Patents

Literature

1153 results about "Superhydrophobe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

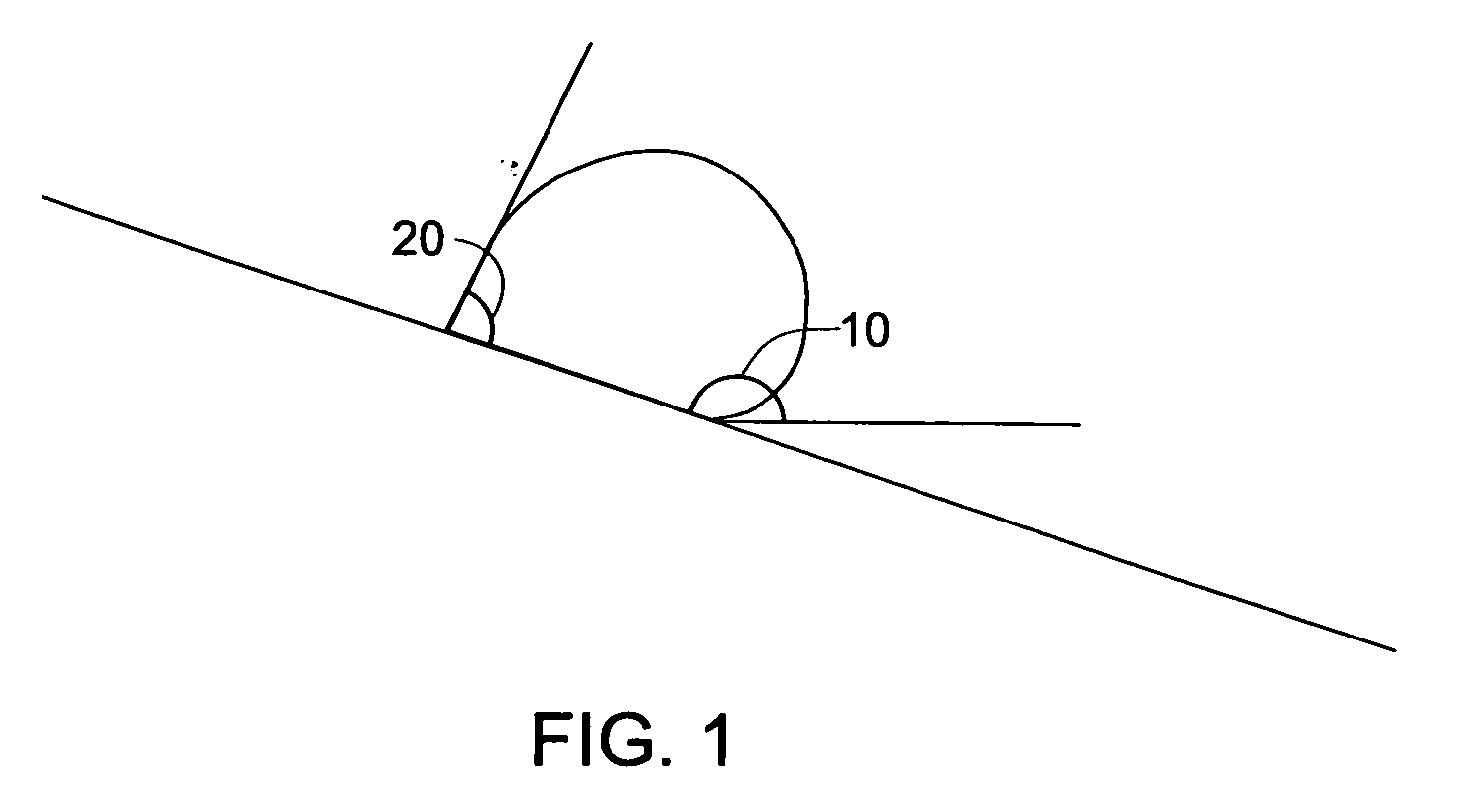

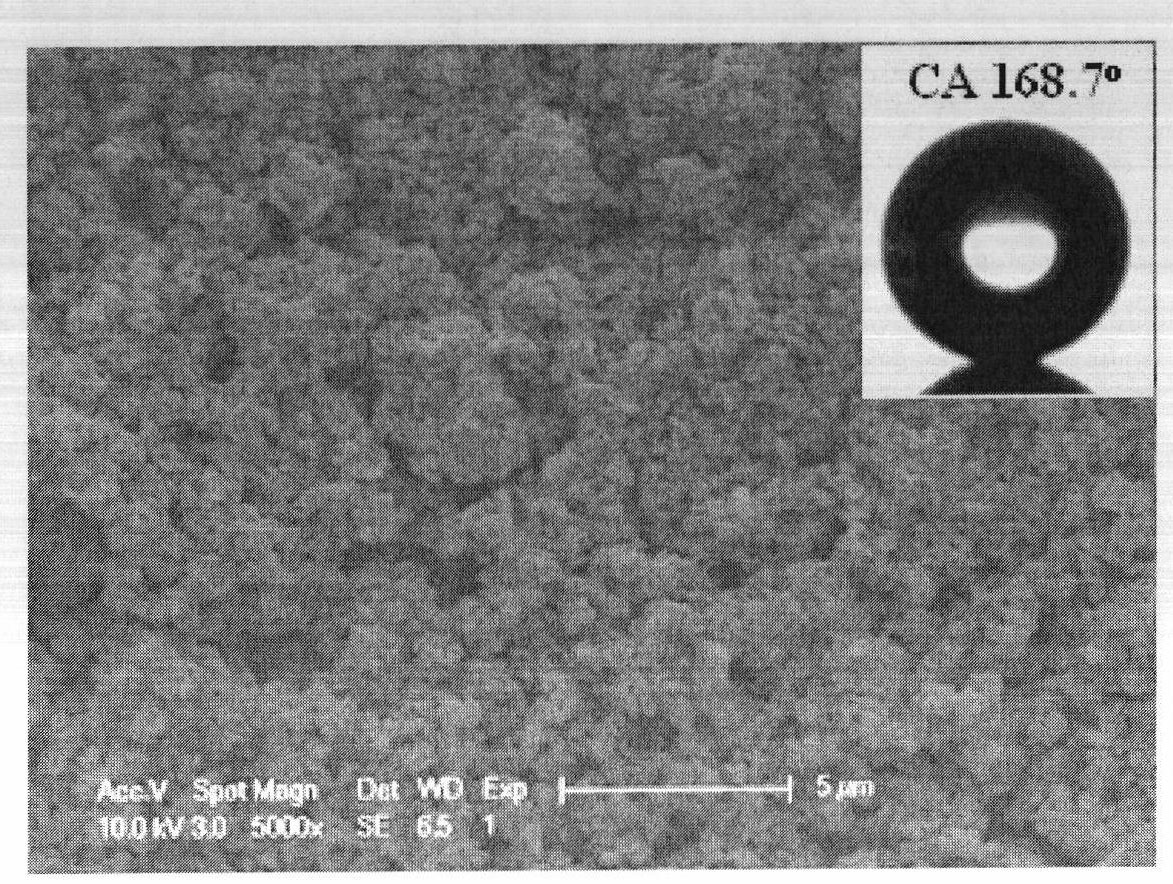

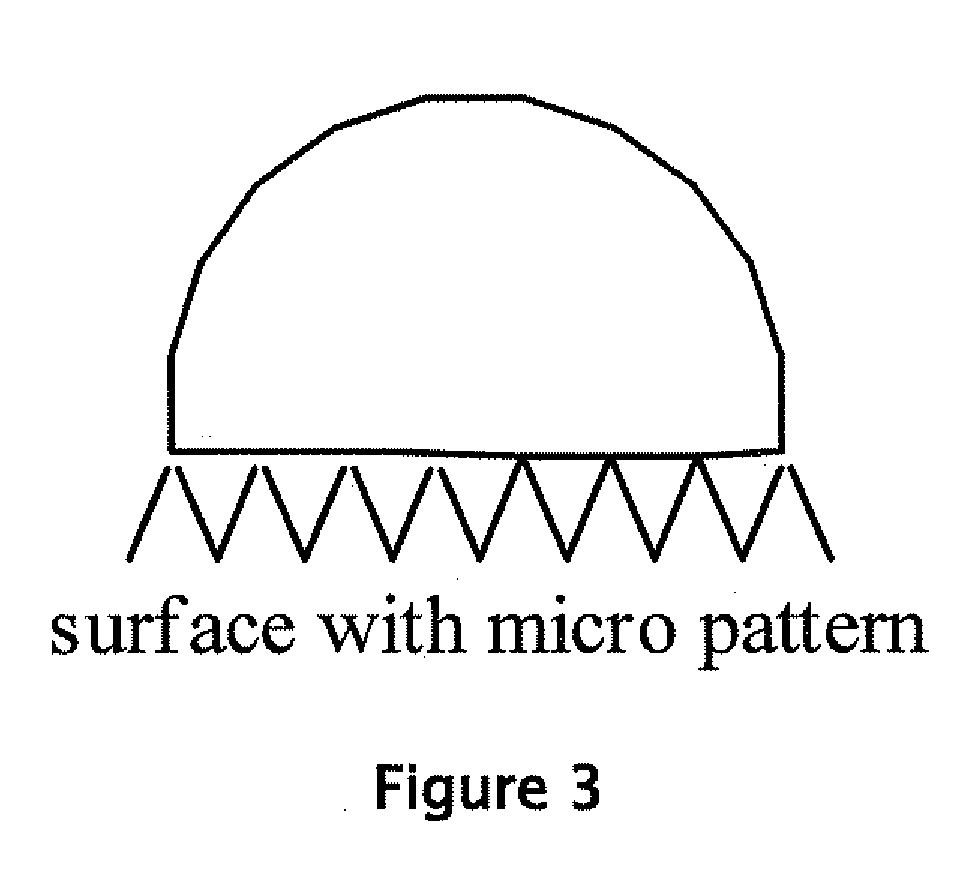

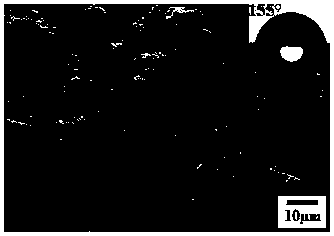

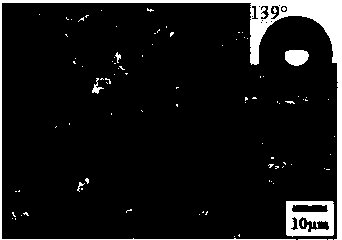

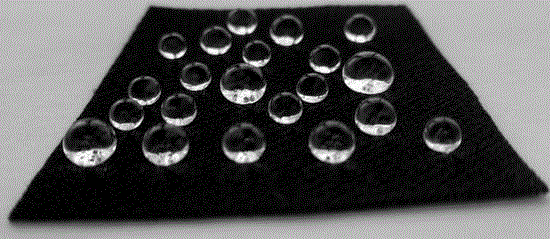

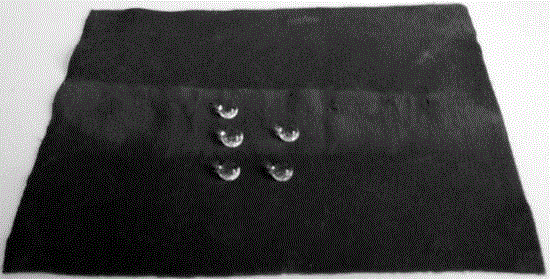

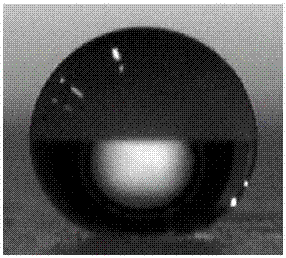

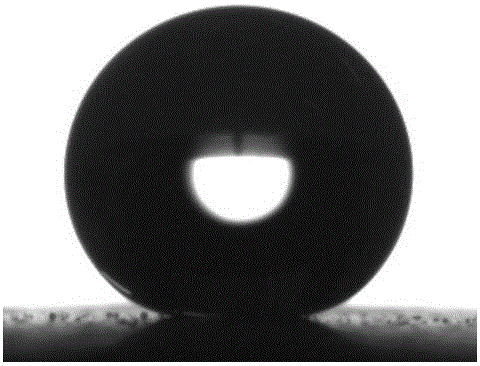

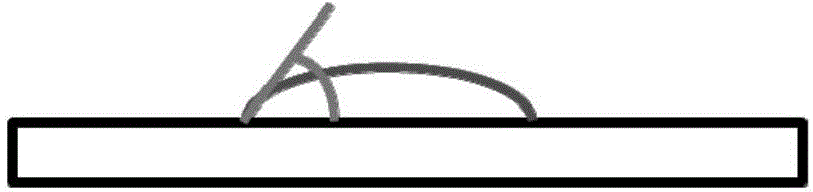

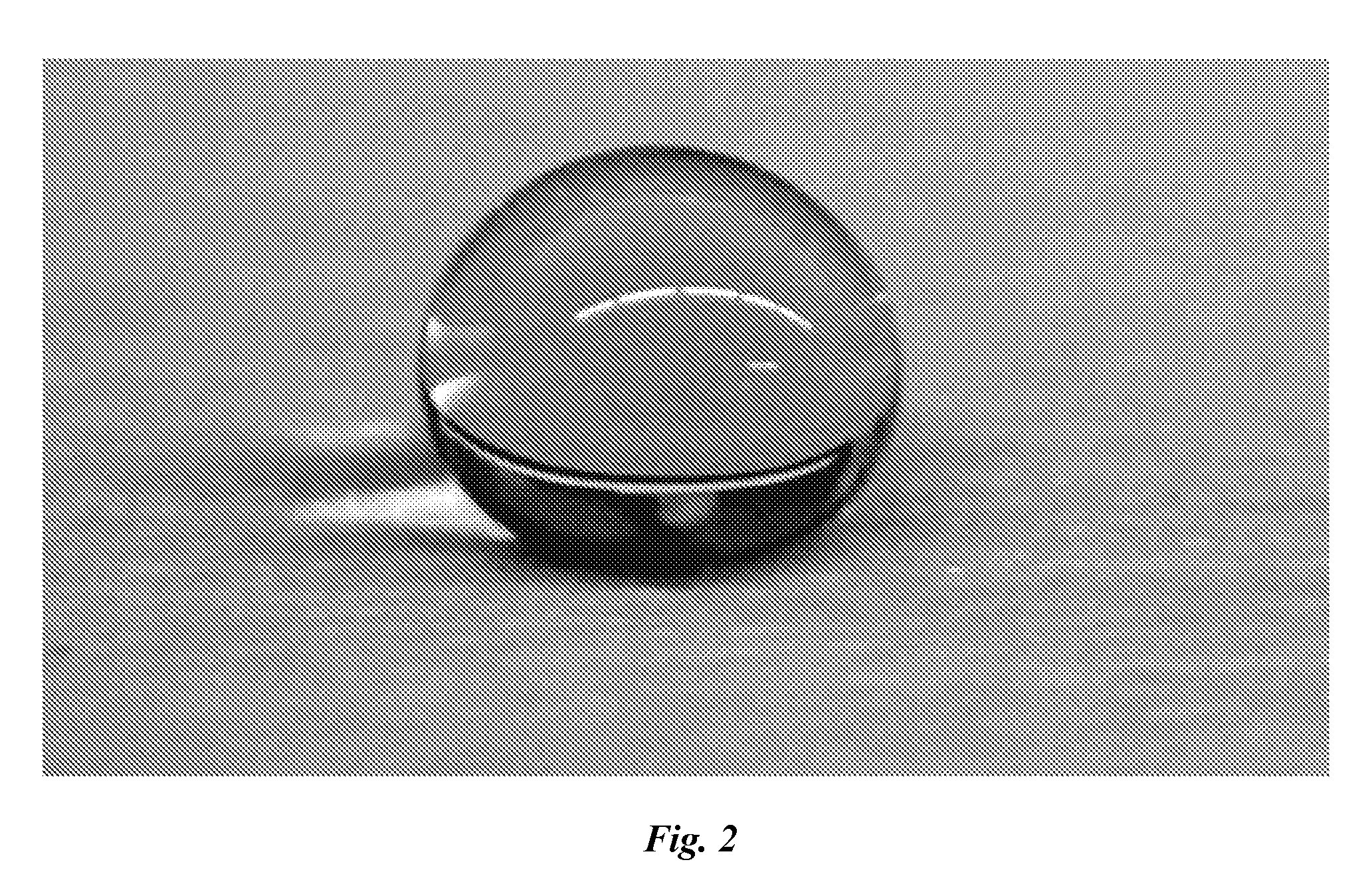

Ultrahydrophobic (or superhydrophobic) surfaces are highly hydrophobic, i.e., extremely difficult to wet. The contact angles of a water droplet on an ultrahydrophobic material exceed 150°. This is also referred to as the lotus effect, after the superhydrophobic leaves of the lotus plant. A droplet striking these kinds of surfaces can fully rebound like an elastic ball, or pancake.

Superhydrophobic coating composition and coated articles obtained therefrom

A coating composition is provided comprising: (i) a fluorinated polymer comprising (a) structural units having the formula (I):—CR1R2—CFX— (I)wherein R1 and R2 are each independently an alkyl group, a fluorine atom, a chlorine atom, a hydrogen atom or a trifluoromethyl group, and X is a fluorine atom, a chlorine atom, a hydrogen atom or a trifluoromethyl group, and (b) structural units comprising at least one type of crosslinkable functional group; (ii) a crosslinking agent; and (iii) a plurality of particles functionalized with a functional group, wherein the functional group on the particles is essentially non-reactive with the fluorinated polymer and with the crosslinking agent. Articles comprising a coating composition described in embodiments of the invention are also provided.

Owner:GENERAL ELECTRIC CO

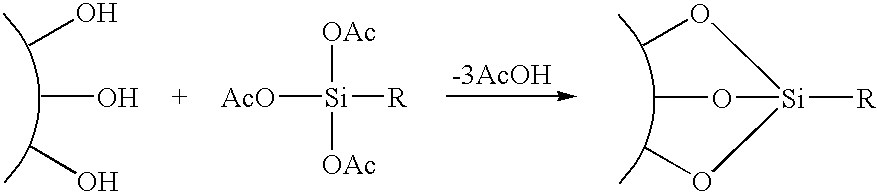

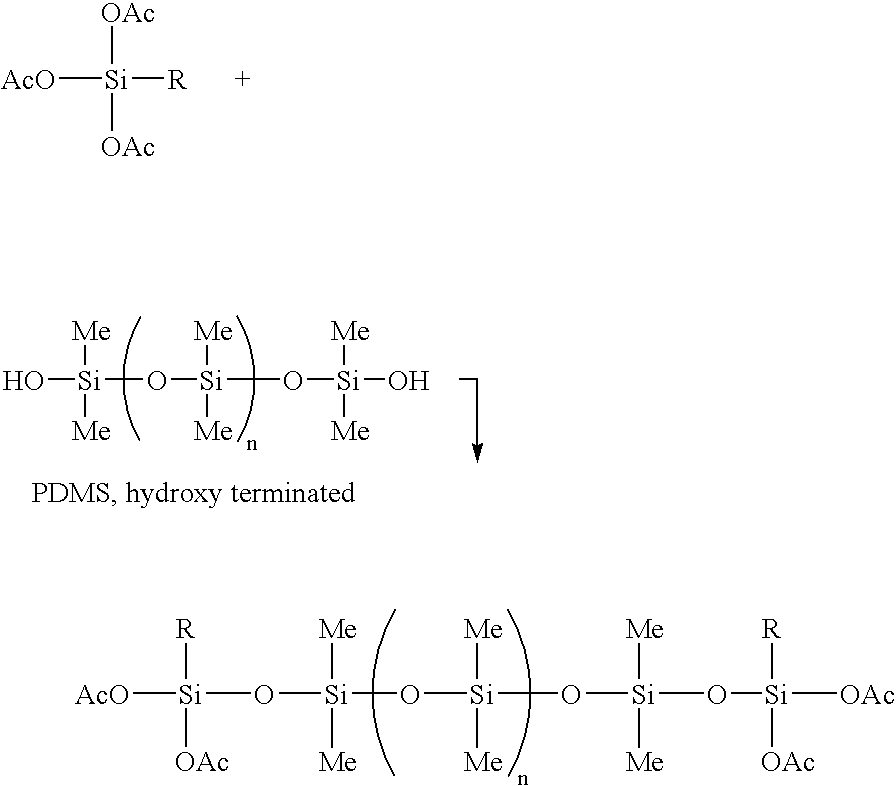

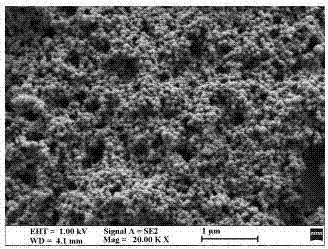

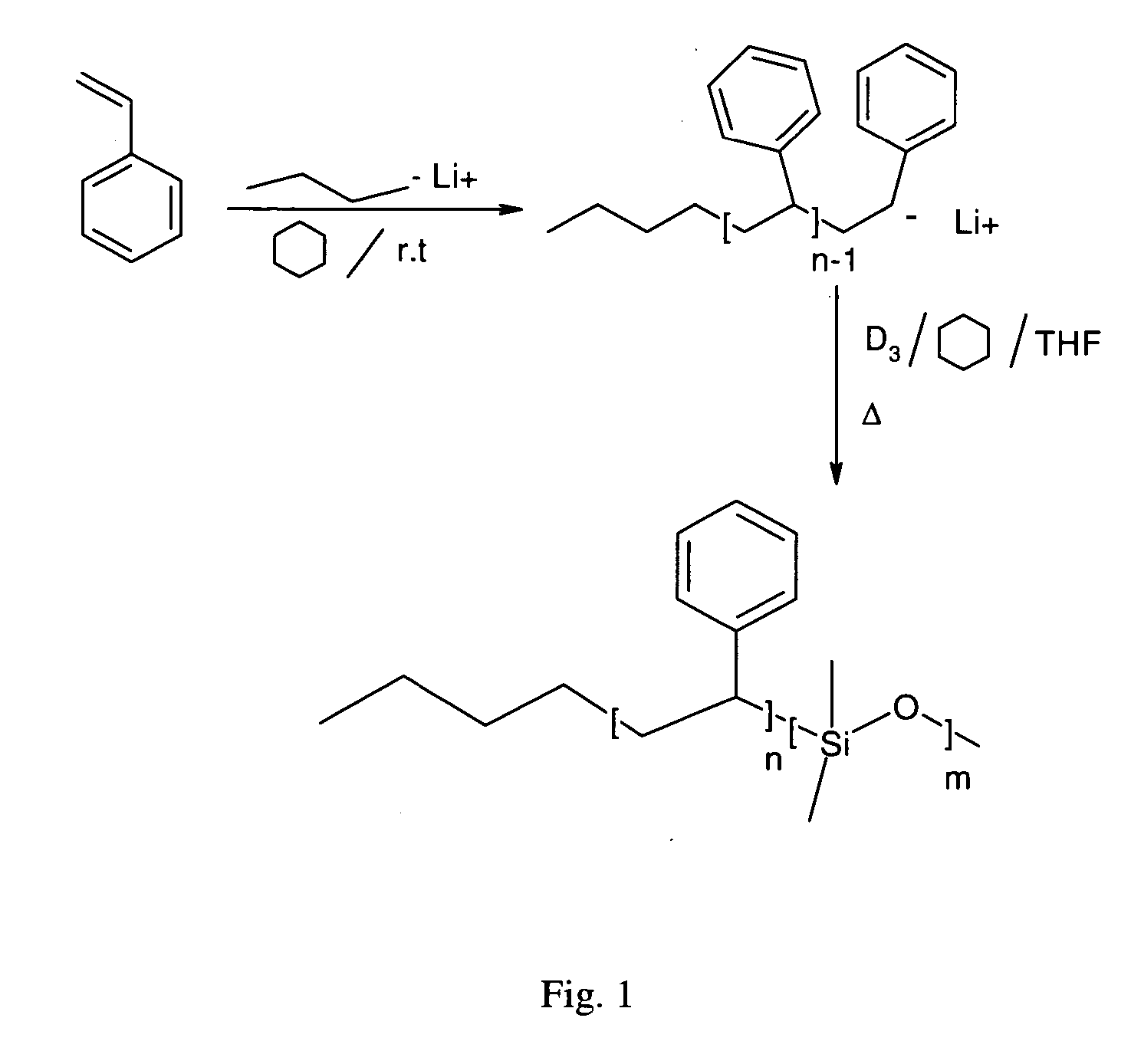

High-durability super-hydrophobic self-cleaning coating material and preparation method thereof

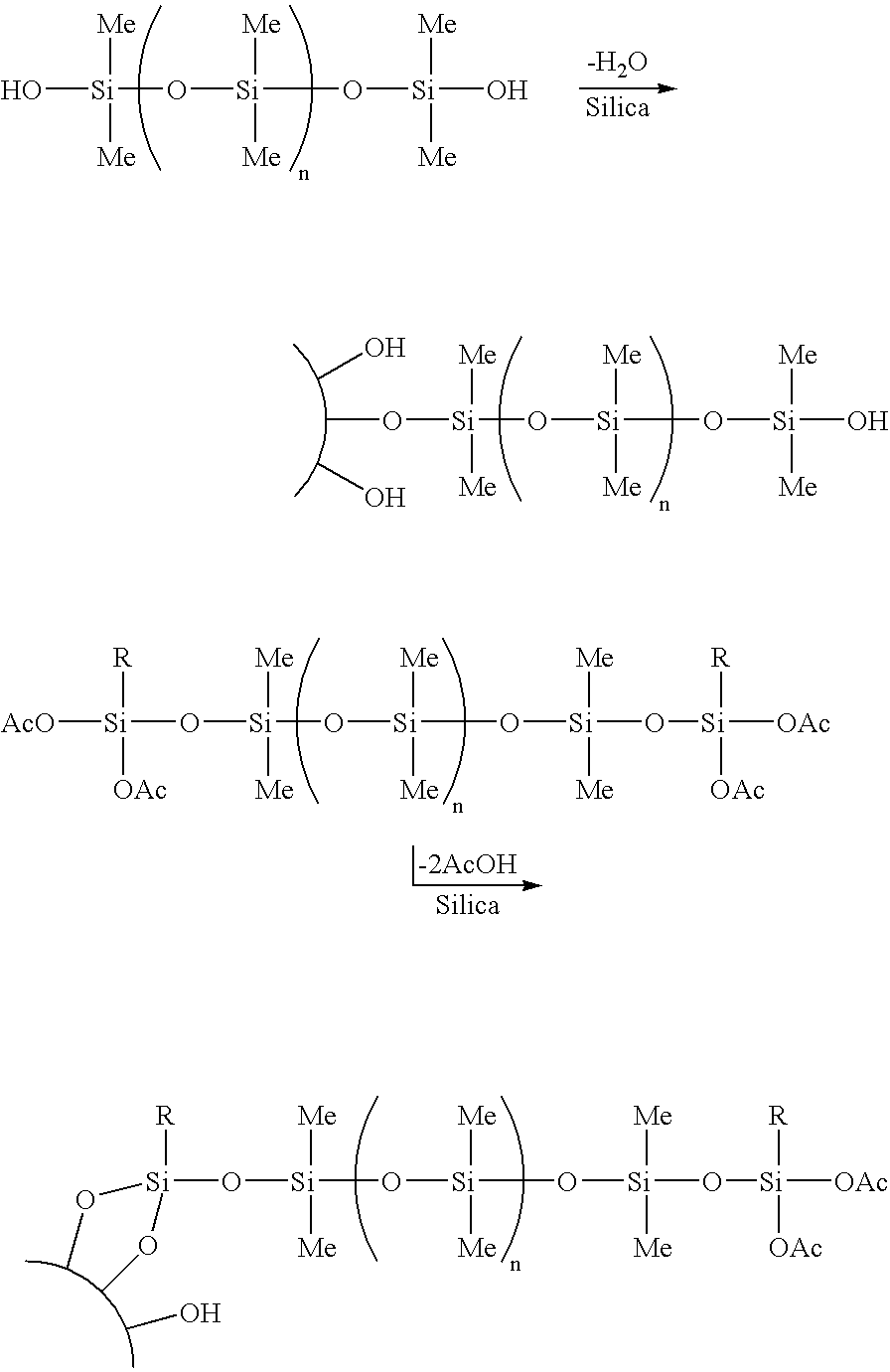

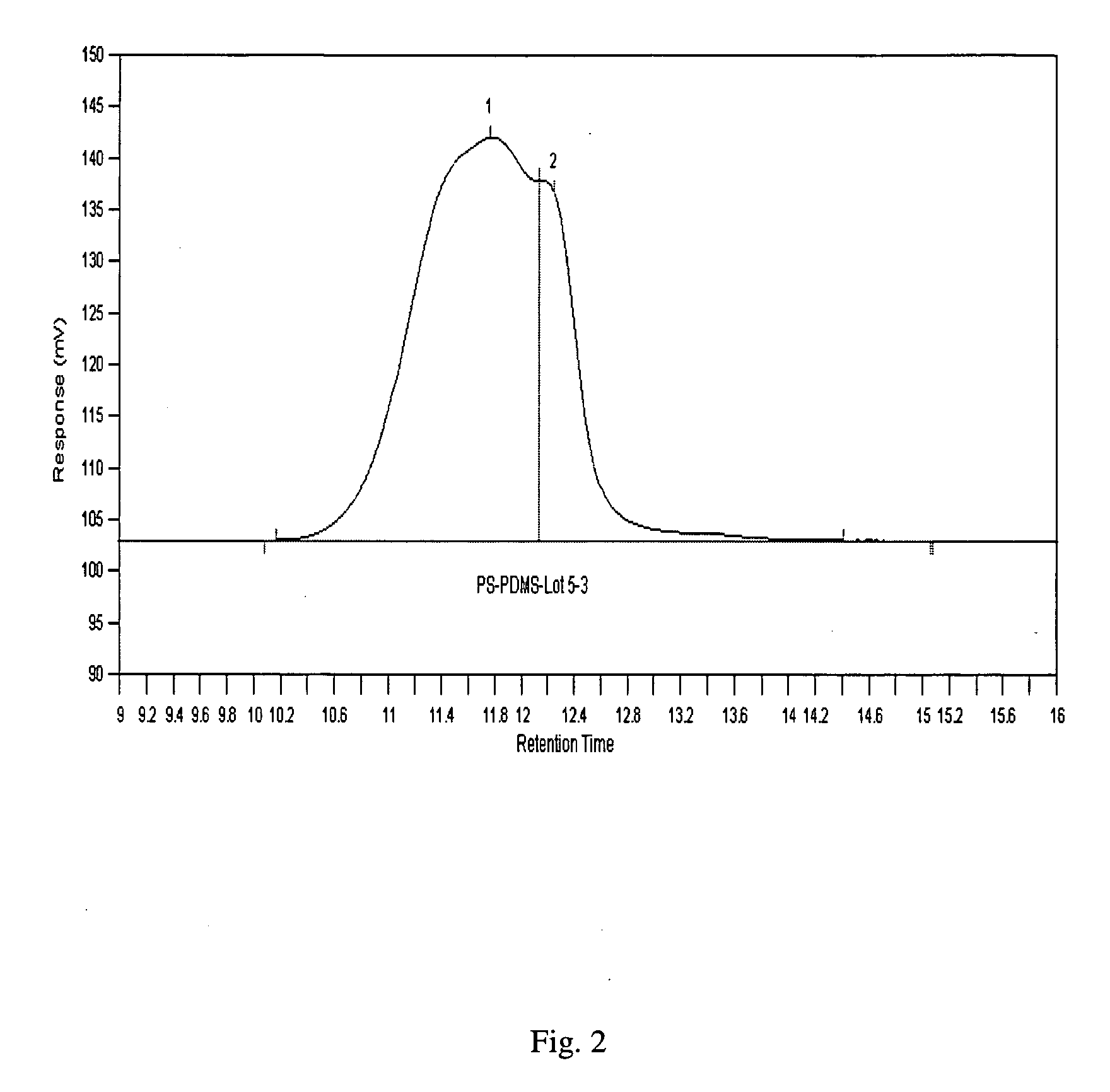

InactiveCN101962514AHas the following advantages: (1) cleanlinessHas the following advantages: (1) has the functionAntifouling/underwater paintsPaints with biocidesDouble bondDimethyl siloxane

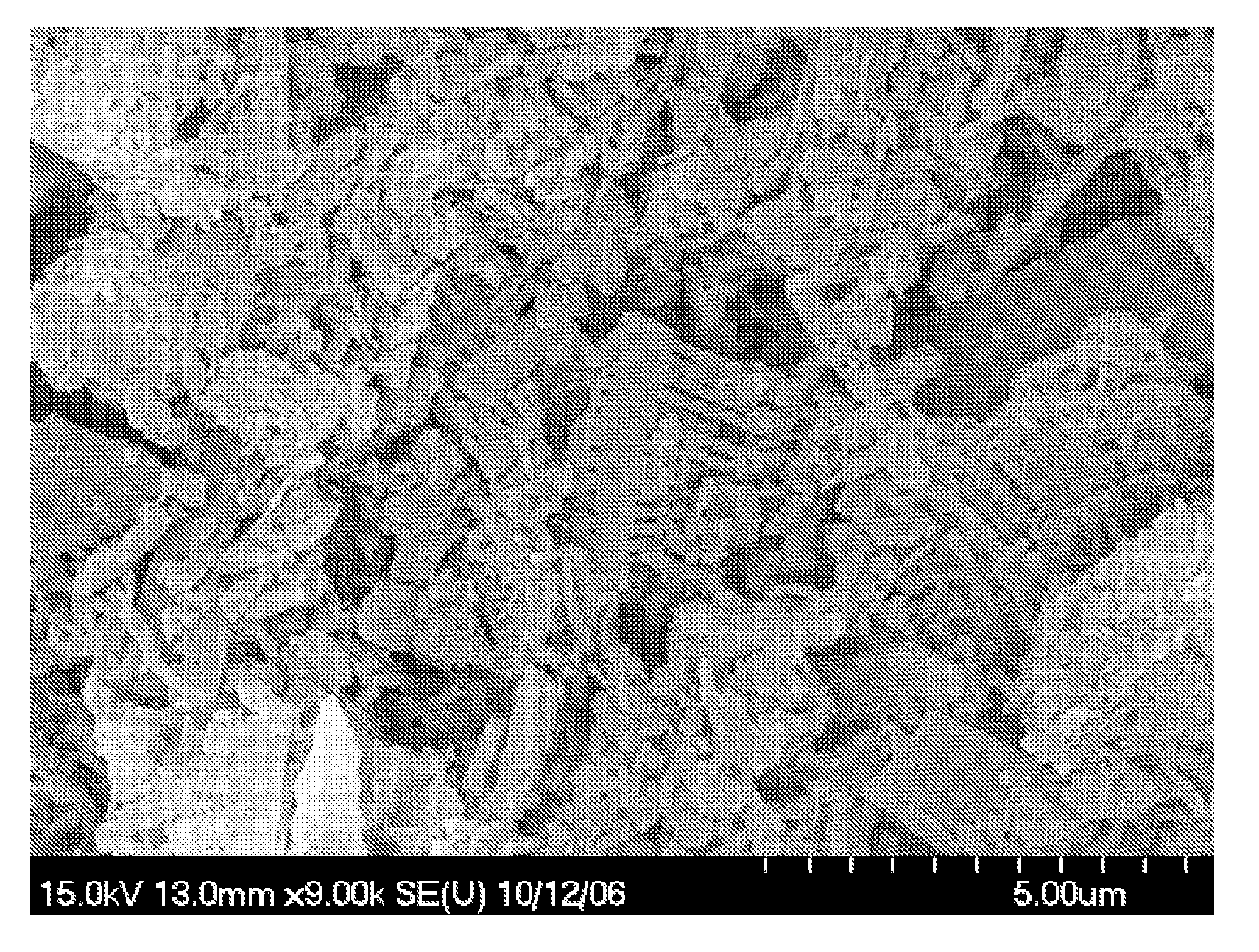

The invention belongs to the technical field of a new chemical material, and in particular relates to a high-durability super-hydrophobic self-cleaning coating material and a preparation method thereof. The coating material of the invention is prepared by curing and drying nanoparticles with photo-catalytic activity, a low-surface-free-energy polymer and a cross-linking agent at the room temperature, wherein the low-surface-free-energy polymer consists of one or more of polysiloxane fluoride, dimethyl silicone polymer and polyphenylene methyl siloxane, which contain active groups, such as hydroxyl alkoxy group, carbon-carbon double bond, silanol group, siloxy group, and the like; the cross-linking agent is hydrogen-containing silicone oil or aminosilane; and the mass content of the photo-catalytic nanoparticles in the coating ranges from 10 to 60 percent. The coating is formed into a micro-nanostructure by nanoparticle self-organization; a super-hydrophobic self-cleaning coating with lotus effect is prepared from the coating and a cross-linked filming matrix with low surface energy; the persistence of a lotus-shaped super-hydrophobic characteristic of the coating is realized by using the photo-catalytic decomposition characteristic of an organic pollutant for the nanoparticles; and thus the material is suitable for large-area construction and has high weathering resistance andprominent self-cleaning characteristic.

Owner:FUDAN UNIV

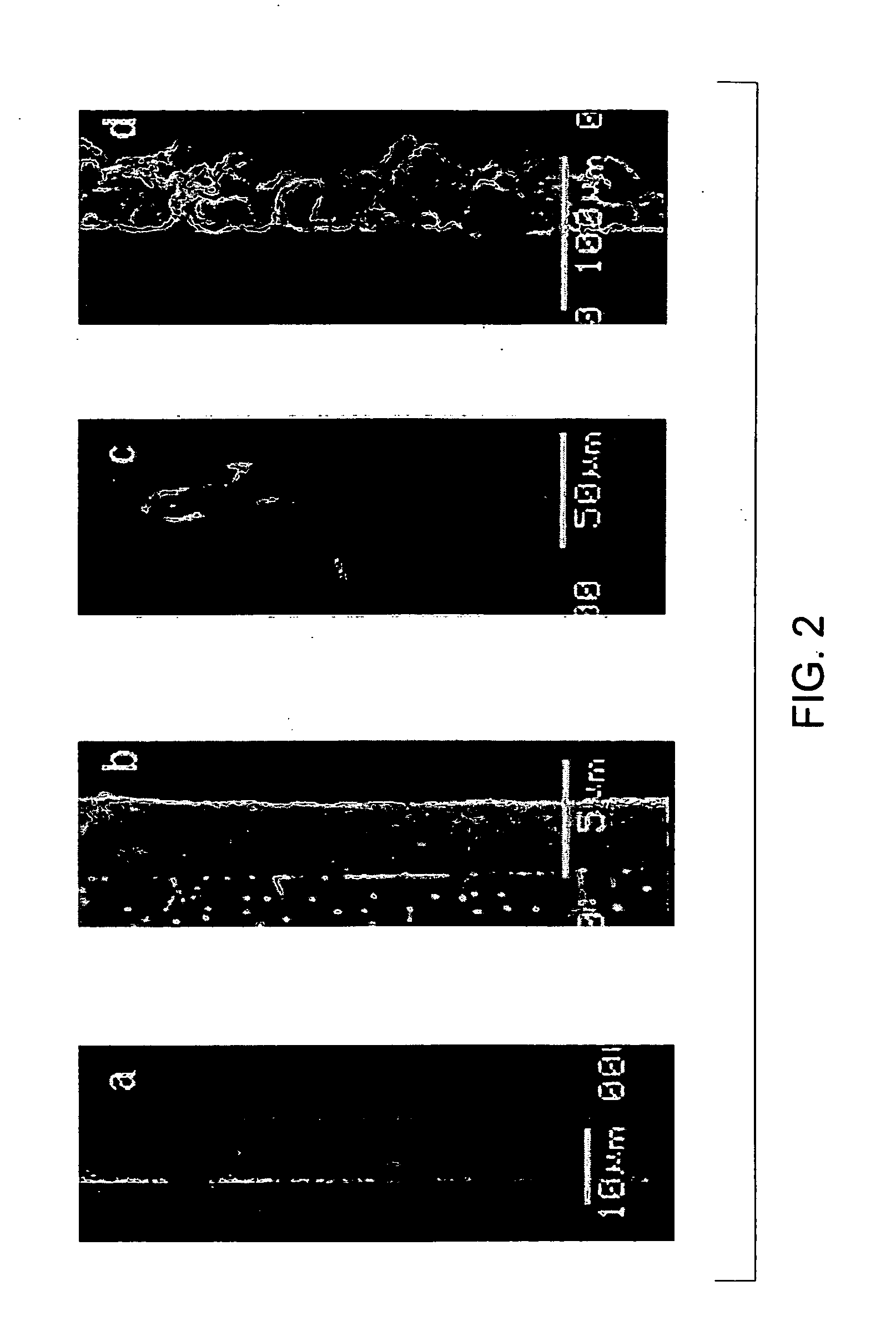

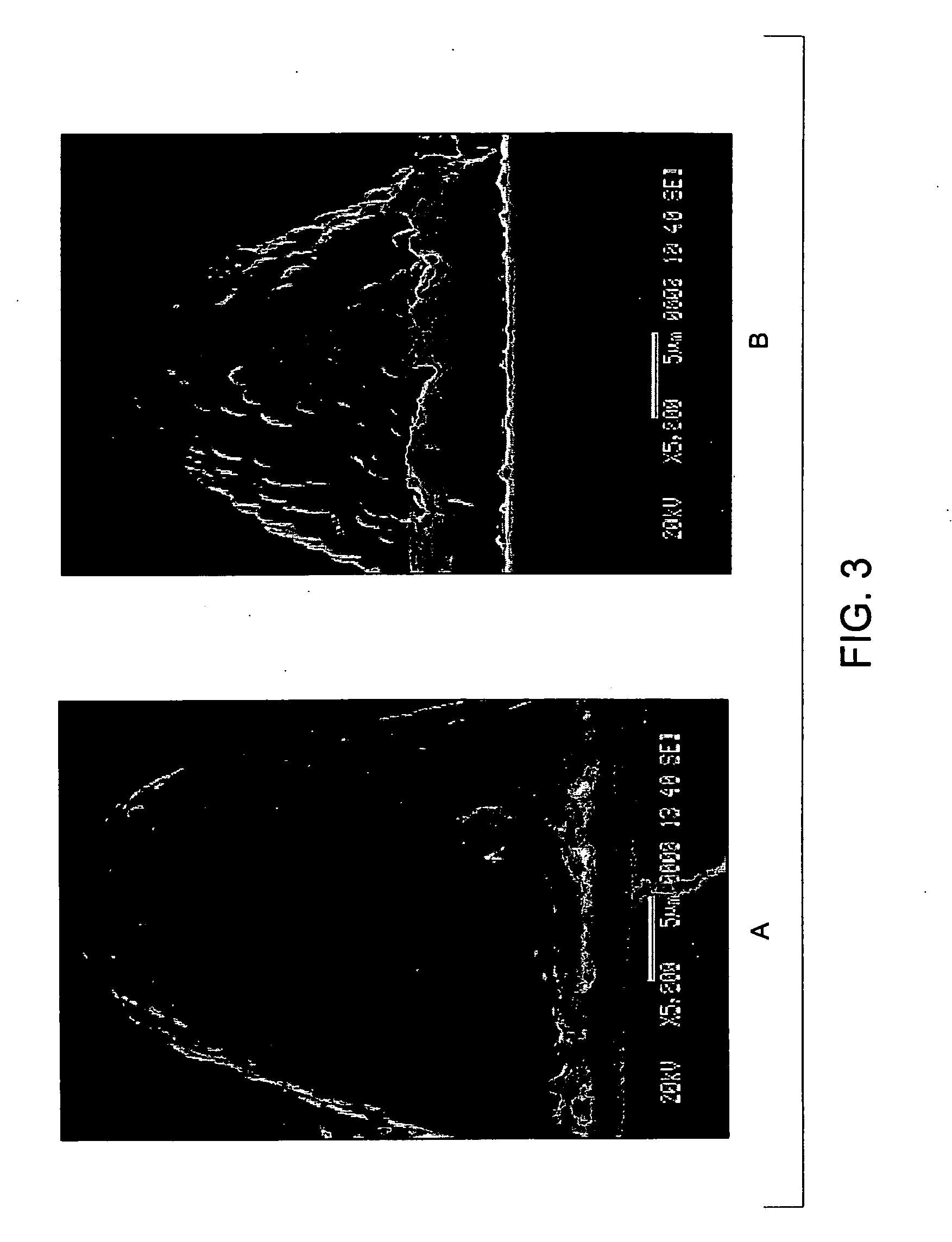

Durable superhydrophobic coating

InactiveUS20070009657A1Increased durabilityDurableCoatingsSpecial surfacesCross-linkSuperhydrophobic coating

A method for forming a hydrophobic coating on the surface of a substrate comprising linking particulate material by polymer strands and cross-linking at least some of the polymer strands. The invention further relates to hydrophobic coatings comprising particles of a particulate material linked together and to a surface by polymer strands, wherein some of the polymer strands are cross-linked. The method of the invention can be used to form superhydrophobic coatings.

Owner:NEWSOUTH INNOVATIONS PTY LTD

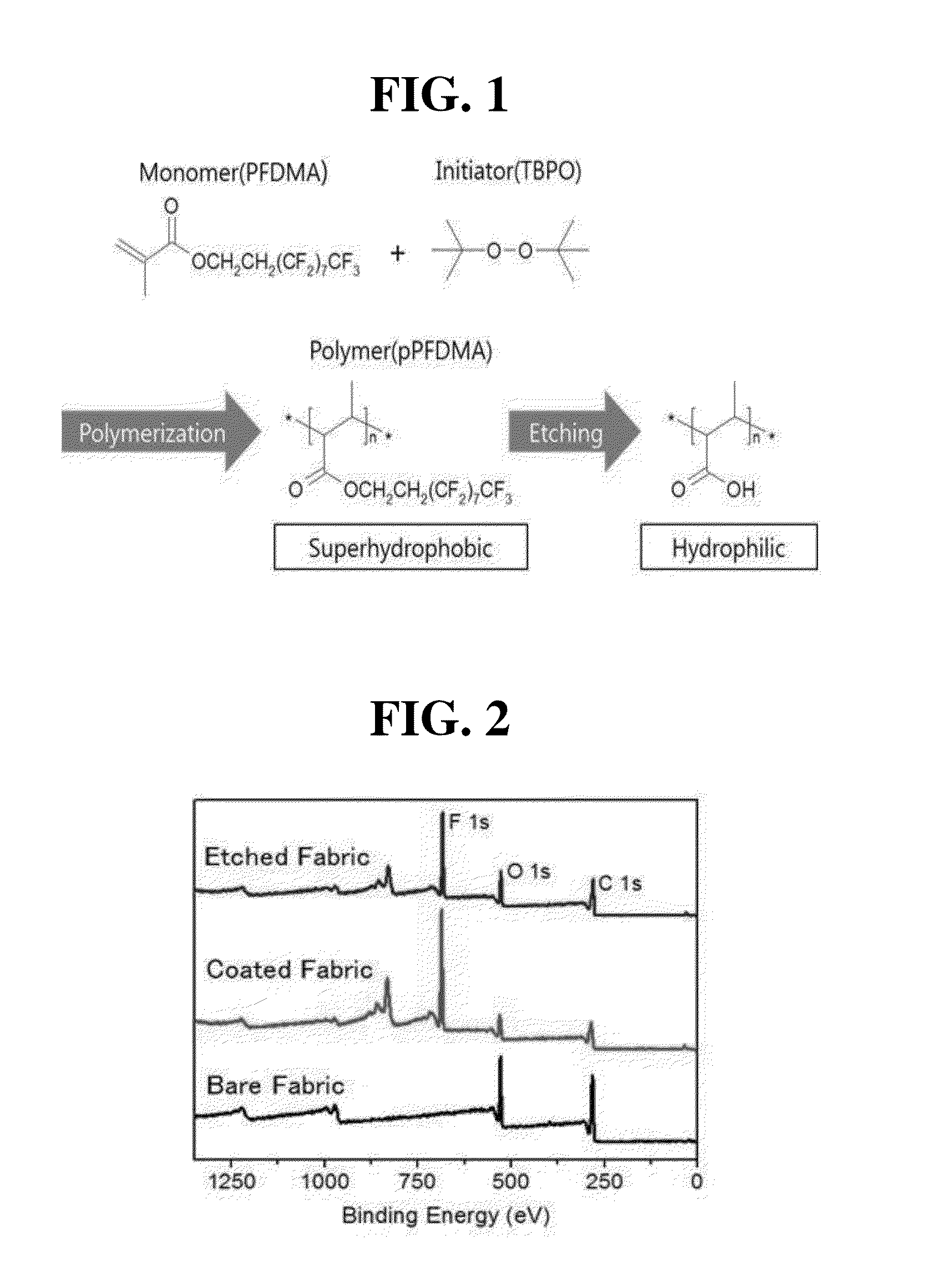

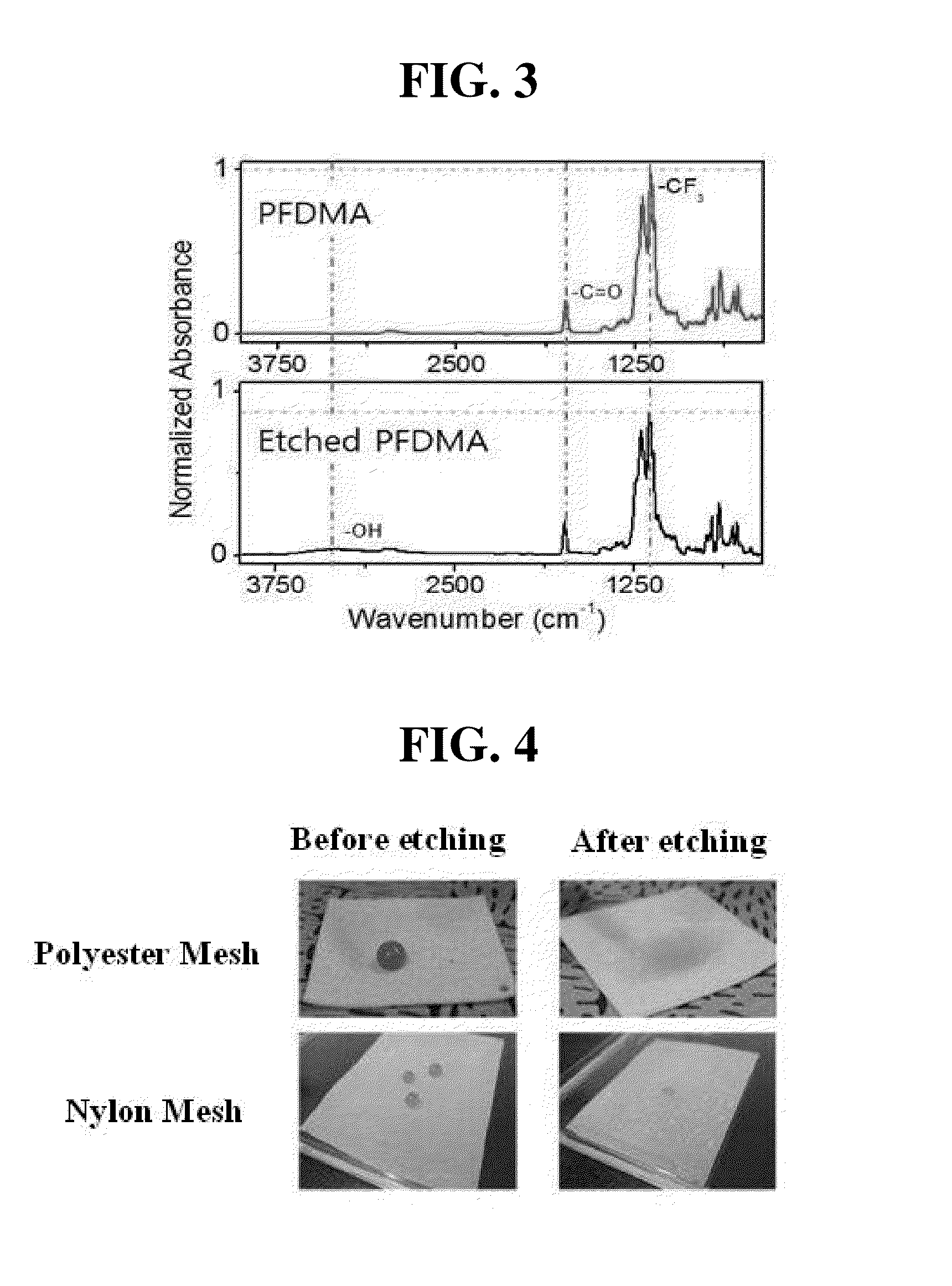

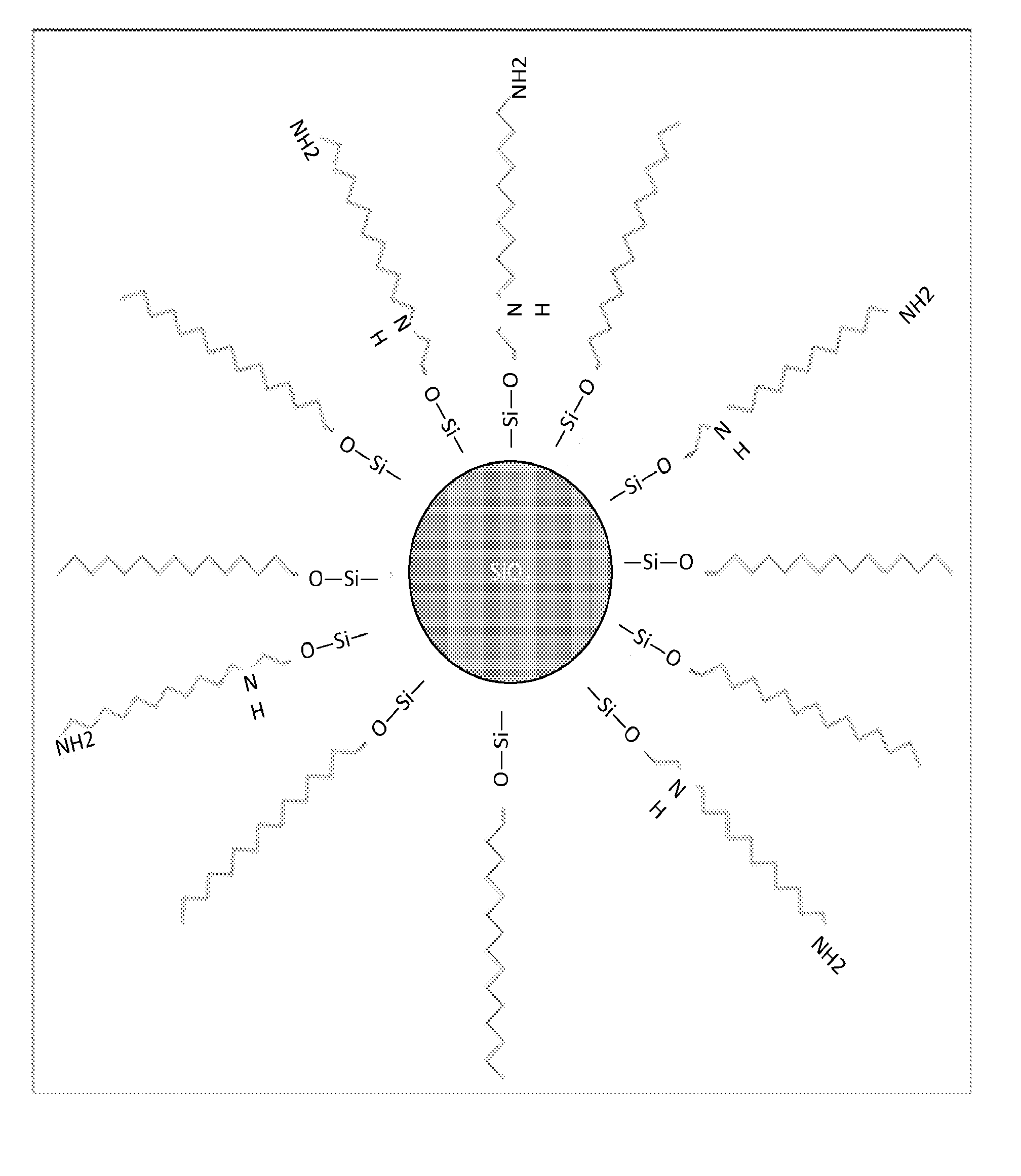

Superhydrophilic and Superhydrophobic Powder Coated Fabric

InactiveUS20090042469A1Fibre treatmentSynthetic resin layered productsSuperhydrophobeSelf-assembled monolayer

Superhydrophilic and superhydrophobic fabrics are taught having a superhydrophilic or superhydrophobic powder disposed on the fabric. The superhydrophilic powder has at least one material of sodium borosilicate glass and porous diatomaceous earth. The powder material has a contiguous interpenetrating structure with a plurality of spaced apart nanostructured surface features. The superhydrophilic powder is switched to superhydrophobic by adding at least one superhydrophobic material of perfluorinated organics, fluorinated organics, and self-assembled monolayers.

Owner:UT BATTELLE LLC

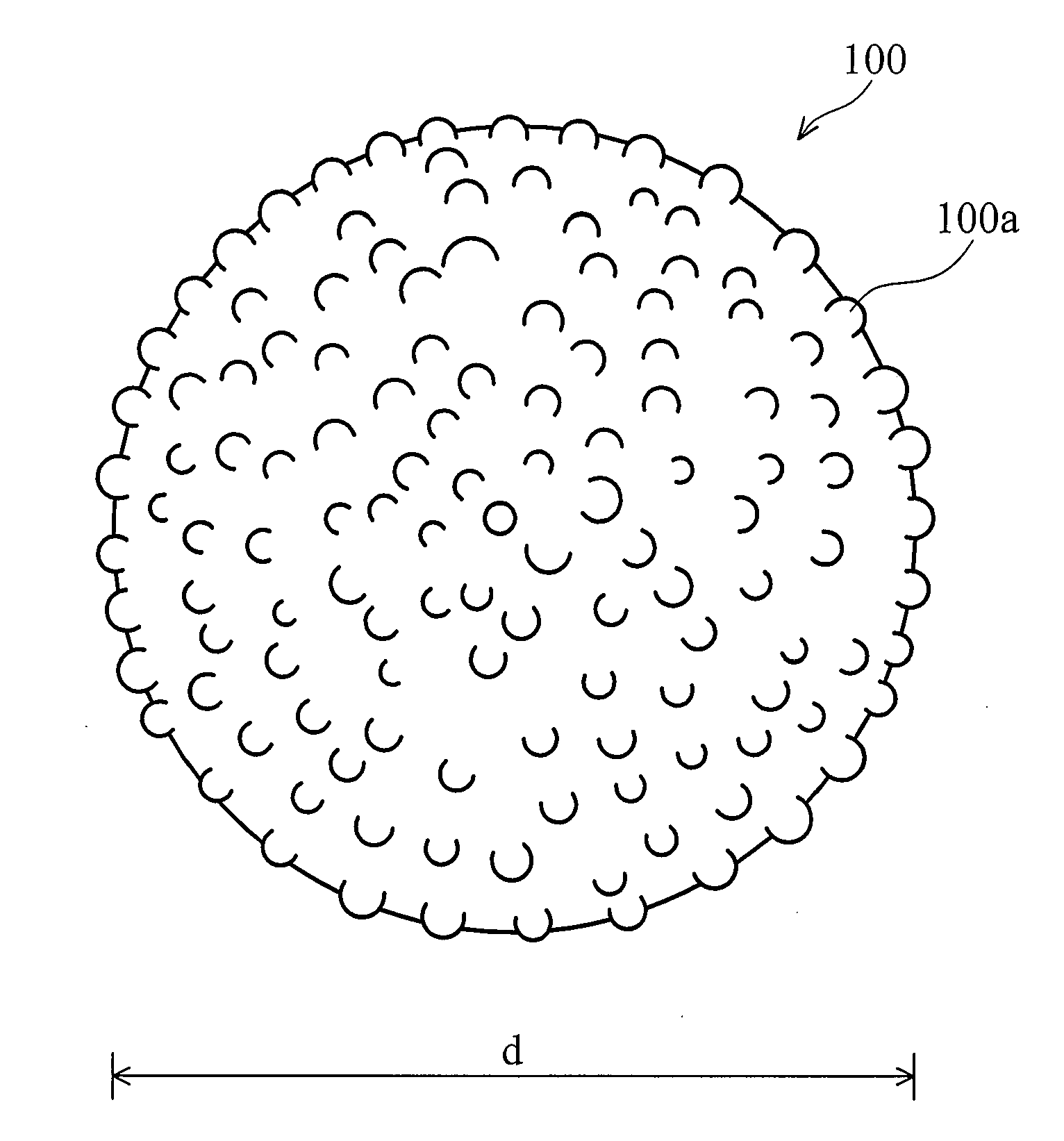

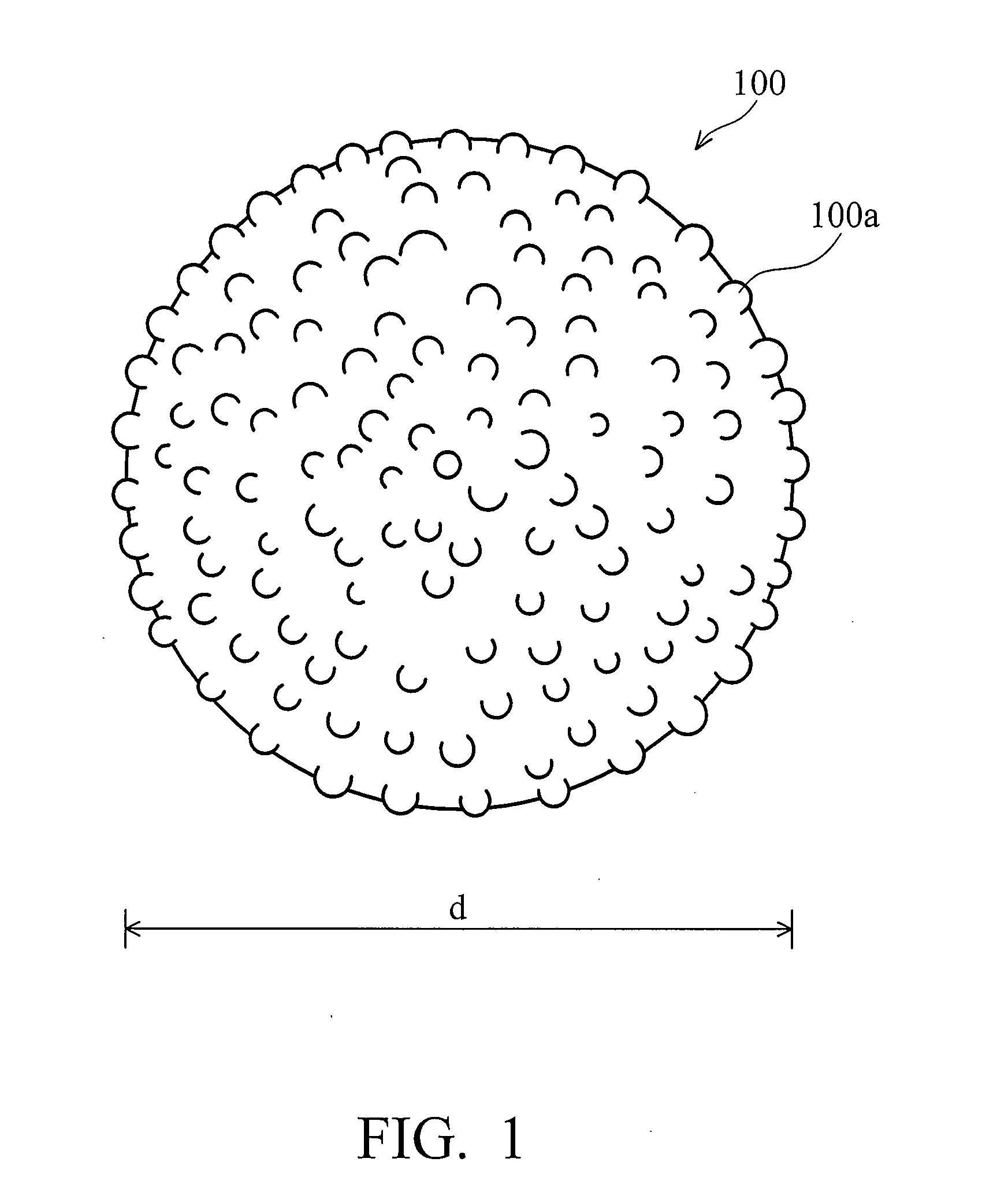

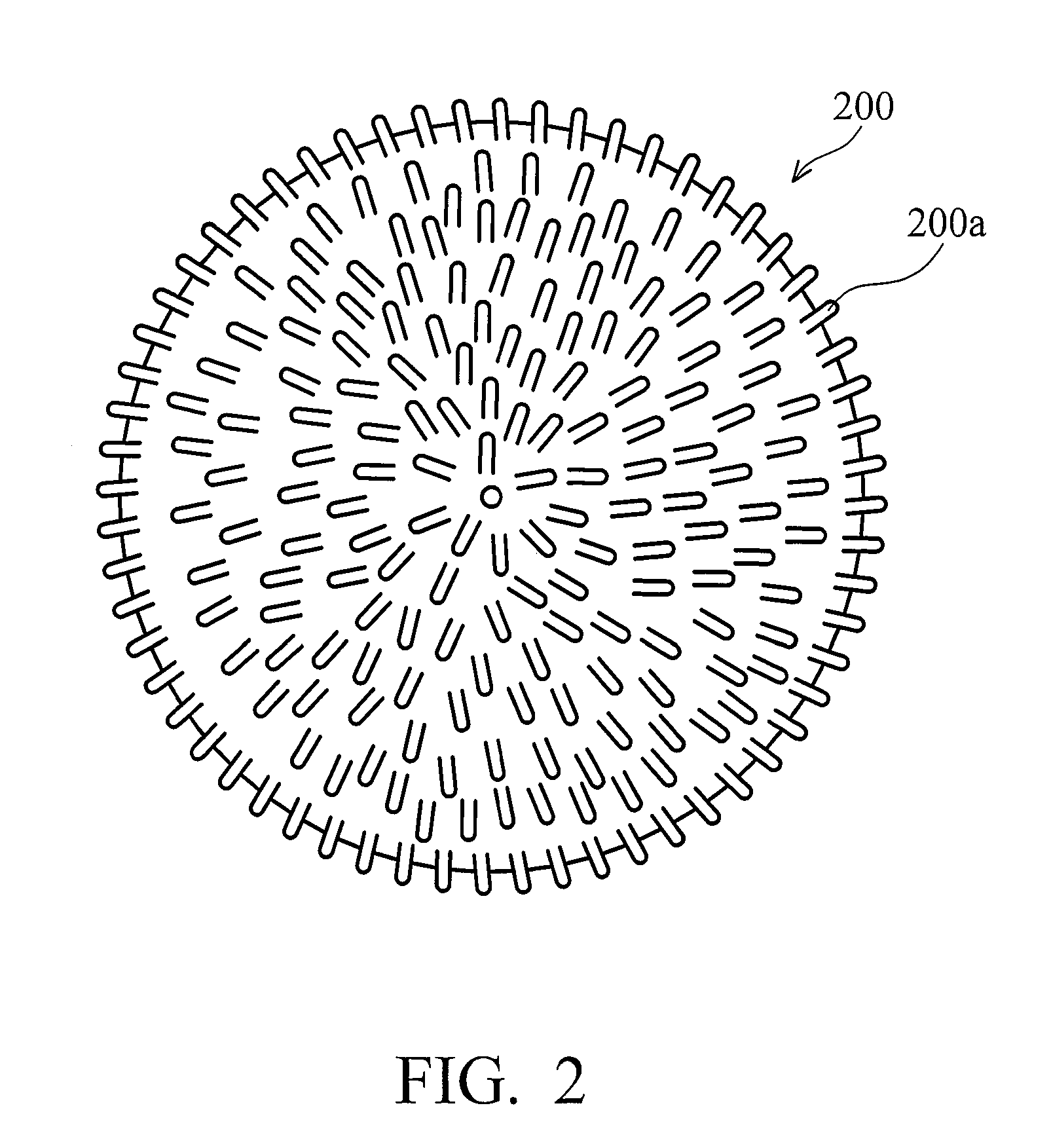

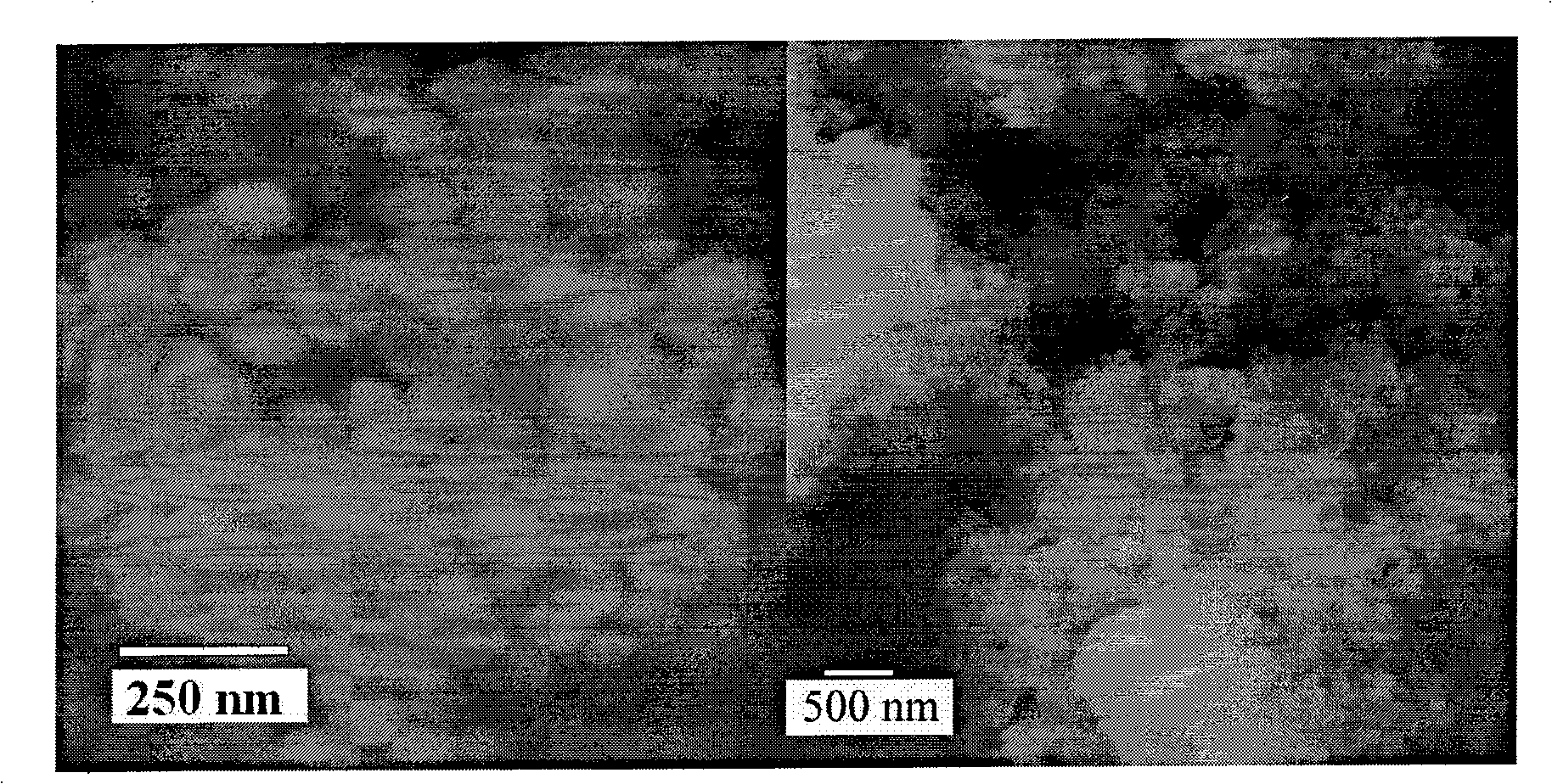

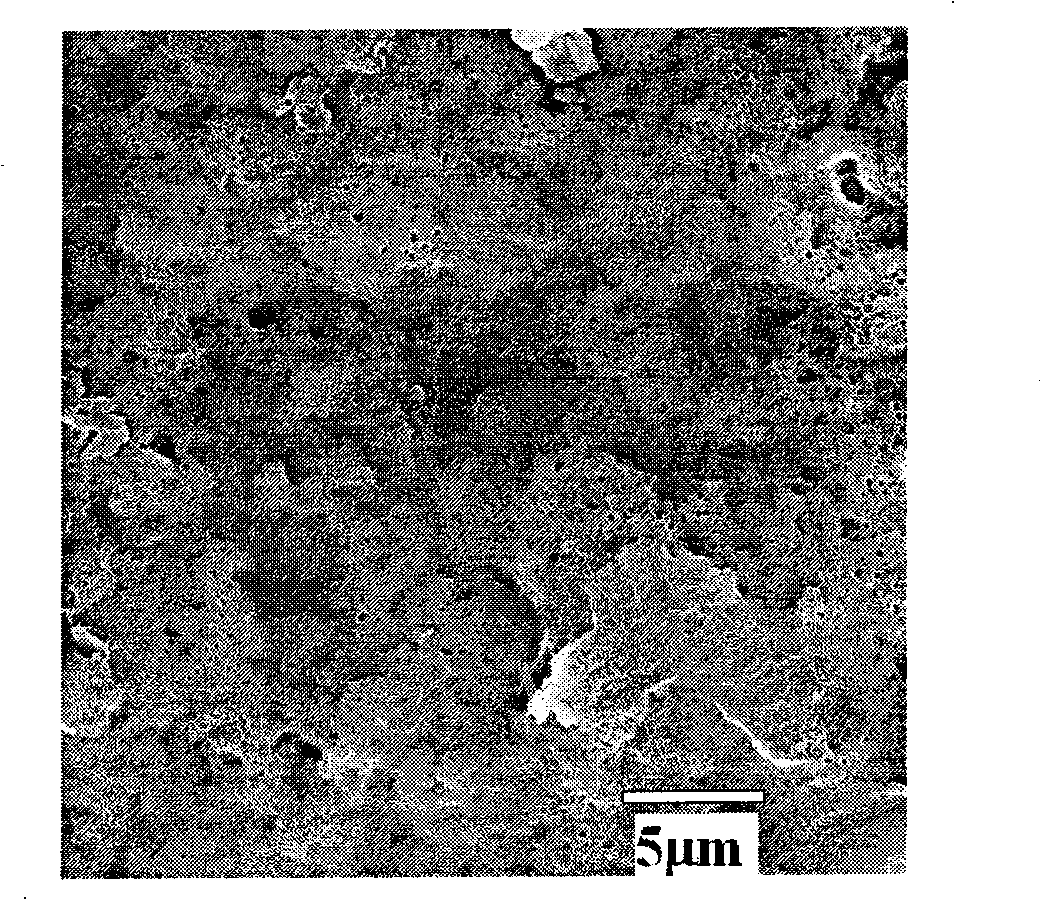

Superhydrophobic and self-cleaning powders and fabrication method thereof

The invention discloses nano / micron binary structured powders for superhydrophobic, self-cleaning applications. The powders are featured by micron-scale diameter and nano-scale surface roughness. In one embodiment, the average diameter is about 1-25 μm, and the average roughness Ra is about 3-100 nm. The nano / micron binary structured powders may be made of silica, metal oxide, or combinations thereof.

Owner:IND TECH RES INST

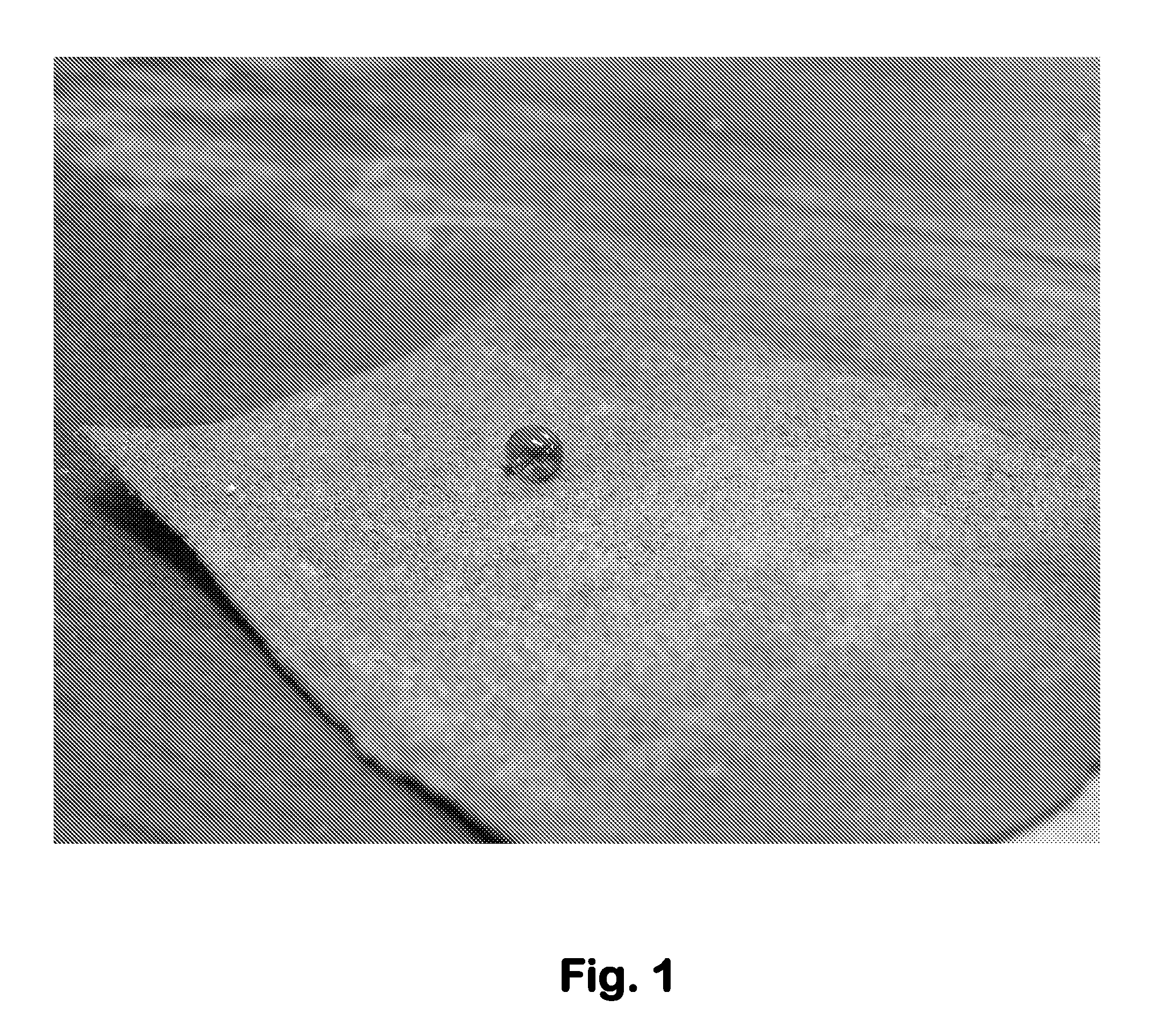

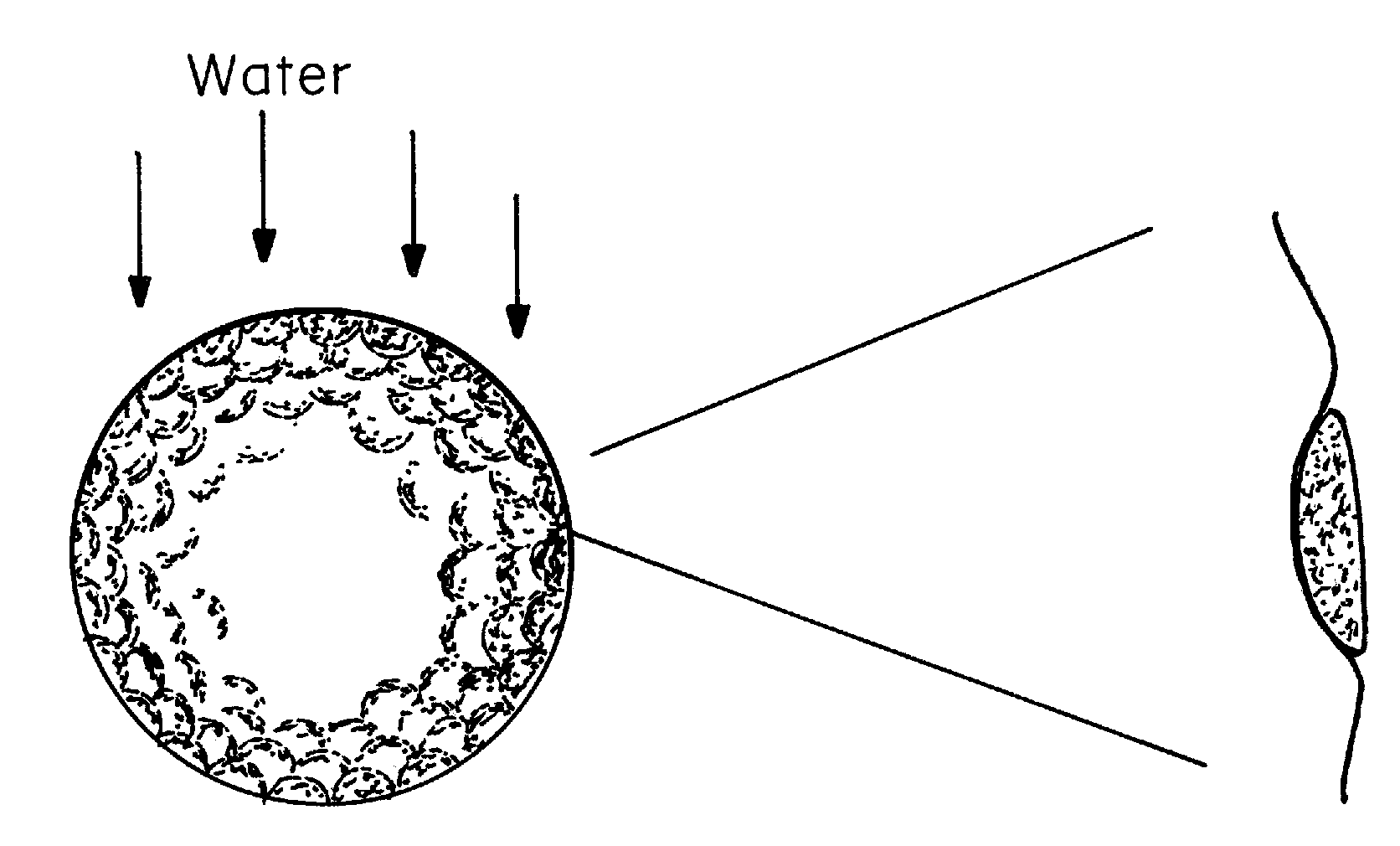

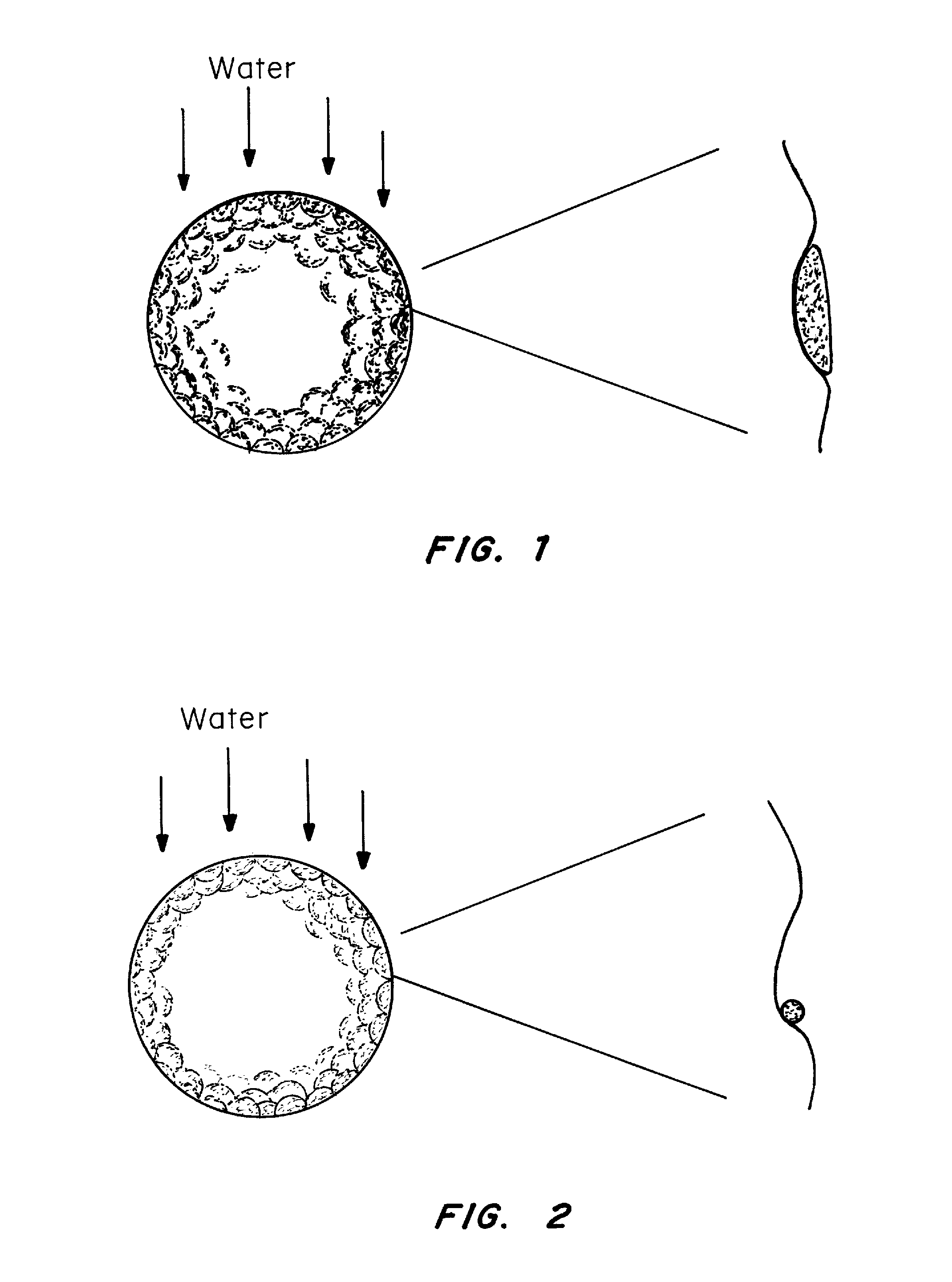

Water Repellant Golf Balls Containing a Hydrophobic or Superhydrophobic Outer Layer or Coating

InactiveUS20080280699A1Improve performanceSynthetic resin layered productsPaper coatingPolymer sciencePolyethylene glycol

Water-repellant, self-cleaning coatings and methods of making and using thereof are described herein. In one embodiment, a hydrophobic or super hydrophobic coating is applied to the surface of a golf ball to make the golf-ball water-repellant and self-cleaning. Suitable coating materials include silicone compounds, silicone compounds, nanoparticles, silanes, fluorocarbon polymers, perfluoroalkyl ethyl methacrylate (PPFEMA) coated polycaprolactone, hydrocarbons, polymer mats made of polystyrene and poly[tetrafluoroethylene-co-(vinylidene fluoride)-co-propylene] (PTVFP); polyethylene glycol with glucose and sucrose in conjunction with a hydrophobic substance; combinations of nanoparticles with polyethylene or polypropylene; high density polyethylene, technical waxes; films of rough particles of metal oxides, polymer binder layers containing a plurality of porous protrusions, and combinations thereof. Suitable coating techniques include, but are not limited to, spraying, dipping, painting, brushing, or wiping (such as applying the coating from a towel or sponge). The coating material or the outer layer of the golf ball may be modified to create nano- or micro roughness or patterns on the surface of the golf ball, which can induce the lotus effect. This roughness or pattern can be created using a variety of techniques known in the art including, but not limited to, etching, top / down methodologies, bottom / up methodologies, or combinations thereof.

Owner:JARVHOLM ERIK JONAS

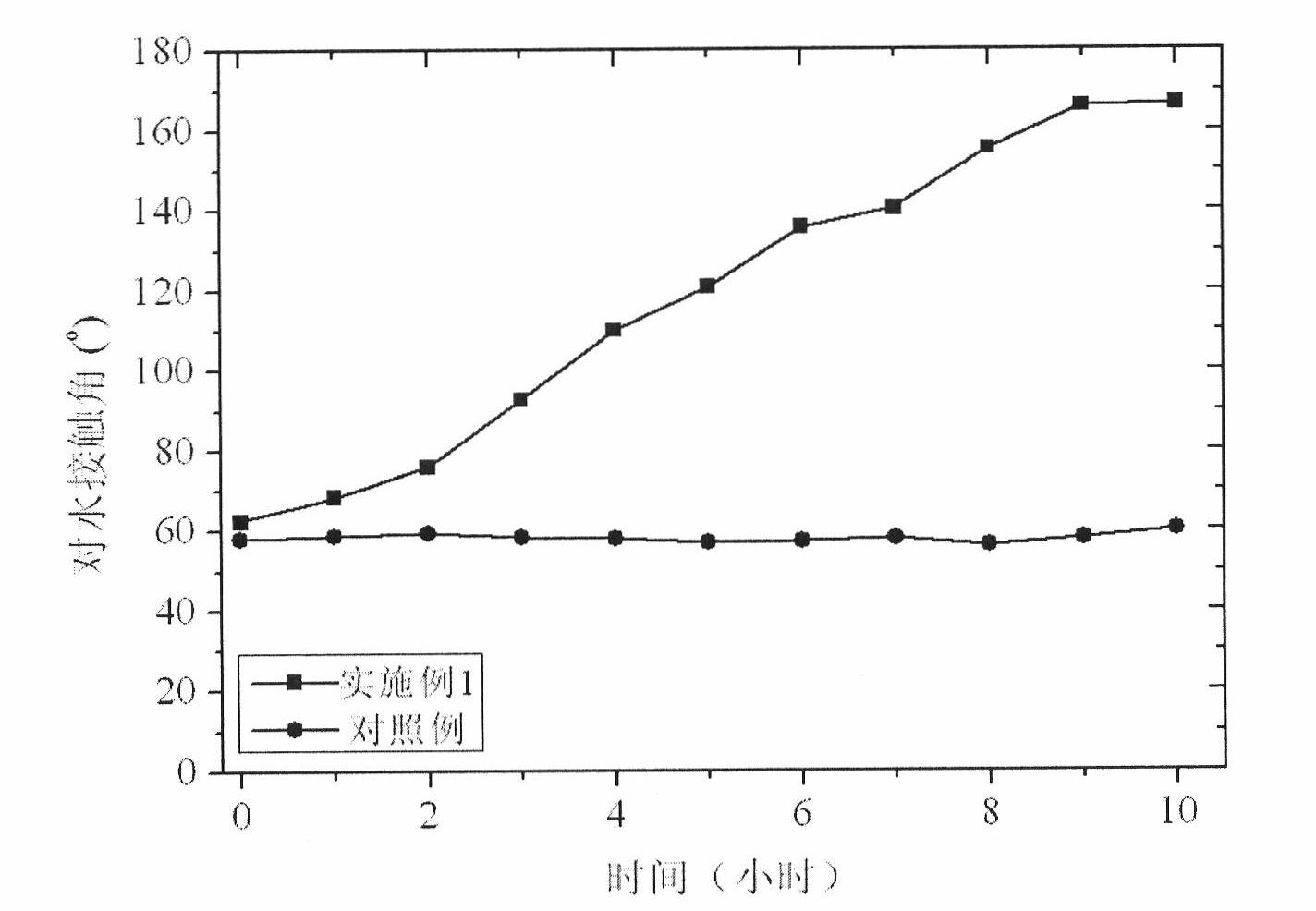

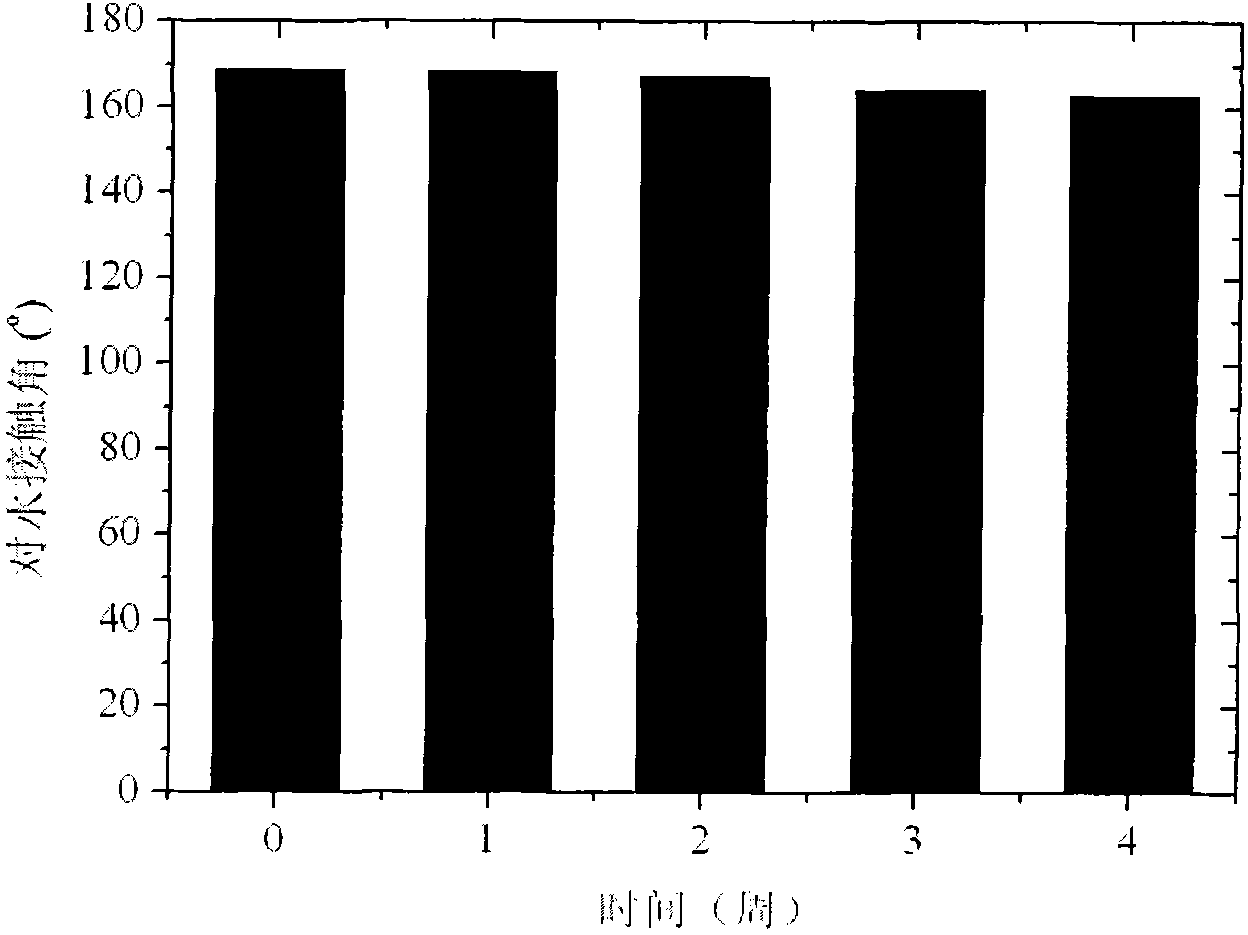

Photocatalytic type self-repairing super-hydrophobic coating and preparation method thereof

ActiveCN103409028ASimple preparation processWith super weather resistancePolyurea/polyurethane coatingsPolyester coatingsSuperhydrophobeOrganic solvent

The invention belongs to the technical field of new chemical materials and relates to a photocatalytic type self-repairing super-hydrophobic coating and a preparation method thereof. The coating comprises the following materials: 10-50 percent of thermoplastic film-forming resin, 5-20 percent of low-surface energy material, 1-10 percent of photocatalytic active nano particles, 5-40 percent of hydrophobicity nano particles and 20-60 percent of organic solvent. The preparation method comprises the following steps: firstly, allowing nano particles to be subjected to fluorosilane modification to obtain the hydrophobicity nano particles; then, weighing all components of the coating for mixing, and performing high-speed shearing dispersing to obtain the coating provided by the invention. The coating can be applied to the surfaces of base materials such as steel material, aluminium alloy, plastic and composite in the way of brushing, spraying and the like, and a lotus leaf type super-hydrophobic coating can be obtained through drying. The coating can realize super-hydrophobic self-repairing through UV irradiation after being polluted by organic pollutant or subjected to mechanical wear by external forces, so that the coating has extremely good super-hydrophobic performance and perdurability, and the long-term using performance under the outdoor environments is also ensured.

Owner:FUDAN UNIV

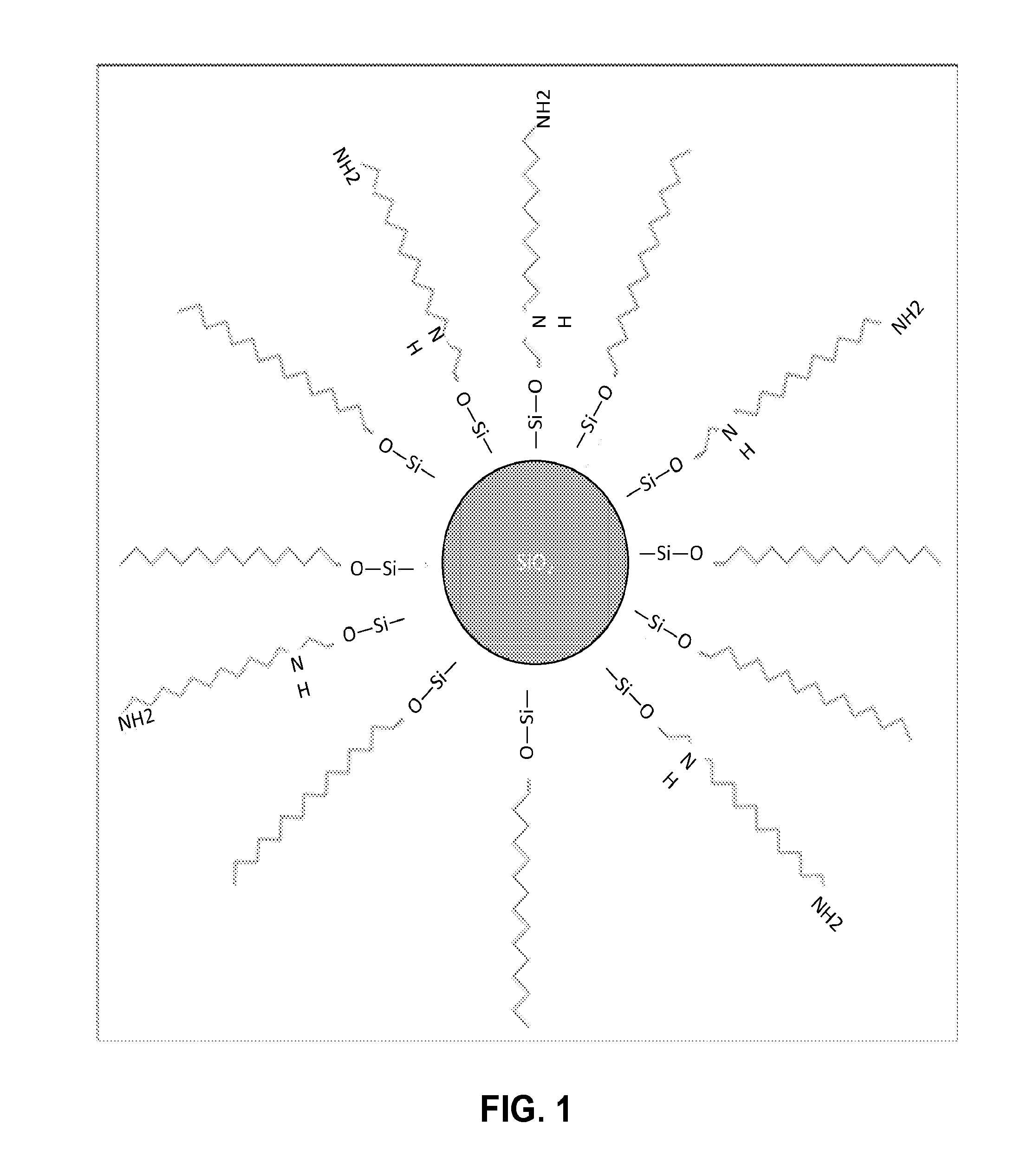

Super hydrophobic cotton fabric and preparation method thereof

The invention belongs to the fabric water-repellent finishing and processing field, in particular relates a super hydrophobic cotton fabric and a preparation method thereof. The preparation method of the super hydrophobic cotton fabric is characterized in that the epoxy-functionalized modification is performed to the cotton fiber of fabric, then aminated nano-SiO2 and epoxy-functionalized nano-SiO2 are used to impregnate the cotton fabric in turn so as to increase the surface roughness of the fabric, finally a low-surface-energy material is adopted to perform hydrophobization treatment to the fabric; the contact angle between the prepared cotton fabric and water drops is more than 150 degrees; the method utilizes the covalent reaction of epoxy groups of cotton fabric, amino groups of nano-SiO2 and epoxy groups of nano-SiO2 to ensure the built rough surface to have good fastness; and the built surface has a large number of Si-OHs and epoxy groups so as to facilitate the chemical combination of the low-surface-energy material and the surface, thus the superhydrophobic property of the prepared fabric has excellent stability.

Owner:SHAANXI UNIV OF SCI & TECH

Transparent super-hydrophobicity wood coating and preparation method thereof

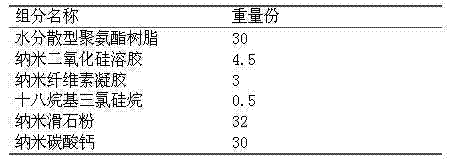

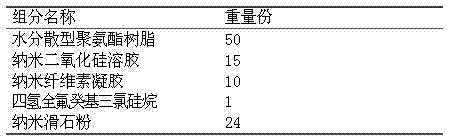

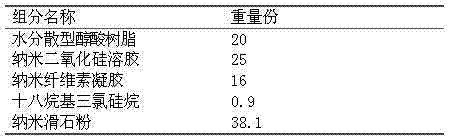

InactiveCN103756541AParticle size controllableHydrophobic hasPolyurea/polyurethane coatingsPolyester coatingsOctadecyltrichlorosilanePolymer science

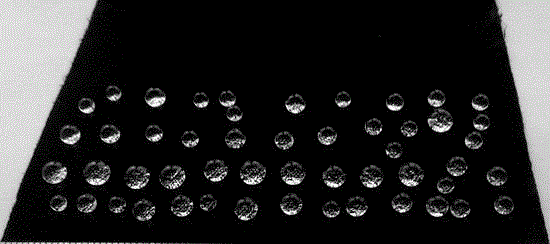

The invention discloses a transparent super-hydrophobicity wood coating which comprises the following components in parts by weight: 20-50 parts of water dispersive polyurethane resin or water dispersive alkyd resin, 4.5-25 parts of nano silica sol, 3-16 parts of nano cellulose gel, 0.1-1 part of octadecyl trichlorosilane or tetrahydroperfluorodecyltrichlorosilane or stearic acid and 0-45 parts of nano talc powder or nano calcium carbonate. A preparation method of the transparent super-hydrophobicity wood coating comprises the following steps: adding matrix resin and filler into a stirring kettle, and stirring uniformly to obtain slurry; grinding the slurry with a sand mill; adding a low-surface energy substance and supported nano silica sol; performing ultrasonic sufficient mixing for 30 minutes to obtain the transparent super-hydrophobicity coating. The transparent super-hydrophobicity wood coating disclosed by the invention has the advantages of low cost, controllable process, adjustable size and good applicability and is suitable for a preparation method of large-area preparation of transparent super-hydrophobicity surface; the prepared super-hydrophobicity film has good self-cleaning property, antifouling property, hydrophobic property, oleophobic property and the like.

Owner:GUANGDONG YIHUA TIMBER IND +1

Preparation method of durable super-hydrophobic fabric

The invention provides a preparation method of a durable super-hydrophobic fabric. The preparation method comprises the following steps: firstly, depositing a polydopamine film on the surface of a common fabric; secondly, depositing silver oxide particles on the surface of the common fabric by using the chelating property of the common fabric to nano-particles; and finally, performing hydrophobic treatment on the fabric by using a low-surface-energy material, thereby obtaining the durable super-hydrophobic fabric. The preparation method provided by the invention has the positive progress effects that the static contact angle of water drops on the surface of the fabric prepared by the method is more than 150 degrees, and the water drops can roll easily on the surface of the fabric. After being washed or rubbed for a long time, the fabric still has excellent super-hydrophobic property; and the preparation method of the super-hydrophobic fabric does not need specific instruments and equipment, is simple to operate and is beneficial for popularization.

Owner:NANCHANG HANGKONG UNIVERSITY

Ultra-discharging water-soluble fluor-silicon-acrylic coatings with nano particles

InactiveCN101307210AWide variety of sourcesInexpensive and easy to obtainEmulsion paintsMechanical propertyNuclear chemistry

The invention discloses a super-hydrophobic water fluorine silicone / acrylic paint containing nanoparticles. The paint is prepared by mixing the compositions by weight percentage: 30 to 65 percent of water, 10 to 40 percent of silicone-acrylate emulsion, 10 to 40 percent of water fluoro-polymer emulsion, 1 to 10 percent of nano-meter oxid particles, 1 to 15 percent of inorganic hole compound and a small quantity of inorganic acid used for adjusting the pH value. The invention also discloses a super-hydrophobic water fluorine silicone / acrylic coating prepared by the paint. The water static wrapping angle of the coating is more than 150 degrees and a rolling angle is lower than 5 degrees. The coating prepared by the paint has the advantages of super-hydrophobicity, excellent mechanical property and easy process, etc. and has the self-cleaning function similar to a lotus leaf.

Owner:胡硕

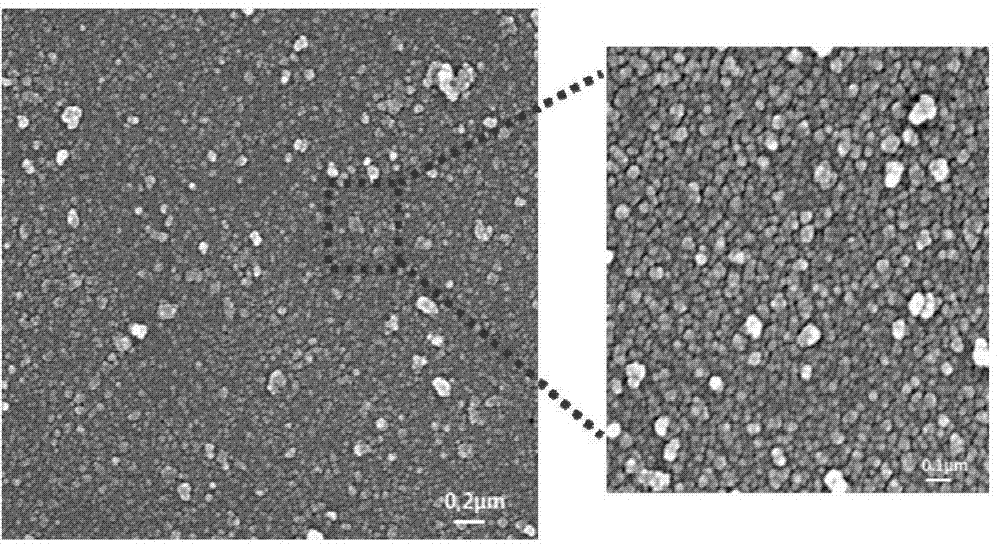

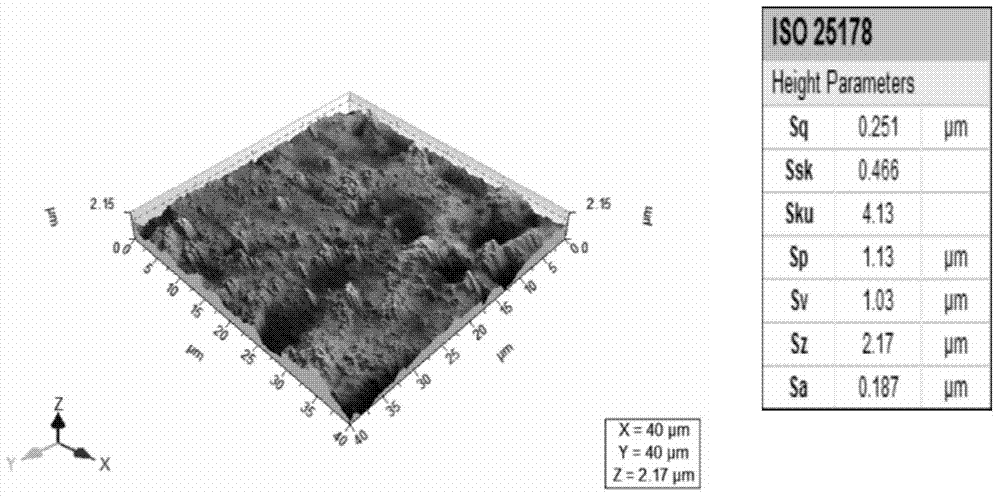

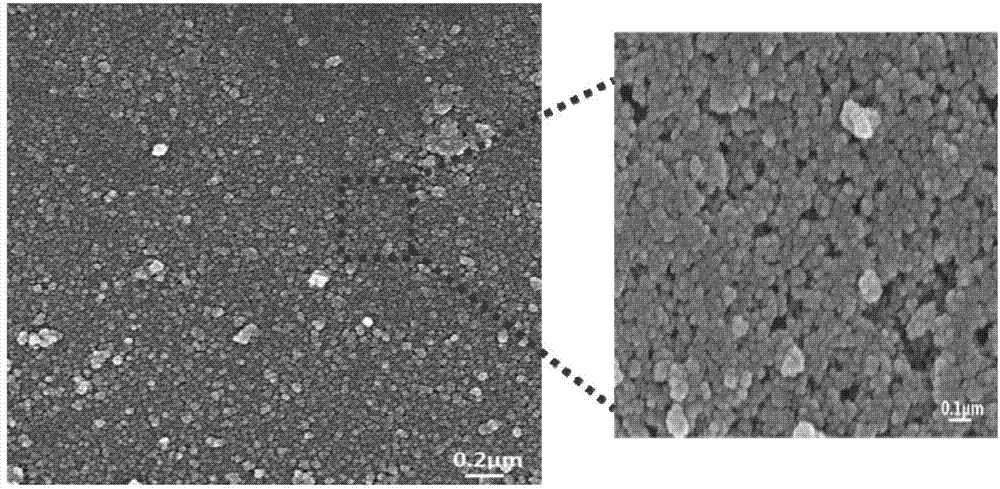

Preparation method of persistent icing-resistant superhydrophobic coating

ActiveCN106883650AImproved long-lasting anti-icing performanceLong-lasting anti-icing performanceAntifouling/underwater paintsPaper coatingSuperhydrophobePolymer science

The invention relates to the field of preparation of superhydrophobic coatings, in particular to a preparation method of a persistent icing-resistant superhydrophobic coating. The preparation method comprises the following steps: firstly, carrying out cleaning and sand-blasting roughen treatment on the surface of a substrate; secondly, blending epoxy resin, a curing agent and a first solvent to obtain an epoxy resin solution; thirdly, dispersing submicron particles and nanoparticles into a second solvent, and then adding a silane coupling agent to obtain particle composite suspension; fourthly, spraying the epoxy resin solution obtained in the second step on the surface of the substrate treated in the first step, and partially curing epoxy resin adhesive; fifthly, spraying the particle composite suspension obtained in the third step on the surface of the substrate obtained in the fourth step and completely curing; sixthly, obtaining the persistent icing-resistant superhydrophobic coating. The persistent icing-resistant superhydrophobic coating disclosed by the invention has the beneficial effects that the superhydrophobic coatings prepared on the surfaces of all the substrates have good durability and firmness and persistent icing-resistant property.

Owner:哈尔滨毓干科技有限公司

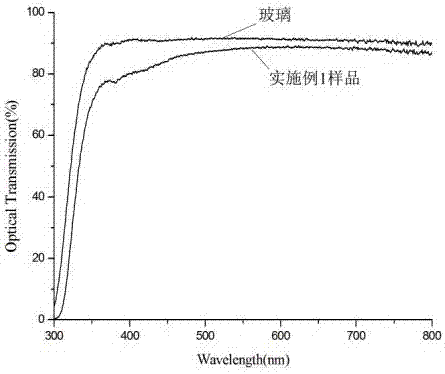

Preparation method of highly transparent wear-resistant superhydrophobic composite coating

ActiveCN107022279AEasy to prepareWide applicabilityEpoxy resin coatingsWear resistantSuperhydrophobic coating

The invention belongs to the technical field of superhydrophobic materials, and particularly relates to a preparation method of a highly transparent wear-resistant superhydrophobic composite coating. Surface-modified nano-silica powder prepared by a sol-gel method is dispersed in anhydrous ethanol to obtain a superhydrophobic coating solution. The surface of a substrate of stone, metal, glass and the like is coated with reactive-diluent-modified E-51 epoxy resin glue, standing is carried out for 1 to 2 hours at room temperature, the superhydrophobic coating solution is used for brushing to obtain the highly transparent wear-resistant superhydrophobic coating. The contact angle between the coating and water is 165 to 175 DEG, a rolling angle is 2 to 5 DEG, the light transmittance of coating glass in the 500 to 650nm is greater than 84%, and at pressure intensity of 2500 Pa, the contact angle between the coating and water is greater than 90 DEG after the coating is rubbed with 320-mesh sandpaper along a line. The preparation method of the coating is simple, environmentally friendly and low in cost, is suitable for the surface of glass, stone, ceramics, wood, metal and the like, and has a wide application prospect.

Owner:FUZHOU UNIV

Superhydrophobic fibers and methods of preparation and use thereof

The present invention relates to fibers exhibiting a water contact angle of above 150° and water contact angle hysteresis of below 15°, methods of producing the same, and applications thereof. The present invention further relates to superhydrophobic fiber mats, methods of producing the same, and applications thereof.

Owner:MASSACHUSETTS INST OF TECH

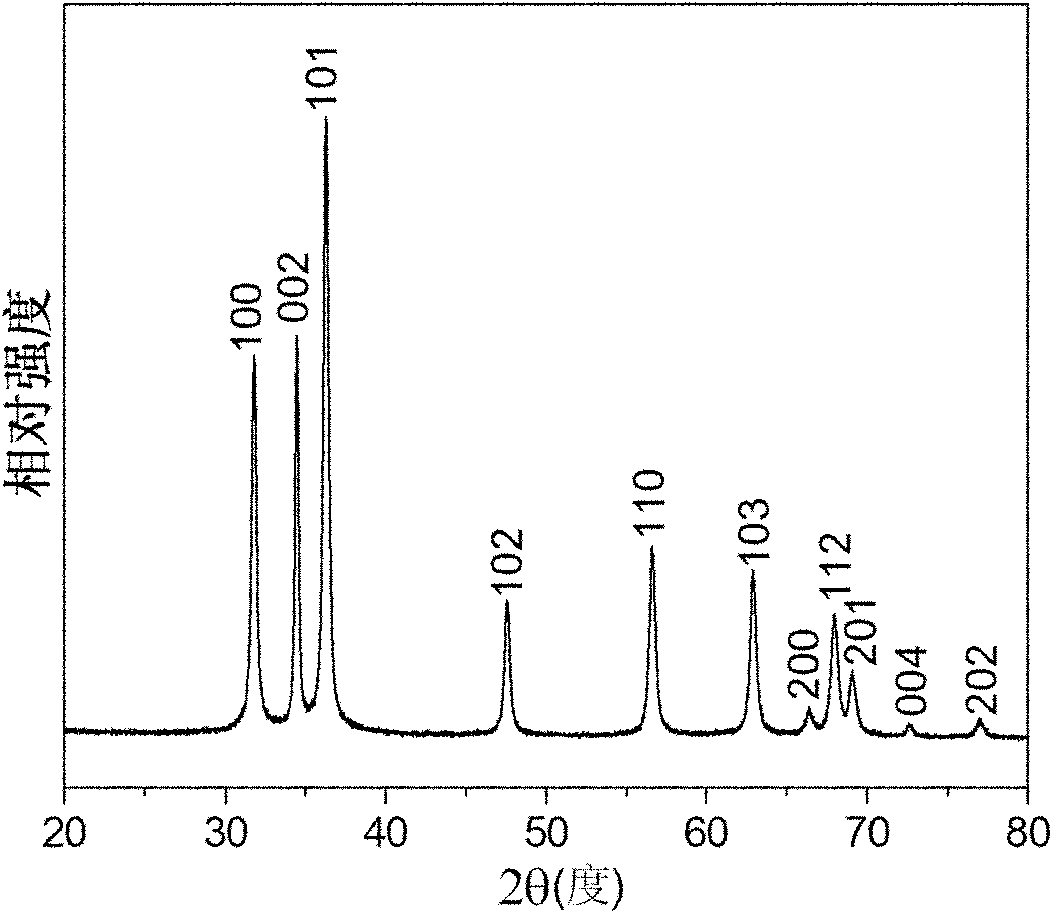

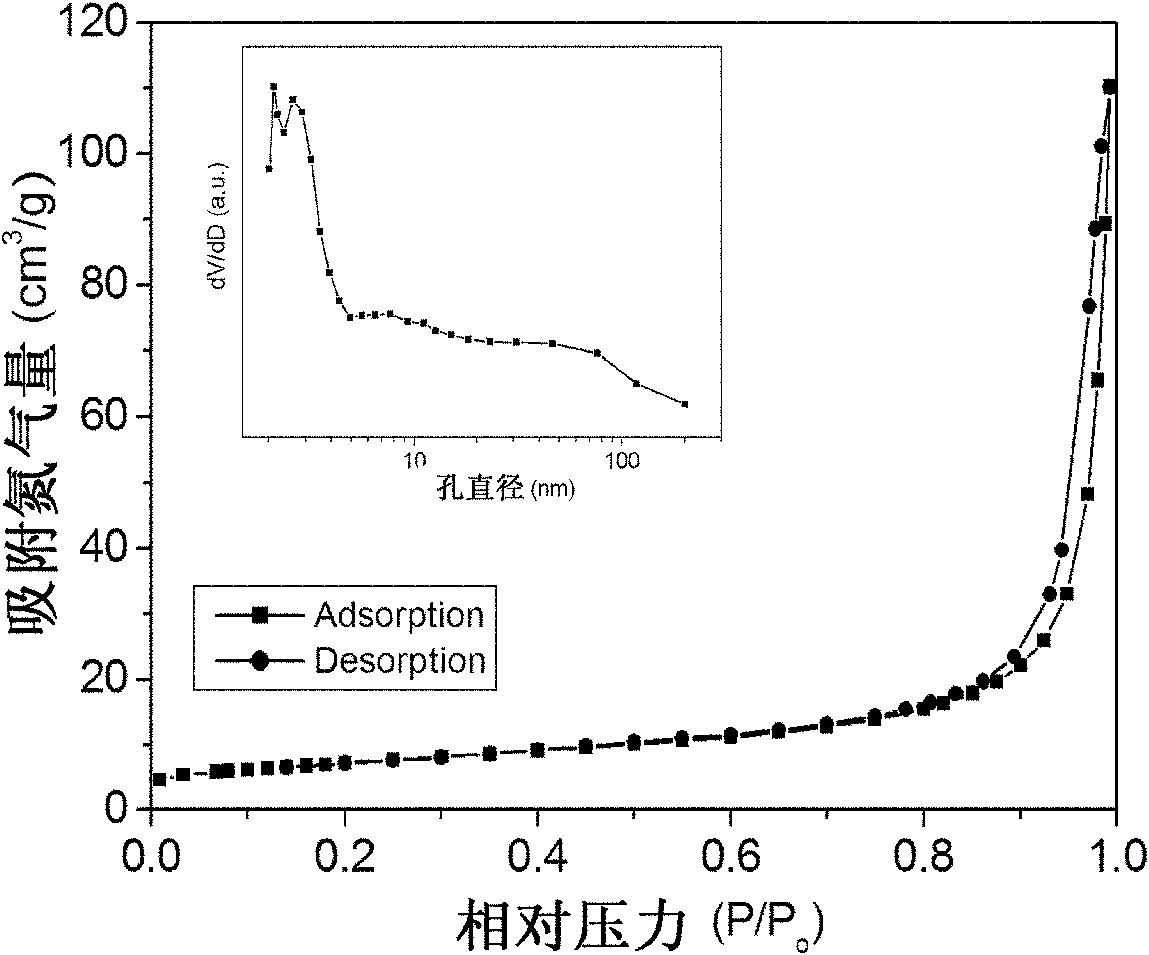

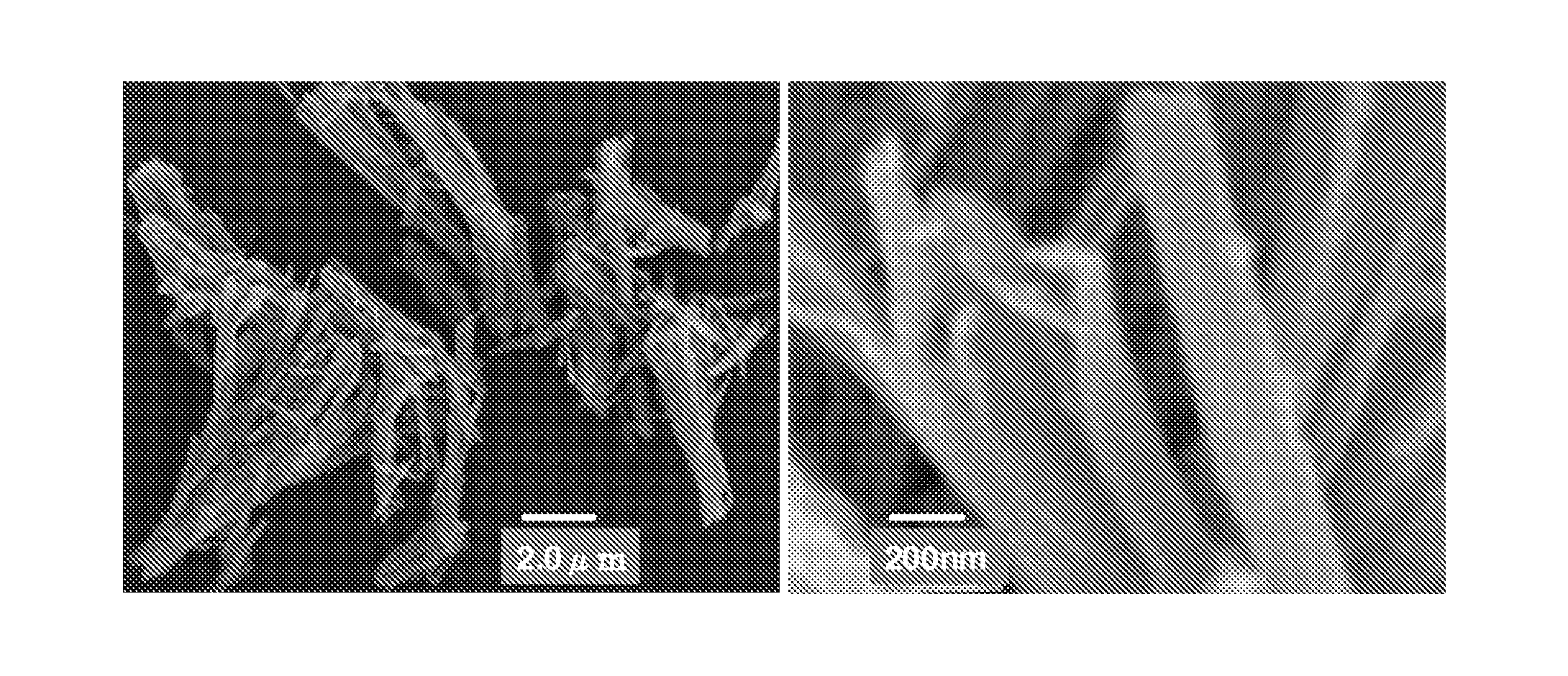

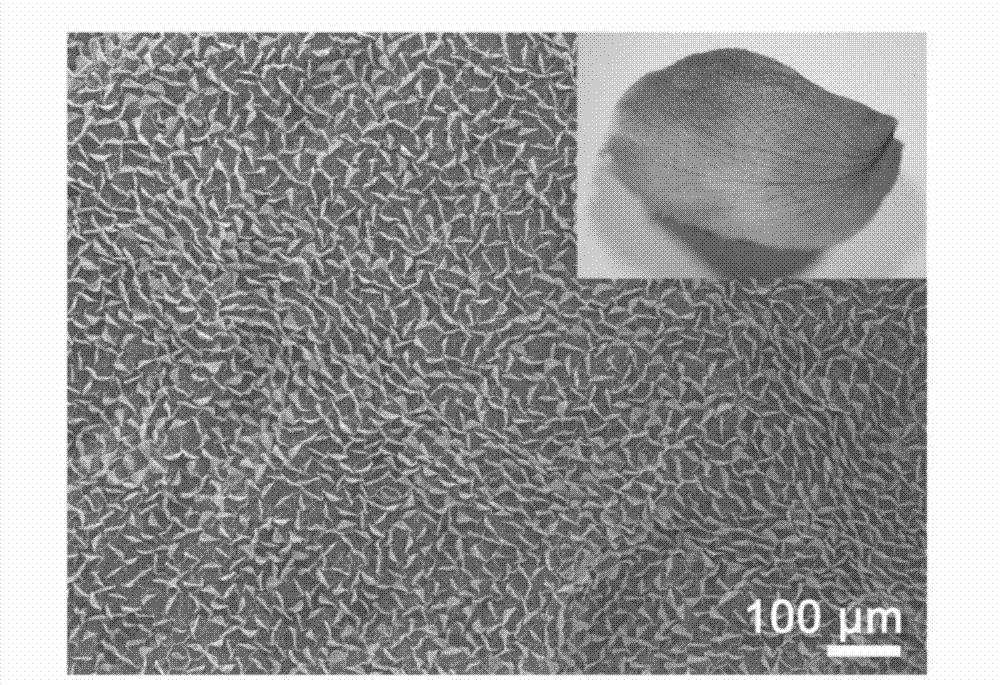

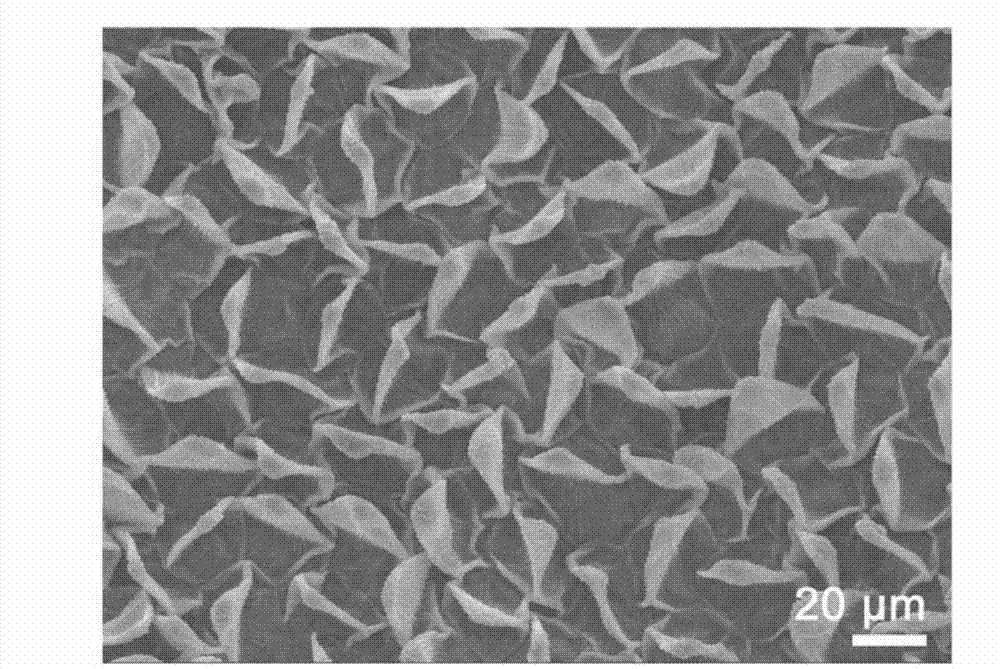

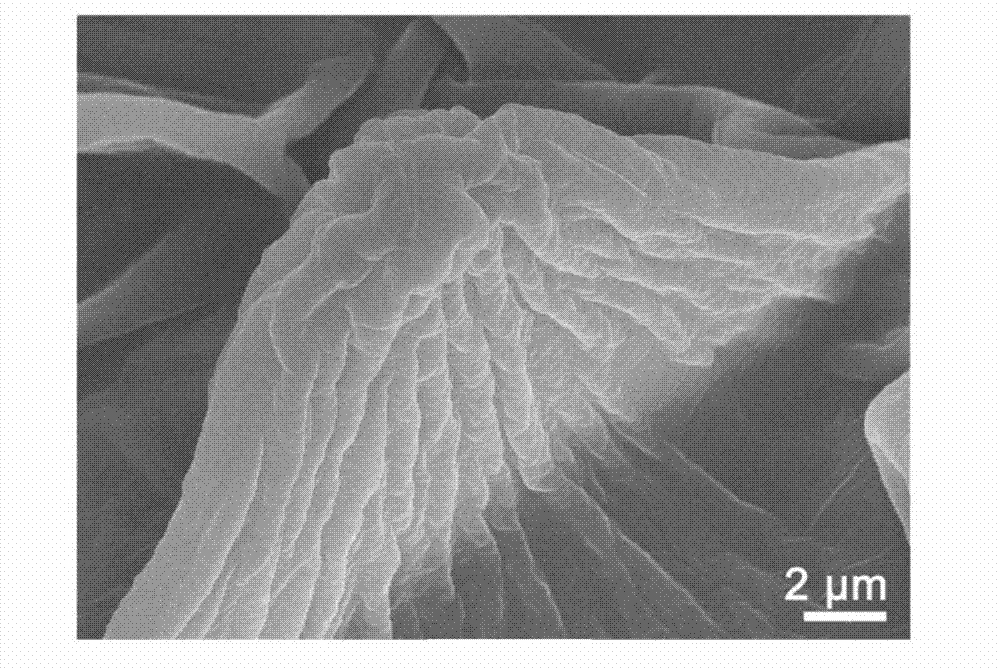

Preparation method and application of double-function micro-nano hierarchical structural zinc oxide power

InactiveCN102101693AAvoid expensiveReduce yieldZinc oxides/hydroxidesNanotechnologyMicro nanoWater soluble

The invention discloses a preparation method and application of double-function micro-nano hierarchical structural zinc oxide power. The preparation method is characterized by comprising the following steps of: dissolving water-soluble zinc salt and sodium hydroxide into an aqueous solvent according to the mole ratio of 1:4-1:7 to obtain a solution; reacting the obtained solution at 80-100 DEG C under a sealed condition to generate white precipitates; and separating, washing and drying the white precipitates to obtain the micro-nano hierarchical structural zinc oxide power. The preparation method has a simple process and a low cost; and in addition, prepared nano-structural zinc oxide has higher photocatalytic activity and superhydrophobic property and good stability.

Owner:ANHUI UNIV OF SCI & TECH

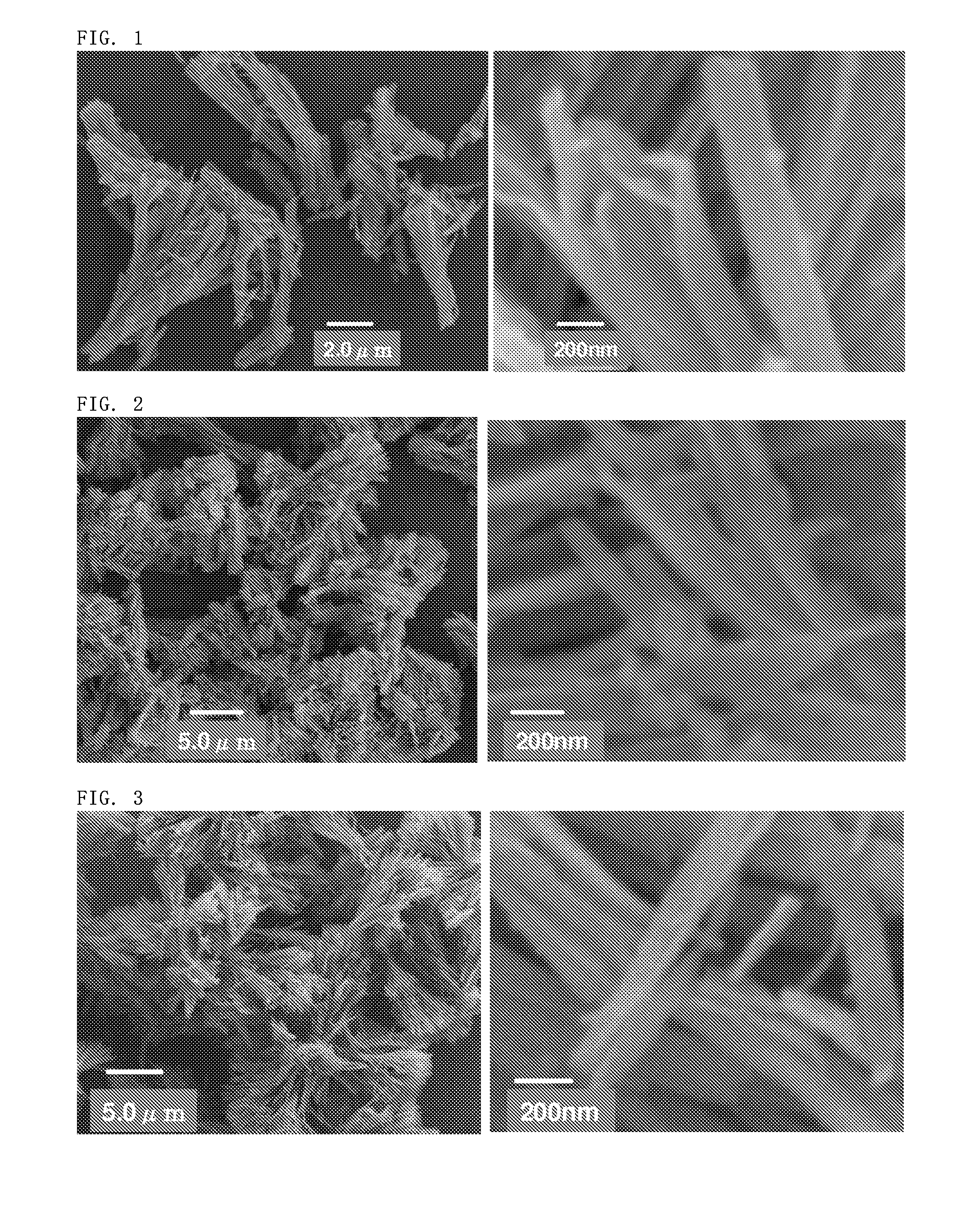

Superhydrophobic powders, structure with superhydrophobic surface, and processes for producing these

A process for producing superhydrophobic powders comprising silica as the main component and the surface of the powders have a contact angle with water of 150° or larger; and a structure having a superhydrophobic surface comprising the powders. The process comprised: introducing hydrophobic groups into the silica present in the surface of aggregates of organic / inorganic composite nanofibers obtained by combining a polymer, which is an organic substance, with silica, which is an inorganic substance, on the order of nanometer or into the silica obtained by calcining the organic / inorganic composite nanofibers and removing the polymer there from; and thereby making powders composed of the aggregates superhydrophobic. Also provided is a superhydrophobic powders obtained by the process. The structure having a superhydrophobic surface is obtained by fixing the superhydrophobic powders to a surface of a solid substrate.

Owner:DAINIPPON INK & CHEM INC +1

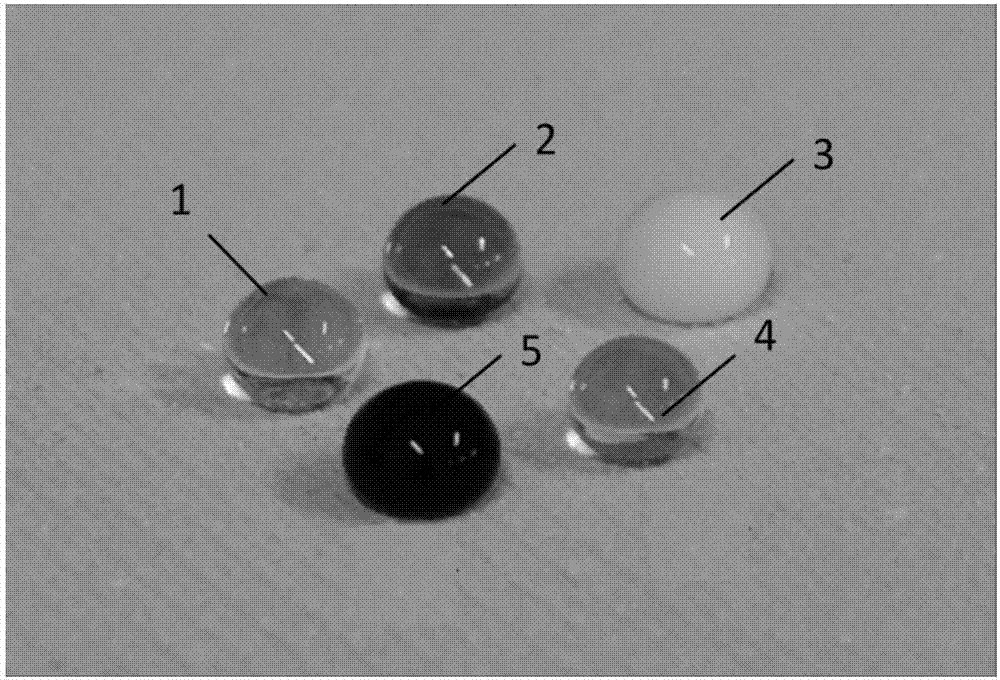

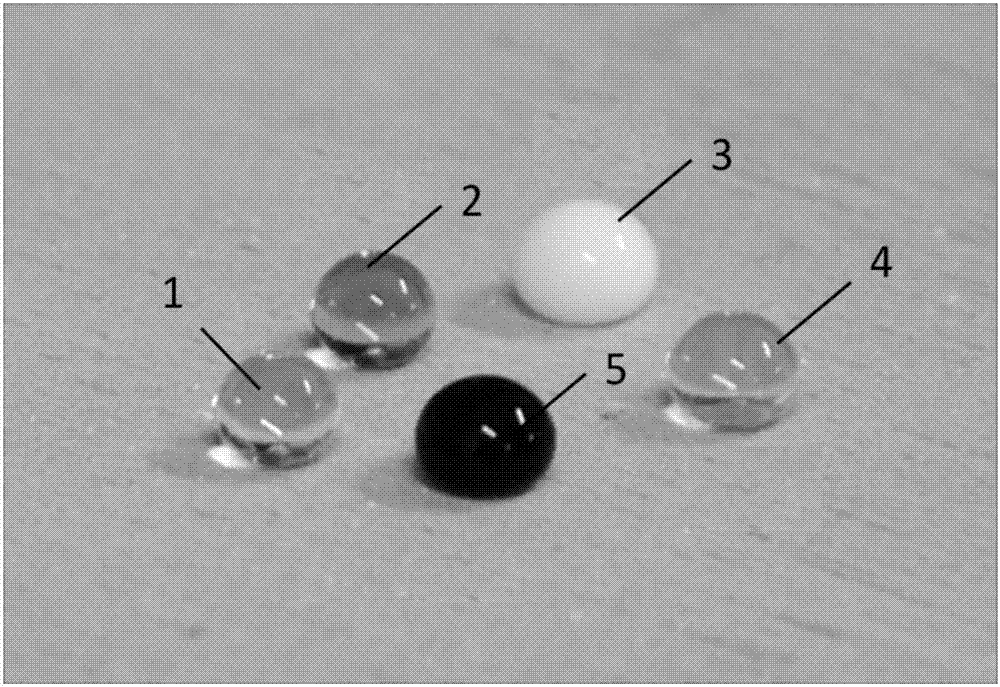

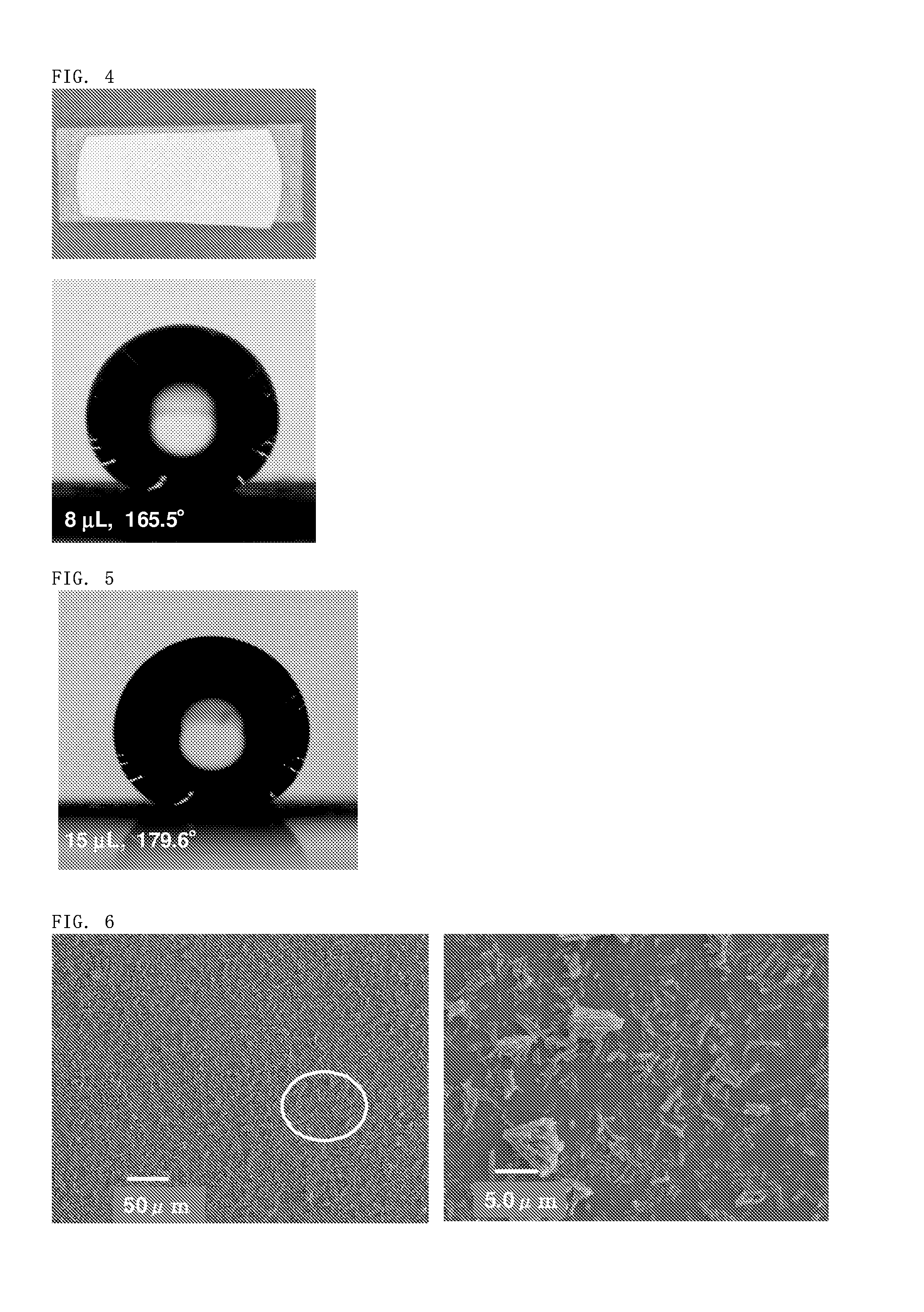

Super-hydrophilic particle hybridized super-hydrophobic coating and preparation method thereof

The invention relates to a super-hydrophilic particle hybridized super-hydrophobic coating and a preparation method thereof. A substrate is ultrasonically cleaned through acetone, absolute ethyl alcohol and deionized water in sequence for 15 min, and oil stain and dust on the surface are removed; then, absolute ethyl alcohol is used for elution, and cold-blast air is used for drying for use. Nanometer SiO2 sol is subjected to fluoroalkyl silane modification, a super-hydrophobic coating spraying solution is obtained, a super-hydrophilic monodisperse sphere type nanometer SiO2 solution, silica powder and glass beads are added into the super-hydrophobic coating spraying solution, stirred to be uniform and sprayed on the substrate, and after solidification, the super-hydrophilic particle hybridized super-hydrophobic coating is obtained. The coating has the low adhesion and super-hydrophobicity, and the condensation and dewfall efficiency and the dewdrop adsorption amount are remarkably high compared with a super-hydrophobic coating. The preparation technology is simple, no pollution is caused, operation is easy, the apparent mass is good, the cost is low, and wide application prospect and huge market benefits are achieved on the aspects of heat exchangers, water collection, seawater desalination and the like.

Owner:SOUTHEAST UNIV

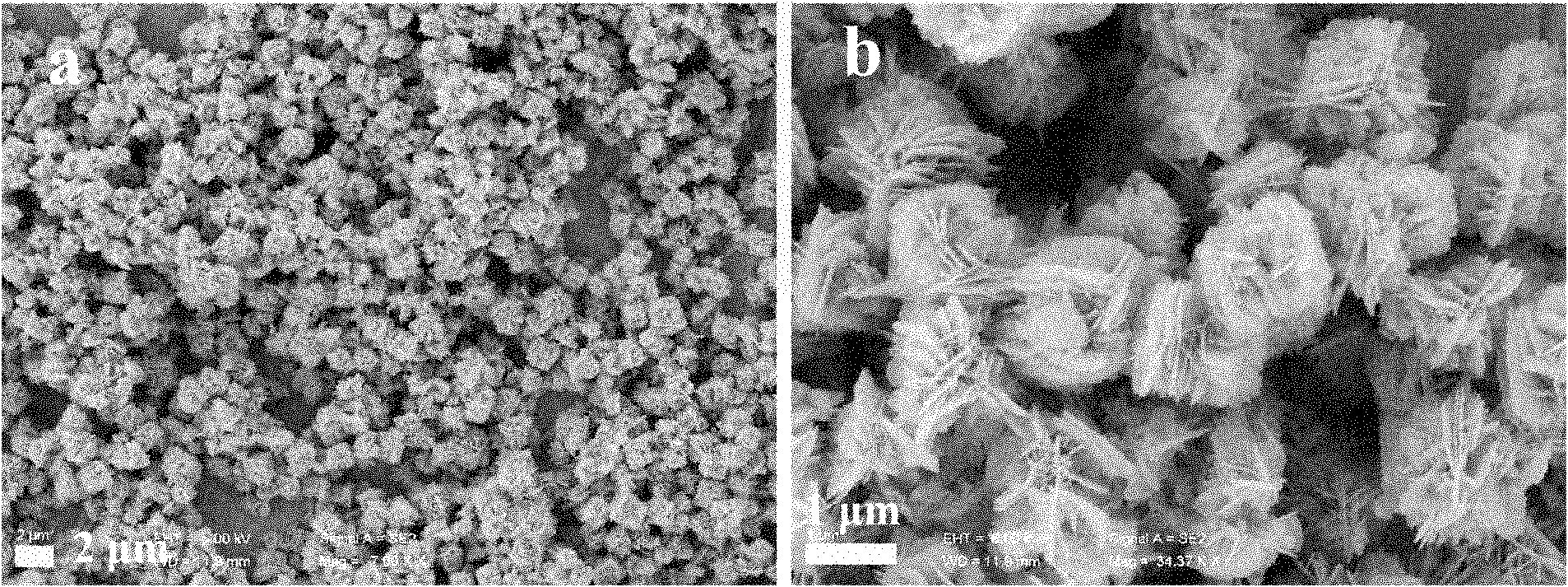

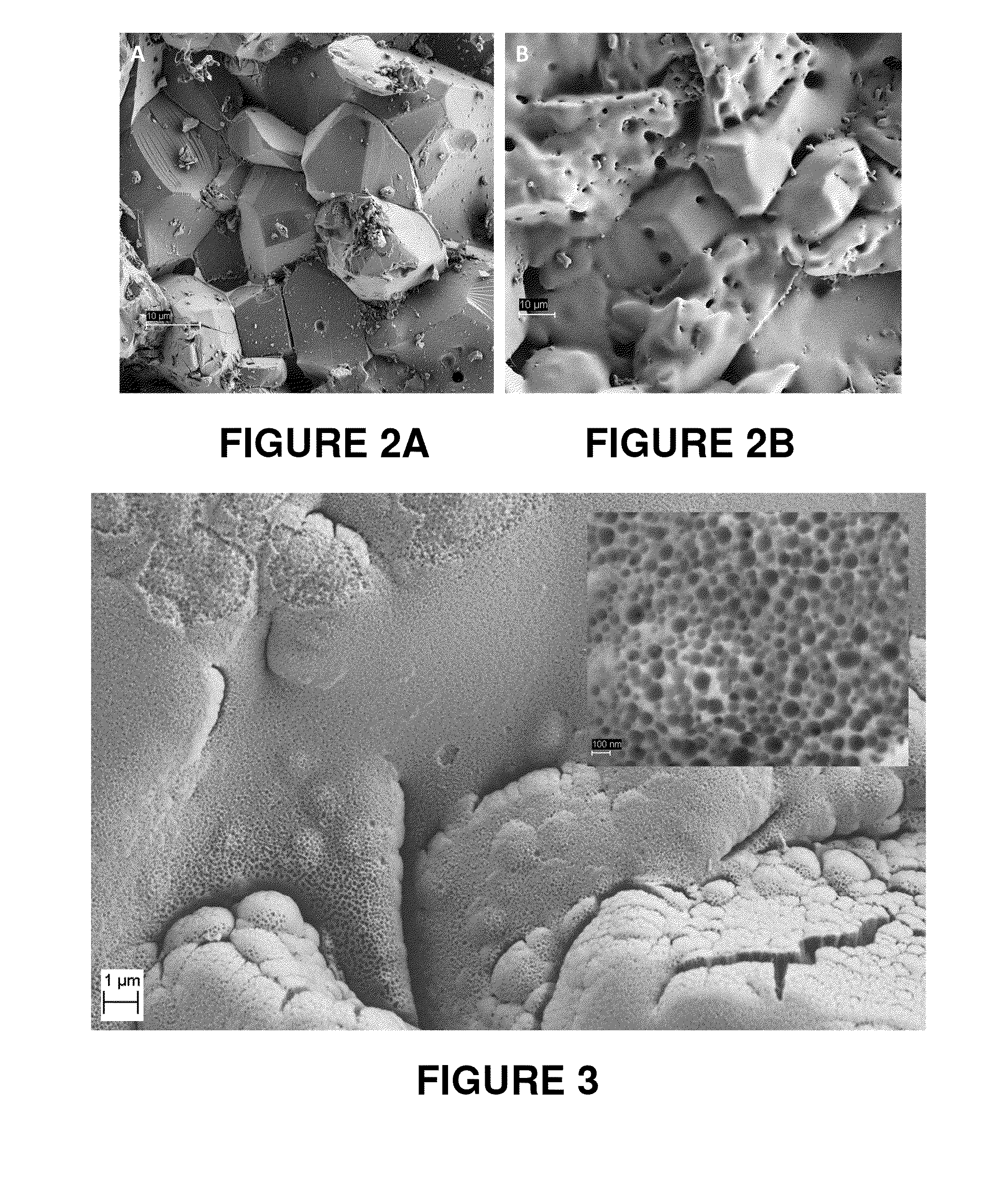

Micro-nanostructure controlled copper-based superhydrophobic surface and preparation method and application thereof

InactiveCN107522161AReduce pollutionEasy to mass manufactureSemi-permeable membranesVolume/mass flow by thermal effectsMicro structureNanowire

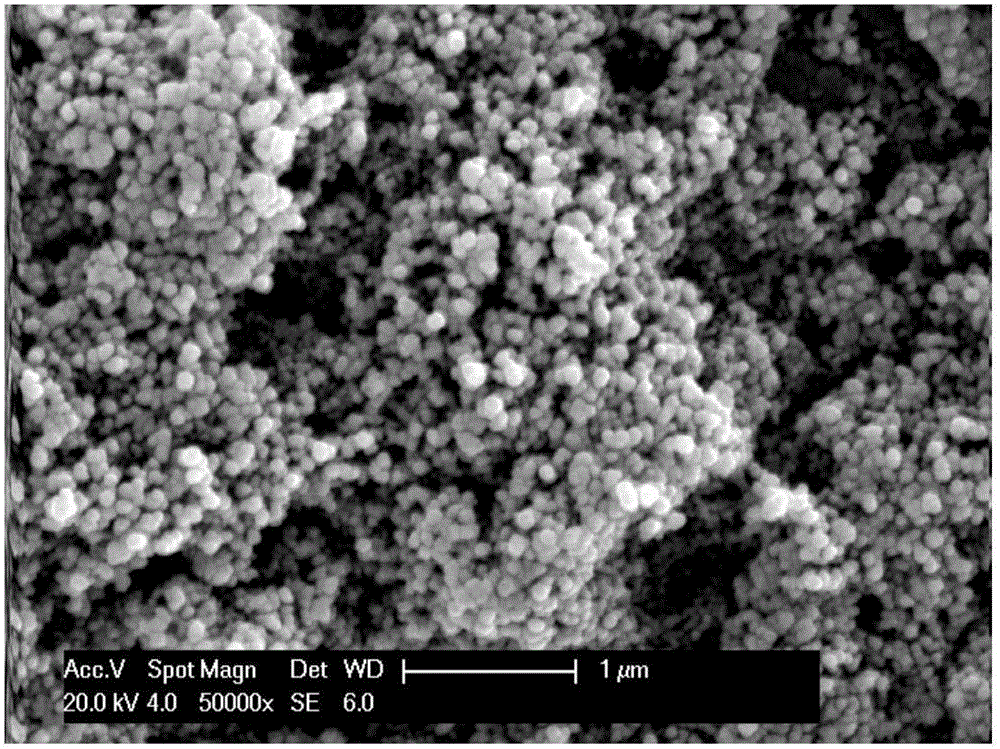

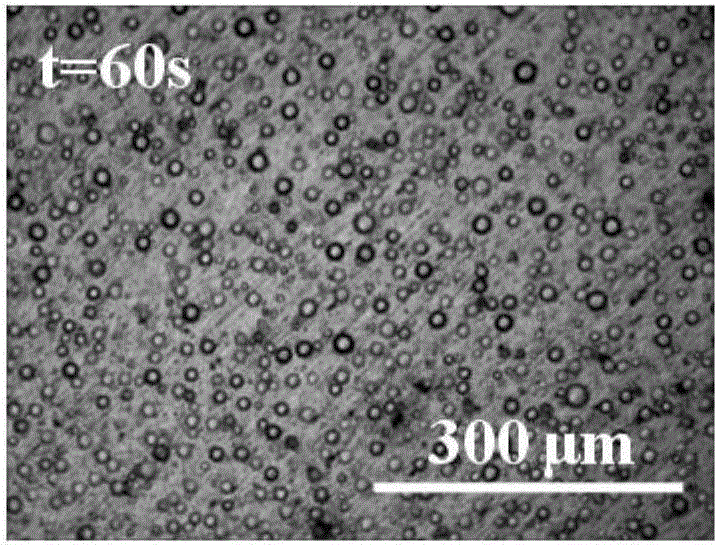

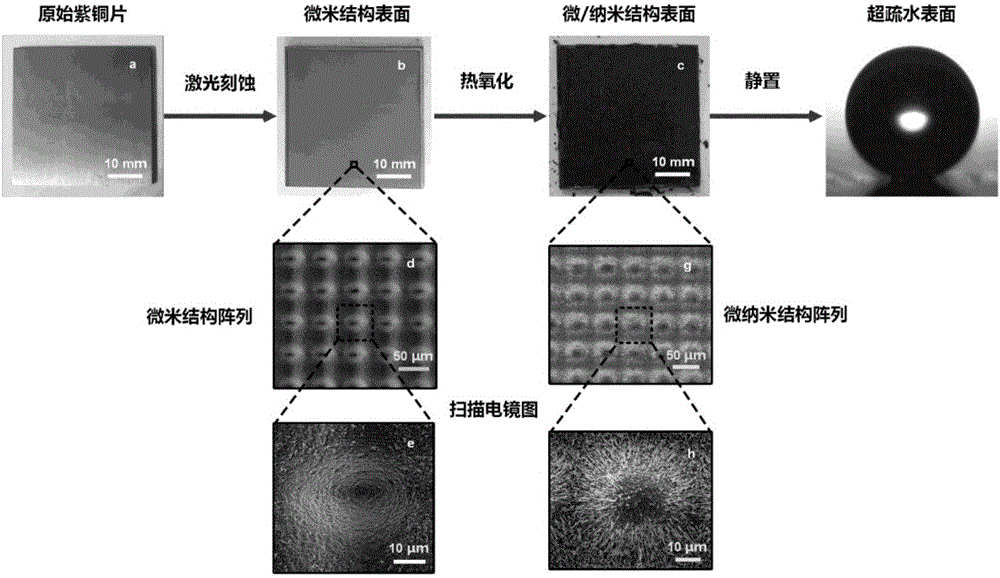

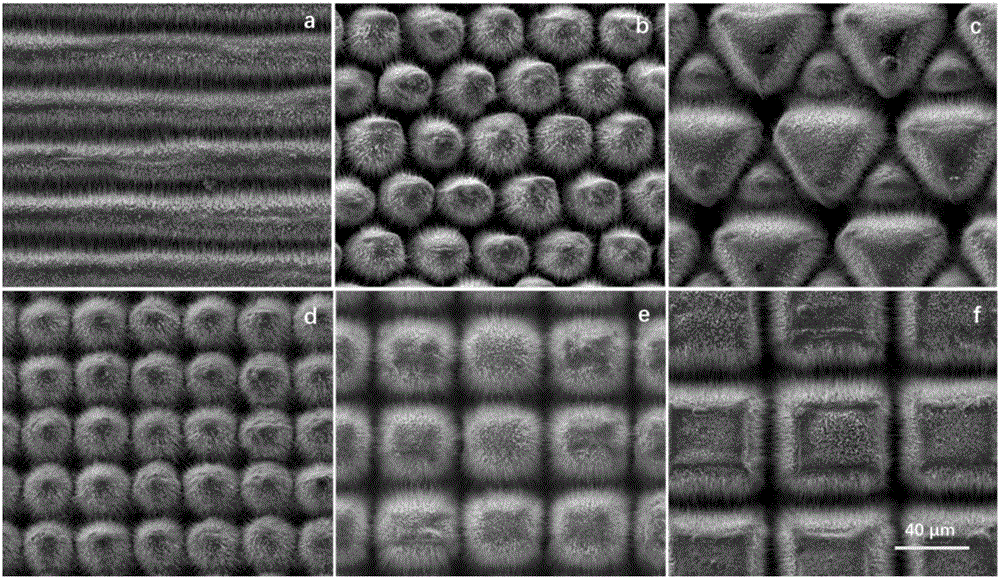

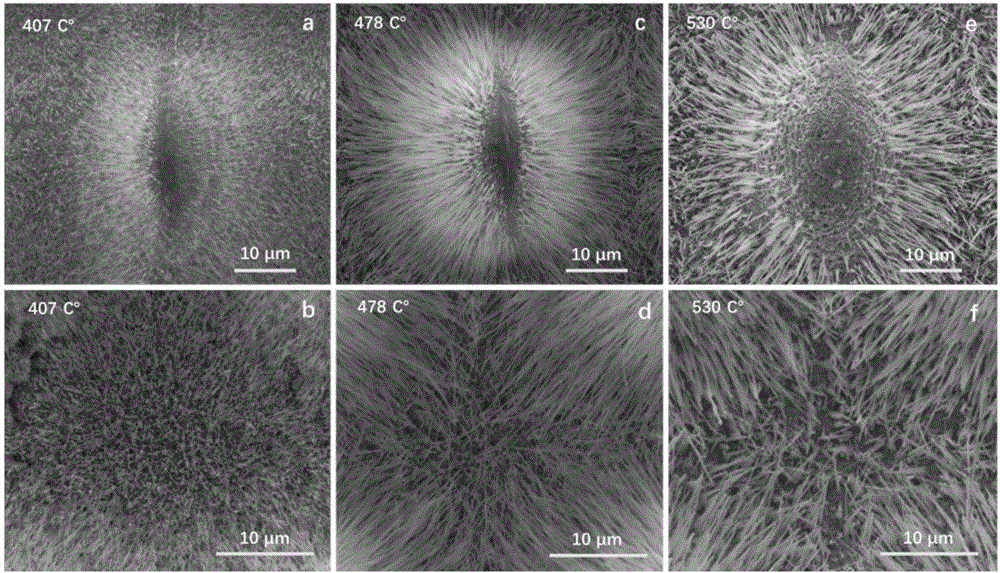

The invention discloses a micro-nanostructure controlled copper-based superhydrophobic surface and a preparation method and application thereof. The copper-based superhydrophobic surface comprises micro structure arrays and nanowires, wherein center spacing of the micro structure arrays is 10 to 500[mu]m, the height of each micro structure array is 5 to 500[mu]m; the nanowires have the diameter of 40 to 200nm, the length of 2 to 50[mu]m and average spacing of 0.1 to 3[mu]m; and the nanowires grow in parallel to the direction of a local normal of the copper-based superhydrophobic surface and has the ingredient being copper oxide. The copper-based superhydrophobic surface can implement liquid droplet bouncing heat exchange of water vapor condensation and can also promote classical droplet condensation so as to reinforce heat exchange. Moreover, the micro-nanostructure controlled copper-based superhydrophobic surface can also be used for the fields of self-cleaning, corrosion resistance, ice prevention, frosting resistance and the like.

Owner:TSINGHUA UNIV

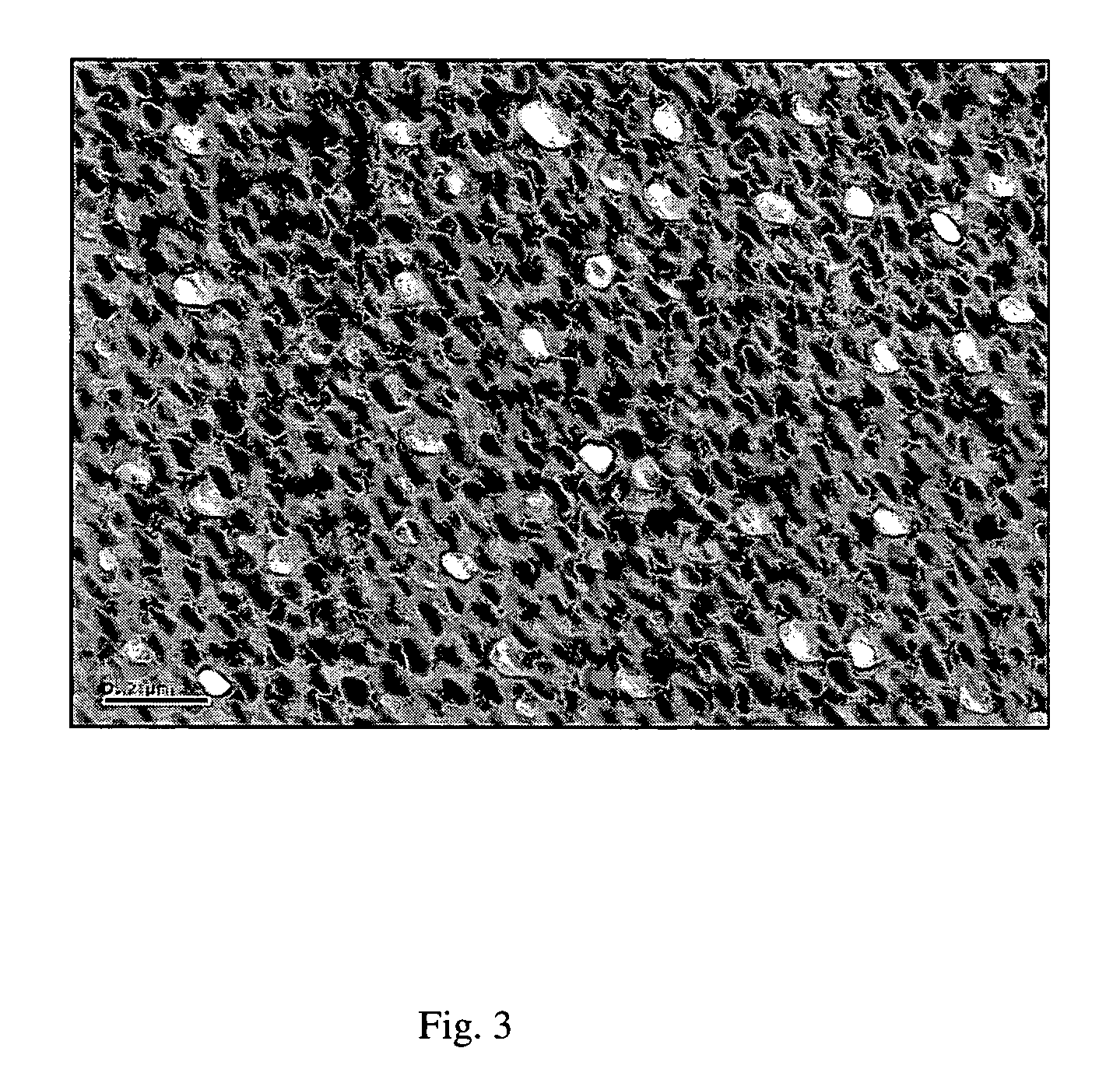

Super-hydrophobic functional material, preparation method and application of the same

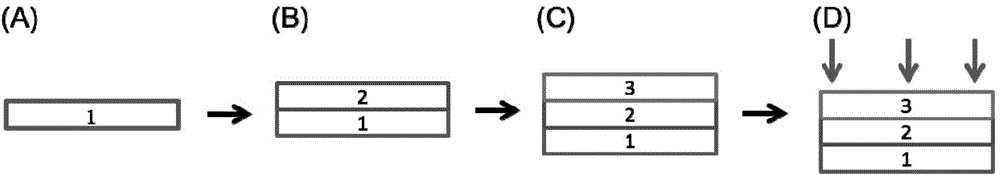

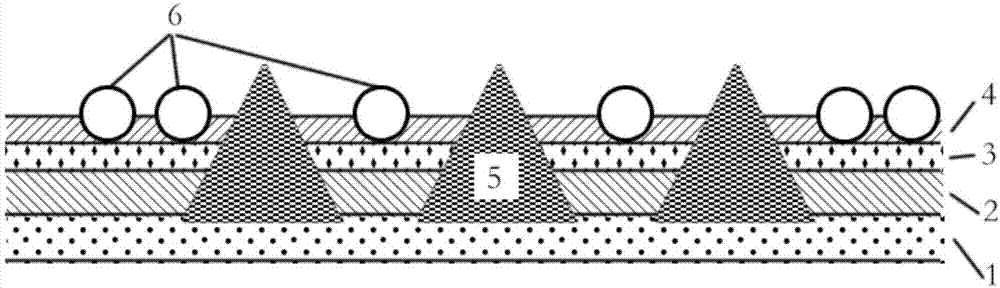

The invention provides a preparation method of a super-hydrophobic functional material. The method comprises the steps: firstly, preparing a PDMS (polydimethylsiloxane) thin film; secondly, dropping a dispersing agent with solid particles on the surface of the PDMS and uniformly dispersing the dispersing agent to form a laminar structure; and finally, processing the laminar structure by ultraviolet irradiation or heating to form the material with super-hydrophobic functions. The contact angle of the material can be up to more than 150 degrees after optimization, and meanwhile, the material has a very small rolling angle, so that the requirement of the super-hydrophobic material is satisfied; water drops on the material are difficult to attach and easy to fall off, so that the material still keeps dry and realizes the self-cleaning function. Particles are located on the outermost layer, so that the decomposition of the PDMS resulting from direct solar radiation is avoided and the other functions such as photocatalysis, sterilization and electric conduction except for the hydrophobicity can be realized by using particles. The preparation method is simple and is capable of satisfying the requirements of the large-scale and high-efficiency production.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

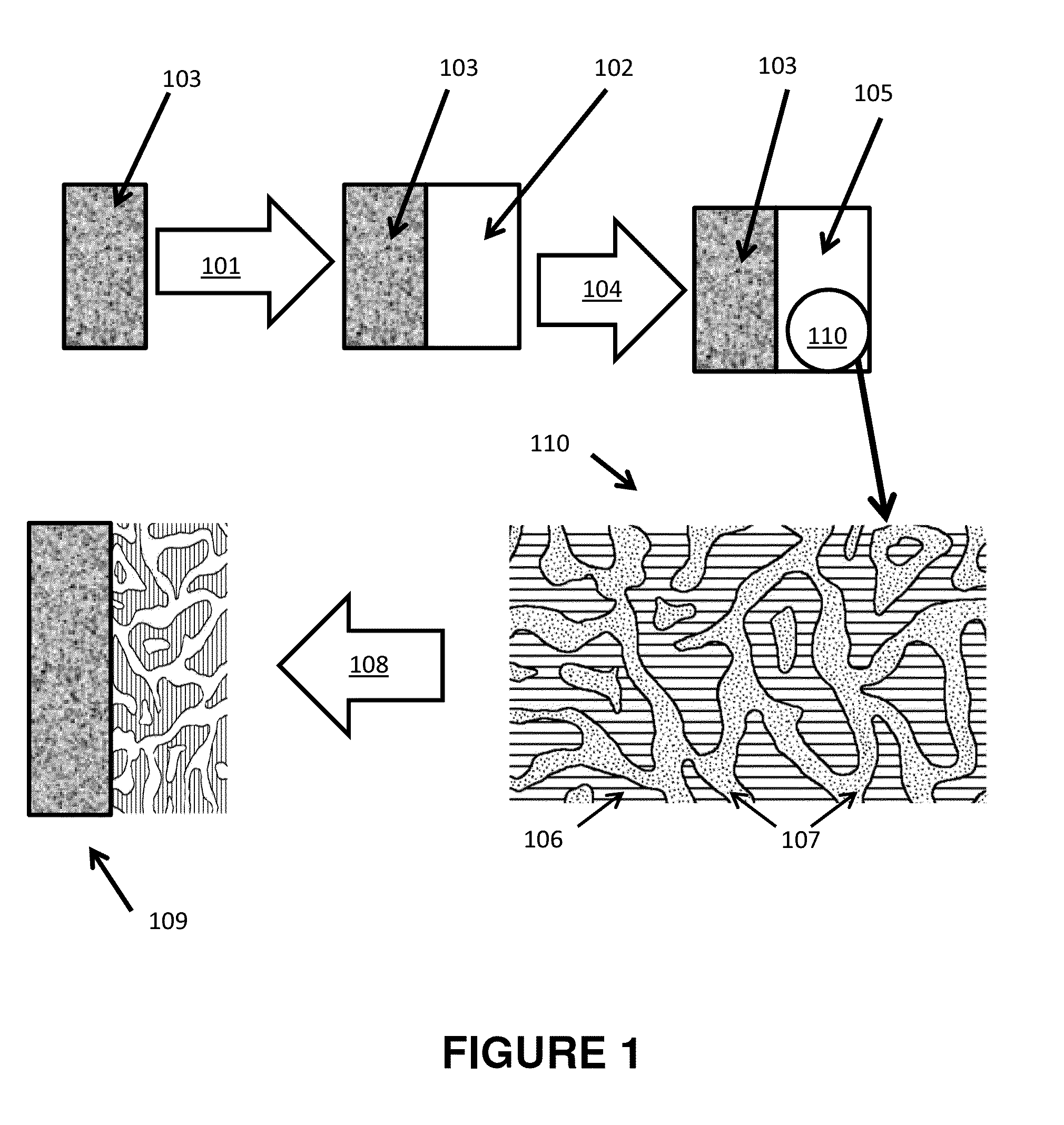

Preparation method of superhydrophilic/superhydrophobic composite nanofiltration membrane

ActiveCN104759214ARealize roughness controlAchieving cut-off separationSemi-permeable membranesPolyelectrolyteOrganic solvent

The invention relates to a preparation method of a superhydrophilic / superhydrophobic composite nanofiltration membrane, belonging to the technical field of membrane separation. The preparation method comprises the following steps: putting a pretreated base membrane in a polycation electrolyte solution, washing with water, putting in a polyanion electrolyte solution, washing with water, and alternately assembling many times to form a predissociation layer; putting the membrane containing the predissociation layer in a soluble calcium salt polycation electrolyte solution, taking out, washing with water, putting in a soluble-silicate-containing polyanion electrolyte solution, taking out, washing with water, and repeating many times to obtain a polyelectrolyte / calcium silicate hydrate superhydrophilic composite nanofiltration membrane; and putting the superhydrophilic membrane in a fluorosilane ethanol water solution, immersing for 40-90 minutes, flushing with deionized water, and drying and solidifying in a drying oven. The superhydrophilic nanofiltration membrane can implement entrapping separation on the water-soluble dye molecules, and the superhydrophobic nanofiltration membrane can implement entrapping separation on organic solvent dye molecules.

Owner:陕西禹慧智通环保科技有限公司

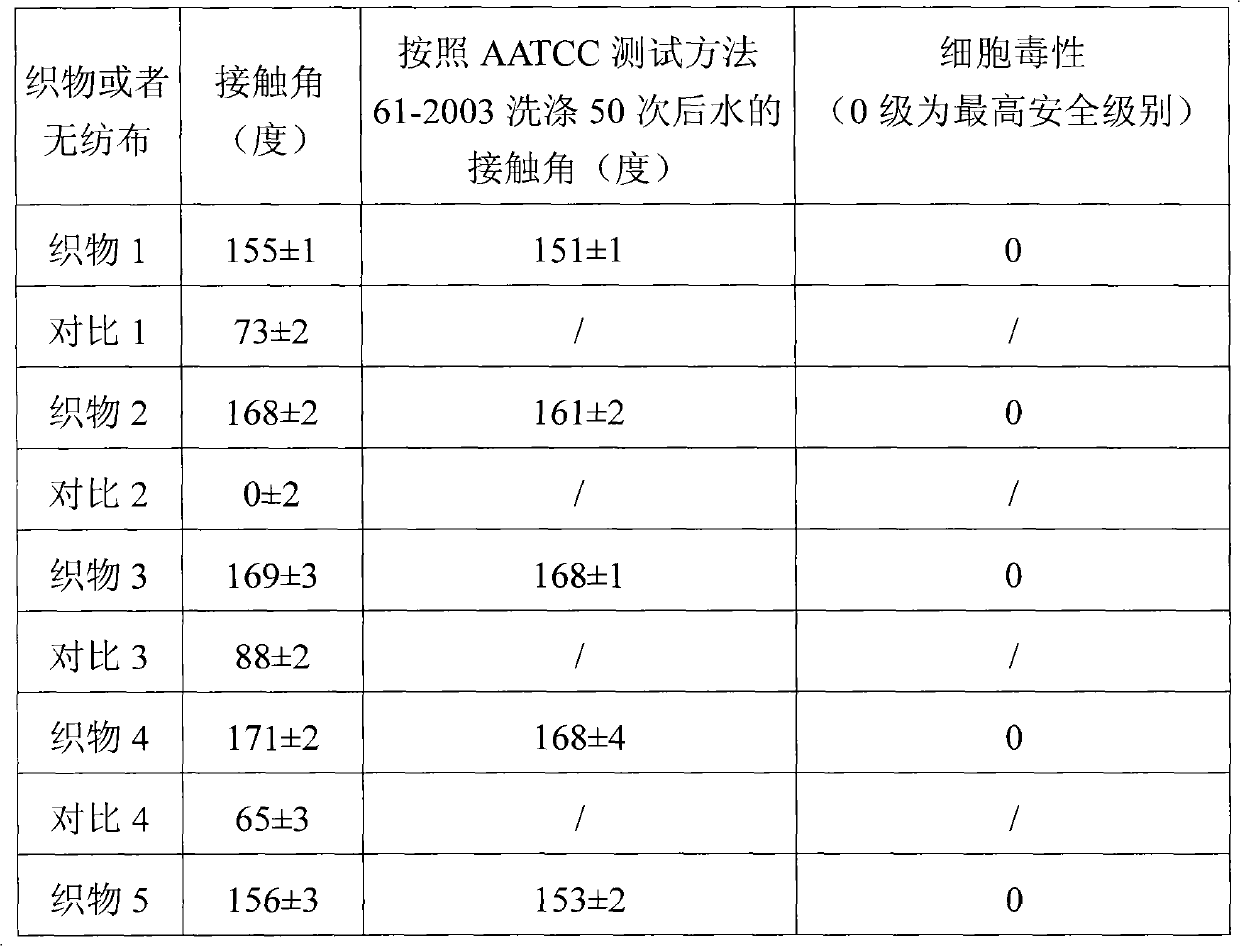

Superhydrophobic fabric or superhydrophobic non-woven fabric and preparation method thereof

The invention provides a preparation method of a superhydrophobic fabric or superhydrophobic non-woven fabric, which comprises the following step of: enabling a fabric containing C-H bonds or a non-woven fabric containing C-H bonds to be subjected to irradiation grafting reaction with a monomer containing long-chain alkane, thus obtaining the superhydrophobic fabric or superhydrophobic non-woven fabric, wherein the monomer containing long-chain alkane is a compound as shown in general formula (1), X is hydrogen or methyl, and n is 10-17, preferably 13-17. The invention overcomes the defects that the existing preparation process of the superhydrophobic fabric or non-woven fabric is complicated, the duration time of the modification effect is short, and the superhydrophobic fabric or non-woven fabric is intolerant of washing, is of certain toxicity, is high in cost and the like, thereby providing a washing-resistant permanent superhydrophobic fabric or non-woven fabric and a preparationmethod thereof. Since the used monomer is a non-fluorine monomer having the advantages of low toxicity, low cost and the like, the invention is beneficial to large-scale industrial production. The general formula (1) is shown in the specification.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

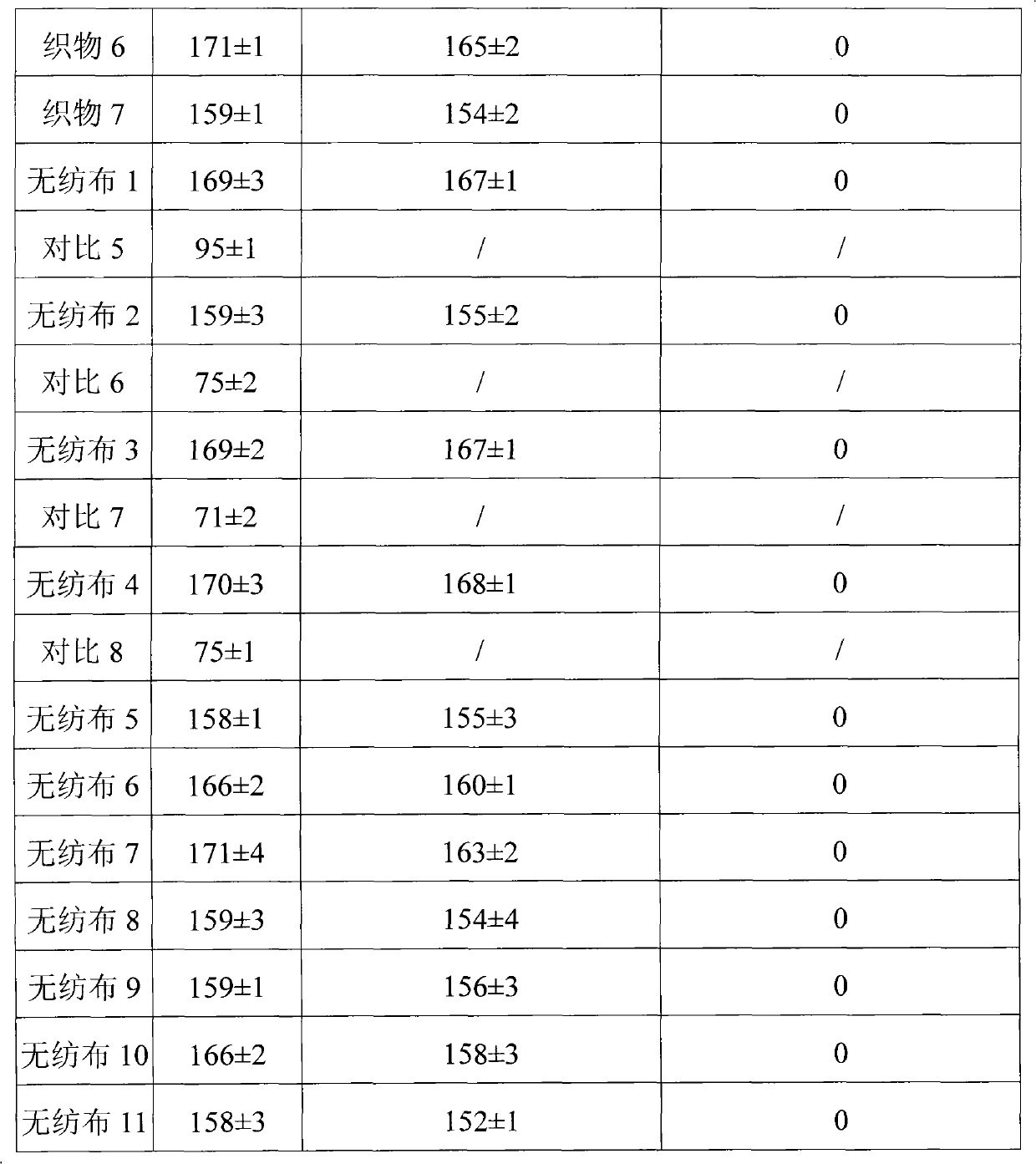

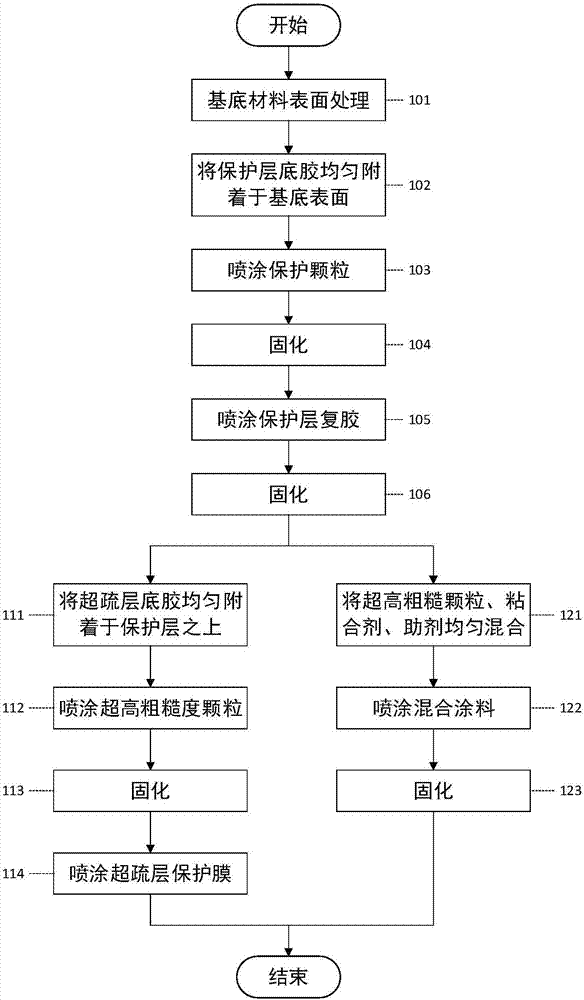

Coating prepared from particles with ultrahigh roughness

ActiveCN107254237AImprove performanceOvercome structurePretreated surfacesPolyurea/polyurethane coatingsSuperhydrophobic coatingLotus effect

The invention provides a superhydrophobic coating prepared from particles with ultrahigh roughness. The superhydrophobic coating is prepared from the following components: particles with protrusions or holes and unsmooth structures, protective particles, a bonding agent and an assistant, wherein the volume ratio of the particles with the protrusions or the holes and the unsmooth structures to the protective particles to the bonding agent is (0.1-7):(1-7):(1-10). A lotus effect technical theory is applied to obtain a super-hydrophobic, underwater superhydrophobic oil or super-amphiphobic surface coating, further the performance of the coating is improved, and the defects of the conventional superhydrophobic coating that the structure is easy to damage, the service life is short and the like are overcome. The prepared coating has super hydrophobic properties (super-hydrophobic, underwater superhydrophobic oil or super-amphiphobic properties), self-cleanness and excellent wear resistance; substrate materials suitable for the coating are glass, plastic, rubber, textiles, paper, metal, cement, ceramic materials or the materials covering other coatings.

Owner:HONGDA TECH BEIJING CO LTD

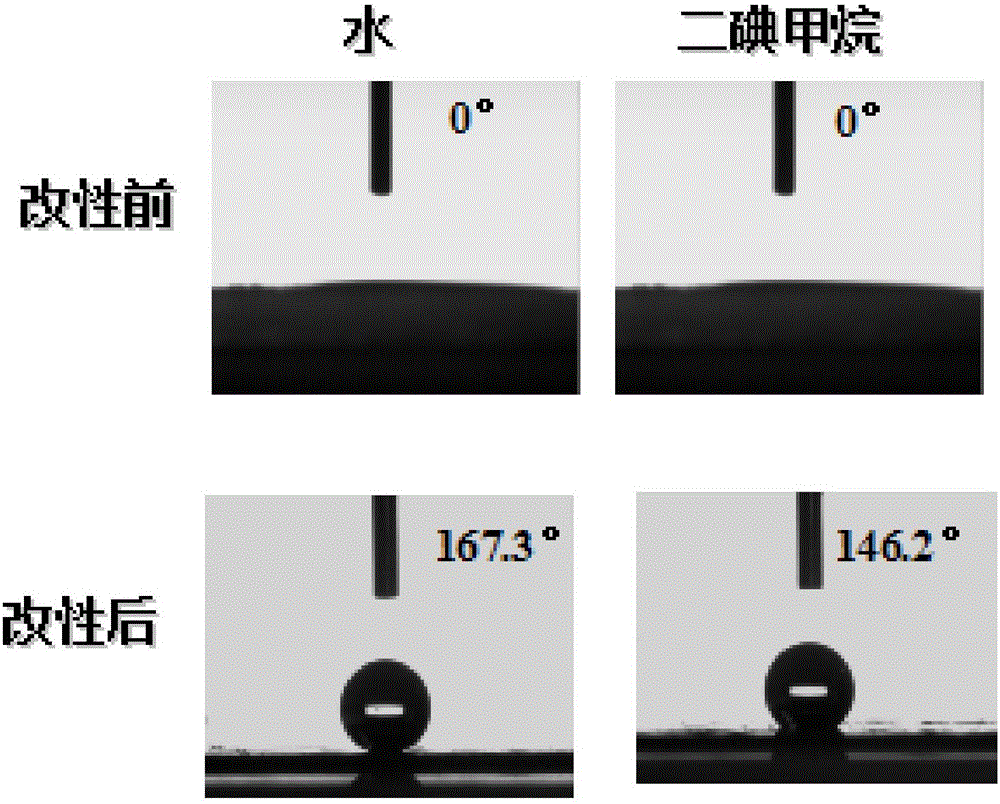

Superhydrophobic oleophobic modification method of porous membrane

ActiveCN106390764AImprove stabilityImprove wear resistanceSemi-permeable membranesDiiodomethaneFiltration

The invention relates to a superhydrophobic oleophobic modification method of a porous membrane, and belongs to the technical field of separation membrane. According to the present invention, based on the self-cleaning bionic principle, fluorosilane-modified SiO2 nanoparticles having low surface energy are dispersed in an organic solution to prepare a uniform dispersion liquid, and a porous membrane is subjected to superhydrophobic oleophobic modification by using a dynamic filtration method to prepare the amphiphobic composite membrane having good stability, wherein the water contact angle of the amphiphobic composite membrane surface can achieve 167.3+ / -1 DEG C, the contact angle of diiodomethane can achieve 145.9+ / -1 DEG C, and the good amphiphobic property is presented; and method has characteristics of no requirement of complex equipment, simple and easy-performing process and short preparation period, and the prepared membrane has characteristics of high flux and good pollution resistance.

Owner:BEIJING UNIV OF TECH

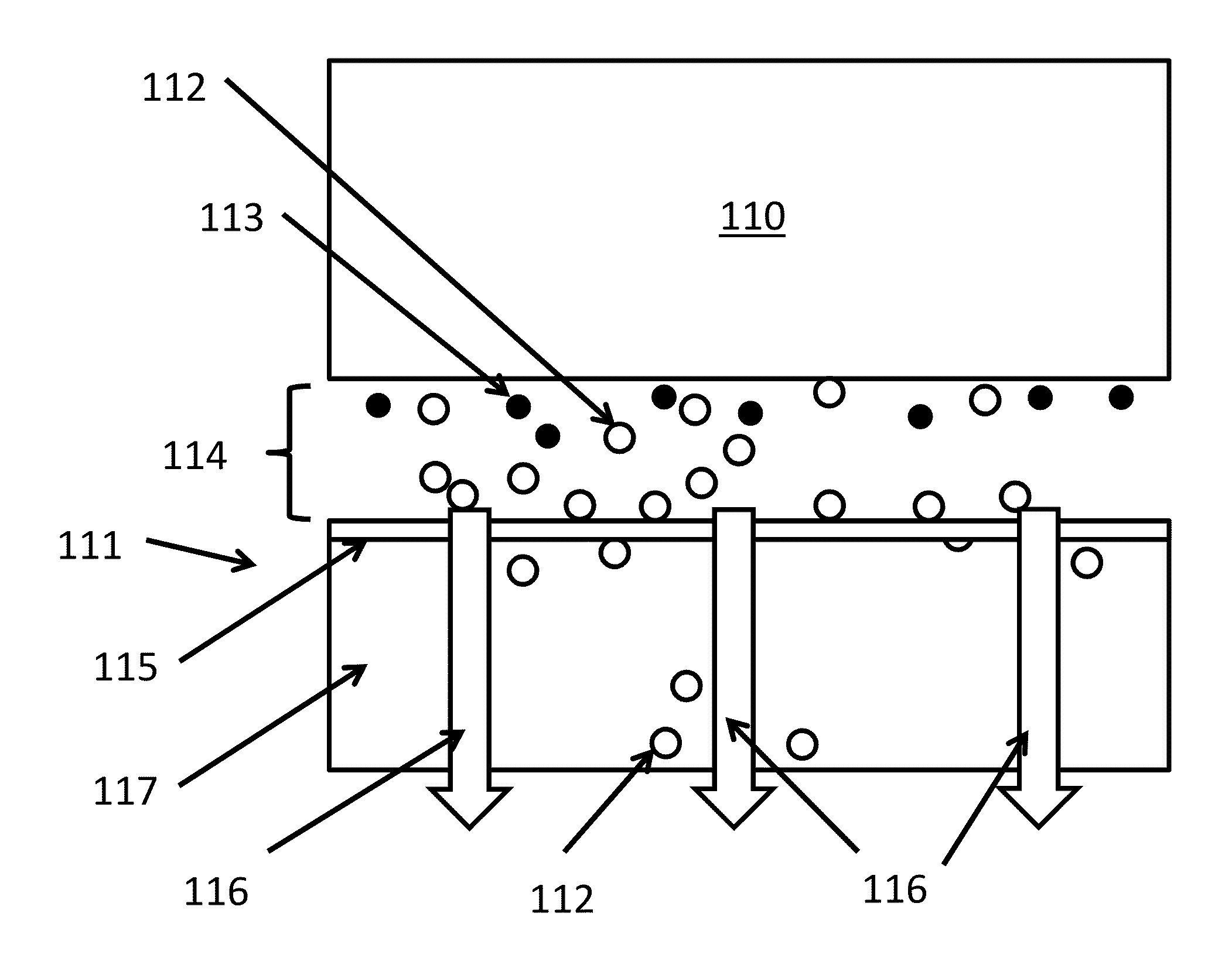

Super-surface selective nanomembranes providing simultaneous high permeation flux and high selectivity

ActiveUS20140116944A1Improve throughputEasy to separateMembranesPaper/cardboard articlesSuperhydrophobeMembrane configuration

Superhydrophobic membrane structures having a beneficial combination of throughput and a selectivity. Methods of making and using the membrane structures.

Owner:UT BATTELLE LLC

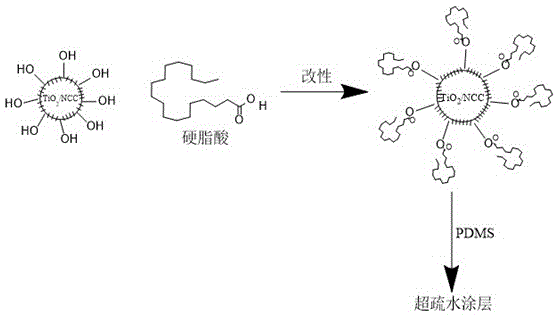

Method for preparing superhydrophobic coating by nano-crystalline cellulose template method

ActiveCN105153819ASimple preparation processImprove adhesionCellulose coatingsSuperhydrophobic coatingStearic acid

The invention provides a method for preparing a superhydrophobic coating by a nano-crystalline cellulose template method. Nano TiO2 with controllable particle diameter is generated on the surface of nano-crystalline cellulose in situ, the surface of nano TiO2 is subjected to hydrophobic modification through stearic acid, absolute ethyl alcohol is a solvent, and sodium dodecyl benzene sulfonate is a dispersant. TiO2 and PDMS (polydimethylsiloxane) which are modified by taking nano-crystalline cellulose (NCC) as the template are compounded and co-blended mechanically, and heat treatment is performed to obtain the superhydrophobic coating. The method has the advantages that as stearic acid serves as the modifier, and hydrophobic-CH3 group is introduced, the surface energy of TiO2 / NCC is reduced; polydimethylsiloxane and TiO2 / NCC are compounded, so that the adhesive force of the coating is improved, a micro / nano coarse structure is formed by interaction between TiO2 / NCC and inorganic nano particles, and accordingly, the shortcoming of poor adhesion of TiO2 / NCC is made up. The method is simple, the prepared coating can be widely added into various coatings to enhance the hydrophobicity, and the wearing resistance of a coating film can be guaranteed to a certain extent.

Owner:NANJING FORESTRY UNIV

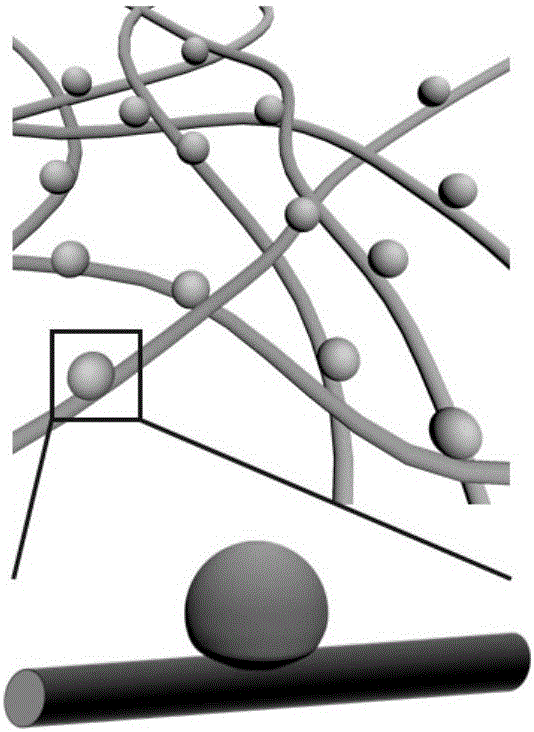

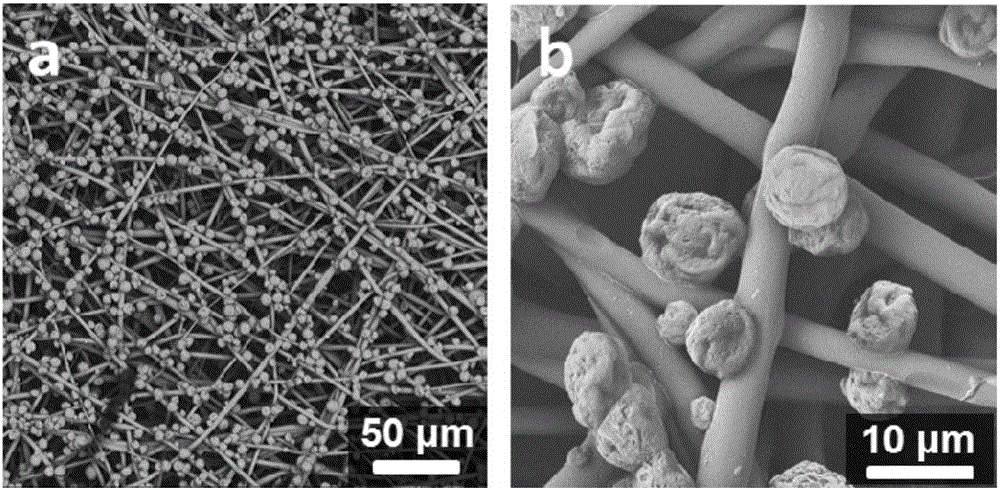

Water scour-resistant superhydrophobic composite membrane and preparation method and application thereof

InactiveCN106167551AExcellent superhydrophobic propertiesImprove water erosion resistanceArtificial thread manufacturing machinesElectro-spinningFiberSuperhydrophobe

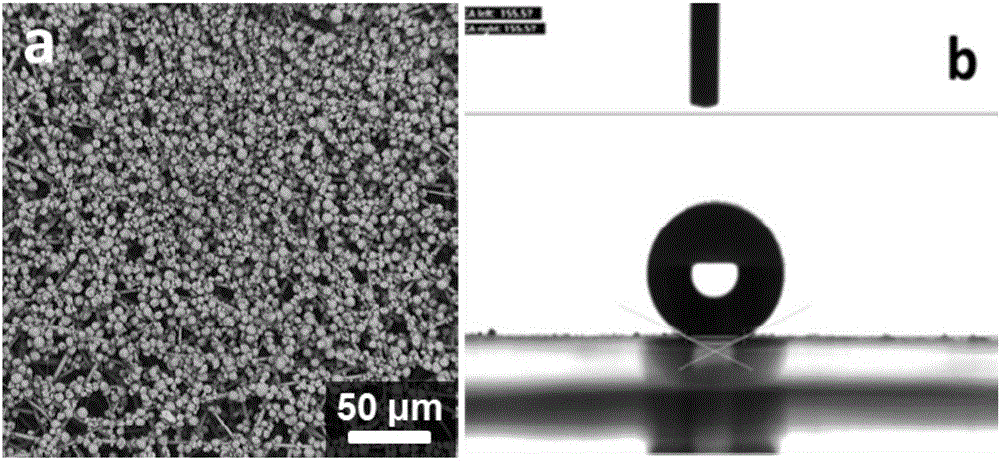

The invention belongs to the field of high polymer materials and discloses a water scour-resistant superhydrophobic composite fiber membrane and a preparation method and application thereof. A composite fiber membrane is prepared into high polymer fibers by adopting a hydrophobic high polymer material through an electrospinning technology; homogeneous or heterogenic hydrophobic high polymer material solution coats the fiber membrane through an electrospinning technology; the composite fiber membrane is subjected to physical or chemical crosslinking treatment, and finally the superhydrophobic composite fiber membrane which is composed of the fibers and microspheres and has the surface provided with a micro-nano structure is obtained. The diameters of the fibers in the water scour-resistant superhydrophobic composite fiber membrane are 100 nm to 20 [mu]m, and the microsphere dimension is 1-30 [mu]m. The micro-nano structure formed by the fibers and the microspheres in the composite fiber membrane is fixed, so that the water scour-resistant superhydrophobic composite fiber membrane has excellent superhydrophobic and scour-resistant performances, can be applied to the fields such as oil-water separation, self-cleaning, antifreezing and antibiosis and have a huge economic benefit potential.

Owner:SOUTH CHINA UNIV OF TECH

Superhydrophobic diatomaceous earth

A superhydrophobic powder is prepared by coating diatomaceous earth (DE) with a hydrophobic coating on the particle surface such that the coating conforms to the topography of the DE particles. The hydrophobic coating can be a self assembly monolayer of a perfluorinated silane coupling agent. The DE is preferably natural-grade DE where organic impurities have been removed. The superhydrophobic powder can be applied as a suspension in a binder solution to a substrate to produce a superhydrophobic surface on the substrate.

Owner:UT BATTELLE LLC

Enhanced Raman detection substrate based on natural biology super-hydrophobic structure surface and preparation method thereof

The invention belongs to the technical field of ultra-sensitive test analysis, and particularly relates to an enhanced Raman detection substrate which can be in mass production and is wide in application, efficient, environment-friendly and based on a natural biology super-hydrophobic structure surface and a preparation method thereof. The PVD (physical vapor deposition) and a self-assembly or chemical plating and coating film technology are utilized to cover a precious metal layer on the natural biology super-hydrophobic surface to form rough and hydrophobic surface enhanced Roman detection hot spot area so that the enhanced Raman detection substrate is formed. The natural super-hydrophobic structure surface is plant pedals, plant leaves or inset wings. The precious metal is gold or silver and the thickness of the precious metal layer ranges from 5 nm to 50 nm. The hydrophobic SERS (surface enhanced Raman scattering) detection substrate has high sensitivity, and the detection limit can reach 10-9. The enhanced Raman detection substrate draws materials from the natural hydrophobic biology surface, so that the sensitivity is high, the performance is stable, the cost is low, and the pollution to the environment is prevented.

Owner:JILIN UNIV

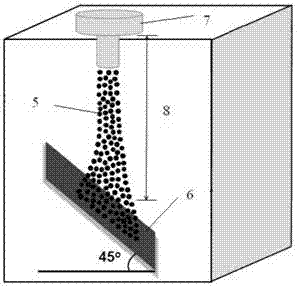

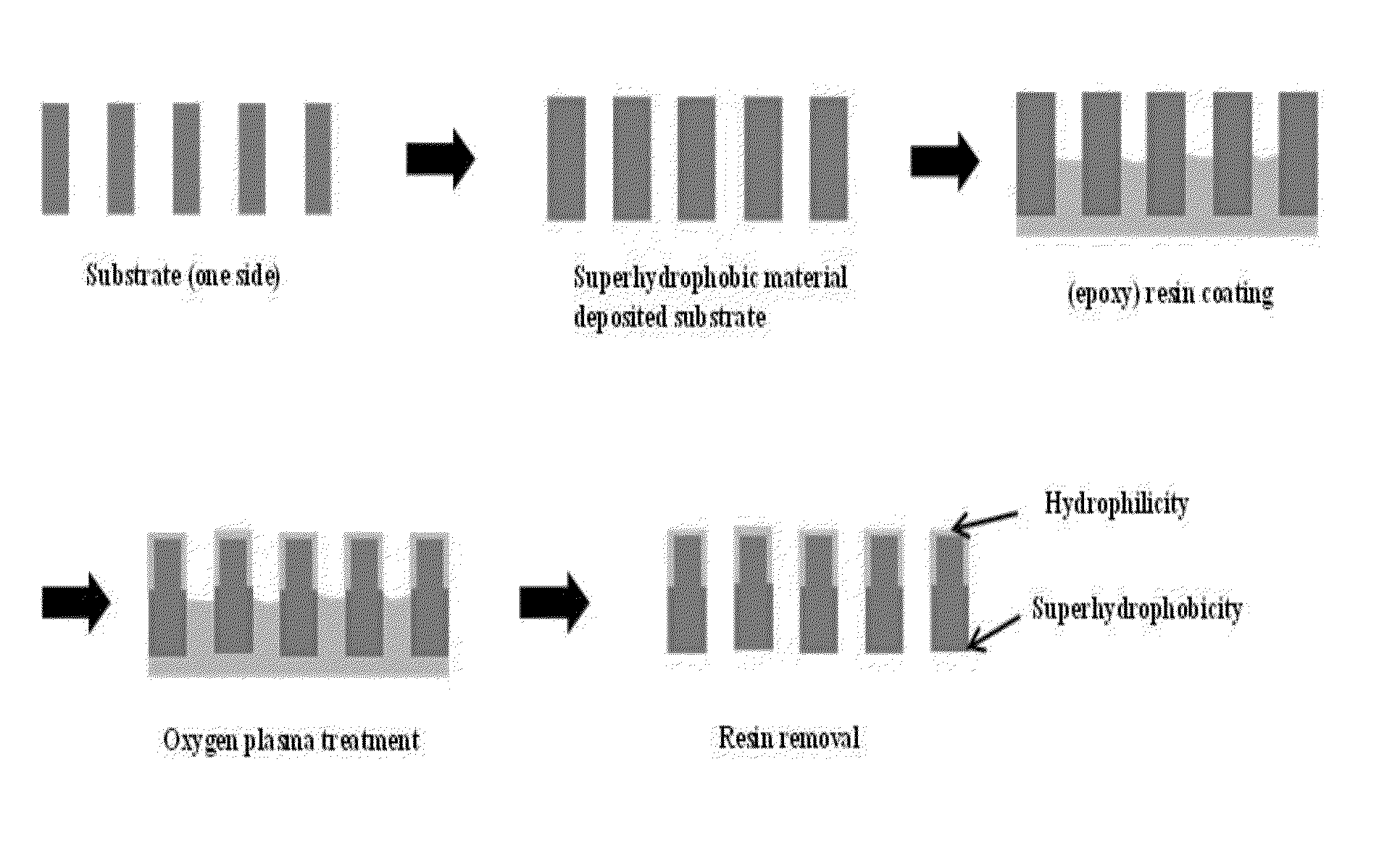

Method of fabricating surface body having superhydrophobicity and hydrophilicity and apparatus of preparing the same

Owner:KOREA ADVANCED INST OF SCI & TECH

Multifunctional superhydrophobic diatomaceous earth for chemical adhesion and color change

Provided herein is a multifunctional particle and methods of forming the same. The multifunctional particle includes: a silica particle; a hydrophobic silane; and a silane coupling agent; where each of the hydrophobic silane and the silane coupling agent are chemically bonded to the surface of the silica particle; where the multifunctional particle is superhydrophobic and chemically reactive.

Owner:VELOX FLOW

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com