Patents

Literature

559results about "Energy recuperation in distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

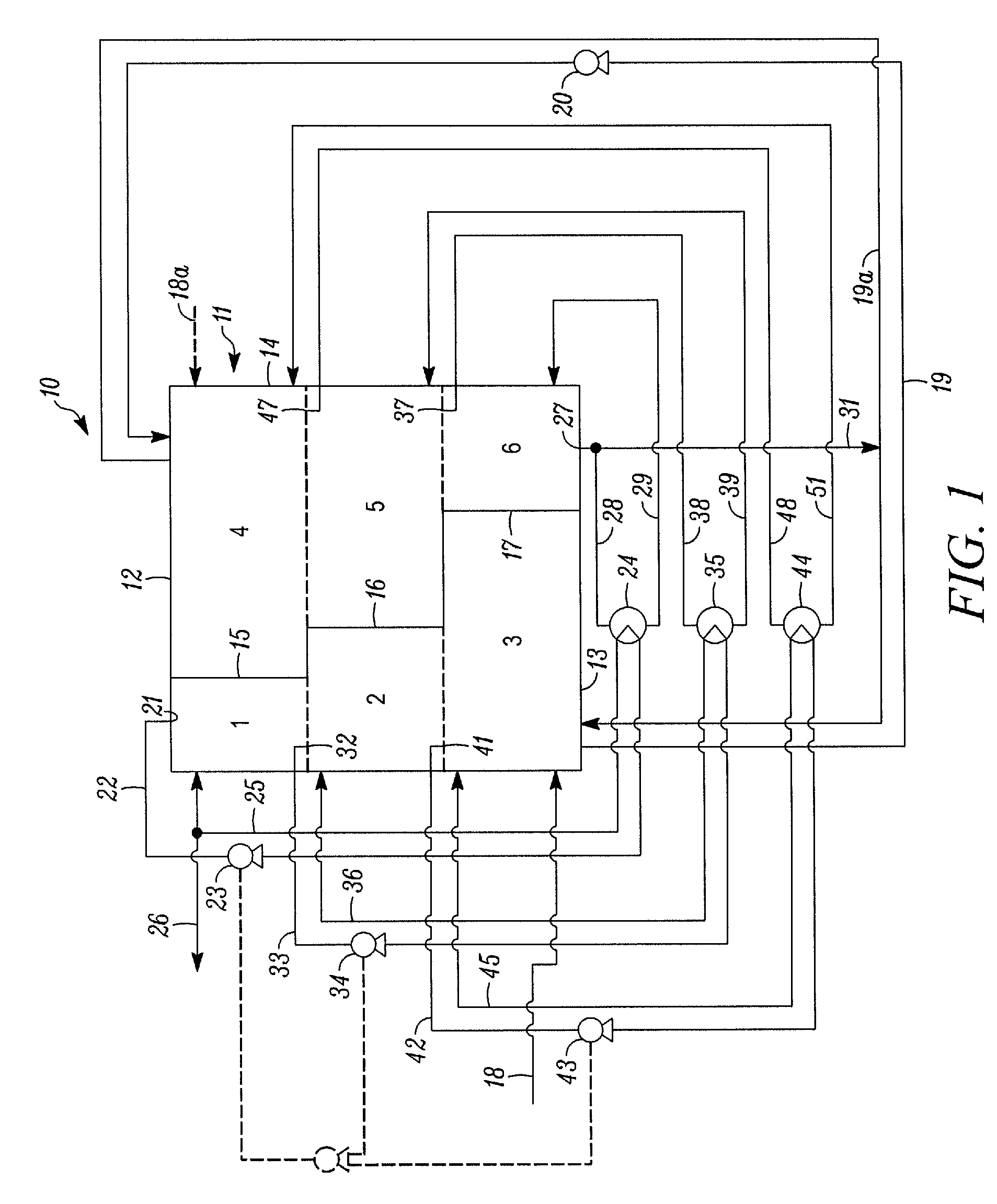

Pressurized vapor cycle liquid distillation

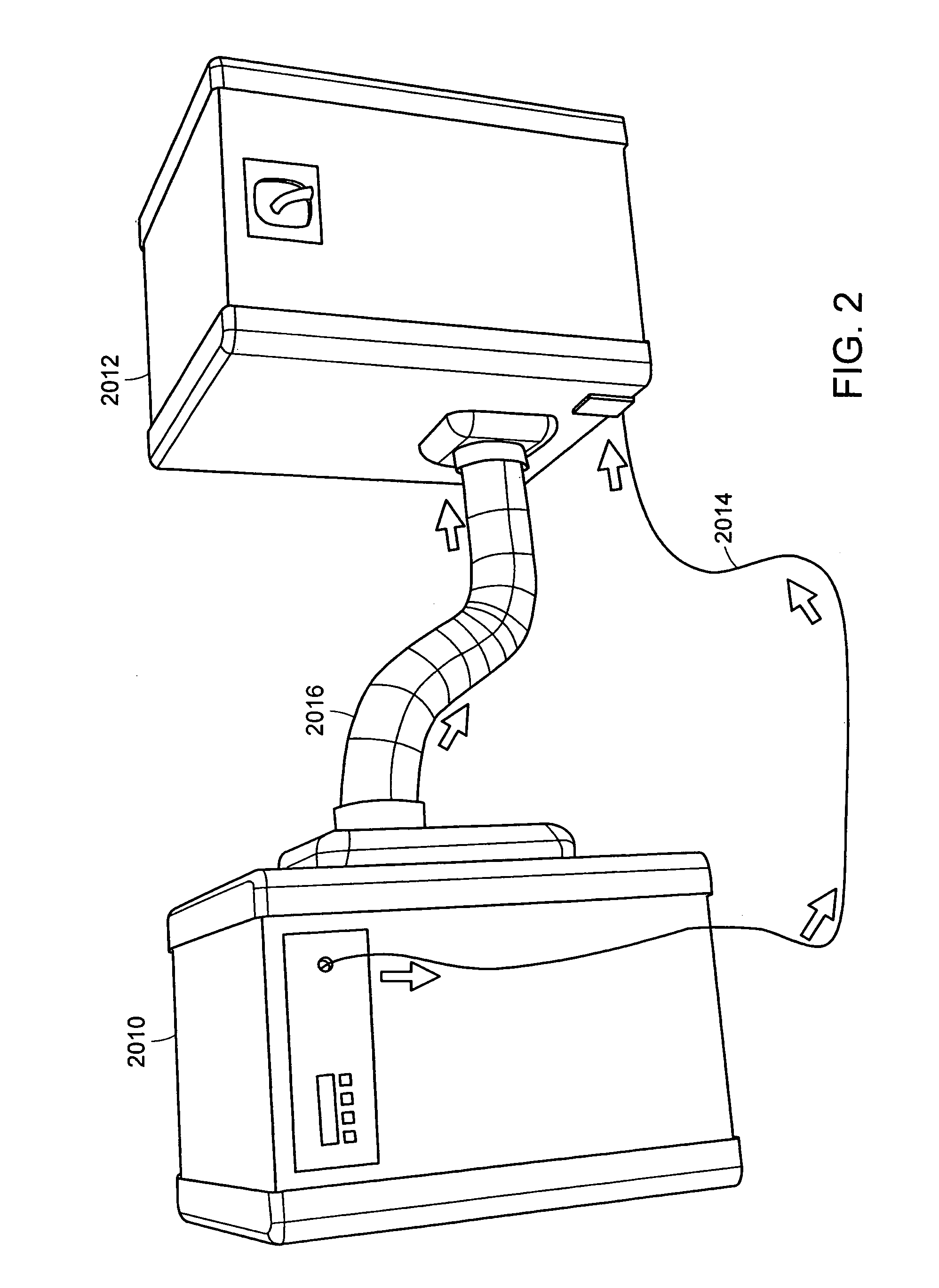

ActiveUS20050016828A1Easy maintenanceMaximize energy efficiencyDistillation regulation/controlUsing liquid separation agentHeat managementDrive shaft

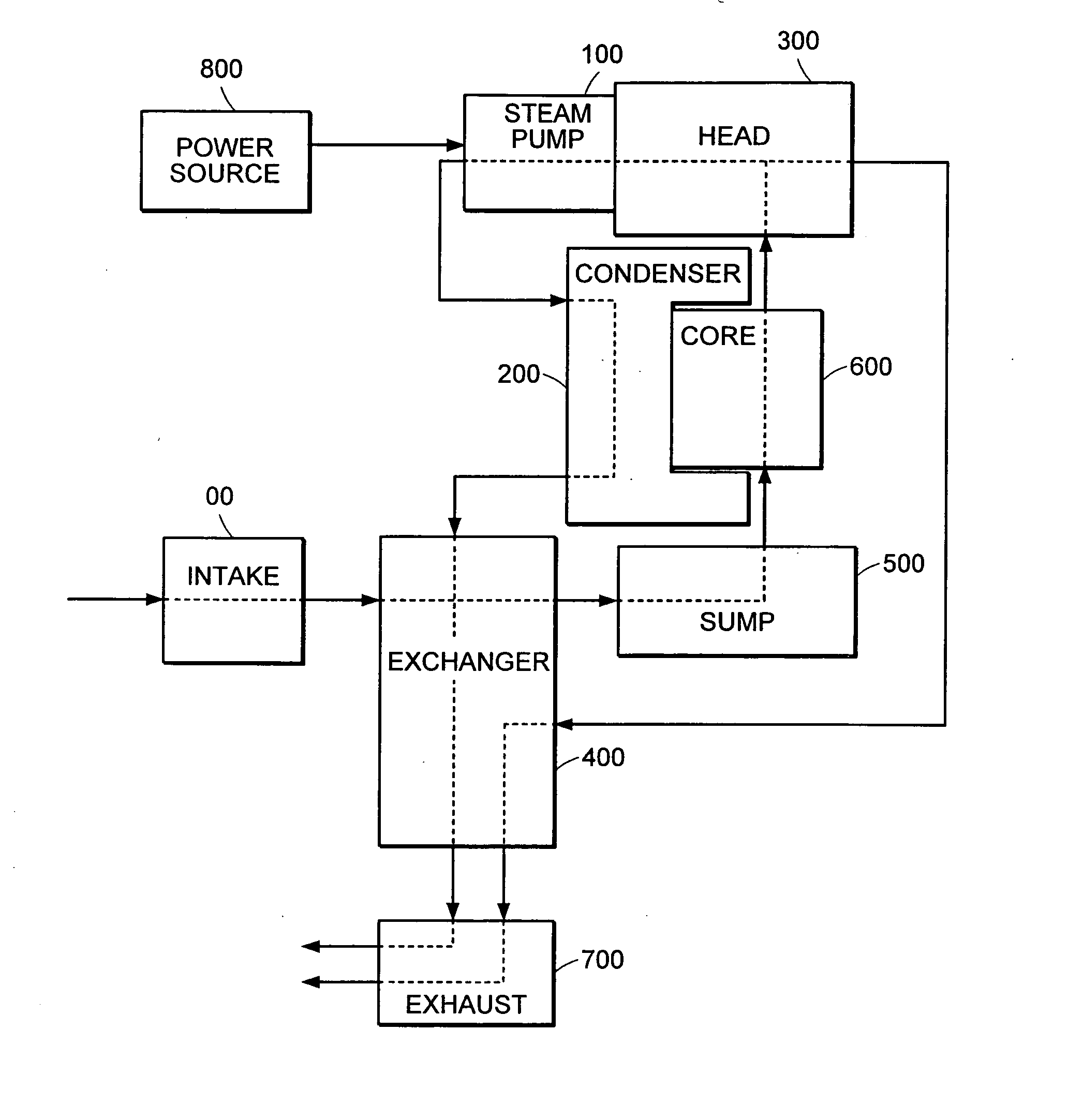

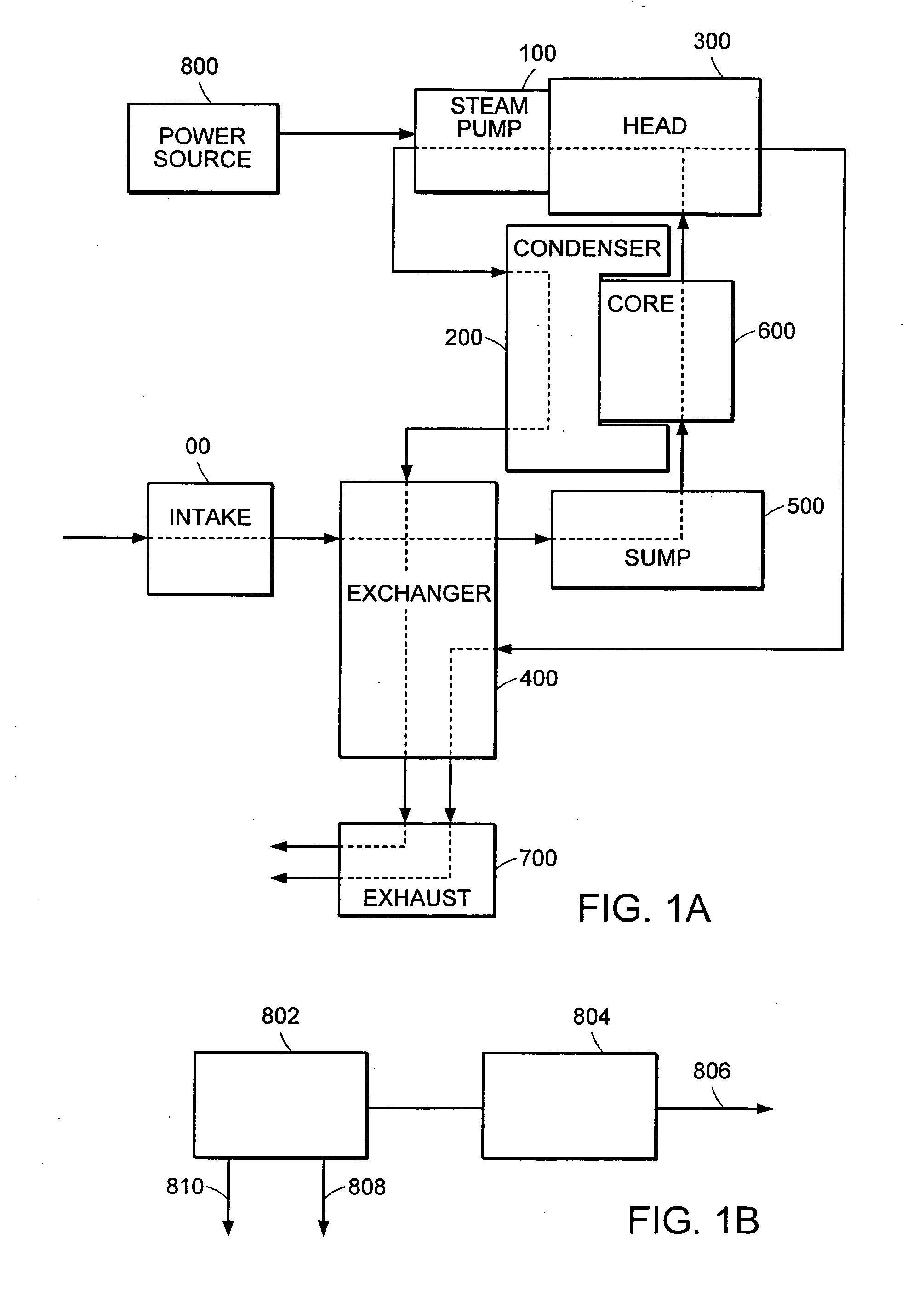

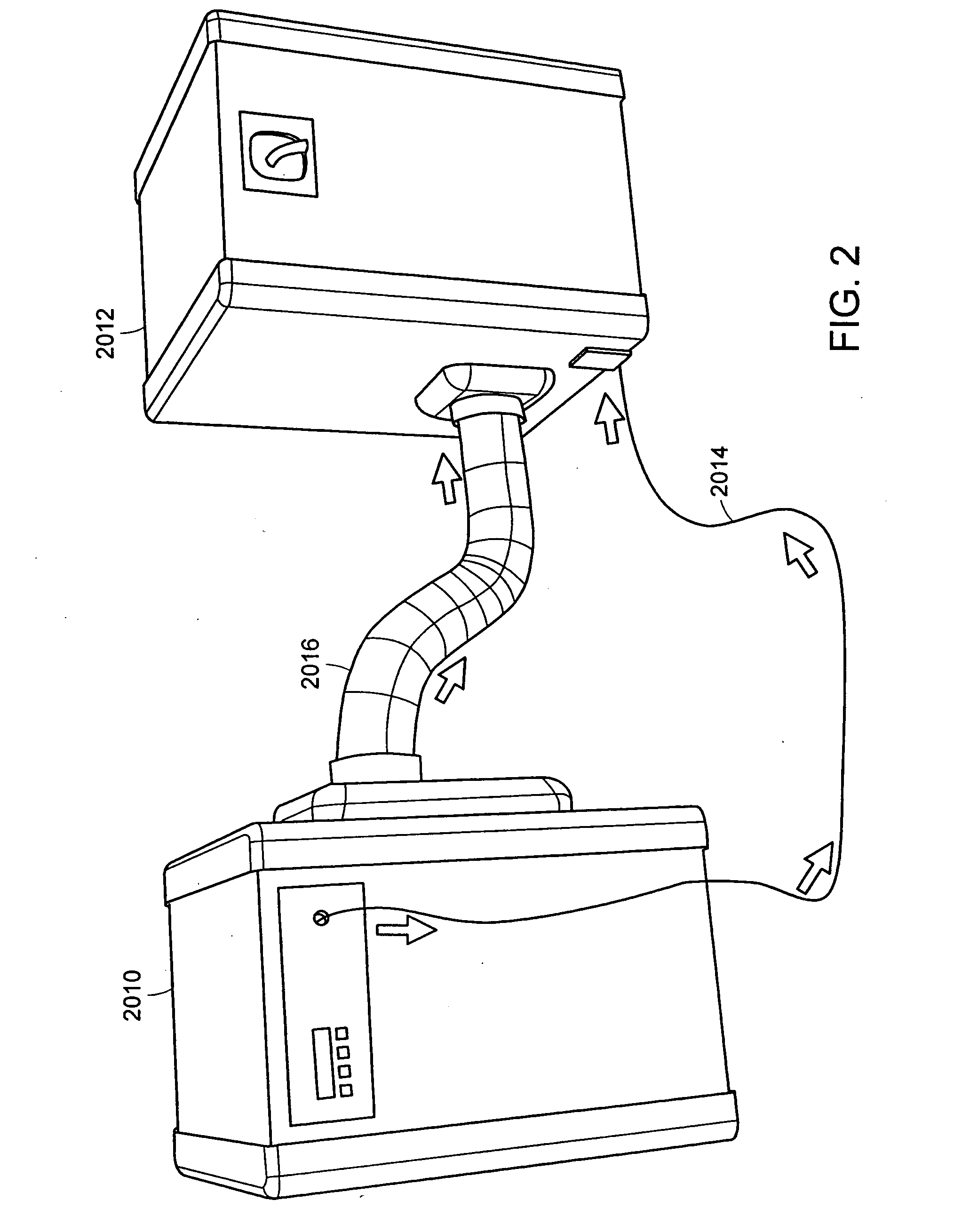

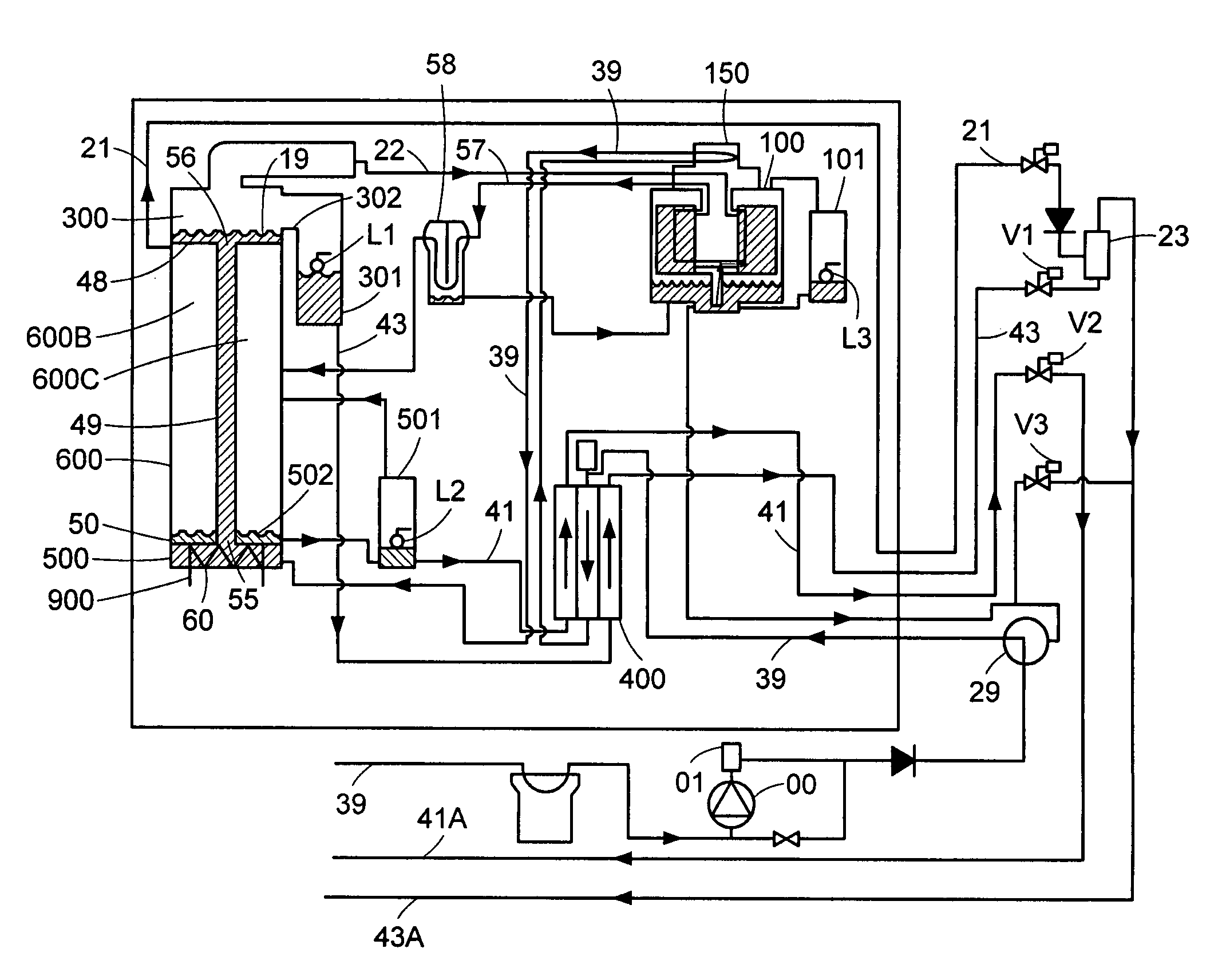

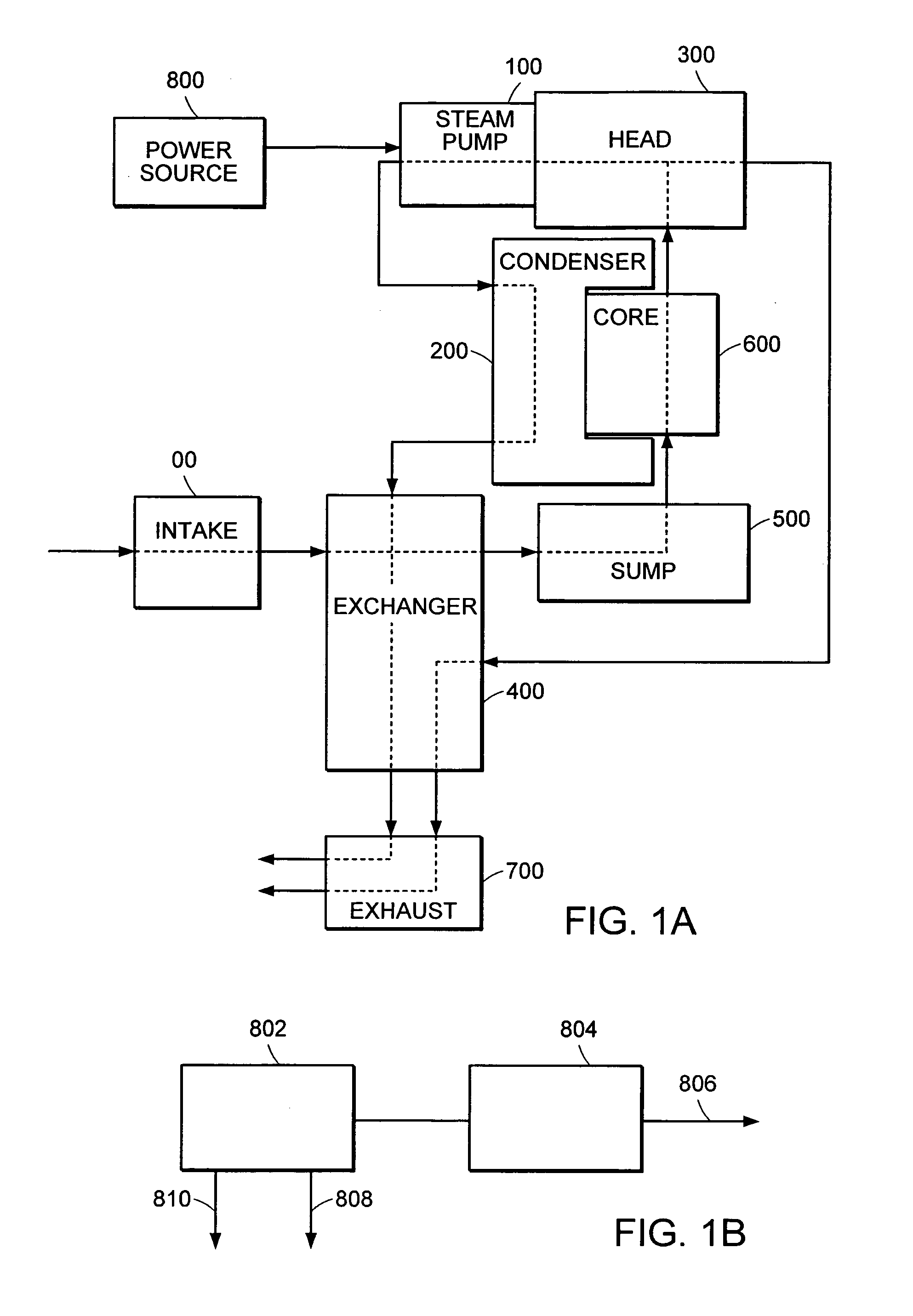

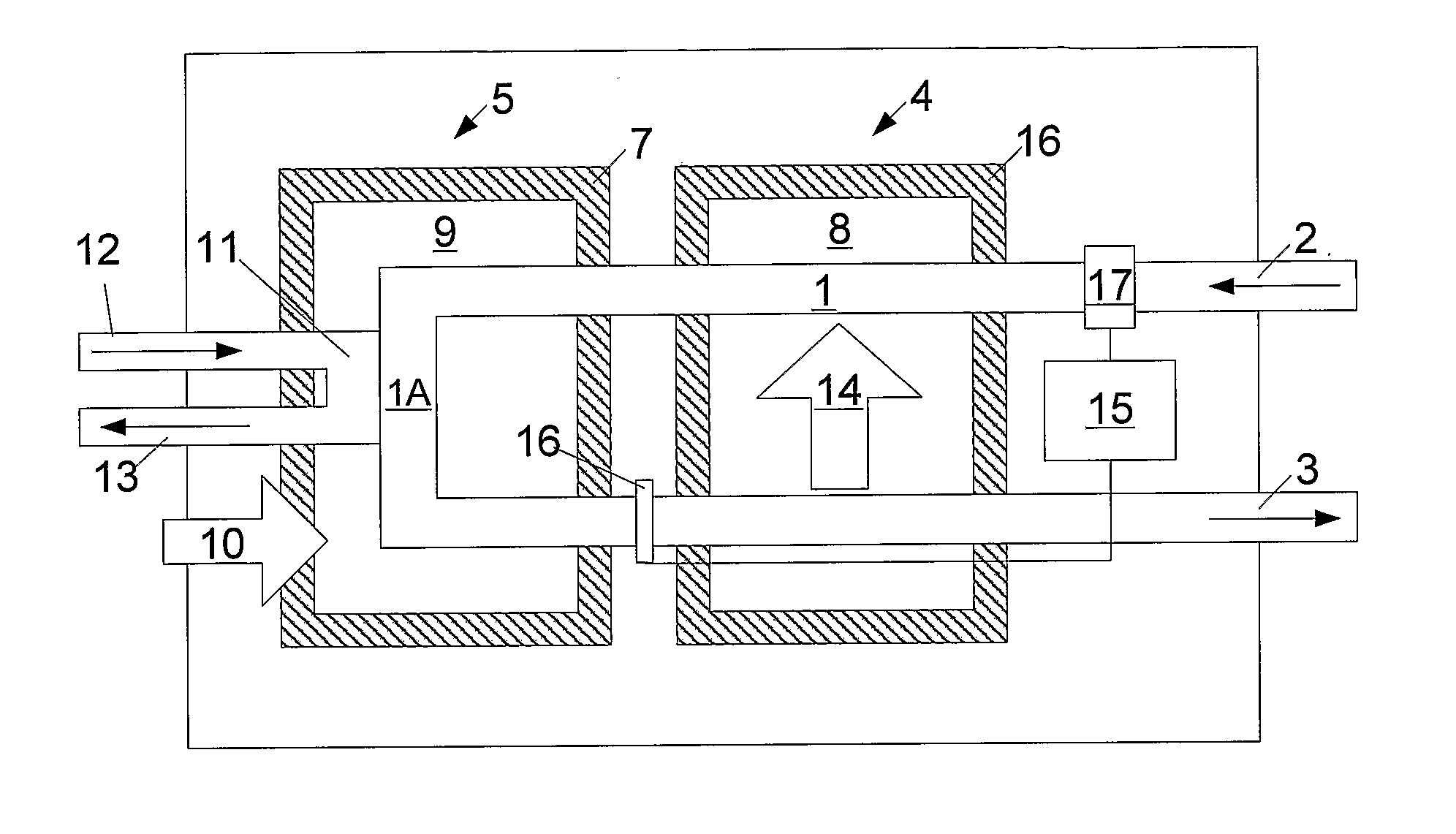

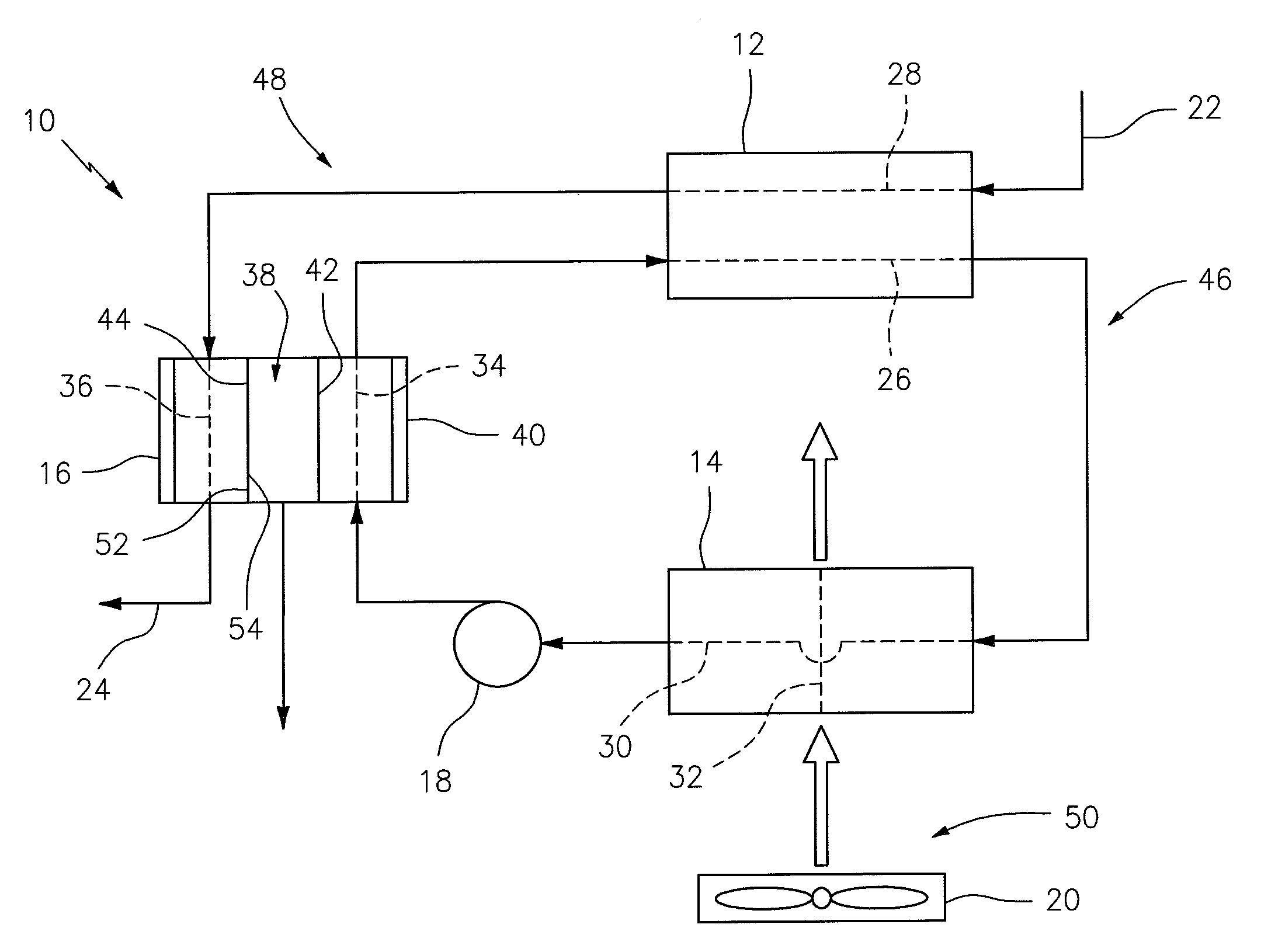

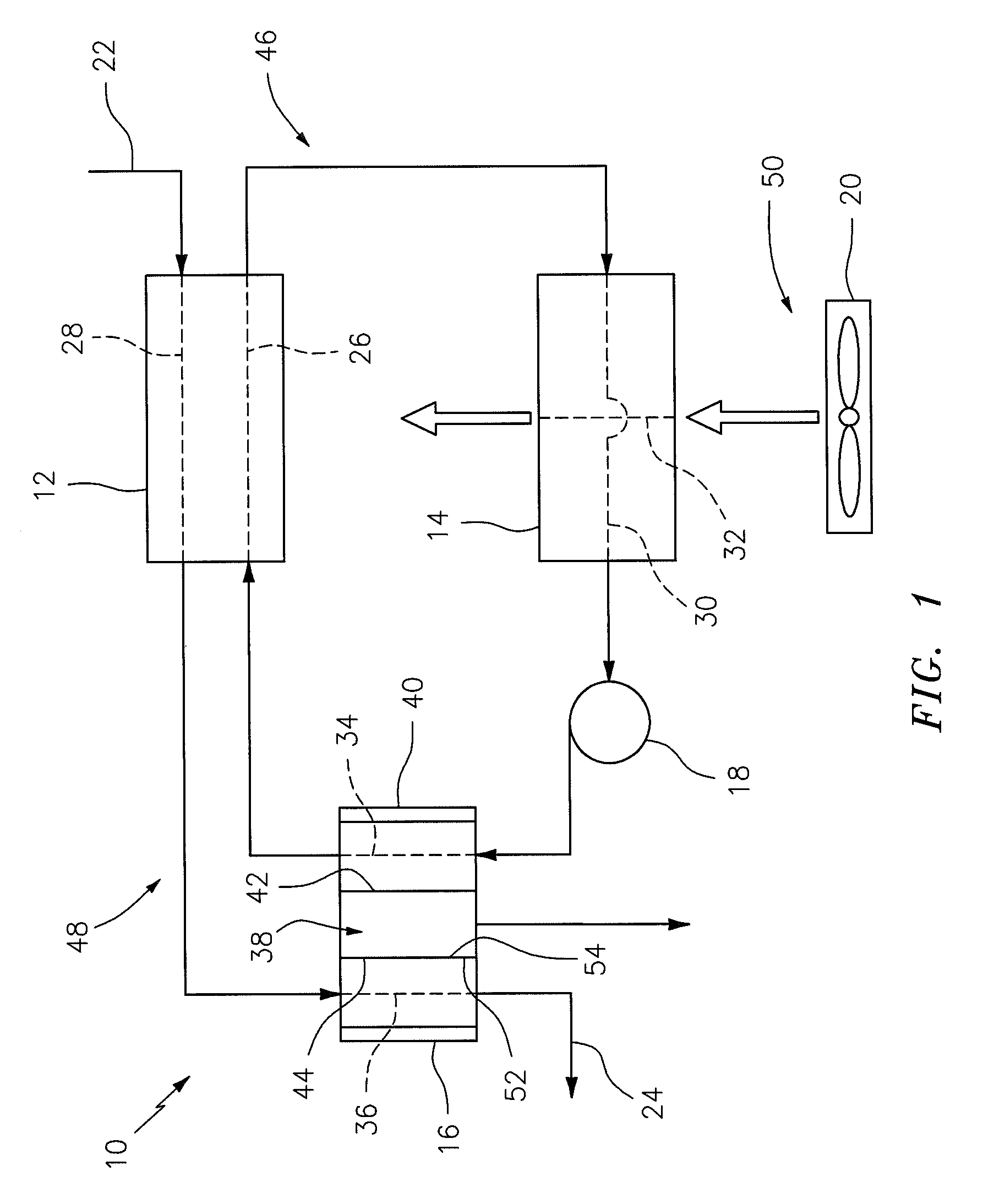

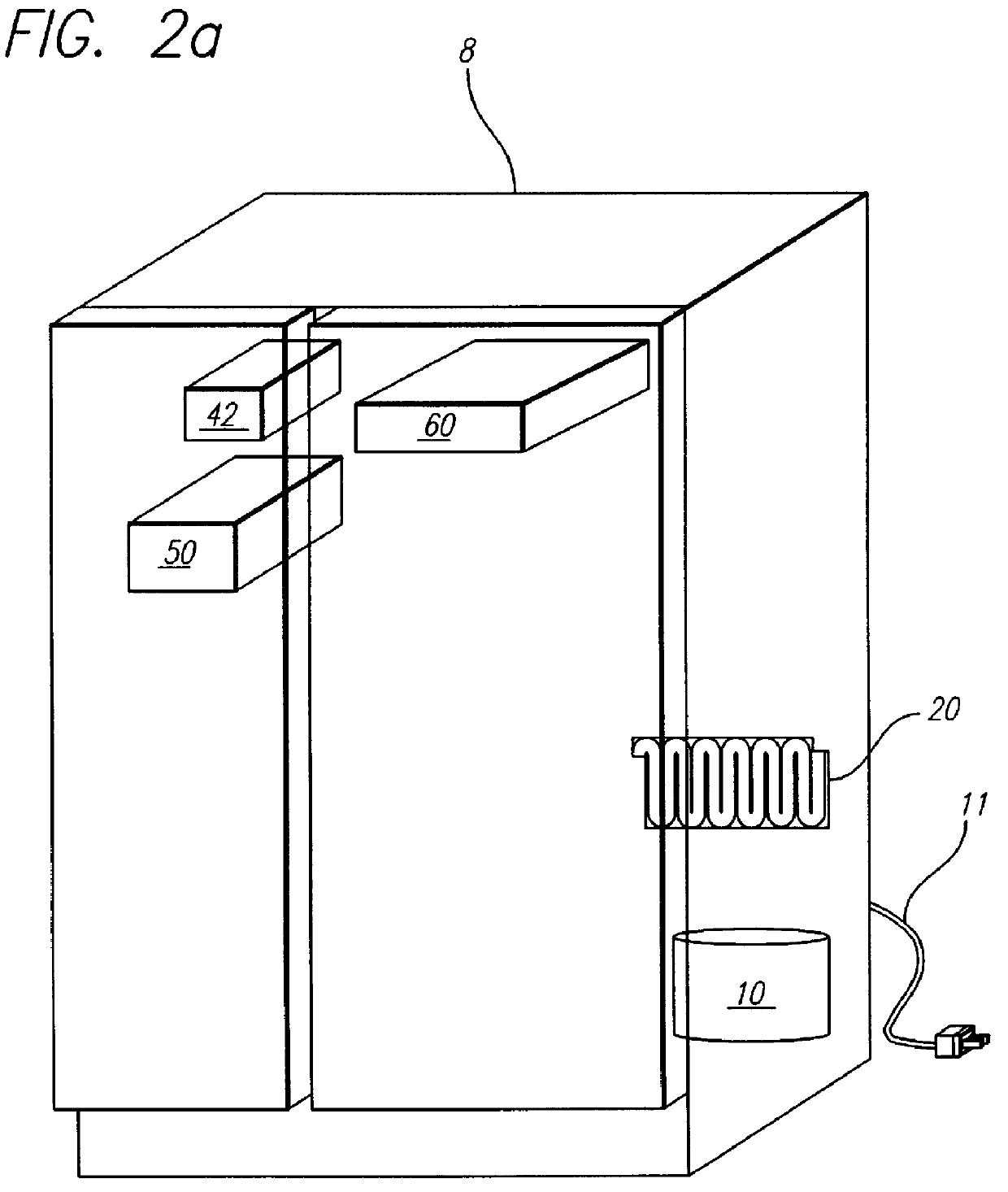

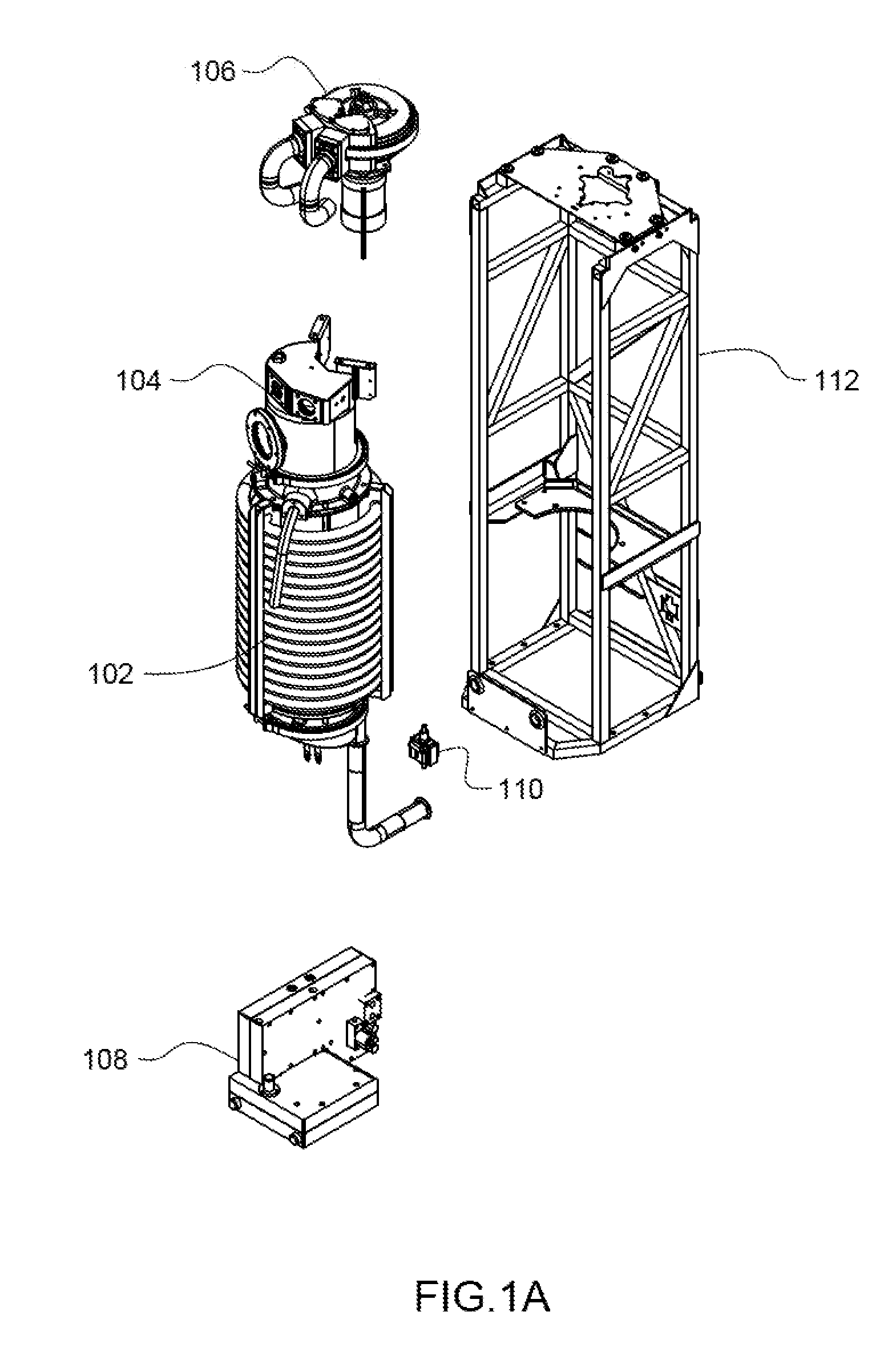

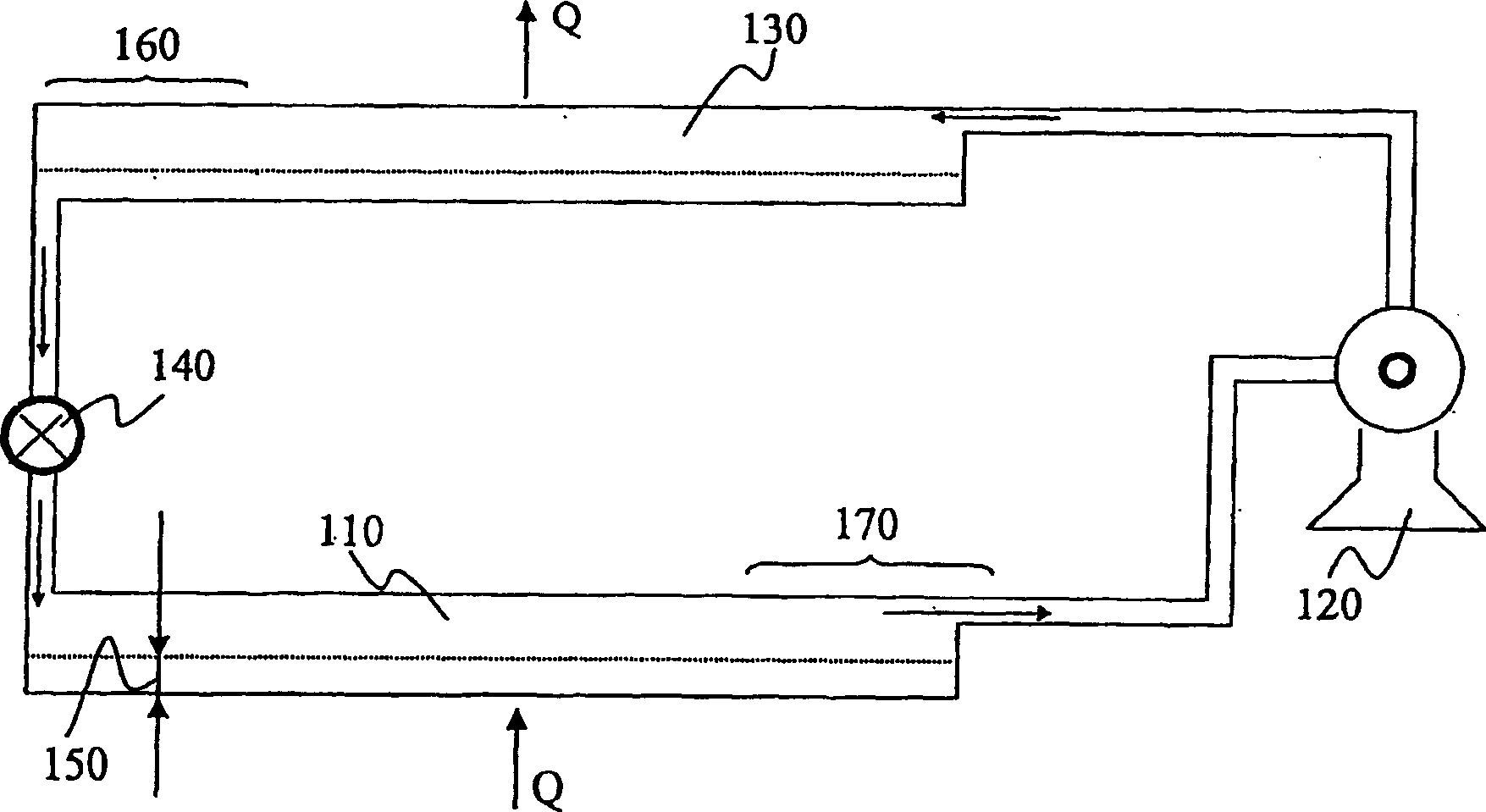

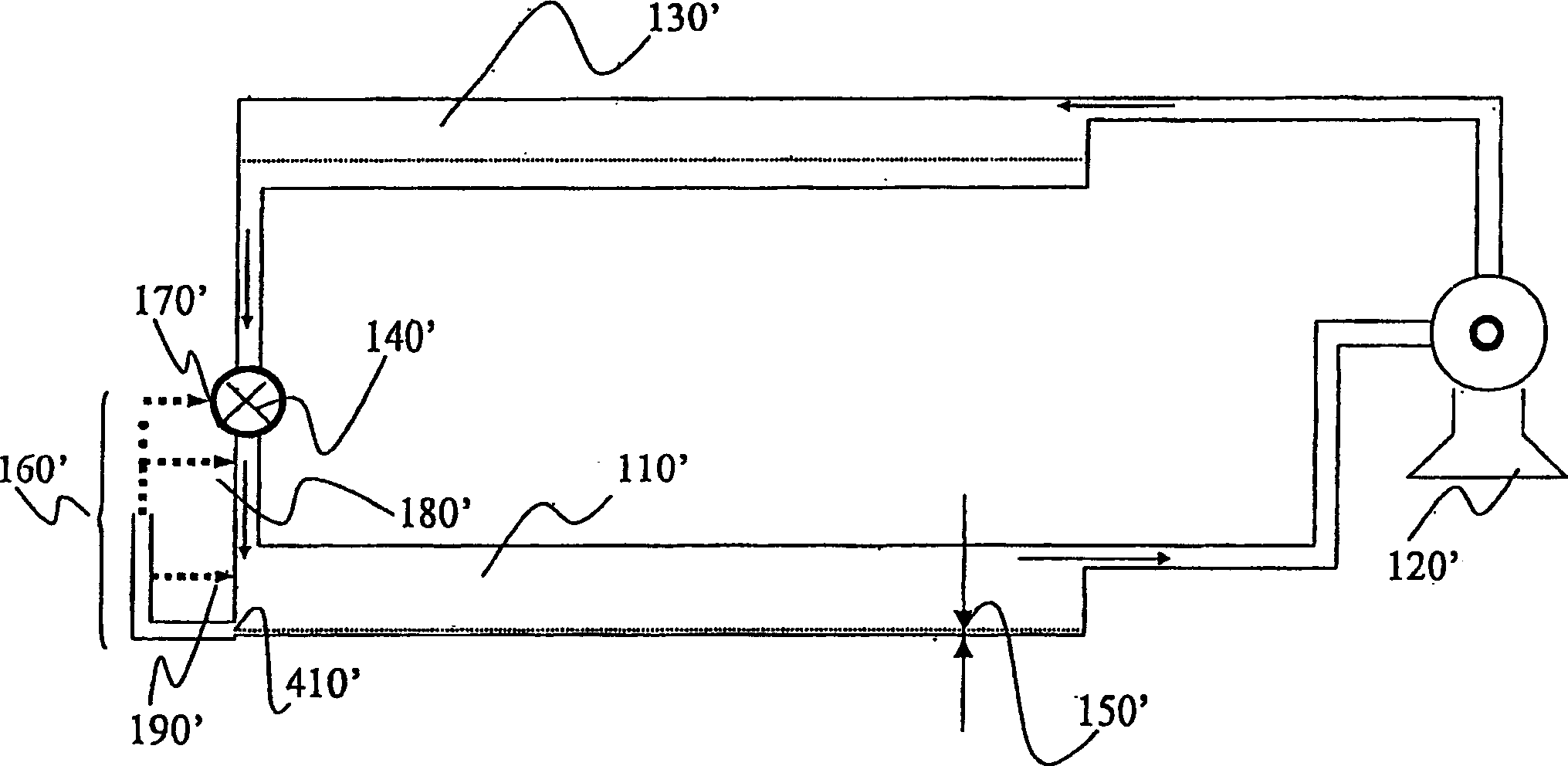

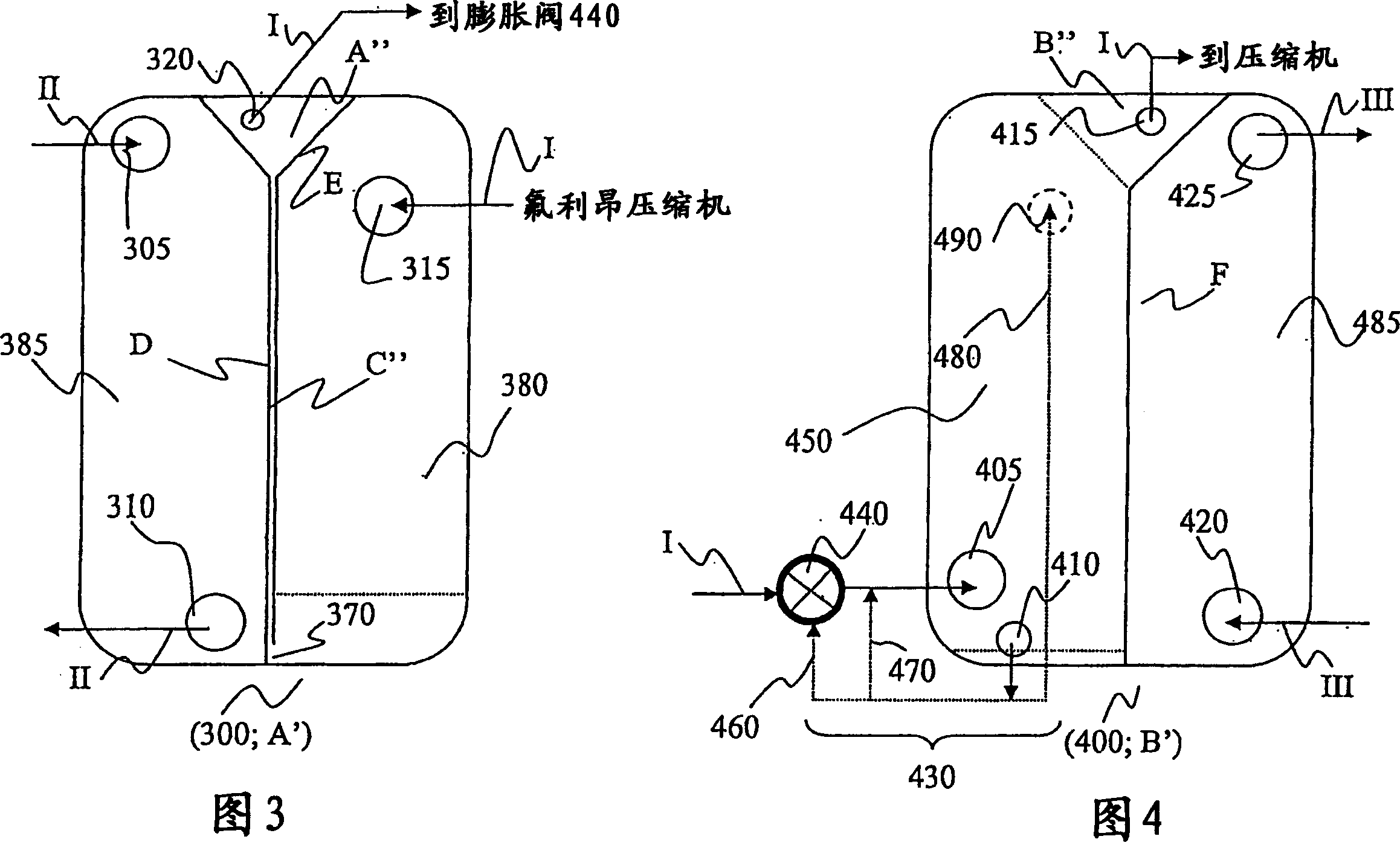

Embodiments of the invention are directed toward a novel pressurized vapor cycle for distilling liquids. In some embodiments of the invention, a liquid purification system is revealed, including the elements of an input for receiving untreated liquid, a vaporizer coupled to the input for transforming the liquid to vapor, a head chamber for collecting the vapor, a vapor pump with an internal drive shaft and an eccentric rotor with a rotatable housing for compressing vapor, and a condenser in communication with the vapor pump for transforming the compressed vapor into a distilled product. Other embodiments of the invention are directed toward heat management, and other process enhancements for making the system especially efficient.

Owner:DEKA PROD LLP

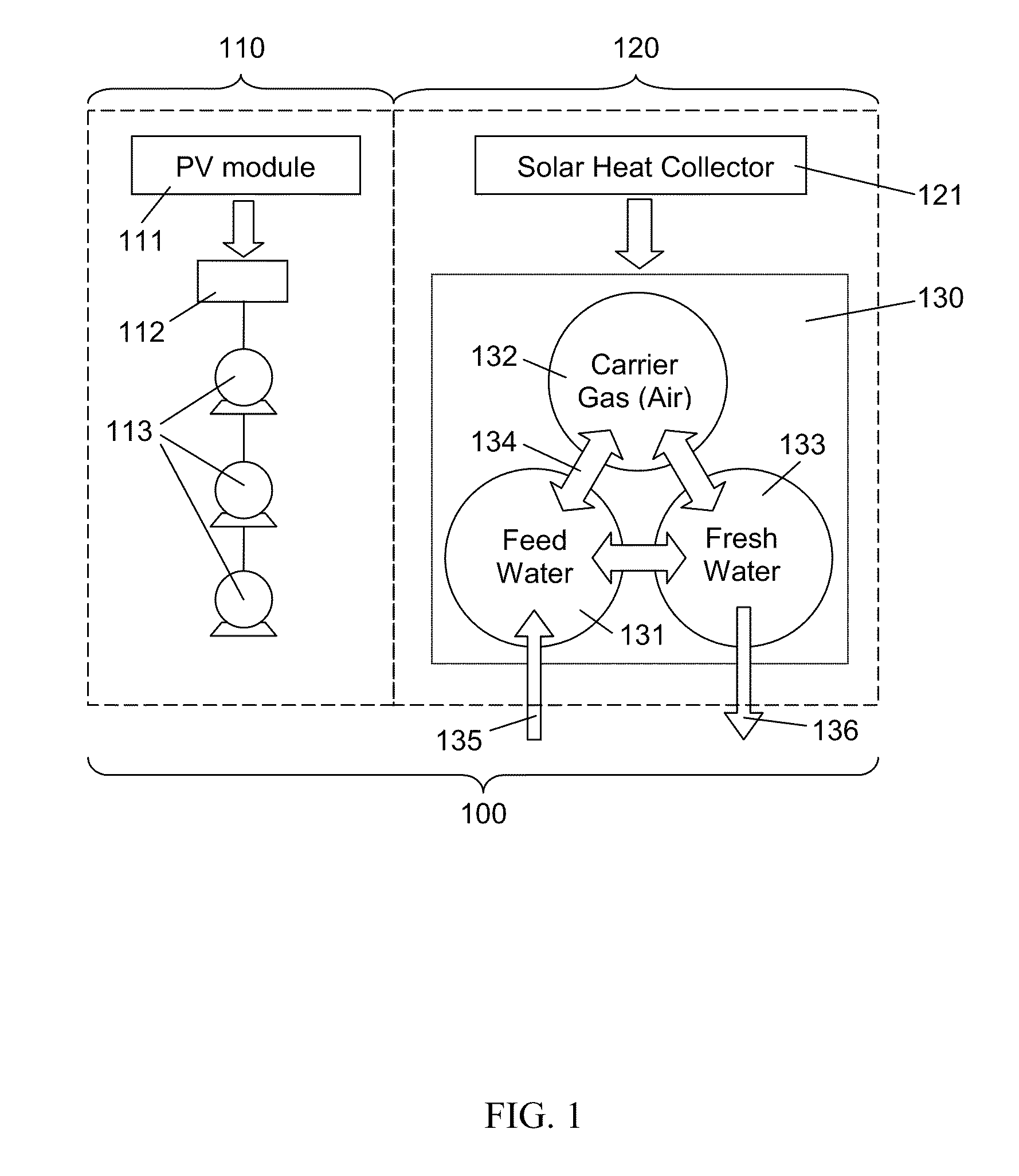

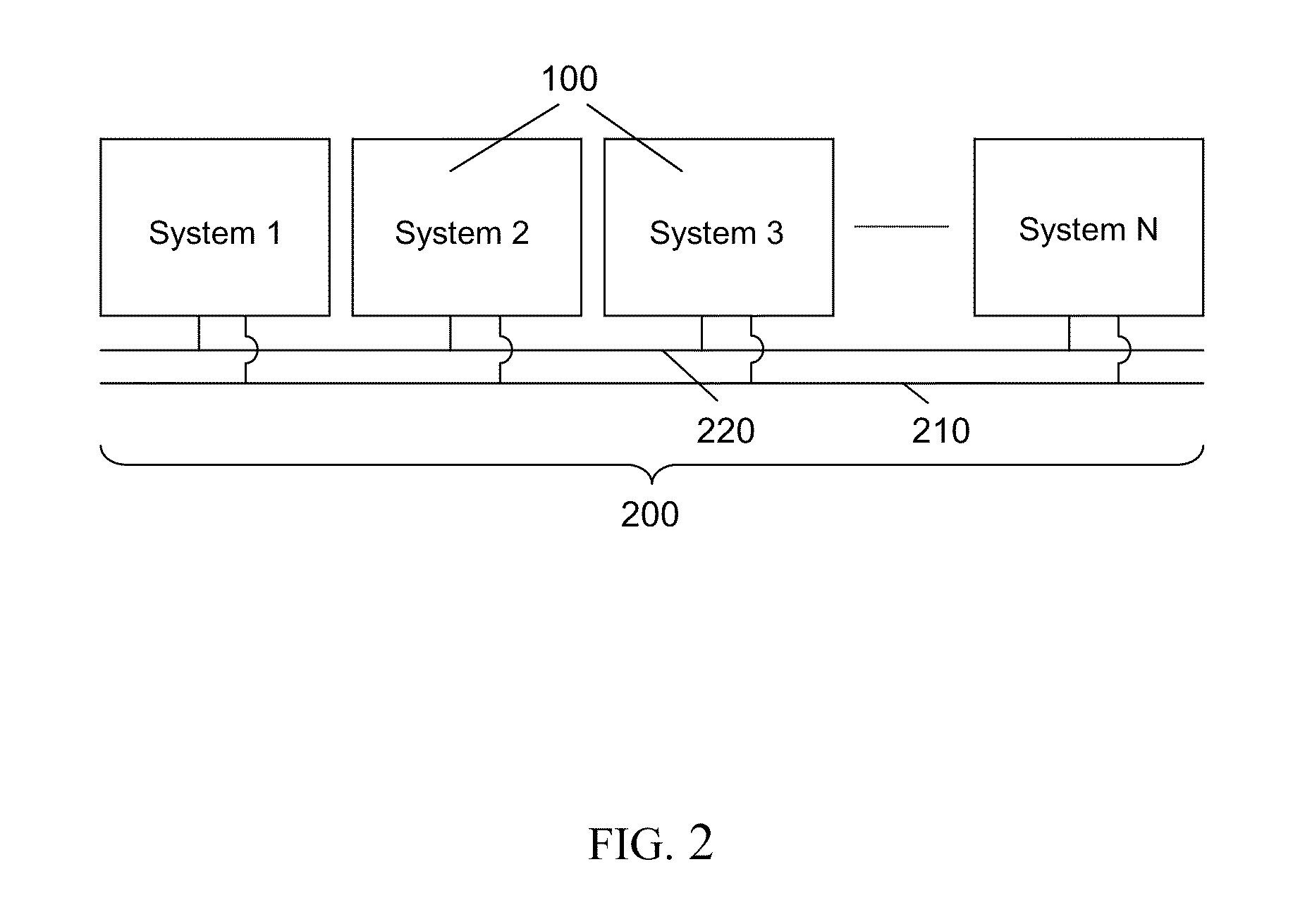

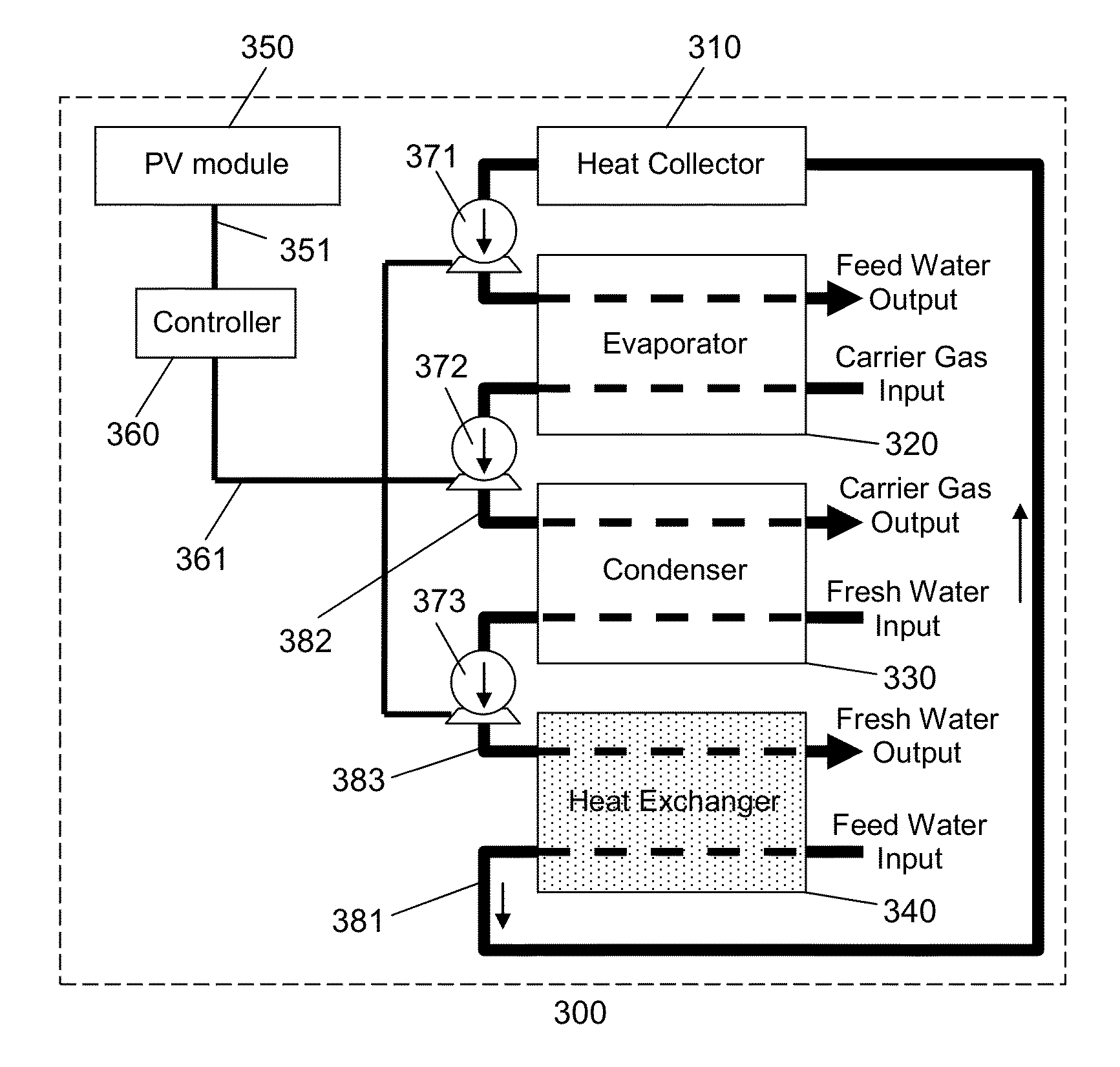

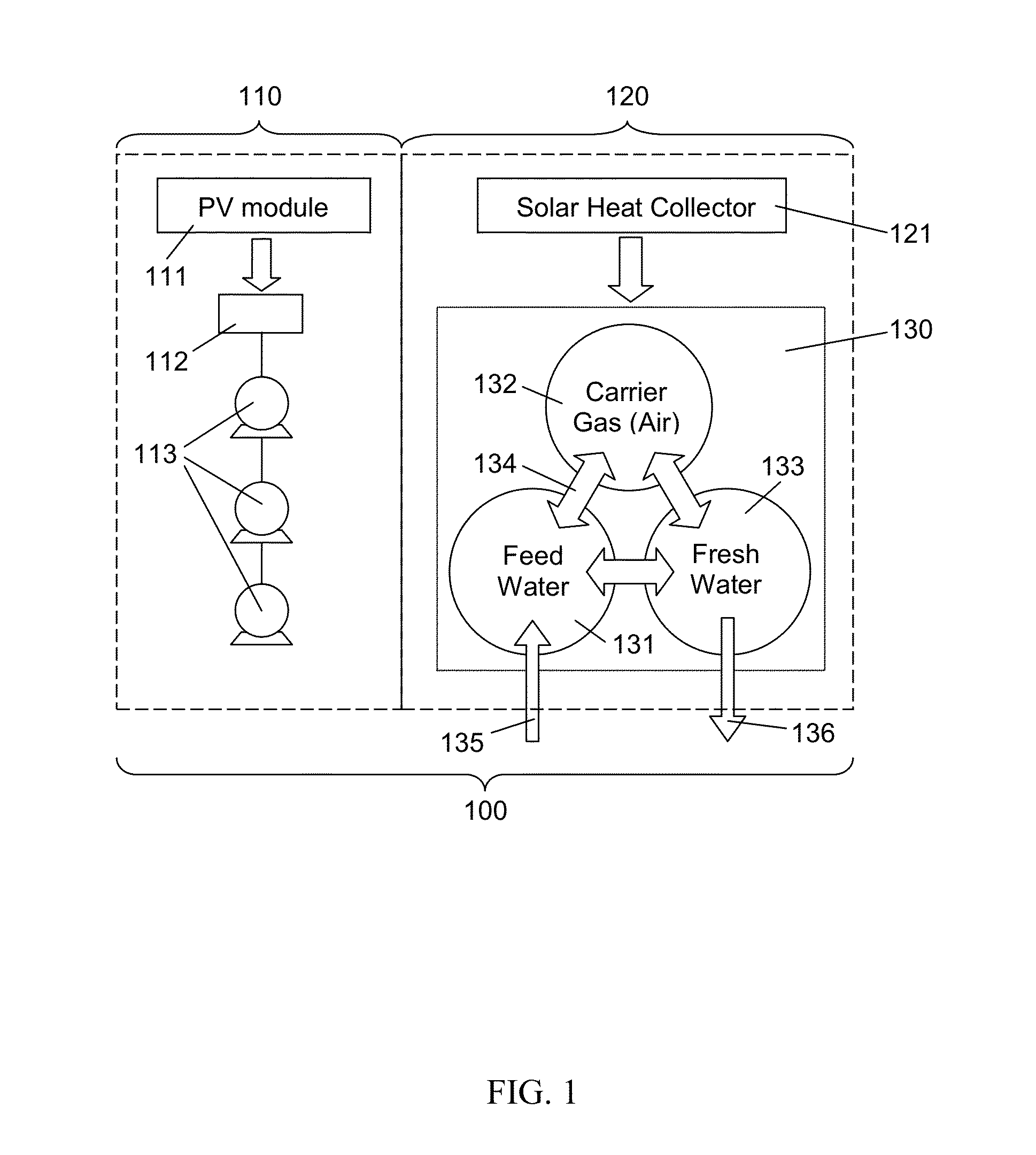

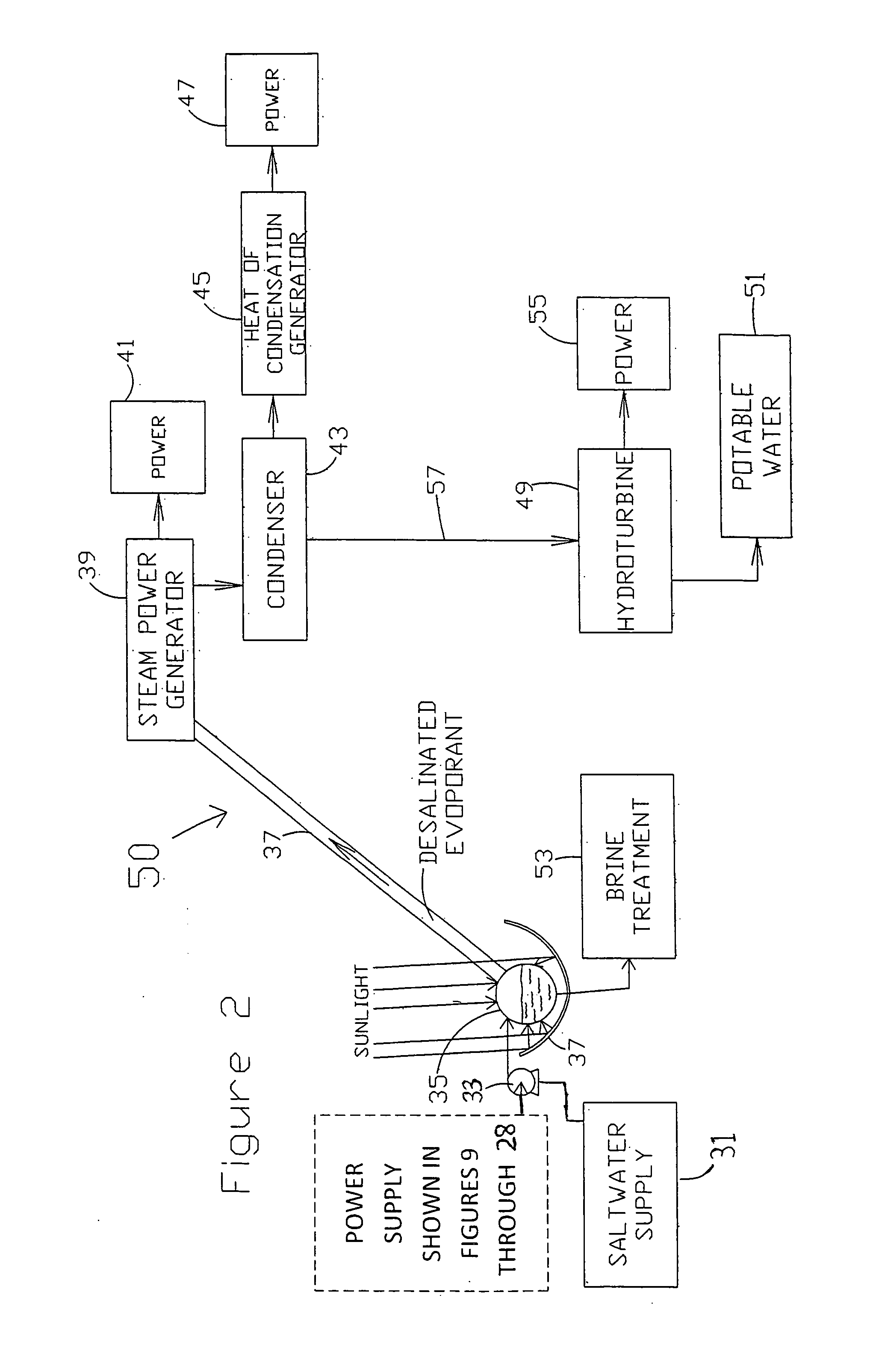

Hybrid solar desalination system

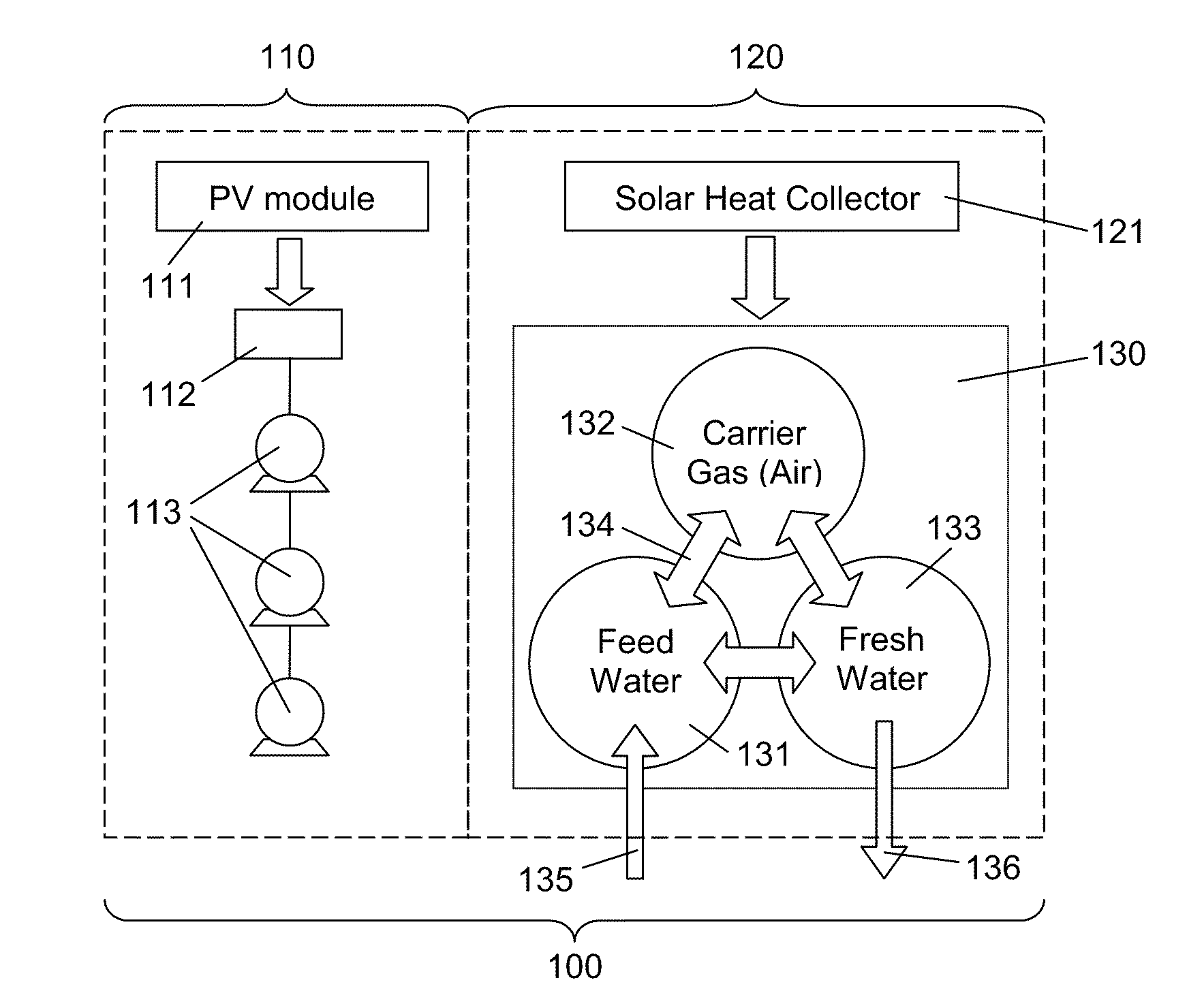

A hydro-thermal exchange unit (HTEU) for desalinating feed water in accordance with a humidification-dehumidification includes feed water, fresh water and gas conduit circuits for transporting feed water, fresh water, and gas, respectively. The unit also includes an evaporator through which a portion of the feed water conduit and the gas conduit pass. The evaporator causes evaporation of a portion of the feed water to produce vapor that is transported through the gas conduit. The unit also includes a condenser through which a portion of the gas conduit and the fresh water conduit pass. The condenser has input and output ports for coupling the gas and fresh water conduit circuits. The condenser extracts moisture from the vapor transported therethrough by the gas conduit. The extracted moisture is discharged through the fresh water conduit. The unit also includes a heat exchanger through which a portion of the fresh water conduit and the feed water conduit pass to thereby extract residual heat from the fresh water such that the residual heat heats the feed water.

Owner:SUNLIGHT PHOTONICS

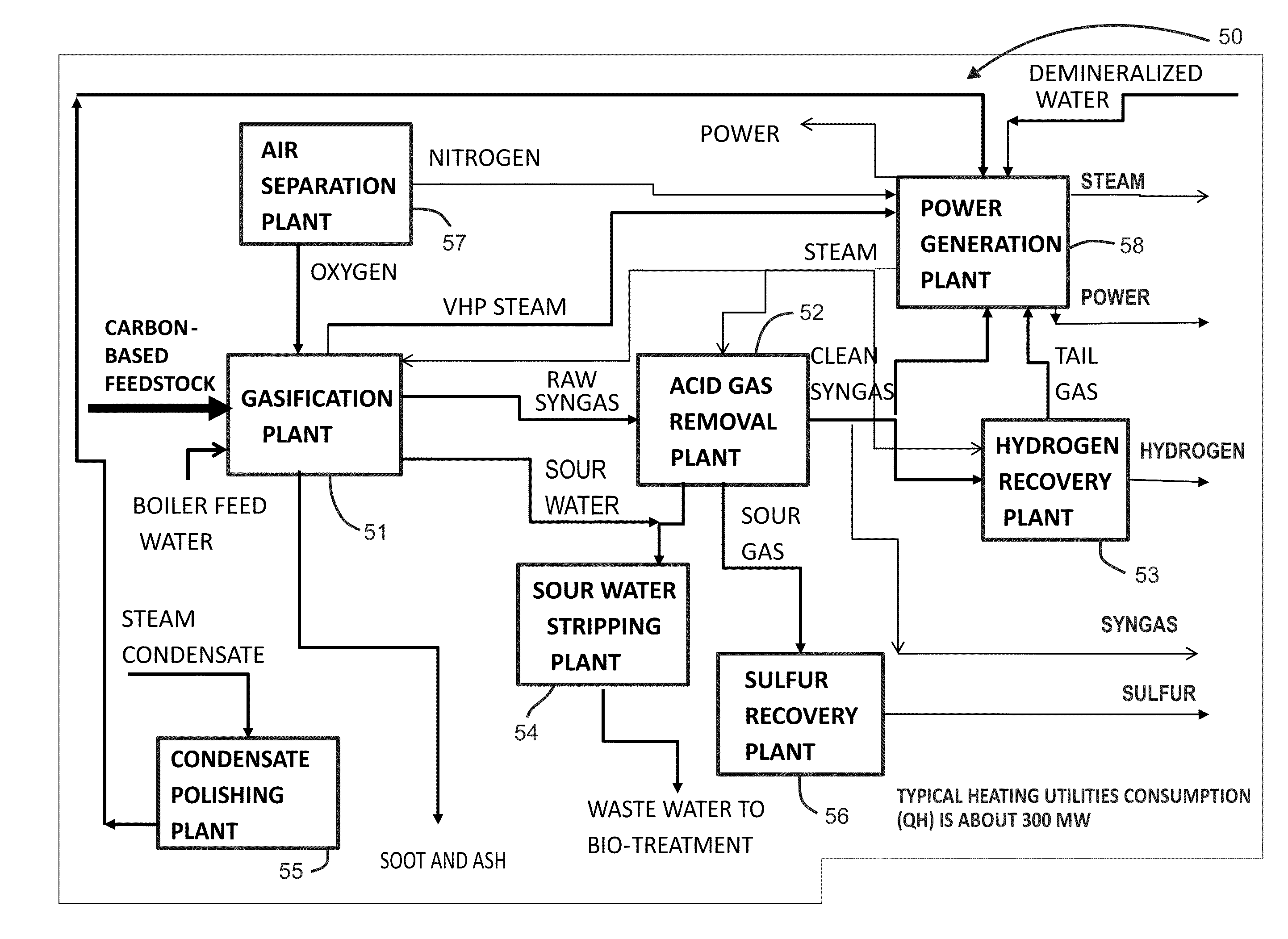

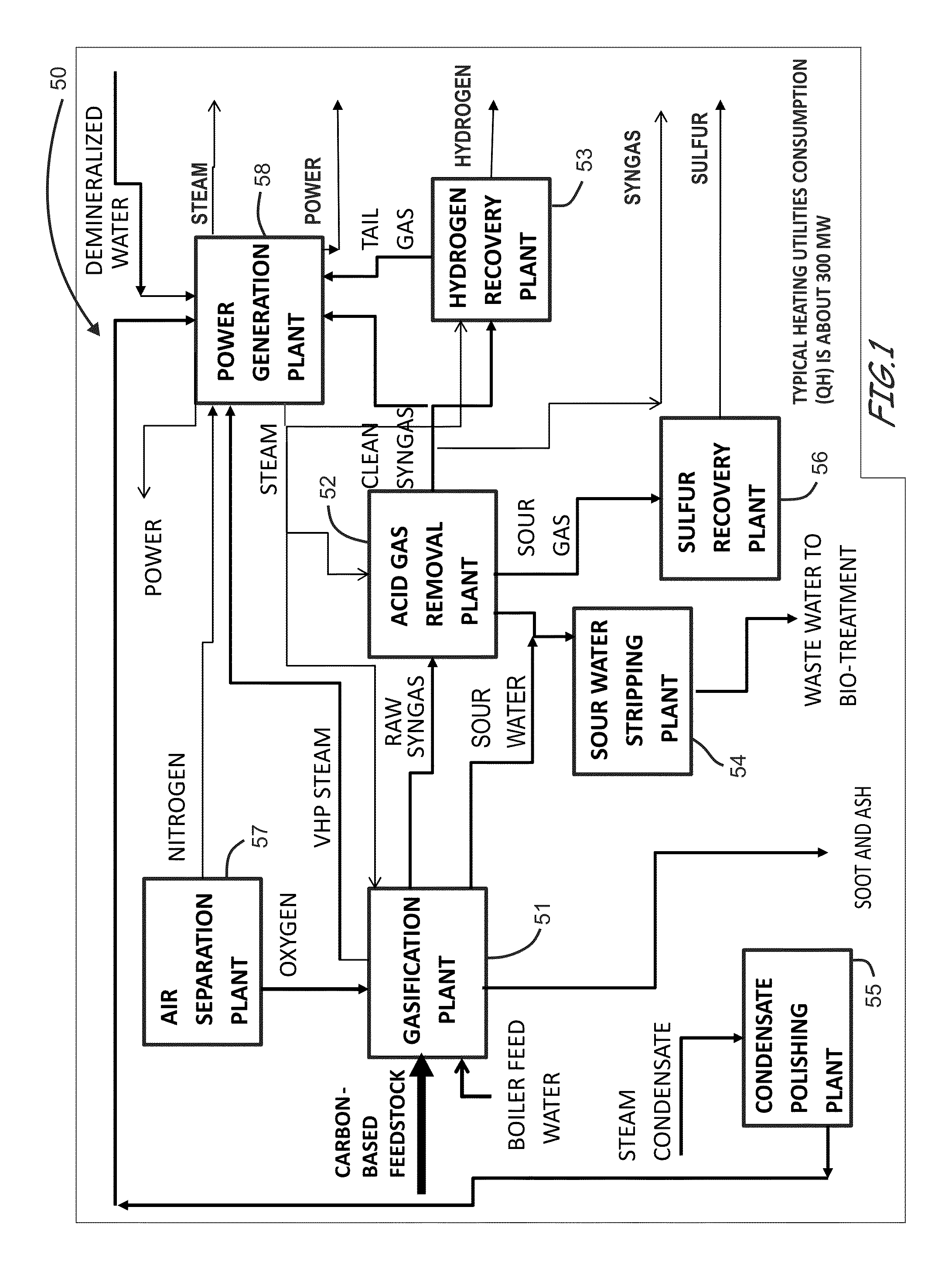

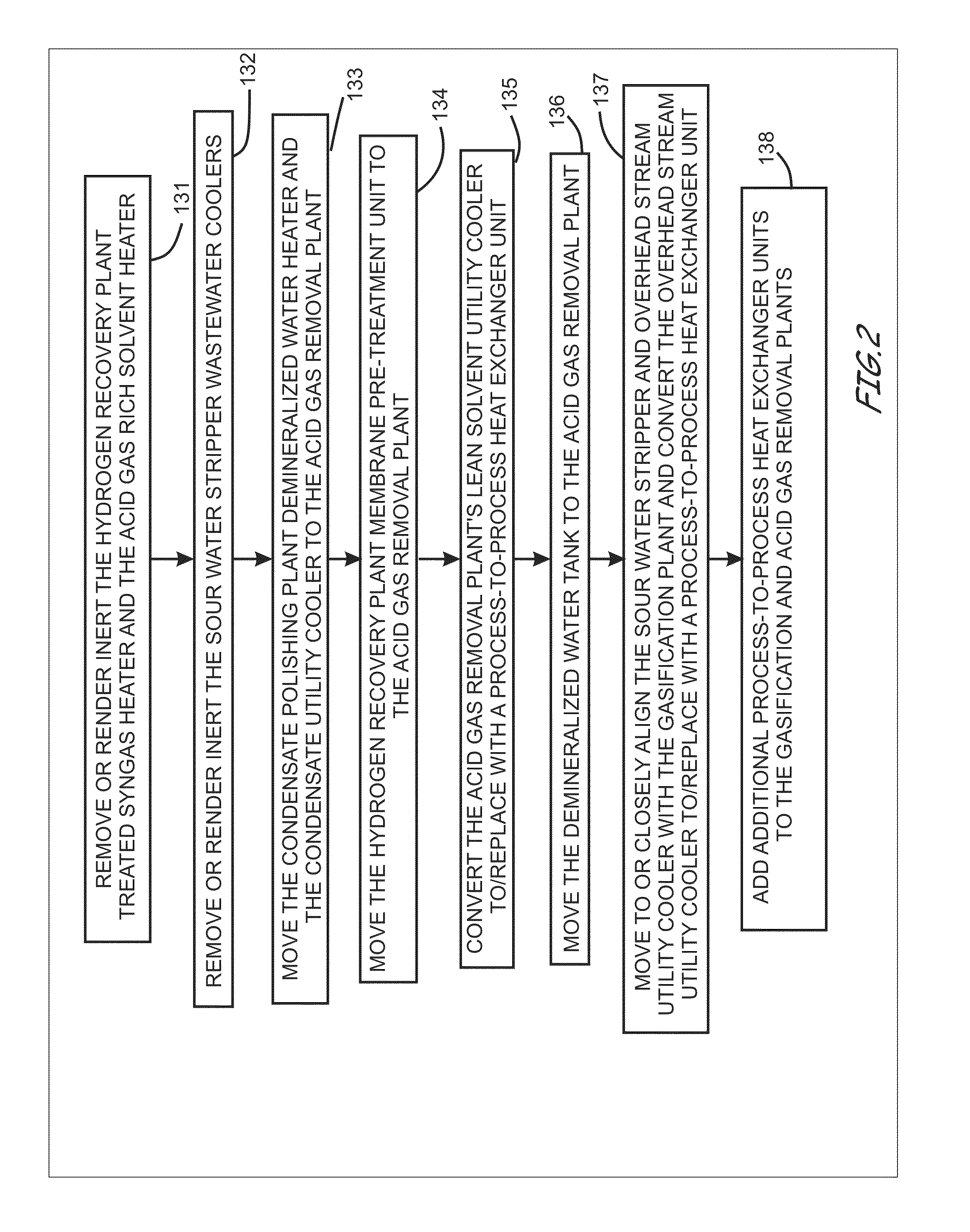

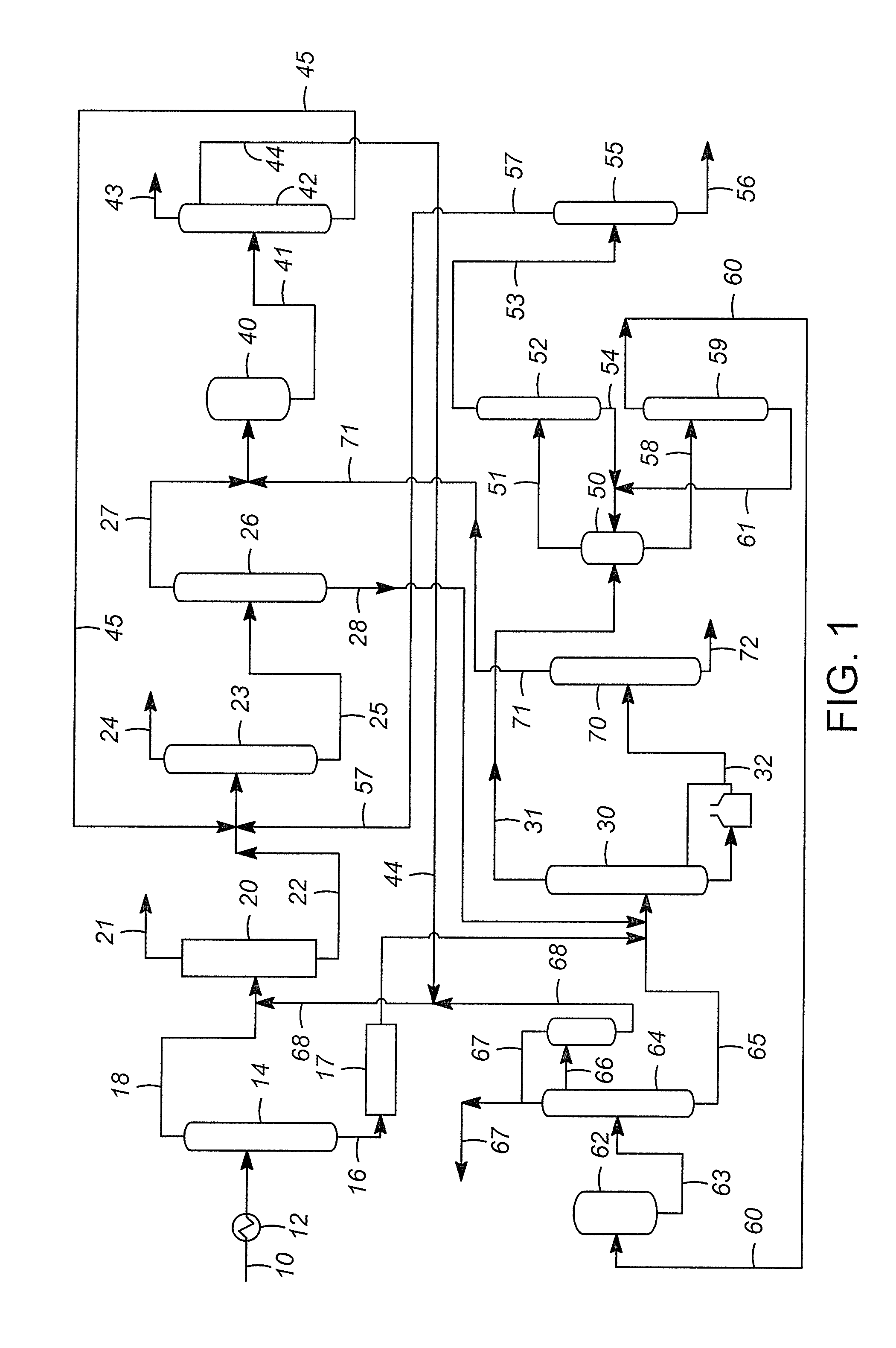

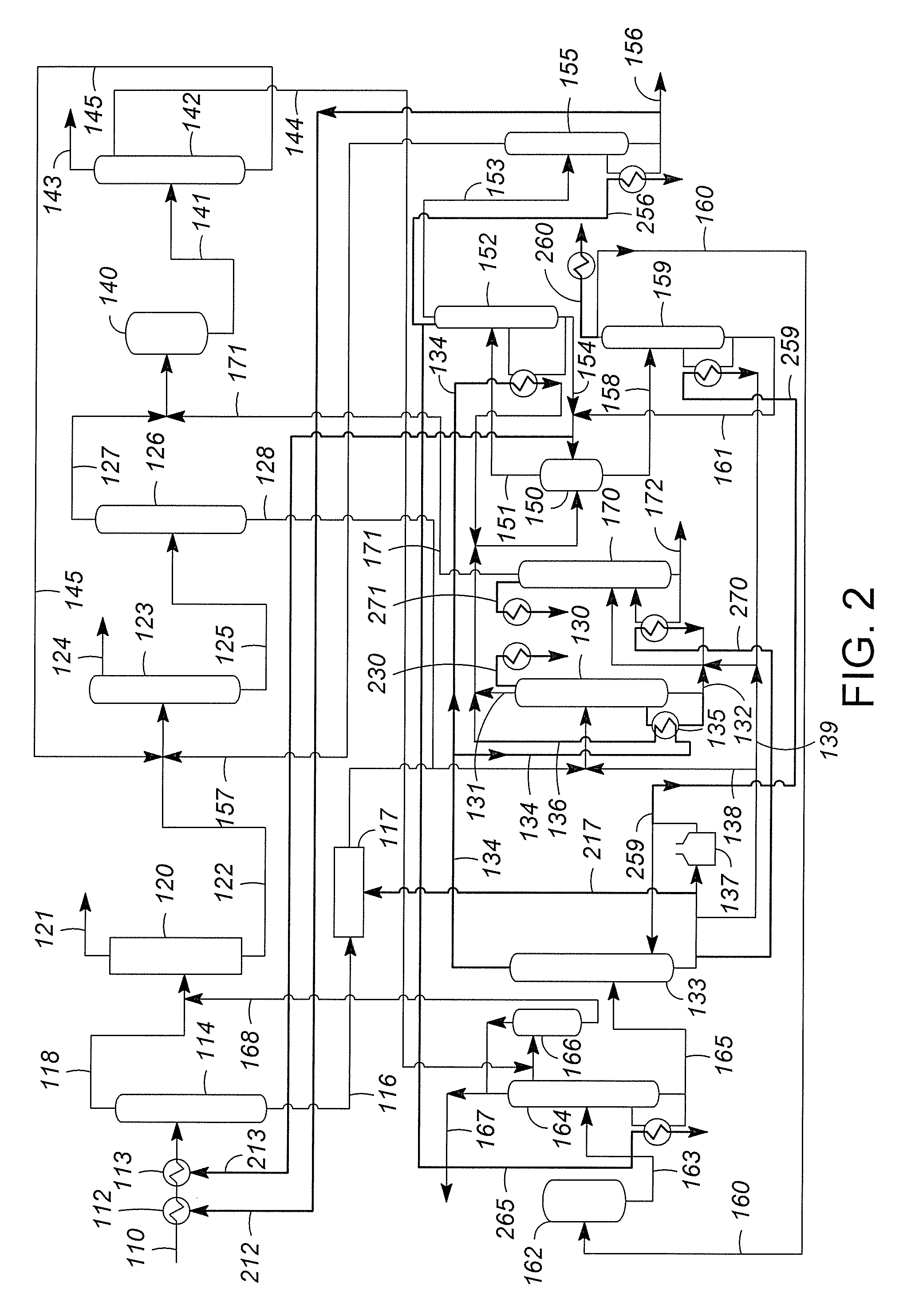

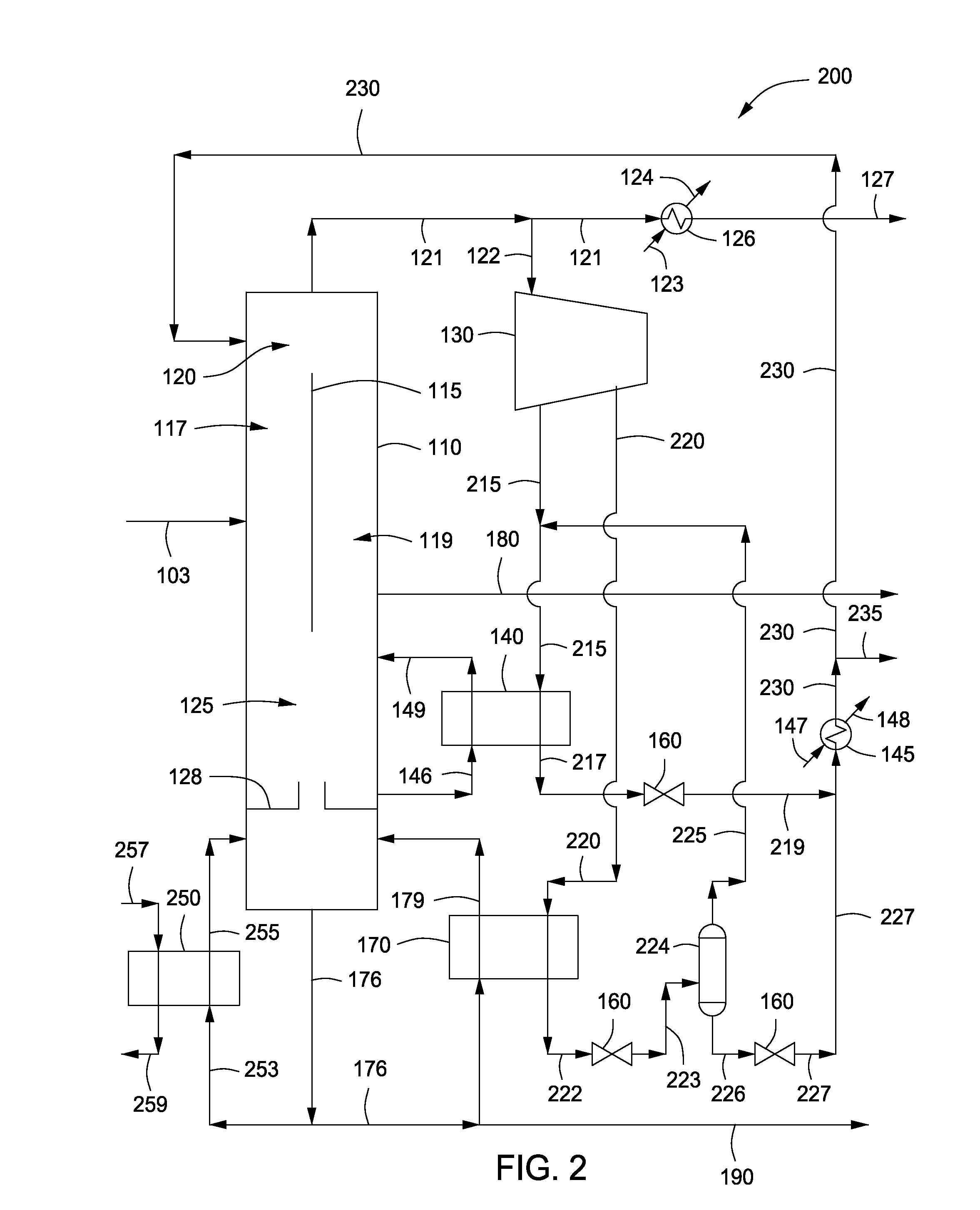

Energy efficient apparatus employing energy efficient process schemes providing enhanced integration of gasification-based multi-generation and hydrocarbon refining facilities and related methods

ActiveUS20150377079A1Less pollutionEasy to modifyProcess control/regulationGasifier mechanical detailsSolventMulti generation

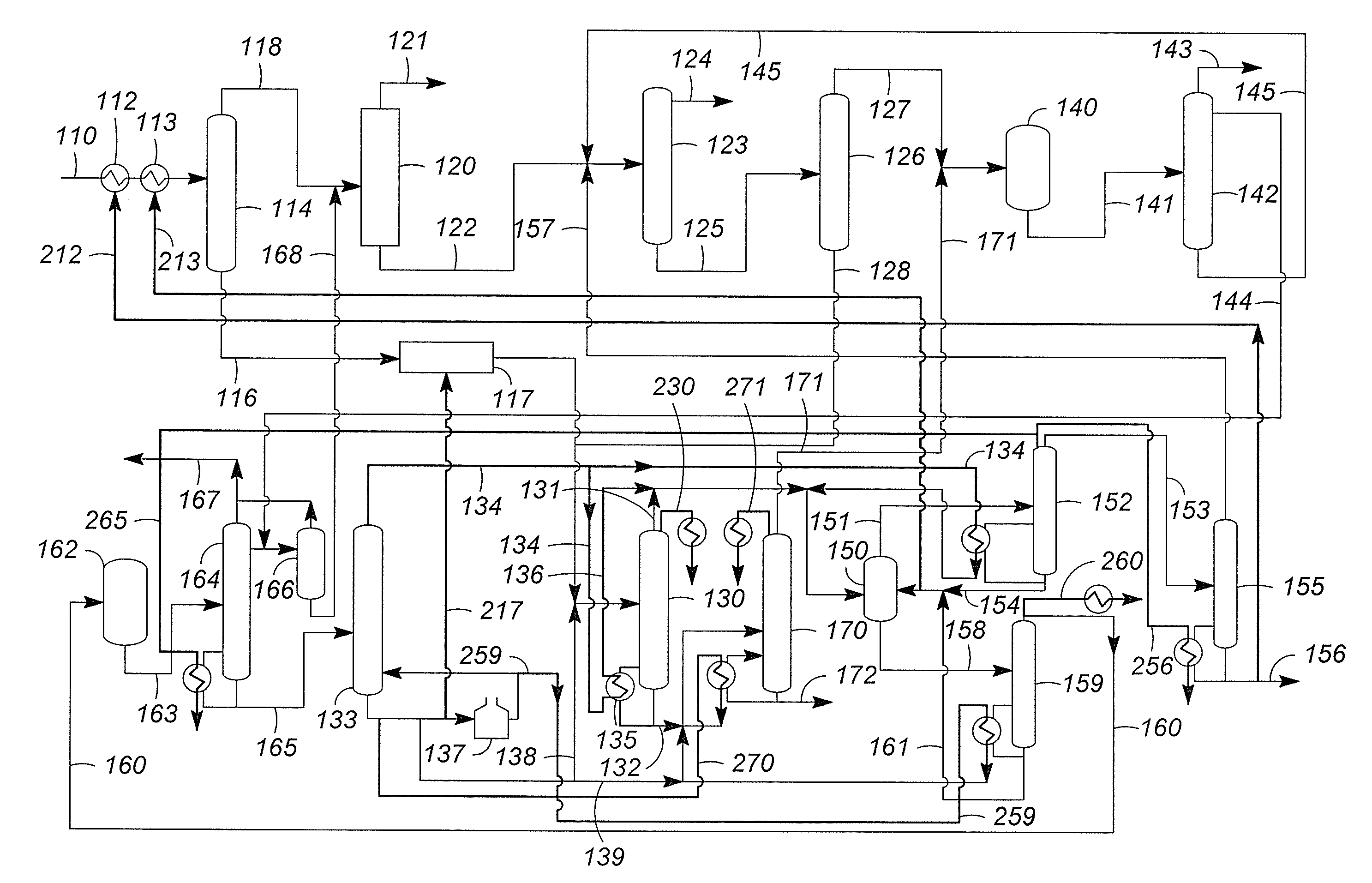

Energy-efficient gasification-based multi-generation apparatus, facilities, or systems, and methods of modifying existing gasification-based multi-generation apparatus and the various conventional thermal coupling arrangements, are provided. Apparatus for managing waste heat recovery through integration of a gasification-based multi-generation facility or other multi-generation system with a hydrocarbon refining facility or other hydrocarbon refining system and methods of providing the respective integration are also provided. An exemplary apparatus includes an integrated site energy management system configured according to one or more process-based thermal coupling schemes comprising one or more thermal coupling arrangements between a gasification-based multi-generation system or facility and a hydrocarbon refining system or facility. The gasification-based multi-generation system or facility can include an acid gas removal system or plant configured to remove acidic contaminants from a raw syngas feed to thereby provide a treated syngas feed, the acid gas removal system or plant containing a separation section including a solvent regenerator, and a gasification system configured to generate the raw syngas feed from a carbon-based feedstock. The hydrocarbon refining system or facility can include an aromatics system or plant containing a xylene products separation section including one or more of the following: an Extract column and a Raffinate column. The integrated site energy management system can include a hot-water system extending between the separation section of the acid gas removal system or plant and the xylene products separation section of the aromatics system or plant, and a plurality of added heat exchanger units providing various advanced thermal coupling arrangements.

Owner:SAUDI ARABIAN OIL CO

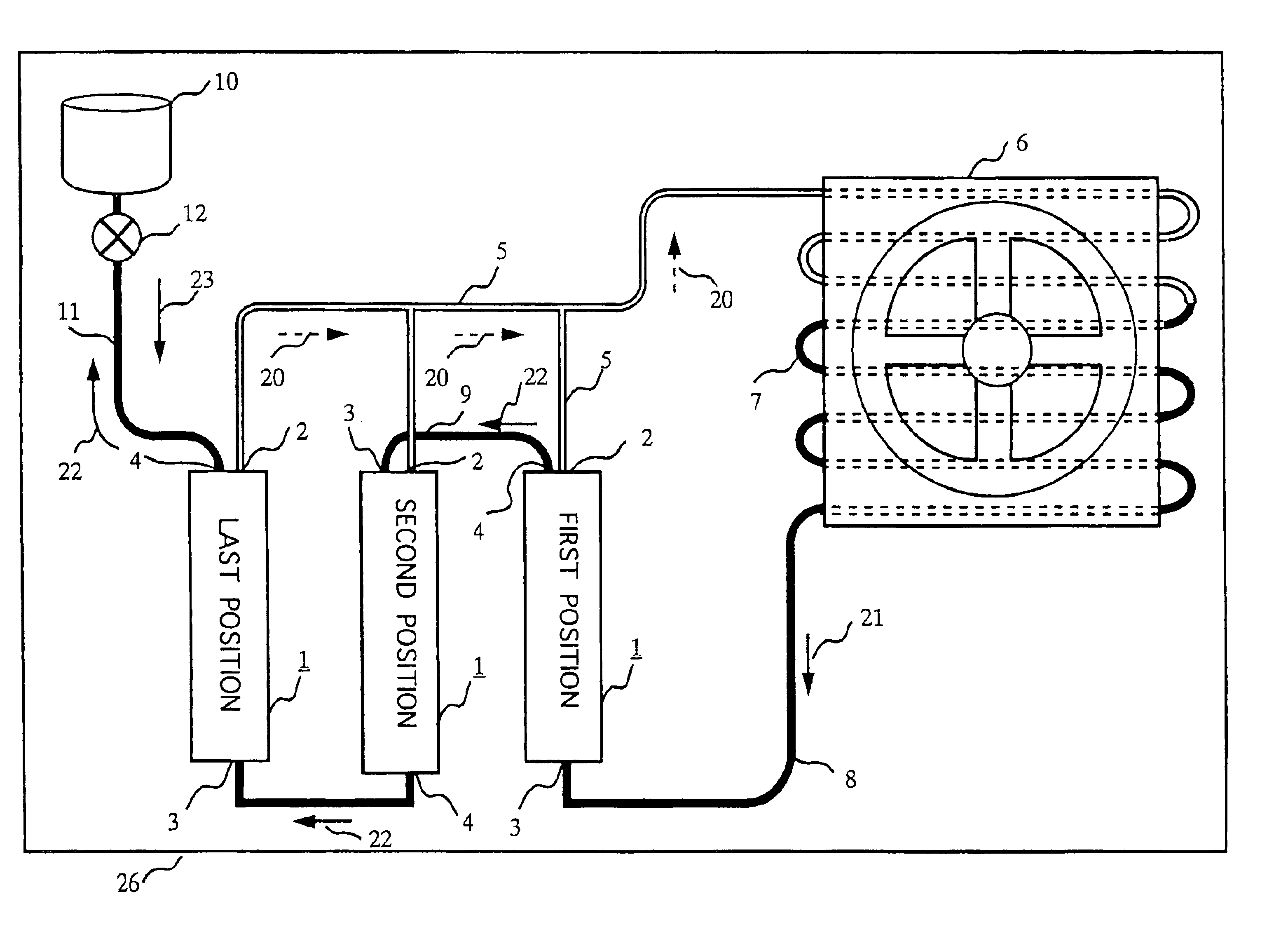

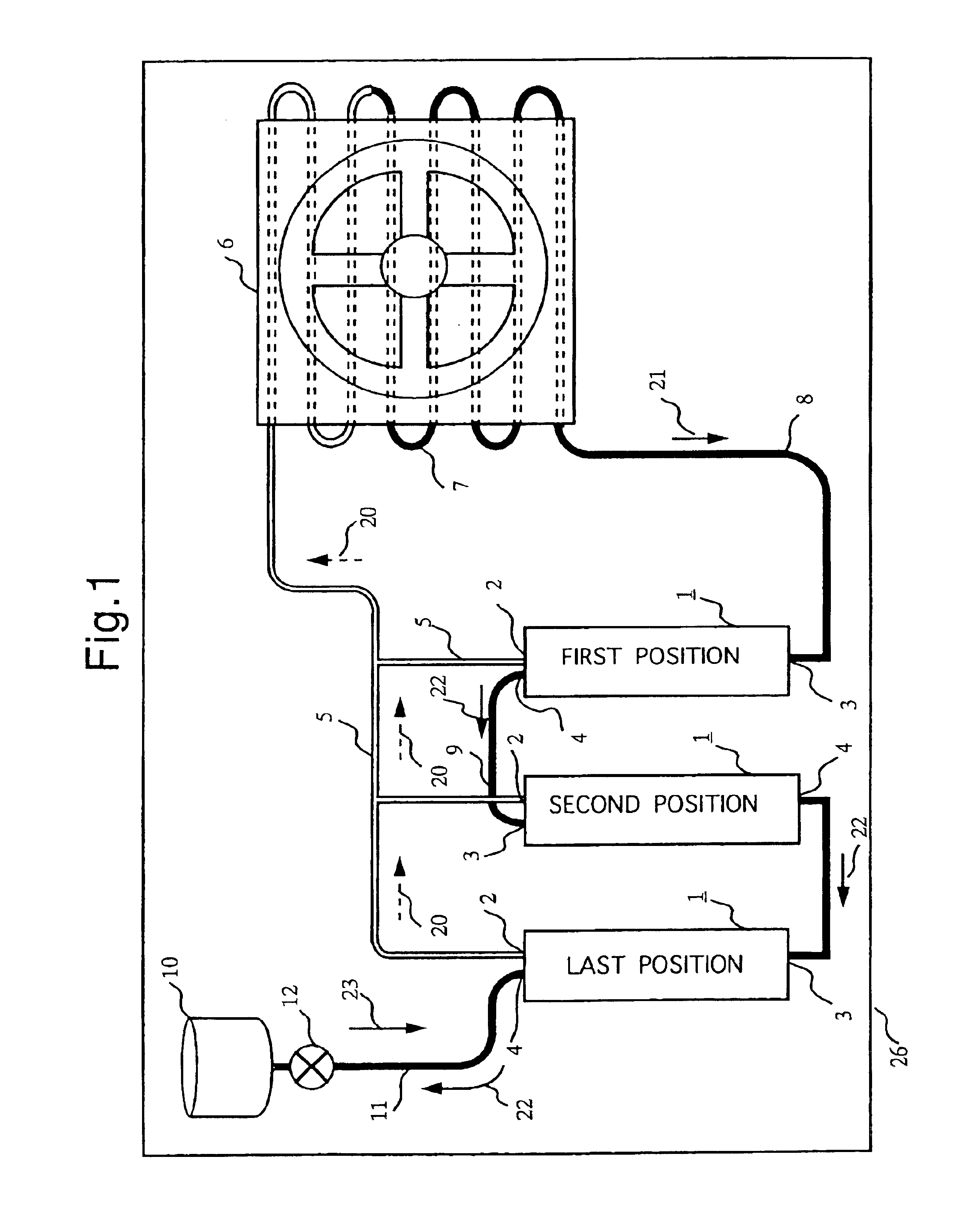

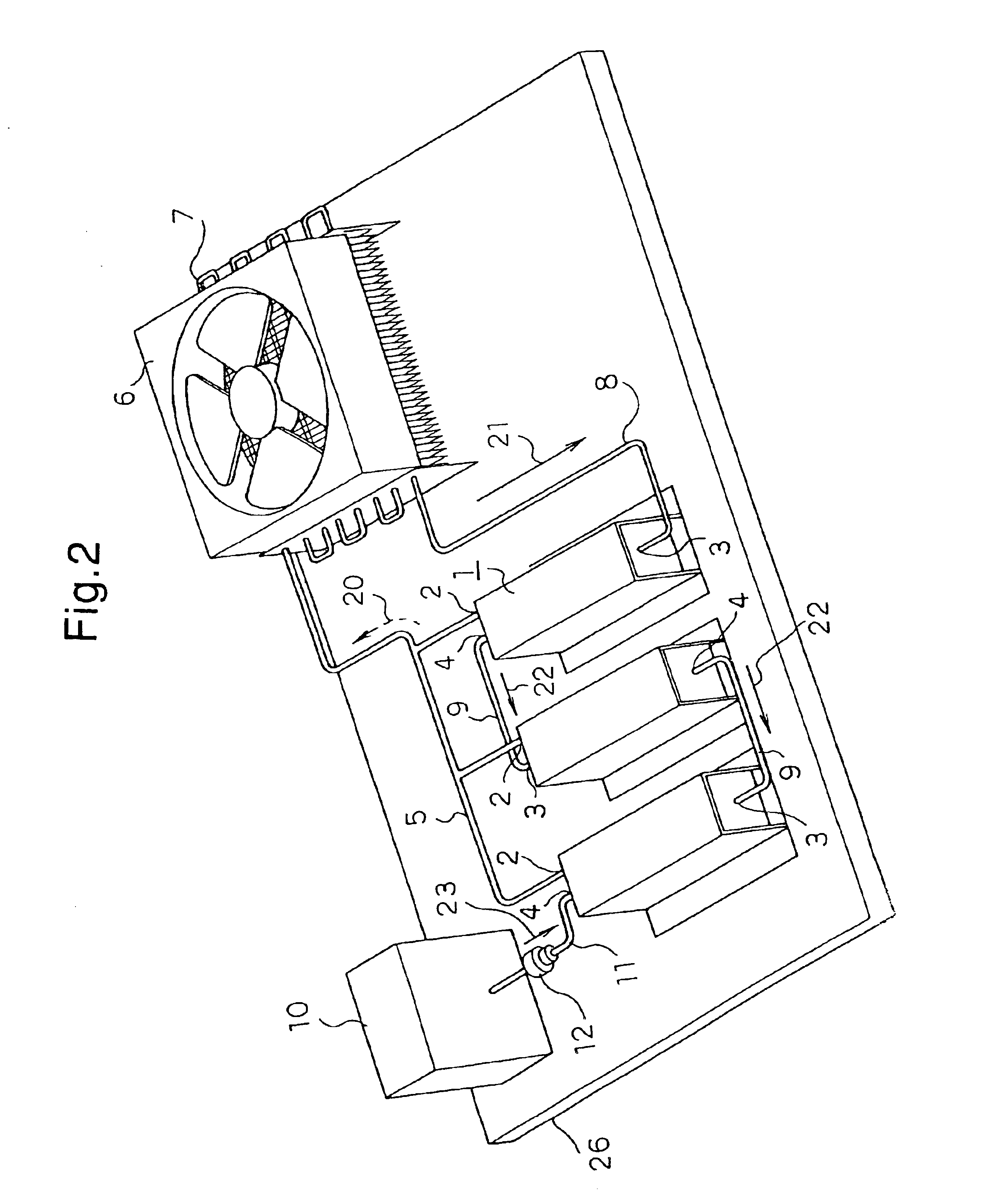

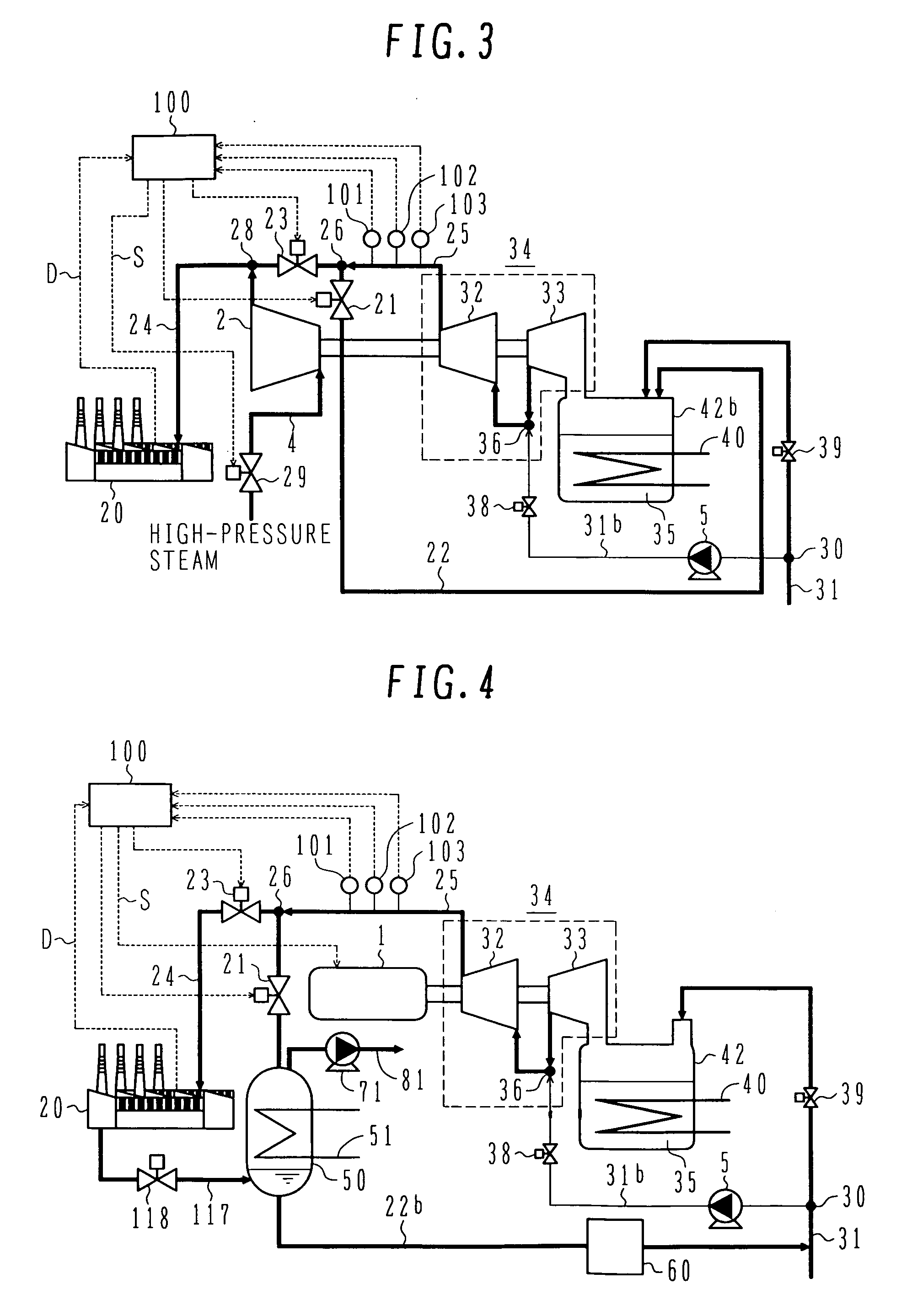

Evaporator, a heat absorber, a thermal transport system and a thermal transport method

InactiveUS6840304B1Air-treating devicesEnergy recuperation in distillationThermal transportLiquid tank

The conventional thermal transport system has disadvantages of the configuration being complex, large, heavyweight and expensive. In the present invention, a plurality of evaporators are connected in series via the liquid flow line, the evaporator of the first position is connected to the condenser via the liquid supply line, the evaporator of the last position is connected to the reservoir tanks for adjusting the amount of the liquid. The liquid amount measuring sensor is installed to measure the amount of the liquid in the liquid reservoir of the evaporator. Based on the measured result of the liquid amount measuring sensor, the control valve operates so as to supply the liquid accommodated in the reservoir tanks to each evaporator.

Owner:MITSUBISHI ELECTRIC CORP

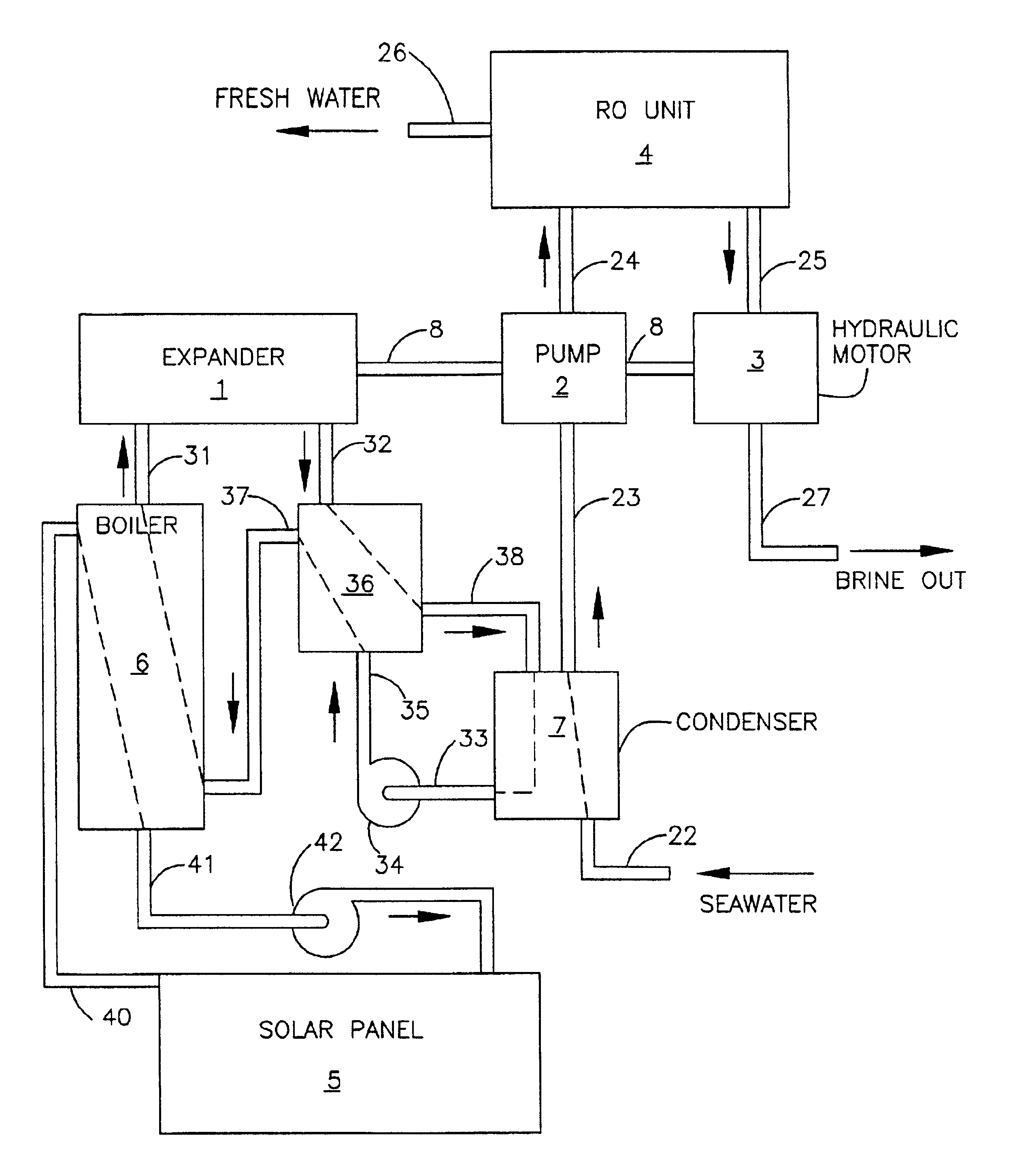

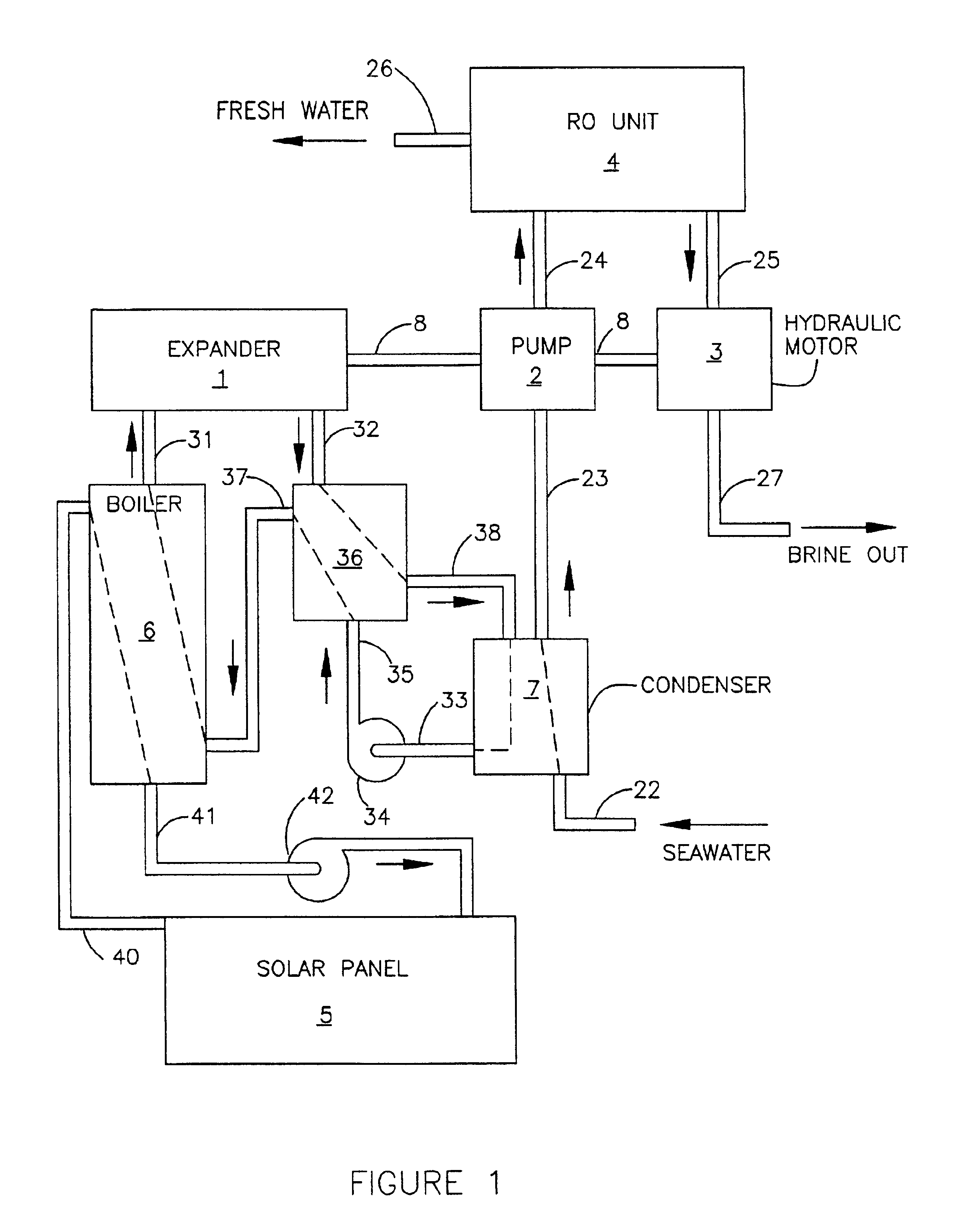

Solar energy desalination system

A desalination system is driven by a solar powered boiler that outputs a pressurized vapor to drive an expander that generates output motive force. A pump is responsive to the motive force to output pressurized saline water. A reverse osmosis unit receives the pressurized saline water to output fresh water and pressurized brine. A recuperator that transfers heat from the expander exhaust to the boiler feed liquid is incorporated to improve the efficiency of the system. In a particular embodiment, a hydraulic motor receives the pressurized brine and outputs an augmenting motive force to the pump. In another embodiment, a novel motorless boiler feed pump is defined.

Owner:PRUEITT MELVIN L

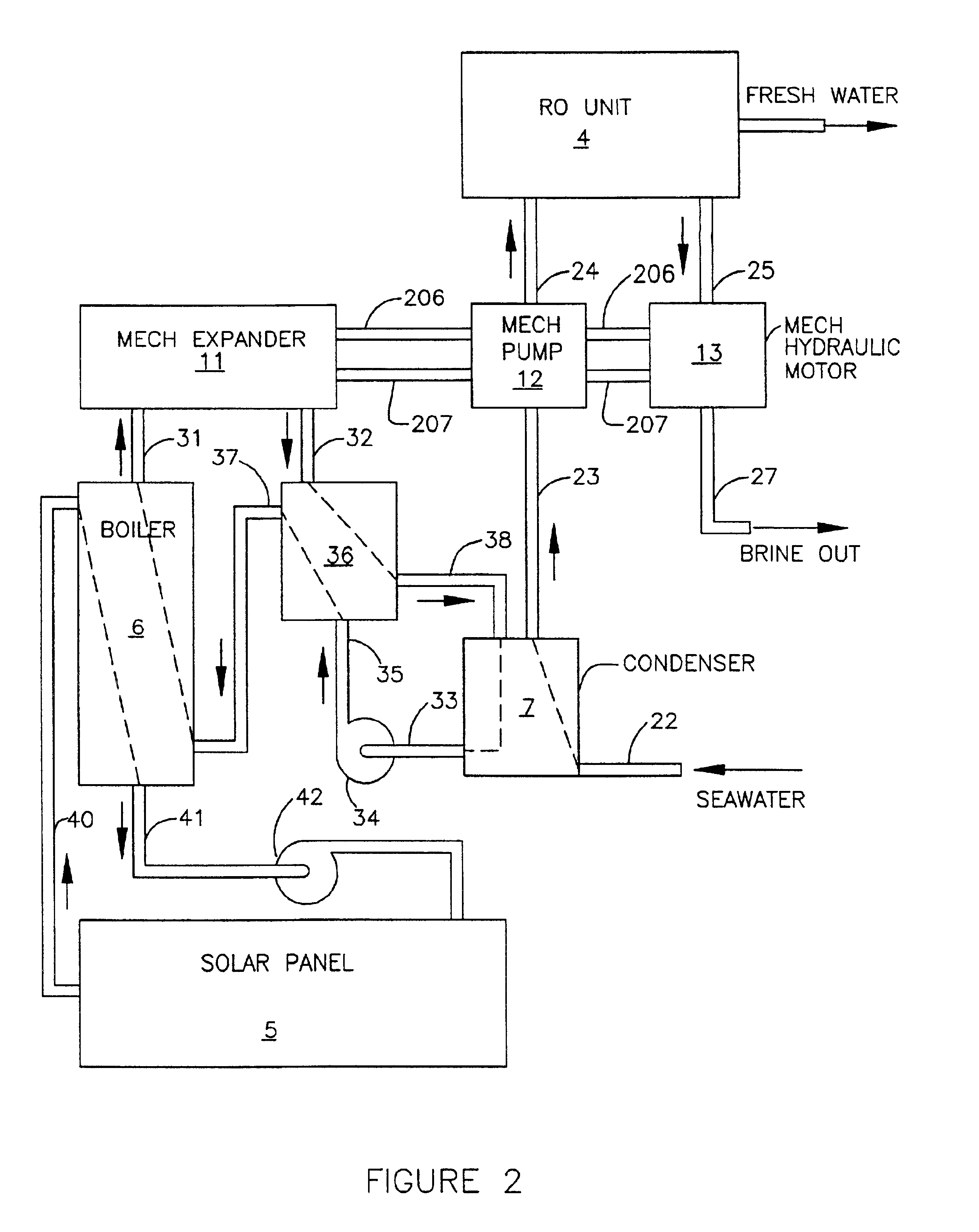

Fluid circuit heat transfer device for plural heat sources

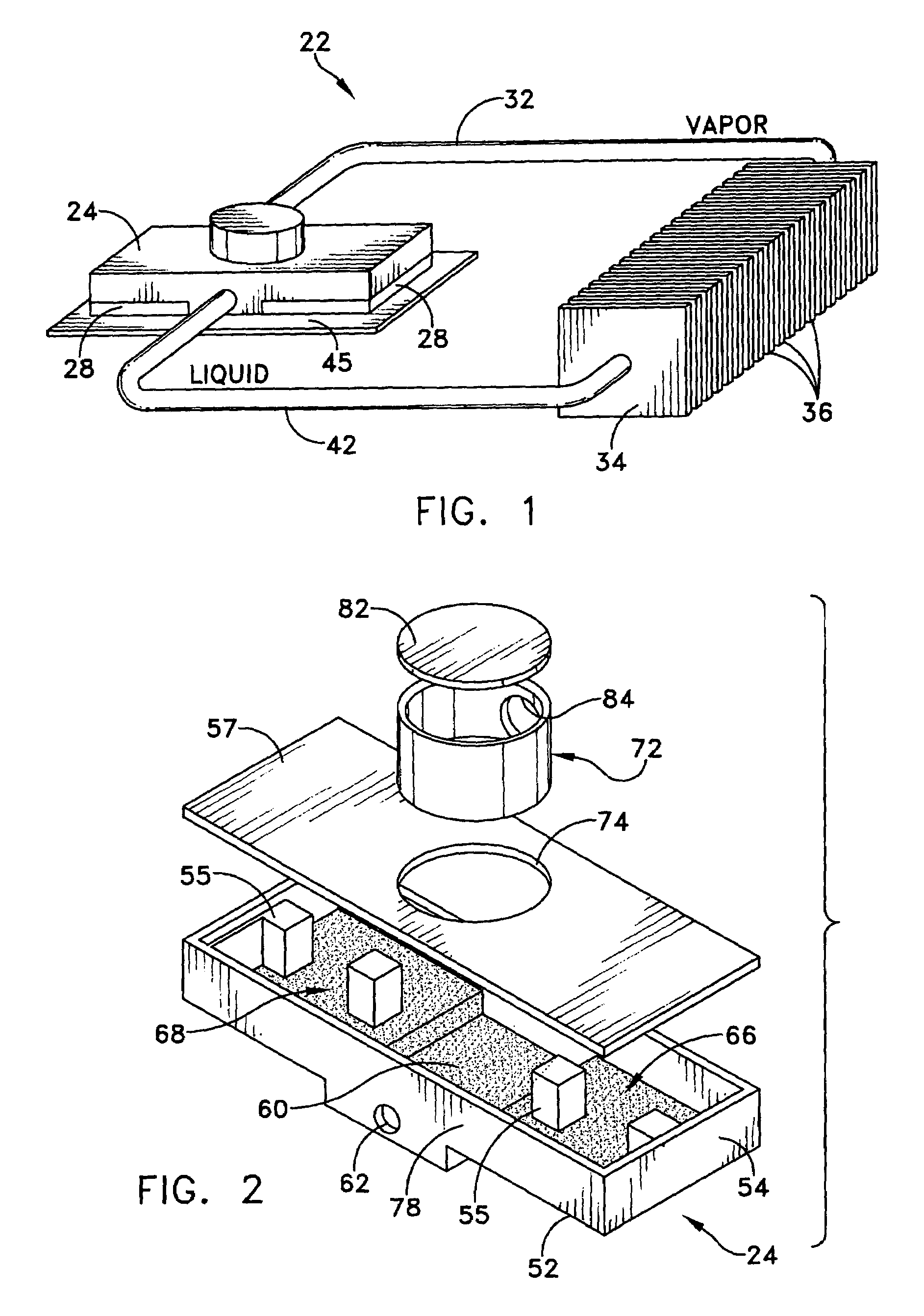

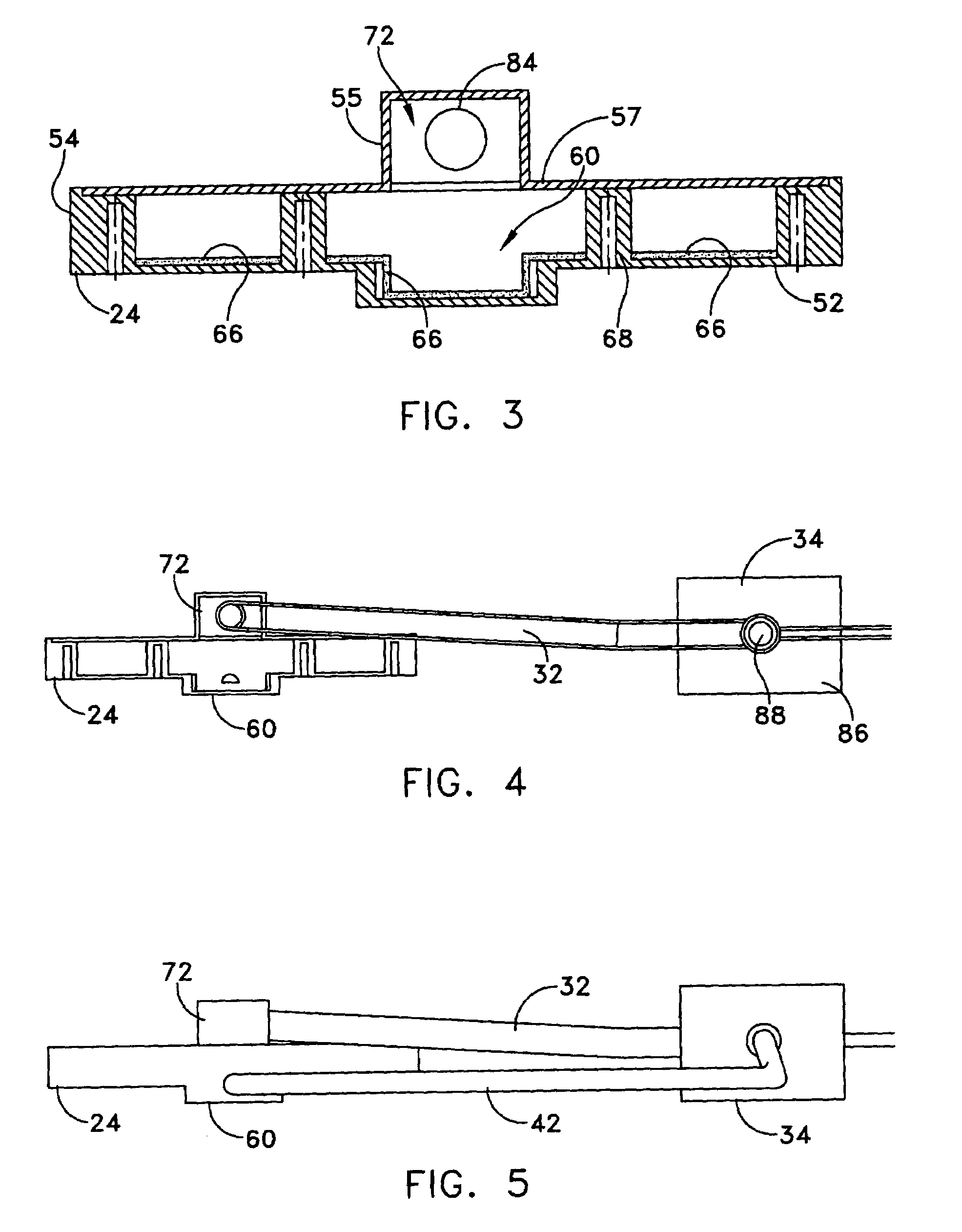

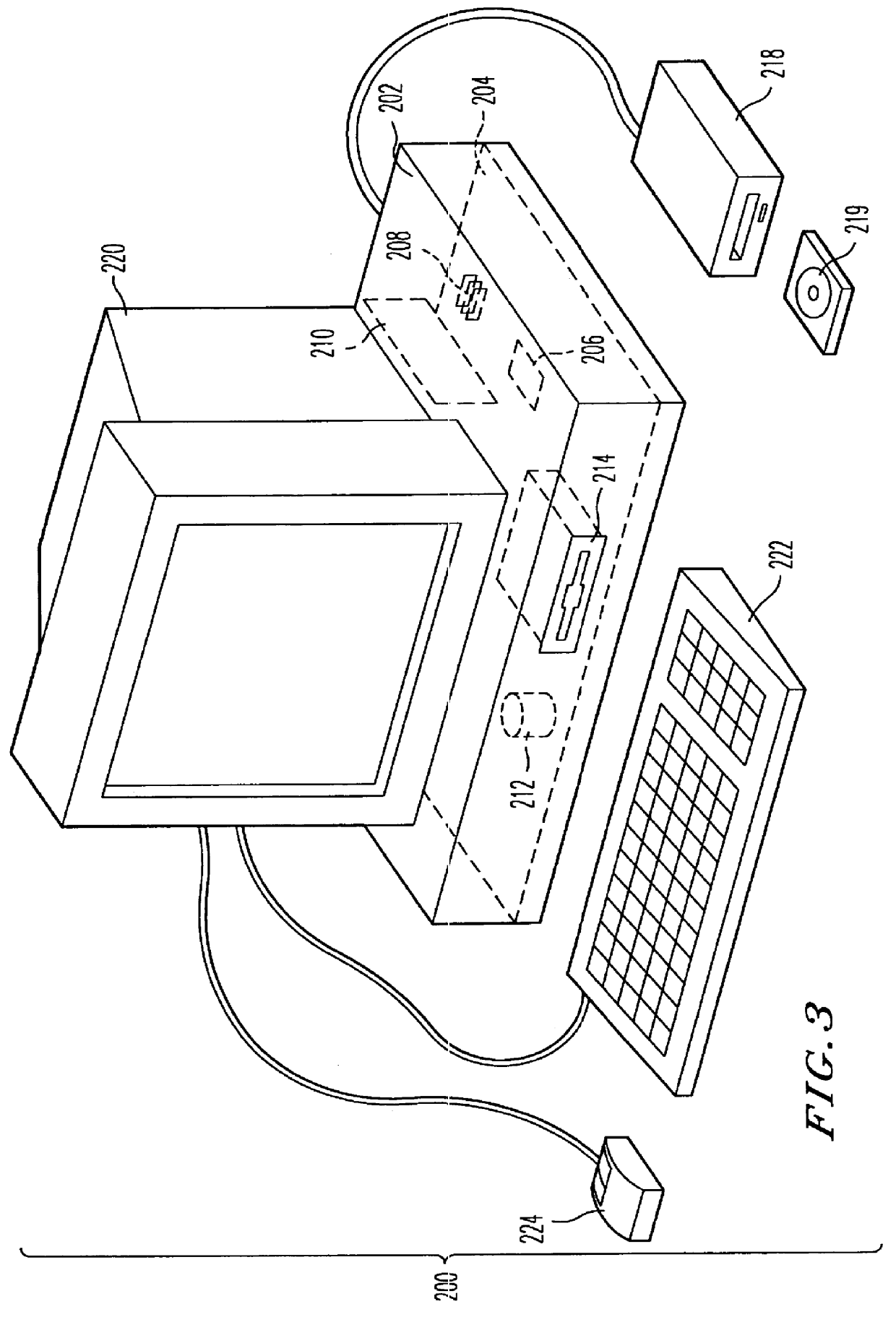

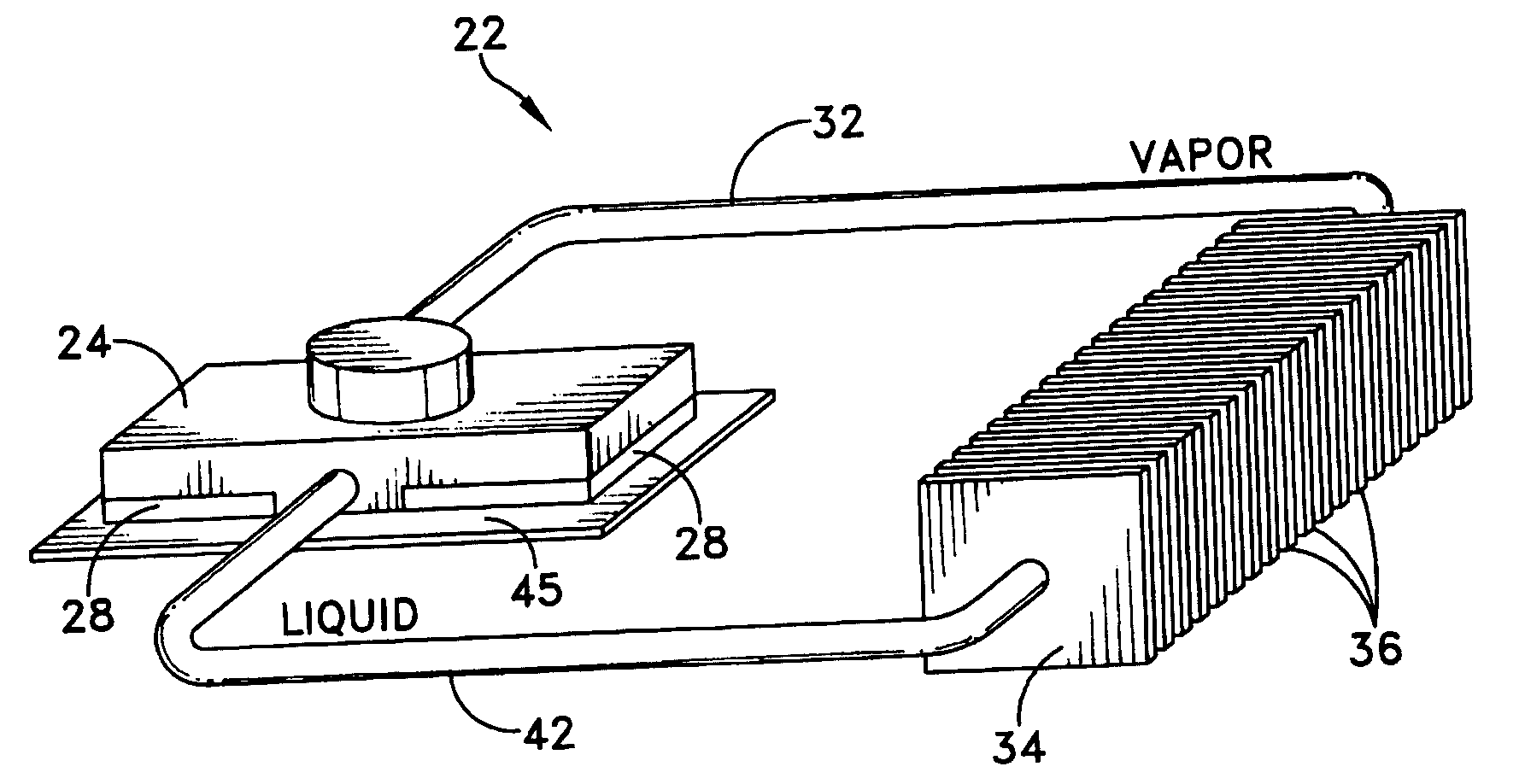

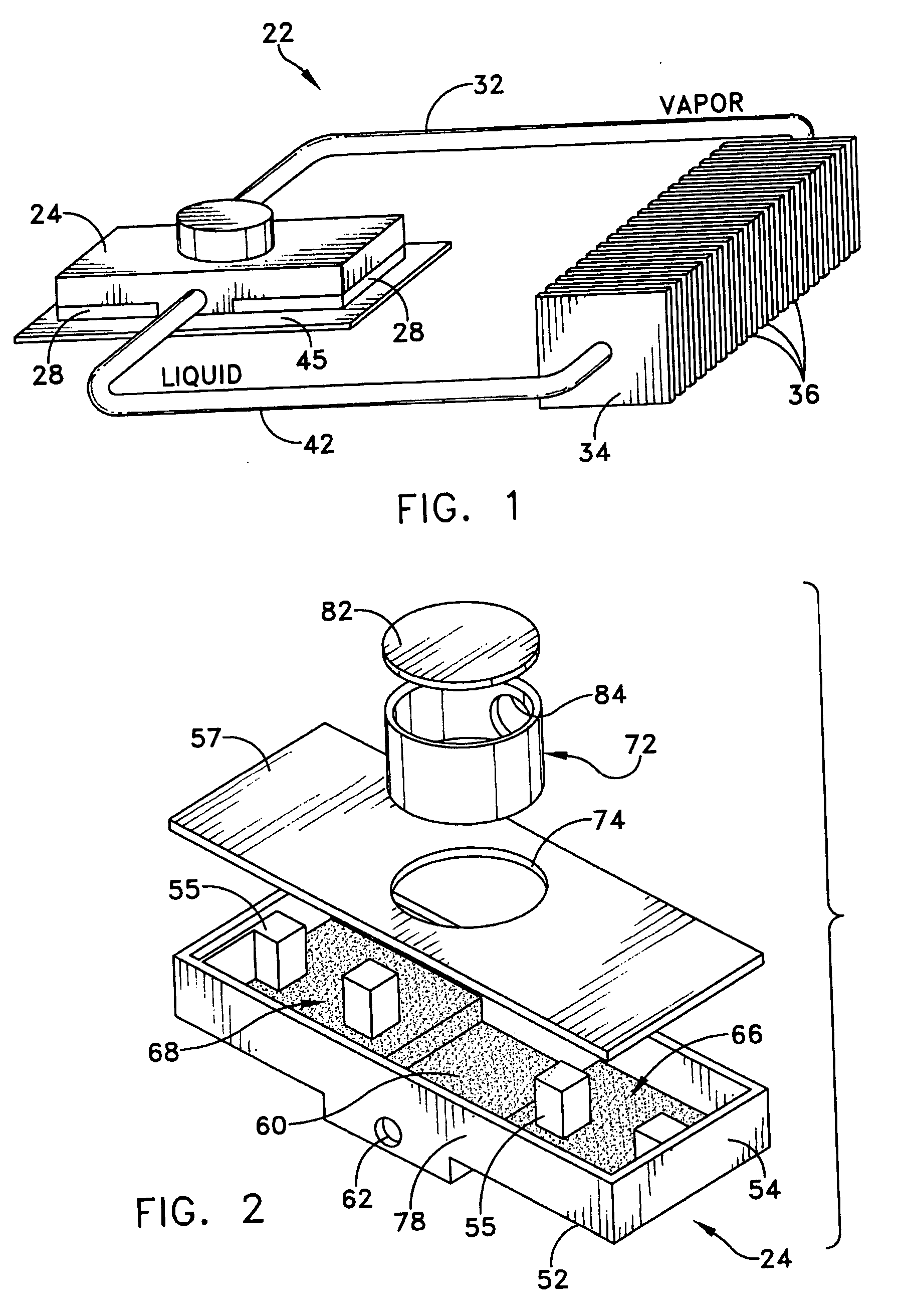

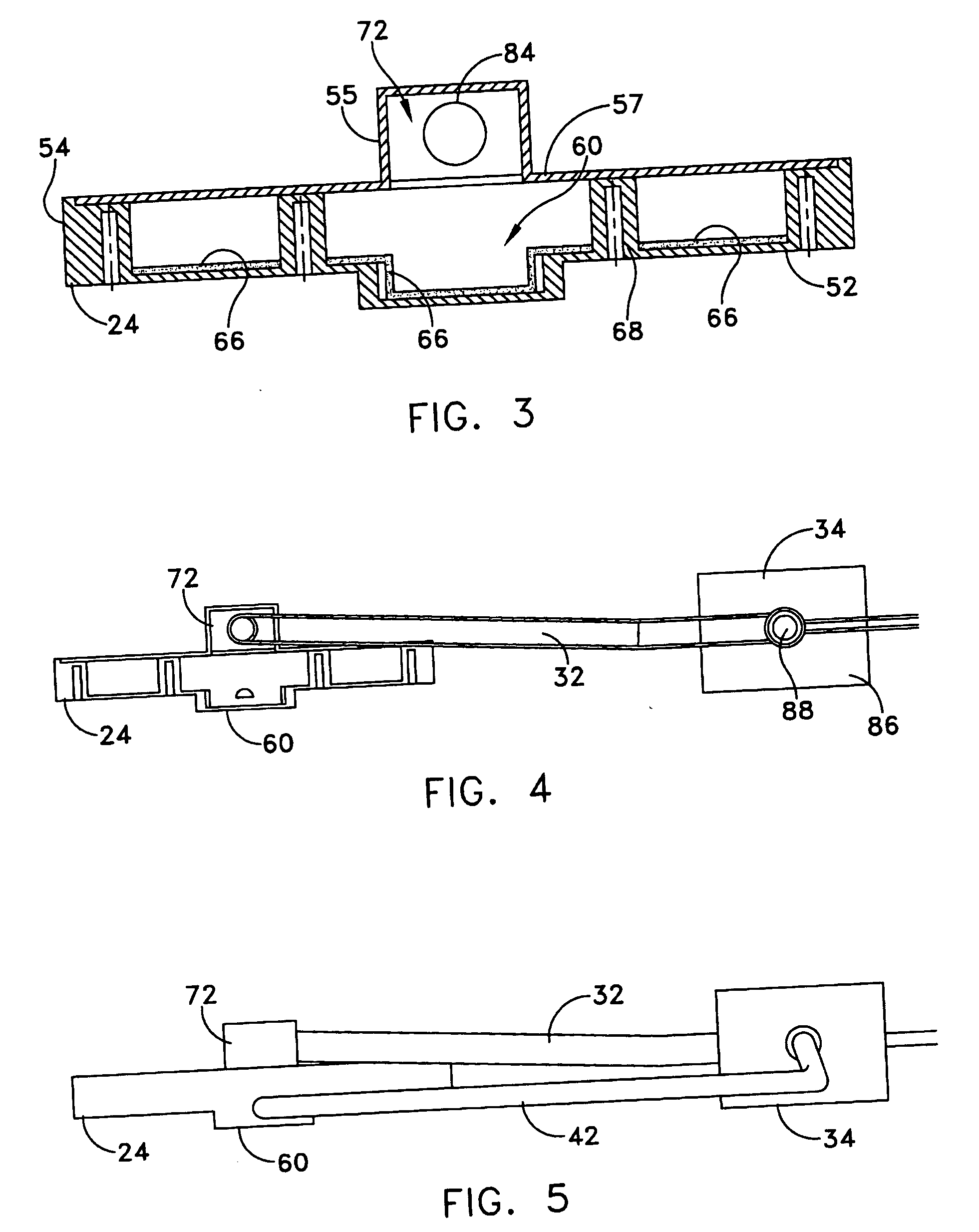

ActiveUS7431071B2Heat dissipationSemiconductor/solid-state device detailsSolid-state devicesWorking fluidEvaporation

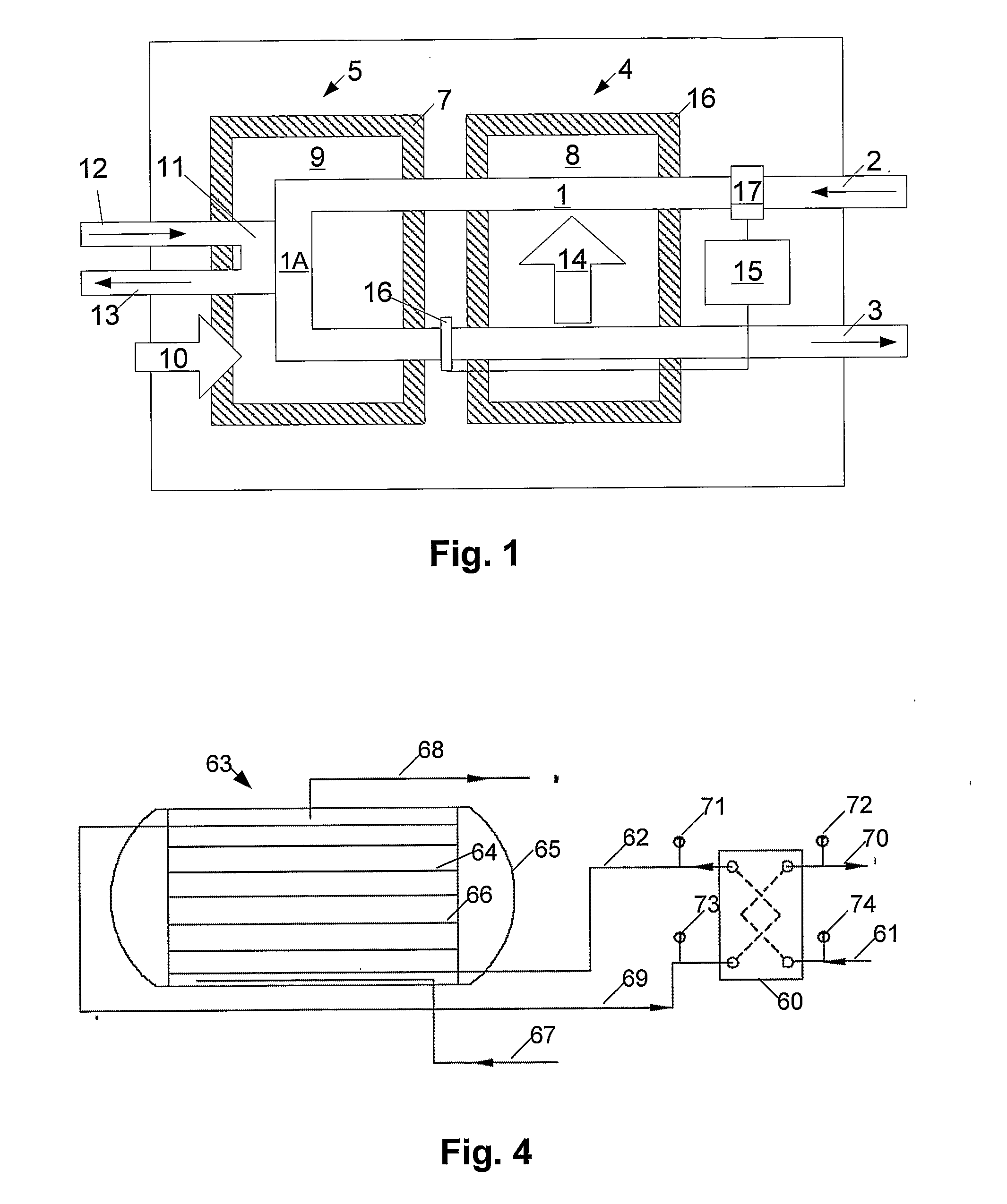

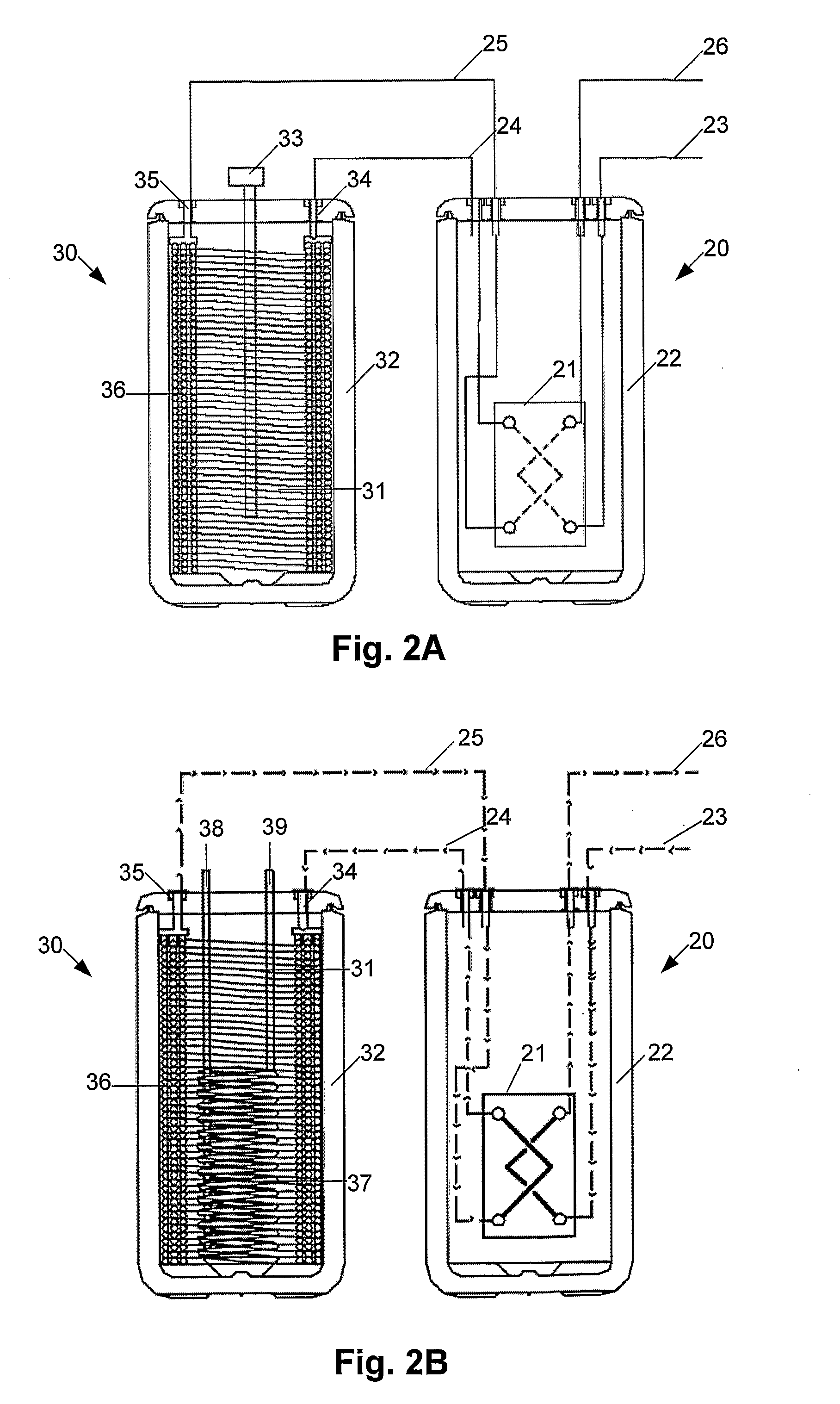

A heat sink or heat transfer device particularly for integrated circuits, uses a phase change working fluid in a cyclic flow path having at least one evaporator that serves multiple heat sources. The evaporator can be an integral vessel made of thermally conductive material to which the multiple heat sources are coupled, preferably at evaporation points that are placed on opposite sides of a fluid reservoir for the liquid phase of the working fluid that feeds the evaporation points via capillary flow through a picking material.

Owner:THERMAL

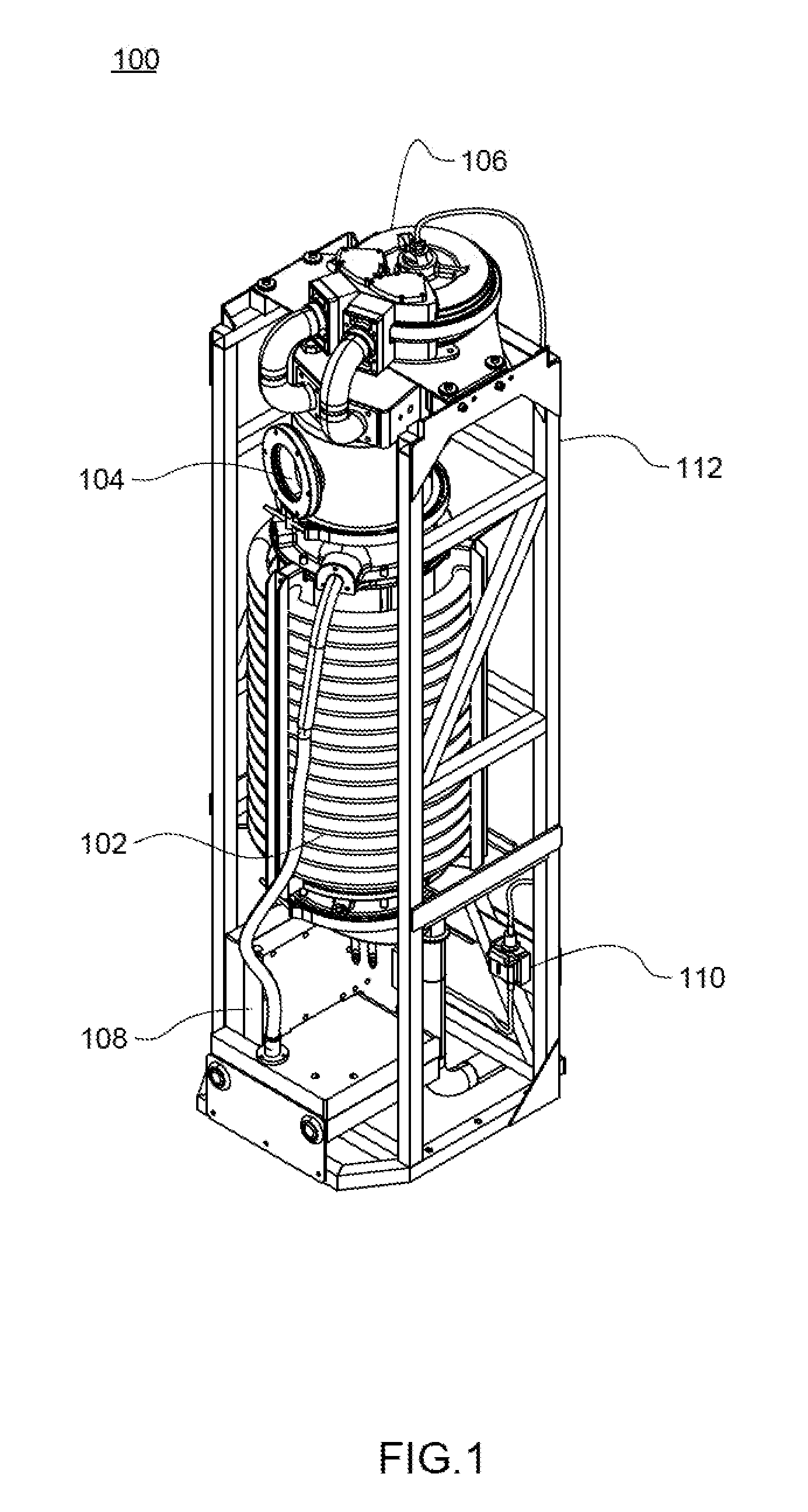

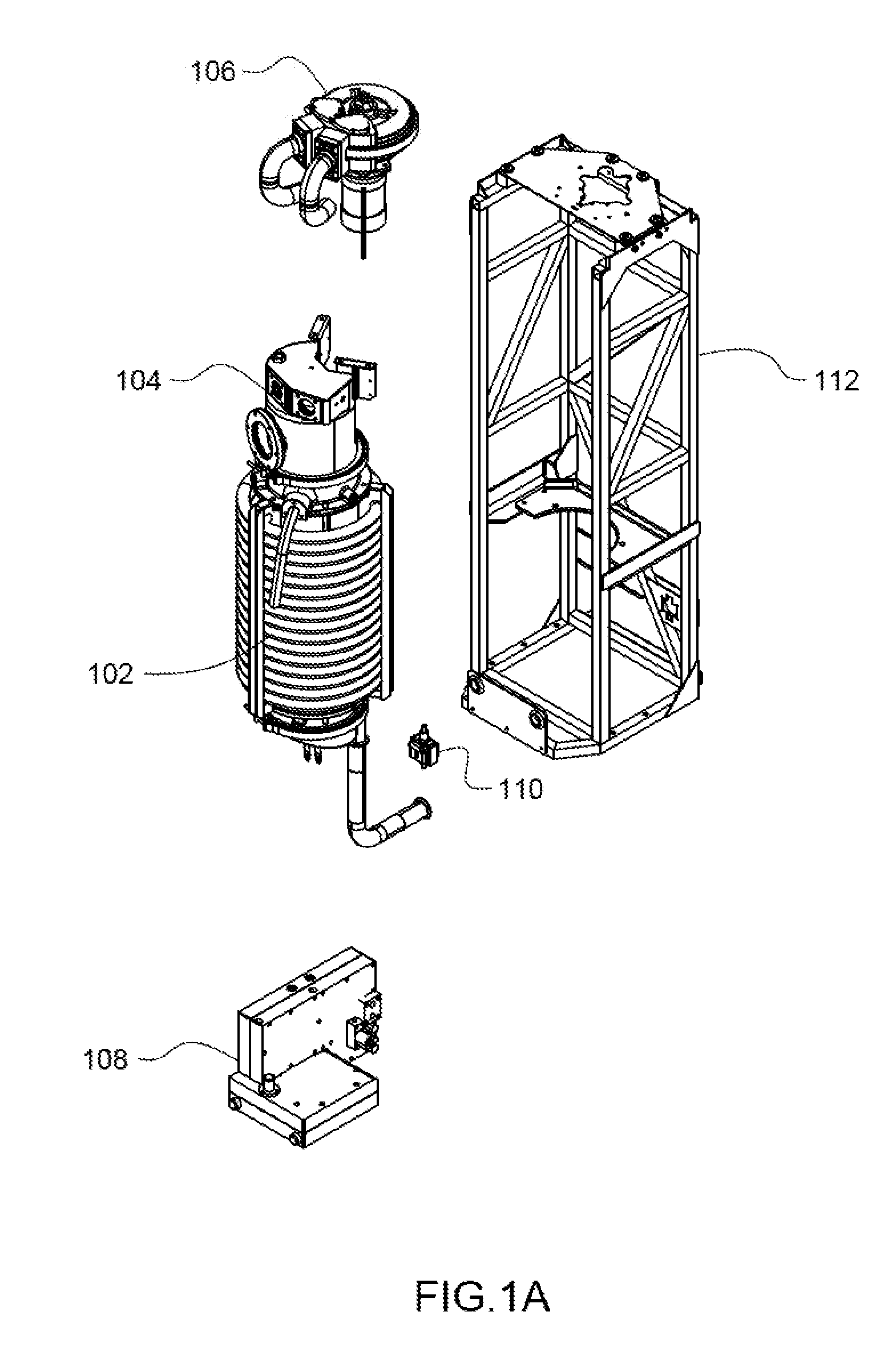

Liquid ring pumps with hermetically sealed motor rotors

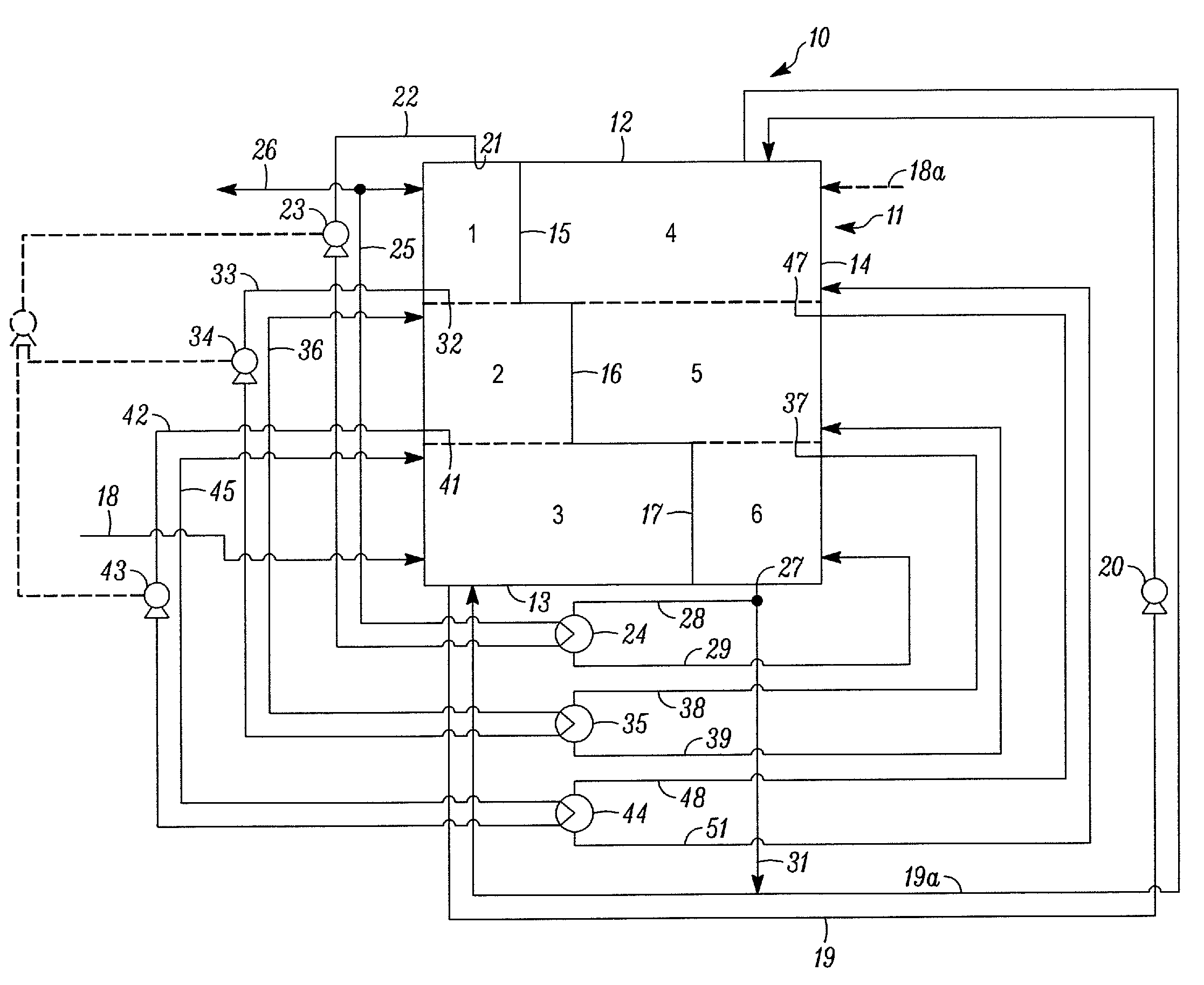

ActiveUS7465375B2Easy maintenanceMaximize energy efficiencyGeneral water supply conservationDistillation regulation/controlDrive shaftDistillation

Owner:DEKA PROD LLP

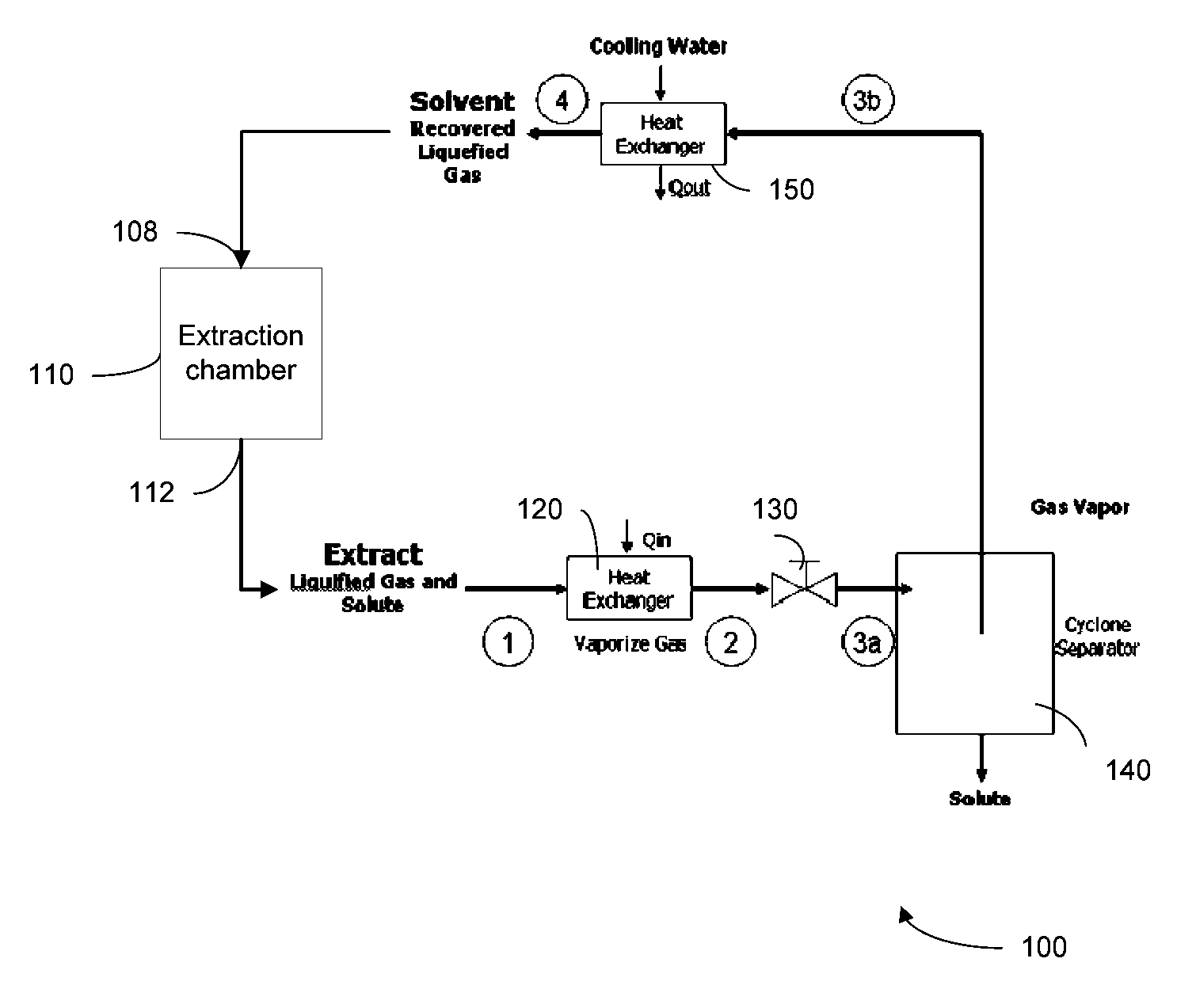

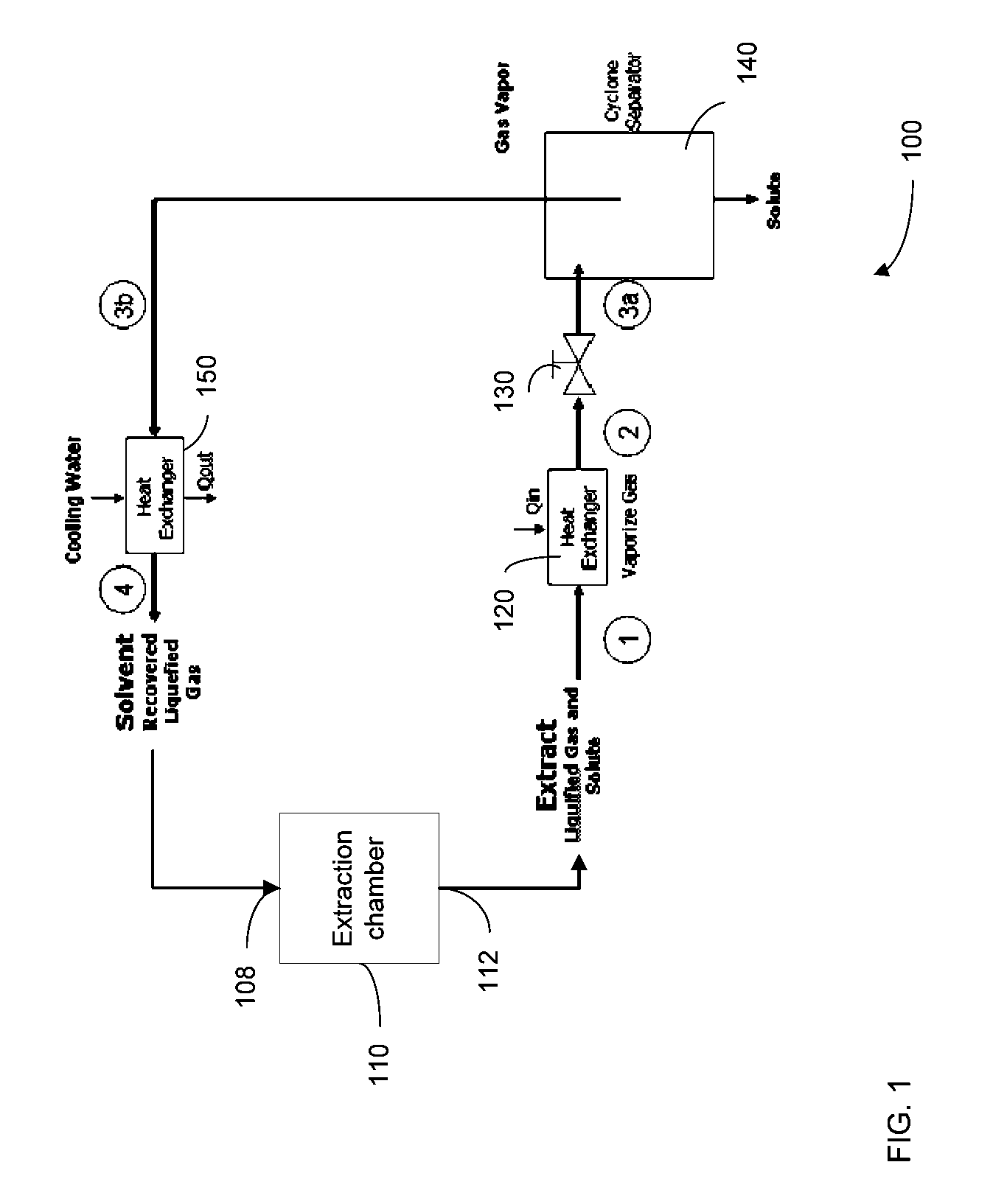

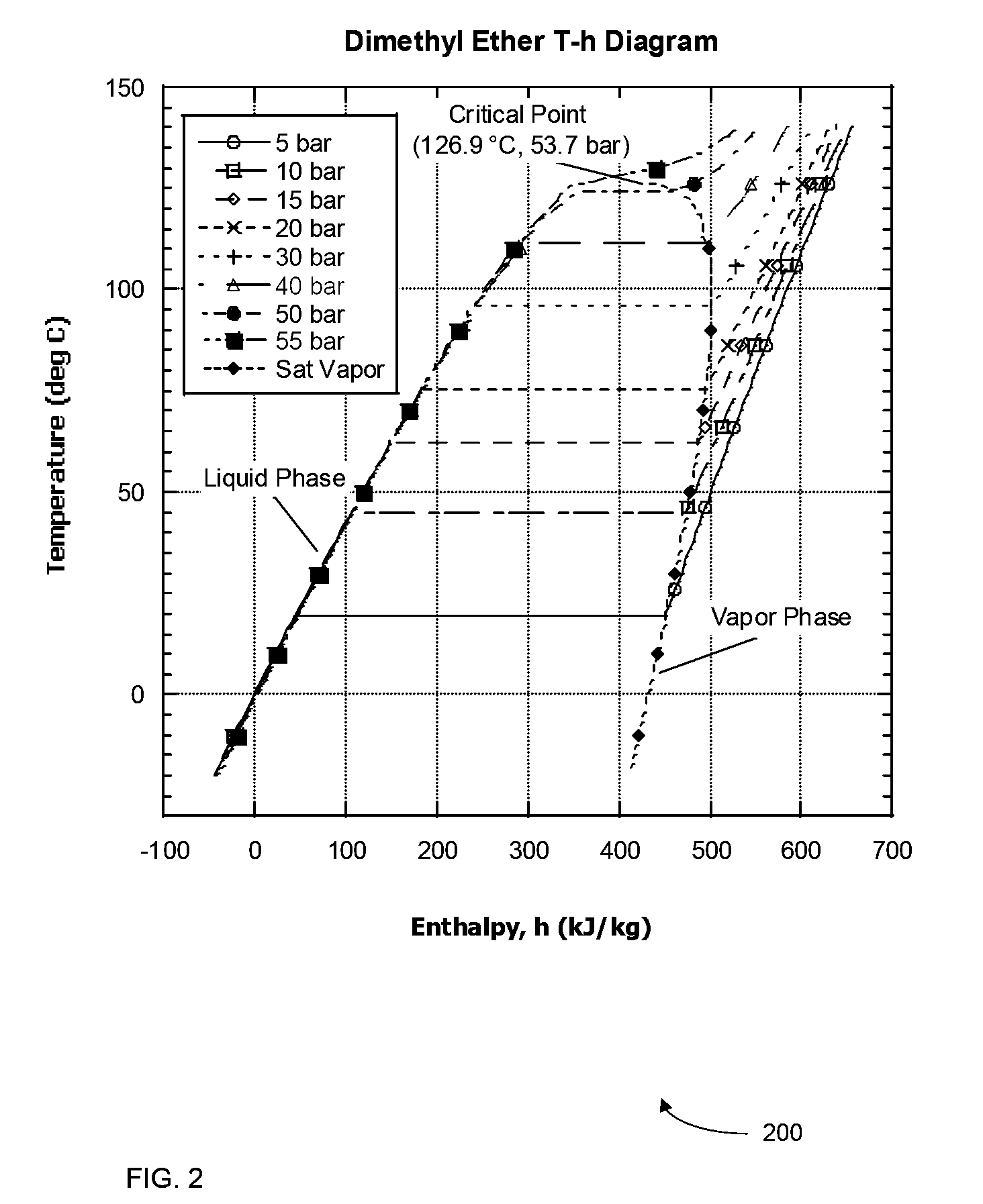

Solvent extraction and recovery

ActiveUS20090166175A1Improve solubilityReduce the amount requiredLiquid degasificationHeat recovery systemsSolubilityProduct gas

Systems and methods for improving dense gas solvent extraction of a solute and recovery of the solvent are provided. A pressure of the solvent / solute mixture obtained from an extraction chamber is increased, e.g. with a pump, thereby providing the mixture above saturation conditions. The increased pressure provides greater solubility of the solute and less solvent being vaporized in a heat exchanger. A buildup of solute in the system is reduced, thus improving system longevity. Also, process conditions of the separation process are isolated from those of the extraction process. Accordingly, the process conditions for the separating process are maintained while the process conditions of the extraction chamber vary with ambient temperature, thus saving cost and energy. This isolation also provides an ability to use, in the gas recovery cycle, a heat pump that can be used for many applications and environmental conditions while still using a conventional refrigerant.

Owner:YOURST MATT T +3

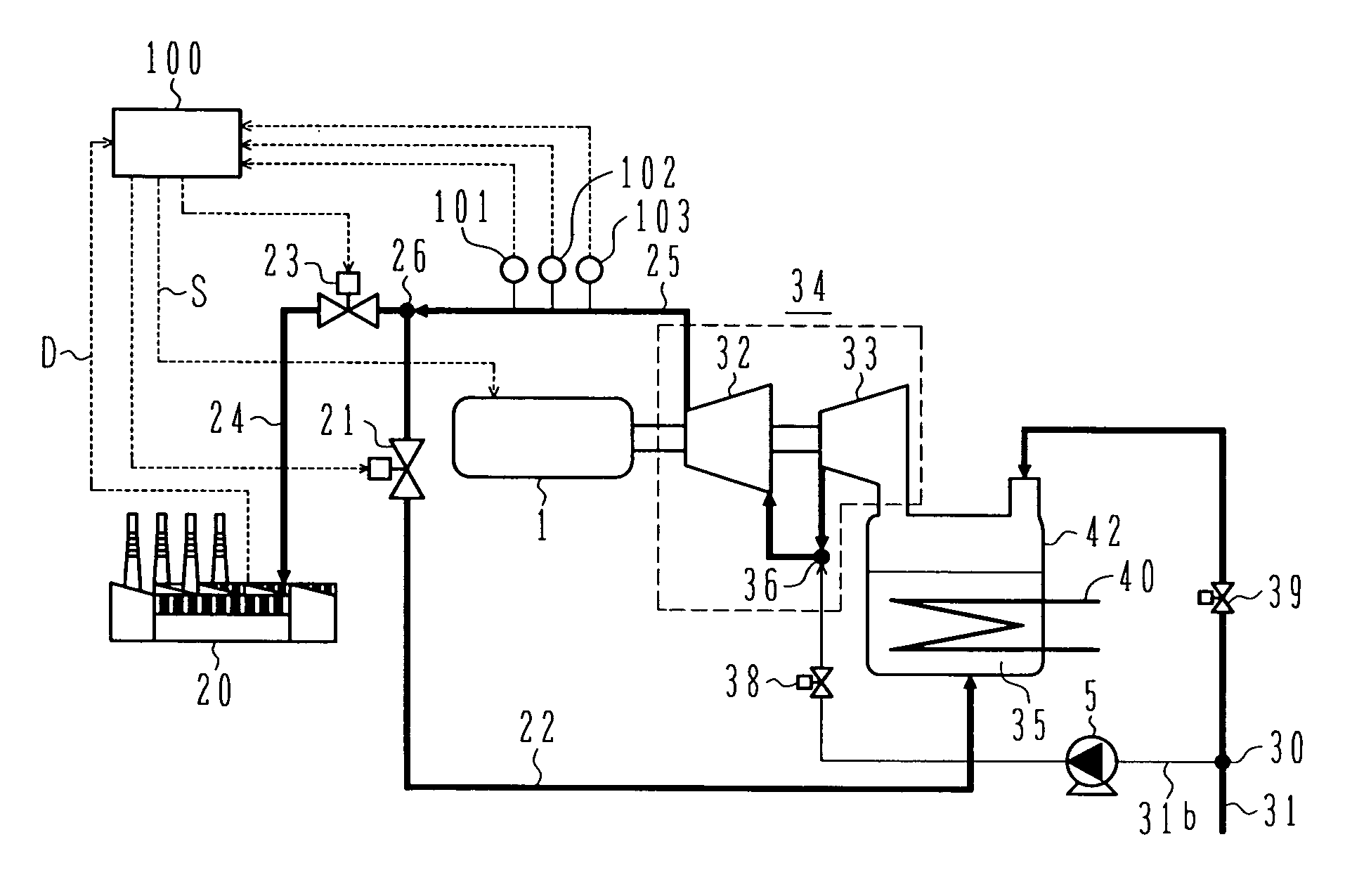

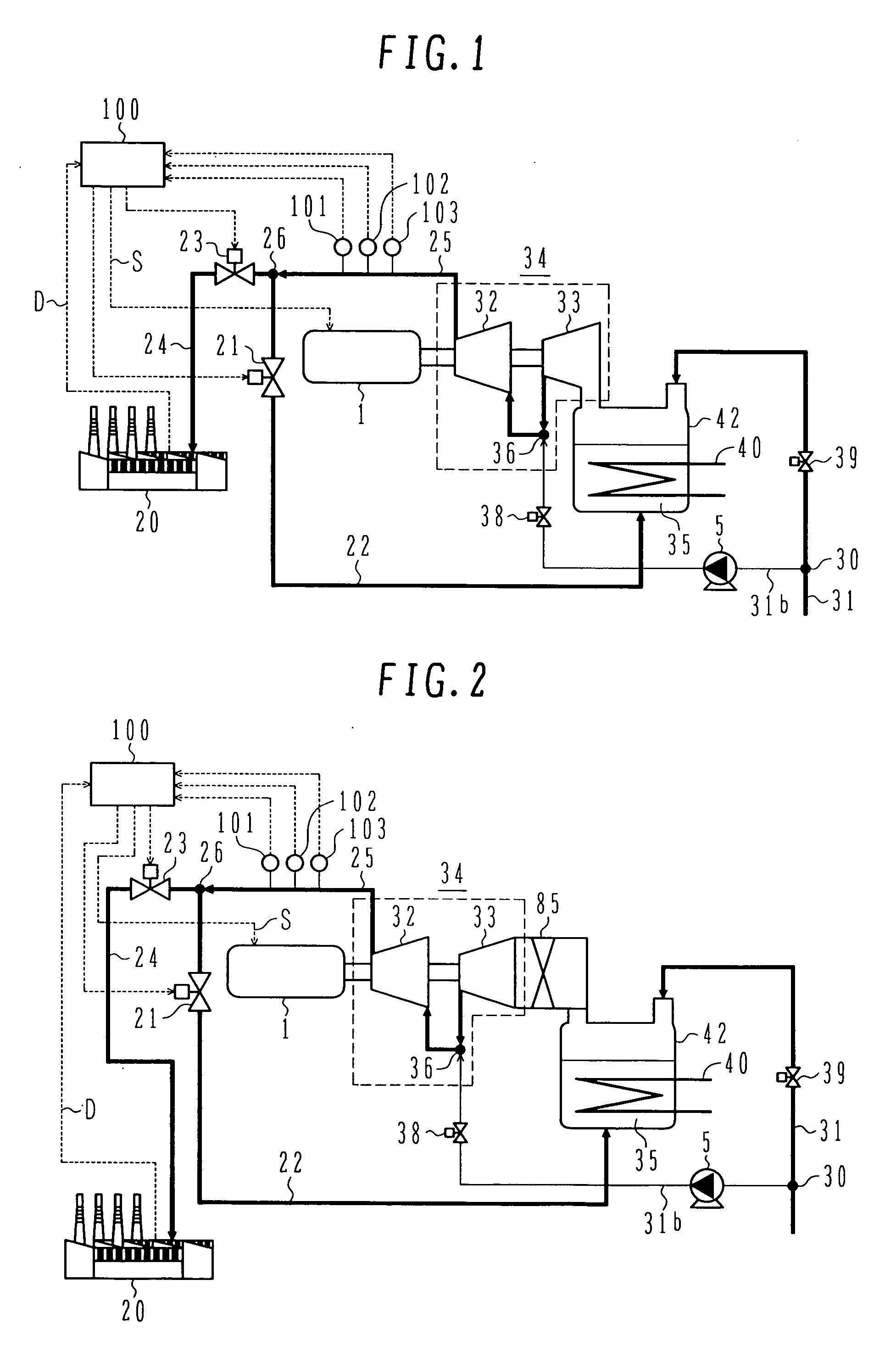

Heat pump system and heat pump operation method

InactiveUS20090126377A1Prevent surgeCompression machines with non-reversible cycleGas turbine plantsLiquid waterEngineering

A compact heat pump system and a heat pump operation method, which can avoid the occurrence of surging in a compressor at startup of a heat pump and can directly supply vapor of a working medium produced by the compressor to an external heat-utilizing facility. The heat pump system comprises an evaporator for recovering heat of an external heat source to a working medium supplied as liquid water from the exterior via a water feed channel, thereby evaporating the working medium, a compressor for compressing the working medium evaporated in the evaporator and increasing temperature of the evaporated working medium, and a driving unit for giving motive power to drive the compressor. The heat pump system further comprises a supply channel for supplying, as a heat source, vapor of the working medium having temperature increased by the compressor to an external heat-utilizing facility, and a return channel branched from the supply channel and introducing the working medium discharged from the compressor to the evaporator.

Owner:HITACHI LTD

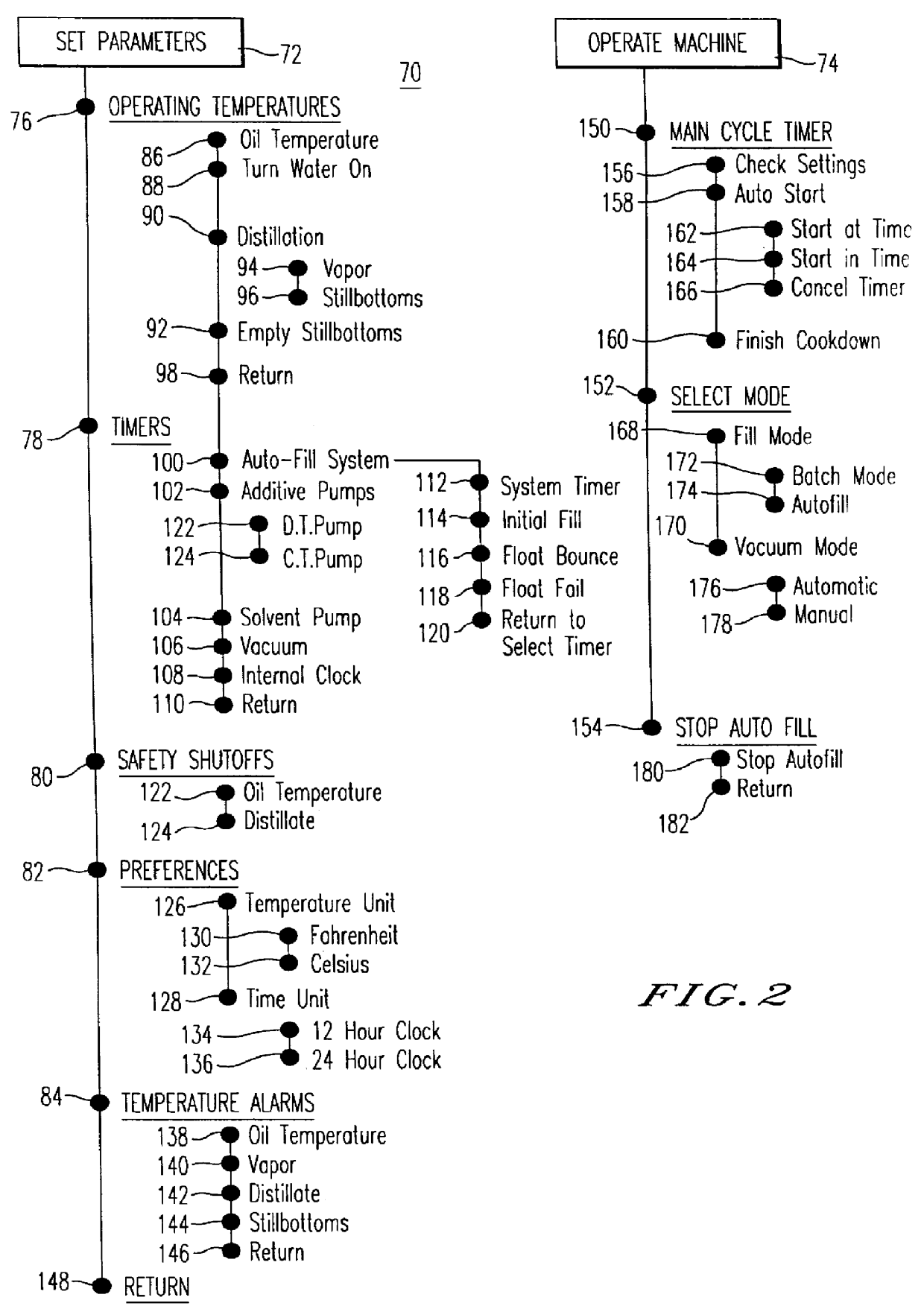

Water vapor distillation apparatus, method and system

ActiveUS9604858B2Water treatment parameter controlDistillation regulation/controlWater vaporControl system

A fluid vapor distillation system. The system includes a control system for controlling a fluid vapor distillation apparatus including a blow down controller for controlling a blow down valve, a source flow controller for controlling a source flow valve, and a blow down level sensor in communication with a blow down controller and a source flow controller, the blow down level sensor sends signals related to the blow down level to the blow down controller and the source flow controller indicative of the blow down level, wherein the source flow controller actuates the source flow valve based at least on the blow down level sensor signals, and wherein the blow down controller actuates the blow down valve based at least on the blow down level sensor signals, whereby the blow down level and the source flow level are maintained using the blow down level sensor signals as input.

Owner:DEKA PROD LLP

Hybrid solar desalination system

Owner:SUNLIGHT PHOTONICS

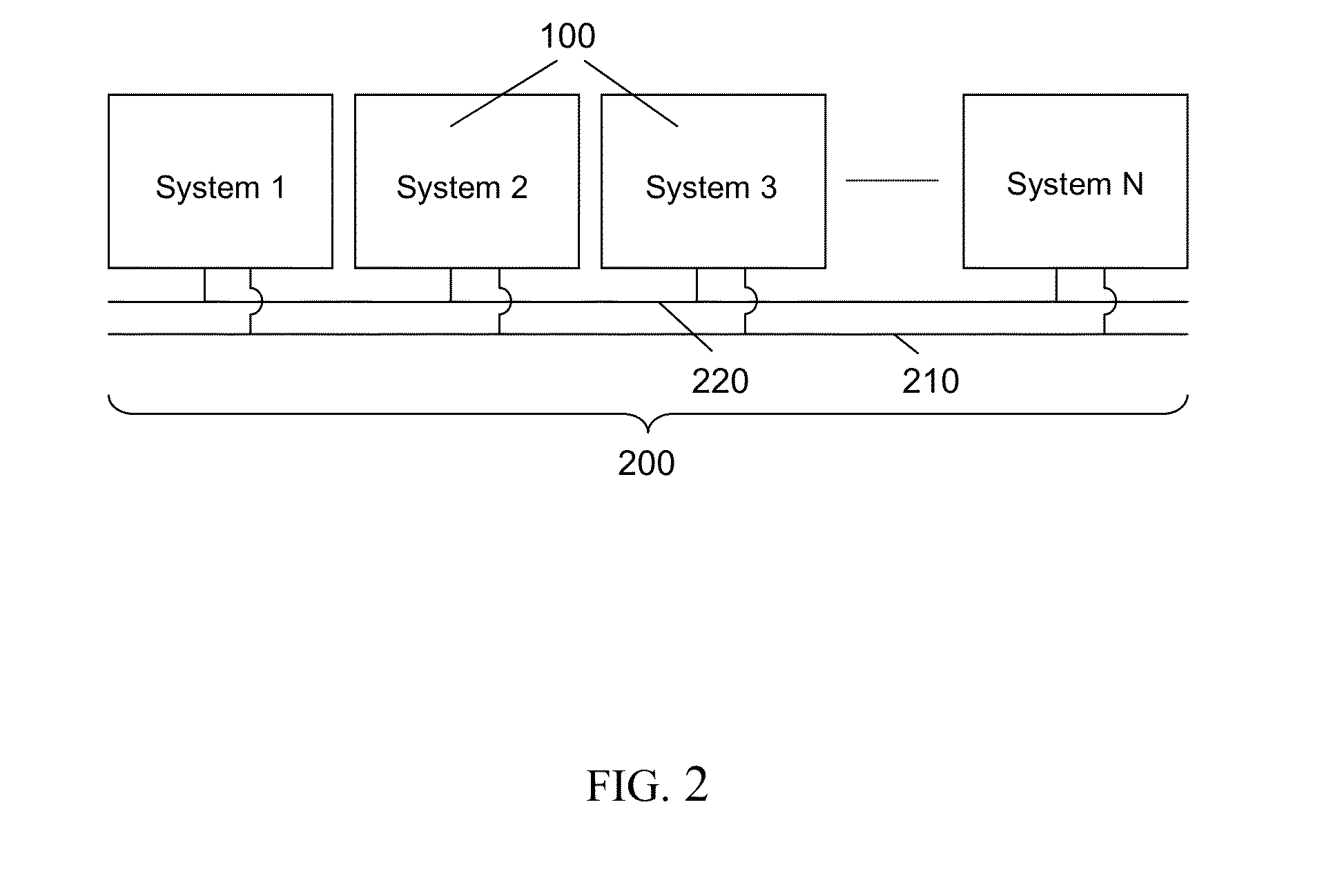

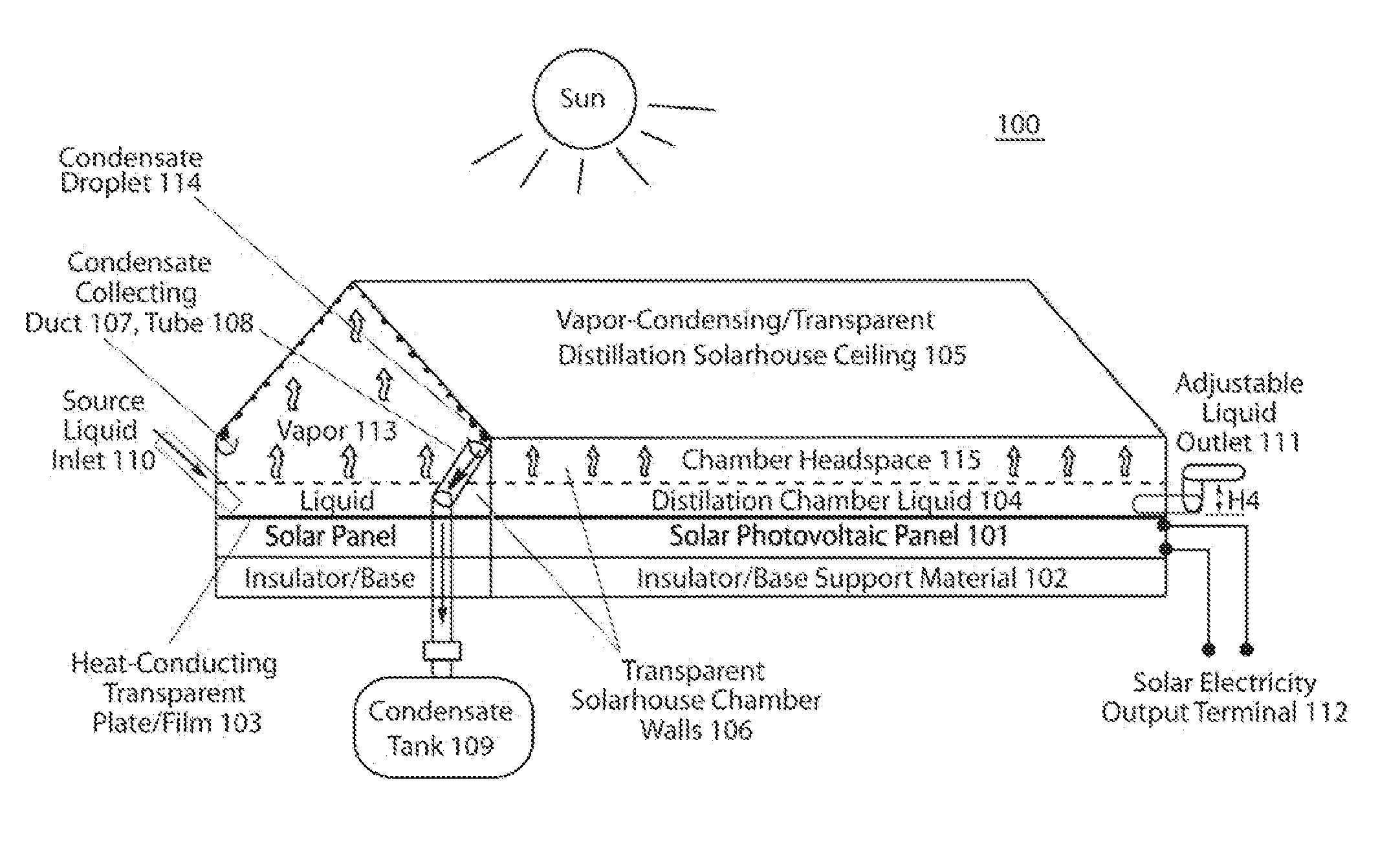

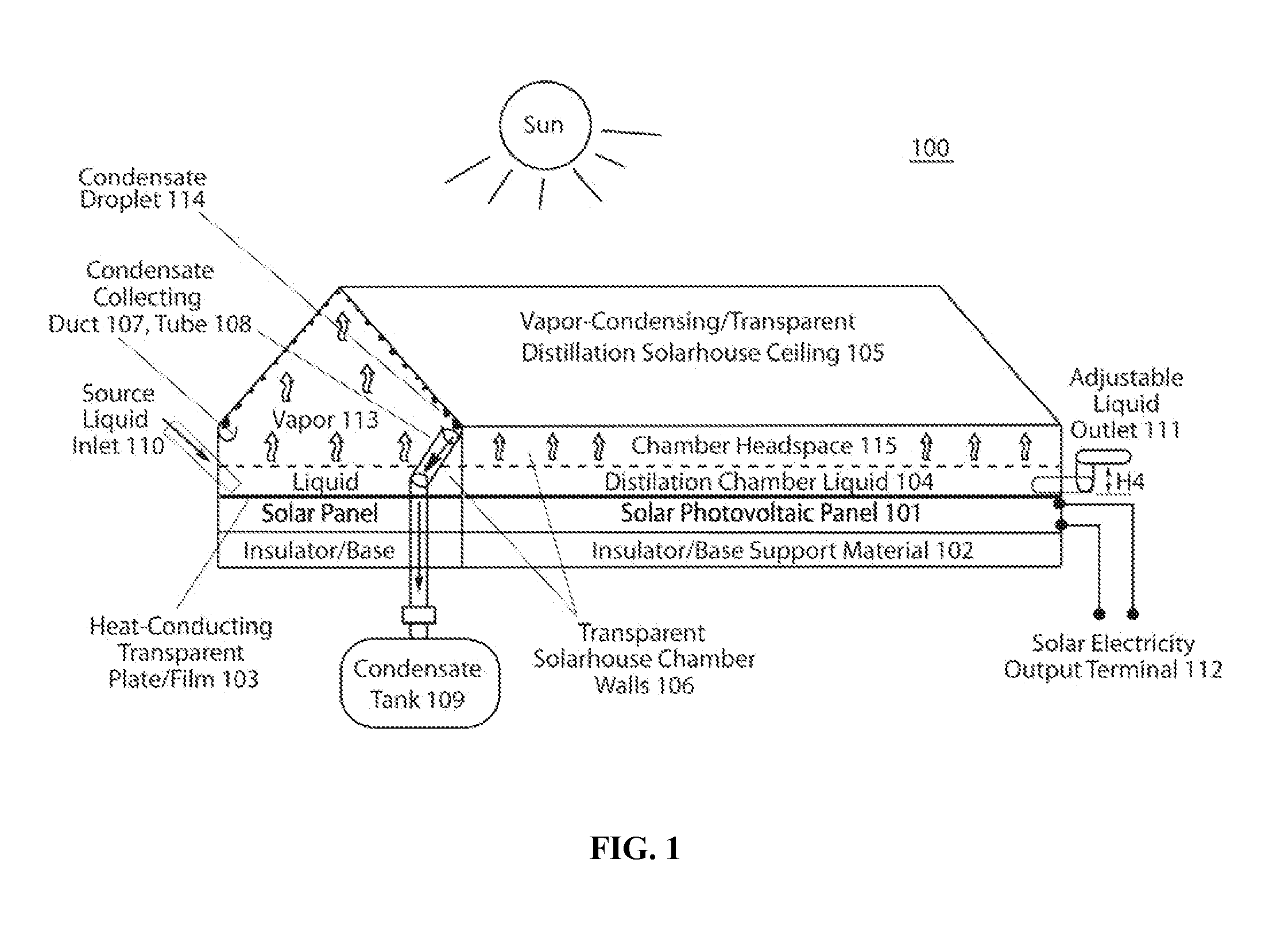

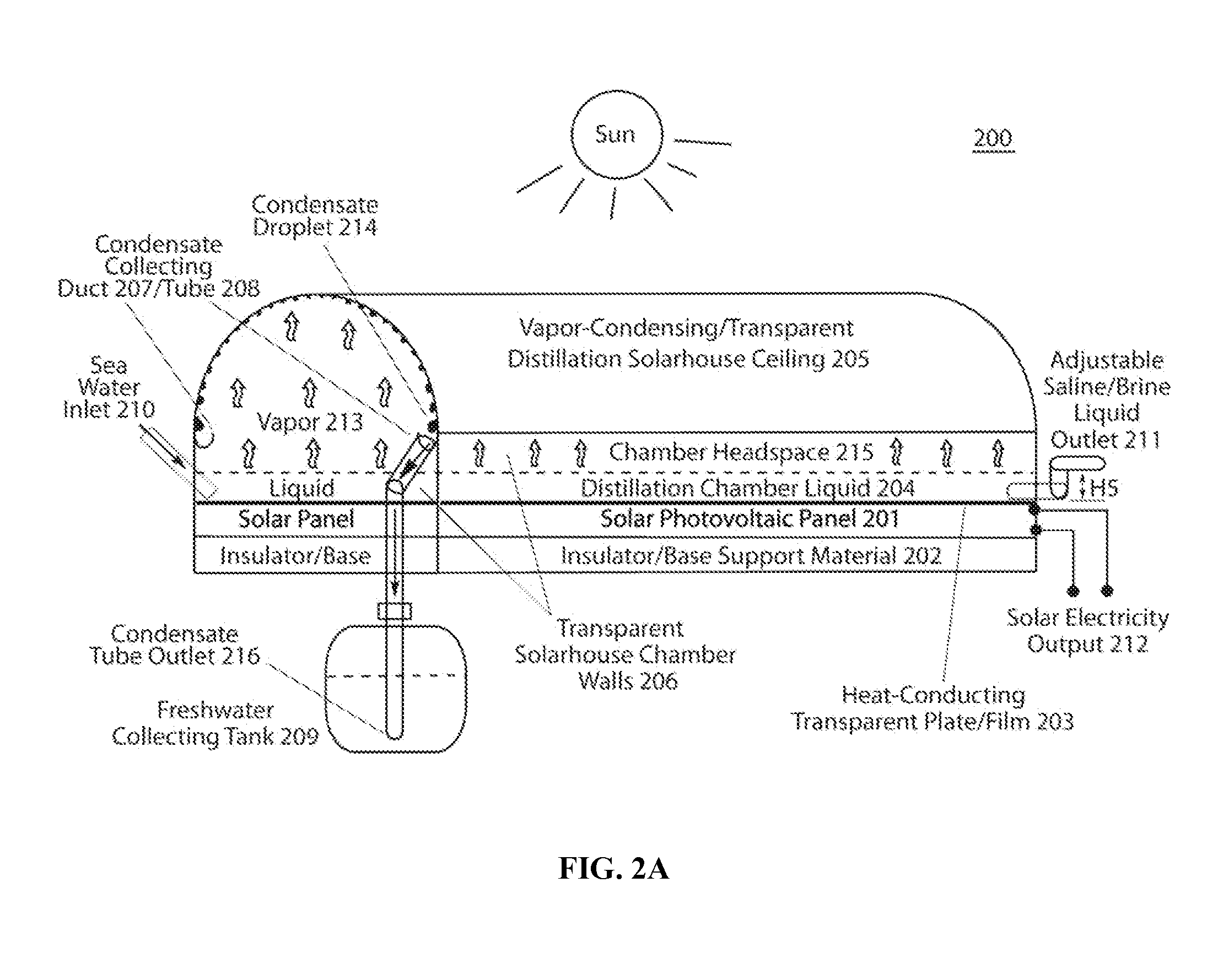

Photovoltaic panel-interfaced solar-greenhouse distillation systems

InactiveUS20150353379A1Improve solar energy utilization efficiencyImprove overall utilizationPhotovoltaic supportsAuxillariesDistillationDaylight

A hybrid photovoltaic panel-interfaced distillation with and without a hydrophobic microporous membrane distillation process is provided that is capable of utilizing solar waste heat to perform liquid distillation while co-generating solar electricity. Solar waste heat co-generated at a photovoltaic panel is effectively utilized by in situ distillation liquid as an immediate heat sink in thermo contact with the photovoltaic panel, thus providing beneficial cooling of the photovoltaic panel and co-making of distillation products while generating electricity with significant improvement on total-process solar energy utilization efficiency. Its enabled beneficial utilization of waste heat can provide a series of distillation-related products such as: freshwater, sea salts, distilled water, distilled ethanol, hot water, hot steam, saline / brine products, and brine photobiological cultures for production of advanced biofuels and bioproducts, in addition to solar electricity.

Owner:LEE JAMES WEIFU

Disinfection System

InactiveUS20070221362A1Reduce the impactReduce impactGeneral water supply conservationRecuperative heat exchangersEngineeringSterilizing Units

Apparatus for disinfecting fluid, the apparatus including a preheat heat exchanger (4) and a disinfection tank (5). The preheat exchanger heats the fluid to a first temperature and includes a first inlet for receiving the fluid (2), a first outlet for supplying preheated fluid at the first temperature, a second inlet for receiving disinfected fluid substantially at a second temperature and a second outlet for supplying the disinfected fluid (3). The disinfection tank heats the fluid to a second temperature and includes a heat source (10), an inlet for receiving the preheated fluid, a heat exchanger coupled to the inlet for heating the preheated fluid to a second temperature to thereby disinfect the fluid (11) and, an outlet coupled to the heat exchanger for providing the disinfected fluid to the second inlet of the preheat heat exchanger.

Owner:INFORM ENERGY

Energy Conservation in Heavy-Hydrocarbon Distillation

ActiveUS20120048720A1Increase contentHydrocarbon by isomerisationChemical industryDistillationEnergy conservation

Owner:UOP LLC

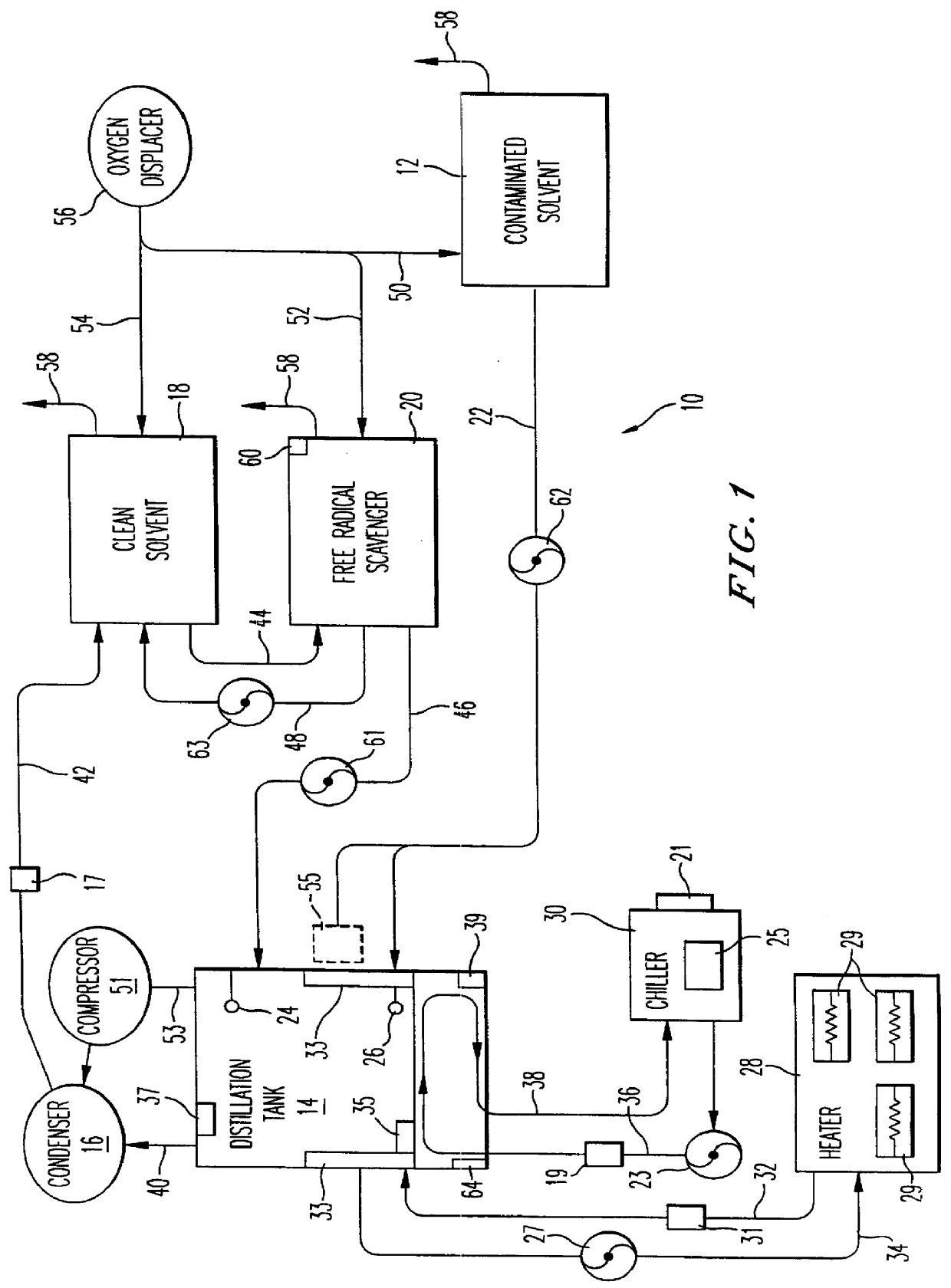

Method and apparatus for recovering and/or recycling solvents

InactiveUS6159345AReduce transportationHeating safetyOrganic chemistrySolvent extractionSolvent vaporDistillation

A method and apparatus for recycling and recovering potentially explosive solvents includes providing a contaminated solvent to a distillation tank, vaporizing the solvent in the distillation tank, thereby producing solvent vapor, condensing the solvent vapor, and adding a free radical scavenger substance to the distillation tank during the heating step. The vapor is then condensed and collected in a clean solvent tank where additional free radical scavenger substance is added to the clean solvent tank. Preferably, contaminated solvent is introduced into the solvent recovery system by providing contaminated solvent into contaminated solvent tank which is connected to the distillation tank, and an oxygen displacer substance is provided to the contaminated solvent tank and the clean solvent tank so as to minimize the amount of free oxygen in the tanks.

Owner:MITSUBISHI KAGAKU IMAGING

Fluid circuit heat transfer device for plural heat sources

ActiveUS20050082158A1Heat dissipationSemiconductor/solid-state device detailsSolid-state devicesWorking fluidEvaporation

A heat sink or heat transfer device particularly for integrated circuits, uses a phase change working fluid in a cyclic flow path having at least one evaporator that serves multiple heat sources. The evaporator can be an integral vessel made of thermally conductive material to which the multiple heat sources are coupled, preferably at evaporation points that are placed on opposite sides of a fluid reservoir for the liquid phase of the working fluid that feeds the evaporation points via capillary flow through a picking material.

Owner:THERMAL

Heat exchange system configured with a membrane contactor

A heat exchange system may include a first heat exchange circuit and a second heat exchange circuit. The first heat exchange circuit may circulate a first working fluid sequentially through a first heat exchanger, a second heat exchanger and a membrane contactor. The second heat exchange circuit may direct a second working fluid sequentially through the first heat exchanger and the membrane contactor, where the second working fluid includes solute and solvent. The first heat exchanger and the membrane contactor may transfer heat energy from the second working fluid to the first working fluid, and the second heat exchanger may transfer heat energy from the first working fluid to a third working fluid. The membrane contactor may extract a portion of the solvent from the second working fluid.

Owner:RTX CORP

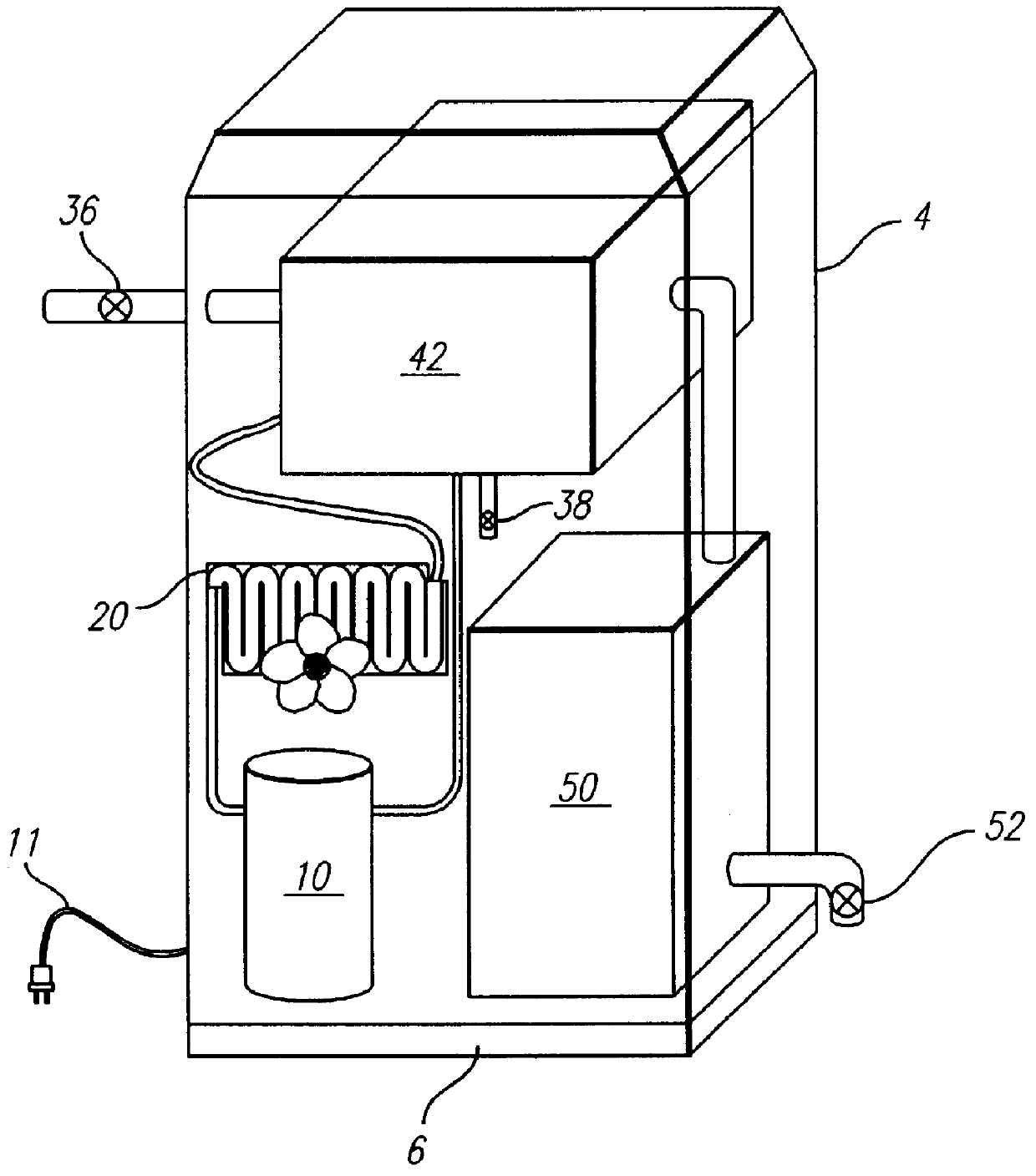

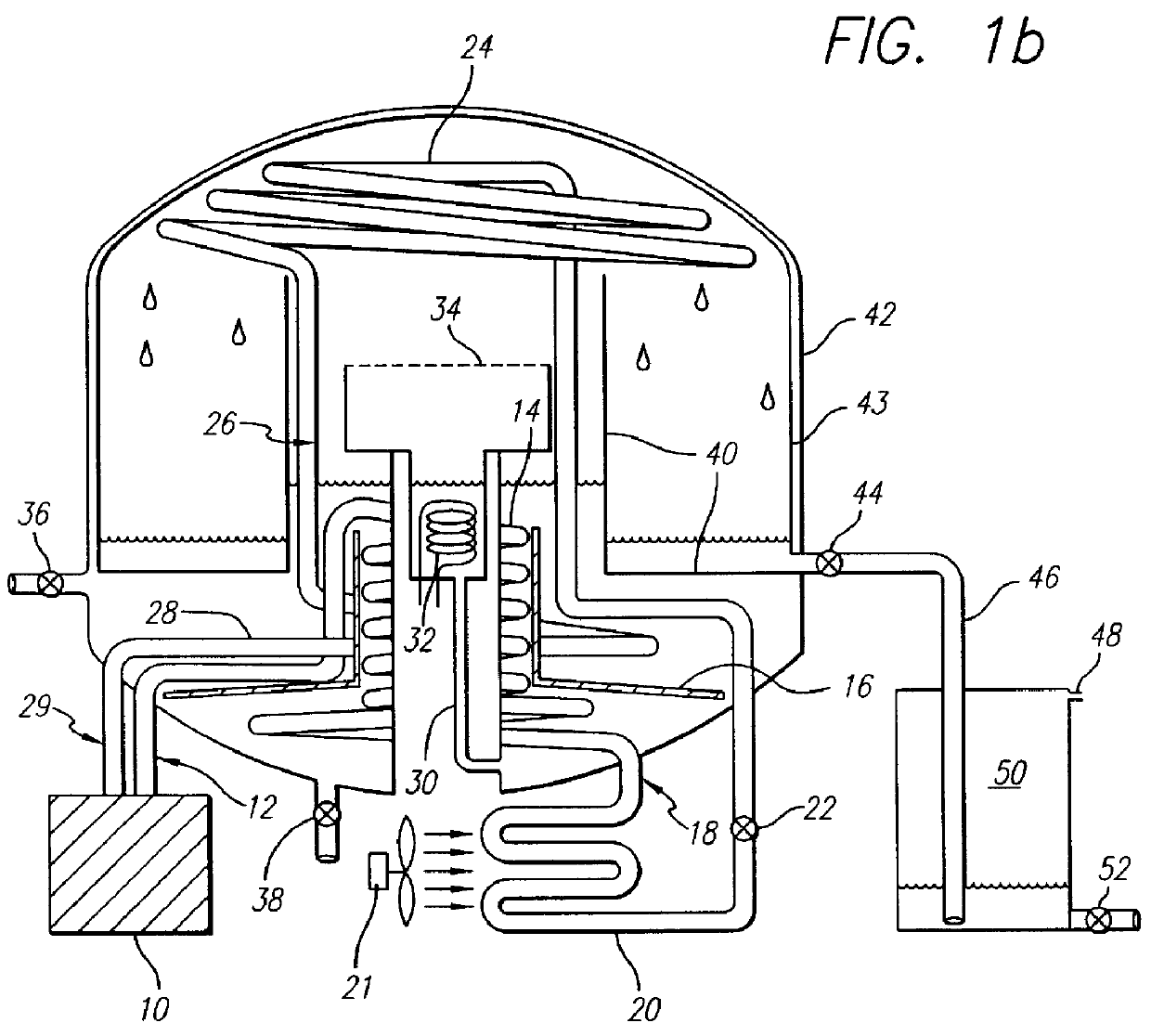

Water vapor distillation apparatus, method and system

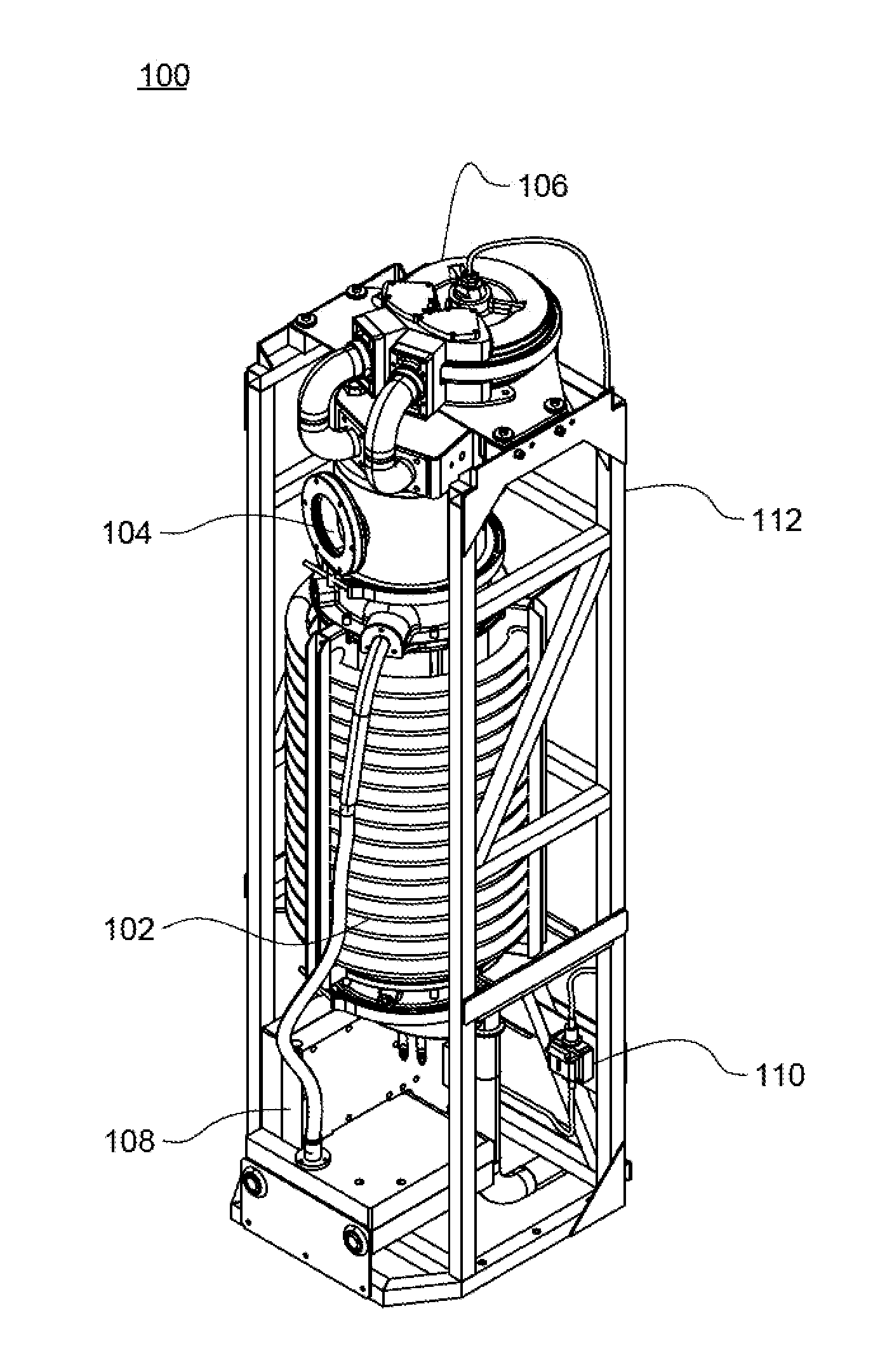

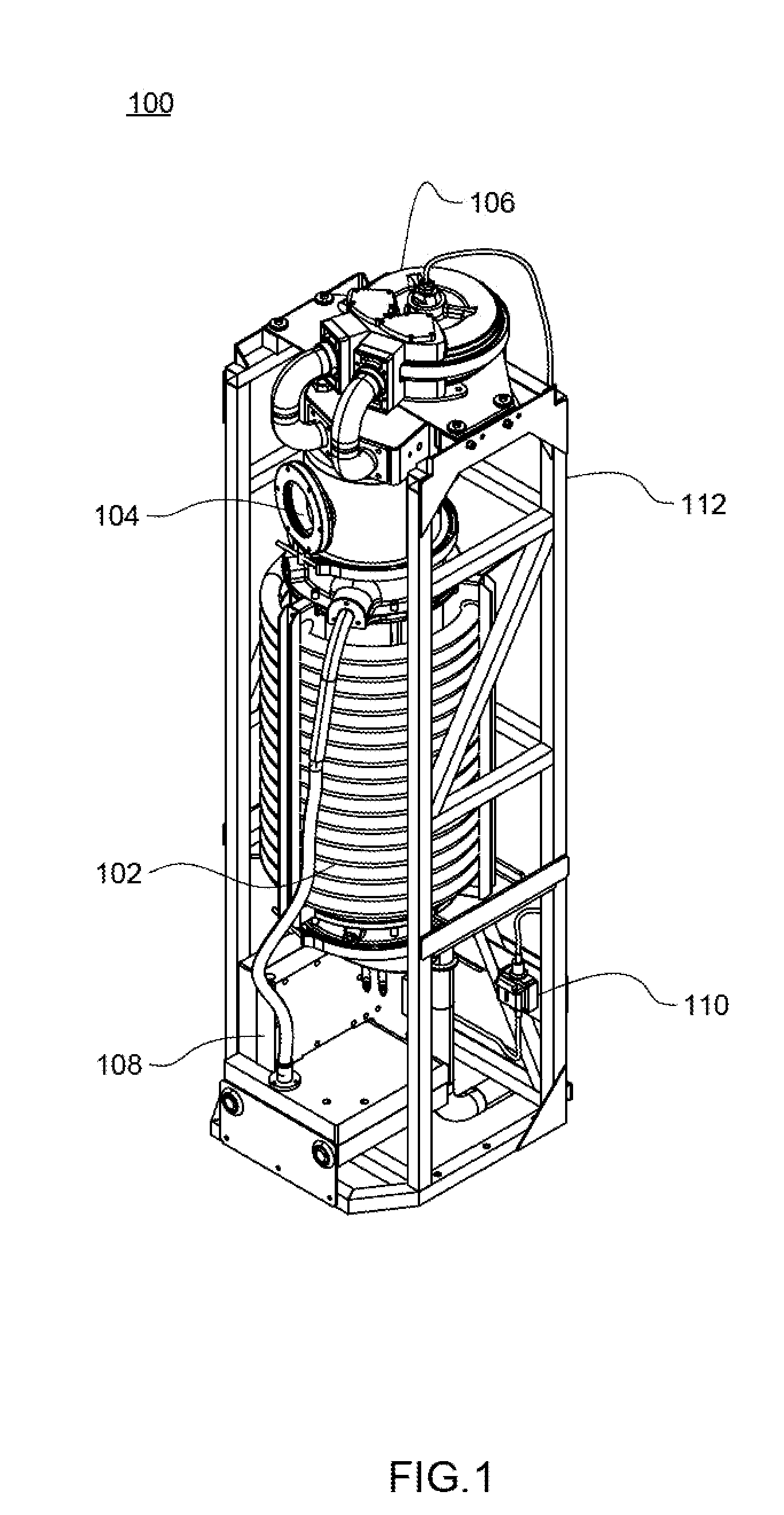

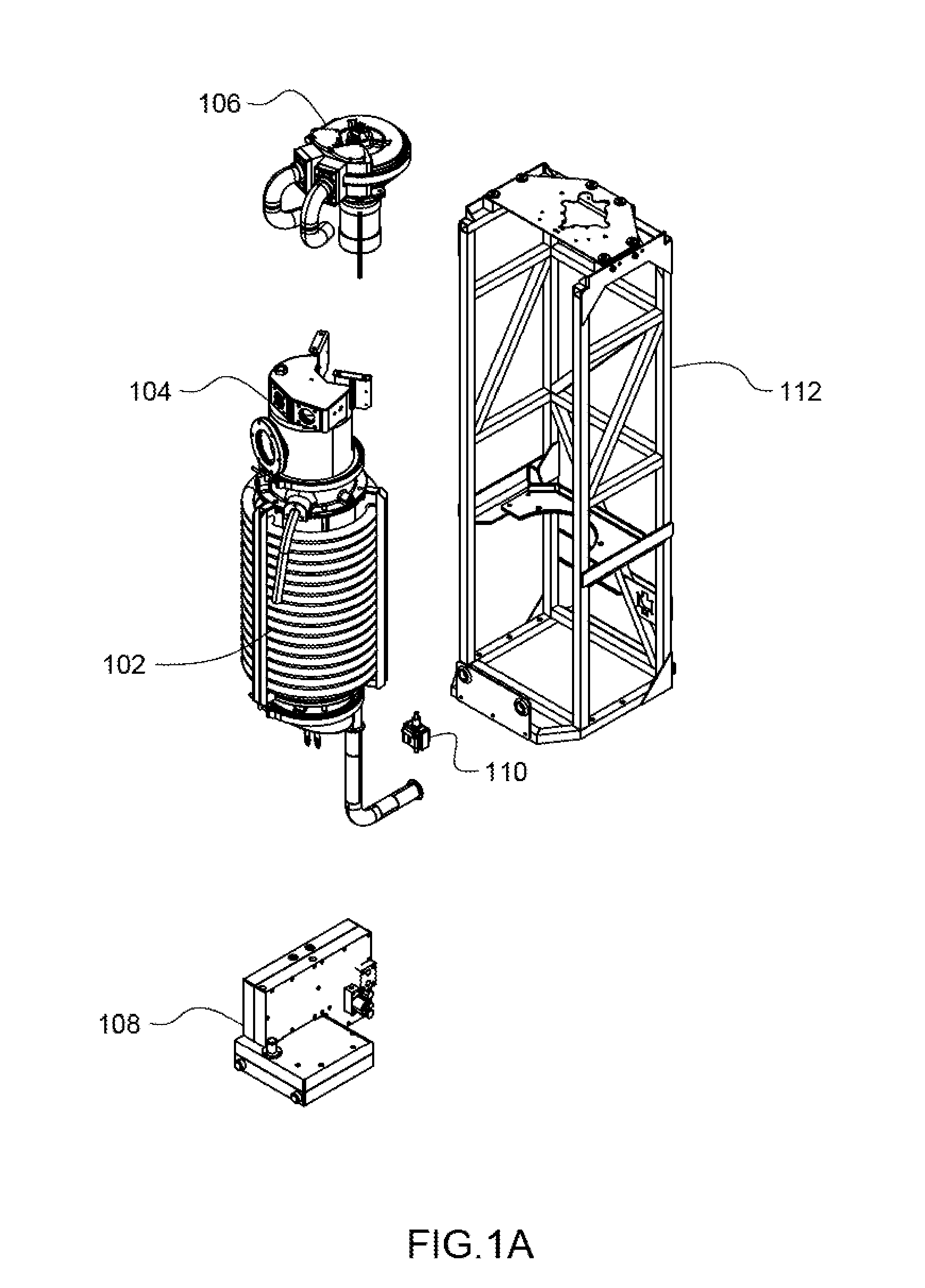

ActiveUS20120006670A1Distillation regulation/controlSpecific water treatment objectivesWater vaporControl system

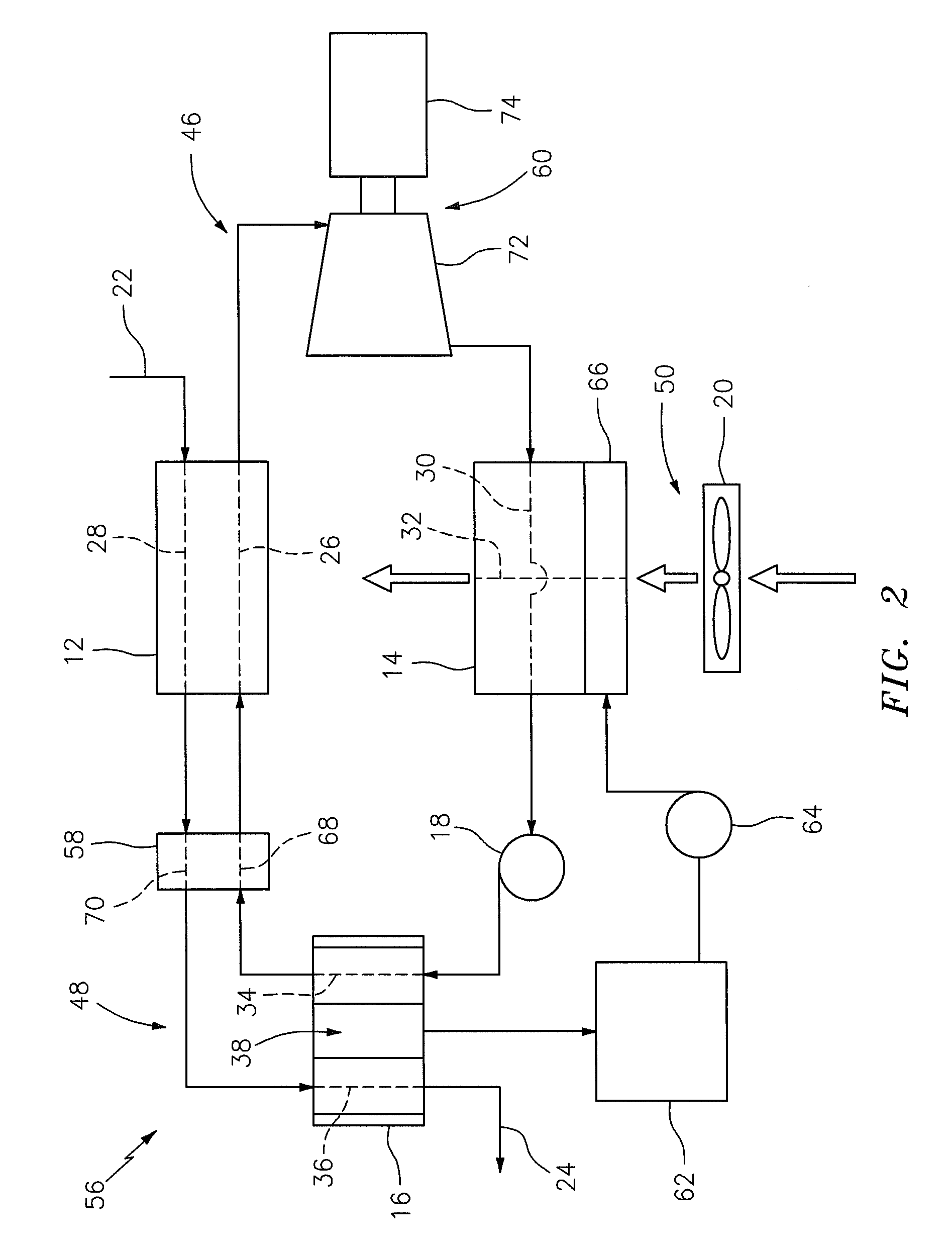

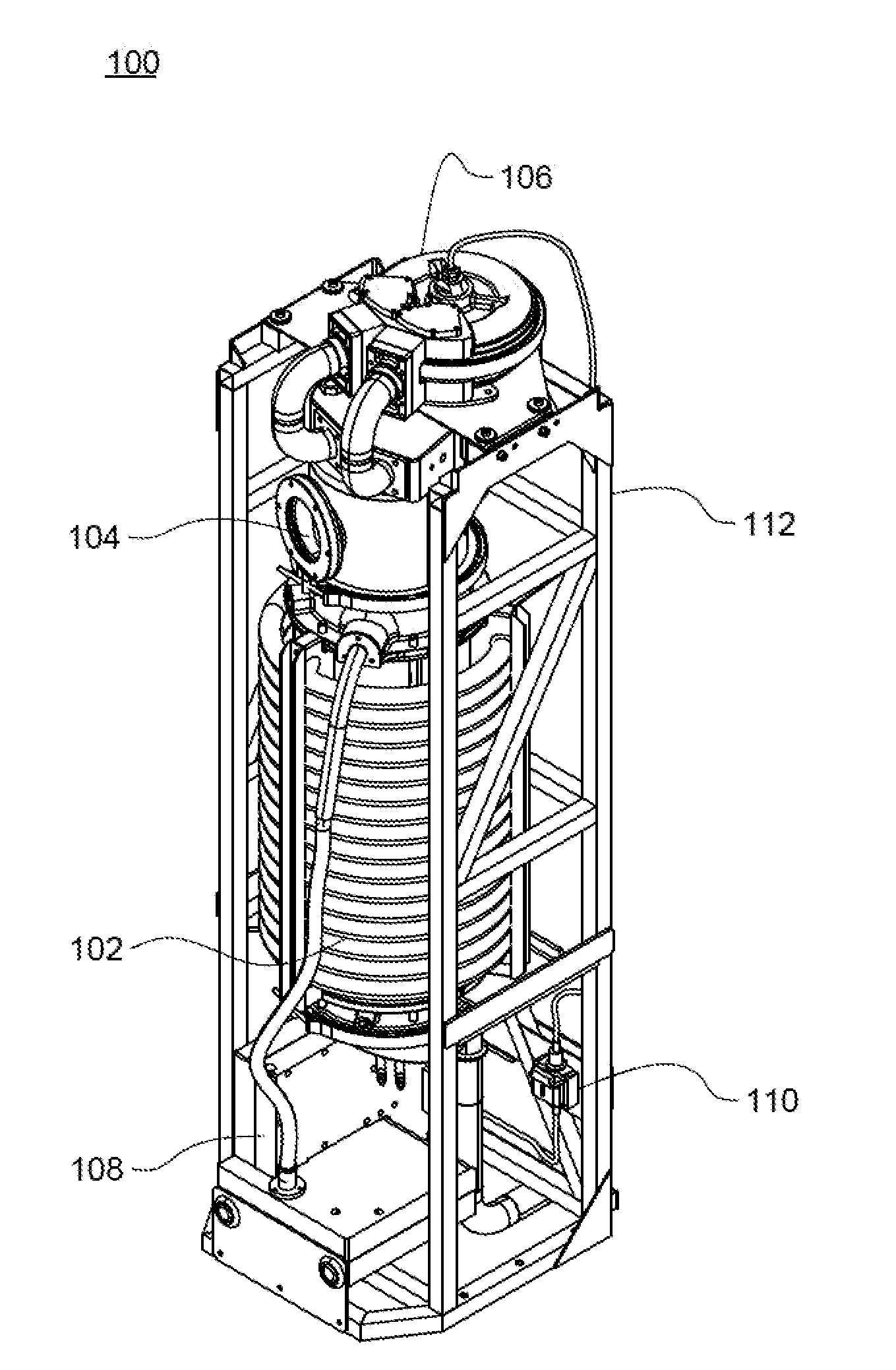

A fluid vapor distillation apparatus. The apparatus includes a source fluid input, and an evaporator condenser apparatus. The evaporator condenser apparatus includes a substantially cylindrical housing and a plurality of tubes in the housing. The source fluid input is fluidly connected to the evaporator condenser and the evaporator condenser transforms source fluid into steam and transforms compressed steam into product fluid. Also included in the fluid vapor distillation apparatus is a heat exchanger fluidly connected to the source fluid input and a product fluid output. The heat exchanger includes an outer tube and at least one inner tube. Also included in the fluid vapor distillation apparatus is a regenerative blower fluidly connected to the evaporator condenser. The regenerative blower compresses steam, and the compressed steam flows to the evaporative condenser where compressed steam is transformed into product fluid. The fluid vapor distillation apparatus also includes a control system.

Owner:DEKA PROD LLP

Compact vacuum distillation device

InactiveUS6010599AReduce problem sizeBoiling pointUsing liquid separation agentDistillation in boilers/stillsAtmospheric airEngineering

An apparatus for batch distilling a liquid at sub-atmospheric pressure, without the aid of a vacuum pump. The apparatus includes an evaporator section having a valved entry port through which a batch of liquid in a first atmospheric condition is added to the evaporator section. A condenser section receives distillate and is in communication with the evaporator section. A valved vent is provided for sealing said apparatus from the outside atmosphere to form a second atmospheric condition which is sealed from the atmosphere after a heating element vaporizes said liquid into an initial sufficient amount of a first vapor to purge the first atmospheric condition from the apparatus through the valved vent. A condenser is disposed for condensing a sufficient amount of the first vapor to form a third atmospheric condition at a pressure below the first atmospheric condition, and for condensing a second vapor to produce distillate.

Owner:AMERICAN TECH GROUP

Water Vapor Distillation Apparatus, Method and System

ActiveUS20140183025A1Water treatment parameter controlDistillation regulation/controlWater vaporControl system

A fluid vapor distillation system. The system includes a control system for controlling a fluid vapor distillation apparatus including a blow down controller for controlling a blow down valve, a source flow controller for controlling a source flow valve, and a blow down level sensor in communication with a blow down controller and a source flow controller, the blow down level sensor sends signals related to the blow down level to the blow down controller and the source flow controller indicative of the blow down level, wherein the source flow controller actuates the source flow valve based at least on the blow down level sensor signals, and wherein the blow down controller actuates the blow down valve based at least on the blow down level sensor signals, whereby the blow down level and the source flow level are maintained using the blow down level sensor signals as input.

Owner:DEKA PROD LLP

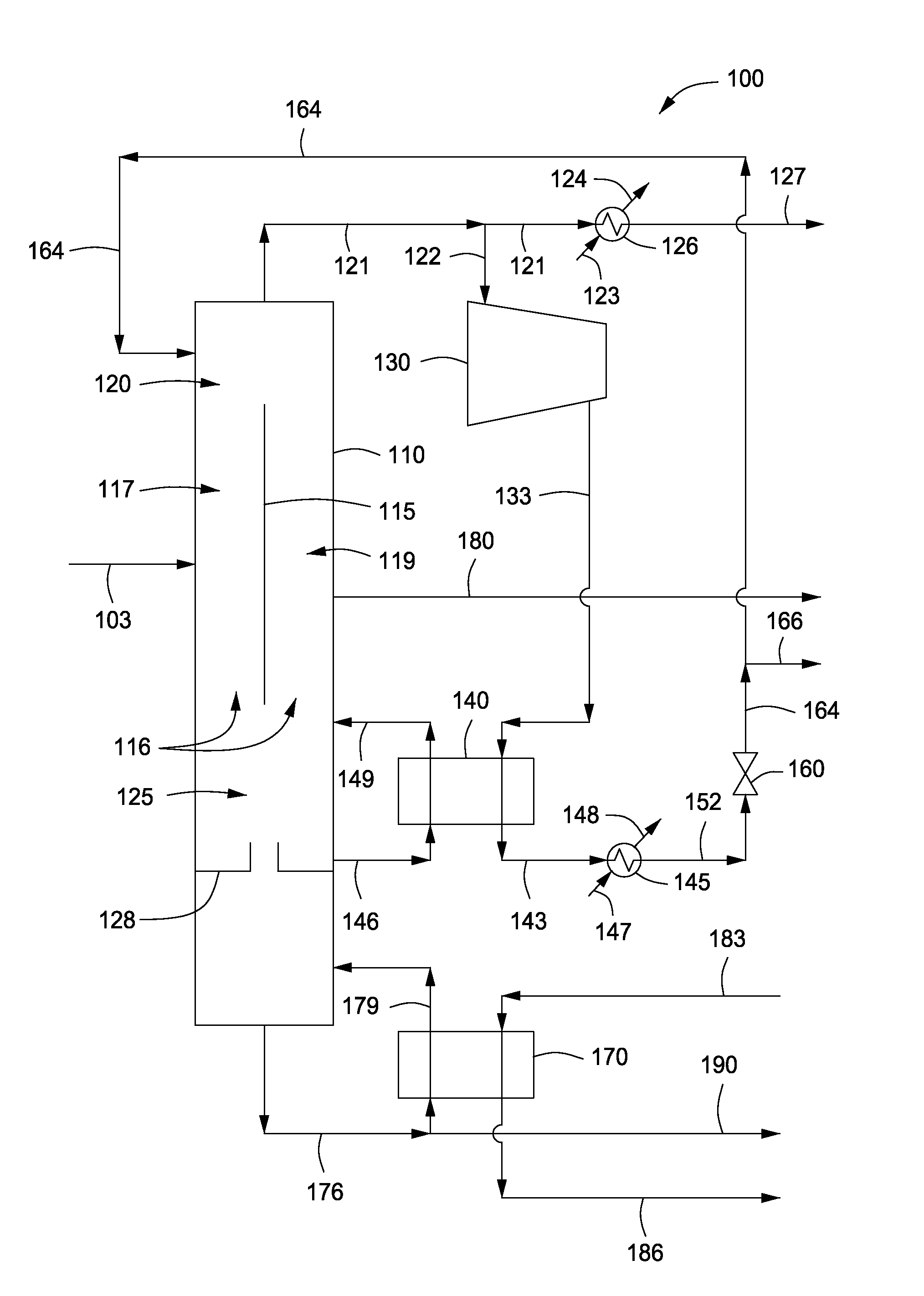

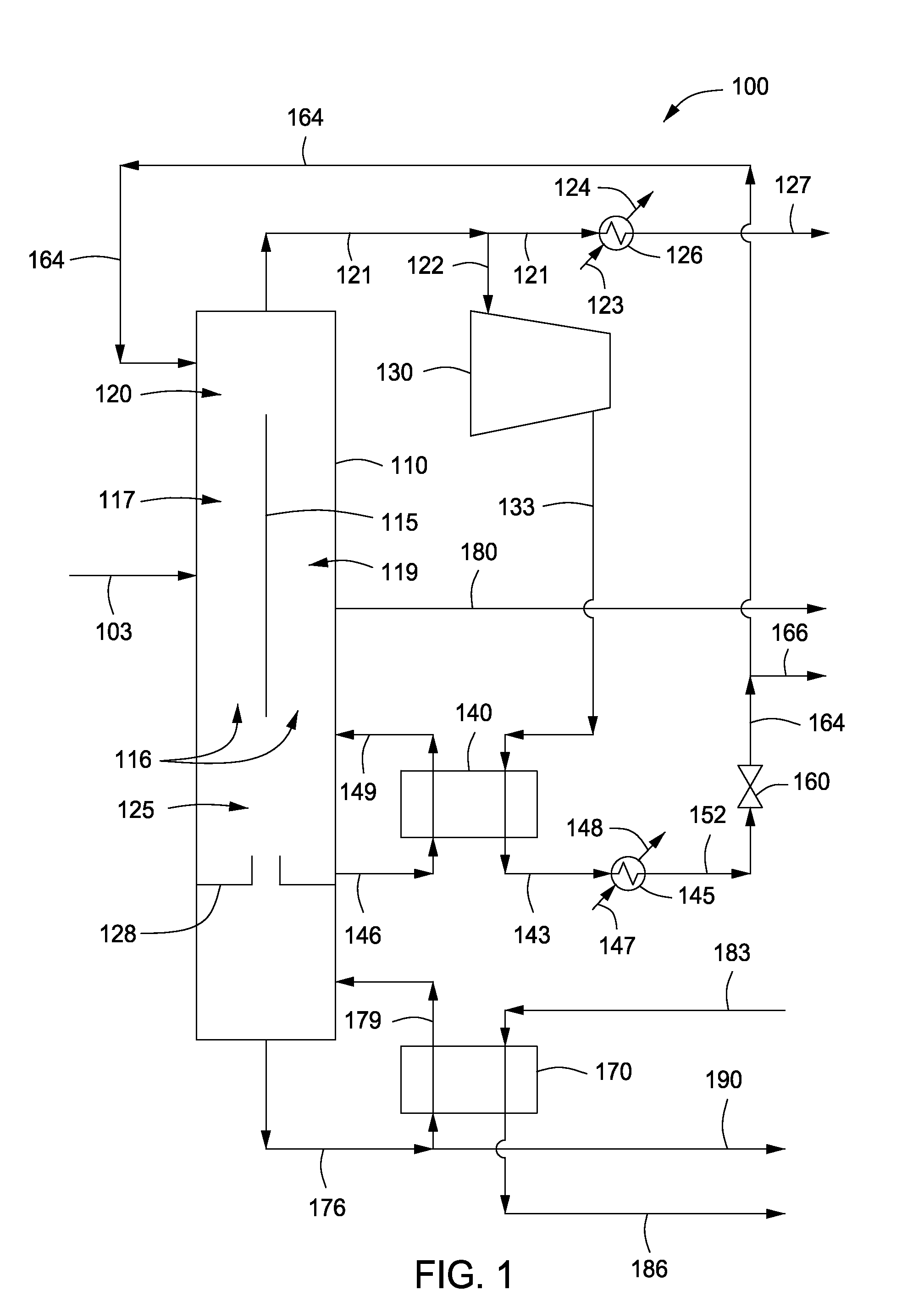

Heat Pump Distillation

ActiveUS20090114524A1Improved and energy-efficientHeat recovery systemsCompression machines with non-reversible cycleDistillationHeat pump

A distillation column is disclosed with a folded design. The column includes a plurality of rectification zones and corresponding stripping zones Each rectification zone is linked to a heat pump or a stage of a heat pump. Overhead vapor from the top rectification zone is compressed and used to heat bottoms liquid from the bottom stripping zone Similarly, overhead vapor from the middle rectification zone is compressed and used to heat liquid from a middle stripping zone and overhead from a lower rectification zone is compressed and used to heat liquid taken from the uppermost or top stripping zone. A single multiple stage heat pump compressor may be utilized as opposed to a plurality of heat pumps Because the heat exchanger from each rectification-stripping zone pair has a lower duty, economical stab-in heat exchangers may be utilized.

Owner:UOP LLC

Dividing wall column with a heat pump

Owner:M W KELLOGG LTD

Method for recovering fluorine-containing emulsifier

ActiveUS20050150833A1Effective recoveryHigh recovery rateSpecific water treatment objectivesWater contaminantsHigh concentrationPresent method

An aqueous solution containing a fluorine-containing emulsifier in a low concentration of at least 1 ppm by mass and at most 1% by mass (e.g., coagulation waste water after an emulsion polymerization of a fluoropolymer and / or an aqueous solution obtained by washing with an aqueous solution a waste gas from a drying process and / or a heat treating process of the fluoropolymer) is subjected to vacuum concentration under a pressure of at most 100 kPa and a temperature of the aqueous solution of at most 100° C. by means of a heating tube surface evaporation type concentrator equipped with a heat pump or the like, and the fluorine-containing emulsifier is recovered from a highly concentrated aqueous solution containing the fluorine-containing emulsifier in a higher concentration of at least 5% by mass. According to the present method, the fluorine-containing emulsifier can be recovered with a high yield from a low-concentration liquid such as coagulation waste water of a fluoropolymer.

Owner:SASAKURA ENG CO LTD +1

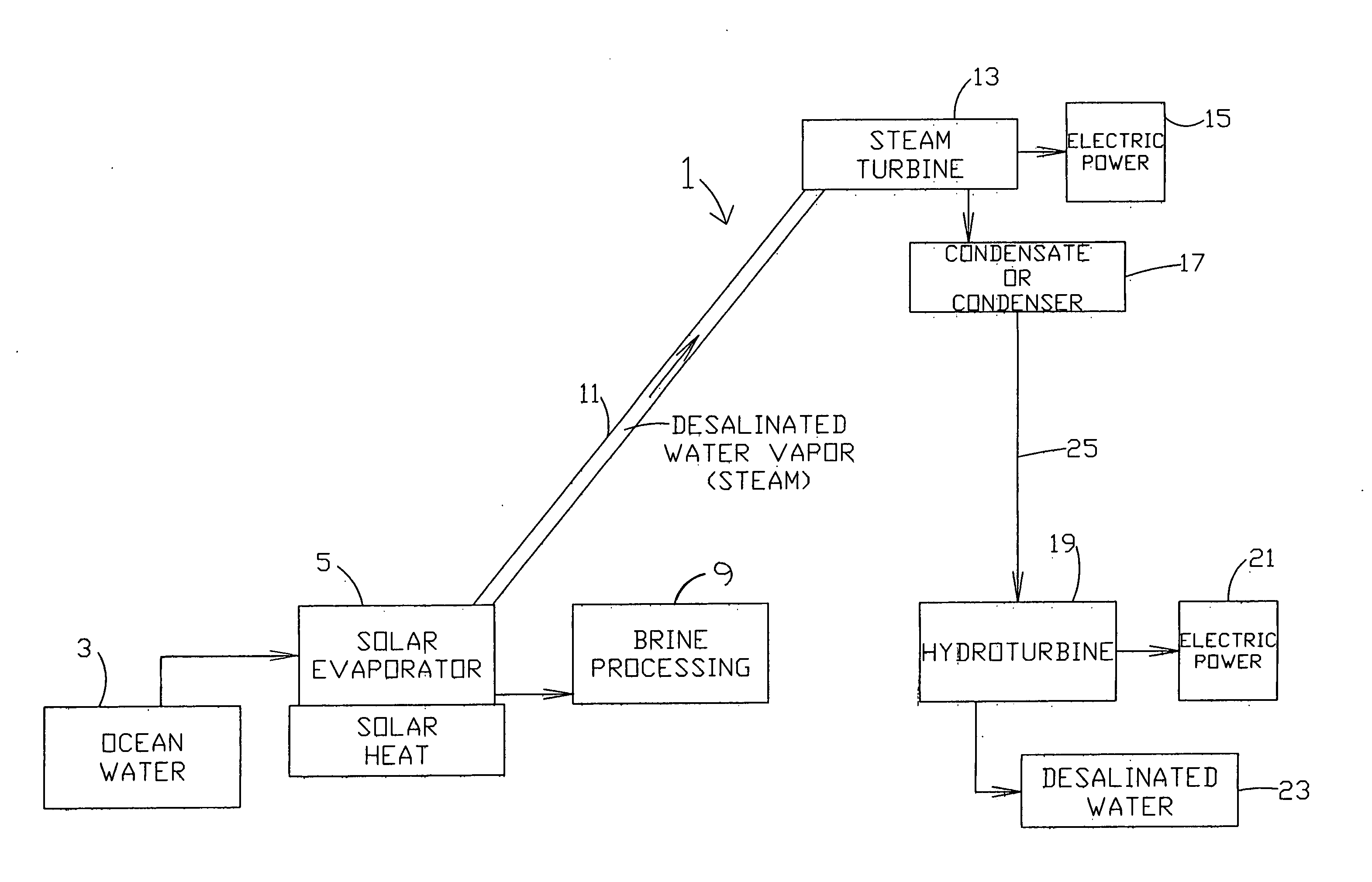

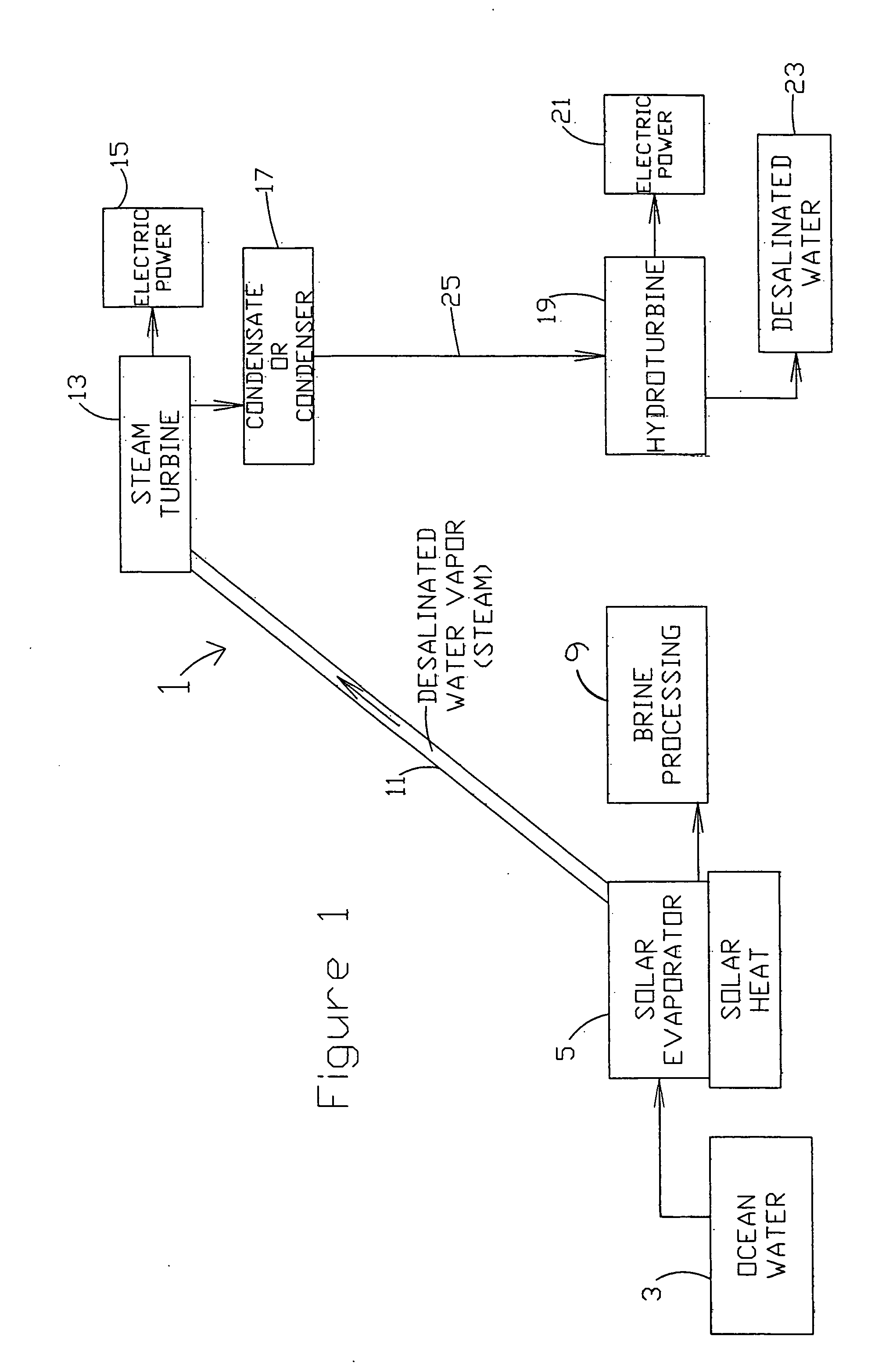

Solar desalination system with reciprocating solar engine pumps

A solar desalination system includes a solar furnace for receiving seawater into a vessel and concentrating sunlight on the vessel to heat that water using solar energy to create desalinated steam. Water is input into the furnace via a pump that is powered by a reciprocating solar engine. The reciprocating solar engine includes a seesawing platform with a closed system of two or more connected containers thereon. Solar heating causes a fluid to move from one container to another causing the platform to reciprocally rotate through a predetermined arc, creating energy that can be harnessed. A riser pipe extending upwardly from the solar furnace carries steam to an electric power-producing steam turbine generator where the steam generates electricity. A drop pipe extending downwardly from the steam turbine generator carries desalinated water to an electric power-producing hydroturbine generator where the water generates electricity and is then removed for subsequent use.

Owner:KENERGY SCI

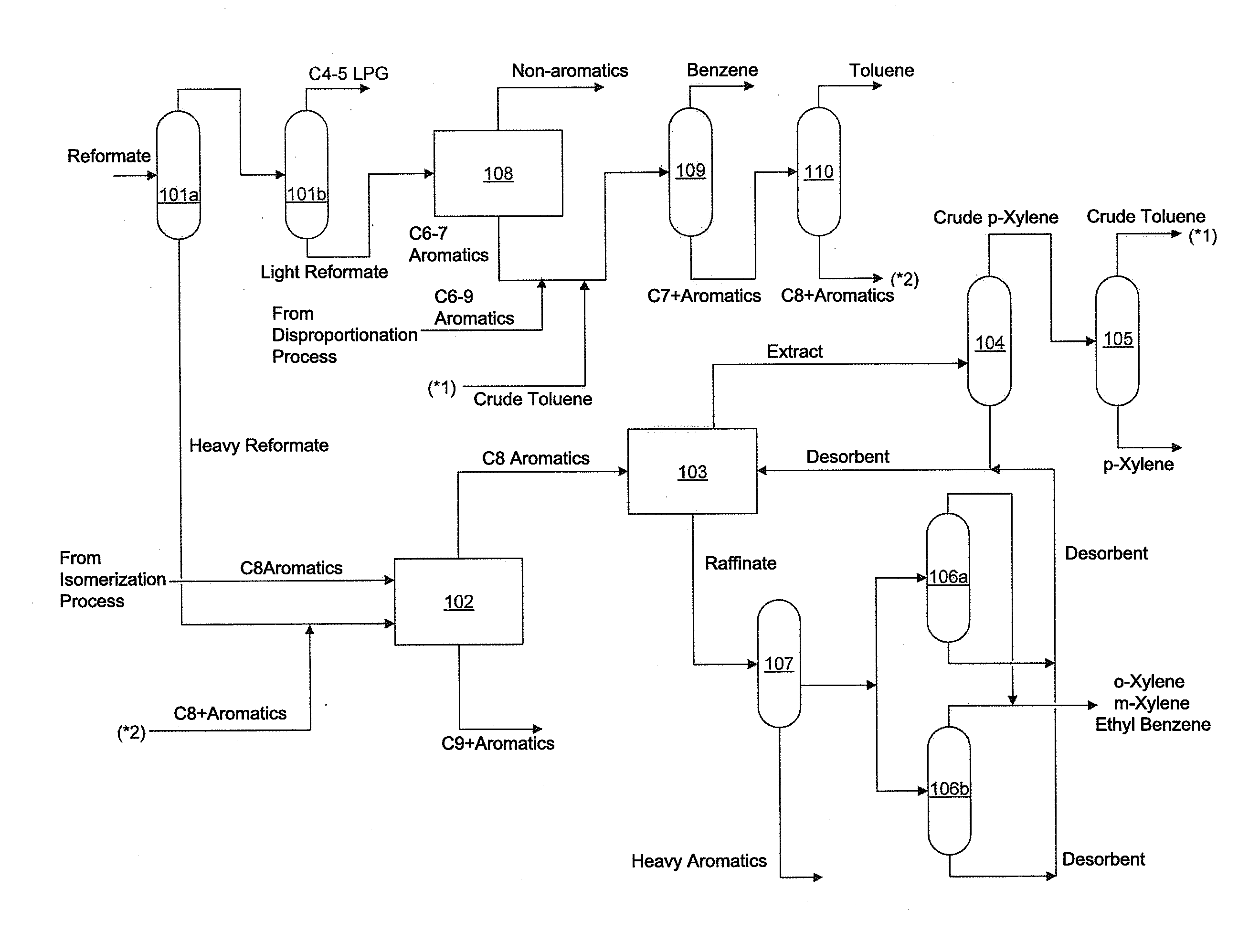

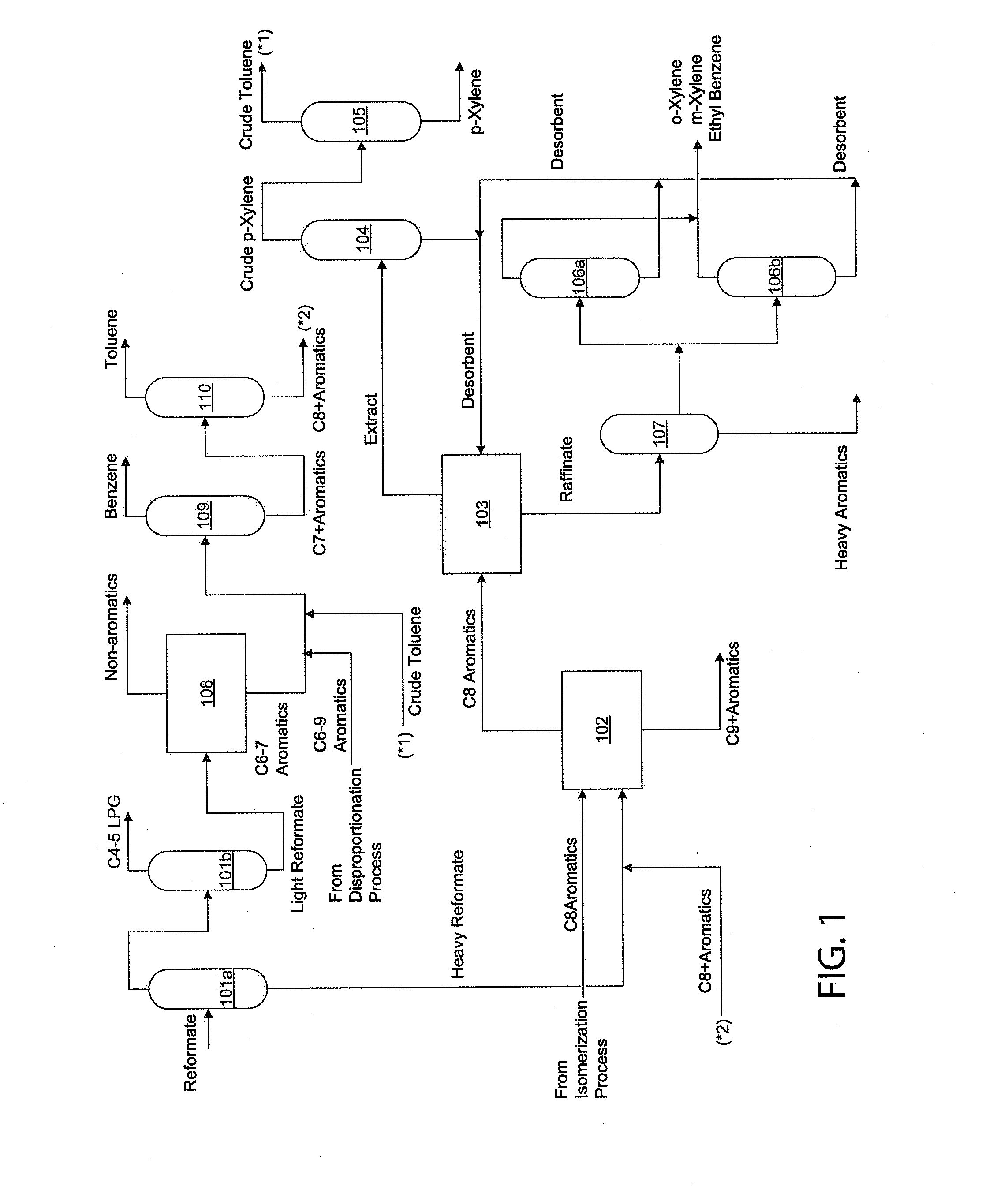

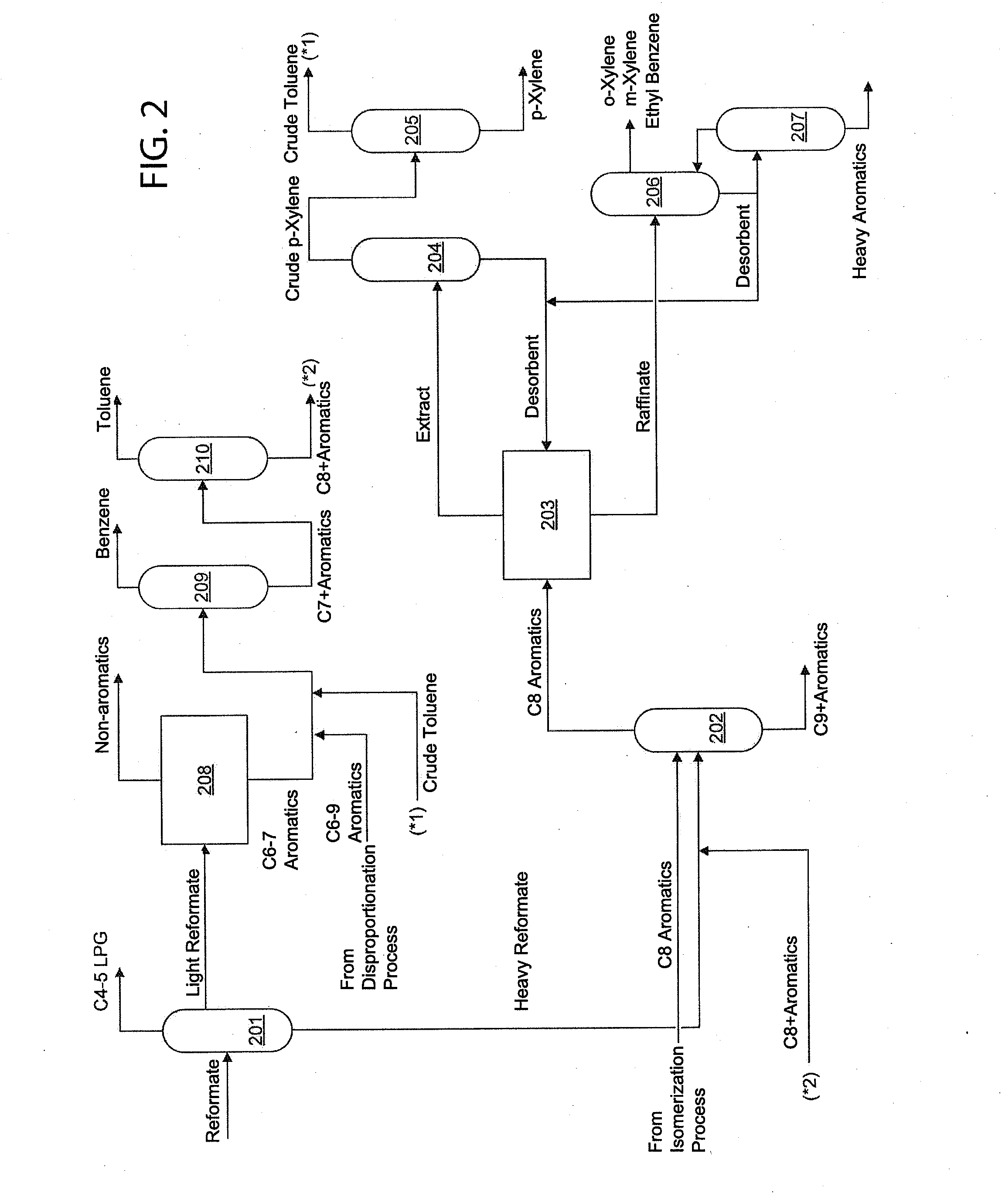

Aromatic hydrocarbon production apparatus

InactiveUS20140142364A1Reduce energy consumptionHydrocarbon distillationDistillation in boilers/stillsDistillationHigh pressure

An apparatus includes a first distillation apparatus for obtaining a fraction enriched in C8+ aromatics; a second distillation apparatus for obtaining a fraction enriched in C8 aromatics; an adsorption separation apparatus for obtaining an extract containing para-xylene and a raffinate containing xylene isomers; a third distillation apparatus for obtaining a fraction enriched in para-xylene; and a fourth distillation apparatus for obtaining a fraction enriched in xylene isomers. The second distillation apparatus includes a high-pressure part including a rectifying section; a low-pressure part including a stripping section; a line for directing overhead vapor of the low-pressure part to a column bottom of the high-pressure part; a line for directing a column bottom liquid of the high-pressure part to a column top of the low-pressure part; and a heat exchange structure for transferring heat from the rectifying section to the stripping section.

Owner:TOYO ENG CORP

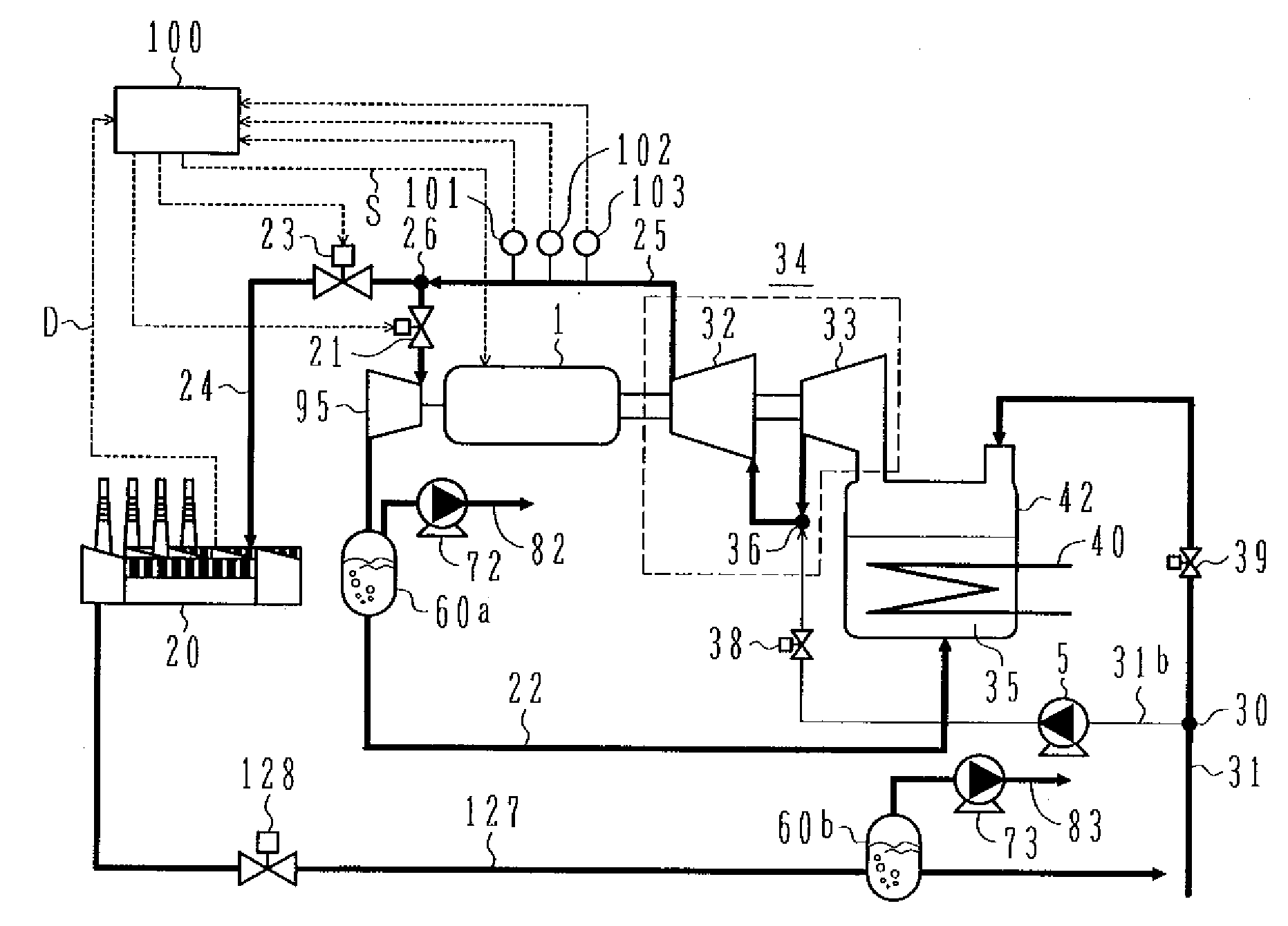

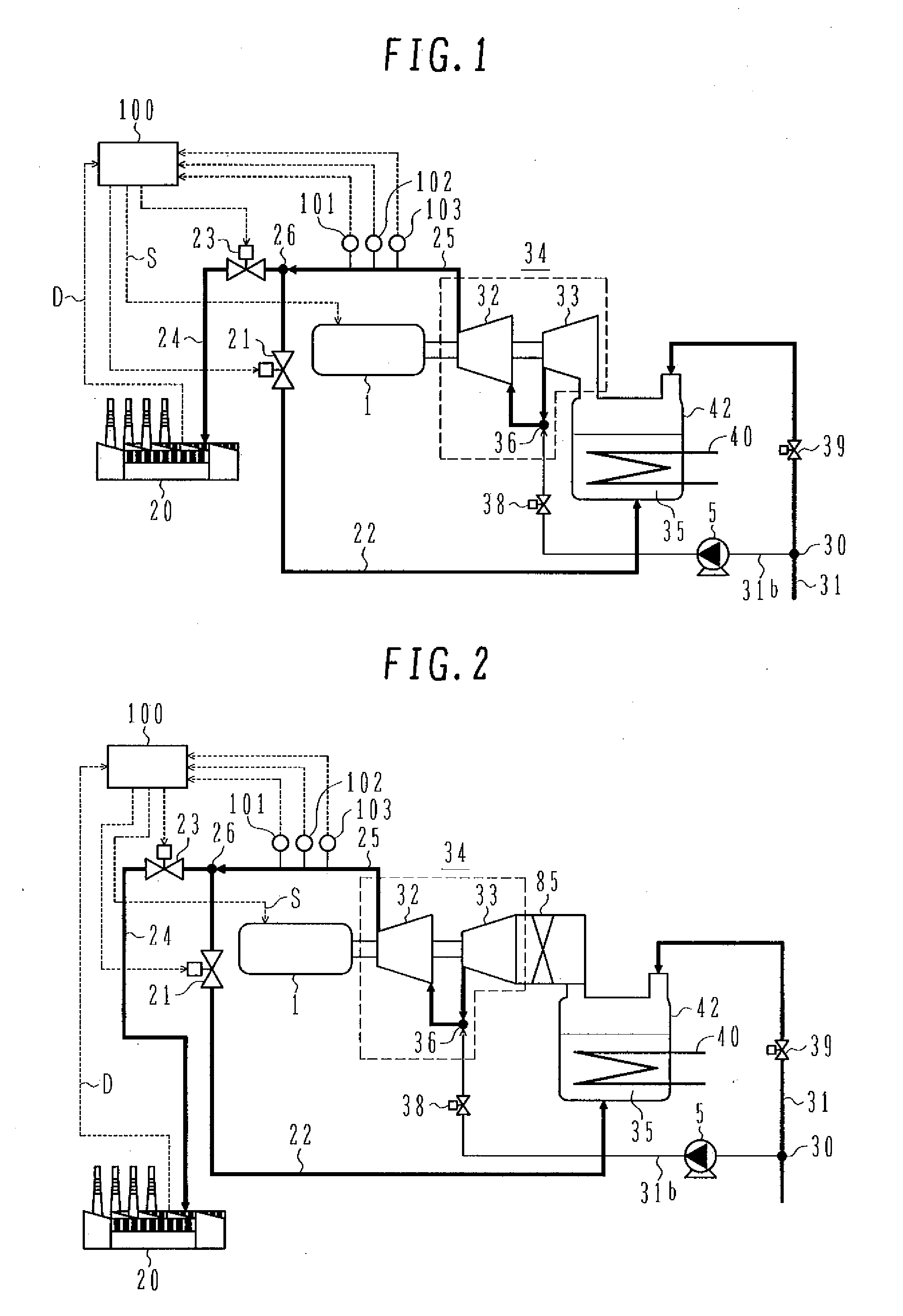

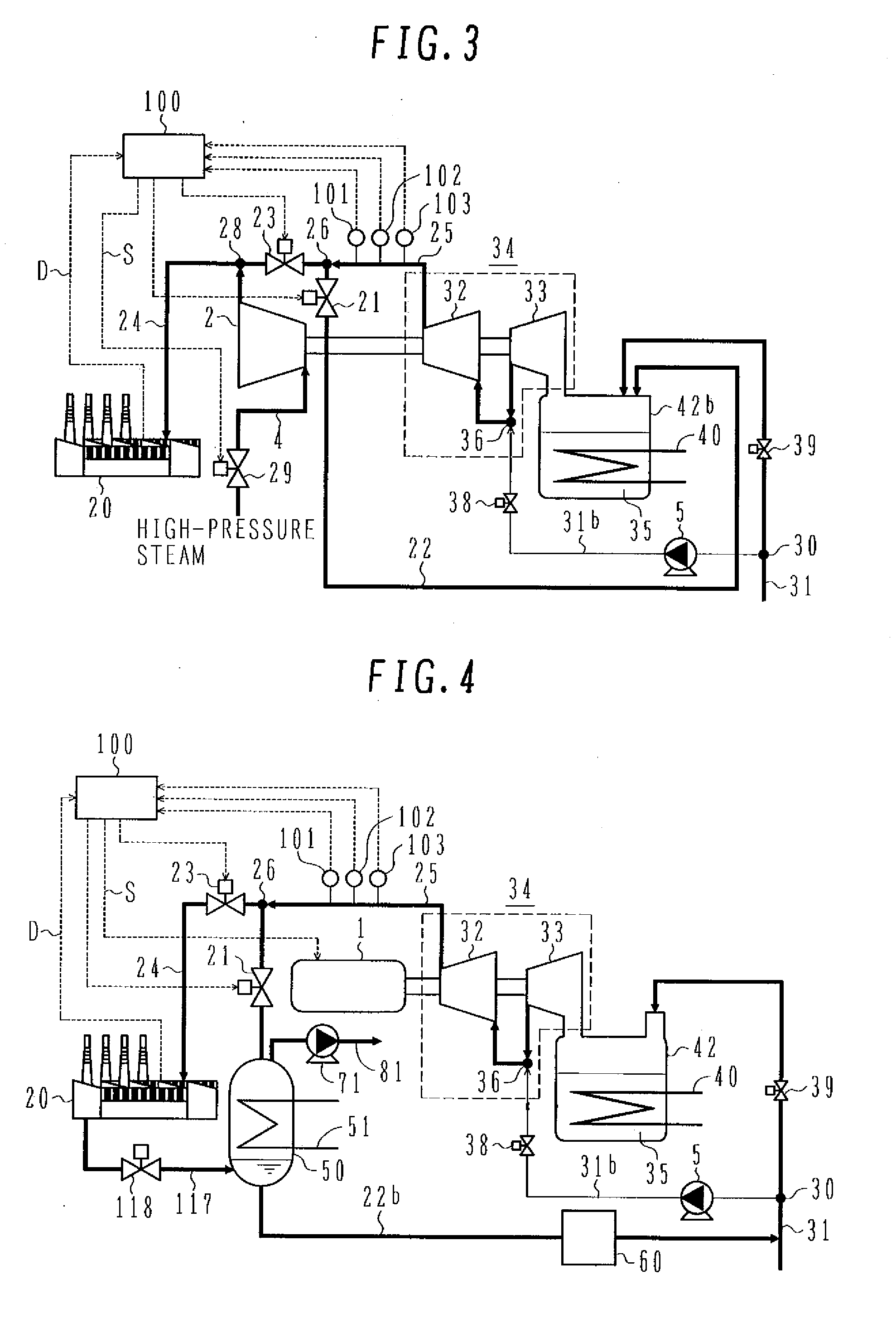

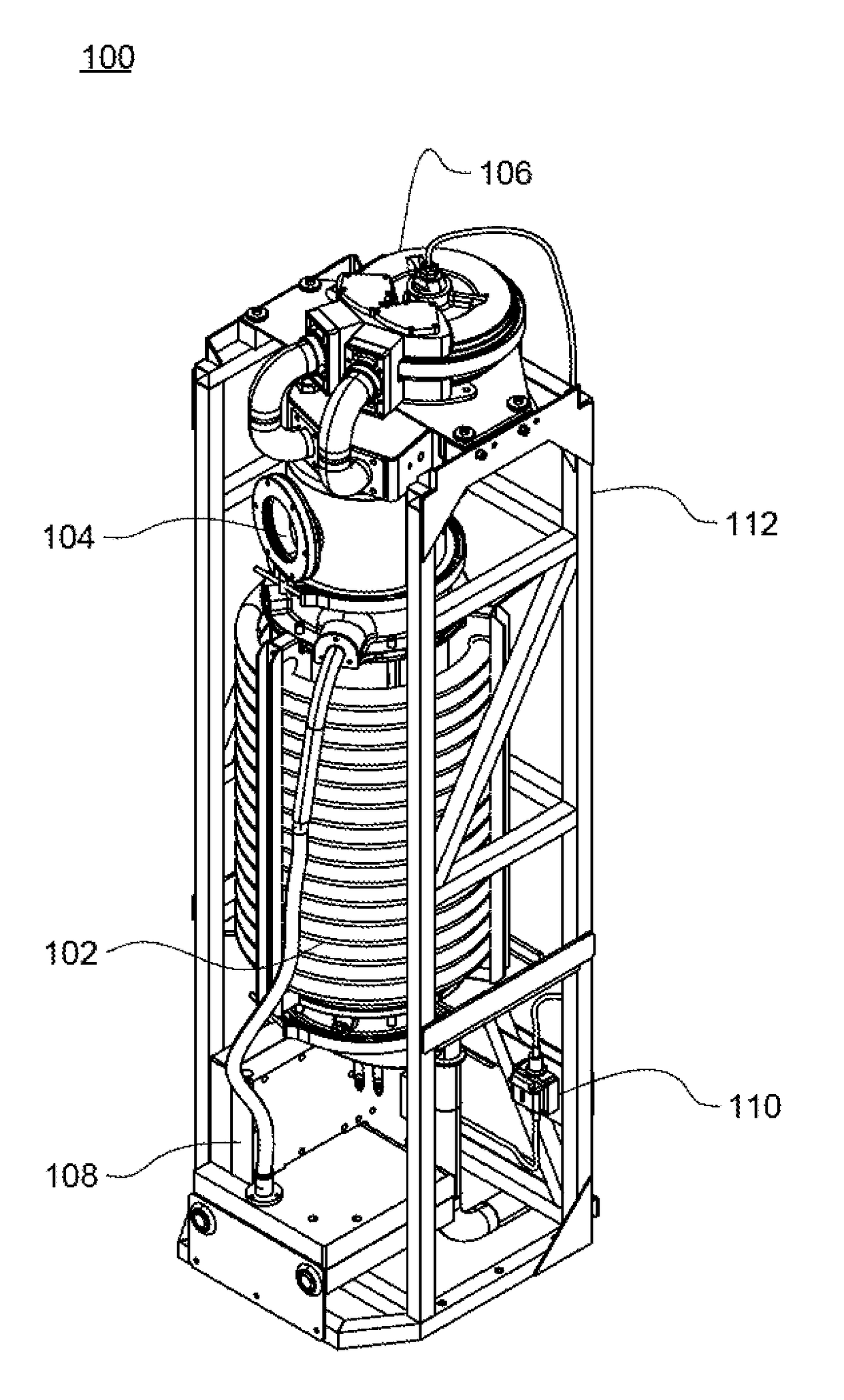

Heat pump system and heat pump operation method

InactiveUS20070000267A1Prevent surgeEnergy recuperation in distillationSteam generationLiquid waterEngineering

A compact heat pump system and a heat pump operation method employs an evaporator for recovering heat of an external heat source to a working medium supplied as liquid water from the exterior via a water feed channel, thereby evaporating the working medium, a compressor for compressing the working medium evaporated in the evaporator and increasing temperature of the evaporated working medium, and a driving unit for giving motive power to drive the compressor. The heat pump system further includes a supply channel for supplying, as a heat source, vapor of the working medium having a temperature increased by the compressor to an external heat-utilizing facility, and a return channel branched from the supply channel and introducing the working medium discharged from the compressor to the evaporator.

Owner:HITACHI LTD

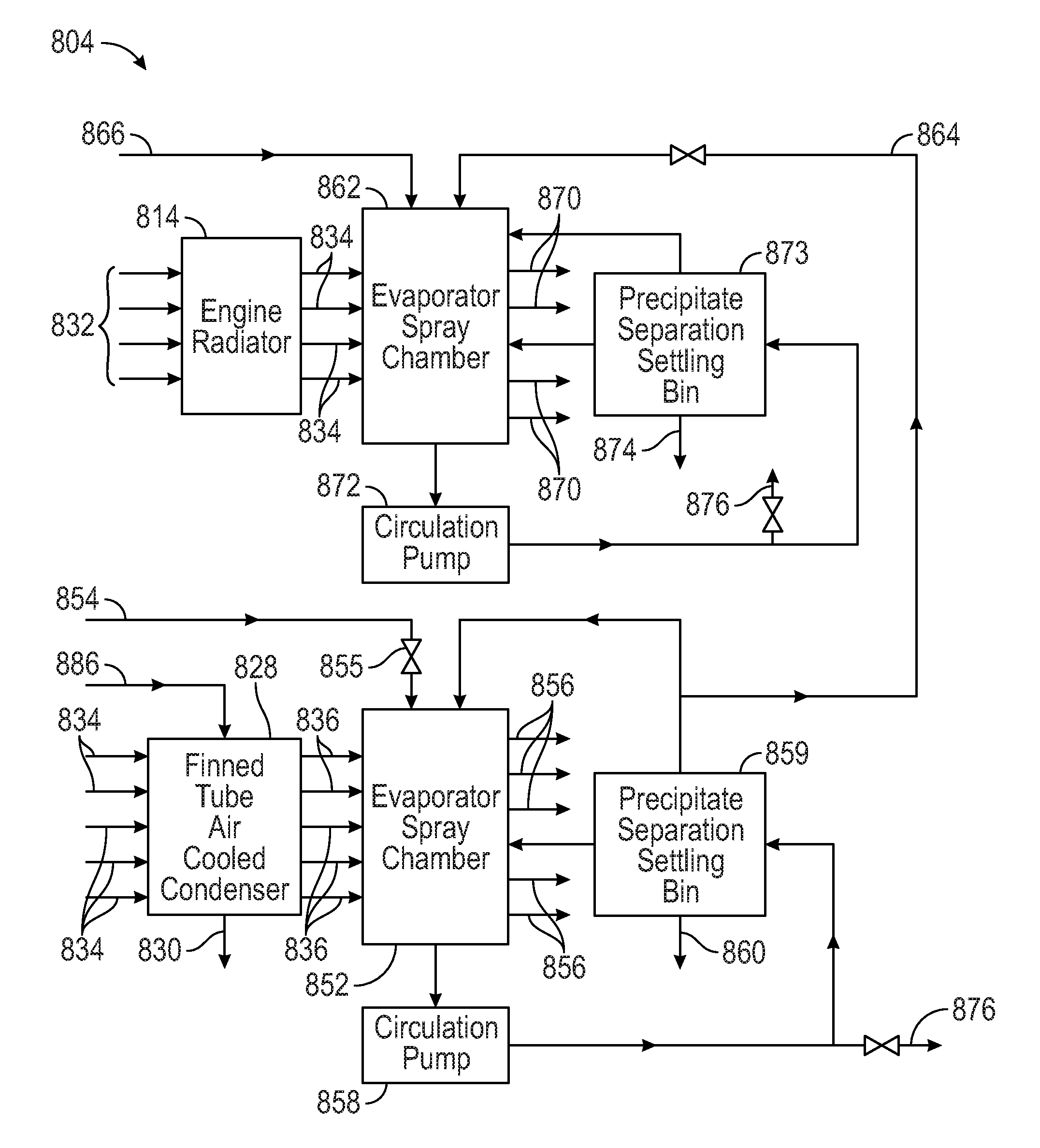

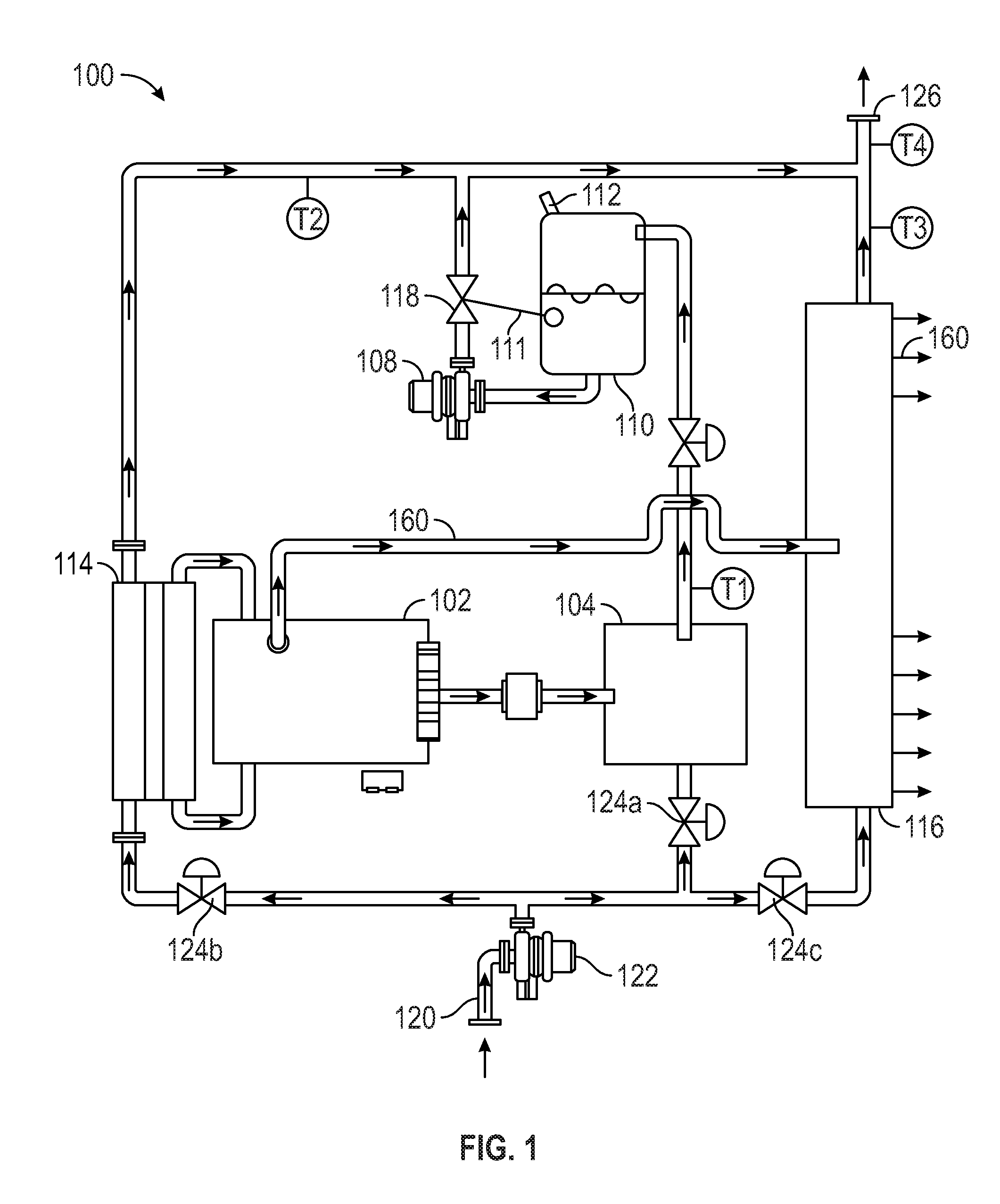

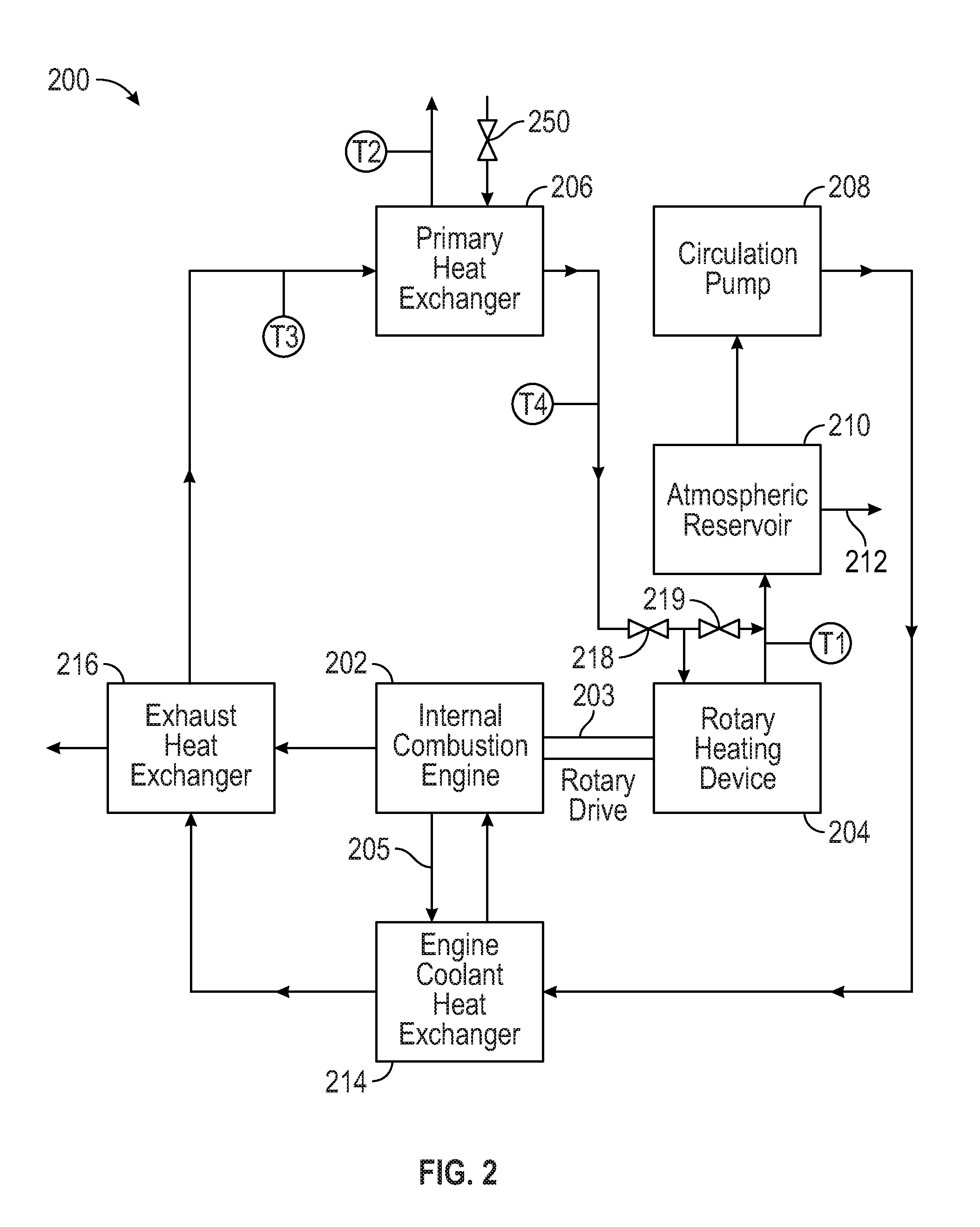

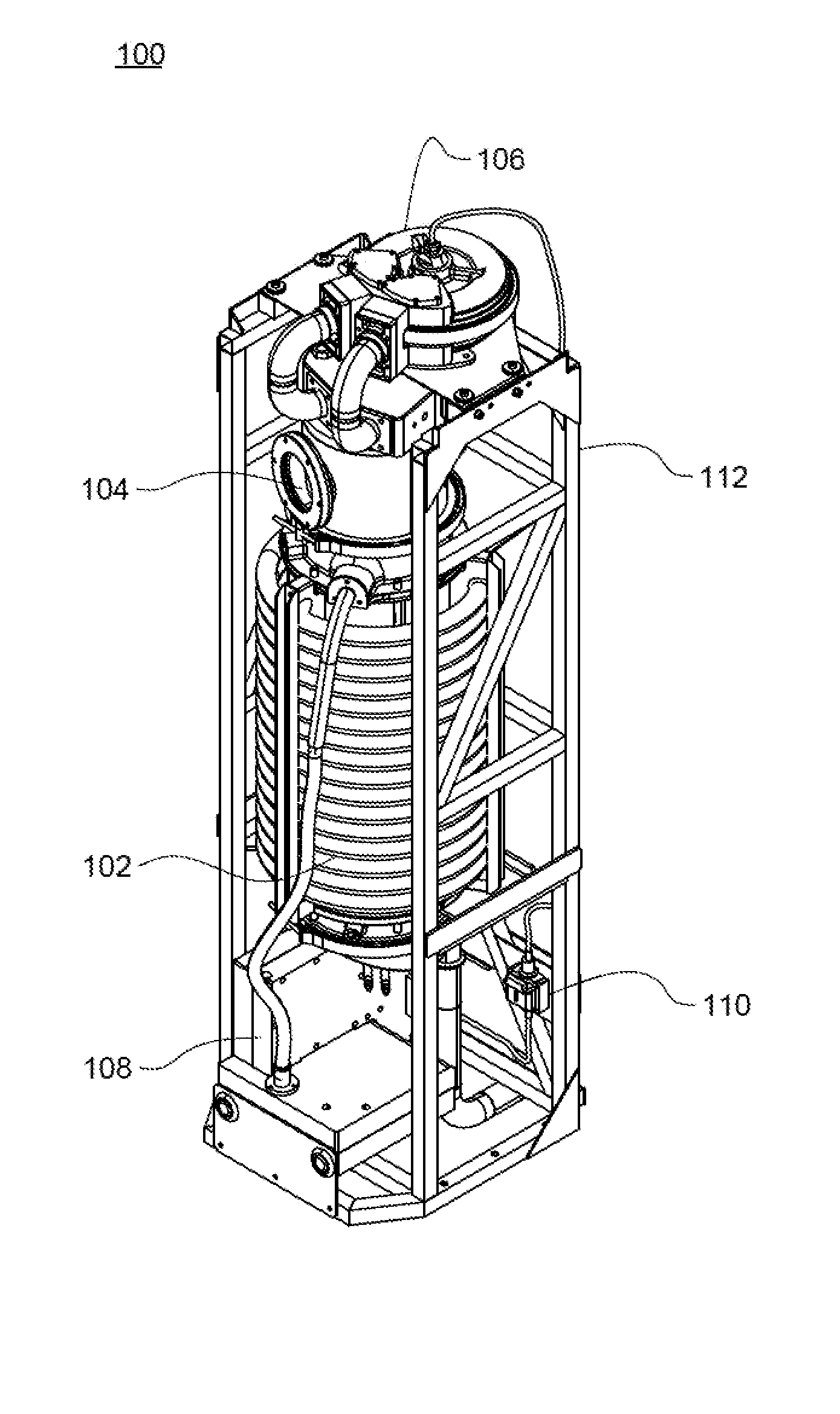

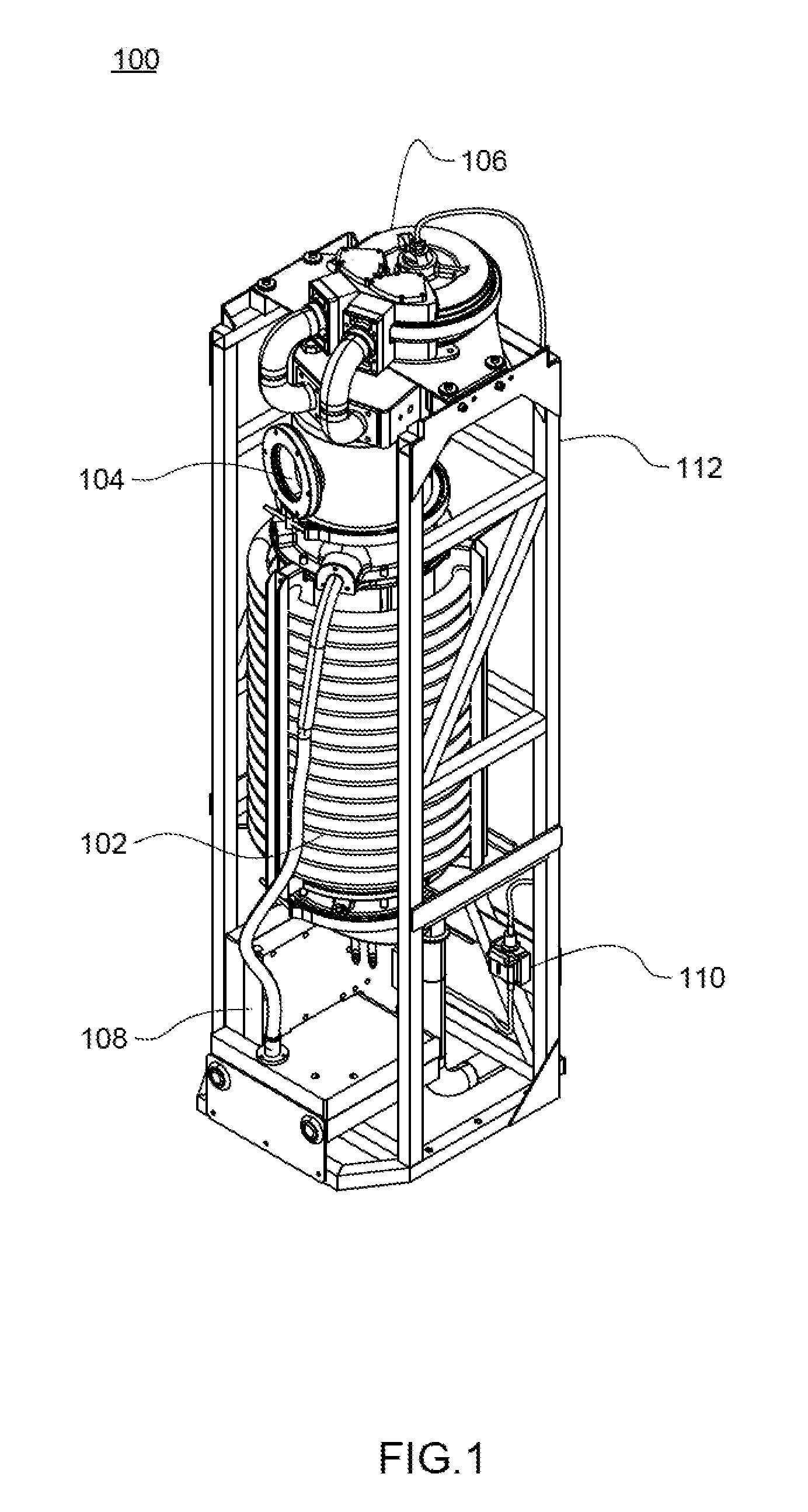

Methods and systems for heating and manipulating fluids

InactiveUS20160258266A1Waste water treatment from quariesTreatment involving filtrationFluid systemChemistry

Owner:FRICK FRLIN ALAN

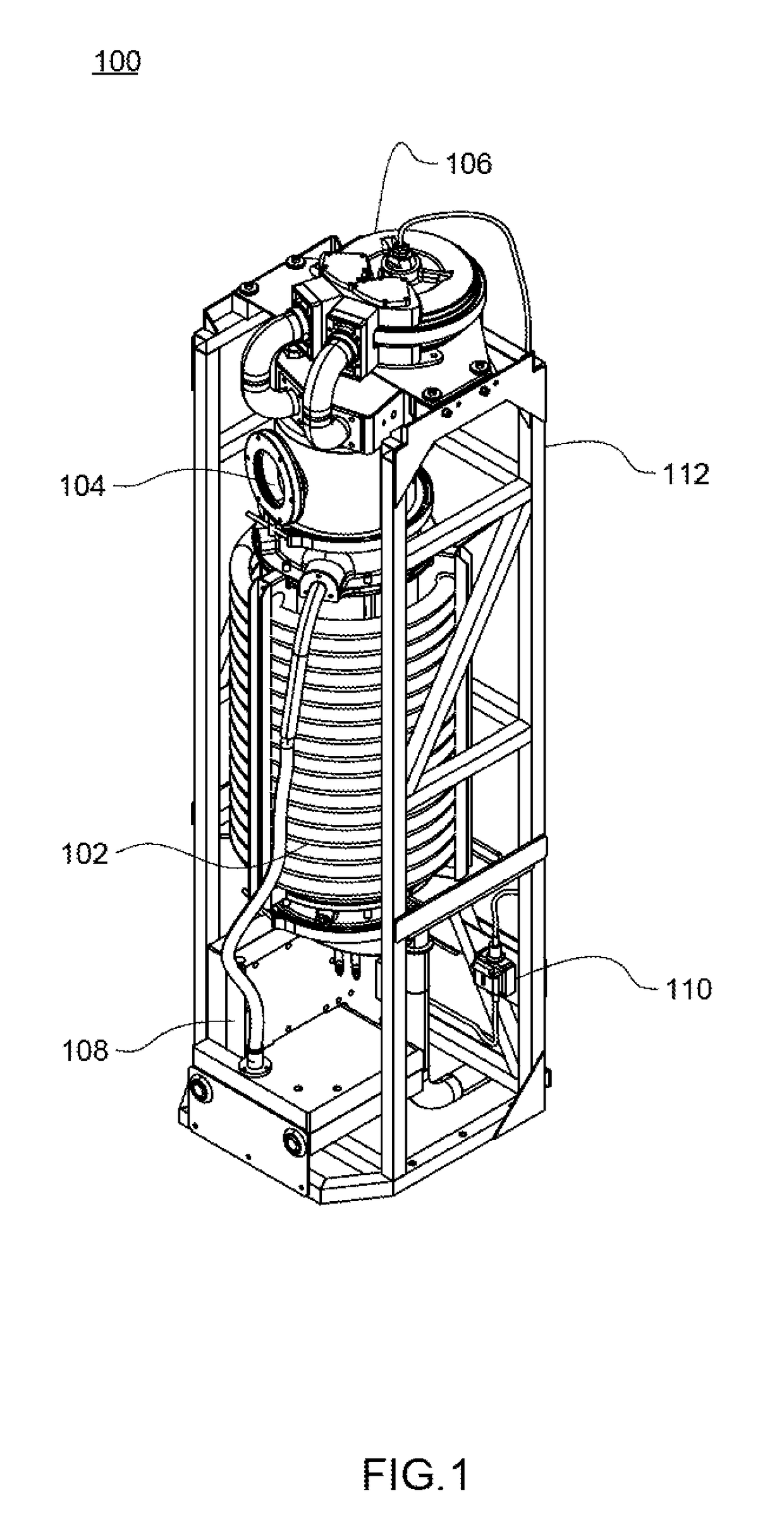

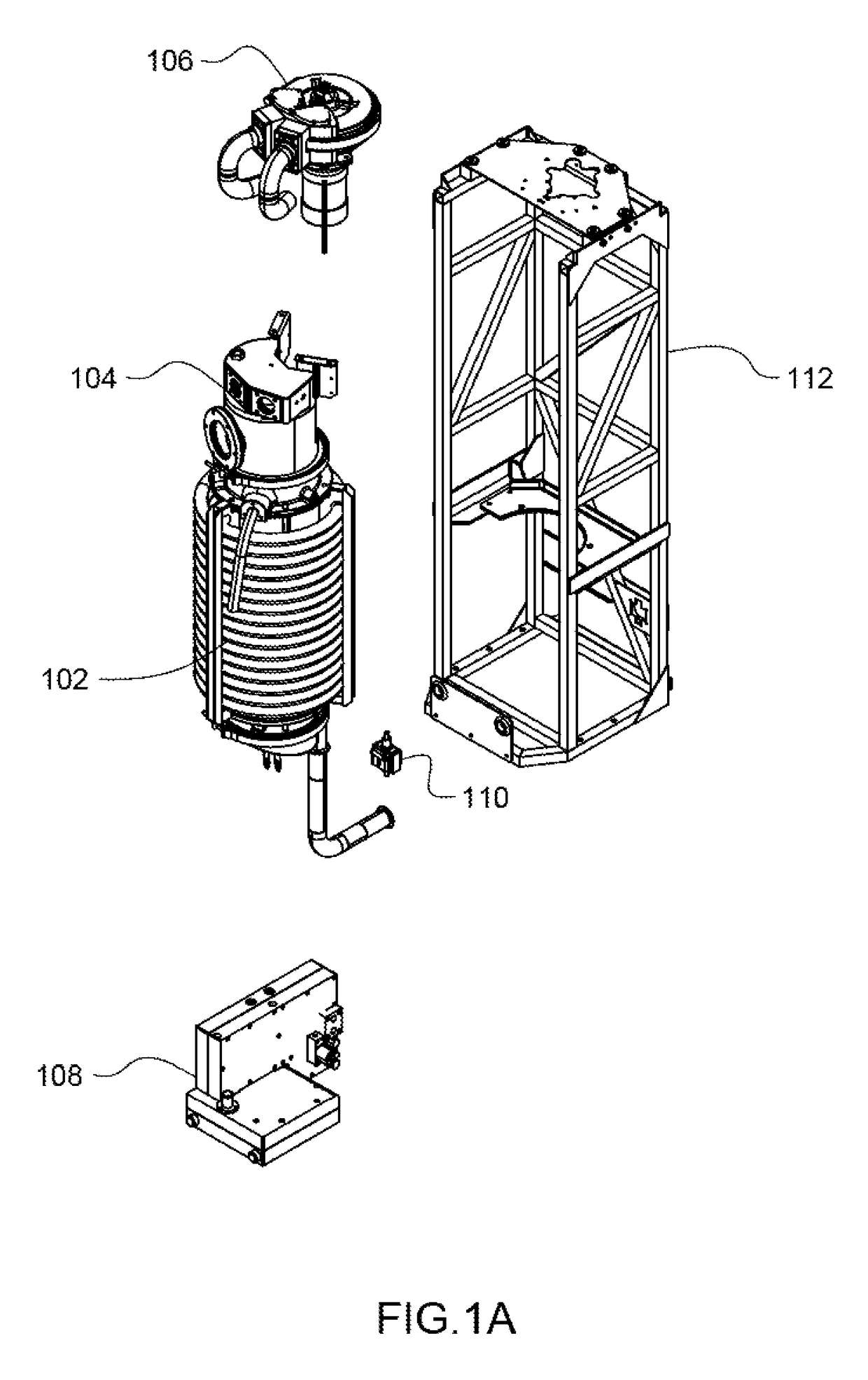

Water vapor distillation apparatus, method and system

ActiveUS8505323B2Lighting and heating apparatusDistillation regulation/controlControl systemDistillation

A fluid vapor distillation apparatus. The apparatus includes a source fluid input, and an evaporator condenser apparatus. The evaporator condenser apparatus includes a substantially cylindrical housing and a plurality of tubes in the housing. The source fluid input is fluidly connected to the evaporator condenser and the evaporator condenser transforms source fluid into steam and transforms compressed steam into product fluid. Also included in the fluid vapor distillation apparatus is a heat exchanger fluidly connected to the source fluid input and a product fluid output. The heat exchanger includes an outer tube and at least one inner tube. Also included in the fluid vapor distillation apparatus is a regenerative blower fluidly connected to the evaporator condenser. The regenerative blower compresses steam, and the compressed steam flows to the evaporative condenser where compressed steam is transformed into product fluid. The fluid vapor distillation apparatus also includes a control system.

Owner:DEKA PROD LLP

Evaporator and heat exchanger with external loop, as well as heat pump system and air conditioning system comprising said evaporator or heat exchanger

An evaporator including an evaporating chamber equipped with a drainage. The drainage drains accumulated liquid from the evaporator's lower parts and includes an external expansion driven injector and / or an external pump. The evaporator can be used e.g. in a heat exchanger, e.g. in a heat pump system or air condition system, and the vacuum driven injector can be integrated with an expansion device of the heat exchanger. A condenser can be used together with the evaporator in a heat exchanger of the plate type realizing an integrated superheater / supercooler. This is accomplished by the definition and use of delimited interacting zones through which the cooling medium circulates under heat exchange with itself.

Owner:DANFOSS AS

Method for recovering fluorine-containing emulsifier

ActiveUS7351342B2Effective recoveryHigh recovery rateSpecific water treatment objectivesWater contaminantsExhaust fumesFluoropolymer

Owner:SASAKURA ENG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com