Ultra-discharging water-soluble fluor-silicon-acrylic coatings with nano particles

A water-based fluorosilicone and nanoparticle technology, which is applied in coatings, latex paints, etc., can solve the problems of high prices and achieve the effects of low cost, wide sources, and easy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Mix 15g deionized water, 10g silicon acrylic emulsion (solid content 35%), 7g polytetrafluoroethylene emulsion (solid content 55%), 3g nano silicon dioxide aqueous dispersion (diameter 5nm, solid content 15%) under stirring and 2g of ammonium bicarbonate, adjust the pH of the mixture to 8-10 with concentrated hydrochloric acid, and stir evenly to obtain a superhydrophobic water-based fluorosilicone-acrylic coating containing nanoparticles.

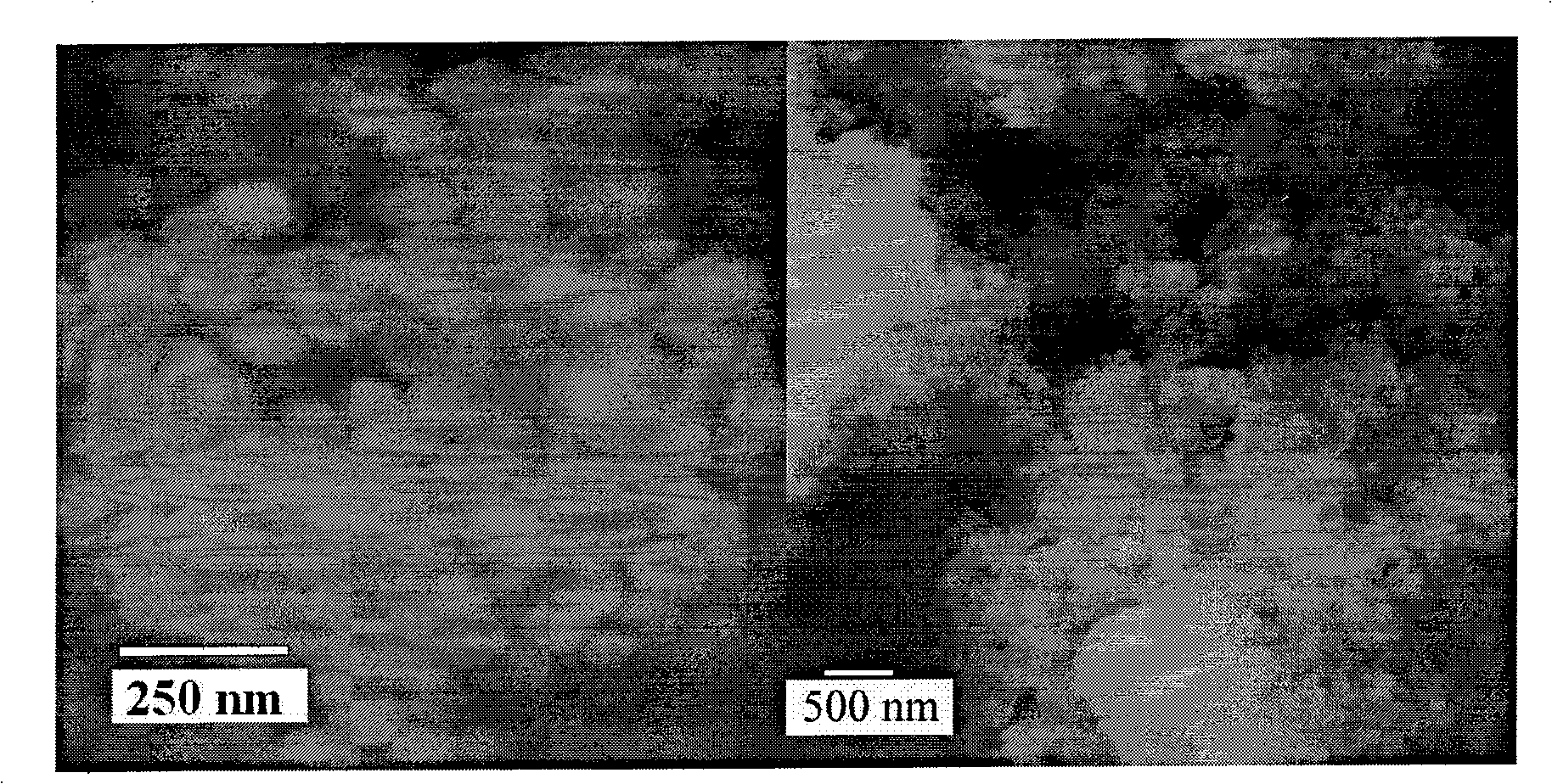

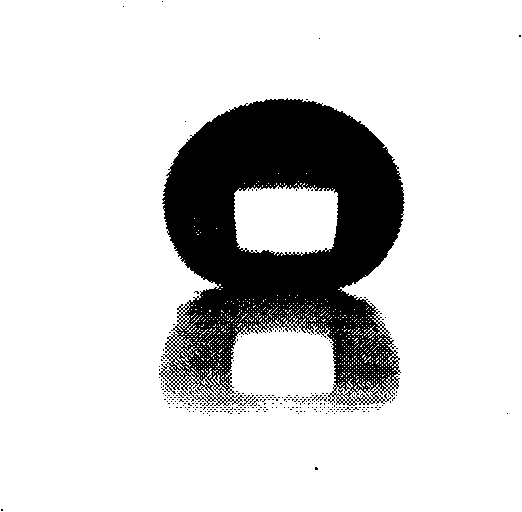

[0037] Thoroughly stir the coating prepared above, apply the coating evenly on the glass surface with a wet film preparation device with a thickness of 90 microns, and dry it at 80° C. for 15 minutes. The resulting white coating is a superhydrophobic water-based fluorosilicone coating (see figure 1 and figure 2 ). From figure 1 and figure 2 We can see that the surface of the superhydrophobic hydrofluorosilicone acrylic coating has a micro-nano binary structure, and there are particles of 120 to 130 nanometers on the nanometer s...

Embodiment 2

[0040] Mix 15g deionized water, 15g silicon acrylic emulsion (solid content 35%), 9g tetrafluoroethylene and perfluorovinyl ether copolymer emulsion (solid content 50%), 1g nano-titanium dioxide (diameter 15nm) and 2g carbonic acid under stirring ammonium hydrogen, adjust the pH of the mixture to 8-10 with concentrated hydrochloric acid, and stir evenly to obtain a super-hydrophobic water-based fluorosilicone-acrylic coating containing nanoparticles.

[0041] Thoroughly stir the coating prepared above, apply the coating evenly on the surface of polyethylene terephthalate (PET) with a wet film preparation device with a thickness of 90 microns, and dry it at 50°C for 15 hours, and the obtained white coating is Superhydrophobic water-based fluorosilicone coating. The wettability of the coating surface was tested with a contact angle tester, and the result showed that the contact angle between the surface and water was 152±2°, and the rolling angle was 4±1°.

Embodiment 3

[0043] Mix 15g deionized water, 8g silicon acrylic emulsion (solid content 35%), copolymer emulsion (solid content 58%) of 12g tetrafluoroethylene and hexafluoropropylene, 4g nano silicon dioxide aqueous dispersion liquid (diameter 4nm) under stirring. , solid content 15%) and 3g of ammonium bicarbonate, adjust the pH value of the mixture to 7-9 with concentrated hydrochloric acid, and stir evenly to obtain a super-hydrophobic water-based fluorosilicone-acrylic coating containing nanoparticles.

[0044] Thoroughly stir the paint prepared above, apply the paint evenly on the surface of the stainless steel plate with a 90-micron thick wet film maker, and dry it at 80°C for 15 minutes. The white coating obtained is the superhydrophobic water-based fluorosilicone coating. The wettability of the coating surface was tested with a contact angle tester, and the result showed that the contact angle between the surface and water was 153±2°, and the rolling angle was 3±2°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com