Converter coal gas high-temperature bag-type dust removing system

A bag-type dust removal and converter gas technology, applied in the direction of manufacturing converters, improving energy efficiency, improving process efficiency, etc., can solve the problems of high investment cost and many failures of electrostatic precipitators, and achieve low system investment and gas dust removal efficiency. The effect of high and high dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

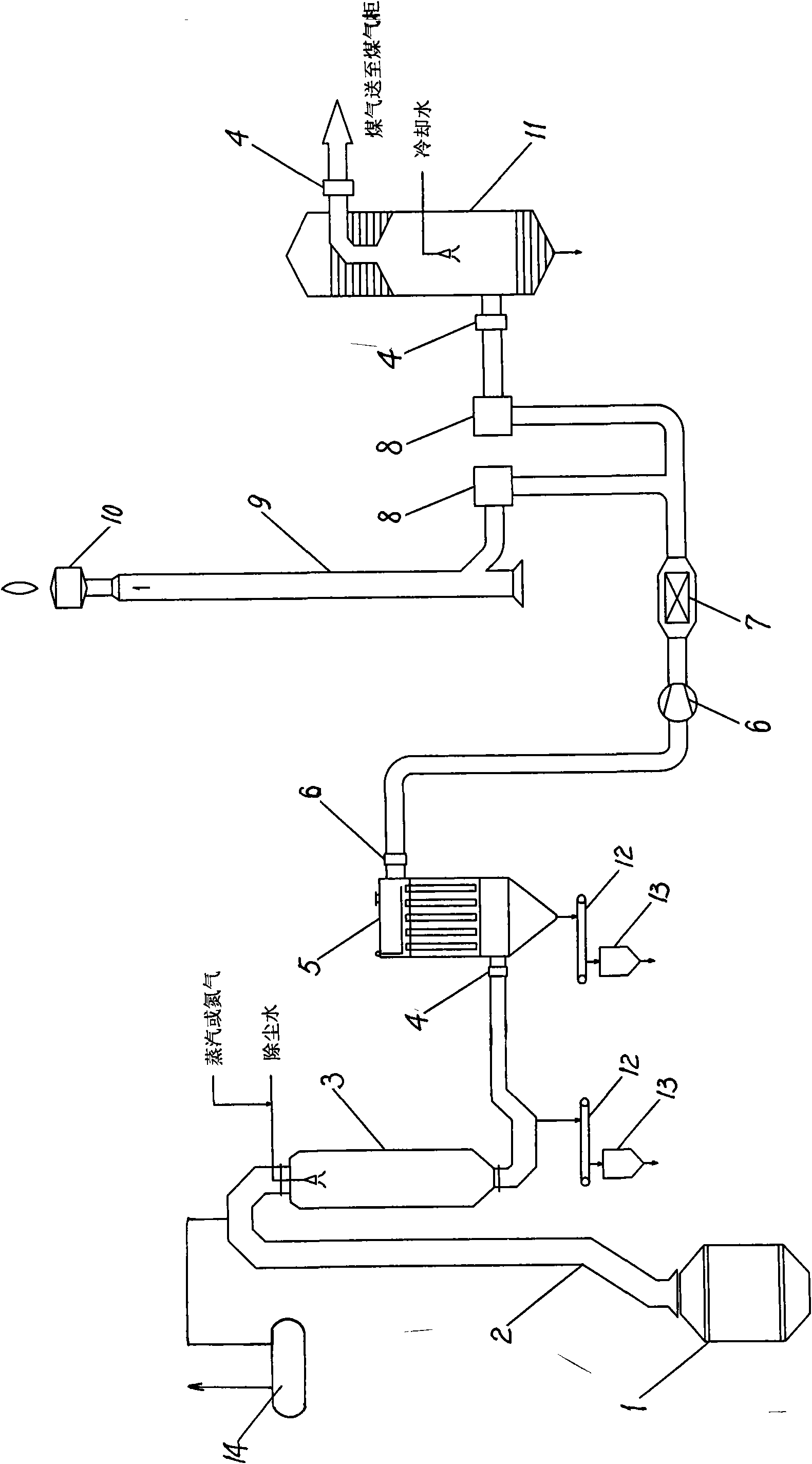

[0012] Referring to the accompanying drawings, the present invention is a high-temperature bag-type dedusting system for converter gas, which includes a converter 1, a high-temperature evaporative cooling tower 3, a high-temperature bag-type dust collector 5, a gas blower 6, a switching valve station, a venting chimney 9, and a glasses valve 4 , a gas cooling tower 11 and an automatic control system, and each device component is connected in sequence through pipelines. In the figure, number 2 is a vaporization cooling flue, number 10 is a burner, number 12 is a chain conveyor, number 13 is an ash hopper, and number 14 is a steam drum. The switching valve station may be the release side switching valve 8 shown in the figure.

[0013] The high-temperature evaporative cooling tower 3 in this system replaces the evaporative cooling tower in the LT system. The high-temperature evaporative cooling tower 3 in this system replaces the sizing or manual diameter-adjusting overflow vent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com