Primary air system

A fresh air system, fresh air technology, applied in ventilation systems, air conditioning systems, ventilation and heating energy recovery systems, etc., can solve problems such as high cost, complex structure and control, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

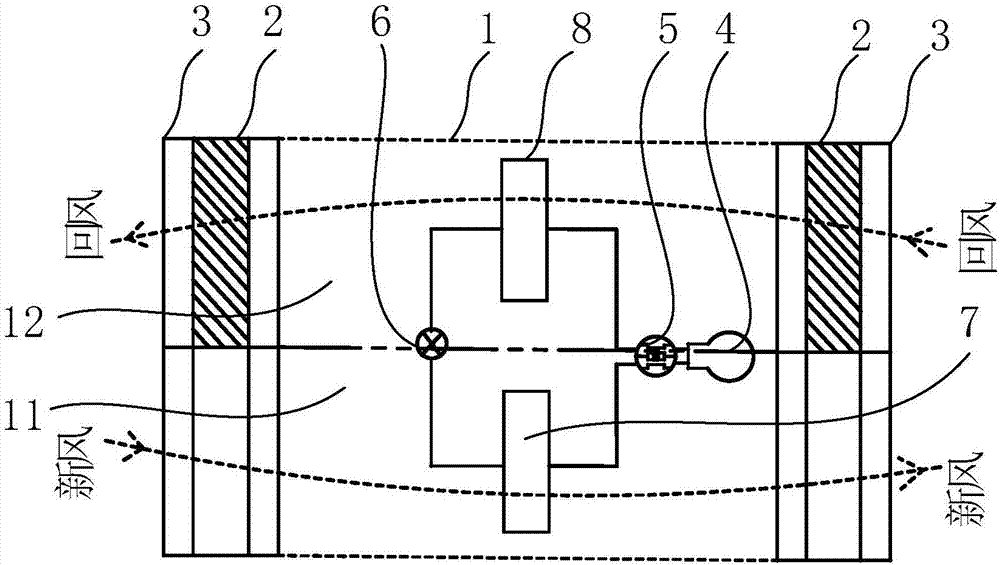

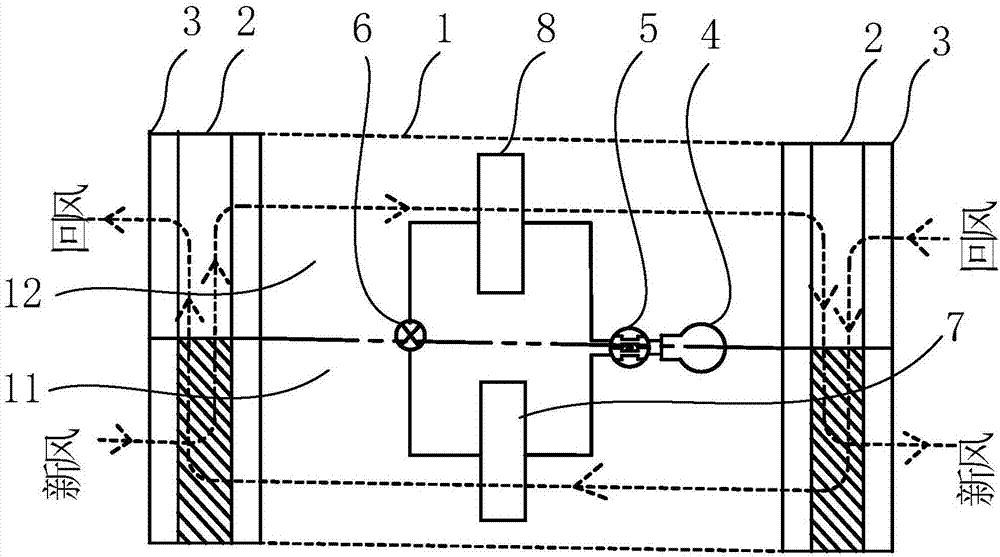

[0063] Such as figure 1 , figure 2 and 4 As shown, the rotating component may include a reversing air duct main body 23 and a rotating shaft, and the reversing air duct main body 23 may be driven to rotate relative to the main air duct 1 by the rotating shaft. The reversing air channel main body 23 may include a first air channel and a second air channel. The reversing air channel main body 23 is in the first working mode when it rotates relative to the main air channel 1, and fresh air enters the first cavity 11 through the first air channel. The return air of the second cavity 12 is discharged through the second air channel, and the reversing air channel 2 is in the second working mode relative to the main air channel 1, and the fresh air enters the second cavity 12 through the first air channel, and the first cavity The return air of 11 is discharged through the second air duct.

[0064] Such as Figure 4 , Figure 5 , Figure 6 As shown, the first air channel may in...

no. 2 example

[0107] Such as Figure 11 , Figure 12 As shown, in the second embodiment, the rotating part may include a windshield structure, the windshield structure may be arranged in the reversing air duct 2, and the windshield structure can rotate relative to the main air duct 1 to allow fresh air to enter the first cavity 11 or the second cavity 12, the return air is discharged through the second cavity 12 or the first cavity 11.

[0108] Such as Figure 13 As shown, the reversing air passage 2 may include a first air chamber 26 and a second air chamber 27, the first air chamber 26 may be provided with a fifth air passage and a sixth air passage, and the second air chamber 27 may be provided with a The seventh and eighth air passages. The windshielding structure may include a first windshielding structure 24 and a second windshielding structure 25 .

[0109] Such as Figure 11 , Figure 12 As shown, the first windshield structure 24 can rotate relative to the main air duct 1 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com