Patents

Literature

501results about How to "Ensure continuous and stable work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solar photovoltaic and commercial power combined power supply system and control method thereof

InactiveCN101951011AEnsure continuous and stable workEfficient power electronics conversionDc-dc conversionElectricityNew energy

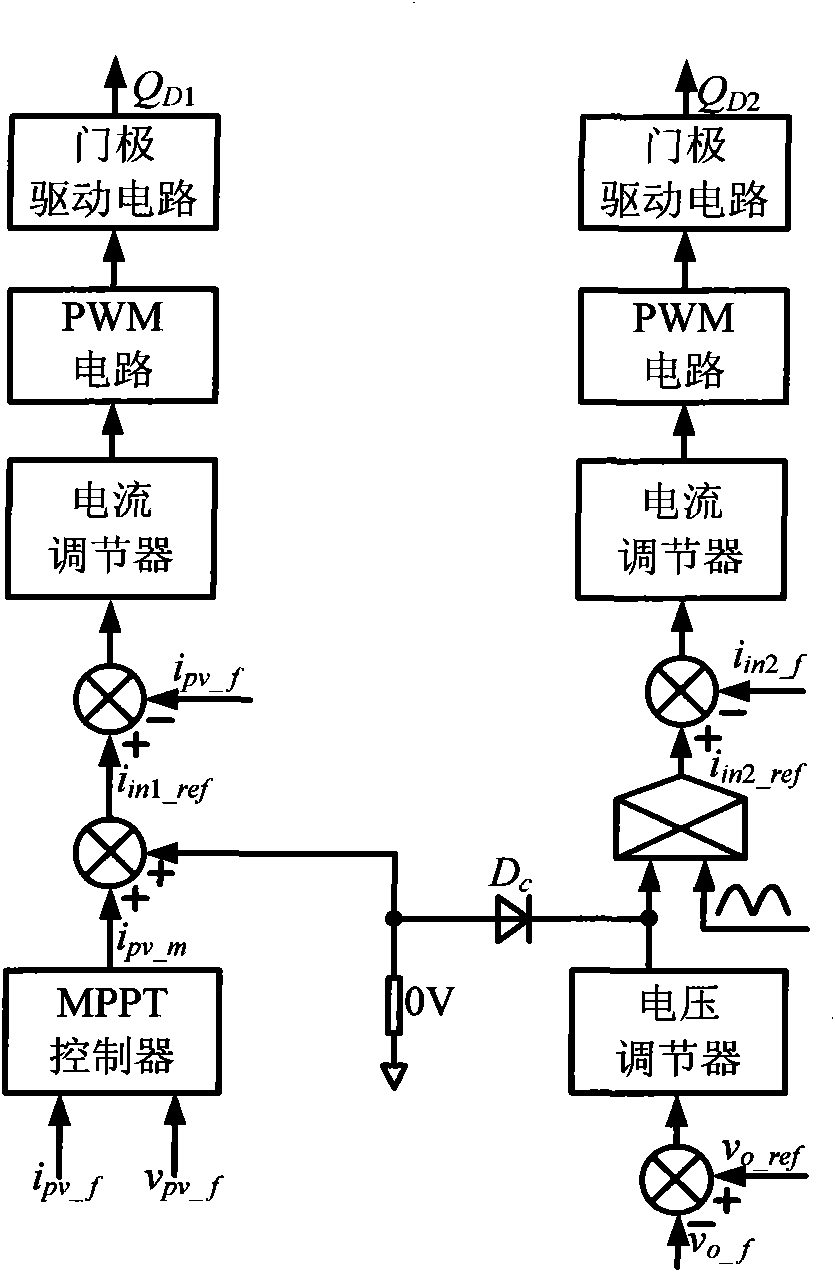

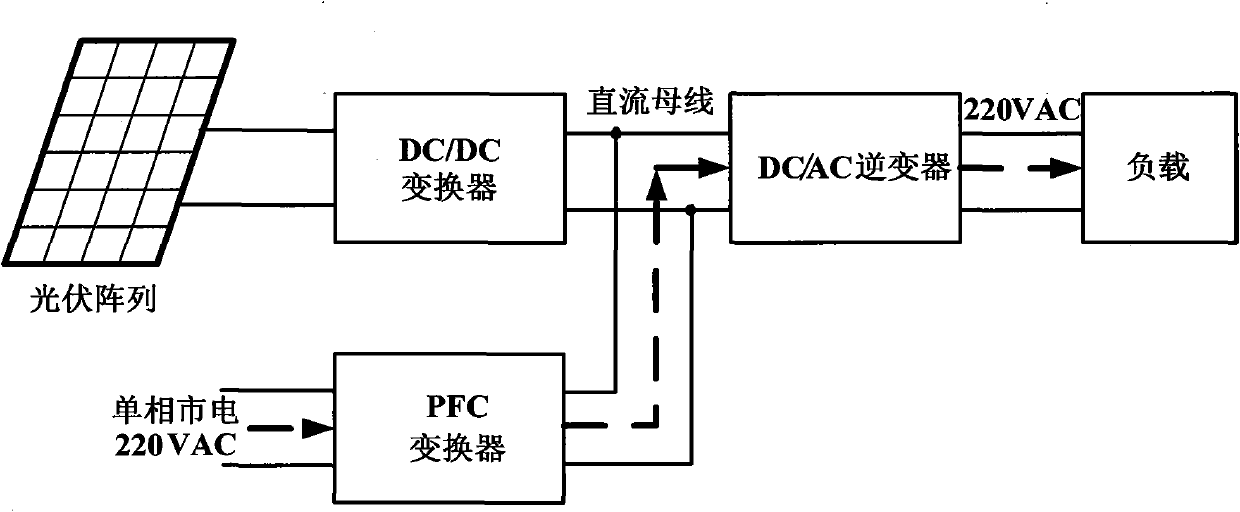

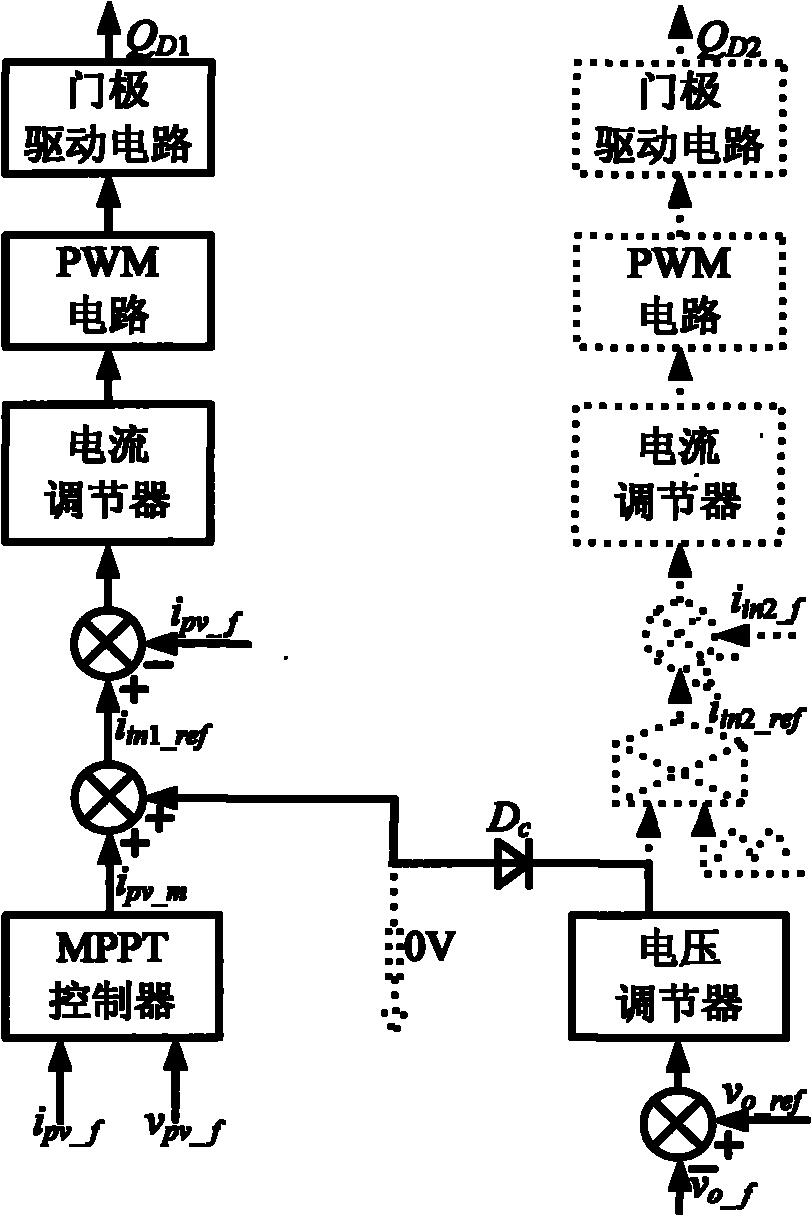

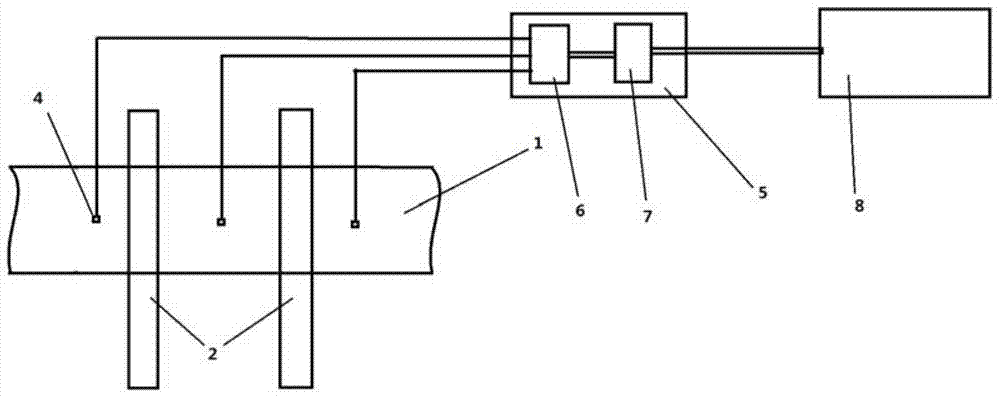

The invention discloses a solar photovoltaic and commercial power combined power supply system and a control method thereof, and belongs to the field of new energy power supply systems. The structure of the system comprises a photovoltaic array, a commercial power supply, a DC / DC converter, a PFC converter and a DC / AC inverter, wherein the photovoltaic array and the commercial power supply are connected with a direct current bus through the DC / DC converter and the PFC converter respectively and supply power to an alternating current load through the DC / AC inverter. In the invention, for fullyutilizing solar, the DC / DC converter can operate with the maximum power of a photovoltaic battery; meanwhile, the commercial power is used as an auxiliary power supply, three power supply modes are realized, and the stable work of the load under various conditions is ensured.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

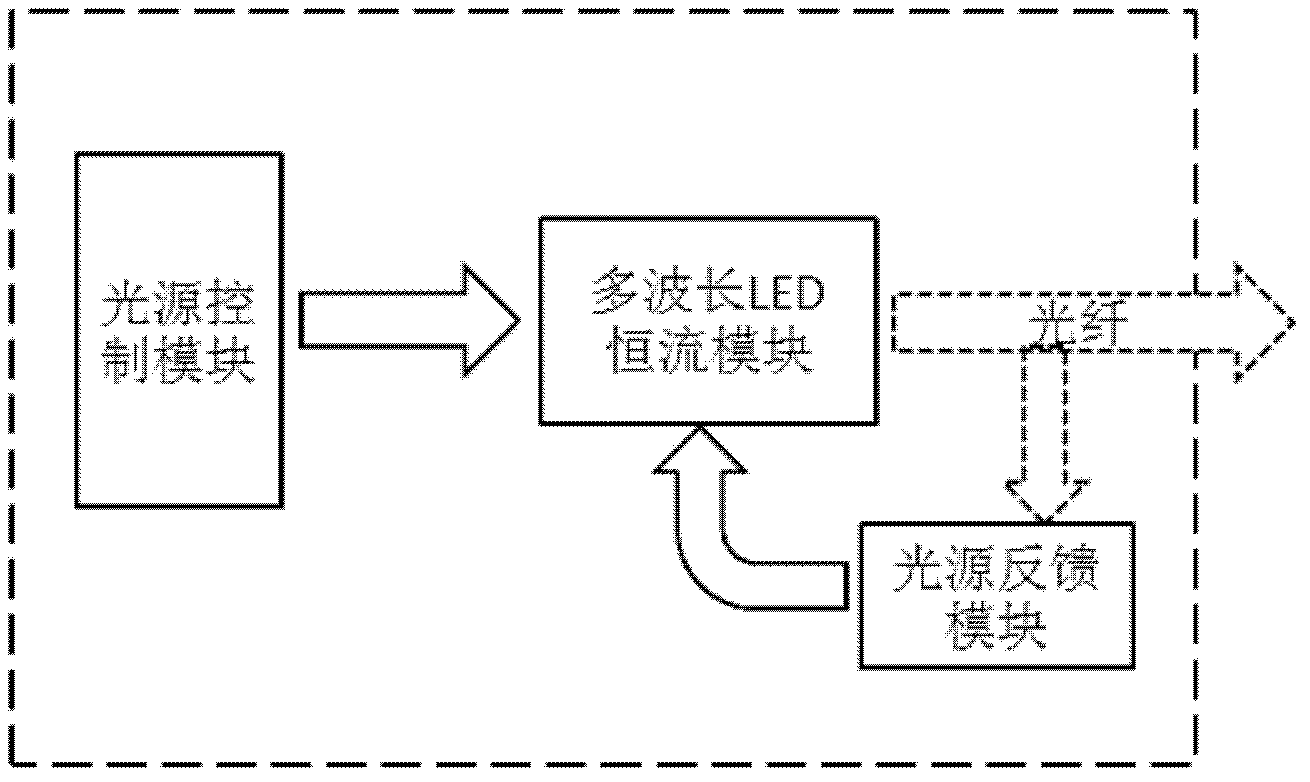

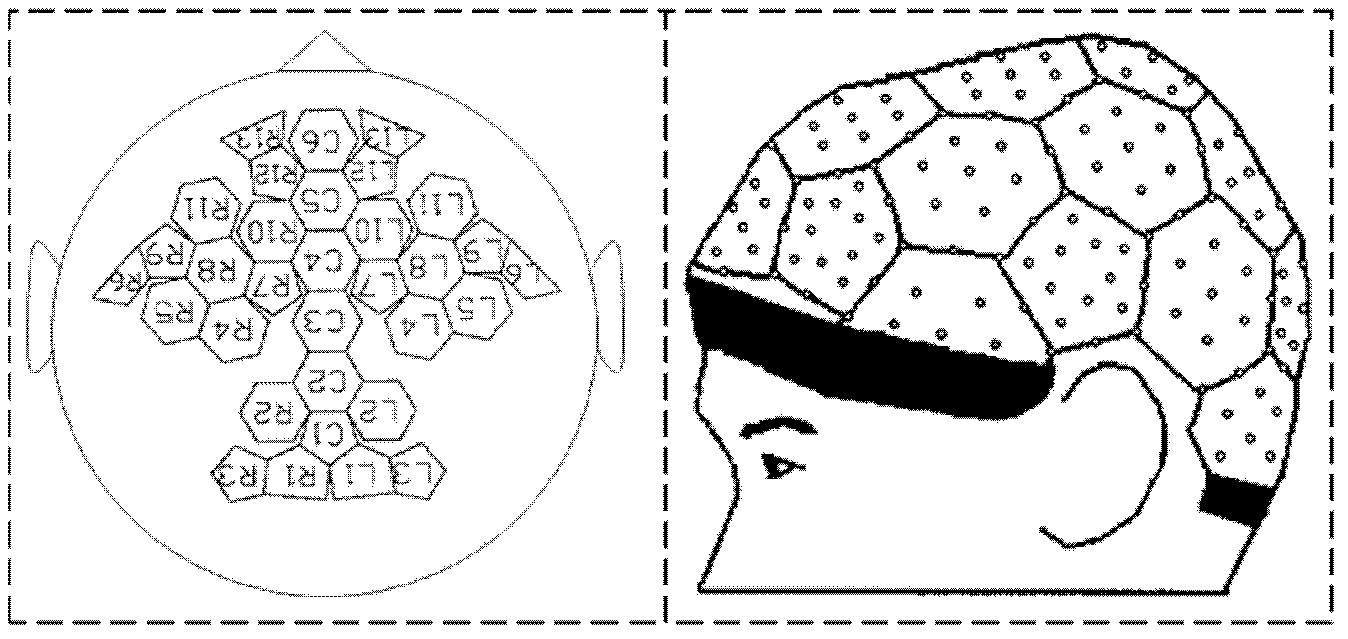

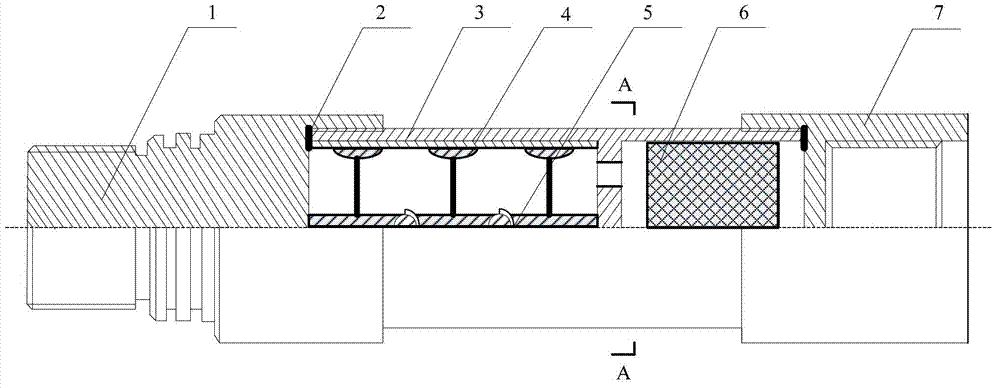

Multi-channel parallel near infrared spectrum imaging system

ActiveCN103156620ALow cost to manufacture and useHigh costDiagnostic recording/measuringSensorsMulti wavelengthInfrared

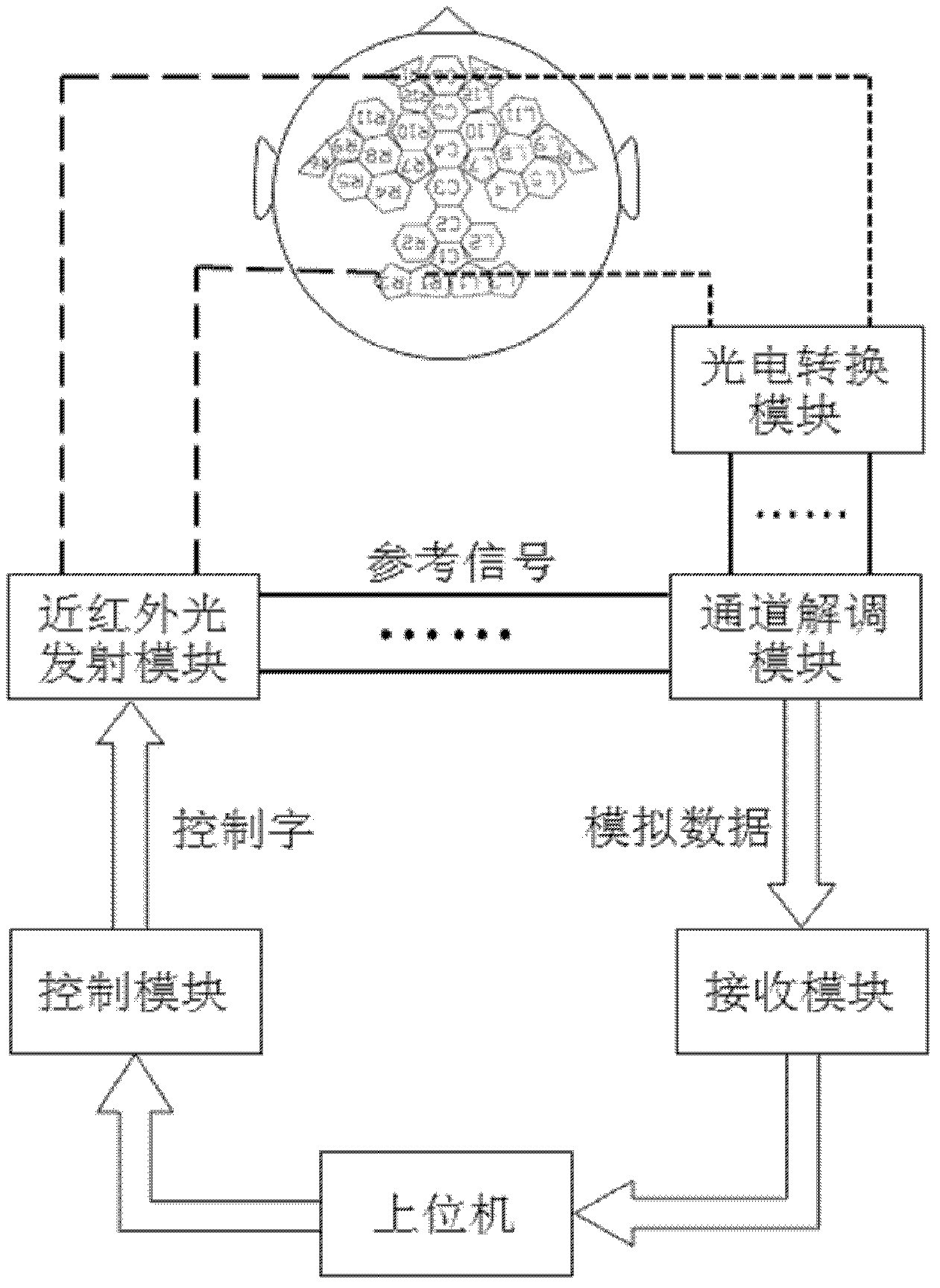

The invention discloses a multi-channel parallel near infrared spectrum imaging system. A multi-wavelength light emitting diode (LED) is applied to finishing emission of near-infrared light. An avalanche photodiode is used for detecting a weak optical signal, the simulating lock-in amplifier technology is used for achieving amplification of the signal, and a near infrared spectrum cerebral function imaging helmet disclosed in Chinese patent application CN200520002784.8 can be used for improving the partial unreasonable design of a self-adaptation head portion. The multi-channel parallel near infrared spectrum imaging system can achieve continuous rapid accurate detection and collection of cerebral blood oxygen signals, overcomes the defect of an existing functional near infrared system, and brings superiority of the near infrared spectrum imaging technology compared with other cerebral function imaging technologies into full play.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

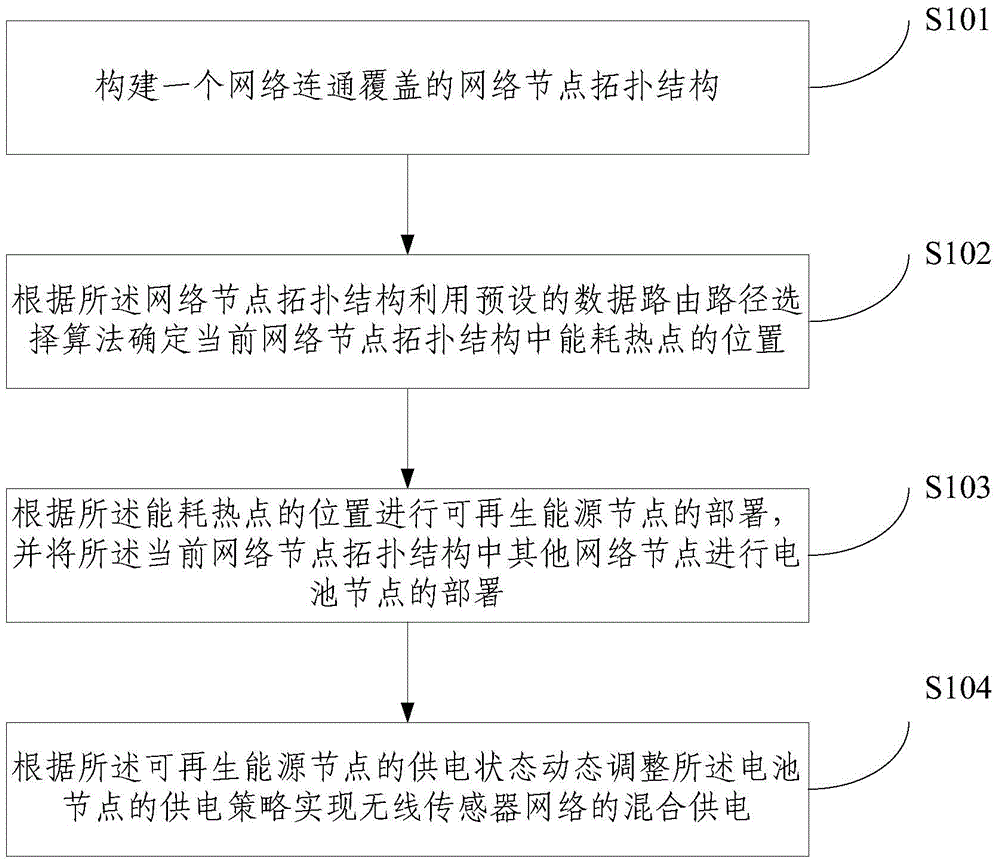

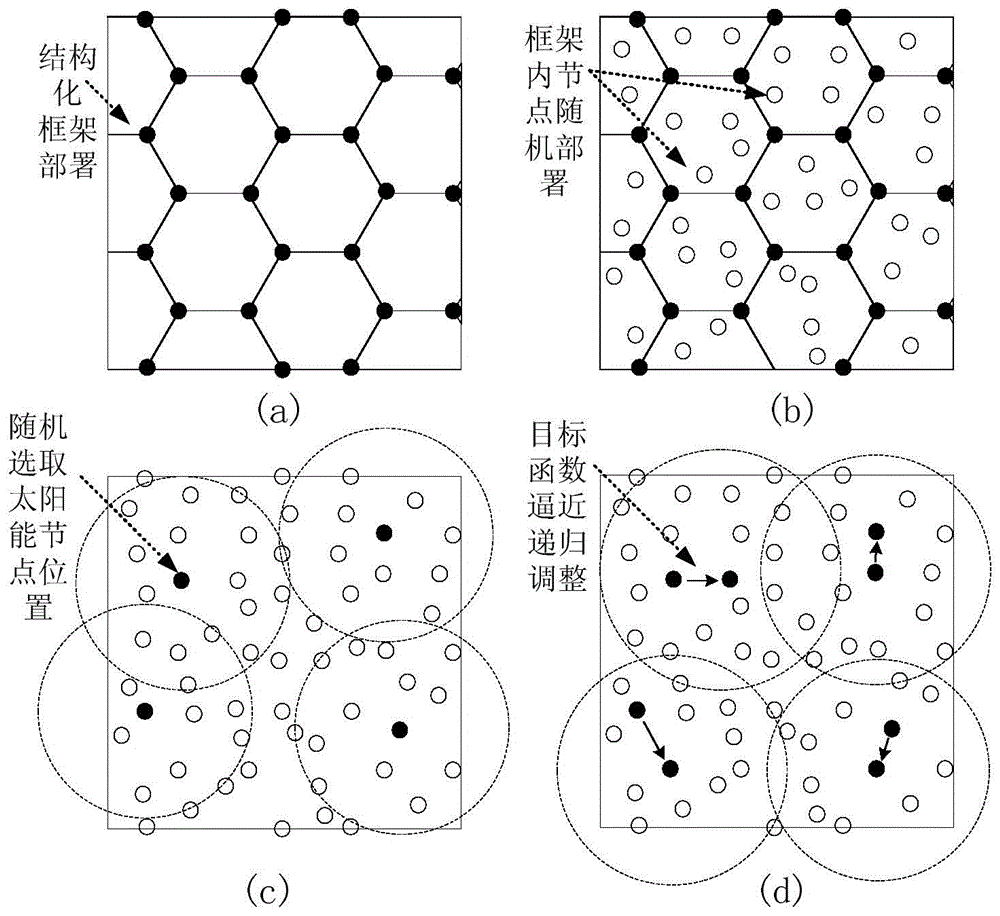

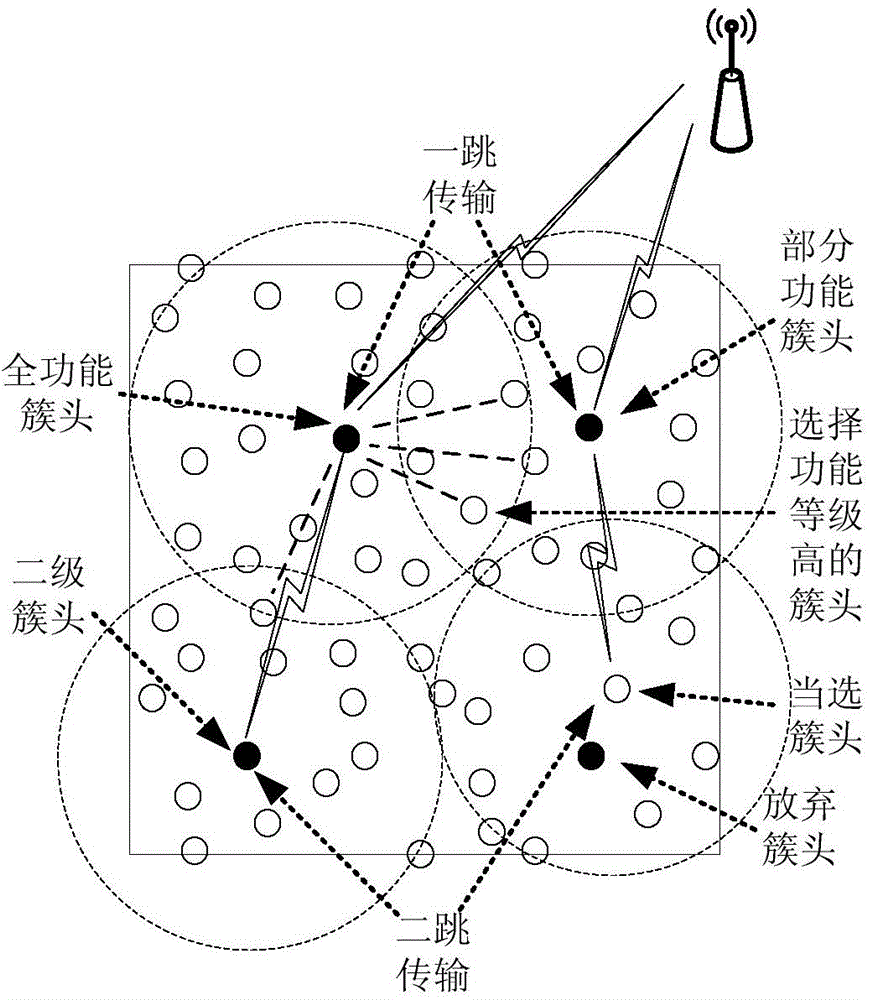

Wireless sensor network node deployment and power supply method

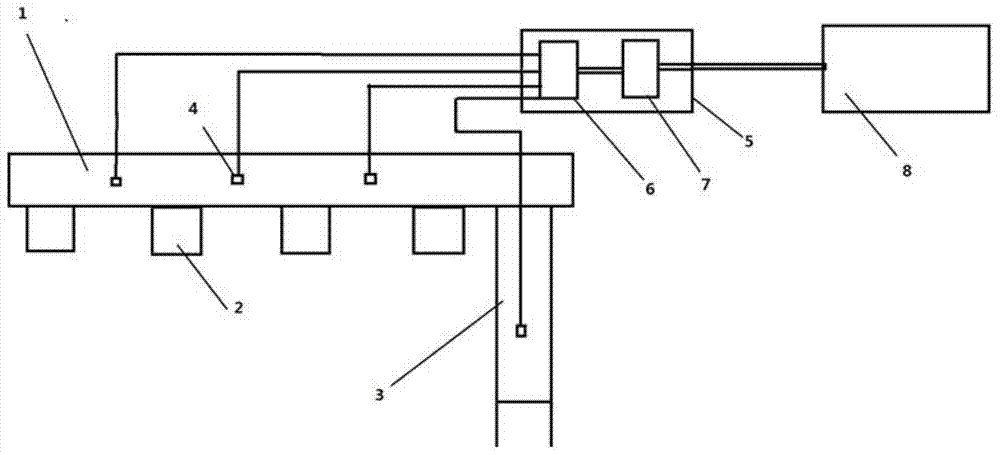

ActiveCN103987055AEnsure continuous and stable workMaximize utilizationPower managementNetwork topologiesWireless sensor networkingNode deployment

The invention relates to a wireless sensor network node deployment and power supply method. The method comprises the steps of establishing a network node topological structure communicated with and covered by a network, determining the positions of energy consumption hotspots in a current network node topological structure by utilizing a preset data routing path selection algorithm according to the network node topological structure, carrying out deployment of renewable energy source nodes according to the positions of the energy consumption hotspots, and carrying out deployment of battery nodes on other network nodes in the current network node topological structure, dynamically adjusting power supply strategies of the battery nodes according to the power supply states of the renewable energy source nodes. Through the wireless sensor network node deployment and power supply method, under the restriction of limited number of the renewable energy source nodes, according to the positions of the energy consumption hotspots of the network, the number and the positions of the renewable energy source nodes can be determined, the combined deployment of different energy source nodes can be completed, the work tasks and the states of different nodes can be determined according to the conditions of collection and transformation of renewable energy sources, and the continuous stable work of the network and the maximized utilization of the renewable energy sources can be achieved.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

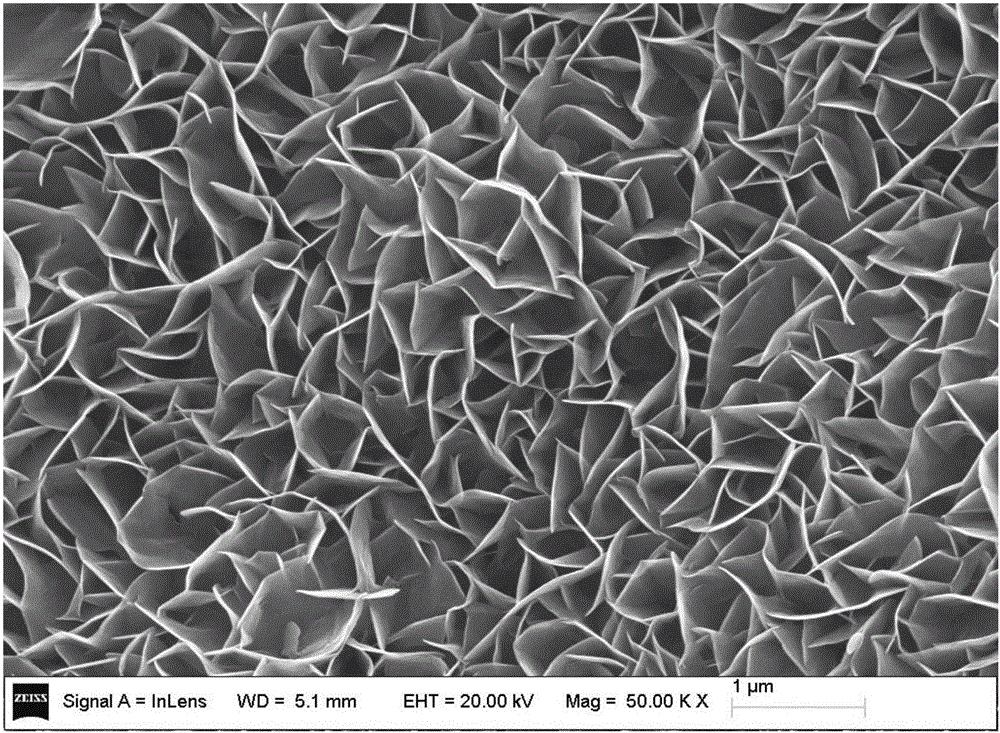

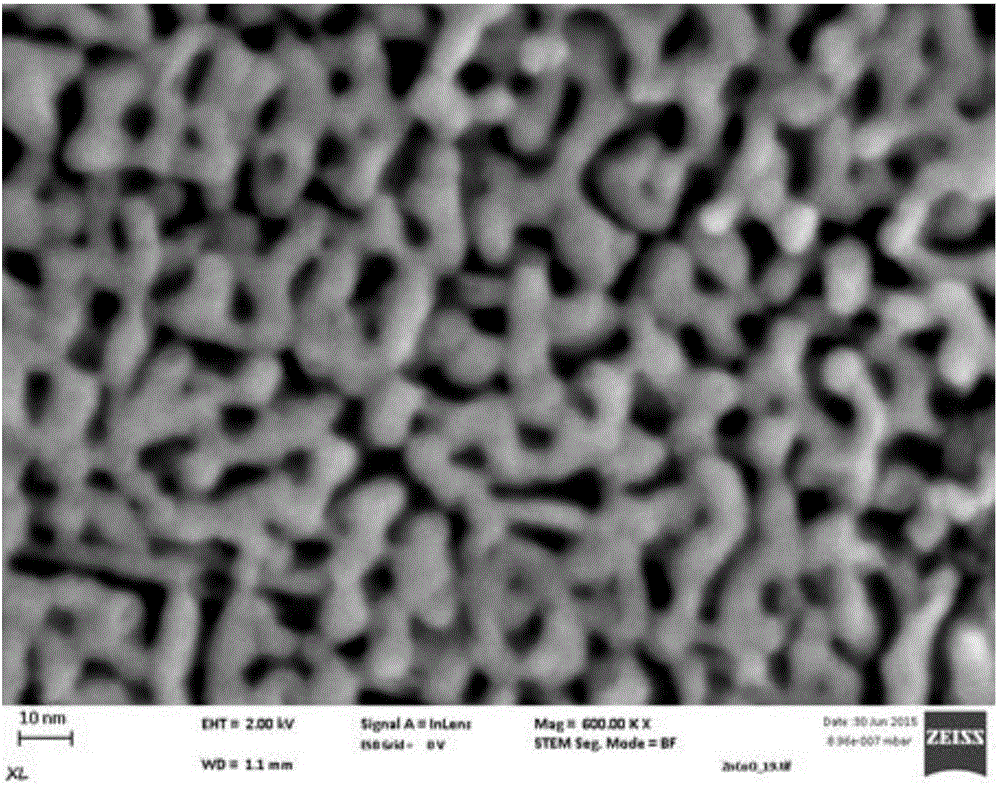

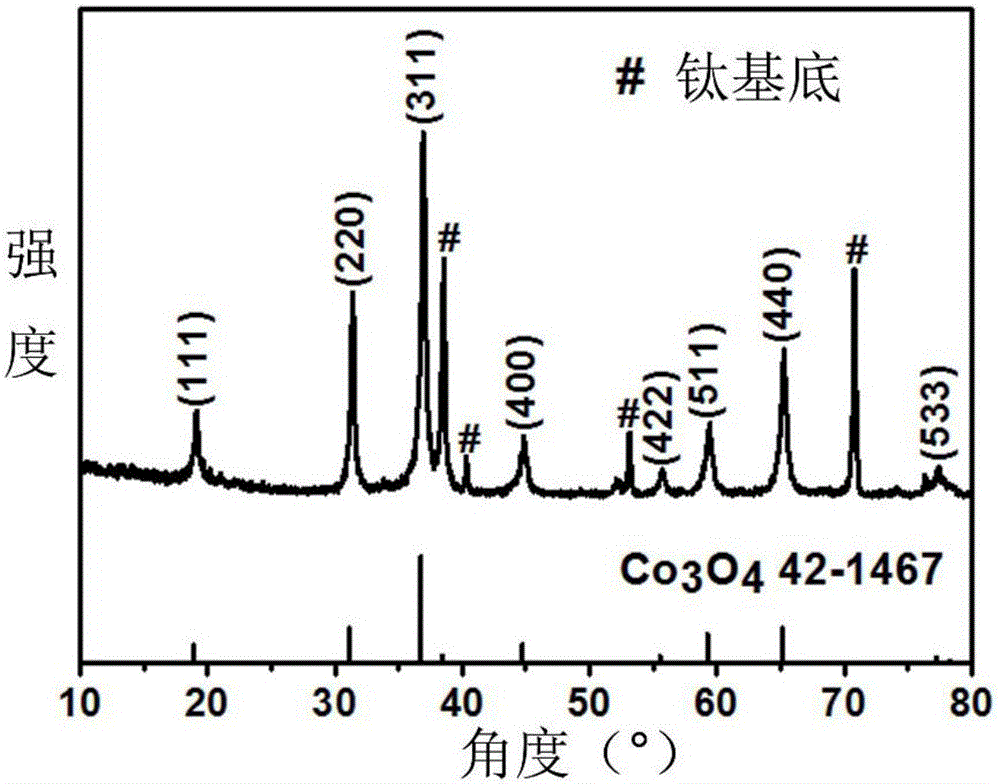

Single-cell-thickness nano porous cobalt oxide nanosheet array electrocatalytic material

InactiveCN106025302AEnsure continuous and stable workExcellent hydrogen evolution reaction performanceMaterial nanotechnologySpecific nanostructure formationDecompositionOxygen

A single-cell-thickness nano porous cobalt oxide nanosheet array electrocatalytic material is characterized in that a metal-doped cobalt oxide primary nanosheet array is perpendicularly grown on a conductive substrate, a porous nanosheet is obtained from each primary nanosheet, and the nanosheets are of porous structure; the material is used as an electrocatalyst for oxygen evolution reaction; the material also has excellent hydrogen evolution performance and may function as a bifunctional catalyst for an alkaline full-decomposition water system. The invention has the advantages that the material can effectively reduce overpotential and peaking potential of oxygen evolution reaction, increase conversion rate of single cobalt atoms and operate stably and continuously in a strong alkali environment; the material has excellent oxygen evolution reaction performance and can be applied as an anode and cathode of a full-decomposition water system, effectively reducing trough voltage; the material is simple to prepare, convenient to operate, low in cost and environment-friendly, and new idea and strategy are provided for the guide design and performance optimization of the bifunctional catalyst for the full-decomposition water system.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

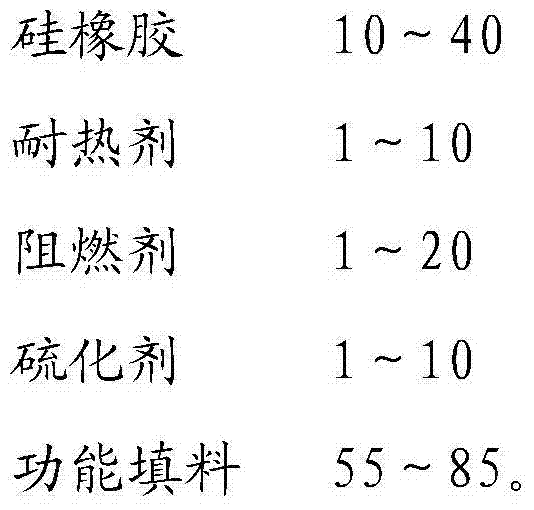

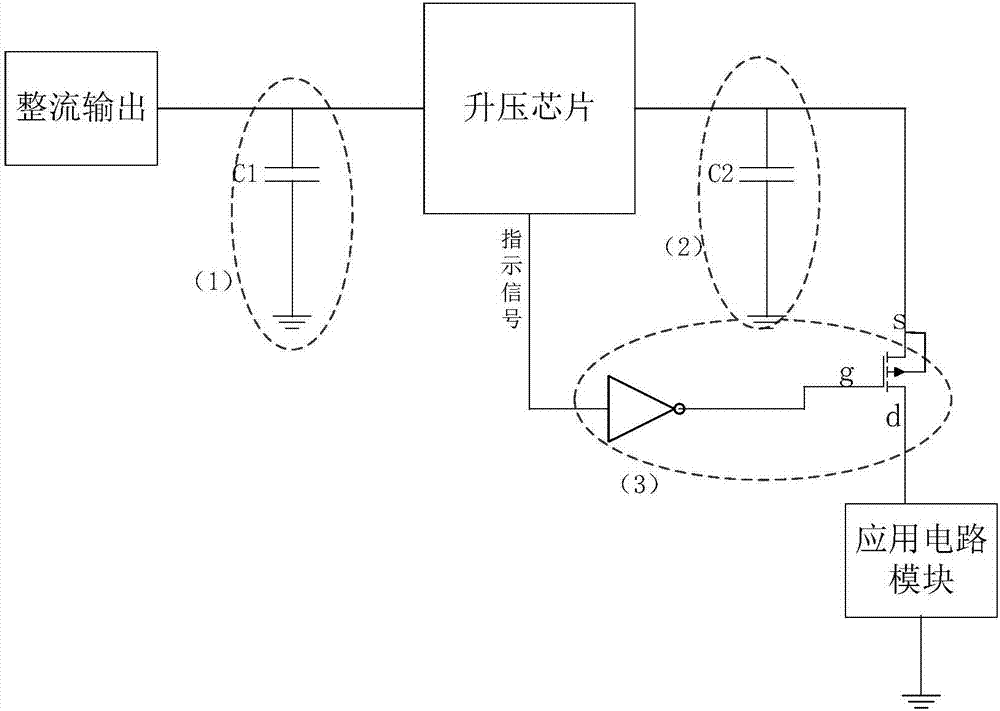

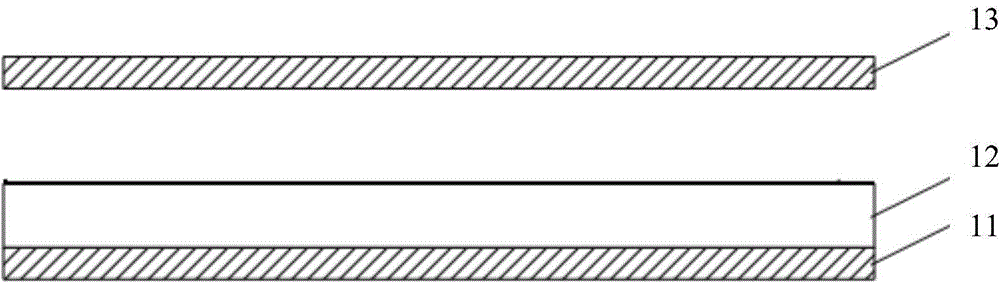

Multifunctional organic silicon thermal interface material

InactiveCN104497574AImprove thermal conductivitySimple preparation processGlass fiberPolyimide membrane

The invention relates to a multifunctional organic silicon thermal interface material. The thermal interface material is formed by compounding the following components in percentage by weight: 10-40% of silicone rubber, 1-10% of a heat resistant agent, 1-20% of a flame retardant, 1-10% of a sulfurizing agent and 55-85% of a functional filler. The thermal interface material is a flaky material formed by mixing the silicone rubber, the heat resistant agent, the flame retardant, the sulfurizing agent and the functional filler according to the proportion, and coating or calendering a mixture on glass fiber cloth or a polyimide film. The organic silicon thermal interface material provided by the invention has high temperature resistance and good heat conduction, insulation and flame retardance, thereby effectively ensuring normal working of electronic equipment.

Owner:SHENZHEN BORNSUN INDAL

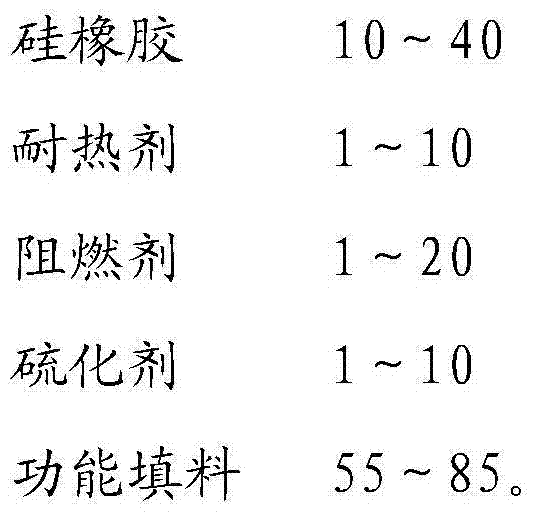

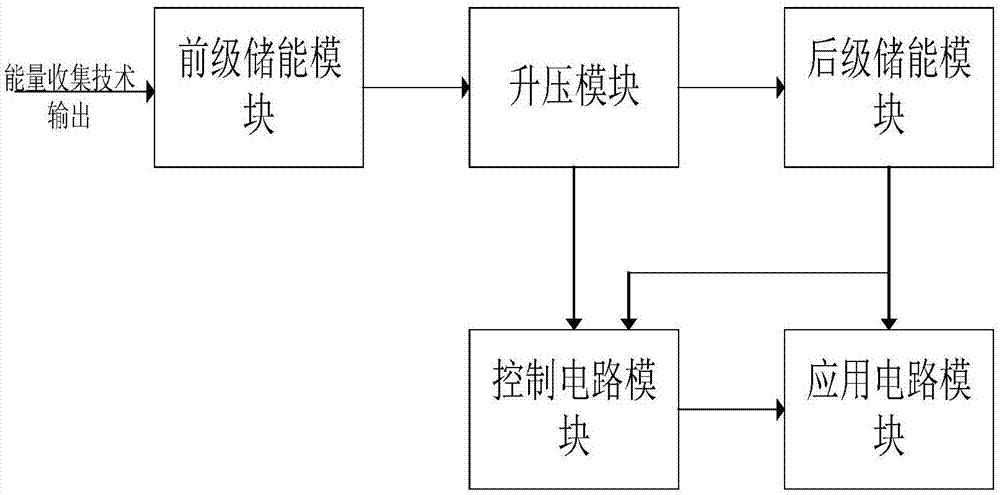

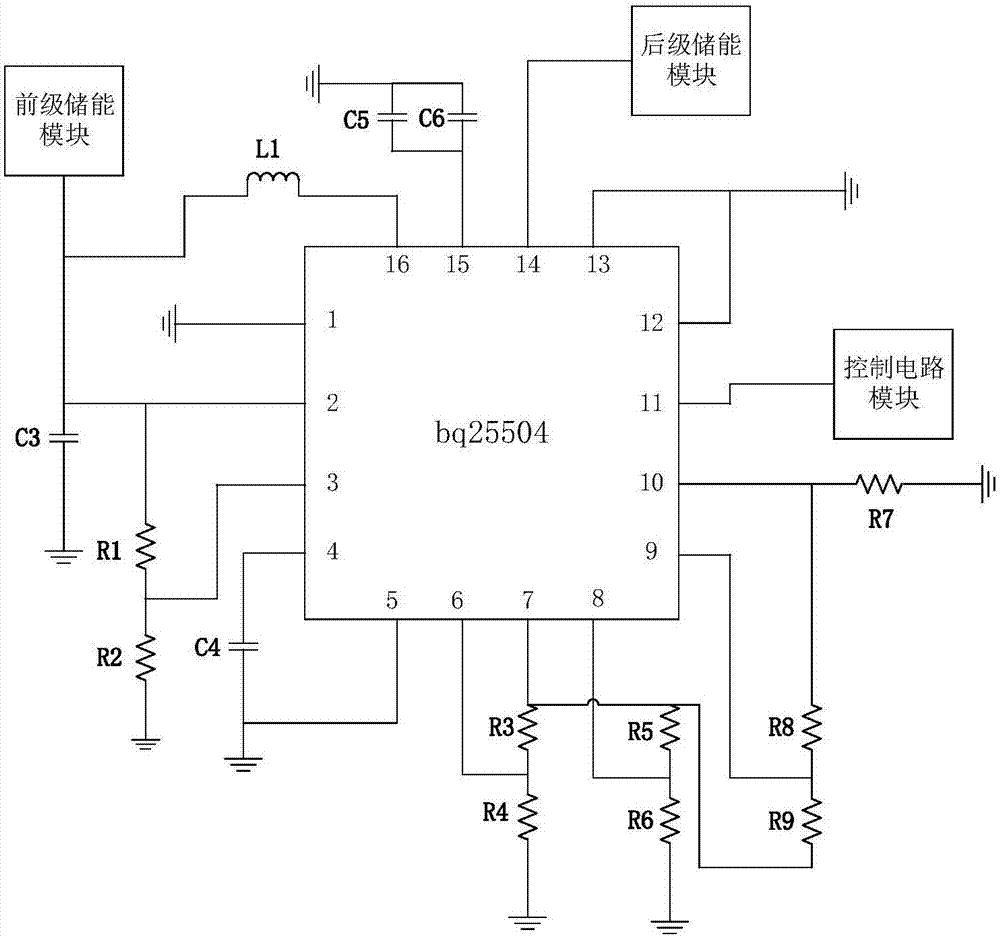

Sensor node power supply management circuit

InactiveCN107394906AGuaranteed to workContinuous working voltageBatteries circuit arrangementsApparatus without intermediate ac conversionSupply managementComputer module

The invention discloses a sensor node power supply management circuit; the sensor node is powered by the energy collection technology; the power supply management circuit comprises a pre-stage energy storage module, a boost module, a rear-stage energy storage module, a control circuit module and an application circuit module; the pre-stage energy storage module is connected with the rear-stage energy storage module and the control circuit module input end through the boost module; the rear-stage energy storage module output end is connected with the control circuit module and the application circuit module input end; the control circuit module output end is connected with the application circuit module input end; the pre-stage energy storage module stores the collected environment energy as the boost module input power supply; the rear-stage energy storage module stores the boosted energy so as to provide energy for the control circuit module and the application circuit module; when two-end voltage of the rear-stage energy storage module changes in a set value scope, the control circuit module controls the application circuit module. The power supply management circuit can reasonably control collected energy to serve as the application circuit energy source, thus enabling the application circuit module to stably work.

Owner:SYSU CMU SHUNDE INT JOINT RES INST +2

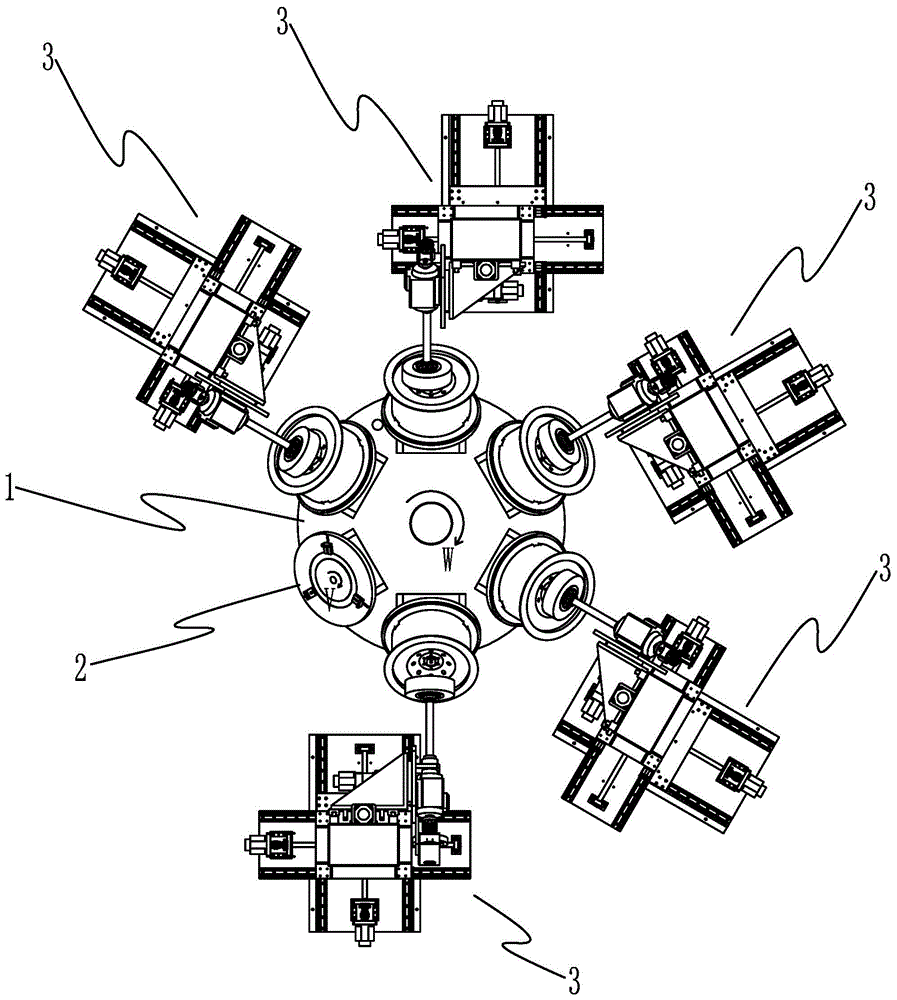

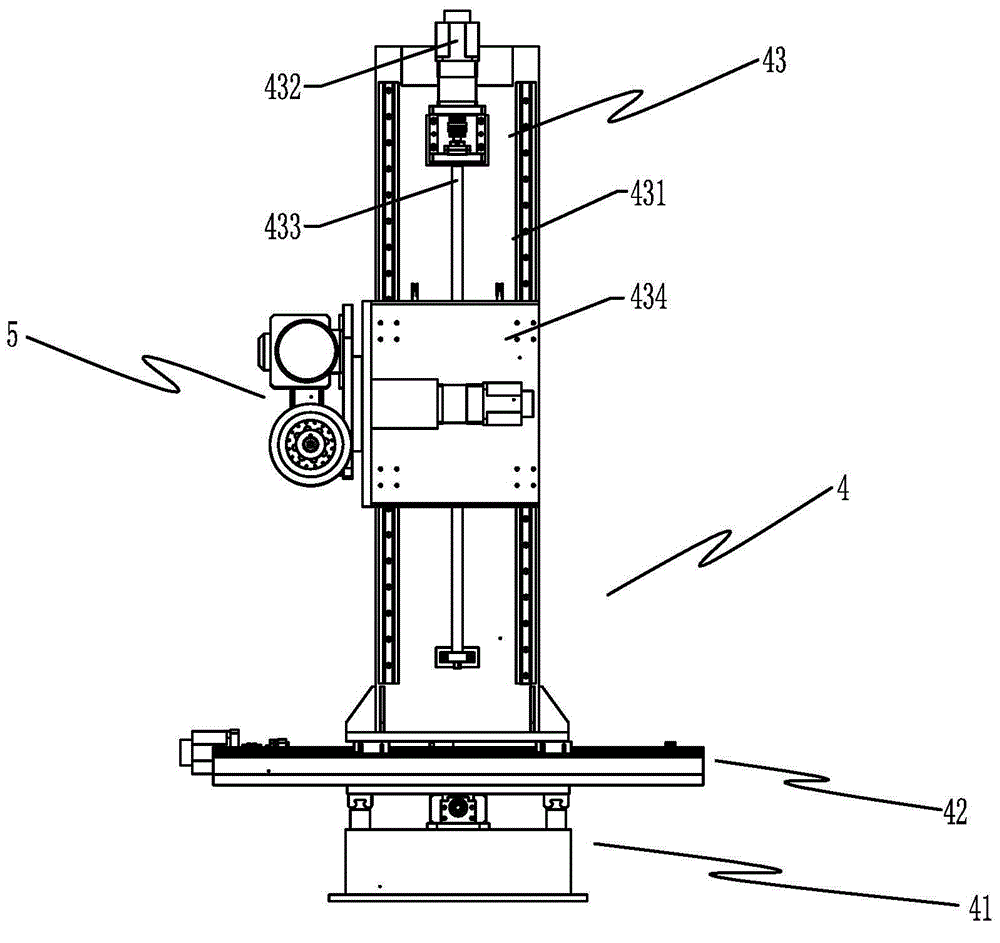

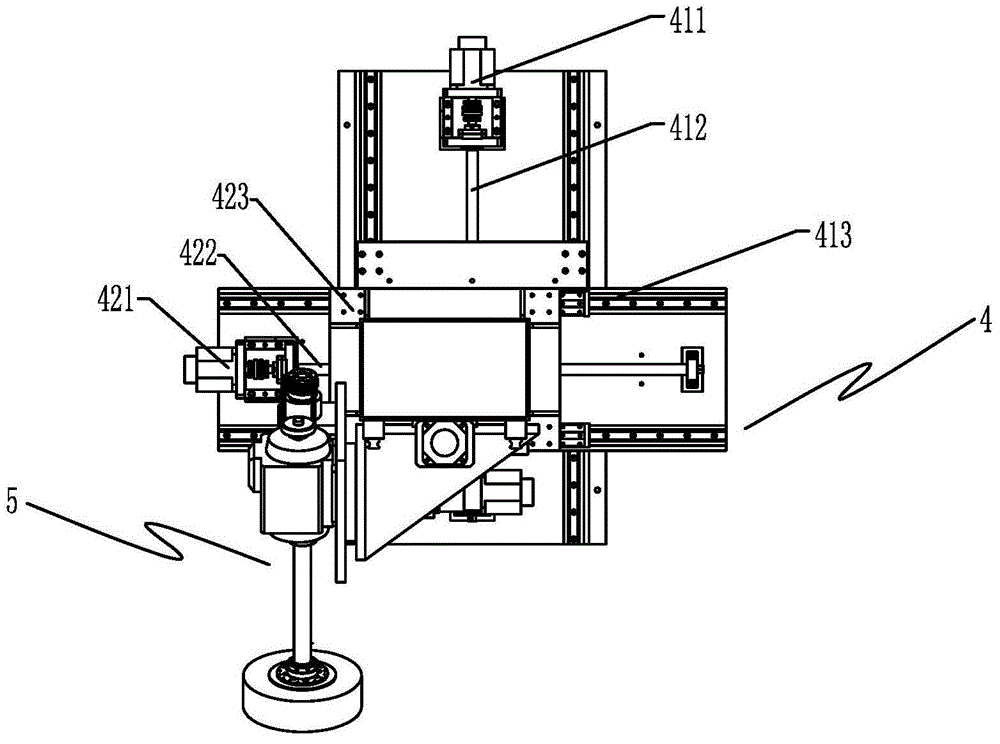

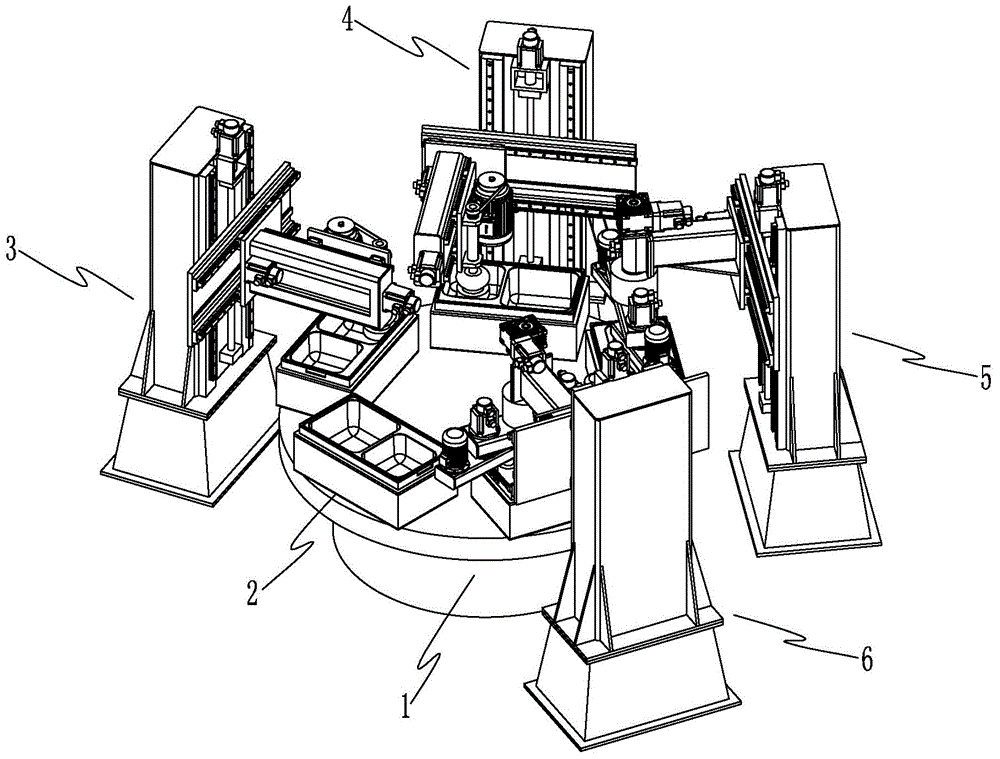

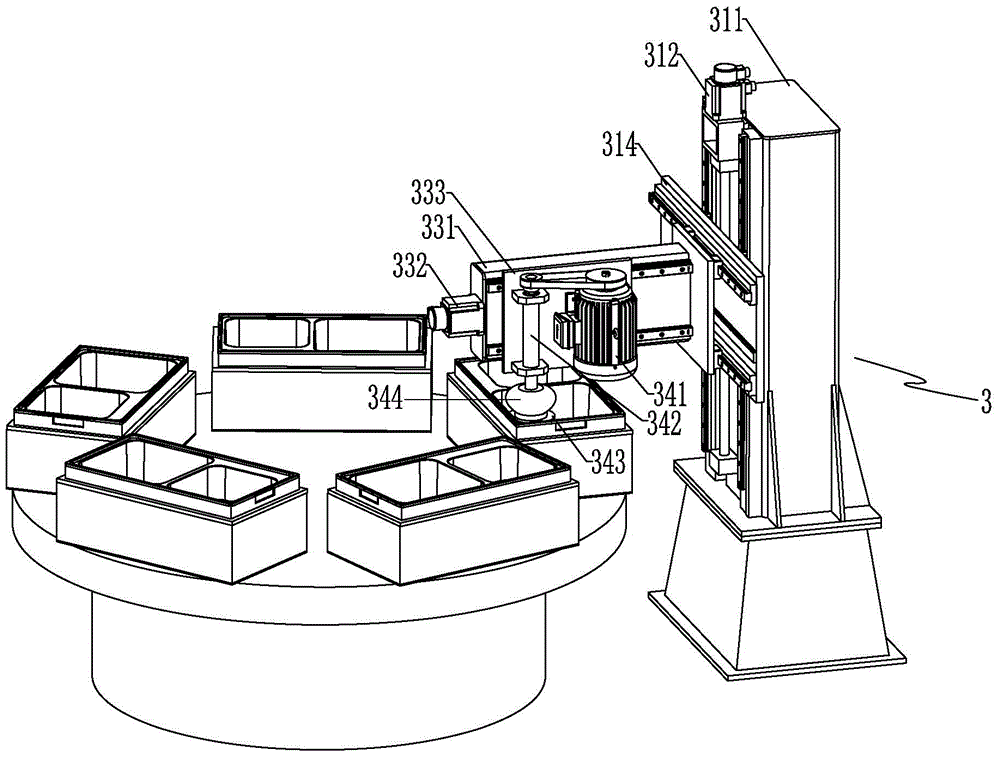

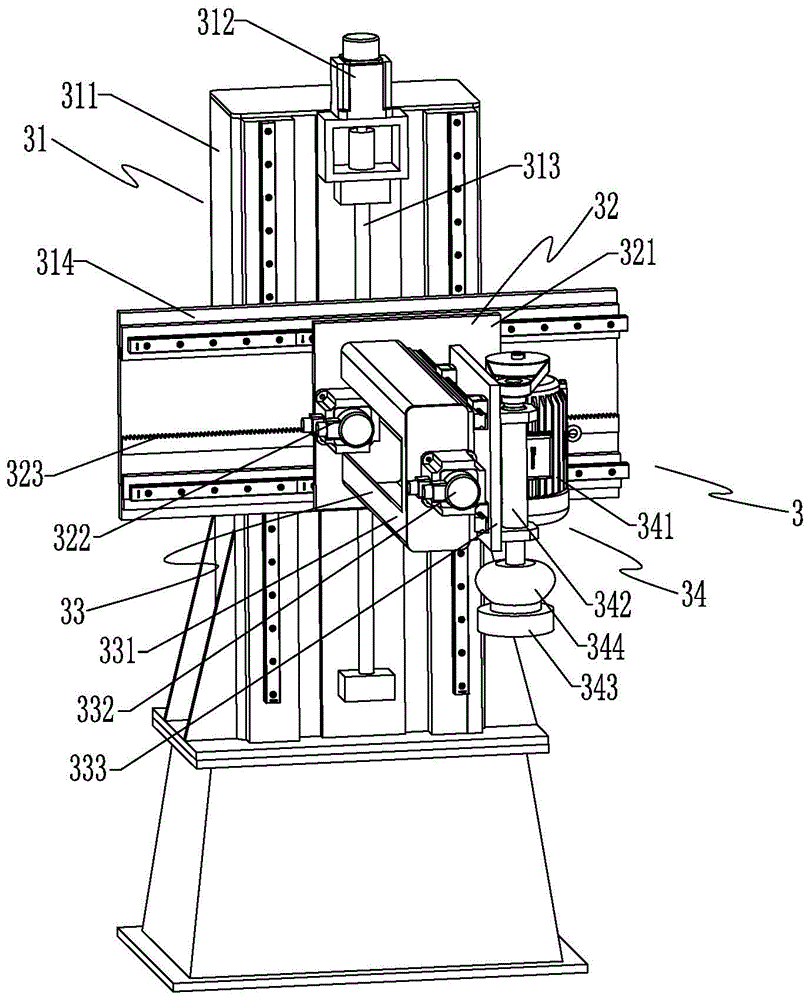

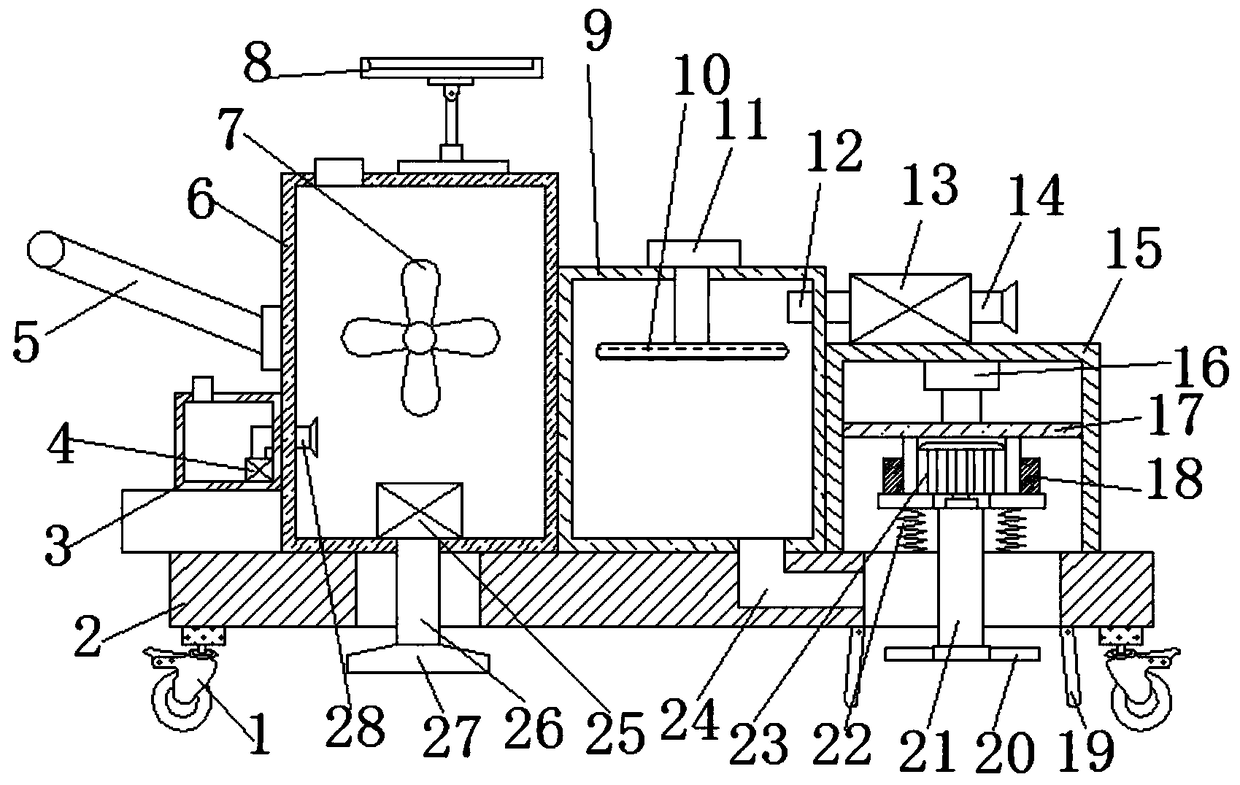

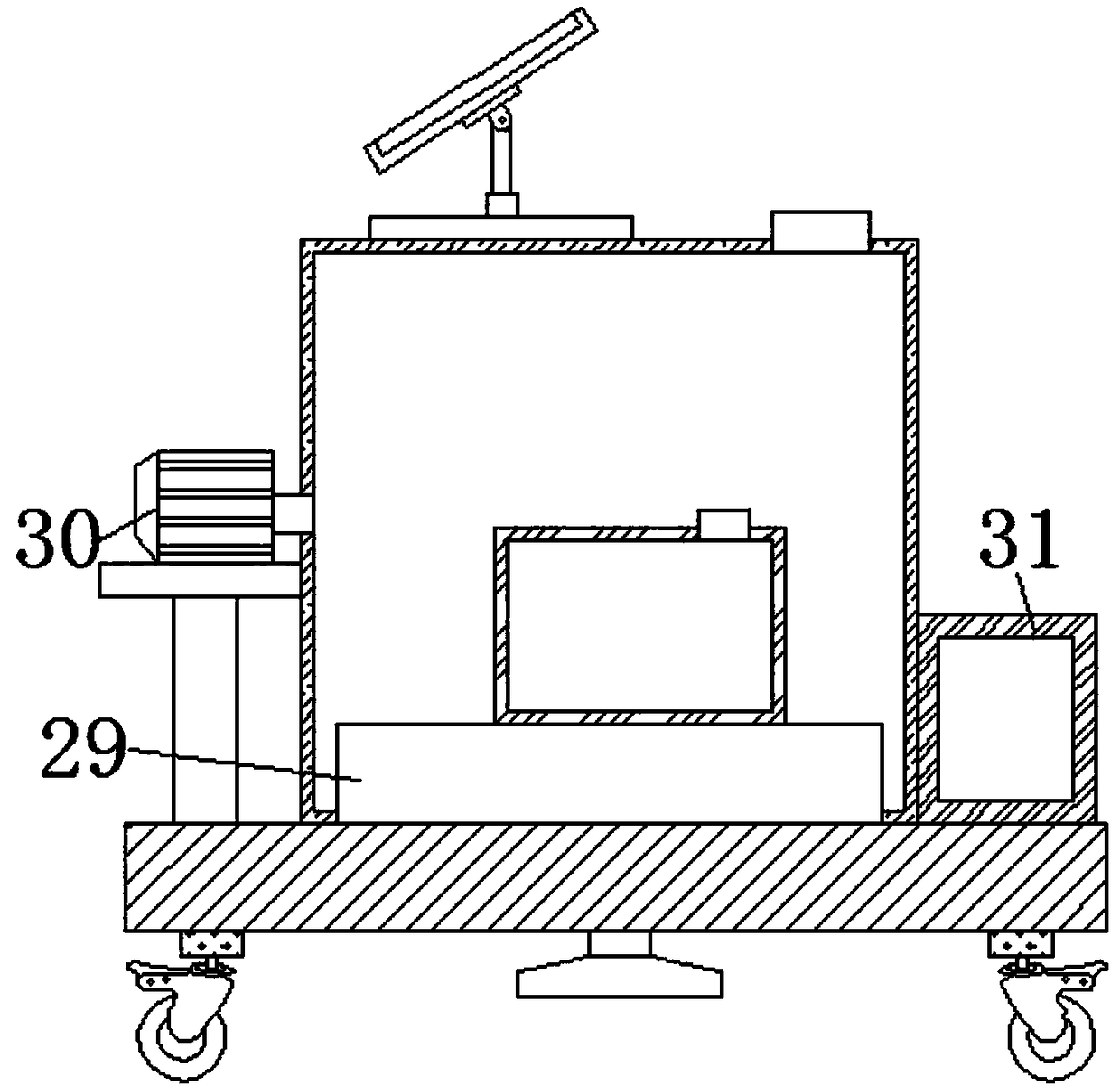

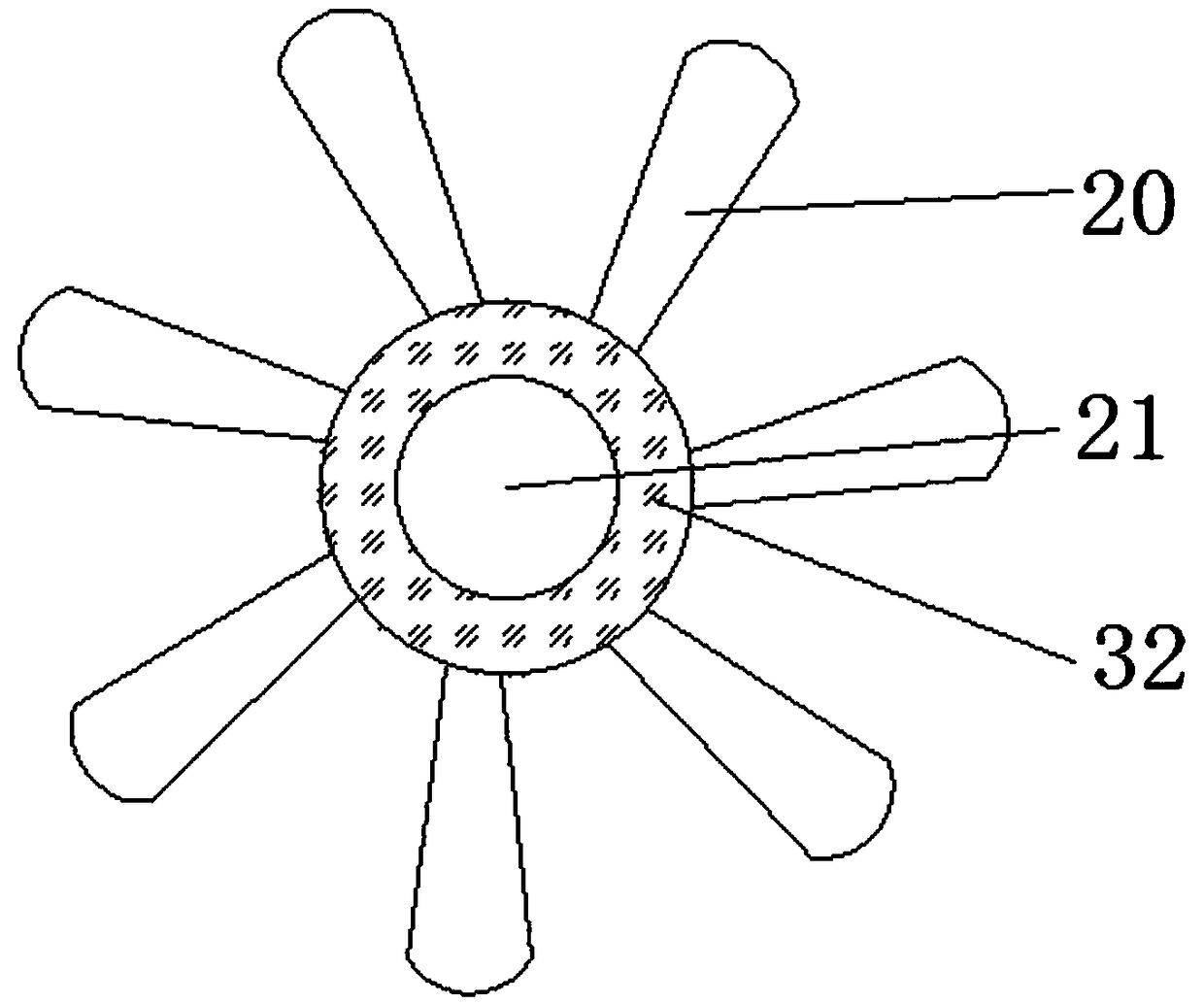

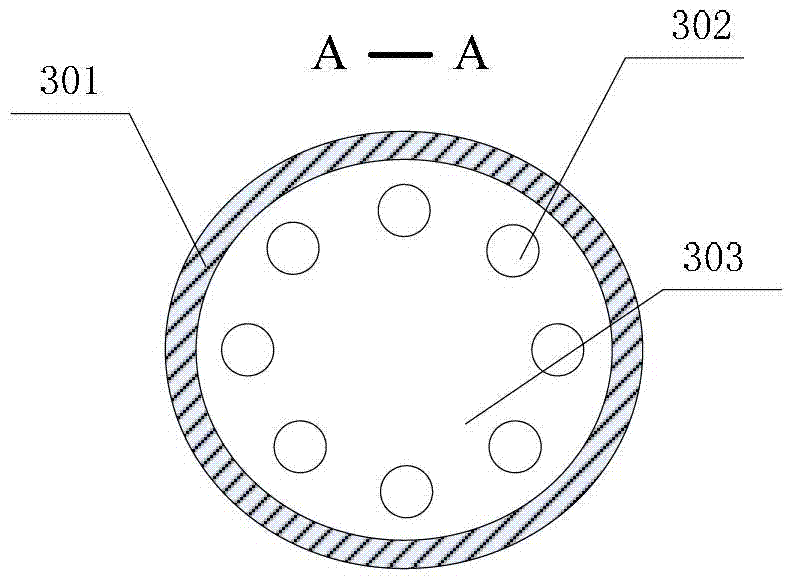

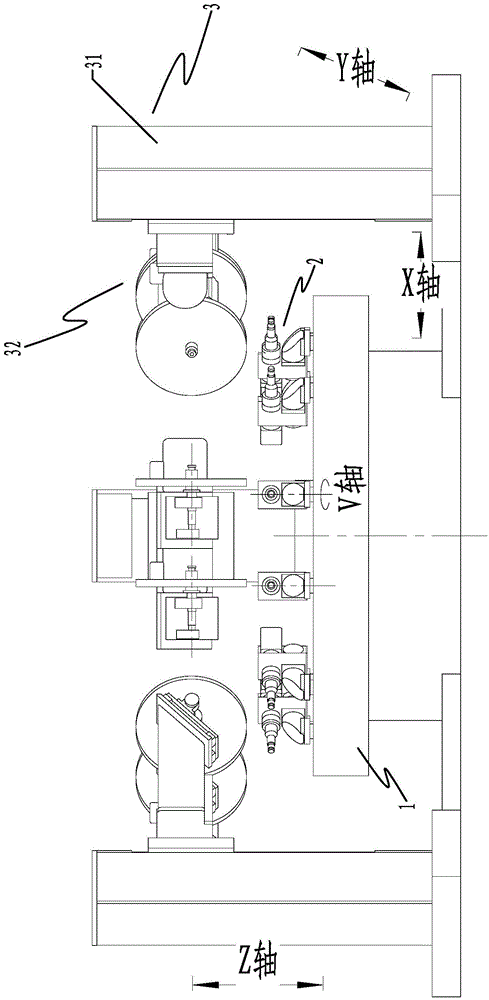

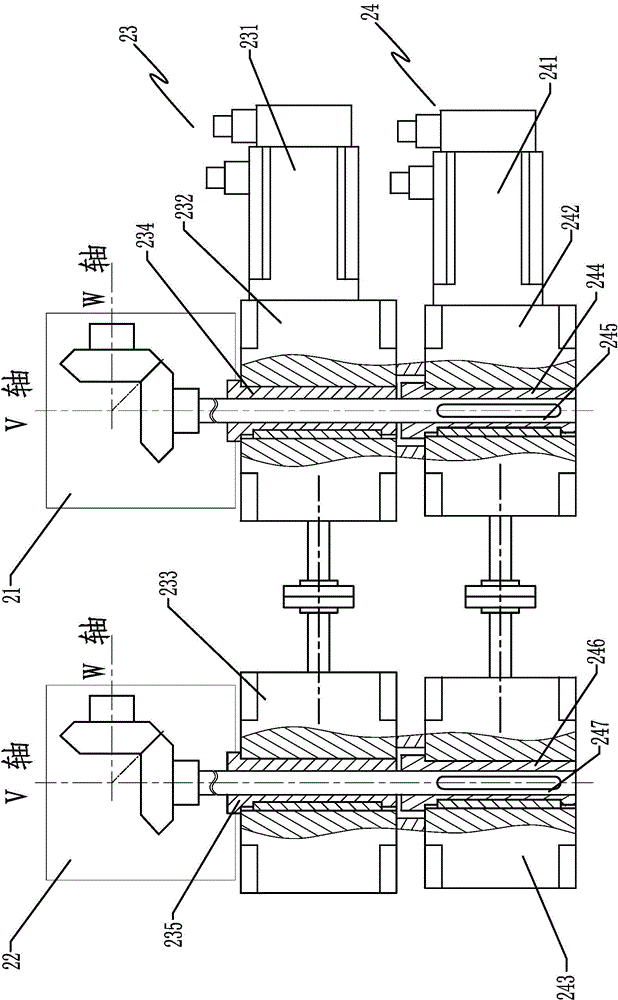

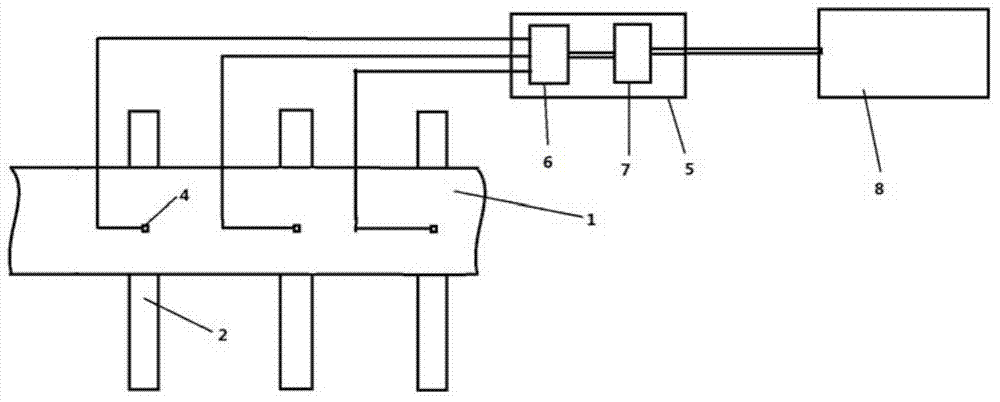

Multi-station circular-disc type novel numerical control automobile hub polishing machine

ActiveCN105014511AStable polishing qualityEnsure continuous and stable workPolishing machinesGrinding drivesNumerical controlCircular disc

The invention discloses a multi-station circular-disc type novel numerical control automobile hub polishing machine. The multi-station circular-disc type novel numerical control automobile hub polishing machine comprises a revolution circular disc assembly in the middle. Autoroatation hub clamp assemblies of multiple stations are evenly arranged on the revolution circular disc assembly in the circumferential direction at equal angles. Asynchronous polishing wheel assemblies of the stations and a loading and unloading station of one station are arranged around the autoroatation circular disc assemblies and correspond to the autoroatation hub clamp assemblies of all the stations. The polishing wheel assembly of each station comprises a three-direction displacement component and a polishing wheel machine head component deflecting at the preset angle along the horizontal axis and arranged on the three-direction displacement component. The polishing machine can achieve four-axis linkage and automatic compensation for the polishing wheel wear radius, and therefore production efficiency is improved greatly; meanwhile, the application range of complex-spoke hub polishing is enlarged, and the stable and consistent hub polishing quality is guaranteed; and the requirement on the experience of operators is lowered, and thus production efficiency and economic benefits are improved.

Owner:广东博科数控机械有限公司

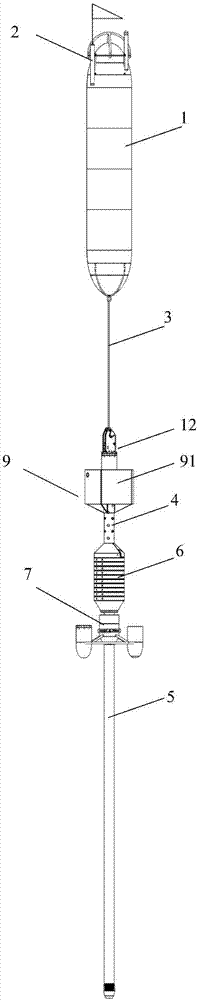

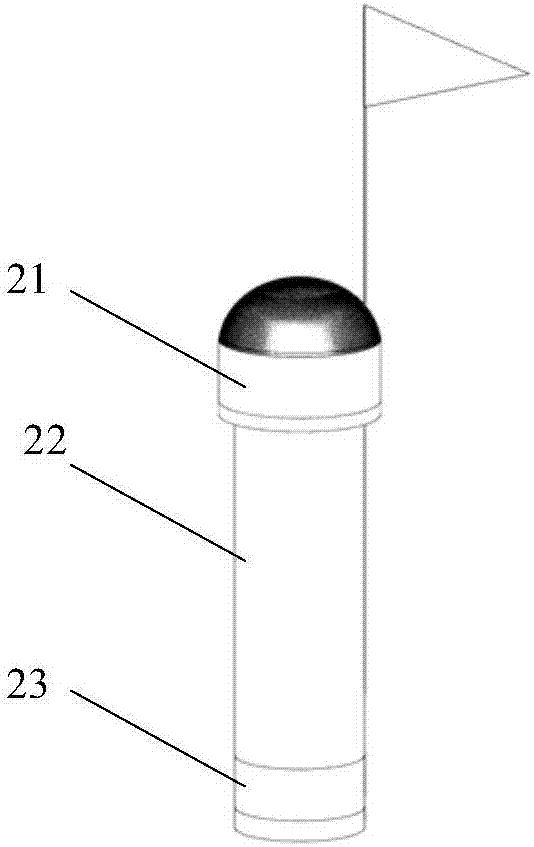

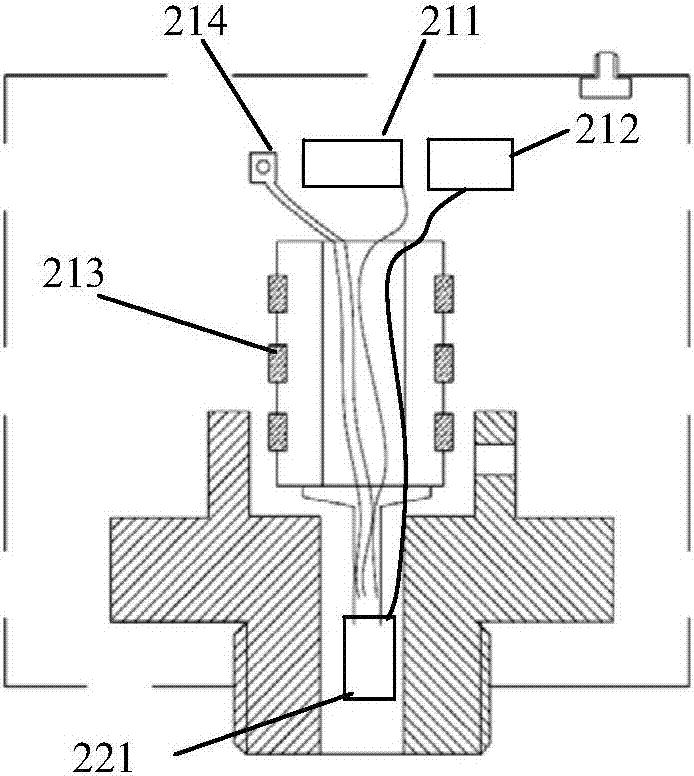

Ultra-deep sea bed sediment ropeless gravity sampling system

ActiveCN106895988AIncrease success rateReduce deliveryWithdrawing sample devicesOcean bottomEngineering

The invention provides an ultra-deep sea bed sediment ropeless gravity sampling system, mainly comprising a recycling unit and a discarding unit; the recycling unit comprises a beacon, a floating component, a rope and a sampler inner tube; the beacon is positioned at the top end of the floating component; the floating component, the rope and the sampler inner tube are connected with each other in sequence; the discarding unit comprises a sampler outer tube, a counterweight and a trigger unlocking mechanism; the counterweight peripherally arranged at the upper portion of the outer wall of the sampler outer tube; the trigger unlocking mechanism sleeves the outer wall of the sampler outer tube below the counterweight. The ultra-deep sea bed sediment ropeless gravity sampling system has higher reliability and safety and has lower cost than existing rope sampling methods.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Multi-station disc type novel numerical control polishing machine for pot type workpieces

ActiveCN104972382AConsistentAchieve consistencyGrinding carriagesPolishing machinesNumerical controlEngineering

The invention discloses a multi-station disc type novel numerical control polishing machine for pot type workpieces. The multi-station disc type novel numerical control polishing machine comprises a rotating disc assembly arranged in the middle. Multi-station pneumatic sucker components are evenly arranged in the circumference direction of the upper surface of the rotating disc assembly with equal angles. A loading and unloading station is arranged in the position, corresponding to one pneumatic sucker component, of the periphery of the rotating disc assembly. Single-polishing wheel assemblies and / or double-polishing wheel assemblies are arranged in the positions, corresponding to the rest of the pneumatic sucker components, of the periphery of the rotating disc assembly. The single-polishing wheel assemblies comprise three-direction displacement components and single-polishing wheel machine head components arranged on the three-direction displacement components. The double-polishing wheel assemblies comprise two-direction displacement components and double-polishing wheel machine head components arranged on the two-direction moving components. The multi-station disc type novel numerical control polishing machine for the pot type workpieces is provided with the single-polishing wheel assemblies and the double-polishing wheel assemblies so that the multi-station disc type novel numerical control polishing machine can meet the requirement for polishing of side walls and bottom faces of pot type workpieces with different shapes and different sizes, the production efficiency is greatly improved, meanwhile, it is ensured that the polishing quality of the pot type workpieces is stable and consistent, occupied area is saved, energy consumption is reduced, and the production efficiency and the economic benefits are greatly improved.

Owner:广东博科数控机械有限公司

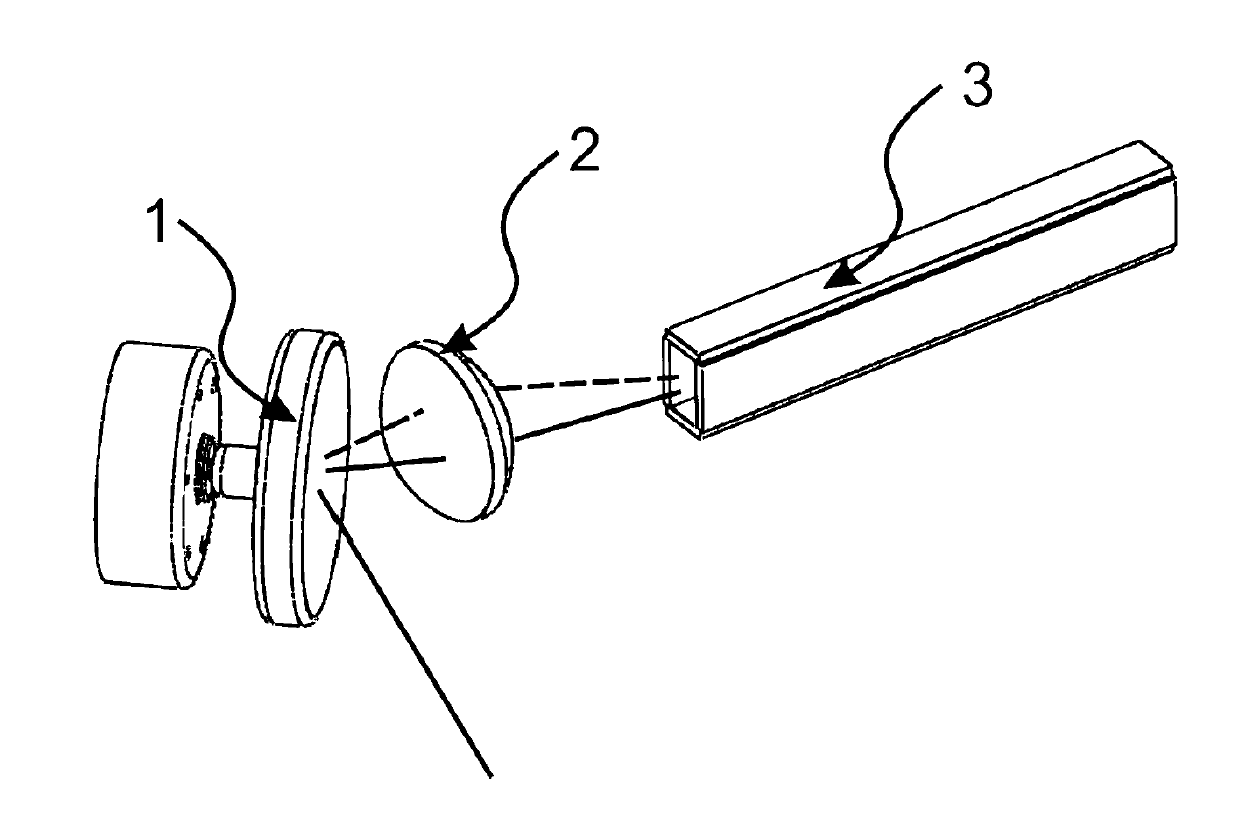

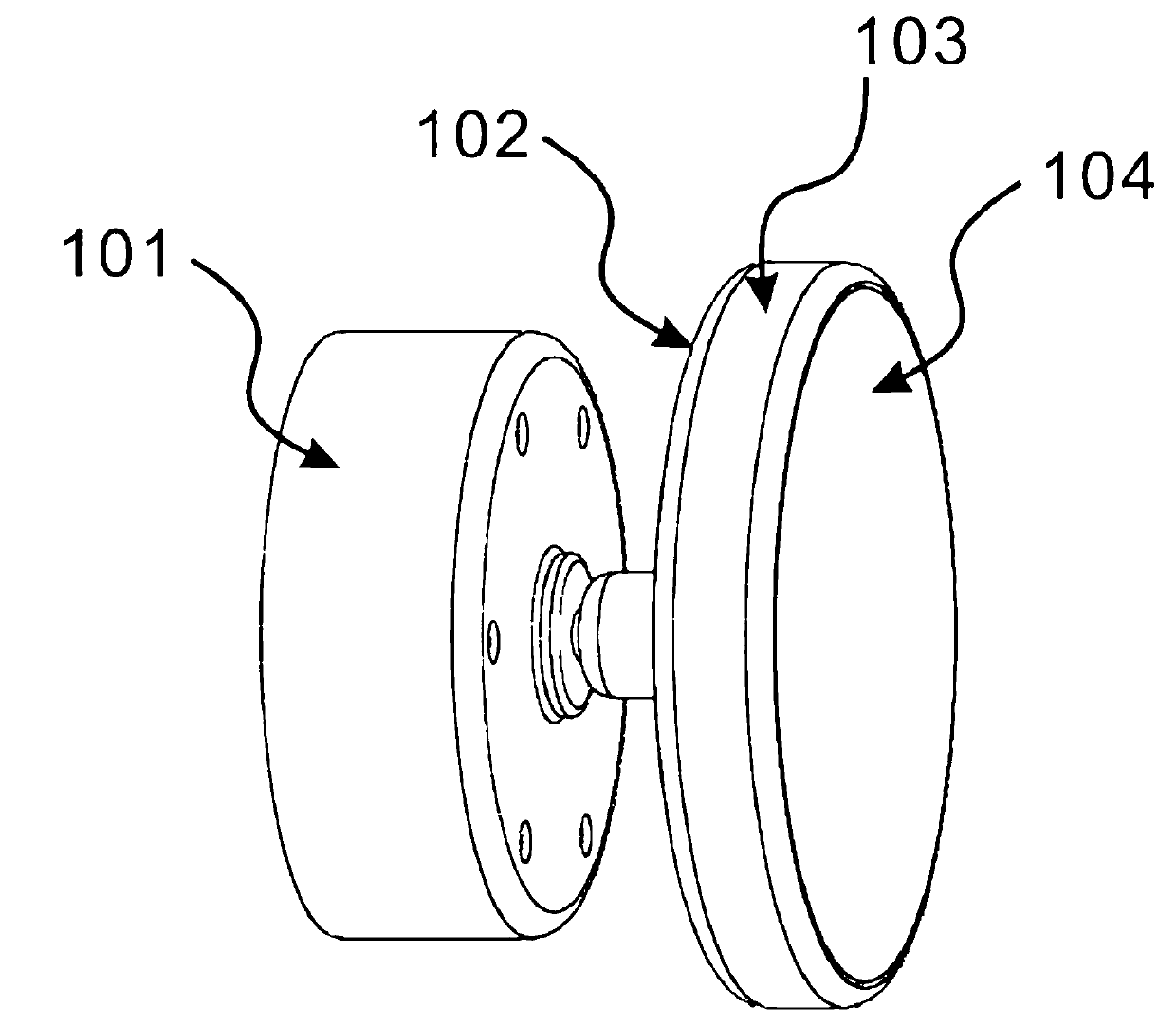

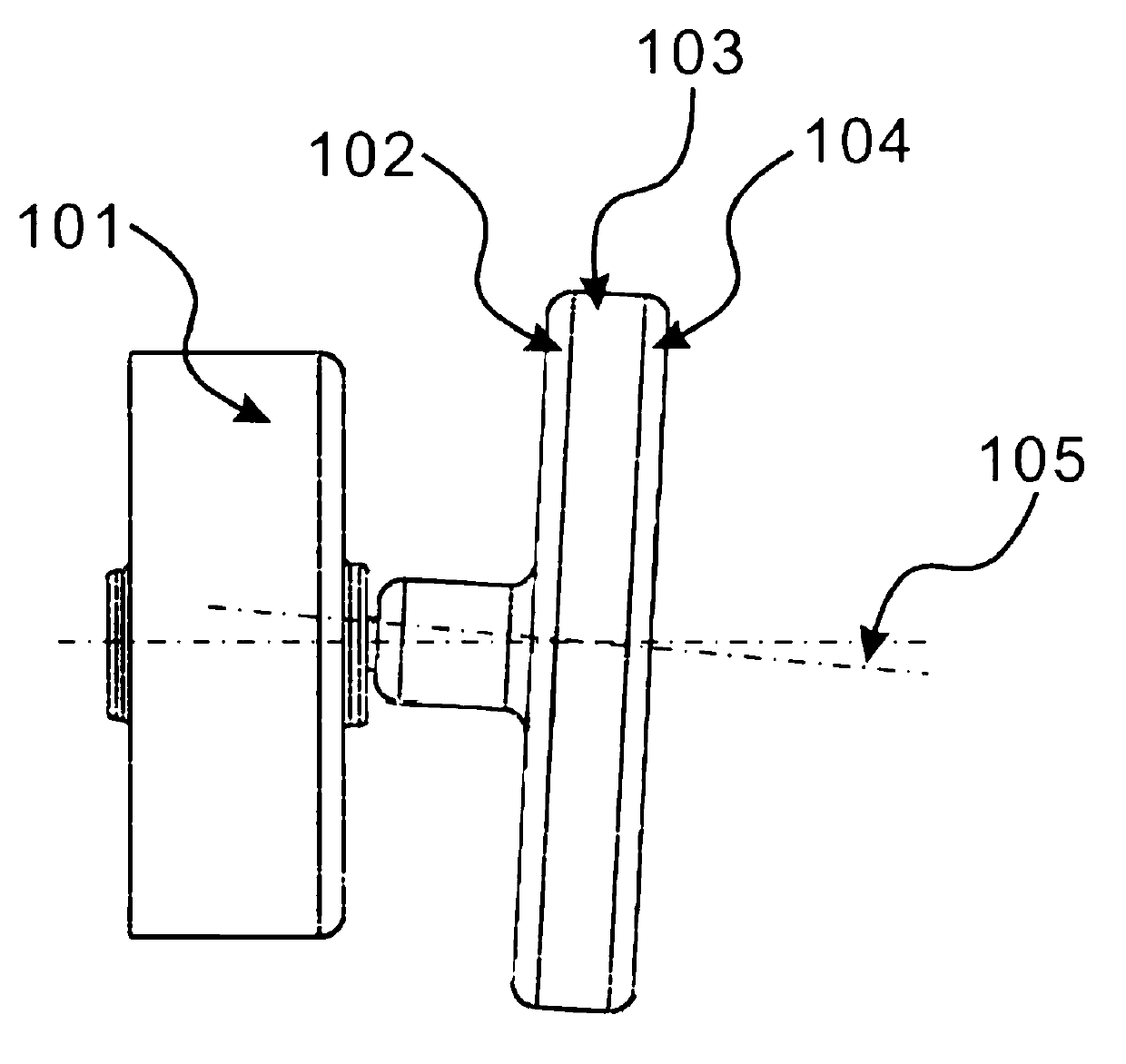

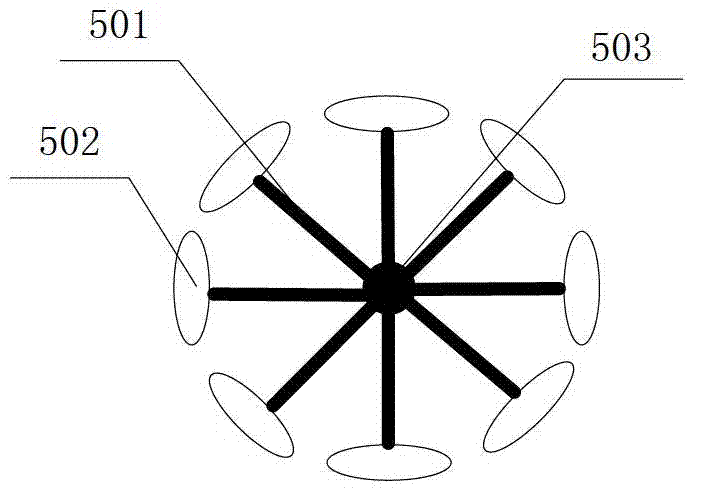

Shimming decoherence device based on rotation reflecting surface and scatterer

ActiveCN103123419AGood speckle removal effectReduce the coherence lengthOptical elementsLight pipeEngineering

The invention relates to the technical field of laser speckle elimination, in particular to a shimming decoherence device based on a rotation reflecting surface and a scatterer. The problem that the existing laser speckle elimination device is poor in speckle elimination effect and image blurring can be caused easily is solved. The shimming decoherence device based on the rotation reflecting surface and the scatterer comprises a decoherence mechanism (1). The decoherence mechanism (1) comprises a motor (101), a reflector (102), a connecting piece (103) and the transparent scatterer (104). The reflector (102) and the scatterer (104) are fixed on two sides of the connecting piece (103) respectively, and an output shaft of the motor (101) is fixedly connected with the back of the reflector (102). A converging lens (2) and a light pipe (3) with a shimming function are sequentially arranged on an output optical path of the decoherence mechanism (1). The shimming decoherence device is reasonable in design and simple in structure and effectively eliminates the laser speckles.

Owner:SHANXI OVISION OPTRONICS CO LTD

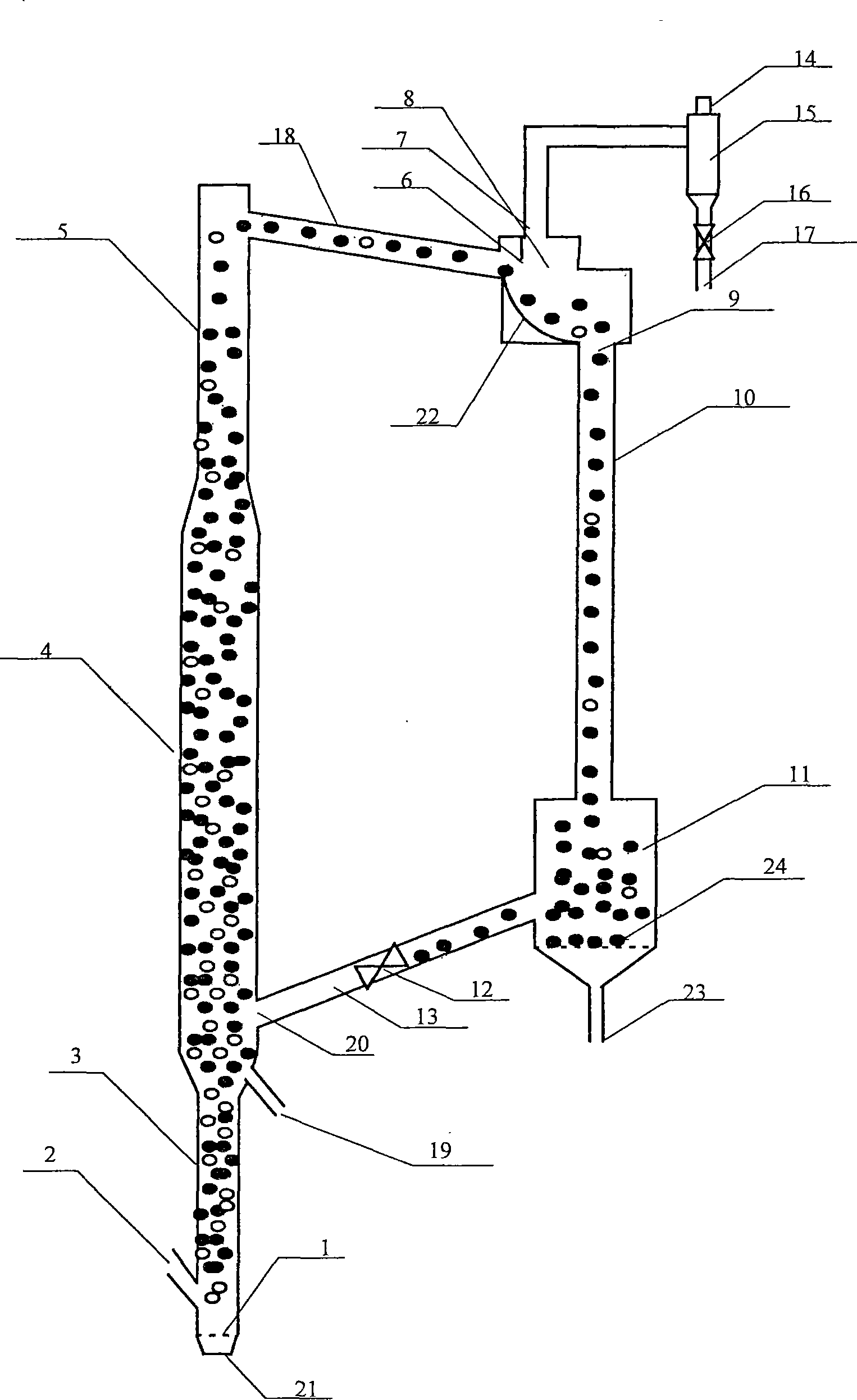

Method for preparing titanic chloride by half cycle fluidization

InactiveCN101475210AReduce agglomerationSolve the conundrum problemFluidised-bed furnacesTitanium halidesNitrogenLower grade

The invention discloses a method for preparing titanium tetrachloride through semi-circulating fluidization, which relates to a method for preparing the titanium tetrachloride. The method takes low-grade high titanium slag and coke as solid raw materials, takes chloride and nitrogen as gas raw materials, and utilizes a semi-circulating fluidized bed to obtain a finished product through a chlorination reaction, cooling and gas-solid separation. The method avoids the agglomeration and adhesion of the particles by circulating coke particles with smaller viscosity and suspending high titanium slag particles with larger viscosity in a fluidized bed reactor, can fully utilize low-grade high titanium slag resource, and has the characteristics of high production efficiency, good product quality, simple and convenient operation, suitability for industrial mass production and the like. The method can be widely applied to the preparation of the titanium tetrachloride by utilizing titanium ore, and is particularly suitable to utilize the low-grade high titanium slag to prepare the titanium tetrachloride.

Owner:CHONGQING UNIV

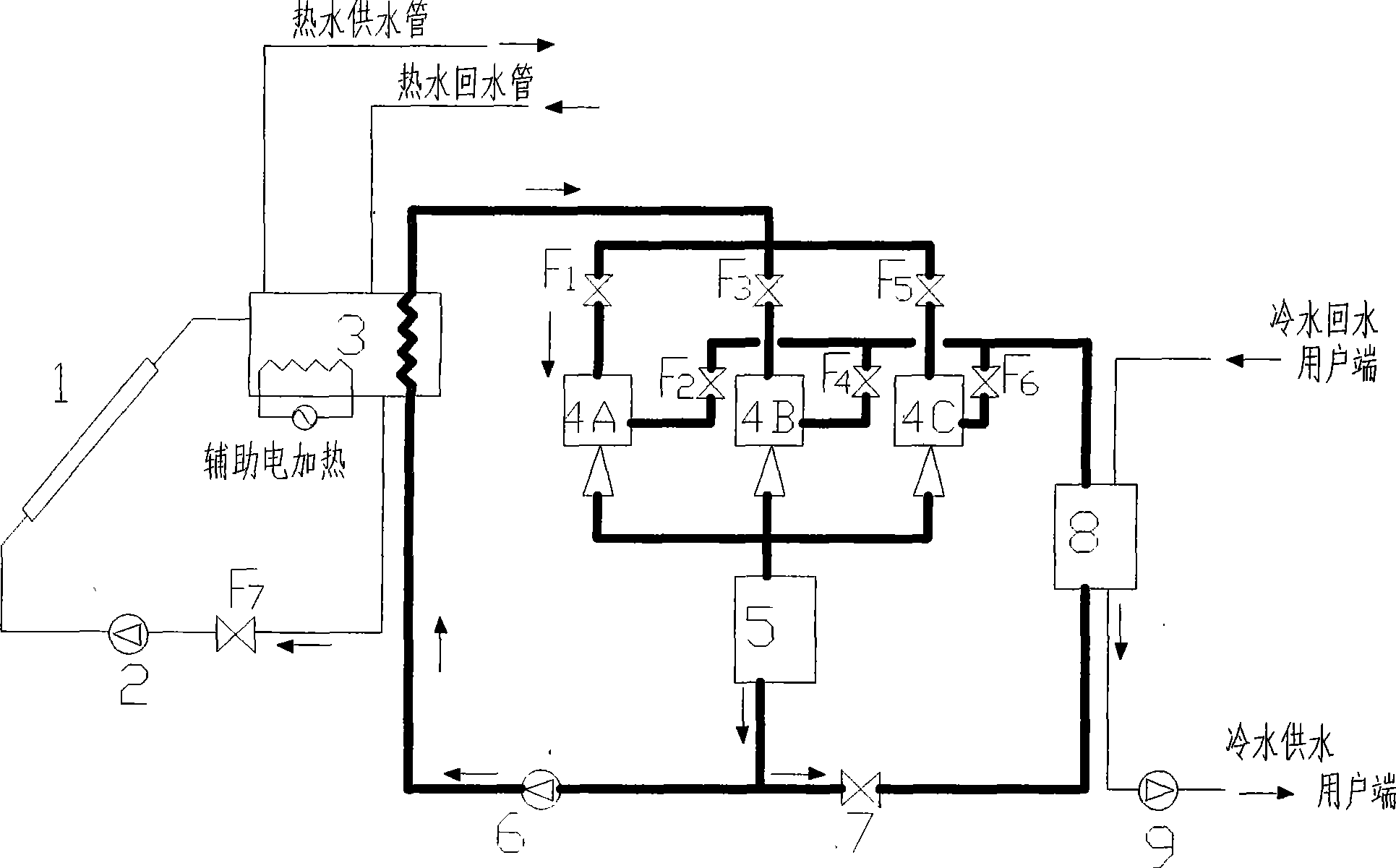

Multi-injector parallel connection type solar injection cooling device

InactiveCN101387457AWide temperature rangeMeet supplySolar heat devicesMachines using refrigerant evaporationCold airConnection type

The invention relates to a multi-ejector parallel type solar ejecting refrigeration unit which utilizes solar energy to supply cold air, which comprises a solar hot-water loop, an ejecting refrigerant loop and an air conditioner water loop. The unit solves the problems that the prior ejecting refrigeration system is only provided with an ejector, the structural dimension of the ejector is fixed and the efficiency of an ejector system is drastically declined directly because operation condition is derivated from design condition. The unit is arranged between a generator and a condenser, and is provided with two or more than two ejectors with different structural dimensions in parallel. The multiple ejectors can meet high-efficiency operation of variable working conditions; and the unit can automatically or manually switch to a proper ejector for working according to solar radiation or weather changing conditions, further ensure that the system operates in refrigeration season with high efficiency, can improve the operation efficiency of the solar ejector system, and realize the aim of supplying the cold air with high efficiency and reasonability, thereby improving the utilization rate of solar energy, saving energy, relieving the pressure of electricity grid at the peak time, and improving the light-heat utilization efficiency.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Power generation effect-improved friction generator and preparation method thereof

ActiveCN104426414AEnsure continuous and stable workReduce viscosityFriction generatorsNanoparticleViscosity

A friction generator (1) and a preparation method therefor. The method comprises: step 1, coating nanometer particles on at least one side of a viscous material film, so as to obtain a nanometer film layer; and step 2, manufacturing a friction generator, wherein a first polymeric material layer (12) and / or a second polymeric material layer (23) and / or an intermediate film layer are composed of the nanometer film layer obtained in step 1. The generator can effectively reduce the viscosity which appears when the viscous material film generates friction on a smooth surface, so that the two friction layers can be separated quickly, and therefore, the friction generator can operate continually and steadily.

Owner:NEWNAGY TANGSHAN

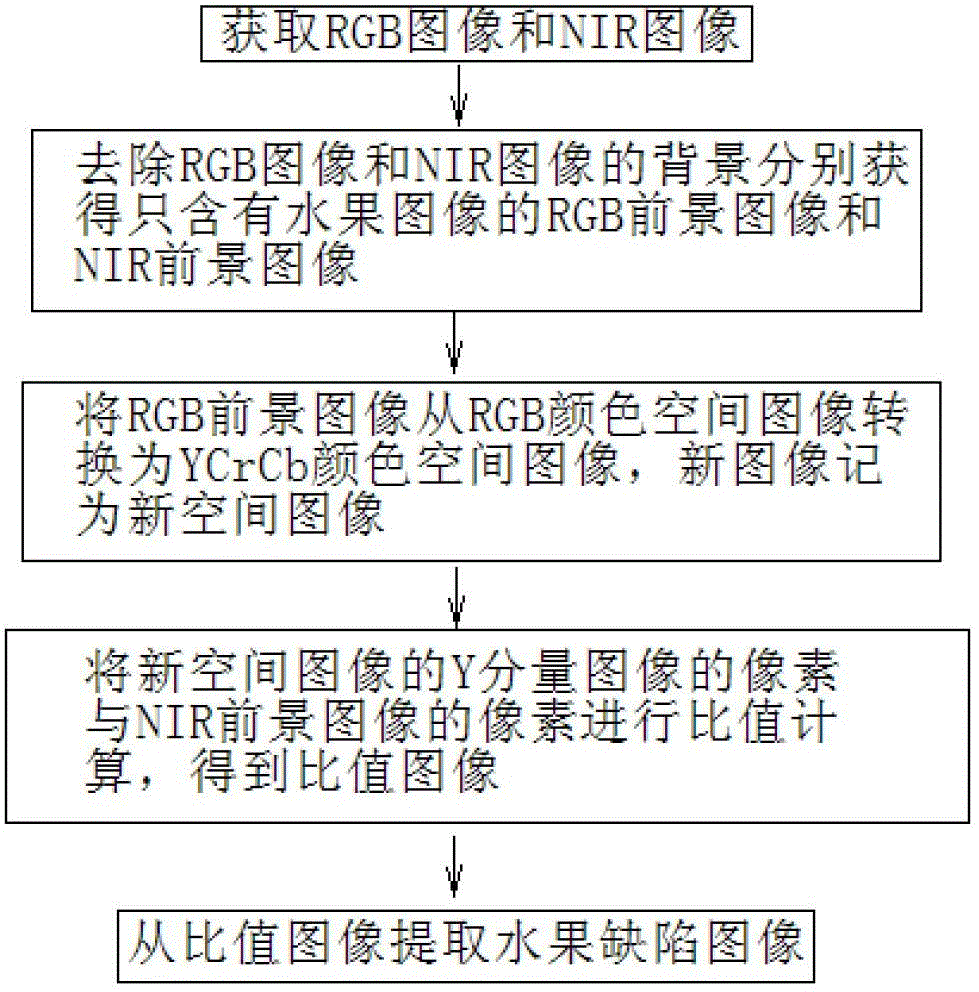

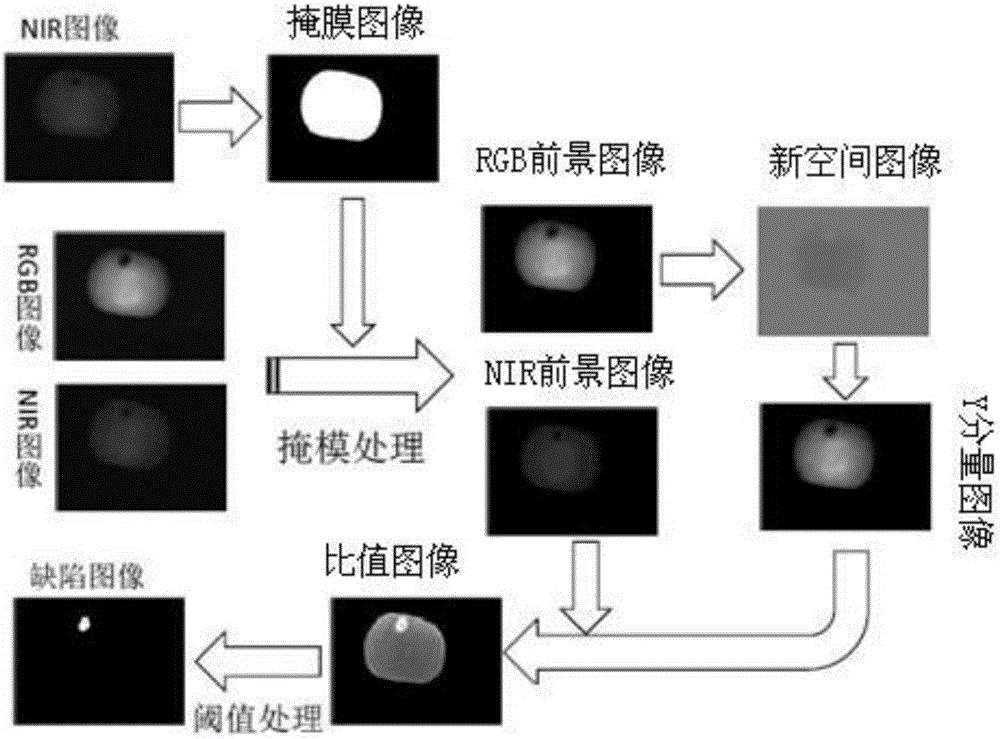

Method for detecting flaw on surface of fruit

InactiveCN103149214AGood stabilityExclusion precisionOptically investigating flaws/contaminationRGB color spaceColor space

The invention provides a method for detecting a flaw on the surface of a fruit by using image processing in the technical field of image processing. The method comprises the following steps of: (1) obtaining a RGB (red, green and blue) image and an NIR (near infrared reflection) image; (2) removing the backgrounds of the RGB image and the NIR image to respectively obtain an RGB foreground image and an NIR foreground image only containing a fruit image; (3) transforming the RGB foreground image into a YCrCb color space image from an RGB color space image, and marking a new image as a new space image; (4) carrying out specific value computation on a Y component image of the new space image and the NIR foreground image to obtain a specific value image; and (5) extracting a fruit flaw image from the specific value image. According to the method, the flaw on the surface of the fruit can be stably, exactly and quickly detected, and the influence caused by the shape and the size of the fruit can be effectively avoided.

Owner:SHANGHAI JIAO TONG UNIV

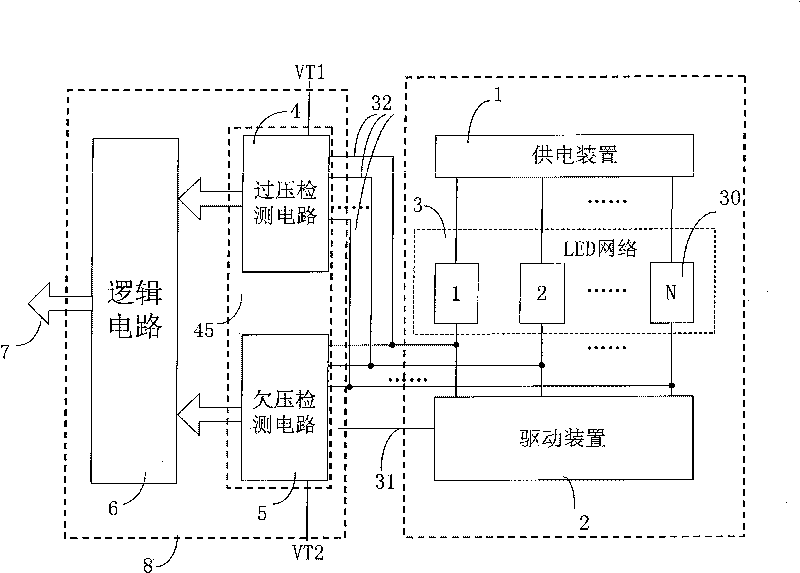

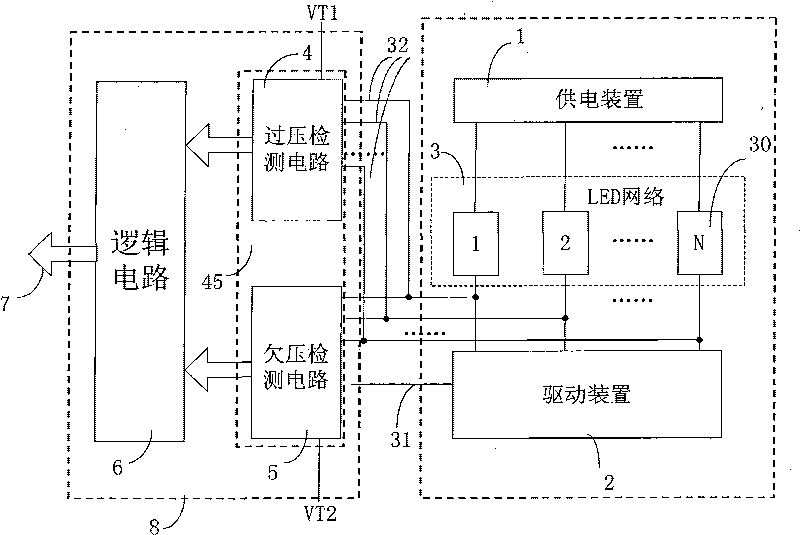

Fault detection device for LED driving circuit and detection method thereof

InactiveCN101762772ARealize real-time detectionFault expansionElectrical testingLogical operationsVoltage reference

The invention relates to a fault detection device for an LED driving circuit and detection method thereof. The fault detection device comprises a voltage detection module and a logic circuit, wherein the voltage detection module respectively compares a difference value between a detection input signal from each group of LEDs and a reference voltage signal from a driving device and setting values from external input, and outputs an identification signal. The logic circuit performs logical operation on the identification signal output from the voltage detection module and outputs a decision signal. When a group or a plurality of groups of LEDs work, the fault detection device can detect open circuit and / or short circuit faults in real time, and is convenient for users to locate faults accurately and take measures for preventing LED faults from expanding, therefore keeping the LED driving circuit stably working for a long period.

Owner:SHANGHAI BEILING

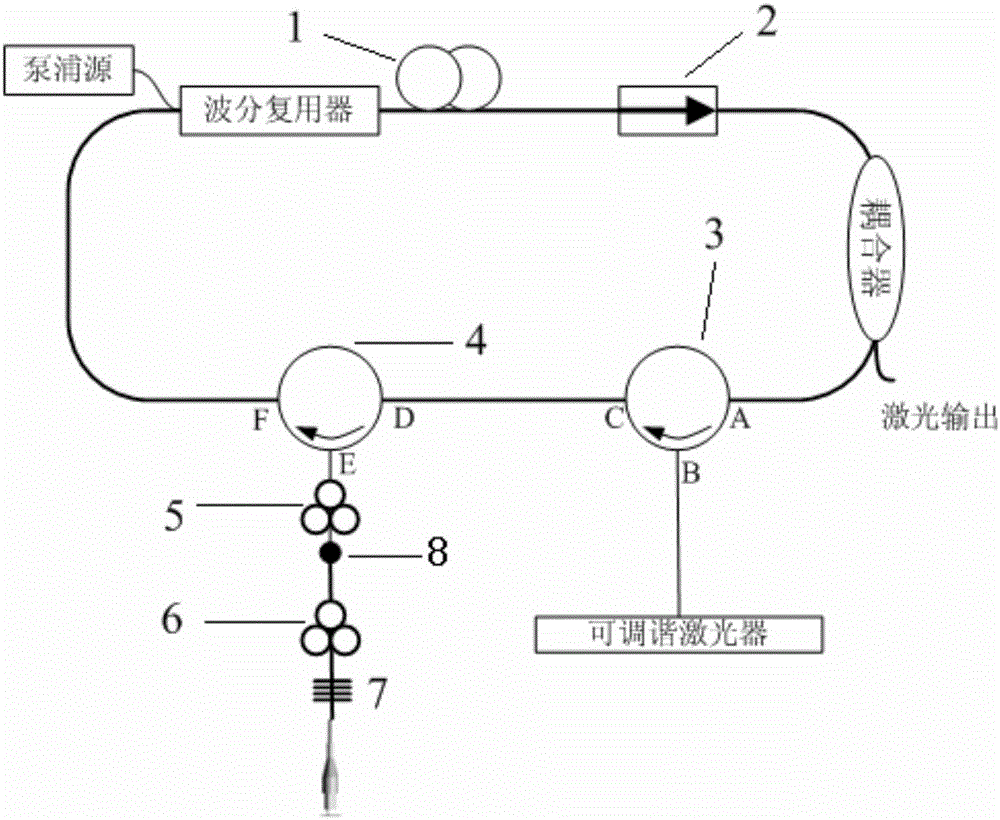

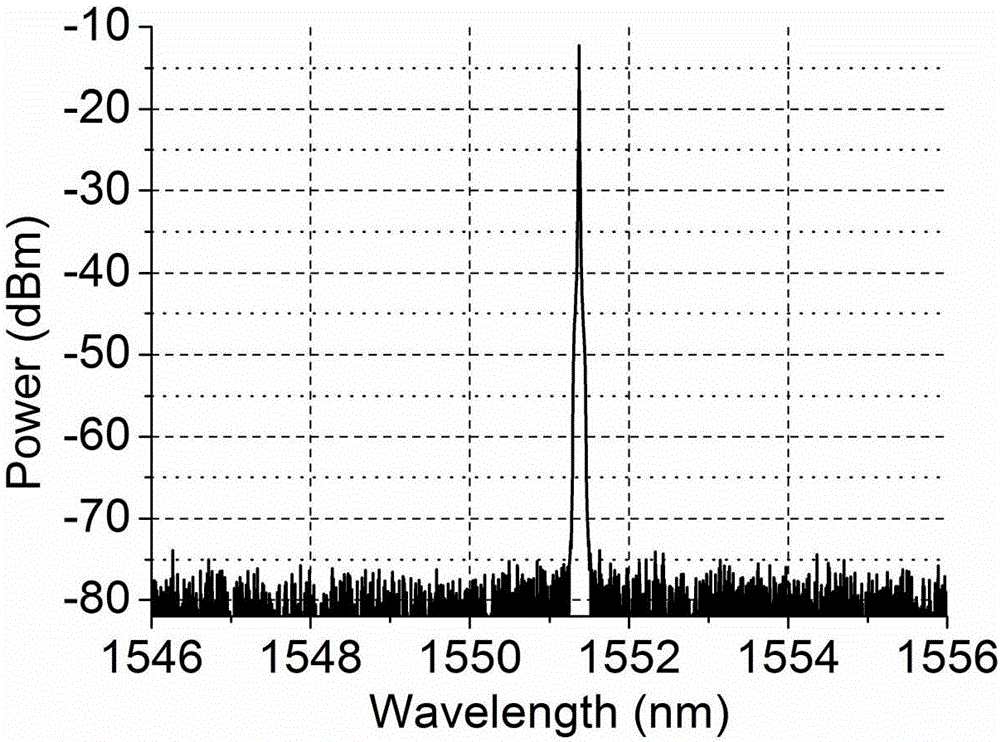

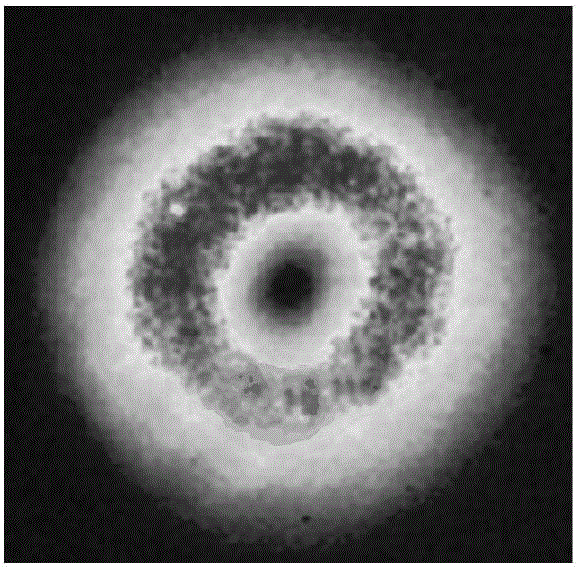

Active ring resonator-based single longitudinal mode low noise narrow band column vector fiber laser

InactiveCN106253039AIncreased Polarization PurityStable output powerActive medium shape and constructionLow noiseGrating

The invention discloses an active ring resonator-based single longitudinal mode low noise narrow band column vector fiber laser. The single longitudinal mode low noise narrow band column vector fiber laser comprises a pumping source, a wavelength division multiplexer, a gain fiber, an isolator, a coupler, a seed source, a first optical circulator, a second optical circulator, a single-mode fiber, a few-mode fiber engraved with a grating, a first polarization controller and a second polarization controller which are connected with one another in a closed end-to-end manner through a fiber coupling way to form a ring optical fiber resonator. The components of the single longitudinal mode low noise narrow band column vector fiber laser adopts an all-fiber coupling mode; the structure is compact, the polarization purity of output column vector laser is high, the coherence is well, a single longitudinal mode working manner is realized, and the spectrum stability is high.

Owner:NANJING UNIV OF POSTS & TELECOMM

Weeding machine facilitating weed storage for agricultural production

PendingCN108901315AStir wellAvoid damageGrass dryingDrying solid materials without heatEngineeringWeed

The invention belongs to the technical field of a weeding machine, in particular to a weeding machine facilitating weed storage for agricultural production. Against the problems that a device lacks aweed collecting device, there is no link for fertilization after weeding, and the device is complicated in structure, the operation is relatively tedious, and solar energy is not made good use of, thefollowing scheme is provided, the weeding machine includes a base, anti-vibration pads are fixed on the outer wall of four corners at the bottom of the base through bolts, universal wheels are fixedon the outer walls of the bottoms of the four anti-vibration pads through bolts, a mounting frame is welded to the outer wall of the top of the base, an electric push rod is fixed on the inner wall ofthe top of the mounting frame through a bolt, a mounting plate is fixed at one end of an electric push rod extension rod through a screw, and two fixed plates are welded to the outer wall of the bottom of the mounting plate. The weeding machine can fuse a pesticide and water in a water tank, an insecticidal effect after weeding is achieved well, rotating knives can be driven to move up and down,and thus weeds of different heights can be cut.

Owner:兰州集智信息技术有限公司

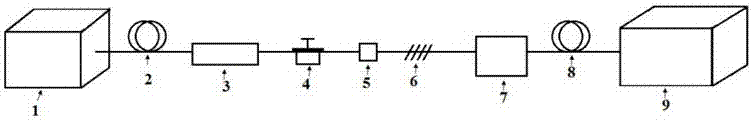

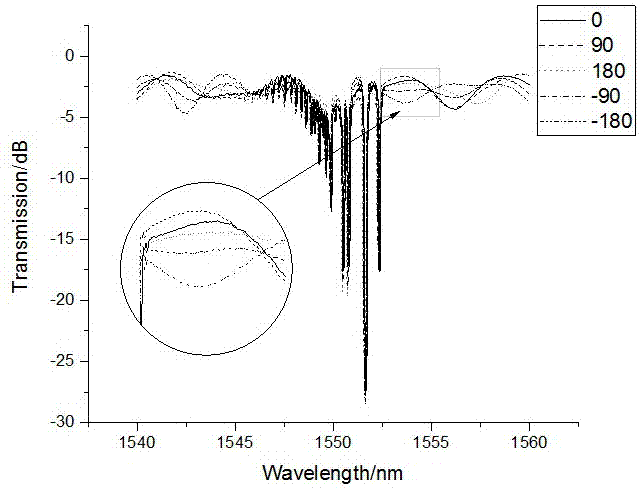

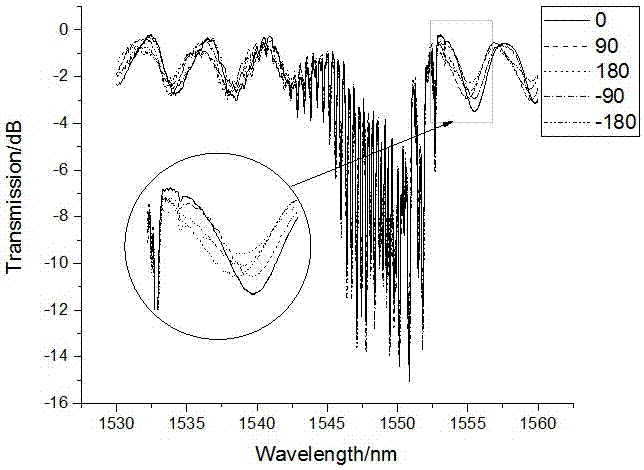

Torsion sensor based on tilted few-mode optical fiber grating

ActiveCN107421469AIncreased sensitivityLess susceptible to interferenceUsing optical meansBroadband light sourceOptoelectronics

The present invention discloses a torsion sensor based on tilted few-mode optical fiber grating, which comprises a broadband light source, a polarizer, a polarization controller, an optical fiber fixing clip, a tilted few-mode optical fiber grating, a optical fiber rotator and a spectrometer, wherein the polarization controller is connected to the optical fiber rotator through the tilted few-mode optical fiber grating; the optical fiber rotator is connected to the spectrometer through the few-mode optical fiber. The optical signal emitted by the broadband light source is transmitted to the polarizer through a single-mode optical fiber to obtain linearly polarized light; the polarization controller is utilized to change the polarization state of the linearly polarized light; and the optical fiber rotator is rotated to make the tilted few-mode optical fiber grating twisted. The tilted few-mode optical fiber grating is excited to a high-order mode and is then transmitted to the spectrometer through the few-mode optical fiber; and the transmission spectrum of the tilted few-mode optical fiber grating is obtained by the spectrometer. The sensor of the invention can utilize the characteristics that the polarization state of the high-order mode of a few-mode optical fiber changes with the torsion of the optical fiber to realize the sensing of the optical fiber torsion by the transmission spectrum of the tilted few-mode optical fiber grating and has higher sensitivity.

Owner:NANJING UNIV OF POSTS & TELECOMM

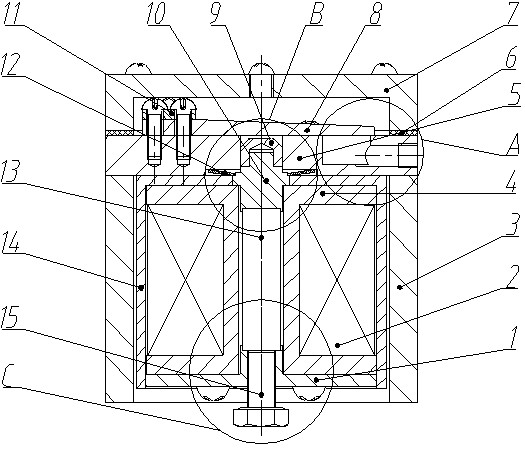

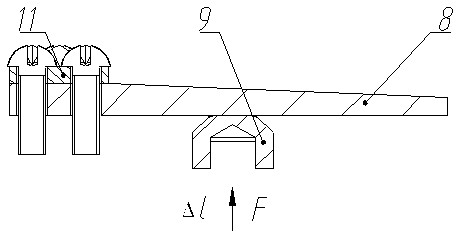

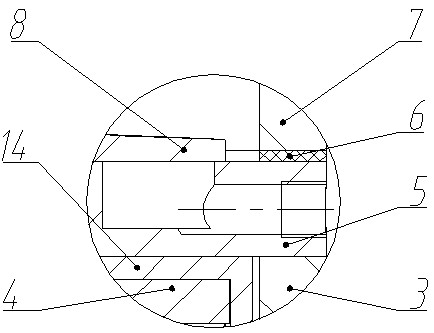

Multidimensional radial pressure measuring device of underground sucker rod

InactiveCN102778311AIncreased sensitivityIncrease radial pressureForce measurementCommunication interfaceSerial line

A multidimensional radial pressure measuring device of a underground sucker rod comprises two parts: underground assemblies and ground accessories; when the measuring device is used in underground measurement, the underground assemblies and the ground accessories are separated and independently work; the underground assemblies are used for adaptively adjusting the data sampling frequency according to the change speed of radial pressure and amplitude index control, and the ground accessories are used for analyzing and processing the radial force data of the sucker rod at the previous time period; when the measuring device is arranged on the ground to perform data analysis, the underground assemblies and the ground accessories are connected through a data communication interface (605) by using a serial line; and the underground measurement data is transferred from a large-capacity flash memory (604). The multidimensional radial pressure measuring device is regular in structure, small in size and capable of measuring the multidimensional radial pressure of the underground sucker rod in real time and satisfying the measurement requirements in narrow spaces and complex working conditions.

Owner:BEIHANG UNIV

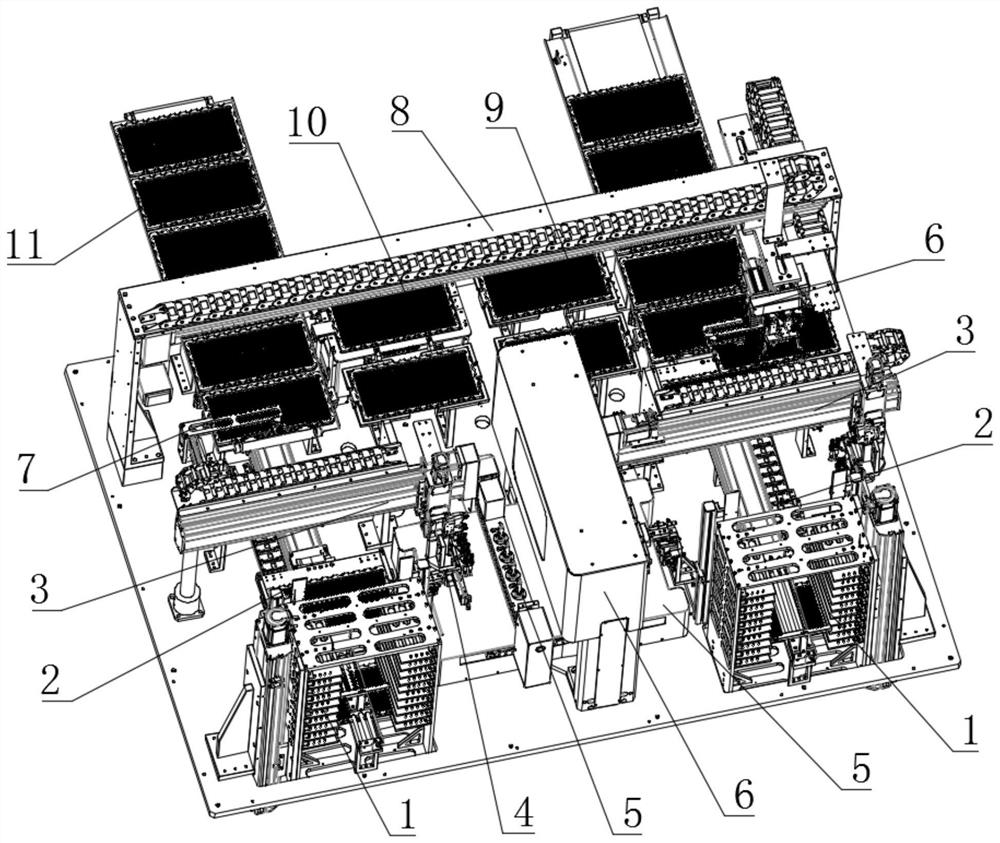

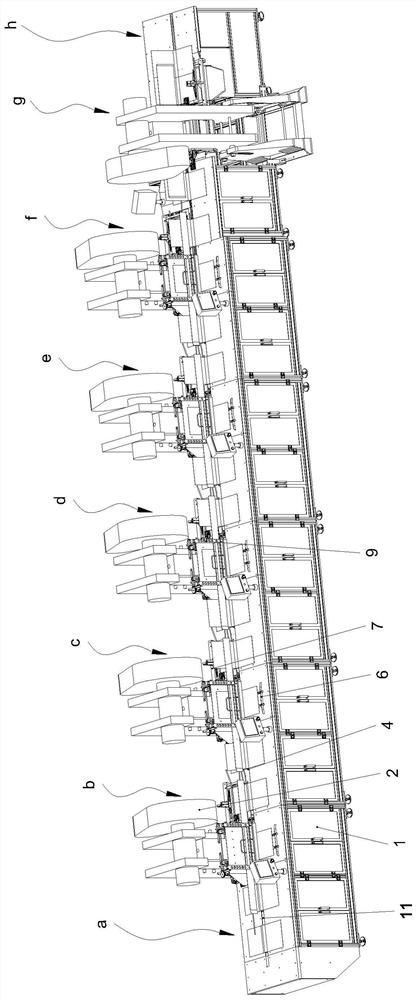

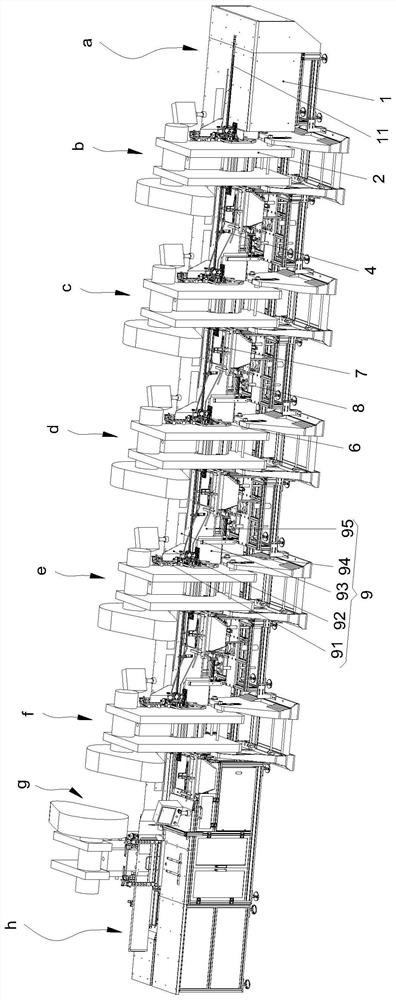

Full-automatic feeding and discharging and multi-station appearance detecting and sorting equipment and method for small parts

ActiveCN113401649AHigh degree of intelligenceCompact layout designFinal product manufactureSortingProcess engineeringIndustrial engineering

The invention discloses full-automatic feeding and discharging and multi-station appearance detecting and sorting equipment and method for small parts. The equipment comprises a material disc feeding mechanism, a product feeding and discharging station, a product transplanting mechanism, a product secondary positioning station, a product detection objective table, a product detection station, a sorting and material changing station, an OK product and NG product sorting mechanism, an NG product placing station, an OK product supplementing and placing station, and an OK product whole disc output mechanism. A material disc reaches a product feeding and discharging station through the material disc feeding mechanism and is moved to a product secondary positioning station through the product transplanting mechanism, the product detection objective table moves and adjusts the angle of a product to detect all the angles of the product, and the OK product and NG product sorting mechanism sorts NG products in the material disc and supplements the OK products at vacant positions. The whole layout design is compact, the space position is fully utilized, the automation degree is high, the production efficiency is high, the compatibility is high, the equipment can be suitable for trays and products of different specifications, and the product detection range is wide.

Owner:GUANGZHOU INTELLIGENT EYES ELECTRIC PRODION

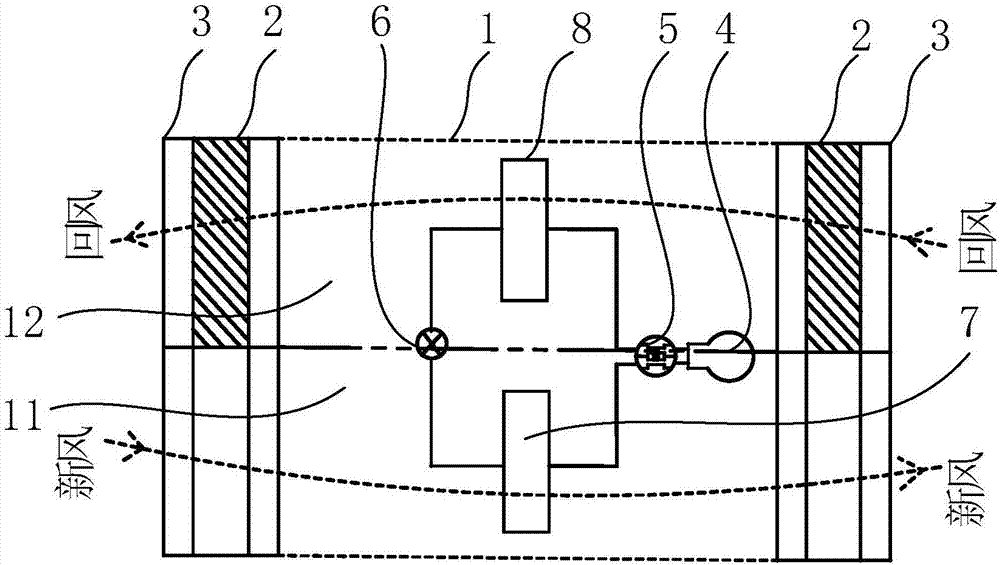

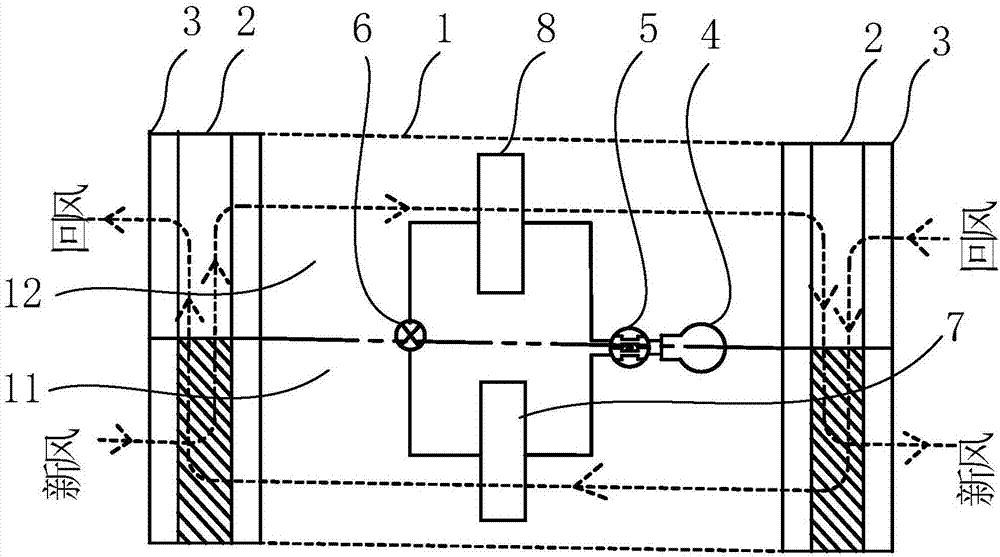

Primary air system

ActiveCN106989473AEnsure continuous and stable workEnergy recovery in ventilation and heatingLighting and heating apparatusEngineeringMoisture absorption

The invention relates to a primary air system. The primary air system comprises a main body air duct and reversing air ducts; the main body air duct comprises a first cavity and a second cavity; moisture absorbing materials capable of absorbing moisture for air flows are arranged in both the first cavity and the second cavity; each reversing air duct comprises a movable part, and the movable part can move relative to the main body air duct to enable the reversing air duct has at least two working modes; when the reversing air ducts are in the first working mode, primary air is sent into a room via the first cavity, the moisture absorbing material in the first cavity can absorb the moisture, and return air is exhausted out of the room via the second cavity; when the reversing air ducts are in the second working mode, the primary air is sent into the room via the second cavity, and the return air is exhausted out of the room via the first cavity; the moisture absorbing material in the second cavity can absorb the moisture; and the moisture absorbing material in the first cavity can be regenerated. Switching of moisture absorption and regeneration of the moisture absorbing materials is realized through switching of the reversing air ducts between the first working mode and the second working mode, and dehumidified primary air can be continuously supplied into the room.

Owner:GREE ELECTRIC APPLIANCES INC

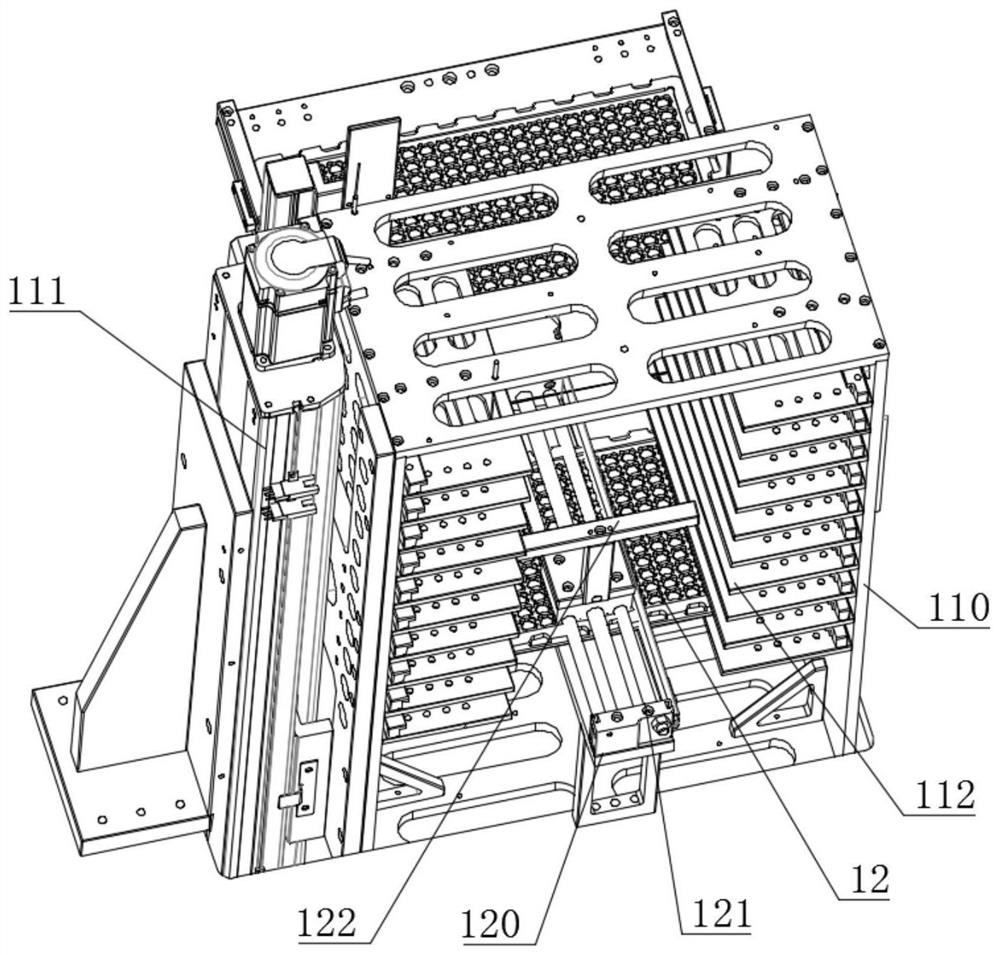

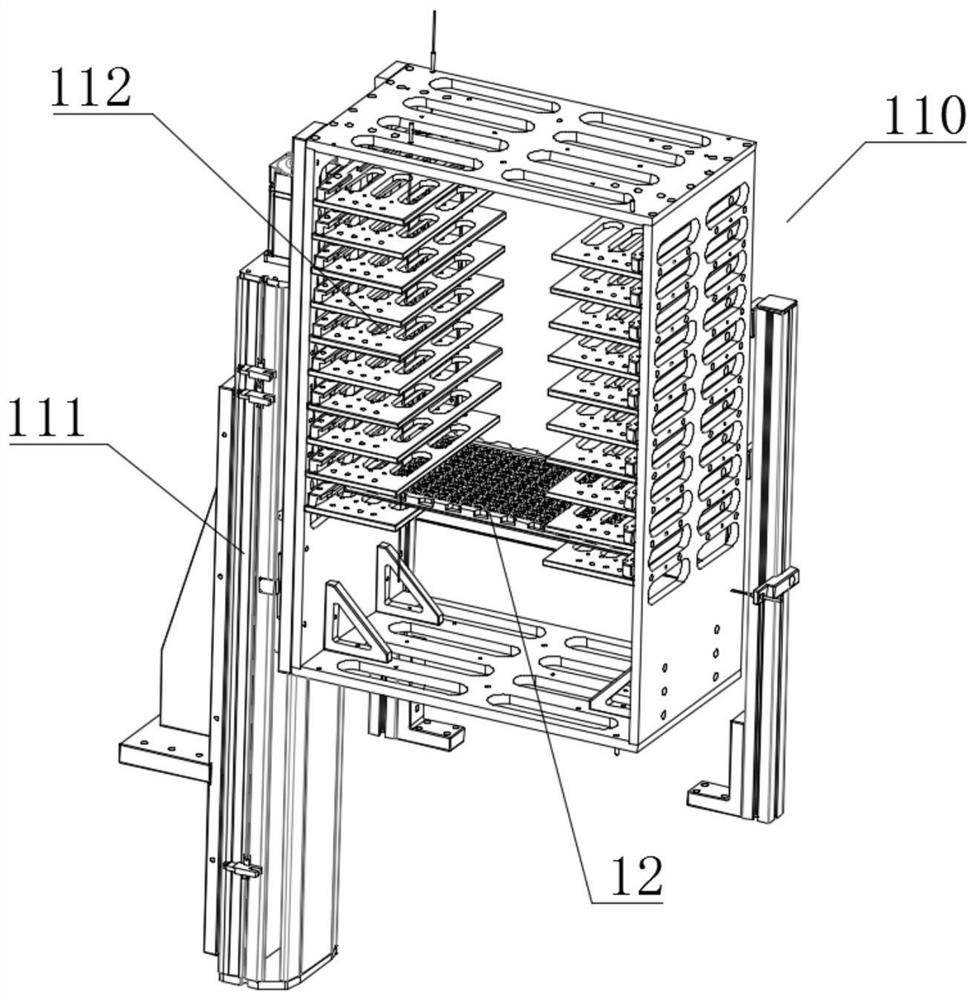

Children special-shaped board book automatic page turning punching production line

ActiveCN111674176AReduce labor intensityEnsure continuous and stable workBook making processesSheet bindingProduction linePunching

The invention discloses a children special-shaped board book automatic page turning punching production line. The production line comprises a working table and punching machines, and further comprisesa pushing device, a sensor, a tidying device, a waste clearing device, a page turning device and a book guide device which are mounted on the working table. The working table is provided with a bookconveying channel. A plurality of punching machines are arranged beside the working table in the book conveying direction in sequence. The punching machines are provided with special cutting dies usedfor punching and shearing book pages. The tidying device is used for locating the pages in the corresponding special cutting dies and matched with the special cutting dies to punch and shear the pages to form the designed shape. The page turning device is located below the waste clearing device and used for turning the current book page to the vertical state and the next book page to the horizontal state in the book conveying process. The book guide device is located above the book conveying channel. The children special-shaped board book automatic page turning punching production line can achieve the functions of completing the automatic page turning process and the punching and shearing forming process in the book conveying process, reduces the labor intensity of workers and improves the production efficiency.

Owner:佛山市金页盈信智能机械有限公司

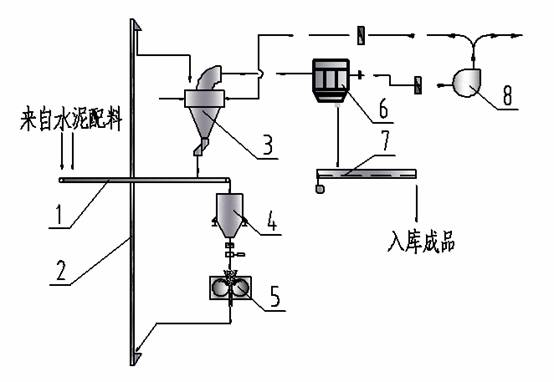

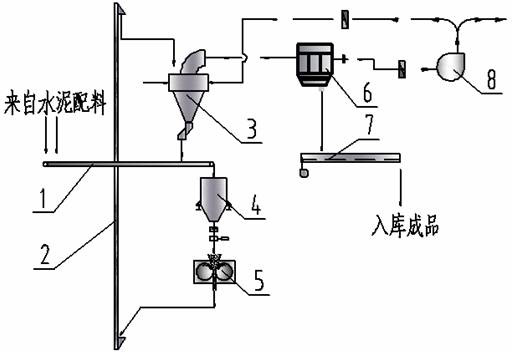

Concrete grinding system for roll squeezer and grinding method thereof

InactiveCN102179273AEnsure continuous and stable workAdapt to large-scaleGrain treatmentsHigh energyBall mill

The invention provides a concrete grinding system for a roll squeezer and a grinding method thereof. The method comprises the following steps: 1) conveying process; 2) extruding and cycling extruding process; and 3) purifying and de-dusting process. The system and the method provided by the invention have the advantages that the concrete grinding system for the roll squeezer and the grinding method thereof are mainly applied to the grinding system of concrete industry; a traditional ball mill grinding system with high energy consumption can be replaced by a concrete grinding device system which comprises a roll squeezer, a powder selector and a bag type dust collector; the balling-free production is realized and the final grinding of material is finished; the cycling extruding process is used for fully utilizing the coarse particle and the new feeding mixing material to reprocess and a steady flow cabin is used for controlling the processing, thereby ensuring the stable continuous work of the roll squeezer; the concrete grinding process for the roll squeezer has the integrated functions of grinding and powder selecting, thereby further reducing the energy consumption caused by the grinding operation and the metal material abrasion and meeting the demand of the large-scale industrial development of grinding system. The concrete grinding system for the roll squeezer and the grinding method thereof provided by the invention are important technical revolutions of grinding industry.

Owner:JIANGSU HAIJIAN

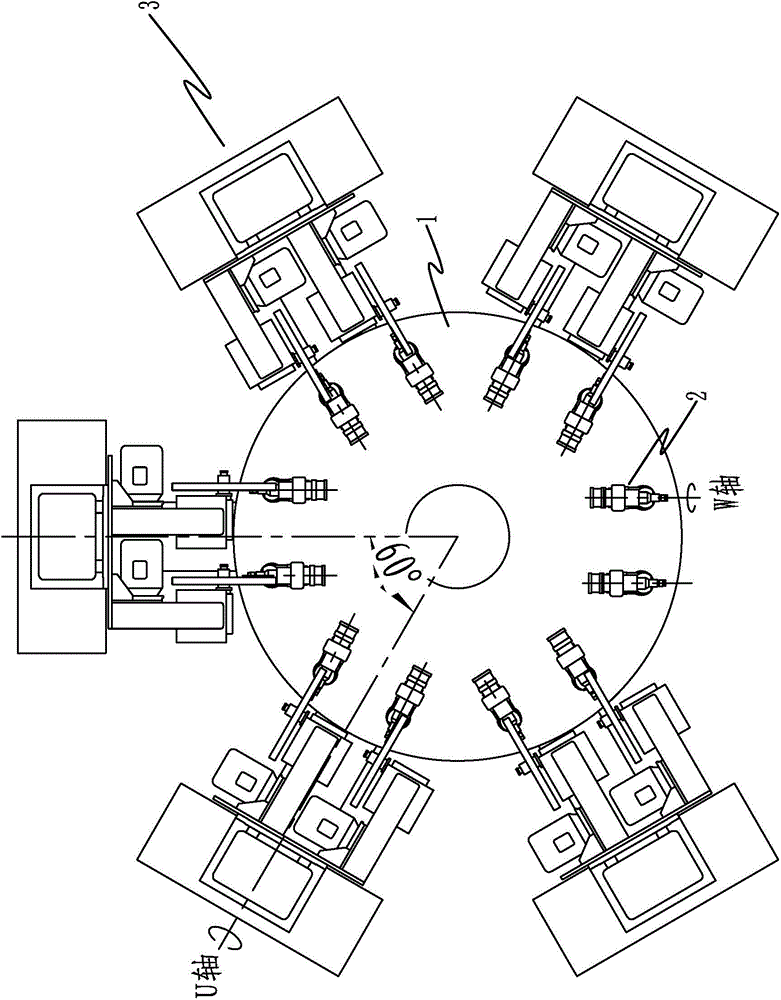

Novel six-station disc-type numerical control cloth wheel buffing machine

ActiveCN104526521AConsistentStable polishing qualityGrinding carriagesPolishing machinesNumerical controlCircular disc

The invention discloses a novel six-station disc-type numerical control cloth wheel buffing machine. The cloth wheel buffing machine comprises a base and a rotating disc arranged in the middle of the base. Five-station double buffing wheel assemblies and an one-station assembly and disassembly station are evenly arranged at the parts, around the rotating disc, of the base, and six-station double workpiece clamp assemblies are evenly arranged at the parts, corresponding to the five-station double buffing wheel assemblies and the assembly and disassembly station, of the rotating disc in an equal-angle mode. Each double buffing wheel assembly comprises a movable stand column and a double buffing wheel structure which is arranged on the stand column and corresponds to one double workpiece clamp assembly. The double workpiece clamp assembly on each station comprises two workpiece chucks matched in a linkage mode. Through rotating the double workpiece clamp assemblies and the double buffing wheel assemblies by one circle each time, twelve workpieces can be buffed, in this way, production efficiency is greatly improved, the application range of buffing complex curved-surface workpieces is enlarged, the stability and uniformity of the quality of workpiece buffing are guaranteed, occupied area is reduced, energy consumption is lowered, and the production efficiency and economic benefits are improved by times.

Owner:广东博科数控机械有限公司

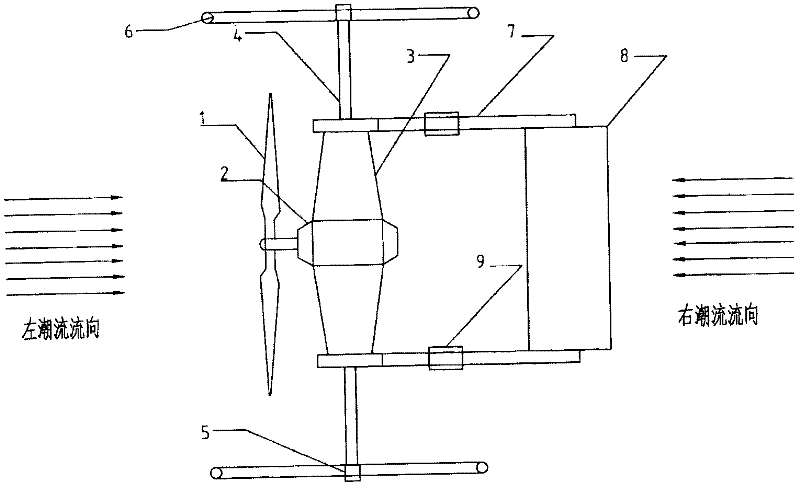

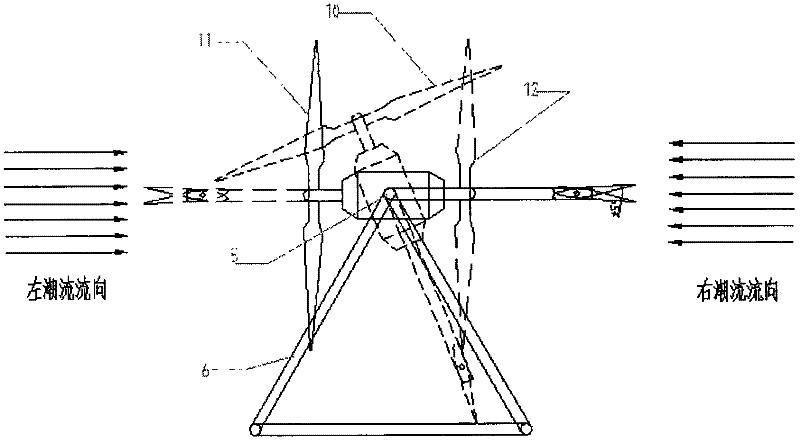

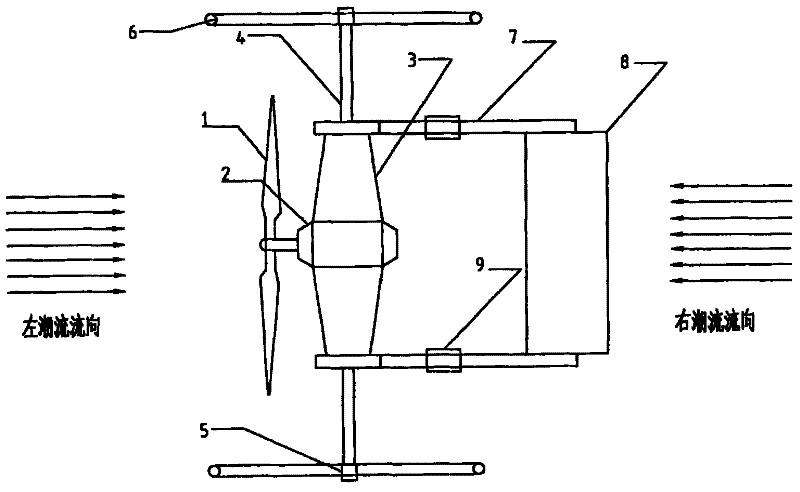

Ocean tide energy horizontal shaft self-compensation bidirectional overall direction regulation generating set

InactiveCN102374104ASimple structureWork reliablyHydro energy generationReaction enginesOcean bottomSelf compensation

Owner:NORTHEAST NORMAL UNIVERSITY

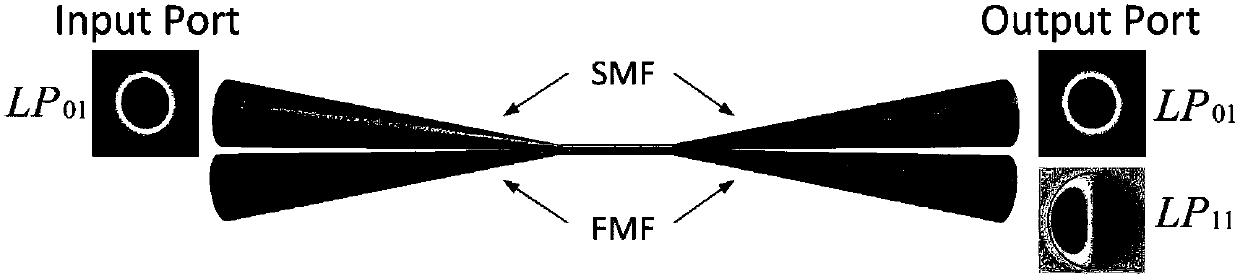

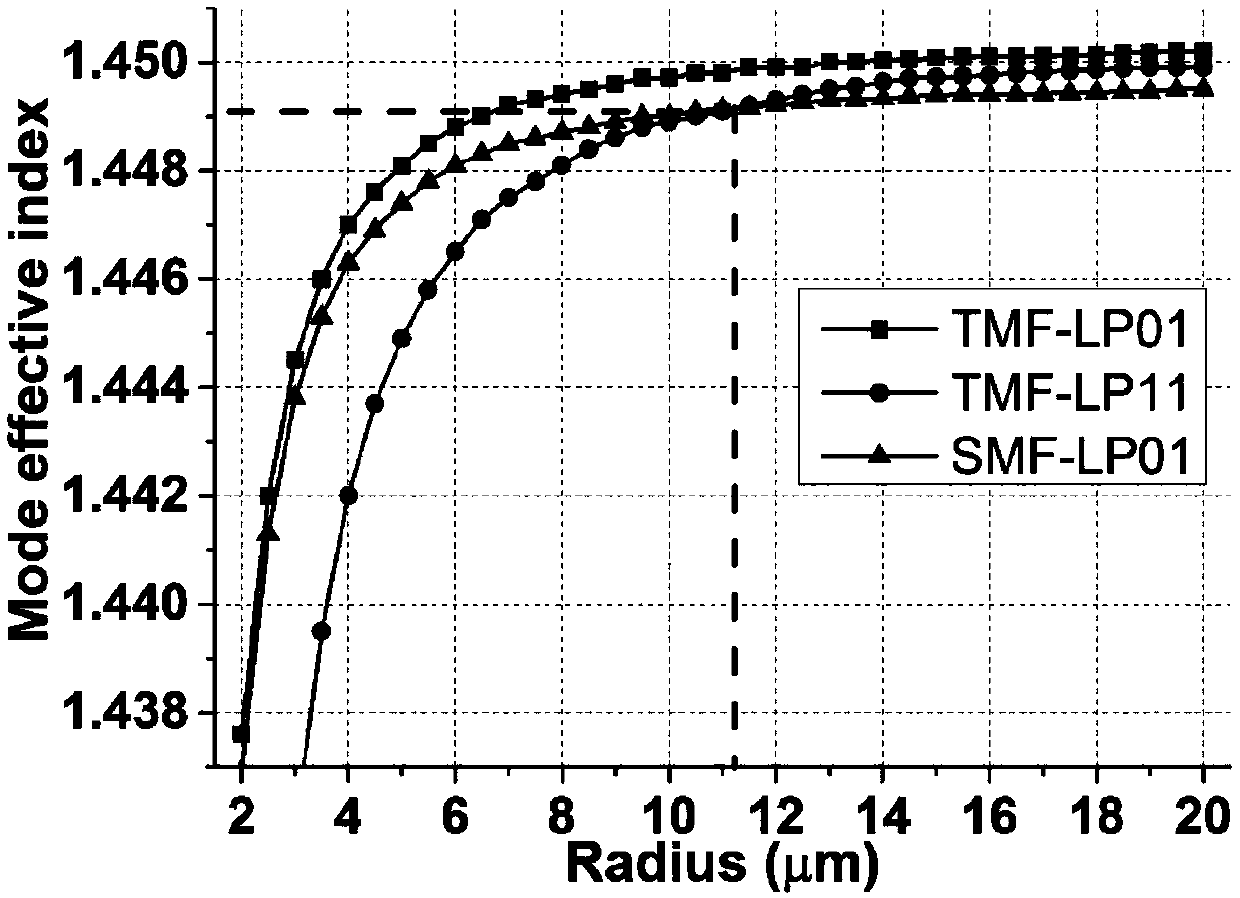

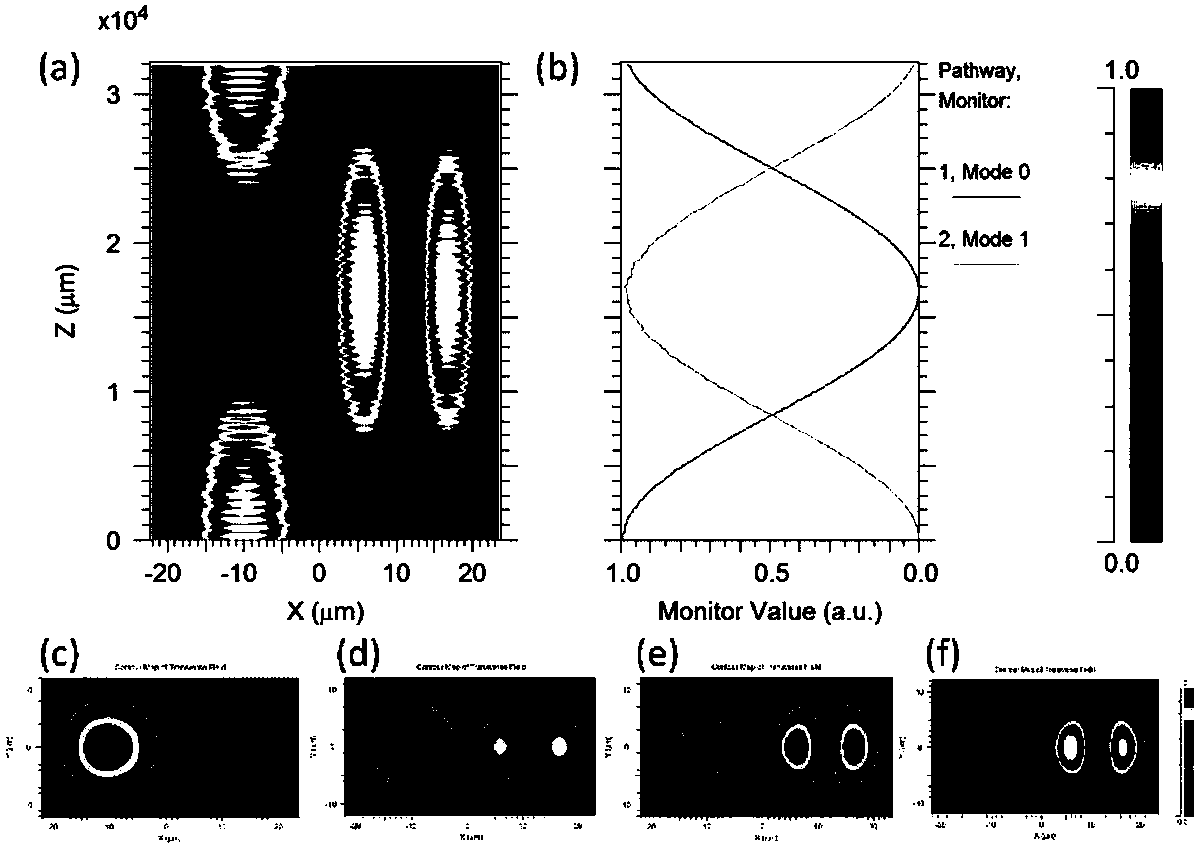

High-efficiency low-loss all-fiber fusion mode selection coupler

InactiveCN108051890ASimple processImprove coupling efficiencyCoupling light guidesOptical waveguide light guideRefractive indexLength wave

The invention discloses a high-efficiency low-loss all-fiber fusion mode selection coupler comprising a less-mode fiber and a single-mode fiber with a coating layer respectively peeled off; the single-mode fiber is specially made; the refractive index of the fiber core of the single mode fiber under a specific wavelength is smaller than the quality of the fiber core refractive index of the less-mode fiber under the same wavelength; the high purity high order mode in the less-mode fiber can be excited without pre-tapering the single-mode fiber or less-mode fiber; a model switching function anda mode separating function are provided. The selection coupler can pack through a packing material. The single-mode fiber and less-mode fiber employ the all-fiber fusion coupling mode, the structure is compact, and the formed mode selection coupler is high in coupling efficiency, high in polarization purity, small in insert loss, and simple in making process.

Owner:NANJING UNIV OF POSTS & TELECOMM

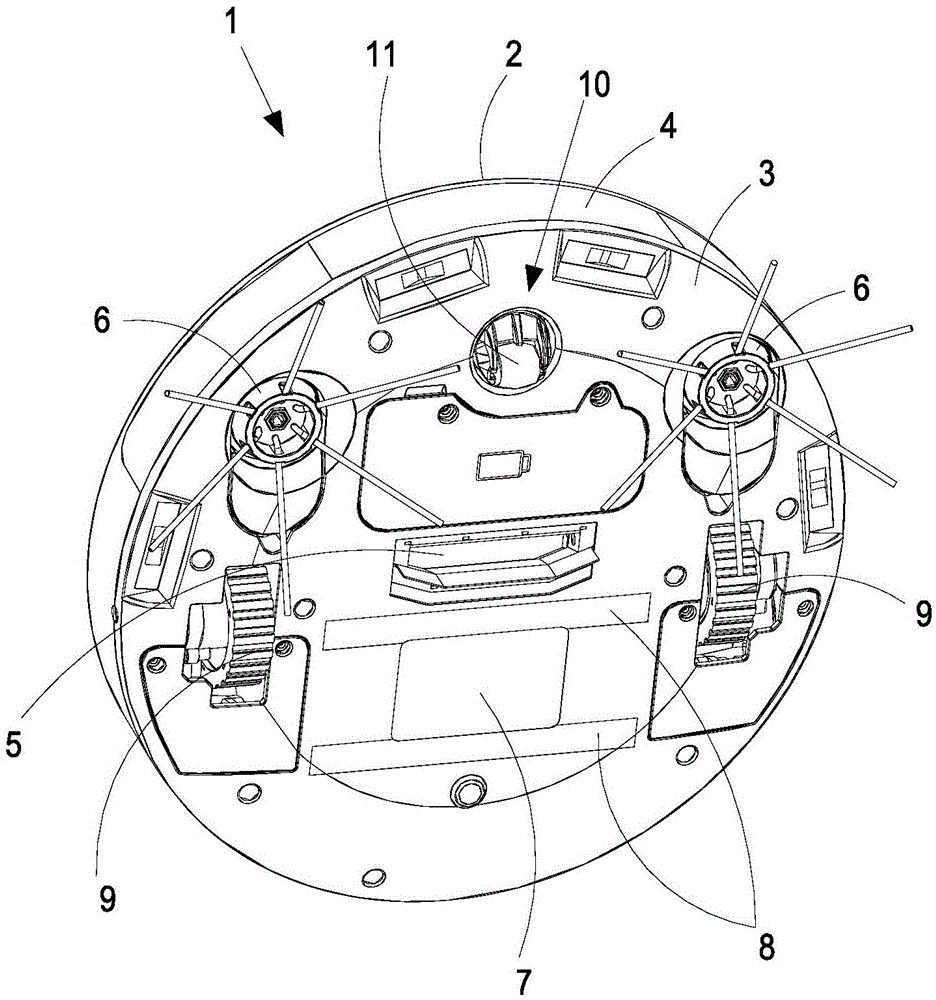

Autonomous mobile robot and control method thereof

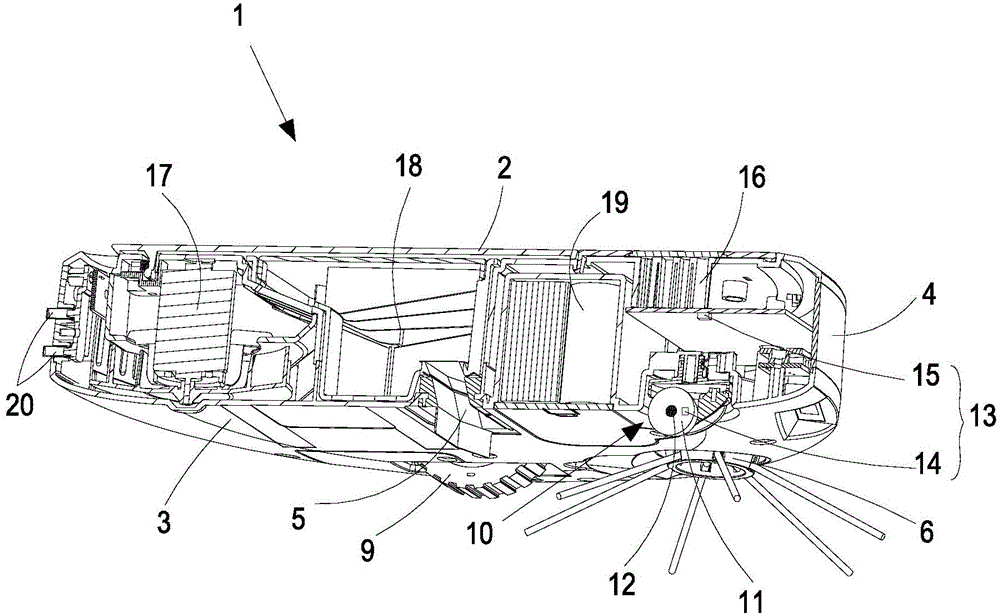

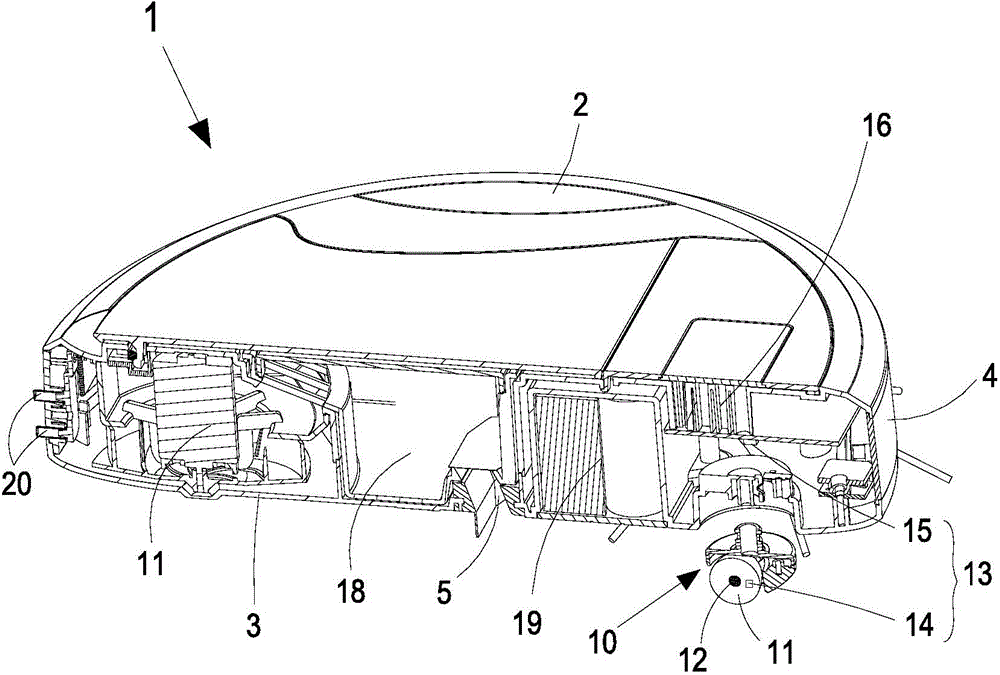

InactiveCN105832252AEnsure continuous and stable workMachine detailsFloor-scrubbing machinesDrive wheelContinuous operation

The invention relates to an autonomous mobile robot and a control method thereof. The robot is provided with a robot body which can move on ground, and comprises at least a driven wheel unit and a driven wheel rotation detection unit. The driven wheel unit comprises a driven wheel which is rotatably arranged on the bottom of the robot body through a rotating shaft. The driven wheel can rotate by movement of the robot body. The driven wheel rotation detection unit comprises at least a magnetic element and a magnetic field induction element. The magnetic element is arranged on the driven wheel and can generate a magnetic field around the driven wheel. The magnetic field induction element is arranged near the driven wheel, and is used to induce variation of the magnetic field which is generated by the magnetic element. When the driven wheel rotates, the magnetic element rotates with the driven wheel, so that the peripheral magnetic field changes regularly. The magnetic field induction element indirectly transmits a message that whether the robot body is in normal operation to a master control unit through detection of magnetic field conversion, so as to provide guarantee for the autonomous mobile robot to realize stable and continuous operation.

Owner:DONGGUAN DIQEE INTELLIGENT CORP LTD

Online measurement method and device for anode current of aluminum electrolytic cell

ActiveCN104120455AEasy to operateSimple structureMeasurement using digital techniquesPower flowMeasurement point

The invention discloses an online measurement method and device for anode current of an aluminum electrolytic cell. The online measurement method comprises the following steps: setting a plurality of main measurement points on an anode beam bus bar or a riser bus bar so as to obtain voltage values of the main measurement points, establishing a resistance network of the beam bus bar according to Kirchhoff voltage and current laws, and calculating the flowing-in current of each anode by utilizing the values of obtained voltage or voltage difference values. The real-time online dynamic acquisition on the flowing-in current of each anode of the aluminum electrolytic cell can be realized by using the measurement method and the device. The long-time stable and reliable online acquisition on the anode current can be realized when the online measurement method and device are applied to the aluminum electrolytic cell.

Owner:湖南阿尔惠特科技股份有限公司

Pneumatic high-speed switch valve driven by giant magnetostriction

InactiveCN102155570AReduce volumeCompact structureOperating means/releasing devices for valvesMagnetostrictive actuatorThermal expansion

The invention discloses a pneumatic high-speed switch valve driven by giant magnetostriction, comprising a giant magnetostrictive actuator and a switch valve. The giant magnetostrictive actuator comprises a shell, a driving coil, a coil framework, a mandril, a giant magnetostrictive rod, an upper magnetic conduction body, a dished spring, a magnetic conduction sleeve, a lower magnetic conduction body and an adjusting bolt. The switch valve comprises a valve port plate, a cantilever core plug, a cantilever cover, a valve cover and a sealing gasket, wherein a cantilever simultaneously plays roles of amplifying displacement and serving as a valve plug and can realize automatic resetting. Due to a rectangular variable cross-section beam structure with optimized size, the valve plug is stressed more reasonably, and the equivalent mass is reduced. The thermal expansion coefficient of the coil framework is close to that of a material for making the giant magnetostrictive rod, and thus the influence of temperature rise on valve port output is restricted. The invention has the remarkable characteristics of small size, large flow, high frequency response, stable working performance, and the like.

Owner:ZHEJIANG UNIV

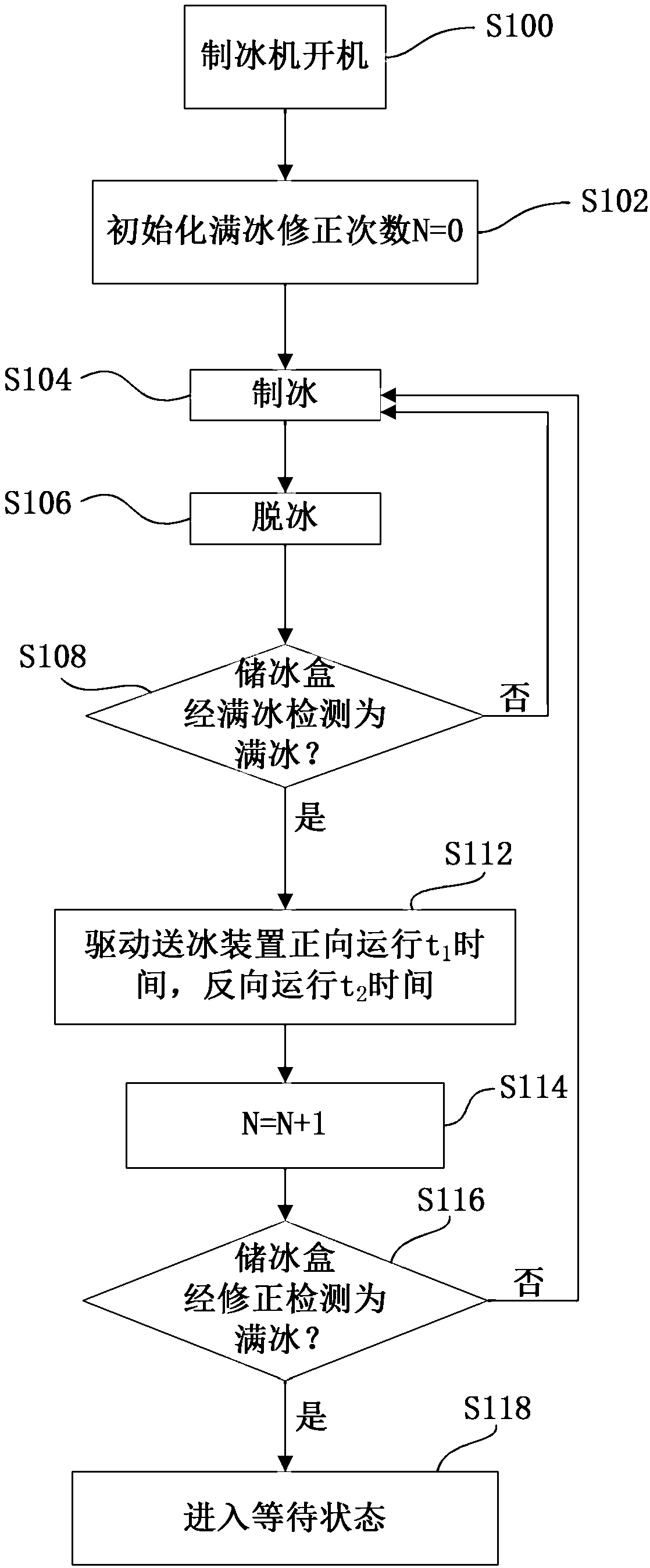

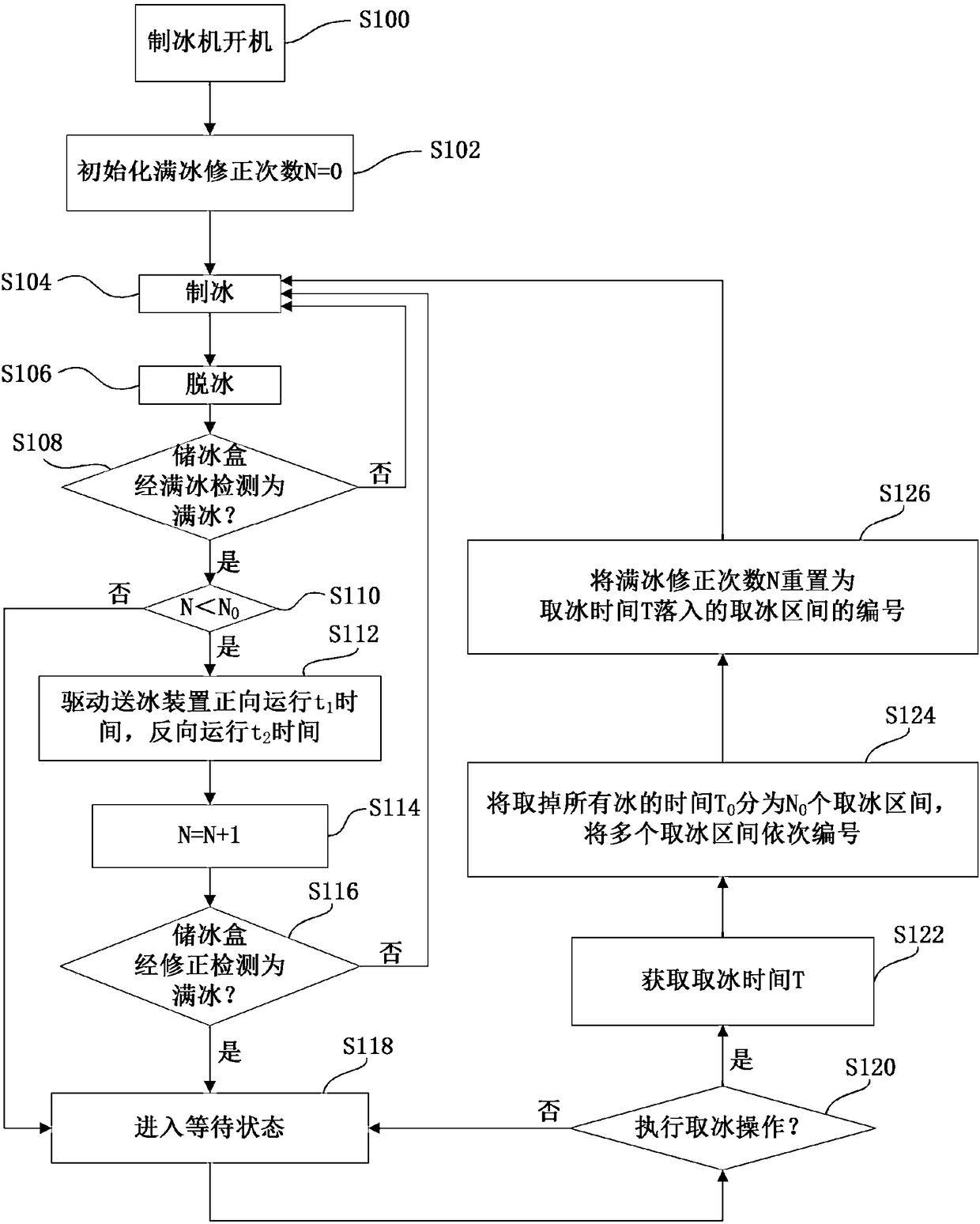

Control method of ice maker

ActiveCN108253676AMaximum ice storage capacityImprove practicalityDomestic cooling apparatusLighting and heating apparatusIce storageEngineering

The invention provides a control method of an ice maker. The ice maker comprises an ice storage box, an ice feeding device which is positioned on the bottom of the ice storage box and can be controlled to rotate, and a detecting device for detecting a full-ice state of the ice storage box. The control method comprises the following steps of: after ice making operation and ice removing operation are sequentially completed in sequence every time, performing full-ice detection for detecting whether the ice storage box is in the full-ice state or not; when the ice storage box is judged to be not in the full-ice state through full-ice detection, performing ice making operation and ice removing operation; when the ice storage box is judged to be in the full-ice state through full-ice detection,driving the ice feeding device to rotate to perform full-ice correction, and recording full-ice correction times once after completing full-ice correction once; and after performing full-ice correction each time, performing correction detection for detecting whether the ice storage box is in the full-ice state or not. The detected results of the detected full-ice state are corrected, so that the problem that the ice storage box is not filled up completely as a result of out-of-level stacking of ice blocks and is mis-declared in the full-ice state is avoided.

Owner:QINGDAO HAIER REFRIGERATOR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com