Patents

Literature

978 results about "MANDRIL" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

MANDRIL is integrated software produced by Leidos UK Ltd (formerly Lockheed Martin UK IS&S Ltd) for the analysis of Tactical Data Links. It is an acronym of Message ANalysis and Data Reduction for the Integration of Links. MANDRIL can decode and analyse recordings of data link traffic from Link 16 (TADIL J), Link 11 (TADIL-A & B), Link 22, VMF and so on.

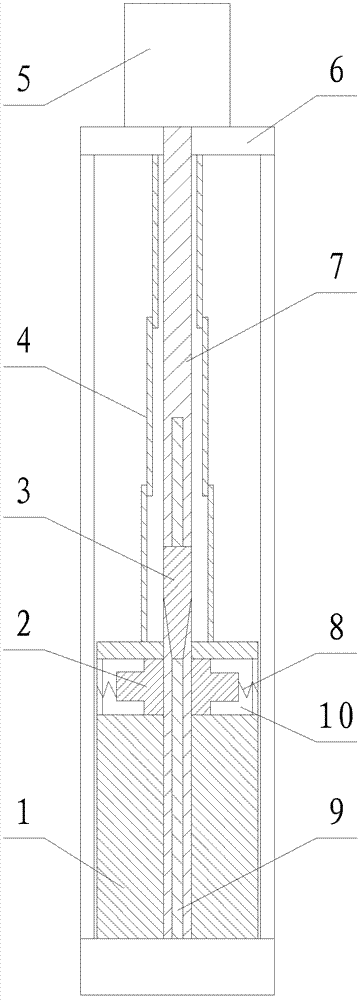

Metal-glass sealing process

InactiveCN101531473AImprove air tightnessHigh insulation resistanceElectric connector introductionCapacitor housing/encapsulationWaxMetallic materials

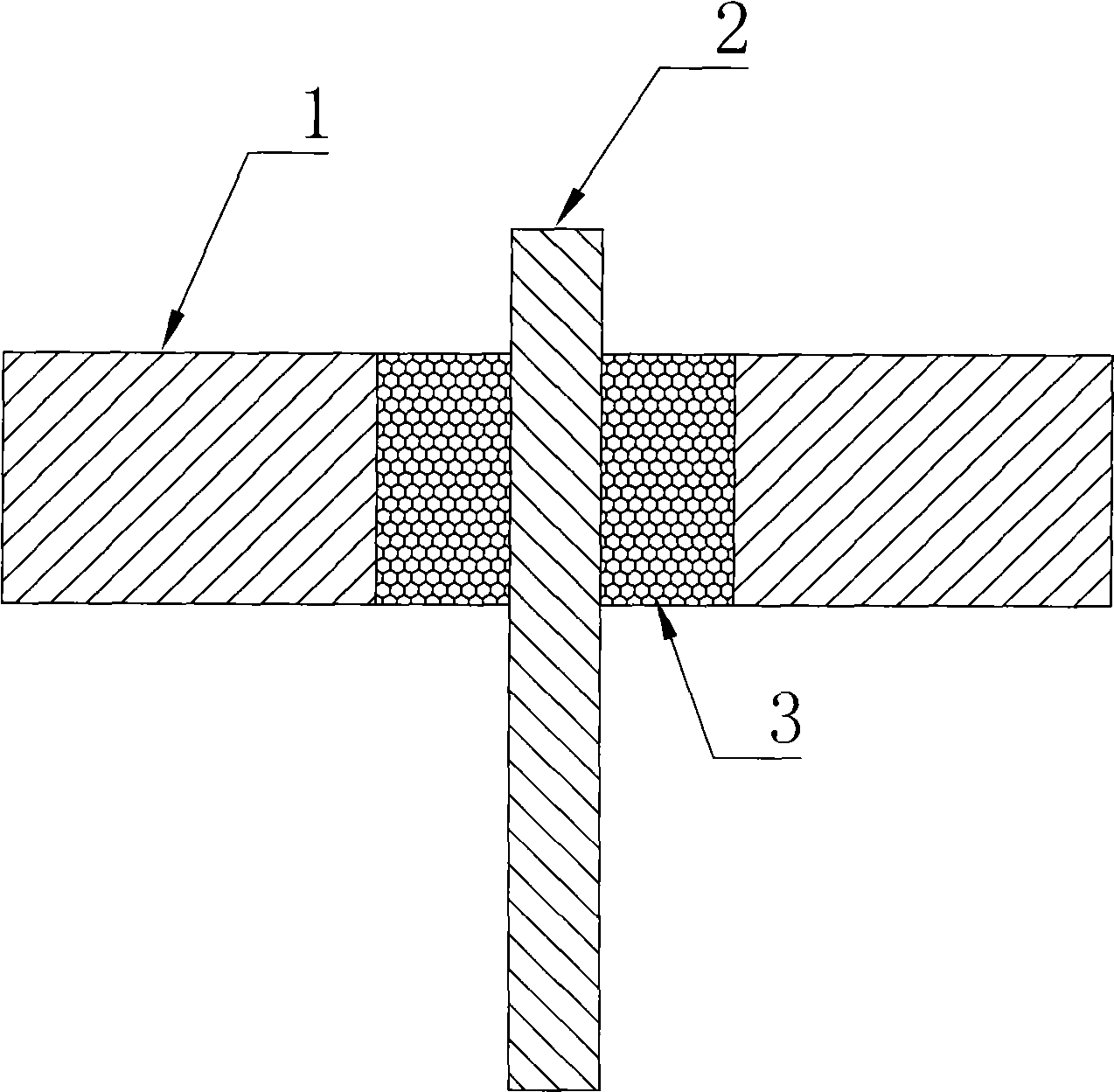

The invention discloses a metal-glass sealing process, which comprises the following steps: according to the expansion coefficient of a metal upper cover being greater than the expansion coefficient of glass and the expansion coefficient of the glass being less than or equal to the thermal expansion coefficient of a metal mandril, selecting sealing glass powder; pressurizing the selected glass powder into a glass blank by a mould, and dewaxing and forming the glass blank in a furnace; respectively putting a metal material and the glass blank into a deoiling solution for treatment, and washing and drying the metal material and the glass blank after the deoiling; and assembling the metal upper cover, the metal mandril and the formed glass blank in a graphite mould, and sintering the assembled graphite mould in a sintering furnace. The metal and glass products sealed by the metal-glass sealing process have good sealing strength, good leakproofness with the leak rate less than 10 <-10>m <3>. Pa / s, and good leakproofness at a high temperature, and can solve the problems of fluid leakage, poor consistency and the like of consumer products. The metal-glass sealing process has strong operability and good consistency of the prepared products, and meets the requirement of mass production.

Owner:西安华泰有色金属实业有限责任公司

Automatic door opener of refrigerator and refrigerator adopting same

ActiveCN104061741AThe process of opening the door is intelligent and labor-savingEasy to moveDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigerated temperature

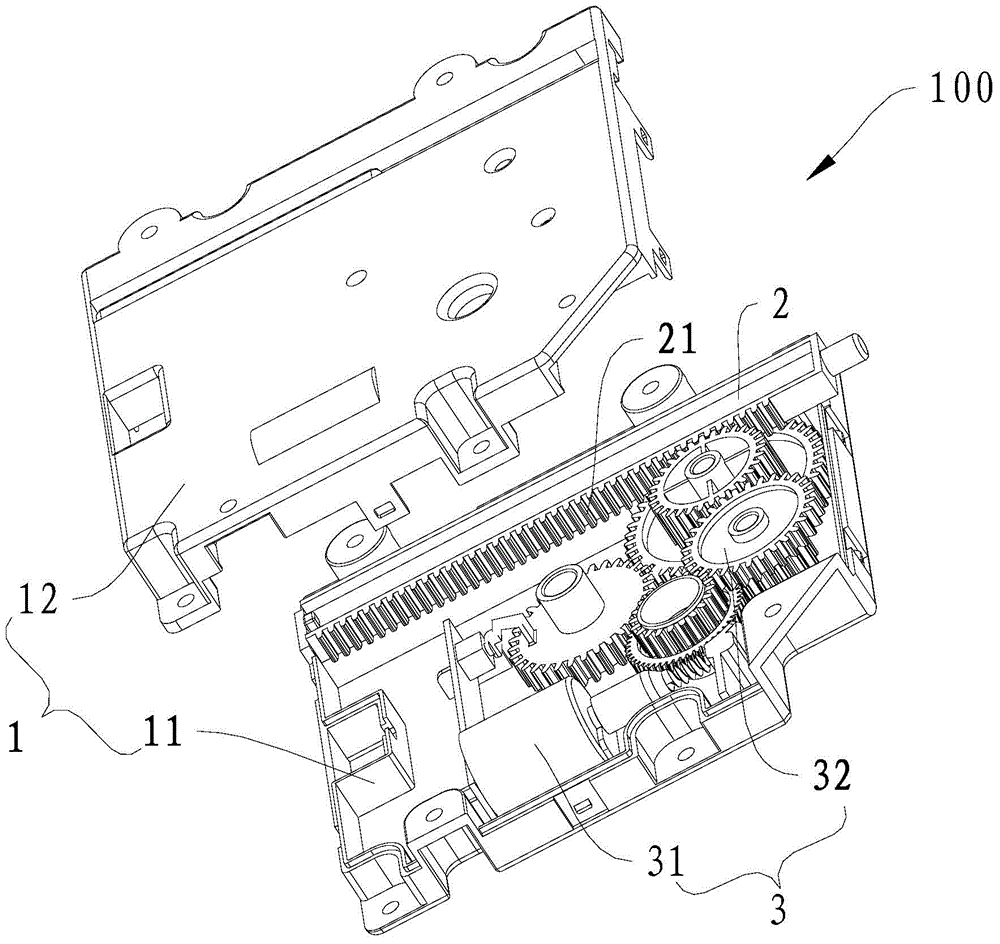

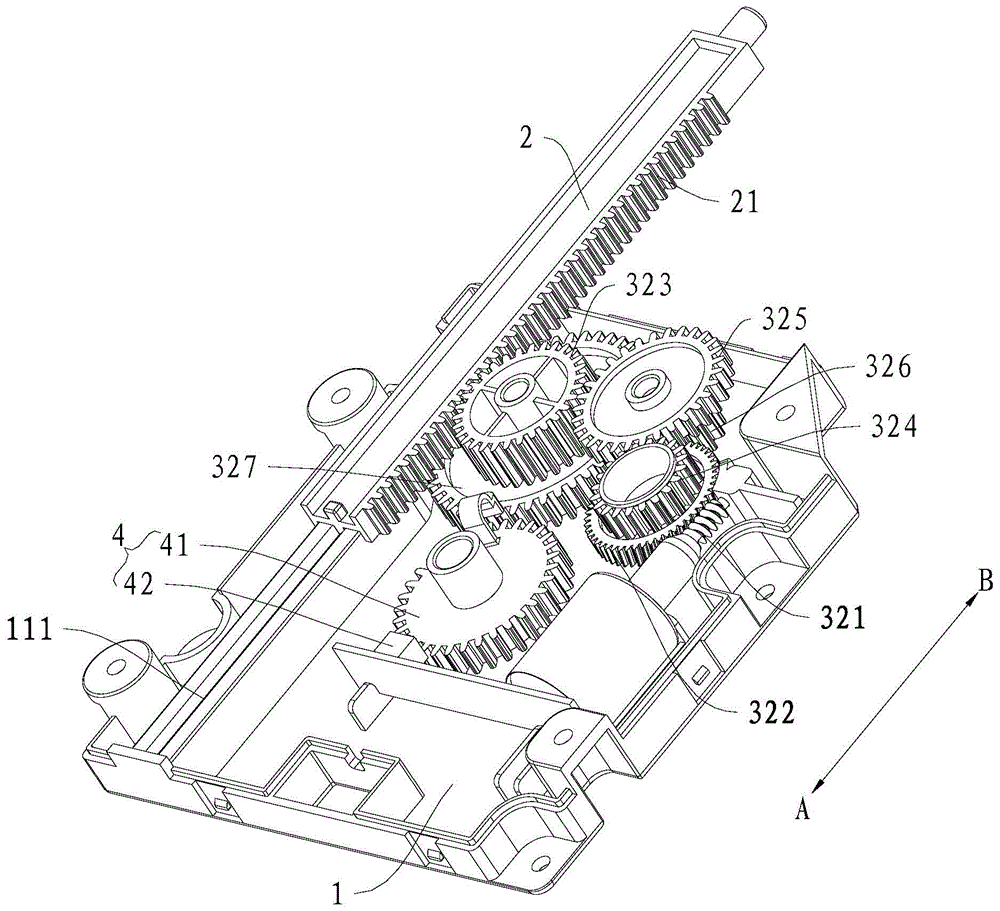

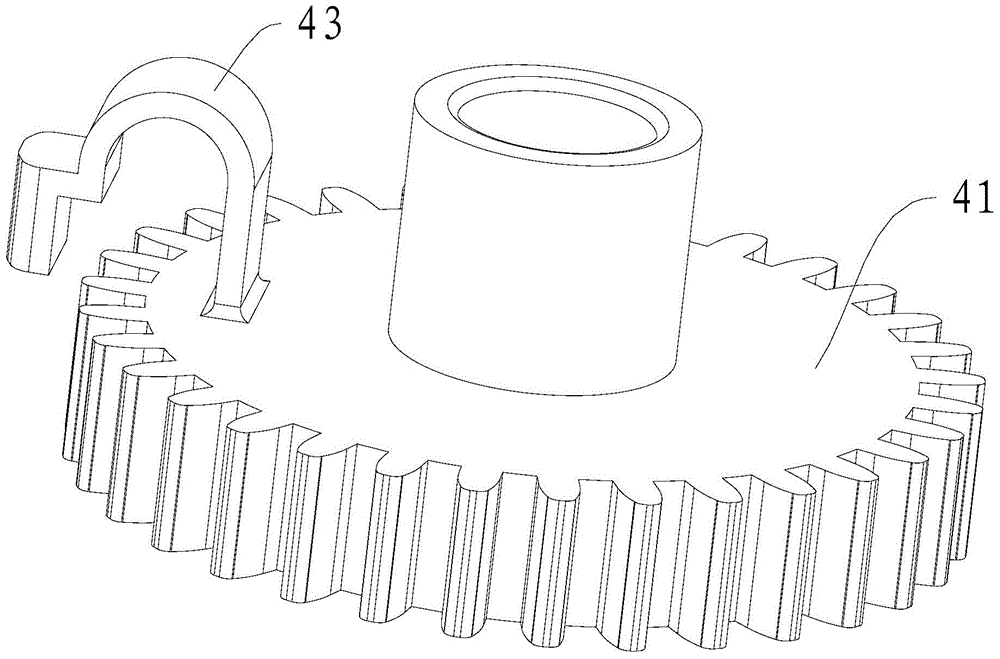

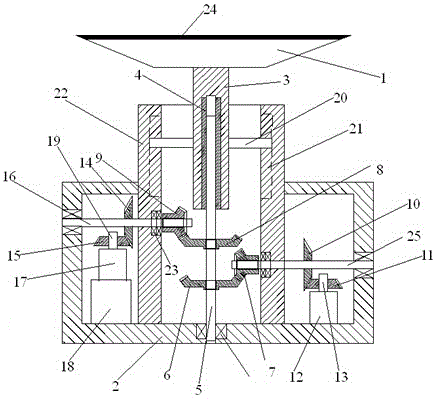

The invention discloses an automatic door opener of a refrigerator and the refrigerator adopting the same. The device comprises a box body, a mandril, a driving component and a control component, wherein the mandril extends out of the box body between the extending position for opening a door and the retraction position for retracting the box body so as to be movably arranged in the box body; the mandril adopts a rectangular rod shape; the driving component is connected with the mandril for driving the mandril to move; the control component is connected with the driving component for controlling the moving direction of the mandril. According to the embodiment of the invention, through adopting the device, the door body of the refrigerator is opened automatically, the door-opening process of the refrigerator is intelligent and labor-saving, and as a result, the refrigerator adopting the automatic door opener is more intelligent.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

Case-making method of silicasol investment casting with elongated hole structure

ActiveCN101480697AShort cycleLow costFoundry mouldsFoundry coresInvestment castingStainless steel wire

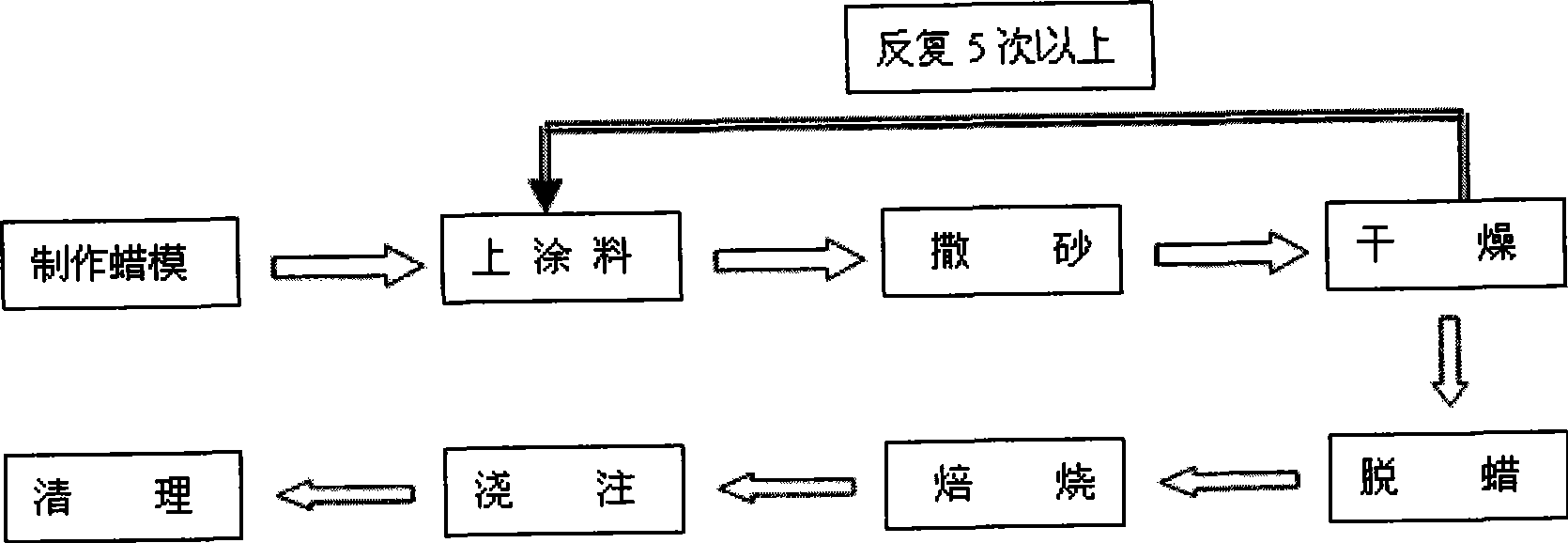

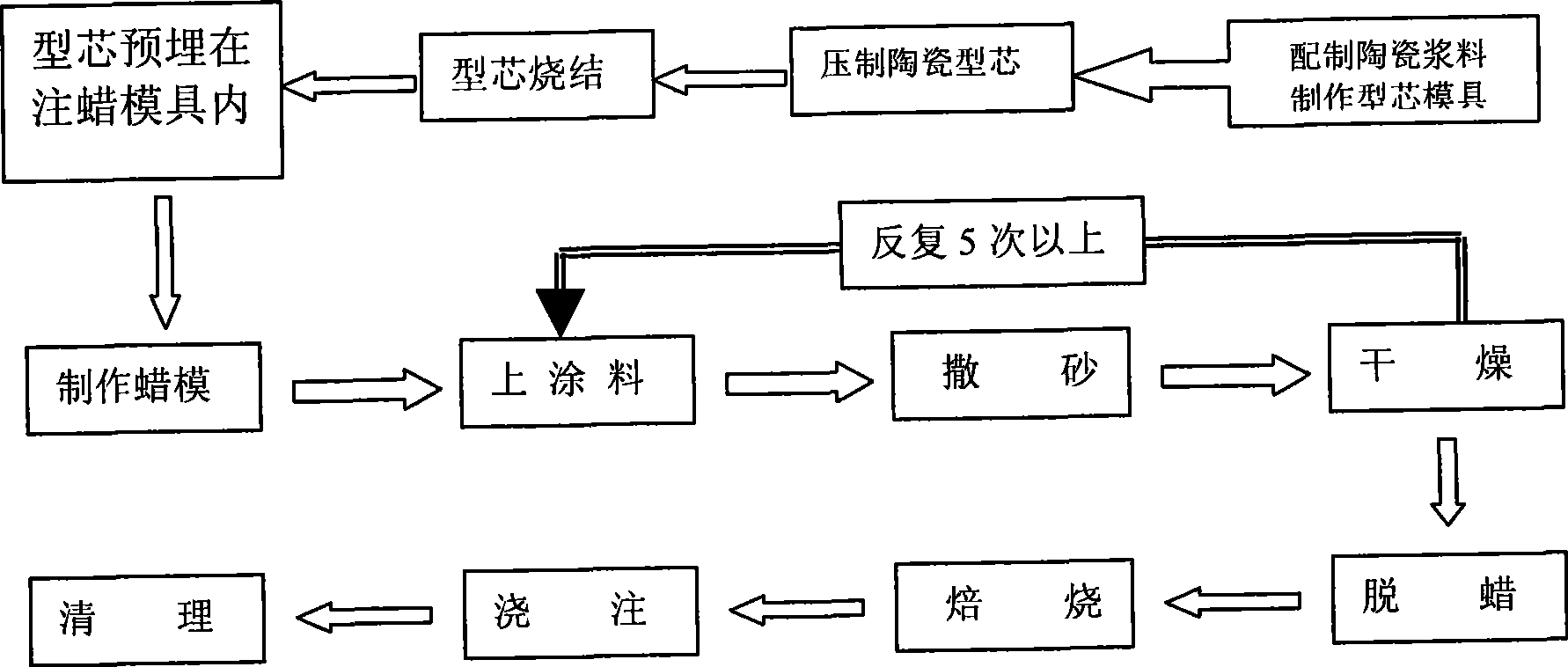

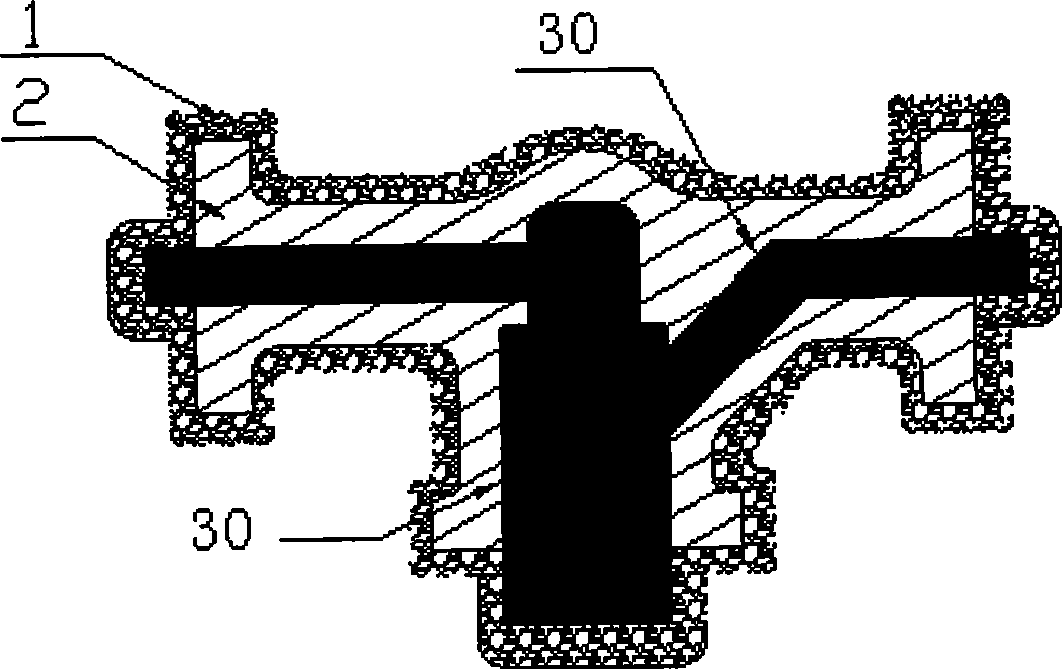

The invention relates to a case making method of a silica sol investment casting with a slender hole structure, and the method is achieved through adopting the following steps of max mould preparation 1, doping 2, sanding 3, drying 4, in-hole grouting 5, continuous case making 6, demaxing 7 as well as roasting and casting 8, wherein the steps between the doping 2 and the drying 4 are adopted for 2-3 times; wherein in the step 5, the in-hole grouting is achieved through the following steps: soft white slime is used for plugging up the lower end and a lateral hole of a part, and a stainless steel wire used for ensuring that a mandril is not fractured at the end part is inserted into the end part of the hole, and the diameter of the stainless steel wire is about 2mm; and sizing agent is injected after the process of plugging up the hole and inserting the wire are ready, and the case making is continued after the sizing agent is solidified. The invention has the advantages that a mold core die is independently manufactured, the period is short, and the cost is low; in addition, the method is not limited by the sorts of the dies and is especially suitable for small amount of products or a single product, and the application is flexible.

Owner:SHANGHAI ZHONGZHOU SPECIAL ALLOY MATERIALS

Laser impact processing method for hole structure

ActiveCN101126117AImprove the strengthening effectExtended structural lifeJet aeroplaneLaser processing

The invention pertains to laser processing technique, relating to an improved treatment for porous structure laser shock. Steps of the treatment are as follows: a mandril or a bush is positioned; an absorption layer and a constraint layer are arranged; the laser shock is treated; the absorption layer constraint layer is cleaned up; the mandril or the bush is taken out from the treated porestructure. The invention improves strengthening effect of angle of the pole, so as to prolong structural life of airplane. The invention especially solves the problem of strengthening a pole of diameter less than 2.5mm which is hard to be strengthened by the prior art.

Owner:BEIJING AVIATION MFG ENG INST CHINA AVIATION NO 1 GRP

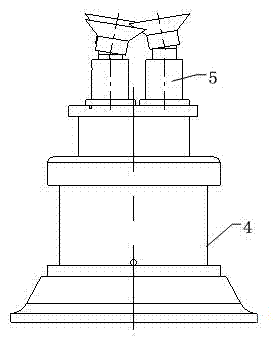

Gear transmission jack

The invention discloses a gear transmission jack which comprises a top tray, a threaded drum, a threaded mandril and gear transmission assemblies, wherein the lower part of the top tray is fixedly connected with the threaded drum; the lower end of the threaded drum is in threaded fitting with the upper end of the threaded mandril; at least two driving motors commonly drive the threaded mandril through the corresponding gear transmission assemblies to rotate, so that rotation of the threaded mandril can drive the threaded drum to rise and fall, to implement that the top tray jacks up and drops down a heavy object. By the arrangement of the two gear transmission assemblies, the jacking capacity of the jack is greatly improved, and the gear transmission efficiency is improved. Supporting of the gear assemblies of the gear transmission jack is also greatly improved, and the use convenience is enhanced; furthermore, due to motor driving, jacking automation is realized.

Owner:ANHUI SCI & TECH UNIV

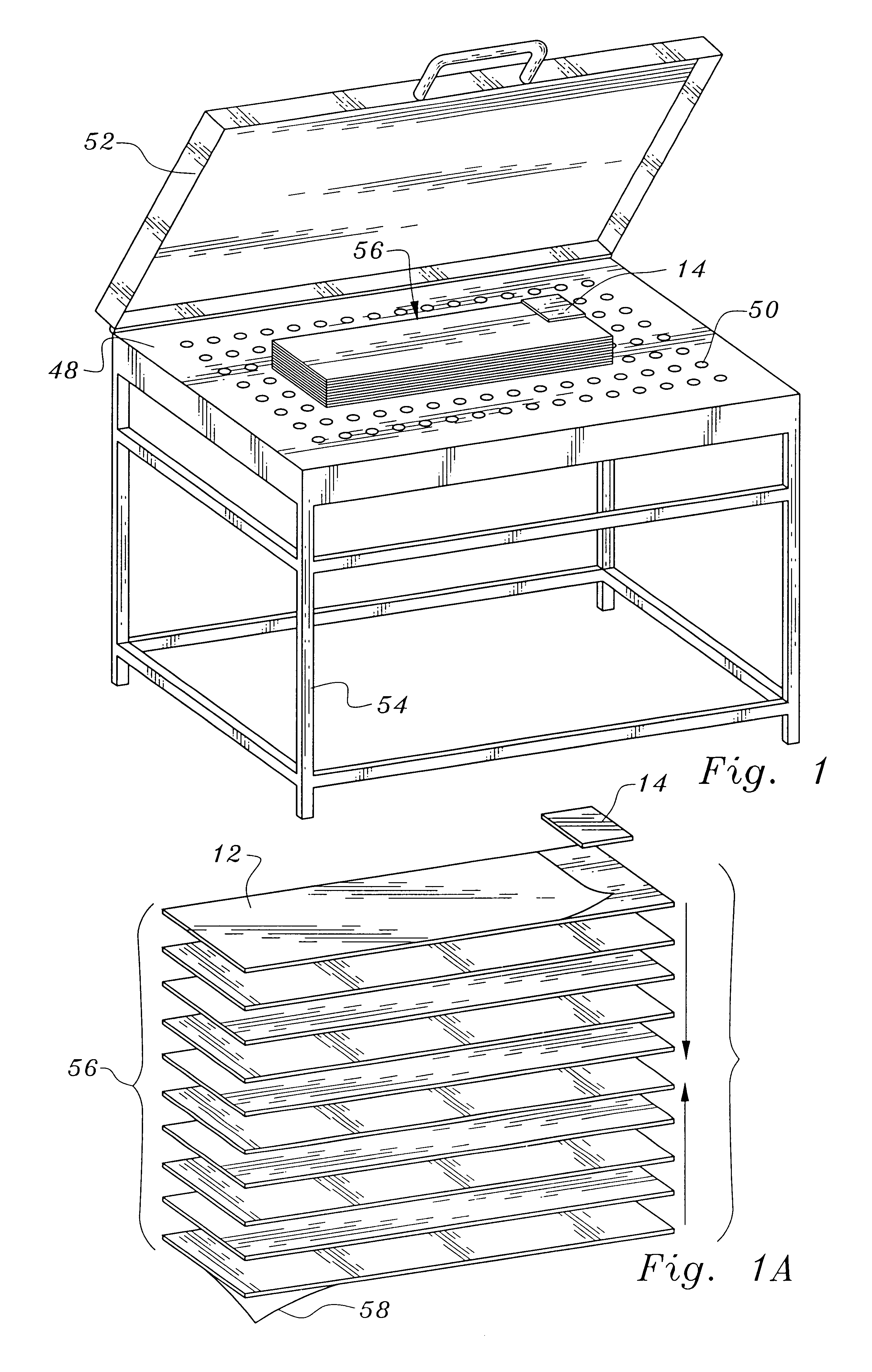

Composite hockey stick handle with resilient shroud

A hand-held implement grip and protectant, preferably for a hockey stick, is described. The invention mainly consists of a blade attached to a composite shaft integrally enshrouded with a rubber sheath. A method of forming the same is also provided as laying up a number of sheets of composite material, wrapping those sheets about a mandril, enshrouding the layup with a rubber sheath, vulcanizing the combination, removing the mandril, and inserting a blade therein.

Owner:HILLERICH & BRADSBY

Clamp for welding multi-sectional thin-wall parts

ActiveCN103521994AAvoid deformationReduce positioning errorsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThin walled

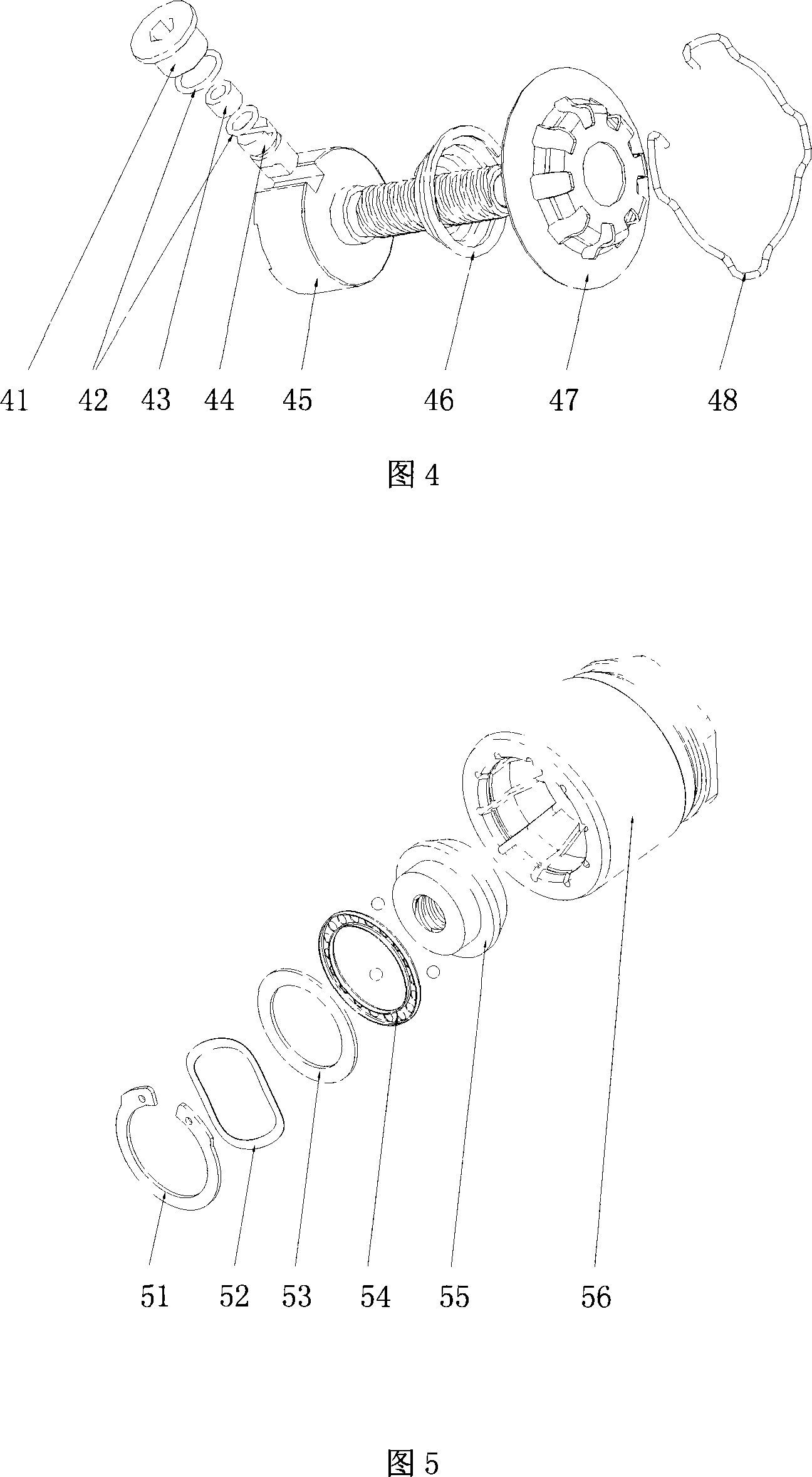

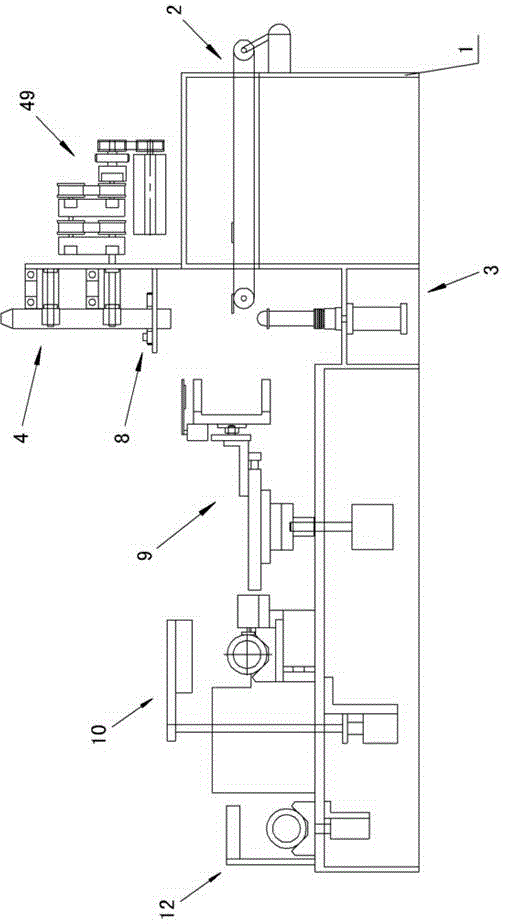

A clamp for welding multi-sectional thin-wall parts comprises a base, a limit ring, a pull rod, a first taper mandril, a lower slide block, a lower expanding block, a second taper mandril, an upper slide block, a guide block, an upper expanding block, a short shaft, a sleeve, a pressing plate, a first nut, a pressing ring, a second nut, a welding device connection shaft, a pressing plate, a pressing cover and a third nut. By means of the clamp for welding the multi-sectional thin-wall parts, the welding of the multi-sectional thin-wall parts can be achieved by primary assembly and welding.

Owner:四川成发普睿玛机械工业制造有限责任公司

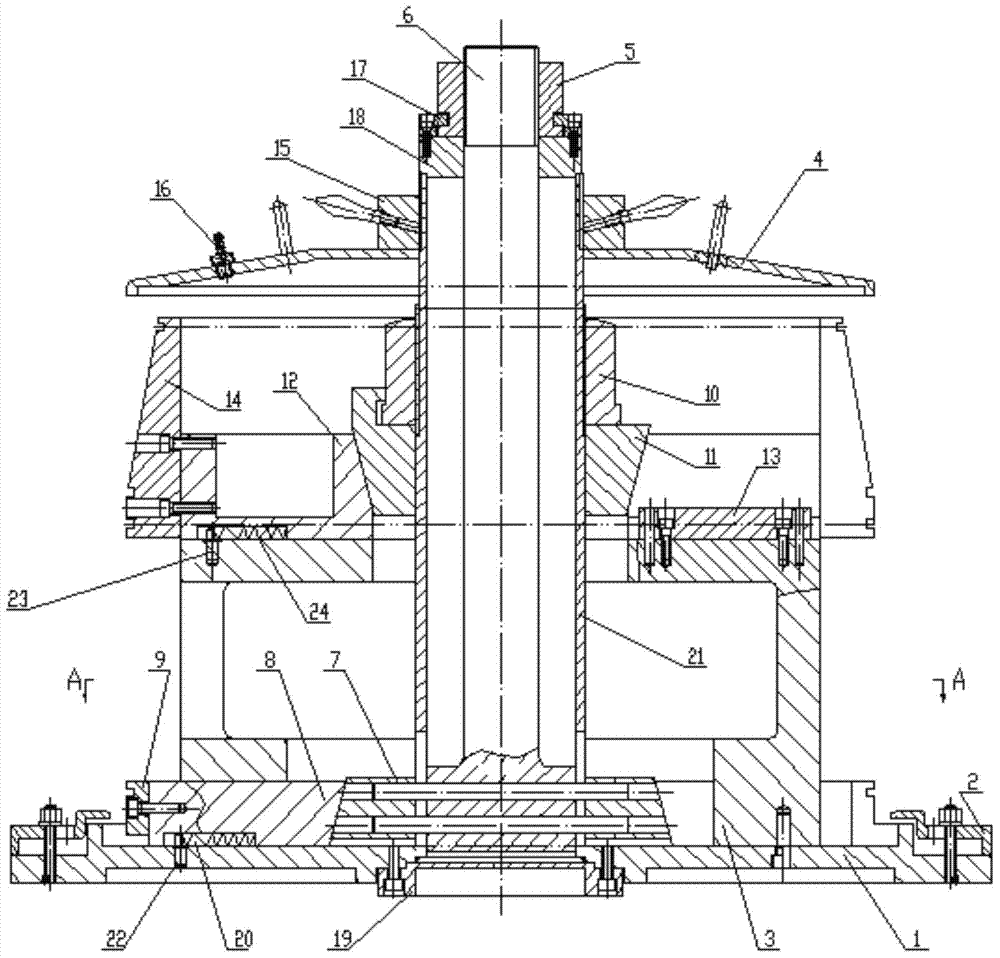

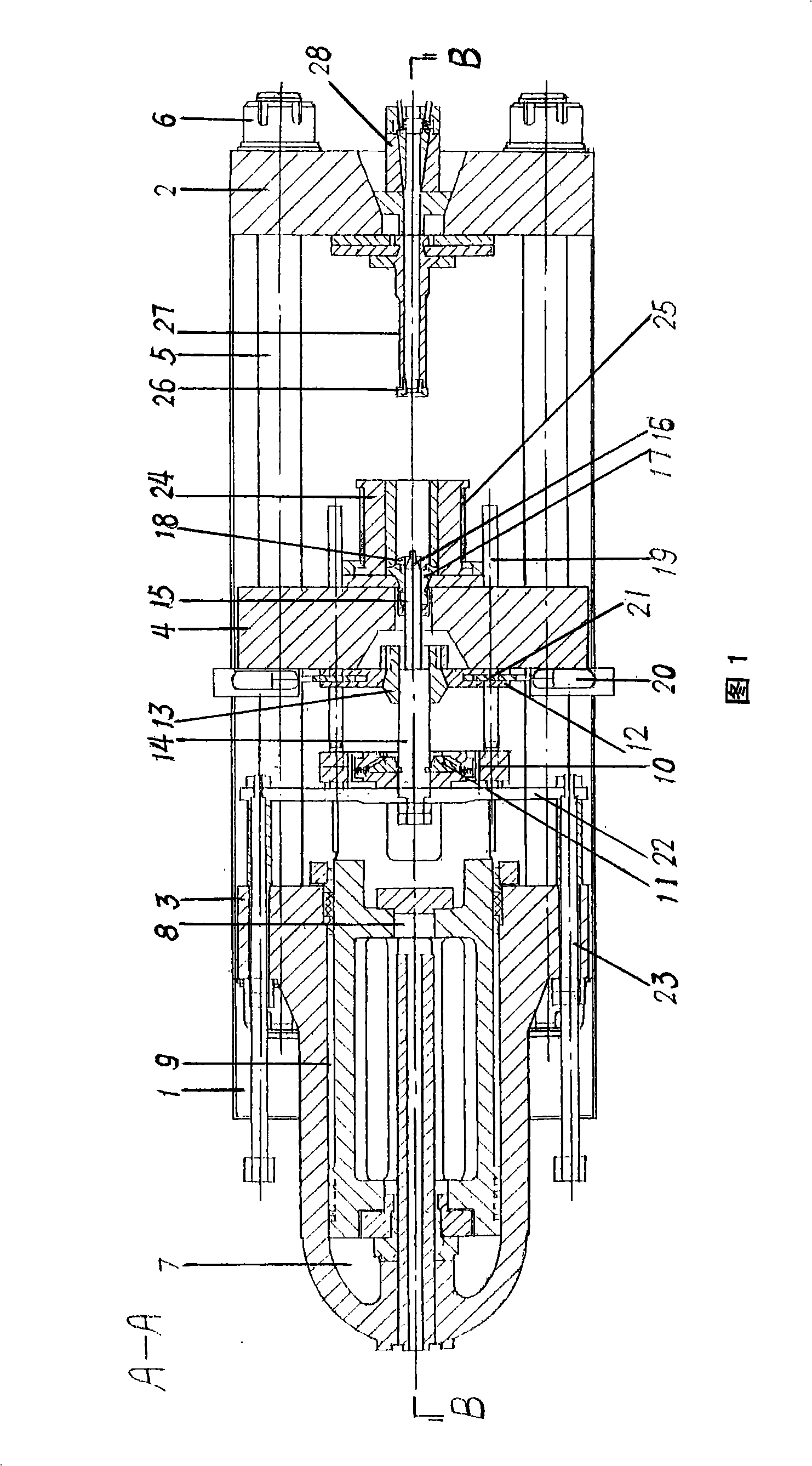

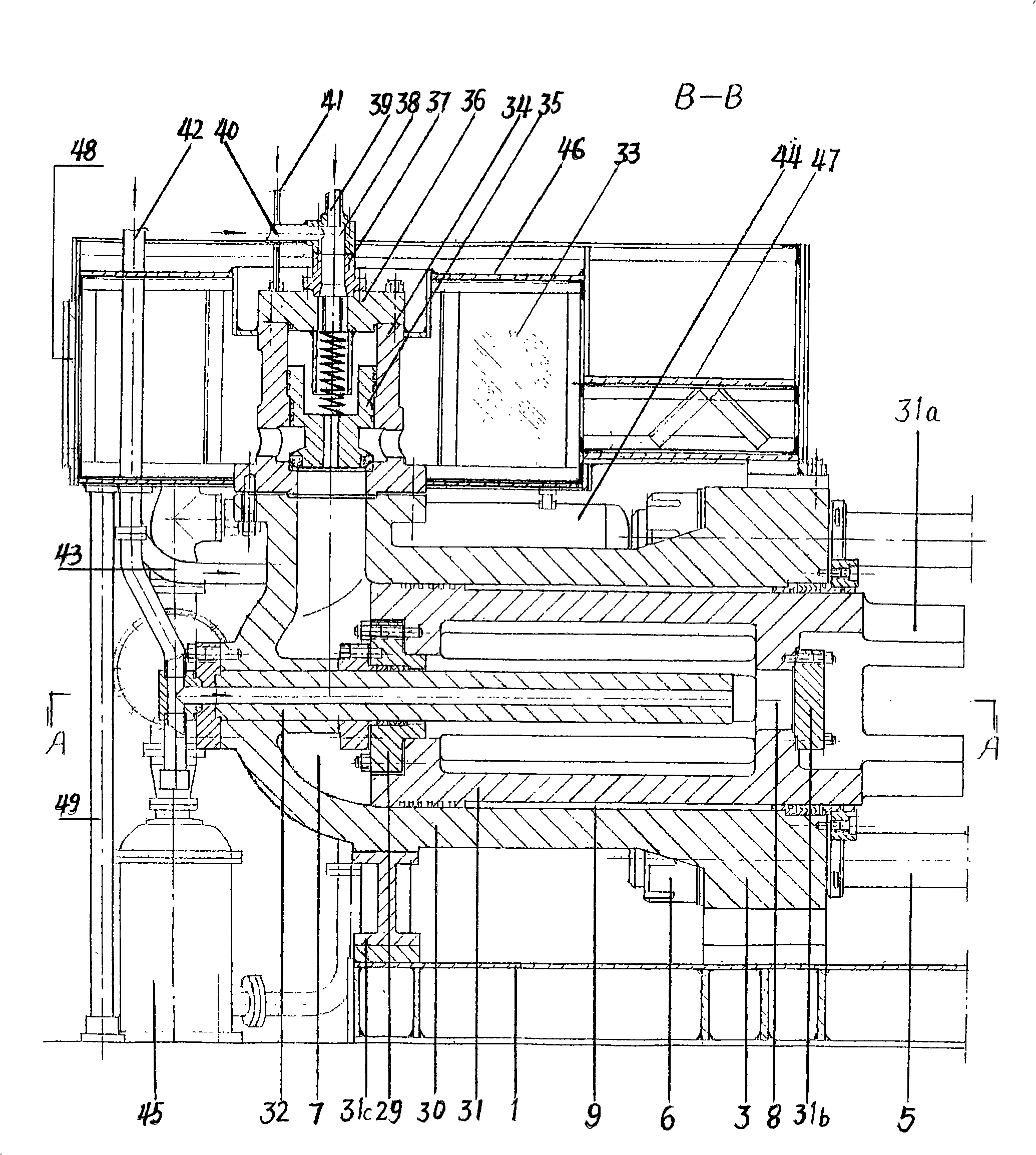

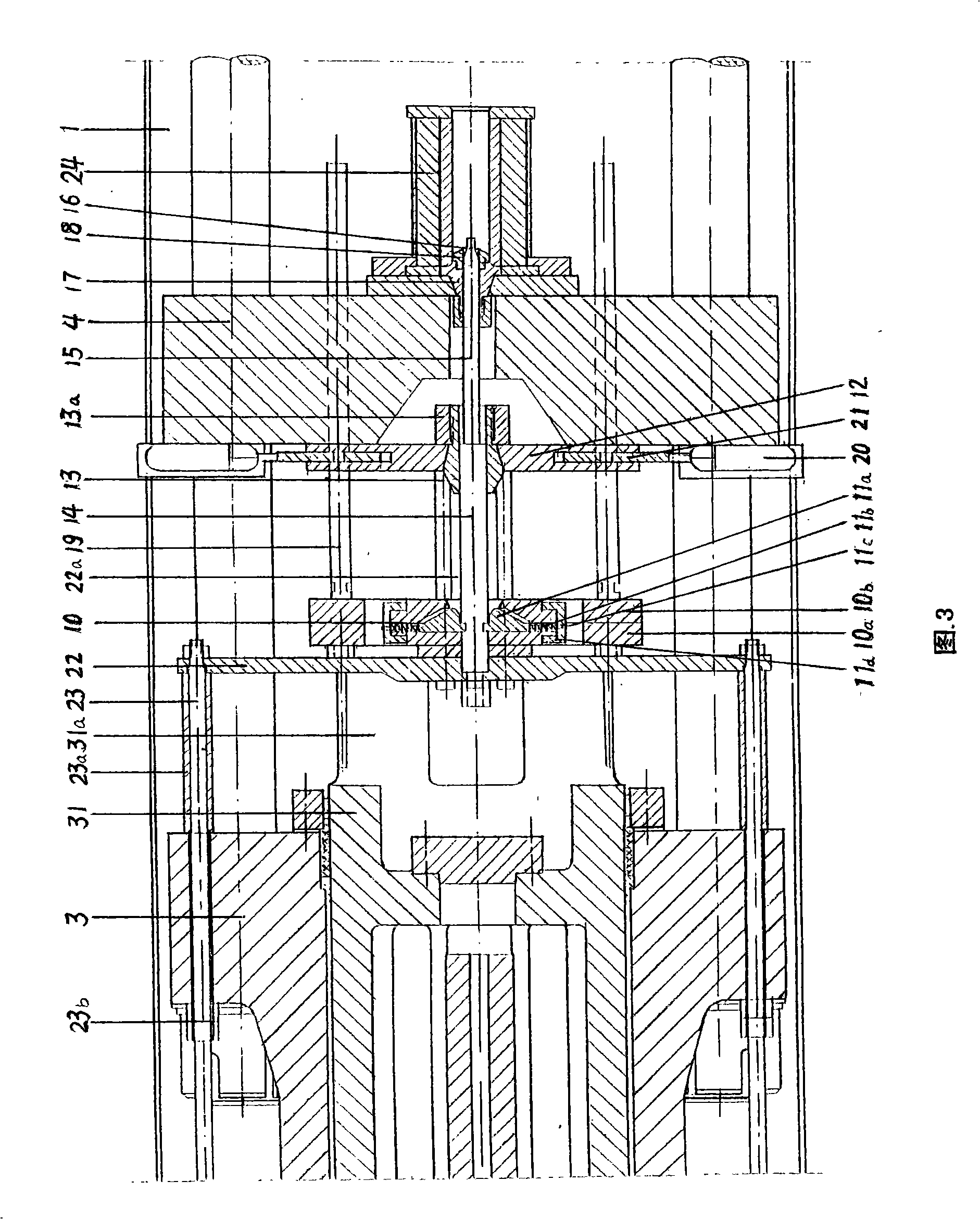

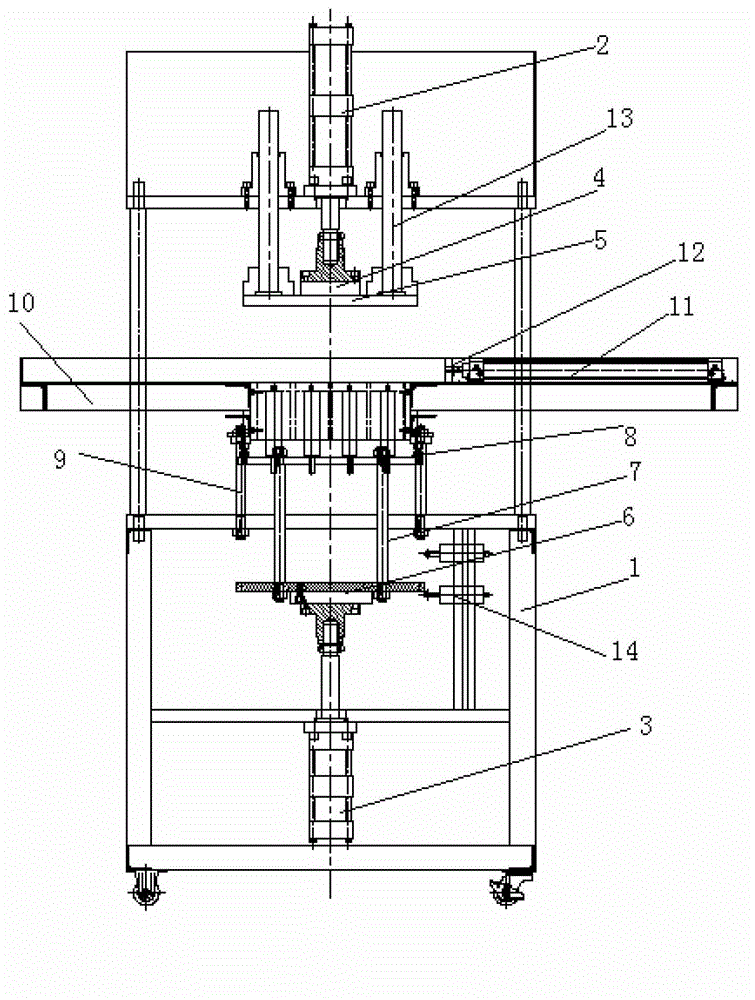

Alloyed steel horizontal type indirect extrusion machine

The invention discloses a horizontal reverse alloy steel extrusion machine, which belongs to the novel technical field of seamless steel pipe and relates to a seamless steel pipe manufacturing facility. The purpose is to settle the problems of complex process, inefficiency, high energy consumption and pollution of the environment with the prior domestic cold drawing techniques of small-bore seamless alloy steel tube. The machine consists of a rigid framework, a liquid-filled combined hydraulic cylinder and a die assembly, wherein, the rigid framework consists of an anterior fixed beam, a posterior fixed beam and an intermediate moving beam on the frame, which are connected in series by a four tensile columns; the liquid-filled combined hydraulic cylinder has a compact structure and is capable of executing the operations of die displacement, material feeding, perforation, extrusion and die removal; the die assembly consists of a perforation and extrusion and automatic switching system, a hot extrusion / molding system and a die removal and disengaging and residual extrusion and cutting system. The machine is capable of achieving once-and-for-all heating and once-and-for-all molding to directly produce finished products of small-bore seamless alloy steel pipes. Compared with forward extrusion, the deviations of the displacement of the piercing mandril and the dies are small, and no friction occurs between the billets and the internal wall of the container, thereby the machine can directly adopt continuous casting billets to extrude small-bore pipes, and has the advantages of simple process, high quality, high efficiency, low energy consumption, etc.

Owner:周家镳

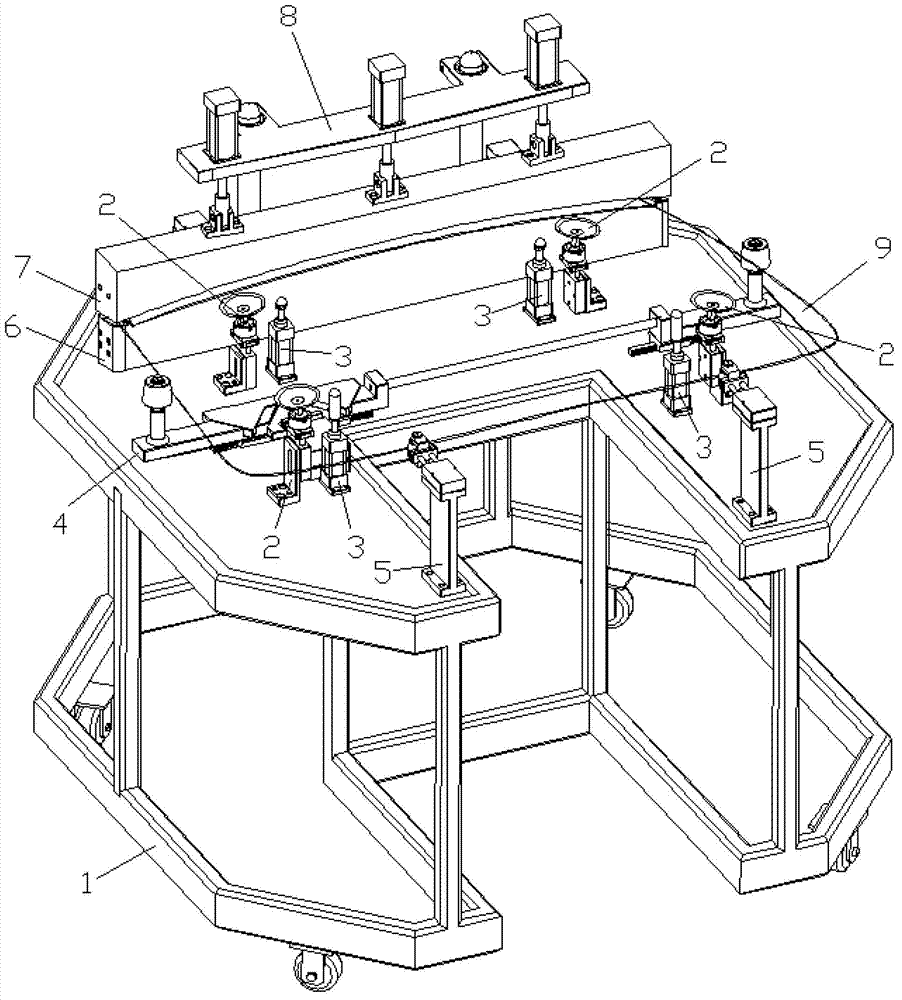

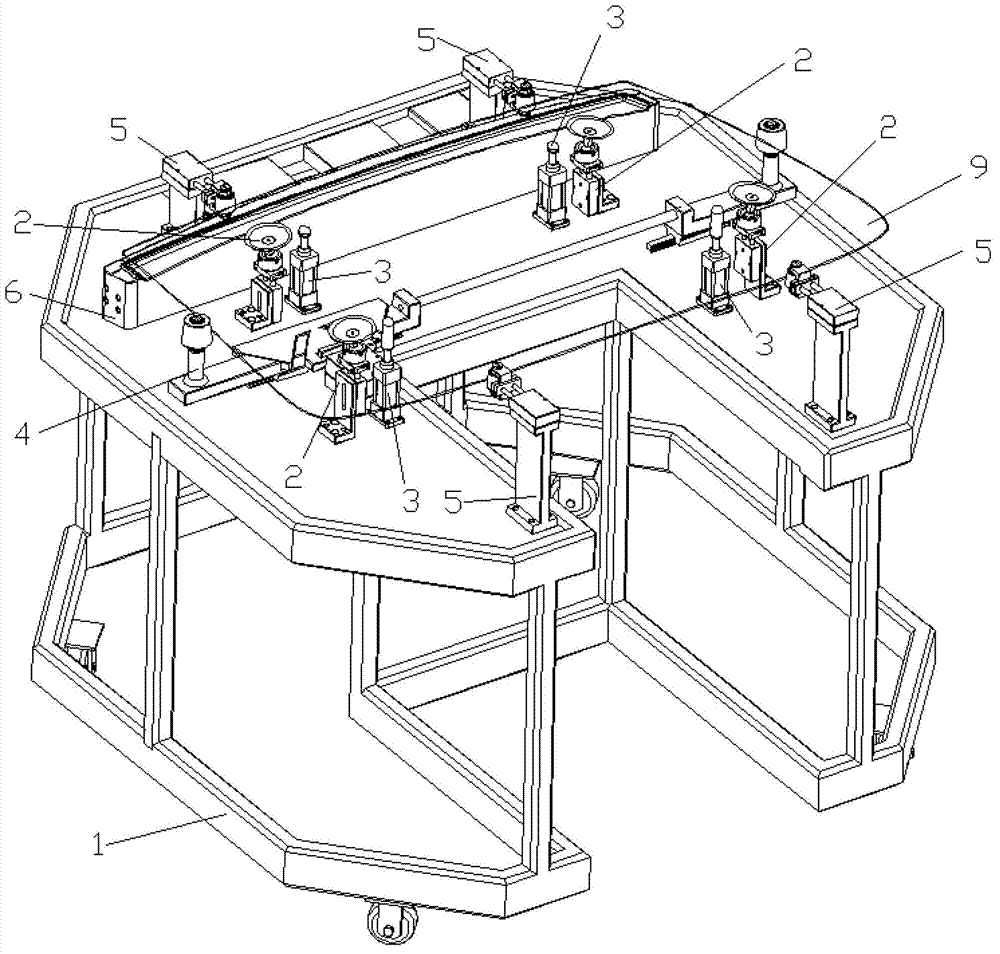

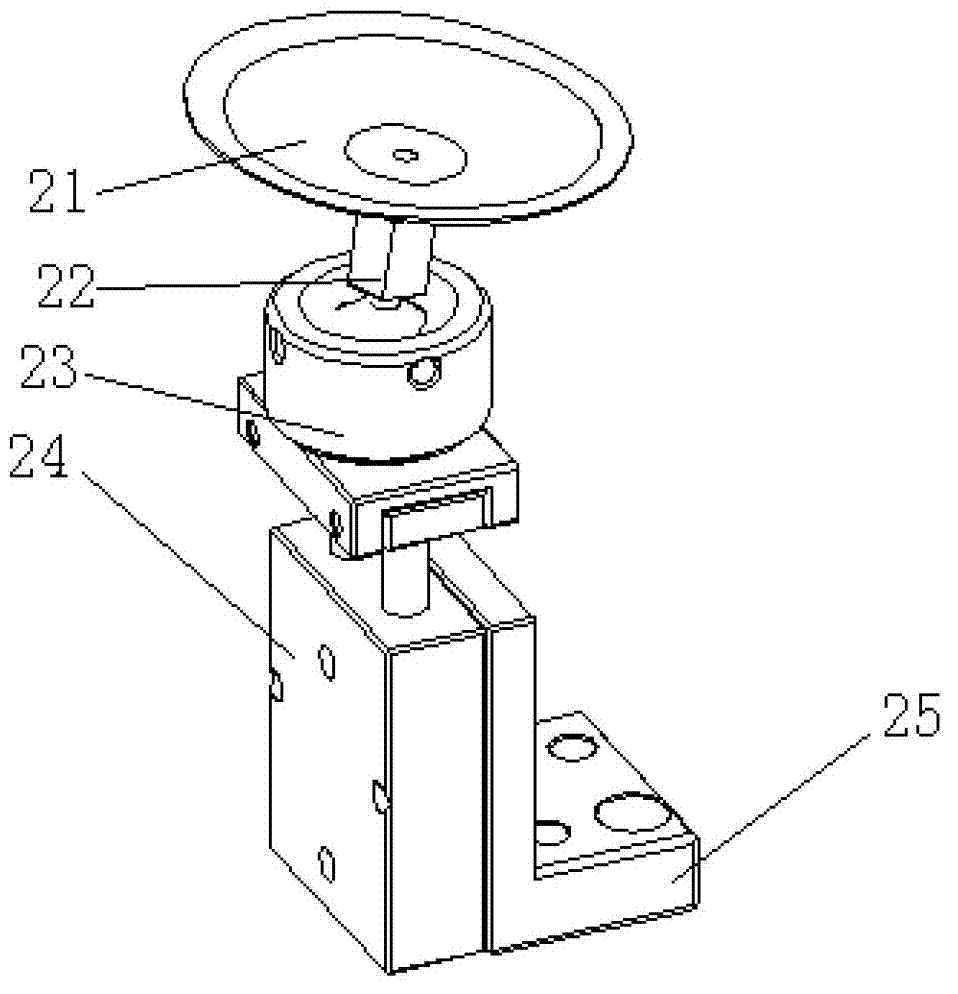

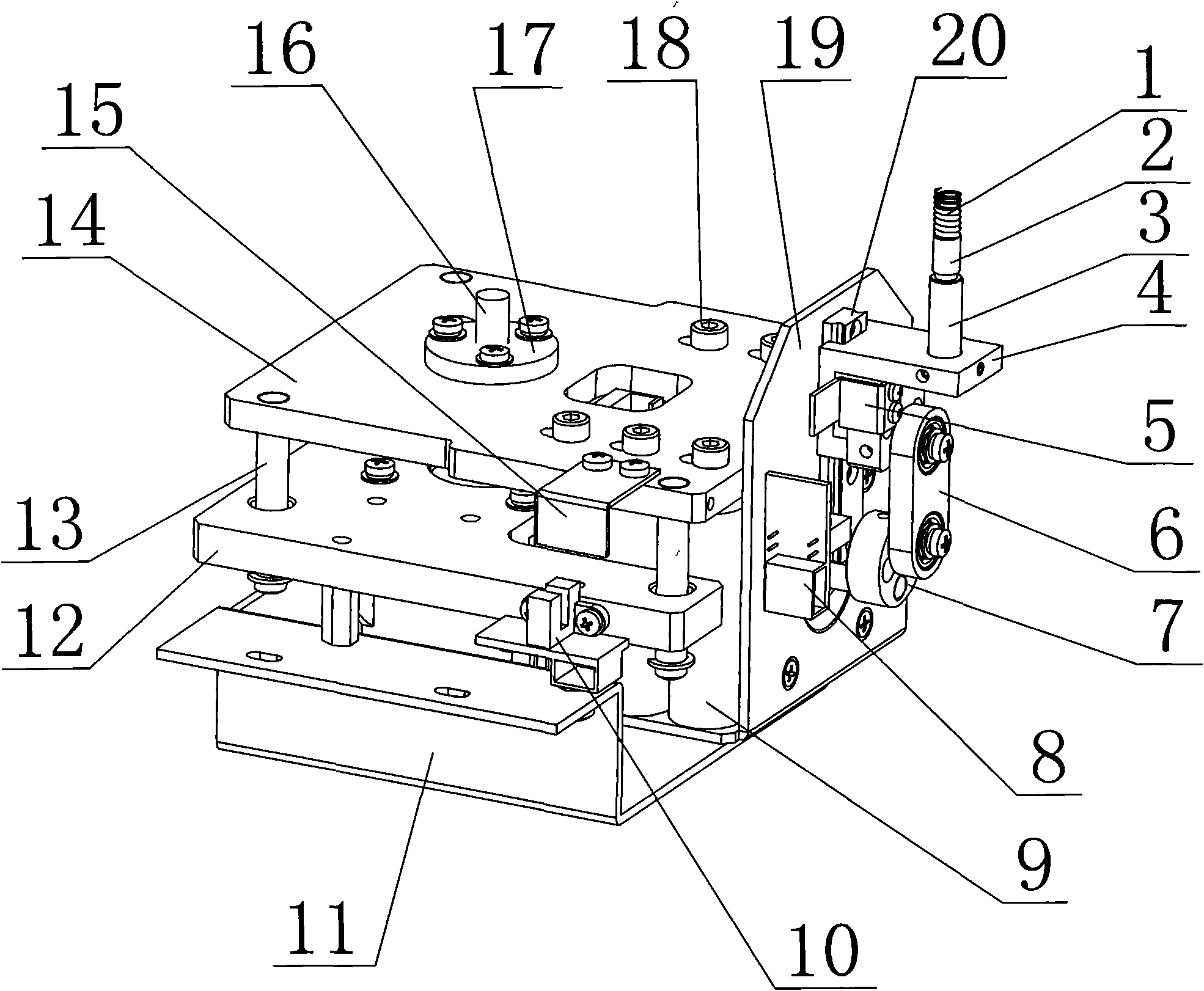

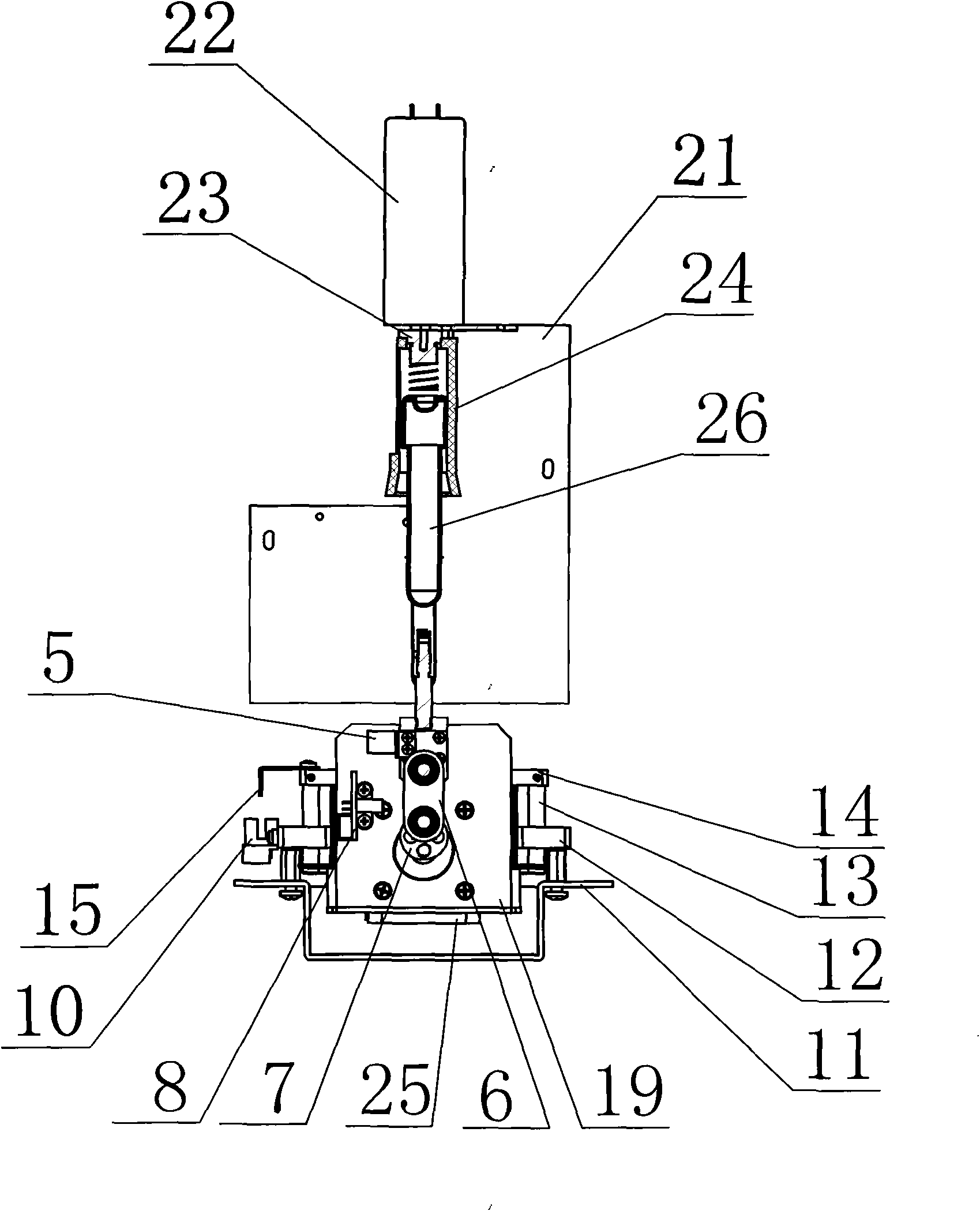

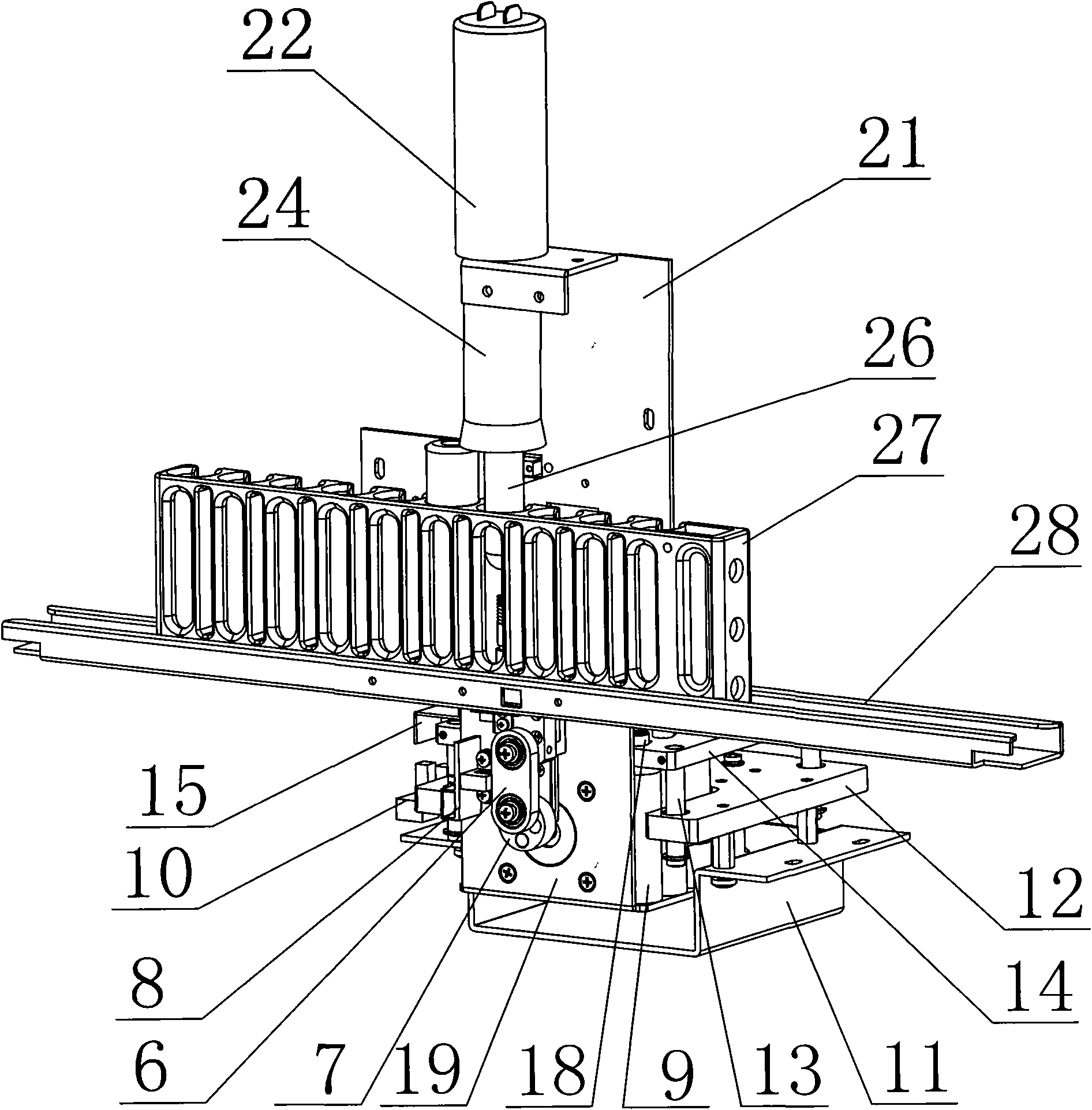

Frock device used for mounting glazing tapes and method thereof

InactiveCN102774447AHigh bonding strengthSimple processVehiclesBonding processTemperature and pressure

The invention relates to the technical field of glass accessories mounting, and particularly relates to a frock device used for mounting glazing tapes and a method of the frock device. The device comprises a sucker device, a mandril device, a lateral positioning device, a longitudinal positioning device, a glazing tape fixing block, a glazing tape pressing block and a pressing block lifting device, wherein the glazing tape fixing block is provided with a locating groove corresponding to the glazing tape in shape; a vacuum hole which is communicated with a gas-type fitting at the side surface of the glazing tape fixing block is formed in the locating groove; and the device is characterized in that the glazing tape fixing block is internally provided with a heating device. The surfaces to be bonded of the glass and the glazing tape are coated with the same first coat, according to the frock device, the glazing tape and the glass are firmly bonded through the first coats under certain temperature and pressure control. The frock device has the advantages of being simple in structure, low in cost, simple in bonding process and good in bond performance, and having low requirements on glass dimensional precision and high yield.

Owner:FUYAO GLASS IND GROUP CO LTD

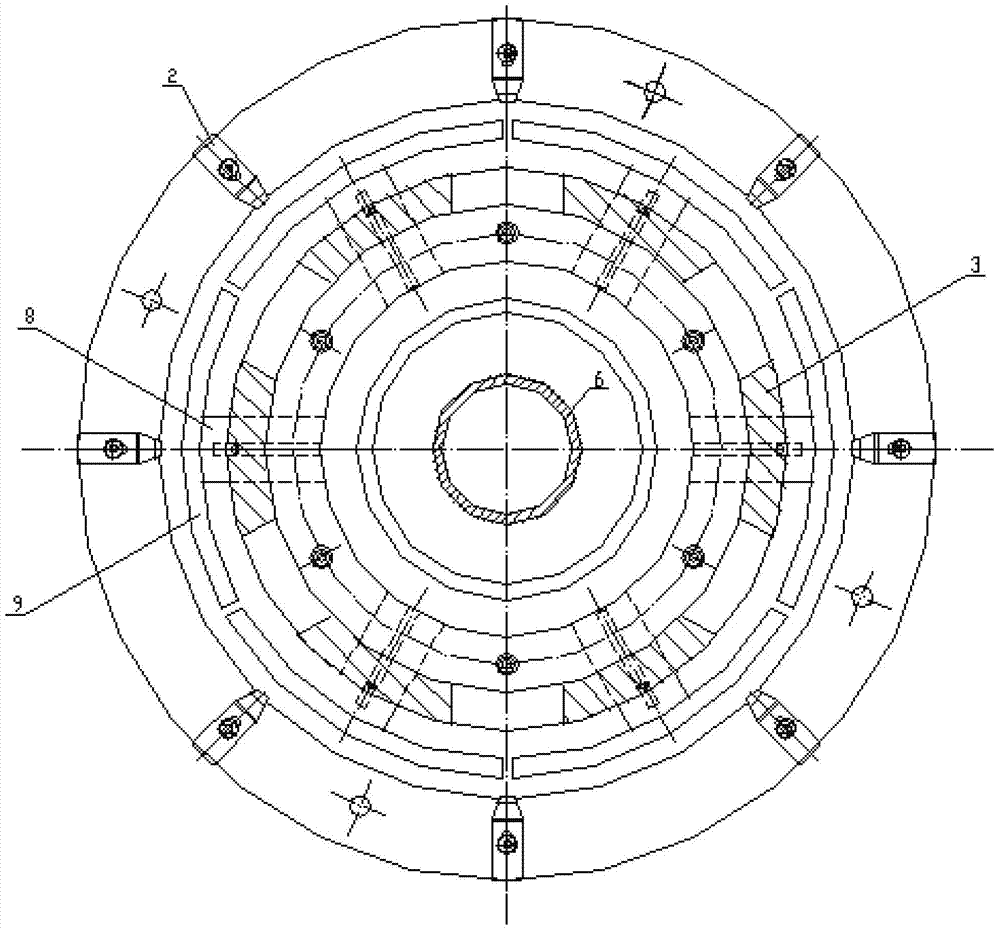

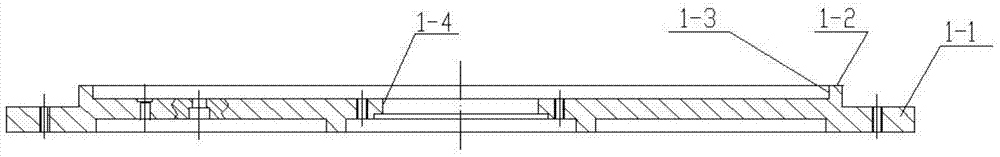

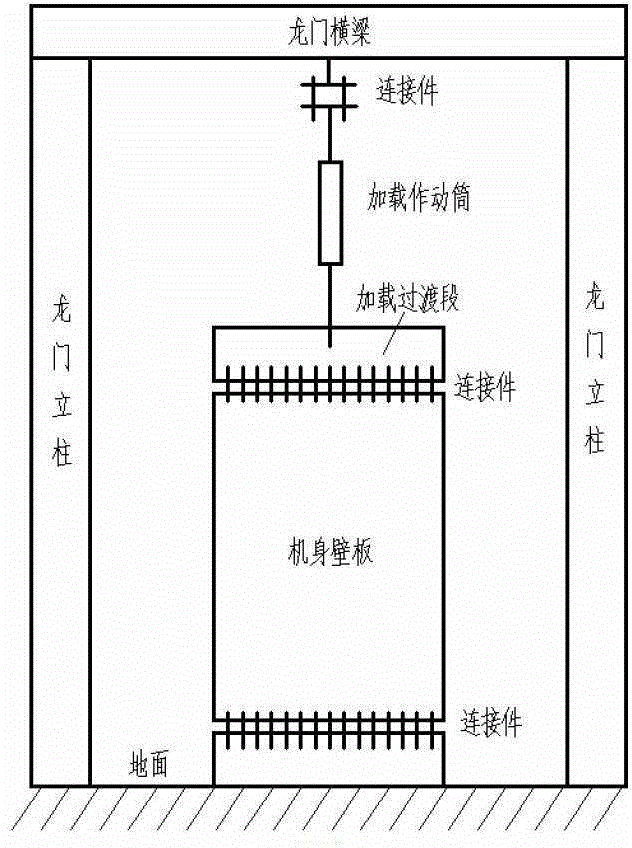

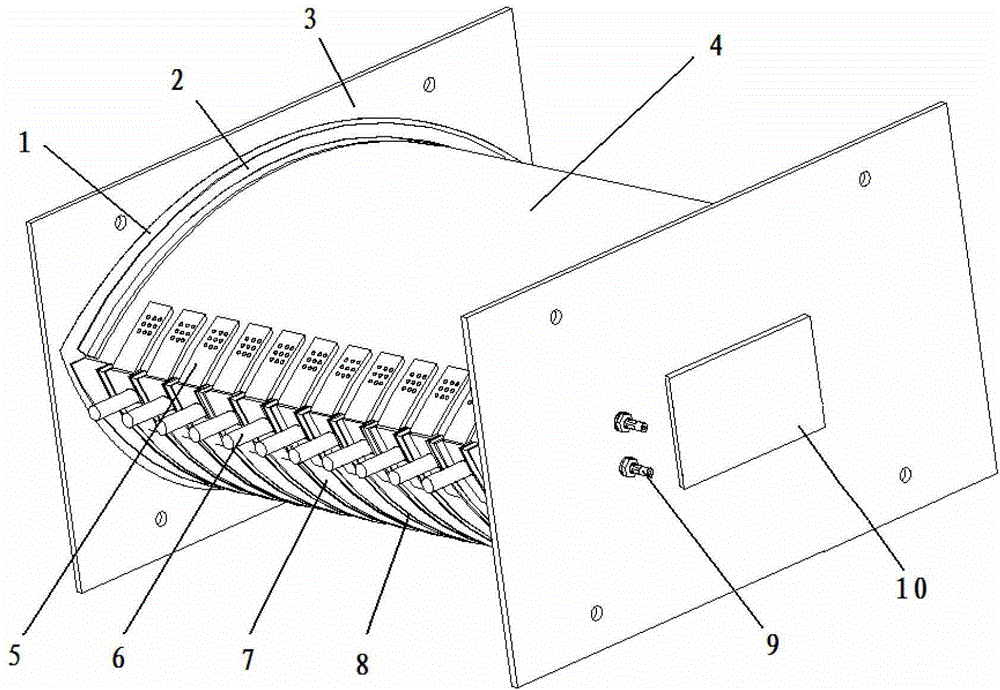

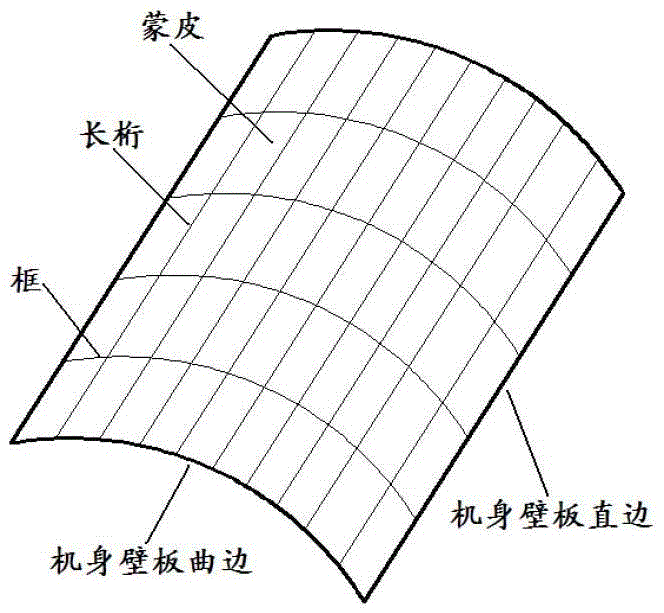

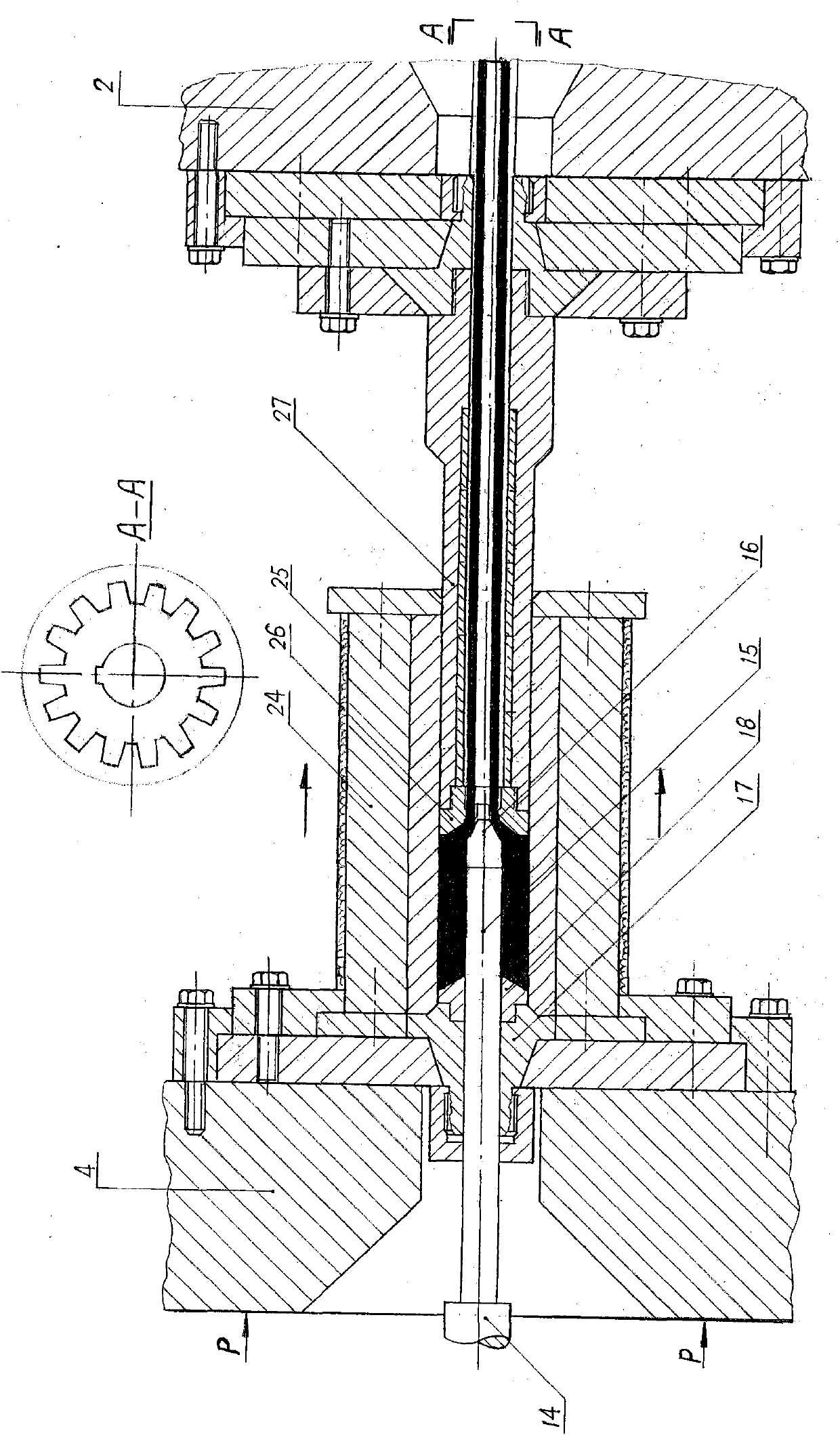

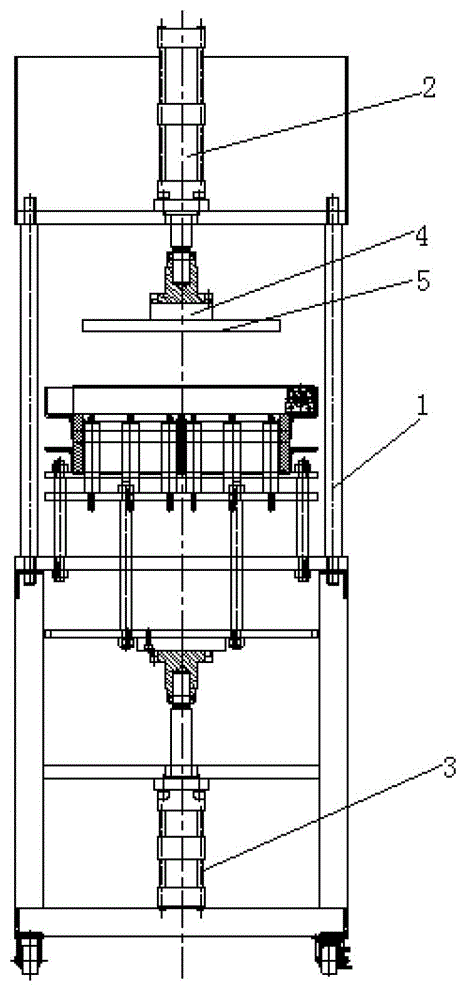

Strength testing device and testing method for fuselage wall plate under action of combined loads

ActiveCN103149075AReduce boundary effectsUniform shear loadMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesInternal pressureKeel

The invention belongs to a strength testing device and a testing method for a fuselage wall plate under the action of combined loads. The strength testing device for the fuselage wall plate under the action of the combined loads comprises corner boxes, airtight end plates, the fuselage wall plate, a hinge, mandrils, keels and arc-shaped rubber plates, wherein the airtight end plates are arranged at two ends of the fuselage wall plate, the corner boxes are arc-shaped components and installed at a combined part between the airtight end plates and the fuselage wall plate, the keels are arc-shaped frames, the keels are connected in a pasting mode through the arch-shaped rubber plates to form a keel group, the mandrils are installed on web plates at two ends of the keel group, and the hinge is arranged on the fuselage wall plate and the keel group and achieves hinged connection of the fuselage wall plate and the keel group. According to the strength testing device and the testing method for the fuselage wall plate under the action of the combined loads, boundary conditions of the fuselage wall plate can be effectively imitated, the combined loads are conveniently used for achieving a strength test, and due to the fact that drawing loads and compressing loads are not used at the same time, the applied combined loads are one kind of or two kinds of or three kinds of internal pressure loads, drawing loads (or compressing loads) and shear loads.

Owner:CHINA AIRPLANT STRENGTH RES INST

Chipless forming method for gear stick and section gear through hot extrusion

InactiveCN101905250AExtend your lifeImprove plasticityExtrusion diesFurnace typesEngineeringThick wall

The invention discloses a chipless forming method for a gear stick and a section gear through hot extrusion by utilizing an alloy steel horizontal type backward extruder, solving the problems that the existing gear cutting process has more working procedures, low efficiency, large metal loss, more operators for machine tool processing and high production cost and the like by utilizing the chip processes of lathing, milling, drilling, inserting and grinding. The method comprises the following steps: an inner cooling combined type double-conical surface gear squeezing die, a recipient and a floating pecker combined mandril are adopted by taking the producing principle of alloy steel thick wall special seamless steel tubes as an example; scale-free heating is rapidly carried out on the blank; lubricating warm-extrusion molding is carried out; center punching, shaft hole slotting and tooth surface extrusion are finished at a time; and the finished product of the gear stick is directly produced, then is subject to waste heat annealing, slicing by wire-electrode cutting and heating process to be manufactured into a finished product. Compared with a chip gear-cutting molding method, the invention has simplified working procedure, few labor, high efficiency, less metal loss, high gear strengthen and reduces the production cost, and then tooth surface precision reaches the standard. The method of the invention is a significant technological innovation of straight tooth and oblique tooth cylindrical gear process technologies.

Owner:周家镳

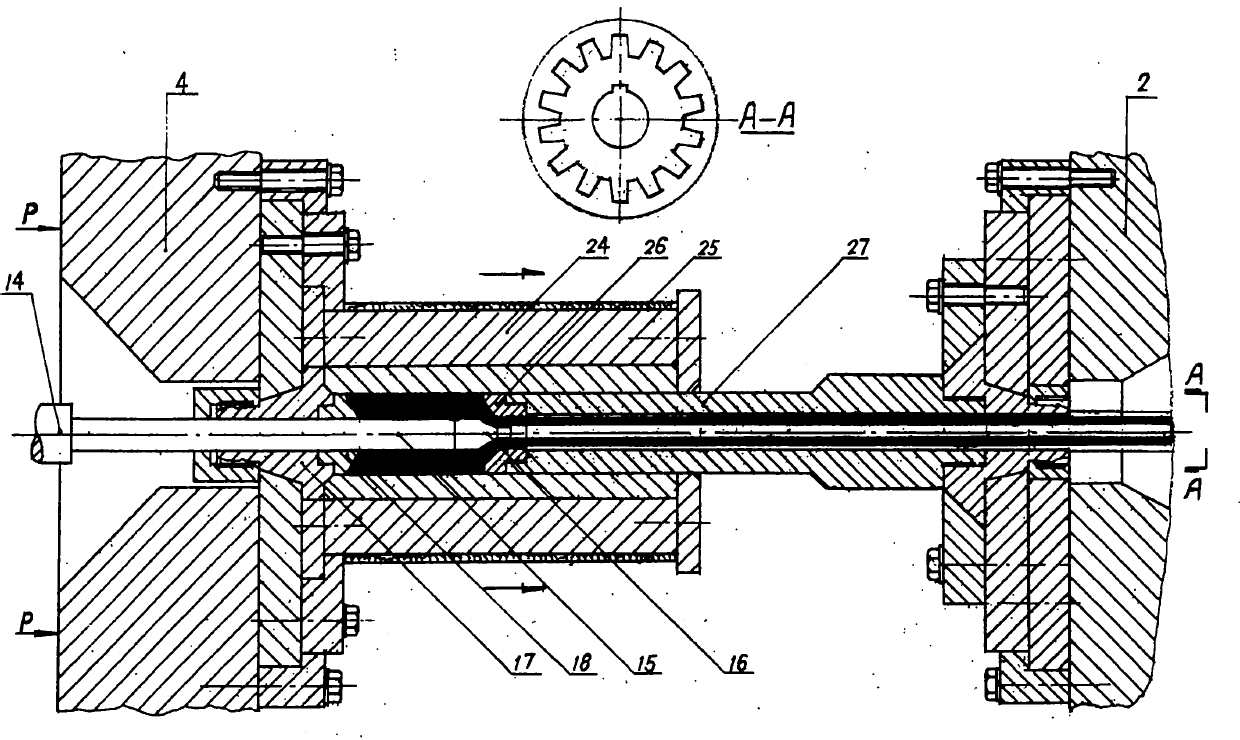

Method for using numerically-controlled pipe bender to process heating constant temperature bending pipe

InactiveCN101185949ARealize the heating effectRealize temperature controlShaping toolsNumerical controlTemperature control

The invention discloses a method making use of numerical control tube bender to heat constant temperature bent tube in the material technology field. The method has the detail steps that a hole is cut on a height direction in the internal part of a round die, and holes are respectively cut on a height direction in the internal parts of a guide die, an anti-crease die and a mandril. A heating medium and a temperature sensor are respectively arranged in the holes. Insulation medium is arranged on the touch area of the lower surface of the round die and a machine body, on the clinching area of the back face of the guide die and a slide block and on the contacting area of the anti-crease die and a support frame thereof. The heating medium and the temperature sensor are respectively connected with a temperature control system which consists of a digital-display temperature control instrument and a solid relay. A temperature control instrument controls the opening and closing of the solid relay through comparing a self-set value with a collected value by the temperature sensor so as to realize a temperature control to the die; the tubes are hot bended -for molding. The invention realizes heating bending in a constant temperature for tubes which are difficult to be transfigured with high shaping accuracy, and is suitable for a batch production.

Owner:SHANGHAI JIAO TONG UNIV

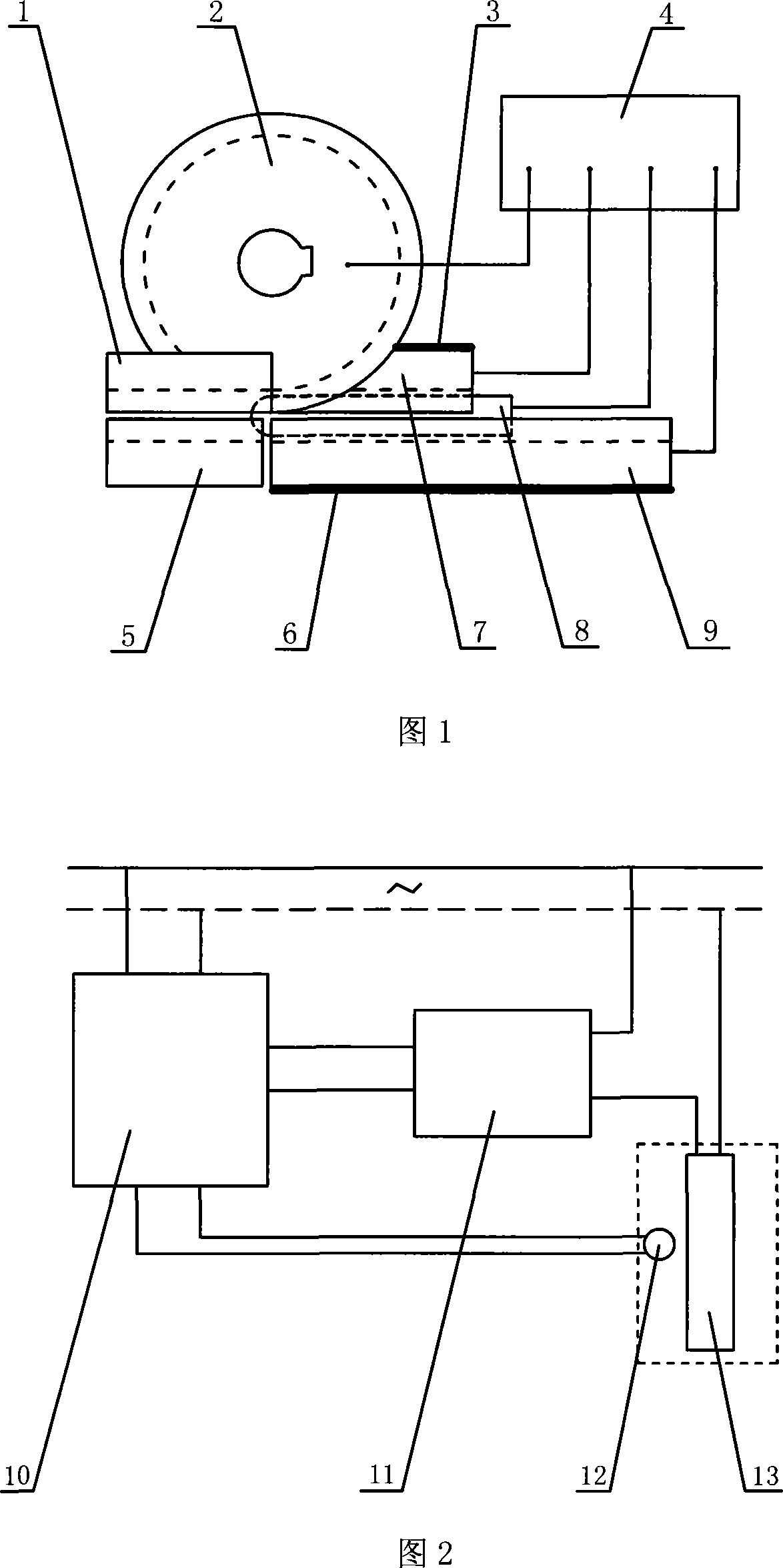

Blending device of blood cell analyzer

ActiveCN102095625ARealize mixing operationWell mixedPreparing sample for investigationBiological testingReciprocating motionScrew thread

The invention discloses a blending device of a blood cell analyzer, mainly comprises a blending mechanism and a lifting mechanism, wherein the blending mechanism comprises a vertical blending mechanism, the vertical blending mechanism comprises a vertical blending motor, a linear guide rail and a slide block which are arranged on a blending motor support, and a blending mandril is fixedly arranged at the top of the slide block; the output shaft of the vertical blending motor is coaxially fixedly connected with an eccentric wheel, and the eccentric wheel is connected with the guide rail and the slide block by virtue of a connecting rod; the lifting mechanism comprises a lifting base plate provided with a lifting motor and guide rods, and the top of each guide rod is connected with a lifting plate; the output shaft of the lifting motor is coaxially fixedly connected with a lifting screw rod, and the other end of the lifting screw rod and a lifting screw rod nut fixed on the lifting plate are in screw thread fit; and the blending motor support is fixed on the lifting plate. By applying the device provided by the invention, a test tube can realize variable speed reciprocating motion in the vertical direction, thus blood samples in the test tube can be blended more conveniently; and the location of the blending mandril in the vertical direction can be controlled, and the degree of automation is higher.

Owner:URIT MEDICAL ELECTRONICS CO LTD

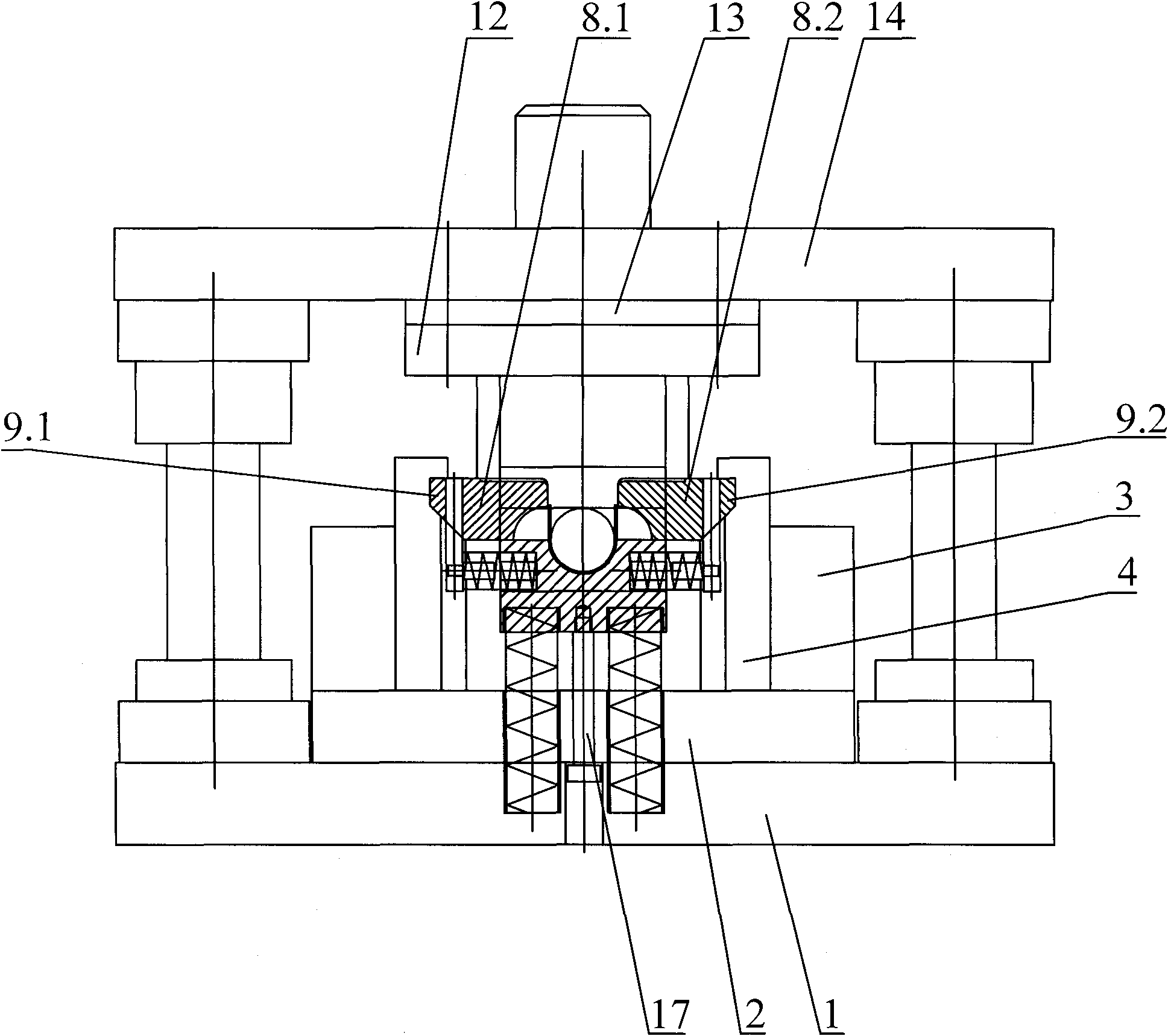

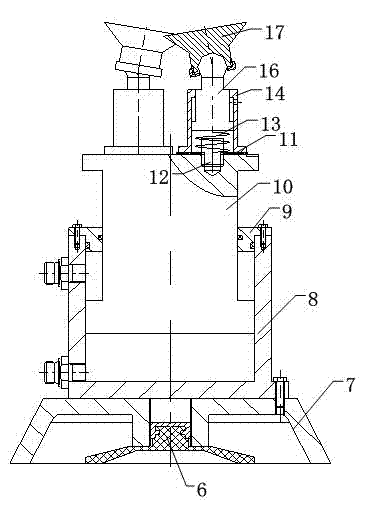

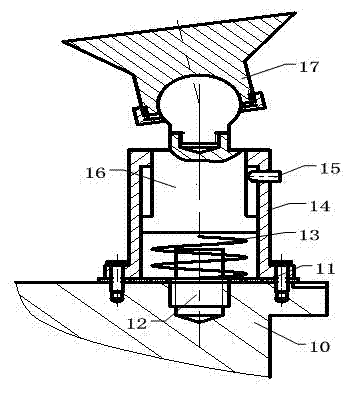

Curled round one-time forming die

The invention relates to a curled round one-time forming die, wherein, the lower surface of an upper template is fixed with an upper base plate, and the upper surface of a lower template is fixed with a lower base plate; lower inserts are intermittently fixed on left and right sides of the upper surface of the lower base plate, and a slide driving slope is arranged on the opposite wall surfaces of the two lower inserts; an elastic jacking block is arranged between the two lower inserts; an elastic jacking screw hole is integrally arranged in the lower template and the lower base plate, and the elastic jacking screw hole is internally equipped with elastic jacking screws; an elastic jacking block groove is arranged on the top end of the elastic jacking block, and a left half block and a right half block are arranged on the elastic jacking block; a left forming wall is arranged on the right corner of the left half block, and a right forming wall is arranged on the left corner of the right half block; a mandril is inserted in a circular hole; the left wall of the left half block is fixed with a left sliding block, and the right wall of the right half block is fixed with a right sliding block; and the left sliding block is equipped with a left sliding slope, and the right sliding block is equipped with a right sliding slope. The die of the invention can achieve curled round one-time forming, thus improving the yield and the quality of products.

Owner:WUXI ZHONGJIE VIBRATION ISOLATORS

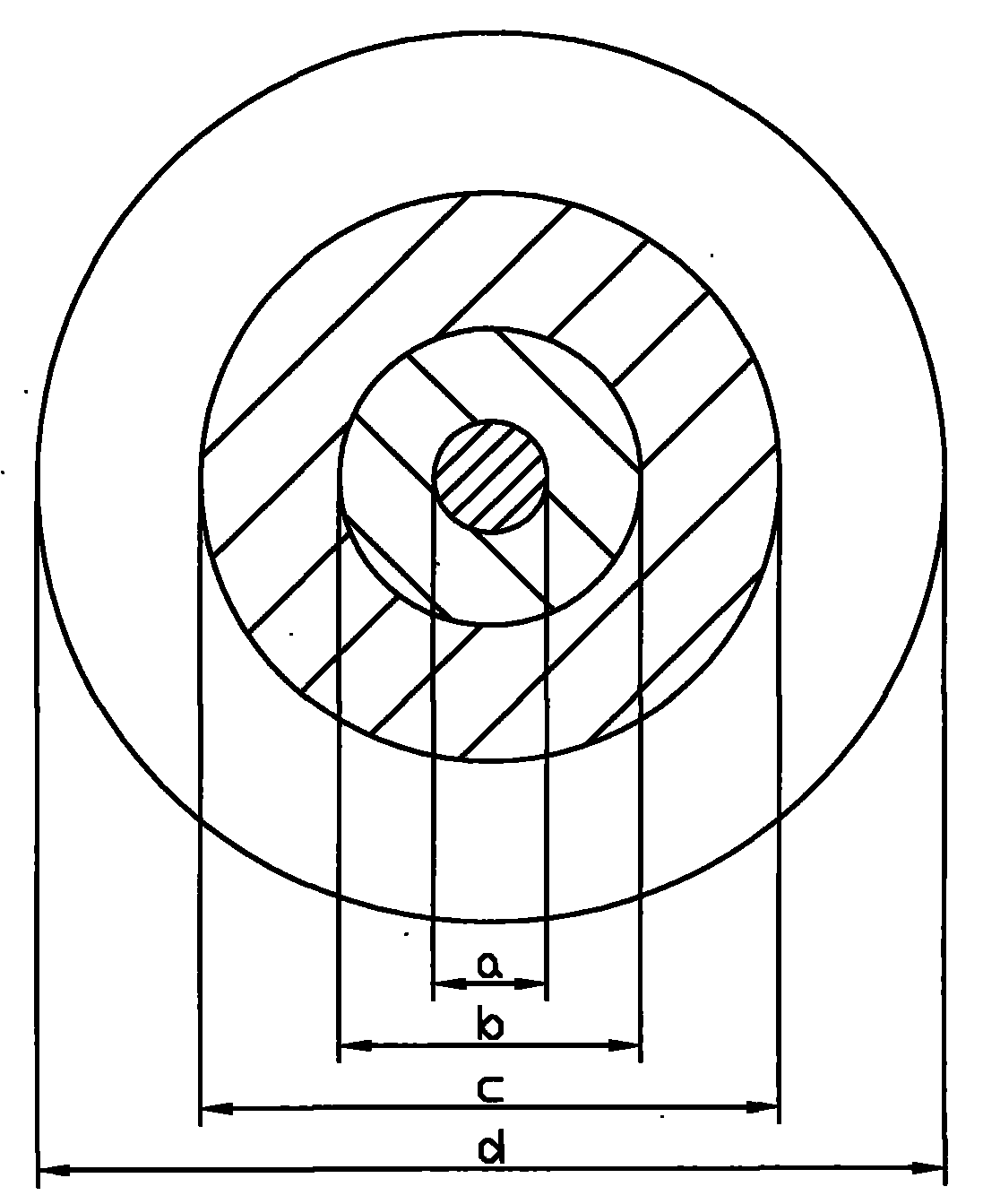

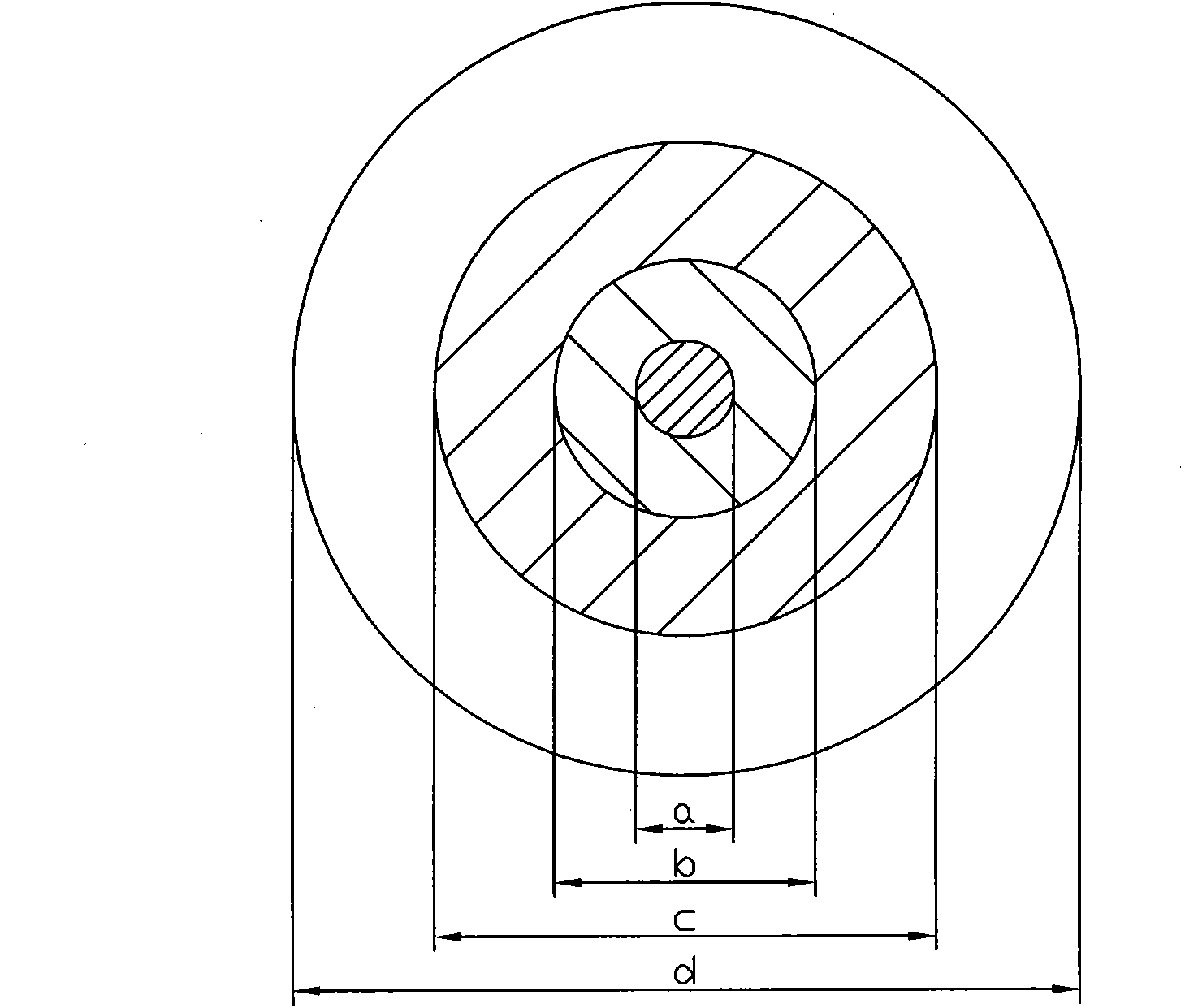

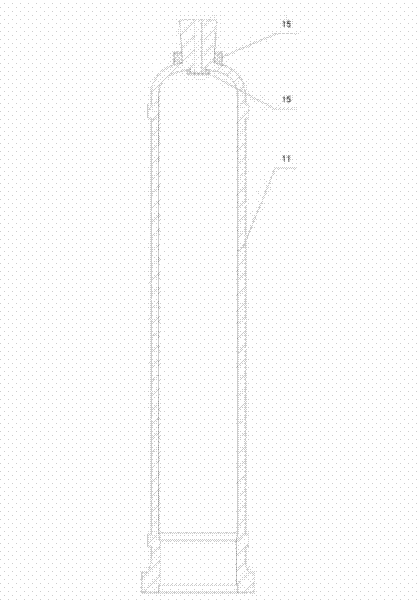

Method for manufacturing large-diameter optical fiber mandril through PCVD process

ActiveCN101811822AReduce manufacturing costReduced Rayleigh scatteringGlass making apparatusUltrasound attenuationResonant cavity

The invention relates to a method for manufacturing a large-diameter low-water peak optical fiber mandril through a high-deposition rate PCVD process, which comprises the following steps that: after a pure quartz liner with the outer diameter of 36 to 65mm is corroded and cleaned, PCVD processing is carried out; the pure quartz liner is arranged in a microwave resonant cavity heat insulation furnace, a microwave resonant cavity has axial reciprocating movement relative to the pure quartz liner, the movement speed is 15 to 30m / min, and the high-frequency power is 5.5 to 20.5kW; the deposition rate in the liner is 2.5 to 5.0g / min, and the single-layered deposition thickness is 1.0 to 3.0mu m; and after the deposition, an electric fusion shrink lathe shrinks to prepare the solid optical fiber mandril, the outer diameter of the mandril is 30 to 61mm, the diameter ratio of a cladding core layer b / a is more than or equal to 1.2 and less than 3.0, and the ratio of the outer diameter of the mandril to the diameter of the core layer c / a is more than or equal to 3.8 and less than 6.0. The method for manufacturing the large-diameter optical fiber mandril through the PCVD process not only has convenient manufacturing process and high deposition rate, but also can meet the design requirement on the diameter ratio of the cladding core layer in a wider scope and the optical fiber performance requirements on low water peak and low attenuation.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

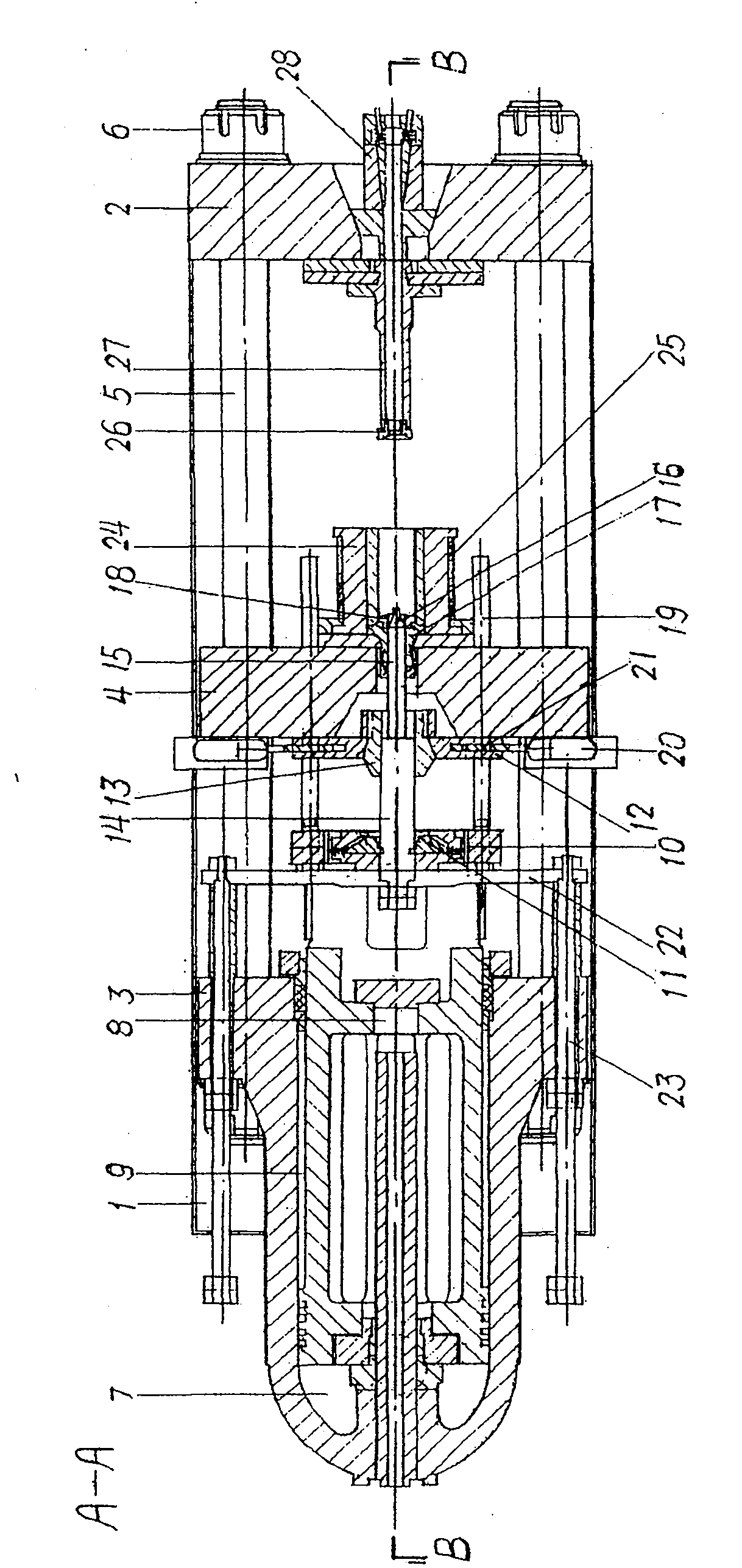

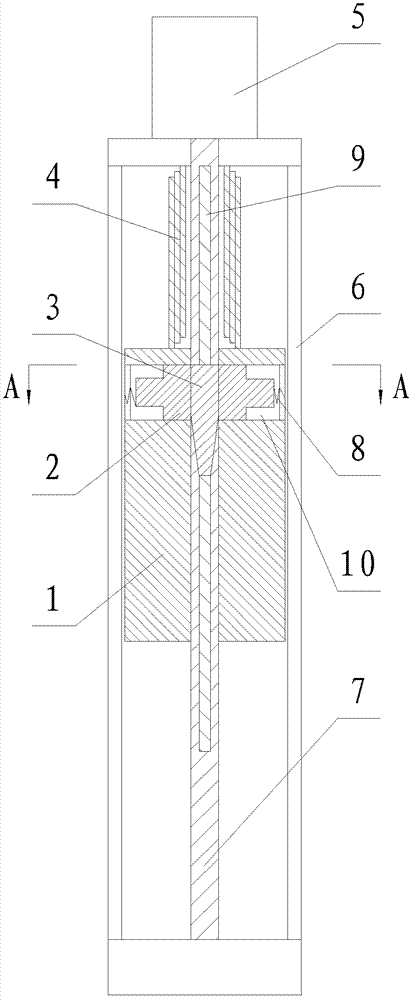

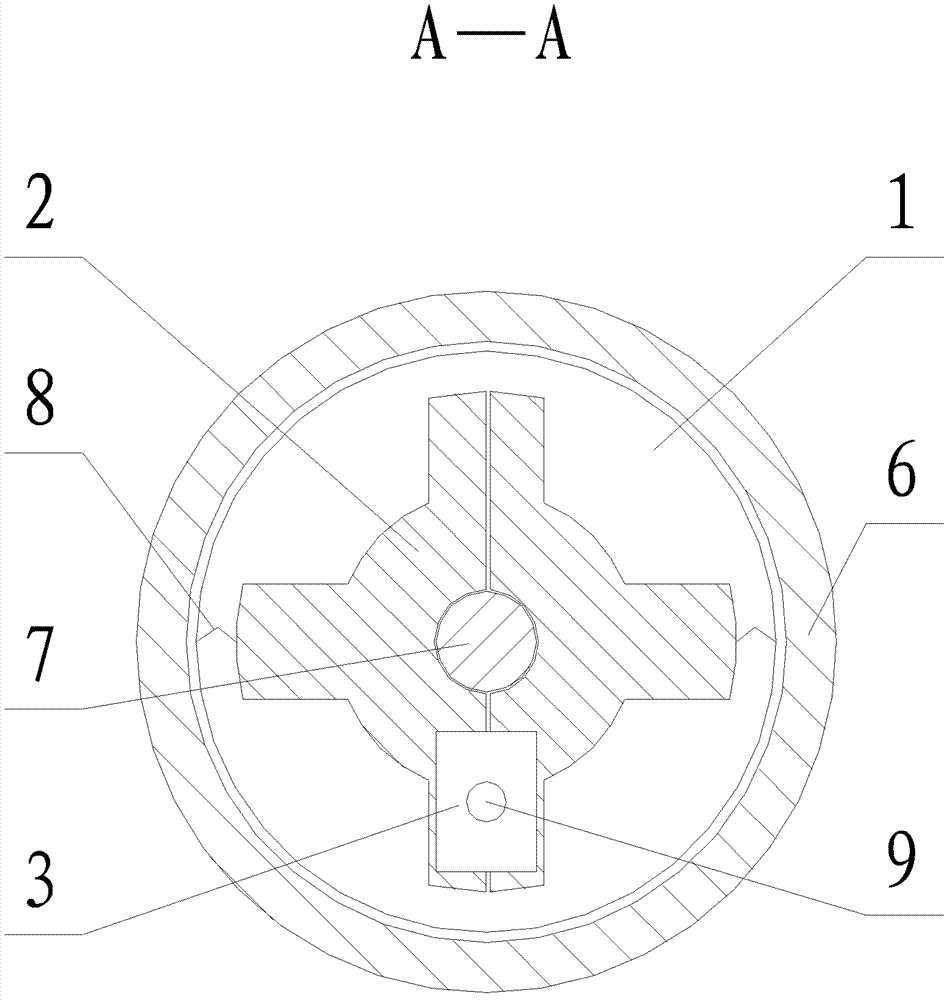

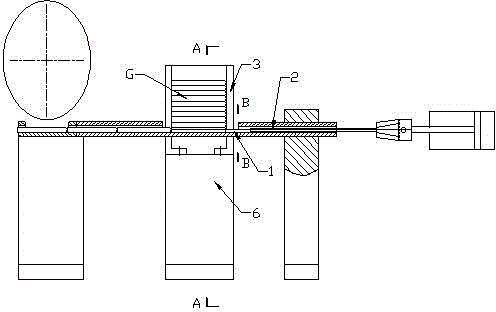

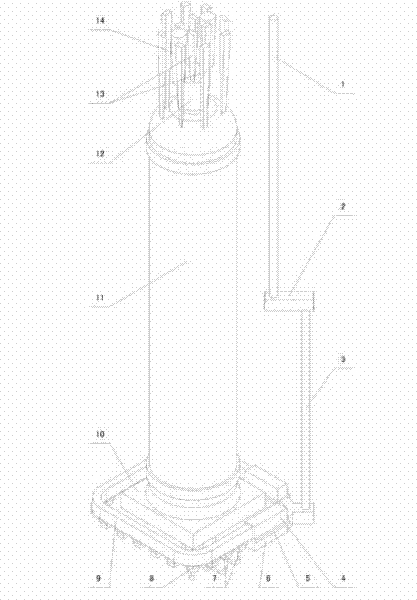

Pneumatic reciprocating tamping device in deep sea

ActiveCN103115792AIncrease sample lengthEasy accessWithdrawing sample devicesElectric machineryEngineering

The invention relates to a pneumatic hammer device and particularly relates to a pneumatic reciprocating tamping device in deep sea, which is suitable for sampling overlong columnar sediments under a deep sea environment. The pneumatic reciprocating tamping device comprises a deep water motor, a deep water pressure tank, and a hammer head, a half nut, a taper pin, a compression cylinder, a lead screw, a spring and a mandril, which are installed in the deep water pressure tank, wherein one end of the lead screw is connected with the output end of the deep water motor, the hammer head is sleeved on the other end of the lead screw, the half nut is located in the hammer head, the spring used for connecting the half nut with the lead screw through threads is connected on the half nut, and the compression cylinder sleeved at the outside of the lead screw is arranged between the upper surface of the hammer head and the bottom surface of the upper end cover of the deep water pressure tank; the mandril is inserted on the hammer head, and the taper pin used for opening the half nut is arranged on the mandril. The pneumatic reciprocating tamping device provided by the invention can be used for enabling a sampling system to repeatedly penetrate deep sea sediments for multiple times, so that the sampling length of the current gravity type deep sea sediment sampling system can be increased greatly, and the sampling length is as long as 20-30 meters to facilitate the condition that scientists can obtain overlong deep sea sediment samples.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

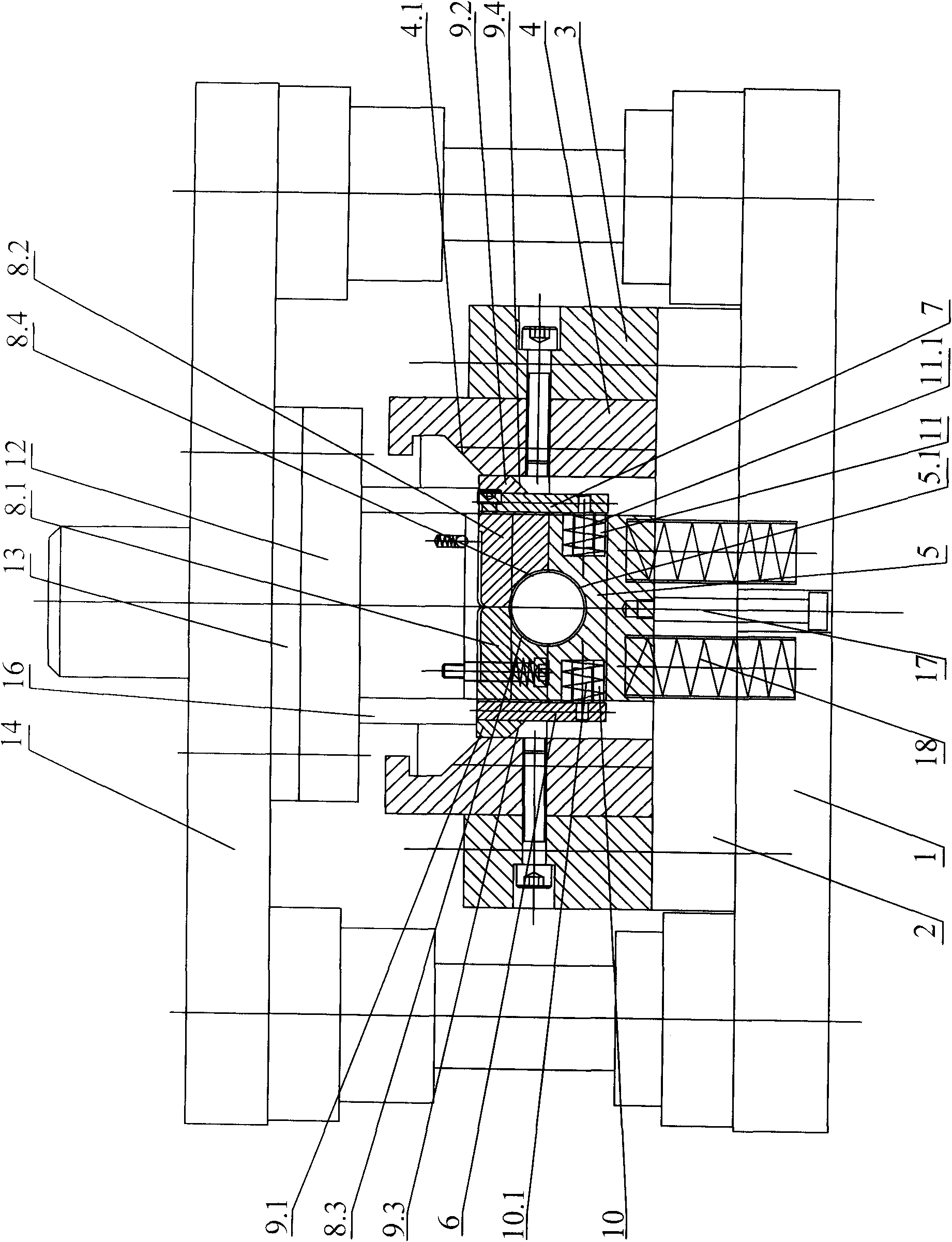

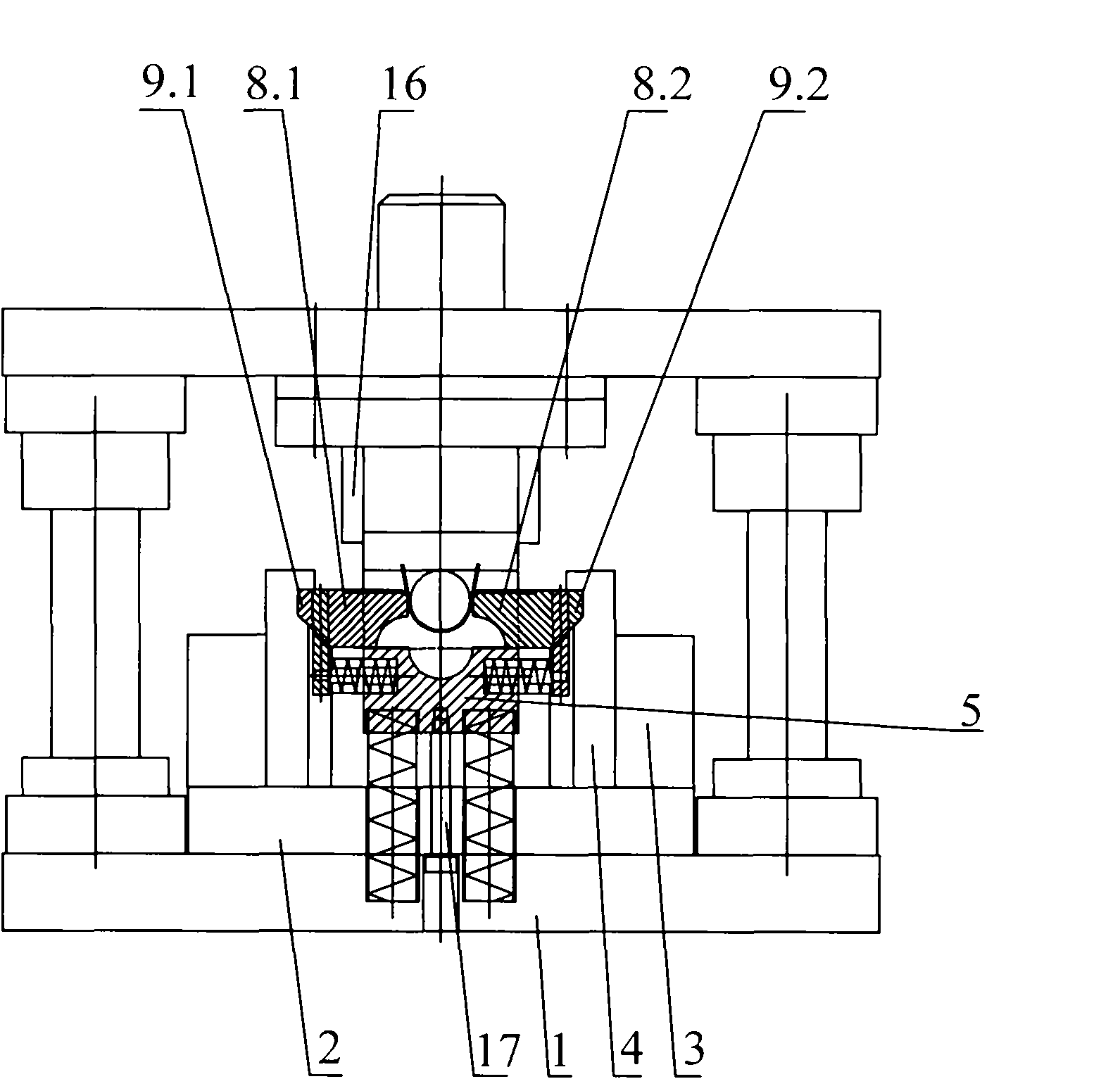

Feed device of minor-diameter rodlike workpiece processing equipment

ActiveCN102873614AStable outputSmall diameterGrinding machine componentsGrinding machinesEngineeringUltimate tensile strength

The invention relates to a feed device of minor-diameter rodlike workpiece processing equipment. The feed device comprises a horizontal feed channel, the front end of which is connected with a part of a cutting device; a pushing mandril which is driven by a power unit and can axially move in the feed channel is arranged at the rear section of the feed channel; a feed box is arranged above the feed channel; a discharge port which directly faces the feed channel is arranged at the bottom of the feed box and rodlike workpieces can pass through the discharge port one by one; a guide slope which enables the rodlike workpieces to roll to the discharge port under the actions of gravities is arranged inside the feed box; and the feed box is installed on a vibrating device and can vibrate up and down along with the vibrating device. The feed device has the advantages that: 1, with the feed device, the workpieces with small diameter and light weight can be discharged successfully, clamping stagnation is reduced, and the movement reliability is improved; 2, the strength of the pushing mandril and the structural strength of the entire guide structure are improved, and the fault of breakage of a small-size pushing mandril is reduced.

Owner:丹阳市盛力机械有限公司

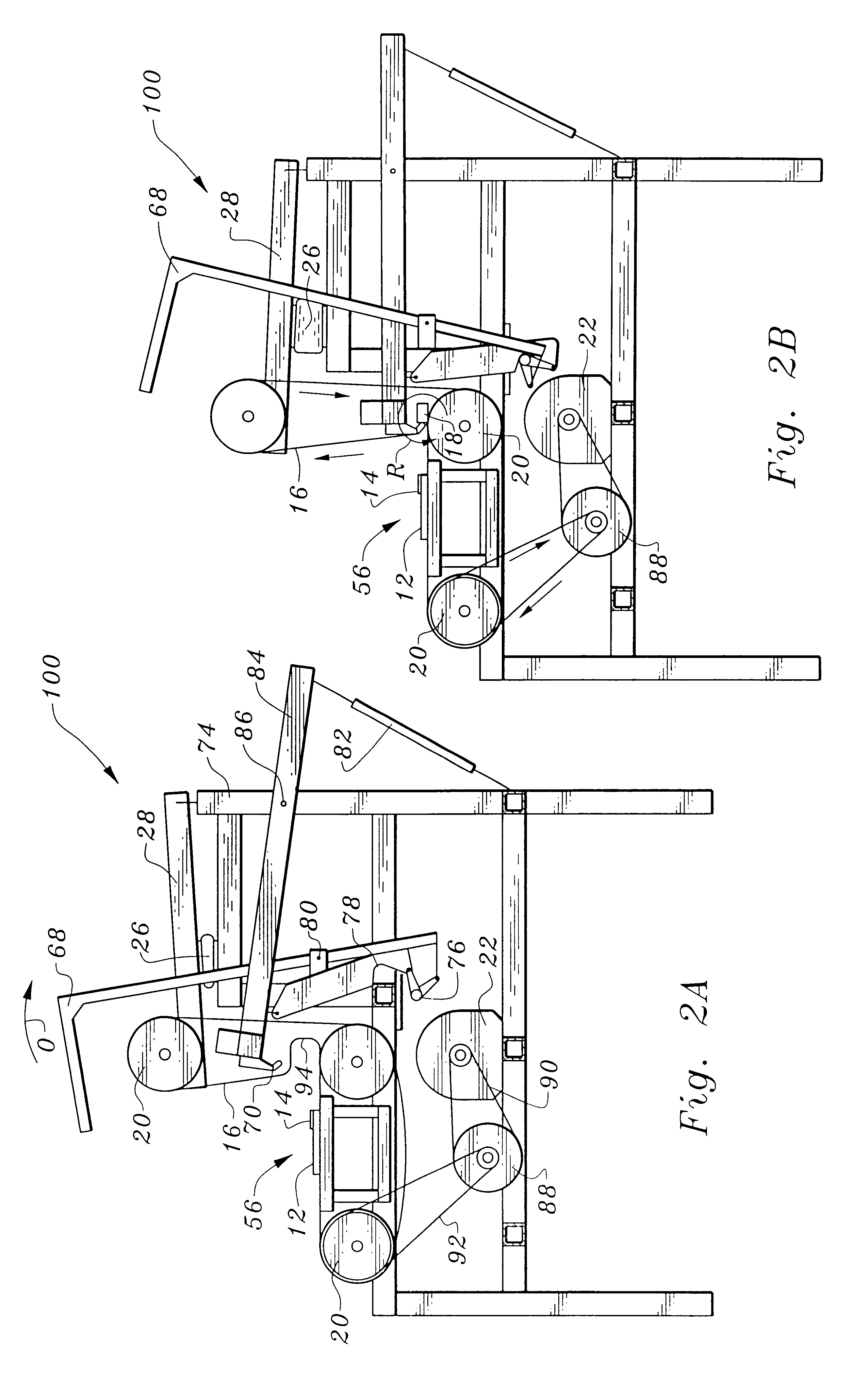

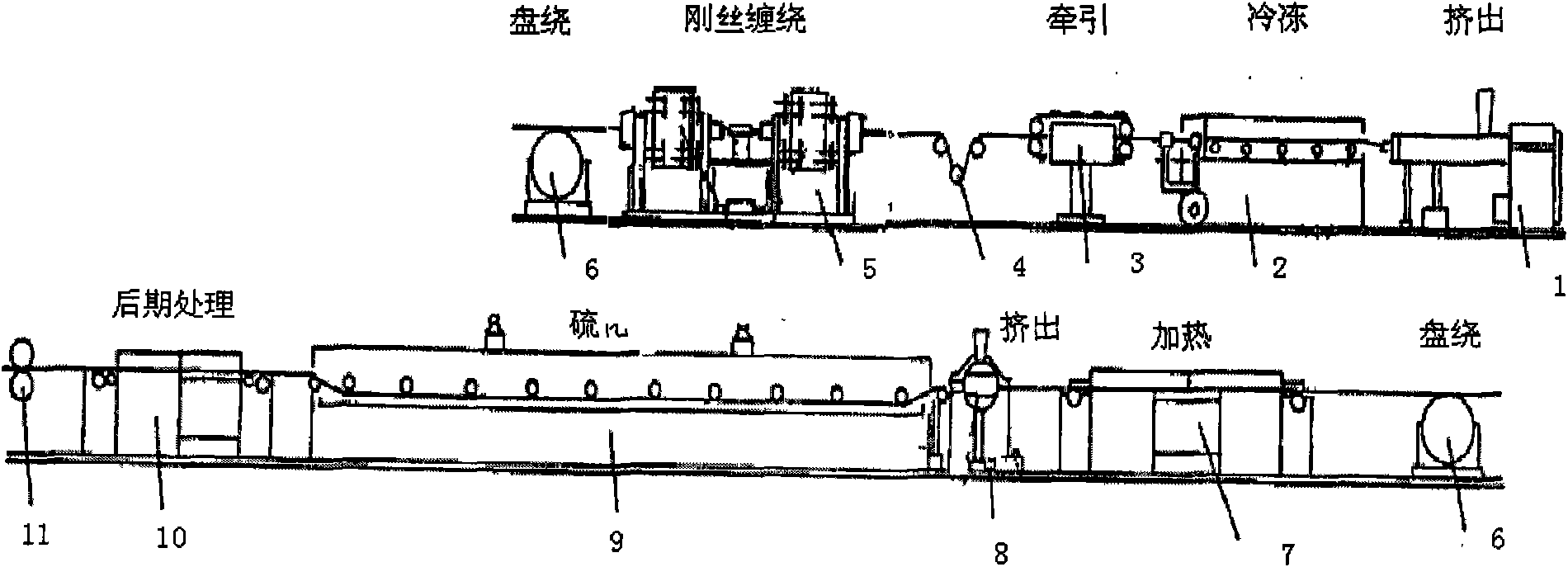

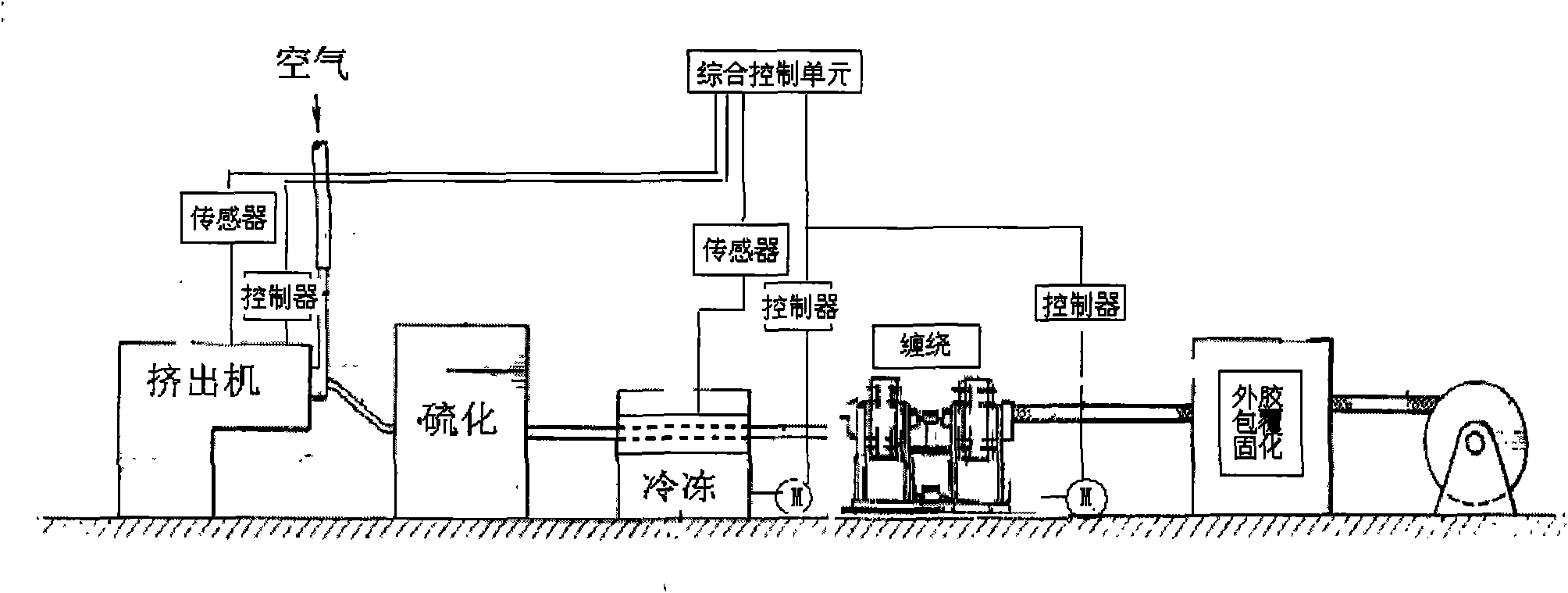

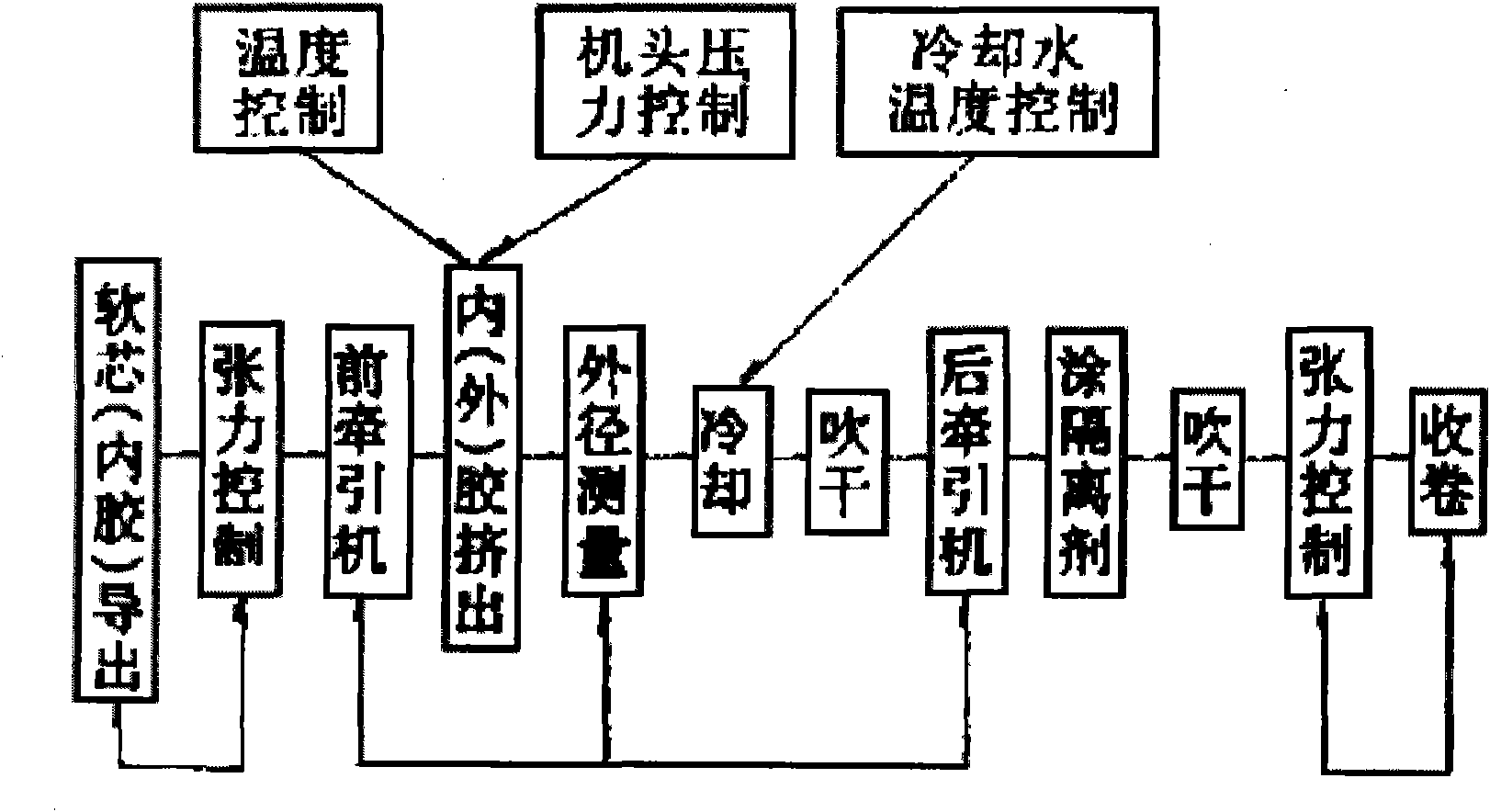

Spiral rubber hose joint production method and its device

InactiveCN102729500AAutomatically adjust the tightnessOvercome the disadvantage of easy wearTubular articlesAutomatic controlEngineering

A spiral rubber hose joint production method and a production technology of a device thereof comprise related equipment such as a rubber hose extruder, a rubber hose refrigerator, a steel wire winding machine, a vulcanizing plant and its dragger and the like, and include a tube wall thickness uniformity automatic adjustment and detection system, a tube and mandril extrusion water-free cooling system, a tube automatic control and winding device, an energy-saving single-disk winding machine, a two-disc winding machine, a draughting mechanism and its combinated control and automatic detection controlling system, a steel wire winding machine noise suppression device, a winding wire breaking detection and control system, a spiral rubber hose refrigerator energy-saving applied technology and temperature detection and automatic temperature control freezing control system, an automatic dehumidifying and drying device during the rubber hose freezing and winding process and its detection and combined control system, and an automatic winding monitoring and control device. In addition, an overall traction drive system and a comprehensive intelligent monitoring system are also designed.

Owner:王东奎

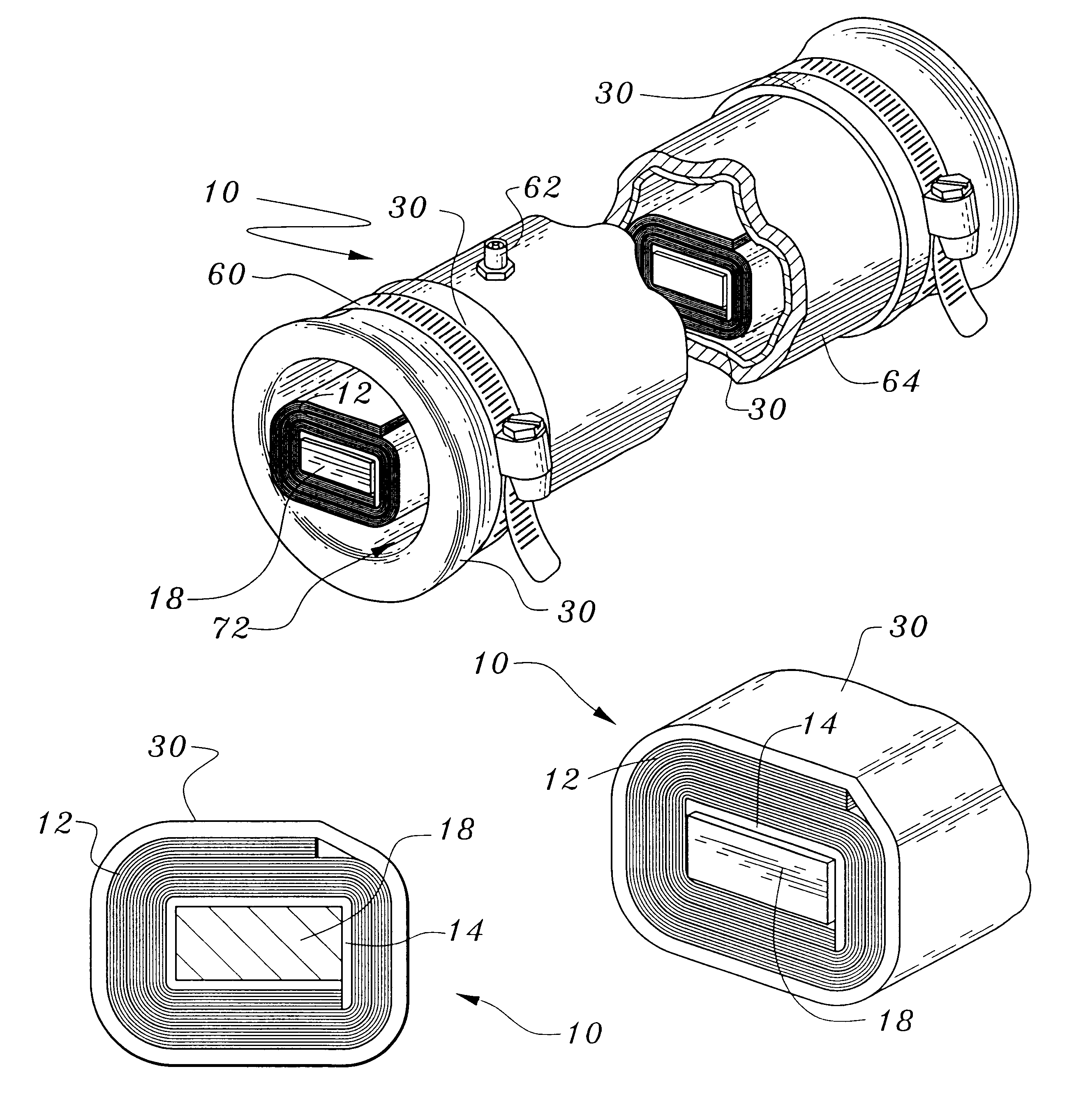

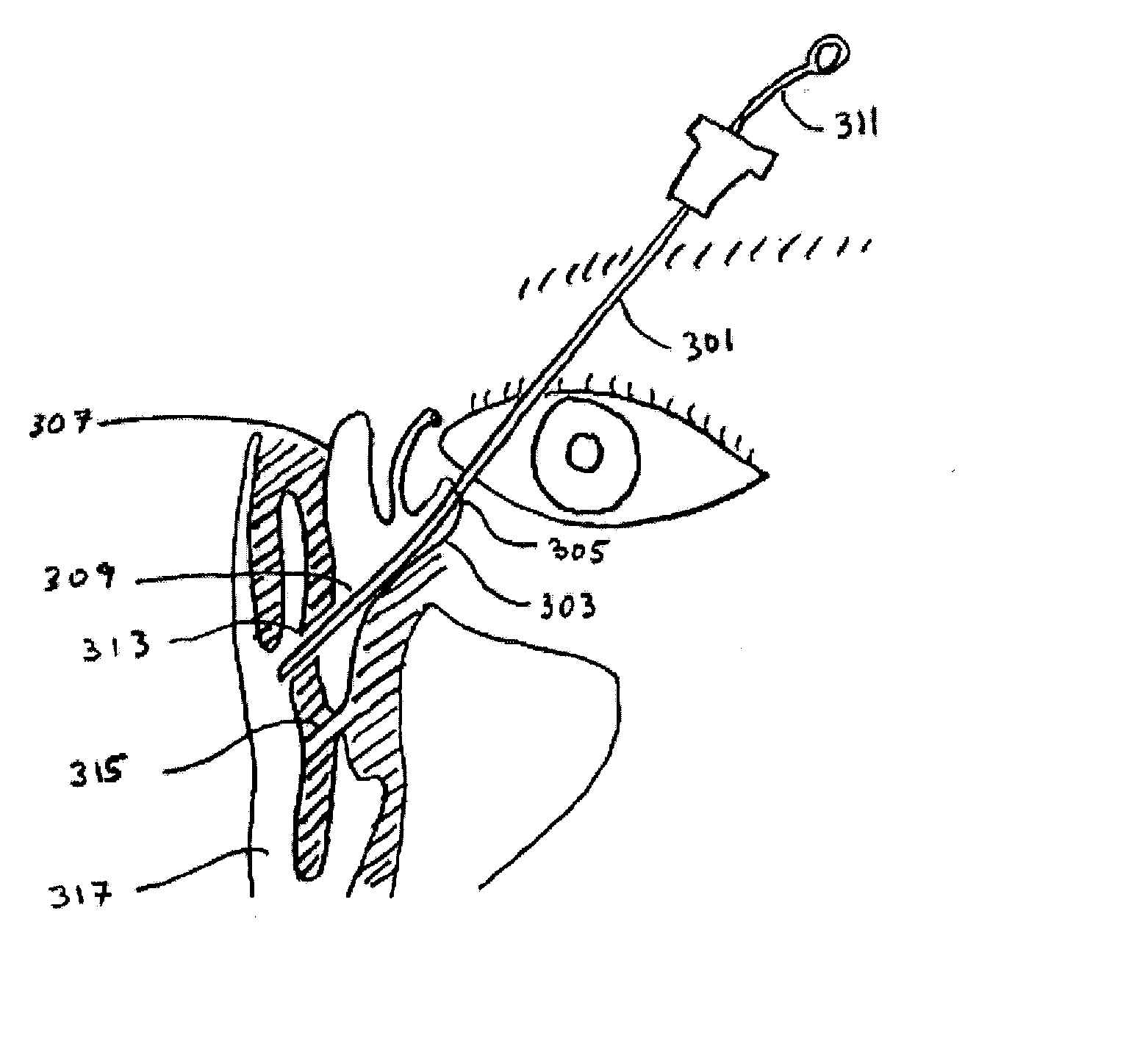

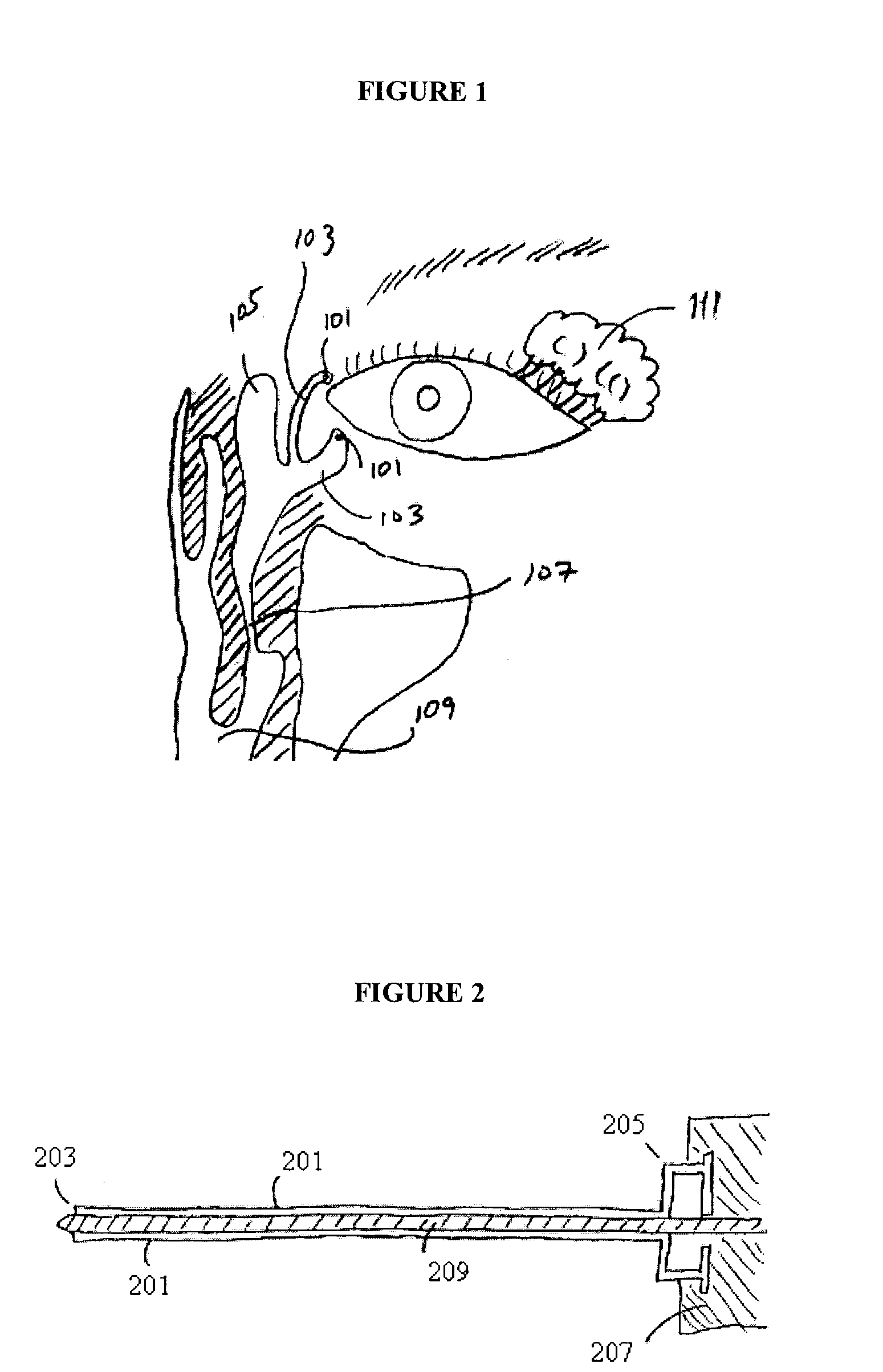

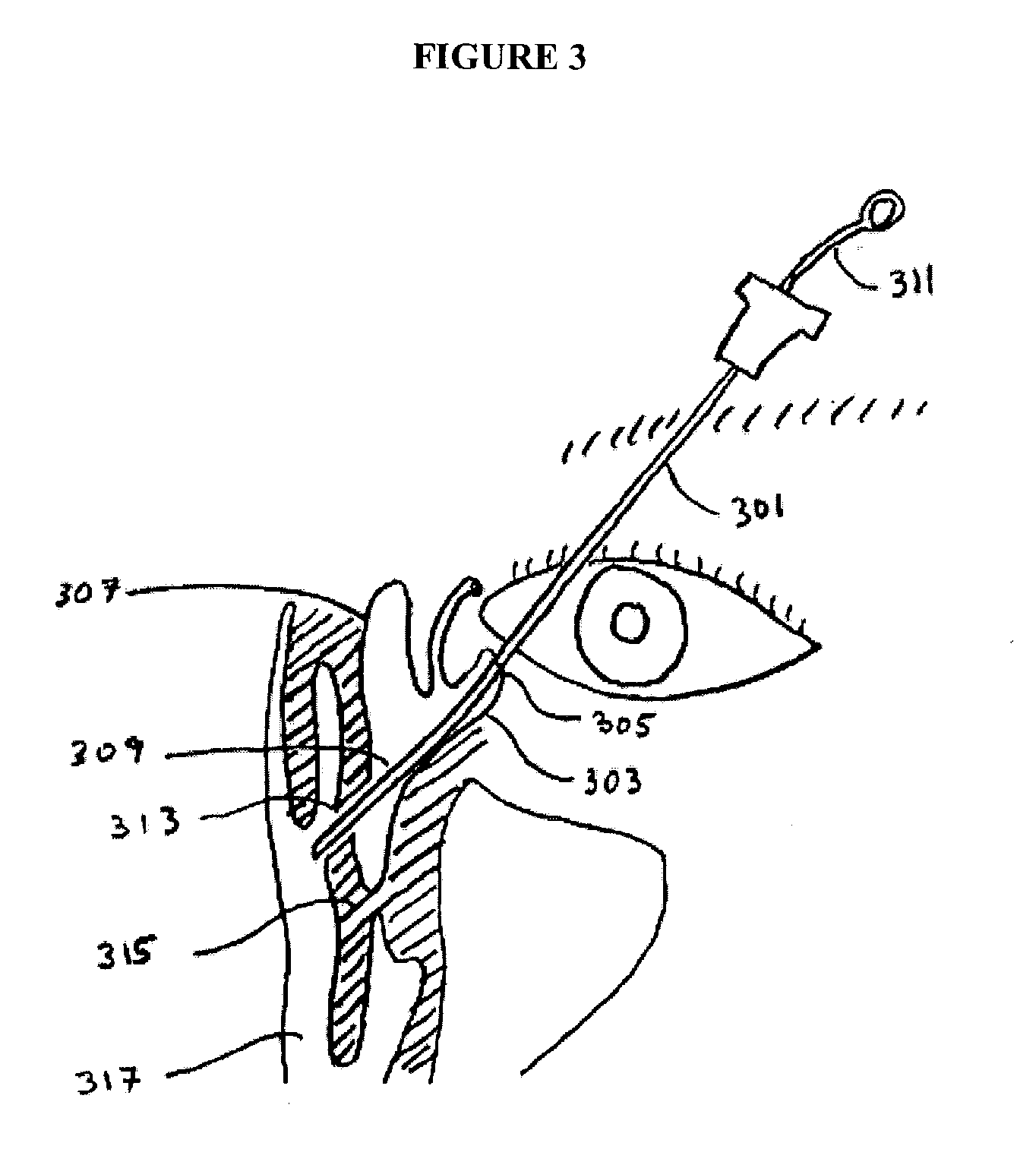

Device and method for dacryocystorhinostomy

InactiveUS20040204704A1Reducing trauma to the nasolachrymal ductReduce insertionEye surgerySurgical instrument detailsFiber bundleMedicine

An introducer and system and method for using the introducer in endoscopic combined laser assisted DCR for treatment of nasolachrymal drainage obstruction (NLDO) is disclosed. An introducer comprising a hollow outer tube and an atraumatic inner mandril is inserted into the lachrymal sac section. The atraumatic inner mandril is removed and (one or more) optical fibers or fiber bundles are inserted for illumination to determine proper position and for ablating a drainage channel. The fiber or bundle is then removed and a DCR intubation set can then be introduced to maintain the drainage channel. One advantage of this device and method is that all aspects of the procedure can be performed through the introducer, thus only requiring a single insertion point, reducing trauma to the lachrymal duct, and reducing the complexity and risk of complication or infection. Another advantage of this device and method is that it can be used with many pre-existing intubation sets used for current DCR procedures, thus the present device and method can easily and cost effectively be introduced as a first line procedure.

Owner:CERAMOPTEC IND INC

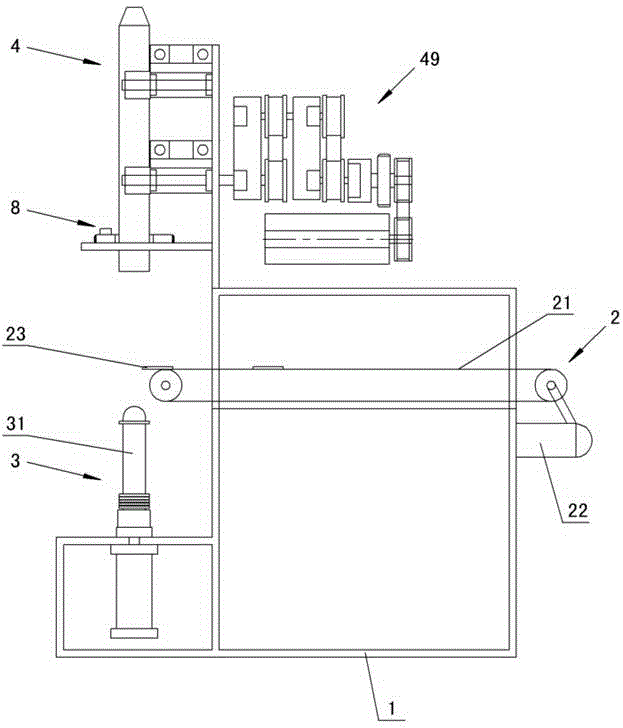

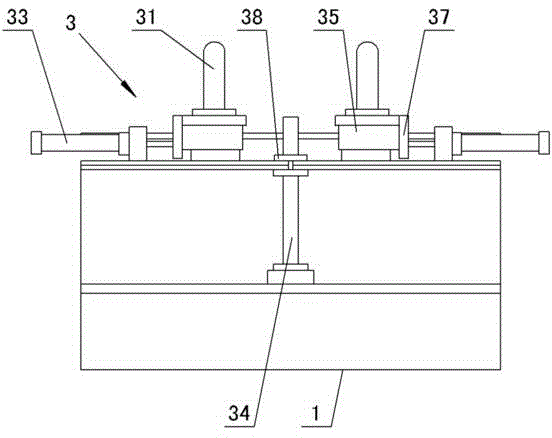

Multifunctional cake forming machine

InactiveCN103141535AImprove molding efficiencySimple and fast operationFood shapingDough extruding machinesMolding machineEngineering

Owner:TONGLING SONGMA FOOD PACKAGE MACHINERY MFG

Method for casting large stamping cylinder casting

InactiveCN102248132AAvoid Casting DefectsImprove pass rateFoundry mouldsFoundry coresSlagCasting defect

The invention discloses a method for casting a large stamping cylinder casting, comprising the following steps of: 1) making a mould; 2) making a sand mould; and 3) pouring and moulding; when the sand mould is made, an upper core cover (19) is embedded in the center of a casting cavity (11) of an upper box, a lower core cover (17) with the same shape and size with the upper core cover (19) is embedded in a sand core (16) inside the casting cavity (11), and a mandril (18) made of iron is sheathed between the upper core cover (19) and the lower core cover (17). By adopting the structure, a gating system, arrangement of a dead head, laying of an cold iron, control of pouring temperature, control of chemical ingredients, control of spheroidization and inoculation and the like are all designed according to the characteristics of the casting, thus the casting defect that slag inclusion, an air hole and the like are produced can be overcome; and the probability that a shrinkage cavity and shrinkage porosity are caused can be reduced, thus the yield of casting finished products can be greatly improved.

Owner:RIYUE HEAVY IND

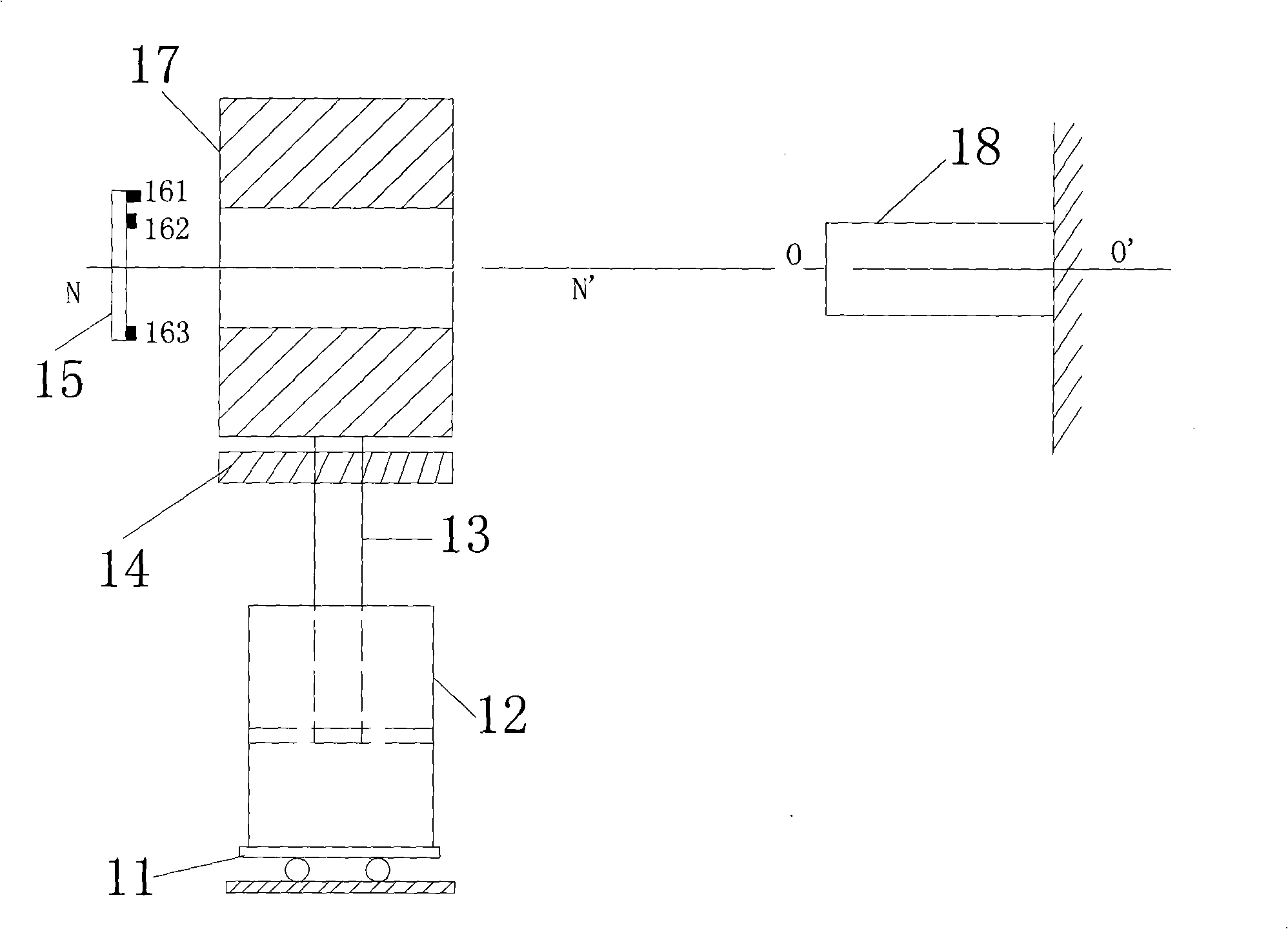

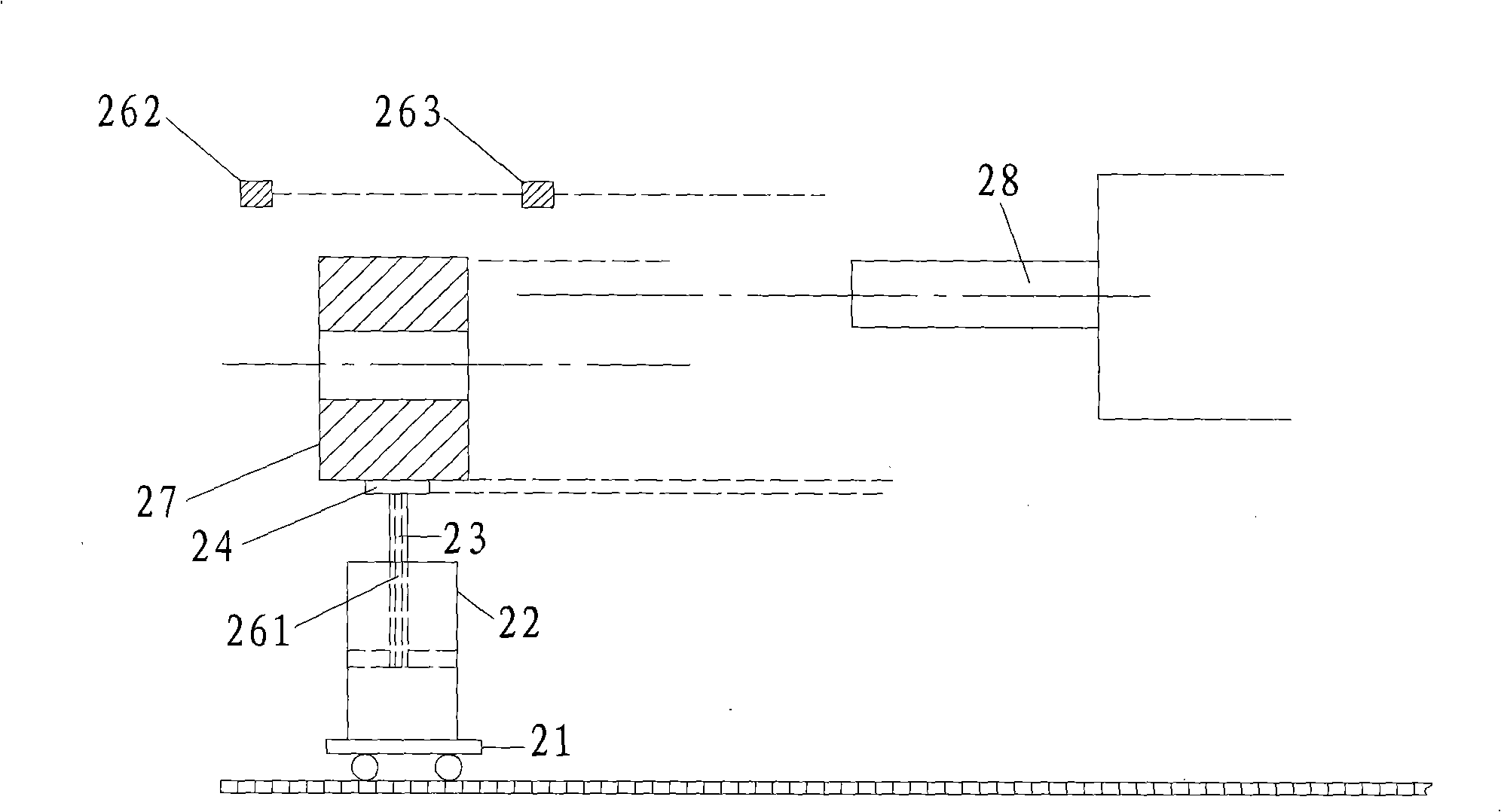

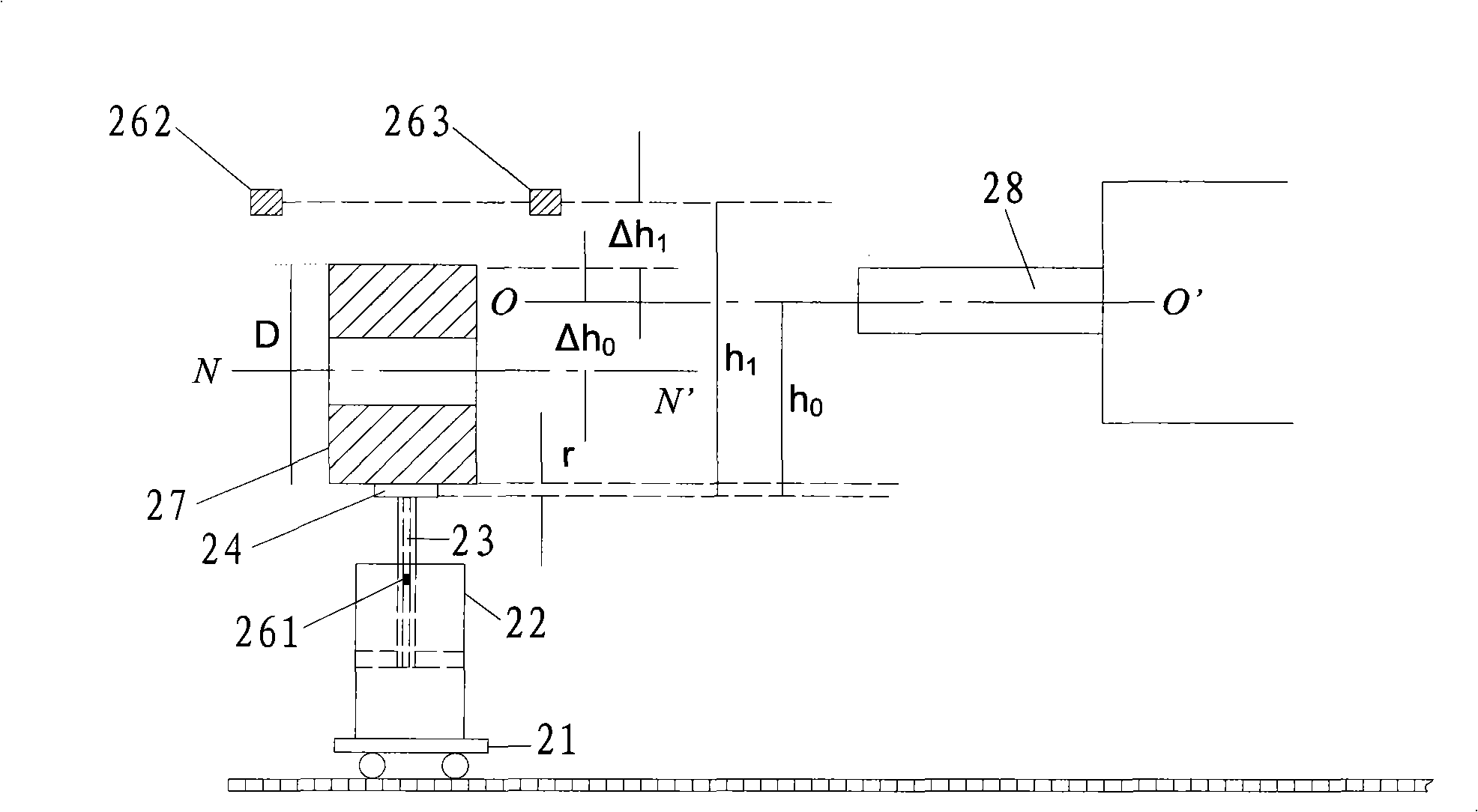

Device and method for coiled material centering and diameter measuring

InactiveCN101537445AHigh precisionDoes not take up spaceUsing optical meansMetal working apparatusHydraulic cylinderEngineering

The invention relates to the filed of coiled profile supplied to a machine and diameter measurement, in particular to a device and a method for coiled material centering and diameter measuring. The device comprises a dolly, a hydraulic cylinder, a mandril and a bracket. The hydraulic cylinder is fixed on the dolly which can move leftwards and rightwards; the mandril is fixed on the piston of the hydraulic cylinder; and the bracket is fixed on the top of the mandril. The device is characterized by also comprising a displacement sensor A, a photoelectric sensor B, a photoelectric sensor C, an analog / digital converter and a PLC; the displacement sensor A is fixed inside the mandril; linear relation exists between position signals generated by the displacement sensor A and the movement distance of the mandrill; the photoelectric sensor B and the photoelectric sensor C are fixed above the bracket and positioned on the same horizontal line; and the displacement sensor A, the photoelectric sensor B and the photoelectric sensor C are all connected with the PLC through the analog / digital converter. The invention has the advantages of simpleness, reliability, convenient installation and high control and measurement accuracy and is beneficial to quantitative statistic.

Owner:上海东大自动化工程有限公司

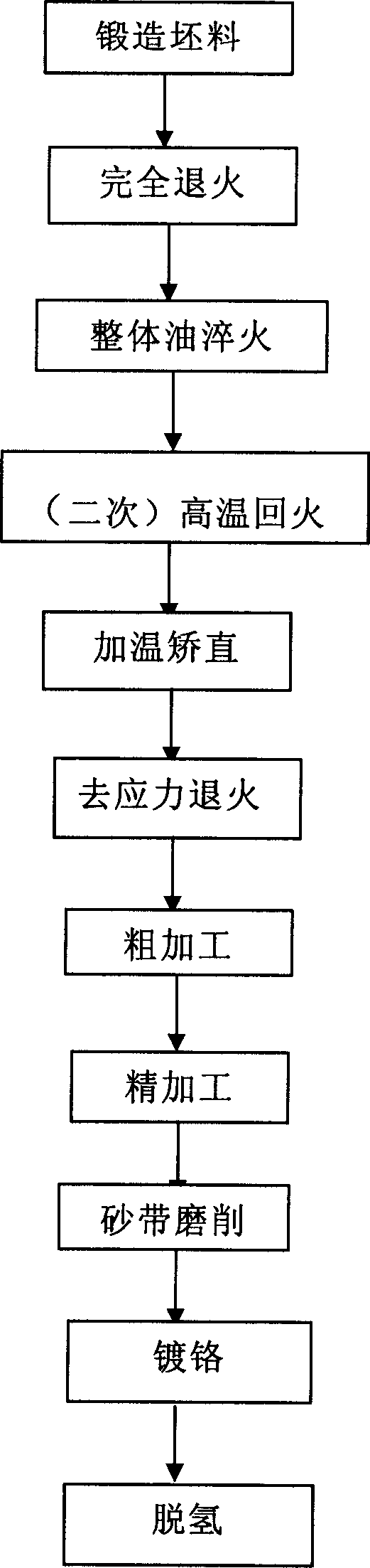

Novel technique for producing mandrel bar

InactiveCN101352796AReasonable preparation processQuality improvementTemperature control deviceMandrelsSocial benefitsIngot

The invention relates to a technique for manufacturing a tube rolling tool of hot rolling seamless steel tube, in particular to a technique for manufacturing a rolling machine mandril of a PQF which belongs to the processing technique of workpiece. The invention provides a novel technique for manufacturing the mandril of a tube rolling; the technical scheme adopted by the technical problem of the invention is as follows: refining a steel ingot-forging and blooming-rolling and shaping-surface rough machining-hardening and tempering processing-fine machining and polishing-surface plating. The technique is characterized in that the rolled mandril has the advantages of smoother surface, less bending degree of a blank as well as a small size tolerance. The technique is characterized in that the basic body of the mandril has a high temperature obdurability and the surface of the mandril has excellent wear-resistance. The technique has the beneficial effects that: the manufacturing technique of the mandril is more reasonable; the potential of a device is fully exerted; the yield rate and the production efficiency are high; the cost is low; the quality of the mandril is excellent; the social benefit is remarkable; besides, the manufacture technique brings broad prospects for manufacturing the mandril of the tube mill.

Owner:赵金发

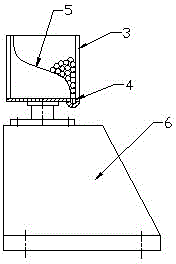

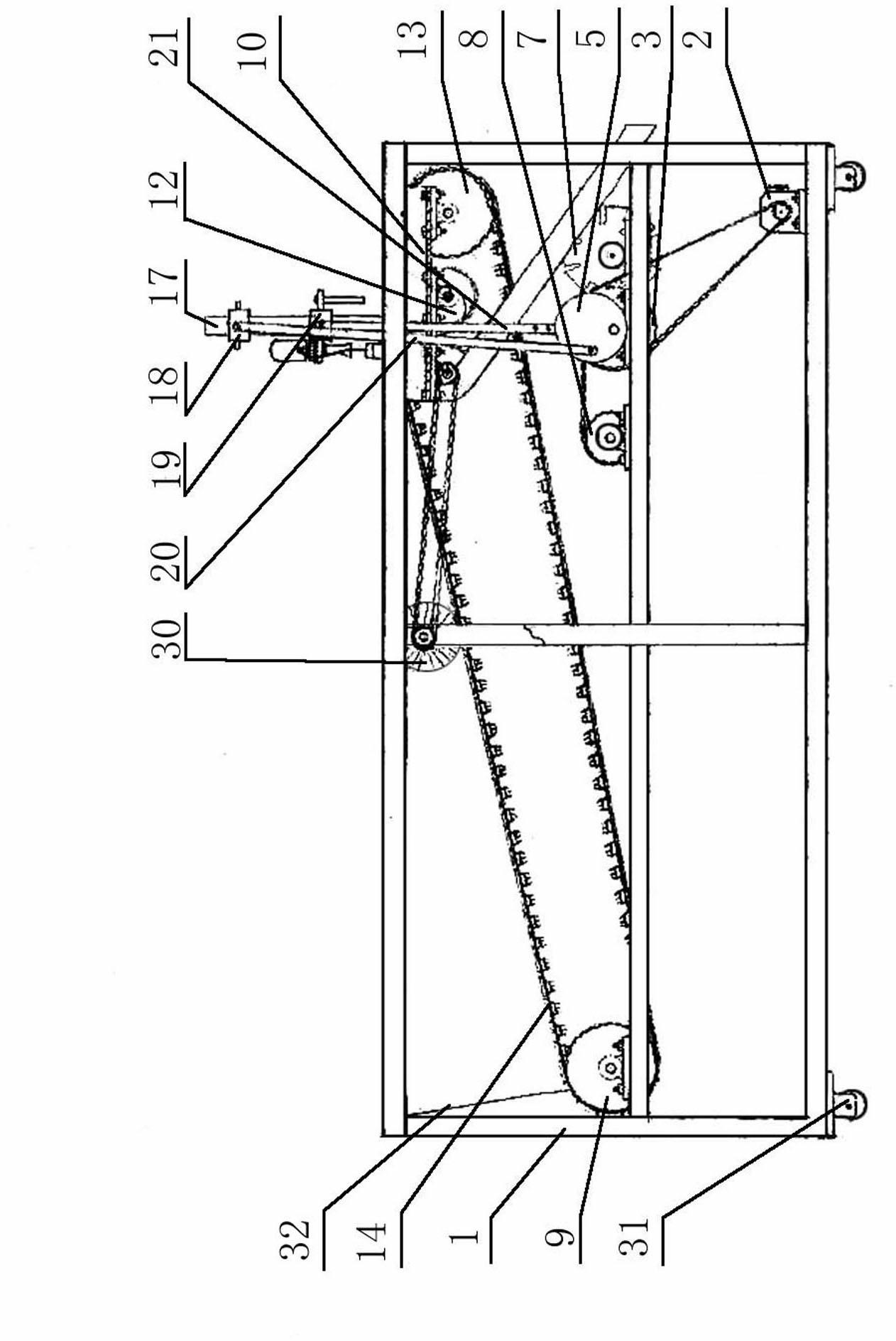

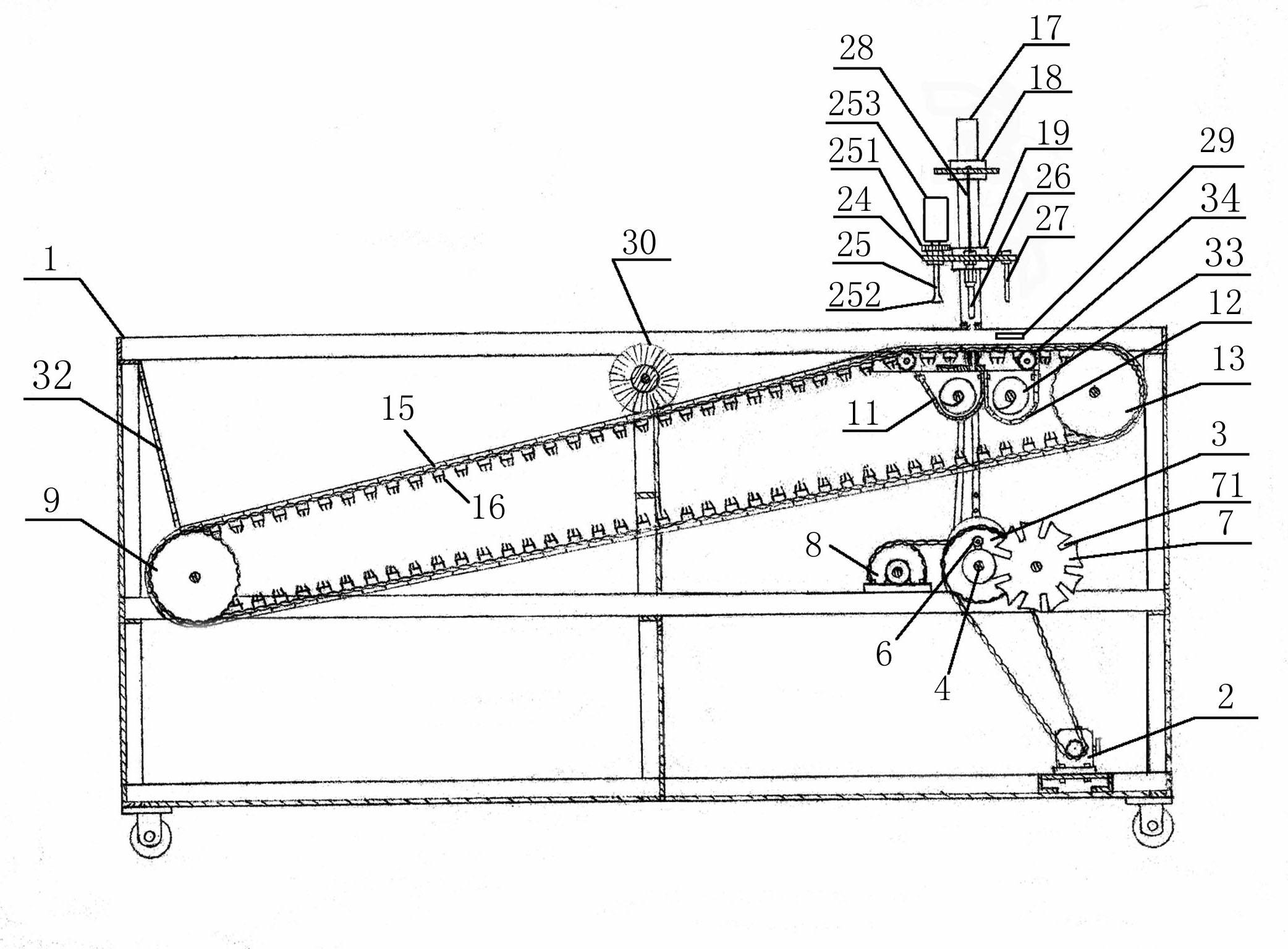

Full-automatic red date pitting machine

The invention discloses a full-automatic red date pitting machine. The full-automatic red date pitting machine solves the problems of high manufacturing cost, low automation degree, low production efficiency and low safety in the conventional red date pitting equipment. The full-automatic red date pitting machine comprises a frame, a motor, a crankwheel and a conveying belt provided with red date grippers, wherein the crankwheel as well as an upper sliding block and a lower sliding block which are correspondingly sleeved on a sliding bar are connected with an upper connecting rod and a lower connecting rod respectively; a red date rotating centralizer, a pitting pipe and a material removal rod are fixed on the lower sliding block from left to right; and a kernel insertion mandril is fixed on the upper sliding block. By the full-automatic red date pitting machine, the automatic, batch and rapid pitting processing of red dates is realized; and the mechanism is simple, effective, stable and safe.

Owner:山西晋泰饲料股份有限公司

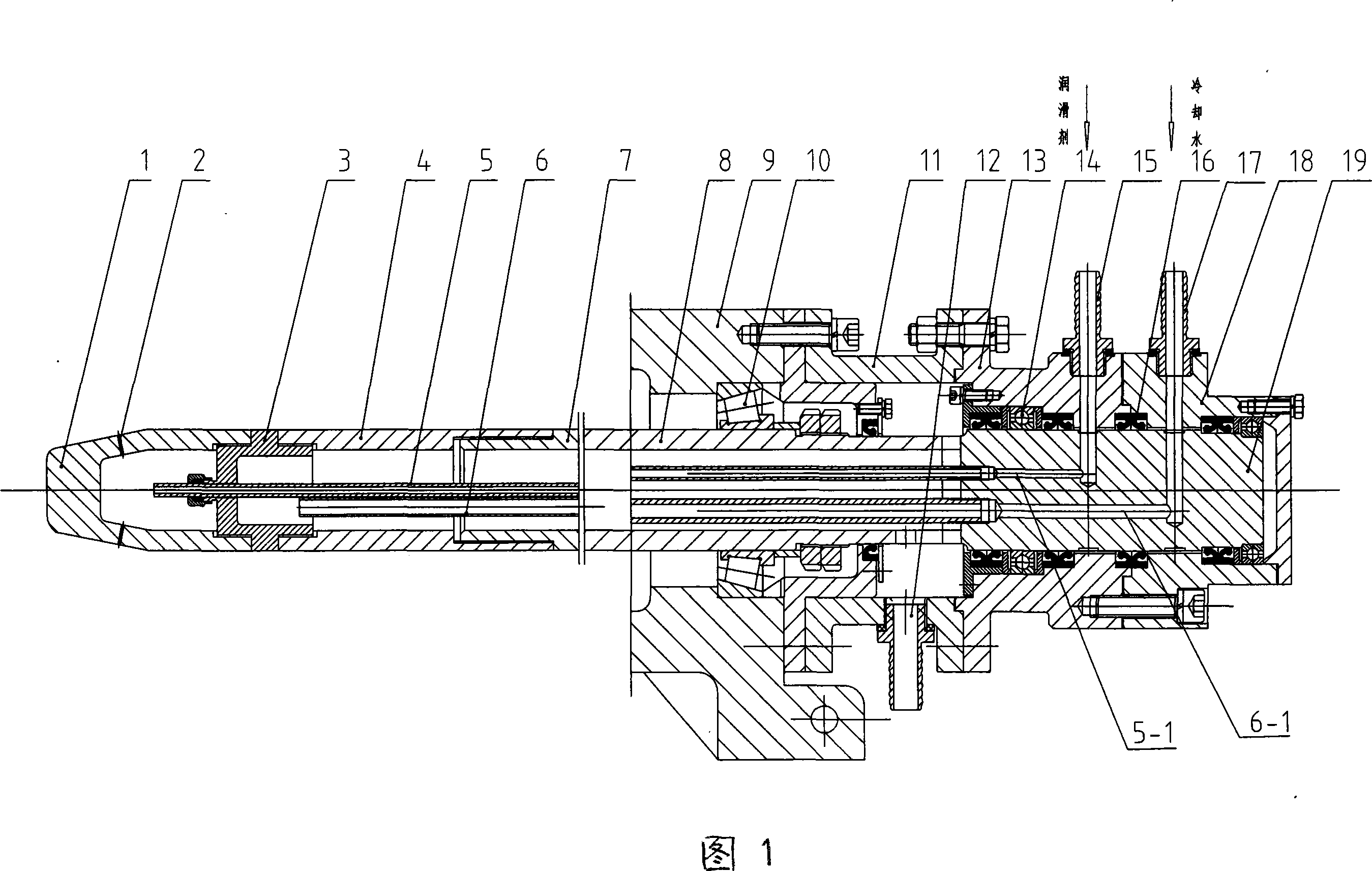

Mobile mandril cooling and lubricating device

InactiveCN101224469AReduce the temperatureExtended service lifeMandrelsMetal rolling arrangementsEngineeringHigh pressure

A cooling lubricant device with a removable mandrel bar relates to metal rolling. In order to avoid the abrasion problem on the mandrel bar at high temperature and pressure during the seamless steel tube rolling process, the method of single mandrel bar cooling and single lubricating systems is generally applied, which degrades the quality of the tube inner wall for the low productivity effect and poor lubrication effect. The mandrel of the invention is a hollow rotary body when in operation and inputs the lubricant and cooling water simultaneously into the mandrel bar which is rotating via the insulation and closure structure between a holder and a connector body, with the lubricant ejecting from the front head of the mandrel to lubricate the tube inner wall while the cooling water, so as to form a circuit within the mandrel bar to cool down the temperature for the mandrel bar. When in the rolling process, not only the mandrel bar can be cooled but also the tube inner wall can be lubricated, which can prolong the service life of the mandrel bar and improve the quality of tube inner wall. Besides, the dosage of the lubricant consumption is decreased, cost is saved and environmental pollution is reduced.

Owner:SHANXI CHUANGQI IND

Supporting device and supporting method for machining propeller blade

InactiveCN102886699AIncrease stiffnessStable supportPositioning apparatusMetal-working holdersHydraulic cylinderPropeller

Owner:JIANGSU UNIV OF SCI & TECH

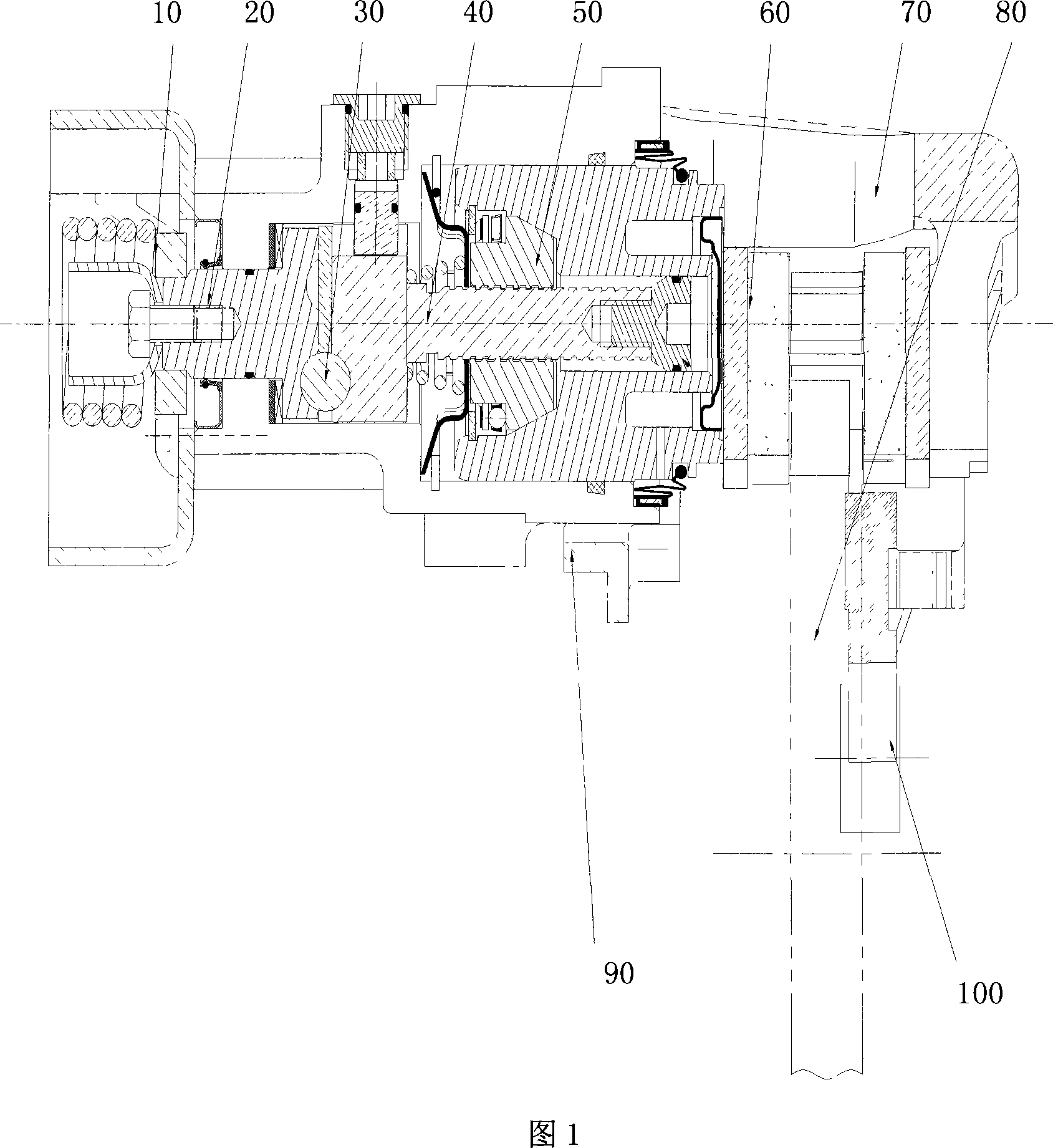

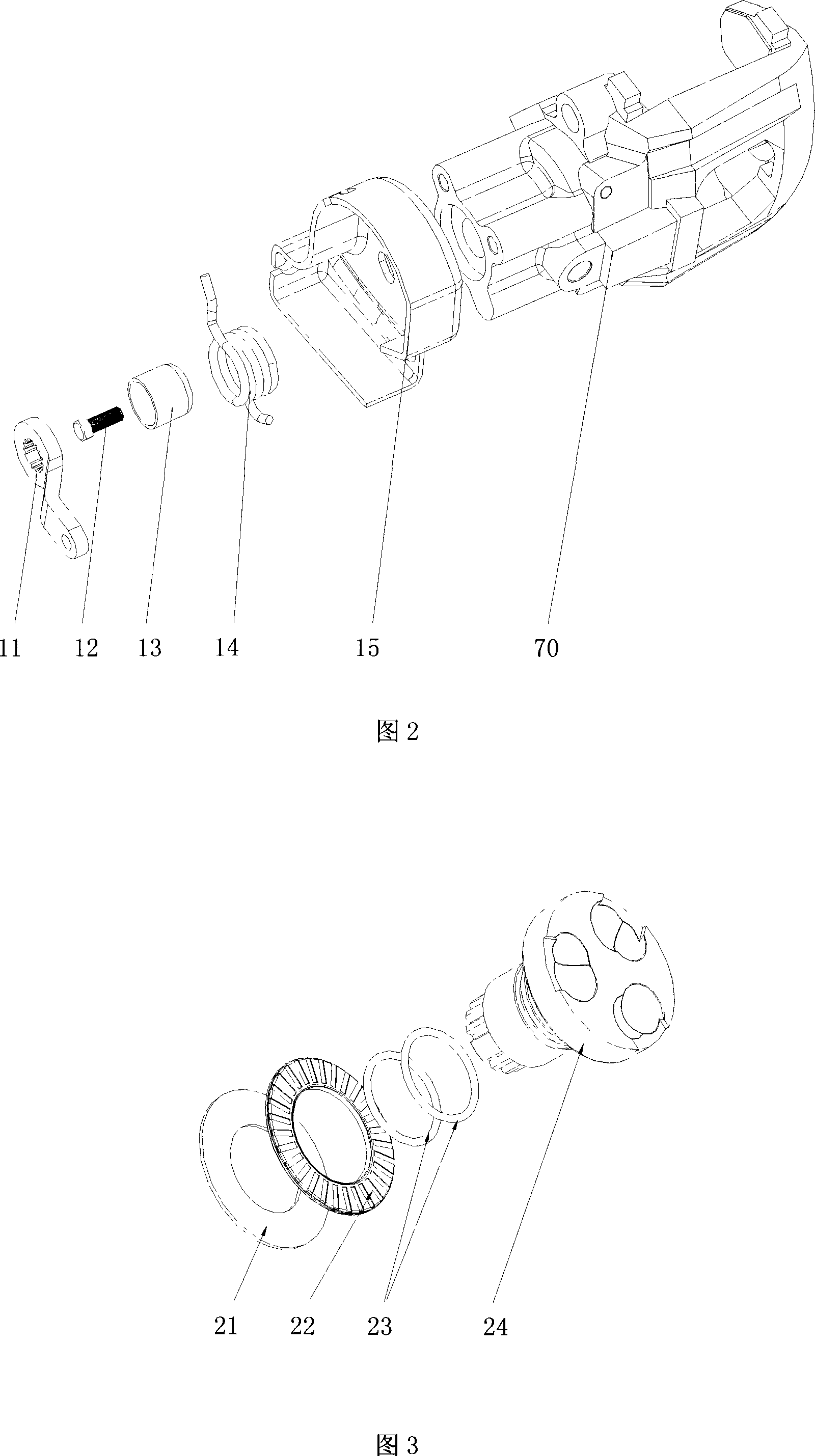

Hydraulic disk type integrated arrestor of floating clamp based on screw drive

ActiveCN101093000AOptimize layoutSmall footprintAxially engaging brakesBrake actuating mechanismsSteel ballEngineering

This invention discloses a hydraulic disk integrated arrester based on a screw driven floating clamp composed of a pull arm component, a mandril component, a steel ball component, a push rod, a piston, a friction block, a caliper and a brake disk connected orderly, in which a clamp floating bracket is connected with the clamp by a guiding bolt, an installation bracket is connected with the floating bracket and fixed on a car bridge by bolts, which applies a special three-lockless screw structure to realize calm transfer of brake force and adjusts the working gap between a friction block and a brake disk automatically.

Owner:WUHAN YOUFIN AUTOPARTS

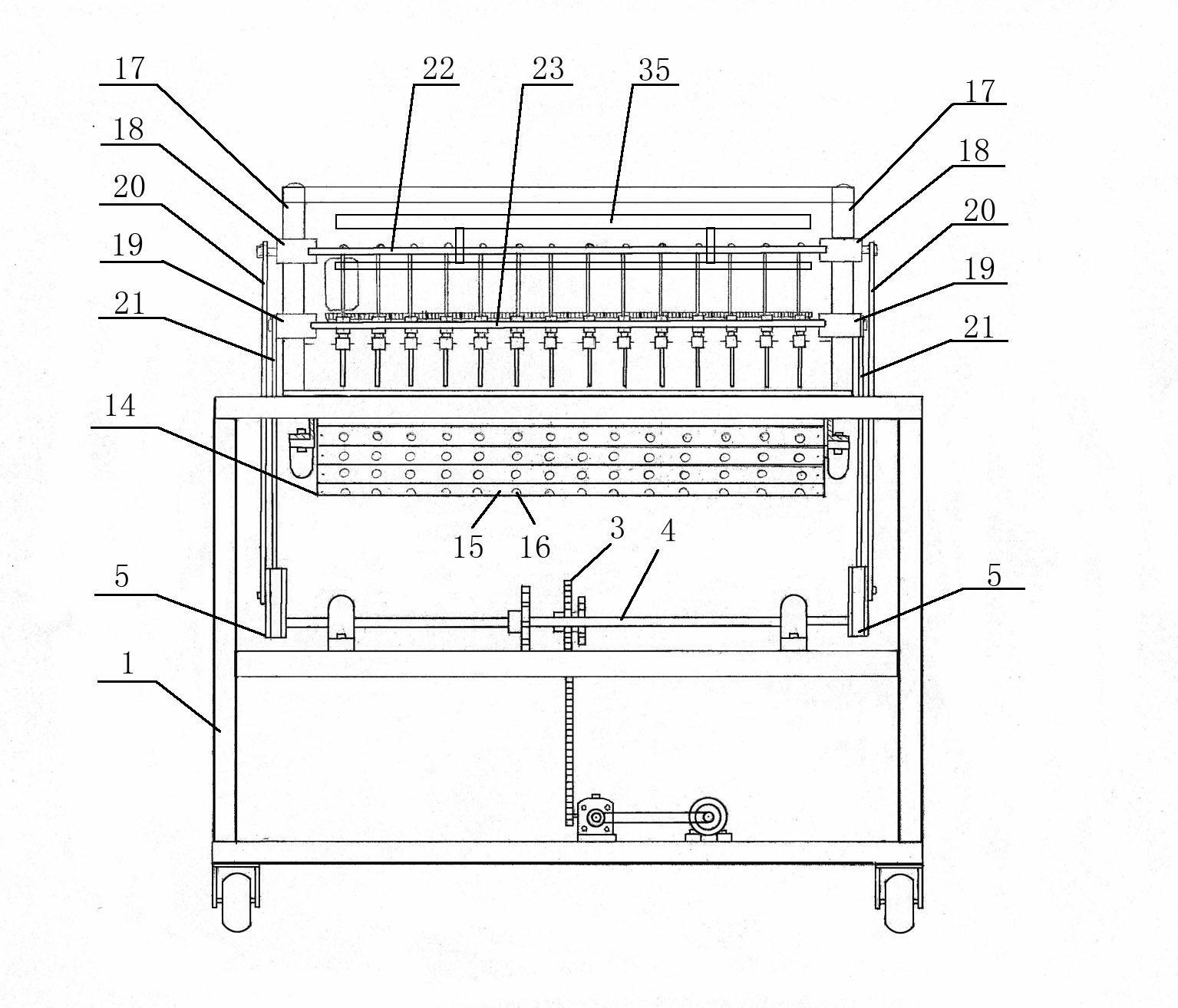

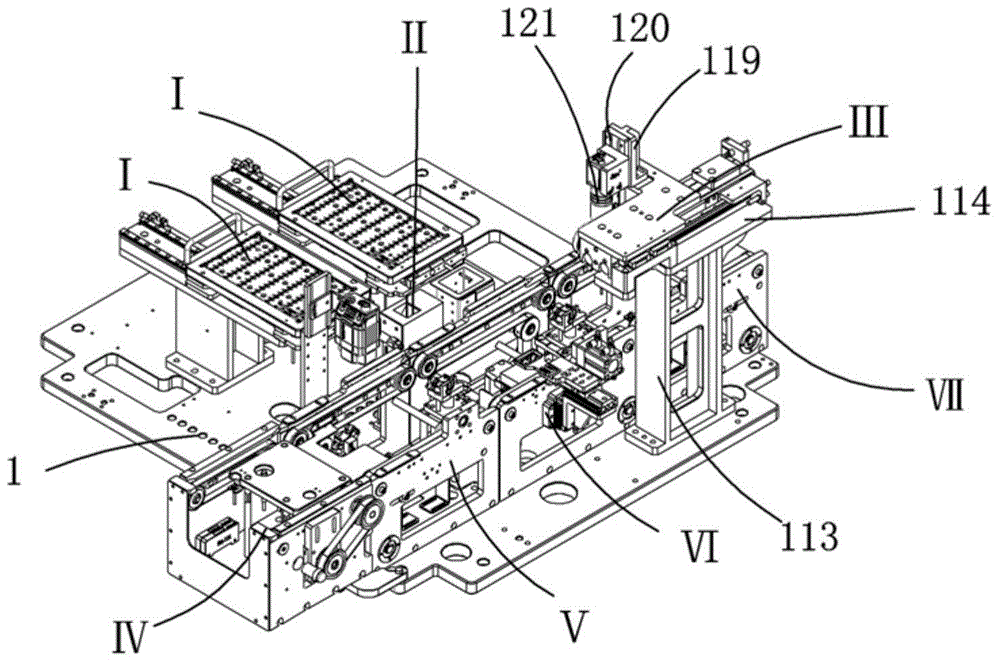

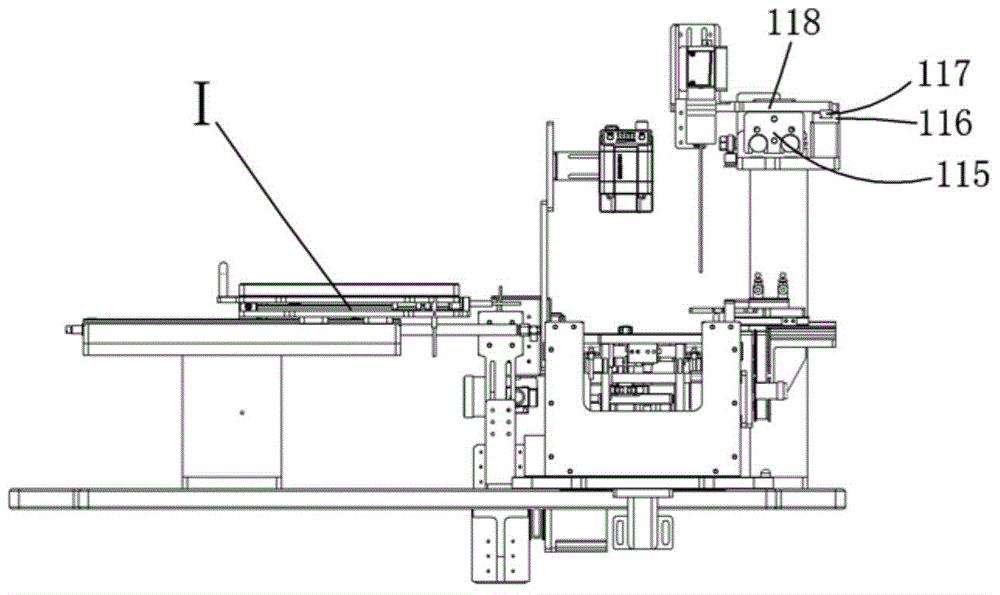

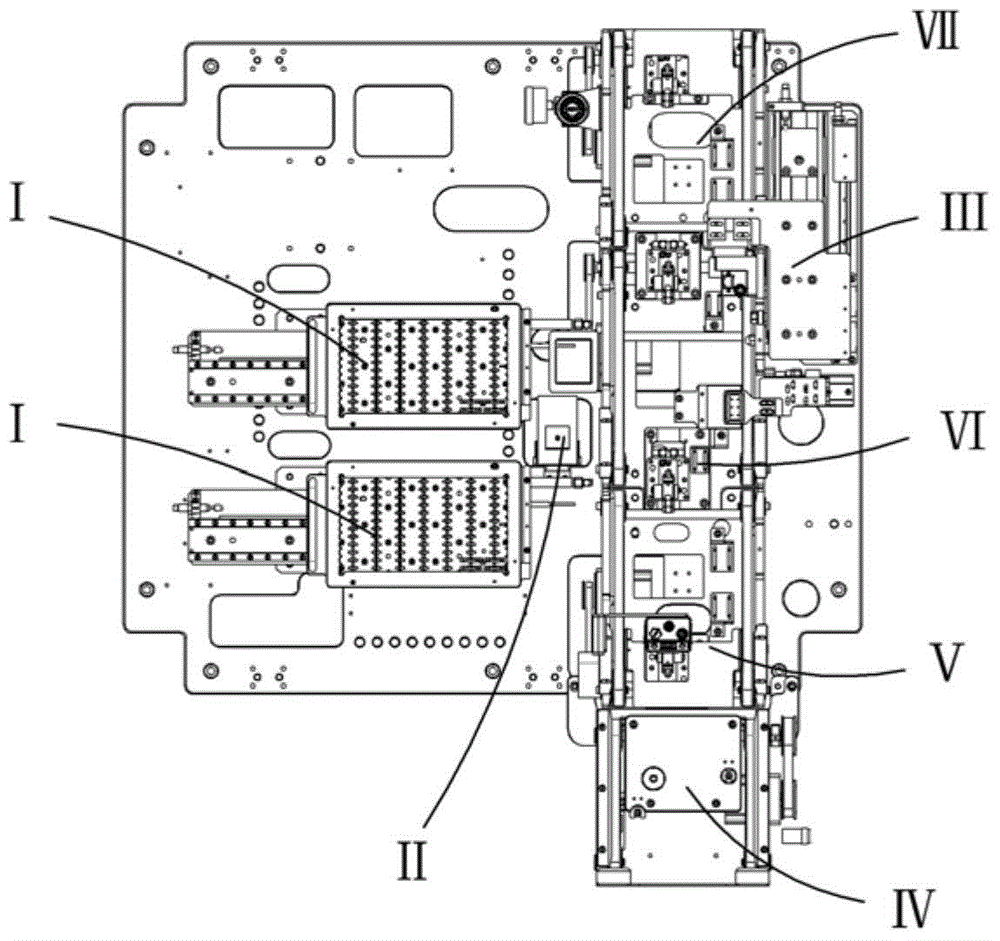

Full-automatic overlapping and packaging processing equipment for bearing retainer

ActiveCN104670545AImprove stacking efficiencyEasy to adjustWrappingWrapper twisting/gatheringEngineeringUltimate tensile strength

The invention discloses full-automatic overlapping and packaging processing equipment for a bearing retainer. The full-automatic overlapping and packaging processing equipment is characterized by comprising a frame, wherein an automatic overlapping and thin film covering mechanism and an automatic edge sealing and thermal shrinkage mechanism are arranged on the frame; the automatic overlapping and thin film covering mechanism comprises a retainer conveying and loading device, an overlapped mandril conveying device, a thin film pipe covering and conveying device, a thin film cutting device and a manipulator transmission device; the automatic edge sealing and thermal shrinkage mechanism comprises a sealing and edge folding device and a thermal shrinkage device. Retainers are automatically overlapped, and a thin film automatically sleeves the overlapped retainer group; then the whole group of retainers are automatically subjected to sealing, pressing and edge folding, and finally the packaging thin film is subjected to thermal shrinkage, so that the package is compacter, and the whole appearance is more attractive; furthermore, all the operations are automatically completed by a cylinder, a motor and the like; the labor intensity of a worker is reduced, and the production efficiency is improved.

Owner:台州市进宇轴承有限公司

Component height difference detecting device

ActiveCN104567697AImprove supply efficiencyReduce labor intensityUsing optical meansHeight differenceAssembly line

The invention relates to a component height difference detecting device. Material is fed in a material feeding assembly line mechanism, and a first assembly line mechanism is capable of blocking a carrier and scanning a serial number of a component through a bar-code scanner; the component is driven by a manipulator to move to the position of a CCD mechanism and to take a picture, and the component position is calibrated; a second assembly line mechanism is capable of separating the carrier from a conveyer belt and blocking the forward movement of the carrier, and the carrier is capable of maintaining level after the carrier is lifted up; the component is placed on the carrier through the manipulator, a material pressing mechanism is driven by a driving air cylinder and a lifting air cylinder to drive a material pressing plate to press the component after the component is placed, a detecting counterpoint mechanism is driven by the manipulator and is transported to the position above the component, a height difference between the component and the datum on the carrier is detected, and after the height difference is detected, the material pressing mechanism is moved out, a mandril is retreated, and the carrier is continuously transported forward to a material discharging assembly line mechanism for material discharging. The component height difference detecting device is used for detecting the height difference on small components of electronic products, the height difference can be confirmed, and the next step of operation is prepared.

Owner:BOZHON PRECISION IND TECH CO LTD

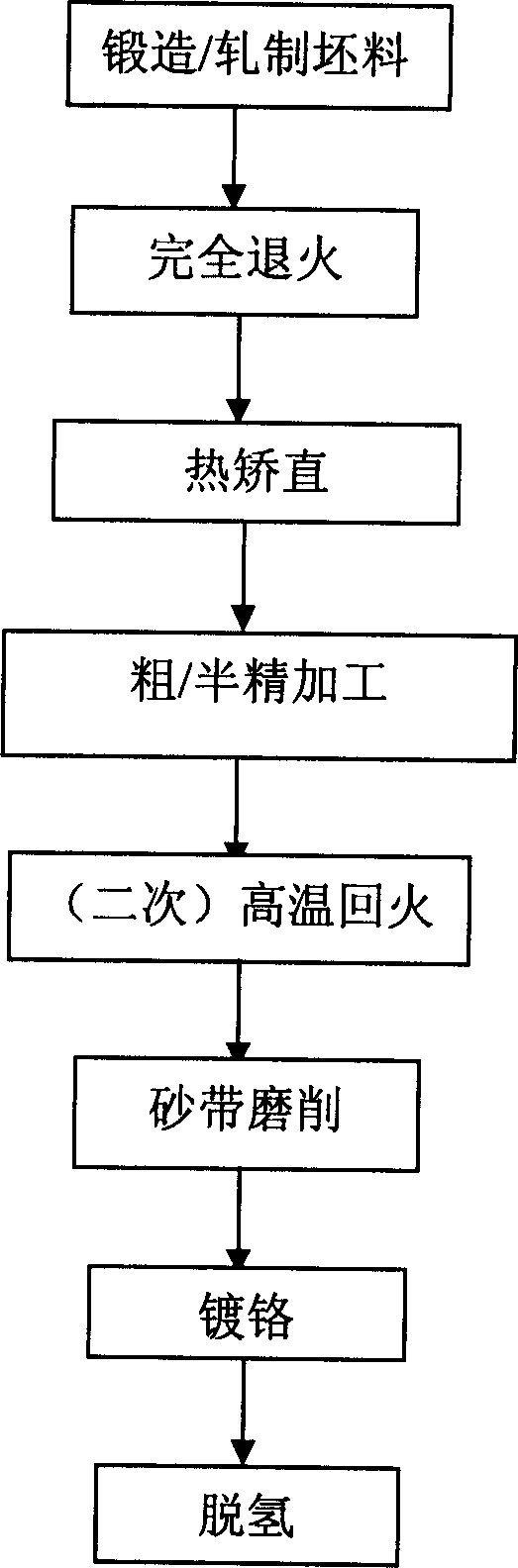

Novel process for manufacturing retained mandrel for continuous rolling of steel pipe

InactiveCN1840286AReduce hardnessLow costMandrelsOther manufacturing equipments/toolsChrome platingContinuous rolling

The invention discloses a steel pipe tandem rolling restraint mandril preparing method, which comprises the following steps: forging / rolling blank; annealing outright; hot straightening; rough / semi-finish; heat hardening; (twice) high tempering; grinding belt; chrome plating; dehydrogenating. The invention reduces the material cost, which improves the blank yield.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com