Patents

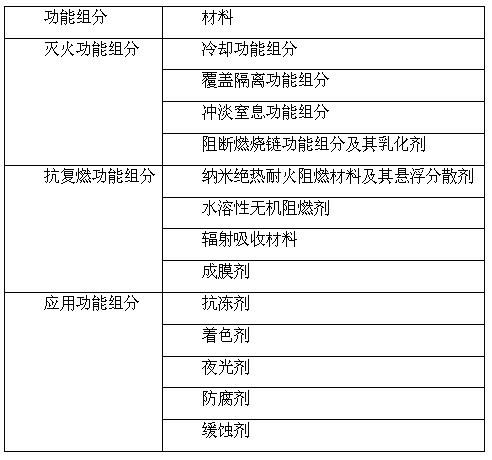

Literature

1693 results about "Solid substance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A substance having a definite shape and volume

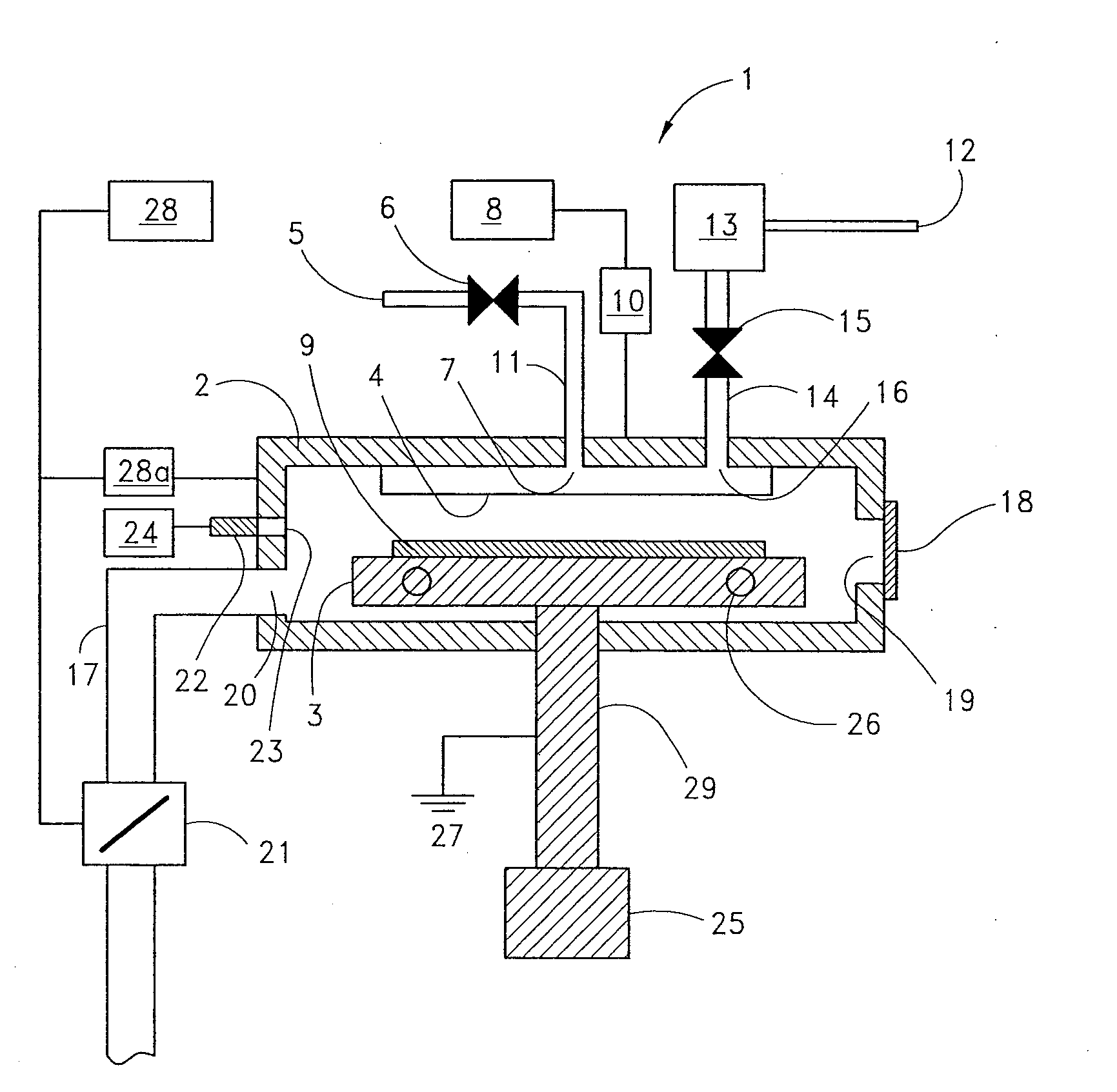

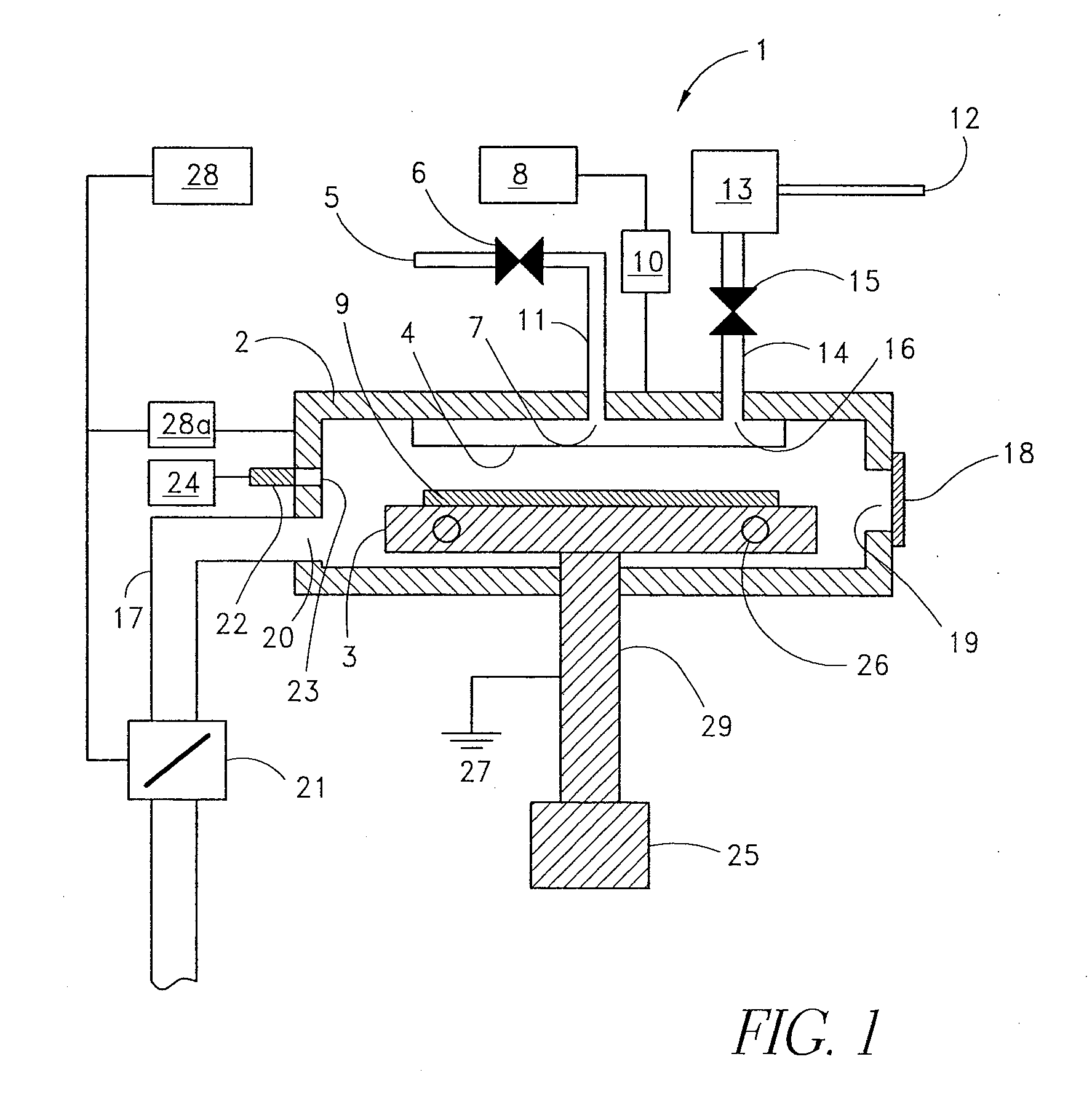

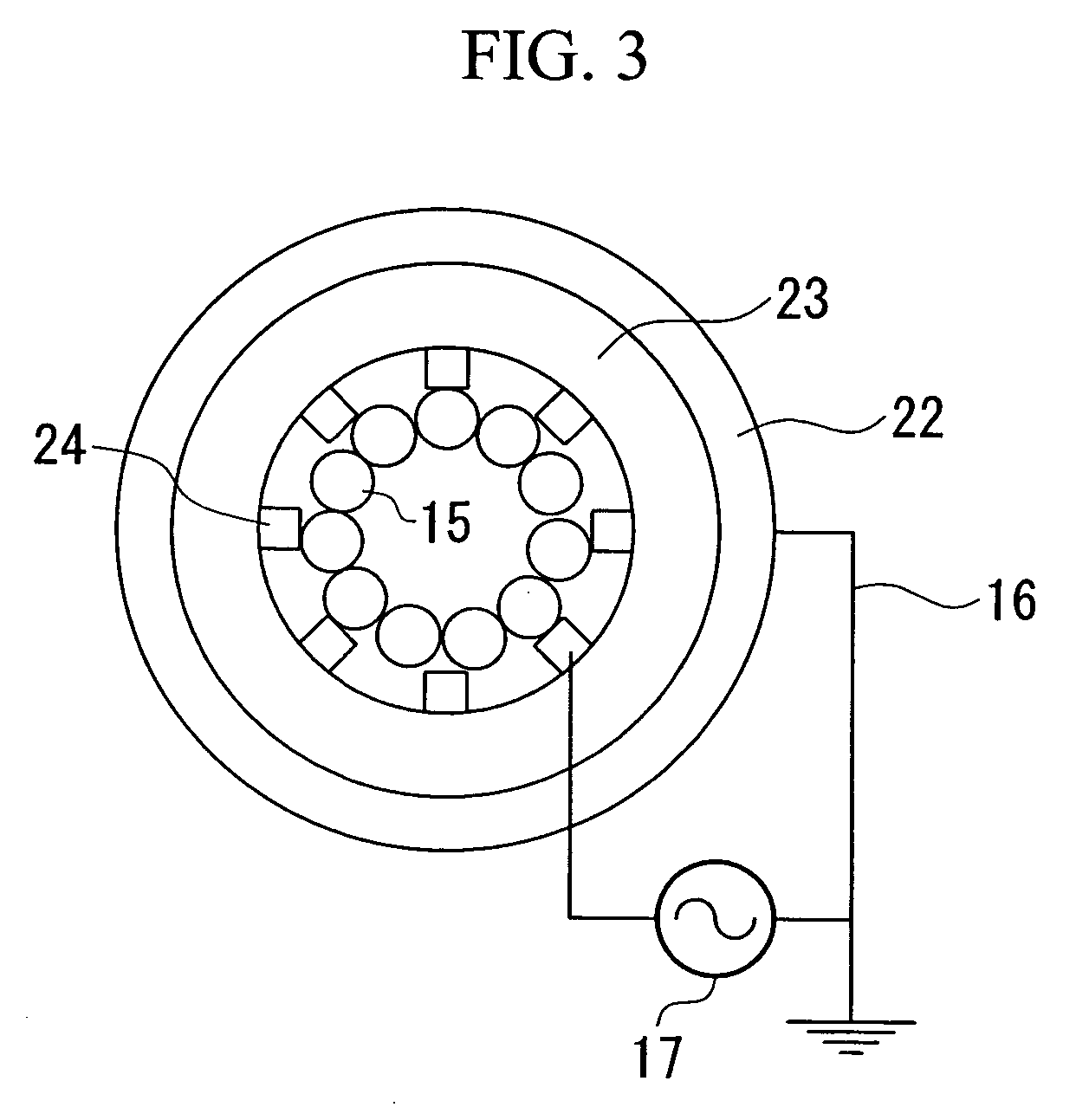

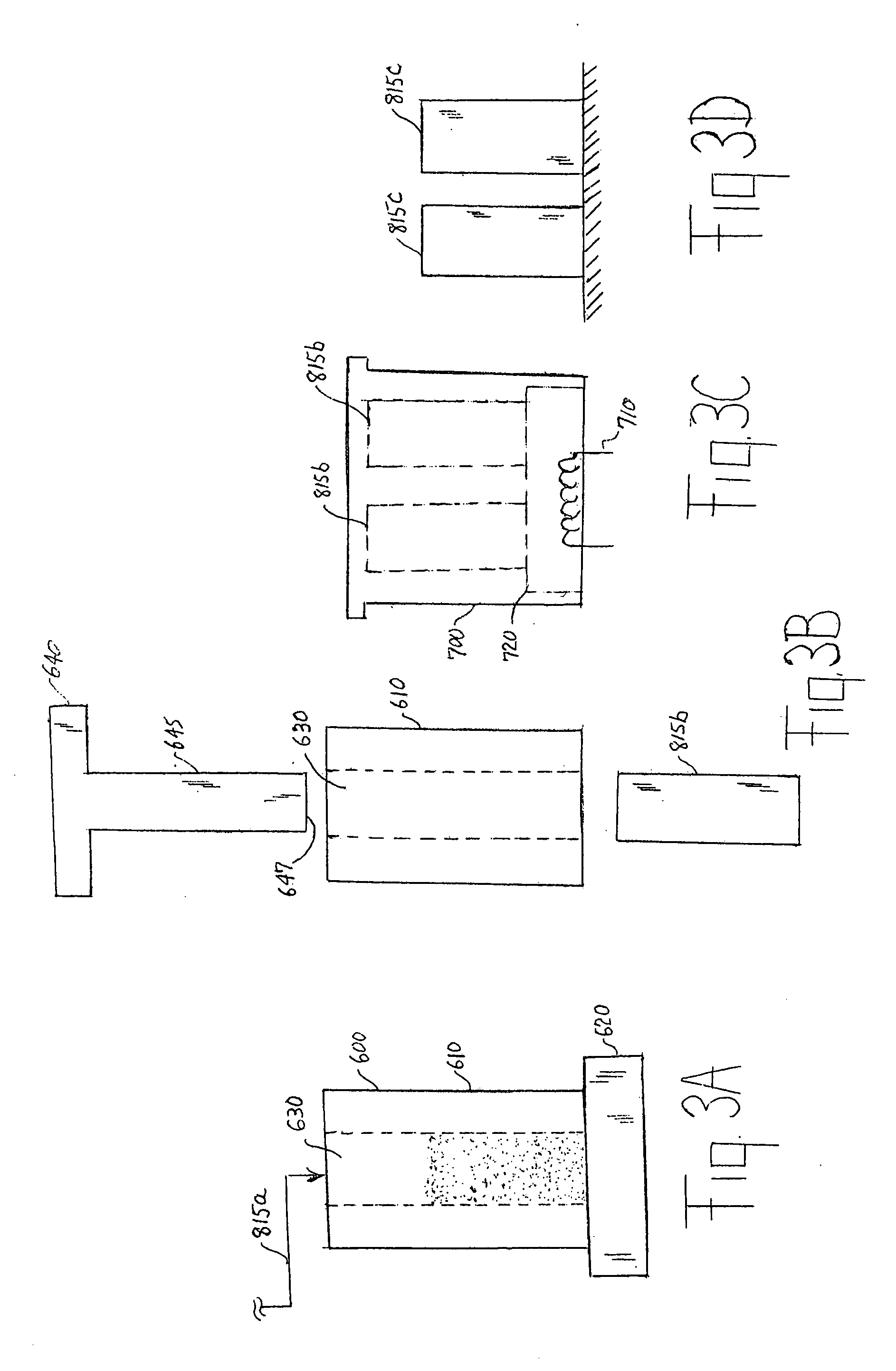

Semiconductor processing with a remote plasma source for self-cleaning

InactiveUS20070227554A1Good effectElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaProduct gas

A plasma CVD device includes a reaction chamber, a remote plasma discharge chamber that is provided remotely from the reaction chamber, and piping that links the reaction chamber and the remote plasma discharge chamber. The remote plasma discharge chamber activates cleaning gas by plasma discharge energy, and the activated cleaning gas is introduced into the inside of the reaction chamber through the piping and changes solid substances that adhere to the inside of the reaction chamber in consequence of film formation, to gaseous substances, thereby cleaning the inside of the reaction chamber. The device is characterized by at least one of the following: (a) the remote plasma discharge chamber generates active species using radio frequency oscillating output energy of a preselected frequency; (b) the piping is made of materials that are not corroded by the active species; or (c) the piping is provided with a through-flow type valve.

Owner:ASM JAPAN

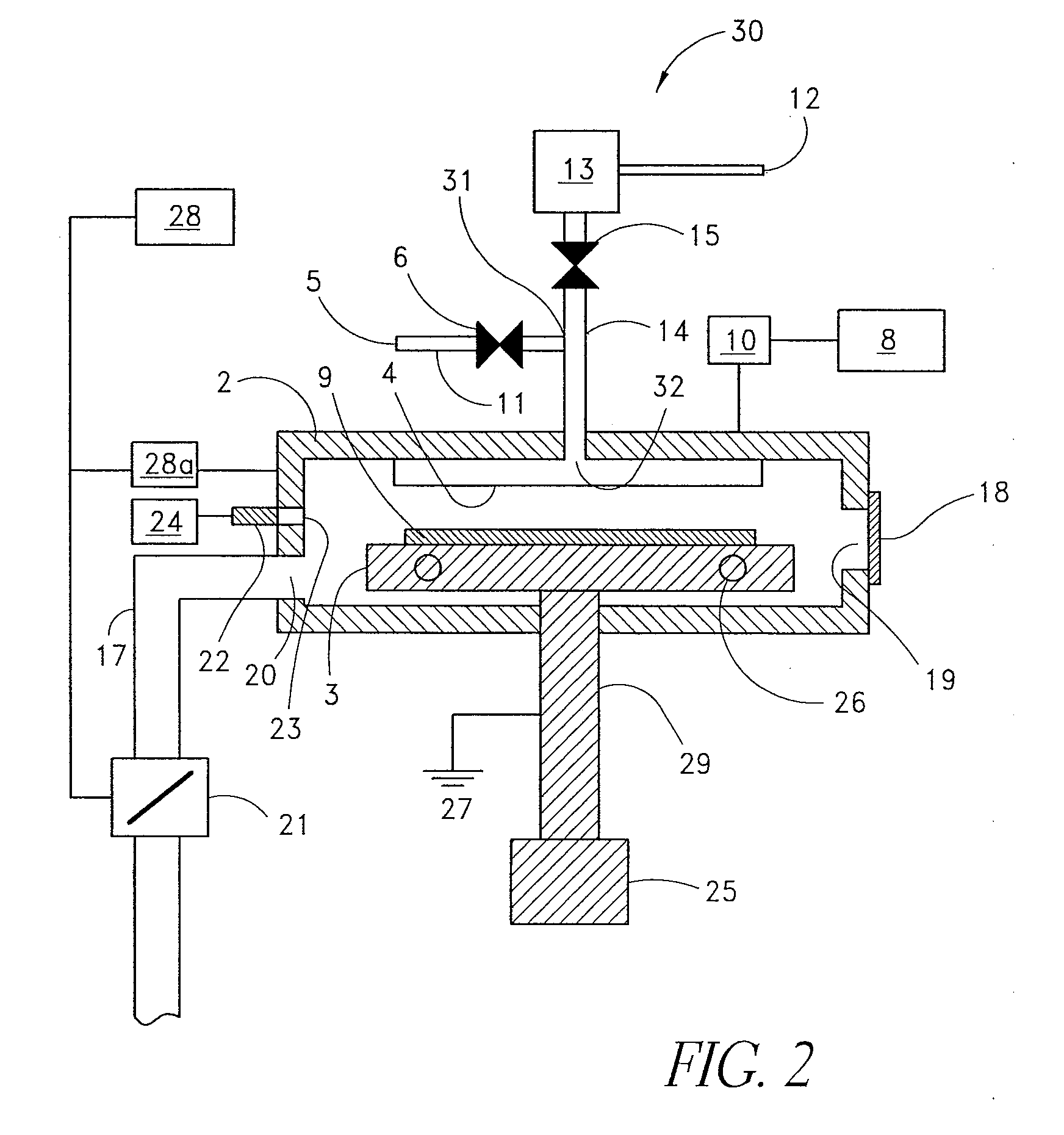

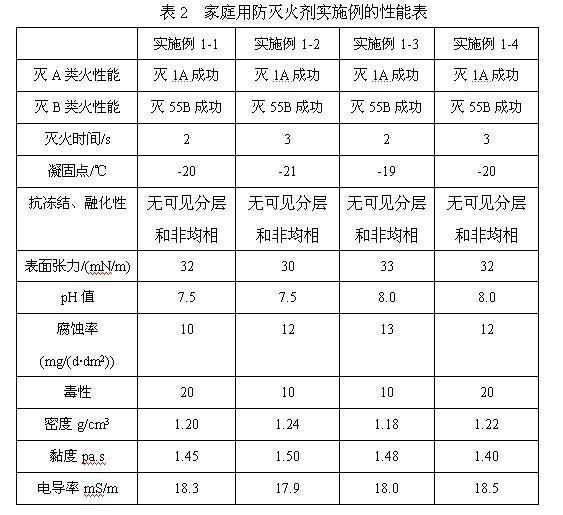

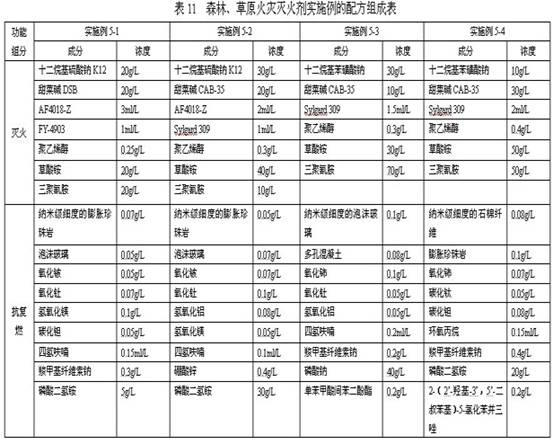

Built-up synergetic class-A/B water extinguishing agent series

The invention discloses a built-up synergetic class-A / B water extinguishing agent series. Class-A fires caused by solid substances (such as woods, cottons, wools, linens, paper) and products thereof and class-B fires caused by liquid or melted solids such as gasoline, kerosene, diesel oil, crude oil, methanol, ethanol, asphalt, paraffin waxes and the like can be put out rapidly through the functions such as heat absorption and cooling, diluting and smothering, insulating and covering, suppressing and blocking combustion chains, and the like which are synergetically performed by various extinguishing functional components, and a high-temperature-resistant thermal-insulation and fire-retarding covering layer is formed on the surface of an inflammable matter by various after-combustion functional components so as to achieve the effect of after-combustion resistance. Because the class A / B fires relate to multiple occasions of daily life and production activities, the extinguishing agent disclosed by the invention can be used in the fields of home fire prevention and extinguishing, urban architecture fire prevention and extinguishing, oil depot and gasoline station fire prevention and extinguishing, vehicle and ship fire prevention and extinguishing, forest and grassland fire prevention and extinguishing, mine fire prevention and extinguishing, confined spaces (such as civil air-defense architectures) fire prevention and extinguishing.

Owner:NANJING UNIV OF SCI & TECH

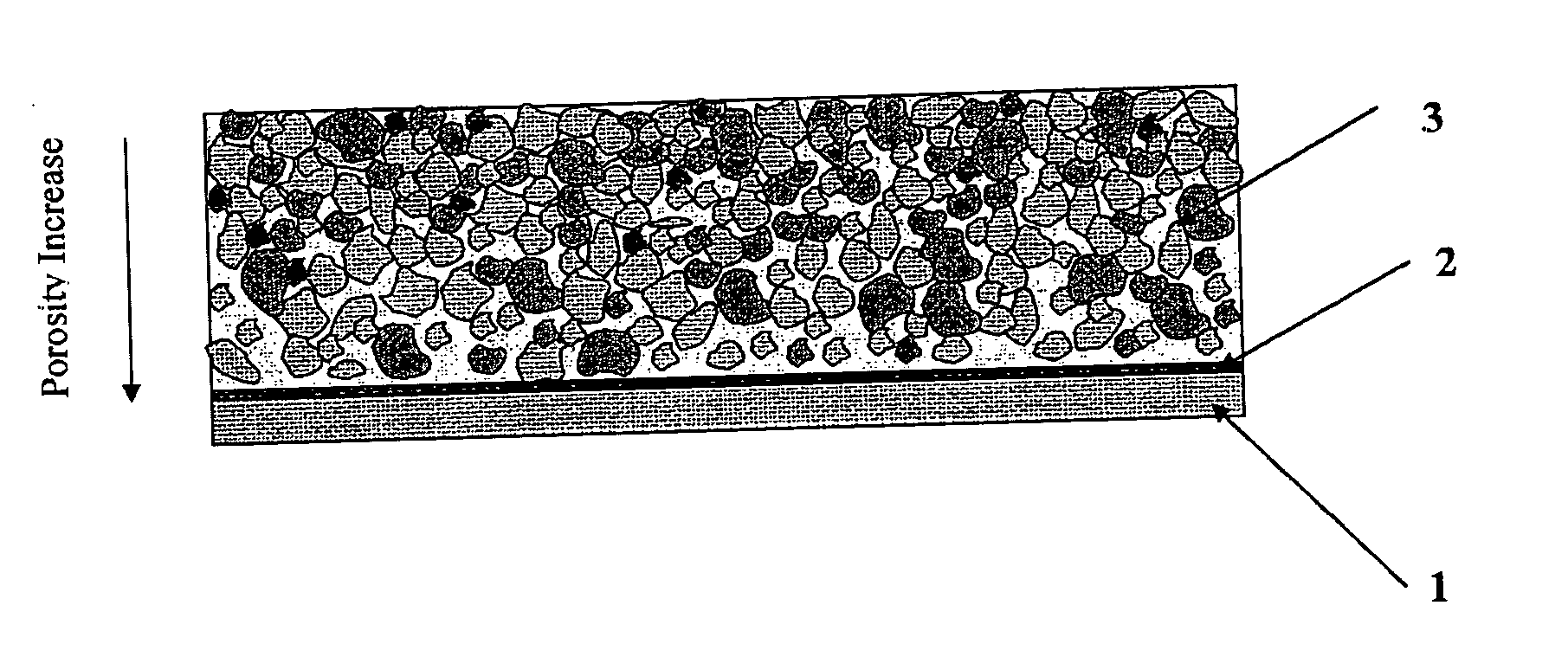

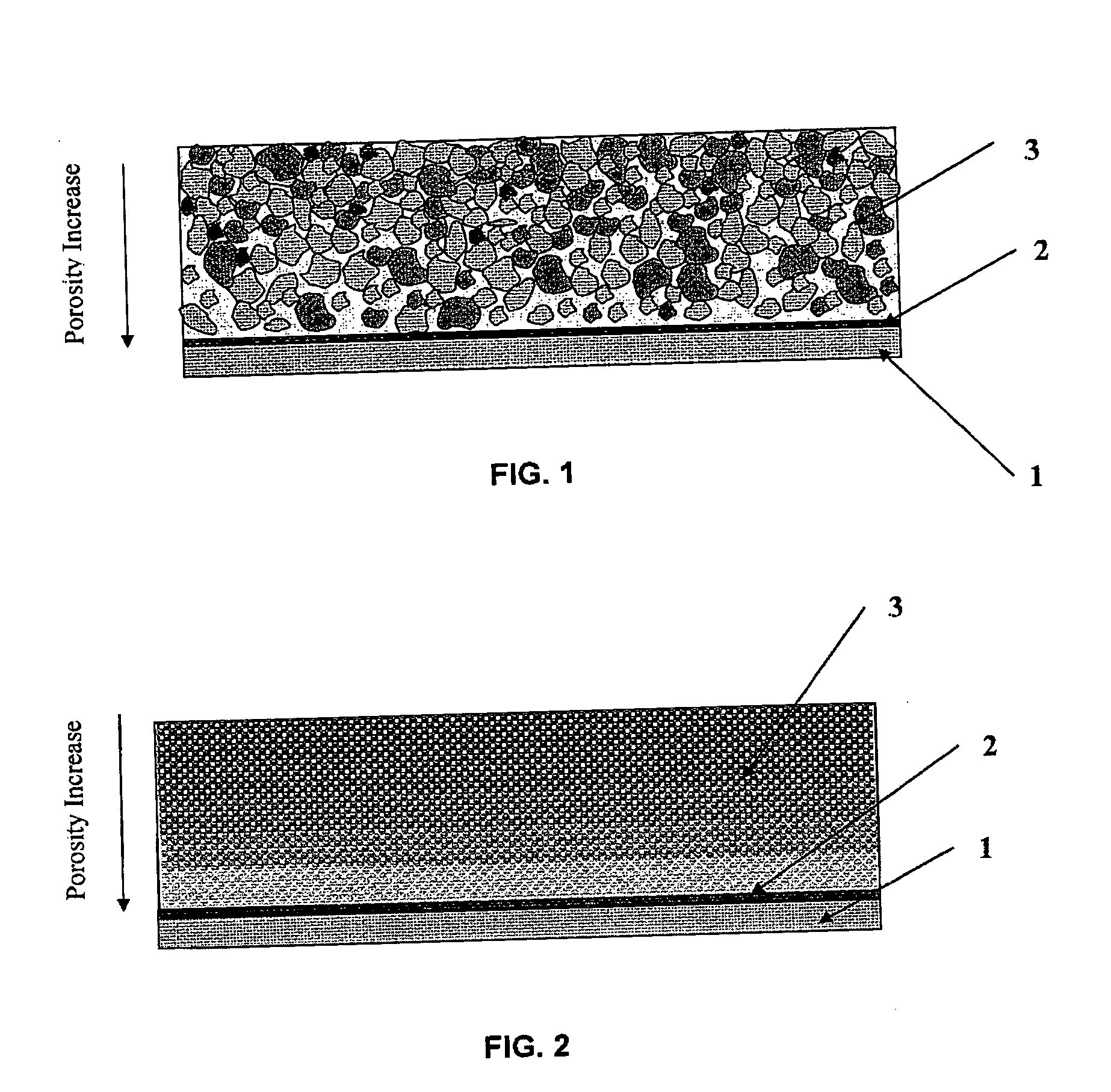

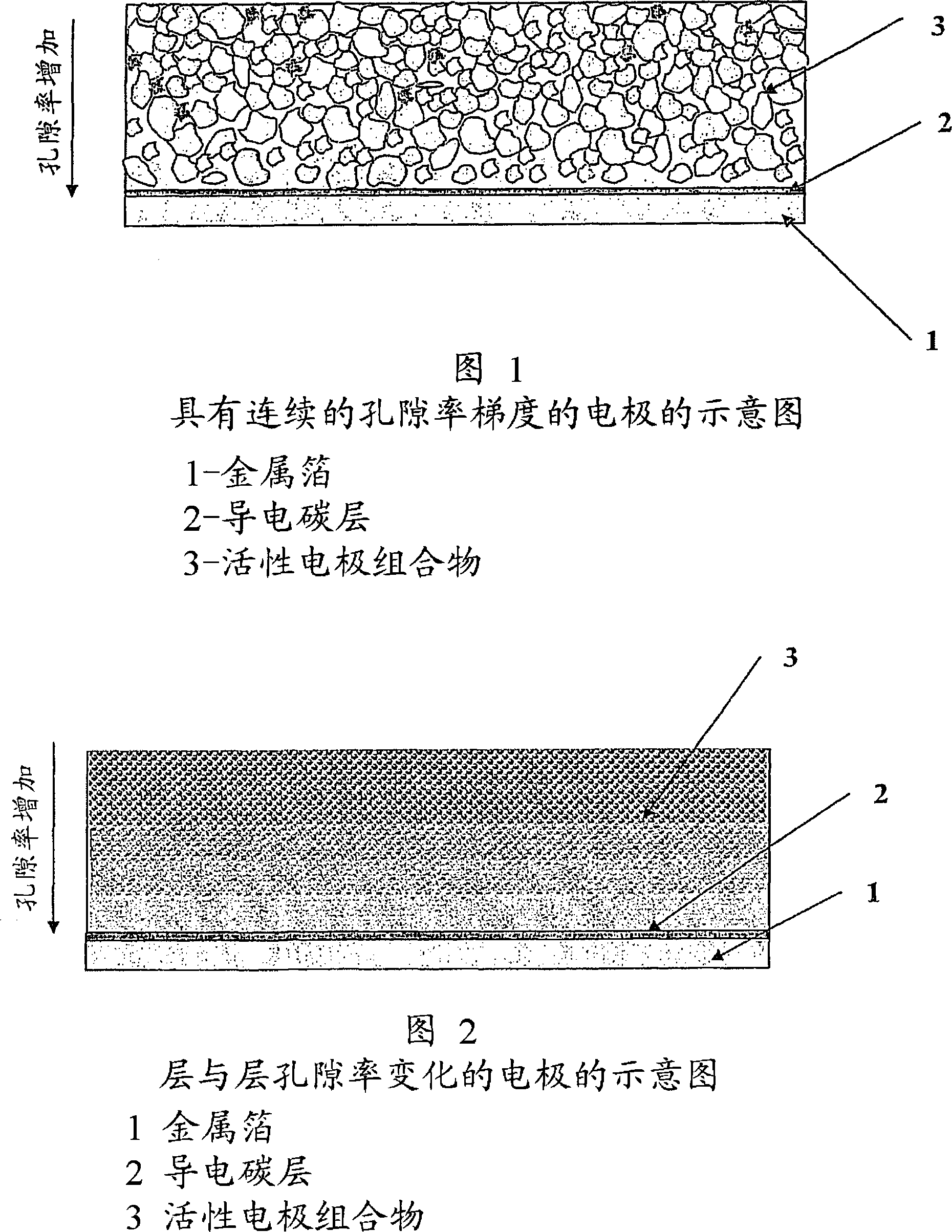

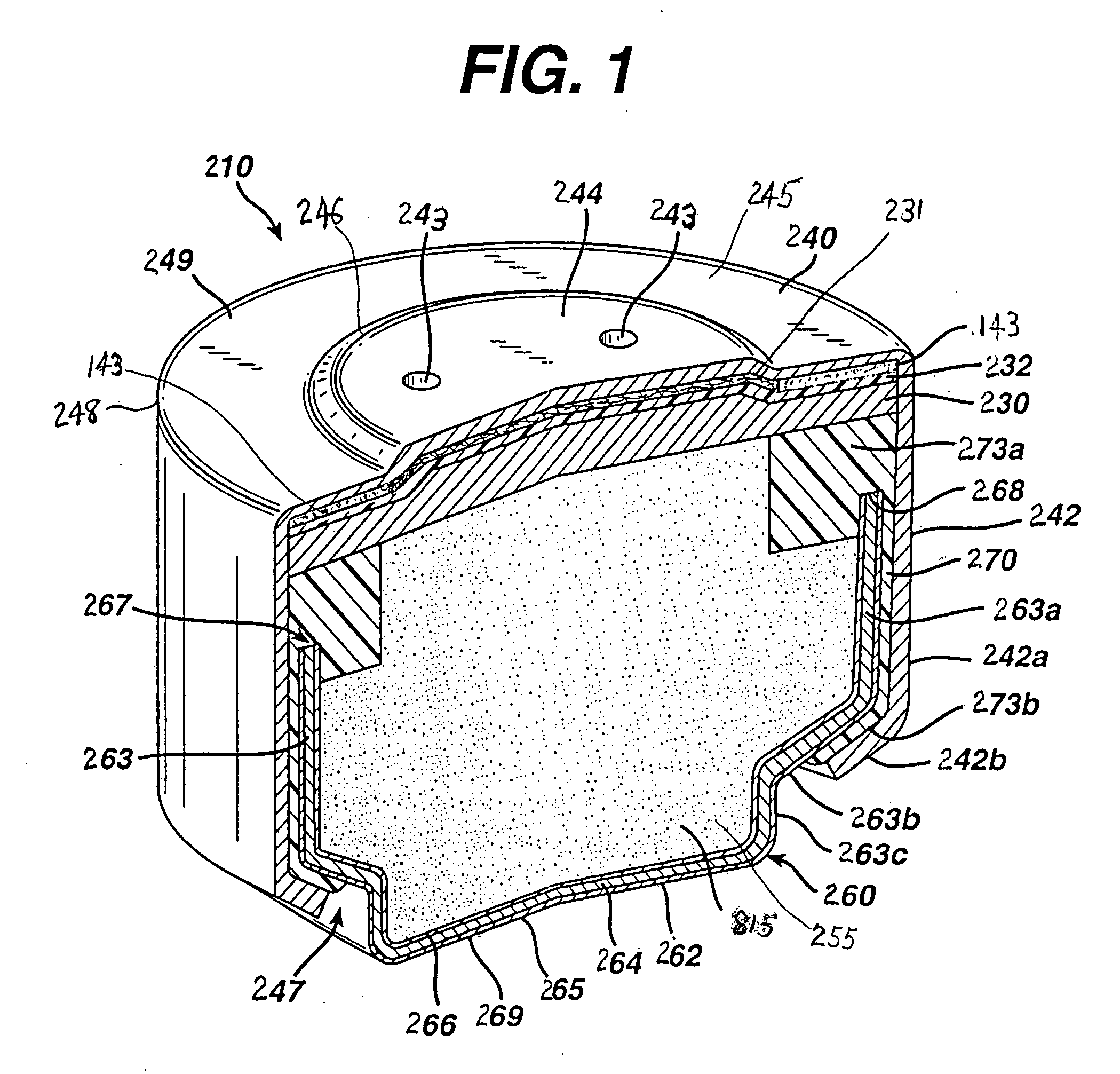

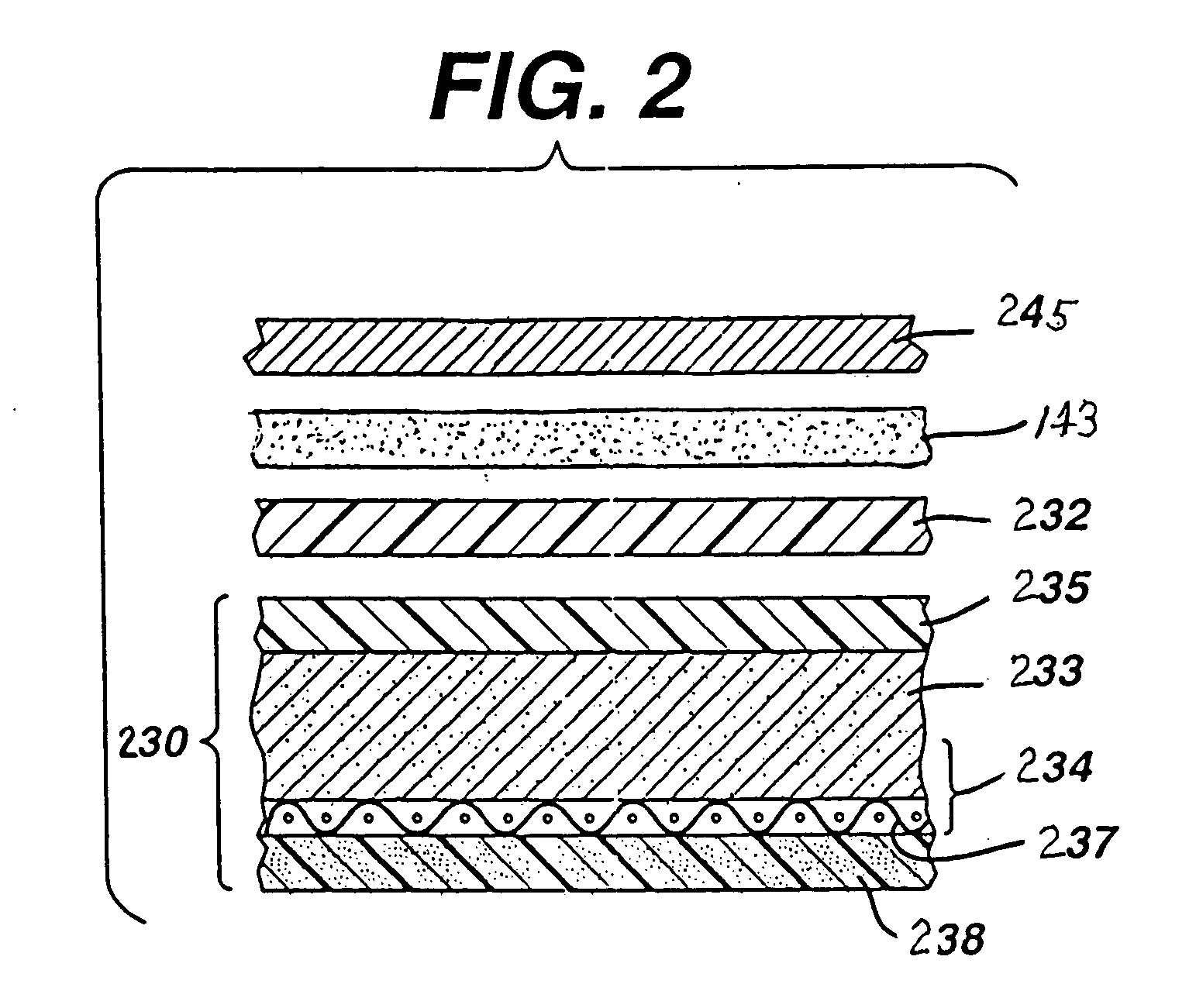

Battery electrode structure and method for manufacture thereof

InactiveUS20060024579A1Increase energy densityReduce porositySecondary cellsActive material electrodesPorosityComposite electrode

There are disclosed solid composite electrodes with electrode active layers that include an electrode active material, an optional election conductive material, an optional binder and other optional additives. The solid composite electrodes are formed by the deposition of an electrode composition (slurry) onto a current collector in one or many layers. The electrode structure may be characterised by a porosity of the electrode composition layer that decreases in a direction from the back side of the layer (close to the current collector) towards the outer side of the layer. The gradient of the decrease in the porosity is controlled by the content of solid substance in the slurry, by the composition of the solvent in the slurry, by the temperature of the layer drying after deposition, as well as by the pressing or calendering conditions for each layer. The electrode structures can be used in for example chemical sources of electric energy such as primary (non-rechargeable) as well as secondary (rechargeable) batteries.

Owner:OXIS ENERGY

Process for removing oil from solid materials recovered from a well bore

InactiveUS6846420B2Low costLower oil levelHollow article cleaningFluid removalSodium hypochlorite solutionResidual oil

The present invention provides a process and an additive package for removing oil from solid material recovered from a well bore, e.g., drill cuttings and produced sand. In this process, the solid material is passed from the well bore to a separation zone. An aqueous acidic solution containing a polymer substituted with an amino group is introduced to the separation zone containing the solid material along with a halogenating agent and optionally one or more surfactants. The polymer, halogenating agent, and optional surfactant constitute the additive package. The polymer substituted with an amino group is preferably chitosan, and the halogenating agent is preferably a sodium hypochlorite solution. The mixture formed in the separation zone is agitated to cause a product of a reaction between the polymer and the halogenating agent to contact the solid material and remove residual oil therefrom.

Owner:HALLIBURTON ENERGY SERVICES INC

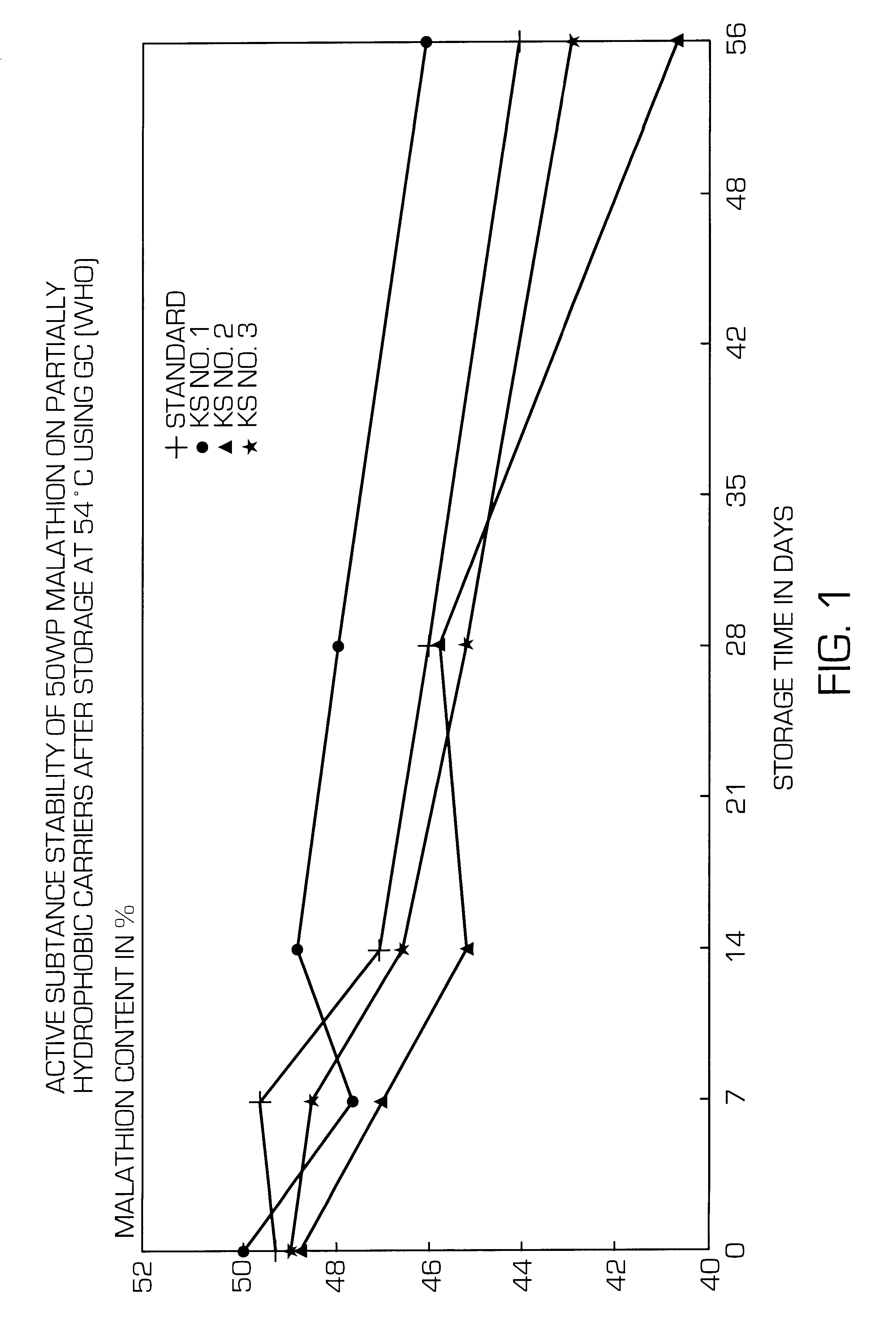

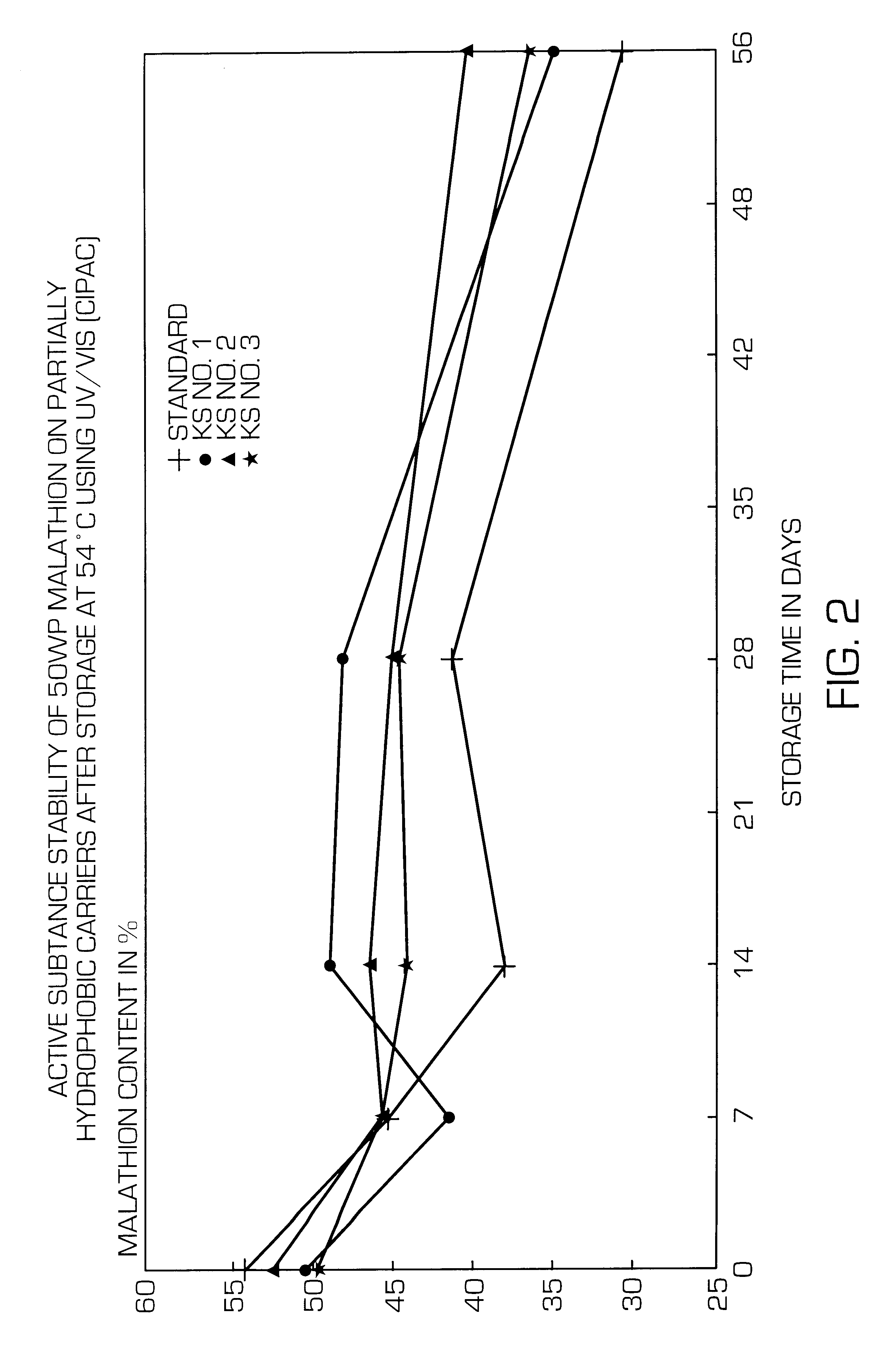

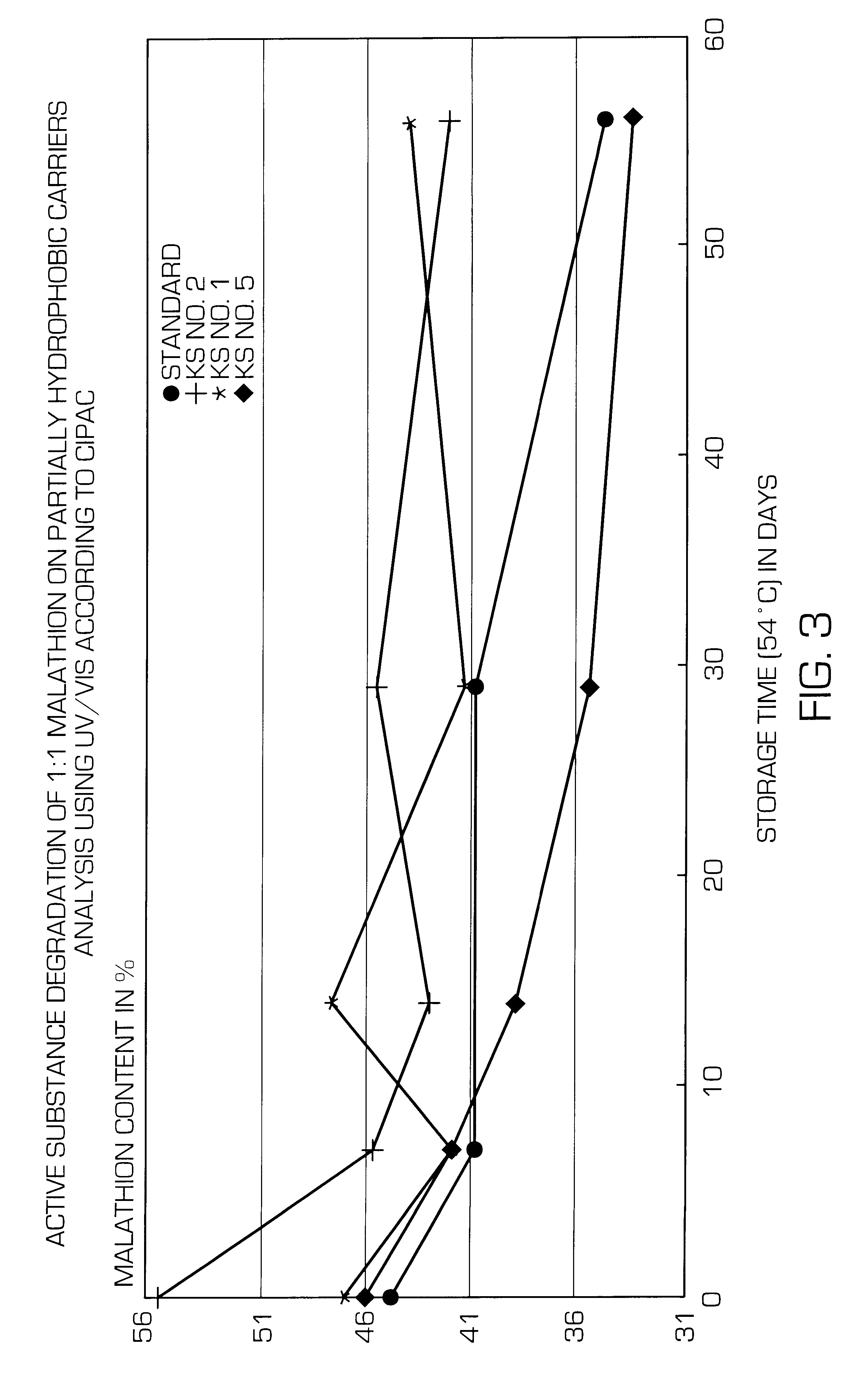

Partially hydrophobic precipitated silicas

A partially hydrophobic precipitated silica having a methanol wettability of 10 to 49%, in particular with a DBP uptake on a dry basis of greater than 250 g / 100 g and a mean particle size of 1 to 12 mum and / or a carbon content of 0.3 to 1.85% and / or a loss on drying of 2.6 to 10.0% and / or a pH value of 5.5 to 10.0, is prepared by mixing the amount of water-repellent agent with the precipitated silica suspension at very short residence time and low pH value, filtering off the solid substance, washing free of salt, drying, post-treating thermally and milling. The partially hydrophobic precipitated silica can be used in active substance formulations and active substance formulations of hydrolysis-sensitive substance and in defoaming agents.

Owner:EVONIK DEGUSSA GMBH

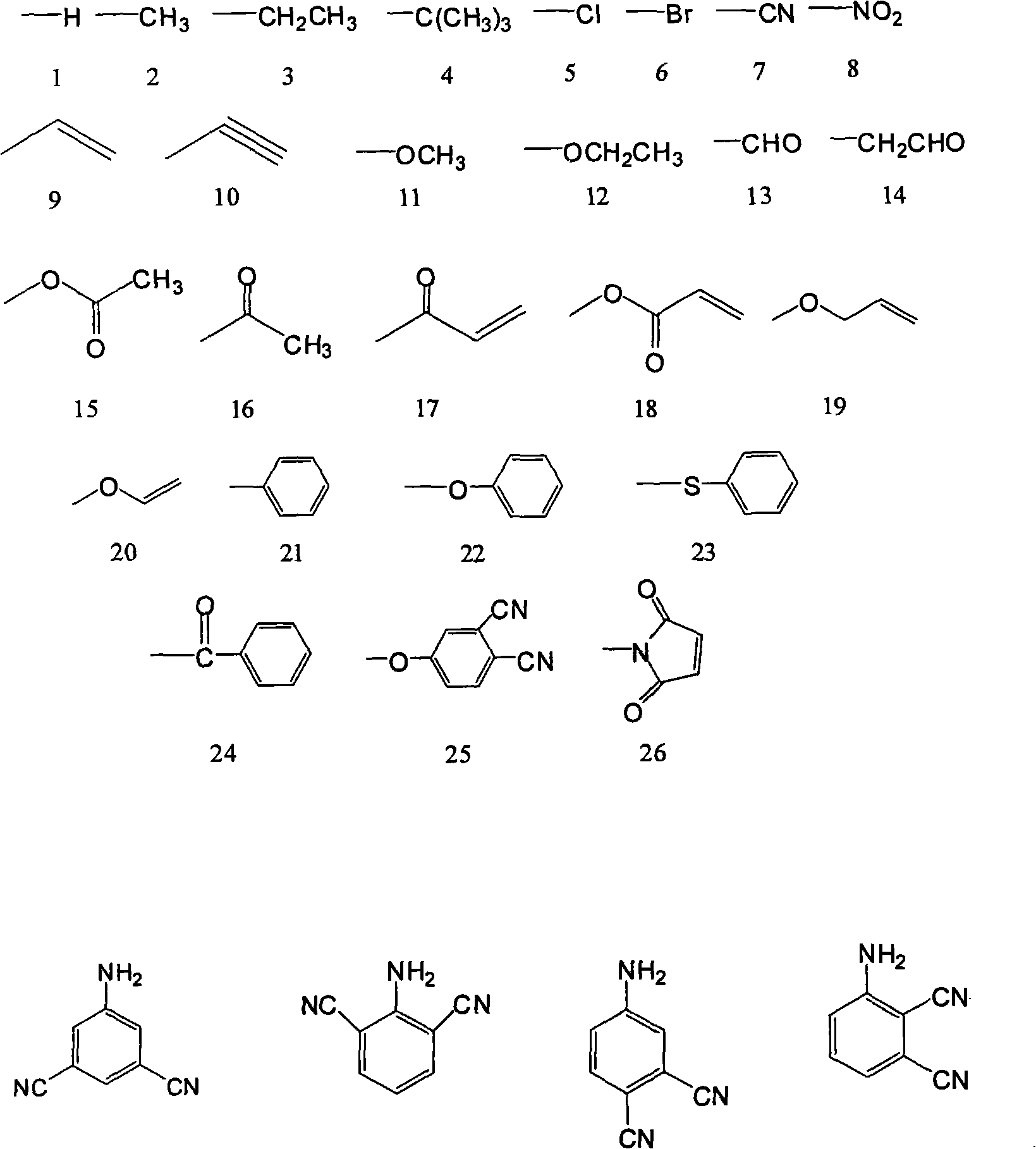

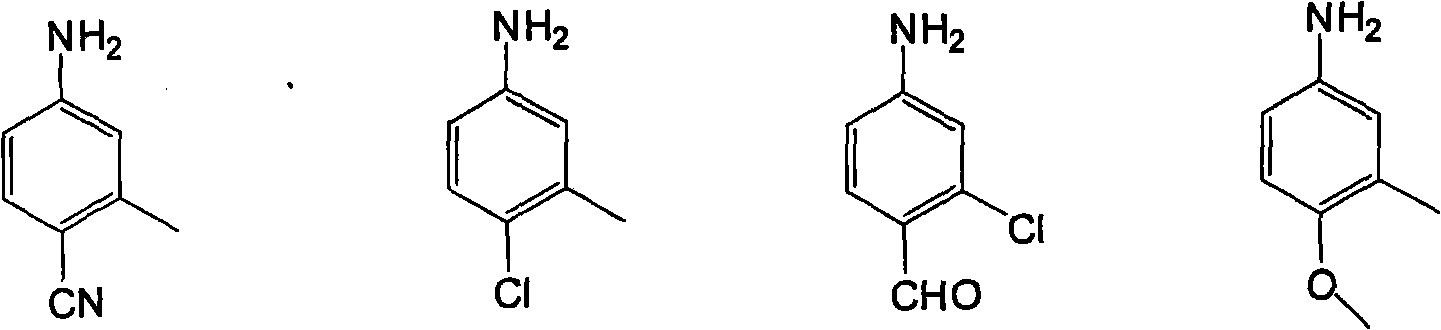

Method for preparing benzoxazine intermediate containing triazine structure

The invention provides a preparation method of triazine structure containing benzoxazine intermediate, which sequentially includes: (1) performing synthetic reaction of aldehyde compound and amine compound at a molar ratio of at least 1:1 which includes adding aldehyde compound and solvent of at least one of clean water, methanol, ethanol, isopropanol, and ethyl acetate into a reactor at the room temperature under the normal pressure to obtain mixed solution with aldehyde mass concentration of no greater than 95%, adding amine compound while stirring, and reacting at 0-100 DEG C under the normal pressure for at least 15 minutes to obtain the reactant liquor; (2) pouring into the cleaning solution, stirring and cleaning, and filtering to collect solid substance, or directly filtering the reactant liquor to collect the solid substance; and (3) drying the solid substance obtained in step (2) at 30-100 DEG C.

Owner:SICHUAN UNIV

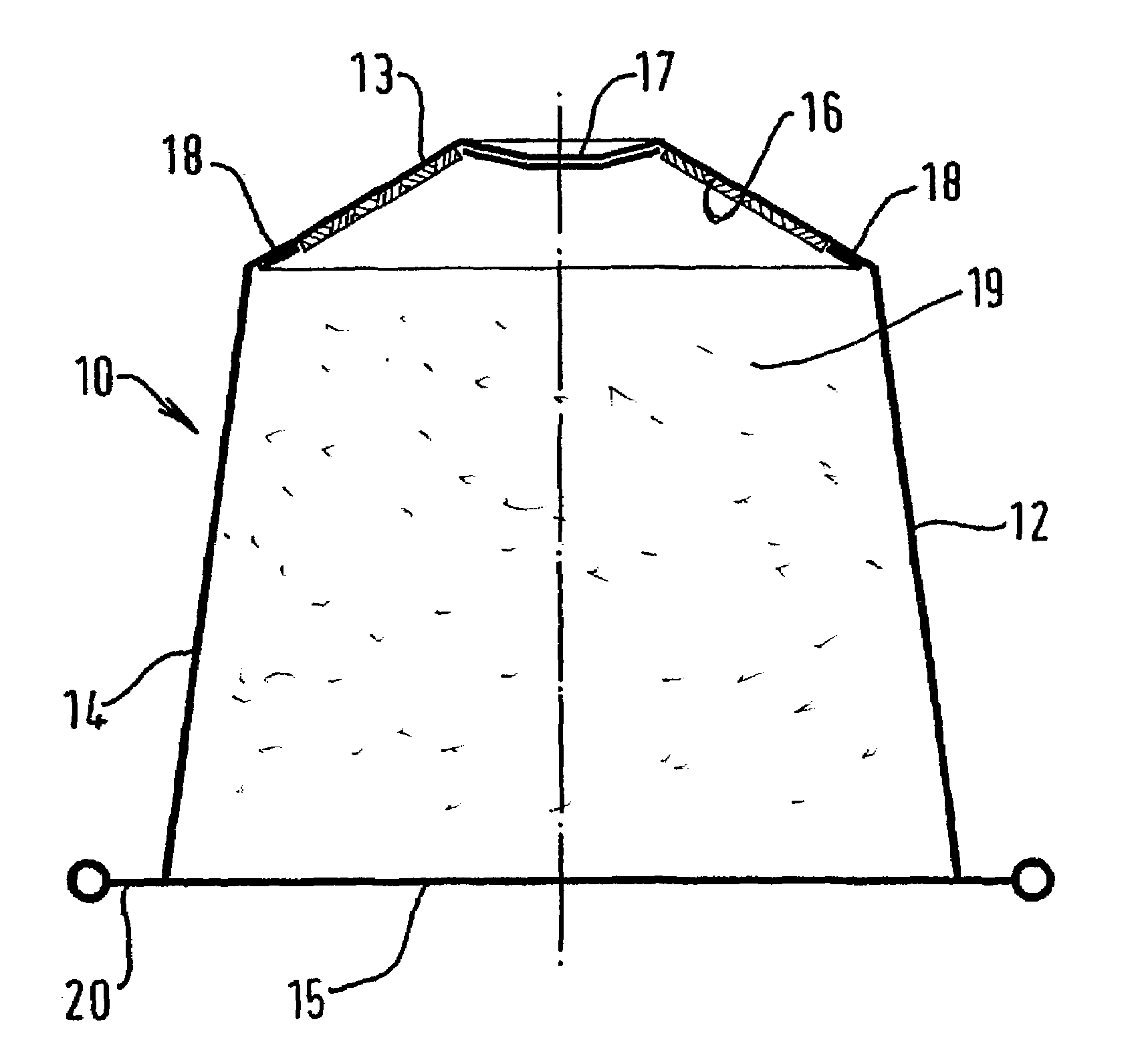

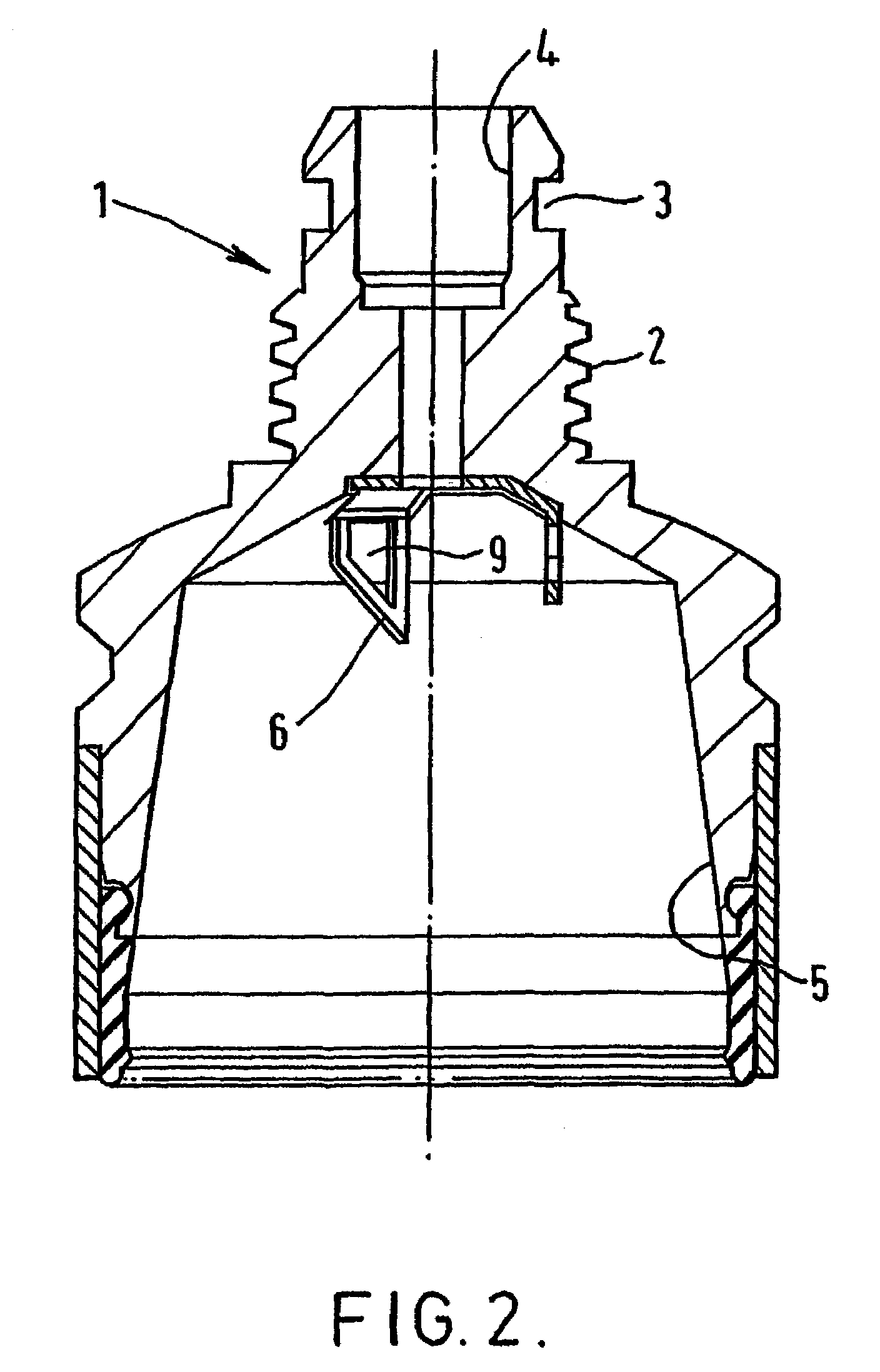

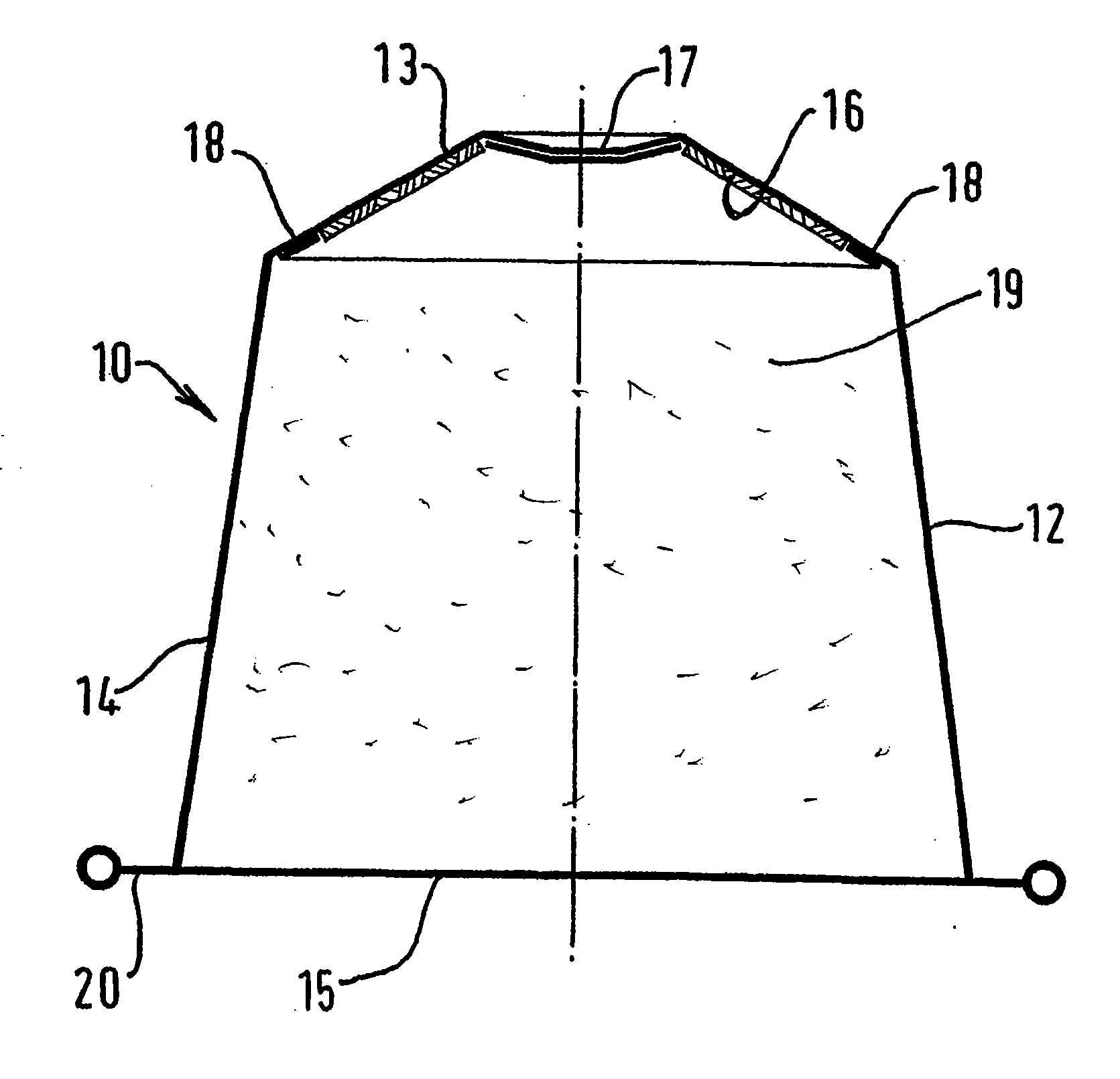

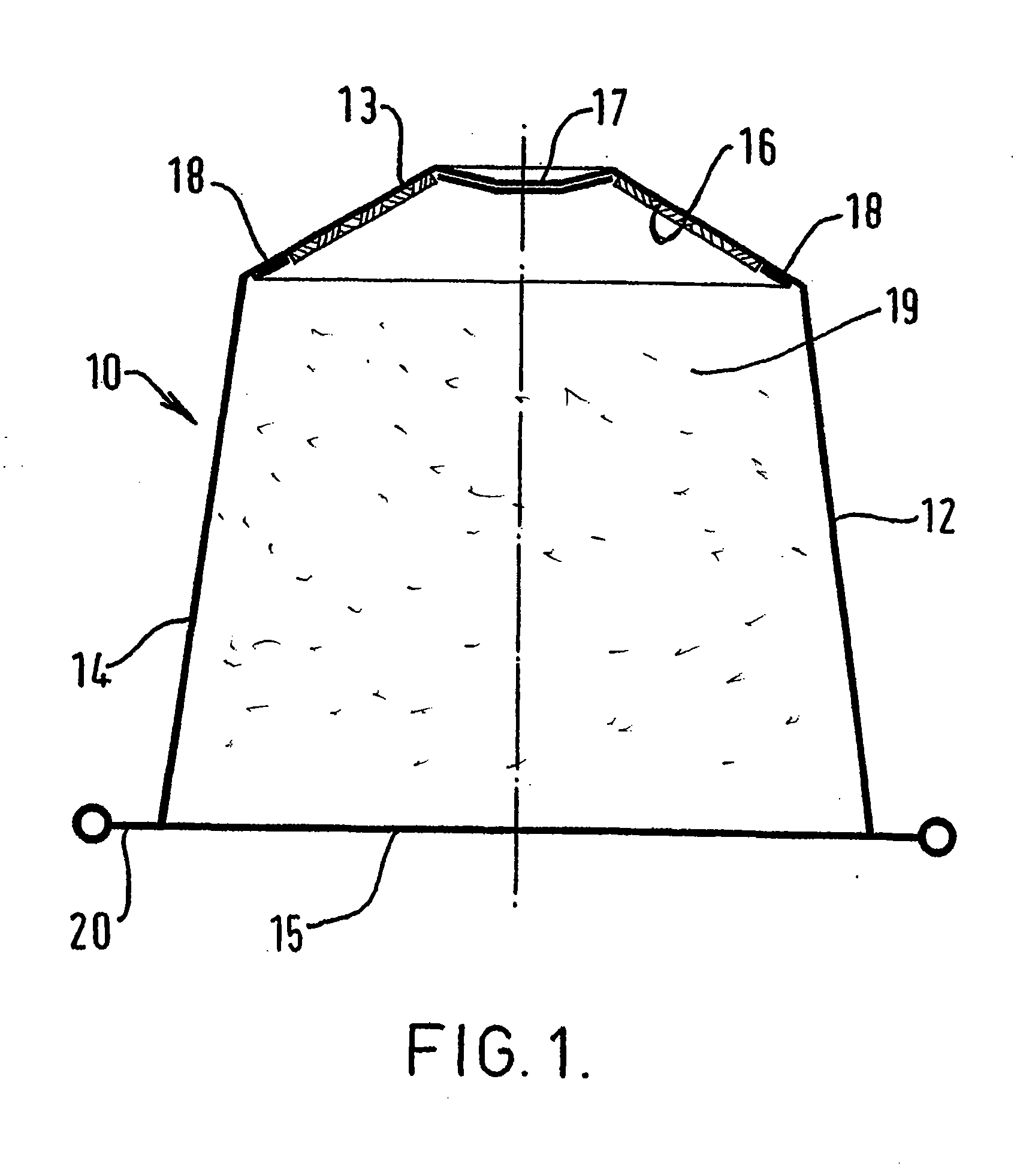

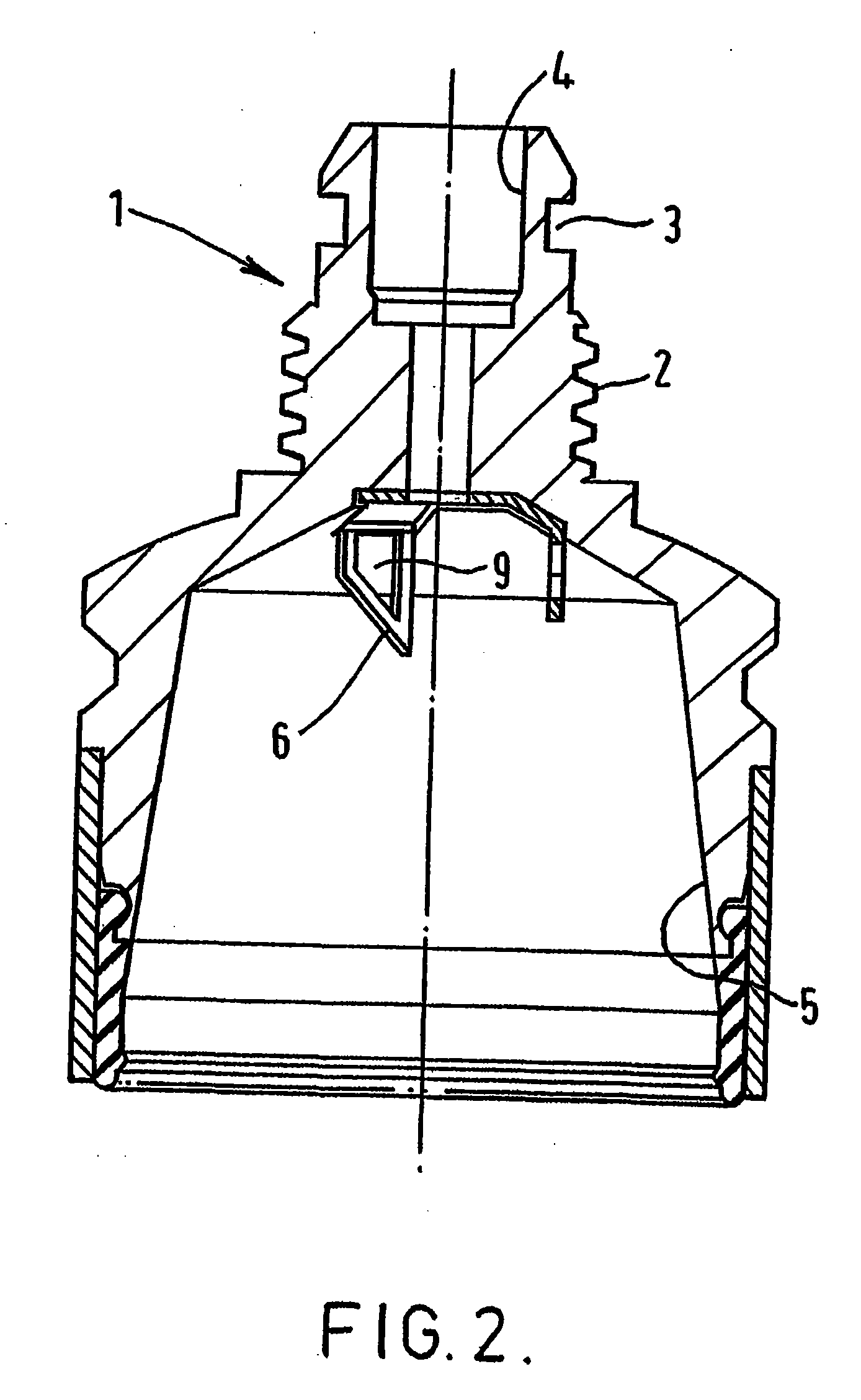

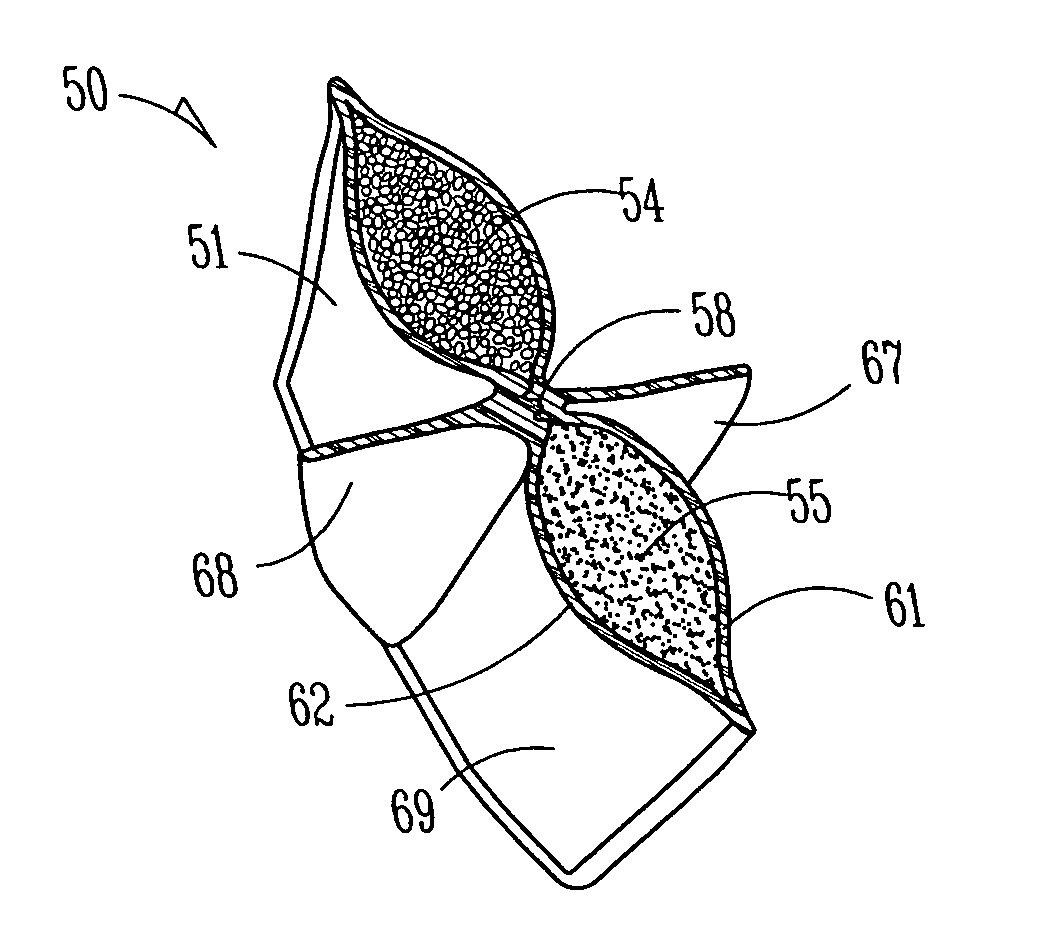

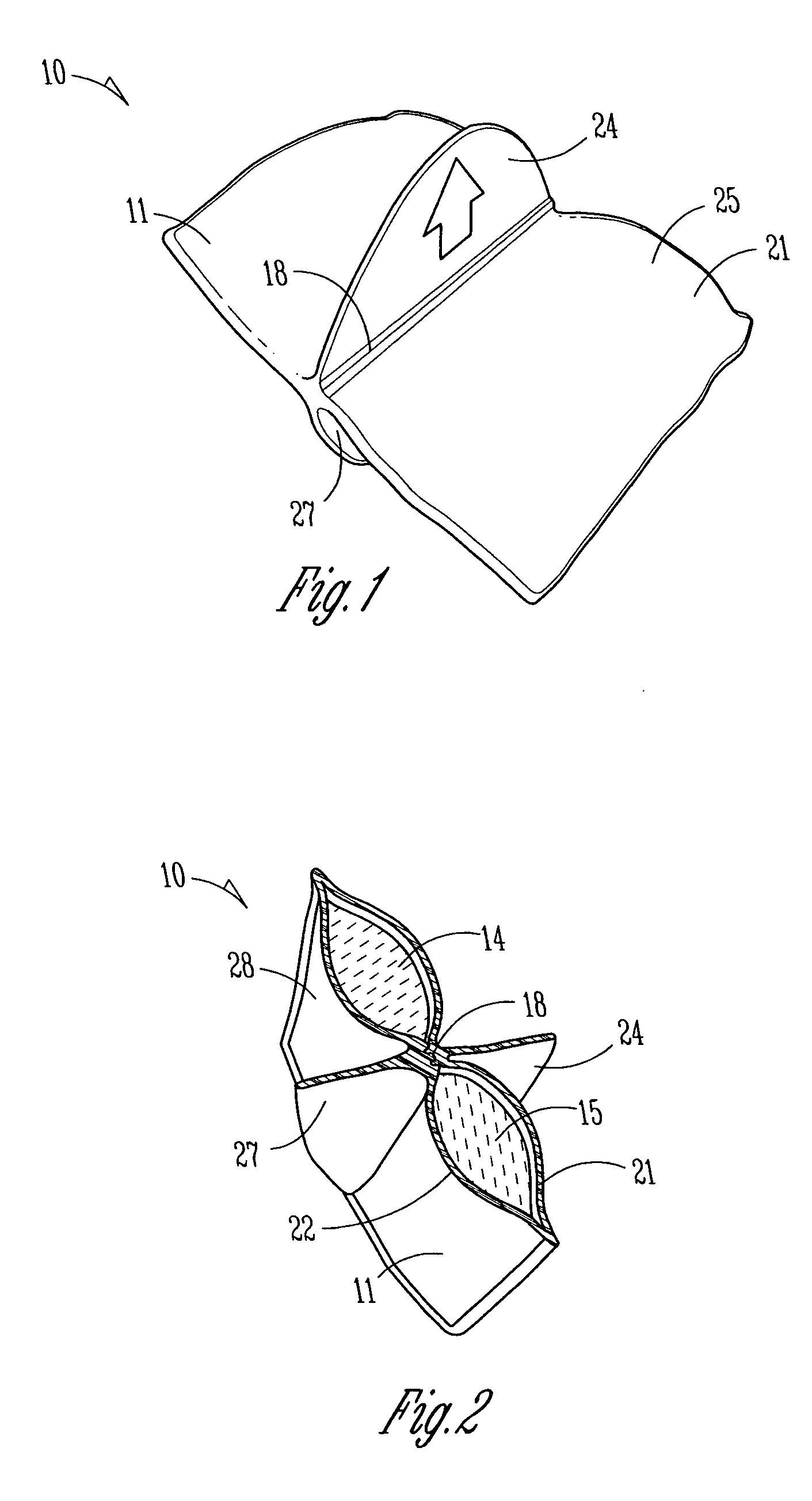

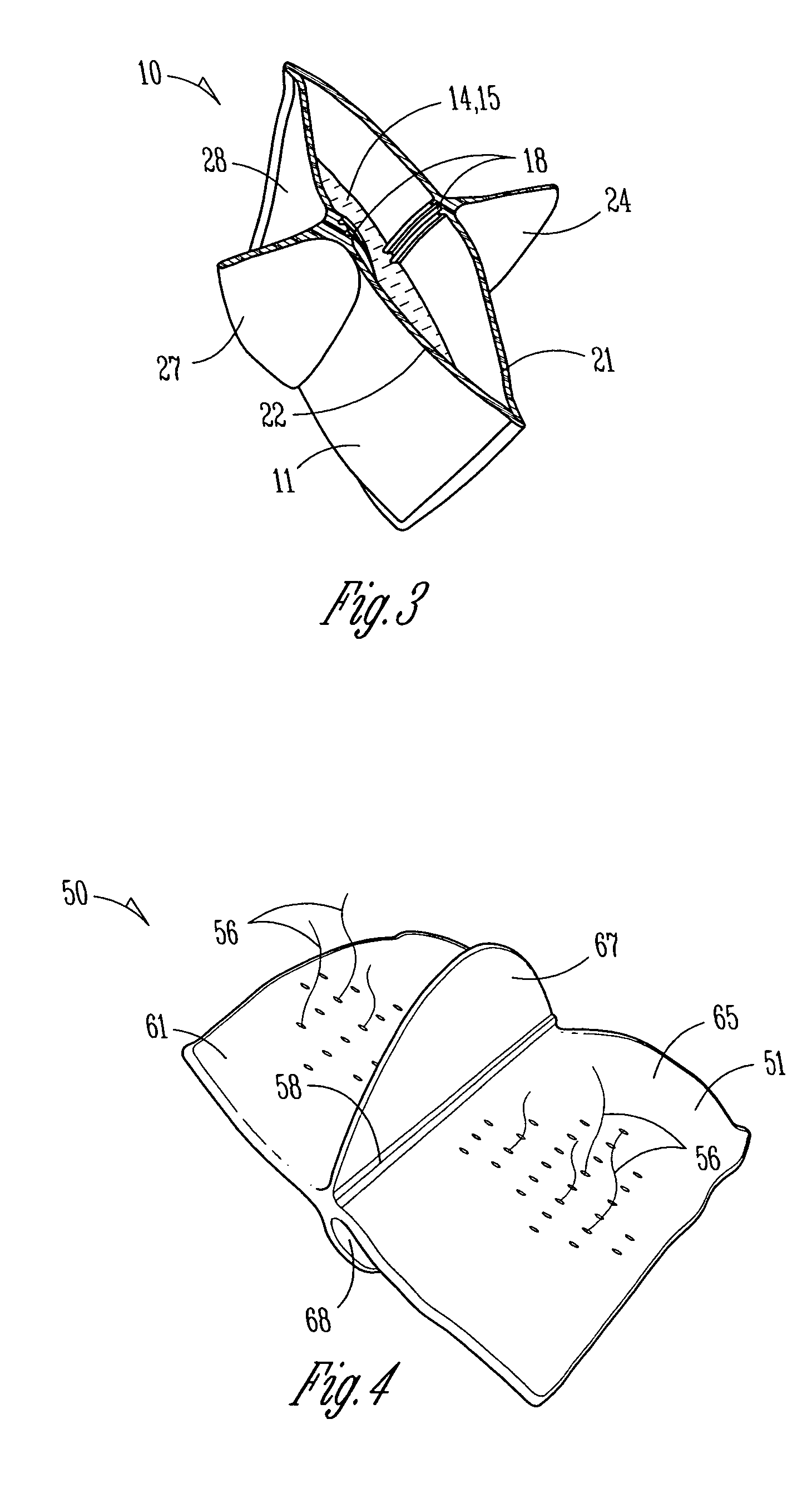

Closed cartridge for preparing a beverage for extraction under pressure

InactiveUS7153530B2Guaranteed retentionEasy to produceReady-for-oven doughsDispensing apparatusEngineeringFrustum

The present invention relates to a closed cartridge (10), for extraction under pressure, comprising a dish (12) with a bottom (13 ) with a central part and a peripheral part and a side wall having substantially the shape of a frustum of a cone and a circular edge with a diameter greater at the bottom and a cover (15) welded to the periphery of the edge of the dish and the cover is intended to be torn only through the effect of the force of the extraction fluid when extraction starts, the cartridge comprising, in the dish at the level of the bottom, a fabric (16) guaranteeing retention of the solid substance when it is opened,in which the fabric guaranteeing retention of solid substance is a sheet of fabric sealed in the bottom of the dish in two zones, on the one hand in the central part (17) and on the other hand in the peripheral part (18) of the bottom (13).

Owner:SOC DES PROD NESTLE SA

Improvements relating to electrode structures in batteries

ActiveCN101002351ASolve the real problemImprove electrochemical utilizationElectrode rolling/calenderingFinal product manufacturePorosityComposite electrode

There are disclosed solid composite electrodes with electrode active layers that include an electrode active material, an optional electron conductive material, an optional binder and other optional additives. The solid composite electrodes are formed by the deposition of an electrode composition (slurry) onto a current collector in one or many layers. The electrode structure is characterised by a porosity of the electrode composition layer that decreases in a direction from the back side of the layer (close to the current collector) towards the outer side of the layer. The gradient of the decrease in the porosity is controlled by the content of solid substance in the slurry, by the composition of the solvent in the slurry, by the temperature of the layer drying after deposition, as well as by the pressing or calendering conditions for each layer. The electrode structures can be used in chemical sources of electric energy such as primary (non-rechargeable) as well as secondary (rechargeable) batteries.

Owner:JOHNSON MATTHEY PLC

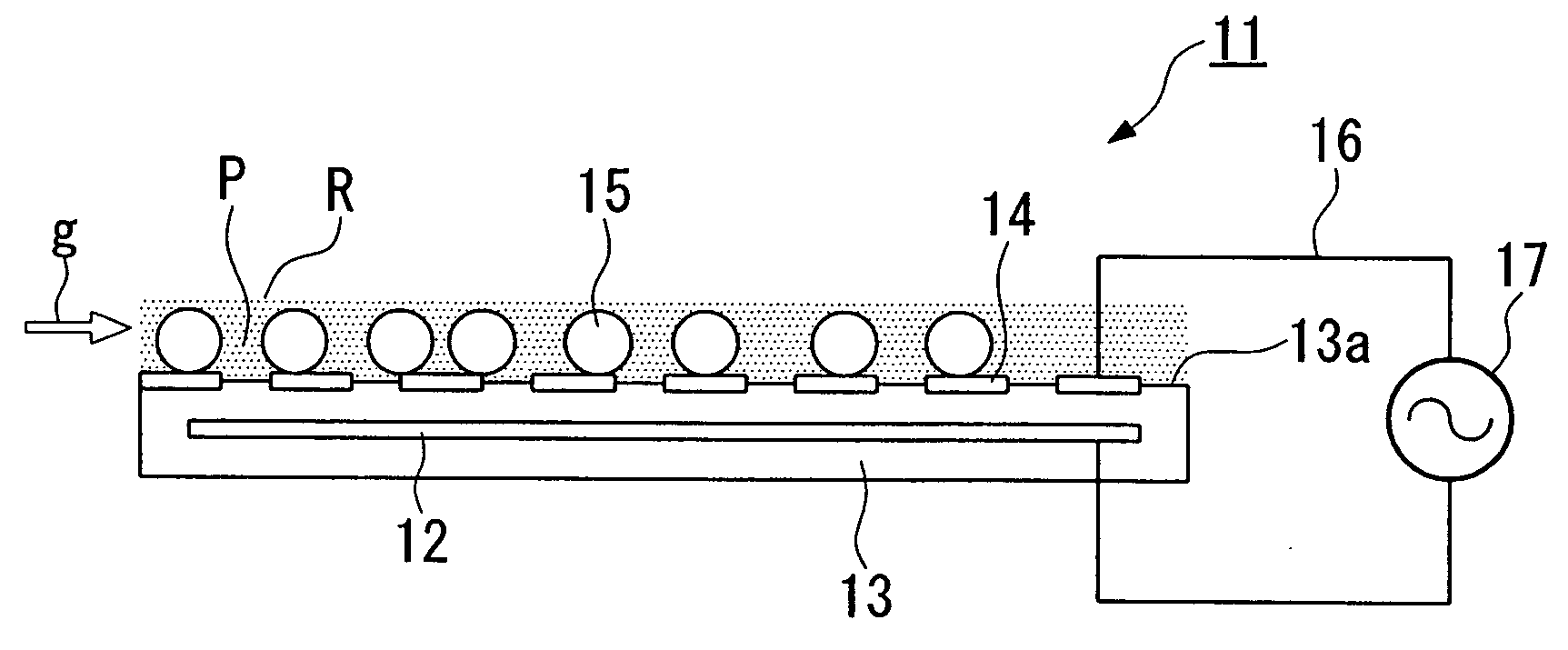

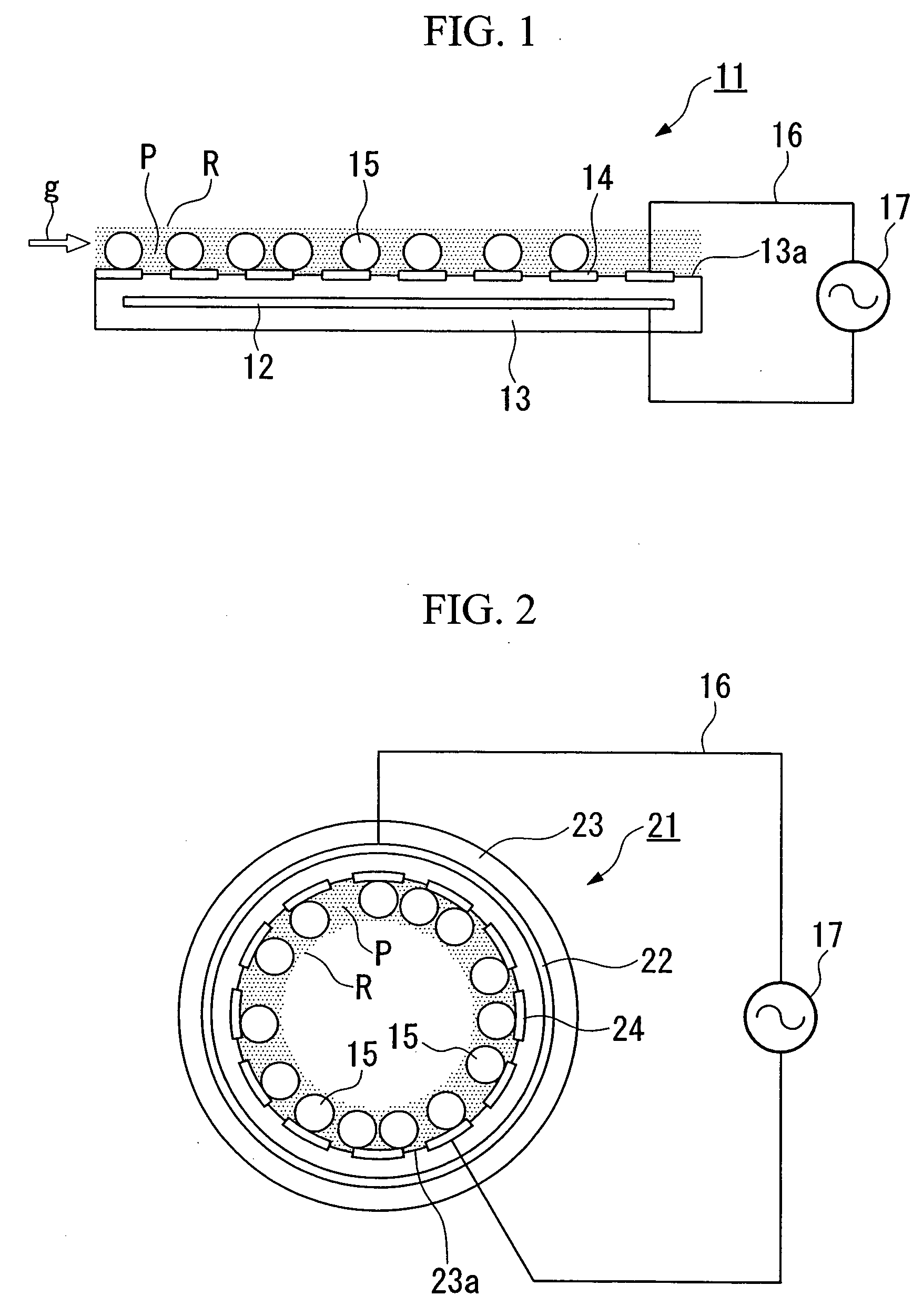

Method and apparatus for gas treatment using non-equilibrium plasma

InactiveUS20050118079A1Low costImprove decomposition efficiencyGas treatmentInternal combustion piston enginesDecompositionCompound (substance)

A gas treatment method is actualized by arranging a plurality of photocatalyst members each including photocatalyst, solid substance, and catalyst in a region of non-equilibrium plasma, which is produced using a surface discharge electrode and into which a treated gas such as an exhaust gas and a harmful gas including harmful chemical substances is introduced and is then subjected to decomposition. The surface discharge electrode comprises a ground electrode, an insulator encompassing the ground electrode, and a plurality of surface electrodes that are arranged relative to the ground electrode via the insulator, by which the non-equilibrium plasma is produced upon electrification. A gas treatment apparatus is constituted by arranging a plurality of surface discharge electrodes, each having a plurality of through holes penetrating in a thickness direction, between which a plurality of photocatalyst members are arranged.

Owner:YAMAHA CORP

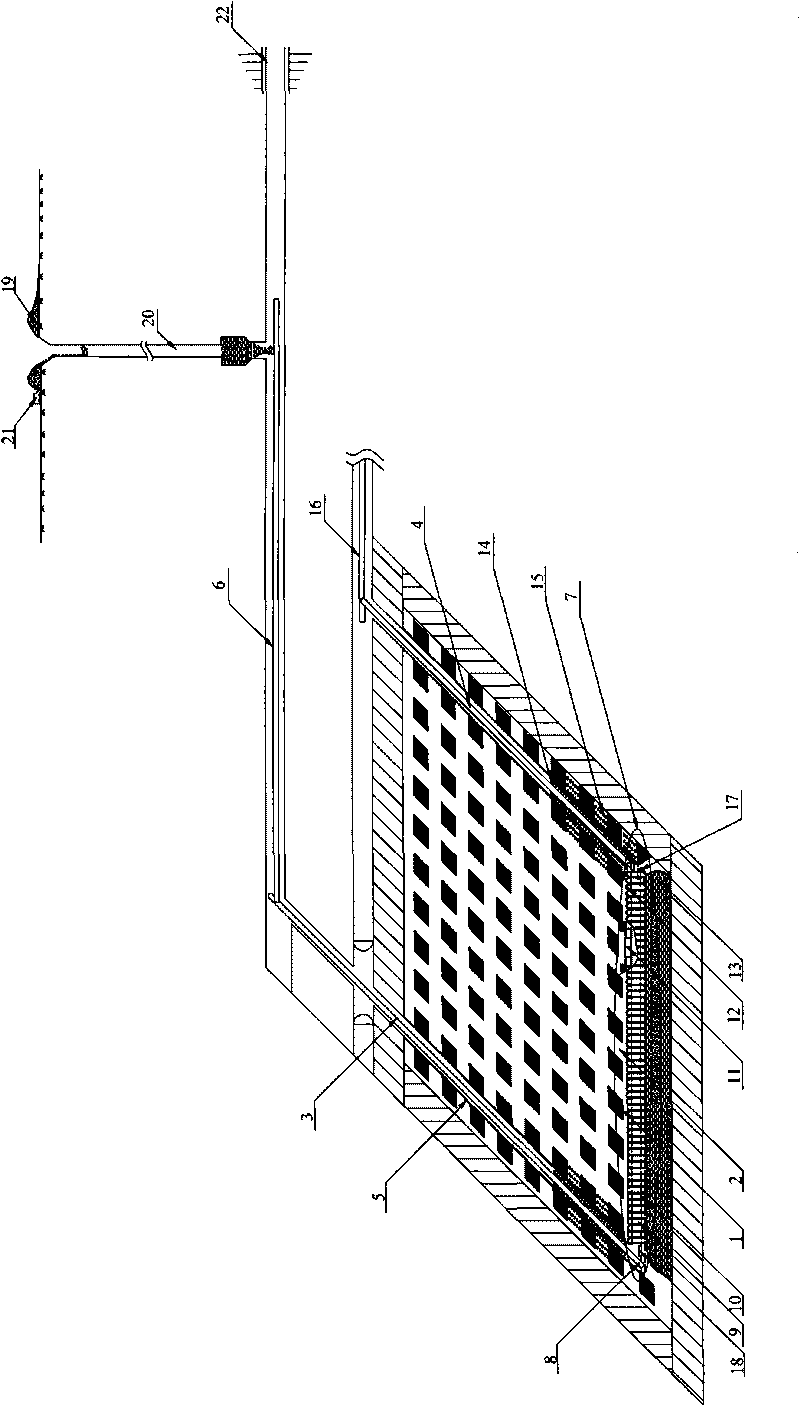

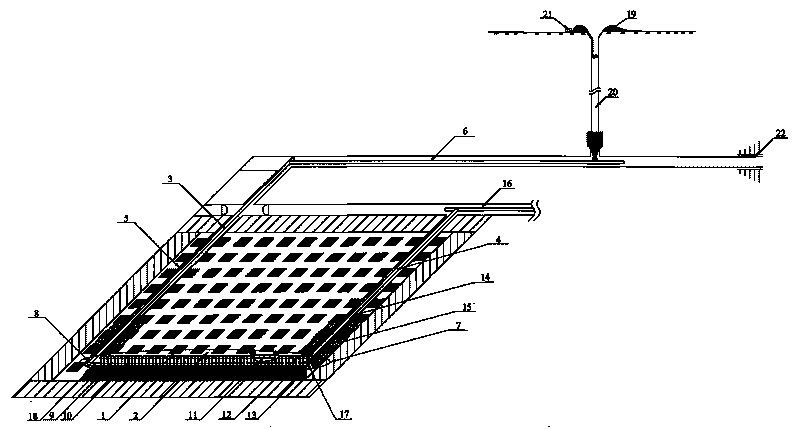

Method for filling solid and fully mechanizing and recovering room type coal pillar

ActiveCN101725352AExtended service lifeHigh recovery rateUnderground miningSurface miningSpontaneous combustionSolid mass

The invention discloses a method for filling solid and recovering and fully mechanizing room type coal pillars, comprising the following steps of: reinforcing and supporting a coal pillar and a coal room top plate in a pre-recovering room type coal pillar area and suspending and hanging a wind curtain to form a solid substance haulage drift and a coal haulage drift which are connected with a large haulage drift; recovering the coal pillars by the conventional method, starting matching equipment after cutting a coal interval and transporting the solid substances to a goaf from the ground for filing and tamping; and cutting coal of next coal interval and filling the goaf, repeating the steps until finishing the recovery of all room type coal pillars. The method not only solves the problems that unstable coal pillar causes the safety accidents due to the superposition of stress of the front part and two sides of a workface because of the recovery of the traditional coal pillar, but also eliminates the potential safety trouble caused by the hurricane, large-area sinking and the like caused by the spontaneous combustion of the room type coal pillar and the large-area caving of hard top plates in the goaf. The invention has simple method, high production efficiency, low cost and over 85 percent of the recovery rate of the coal pillars.

Owner:CHINA UNIV OF MINING & TECH

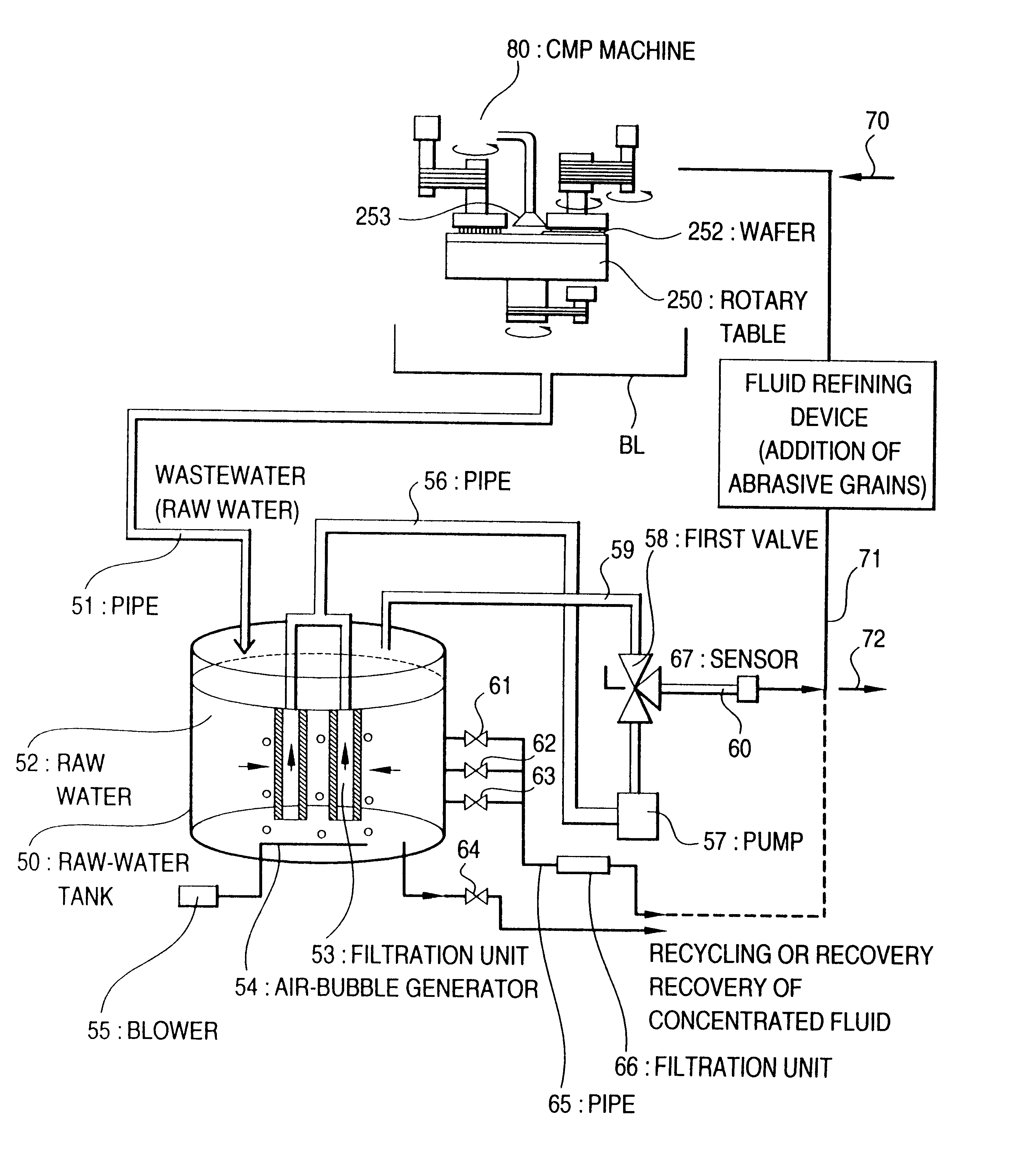

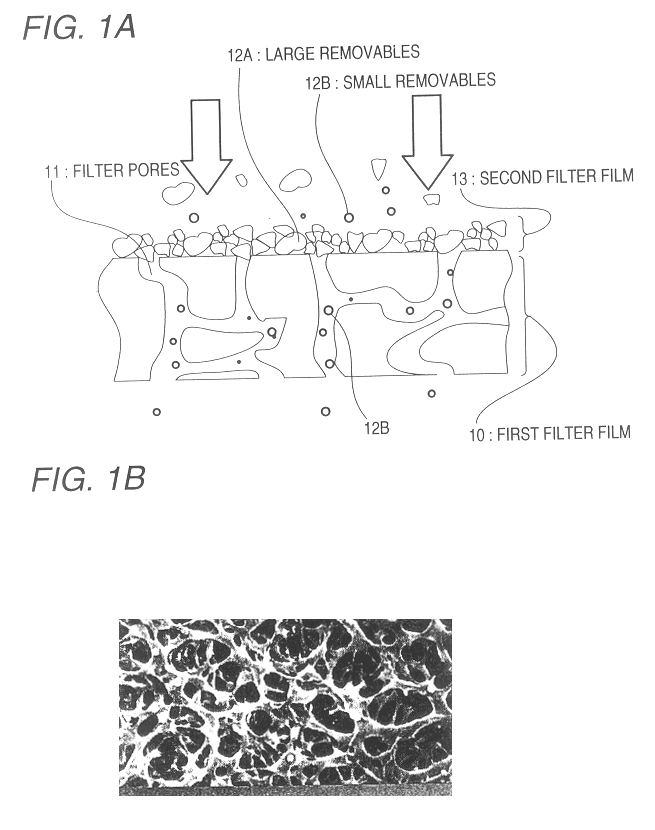

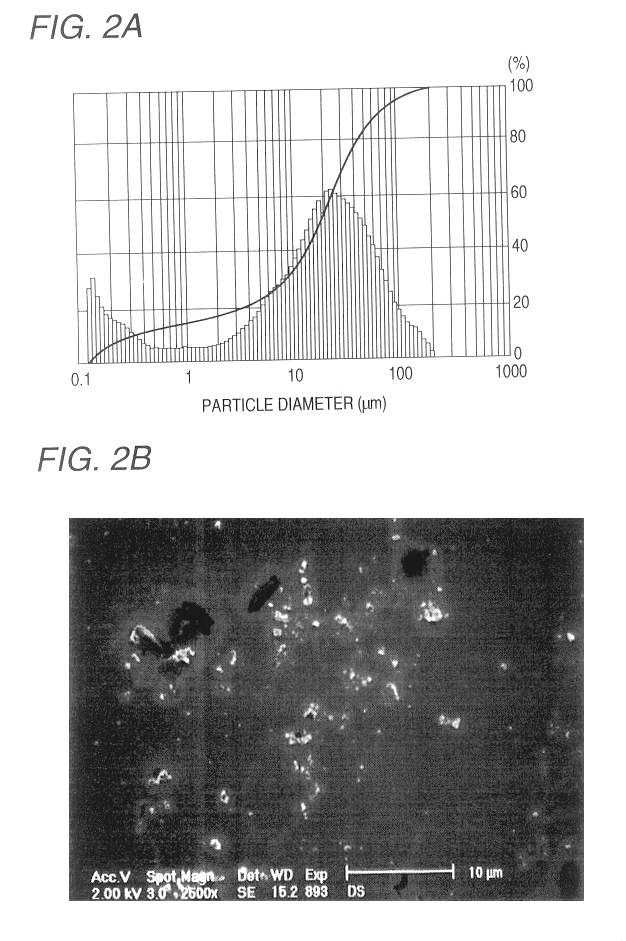

Method of filtering a fluid

InactiveUS6461524B1UltrafiltrationSemiconductor/solid-state device manufacturingFiltrationAcoustic wave

A fluid is filtered by first preparing a filter which includes a base filter and solid substances provided on the base filter, such that the solid substances differ from objects within the fluid to be filtered that are removed by the filter. The objects of filtration are filtered by supplying the fluid to the filter. During filtration, a force is applied to the filter to move the solid substances and objects deposited on the filter. The application of such force thus allows continuous filtration through the filter. The force can take the form of application of rising bubbles, a mechanical vibration or sonic waves to the filter. The filtration method is useful in processing fluid waste from mechanical processes, such as CMP steps.

Owner:PANASONIC CORP

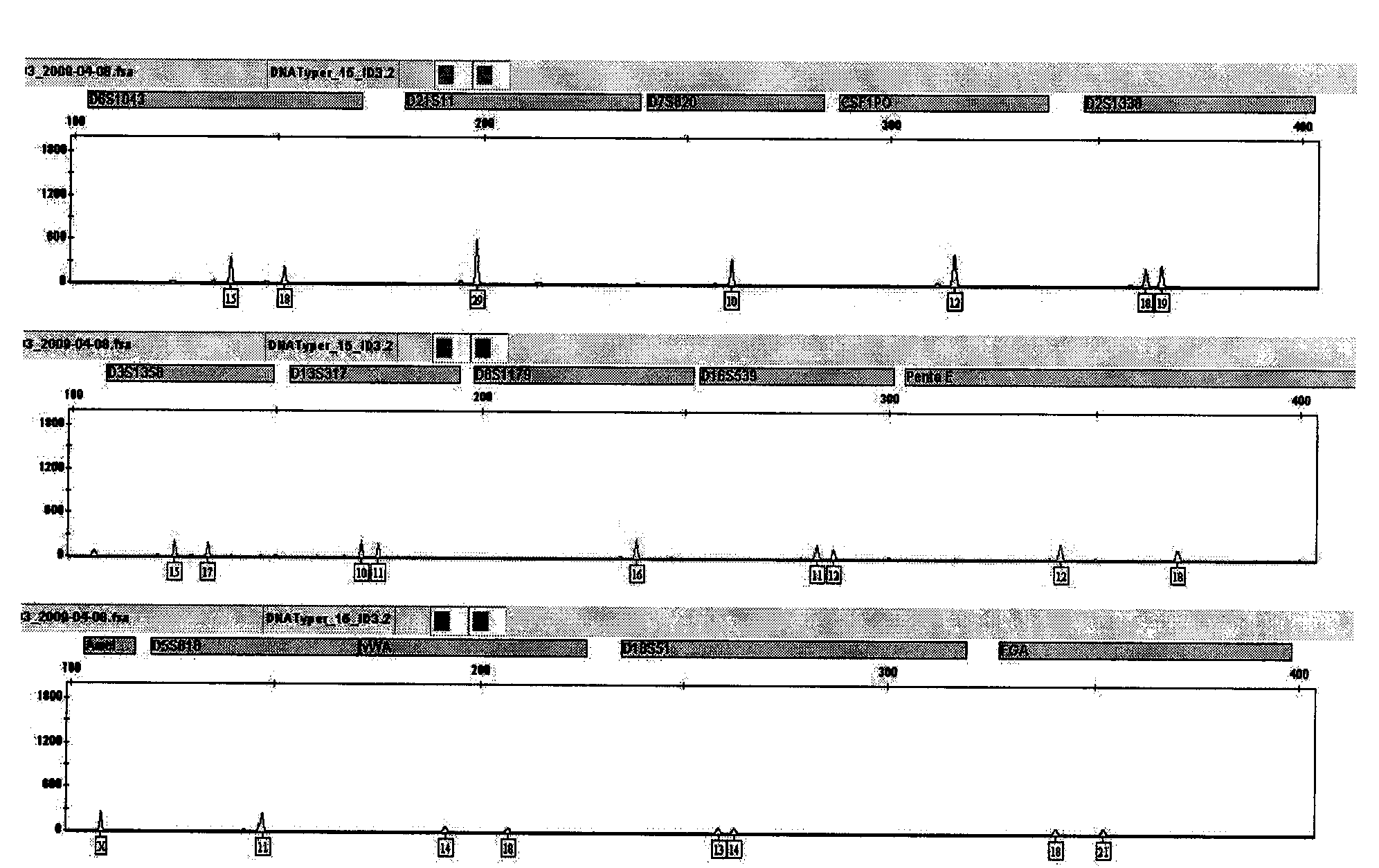

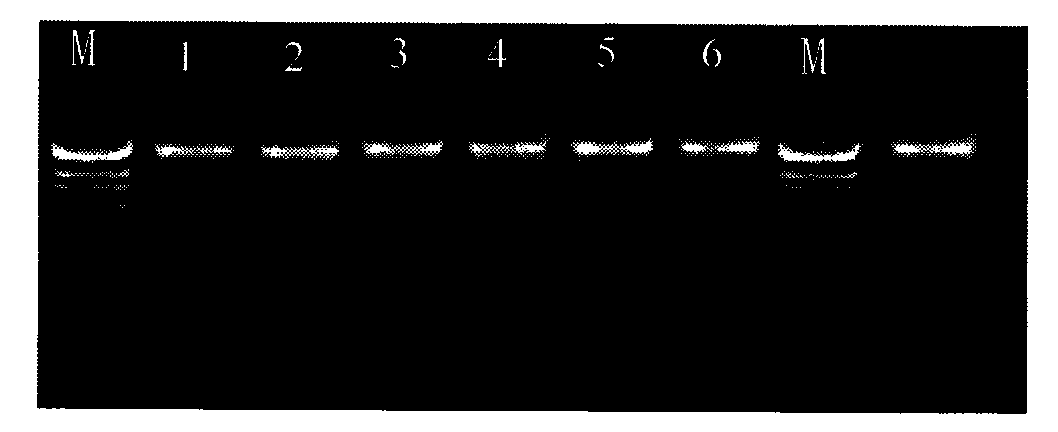

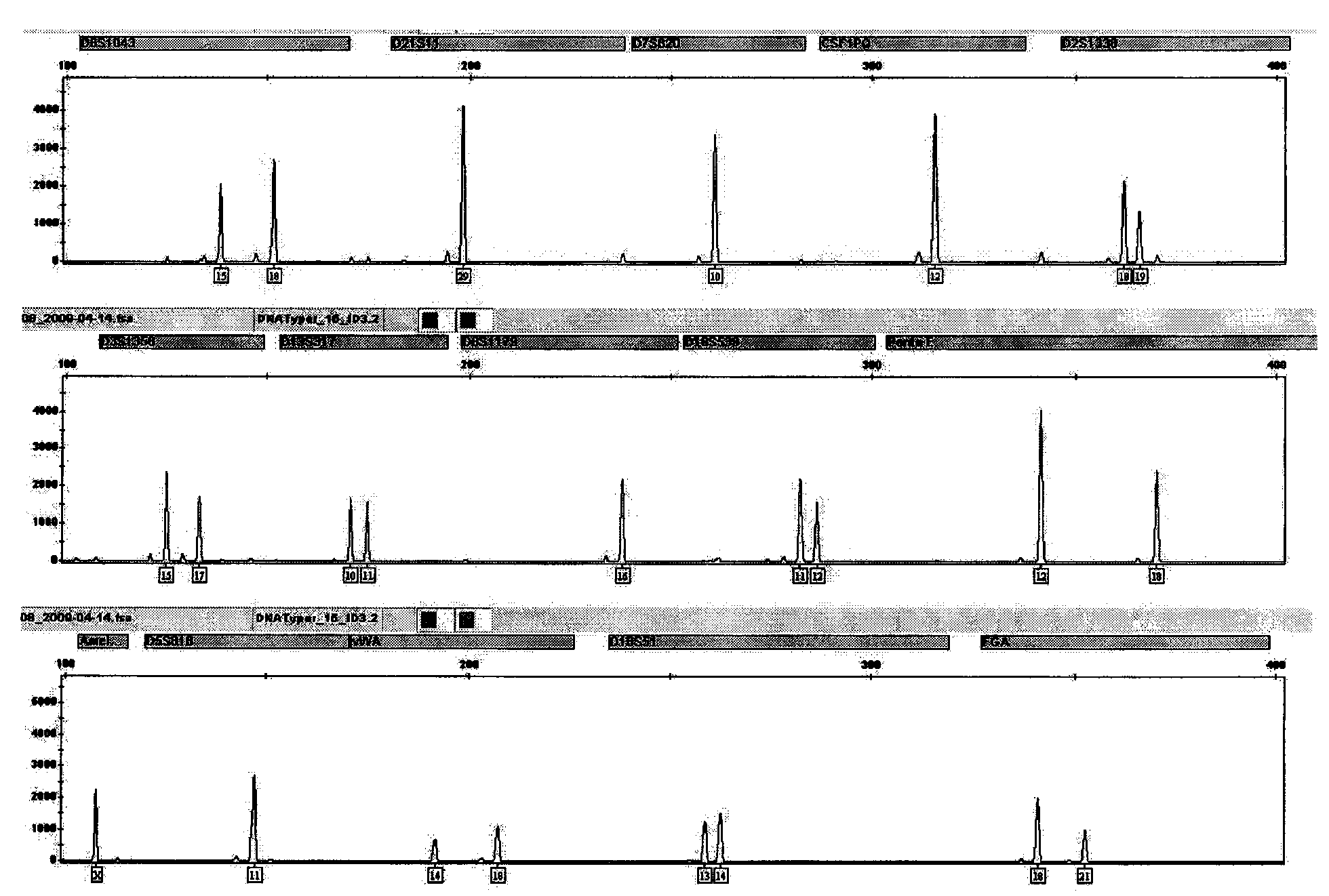

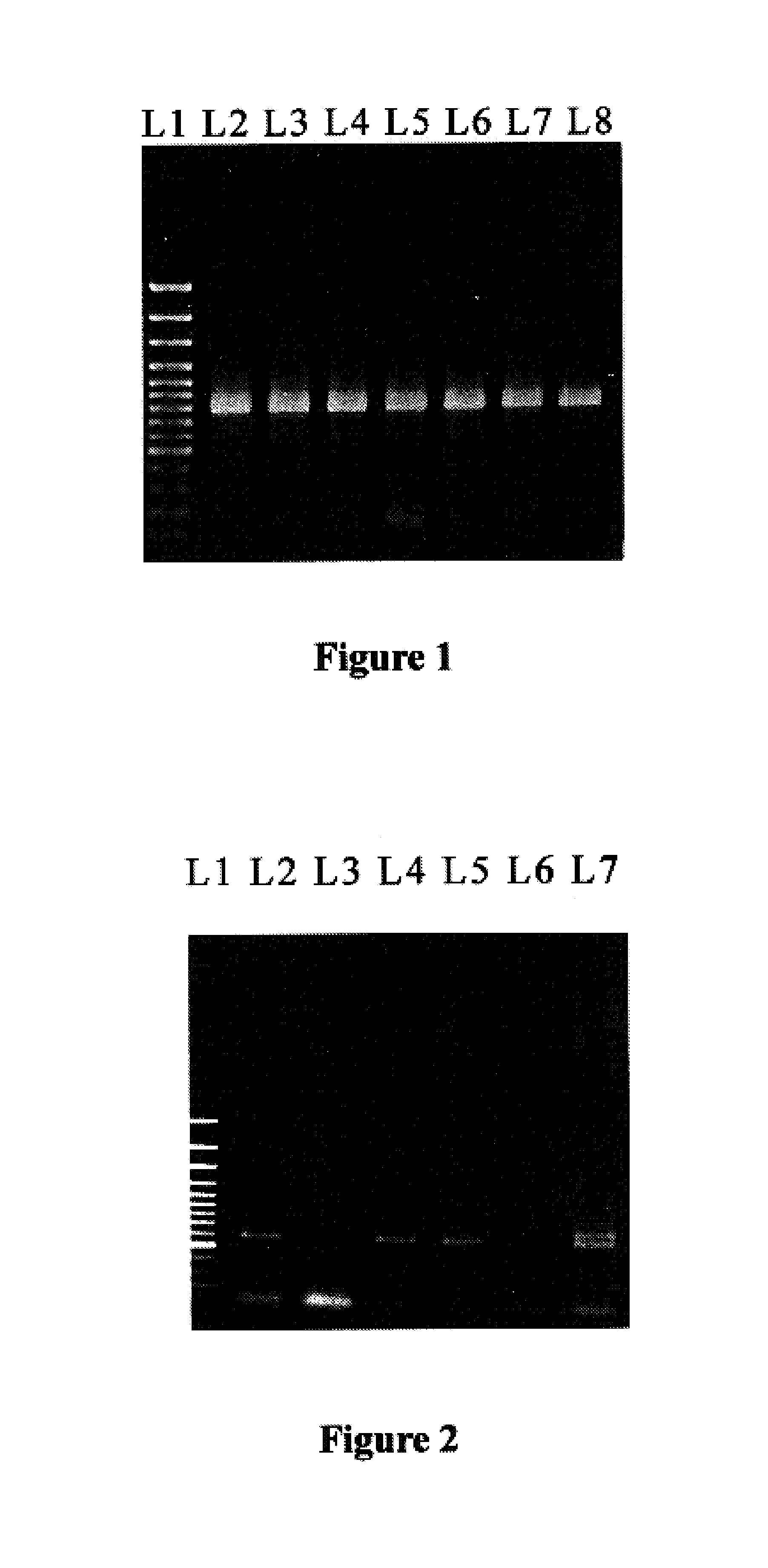

Method for extracting and purifying DNA

InactiveCN101613697AEasy to operateImplement extractionSugar derivativesDNA preparationBiological cellLysis

The invention discloses a method for extracting and purifying DNA, comprising the following steps: 1) pre-treatment: a biological sample is in contact with pre-treated lysis solution, and solid substance adhering to biological cells is removed to obtain rude lysis solution; 2) nucleic acid adsorption: the rude lysis solution obtained in step 1 is mixed with lyse combined liquid and magnetic bead suspension to form a solution system containing magnetic nanosphere-DNA composite body, and the magnetic nanosphere-DNA composite body in the solution system is collected; 3) washing: the magnetic nanosphere-DNA composite body obtained in step 2 is successively washed with a cleaning solution I and a cleaning solution II, and then DNA is dissolved out by spent regenerant. The method provided by the invention has 90% of the DNA extracting efficiency, the extracted DNA can be used in down stream analysis operation, such as STR multiplex amplification, DNA sequencing, DNA quantitation and the like.

Owner:INST OF FORENSIC SCI OF MIN OF PUBLIC SECURITY

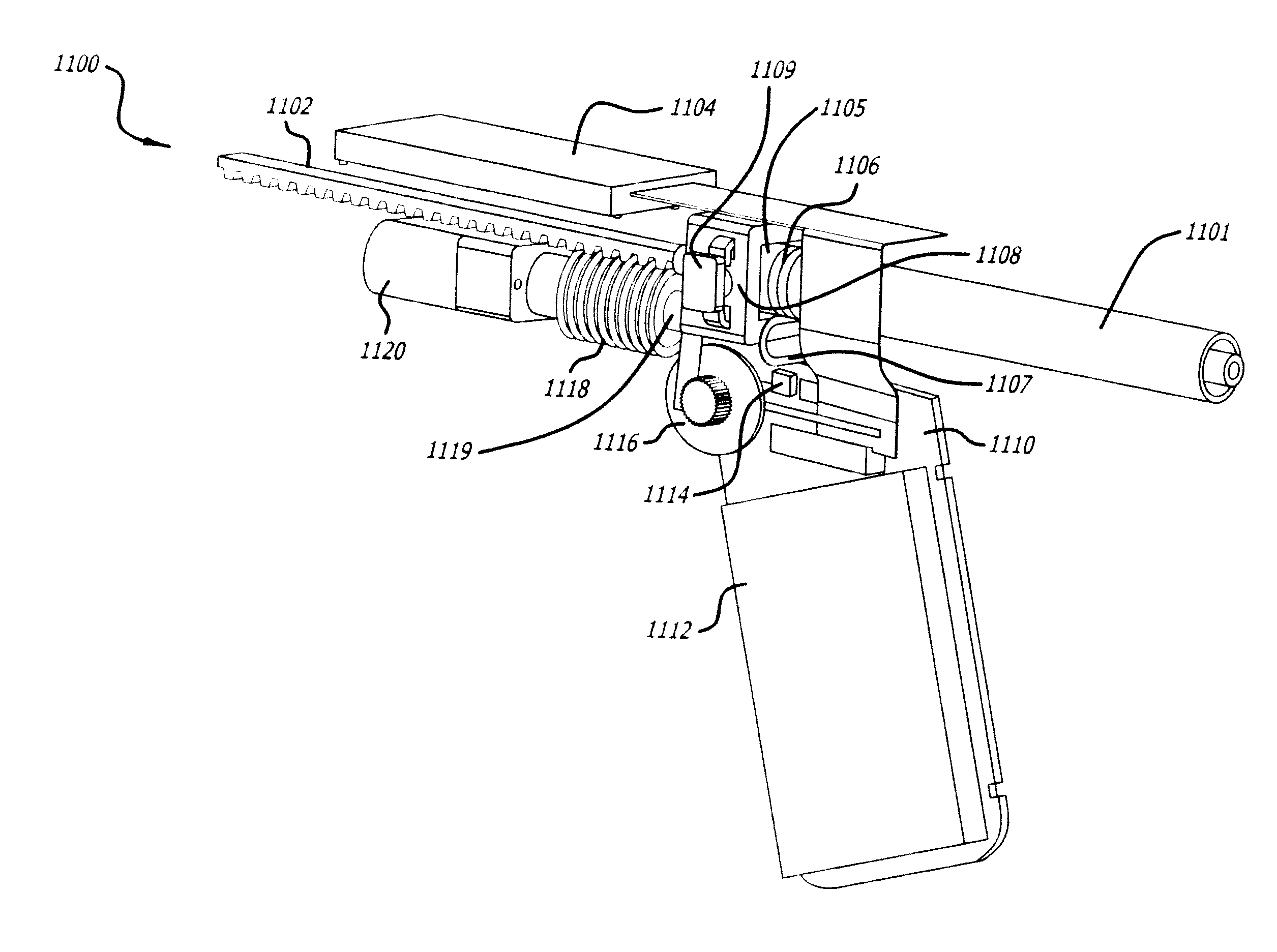

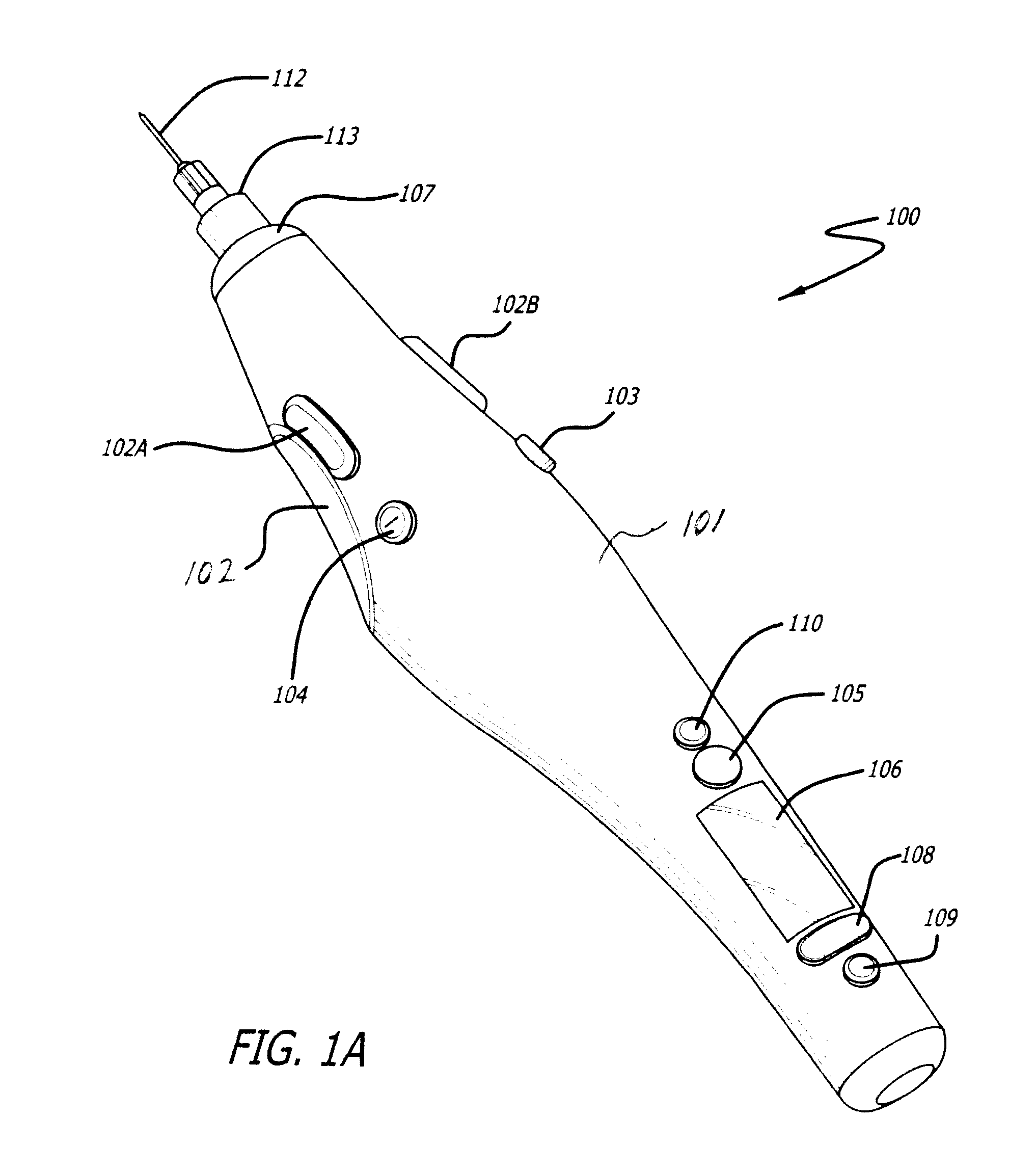

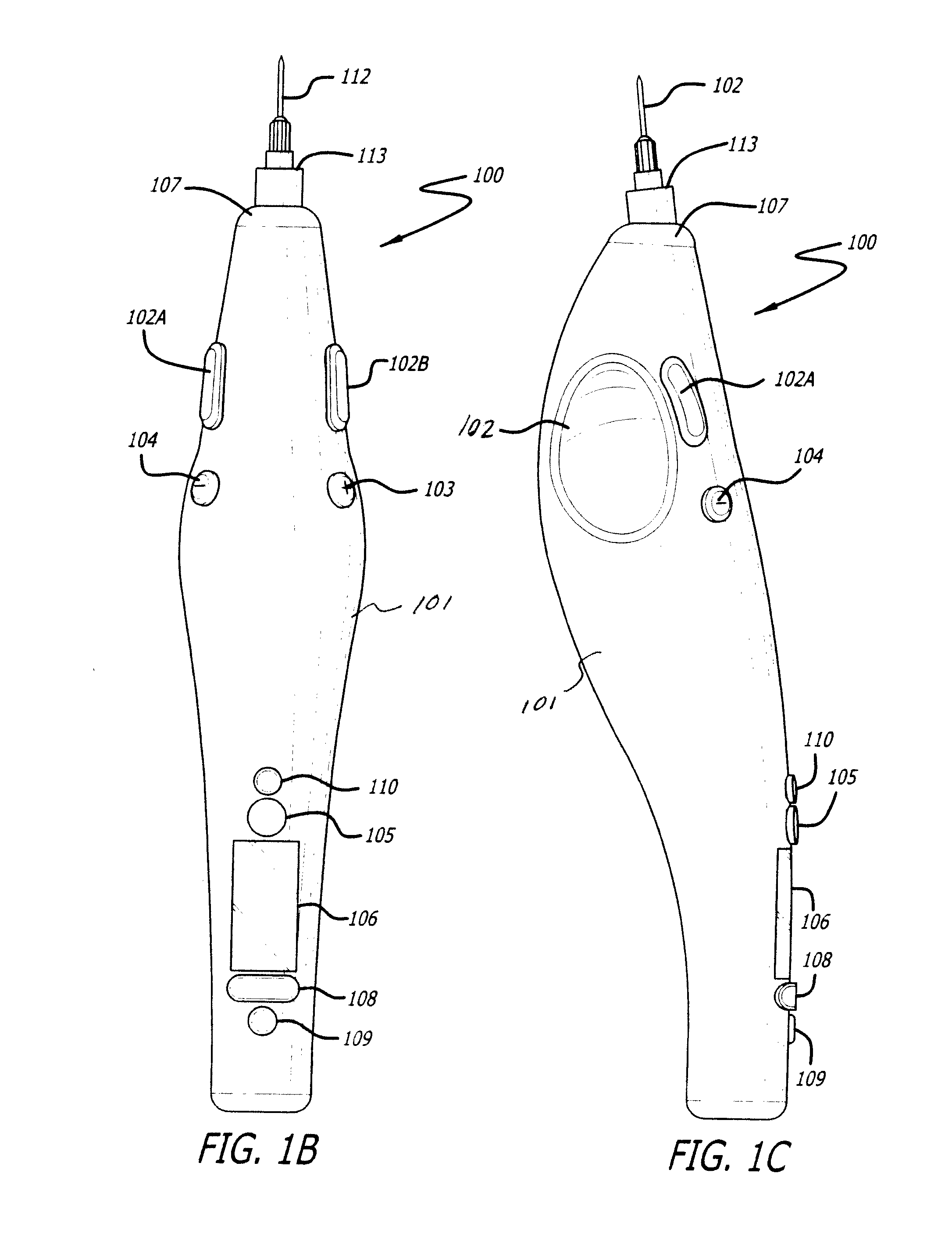

Injection device for soft-tissue augmentation fillers, bioactive agents and other biocompatible materials in liquid or gel form

Described herein are injection devices capable of automatically injecting substances into the soft tissue of a patient. The devices can inject low to high viscosity materials at predetermined, user selected injection rates, allowing the operator more control than a traditional syringe. The devices can allow mixing of more than one substance and / or reconstitution of a solid substance for injection. The injection devices described herein can allow the operator to easily inject one or more low to high viscosity liquid or gel soft-tissue augmentation fillers, one or more drugs, one or more other biocompatible materials, or combinations thereof.

Owner:ALLERGAN INC

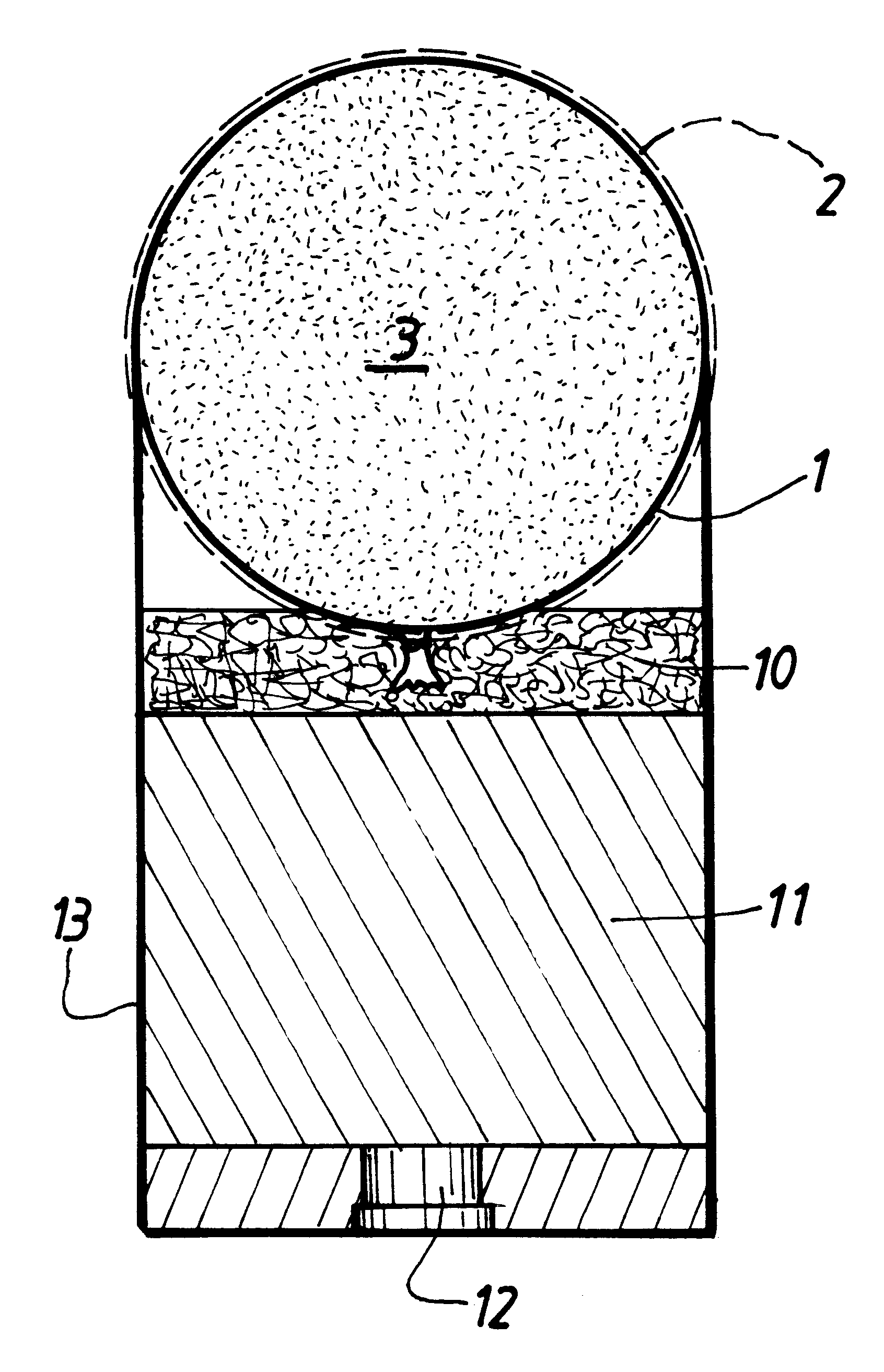

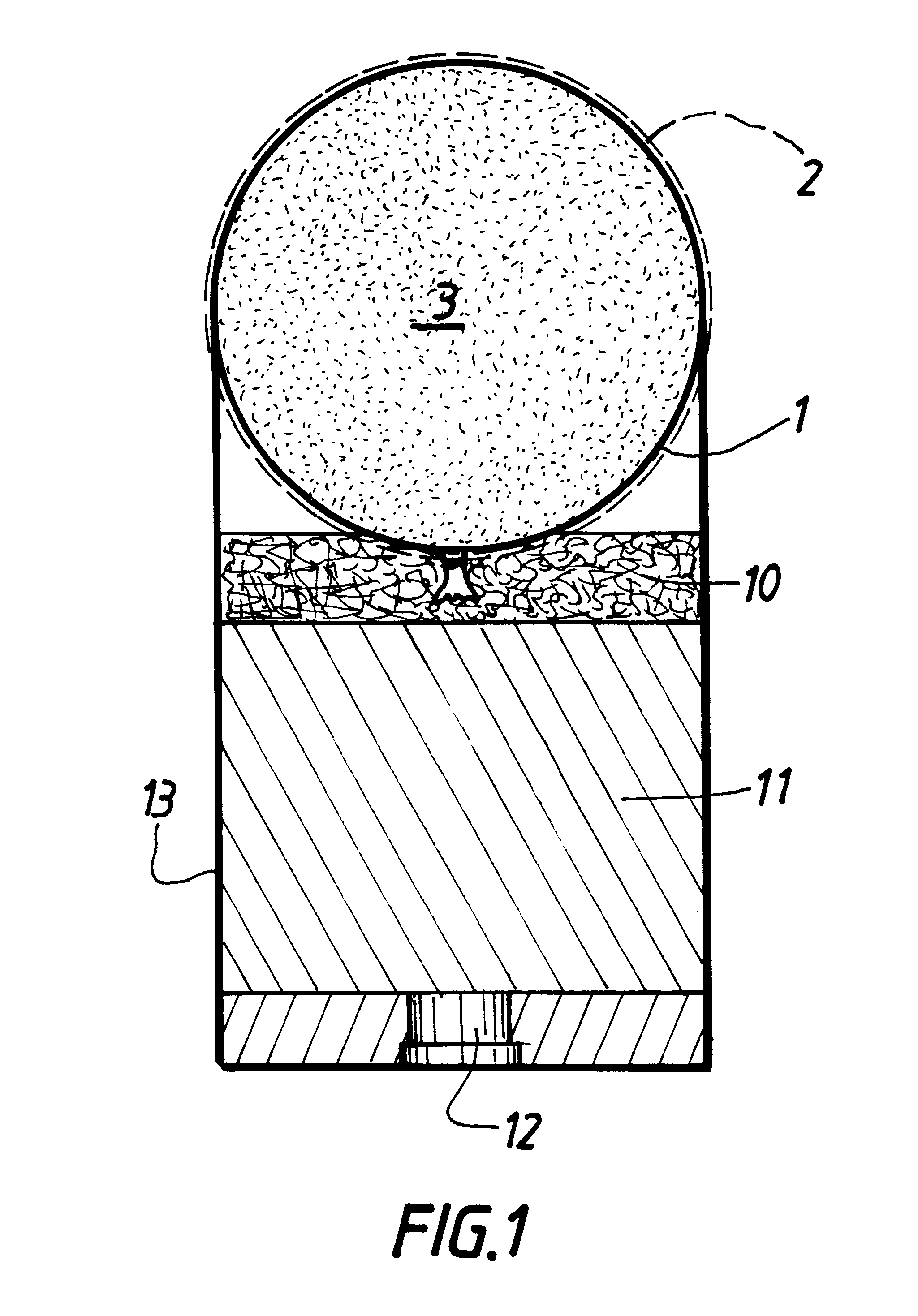

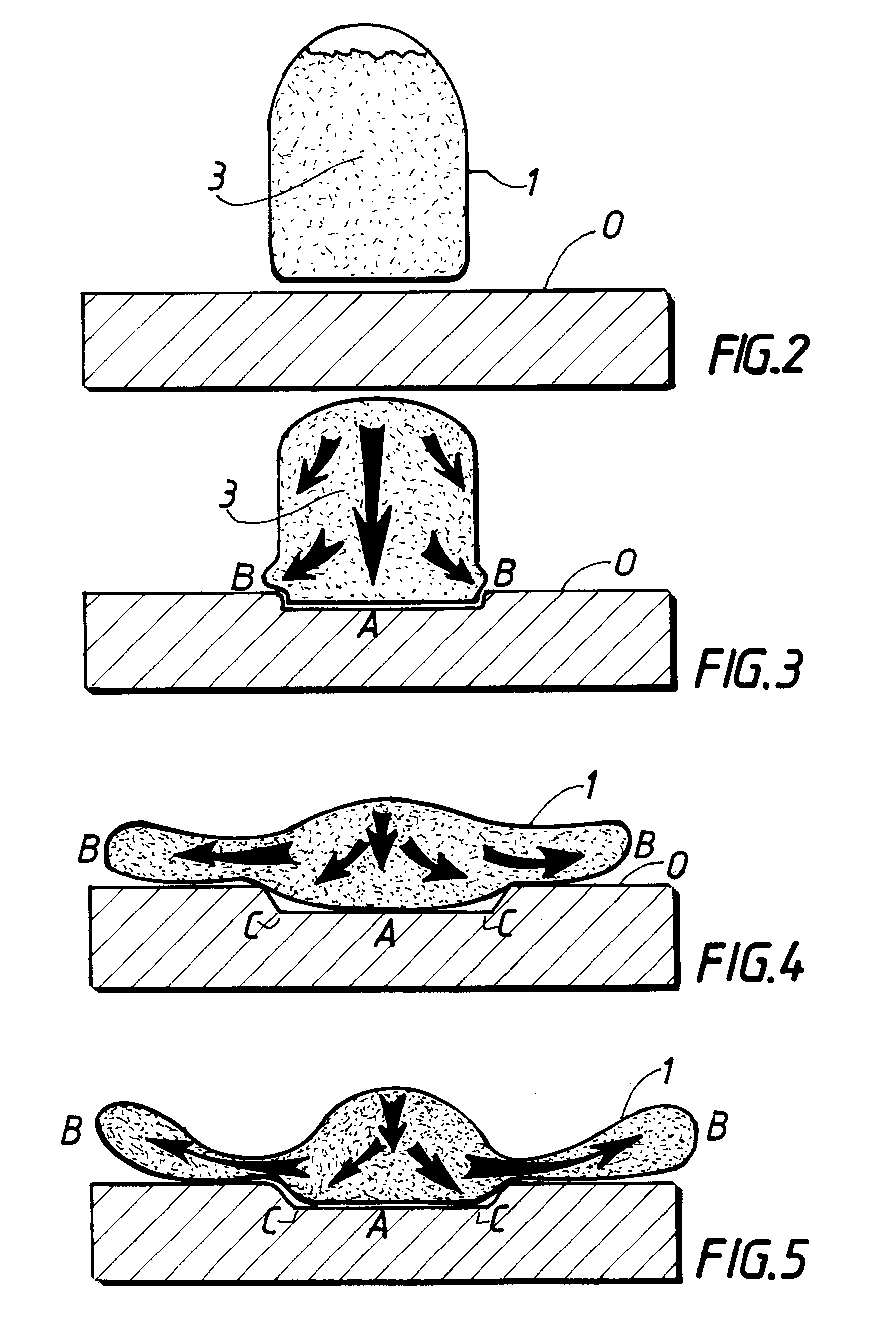

Non-lethal projectile with fine grain solid in elastic infrangible envelope

InactiveUS6302028B1Mitigate such drawbackEasy to adaptAmmunition projectilesTraining ammunitionEngineeringProjectile

A very highly deformable projectile comprising at least one envelope that is fine, flexible, and elastic, filled with a divided solid substance, deformation thereof occurring only on impact, and of a diameter that is sufficient to limit penetration on impact with energy being rapidly spread out by instantaneous enlargement.

Owner:SAE ALSETEX

Method of marking solid or liquid substances with nucleic acid for anti-counterfeiting and authentication

InactiveUS7115301B2Good miscibilitySmall differenceStampsPreparing sample for investigationWater insolubleSolvent

A method of marking a solid article or substance includes the steps of dissolving a water-insoluble medium in a first solvent to form a first mixture, mixing a nucleic acid solution with an intermediate solution to form a second mixture, mixing the second mixture with the first mixture to form a homogenous third mixture, marking the article or substance with the third mixture containing the nucleic acid; and drying the marked article or substance. Through the addition of an intermediate solution, the miscibility between the nucleic acid solution and the medium is increased and a homogenous solution is formed. For marking solid substances or articles, the water-insoluble medium containing known nucleic acid taggants is spread on the target solid substances or articles. For marking liquid, the target liquid is mixed with the water-insoluble media containing known nucleic acid taggants. As a result, the target liquid is labeled with nucleic acid.

Owner:APDN INC

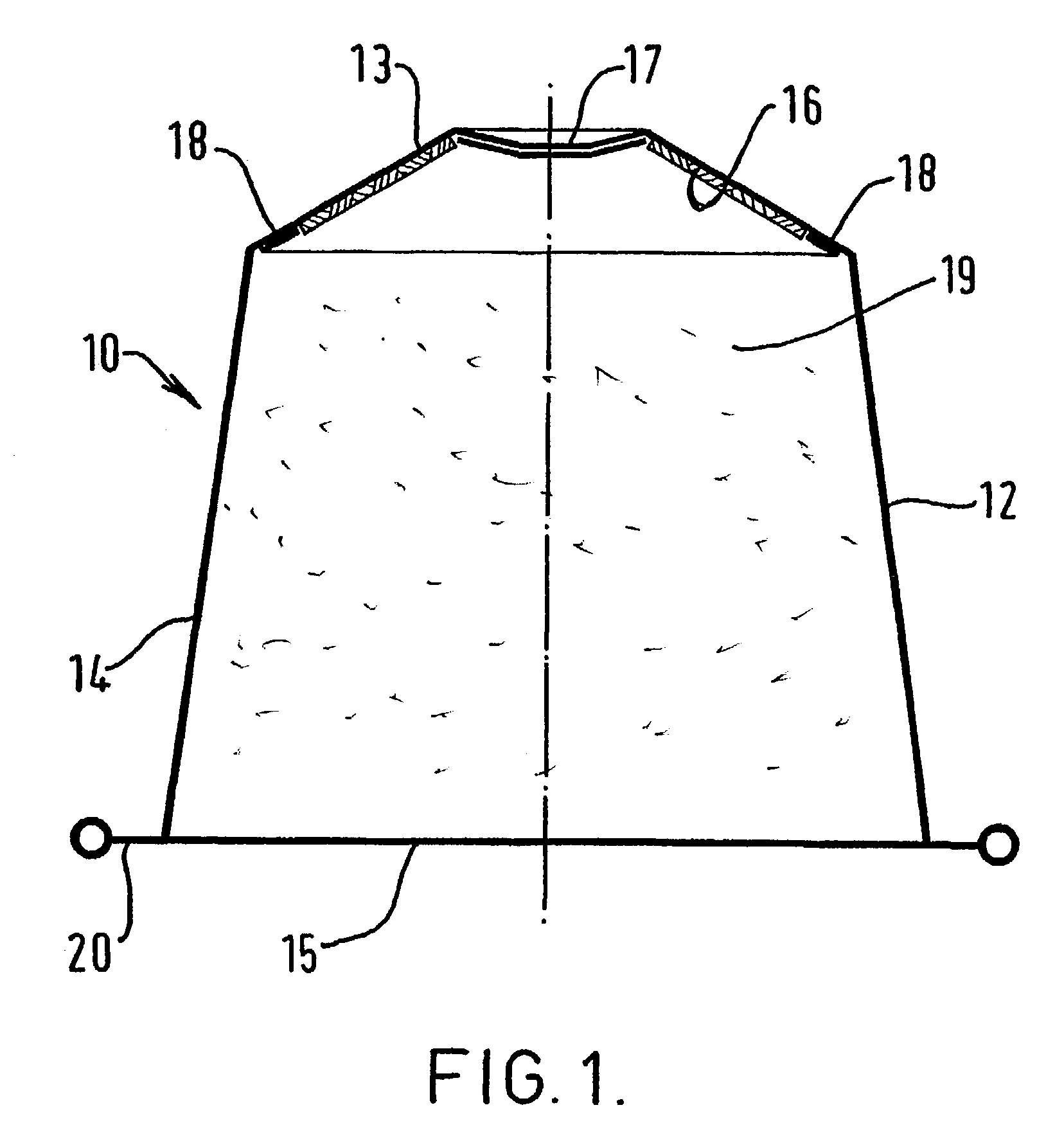

Closed cartridge for preparing a beverage for extraction under pressure

InactiveUS20070068395A1Easy to produceSatisfactory closureDispensing apparatusBeverage vesselsEngineeringStructural engineering

The present invention relates to a closed cartridge (10), for extraction under pressure, comprising a dish (12) with a bottom (13) with a central part and a peripheral part and a side wall having substantially the shape of a frustum of a cone and a circular edge with a diameter greater at the bottom and a cover (15) welded to the periphery of the edge of the dish and the cover is intended to be torn only through the effect of the force of the extraction fluid when extraction starts, the said cartridge comprising, in the dish at the level of the bottom, a means (16) guaranteeing retention of the solid substance when it is opened, in which the means guaranteeing retention of solid substance is a sheet of fabric sealed in the bottom of the dish in two zones, on the one hand in the central part (17) and on the other hand in the peripheral part (18) of the said bottom (13).

Owner:SOC DES PROD NESTLE SA

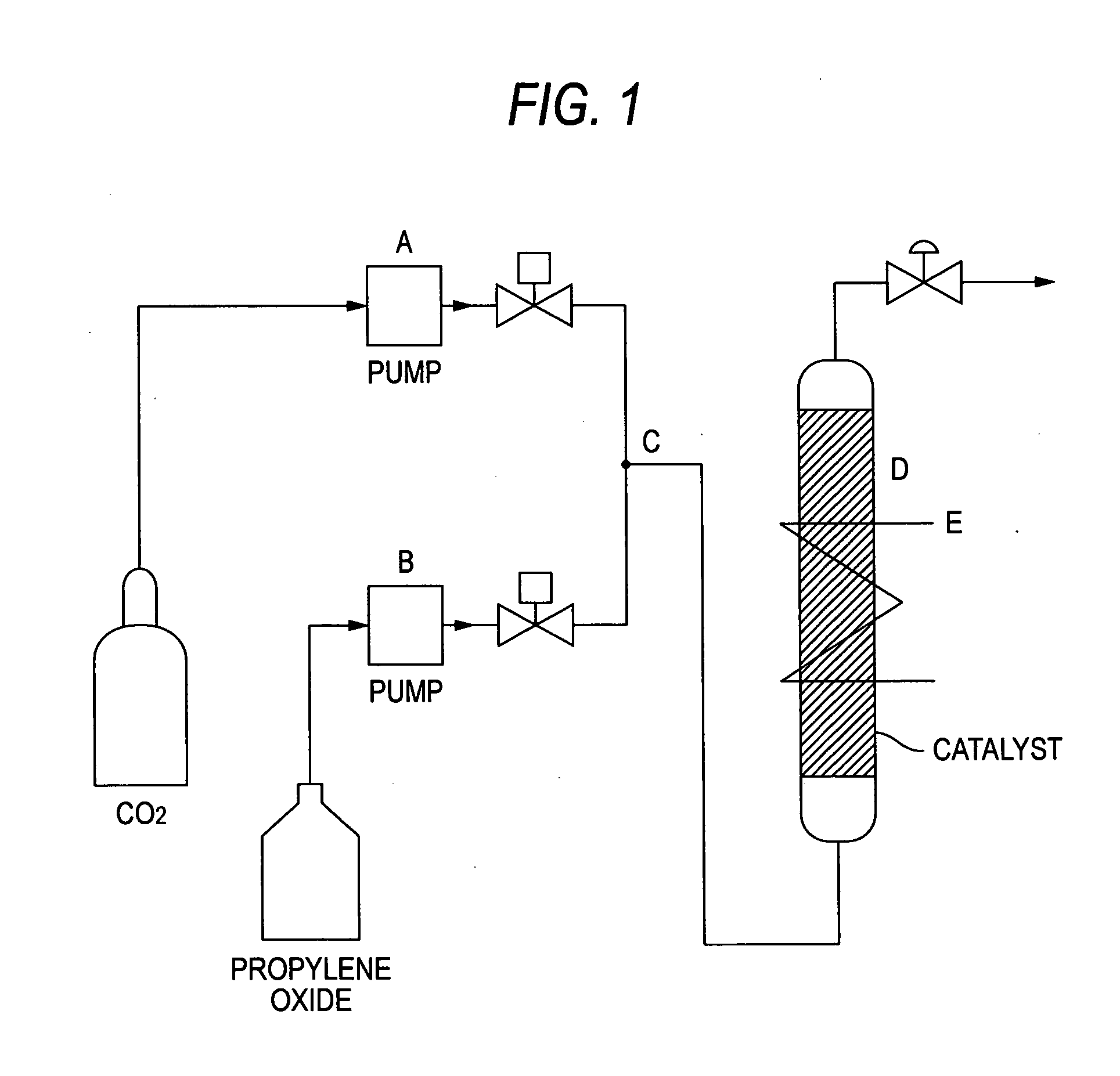

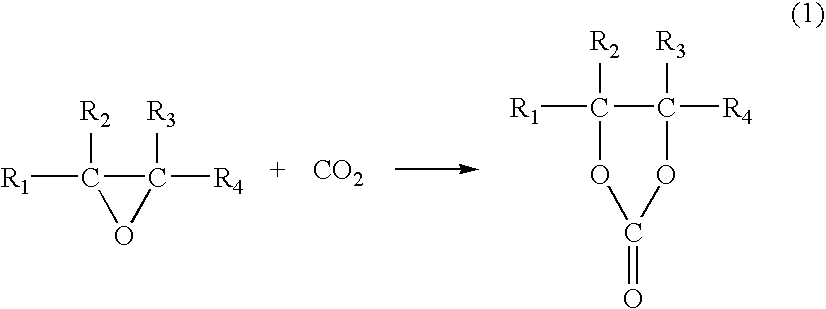

Catalyst for Cyclic Carbonate Synthesis

InactiveUS20080214386A1High yieldSolution to short lifeOrganic chemistryMolecular sieve catalystsPhosphoniumPhosphonium salt

Provided are a solid catalyst which gives a cyclic carbonate at a high yield and a high selectivity, which is stable and which may be readily separated after reaction; and a method of industrially advantageous, inexpensive and safe production of a cyclic carbonate by the use of the catalyst. The catalyst contains an inorganic solid substance having a surface modified with an ionic substance containing a Group 15 element; or contains an ionic substance containing a Group 15 element, and an inorganic solid substance. The modifying group for surface modification of an inorganic solid substance is an ionic substance containing a Group 15 element. The ionic substance containing a Group 15 element is at least one substance selected from organic phosphonium salts, organic ammonium salts, organic arsonium salts and organic antimonium salts.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Fluororesin mixture, copper-clad plate prepared therefrom and manufacturing method thereof

ActiveCN101838431AImprove dipping qualityUniform glue contentGlass/slag layered productsMetal layered productsVinyl etherGlass fiber

The invention relates to a fluororesin mixture, a copper-clad plate prepared therefrom and a manufacturing method thereof. The fluororesin mixture contains the following two substances as necessary components in 100 parts by weight of an organic solid substance: 90-99 parts of polytetrafluoroethylene (PTFE) emulsions and 1-10 parts of polytetrafluoroethylene perfluoroalkyl vinyl ether (PFA) emulsions. The copper-clad plate prepared from the fluororesin mixture comprises a plurality of superimposed varnished cloths and copper foil coating one or two surfaces of the varnished cloths, and each varnished cloth comprises a glass fiber cloth and the fluororesin mixture attached to the dipped and dried glass fiber cloth. The fluororesin mixture is prepared by using the PTFE emulsions as main resins and can dip the glass fiber cloths many times under the condition that the PTFE sintering temperature is330 DEG C to prepare the vanished cloths, and the vanished cloths prepared from the fluororesin mixture has the advantages of good gum dipping quality, level surface, flexibility and easy operation; and besides, the copper-clad plate made from the fluororesin mixture has excellent dielectric performance which meets the dielectric performance requirement of the high-frequency communication field for a base plate material, and has simple making method and process and is beneficial to industrial continuous production.

Owner:GUANGDONG SHENGYI SCI TECH

Zinc/air cell with improved anode

InactiveUS20050003271A1Eliminate disadvantagesSufficient structural integrityFuel and primary cellsAlkaline accumulatorsSolid massPolyvinyl alcohol

A method of forming an anode comprising zinc for a zinc / air cell. The method involves mixing zinc particles with binders including preferably polyvinylalcohol, surfactant and water to form a wet paste. The wet paste is compacted and molded into the near shape of the cell's anode cavity and then heated to evaporate water. A solid porous zinc mass is formed wherein the zinc particles are held bound within a network with microscopic void spaces between the zinc particles. The solid mass can be inserted into the cell's anode cavity and aqueous alkaline electrolyte, preferably comprising potassium hydroxide, then added. The solid mass absorbs the aqueous electrolyte and expands to fill the anode cavity to form the final fresh anode.

Owner:DURACELL U S OPERATIONS

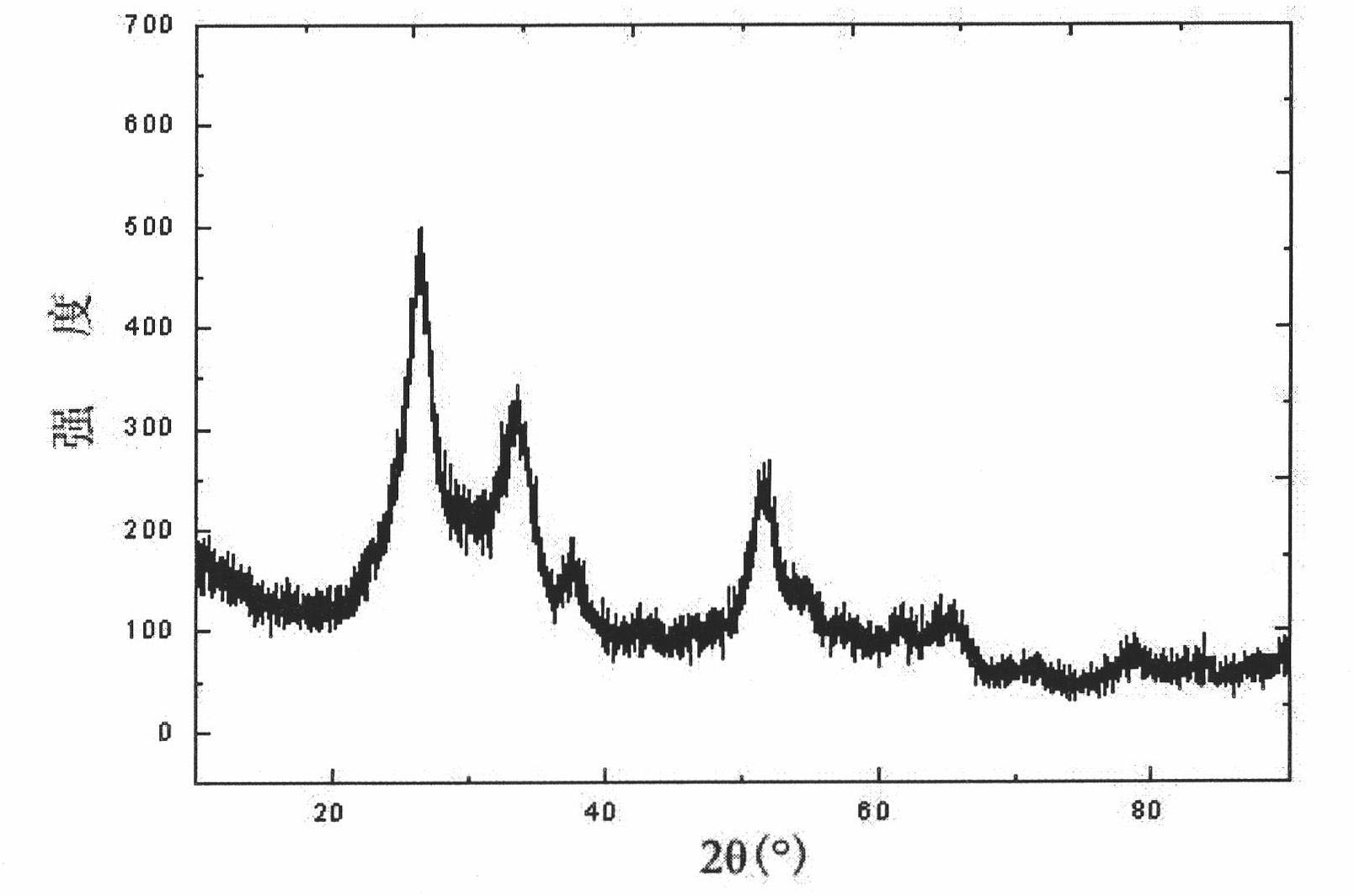

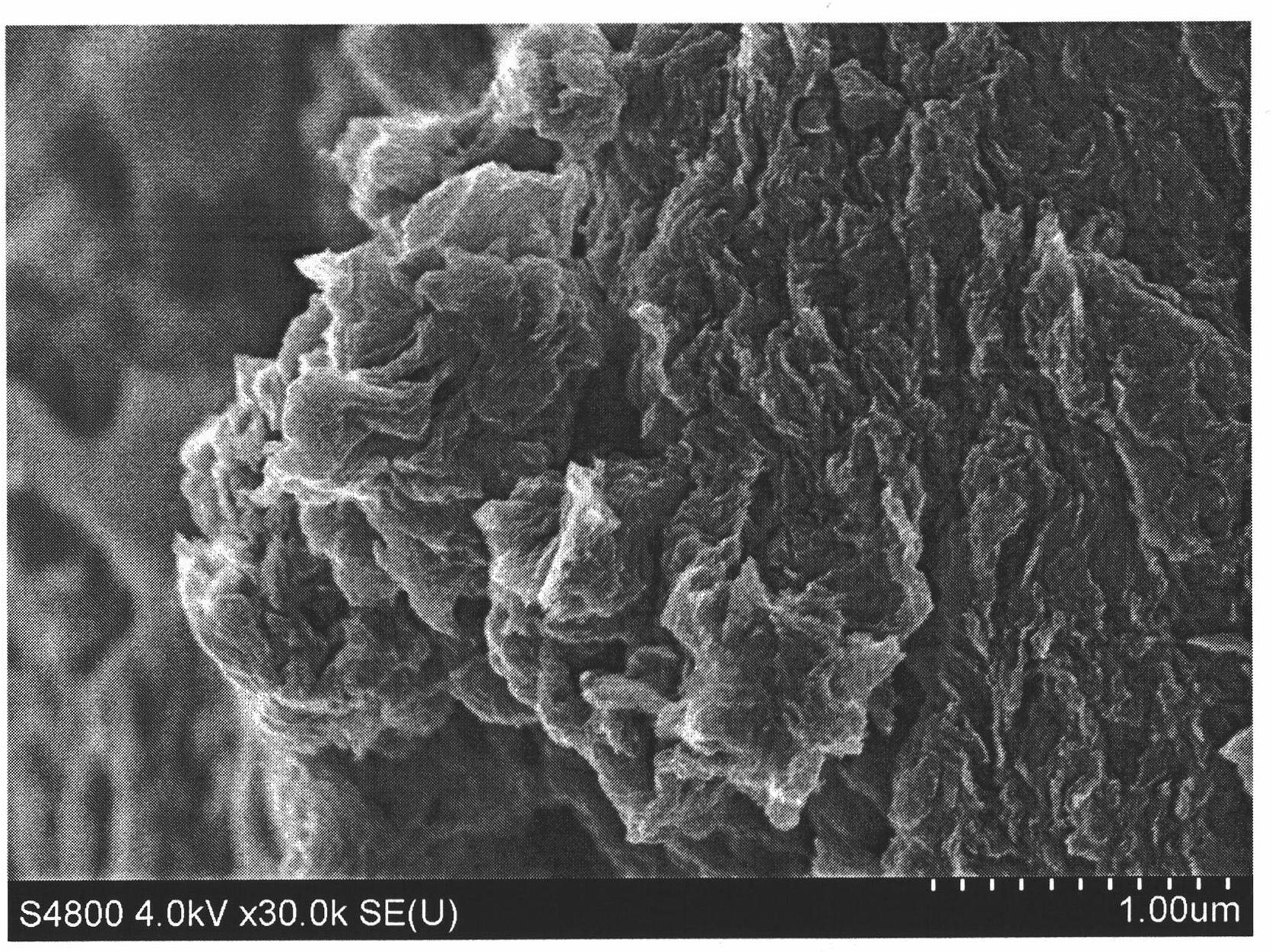

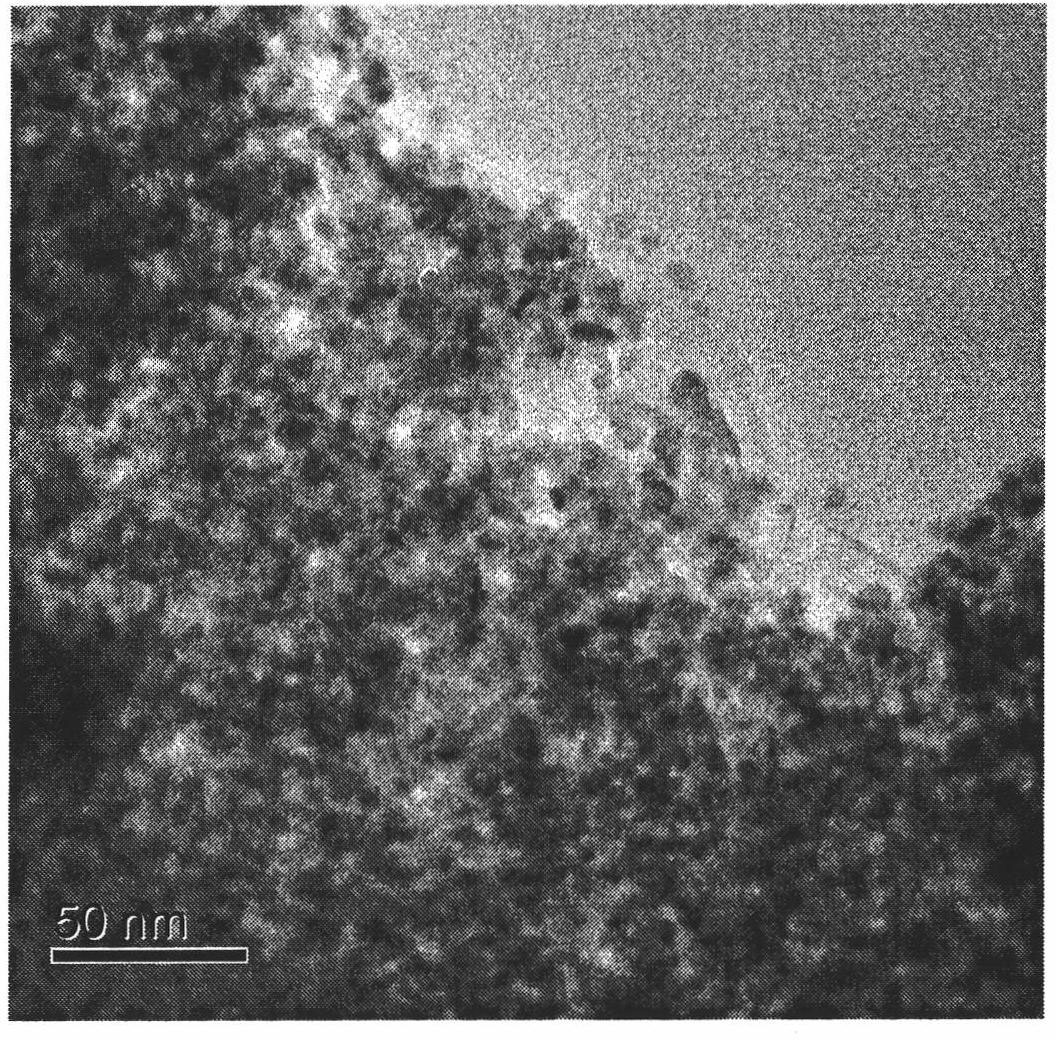

Preparation method of stannic oxide or metallic tin and grapheme lamella composite material

ActiveCN102255072AImprove structural stabilityImprove electrochemical performanceCell electrodesTin dioxideHYDROSOL

The invention provides a preparation method of a stannic oxide and grapheme lamella composite material. The preparation method comprises the following steps of mixing at least one organic solvents, graphene oxide lamella hydrosol and at least one tin salt, heating the mixture at a temperature of 60 to 200 DEG C for 0.5 to 12 hours to obtain a solid substance, and heating the solid substance in the inert gas atmosphere at a temperature of 400 to 700 DEG C for 0.5 to 10 hours. The invention also provides a preparation method of a metallic tin and grapheme lamella composite material. The preparation method comprises the following step of preparing a stannic oxide and grapheme lamella composite material through the preparation method of a stannic oxide and grapheme lamella composite material, and heating the prepared stannic oxide and grapheme lamella composite material in the reducing gas atmosphere at a temperature of 400 to 1000 DEG C for 0.5 to 4 hours. The preparation methods of the invention can improve a structural stability and an electrochemical performance of a material and is beneficial to improve a high-speed charging and discharging performance and a conductivity of a composite material. The preparation methods have the characteristics of cheap and easily available raw materials, simple process, and good applicability for industrial continuous production.

Owner:陕西埃普诺新能源科技有限公司

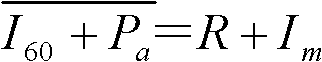

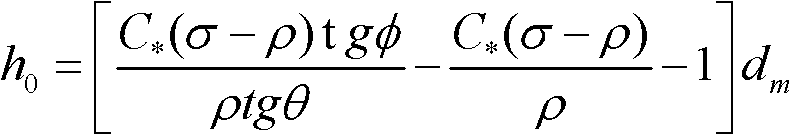

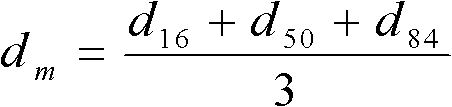

Debris flow early warning method

The invention discloses a debris flow early warning method. Aiming at the technical problem that the prior art cannot solve calculation and determination of early warning rainfall threshold value of a debris flow early warning system in a basic data information lacking region, the invention provides the debris flow early warning method applied in the basic data information lacking region. The method comprises the following steps of: arranging rainfall monitoring sites at reasonable places of a debris flow valley; taking the sum of 1hr rainfall intensity value of rainfall data of the rainfall monitoring sites and early affected rainfall value as an early warning rainfall threshold value; calculating and determining the early warning rainfall threshold value of each site based on a debris flow starting mechanism by using the data of rainfall, hydrographic characteristic, terrain in the valley, loose solid substances and the like of a debris flow early warning region, presetting each threshold value in the early warning system, and judging whether to start the early warning system for early warning through the real-time comparison result of the real-time rainfall data and the threshold values. In the method, the principle is reliable, the calculation process is scientific and simple, implementing equipment is simple and installation is convenient, and the method can be universally applied to the requirements of debris flow early warning of various debris flow regions.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

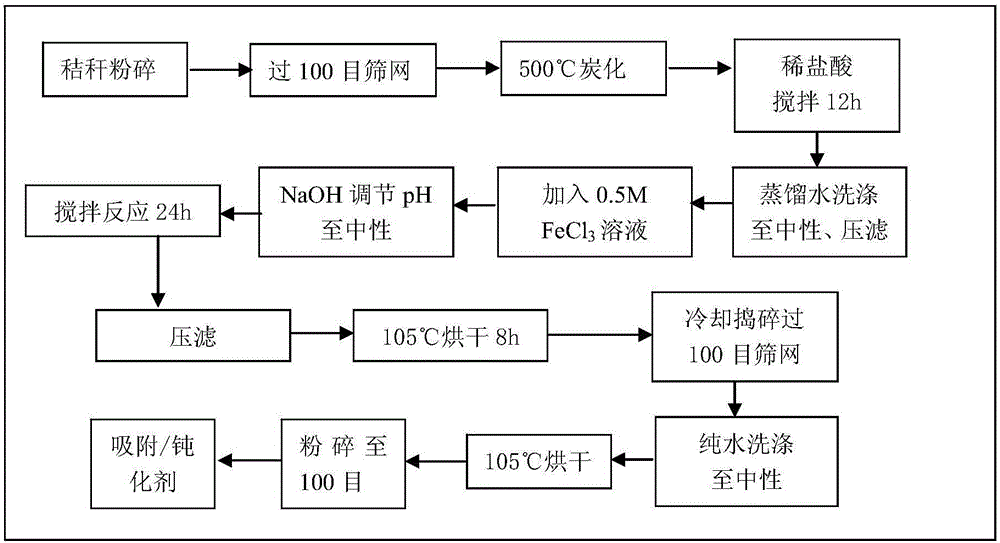

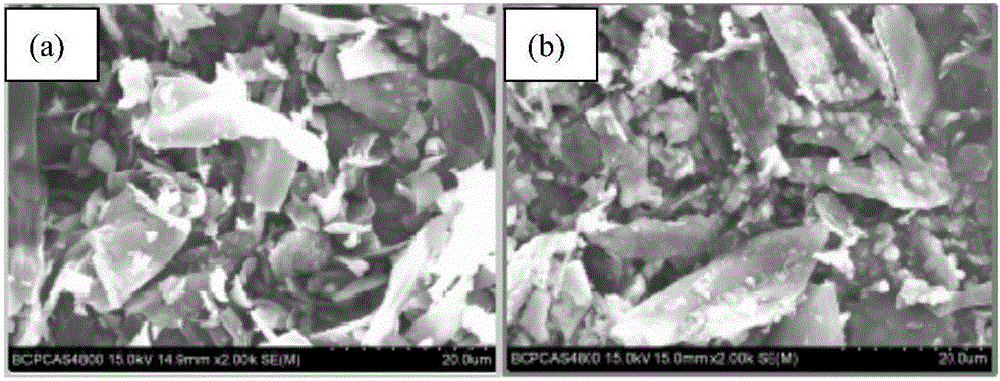

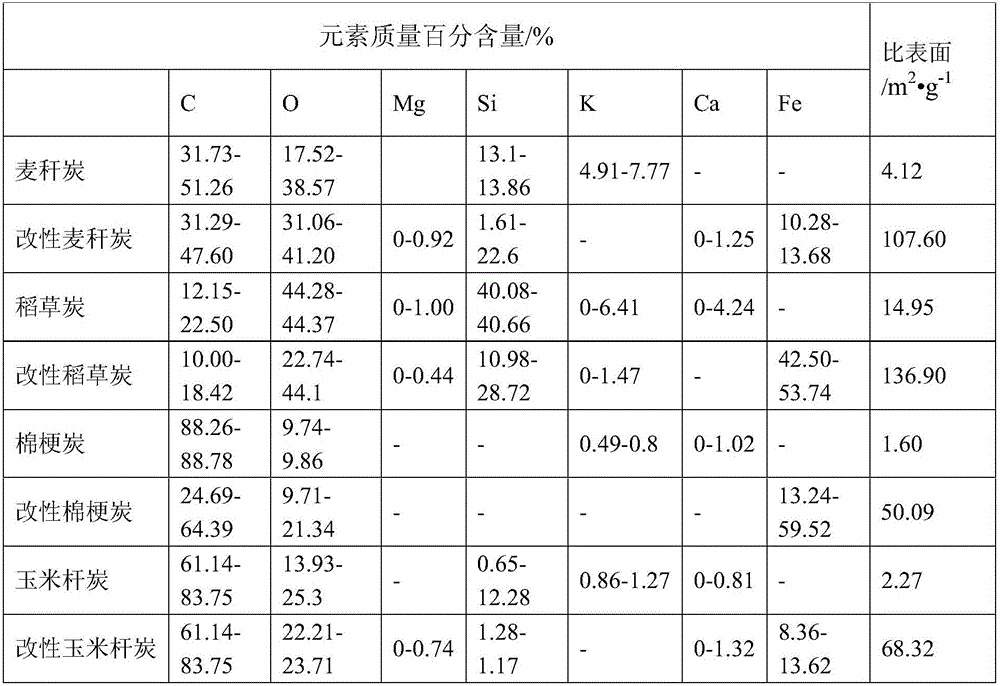

Modified biomass charcoal for treating arsenic pollution as well as preparation method and application of modified biomass charcoal

InactiveCN105944668AImprove stabilityLow carbonization temperatureOther chemical processesWater contaminantsArsenic pollutionFood safety

The invention provides modified biomass charcoal for treating arsenic pollution as well as a preparation method and an application of the modified biomass charcoal. The preparation method of the modified biomass charcoal comprises steps as follows: (1) biomass raw materials are charred, and the biomass charcoal is obtained; (2) the biomass charcoal is subjected to a reaction with a hydrochloric acid solution, solid-liquid separation is performed, a solid substance is obtained, is washed till the pH is neutral and then is dried, and the pretreated biomass charcoal is obtained; (3) the pretreated biomass charcoal and a FeCl3 solution are subjected to a reaction under the condition that the solution pH is neutral, solid-liquid separation is performed after the reaction, and mud cake is obtained; (4) the mud cake is dried and then washed till the pH is neutral, solid-liquid separation is performed, an obtained solid is dried for a second time, and the modified biomass charcoal is obtained. The modified biomass charcoal has large specific surface area and high iron content; the preparation method is simple and easy to operate; the modified biomass charcoal can be applied to treatment of arsenic waste and passivation of arsenic in farmland soil, and food safety is guaranteed.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

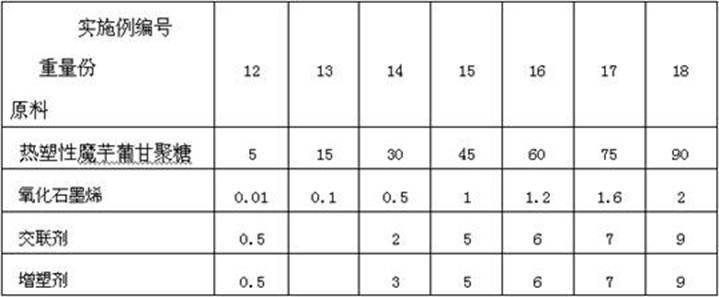

Thermoplastic konjac glucomannan/graphene oxide compound material and preparation method thereof

The invention discloses a thermoplastic konjac glucomannan / graphene oxide compound material and a preparation method thereof. The invention is characterized in that the compound material comprises the following components according to parts by weight: 1 to 99 parts of thermoplastic konjac glucomannan, 0.001 to 2 parts of graphene oxide, 0 to 10 parts of cross-linking agent and 0 to 10 parts of plasticizing agent; and the preparation method comprises the following steps of: proportioning; adding the thermoplastic konjac glucomannan into an ethanol or water solution of the graphene oxide, stirring for 5 to 10 hours, filtering and drying solid substances; then, drying after stirring and mixing with the cross-linking agent and the plasticizing agent in a mixing machine evenly; and afterwards, placing into a double-screw extrusion machine, extruding after carrying out melt blending at the temperature of 100 to 140 DEG C for 5 to 15 minutes, and granulating so as to prepare the compound material. The compound material has favorable processing performance, has excellent adsorbability, thermal stability and mechanical toughness, can be biologically degraded, can be regenerated, has no pollution to the environment and can be widely applied to the fields of chemical engineering, medicine, environmental protection, capital construction and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Package for segregating and mixing substances

Owner:KIMBERLY-CLARK WORLDWIDE INC

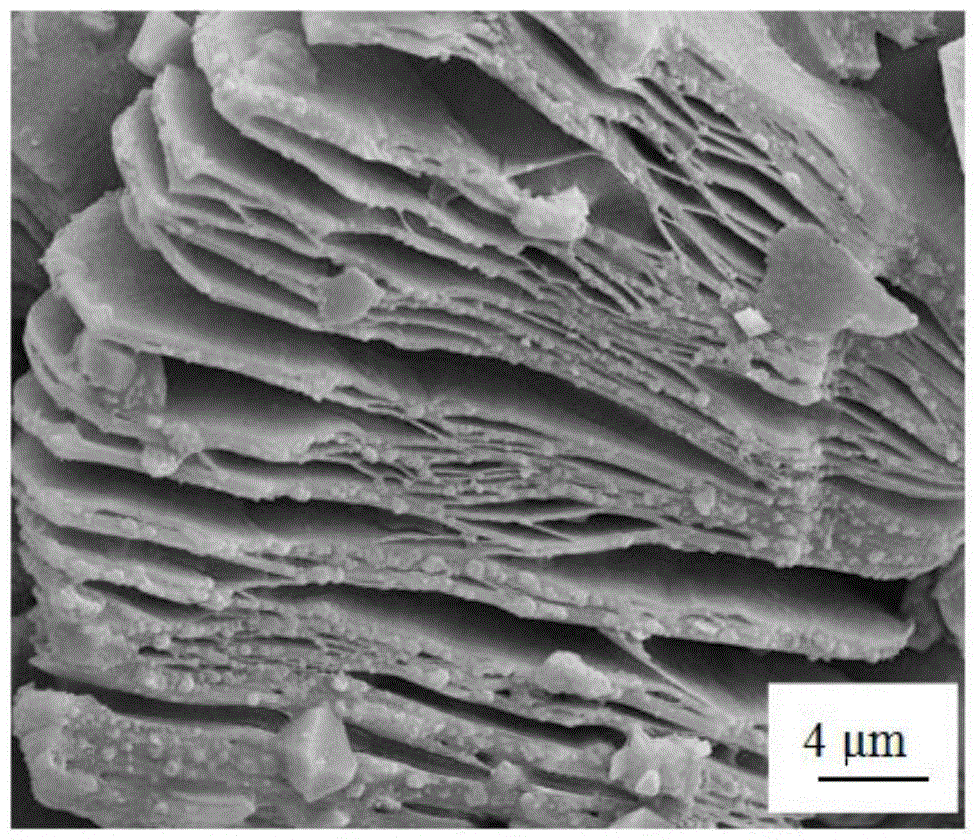

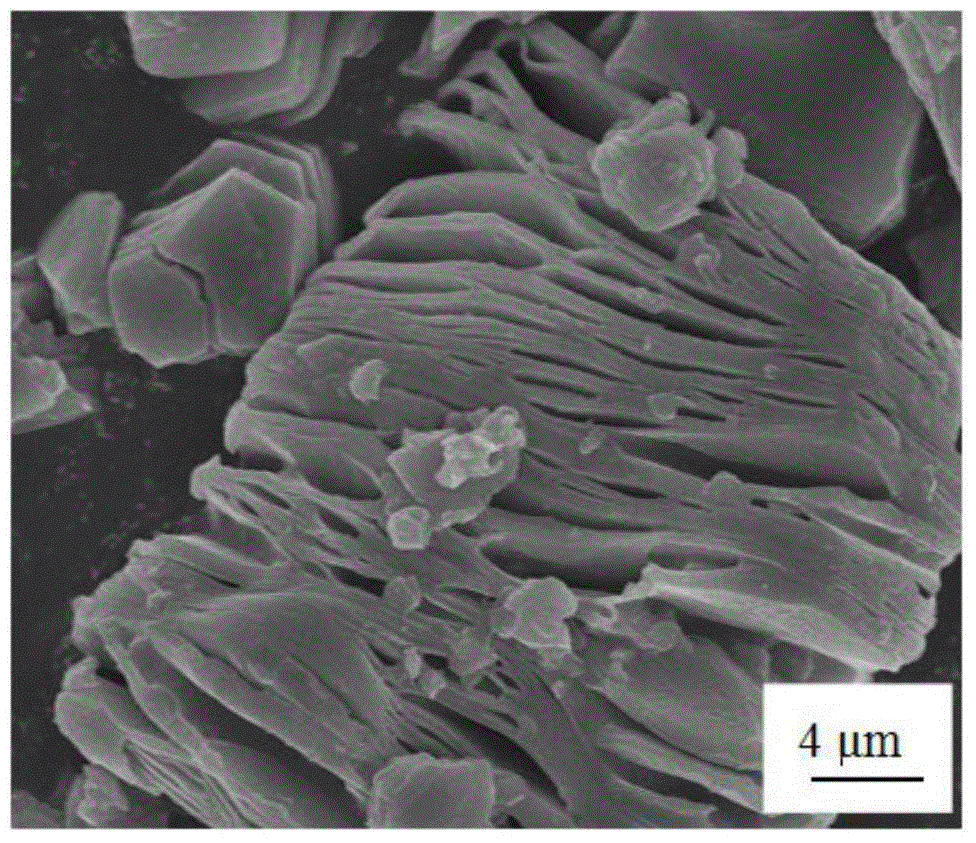

Rapid-heating-assisted ultrasonic stripping method for two-dimensional nanometer Ti3C2 lamella

The invention discloses a rapid-heating-assisted ultrasonic stripping method for a two-dimensional nanometer Ti3C2 lamella, relates to a method for stripping a two-dimensional nanometer Ti3C2 lamella, and aims at solving the problem of poor stripping effect of the existing method for stripping the two-dimensional nanometer Ti3C2 lamella. The method comprises the steps of firstly, preparing Ti3AlC2 powder; secondly, preparing stacked lamellar Ti3C2Tx powder, and then, immediately placing the stacked lamellar Ti3C2Tx powder into a thermal treatment furnace after vacuumizing; then, adding the powder in a pipe into an organic solvent after cooling, and centrifuging after stirring to obtain a solid substance; and vibrating and dispersing after adding deionized water into the solid substance, filtering to obtain a powdery sample, and drying to obtain the two-dimensional nanometer Ti3C2 lamella. The ratio of single-layer or n-layer nano lamellas in the two-dimensional nanometer Ti3C2 lamella stripped by using the method disclosed by the invention is relatively high (n<10). The rapid-heating-assisted ultrasonic stripping method for the two-dimensional nanometer Ti3C2 lamella is applied to the fields of synthesis and preparation of nano ceramic materials.

Owner:HARBIN INST OF TECH

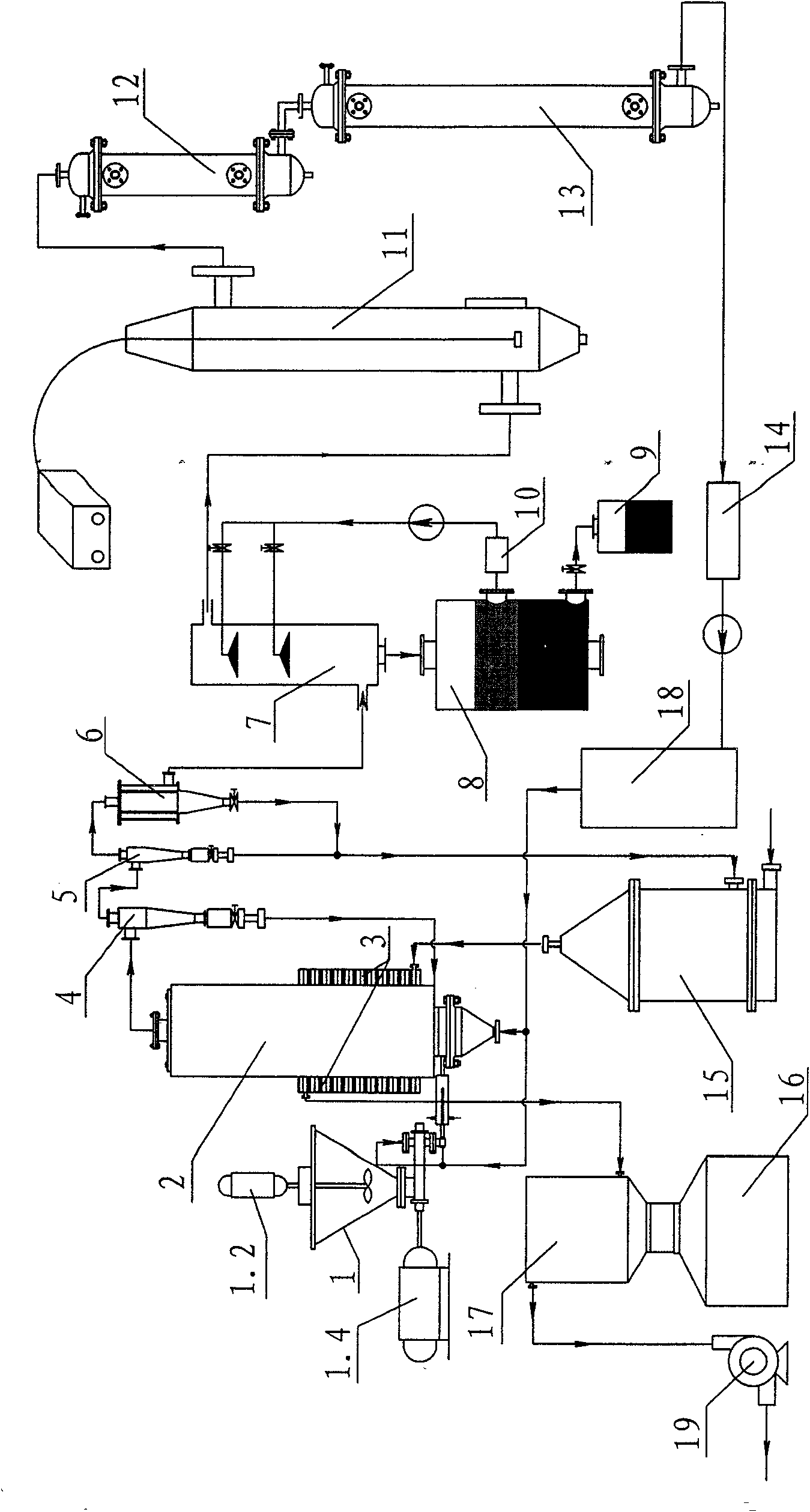

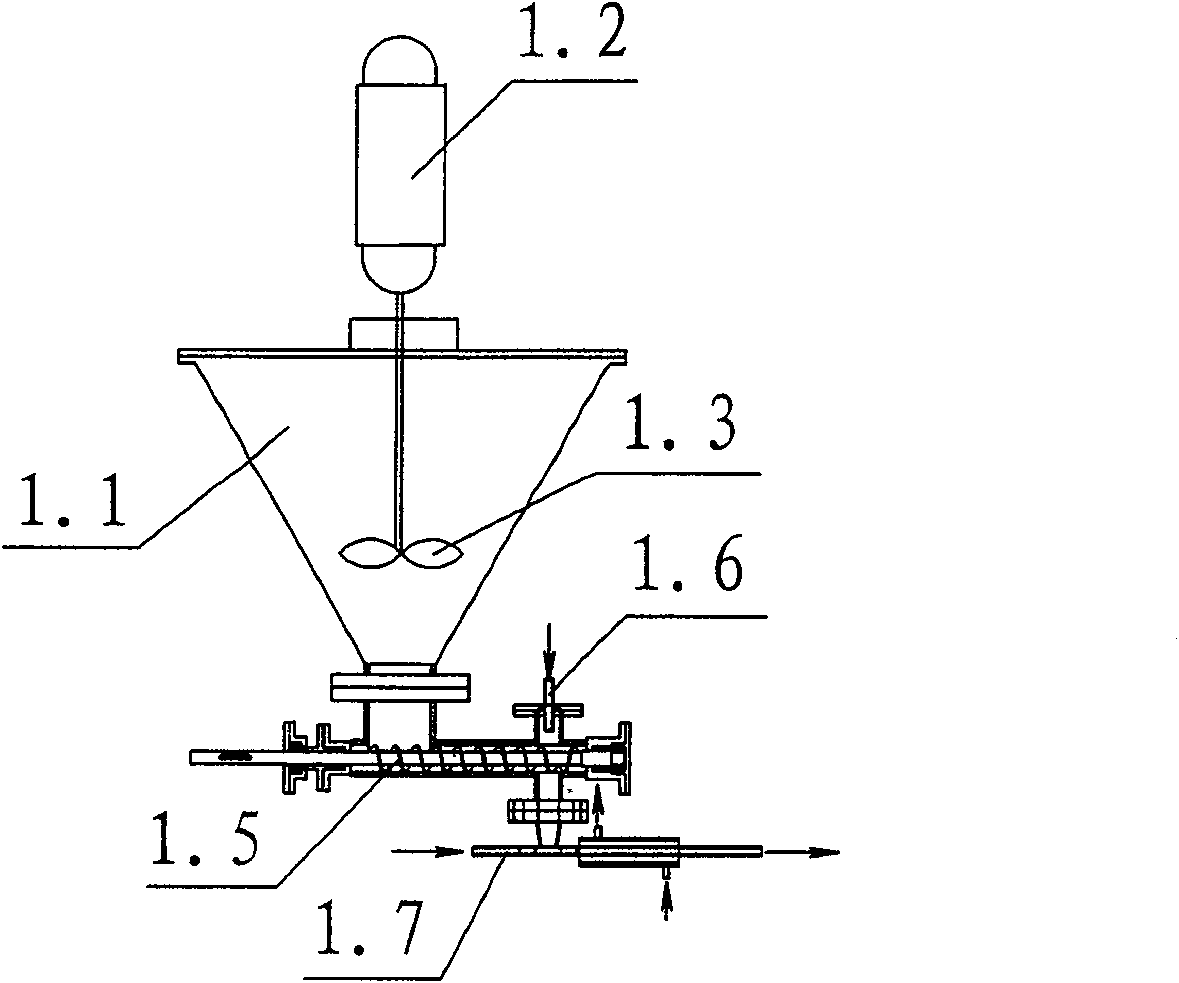

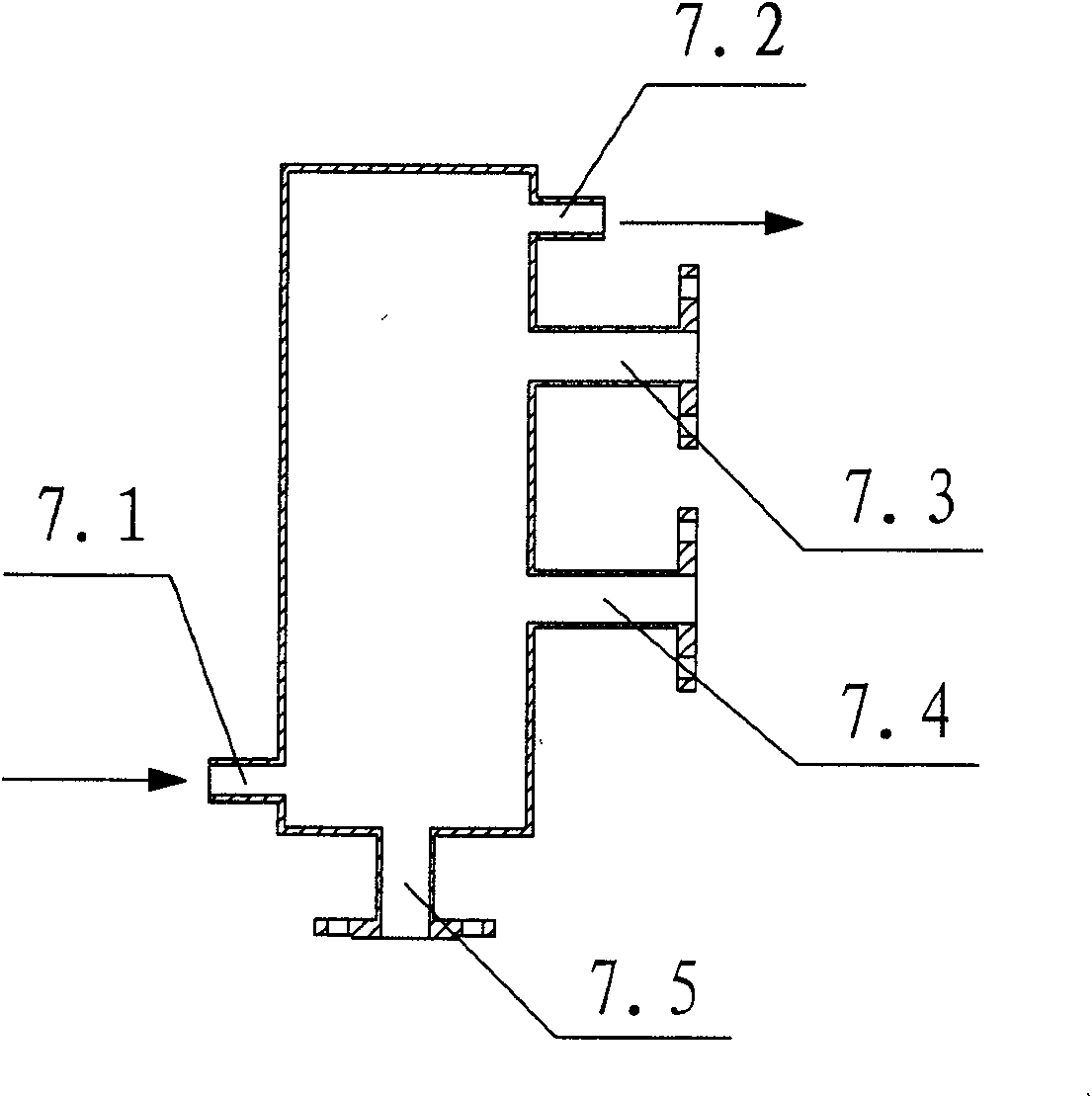

Method for preparing liquid fuels by self-heating self-circulating thermal cracking of biomass and device thereof

InactiveCN101560405ARealize self-heatingAvoid secondary reactionsLiquid hydrocarbon mixture productionCycloneElectricity

The invention relates to a method for preparing liquid fuels by self-heating self-circulating thermal cracking of biomass and a device thereof. Solid substances and carbon can be effectively reclaimed through a two-stage cyclone separator and a carbon filter, most of heavy oil components in thermal cracking volatile components are collected by adopting spray condensing, micro oil drops in the volatile components are further caught by electric catching, light oil components are complementally collected by cooling through a final dividing wall type water cooler, the volatile components are gradually cooled at an inlet of a cooling system at a temperature of 200 DEG C to collect biological oil, and finally, condensable parts in the volatile components are basically collected at an outlet at a temperature of below 30 DEG C. Through quick thermal cracking technology and stepped cooling and collecting processes, cellulose biomass wastes are converted into the liquid fuels of different levels, and simultaneously, volatile gas and coke products in the thermal cracking process are reclaimed and utilized to realize self-heating for a complete thermal cracking system and save cost.

Owner:顾赛 +1

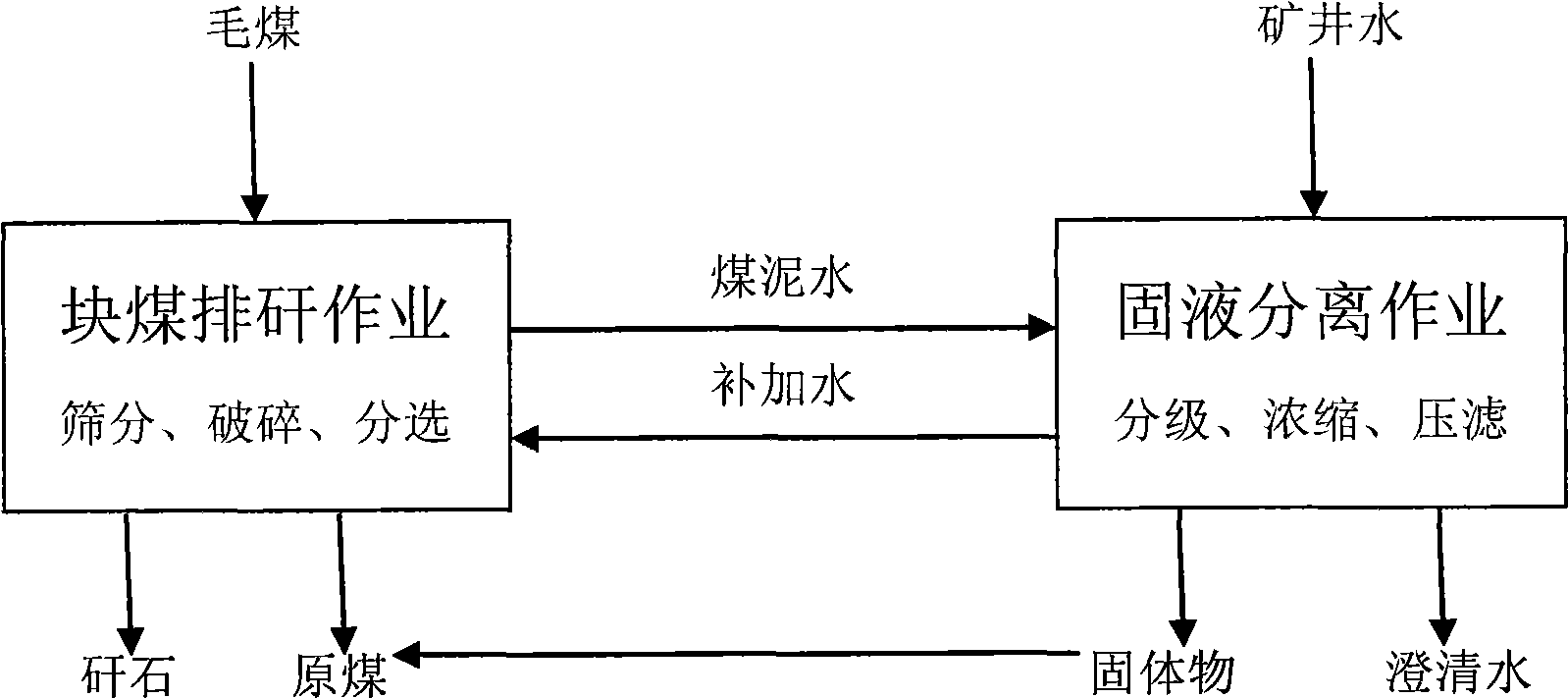

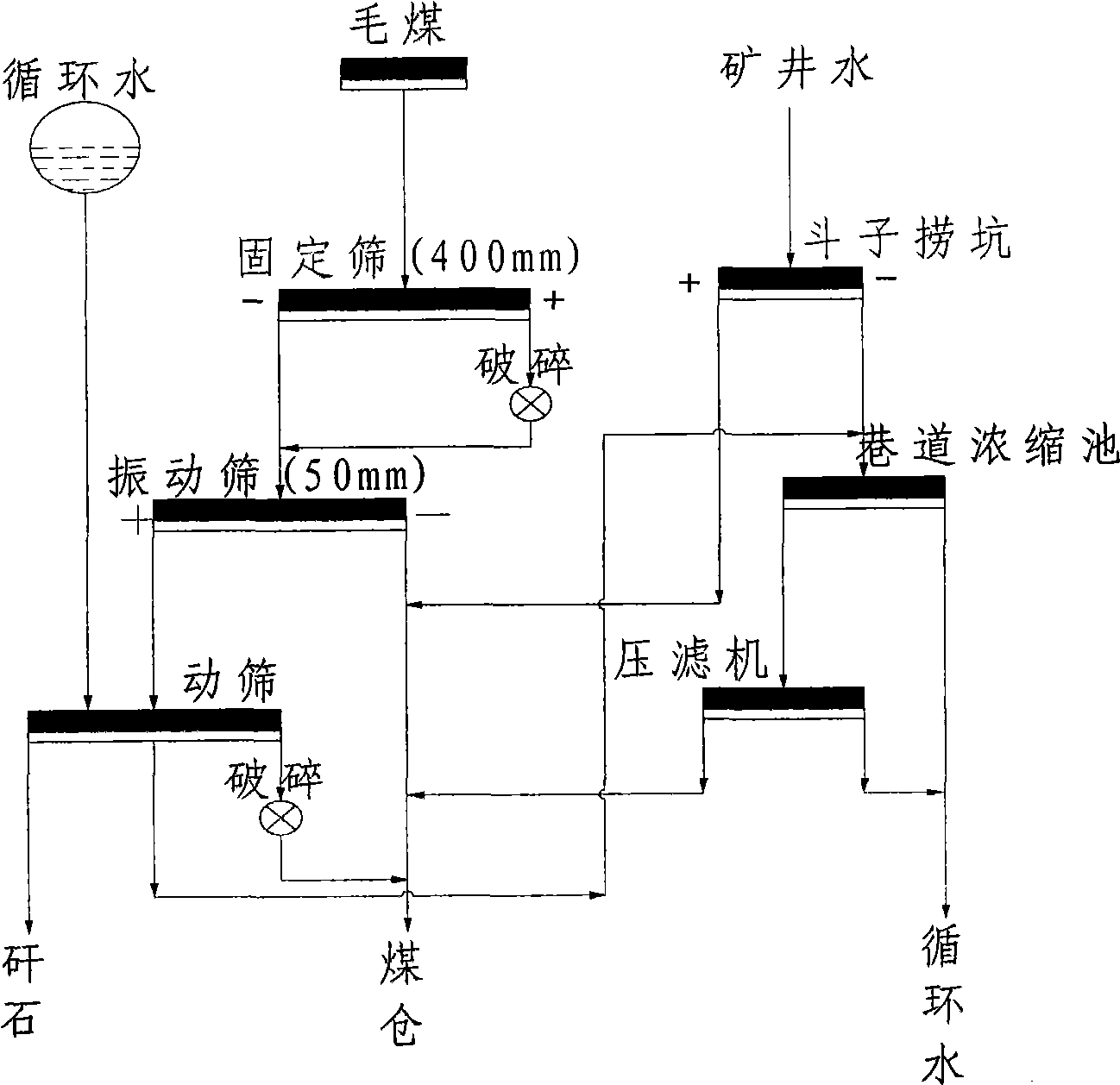

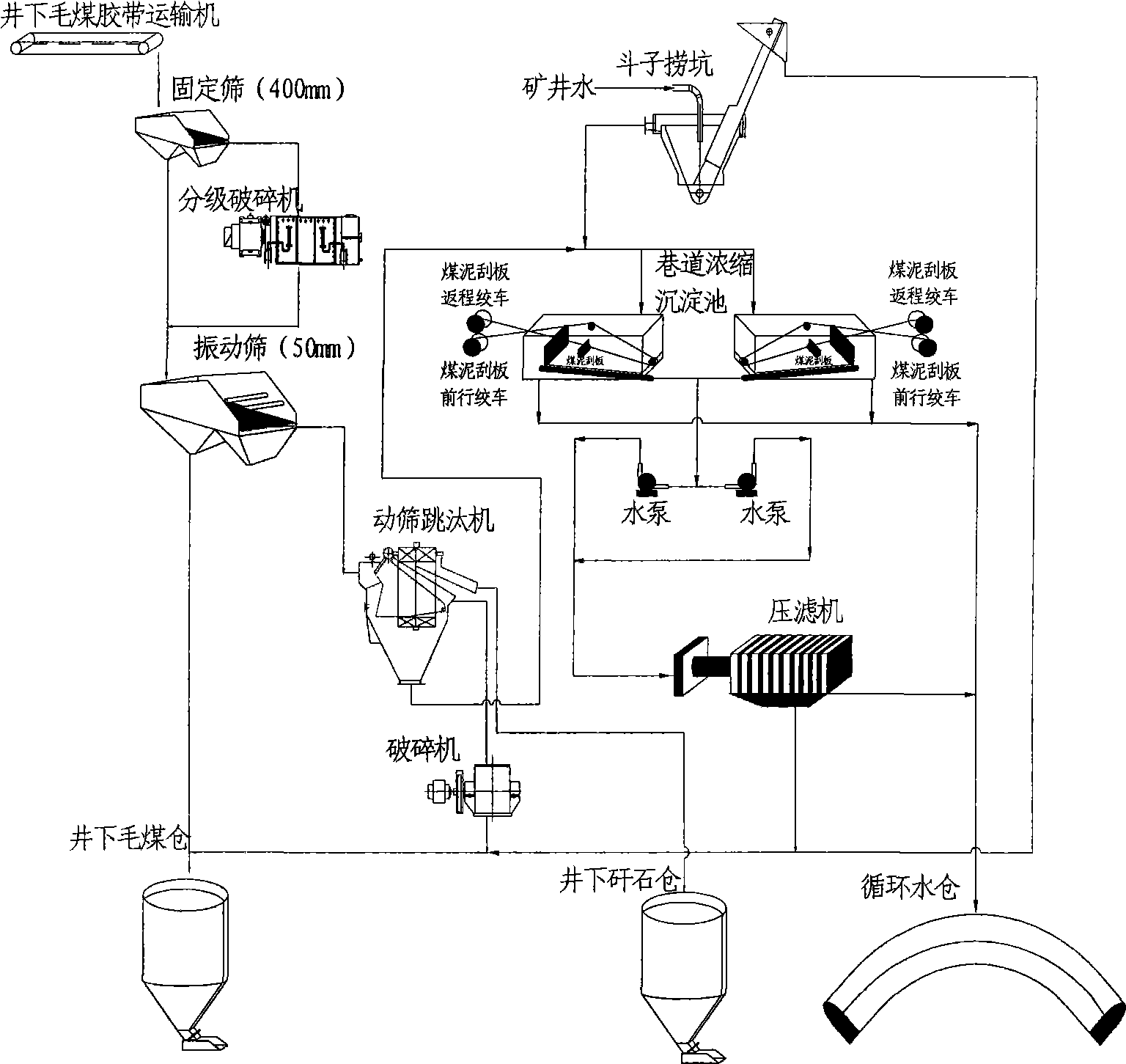

Down-hole gross coal dirt-discharging and mine water treating combined process

An underground gross coal gangue removal and mine water treatment combined process is characterized in that the process comprises two parts: gangue removal operation from lump coal and mine water solid-liquid separation operation, wherein, the gangue removal operation from lump coal comprises screening, crushing and separation steps, and the mine water solid-liquid separation operation comprises hydraulic classification, concentration and pressure filtration steps; by the gangue removal operation from lump coal, chunks of gangues in the gross coal are removed, and simultaneously the large particles thereof are crushed into appropriate size; by the mine water solid-liquid separation operation, the solid substances in the mine water are recycled to a coal streamline, and simultaneously the clear overflow water is delivered to a underground water sump; the coal muddy water generated by the gangue removal operation from lump coal is delivered to a mine water solid-liquid separation system for treatment and the mine water solid-liquid separation system provides water for washing and selection for the gangue removal operation from lump coal, so the coal muddy water and the water for washing and selection are combined into an organic whole.

Owner:HENAN POLYTECHNIC UNIV

Lithium ion battery aqueous anode slurry and preparation method thereof

ActiveCN103579579AReduce pollutionGood capacityCell electrodesSecondary cellsAdhesiveCarbon nanotube

The invention discloses a lithium ion battery aqueous anode slurry consisting of the following components in percentage by weight: 40-50% of anode active material, 1-10% of carbon nanotube, 0-5% of conductive agent, 1-3% of aqueous adhesive and 40-50% of de-ionized water. Furthermore, the invention discloses a preparation method of the lithium ion battery aqueous anode slurry, and the preparation method mainly comprises the following steps: (1) preparing a premix liquid; (2) preparing a conductive adhesive liquid; (3) dispersing for the first time; (4) dispersing for the second time; (5) defoaming and standing. The preparation method is simple in processing step, strong in feasibility and suitable for mass industrial production; the prepared lithium ion battery is excellent in both capacity and circulating performance, and can be used for effectively solving the problems of an existing aqueous anode slurry preparation method which has difficulty in uniformly dispersing the conductive agent, the anode active material and other solid materials and is high in possibility of aggregation, relatively poor in consistency of the prepared aqueous anode slurry, not high in stability and easy to settle.

Owner:WANXIANG 123 CO LTD

Methylene oxide scavenging agent

The present invention relates to a formaldehyde scavenger and is characterized in that the formaldehyde scavenger is the amino acid under the alkali condition. The formaldehyde scavenger can be carried by paper or cloth, and can also be a solid substance or a water solution. The formaldehyde scavenger is used to remove formaldehyde in the air. Moreover, the formaldehyde scavenger can be used to stop emission of formaldehyde from the furniture and decoration materials. The formaldehyde scavenger is odourless, intoxicant, involatile, safe and environment-friendly.

Owner:张旭鹏

Method for processing instant tea powder

ActiveCN101189990AAvoid lostInhibit deteriorationPre-extraction tea treatmentTea extractionInstant teaFlavor

The invention provides a method that takes fresh tea leaves as raw materials to process instant tea powder, which can prevent loss and deterioration of nutrition substance when in the tea manufacturing process. The technique is that: when the raw material is extracted, pectinase is added to enhance extraction rate of the tea leaves and to extract solid substance from solution after the processes of extracting, enzymatic hydrolysis, filtration, condensation and drying, etc. of the raw materials; then tannase is added for enzymatic hydrolysis, so as to resolve the deposition problem of the tea soup and to reduce the bitterness of the instant tea powder and improve the dissolution ability of the tea powder in cold water. The technologies of membrane separation and condensation are adopted in filtration and condensation process; and spray drying or vacuum freeze drying is adopted in drying process; therefore, the whole production process is carried out at relatively low temperature, which maximally preserves the nutrition substances and flavor substances, and the produced instant tea powder is abundant in nutrition and has fresh and soft taste.

Owner:DAMIN FOODSTUFF ZHANGZHOU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com