Patents

Literature

3042 results about "Acid washing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acid Wash. Acid Washing is done by emptying the pool and spraying it with a small, diluted amount of special acid. This acid will remove a thin layer of pool plaster and the mineral buildup that is coating the top of the plaster to reveal a bright, new layer of plaster underneath This process is quite safe when done by an experienced professional...

Liquid phase process for C8 alkylaromatic isomerization

InactiveUS6872866B1Saving considerable capitalImprove stabilityHydrocarbon by isomerisationMolecular sieve catalystsIsomerizationAcid washing

A liquid or partially liquid phase process for isomerizing a non-equilibrium mixture of xylenes and ethylbenzene uses a zeolitic catalyst system preferably based on zeolite beta and on pentasil-type zeolite. The invention obtains an improved yield of para-xylene from the mixture relative to prior art processes in a more economical manner. A preferred beta zeolite is a surface-modified zeolite beta resulting from acid washing of a templated native zeolite at conditions insufficient to effect bulk dealumination. A preferred pentasil zeolite is a MTW-type with a silica-to-alumnina ratio between 20 and 45.

Owner:UOP LLC

Preparation method of porous structured active carbon

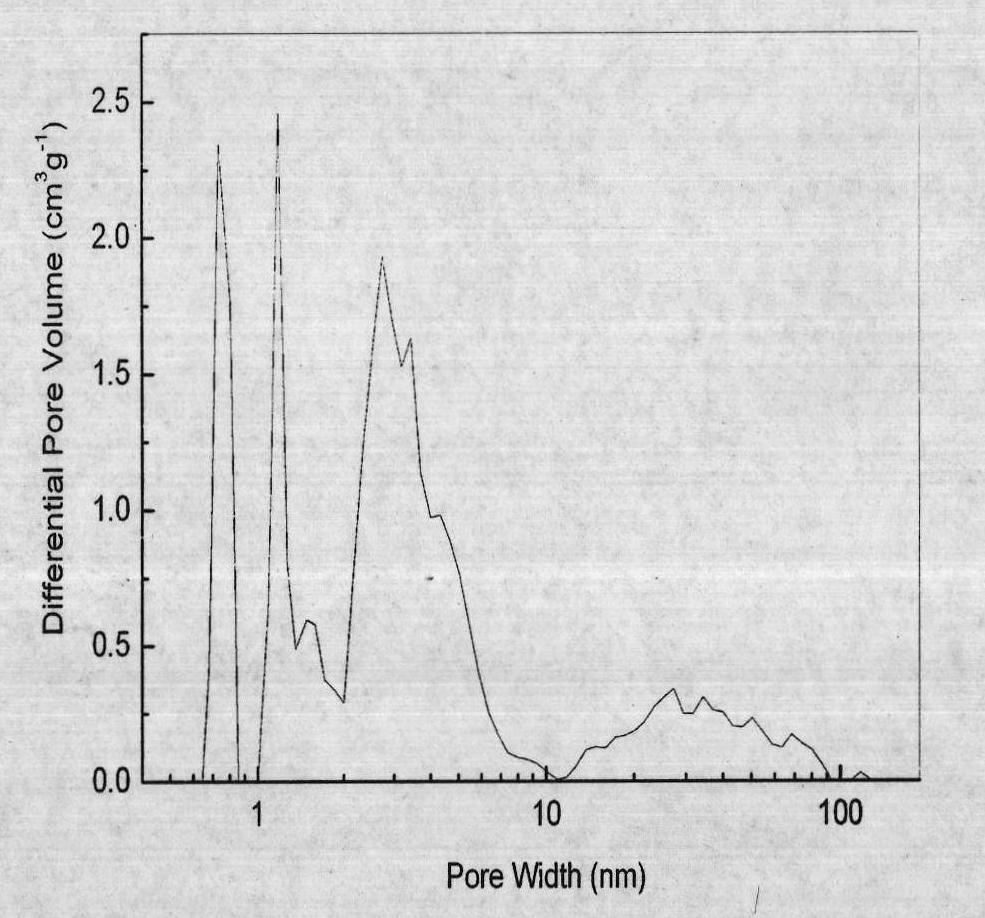

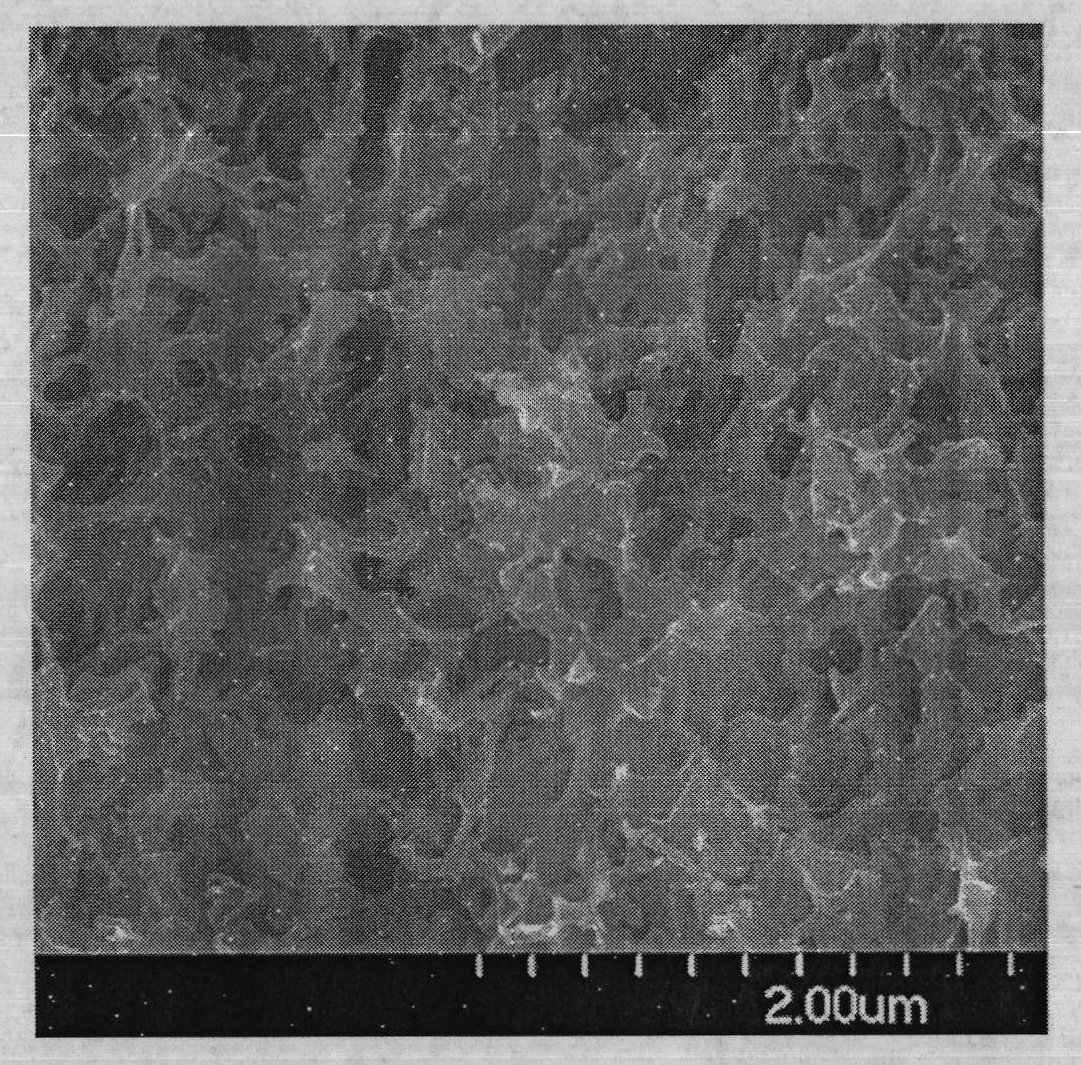

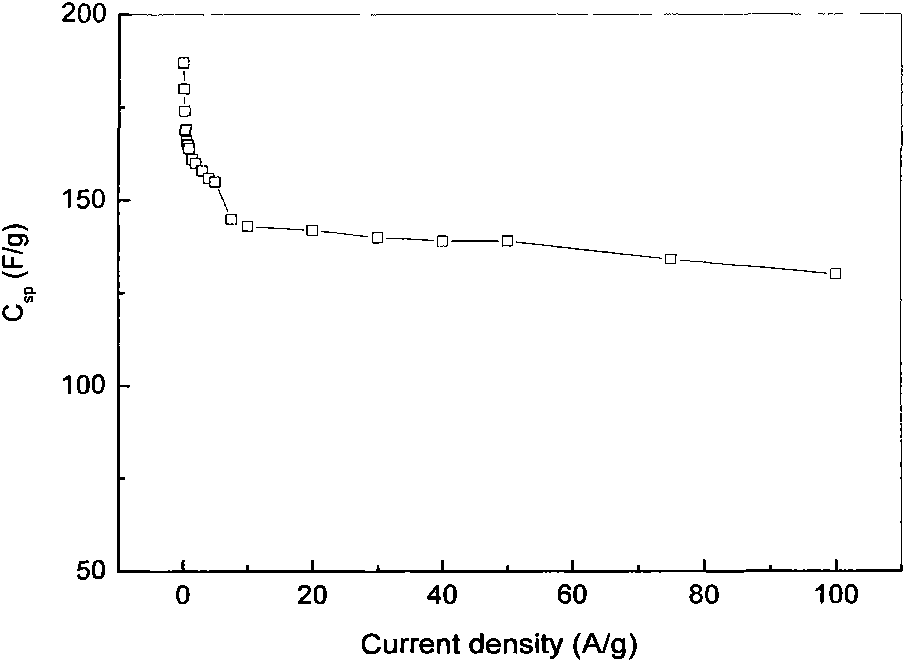

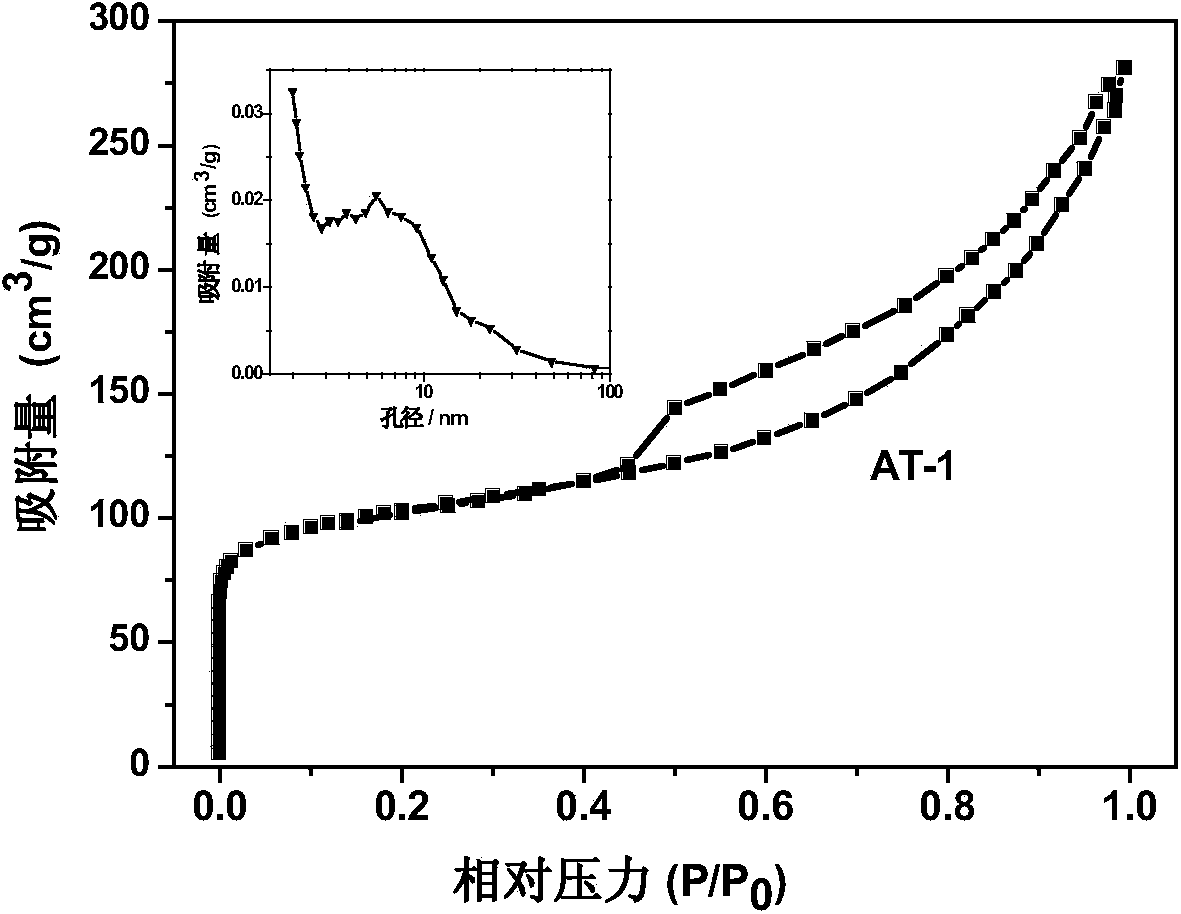

The invention provides a preparation method of porous structured active carbon. The preparation method comprises the following steps of: drying animal bones serving as raw materials; pre-carbonizing at the temperature of 400 to 500 DEG C under the protection of an inert gas; crushing into powder; adding an activating agent into the powder; performing chemical activation under the protection of the inert gas; cooling and taking a product out; and performing aftertreatment process such as acid-washing, water-washing and drying to obtain the porous structured active carbon, wherein the product prepared at 850 DEG C has the specific surface area of 2,157 square meters per gram and the pore volume of 2.26 cubic centimeters per gram; the pores are in a three-dimensional distribution of micropores, mesopores and macropores. By taking organic substances and inorganic substances in the animal bones as a carbon source and a natural template with a special pore structure, the preparation method overcomes the defects of requirement on a template and difficulty in immersing pores in a template by using a carbon precursor, prepares the porous active carbon, and is low in cost and simple in process.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of iron-carbon micro-electrolytic filler

InactiveCN101704565ALarge specific surface areaImprove responseWater contaminantsWater/sewage treatmentActivated carbonPowder mixture

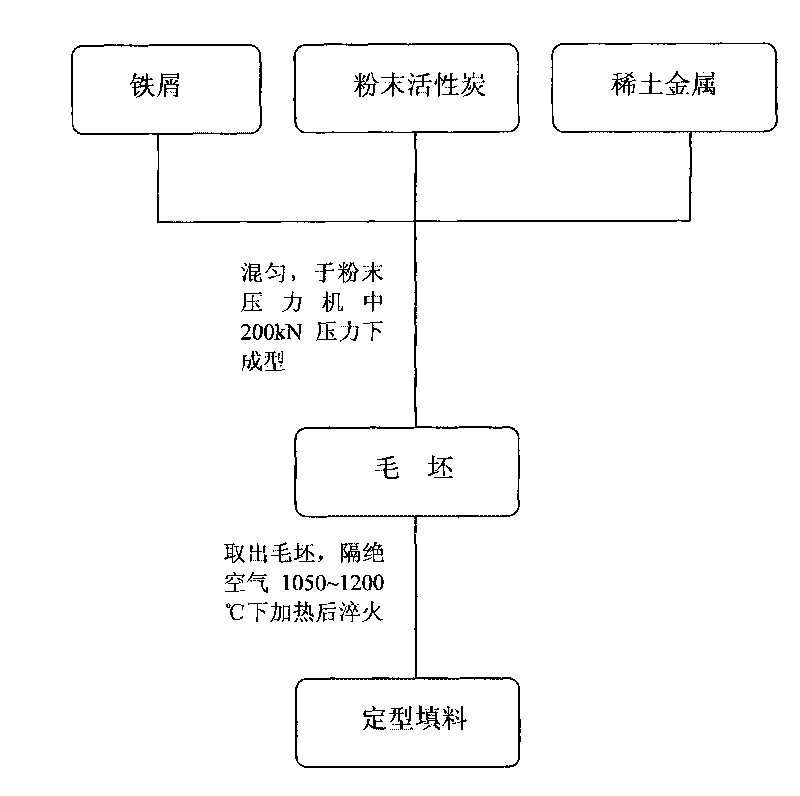

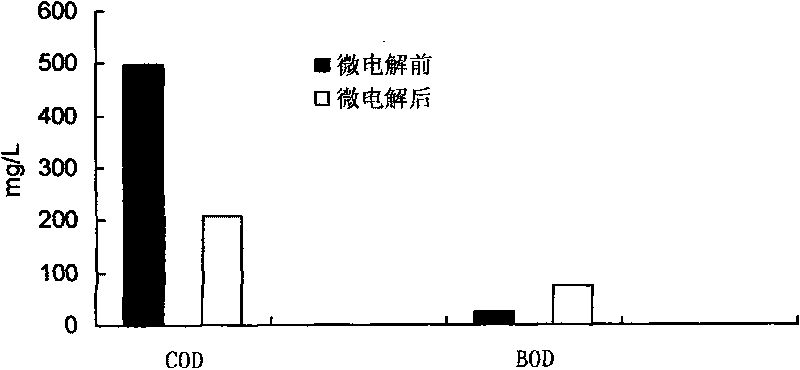

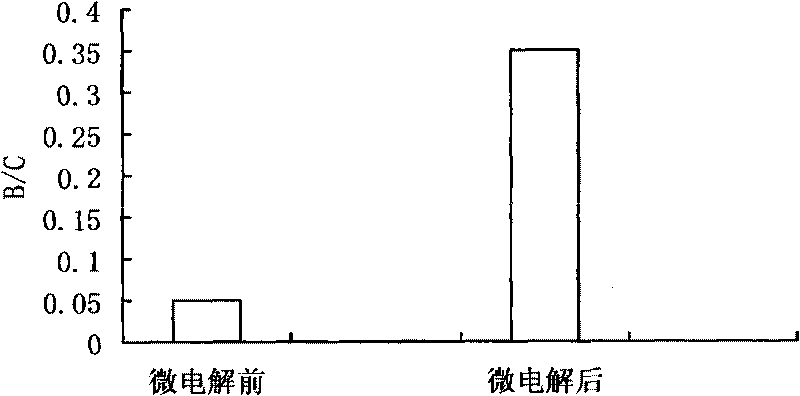

A preparation method of iron-carbon micro-electrolytic filler relates to a preparation method of the micro-electrolytic filler for treating wastewater, comprising the following steps: using scrap iron with grain diameter of less than 60 meshes, active carbon powder with grain diameter of less than 100 meshes and rare-earth metal powder as raw materials; using hydrochloric acid solution with mass percentage of 5% for acid washing the scrap iron to activate the scrap iron; mixing the scrap iron with the active carbon powder and the rare-earth metal powder on mass percent of 85%: (14.91-14.00)%: (0.01-0.09)%; using a press machine to add the powder mixture to a Bauer ring-shaped mould for molding at 200 kN; demolding to obtain rough product; heating the rough product for 90-100 min at 1050-1200 DEG C in the absence of air; and then annealing to obtain the iron-carbon micro-electrolytic filler. The iron-carbon micro-electrolytic filler has good specific surface, excellent micro-electrolytic effect and simple technique, and is capable of effectively preventing passivation of the filler surface and hardening of the filler; moreover, the preparation method is easy to promote and suitable for industrial production.

Owner:TONGJI UNIV

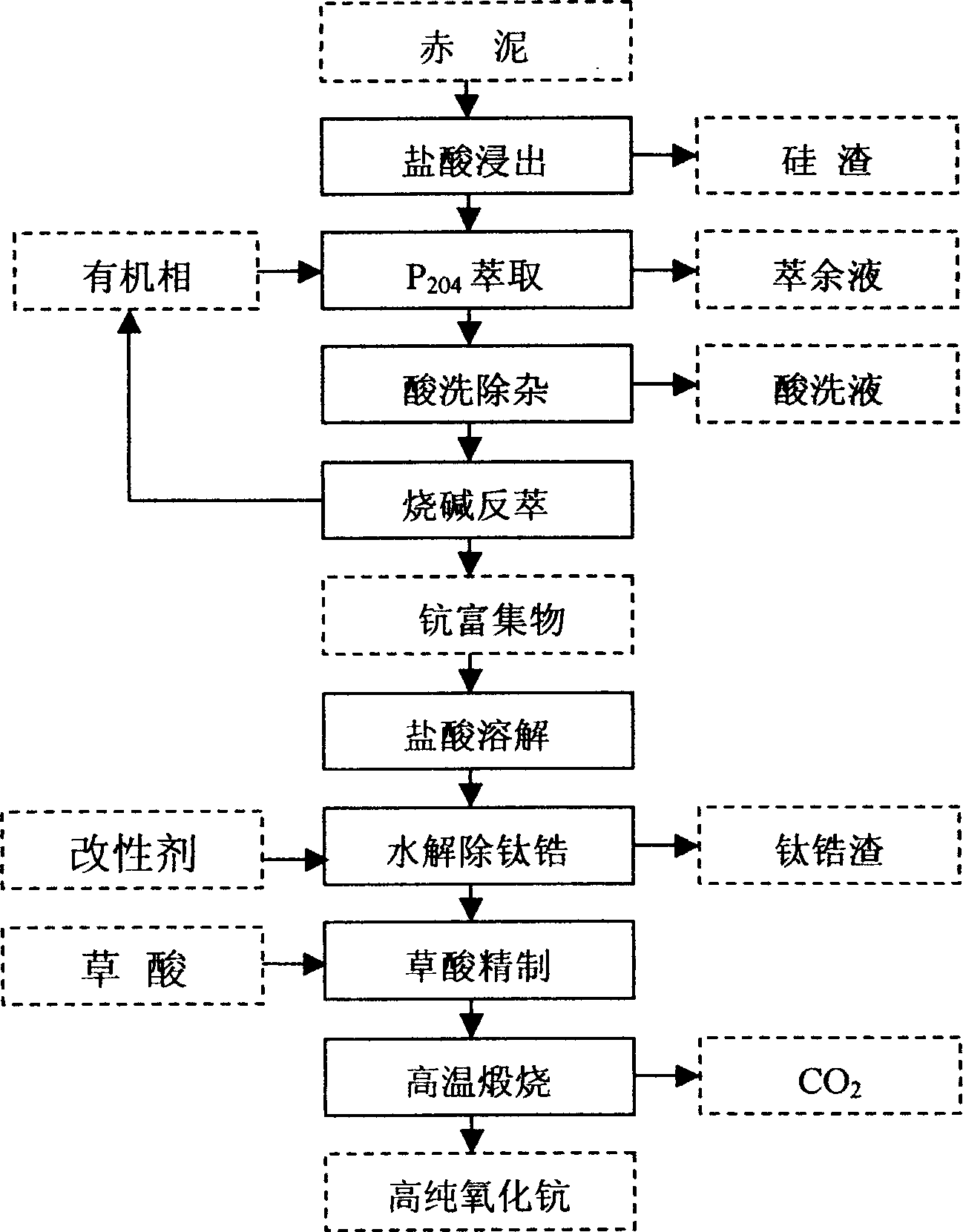

Method for extracting scandium from red mud

InactiveCN1844421AImprove protectionSimple processProcess efficiency improvementRed mudDecomposition

The invention relate to a method of extracting scandium from red mud, the method utilize the red mud that come from the process of producing aluminum oxide from alumyte, in accordance with specific characteristics of red mud, applying hydrochloric acid leach, P204 abstraction, acid-washing edulcoration, sodium-hydroxide back extraction, ammonia modifier hydrolytic decomposition zirconium and titanate in hydrochloric acid solution, oxalic acid precipitating scandium and medium temperature calcining technique, the purity of final production Sc2O3 is 99.9%. Extracting scandium from red mud change refuse into available material, save mineral resources, benefiting environmental conservation. The invention also fills up the study vacant of isolation technique in high-strength zirconium titanate and scandium.

Owner:汪友华

Treatment technology of producing sulfuric acid from alkylated spent sulfuric acid through high temperature decomposition

ActiveCN1751984ARealize lysis treatmentAvoid secondary pollutionSulfur-trioxide/sulfuric-acidDecompositionContact method

A process for preparing sulfuric acid from used alkylating sulfuric acid by high-temp cracking includes such steps as heating to 1000-1100 deg.C, cracking, acid washing for cleaning, converting twice by contact method, and absorbing twice to obtain qualified sulfuric acid for reuse. It has high recovering rate.

Owner:PETROCHINA CO LTD

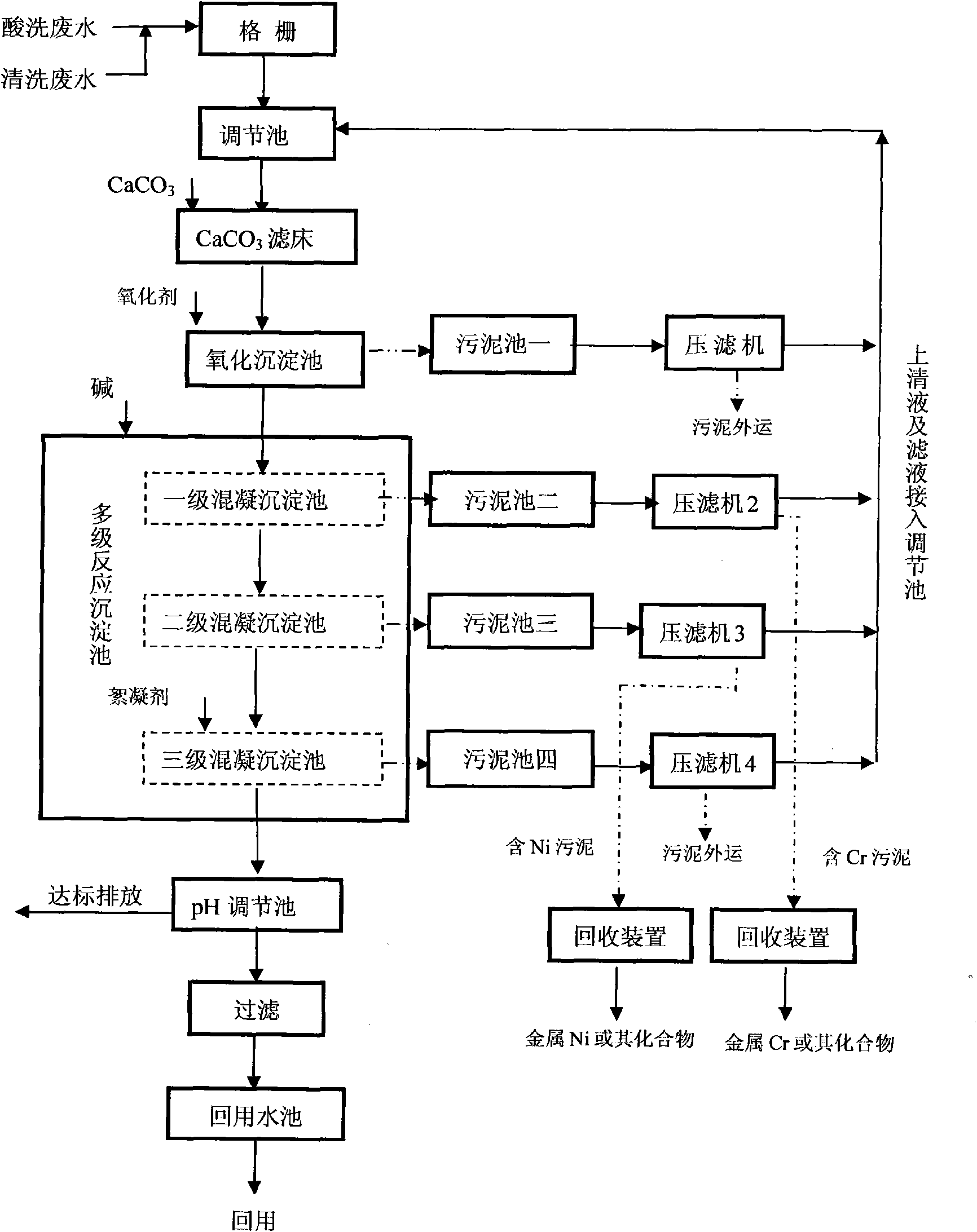

Recycling processing method for stainless steel processing process wastewater grading precipitation

InactiveCN101648757AHigh recycling valueSludge treatment by de-watering/drying/thickeningPhotography auxillary processesThree levelAcid washing

The invention relates to a recycling processing method for a stainless steel processing process wastewater grading precipitation, which comprises the following steps: (1) deslagging and homogenizing acid-washing residual liquid and washing wastewater; (2) adjusting the pH to 4.0-5.5 by a CaCO3 filter bed to generate CaF2; (3) oxidizing Fe<2+> into Fe<3+> by an oxidizing agent to generate sedimentsof Fe(OH)2 and Fe(OH)3; after the Fe(OH)2 , the Fe(OH)3 and the CaF2 are deposited, recovering; (4) carrying out three-level alkali adding coagulation precipitation on the supernatant liquid of an oxidation precipitation pool; adjusting the pH to obtain a Cr sediment in the first-level alkali adding coagulation precipitation; acquiring a Ni sediment in the second-level alkali adding coagulation precipitation; carrying out the third-level alkali adding coagulation precipitation and adding a flocculating agent to remove residual heavy metal ions so that discharge water reaches the standard, wherein the alkali added into a grading reaction precipitation pool is NaOH, Ca(OH)2, CaO or Na2 CO3; (5) regulating the pH of the discharge water of the grading reaction precipitation pool to 6.0-8.0; discharging 0-20 percent of wastewater and filtering residual F<-> and suspended matters of 80-100 percent of wastewater to reach the standard and recycle; and (6) recycling the Cr-Ni metal or the compound thereof from the Cr sediment and the Ni sediment acquired by a third-level coagulation precipitation pool by a recycling device.

Owner:ZHEJIANG UNIV

Laminated titanium-alloy thin-plate assembled connecting method

ActiveCN101028686AConsistent physical propertiesAvoid intensityOther manufacturing equipments/toolsNon-electric welding apparatusTectorial membraneAcid washing

A technology for combining multiple layers of Ti-alloy sheet includes such steps as blanking, acid washing, baking, sticking protective film, coating welding inhibitor, removing said protective film, welding technological edges, installing die set, heating the forming apparatus, diffusion joining, pneumatic expansion shaping, cooling and removing said technological edges. Its product can be used for wing, fin, or blade.

Owner:SICHUAN FUTURE AEROSPACE IND LLC

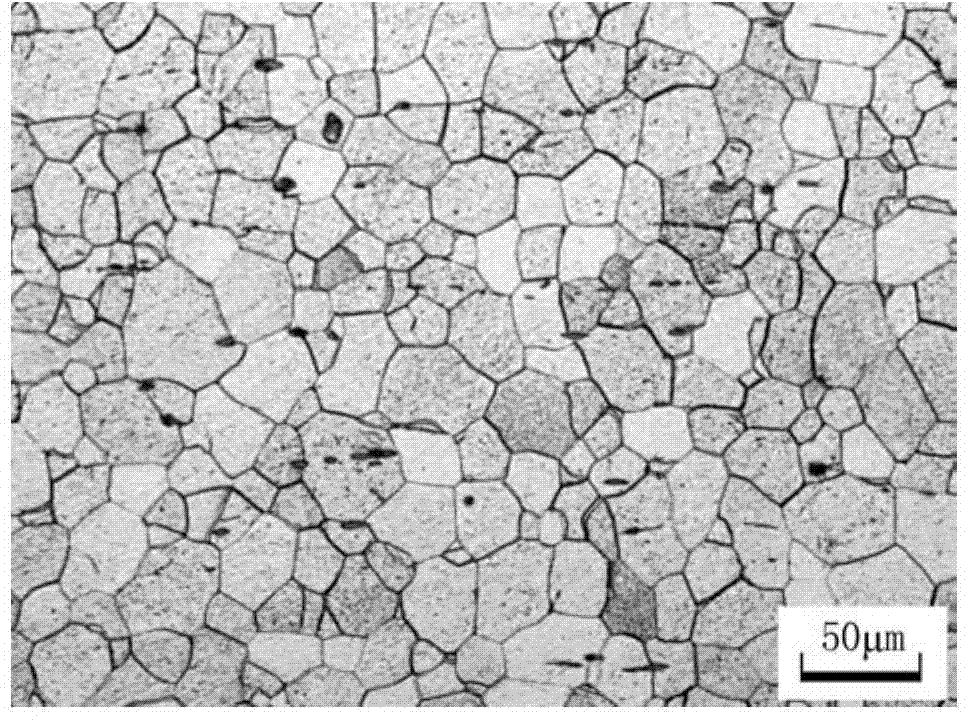

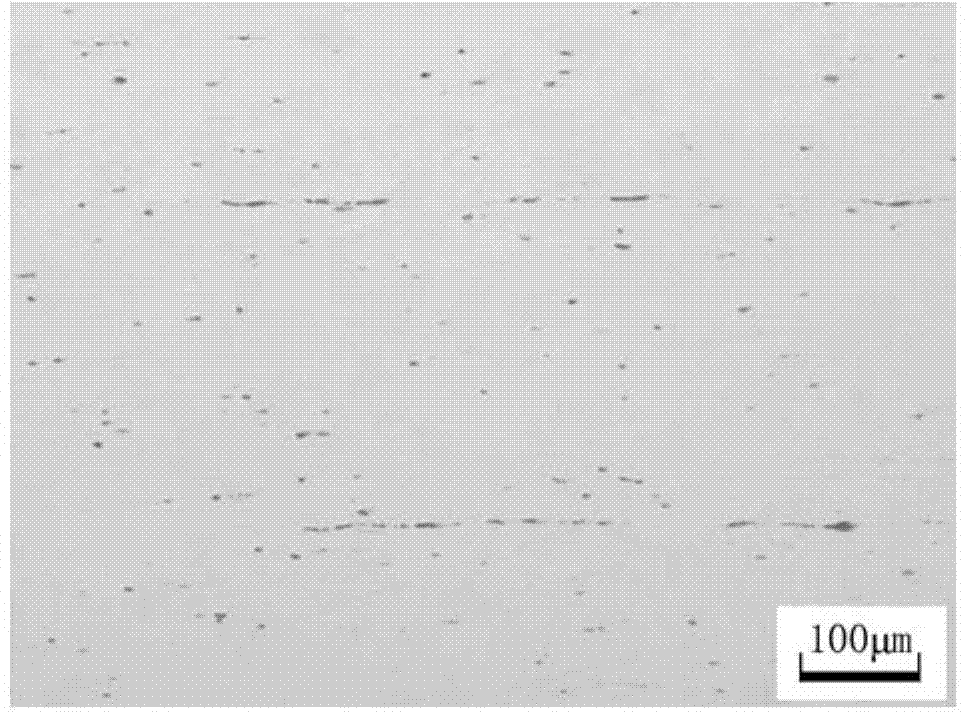

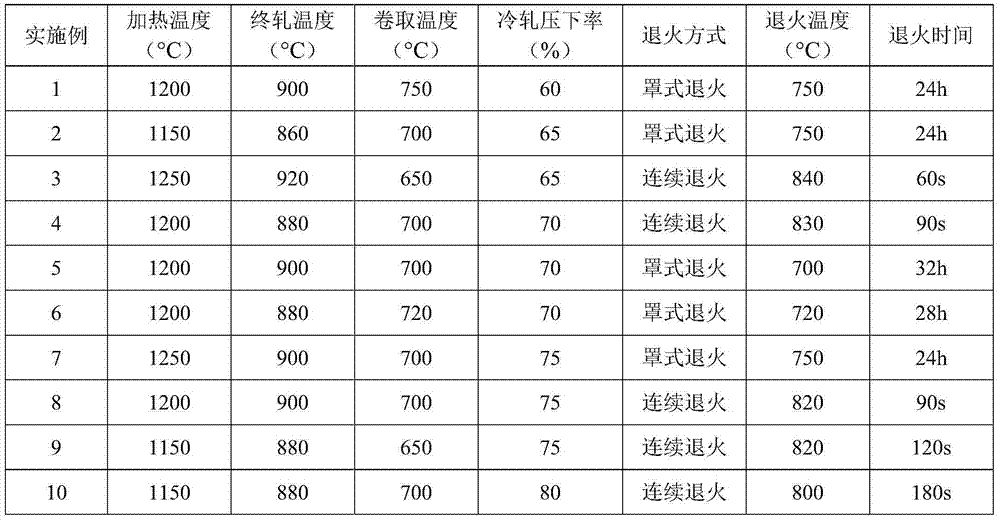

Enamel steel with scaling resistance and manufacturing method thereof

InactiveCN103484757ASimple chemical compositionReduce smelting costTemperature control deviceReduction rateAcid washing

The invention discloses enamel steel with scaling resistance. The enamel steel is prepared from the following components in percentage by weight: 0.0020-0.0050% of C, 0.30-0.50% of Mn, 0.0050-0.0100% of Si, 0.010-0.015% of P, 0.011-0.020% of S, 0-0.010% of Als, 0.011-0.020% of O and the balance of Fe and other inevitable impurities. A manufacturing method sequentially comprises the following steps: pretreatment of molten iron, smelting by a converter, refining, continuous casting, hot continuous rolling, acid washing, cold continuous rolling, annealing and finishing, wherein the heating temperature for hot continuous rolling is 1150-1250 DEG C, the finish rolling temperature is 860-920 DEG C, the winding temperature is 650-750 DEG C, and the cold rolling reduction rate of cold continuous rolling is 60-80%. The enamel steel disclosed by the invention has no scaling phenomenon and low production difficulty, and is suitable for being applied to the technical field of iron and steel smelting.

Owner:WUHAN IRON & STEEL (GROUP) CORP

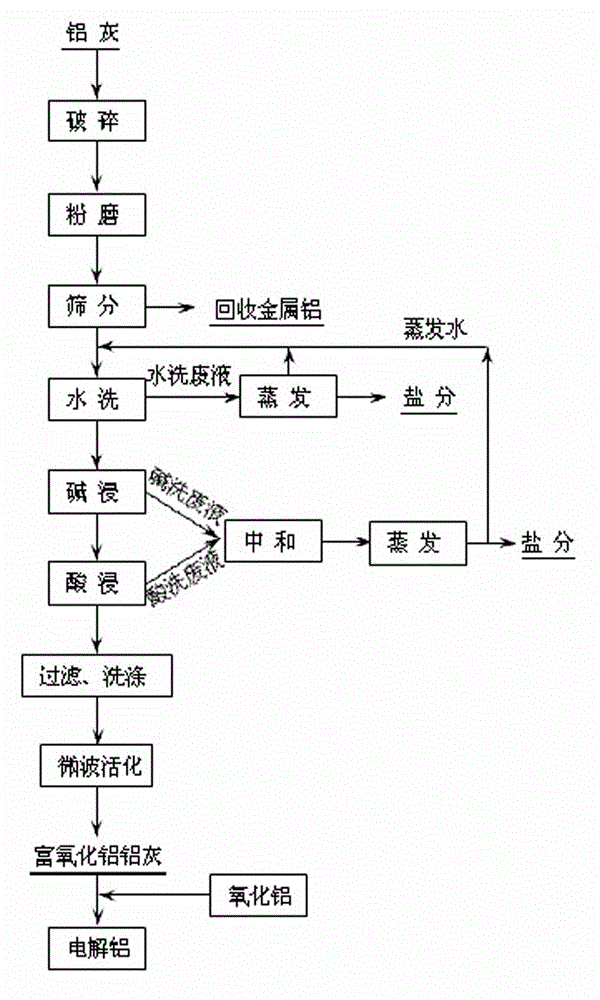

Resource utilization method of aluminum ash

ActiveCN103555955AEfficient recyclingComprehensive recyclingProcess efficiency improvementLiquid wasteMicrowave

The invention discloses a resource utilization method of aluminum ash. The method comprises the following steps: by taking primary slag and flammable dross generated in a smelting process of electrolytic aluminum, and aluminum ash such as salt slag and scum generated in a coarse aluminum refining and processing process as raw materials, recovering aluminum through process steps of crushing, grinding and vibrating screening; and then, respectively carrying out technologies such as washing, pressurized alkaline leaching and normal pressure acid leaching to obtain aluminum oxide-rich aluminum ash. The aluminum ash dried and activated by microwaves returns to an aluminum cell. After the acid-washing liquid waste and alkali-washing waste are effectively neutralized, the acid-washing liquid waste and alkali-washing waste are concentrated and evaporated to recover effective salt. The process provided by the invention can realize resource utilization of aluminum ash on the spot, and is simple and easy to operate and low in production cost, so that the environmental pollution and resource waste caused by aluminum ash are avoided.

Owner:KUNMING METALLURGY INST

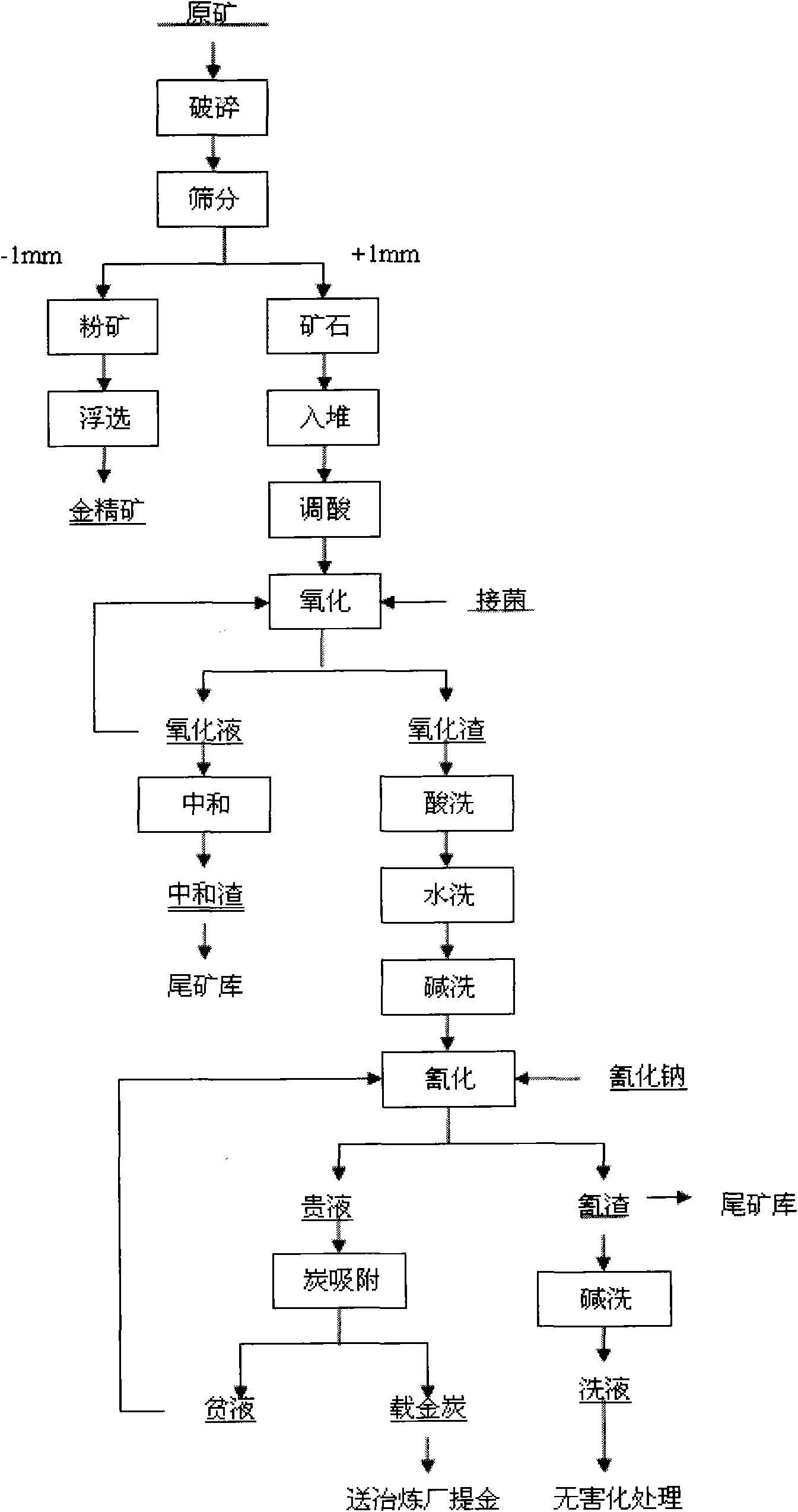

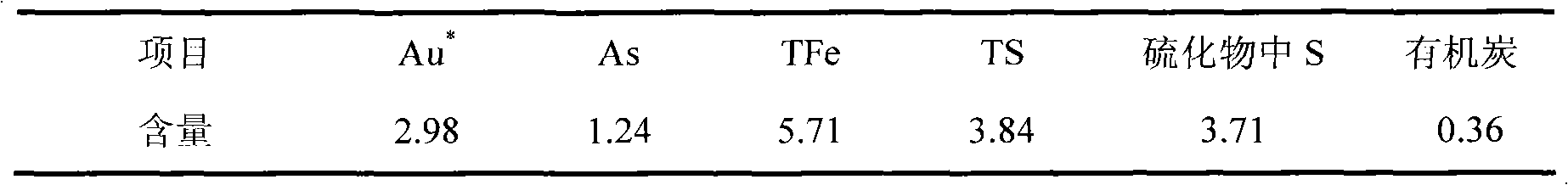

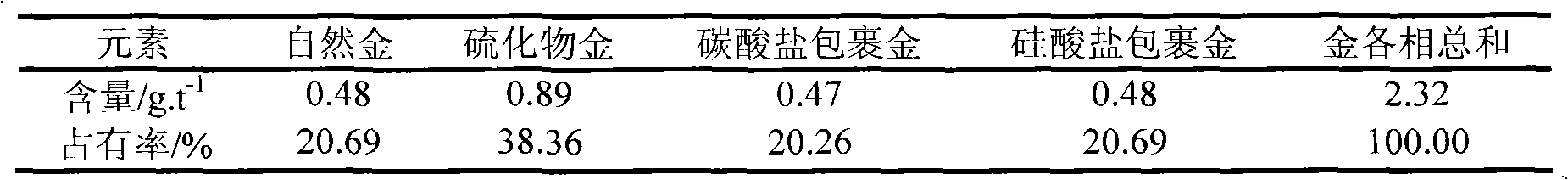

Process for extracting gold from low-grade difficultly-treatable gold ore containing arsenic and carbon

The invention relates to a process for extracting gold from low-grade difficultly-treatable gold ore containing arsenic and carbon. The process is characterized in that: the gold ore has the characteristics of high clay mineral content, large fine ore amount after grinding, and the like. The process comprises the following steps of: grinding raw ore to 10 to -30 millimeters; sieving ore through a sample sieve of 1 to -2 millimeters or washing the ore with water so as to separate fine ore from the ore; floating gold concentrate by using the obtained fine ore; performing direct heap leaching on ore of +2 millimeter and performing biological oxidation; performing medium transformation such as acid washing, water washing, alkali washing and the like on the biologically-oxidized ore and cyaniding directly so as to extract gold, wherein gold is extracted from the floated gold concentrate by biological oxidation-cyaniding and carbon soaking-pressure oxidation-cyaniding and gold extraction or baking, oxidation and cyaniding. Due to the adoption of the process, the problem of permeability of gold ore is solved and the gold extracting rate is effectively increased from 2 to 5 percent during direct heap leaching and cyaniding to 55 to 65 percent. The process has the advantages of simple process, high gold extracting rate, low pollution, high benefit and the like.

Owner:ZIJIN MINING GROUP

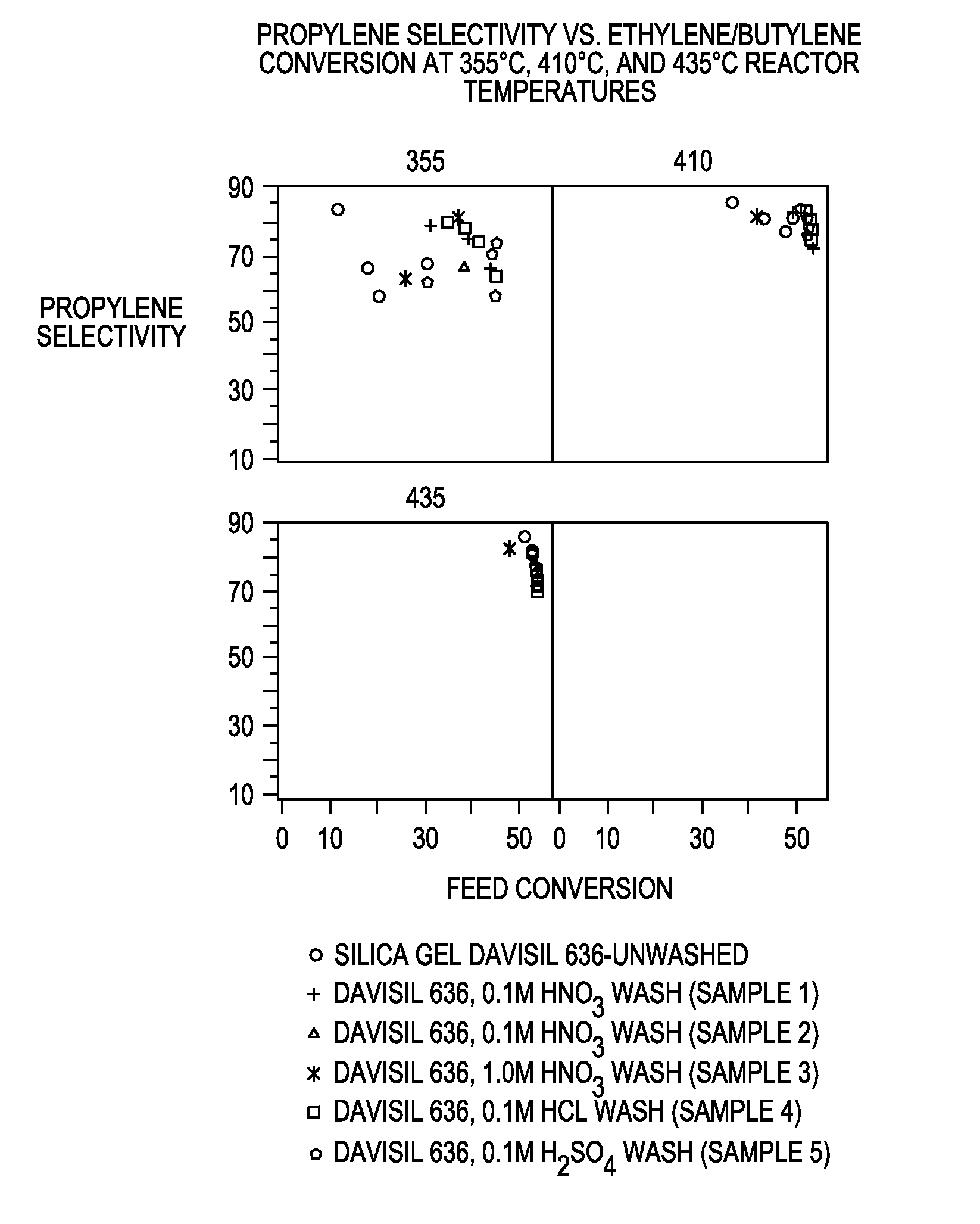

Acid Washed Silica Supported Catalysts and Their Use in Olefin Metathesis

ActiveUS20110196185A1High activitySelectivity is compromisedCatalystsHydrocarbon preparation catalystsButeneAcid washing

Acid washing of silica supports, used for supported tungsten catalysts, improves the activity of the resulting catalyst (i.e., its conversion level at a given temperature) for the metathesis of olefins, without compromising its selectivity to the desired conversion product(s). Exemplary catalysts and processes include those for the production of valuable light olefins such as propylene from a hydrocarbon feedstock comprising ethylene and butylene.

Owner:UOP LLC

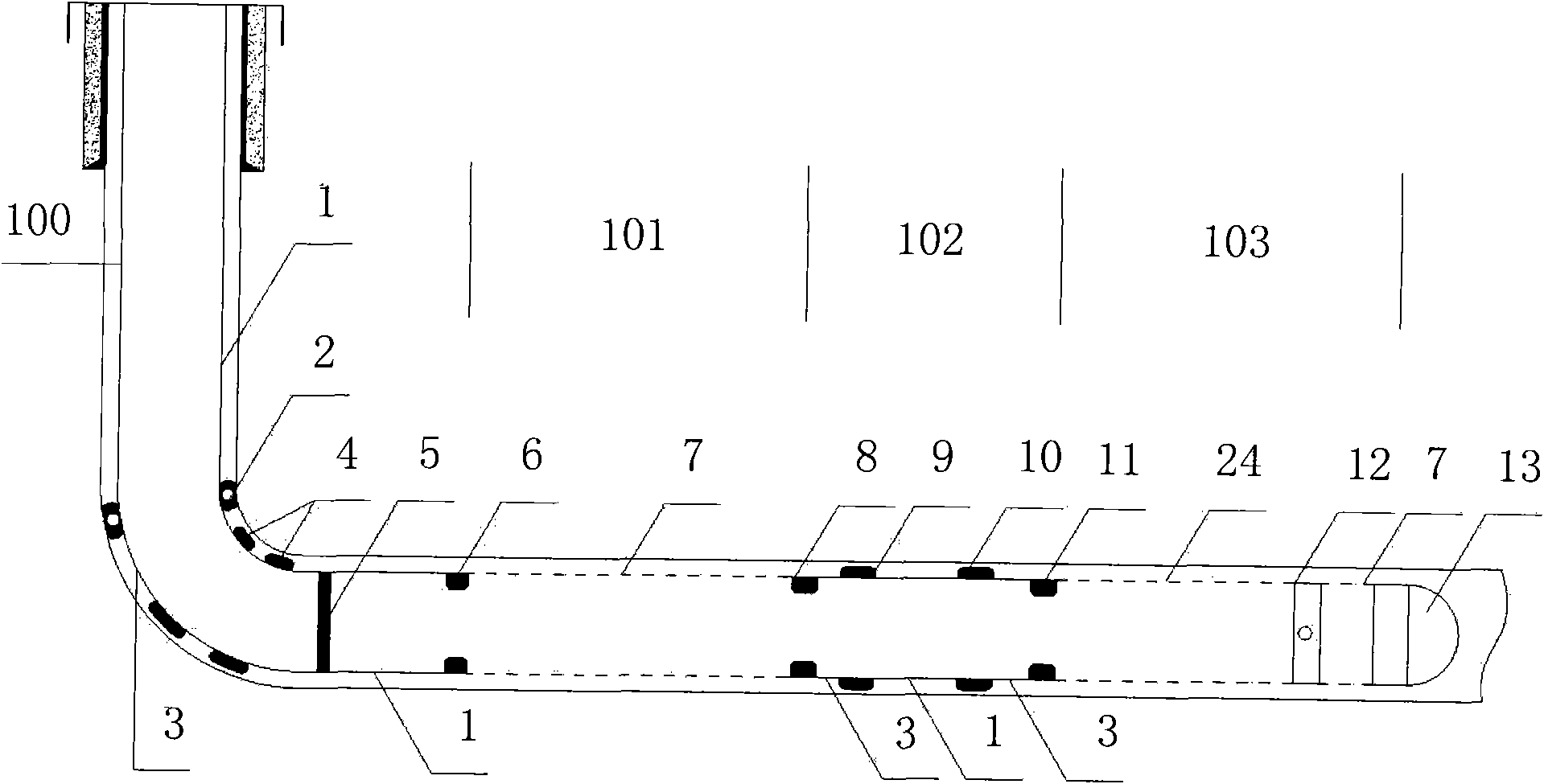

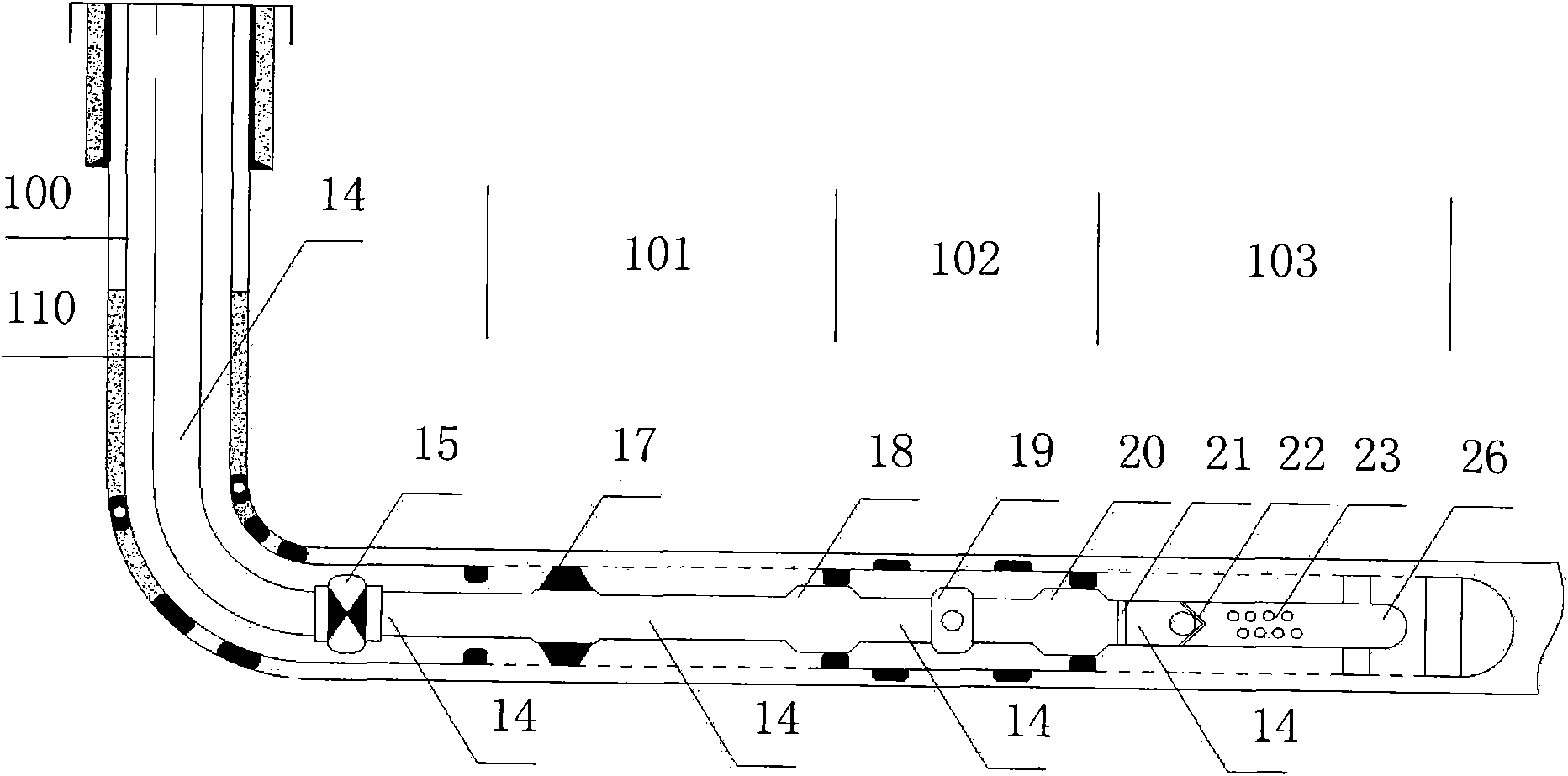

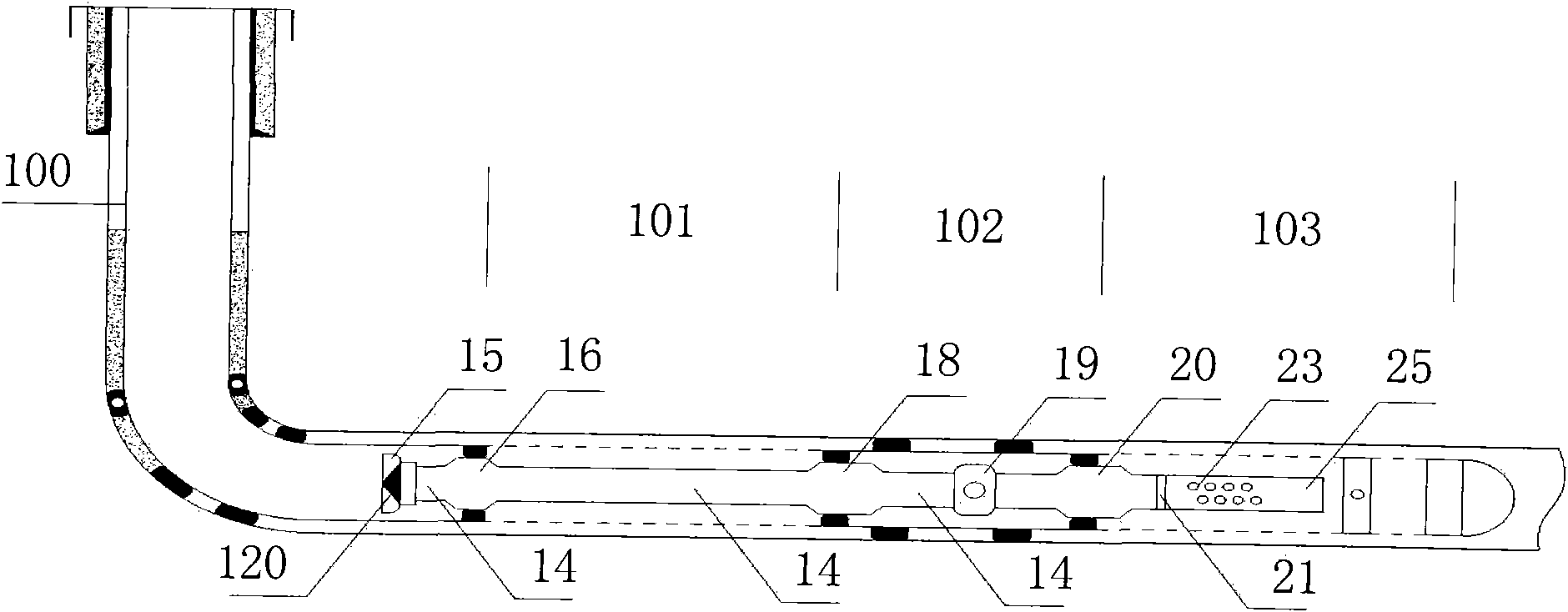

Well completion and oil production string of horizontal well and well completion and oil production processes thereof

ActiveCN101864921AImprove segmental sealing effectDelayed ConingDrilling rodsFluid removalAcid washingOil water

The invention relates to a well completion and oil production string of a horizontal well and well completion and oil production processes. In order to overcome the defect that in traditional horizontal well open hole sand-proof screening pipe well completion construction, an open hole packer at a horizontal section cannot effectively seal and separate oil and water layers because of irregular well diameter, a well completion string is fixedly arranged at the horizontal well section in an open hole well bore; a grading hoop, a casing short section, an external casing packer I, a blind plate, a casing, a layered seal tube I, an upper screening pipe, a layered seal tube II, a second casing short section, an external casing packer II, the other casing, an external casing packer III, a third casing short section, a layered seal tube III, a lower screening pipe, a wash-down valve, the lower screening pipe and a guiding shoe of the well completion string are sequentially and fixedly connected; and an acid washing string, a string for sealing up and producing oil from down, a string for sealing down and producing oil from up or a commingled production string is arranged in the well completion string. The invention has the beneficial effects that the well completion process of the horizontal well is combined with a post oil production technology, the sectioned sealing effect between the well completion string and the open hole well bore is improved, bottom water coning is delayed, and the purposes of controlling water and increasing oil are achieved.

Owner:DAGANG OIL FIELD GRP +1

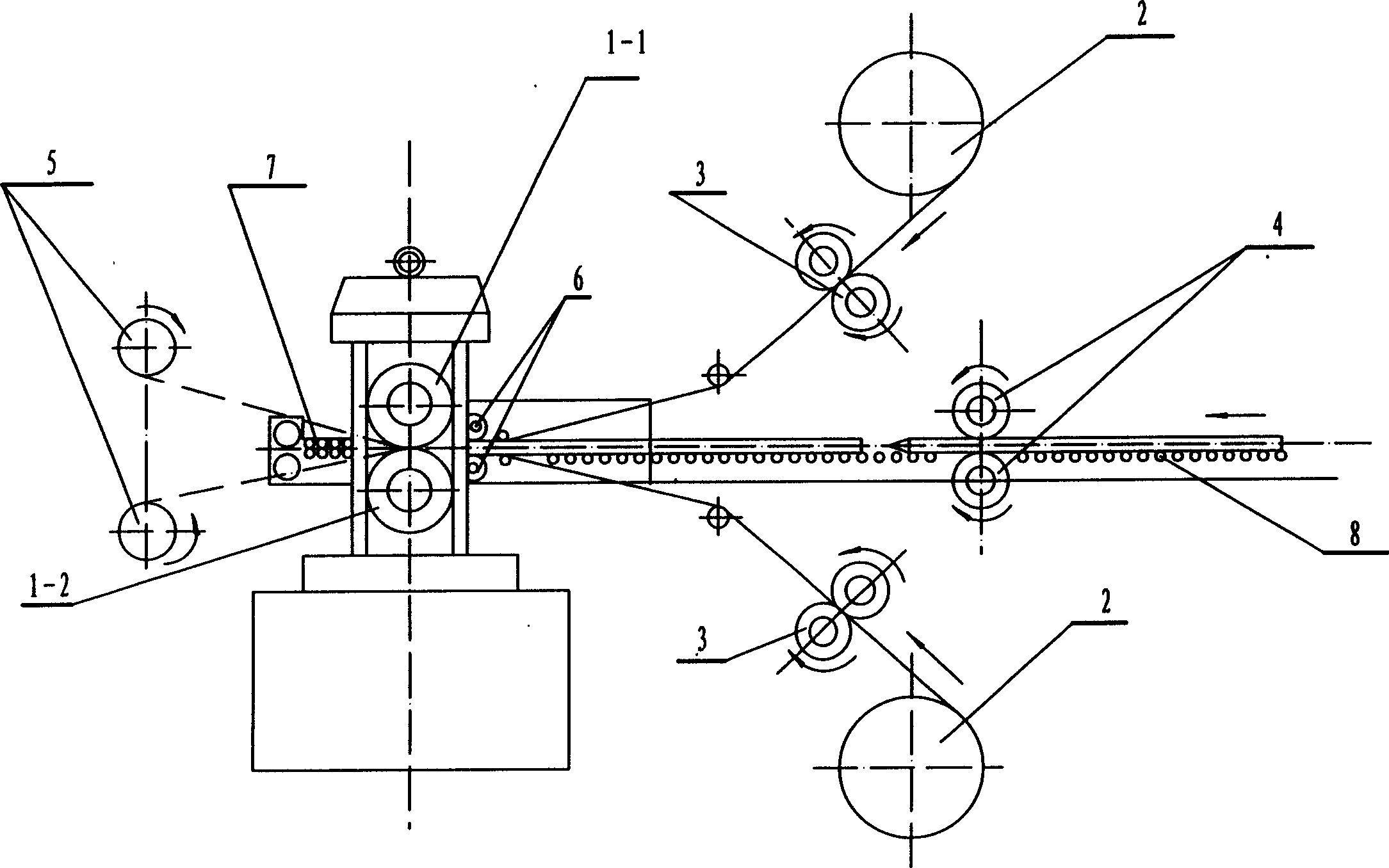

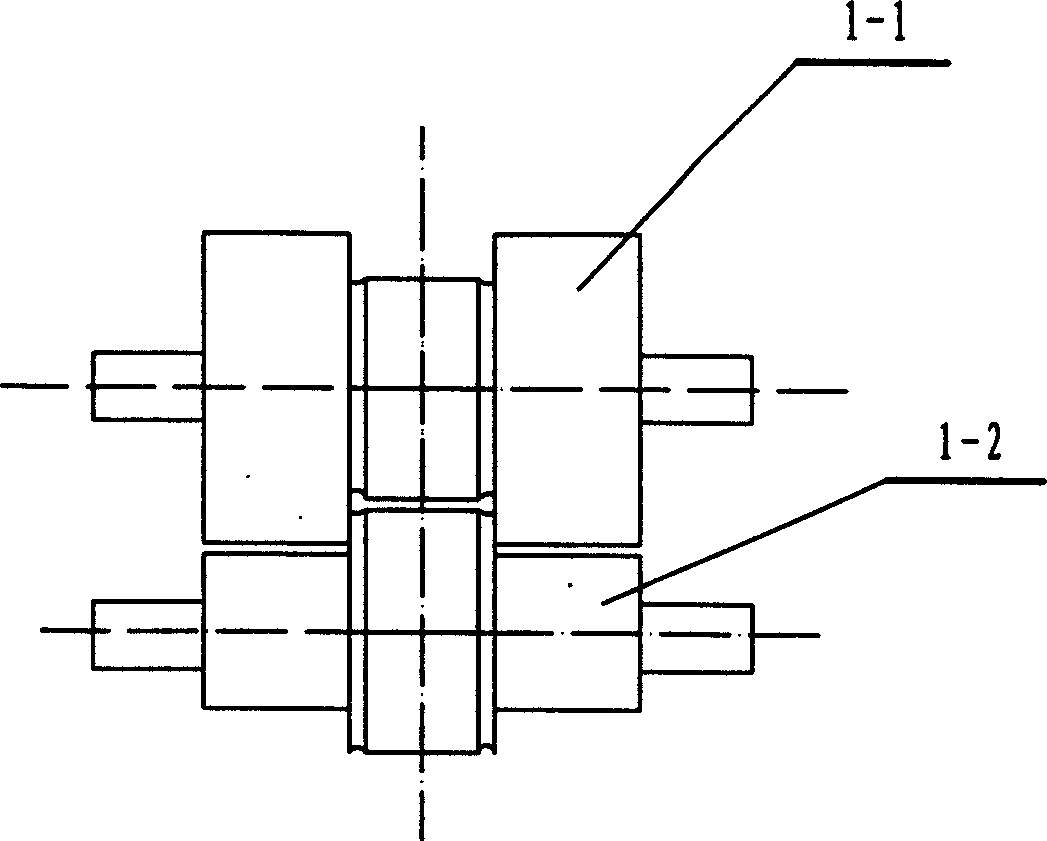

Rolling method and apparatus for copper-aluminium double-face composite board

A technology for rolling the composite Cu-Al plate includes such steps as preheating the copper band and aluminium plate respectively at different temp for different time, acid washing of copper band, alkali washing of aluminium plate, brushing surface by steel wire brush, rolling by a pair of upper concave roller and lower convex roller, annealing in inertial gas, and straightening.

Owner:SHENYANG POLYTECHNIC UNIV

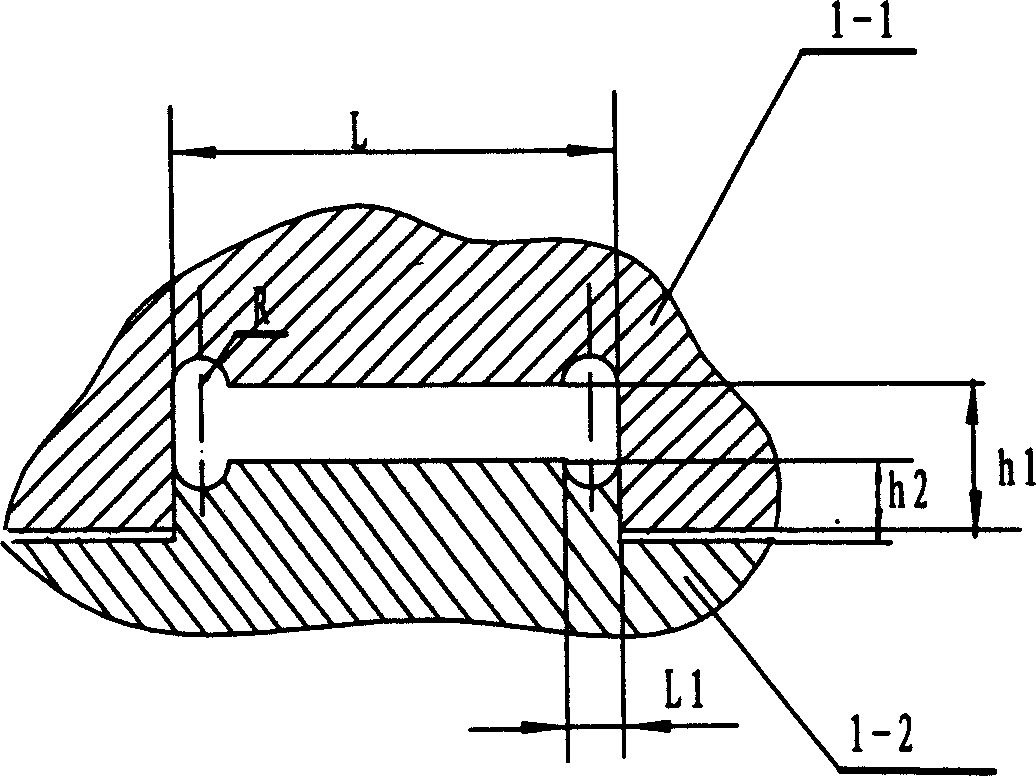

Method for removing scales on surface of hot-rolled stainless steel strip

InactiveCN102719831AAchieve mechanical picklingReduce consumptionWork treatment devicesMetal rolling arrangementsHydrofluoric acidAbrasive blasting

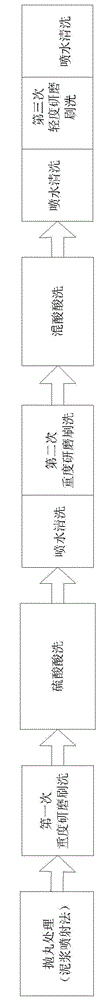

The invention discloses a method for removing scales on the surface of a hot-rolled stainless steel strip. The method comprises the following steps of: performing abrasive blasting treatment on the hot-rolled stainless steel strip to be treated, wherein the abrasive blasting treatment refers to spraying of mixed slurry of water and an abrasive material, and the percent by volume of the abrasive material in the slurry is 30%-40%; after the abrasive blasting treatment, performing primary grinding and scrubbing on the steel strip; after the primary grinding and scrubbing, performing acid-washing on the steel strip with diluted sulphuric acid; cleaning the steel strip subjected to acid-washing by the diluted sulphuric acid by water, and then performing secondary grinding and scrubbing on the steel strip; after the secondary grinding and scrubbing on the steel strip, performing acid-washing on the steel strip with mixed acid of nitric acid and hydrofluoric acid; and after the acid-washing with the mixed acid, cleaning the steel strip with water, then performing third grinding and scrubbing on the steel strip, and finally, washing the steel strip with water. With the slurry spraying technique, as the abrasive material is mixed with the water, the scales on the surface of the hot-rolled stainless steel strip can be removed more effectively; and the consumption quantity of acid in subsequent steps is greatly reduced.

Owner:WISDRI ENG & RES INC LTD

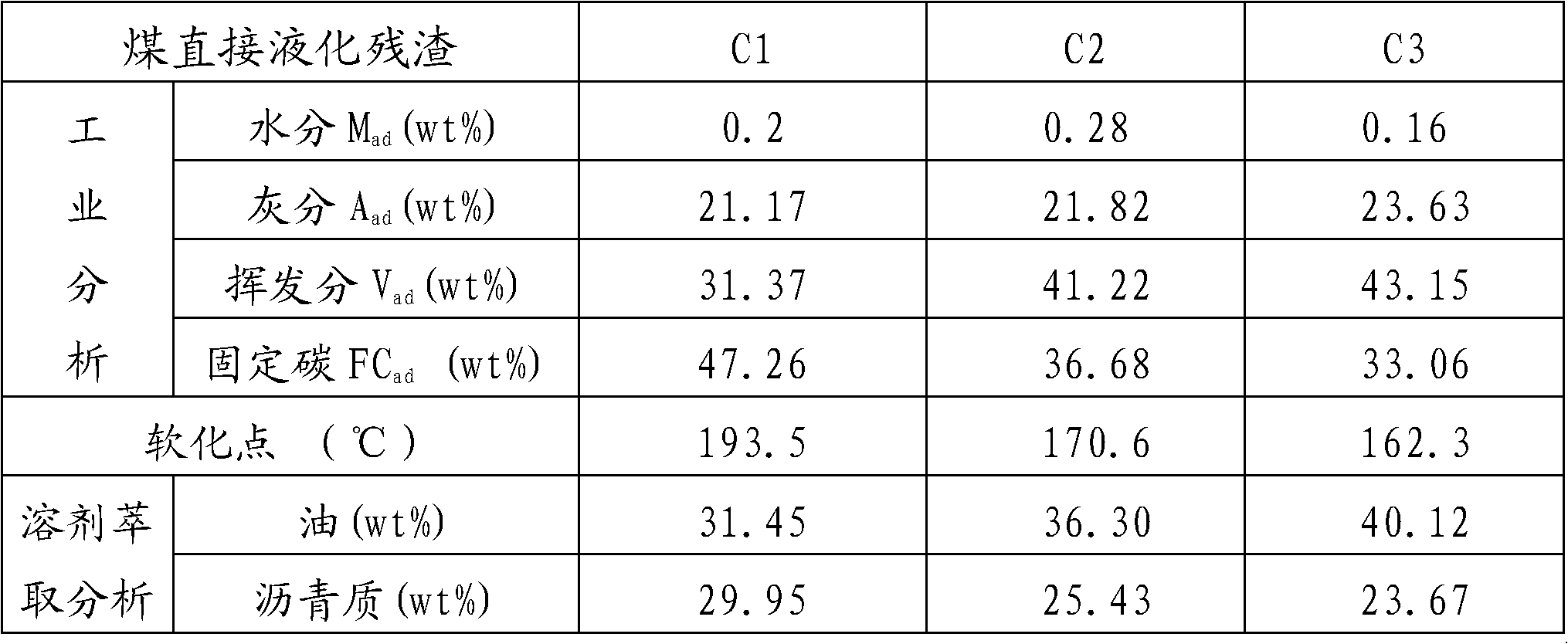

Method for preparing activated carbon by utilizing direct coal liquefaction residue

InactiveCN102153081AExpand sourceImprove coal liquefaction technologySolid waste disposalAcid washingCarbonization

The invention provides a method for preparing activated carbon by utilizing direct coal liquefaction residue as a raw material. The method includes the steps as follows: (1) adding smashed direct coal liquefaction residue together with KNO3, KOH and absolute alcohol into water, stirring to be uniform under room temperature, and later drying the obtained mixture to obtain a dry material; (2) placing the prepared dry material in a carbonization furnace, conducting preoxidation in the atmosphere of air, conducting carbonization-activation in the atmosphere of inertia gas, and then obtaining coarse activated carbon; and (3) acid-washing and deashing the prepared coarse activated carbon to obtain finished activated carbon. The method is simple in preparation process route, uses conventional equipment and has universality to the raw material. The obtained activated carbon has not only characteristics of high specific surface area, developed micropores and low ash content, but also controllable output, higher productivity, suitability for production in batches, and better technological and economic benefits.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Method for processing metastable beta-type titanium alloy plate

The invention relates to a method for processing a metastable beta-type titanium alloy plate and belongs to the technical field of titanium alloy processing. The invention aims to overcome defects in the prior art, provides technology for processing a Ti-15-3 alloy plate and improves the cold working performance of alloy. The method for processing the metastable beta-type titanium alloy plate comprises the following steps of: smelting the titanium alloy plate into an ingot, charging at the temperature of between 800 and 850 DEG C and keeping the temperature for 100 to 150 minutes, raising the temperature to between 1,100 and 1,150 DEG C and keeping the temperature for 240 to 360 minutes, and finishing the first fire by repeatedly upsetting and drawing; drawing unidirectionally until cogging is finished so as to obtain a blank; sawing and rolling the plate blank into a hot-rolled plate blank with the thickness of 4 to 10 mm at the temperature of between 850 and 1,000 DEG C; and cold rolling to obtain a plate with the thickness of 1 to 3 mm after annealing and alkaline and acid washing. By controlling the rolling temperature, the deformation degree and the cooling speed after deformation, the method controls the structure of a forging stock to fully break the forging stock, and effectively suppresses phase precipitation resulting in a brittle alloy. Therefore, the cold working plasticity and cold working performance are improved.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Niobium-containing high-strength hot-galvanized steel plate and production method thereof

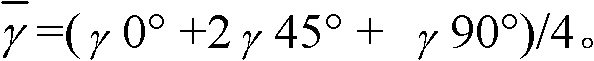

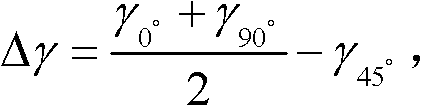

The invention relates to a niobium-containing high-strength hot-galvanized steel plate and a production method thereof. The invention provides a high-gamma-average-value low-Delta gamma-value structural niobium-containing high-strength hot-galvanized steel plate and a manufacturing method thereof. The niobium-containing high-strength hot-galvanized steel plate comprises the following components in percentage by mass: 0.03-0.1% of C, at most 0.05% of Si, 0.5-0.9% of Mn, at most 0.025% of P, at most 0.015% of S, at most 0.005% of N, at most 0.005% of Ti, 0.03-0.06% of Nb, 0.01-0.08% of Al, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: carrying out hot rolling on a steel billet, reeling, and carrying out acid washing, cold rolling, and carrying out hot galvanizing. The gamma average value of the Nb-containing high-strength hot-galvanized steel plate is greater than or equal to 1.3, the Delta gamma value is less than or equal to 0, the yield strength is greater than or equal to 460 MPa, the tensile strength is greater than or equal to 570 MPa, and the elongation at break is greater than or equal to 28%. The invention can ensure favorable forming property on the premise of ensuring high strength.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

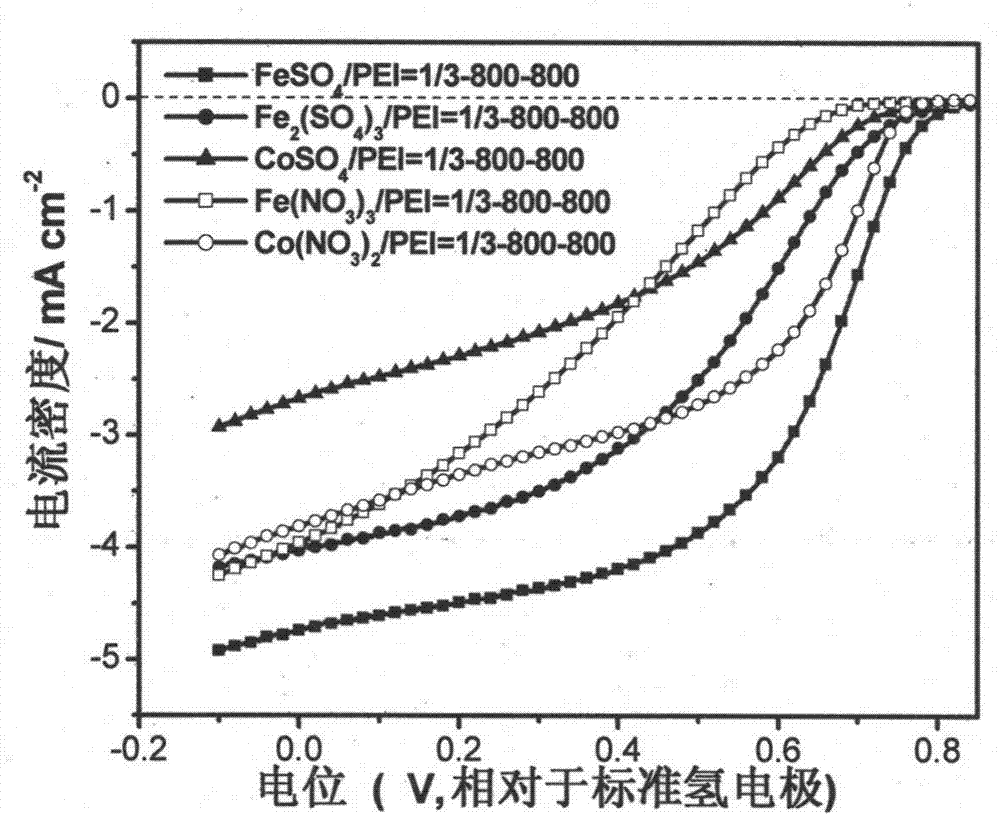

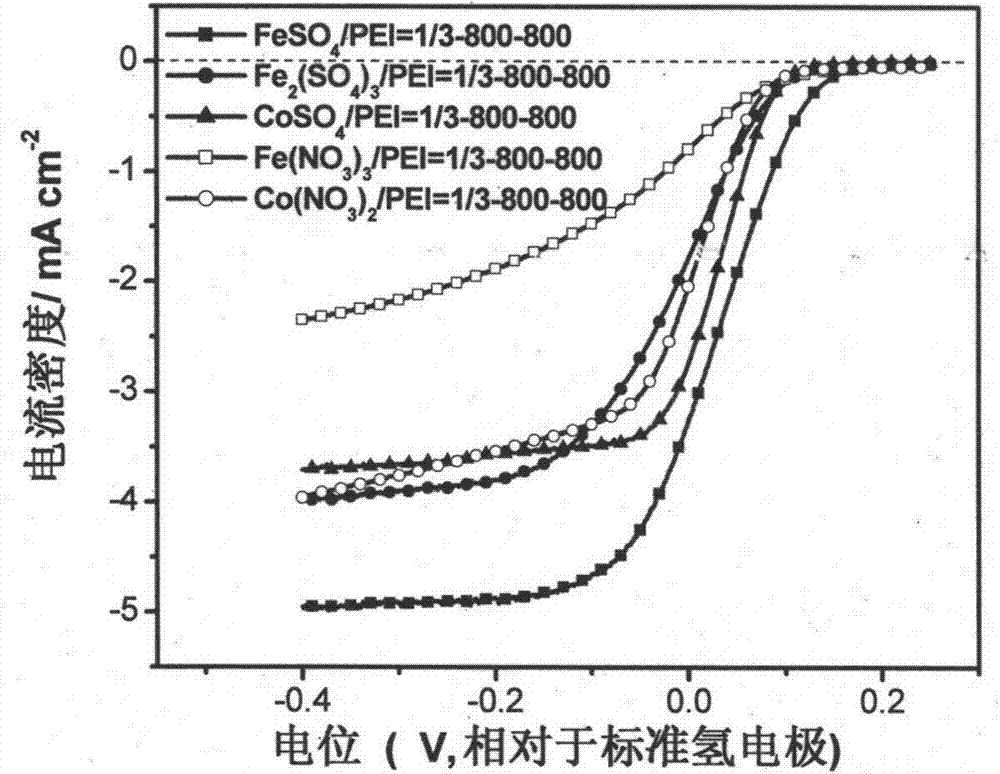

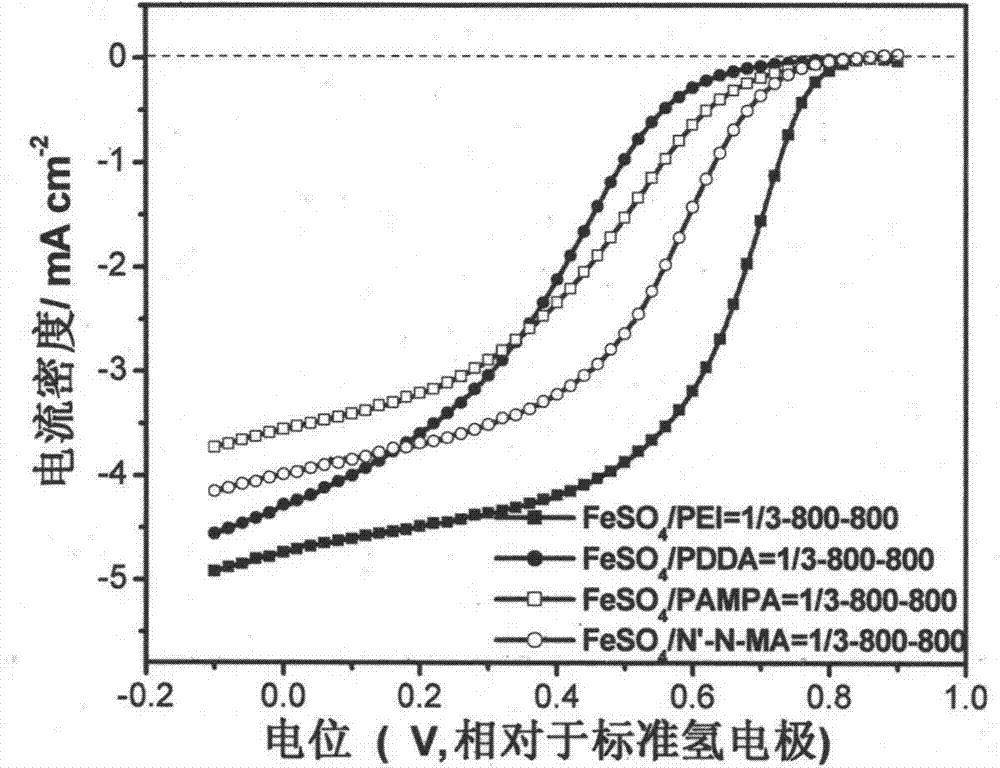

Metal-free nitrogen-doped functionalized mesoporous carbon catalyst and preparation method and applications thereof

InactiveCN103566961AHigh catalytic activityAvoid defects such as deactivation (corrosion)Physical/chemical process catalystsCell electrodesStrong acidsAcid washing

The invention relates to a metal-free nitrogen-doped functionalized mesoporous carbon catalyst and preparation method and applications thereof. A precursor of the metal-free nitrogen-doped functionalized mesoporous carbon catalyst comprises the following components in percentage by mass: 20-85% of template agent, 10-75% of nitrogen compound, and 5-50% of transition metal salt. The nitrogen compound is carbonized at high temperature under the existence condition of transition metal, to form a high-nitrogen-content pyridine and graphite nitrogen (Nx-C) composite structure, and the catalytic activity of oxygen can be remarkably enhanced; the transition metal in the nitrogen-doped mesoporous carbon catalyst can be removed through acid pickling, so that the inactivation (corrosion) of the catalyst containing the transition metal under the conditions of strong acid and strong alkali can be avoided, the characteristics of being high in stability, not easy to poison and the like can be achieved, and the metal-free nitrogen-doped functionalized mesoporous carbon catalyst has excellent application prospects in the fields of treating waste water of fuel batteries, metal-air batteries, supercapacitors, energy-storage batteries, microbial fuel cells, and the like.

Owner:DONGHUA UNIV

Method for preparing biodegradable magnesium alloy intravascular stent

The invention discloses a method for preparing a biodegradable magnesium alloy intravascular stent in the technical field of biological materials. The method comprises the following steps of: performing stress relief annealing treatment on a magnesium alloy extrusion bar of phi20mm; processing the annealed bar into a tube blank, and extruding the tube blank; performing stress relief annealing treatment on the extruded capillary tube; cutting the annealed capillary tube to form a stent blank by laser; acid-washing and ultrasonically cleaning the cut stent in an ultrasonic cleaner to remove thecut residues; and performing electrochemical polish, ultrasonic cleaning and passivation on the stent. The extruded magnesium alloy capillary tube has uniform tube wall thickness and smooth surface, the tensile strength of the capillary tube can reach 320 to 370MPa, the yield strength can reach 260 to 300MPa, the elongation can reach 24 to 30 percent, and the corrosion rate of the capillary tube in simulated body fluid is 0.14 to 0.24mm / year. The polished intravascular stent has flat, smooth and bright internal and external surfaces. The preparation method provided by the invention can prepare the biodegradable intravascular stent meeting the clinical requirement.

Owner:SHANGHAI INNOVATON MEDICAL TECH CO LTD

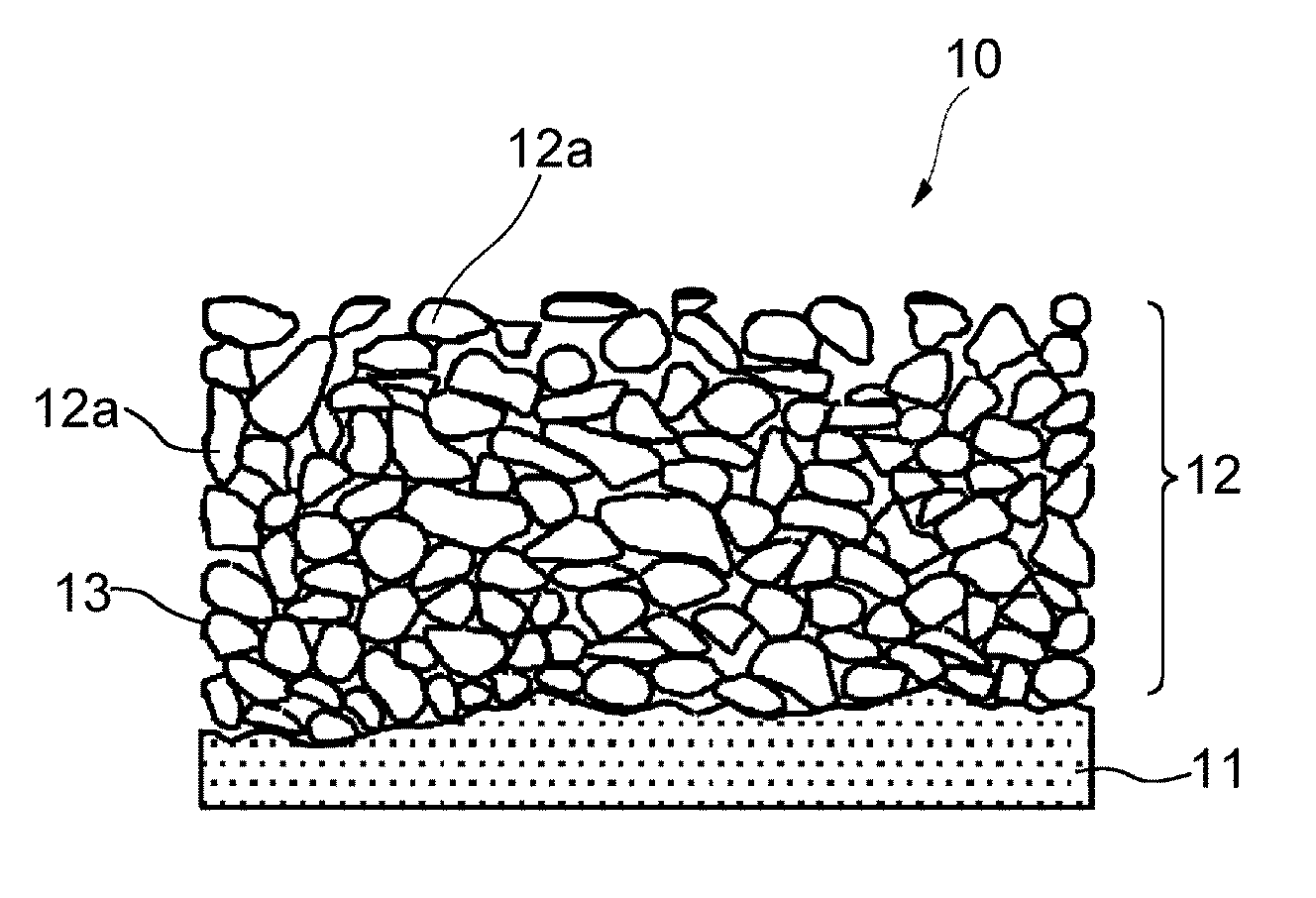

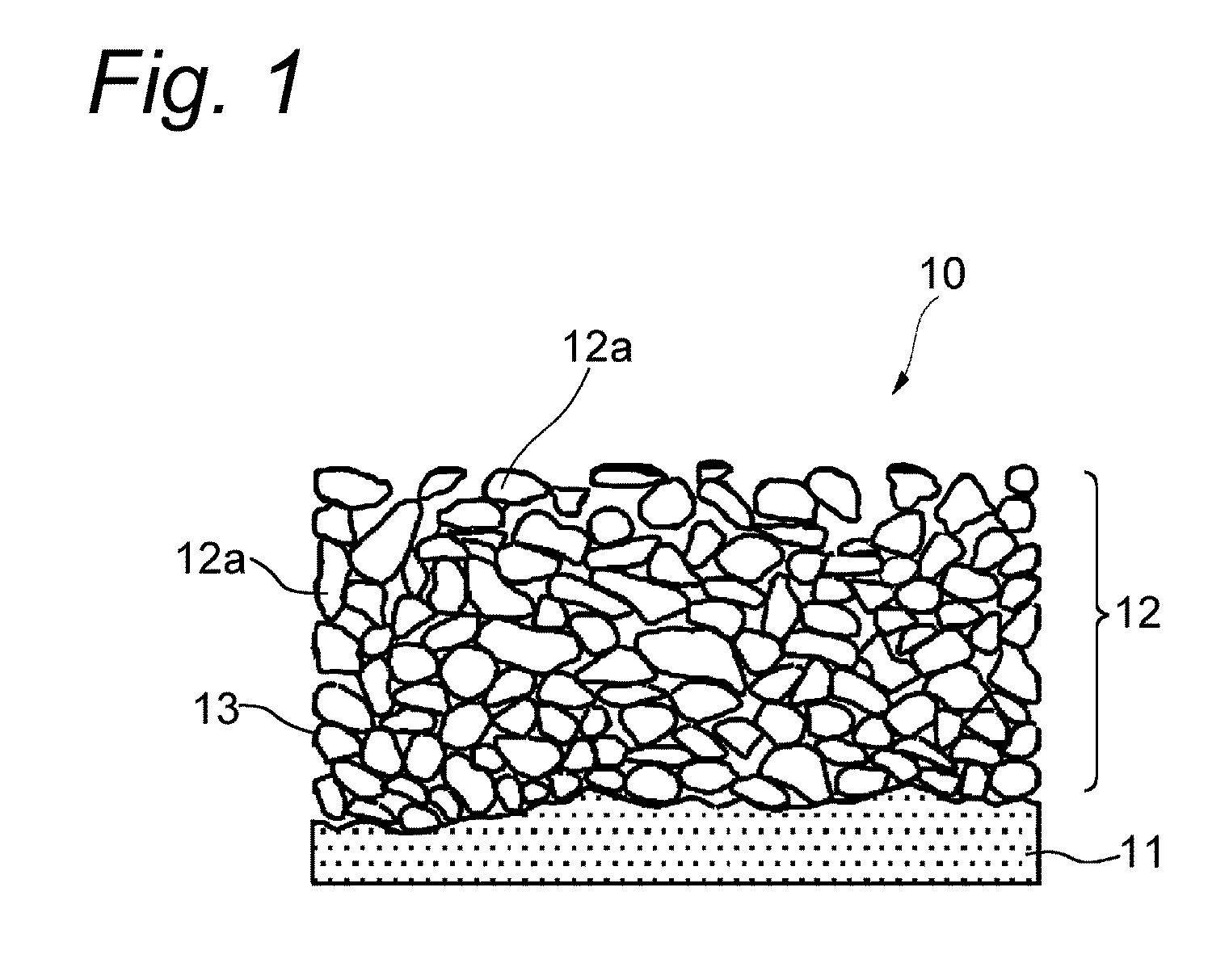

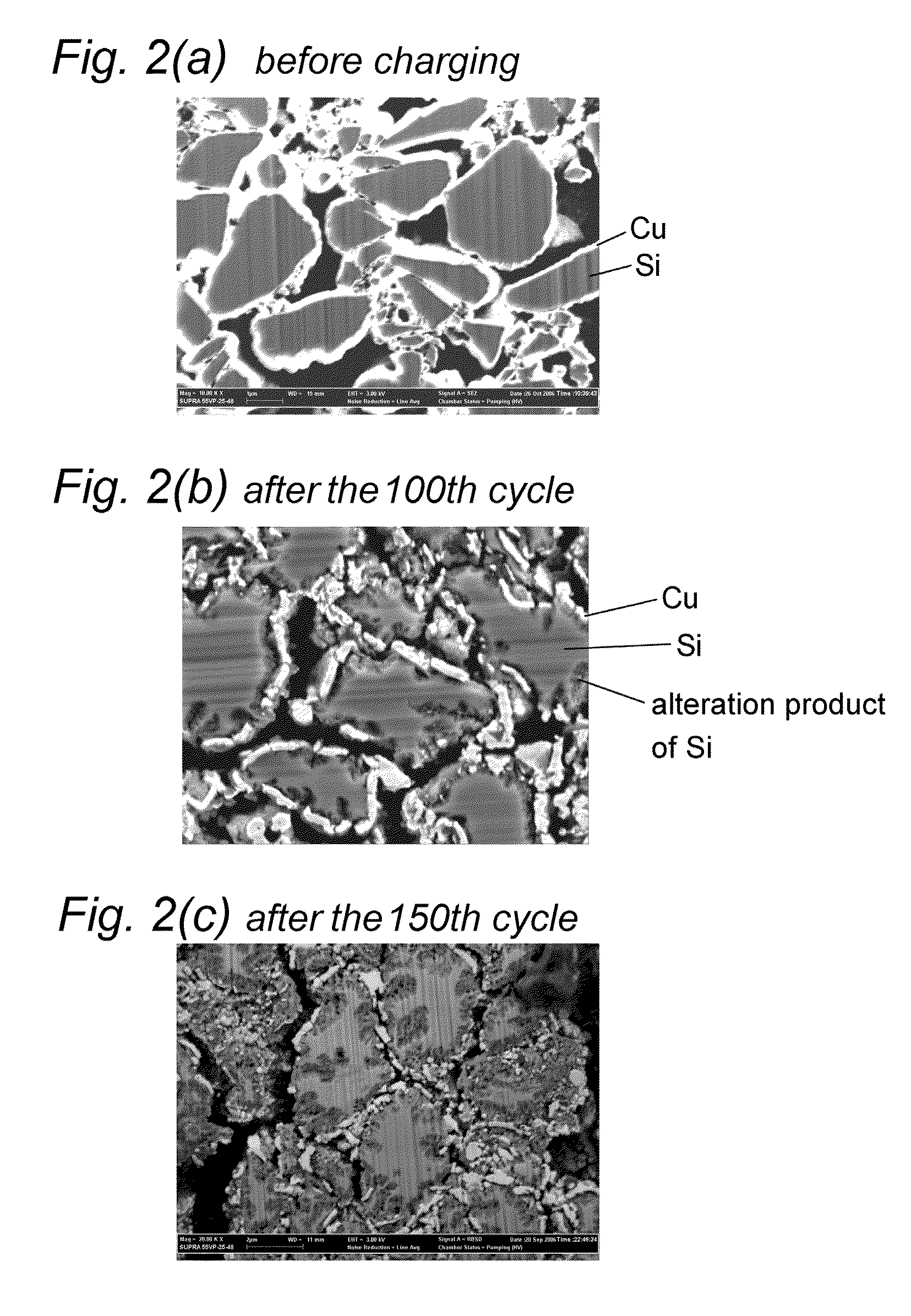

Nonaqueous secondary battery and method of producing the same

InactiveUS20100136437A1Improve performanceFinal product manufactureElectrode carriers/collectorsAcid washingSlurry

A nonaqueous secondary battery having a negative electrode containing a silicon active material and a nonaqueous solvent containing a fluorine-containing solvent. The active material layer has a fluorine content of 5 to 30 wt % based on the silicon content after at least 100 charge / discharge cycles at a rate of 50% or more of the battery's capacity. The battery is suitably produced by a method including applying a slurry containing silicon active material particles to a current collector, electroplating the resulting coating layer using a plating bath at a pH higher than 7 to coat at least part of the surface of the particles with copper, acid washing the coating layer to make a negative electrode, assembling the negative electrode together with a positive electrode, a separator, and a nonaqueous electrolyte containing a fluorine-containing solvent into a nonaqueous secondary battery, and subjecting the battery to a first charge operation at a low rate of 0.005 to 0.03 C.

Owner:MITSUI MINING & SMELTING CO LTD

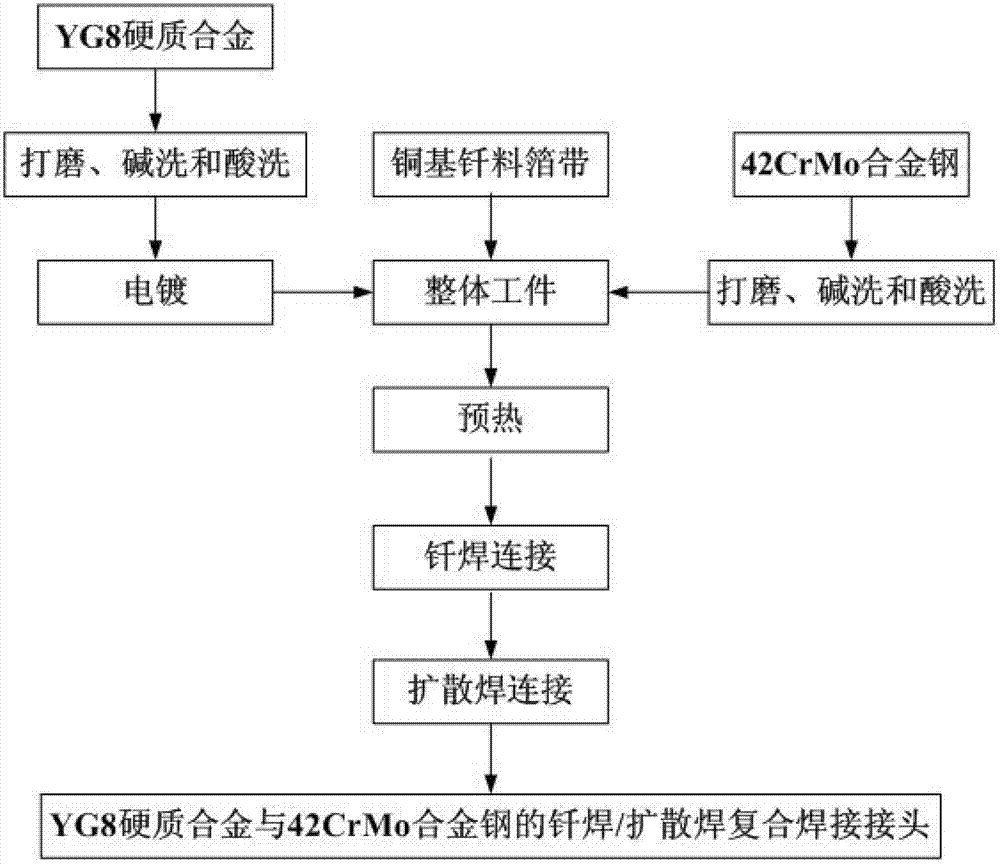

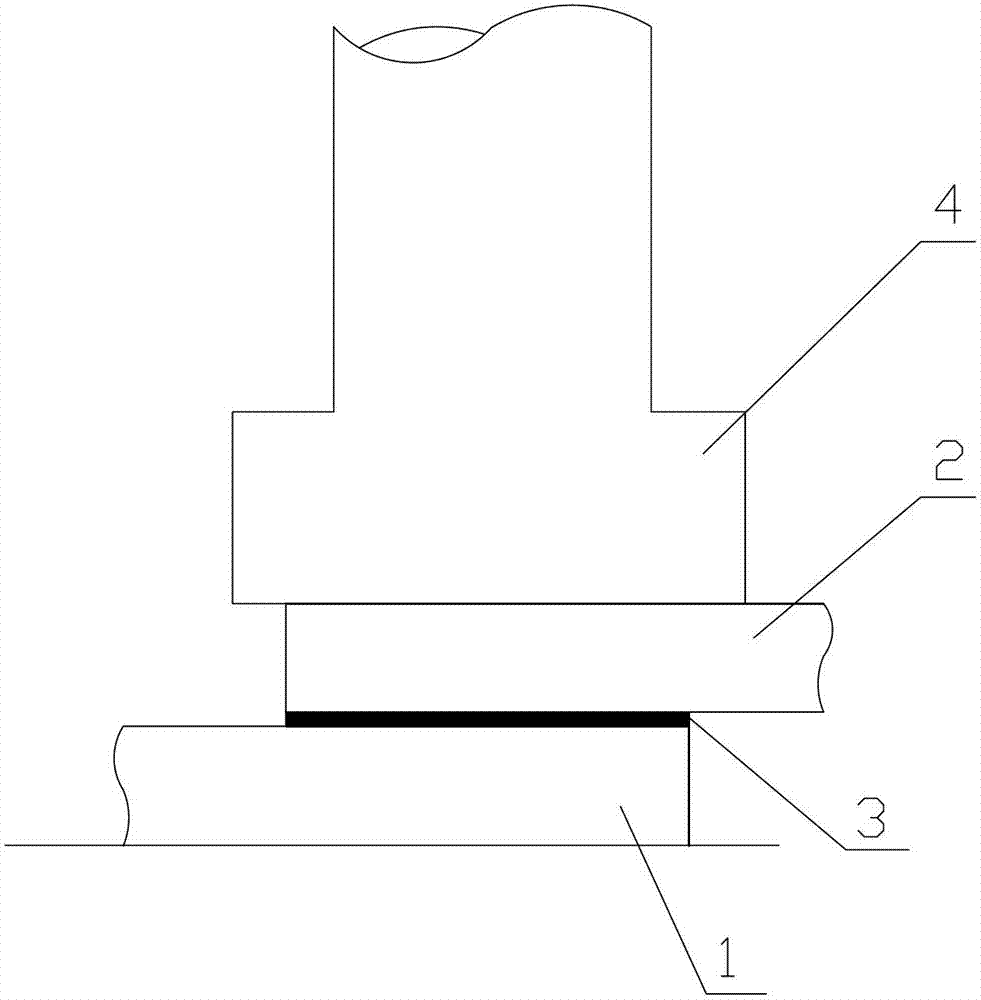

Soldering/diffusion welding hybrid welding method for cemented carbide and alloy steel

InactiveCN102922154AHigh bonding strengthGood mechanical propertiesSoldering apparatusWelding/soldering/cutting articlesAcid washingBond strength

The invention provides a soldering / diffusion welding hybrid welding method for a cemented carbide and alloy steel. The method comprises the following steps of: performing the procedures of grinding, alkali washing and acid washing on the YG8 cemented carbide and the 42CrMo alloy steel sequentially, and then, electroplating a nickel coating on the surface of the YG8 cemented carbide; lapping the YG8 cemented carbide and the 42CrMo alloy steel, and paving a copper-based solder foil strip in a lapping area, thus obtaining a whole workpiece; and performing soldering / diffusion welding hybrid welding on the whole workpiece in a vacuum soldering furnace, thus obtaining a soldering / diffusion welding hybrid welding joint of the YG8 cemented carbide and the 42CrMo alloy steel. The welding joint subjected to the soldering / diffusion welding hybrid welding is high in bonding strength and small in residual stress, has a smooth and dense surface, and is smooth and attractive; and moreover, during the welding process, the welded workpiece is not easily oxidized and is subjected to small deformation, the service life of the workpiece is obviously prolonged, and thus the method is an ideal welding technology for realizing dissimilar welding of cutting teeth and cutting tools.

Owner:XIAN UNIV OF SCI & TECH

Method for producing cold-rolling low-carbon aluminum killed steel with uniform through plate mechanical property

ActiveCN102174683AImprove the uniformity of the mechanical properties of the plateThe mechanical properties of the plate are uniformMetal rolling arrangementsSteelmakingAcid washing

The invention discloses a method for producing cold-rolling low-carbon aluminum killed steel with a uniform through plate mechanical property, which belongs to the technical field of steel rolling. The method comprises the following process flows of: performing krypton (KR) desulfuration treatment, performing steelmaking by using the conventional converter, performing composition adjustment system (CAS) / relative humidity (RH) refining treatment, continuously casting, and performing hot loading and hot feeding; performing rough rolling, performing precision rolling, performing laminar cooling, and reeling; unreeling, performing acid washing, performing continuous cold rolling, and reeling; and unreeling, washing, continuously annealing, smoothing, and reeling. The method is characterized in that: the cold-rolling low-carbon aluminum killed steel which has the width of 750 to 1,580 mm, the thickness of 0.25 to 2.5 mm and the uniform through plate property is produced by a 2,250 mm or 1,580 mm continuous hot rolling machine set, a 1,700 mm acid rolling machine set and a 1,700 mm continuous annealing machine set. A trace amount of B is added into the low-carbon aluminum killed steel to appropriately improve finish rolling temperatures and appropriately reduce rolling process parameters such as reeling temperatures, annealing temperatures and the like, so that thick boron nitride (BN) is fully separated out; and thin dispersed aluminum nitride (AlN) is effectively prevented from being separated out, so that the uniformity of the through plate mechanical property of the cold-rolling low-carbon aluminum killed steel is improved.

Owner:SHOUGANG CORPORATION

Method for producing color-coated plate for structure with yield strength of more than or equal to 550 MPa

InactiveCN102363857APrevent rustNo foamingHot-dipping/immersion processesAcid washingCooling chamber

The invention relates to a method for producing color-coated steel sheet for a structure. The method comprises the following steps of: smelting, namely desulfurizing by molten iron, smelting by a converter, casting continuously to form a blank and performing hot rolling; performing acid washing; performing cold milling; annealing continuously; performing hot dipping on aluminum and zinc; and polishing, straightening, performing color coating and packaging for later use. In the method, the yield strength RP 0.2 (or ReH) is between 550 and 600 MPa; the tensile strength Rm is between 560 and 610MPa; and the percentage elongation after break A80 mm is more than or equal to 6 percent. A neutral salt mist test is performed for 1,200 hours, a coating does not have bubbling and corrosion phenomena. At present, the annealed color-coated plate of which the metallographic structure is ferrite and pearlite or the ferrite and free cementite or the ferrite and the pearlite and less free cementite cannot achieve the effect, and the production cost can be reduced by 10 to 15 percent. By the method, special occasions which have high-yield strength and are used for cooling chambers of automobiles,arch coverings and the like can be met, and a process is simple and easy to implement.

Owner:武钢集团有限公司

Preparation method of nitrogen-doped carbon nanotube wrapped metal iron-cobalt alloy composite material

InactiveCN108160077ARaw materials are easy to getLow costMetal/metal-oxides/metal-hydroxide catalystsElectrodesFiltrationAcid washing

Belonging to the technical field of material preparation, the invention relates to a preparation method of a nitrogen-doped carbon nanotube wrapped metal iron-cobalt alloy composite material (FeCo-NCNTs). The technical scheme includes: firstly, dissolving a metal salt and a carbon-nitrogen source in water, ethanol or ethylene glycol, mixing the substances evenly, and then performing drying and grinding to obtain a precursor; then putting the precursor in a tubular furnace, in a nitrogen atmosphere, conducting programmed heating to a roasting temperature, and conducting high temperature roasting and grinding to obtain a black powder sample; and then subjecting the black sample to pickling treatment until the pH value of the solution is neutral, and conducting pumping filtration and naturaldrying, thus obtaining the nitrogen-doped carbon nanotube wrapped metal iron-cobalt alloy composite material (FeCo-NCNTs). The obtained composite material can be used as a good electrocatalytic hydrogen evolution catalyst. The composite material prepared by the method provided by the invention has the characteristics of easily available raw materials and low cost, and has important significance inelectrochemical application.

Owner:JIANGSU UNIV

Method for preparing grade porous ZMS (Zeolite Socony Mobil)-5 molecular sieve by acid-base coupling

The invention relates to a method for preparing a ZSM (Zeolite Socony Mobil)-5 in a grade structure, and specifically relates to a method for preparing a grade porous ZMS-5 molecular sieve by acid-base coupling. The method comprises the following steps: mixing commercial ZSM-5 and alkali liquor in proportion, and heating and stirring to form a suspension; filtering the suspension; washing the filter cakes by water or acidic liquor; and finally, carrying out ion exchange by using acidic ammonium salt liquor; and then, roasting to obtain the grade porous ZMS-5 molecular sieve. The method provided by the invention aims to prepare the ZSM-molecular sieve rich in secondary mesopores. Firstly, part of aluminum silicon species in the ZSM-5 is removed in an environment-friendly alkali treatment manner to prepare the ZSM-5 molecular sieve with a secondary pore structure. Based on the secondary pore formed, undefined structures on the surface of the ZSM-5 and in the duct are dissolved out by way of acid washing or ion exchange. Meanwhile, the pore volume and the specific surface area of the secondary mesopore-enriching ZSM-5 molecular sieve are improved. Through the acid-base coupling treatment, the distribution state of aluminum outside the framework on the surface of the ZSM-5 is improved, so that the secondary mesopore-enriching ZSM-5 molecular sieve prepared by the method has a huge application potential in catalytic cracking and hydrocracking.

Owner:PETROCHINA CO LTD +1

High carbon hot-rolled steel sheet and method for manufacturing the same

InactiveUS20050199322A1High tensile strengthImprove ductilityQuenching agentsMetal rolling arrangementsHigh carbonCarbide

The high carbon hot-rolled steel sheet contains, in terms of percentages of mass, 0.10 to 0.7% C, 2.0% or less Si, 0.20 to 2.0% Mn, 0.03% or less P, 0.03% or less S, 0.1% or less Sol.Al, 0.01% or less N, and the balance being Fe and inevitable impurities, and has a structure of ferrite having 6 μm or less average grain size and carbide having 0.10 μm or more and less than 1.2 μm of average grain size. The volume ratio of the carbide having 2.0 μm or more of grain size is 10% or less. The volume ratio of the ferrite containing no carbide is 5% or less. The manufacturing method thereof has the steps of hot-rolling, primary cooling, holding, coiling, acid washing, and annealing. The primary cooling step is to cool the hot-rolled steel sheet down to cooling termination temperatures ranging from 450° C. to 600° C. at cooling rates of higher than 120° C. / sec. The holding step is to apply secondary cooling to hold the primarily cooled hot-rolled steel sheet at a temperature range from 450° C. to 650° C. until coiling.

Owner:JFE STEEL CORP

Method for harmless and recycling treatment of stainless steel acid washing waste water neutralization sludge

ActiveCN101982433ASolve the problem of sediment lossImprove water qualitySludge treatmentMultistage water/sewage treatmentSludgeAcid washing

The invention discloses a method for harmless and recycling treatment of stainless steel acid washing waste water neutralization sludge, belonging to the field of harmful and valuable heavy metal resource recovery. The stainless steel acid washing waste water neutralization sludge is leached out by sulphuric acid, harmful and poisonous metals manganese, nickel and chromium enter into the leachate, and harmless treatment is carried out on the sludge. Separation, enrichment and recovery of metal resources of iron, manganese, chromium and nickel in the leachate are realized by adopting goethite method, potassium permanganate oxidation method, anion resin exchange method and chelate resin absorption method respectively, and effluent up to the standard is discharged after treatment or is returned to water consuming link in technologic process. The method of the invention has short technological flow, simple operation, management convenience, high recovery rate of valuable metal resources of manganese, nickel and chromium, recycling of multiple valuable metals is realized while the sludge is subject to harmless treatment, and unification of economic benefit, environmental benefit and social benefit is realized.

Owner:NANJING UNIV

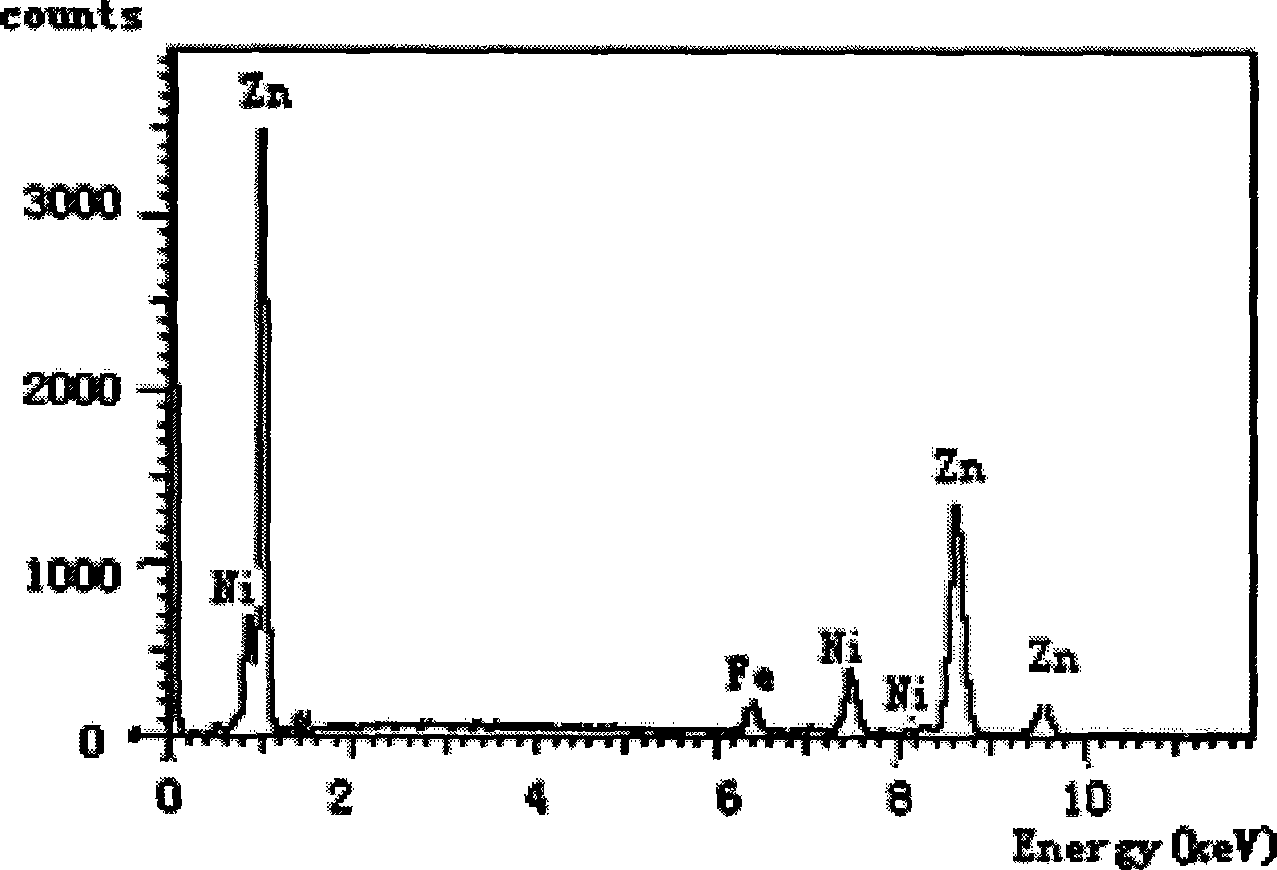

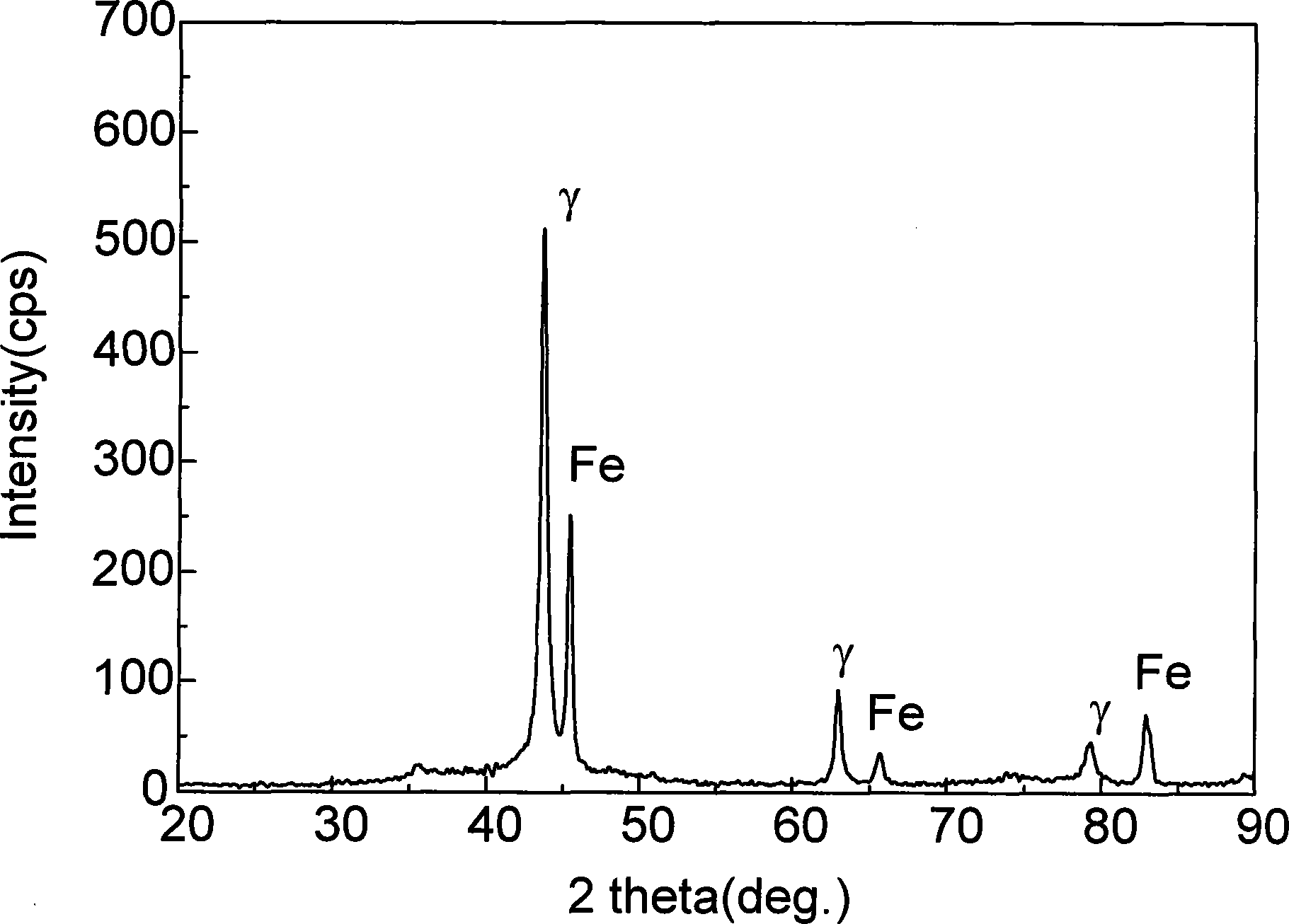

Method for plating zinc-nickel alloy in alkaline electroplate liquid

InactiveCN101240437ASolve the problem of large compositional changesImprove current efficiencyWater basedOrganic solvent

The invention discloses a method for electroplating alkaline Zn-Ni alloy, comprising the steps of: preparing alkali wash and acid wash, preparing electroplating Zn-Ni alloy plating solution, mechanical grinding, degreasing with organic solvent or water-based detergent, alkali washing, acid washing and electroplating. The invention provides a stable electroplating solution formula and complete electroplating process. The coating electroplated by the method is proved to have good flat surface, uniform coating distribution and alloy distribution, the coating is single gamma-phase, the nickel has a content of 10% to 15%; the coating has superior corrosion resistance, red rust appears on the non-passivated Zn-Ni coating after 1500 hours in a neutral salt spray test; compared with general alkali electroplating solution, the coating has high current efficiency, reaching up to 80% to 90%.

Owner:BEIHANG UNIV

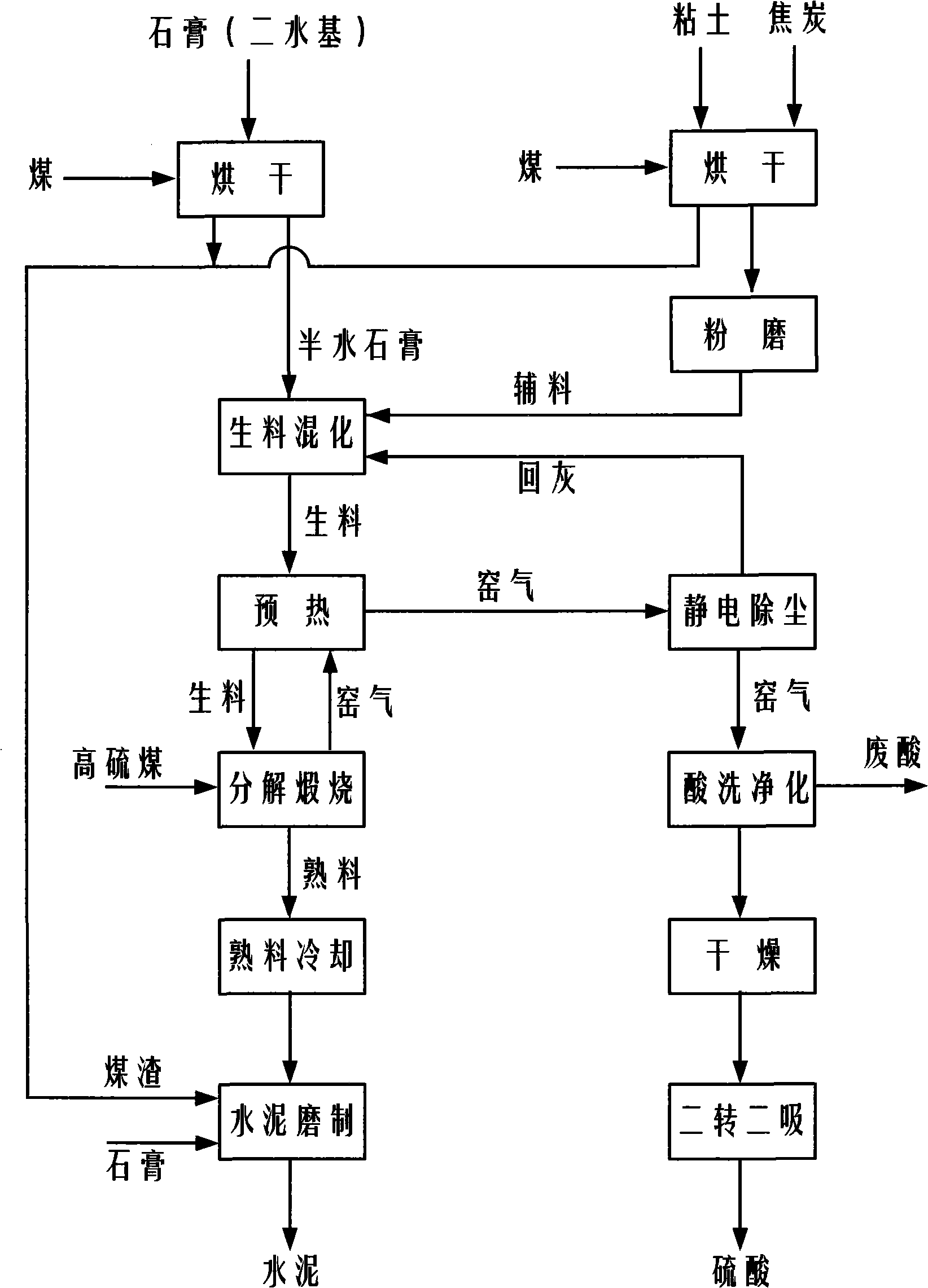

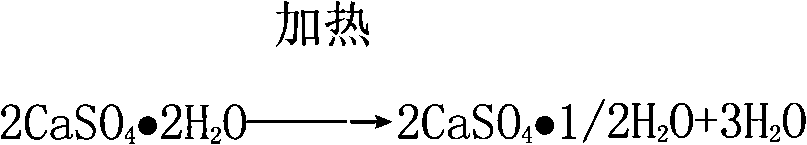

Improved preparation technique for preparing sulphuric acid and cement with gypsum

ActiveCN101343047AEliminate pollutionAlleviate supply shortagesCement productionSulfur-trioxide/sulfuric-acidSource materialAcid washing

The invention provides an improved production process of utilizing gypsum to produce sulfuric acid and cement, which relates to the sulfuric acid and cement industry production technology, and the resource comprehensive utilization and environmental protection governing field of the industrial byproduct gypsum. The improved production process is characterized in that natural gypsum with the CaSO4*2H2O as the main composition or the industrial byproduct gypsum is adopted as the main source material; clay, coke and fly ash clinker are used as supplementary materials; the half-water drying gypsum flow, the single stage powder grinding, raw material mixing melting, suspension preheater kiln decomposing calcination, closing diluted acid washing and purification, two-turning and two-suction processes are adopted; the sulfuric acid and cement products are prepared through six steps of source material homogenizing, drying and dehydration, raw material preparation, clinker burning, kiln gas acid production and cement grinding; the improved production process has the advantages of wide range source material, solving the land occupation and environmental pollution problems of the gypsum waste residue, realizing the circulation utilization of sulfur resource, adopting a plurality of new processes and devices, realizing the large scale production easily, advanced technology, mature process, easy operation in production control, low energy consumption, high benefit, no waste water and waste residues exhaust.

Owner:SHANDONG LUBEI ENTERPRISE GROUP

Stainless steel passivation process

InactiveCN101787525ALow environmental requirementsShorten the timeMetallic material coating processesRoom temperatureAcid washing

The invention relates to a surface treatment process for stainless steel, in particular to a stainless steel passivation process. The process comprises the following steps of: dipping a stainless steel workpiece in an alkali degreasing solution for 10-30 seconds under a normal temperature condition; washing the workpiece by using water at the normal temperature; acid washing: acid washing the workpiece for 50-60 seconds by using a nitric acid solution at the normal temperature; washing the workpiece by using water at the normal temperature; soaking the workpiece in a passivation solution for 40-50 seconds at the normal temperature, wherein the passivation solution contains nitric acid and sodium dichromate; washing the workpiece by using water at the normal temperature; heating purified water to be higher than 75 DEG C, and putting and soaking the passivated and cleaned workpiece into the purified water for 4-5 seconds; taking out the workpiece and airing. The invention greatly saves the time for passivating the stainless steel workpiece, reduces the production requirements of the workpiece and ensures that the process is more suitable for practical production.

Owner:SICHUAN GUANGHAN HUAWEI ALUMINUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com