Patents

Literature

309results about How to "Improve heat exchange effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

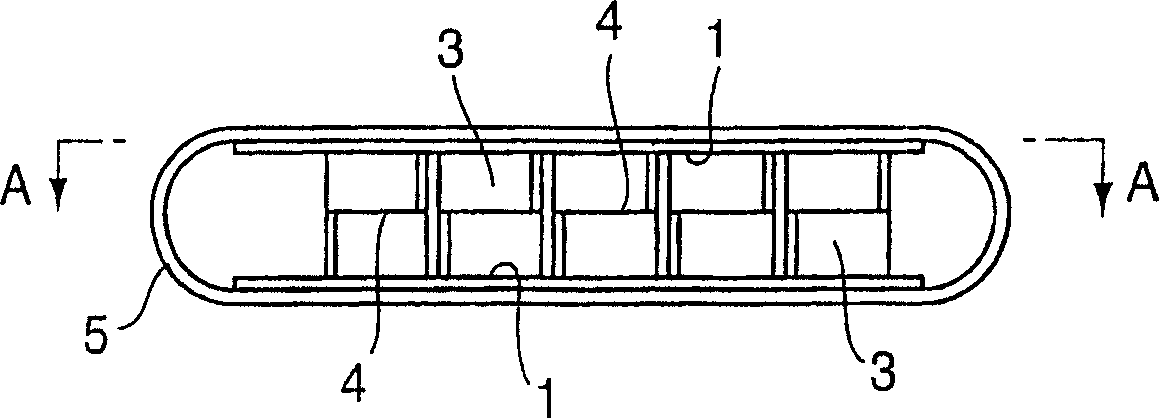

Heat exchanger

InactiveCN1849495AEliminate Assembly ProblemsAsymmetric cross-sectional profileHeat exchanger casingsPlate heat exchangerEngineering

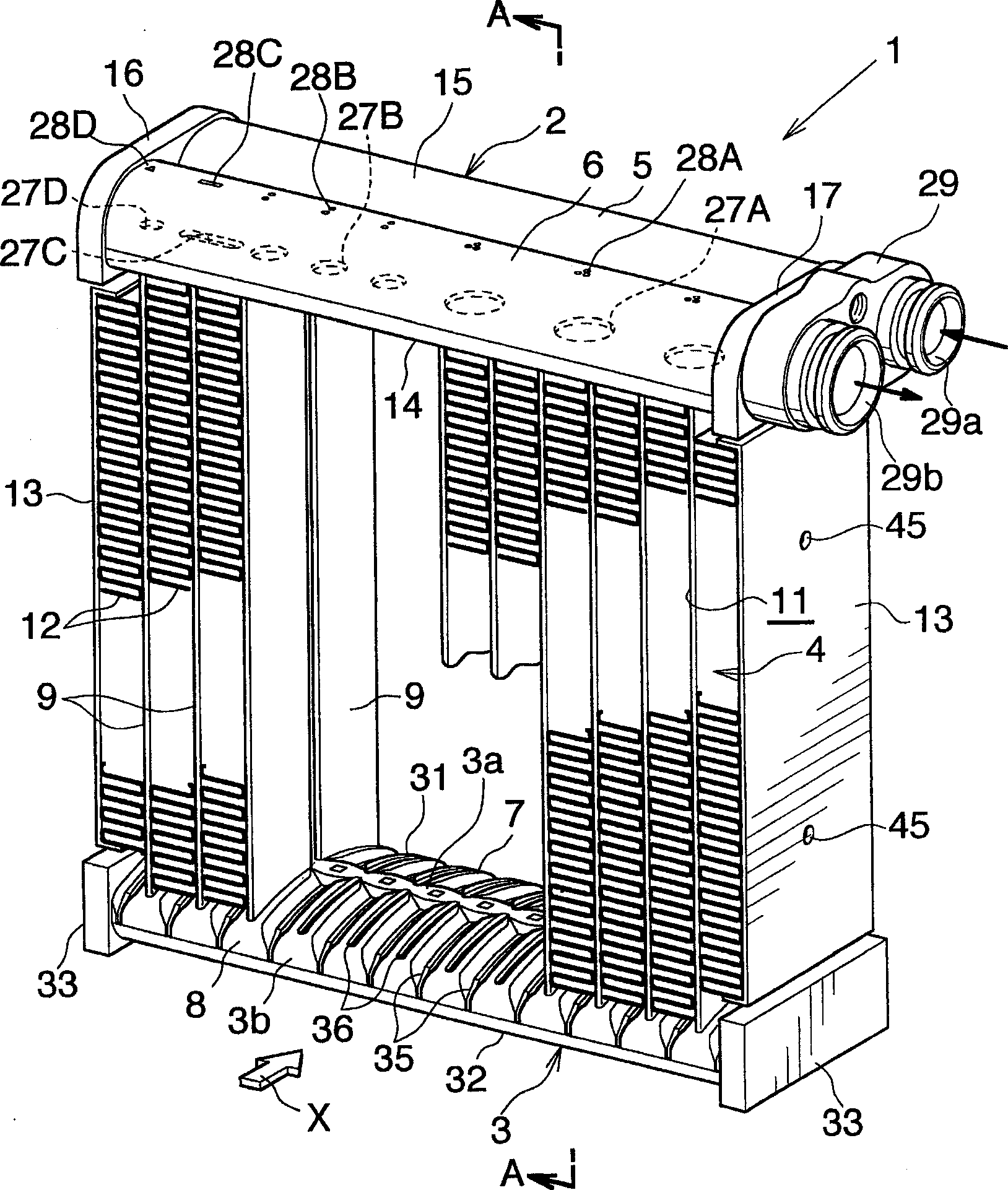

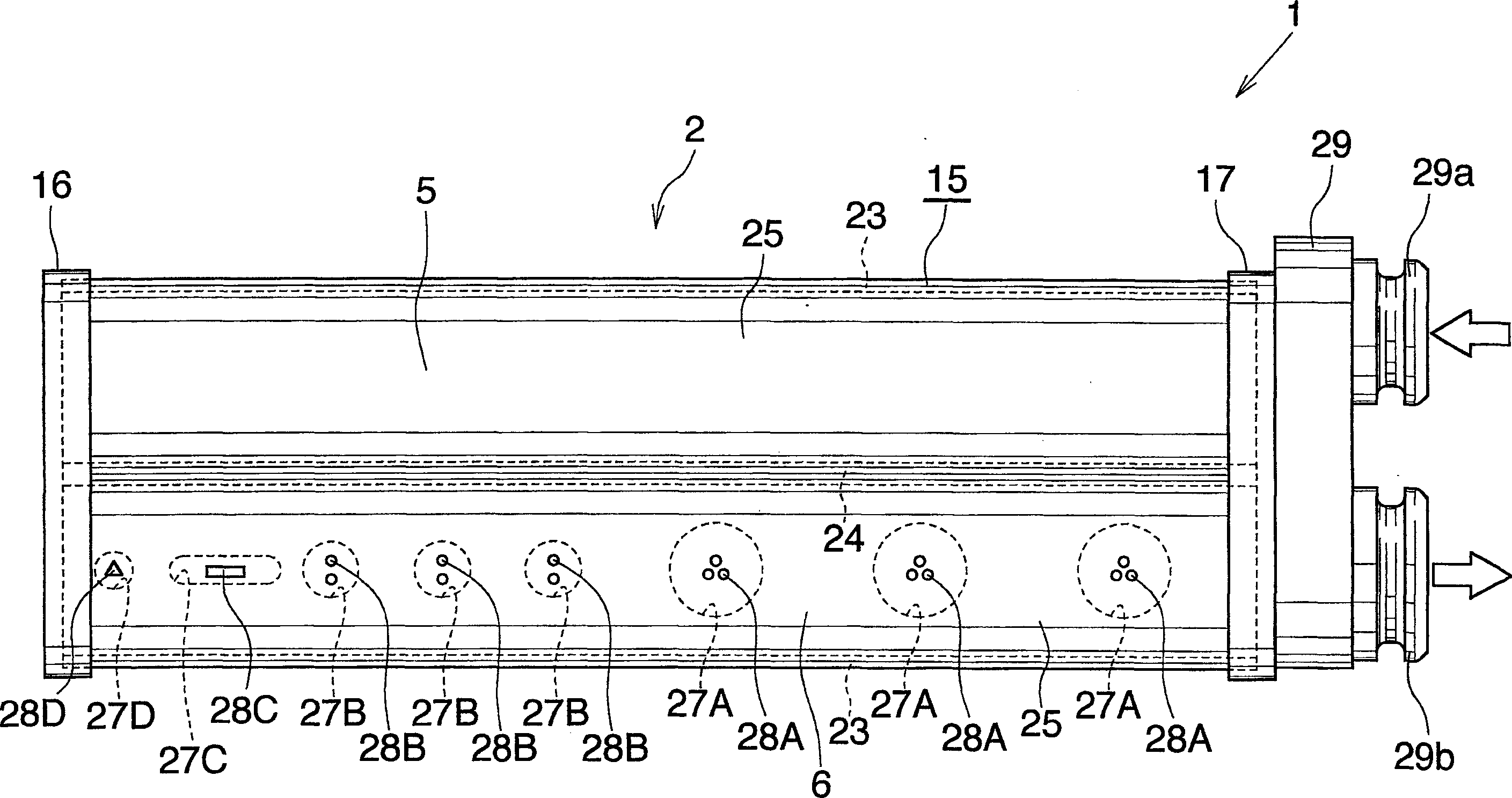

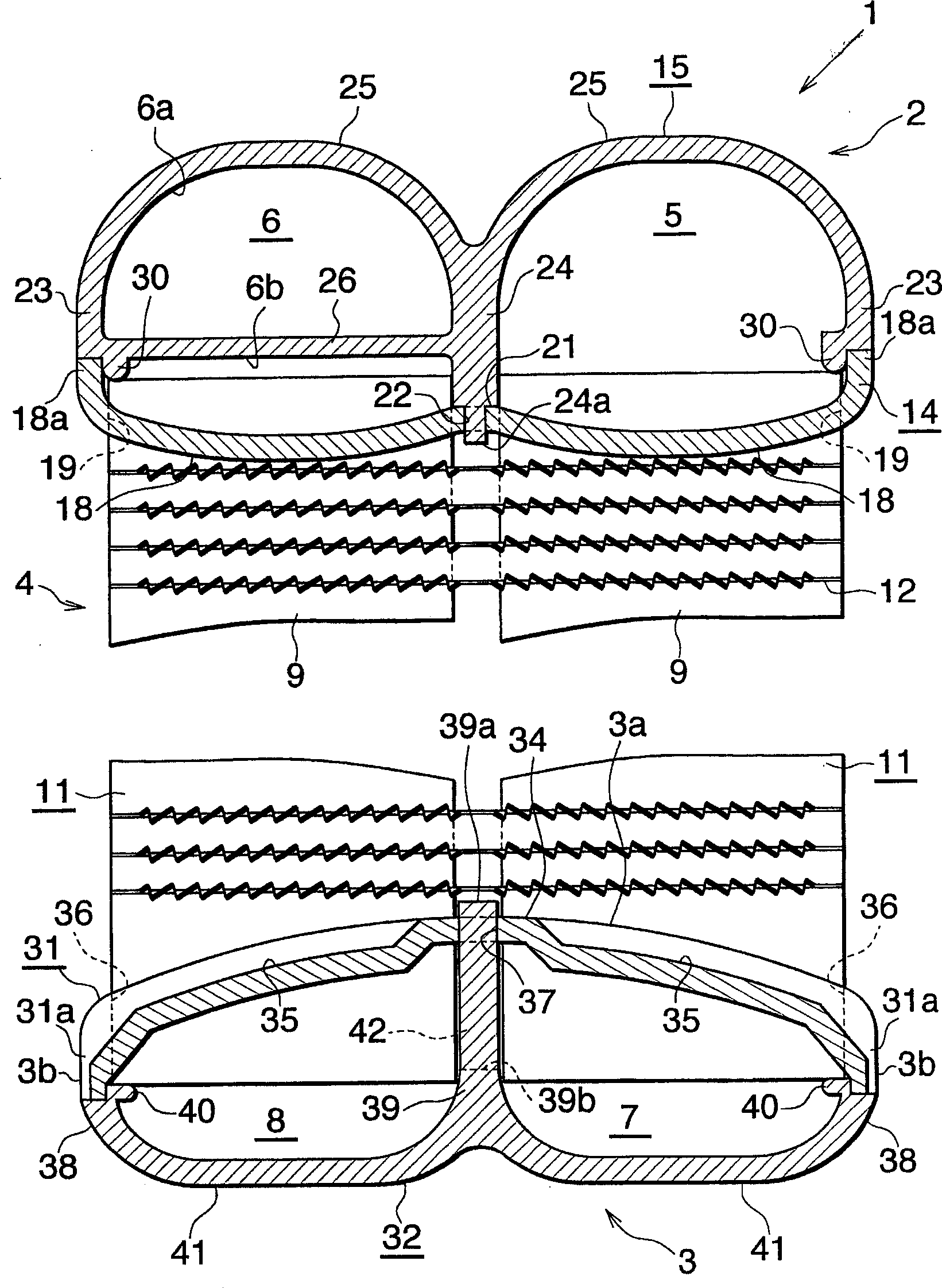

A heat exchanger (1), comprising: a heat exchange core (4) composed of a plurality of heat exchange tubes (9), a refrigerant inlet header (5) arranged toward one end of each heat exchange tube, and a refrigeration A refrigerant outlet header (6), and a refrigerant inflow header (7) and a refrigerant outflow header (8) disposed toward the other end of each heat exchange tube. The interior of the outlet header on which some of the heat exchange tubes are joined to communicate with the space (6b) is divided into two spaces (6a, 6b) by a flow-dividing resistance plate (26). A plurality of refrigerant circulation holes (27A-27D) having different shapes and / or sizes are formed in the resistance plate (26). The outlet headers have markings (28A-28D) on the outer surface for identifying the location of the refrigerant flow holes (27A-27D) and representing the shape and / or size of said holes. The heat exchanger exhibits high heat exchange performance when used as an evaporator.

Owner:SHOWA DENKO KK

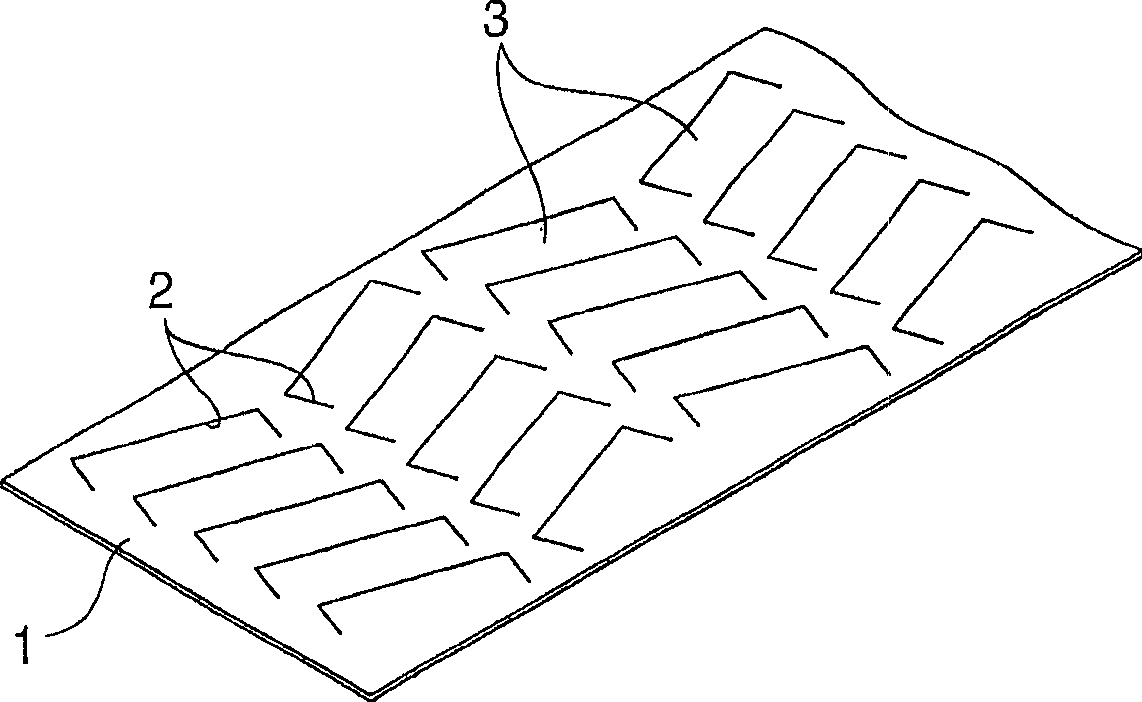

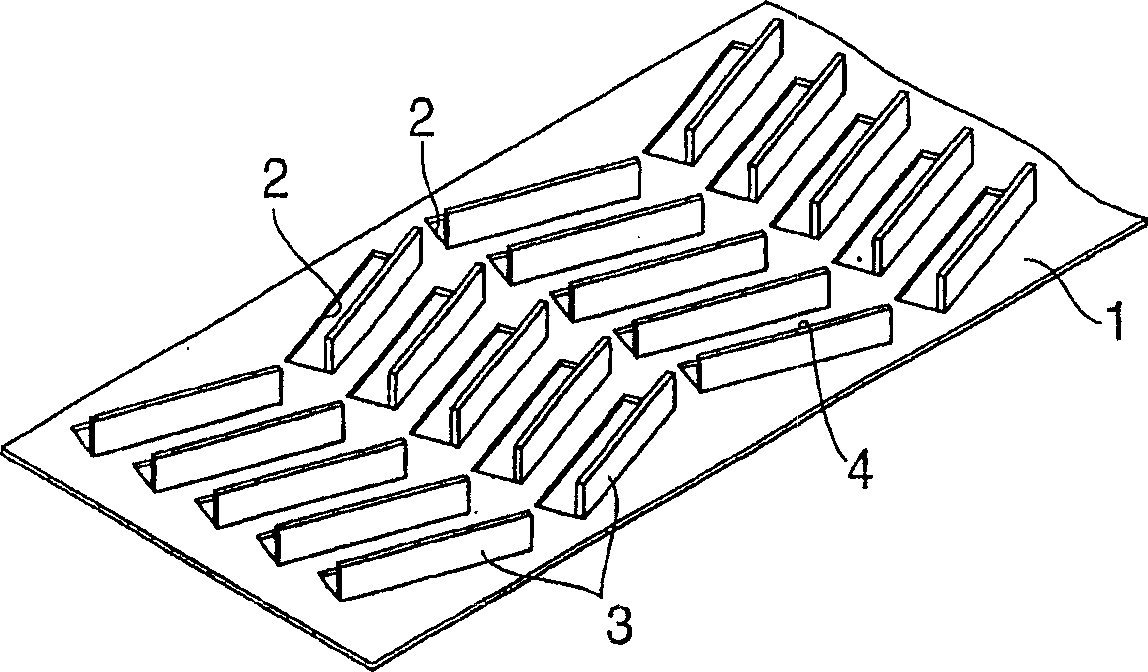

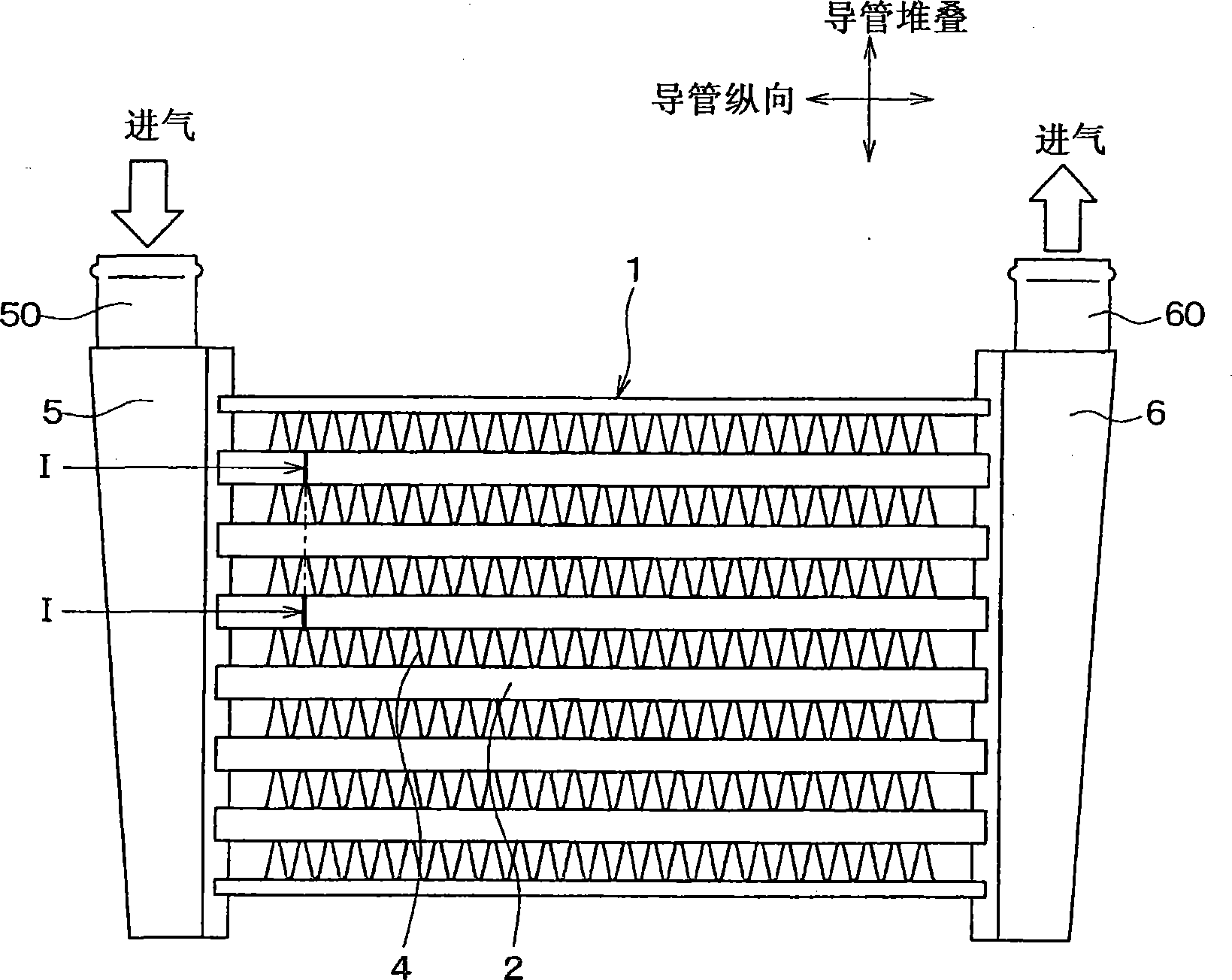

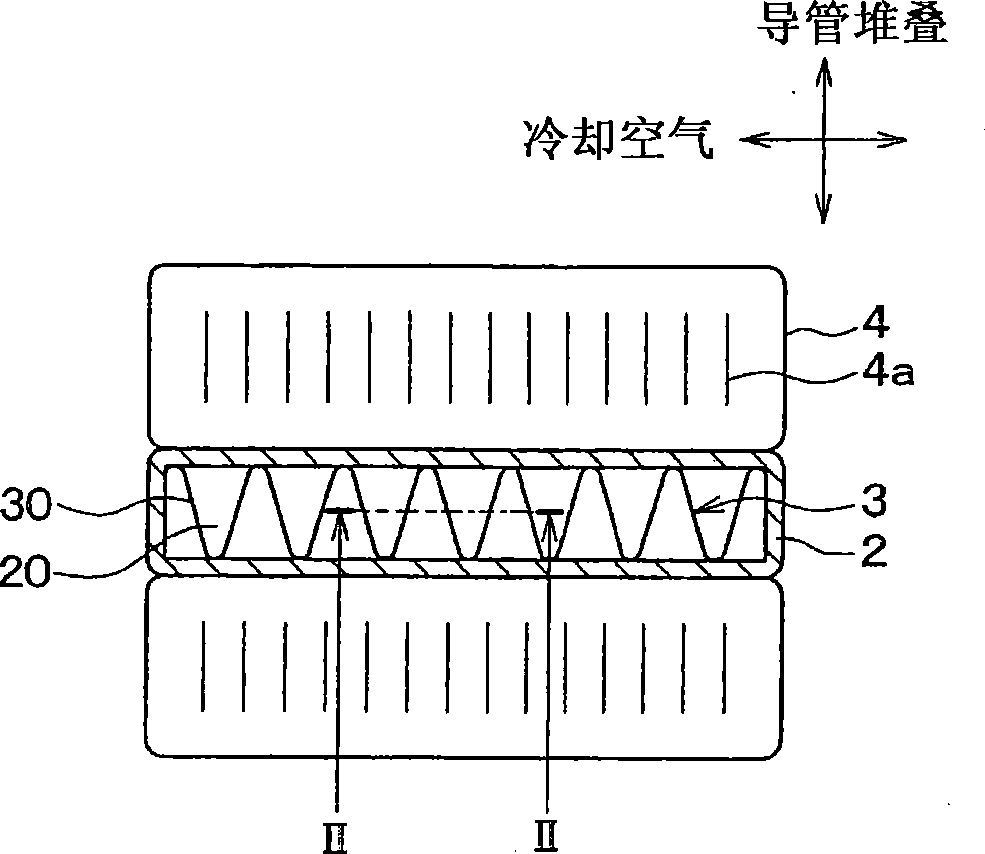

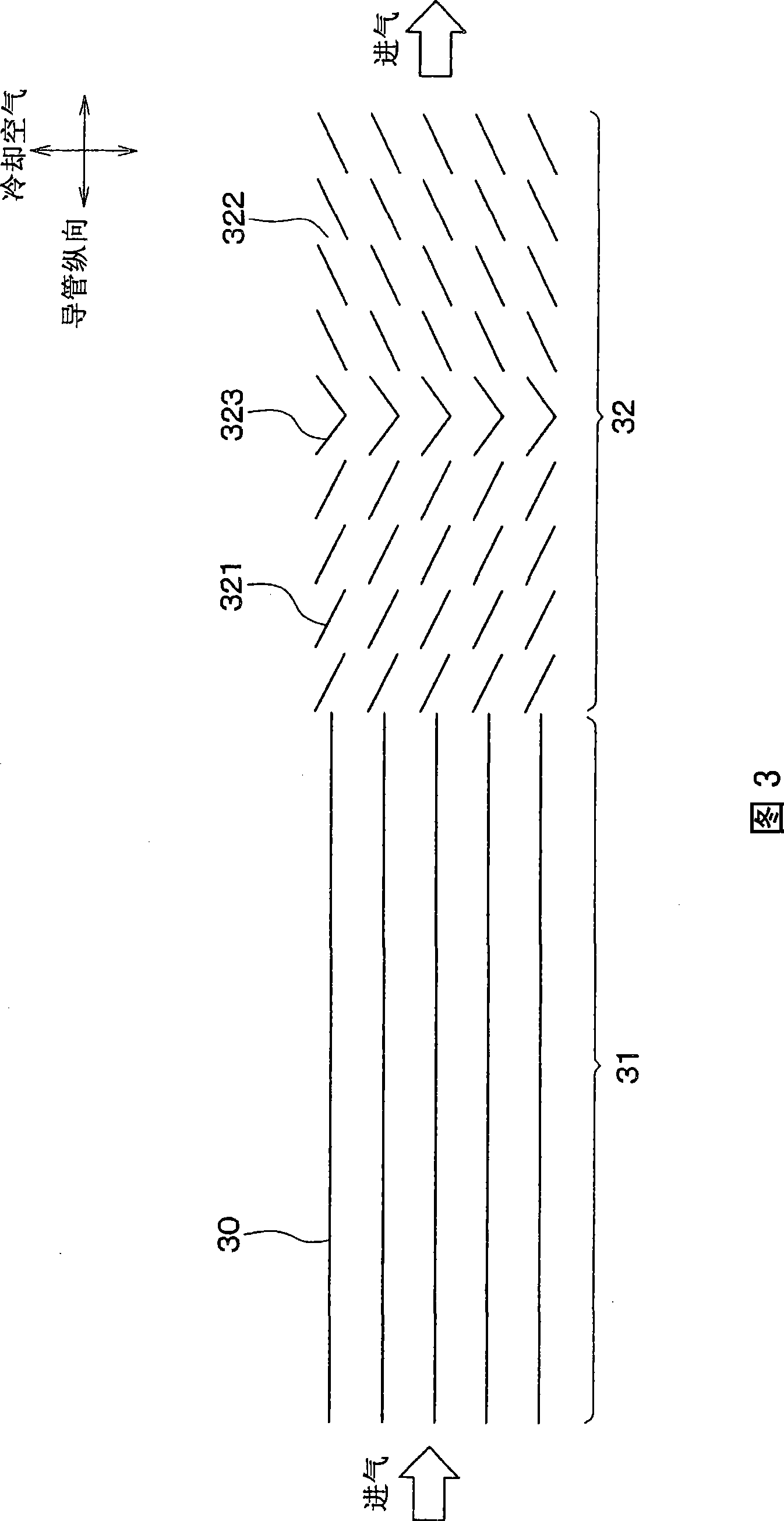

Fin, method of fabricating the same and heat exchanger tube, heat exchanger and gas cooling apparatus

InactiveCN1755316ASpeed up heat exchangeImprove cooling efficiencyInternal combustion piston enginesNon-fuel substance addition to fuelShell and tube heat exchangerEngineering

The invention relates to a shell and tube heat exchanger used as a coolant mechanism. The shell and tube heat exchanger comprises a plate-fin arranged inside or outside a heat exchanger tube, and at least one heat exchanger tube internally provided with the plate-fin. Through the heat exchanger has simple structure and easy manufacture, the heat exchanger can still limberly process fluid bodies with different shapes, promote the effective heat exchanging action of the fluid bodies, obtain good cooling efficiency, and can process a plurality of fluid bodies. The plate-fin that the invention relates to is the plate-fin for stirring liquid; the plate-fin is arranged inside or outside the heat exchanger tube to lead the fluid bodies which is composed of cooled medium or refrigeration medium to flow inside or outside the heat exchanger tube, thus impingiment flow or vortex flow with stirring action are generated; the plate-fin is arranged inside or outside the heat exchanger tube, and thus the blade edges of the plate-fin are butted and jointed up and down to enable the blade edges opposite to each other, and each butted and jointed blade edges are crossed with each other. The invention also relates to a method for manufacturing the plate-fin as well as the heat exchanger tube internally provided with the plate-fin, and the heat exchanger or an EGR gas cooling device provided with at least one heat exchanger tube.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

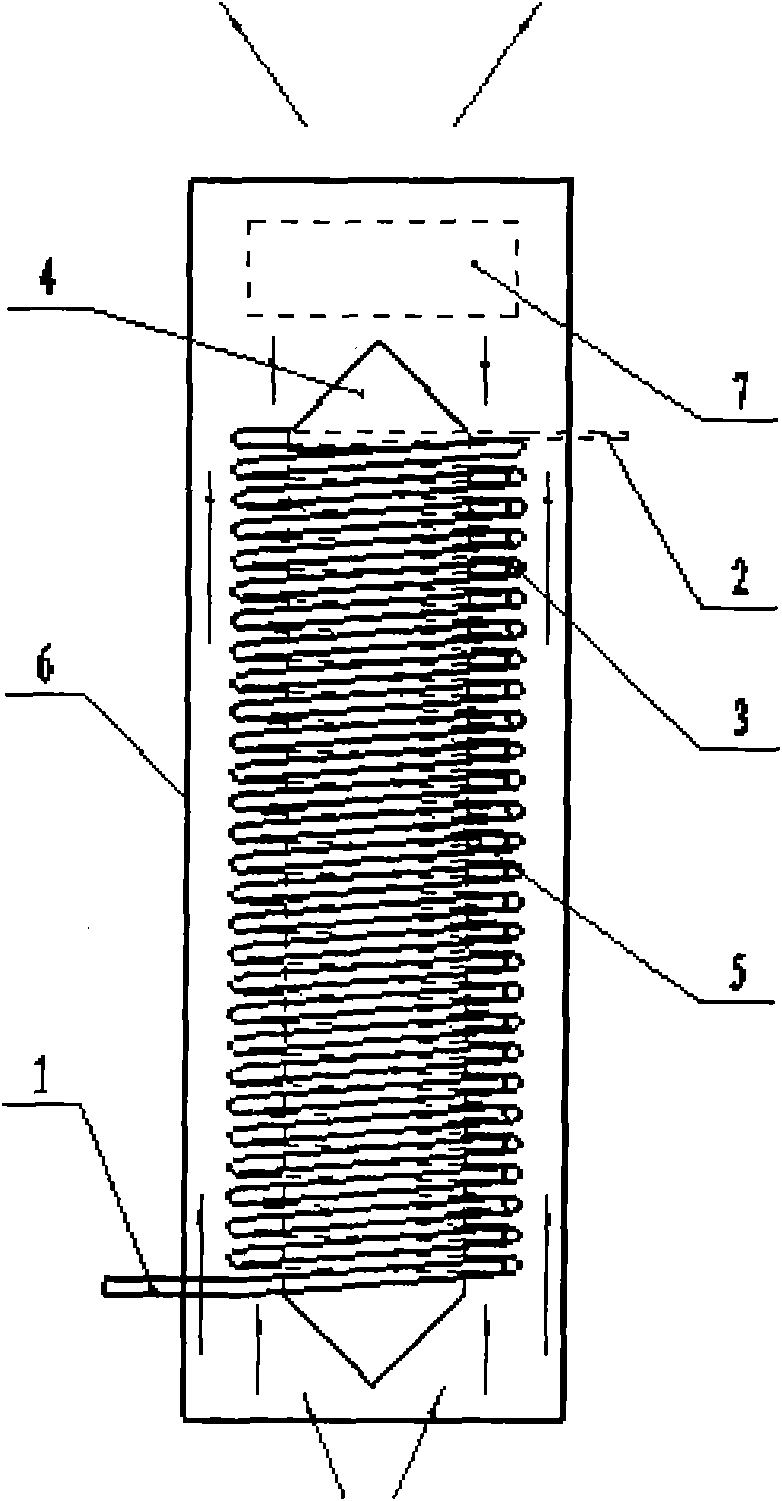

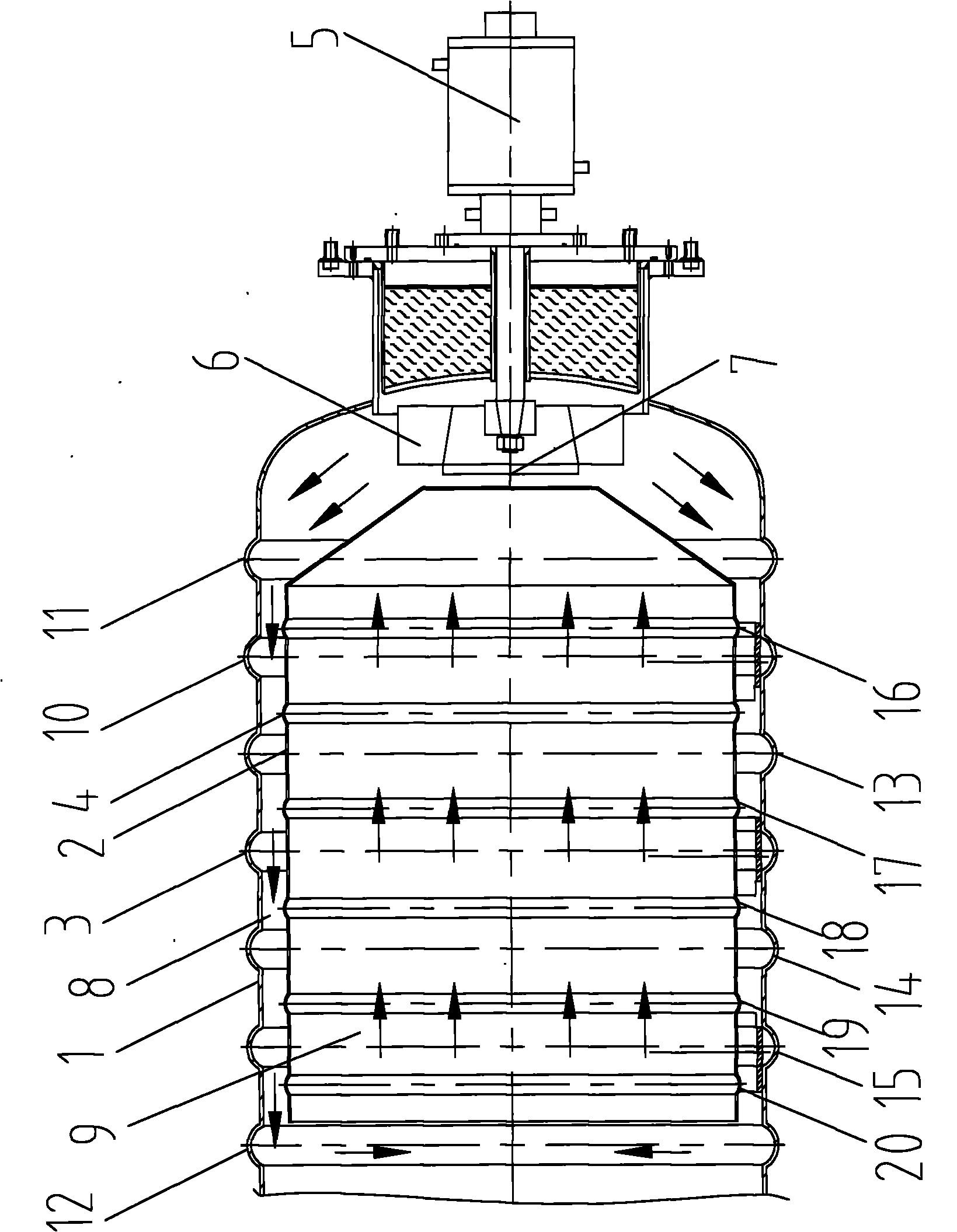

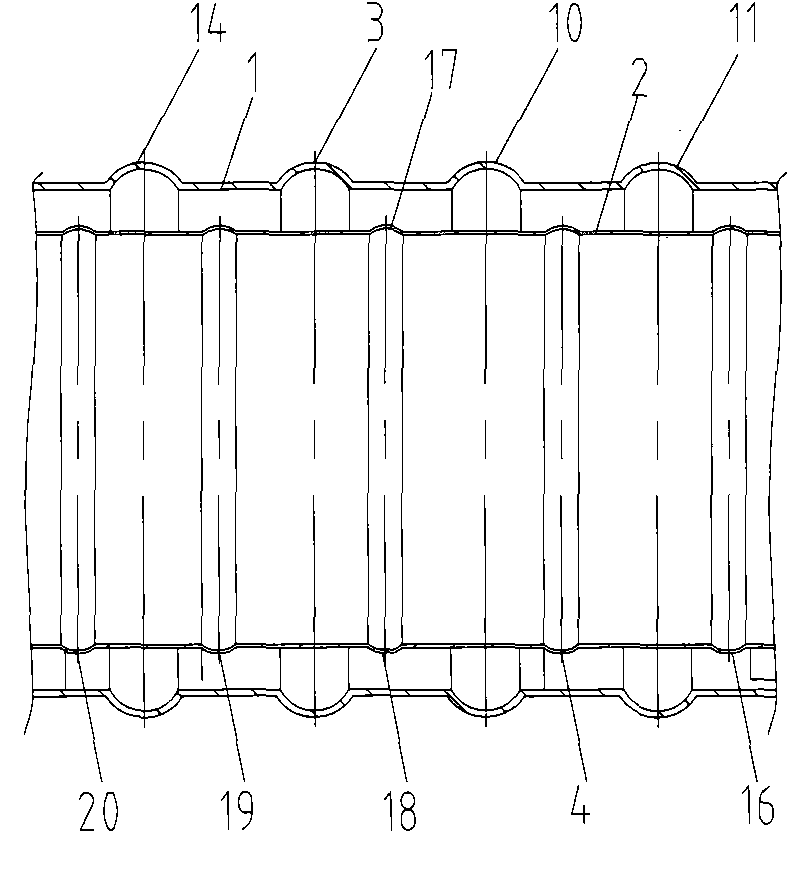

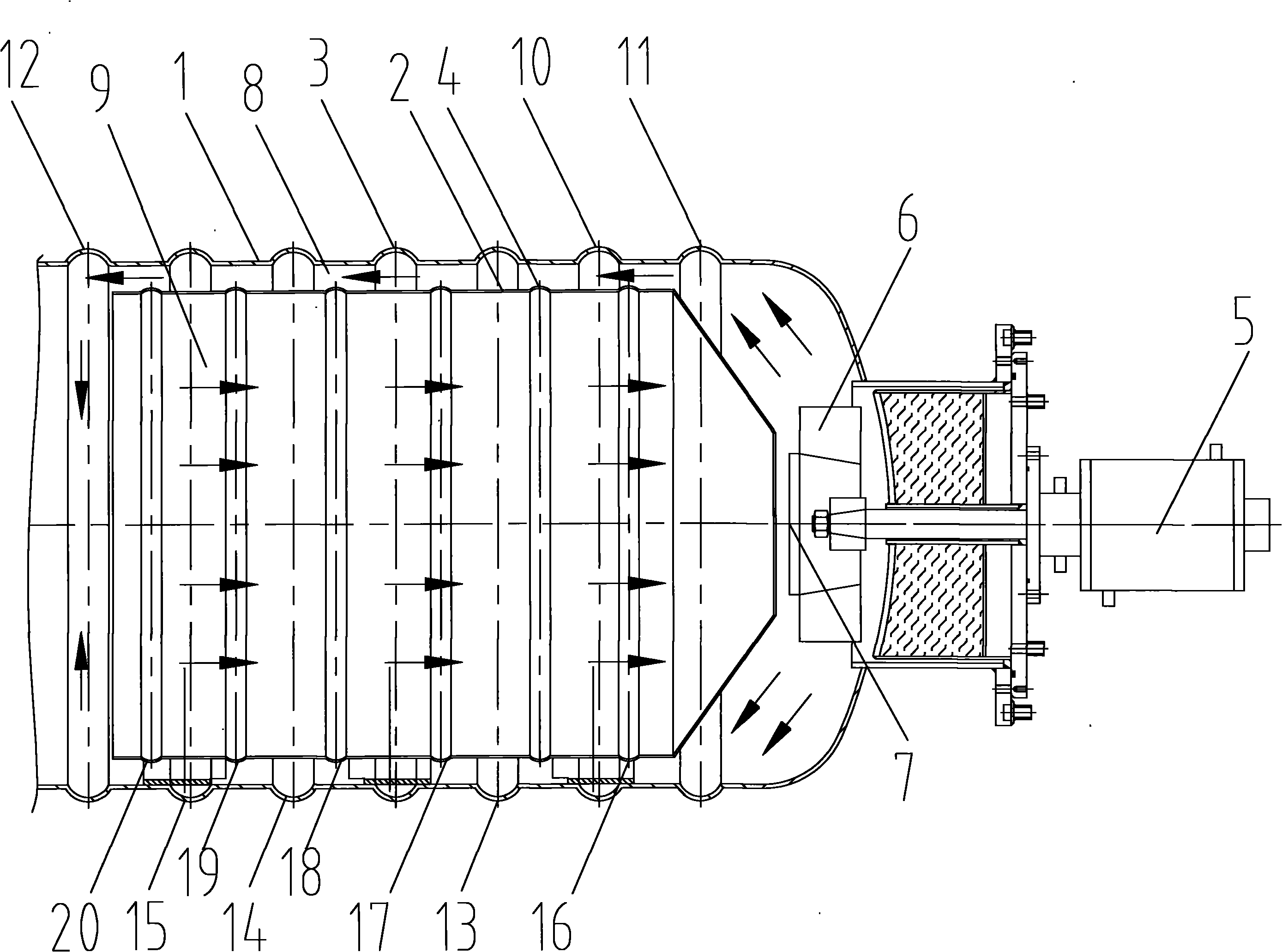

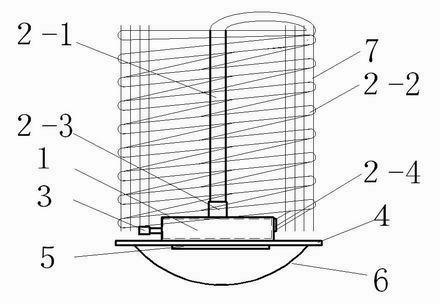

Heat exchanger with corrugated pipe coil structure provided with internal duct and external duct

InactiveCN101619944ASmooth heat convectionModularElectrolysis componentsChemical industryLiquid mediumEngineering

The invention discloses a heat exchanger with a corrugated pipe coil structure provided with an internal duct and an external duct, which comprises an inlet, an outlet, a corrugated pipe, a dome, an internal ring bushing, an external ring bushing, a fan and a bracket. When fluid media to be in heat exchange flow in the corrugated pipe in the heat exchanger from the inlet, form a turbulent flow in a pipe wall with a corrugated structure and carry out heat exchange with air in the internal duct and the external duct outside the corrugated pipe via the wall of the corrugated pipe, the fan discharges air in the internal duct and the external duct, and the fluid media are discharged from the outlet after the heat exchange performed in the corrugated pipe in a spiral way. The heat exchanger has the advantages of high heat exchanger effectiveness, simple structural technology, light weight, integration, and the like, and the fluid media in the pipe coil after the heat exchange have even temperature, thereby the heat exchanger can be used for heat exchange of air, liquid and air-liquid mixing substances. When the corrugated pipe adopts resistant materials, the heat exchanger can be used for heat exchange for corrosive liquid media.

Owner:南京容宇能源科技有限公司

Heat exchanger having different flowing paths

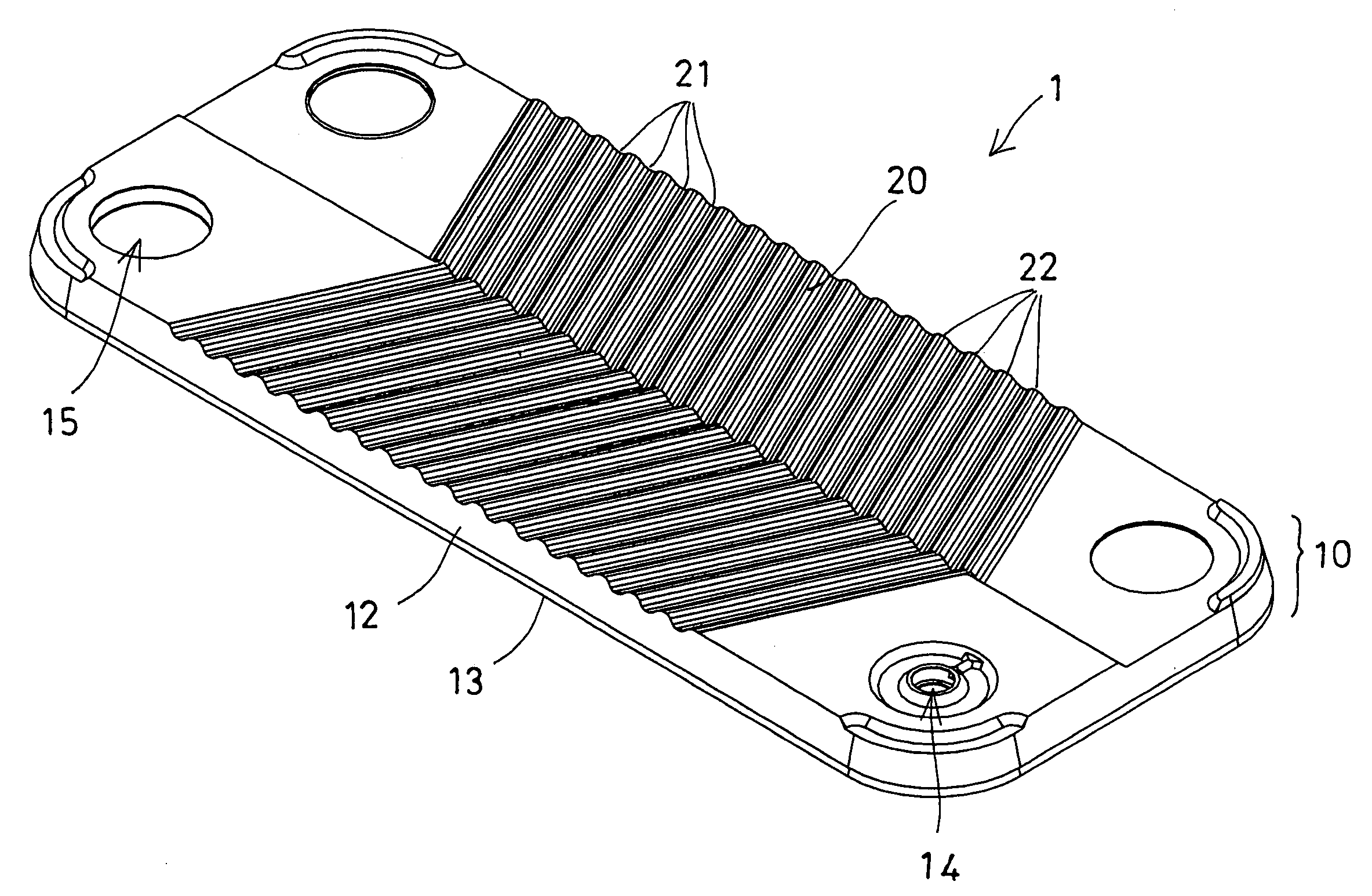

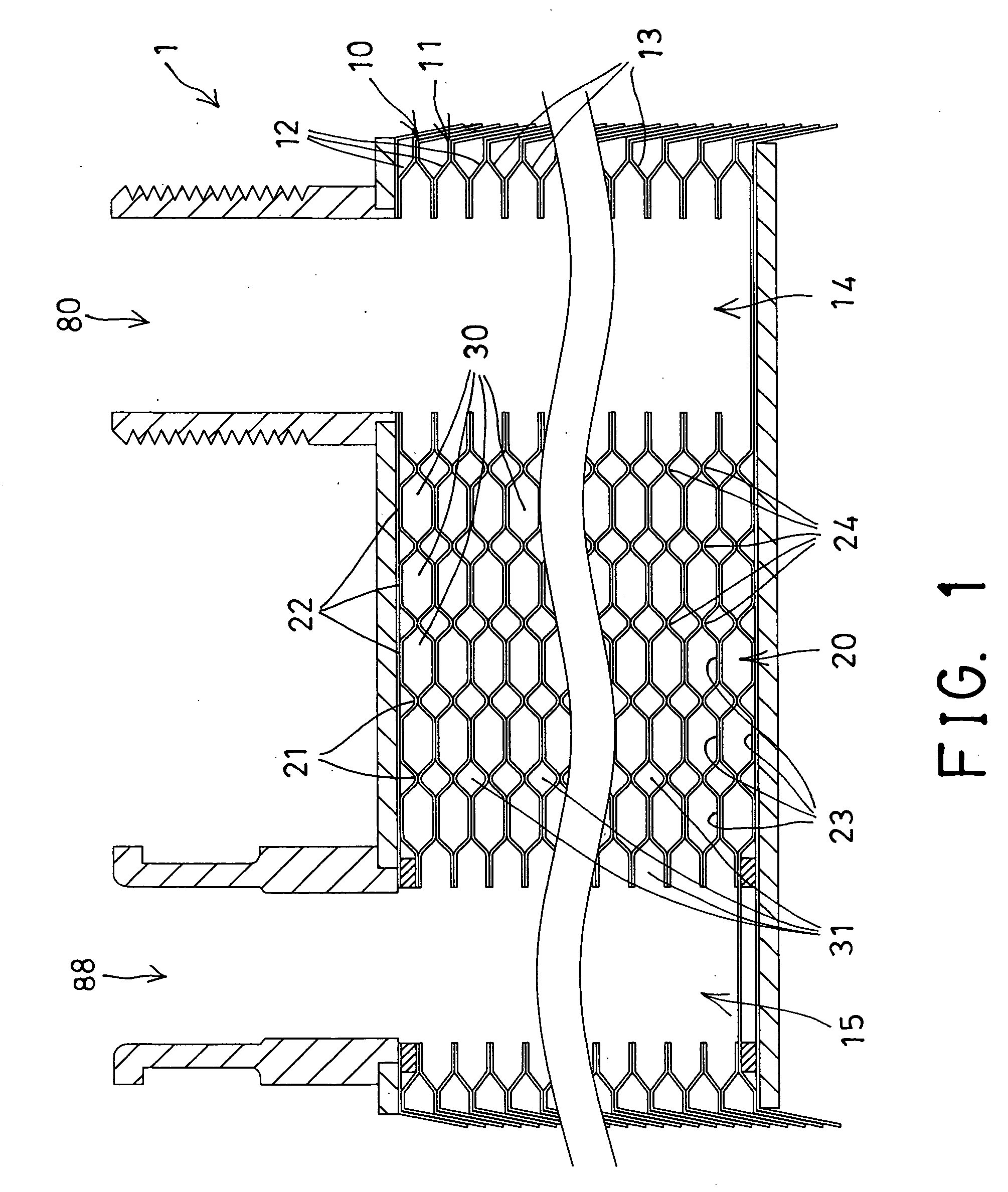

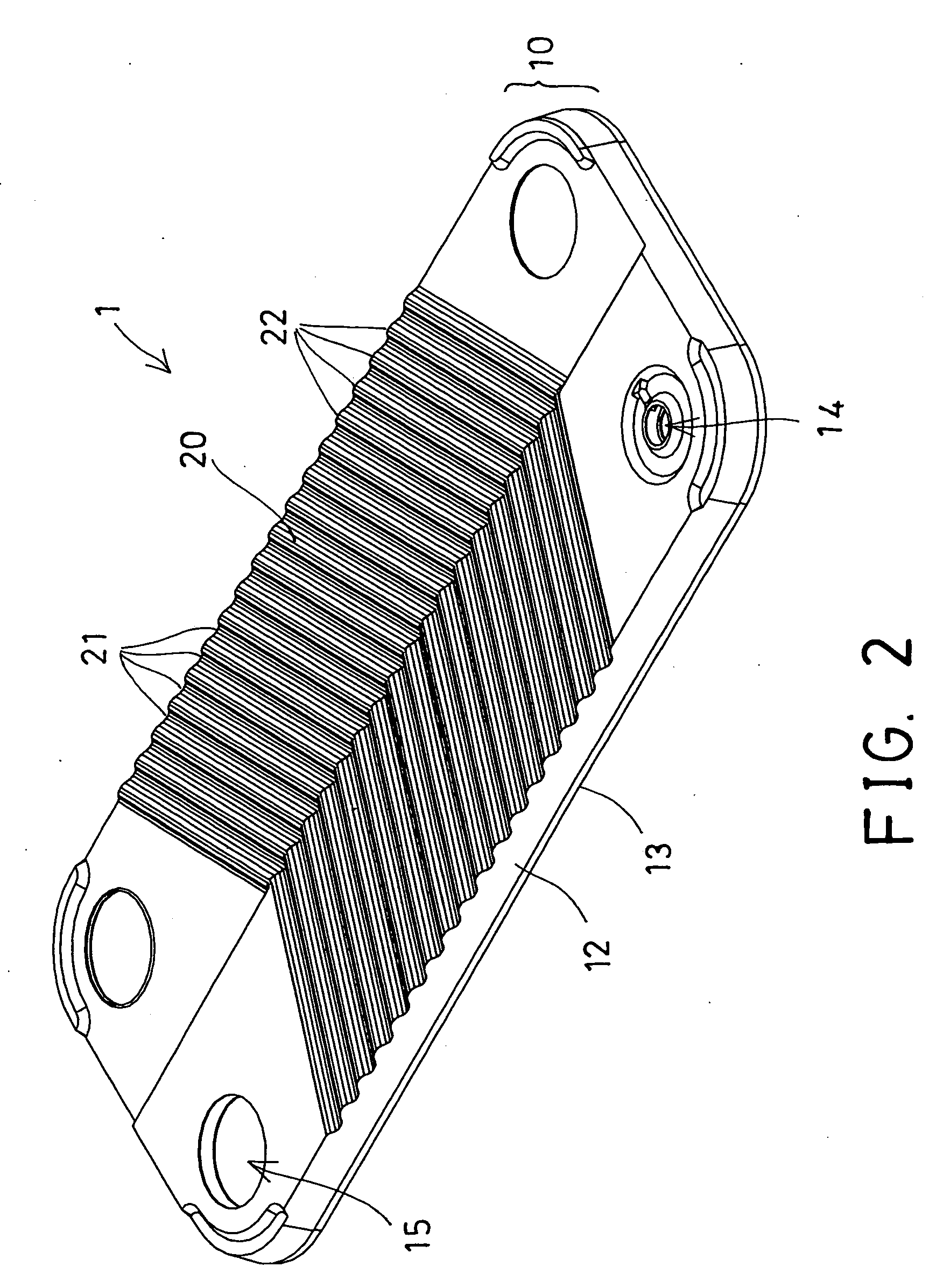

InactiveUS20070261833A1Improve heat exchange effectHeat exchanger casingsLaminated elementsEngineeringMechanical engineering

A heat exchanger includes a number of plate sets disposed one above the other or superposed with each other, and each plate sets includes an upper plate and a lower plate for forming one or more conduits between the upper and the lower plates, and for forming one or more ducts between the lower and the upper plates of different plates, the plates include an opening communicating and coupled to the conduits for receiving one heat medium, and an orifice communicating and coupled to the ducts for receiving a different heat medium and for separating the heat media from each other, and for allowing the heat media to have different flowing quantity from each other.

Owner:KAORI HEAT TREATMENT COMPANY

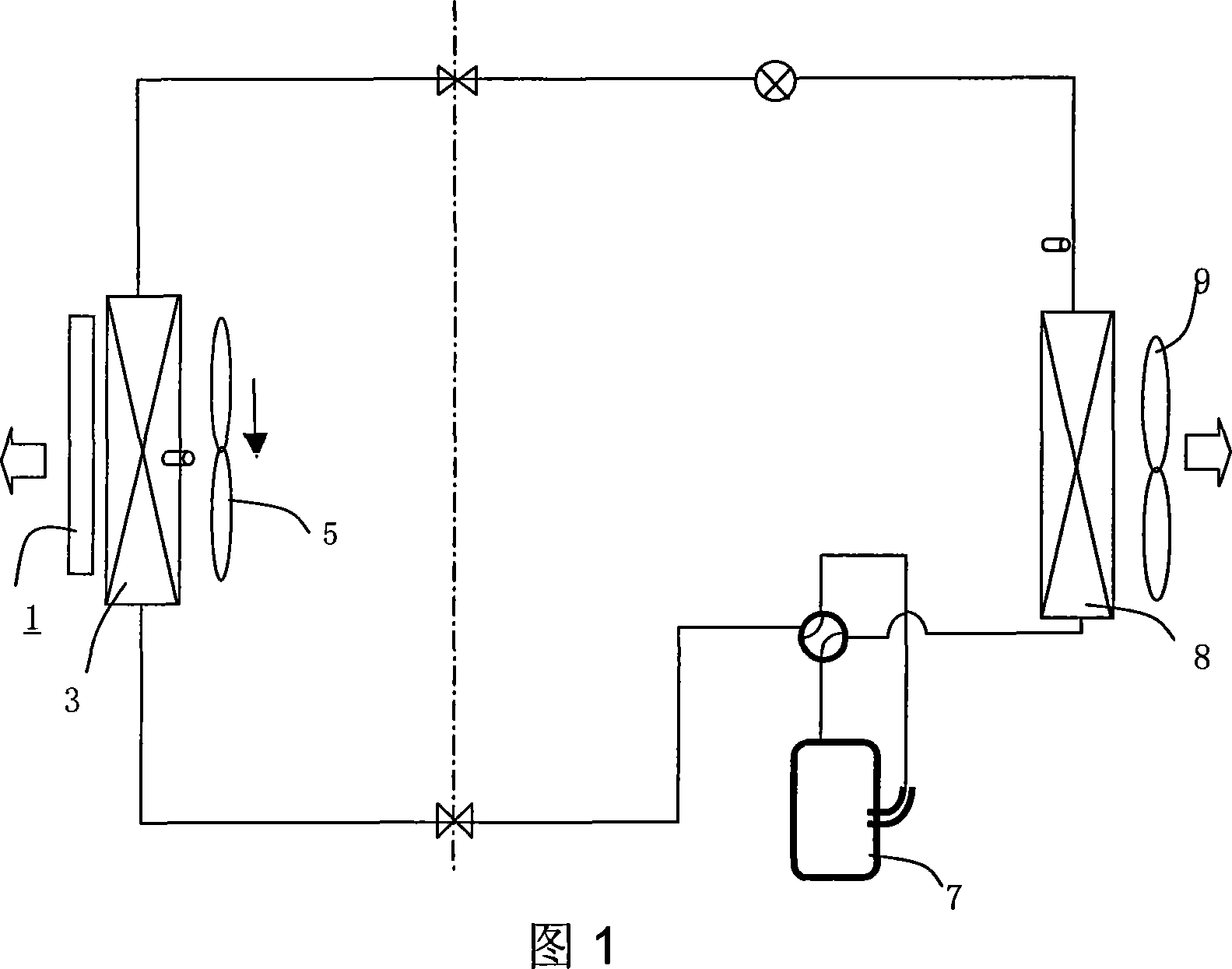

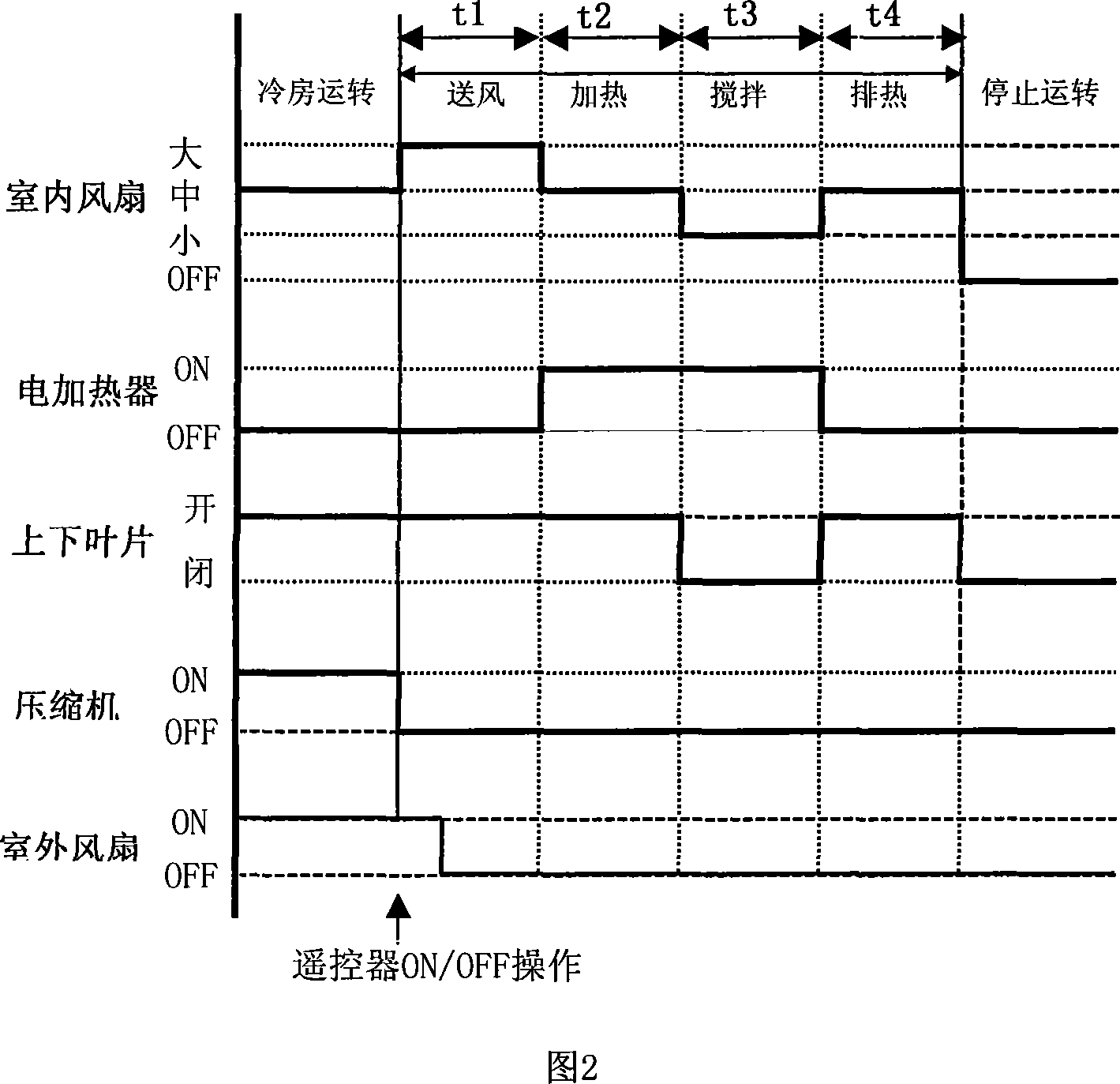

Control method of air-conditioning

ActiveCN101033880AInhibit bacterial growthImprove heat exchange effectSpace heating and ventilation safety systemsLighting and heating apparatusHeat rejectionEvaporator

The invention discloses a controlling method of an air condition which includes the compressor, the room heat exchanger, the room fan and the controlling device. The character is in that: the electrical heater is set on the upper side of the room heat exchanger. The controlling method includes at least the follow processes: heating, the electrical heater heats and dries the room heat exchanger; mix, the mixing wind circles in the room machine; heat rejection, discharge the hot wind out of the room machine. After the air condition refrigerating or sucking the humid, the invention uses the linkage of the electrical heater, the room fan and up-down fans. It not needs to start the compressor but can do the drying operation to make the evaporator dry and move the dirty of the fan surface to inhibit the bacterium growth in evaporator surface. So it can improve the heat exchanging effect and prolong the using life.

Owner:PANASONIC HOME APPLIANCES AIR CONDITIONING GUANGZHOU CO LTD

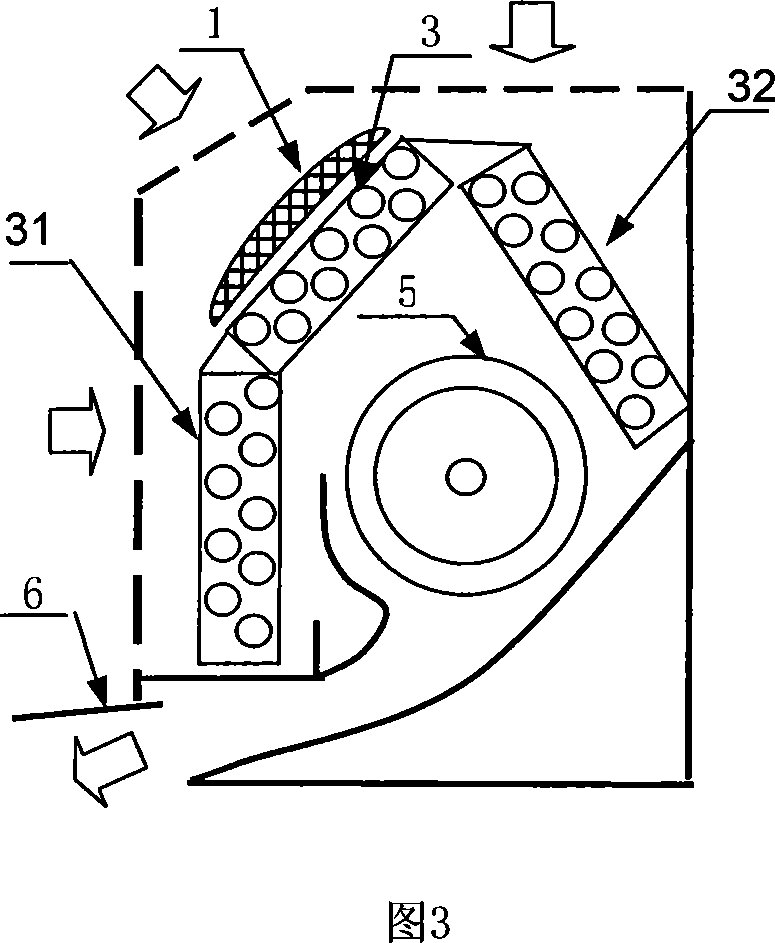

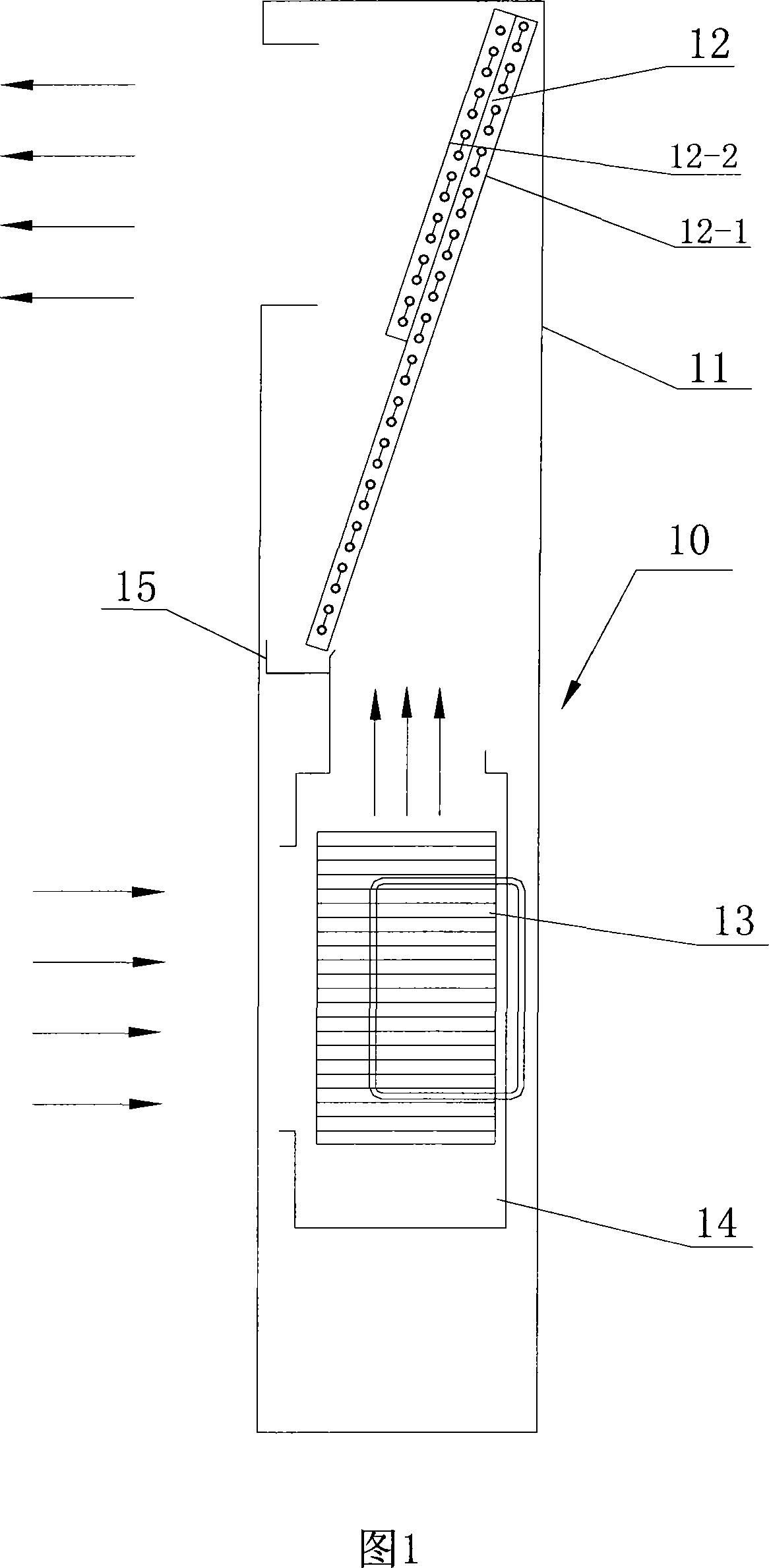

Evaporator and cabinet type air conditioner indoor machine employing same

InactiveCN101105352AUniform heat exchangeGive full play to the heat exchange capacityEvaporators/condensersAir conditioning systemsWind fieldEngineering

The invention provides an evaporator and a cabinet air conditioner indoor unit equipped with the evaporator. Aiming at the wind field characteristics of the evaporator of blast type cabinet air conditioner, the invention improves the structure of evaporator of indoor unit. The lower part of the evaporator that has poor heat exchange adopts single-row evaporator design, and the upper part of the evaporator hat has sufficient heat exchange adopts double-row evaporator design. Thus, the heat exchange capability of each part of the evaporator can be fully utilized, so that all parts of the evaporator have uniform heat exchange, either assuring the heat exchange performance of the cabinet air conditioner or reducing cost. The invention has good heat exchange performance when being applied to the blast type conditioner indoor unit.

Owner:HISENSE +1

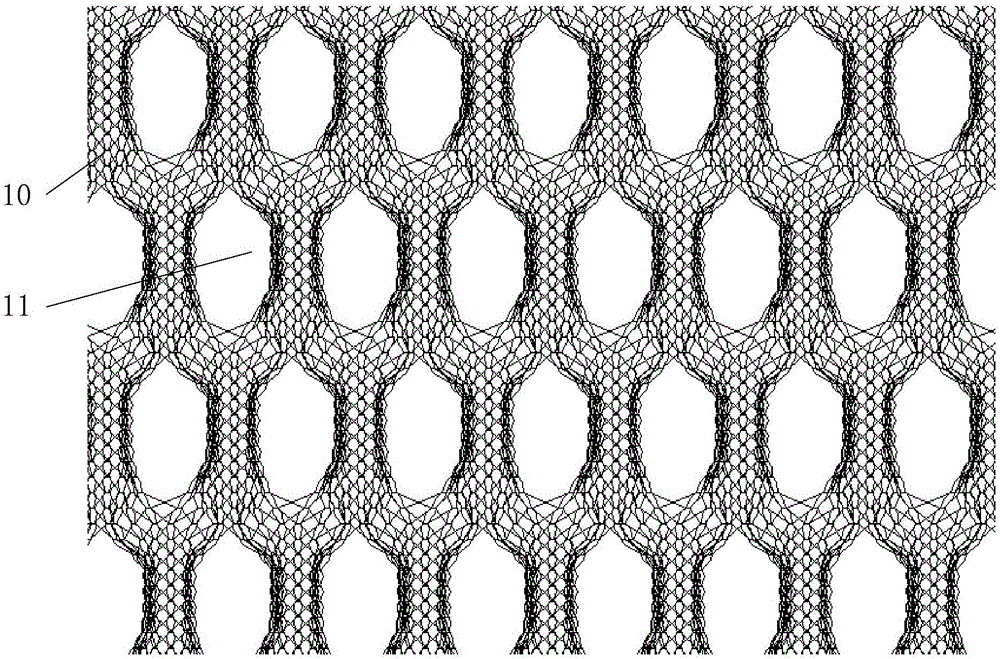

Air mesh cloth with tapered meshes and manufacturing method thereof

The invention provides an air mesh cloth with tapered meshes. The air mesh cloth comprises a surface layer, a bottom layer and a middle layer used for connecting the surface layer and the bottom layer. The surface layer is provided with first meshes uniformly. The bottom layer is uniformly provided with a plurality of second meshes arranged at the same axis of the first meshes. The cross section area of the first meshes is bigger than the cross section area of the second meshes. The middle layer has a cavity between the first meshes and the second meshes. The invention also provides a manufacturing method of the air mesh cloth. The air mesh cloth is capable of forming tapered meshes between the first meshes and the second meshes. The external air of shoes flows from the second meshes to the tapered meshes and fast spreads into shoes when the air volume is enlarged. The internal hot air of shoes flows the first mesh to the tapered meshes under the actuation of impulsion generated by shoes movement. When flowing through the second meshes, the air is compressed to release thermal energy; thus, the air exchanging effects and the heat exchanging effects are relatively good.

Owner:SINCETECH FUJIAN TECH CO LTD

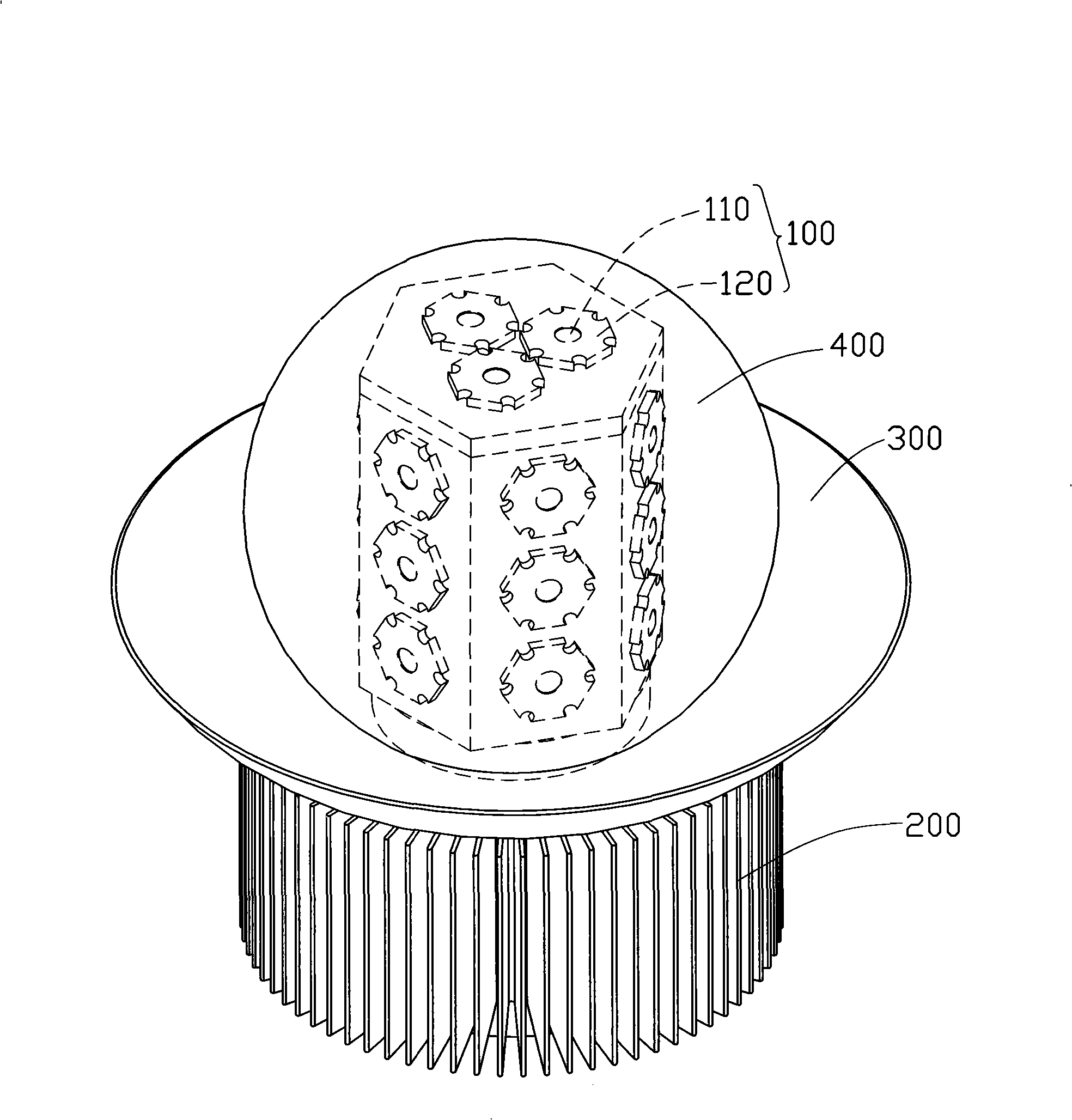

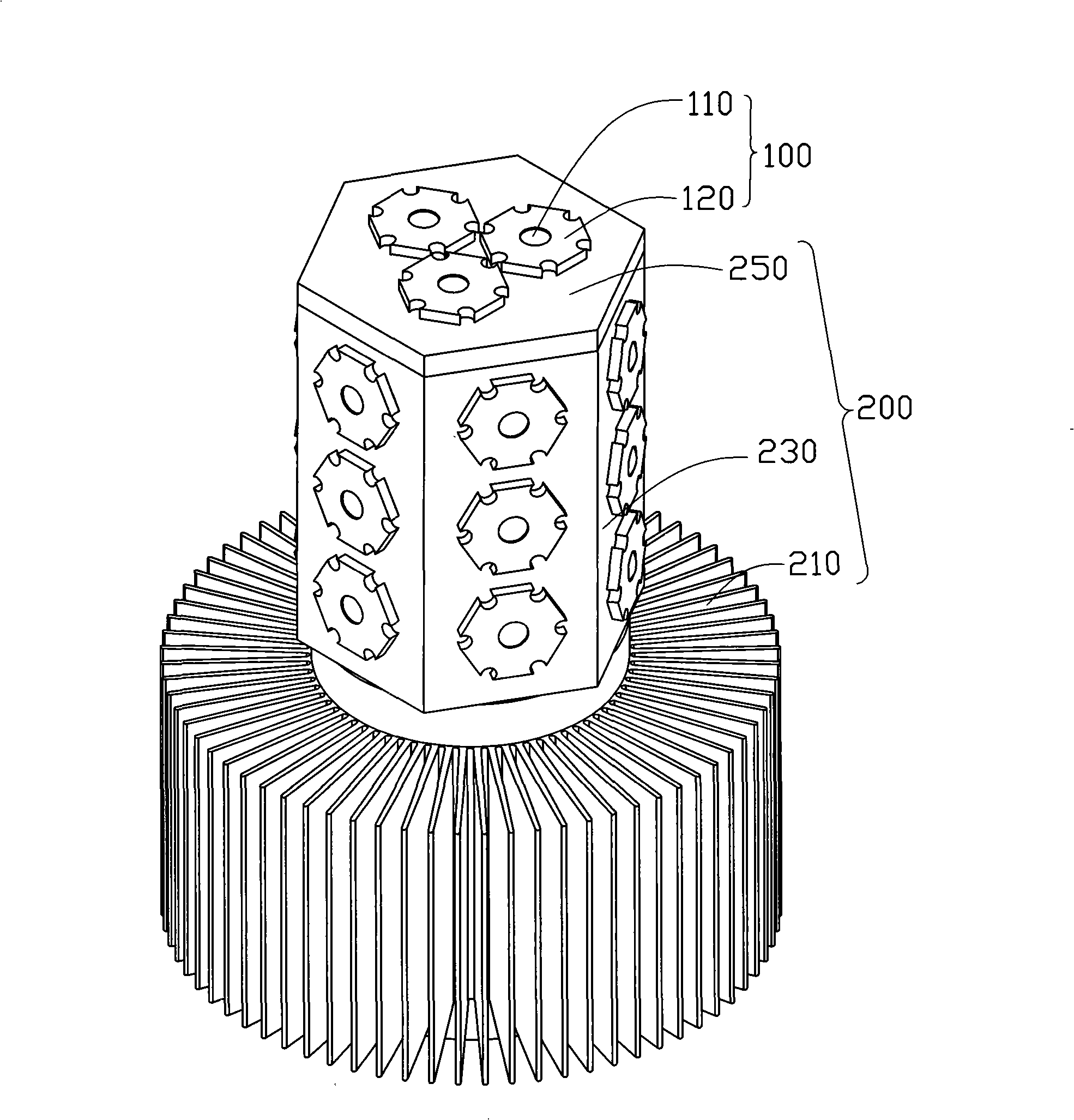

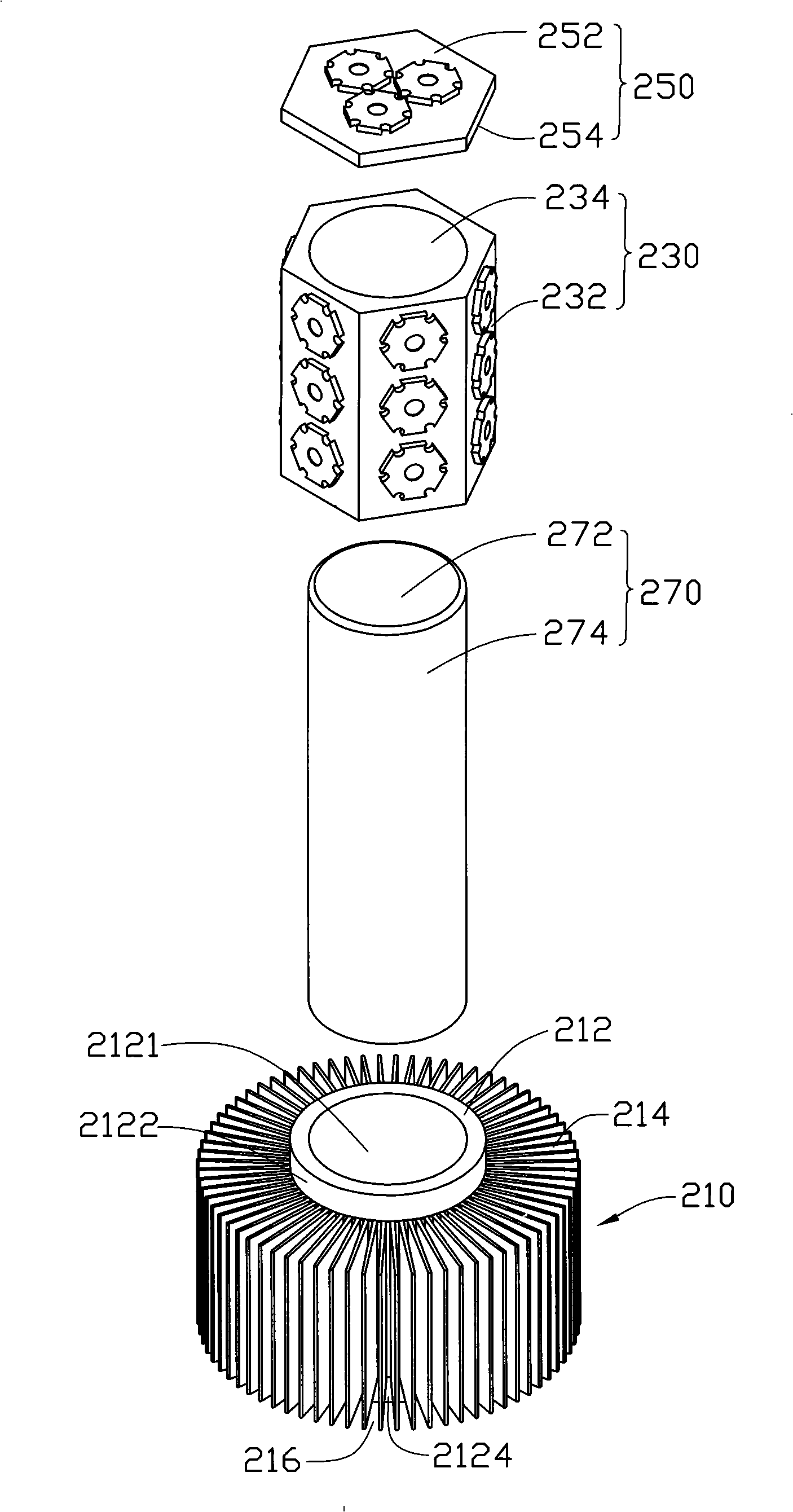

LED lamp

InactiveCN101349412AIncrease contact areaImprove heat exchange effectPoint-like light sourceSemiconductor/solid-state device detailsEngineeringHeat sink

A light emitting diode lamp comprises a lamp cover, a plurality of light emitting diodes located in the lamp cover and a radiating module, wherein the radiating module comprises a heat absorption portion located in the lamp cover, a radiating portion located outside the lamp cover and a heat pipe connecting the heat absorption portion and the radiating portion. The radiating portion comprises a hollow base and a plurality of radiating fins arranged on the base. The heat pipe penetrates through the base of the radiating portion and the heat absorption portion, and is tightly wrapped by the base of the radiating portion and the heat absorption portion. The heat absorption portion is equipped with the light emitting diodes. The heat pipe is wrapped by the radiating portion and the heat absorption portion, thereby increasing the contact area among the heat pipe, the radiating portion and the heat absorption portion, and favoring the heat exchanging among the heat pipe, the radiating portion and the heat absorption portion. The heat pipe can be sufficiently utilized to fast transfer the heat generated by the light emitting diodes to the radiating portion, thereby increasing the radiating efficiency of the radiating module.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

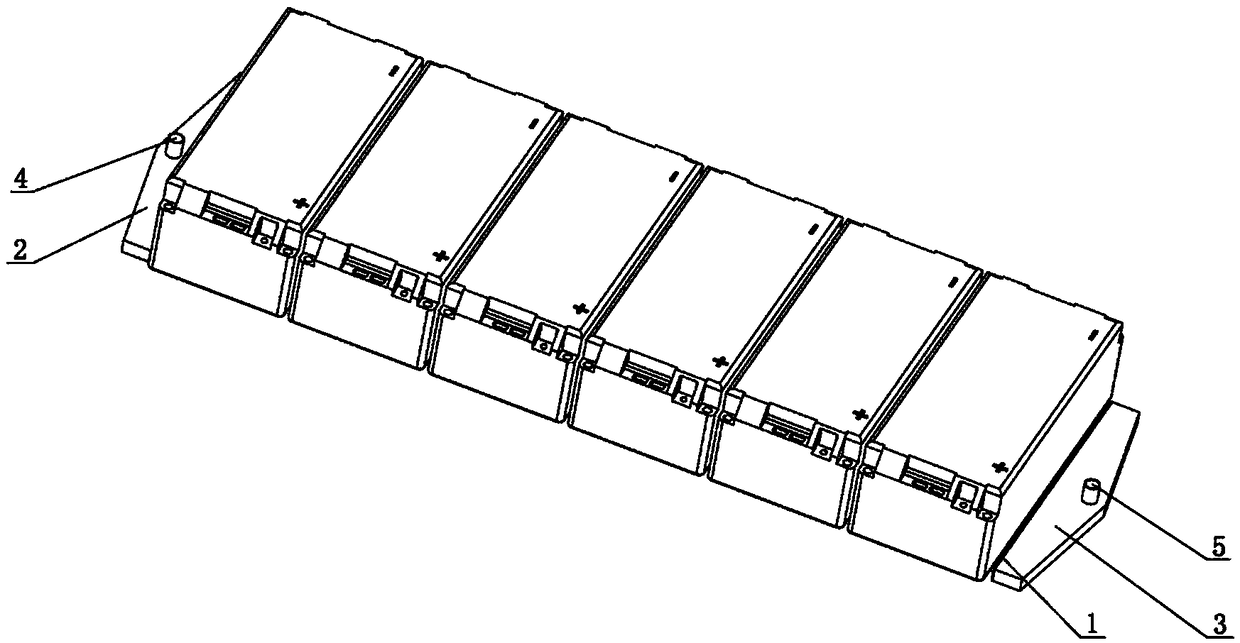

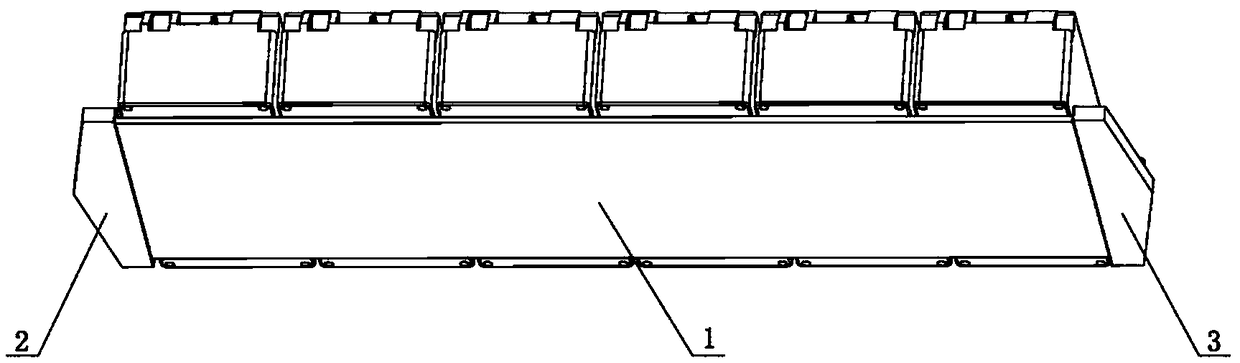

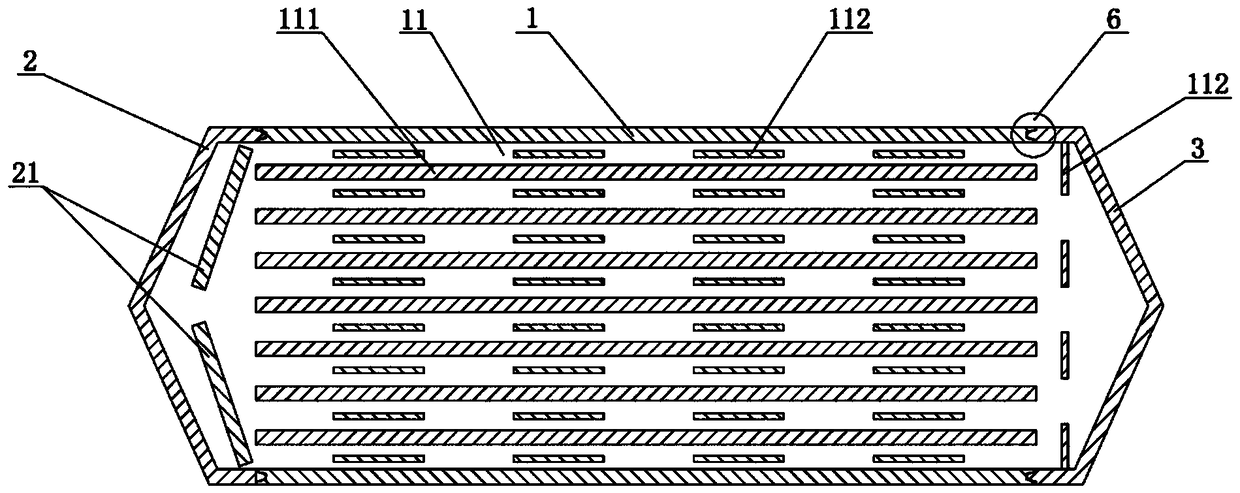

A liquid-cooled plate for power battery of electric vehicle

A liquid-cooled plate for a power battery of an electric vehicle belongs to the technical field of electric vehicles, the liquid-cooled plate for a power battery of an electric vehicle comprises an integrally formed liquid-cooled plate body, both ends of the liquid-cooled plate body are provided with openings and a flow channel structure is arranged inside the liquid-cooled plate body, the two ends of the liquid-cooled plate body are connected with a first hollow end plate and a second hollow end plate communicating with the liquid-cooled plate body in a sealing manner, a water inlet joint isarranged on the first hollow end plate, a water outlet joint is arranged on the second hollow end plate, the invention has the beneficial effect that, the electric vehicle power battery liquid-cooledplate has the advantages of simple and stable overall structure, low manufacturing cost, increases heat exchange contact area and contact time with the power battery module, improved heat exchange efficiency, improved cooling effect of the power battery module, and light overall weight, which meets the lightweight requirements of the whole vehicle.

Owner:奇瑞新能源汽车股份有限公司

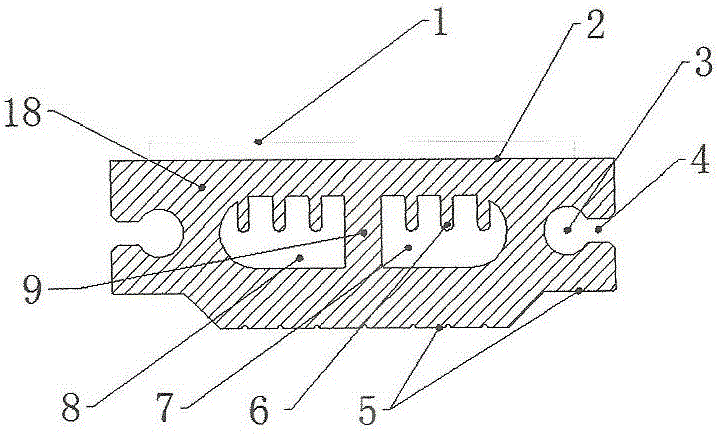

Heat exchanger

InactiveCN101441041AImprove heat exchange effectCombustion enginesStationary conduit assembliesPlate heat exchangerEngineering

The invention discloses a heat exchanger, in which a tube is adapted to exchange heat between a first fluid flowing therein and a second fluid flowing through outside of the tube, and an inner fin is disposed in the tube to divide a flow passage in the tube into a plurality of flow paths. The inner fin includes a plurality of fin portions with different specifications, and the fin portions are arranged in series with respect to a flow direction of the first fluid. Furthermore, the fin portion with the smallest flowing resistance of the first fluid among the plurality of fin portions is arranged on an upstream side of the flow direction of the first fluid with respect to at least an another fin portion. Accordingly, heat exchange performance in the entire heat exchanger can be effectively improved.

Owner:DENSO CORP

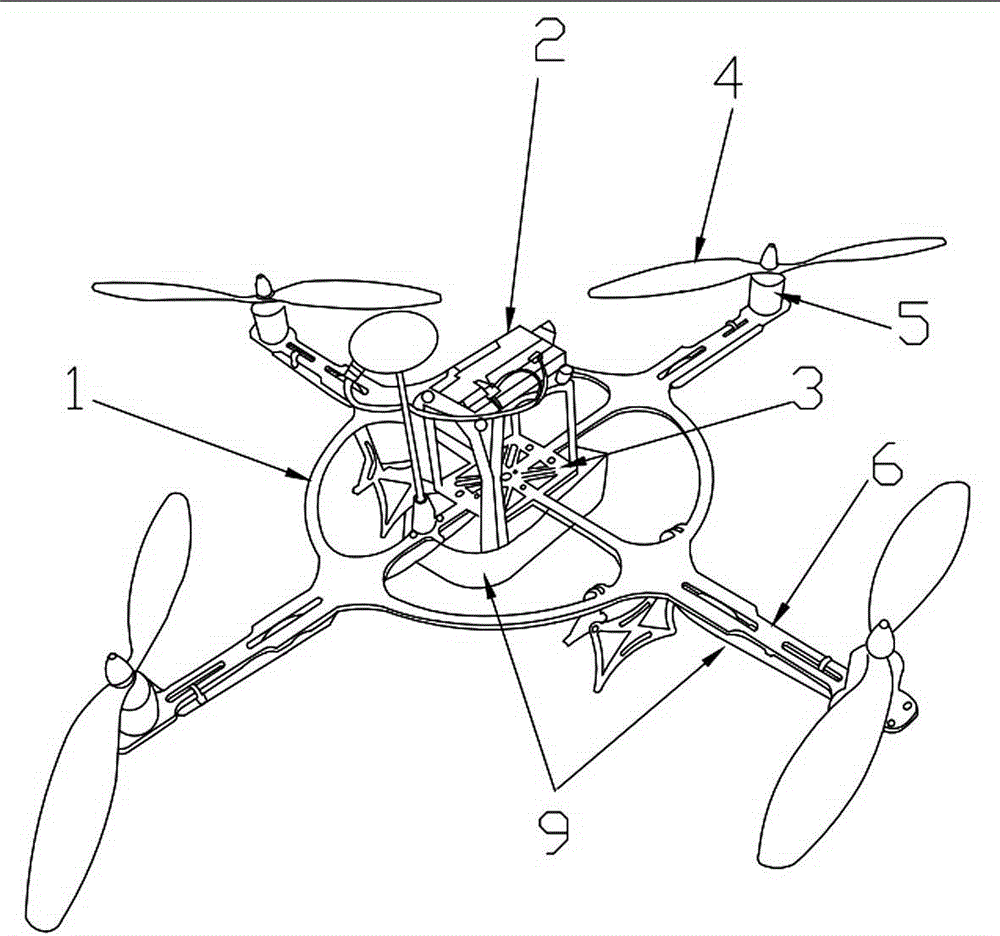

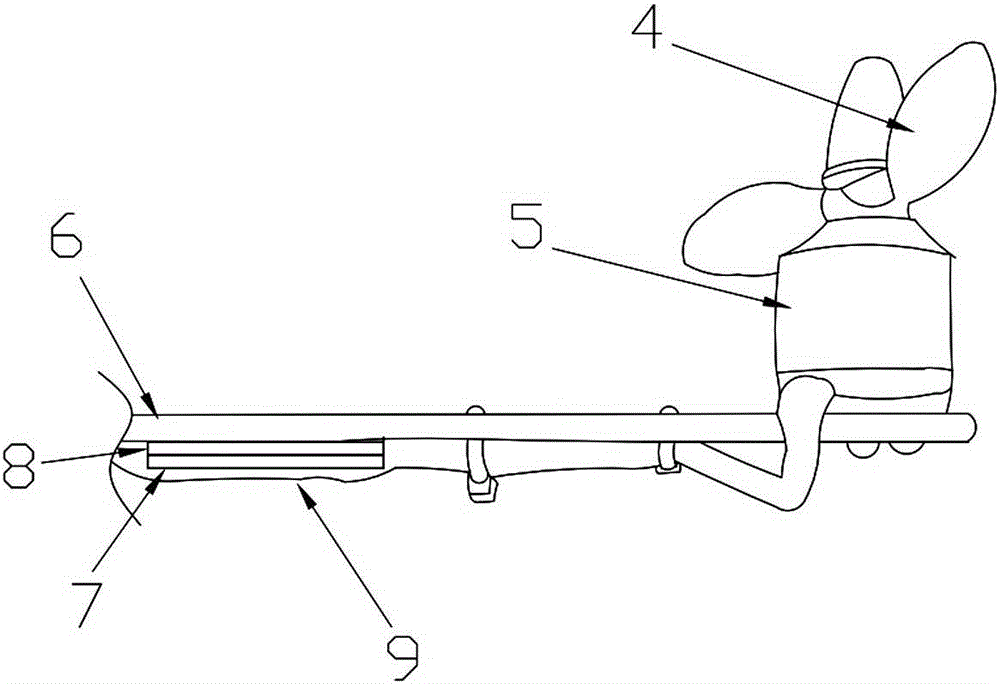

Fireproof unmanned aerial vehicle system for fire site surveying

InactiveCN105292451AIt has the function of fire resistance and high temperature resistanceEnsure continuous and stable workAircraft componentsRotocraftControl signalUncrewed vehicle

The invention relates to the field of flight equipment and discloses a fireproof unmanned aerial vehicle system for fire site surveying. The fireproof unmanned aerial vehicle system comprises an unmanned aerial vehicle and a fine controller controlling the unmanned aerial vehicle in a wireless communication mode. Electronic speed regulators are installed on corresponding arms respectively, and semiconductor chilling plates are arranged between the electronic speed regulators and the arms. The fireproof unmanned aerial vehicle system further comprises two or more signal bridging devices arranged independently and used for carrying out mutual bridging and realizing wireless bridging between the unmanned aerial vehicle and the fine controller. According to the fireproof unmanned aerial vehicle system, the whole is made of fireproof material resistant to high temperature, and therefore the unmanned aerial vehicle can be operated normally and carry out surveying after entering a high-temperature fire site; the semiconductor chilling plates are arranged for dissipating heat of the electronic speed regulators, and therefore the temperature of the electronic speed regulators does not exceed the highest limit temperature even in the fire site; the multiple signal bridging devices are arranged and are used for bridging controlling signals and data signals, and therefore the unmanned aerial vehicle and the fine controller can realize continuous communication.

Owner:DONGGUAN JIFEI ROBOT CO LTD

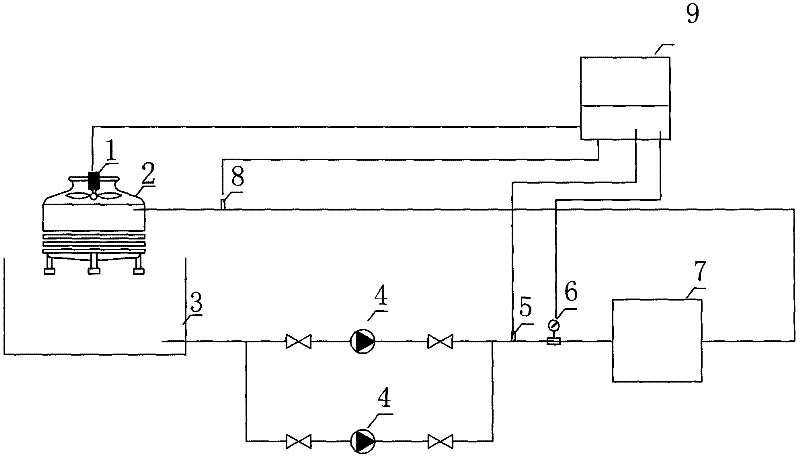

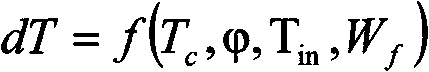

Integrated optimization control method for circulating water system

ActiveCN102339018ARun energy savingGood heat exchange effectAdaptive controlInlet temperatureAir volume

The invention relates to the technical field of information and control, and relates to an automation technology, in particular to an integrated optimization control method for a circulating water system. The method comprises the following steps of: detecting an ambient temperature, ambient humidity, a circulating water cooling tower inlet temperature, an outlet temperature, cooling water pump energy consumption and cooling tower fan energy consumption by using a control system; controlling the flow quantity of a cooling water pump and the air quantity of a cooling tower fan in a variable frequency speed control mode; calculating the optimal regulating quantity of the air quantity of the cooling tower fan and the flow quantity of the cooling water pump in order to reach the lowest energy consumption under the condition of the conventional heat exchange quantity required by actual production according to acquired parameters; and controlling terminal equipment by using a frequency conversion actuating mechanism. The method has the advantages of reducing energy consumption, saving energy and water, and the like, and can be widely applied to occasions where cooling towers are used.

Owner:HANGZHOU JINLI ENERGY SAVING TECH

Air preheater and production process suitable for same

InactiveCN101625128ASolve the defect of easy adhesion of carbon black powderIncrease in sizePigmenting treatmentCombustion processAir preheaterEngineering

The invention discloses an air preheater comprising an air heater main body. The air heater main body is internally provided with a heat exchanger tube and is provided with a water inlet on the side wall, wherein the water inlet corresponds to the lower part of the heat exchanger tube and is connected with a pulse flushing device. A carbon black production process of the air preheater comprises an air preheater cleaning step comprising the following steps: enabling the pulse flushing device to flash water to the water inlet of the air preheater; enabling carbon black smoke to enter the lower part of the air preheater for pulse flushing; and momentarily atomizing the water entering the air preheater and rapidly increasing the size so that the carbon black smoke in the heat exchanger tube abruptly changes, has a pulse jitter effect and shakes carbon black powder remained on the inner wall of the heat exchanger tube to enter the next link along with the carbon black smoke. Accordingly, the carbon black powder in the carbon black smoke can not generate an attaching layer on the inner wall of the heat exchanger tube to keep the favorable heat-exchanging effect of the heat exchanger tube.

Owner:NINGBO DETAI CHEM

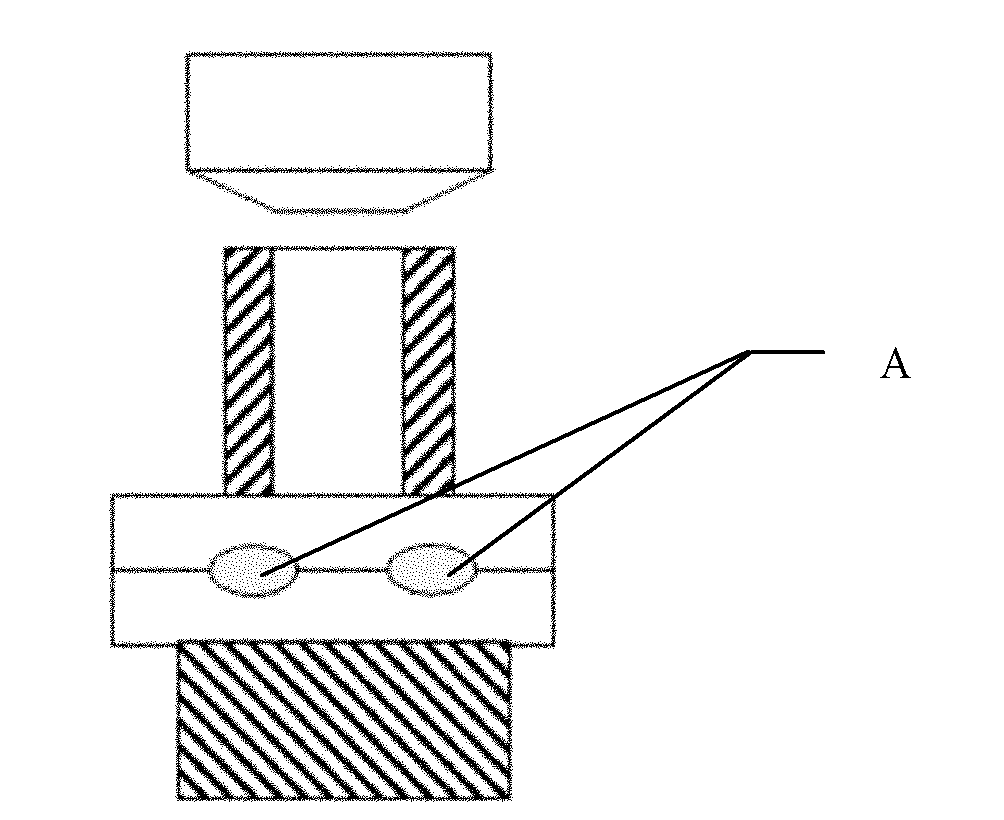

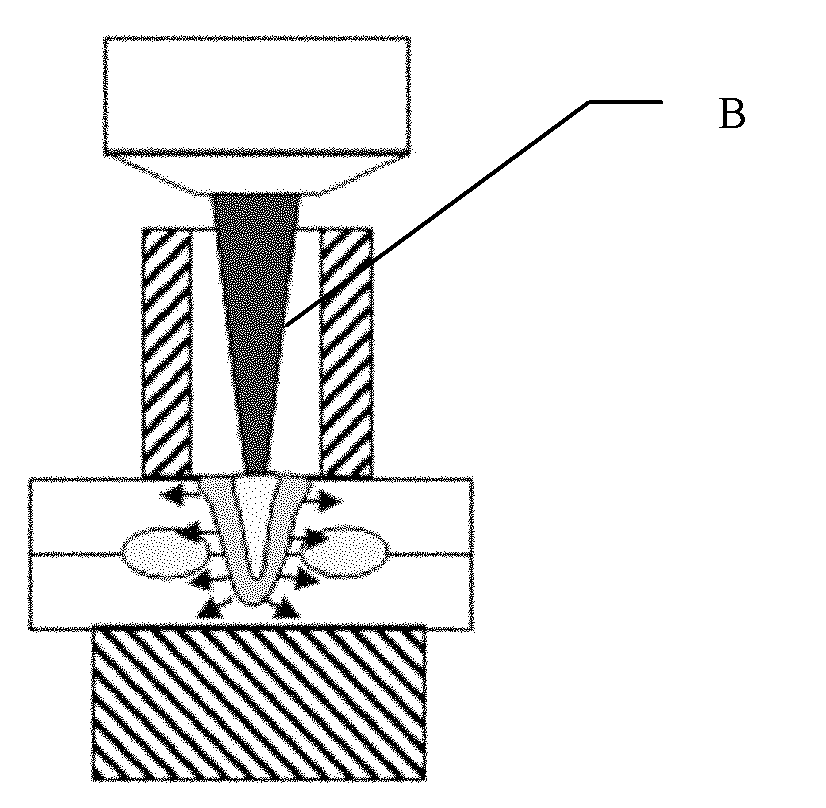

Coaxial composite welding method of laser spot welding and resistance spot welding

InactiveCN101934432AImprove mechanical propertiesIncreased tear resistanceLaser beam welding apparatusSpot weldingLaser beams

The invention discloses a coaxial composite welding method of laser spot welding and resistance spot welding, belonging to the technical field of welding. The method solves the problem of poor welding spot performance when the laser spot welding technology is,applied to an aluminum alloy material. The welding method of the invention is based on the existing resistance spot welding method of the base material to be welded. A top electrode in the laser spot welding method uses a hollow electrode. When performing the resistance spot welding on the base material to be welded, a laser beam passes through the center of the hollow electrode to perform the laser spot welding on the base material to be welded, so as to realize the coaxial composite of the laser spot welding and the resistance spot welding. The method of the invention is used as a welding technology.

Owner:HARBIN INST OF TECH

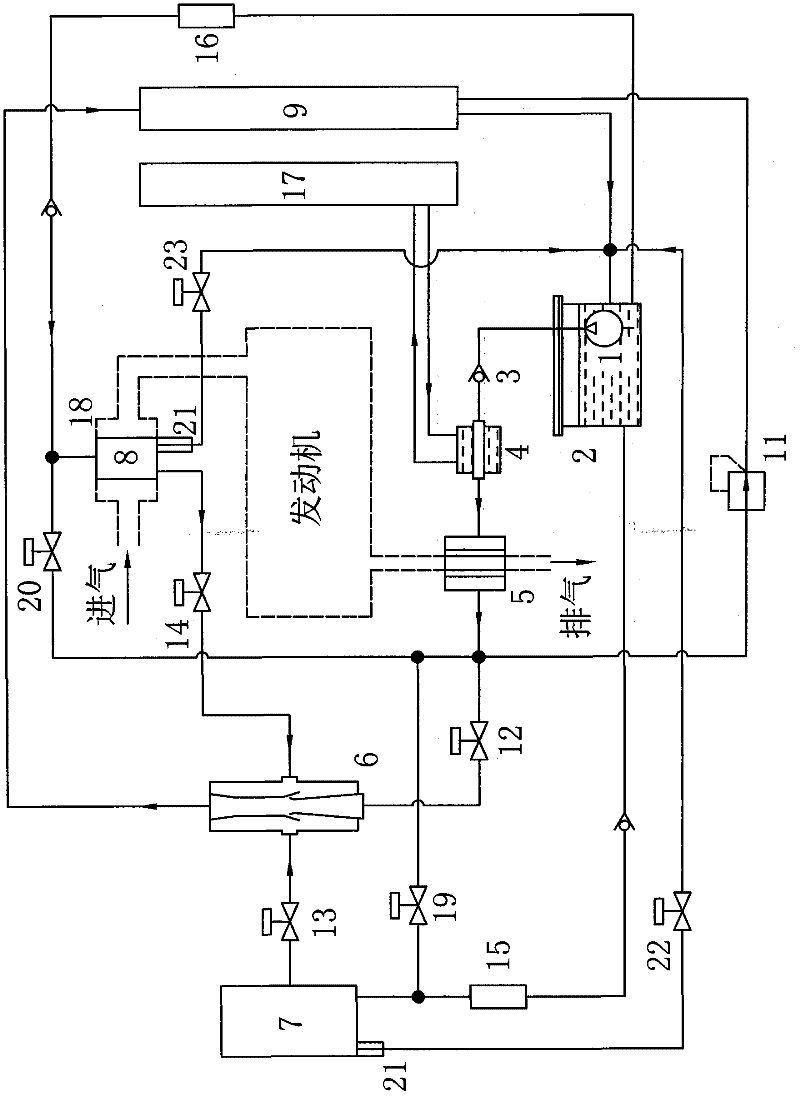

Air temperature adjusting system for heat exchange type vehicles and vessels

InactiveCN102538287AImprove working conditionImprove cooling effectInternal combustion piston enginesExhaust apparatusLiquid storage tankEngineering

The invention relates to an air temperature adjusting system for heat exchange type vehicles and vessels, which comprises an evaporator using alcohol refrigerant, condenser, an ejecting and sucking device, a pump, a heater and a liquid storage tank. The ejecting and sucking device is capable of sucking refrigerant in the evaporator and outputting the refrigerant to the condenser, and the heater is capable of absorbing heat of engine tail gas by means of heat exchanging to vaporize the refrigerant. The heater is connected between the ejecting and sucking device and the pump through a pipe, and the evaporator comprises both of or one of an air-conditioning evaporator and a cooling evaporator. The evaporator is disposed on an engine air inlet pipe or arranged in an engine air inlet filter and used for cooling air flowing into an engine, dropping of air inlet temperature can improve air sucking efficiency of the engine, the engine can be in or close to the optimum operating state, engine power is improved, fuel consumption is reduced, and waste gas emission is reduced.

Owner:张伟

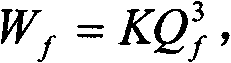

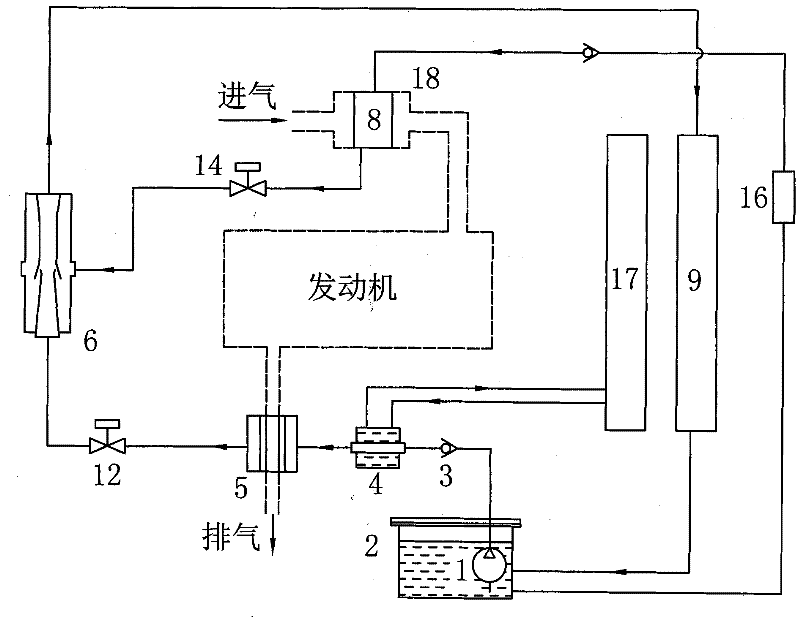

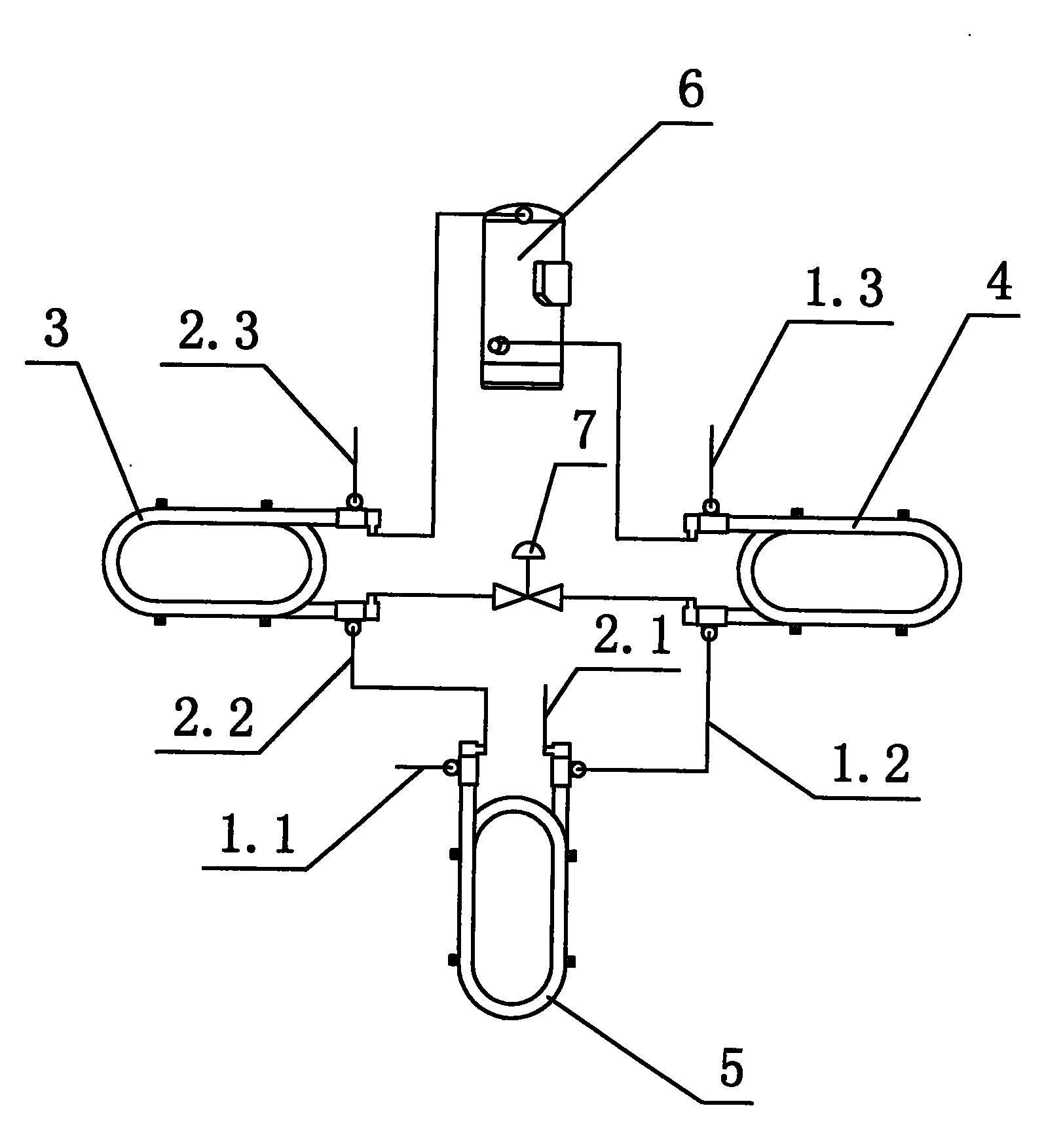

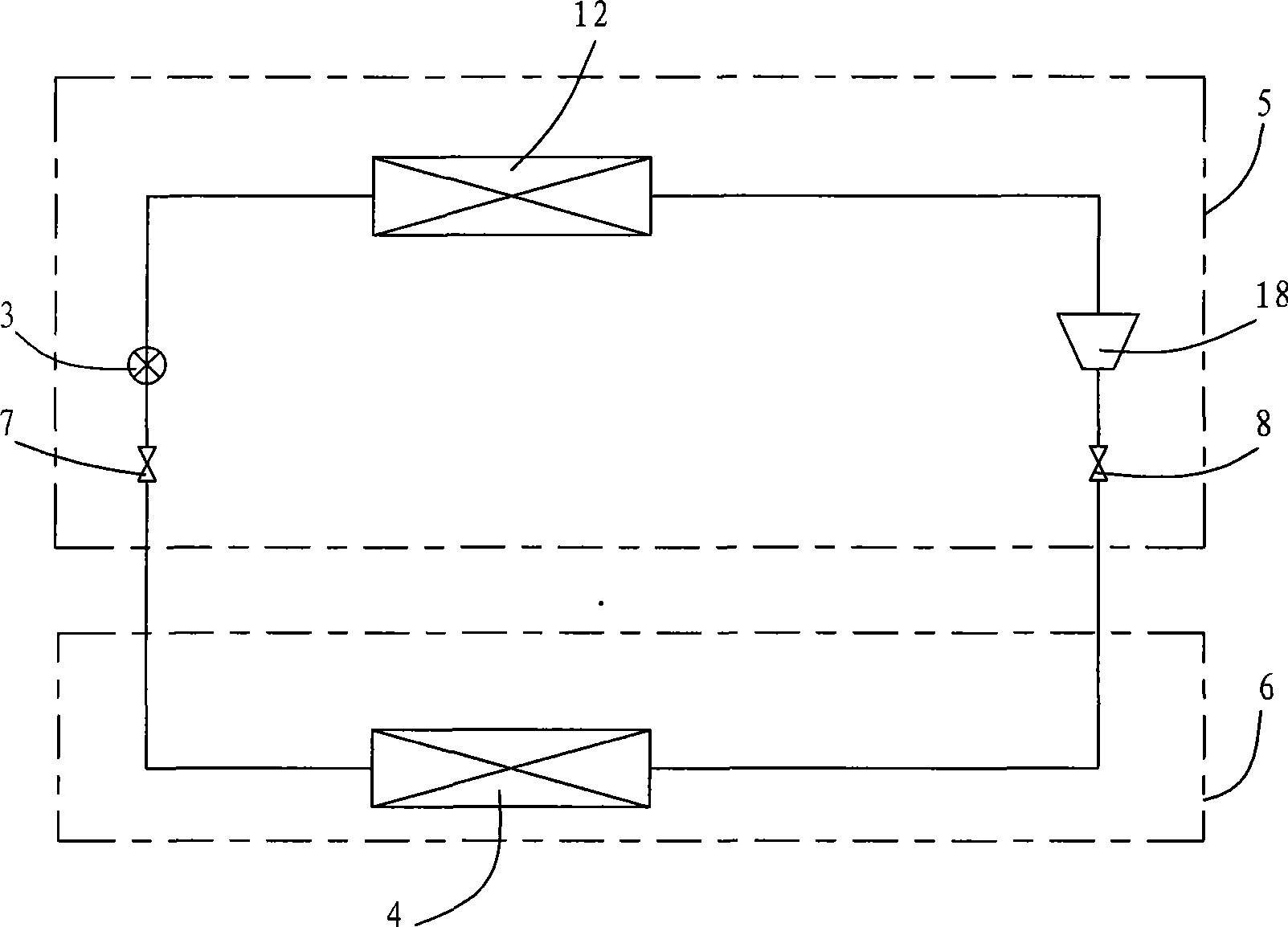

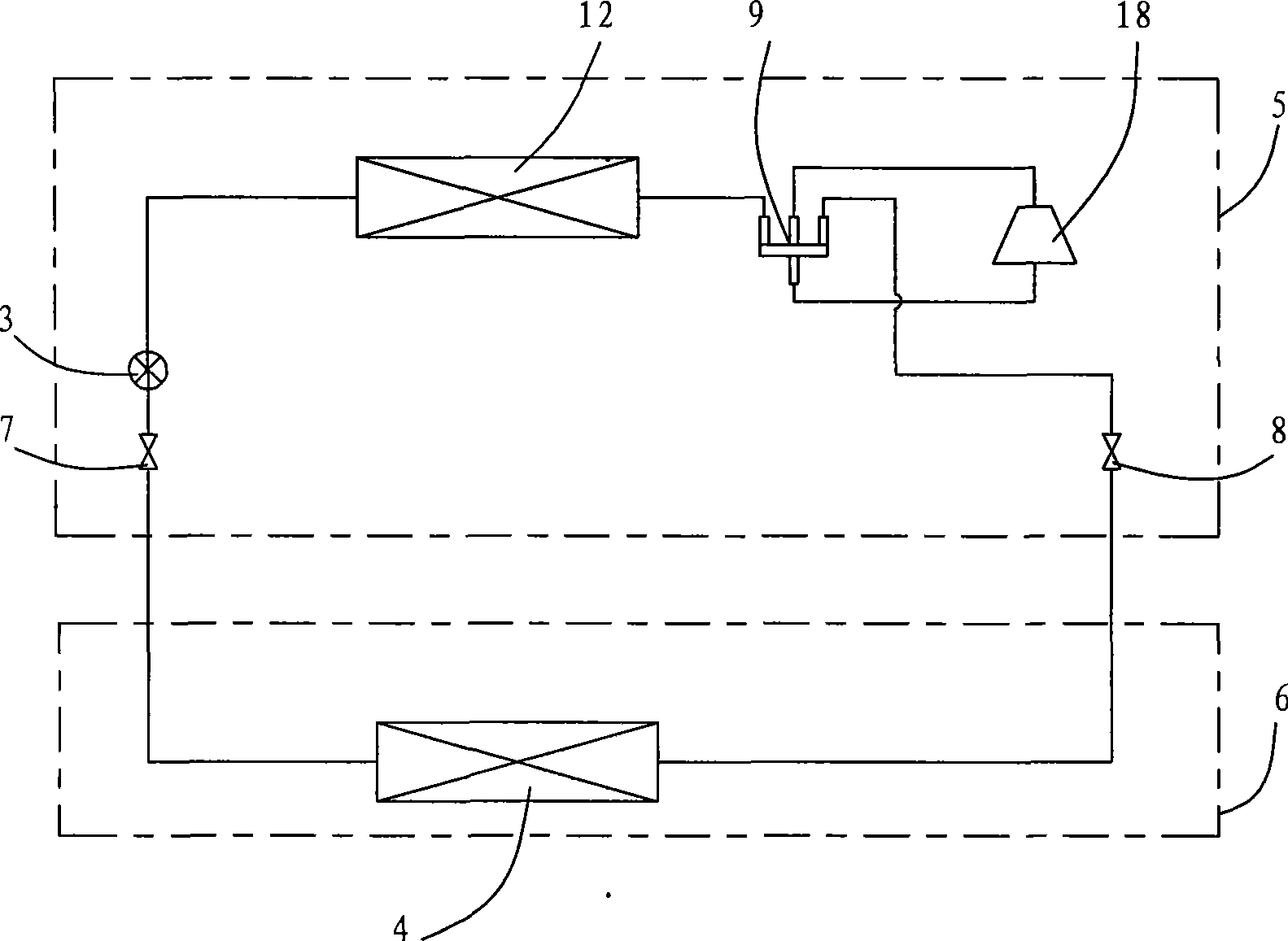

Wastewater source heat pump water heater of residential buildings

ActiveCN101818938BImprove utilizationReduce the temperatureFluid heatersEnergy efficient heating/coolingBusiness efficiencyPlate heat exchanger

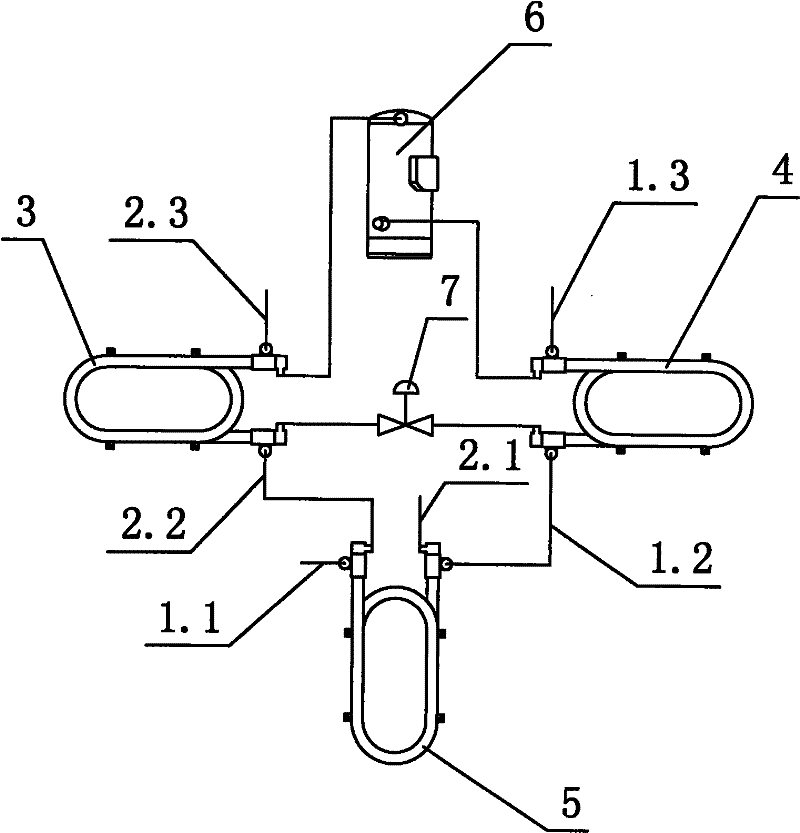

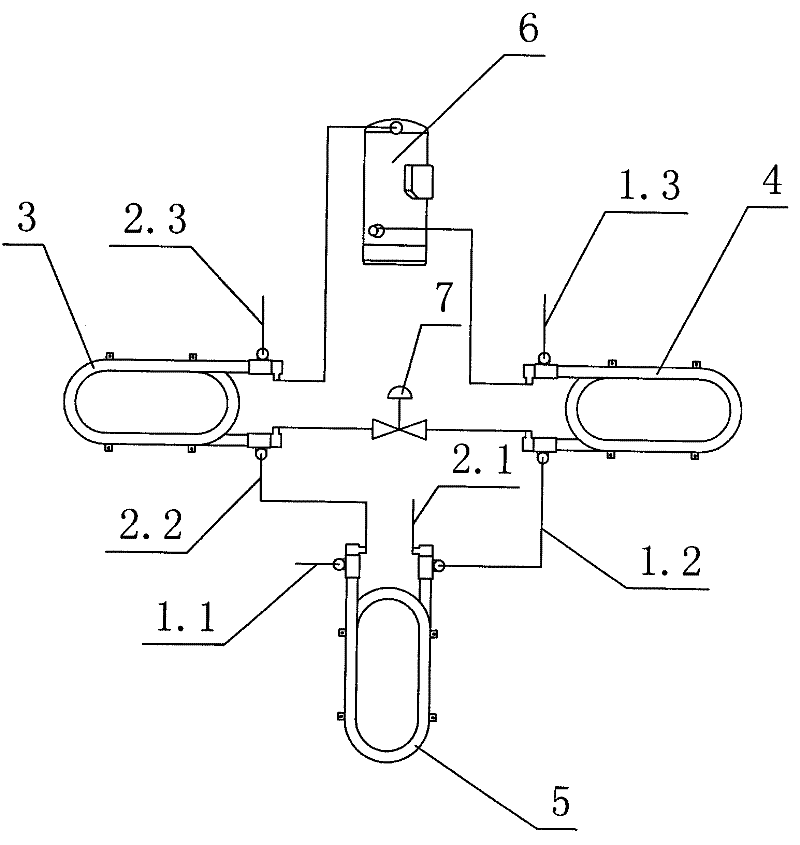

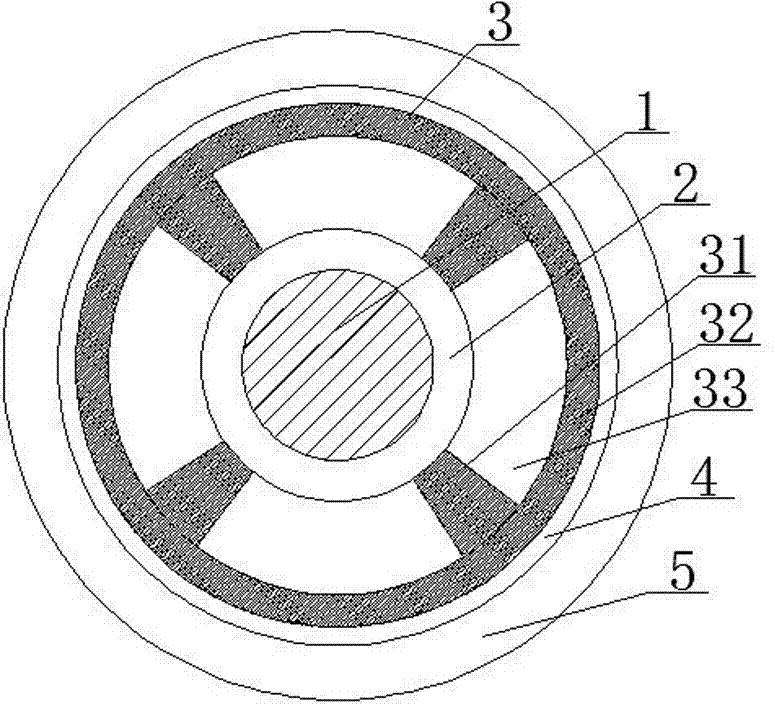

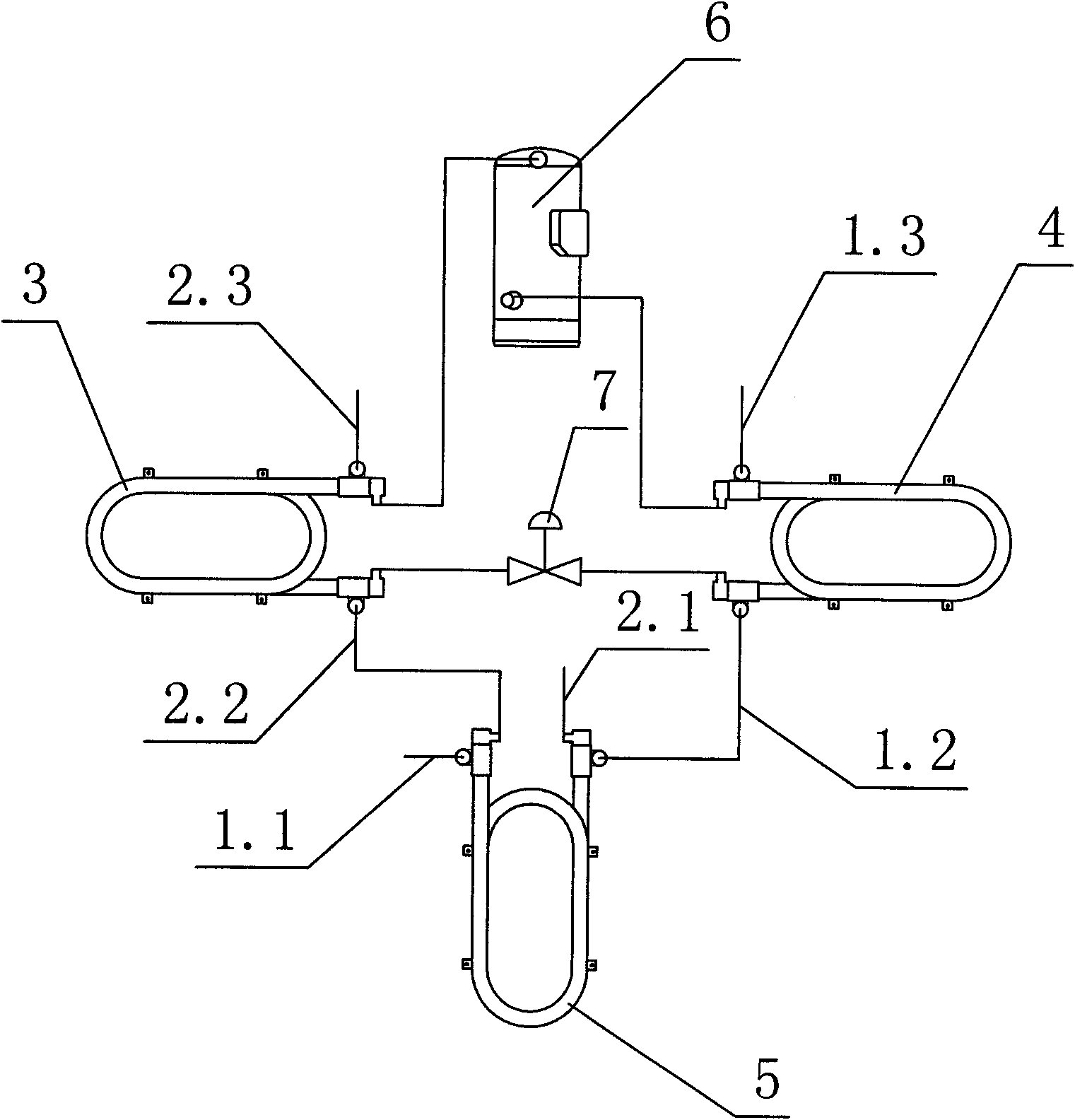

The invention discloses a wastewater source heat pump water heater of residential buildings. The water heater comprises a refrigerant circulation loop, a wastewater collecting pipe (1.1), a wastewater discharge pipe (1.3), a running water pipe (2.1), a heating pipe (2.3), a wastewater heat recovery exchanger (5), a hot water transition pipe (2.2) and a wastewater transition pipe (1.2), wherein the wastewater collecting pipe (1.1) is communicated with the wastewater heat recovery exchanger (5), the wastewater heat recovery exchanger (5) is communicated with the wastewater transition pipe (1.2), the wastewater transition pipe (1.2) is communicated with a wastewater heat exchanger (4); and the running water pipe (2.1) is communicated with the wastewater heat recovery exchanger (5), the wastewater heat recovery exchanger (5) is communicated with the hot water transition pipe (2.2), and the hot water transition pipe (2.2) is communicated with a hot water heat exchanger (3). The energy efficiency ratio of the heat pump water heater is high and the condition that the compressor is damaged due to overload operation can be avoided.

Owner:NINGBO AUX ELECTRIC

Flexible cable used for new energy automobile

ActiveCN107039117AImprove eliminationMeet special use requirementsRubber insulatorsInsulated cablesInsulation layerElectrical conductor

The invention discloses a flexible cable used for a new energy automobile. The cable comprises a conductor and an insulation layer used for wrapping the conductor. The outer part of the insulation layer is provided with a cooling layer in a wrapped manner, and at least one cooling medium channel extended along the length direction of the insulation layer is disposed in the cooling layer, and is used to introduce the cooling medium for the cooling and the heat dissipation of the insulation layer. Heat energy radiated by the insulation layer outwardly is effectively, reliably, quickly, and greatly eliminated by the cooling medium, and then the heat energy radiated on the outer part of the cooling layer is reasonable, controllable, and safe, and then the special use requirement of the new energy automobile is satisfied. The flexible cable is in service and operated reliably, safely, and stably in various severe environments, and has advantages of simple structure, convenient forming, small forming difficulty, low forming costs, compact structure, good flexibility, excellent heat dissipation effect, high flame resistant performance, high reliability, good safety performance, and strong practicability.

Owner:TBEA DEYANG CABLE CO LTD

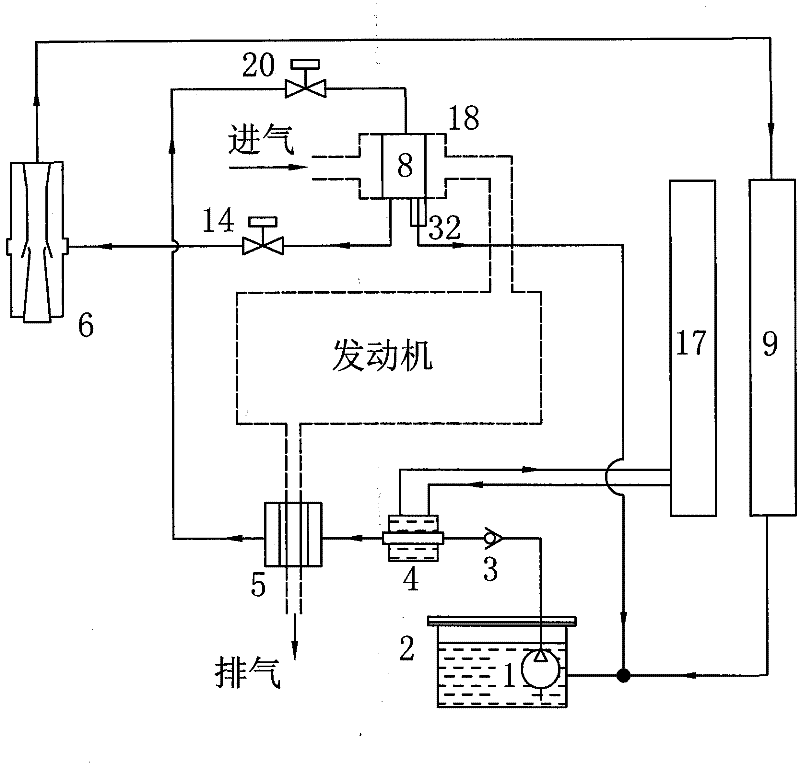

Wastewater source heat pump water heater of residential buildings

ActiveCN101818938AImprove utilizationReduce the temperatureFluid heatersEnergy efficient heating/coolingPlate heat exchangerBusiness efficiency

The invention discloses a wastewater source heat pump water heater of residential buildings. The water heater comprises a refrigerant circulation loop, a wastewater collecting pipe (1.1), a wastewater discharge pipe (1.3), a running water pipe (2.1), a heating pipe (2.3), a wastewater heat recovery exchanger (5), a hot water transition pipe (2.2) and a wastewater transition pipe (1.2), wherein the wastewater collecting pipe (1.1) is communicated with the wastewater heat recovery exchanger (5), the wastewater heat recovery exchanger (5) is communicated with the wastewater transition pipe (1.2), the wastewater transition pipe (1.2) is communicated with a wastewater heat exchanger (4); and the running water pipe (2.1) is communicated with the wastewater heat recovery exchanger (5), the wastewater heat recovery exchanger (5) is communicated with the hot water transition pipe (2.2), and the hot water transition pipe (2.2) is communicated with a hot water heat exchanger (3). The energy efficiency ratio of the heat pump water heater is high and the condition that the compressor is damaged due to overload operation can be avoided.

Owner:NINGBO AUX ELECTRIC

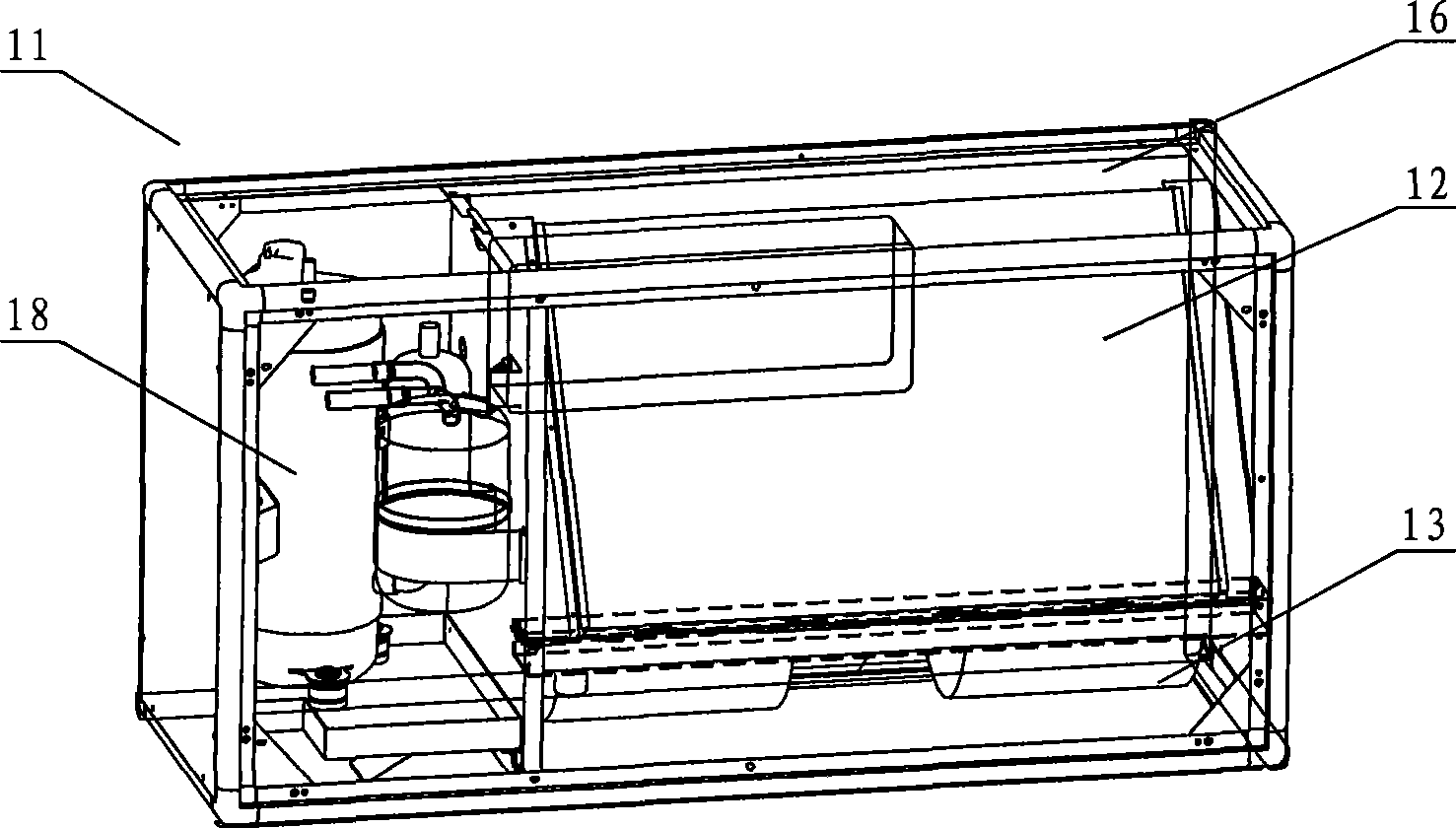

Indoor unit for base station separate air-conditioning device

InactiveCN101520212AReduce noise nuisanceImprove securityCompressorSpace heating and ventilation safety systemsEngineeringAir conditioning

The invention provides an indoor unit for a base station separate air-conditioning device. The indoor unit comprises a shell; the inside of the shell is provided with a fan blowing air toward the indoor and an indoor heat exchanger; the upper part of the shell is provided with an air inlet, and the air inlet is covered with a filter net; the indoor unit also comprises more than one compressor and a throttle mechanism; the compressor is arranged on one side of the indoor unit, and the indoor heat exchanger and the fan are arranged on the other side of the indoor unit, or the compressor is arranged on the lower part of the indoor unit, and the indoor heat exchanger and the fan are arranged on the upper part of the indoor unit; one end of the throttle mechanism is connected with an outdoor heat exchanger, while the other end is connected with the indoor heat exchanger; the indoor heat exchanger is whole type or separate type, and is inverse L-shaped; and the included angle between the long side edge and the short side edge of the indoor heat exchanger is alpha which is between 30 and 120 degrees. The indoor unit has the characteristics of low production cost, high safety degree, small volume, small overall size, flexible assembly and convenient operation.

Owner:GUANGDONG MIDEA ELECTRIC APPLIANCES CO LTD

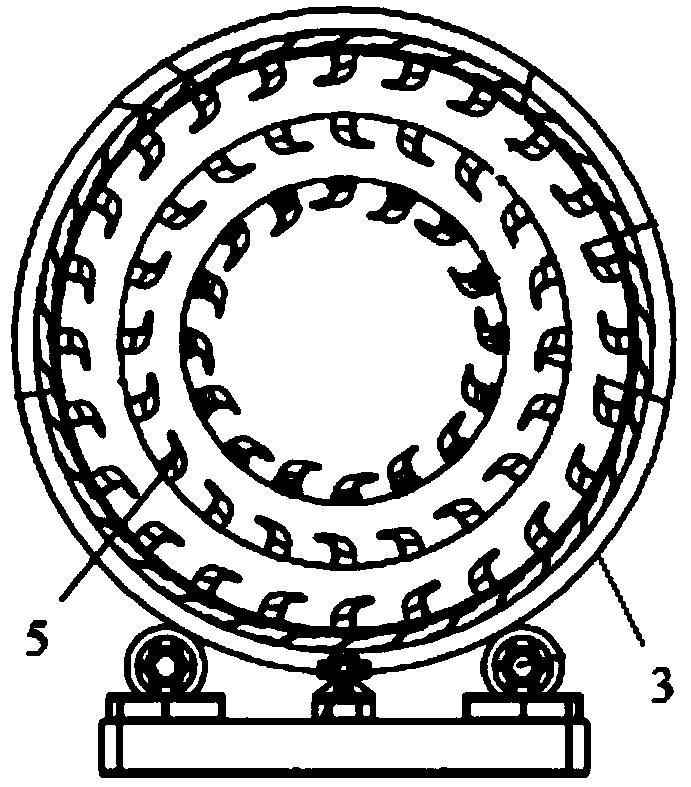

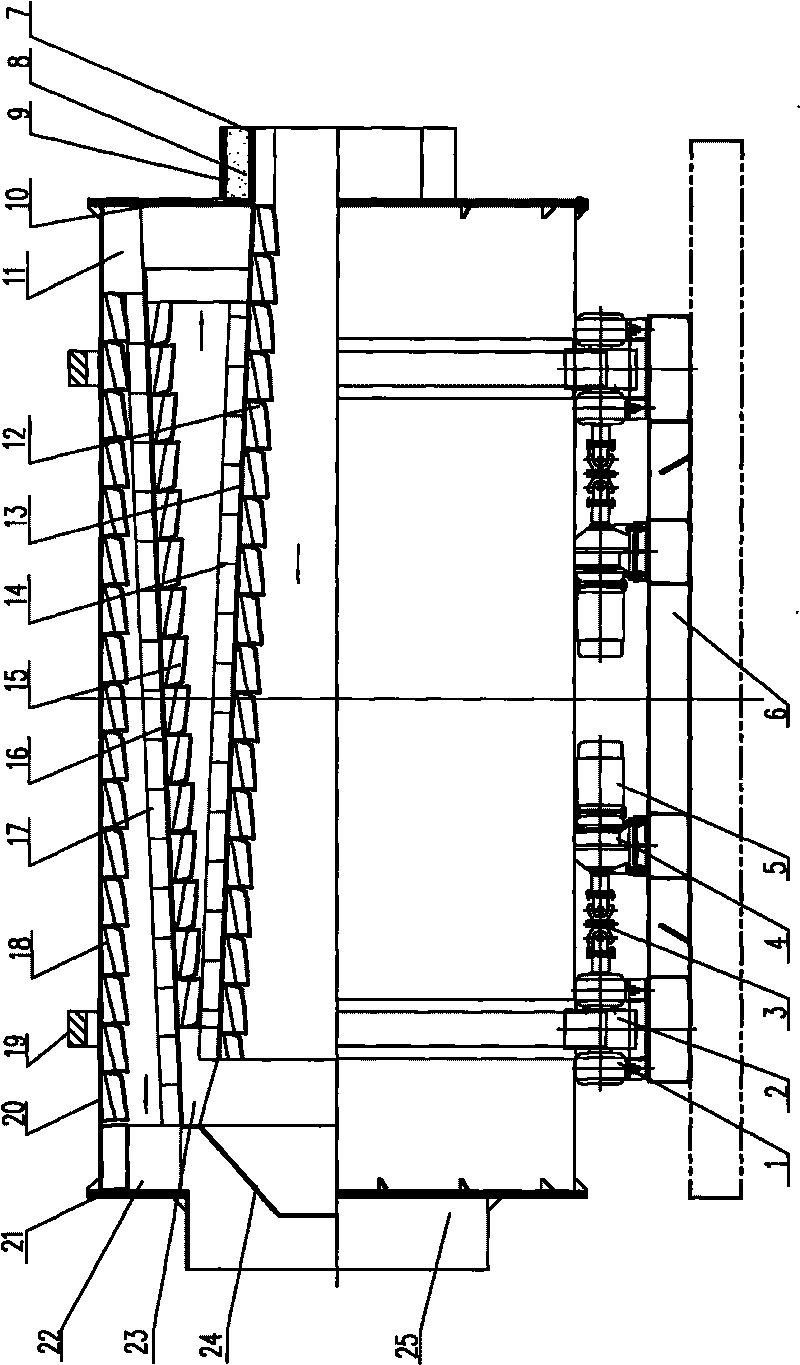

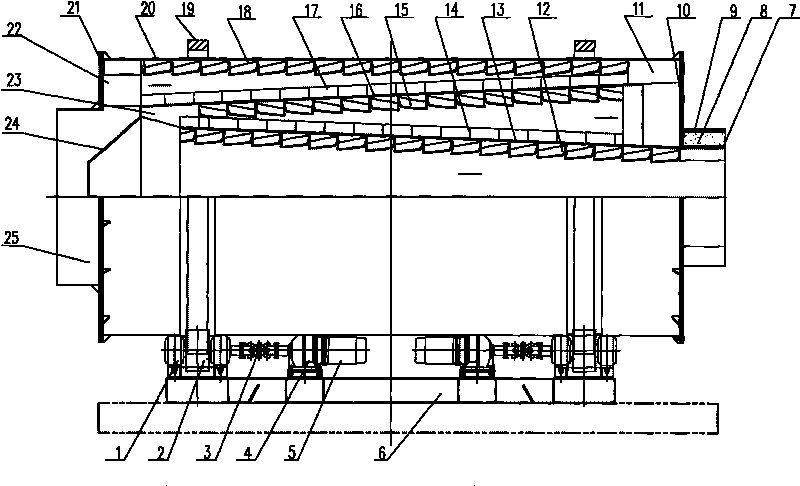

Strong convection structure on heat treatment furnace

InactiveCN101993990AIncrease the heat exchange areaDistribution high speedFurnace typesHeat treatment furnacesEngineeringCentrifugal fan

The invention discloses a strong convection structure on a heat treatment furnace. The convection structure comprises a furnace pipe, an air guide cylinder and a centrifugal fan, wherein the internal peripheral surface of the furnace pipe is outwards extruded on the inner surface of the same to form a plurality of ring-shaped grooves, the internal peripheral surface of the air guide cylinder in the furnace pipe is outwards extruded on the external surface of the furnace pipe to form a plurality of ring-shaped bulges, the vanes of the centrifugal fan arranged in the furnace pipe extend into the furnace pipe hermetically through the port of the furnace pipe, and gas inside the furnace can form high-speed strong convection under the effect of the centrifugal fan. The convection structure on the heat treatment furnace can ensure that gas inside furnace is more uniform in distribution, the cooling speed is faster, and the finished product rate of forgings is improved.

Owner:SUZHOU ZHONGMENZI TECH

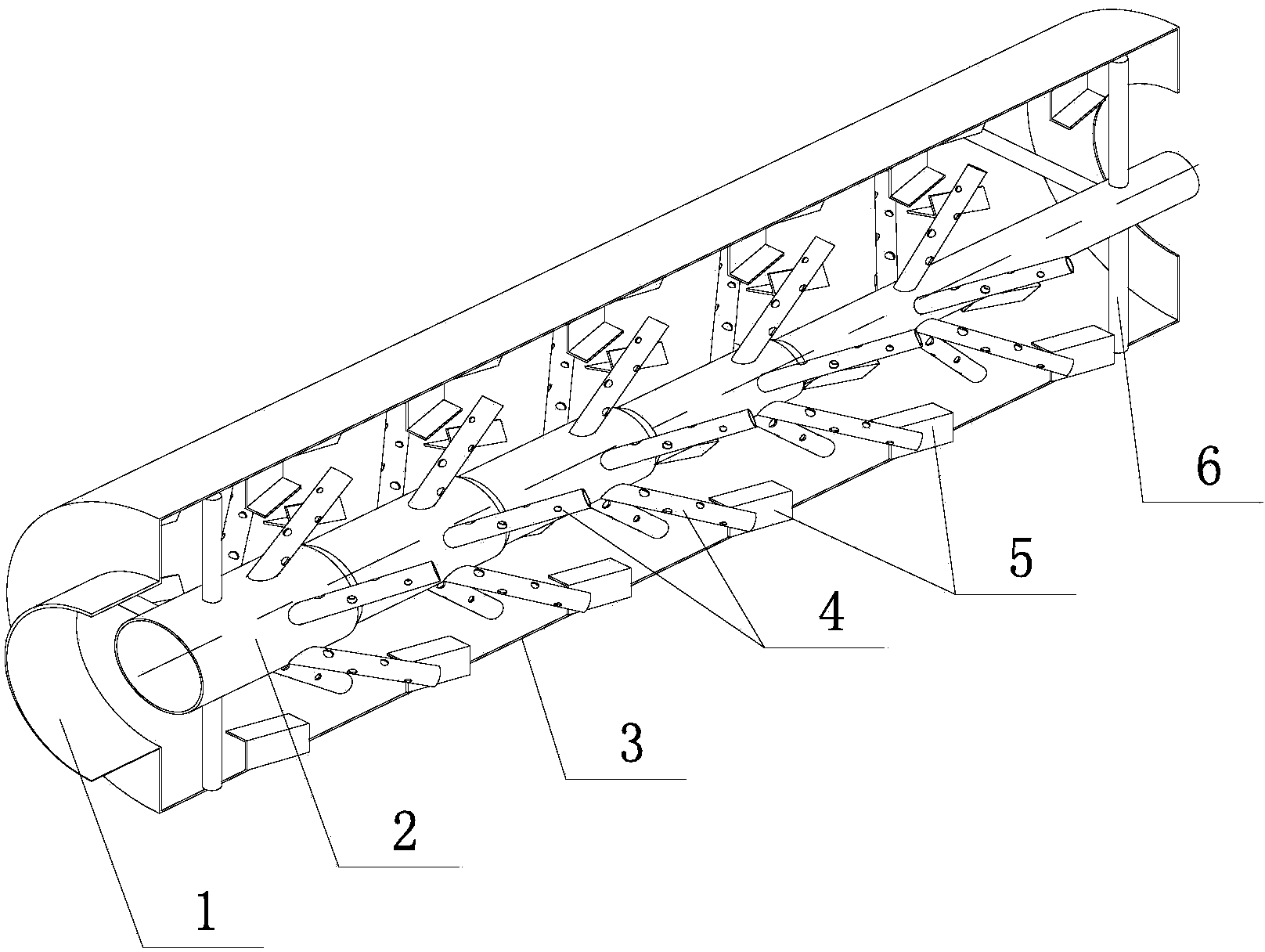

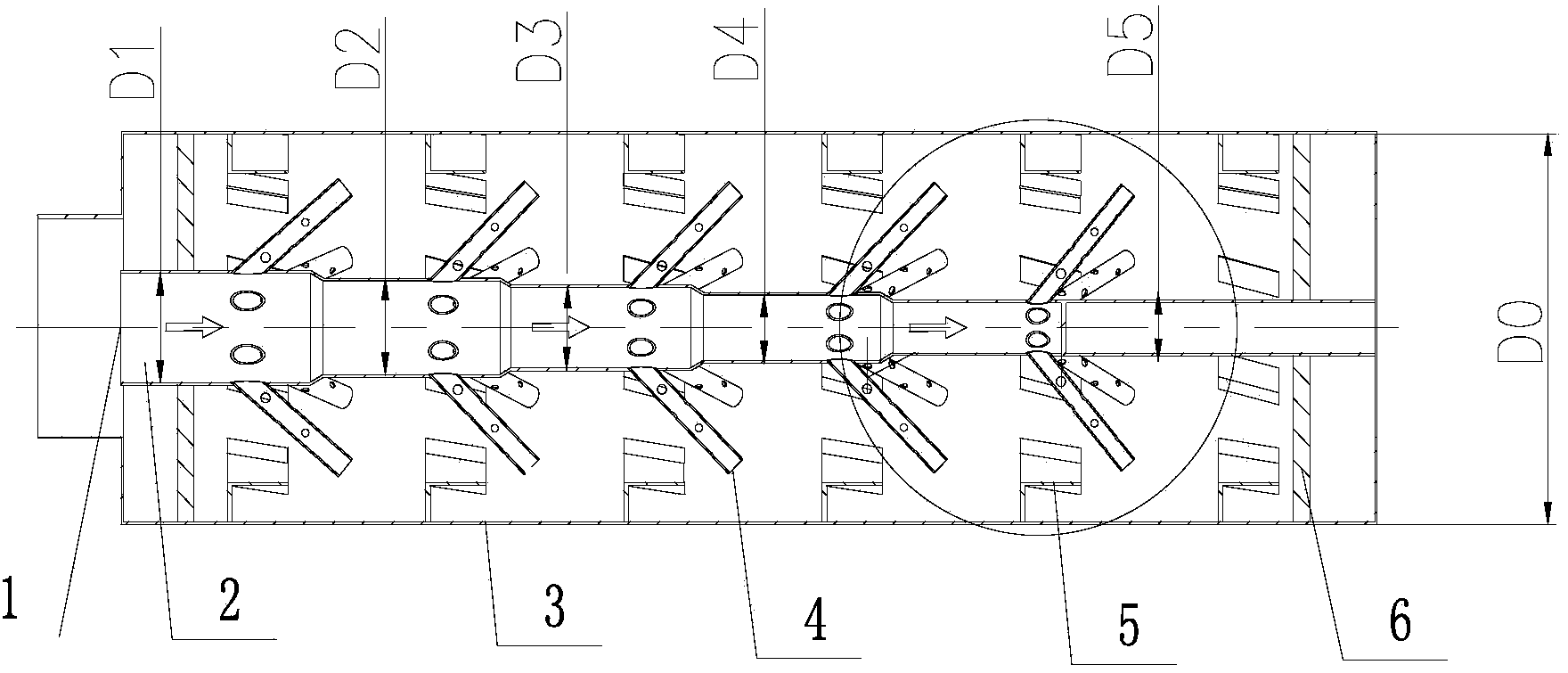

Drying drum

ActiveCN103673580AImprove heat exchange effectIncreased turbulence intensityDrying gas arrangementsDrying chambers/containersEngineeringEnergy consumption

The invention discloses a drying drum which comprises a drum body (3), a main drainage pipe (2) and branch drainage pipes (4), wherein hot airflow is input into the main drainage pipe (2) and the branch drainage pipes (4). The main drainage pipe axially extends into an inner cavity of the drum body from an inlet end (1) of the drum body, the branch drainage pipes are communicated with the main drainage pipe and used for draining hot airflow in the main drainage pipe to the inner cavity, and therefore turbulent flow is formed. When the hot airflow is input into the inlet end, a major part of the hot airflow enters the main drainage pipe, a small part of the hot airflow enters the space formed between the main drainage pipe and the inner wall of the drum body, and the hot airflow in the main drainage pipe flows everywhere in the inner cavity of the drum body through the branch drainage pipes which extend in the radial direction. The airflow which flows into the branch drainage pipes from the main drainage pipe and then is sprayed out has the higher speed, speed difference exists between the airflow and the hot airflow directly flowing into the inner cavity, a flow field in the inner cavity of the drum body generates strong disturbance due to the speed difference and the rotation of the drum, and turbulence intensity is enhanced, so that the good heat convection effect is good, and the energy consumption use ratio is improved.

Owner:ZOOMLION HEAVY IND CO LTD

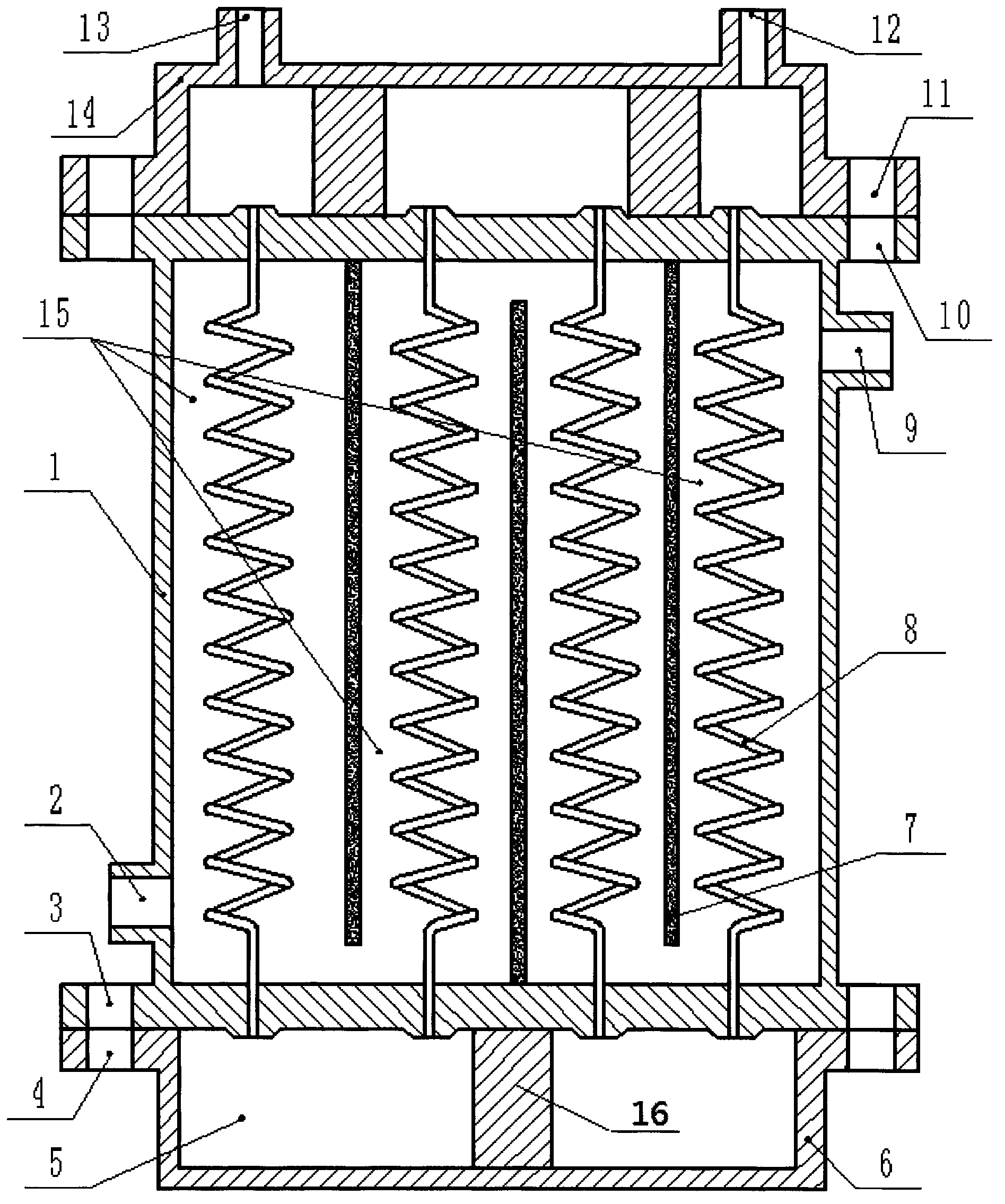

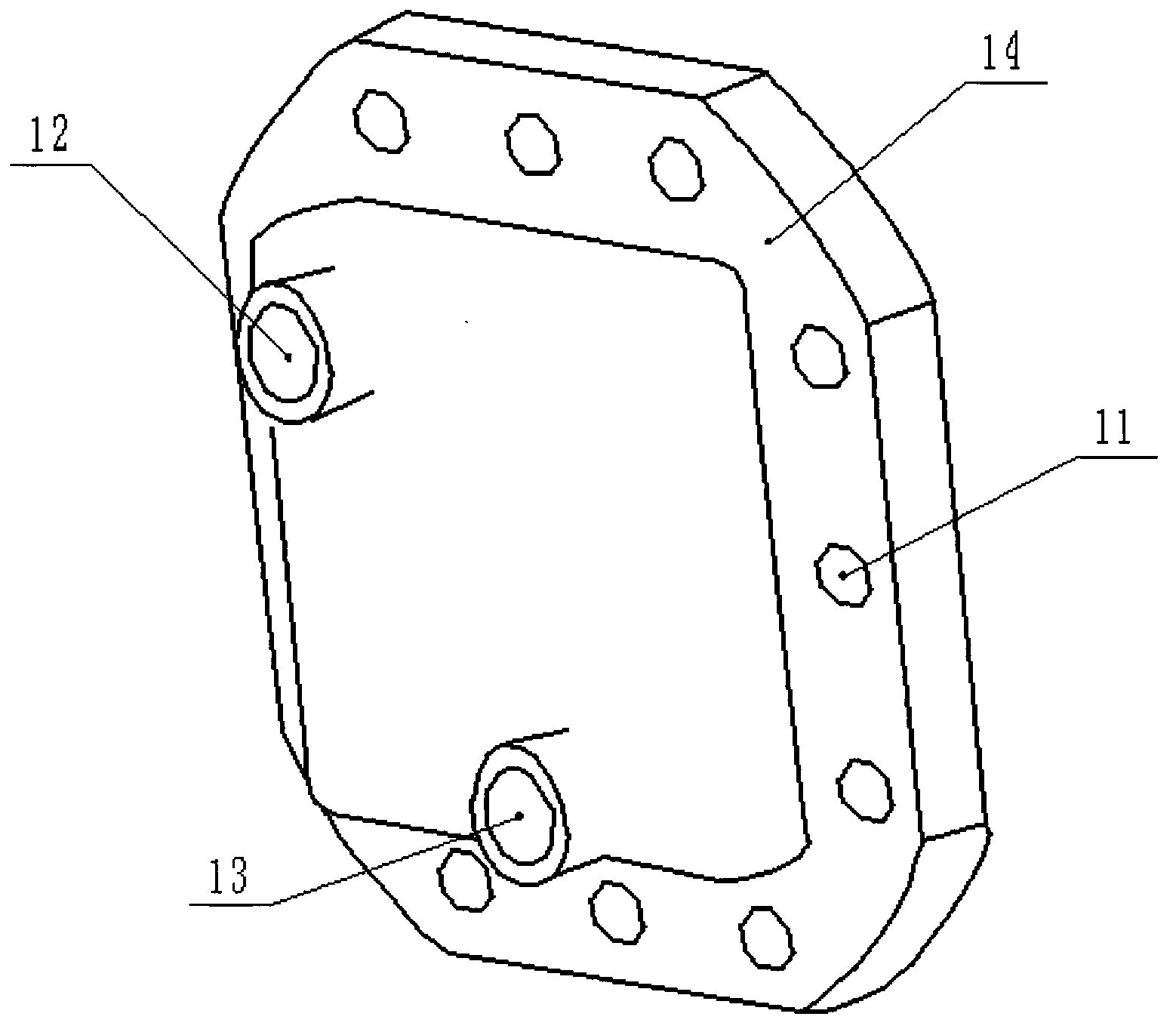

Heat exchanger

InactiveCN104315893ASimple structureSmall footprintHeat exchanger casingsStationary tubular conduit assembliesCold mediumEngineering

The invention discloses a heat exchanger. The heat exchanger comprises a cooling tank body, longitudinal baffle plates and an upper end cover, wherein the section of the cooling tank body is square; four groups of tubes are transversely spaced away from one another in the cooling tank body along the horizontal direction; each group of tubes longitudinally comprise at least two tubes along the horizontal direction; one longitudinal baffle plate is arranged between every two adjacent groups of tubes; the longitudinal baffle plate on the left side is arranged between the first group of tubes and the second group of tubes; the middle longitudinal baffle plate is arranged between the second group of tubes and the third group of tubes; the longitudinal baffle plate on the right side is arranged between the third group of tubes and the fourth group of tubes. The heat exchanger has the characteristics of simple structure, arrangement of a plurality of groups of tubes, small occupied space, long cooling tube pass and good cooling effect; the heat exchange contact area between a heat medium flow and a cold medium flow of the spiral tubes is increased, the hot medium flow and the cold medium flow form a reverse flow, a hot medium and a cold medium both have higher temperature difference in the entire flow process, and the heat exchange effect is good.

Owner:WUXI YUDA HEAT EXCHANGER

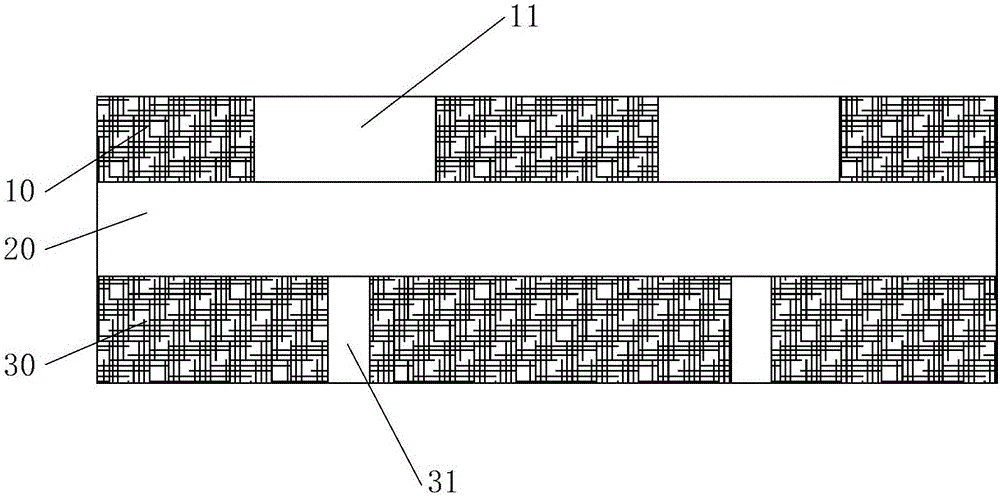

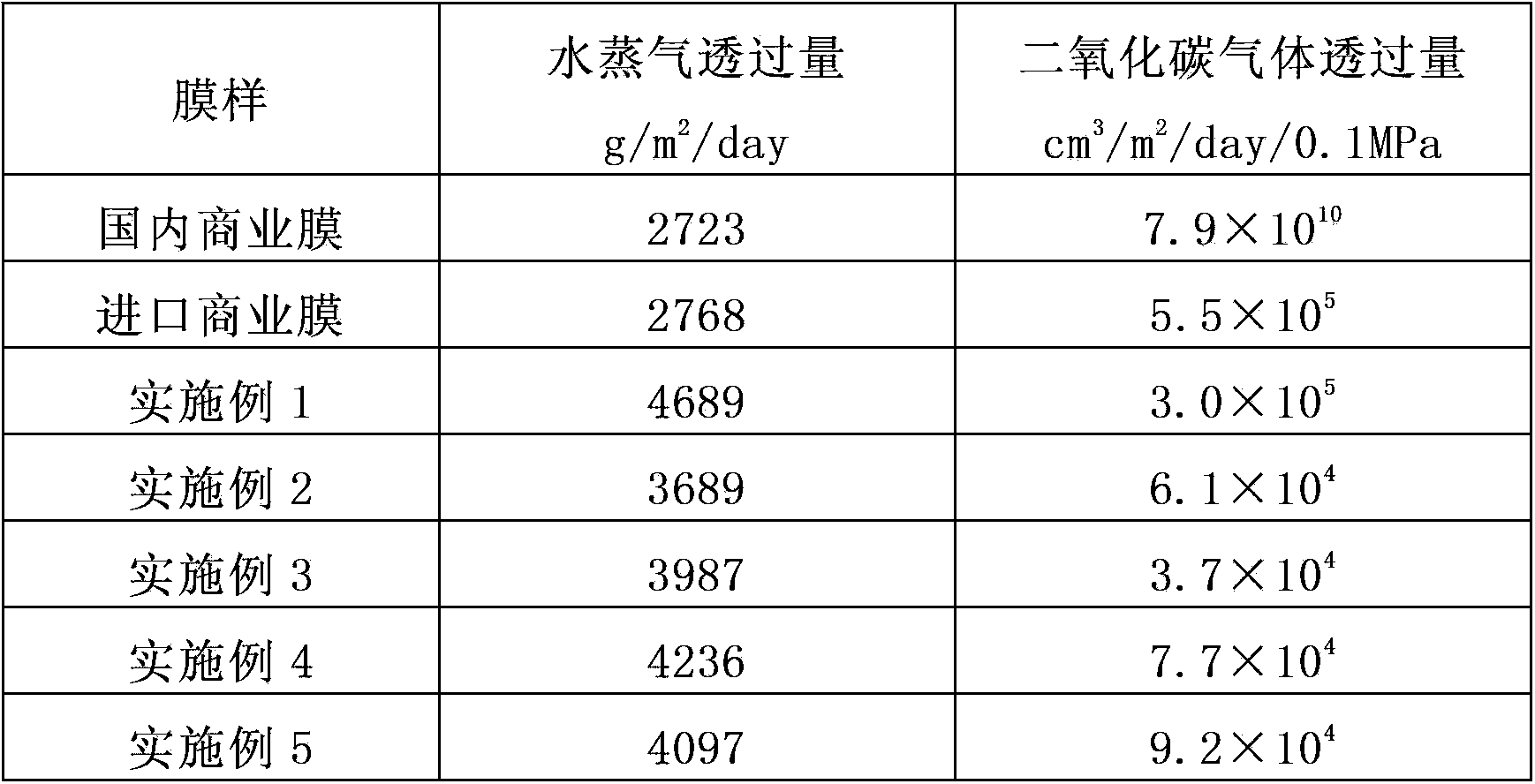

Novel efficient total heat exchange membrane and total heat exchanger

ActiveCN103877864AGood moisture permeabilityImprove heat exchange effectSemi-permeable membranesLighting and heating apparatusInorganic saltsPlate heat exchanger

The invention discloses a novel efficient total heat exchange membrane and a total heat exchanger. The total heat exchange membrane includes: a first support layer, which comprises a first high polymer, a first moisture absorbent, an antibacterial agent, an inorganic functional additive, and an inorganic salt; an active layer, which contains a second high polymer, a second moisture absorbent; and an optional second support layer. The first support layer is located between the second support layer and the active layer. The invention also discloses a preparation method of the total heat exchange membrane and the total heat exchanger using the membrane. The total heat exchange membrane provided by the invention has the advantages of excellent moisture permeability, effective blocking of harmful gas, good heat exchange performance, and less mixing of air supply and air exhaust, can provide fresh air to the indoor, remove foul and harmful air, and simultaneously recover sensible heat and latent heat.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

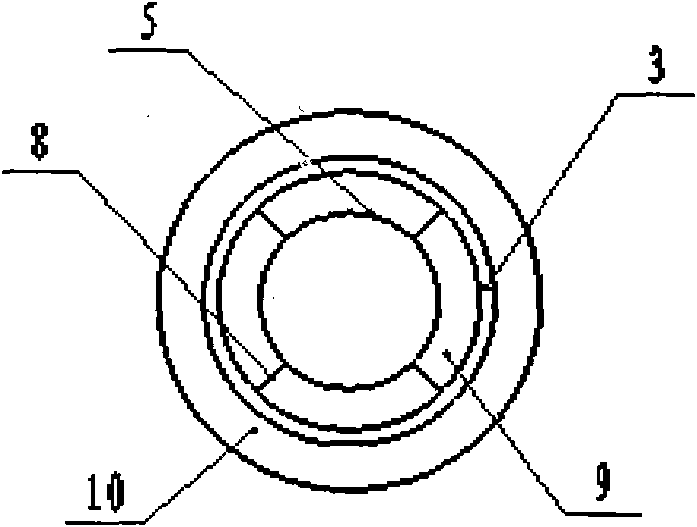

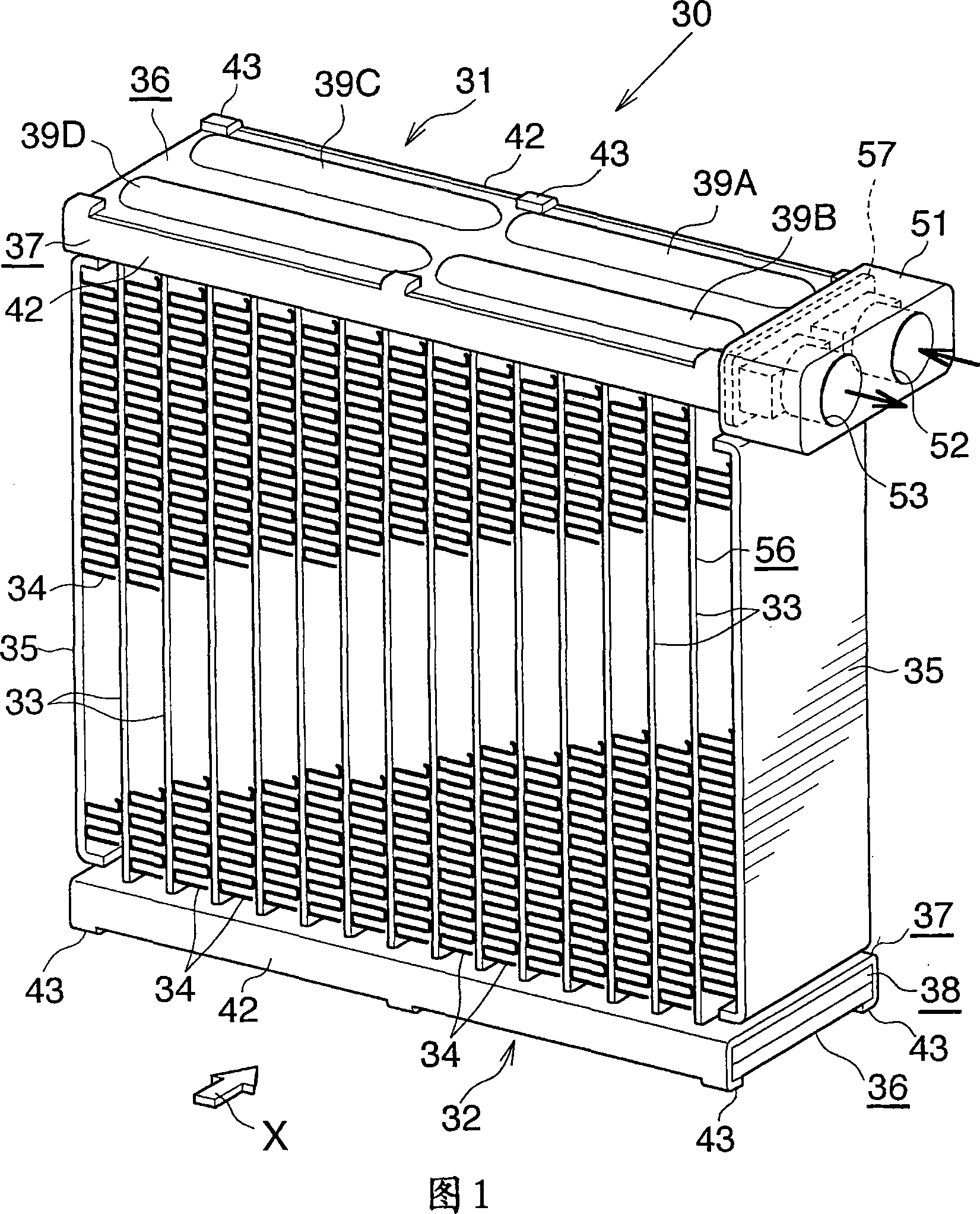

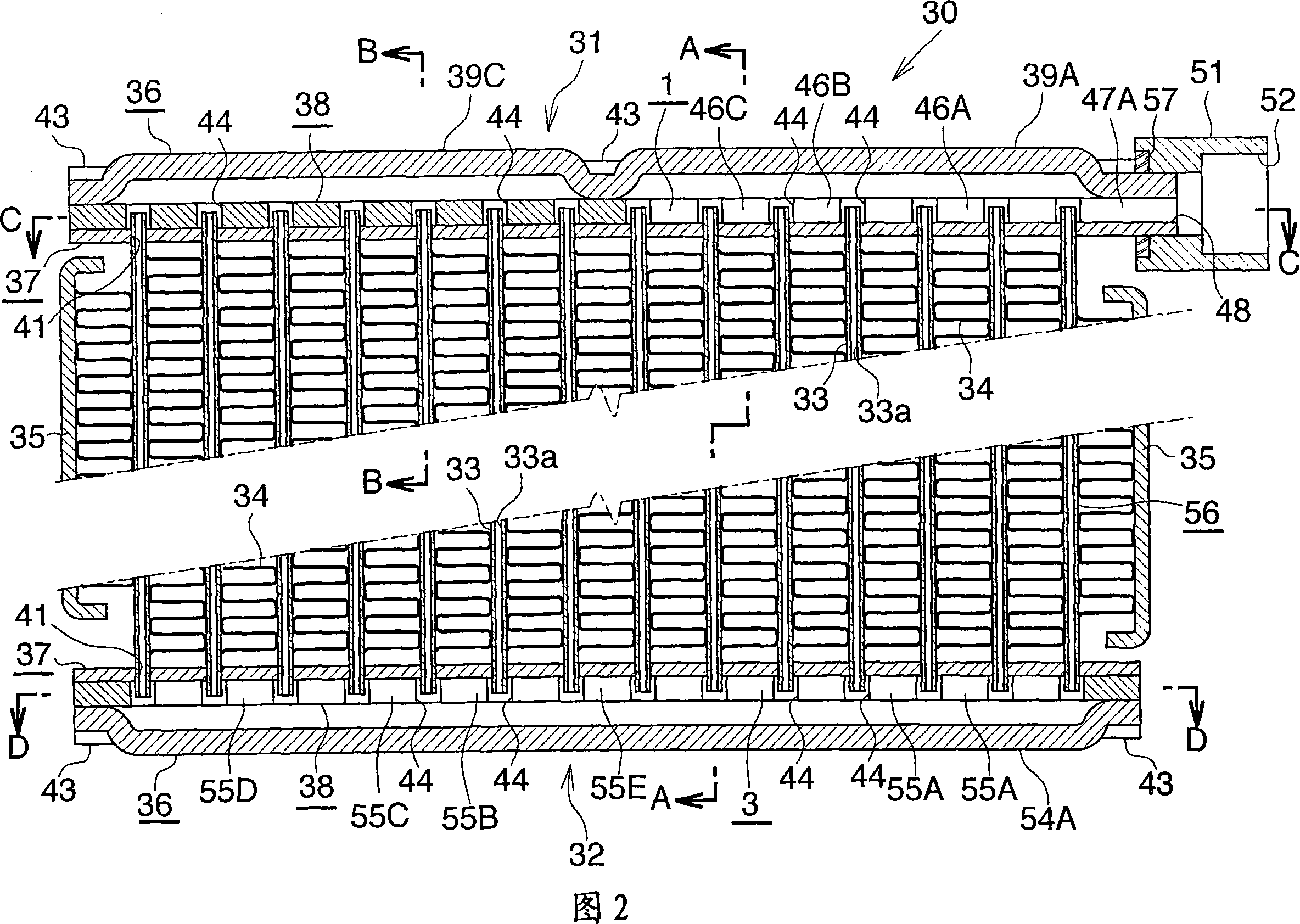

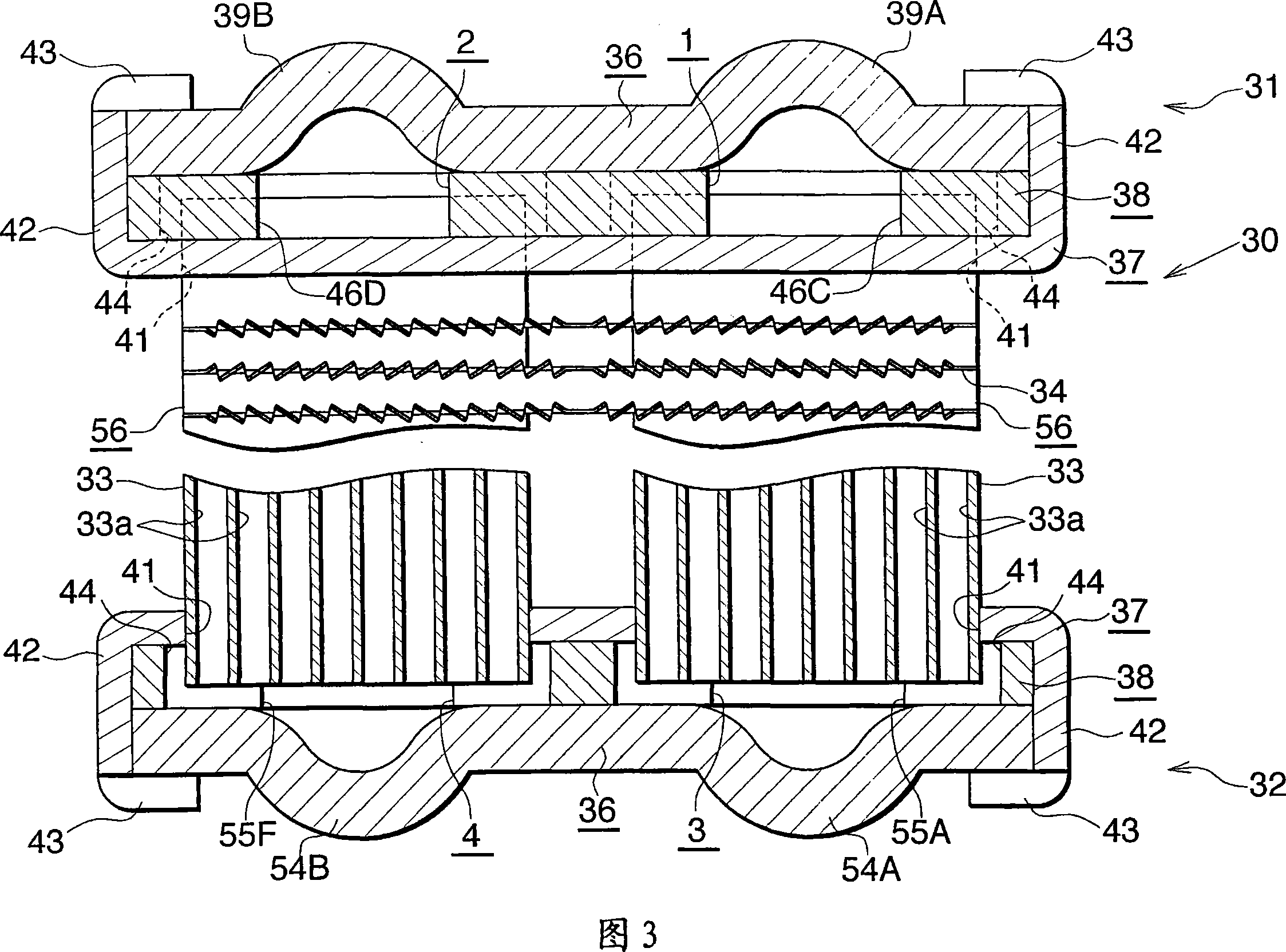

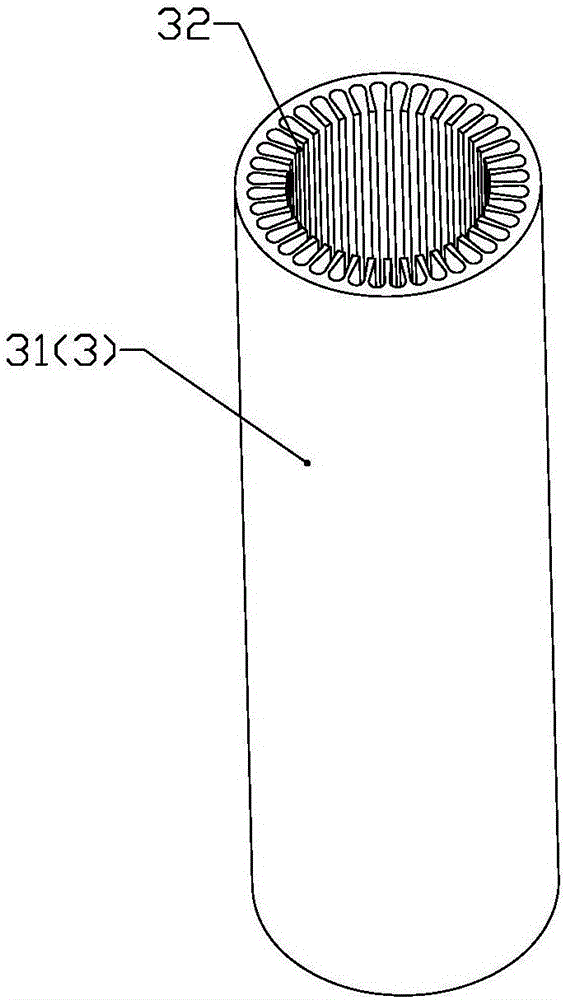

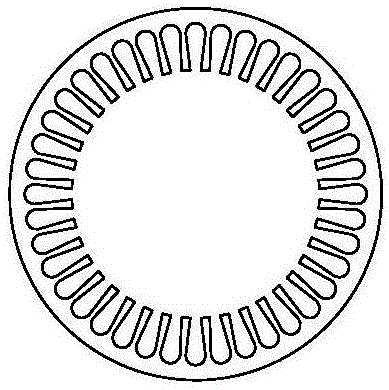

Heat exchanger

InactiveCN1938554AReduce in quantityImprove heat exchange efficiencyCompression machines with non-reversible cycleEvaporators/condensersRefrigerantEvaporator

An evaporator 30 has a header tank 31 comprising a header forming plate, a tube connecting plate 37 and an intermediate plate 38. The header forming plate is provided with outward bulging portions. A plurality of tube insertion holes are formed in the tube connecting plate 37. Communication holes 44 are formed in the intermediate plate 38 for causing the tube insertion holes to communicate with the interior of the corresponding outward bulging portion therethrough. At least one of the outward bulging portions serves as a refrigerant passing outward bulging portion for a refrigerant to flow therethrough longitudinally of the bulging portion. All the communication holes 44 in communication with the refrigerant passing bulging portion are held in communication by communication portions 46A to 46C for the communication holes 44 and the communication portions 46A to 46C to provide a refrigerant passageway 1. The refrigerant passageway 1 is altered in cross sectional area along the longitudinal direction thereof by adjusting the width of the communication portions 46A to 46C. The evaporator 30 is reduced in the number of components, can be fabricated by efficient work and exhibits improved heat exchange performance.

Owner:SHOWA DENKO KK

Corrosion inhibiting anti-scaling agent

InactiveCN1715215AGood dispersionEnhanced inhibitory effectScale removal and water softeningSulfonateMercaptobenzothiazole

The present invention belongs to the field of chemical technology, and discloses one kind of corrosion inhibiting descaling agent. The corrosion inhibiting descaling agent contains mercaptobenzothiazole, hydroxy ethylidene diphosphonic acid, acrylic acid-acrylate-sulfonate copolymer, sodium humate, lignin, sodium hydroxide and water. The corrosion inhibiting descaling agent of the present invention is suitable for central air conditioning system, cooling water system, etc. After being added into circulating water system, the corrosion inhibiting descaling agent of the present invention can form one compact protecting layer on the surface of equipment or pipeline to reach effective corrosion inhibiting and scale-preventing effect.

Owner:SHANGHAI WANSEN WATER TREATMENT CO LTD

Three-cylinder dryer of dry-mixed mortar station

InactiveCN101701761AImprove heat exchange effectImprove drying efficiencyDrying chambers/containersDrying solid materialsPulp and paper industryEngineering

The invention relates to a three-cylinder dryer of a dry-mixed mortar station, which comprises a drying cylinder, a feeding pipe, a discharging pipe and a rotary driving device, wherein the drying cylinder comprises an outer cylinder body, a conical middle cylinder body and a conical inner cylinder body, and inner lifting boards with columnar curved surfaces which are arranged spirally are formed on inner walls of the outer cylinder body, the conical middle cylinder body and the conical inner cylinder body respectively; a bottom board which is in the shape of a truncated cone is welded at the small end of the conical middle cylinder body, and the bottom board is fixed with a left side board of the drying cylinder and the left inner end of the outer cylinder body together through a plurality of arc-shaped blade-shaped connecting material guide boards II; the big end of the conical middle cylinder body is welded with a right side board of the drying cylinder and the right inner end of the outer cylinder body together through a plurality of arc-shaped blade-shaped connecting material guide boards I; and the small end of the conical inner cylinder body is welded on the right side board of the drying cylinder, and the big end of the conical inner cylinder body is fixedly connected with the interior of the bottom board of the middle cylinder body together through a plurality of arc-shaped blade-shaped connecting material guide boards III. The three-cylinder dryer has compact structure and high drying efficiency.

Owner:徐州沃土资产管理有限公司

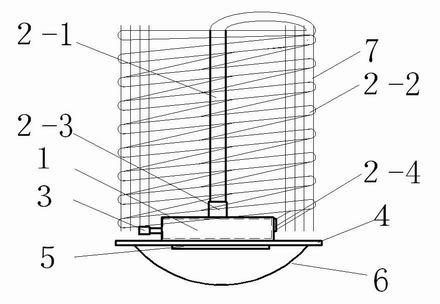

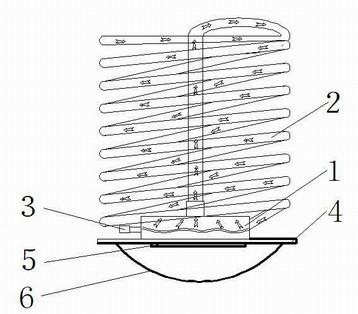

Heat pipe radiator for high-power LED lamp

InactiveCN102563585ABest delivery designImprove heat exchange effectPoint-like light sourceLighting heating/cooling arrangementsLight sourceEngineering

The invention belongs to radiating equipment, and particularly relates to a heat pipe radiator for a high-power LED lamp, which comprises an LED light source, a hollow box-shaped evaporation cavity and a pipeline connected onto the evaporation cavity, the evaporation cavity and the pipeline form a closed circulation loop, the evaporation cavity is provided with an evaporation port, a return port and a filling port, and the position of the evaporation port is higher than that of the return port. The heat pipe radiator solves the problems of low radiating efficiency, heavy weight and the like of an existing LED lamp aluminum profile radiator, light attenuation of LEDs is slowed down, and further the service life of the heat pipe radiator is prolonged.

Owner:郭琛

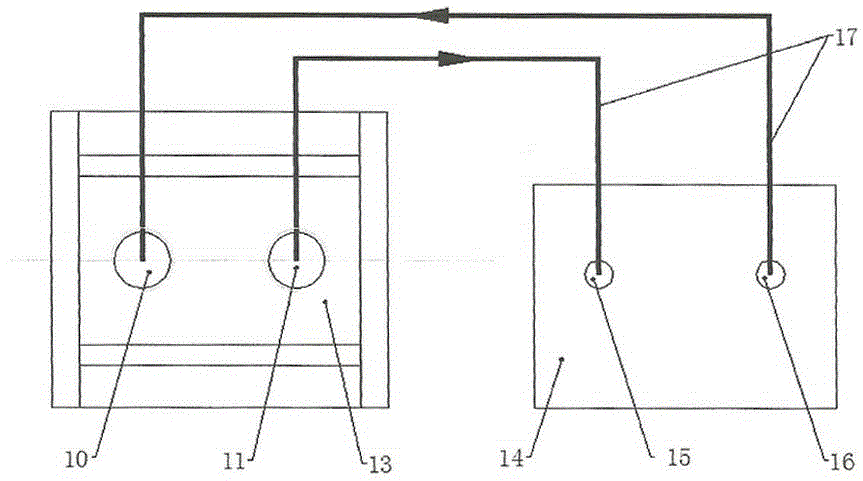

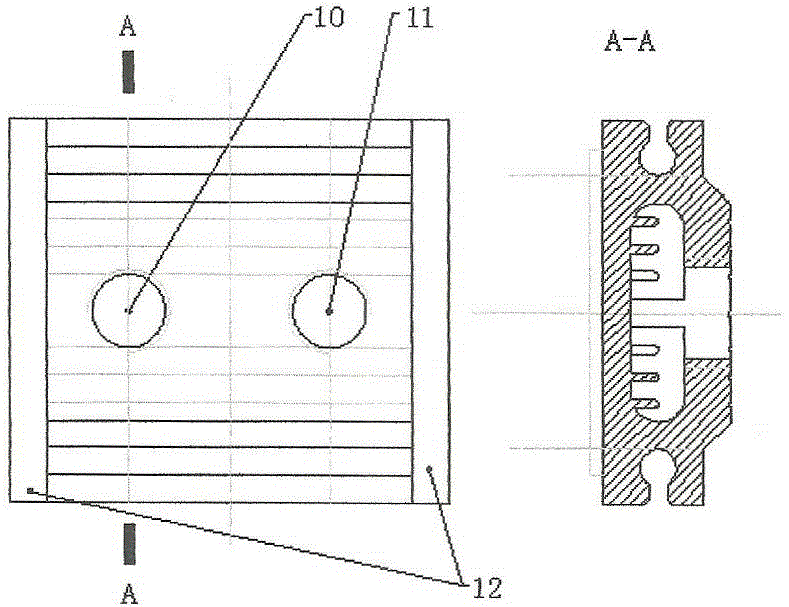

High-power plane heating unit liquid-cooling heat dissipating device and manufacturing method thereof

InactiveCN104457347ASize can be large or smallHighly integratedIndirect heat exchangersCooling/ventilation/heating modificationsEngineeringMachining

The invention discloses a high-power plane heating unit liquid-cooling heat dissipating device which comprises a cooling liquid driving device (14) and a heat dissipator (13). The heat dissipator (13) is composed of a heat dissipating sectional material (18) and sealing plug blocks (12), the heat dissipating sectional material (18) is a flat-section structure with cavities, a heat dissipating face (2) and mounting faces (5) used for mounting of a plane heating unit are arranged on the surface of the heat dissipating sectional material (18), cooling liquid channels and mounting pipelines (3) are arranged inside the heat dissipating sectional material (18), and a liquid inlet (10) and a liquid outlet (11) of the heat dissipator are communicated with the cooling liquid channels. By adoption of the structure, the heat dissipating sectional material is formed at a time, can be cut according to the shape of the plane heating unit and can be provided with the liquid inlet and the liquid outlet at different positions, heat dissipating devices of different heat dissipating structures can be manufactured only through simple machining, multiple heat dissipators can be assembled in parallel to be matched with the width of the plane heating unit, and heat dissipating requirements of the plane heating units in different shapes are met.

Owner:HANGZHOU JIASEN TECH

Light-weight safe battery cell support, and power battery pack

ActiveCN106252549ALight weightReduce manufacturing costSecondary cellsCell component detailsGlass fiberPower battery

The invention discloses a light-weight safe battery cell support, and a power battery pack. According to the light-weight safe battery cell support, a support main body is a noncombustible foamed block prepared from a macromolecule resin, a foaming agent, glass fiber, and stone powder via chemical foaming, air holes of the noncombustible foamed block formed after foaming are filled with inert gas such as carbon dioxide, nitrogen gas, and ammonia gas; first circular holes are uniformly distributed in the support main body, the support main body is penetrated by the first circular holes from top to bottom, and the first circular holes are formed in shaping process of the support main body. The core parts of the light-weight safe battery cell support comprise the support main body; the light-weight safe battery cell support is prepared via foaming of organic resins, is light, and can be recycled effectively; and production cost is reduced.

Owner:山东豪驰智能汽车有限公司

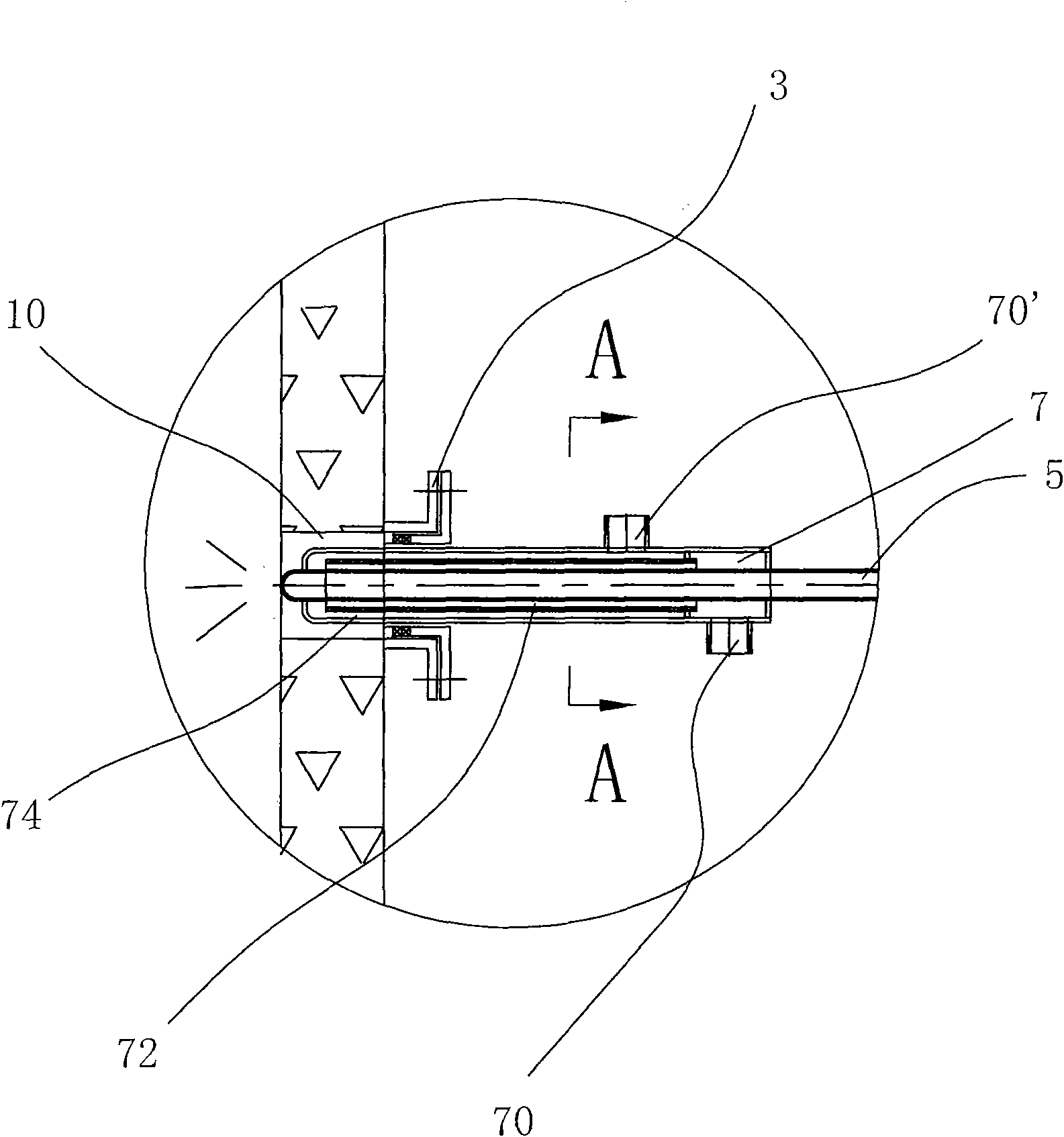

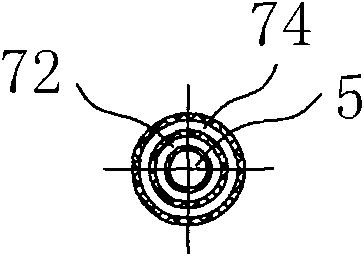

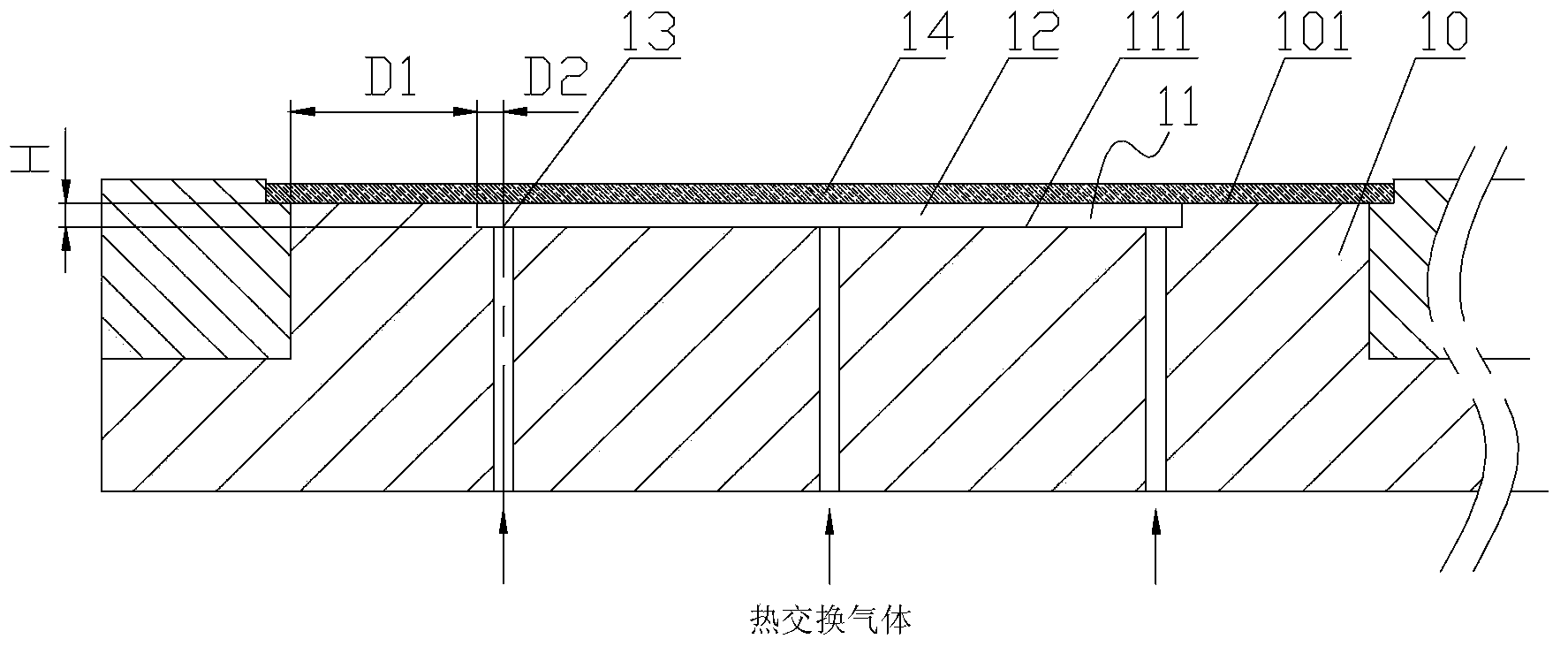

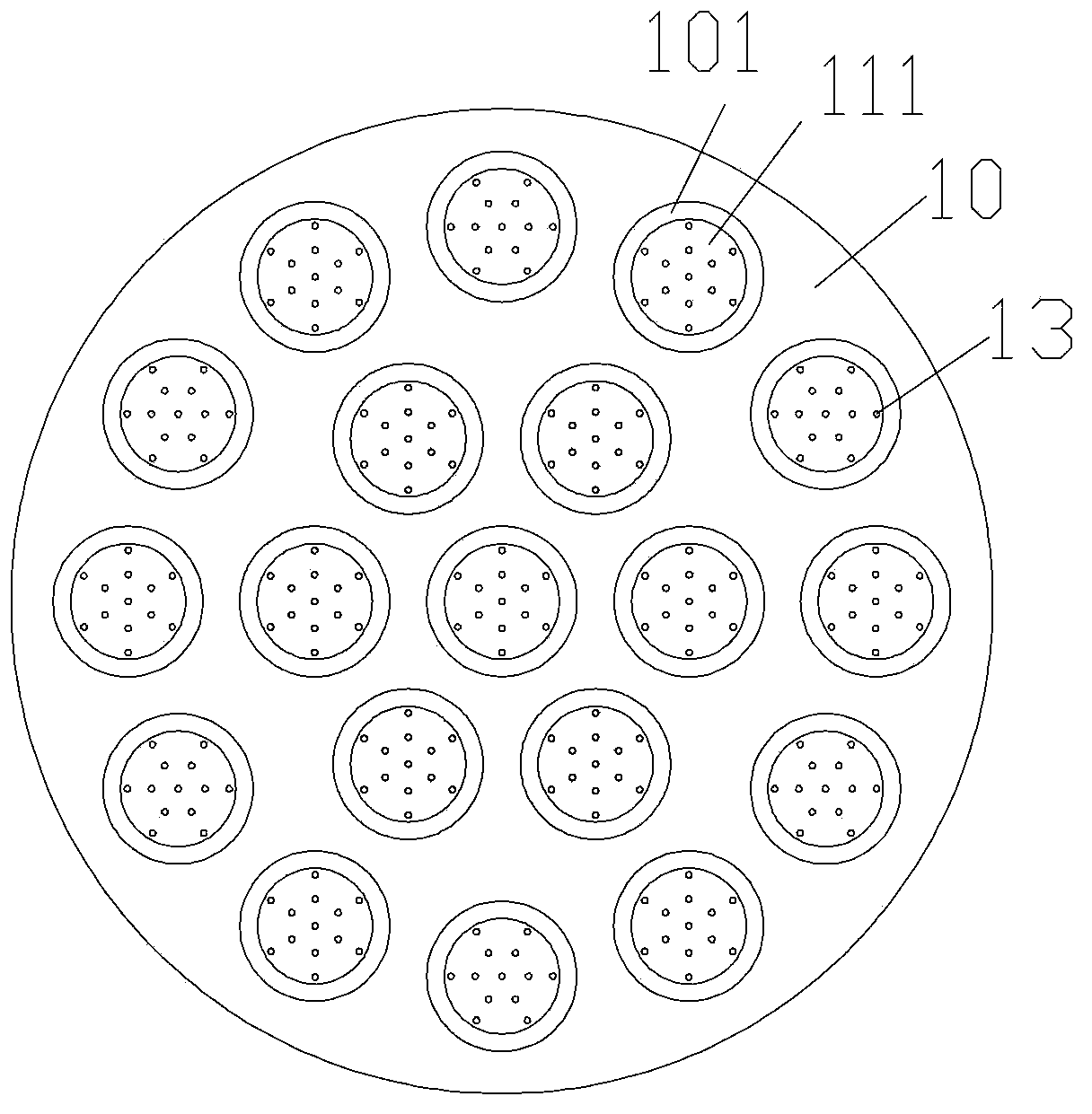

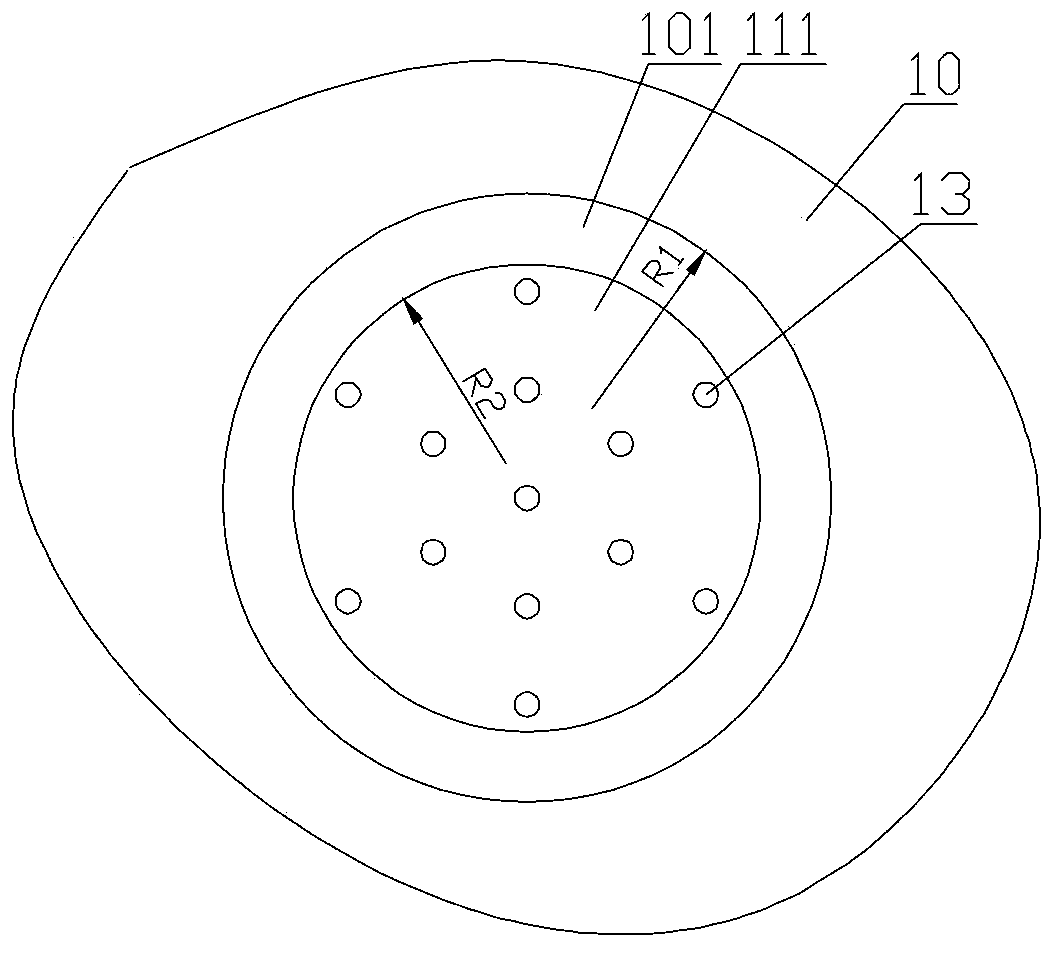

Pallet and plasma processing equipment

InactiveCN104124127AImprove temperature uniformityReduce leakageElectric discharge tubesSemiconductor/solid-state device manufacturingMaximum diameterEngineering

Disclosed are a pallet (10) and a plasma machining apparatus. The pallet (10) is used for bearing a machined work-piece (14), and adjusting the temperature of the machined work-piece (14) by means of a heat exchange gas, wherein at least one bearing region of the machined work-piece is formed on the upper surface of the pallet (10); the shape and size of each bearing region of the machined work-piece are corresponding to the machined work-piece (14) to be borne; at least one recess (11) which is recessed towards the lower surface of the pallet is formed in a non-edge region (111) of each bearing region of the machined work-piece; the maximum diameter of a notch of each recess (11) is smaller than the minimum diameter of the borne surface of the machined work-piece (14) to be borne; intake holes (13) are distributed on the bottom surface of the recess (11); and the intake holes (13) are connected to a gas source of the heat exchange gas. The pallet (10) can not only improve the efficiency and uniformity of heat exchange between the heat exchange gas and the machined work-piece (14), but can also reduce the leakage amount of the heat exchange gas.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com