Fin, method of fabricating the same and heat exchanger tube, heat exchanger and gas cooling apparatus

A heat exchanger tube and cooled technology, applied in the fields of fins, manufacturing, heat exchanger tubes, heat exchangers and gas cooling devices, can solve the problems of deterioration of durability, reduction of charging efficiency, increase of fuel cost, etc., to achieve Good cooling efficiency, effect of promoting heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

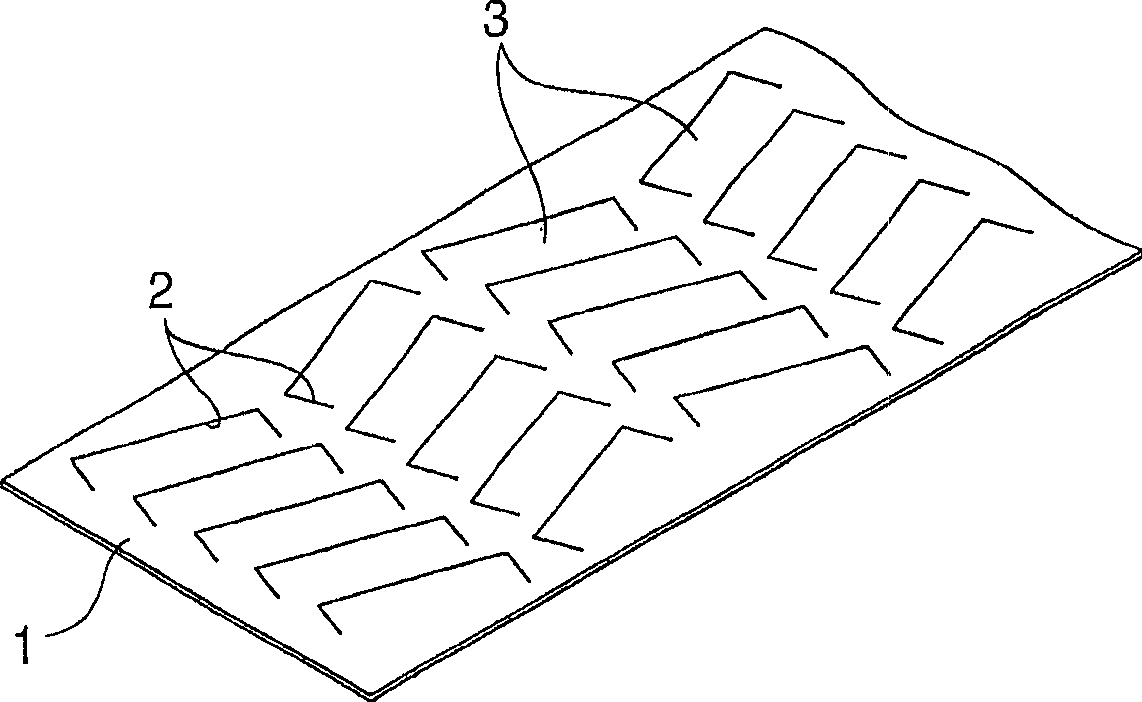

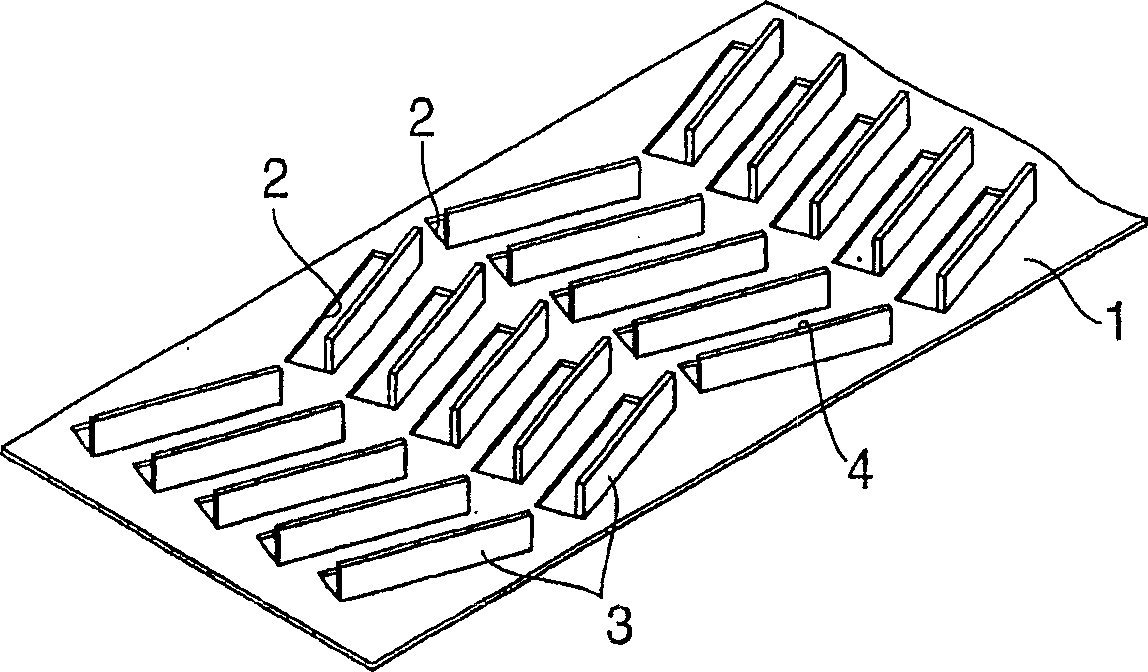

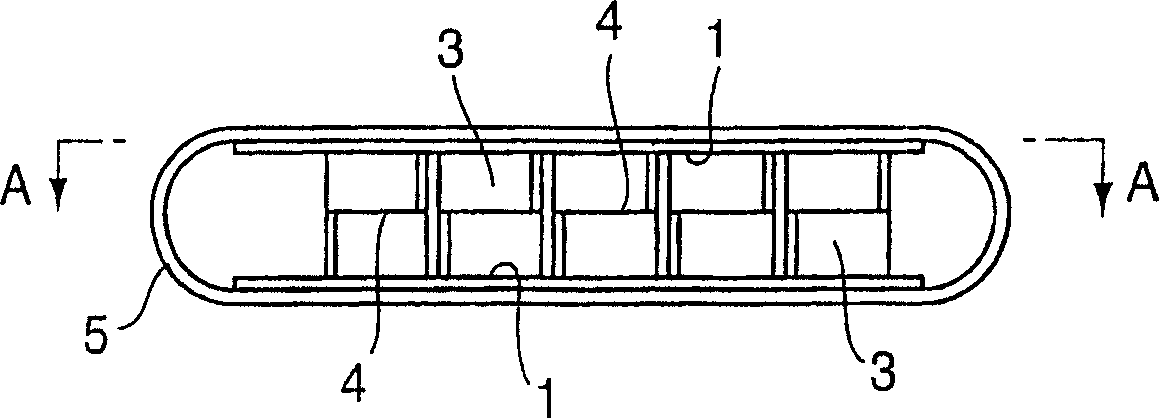

[0046] As shown in FIG. 1, according to the plate fin 3 for agitating fluid according to the first embodiment of the present invention, a thin plate made of austenitic stainless steel SUS304, SUS316 or the like and having a thickness of about 0.1 to 0.5 mm is made into a predetermined size. Rectangular shape to provide excavation material, pressing two sheets of sheet material to form a plurality of cutouts 2 similar to grooves and having a predetermined size, the direction of the cutouts can be as follows Figure 1A The alternation shown is different. Next, cut the notched portion of the remaining cut-out portion 2 and erect it perpendicular to the surface of the plate, thus forming a plate 1 with a fluid-stirring plate fin 3 oriented in its respective Alternately different on the rows, the blade edge 4 of the plate fin consists of linear lines inclined to the longitudinal direction. Thereafter, by preparing two supplied plates 1 and butting the blade edges 4 of the plate fi...

Embodiment 2

[0049] attached Figure 5B The illustrated fluid agitating plate fin 3 is similar to that of Example 1, except that the plate is constructed by joining the two plates of Example 1 longitudinally, on the left and right plates bordering the middle fold 1a-3 provided with a predetermined cutout portion, Figure 5A The shown plate fin 3a for agitating the fluid is formed by erecting the remaining notch portion of the outer cutout, after which the plate is folded at the middle fold 1a-3, and the plate 1 (1a-1) Butt with the respective blade edges 4a of the plate fins 3a formed on the plate 2 (1a-2) to stir the fluid, so that they are opposite to each other, similar to Embodiment 1, thus completing a heat exchanger with the plate fins 3a built in Tubes Similar to Example 1, this heat exchanger tube was subjected to a cooling test by an EGR gas cooling device (shell-and-tube heat exchanger), and as a result, this Example could obtain the same cooling efficiency as Example 1.

Embodiment 3

[0051] A fluid-stirring plate fin 3b similar to that of Embodiment 1 is provided, except that the shape of the fluid-stirring plate fin formed on the plate is to replace the fluid-stirring of Embodiment 1 or Embodiment 2 by bending the blade edge 4a in the longitudinal direction. The plate fins 3 and 3a are obtained when by using the fins 3b to compose the heat exchanger tubes of the plate fins 3b with the agitation fluid built in, and setting the heat exchanger tubes to the EGR gas cooling device to receive cooling similar to Example 1 During the test, by comparing with Example 1, it can be determined that the cooling efficiency is further improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com