Patents

Literature

62 results about "Negative energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

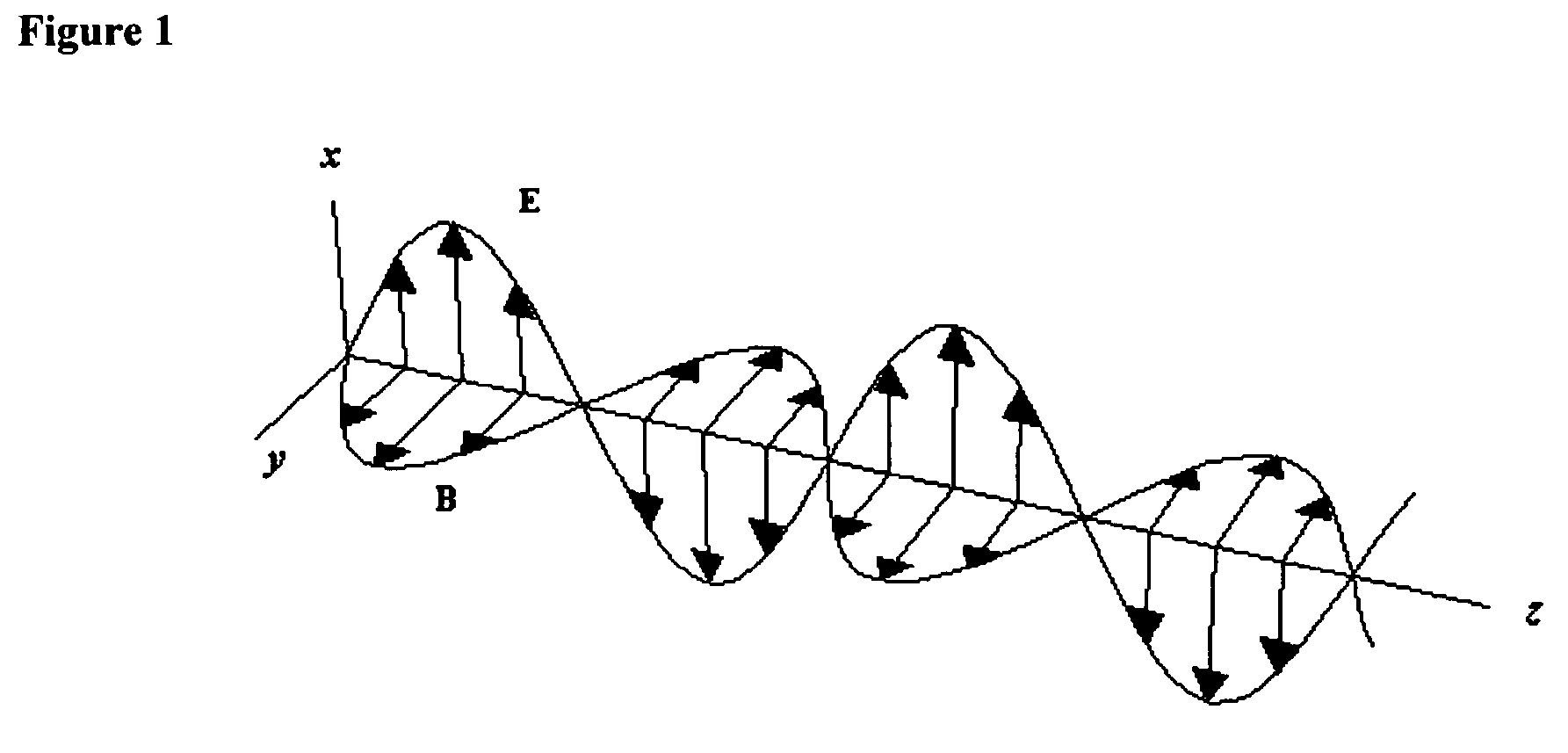

Negative energy is a concept used in physics to explain the nature of certain fields, including the gravitational field and various quantum field effects. In more speculative theories, negative energy is involved in wormholes which may allow for time travel and warp drives for faster-than-light space travel.

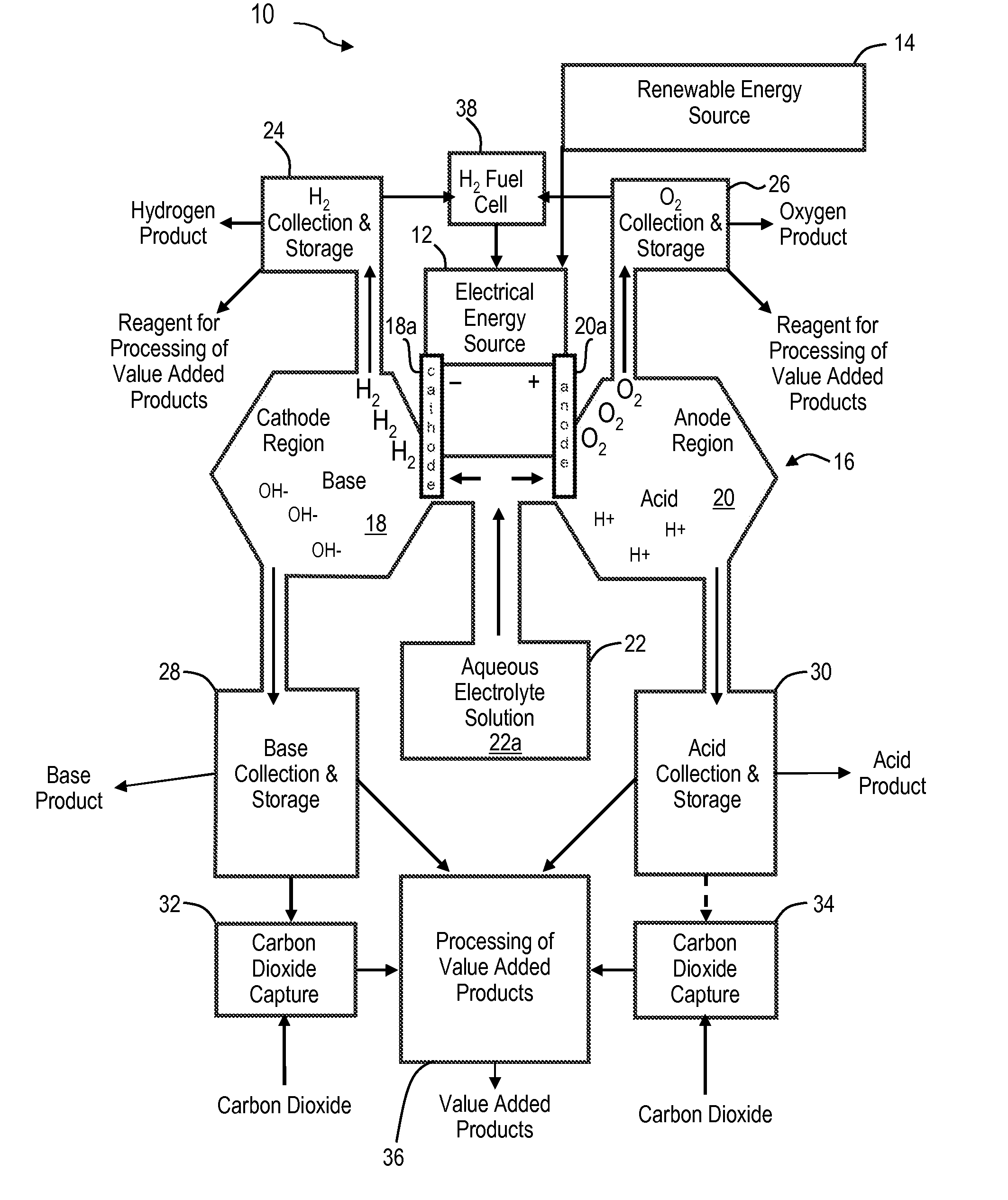

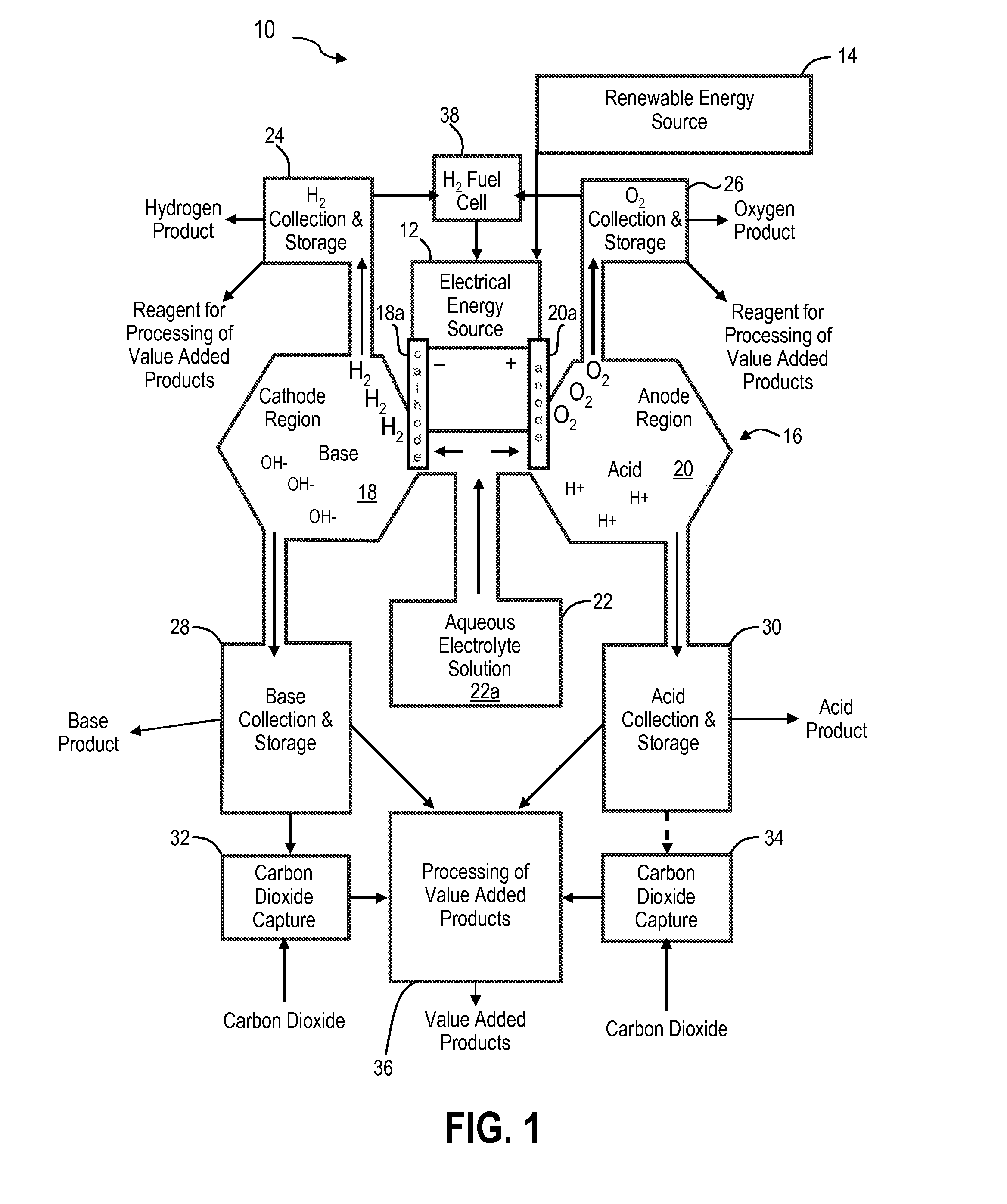

Renewable energy system for hydrogen production and carbon dioxide capture

The present invention is an integrated system for the production of hydrogen and the removal of carbon dioxide from the air or gas streams. The integrated system includes an energy source for generating electrical energy and a water source coupled to the energy source. The water source includes ionic electrolytes. The energy source supplies energy to the water source to electrolyze water to produce hydrogen gas, oxygen gas, acid and base. The carbon dioxide reacts with the base. In some embodiments, the energy source is a renewable energy source. The integrated system produces substantially no carbon dioxide and when combined with a renewable energy source, produces clean hydrogen fuel and reduces atmospheric carbon dioxide, resulting in carbon dioxide negative energy and manufacturing strategies.

Owner:SULFURCYCLE INTPROP HLDG CO LLC

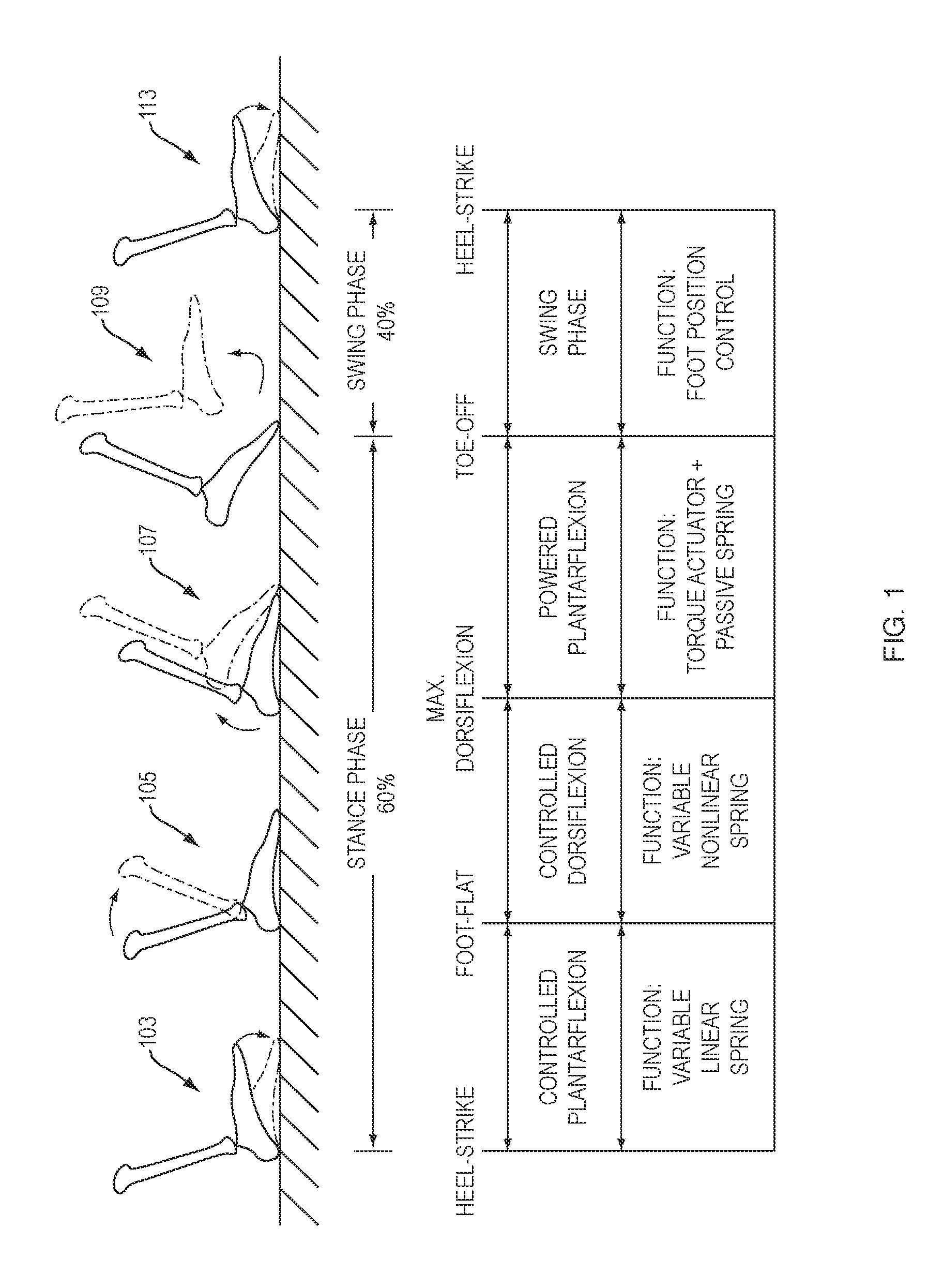

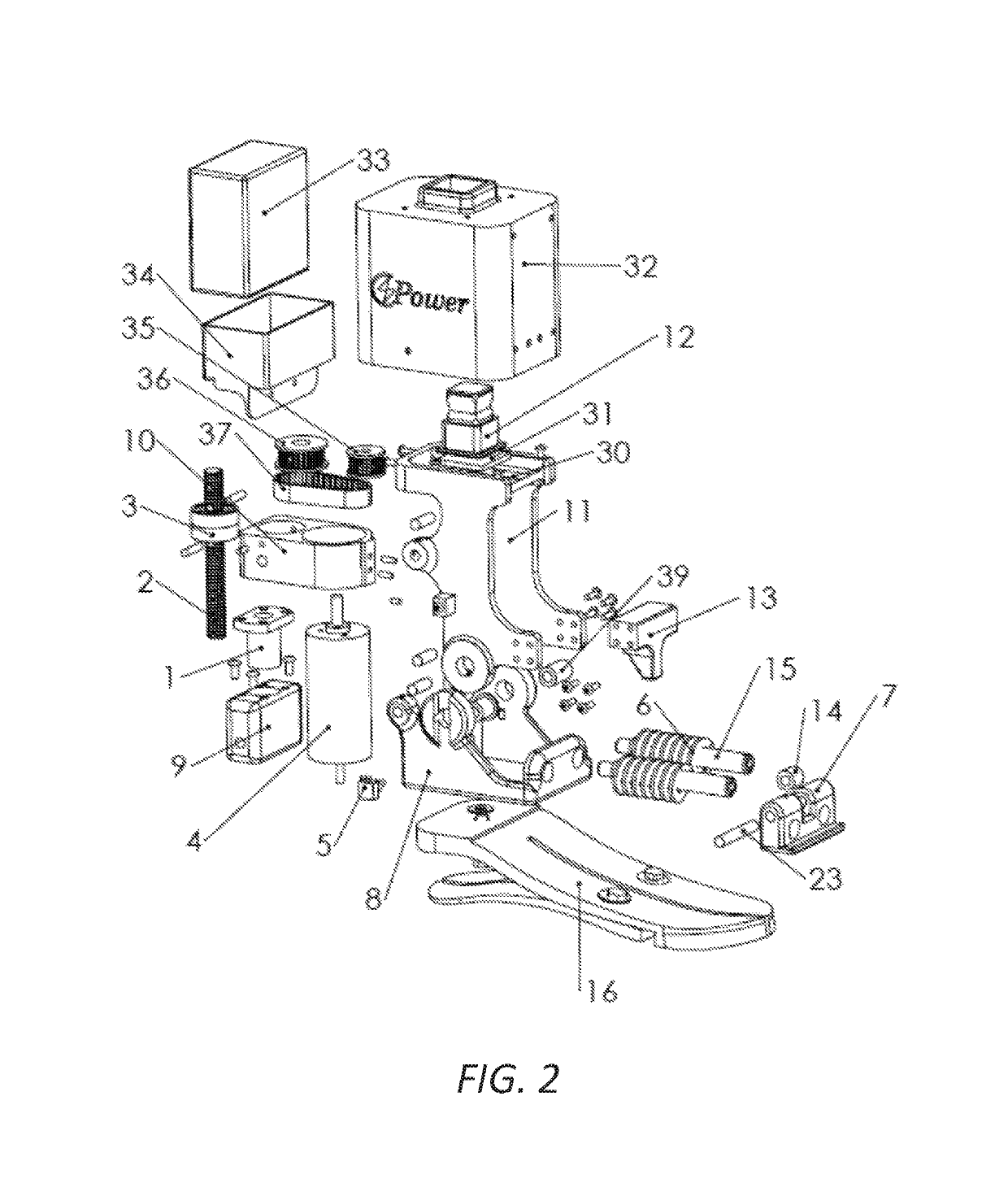

Artificial Human Limbs and Joints Employing Actuators, Springs, and Variable-Damper Elements

ActiveUS20110264230A1Improve performanceLight weightJoint implantsArtificial legsMusculoskeletal structureArtificial joints

Biomimetic Hybrid Actuators employed in biologically-inspired musculoskeletal architectures employ an electric motor for supplying positive energy to and storing negative energy from an artificial joint or limb, as well as elastic elements such as springs, and controllable variable damper components, for passively storing and releasing energy and providing adaptive stiffness to accommodate level ground walking as well as movement on stairs and surfaces having different slopes.

Owner:MASSACHUSETTS INST OF TECH

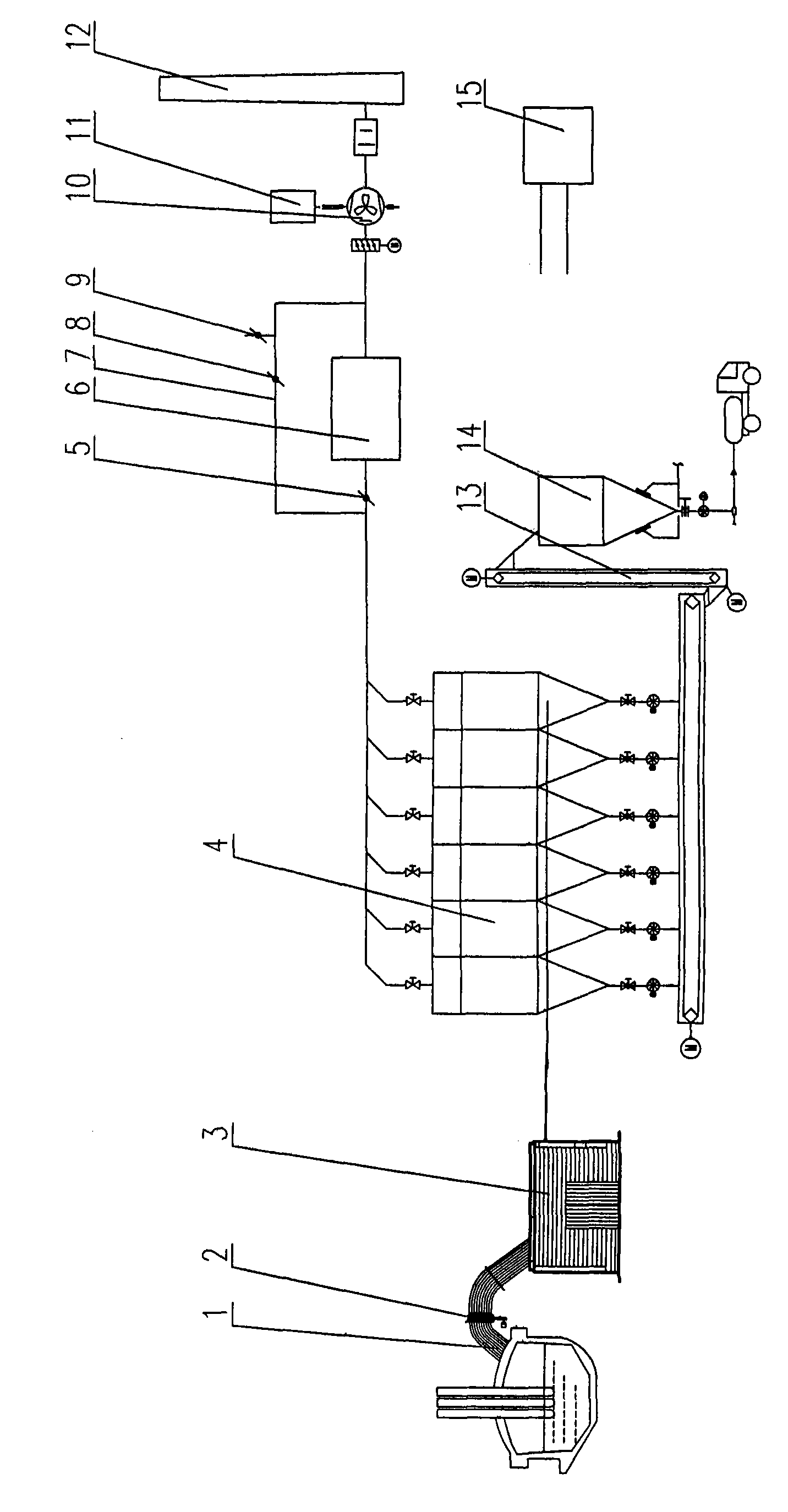

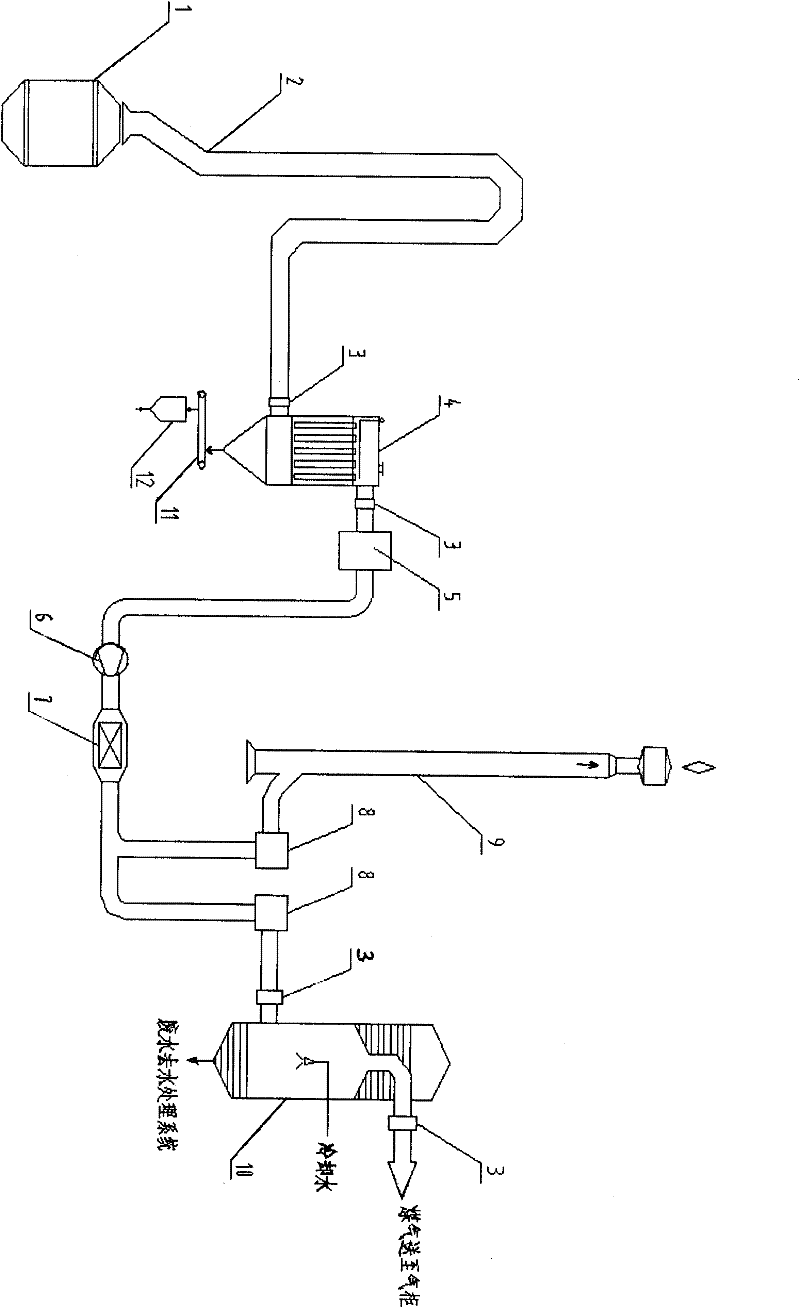

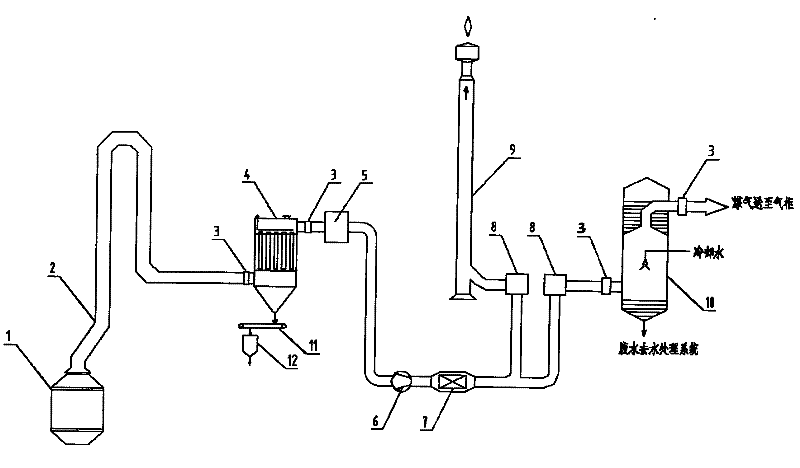

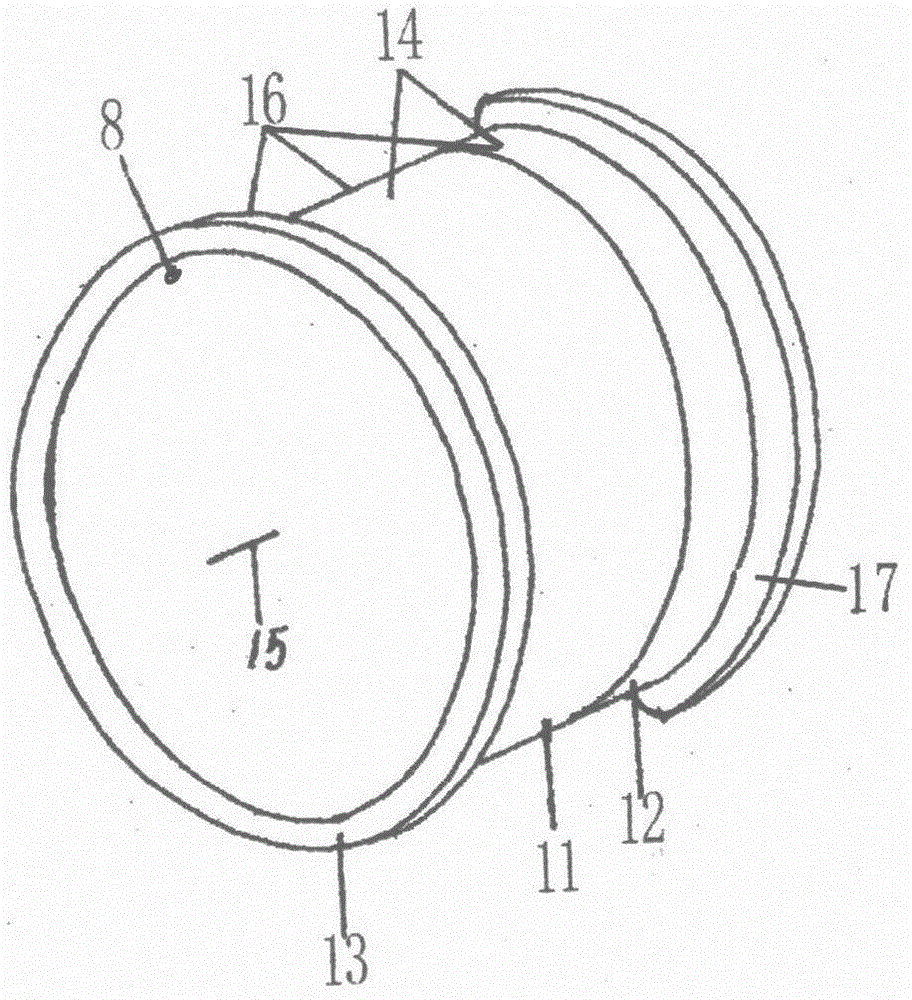

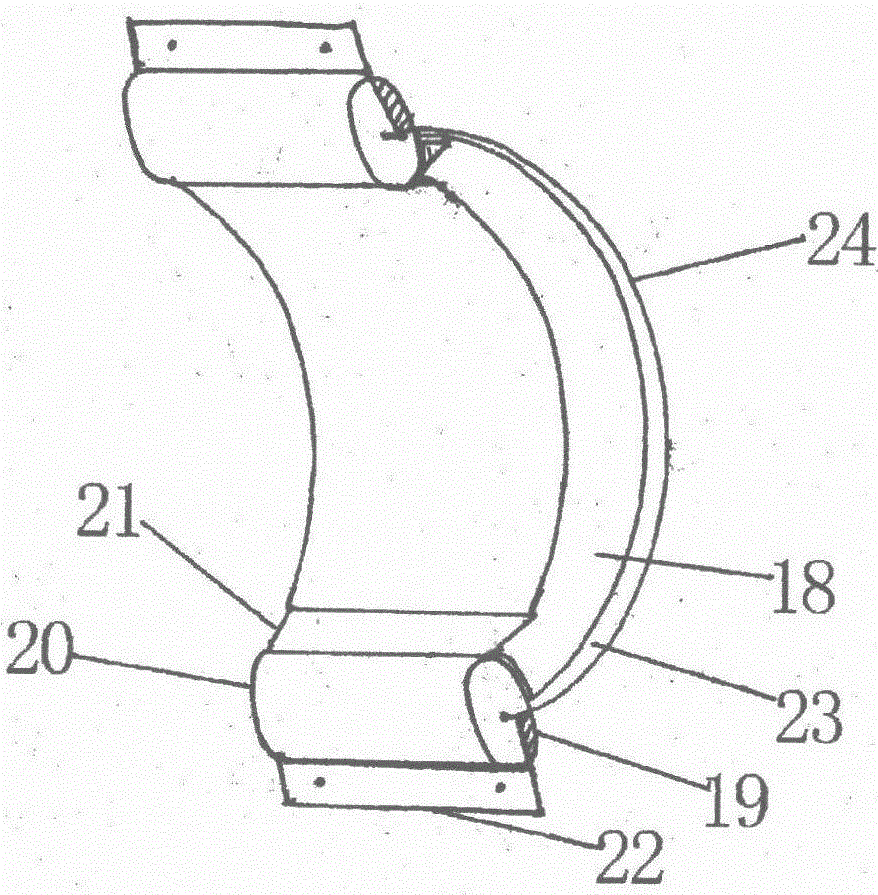

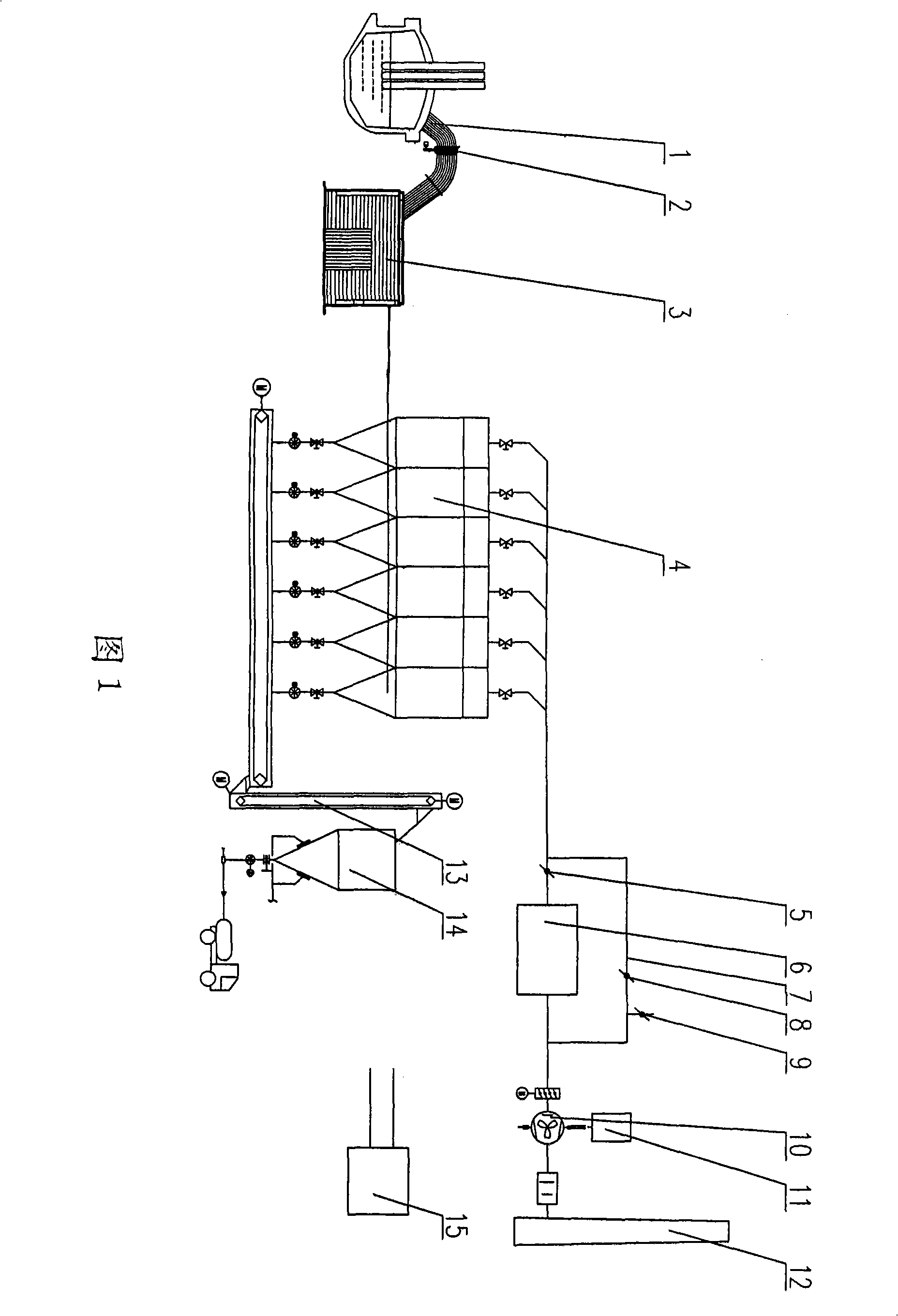

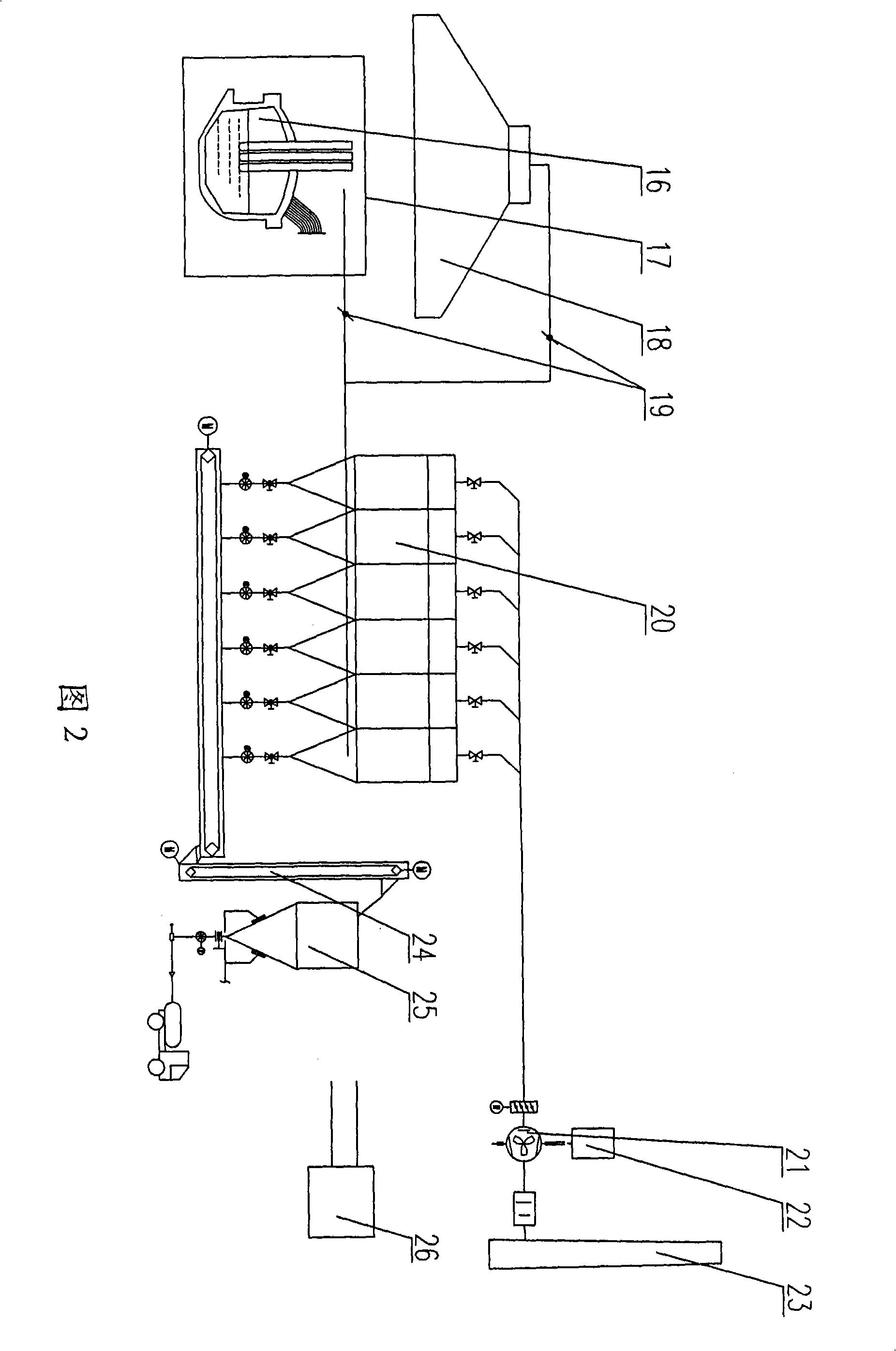

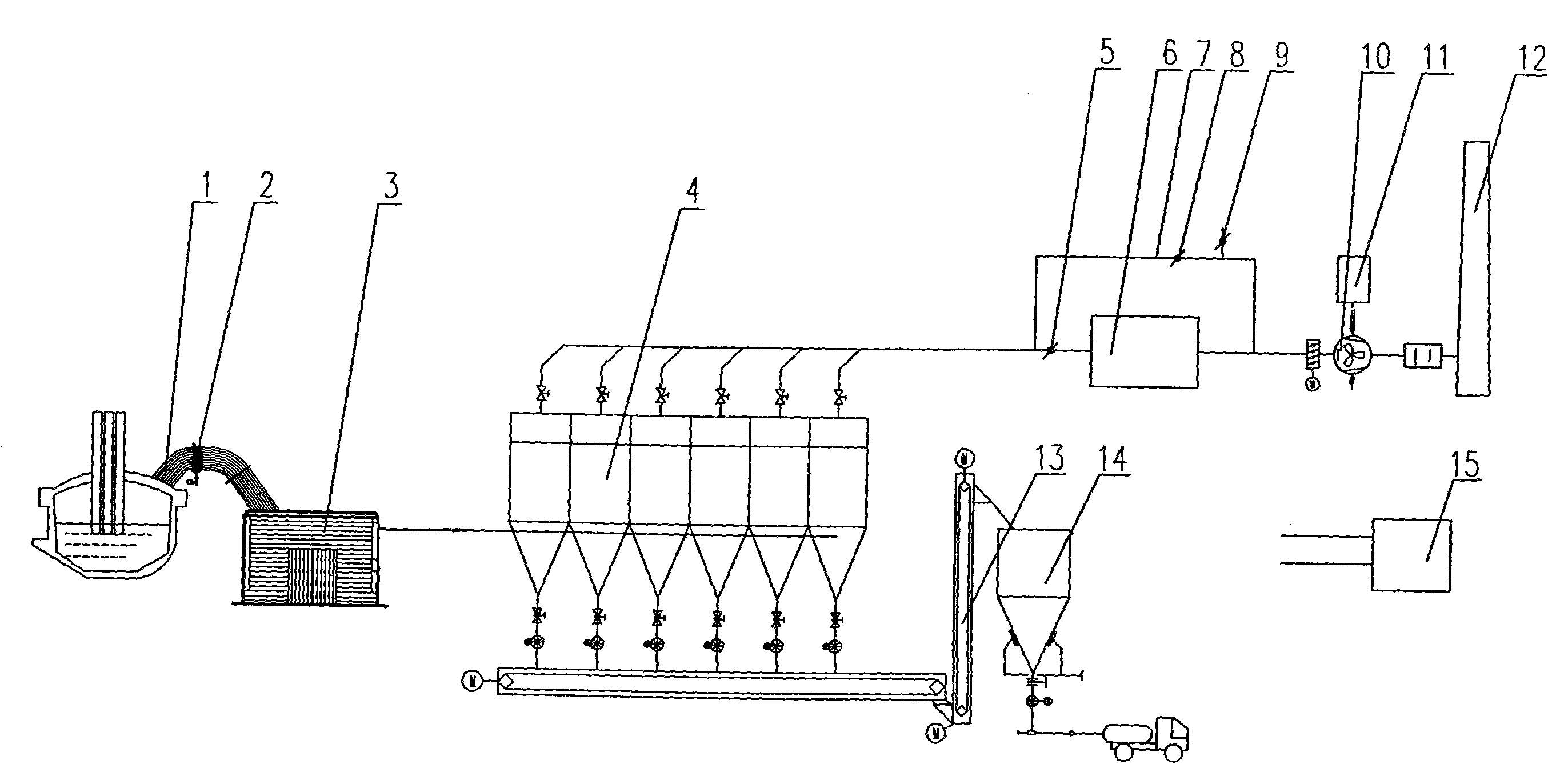

Flue gas waste heat recovery and negative energy consumption dust-removal system for electric stove

InactiveCN101539369AEasy to recycleSave on wear and maintenance costsDispersed particle filtrationIncreasing energy efficiencyCombustion chamberEvaporation

The invention relates to a flue gas waste heat recovery and negative energy consumption dust-removal system for an electric stove, comprising a first flue gas dust-removal and waste heat recovery system for the electric stove which is connected with the smoke hole of the electric stove to absorb high temperature flue gas generated by the electric stove during smelting phase and a secondary flue gas dust-removal system for the electric stove which is in charge of absorbing the flue gas generated by the electric stove during charging and tapping phase. The first flue gas dust-removal and waste heat recovery system for the electric stove comprises a water cooling travelling tube, an evaporation cooling device, a high temperature resistant dust remover, a waste heat boiler, a dust removal fan and a chimney; wherein the evaporation cooling device replaces the original water cooling flue gas path and combustor. The secondary flue gas dust-removal system for the electric stove comprises a collecting cover, a dust remover worked at normal temperature, a dust removal fan and a chimney. The invention is high in dust removal efficiency and high in vapor recovery rate, saves a first cooling device and a secondary cooling device, reduces device investment and maintenance charge and prolongs the service life of the filter pocket of the dust remover.

Owner:BAOSTEEL ENG & TECH GRP

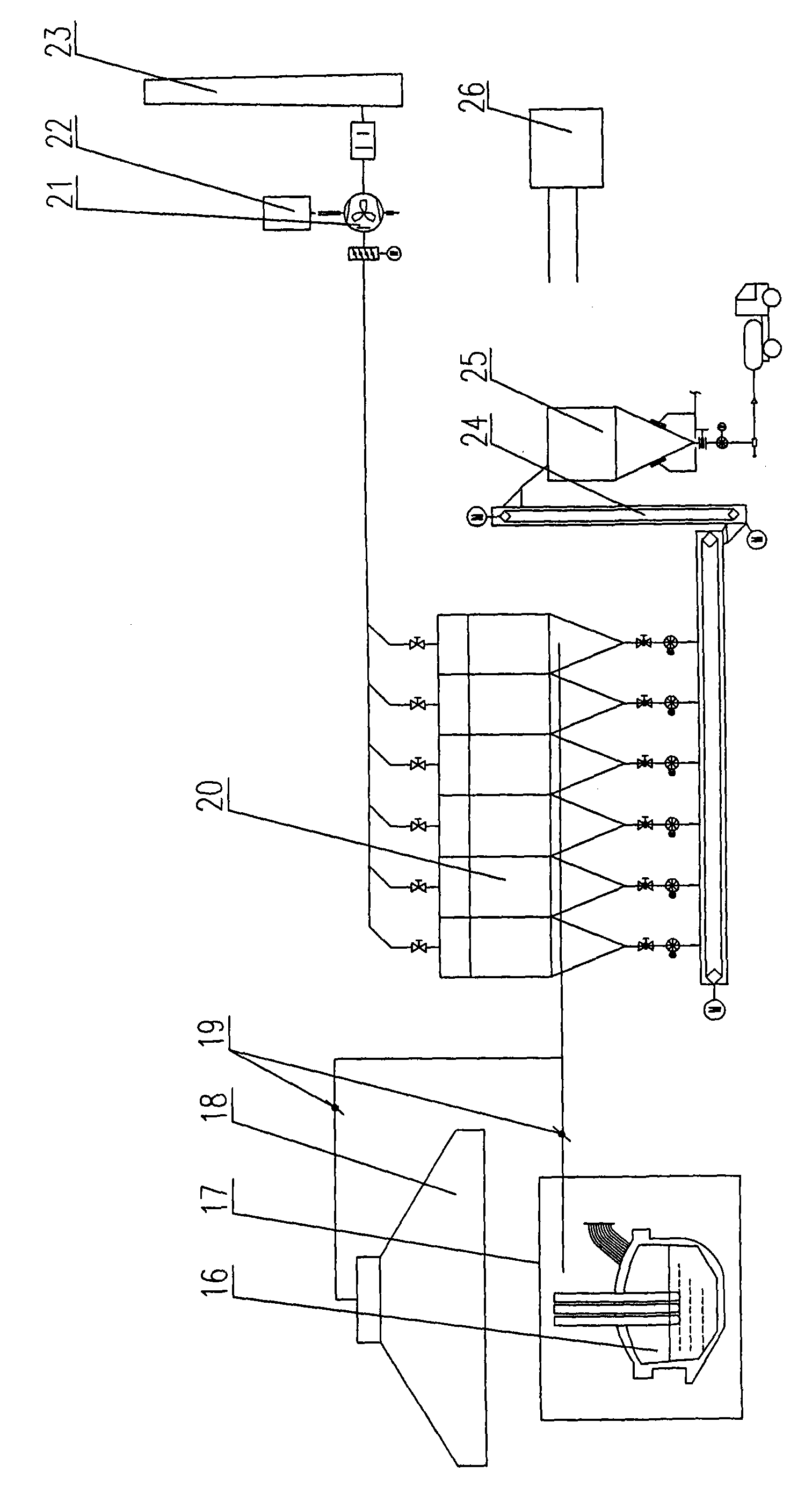

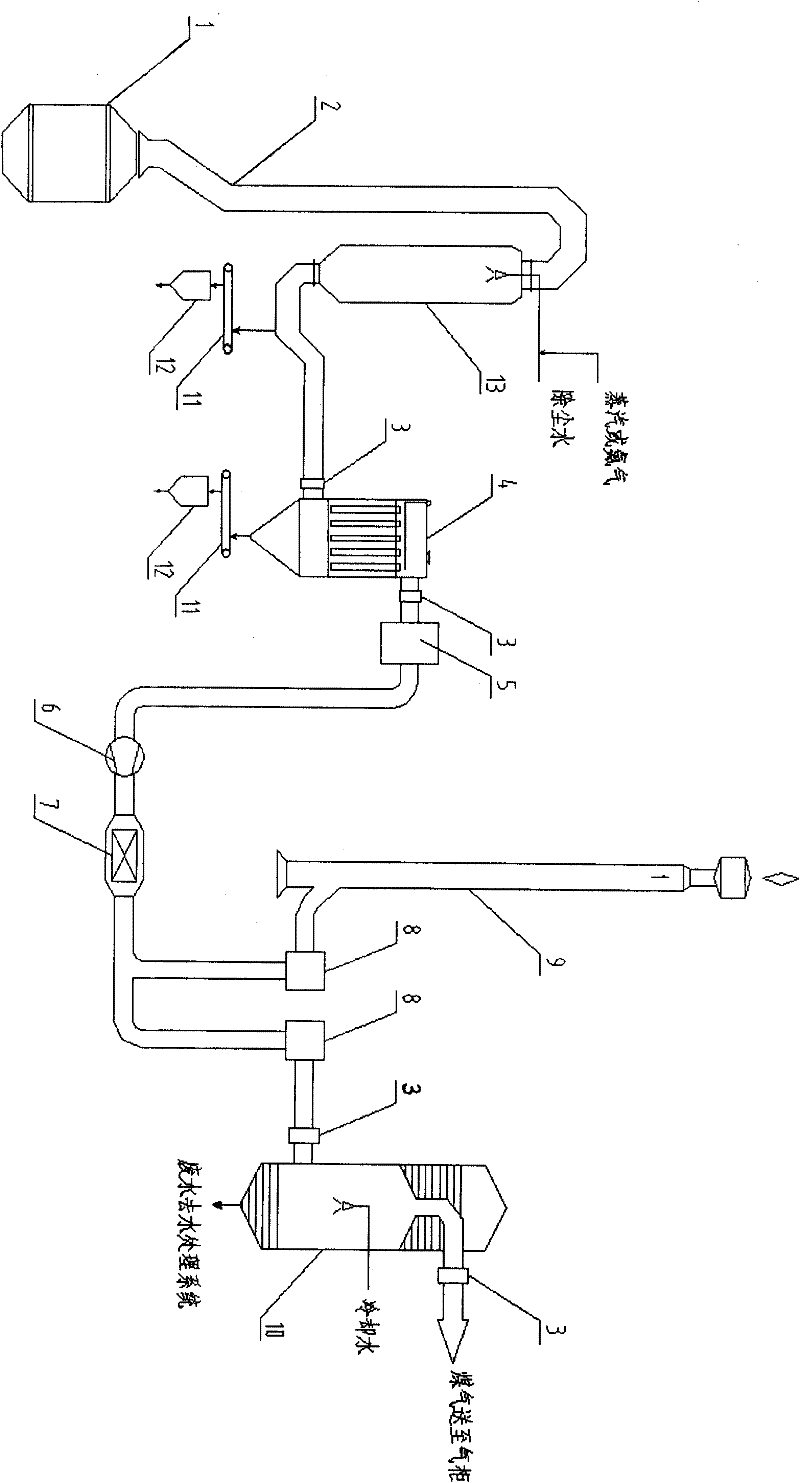

Converter coal gas high-temperature bag-type dust removing system

InactiveCN101550466AImprove dust removal efficiencyEasy to recycleManufacturing convertersIncreasing energy efficiencyCooling towerAutomatic control

The invention relates to a converter coal gas high-temperature bag-type dust removing system which comprises a converter, a high-temperature evaporative cooling tower, a high-temperature bag-type dust remover, a coal gas blower, a changeover valve station, a blow-off chimney, a spectacle valve, a coal gas cooling tower and an automatic control system which are connected in sequence through pipelines. The high-temperature evaporative cooling tower substitutes an evaporative cooling tower in an LT system or substitutes a sizing or manual diameter-regulating overflow venturi tube or a saturated spraying tower in an OG system; and the high-temperature bag-type dust remover substitutes an electrostatic dust remover in the LT system or an automatic diameter-regulating venturi tube or a circular seam washer in the OG system. The invention is called as a converter coal gas BG dry-method remover for short, has the advantages of high coal gas dust removing efficiency, lower system operation resistance and energy consumption, high coal gas recovery rate, and the like, has no problems of system blockage and secondary pollution of water, is not only in accordance with the strict environment protection requirements, but also can reclaim coal gas and realize converter negative-energy steel making.

Owner:BAOSTEEL ENG & TECH GRP

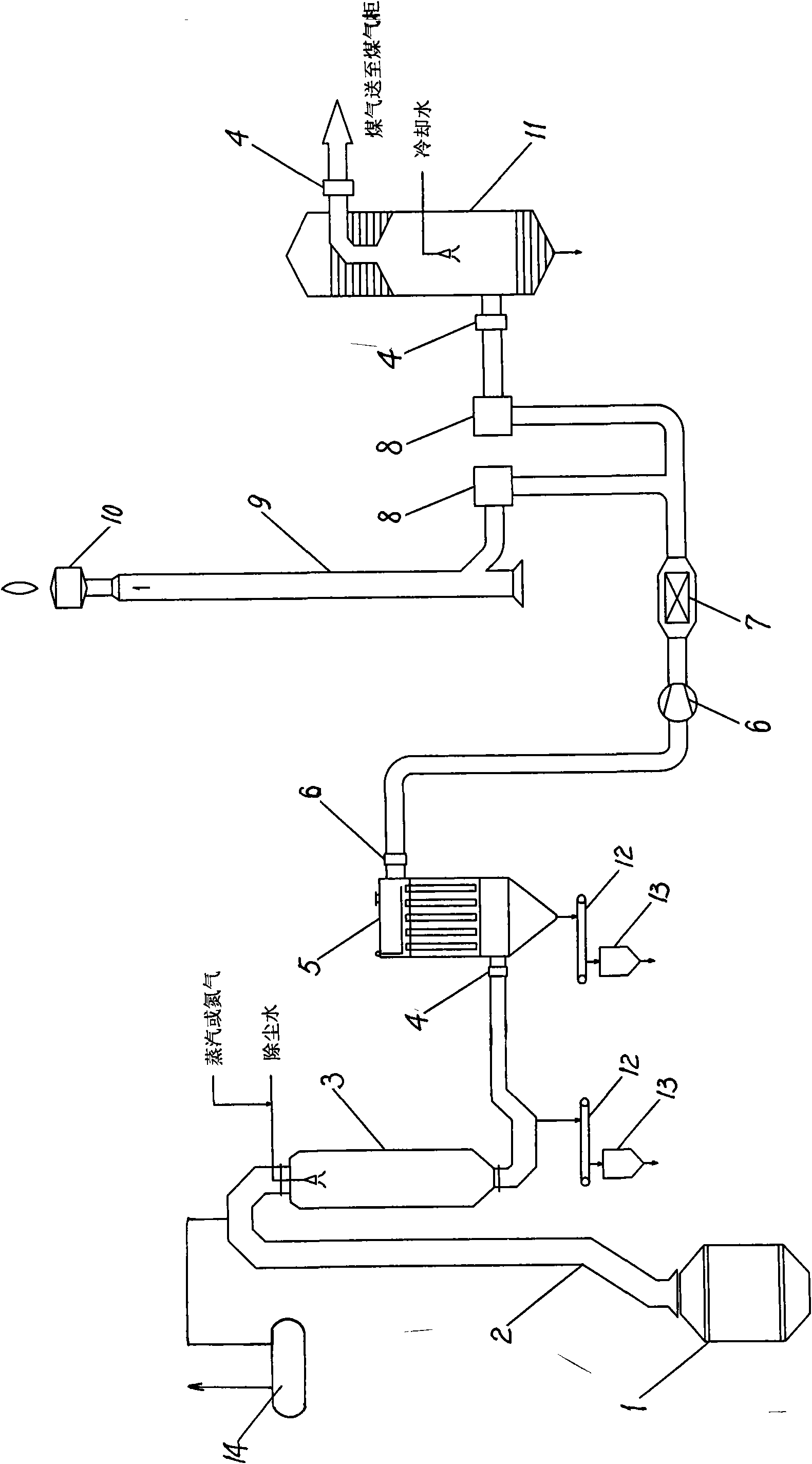

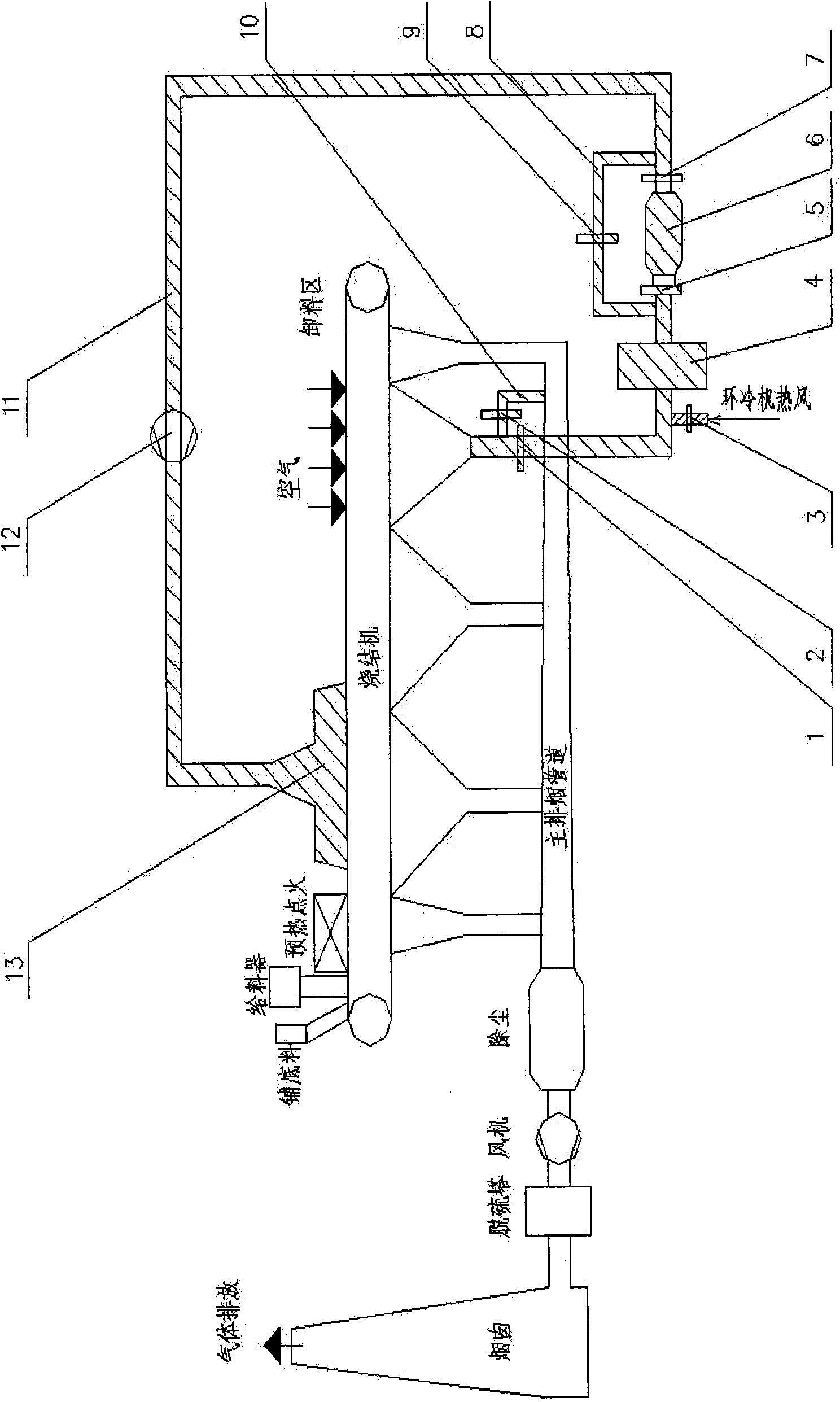

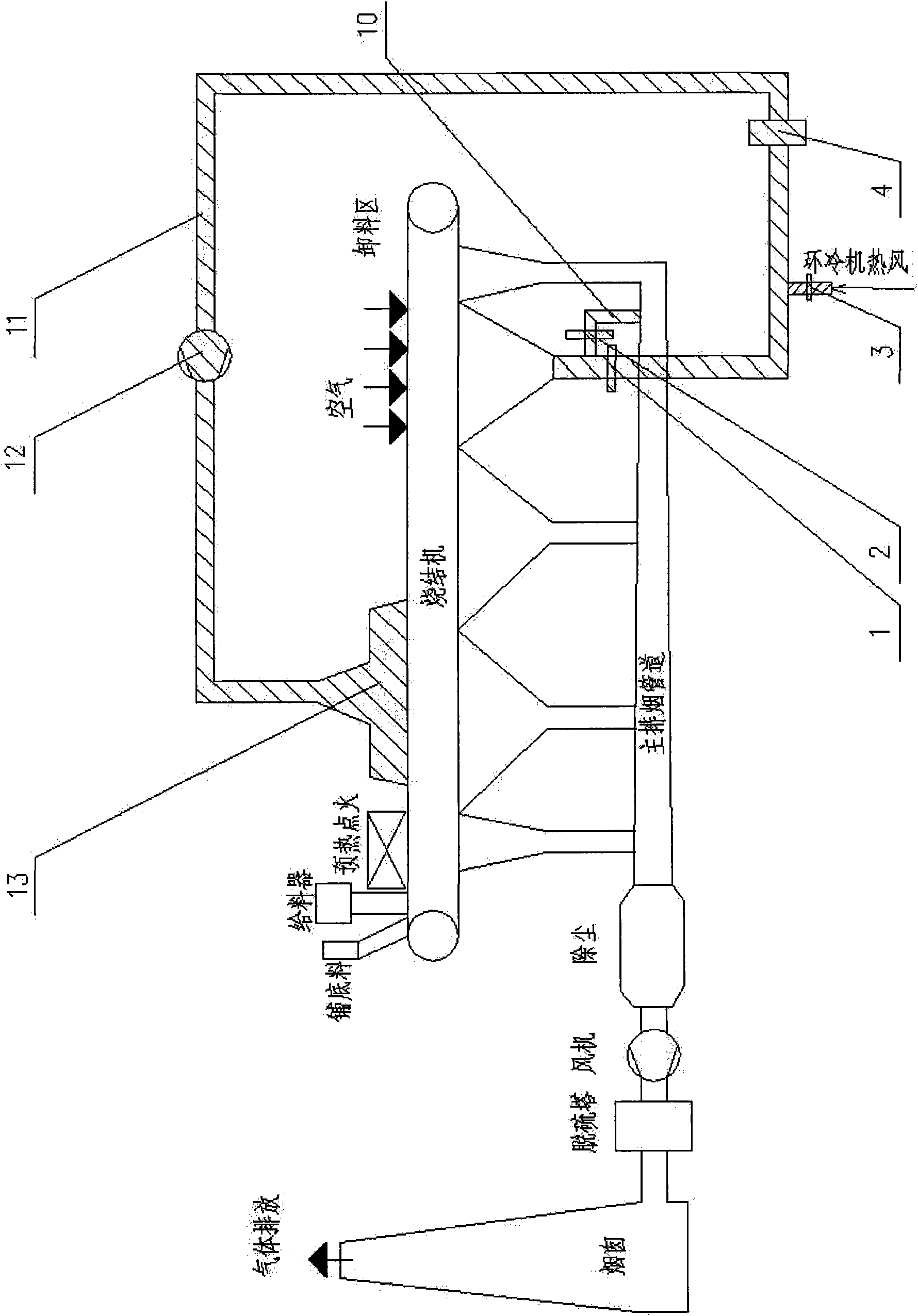

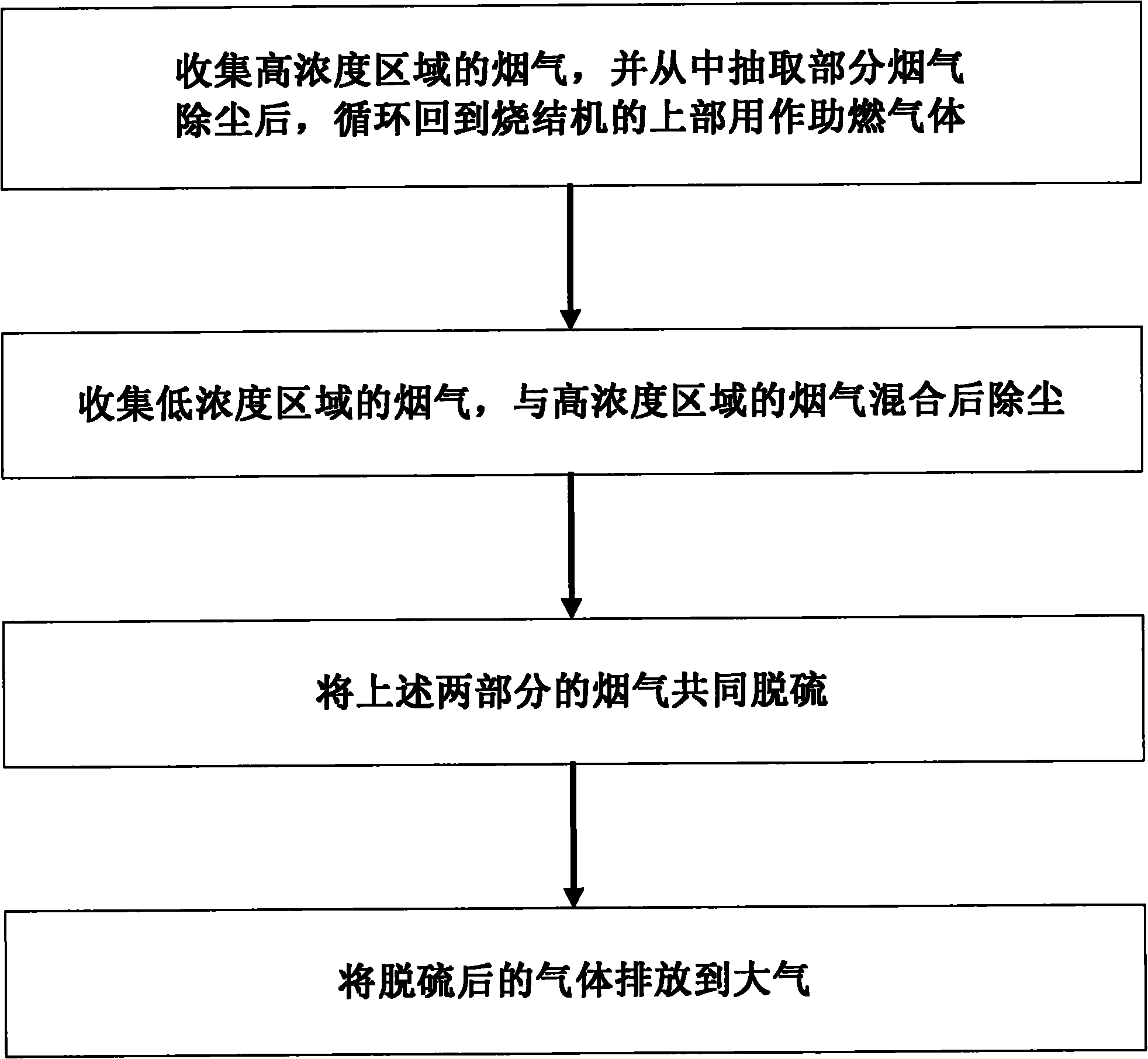

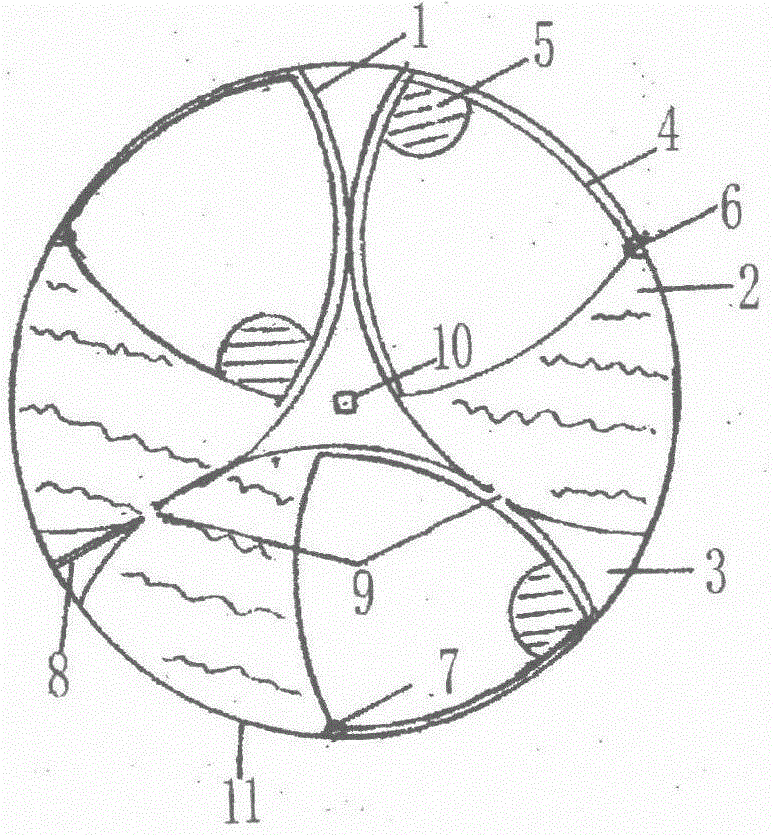

Negative energy consumption dioxin emission reducing system of sintering machine and method thereof

InactiveCN101829482AReduce usageImprove energy savingLighting and heating apparatusDispersed particle separationHigh concentrationAtmospheric air

The invention relates to a negative energy consumption dioxin emission reducing system of sintering machine and a method thereof. The system comprises a main flue, a dust remover, a bypass flue, a circulating flue, a circulating fan and a circulating gas hood. A high-concentration area wind chamber is arranged in an area accounting for 55 to 95 percent of the length from a sintering machine head to a machine tail of a sintering machine trolley; a low-concentration area wind chamber is connected with the main flue to reach a flue sequentially from the dust remover, the fan and a desulfurizing tower so as to exhaust smoke into air; a circulating gas hood is covered above the sintering machine trolley; the high-concentration area wind chamber is connected with the circulating gas hood through the circulating flue; and the circulating flue is provided with the dust remover and the circulating fan. The method comprises the following steps of collecting the smoke, removing dust, mixing the smoke of the low-concentration area with the smoke of the high-concentration area to remove the dust, performing desulfuration on the smoke, exhausting the smoke into the air and the like. The system has the advantages of simple and convenient construction, installation, operation management and maintenance, shorter construction period, the negative cost operation for emission reduction of the dioxin, and obvious energy-conservation and emission-reduction effects.

Owner:BAOSTEEL ENG & TECH GRP

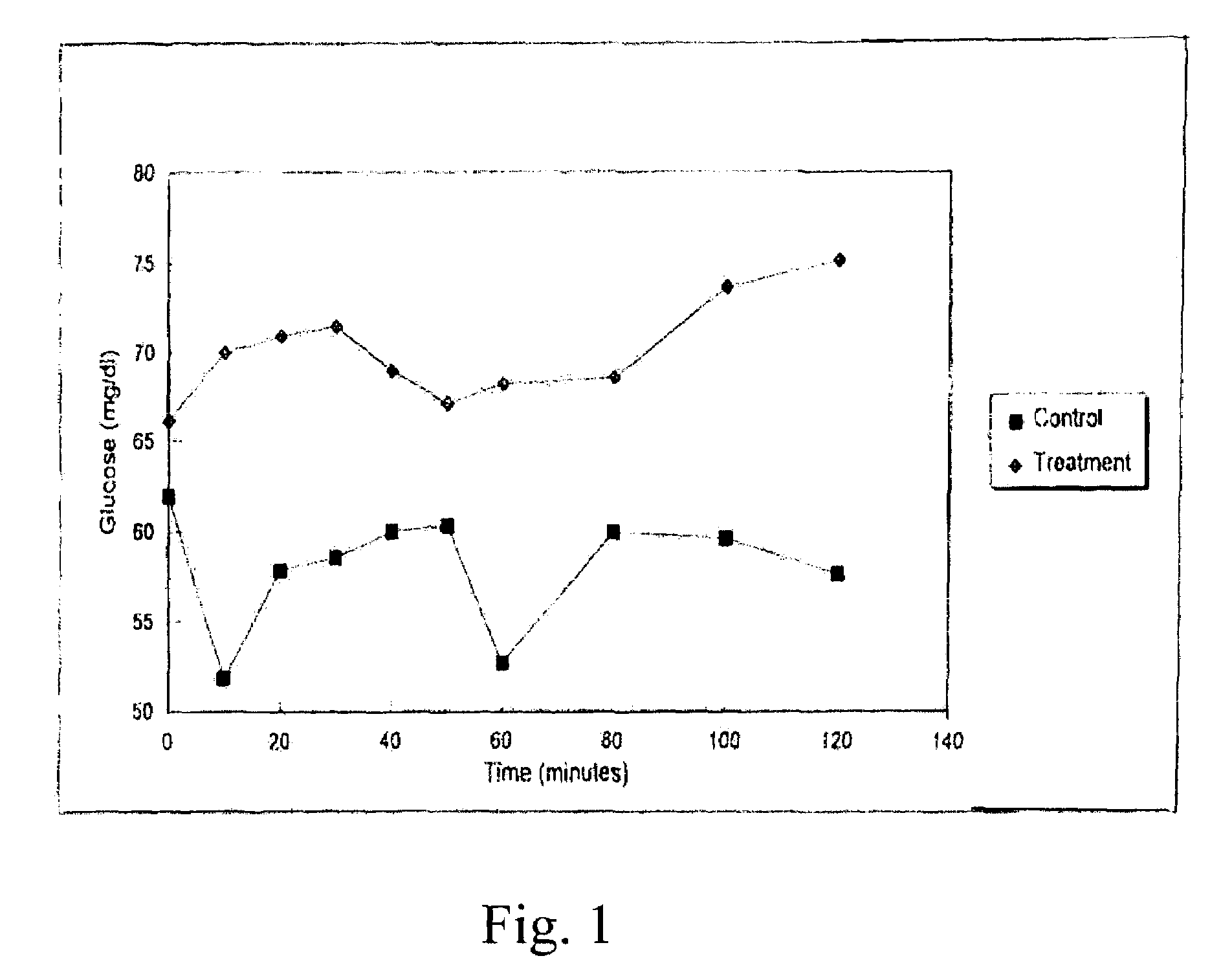

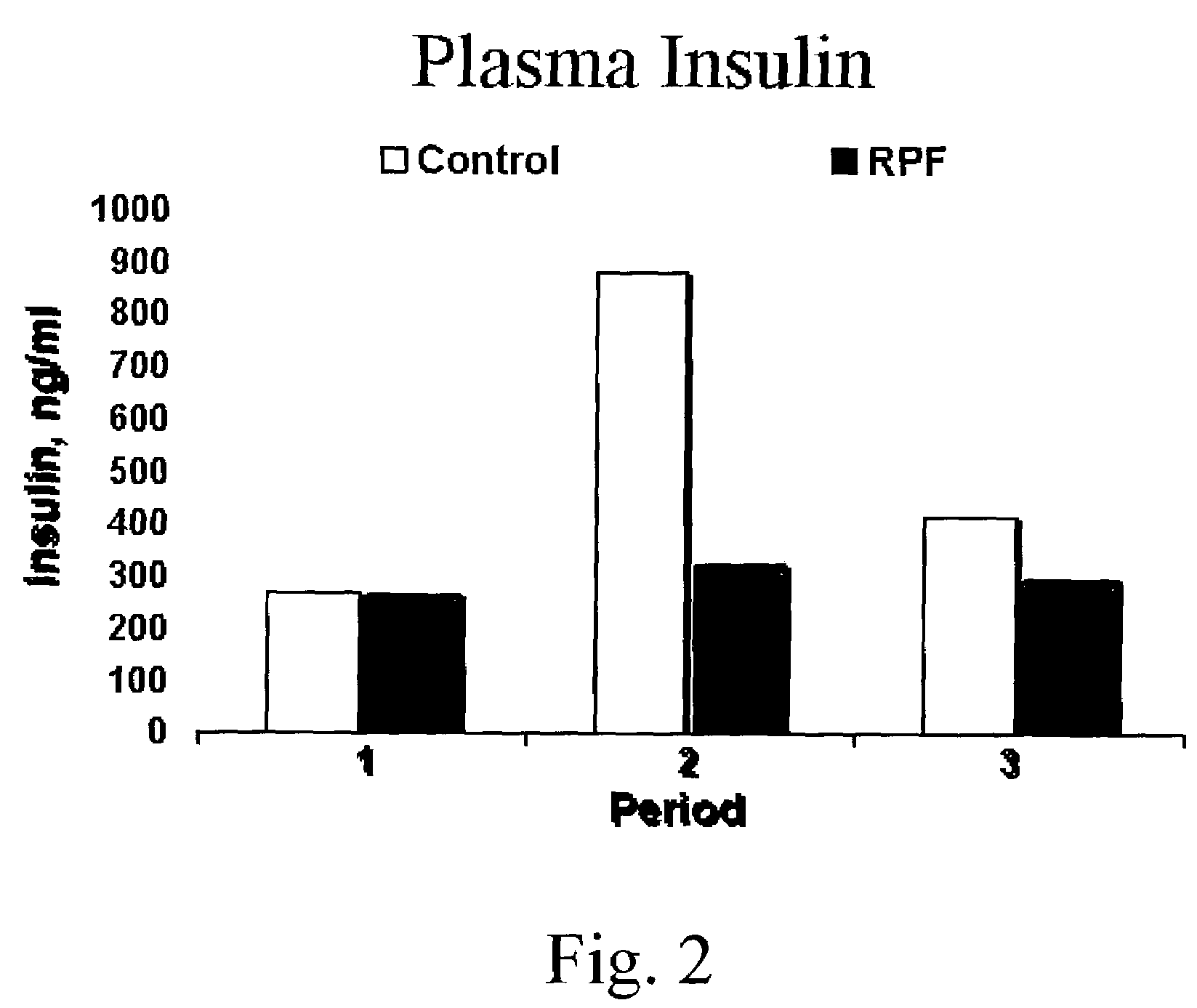

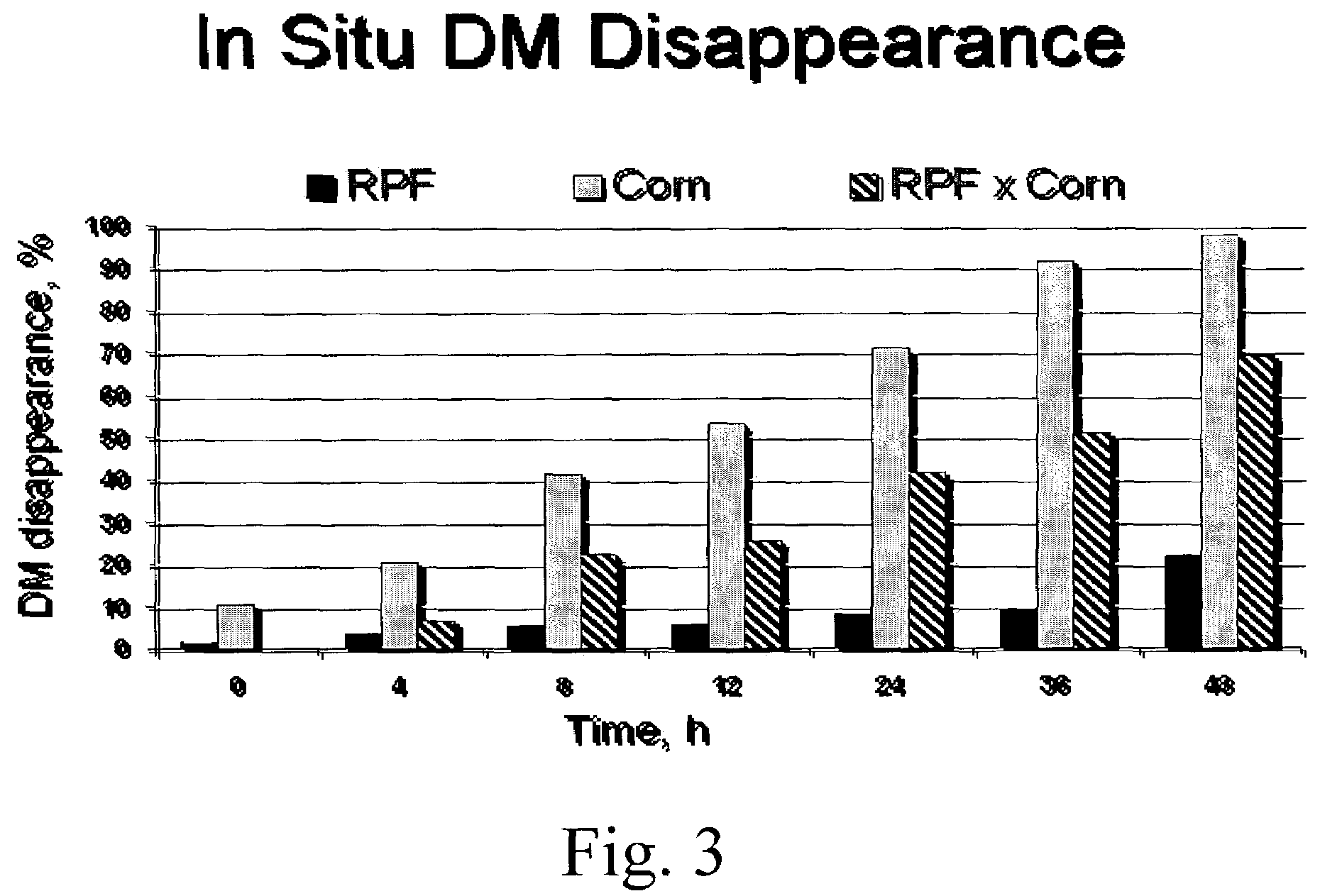

Carbohydrate ruminant feed energy supplement and method

InactiveUS7303775B1Prevent and alleviate effect of negativeProvide protectionAnimal feeding stuffAccessory food factorsRuminant animalNegative energy

A carbohydrate ruminant feed energy supplement and method for alleviating a negative energy balance in ruminant animals. includes forming a ruminally protected carbohydrate, preferably non insulin stimulating, and feeding the ruminally protected carbohydrate to a ruminant animal.

Owner:PENN STATE RES FOUND +2

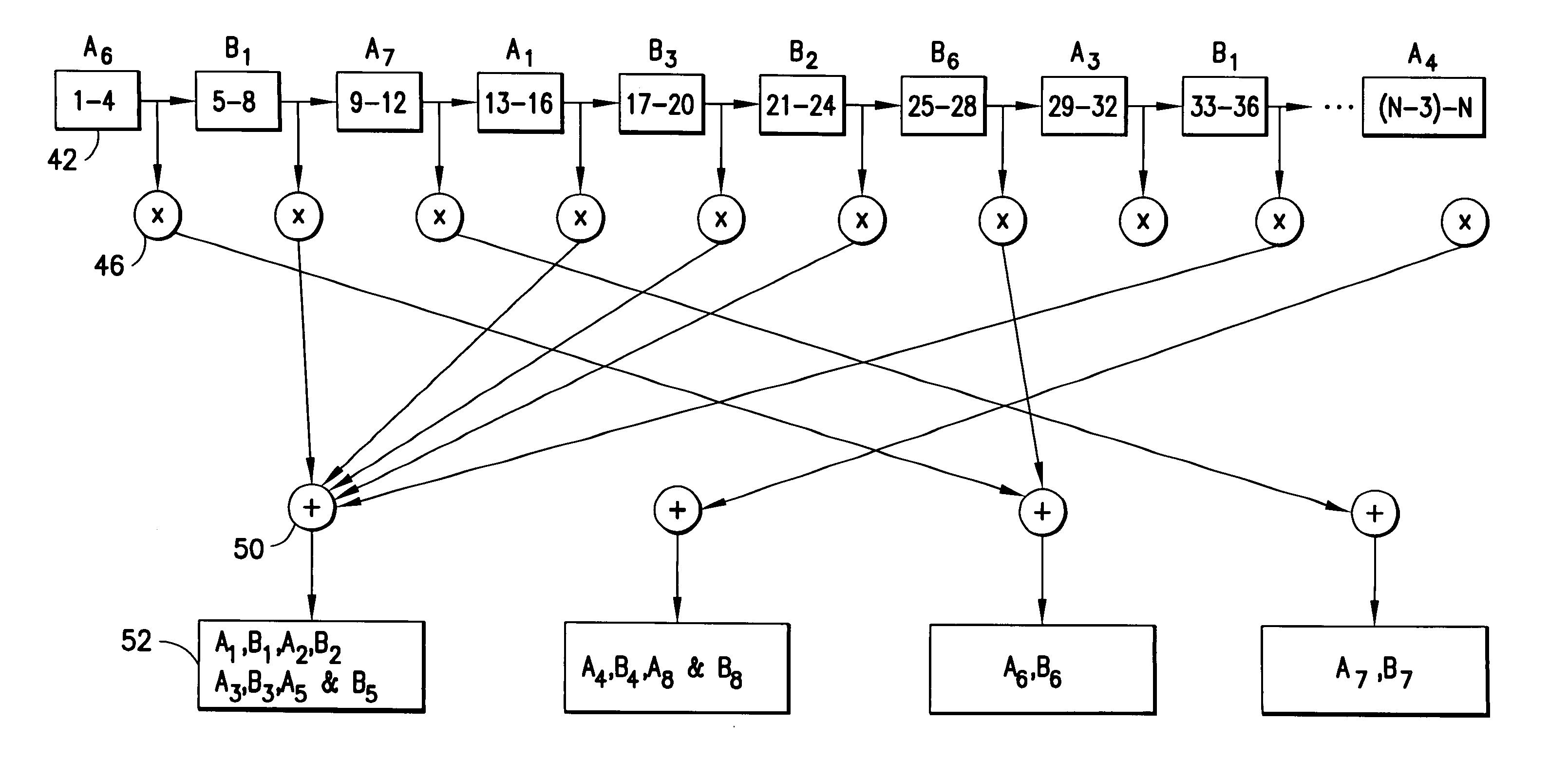

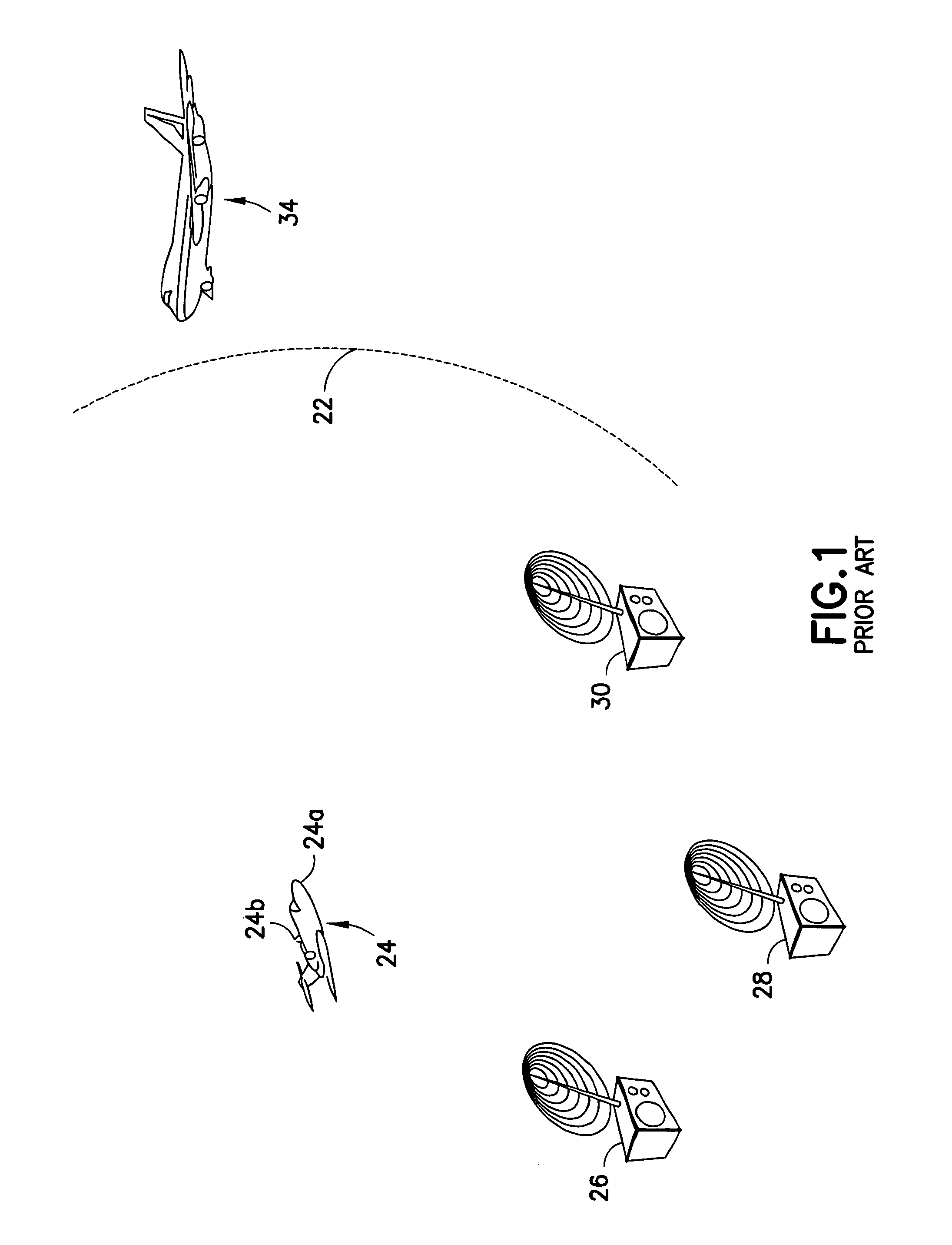

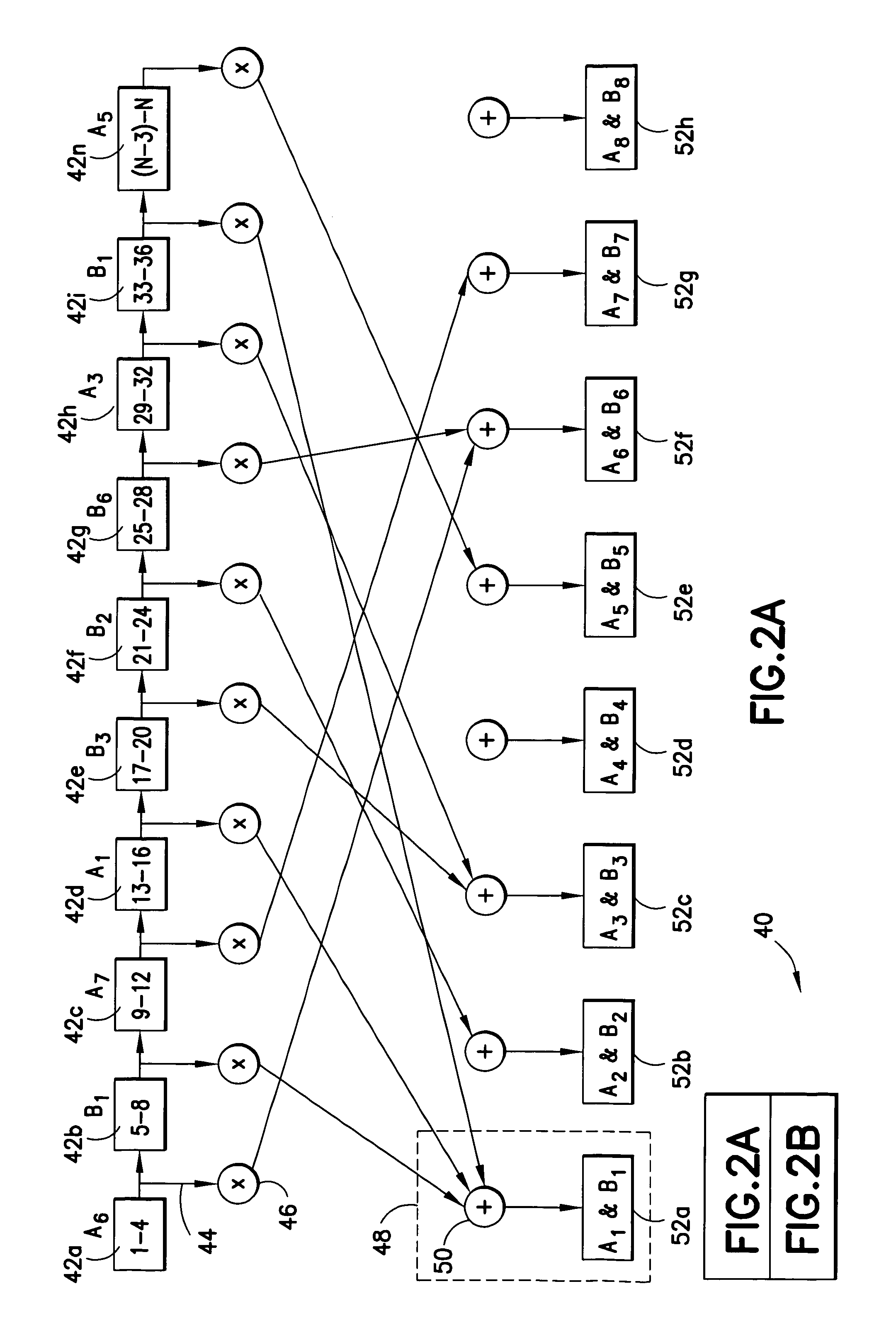

Sub-sequence accumulation filter and method

ActiveUS7606292B1Reduce in quantityAmplitude-modulated carrier systemsRadio transmissionProcessor registerParallel computing

A parallel correlator and method includes temporarily storing in a series of P sequence registers, each of length R1, serial bit-sequences of a code of length N=P*R1. In a first-level of processing, certain unique bit sequences are inverted to reduce the number of unique bit sequences by half. Identical bit-sequences are then combined and temporarily stored in a first-level sub-accumulation register. Alternatively, bit sequences differing by only one bit may be combined in a common first-level sub-accumulation register. Further levels of similar processing may be imposed, where each subsequent level taps and inverts only a portion of the bits in the above level of processing, thereby reducing the number of unique bit sequences. Finally, all negative energy is combined in one register position, inverted, and added to all positive energy in the other register positions. When the spreading code was aligned among the series of sequence registers, the energy is added coherently and an energy peak is output, indicating alignment of the spreading code in the sequence registers.

Owner:L3 TECH INC

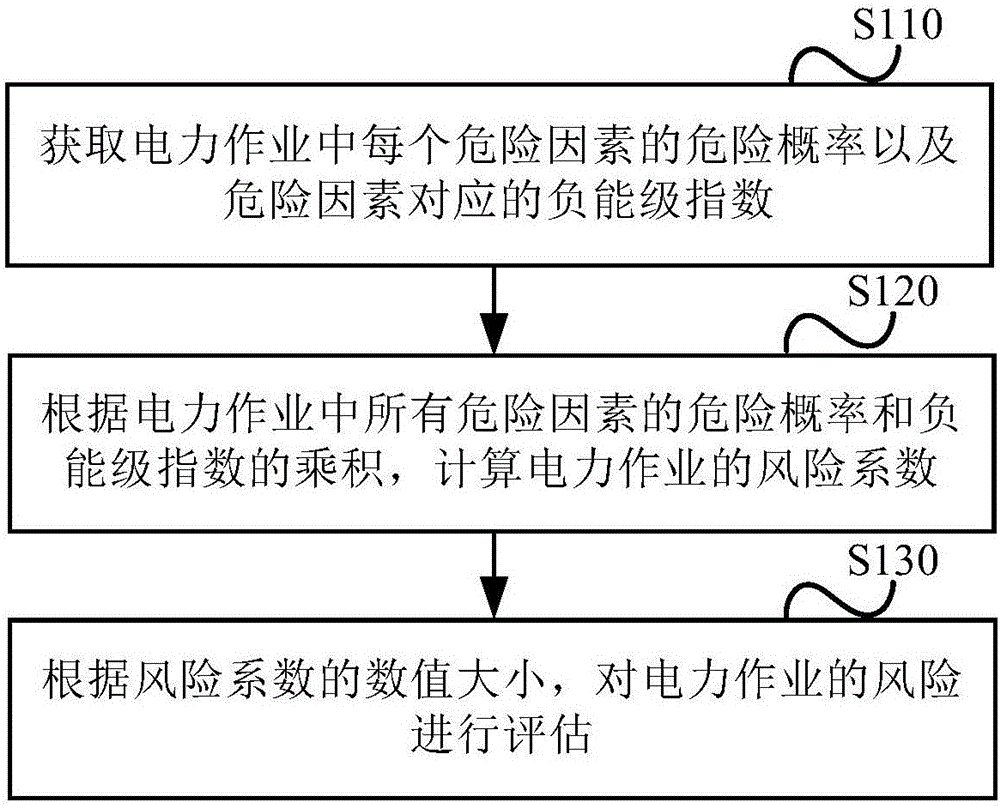

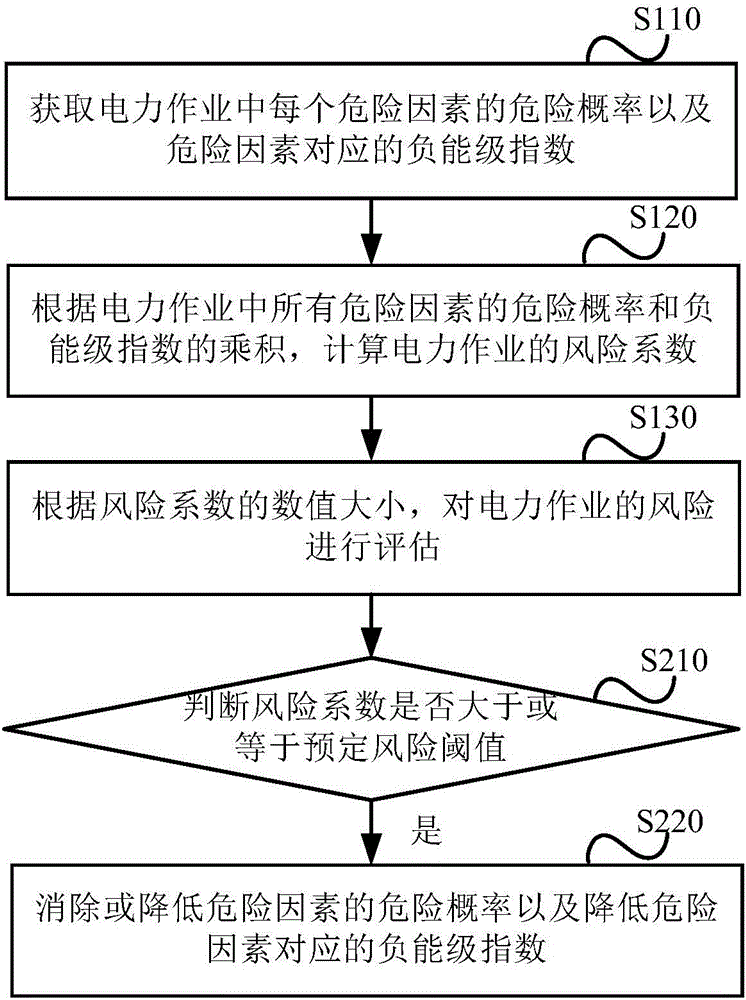

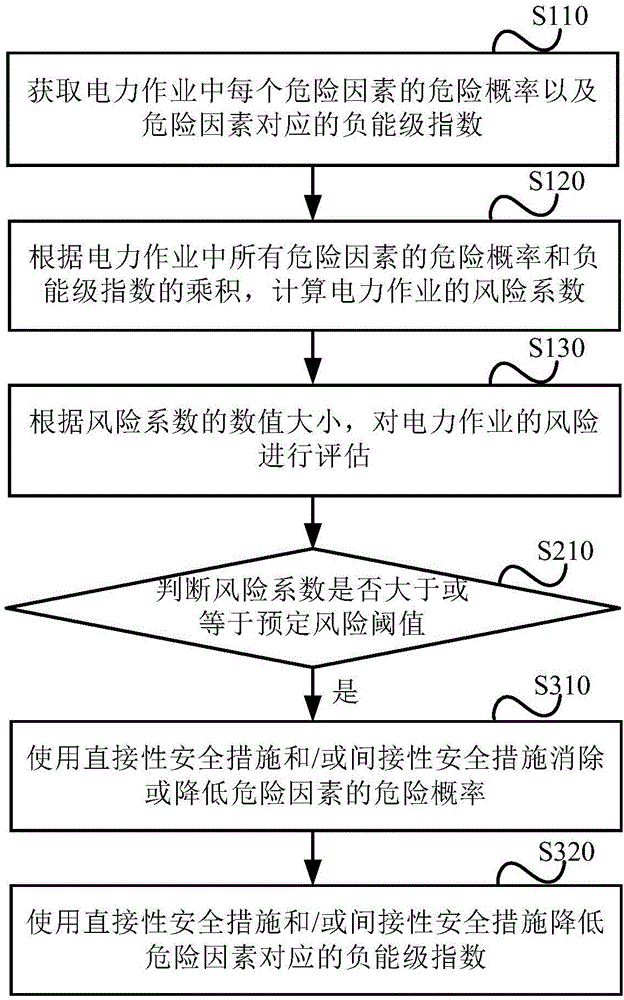

Power operation risk assessment method and system

The embodiment of the present invention discloses an electric power operation risk assessment method and system, wherein the electric power operation risk assessment method includes: obtaining the danger probability of each dangerous factor in the electric power operation and the negative energy level index corresponding to the dangerous factor, wherein, The risk factors include dangerous electrical equipment and electrical environment; the risk coefficient of the electrical operation is calculated according to the product of the danger probability of all the risk factors in the electrical operation and the negative energy level index; size, to assess the risk of the electrical work in question. The technical solution of the invention can qualitatively and quantitatively analyze the risk of electric power operation, and reduce the error of electric power operation risk assessment.

Owner:HUANENG POWER INTERNATIONAL +1

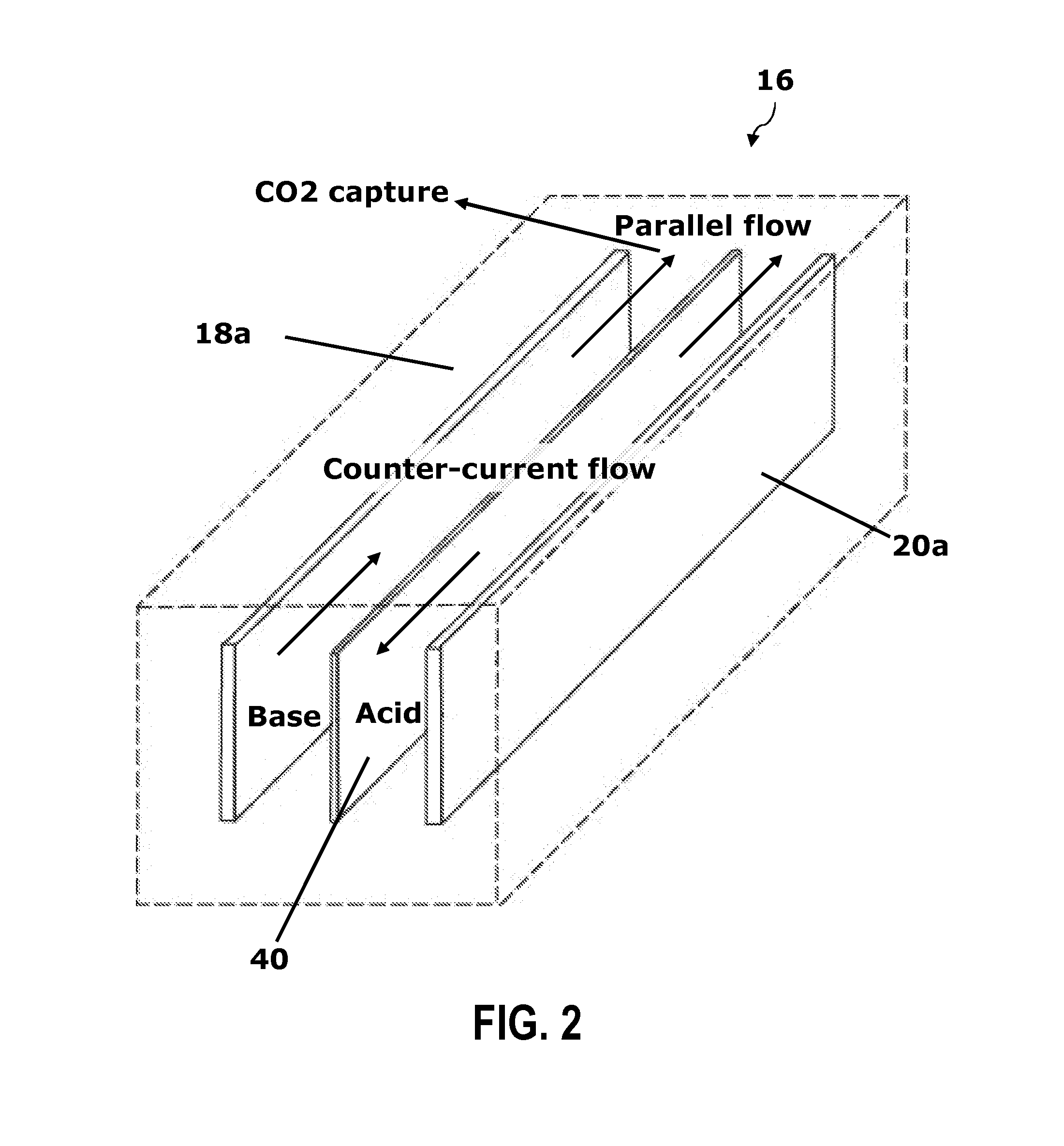

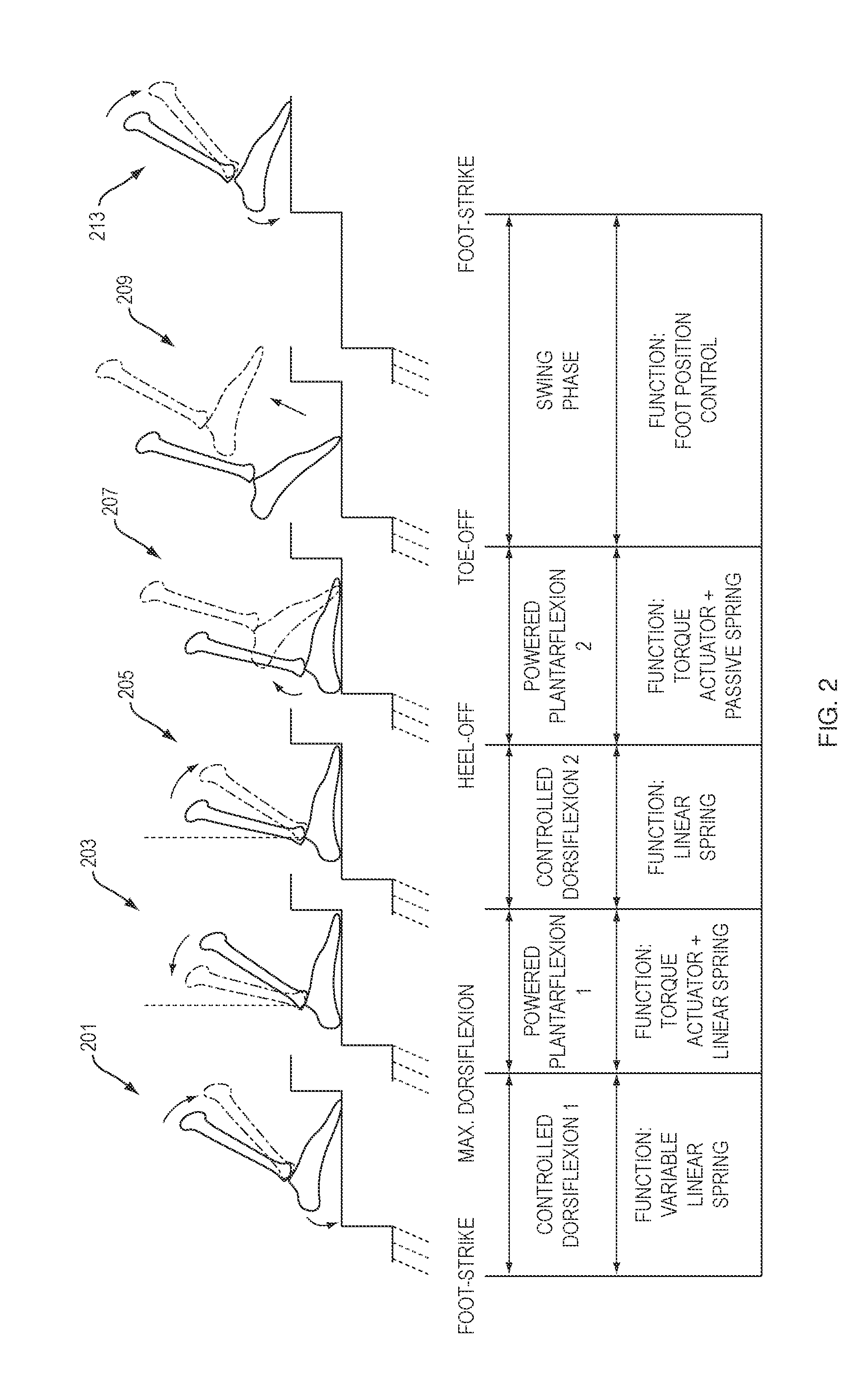

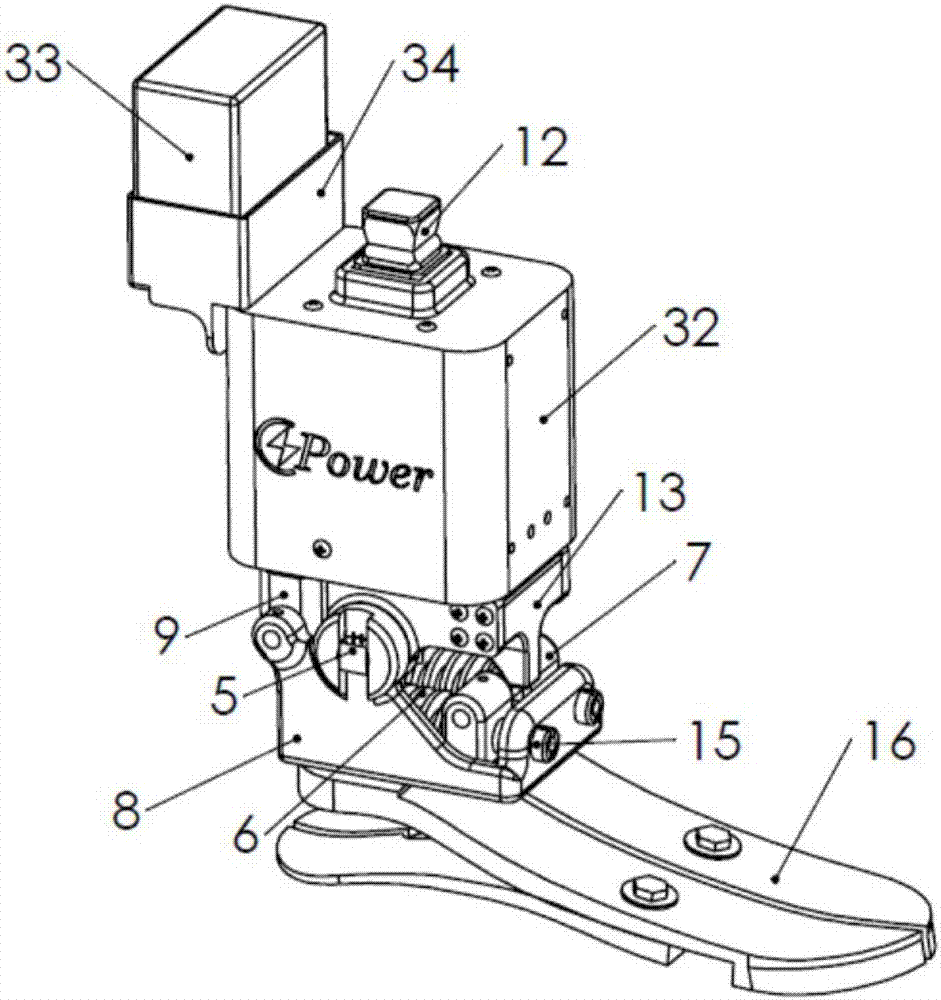

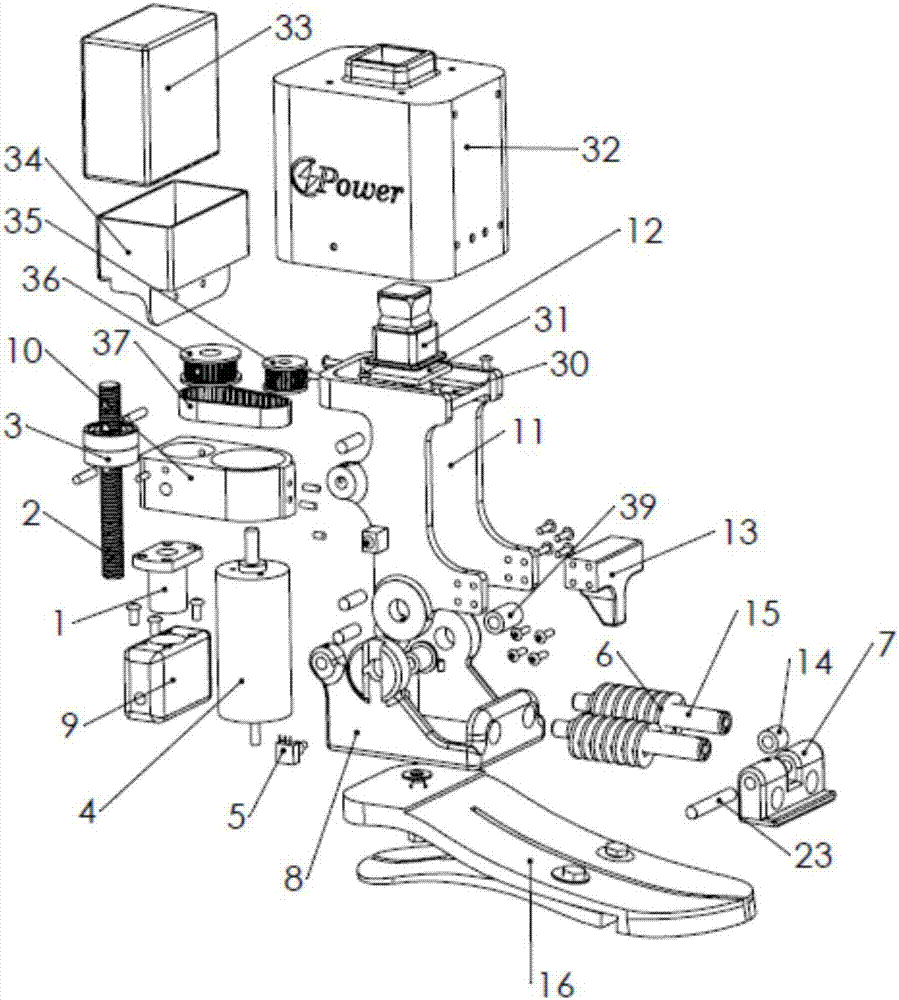

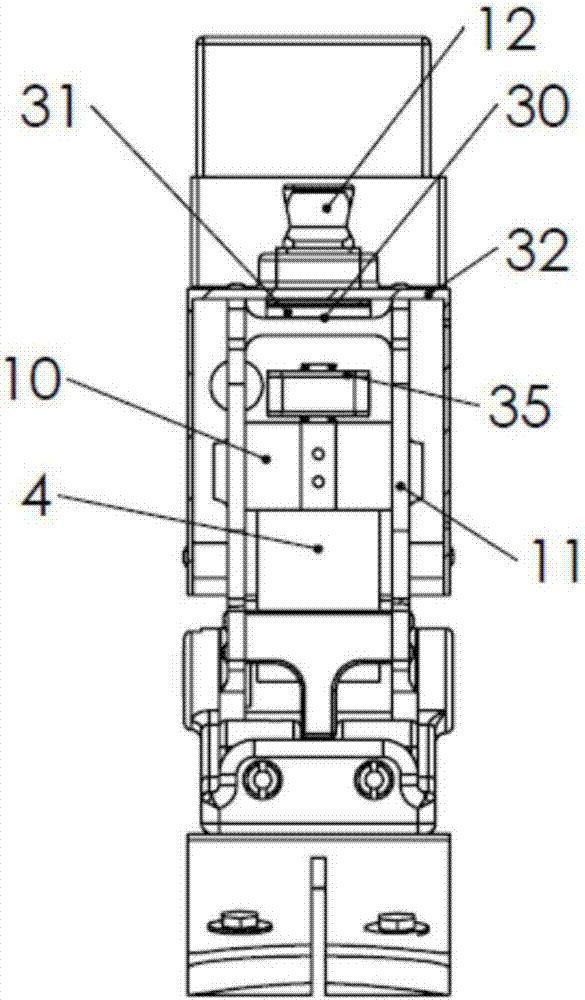

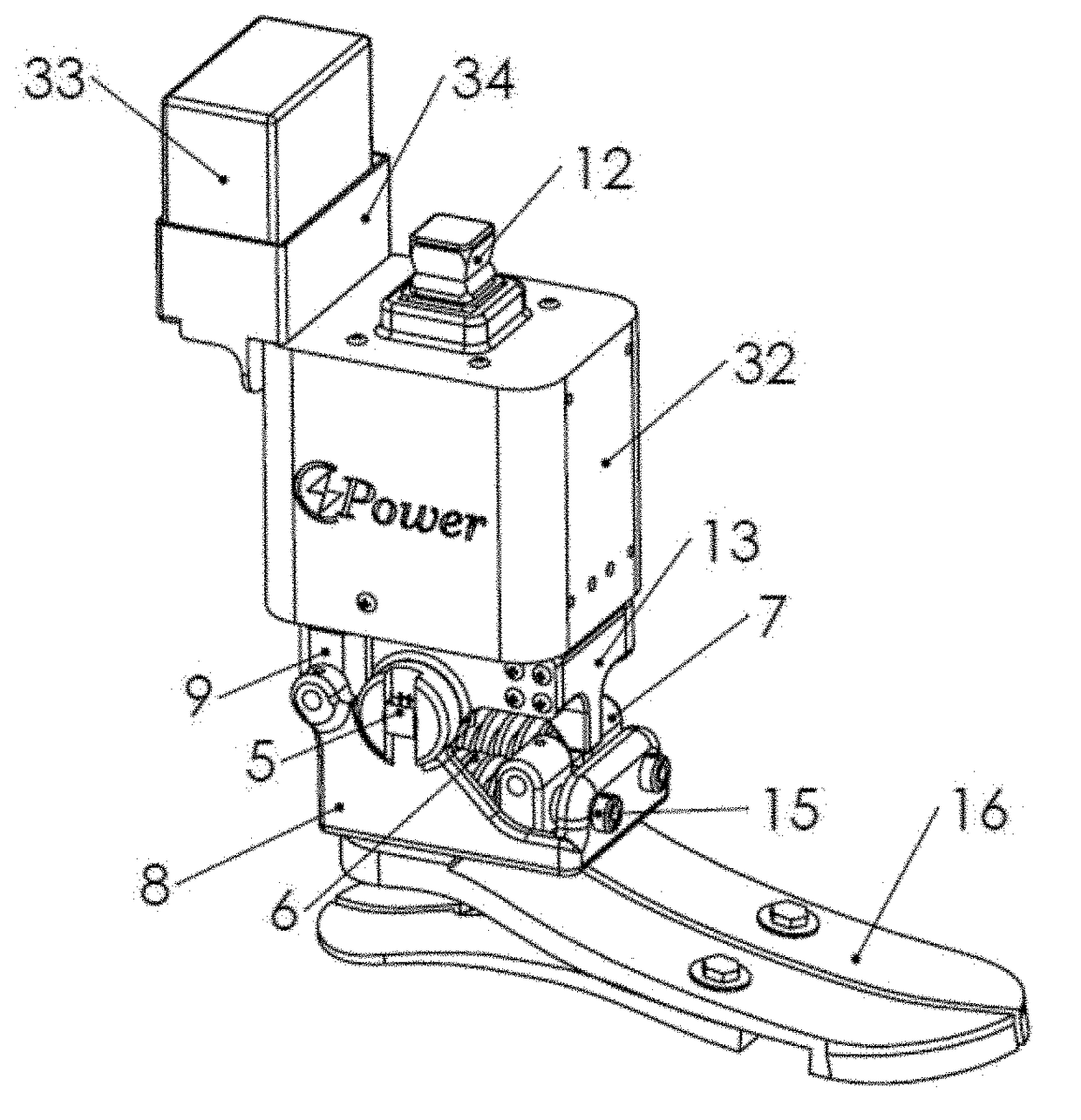

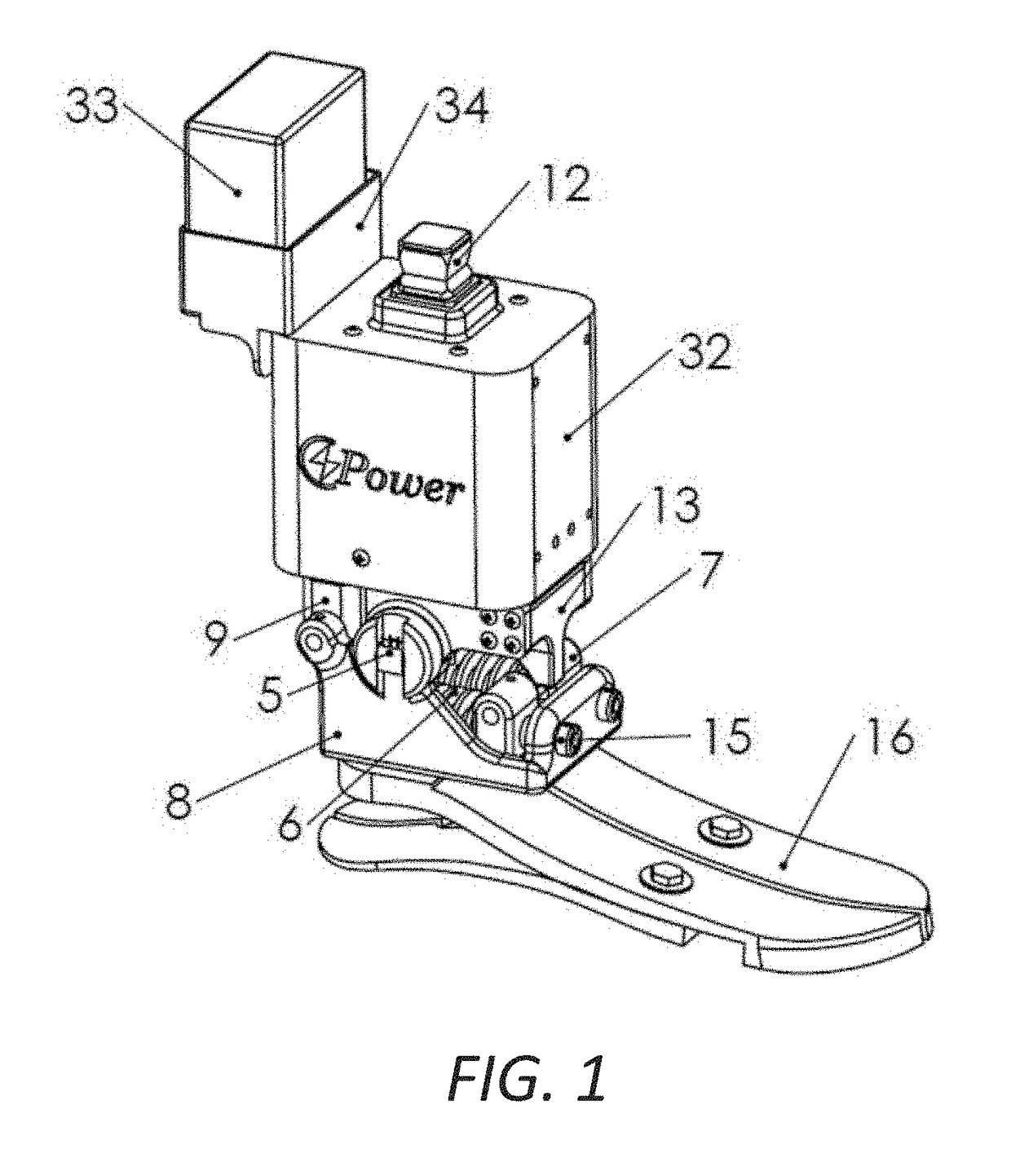

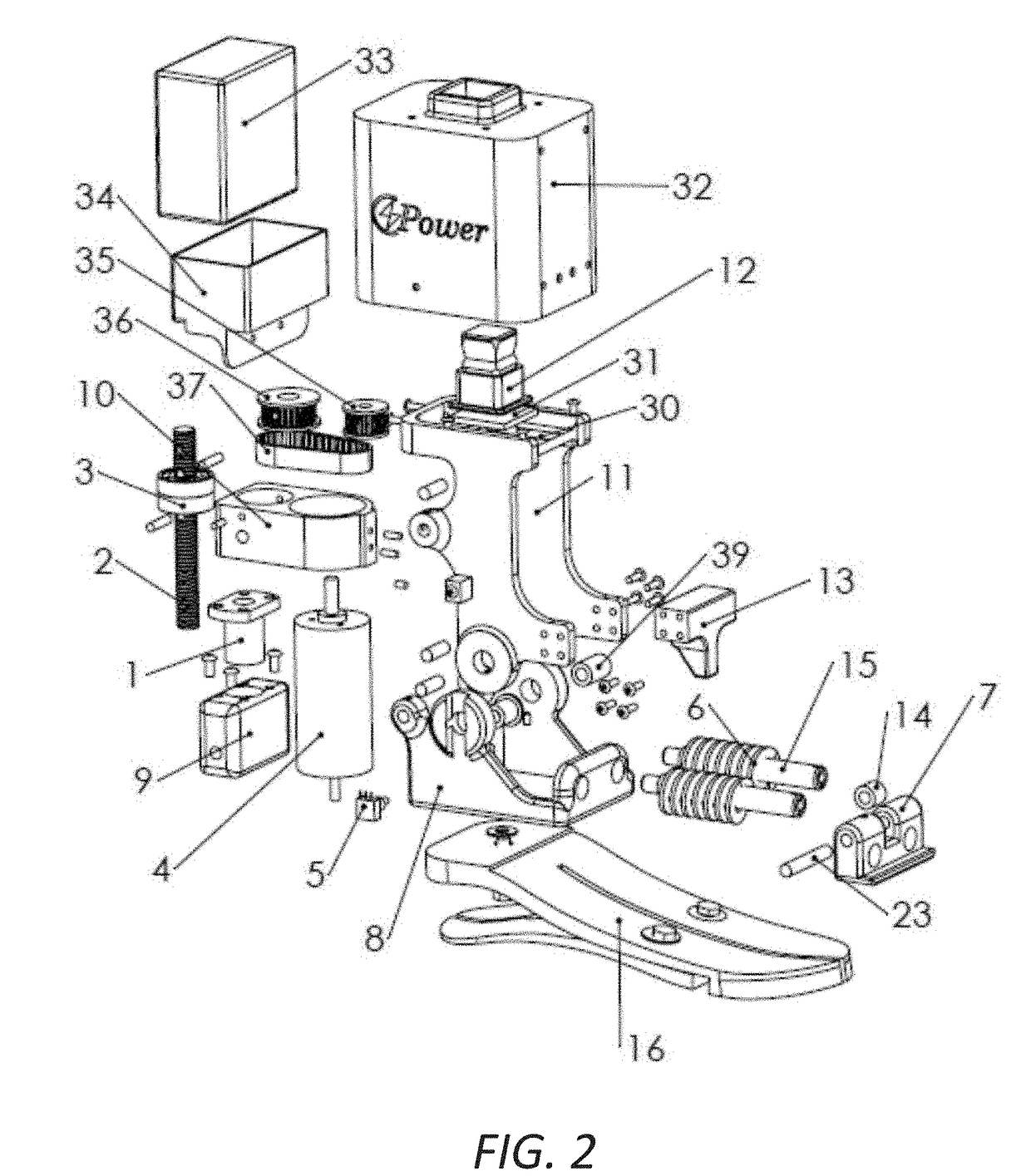

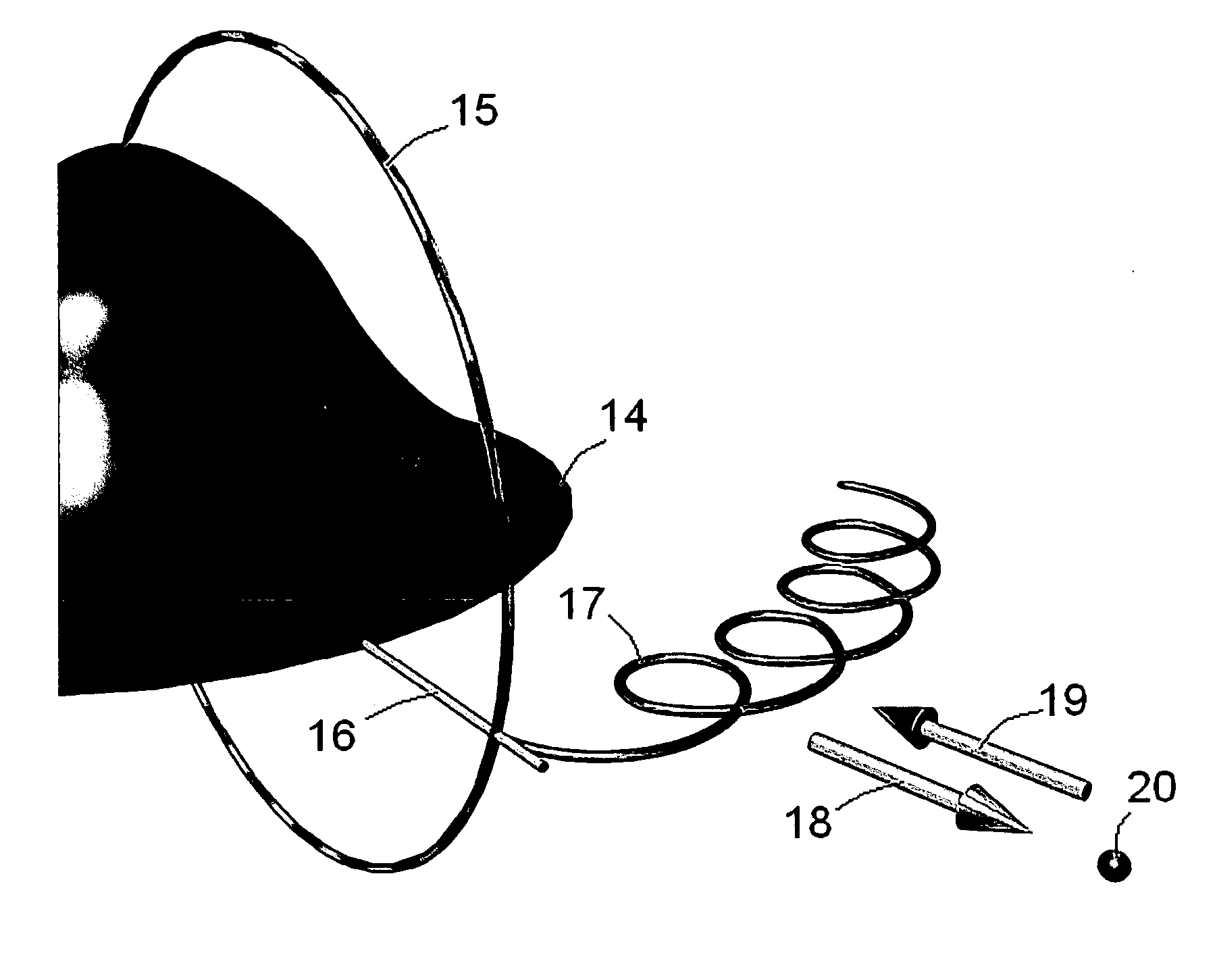

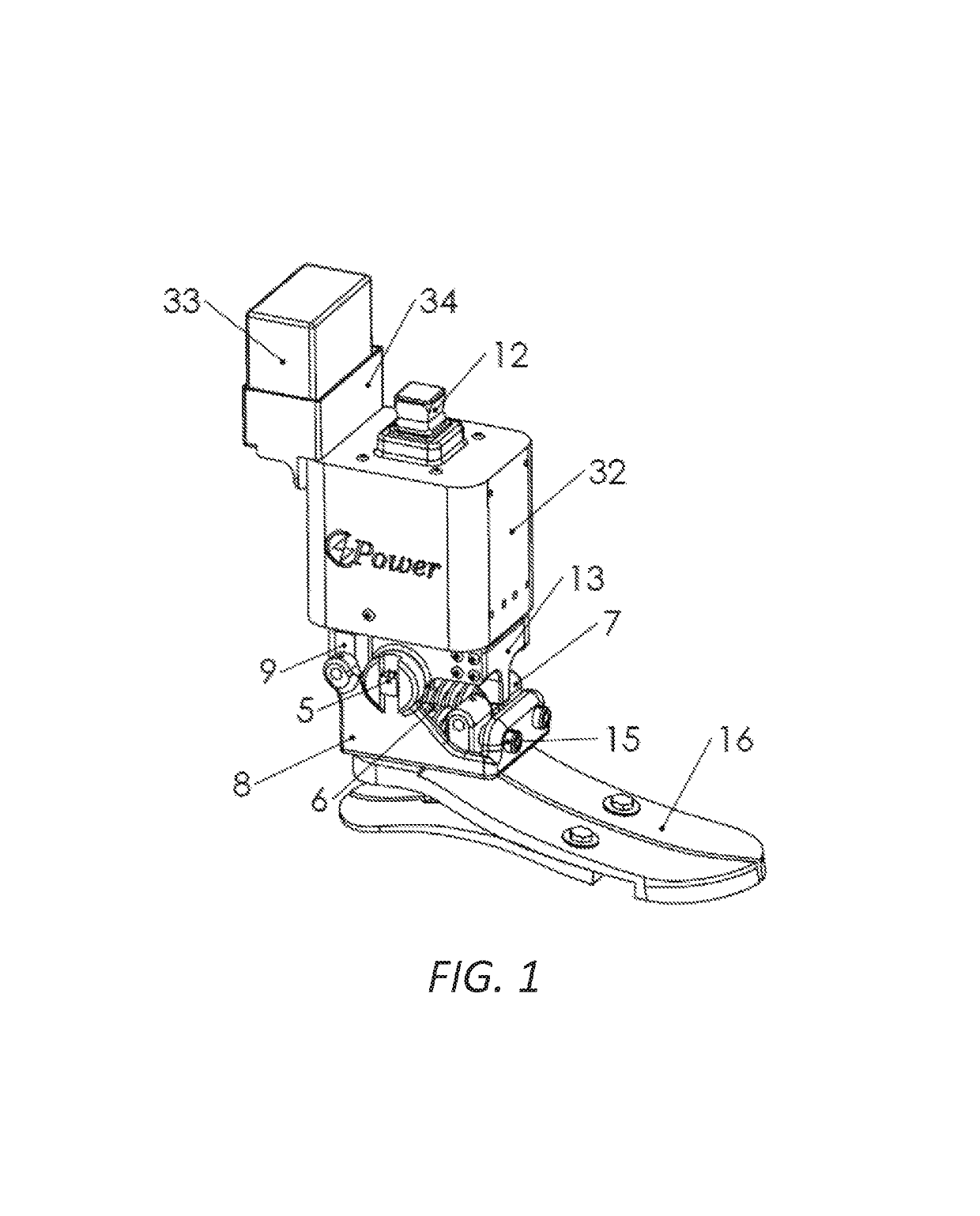

Ankle-foot prosthesis device

A powered ankle-foot prosthesis and associated methods of use are described herein. Such prostheses can employ an actuator and elastic components, the actuator being controlled to deliver net positivework to propel the wearing amputee forward and the elastic components being used to store and release negative energy to improve efficiency. Elastic components can be linear springs coupled with a cam and configured in parallel to the actuator. The cam profile can be designed to generate a desired spring torque versus angle curve rather than a spring stroke versus angle curve, thereby reproducinghuman ankle controlled dorsiflexion stiffness. Such configurations improve system energy efficiency and reduce both actuator torque and power requirements. Such prostheses can also operate in a passive mode, in which a nearly normal gait can be achieved even without powered assist.

Owner:THE CHINESE UNIVERSITY OF HONG KONG

Quinoa biscuit

InactiveCN107347958AInhibit synthesisAccelerate decomposition and conversionDough treatmentModified nutritive productsMomordica grosvenoriNegative energy

The invention belongs to a batter, dough or mixture before backing and provides a quinoa biscuit. The quinoa biscuit is made from quinoa powder, momordica grosvenori sugar substitute, linseed oil, white kidney bean powder, natural cucurbit and vegetable powder, wheat powder, eggs, yeast, maltodextrin, sorbitol and corn starch. The quinoa biscuit integrates the three scientific concepts of low glycemic index, negative energy balance and nutrition balance and thoroughly overcomes various shortcomings of traditional weight losing. The quinoa biscuit replaces meals, adjusts the metabolism function of the human body, inhibit fat synthesis, improves the glycogen storage ability of the liver and muscles, supplements the nutrition required by the human body and achieves healthy balance, the fat problem is solved from the source, slimming is easy, and the body is built.

Owner:田晓露

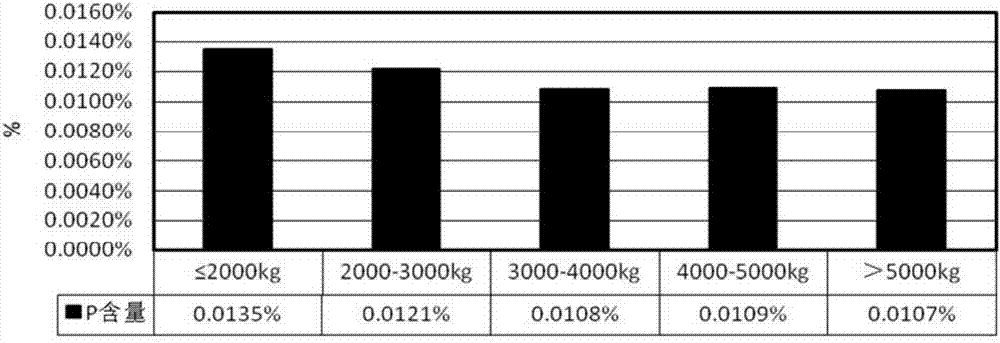

Method for improving coal gas recovery of semi-steel steel-making dry dedusting system

InactiveCN102912075AEasy to recycleIncrease profitManufacturing convertersDifferential pressureEngineering

The invention provides a method for improving coal gas recovery of a semi-steel steel-making dry dedusting system. The method includes the following steps: monitoring the volume concentration of carbon monoxide and oxygen in dedusted smoke; collecting the dedusted smoke under the conditions that the volume concentration of carbon monoxide is not less than 33% and the volume concentration of oxygen is not more than 1%; lowering a movable smoke hood of a converter after the converter starts converting for 20-60s so as to keep the space between the movable smoke hood of the converter and the mouth of the converter within 200-350mm, and controlling the micro differential pressure at the mouth of the converter within 5-10mbar; and moreover, controlling the rotational speed of a fan of the dry dedusting system within 1300-1400rpm during loading period of the converter, controlling the rotational speed of the fan within 1000-1150rpm during the converting process, and controlling the rotational speed of the fan within 1000-1100rpm during the tapping and splashing process. The method provided by the invention can improve the coal gas recovery of the semi-steel steel-making dry dedusting system, and as a result, the energy utilization ratio as well as the negative energy steel-making level can be improved.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

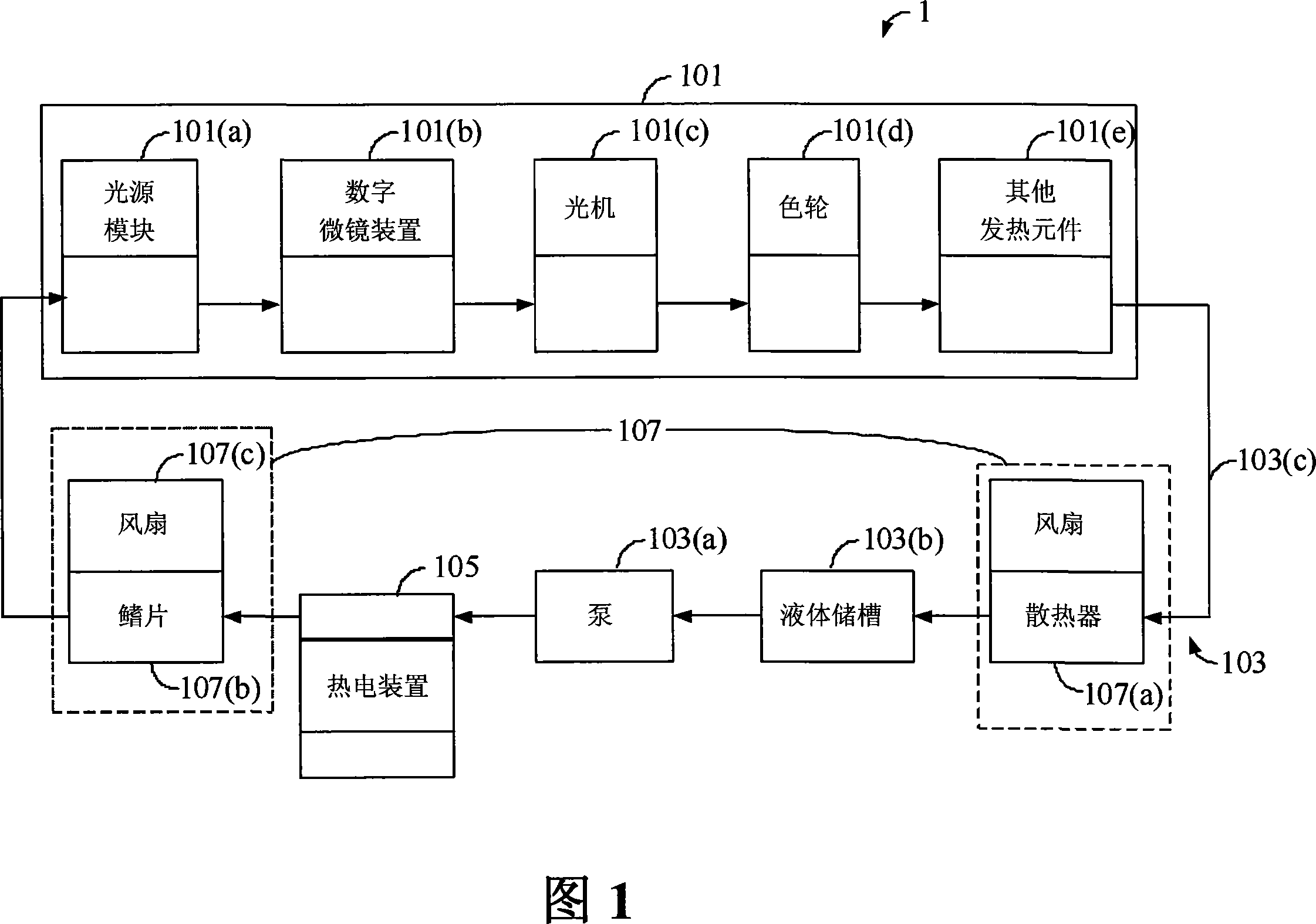

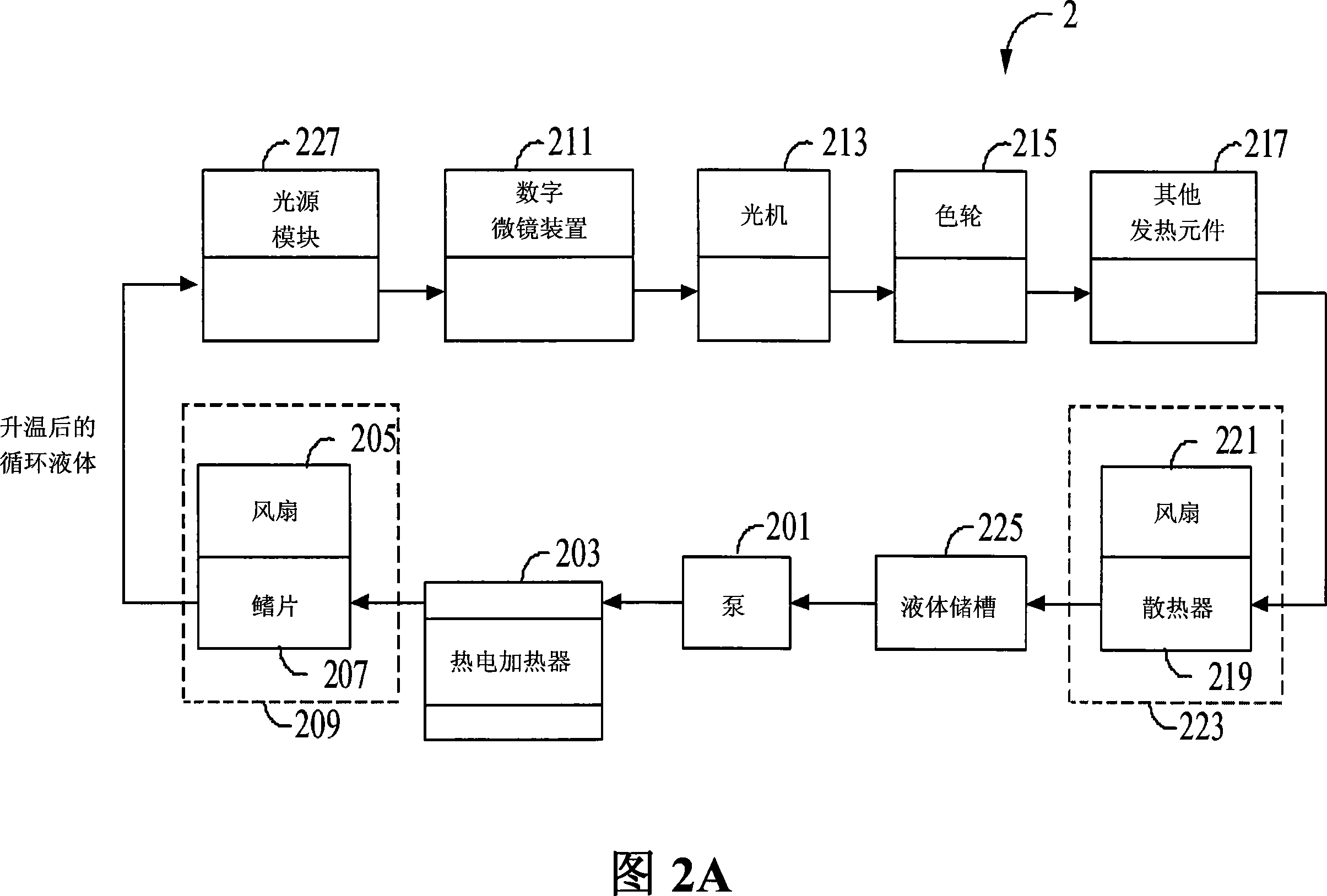

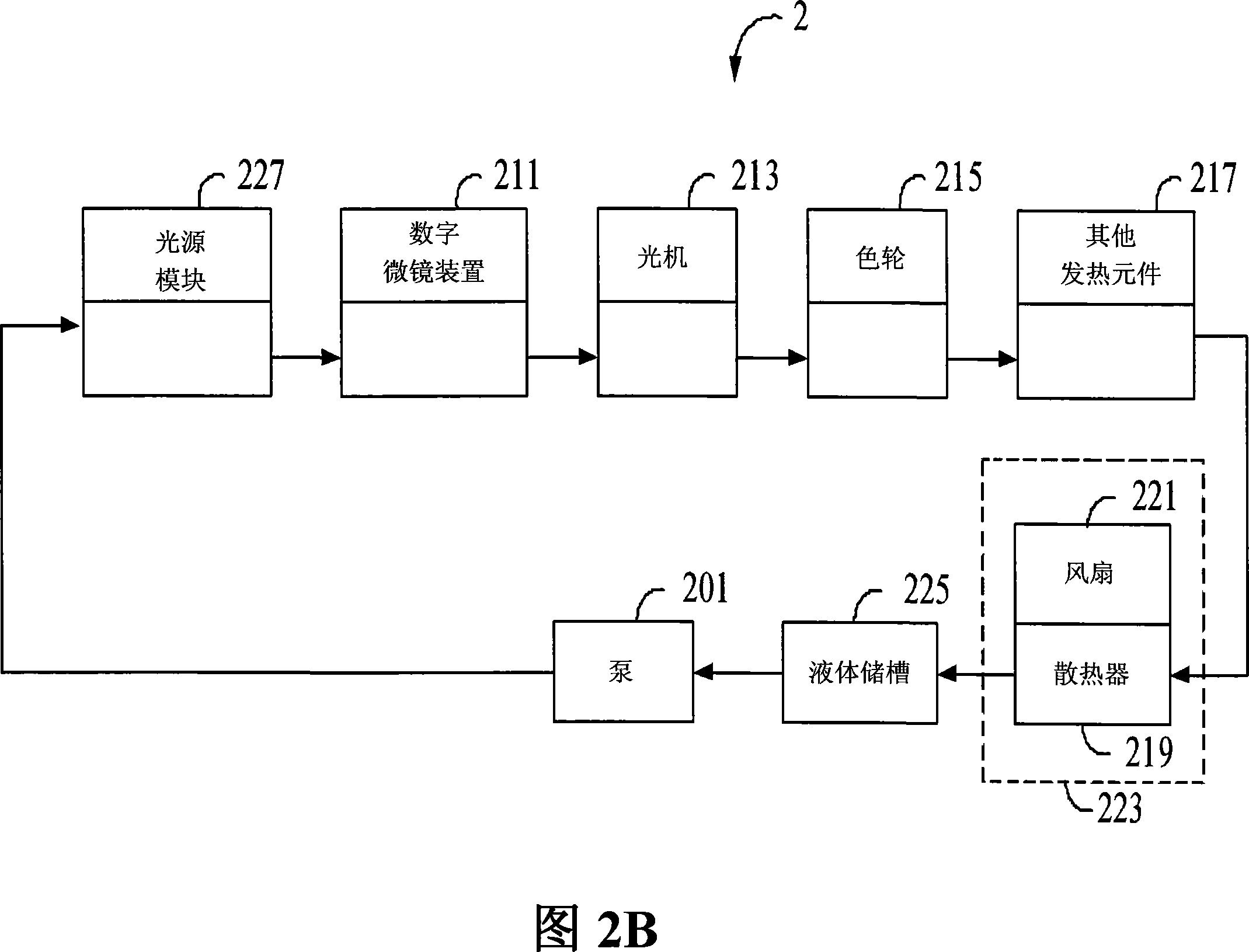

Projection device

InactiveCN101063797AGuaranteed working temperatureProper working temperatureTemperatue controlProjectorsTemperature controlThermal energy

This invention relates to one projection device with temperature control system, which comprises at least one light element, wherein the temperature control system has liquid tube system, thermal energy generation device and deliver device; the tube system is set along at least one light element; the energy device can generate positive or negative energy in environment and then thermal energy through aid device along liquid tube system without outer impact; the sustain projection device is set in one needed work temperature to keep temperature balance.

Owner:DELTA ELECTRONICS INC

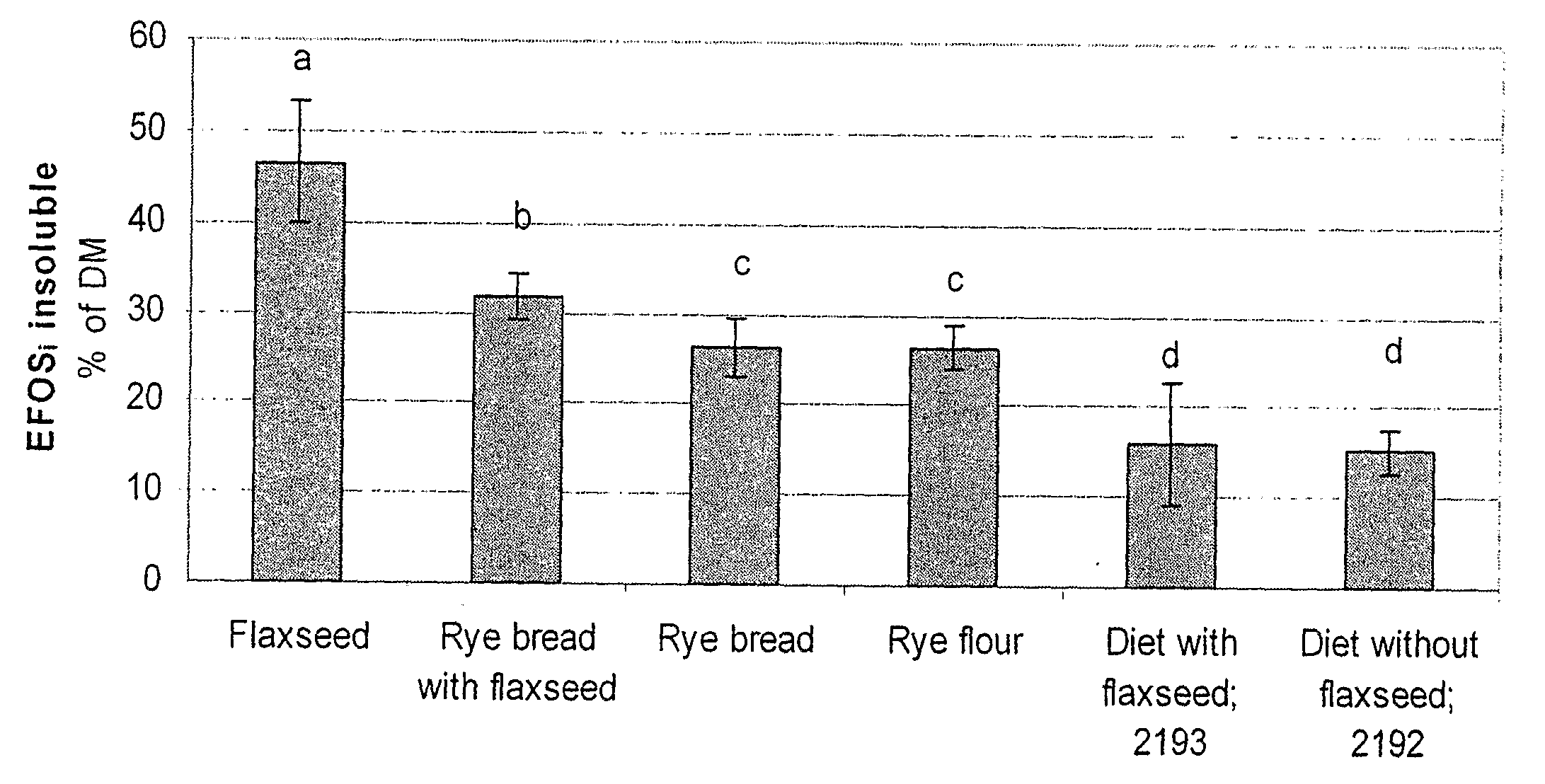

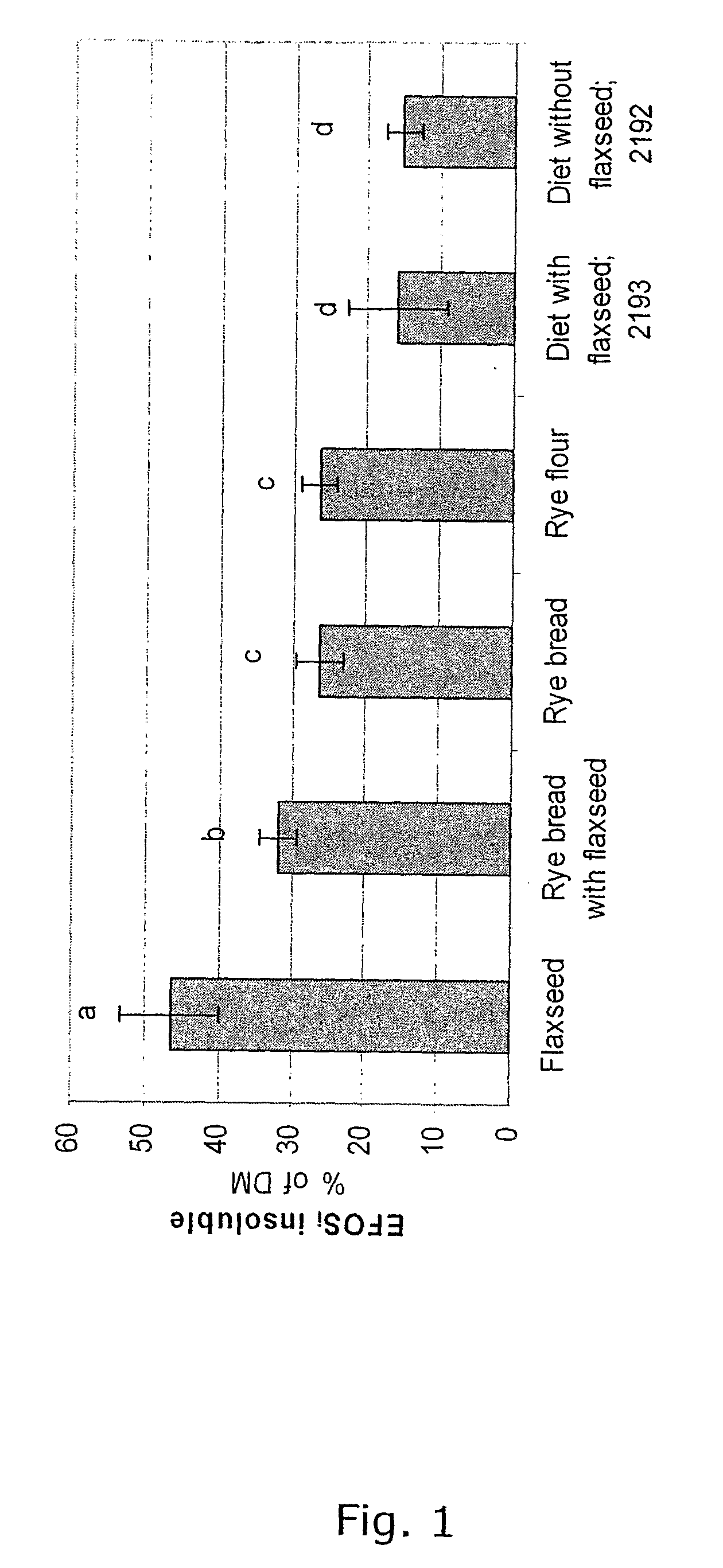

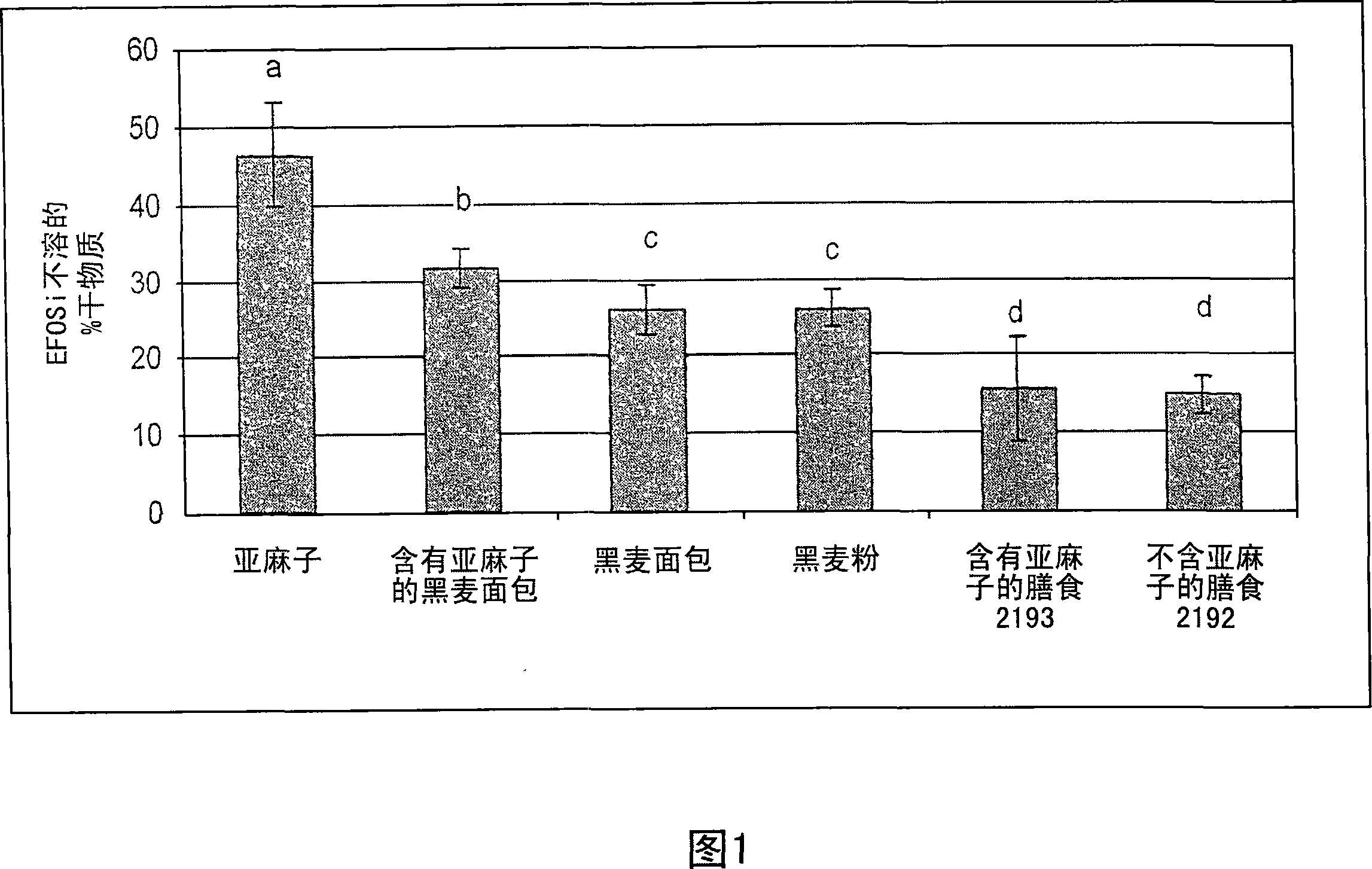

Flaxseeds for Body Weight Management

ActiveUS20070292542A1Induce energy balanceInduce weight lossBiocideDough treatmentWeight gainingAdditive ingredient

The present invention relates to methods for reducing fat uptake in the gastrointestinal tract of a mammal in order to prevent a positive energy balance, weight gain, overweight and obesity, and to induce a negative energy balance and weight loss in subjects who wish to reduce their body weight. In particular, food and / or beverage ingredients and dietary supplements of the present invention comprises flaxseeds useful for increasing faeca fat excretion from the gastrointestinal tract.

Owner:UNIVERSITY OF COPENHAGEN

Ankle-Foot Prosthesis Device

ActiveUS20180085237A1Reduce energy consumptionNegative mechanical energyArtificial legsElastic componentActuator

A powered ankle-foot prosthesis and associated methods of use are described herein. Such prostheses can employ an actuator and elastic components, the actuator being controlled to deliver net positive work to propel the wearing amputee forward and the elastic components being used to store and release negative energy to improve efficiency. Elastic components can be linear springs coupled with a cam and configured in parallel to the actuator. The cam profile can be designed to generate a desired spring torque versus angle curve rather than a spring stroke versus angle curve, thereby reproducing human ankle controlled dorsiflexion stiffness. Such configurations improve system energy efficiency and reduce both actuator torque and power requirements. Such prostheses can also operate in a passive mode, in which a nearly normal gait can be achieved even without powered assist.

Owner:THE CHINESE UNIVERSITY OF HONG KONG

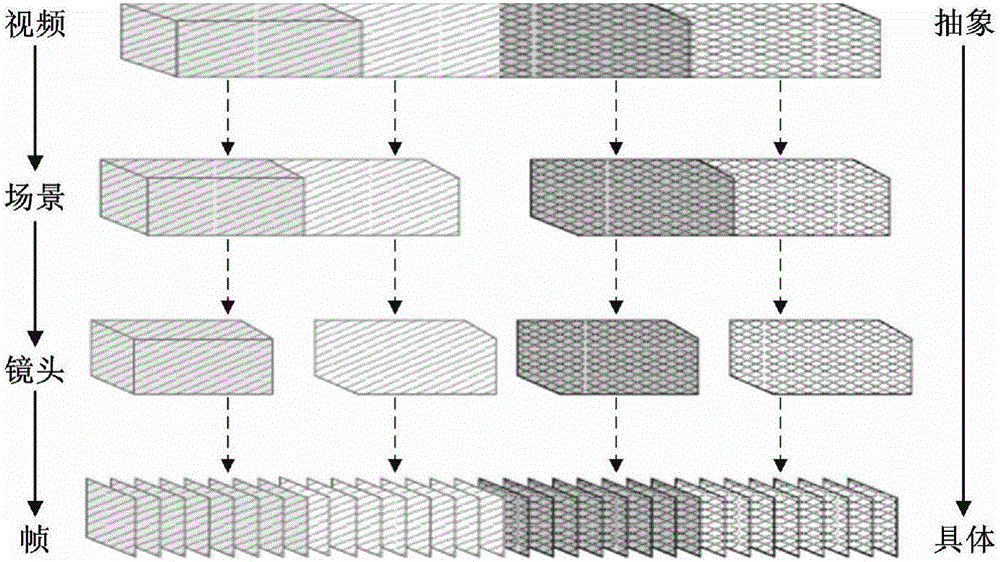

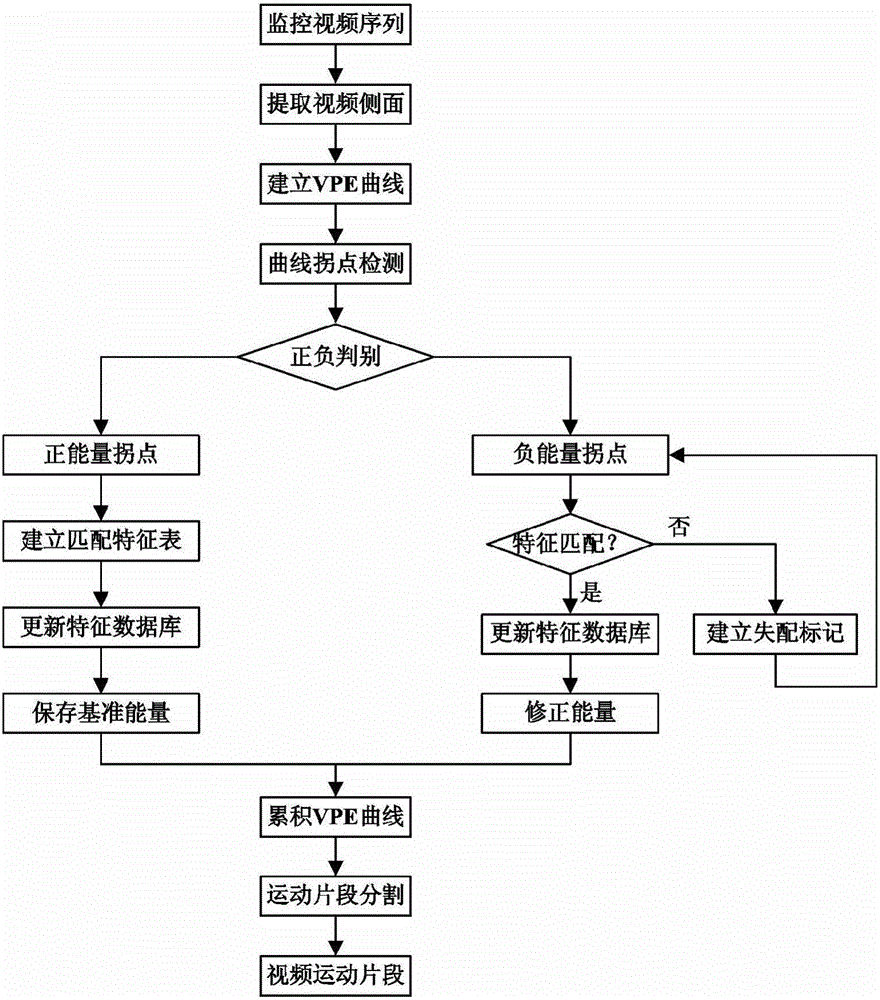

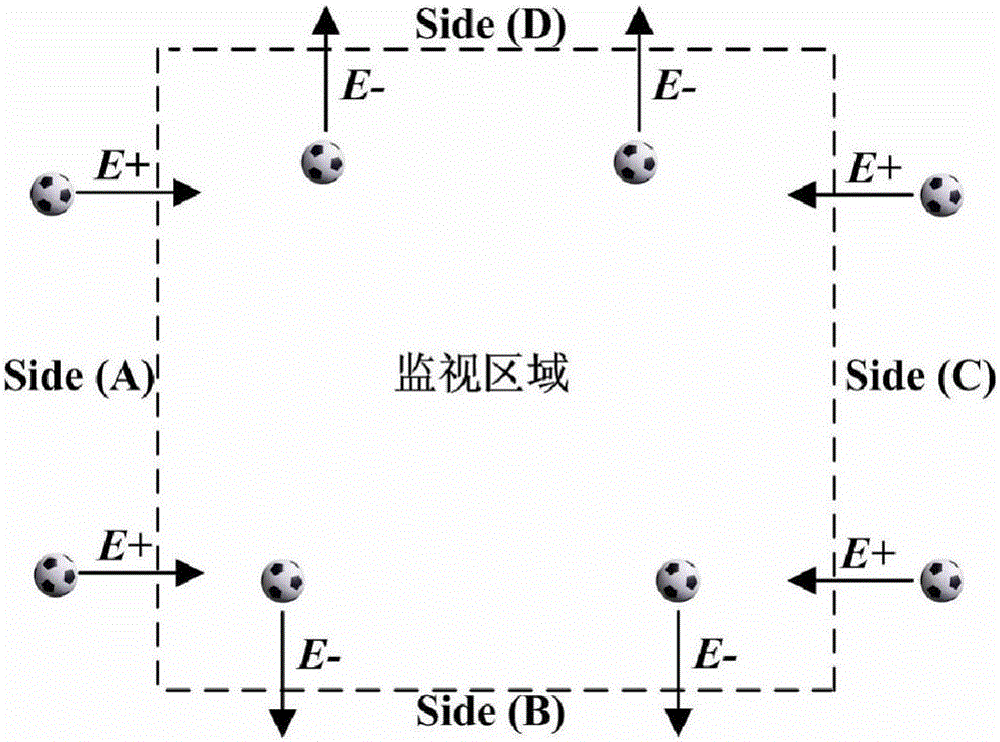

Monitoring video motion fragment segmentation method based on visual perception energy

ActiveCN106127813AReduce data volumeImprove accuracyImage analysisVisual monitoringImaging processing

The invention discloses a monitoring video motion fragment segmentation method based on visual perception energy, and relates to the technical field of an image processing method. The method comprises the following steps that the side surface of a monitoring video sequence is extracted at the boundary of moving in and out of a visual monitoring area of a moving target, and target deformation on the video side surface is analyzed and a VPE curve is established; the inflection points of the VPE curve are detected and the positive and negative energy inflection points are processed; statistics of the VPE of all the positive energy inflection points and the corrected VPE of the negative energy inflection points is performed, and a cumulative VPE curve is drawn; and monitoring video motion fragment segmentation is performed according to the cumulative VPE curve, wherein the VPE refers to visual perception energy. According to the method, the accuracy of monitoring video motion fragment segmentation is enhanced and the video data volume requiring processing is greatly reduced.

Owner:XIAMEN TONGJING INTELLIGENT TECH CO LTD

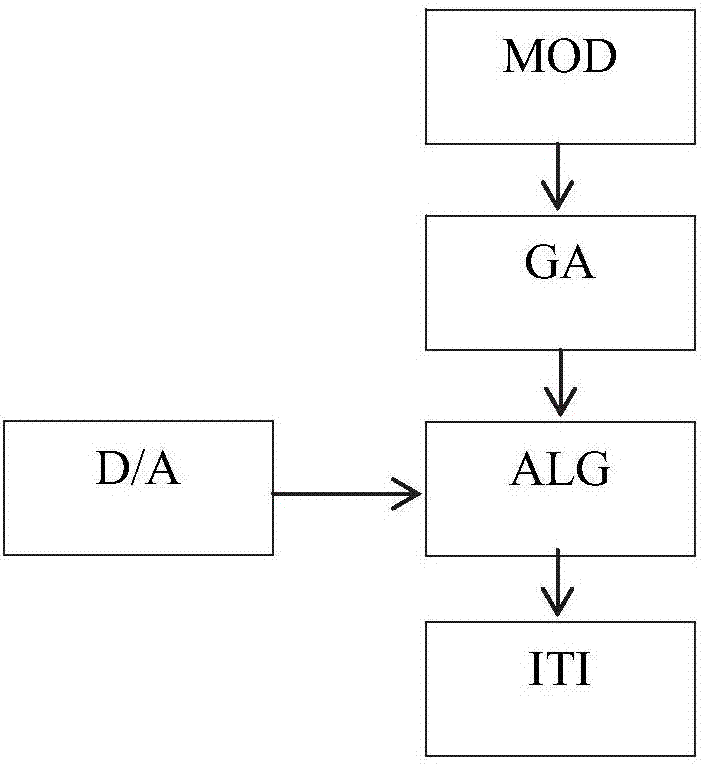

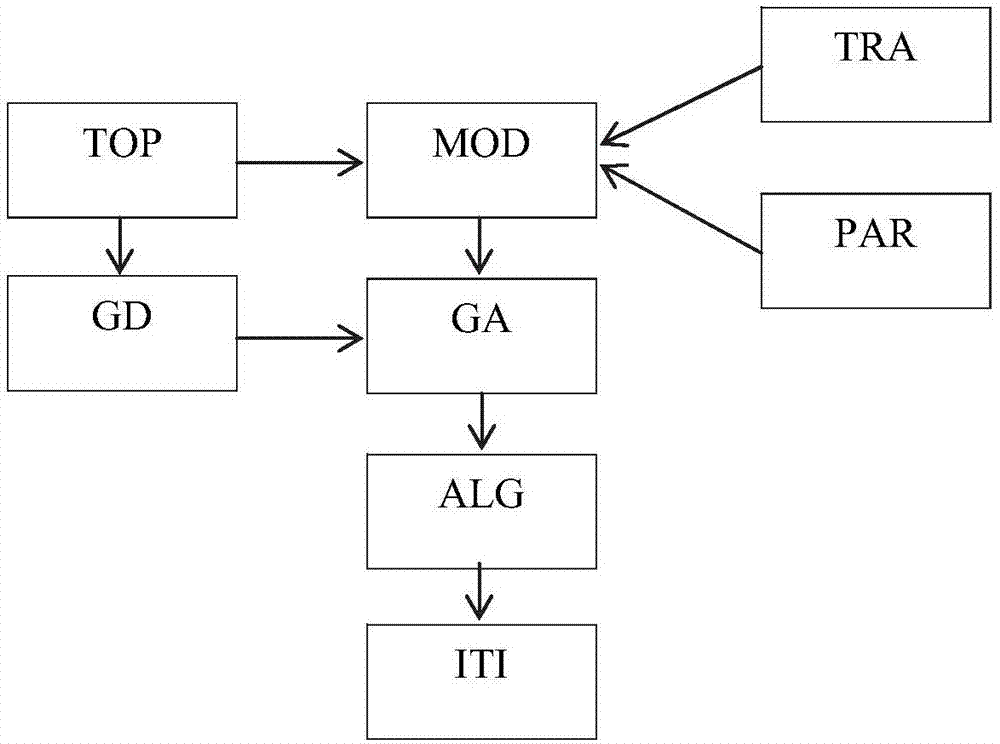

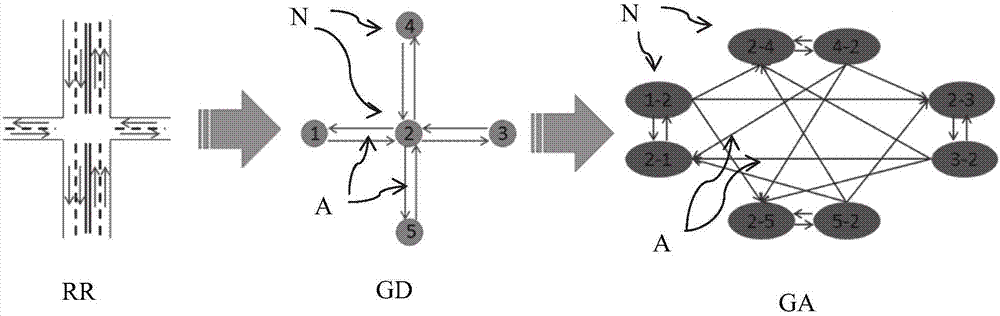

Method for determining an itinerary minimising the energy consumption of a vehicle by means of an adjunct graph

InactiveCN107972673ANavigational calculation instrumentsControl devicesEnergy consumption minimizationVehicle dynamics

The present invention relates to a method for determining a route (ITI) that minimizes the energy consumption of a vehicle based on a vehicle dynamics model (MOD) that uses a shortest path algorithm (ALG) that is dependent on vehicle speed and acceleration, line graph (GA) construction, and suitable for negative energy.

Owner:INST FR DU PETROLE

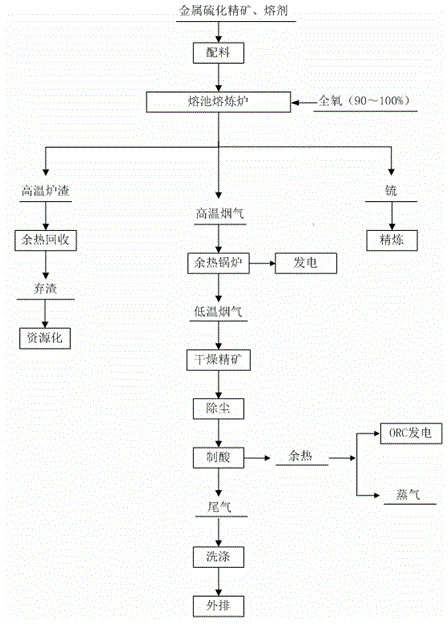

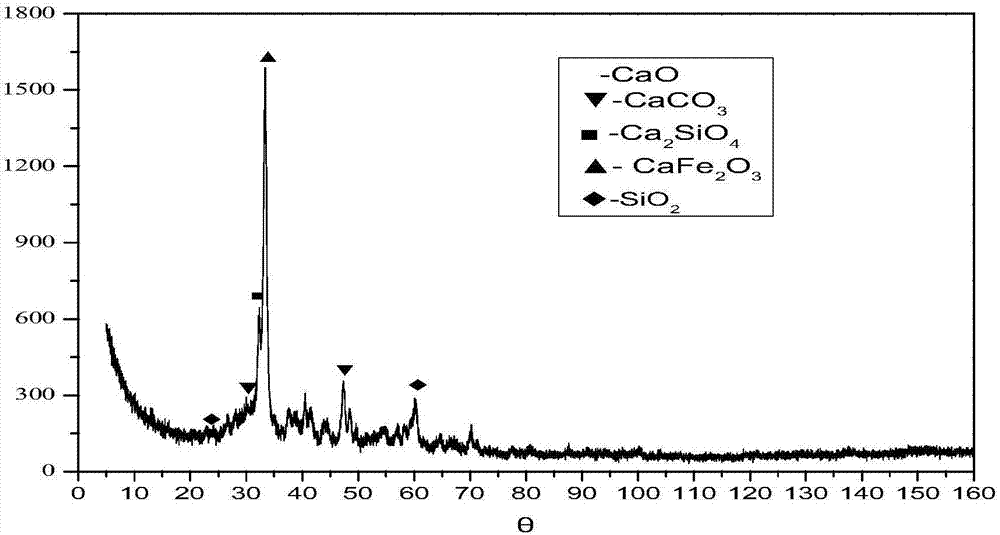

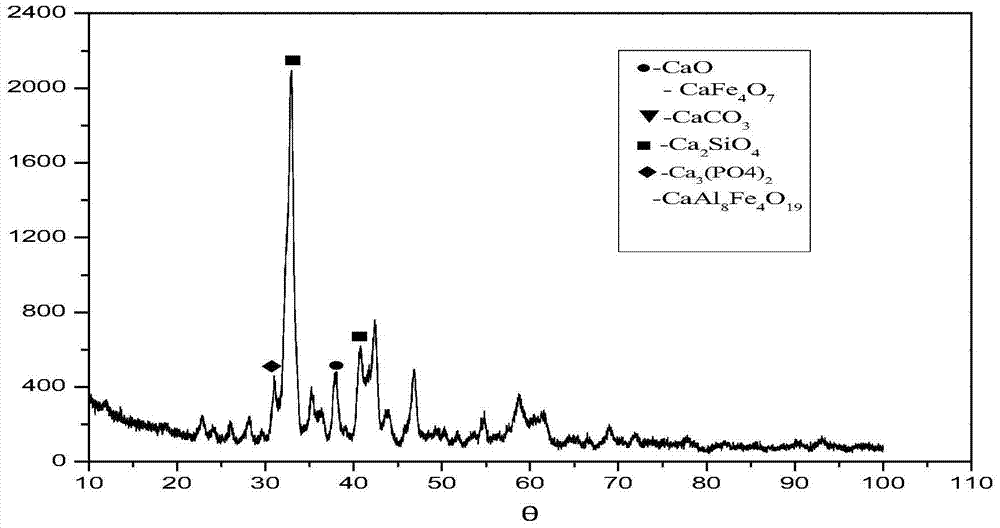

Metal sulfide ore all-oxygen negative-energy pyrogenic smelting method

ActiveCN104593616ARealize full oxygen negative energy pyrometallurgyRealize negative energy smeltingRotary drum furnacesCrucible furnacesMelting tankHigh energy

The invention relates to a metal sulfide ore all-oxygen negative-energy pyrogenic smelting method, belonging to the technical field of nonferrous metals. The method comprises the following steps: carrying out oxidizing smelting on the metal sulfide concentrate in a bath smelting furnace, wherein in the redox smelting process, 90-100 vol% all-oxygen is sprayed by a spray gun in a top blowing or side blowing mode to convert metal sulfides into metal oxides; and after the oxidizing smelting is finished, obtaining furnace slag and sulfonium, wherein high-temperature flue gas generated in the process is recovered by a waste heat boiler for power generation, low-temperature flue gas from the waste heat boiler is dedusted by an electrostatic dust collector after being used for drying the concentrate, the dedusted flue gas is used for preparing 98 wt.% sulfuric acid, heat released by acid preparation is subjected to waste heat recovery, and the waste heat is used for ORC power generation or directly used for producing steam. The method lowers the smelting cost, reduces the pollution discharge, implements high-efficiency energy utilization by the high-energy-consumption metallurgical enterprises, and has certain economic benefits and environmental benefits.

Owner:KUNMING UNIV OF SCI & TECH

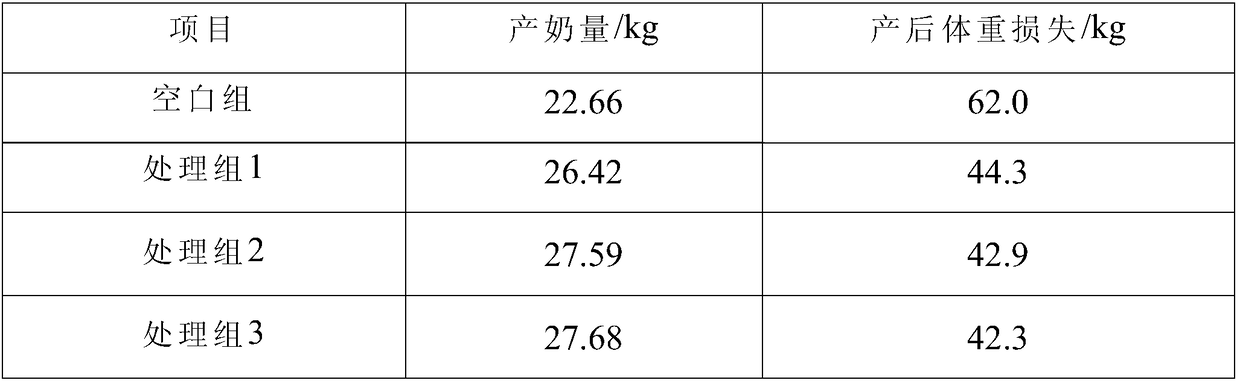

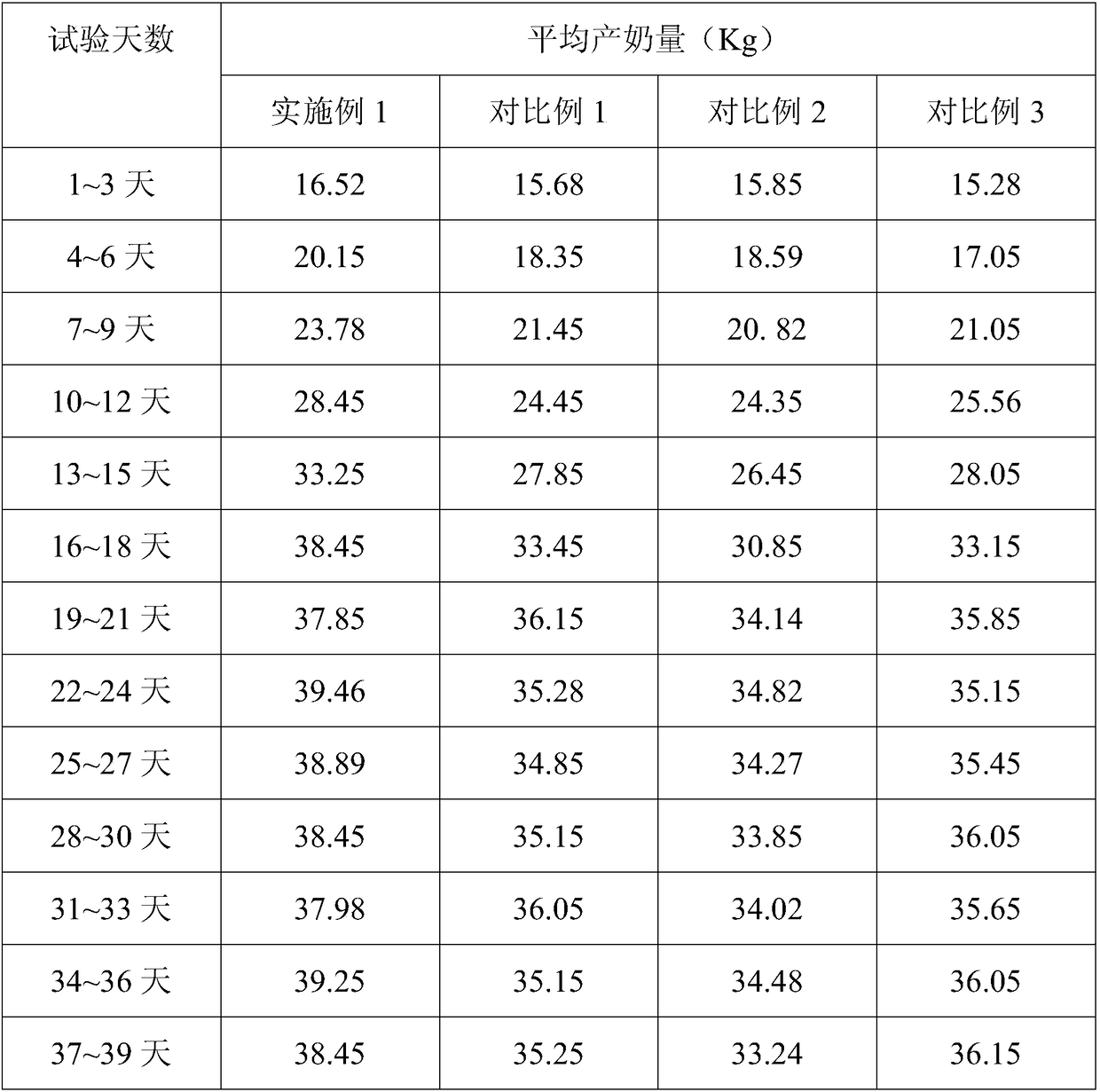

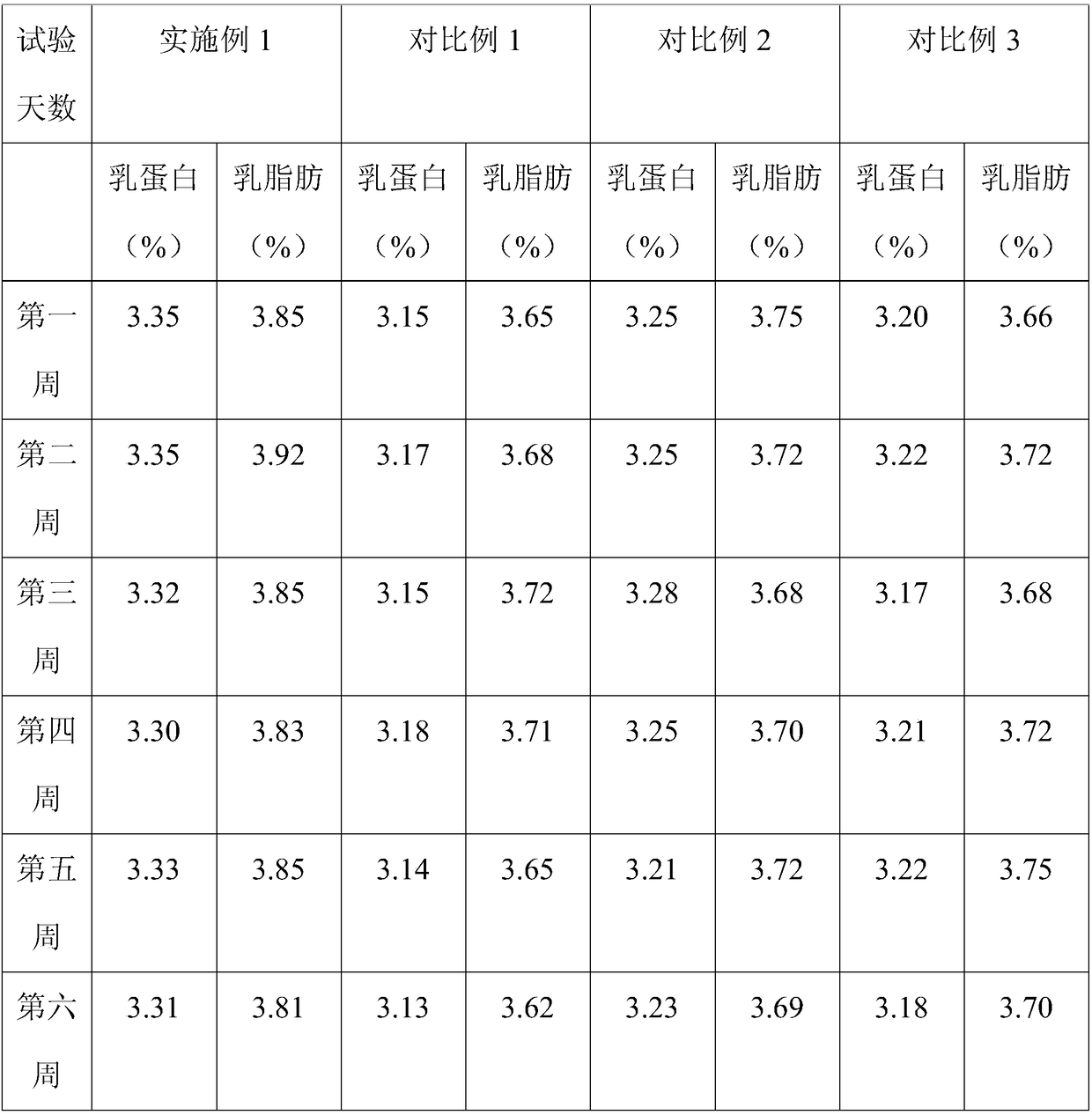

Rumen bypass glucose microcapsule and preparation method thereof

PendingCN109170251AReduce degradation rateIncrease milk productionAccessory food factorsWorking-up animal fodderSmall intestineD-Glucose

The invention discloses a rumen bypass glucose microcapsule and a preparation method thereof. The glucose microcapsule of the invention can realize high effective passage rate of glucose in the rumenand can be fully absorbed in the small intestines. Adding the rumen bypass glucose microcapsule to dairy cow diet in a late perinatal period can effectively reduce the negative energy balance in earlylactation, reduce postpartum weight loss of dairy cows, and increase milk production.

Owner:HEBEI AGRICULTURAL UNIV.

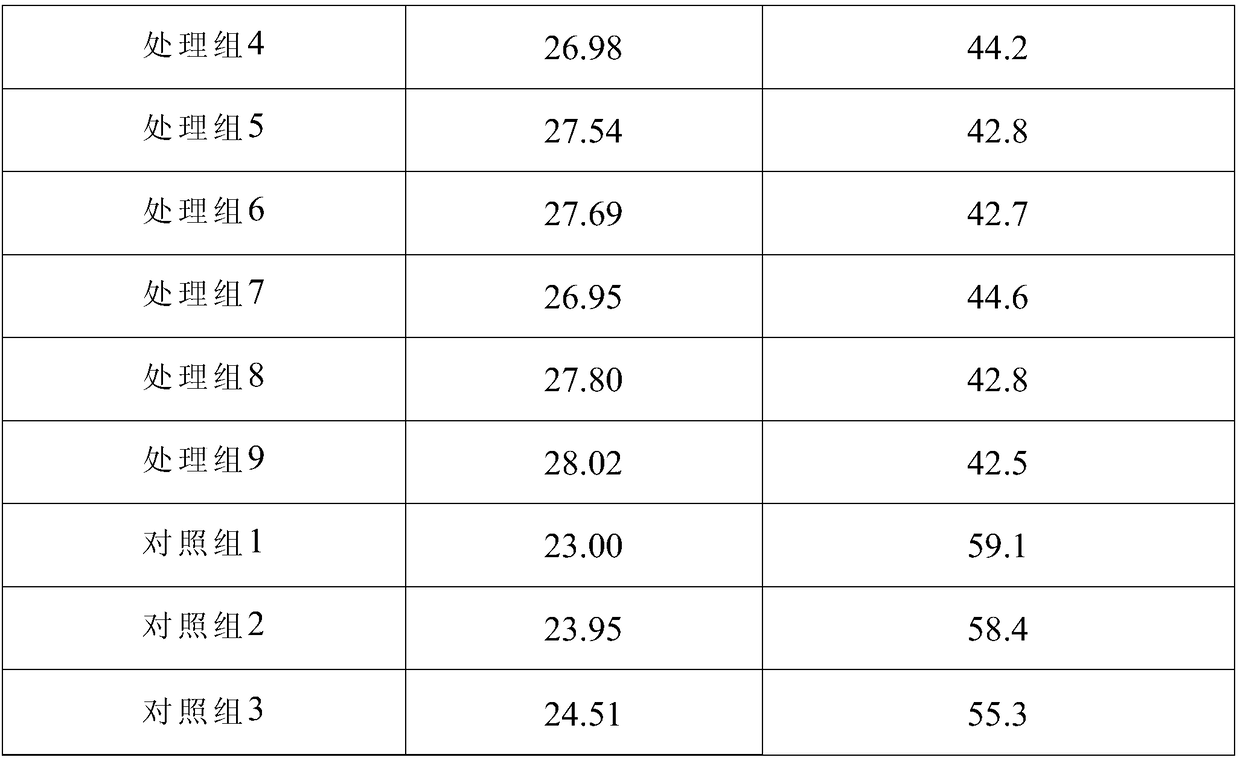

Concentrate supplement for cow in lactation period and preparation method thereof

InactiveCN108991240AImprove lactation performanceResolving Negative Energy Balance in Early LactationFood processingAnimal feeding stuffAdditive ingredientRumen

The invention relates to the technical field of feed processing, in particular to a concentrate supplement for a cow in a lactation period and a preparation method thereof. The concentrate supplementis prepared from DDGS, expanded soybeans, expanded soybean meal, sprayed corn husk, rumen fat powder, soybean lecithin powder, rumen glucose, molasses, baking soda, lysine and the like. In the concentrate supplement which is added with the components, such as the rumen glucose and the lysine, the rumen fat powder and the soybean lecithin powder are combined for use to achieve a synergistic effect,so that the problem of negative energy balance of the cow in an early lactation period can be solved better; the absorption of energy and nutritional ingredients in daily ration of the cow can be improved; the lactating capacity of the cow in the early lactation period can be played; a lactating peak can be reached more quickly after childbirth; the lactating peak period can be prolonged; the milk yield and milk quality are improved. A preparation method of the concentrate supplement for the cow in the lactation period disclosed by the invention is easy to operate, easy to control, and suitable for industrial popularization and application.

Owner:河南全赫饲料有限公司

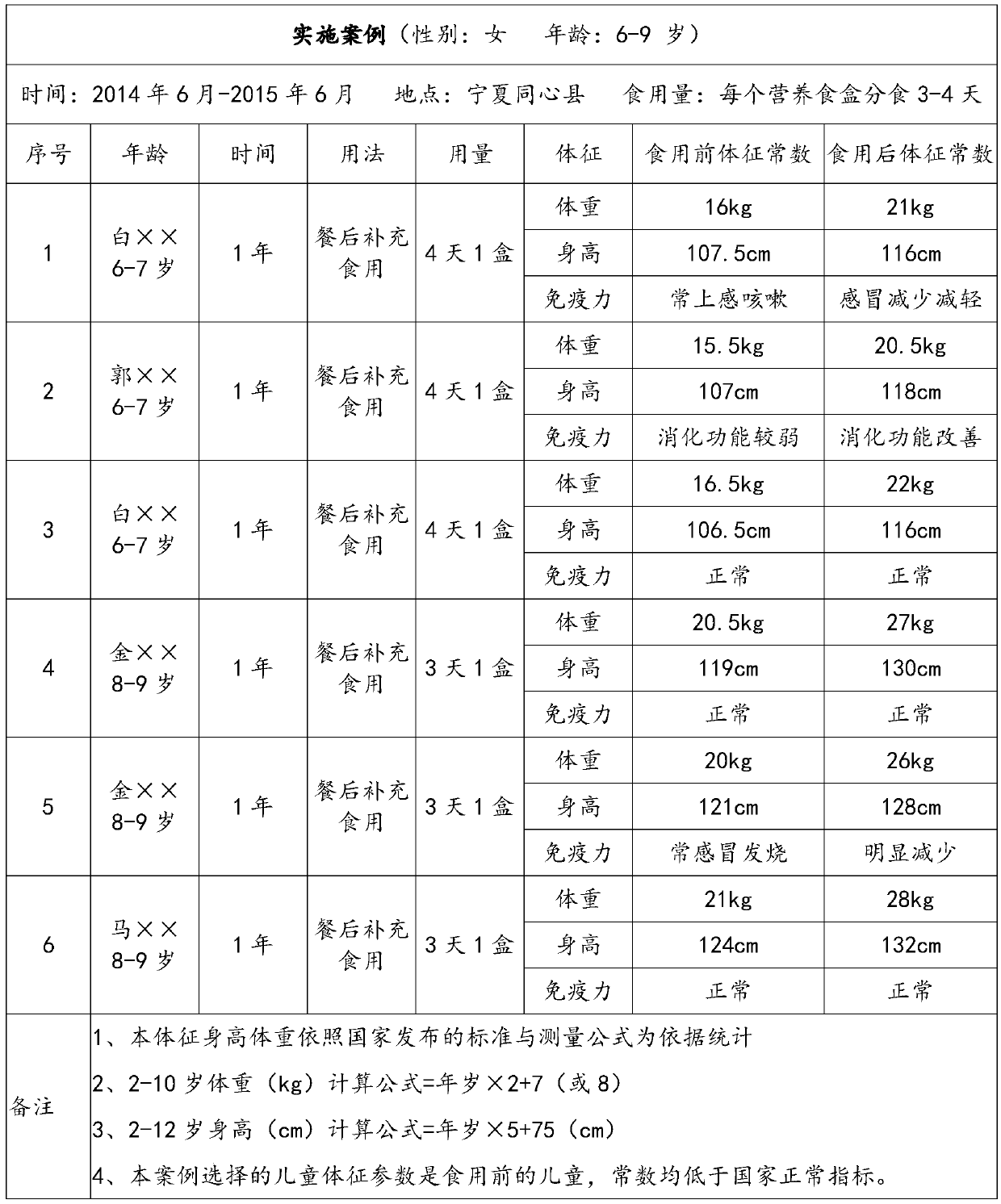

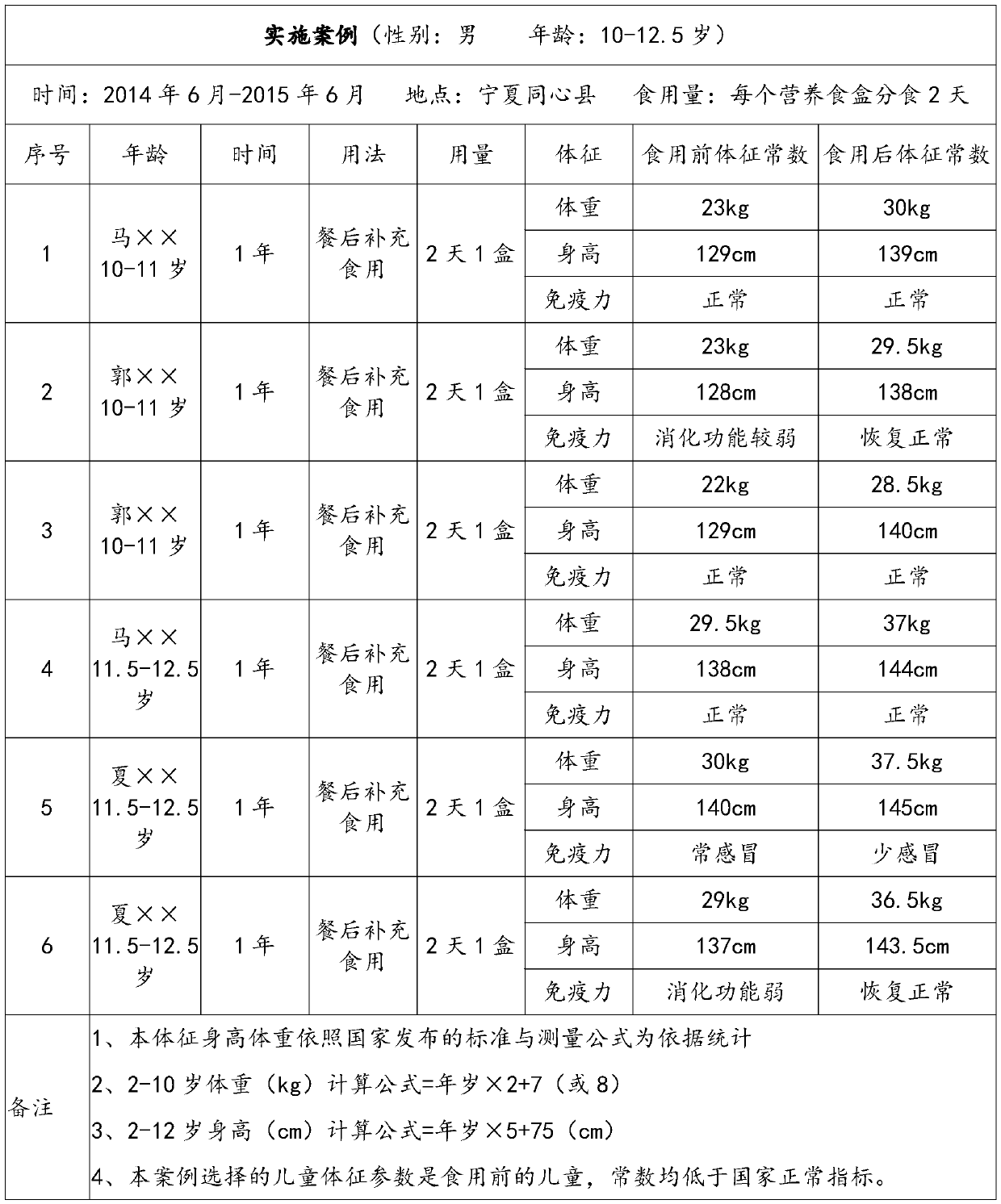

Child nutrient multifunctional food and preparing and eating method thereof

InactiveCN105495579AEnhance physical fitnessImprove intelligenceDough treatmentBakery productsNutritional scienceConjugated protein

The invention relates to the field of food, in particular to a child nutrient multifunctional food. The child nutrient multifunctional food comprises staple food biscuits, conjugated protein amino acid oral liquid and a saponin polysaccharide microelement dried fruit packet. The child nutrient multifunctional food accords with bioscience and nutritional science principles, is reasonably prepared, aims to provide love to underprivileged children lack of nutrition, and subsidizes negative energy of nutrition lack with more substance positive energy, and embodiments prove that the child nutrient multifunctional food can serve child health with proper, balanced, high quality and sustainable nutrition manners, can enhance physique, intelligence and immunity of children.

Owner:BEIJING ZHENPUHUI BIOSCI TECH INST

Hematite health care ceramic tile and preparation method thereof

InactiveCN104860670AHigh temperature resistantHigh strengthCeramicwareNegative energySODIUM DODECYL BENZENE SULFONATE

The invention discloses a hematite health care ceramic tile and a preparation method thereof. The hematite health care ceramic tile is prepared by the raw materials in parts by weight as follows: 33-47 parts of spinel, 24-36 parts of hematite, 15-25 parts of crystal salt ore, 12-21 parts of graphite tailings, 9-18 parts of granite waste material, 5-10 parts of nanometer molecular sieve, 8-16 parts of barium metaborate, 5-10 parts of basic magnesium chloride, 4-8 parts of sodium tripolyphosphate, 3-6 parts of hydroxypropyl guar gum powder, 1-2 parts of sodium dodecyl benzene sulfonate and 18-26 parts of compound clay. The hematite and crystal salt ore are added in the ceramic tile, so that the ceramic tile can release a large number of anions, far infrared ray and pulsed magnet field which are useful for human health, has certain healthcare function to human body, and can absorb and eliminate body negative energy, promote body vitality, improve health condition, activate cell, promote metabolism, gain blood circulation and balance endocrine system. The ceramic tile has characteristics of being resistant to high temperature, high in strength, resistant to wear, and resistant to acid and alkali corrosivity, and has important economic benefit and social benefit.

Owner:安徽省亚欧陶瓷有限责任公司

Flaxseeds for body weight management

The present invention relates to methods for reducing fat uptake in the gastrointestinal tract of a mammal in order to prevent a positive energy balance, weight gain, overweight and obesity, and to induce a negative energy balance and weight loss in subjects who wish to reduce their body weight. In particular, food and / or beverage ingredients and dietary supplements of the present invention comprises flaxseeds useful for increasing faeca fat excretion from the gastrointestinal tract.

Owner:ROYAL DANISH VETERINARY & AGRI COLLEGE

Converter fume high-temperature bag dust removal and recycling and secondary steam recycling system

InactiveCN101736117BImprove purification efficiencyEasy to recycleIncreasing energy efficiencyManufacturing convertersCooling towerOutput device

The invention relates to a converter fume high-temperature bag dust removal and recycling and secondary steam recycling system, which comprises a converter, a vaporizing flue cooling device, a high-temperature bag dust collector, an exhaust-heat boiler, a speed regulation fan, a switching valve station, a diffusing chimney, a gas cooling tower, a plurality of glasses valves, a dust output device and a dust storage bin. The high-temperature bag dust collector performs purification treatment on the fume till the temperature of 800 DEG C at an opening of the vaporizing flue; the exhaust-heat boiler is arranged at the opening of the high-temperature bag dust collector for performing the secondary recycling of the steam. The exhaust-heat boiler is connected with the speed regulation fan; an outlet of the speed regulation fan is connected with the switching valve station, the diffusing chimney and the glasses valves and then connected with the gas cooling tower. The gas cooling tower is arranged in front of an inlet of a gas chamber. Due to the adoption of the converter fume high-temperature bag dust removal technology and the recycling of the secondary high-temperature fume exhaust heat (secondary steam recycling) below 800 DEG C, the purification efficiency of the fume is high, the system operates safely and stably, the energy consumption is low, the recycled amount of the steam and gas is high, the system blockage and secondary water pollution are absent, and the negative energy steel-making and continuous casting are realized.

Owner:BAOSTEEL ENG & TECH GRP

Photon spacecraft

InactiveUS20060144035A1Effective mass reductionCosmonautic vehiclesCosmonautic propulsion system apparatusSpacecraft propulsionEngineering

A spacecraft propulsion system utilizing photon particles to create negative energy over the hull in order to generate a lift force on the hull.

Owner:ST CLAIR JOHN QUINCY

A method for increasing the molten iron ratio of converter and reducing smelting cost

ActiveCN104762435BLow costQuality improvementManufacturing convertersProcess efficiency improvementSmelting processHeat balance

The invention discloses a method for reducing the smelting cost by improving the molten iron ratio of a converter. The advantages of low price and stable quality of molten iron are used, the total recovery amount of scrap steel self-made in a company is calculated and the steel making molten iron ratio of the converter is improved to reduce the cost of a metal material entering the converter, excess heat brought by the molten iron is used, and the appropriate proportion of the molten iron entering the converter, slag residual and reducing operation, converter heat balance, converter slagging auxiliary material substitution and smelting process dephosphorization control are researched to reduce the converter steel and slag cost and the medium cost in order to realize negative energy steel making, energy saving and emission reduction.

Owner:NANJING IRON & STEEL CO LTD

Ankle-foot prosthesis device

ActiveUS10406000B2Reduce energy consumptionReduce the required powerArtificial legsElastic componentProsthesis

A powered ankle-foot prosthesis and associated methods of use are described herein. Such prostheses can employ an actuator and elastic components, the actuator being controlled to deliver net positive work to propel the wearing amputee forward and the elastic components being used to store and release negative energy to improve efficiency. Elastic components can be linear springs coupled with a cam and configured in parallel to the actuator. The cam profile can be designed to generate a desired spring torque versus angle curve rather than a spring stroke versus angle curve, thereby reproducing human ankle controlled dorsiflexion stiffness. Such configurations improve system energy efficiency and reduce both actuator torque and power requirements. Such prostheses can also operate in a passive mode, in which a nearly normal gait can be achieved even without powered assist.

Owner:THE CHINESE UNIVERSITY OF HONG KONG

Cow feed for promoting physical rehabilitation of postpartum cows and reducing postpartum diseases and preparation method thereof

InactiveCN106071150APromote physical recoveryImprove the immunityFood processingAnimal feeding stuffDiseaseMedicine

The invention relates to cow feed for promoting physical rehabilitation of postpartum cows and reducing postpartum diseases and a preparation method thereof. The feed containing radix astragali, largehead atractylodes rhizome and angelica sinensis has the efficacy of invigorating qi for consolidating superficies and tonifying kidney and spleen, and can nourish weak postpartum cows, promote physical rehabilitation of postpartum cows, reduce postpartum diseases, enhance immunity of cows, change the negative energy balance of cows, increase milk yield, and improve economic benefit of cow breeding.

Owner:ANHUI WANSHAN FOODS

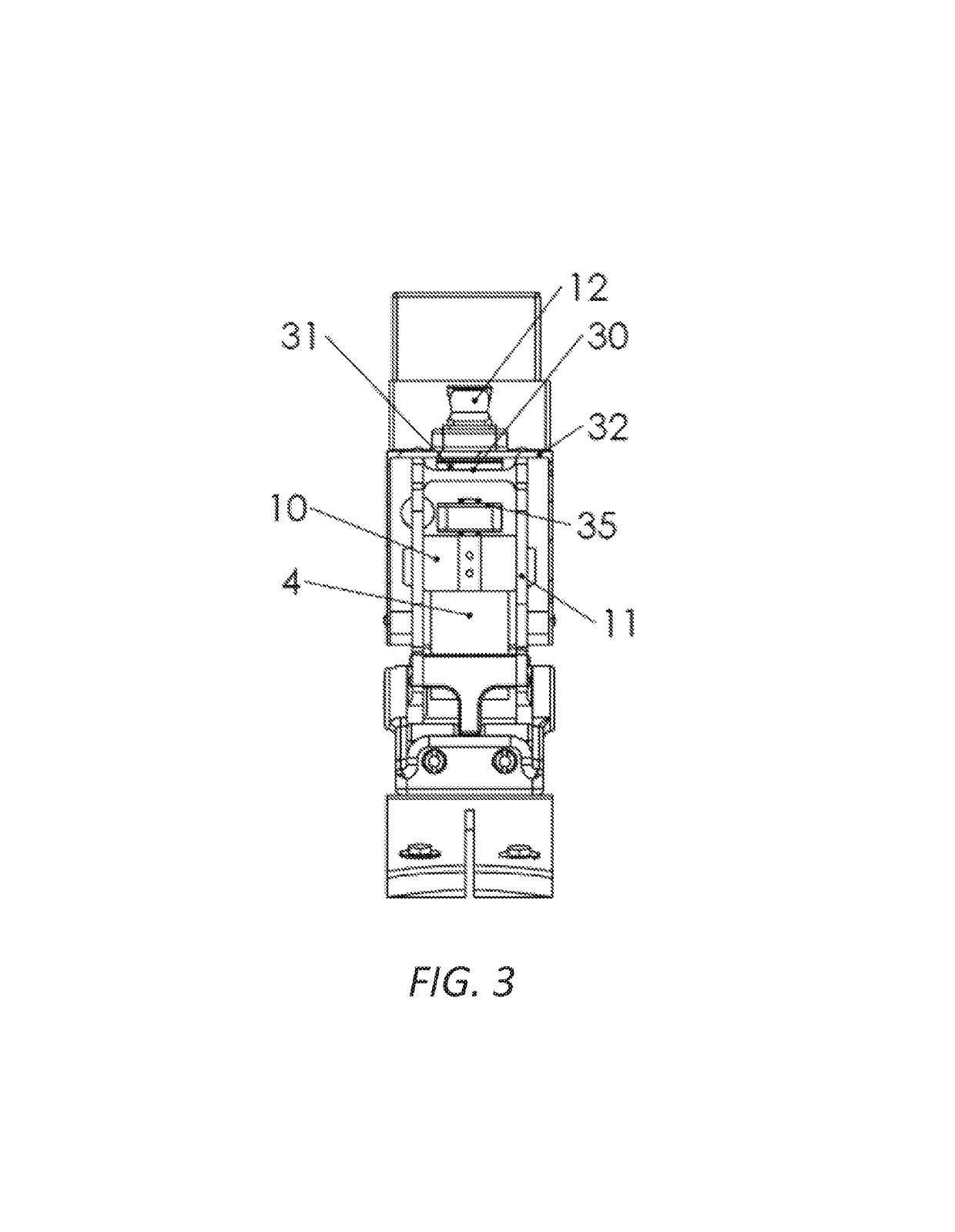

Method for calculating energy recovery rate of braking energy recovery system

InactiveCN107310397AReduce development costsElectrodynamic brake systemsVehicular energy storageElectrical batteryEnergy recovery

The invention provides a method for calculating energy recovery rate of a braking energy recovery system. The method comprises the following steps: (1) collecting battery voltage signal data and battery current signal data; (2) using a function to separate the battery current signal data into positive currents and negative currents; (3) calculating the power corresponding to the positive currents and the negative currents; (4) calculating the energy corresponding to the positive currents and the negative currents by the integral of power over time; (5) calculating the ratio of positive energy to negative energy to obtain the corresponding energy recovery rate. Compared with a method of calculating the system recovery rate through multiple experiments by manually and forcibly turning on or shutting down the braking energy recovery system, the method provided by the invention is efficient and fast, and can better save manpower and equipment cost so as to save development cost for businesses.

Owner:CHERY AUTOMOBILE CO LTD

Floating machine

The invention provides a floating machine. A kinetic energy forming device of the floating machine comprises a progressive floating device and a sealing water device matched with the progressive floating device. The progressive floating device and the sealing water device are arranged on the two sides of a primary floating device correspondingly to sublate positive and negative energy of each side of the primary floating device, so that buoyancy energy on one side of the primary floating device can be sustainably and automatically generated, gravitational energy of the other side of the primary floating device can be progressively accumulated, and the buoyancy energy and the gravitational energy can be combined so as to be output. According to the floating machine, the primary floating device comprises a device capable of switching and enlarging the buoyancy energy into gravitational energy, so that working efficiency is further improved. The floating machine use gas but does not burn gas, use water but does not consume water, and used water is little; and the floating machine is economical, environmentally friendly, portable and efficient.

Owner:洪为帮

Flue gas waste heat recovery and negative energy consumption dust-removal system for electric stove

InactiveCN101539369BEasy to recycleSave on wear and maintenance costsDispersed particle filtrationIncreasing energy efficiencyCombustion chamberEvaporation

Owner:BAOSTEEL ENG & TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com