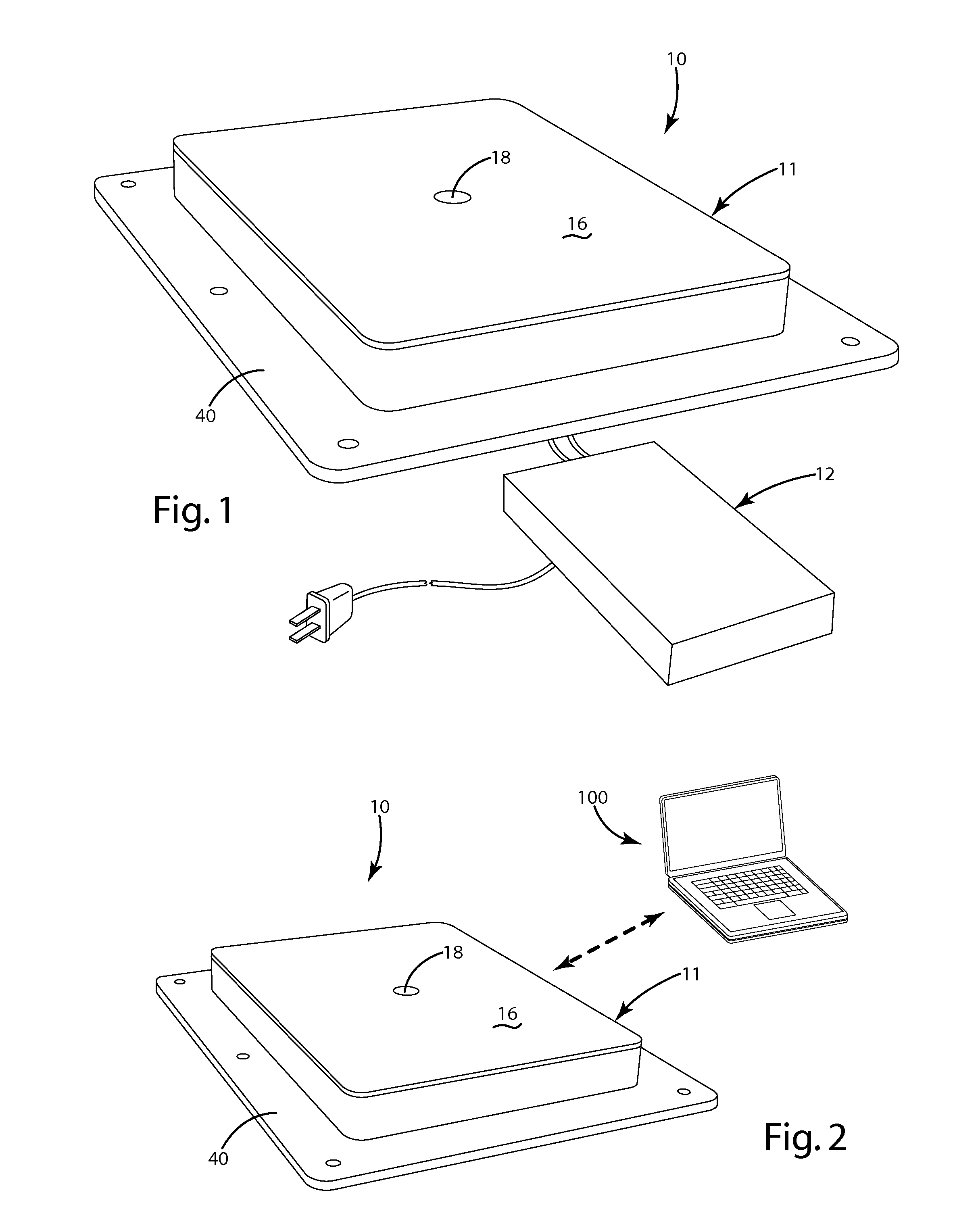

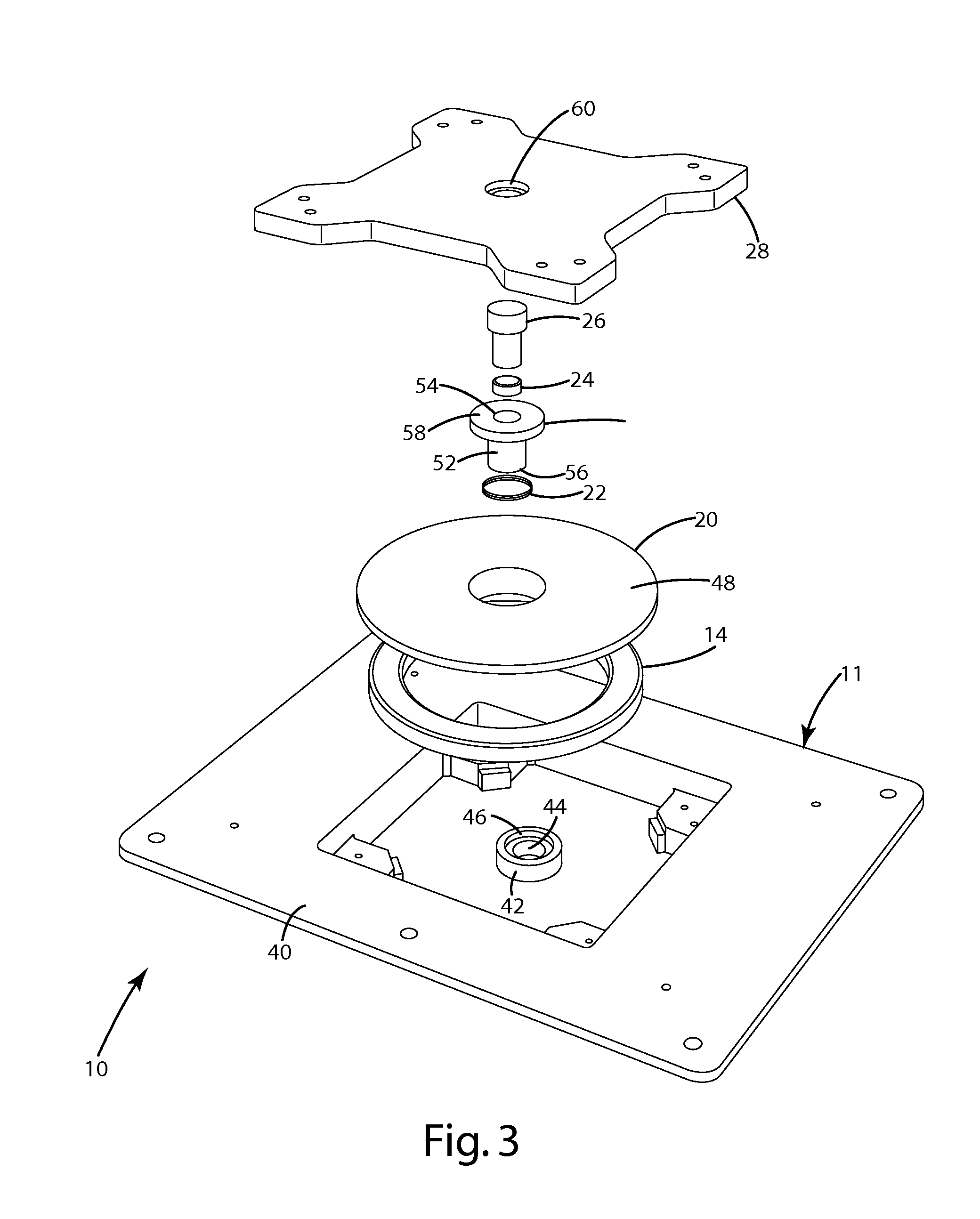

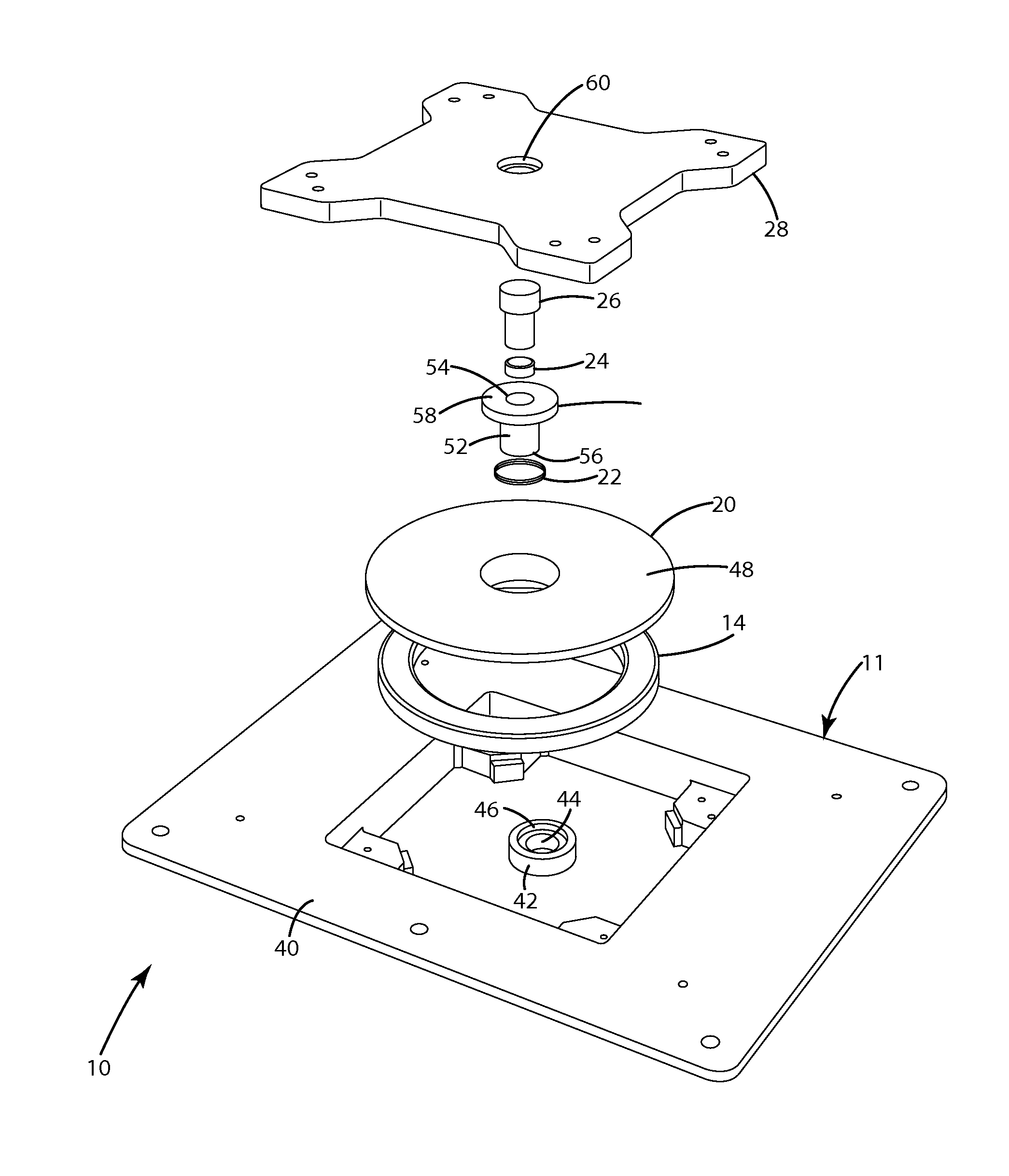

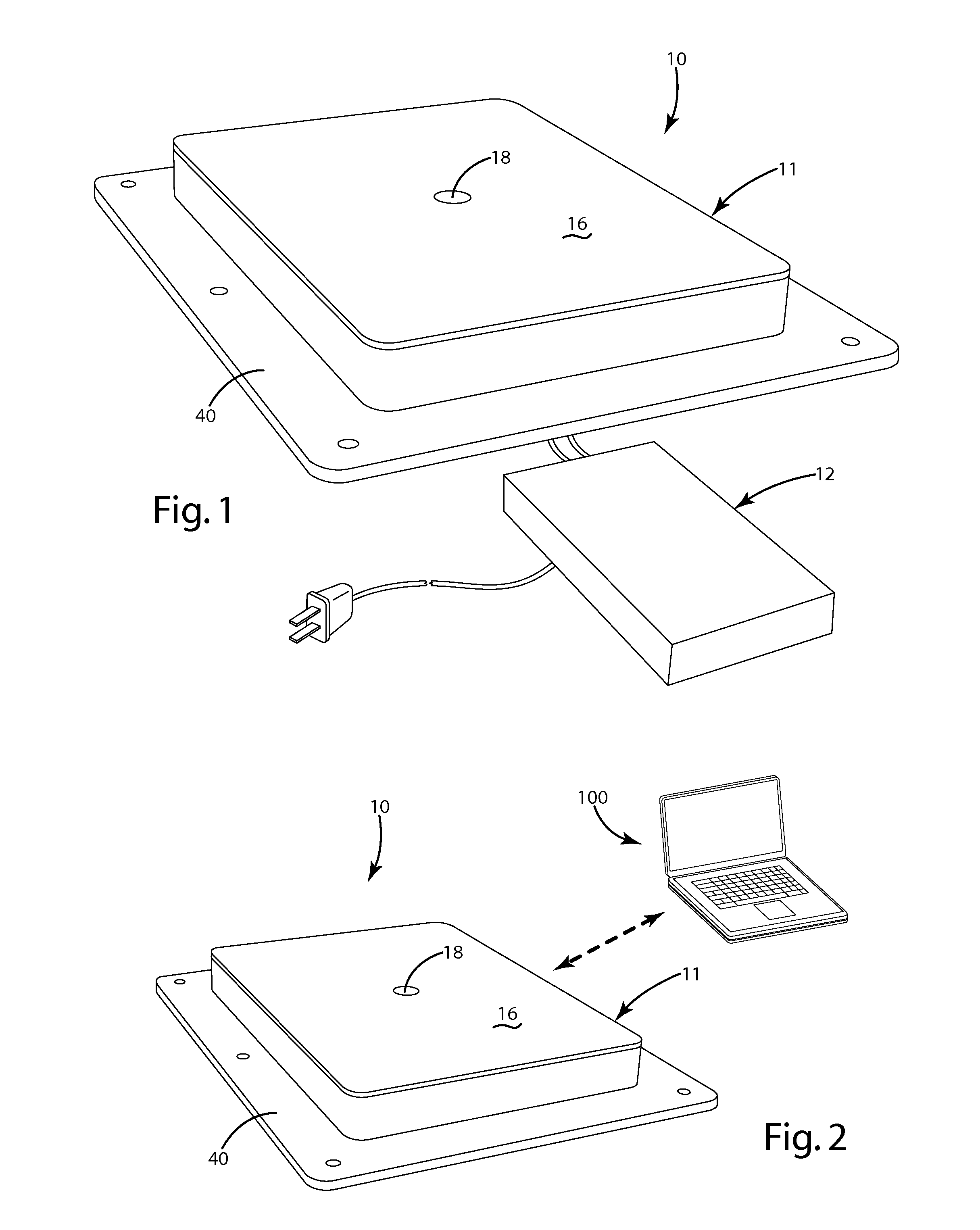

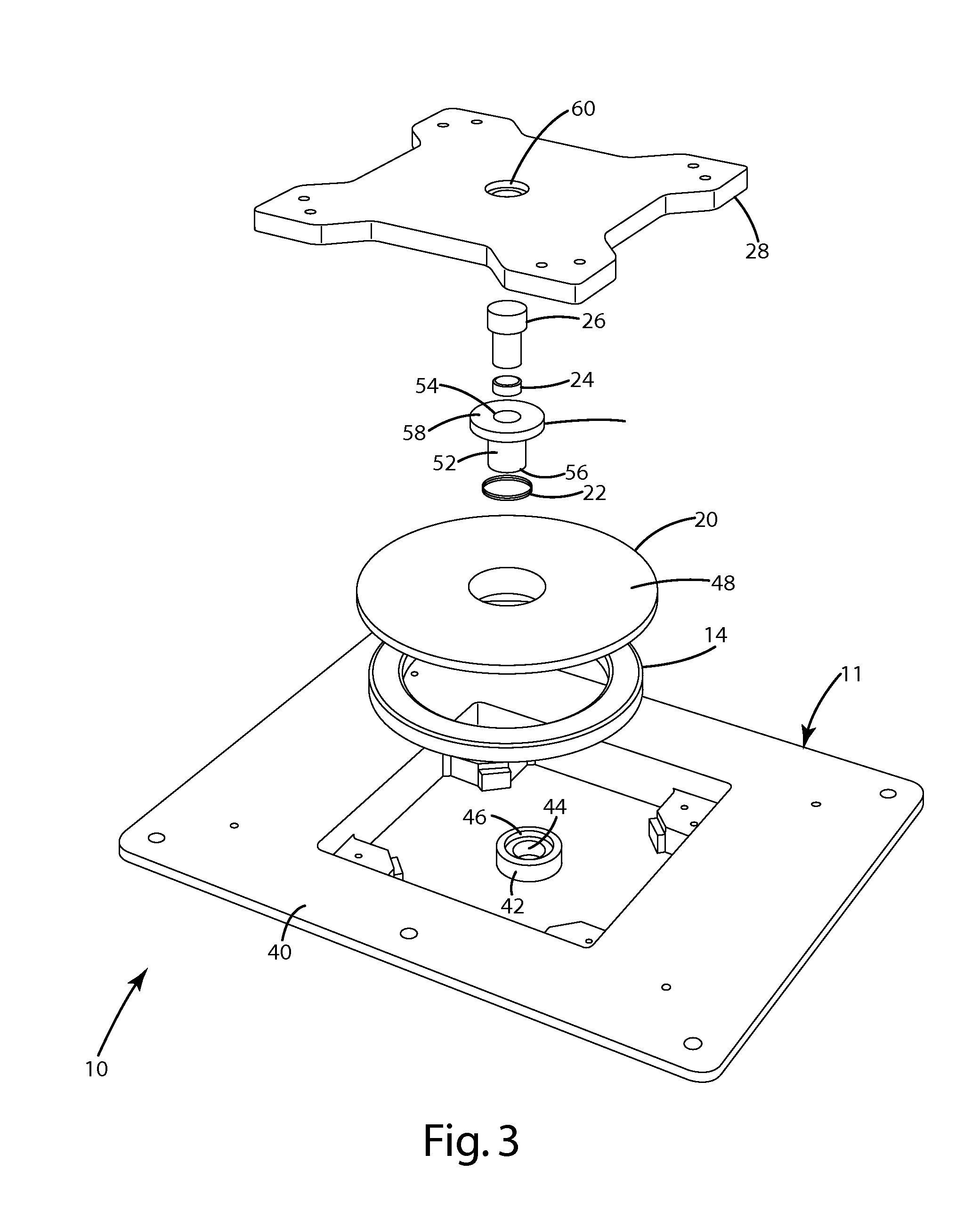

ActiveUS8373310B2Reduced footprintSimple mechanical structureBatteries circuit arrangementsElectromagnetic wave systemCharging stationMajor and minor

In one aspect, the present invention provides a wireless power supply having a plunger for mechanically interconnecting a remote device with the power supply. The plunger may be extendable / retractable to interfit with the remote device. In a second aspect, the present invention provides a wireless power supply with a movable primary that allows for close alignment between the primary and the secondary when the remote device is disposed within a range of different positions with respect to the charging surface. The movable primary may, for example, be coupled to the remote device by a peg, a plunger or a magnet. Alternatively, the position of the movable primary may be adjusted manually. In a third aspect, the present invention provides a charging bowl having a plurality of charging stations disposed about a common axis. Each charging station may include a movable primary that permits some freedom in positioning of the remote device on the charging surface. In a fourth aspect, the present invention provides a wireless power supply having a manually movable primary.

Owner:PHILIPS IP VENTURES BV

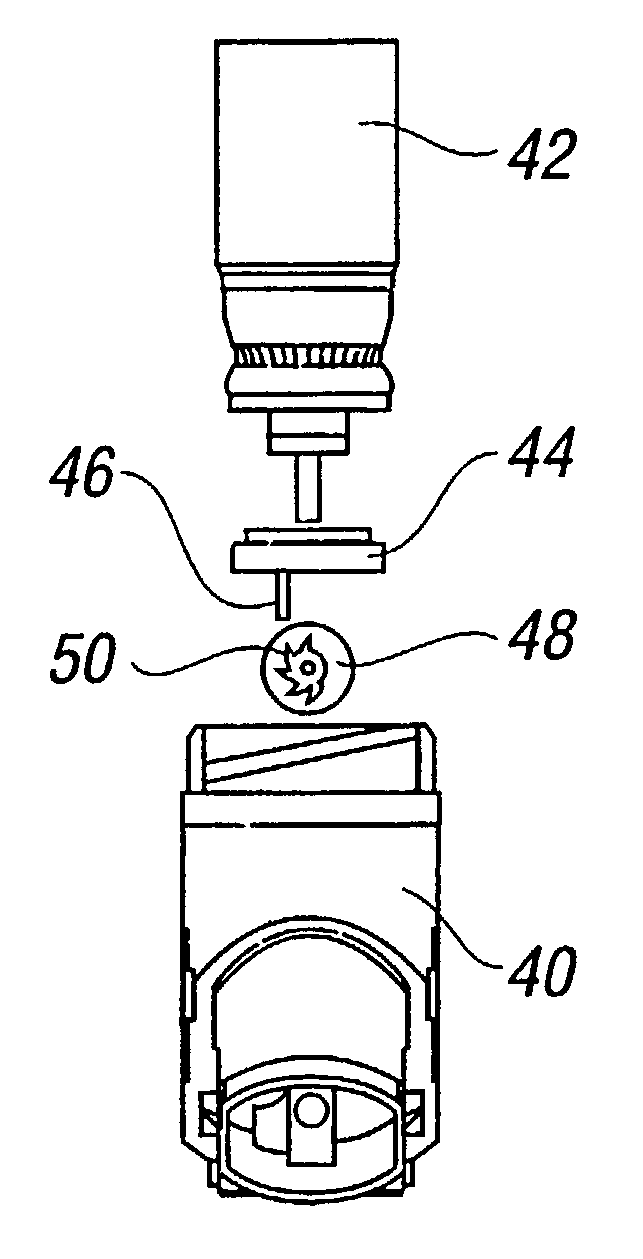

Inductive power supply

ActiveUS20110006611A1Reduced footprintSimple mechanical structureBatteries circuit arrangementsElectromagnetic wave systemCharging stationPlunger

In one aspect, the present invention provides a wireless power supply having a plunger for mechanically interconnecting a remote device with the power supply. The plunger may be extendable / retractable to interfit with the remote device. In a second aspect, the present invention provides a wireless power supply with a movable primary that allows for close alignment between the primary and the secondary when the remote device is disposed within a range of different positions with respect to the charging surface. The movable primary may, for example, be coupled to the remote device by a peg, a plunger or a magnet. Alternatively, the position of the movable primary may be adjusted manually. In a third aspect, the present invention provides a charging bowl having a plurality of charging stations disposed about a common axis. Each charging station may include a movable primary that permits some freedom in positioning of the remote device on the charging surface. In a fourth aspect, the present invention provides a wireless power supply having a manually movable primary.

Owner:PHILIPS IP VENTURES BV

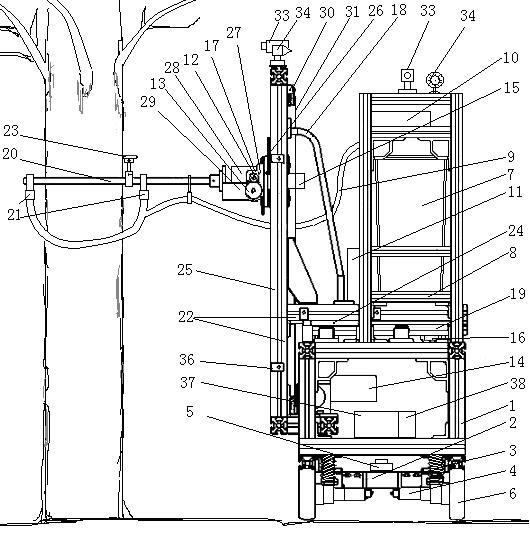

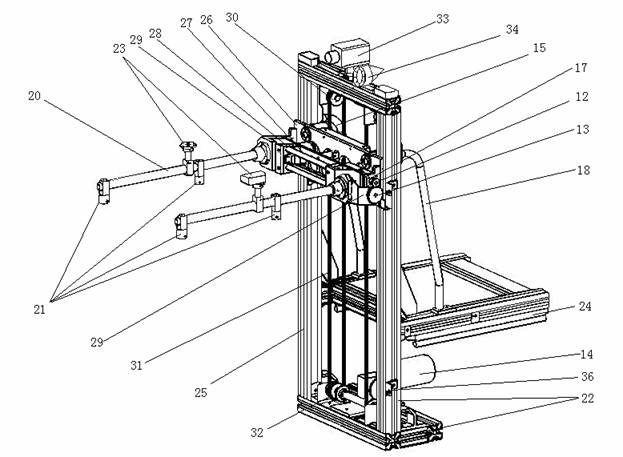

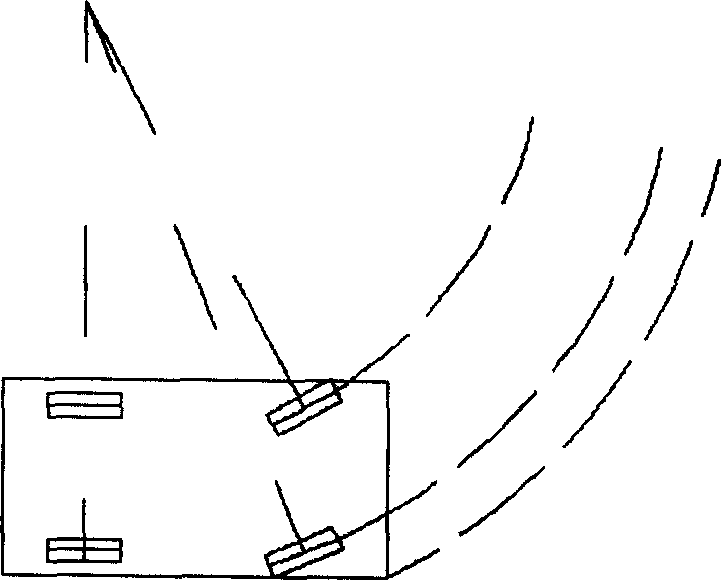

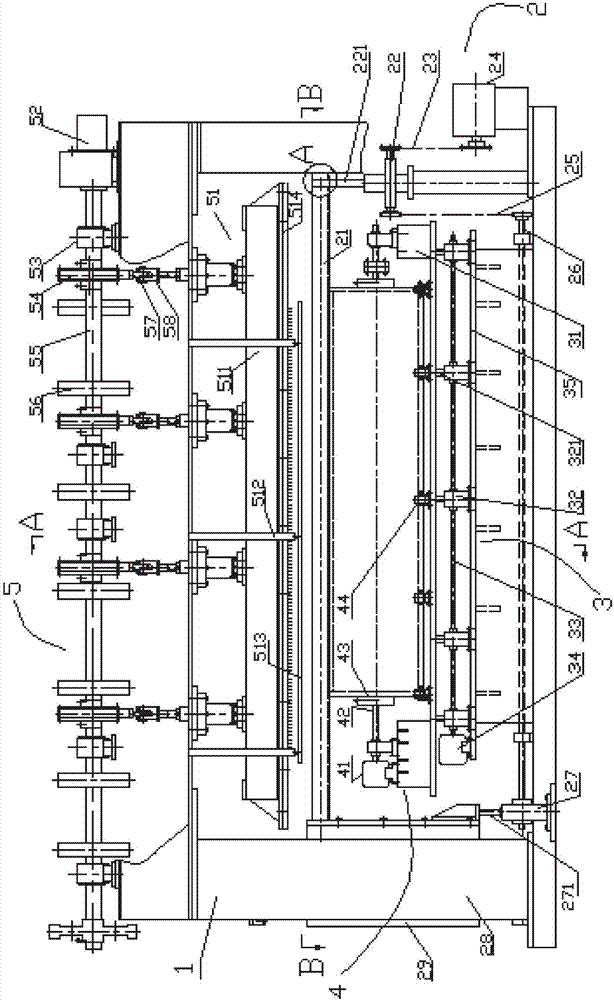

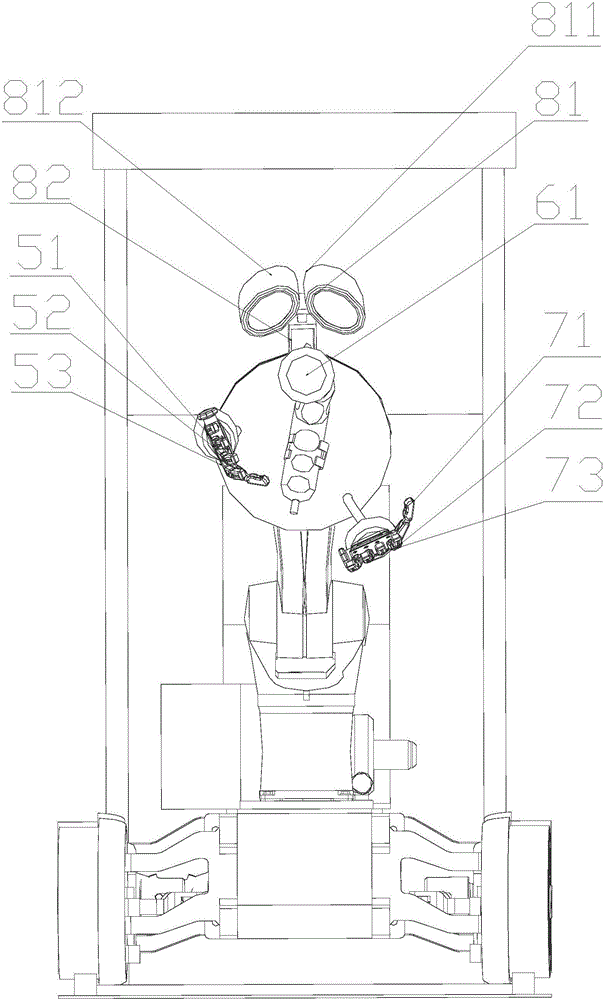

Intelligent tree trunk white paining robot

InactiveCN102151634AImprove work efficiencyQuality improvementLiquid spraying apparatusPlant protectionProgrammable logic controllerTree trunk

The invention discloses an intelligent tree trunk white painting robot and belongs to the related fields of urban and garden greening equipment. The intelligent tree trunk white painting robot comprises a machine frame system, a robot traveling system, a lime slurry supply system, an automatic white painting execution system and a real-time detection system. Adopting a spray painting mode for white painting of tree trunks, the robot can automatically walk along a side pavement and quickly and efficiently spray lime solution onto trees along the side pavement. In a real-time detection system, a digital compass, a laser sensor and a vision system are adopted to realize the semi-automatic searching of tree trunks and tree trunk automatic positioning, an ultrasonic transducer is adopted to realize automatic obstacle avoidance, and the whole-process real-time monitoring with a personal computer (PC) and a programmable logic controller (PLC) is realized. When the intelligent tree trunk white painting robot is used, coating is saved and the painting effect is optimized; and the robot automatically performs white painting of trees along the side pavement, the working efficiency is improved, labor force is saved, and the goals of intelligent control and green environmental sanitation are fulfilled.

Owner:SHANGHAI UNIV

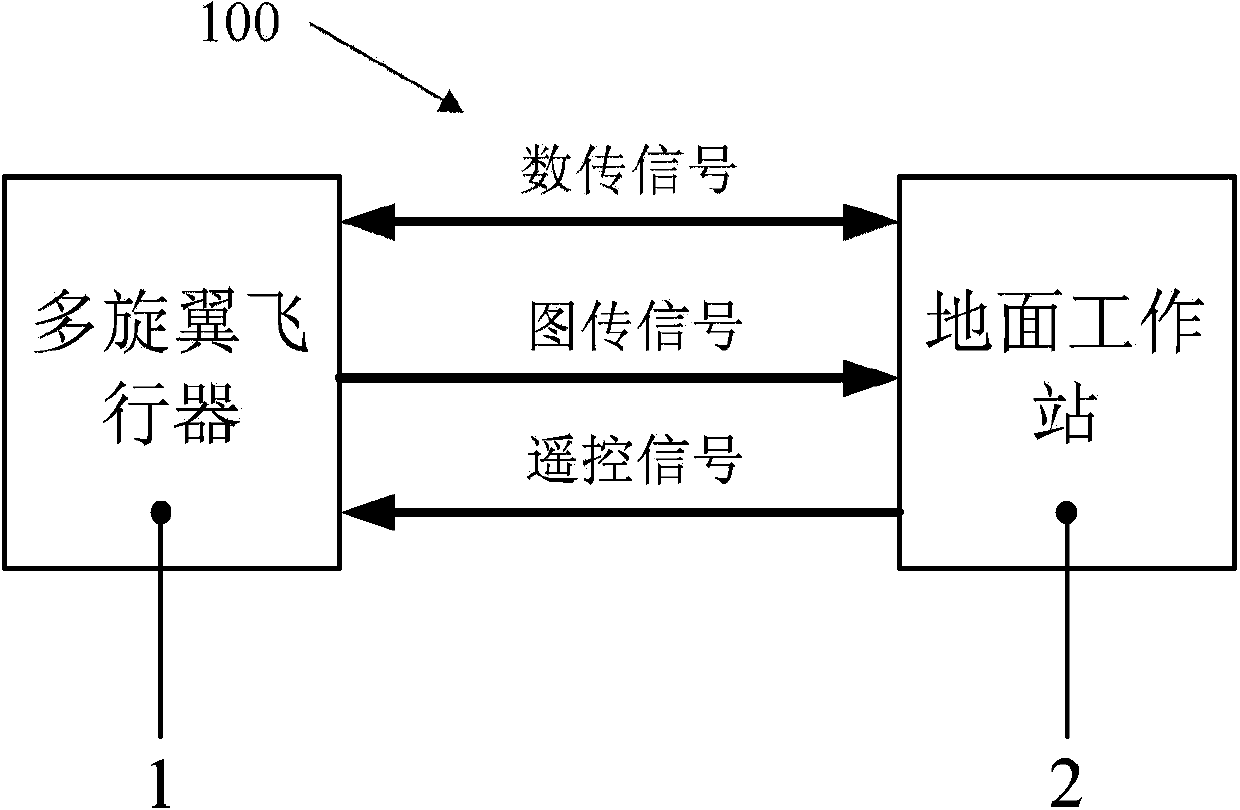

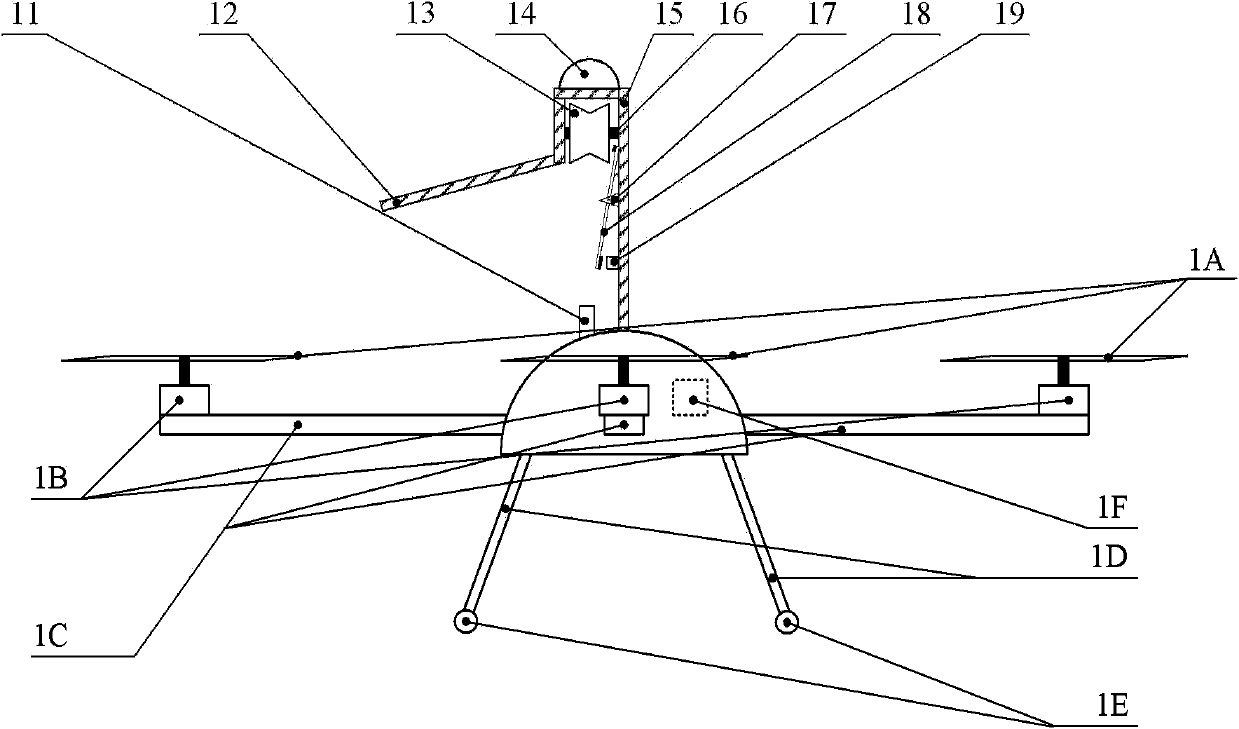

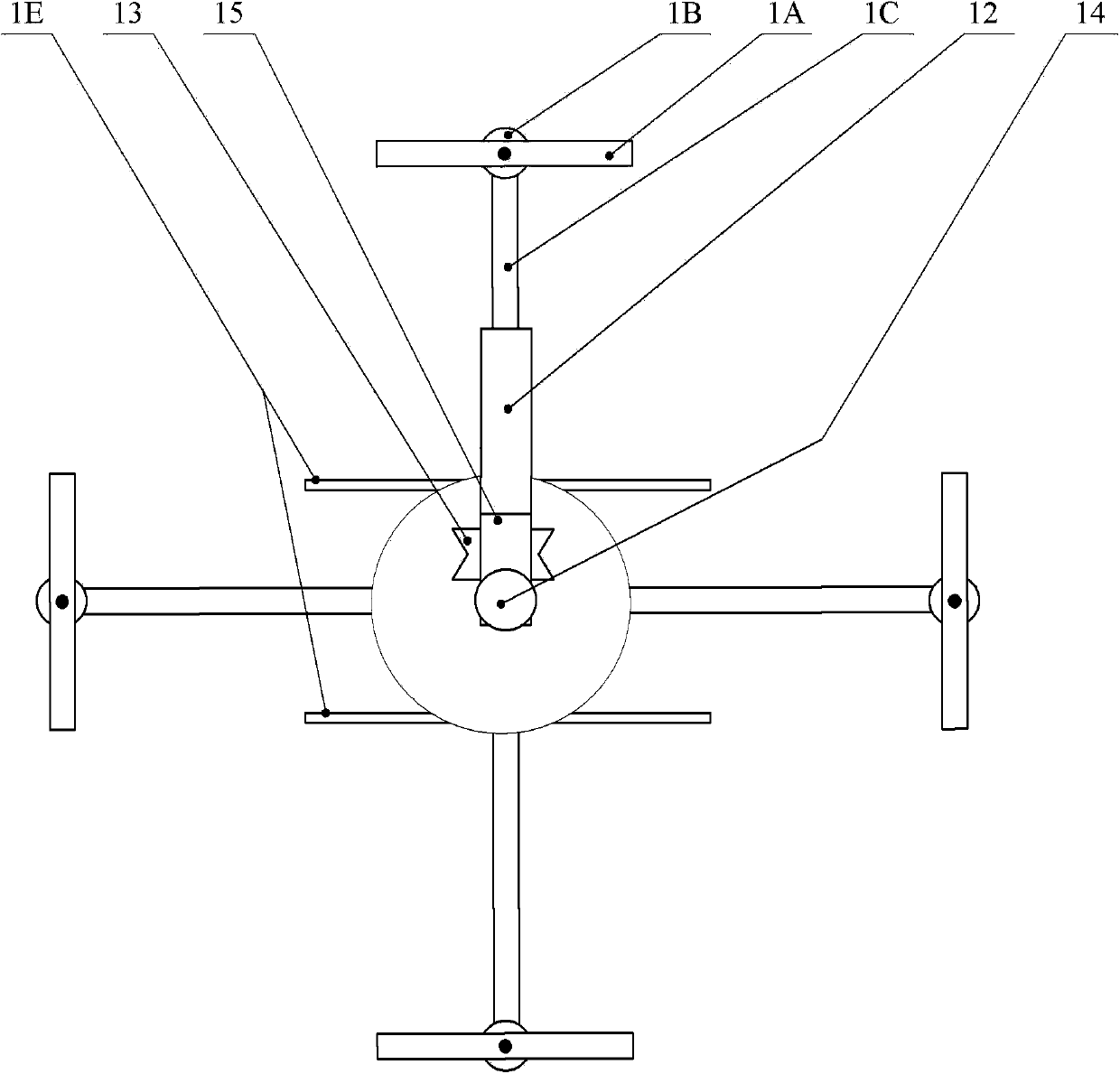

Multi-rotor aircraft for patrolling power line, and system based on same

ActiveCN103612756AImprove securityEnsure safetyClosed circuit television systemsPosition/course control in three dimensionsElectric powerHelicopter rotor

The invention discloses a multi-rotor aircraft for patrolling a power line; the multi-rotor aircraft can fly and is mounted on a power line so as to be used for patrolling the power line. The multi-rotor aircraft is provided with a mounted pulley, a mounting guide plate and a mounting bracket, wherein the mounted pulley is in contact with the power line, so that the multi-rotor aircraft is mounted on the power line; the mounted guide plate is used for guiding the multi-rotor aircraft to move towards the power line so as to complete mounting when the multi-rotor aircraft is to be mounted on the power line; the mounted bracket is used for supporting the mounted pulley and the mounting guide plate. The multi-rotor aircraft for patrolling the power line can be used for safely and reliably patrolling the power line within a large patrolling range with high accuracy.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

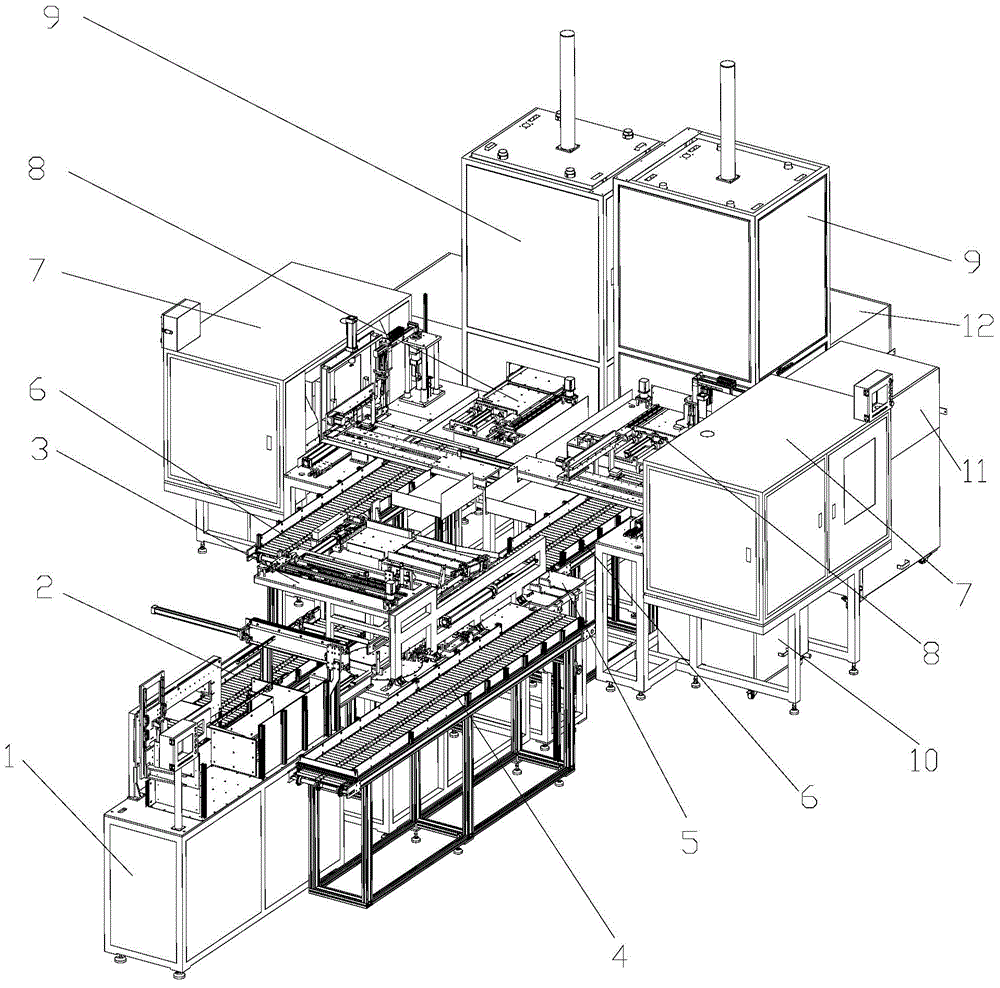

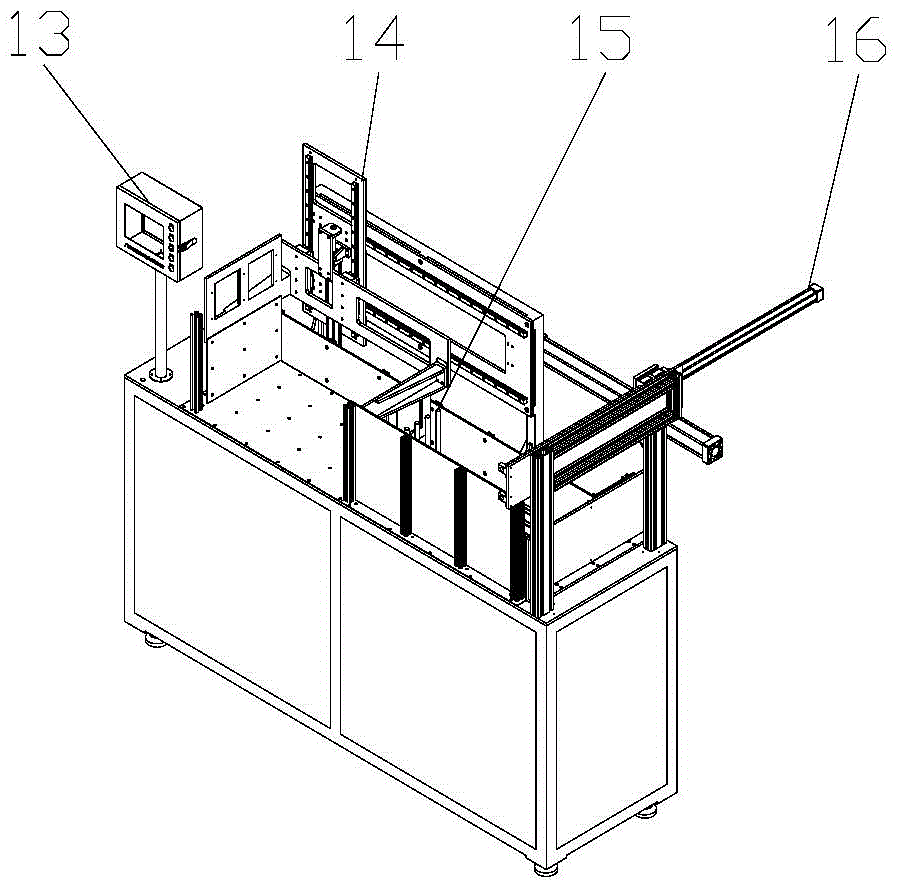

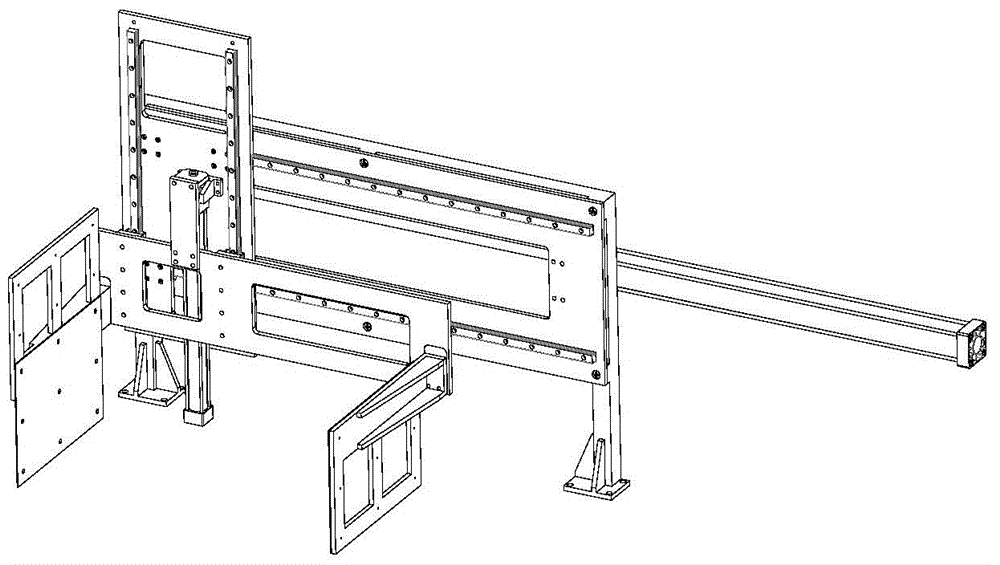

Novel waste power battery full-automatic dismantling device and method

ActiveCN104157927AReduce loss costReduce cooling costsSolid waste disposalWaste accumulators reclaimingPower batteryMaterial distribution

The invention relates to a novel waste power battery full-automatic dismantling device including: 1, a loading mechanism, 2, a loading conveyer, 3, a four-station material poking mechanism, 4, material distribution conveyers, 5, cutting devices, 6, separation feeding mechanisms, 7, separators, 8, outer shell storage boxes, and 9, electric core storage boxes. Along the power battery heading direction, the loading mechanism, the loading conveyer, the four-station material poking mechanism, the material distribution conveyers, the cutting devices, the separation feeding mechanisms and the separators are successively arranged; the outer shell storage boxes and the electric core storage boxes are respectively connected with the separators. The invention also relates to a novel waste power battery full-automatic dismantling method. The device has the advantages of simple structure and high dismantling efficiency, adopts a battery mechanical dismantling way integrating electrode head end one-time cutting and electric core clipping-out, and belongs to the power battery recycling processing field.

Owner:GUANGDONG BRUNP RECYCLING TECH +3

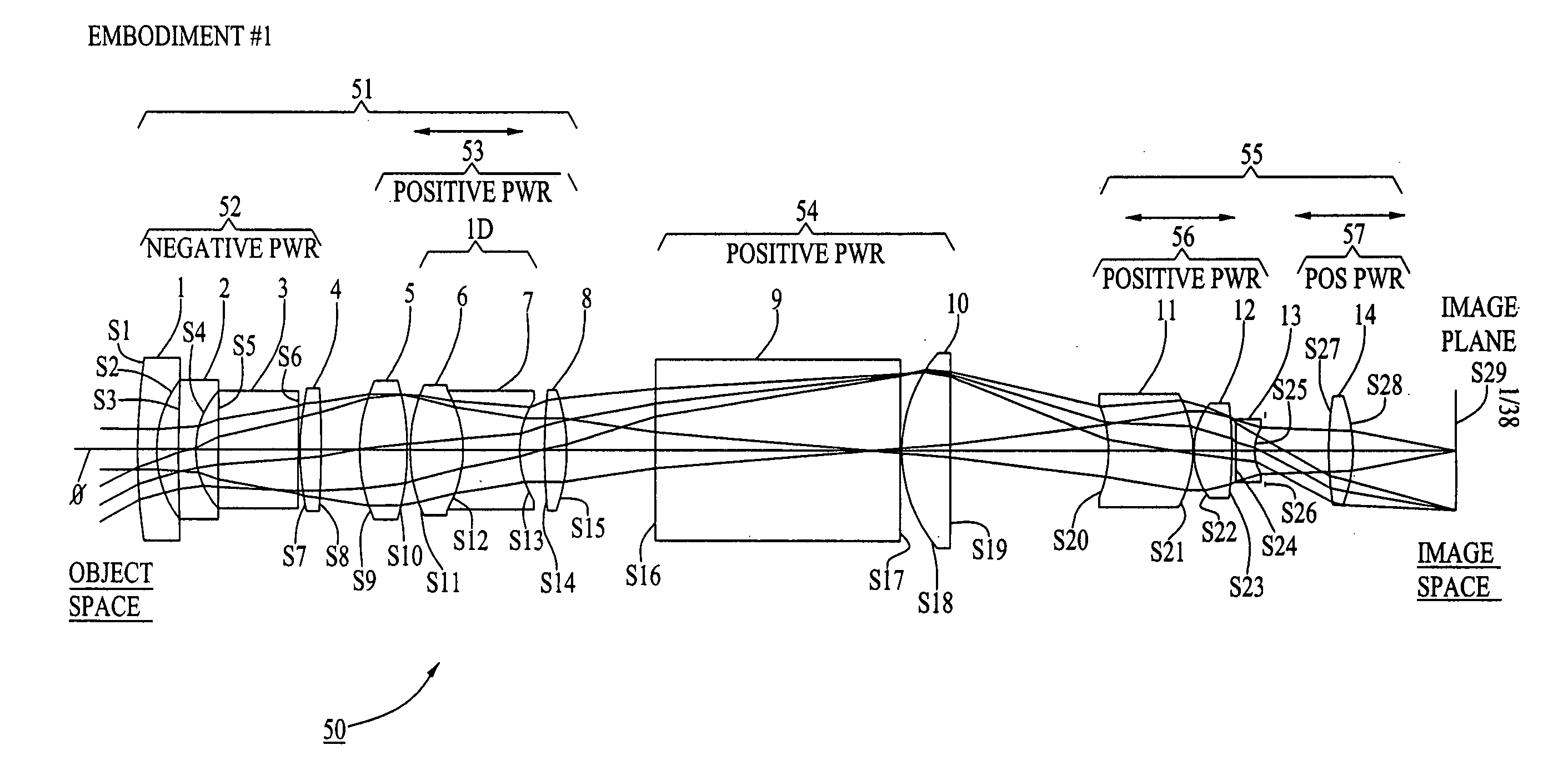

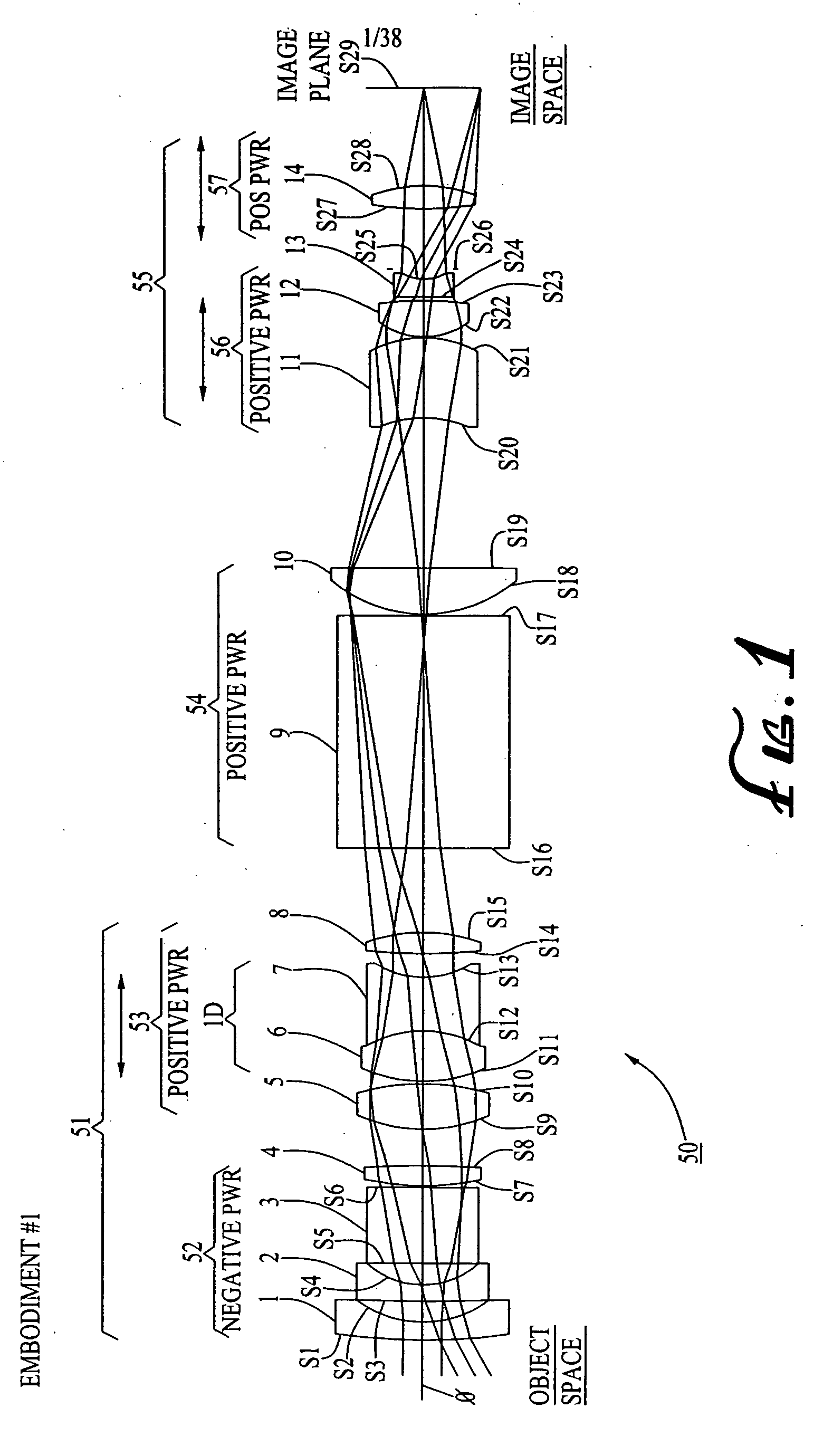

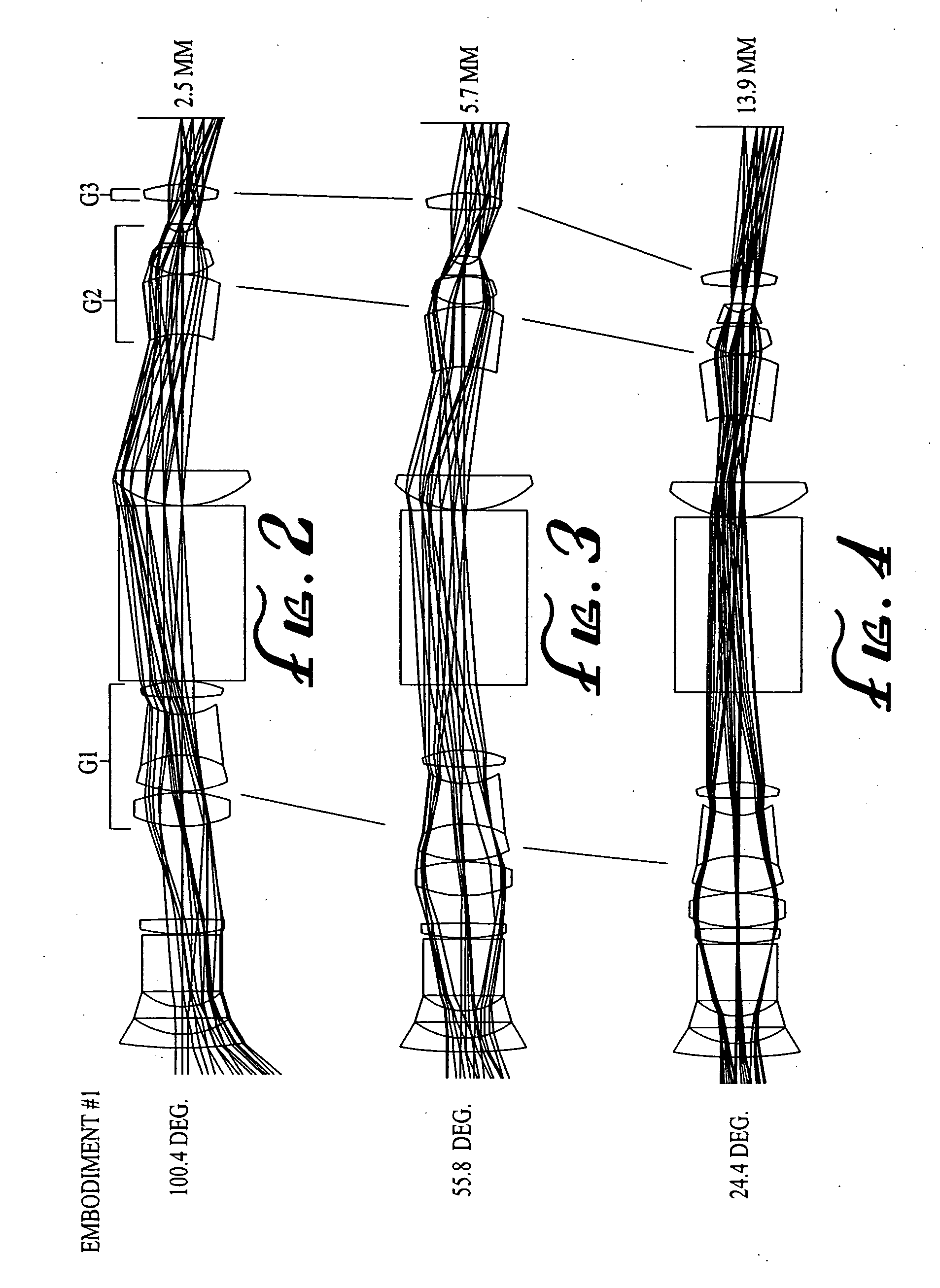

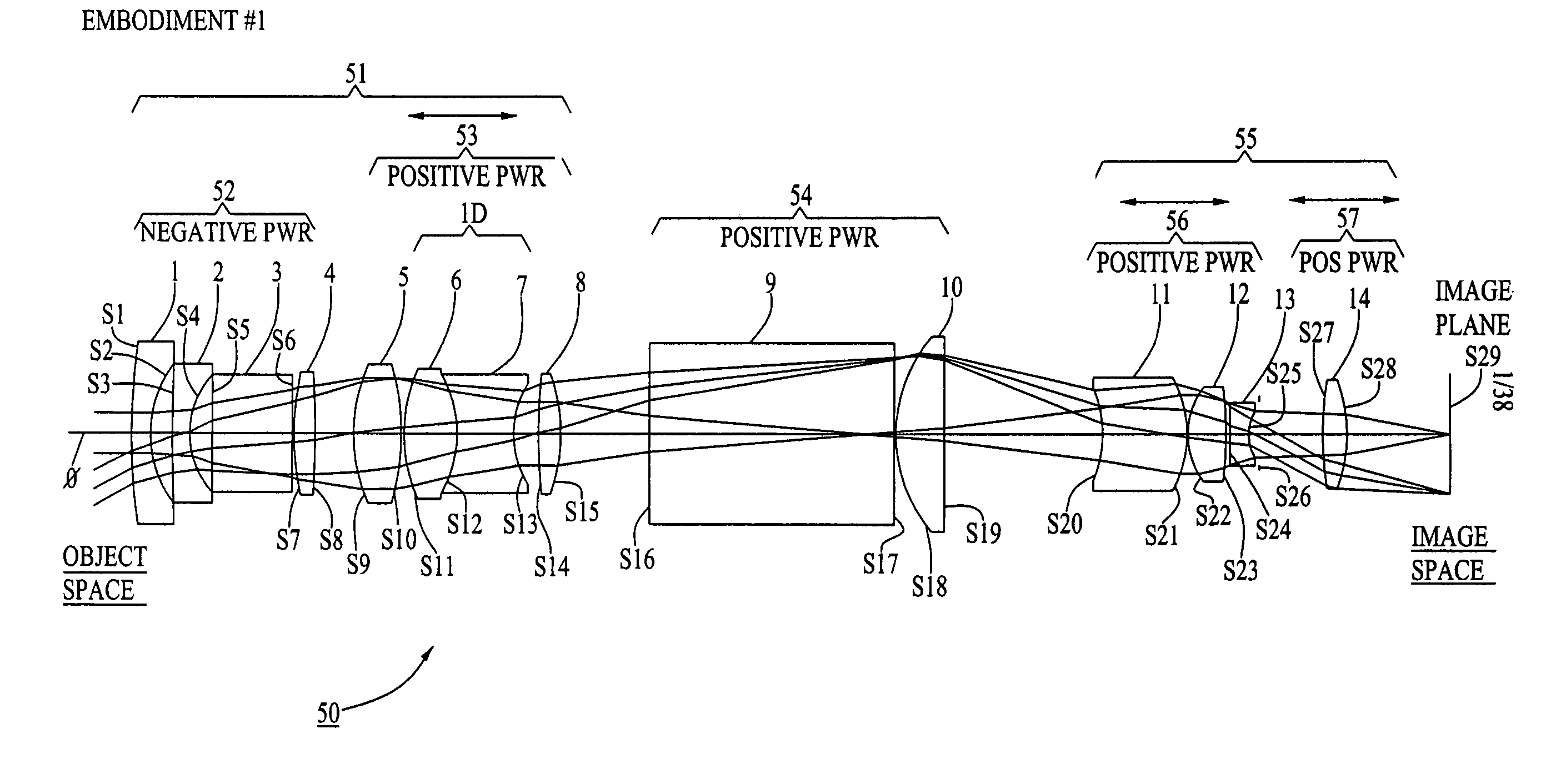

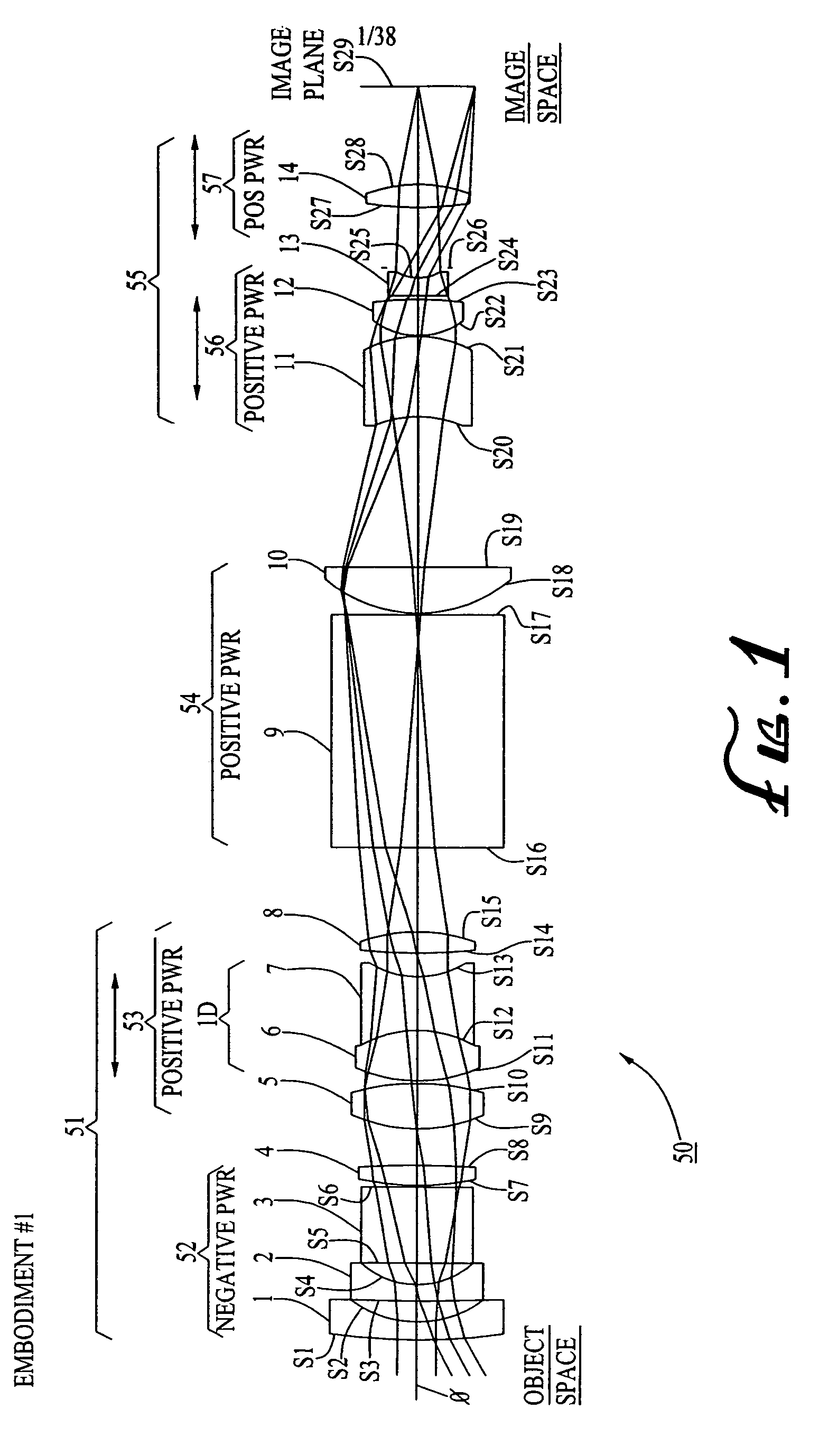

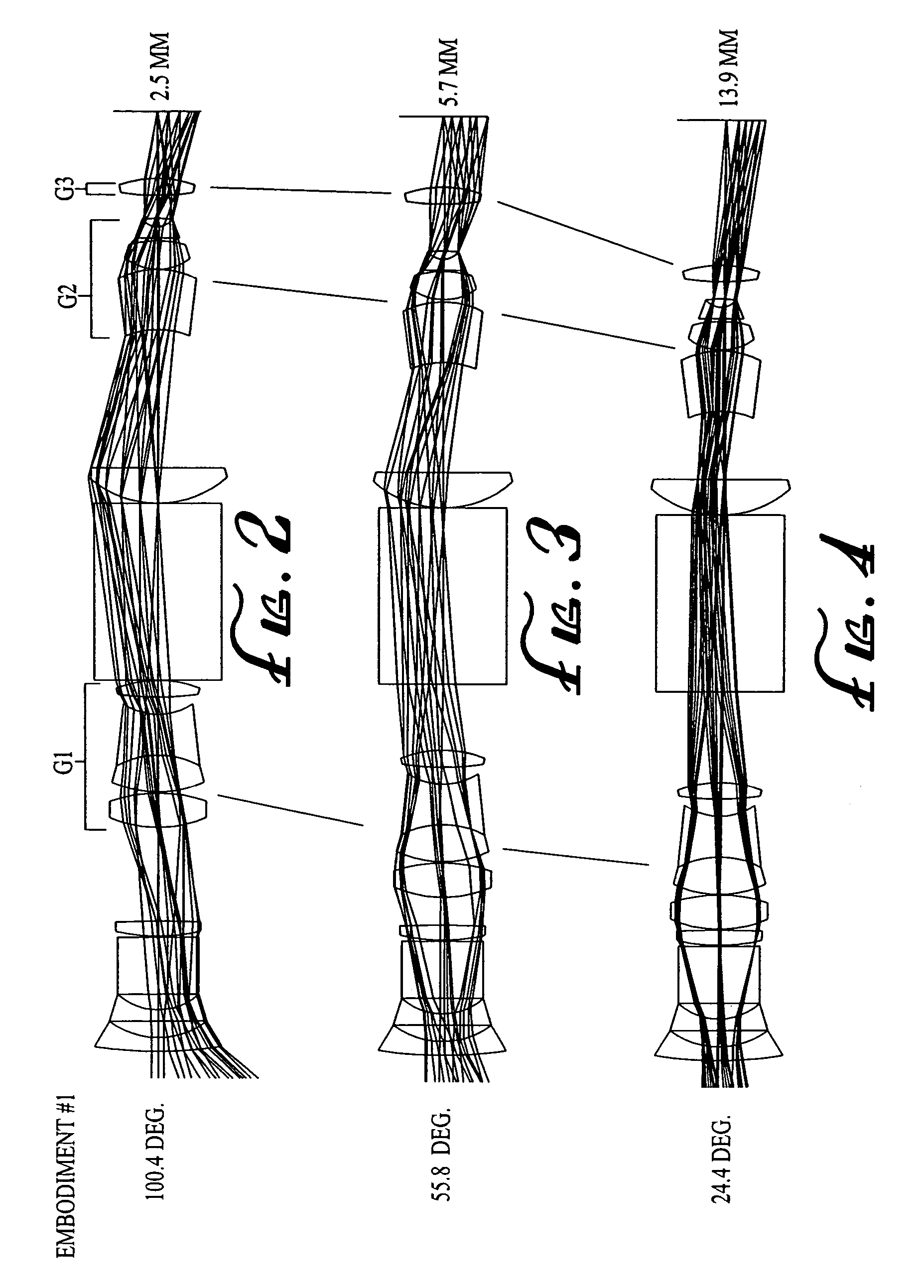

Wide-range, wide-angle compound zoom with simplified zooming structure

A zoom lens is disclosed having a zoom ratio larger than four with a field of view at the short focal length position larger than 85 degrees and with a minimal number of moving groups. The zoom lens utilizes a compound zoom structure comprising an NP or NPP zoom kernel followed by a P or PP zoom relay, with only two or three moving groups that can be used for both zooming, focusing and athermalization. An overall compact package size is achieved by the use of prisms to fold the optical path in strategic locations. An optional variable power liquid cell can provide close focusing with little or no focus breathing.

Owner:PANAVISION INT LP +1

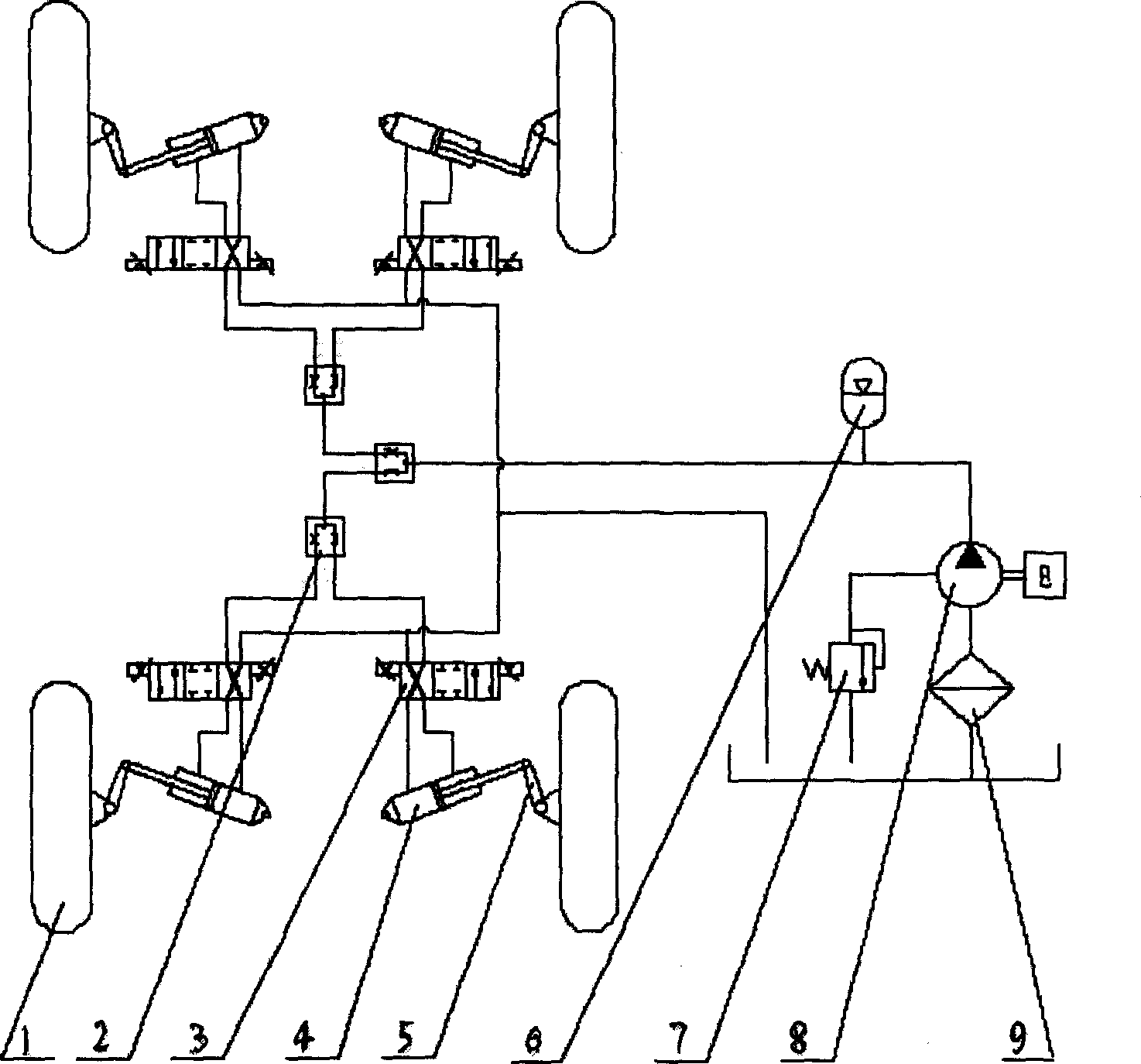

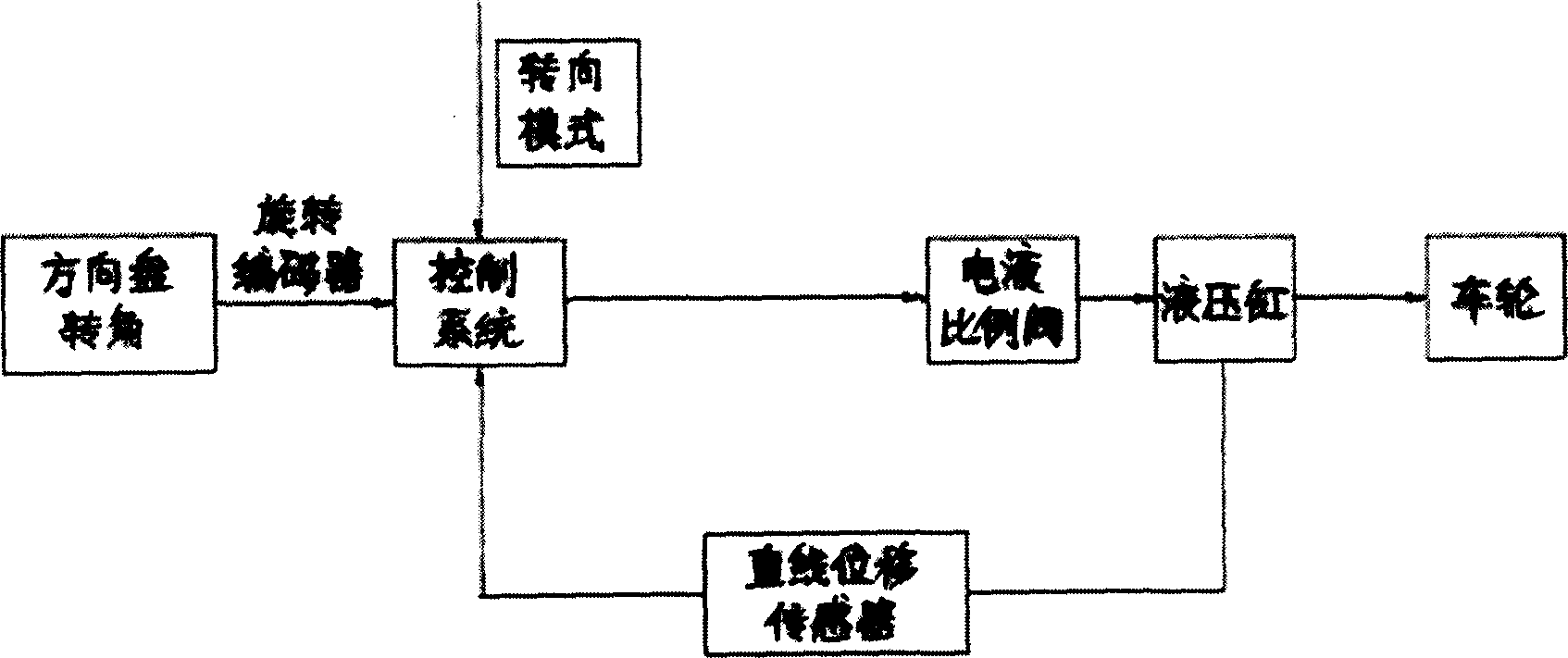

Separated steering device for vehicular four wheels and its control method

The invention relates to domain of special purpose vehicle and especially to a separate four-wheel steering device of vehicle and controlling means, which is mainly used in steering system of special purpose vehicle to guarantee steering behavior. The device comprises steering knuckle arm, steering hydraulic cylinder, electro-hydraulic proportional control valves, and accumulator, easing valve, hydraulic pump, clarifier and electronic control system. The invention is characterized in that every wheel is controlled by independent oil-hydraulic cylinder, electronic control system comprises steering emulator, signal processor and measuring apparatus of displacement line and hydraulic pump driven by engine in steering hydraulic system controls hydraulic cylinder of steering system via electro-hydraulic proportional control valves of steering system. Hydraulic cylinder connects with linear movement pickup to feed variable of displacement line of hydraulic cylinder back to CPU. System adopts closed-loop control. Control circuit equips system failure diagnosis element to realize alarm when system steering error occurs and steering mode switching control unit to complete steering mode switching of vehicle.

Owner:JIANGSU UNIV

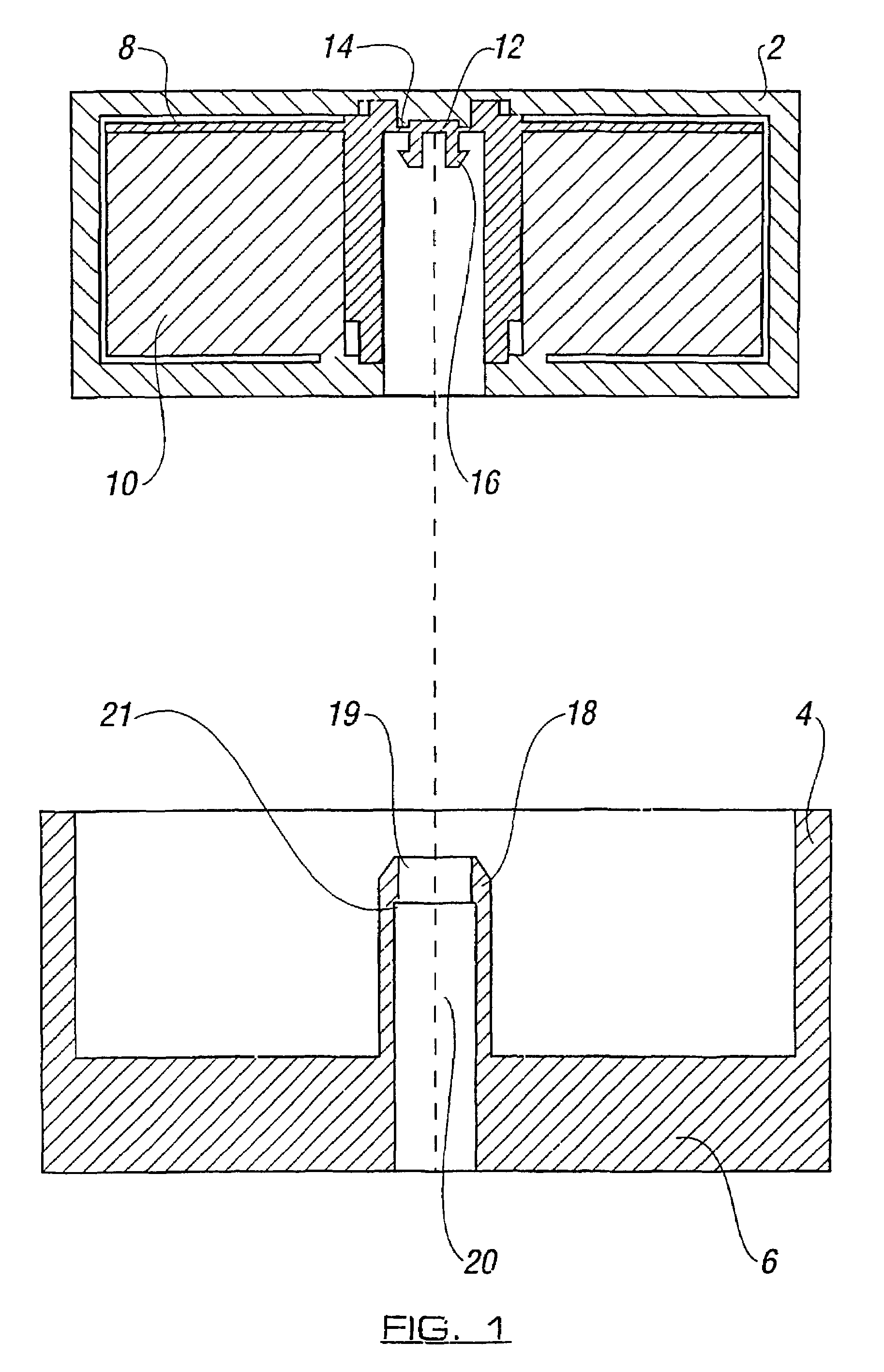

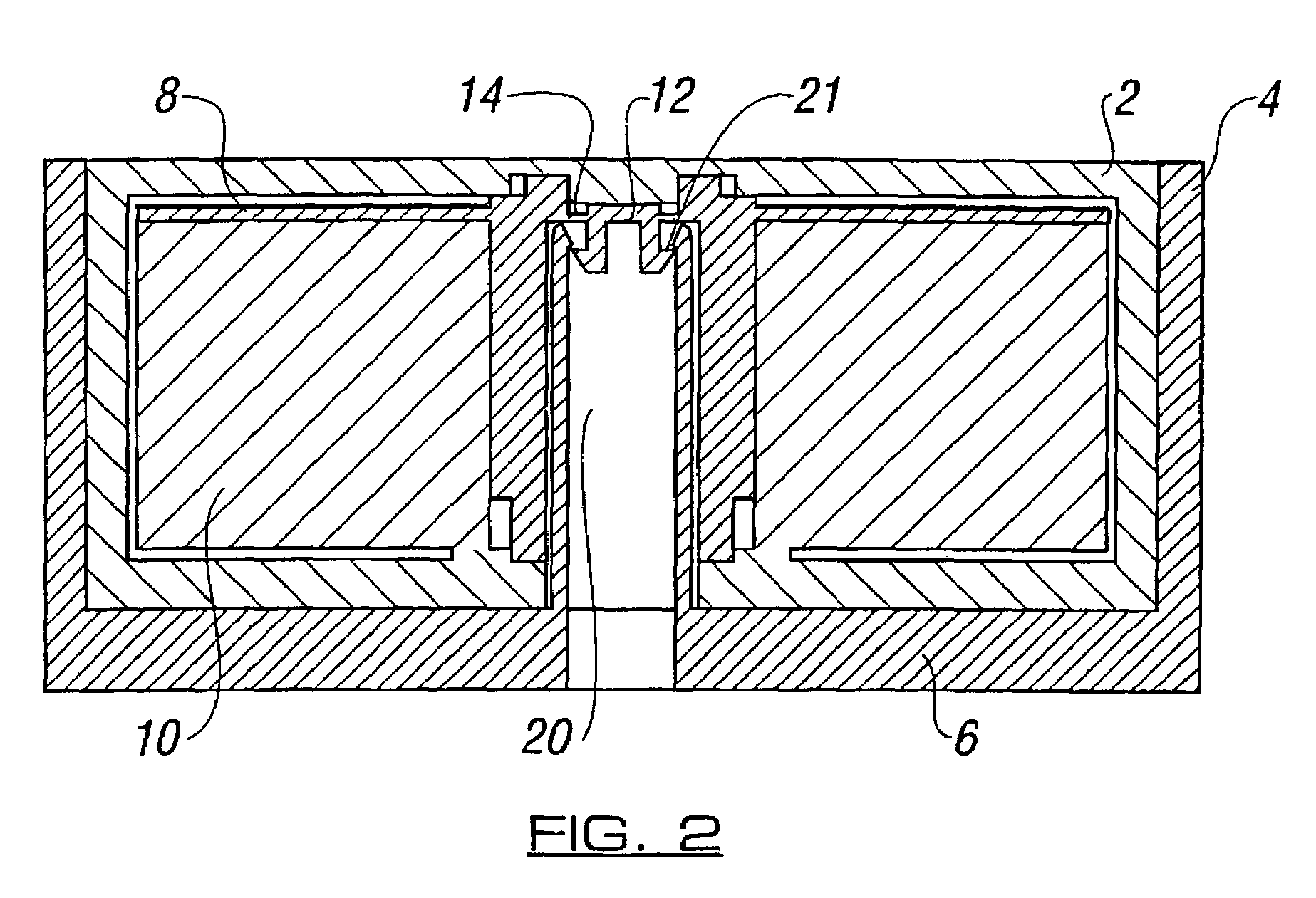

Refillable device with counting means

InactiveUS7080642B2Increase equipment costSimple mechanical structureRespiratorsMedical devicesNeedle Free InjectionMedical device

A refillable medical device comprising a base unit (4) adapted to be engaged with a refill unit (2), the device comprising means for counting the number of different refill units which are engaged with the base unit (4). The device may be in the form of a dry powder or pressurised aerosol inhaler, needleless injector, intravenous drip system etc. The device may comprise means to disable the device after a predetermined number of refill units have been used with the base.

Owner:3M INNOVATIVE PROPERTIES CO

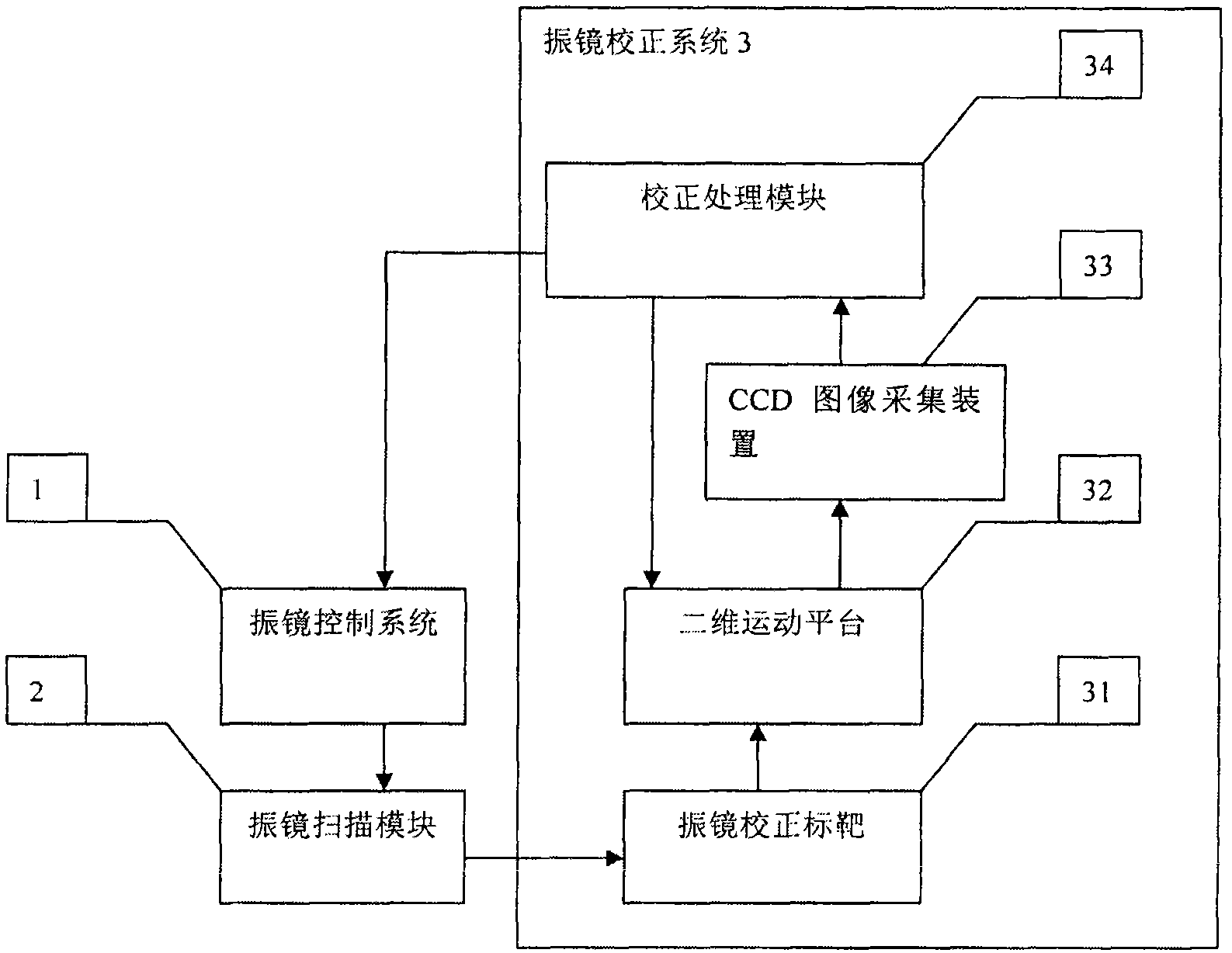

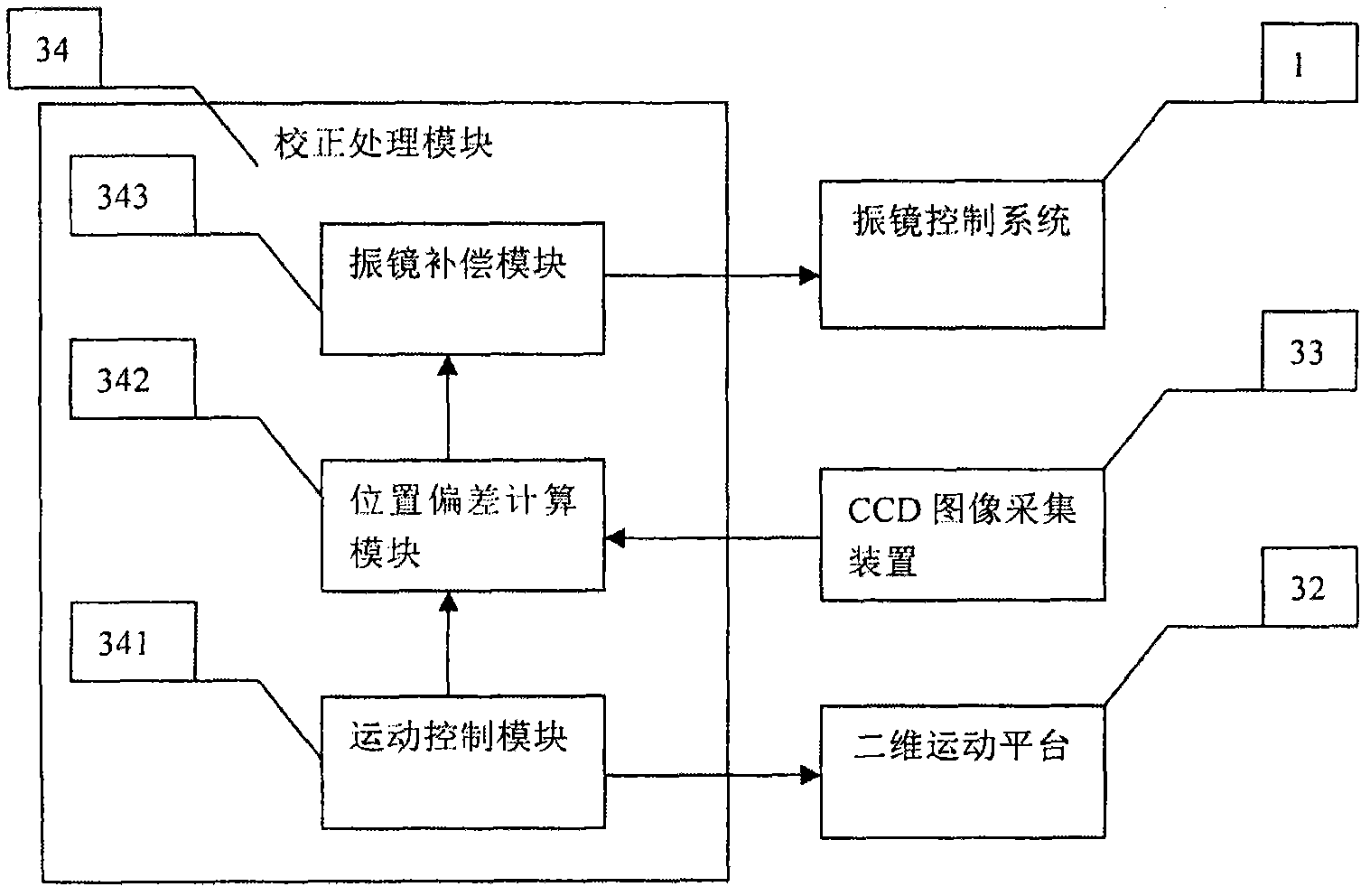

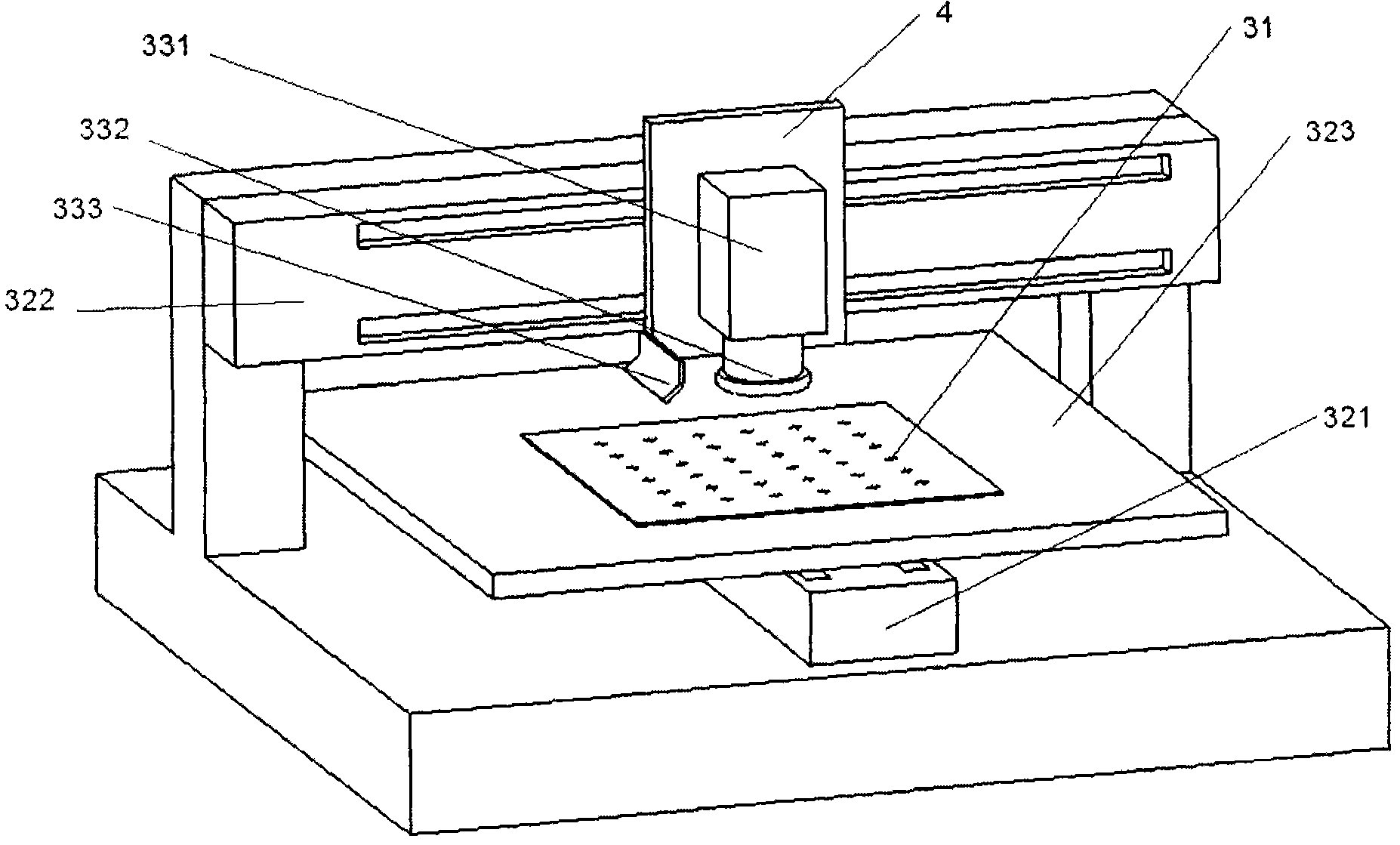

Precision vibration mirror correction system and method

InactiveCN102152007AHigh precisionGuaranteed measurement accuracyLaser beam welding apparatusLaser processingCorrection method

The invention is applicable to the technical field of laser processing, and provides a precision vibration mirror correction system and a precision vibration mirror correction method. The vibration mirror correction system comprises a vibration mirror correction target, a charge coupled device (CCD) image acquisition device, a two-dimensional motion platform device and a correction processing module, wherein an appointed mark point is marked on the correction target by a vibration mirror scanning module through laser reflection; the CCD image acquisition device performs image acquisition on a standard mark point marked by a vibration mirror; the two-dimensional motion platform device executes a high-precision positioning motion so as to guarantee the positioning precision; and the correction processing module calculates an image acquired by the CCD image acquisition device, finds out a position deflection of the mark point of the vibration mirror correction target and generates a vibration mirror compensation file to correct the vibration mirror. The vibration mirror correction system can realize high-precision correction of the vibration mirror conveniently and quickly.

Owner:BEIJING JCZ TECH

Small diameter felt cover needling machine

InactiveCN106988023AQuality improvementSimple mechanical structureNeedling machinesMechanical engineering

The invention relates to a small diameter felt cover needling machine. The small diameter felt cover needling machine comprises a rack, an assembly and disassembly part, a platform support part, a carrier roller support part and a needling part, the assembly and disassembly part, the platform support part, the carrier roller support part and the needling part are all arranged on the rack, the assembly and disassembly part completes assembly and disassembly of a felt cover product, the needling part completes needling motion, the platform support part is mainly used for achieving support for parts like a drum and motion of a support platform, and the carrier roller support part completes support for a carrier roller. According to the small diameter felt cover needling machine, a felt cover with good quality and a small size can be produced, and the technical problem in the prior art is solved that a common needling machine cannot produce the felt cover with the good quality and the small size.

Owner:SHANGHAI INST OF TECH

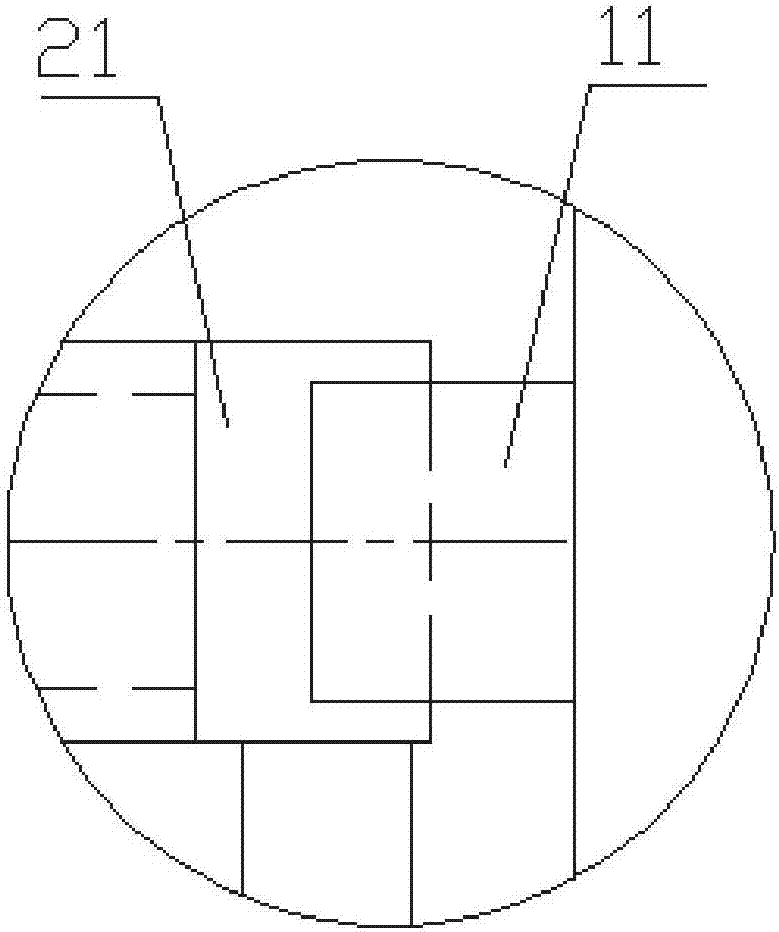

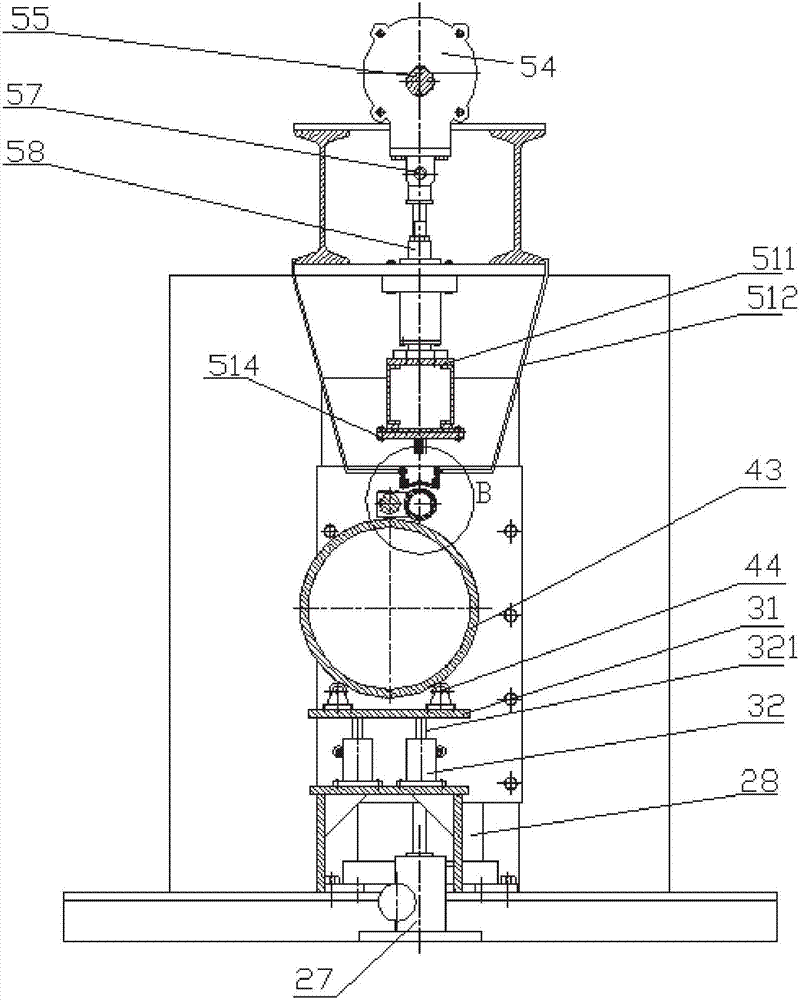

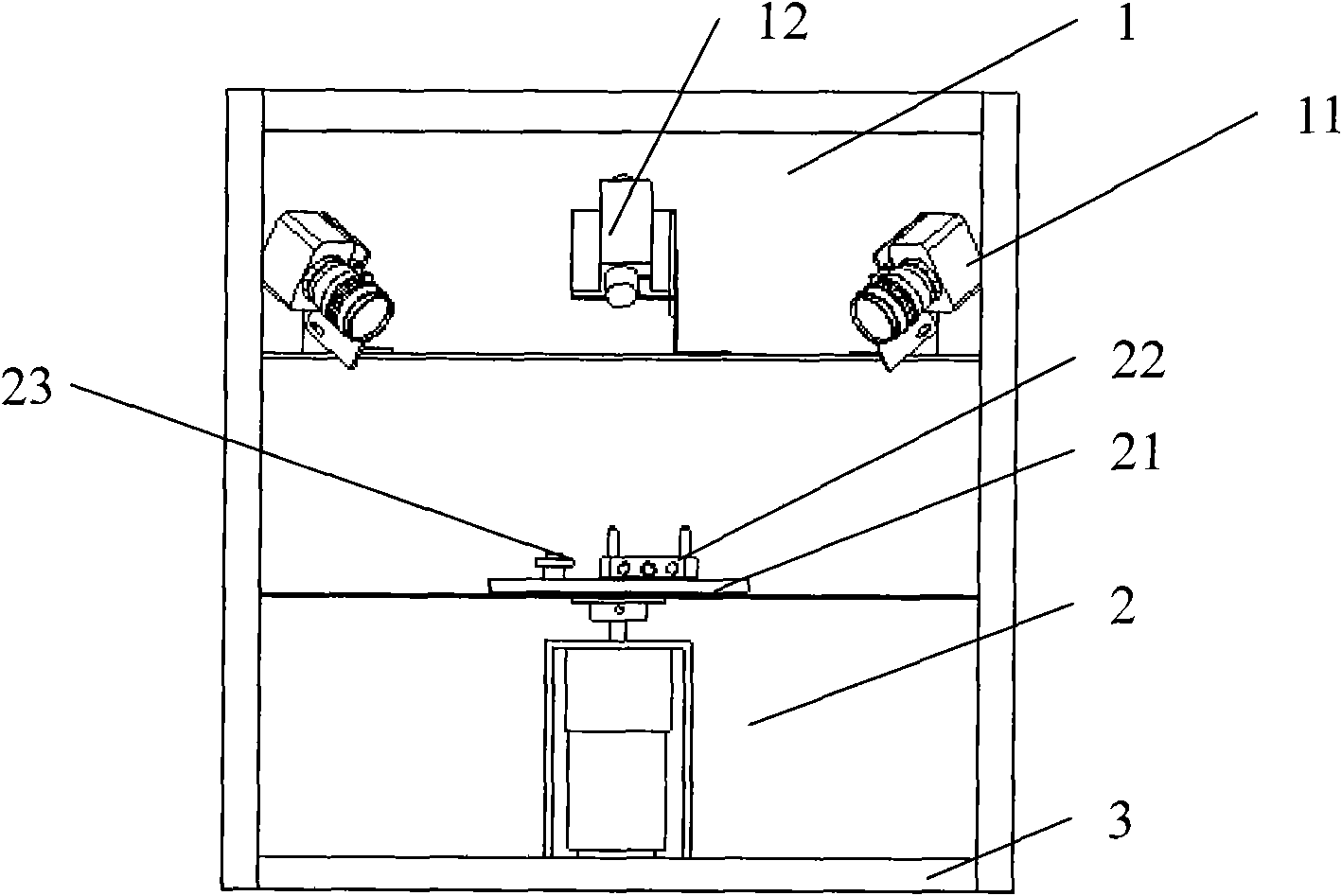

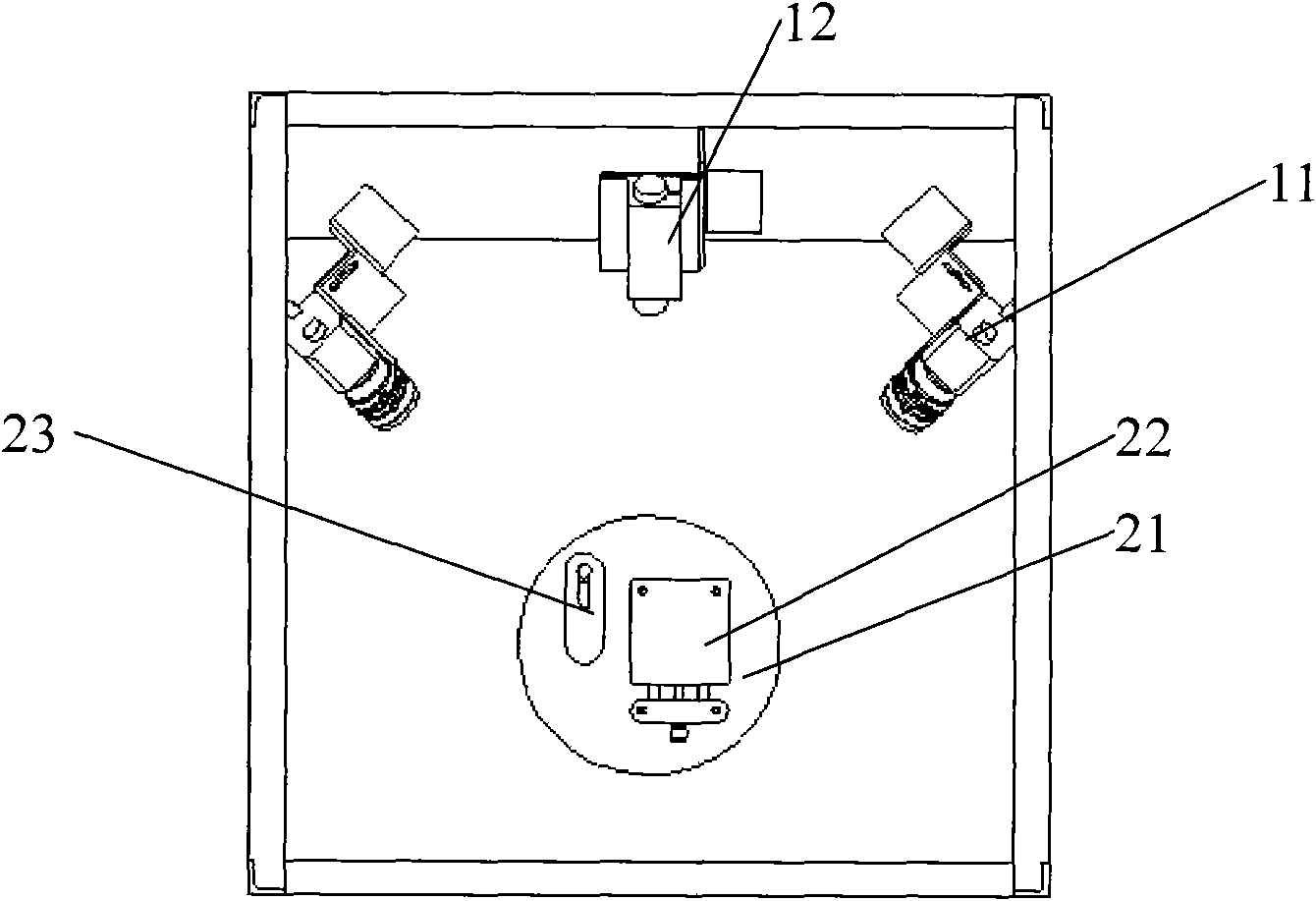

Computer binocular vision denture scanning device and three-dimensional reconstruction method thereof

InactiveCN102062588ASimple mechanical structureSimple control methodUsing optical meansReconstruction methodDenture surface

The invention relates to a computer binocular vision denture scanning device and a three-dimensional reconstruction method thereof. The device comprises a linearly structured light vision collection part, a rotary measuring bed, a control part of the rotary measuring bed, and a box, wherein two high resolution digital charge coupled device (CCD) cameras are positioned on the central sides above the rotary measuring bed and the control part of the rotary measuring bed and symmetrically distributed by taking the linearly structured light laser as the centre in the linearly structured light vision collection part; first and second accessories in the rotary measuring bed and the control part of the rotary measuring part are arranged on the rotary measuring bed; the rotary measuring bed is driven by a driving mechanism to rotate; and the structures are arranged in the box. The method comprises: placing a denture on the rotary measuring bed; allowing the linearly structured light laser to project laser on the denture; driving the rotary measuring bed to rotate continuously by the driving mechanism; and taking pictures by two CCD cameras and transmitting the pictures to an external control computer to process the pictures to obtain three-dimensional data on the denture surface. In the invention, the mechanical structure and the control method need no various speed control, have no requirement on precision of spindle rotation of a motor, and are convenient to operate and high in scanning precision.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

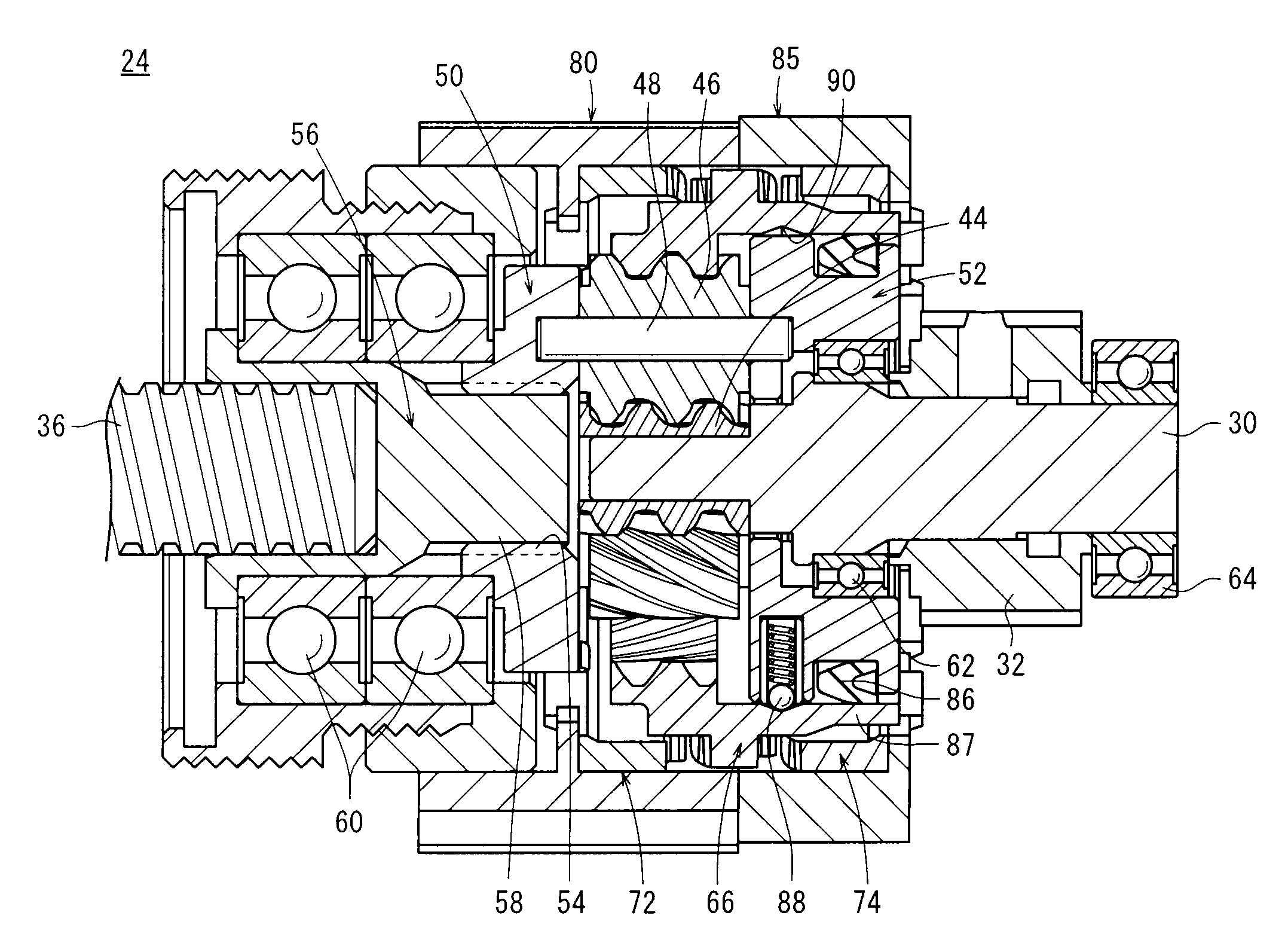

Automatic speed reduction ratio switching apparatus

ActiveUS8303458B2Reliably obtainedImprove accuracyToothed gearingsGearing controlGear wheelEngineering

An automatic speed reduction ratio switching apparatus is equipped with a sun gear connected to an input shaft, first and second carriers connected to a feed screw shaft, planetary gears meshed with the sun gear and which are mounted rotatably in the first and second carriers, and an internal gear meshed with the planetary gears and which is capable of movement in an axial direction. A packing member is arranged between the internal gear and the second carrier, for regulating movement in the axial direction of the internal gear, while enabling movement of the internal gear in the axial direction when a thrust force is applied at or above a predetermined value.

Owner:SMC CORP

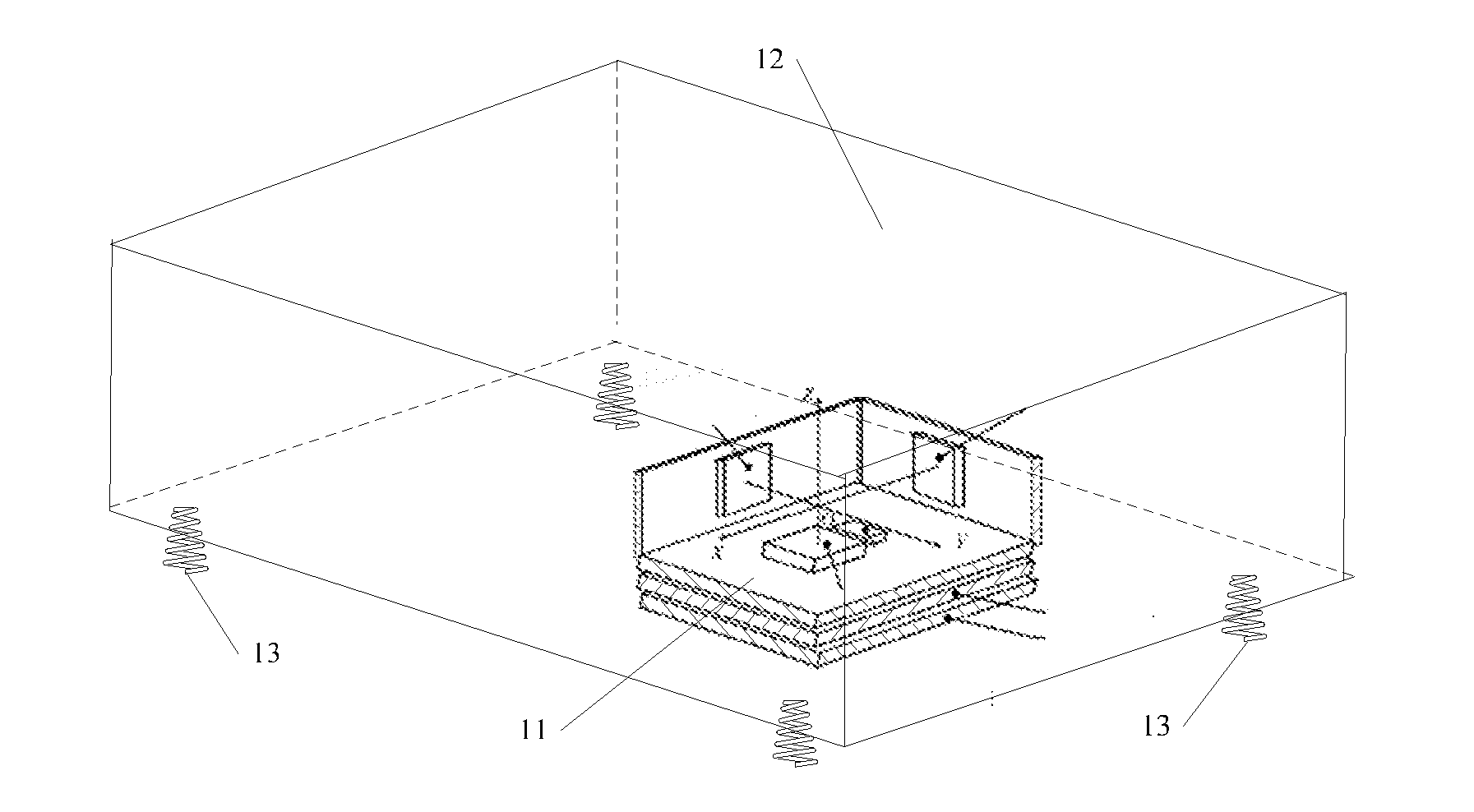

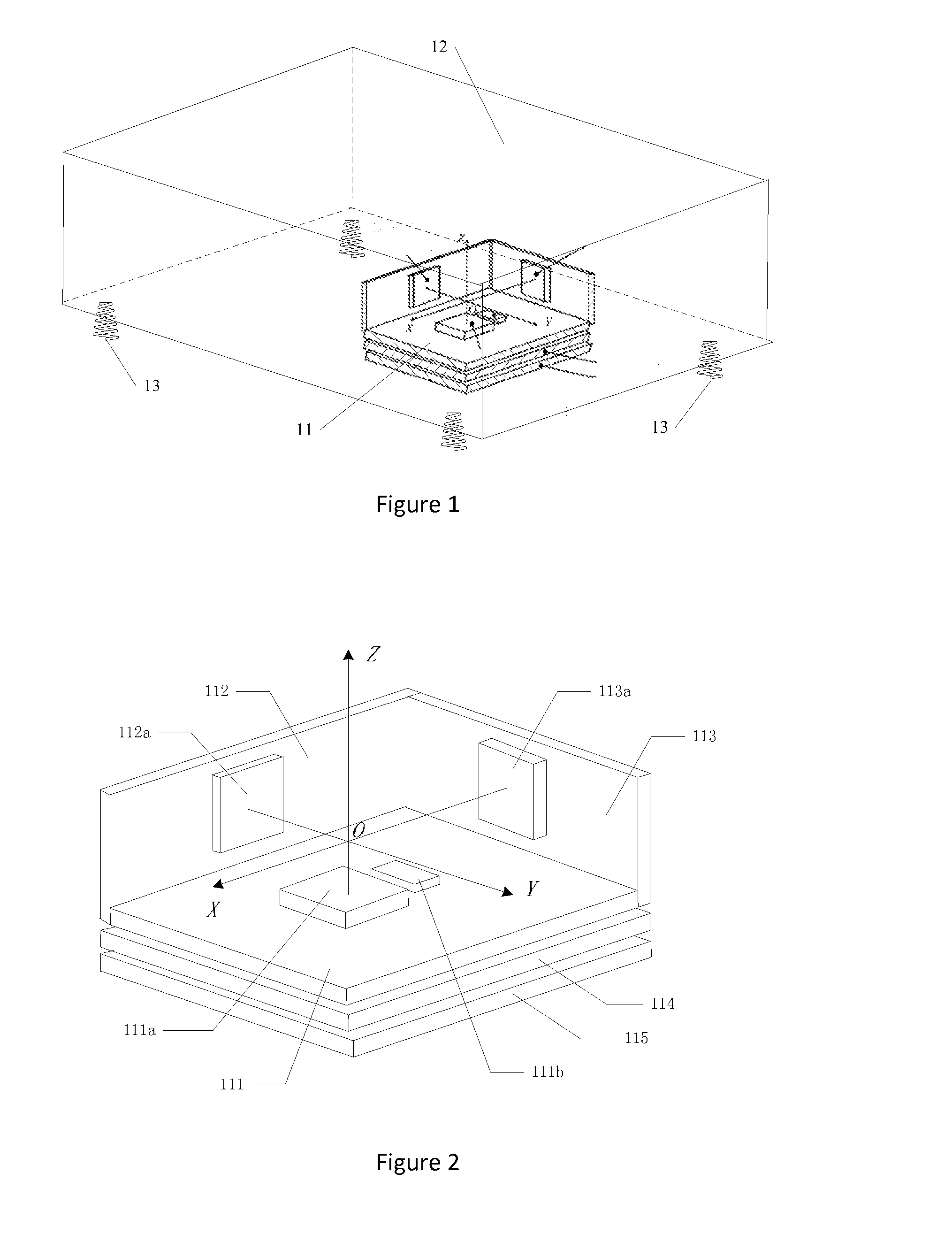

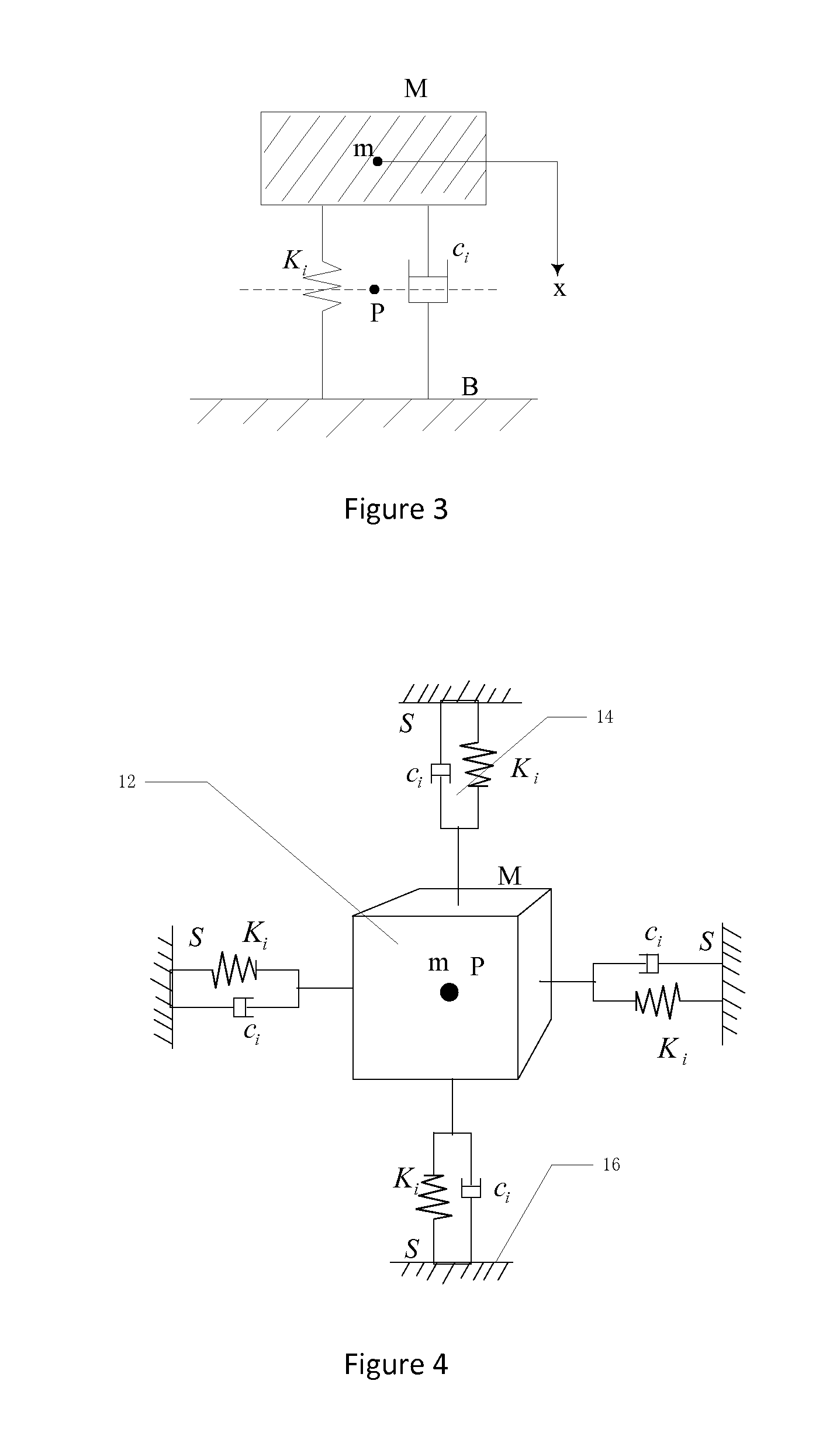

Micro inertial measurement system

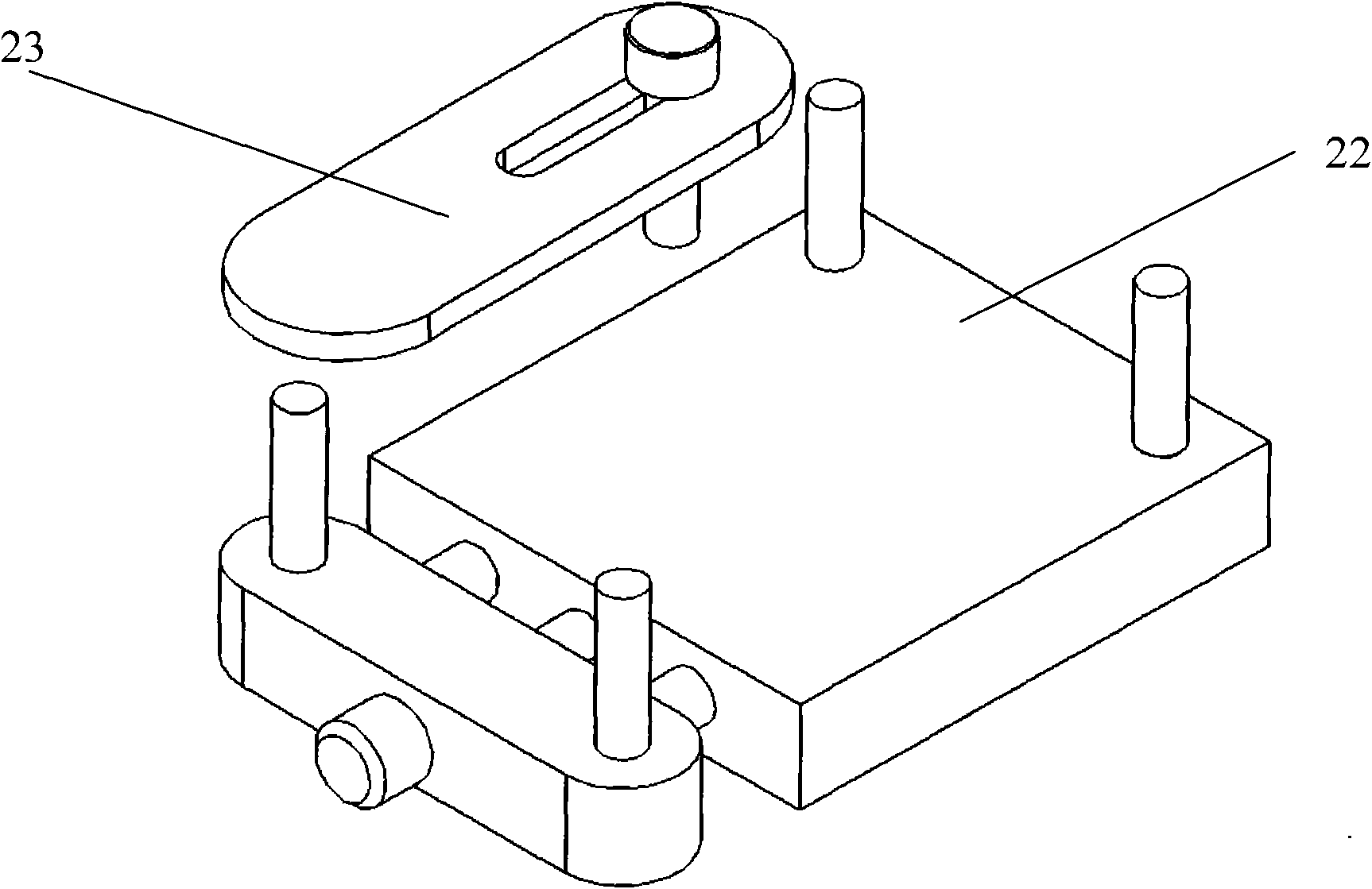

ActiveUS20130111993A1Improve rigiditySimple mechanical structureNon-rotating vibration suppressionNavigation by speed/acceleration measurementsEngineeringInertia

A micro inertial measurement system includes a housing, a sensing module, and a damper. The sensing module includes a rigid sensing support, a measuring and controlling circuit board mounted on the rigid sensing support and an inertial sensor set on the measuring and controlling circuit board. The inertial sensor includes a gyroscope and an accelerometer. The sensing module is mounted in the housing. The damper is mounted in the housing and set in the gap between the sensing module and the inside wall of the housing. By use of the above-mentioned structure, the noise immunity of the inertial measuring system can be greatly improved, and the volume and weight of the inertial measuring system can be greatly reduced.

Owner:SZ DJI TECH CO LTD

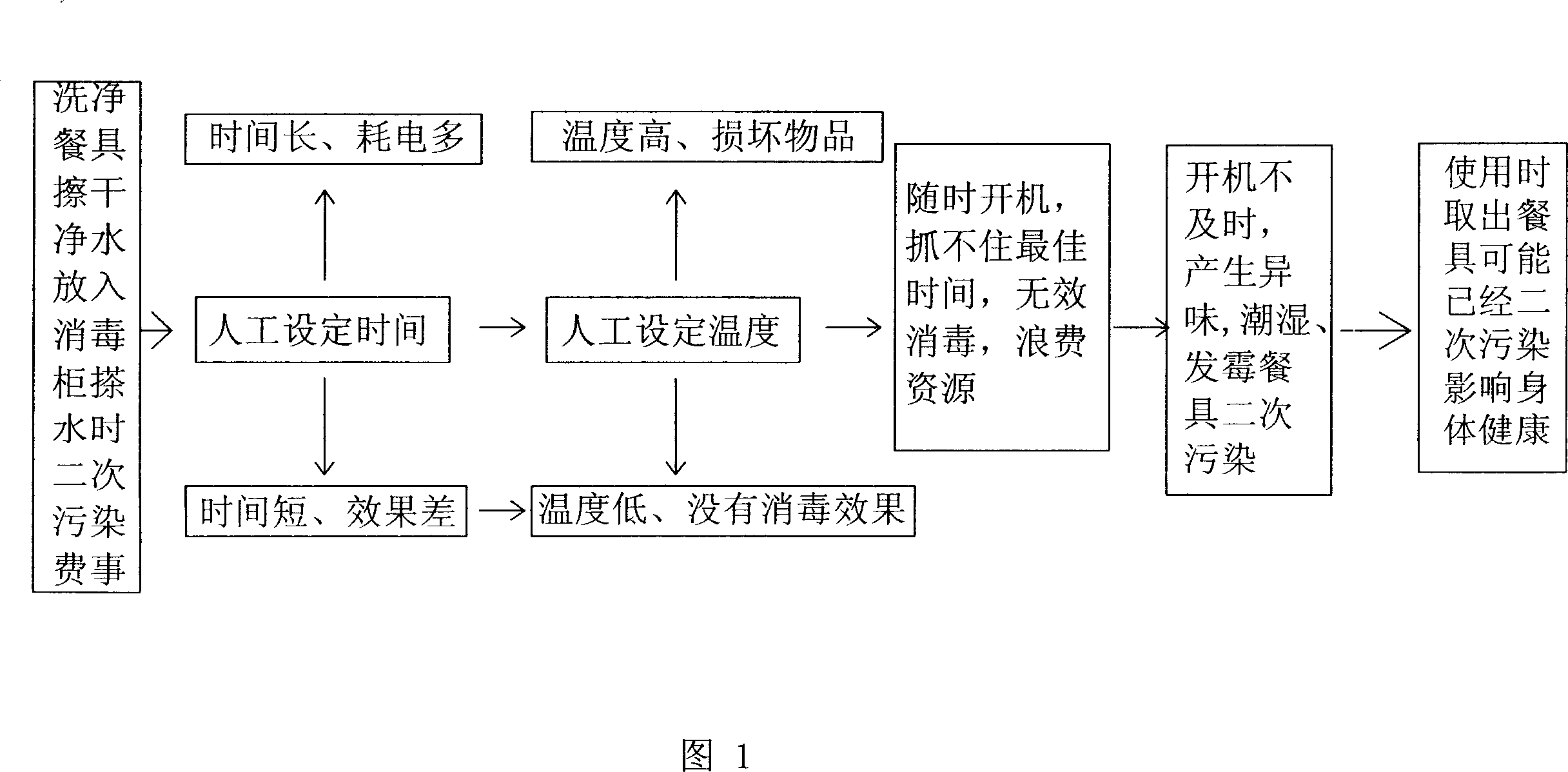

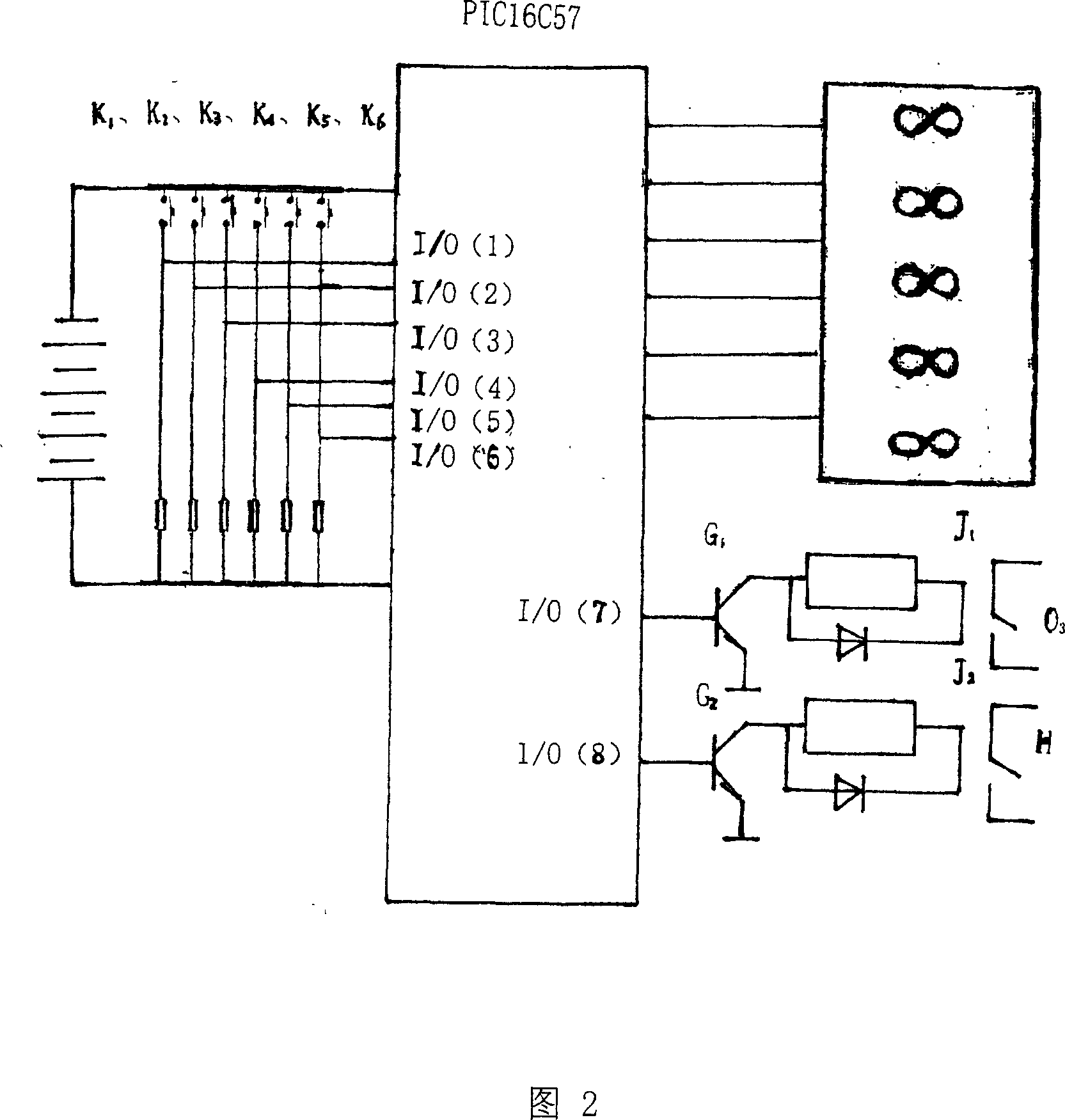

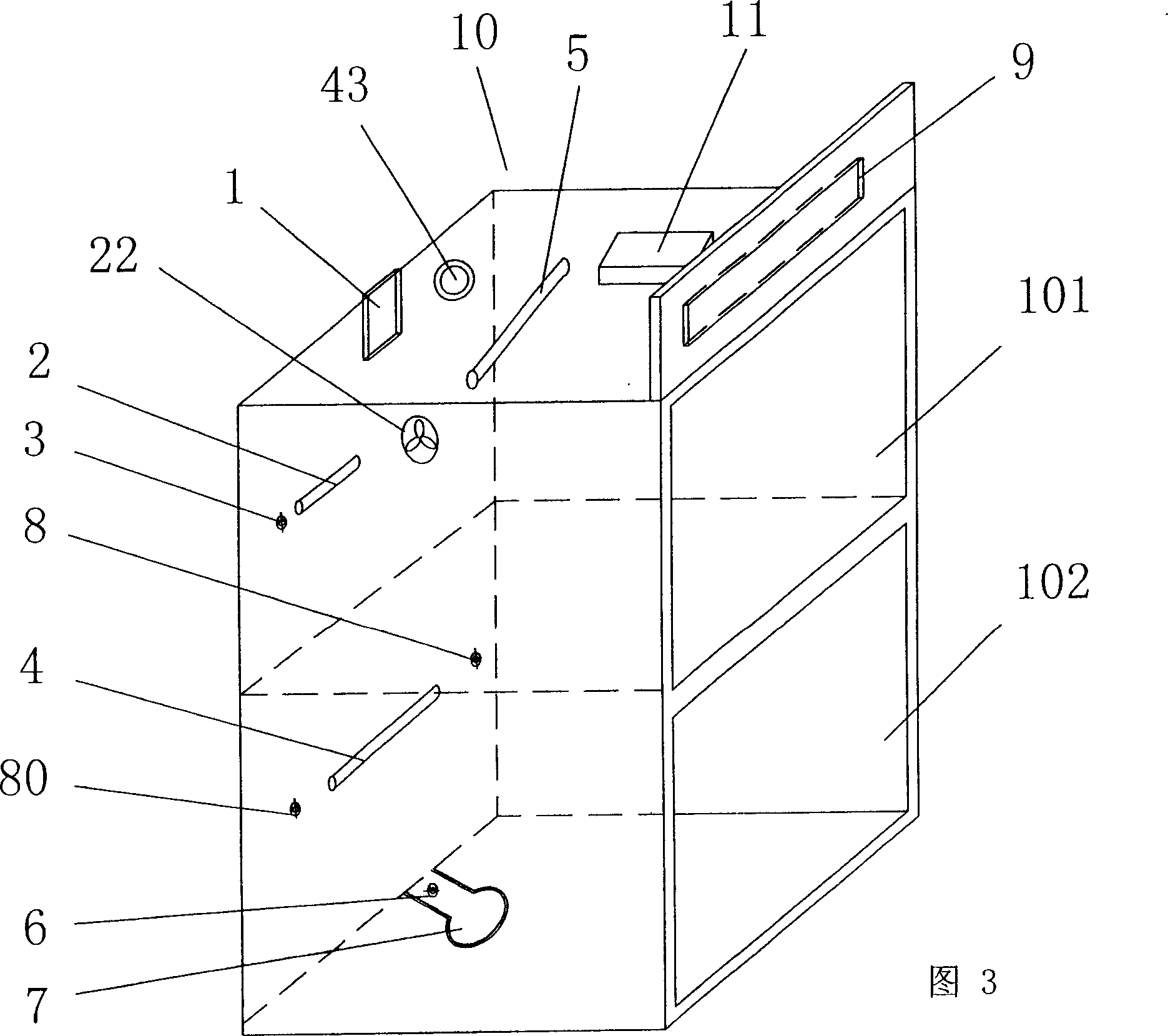

Intelligent-tracking-monitoring disinfecting cabinet and its tracking-monitoring-disinfecting method

ActiveCN1977979AThe principle is simpleImprove power utilizationLavatory sanitoryHeatEngineeringDisinfection methods

The present invention relates to an intelligent monitoring sterilizing cabinet and its automatic monitoring sterilizing method. It is characterized by that it includes a cabinet body, power supply board and control panel placed on the panel of cabinet body. The described cabinet body is formed from upper chamber and lower chamber, an upper chamber heating device is placed in the upper chamber interior, a lower chamber heating device is placed in the lower chamber interior. In the sterilizing cabinet interior an intelligent control system is set, said intelligent control system includes a temperature detection device, a humidity detection device and a computer plate. Besides, said invention also provides the working principle of said intelligent monitoring sterilizing cabinet and its concrete operation method.

Owner:QINGDAO HAIER WISDOM KITCHEN APPLIANCE CO LTD +1

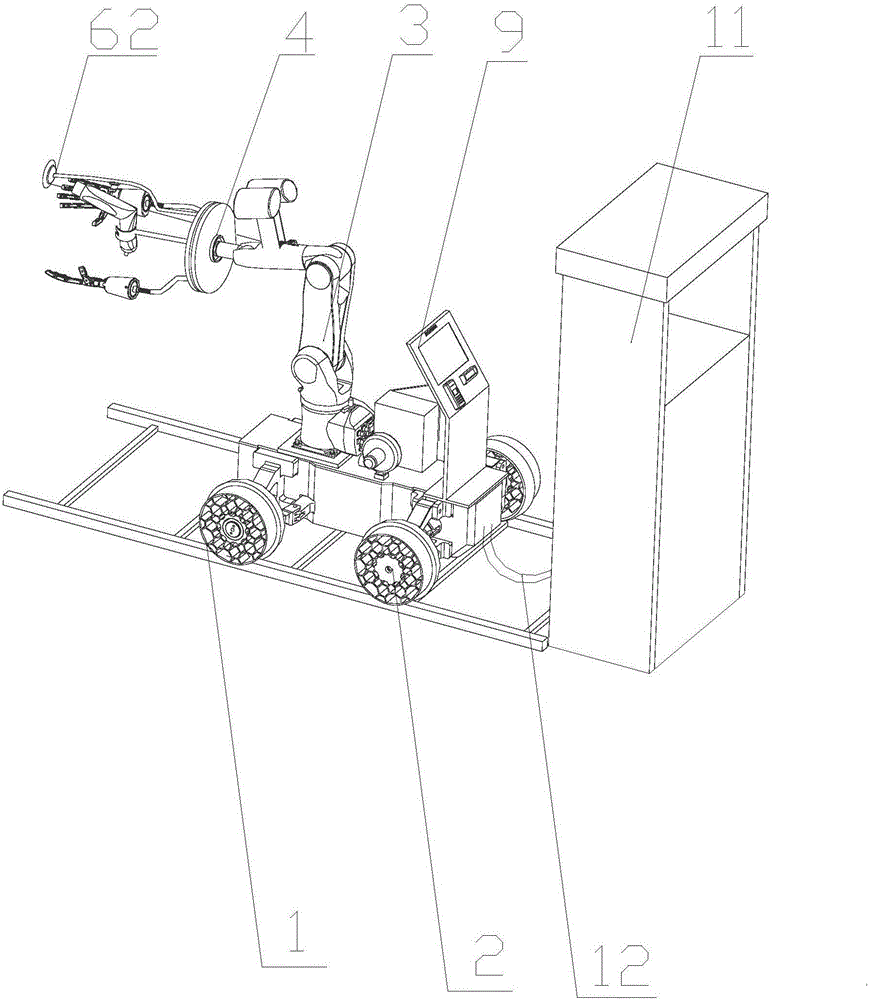

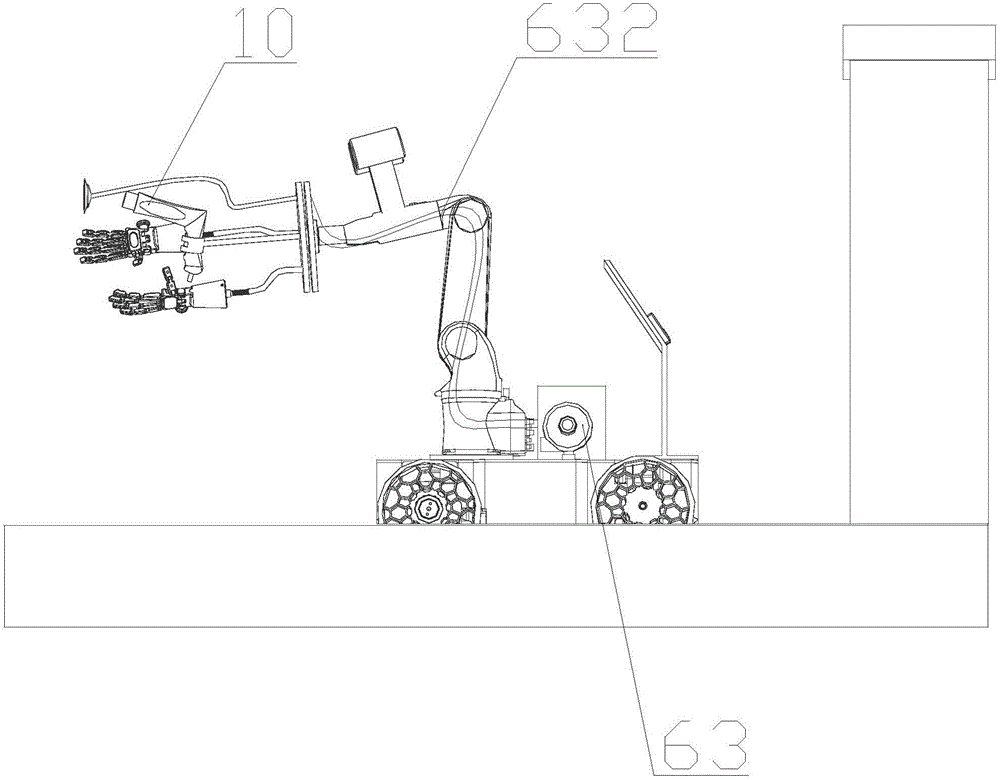

Full-automatic oiling serving robot for unmanned oiling station and oiling serving method

ActiveCN105666502ASolve the problem of unmanned implementationFully automatedGripping headsInteraction systemsFuel tank

The invention relates to a full-automatic oiling serving robot for an unmanned oiling station.The full-automatic oiling serving robot comprises an external-expansion type rail, a movable intelligent platform, an industrial mechanical arm, a function switching rotating disc, a humanoid mechanical gripper, an electric suction cup, a touch mechanical gripper, a machine vision system, a man-computer interaction system, an oiling gun, an oiling machine, an oil pipe and a control cabinet.Automatic station switching of different kinds of devices is achieved through the function switching rotating disc in cooperation with supports with different functions and the like, and switching efficiency is improved; full-automatic oiling operation of different vehicles is achieved by using the humanoid mechanical gripper, the electric suction cup and the touch gripper in a matched mode, and the serving range of the robot is expanded; shape and position identification of outer cover plates and oil tank covers of automobiles is achieved in combination with the machine vision system, and the functions of monitoring and identifying the running condition, automobile license plates, owner identity and the like are further achieved; due to the cooperation of the human-computer interaction system, the types of the automobile oiling services of the full-automatic oiling serving robot are richer, and the application range is wider.

Owner:SHANDONG GUOXING SMARTECH CO LTD

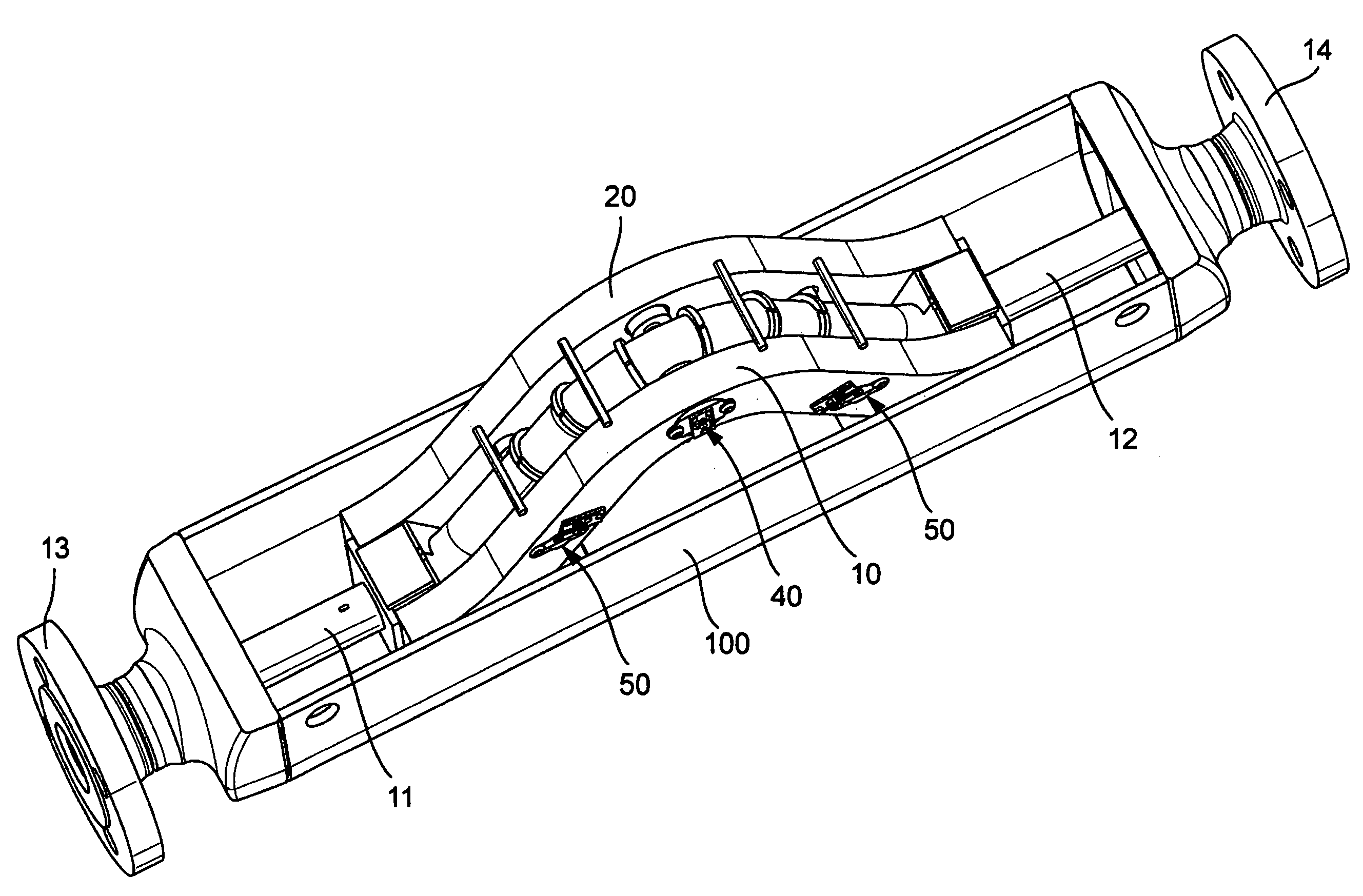

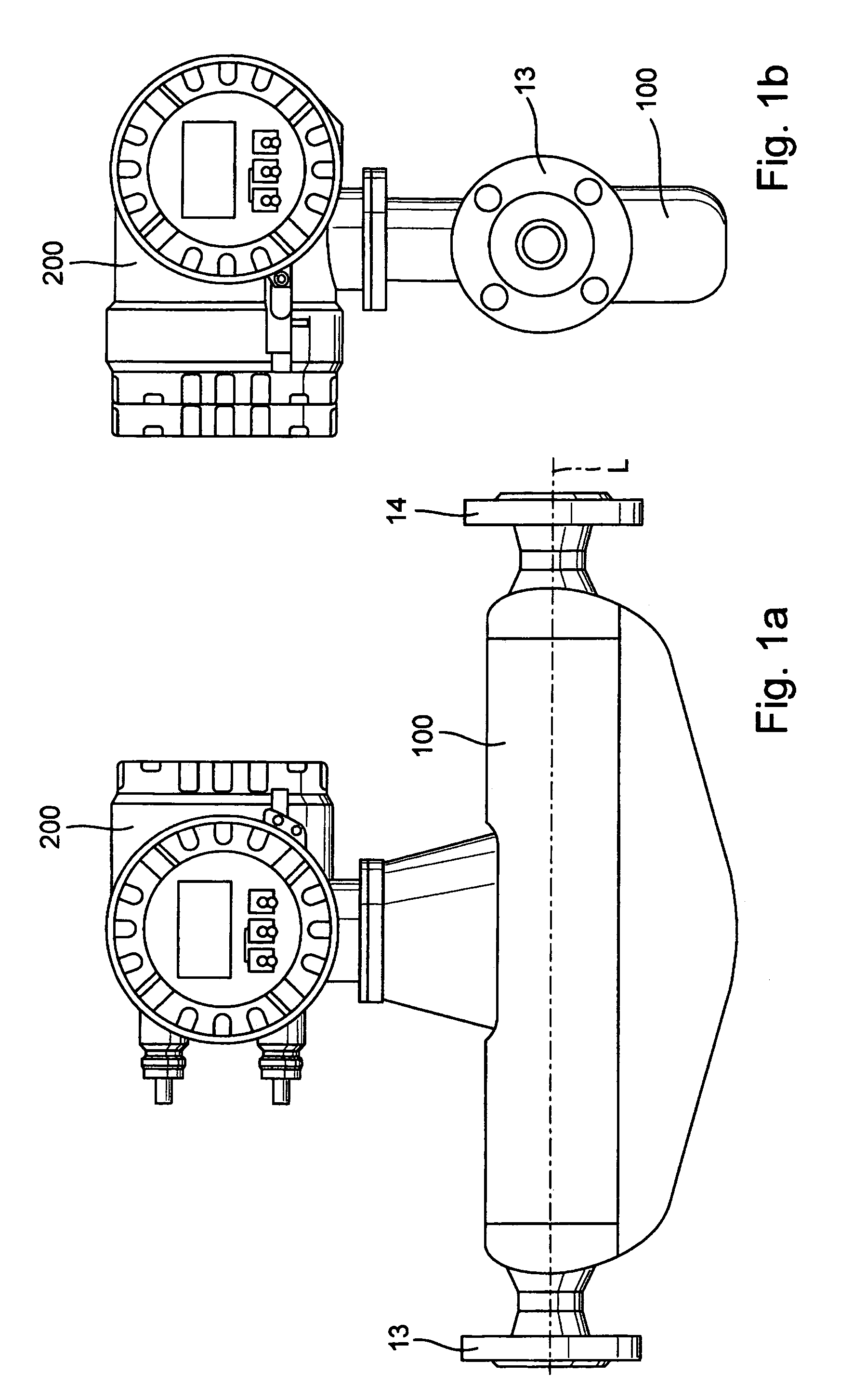

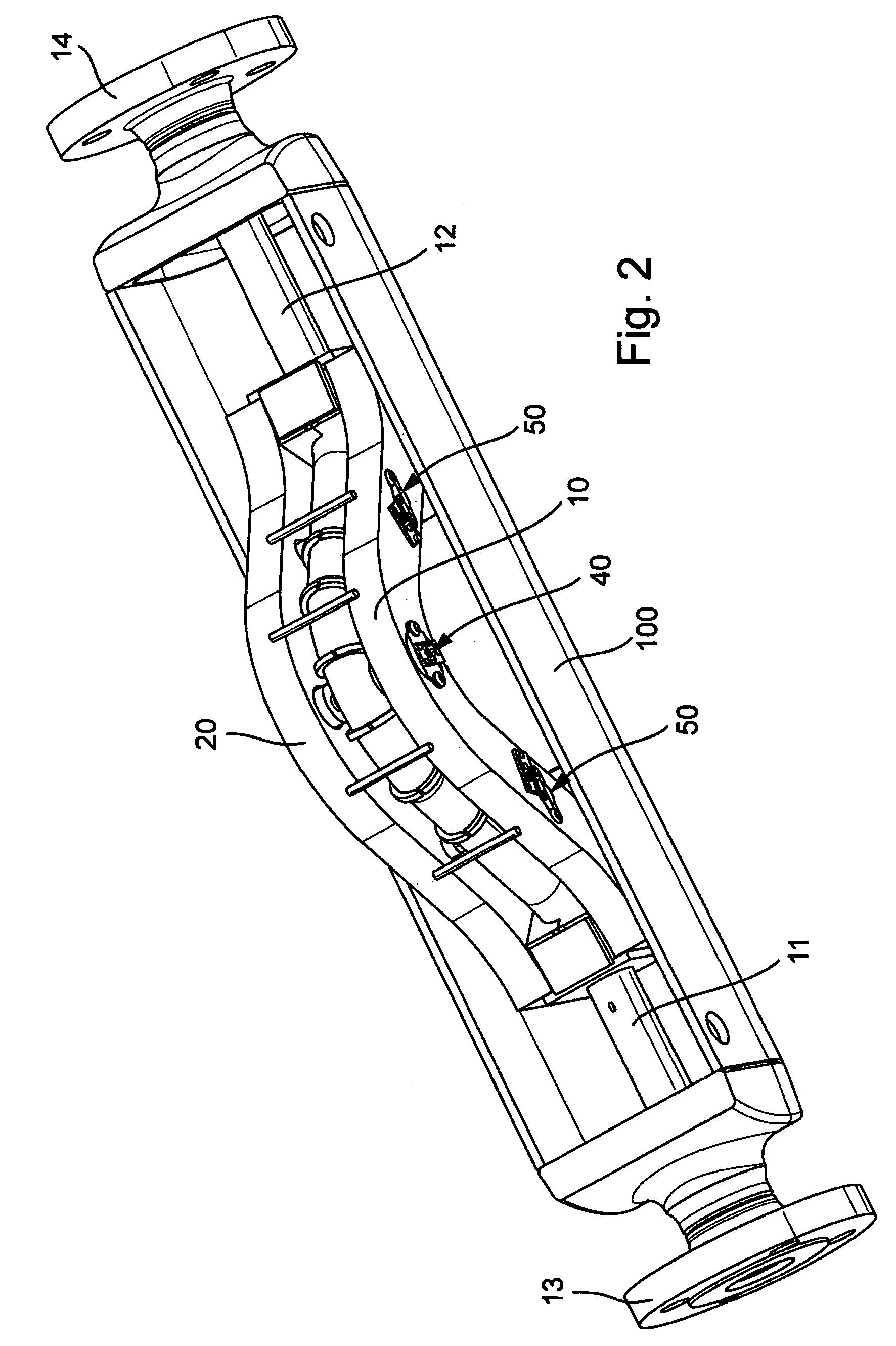

Measuring transducer of vibration-type

ActiveUS7325462B2Simple mechanical structureReduce complexityDirect mass flowmetersCouplingTransducer

The measuring transducer includes a transducer housing, as well as an internal part arranged in the transducer housing. The internal part includes at least one curved measuring tube vibrating, at least at times, during operation and serving for conveying the medium, as well as a counteroscillator affixed to the measuring tube on the inlet-side, accompanied by formation of a coupling zone, and to the measuring tube on the outlet-side, accompanied by the formation of a coupling zone. The internal part is held oscillatably in the transducer housing, at least by means of two connecting tube pieces, via which the measuring tube communicates during operation with the pipeline and which are so oriented with respect to one another, as well as with respect to an imaginary longitudinal axis of the measuring transducer, that the internal part can move during operation in the manner of a pendulum about the longitudinal axis. Counteroscillator of the measuring transducer of the invention is formed by means of two counteroscillator plates, of which a first counteroscillator plate is arranged on the left side of the measuring tube and a second counteroscillator plate is arranged on the right side of the measuring tube.

Owner:ENDRESS HAUSER FLOWTEC AG

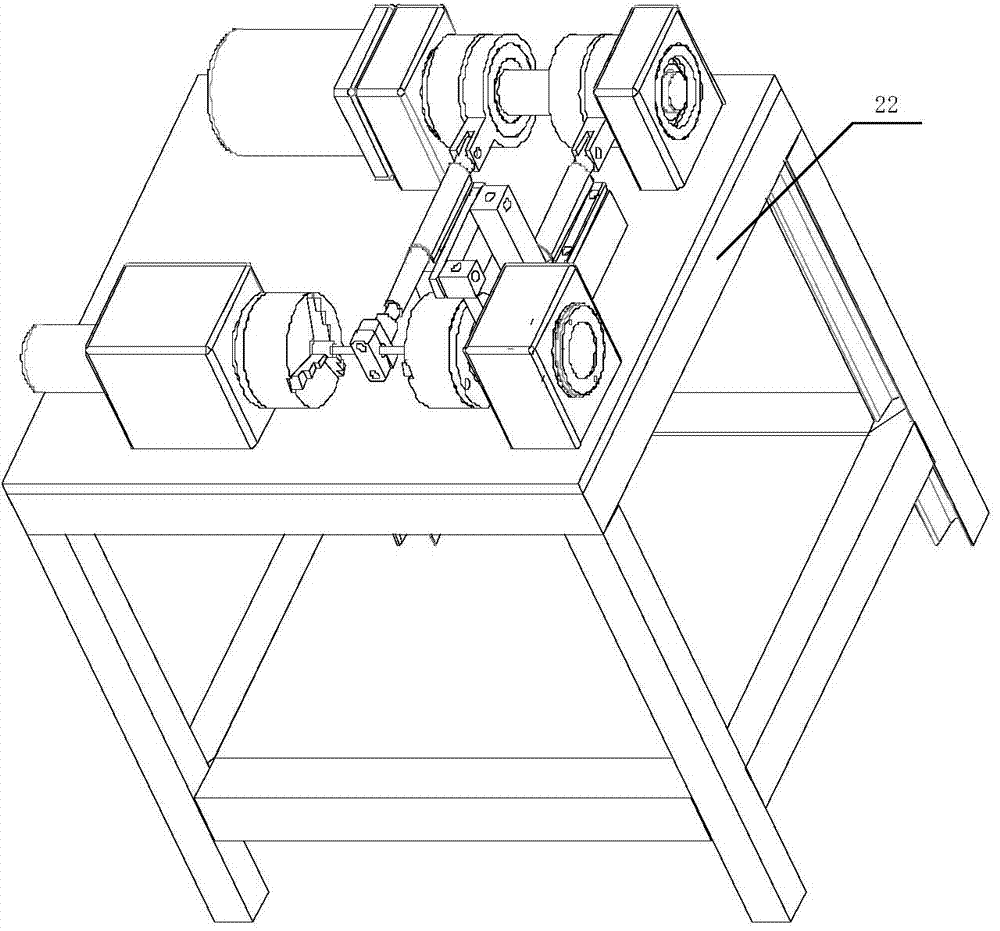

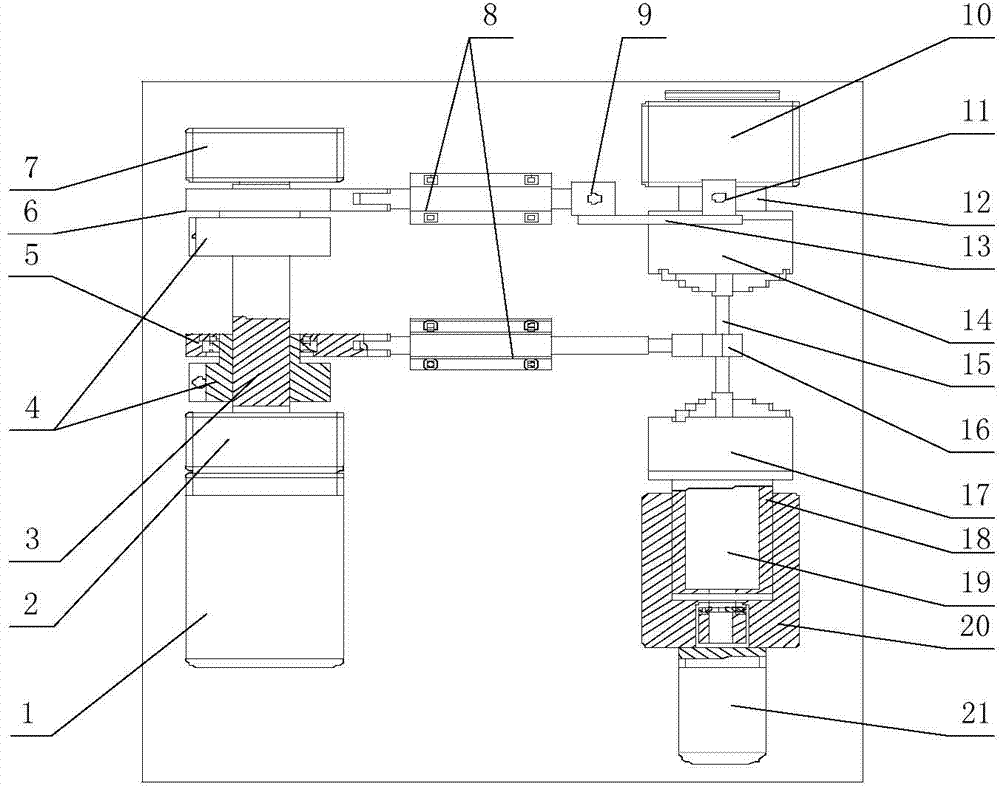

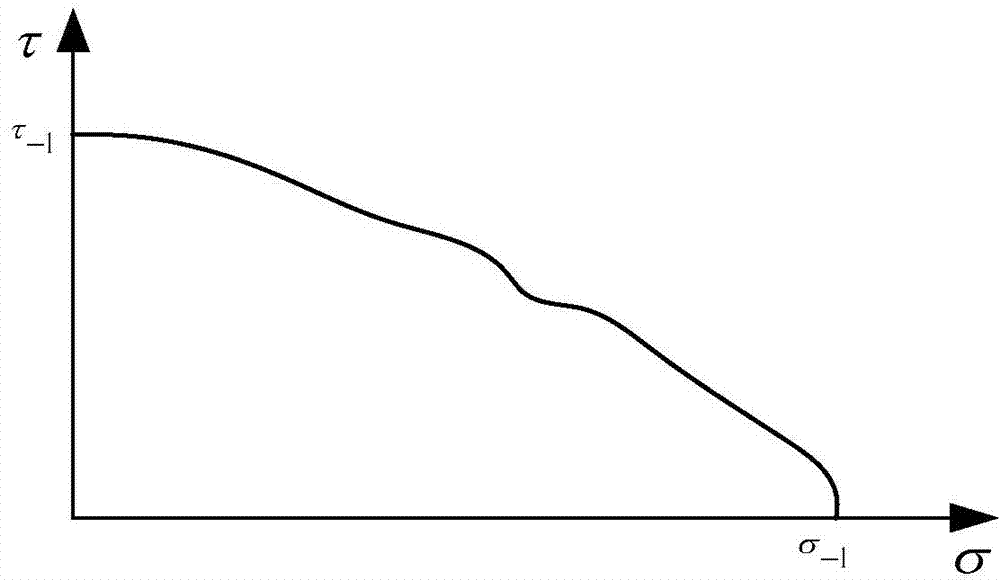

Pulling and bending multi-axis loading fatigue testing machine

InactiveCN103900916ASimple mechanical structureEasy to operateMaterial strength using repeated/pulsating forcesTorsion fatigueFatigue testing

The invention provides a pulling and bending multi-axis loading fatigue testing machine. The pulling and bending multi-axis loading fatigue testing machine is mainly characterized in that a stepping motor arranged on a rack is connected with one side of a chuck A by a screw rod and a hollow stretching shaft and can be used for testing a stretching fatigue of a test piece; a stepping motor B is connected with an eccentric shaft; the eccentric shaft is provided with an eccentric wheel, a bent connection rod and a bent force applying mechanism and can be used for detecting the bending fatigue of the test piece; the eccentric shaft is further provided with an eccentric wheel and a torsion connection rod and is connected with a hollow torsion shaft by a connection rod, a transition connection rod and a torsion rocker; the hollow torsion shaft is connected with the chuck B and can be used for detecting the torsion fatigue of the test piece. The pulling and bending multi-axis loading fatigue testing machine has the advantages of simple mechanical structure, easiness for operation, small power of the stepping motors and the like, and can be used for finishing tests of the fatigue performances of test piece materials from single stretching, bending and torsion to multi-shaft difficult combination loading conditions.

Owner:YANSHAN UNIV

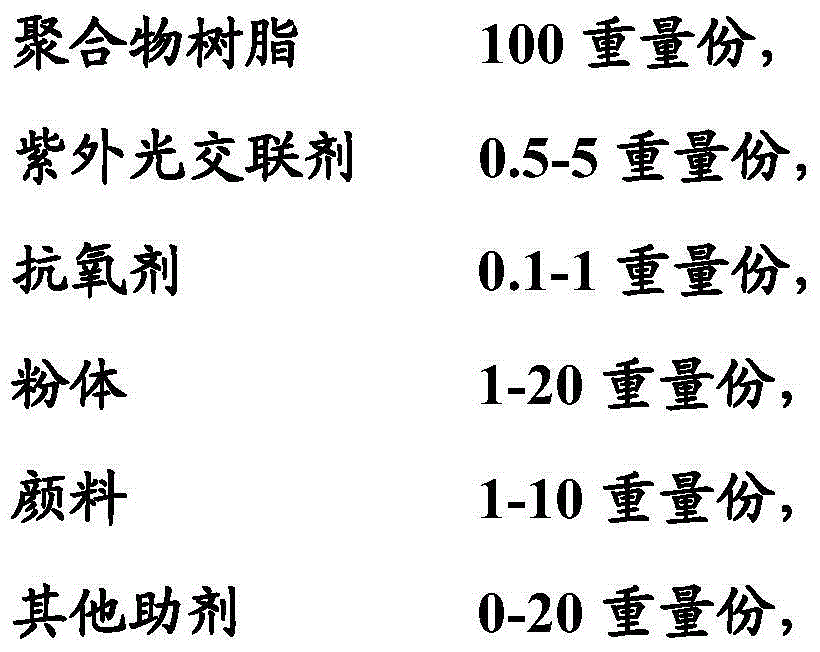

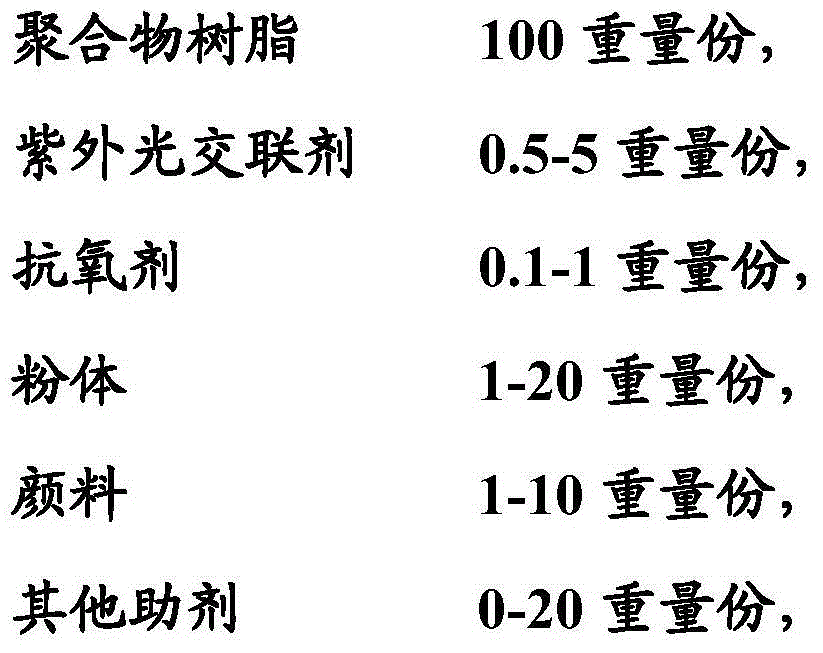

Ultraviolet light crosslinked polymer material used for 3D printing, and preparation method and application thereof

The invention relates to an ultraviolet light cross-linked polymer material used for 3D printing, and a preparation method and an application thereof. Raw materials of the material comprise, by weight, 100 parts of polymer resin, 0.5-5 parts of an ultraviolet light cross-linking agent, 0.1-0.5 parts of an antioxidant, 1-20 parts of powder, 1-10 parts of a pigment and 0-20 parts of other assistant. The light cross-linking agent absorbs ultraviolet lights with specific wavelengths under ultraviolet light irradiation to generate high molecular chain free radicals, so a series of a rapid polymerization reaction is generated to the polymer resin crosslink in a 3D printing process in order to form a three-dimensional net structure. The heat resistance, the chemical corrosion resistance and the mechanical strength of the cross-linked polymer material are greatly improved, so the polymer resin has a wide application prospect in 3D printing materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI

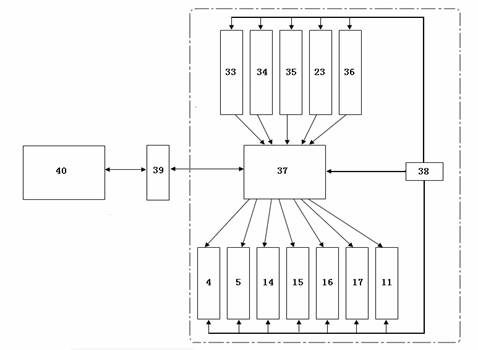

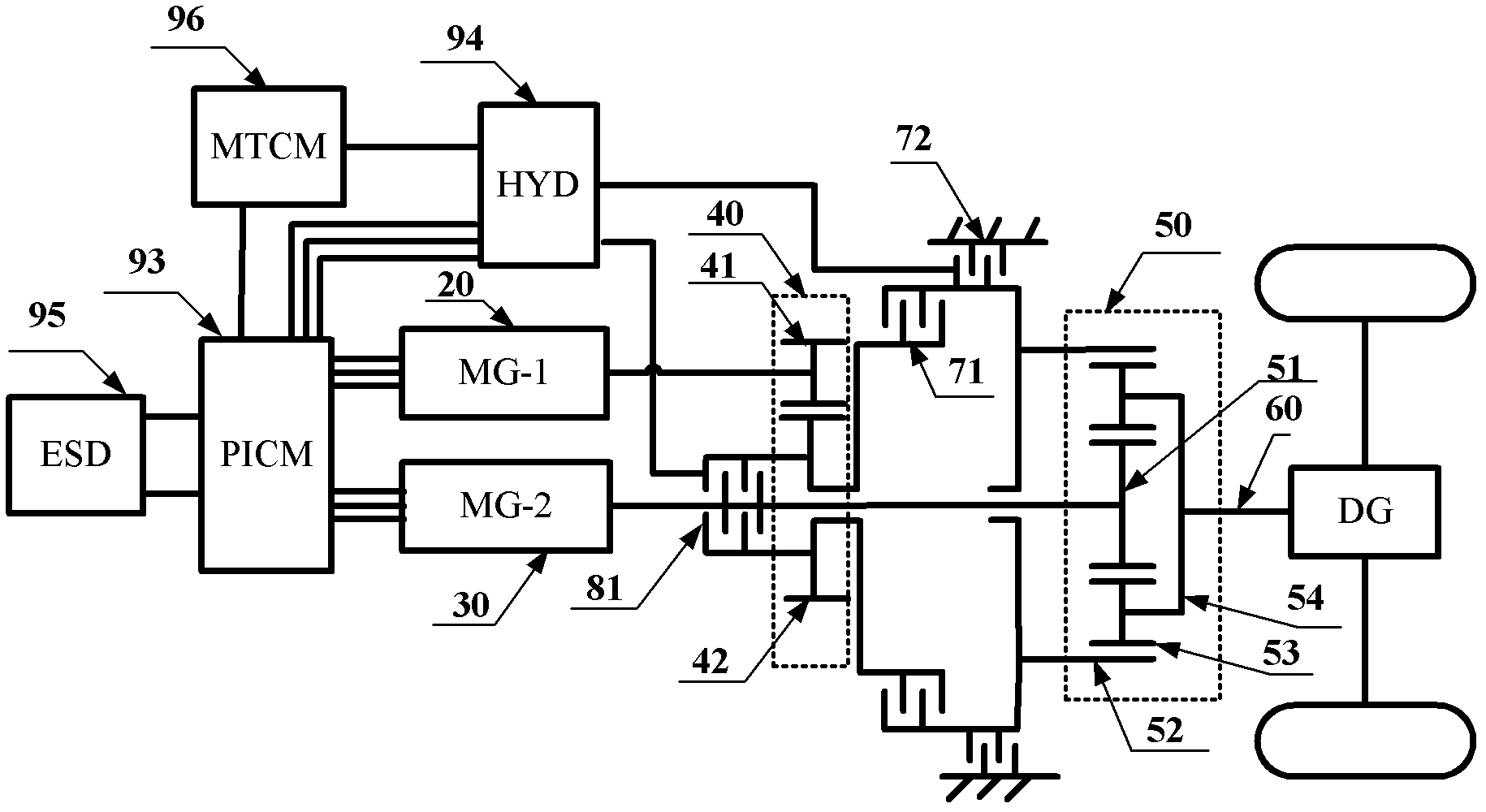

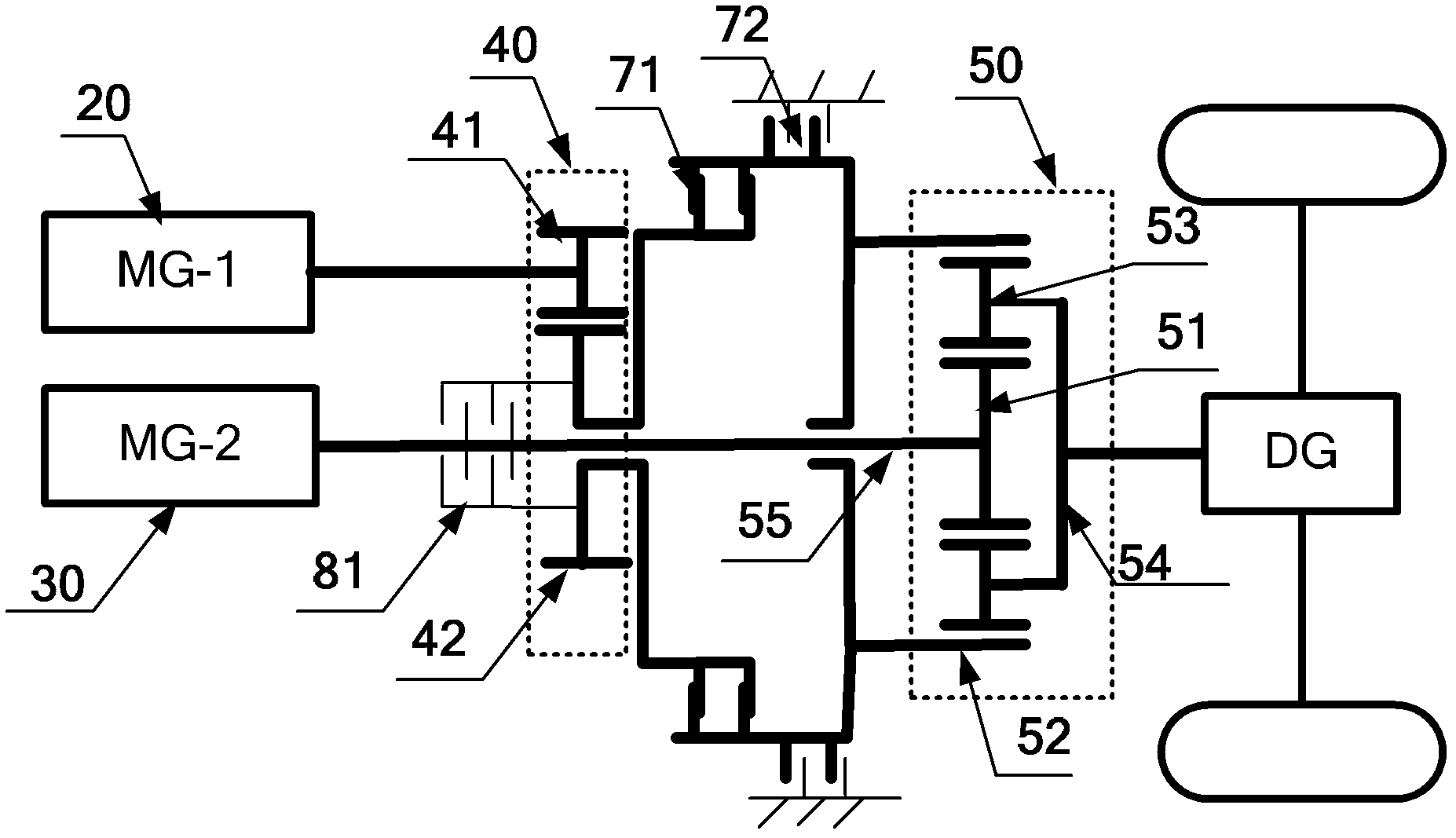

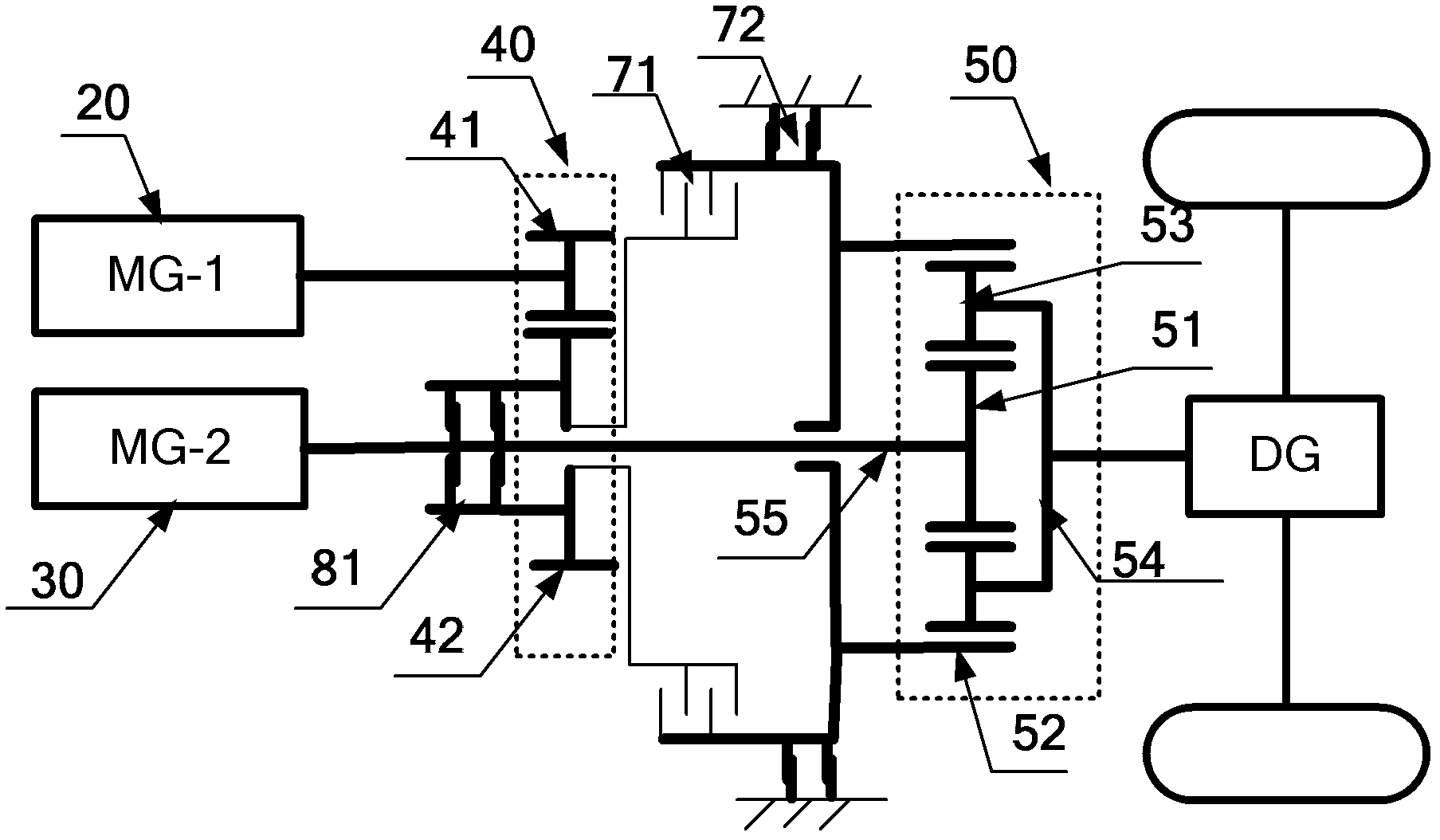

Electric vehicle, double-motor coupling speed change gear thereof and control system of double-motor coupling speed change gear

ActiveCN102555791ASimple mechanical structureEasy to operateElectric propulsion mountingElectric machinesControl systemElectric vehicle

The invention provides an electric vehicle, a double-motor coupling speed change gear thereof and a control system of the double-motor coupling speed change gear. The double-motor coupling speed change gear comprises a fixed-axis gear mechanism, a planet gear mechanism, a linkage control device and a torque coupling control device, the fixed-axis gear mechanism is connected with a first motor and provided with a power output gear, the planet gear mechanism is connected with a second motor and consists of a sun gear, an inner gear ring, a plurality of planet gears and a planet carrier, the sun gear is connected with the second motor, power is outputted by the planet carrier, the linkage control device is provided with a first position and a second position, the power output gear and the inner gear ring are in coupled transmission when the linkage control device is arranged at the first position, the inner gear ring is locked when the linkage control device is arranged at the second position, the torque coupling control device is provided with a first position and a second position, the power output gear and a center shaft of the sun gear are in coupled transmission when the torque coupling control device is disposed at the first position, and the power output gear is not in transmission with the center shaft of the sun gear when the torque coupling control device is disposed at the second position. The invention further provides the control system of the double-motor coupling speed change gear and the electric vehicle provided with the double-motor coupling speed change gear. The device is simple in structure and convenient in control.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Wide-range, wide-angle compound zoom with simplified zooming structure

A zoom lens is disclosed having a zoom ratio larger than four with a field of view at the short focal length position larger than 85 degrees and with a minimal number of moving groups. The zoom lens utilizes a compound zoom structure comprising an NP or NPP zoom kernel followed by a P or PP zoom relay, with only two or three moving groups that can be used for both zooming, focusing and athermalization. An overall compact package size is achieved by the use of prisms to fold the optical path in strategic locations. An optional variable power liquid cell can provide close focusing with little or no focus breathing.

Owner:PANAVISION INT LP +1

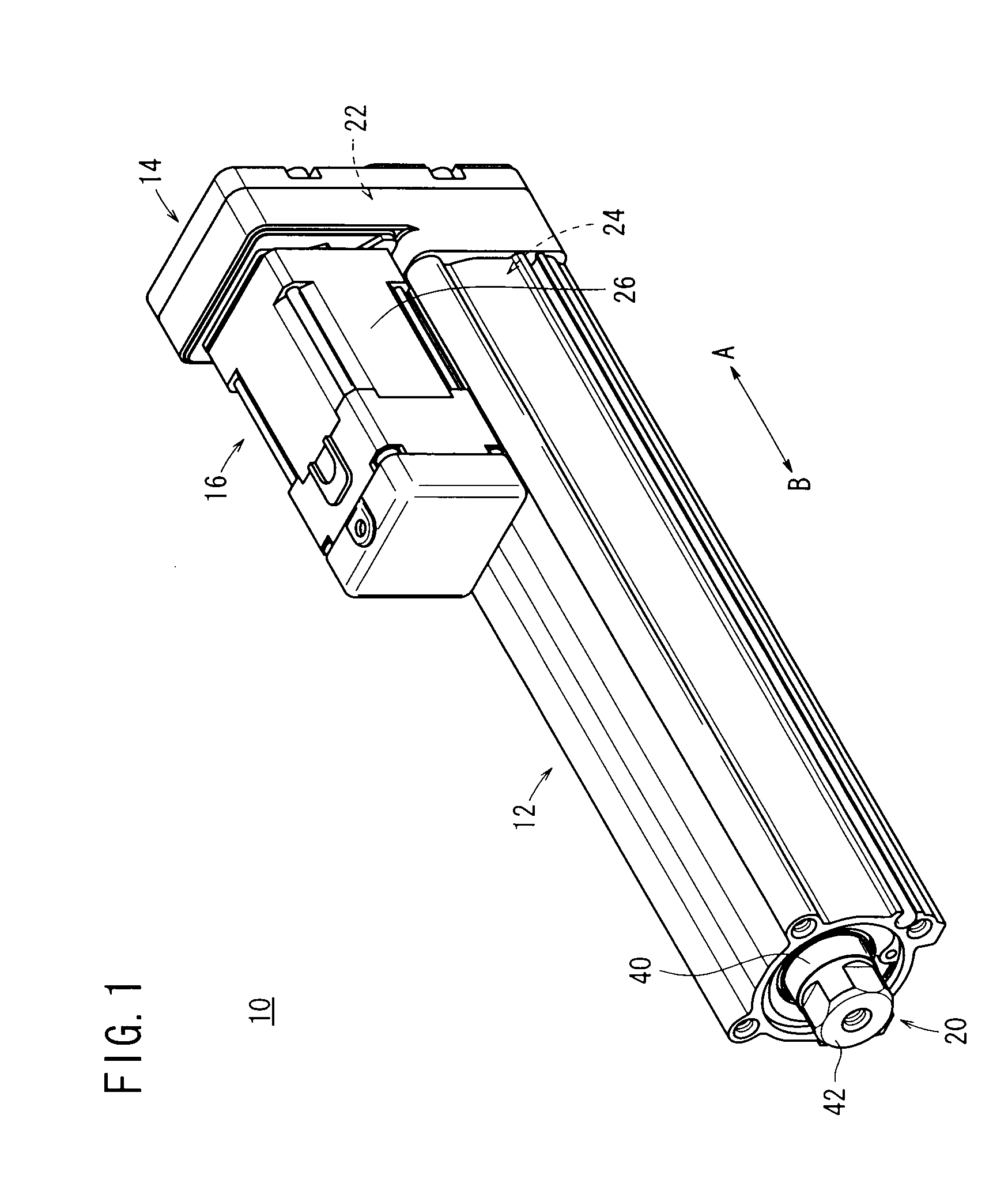

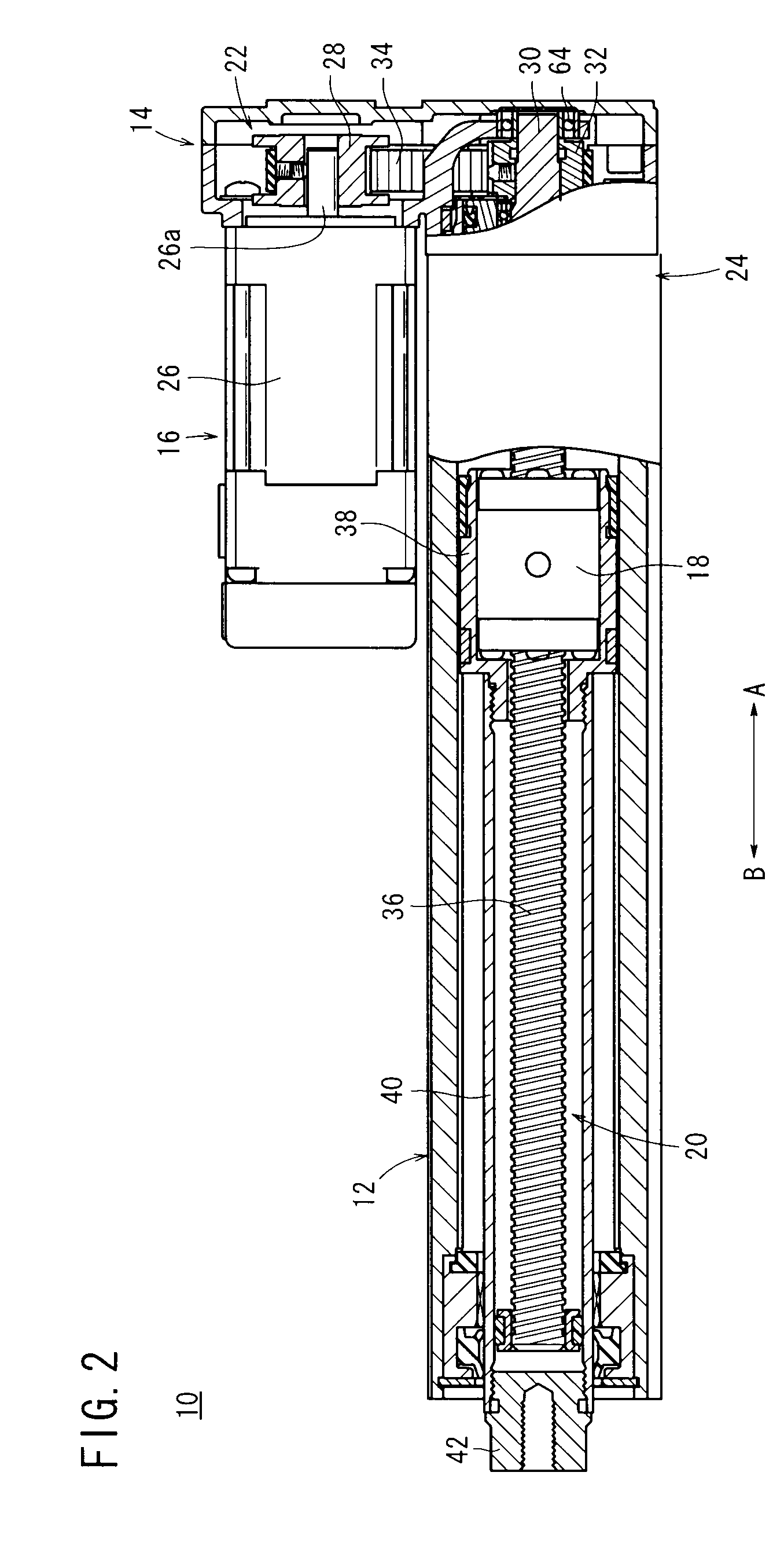

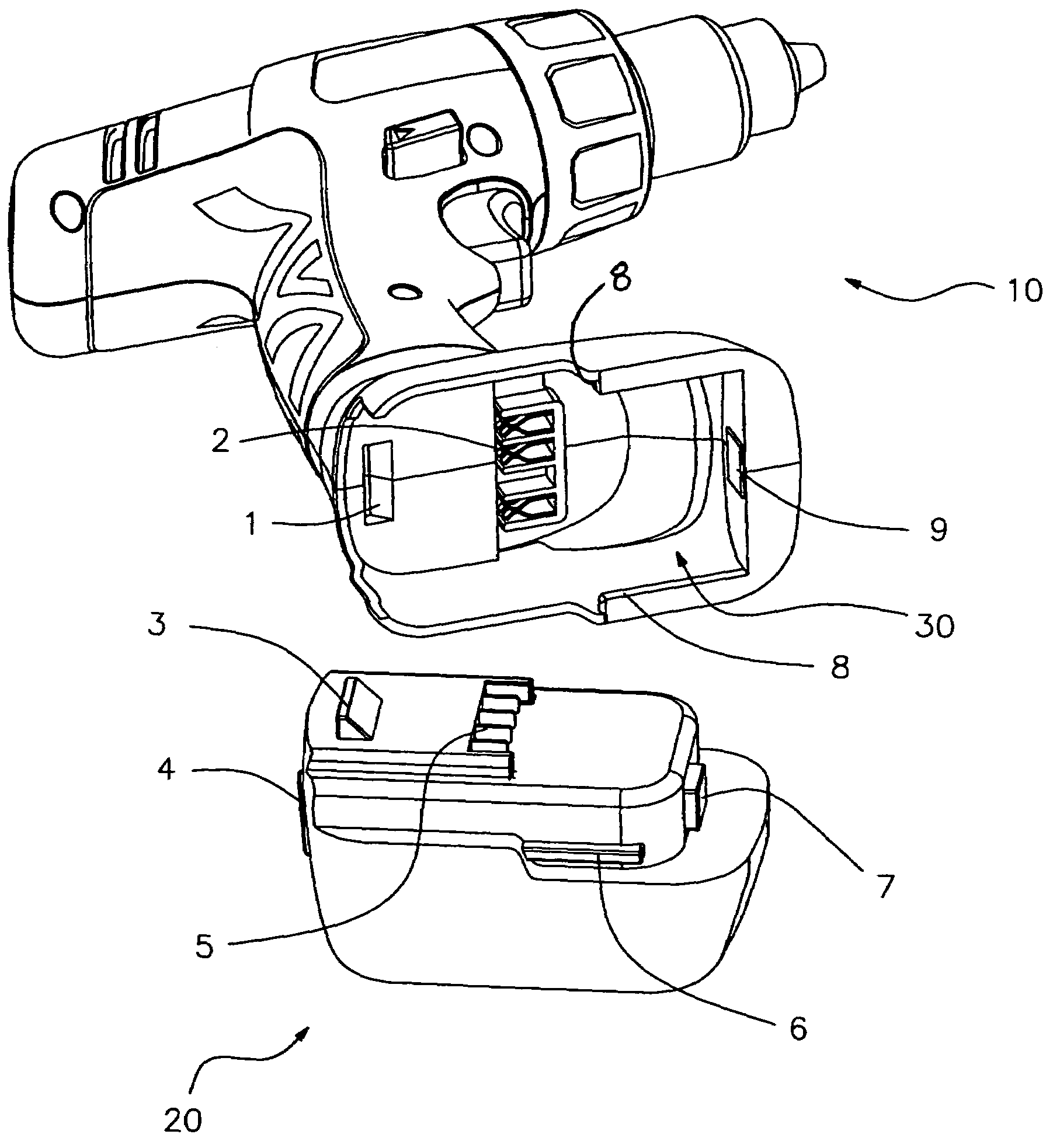

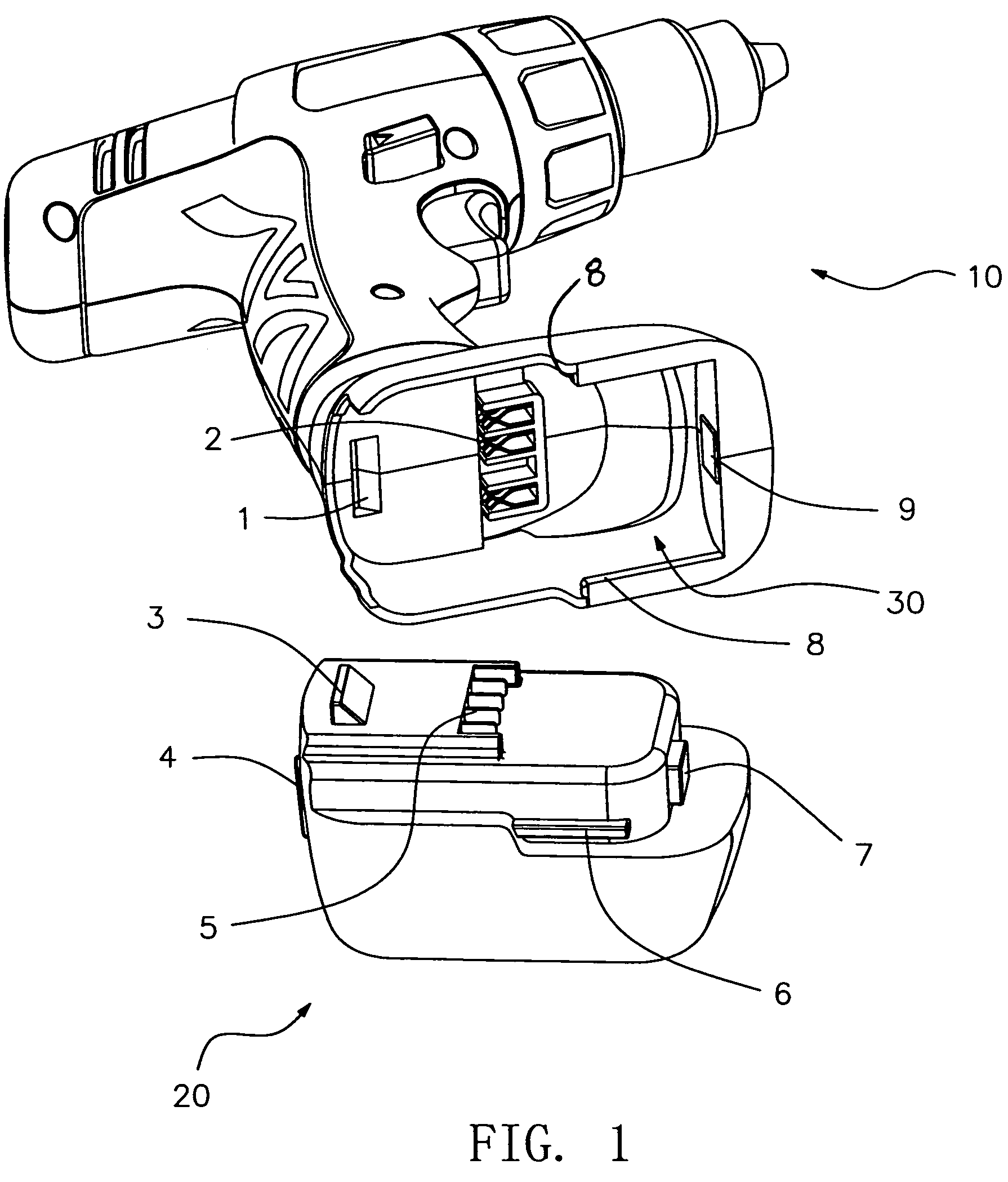

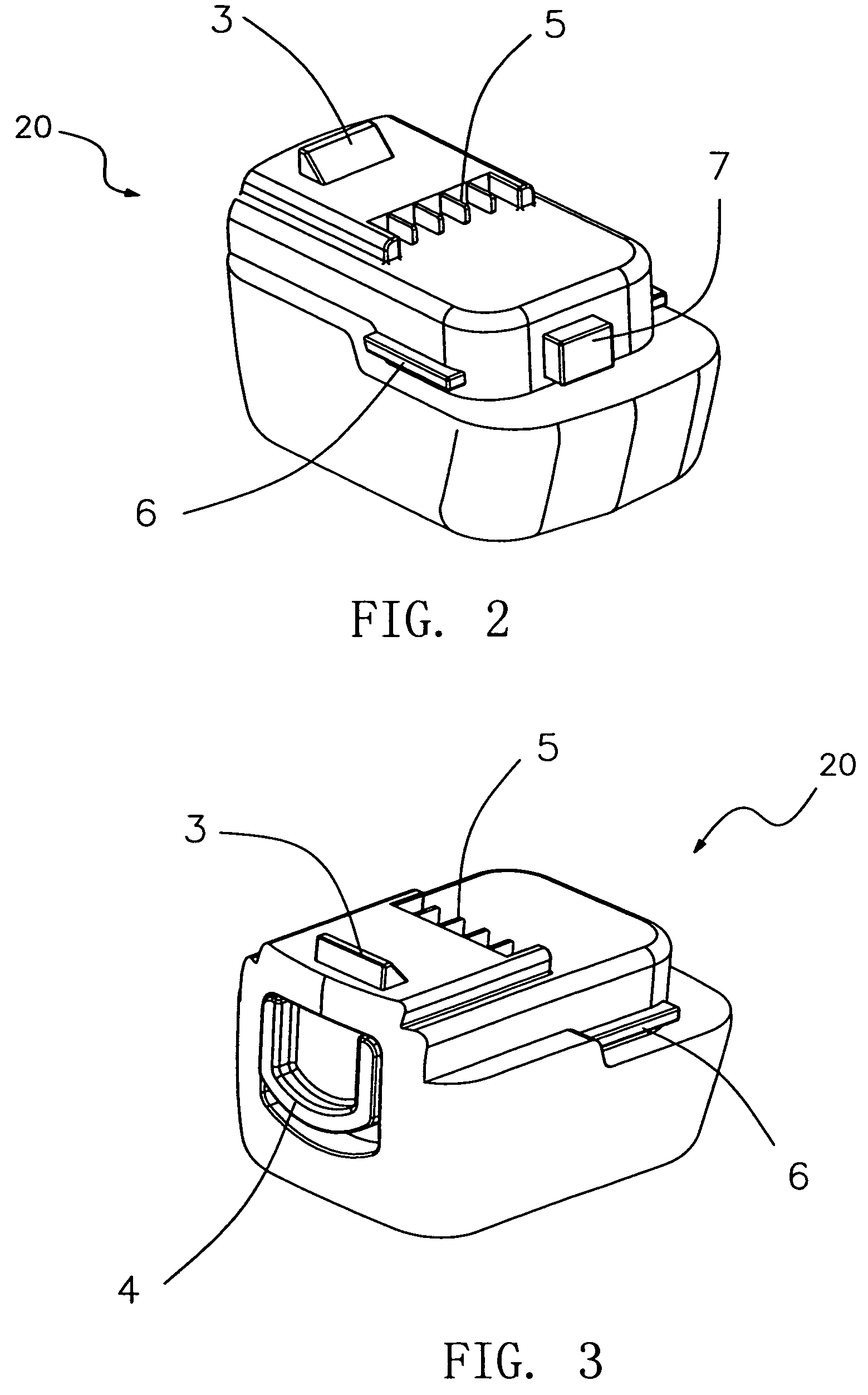

Power tool with battery power supply

InactiveUS7243734B2Durable and reliable attachment mechanismAvoid electrical connectionBatteries circuit arrangementsDrilling rodsElectricityElectrical battery

The present invention relates to a power tool with battery power supply comprising a main body and a detachable battery package which are connected with each other via a securing frame and a locking assembly. The securing frame includes a guiding device, an locking / unlocking button located on one of the main body and the battery package. An electrical connection is provided between a motor in the main body and the battery package, and includes a plurality of electrode connectors and corresponding electrode contact tabs. A mechanism for creating a non-mechanical force is located between the main body and the battery package for pushing the battery package out of the securing frame. With such a mechanism, when the battery package is required to be replaced by another one or detached for charging, it is merely necessary to press the unlocking button downward, and the battery package then automatically slides out of the securing frame via the effect of the force so as to facilitate detaching the battery package from the main body of the power tool.

Owner:NANJING CHERVON IND

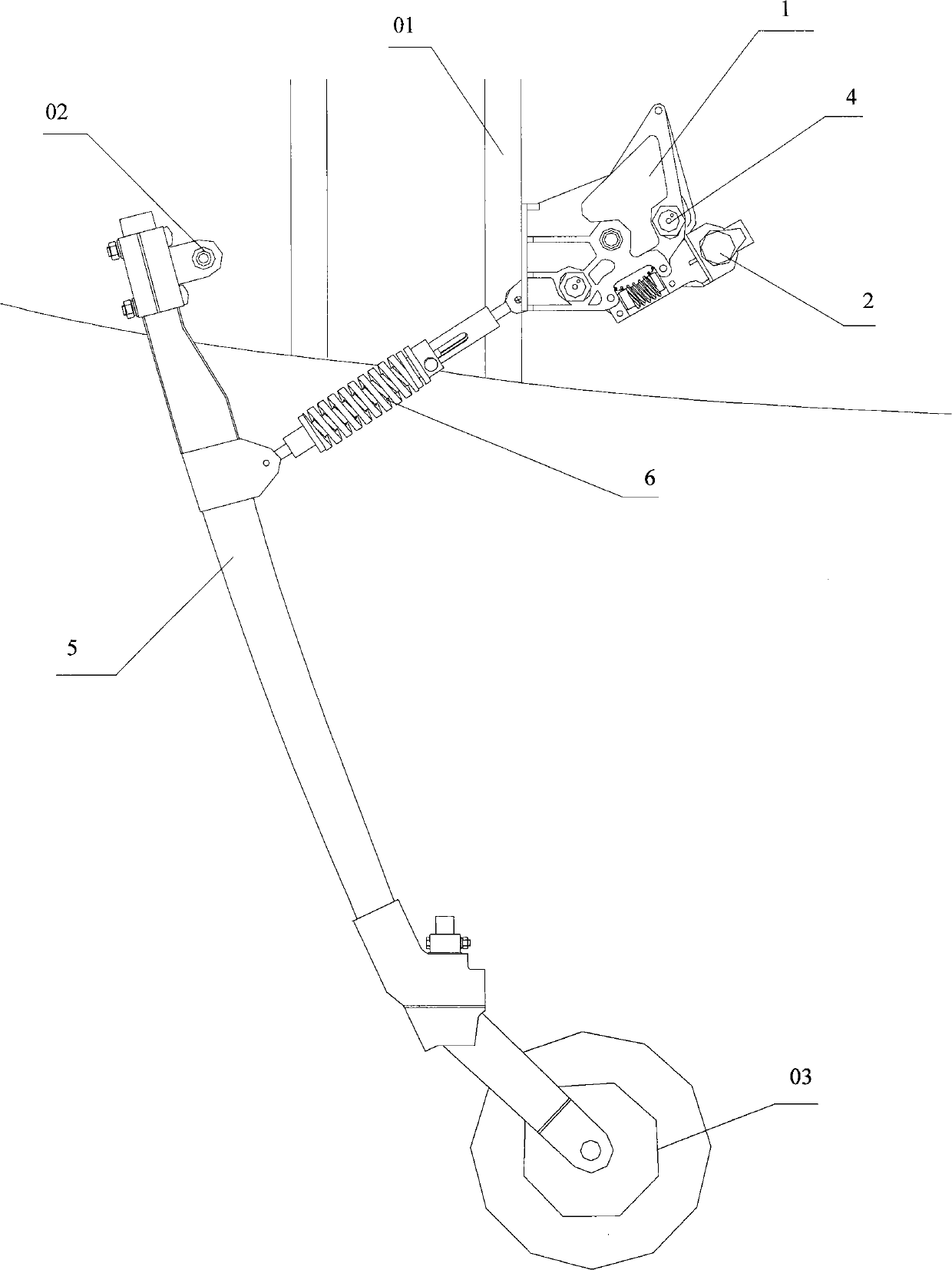

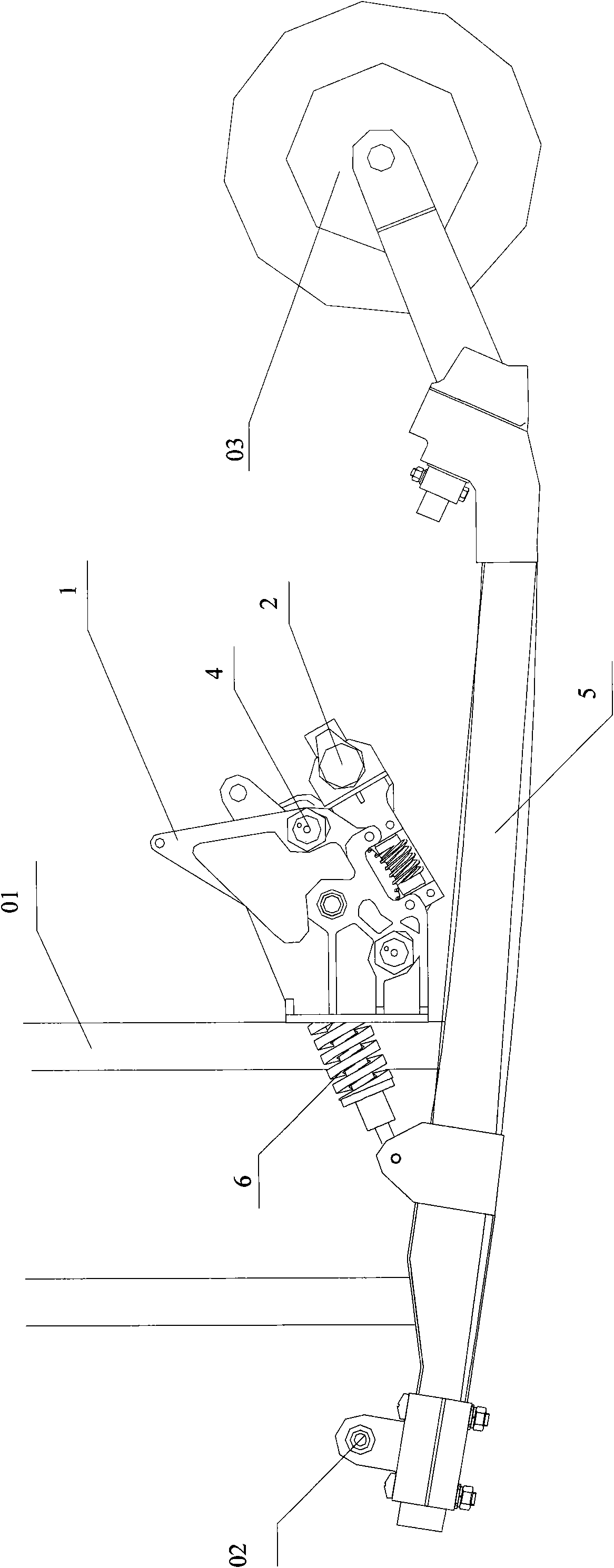

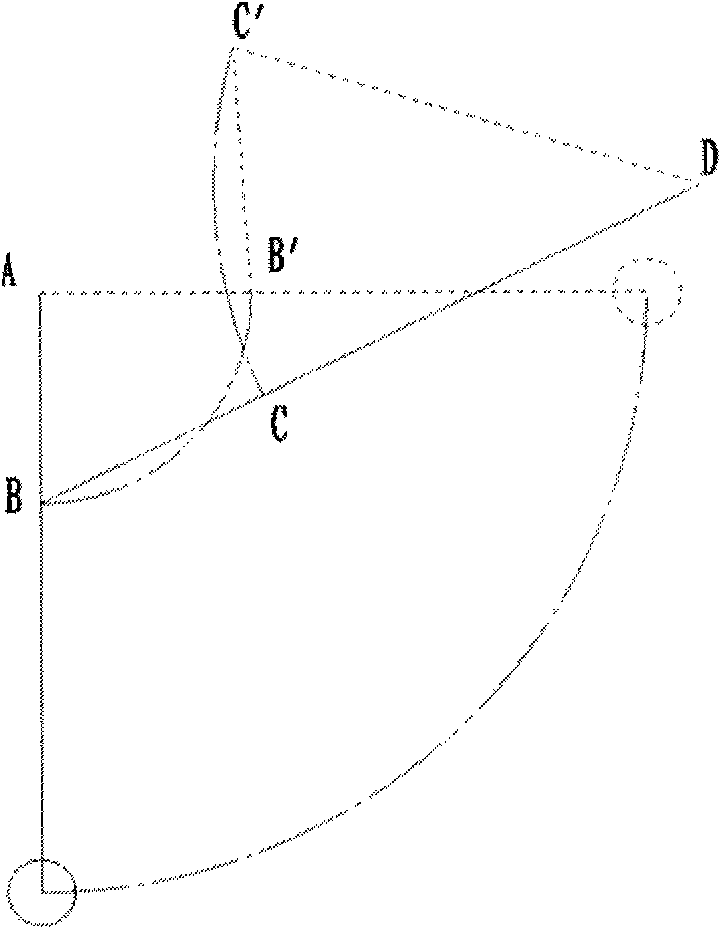

Unmanned plane undercarriage control system

ActiveCN101767649ASimple mechanical structureSimple electric drive equipmentUndercarriagesElectric driveLoad carrying

The invention discloses an unmanned plane undercarriage control system which comprises a control mechanism, a drive part, a control part, a sensor part, an undercarriage arm and a damper rod, wherein, the control mechanism has a worm wheel and worm structure, one end of the rocker of the control mechanism is fixedly connected with the worm wheel and the other end is connected with one end of the damper rod, the other end of the damper rod is connected with the upper part of the undercarriage arm through a pin roll, one end of the worm is connected with the drive part, the sensor part is arranged in the upper limit hole and the lower limit hole of the control mechanism, the control mechanism is fixedly arranged on the load-carrying structure of the plane body, the upper end of the undercarriage arm is connected with the plane body through a load-carrying rotating shaft on the plane body and the lower end of the undercarriage arm is connected with the front wheel of the plane, the control part is arranged on the avionics frame of the plane and respectively abutted with the drive part and the drive part through cables. The invention uses the simple mechanical structure, the simple electric drive apparatus and the spring-type damper rod and needs no supplementary structures or power-assisted devices for support, having a small volume and occupying little space. The invention can realize locking of the undercarriage up and down stations under the coordination of the worm wheel and worm structure, the crank link mechanism and the brushless motor static brake resistance.

Owner:CAIHONG DRONE TECH CO LTD

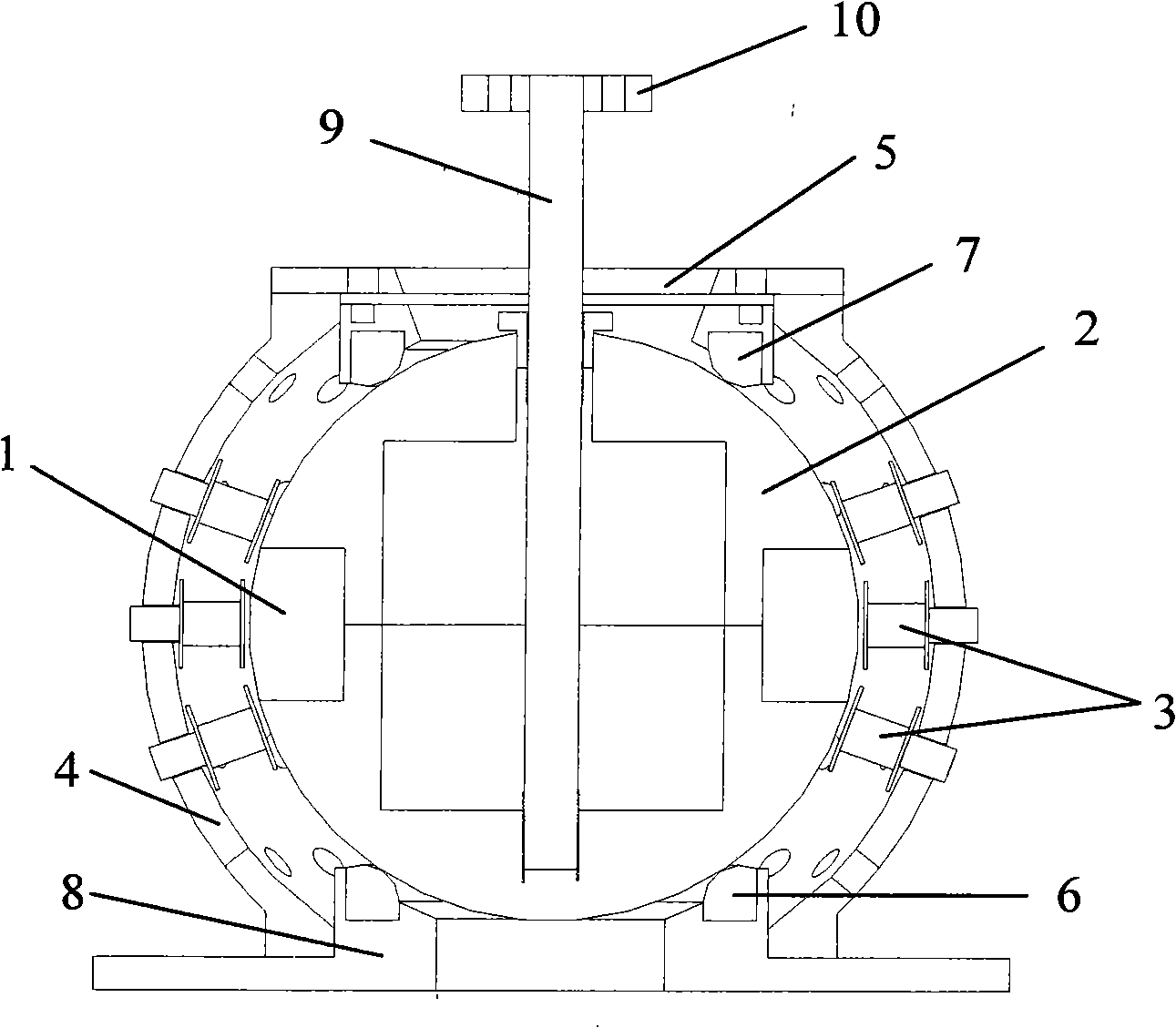

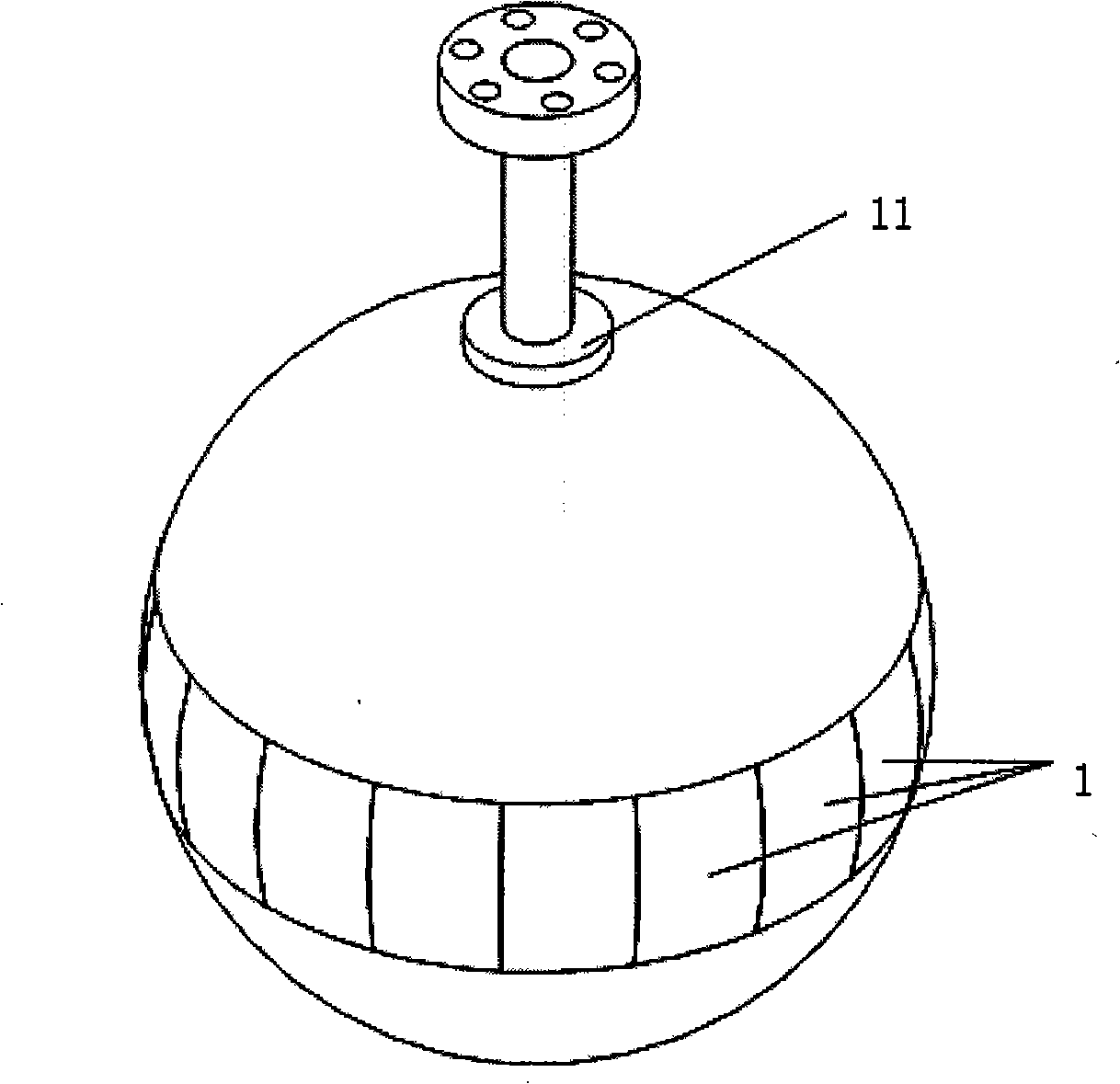

Three-freedom Halback array permanent magnetism sphericity synchronous motor

InactiveCN101282070AHigh positioning accuracySimple mechanical structureMagnetic circuit rotating partsSynchronous machine detailsFixed bearingSynchronous motor

The invention relates to a three-freedom degree Halbach array permanent magnetism spherical synchronous motor, belonging to spherical electric machine manufacturing technical field, which comprises a base, a support bearing positioned on the base, a spherical rotor body, an outside stator, an output shaft, the spherical rotor body comprises a hollow spherical rotor yoke made by non-guide magnetism materials and a Halbach array permanent magnetism body, the output shaft is through the upper of the hollow spherical rotor yoke and is fixingly connected with the hollow spherical rotor yoke, column-shaped slots are provided around a cycle of the hollow spherical rotor yoke equator, the Halbach array permanent magnetism body are fixed evenly on one cycle of the rotor yoke equator along the column-shaped slots, the contact surface of the rotor yoke lower and the support bearing is ring-shaped arc surface; the outer stator comprises a stator casing and multi-row coils, an adjustable fixing bearing is provided on the lower side of the stator casing cover. The spherical synchronous motor of the invention can realize three-freedom degree movement, has simple mechanical structure and improved dynamic and static performance of the drive system.

Owner:TIANJIN UNIV

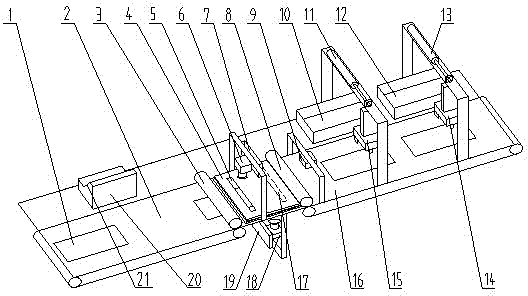

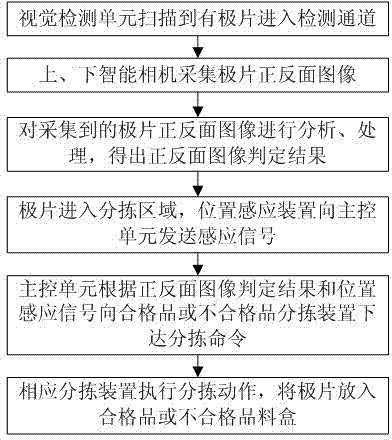

On-line lithium battery pole piece surface defect detection sorting system and method

InactiveCN103785627AAvoid secondary damageSimple mechanical structureSortingHuman–machine interfaceControl engineering

The invention discloses an on-line lithium battery pole piece surface defect detection sorting system and method. The synchronous real-time on-line detection on positive and reverse sides of pole pieces is realized through a pole piece conveying device, a pole piece identification and detection part, a pole piece master control unit, a pole piece sorting device and a human machine interface part; a mechanical structure of the system is simple, the detection on the positive and reverse sides of the pole pieces can be realized in the system through a simple detection channel, and the system is simple, feasible and low in cost. The detection speed is high, the general detection speed is superior to 2 pieces per second, the detection precision is high, and an embedded visual identification detection technology adopted by the system has the high precision with the omission ratio of 0 and the error detection rate of less than 2 percent. According to the pole piece detection sorting device, the secondary damage of the pole pieces is avoided. The actionability is high, and the system is long in operating time, can operate for long time in the industrial field and has the advantages of convenience in maintenance, high portability and the like.

Owner:HENAN UNIV OF SCI & TECH

Frog jump robot

The invention discloses a frog jump robot. A motor is used as a power element; devices such as an overrunning clutch, a gear toothed belt and the like are used as transmission mechanisms; a slide block can move on a guide rail under the drive of the motor through the transmission devices; and double legs of the robot stretch or retract under the drive of the slide block so as to finish jump motion. After the robot jumps, the double legs immediately retract to perform air posture adjustment, and the double legs are fully retracted by using self gravity potential and kinetic energy at the monument of landing to perform posture adjustment again. The energy utilization rate of the power element is improved, reclamation and reutilization of energy during jumping are realized, the flexibility of the robot is increased, and the jumping capability of the robot is promoted.

Owner:BEIJING UNIV OF TECH

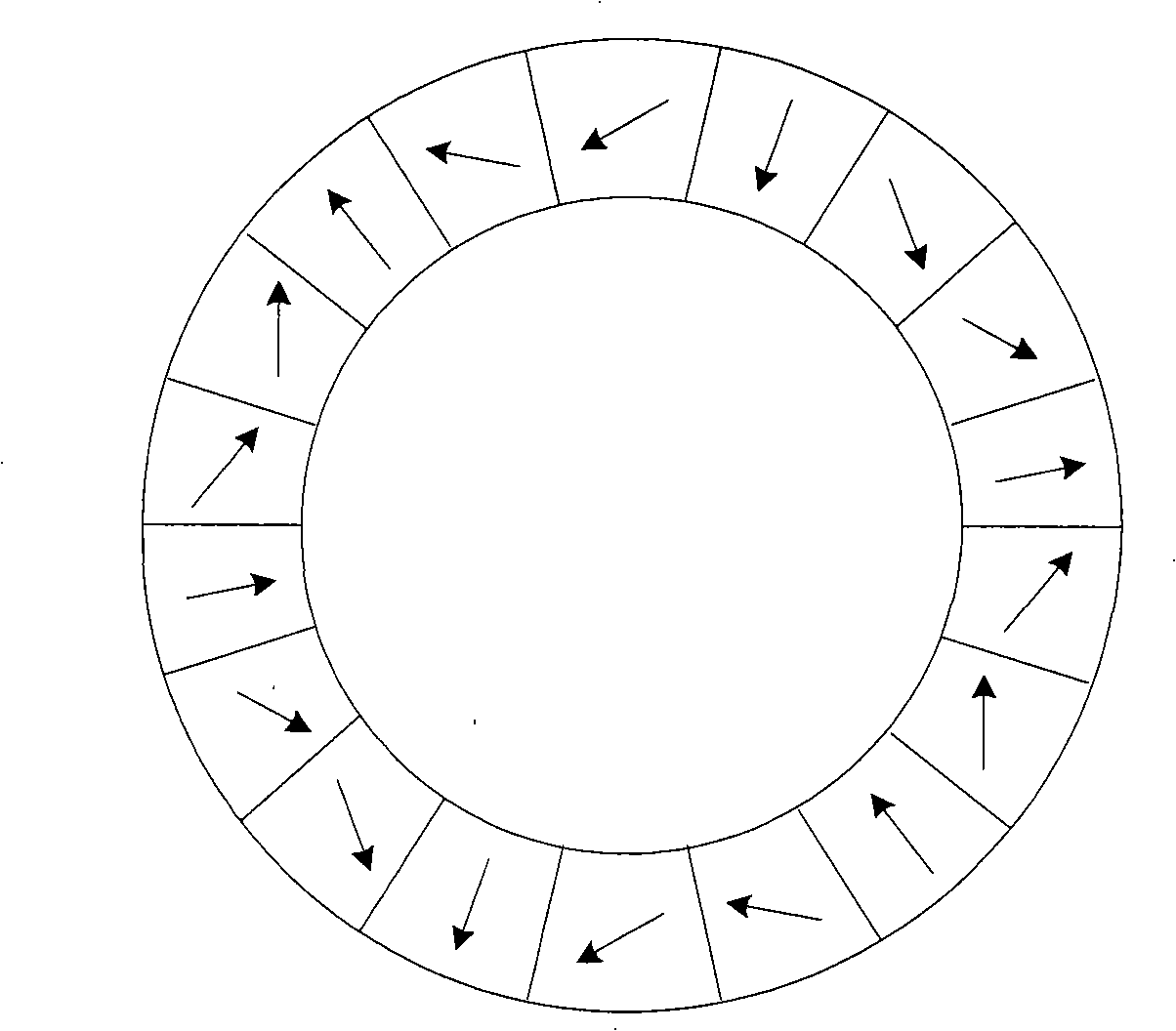

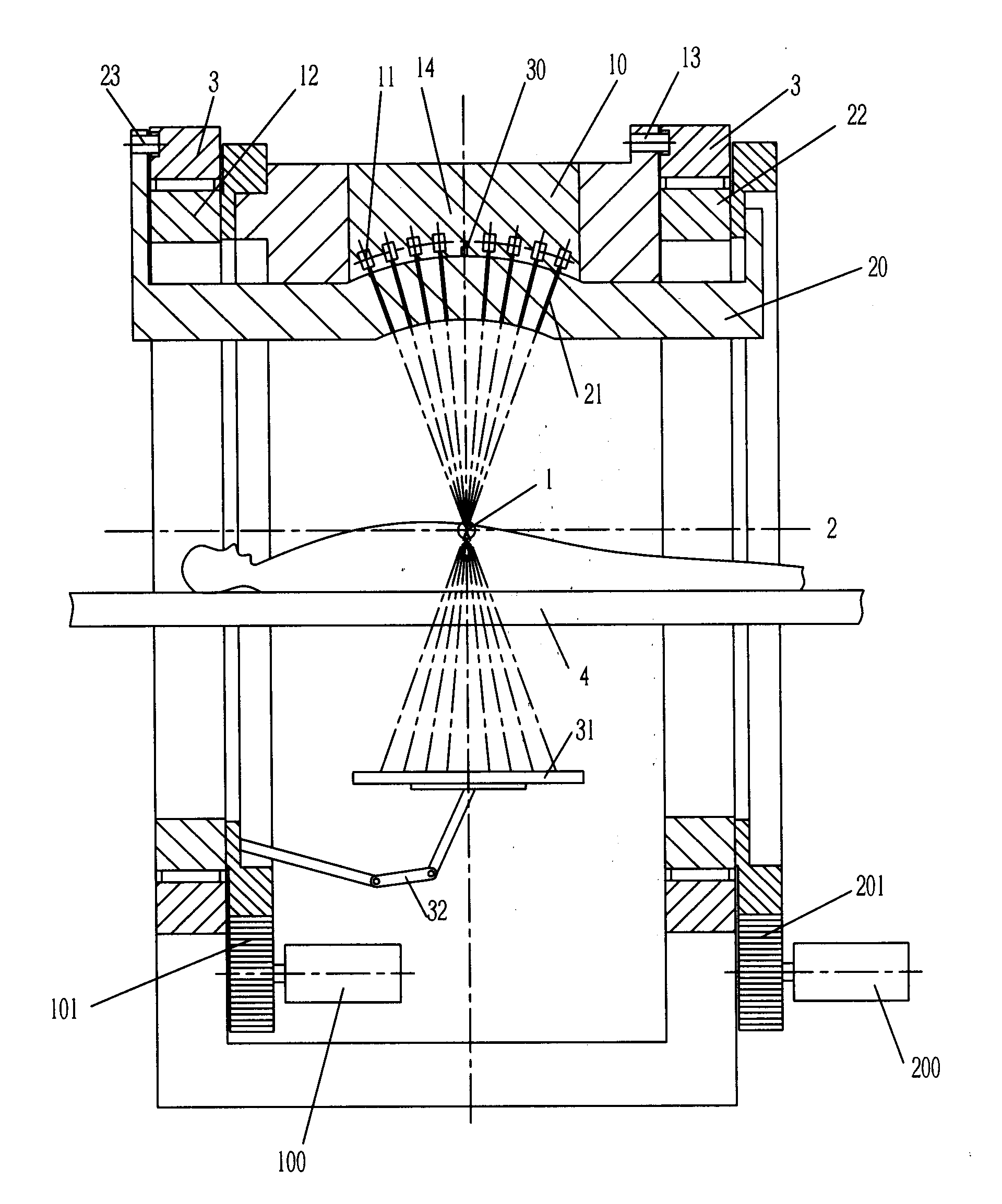

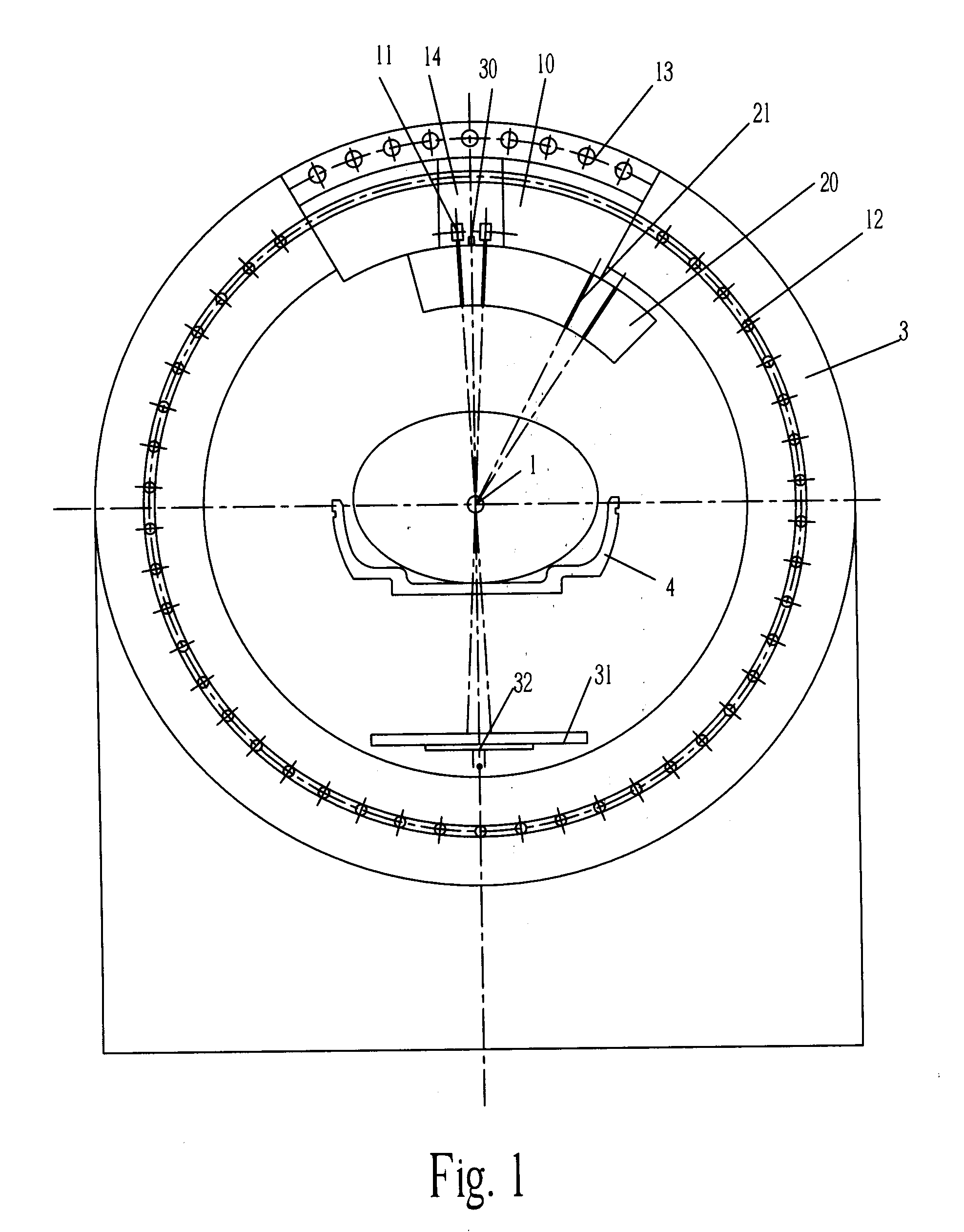

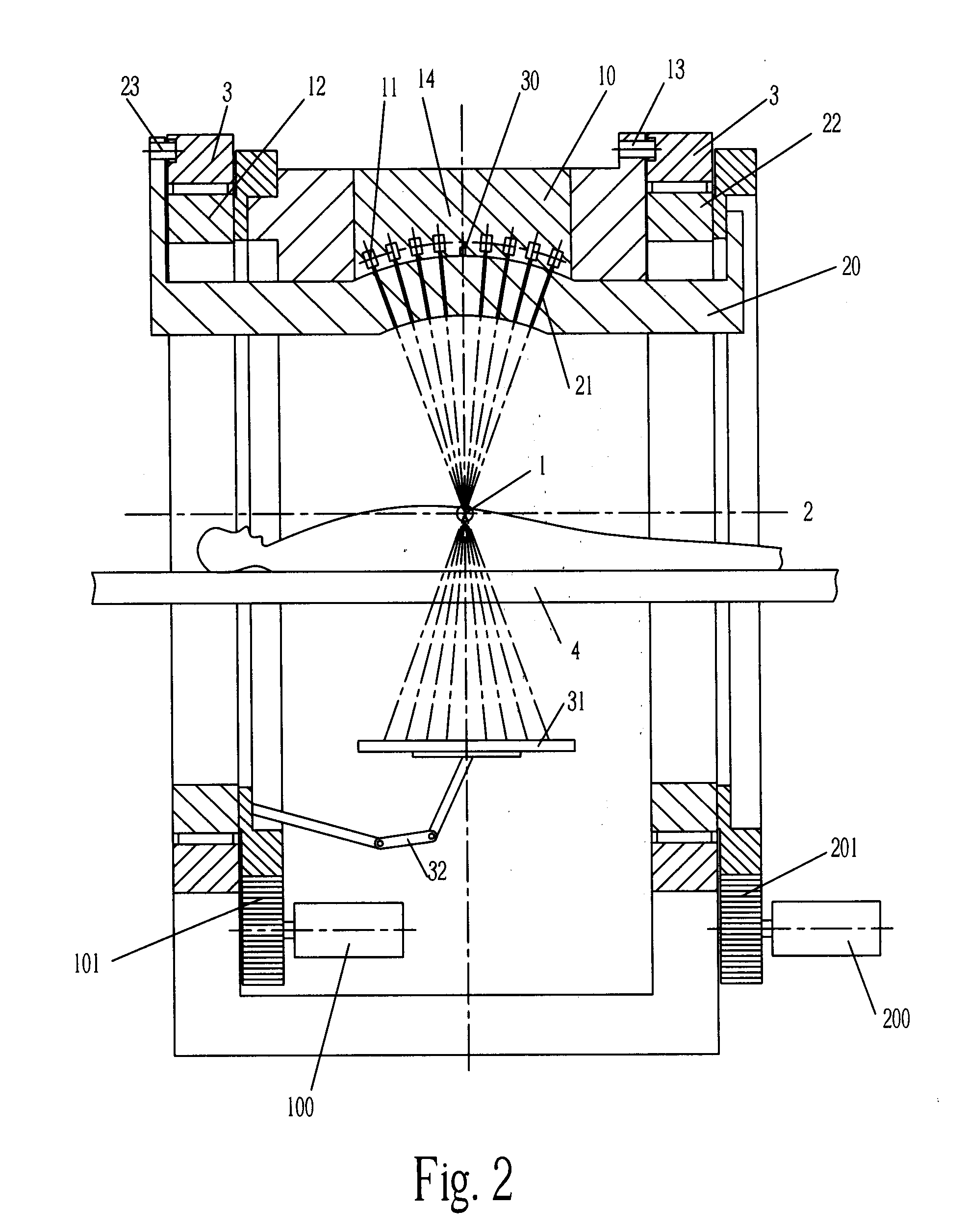

Radiotherapy Device

ActiveUS20090086909A1Expand the treatment spaceLow costHandling using diaphragms/collimetersX-ray apparatusRotational axisLight beam

The invention involves a rotary focused gamma-ray radiotherapy device. The invention includes a frame, a rotary ring positioned at the frame, and a source carrier and a collimator carrier that can rotate around a rotary axis respectively. The source carrier is equipped inside with multiple radiation sources. The collimator carrier is equipped inside with a corresponding beam channel to the radiation sources, which focus at a shared focus of the rotary axis through the beam channel. The source carrier and the collimator carrier are connected at both ends with the rotary ring and the frame, respectively. The single-layer and double-support structure of the source carrier and the collimator carrier adopted in the invention enlarges the treatment space, lowers manufacturing cost and difficulty, simplifies the mechanical structure, increases support rigidity of the source carrier and the collimator carrier, ensuring long-lasting and steady coaxial rotation of source carrier and collimator carrier, as well as position accuracy of the focusing center in the therapeutic system. Therefore, a precision radiotherapy is realized with improved radiotherapy effect.

Owner:SHEN ZHEN HYPER TECH SHENZHEN

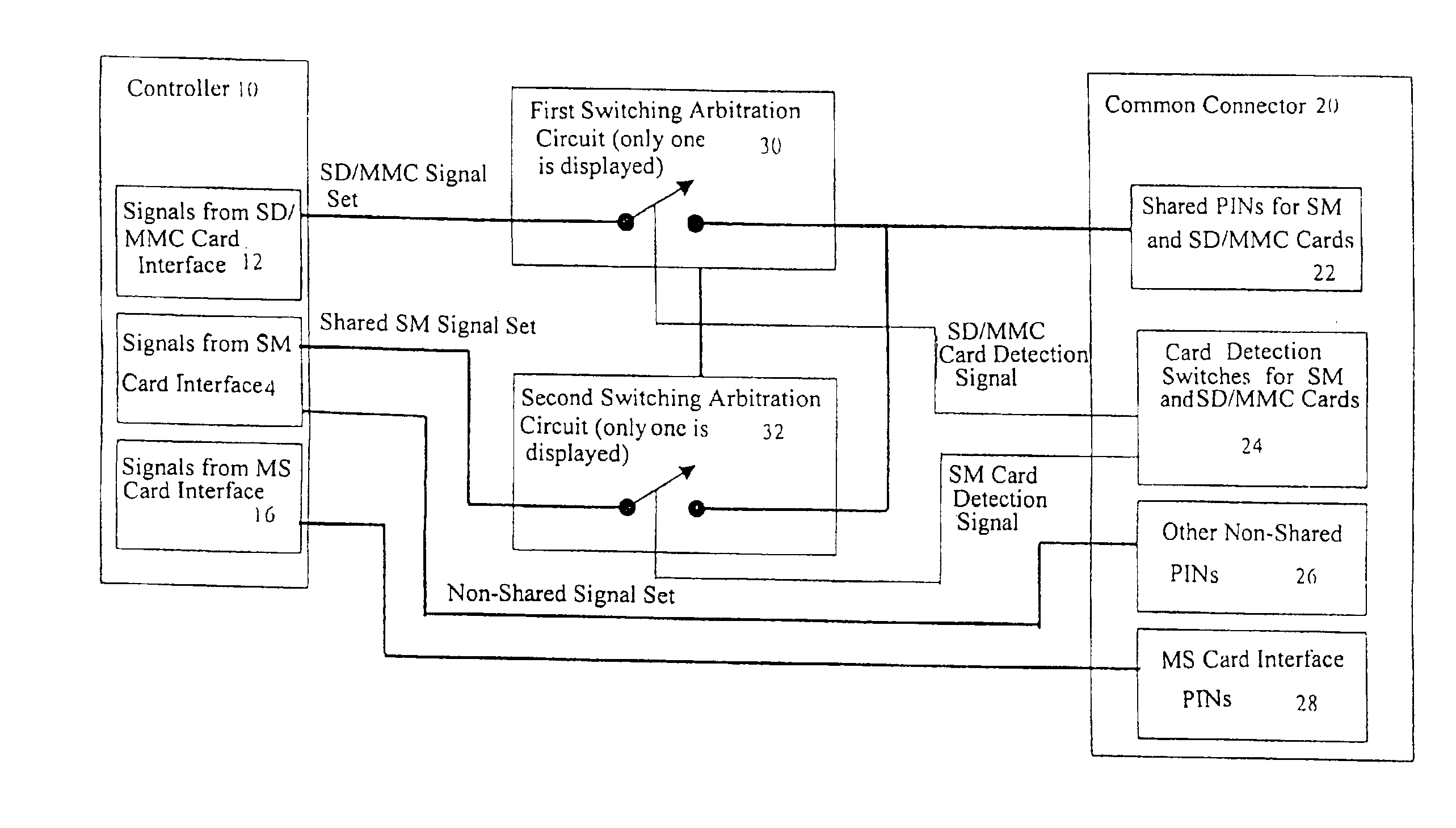

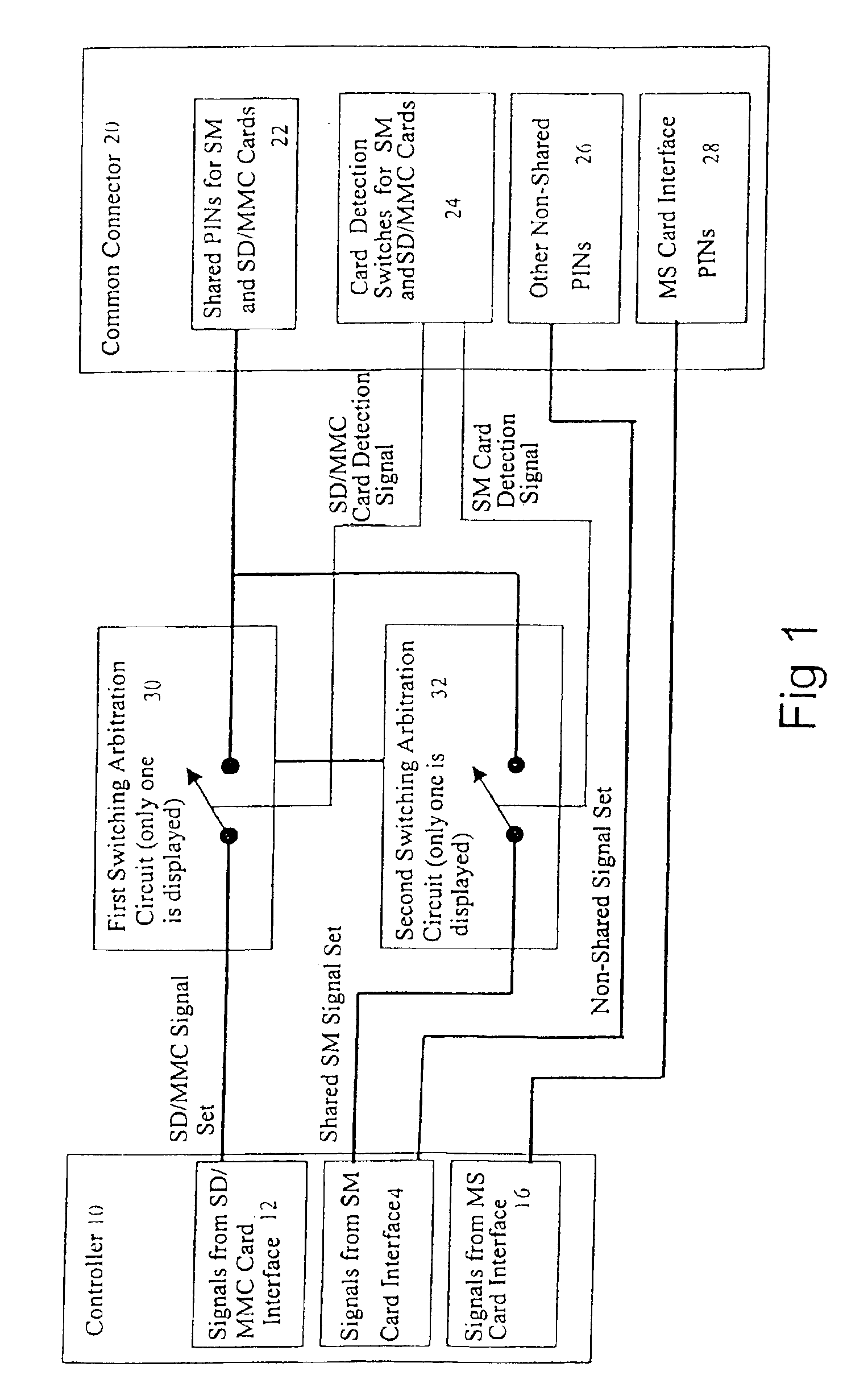

Common connector for memory cards and switching arbitration method for shared pins of a connector

InactiveUS6857038B2Promote popularizationImprove efficacyElectric discharge tubesIncorrect coupling preventionBaseboardEngineering

The present invention relates to a common connector for memory cards and a switching arbitration method for the shared Pins of the connector, i.e., a common connector which allows many different types of memory cards to be inserted in and fixed at different times. A multiple of rows / sets of different types of Pins are devised on one side of a baseboard of the common connector. And particularly, a set of shared Pins enables identification of interface signals from SD / MMC cards or SM cards. Under the control of corresponding memory card detection switches and switching arbitration circuits, the shared Pins can be connected to interface signals from a SD / MMC card or a SM card. Therefore, such a structure not only reduces the size of the common connector but also supports a multiple of types of memory cards.

Owner:CARRY COMPUTER ENGINEERING CO LTD

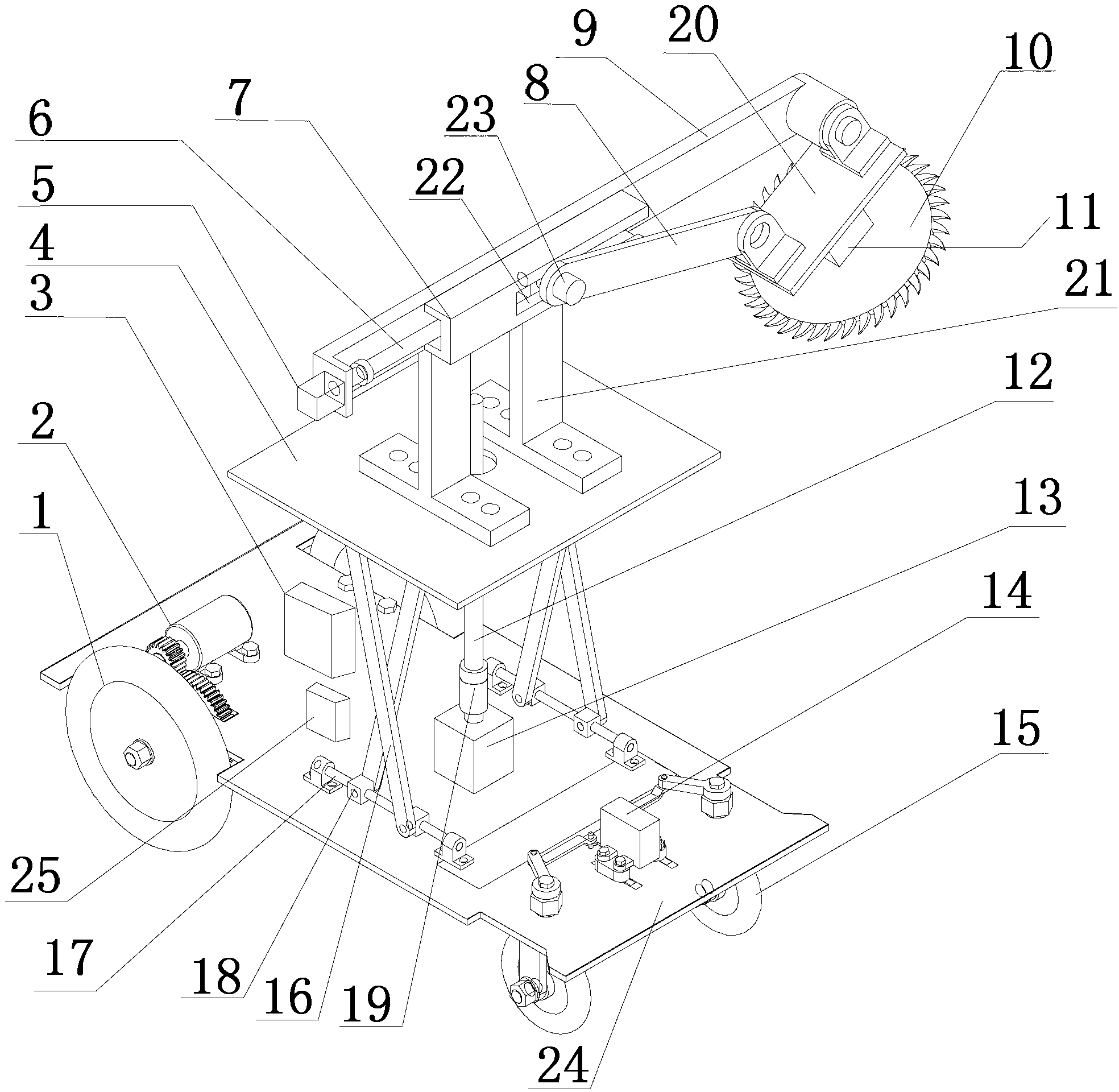

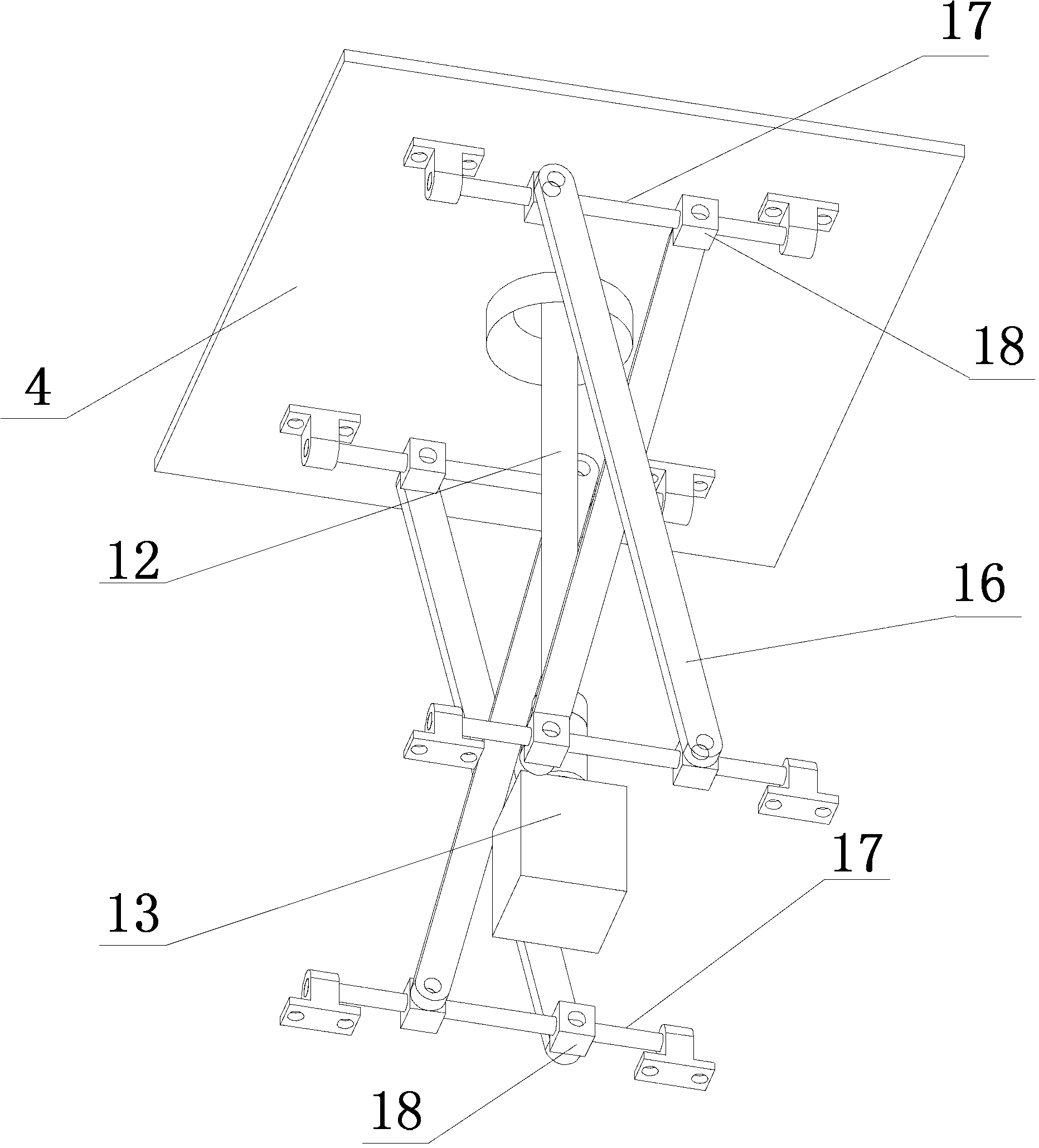

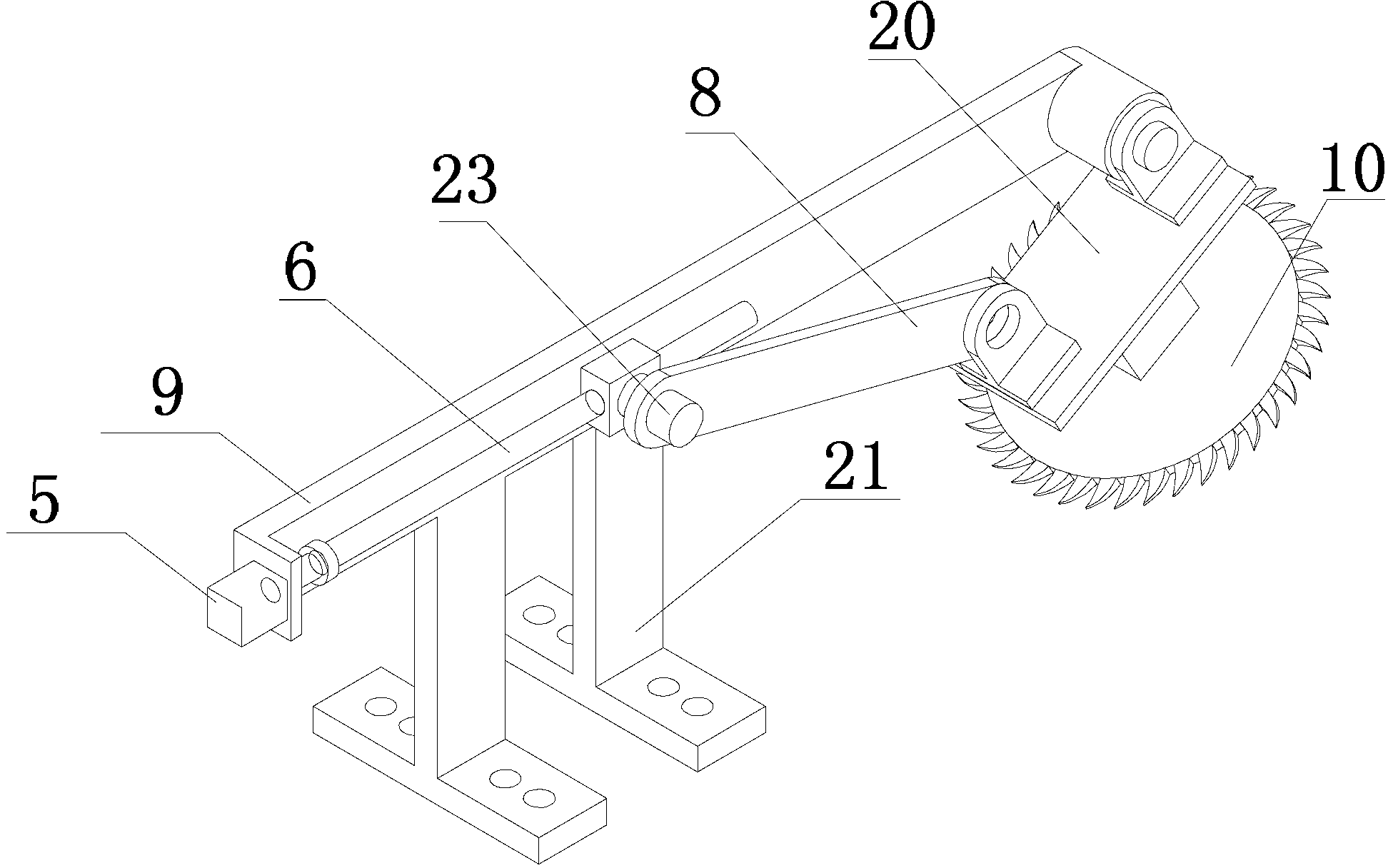

Lifting-type hedgerow trimmer

InactiveCN103283508AReduce riskReduce labor intensityCuttersCutting implementsElectricityEngineering

A lifting-type hedgerow trimmer comprises a trimming device, a lifting device, a guide walking device, a control device and a power source, wherein the trimming device is used for carrying out trimming operation and is arranged on the lifting device, the lifting device is used for adjusting the height of the trimming device and is arranged on the guide walking device, the guide walking device is used for adjusting walking, walking speed and walking direction of the hedgerow trimmer, the control device is respectively in electric connection with the trimming device, the lifting device and the guide walking device, receives signals sent by a remote controller and controls the trimming device, the lifting device and the guide walking device to run or stop, and the power source is used for supplying electricity to the control device, the trimming device, the lifting device and the guide walking device. The lifting-type hedgerow trimmer can relieve the labor intensity of hedgerow plant trimming, improves work efficiency, reduces the dangerousness in the trimming operation, and realizes multiple-modeling and multi-mode trimming of road green belts and park scenery trees.

Owner:SHANGHAI DIANJI UNIV

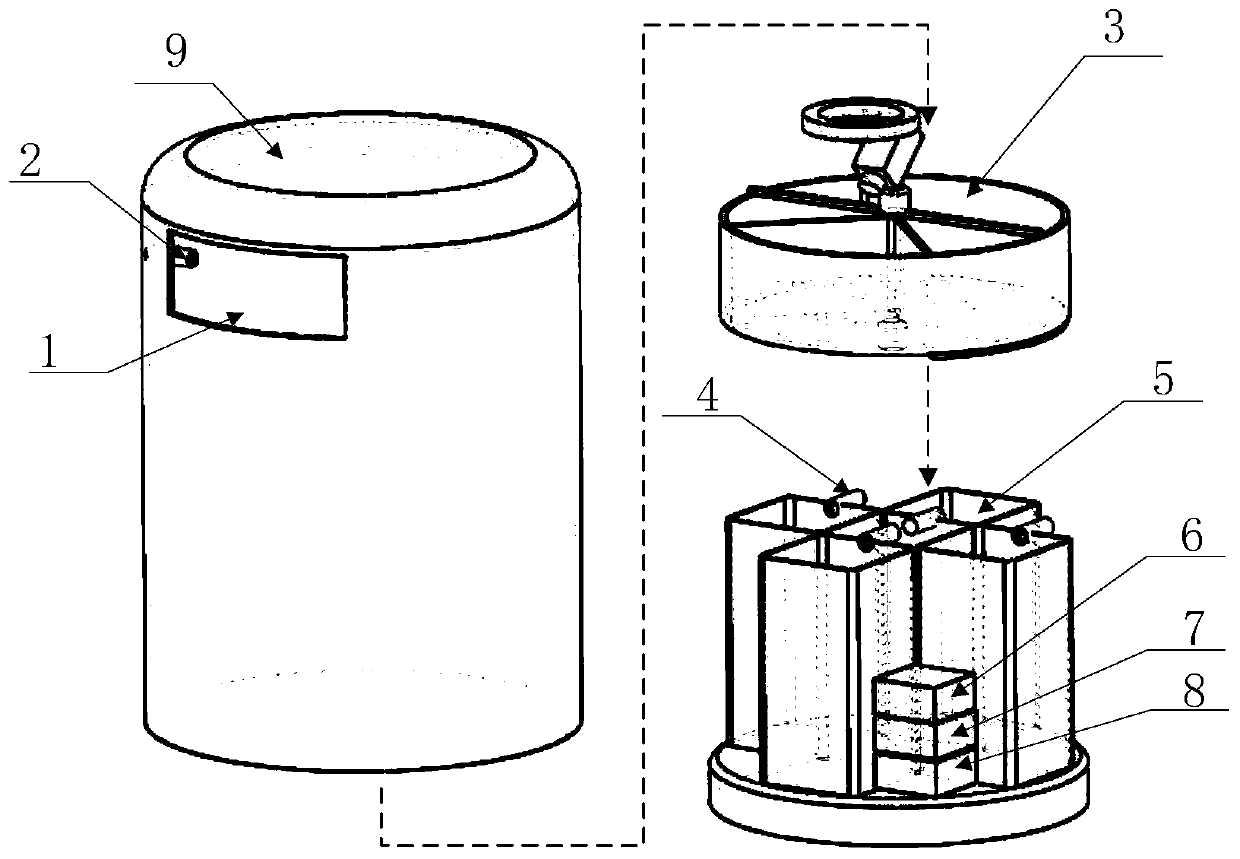

Garbage can capable of automatic classifying based on visual recognition and classifying method

InactiveCN110861852AImprove accuracyRealize handlingWaste collection and transferRefuse receptaclesComputer hardwarePhotoswitch

The invention discloses a garbage can capable of automatic classifying based on visual identification and a classifying method. The garbage can comprises a garbage throwing opening, a first photoelectric switch sensor, an identifying and classifying tray, second photoelectric switch sensors, sub garbage cans, an image identification component, an STM32 controller, a double-path stepping motor driver and a garbage can shell, wherein the garbage throwing opening is formed in the side wall of the garbage can shell; the first photoelectric switch sensor is arranged in the garbage throwing opening;a plurality of sub garbage cans are arranged in the garbage can shell; a second photoelectric switch sensor is mounted in a can opening position of each sub garbage can; the identifying and classifying tray is arranged in the garbage can shell and is located above the sub garbage cans; the identifying and classifying tray comprises a garbage tray, a V-shaped baffle stepping motor, a camera, a V-shaped baffle, a support frame, a rotary baffle stepping motor and a rotary baffle. According to the garbage can, the camera is used for collecting garbage images; a TensorFlow deep learning frameworkis adopted; through transfer training of a model, the accuracy rate of garbage identification is increased.

Owner:石家庄邮电职业技术学院

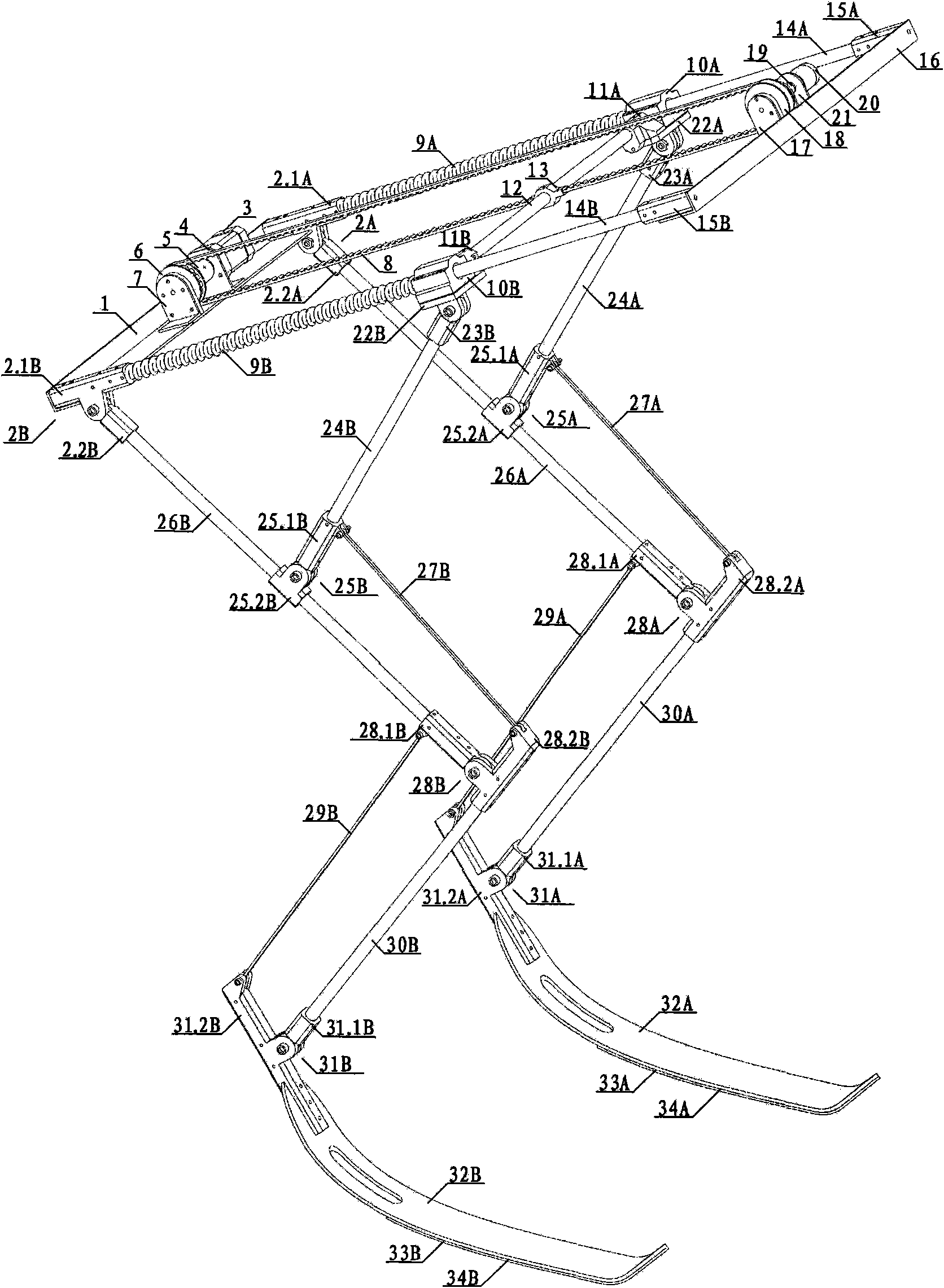

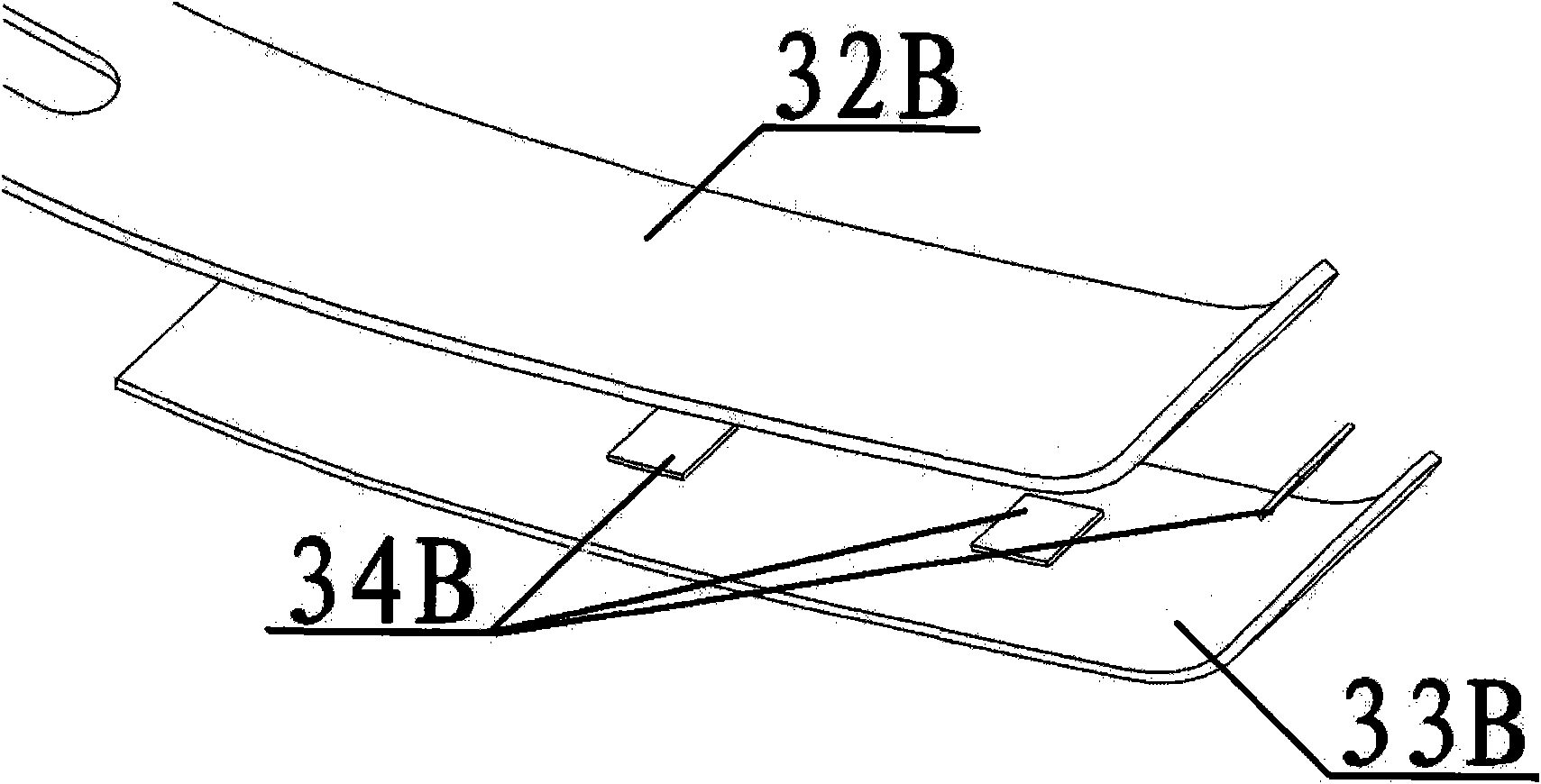

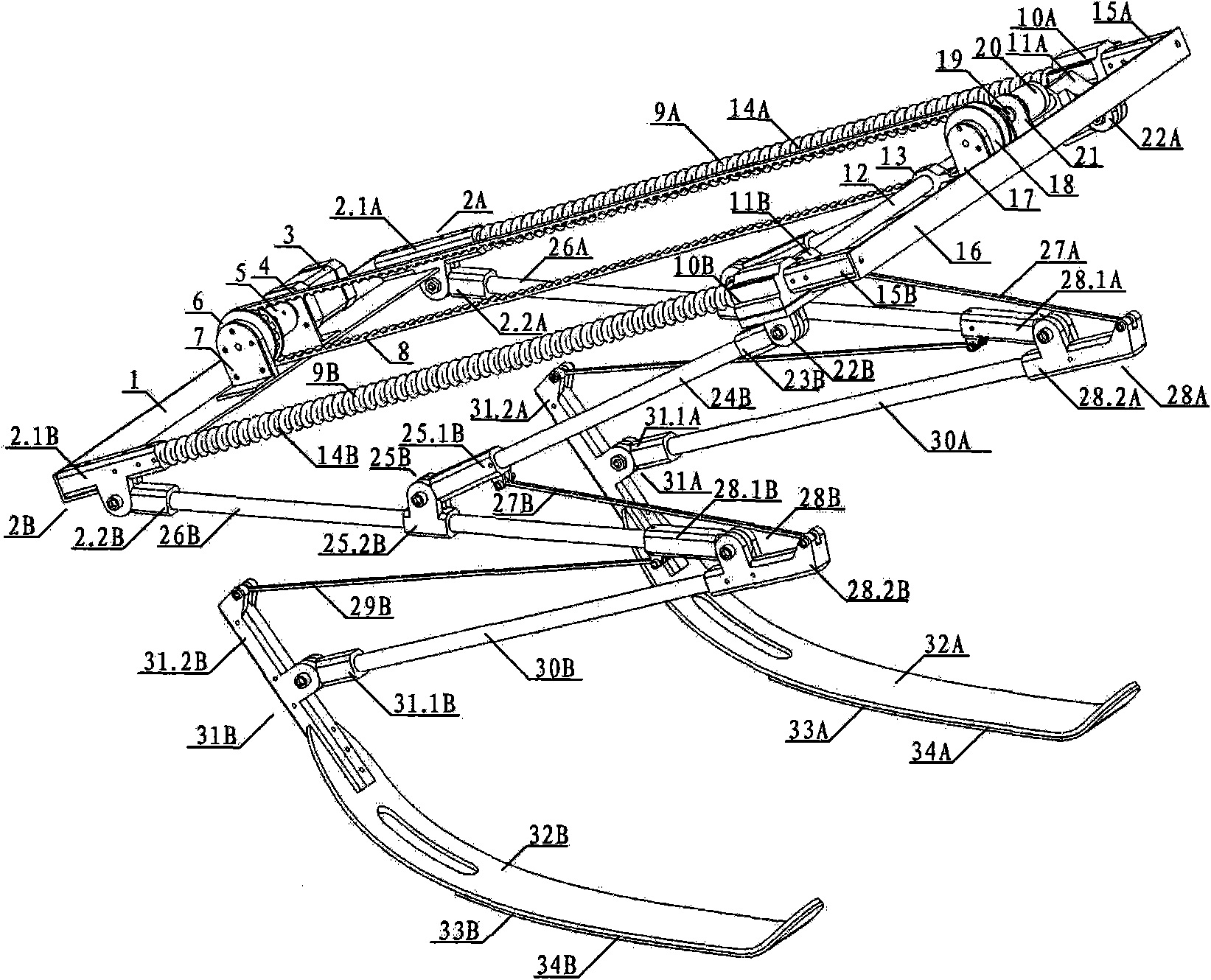

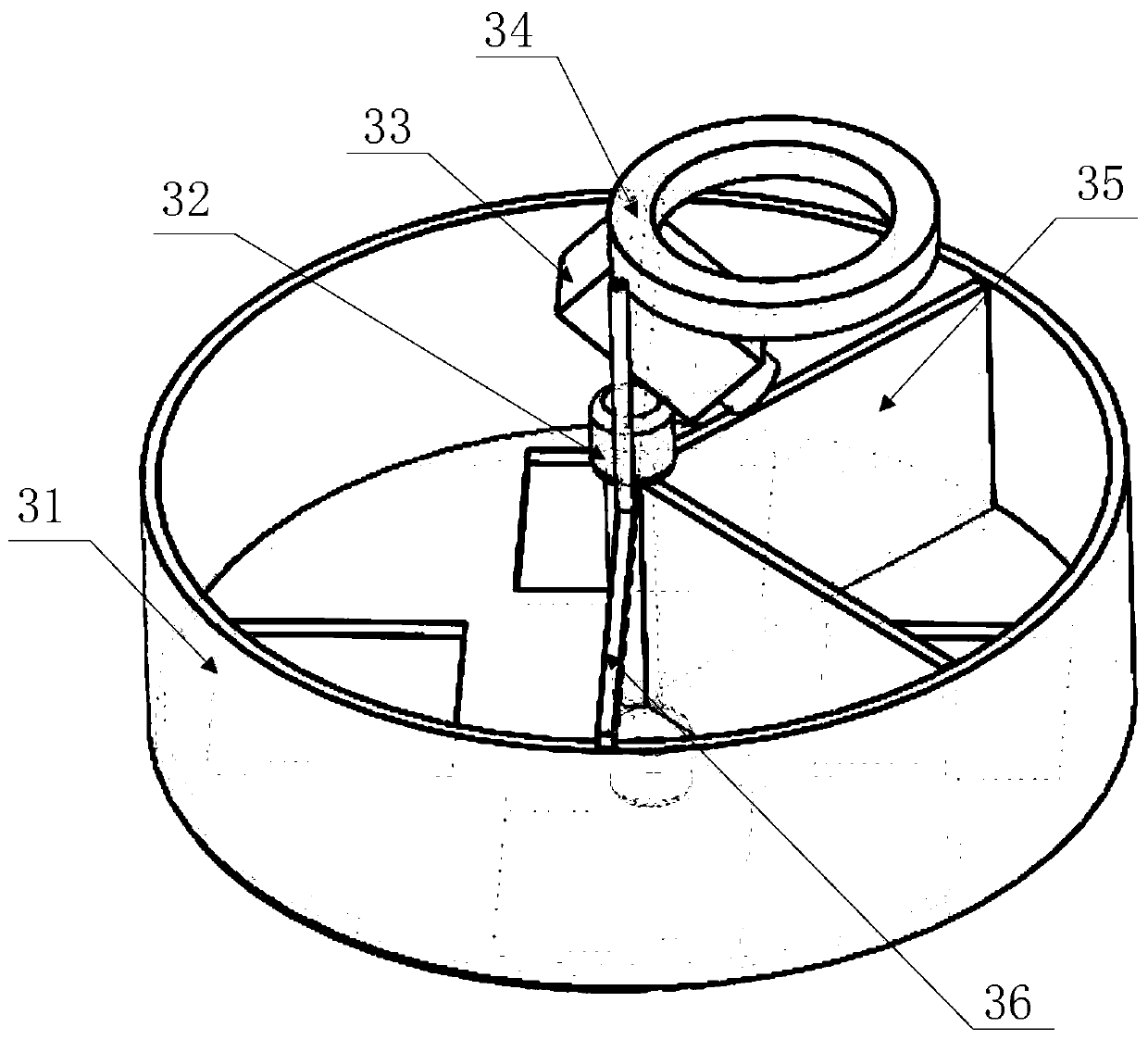

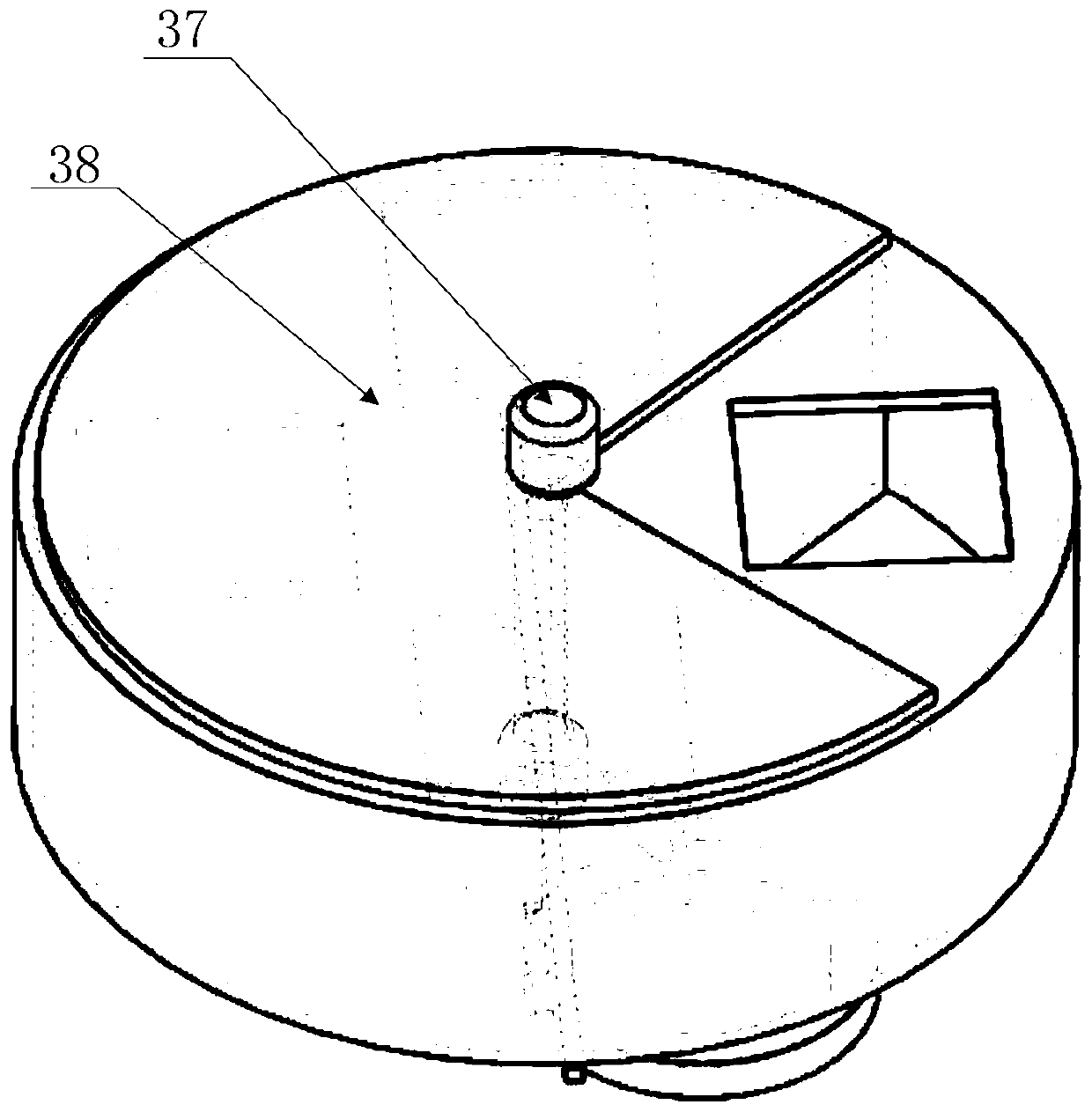

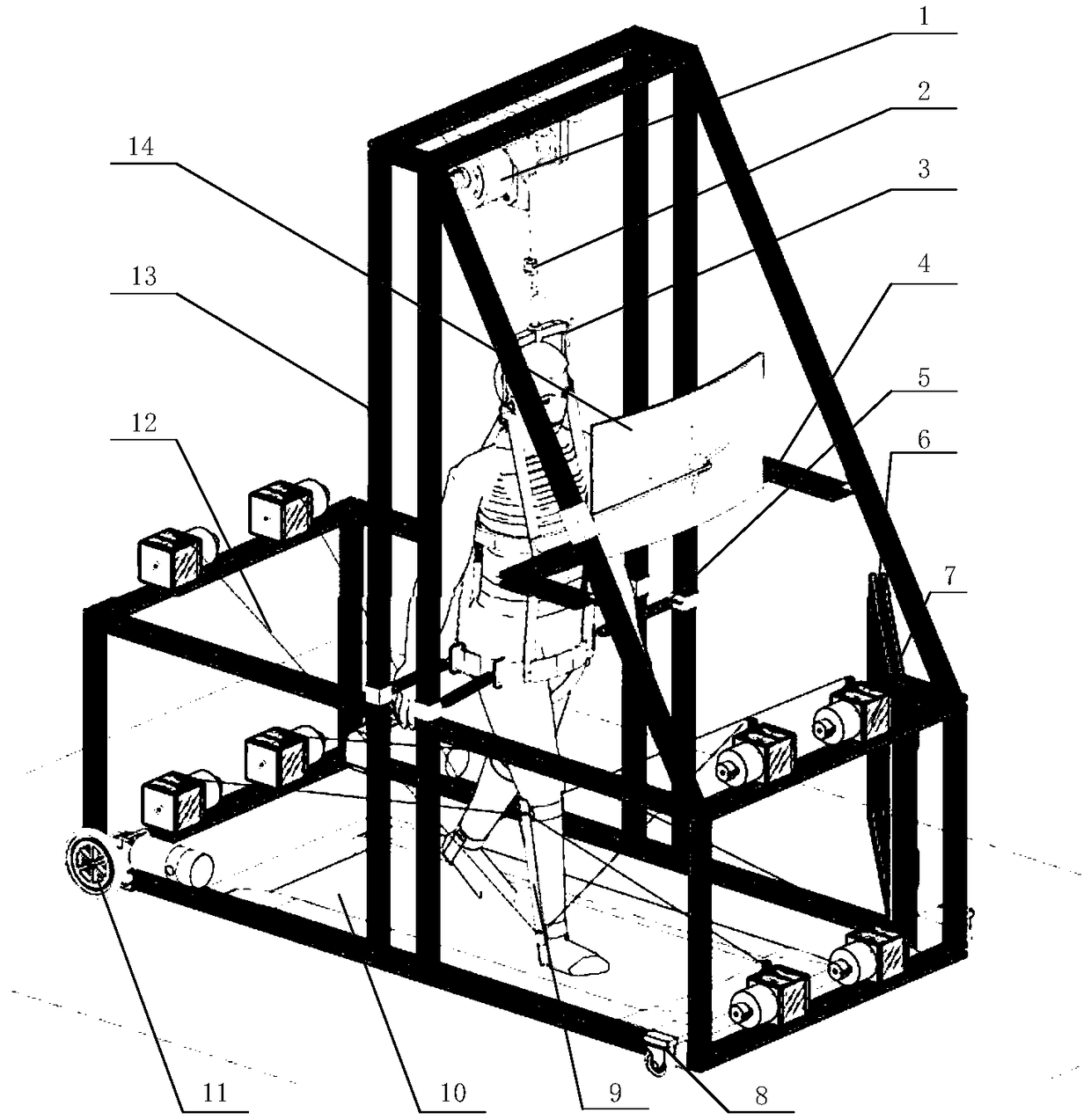

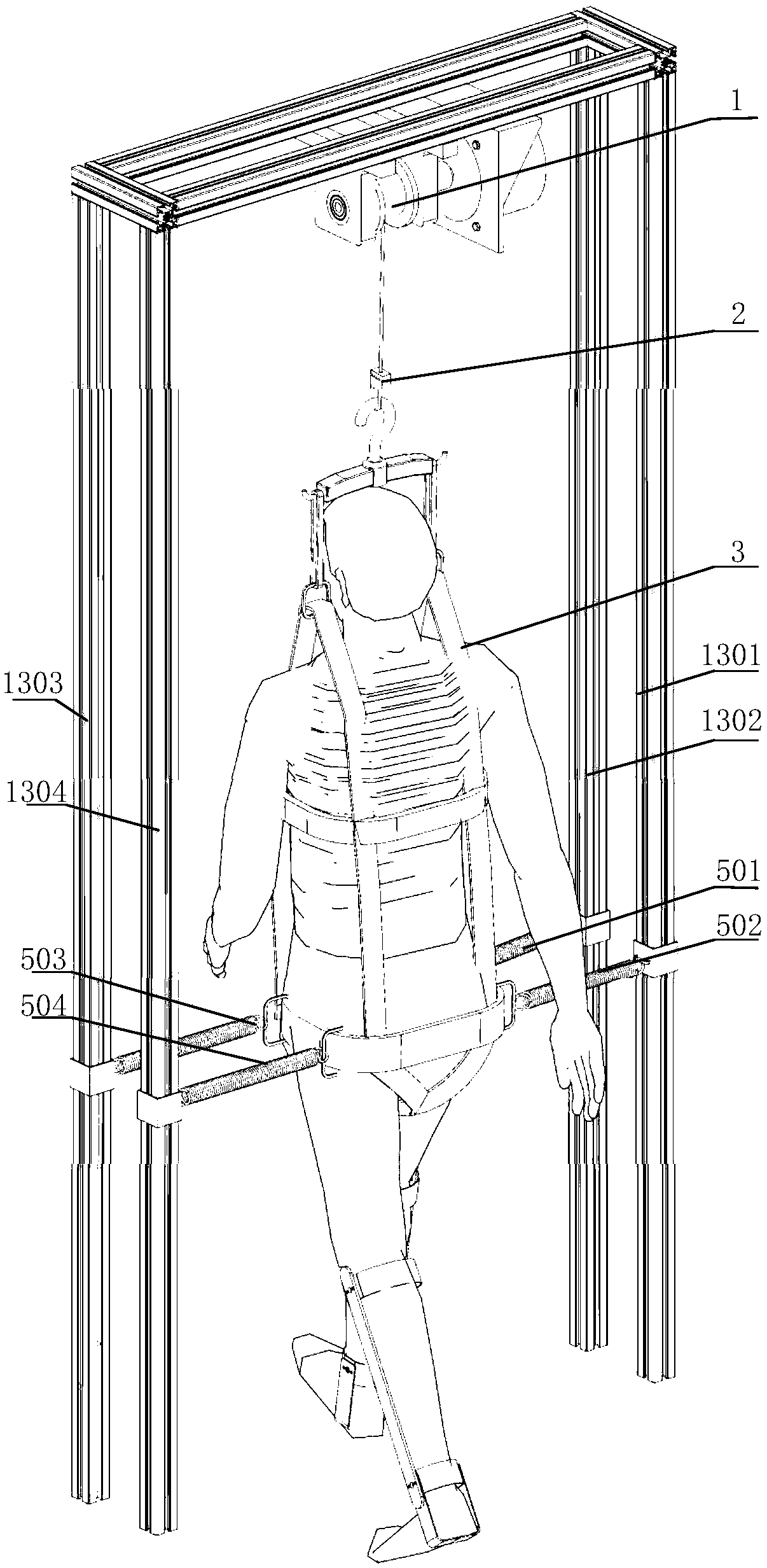

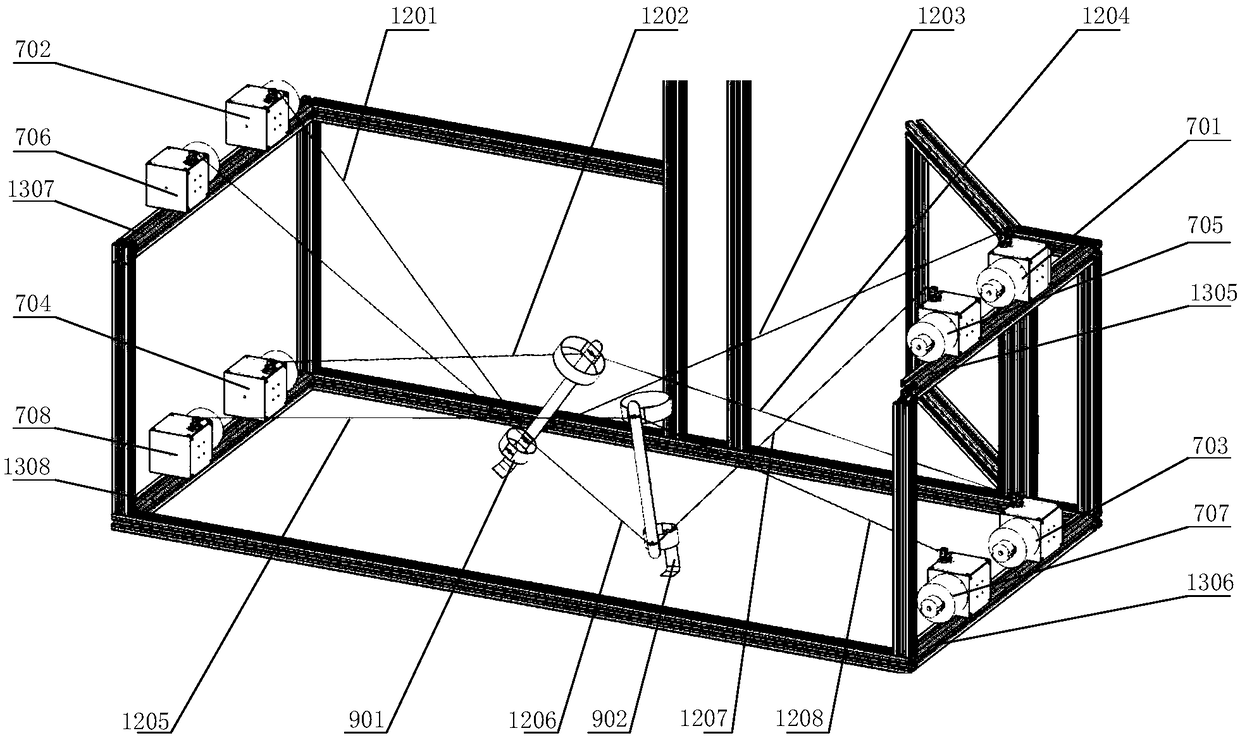

Movable parallel wire driven lower limb rehabilitation robot and implementation method thereof

ActiveCN108606907AEnsure safetyAchieve coordinated movementChiropractic devicesWalking aidsDrive wheelEngineering

The invention relates to a movable parallel wire driven lower limb rehabilitation robot and an implementation method thereof. The robot comprises a suspension weight reducing unit, a tension sensor, safety straps, a safety handrail, a spring, a door fence, wire driving units, universal driven wheels, a leg wearing device, a treadmill, rear driving wheels, wires, a supporting frame and a liquid crystal display screen. The whole robot is of a truss structure formed by the supporting frame, and the suspension weight reducing unit on the upper portion is connected with the safety straps through the wires; the movement of the waist of a patient is constrained through four groups of springs between four vertical beams on the left and on the right and between the safety straps; the liquid crystalscreen is arranged above the safety handrail on the front portion of the robot; the patient and a wheelchair enter and go out through the left door fence; four cross beams at corresponding positionsof an affected limb sagittal plane on each side are provided with the four wire driving units; the affected limb is driven for rehabilitation training by pulling the leg wearing device through the wires; the universal driven wheels are installed on the front portion of the bottom of the robot, and the rear driving wheels are arranged on the rear portion of the robot. The robot can achieve gait training and walking training in passive, power-assisted and active modes.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com