Curled round one-time forming die

A technology for forming molds and templates, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of unstable finished product size, multi-equipment labor, and large cumulative errors, so as to reduce investment, avoid cumulative errors, and improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

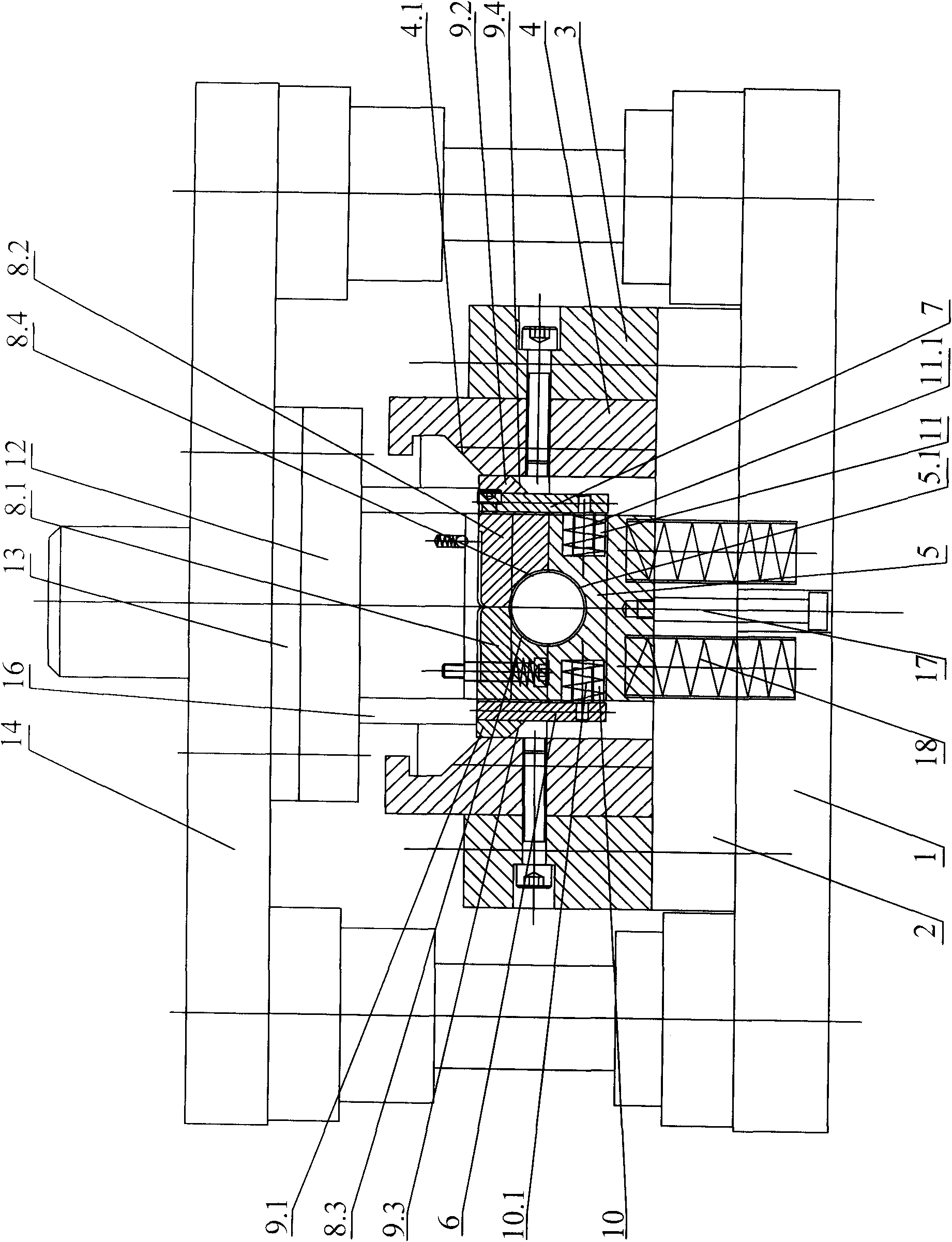

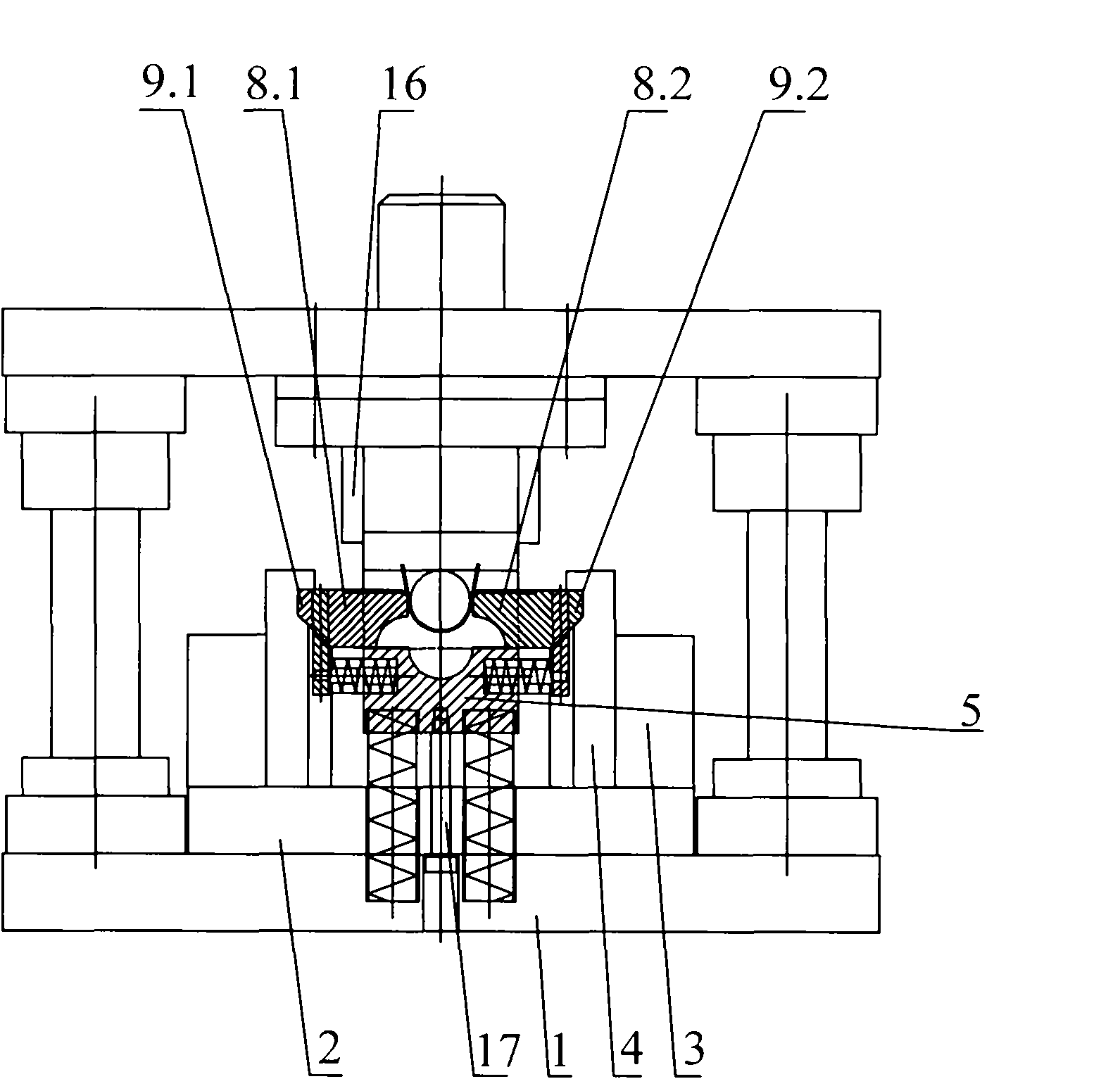

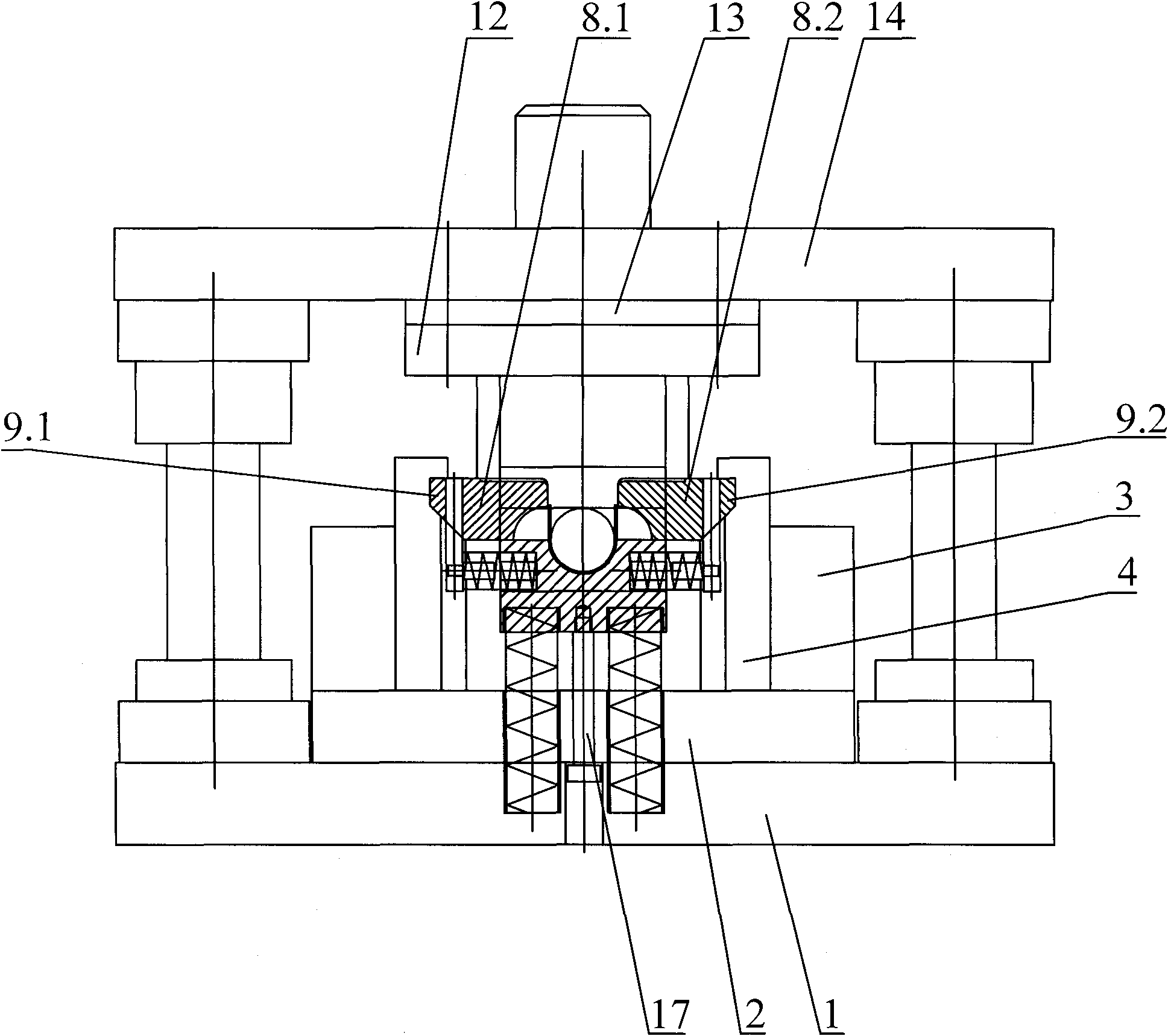

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0015] As shown in the figure: the rolling round one-time forming mold includes an upper template 14 and a lower template 1. The lower surface of the upper template 14 is fixedly provided with an upper backing plate 13, and the upper surface of the lower template 1 is fixedly provided with a lower backing plate 2. The upper surface of the backing plate 2 is fixedly provided with lower inserts 4 at left and right intervals, and the upper surface of the lower backing plate 2 outside the lower insert 4 is provided with a lower fixing plate 3, and the lower fixing plate 3 is fixedly connected with the lower insert 4, and the two lower inserts The opposite wall surface of the block 4 is provided with a slide block driving slope 4.1, and a spring top block 5 is provided between the two lower inserts 4, and a spring top screw hole is integrally provided in the lower te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com