Method for preparing liquid fuels by self-heating self-circulating thermal cracking of biomass and device thereof

A self-circulating, liquid fuel technology, which is applied in the preparation of liquid hydrocarbon mixtures and the petroleum industry, etc., can solve the problems of lack of technical support for large-scale applications, and achieve the effects of short gas phase residence time, cost reduction, and gas phase residence time avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

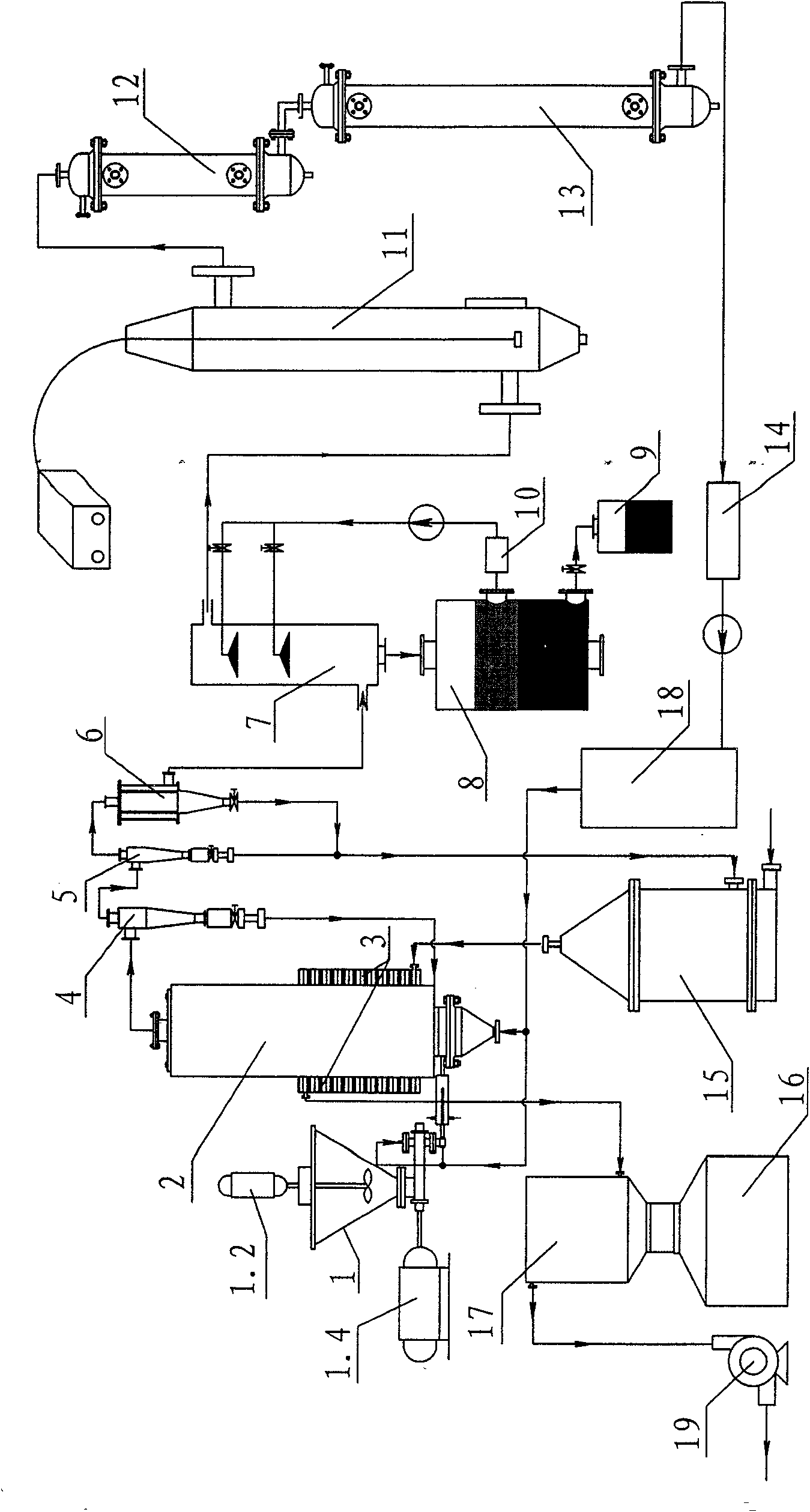

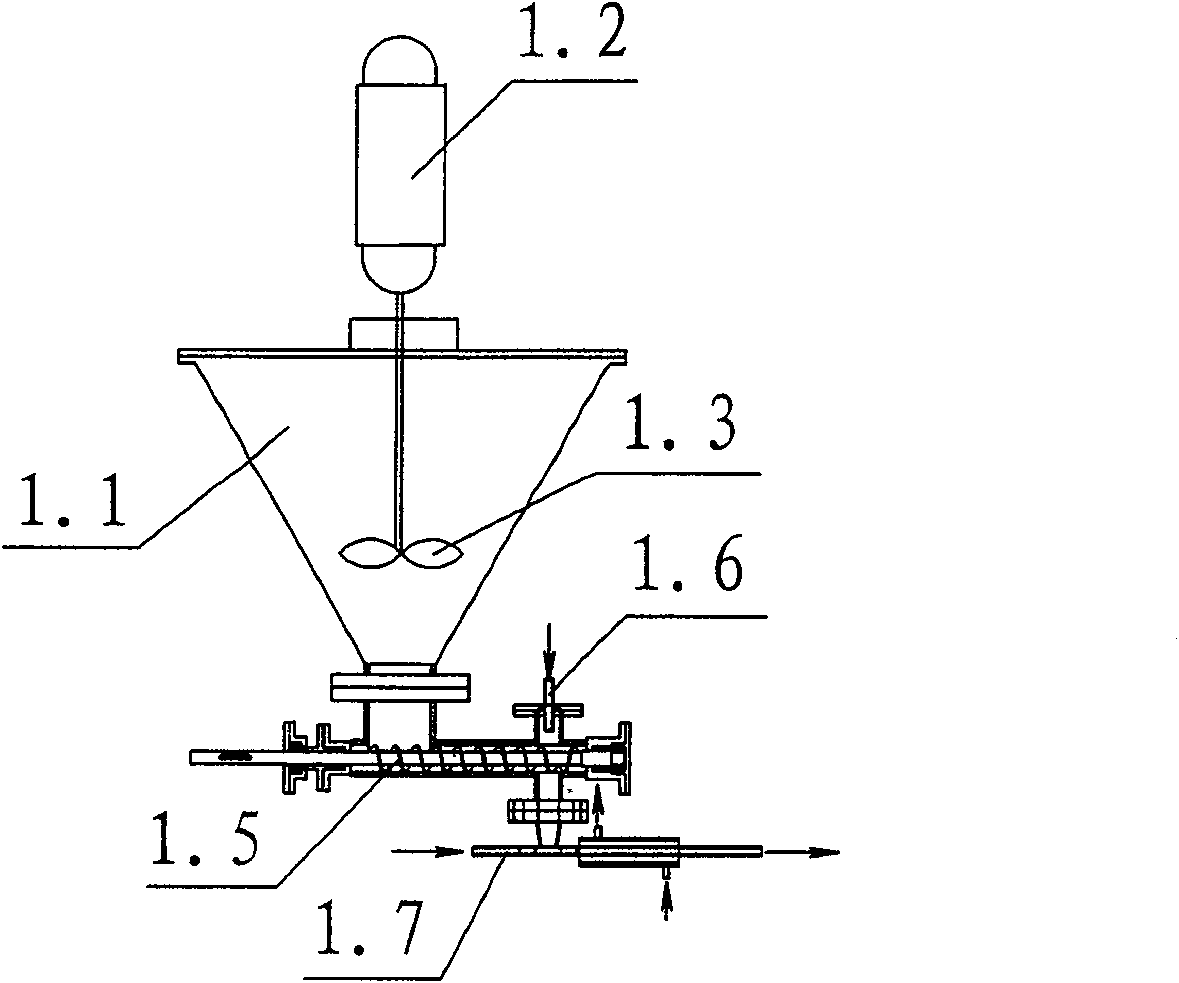

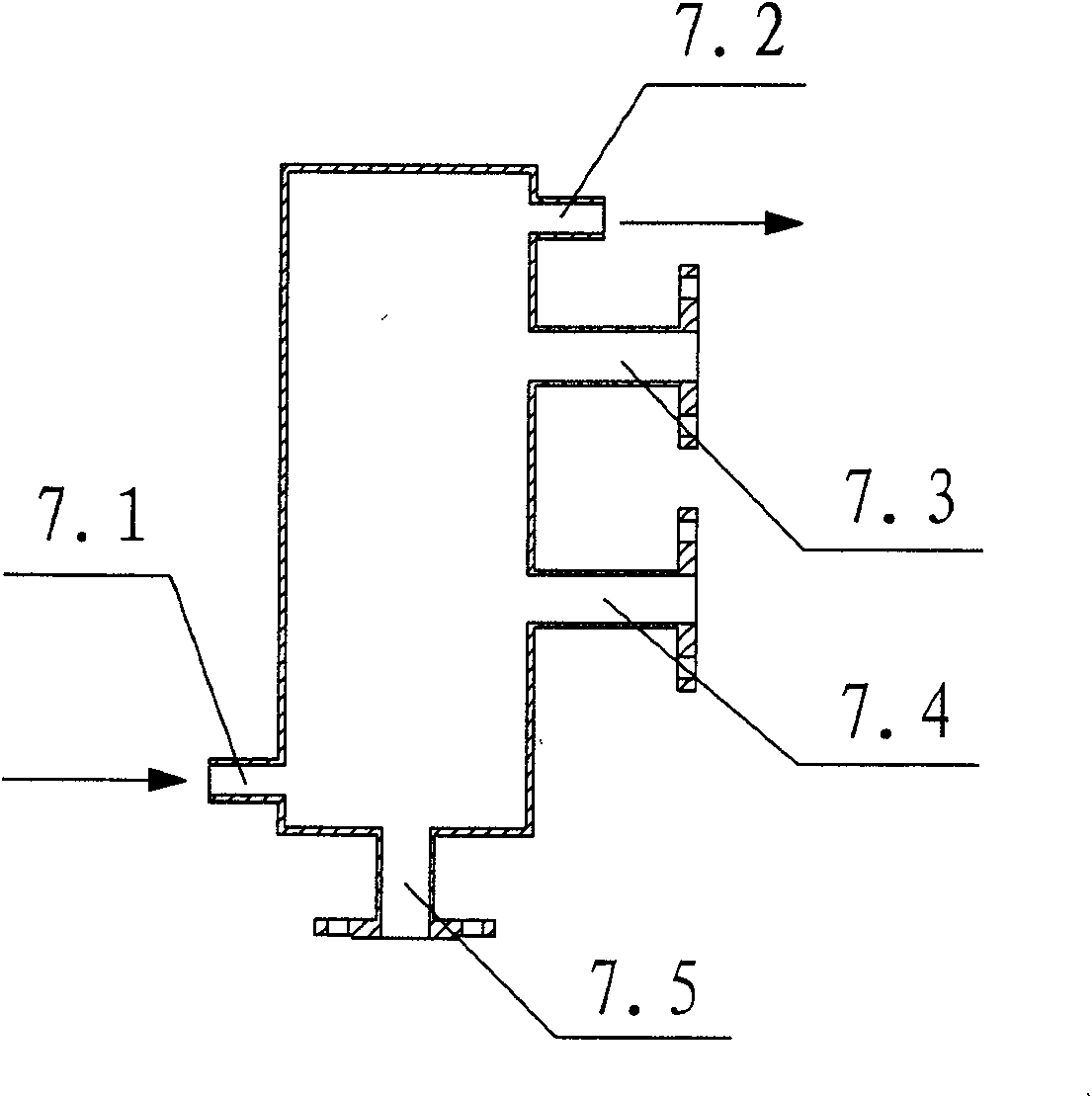

[0058] The biomass raw material is first fed into the hopper 1.1 by means of the traditional feeding method, and the combined feeding device 1 sends the biomass raw material into the fluidized bed reactor 2 connected to it, and the raw material entering the fluidized bed reactor 2 is The phase bed is flash-heated to reach the optimal reaction temperature of about 500°C. The raw material is rapidly decomposed by heat to release volatile matter, and is quickly taken away from the fluidized bed reactor 2 by the fluidized wind within less than 1 second, and pyrolyzed The solid product char is also entrained out of the fluidized bed reactor 2 by air force at the same time. The carbon and volatile matter mixture from the reactor enters the gas-carbon separation system, and the gas-carbon mixture first enters the secondary cyclone separator 5, wherein about 95% of the carbon is separated by the cyclone separator, and the primary cyclone separator 4 The high-temperature solids are dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com