Semiconductor processing with a remote plasma source for self-cleaning

a plasma source and semiconductor technology, applied in chemical vapor deposition coatings, coatings, chemistry apparatuses and processes, etc., can solve problems such as increased operation costs, damage to the surface of electrodes, and defects in manufactured semiconductor circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

Main Structures

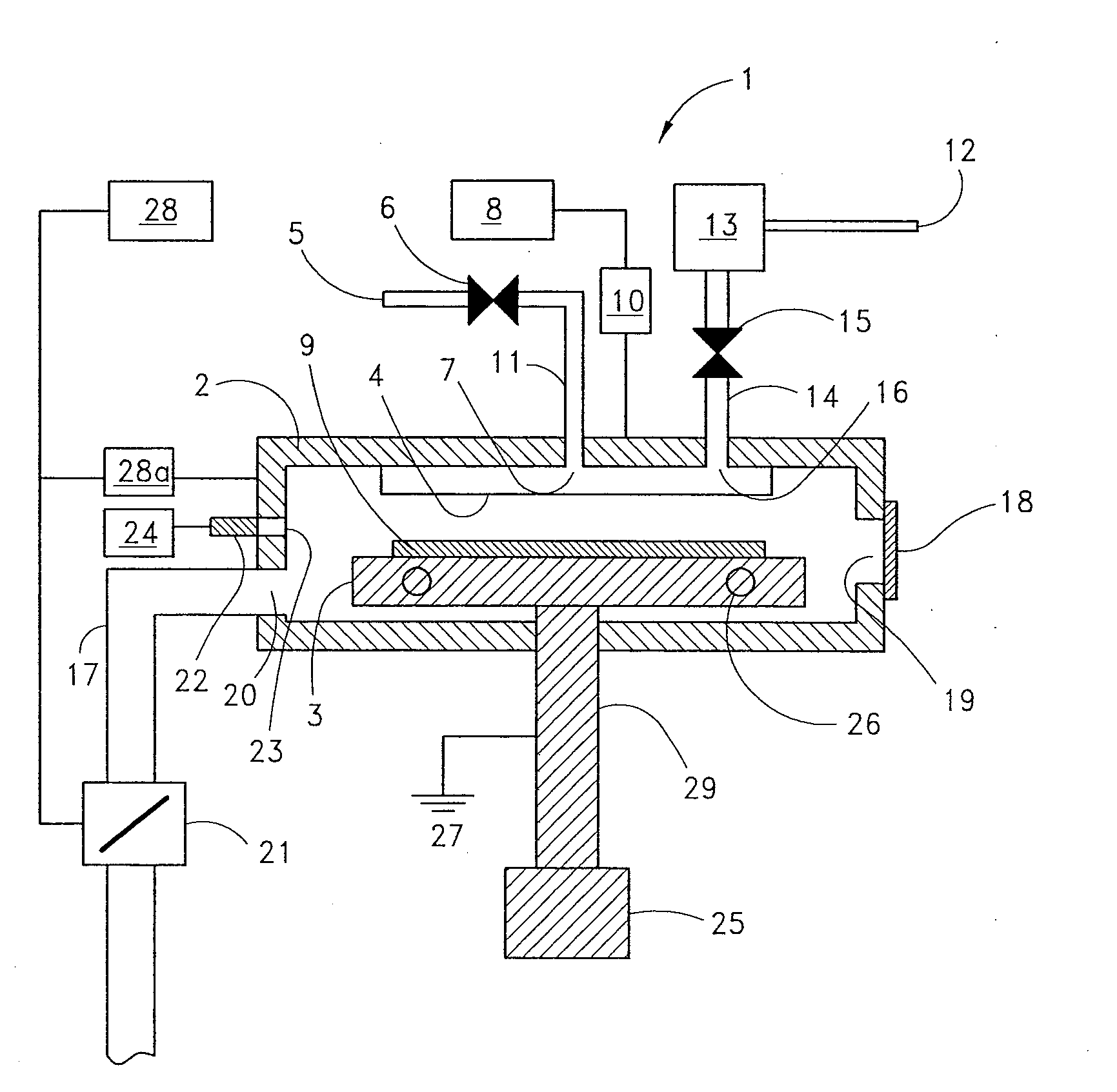

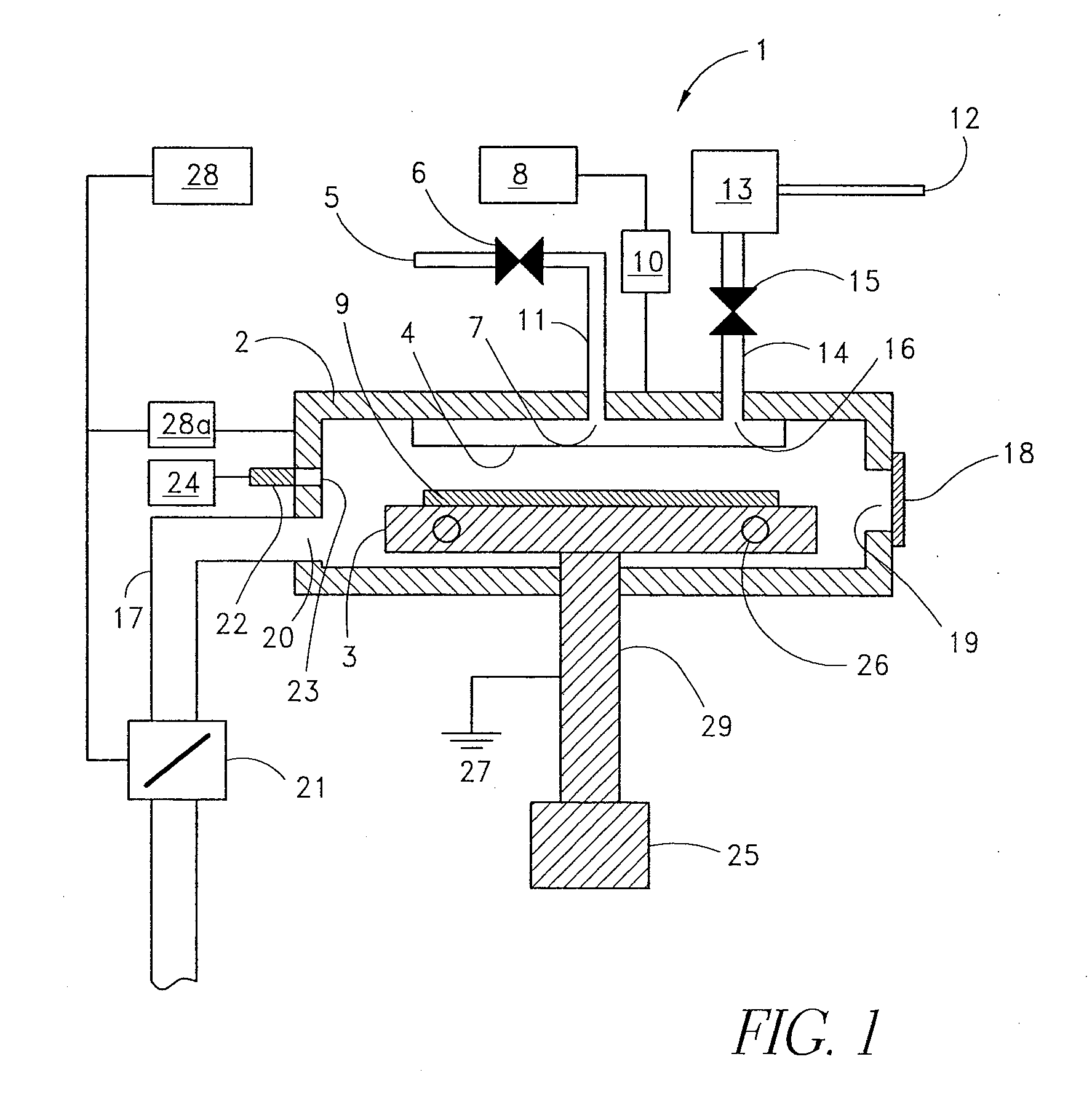

[0071] A first embodiment will be explained with reference to FIG. 1.

[0072]FIG. 1 is a schematic cross section of an exemplary a plasma CVD device according to this embodiment. A plasma CVD device 1, which is used to form a thin film on a semiconductor wafer 9 or other substrate, comprises a reaction chamber 2, a support 3 provided within the reaction chamber to support the semiconductor wafer 9, a showerhead 4 that is positioned to face the support 3 and is used to jet out reaction gas uniformly onto the semiconductor wafer 9, an outlet 20 to exhaust reaction gases and byproducts from the reaction chamber 2, and a remote plasma discharge chamber 13. The remote plasma discharge chamber 13 is positioned remotely from reaction chamber 2 and is linked to the showerhead 4 via piping 14 and valve 15. The remote plasma discharge chamber 13 has characteristics wherein it generates active species using radio-frequency oscillating output energy of the designated frequency a...

embodiment 2

Structures

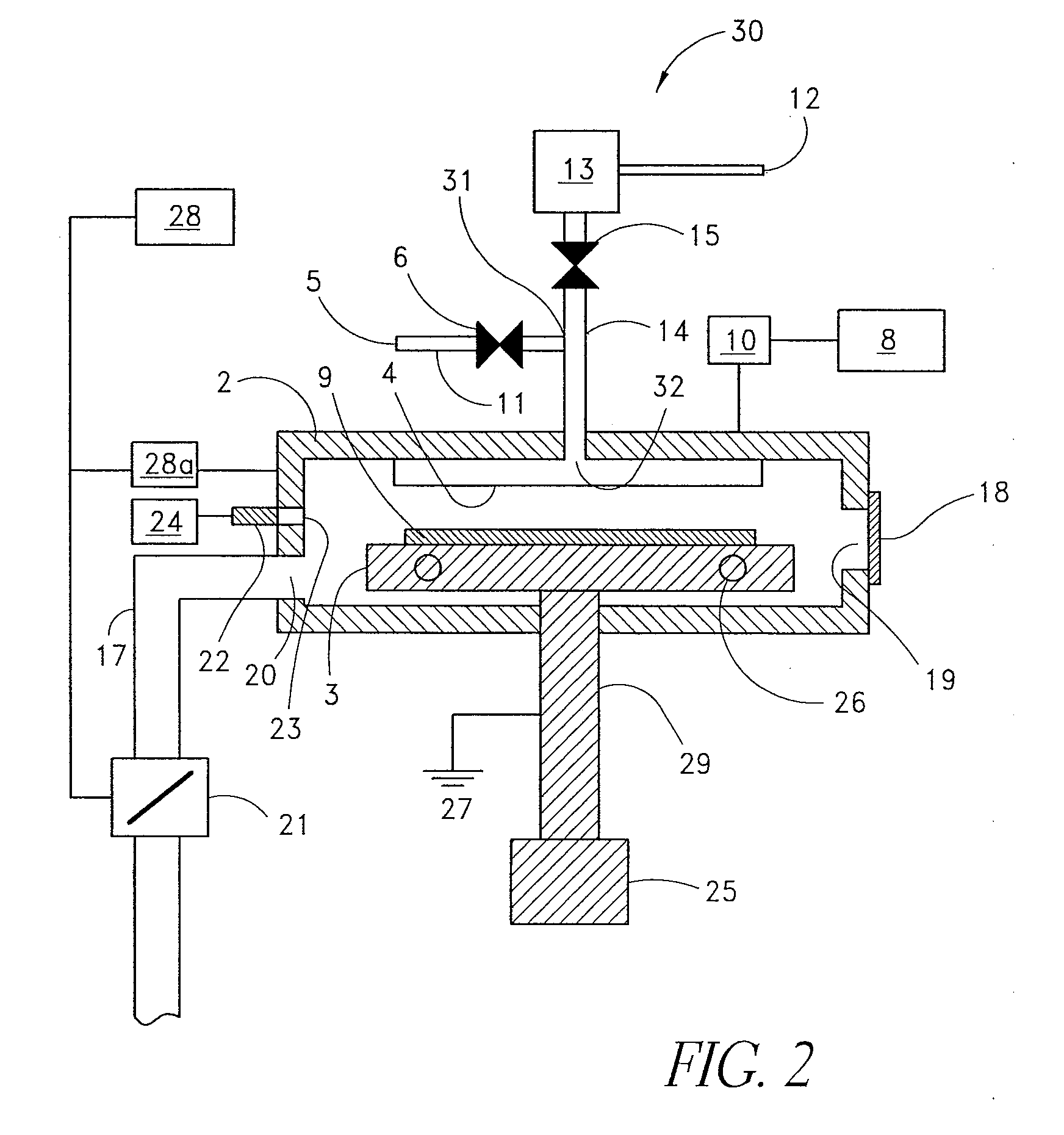

[0091]FIG. 2 shows another example according to this embodiment. Unlike the plasma CVD device 1 of FIG. 1, a plasma CVD device 30 of FIG. 2 includes a link between one end of the reaction conduit 11 and piping 14 at abjection 31 positioned between the remote plasma discharge chamber 13 and a gas exit port 32. Reaction gas and cleaning gas are mixed at the junction 31 and are brought into a showerhead 4 from one gas inlet port 32. The device 30 can be otherwise similar to the device 1 of FIG. 1.

[0092] In the illustrated example, the valve 15 is set up at the plasma discharge chamber side before the junction 31. For the internal surface of the piping 14 and the valves 6, 15, preferably fluorine-passivated aluminum, aluminum alloy, stainless steel or nickel material is used, but aluminum or aluminum alloy can also be used. For sealing materials of the valves 6, 15, preferably fluorocarbon polymers such as PTFE (polytetrafluoroethylene), PFA (tetrafluoroethylene·perfluoroal...

embodiment 3

Main Structures

[0095]FIG. 3 is a schematic diagram showing a cross sectional view of a preferable implementation example of a plasma CVD device according to this embodiment. A plasma CVD device 1, which is used to form a thin film on a semiconductor wafer 9 or other substrate, comprises a reaction chamber 2, a support 3 provided within the reaction chamber 2 to place the semiconductor wafer 9, a showerhead 4 that positioned facing the support 3 and is used to inject reaction gas uniformly onto the semiconductor wafer 9, an outlet 20 to exhaust the inside of reaction chamber 2. The remote plasma discharge chamber 13 is positioned remotely from reaction chamber 2 and is linked to the showerhead 4 via piping 14 and valve 15. The remote plasma discharge chamber 13 has characteristics wherein it generates active species using radio-frequency oscillating output energy of the designated frequency.

[0096] On one side of the reaction chamber 2, an opening 19 is formed and the reaction cham...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com