Patents

Literature

1550 results about "Gas cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gas Cooling. Gas cooling equipment is necessary in compressor stations to remove heat from the gas stream between stages of compression intercoolers or after the final stage of compression (aftercoolers). Heat exchangers are used to remove heat from gas streams, reduce cooling water temperature, lower oil temperature or to cool compressed air.

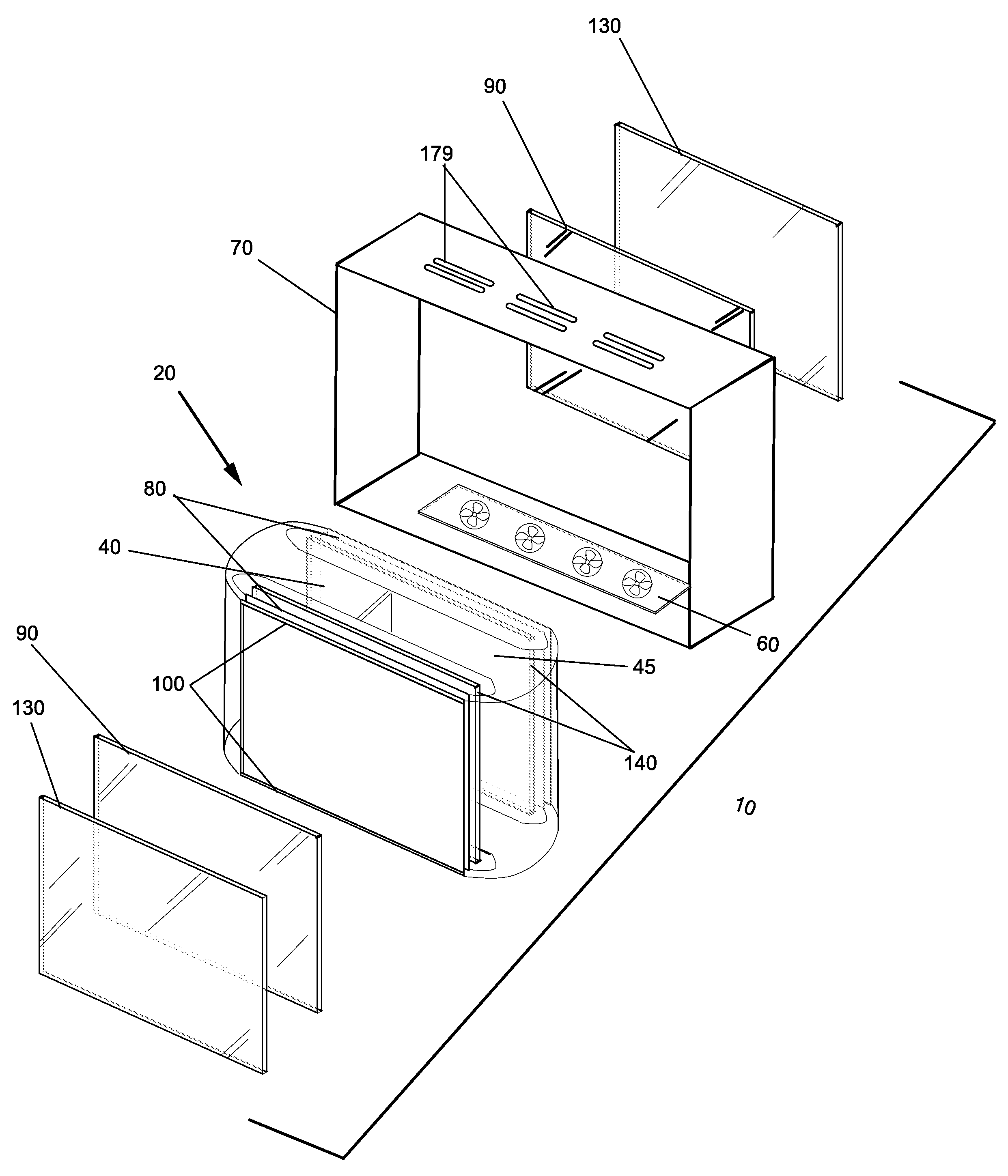

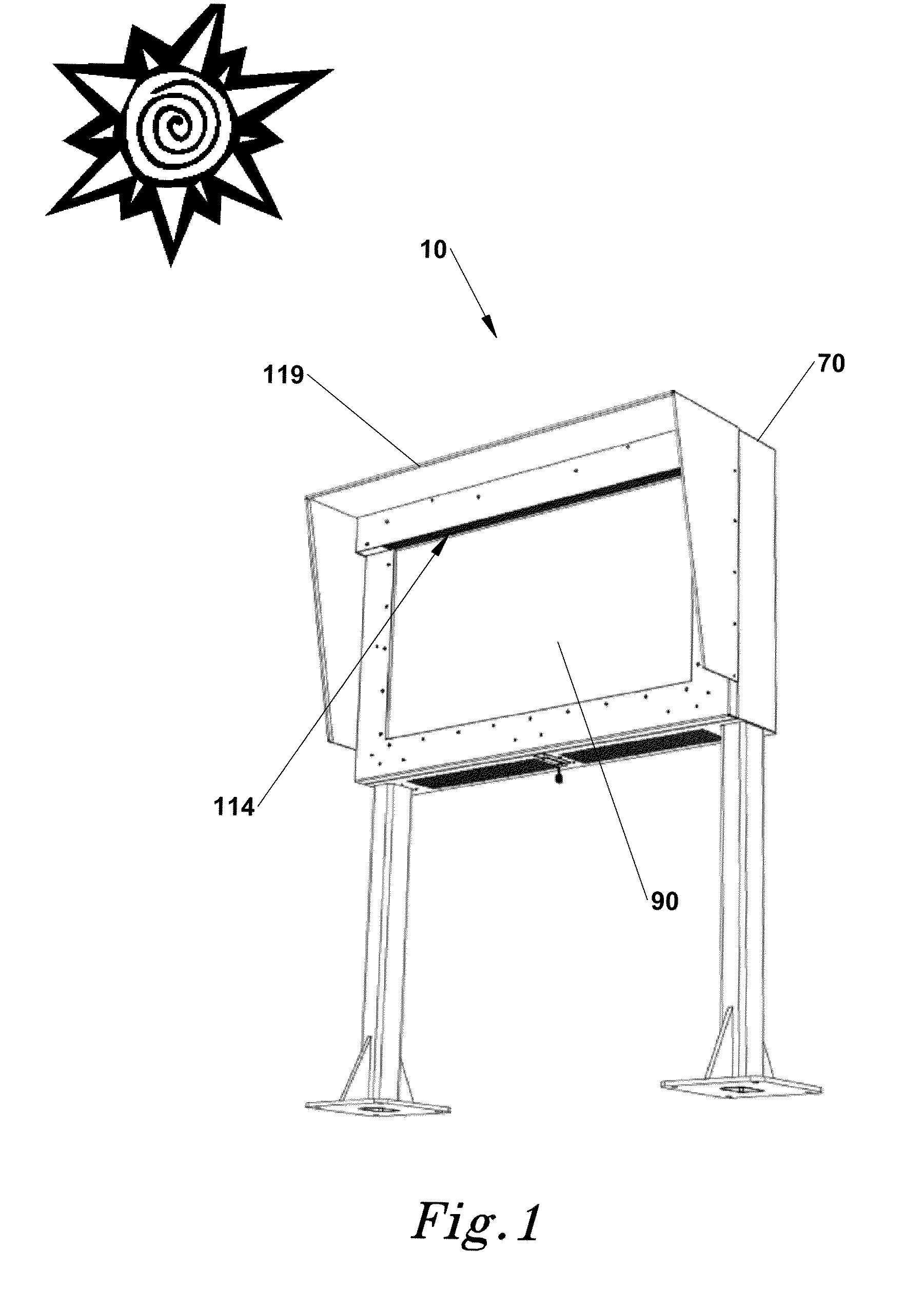

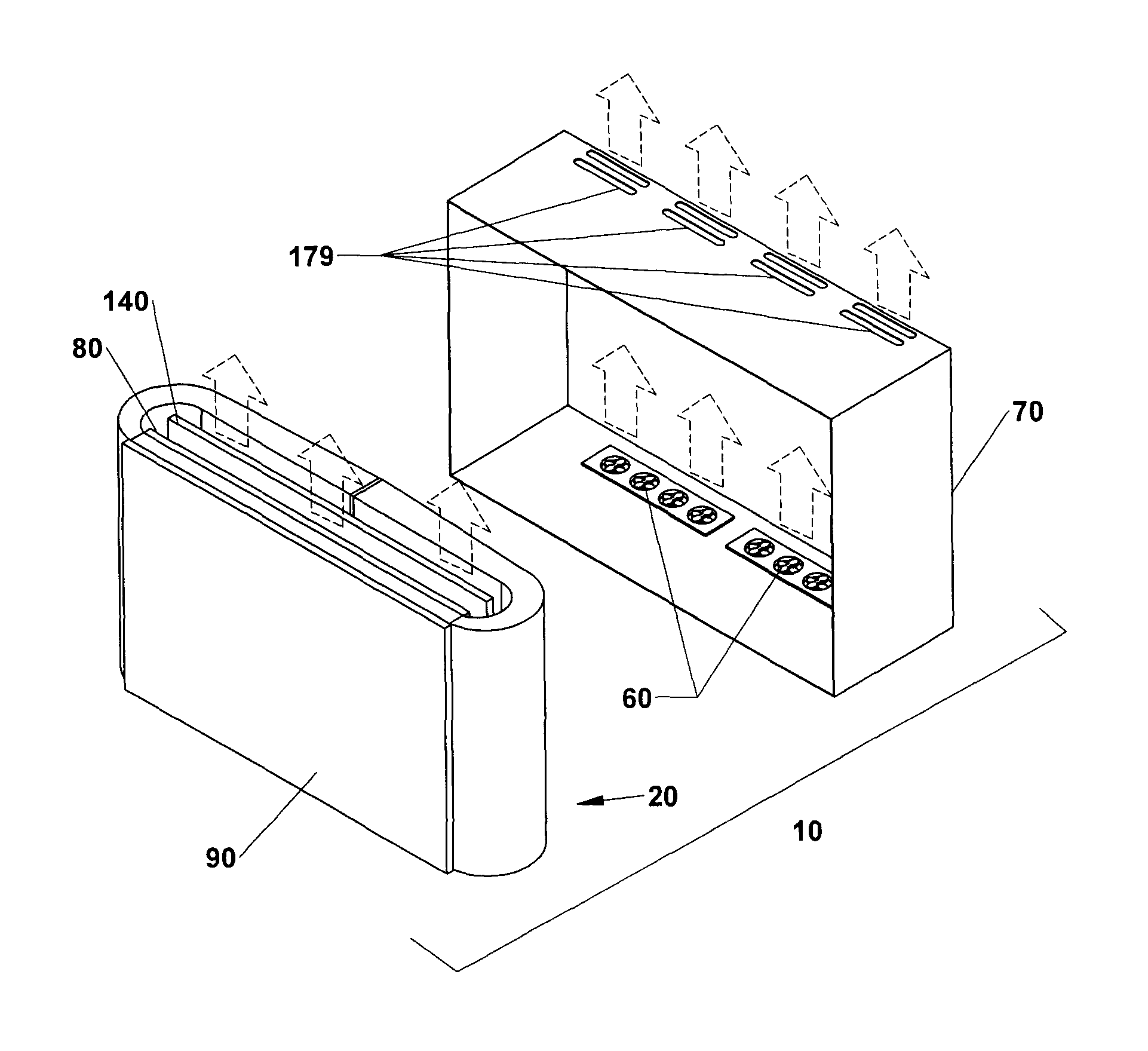

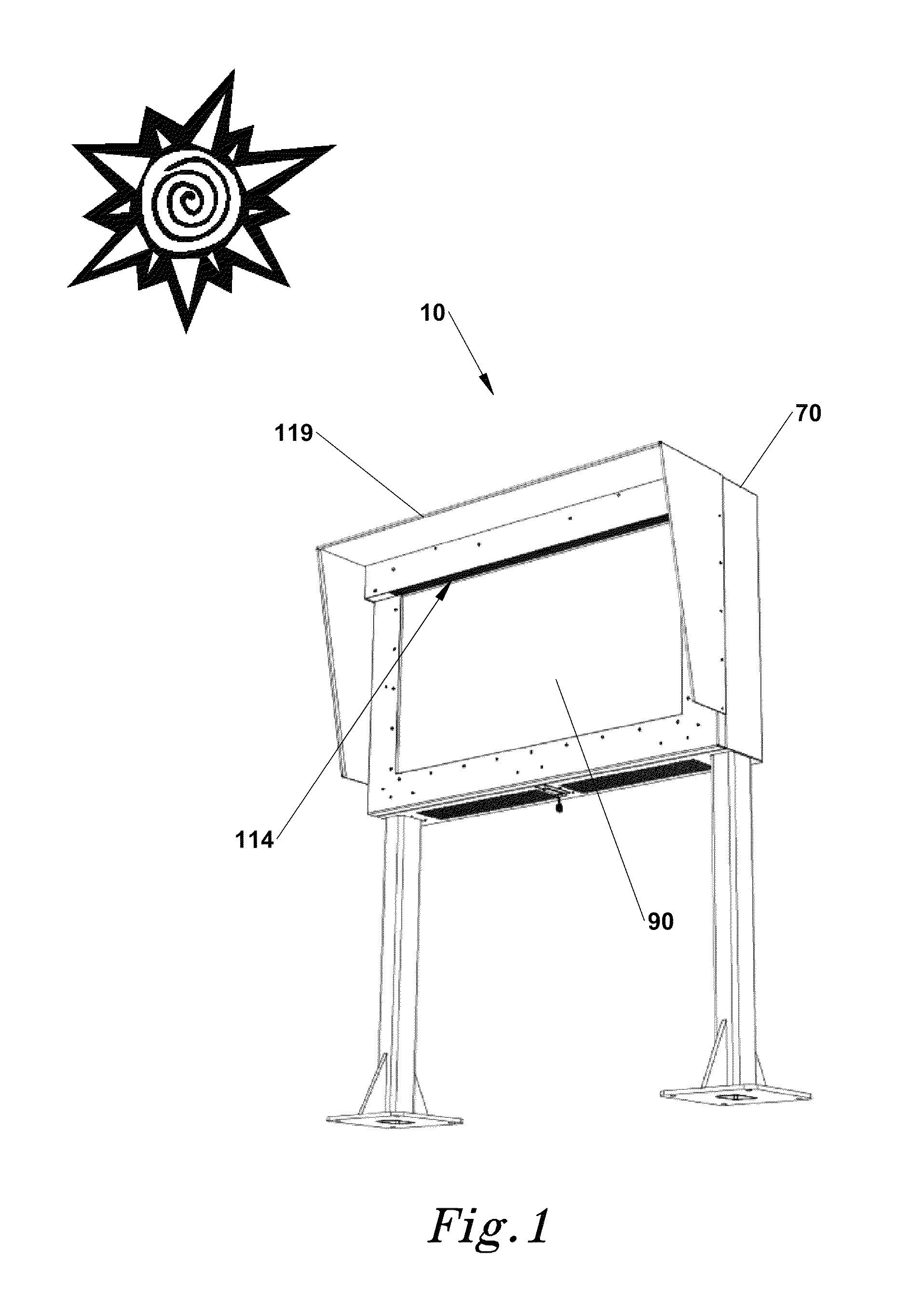

Shared Isolated Gas Cooling System for Oppositely Facing Electronic Displays

ActiveUS20100226091A1Increase heat productionBrighter backlightsSemiconductor/solid-state device detailsSolid-state devicesNuclear engineeringImaging quality

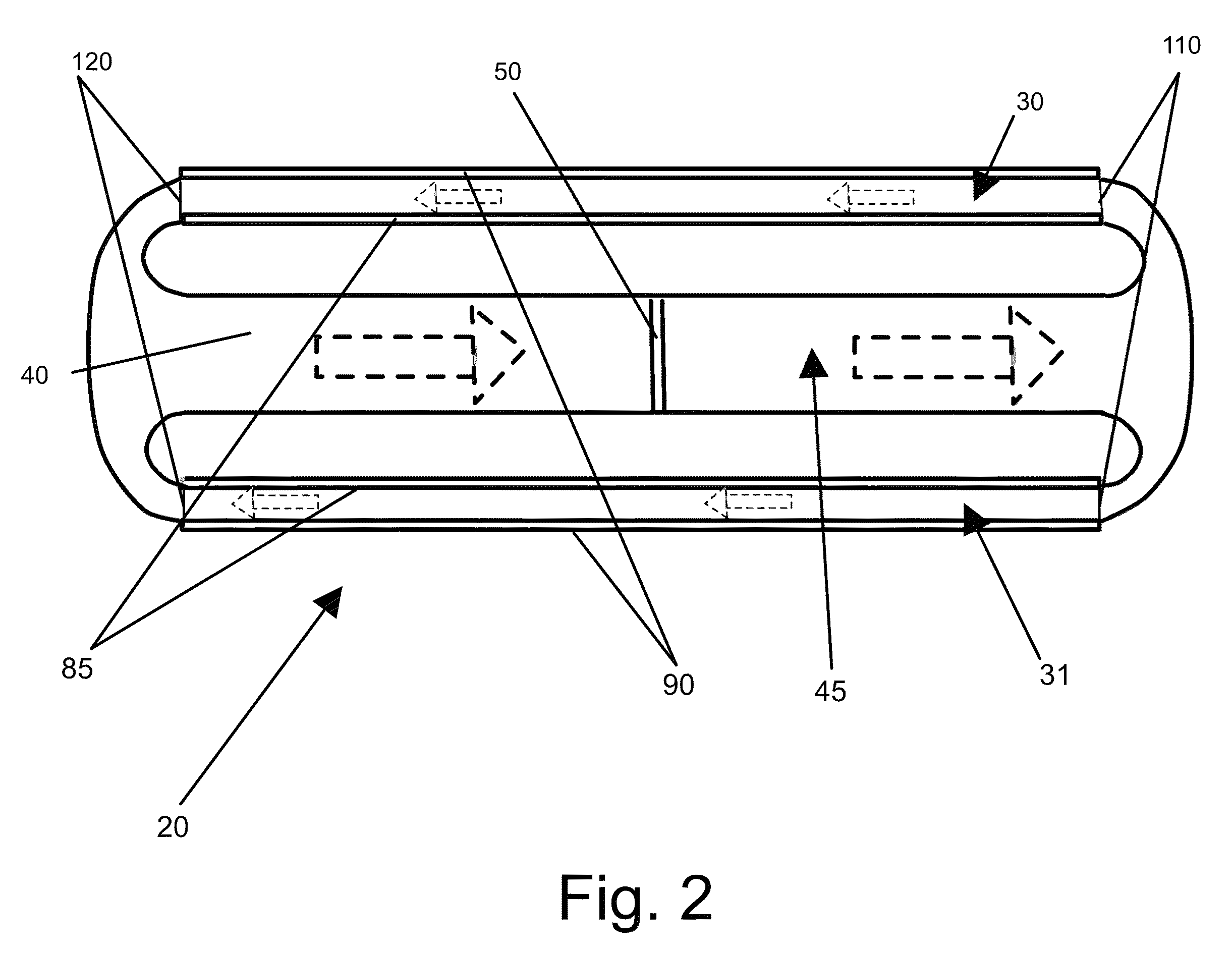

A system and method for cooling back to back electronic displays. Transparent first and second gas chambers are co-existive with the front display surfaces of the first and second electronic displays. A closed loop of isolated gas enters the first and second gas chambers and contacts the front surfaces of the electronic displays, where it may extract heat from the front display surfaces. The isolated gas is then directed into a cooling chamber where it is cooled and re-introduced into the first and second gas chambers. Fans may be used to propel the isolated gas through the cooling chamber and the first and second gas chambers. The circulating gas removes heat directly from the electronic display surfaces. The isolated gas is transparent or at least semi-transparent to ensure that the image quality of the electronic displays is minimally impacted.

Owner:MFG RESOURCES INT INC

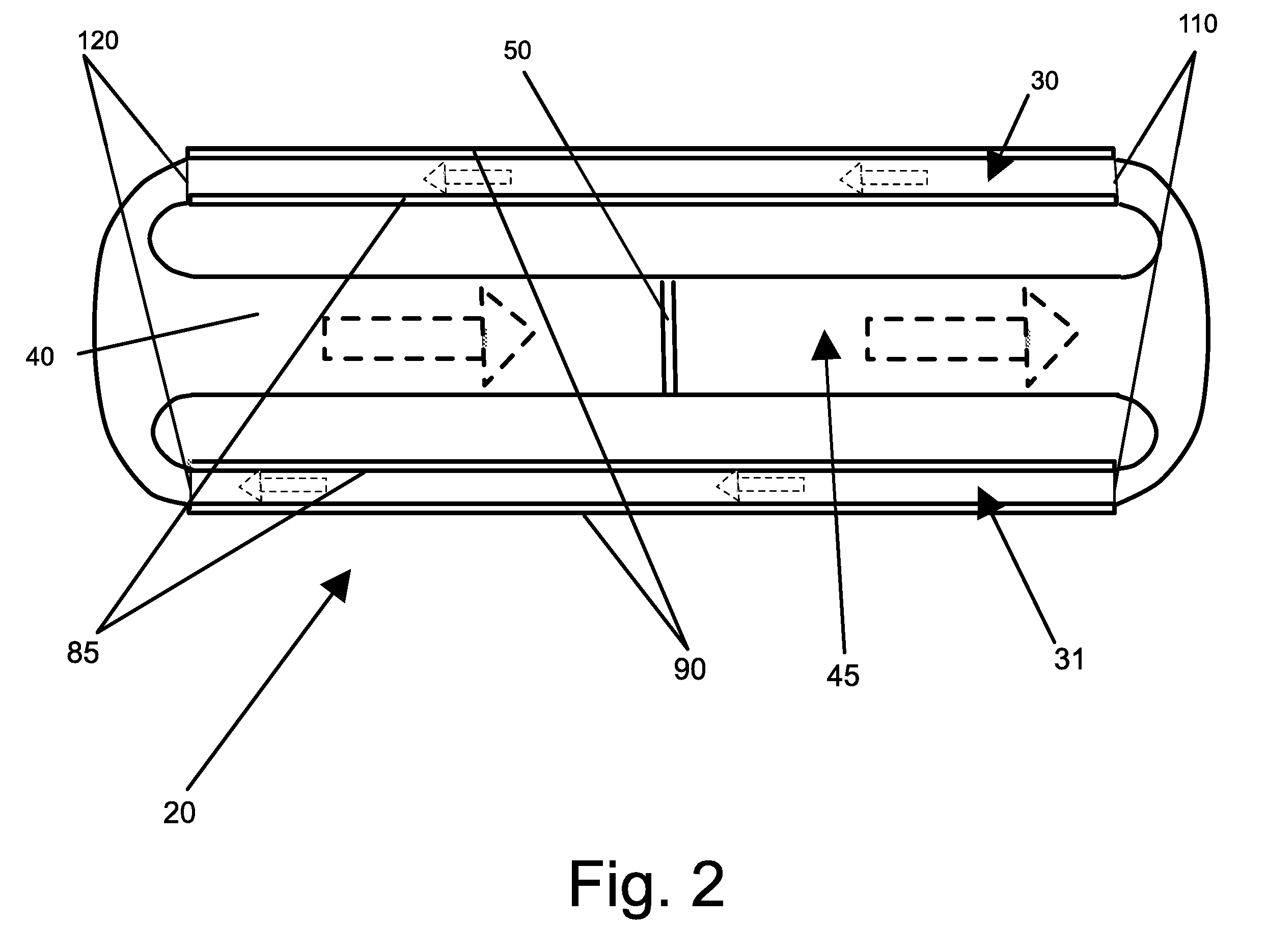

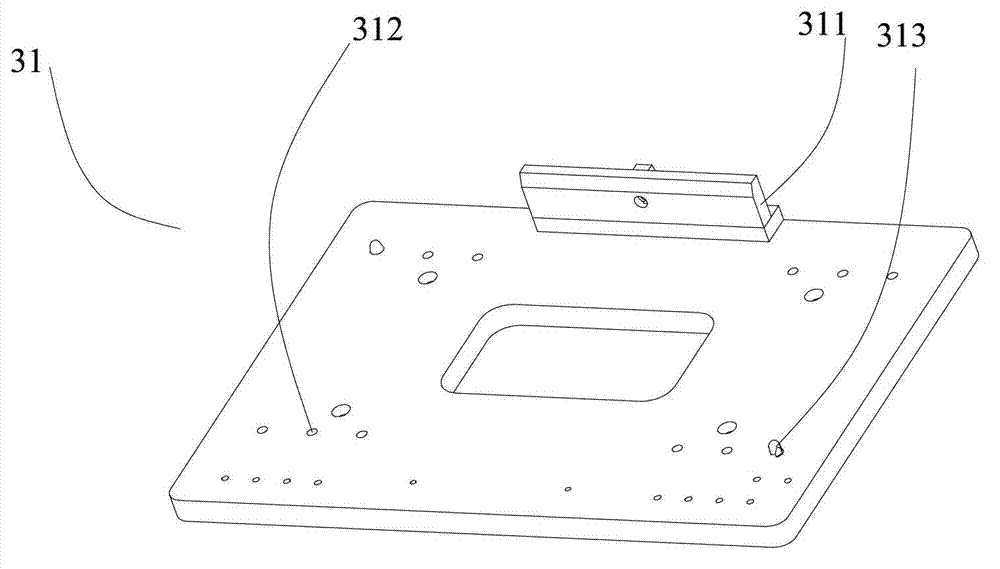

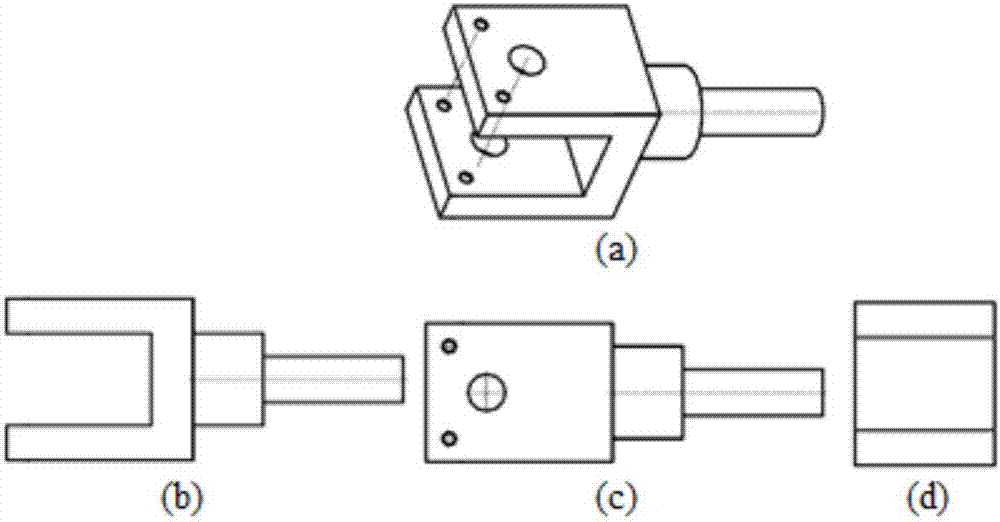

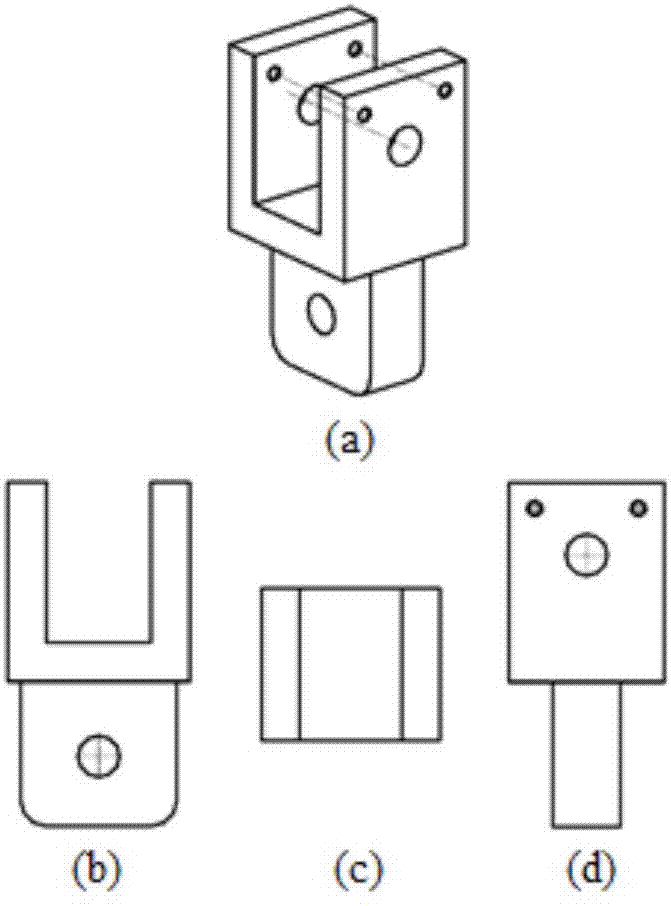

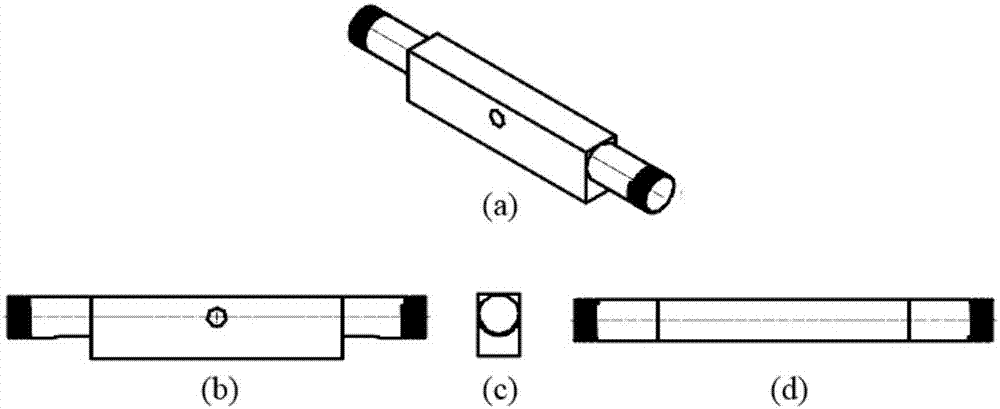

Combined additive and subtractive manufacturing machine tool

ActiveCN104384936AGuaranteed complexityGuaranteed processing effectOther manufacturing equipments/toolsUltrasonic vibrationMachining process

The invention belongs to the field of machine tool design, and relates to a combined additive and subtractive manufacturing machine tool, which comprises a body, a workbench, a main shaft, a numerical control system, a subtractive machining module and an additive manufacturing module. According to the combined additive and subtractive manufacturing machine tool, the additive manufacturing module is controlled by the numerical control system to form a basic structure of a required part on the workbench, then the subtractive machining module is controlled by the numerical control system to perform subtractive machining on the basic structure obtained by additive manufacturing, a function of applying ultrasonic vibration to a cutter and a gas cooling function are realized in a subtractive machining process, and the whole combined additive / subtractive manufacturing process is finally implemented. The combined additive and subtractive manufacturing machine tool can be used for realizing the efficient and precise combined additive and subtractive manufacturing of the component, the manufacturability of a complex part is improved, the production cycle is shortened, and the manufacturing accuracy of the complex part is ensured.

Owner:DALIAN UNIV OF TECH

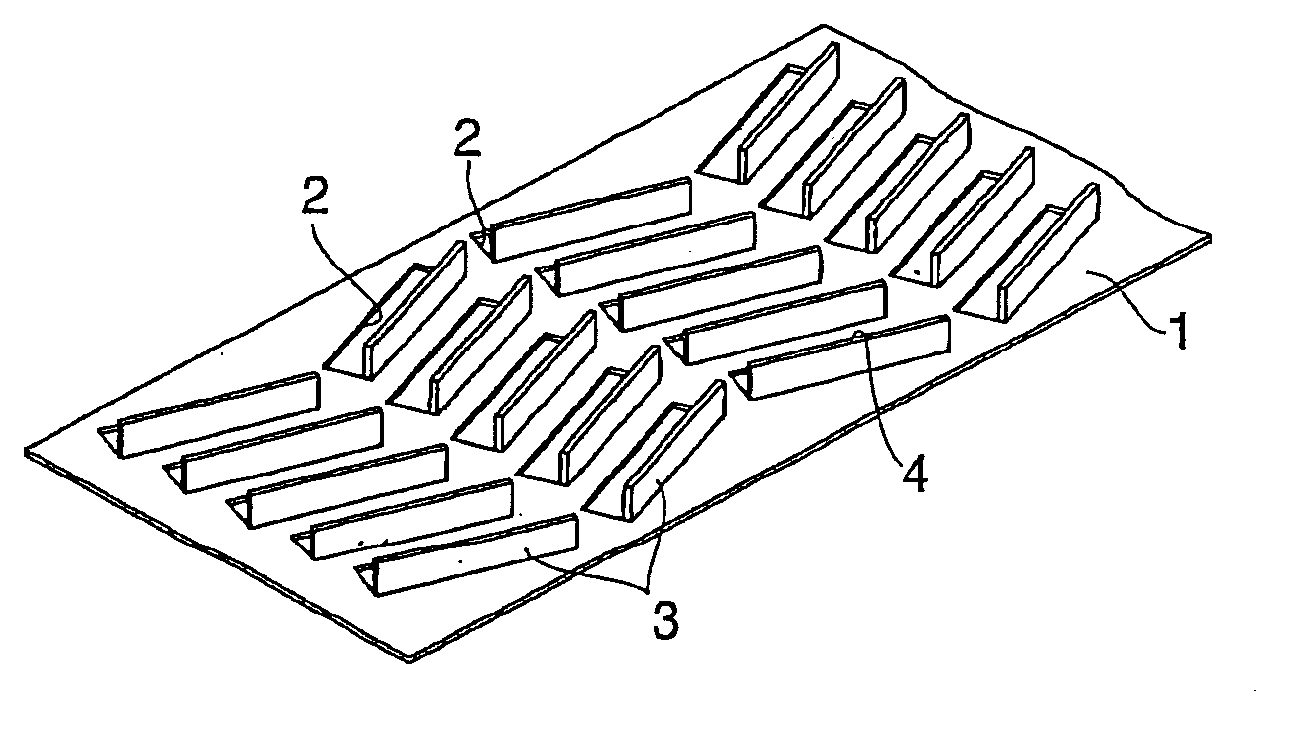

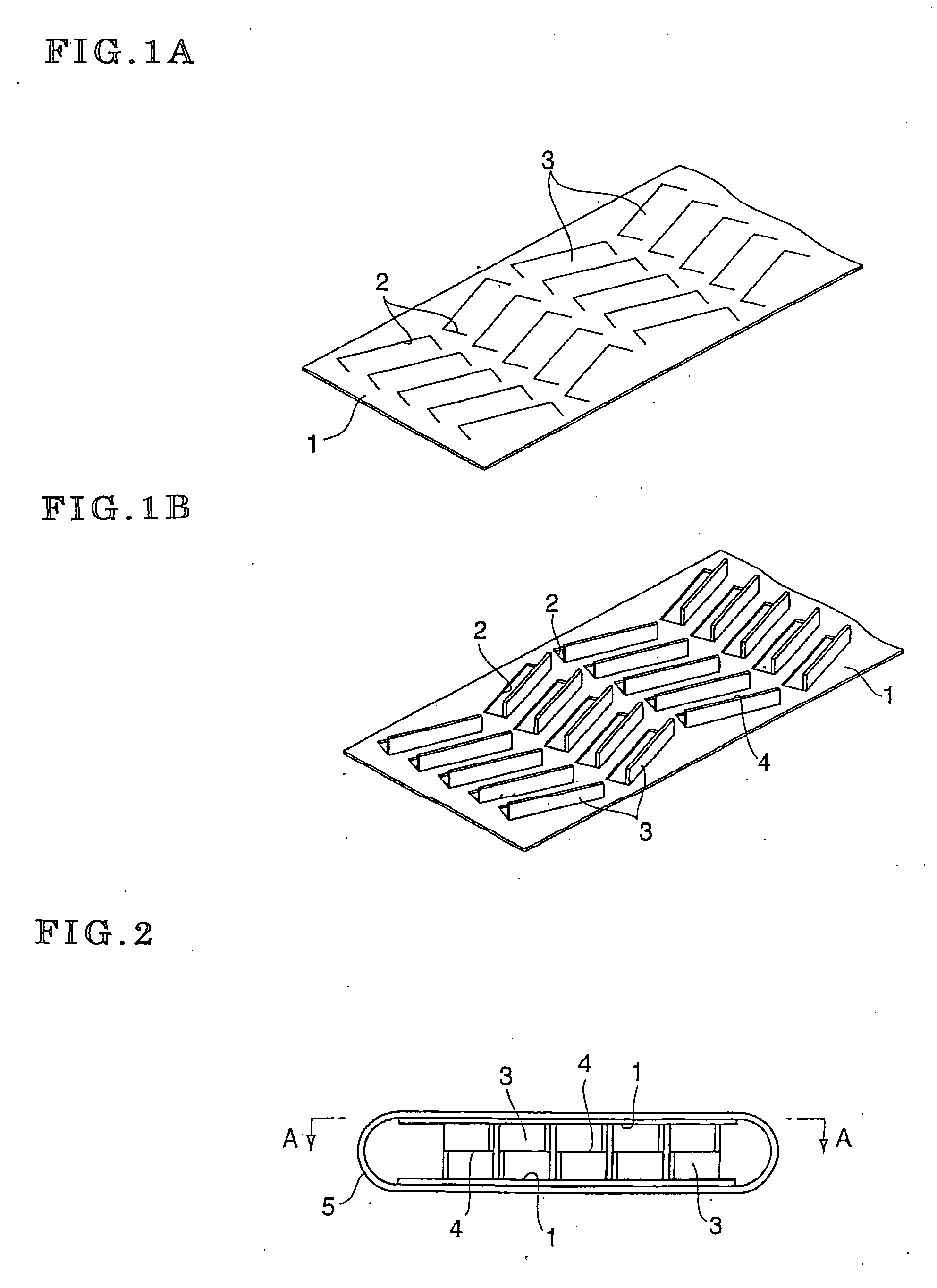

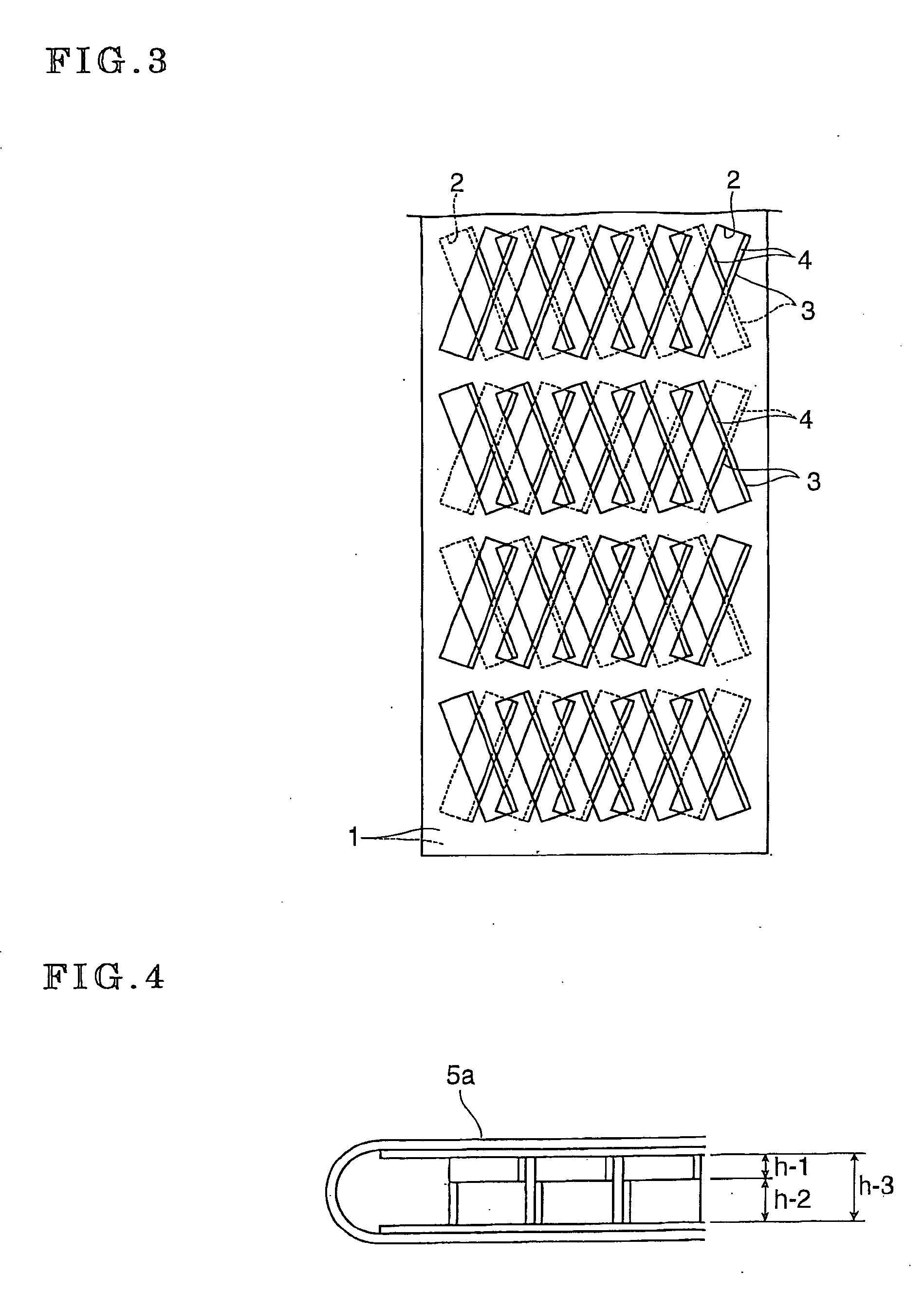

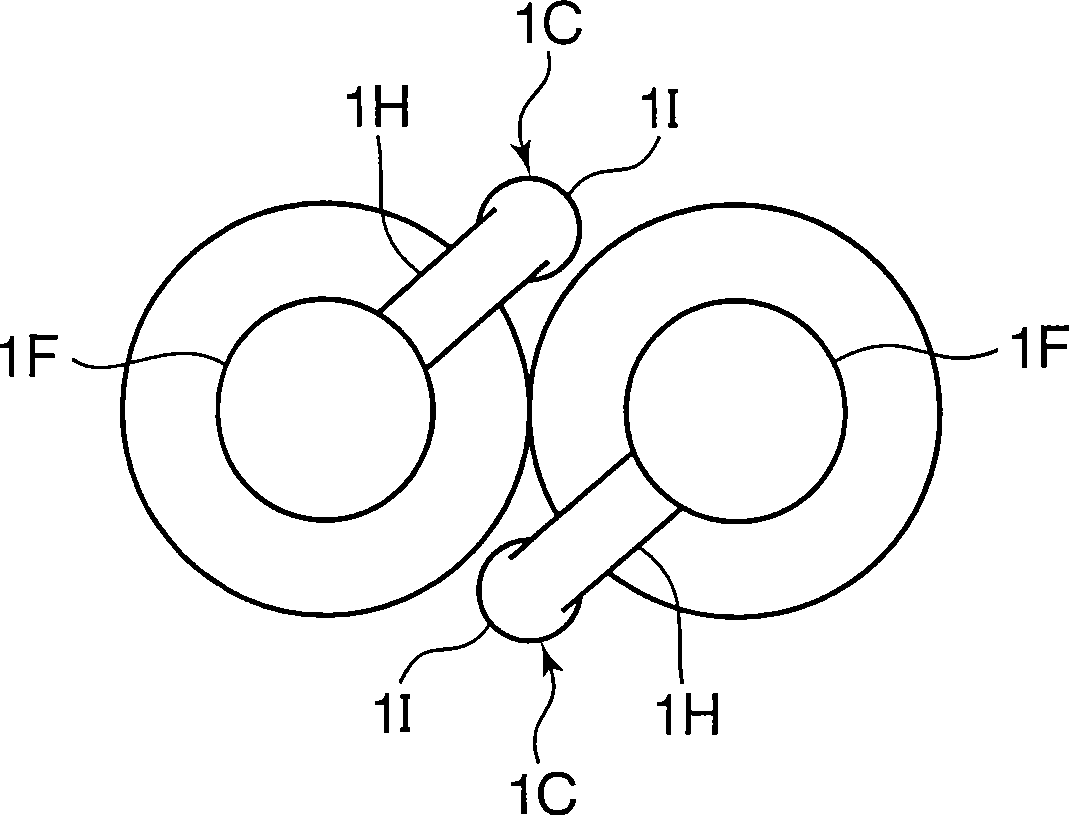

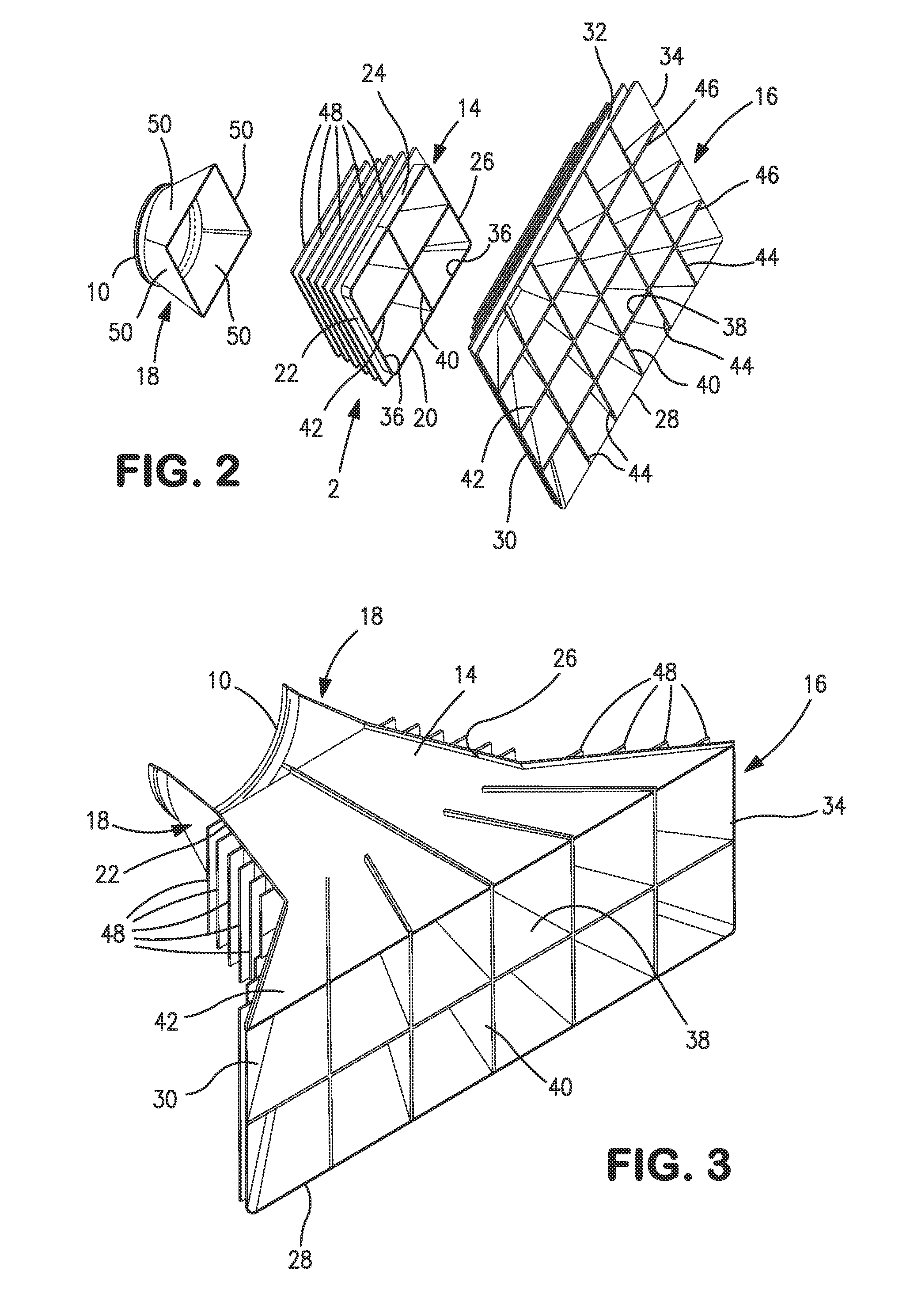

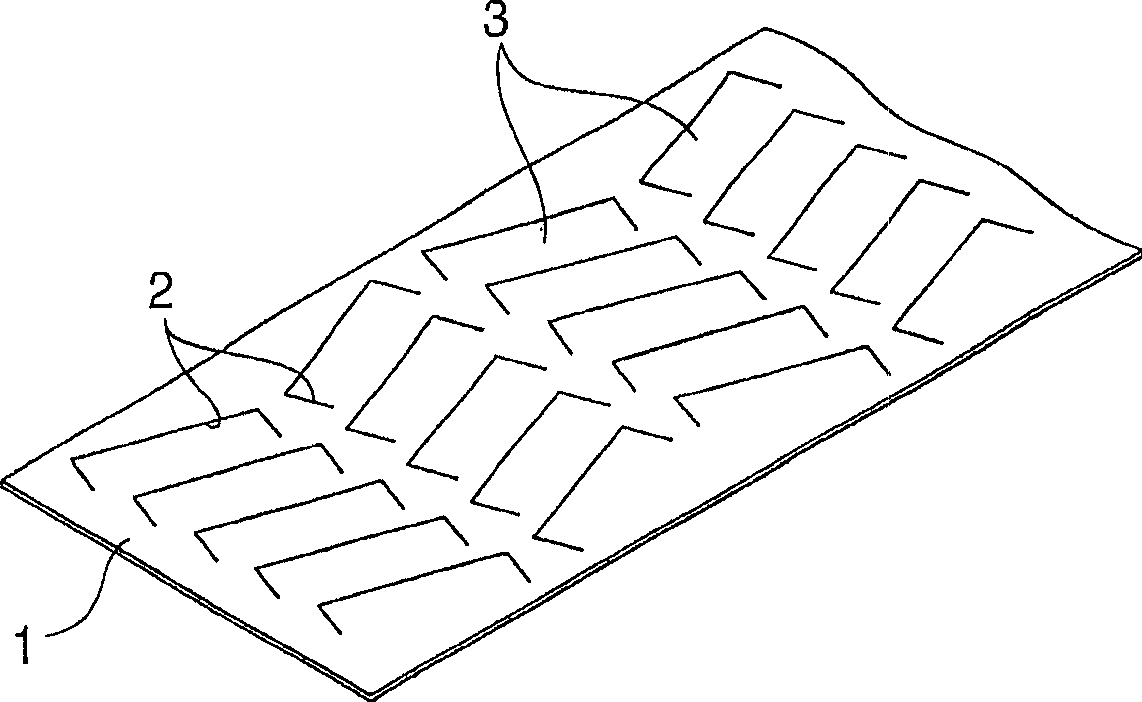

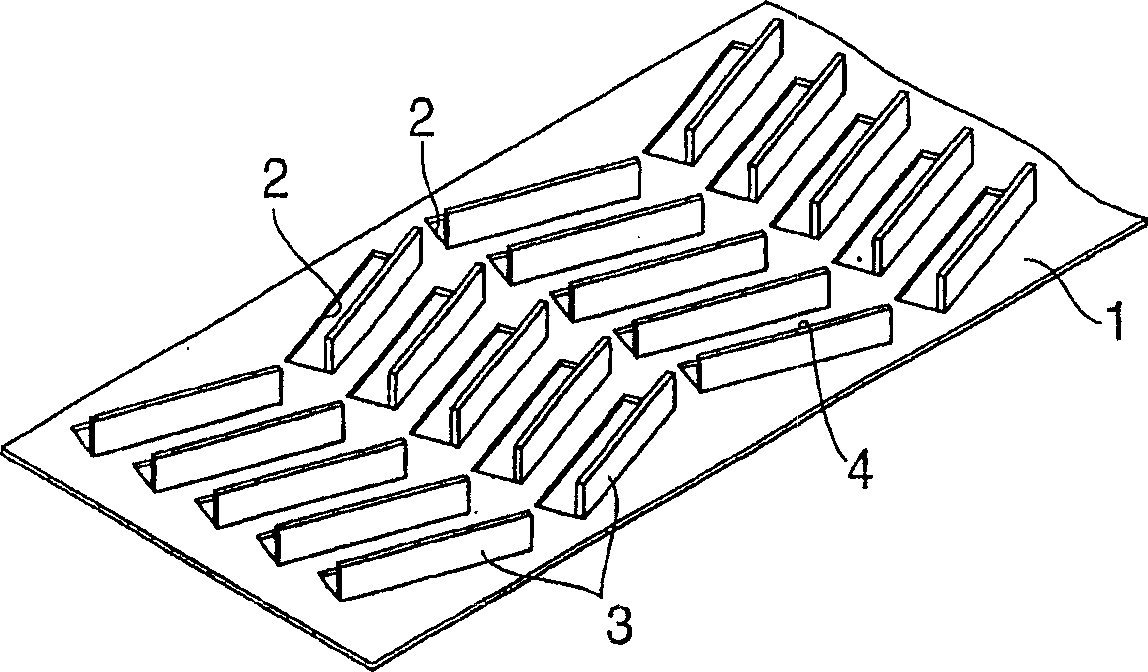

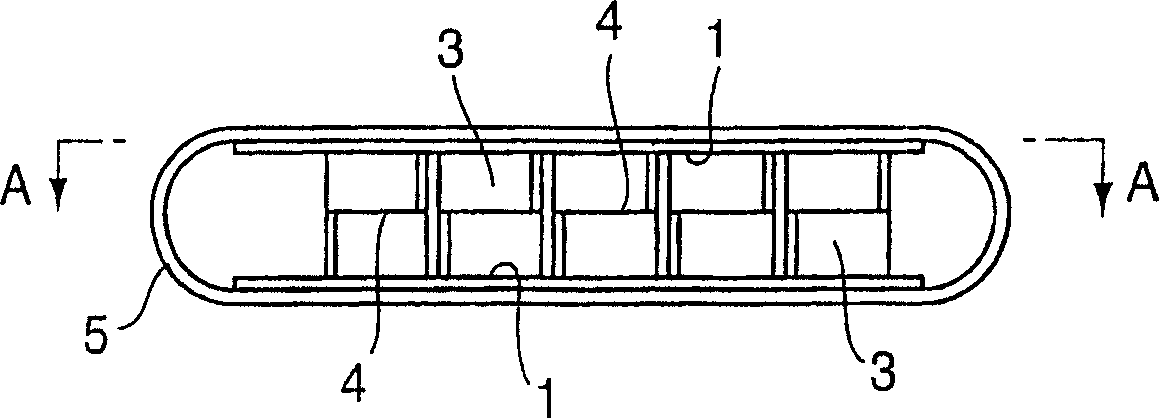

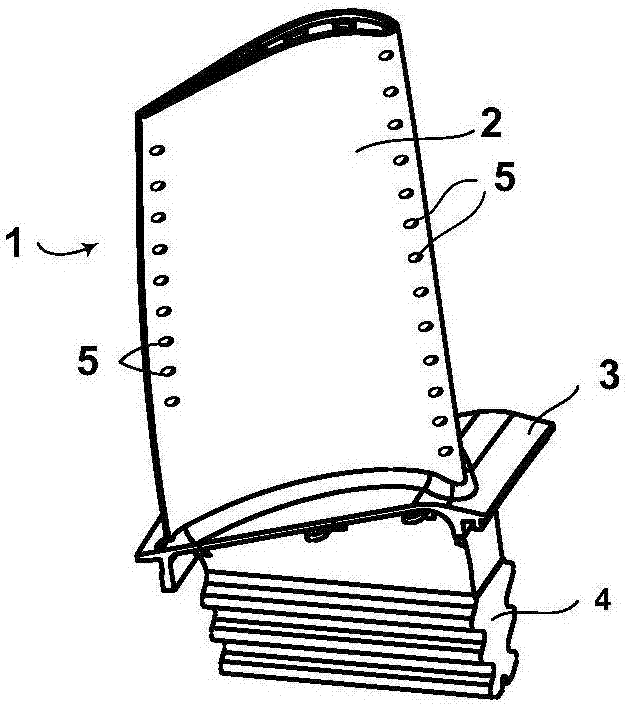

Fluid agitating fin, method of fabricating the same and heat exchanger tube and heat exchanger or heat exchanging type gas cooling apparatus inwardly mounted with the fin

InactiveUS20060016582A1Improve cooling efficiencyEfficiently agitatedInternal combustion piston enginesNon-fuel substance addition to fuelEngineeringCooling fluid

A fluid agitating plate fin is mounted to a heat exchanger tube to agitate a cooling fluid and to create a turbulent flow. Edges of the plate fins are opposed to each other and the opposed butted blade edges cross each other.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

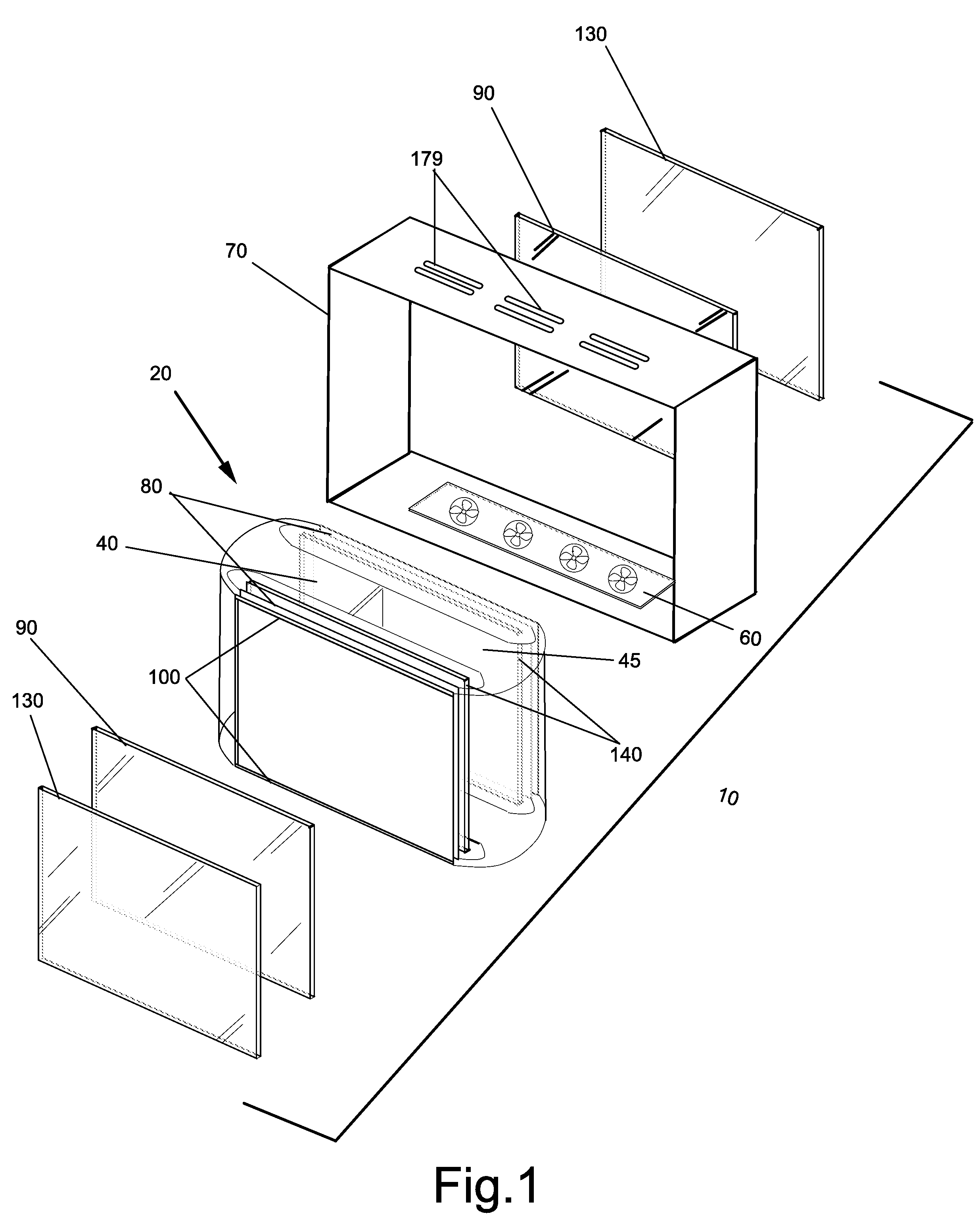

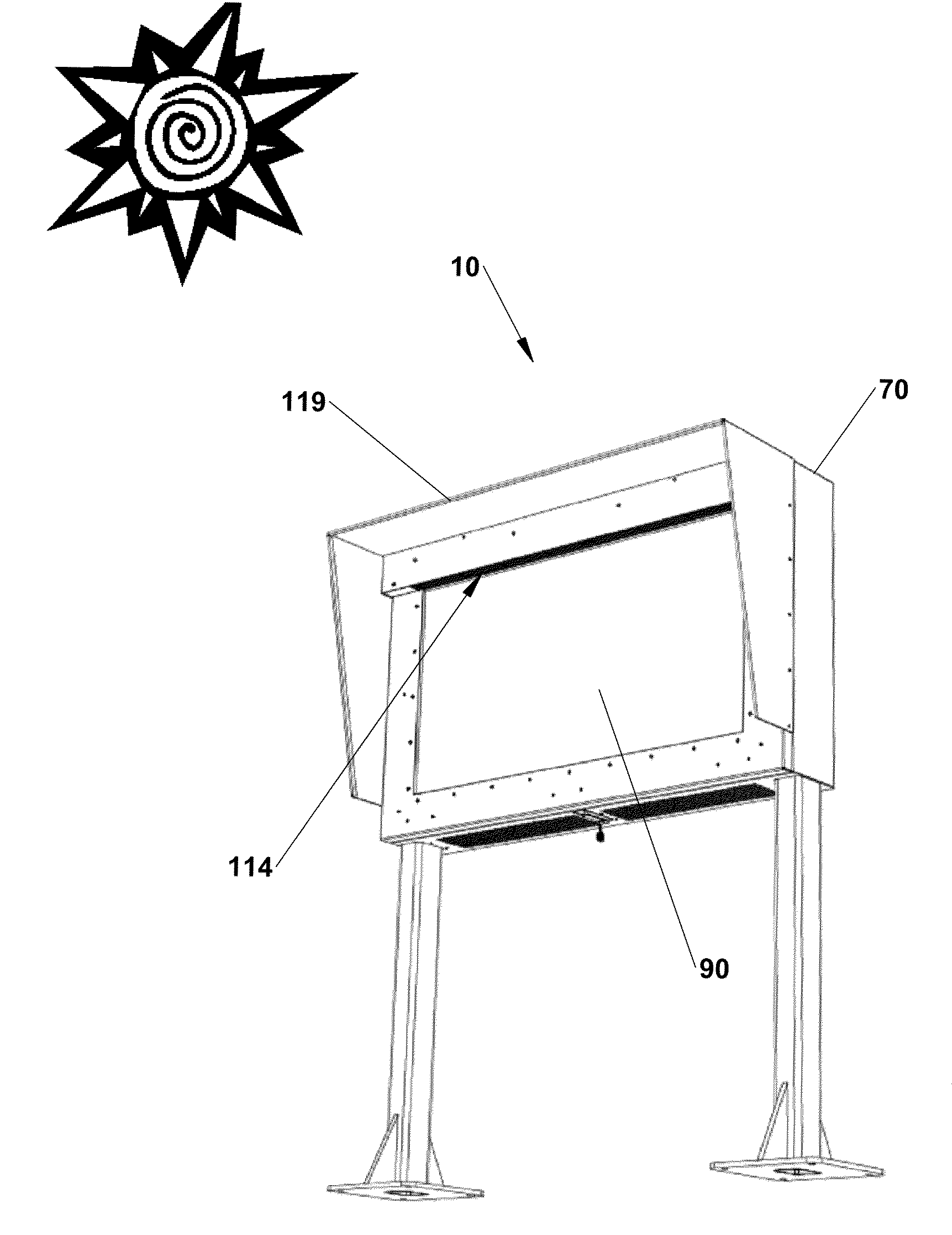

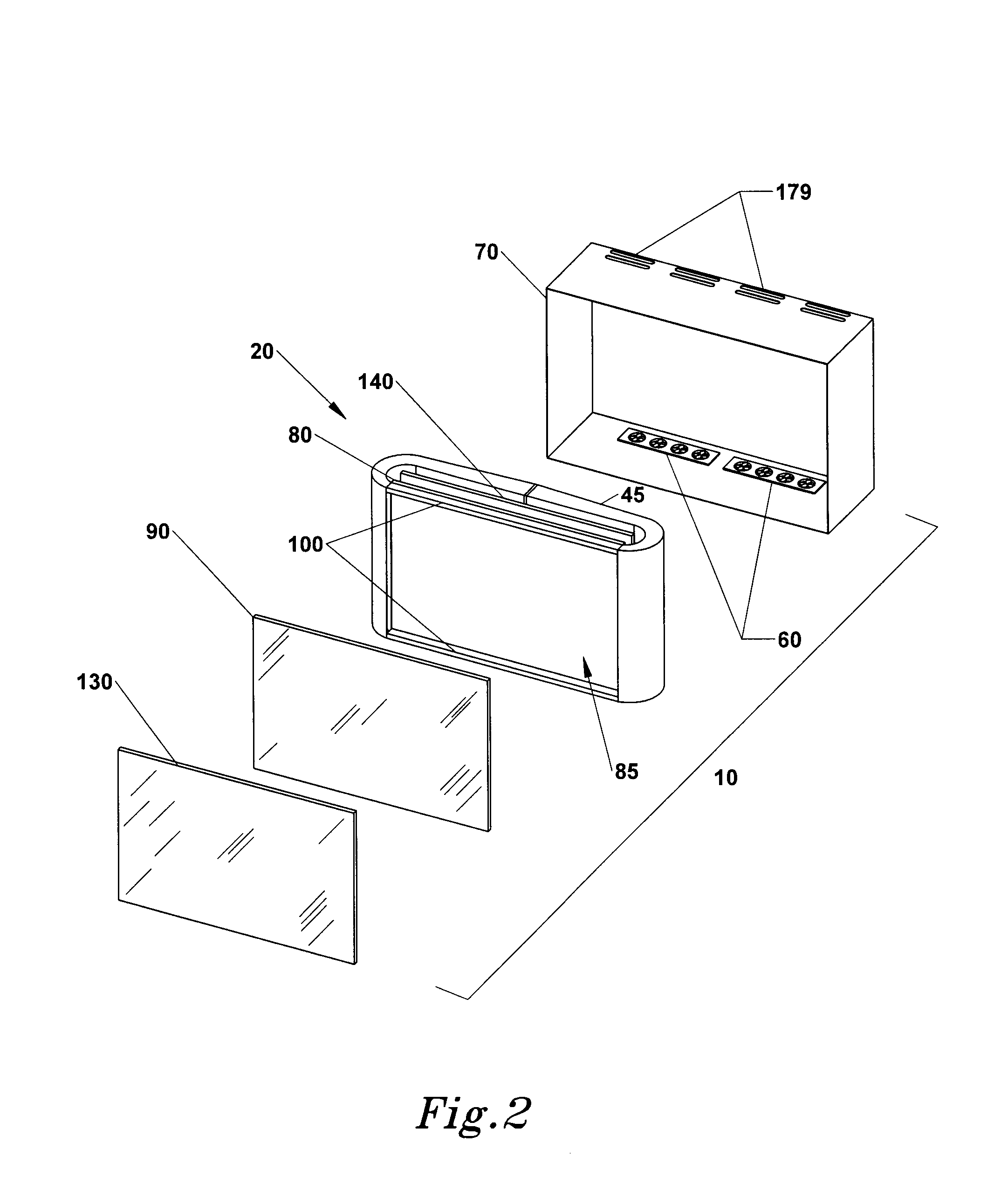

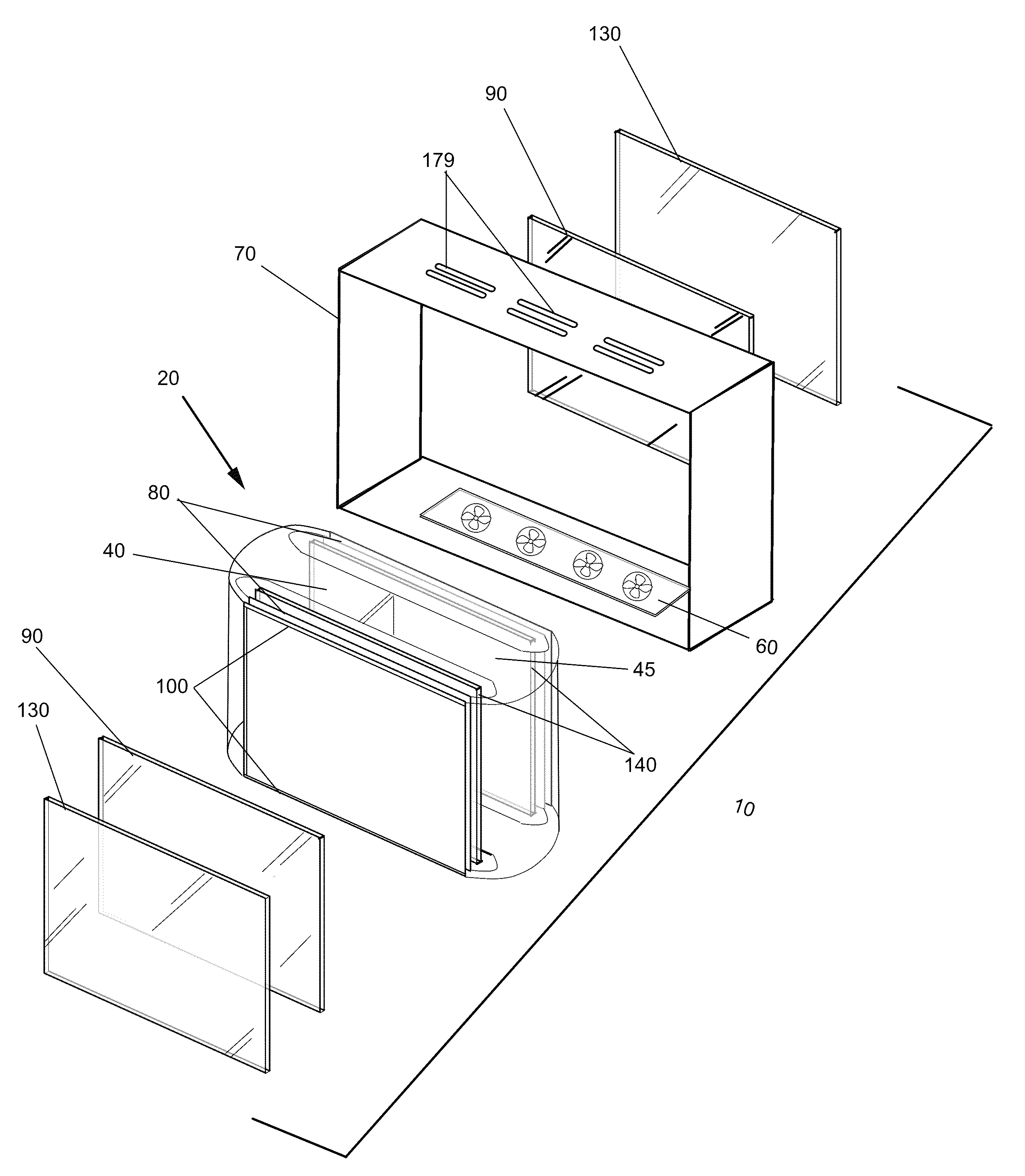

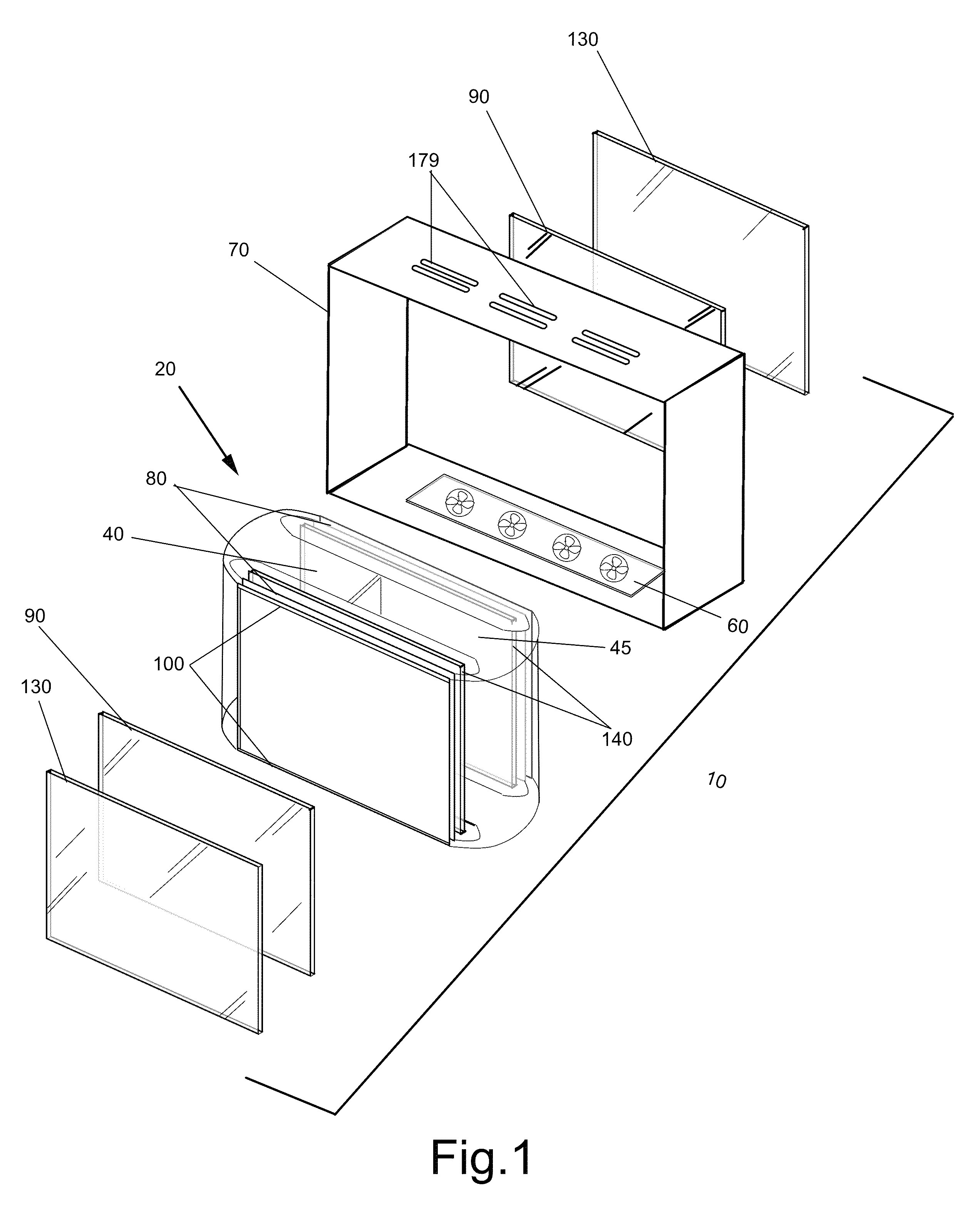

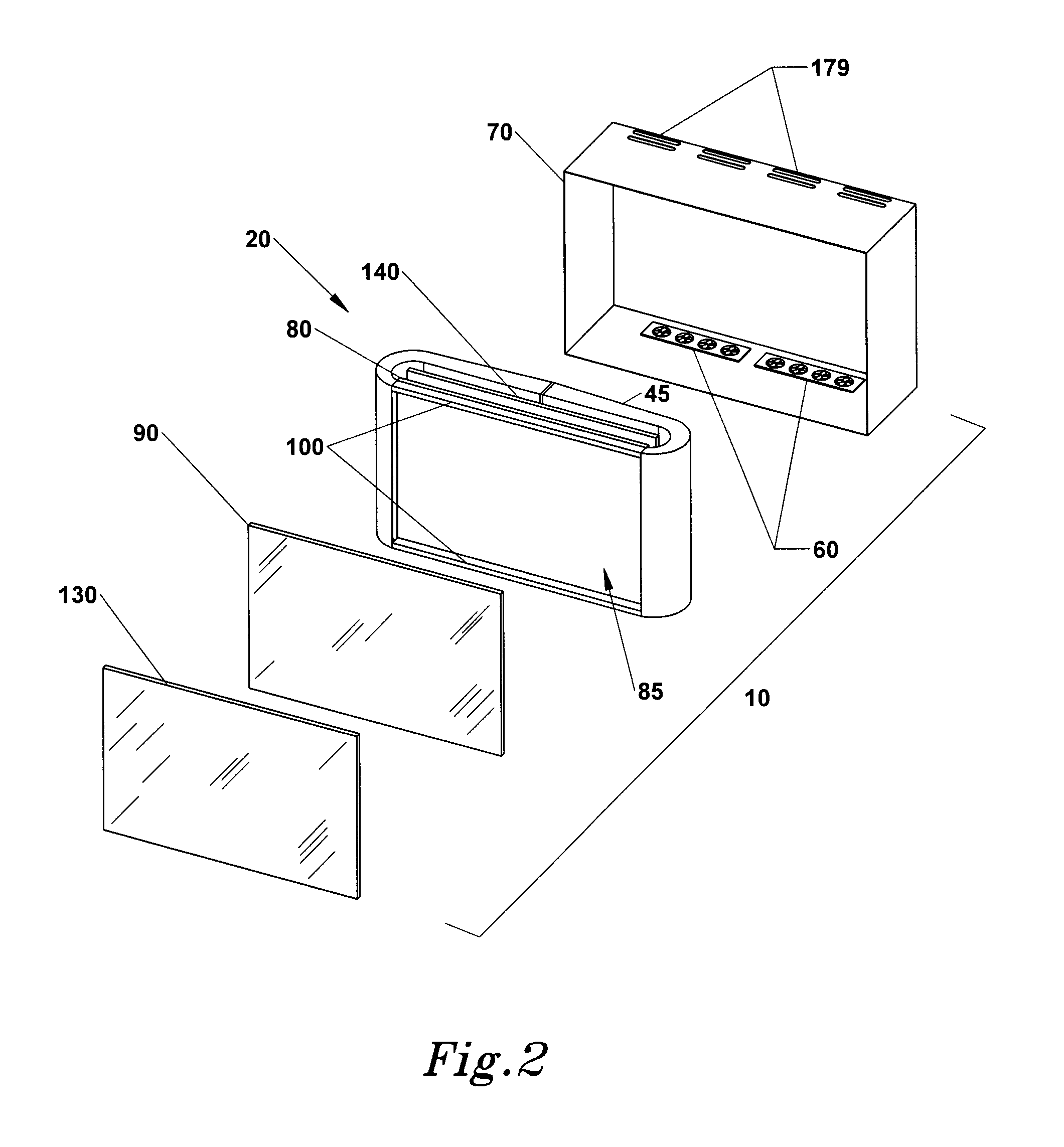

Isolated Cooling System Having an Insulator Gap and Front Polarizer

ActiveUS20090135365A1Guard against solar loadingReduce displayNon-linear opticsCooling/ventilation/heating modificationsImaging qualityNuclear engineering

An exemplary embodiment relates to a cooling system and a method for cooling an electronic display. A preferred embodiment includes a transparent gas cooling chamber. The transparent gas cooling chamber may have a linear polarizer. The components in the system are preferably housed within the electronic display housing. The cooling chamber defines a gas compartment that is anterior to and coextensive with the electronic display surface. Fans may be used to propel the isolated gas through the cooling chamber. The circulating gas removes heat directly from the electronic display surface by convection. The isolated gas is transparent or at least semi-transparent. The image quality of an exemplary embodiment remains essentially unchanged, even though the gas is flowing through a narrow channel over the visible face of the electronic display surface.

Owner:MFG RESOURCES INT INC

Shared isolated gas cooling system for oppositely facing electronic displays

ActiveUS8373841B2Temperature fluctuationImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesNuclear engineeringImaging quality

A system and method for cooling back to back electronic displays. Transparent first and second gas chambers are co-existive with the front display surfaces of the first and second electronic displays. A closed loop of isolated gas enters the first and second gas chambers and contacts the front surfaces of the electronic displays, where it may extract heat from the front display surfaces. The isolated gas is then directed into a cooling chamber where it is cooled and re-introduced into the first and second gas chambers. Fans may be used to propel the isolated gas through the cooling chamber and the first and second gas chambers. The circulating gas removes heat directly from the electronic display surfaces. The isolated gas is transparent or at least semi-transparent to ensure that the image quality of the electronic displays is minimally impacted.

Owner:MFG RESOURCES INT INC

Hybrid liquid-air cooled module

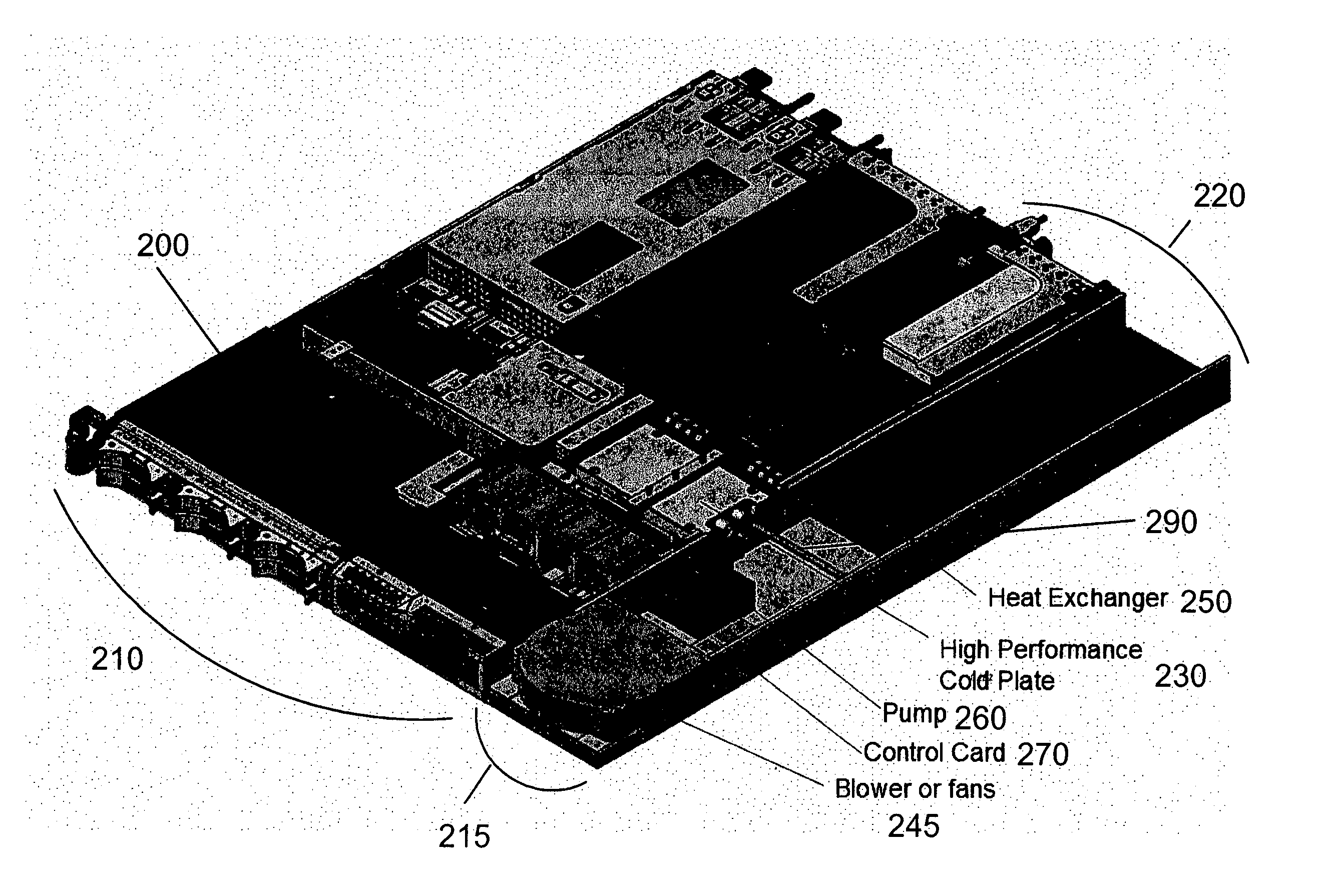

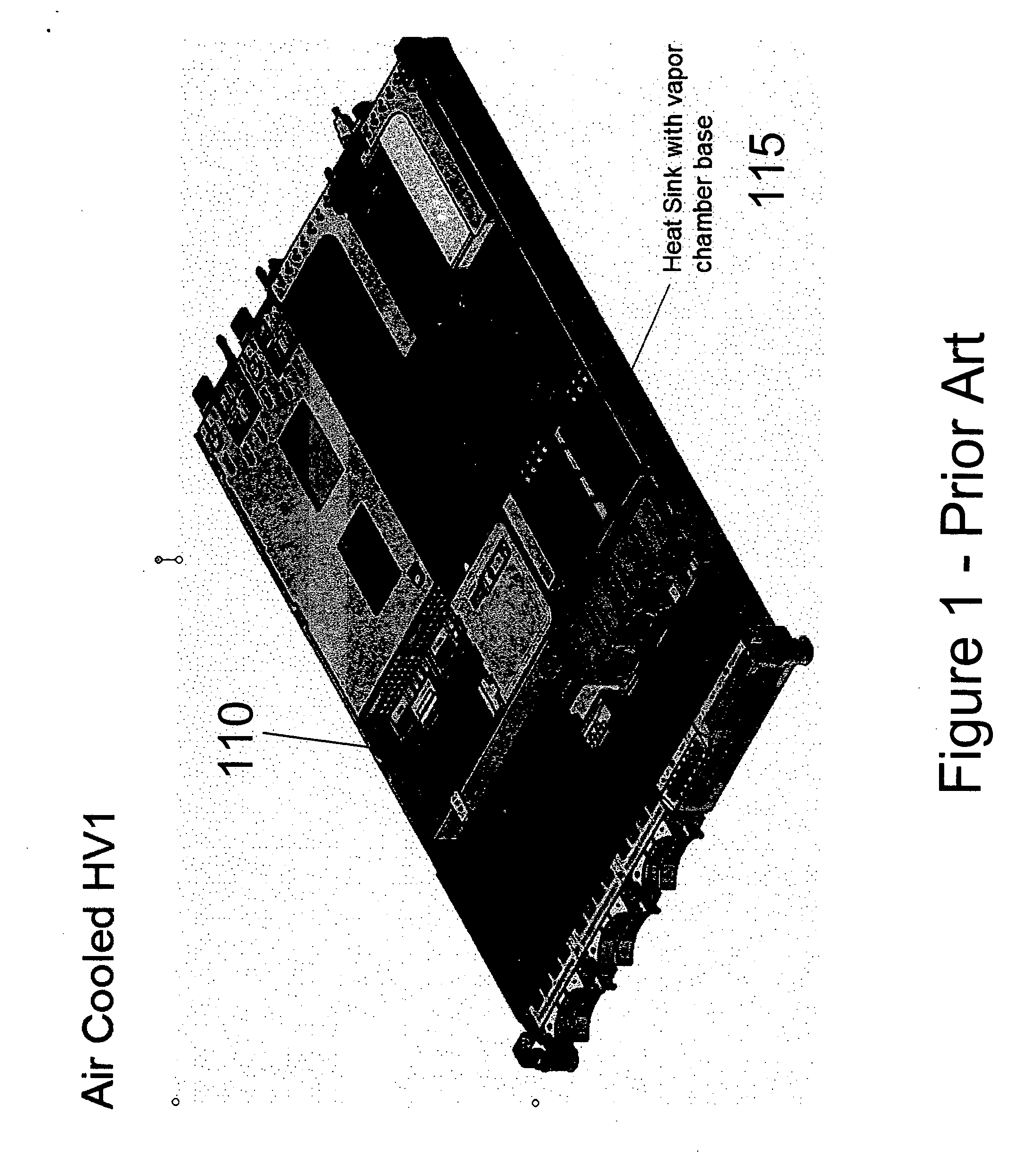

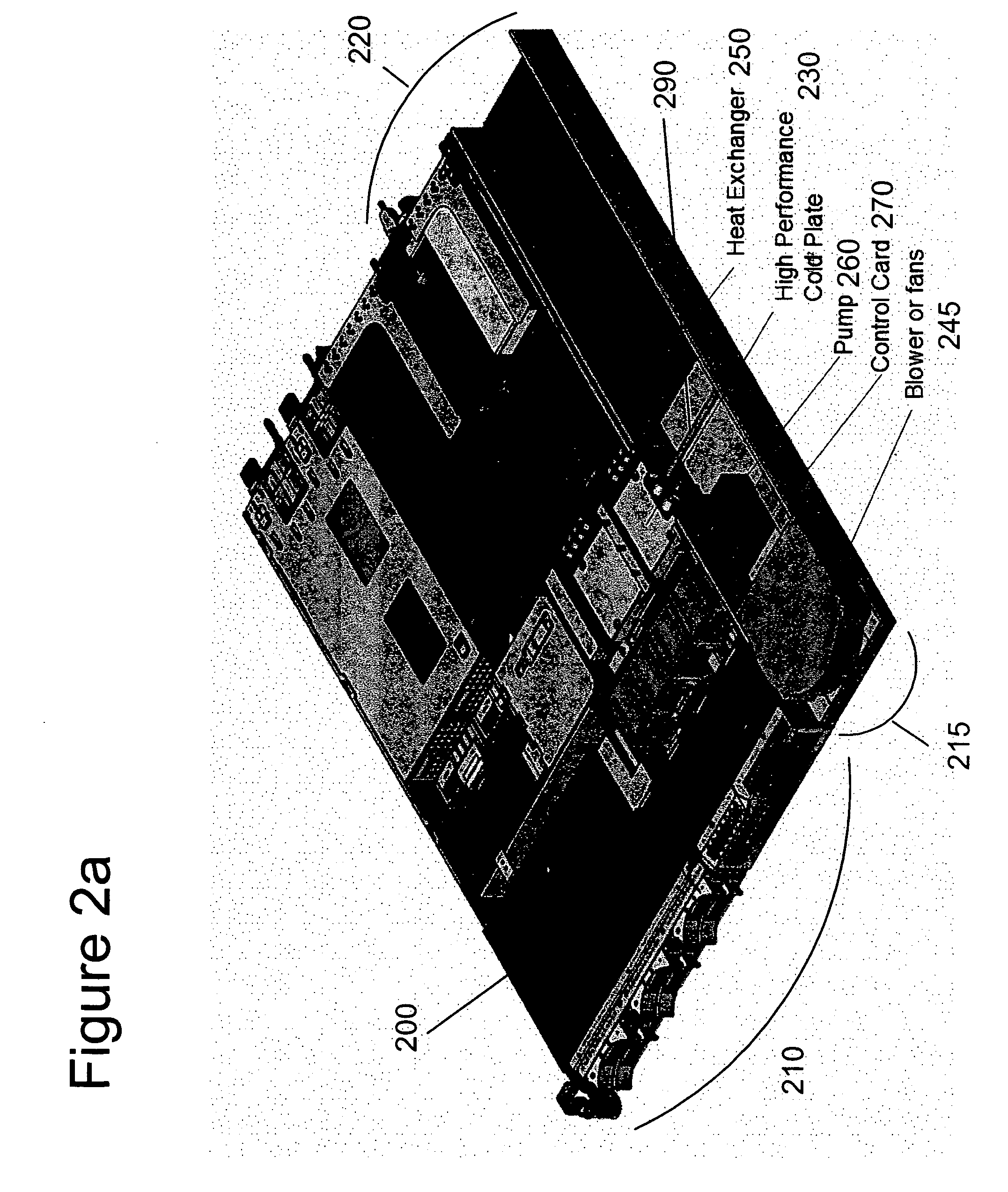

InactiveUS20070121295A1Overcomes shortcomingEnhanced advantageDigital data processing detailsCooling/ventilation/heating modificationsNuclear engineeringClosed loop

A method and incorporated hybrid air and liquid cooled module for cooling electronic components of a computing system is disclosed. The module is used for cooling electronic components and comprise a closed loop liquid cooled assembly in thermal communication with an air cooled assembly, such that the air cooled assembly is at least partially included in the liquid cooled assembly.

Owner:IBM CORP +1

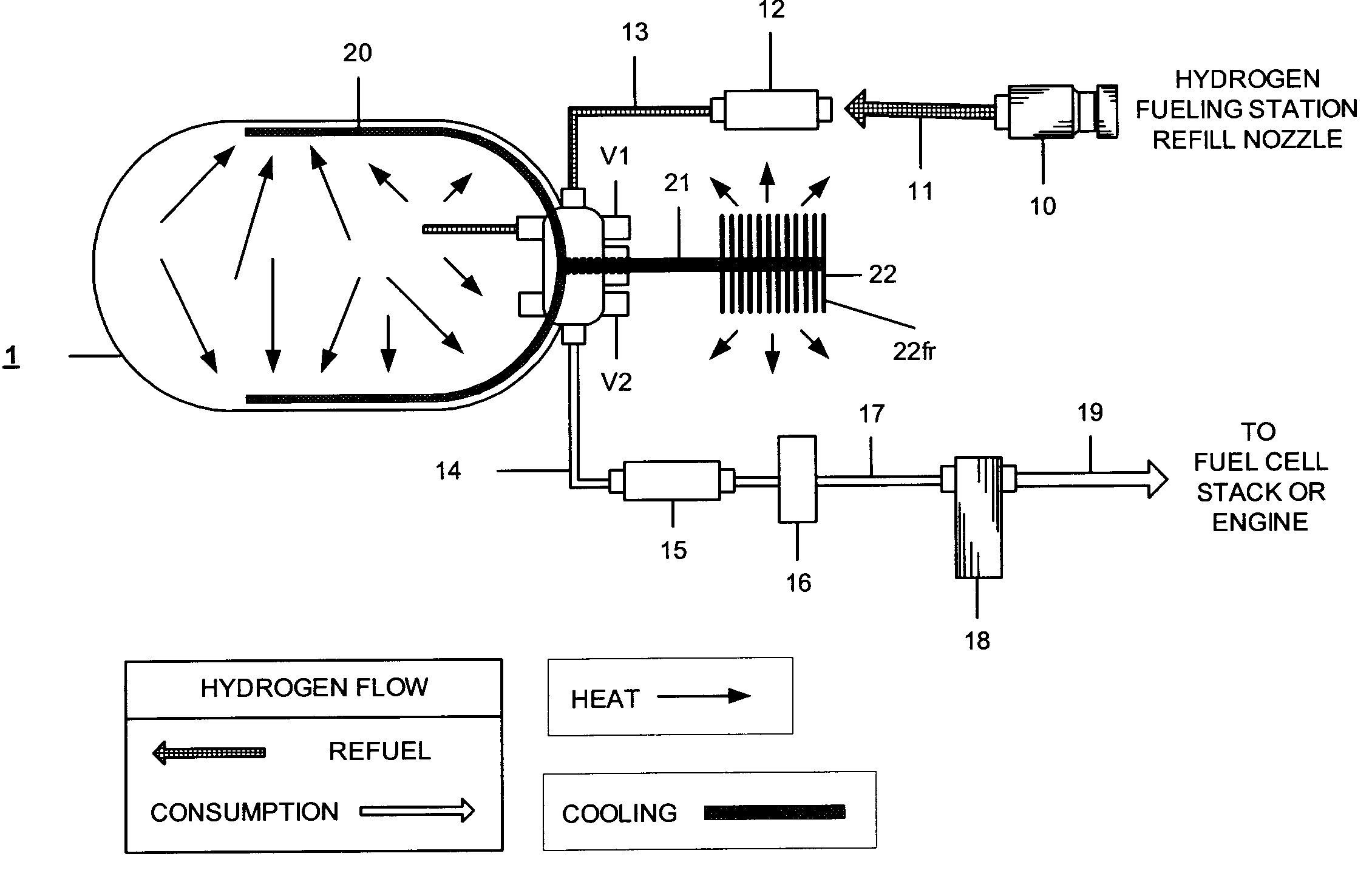

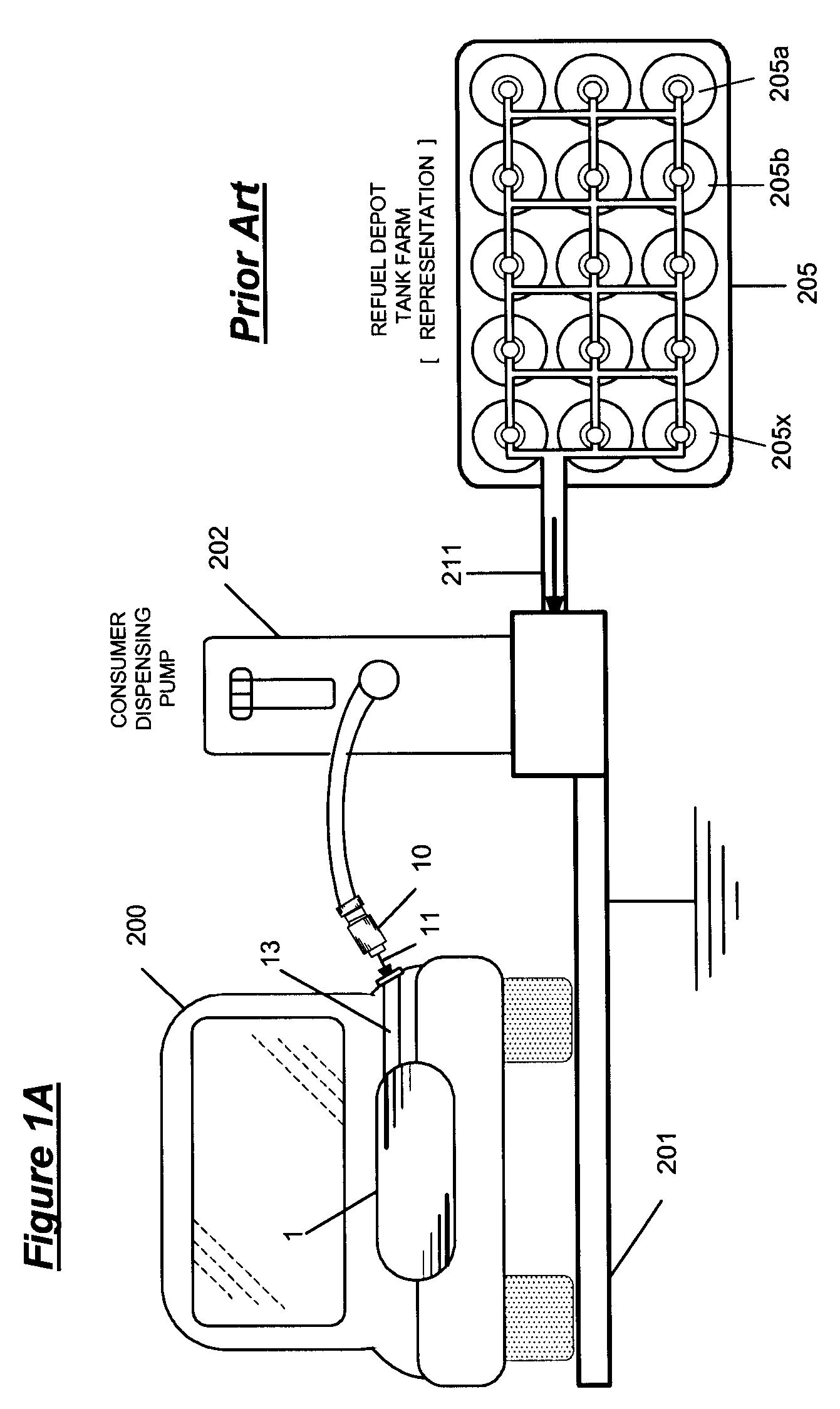

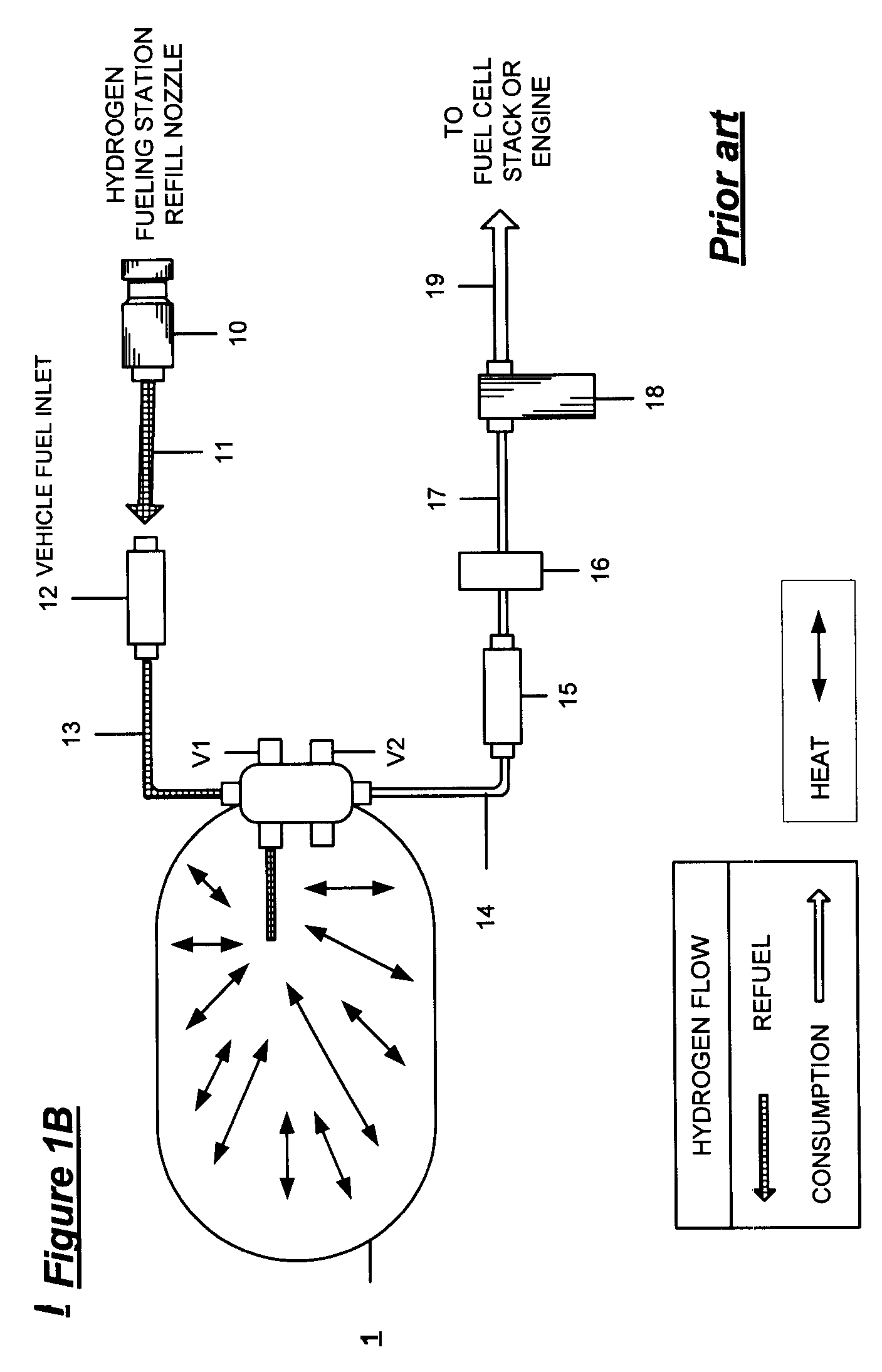

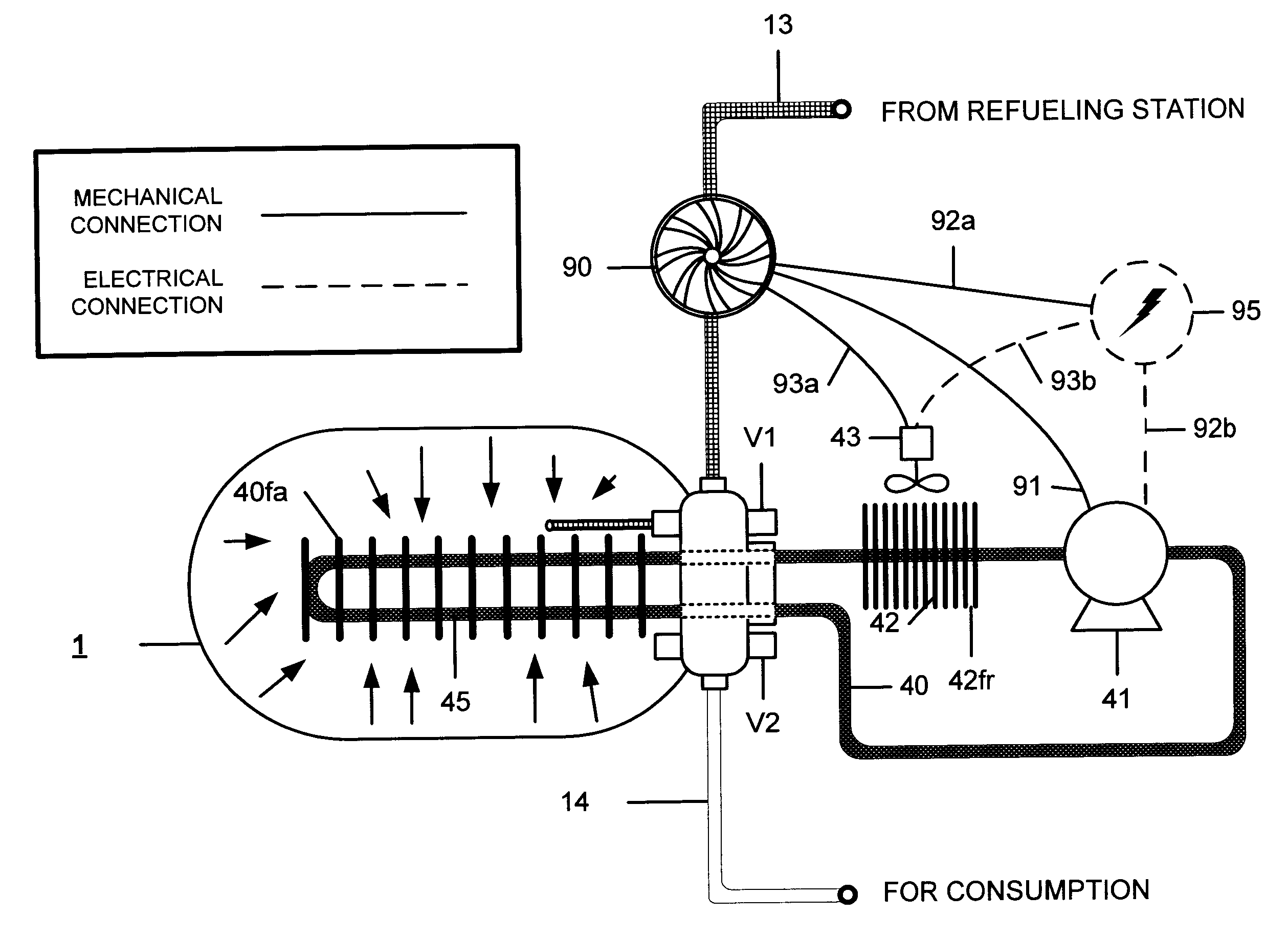

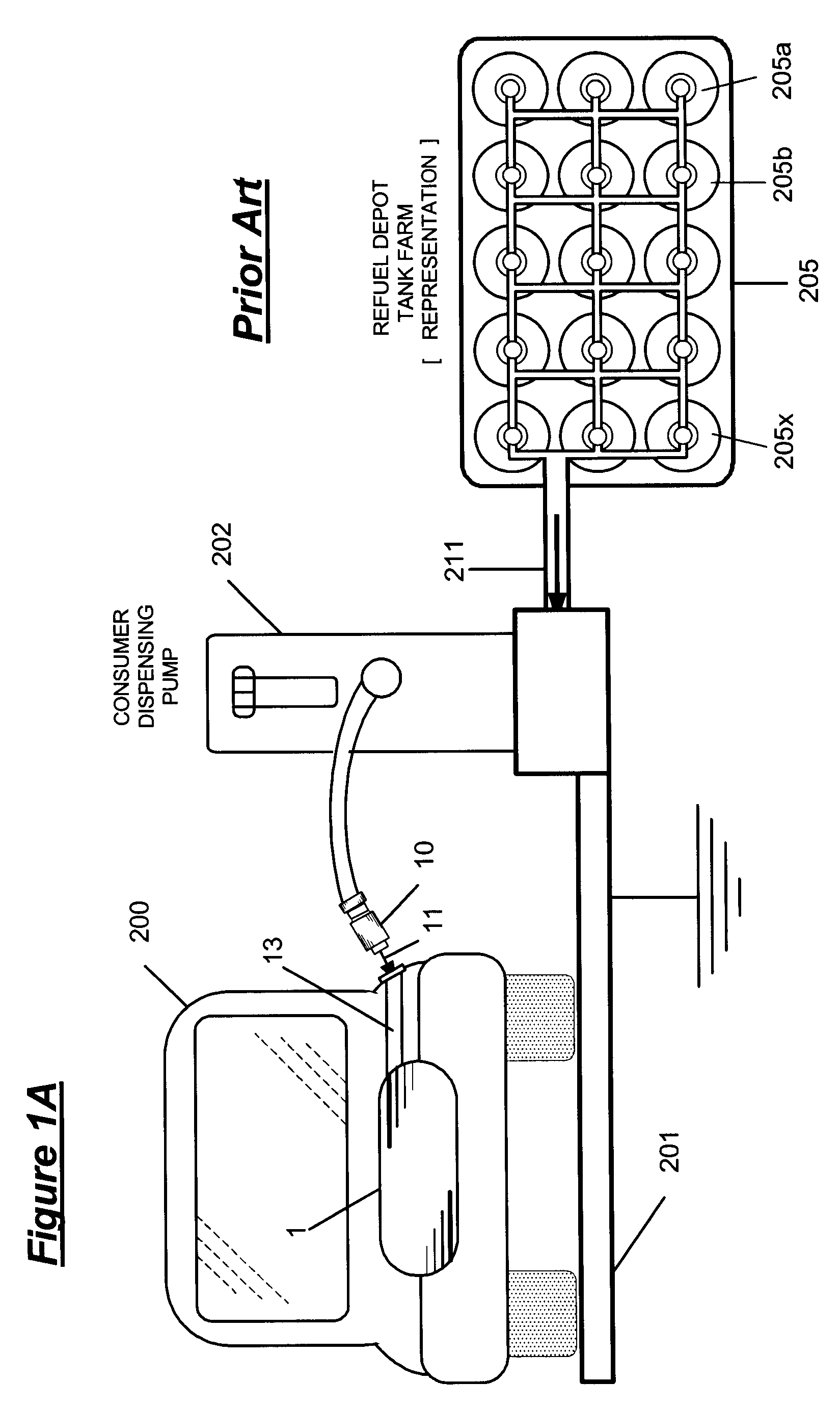

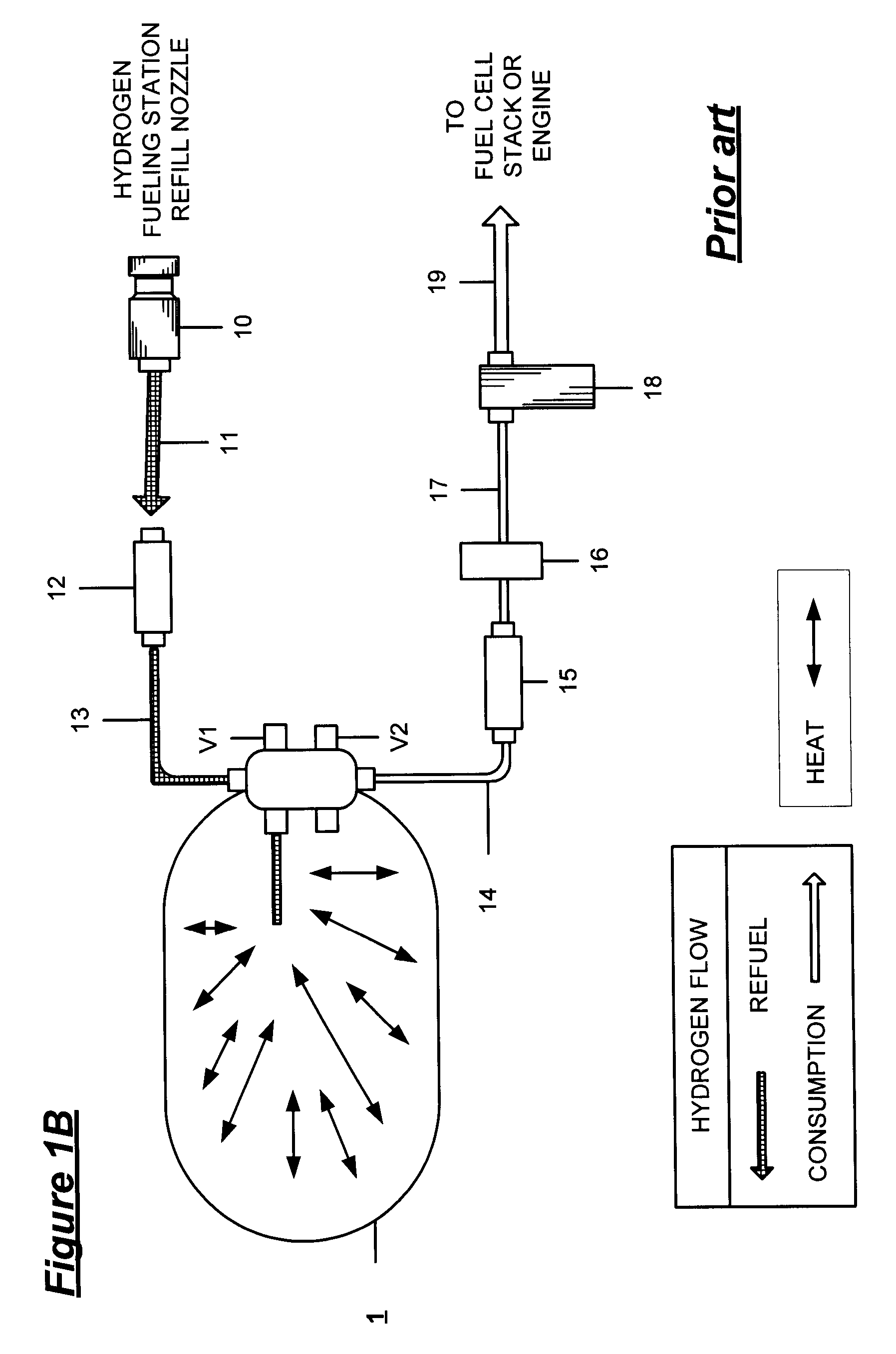

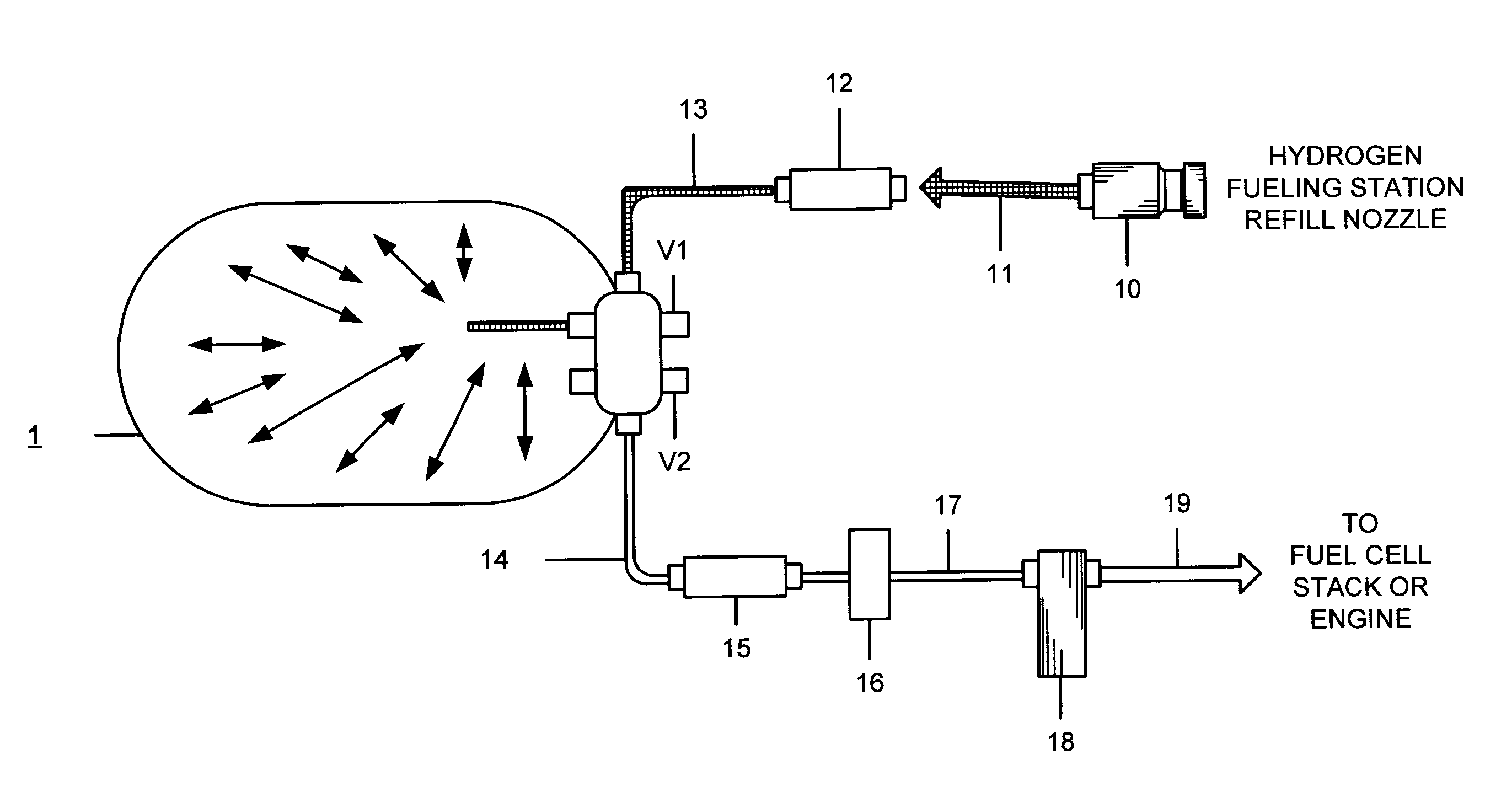

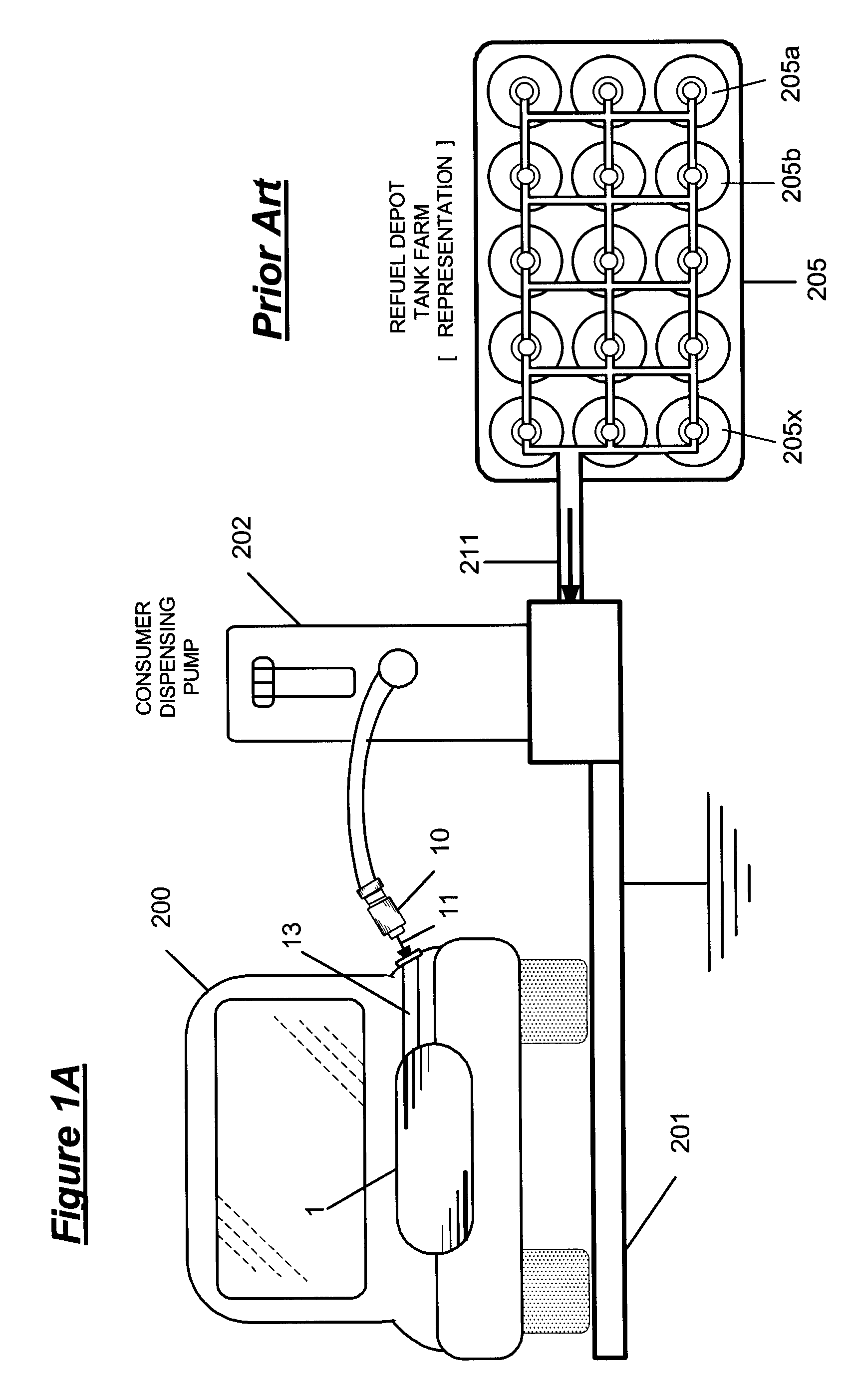

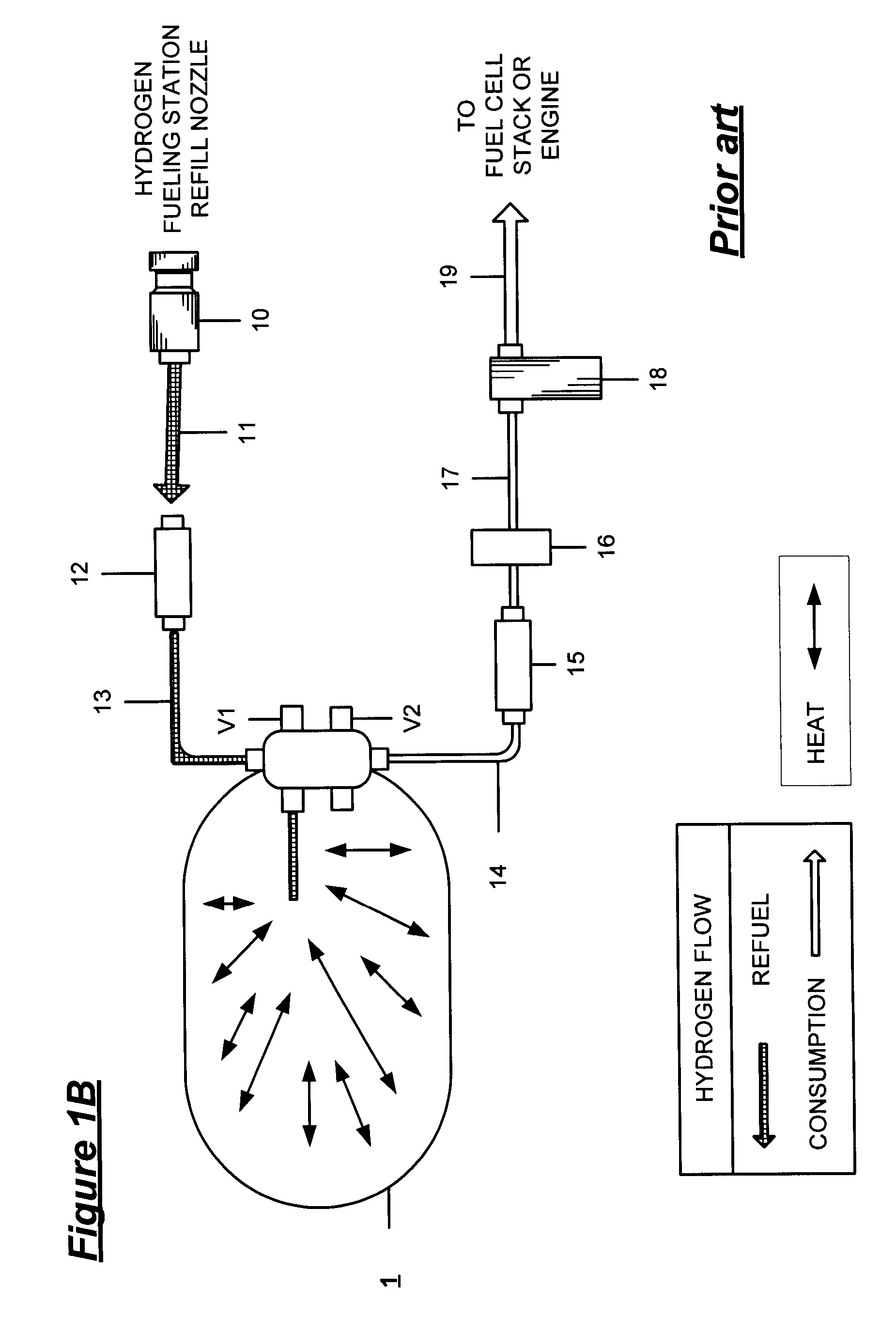

Gas cooling methods for high pressure fuel storage tanks on vehicles powered by compressed natural gas or hydrogen

ActiveUS7377294B2Improve refueling efficiencyIncrease efficiency and refueling capacityGlovesGas handling applicationsThermal energyCompressed natural gas

At a high pressure refuel depot that dispenses high pressure hydrogen or compressed natural gas to vehicles, the thermal energy (heat) generated by the high flow rate of the high pressure refueling gas is evacuated from the on board fuel tank[s] of vehicles eliminating the need for refueling pre treatments such as a slow fill, secondary precooling, and pressure overfill otherwise used to achieve a full vehicle tank refill. In an example, a high pressure fuel depot refilling line is operatively interconnected to an on board vehicle tank having a gas flow circuit wherein the refuel gas itself is circulated within the on board tank to absorb the compression heat of refueling and then to an external radiator before being released into the tank.

Owner:HONDA MOTOR CO LTD

Isolated cooling system having an insulator gap and front polarizer

ActiveUS8879042B2Guard solar loadingReduce loadSubstation/switching arrangement cooling/ventilationNon-linear opticsImaging qualityNuclear engineering

An exemplary embodiment relates to a cooling system and a method for cooling an electronic display. A preferred embodiment includes a transparent gas cooling chamber. The transparent gas cooling chamber may have a linear polarizer. The components in the system are preferably housed within the electronic display housing. The cooling chamber defines a gas compartment that is anterior to and coextensive with the electronic display surface. Fans may be used to propel the isolated gas through the cooling chamber. The circulating gas removes heat directly from the electronic display surface by convection. The isolated gas is transparent or at least semi-transparent. The image quality of an exemplary embodiment remains essentially unchanged, even though the gas is flowing through a narrow channel over the visible face of the electronic display surface.

Owner:MFG RESOURCES INT INC

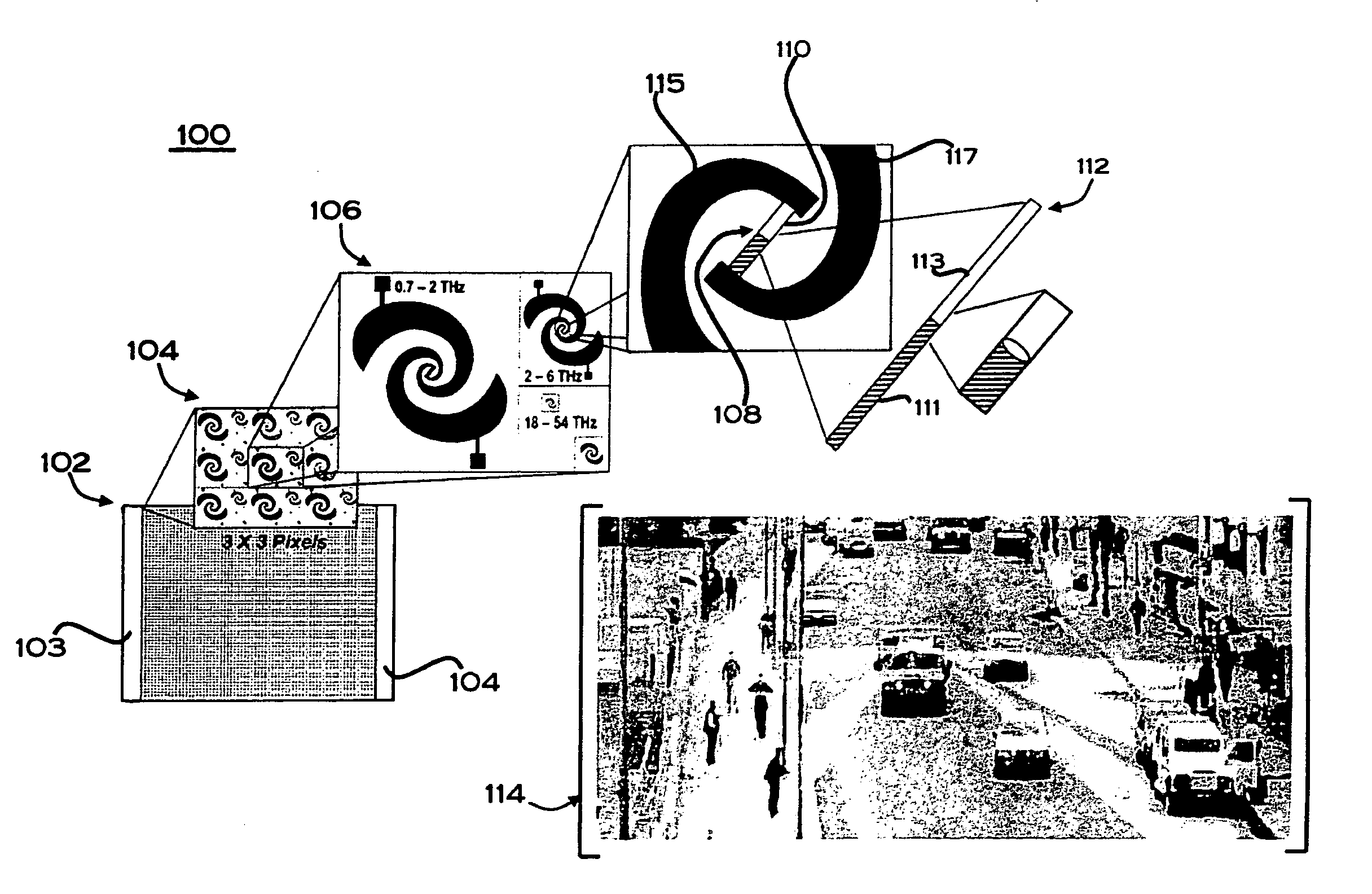

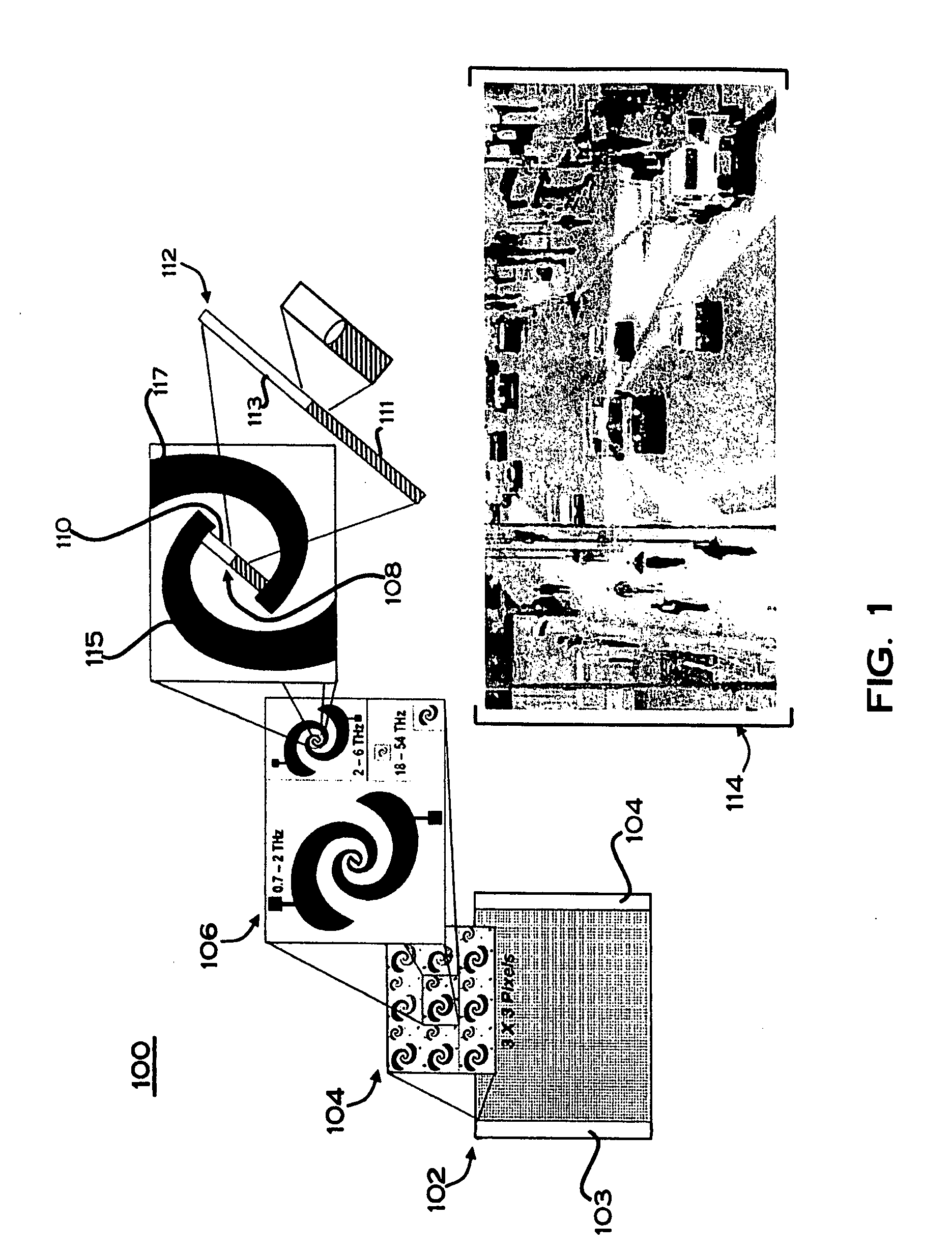

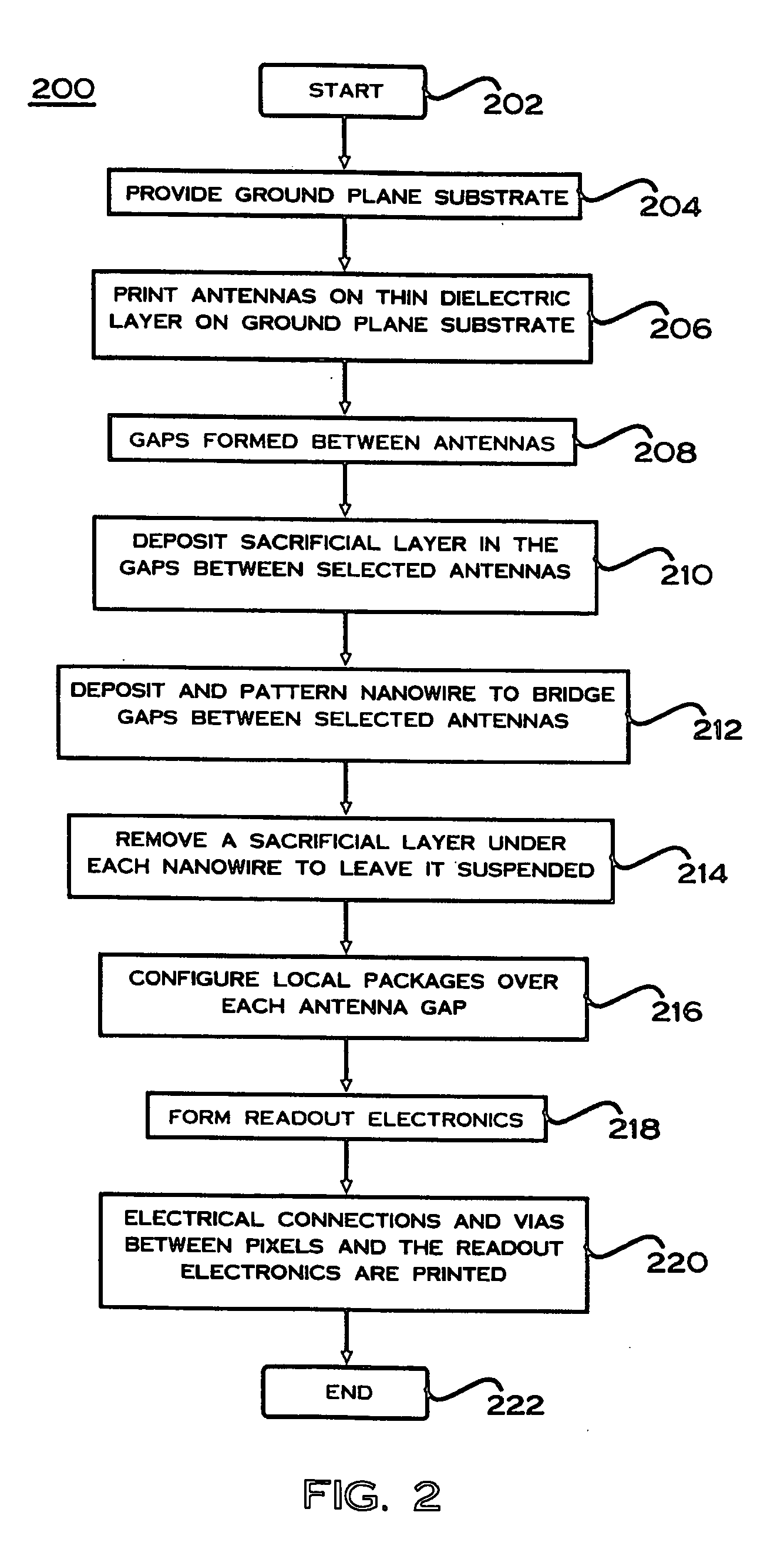

Nanowire multispectral imaging array

ActiveUS20090072145A1Decreases thermal time constantImprove manufacturabilitySpectrum investigationSolid-state devicesNanowireRC time constant

A multispectral imaging array system and method of forming the same. A substrate and a group of antennas can be located with respect to one another on the substrate, such that respective gaps are formed between each antenna group and wherein different antenna sizes may be used for different spectral ranges. Additionally, one or more nanowires can be located within one or more gaps among the respective gaps, such that the nanowires in communication with the antennas and the substrate comprise a multispectral imaging system in which the use of the nanowire(s) decreases the thermal time constant and therefore the read out rate from the antennas while decreasing the ambient gas cooling speed relative to the read out rate to increase the manufacturability of the multispectral imaging array system.

Owner:HONEYWELL INT INC

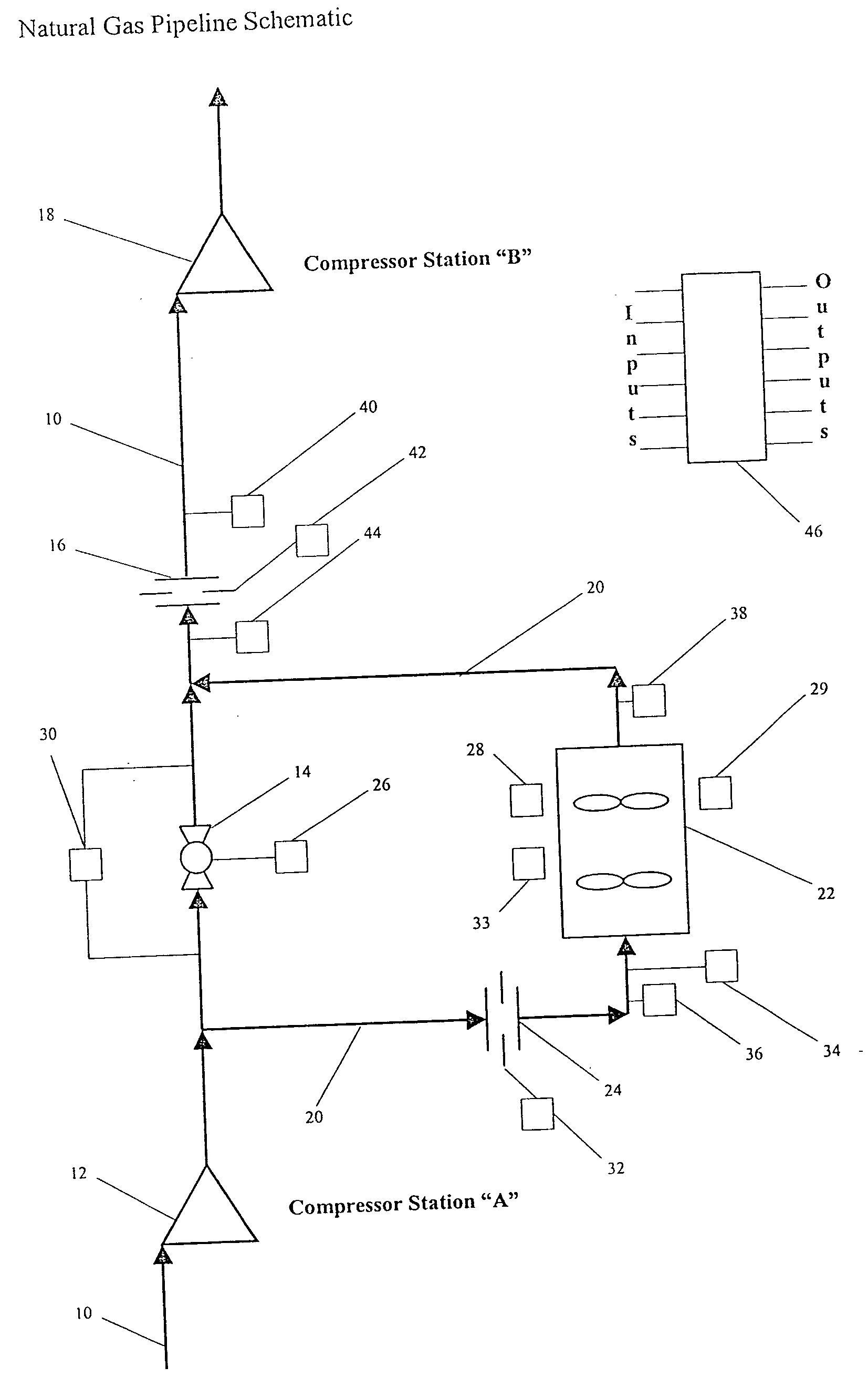

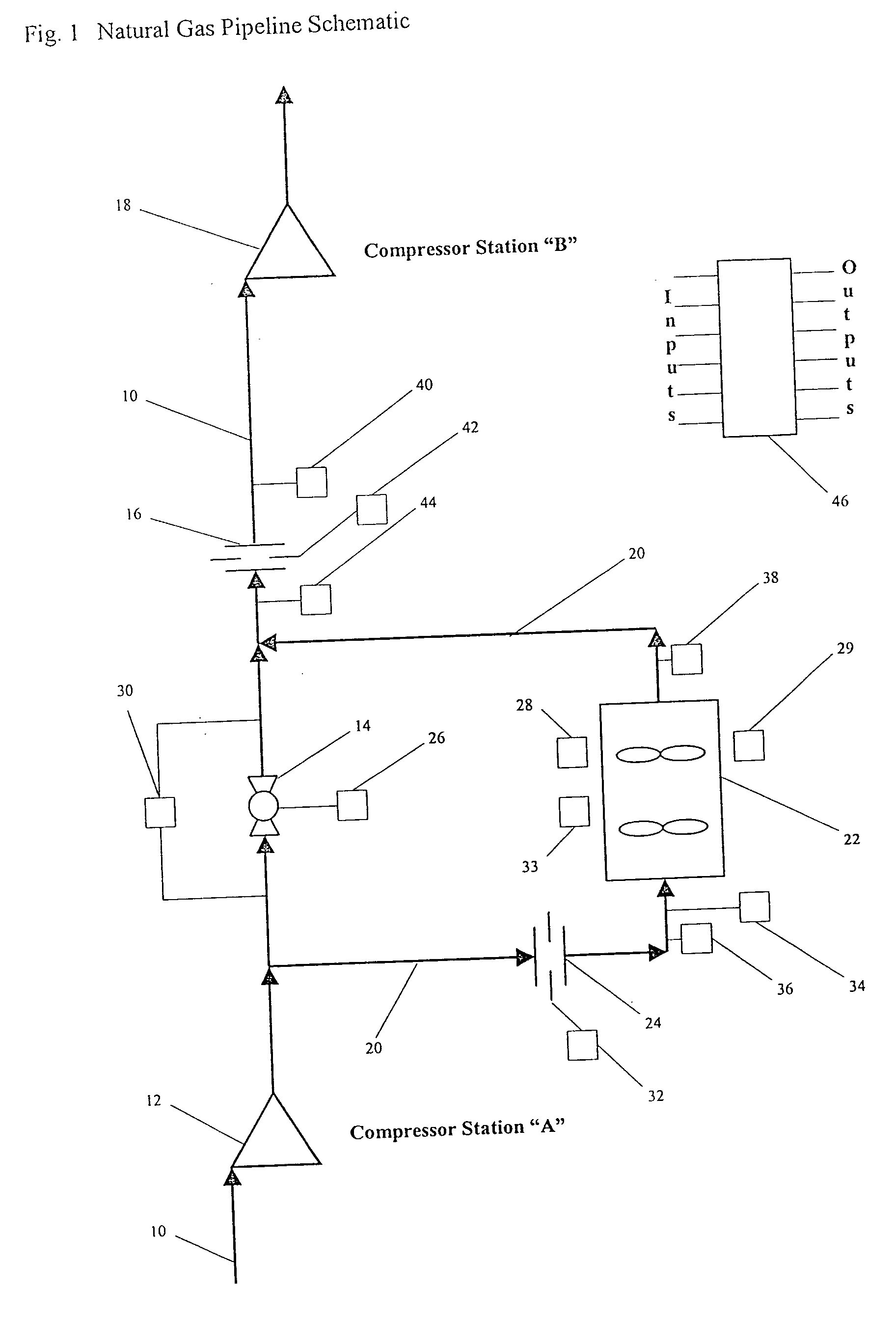

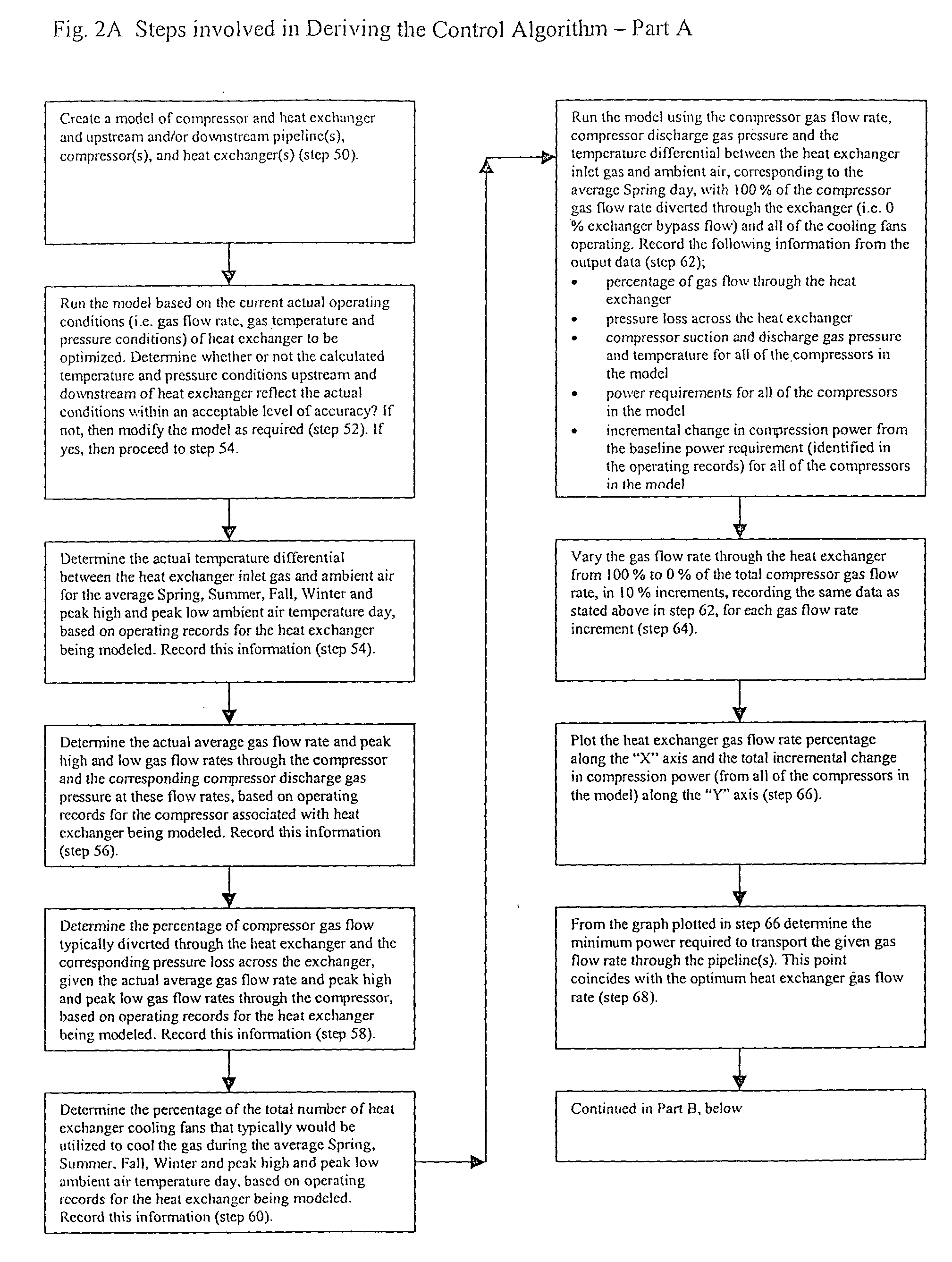

Heat exchanger optimization process and apparatus

InactiveUS20050034467A1Speed up the gas flowImprove heat transfer performanceSolidificationLiquefactionStream flowEngineering

An electronic HEMD determines the optimum balance between gas cooling and heat exchanger pressure loss, for any given operating condition, and adjusts the gas flow rate through the exchanger accordingly, to yield the maximum net power savings (and thereby energy savings) afforded by the exchanger. Maintaining the optimum balance between cooling and exchanger pressure loss reduces the amount of energy required to transport a given volume of gas through a pipeline and thereby increases the transmission efficiency of the gas pipeline system. A method of operating a heat exchanger on a natural gas transmission pipeline using a control algorithm that in turn controls the position of a heat exchanger bypass valve. The current operating conditions of the upstream compressor and gas cooling system are continually monitored for any changes and the control algorithm determines, the optimum flow through the heat exchanger and initiates a command signal to the exchanger bypass valve operator to move the bypass valve and thereby increase or decrease the gas flow rate through the exchanger, as required, until the optimum balance between gas cooling and heat exchanger pressure loss has been achieved.

Owner:VARNEY BRIAN WILSON

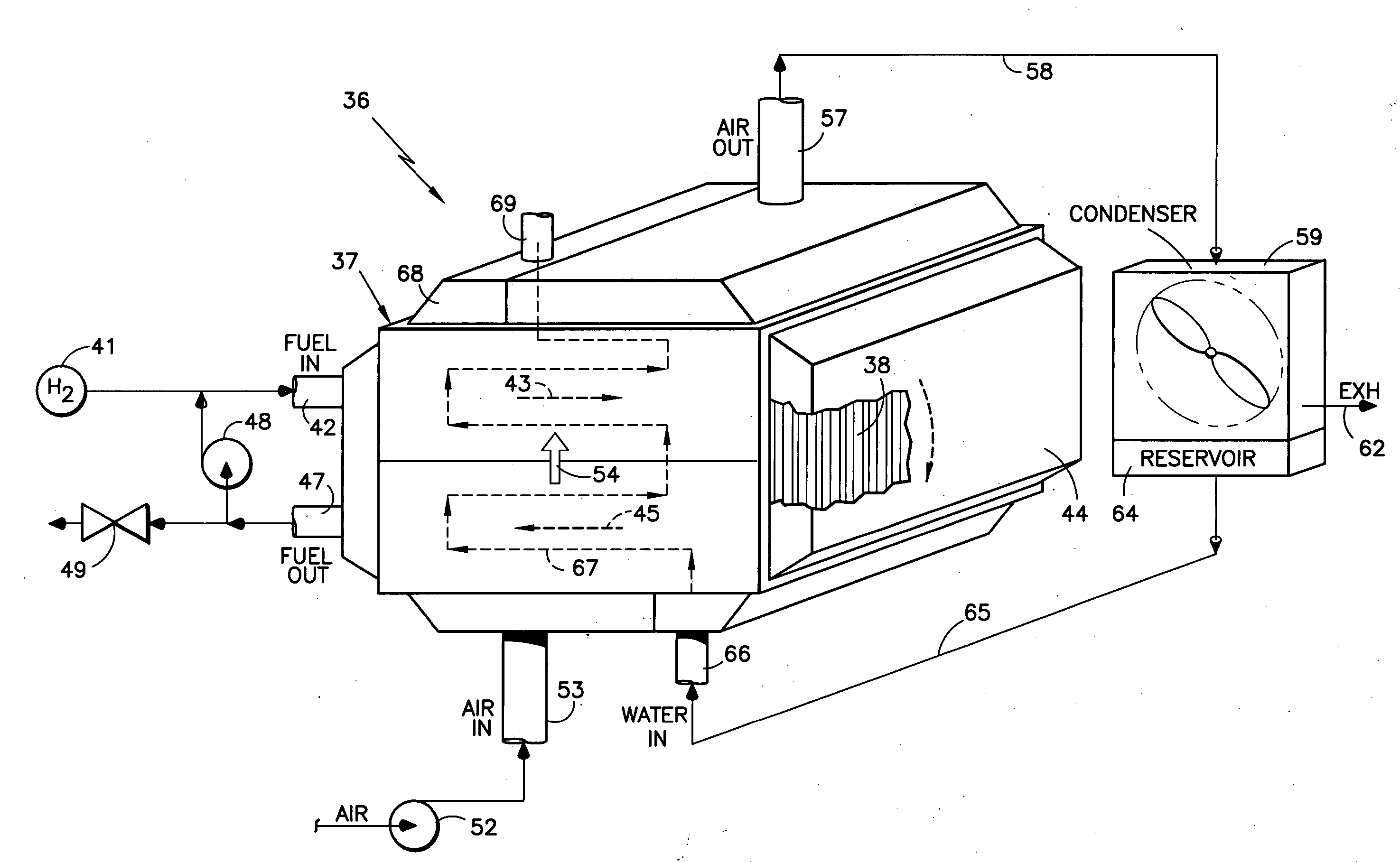

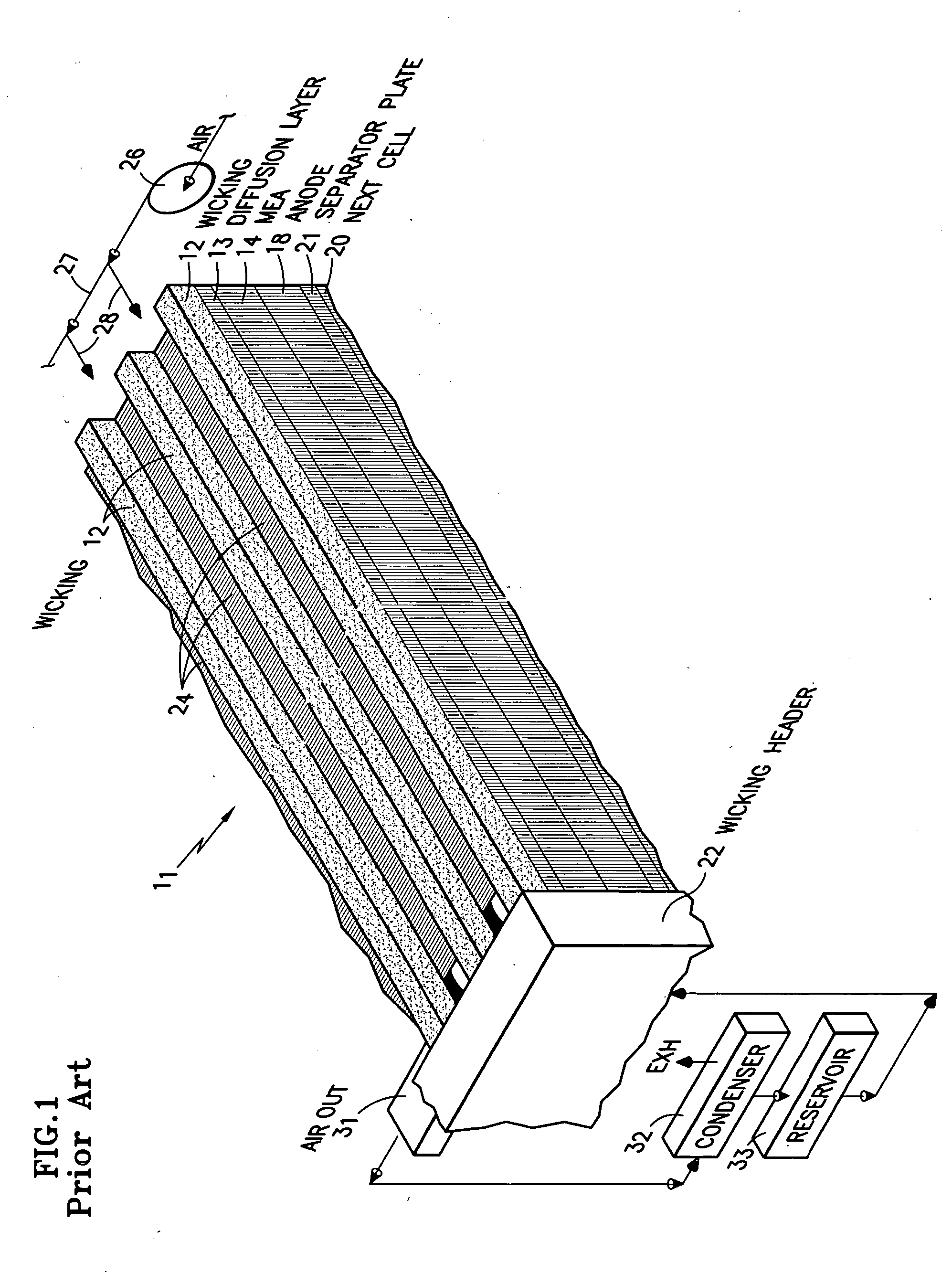

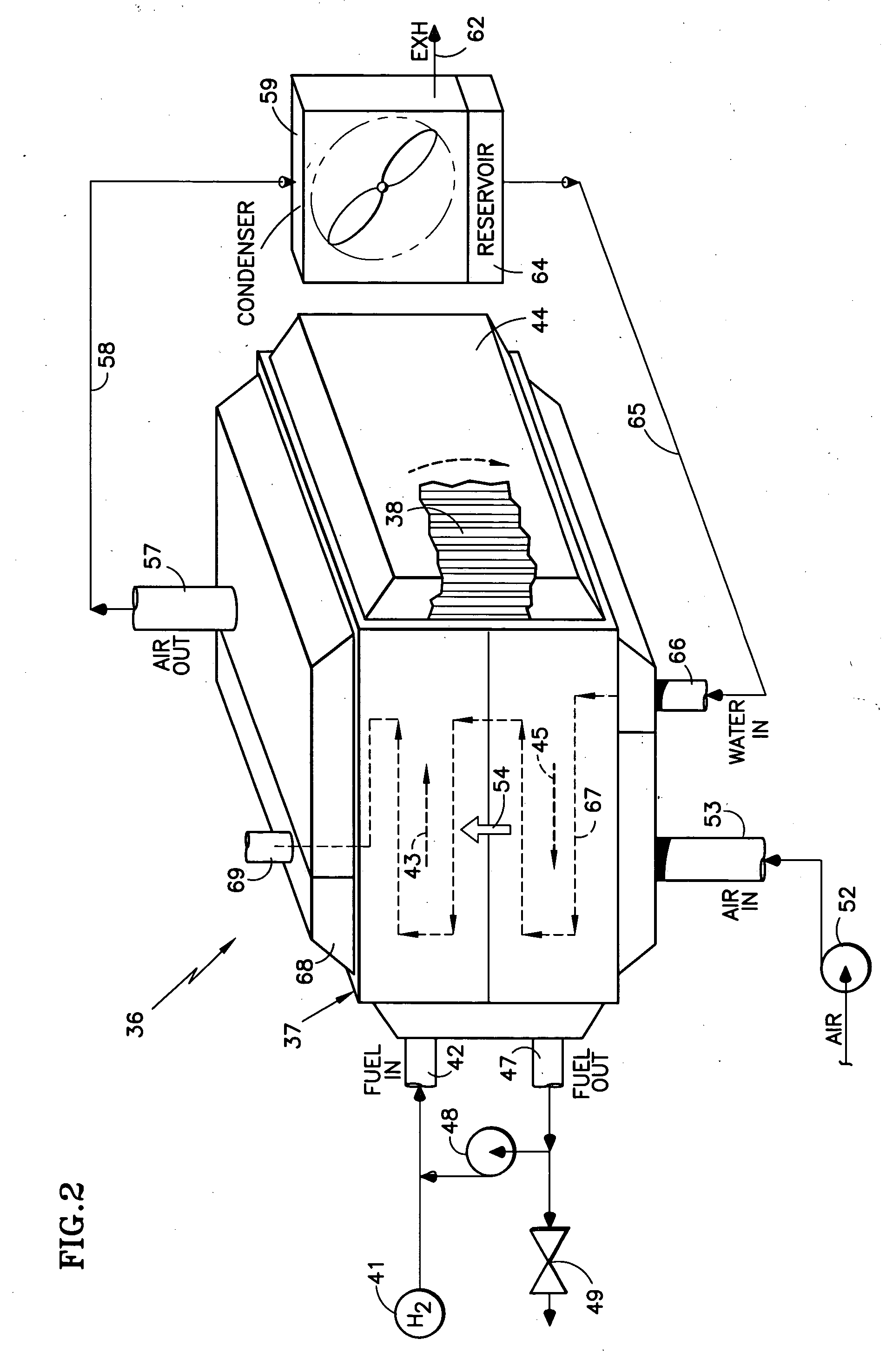

Fuel cells evaporative reactant gas cooling and operational freeze prevention

ActiveUS20060141331A1Increase the areaHigh densityFuel cells groupingFuel cell auxillariesFuel cellsWater channel

Fuel cells (38) have water passageways (67; 78, 85; 78a, 85a) that provide water through reactant gas flow field plates (74, 81) to cool the fuel cell. The water passageways may be vented to atmosphere (99), by a porous plug (69), or pumped (89, 146) with or without removing any water from the passageways. A condenser (59, 124) receives reactant air exhaust, may have a contiguous reservoir (64, 128), may be vertical, (a vehicle radiator, FIG. 2), may be horizontal, contiguous with the top of the fuel cell stack (37, FIG. 5), or below (124) the fuel cell stack (120). The passageways may be grooves (76, 77; 83, 84) or may comprise a plane of porous hydrophilic material (78a, 85a) contiguous with substantially the entire surface of one or both of the reactant gas flow field plates. Air flow in the condenser may be controlled by shutters (155). The condenser may be a heat exchanger (59a) having freeze-proof liquid flowing through a coil (161) thereof, the amount being controlled by a valve (166). A deionizer (175) may be used.

Owner:AUDI AG

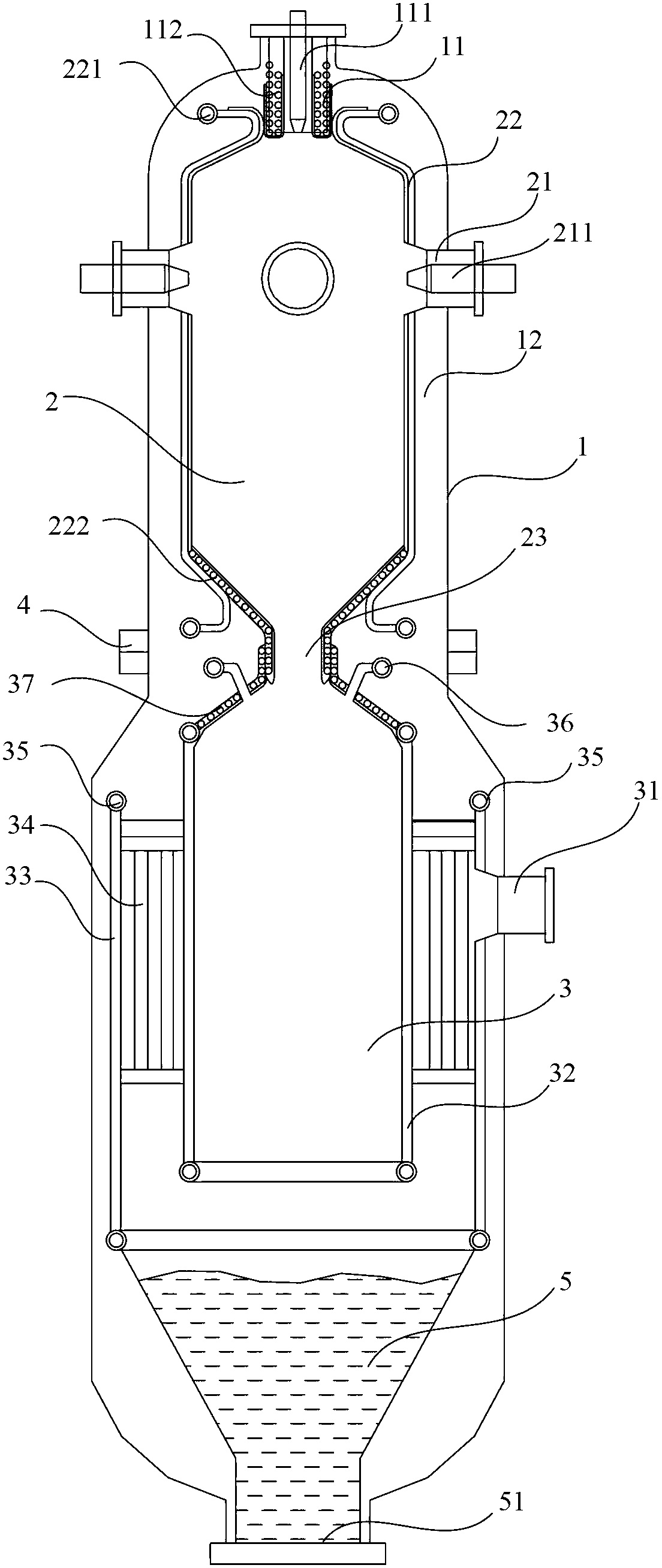

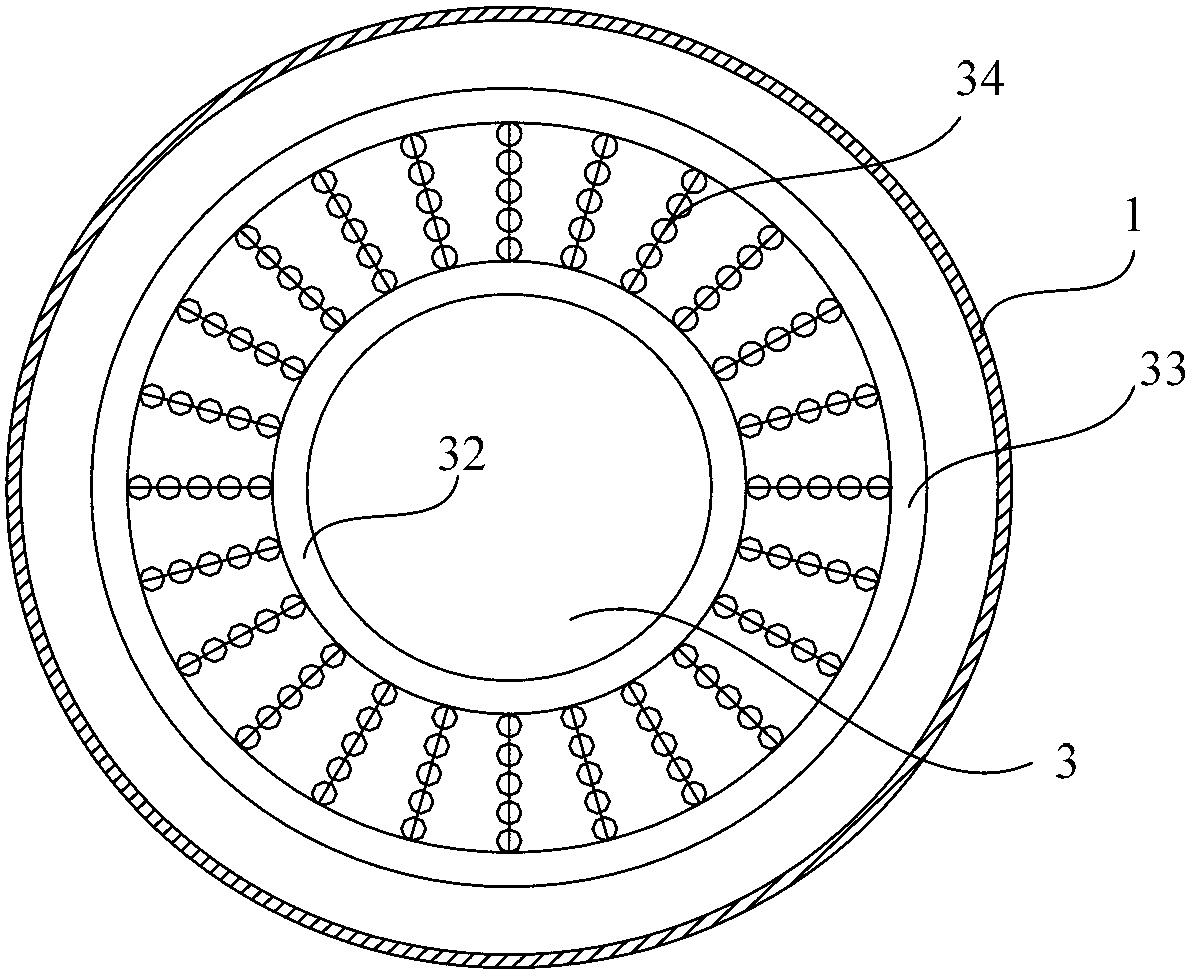

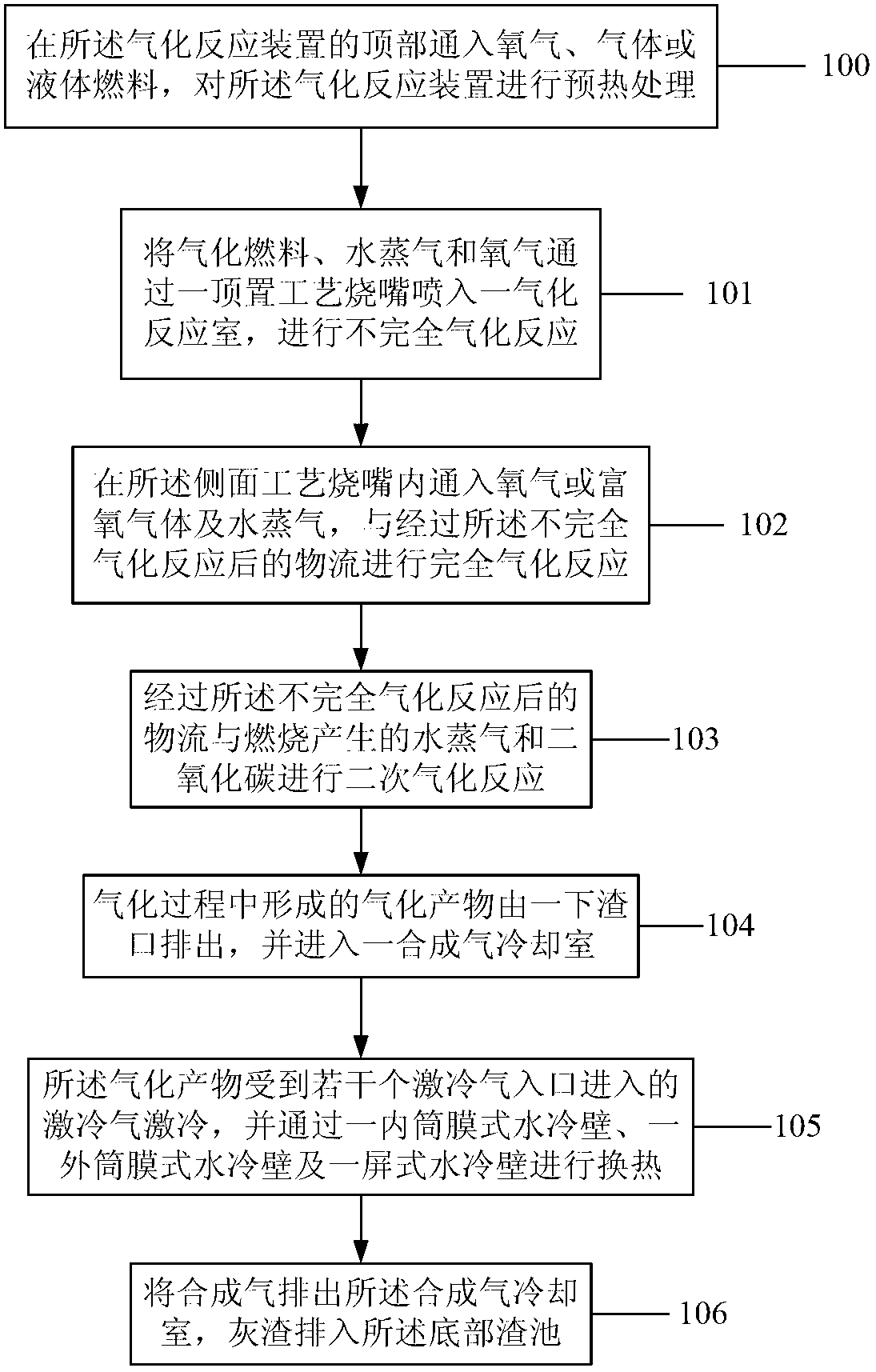

Staged-pressurization gasification reaction device for dry pulverized coal and gasification method thereof

InactiveCN102703129AEffective cooling and solidificationReduce size areaGranular/pulverulent flues gasificationSyngasSlag

The invention discloses a staged-pressurization gasification reaction device for dry pulverized coal. A first burner chamber internally provided with a top-arranged process burner is arranged at the top part of the gasification reaction device; a layer of second burner chamber internally provided with a side-surface process burner is arranged on the side surface at the upper part of the gasification reaction device and along the peripheral direction; a slag hole is also arranged in the bottom of the gasification reaction device; multiple chilling gas inlets are arranged at the upper end part of a synthesis gas cooling chamber; and further, the synthesis gas cooling chamber is also provided with an inner cylinder membrane wall, an outer cylinder membrane wall and a screen wall. The invention further discloses a gasification method, which includes steps as follows: S1, gasified fuel, water vapor and oxygen are sprayed into the gasification reaction chamber for incomplete gasification reaction; S2, oxygen or oxygen rich gas and water vapor are injected into the side surface process burner so as to carry out complete gasification reaction and secondary gasification reaction; S3, gasified products enter the synthesis gas cooling chamber from the slag hole; and S4, synthesis gas is discharged from the synthesis gas cooling chamber, and ash residues are discharged into a bottom slag basin. According to the invention, the service life of the furnace liner is prolonged, and the practical operation flexibility is enhanced.

Owner:SHANGHAI BOILER WORKS

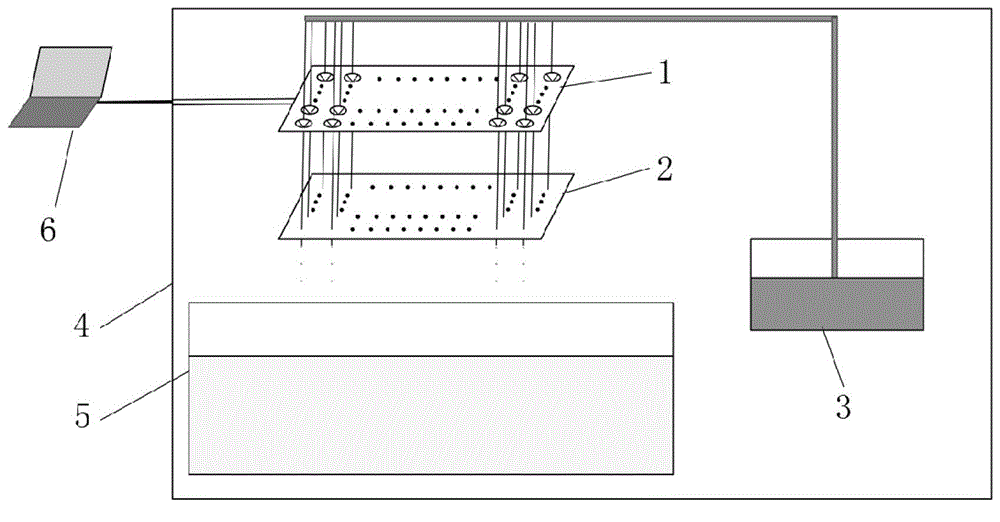

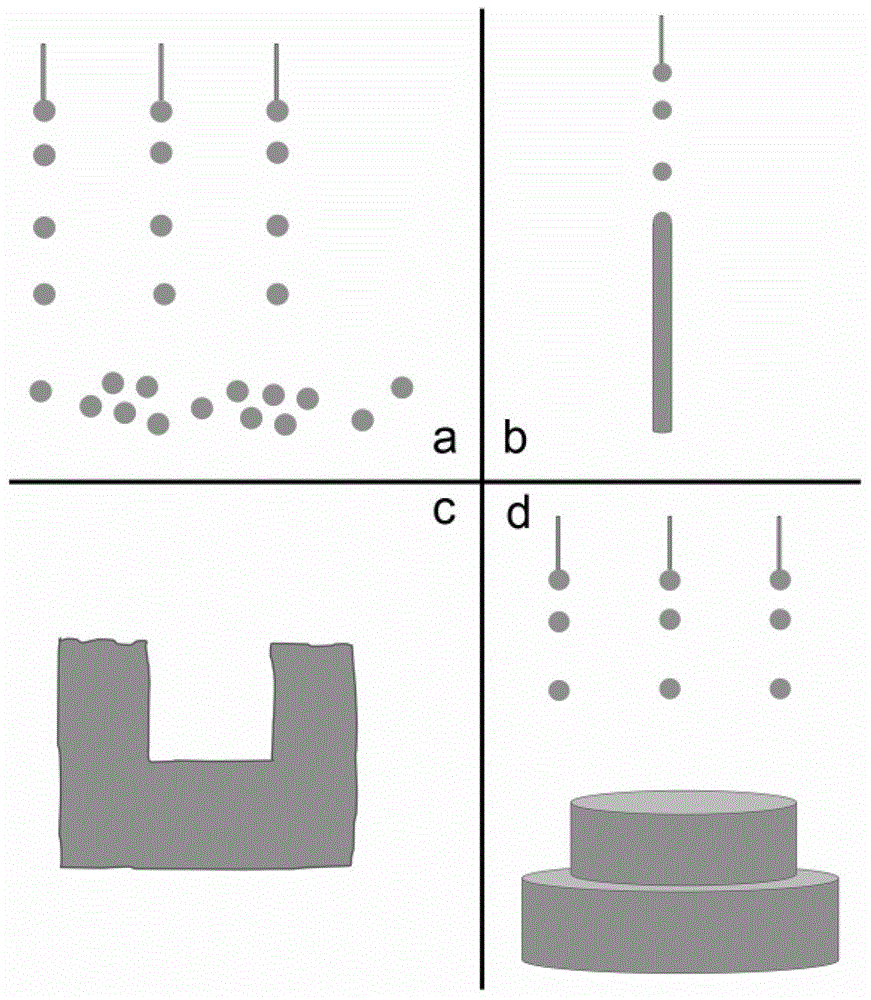

Low-melting-point metal multi-dimensional structure liquid phase printing system and method

The invention provides a low-melting-point metal multi-dimensional structure liquid phase printing system. The low-melting-point metal multi-dimensional structure liquid phase printing system comprises an injection pump array, an injection needle array, a liquid metal tank, a thermostat, a thermostatic bath and a control unit. The injection pump array includes m*n of injection pumps and an inlet of every injection pump is connection with the liquid metal tank. Injection needles are perpendicular to the thermostatic bath and liquid inlets of the injection needles are connected to outlet ends of the injection pumps respectively. The control unit is connected to the injection pump array. A low-melting-point metal multi-dimensional structure liquid phase printing method uses the smart control mechanism of fluid for applying effective buffer, crushing and buoyancy actions to liquid metal injection droplets, and the liquid cooling treatment more efficient than a traditional gas cooling mode can be provided for enabling liquid metal injected into a liquid phase environment to be quickly solidified due to the large heat capacity, so that short-time forming of a multi-dimensional structure is achieved, and meanwhile the oxidation not easy to avoid in a traditional method is reduced.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

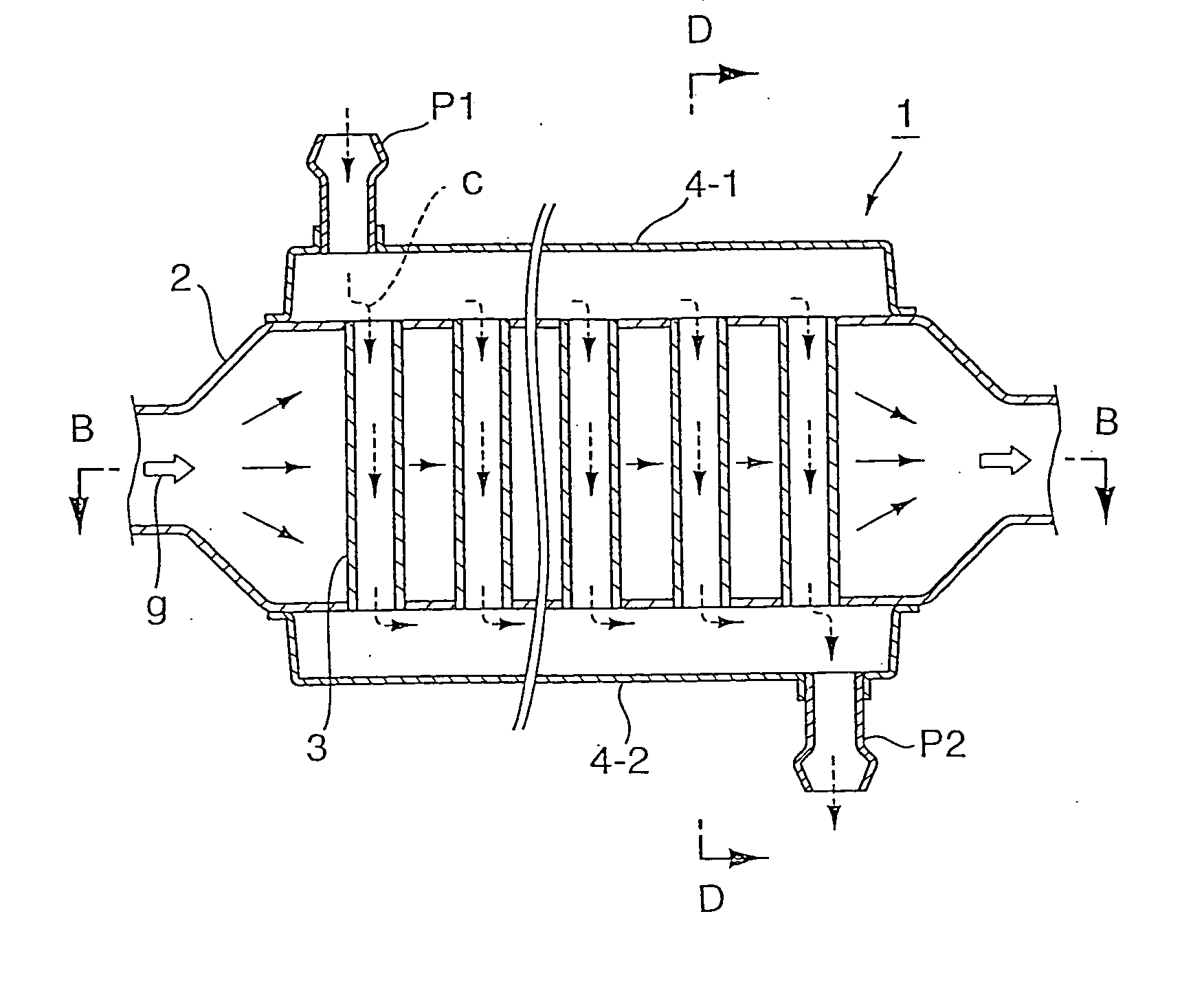

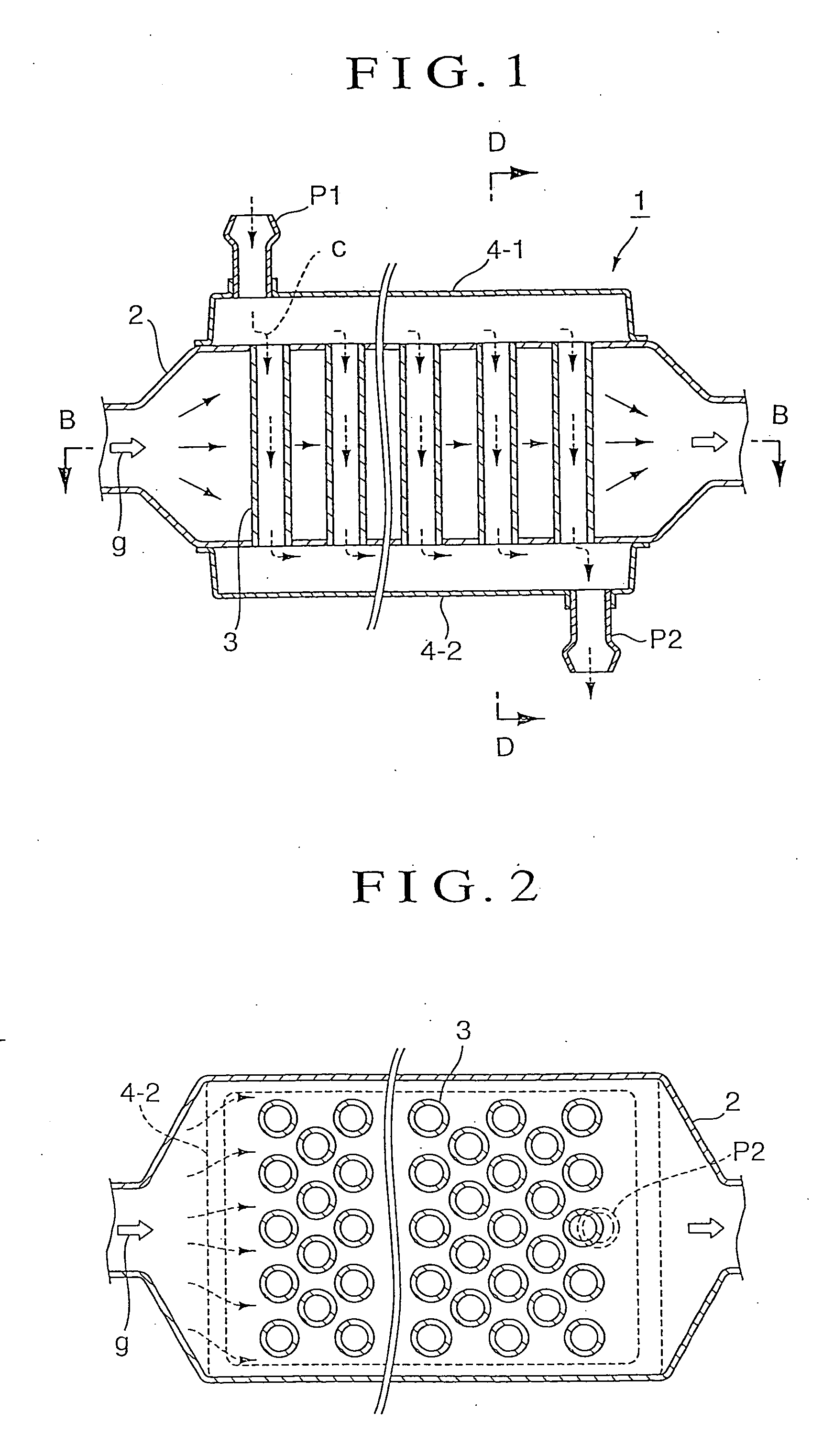

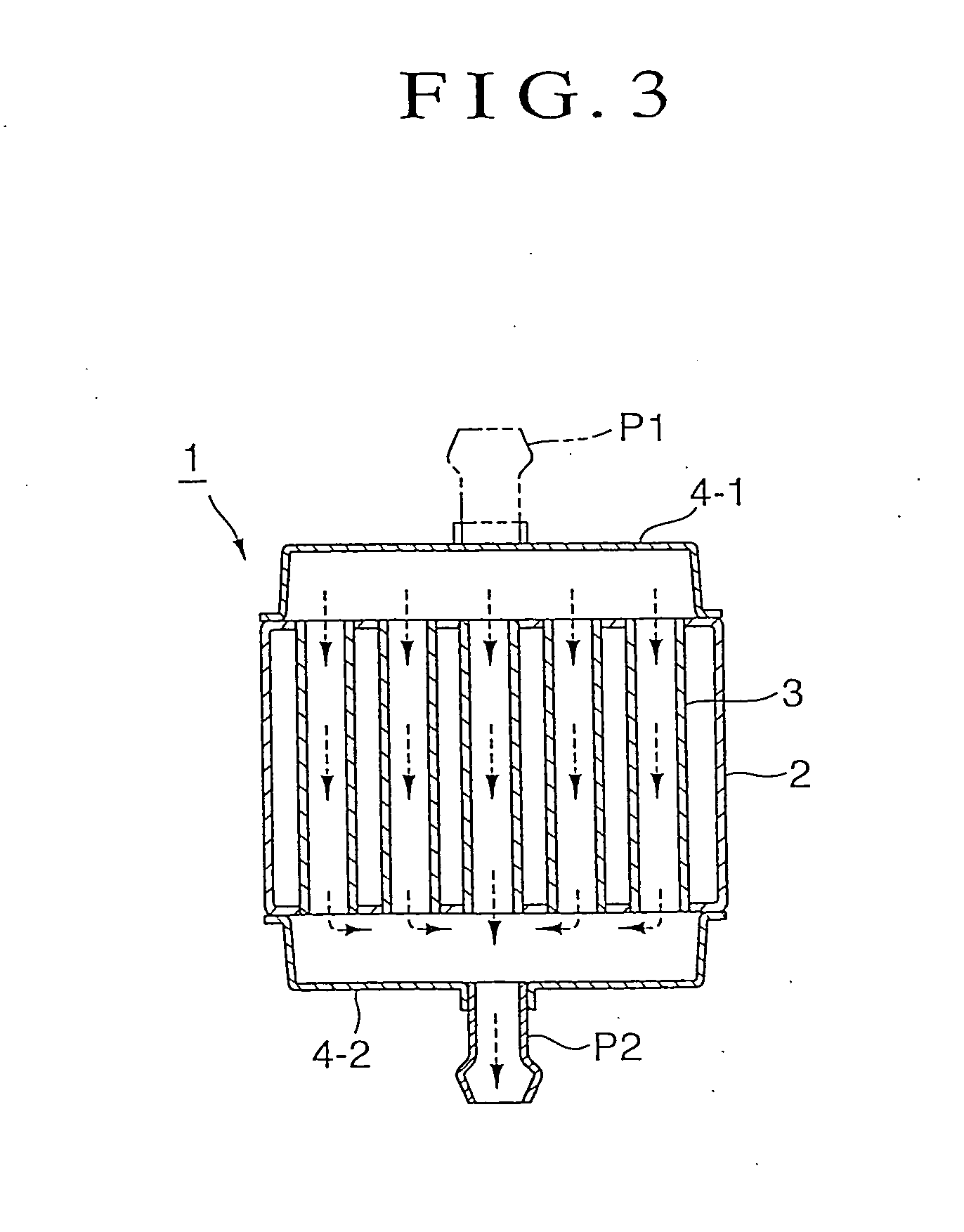

Gas cooling device

InactiveUS20050098307A1Easy to manufactureLow costAir-treating devicesNon-fuel substance addition to fuelProduct gasEngineering

A gas cooling device capable of efficiently cooling a gas such as an EGR gas, etc. is provided. A multiplicity of cooling pipes perpendicularly intersecting a gas flow direction in a gas pipe for a gas such as an EGR gas, etc. are provided to extend through an outer peripheral wall of the gas pipe, a cooling jacket is provided on an outer surface of the gas pipe on both sides of a group of the cooling medium pipes in an axial direction, or on the entire outer surface of the gas pipe, and the gas in the gas pipe is cooled by a cooling medium flowing through the cooling pipes.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

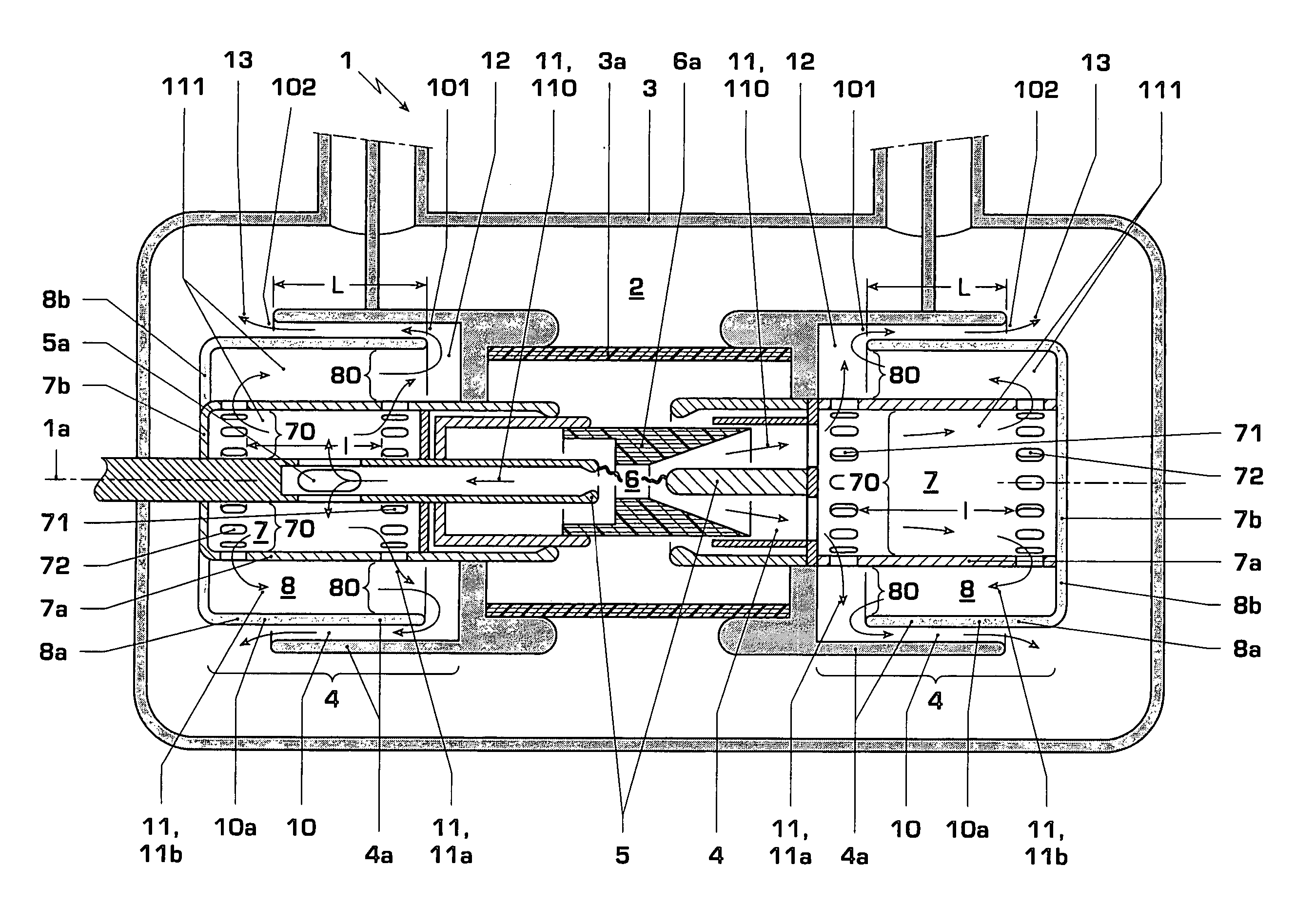

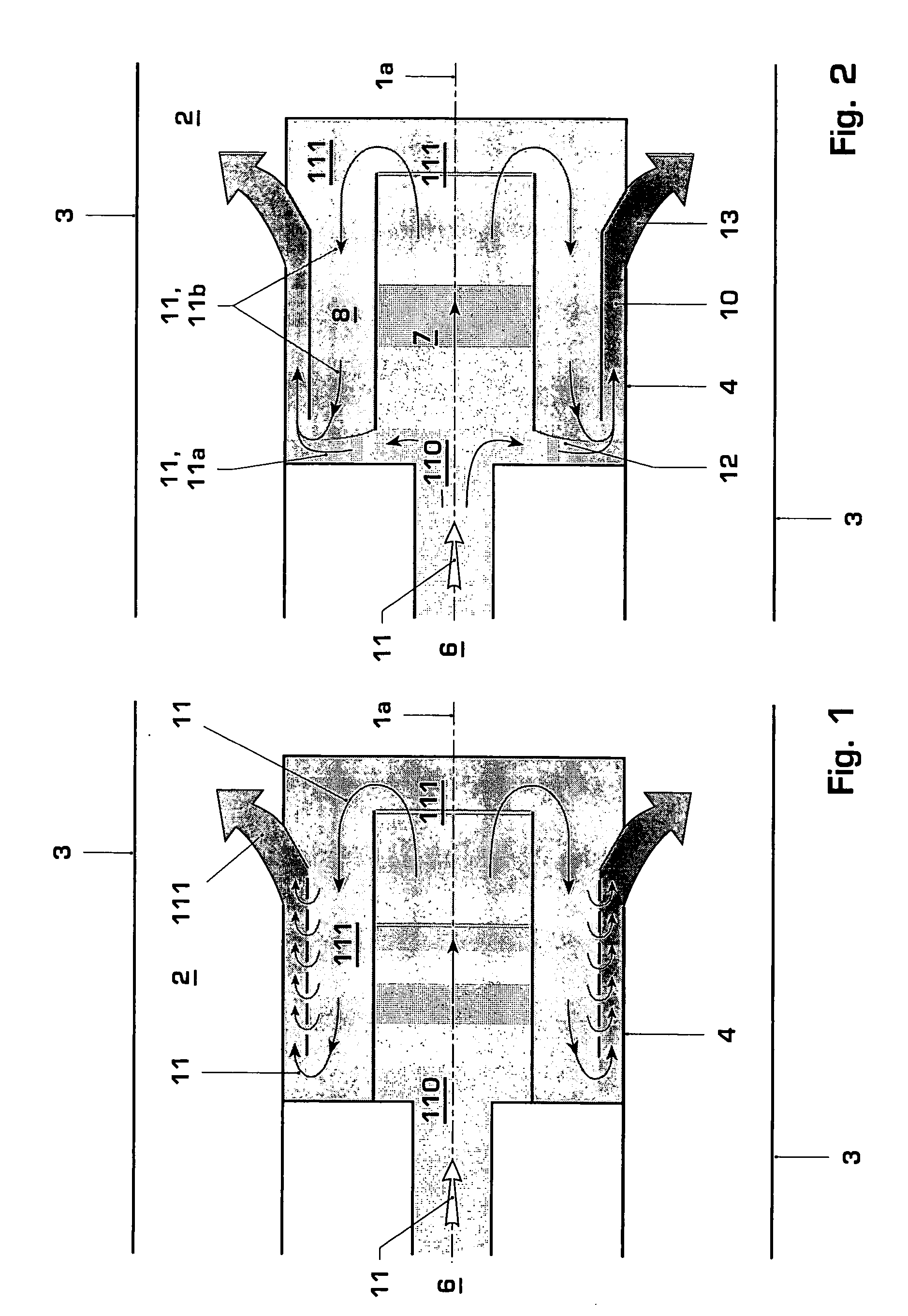

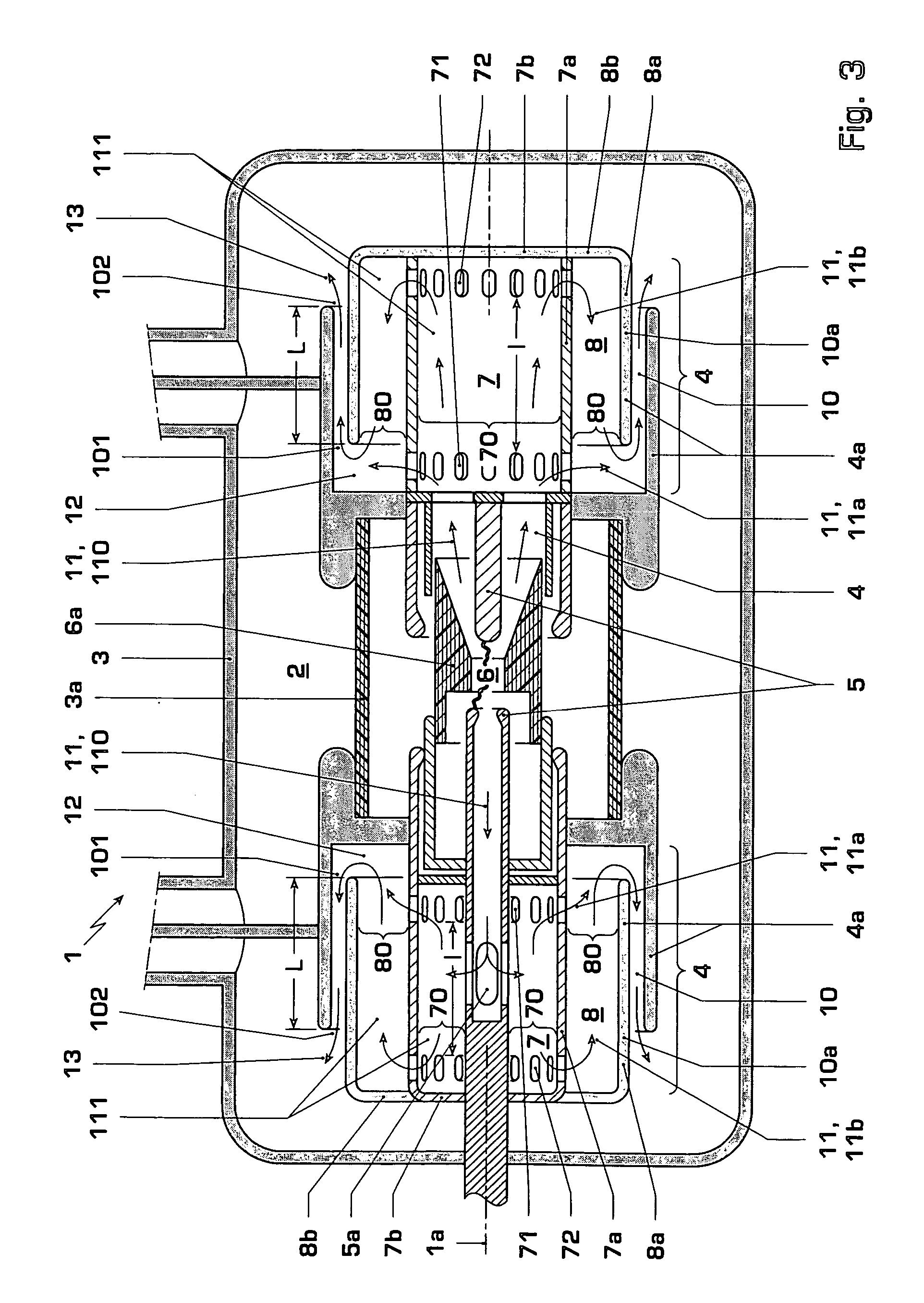

High-voltage circuit breaker with improved circuit breaker rating

ActiveUS20070068904A1Improve cooling effectEffective dielectric recoveryProtective switch detailsHigh-tension/heavy-dress switchesProcess engineeringQuenching

An electrical breaker device, in particular a high-voltage circuit breaker, and a method for improved quenching gas cooling are disclosed. Cold gas is stored intermediately in the exhaust region, and a first partial gas flow is guided to bypass the intermediately stored cold gas and to flow off into the breaker chamber, the intermediately stored cold gas being forcibly displaced out of the exhaust region with the aid of a second partial gas flow and being mixed with the first partial gas flow before flowing off into the breaker chamber housing. Exemplary embodiments relate, inter alia, to the design of the intermediate storage volume for the cold gas and to auxiliary means for precooling the hot quenching gas. Advantages are, inter alia, improved quenching gas cooling, an increased circuit breaker rating and / or a more compact breaker design.

Owner:HITACHI ENERGY SWITZERLAND AG

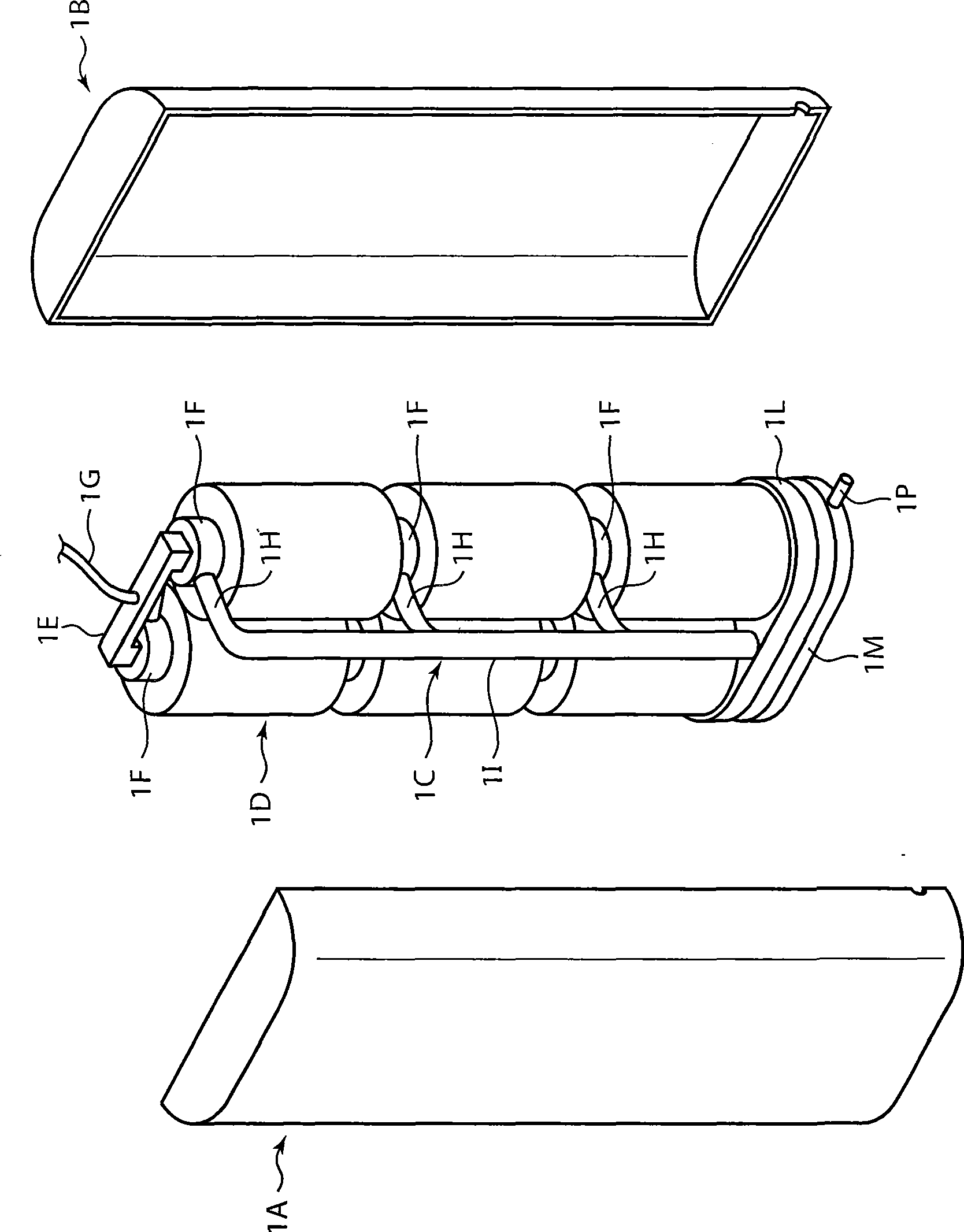

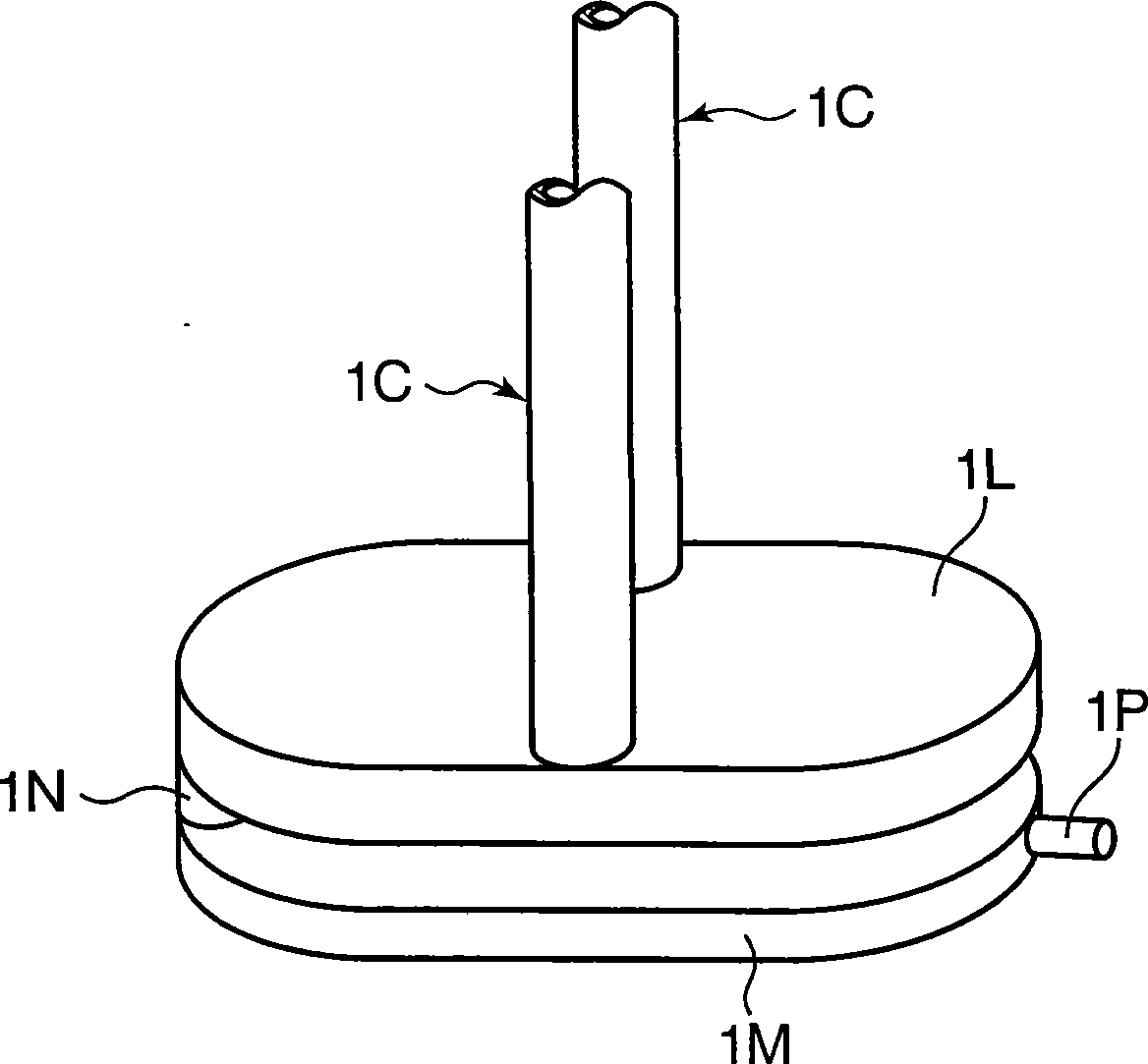

Battery pack, battery-mounted device and connection structure for battery pack

ActiveCN101523637AReduce the temperatureAvoid burnsSmall-sized cells cases/jacketsVent arrangementsTrappingBattery capacity

Disclosed is a battery pack securing safety by preventing a battery contained in the battery pack from coming into a burning state even when the battery discharges a high-temperature gas in an abnormal state. Specifically disclosed is a battery pack having an exhaust duct (1C) for flowing a gas discharged from a battery, wherein the temperature of the gas is decreased in the exhaust duct (1C) and then the gas is discharged to the outside. The flow channel area of the exhaust duct (1C) is set at not less than 0.5 mm<2> and not more than 15 mm<2> per 1 Ah of the battery capacity. The exhaust duct (1C) is provided with a gas cooling portion (1L) and a spark trapping portion (1M).

Owner:PANASONIC CORP

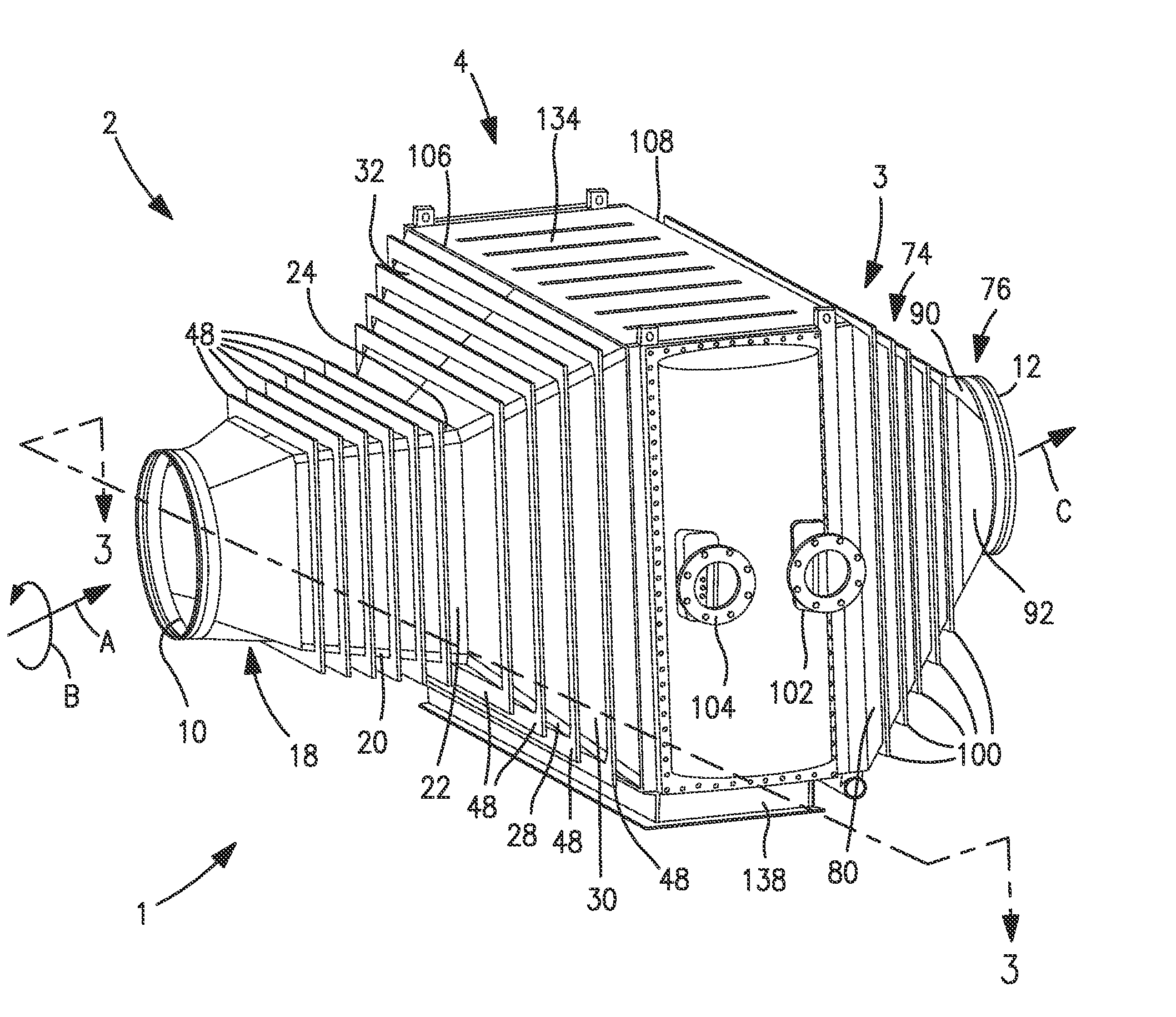

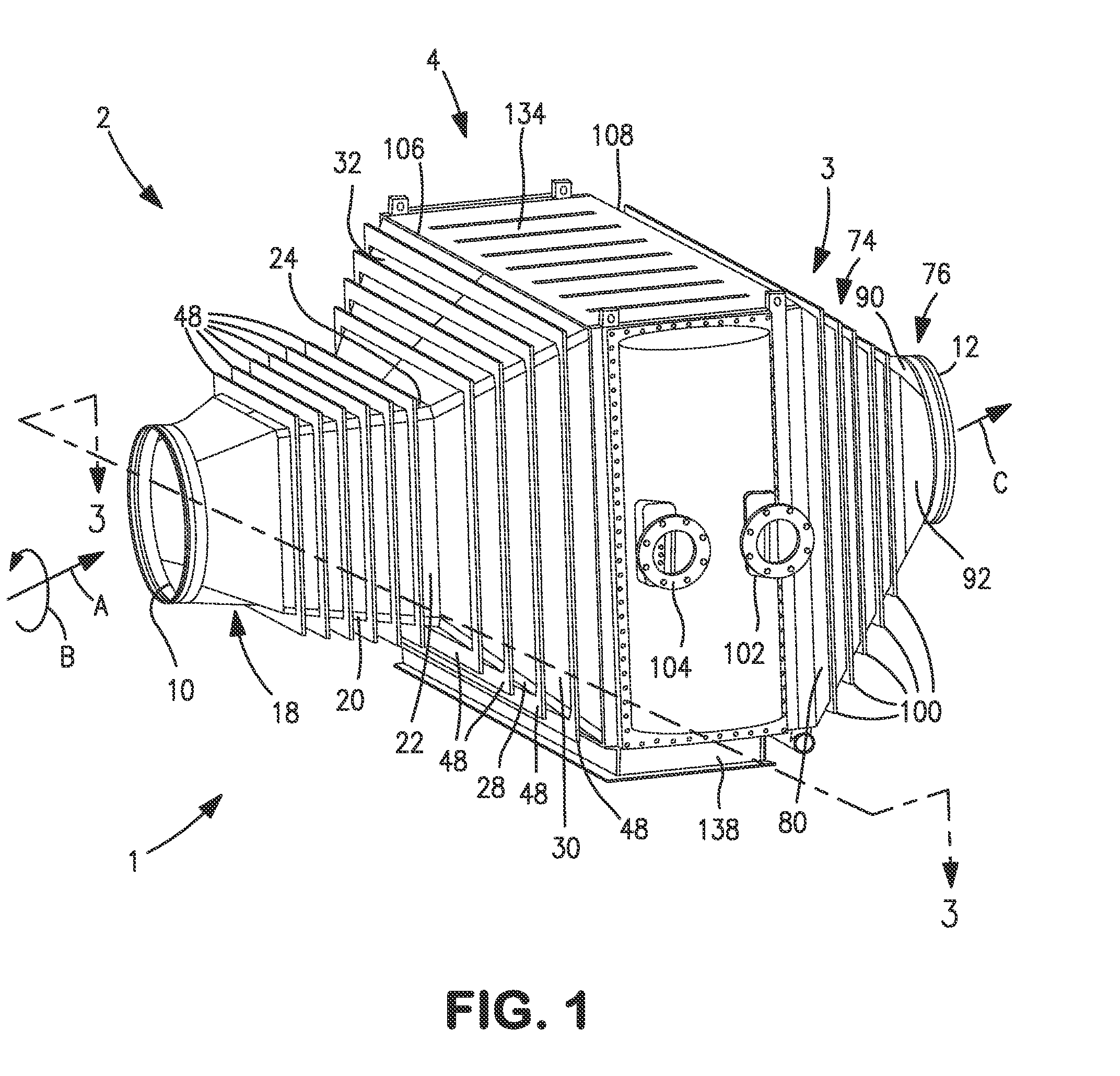

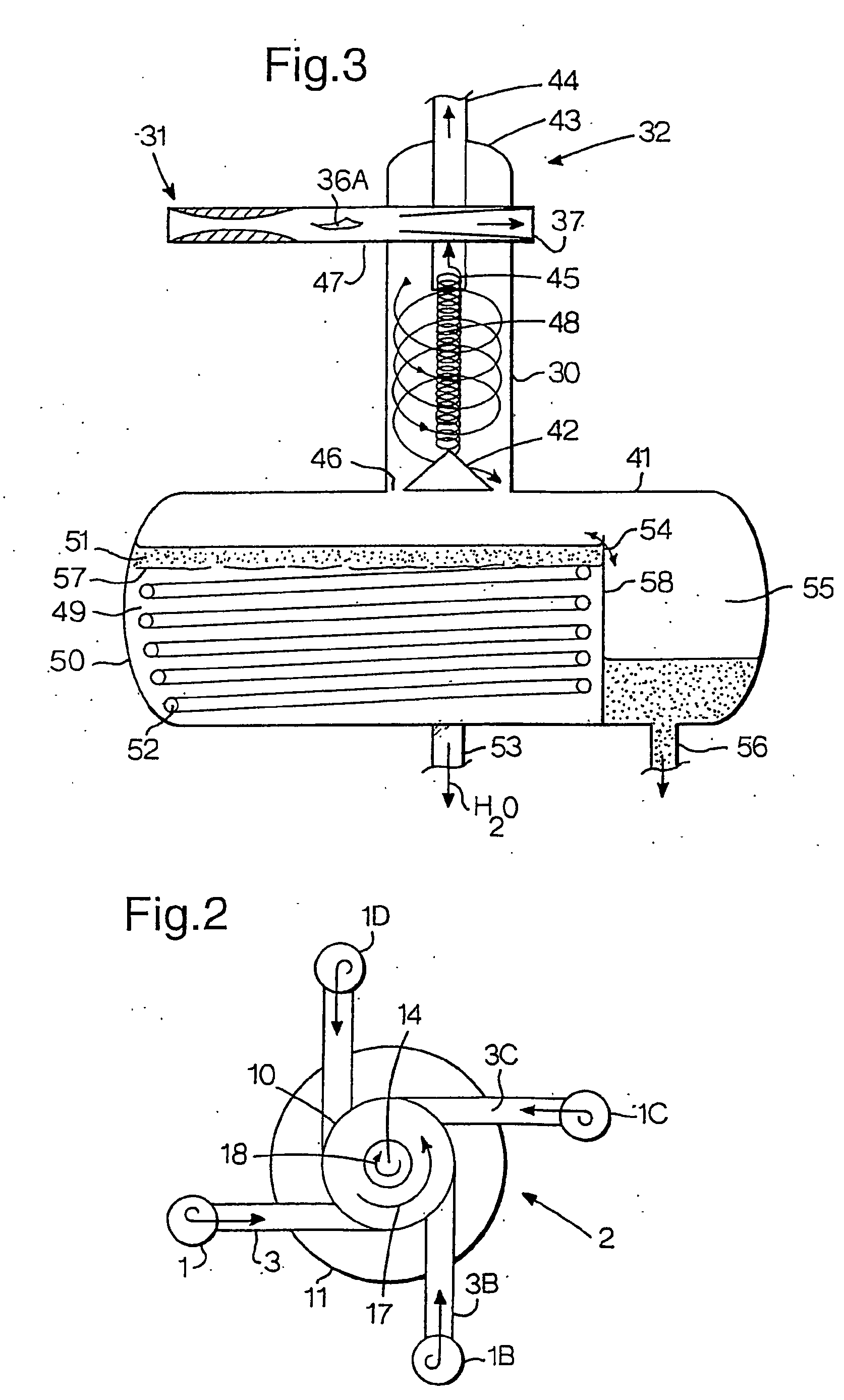

Compressed gas cooling apparatus

InactiveUS20140000841A1Lower overall pressure dropReduced flow separationReinforcing meansPump componentsEngineeringGas cooling

A compressed gas cooling apparatus in which gas from an upstream compression stage enters an inlet section from an inlet opening and flows to a heat exchanger that cools the gas. The cooled gas then flows from the heat exchanger to the outlet section where the gas is discharged from an outlet opening. Pressure drop within the apparatus is decreased by providing the inlet and outlet sections with ever increasing and decreasing cross-sectional flow areas. In order to further decrease pressure drop due to a swirl within the gas flow imparted from the upstream compression stage, the inlet section is provided with first and second subsections wherein the cross-sectional flow area of the first subsection increases at lesser rate than the second subjection. Alternatively, or in addition, the inlet section can be provided with partitions to divide the gas flow into subflows in order to lessen pressure drop from swirl.

Owner:PRAXAIR TECH INC

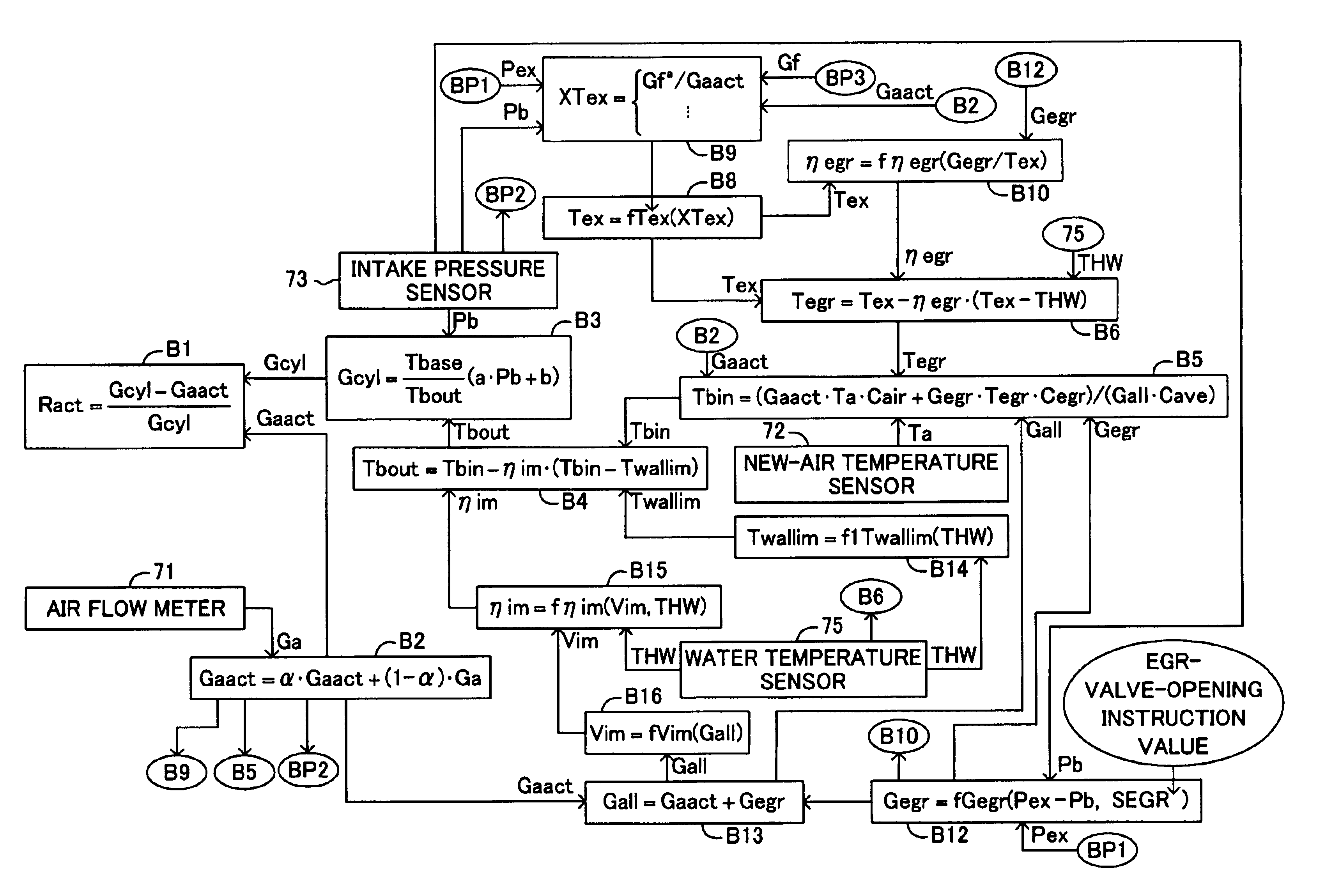

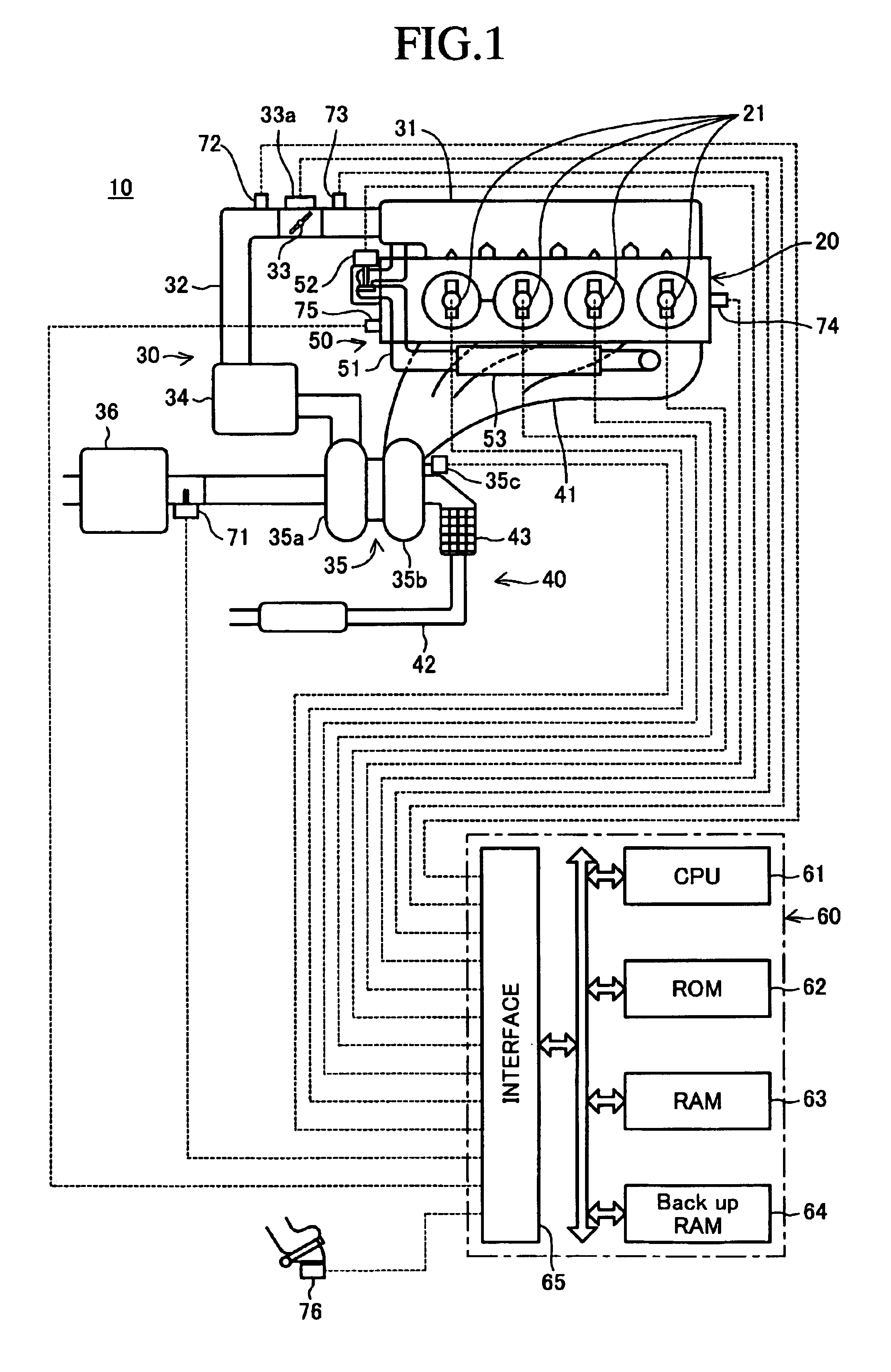

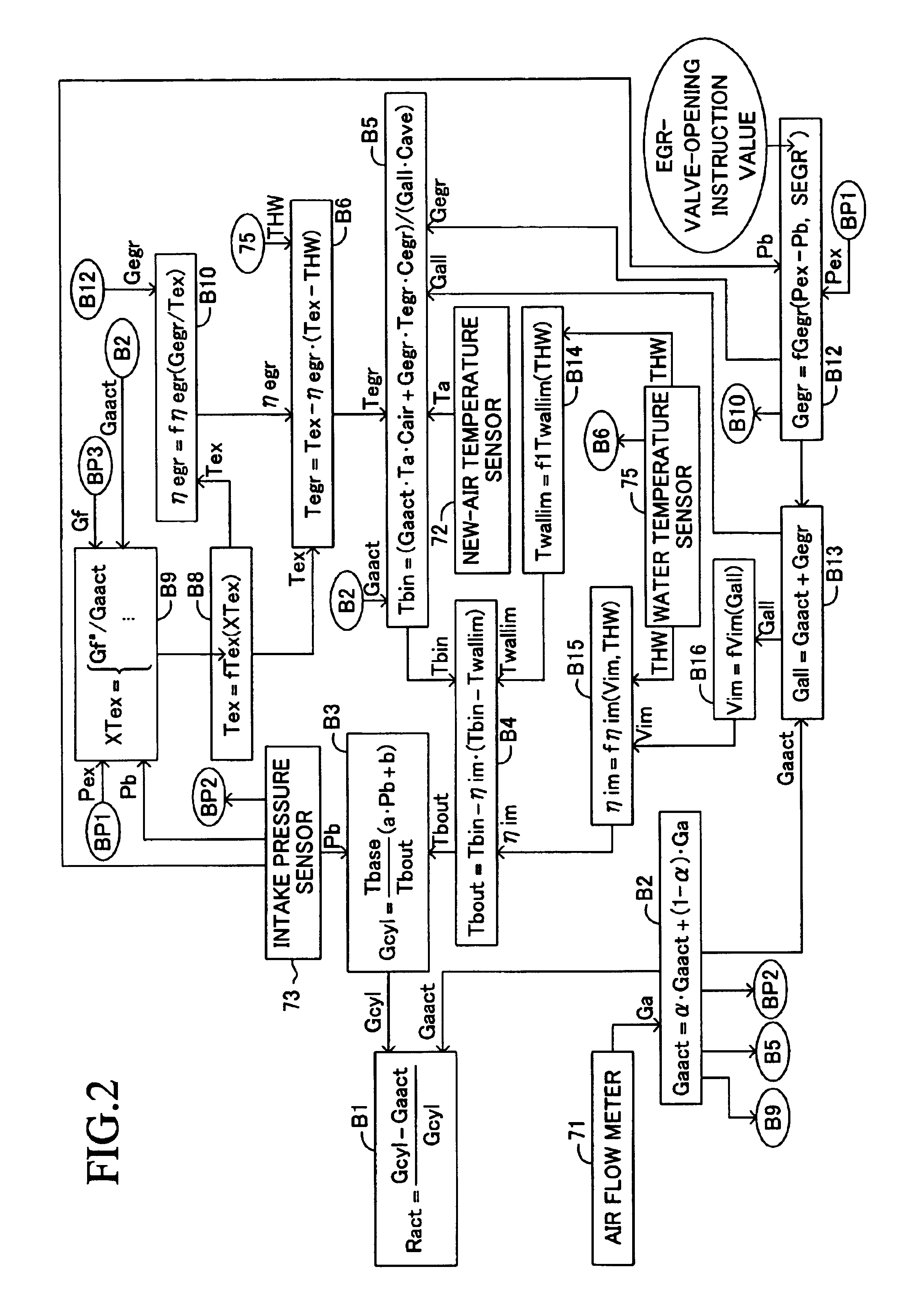

EGR-gas temperature estimation apparatus for internal combustion engine

InactiveUS6993909B2Accurate estimateReduce the temperatureElectrical controlNon-fuel substance addition to fuelEngineeringInternal combustion engine

An EGR-gas temperature estimation apparatus for an internal combustion engine which has an exhaust circulation pipe and an EGR-gas cooling apparatus. The estimation apparatus obtains the cooling efficiency ηegr of the EGR-gas cooling apparatus from the temperature Tex of EGR gas at the inlet of the exhaust circulation pipe and the flow rate Gegr of the EGR gas, and obtains the temperature THW of engine cooling water, used as a coolant for the EGR-gas cooling apparatus. Subsequently, the estimation apparatus calculates the temperature Tegr of the EGR gas at the outlet of the exhaust circulation pipe by the expression Tegr=Tex−ηegr·(Tex−THW). Since the cooling efficiency ηegr greatly changes depending on the EGR-gas flow rate Gegr and the EGR-gas temperature Tex, the estimation apparatus can accurately estimate the cooling efficiency ηegr, and therefore can accurately estimate the EGR-gas temperature Tegr.

Owner:TOYOTA JIDOSHA KK

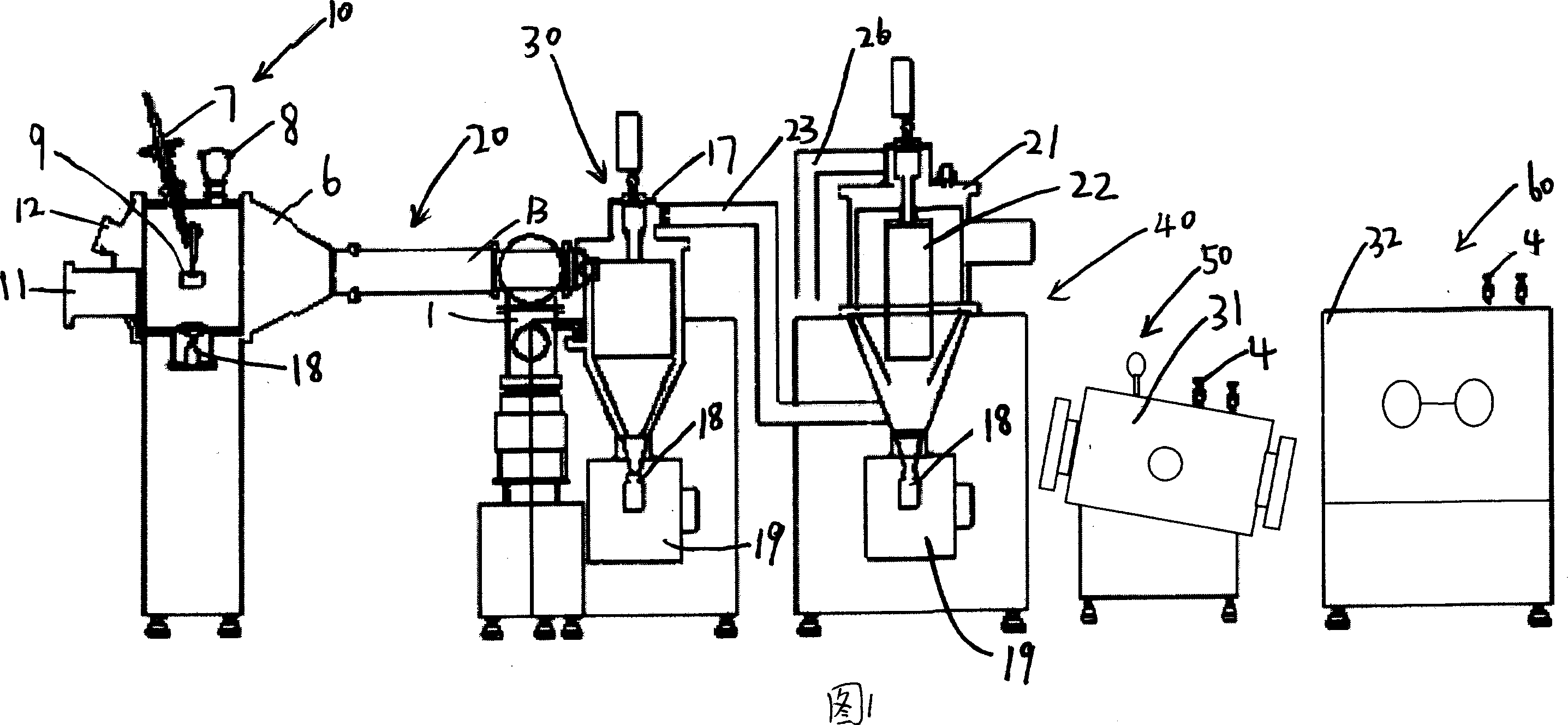

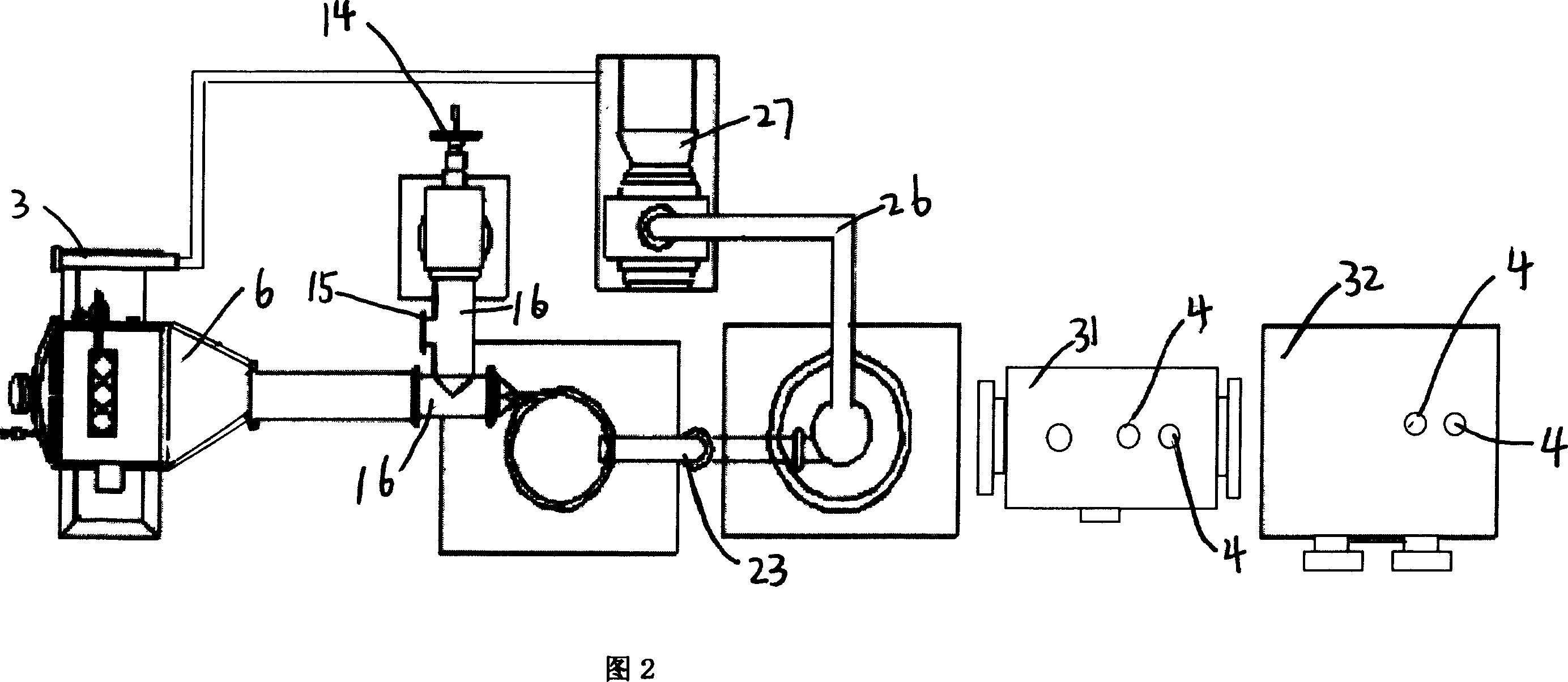

Continuous production apparatus for nano metal powder

The invention discloses a nanometer metal powder continuous producing device, comprising a vacuum measuring aerating system, a plasma / sensitive heating evaporating powder preparing system, a particle controlling system, a nanometer metal powder cyclone grading collecting system, a nanometer powder catching collecting system, a gas cooling circulating system, a water cooling circulating system, an electric controlling detecting system, a metal nanometer powder inactivating system and a powder vacuum packing storing system. The invention has high vacuum and three-gun structure, uses plasma constant-weight packing storing device, and plasma / electromagnetic sensitive evaporation or the like to realize continuous production of nanometer metal powder, change gas component and flux or the like.

Owner:MIYOU GROUP

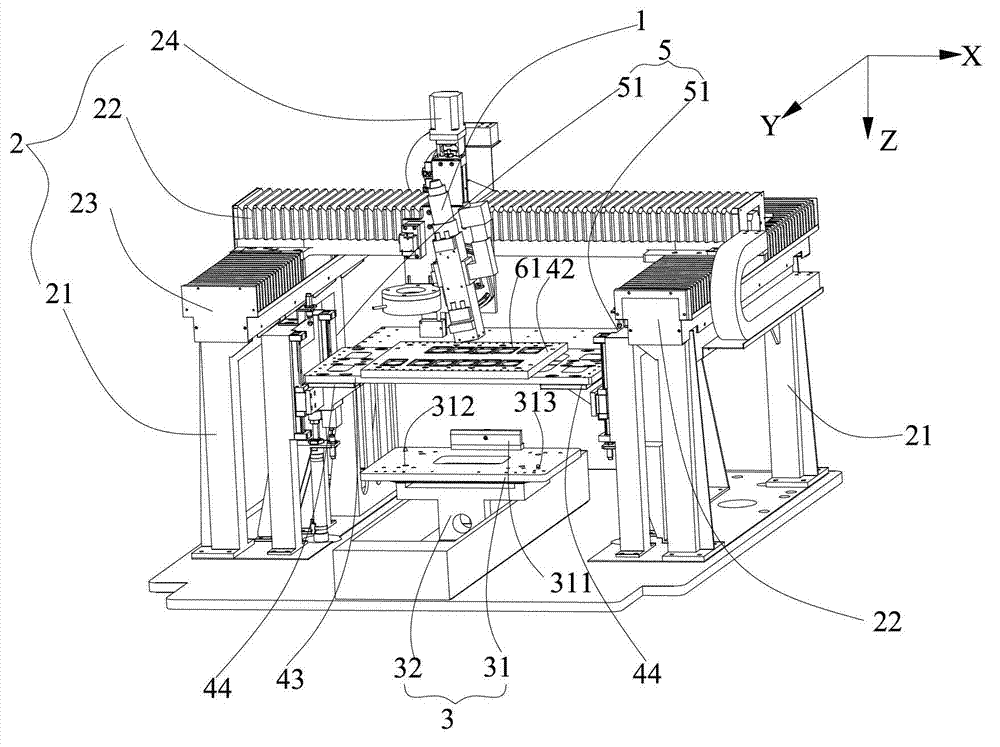

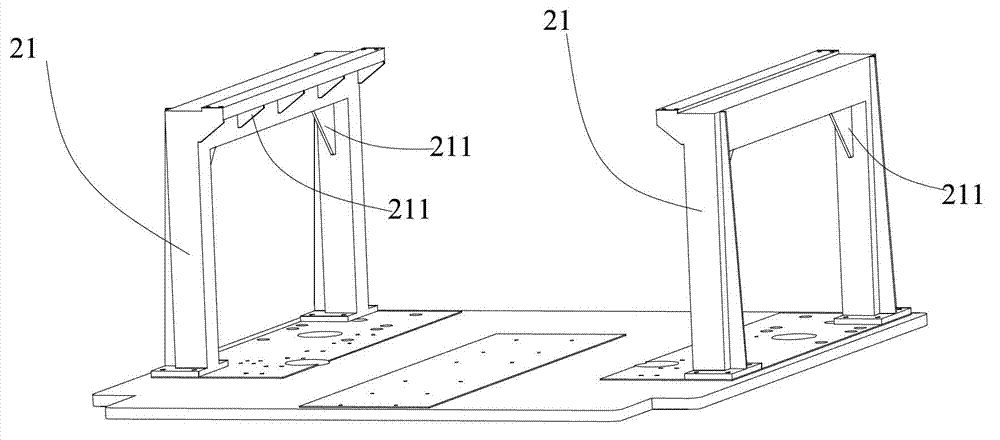

Full-automatic laser welder

ActiveCN103240527AGuaranteed compression effectSolving Automatic Laser Welding ProblemsLaser beam welding apparatusPortal frameLaser

The invention provides a full-automatic laser welder comprising a laser head, a laser head servo mechanism, a feeding and discharging device, a pressing mechanism and a transmission mechanism. The pressing mechanism comprises a plurality of pressing blocks and a pressing block support, wherein each pressing block is provided with a passage for laser emitted by the laser head to pass; and the pressing block support is elastically connected with each pressing block. The transmission mechanism is connected to the pressing block support to drive the pressing block support to move vertically so as to press or separate from corresponding connecting pieces. The laser head servo mechanism can further comprise two portal frames which are bilaterally and symmetrically arranged relative to the feeding and discharging mechanism along the X-direction, and each portable frame is provided with reinforcing ribs. The transmission mechanism can comprise a pair of transmission components which is bilaterally and symmetrically arranged relative to the feeding and discharging mechanism. The full-automatic laser welder can further comprise a gas cooling mechanism, a welding positioning unit and a controller. Therefore, pressing effects of welding spots of workpieces at different heights are guaranteed, welding temperature is lowered effectively, stability of a welding process is guaranteed, and welding optimal rate and efficiency are quite high.

Owner:CONTEMPORARY AMPEREX TECH CO

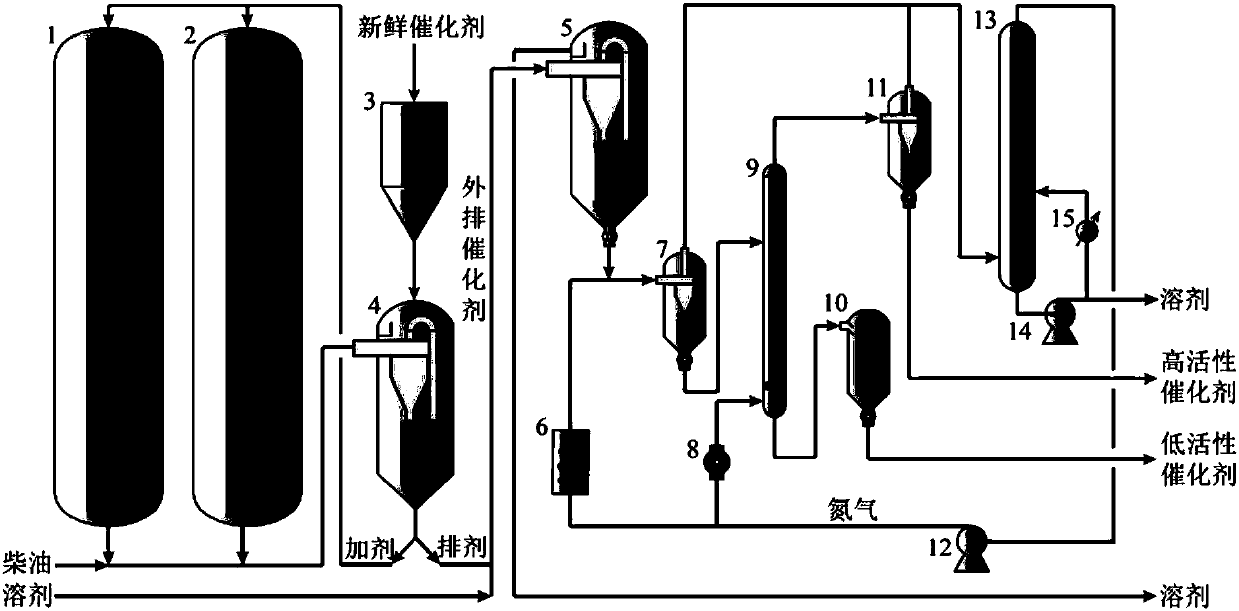

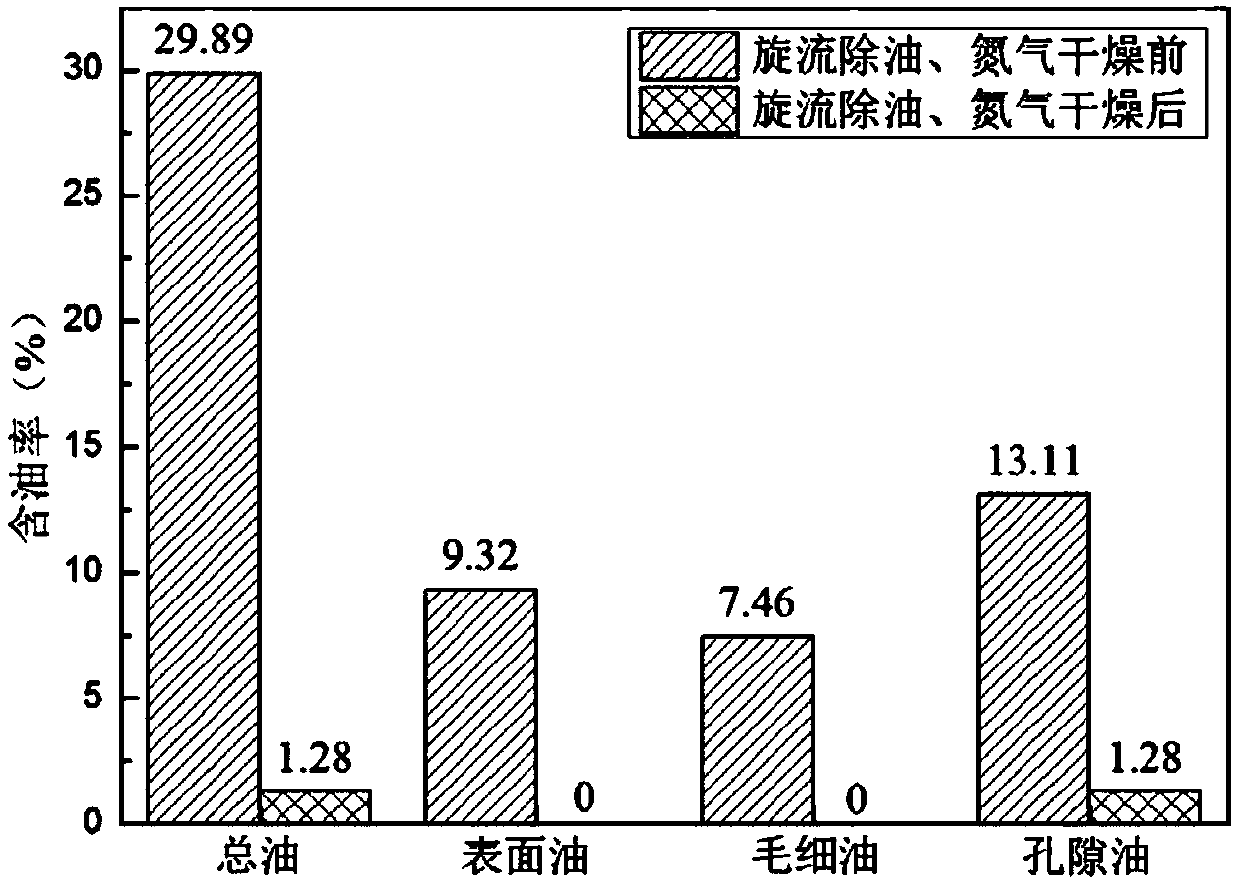

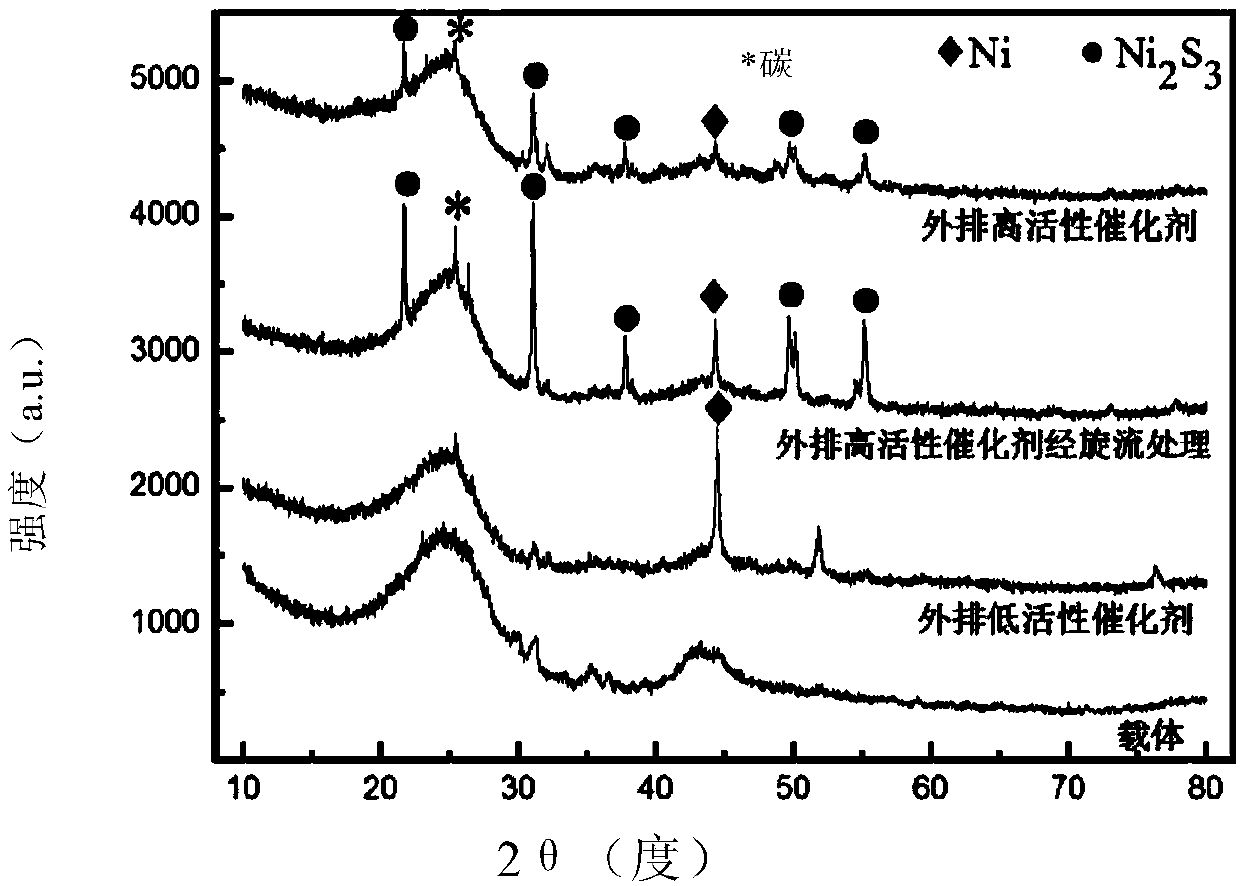

Method and apparatus for treating, sorting and recycling oil-containing discharged catalyst

ActiveCN107597201AHigh oil removal efficiencyIncrease update rateCatalytic crackingDispersed particle separationEngineeringProduct gas

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION +1

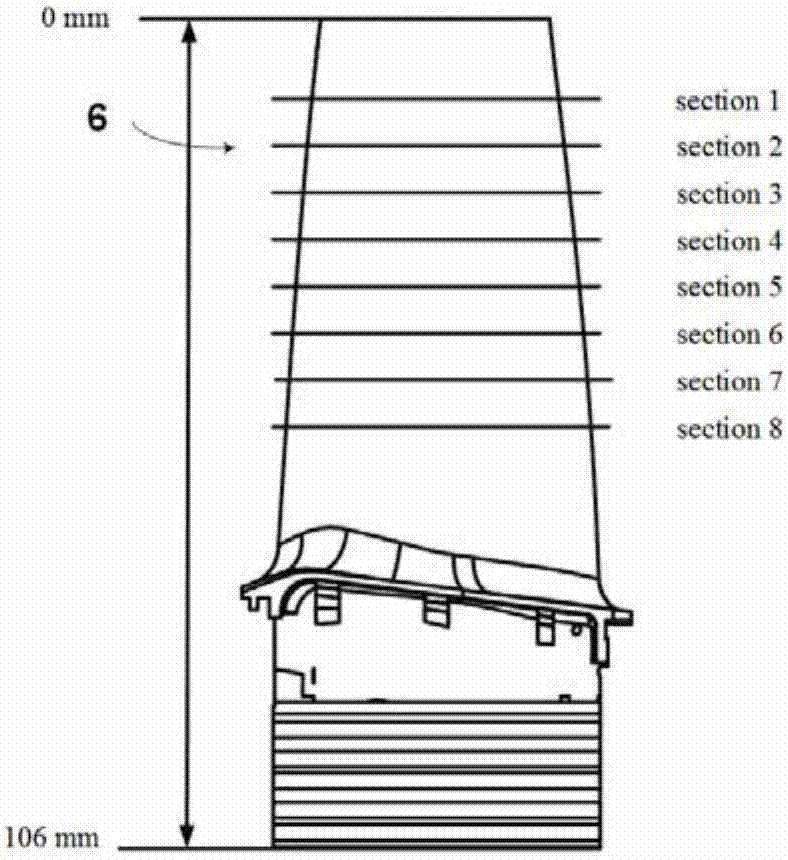

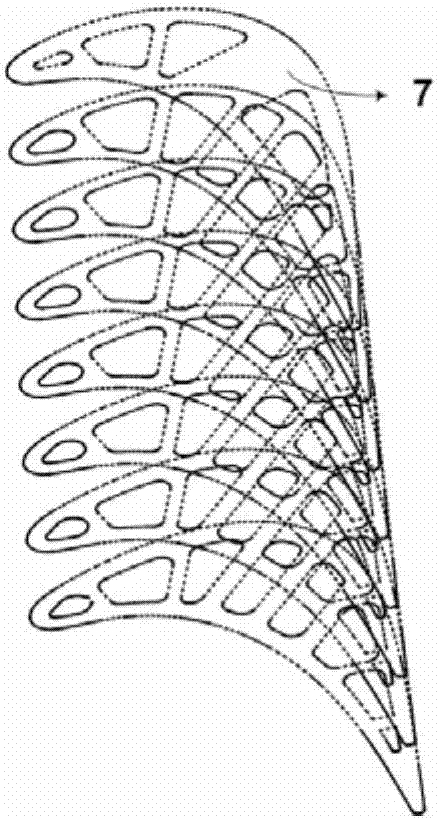

Thermal mechanical fatigue test system and method for performing hollow turbine blade superposed high-cycle vibration

ActiveCN107421984AAccurate test lifeEnsure safetyMaterial heat developmentTurbine bladeWater cooling

The invention relates to a thermal mechanical fatigue test system and method for performing hollow turbine blade superposed high-cycle vibration. The test system comprises a high / low-cycle load loading subsystem, a temperature load loading subsystem, a cooling subsystem and a load coordination control subsystem, wherein the high / low-cycle load loading subsystem is used for independently applying high / low-cycle loads to turbine blades which are stably clamped by a special fixture; the temperature load loading subsystem is used for heating assessment sections of the turbine blades; the cooling subsystem comprises a water cooling part and an air cooling part; the water cooling part is used for cooling in a test process; the air cooling part is used for coordinating a temperature cycle in the test and simulating cooling conditions inside the blades; and the load coordination control subsystem is used for controlling each system to operate in a coordinated manner. According to the test system disclosed by the invention, the stress field, temperature field and vibration conditions in the assessment section service process of the turbine blades and the cooling conditions inside the blades can be simulated, the thermal mechanical fatigue test for superposed high-cycle vibration of the turbine blades is performed, and a guarantee is provided for safe and reliable operations of aircraft engines.

Owner:BEIHANG UNIV

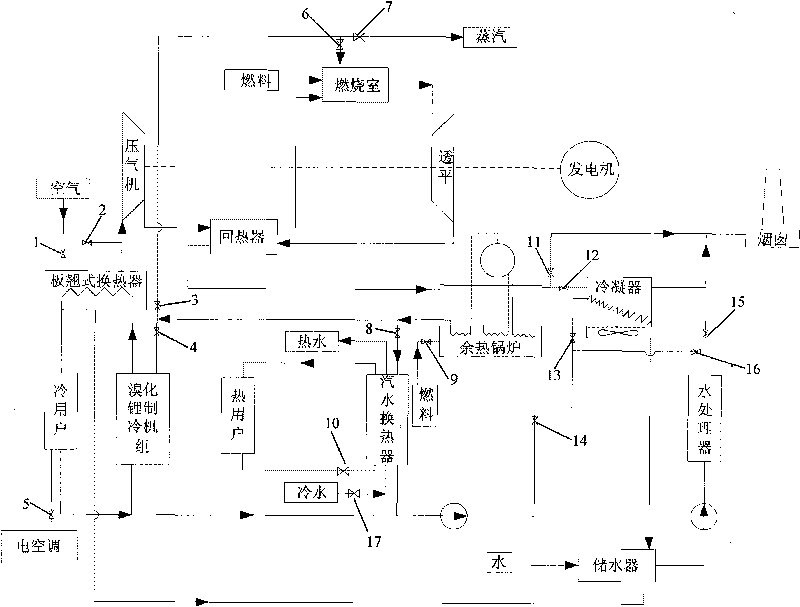

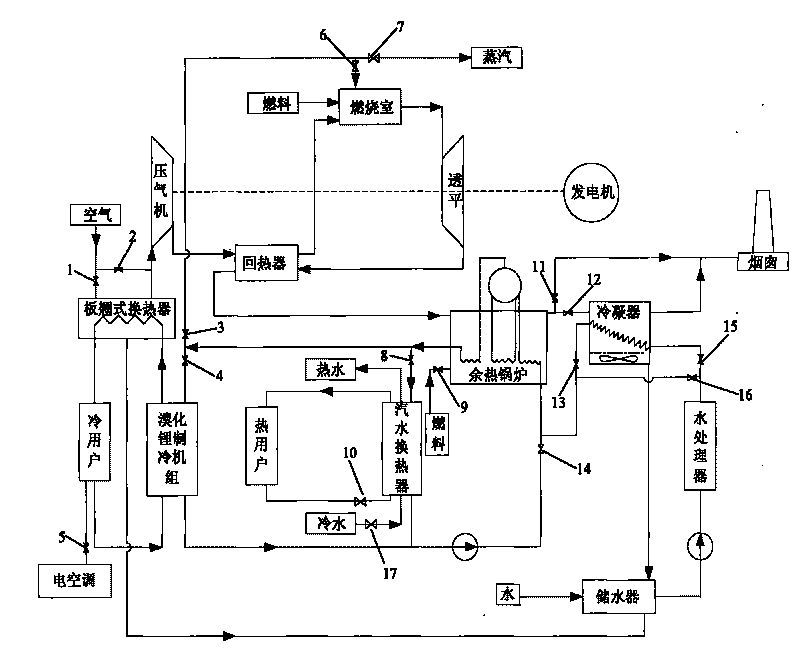

Heat and cool power cogeneration system of integrated multi-functional efficient mini-type gas turbine

InactiveCN101761392AIncrease power generationImprove power generation efficiencyClimate change adaptationGas turbine plantsElectricityCogeneration

The invention proposes a heat and cool power cogeneration system of an integrated multi-functional efficient mini-type gas turbine, which belongs to the novel heat and cool power cogeneration system device. To solve the frequent mismatching of cold and heat load and low efficiency operation of the conventional cogeneration system, measures such as steam reinjection, inlet gas cooling, gas fume and condensate water recovery are introduced on the basis of the heat and cool power cogeneration system of the mini-type gas turbine; in addition, the number of steam outlets and hot-water outlets is increased, thus forming the heat and cool power cogeneration system of the integrated multi-functional efficient mini-type gas turbine. The system is provided with various operation modes suitable for different occasions, can effectively solve the problem of mismatching of cold and heat load of the cogeneration system, so that the system can keep working in highly efficient mode.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

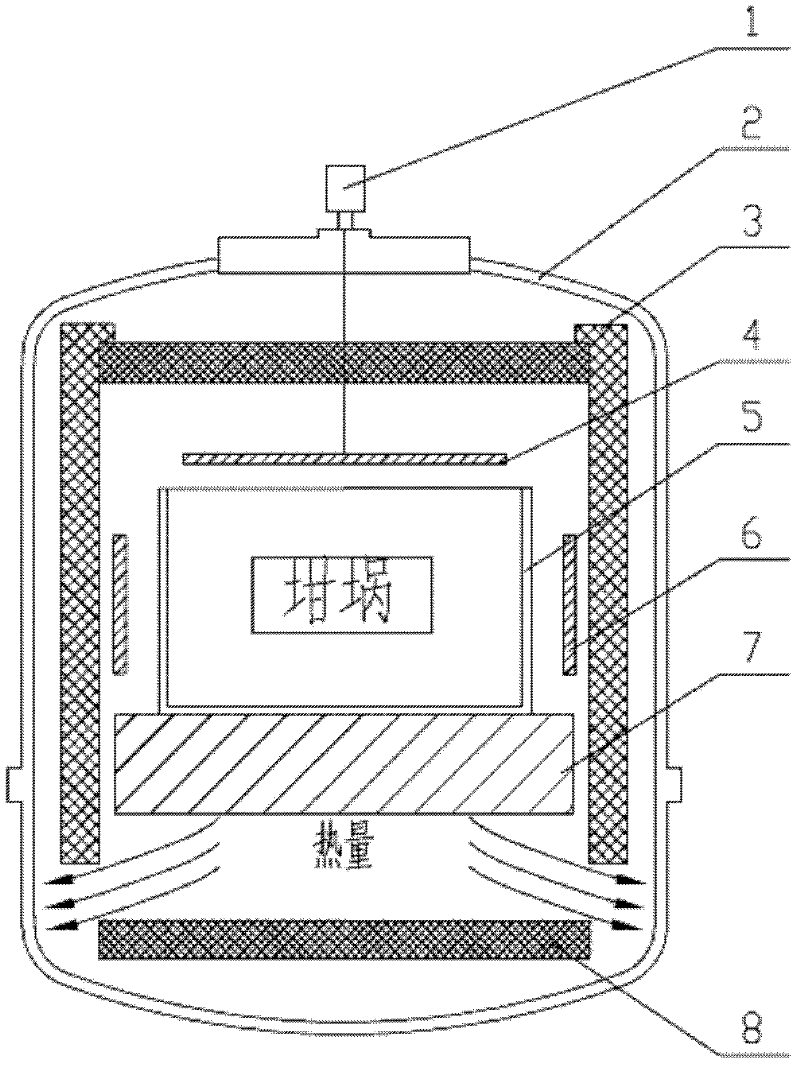

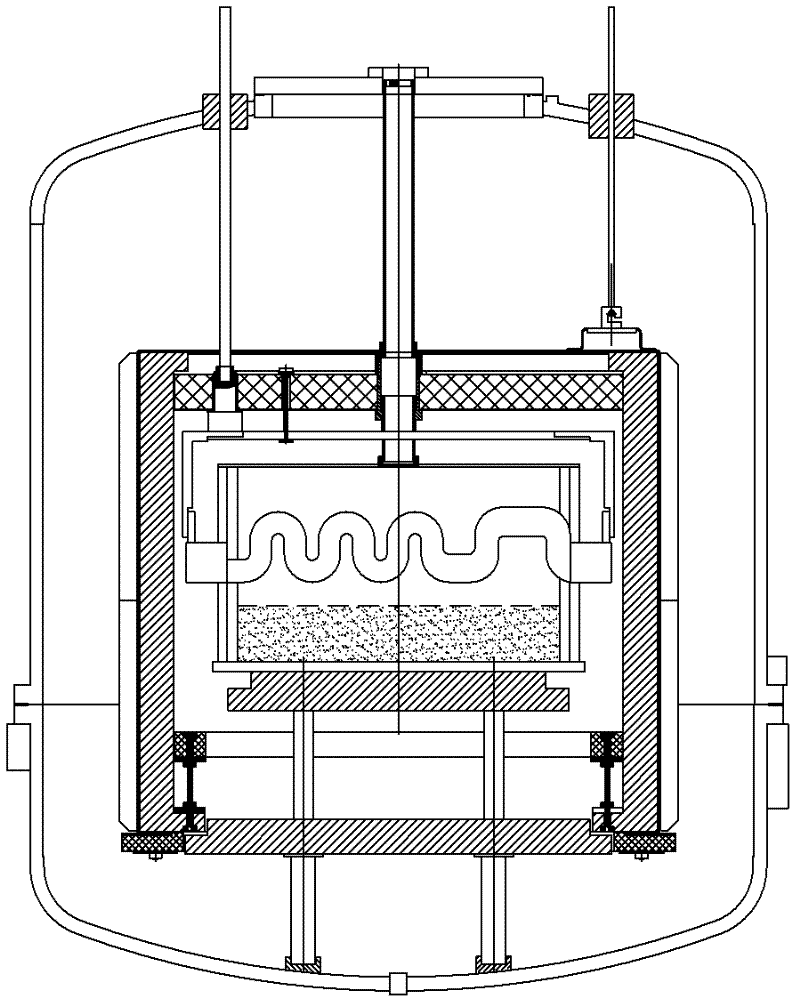

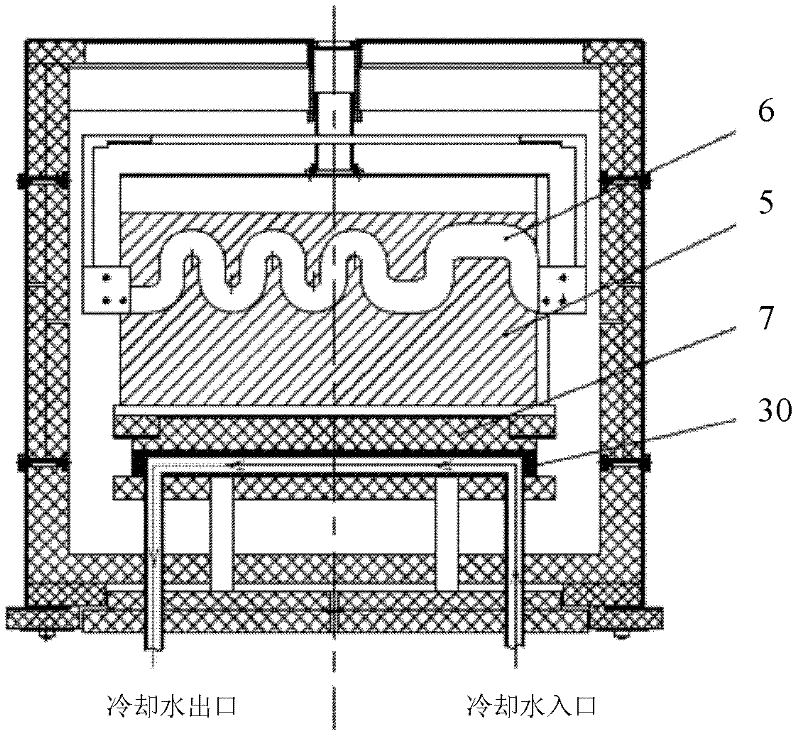

Closed cooling system of gas cooled polysilicon ingot furnace

ActiveCN102234837APrecise temperature controlEasy to controlPolycrystalline material growthSingle crystal growth detailsNuclear engineeringCrucible

The invention relates to the manufacture technical field of polysilicon ingot furnaces, and aims to provide a closed cooling system of a gas cooled polysilicon ingot furnace. The system comprises a heat exchange platform positioned on a supporting column and used for placing a crucible, wherein a cooling gas channel is arranged in the heat exchange platform; a gas inlet and a gas outlet at two ends of the cooling gas channel are respectively connected with a cooling gas inlet pipeline and a cooling gas outlet pipeline; and the heat exchange platform, the cooling gas inlet pipeline, the cooling gas outlet pipeline, a cooling gas power pump group and a cooler form a closed circulation loop of the cooling gas. Compared with the cooling method of radiation cooling and water cooling, the system related by the invention has strong gas cooling control capacity and high industrial controllability; the gas is fed into the heat exchange platform evenly, so that the whole temperature of the heatexchange platform is even, which is in favor of even nucleation of a silicon melt at the bottom of the crucible; and the reducing speed of the temperature at the bottom of the crucible can be precisely controlled during the crystal growth.

Owner:ZHEJIANG JINGSHENG MECHANICAL & ELECTRICAL +1

Fin, method of fabricating the same and heat exchanger tube, heat exchanger and gas cooling apparatus

InactiveCN1755316ASpeed up heat exchangeImprove cooling efficiencyInternal combustion piston enginesNon-fuel substance addition to fuelShell and tube heat exchangerEngineering

The invention relates to a shell and tube heat exchanger used as a coolant mechanism. The shell and tube heat exchanger comprises a plate-fin arranged inside or outside a heat exchanger tube, and at least one heat exchanger tube internally provided with the plate-fin. Through the heat exchanger has simple structure and easy manufacture, the heat exchanger can still limberly process fluid bodies with different shapes, promote the effective heat exchanging action of the fluid bodies, obtain good cooling efficiency, and can process a plurality of fluid bodies. The plate-fin that the invention relates to is the plate-fin for stirring liquid; the plate-fin is arranged inside or outside the heat exchanger tube to lead the fluid bodies which is composed of cooled medium or refrigeration medium to flow inside or outside the heat exchanger tube, thus impingiment flow or vortex flow with stirring action are generated; the plate-fin is arranged inside or outside the heat exchanger tube, and thus the blade edges of the plate-fin are butted and jointed up and down to enable the blade edges opposite to each other, and each butted and jointed blade edges are crossed with each other. The invention also relates to a method for manufacturing the plate-fin as well as the heat exchanger tube internally provided with the plate-fin, and the heat exchanger or an EGR gas cooling device provided with at least one heat exchanger tube.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

Parametric machining method of air film cooling holes for precision casting turbine blades

ActiveCN107506519AImprove machining accuracyGuaranteed forming accuracyGeometric CADDesign optimisation/simulationTurbine bladeCooling effect

A parametric machining method of air film cooling holes for precision casting turbine blades relates to turbine blades. The method provides errors including casting deformation of components, positioning errors of clamps, and blade movement and deformation during small hole machining so as to achieve parametric accurate machining of hollow turbine blade air film holes. Through solving and calculating propagation and accumulation of error during air film machining, correcting design parameters of air film holes and processing the air film holes according to air film hole shape and location parameters which are the center point of the film hole, the normal of the film hole, and the hole depth of the air film hole after correction, the processing accuracy of the air film holes is increased and the cooling efficiency of turbine blades is increased. This method has important theoretical significance and application value for precise forming of hollow turbine blade, avoids the present situation of air cooling efficiency reduction in the field of air film hole processing, ensures the precision of air film hole forming and achieves the air cooling effect consistent with the design requirements.

Owner:XIAMEN UNIV +1

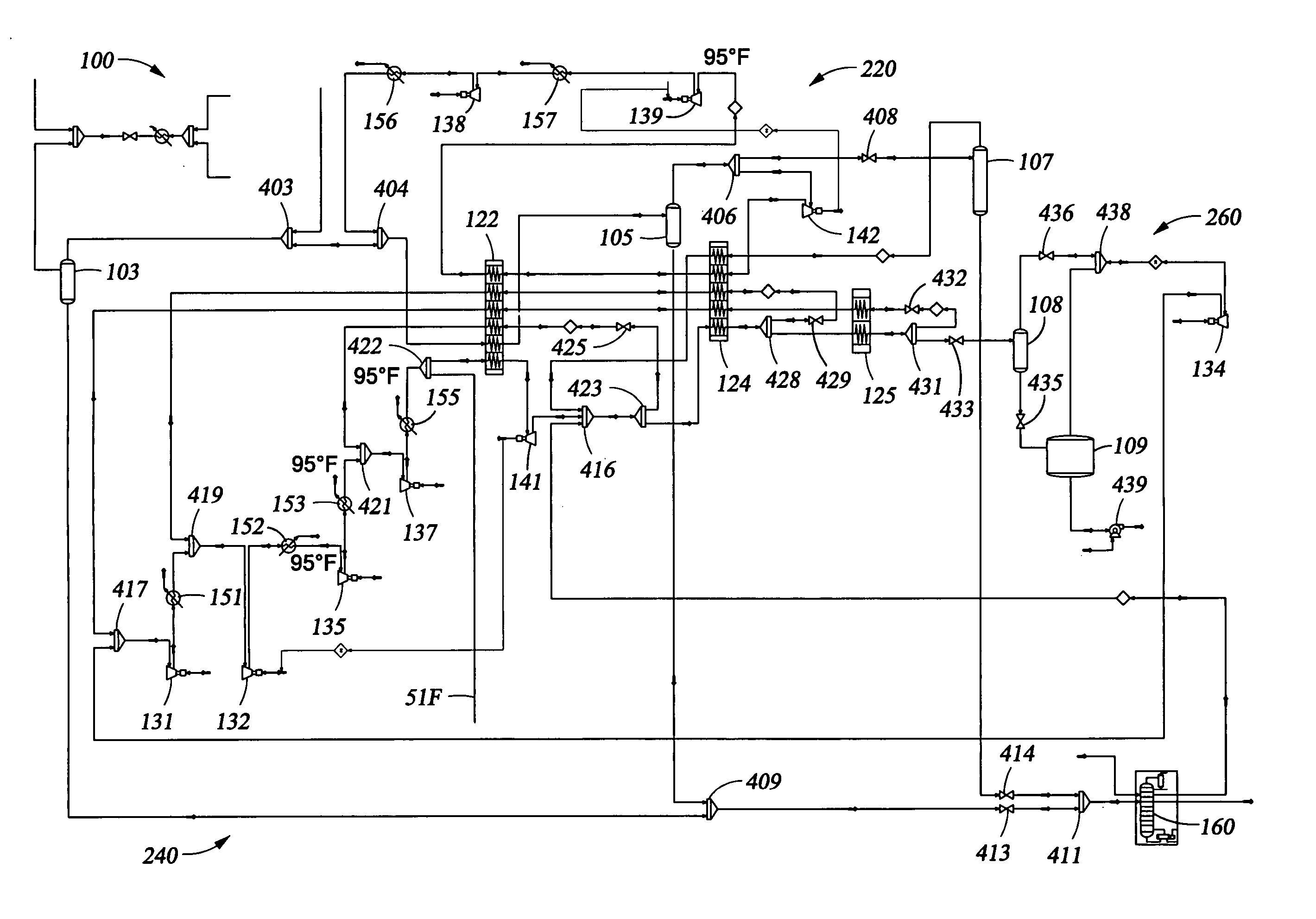

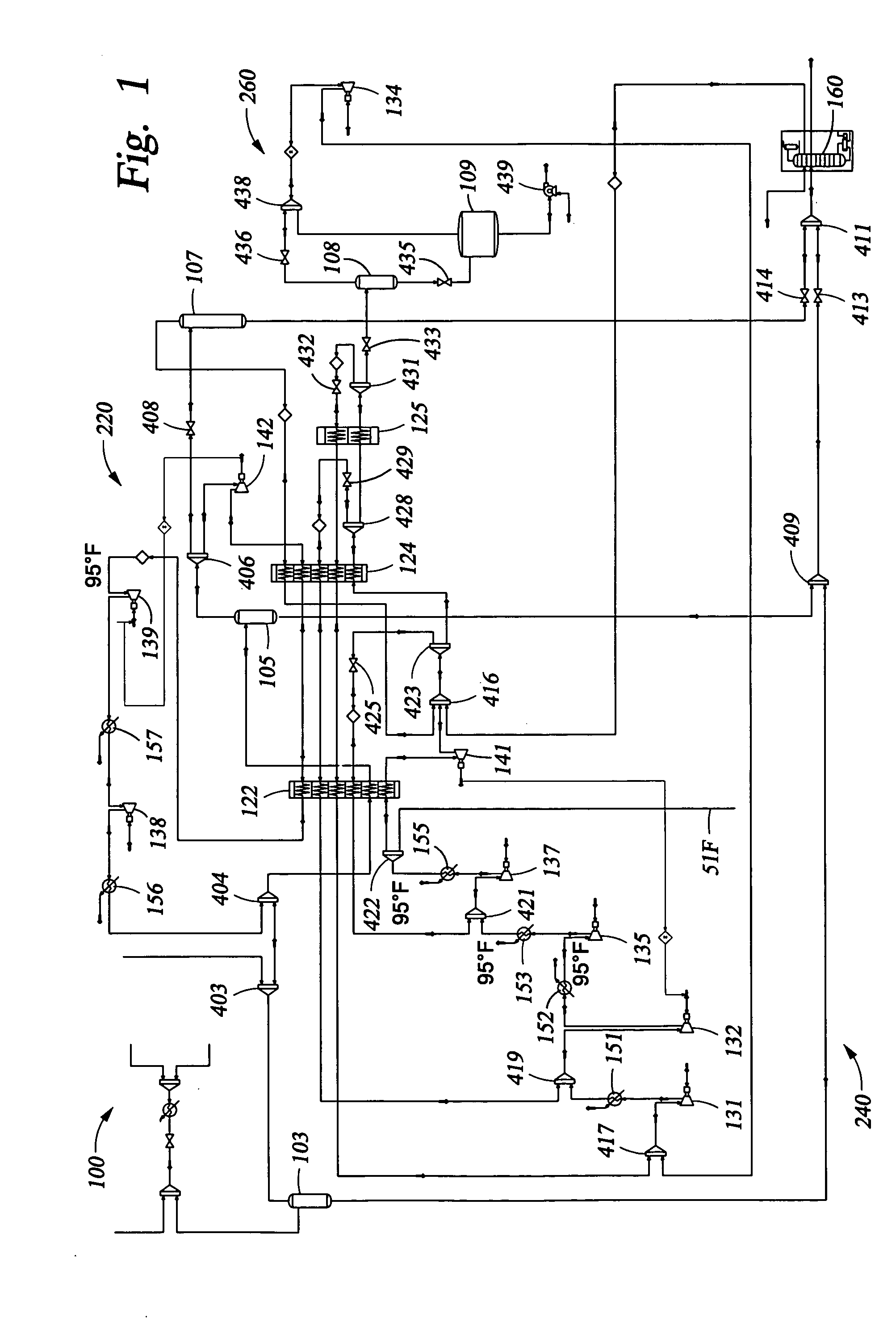

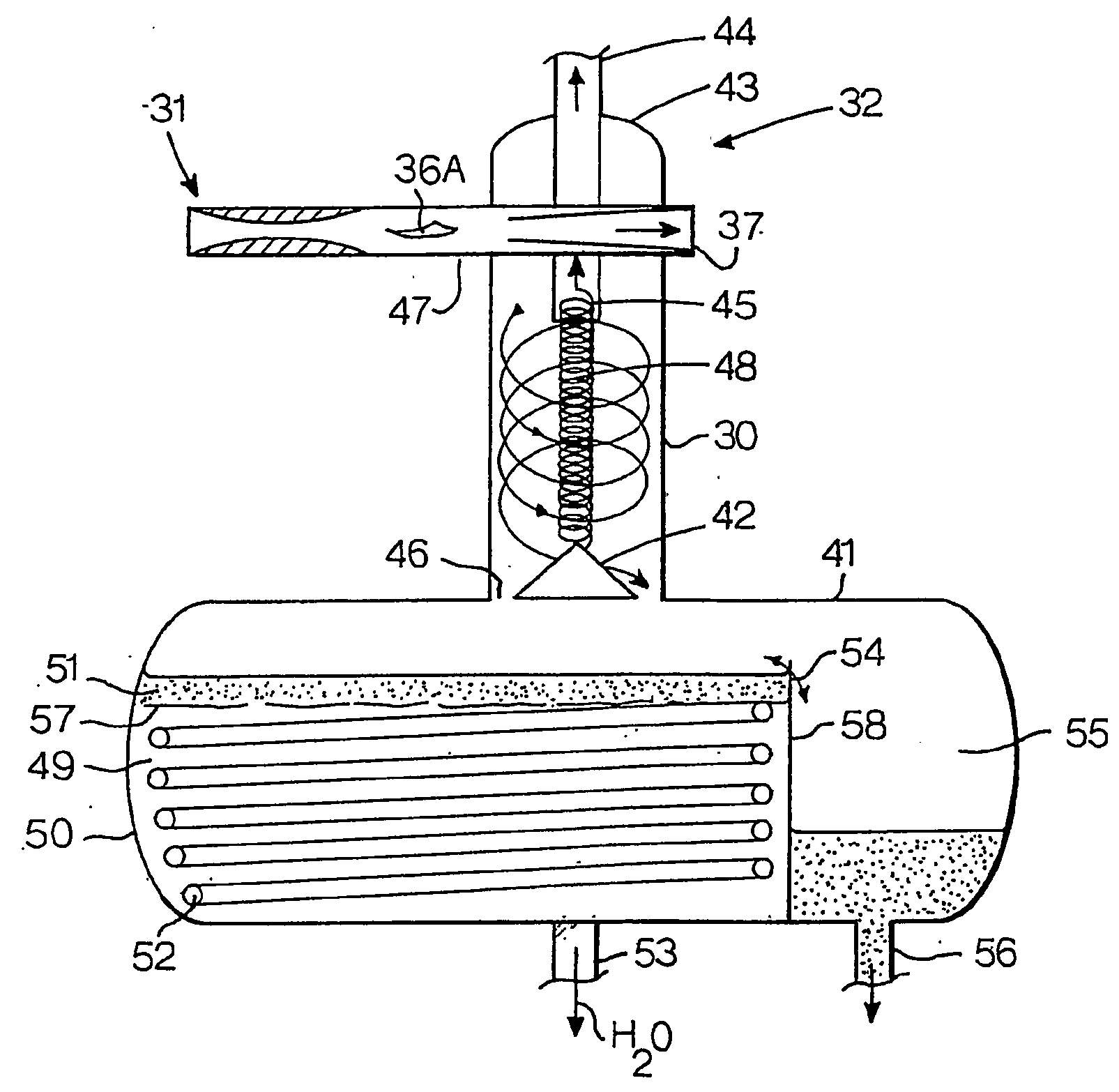

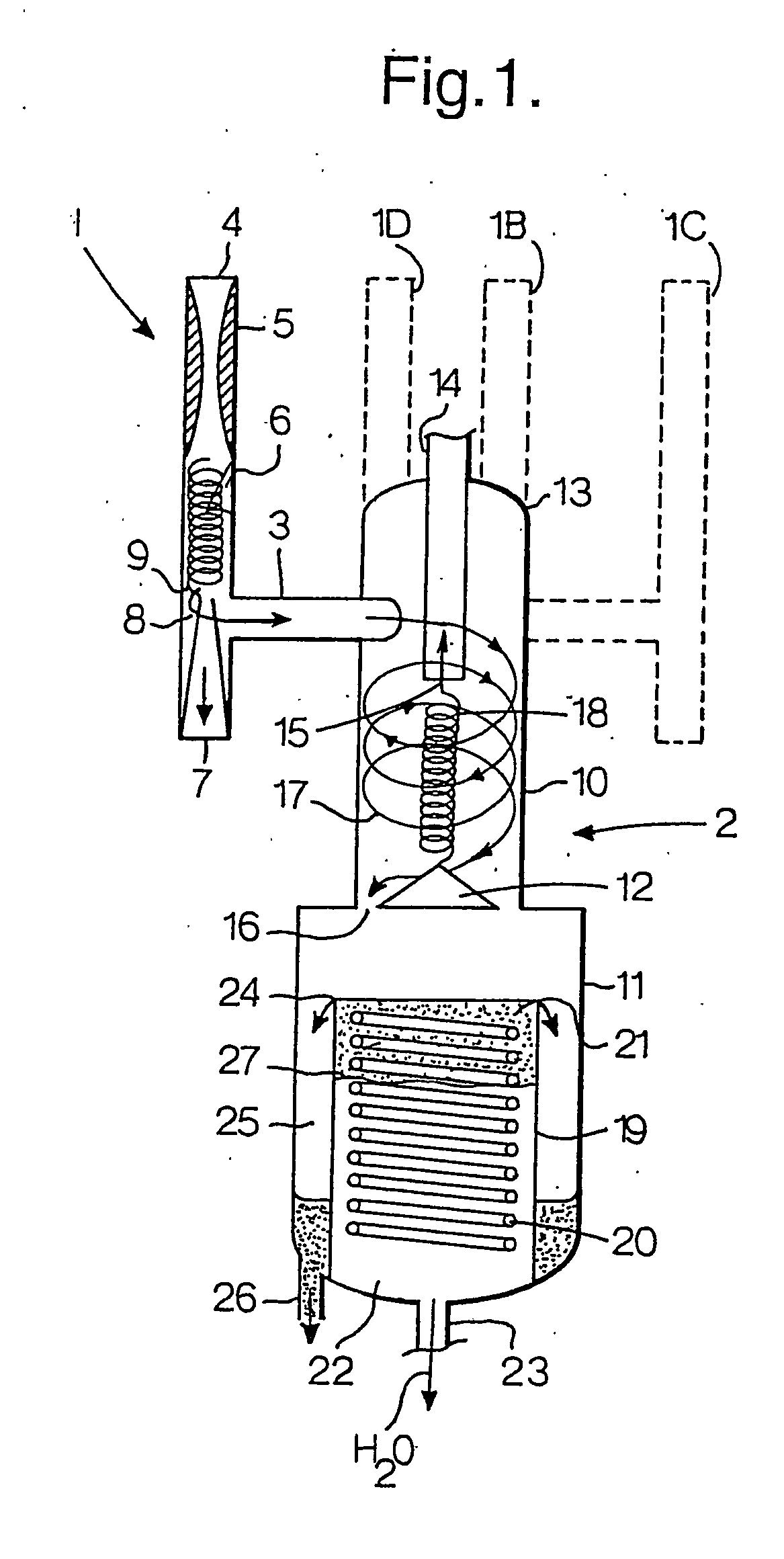

Pressure powered cooling system for enhancing the refill speed and capacity of on board high pressure vehicle gas storage tanks

ActiveUS7637292B2Improve refueling efficiencyIncrease efficiency and refueling capacityVessel mounting detailsVessel geometry/arrangement/sizeFuel tankMechanical energy

Owner:HONDA MOTOR CO LTD

Apparatus and methods for processing hydrocarbons to produce liquified natural gas

An apparatus for and process for recovering LNG from reservoir natural gas which includes circulating a portion of the natural gas thru a gas cooling loop that includes heat exchanges, an expansion zone and compression zone. The process also includes removing liquids from the gas cooling loop, distilling those liquids to recover a distilled gas. The process also includes compressing and expanding various portions of the distilled gas and passing those portions thru heat exchangers shared with the gas cooling loop to effect heating / cooling as desired. The process also includes removing a portion of the LNG cooling loop as LNG product.

Owner:MUSTANG ENG

Pressure Powered Cooling System for Enhancing the Refill Speed and Capacity of On Board High Pressure Vehicle Gas Storage Tanks

ActiveUS20070000561A1Reduce energy lossImprove refueling efficiencyVessel mounting detailsVessel geometry/arrangement/sizeFuel tankMechanical energy

Apparatus wherein the compression heat of refueling of an on board vehicle tank is evacuated from the interior of the on board tank by a heat absorber within the tank through a radiator external to the tank and in which a coolant circulating from the heat absorber within the tank to the external radiator [and / or an associated blower system] is powered by the mechanical energy of the refueling gas as the gas traverses a turbine from the high pressure refuel depot to the low pressure on board tank. The turbine powers the gas cooling system.

Owner:HONDA MOTOR CO LTD

Multistage fluid separation assembly and method

A multistage fluid separation assembly is disclosed, which includes one or more primary gas cooling devices which each have liquefied and / or solidified condensables enriched fluid outlet, and, a secondary fluid separation vessel having a tubular vertical section. The vessel is connected to the condensables enriched fluid outlet of the primary gas cooling device(s) via a tangential conduit which injects the condensables enriched fluid tangentially into the tubular section such that a tertiary stream of liquified and / or solidified condensables is induced by gravity and centrifugal forces to swirl in downward direction alongside the inner surface of the tubular section into a liquid collecting tank at or near the bottom of the vessel for collecting a tertiary mixture of liquified and / or solidified condensables. The tank is provided with one or more heaters for heating the tertiary mixture to reduce the amount of solidified condensables, such as wax, paraffins and hydrates, and with one or more liquid outlets.

Owner:TWISTER BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com