Patents

Literature

6892 results about "Atmospheric air" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for sterilizing medical appliance

InactiveCN1634601AAvoid influenceImprove sterilization effectDiagnosticsSurgeryVacuum pressureMicrowave

A medical instrument sterilization method is disclosed, which characterizes in following process: pending medical instrument for sterilization treatment being placed in a closed container, then being vacuum pumped, the vacuum pressure of the container being controlled between 1 Pa to 1500 Pa, air and / or oxygen and / or inert gases are charged to closed container and the vacuum pressure being between 1 Pa to 1500 Pa, microwave is fed, the favorable power of which should make the gas charged into the container to generate ionization, the microwave be cut after the sterilization, then air being charged to release vacuum to finish the whole process.

Owner:吉林省中立实业有限公司

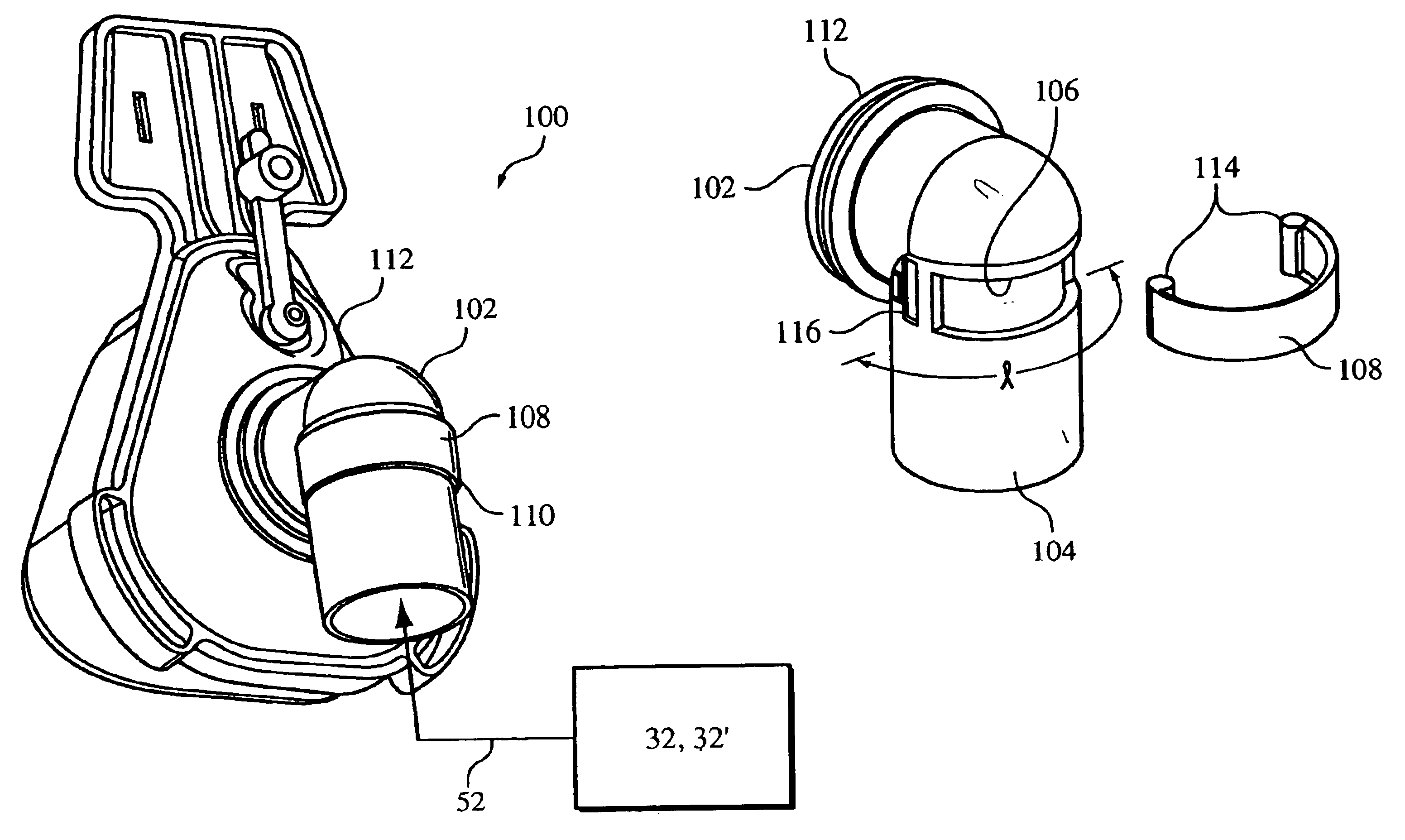

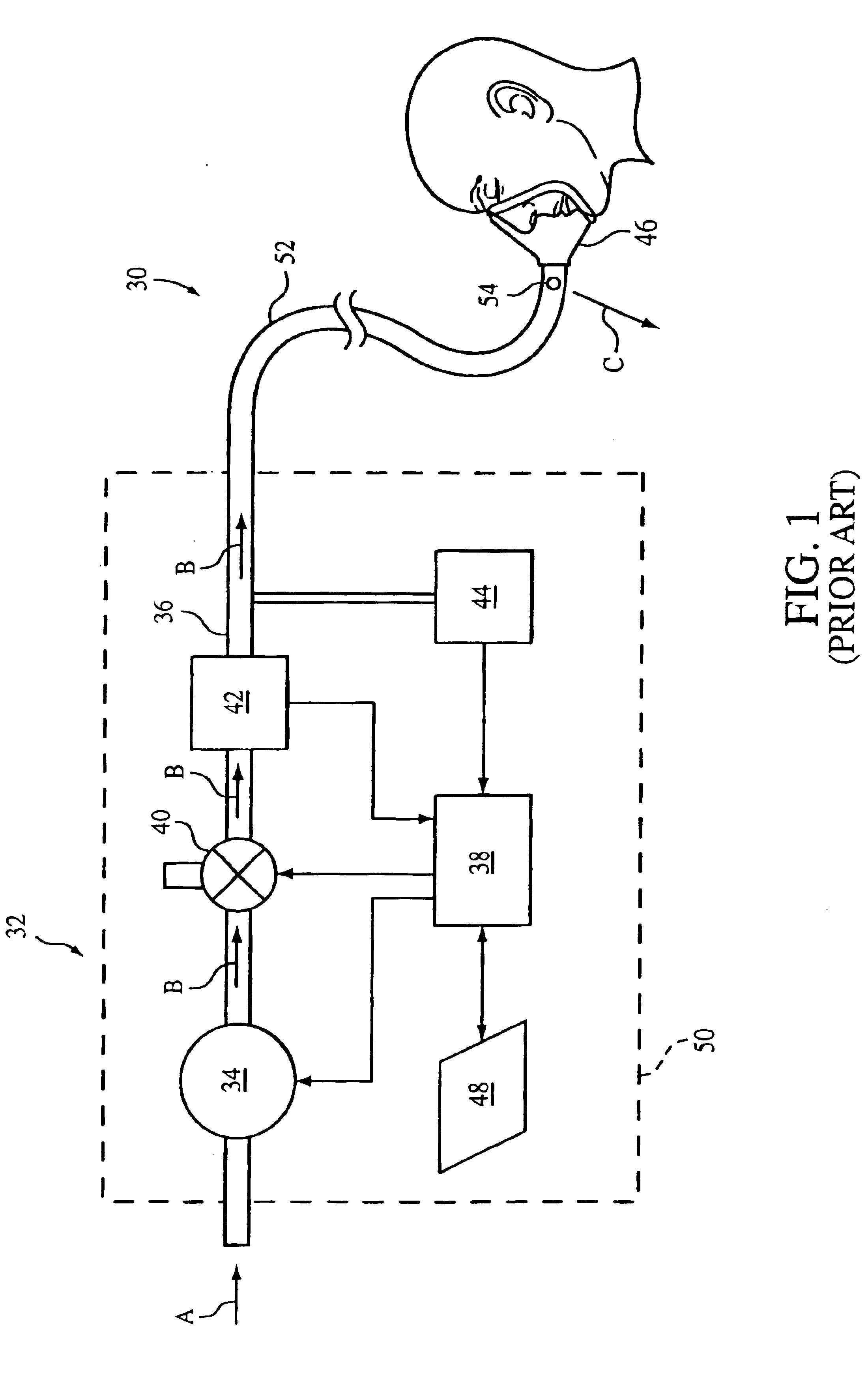

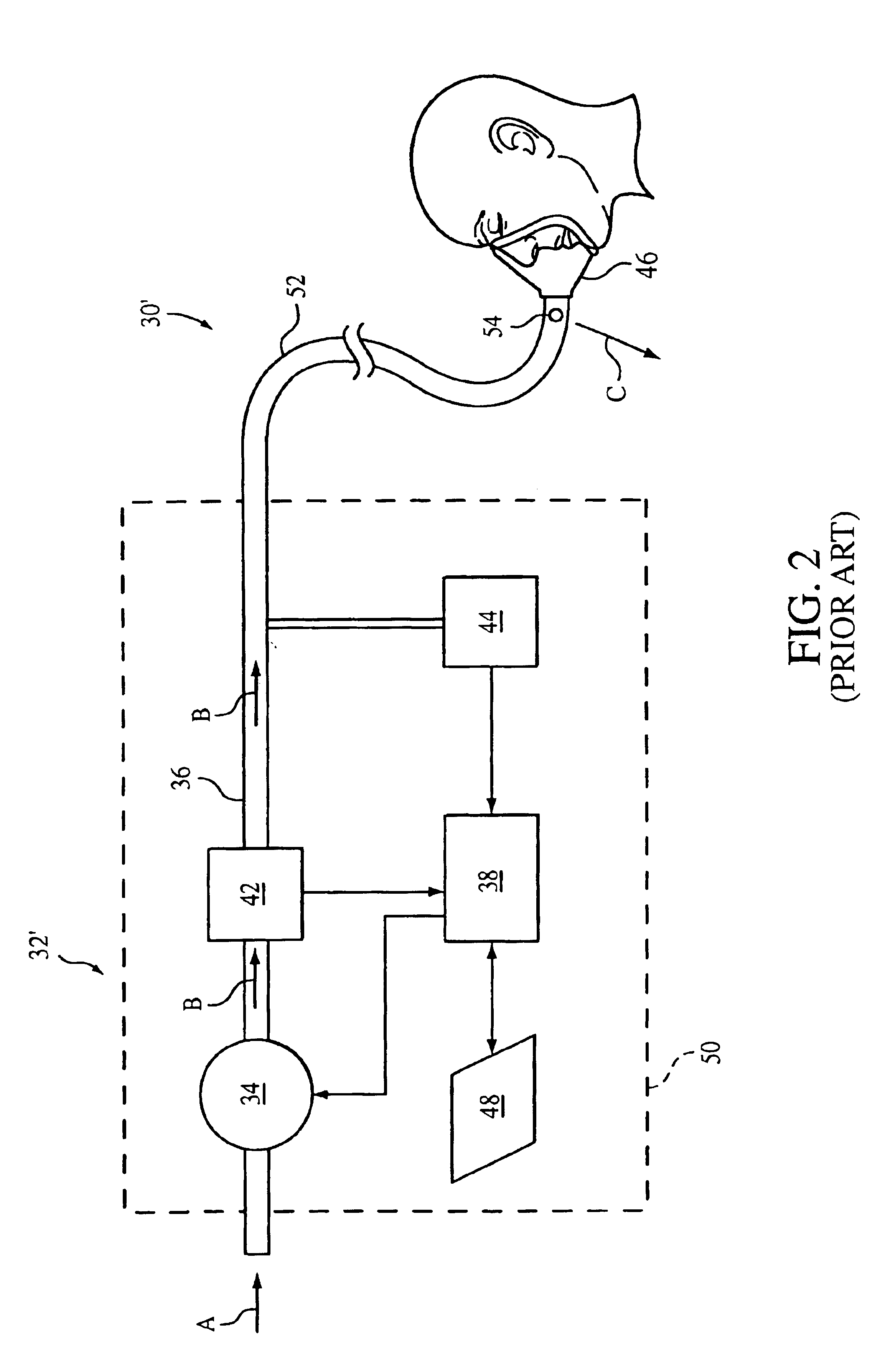

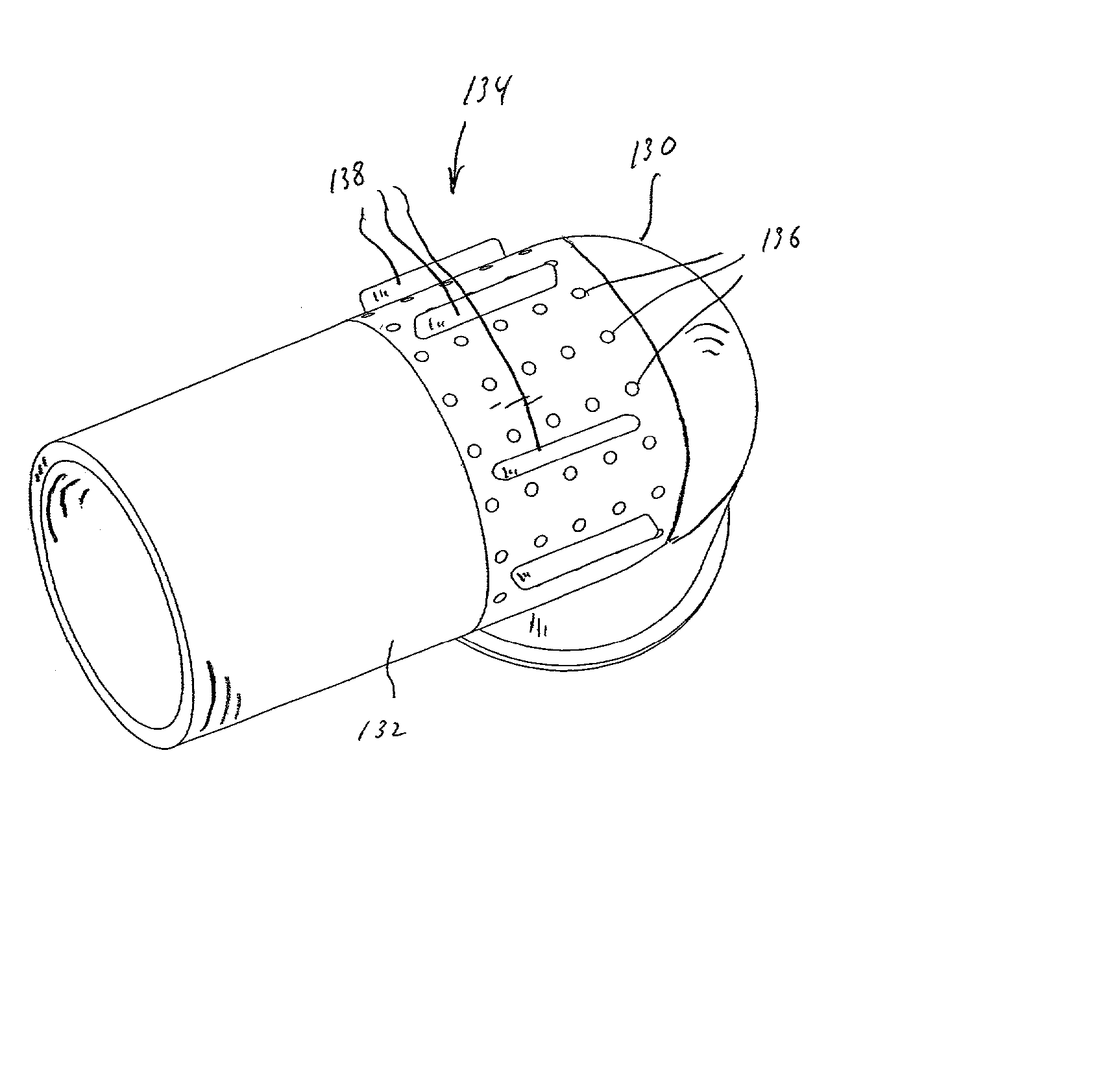

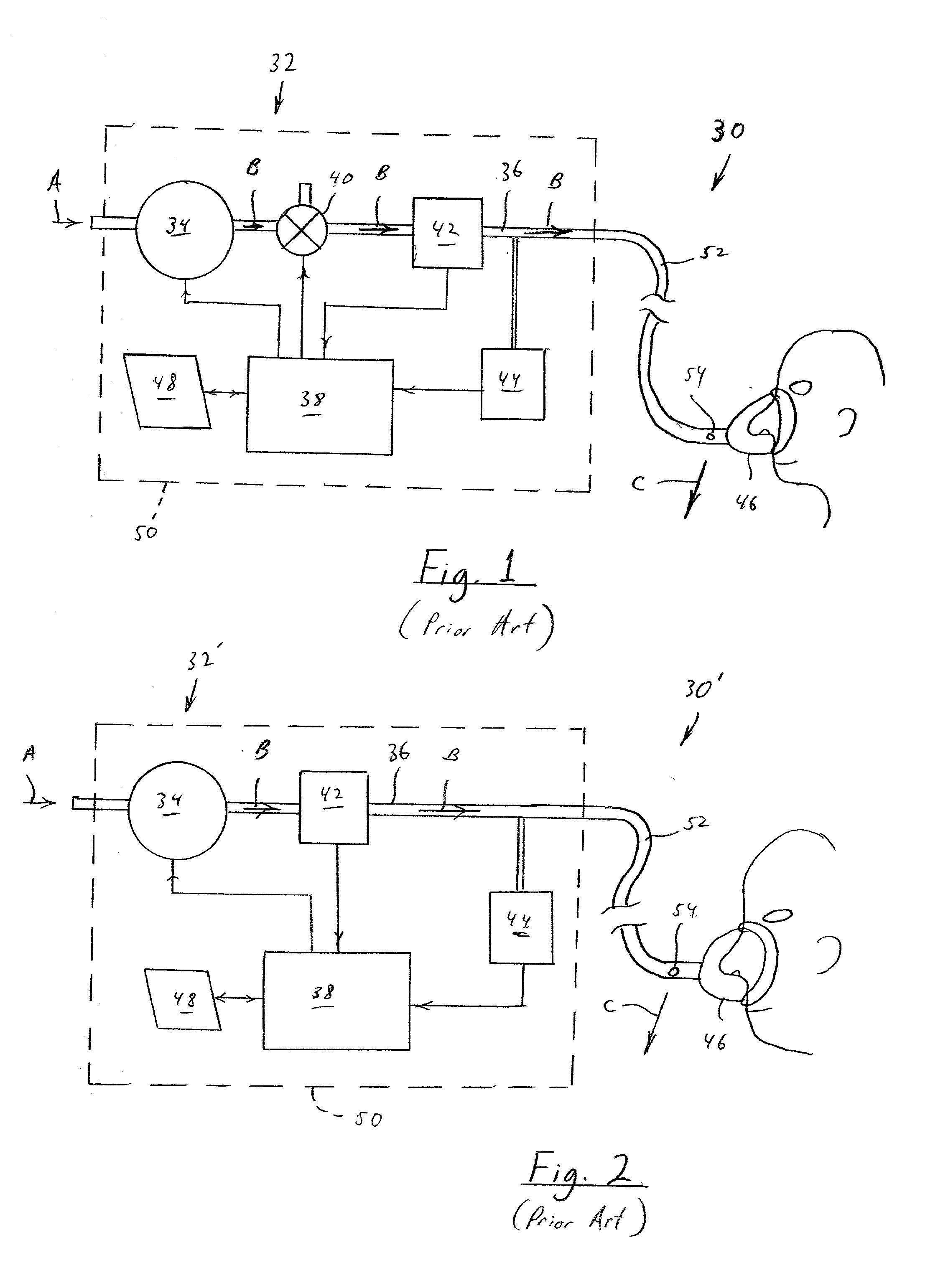

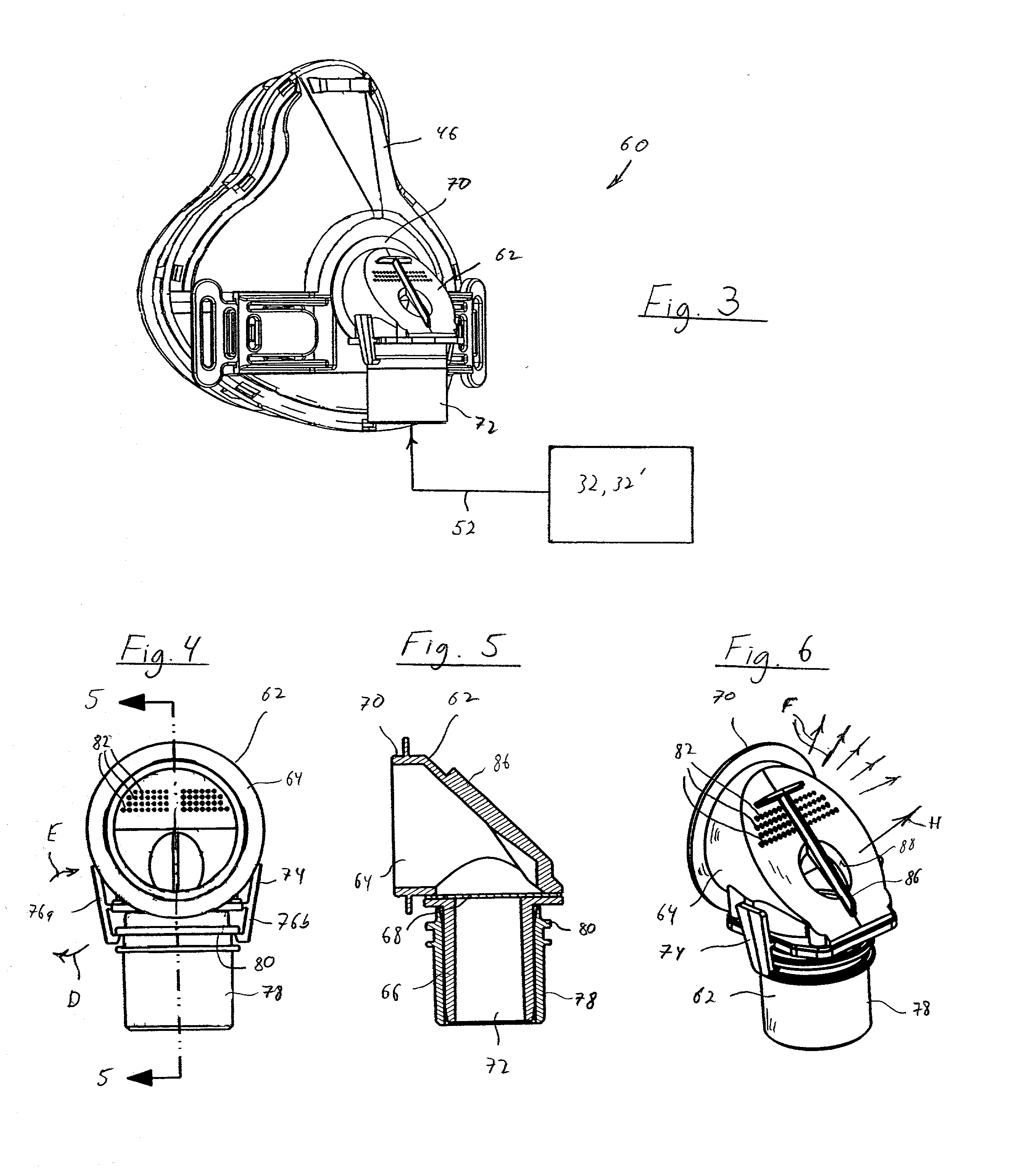

Exhaust port assembly for a pressure support system

InactiveUS6851425B2Noise minimizationArea minimizationBreathing masksRespiratory masksSupporting systemAtmospheric air

An exhaust port assembly comprising a conduit carries a flow of gas. A vent assembly having a fixed exhaust area is provided on the conduit for venting a flow of exhaust gas from within the conduit to ambient atmosphere. The vent assembly is configured so as to minimize noise associated with the flow of exhaust gas passing to atmosphere, diffuse the flow of exhaust gas passing to ambient atmosphere over a relatively large area, and minimize the area occupied by the venting assembly on the conduit.

Owner:RIC INVESTMENTS LLC

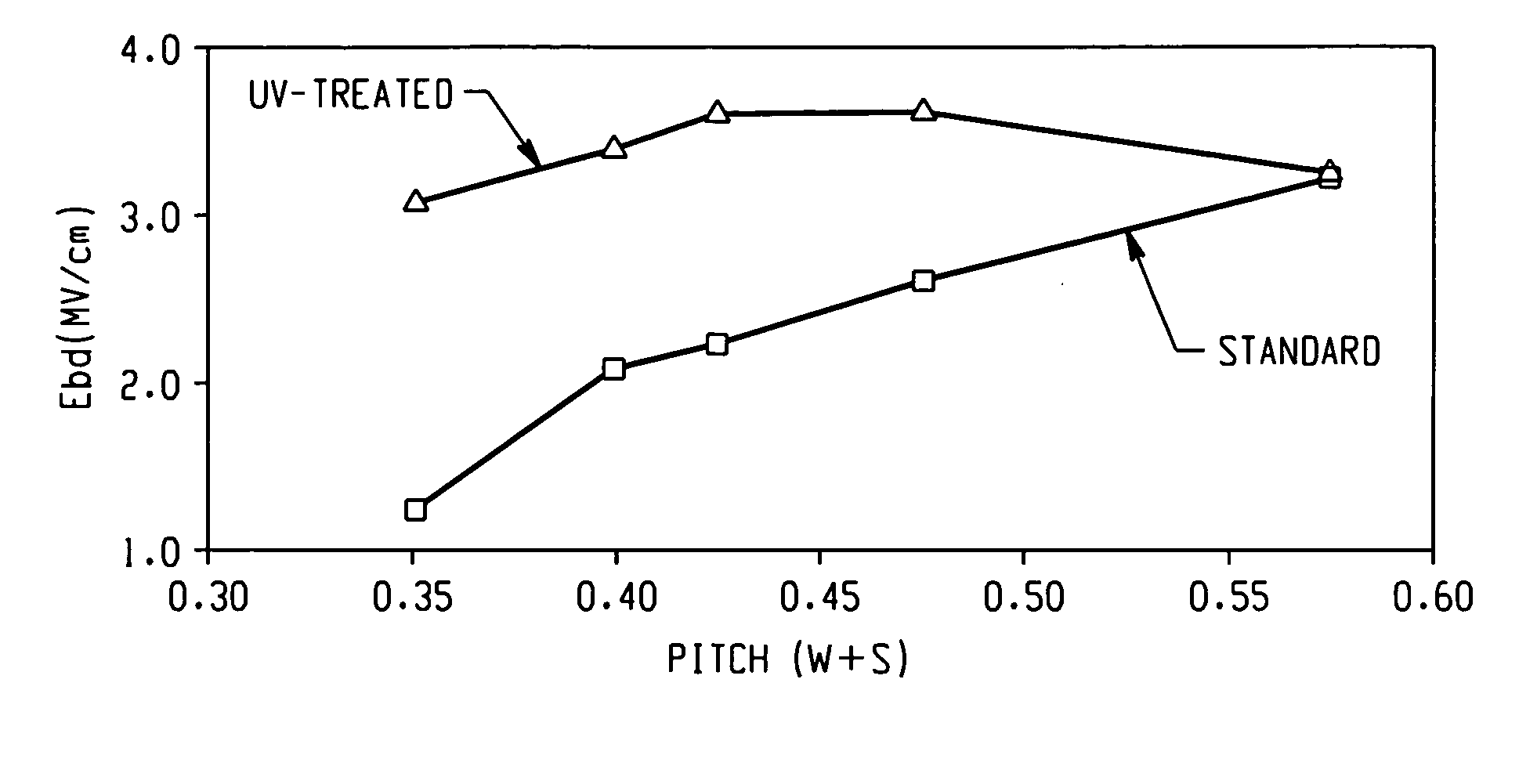

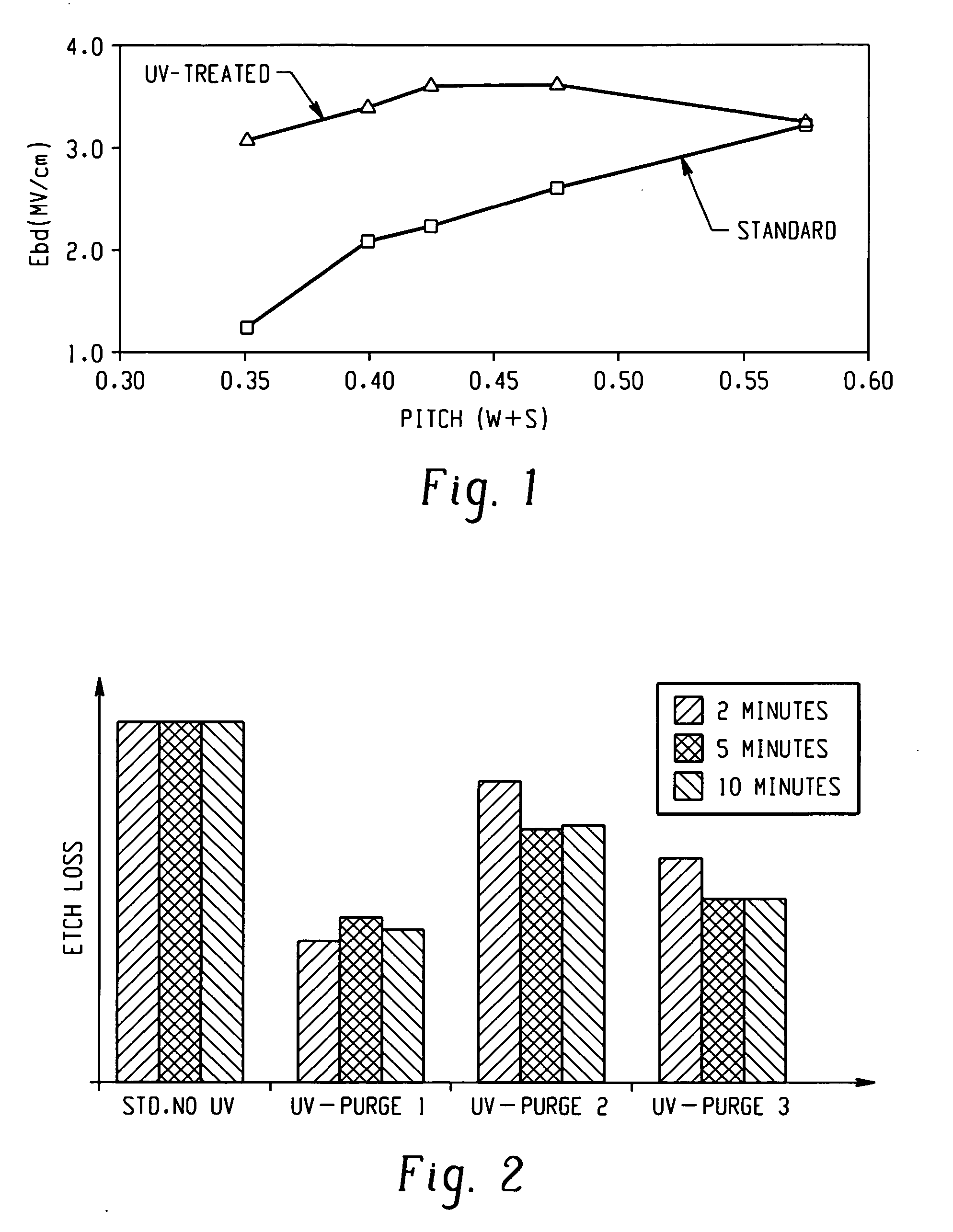

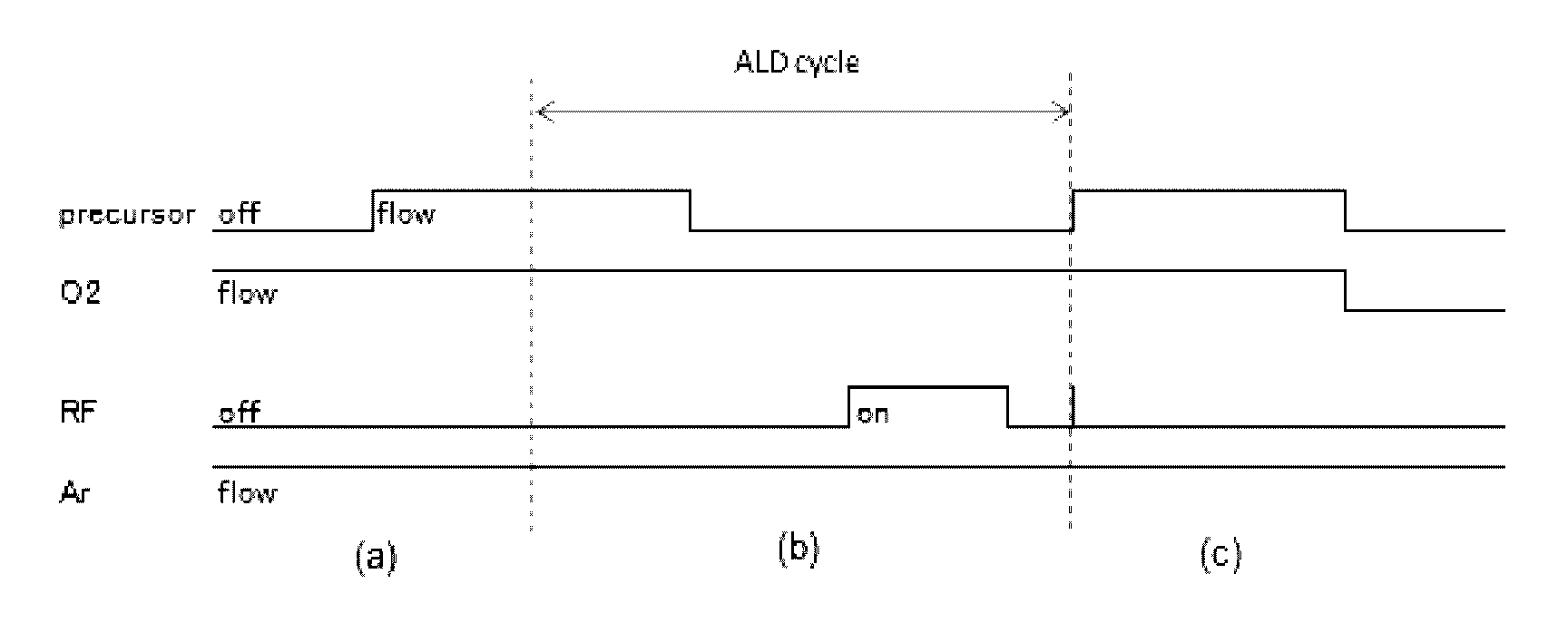

Ultraviolet assisted pore sealing of porous low k dielectric films

InactiveUS20060105566A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingAtmospheric airCarbonization

Processes for sealing porous low k dielectric film generally comprises exposing the porous surface of the porous low k dielectric film to ultraviolet (UV) radiation at intensities, times, wavelengths and in an atmosphere effective to seal the porous dielectric surface by means of carbonization, oxidation, and / or film densification. The surface of the surface of the porous low k material is sealed to a depth less than or equal to about 20 nanometers, wherein the surface is substantially free of pores after the UV exposure.

Owner:AXCELIS TECHNOLOGIES

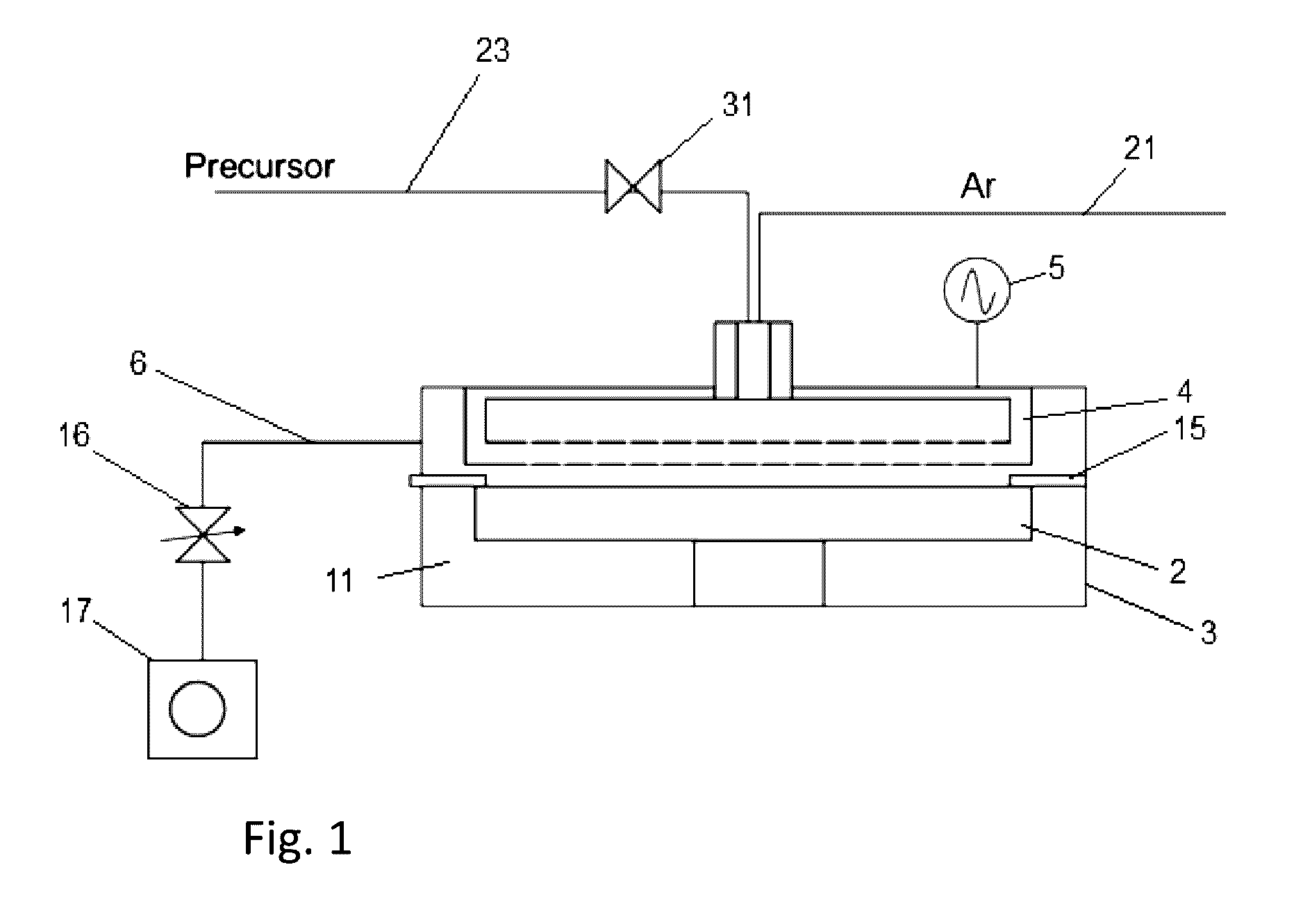

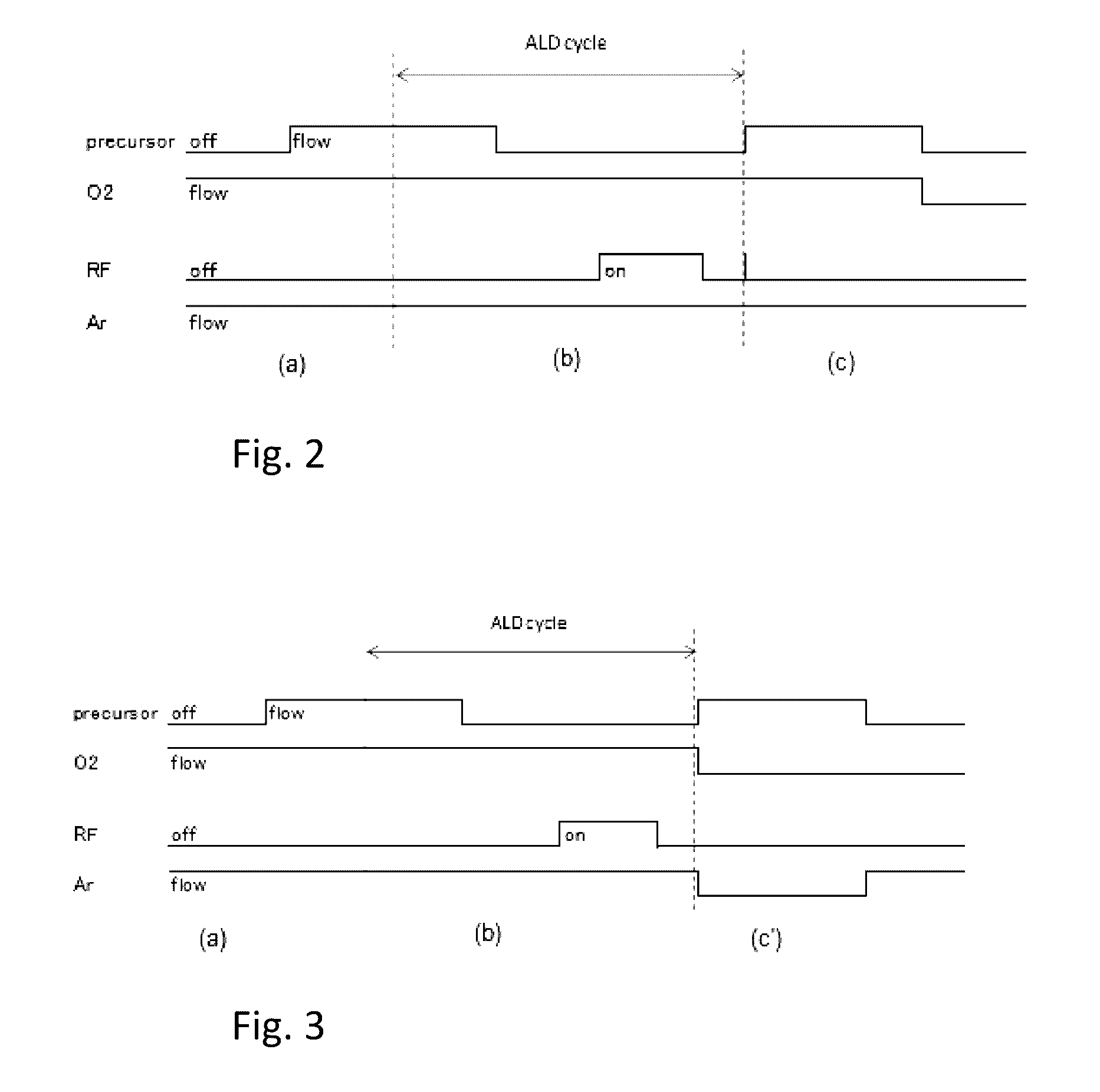

Method for hydrophobization of surface of silicon-containing film by ALD

ActiveUS9478414B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingAtmospheric airChemical adsorption

A method is for hydrophobization of a surface of a silicon-containing film by atomic layer deposition (ALD), wherein the surface is subjected to atmospheric exposure. The method includes: (i) providing a substrate with a silicon-containing film formed thereon; and (ii) forming on a surface of the silicon-containing film a hydrophobic atomic layer as a protective layer subjected to atmospheric exposure, by exposing the surface to a silicon-containing treating gas without exciting the gas. The treating gas is capable of being chemisorbed on the surface to form a hydrophobic atomic layer thereon.

Owner:ASM IP HLDG BV

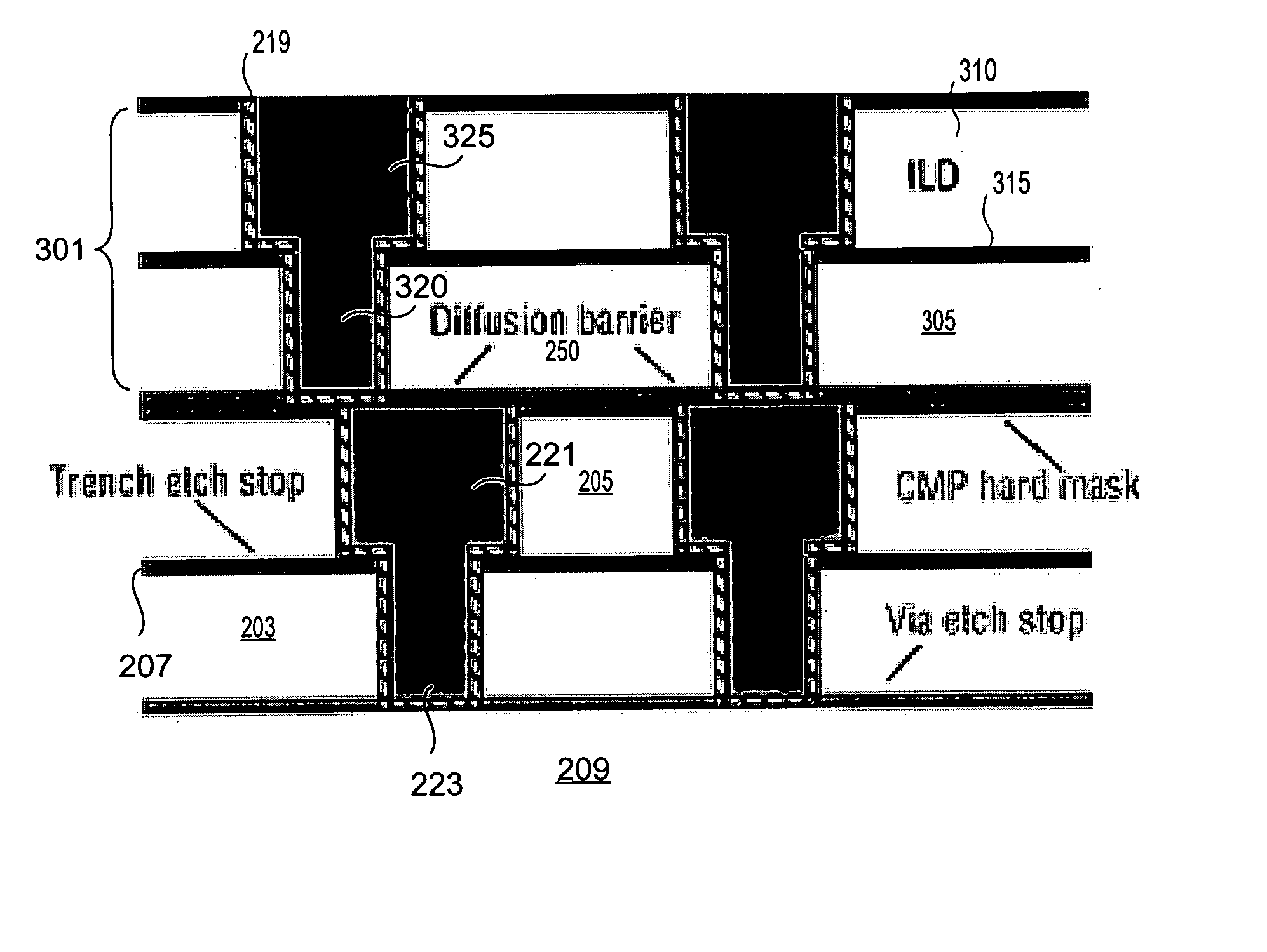

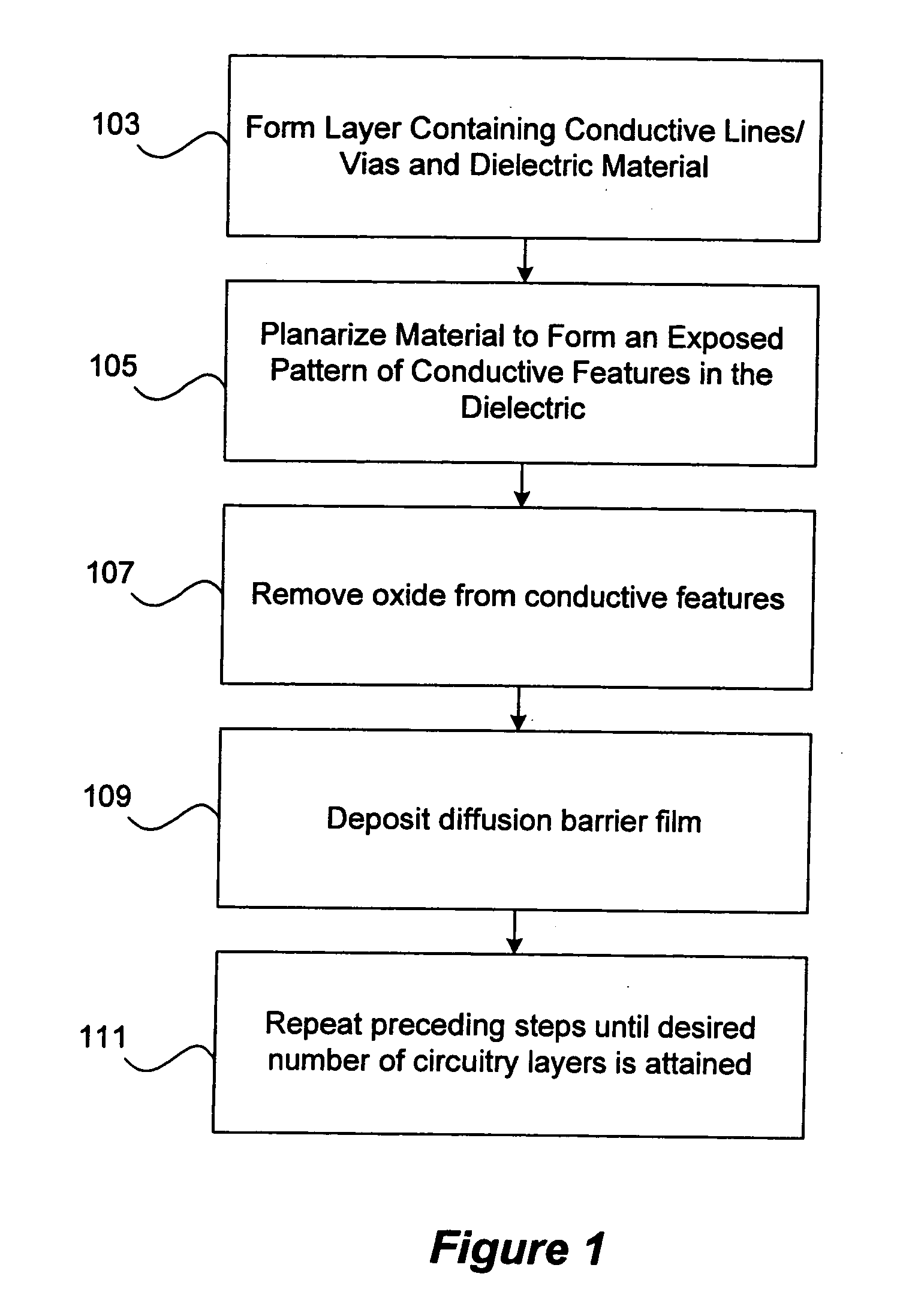

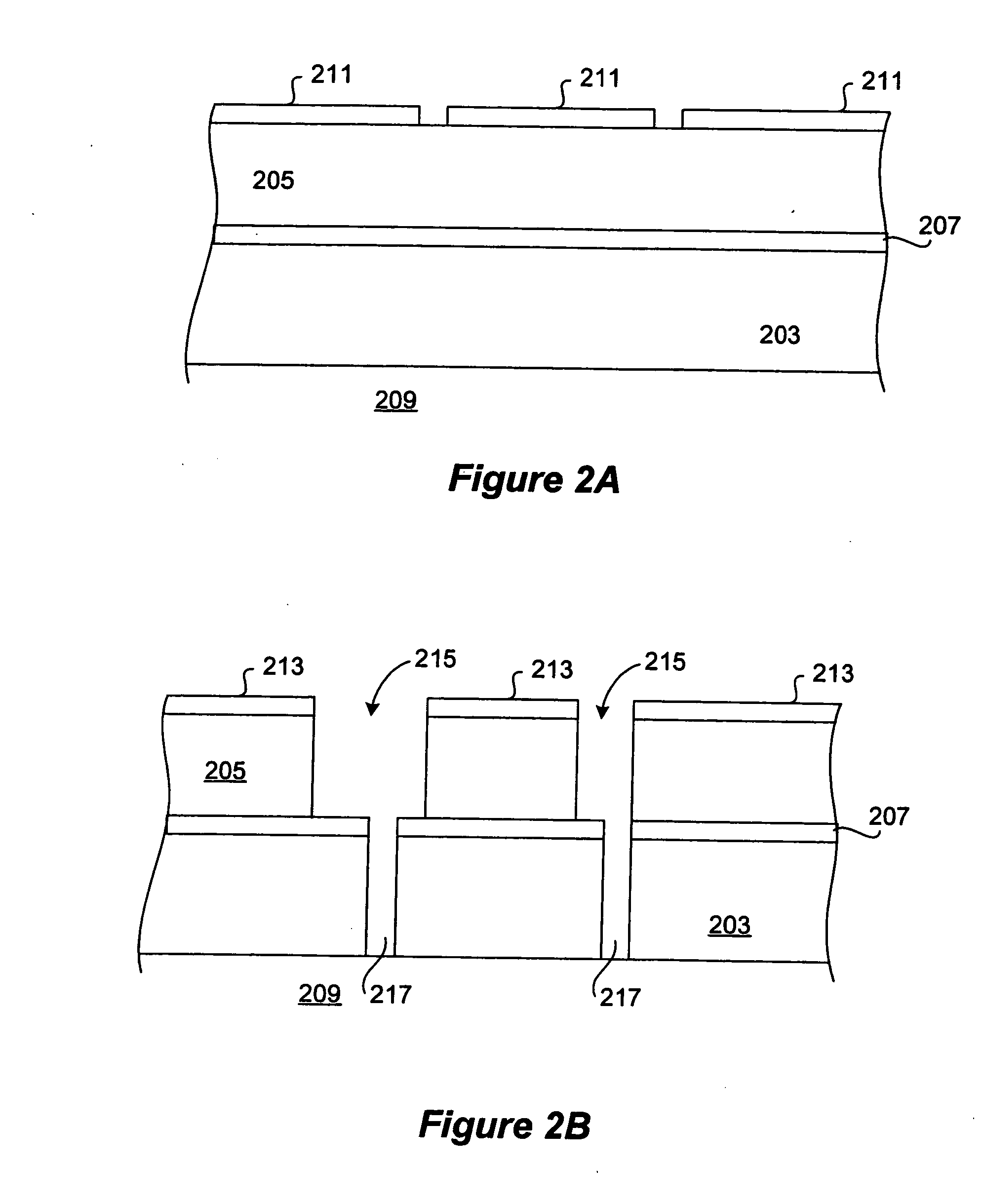

Novel film for copper diffusion barrier

InactiveUS20060019486A1Semiconductor/solid-state device detailsSolid-state devicesAtmospheric airBoron nitride

The present invention provides a low dielectric constant copper diffusion barrier film suitable for use in a semiconductor device and methods for fabricating such a film. Some embodiments of the film are formed of a silicon-based material doped with boron. Other embodiments are formed, at least in part, of boron nitride. Some such embodiments include a moisture barrier film that includes oxygen and / or carbon. Preferred embodiments of the copper diffusion barrier maintain a stable dielectric constant of less than 4.5 in the presence of atmospheric moisture.

Owner:NOVELLUS SYSTEMS

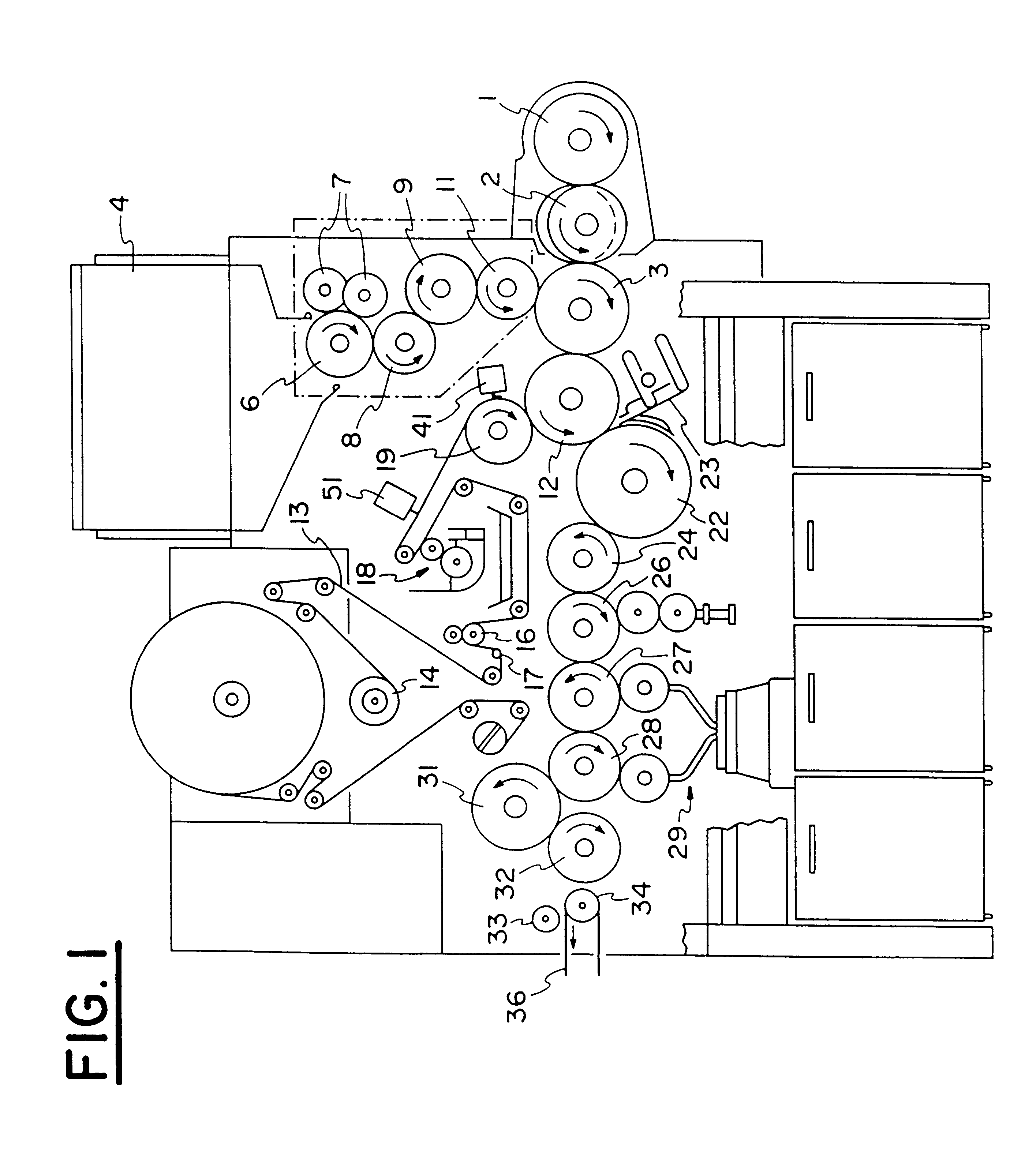

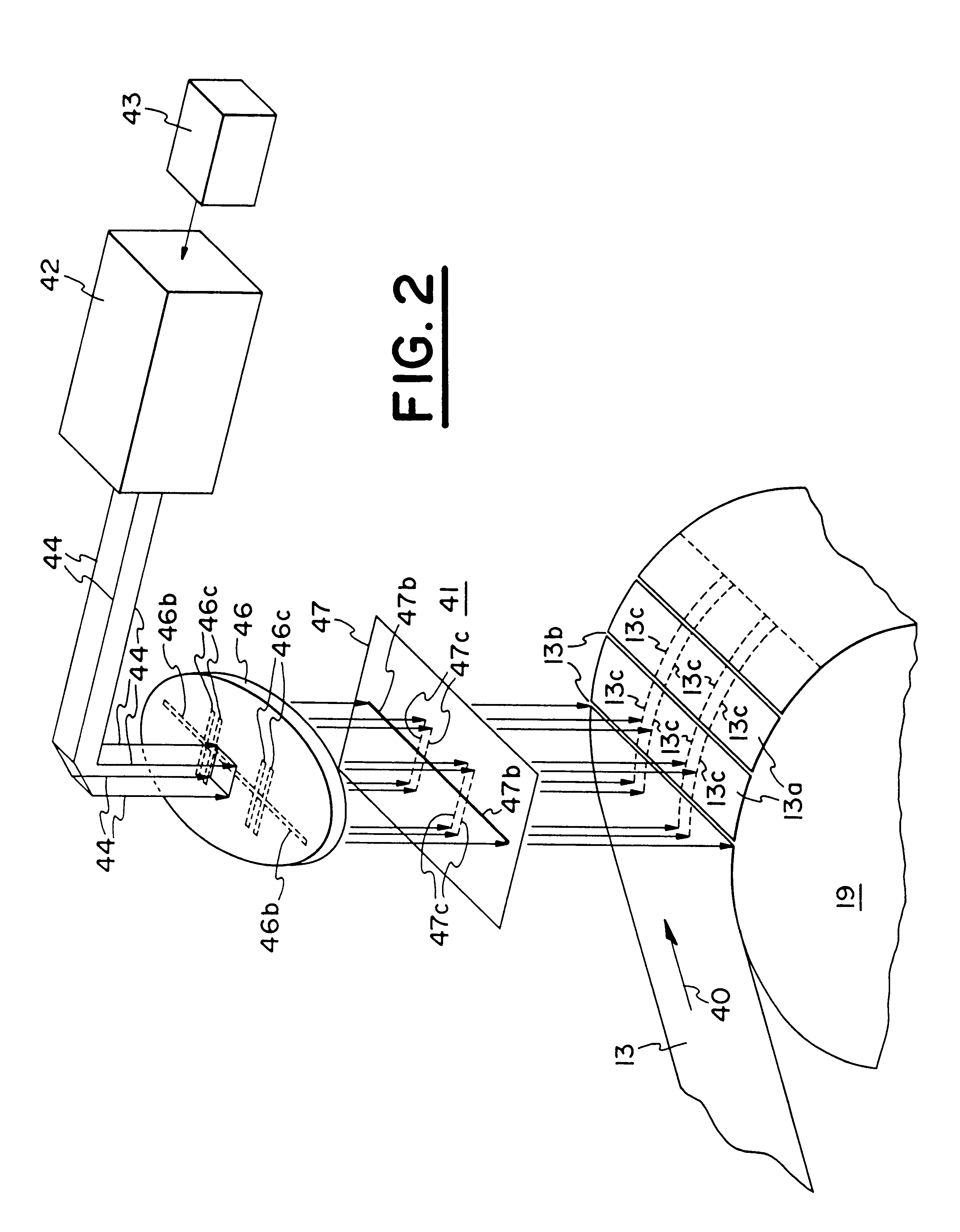

Method of and apparatus in a filter tipping machine for manipulating a web

InactiveUS6229115B1More reliableLess expensiveCigarette manufactureLaser beam welding apparatusFiberAdhesive

A running web of tipping paper (one side of which is coated with a film of adhesive) in a filter cigarette making machine is subdivided into discrete uniting bands and / or is perforated by resorting to a single source or to two discrete sources of coherent radiation. Each source is associated with a control unit which initiates the emission of short-lasting flashes of coherent radiation. Such radiation is caused to impinge upon a diffractive focusing lens which focuses coherent radiation upon one or more masks having openings for coherent radiation which is to sever the web along transversely extending linear zones and / or to provide the web with desired arrays of perforations. The perforations permit atmospheric air to enter the column of tobacco smoke in a filter cigarette wherein the tobacco-containing portion and the filter mouthpiece are united by a perforated adhesive-coated uniting band.

Owner:HAUNI MASCHINENBAU AG

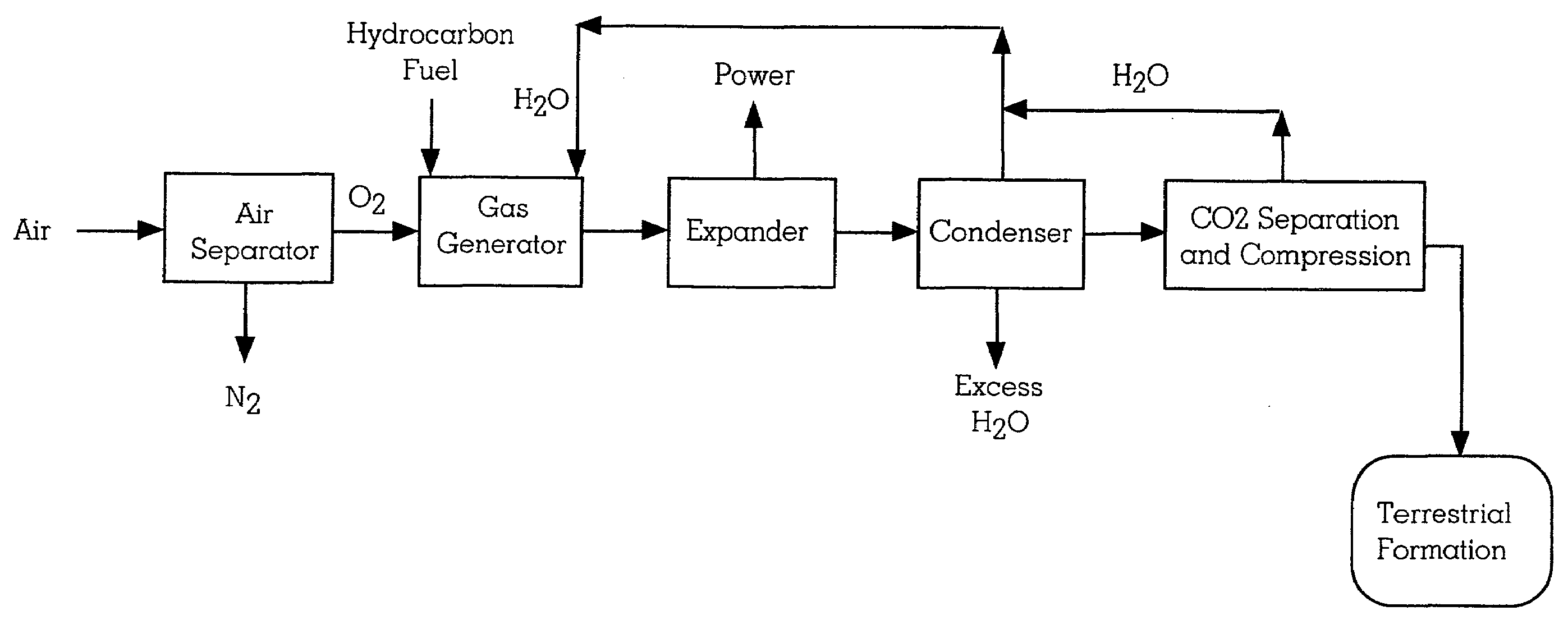

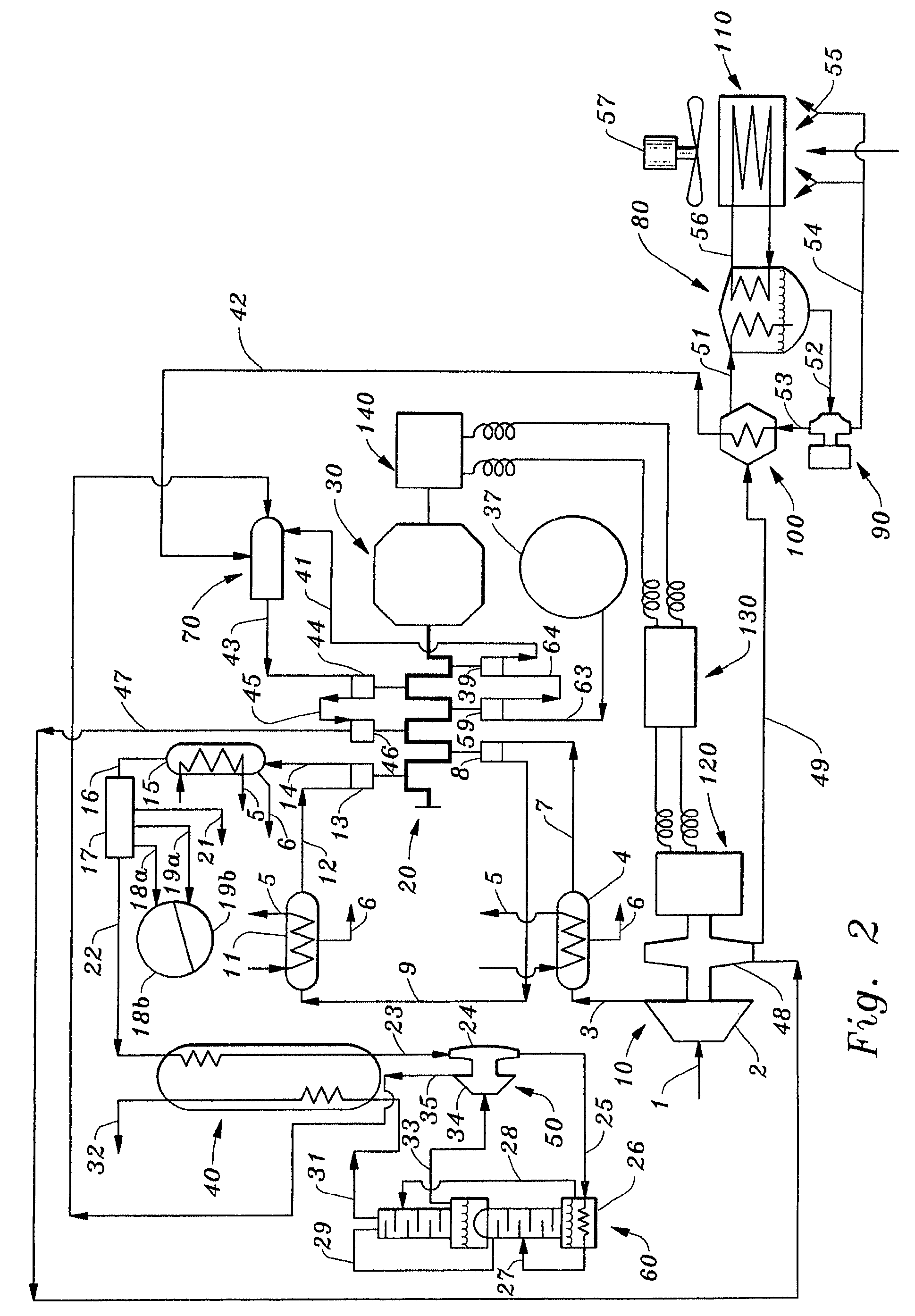

Hydrocarbon combustion power generation system with CO2 sequestration

InactiveUS7043920B2Eliminate needReduce electricity demandReciprocating combination enginesSolidificationAtmospheric airOxygen

A low or no pollution engine is provided for delivering power for vehicles or other power applications. The engine has an air inlet which collects air from a surrounding environment. At least a portion of the nitrogen in the air is removed. The remaining gas is primarily oxygen, which is then routed to a gas generator. The gas generator has inputs for the oxygen and a hydrocarbon fuel. The fuel and oxygen are combusted within the gas generator, forming water and carbon dioxide. The combustion products are then expanded through a power generating device, such as a turbine or piston expander to deliver output power for operation of a vehicle or other power uses. The combustion products are then passed through a condenser where the steam is condensed and the carbon dioxide is collected or discharged. A portion of the water is routed back to the gas generator. The carbon dioxide is compressed and delivered to a terrestrial formation from which return of the CO2 into the atmosphere is inhibited.

Owner:CLEAN ENERGY SYST

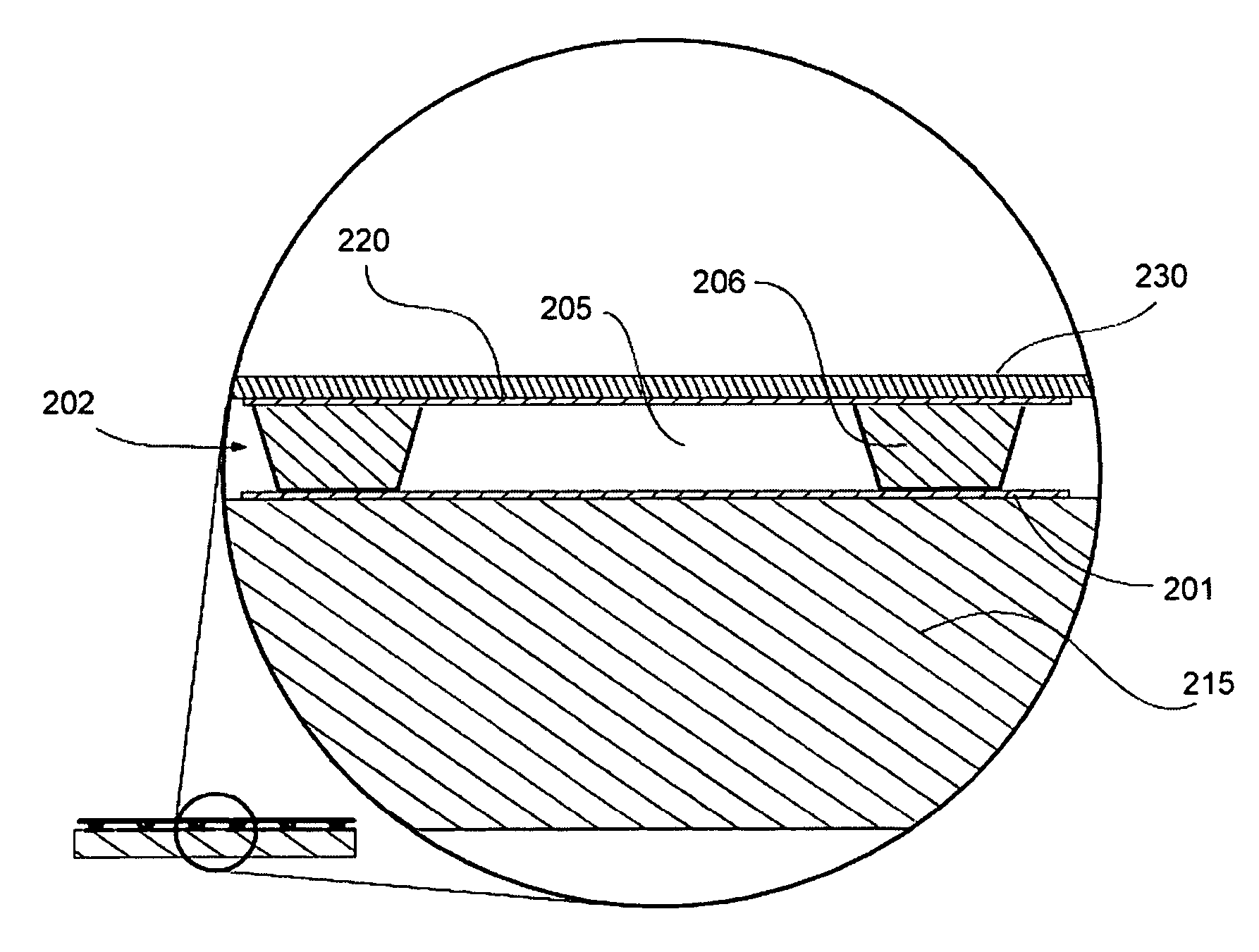

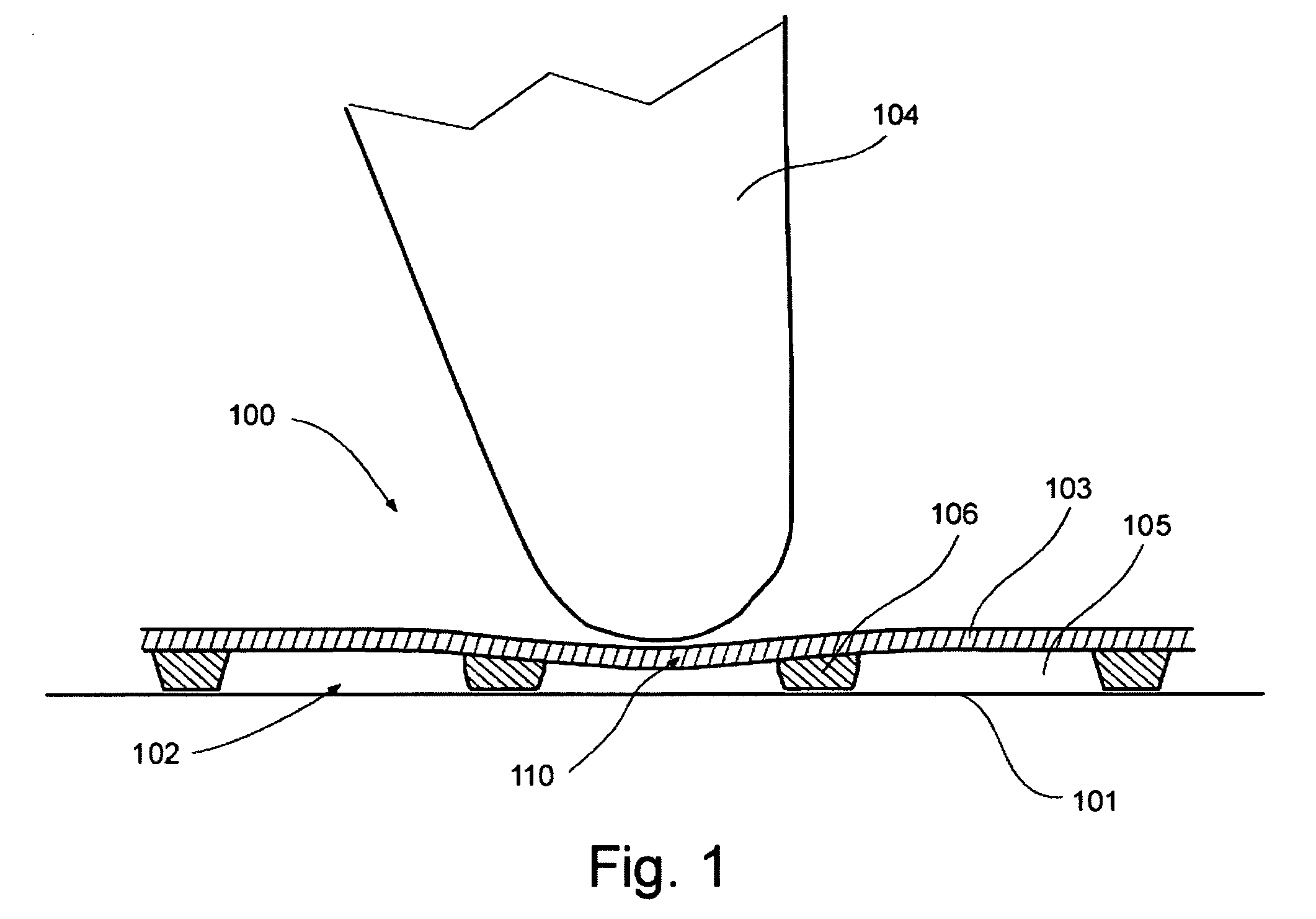

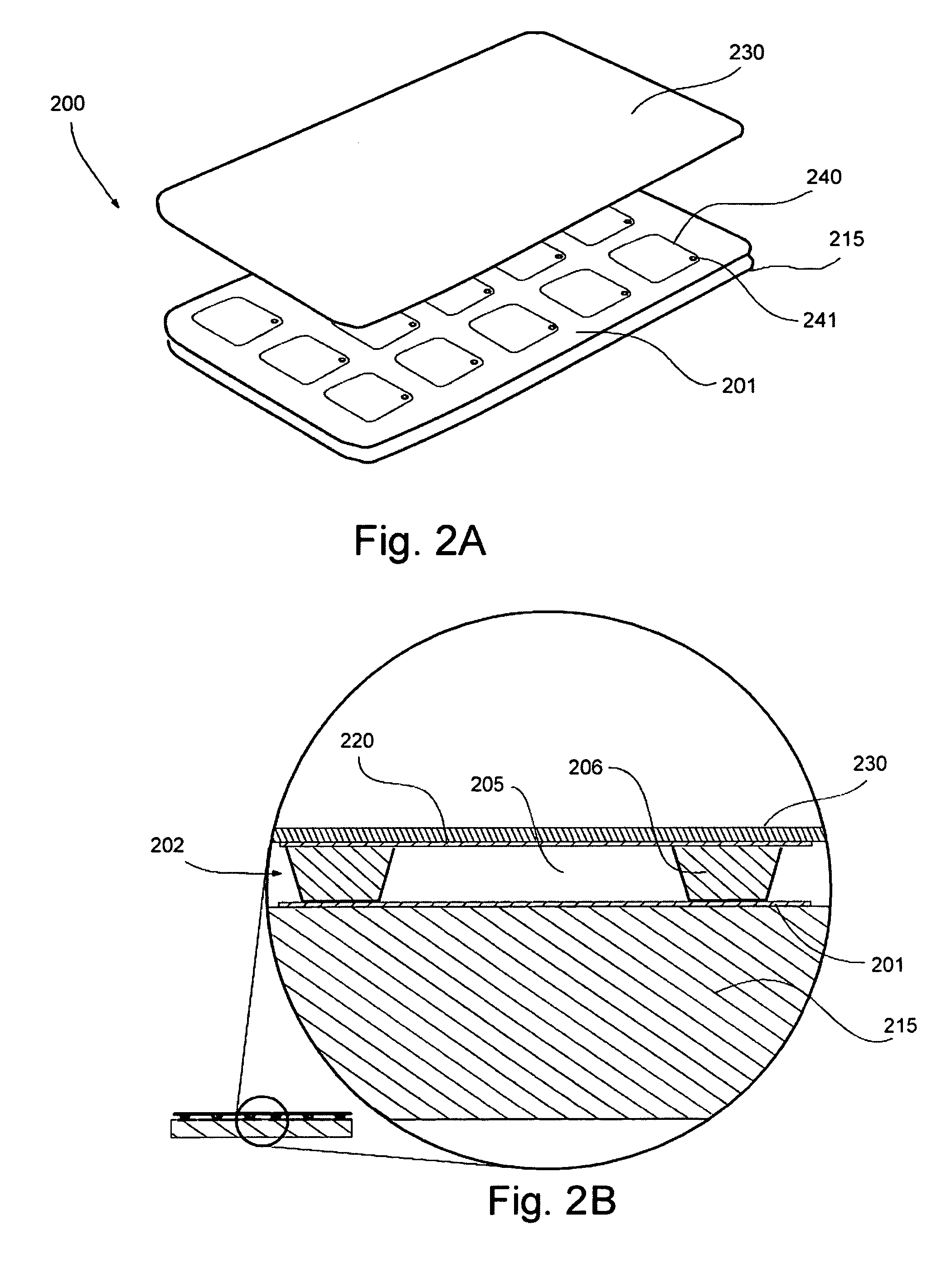

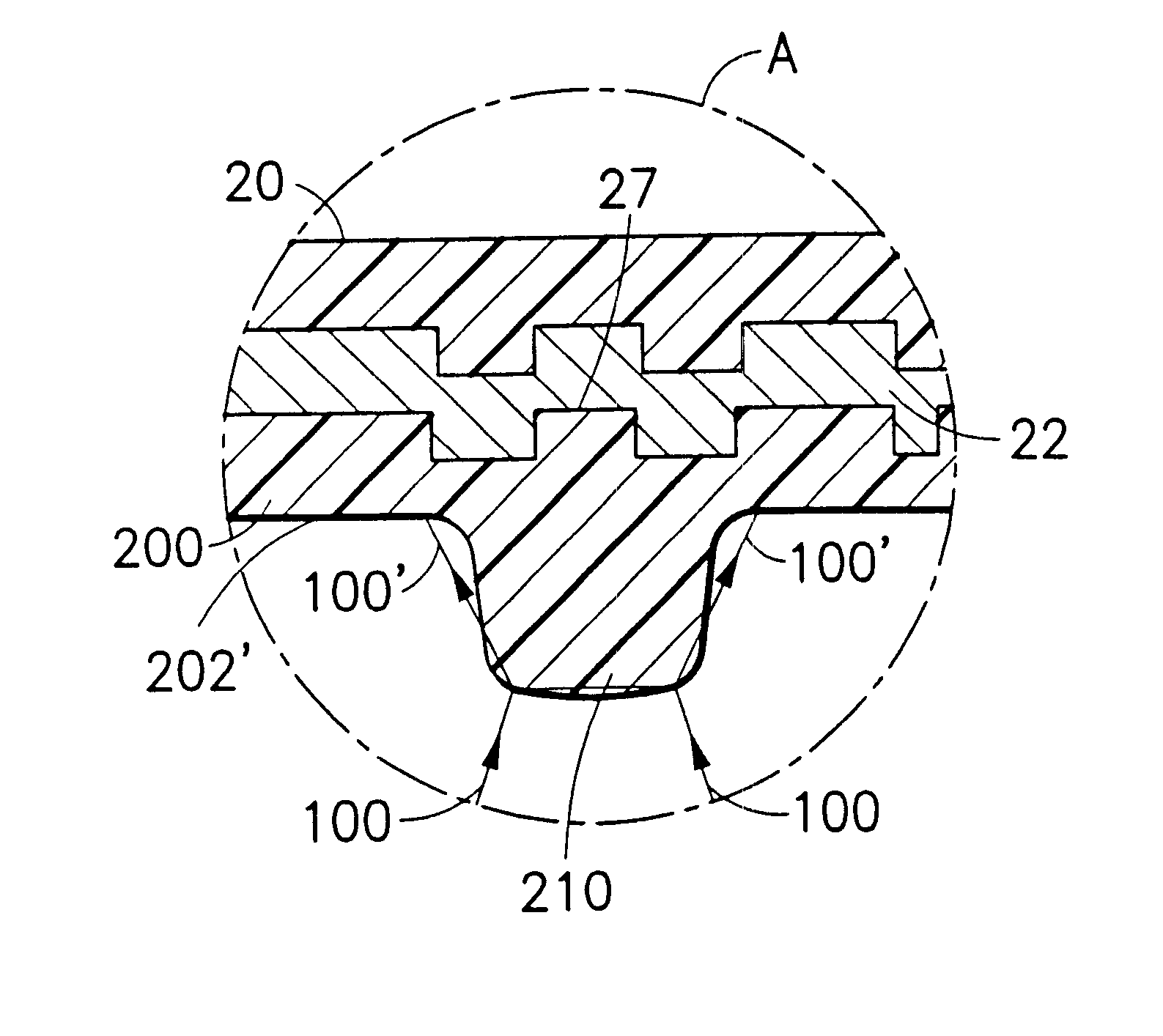

Reconfigurable tactile sensor input device

InactiveUS7609178B2Low production costSmall sizeInput/output for user-computer interactionElectronic switchingCapacitanceAtmospheric air

A reconfigurable tactile input device includes a first rigid electrode layer, a compressible dielectric structure, and a second flexible electrode layer forming together a tactile sensor with appropriate electrode connection means to a control means. The control means may include a mixed-signal IC mounted next to the input device in a compact package and capable of measuring capacitance in real time. The dielectric structure may include a matrix of compressible geometric elements with voids therebetween optionally vented to atmosphere, making the entire assembly thin and facilitating its use for mobile phones and other small, portable electronic devices. Some embodiments provide the user wit tactile feedback upon compression of the electrodes. An optional flexible display may be mounted over the input device to indicate the present configuration to the user.

Owner:WISETOUCH CO LTD

Methods and devices for the production of Hydrocarbons from Carbon and Hydrogen sources

InactiveUS20080283411A1Reduce the environmentEasy to controlPhotography auxillary processesInternal combustion piston enginesElectrolysisAtmospheric air

Devices and methods are described for converting a carbon source and a hydrogen source into hydrocarbons, such as alcohols, for alternative energy sources. The influents may comprise carbon dioxide gas and hydrogen gas or water, obtainable from the atmosphere for through methods described herein, such as plasma generation or electrolysis. One method to produce hydrocarbons comprises the use of an electrolytic device, comprising an anode, a cathode and an electrolyte. Another method comprises the use of ultrasonic energy to drive the reaction. The devices and methods and related devices and methods are useful, for example, to provide a fossil fuel alternative energy source, store renewable energy, sequester carbon dioxide from the atmosphere, counteract global warming, and store carbon dioxide in a liquid fuel.

Owner:PRINCIPLE ENERGY SOLUTIONS

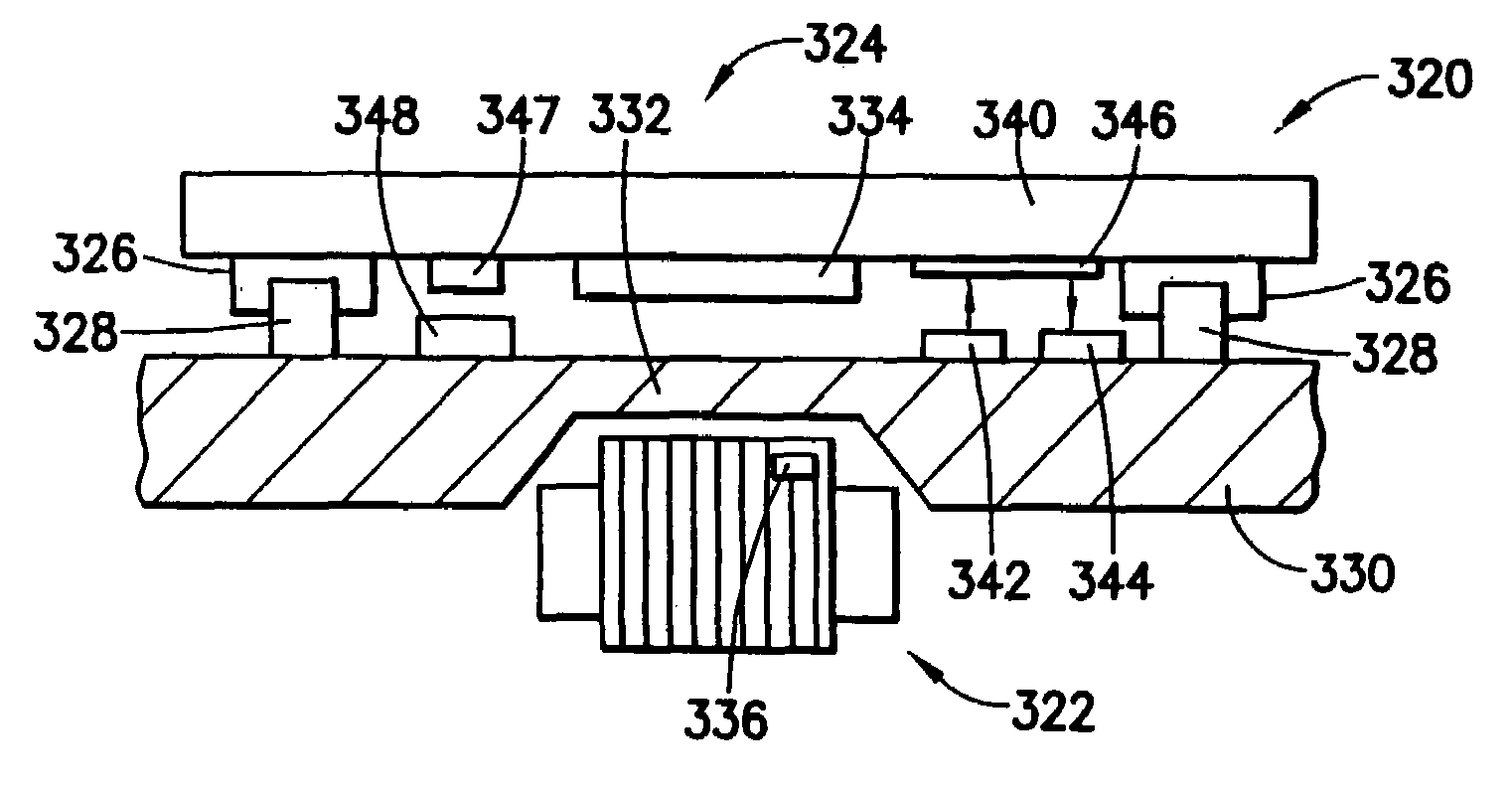

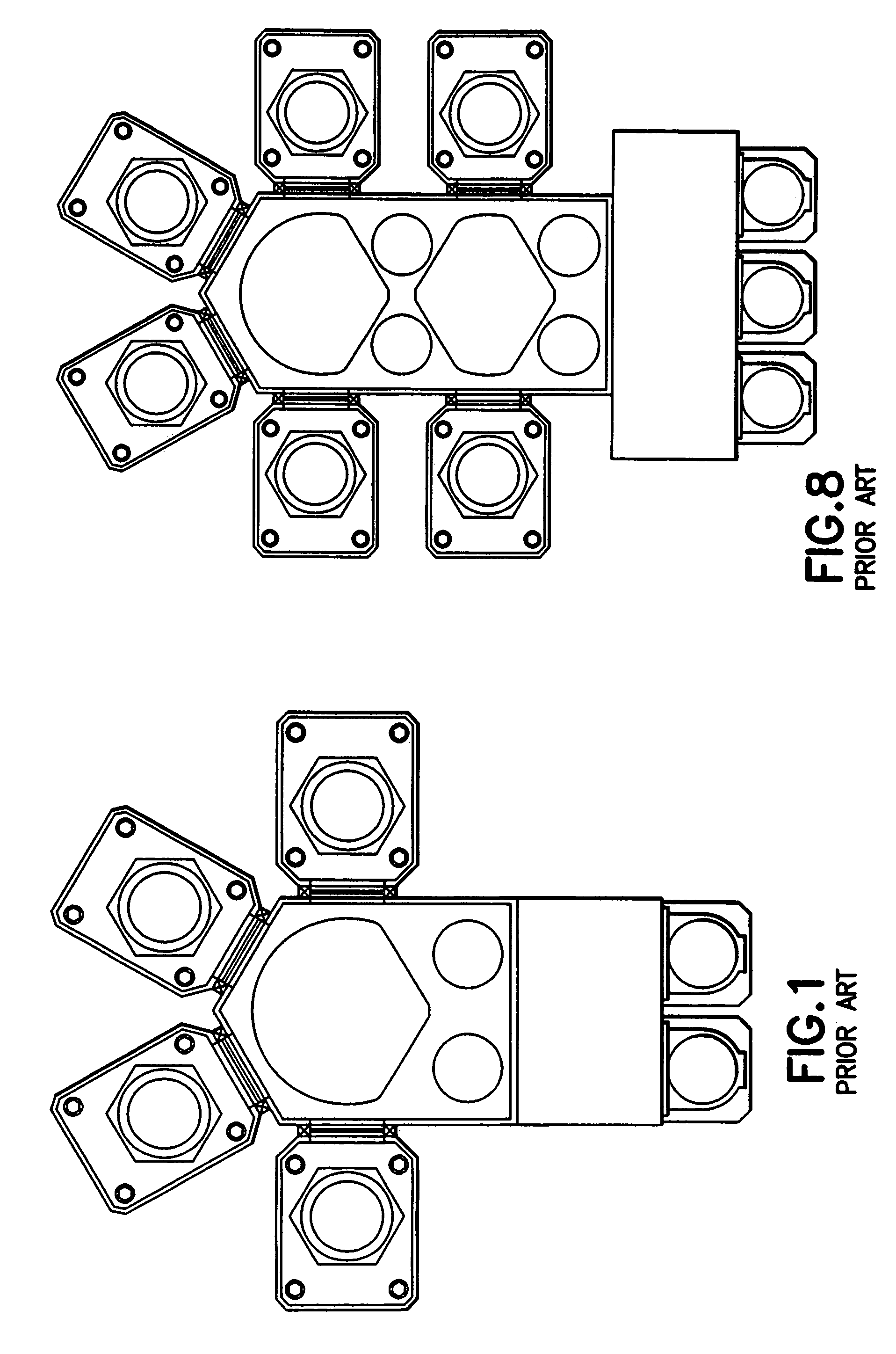

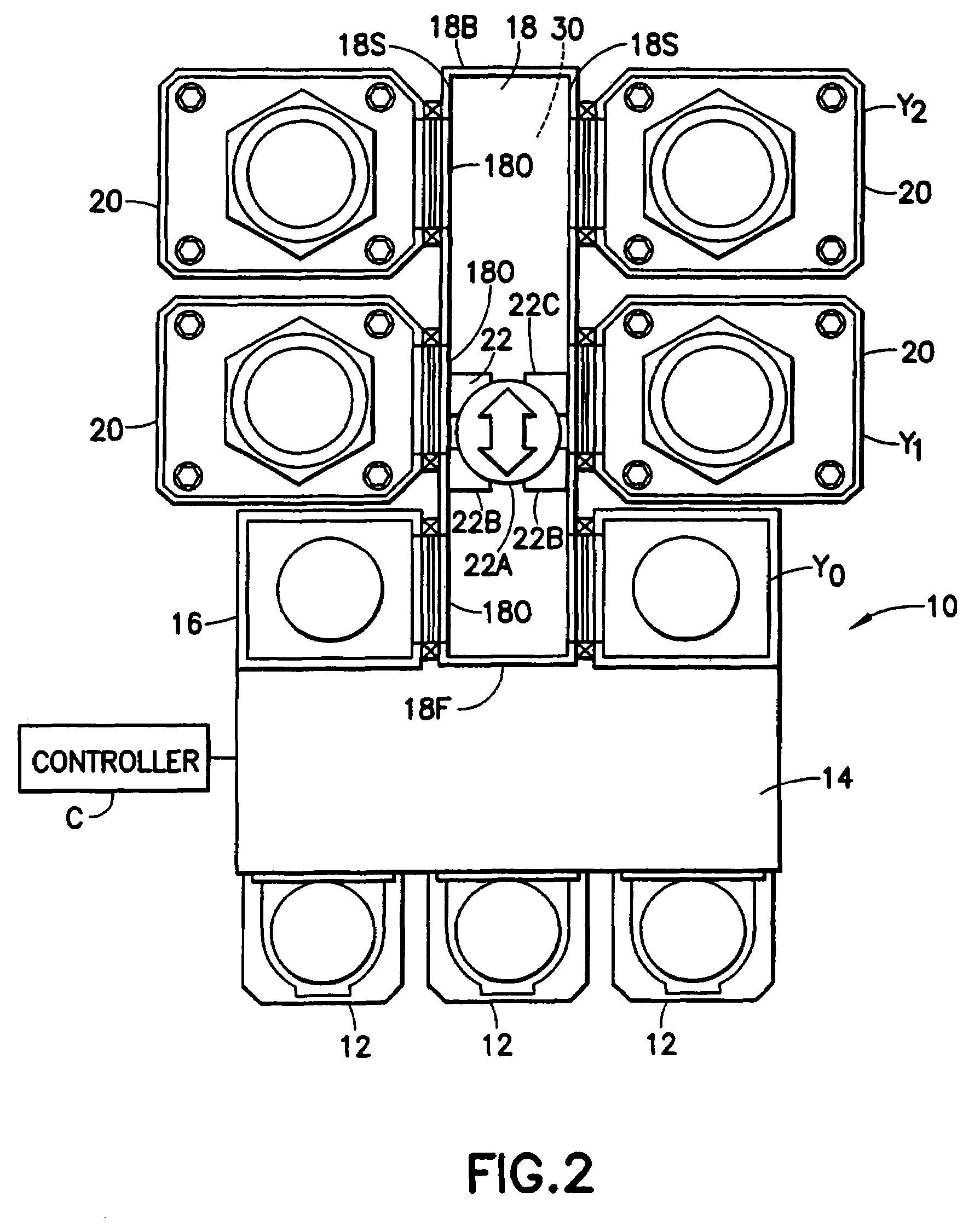

Exhaust port assembly for a pressure support system

An exhaust port assembly comprising a conduit carries a flow of gas. A vent assembly having a fixed exhaust area is provided on the conduit for venting a flow of exhaust gas from within the conduit to ambient atmosphere. The vent assembly is configured so as to minimize noise associated with the flow of exhaust gas passing to atmosphere, diffuse the flow of exhaust gas passing to ambient atmosphere over a relatively large area, and minimize the area occupied by the venting assembly on the conduit.

Owner:RIC INVESTMENTS LLC

Methods and apparatus for rendering an optically encoded medium unreadable

InactiveUS6338933B1Photography auxillary processesPhotosensitive materialsOptical radiationAtmospheric air

Methods and apparatus are provided for making an optically readable media unreadable. The method includes steps of (a) providing the media with an optically activated mechanism that degrades the reflectivity of a surface wherein information is encoded; (b) exposing the media to optical radiation for reading out the information; and, during the step of exposing, (c) initiating the operation of the optically activated mechanism. In this embodiment the step of initiating includes steps of (d) generating singlet oxygen in a layer disposed on the media; and (e) reacting the singlet oxygen with a metal-containing layer for oxidizing the surface of the metal-containing layer, thereby degrading the reflectivity of the surface. In a further aspect the optically activated mechanism causes a defocusing of a readout beam, thereby degrading reflection of the readout beam from a surface wherein information is encoded. In another embodiment the method deforms a surface of the layer resulting in readout beam aberration or in an inability to correctly stay on track. In another embodiment a portion of the surface is removed to the atmosphere, such as by evaporation of sublimation. In this embodiment a layer of the media is comprised of a volatile component and at least one other component. Removing at least some of volatile component by evaporation or sublimation causes an increase in at least one of photoabsorption or scattering or surface roughness with the remaining component, thereby rendering at least a portion of encoded information of the media unreadable, or affecting the tracking operation.

Owner:FLEXPLAY TECH INC

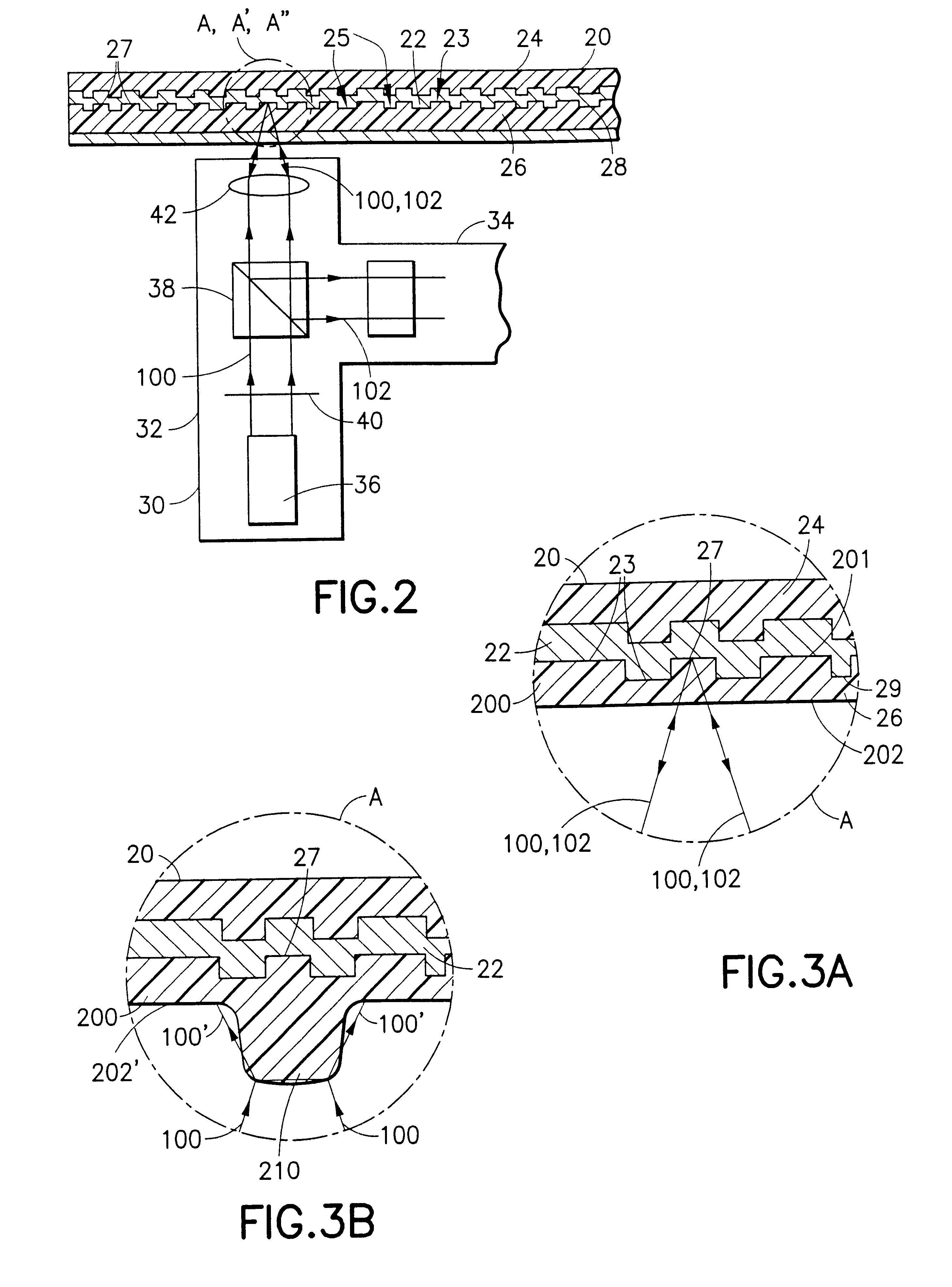

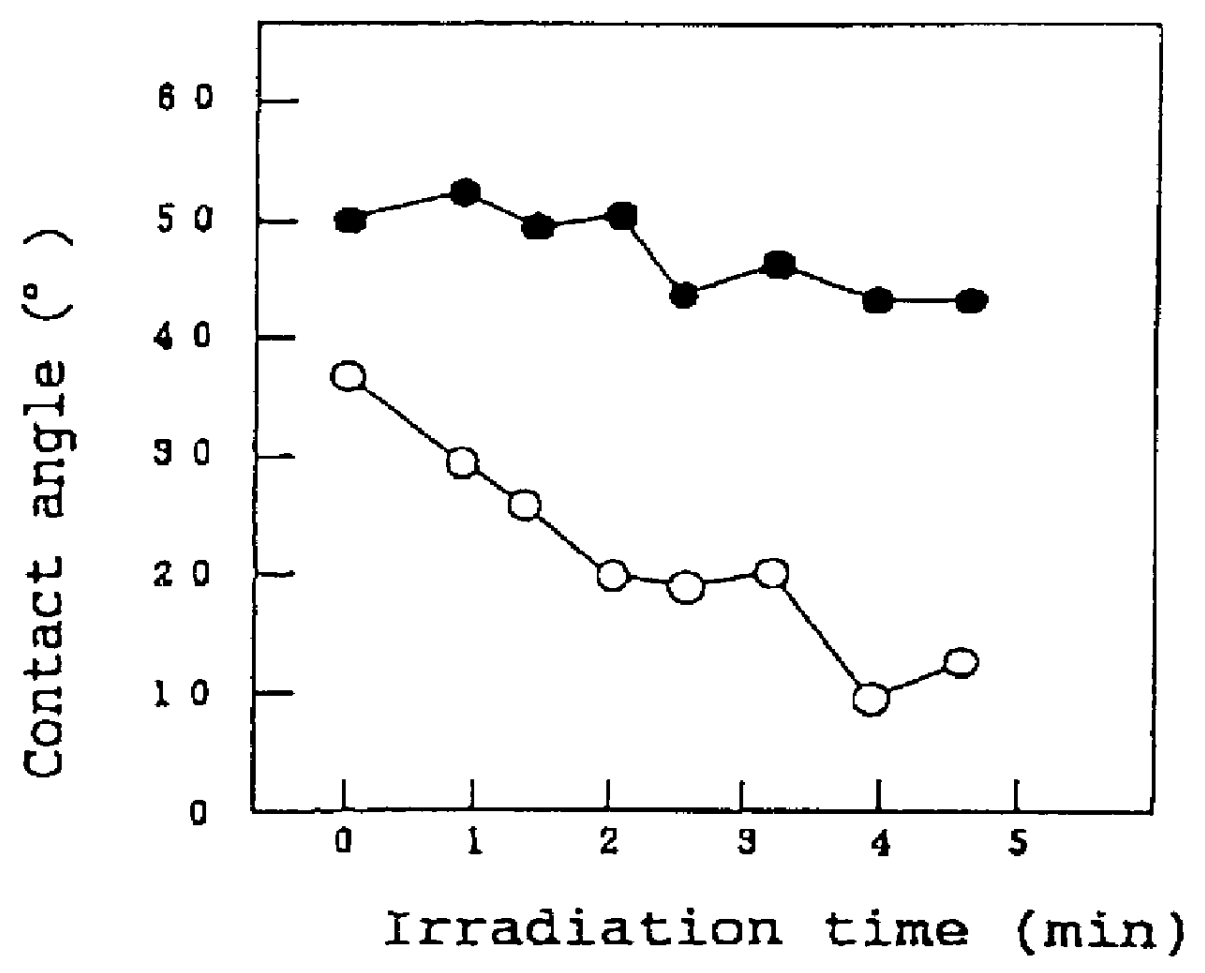

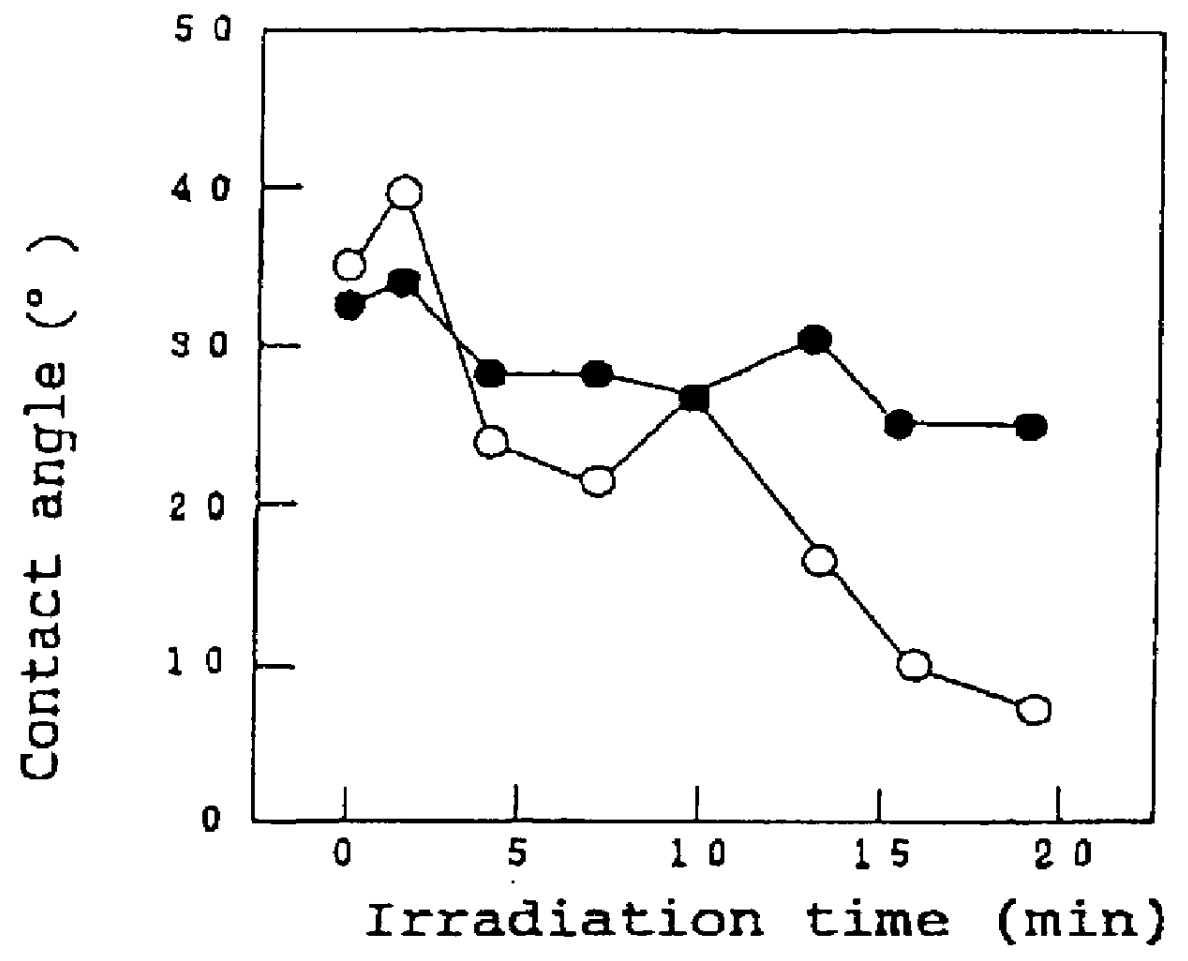

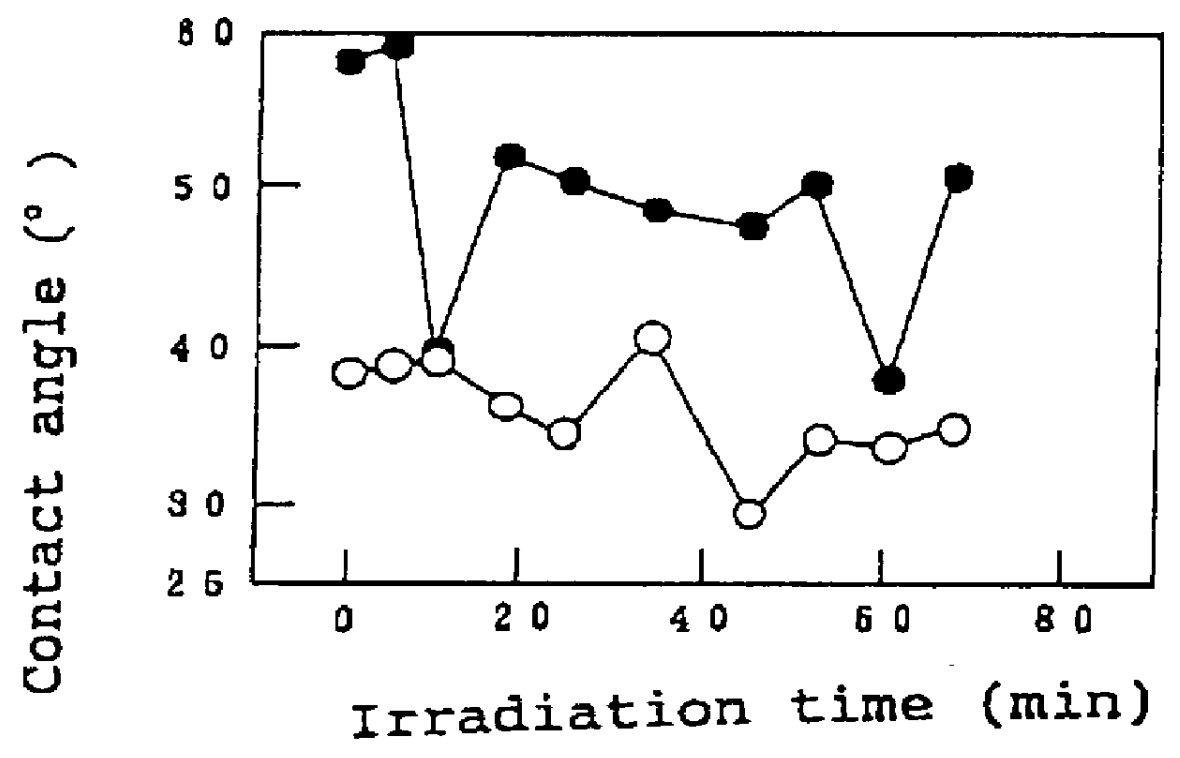

Method for photocatalytically hydrophilifying surface and composite material with photocatalytically hydrophilifiable surface

InactiveUS6090489AImproved oil repellencyEasy to disassembleOther chemical processesPretreated surfacesAtmospheric airSolid acid

A method for hydrophilifying the surface of a substrate by taking advantage of photocatalytic action. The substrate has a photocatalytic titania coating (10). The surface of the photocatalytic coating (10) bears the solid acid that increases a hydrogen bond component ( gamma Sh) in the surface energy in the solid / gas interface of the coating. Photoexcitation of the photocatalyst enhances the hydrogen bond component ( gamma Sh) in the surface energy of the photocatalytic coating (10), accelerating the physical adsorption of molecules of water in the atmosphere through a hydrogen bond (16) onto hydrogen atoms in a terminal OH group (12), bonded to a titanium atom, and a bridge OH group (14) on the surface of the coating. This results in the formation of a high density, physically adsorbed water layer (18) on the surface of the photocatalytic coating (10), thus permitting the surface of the substrate to be easily hydrophilified. The method is applicable to antifogging, antifouling, selfcleaning and cleaning of articles.

Owner:TOTO LTD

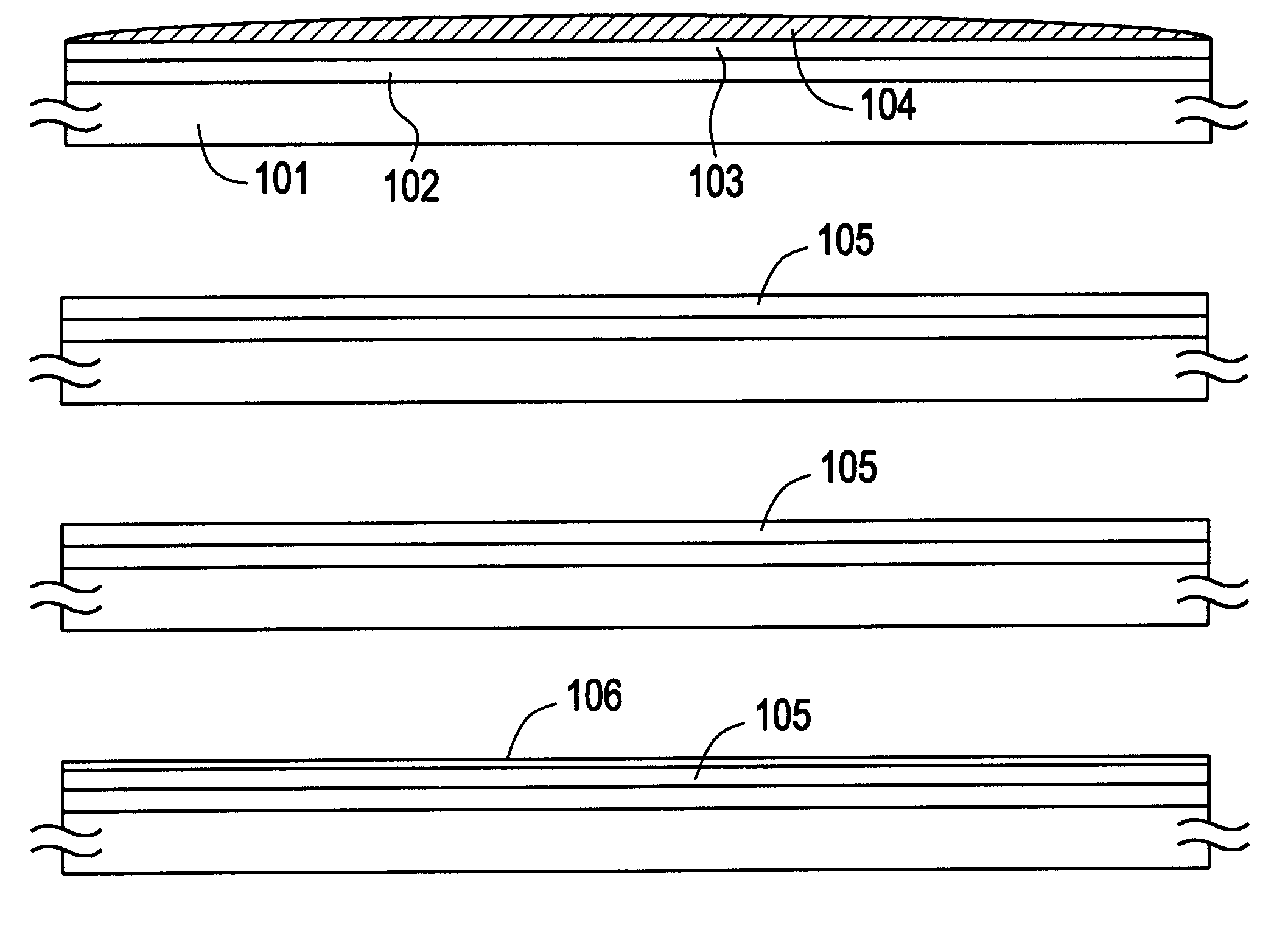

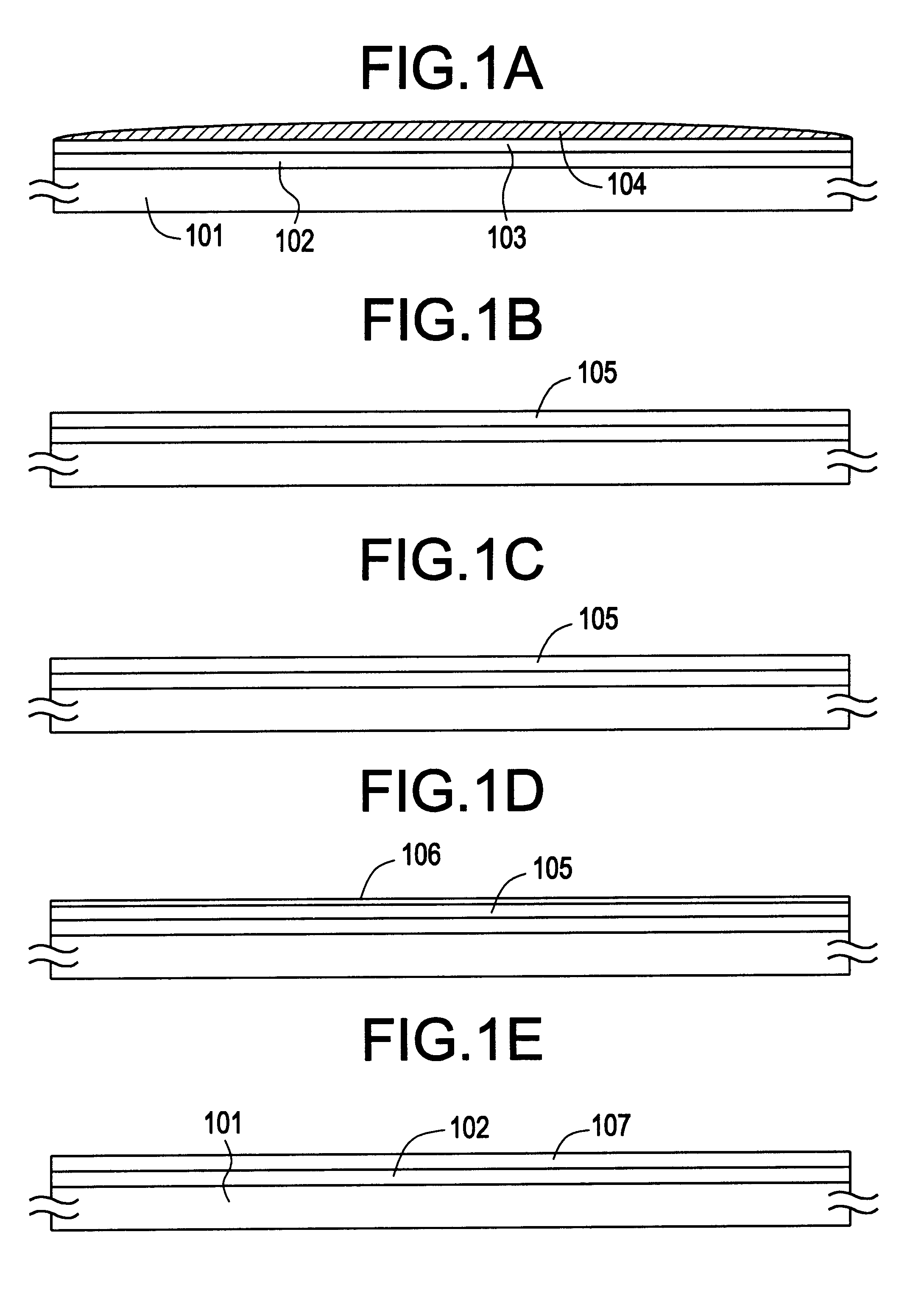

Method for fabricating a semiconductor device

InactiveUS6180439B1Promote crystallizationReduce concentrationTransistorSolid-state devicesAtmospheric airLaser light

Concentration of metal element which promotes crystallization of silicon and which exists within a crystalline silicon film obtained by utilizing the metal element is reduced. A first heat treatment for crystallization is performed after introducing nickel to an amorphous silicon film 103. Then, laser light is irradiated to diffuse nickel element which is concentrated locally. After that, another heat treatment is performed within an oxidizing atmosphere at a temperature higher than that of the previous heat treatment. At this time, HCl or the like is added to the atmosphere. A thermal oxide film 106 is formed in this step. At this time, gettering of the nickel element into the thermal oxide film 106 takes place. Then, the thermal oxide film 106 is removed. Thereby, a crystalline silicon film 107 having low concentration of the metal element and a high crystallinity can be obtained.

Owner:SEMICON ENERGY LAB CO LTD

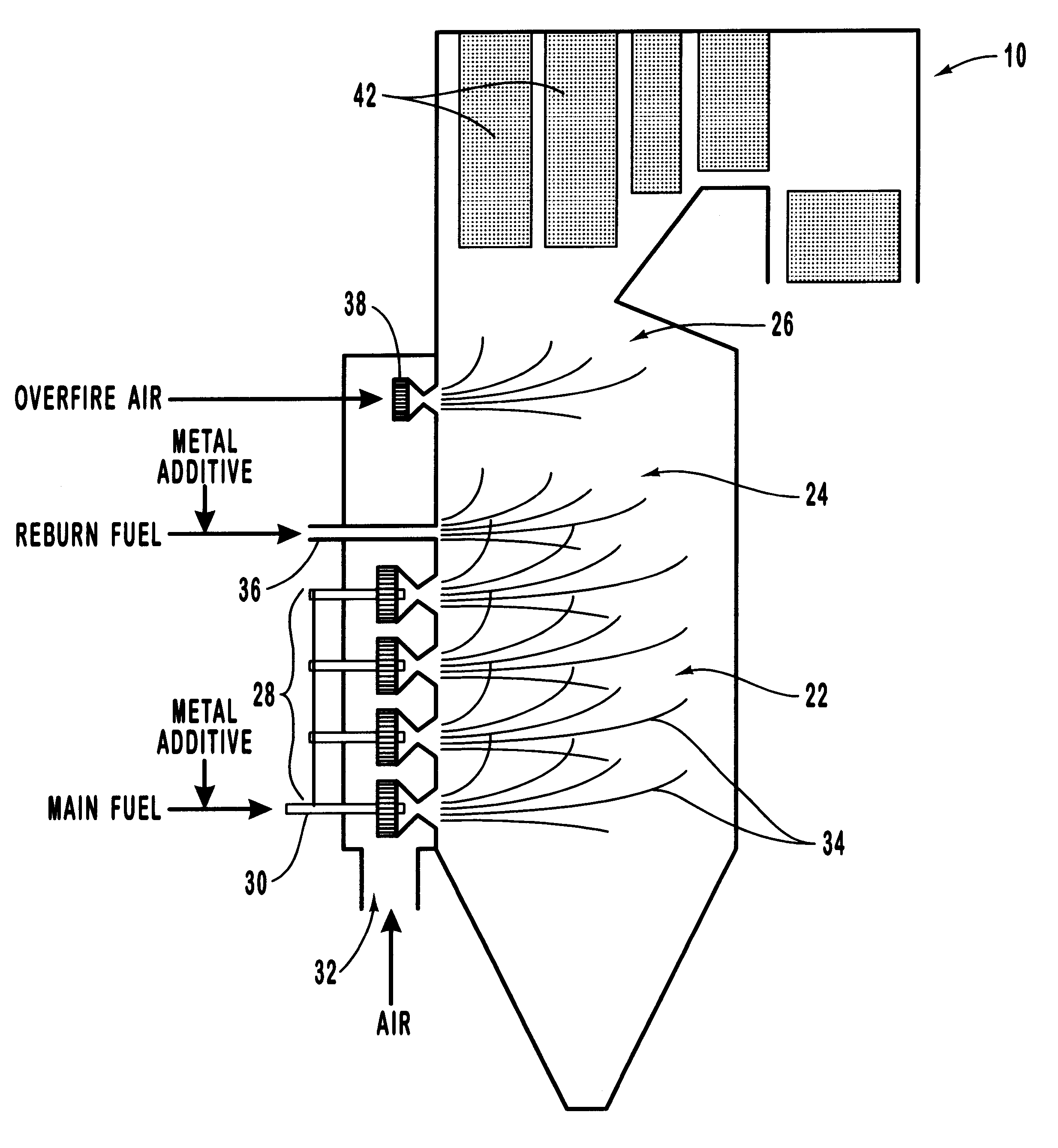

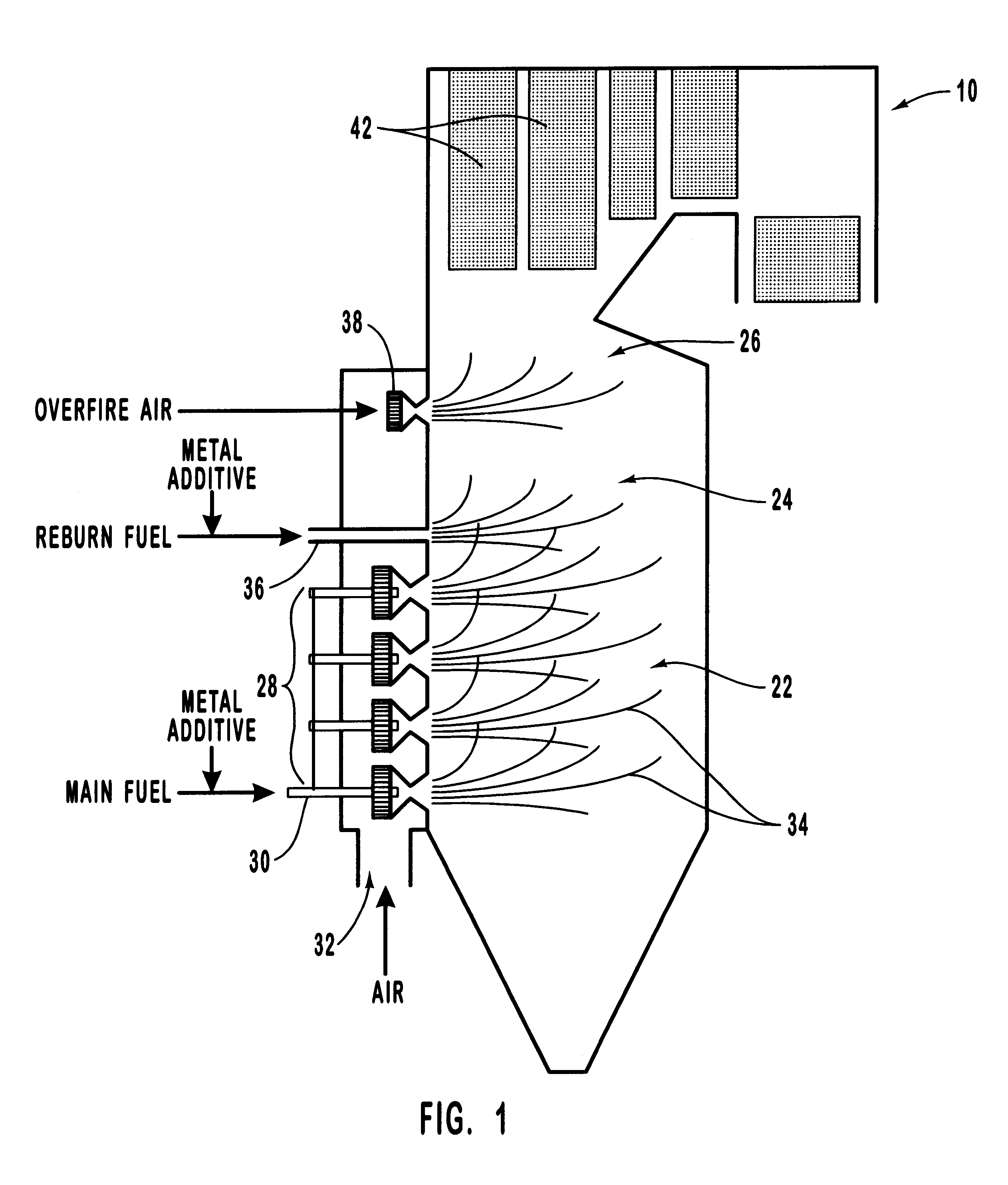

Method for reducing NOX in combustion flue gas using metal-containing additives

InactiveUS6206685B1Improved control deviceSure easyDispersed particle separationSolid fuel combustionAtmospheric airNitric oxide

Various methods for decreasing the amount of nitrogen oxides released to the atmosphere as a component of combustion gas mixtures are provided. The methods specifically provide for the removal of nitric oxide and nitrogen dioxide (NOx) from gas mixtures emitted from stationary combustion systems. In particular, methods for improving efficiency of nitrogen oxide reduction from combustion systems include injecting metal-containing compounds into the main combustion zone and / or the reburning zone of a combustion system. The metal containing compounds react with active combustion species, and these reactions change radical concentrations and significantly improve NOx conversion to molecular nitrogen. The metal-containing additives can be injected with the main fuel, in the main combustion zone, with secondary or reburning fuel addition, or at several locations in the main combustion zone and reburning zone. Optionally, nitrogenous reducing agents and / or overfire air can be injected downstream to further increase NOx reduction.

Owner:GE ENERGY & ENVIRONMENTAL RES

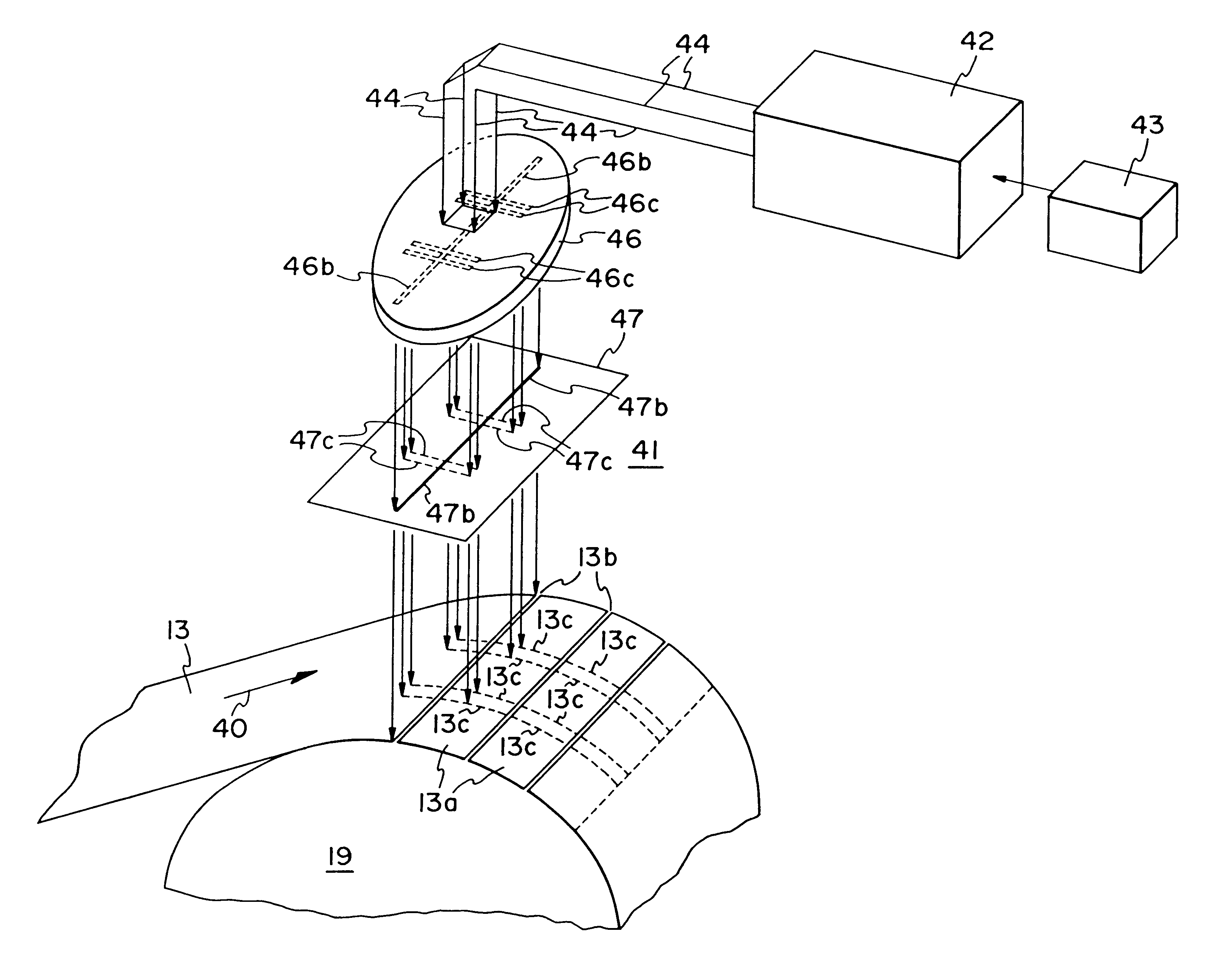

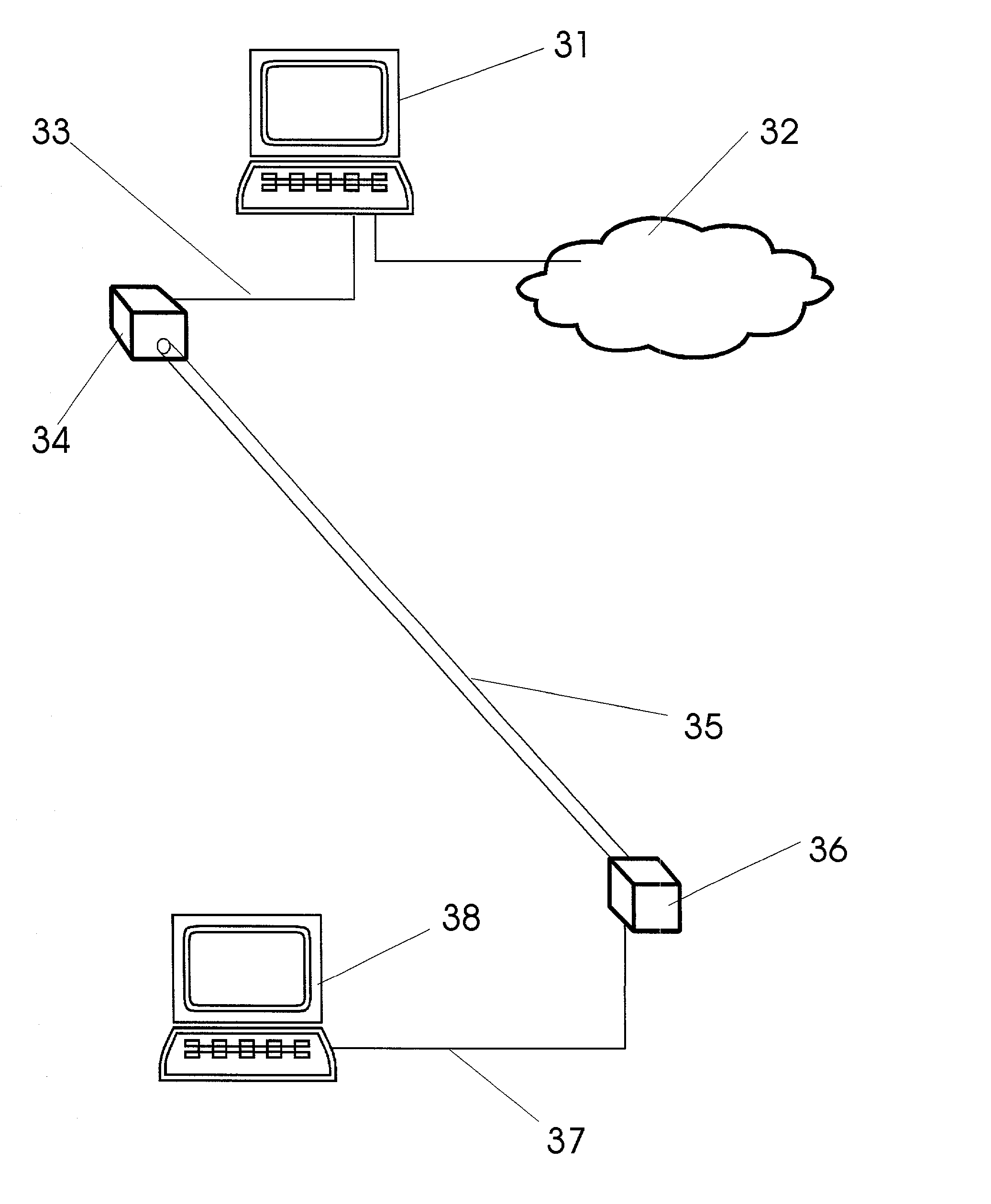

Free space optical communications link tolerant of atmospheric interference

InactiveUS20040208602A1Improve reliabilityIncrease resistanceElectromagnetic transmissionUltrasound attenuationTransceiver

Free space optical communications systems which resist atmospheric attenuation of optical beams is presented. Very long link distances remain highly reliable despite fog and other inclement weather conditions which otherwise tend to hamper optical transmissions in an atmospheric air column. Systems include primary elements as follows: a plurality of transceivers and at least one air column optical path. Each transceiver includes specialized light sources which produce radiation in the Mid-IR spectral region. In addition, these sources are very compact and well organized in view of their intended deployment environment. Further, special modulation means are joined with particular light sources to address high bandwith needs. In addition, specialized detection strategies are presented whereby sensitivity is improved. Alternative versions and configurations directed to specialized function are also described in detail.

Owner:PLANTE JAMES

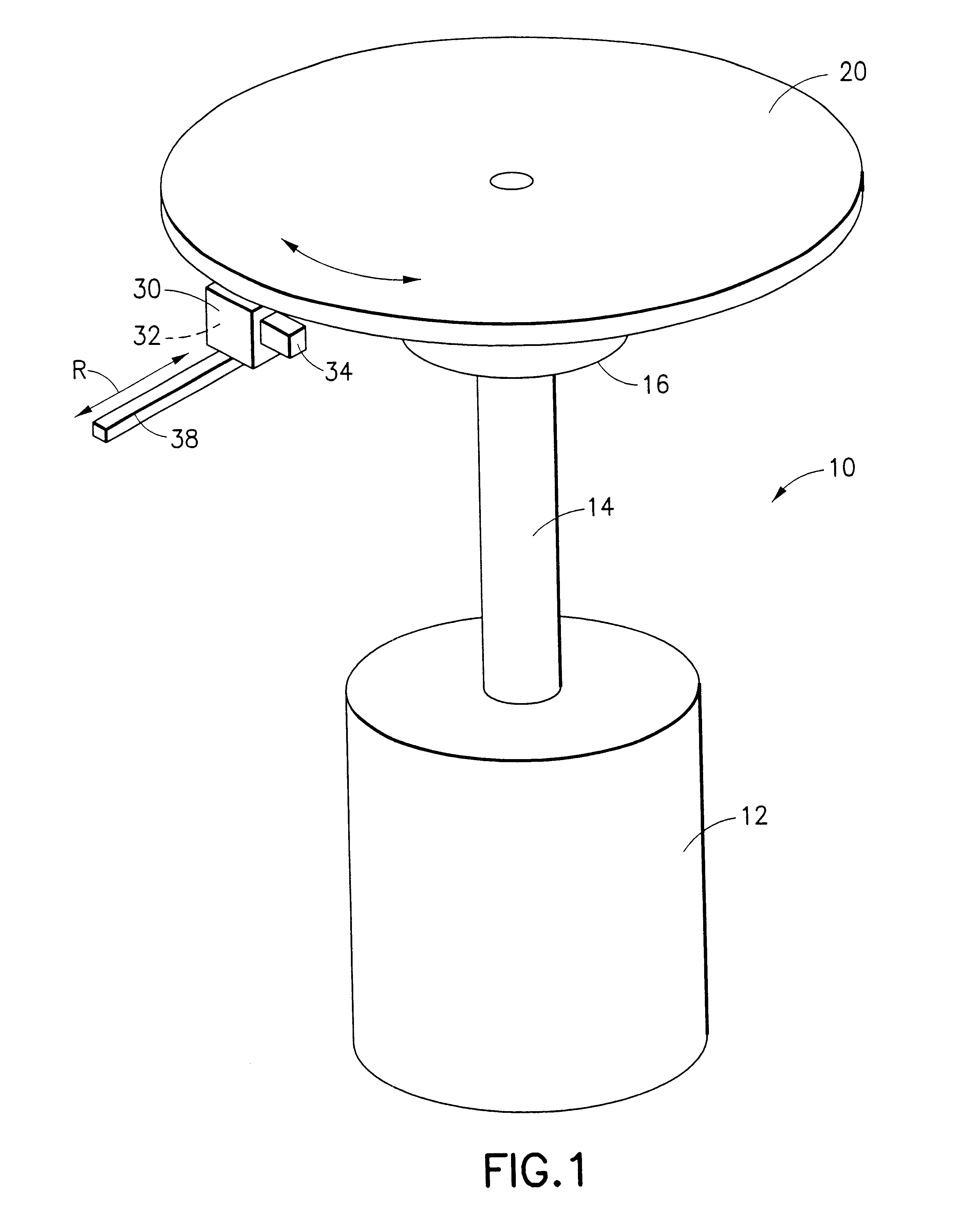

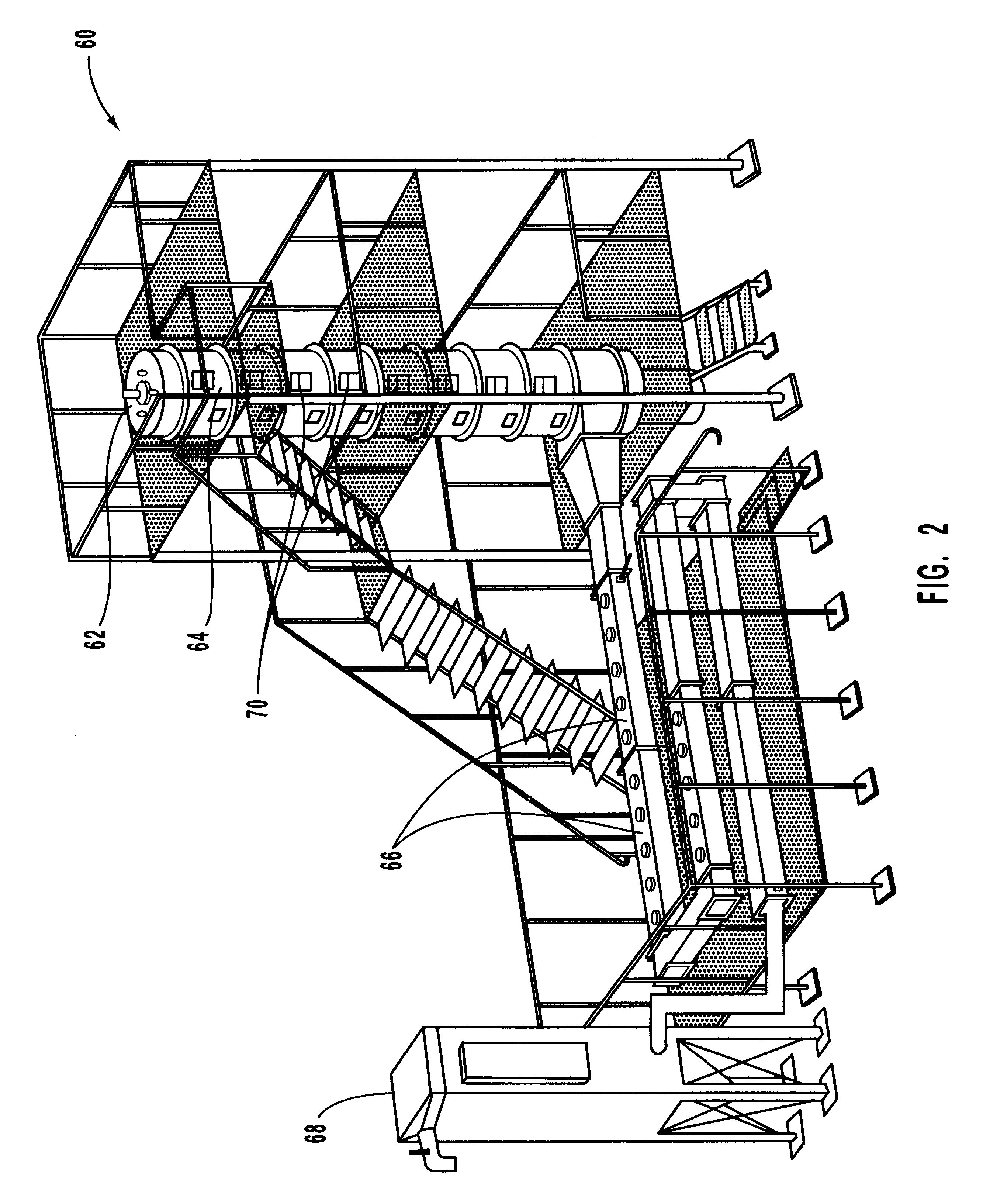

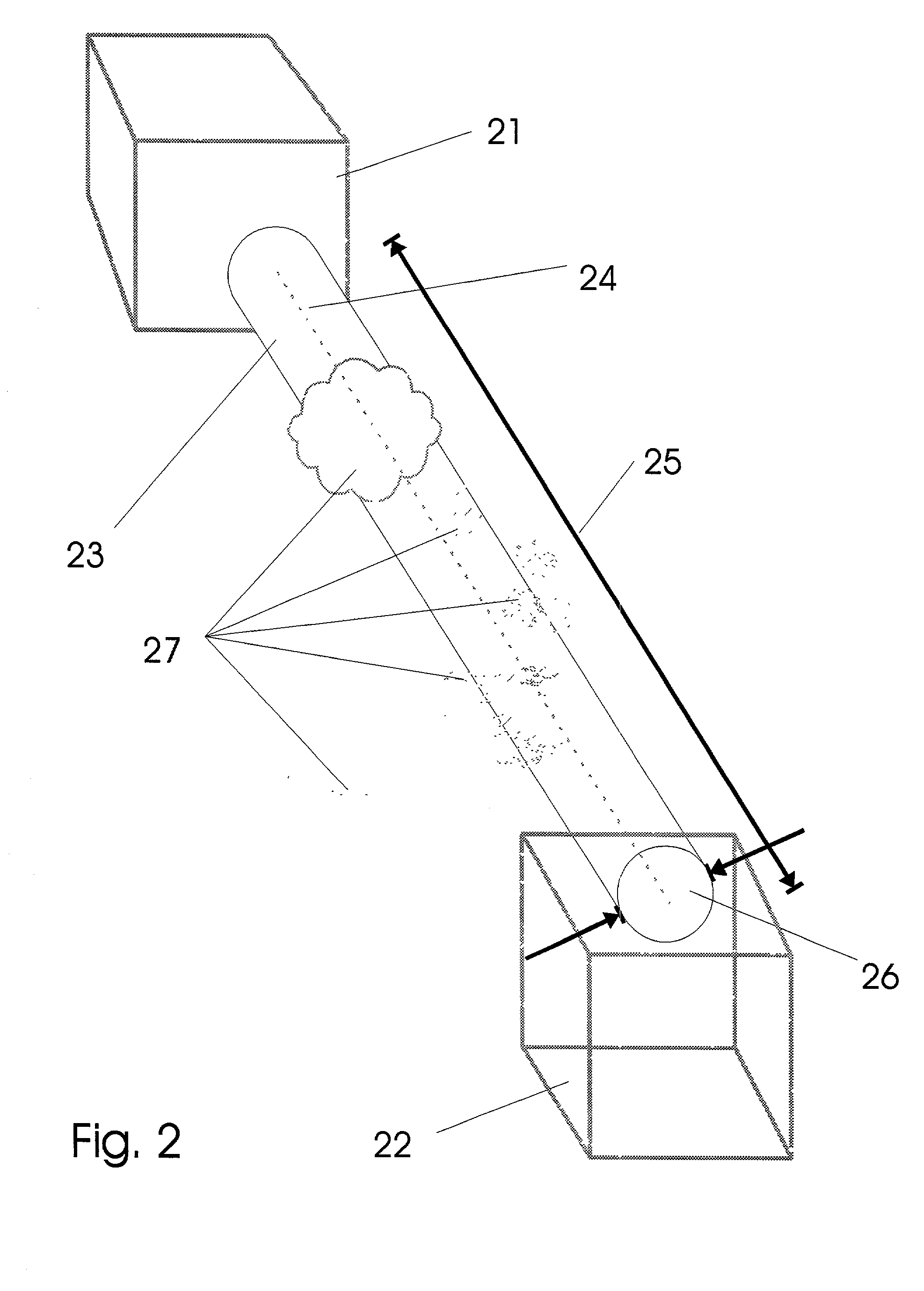

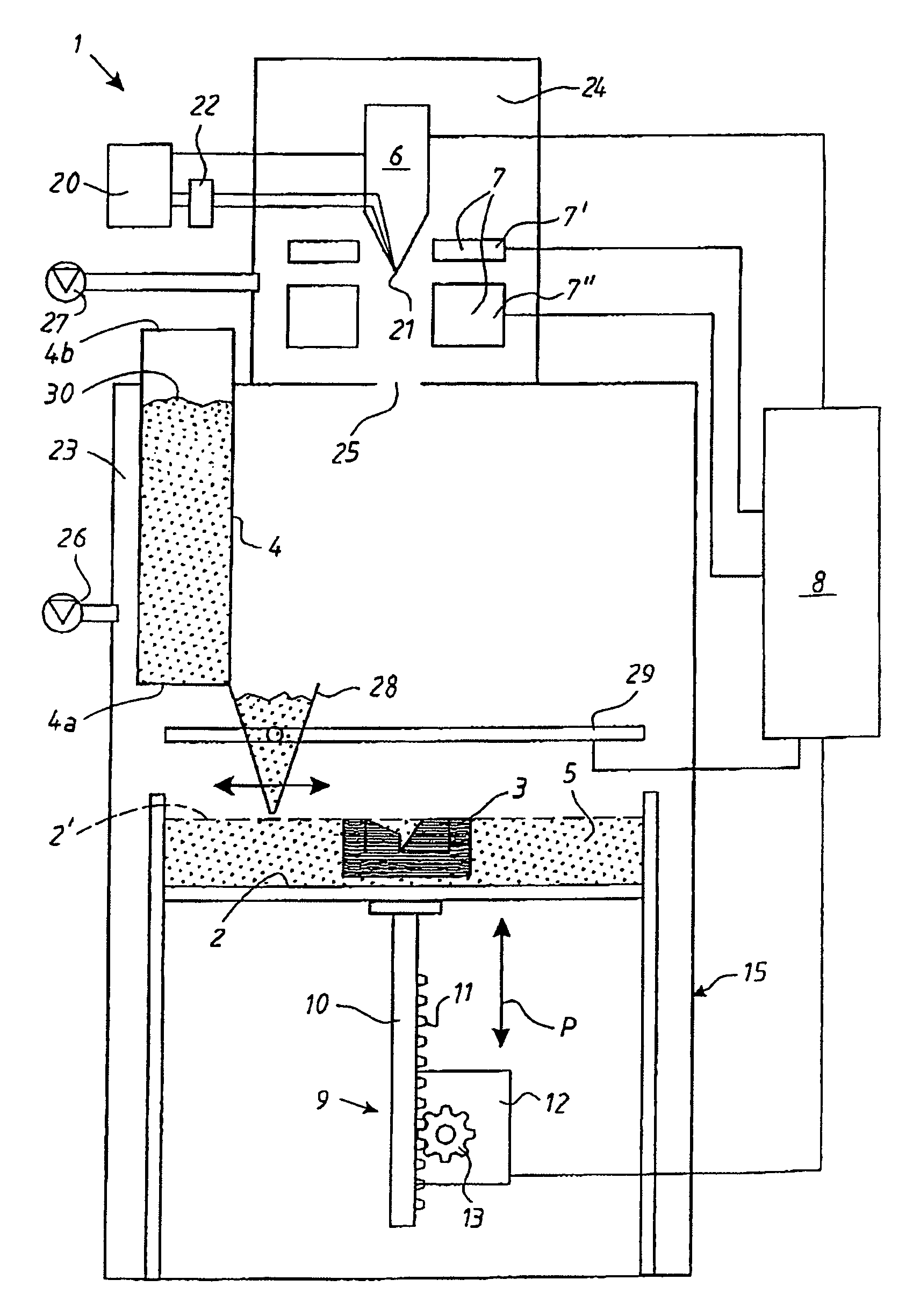

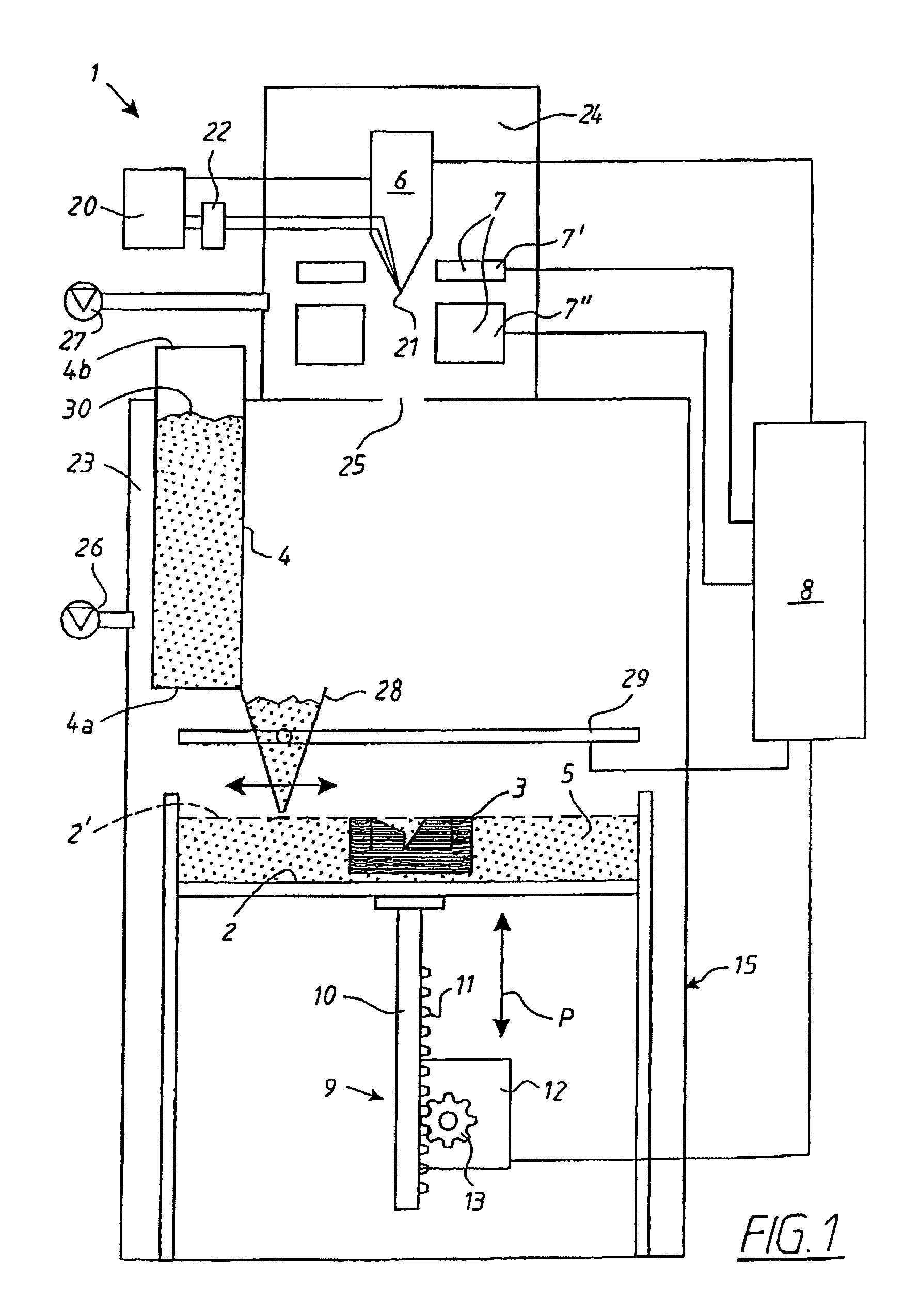

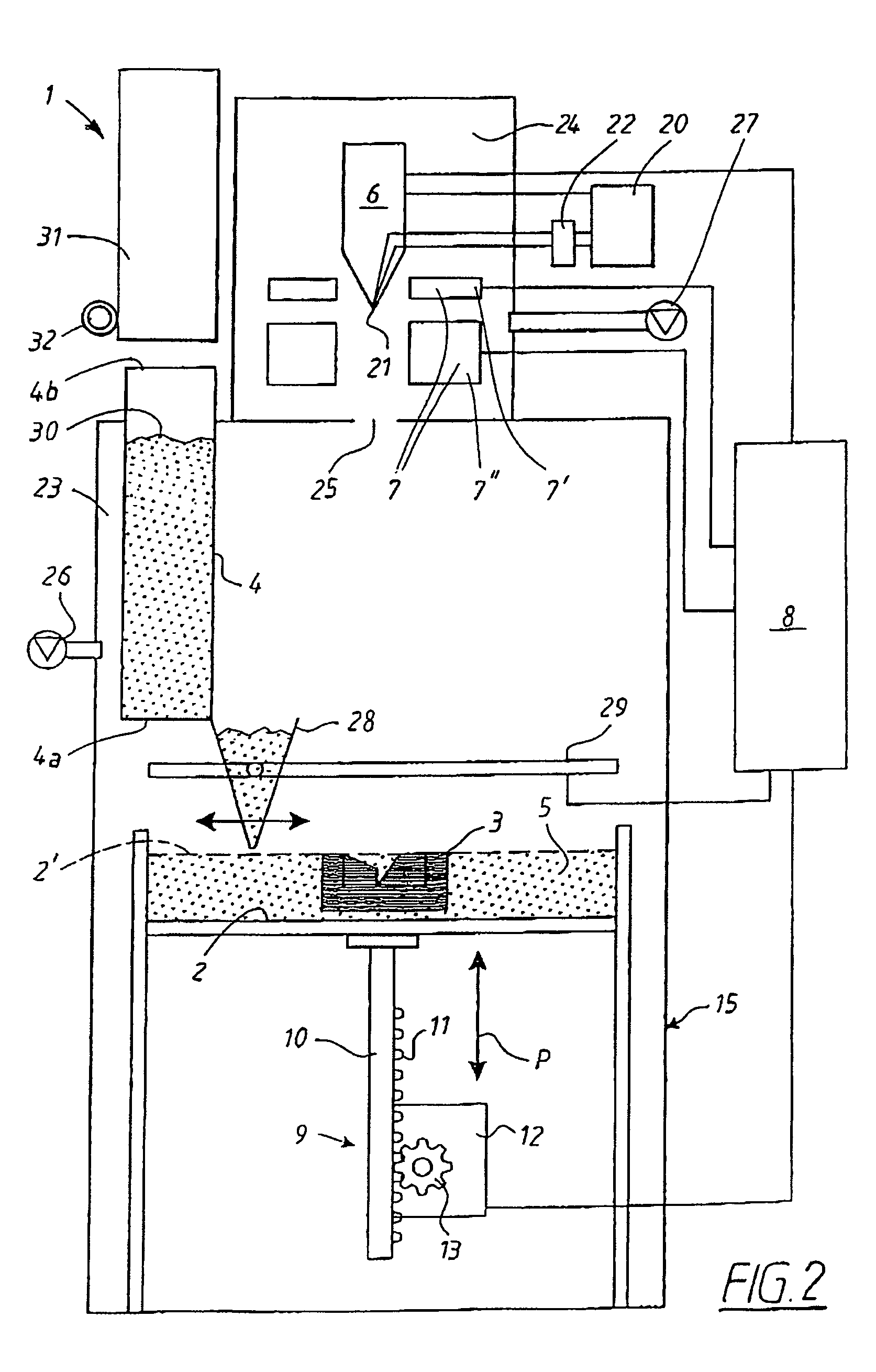

Arrangement for the production of a three-dimensional product

The invention relates to an arrangement for the production of a three-dimensional product, which arrangement comprises a work bench on which the said three-dimensional product is to be constructed, a powder dispenser which is arranged to apply a thin layer of powder onto the work bench to create a powder bed, an irradiation gun for transmitting energy to the powder so that melting of the powder takes place, the arrangement comprising a casing within which the pressure is reduced in relation to the atmospheric pressure and within which the work bench and the irradiation gun are located, with the powder dispenser, or a supply pipe connected to the powder dispenser, being arranged partially outside the casing.

Owner:ARCAM AB

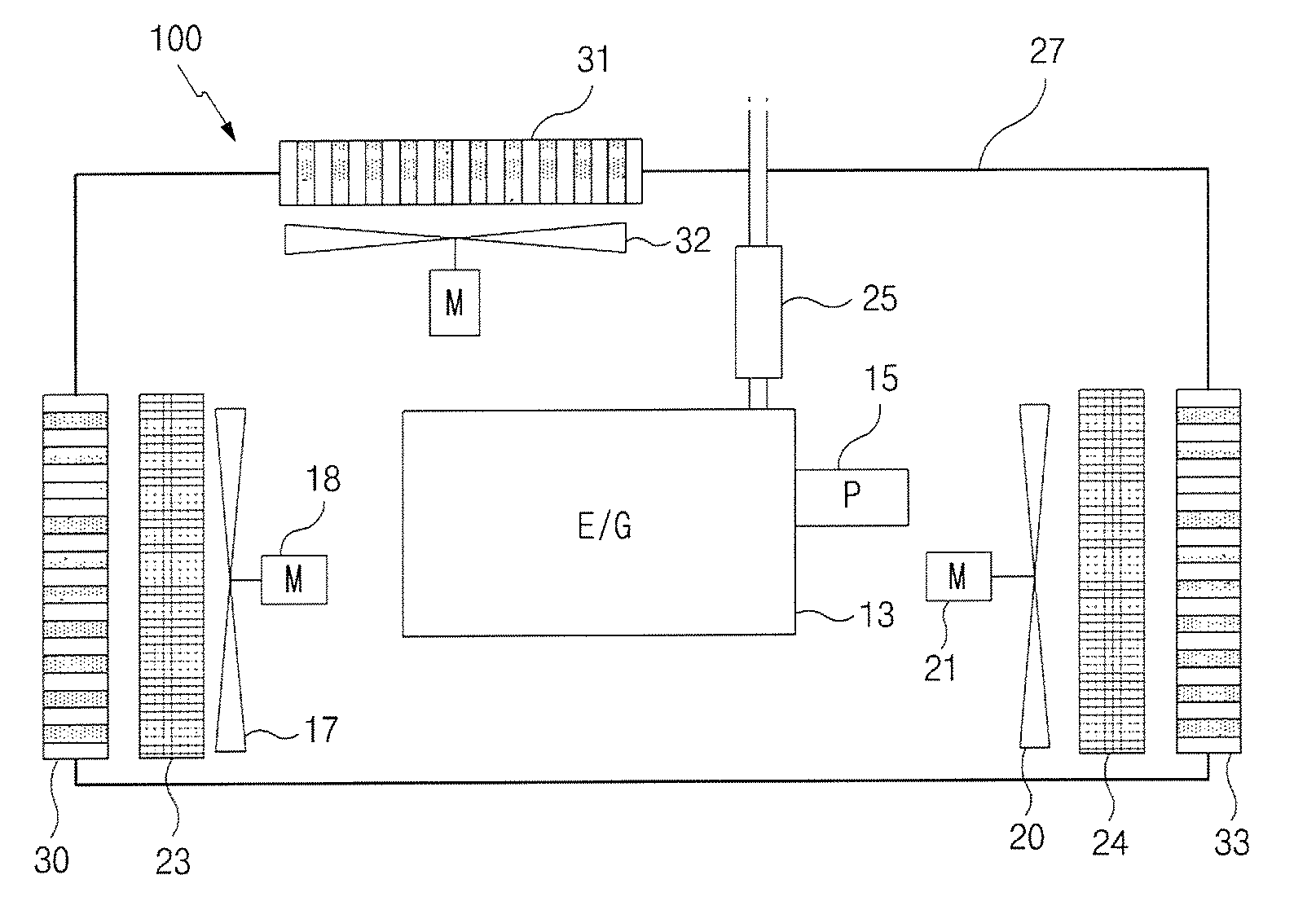

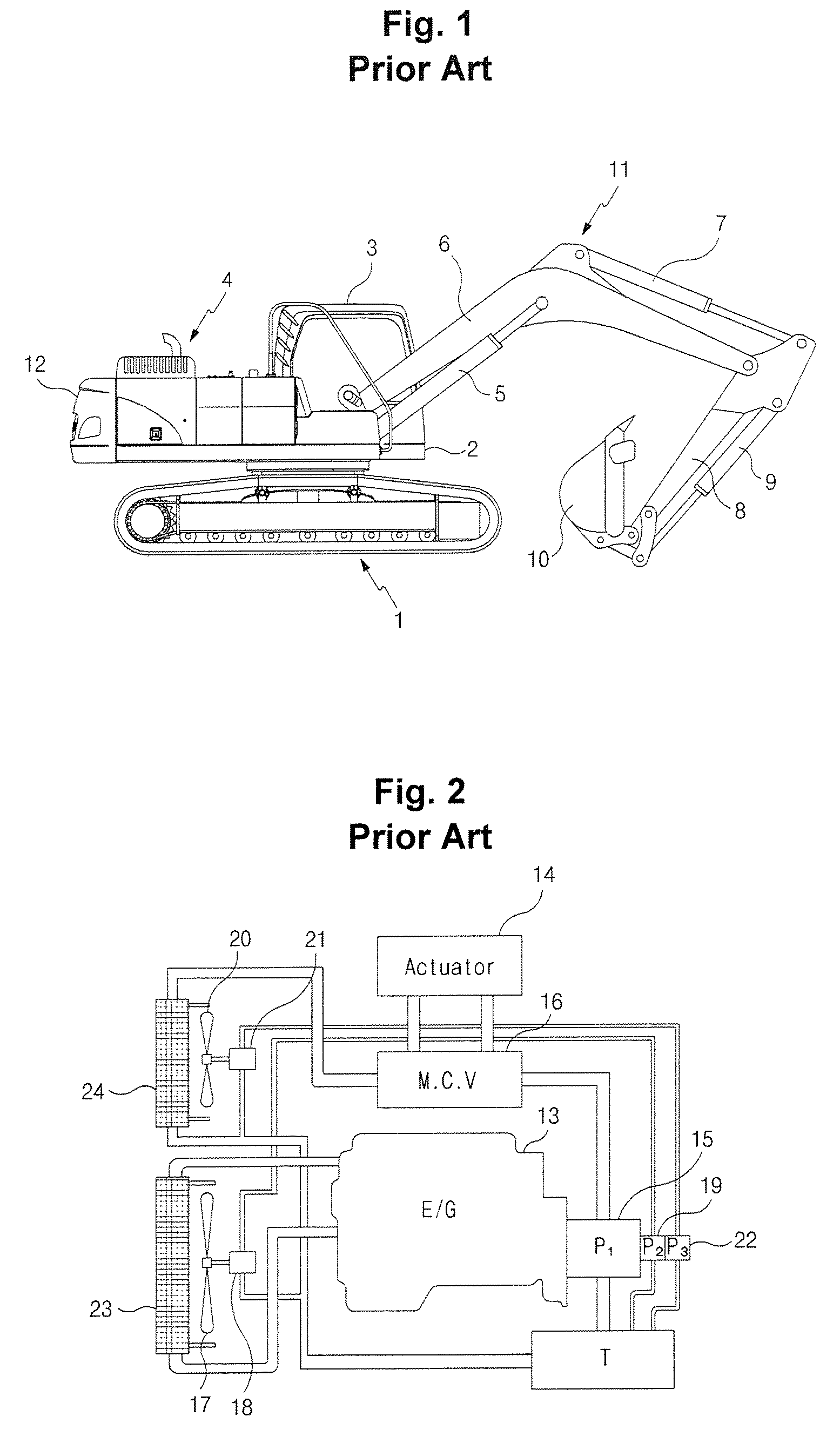

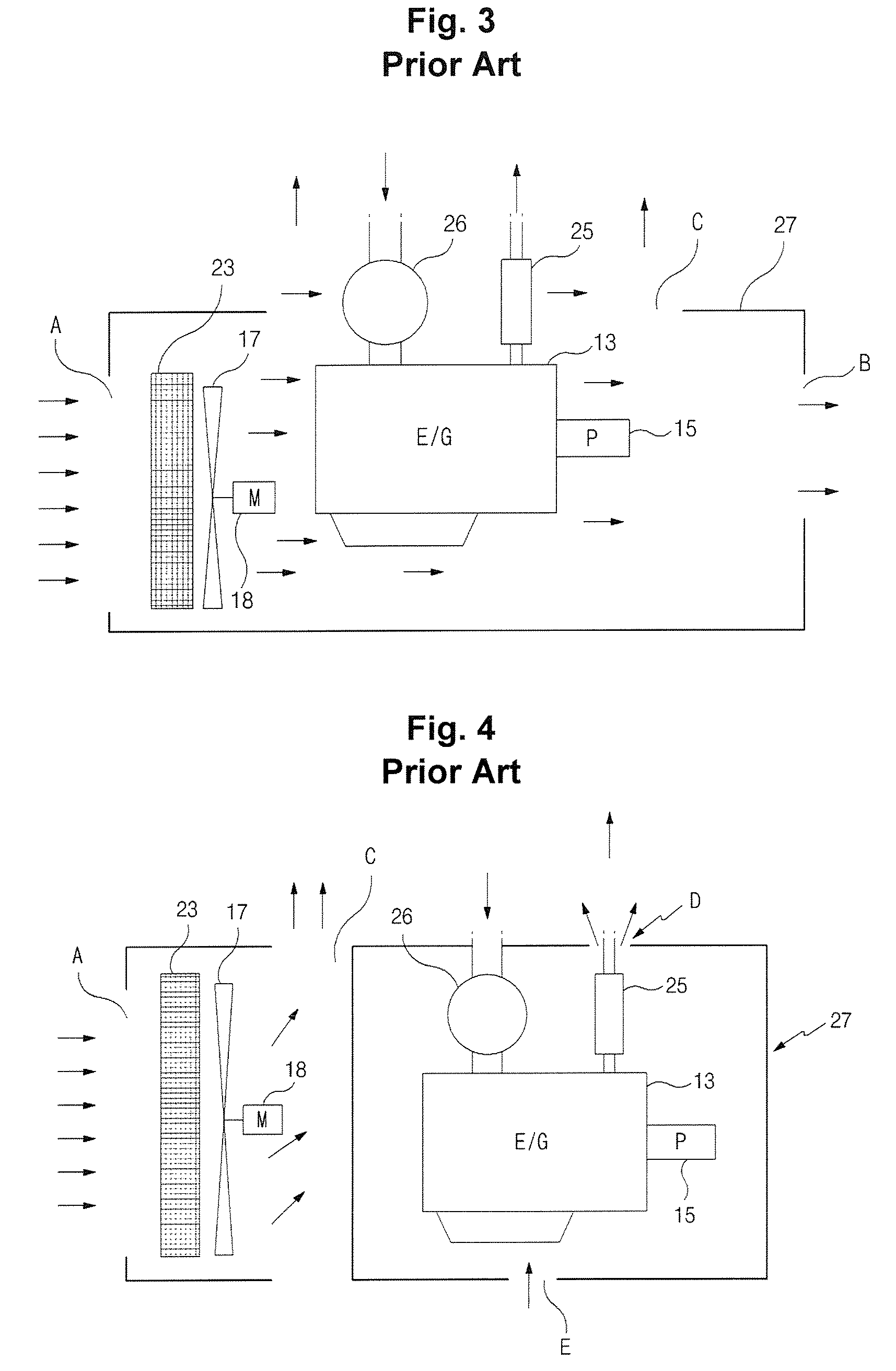

Engine room for construction equipment

InactiveUS8196555B2Reduce noiseAvoid componentsCoolant flow controlExhaust apparatusInhalationAtmospheric air

An engine room for construction equipment is provided, which can minimize emission of noise generated in an engine room due to driving of an engine and a ventilating fan to an outside of the engine room by absorbing the noise through a noise trap, and can improve the cooling performance of corresponding components by smoothing inhalation / discharge of an external air to / from the airtight engine room. The engine room for construction equipment includes a radiator cooling water for cooling the engine, a muffler discharging an exhaust gas from an engine to the atmosphere, a first noise trap installed in an inlet port to absorb noise generated in the engine room and emitted to an outside, a second noise trap installed in an outlet port to absorb the noise generated in the engine room and emitted to the outside, a radiator fan inhaling the external air through the first noise trap and making the inhaled external air pass through the radiator and the circumference of the engine, a discharge fan discharging the air in the engine room to the outside through the second noise trap, and an outer wall forming an airtight space for accommodating therein the engine, the muffler, the radiator fan, the hydraulic pump, and the discharge fan that generate the noise.

Owner:VOLVO CONSTR EQUIP HLDG SWEDEN AB

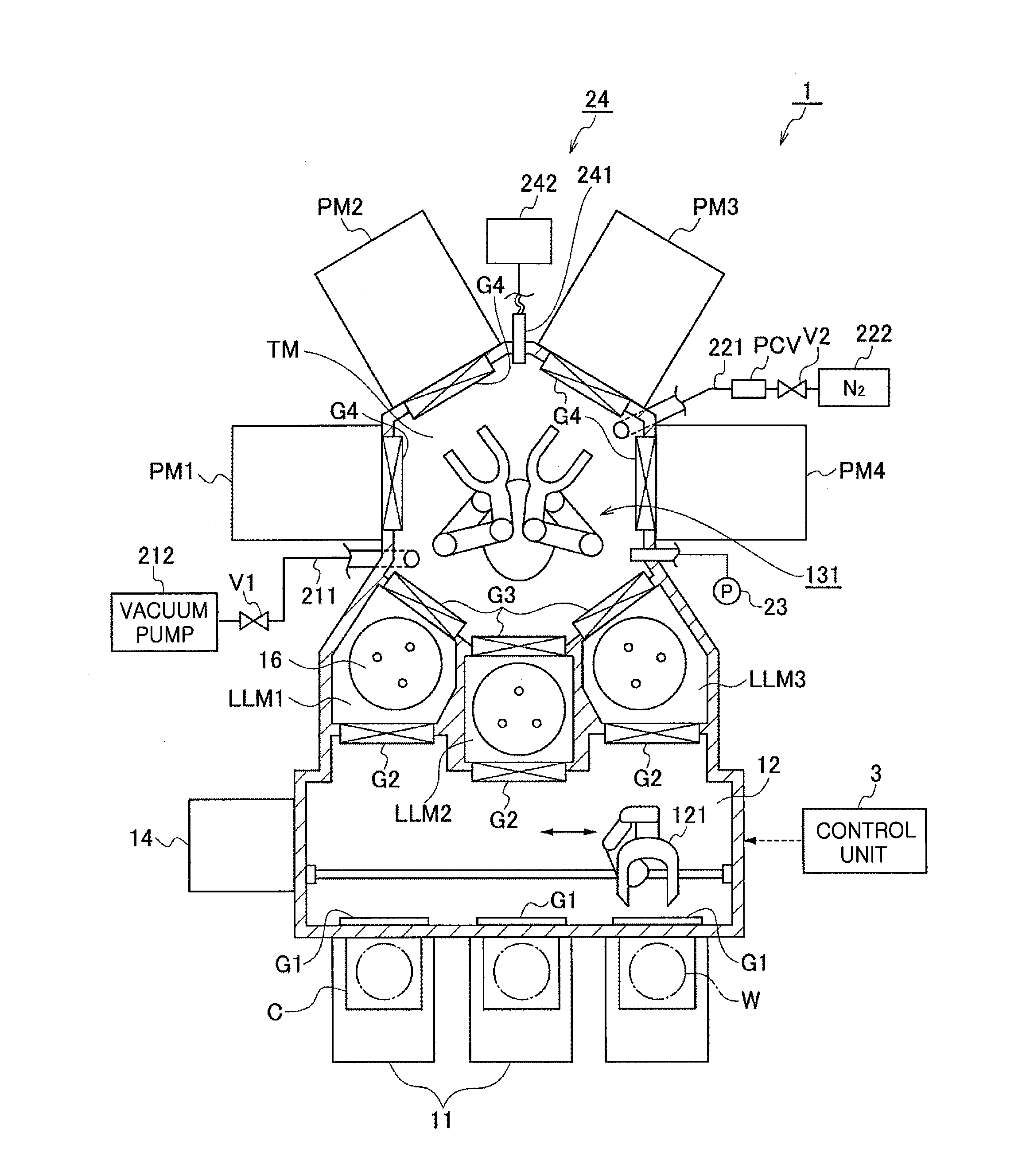

Leakage determining method, substrate processing apparatus and storage medium

InactiveUS20160169766A1Reduce the amount requiredDetection of fluid at leakage pointSemiconductor/solid-state device manufacturingTemporal changeAtmospheric air

Owner:TOKYO ELECTRON LTD

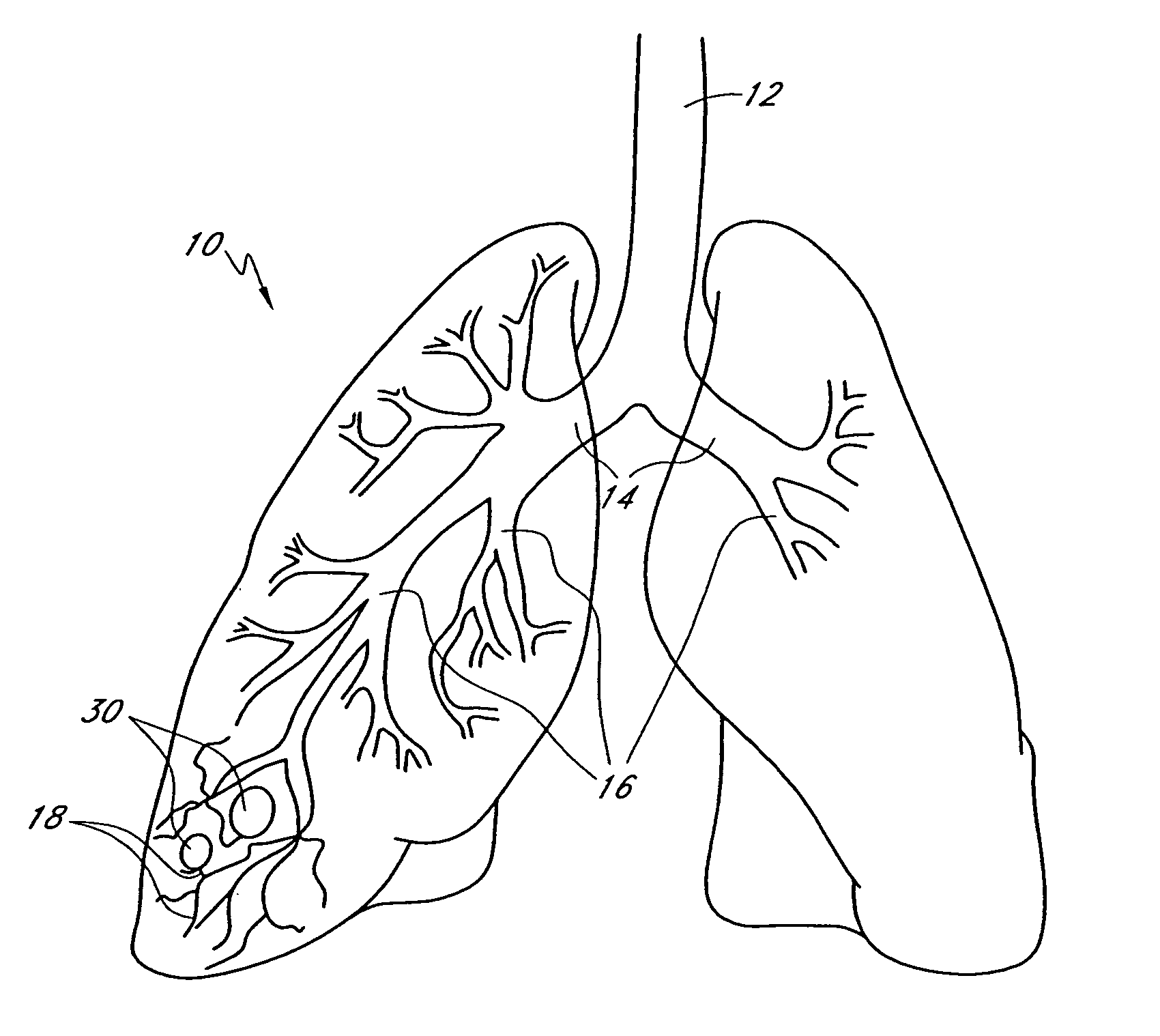

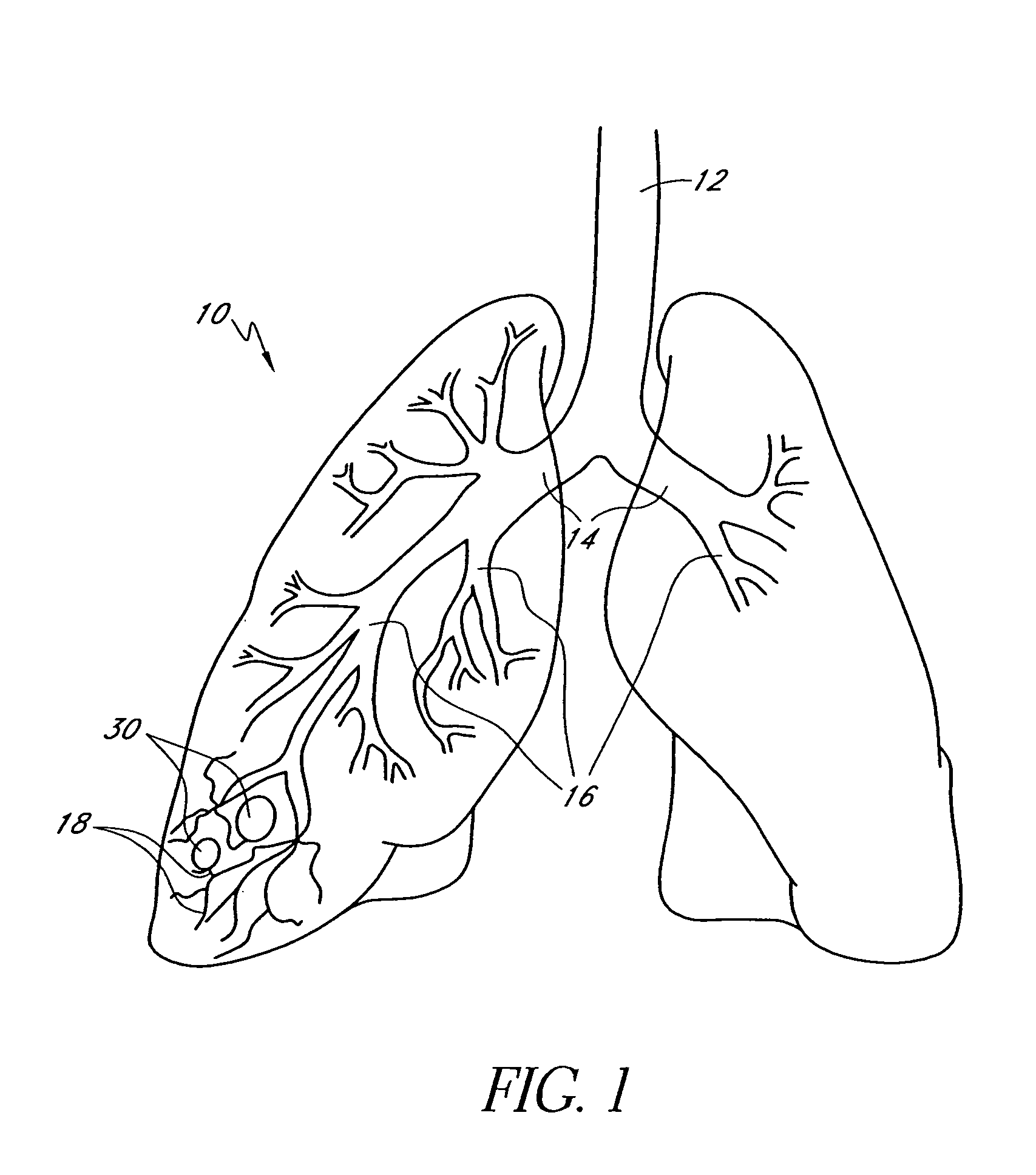

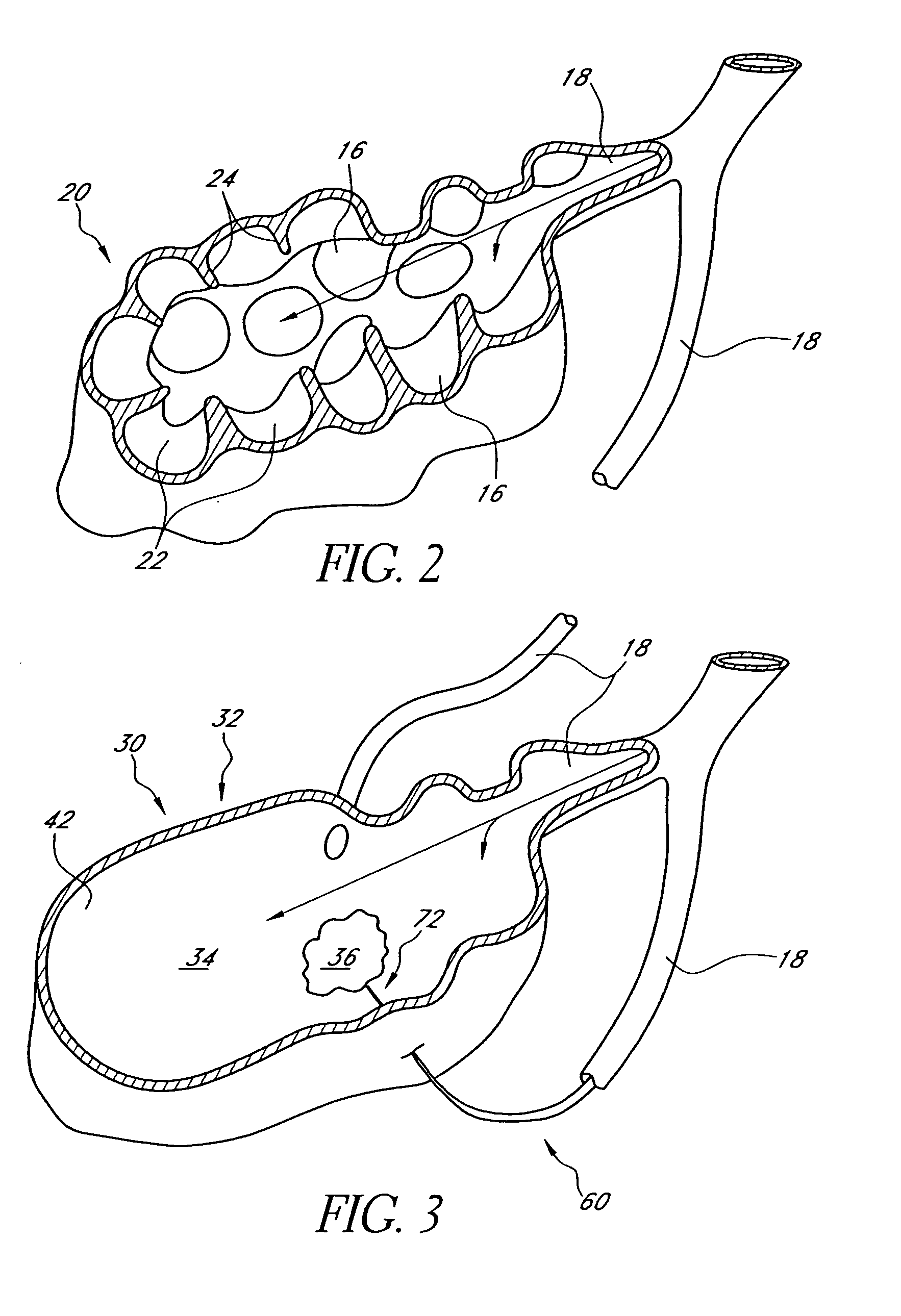

Bronchoscopic lung volume reduction method

InactiveUS7100616B2Reduce riskEffective lung volume reductionRespiratorsBronchiAirway occlusionAtmospheric air

A method of minimally invasively reducing a volume of a hyper-inflated target section of diseased lung comprising the steps of introducing a bronchoscope into a patient's airway to a position adjacent the target section and equilibrating air within the target section with atmospheric air to at least partially deflate the target lung section; injecting an inflammation-causing substance into the target section to precipitate adhesion of the walls within the target lung section, preventing substantial re-inflation of the target section by occluding an airway upstream of the target section for a period of time, and removing the airway occlusion after the target section has substantially permanently been reduced in volume. The injected substance can be autologous blood or a constituent thereof.

Owner:GYRUS ACMI INC (D B A OLYMPUS SURGICAL TECH AMERICA)

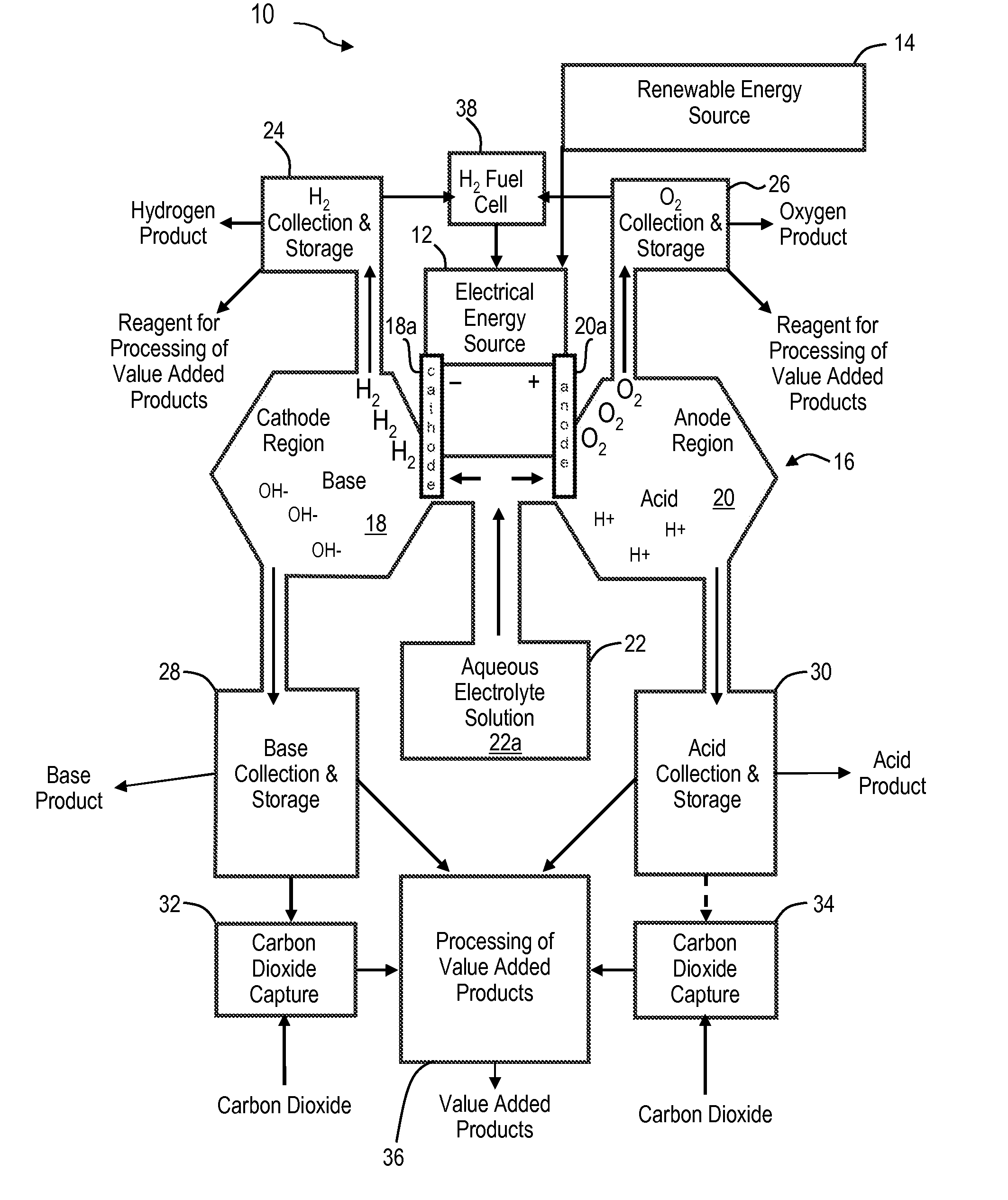

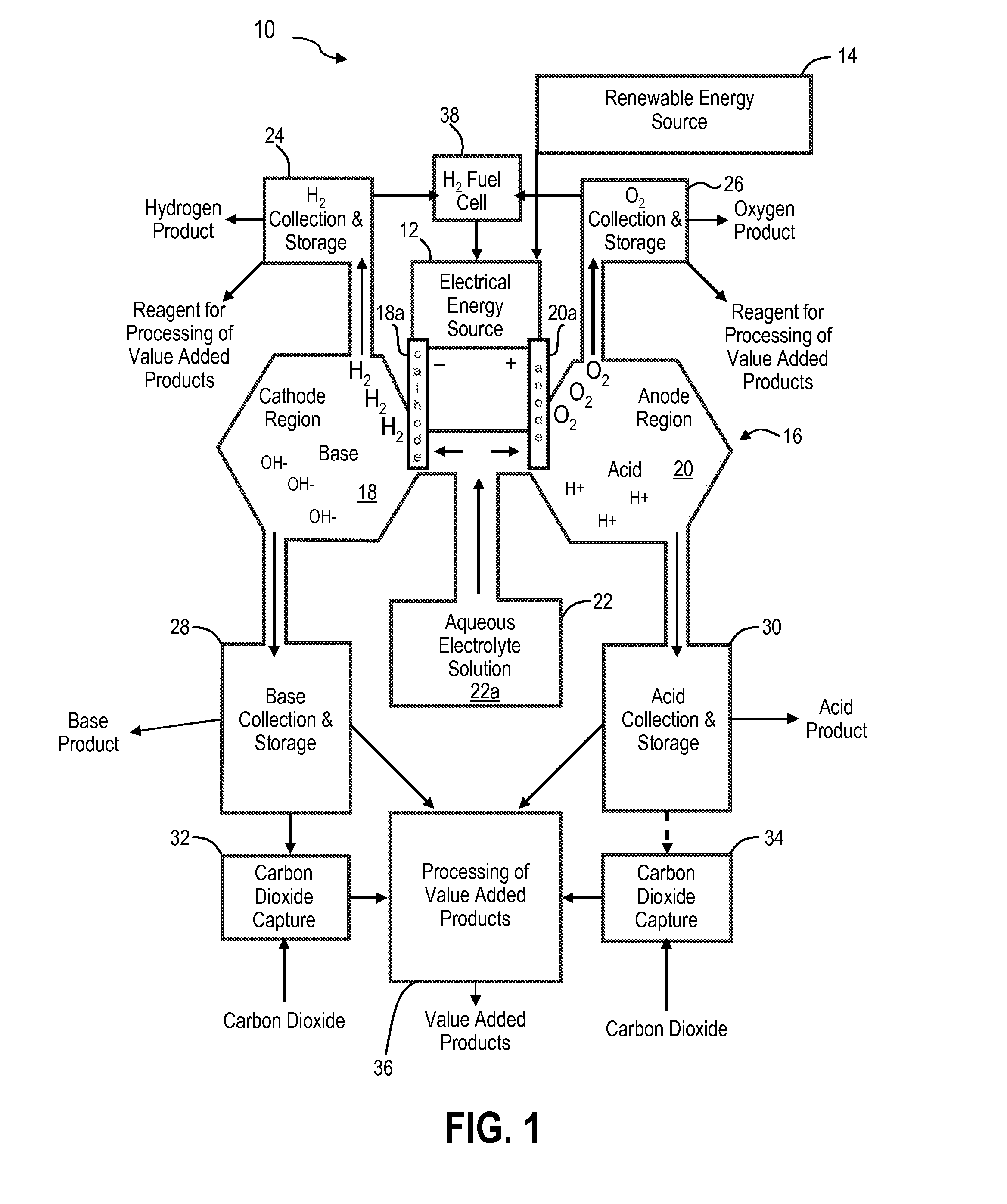

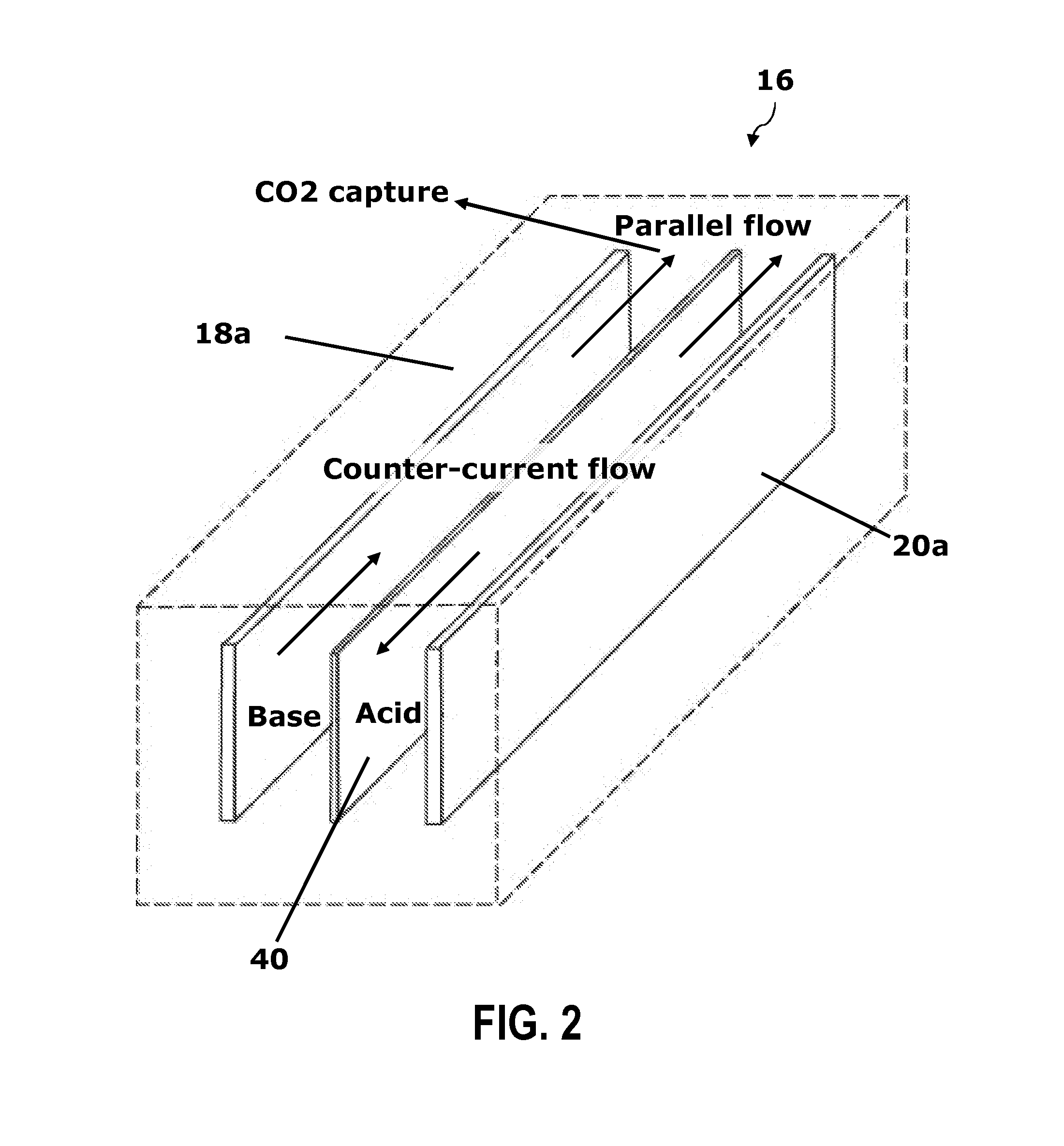

Renewable energy system for hydrogen production and carbon dioxide capture

The present invention is an integrated system for the production of hydrogen and the removal of carbon dioxide from the air or gas streams. The integrated system includes an energy source for generating electrical energy and a water source coupled to the energy source. The water source includes ionic electrolytes. The energy source supplies energy to the water source to electrolyze water to produce hydrogen gas, oxygen gas, acid and base. The carbon dioxide reacts with the base. In some embodiments, the energy source is a renewable energy source. The integrated system produces substantially no carbon dioxide and when combined with a renewable energy source, produces clean hydrogen fuel and reduces atmospheric carbon dioxide, resulting in carbon dioxide negative energy and manufacturing strategies.

Owner:SULFURCYCLE INTPROP HLDG CO LLC

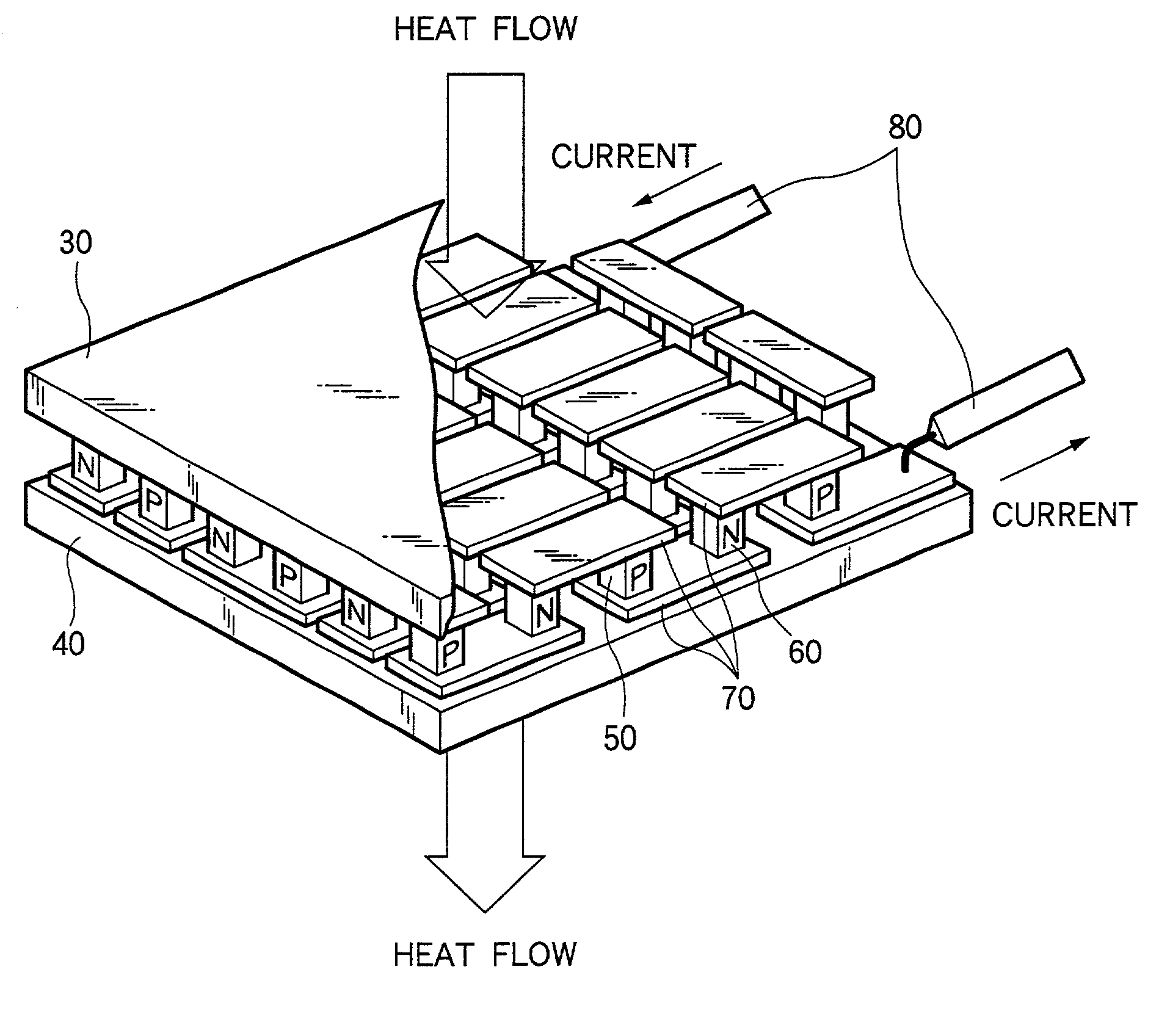

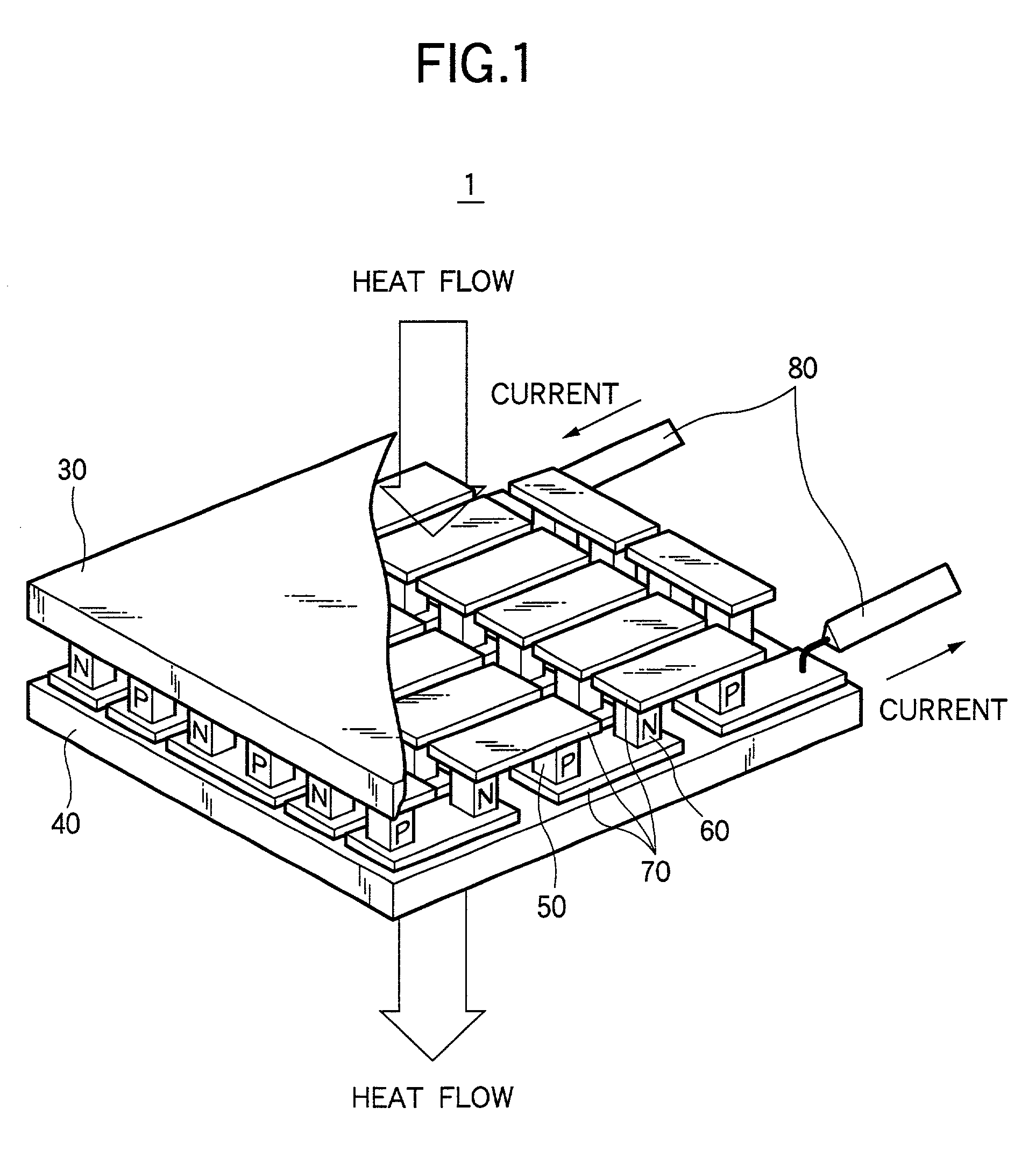

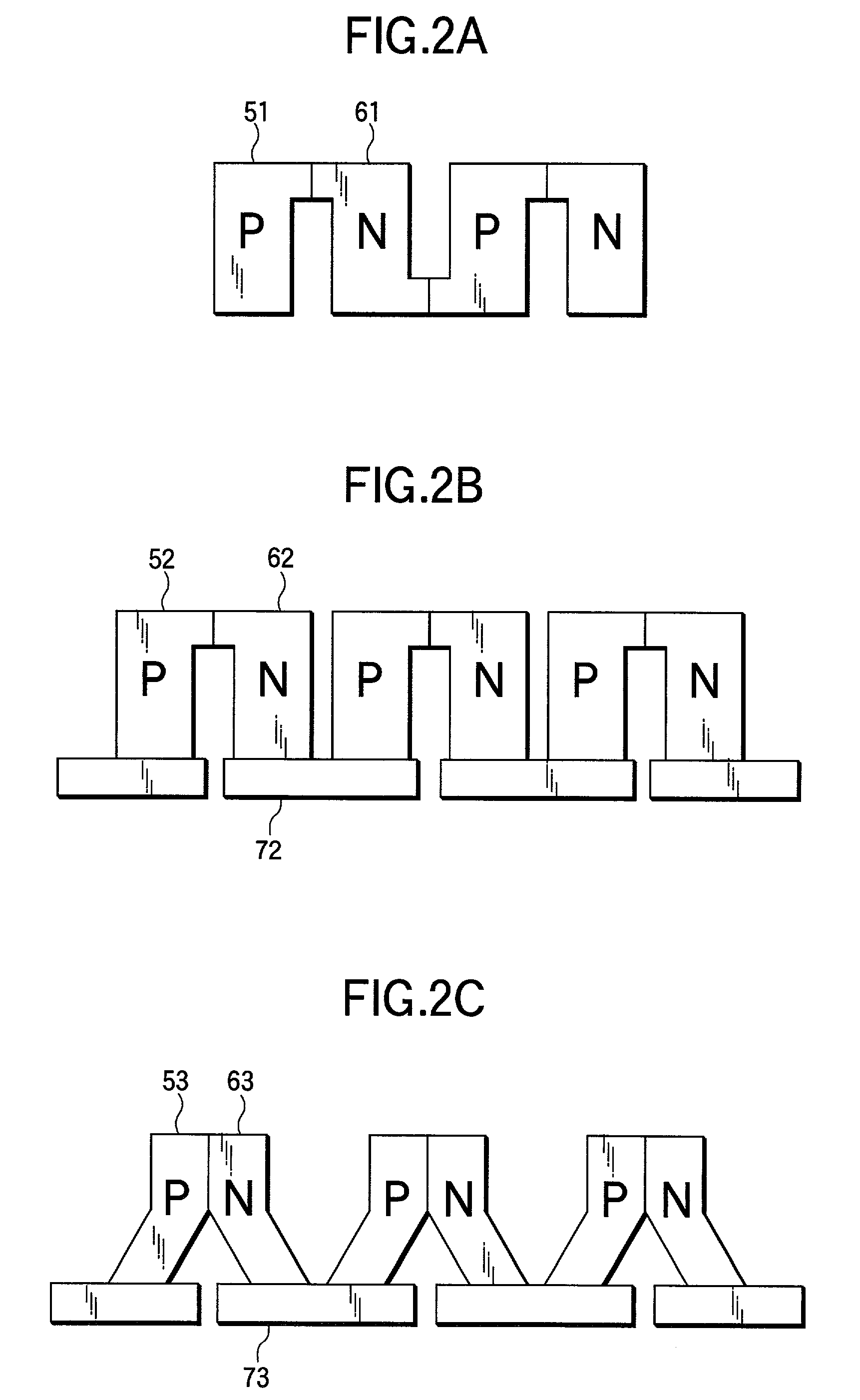

Thermoelectric module

InactiveUS20020024154A1Improve featuresSpeed up the conversion processThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric materialsAtmospheric air

A thermoelectric module comprising an N-type thermoelectric element having excellent characteristics in atmospheric air even when the temperature rises to a medium-to-high temperature region of about 500° C. and, further, improving the conversion efficiency of a thermoelectric module, by the combination of an excellent P-type thermoelectric material and an excellent n-type thermoelectric material containing a compound having a skutterudite structure, the module comprising an N-type thermoelectric elements each containing a compound having a skutterudite structure, P-type thermoelectric elements each connected directly or by way of a metal member to the N-type thermoelectric elements and containing an Mn-Si series compound,

Owner:KOMATSU LTD

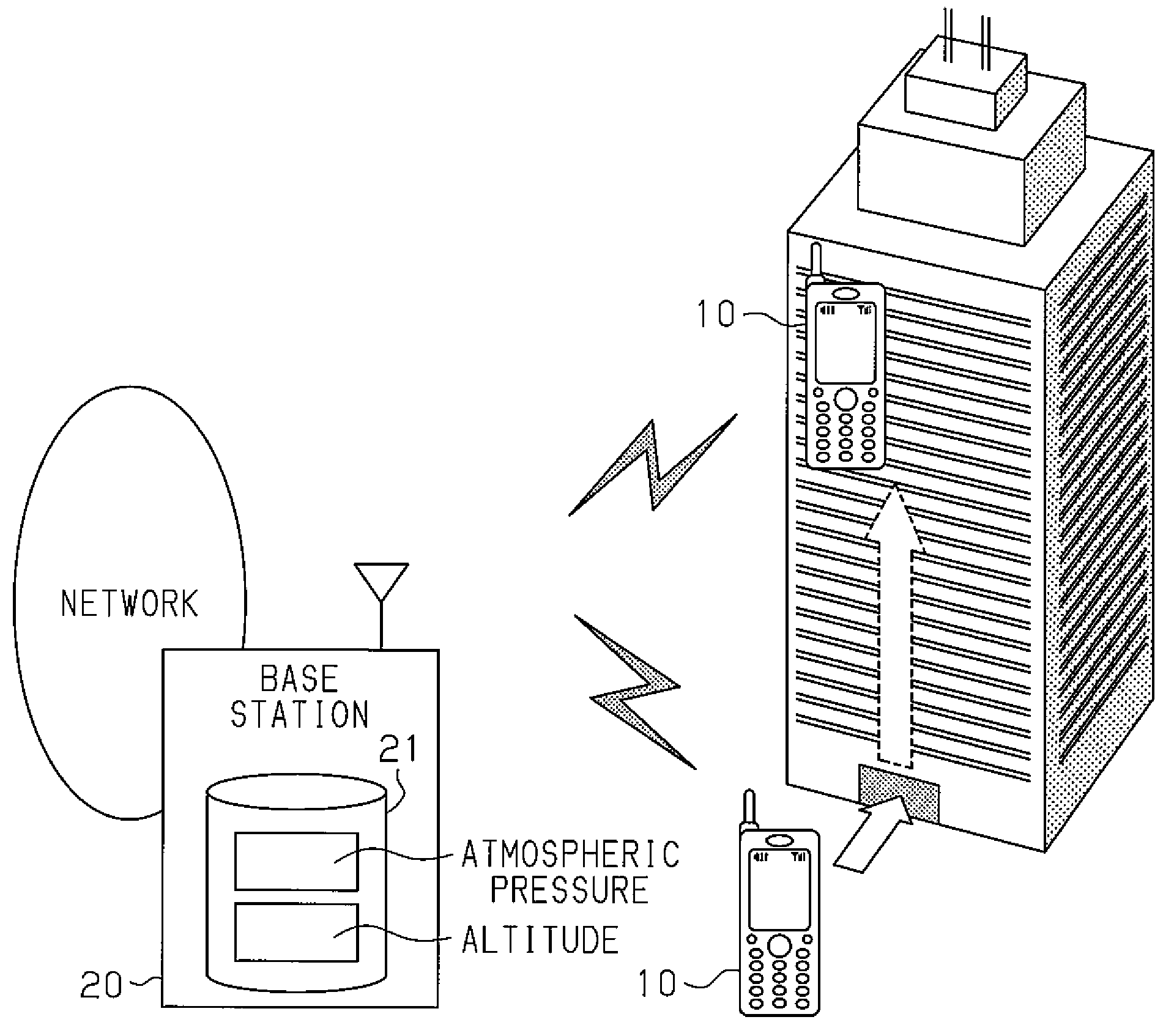

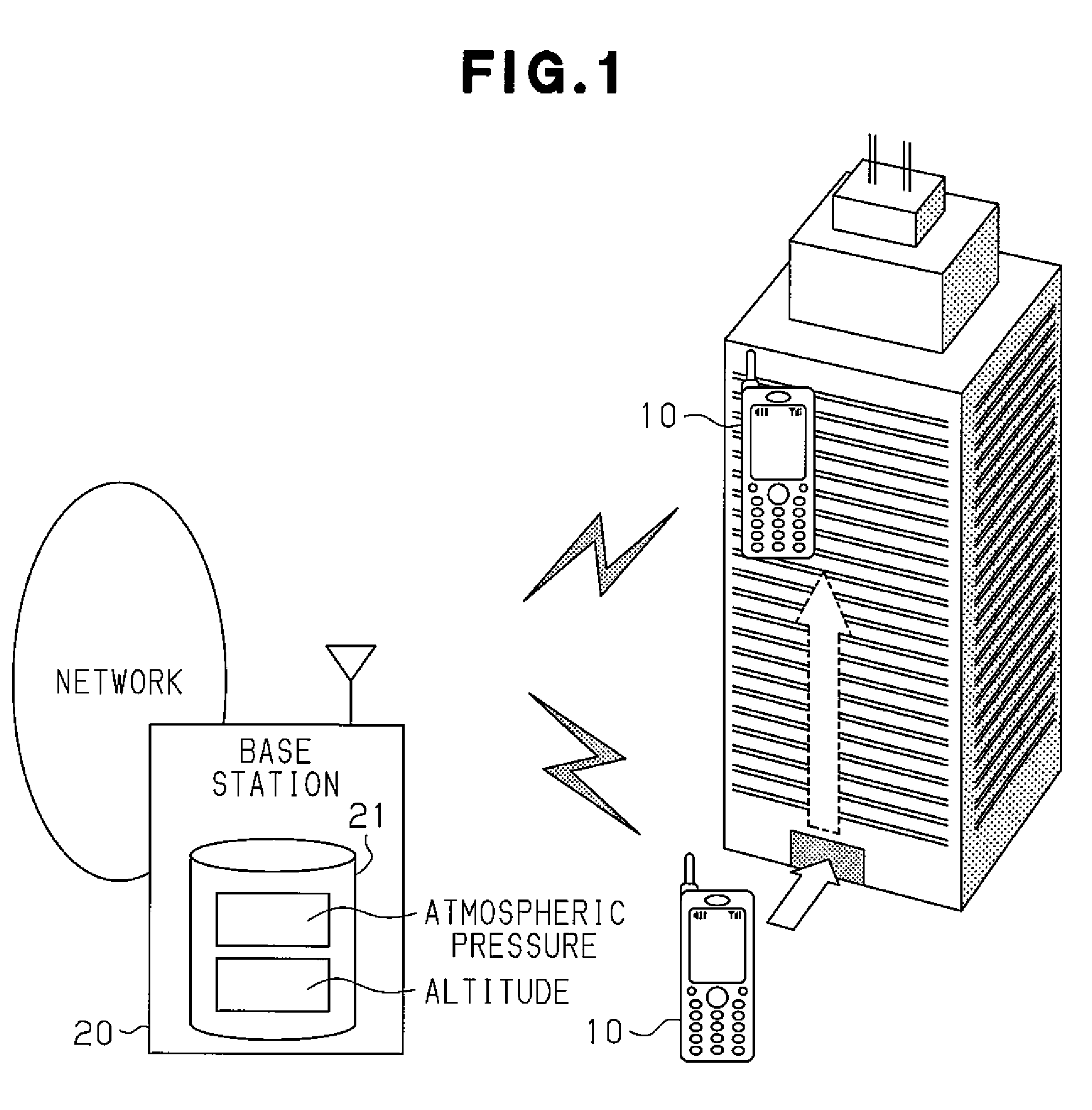

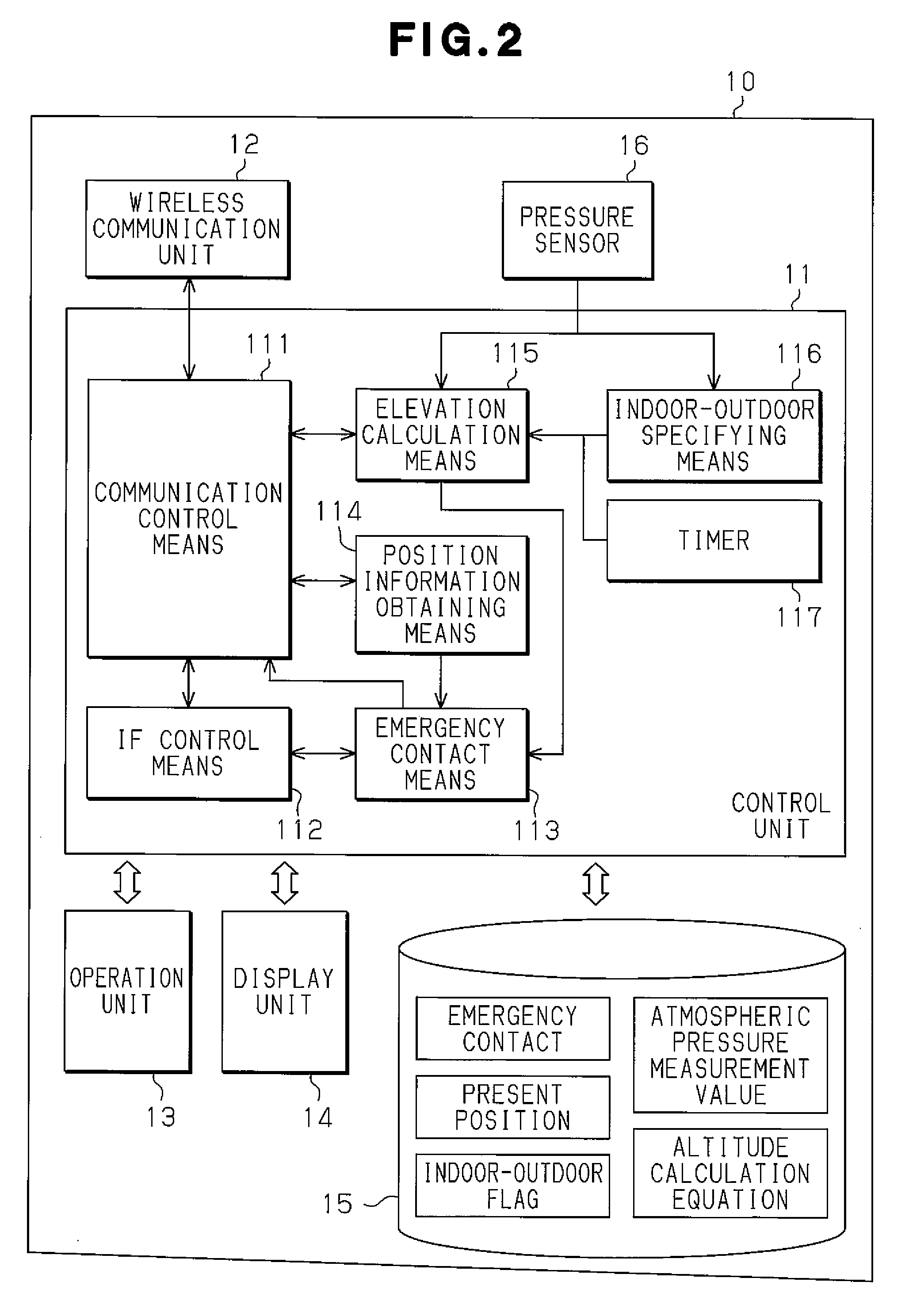

Apparatus, method, and program for outputting present position

InactiveUS20090286556A1Instruments for road network navigationNavigational calculation instrumentsAtmospheric airData memory

An apparatus, method and program for outputting a present position that enables a user to be located with further accuracy even in a multi-level area. A control unit periodically sends a reference atmospheric pressure information obtaining request to a base station and obtains reference atmospheric pressure information including the atmospheric pressure and altitude of the base station from the base station and stores the obtained information in a data storage. The control unit uses the measurement value of atmospheric pressure obtained from a pressure sensor and an altitude calculation equation including the reference atmospheric pressure information to periodically calculate and record in the data storage the altitude of the present position. When an emergency button is pushed, the control unit issues to an emergency contact an emergency notification including the present altitude or the altitude recorded in the data storage.

Owner:FREESCALE SEMICON INC

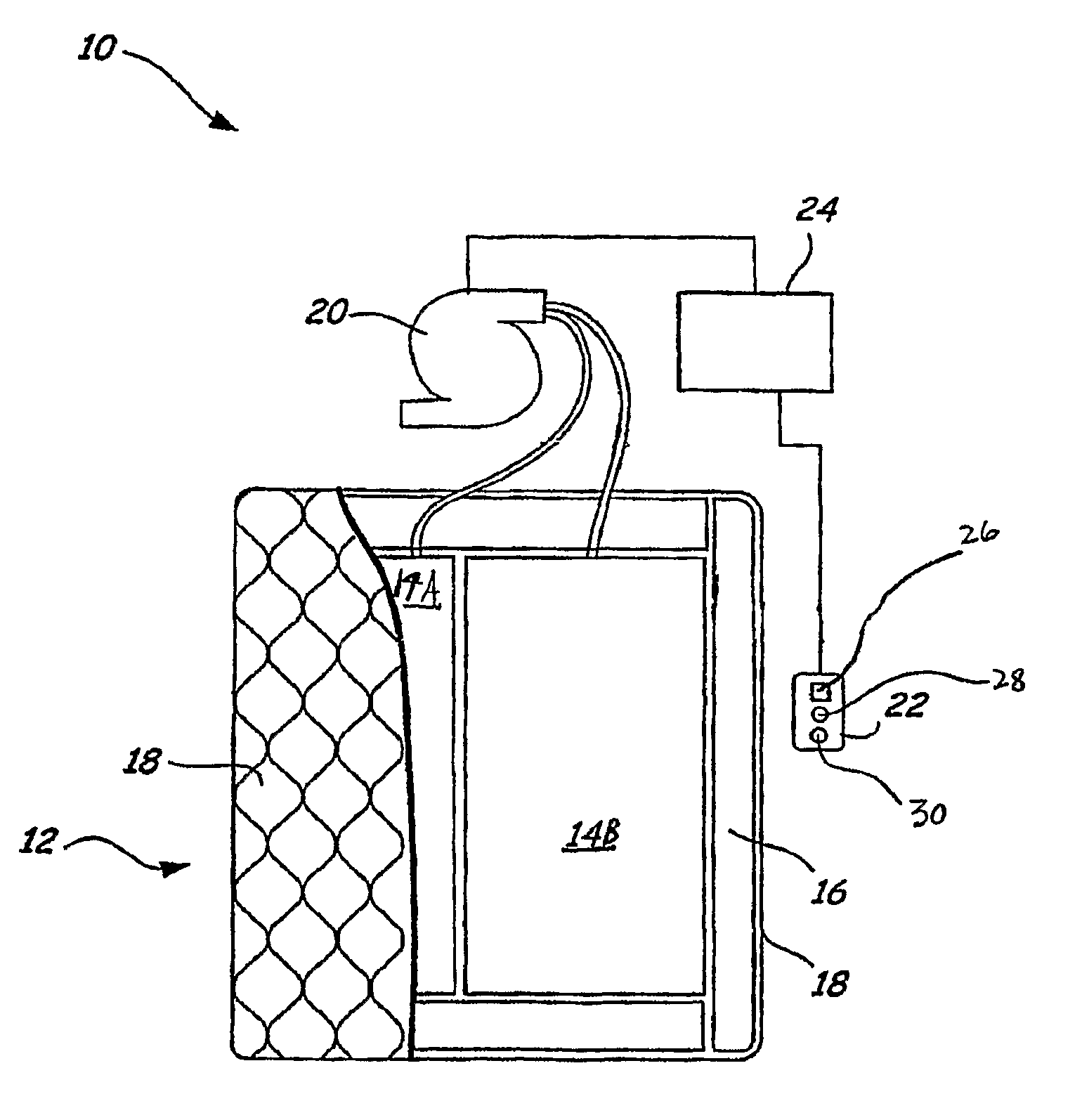

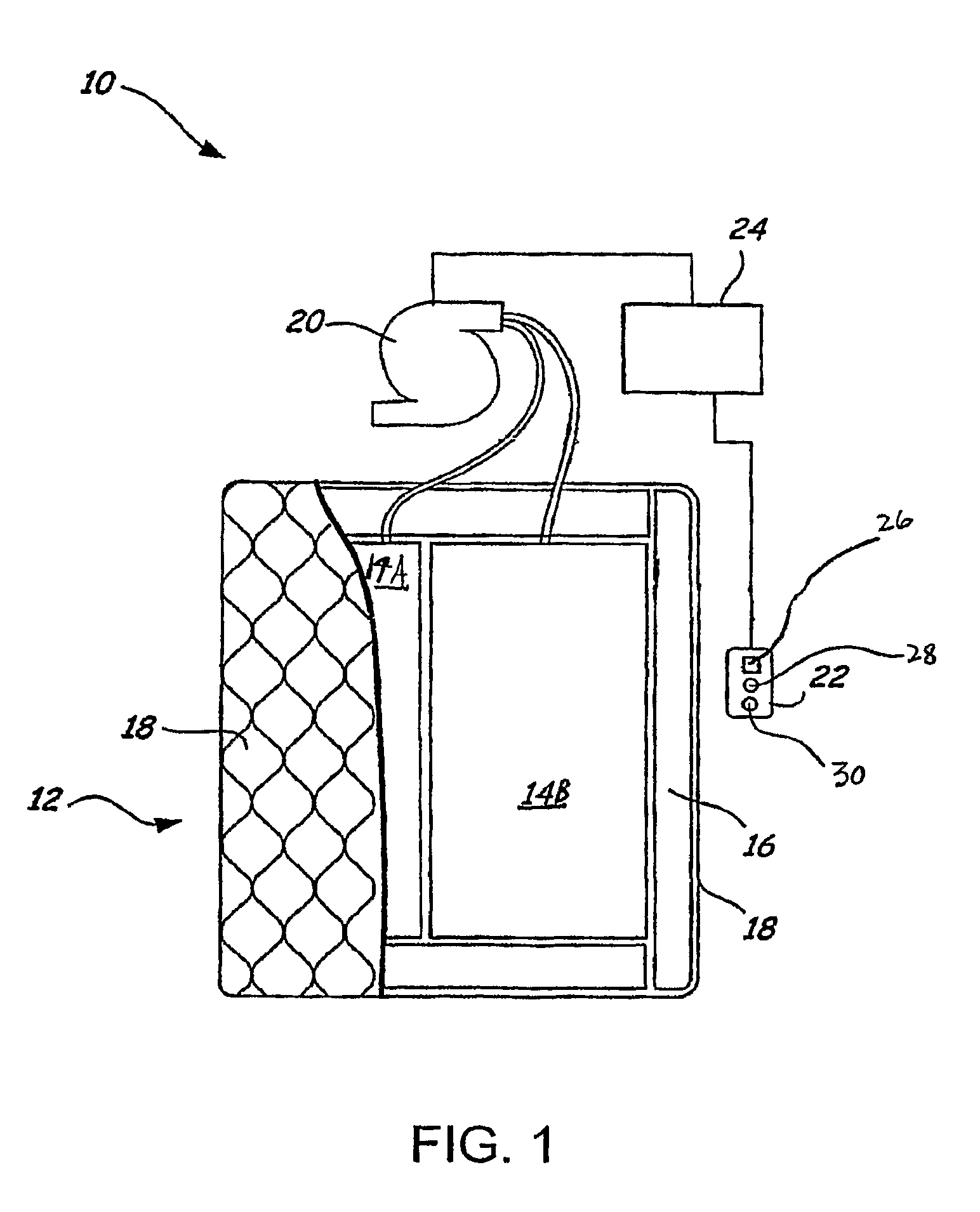

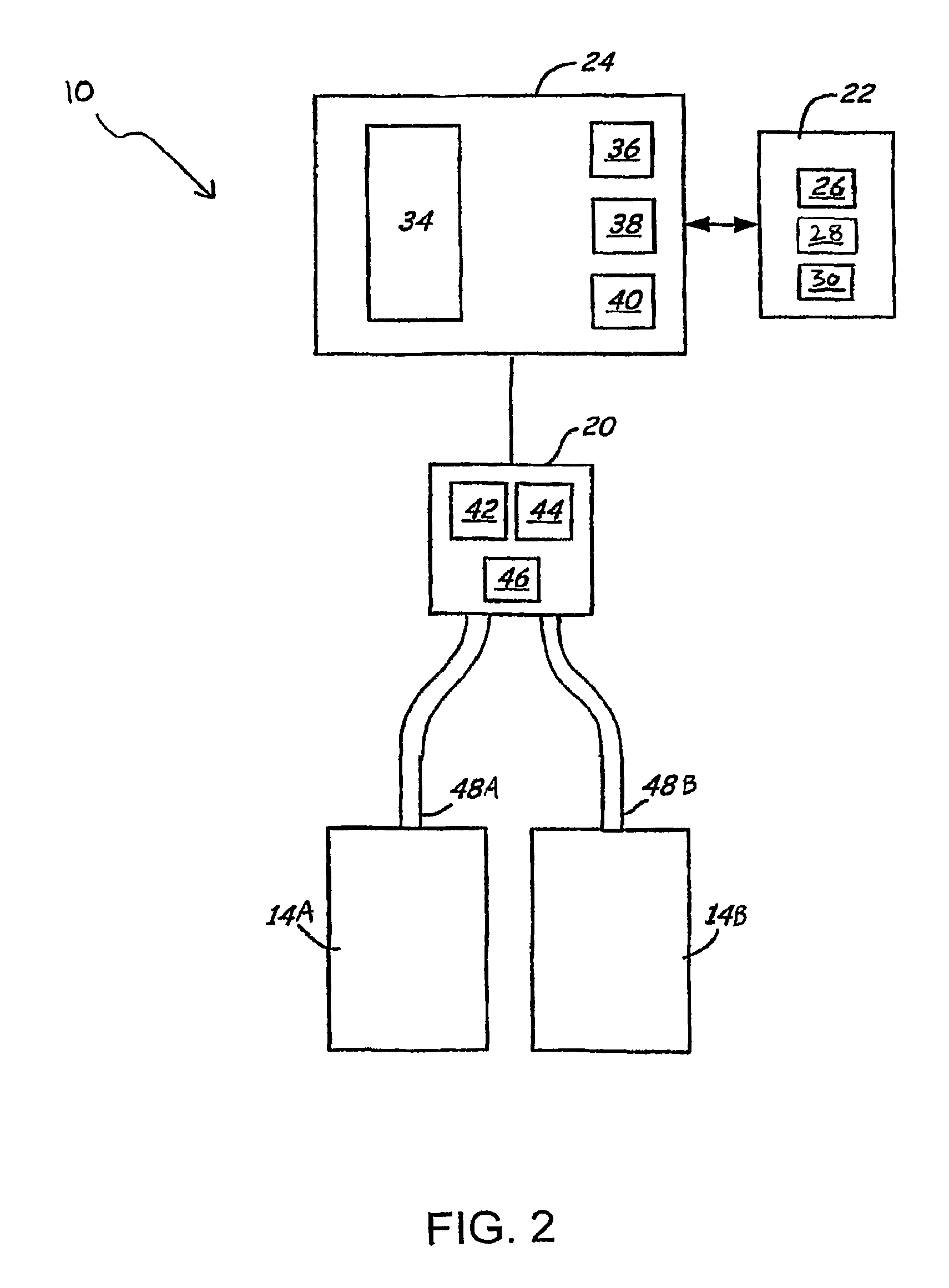

System and method for detecting a leak in an air bed

ActiveUS8336369B2Detection of fluid at leakage pointMeasurement of fluid loss/gain rateAtmospheric airEngineering

Owner:SLEEP NUMBER CORP

Gas separation by combined pressure swing and displacement purge

InactiveUS6902602B2Improve efficiencyAvoid pollutionGas treatmentIsotope separationSyngasAtmospheric air

Owner:AIR PROD & CHEM INC

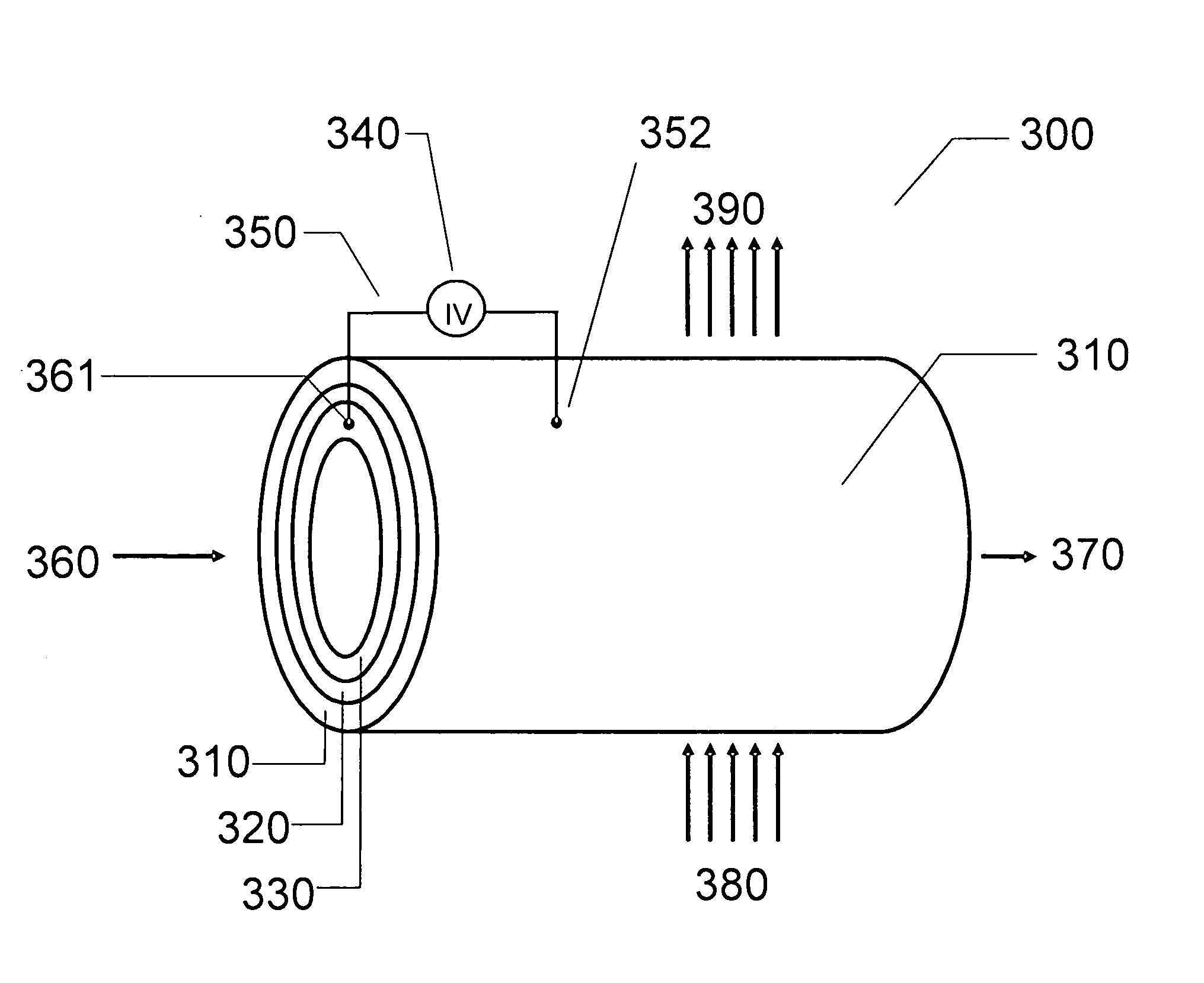

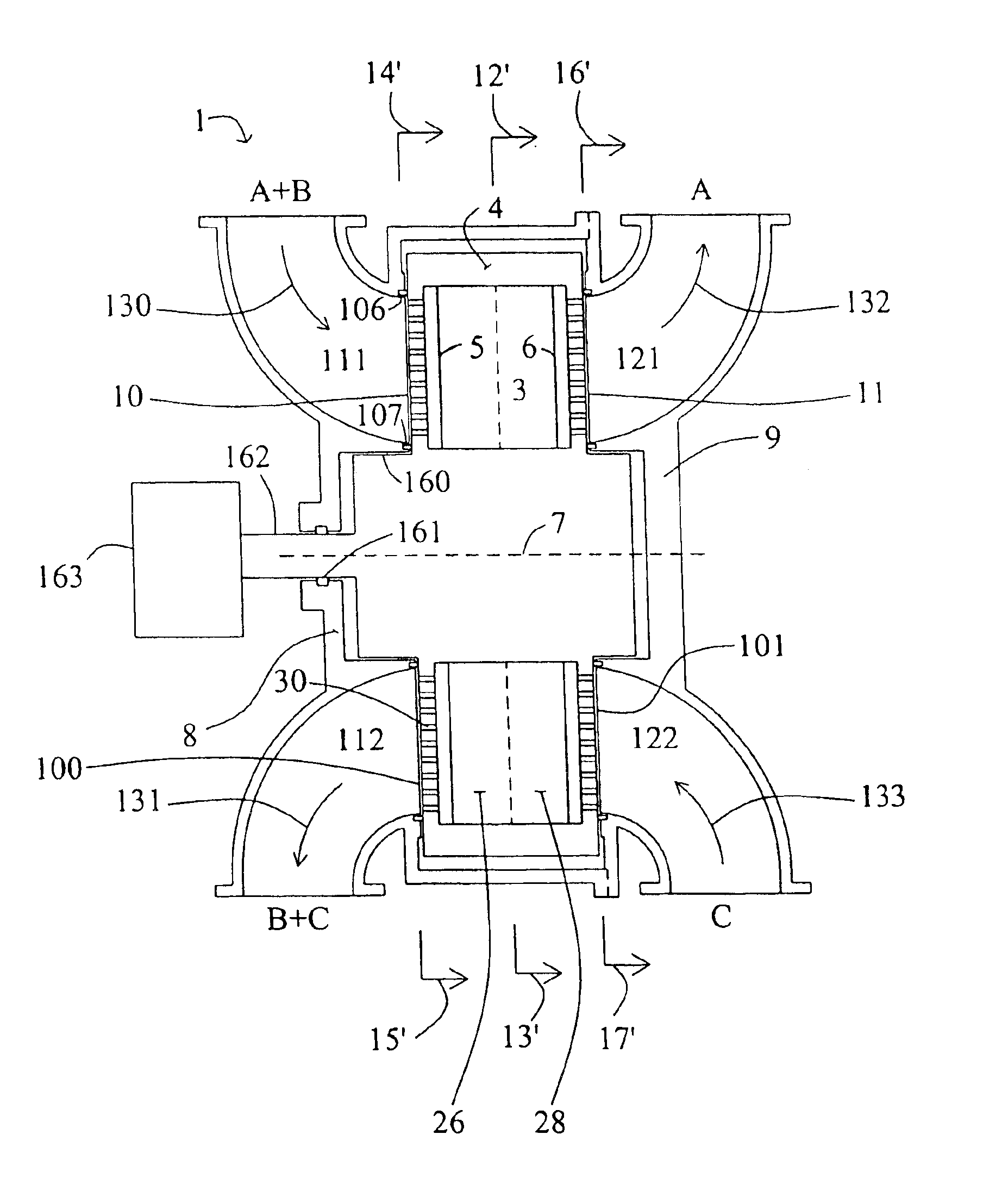

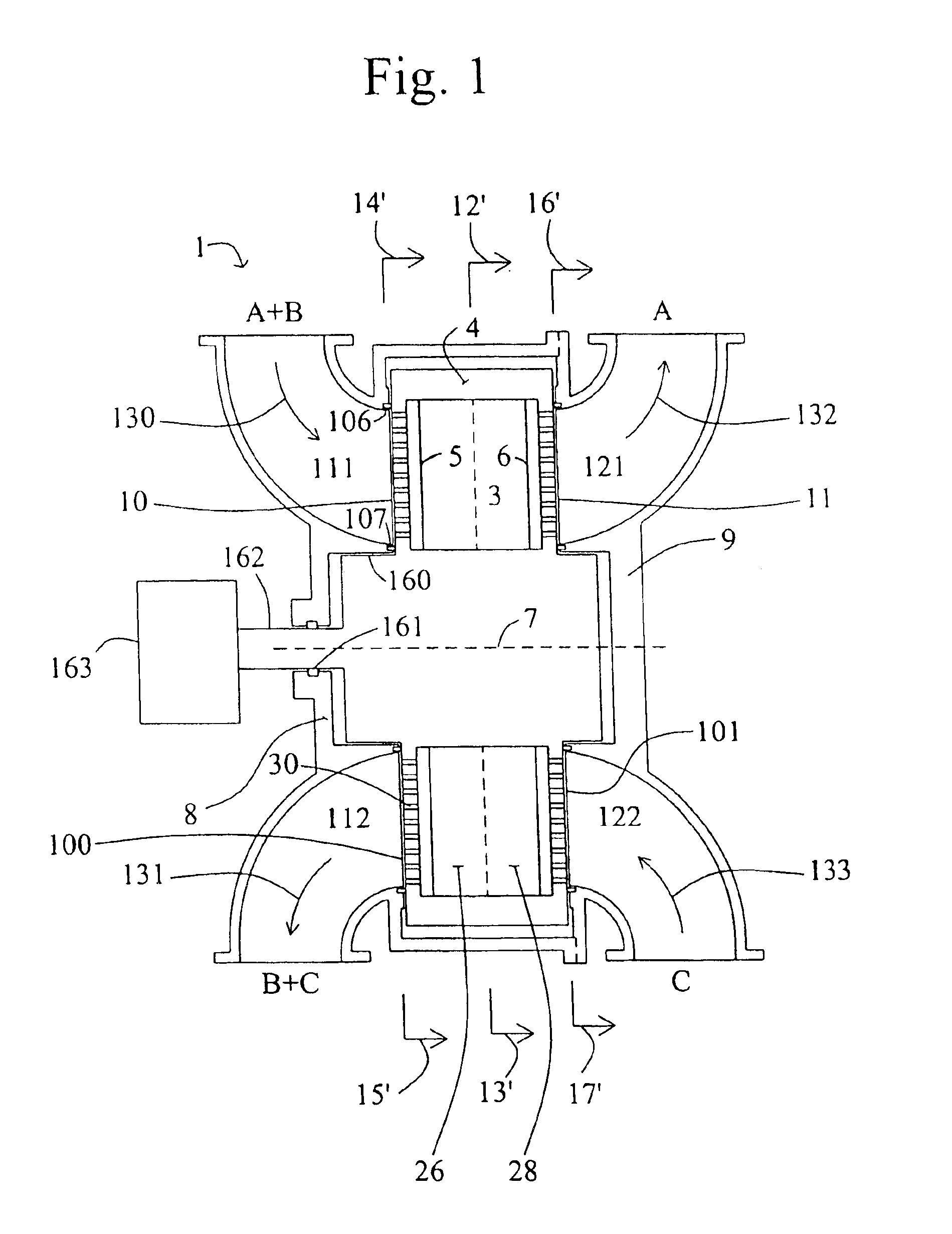

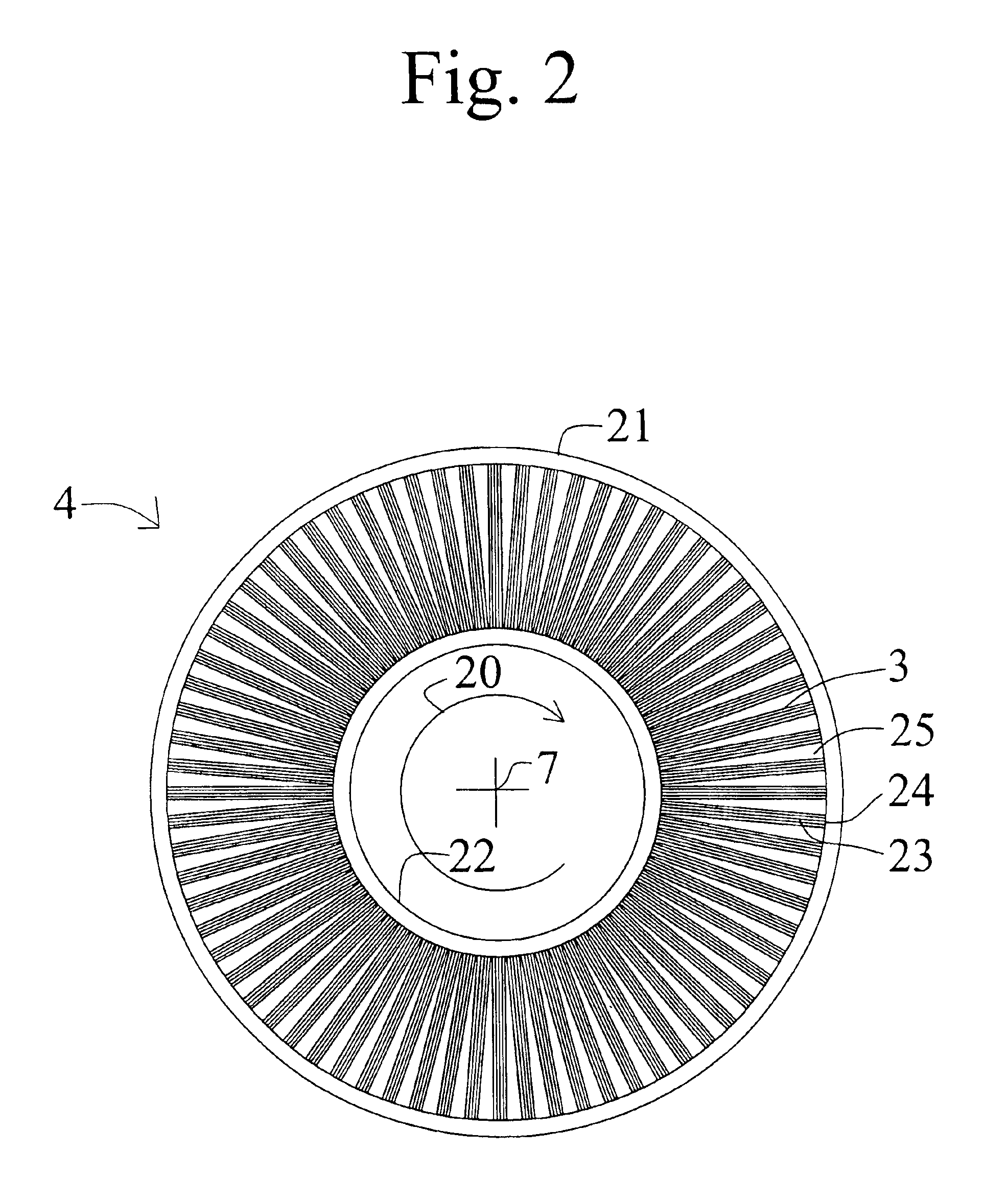

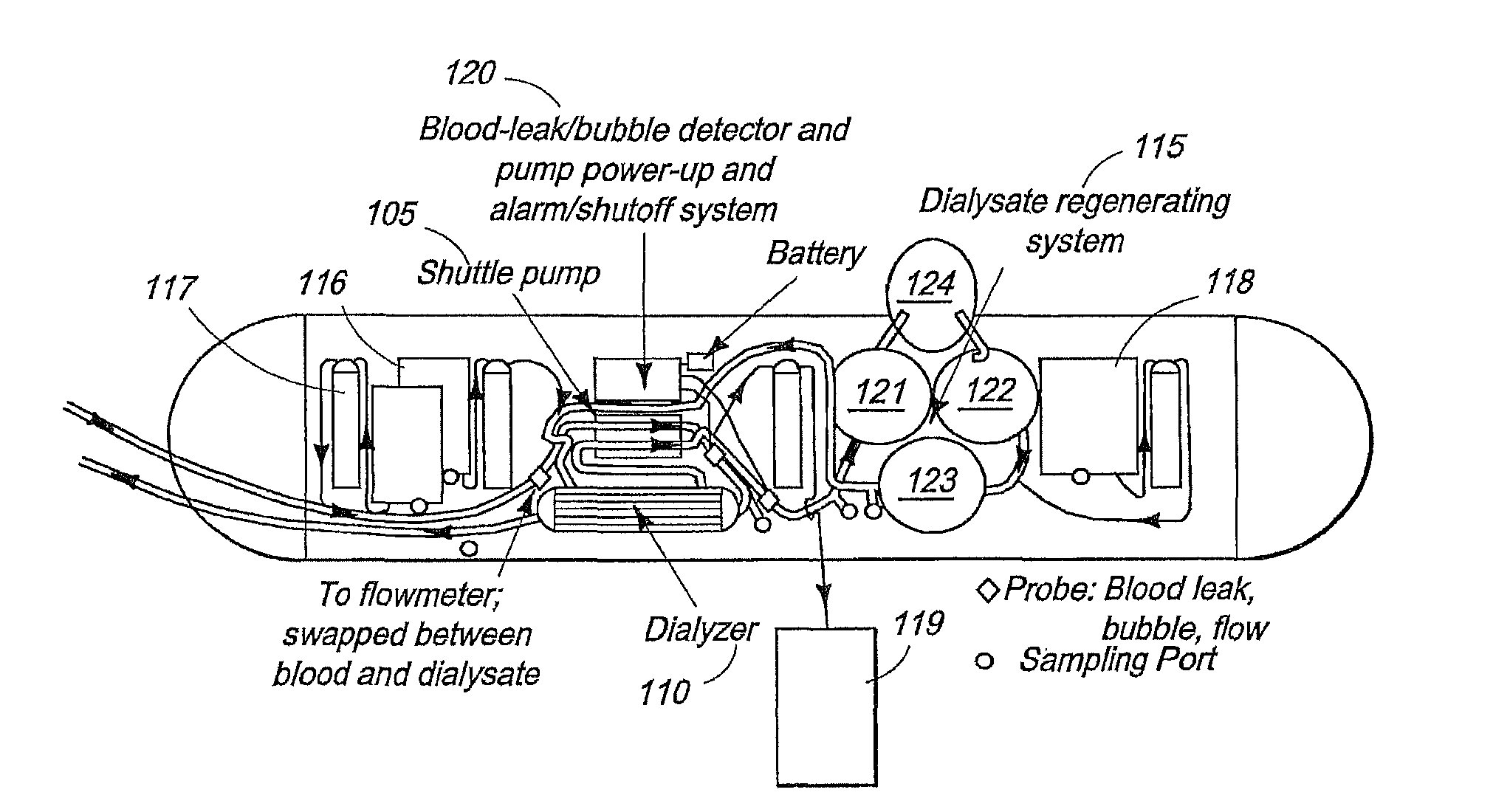

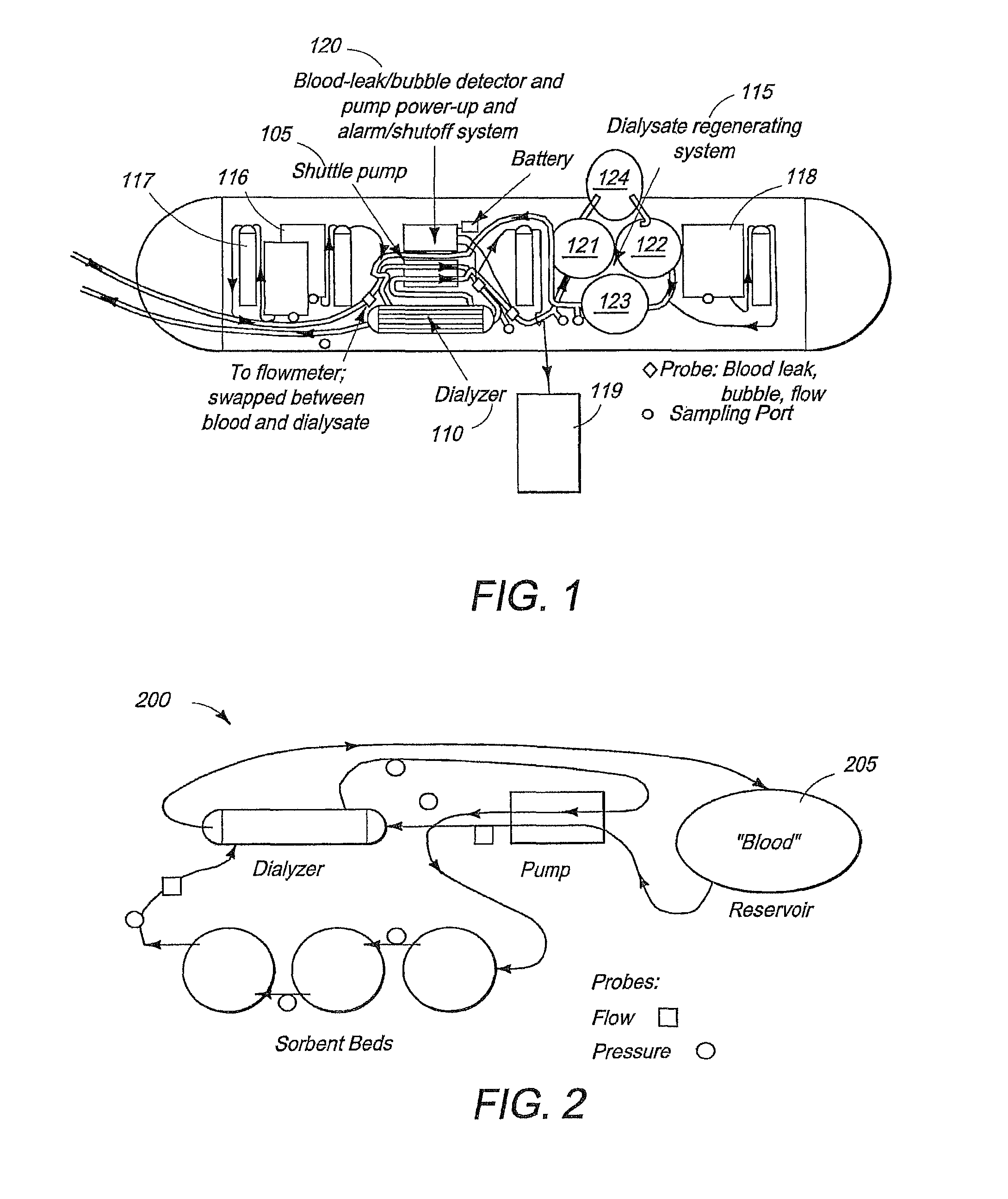

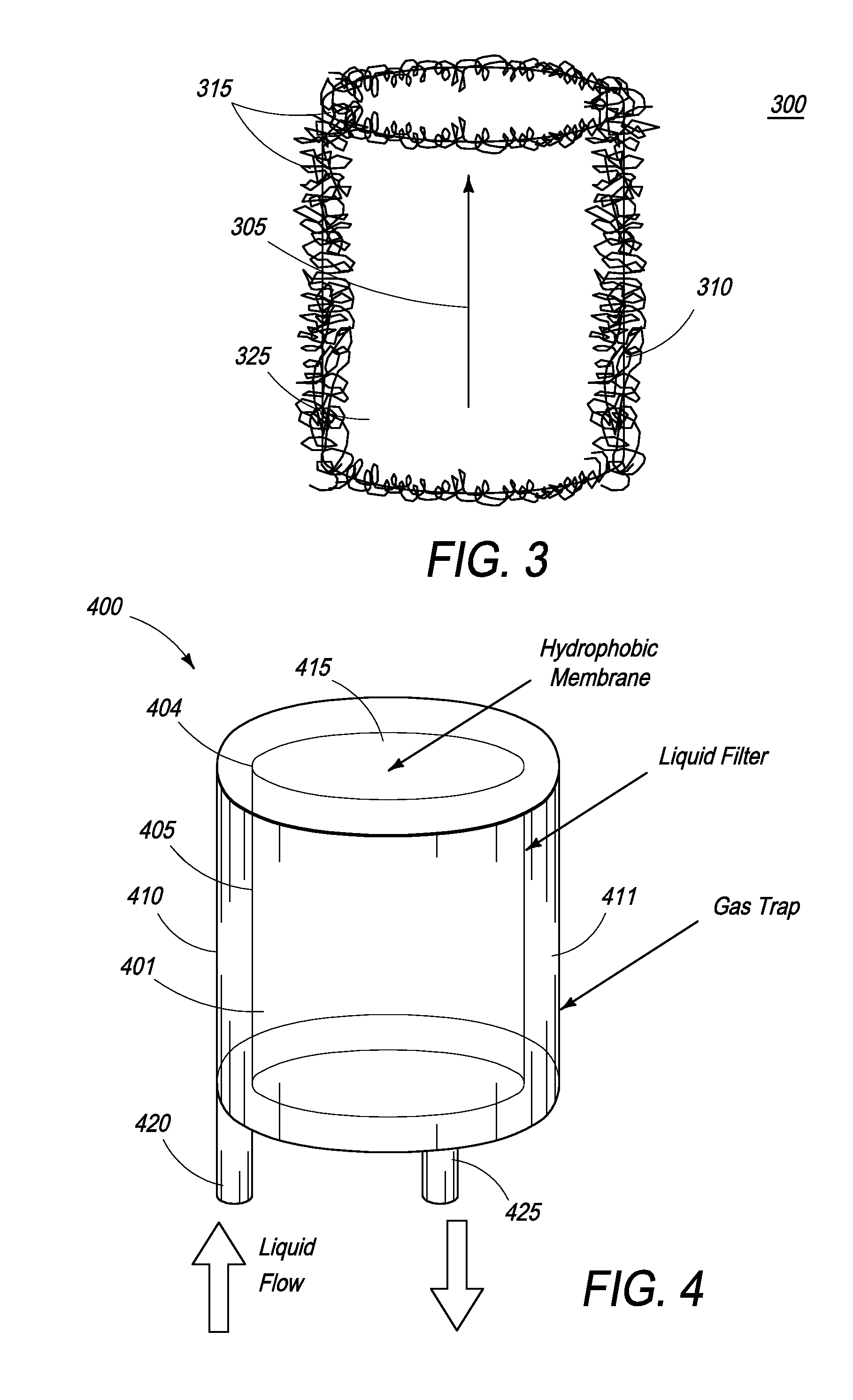

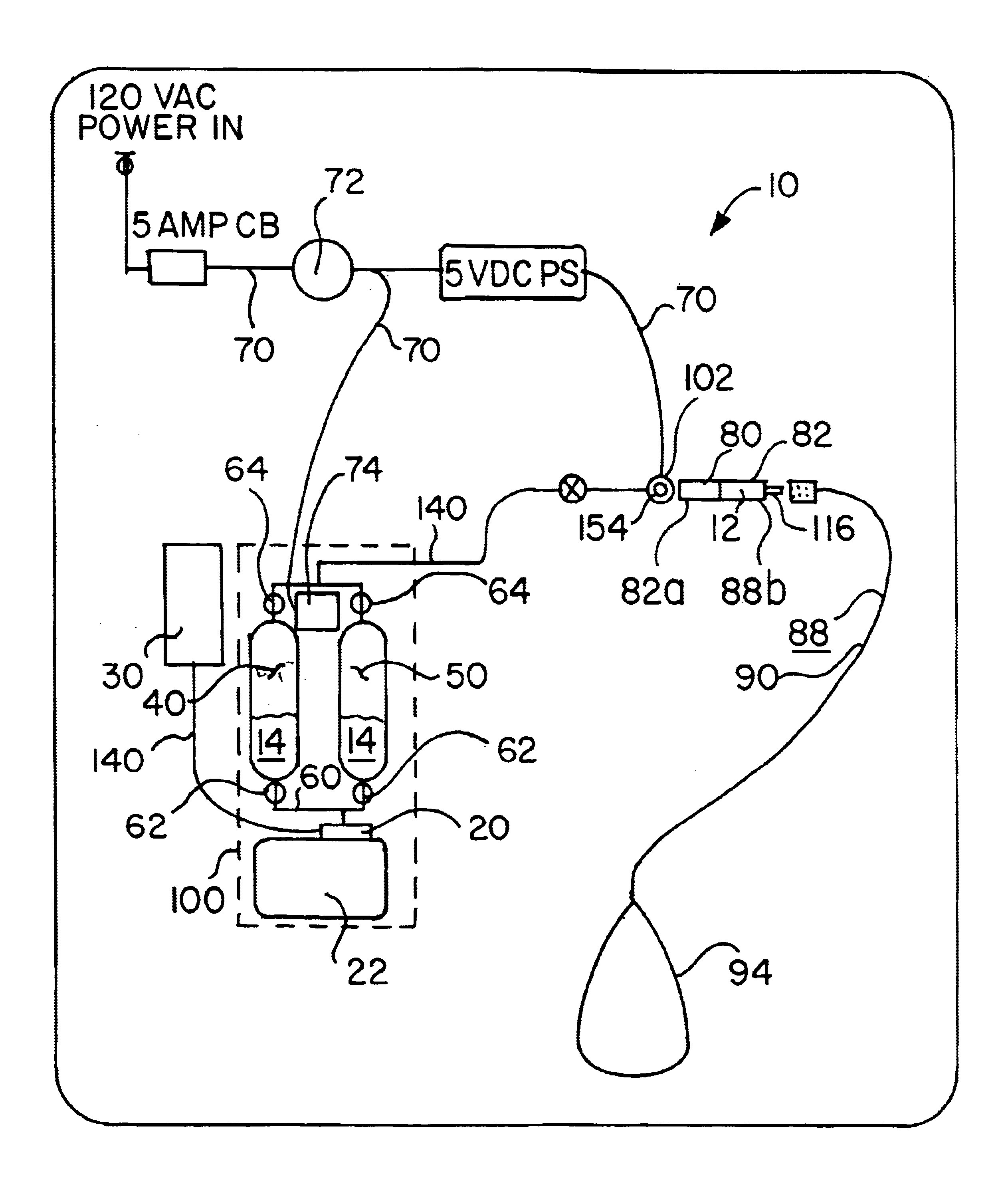

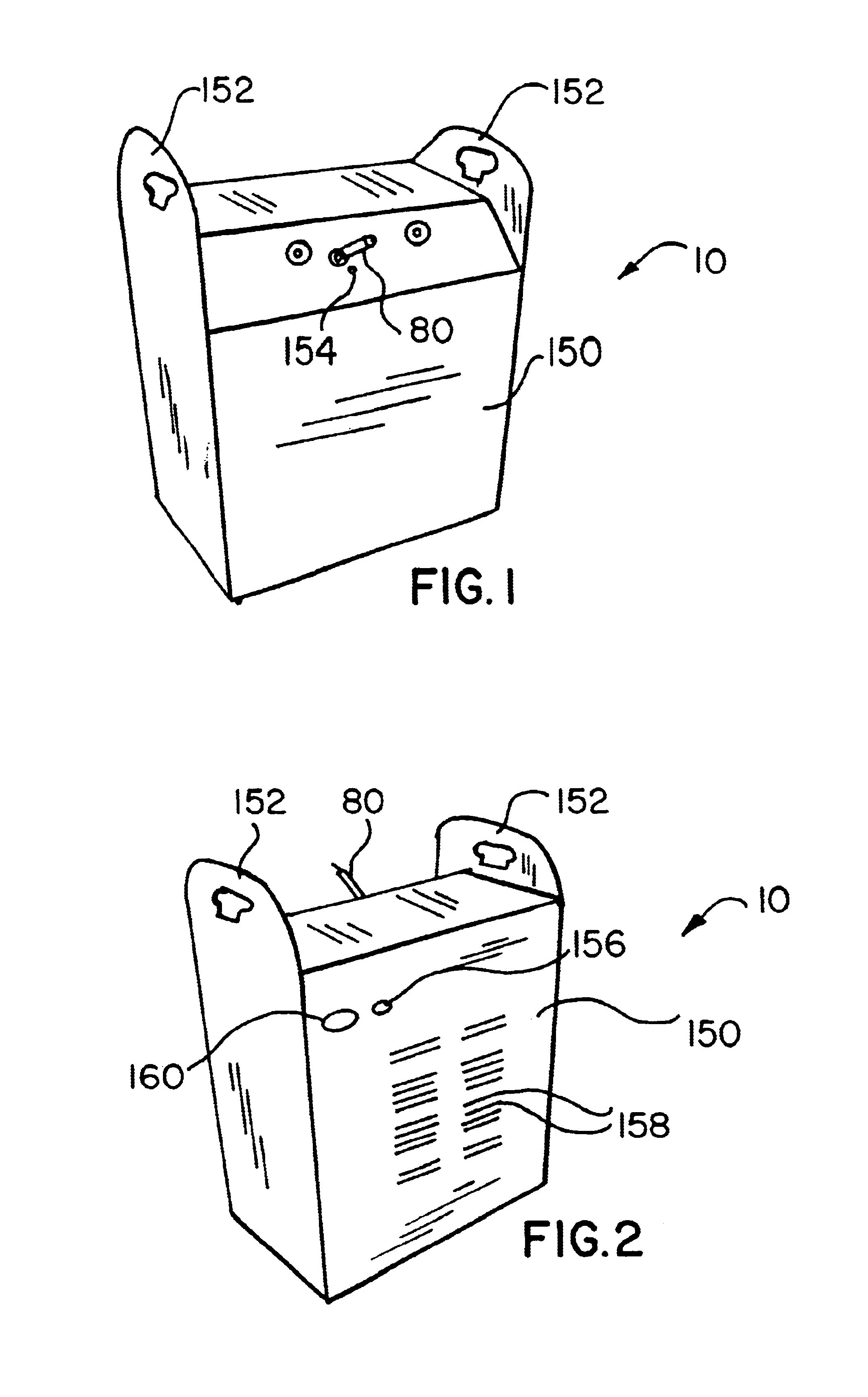

Carbon dioxide gas removal from a fluid circuit of a dialysis device

InactiveUS8034161B2Efficient removalSmall sizeSemi-permeable membranesSolvent extractionAtmospheric airProduct gas

The present invention is directed to degassing devices for dialysate circuits. One embodiment has a first housing and a second housing positioned within the first housing in an annular relationship. A second embodiment comprises a dialysate regeneration system with urease, a dialyzer, and a housing with an external wall, where the external wall is exposed to atmosphere and comprises a material that passes gas but does not pass liquid and where the housing is positioned between the urease and dialyzer.

Owner:FRESENIUS MEDICAL CARE HLDG INC

Oxygen concentrating aroma mixing breathable air delivery apparatus and method

InactiveUS6866041B2Operating means/releasing devices for valvesOther heat production devicesAtmospheric airAir compressor

An apparatus for concentrating the oxygen content of and injecting aroma into a stream of air and delivering the stream of air to the nostrils of a person includes an air intake filter in fluid communication with the air compressor for drawing a stream of air out of the surrounding atmosphere; a sieve bed in fluid communication with the air intake means, each sieve bed containing a quantity of nitrogen absorption material and having sieve bed input and output valve mechanism; so that the sieve bed extracts nitrogen from the air stream so that the proportion of oxygen exiting the sieve bed is elevated, and as the input valve mechanism closes, the sieve bed output valve mechanism opens and vents absorbed nitrogen from the sieve bed to the atmosphere; an aroma chamber containing aroma releasing material in fluid communication with the output valve mechanism.

Owner:EVOLUTION

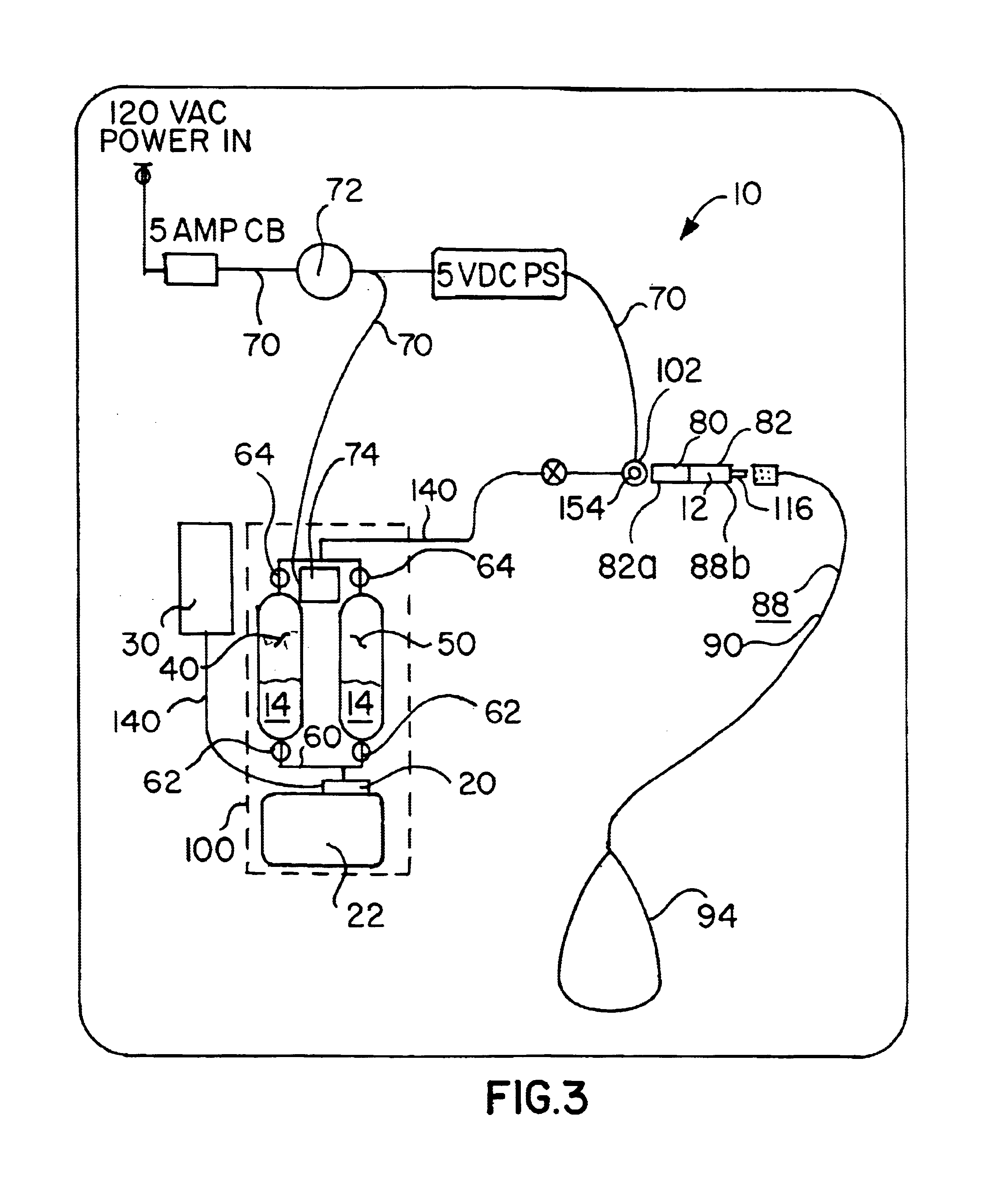

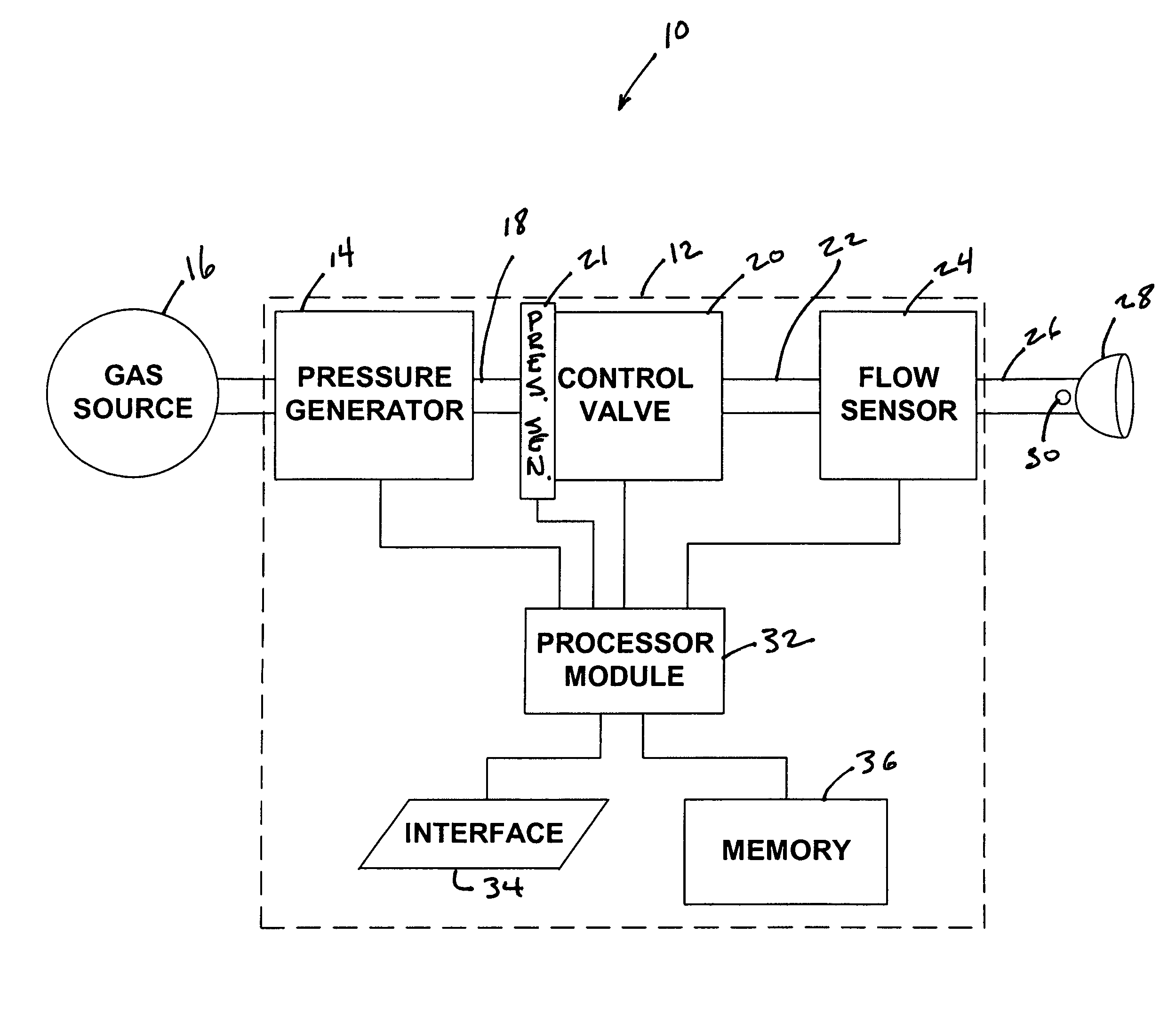

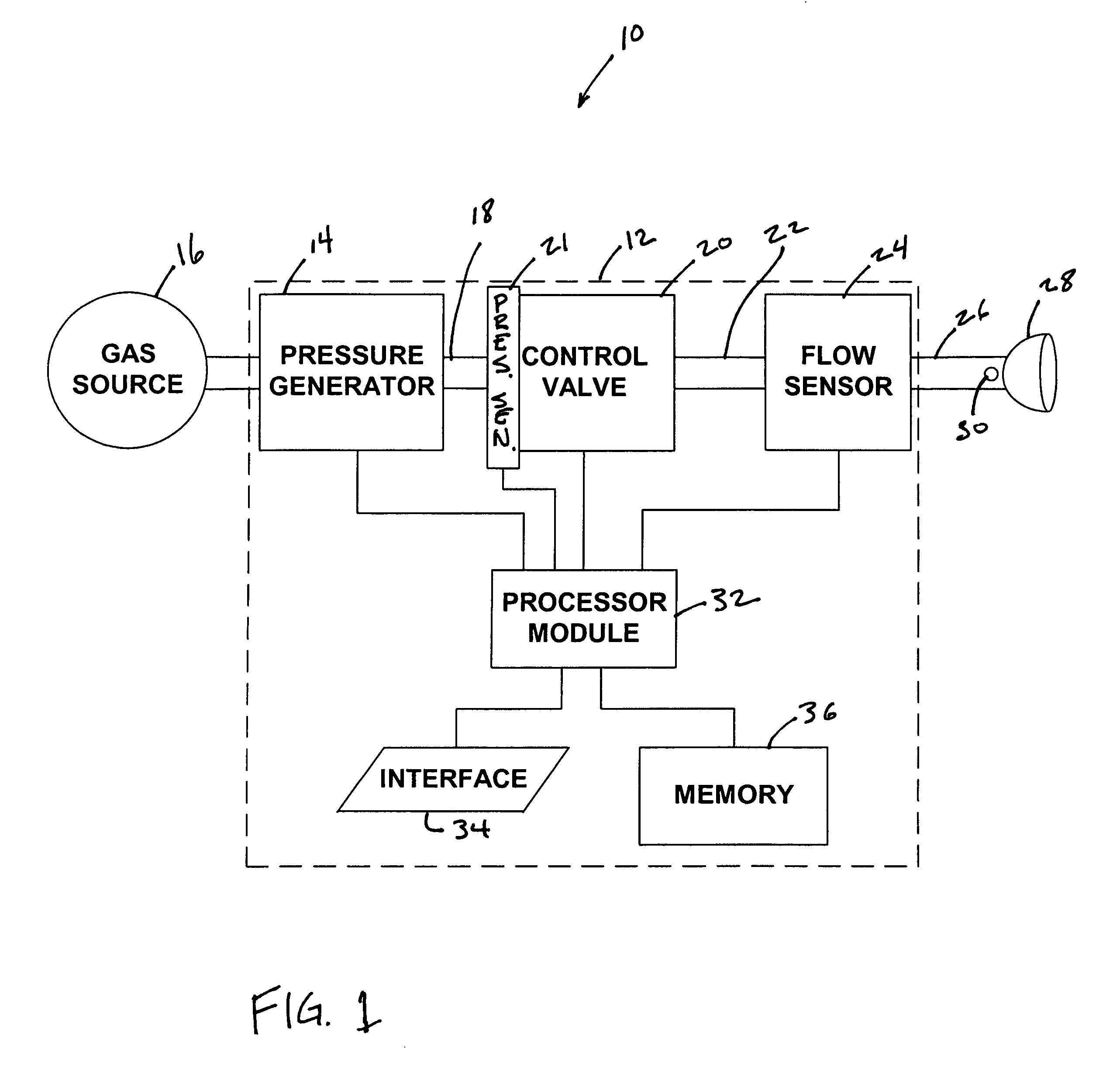

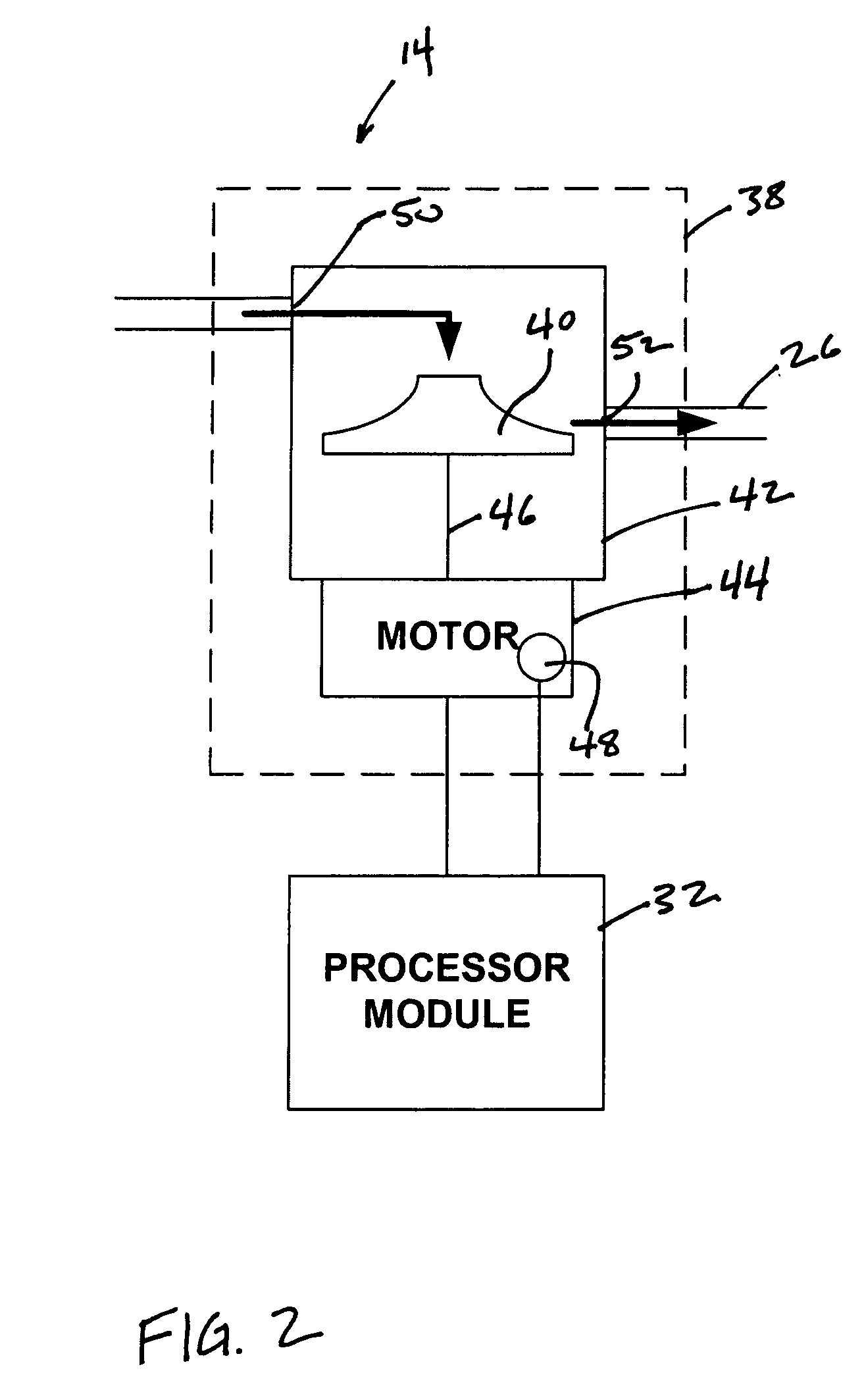

Respiratory device measurement system

ActiveUS20060283450A1RespiratorsOperating means/releasing devices for valvesAtmospheric airBreathing gas

A gas delivery system comprising a pressure generator, a pressure sensor, a control valve, and a processor. The pressure generator pressurizes breathable gas for delivery to a patient. The pressure sensor measures a pressure difference between the pressurized breathable gas and atmospheric pressure. The control valve is disposed downstream from the pressure generator and is constructed and arranged to control a flow rate of the pressurized breathable gas. The processor controls the control valve to bring the flow rate of the pressurized breathable gas to substantially zero while the pressure generator is operating and, when the flow rate is substantially zero, determines at least one of atmospheric pressure, an atmospheric air density, or a density correction factor based at least in part on the pressure difference between the pressurized breathable gas and the atmospheric pressure.

Owner:PHILIPS RS NORTH AMERICA LLC

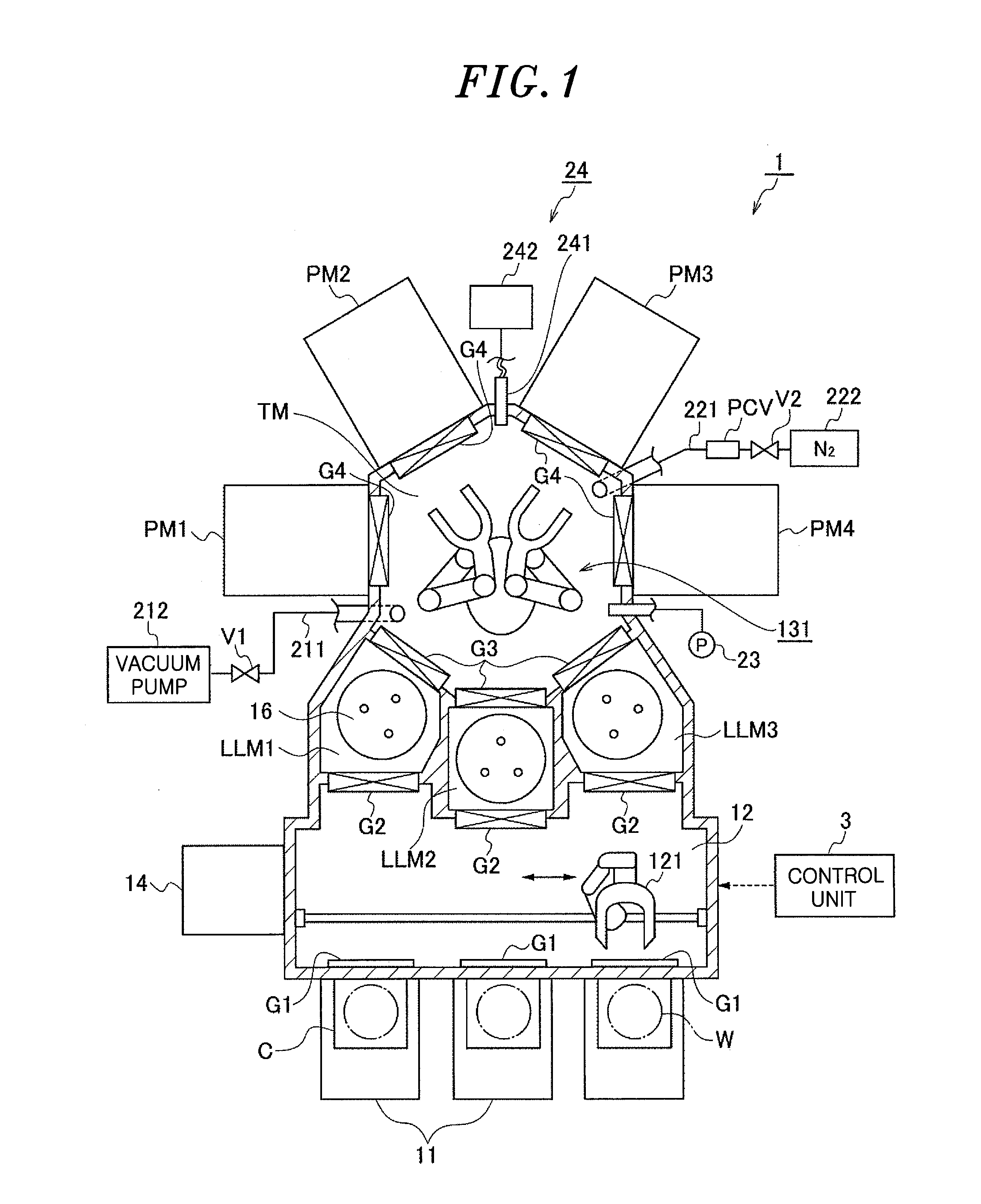

Substrate processing apparatus

A semiconductor workpiece processing apparatus having a first chamber, a transport vehicle, and another chamber. The first chamber is capable of being isolated from an outside atmosphere. The transport vehicle is located in the first chamber and is movably supported from the first chamber for moving linearly relative to the first chamber. The transport vehicle includes a base, and an integral semiconductor workpiece transfer arm movably mounted to the base and capable of multi-access movement relative to the base. The other chamber is communicably connected to the first chamber via a closable opening of the first chamber. The opening is sized to allow the transport vehicle to transit between the first chamber and the other chamber through the opening.

Owner:BOOKS AUTOMATION US LLC

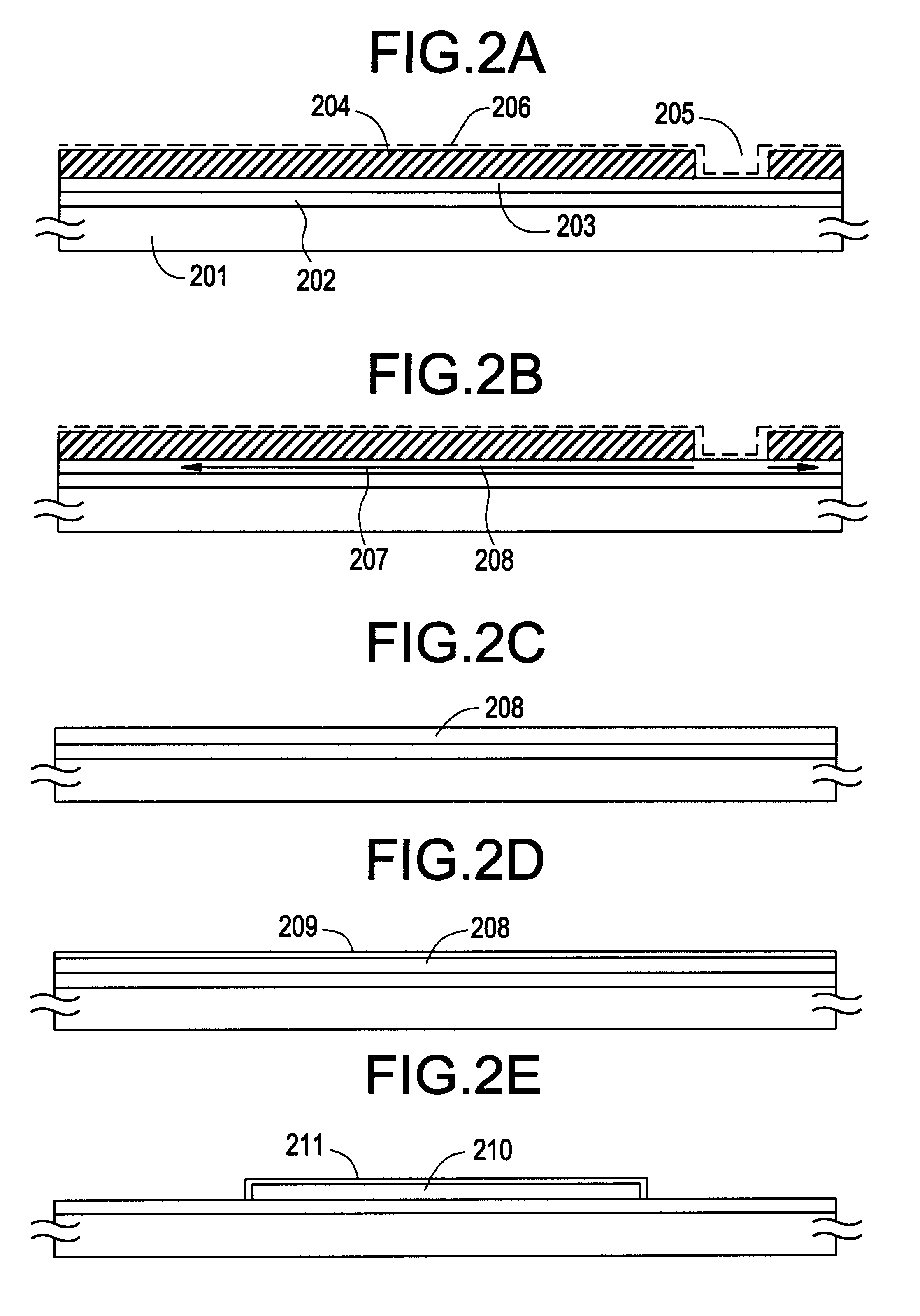

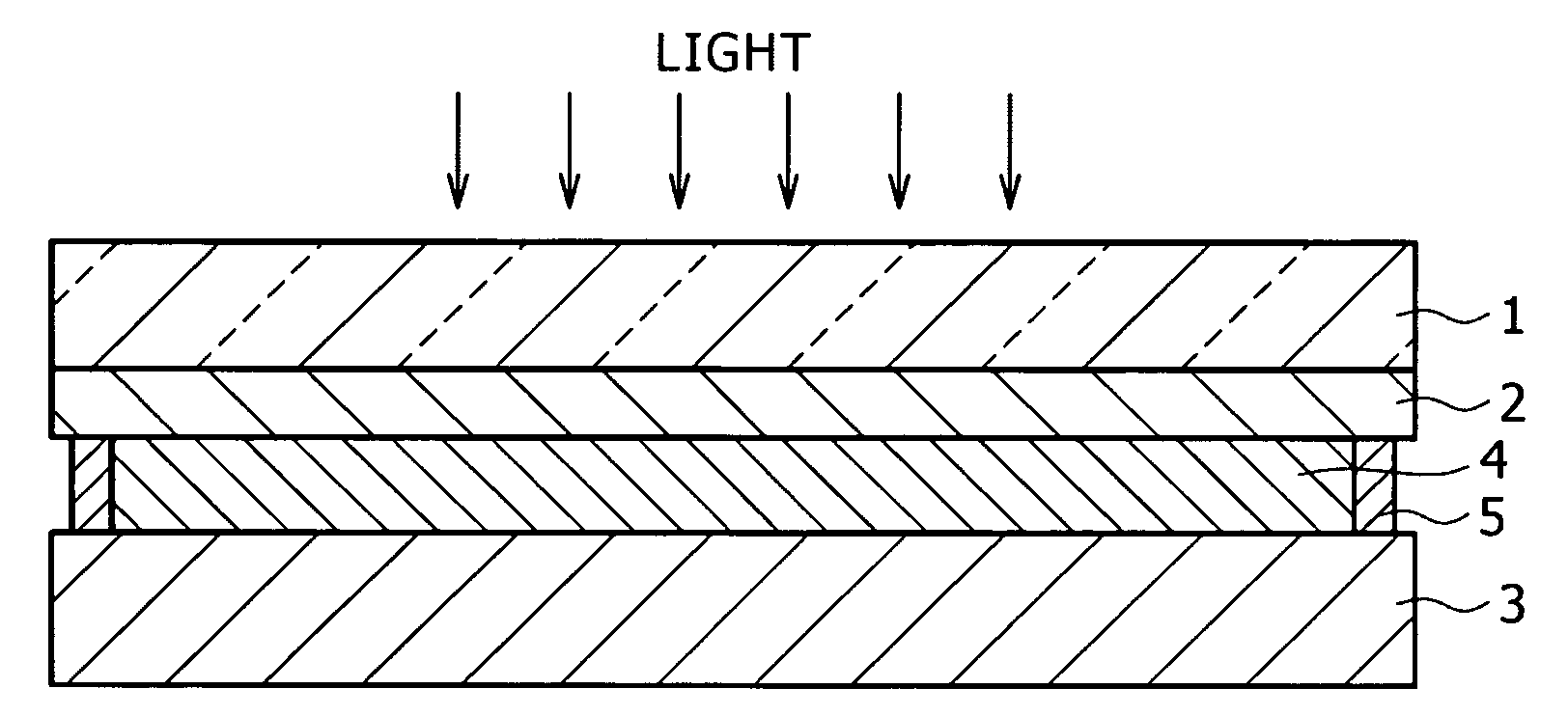

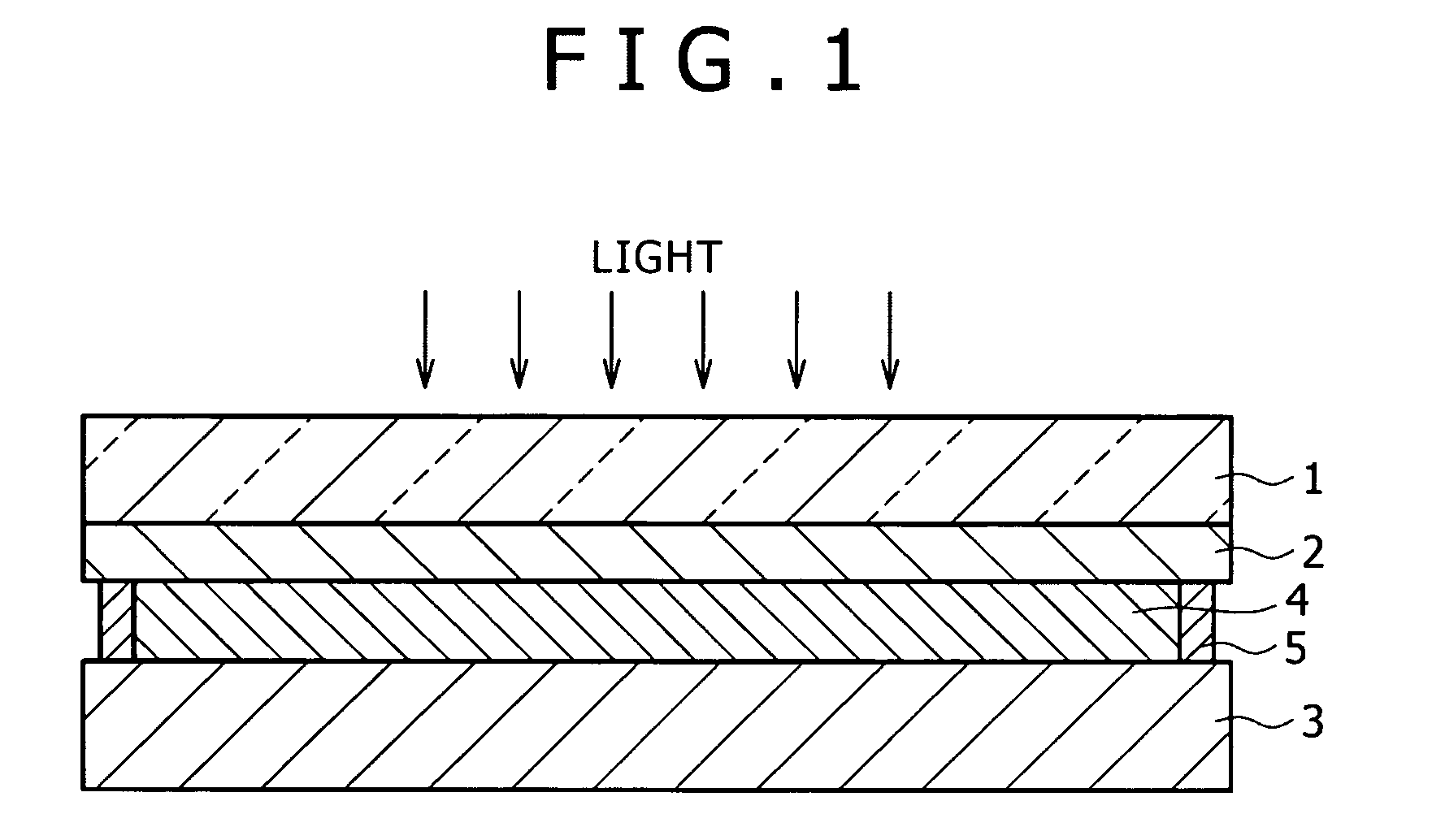

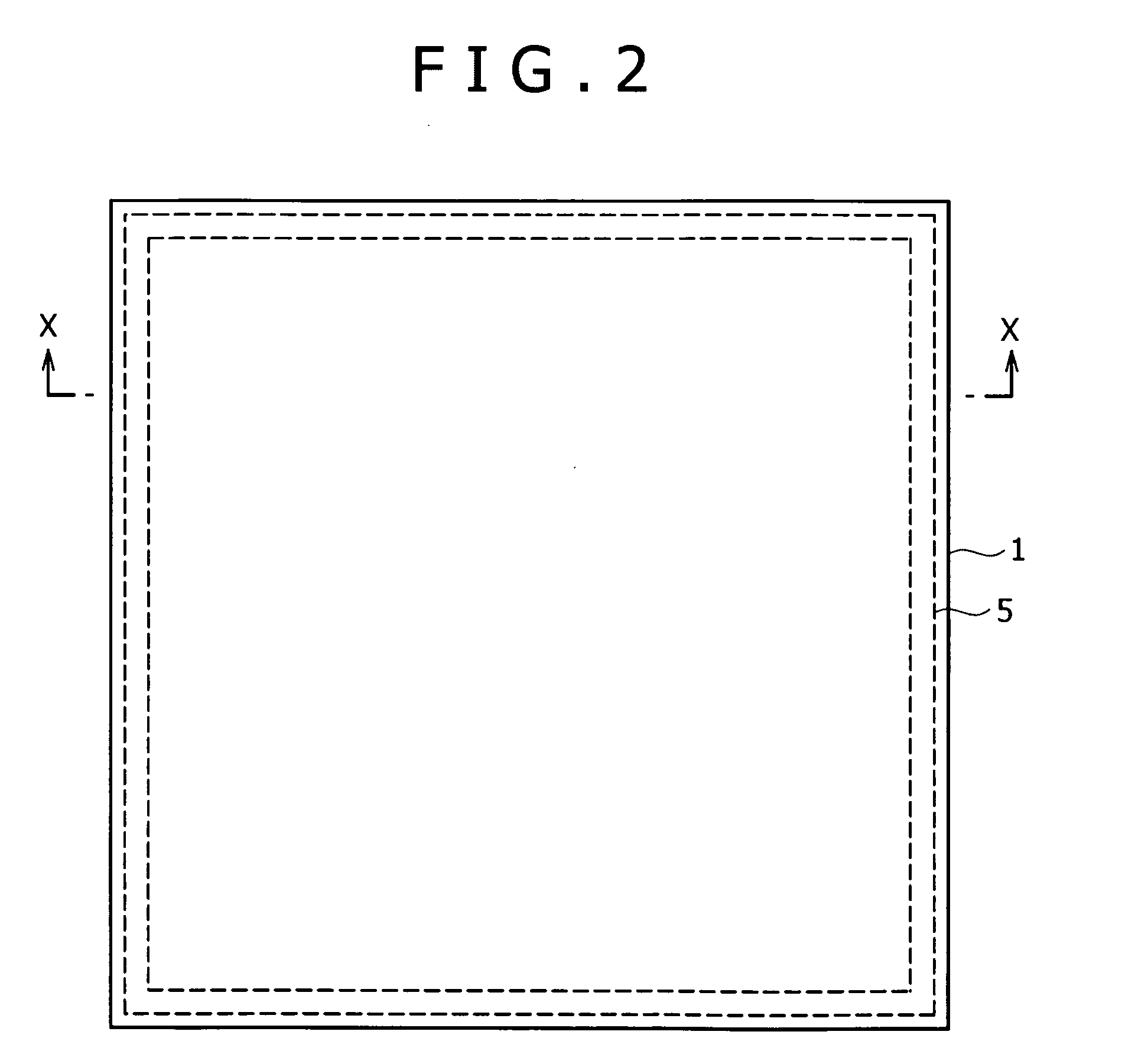

Dye-sensitized photoelectric conversion device and method of manufacturing the same

InactiveUS20100101648A1Reduced durabilityReduced strengthElectrolytic capacitorsFinal product manufactureAtmospheric airPhotoelectric conversion

A method of manufacturing a dye-sensitized photoelectric conversion device is provided by which a dye-sensitized photoelectric conversion device being excellent in strength and durability and free of any projection, as a result of the absence of need for an end seal, can be fabricated through simple manufacturing steps. In manufacturing a dye-sensitized photoelectric conversion device which has an electrolyte between a dye-sensitized semiconductor layer and a counter electrode and which also has a first armor member provided on the outside of the dye-sensitized semiconductor layer and a second armor member provided on the outside of the counter electrode, a sealing material and the electrolyte are formed at predetermined locations of one or both of the first armor member and the second armor member, thereafter the first armor member and the second armor member, with the sealing material and the electrolyte sandwiched therebetween, are adhered to each other with the sealing material under a gas pressure of not higher than the atmospheric air pressure and not lower than the vapor pressure of the electrolyte.

Owner:SONY CORP

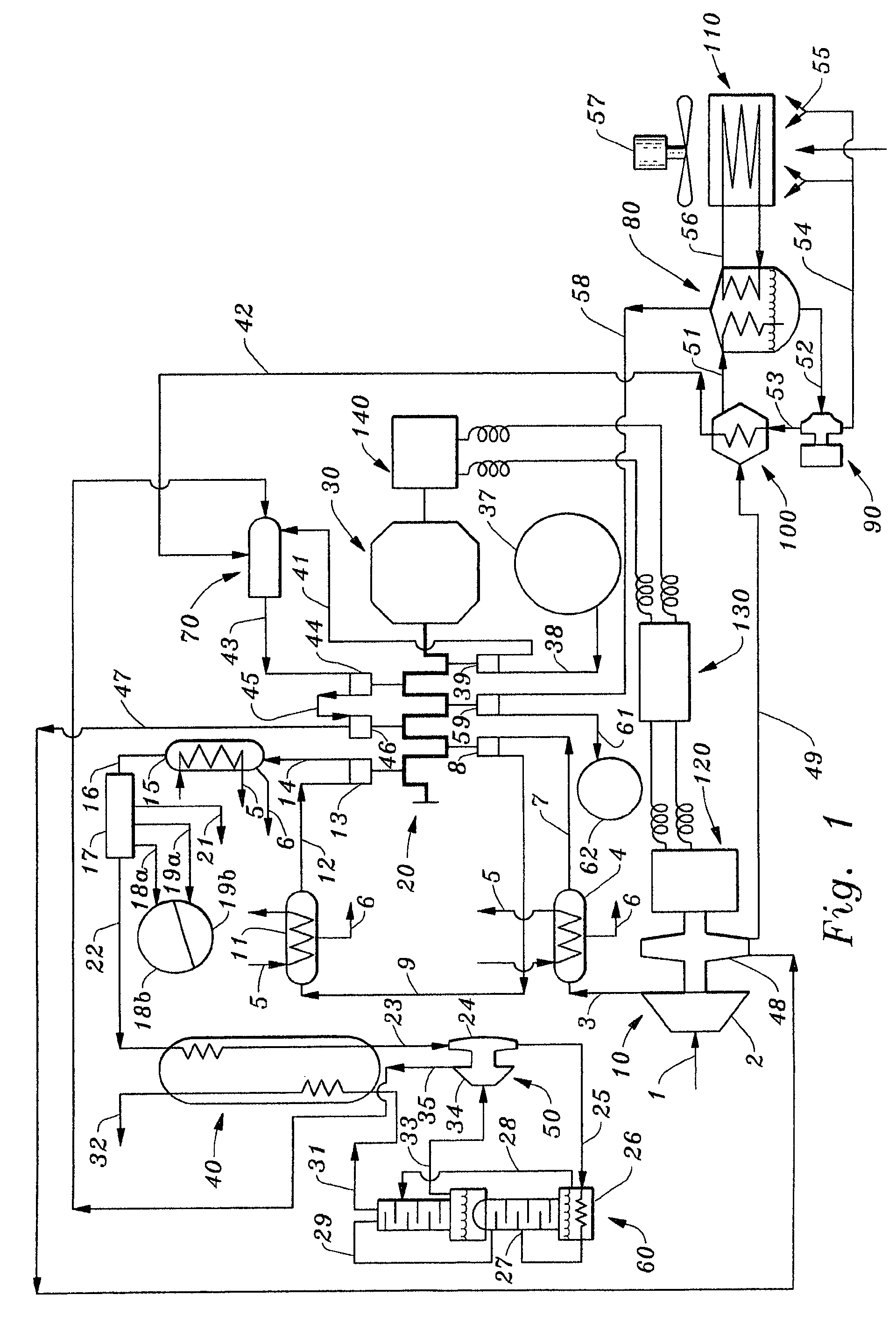

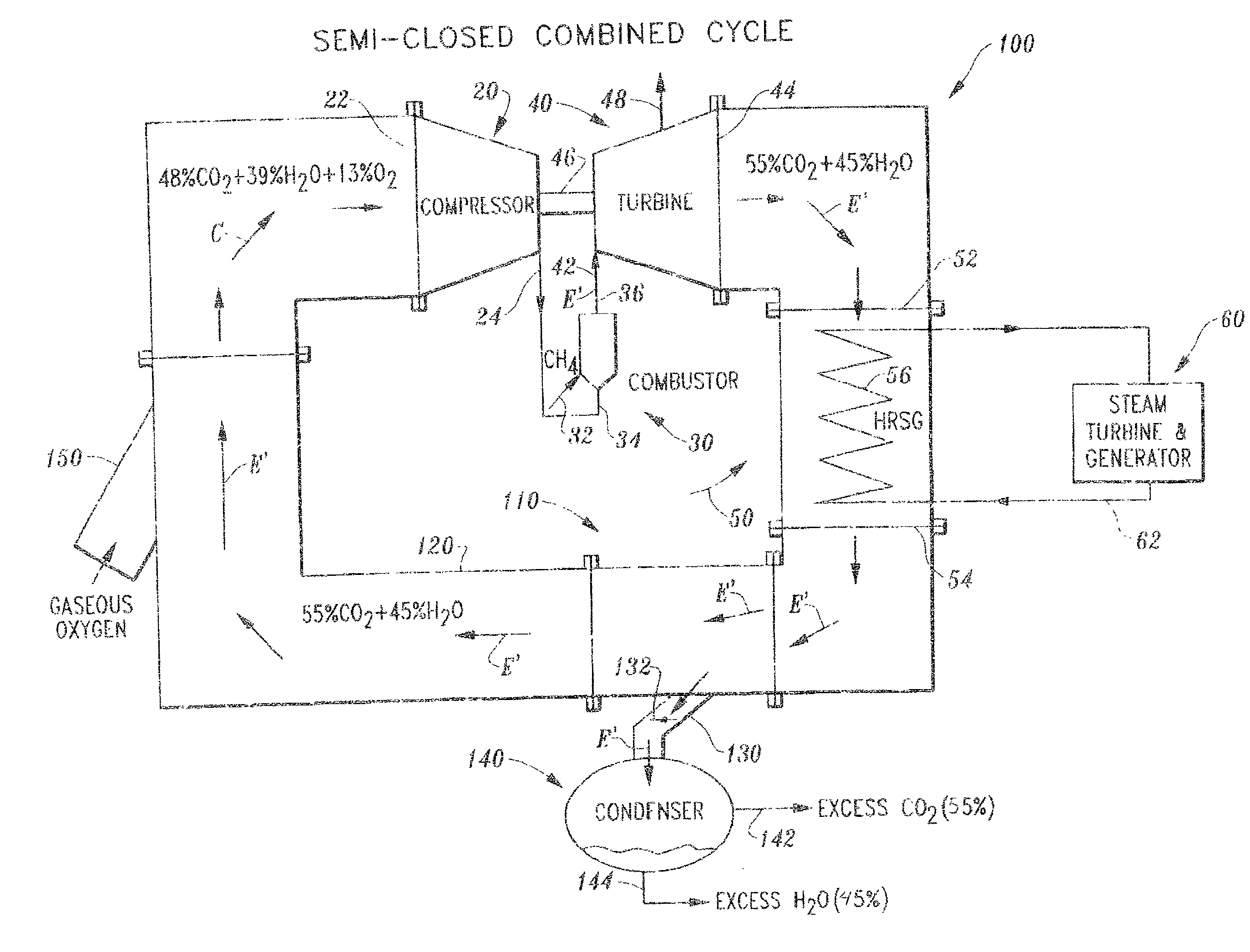

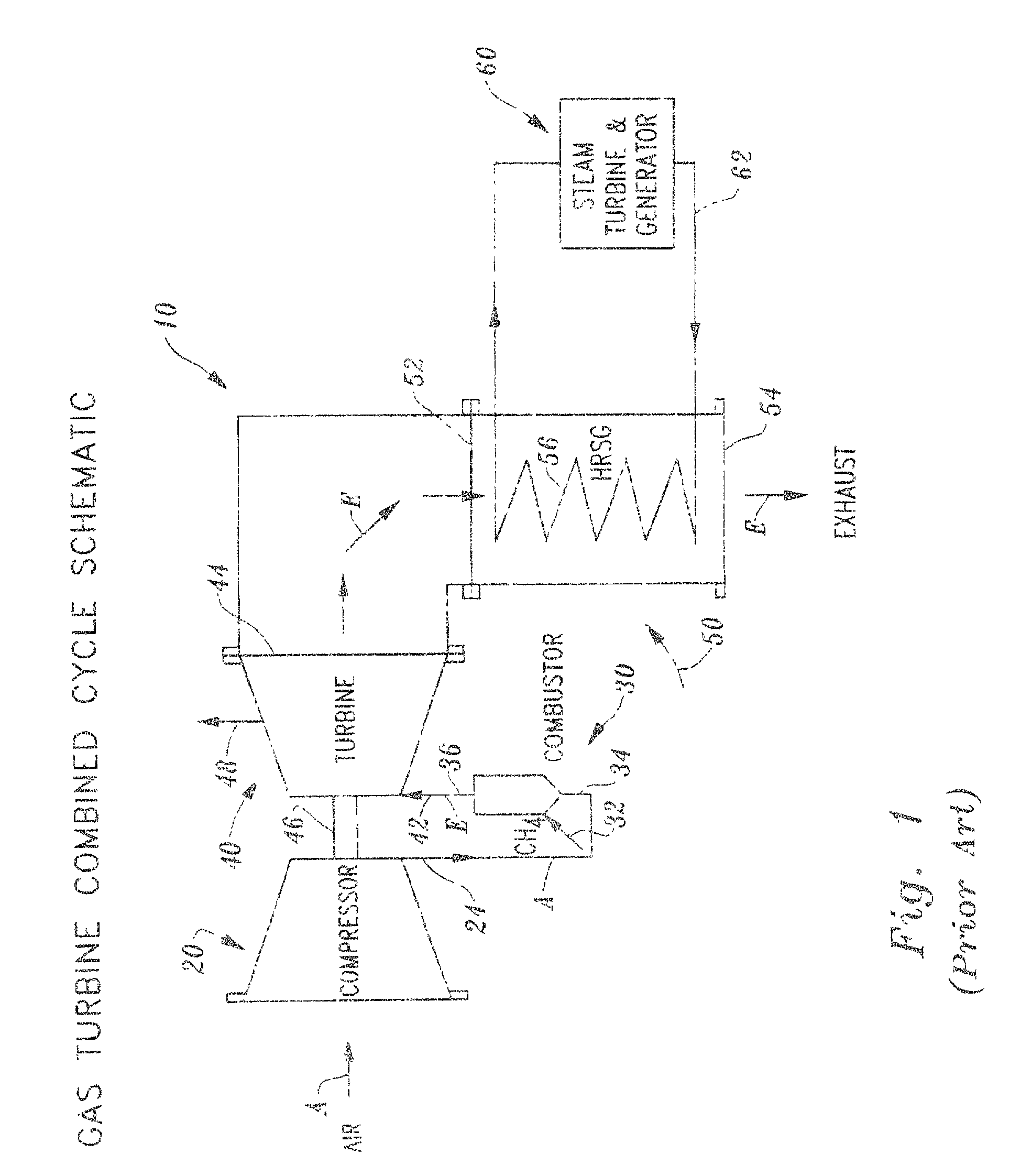

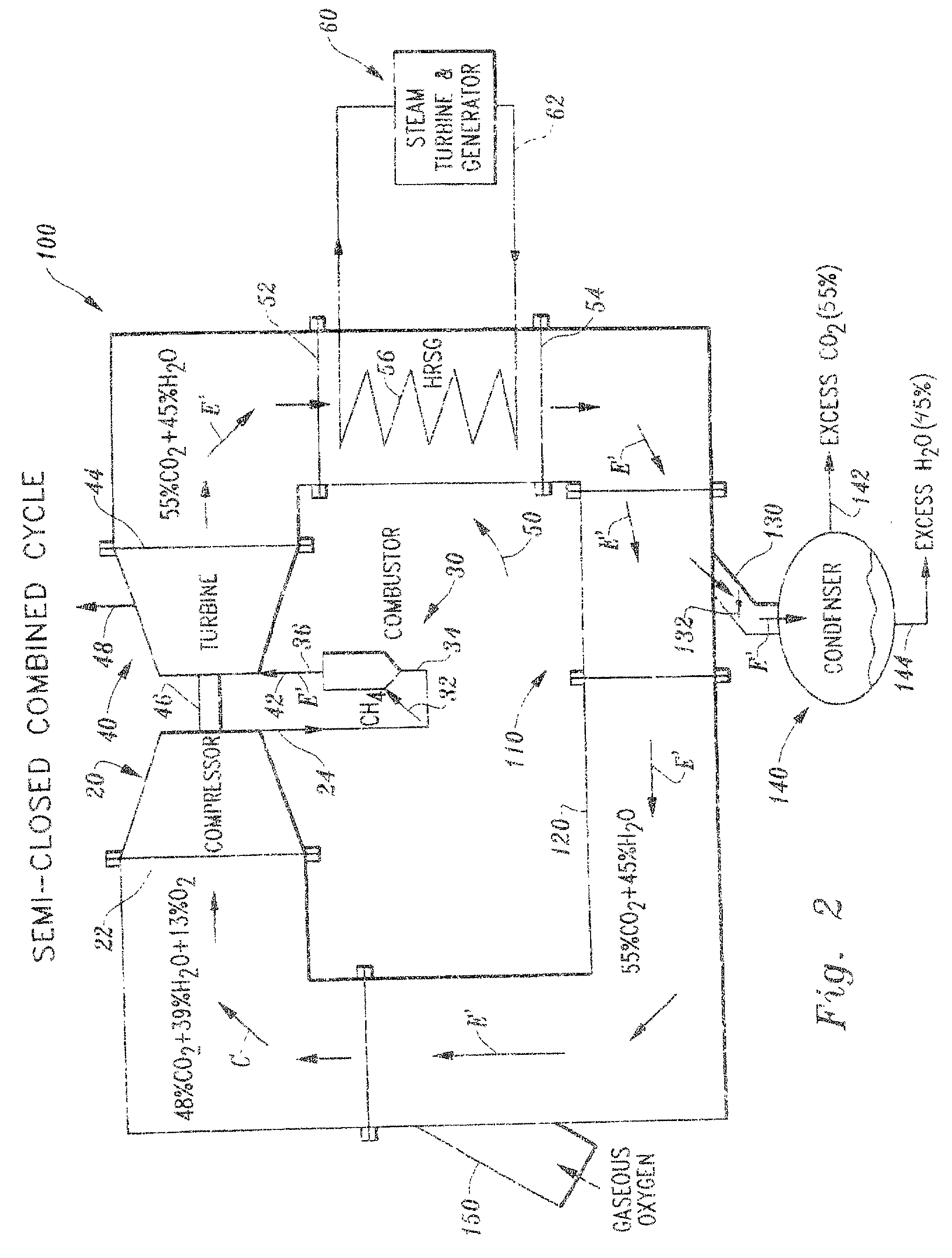

Semi-closed brayton cycle gas turbine power systems

InactiveUS20020023423A1Efficient collectionEliminate emissionsEnergy industryEfficient propulsion technologiesAtmospheric airElectric power system

A semi-closed combined cycle power system 100 is provided which can also convert an open combined cycle gas turbine 10 into a non-polluting zero emissions power system. The prior art open combined cycle gas turbine 10 includes a compressor 20 which compresses air A' and combusts the air A' with a fuel, such as natural gas. The products of combustion and the remaining portions of the air form the exhaust E' which is expanded through the turbine 40. The turbine 40 drives the compressor 20 and outputs power. The exhaust E' exits the turbine 40 and then can optionally be routed through a heat recovery steam generator 50 to function as a combined cycle. According to this invention, the exhaust E' is not emitted into the atmosphere, but rather is routed to a divider 110. The divider 110 includes two outlets for the exhaust E' including a return duct 120 and a separation duct 130 which both receive a portion of the exhaust E'. The return duct 120 routes a portion of the exhaust E' back to the compressor 20. Before reaching the compressor 20, an oxygen duct 150 adds additional oxygen to the exhaust E' to form a gas mixture C which includes CO2 and steam from the exhaust E' and oxygen from the oxygen duct 150. This gas mixture C has characteristics which mimic those of air, so that the compressor 20 need not be modified to effectively compress the gas mixture C. The gas mixture C is compressed within the compressor 20 and routed to the combustor 30 where the fuel combusts with the oxygen of the gas mixture C' and produces exhaust E' which is substantially entirely CO2 and steam. This exhaust E' is routed through the turbine 40 and expanded to drive the compressor 20 and output power. The exhaust E' exits the turbine 40 and is routed back to the divider 110, preferably by way of a heat recovery steam generator 50 or other heat removal device, so that the semi-closed cycle operates as a combined cycle power system 100. The divider 110 directs a portion of the exhaust E' to a separation duct 130 which leads to a condenser 140. In the condenser 140 the exhaust E' is separated by condensation of the steam / water portion of the exhaust and removal of the remaining CO2 as gas from the condenser 140. The only exhaust from the semi-closed power system 100 is water and CO2 from the condenser. The CO2 exhaust is substantially pure and ready for appropriate further handling and disposal. Hence, no pollutants are emitted from the semi-closed power system 100. The return duct 120 can

Owner:CLEAN ENERGY SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com