Patents

Literature

12066 results about "Self cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of self-cleaning of carbon-based film

InactiveUS20070248767A1Hollow article cleaningVacuum evaporation coatingNitrogen oxidePlasma reactor

A method of self-cleaning a plasma reactor upon depositing a carbon-based film on a substrate a pre-selected number of times, includes: (i) exciting oxygen gas and / or nitrogen oxide gas to generate a plasma; and (ii) exposing to the plasma a carbon-based film accumulated on an upper electrode provided in the reactor and a carbon-based film accumulated on an inner wall of the reactor.

Owner:ASM JAPAN

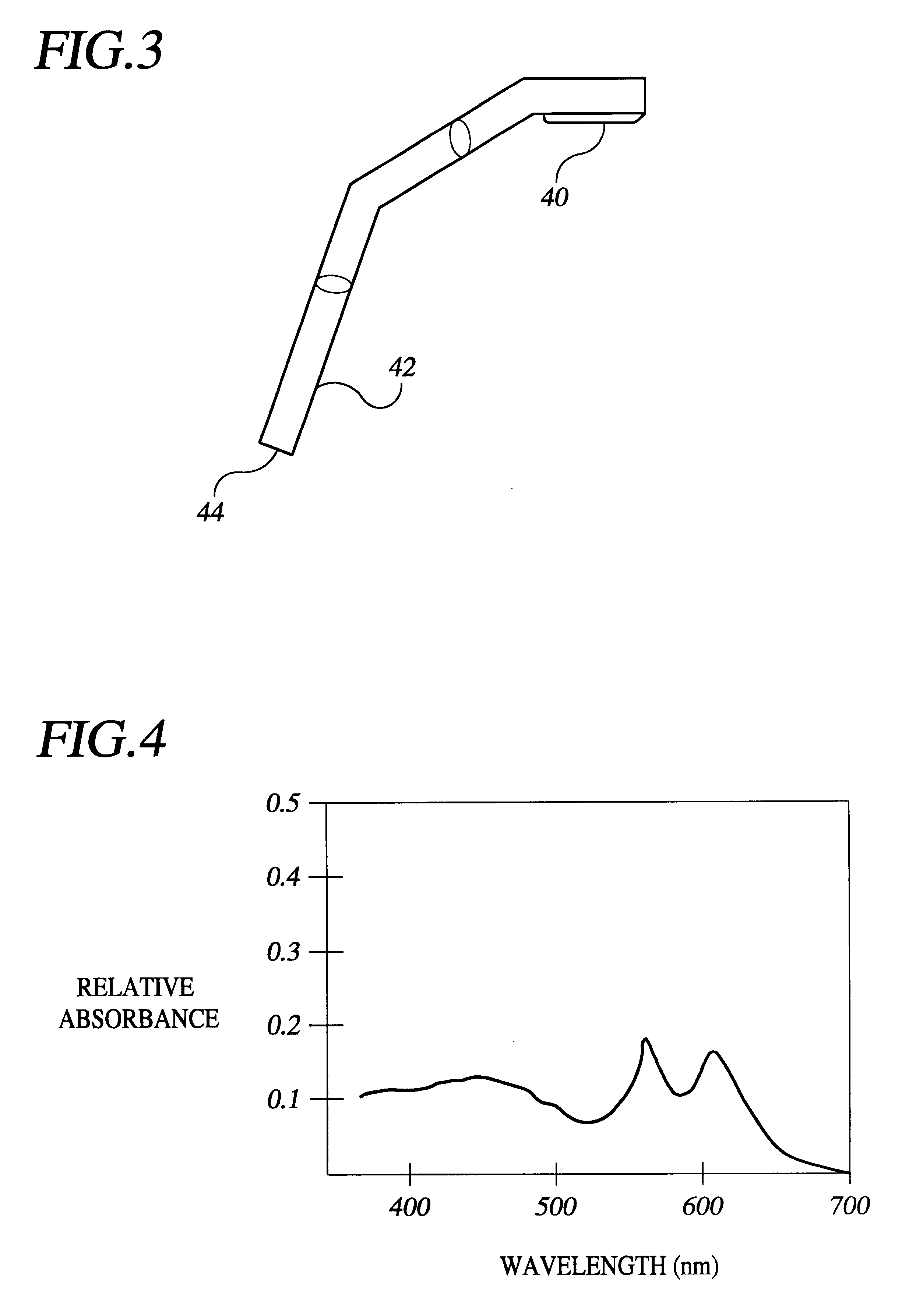

Method and tools for oral hygiene

InactiveUS6561808B2Increase motivation for treatmentImprove adhesionCosmetic preparationsImpression capsOral diseasePhotosensitizer

A method and material for self-cleaning of the teeth and mouth using a source of light in the visible range in conjunction with a photosensitive oral hygiene composition possessing a broad absorption spectrum in the visible range. The invention selectively eliminates harmful bacteria by use of a photosensitive agent and a light source. The present invention involves the use of a light-providing dental device to activate a photosensitive agent and destroy harmful bacteria in the oral cavity. It prevents or deters oral diseases, inflammations, and infections.

Owner:BIOLITEC UNTERNEHMENSBETEILLIGUNGS II AG

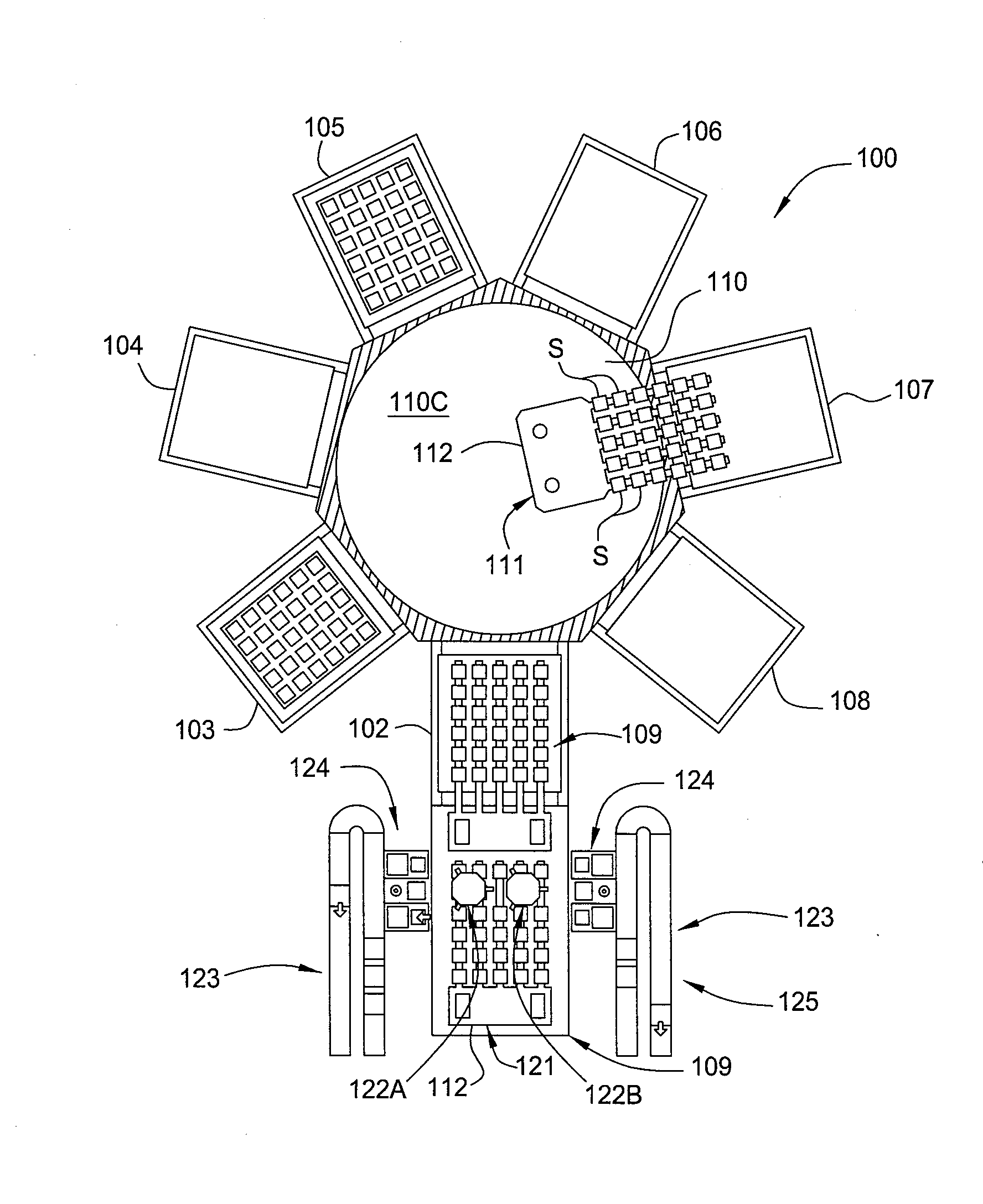

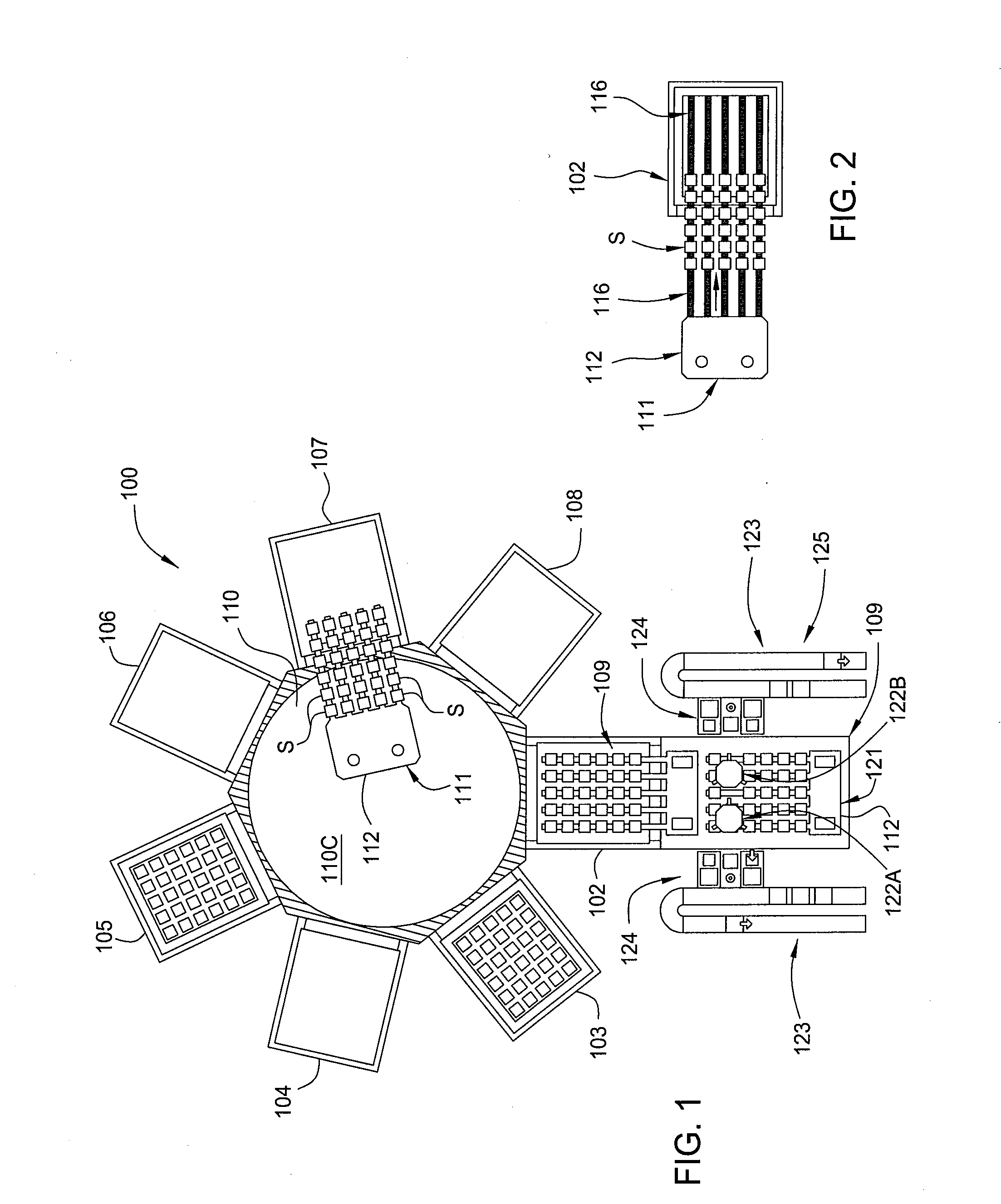

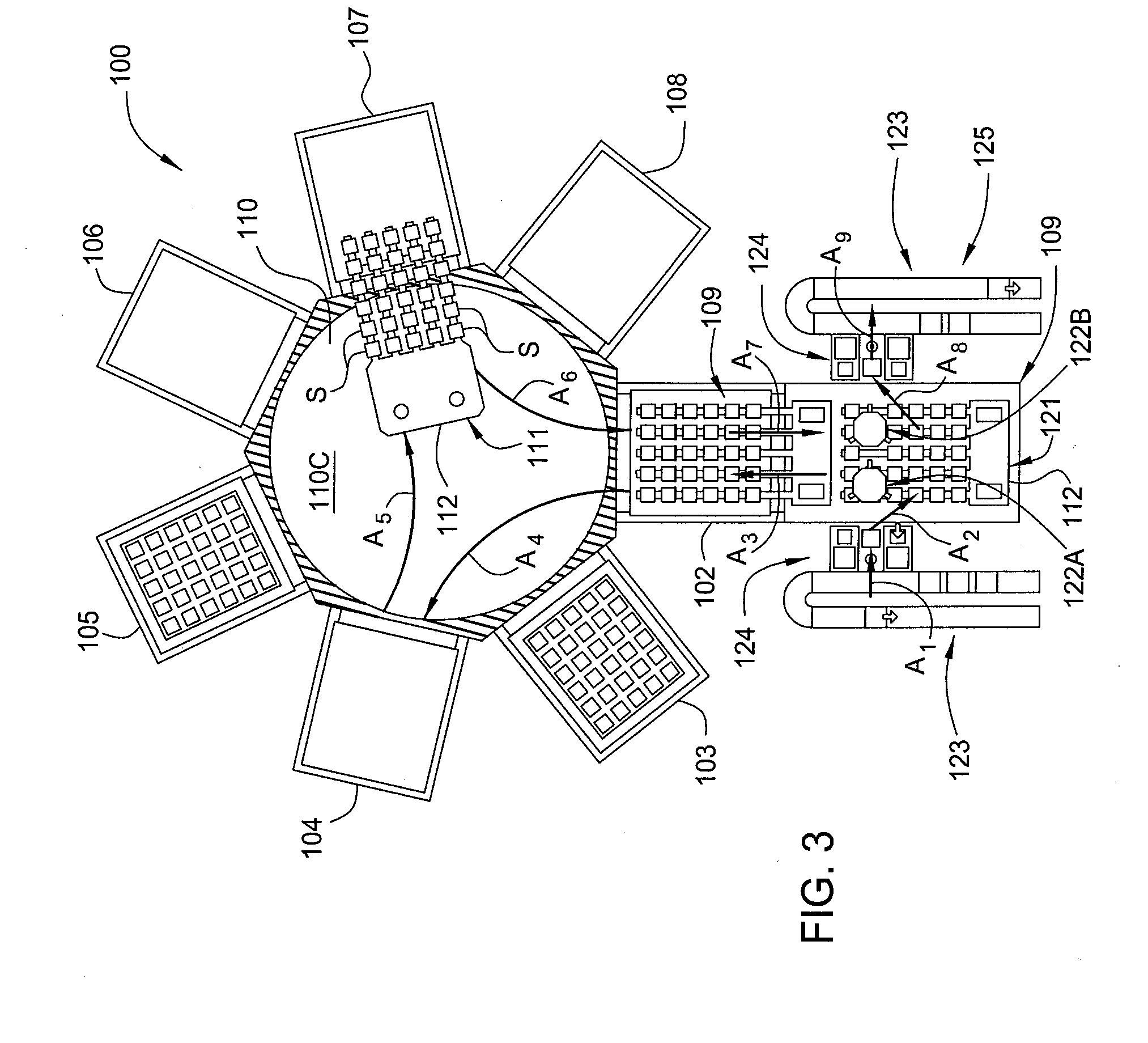

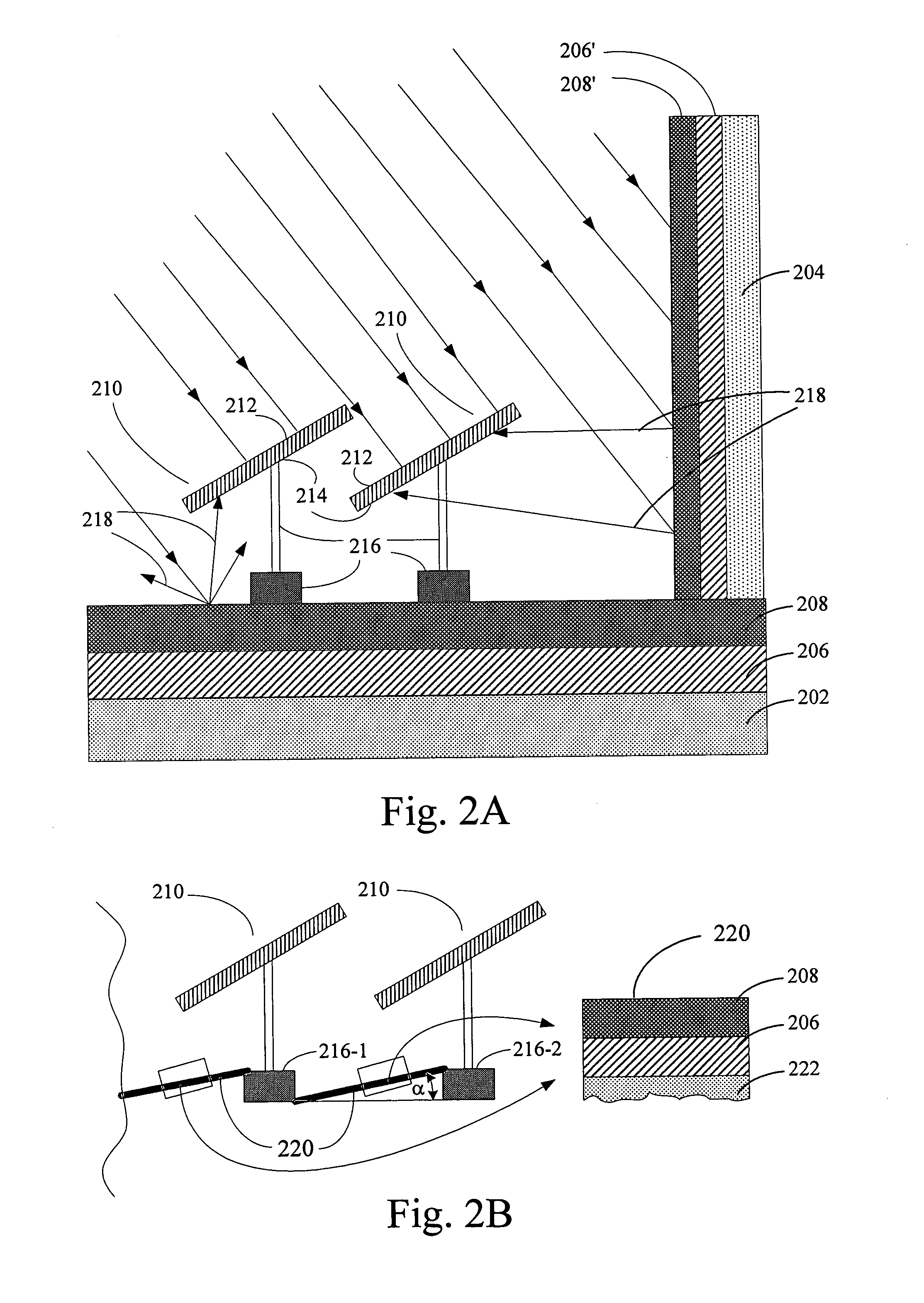

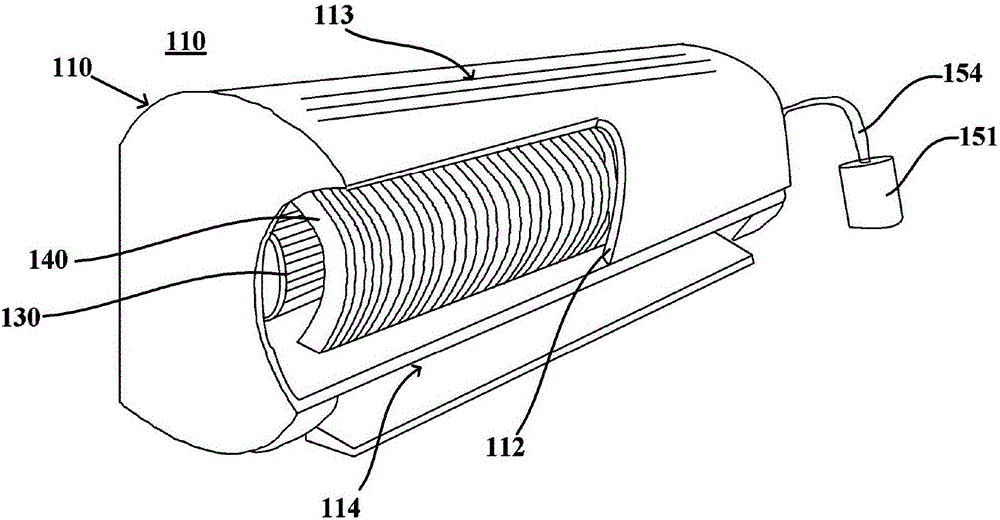

Self-cleaning susceptor for solar cell processing

An apparatus and method for processing substrates are provided. In one embodiment, a susceptor for an apparatus for processing a substrate includes a plurality of segments aligned to form a substrate support surface, each segment having one or more flat surfaces for supporting the substrate, and an opening that extends along an axis of rotation. The susceptor also includes a plurality of rotatable shafts, each shaft positioned in the opening of one of the segments. The method of processing a batch of substrates includes transferring at least one substrate in the batch into a processing chamber and onto a susceptor, processing the at least one substrate within the chamber, transferring the at least one substrate out of the processing chamber, and removing debris from the substrate support surface by rotating the segments to dump any debris on the substrate support surface onto a chamber floor where it will remain during further processing.

Owner:APPLIED MATERIALS INC

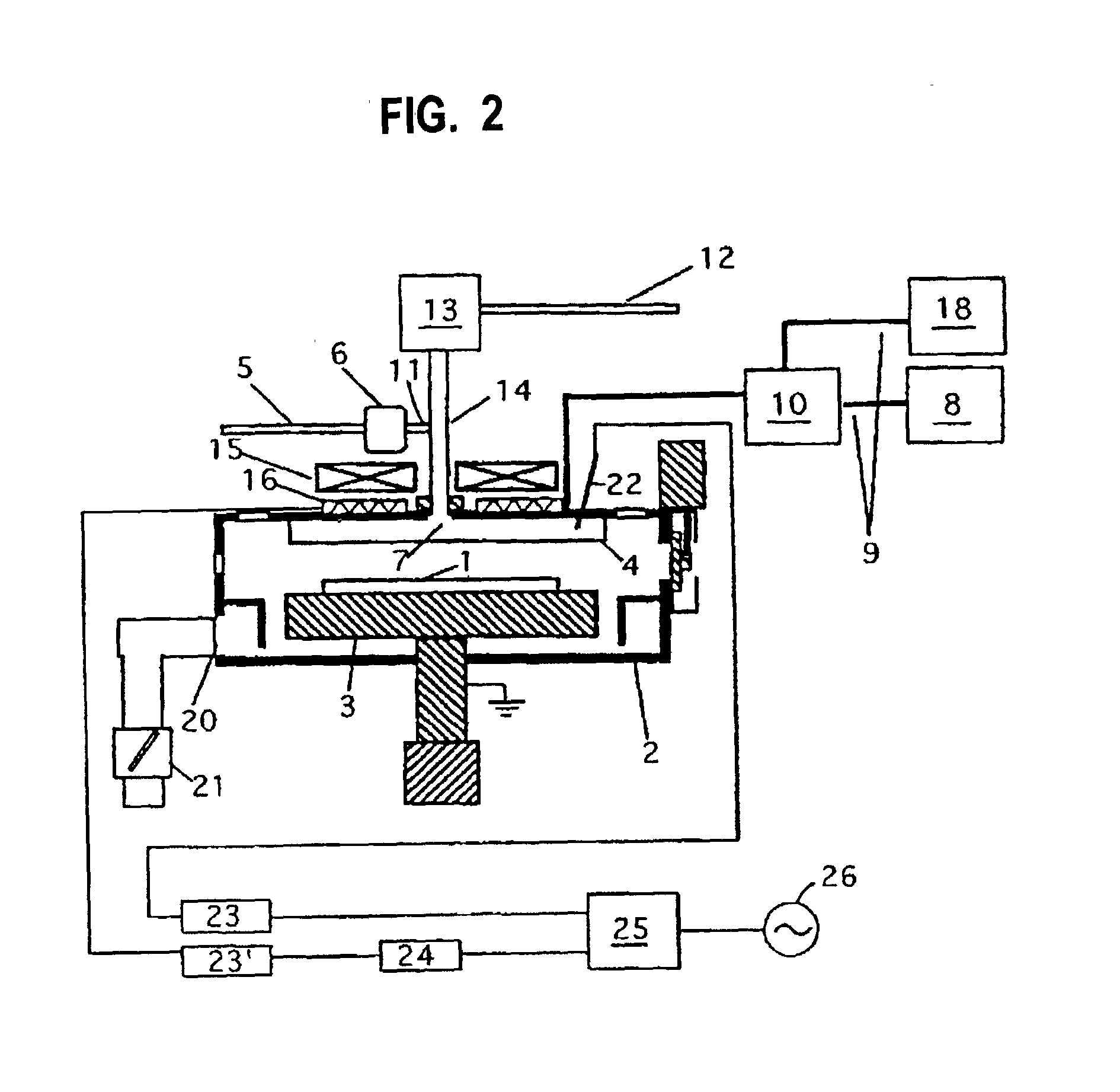

Semiconductor processing with a remote plasma source for self-cleaning

InactiveUS20070227554A1Good effectElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaProduct gas

A plasma CVD device includes a reaction chamber, a remote plasma discharge chamber that is provided remotely from the reaction chamber, and piping that links the reaction chamber and the remote plasma discharge chamber. The remote plasma discharge chamber activates cleaning gas by plasma discharge energy, and the activated cleaning gas is introduced into the inside of the reaction chamber through the piping and changes solid substances that adhere to the inside of the reaction chamber in consequence of film formation, to gaseous substances, thereby cleaning the inside of the reaction chamber. The device is characterized by at least one of the following: (a) the remote plasma discharge chamber generates active species using radio frequency oscillating output energy of a preselected frequency; (b) the piping is made of materials that are not corroded by the active species; or (c) the piping is provided with a through-flow type valve.

Owner:ASM JAPAN

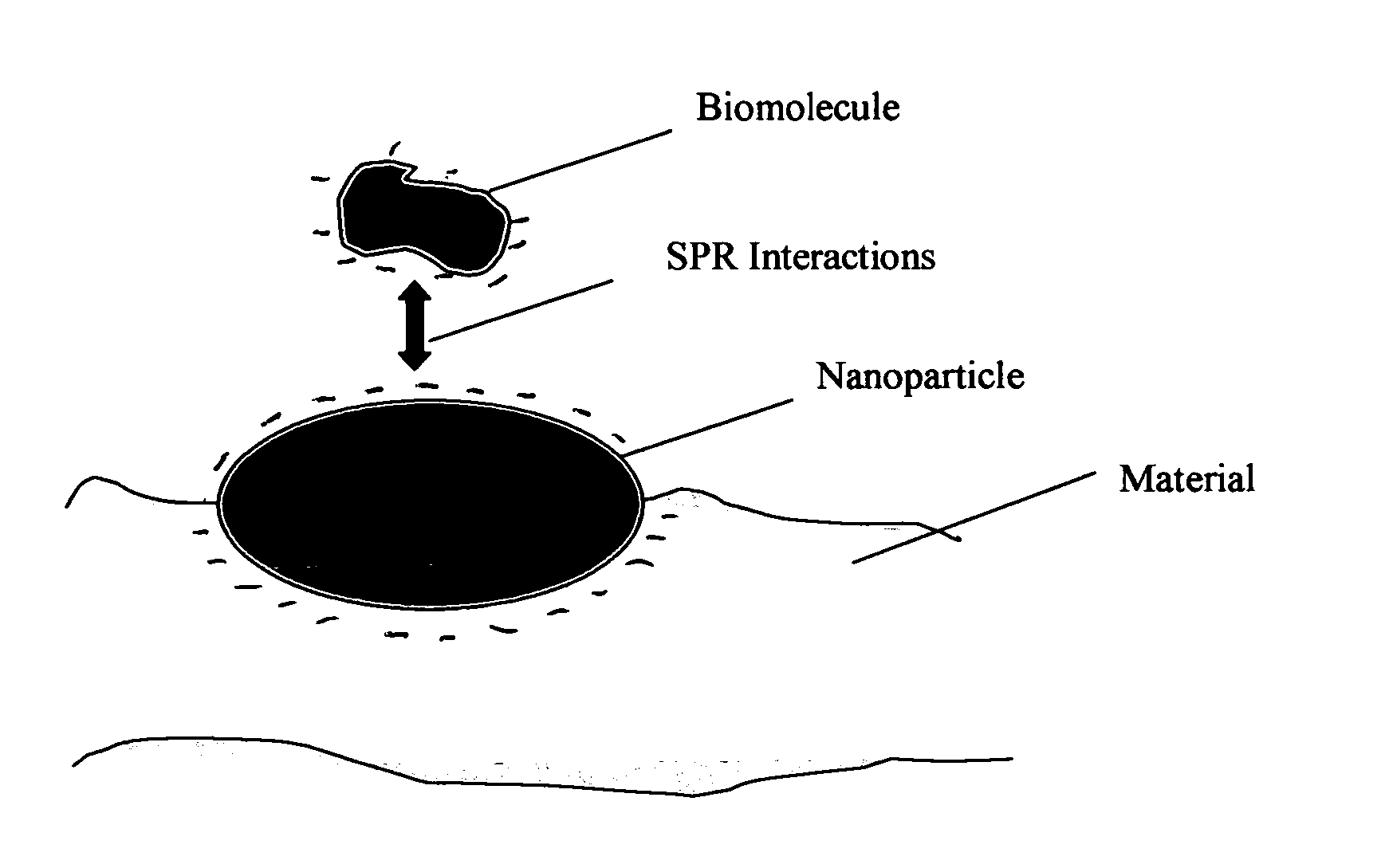

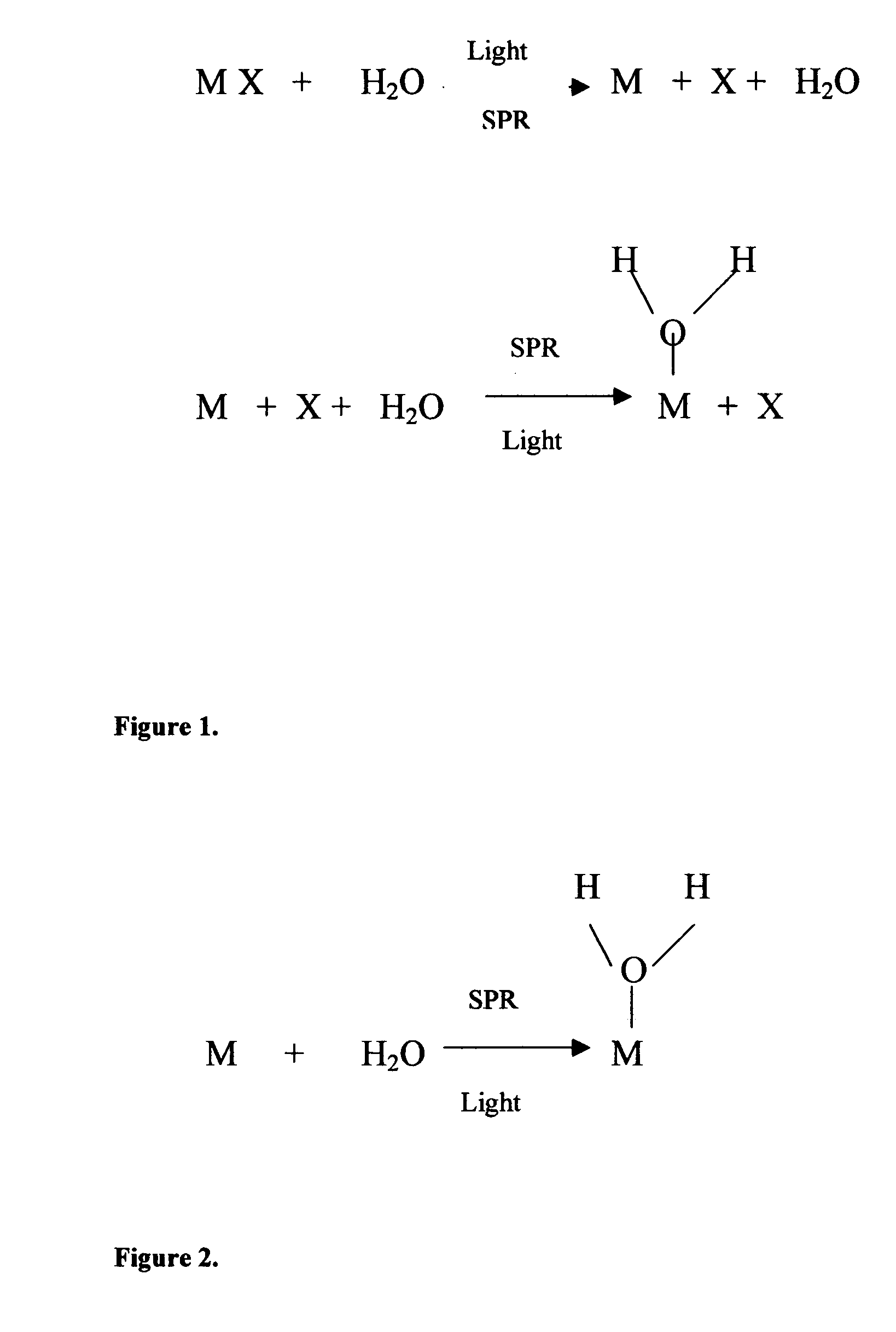

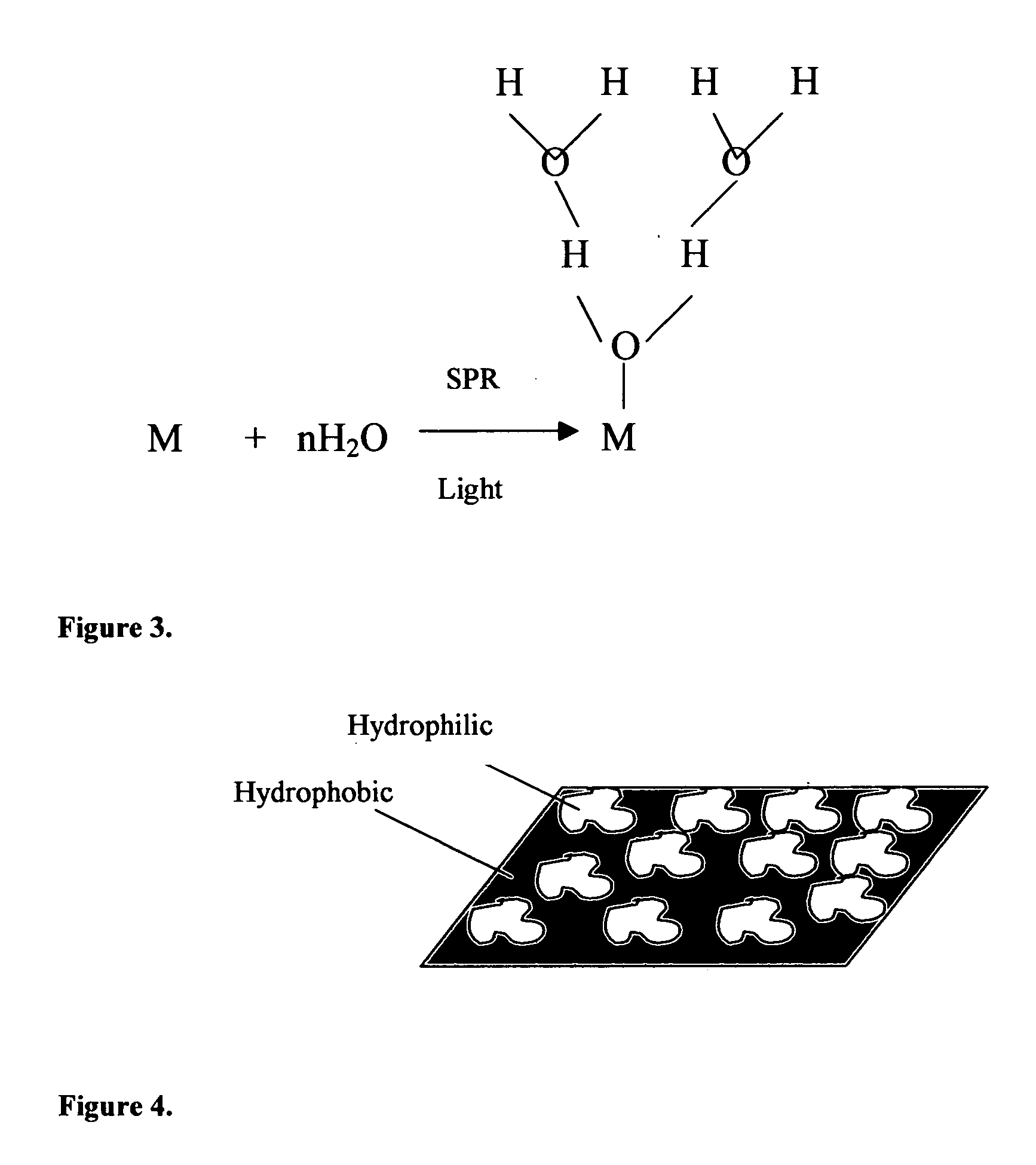

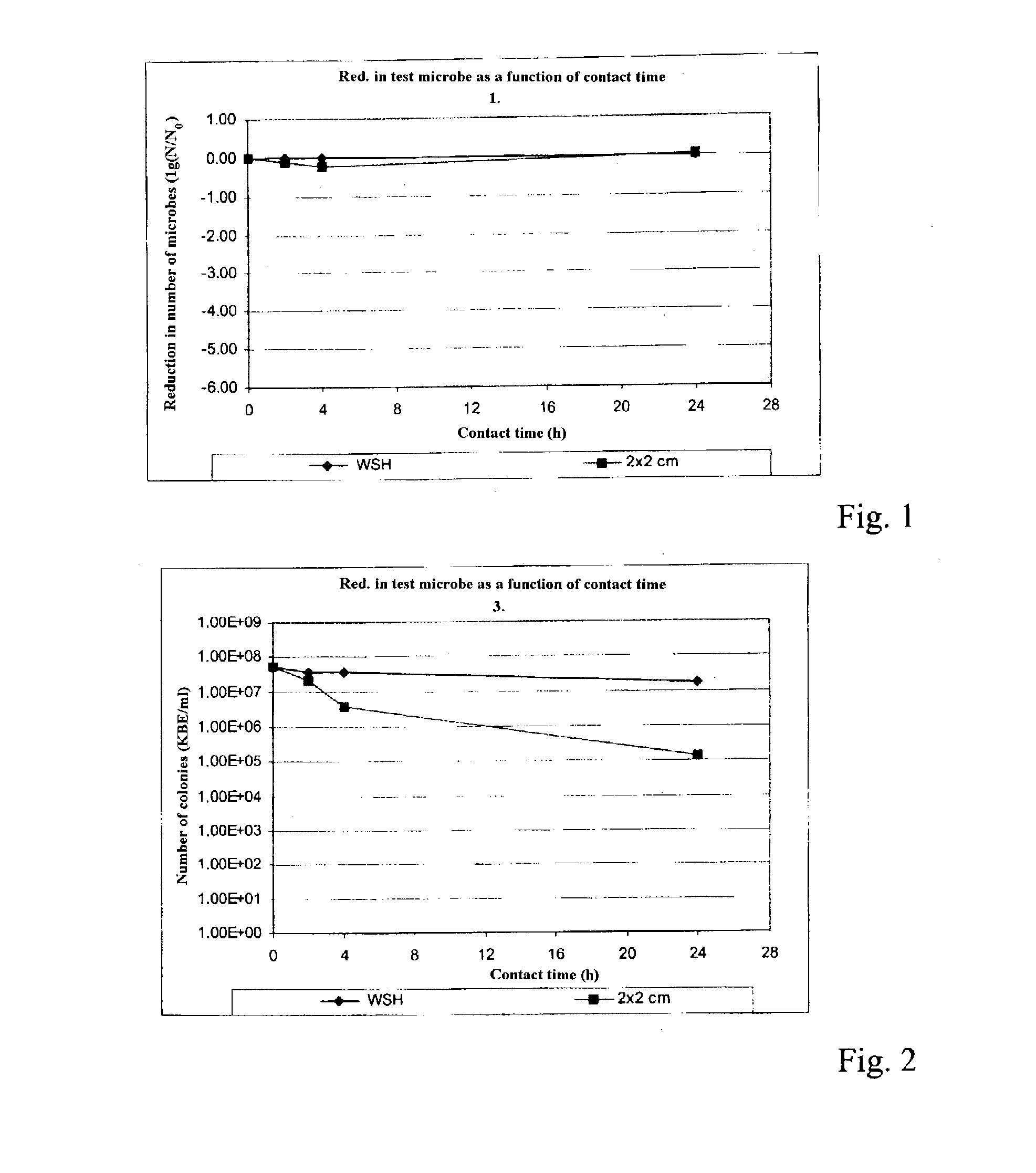

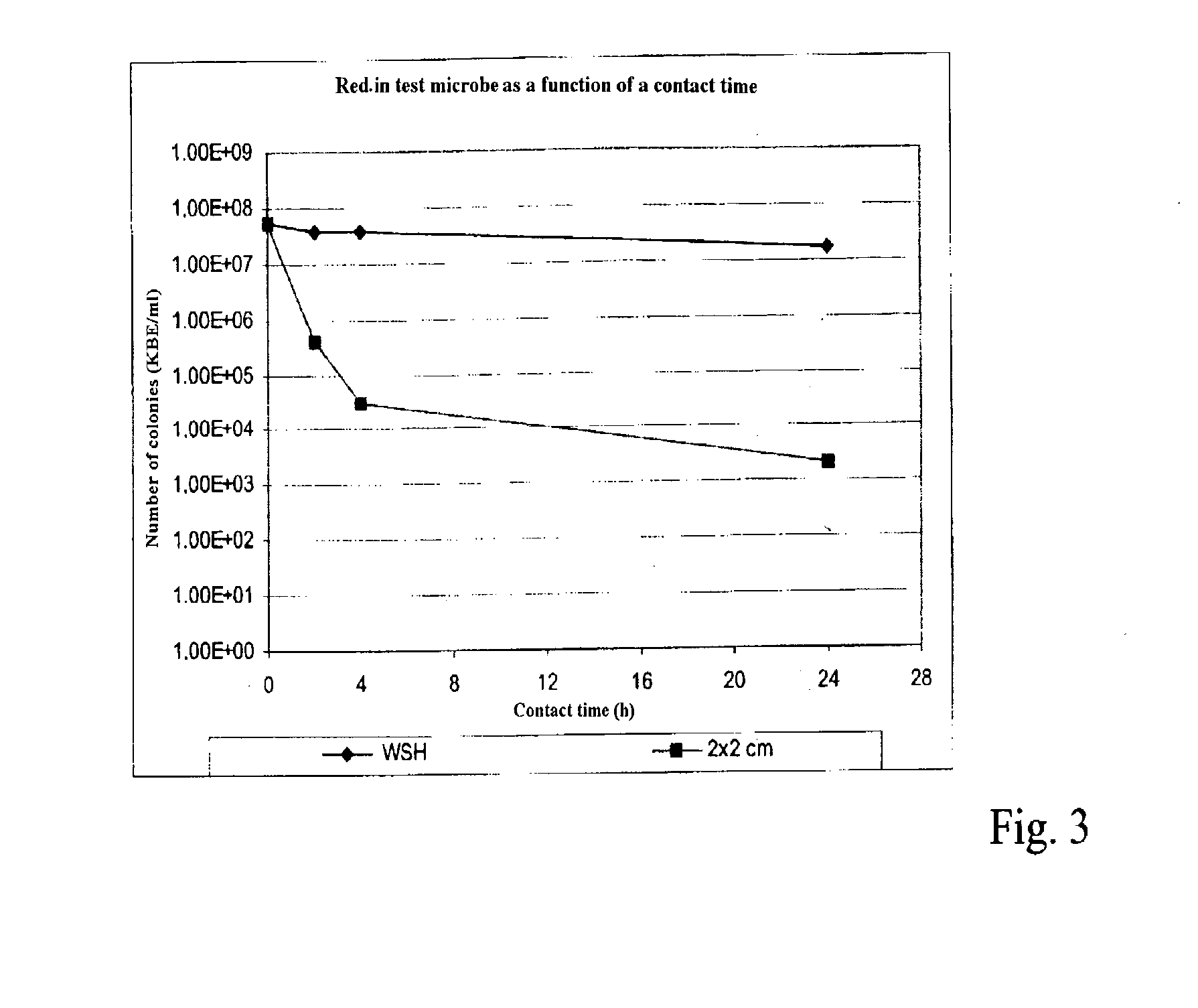

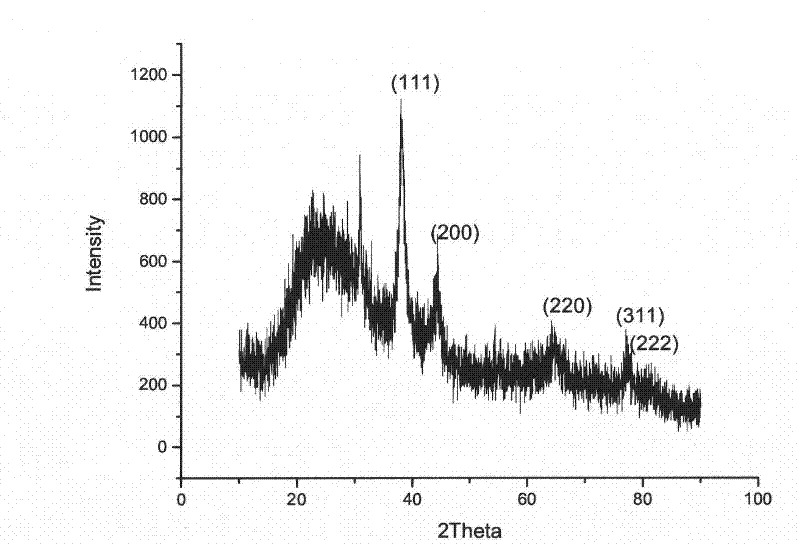

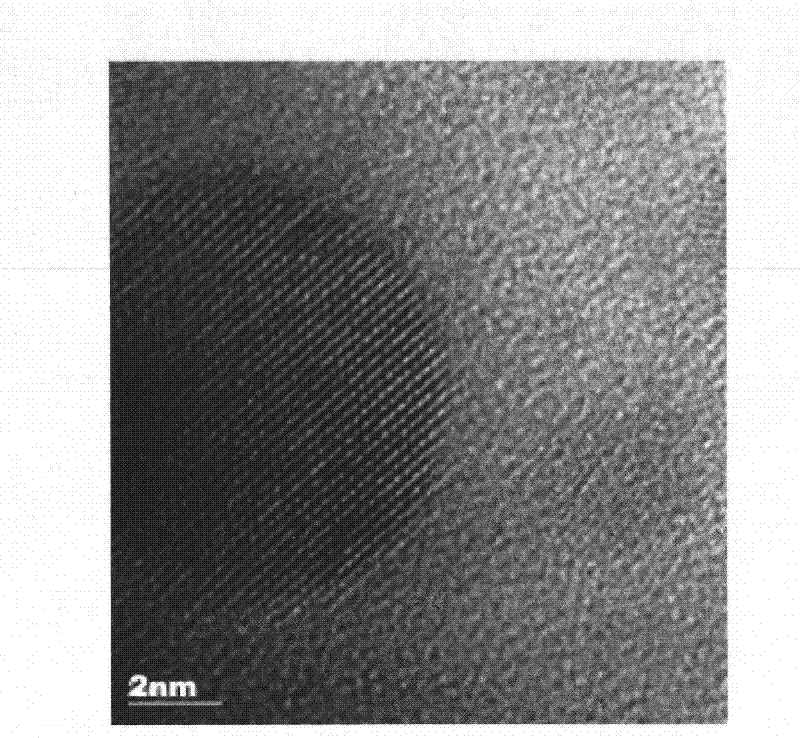

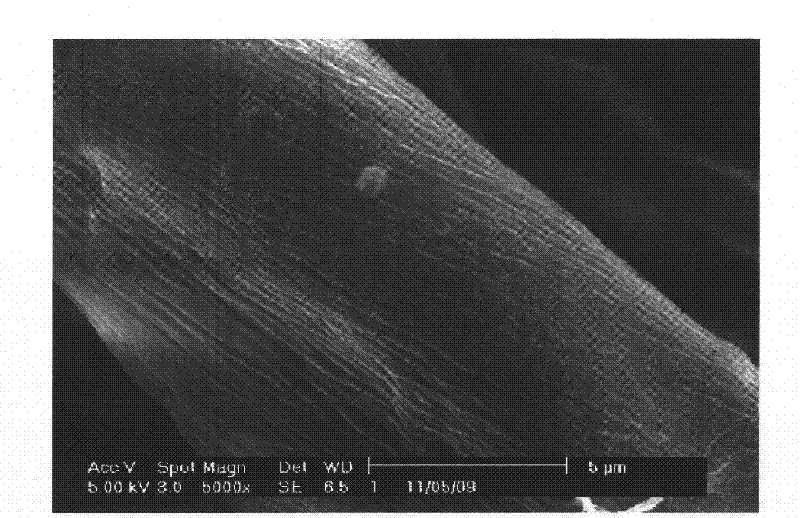

Method of plasmon-enhanced properties of materials and applications thereof

InactiveUS20050164169A1Bioreactor/fermenter combinationsMaterial nanotechnologyInfraredThermochromism

Methods and applications of surface plasmon resonance-enhanced antibacterial, anti-adhere, adhere, catalytic, hydrophilic, hydrophobic, spectral change, biological and chemical decomposition properties of materials with embedded nanoparticles are disclosed. A method of the nonlinear generation of surface plasmon resonance enables the use of light with wavelengths from X-Ray to IR to enhance properties of materials by several orders of magnitude. The nanoparticle size is crucial for the enhancement and their size is considered to be in the proposed methods and applications within a range of 0.1 nm to 200,000 nm. The nanoparticles preferably are made of noble metals and / or semiconductor oxides. The invention describes a very broad spectrum of applications of surface plasmon resonance-enhanced properties of materials with embedded nanoparticles, from environmental cleanup by road pavement and construction materials, self-cleaning processes of surface materials, thermochromic effects on heat blocking materials, corrosion preventing paint, to sanitization by antibacterial textile fabrics, filters, personal clothing, contact lenses and medical devices.

Owner:SPR ADVANCED TECH INC

Self-cleaning lotus effect surfaces having antimicrobial properties

A self-cleaning or lotus-effect surface that has antimicrobial properties, commercial products comprising such a surface, and uses thereof. A process for the production of an antimicrobial self-cleaning or lotus-effect surface in which one or more antimicrobial polymer(s) is secured to a surface-coating system for securing structure-formers to generate a self-cleaning surface. This method lastingly binds antimicrobial polymers to the self-cleaning surface. Commercial products comprising an antimicrobial self-cleaning or lotus-effect surface.

Owner:CREAVIS GES FUER TECH

A kind of antibacterial composition and its application

InactiveCN102258064AExtended cleaning cycleTo achieve the effect of saving waterBiocideAntifouling/underwater paintsSodium PyrithioneNonwoven fabric

The invention relates to an antibacterial composition, comprising an organic antibacterial component containing at least one pyrithione salt, a pyrithione complex or an adduct thereof, an aqueous solution containing one or more metal ions or its The inorganic antibacterial component of the complex aqueous solution or its nanometer metal hydrosol or its nanometer metal oxide hydrosol and its composition, and the mass ratio of the organic antibacterial component to the inorganic antibacterial component is 1:100-50:1, It also includes other auxiliary agents, and its mass percentage in the antibacterial composition described in the patent is 0.001-20%. The antibacterial composition of the present invention can form a nanoparticle film on the surface of base materials such as natural fabrics, non-woven fabrics, clothing, bedding, toiletries, household items, medical care supplies, and filter screens, and realize its antibacterial properties through the nanoparticle film. Antibacterial, anti-mite, deodorizing and self-cleaning functions. The antibacterial composition of the invention is safe to use and can be used in medical treatment and life to protect people's health.

Owner:赵正坤

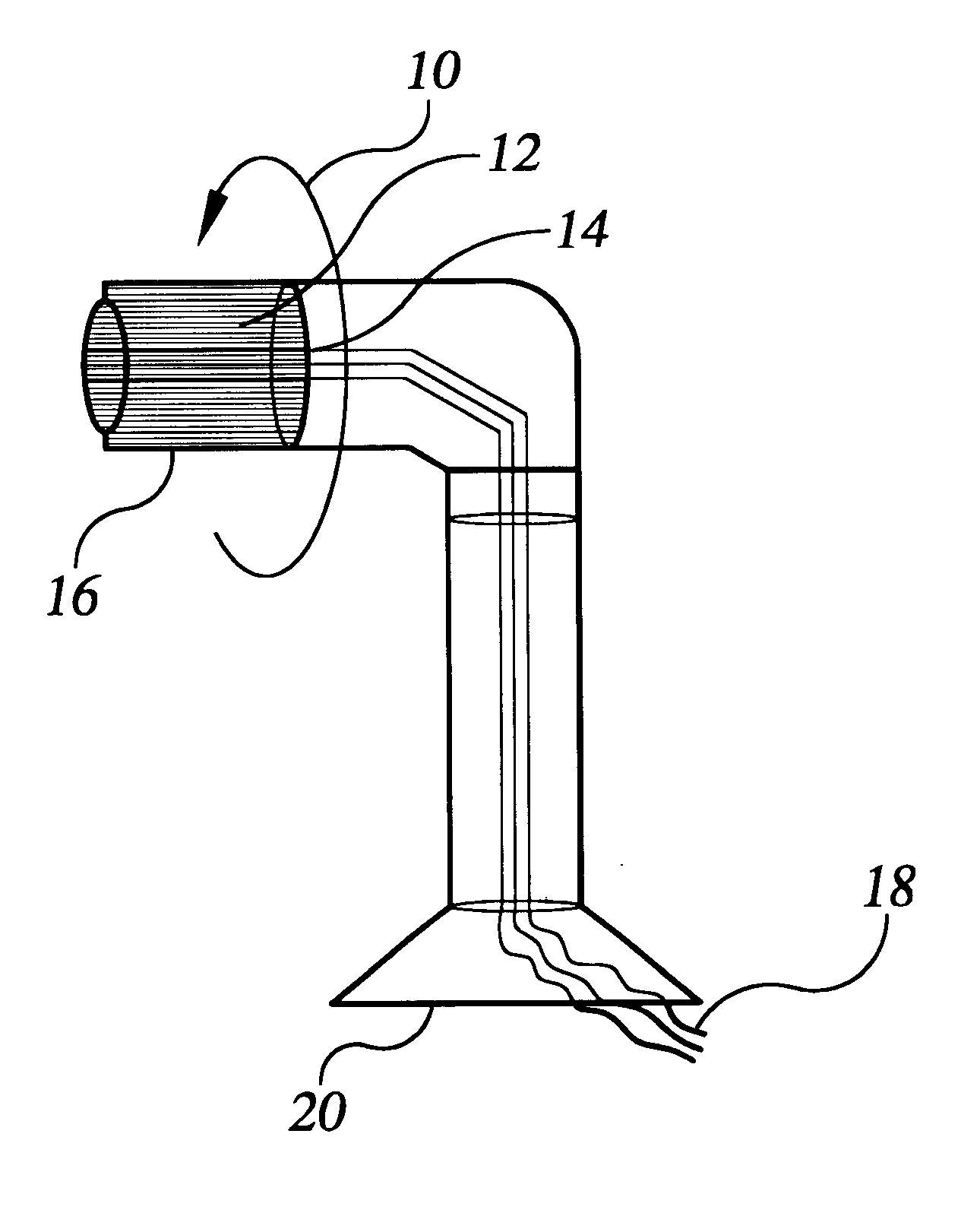

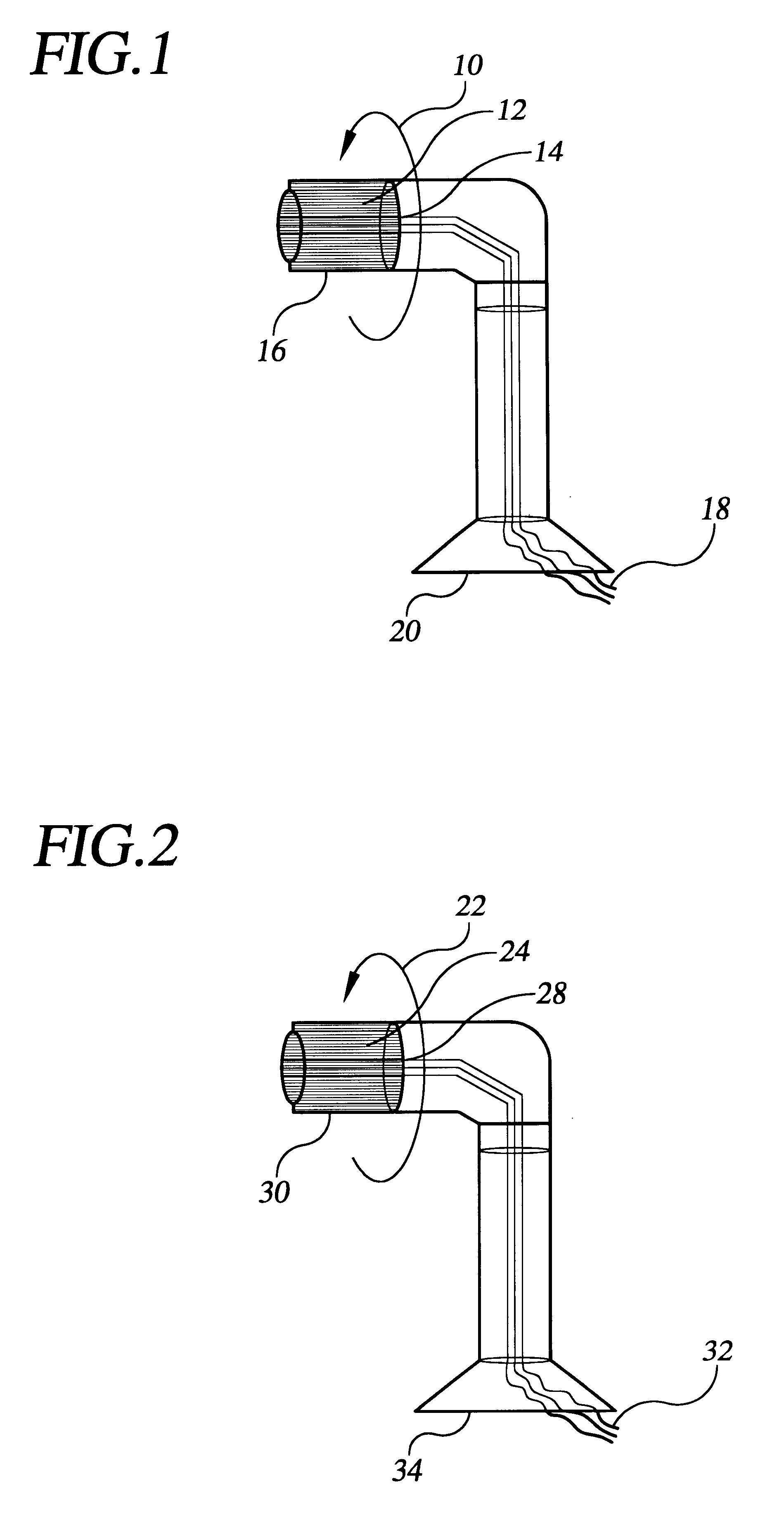

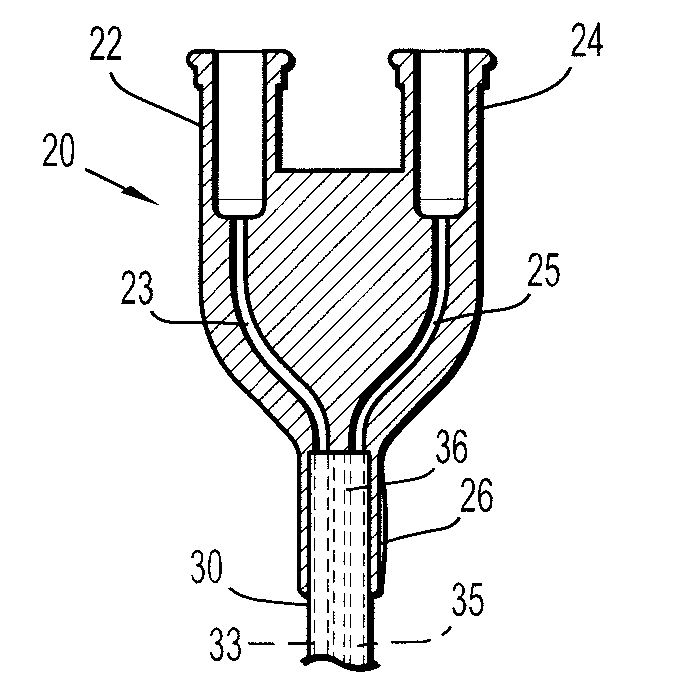

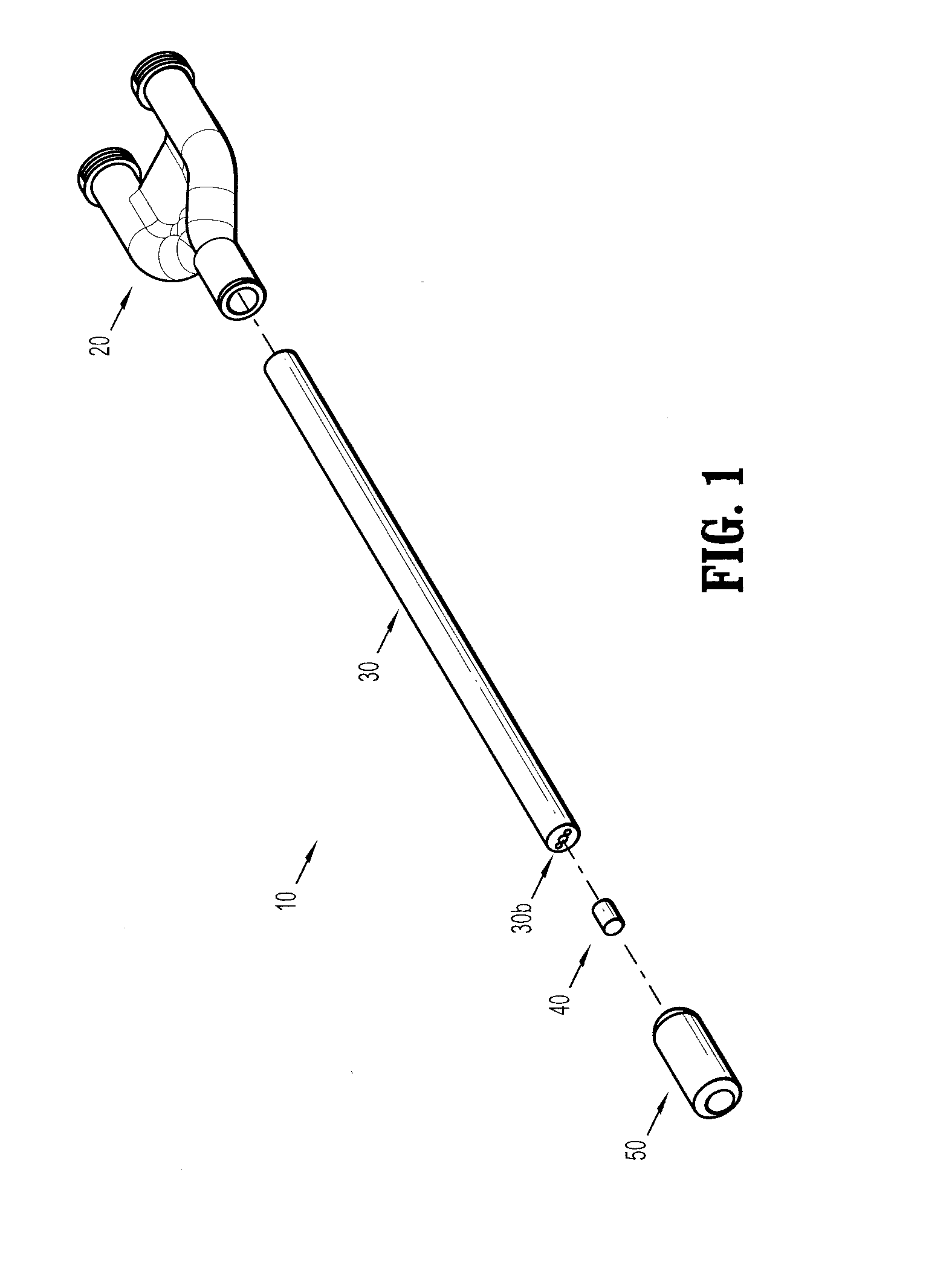

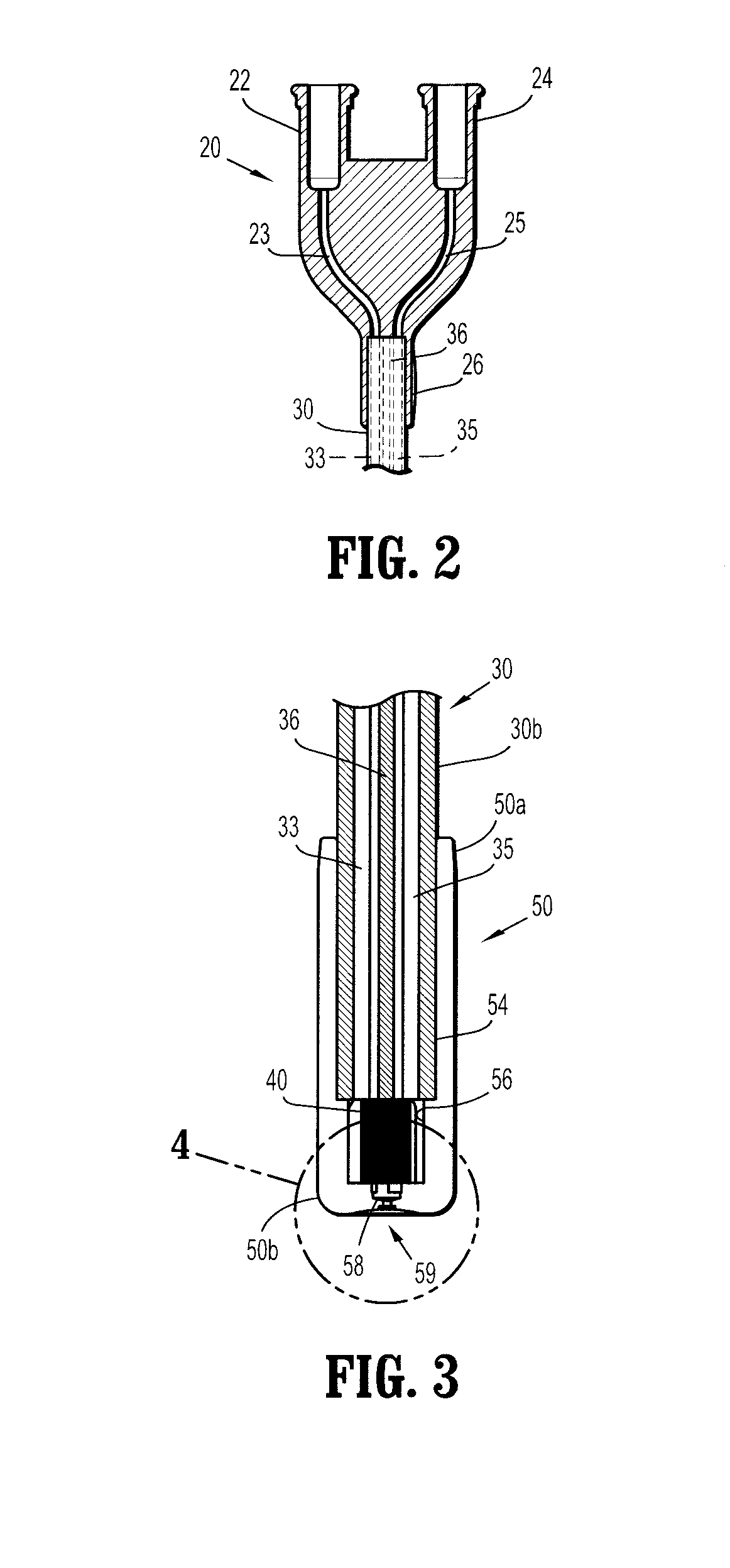

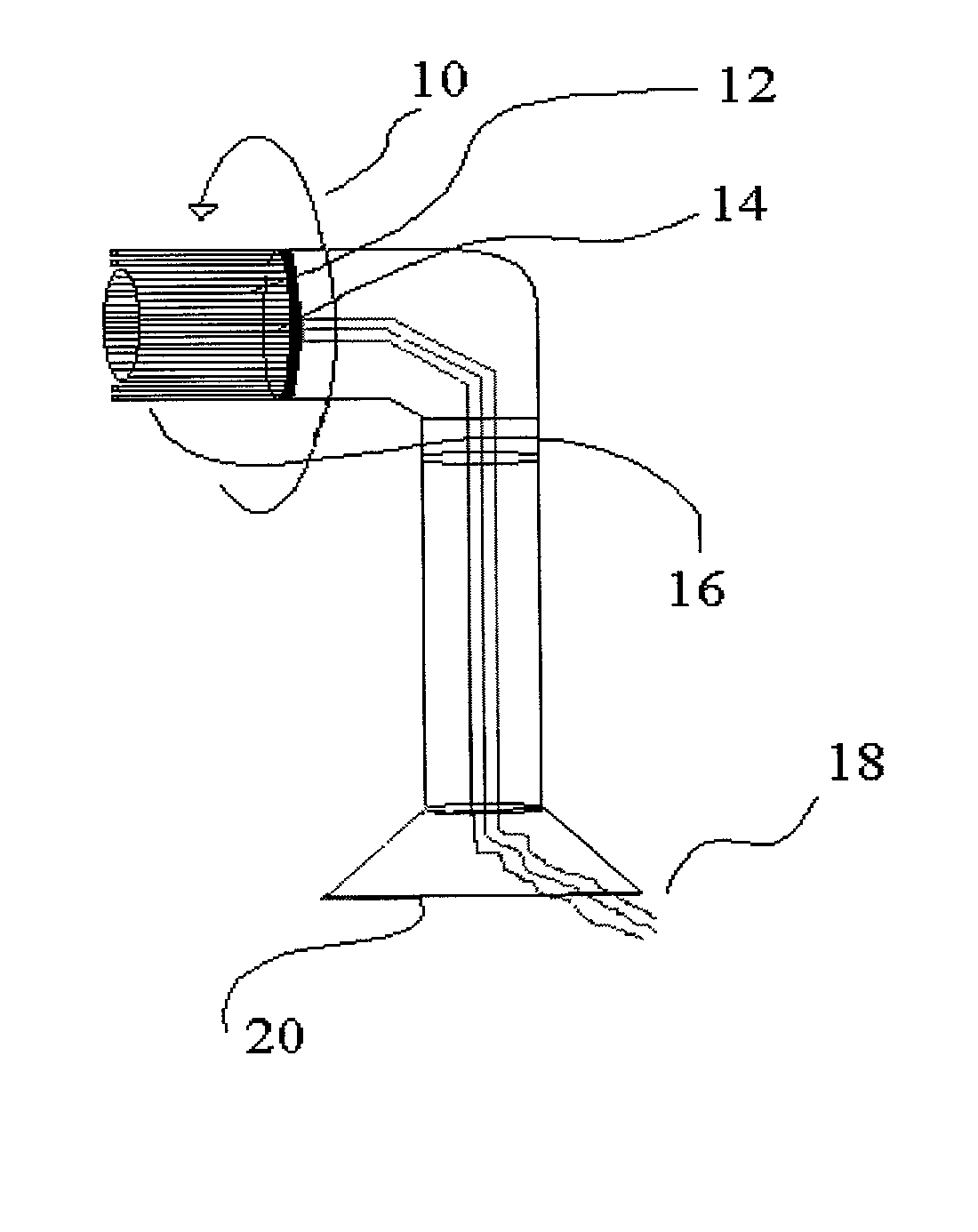

Self-cleaning spray tip

ActiveUS20100096481A1Clear obstructionFlow mixersTransportation and packagingBiomedical engineeringNozzle

A spray tip assembly capable of self-clearing is provided. The spray tip assembly includes a distal end including an outlet. The outlet defines at least a first configuration during a first condition and at least a second configuration during a second condition. The distal end may be configured to at least one of flex and expand such that the outlet changes from the first configuration to the second configuration.

Owner:CONFLUENT SURGICAL

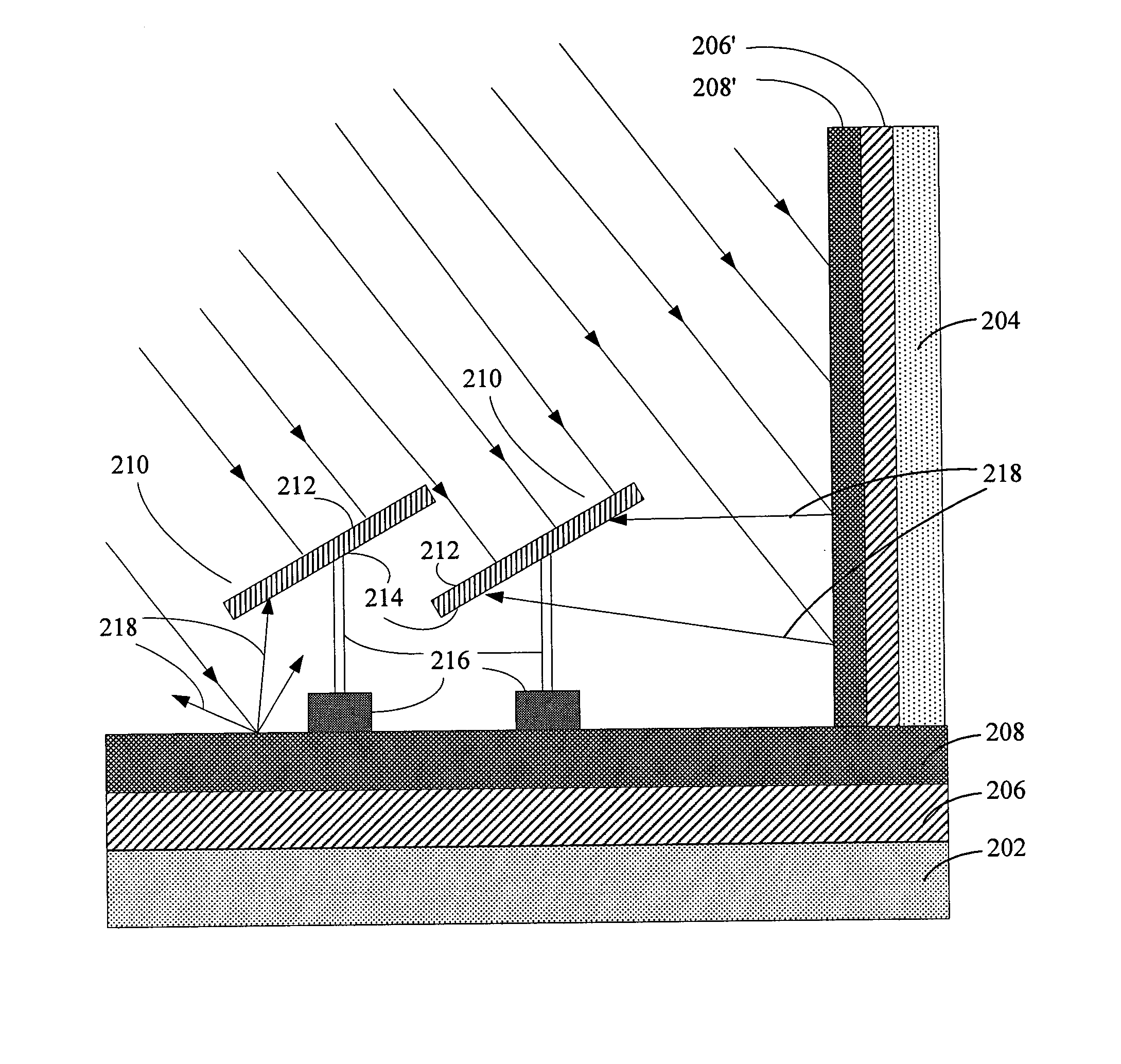

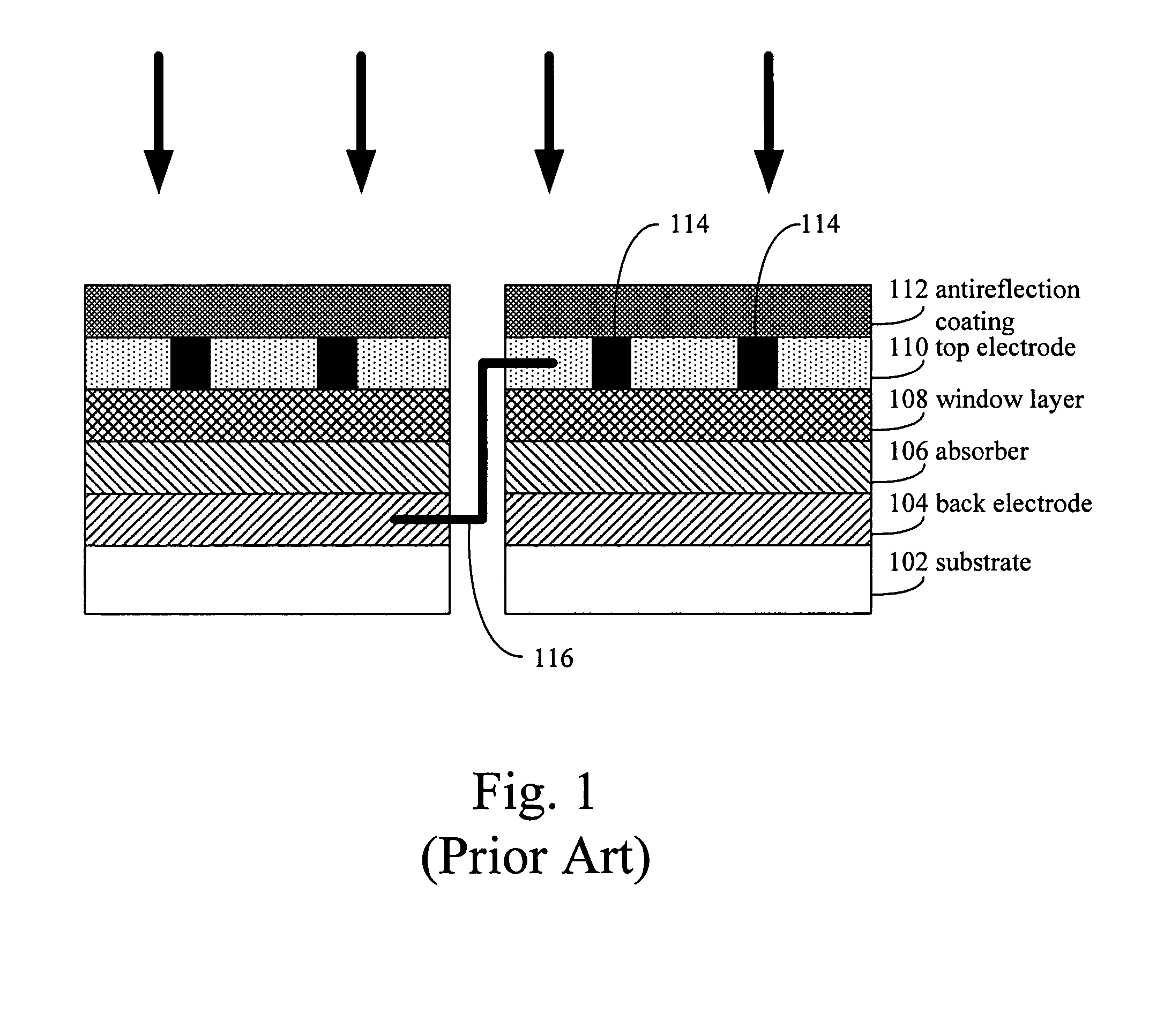

Self-cleaning protective coatings for use with photovoltaic cells

InactiveUS20070017567A1Maintain efficiencyTime-consuming effortPV power plantsSynthetic resin layered productsCells panelAlbedo

Systems and materials to improve photovoltaic cell efficiency by implementing a self-cleaning function on photovoltaic cells and on albedo surfaces associated with photovoltaic cell assemblies are provided. Materials for protecting albedo surfaces that surround photovoltaic cell assemblies, thereby maximizing energy input into the photovoltaic cell assemblies, are provided. Materials for self-cleaning photovoltaic cell panels, thereby maintaining their efficiency, are provided. Portable albedo collecting devices associated with photovoltaic cell assemblies are provided.

Owner:BARNES CHRISTOPHER

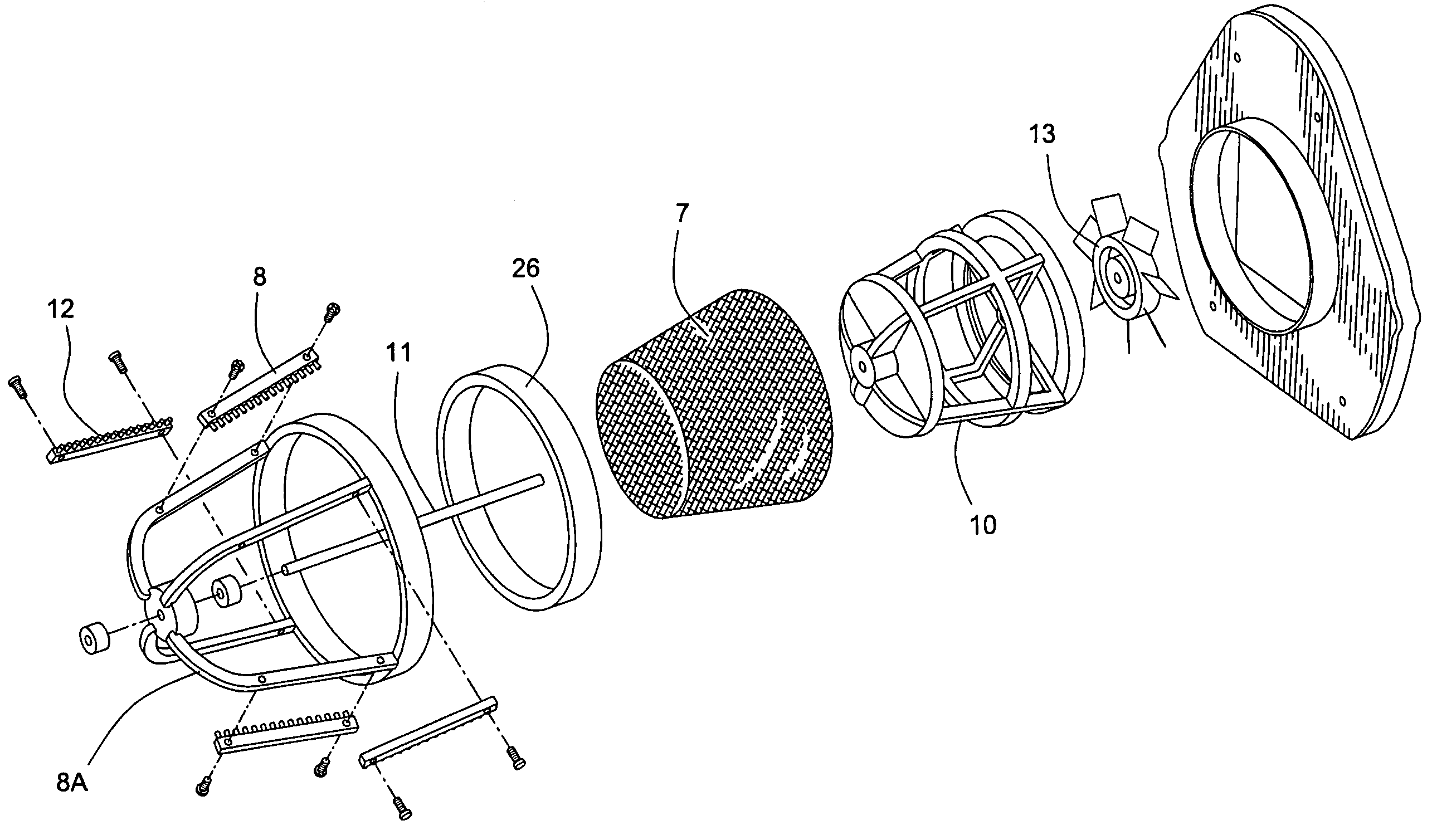

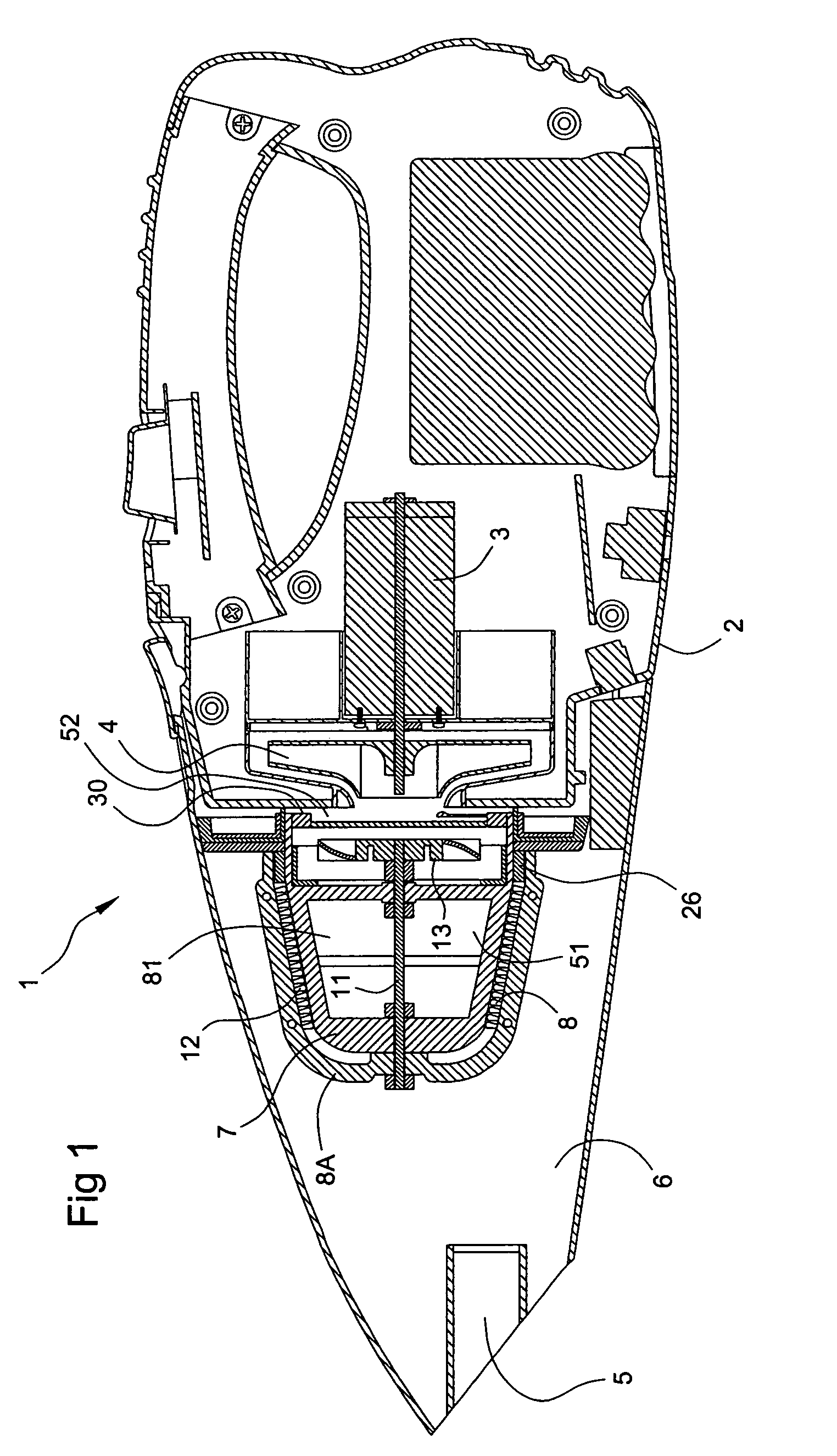

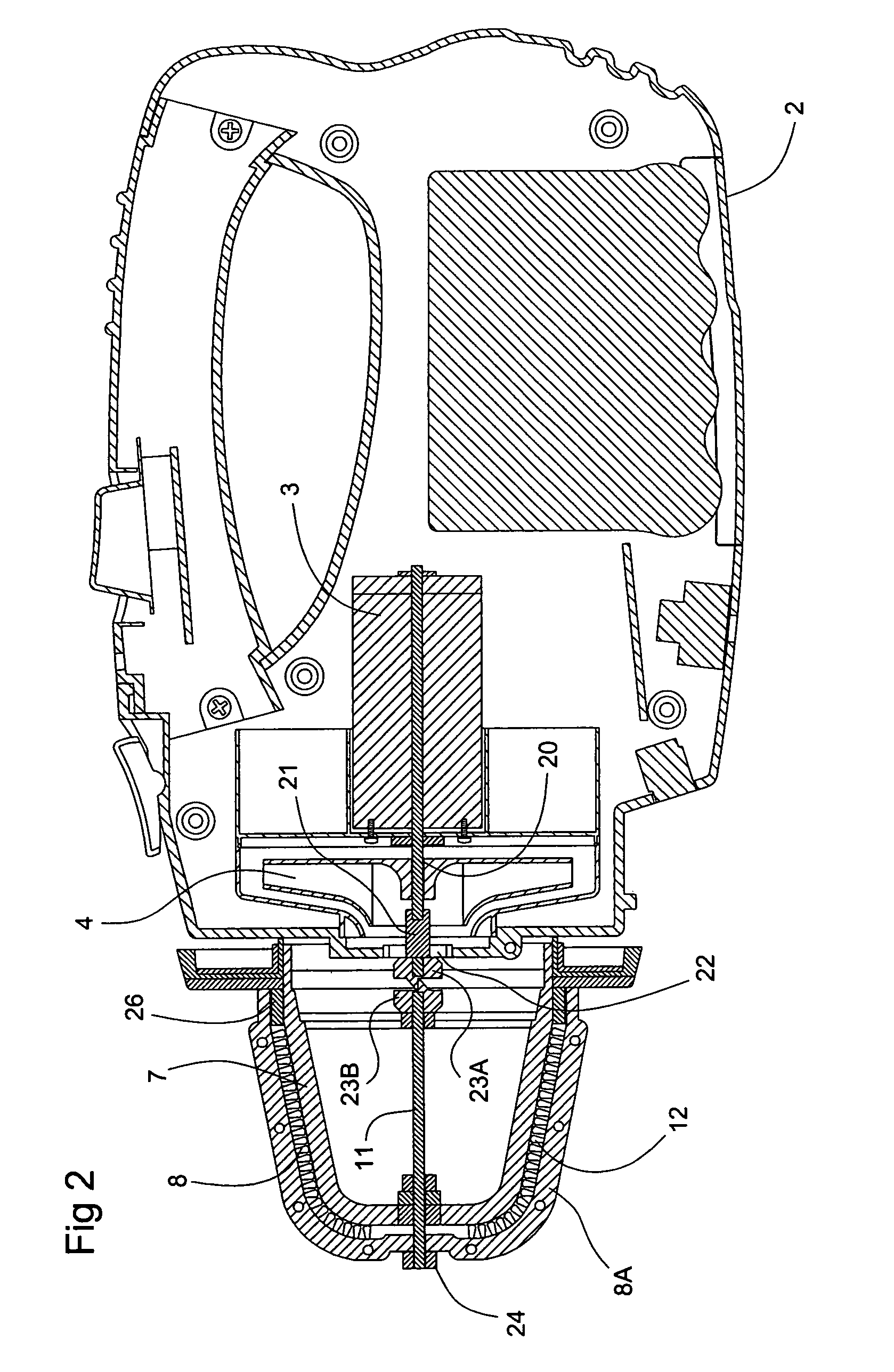

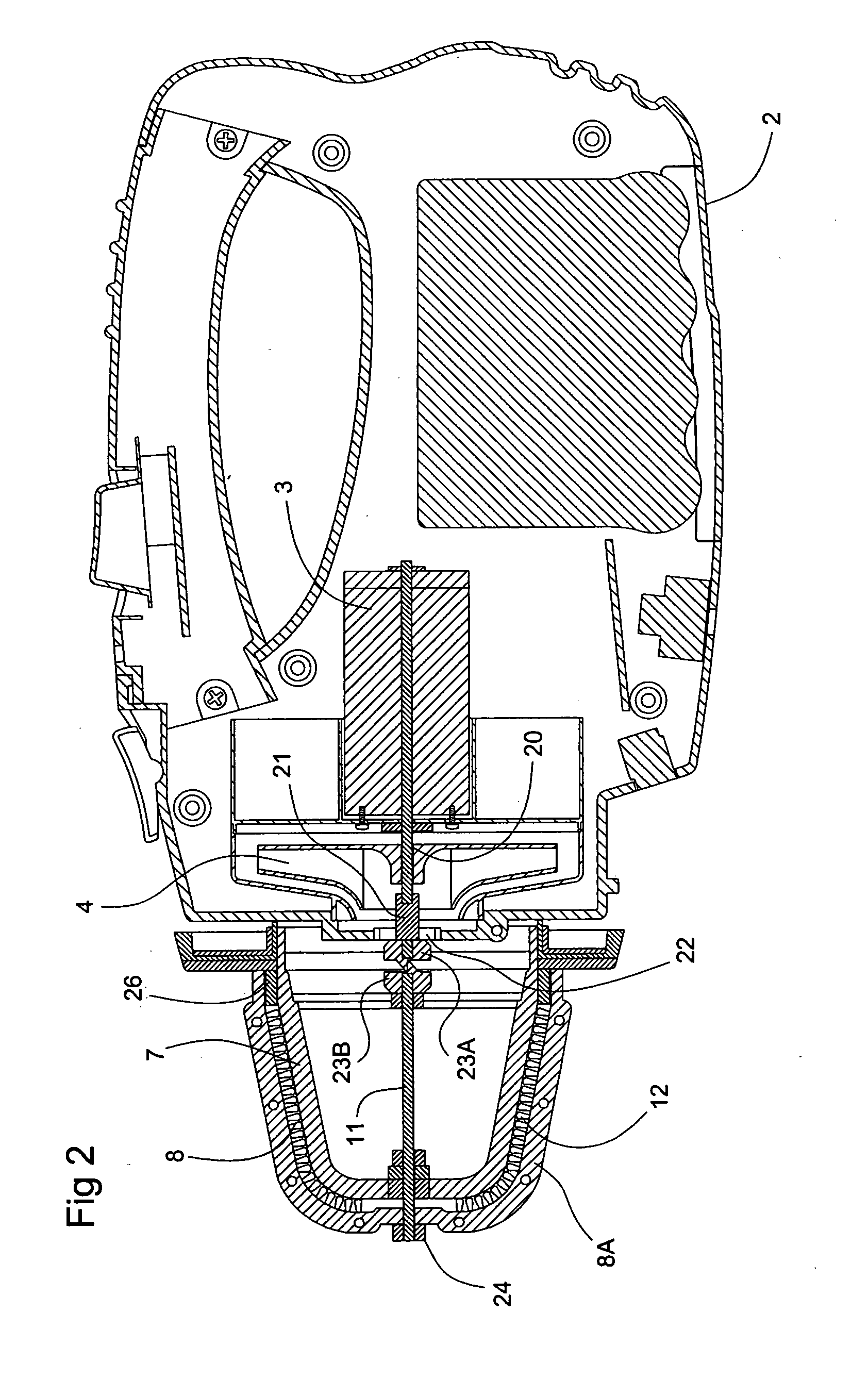

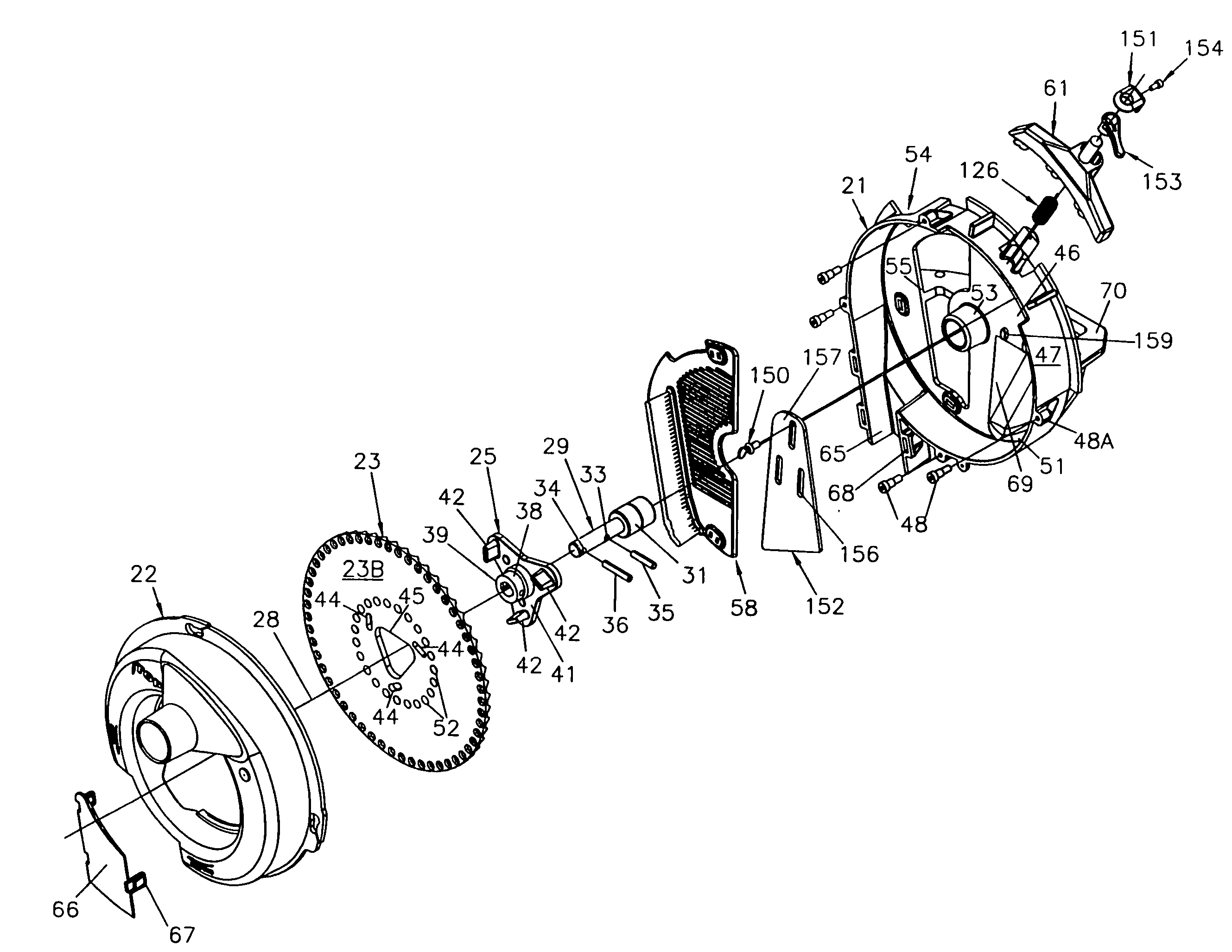

Self cleaning filter and vacuum incorporating same

InactiveUS7351269B2Extend usefulNot lose power with timeCleaning filter meansSuction filtersBristleReduction drive

A brush configured to move repeatedly over a vacuum filter. The brush will remove dust particles to prevent them from clogging the filter. In the preferred embodiment, the brush is mounted on a revolving shaft. As the shaft turns it moves the bristles of the brush over the surface of the filter, whereby dust particles may be dislodged. In one embodiment, the shaft is attached to the vacuum motor and is turned directly by the motor. In this embodiment a speed reducer may be employed to slow the rate of rotation of the brush. In another embodiment, a turbine is attached to the shaft. The turbine is placed in the path of the air stream moving through the vacuum. The air passing through the turbine cause it and the shaft to rotate, thereby reducing the load on the motor.

Owner:YAU LAU KWOK

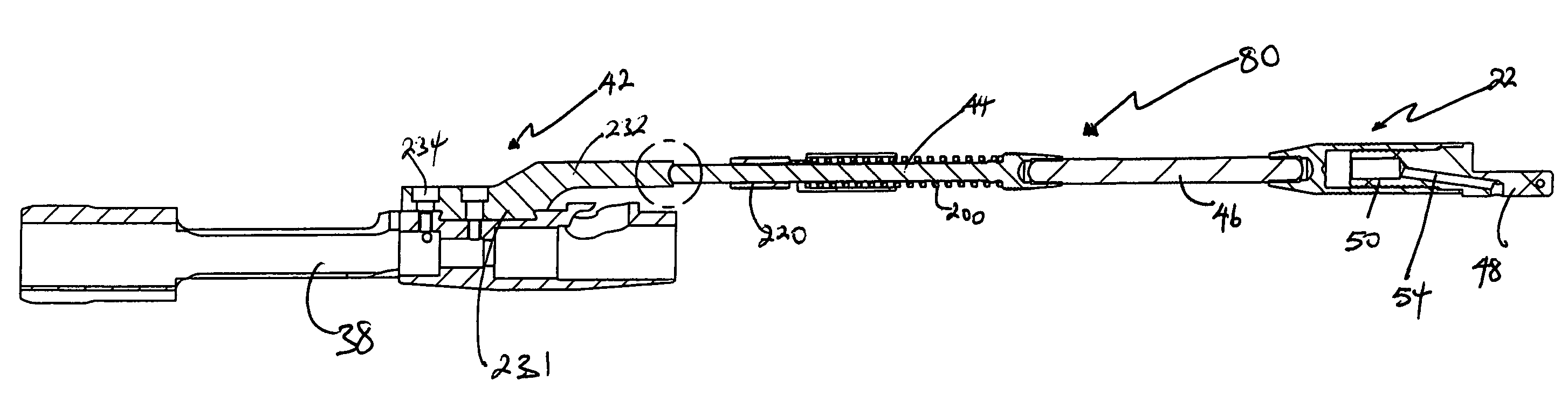

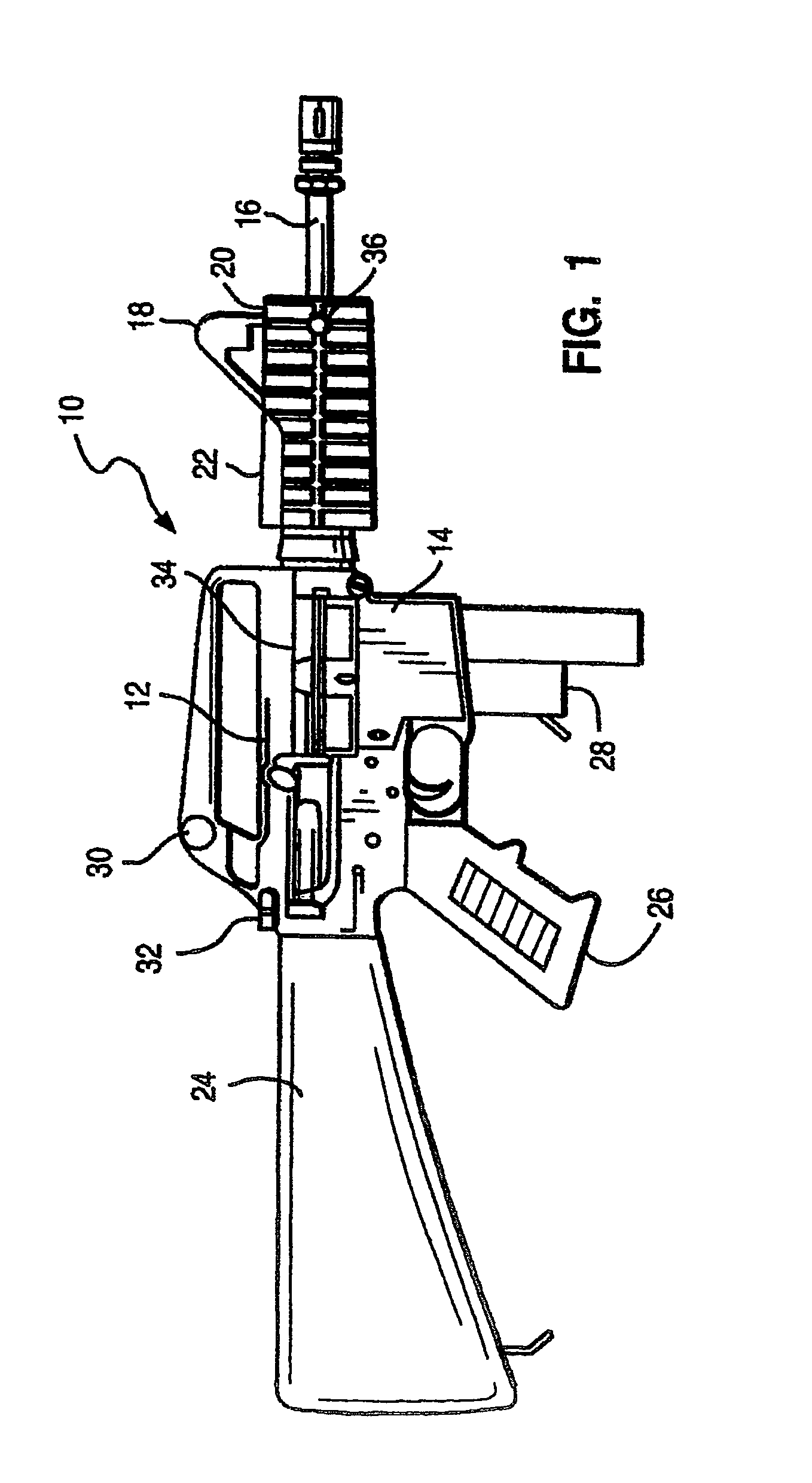

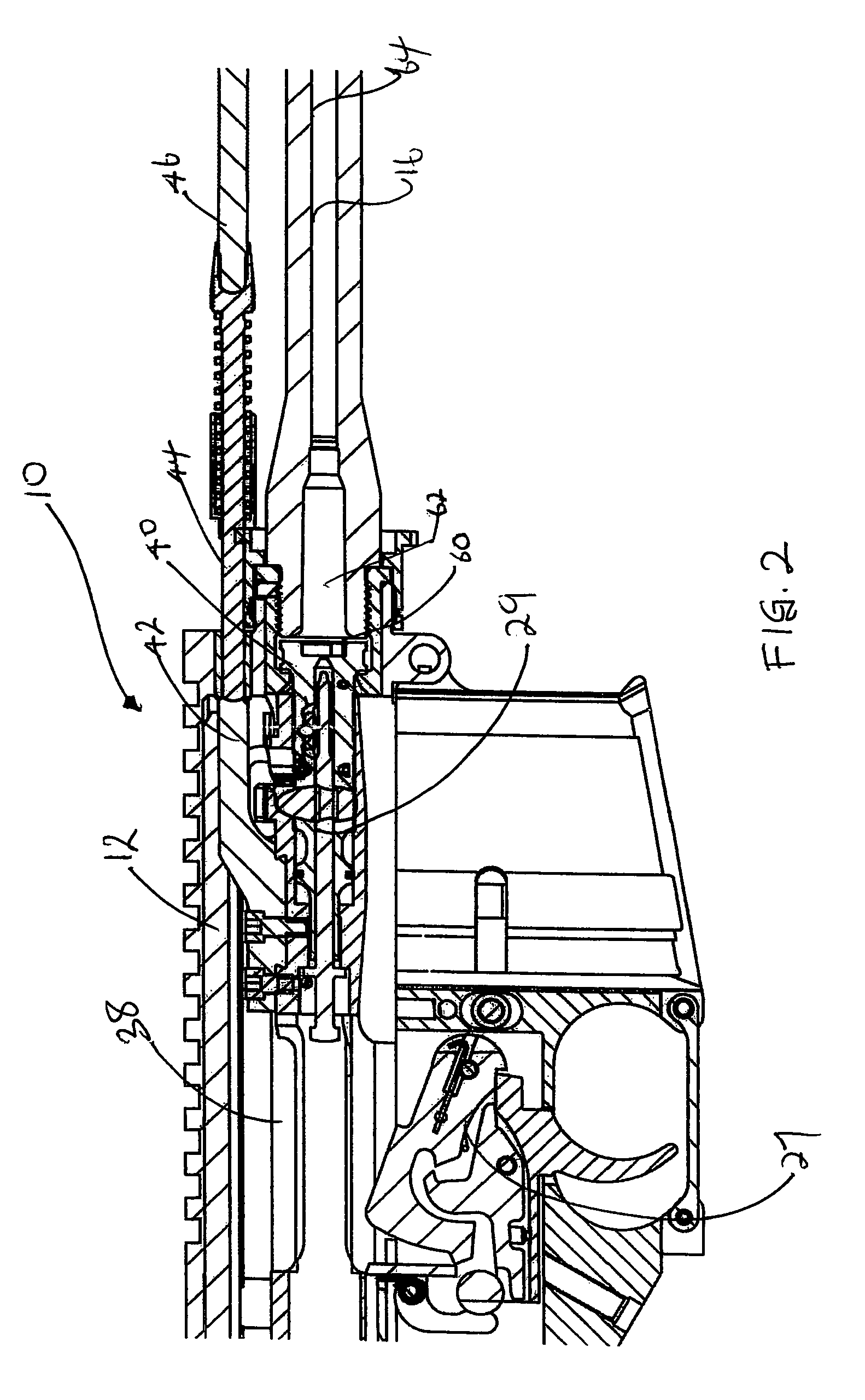

Self-cleaning gas operating system for a firearm

Owner:LWRC INTERNATIONAL

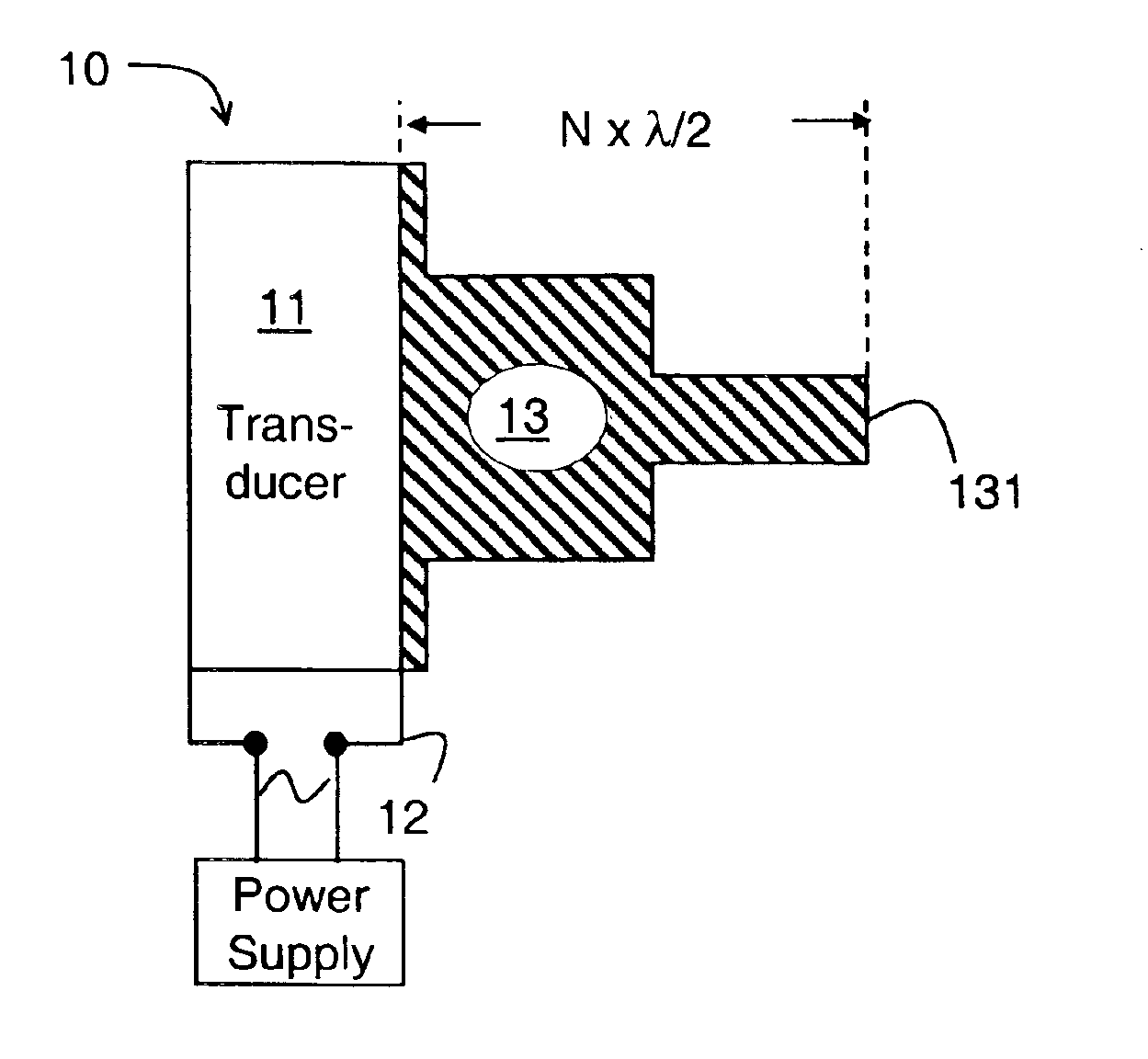

Deposition monitoring system

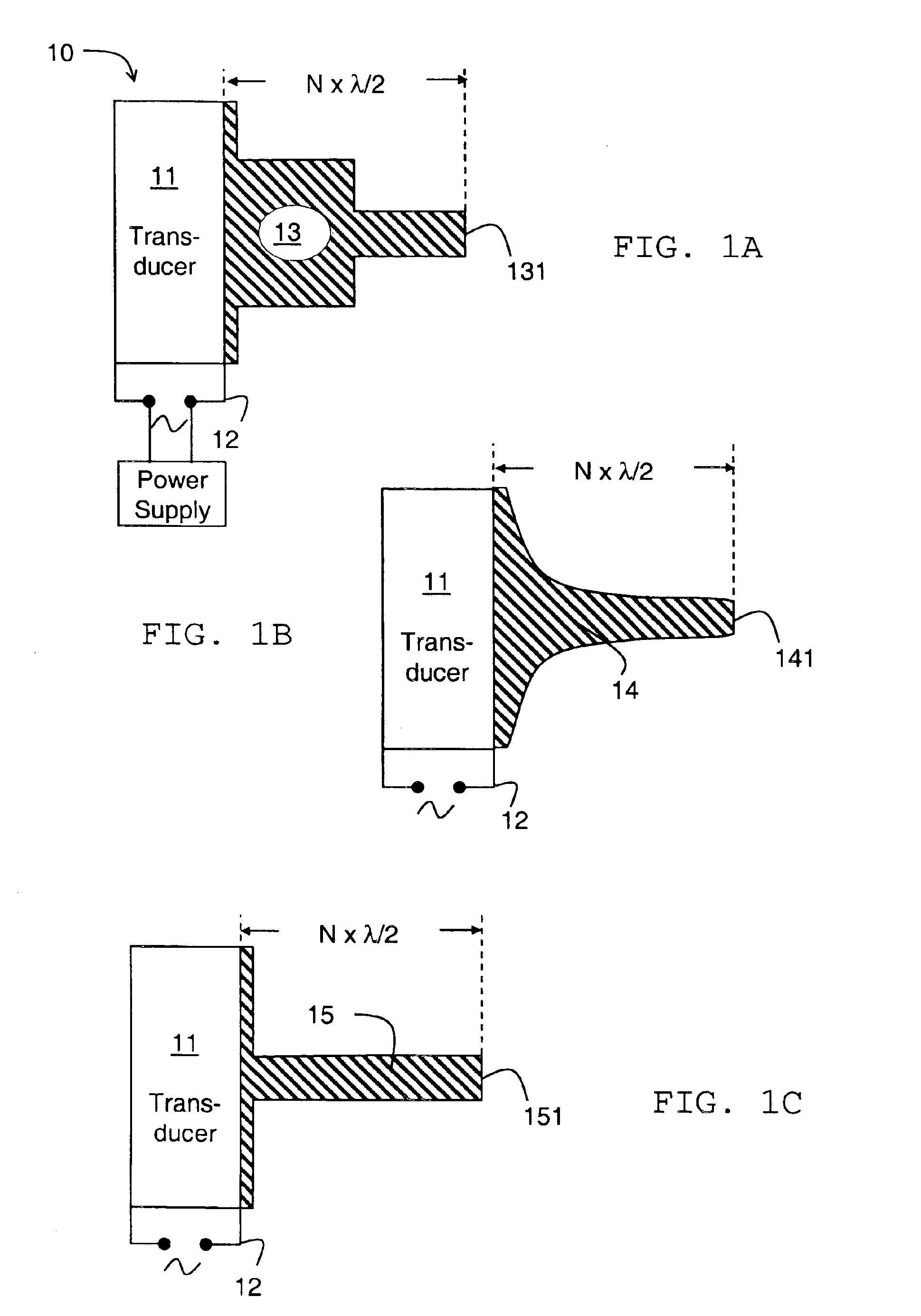

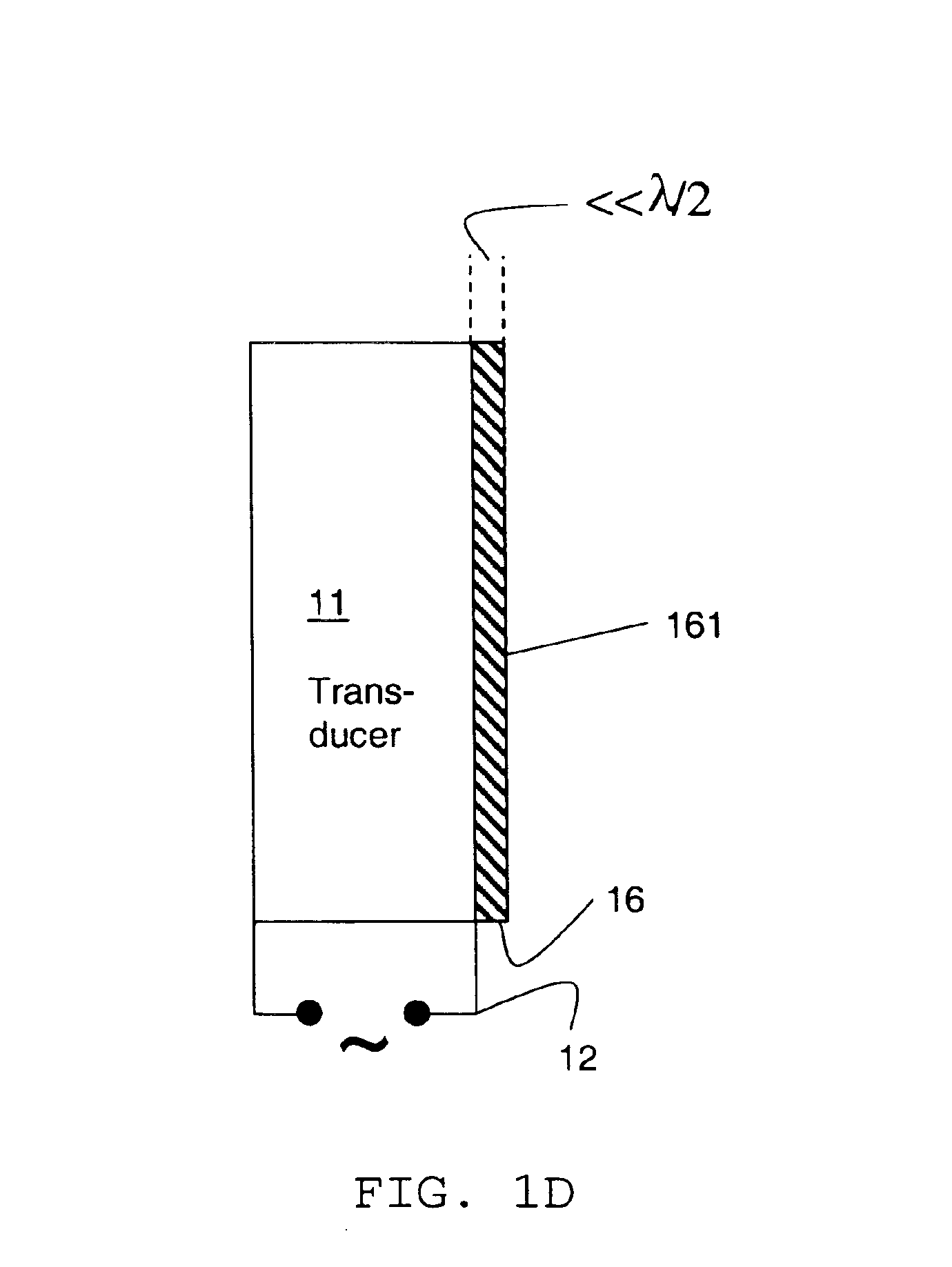

InactiveUS6880402B1Increase deposition thicknessConveniently determinedVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesMonitoring systemOperation mode

Described is an apparatus for detecting and removing deposits from a surface exposed to wellbore fluids. The apparatus can monitor the rate of deposition and subsequently remove the deposited material. The combination of detection apparatus and removal apparatus provides an instrument with self-cleaning operation mode.

Owner:SCHLUMBERGER TECH CORP

Self cleaning filter and vacuum incorporating same

InactiveUS20050132528A1Slow rate of rotationReduce loadCleaning filter meansSuction filtersBristleReduction drive

A brush configured to move repeatedly over a vacuum filter. The brush will remove dust particles to prevent them from clogging the filter. In the preferred embodiment, the brush is mounted on a revolving shaft. As the shaft turns it moves the bristles of the brush over the surface of the filter, whereby dust particles may be dislodged. In one embodiment, the shaft is attached to the vacuum motor and is turned directly by the motor. In this embodiment a speed reducer may be employed to slow the rate of rotation of the brush. In another embodiment, a turbine is attached to the shaft. The turbine is placed in the path of the air stream moving through the vacuum. The air passing through the turbine cause it and the shaft to rotate, thereby reducing the load on the motor.

Owner:YAU LAU KWOK

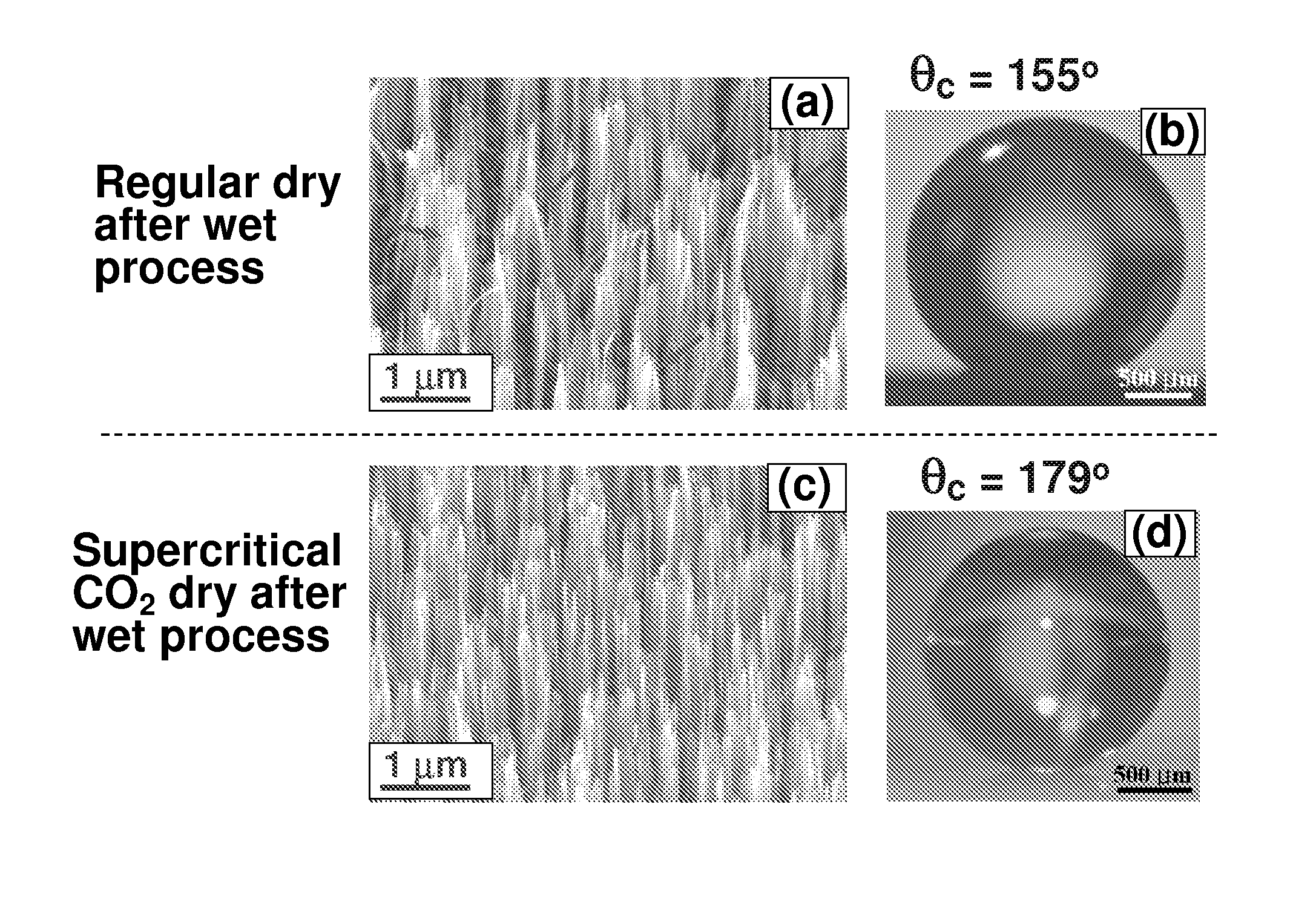

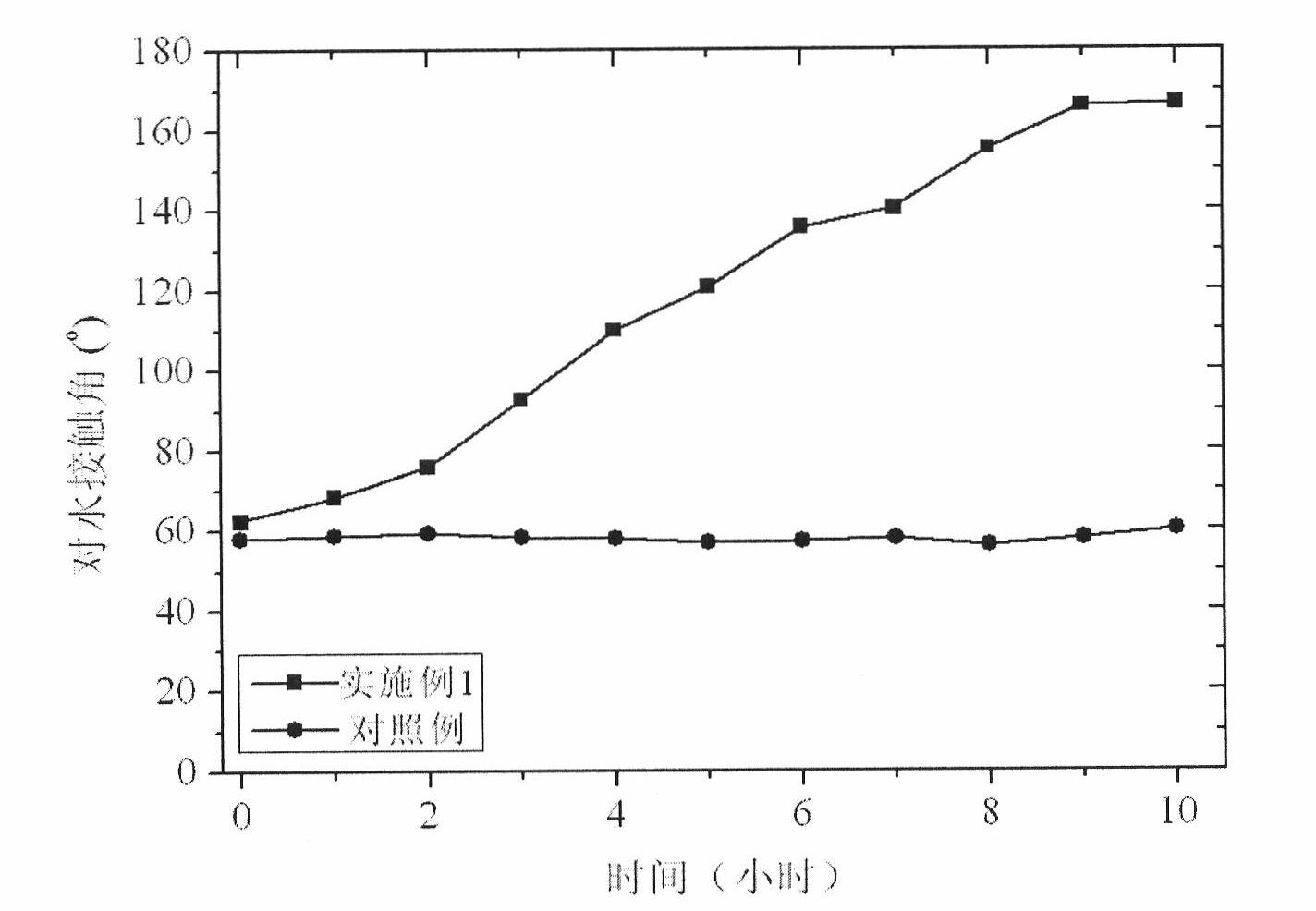

Method for preparing epoxy resin super-hydrophobic coat

InactiveCN101575478ASimple processGood repeatabilityLiquid spraying plantsMovable spraying apparatusEpoxySilica particle

The invention discloses a method for preparing an epoxy resin super-hydrophobic coat, comprising the following steps: (1), preparing collosol of the coat: dissolving silicon dioxide particles in a solvent, adding a silane coupling agent, heating and stirring for reaction, adding an epoxy resin paint and a hydrophobing agent, stirring for reaction, and obtaining the collosol of the coating layer; (2) coating film on the surface of a substrate material: coating the collosol obtained in the step (1) on the surface of the substrate through the way of lifting-pulling coating film, rotationally coating, curtain coating or spraying, after lifting, placing statically at the room temperature for using; and (3) heating and curing: putting the substrate material coated by the film in the step (2) in an oven, raising temperature to heat to make the epoxy resin cure and cross, taking out to obtain the epoxy resin super-hydrophobic coat. The invention has the advantages of easy technique, easily obtained raw materials, low cost and good repeatability; and the obtained coat has good super-hydrophobicity and self-cleaning performance for the industrial production of the super-hydrophobic paint properly.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

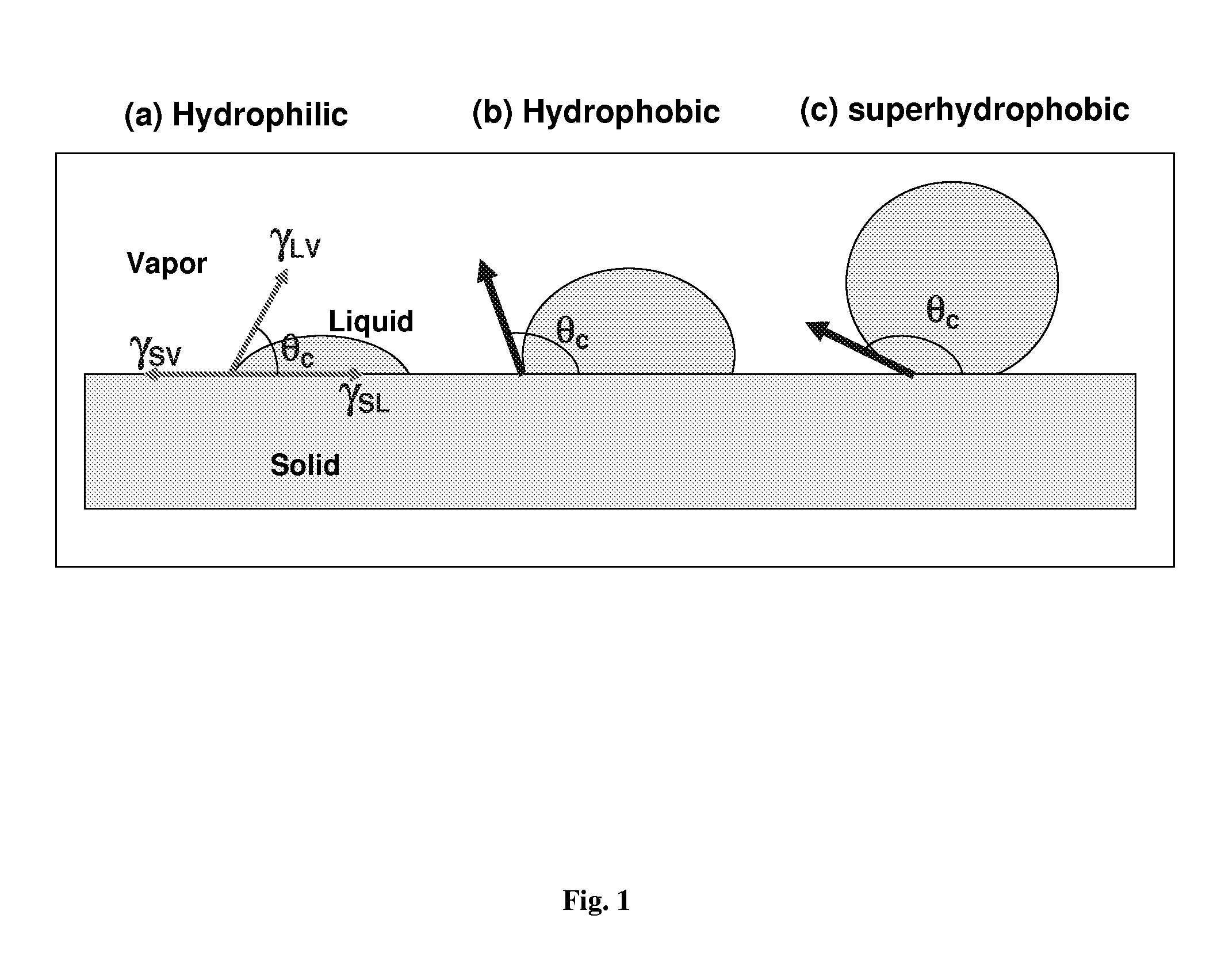

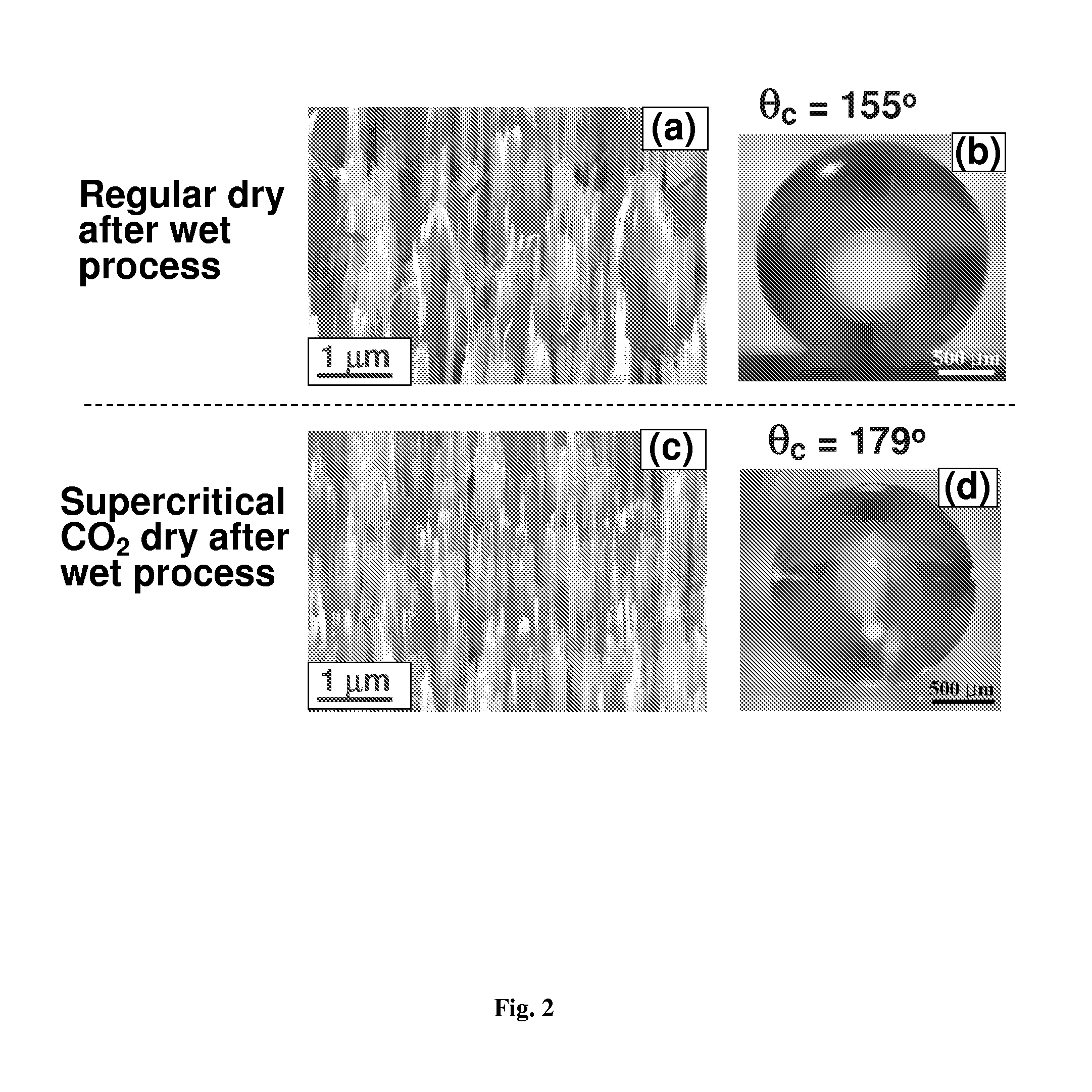

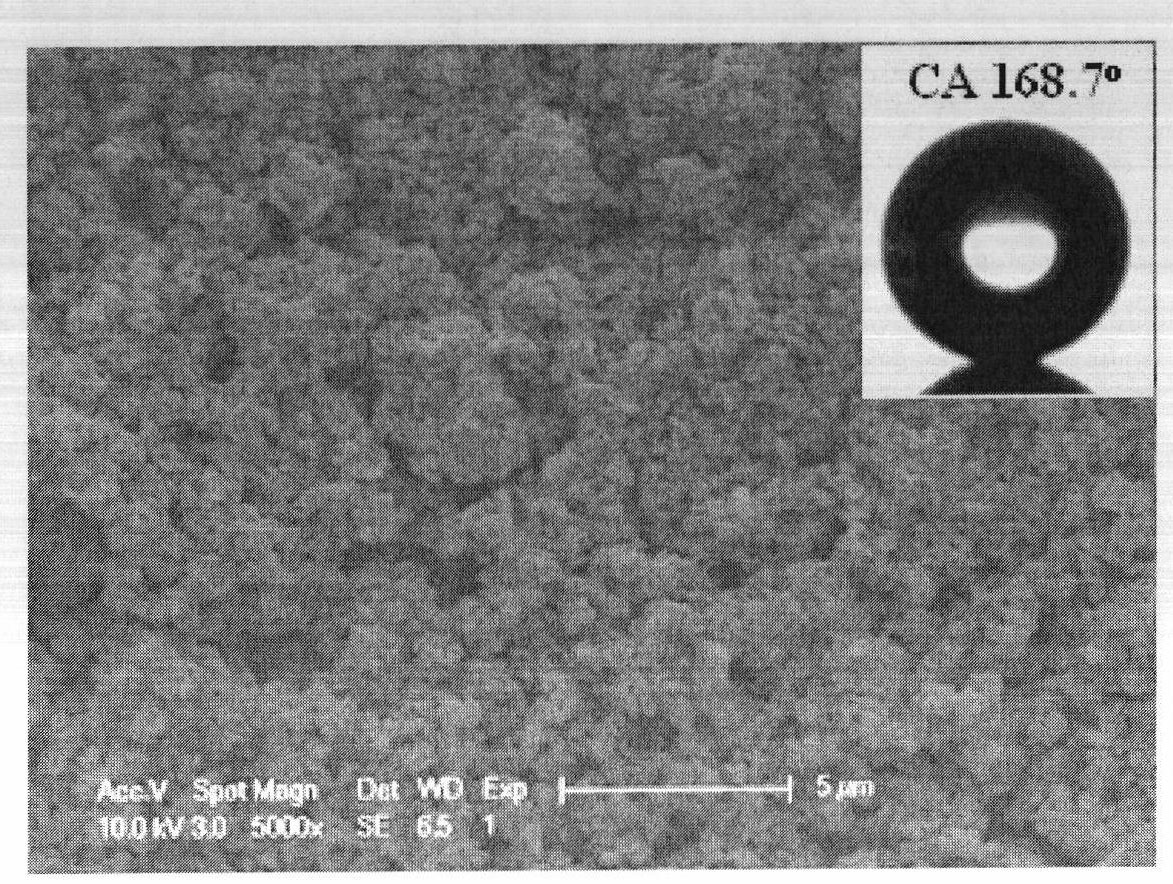

Nanostructured superhydrophobic, superoleophobic and/or superomniphobic coatings, methods for fabrication, and applications thereof

Systems, techniques and applications for nanoscale coating structures and materials that are superhydrophobic with a water contact angle greater than about 140° or 160° and / or superoleophobic with an oil contact angle greater than about 140° or 160°. The nanostructured coatings can include Si or metallic, ceramic or polymeric nanowires that may have a re-entrant or mushroom-like tip geometry. The nanowired coatings can be used in various self-cleaning applications ranging from glass windows for high-rise buildings and non-wash automobiles to pipeline inner surface coatings and surface coatings for biomedical implants.

Owner:RGT UNIV OF CALIFORNIA

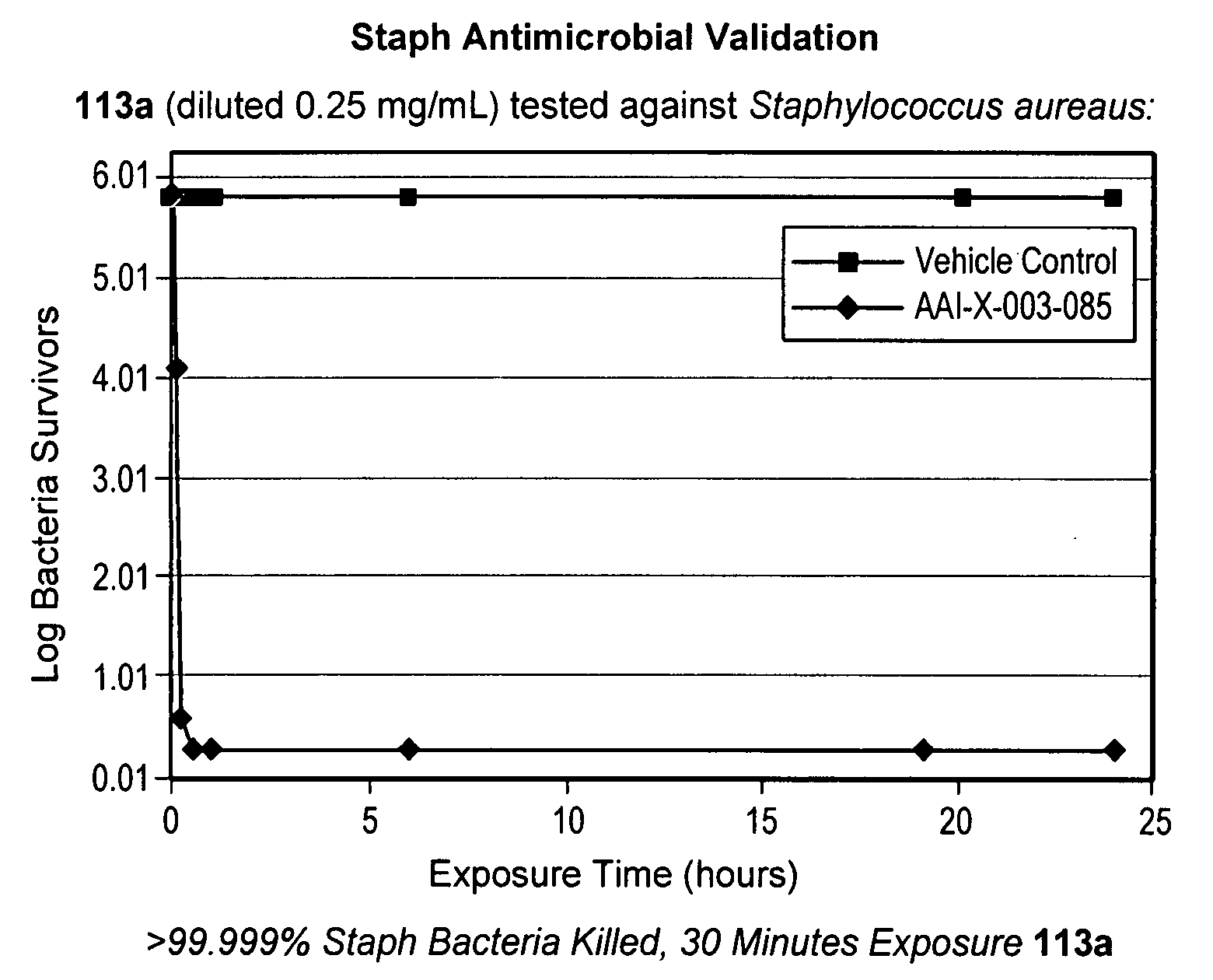

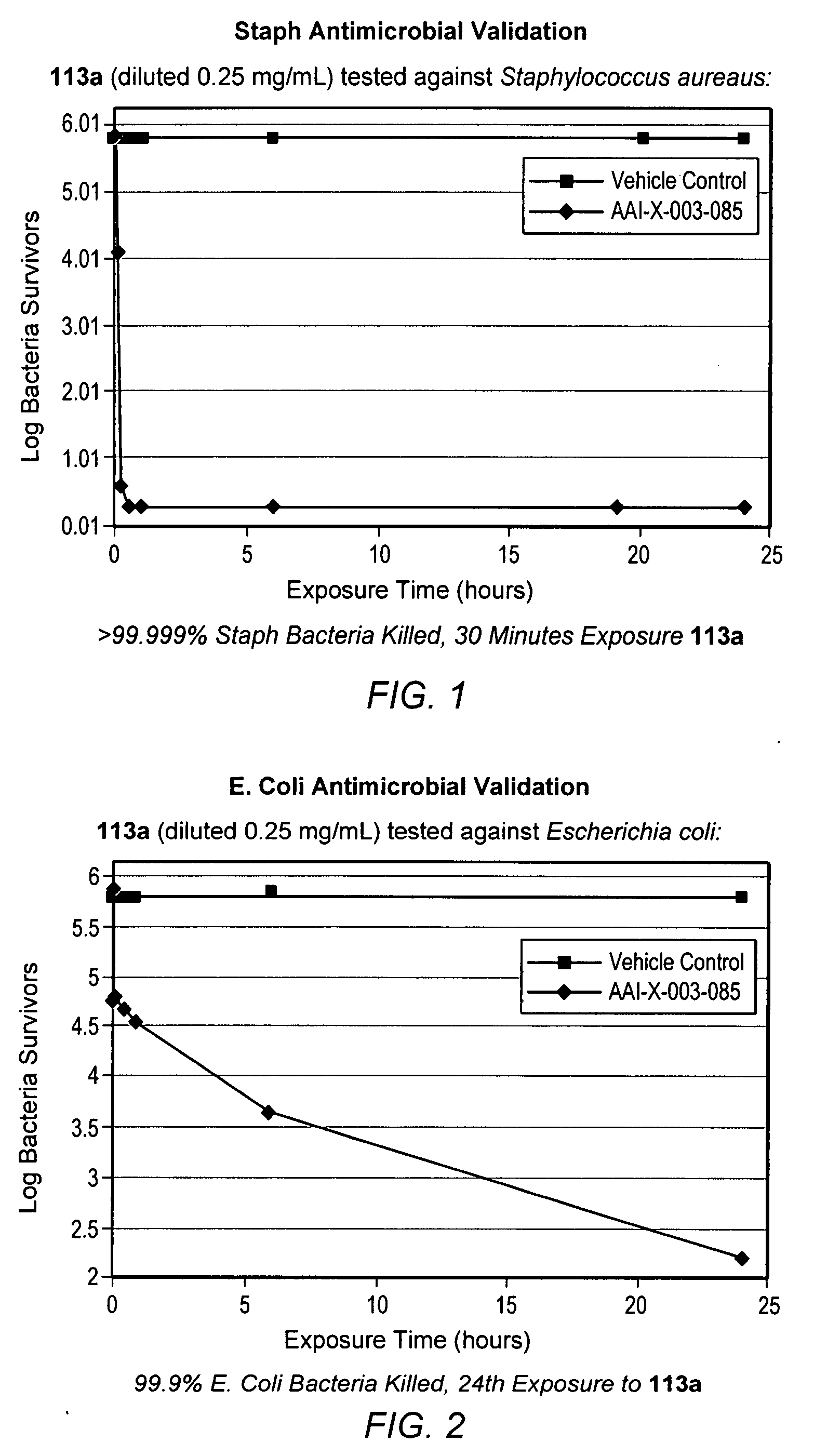

Methods and systems for coating a medical device

ActiveUS20080020127A1High activityImprove solubilityCosmetic preparationsMaterial nanotechnologyPolycyclic compoundAmmonium compounds

A coating system and method are described. In some embodiments, a system may include a composition. The composition may include one or more bridged polycyclic compounds. At least one of the bridged polycyclic compounds may include at least two cyclic groups, and at least two of the cyclic groups may include quaternary ammonium moieties. In some embodiments, a method may include applying a coating to a surface of a medical device. The coating may be antimicrobial. A coating may include antimicrobial bridged polycyclic compounds. Bridged polycyclic compounds may include quaternary ammonium compounds. Bridged polycyclic compounds based coating systems may impart self-cleaning properties to a surface.

Owner:ALLACCEM

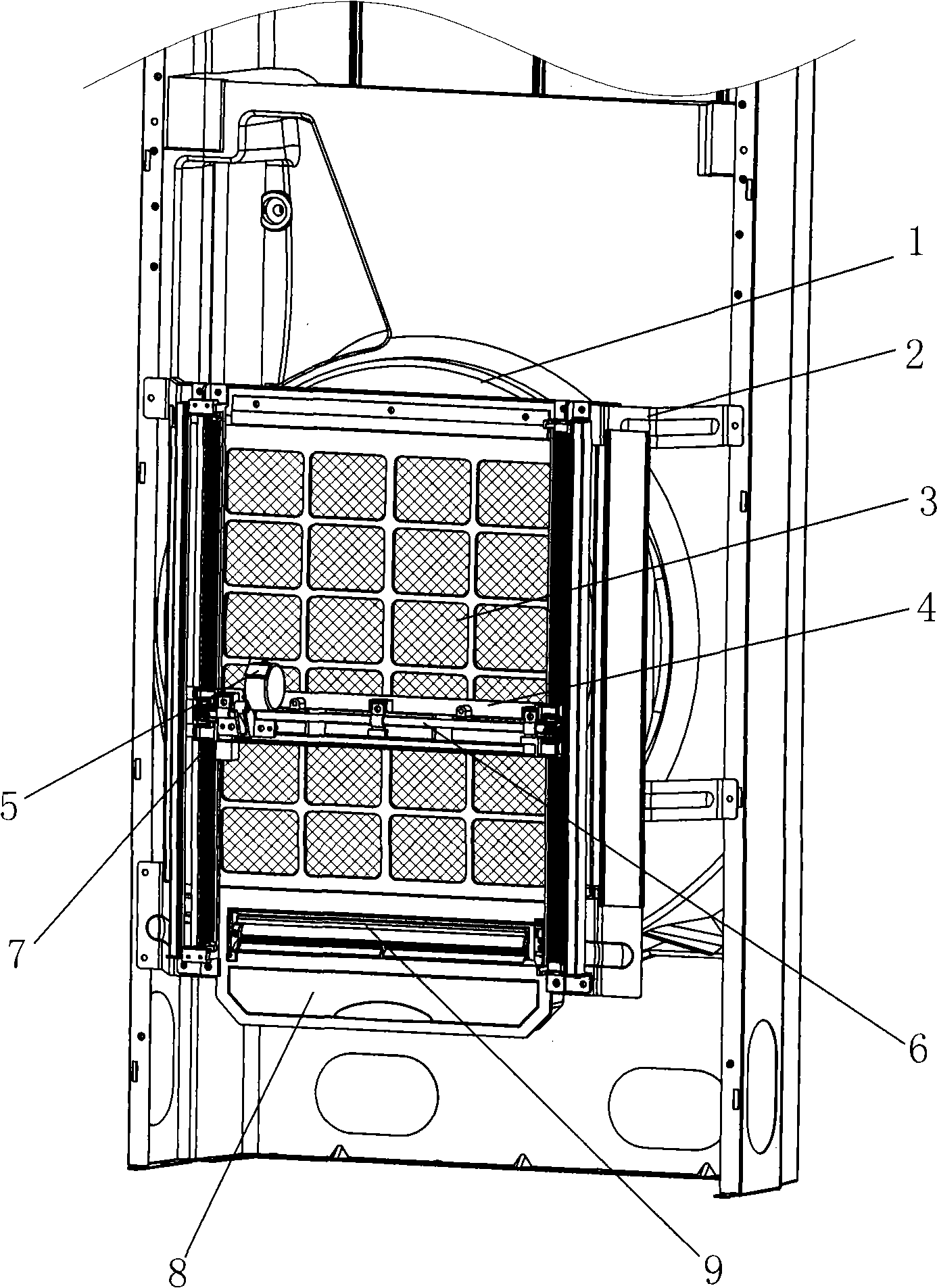

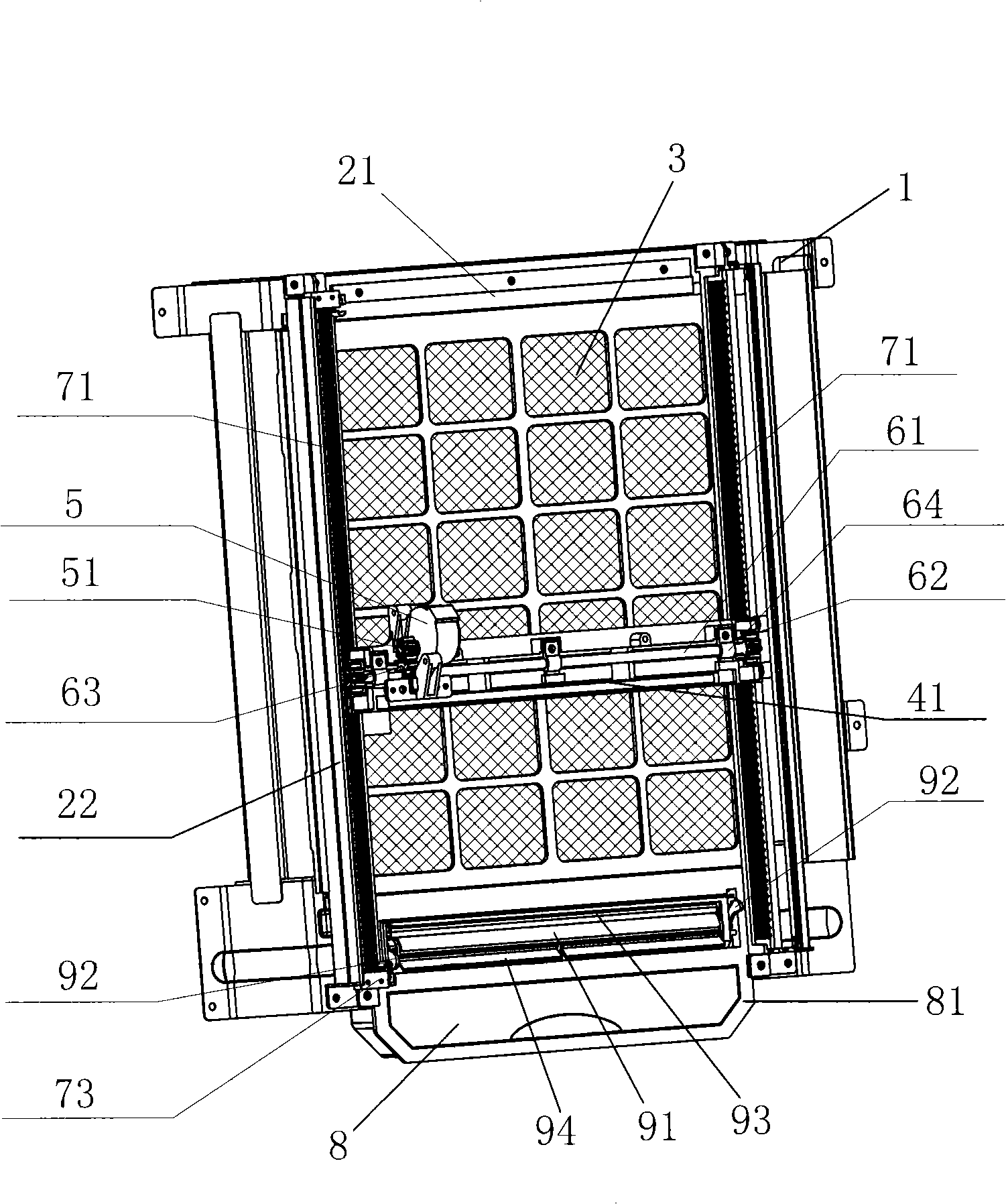

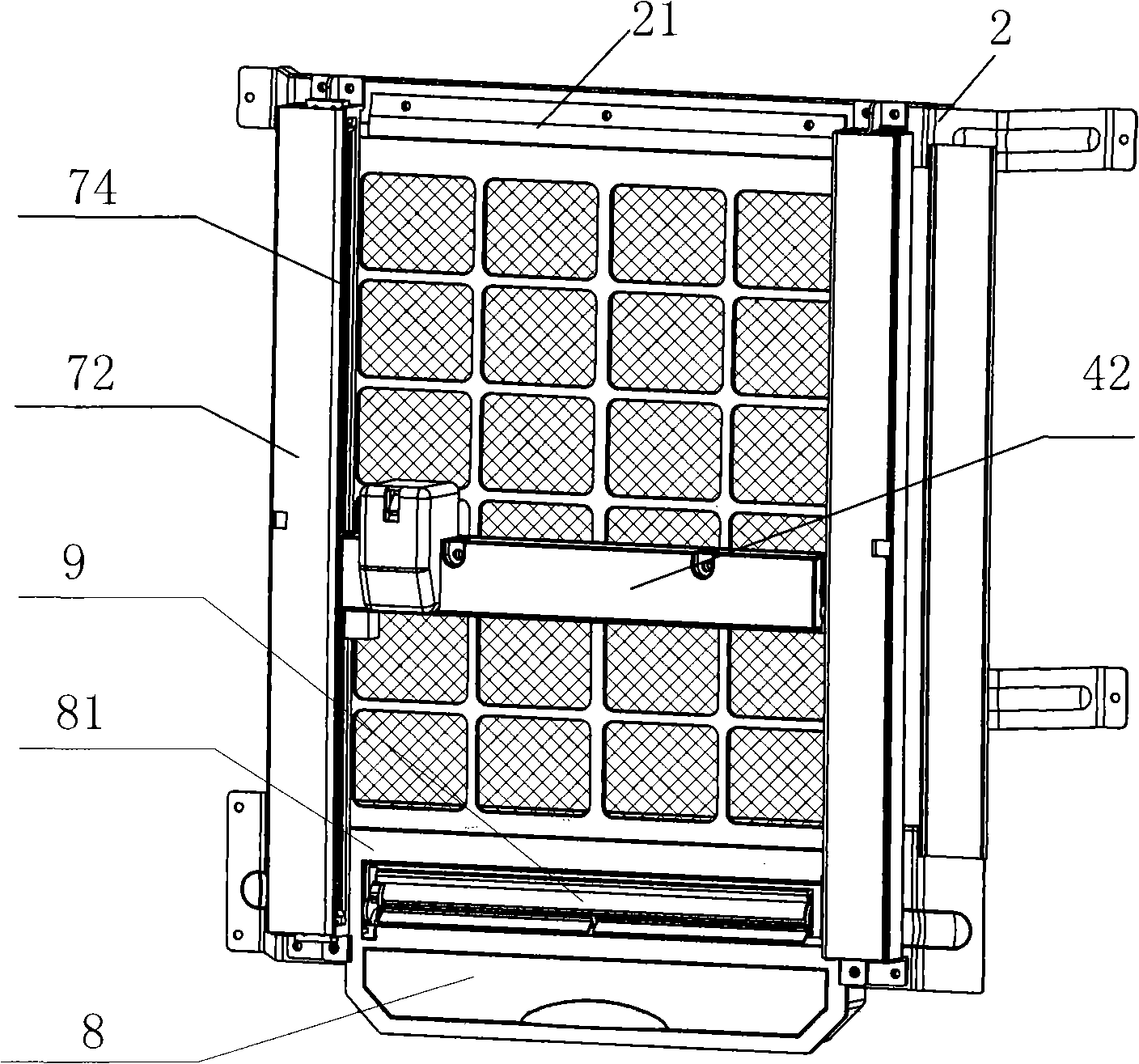

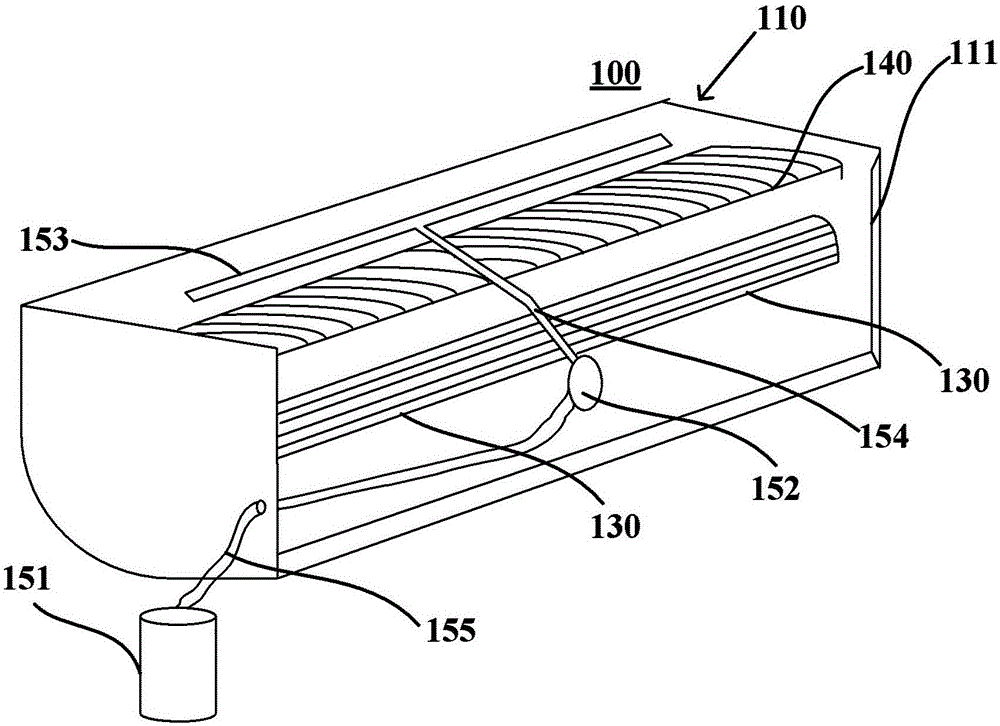

Air conditioner filter screen self-cleaning device

ActiveCN101290151AGuaranteed cleanlinessGuarantee the quality of workMechanical apparatusDispersed particle filtrationDrive motorSelf cleaning

The invention discloses a self-cleaning device for an air conditioner filter screen, which is arranged on filter screen brackets at an air passage spiral casing air inlet of a cabinet air conditioner and is arranged outside the filter screen, an upper bracket and a lower bracket are provided with filter screen guide rails with slots, the filter screen is fixed on the filter screen brackets through the slots of the guide rails, a filter screen cleaning device comprises a cleaning component with a brush, a drive motor fixed on the cleaning component, a driving mechanism connected with the drive motor, a rack set arranged at the left side part and the right side part of the filter screen and a dust box arranged under the filter screen and used for collecting dust; a dust exchange device is arranged between the dust box and the filter screen; the drive motor connected with the driving mechanism drives the cleaning component to slide up and down along the rack set adhering to the filter screen in order to enable the brush to clean dust down; the cleaning component slides down to pass through the dust exchange device and cleans the dust down in the dust exchange device, and then the dust exchange device pours the dust to the dust box. The self-cleaning device for air conditioner filter screen saves time and labor and can be cleaned at any time without disassembling.

Owner:HAIER GRP CORP +1

Surfaces which are self-cleaning by hydrophobic structures, and a process for their production

A process for producing self-cleaning surfaces, in which an at least partially hydrophobic, surface structure is formed by securing particles on a polymer surface, which comprises applying, to the polymer surface, at least one solvent which comprises the particles and which solvates the polymer surface, and securing at least part of the particles to the polymer surface by removing the solvent; self-cleaning surfaces obtained by the process; and objects containing self-cleaning surfaces obtained by the process.

Owner:CREAVIS GES FUER TECH

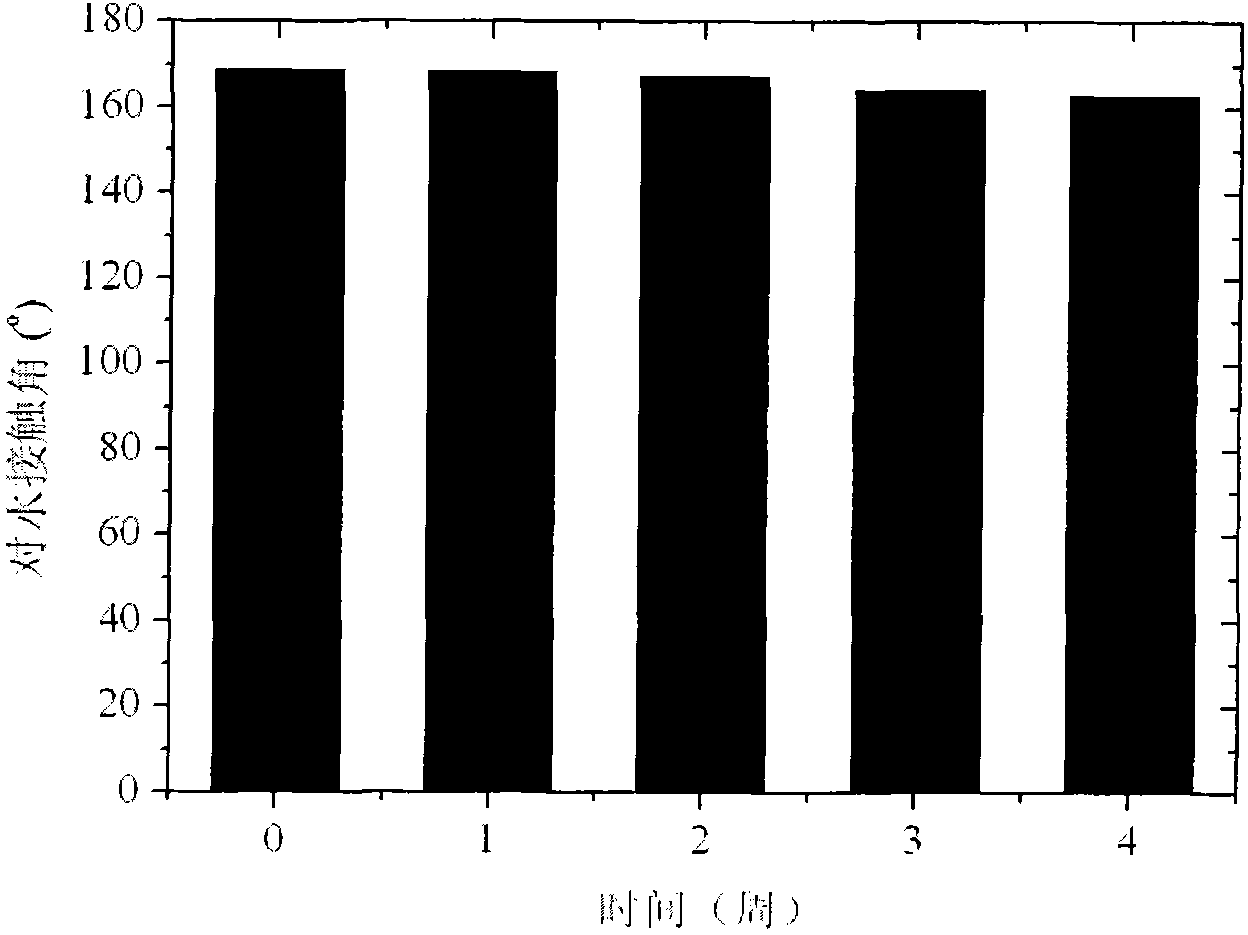

High-durability super-hydrophobic self-cleaning coating material and preparation method thereof

InactiveCN101962514AHas the following advantages: (1) cleanlinessHas the following advantages: (1) has the functionAntifouling/underwater paintsPaints with biocidesDouble bondDimethyl siloxane

The invention belongs to the technical field of a new chemical material, and in particular relates to a high-durability super-hydrophobic self-cleaning coating material and a preparation method thereof. The coating material of the invention is prepared by curing and drying nanoparticles with photo-catalytic activity, a low-surface-free-energy polymer and a cross-linking agent at the room temperature, wherein the low-surface-free-energy polymer consists of one or more of polysiloxane fluoride, dimethyl silicone polymer and polyphenylene methyl siloxane, which contain active groups, such as hydroxyl alkoxy group, carbon-carbon double bond, silanol group, siloxy group, and the like; the cross-linking agent is hydrogen-containing silicone oil or aminosilane; and the mass content of the photo-catalytic nanoparticles in the coating ranges from 10 to 60 percent. The coating is formed into a micro-nanostructure by nanoparticle self-organization; a super-hydrophobic self-cleaning coating with lotus effect is prepared from the coating and a cross-linked filming matrix with low surface energy; the persistence of a lotus-shaped super-hydrophobic characteristic of the coating is realized by using the photo-catalytic decomposition characteristic of an organic pollutant for the nanoparticles; and thus the material is suitable for large-area construction and has high weathering resistance andprominent self-cleaning characteristic.

Owner:FUDAN UNIV

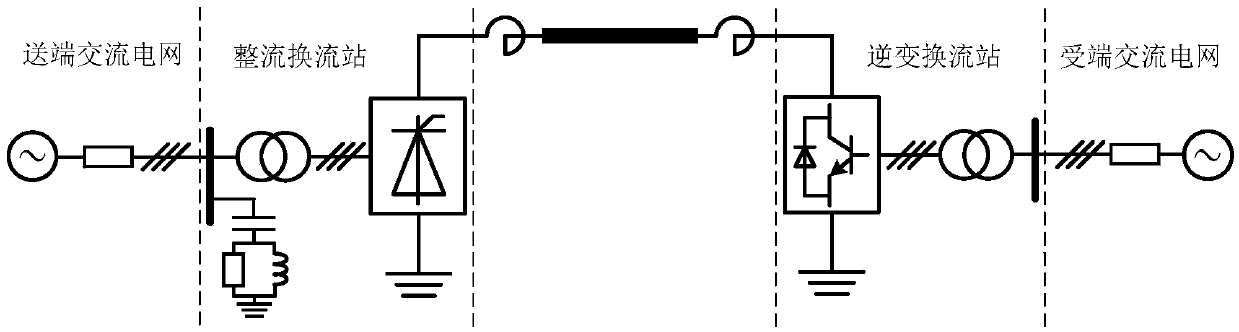

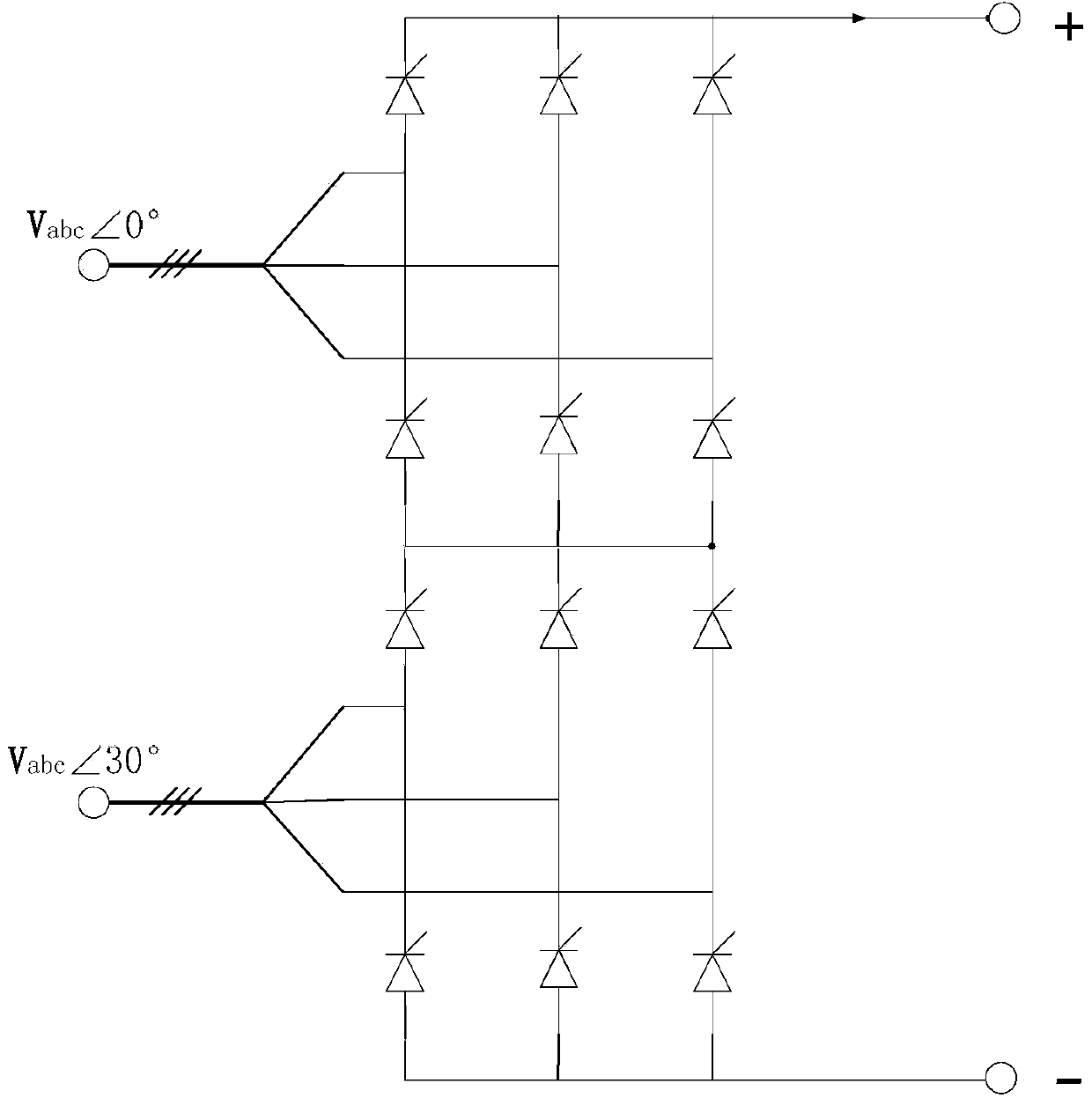

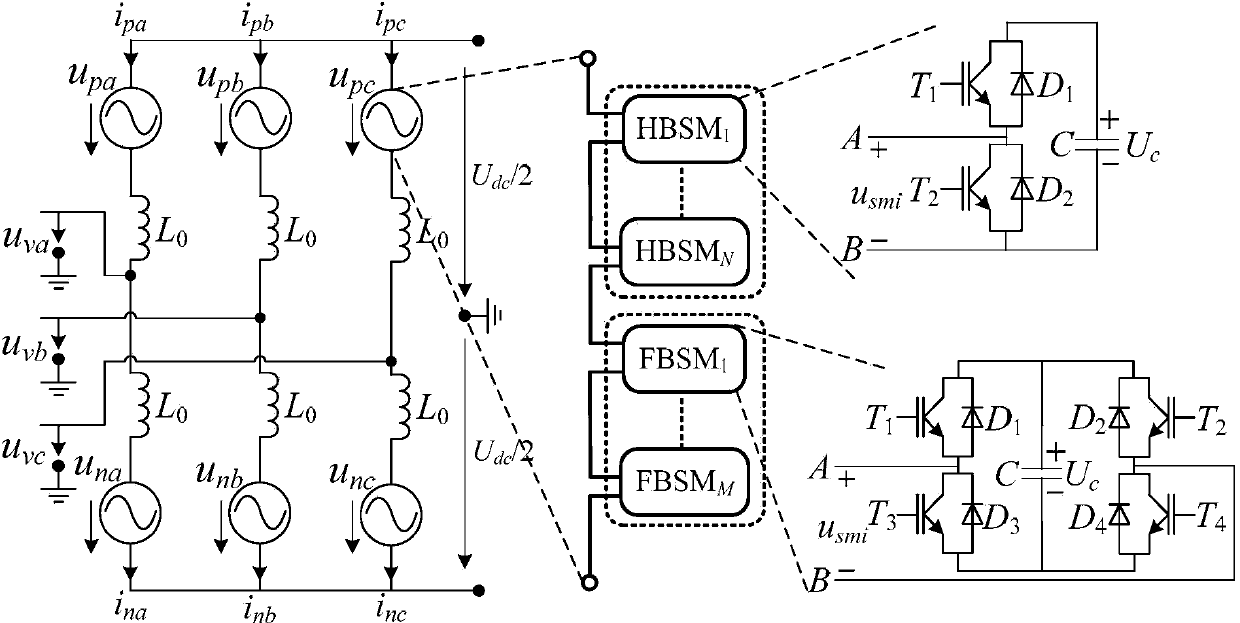

Mixed MMC-based mixed direct current power transmission system

InactiveCN103701145ANo risk of commutation failureWith DC fault self-clearing capabilityAc-dc conversionElectric power transfer ac networkHybrid typeFull bridge

The invention discloses a mixed MMC-based mixed direct current power transmission system, comprising a rectifying converter station and an inversion converter station, wherein the inversion converter station adopts a mixed MMC. The direct current power transmission system has the active and reactive decoupling control capacity, can transmit power to a reactive network without the phase change failure risk and has direct current fault self-cleaning capacity; under the condition that a feeding end alternating current system has a fault; the mixed MMC has the capacity of outputting a negative level by using a full-bridge submodule, the direct current voltage output by the system can be reduced under the premise of ensuring the controllability and stability of the system, the direct current voltage can be matched with the direct current voltage of a rectifying station, and the direct current power is maintained to be continuously transmitted; due to the optimization on the number of two types of submodules in the mixed MMC, the use number of power electronic components is greatly reduced and the investment cost is reduced under the condition that the mixed modularized multi-level converter meets the stable and transient operation demands of the direct current system.

Owner:ZHEJIANG UNIV +1

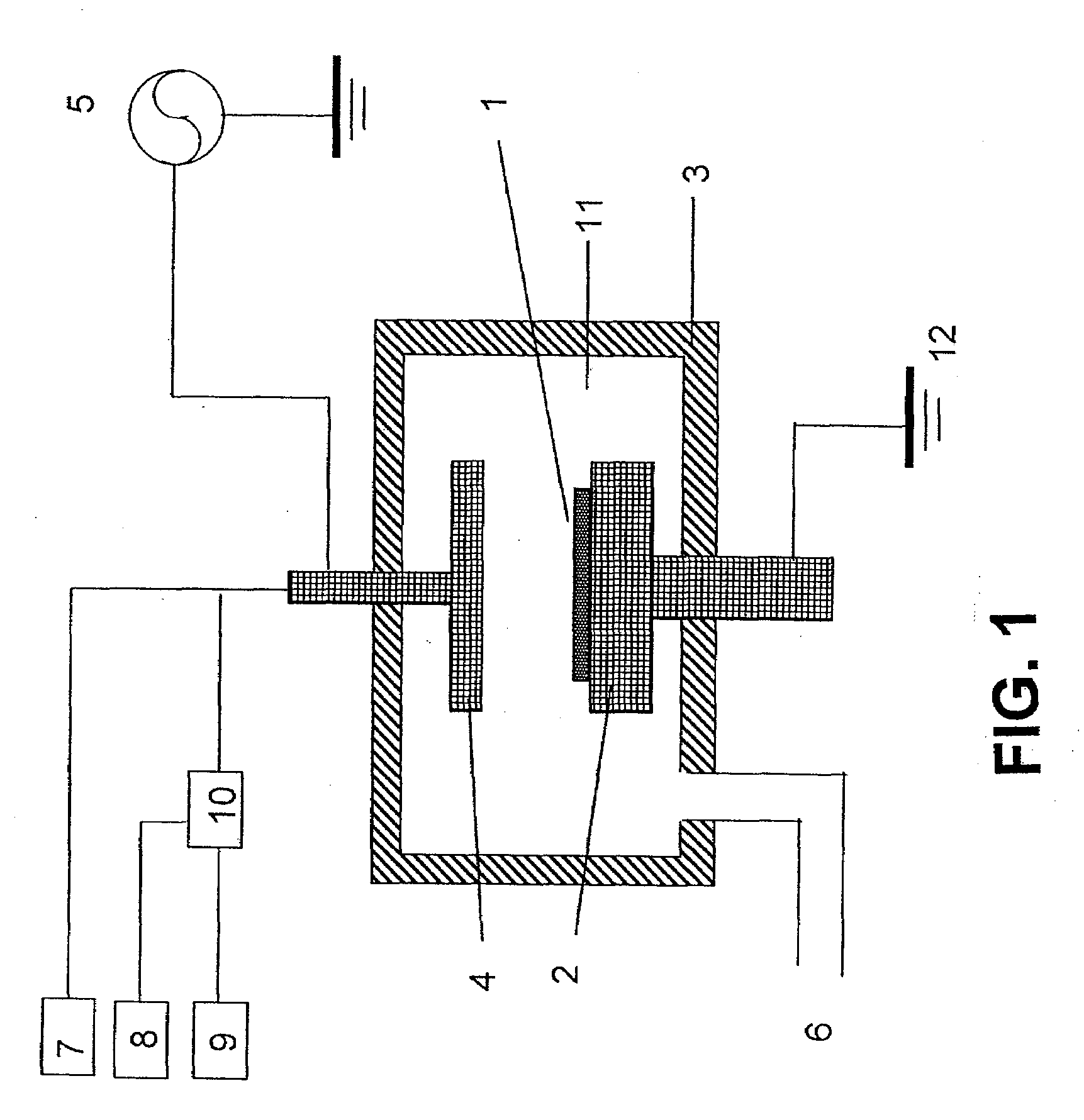

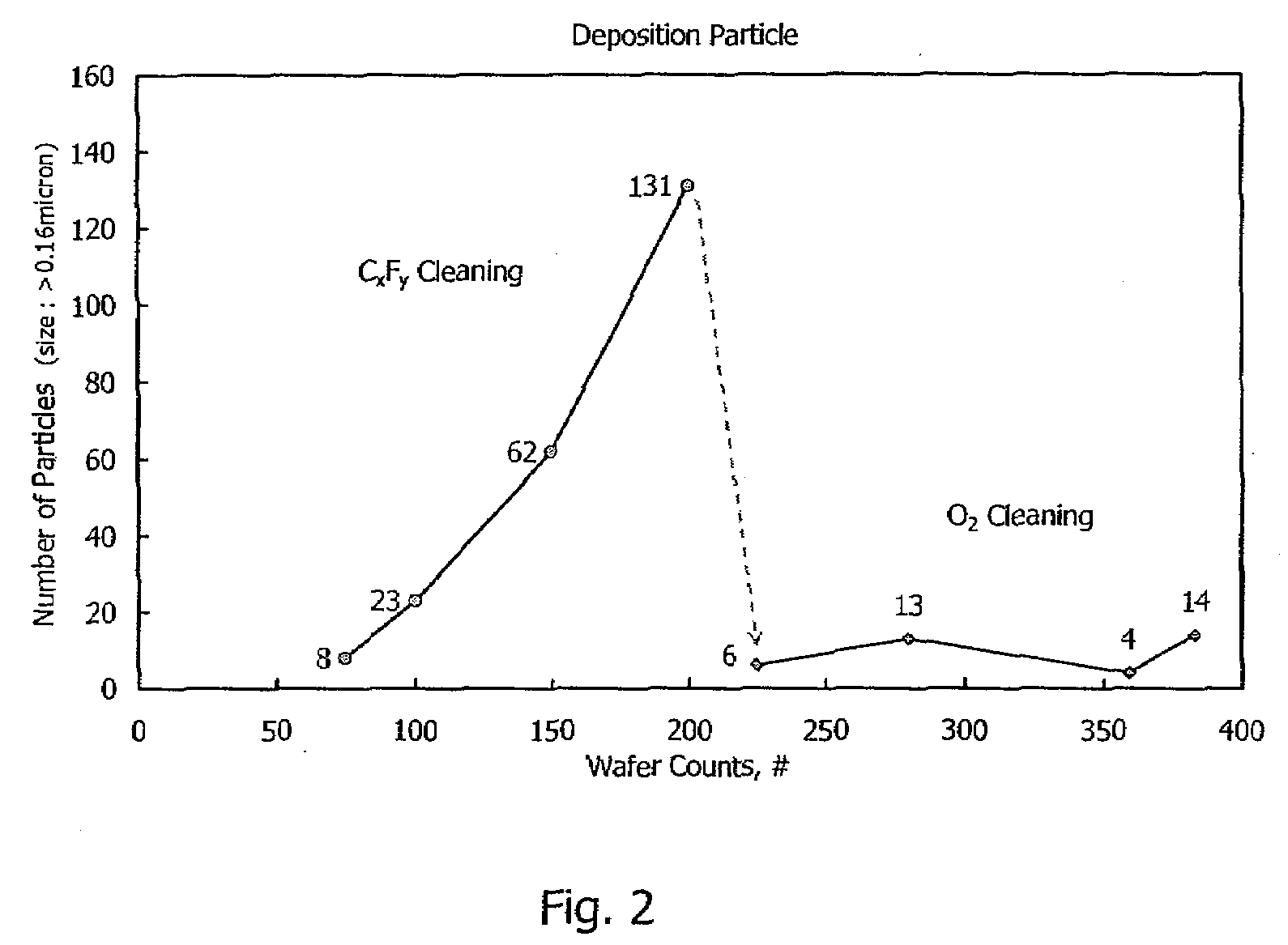

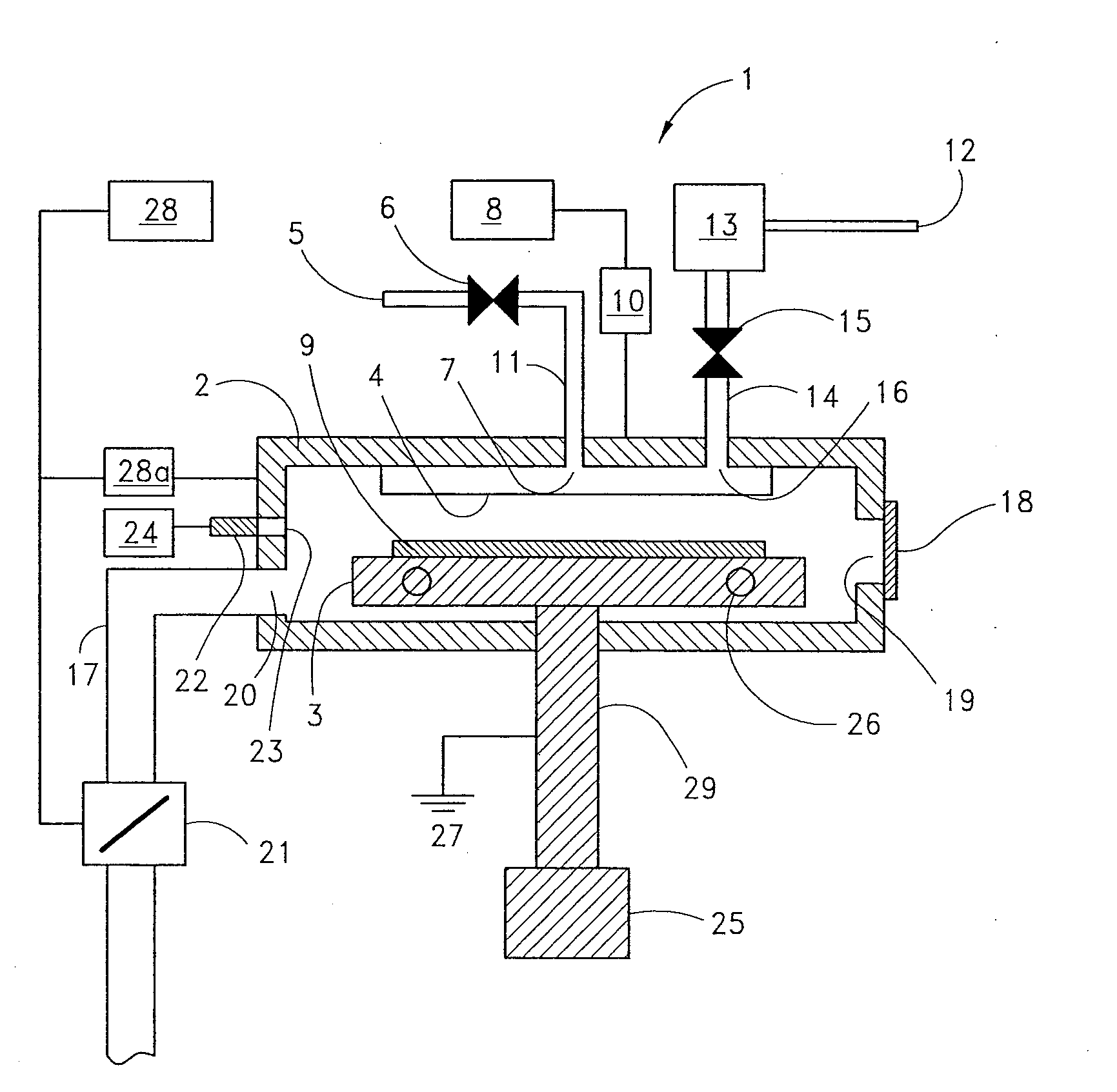

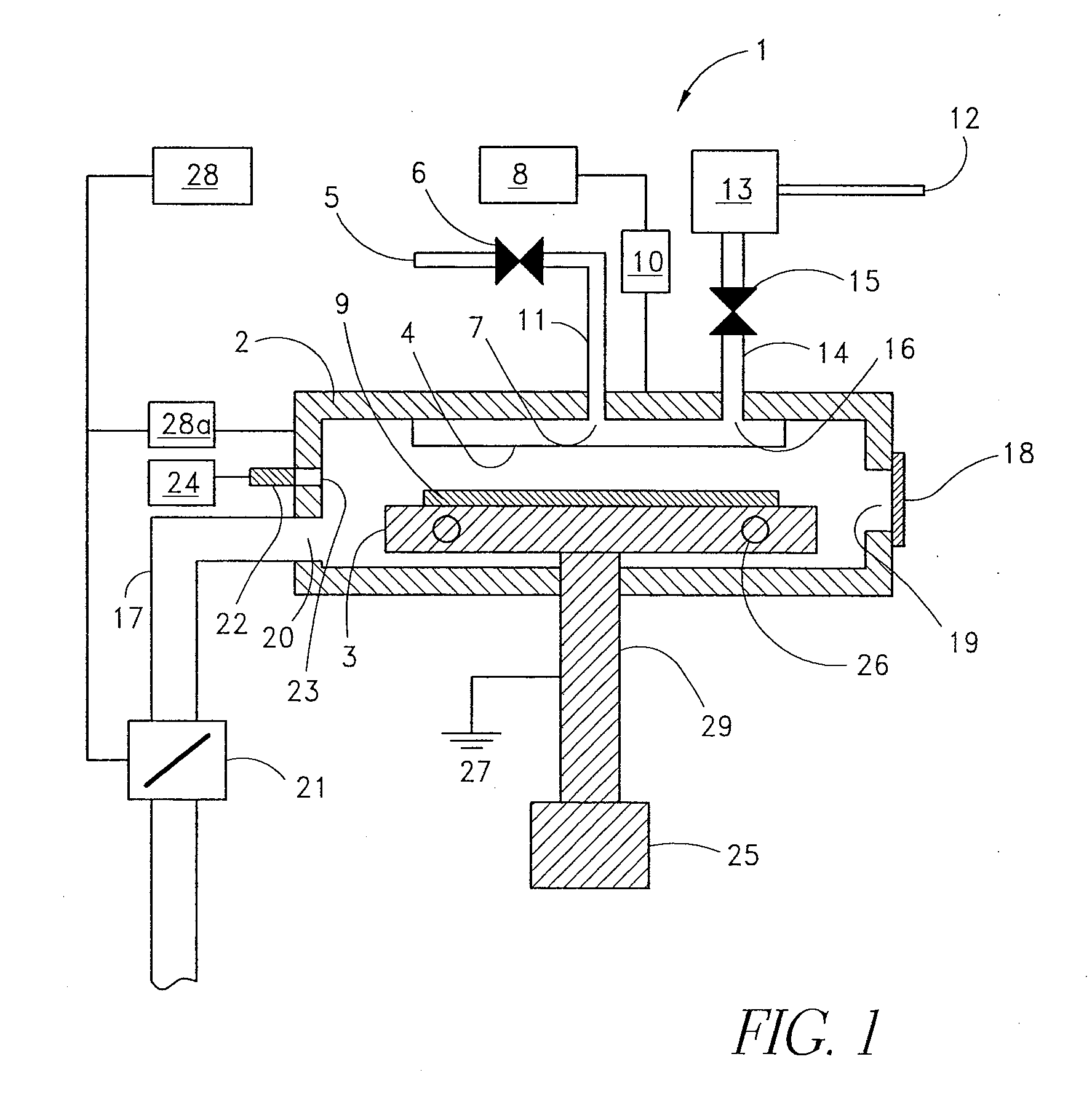

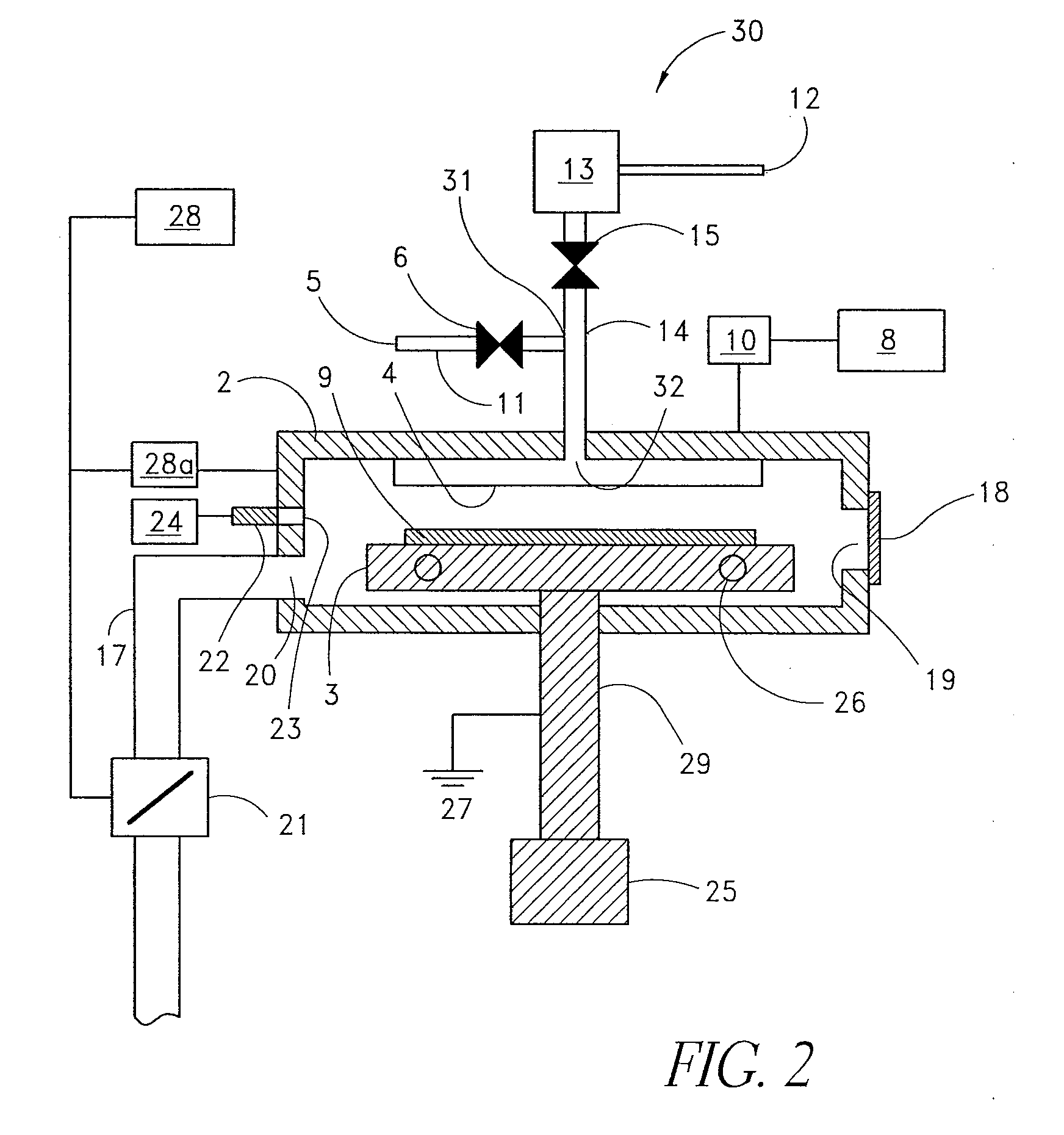

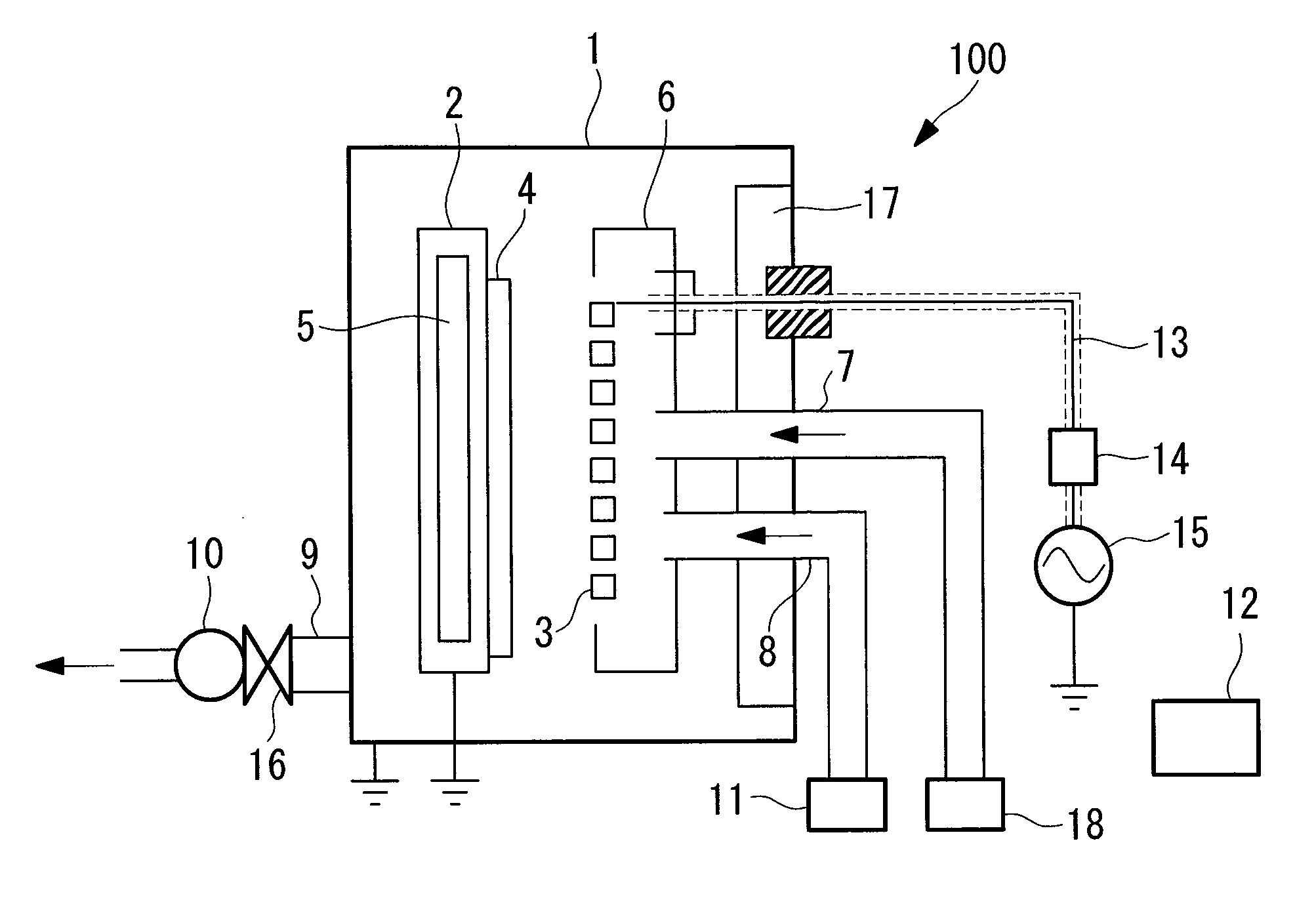

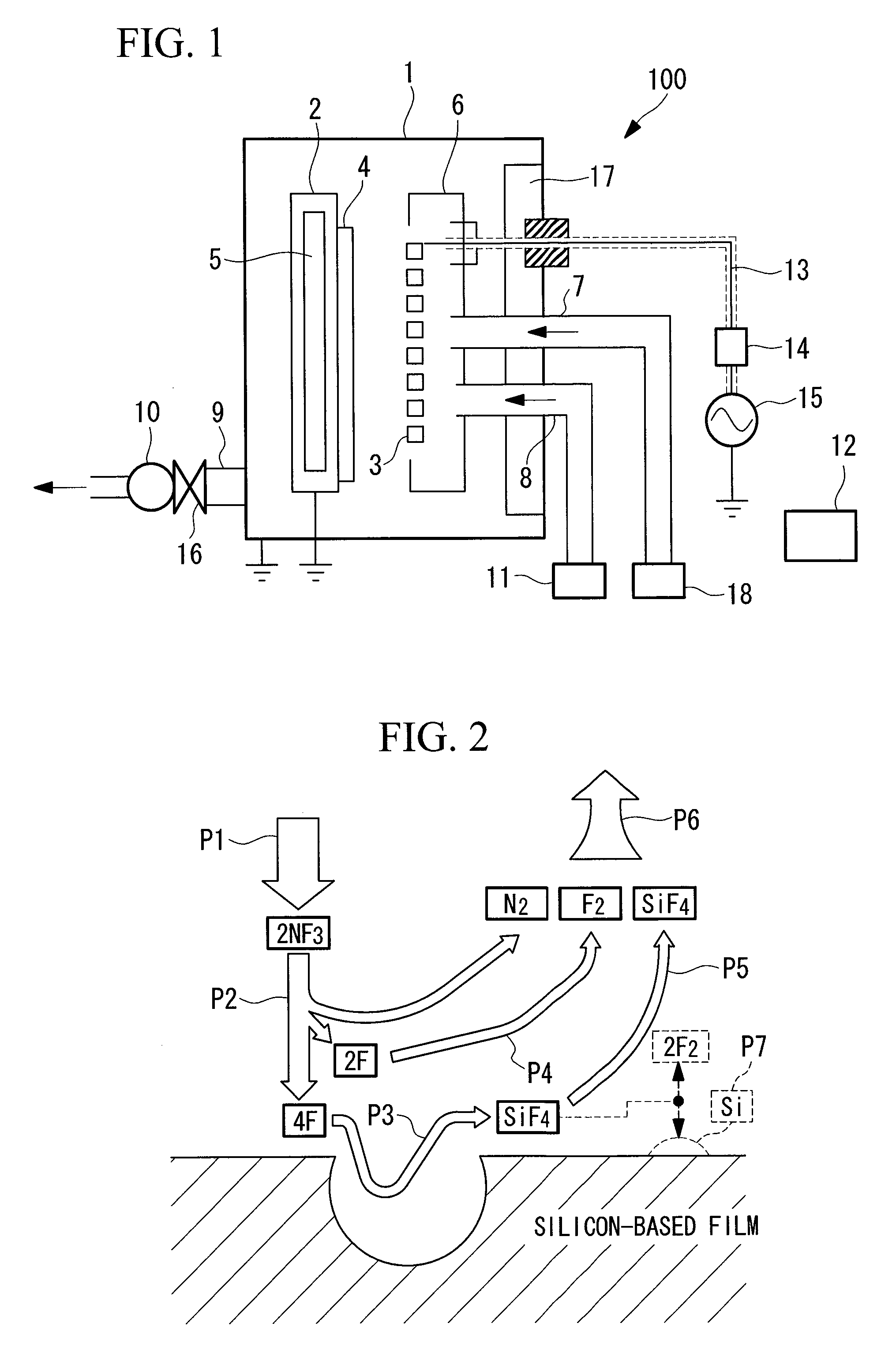

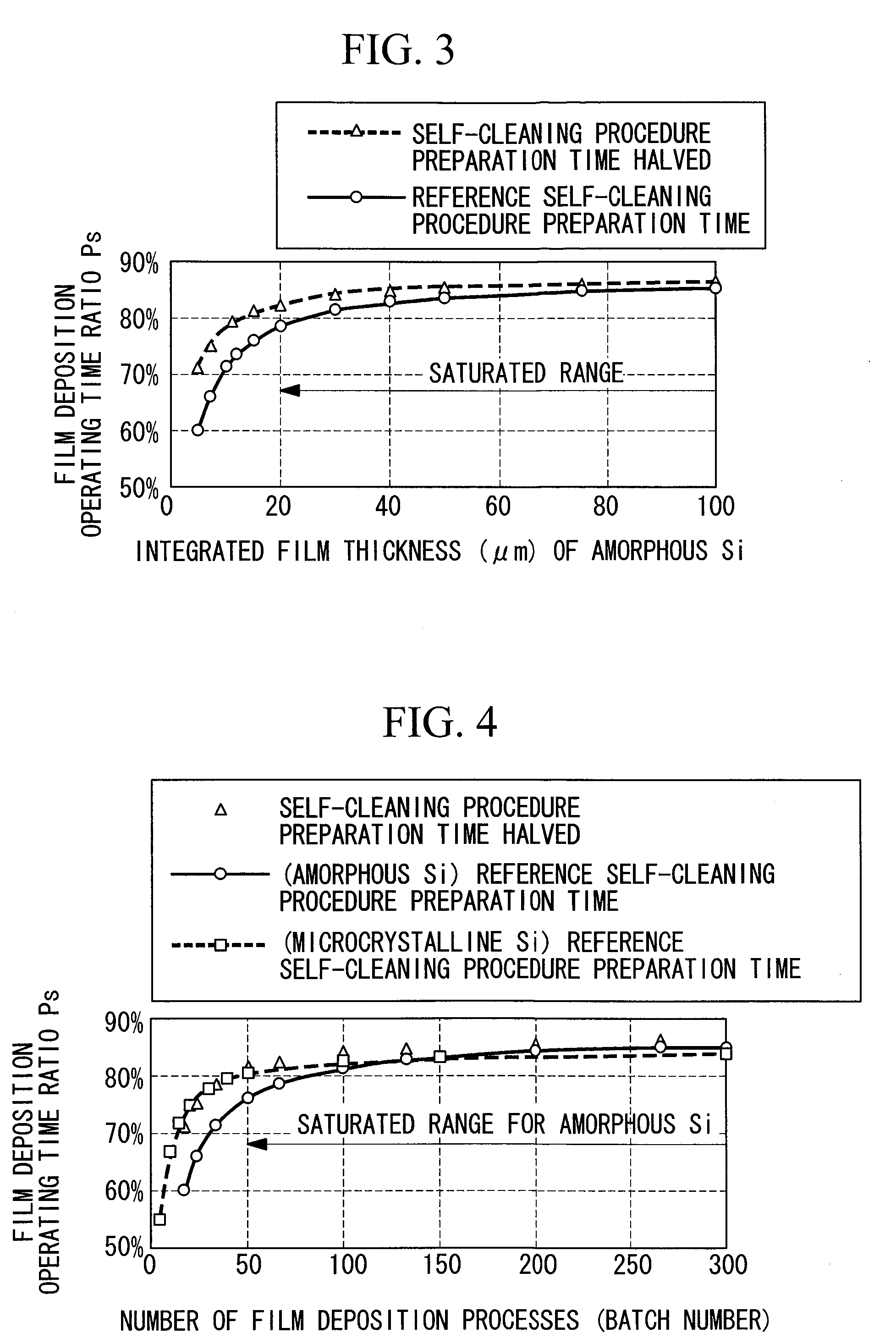

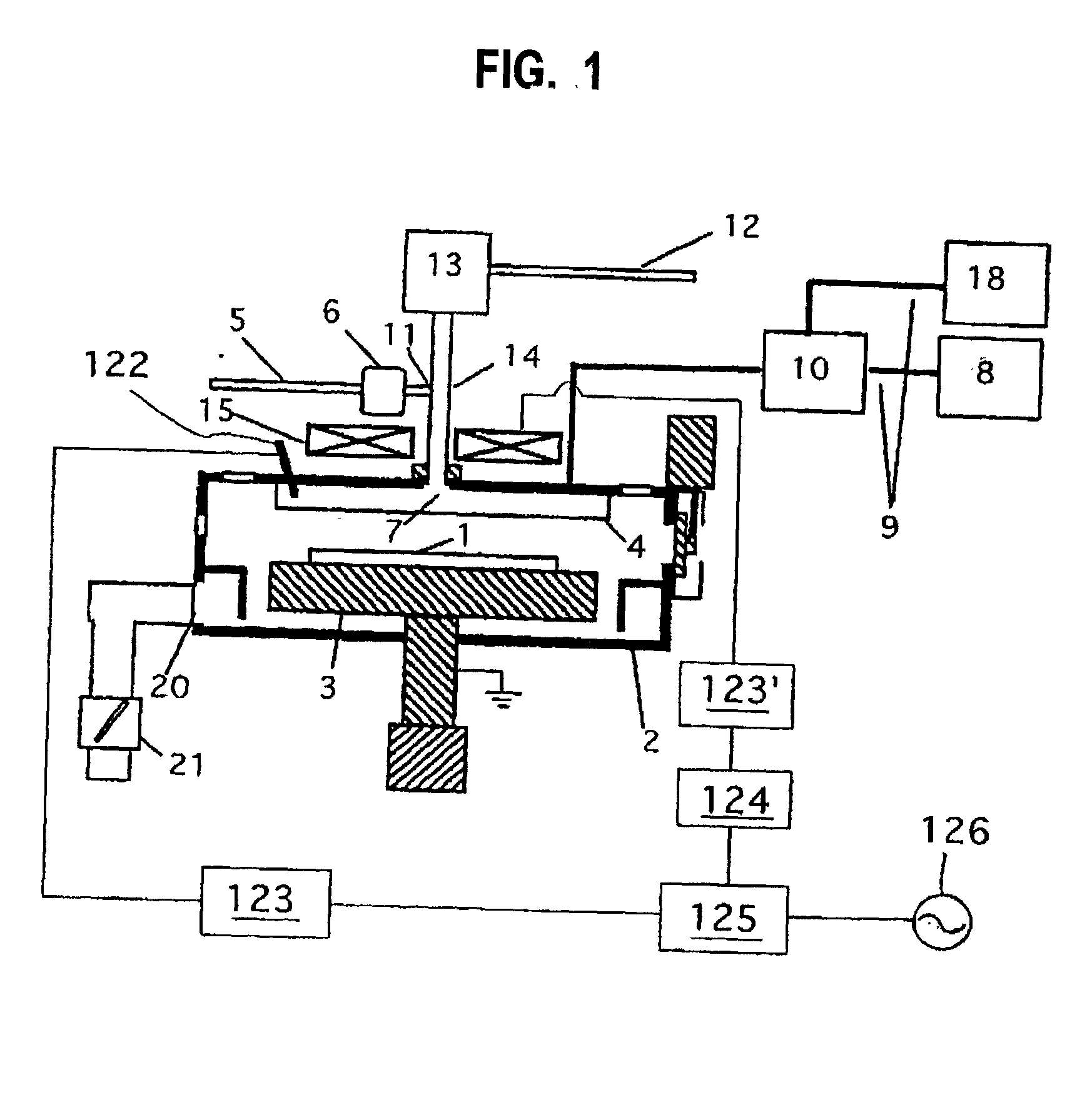

Vacuum processing apparatus and operating method for vacuum processing apparatus

InactiveUS20100310785A1Easy to set upEasy to changeElectric discharge tubesHollow article cleaningEngineeringOperational approach

It is an object of the invention to provide a vacuum processing apparatus that enables setting a timing interval between self-cleaning procedures simply and so as to have general-use, enables significantly lengthening this timing interval, and improves the production efficiency. In a plasma CVD apparatus (100) that carries out self-cleaning procedure by feeding a cleaning gas into a film deposition chamber (1) in which film deposition processing is carried out on a substrate (4), the timing interval between self-cleaning procedures is set in a range in which a film deposition operating time ratio (Ps) is converged with respect to an increase in a film deposition process amount, where the film deposition operating time ratio (Ps) is represented by the proportion of a film deposition-related operating time (Tt) in the sum of the film deposition-related operating time (Tt) and a cleaning-related operating time (Tc).

Owner:MITSUBISHI HEAVY IND LTD

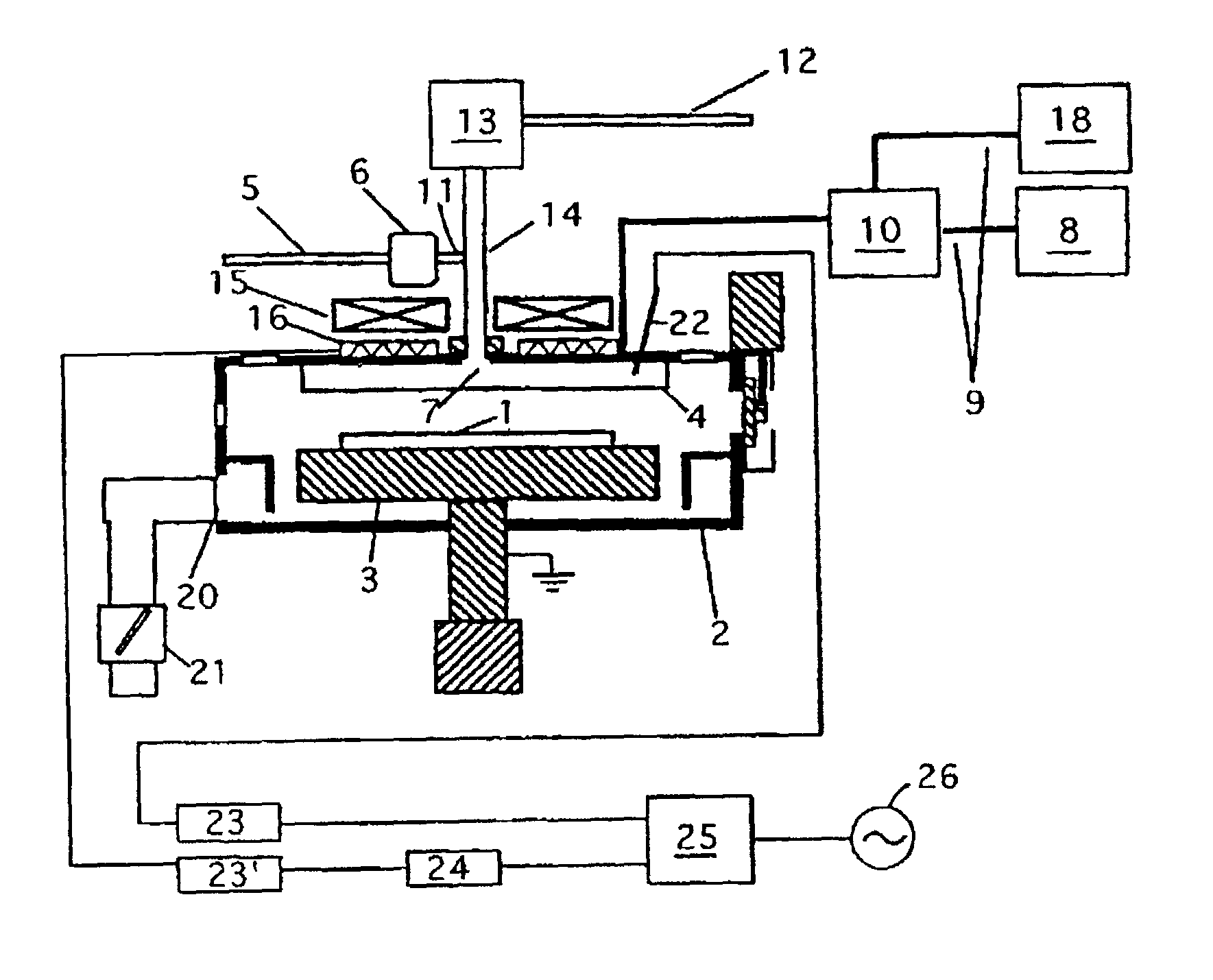

Plasma CVD apparatus conducting self-cleaning and method of self-cleaning

InactiveUS20030097987A1Electric discharge tubesSemiconductor/solid-state device manufacturingTemperature controlRemote plasma

A plasma CVD apparatus conducting self-cleaning comprises a reaction chamber, a susceptor, a showerhead, a temperature controlling mechanism for directly controlling the temperature of the showerhead at a temperature of 200° C. to 400° C., a remote plasma discharge device provided outside the reaction chamber, and a radio-frequency power source electrically connected to either of the susceptor or the showerhead.

Owner:ASM JAPAN

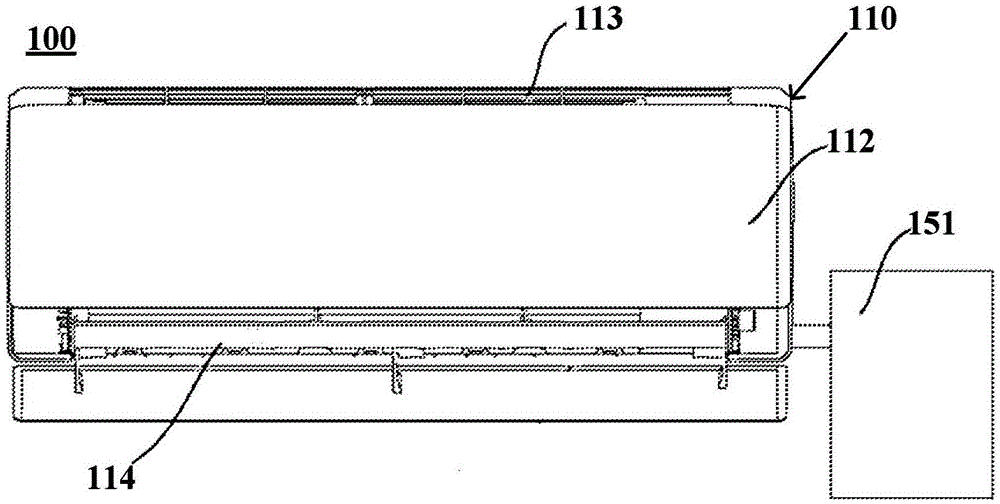

Air conditioner with self-cleaning function and control method for air conditioner

InactiveCN107525216AWith self-cleaning functionIncrease the degree of frost condensationSpace heating and ventilation safety systemsLighting and heating apparatusWorking environmentEngineering

The invention provides an air conditioner with a self-cleaning function and a control method for the air conditioner. An indoor unit of the air conditioner is equipped with an indoor unit fan, an indoor unit heat exchanger, a humidifying assembly and a humidity sensor, wherein the humidifying assembly is provided with a spray hole which is formed in the indoor unit and is positioned at the air inlet upstream of the indoor unit heat exchanger. The control method comprises the following steps of: receiving a trigger that the air conditioner starts a self-cleaning function; controlling the indoor unit heat exchanger to operate in an evaporator mode and closing the indoor unit fan; judging whether humidity, detected by the humidity sensor, of an indoor unit working environment is lower than a preset temperature threshold value or not, starting the humidifying assembly if the humidity is lower than the preset temperature threshold value, spraying out water mists through the spray hole, and improving frosting degree at the indoor unit heat exchanger; and after determining that the indoor unit heat exchanger reaches a set defrosting condition, controlling the indoor unit heat exchanger to defrost, and taking away attached pollutants by water formed by defrosting, thereby realizing self-cleaning of the indoor unit heat exchanger. According to the scheme adopted by the invention, the self-cleaning effect is obviously improved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

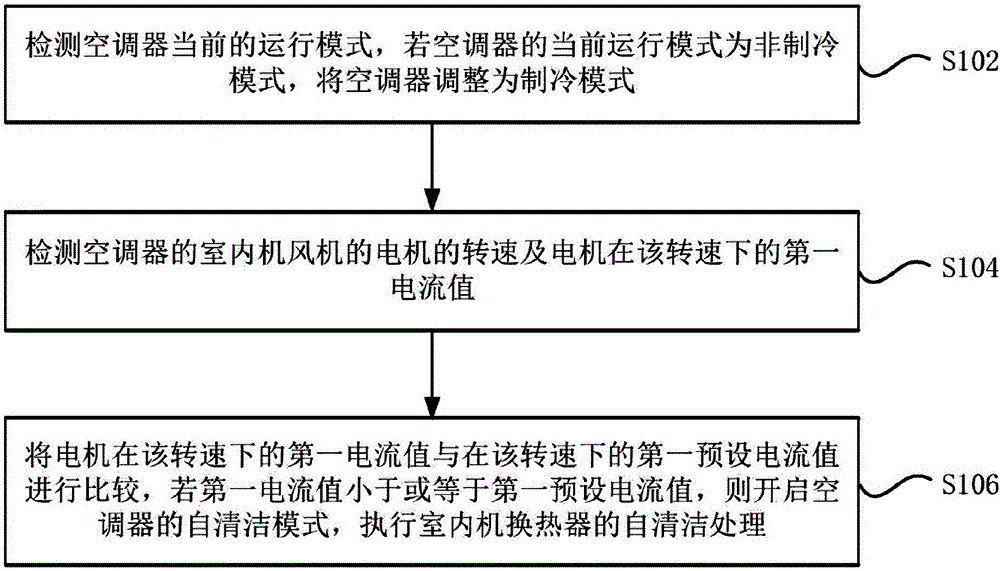

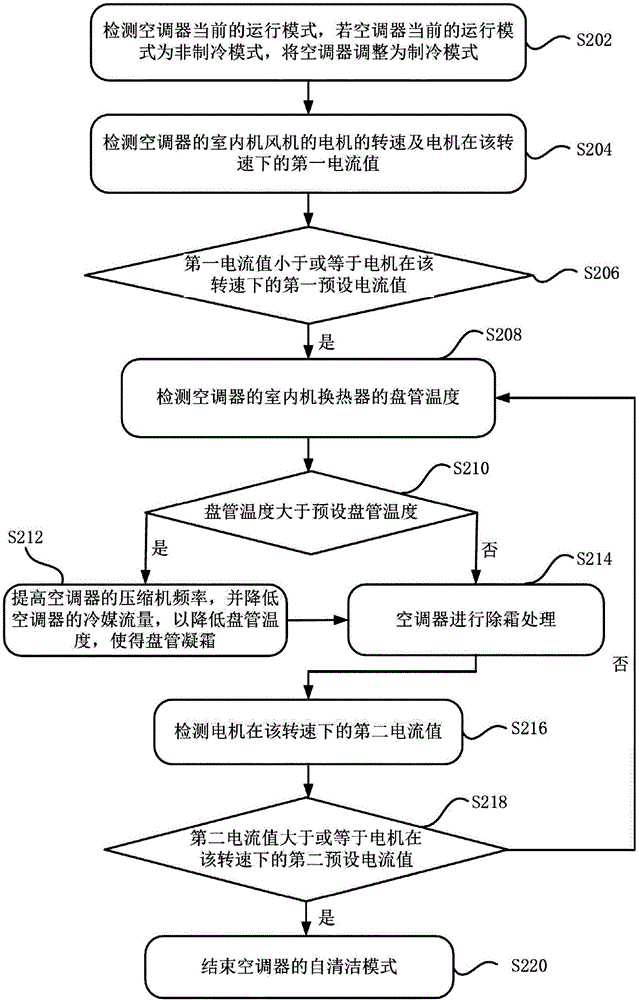

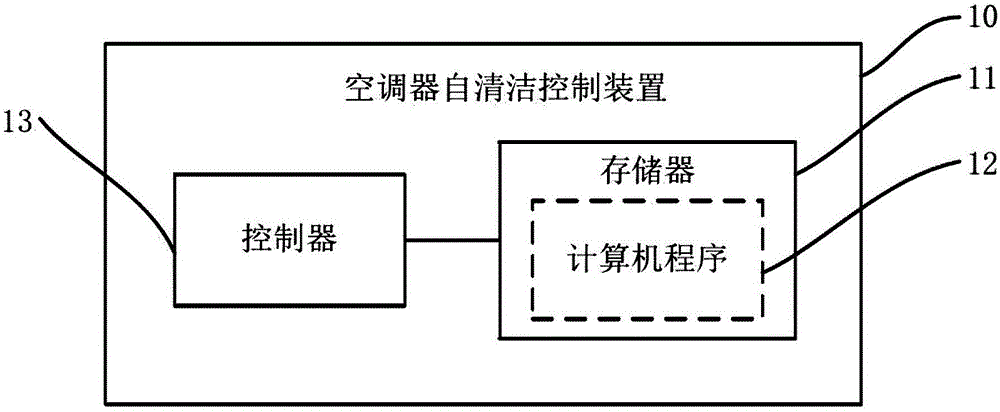

Self-cleaning control method and device for air conditioner

InactiveCN107525209AHigh precisionImprove user experienceSpace heating and ventilation safety systemsLighting and heating apparatusElectric machineOperation mode

The invention provides a self-cleaning control method and device for an air conditioner. The self-cleaning control method comprises the steps that the current operation mode of the air conditioner is detected, and if the current operation mode of the air conditioner is a non-refrigerating mode, the air conditioner is adjusted to be in a refrigerating mode; the rotating speed of a motor of a fan of an indoor unit of the air conditioner and the first current value of the motor under the rotating speed are detected; and the first current value of the motor under the rotating speed is compared with a first preset current value of the motor under the rotating speed, if the first current value is smaller or equal to the first preset current value, a self-cleaning mode of the air conditioner is started, and self-cleaning treatment of a heat exchanger of the indoor unit is carried out. The air conditioner can start the self-cleaning function automatically, and the self-cleaning effect of the air conditioner is promoted.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

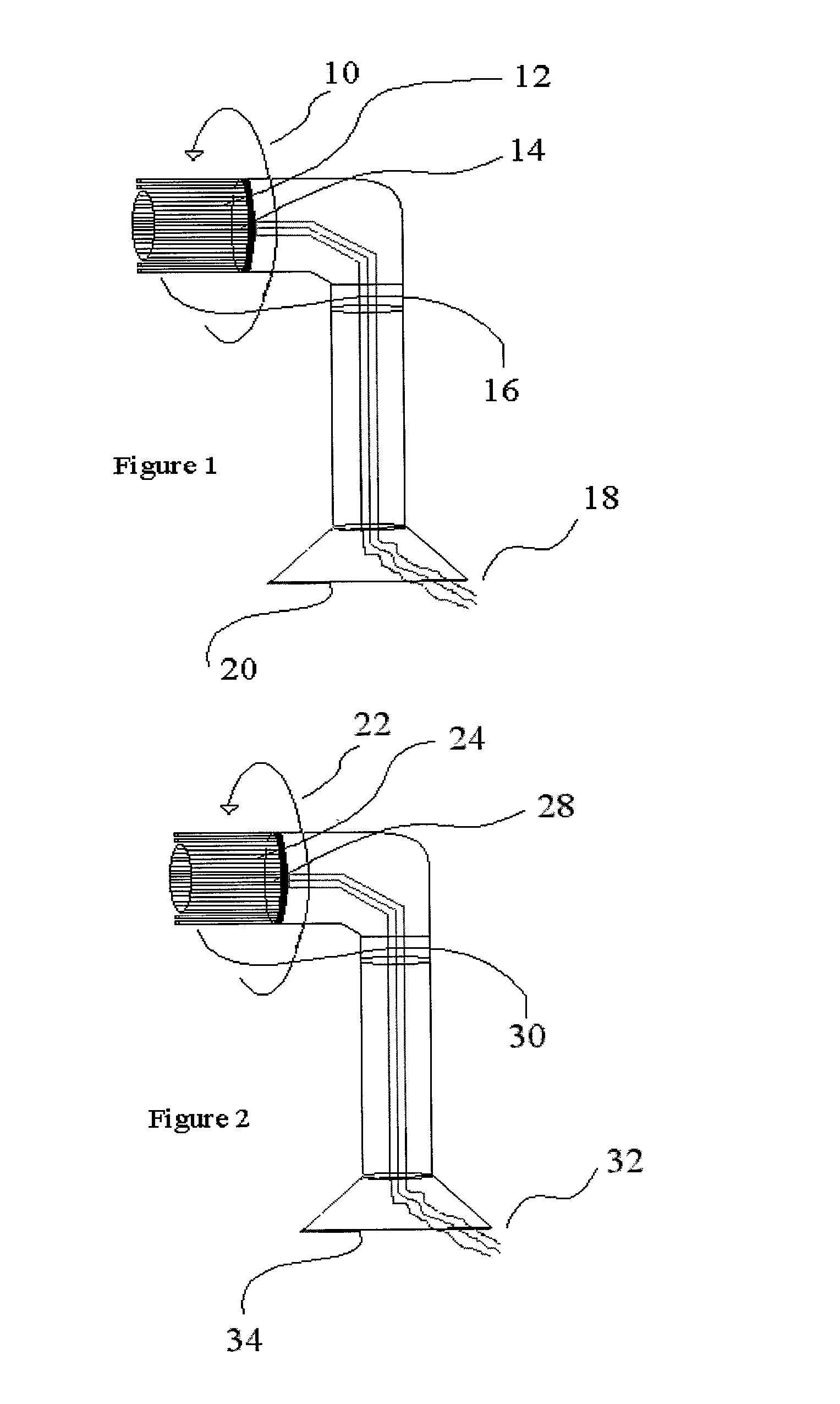

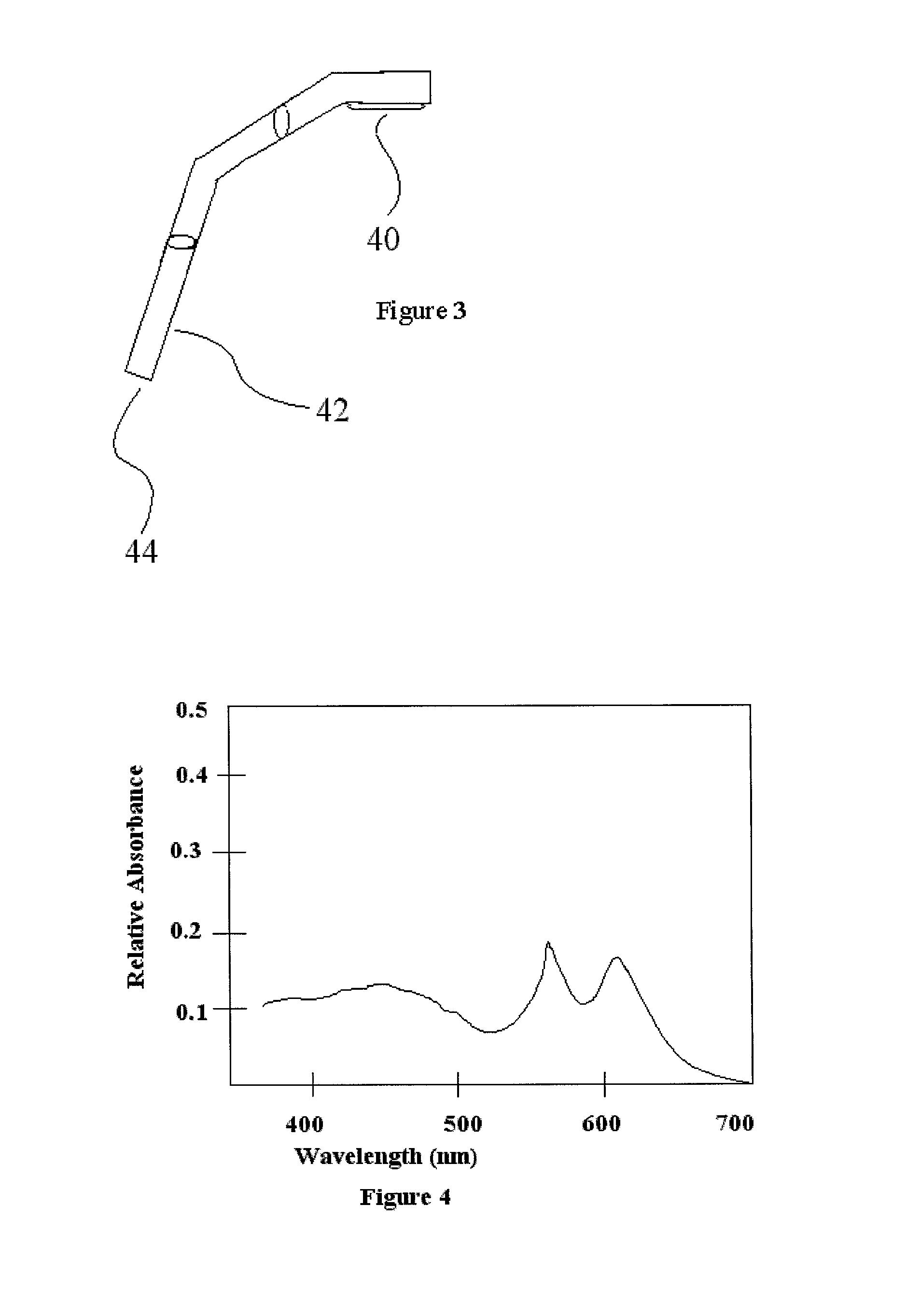

Method and tools for oral hygiene

InactiveUS20030059738A1Enhance the destructive effectSafe for self-treatmentCosmetic preparationsImpression capsOral diseasePhotosensitizer

A method and material for self-cleaning of the teeth and mouth using a source of light in the visible range in conjunction with a photosensitive oral hygiene composition possessing a broad absorption spectrum in the visible range. The invention selectively eliminates harmful bacteria by use of a photosensitive agent and a light source. The present invention involves the use of a light-providing dental device to activate a photosensitive agent and destroy harmful bacteria in the oral cavity. It prevents or deters oral diseases, inflammations, and infections.

Owner:BIOLITEC UNTERNEHMENSBETEILLIGUNGS II AG

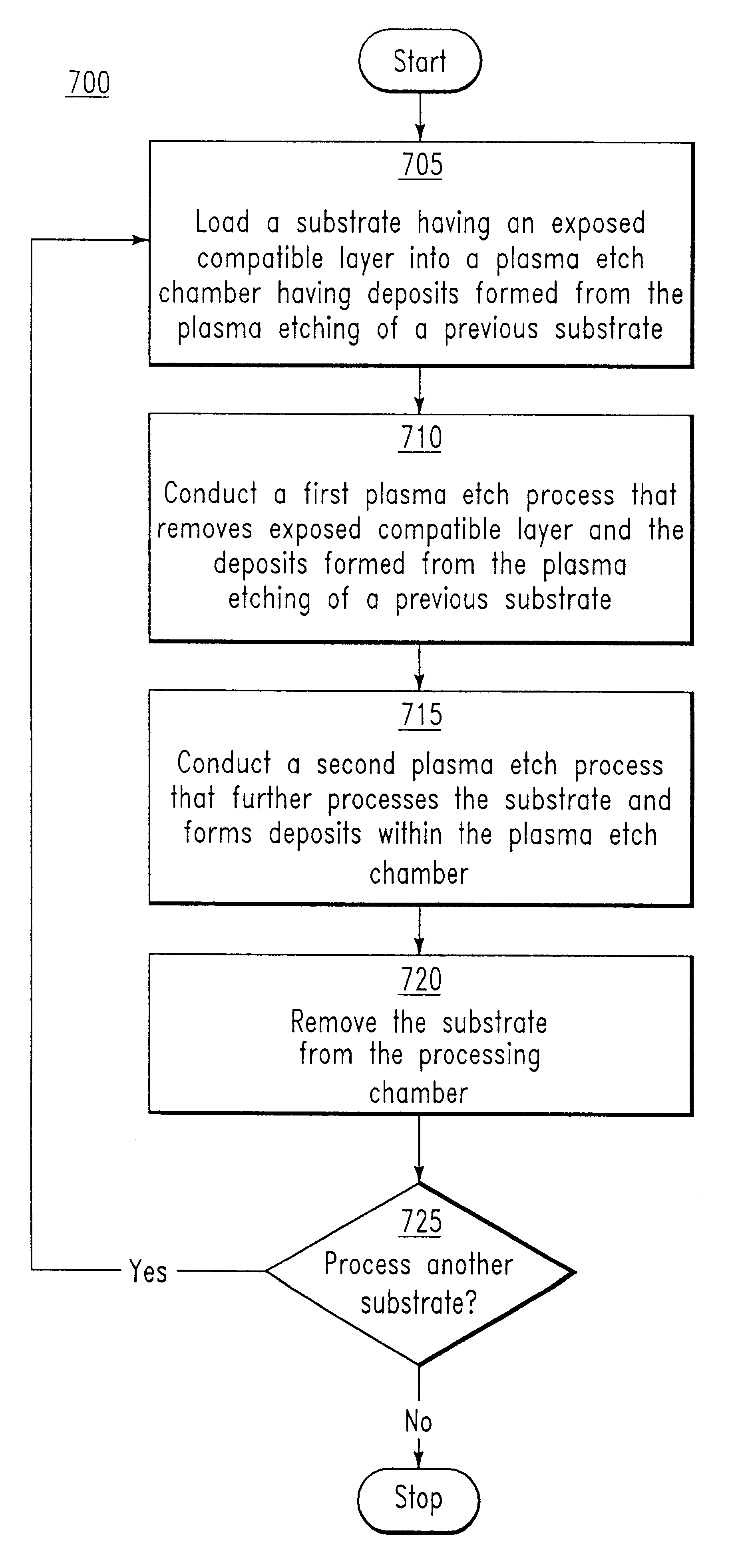

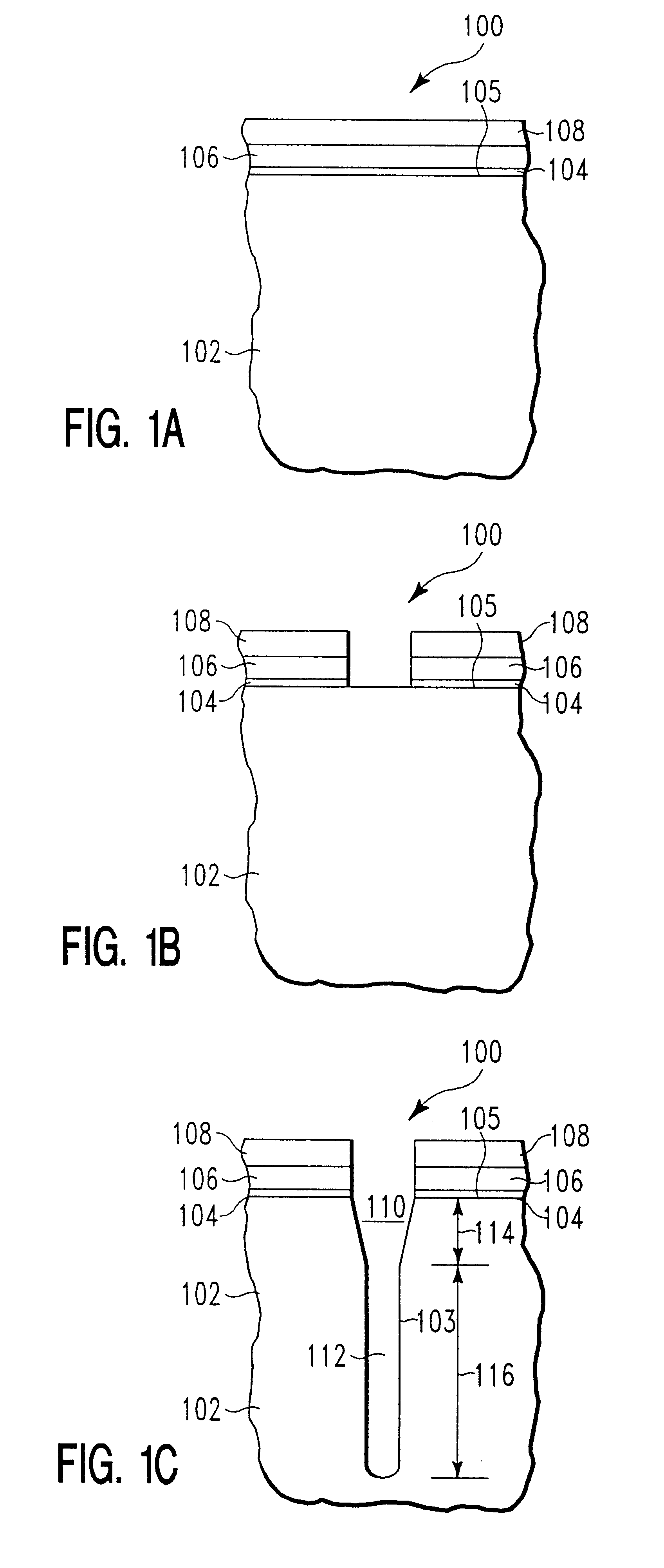

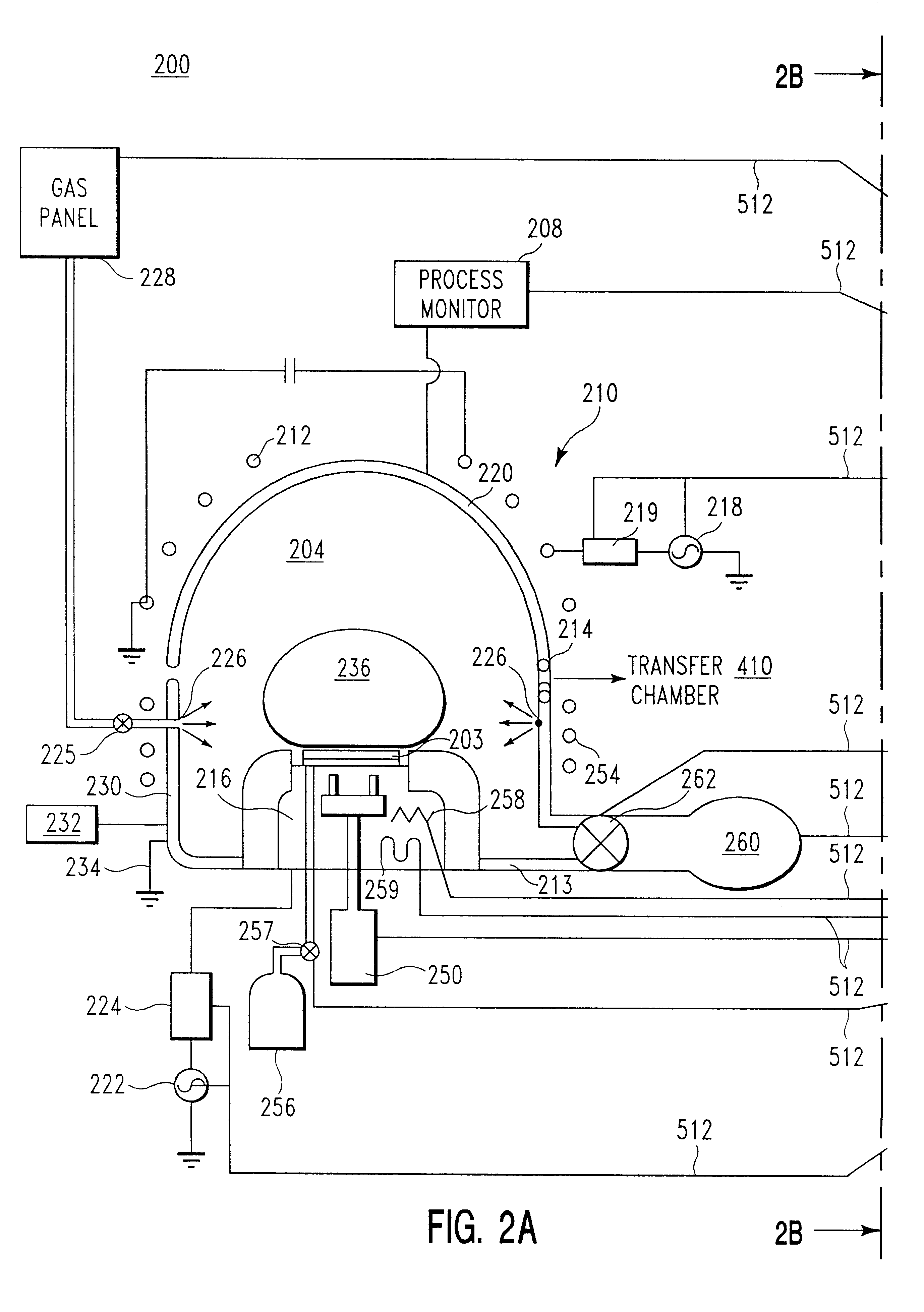

Self cleaning method of forming deep trenches in silicon substrates

This invention is directed to a method for etching films on semiconductor substrates and cleaning etch chambers. The method includes an improved processing sequence and cleaning method where residue formed from processing a previous substrate are cleaned by the etching process used to remove an exposed layer of material from the present substrate. The process provides improved substrate throughput by combining the step to clean residue from a previous substrate with an etch step conducted on the present substrate. Applicants have found the method particularly useful in processing structures such as DRAM stacks, especially where the residue is formed by a trench etched in the previous silicon substrate and the exposed layer etched from the present substrate is silicon nitride.

Owner:APPLIED MATERIALS INC

Hydrophobic self-cleaning coating composition

InactiveUS20080250978A1Efficient use ofSolve the lack of resistanceSemiconductor/solid-state device manufacturingMixingWater basedMineral spirit

The present invention provides a water based, low VOC super hydrophobic coating composition that can be used to make wet and dry dirt repellent surfaces to keep the surfaces clean for a reasonable period of time. The coating utilizes hydrophobic nanoparticles dispersed in water. This treatment produces a virtually transparent coating releasing very little or no VOC compounds whereas previous coatings of comparable hydrophobicity release up to 99 percent VOC compounds. The coating can be applied by a simple, single application method and the super hydrophobic property can be achieved by drying at room temperature for 5 to 10 minutes. A preferred coating can be easily removed and renewed when desired. The aqueous hydrophobic self cleaning coating composition that can be applied by conventional methods such as by spraying the composition onto a surface creating a wet and dry dirt repellent coating on the surface. The hydrophobic self cleaning coatings are used on exterior automotive and boat surfaces, and in many other applications, to produce a self cleaning surface, reduce adherence of dirt and contaminants to a treated surface, and reduce drag in some applications providing an energy savings. The coating solves the problem of poor resistance to UV light, opaque appearance, and / or abrasion found in previous coatings of similar nature. A preferred coating has good resistance to UV light and some resistance to abrasion. Clear, nearly transparent and translucent coatings are produced as compared to conventional coatings of comparable hydrophobicity which are typically white or opaque. The coating can be applied by a single and easy spraying method and the super hydrophobic property can be achieved by drying the film by evaporation of the solvent wetting solution and water based carrier at ambient temperature for 5 to 10 minutes. Embodiments of the hydrophobic self-cleaning coating composition can be produced resulting in a clear coating or in some cases a translucent dirt repellant film or coating on painted material, plastic, metal, glass, ceramic, fiberglass or a polymer substrate. The coating typically utilizes hydrophobic nanoparticles of fumed silica and / or titania wetted by a hydrophilic solvent such as acetone for no VOC applications, or with mineral spirits, alcohol or a light distillate if VOC are not a consideration, together with a selected surfactant typically having an HLB value in a range of from 9 to 13.At least one preferred coating composition comprising an effective amount of a treated fumed silica wetted with a solvent and dispersed in water, upon drying, resulted in a coated surface providing a contact angle of at least 165 degrees and a surface energy below 12 dynes / centimeter as compared to water having a contact angle of from 65 to 80 degrees on a noncoated surface. The composition imparts a degree of hydrophobicity to a surface so that the surface will have a tilt angle of sliding of less than 2 degrees as compared to water on a noncoated surface having a tilt angle of sliding of 90 degrees or higher. The coating composition is removed by washing with a detergent or applying pressure to the coating wiping same from the treated surface. Exposure to water in the form of rain or snow does not remove the coating composition.

Owner:ASHLAND LICENSING & INTPROP LLC

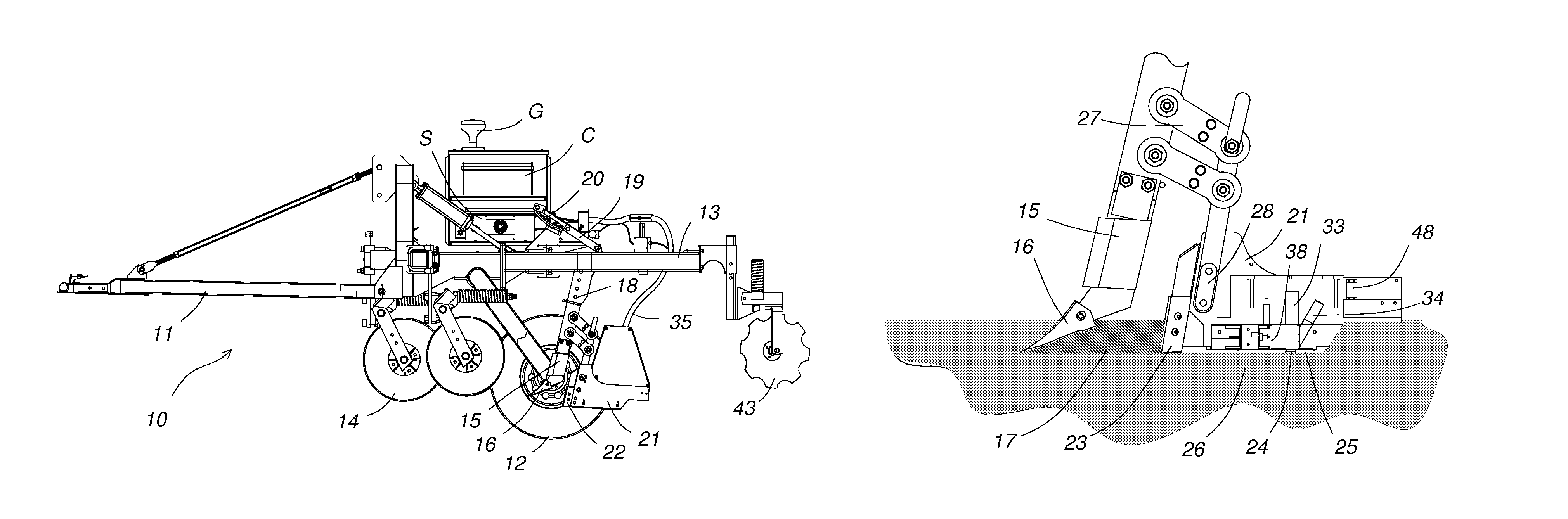

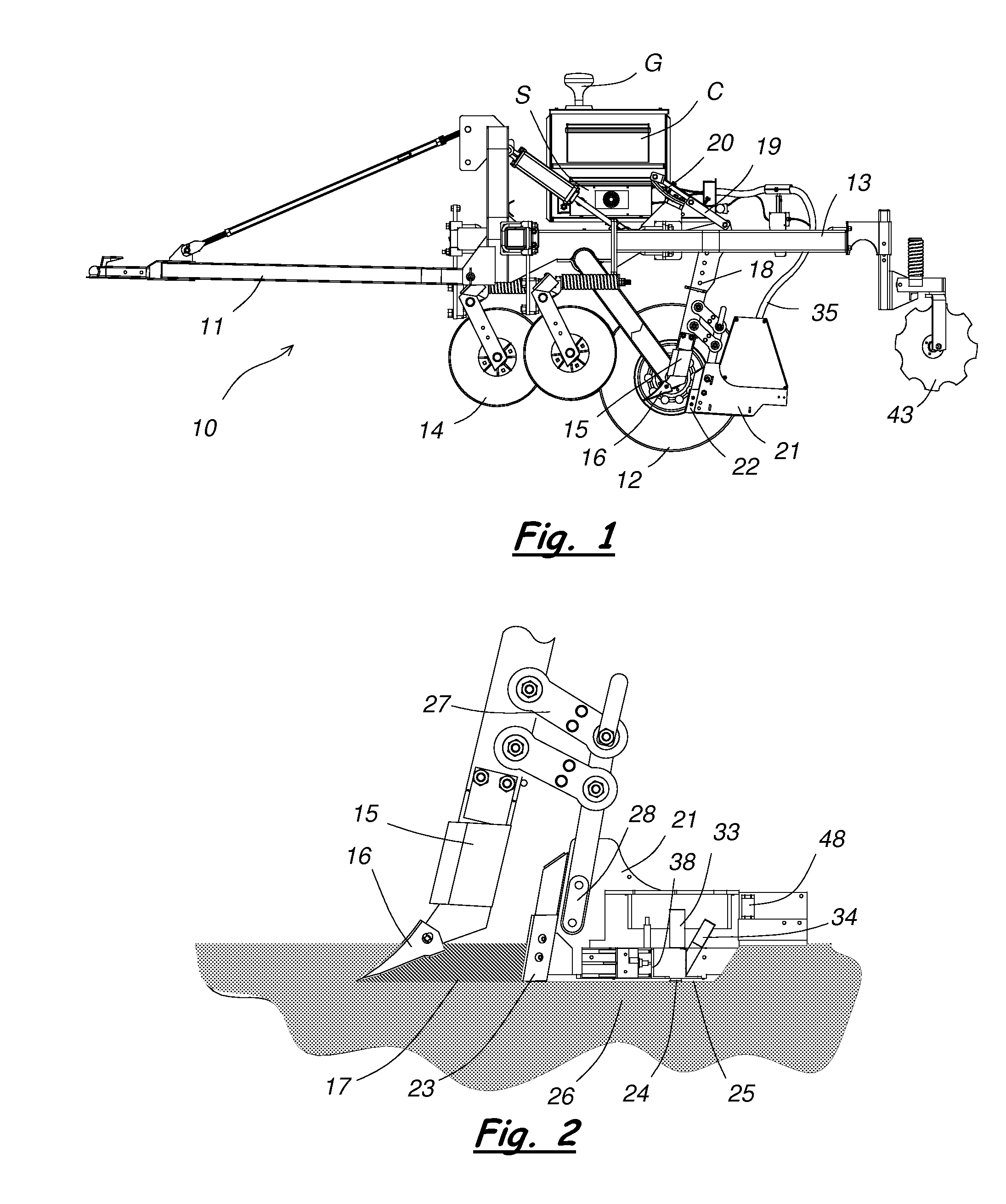

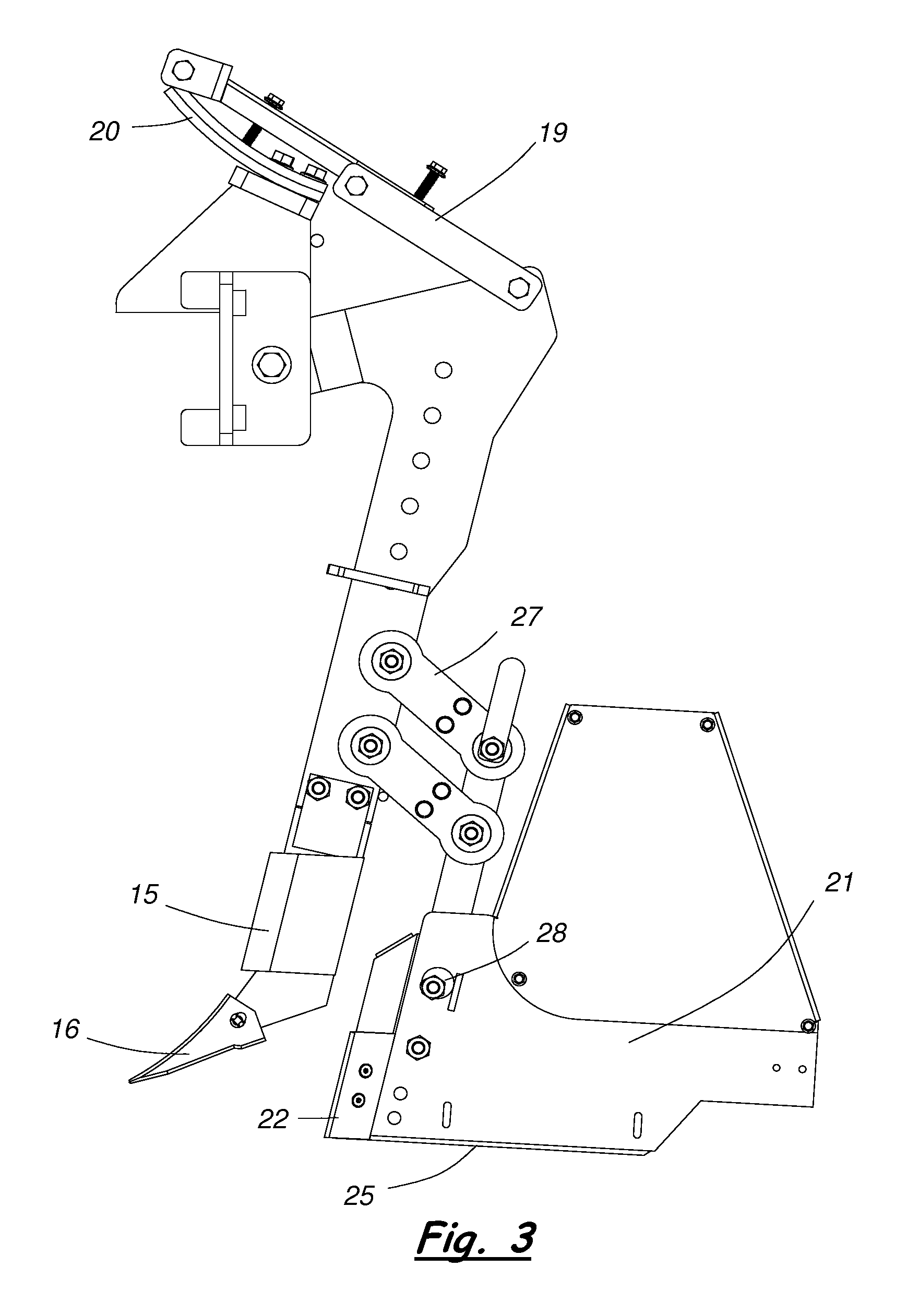

Mobile soil mapping system for collecting soil reflectance measurements

InactiveUS8204689B2Compensation driftOptical prospectingMaterial analysis by optical meansReflectivity measurementExternal reference

A mobile soil mapping system includes an implement for traversing a field to be mapped, and a reflectance module carried by the implement for collecting spectroscopic measurements of soil in the field. The reflectance module has a light source, an optical receiver for transmitting light to a spectrometer, and a shutter system that alters the optical path between the light source and the optical receiver. The shutter system allows the system to automatically collect a dark reference measurement and a known reference material measurement at timed intervals to compensate for drift of the spectrometer and the light source. A self-cleaning window on the reflectance module has a lower surface maintained in firm contact with the soil during operation. External reference blocks are used to calibrate the system to ensure standardized, repeatable data. Additional sensors are carried by the implement to collect other soil data, such as electrical conductivity and temperature.

Owner:VERIS TECH

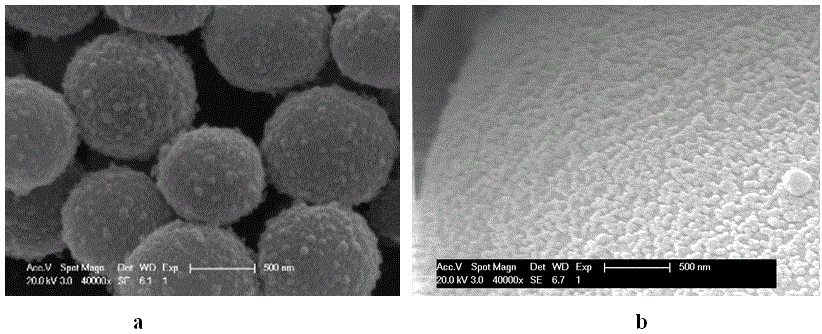

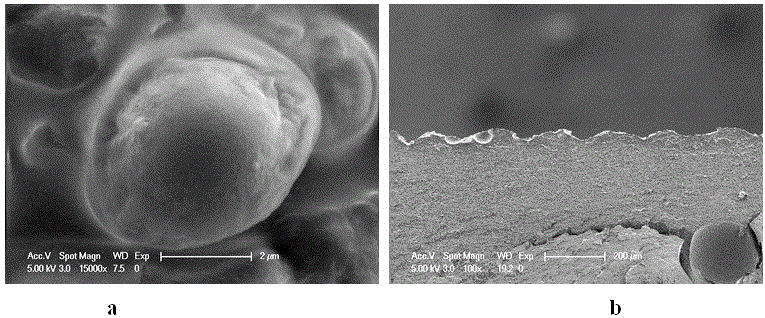

Micro-nano coating material with low surface energy and preparation method thereof

ActiveCN106085070AEasy to control surface topographyEasy to control the size of the surface energyPolyurea/polyurethane coatingsPowdery paintsEtchingMicrosphere

The invention belongs to the technical field of functional materials, and particularly relates to a micro-nano coating material with low surface energy and a preparation method thereof. The preparation method comprises the following steps of mixing composite microspheres with micro sodium structure and hydrophobic nature, matrix resin with contact angle more than 90 degrees with coating film, solvent, powder, and additive, and adopting a co-mixing method, an in-situ emulsion polymerizing method, an in-situ solution polymerizing method, an in-situ concentration and polymerizing method, an in-situ addition and polymerizing method and the like, so as to prepare the coating material with micro-nano structure; performing spraying, brushing, roll coating, photo-etching, 3D (three-dimensional) printing, mechanical processing and the like, drying and curing at the temperature of 0 to 1000 DEG C, and coating the coating material with micro-nano structure onto different matrix surfaces, so as to obtain the micro-nano coating material with low surface energy and groove structure. The micro-nano coating material has the advantages that the preparation technology is simple, the coating hardness is high, the water-resistant property is good, the adhesion force to different matrix surfaces is strong, and the micro-nano coating material can be used for self-cleaning, resistance-reducing, denoising, anti-icing and other functional materials.

Owner:FUDAN UNIV

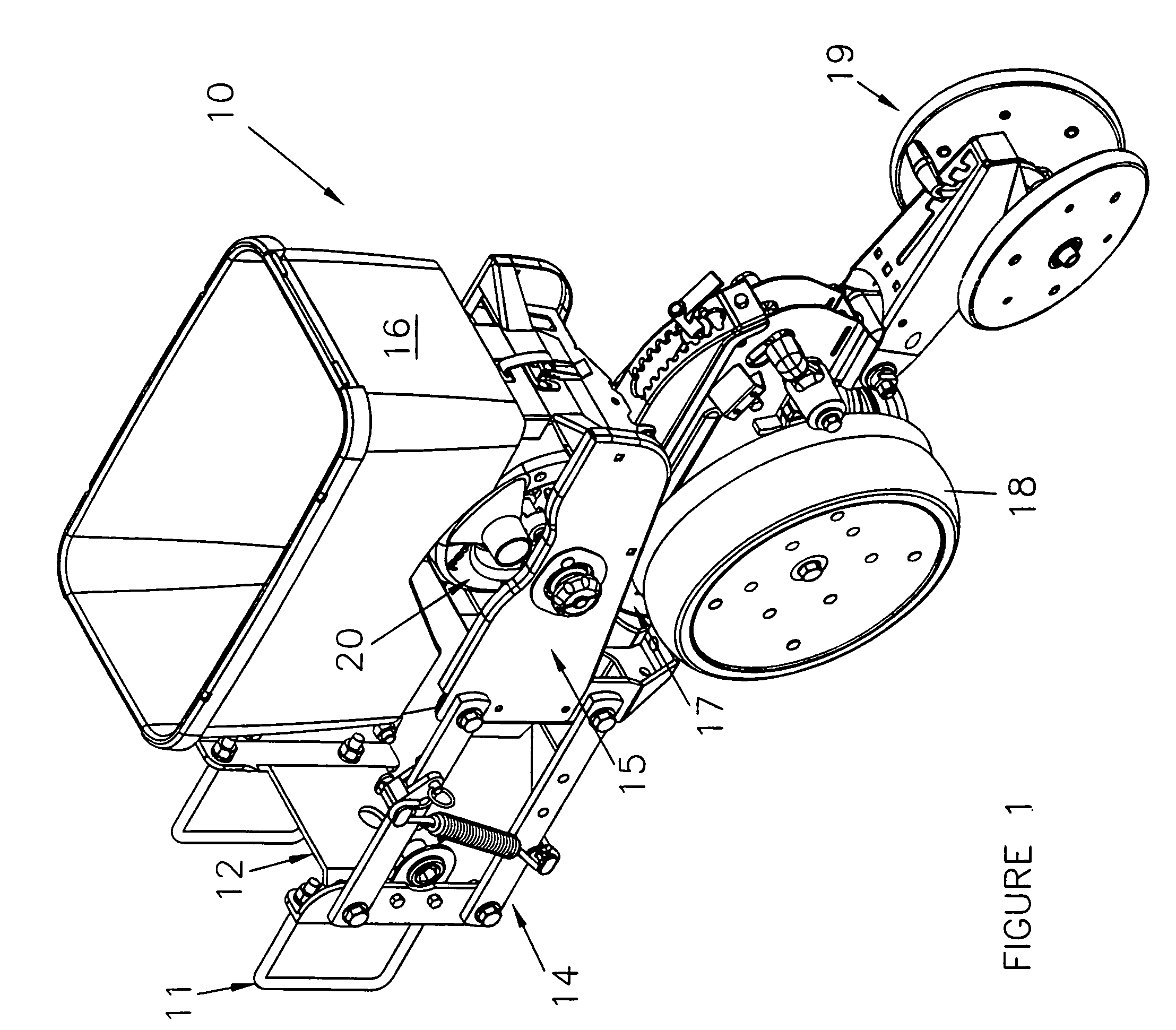

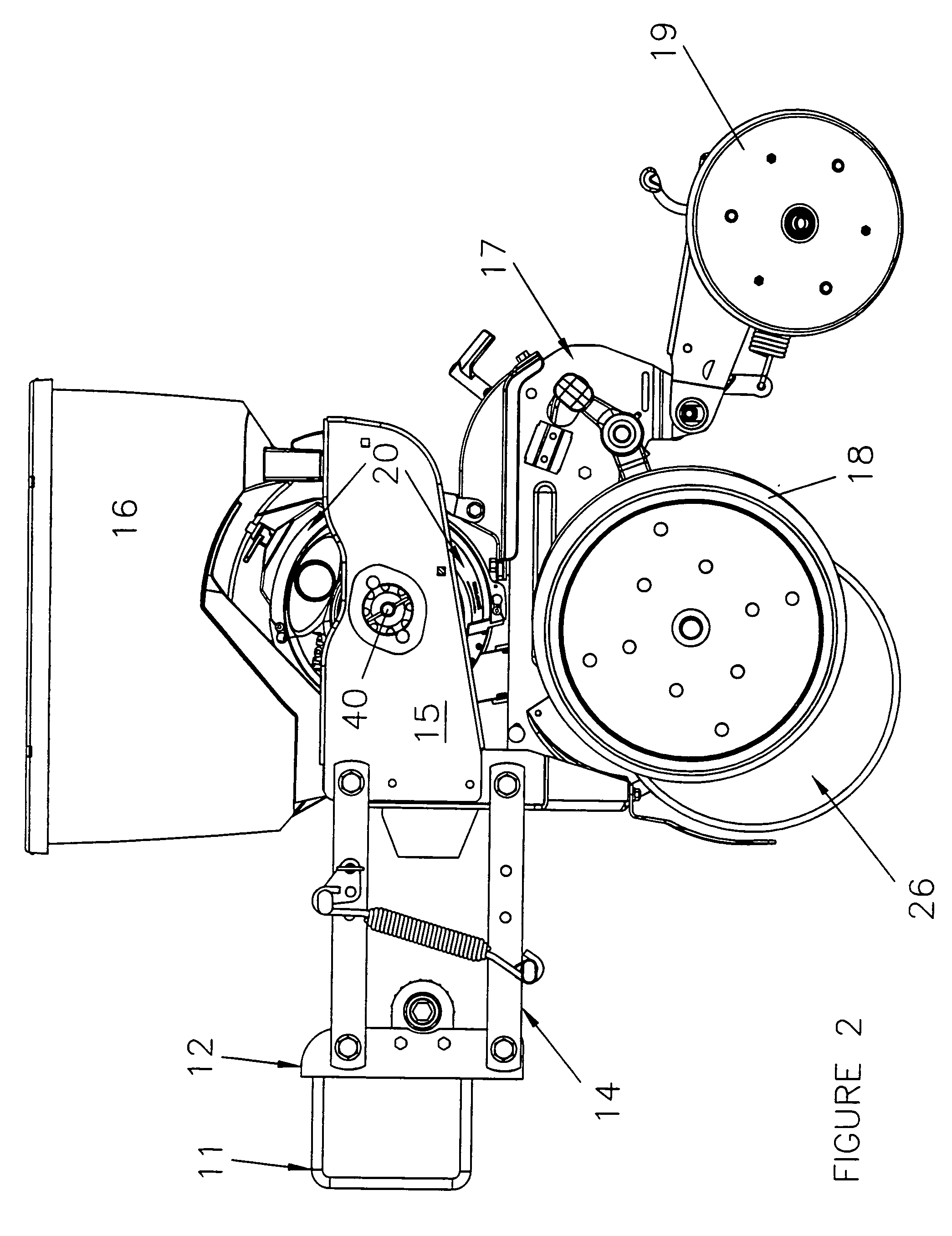

Air seed meter

InactiveUS20050204972A1Increase the sectionSolve fouling and cloggingPotato plantersFurrow making/coveringCircular discVisual inspection

An air seed meter for an agricultural planter includes a vacuum cover which has a central opening which exposes the central portion of the seed disc to the exterior. The central opening of the vacuum cover is centered on a location offset from the axis of rotation of the seed disc. This reduces disc wear at the disc-vacuum cover interface, and renders the disc more accessible for self-cleaning, visual inspection and verification of the proper disc. Openings in the central, open portion of the disc, the back wall of the seed housing and the side wall of the seed housing cooperate to equalize the air pressure in the seed reservoir to atmospheric pressure and reduce or eliminate reverse air currents in the discharge chute. An adjustable brush with three separate stations cooperates with an edge-release, beveled disc to apply a progressively more forceful singulation force to eliminate duplicate seeds.

Owner:KINZE MFG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com