Method for plating zinc-nickel alloy in alkaline electroplate liquid

A technology of zinc-nickel electroplating and alkaline plating solution, which is applied in the field of electroplating zinc-nickel alloy, can solve the problems of low nickel content in the plating layer and low cathode current efficiency, and achieve the effects of low cost of plating solution, high current efficiency and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

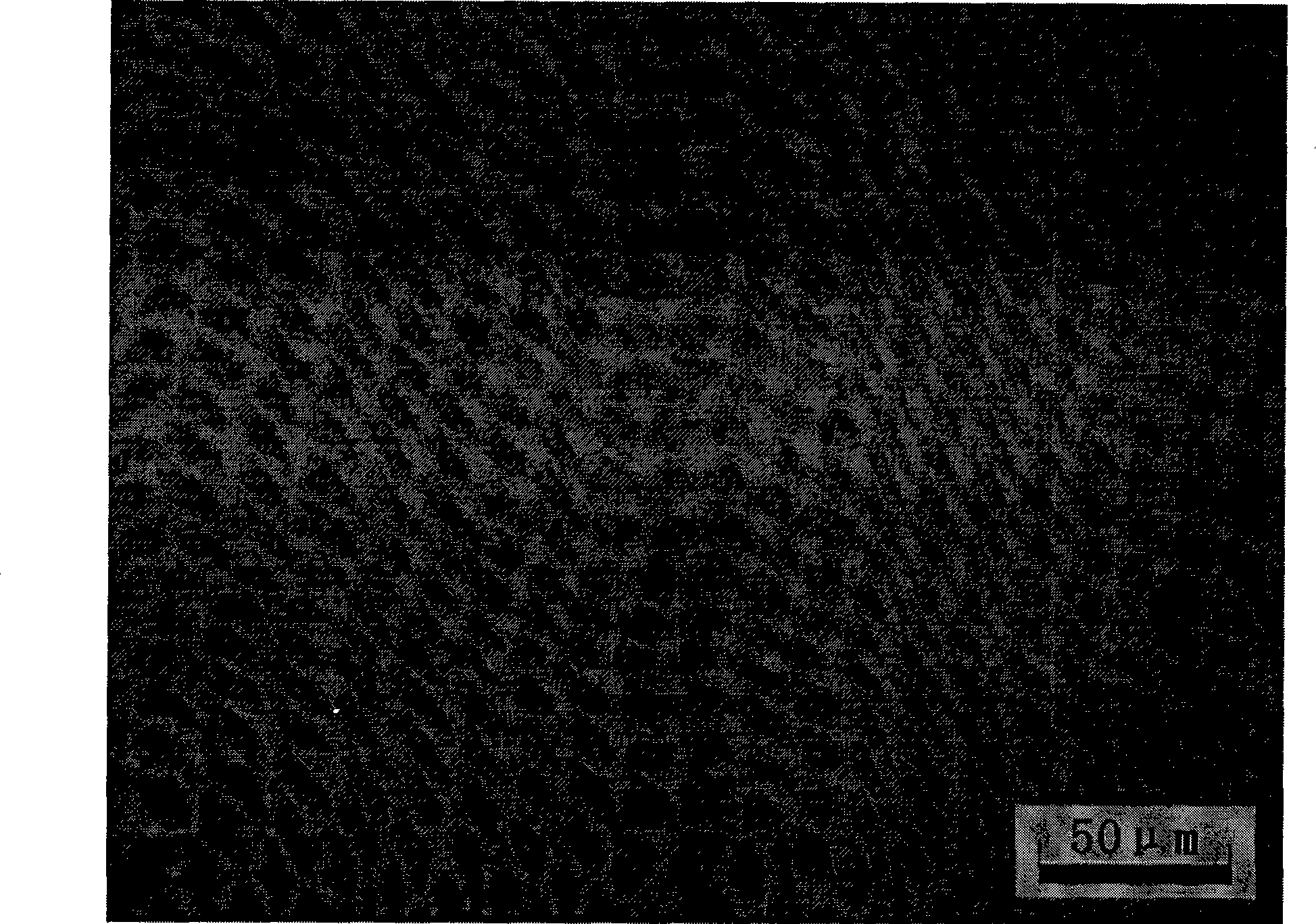

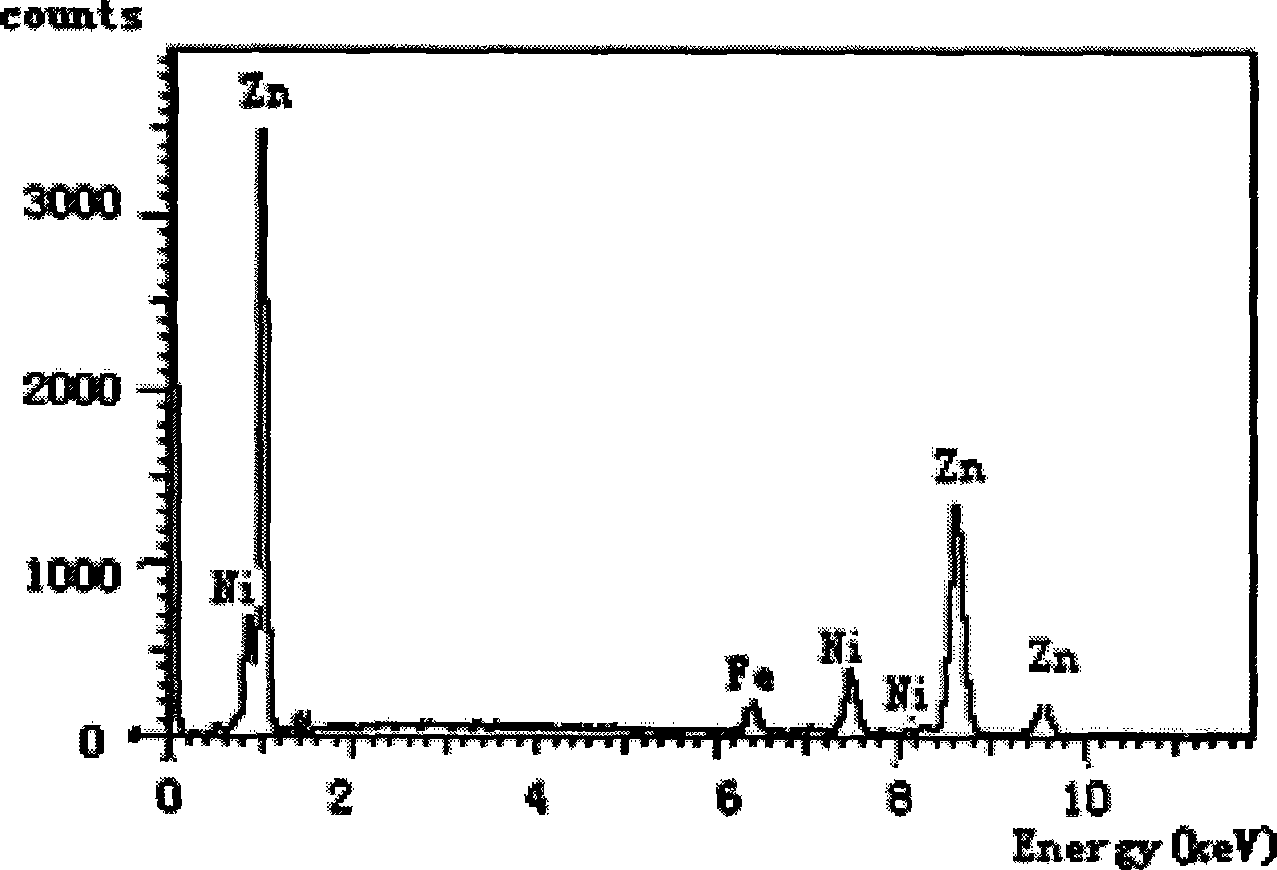

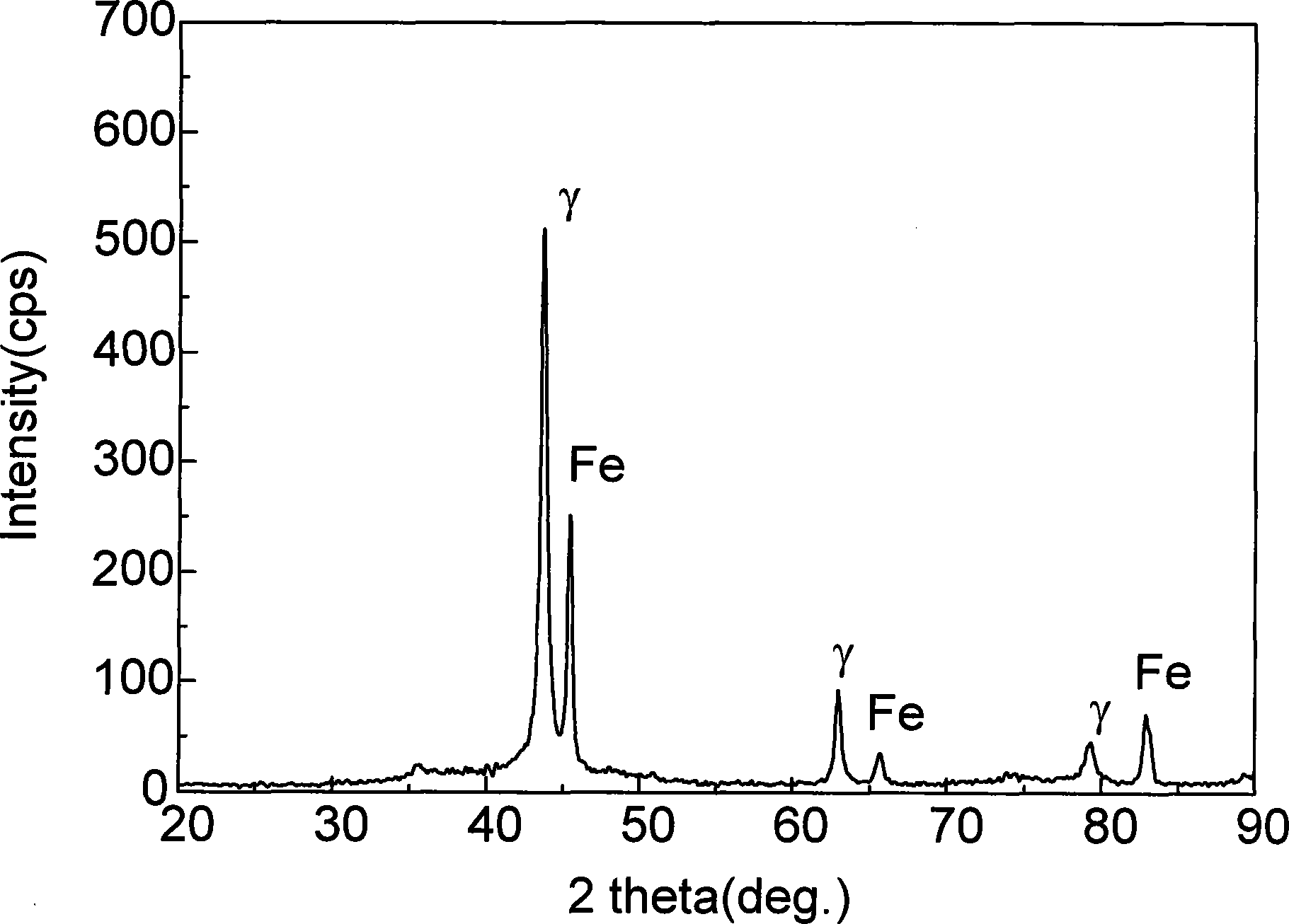

[0051] Embodiment one: Electroplated zinc-nickel alloy coating on 30CrMnSiA steel substrate.

[0052] The first step is to prepare alkaline cleaning solution, pickling solution and electroplating solution.

[0053] Each liter of alkaline washing solution contains: NaOH 70g, NaOH 3 PO 4 12H 2 O 30g, Na 2 CO 3 10H 2 O 30g, Na 2 SiO 3 ·nH 2 O 30g. The rest is water.

[0054] Each liter of pickling solution contains 6mL of HCl.

[0055] Each liter of alkaline zinc-nickel alloy electroplating solution contains: ZnO 10g, NiSO 4 5g, NaOH 120g, complexing agent tetraethylenepentamine 3mL, triethanolamine 38mL, ammonia water 10mL, additive DE 1.5mL, CTAB 2g, brightener ZB 3mL, vanillin 0.2g, and the rest is water.

[0056] The second step is to mechanically polish and clean the plated parts.

[0057] Grind the substrate of the plated part to 1000 with aluminum oxide sandpaper # For sandpaper, use organic solution ethanol to ultrasonically clean the surface of the subst...

Embodiment 2

[0067] Embodiment two: Electroplated zinc-nickel alloy coating on stainless steel substrate.

[0068] The first step is to prepare alkaline cleaning solution, pickling solution and electroplating solution.

[0069] The preparation of alkaline washing solution and pickling solution is the same as in Example 1.

[0070] Electroplating solution is ZnO, NiSO 4 , NaOH, ammonium citrate, tetraethylenepentamine, triethanolamine, EDTA, phytic acid, DE, thiourea, and each liter of alkaline zinc-nickel alloy plating solution contains: ZnO 20g, NiSO 4 10g, NaOH 100g, complexing agent amine citrate 15g, tetraethylenepentamine 20mL, triethanolamine 40mL, EDTA 15g, additive phytic acid 0.15mL, DE 9mL, brightener thiourea 1g, the rest is water.

[0071] The second step is to mechanically polish and clean the plated parts.

[0072] Use sandpaper to polish the surface of the plated part to 1000 # , choose the organic solution acetone to ultrasonically clean the surface of the substrate ...

Embodiment 3

[0080] Embodiment three: A zinc-nickel alloy coating is electroplated on a copper substrate.

[0081] The first step is to prepare alkaline cleaning solution, pickling solution and electroplating solution.

[0082] Preparation of alkali washing solution and pickling solution is the same as in Example 1.

[0083] Alkaline zinc-nickel alloy plating solution is ZnO, NiSO 4 , NaOH, potassium sodium tartrate, tetraethylenepentamine, triethanolamine, sodium phytate, DE, saccharin, and contains 30g of ZnO, NiSO 4 13g, NaOH 140g, complexing agent potassium sodium tartrate 20g, tetraethylenepentamine 20mL, triethanolamine 80mL, additives sodium phytate 0.15g and DE 15mL, brightener saccharin 1g, and the rest is water.

[0084] The second step is to mechanically polish and clean the plated parts.

[0085] Grind the substrate of the plated part to 1000 with aluminum oxide sandpaper #, select the organic solution acetone to ultrasonically clean the surface of the substrate for 15 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com