Pneumatic high-speed switch valve driven by giant magnetostriction

A giant magnetostrictive, high-speed switching valve technology, applied in the direction of valve details, valve devices, engine components, etc., can solve the problem of small operating frequency and achieve the effects of suppressing adverse effects, simplifying the structure, and compacting the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

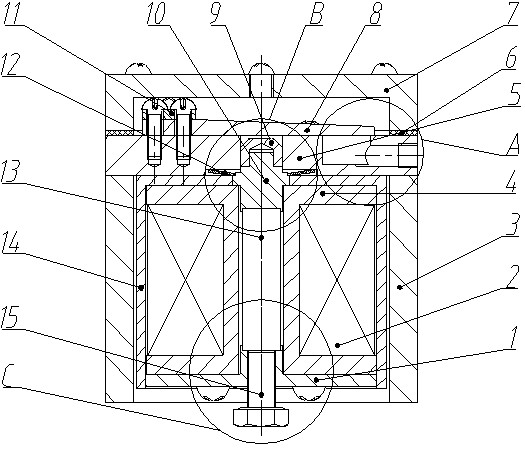

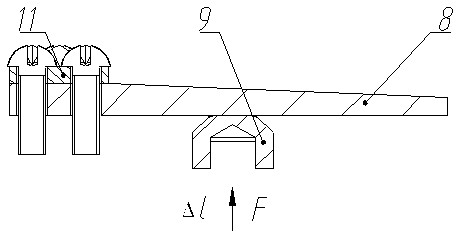

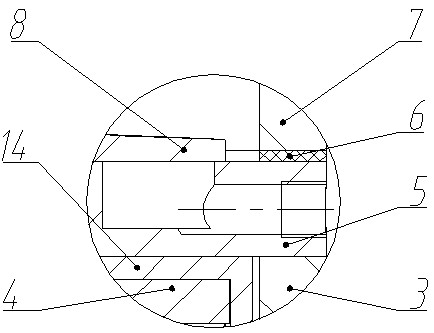

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the present invention includes giant magnetostrictive actuators and switching valves, wherein:

[0028] 1) Giant magnetostrictive driver: including shell 3, drive coil 2, I-shaped coil skeleton 4, ejector rod 9, giant magnetostrictive rod 13, upper magnet guide 10, disc spring 12, magnetic guide sleeve 14, lower guide magnet 1 and adjusting bolt 15; the magnetic guide sleeve 14 is coaxially installed in the shell 3, and the magnetic guide sleeve 14 is equipped with an I-shaped skeleton 4 wound with a drive coil 2, and the small end of the lower magnet guide 1 is inserted into the center of the lower end of the I-shaped skeleton 4 In the hole, the lower end of the I-shaped coil bobbin 4 is threadedly connected to the large end surface of the step of the lower magnet gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com