Heat exchanger

A heat exchanger, one-to-one corresponding technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problem of long heat exchanger pipeline, poor cooling effect, heat exchanger pipeline and There are not many problems such as the contact area of the cooling medium, so as to achieve the effect of long cooling tube path, small occupied space and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

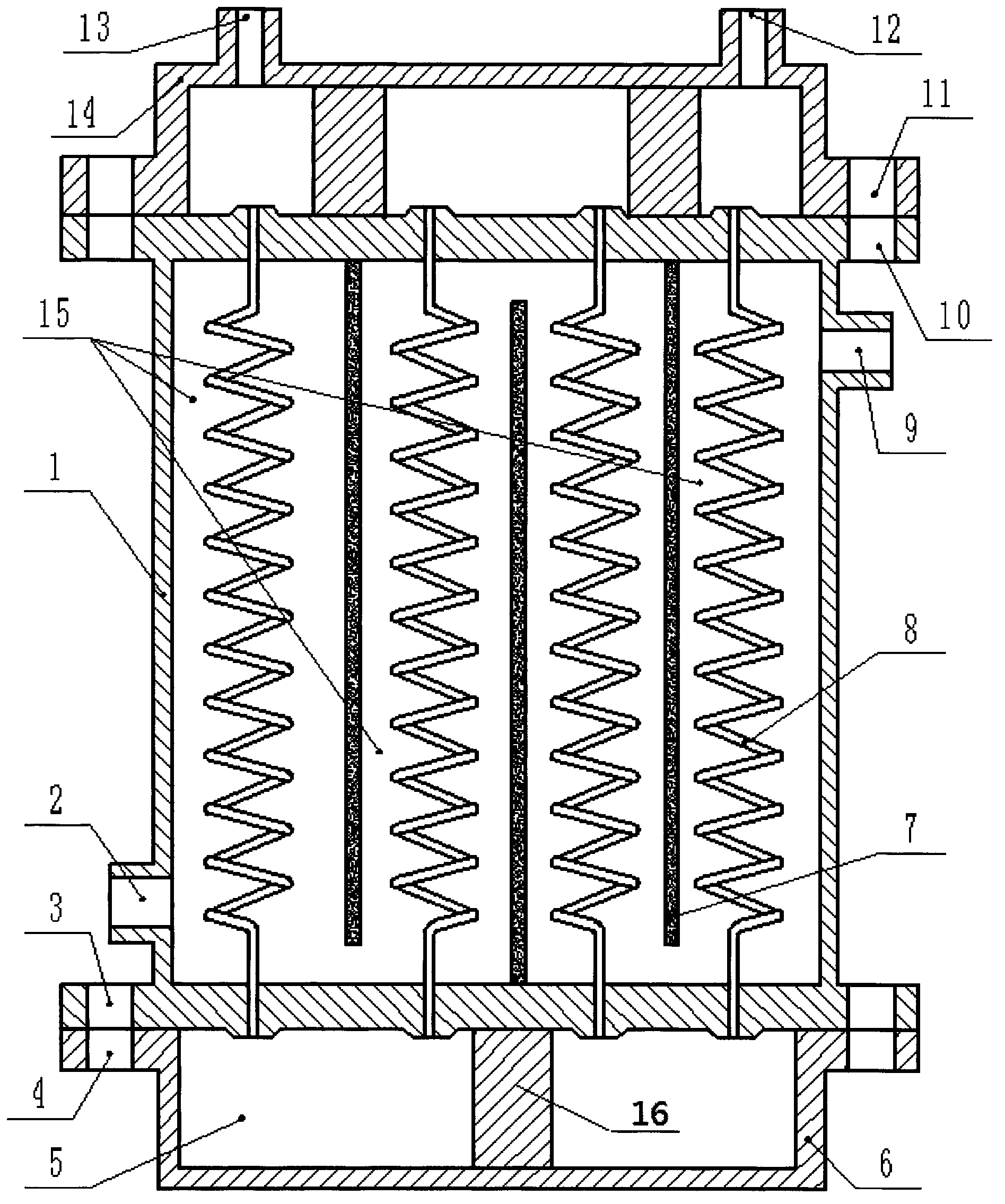

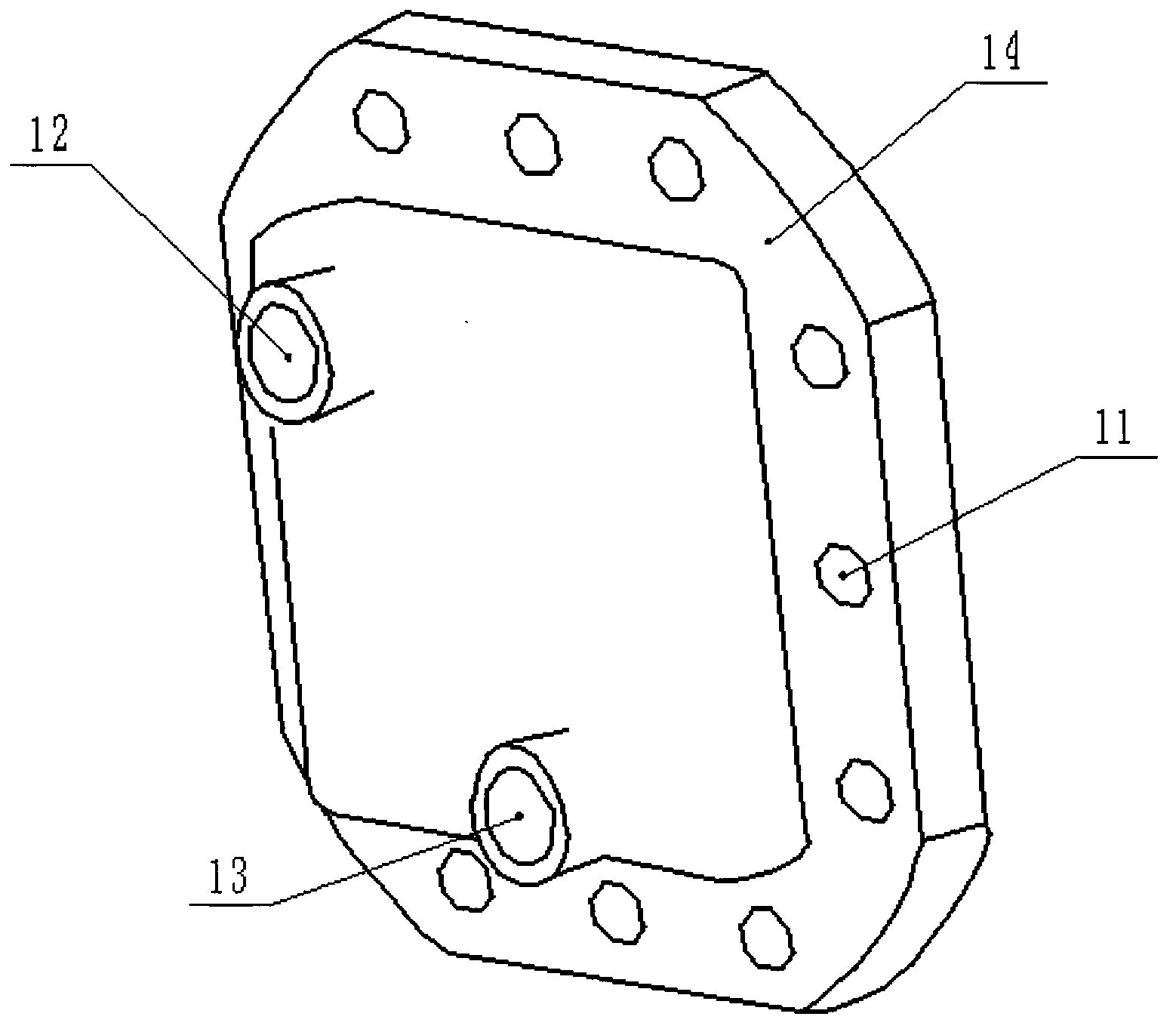

[0014] see Figure 1-2 , a heat exchanger, including a cooling tank 1, a longitudinal baffle 7 and an upper end cover 14; the cross-section of the cooling tank 1 is square, and four sets of tubes 8 are arranged horizontally and laterally in the cooling tank 1 , each group of tubes 8 is provided with at least two along the horizontal and vertical directions, and the tubes 8 are helical. The design of the helical tubes increases the pipeline stroke of the tubes 8 and improves the heat exchange effect. Wherein, each adjacent two groups A longitudinal baffle 7 is arranged between the tubes 8, the longitudinal baffle 7 on the left side is arranged between the first group of tubes 8 and the second group of tubes 8, and the middle longitudinal baffle 7 is arranged on the second group of tubes 8. Between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com