On-line lithium battery pole piece surface defect detection sorting system and method

A sorting system and lithium battery technology, applied in sorting and other directions, to achieve the effects of good implementability, fast detection speed, and avoiding secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

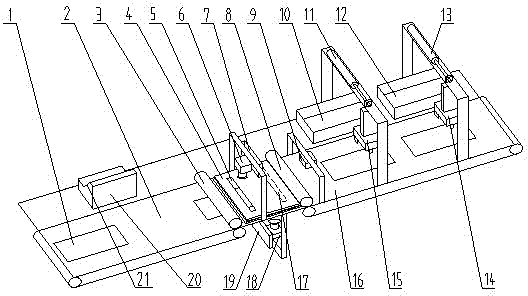

[0027] As shown in the figure, the online detection and sorting system for surface defects of lithium battery pole pieces includes:

[0028] The pole piece conveying device, after passing the pole piece uninterruptedly through the detection area of the pole piece detection device for detection, then sends the pole piece to the sorting area of the pole piece sorting device;

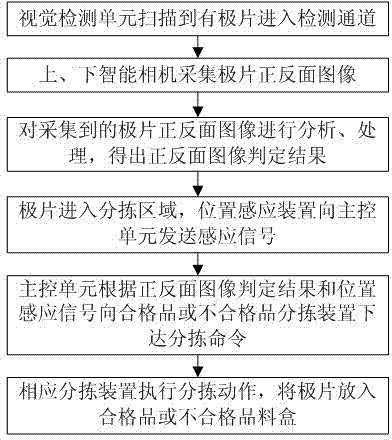

[0029] The pole piece identification and detection device includes an upper collection and detection device and a lower collection and detection device that simultaneously identify the front and back sides of the pole piece. Below, real-time acquisition, analysis and processing of the front and back images of the pole piece, and the processing results are sent to the main control unit of the pole piece;

[0030] The pole piece main control unit is used to realize the control of the pole piece conveying device, the acquisition of the processing result of the pole piece identification and detection devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com