Patents

Literature

36results about How to "Avoid violent friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

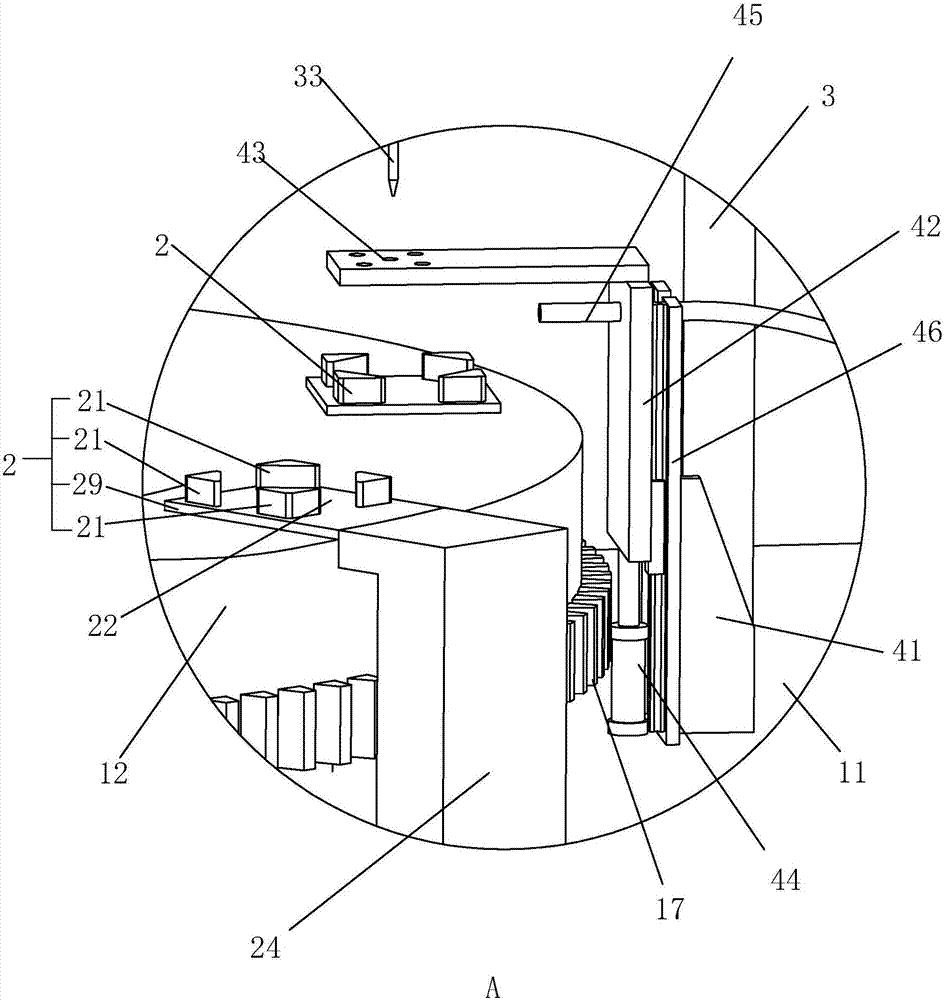

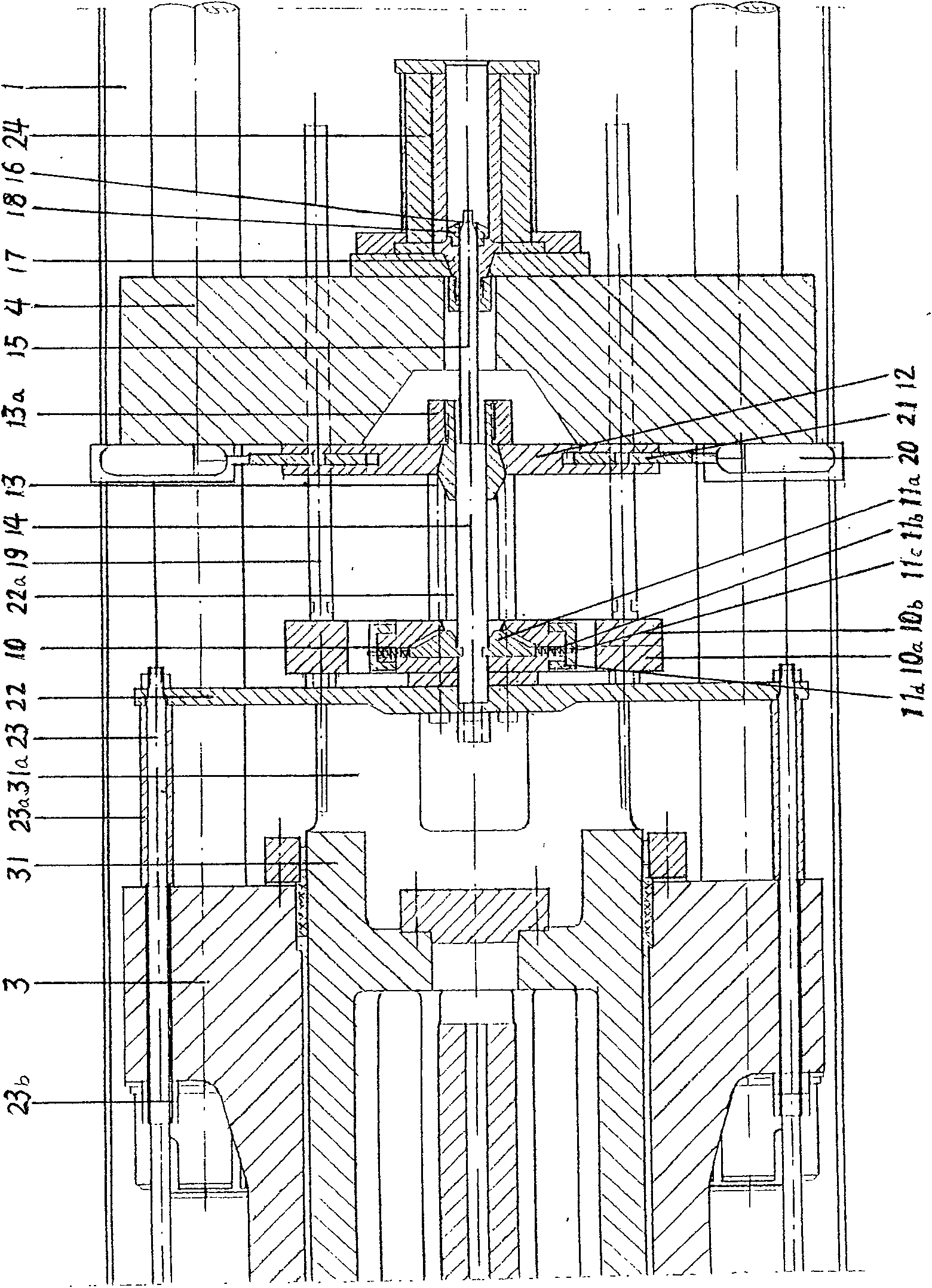

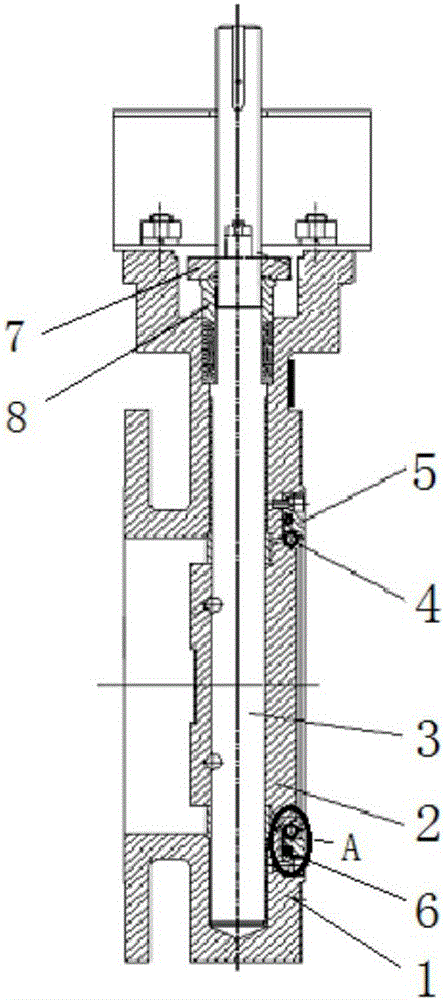

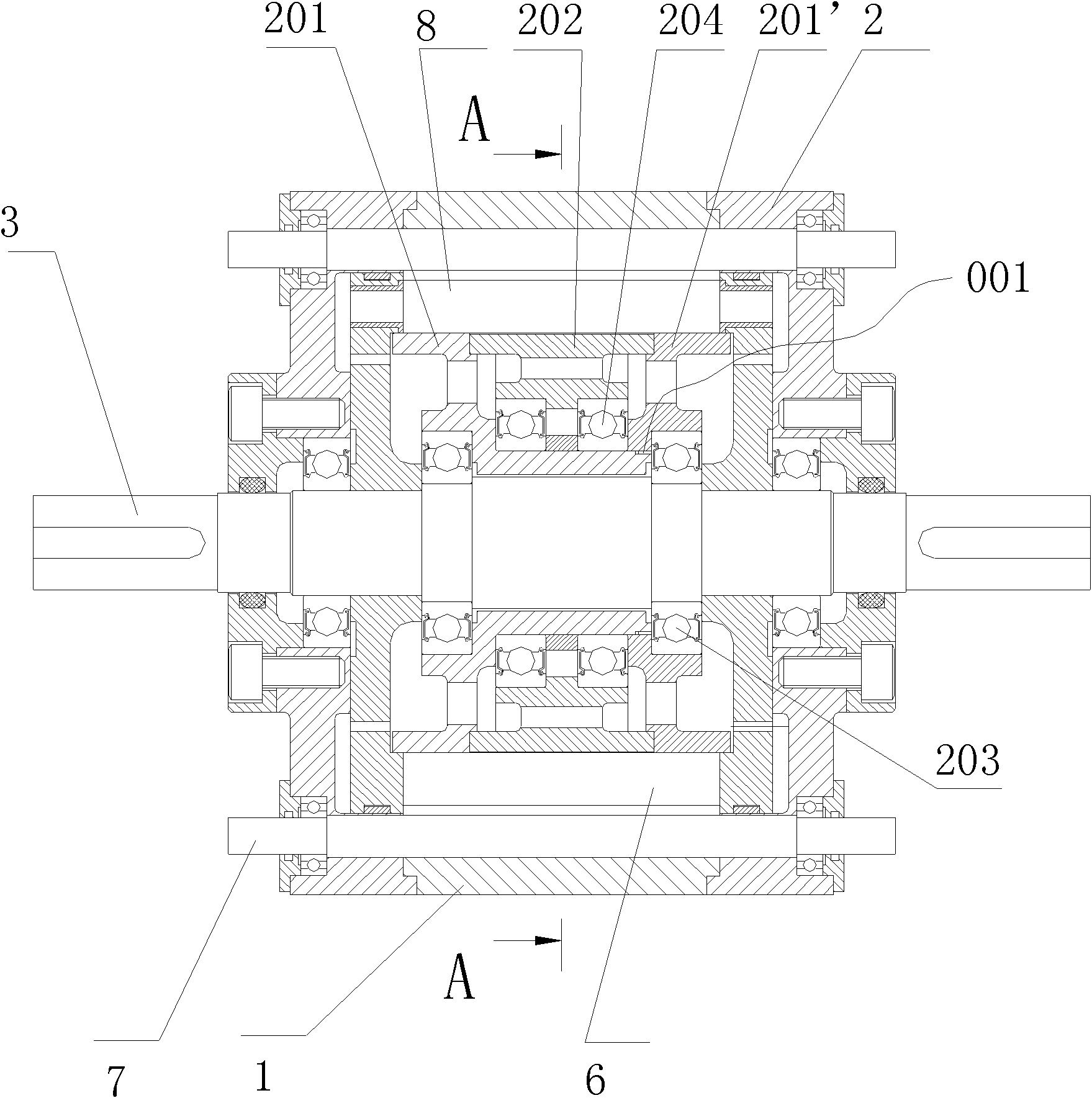

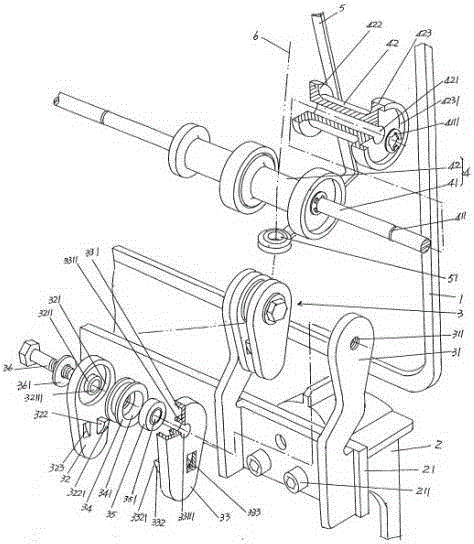

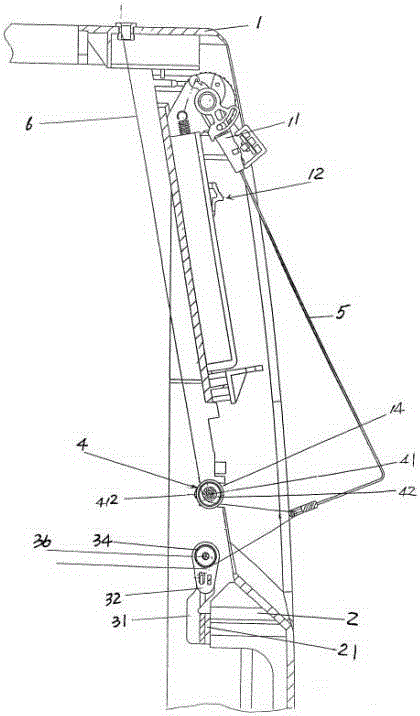

Alloyed steel horizontal type indirect extrusion machine

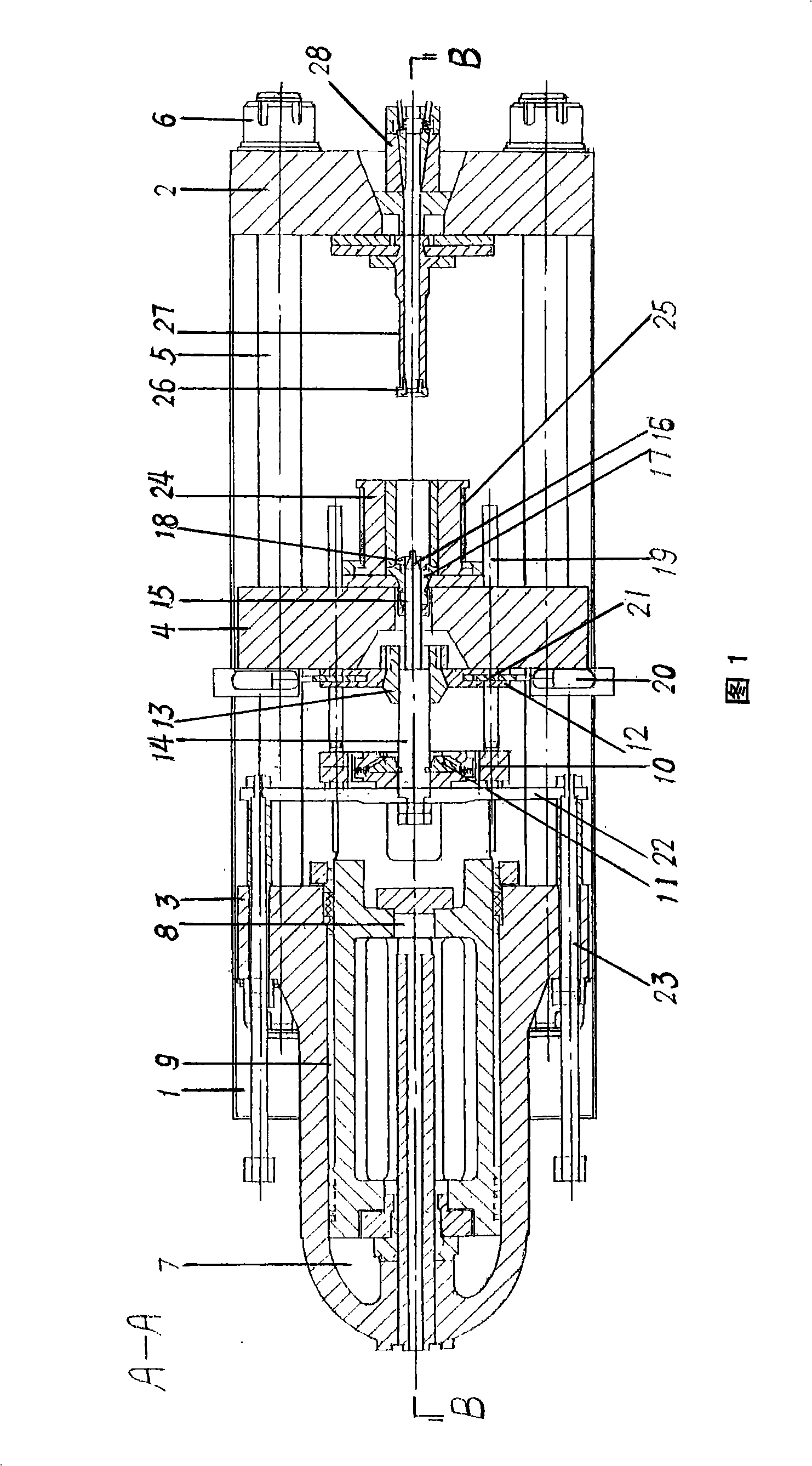

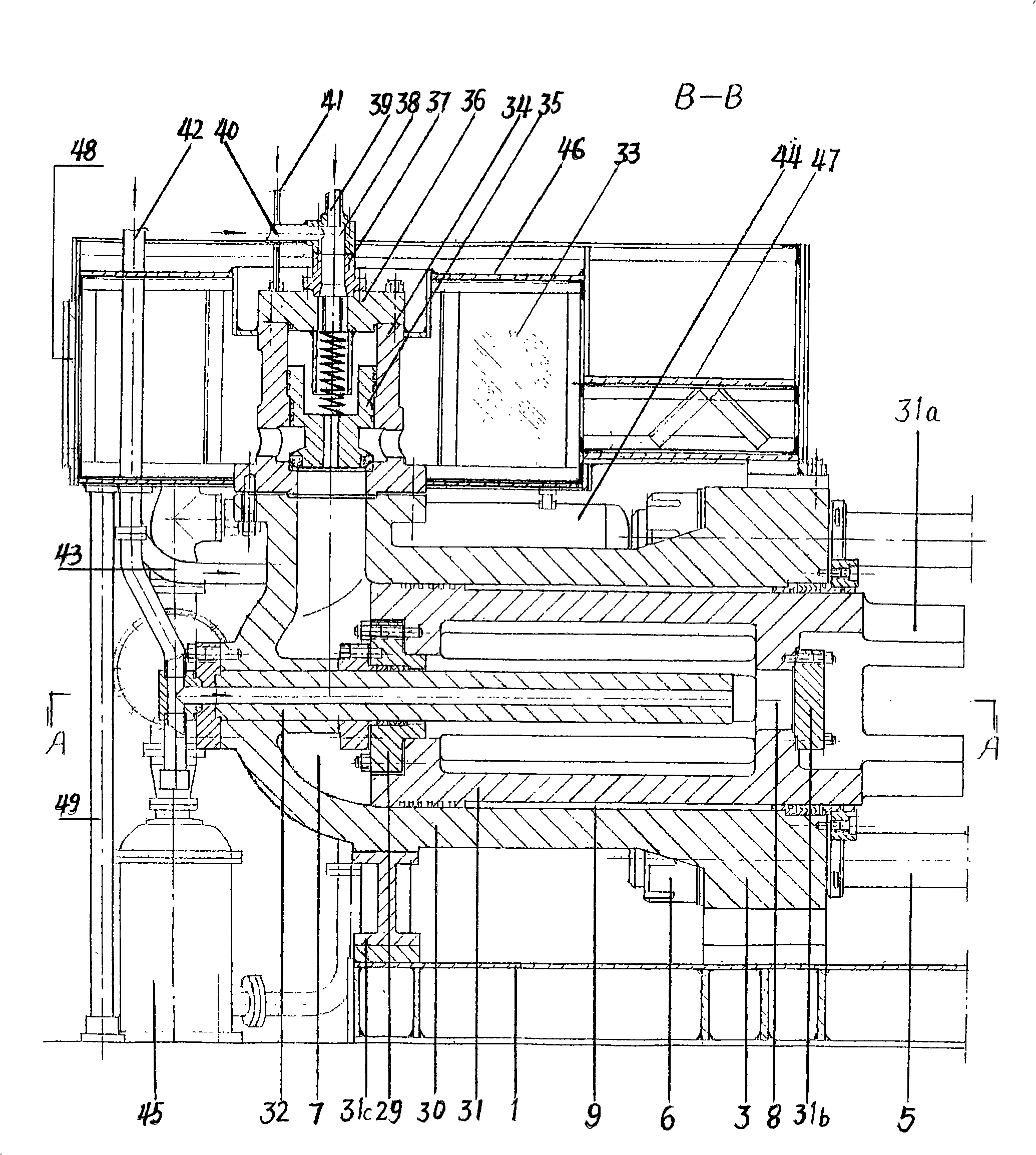

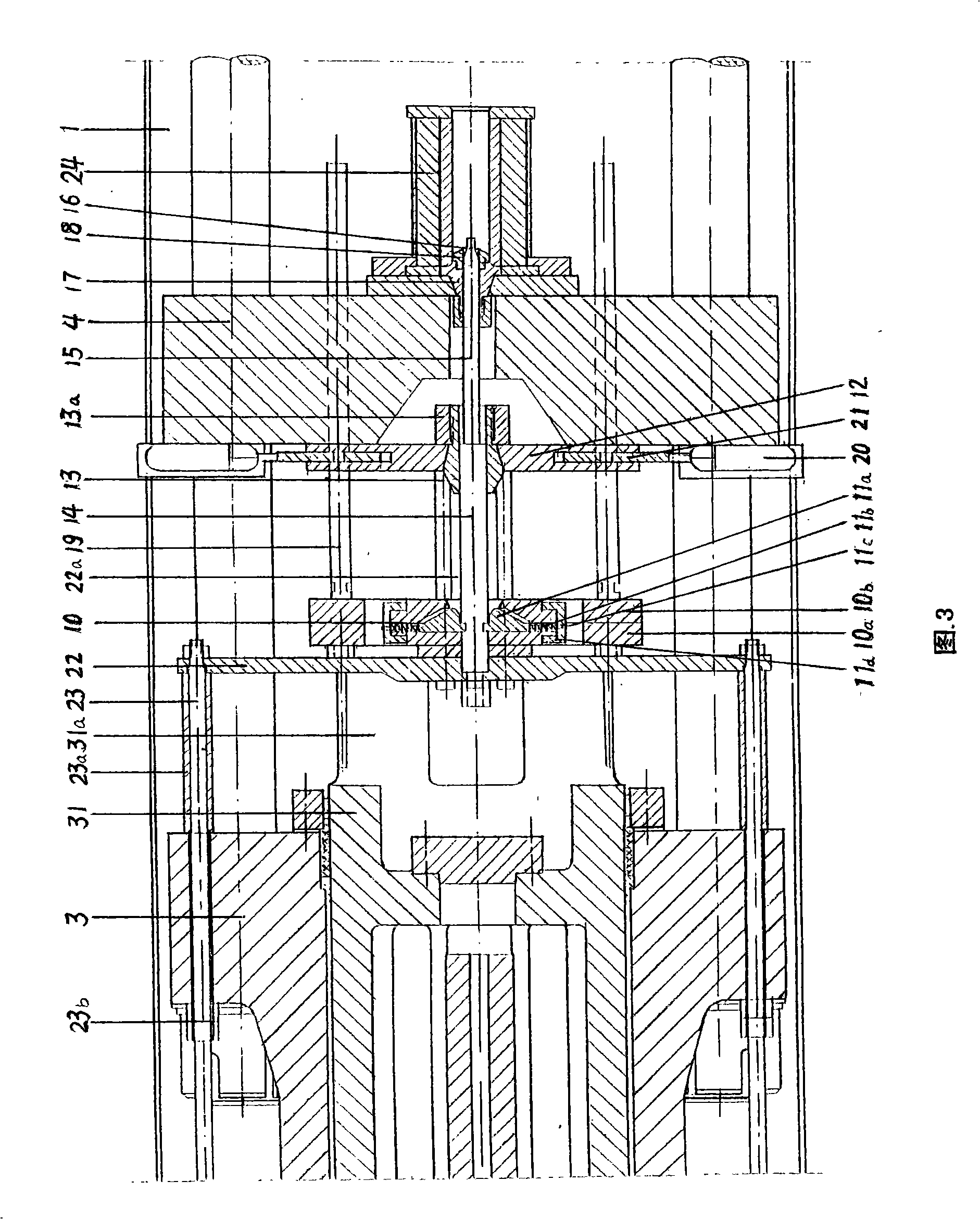

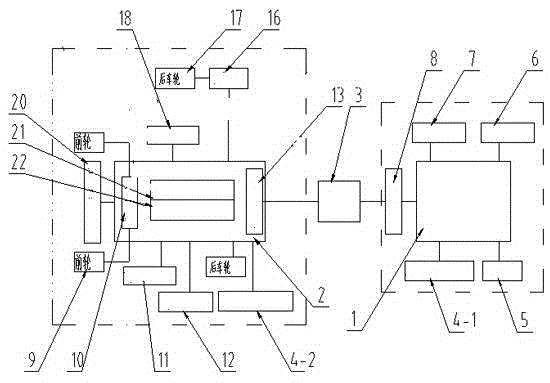

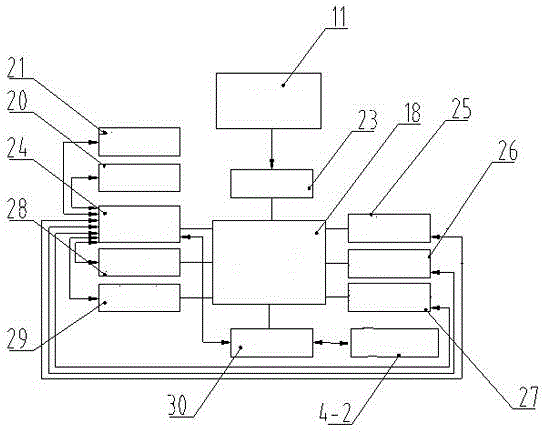

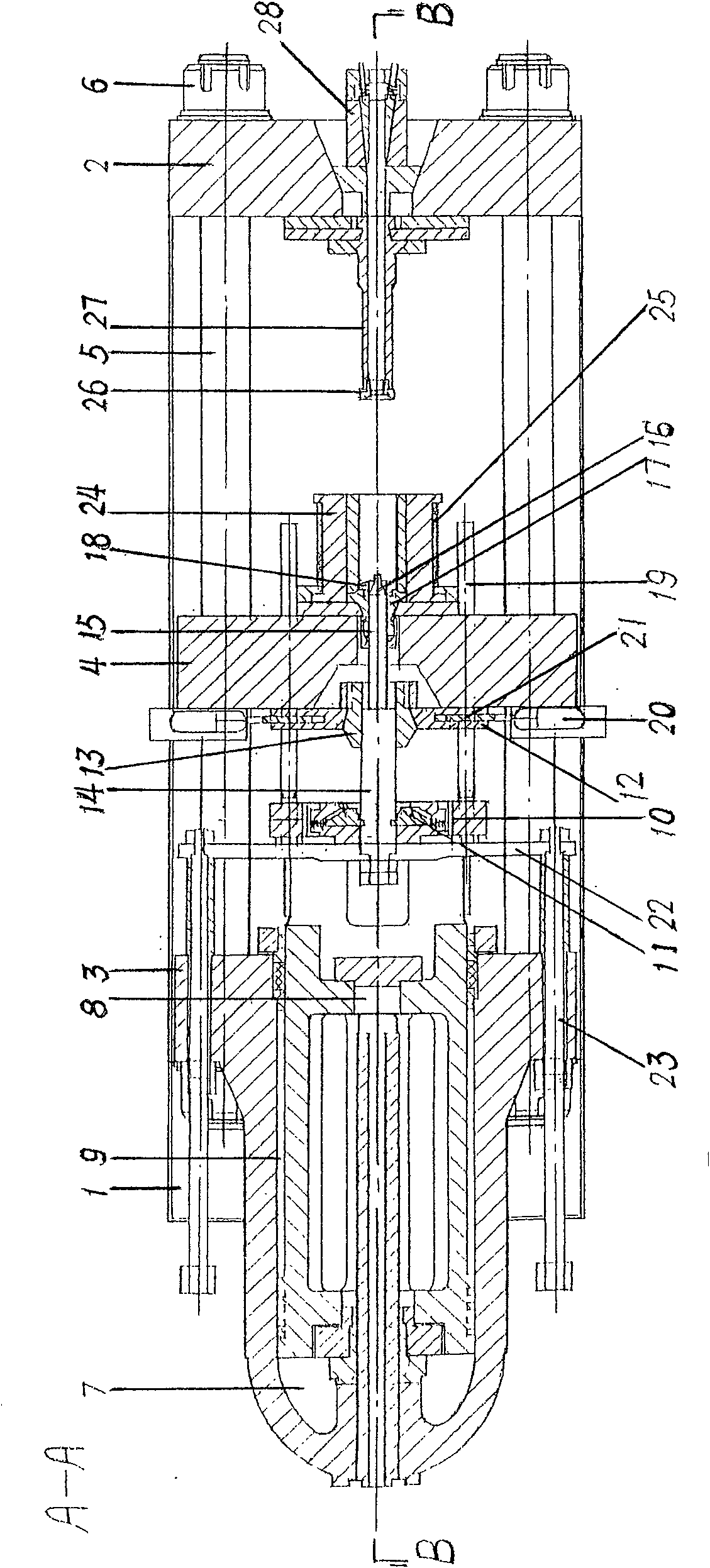

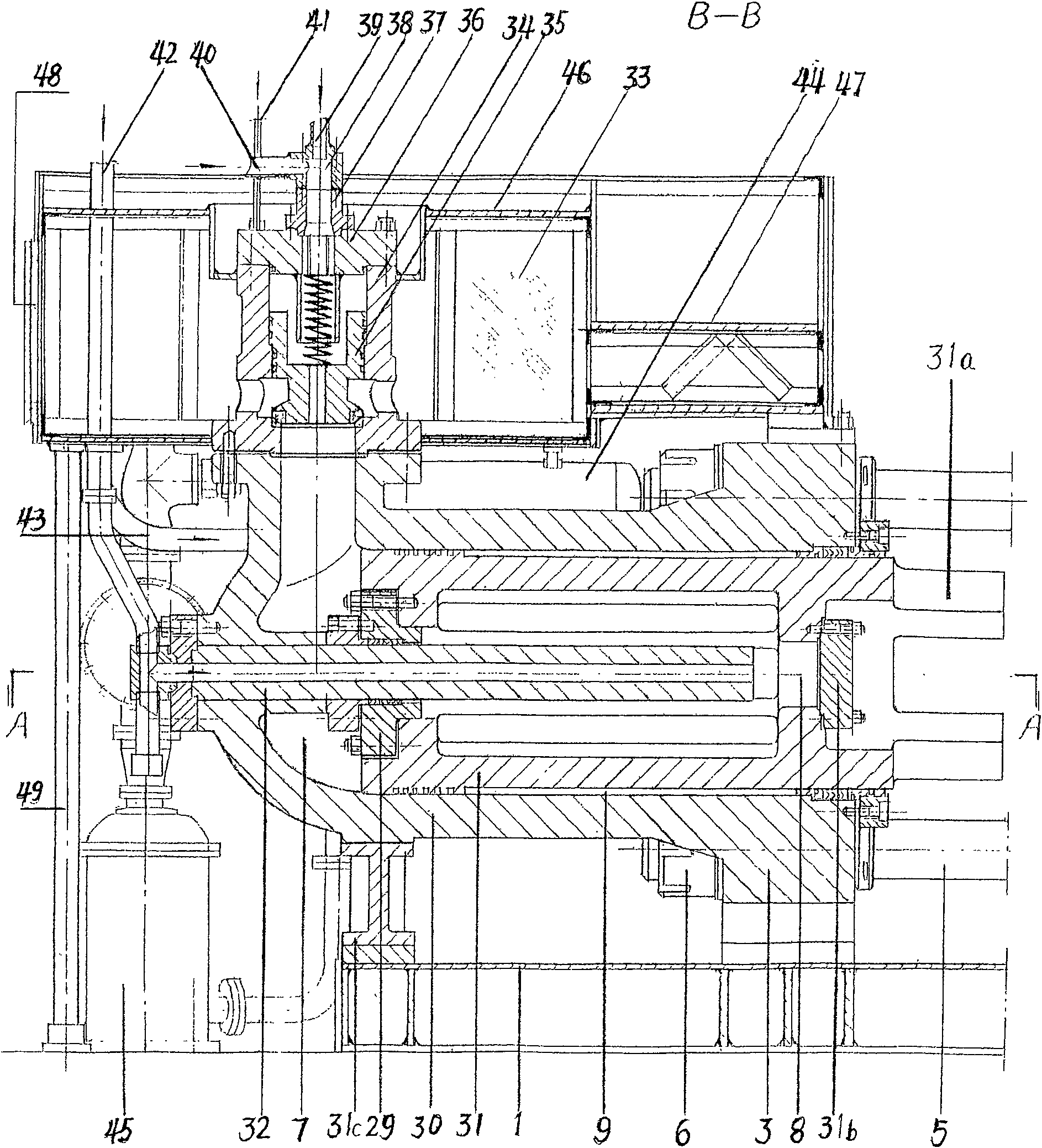

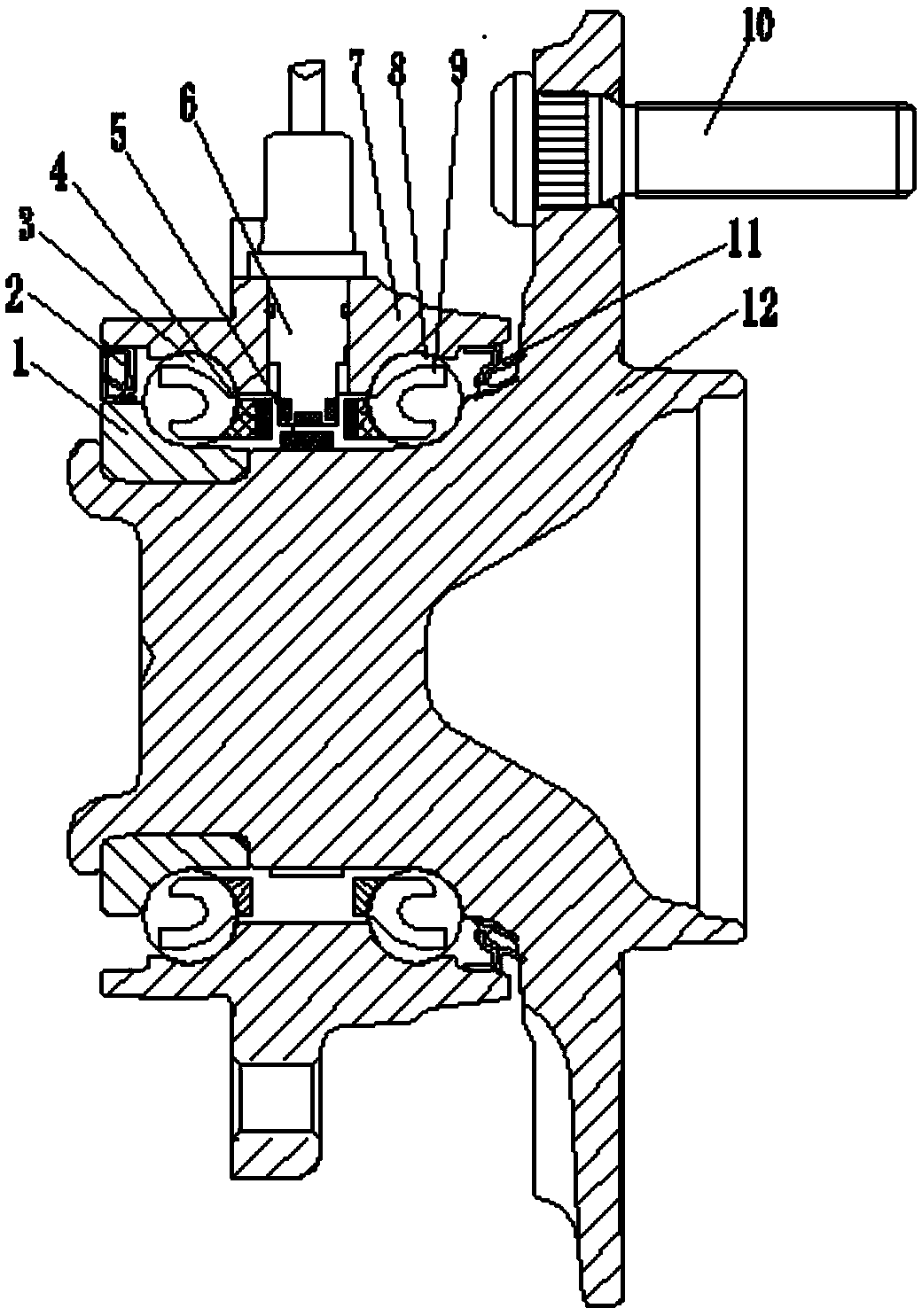

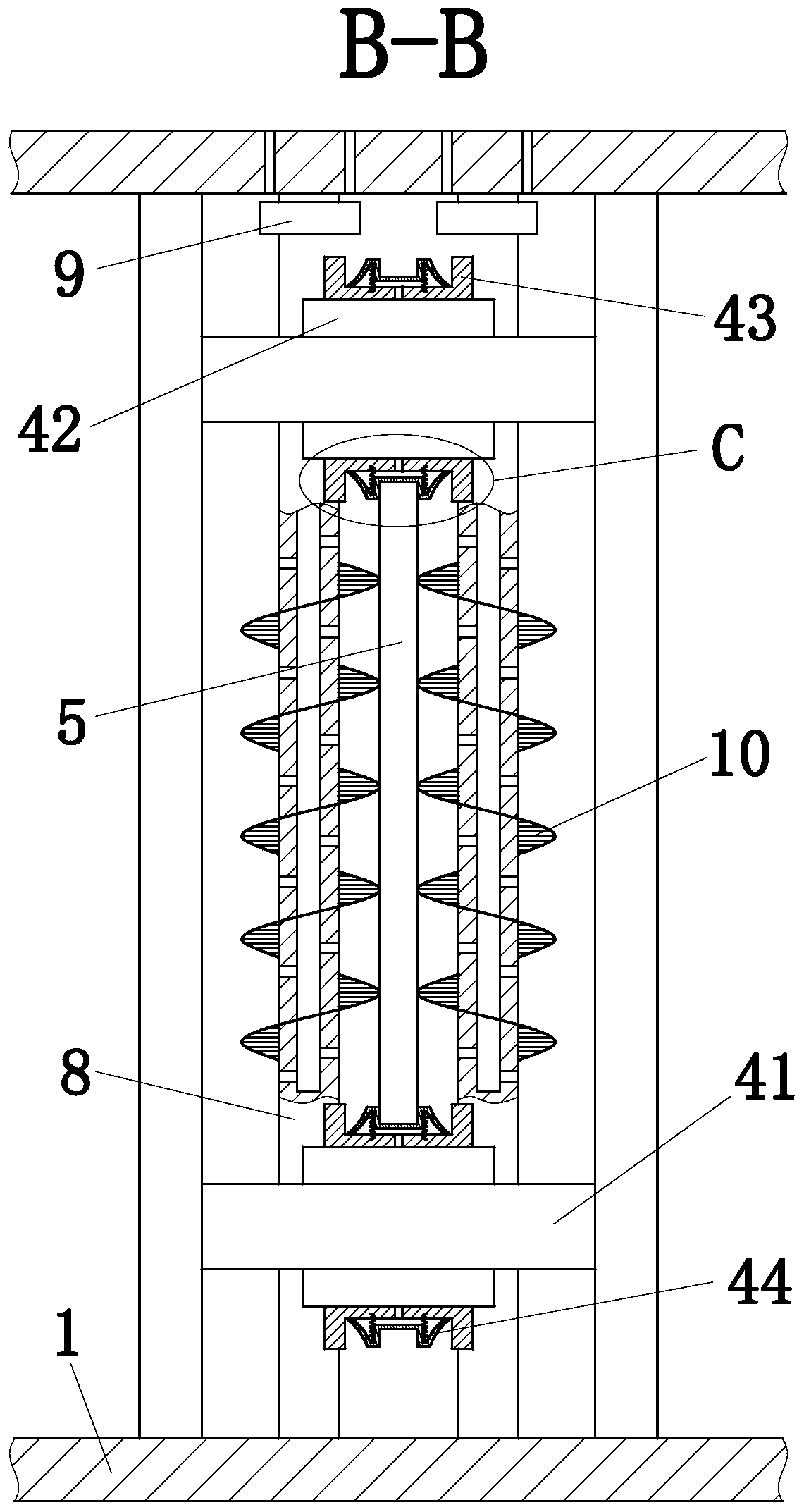

The invention discloses a horizontal reverse alloy steel extrusion machine, which belongs to the novel technical field of seamless steel pipe and relates to a seamless steel pipe manufacturing facility. The purpose is to settle the problems of complex process, inefficiency, high energy consumption and pollution of the environment with the prior domestic cold drawing techniques of small-bore seamless alloy steel tube. The machine consists of a rigid framework, a liquid-filled combined hydraulic cylinder and a die assembly, wherein, the rigid framework consists of an anterior fixed beam, a posterior fixed beam and an intermediate moving beam on the frame, which are connected in series by a four tensile columns; the liquid-filled combined hydraulic cylinder has a compact structure and is capable of executing the operations of die displacement, material feeding, perforation, extrusion and die removal; the die assembly consists of a perforation and extrusion and automatic switching system, a hot extrusion / molding system and a die removal and disengaging and residual extrusion and cutting system. The machine is capable of achieving once-and-for-all heating and once-and-for-all molding to directly produce finished products of small-bore seamless alloy steel pipes. Compared with forward extrusion, the deviations of the displacement of the piercing mandril and the dies are small, and no friction occurs between the billets and the internal wall of the container, thereby the machine can directly adopt continuous casting billets to extrude small-bore pipes, and has the advantages of simple process, high quality, high efficiency, low energy consumption, etc.

Owner:周家镳

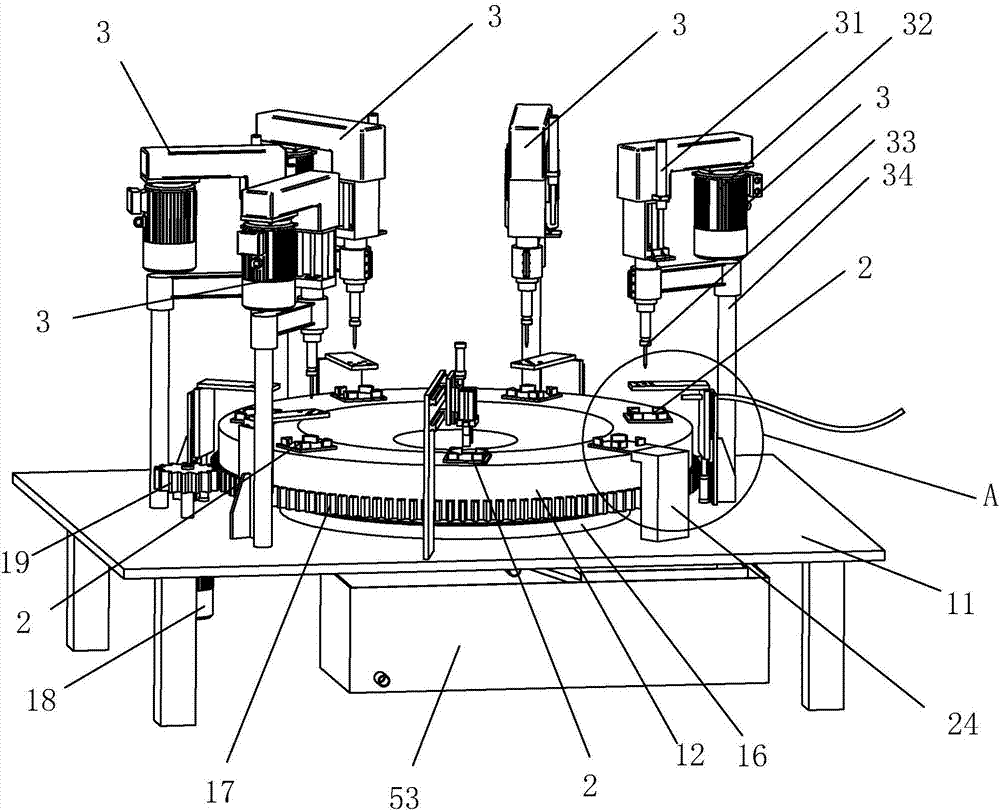

Automatic fine drilling machine

ActiveCN106944643AAchieve the effect of circulationReduce pollutionMaintainance and safety accessoriesDrill jigsEngineeringMachining

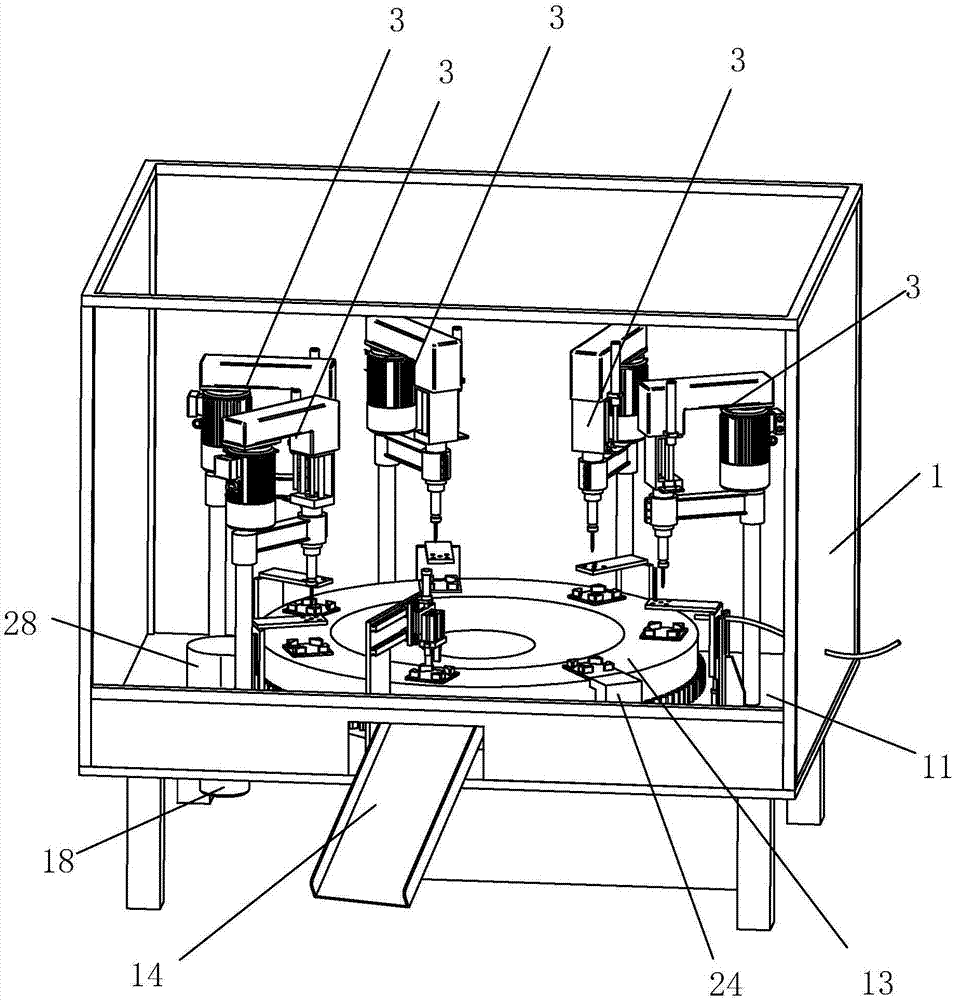

The invention discloses an automatic fine drilling machine. The automatic fine drilling machine comprises a support plate, a working disc rotating in the horizontal direction is rotatably connected to the support plate, a plurality of clamping bases used for containing objects are arranged on the working disc, the support plate is provided with a driving device used for driving the working disc to rotate and comprises a feeding inlet and a discharging outlet along the rotating track of the working disc, a plurality of drilling stations are arranged between the feeding inlet and the discharging outlet along the rotating track of the working disc, each drilling station corresponds to one clamping base, and the drilling stations machine objects arranged on the clamping bases through the lifting action of drill bits. According to the automatic fine drilling machine, a plurality of the clamping bases are arranged in the circumferential direction of the working disc, multiple objects arranged on the clamping bases can be machined simultaneously in the rotating process of the working disc, therefore, the drilling and machining efficiency is improved, automation, high precision, high reliability, safety, environmental friendliness and energy saving are achieved, and repairing and maintaining are convenient.

Owner:苏州宝罗机械工程有限公司

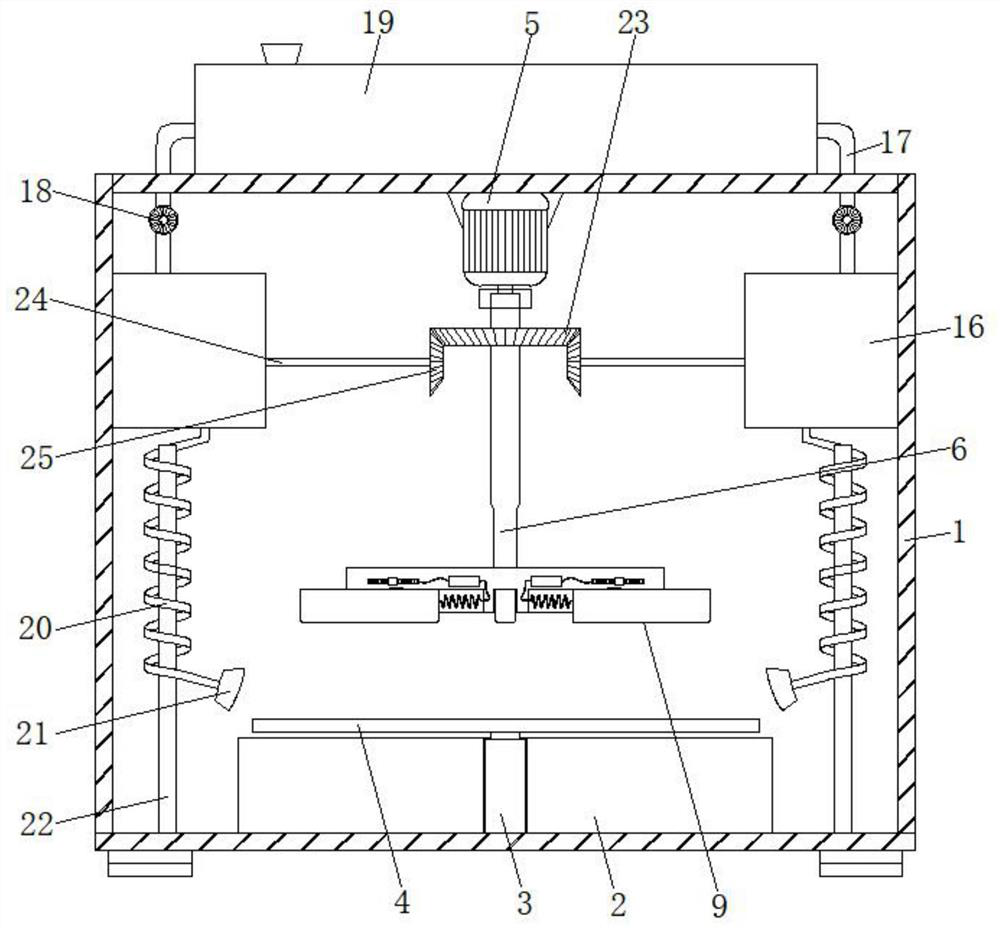

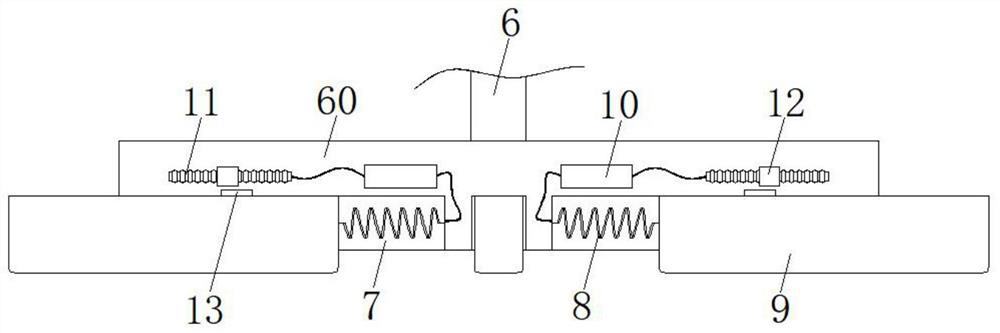

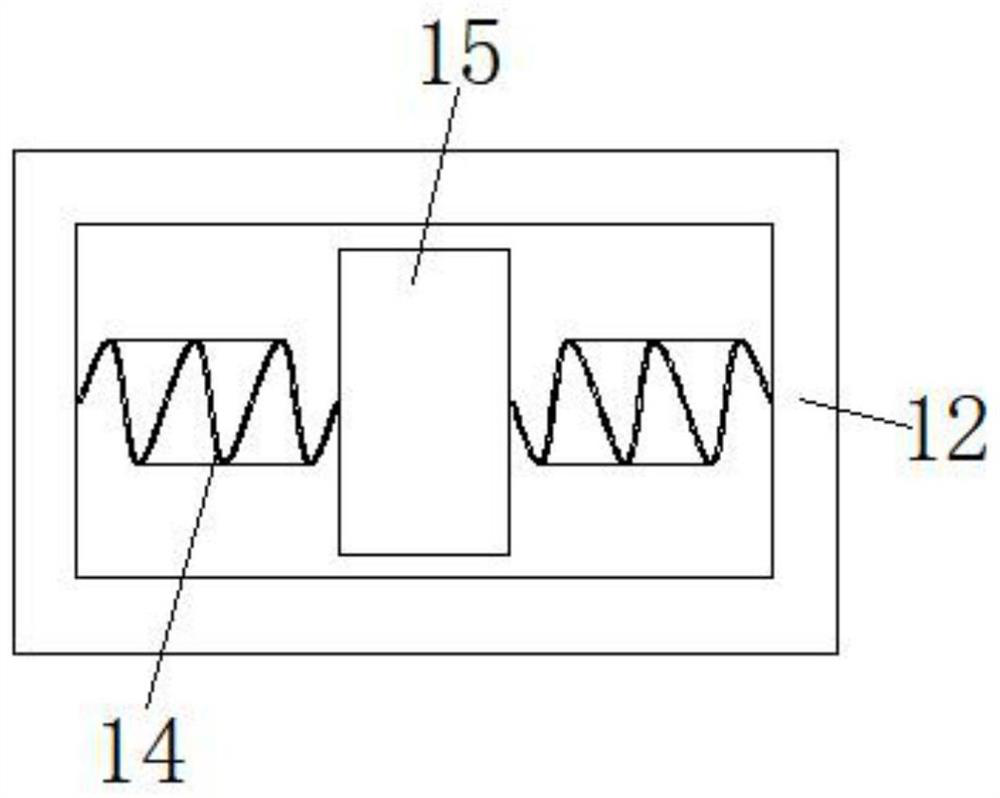

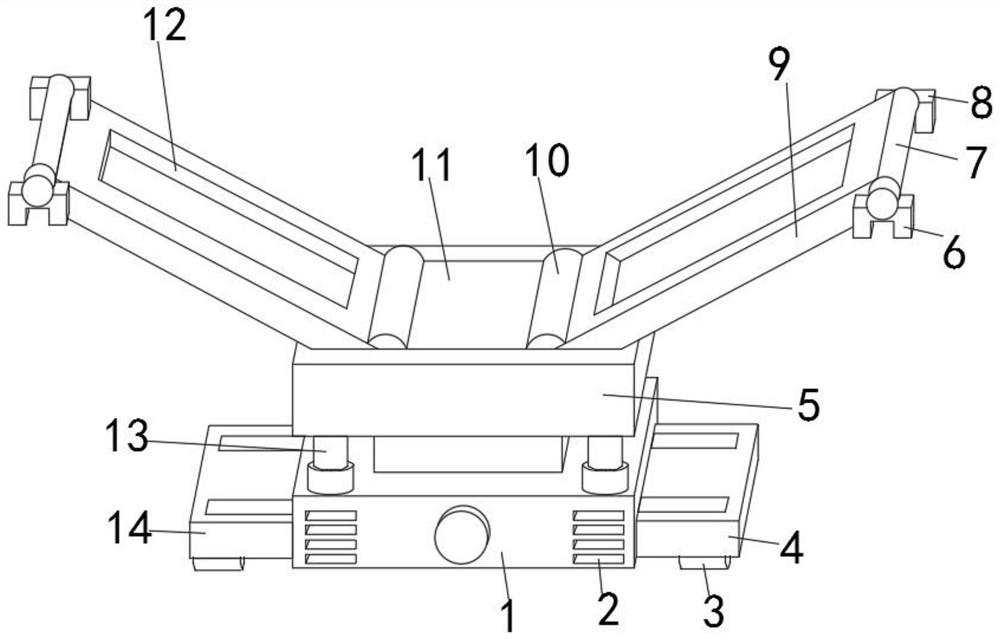

Mop cleaning dewaterer

InactiveCN104644093AImprove cleaning effectAvoid vibrationCarpet cleanersFloor cleanersEngineeringMechanical engineering

Owner:CHINA THREE GORGES UNIV

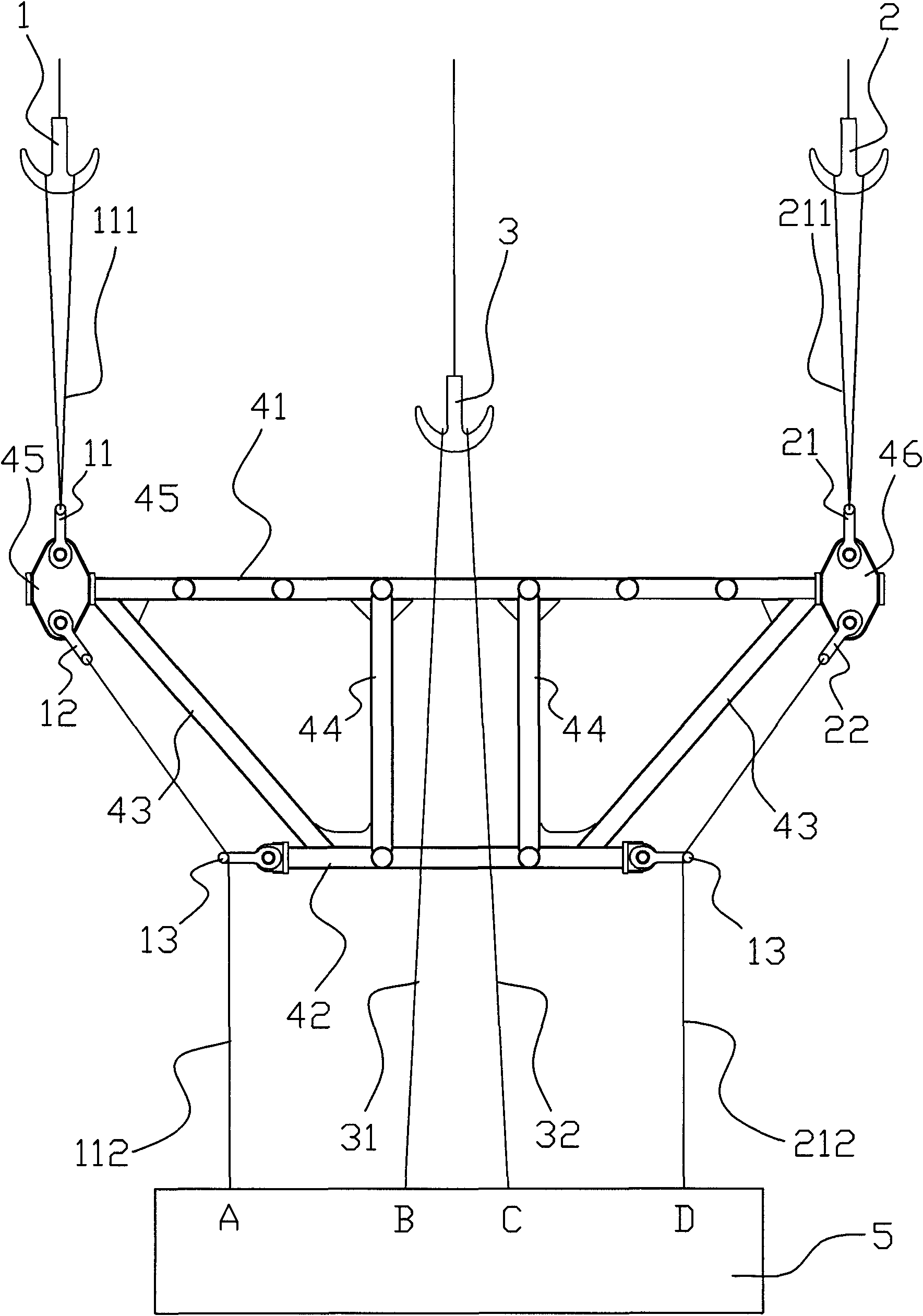

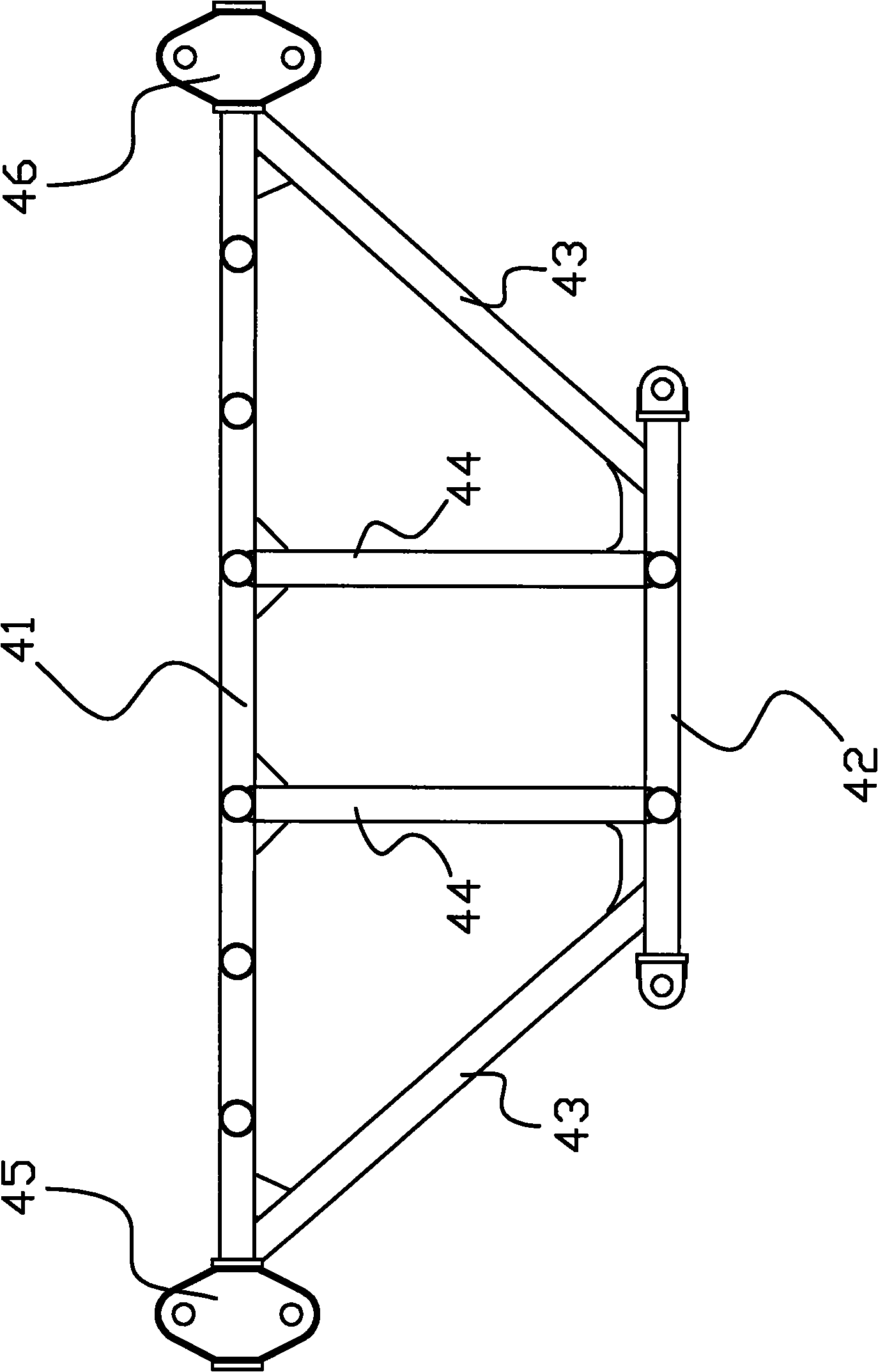

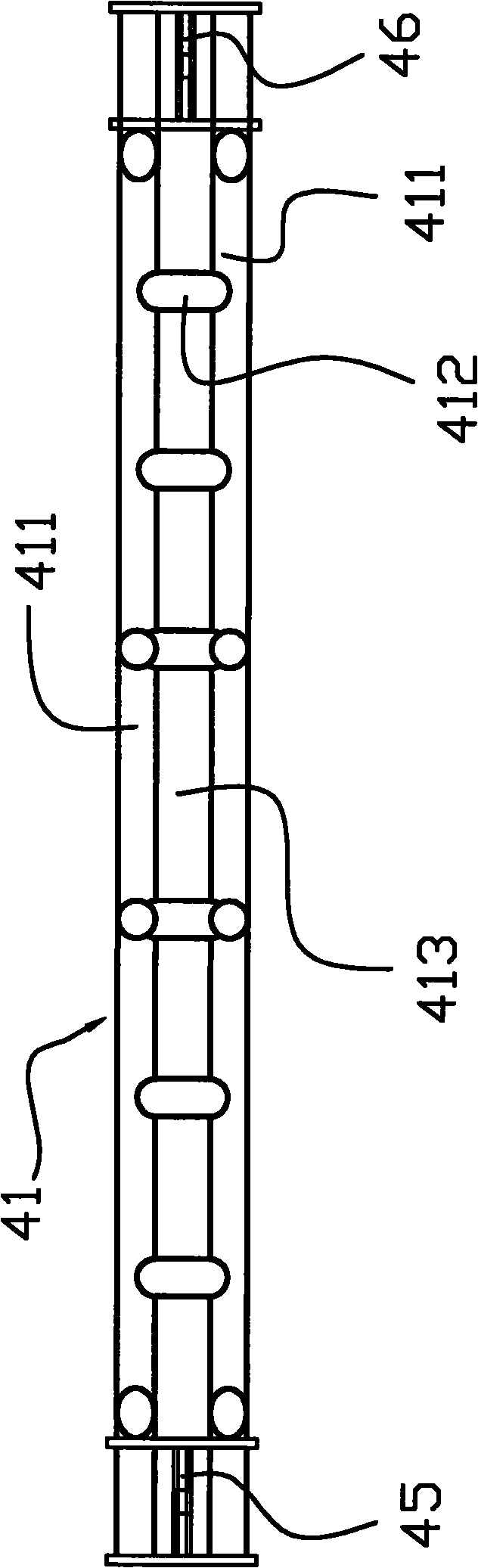

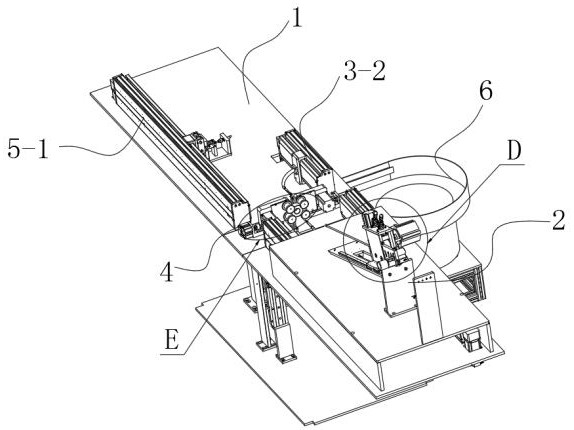

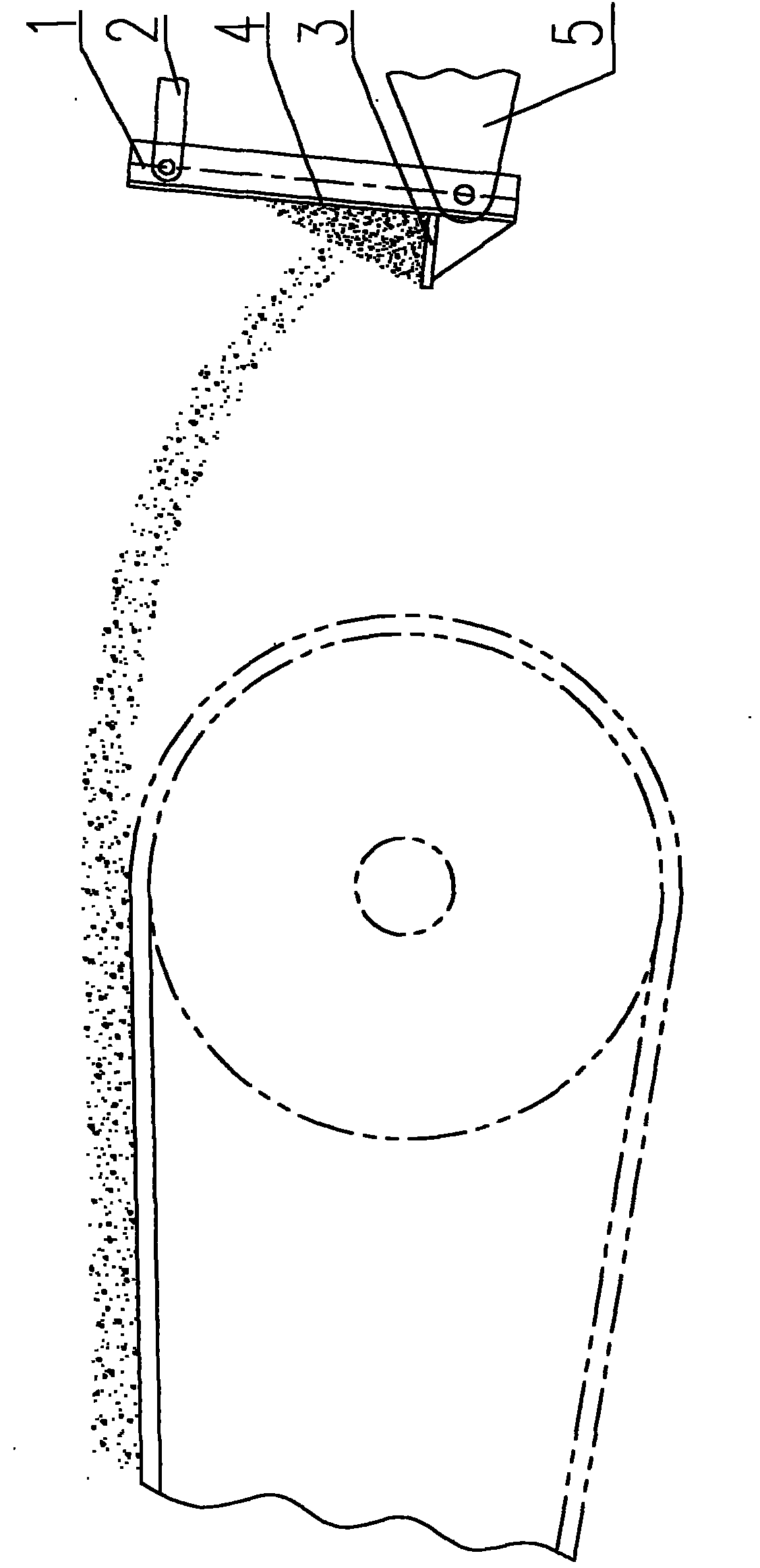

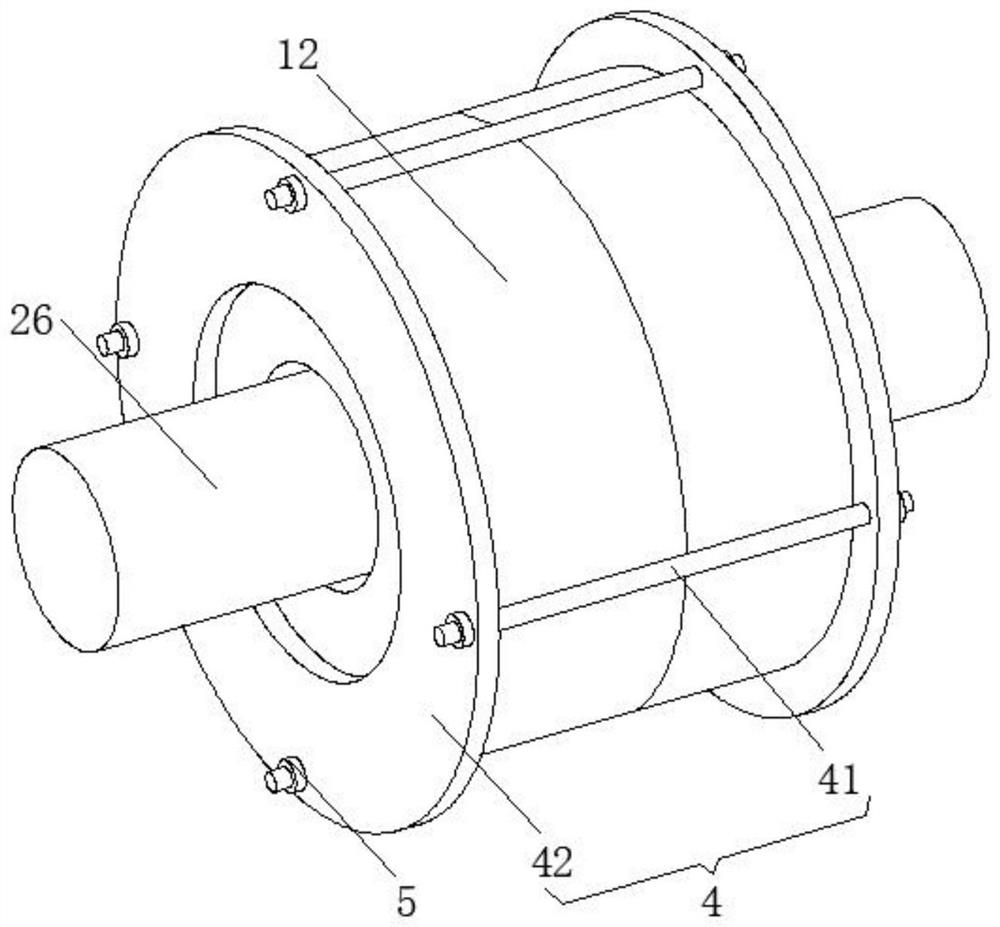

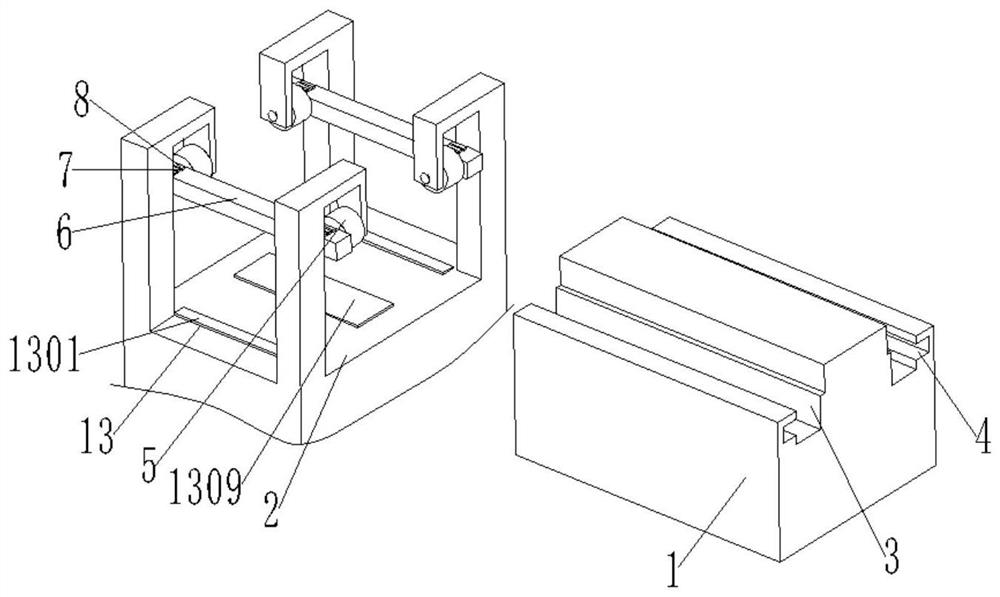

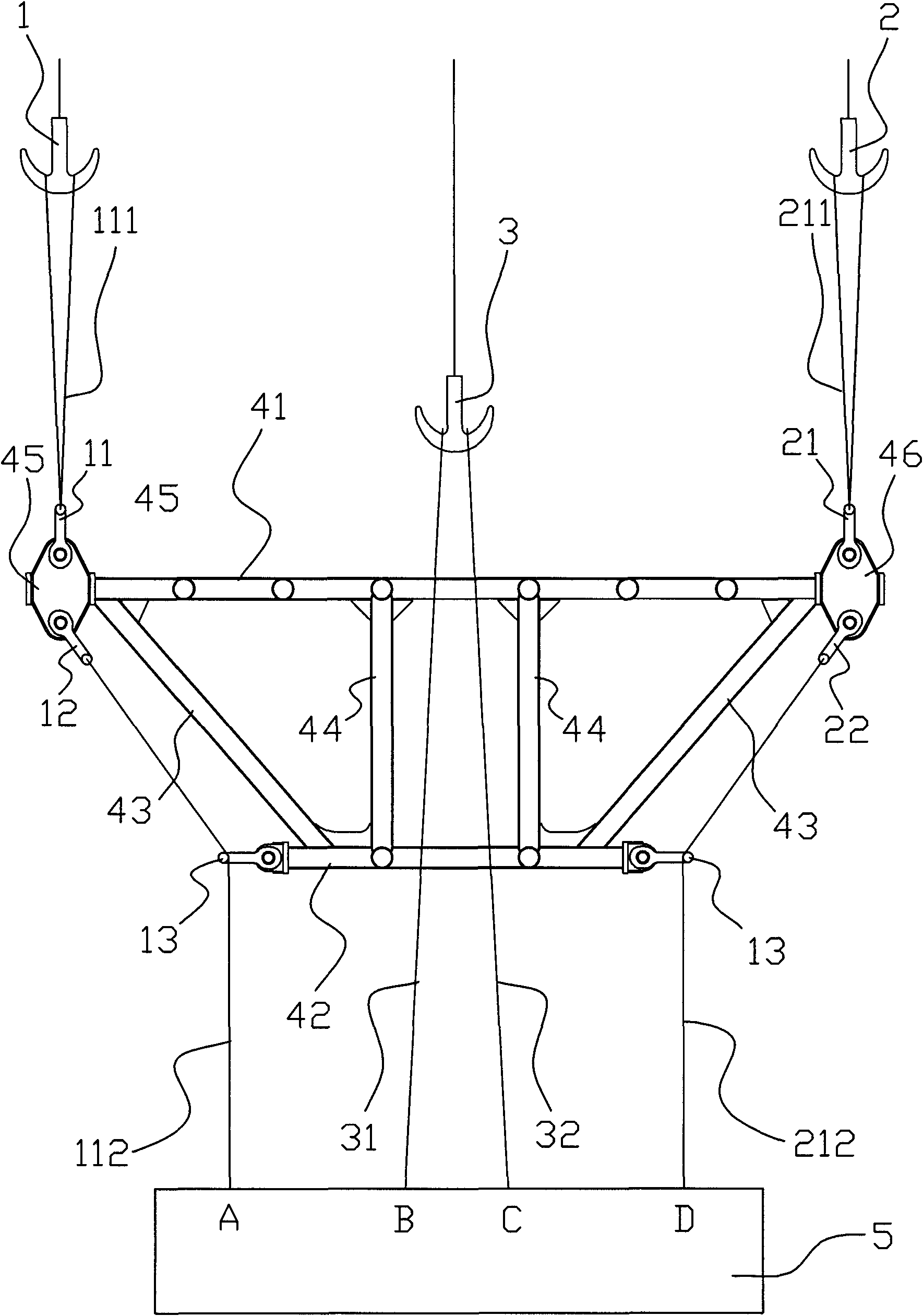

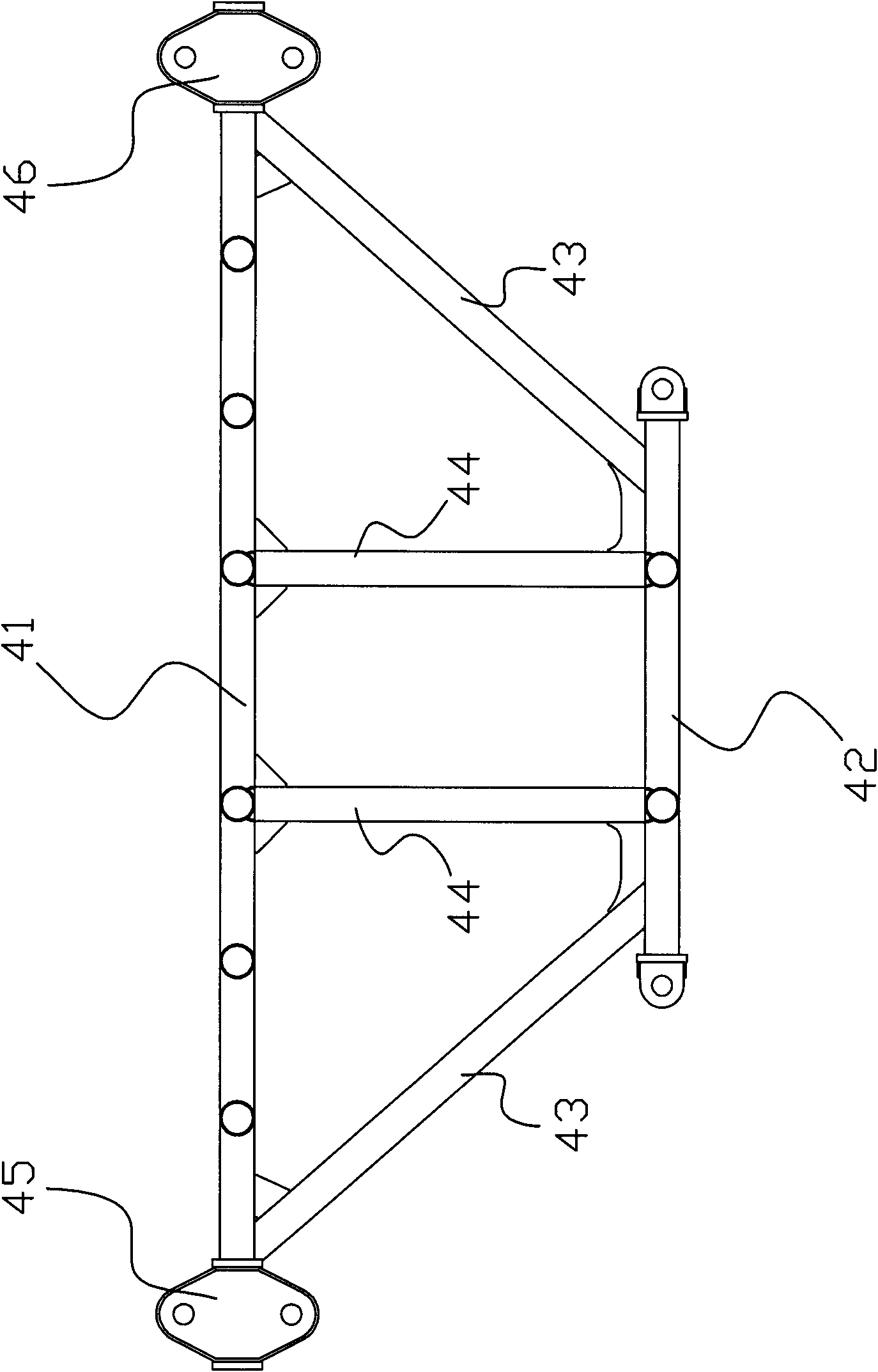

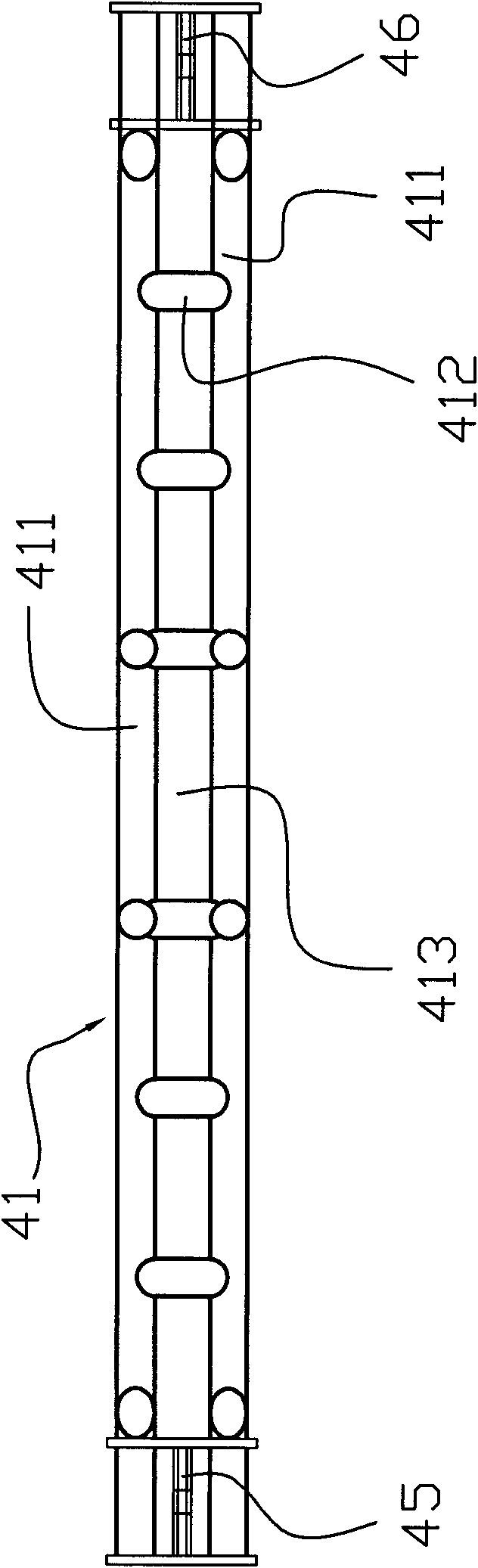

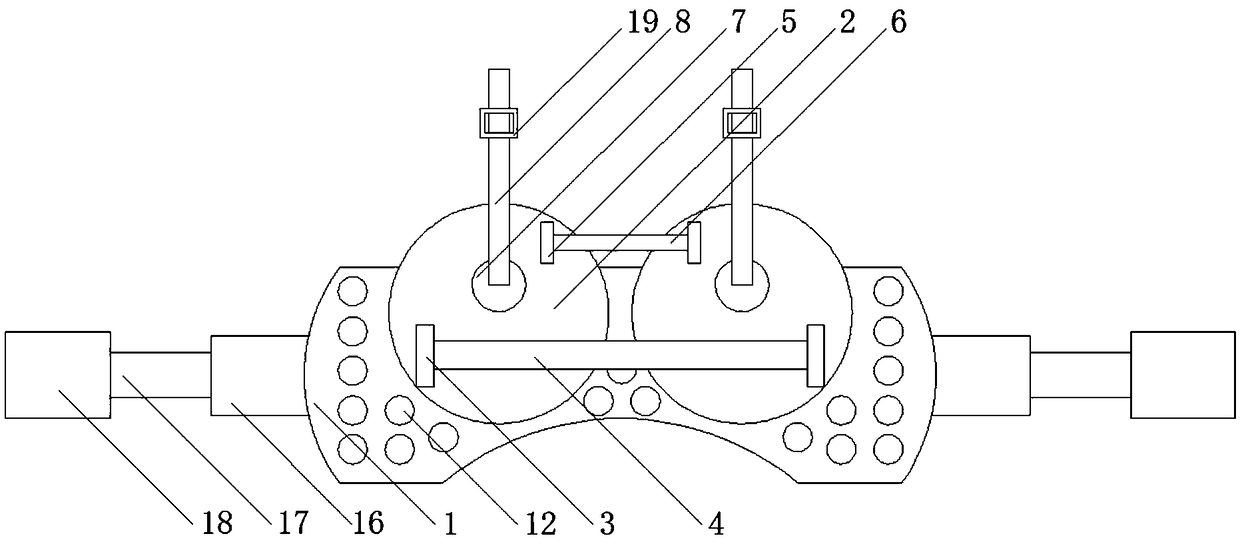

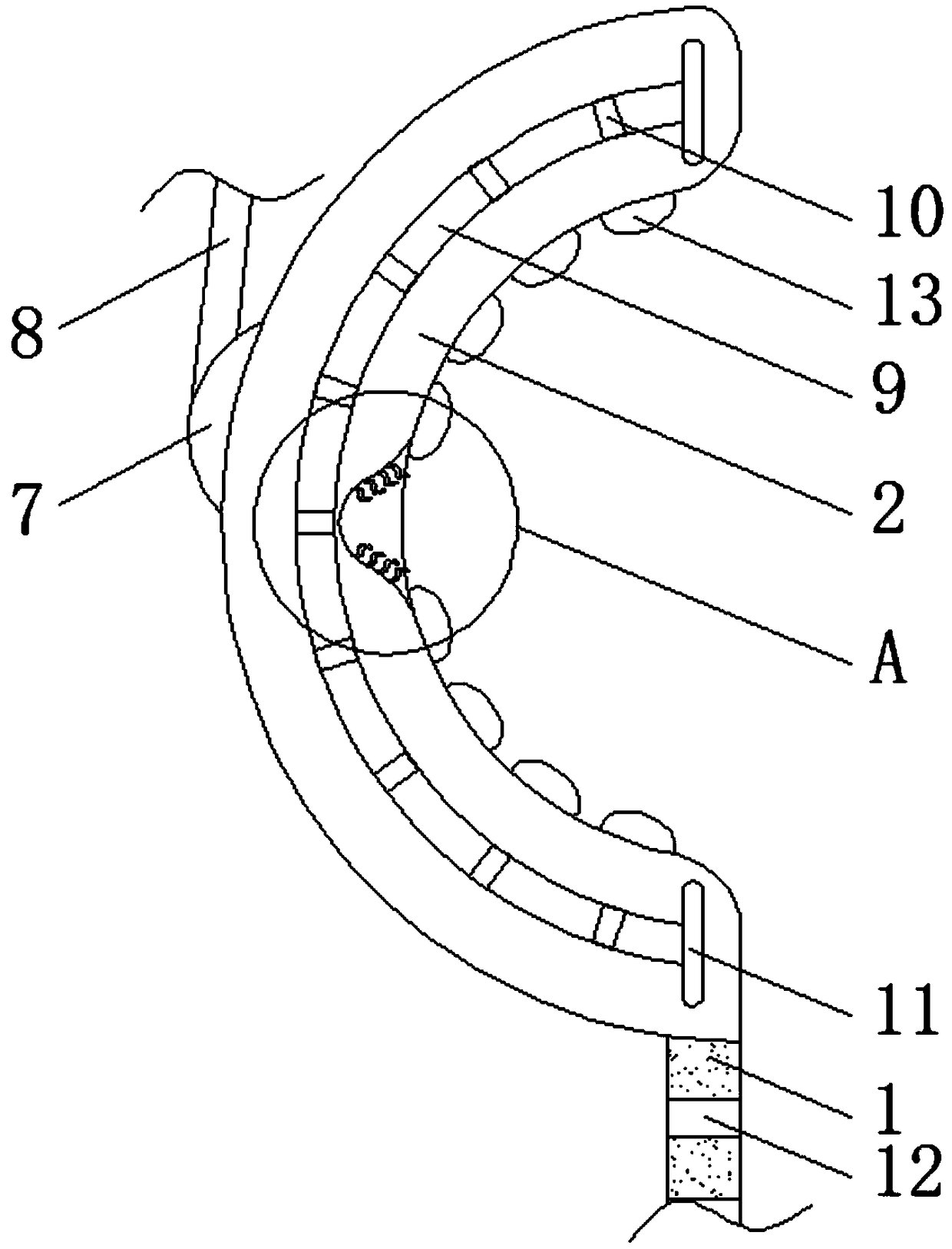

Suspension apparatus of ship main engine

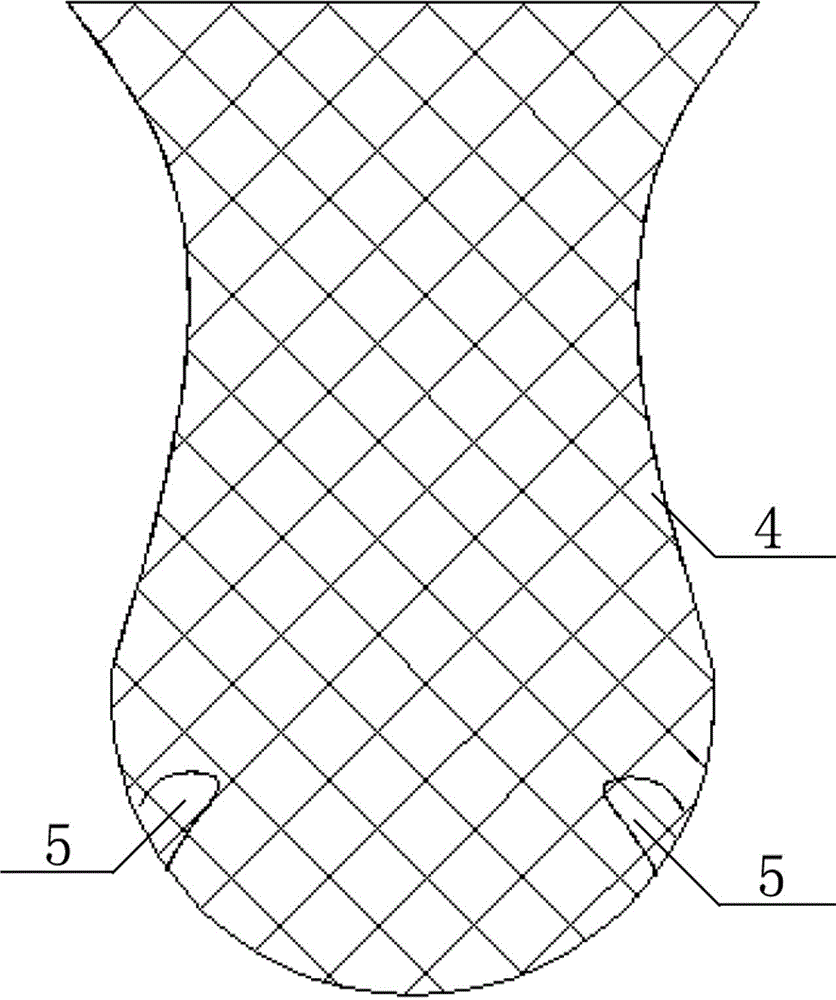

The invention relates to a suspension apparatus of a ship main engine. The suspension apparatus comprises wire ropes, and further comprises a suspension frame. A left end on the top of the suspension frame is connected with a first traction part through a first wire rope (111). A right end on the top of the suspension frame is connected with a second traction part through a second wire rope (211). A left end on the bottom of the suspension frame extends to a first suspension point (A) of a main engine (5) through a third wire rope (112). A right end on the bottom of the suspension frame extends to a fourth suspension point (D) of the main engine (5) through a fourth wire rope (212). A middle portion of the suspension frame is provided with space, wherein a middle wire rope passes through the middle portion of the suspension frame from top to bottom, and extends to a corresponding second suspension point (B) and a corresponding third suspension point (C) in the space. An upper end of the middle wire rope is connected with a third traction part. Compared to the prior art, the apparatus provided by the present invention has the following advantages that: the structure of the apparatus is simple; the pulley block is not required; the apparatus is easy to be used; the production cost of the apparatus is low; the suspension beam structure of the apparatus is solid and stable so as to provide longer service life.

Owner:ZHEJIANG ZHENGHE SHIPBUILDING

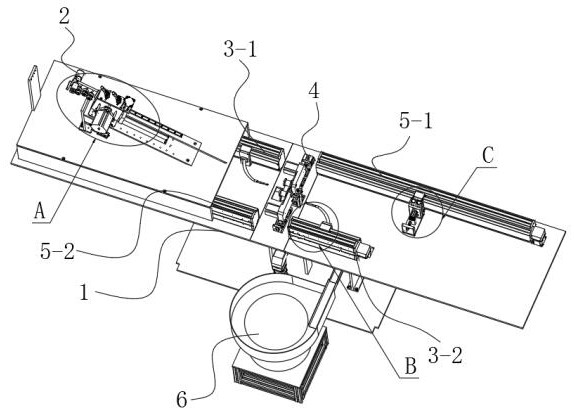

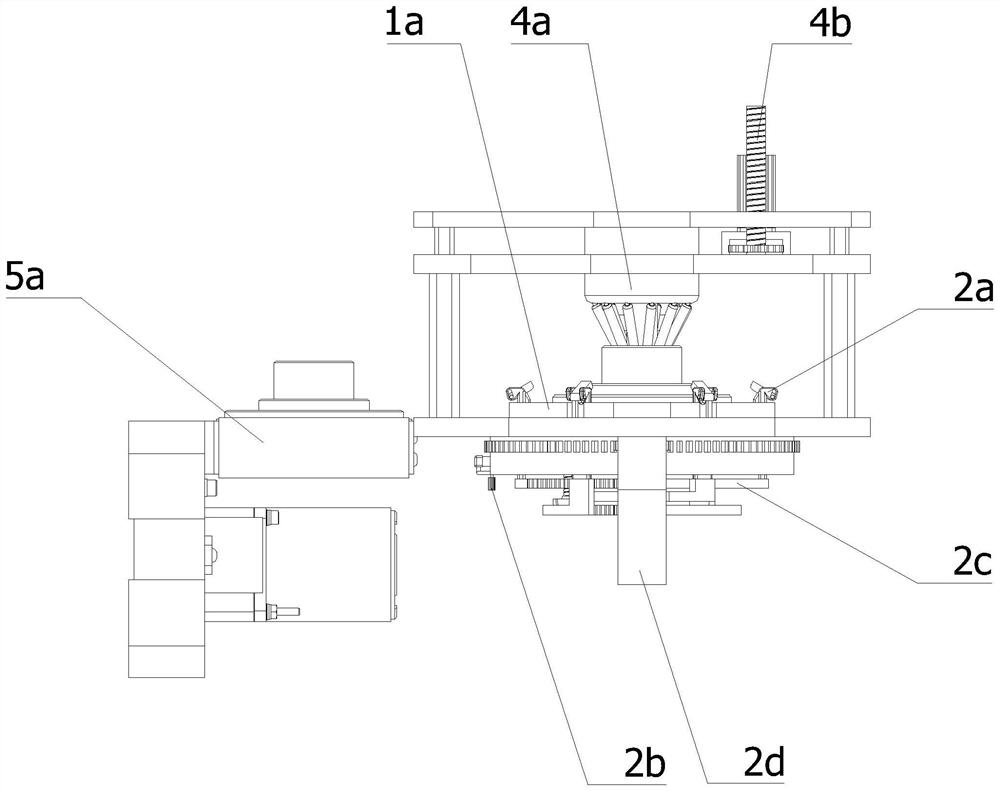

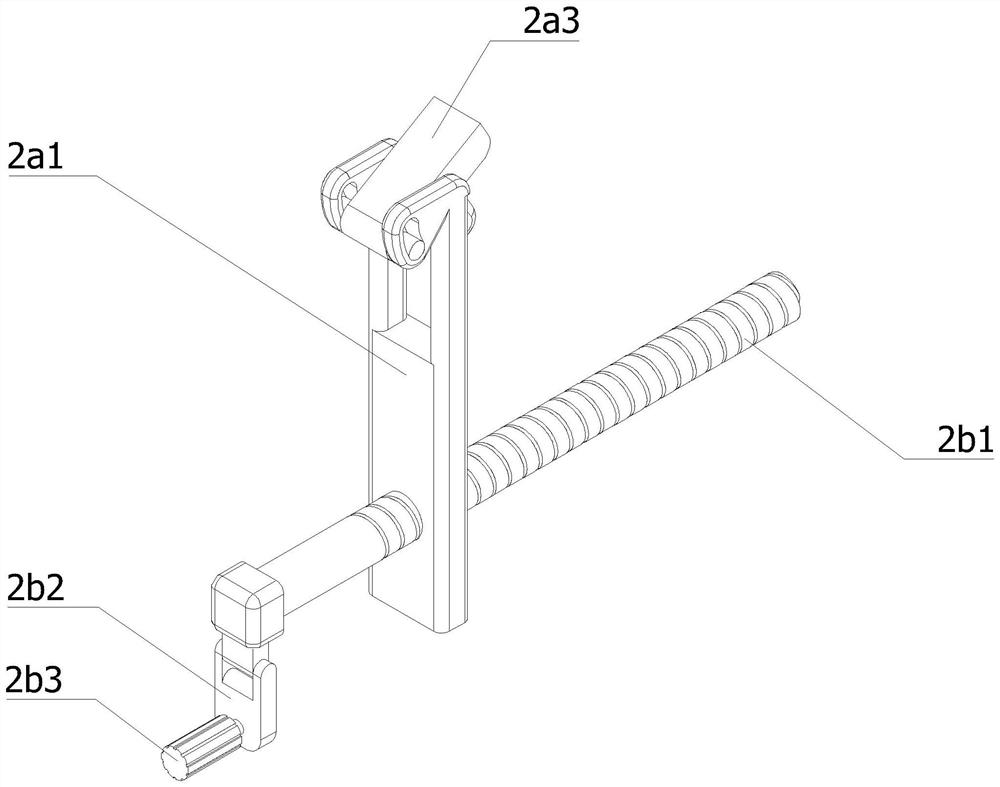

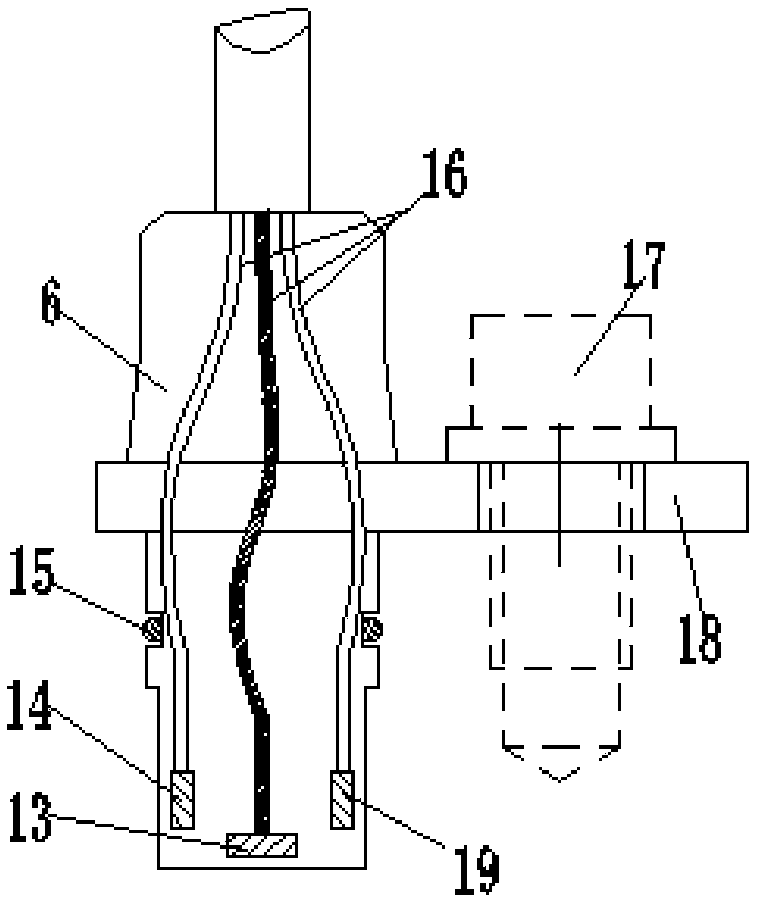

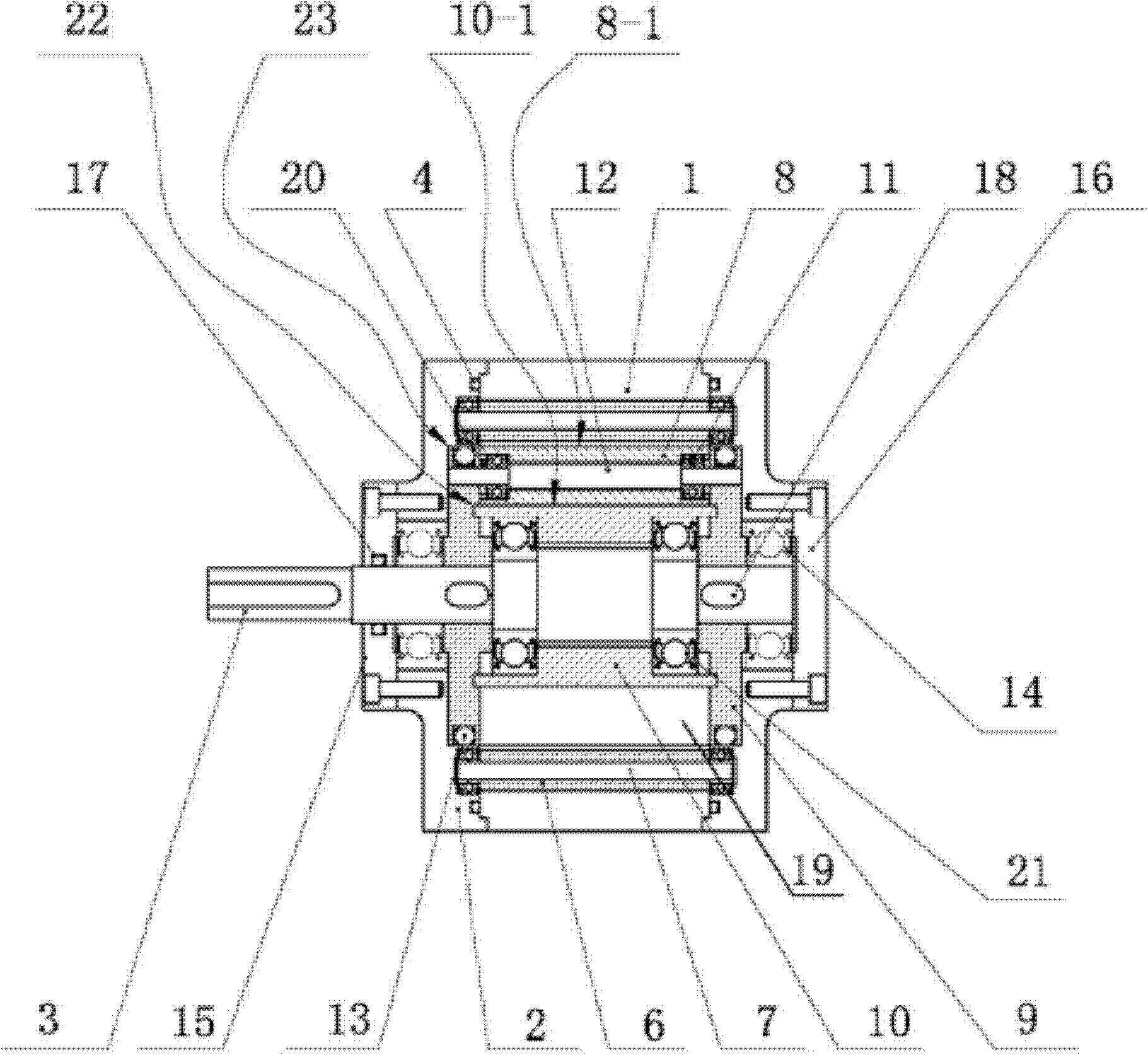

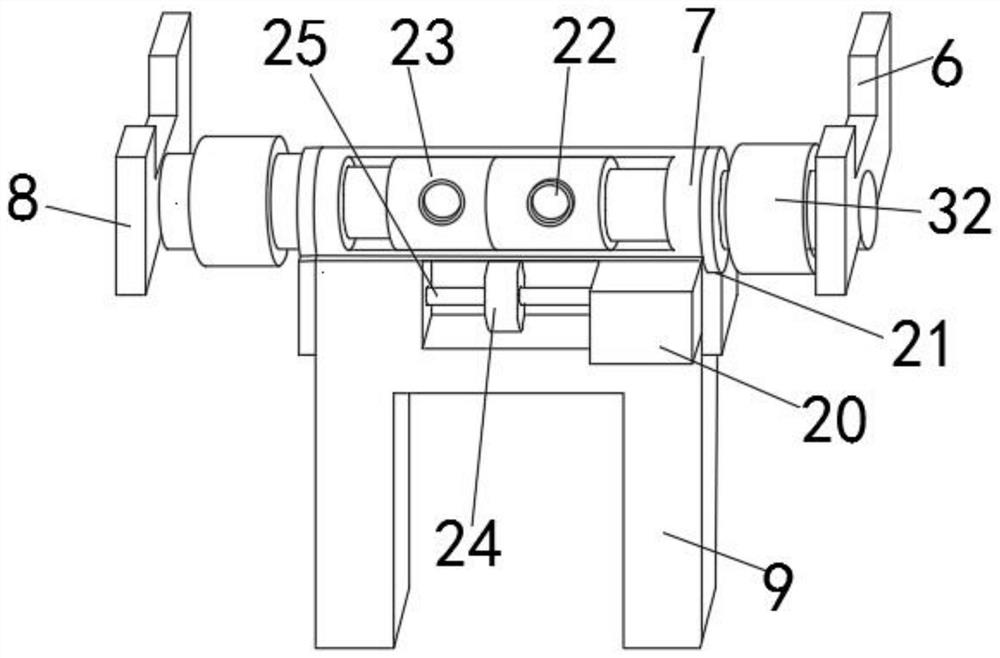

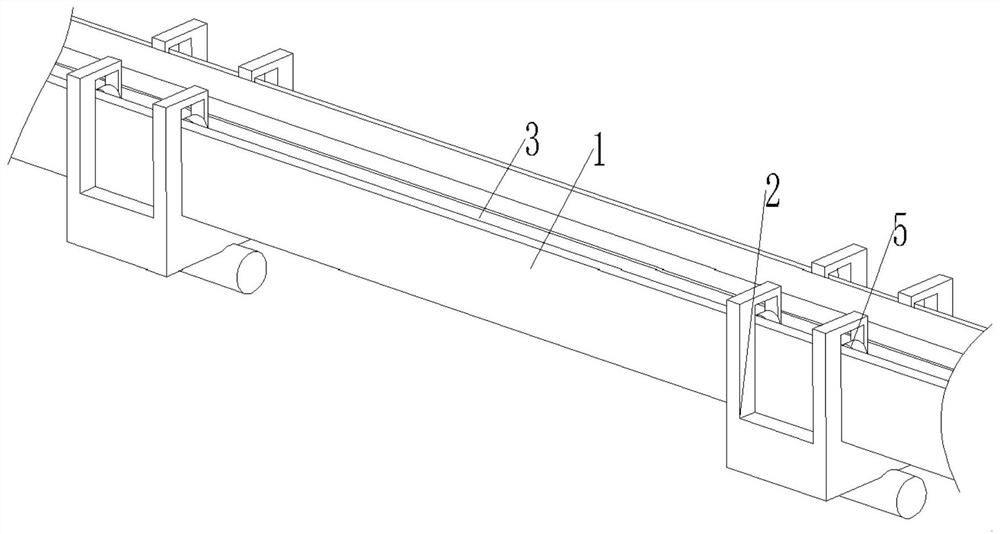

Full-automatic magnetic ring inductor winding machine capable of winding long wire

PendingCN111640574AIncrease the itineraryPrevent deformationCoils manufactureWinding machineInductor windings

The invention discloses a full-automatic magnetic ring inductor winding machine capable of winding a long wire. The full-automatic magnetic ring inductor winding machine comprises a winding machine body, wherein the surface of the winding machine body is fixedly connected with a first wire hooking mechanism, a second wire hooking mechanism, a magnetic ring clamping mechanism, a first range extending mechanism and a second range extending mechanism, and the first wire hooking mechanism, the second wire hooking mechanism, the first range extending mechanism and the second range extending mechanism are symmetrically distributed along the center line. The invention belongs to the technical field of automatic winding processing of magnetic ring inductors. According to the invention, a horizontal structure is adopted, so that a mode that a copper wire is hooked from the middle starting point can be realized, and wire hooking can be performed from left side and right side; and the copper wireis doubled in length through the range extending and wire hooking mechanism, the range extending and wire hooking mechanism uses a roller structure to hook the wire, and a sliding friction mode whena crochet hook is used for hooking the wire is changed into a rolling friction mode, so that the damage to an enameled insulating layer of an enameled copper wire is greatly reduced so as to achieve the full-automatic wire hooking of a long magnetic ring inductor wire.

Owner:黄日元

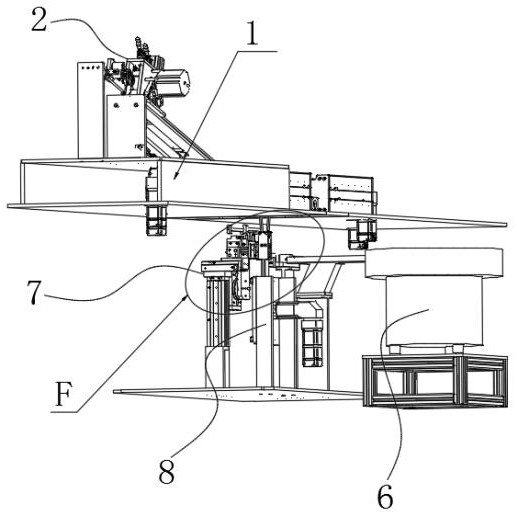

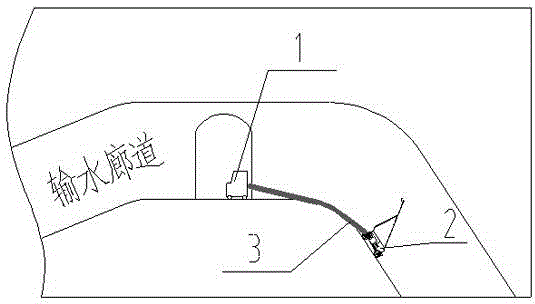

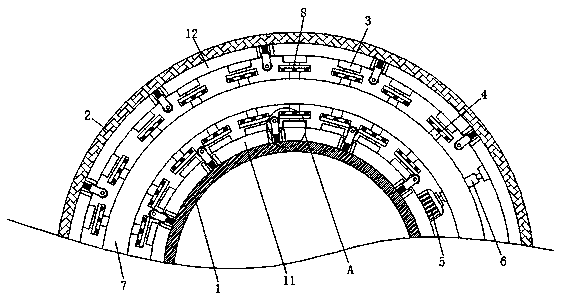

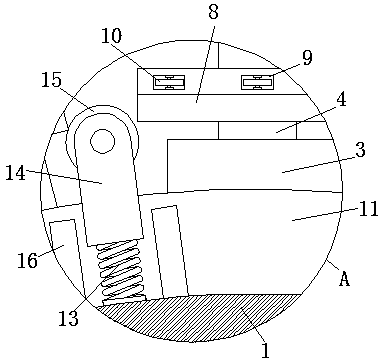

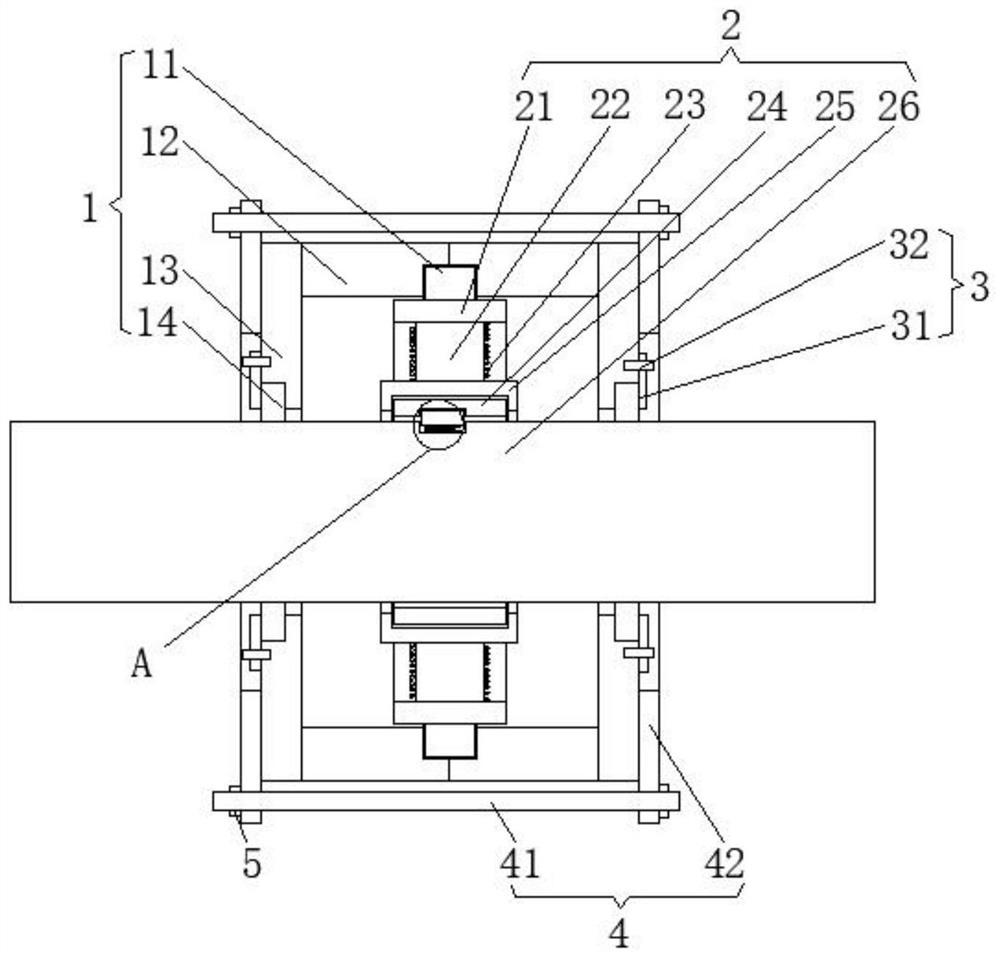

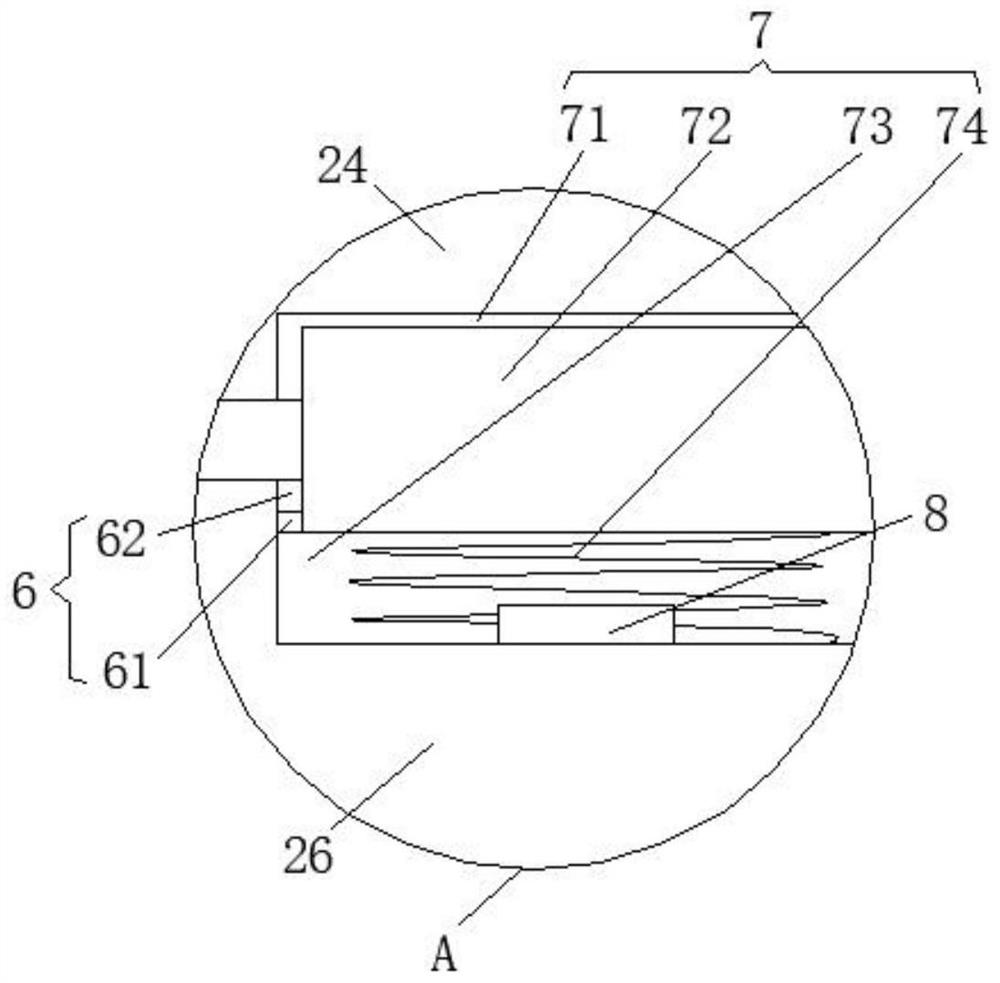

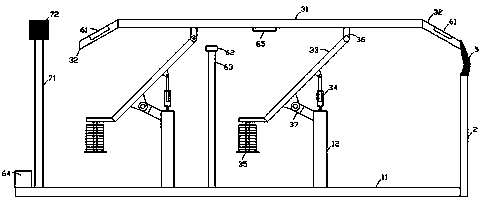

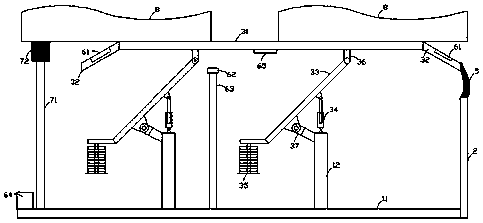

Rapid intelligent detection system and rapid intelligent detection method for inclined shaft section of water delivery gallery

ActiveCN104833680ADrive precisionMeet the requirements of quick maintenanceOptically investigating flaws/contaminationHigh definitionCommunication device

Disclosed are a rapid intelligent detection system and a rapid intelligent detection method for an inclined shaft section of a water delivery gallery. The system comprises an operating platform and a detection trolley. The operating platform is connected with the detection trolley through a cable. A ballast water tank is arranged on the operating platform. A high-definition infrared camera is arranged on the detection trolley and looks around and scans by 360 degrees along the vertical movement direction of the detection trolley, and data are transmitted outwardly by a wireless communication device. The method includes scanning a first profile of an inclined shaft of the water delivery gallery, positioning chromatic aberration of the first profile of the inclined shaft of the water delivery gallery, judging the first profile of the inclined shaft of the water delivery gallery, moving to and scanning a second profile of the inclined shaft of the water delivery gallery, positioning chromatic aberration of the second profile of the inclined shaft of the water delivery gallery, judging the second profile of the inclined shaft of the water delivery gallery, repeating the steps until moving to a Yth profile of the inclined shaft of the water delivery gallery, and completing scanning, chromatic aberration positioning and judging of the Yth profile. The rapid intelligent detection system and the rapid intelligent detection method have the advantages that defects of the profiles of the water delivery gallery of a ship lock can be recognized and positioned rapidly and accurately, so that the defects such as low manual detection efficiency and poor effect are overcome.

Owner:CHINA THREE GORGES CORPORATION +1

Alloyed steel horizontal type indirect extrusion machine

The invention discloses a horizontal reverse alloy steel extrusion machine, which belongs to the novel technical field of seamless steel pipe and relates to a seamless steel pipe manufacturing facility. The purpose is to settle the problems of complex process, inefficiency, high energy consumption and pollution of the environment with the prior domestic cold drawing techniques of small-bore seamless alloy steel tube. The machine consists of a rigid framework, a liquid-filled combined hydraulic cylinder and a die assembly, wherein, the rigid framework consists of an anterior fixed beam, a posterior fixed beam and an intermediate moving beam on the frame, which are connected in series by a four tensile columns; the liquid-filled combined hydraulic cylinder has a compact structure and is capable of executing the operations of die displacement, material feeding, perforation, extrusion and die removal; the die assembly consists of a perforation & extrusion & automatic switching system, a hot extrusion / molding system and a die removal & disengaging & residual extrusion & cutting system. The machine is capable of achieving once-and-for-all heating and once-and-for-all molding to directly produce finished products of small-bore seamless alloy steel pipes. Compared with forward extrusion, the deviations of the displacement of the piercing mandril and the dies are small, and no friction occurs between the billets and the internal wall of the container, thereby the machine can directly adopt continuous casting billets to extrude small-bore pipes, and has the advantages of simple process, high quality, high efficiency, low energy consumption, etc.

Owner:周家镳

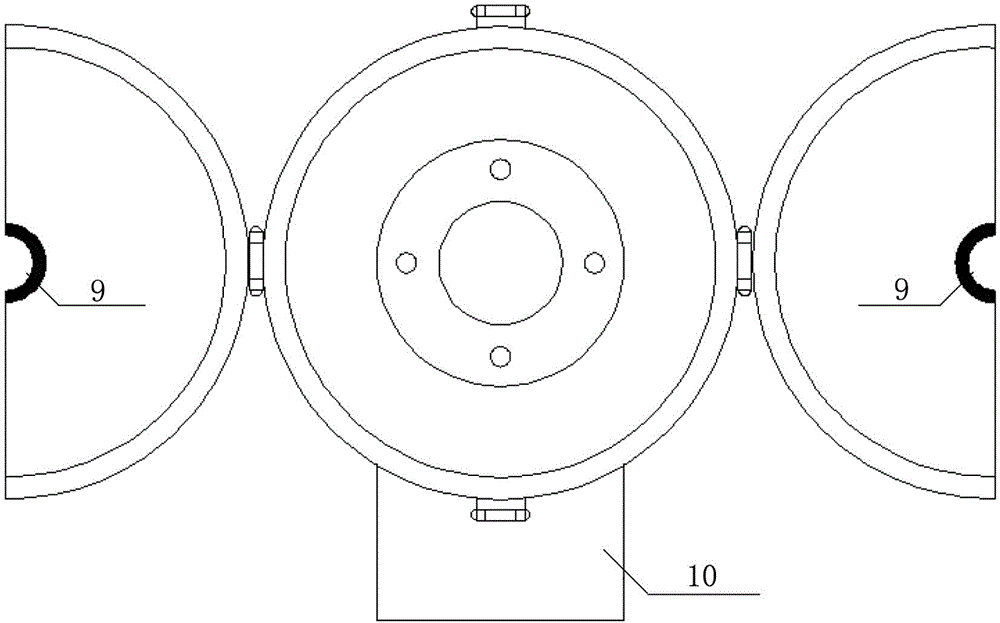

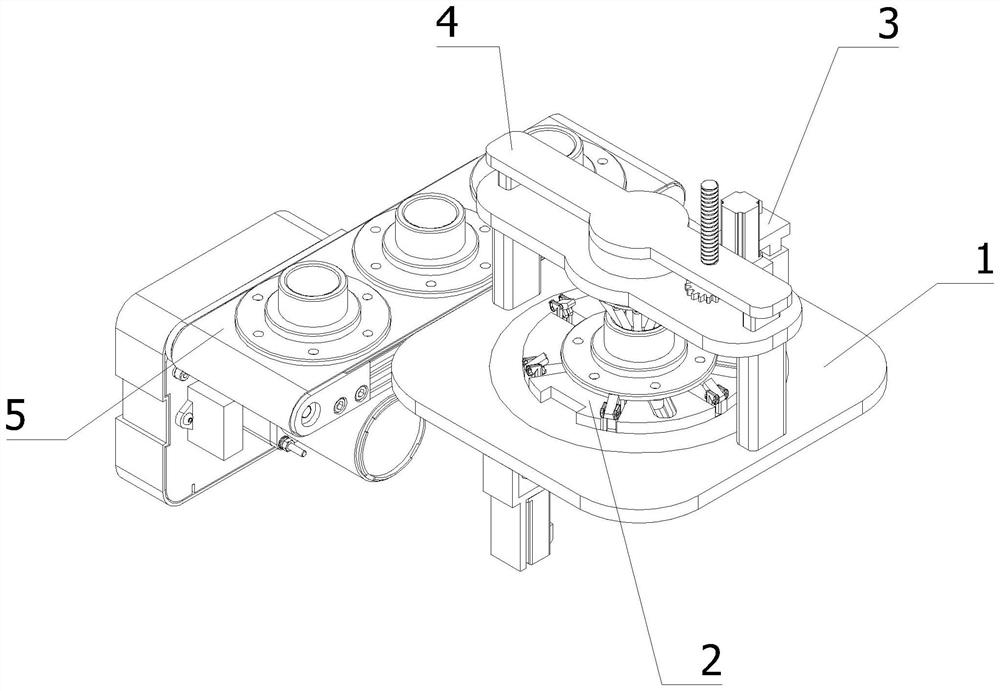

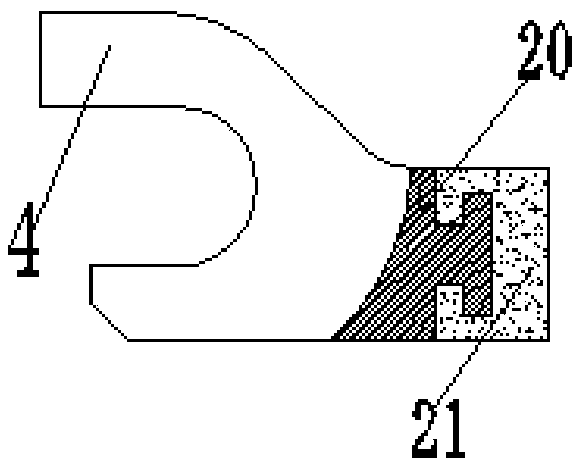

Deburring tool for new energy automobile air conditioner electromagnetic clutch hub machining

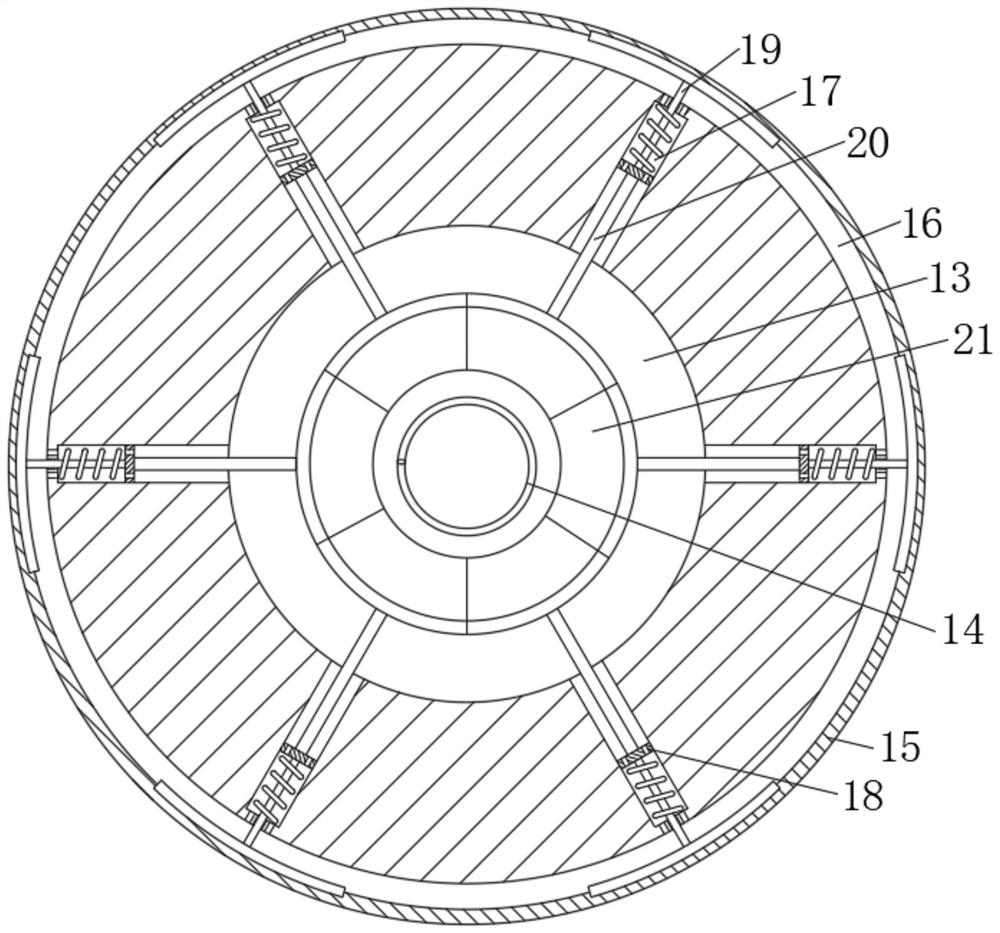

InactiveCN114770269AFast and stable fixationSolve technical problems of clampingEdge grinding machinesGrinding carriagesRotary stageElectromagnetic clutch

The invention relates to the field of automobile spare parts, in particular to a deburring tool for new energy automobile air conditioner electromagnetic clutch hub machining, which comprises a rack and a polishing assembly, and the polishing assembly is mounted on the rack; the rack comprises a rotating table, and a plurality of first sliding rails are arranged on the rotating table; the device further comprises a fixing device, the fixing device comprises clamping jaws and a linear driving assembly, the multiple clamping jaws correspond to the first sliding rails one to one, each clamping jaw comprises a first installation base, a fixing shaft, a chuck and a torsional spring, the first installation bases are installed on the first sliding rails in a sliding mode, the fixing shafts are fixedly arranged on the first installation bases, the chuck is rotatably connected to the fixing shafts in a sleeving mode, and the linear driving assembly is arranged on the linear driving assembly. The chuck is in an L shape, the torsional spring is fixedly installed on the fixing shaft, one end of the torsional spring is fixedly connected with the chuck, the linear driving assembly is fixedly installed on the rotating table, and the driving end of the linear driving assembly is in transmission connection with the first installation base. According to the hub deburring tool, the defects that an existing deburring tool is unstable in hub fixing or too complex in structure and too high in cost are overcome.

Owner:LISHUI UNIV

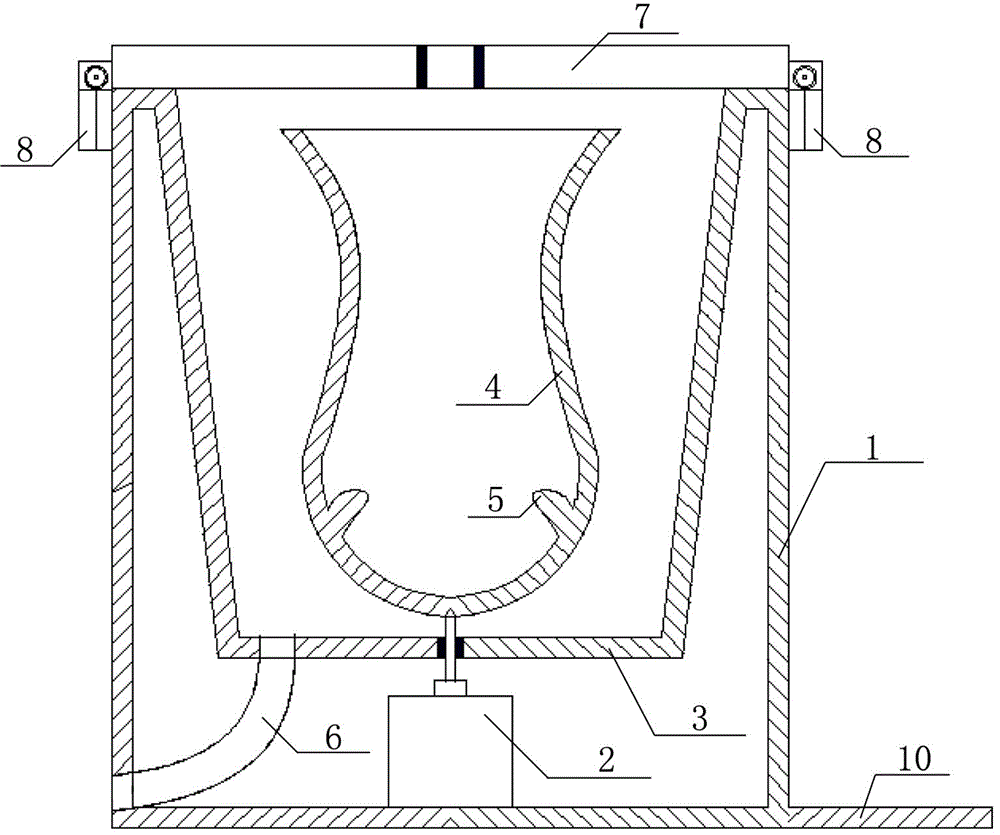

Integrated ABS sensor automobile hub bearing unit

PendingCN108608803ASignal output is precise and fastMonitor running statusHubsEngineeringCircular surface

The invention provides an integrated ABS sensor automobile hub bearing unit. The integrated ABS sensor automobile hub bearing unit is characterized in that an inner ring is fastened on the outer circle of the end part of an internal flange plate; a first raceway is arranged between the inner ring of and an external flange plate; a first magnetic cage is mounted in the first raceway; a first rolling body is mounted in a pocket of a first magnetic cage; an internal side sealing ring is arranged between the inner ring and the external flange plate; a second raceway is arranged between the external circular surface of the other end of the internal flange plate and the internal circular surface of the external flange plate; a second magnetic cage is mounted in the second raceway; a second rolling body is mounted in a pocket of a second magnetic cage; an external side sealing ring is arranged at root parts of the internal flange plate and the external flange plate; a gear ring is arranged ina position, between the first rolling body and the second rolling body, on the external circular surface of the internal flange plate; a three-chip ABS sensor is inserted in a circular through hole formed in the middle part of the external flange plate; and a three-chip ABS sensor fixing ring is fixed on the external flange plate by using an internal hexagonal bolt.

Owner:HUBEI NEW TORCH SCIENCE & TECHNOLOGY CO LTD

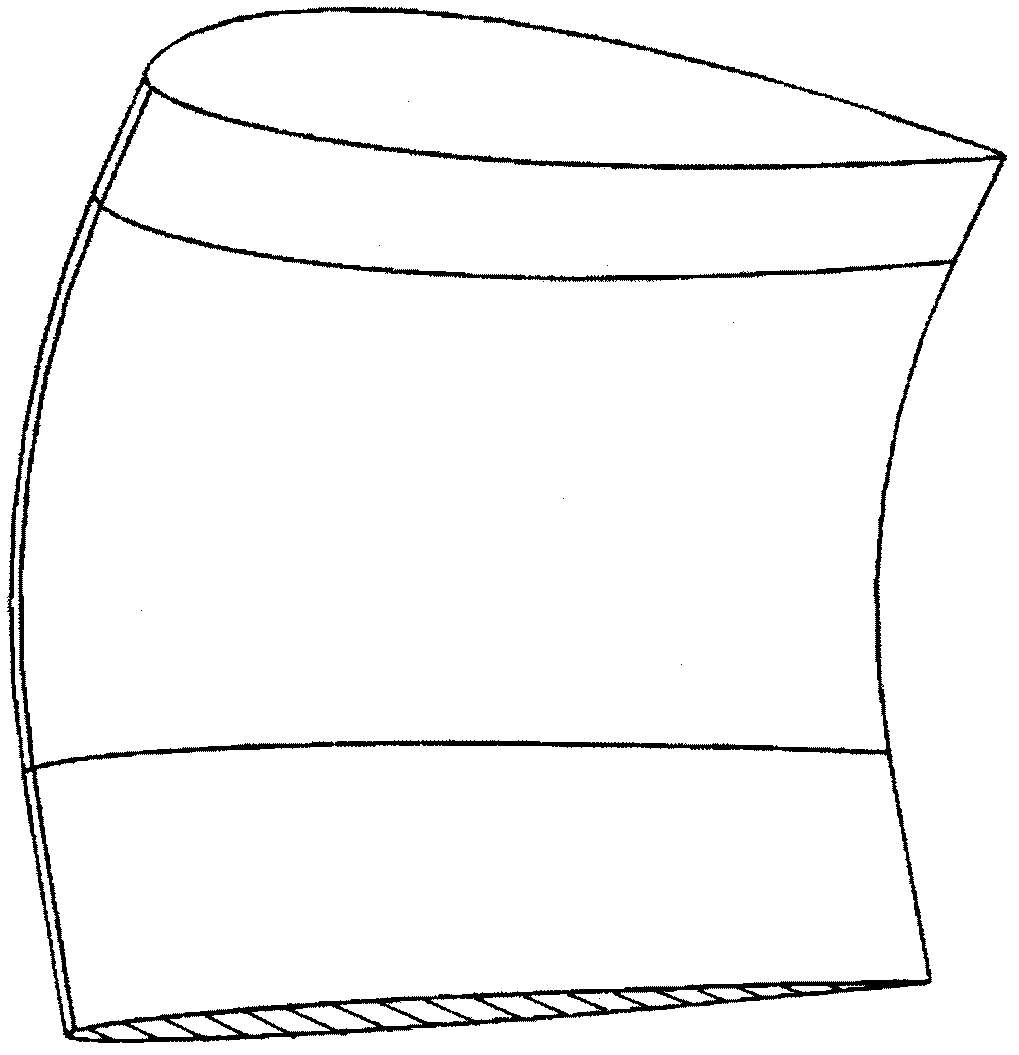

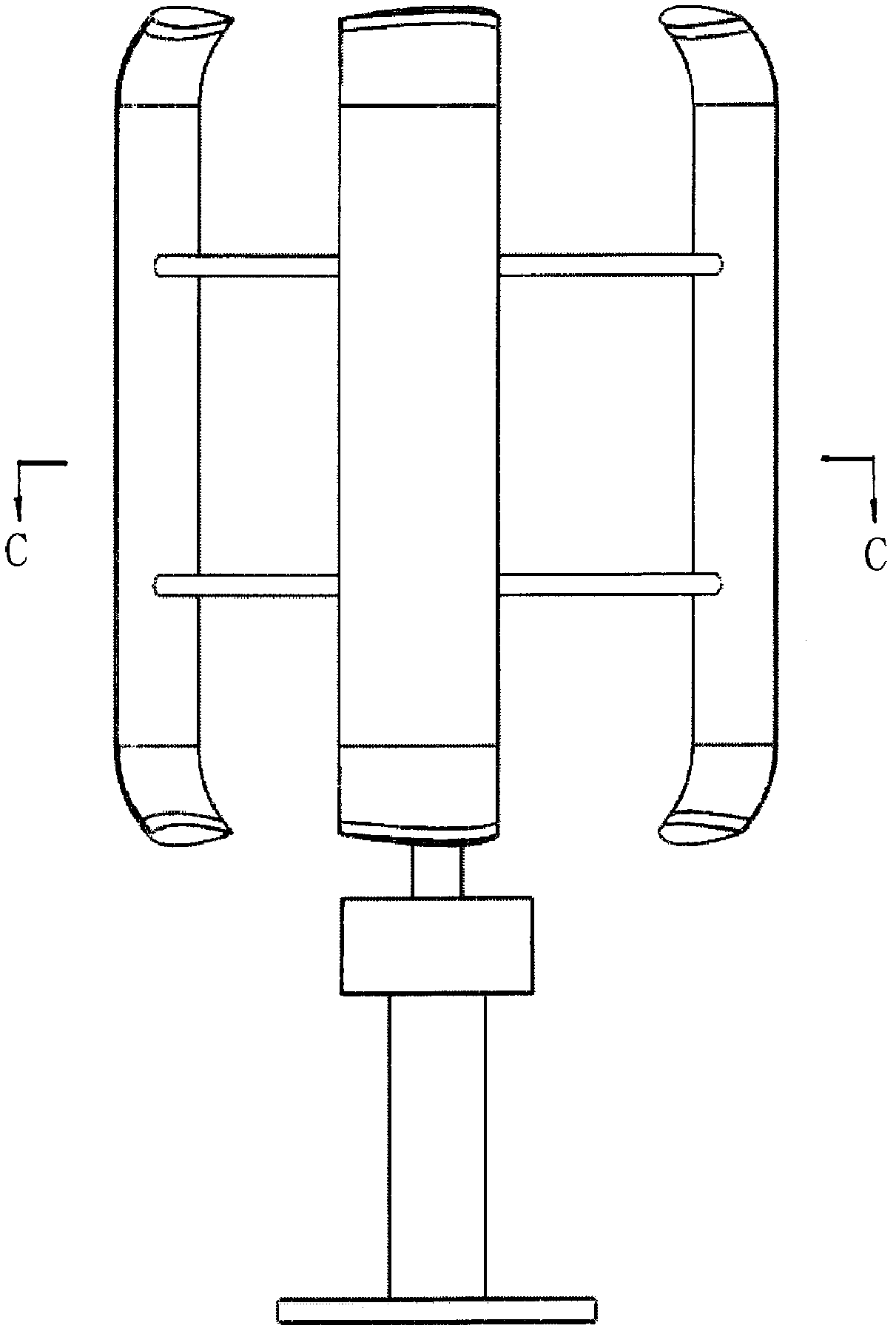

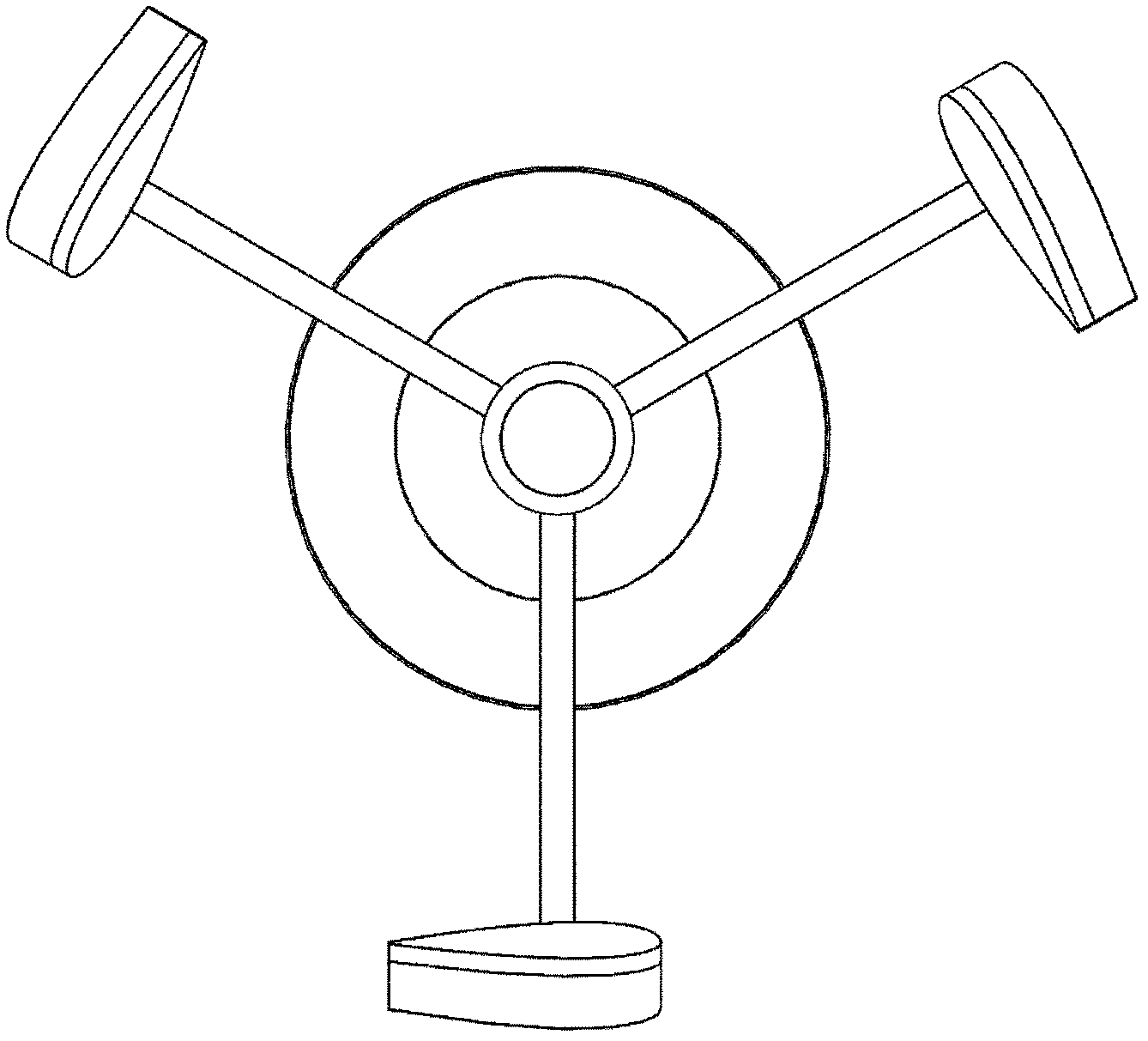

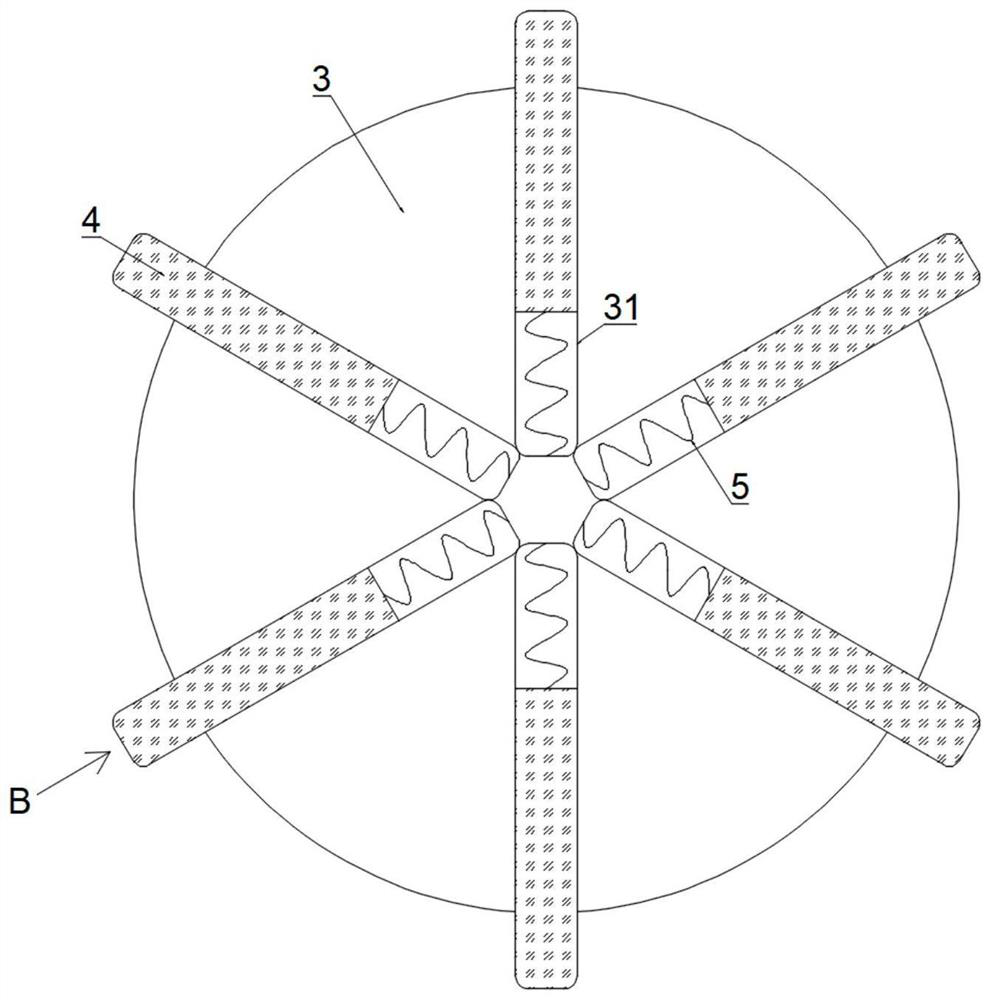

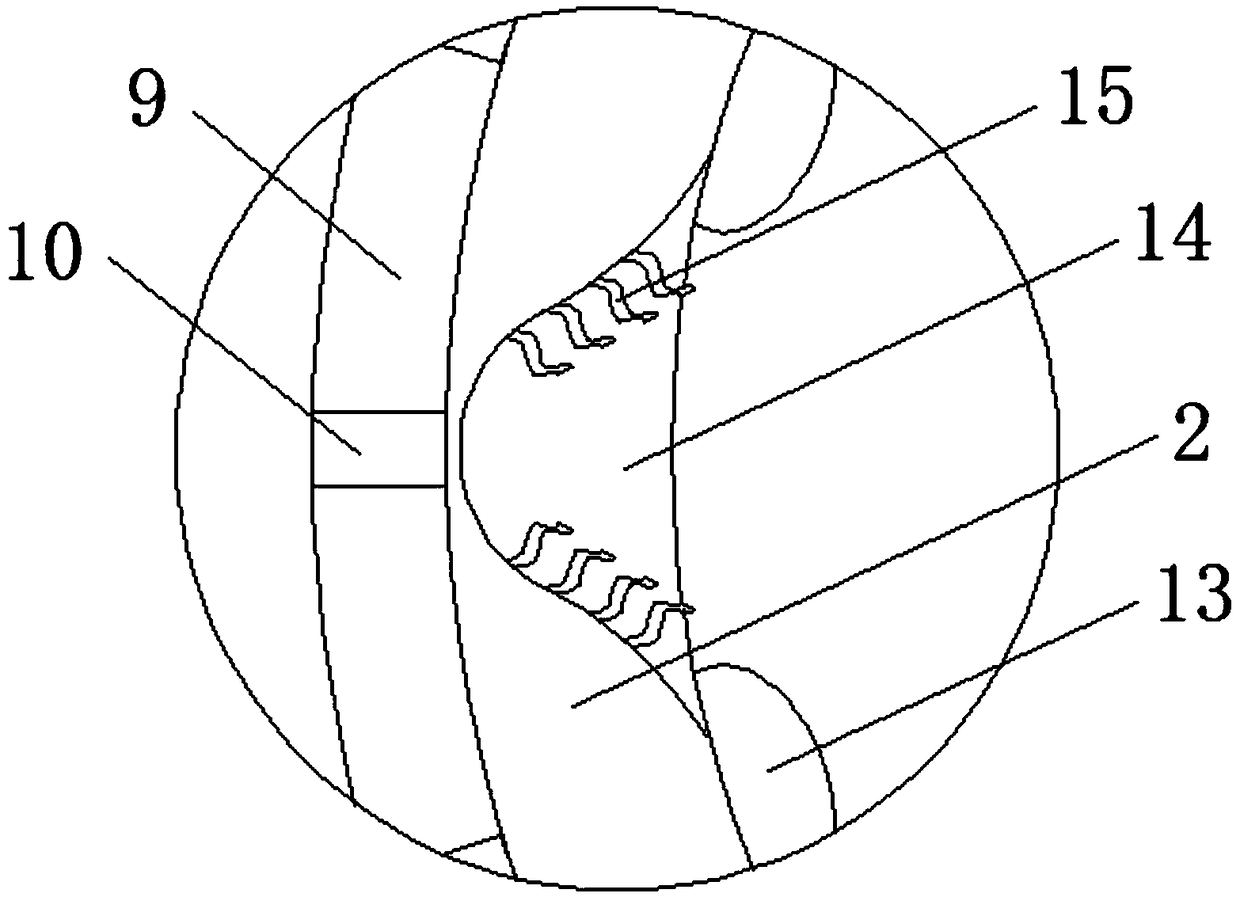

Blade and impeller of vertical shaft wind driven generator

InactiveCN102619697AAvoid violent frictionAvoid cutting actionMachines/enginesRenewable energy generationImpellerWind driven

The invention relates to a vertical shaft wind driven generator, in particular to a blade and an impeller which are capable of improving the efficiency of the vertical shaft wind driven generator and running stably without noise. The blade of the vertical shaft wind driven generator consists of a main wing and auxiliary wings, wherein the cross section of the blade is wing-shaped, and the auxiliary wings are bent towards a wheel axle, are arranged in vertical symmetry and are connected with a main wing section to form the blade. According to the blade with a bent structure and the impeller consisting of the blade, when the blade rotates around the center line of the wheel axle, an auxiliary wing section can reduce the loss of swirling airflow of the blade, so that the efficiency of the wind driven generator is improved; the rotation moment of the blade can be increased, and low-wind-speed start and operation of the impeller are realized; and the bending stress of the blade can be reduced, the blade is lighter, the rotating speed of the blade is higher, and the operation stability of the impeller is enhanced. The blade has a streamline shape, so intense friction and cutting with the airflow are avoided, and the noise of the wind driven generator can be eliminated.

Owner:赵立华

Electric control type polishing device with adjustable polishing radius

InactiveCN112792715AImprove polishing efficiencyIncrease polishing radiusPolishing machinesGrinding drivesPolishingElectric machinery

The invention discloses an electric control type polishing device with an adjustable polishing radius, and relates to the technical field of polishing devices.The electric control type polishing device comprises a fixing frame, wherein a driving motor is mounted on the top of the fixing frame, an output end of the driving motor is coaxially and fixedly connected with a control block, a rotating speed sensor is mounted at the output end of the driving motor, the control block is rotatably connected to the bottom of the fixing frame, a plurality of narrow-opening sliding grooves are formed in the bottom of the control block in a radial mode, and the ends, far away from the control block, of the narrow-opening sliding grooves penetrate through the control block and are internally connected with sliding blocks in a sliding mode. When a large plane of a workpiece is polished, the rotating speed of the output end of the driving motor is increased to drive the control block to rotate at a high speed, the sliding blocks connected to the control block in a sliding mode control part of an elastic force of a spring under a centrifugal effect, and the sliding blocks slide outwards along the narrow-opening sliding grooves in the control block, so that a polishing radius of each sliding block is increased, and the polishing range is enlarged, and meanwhile, the polishing efficiency to the surface of the workpiece is doubly improved in a high rotating speed state.

Owner:杭州永智信息科技有限公司

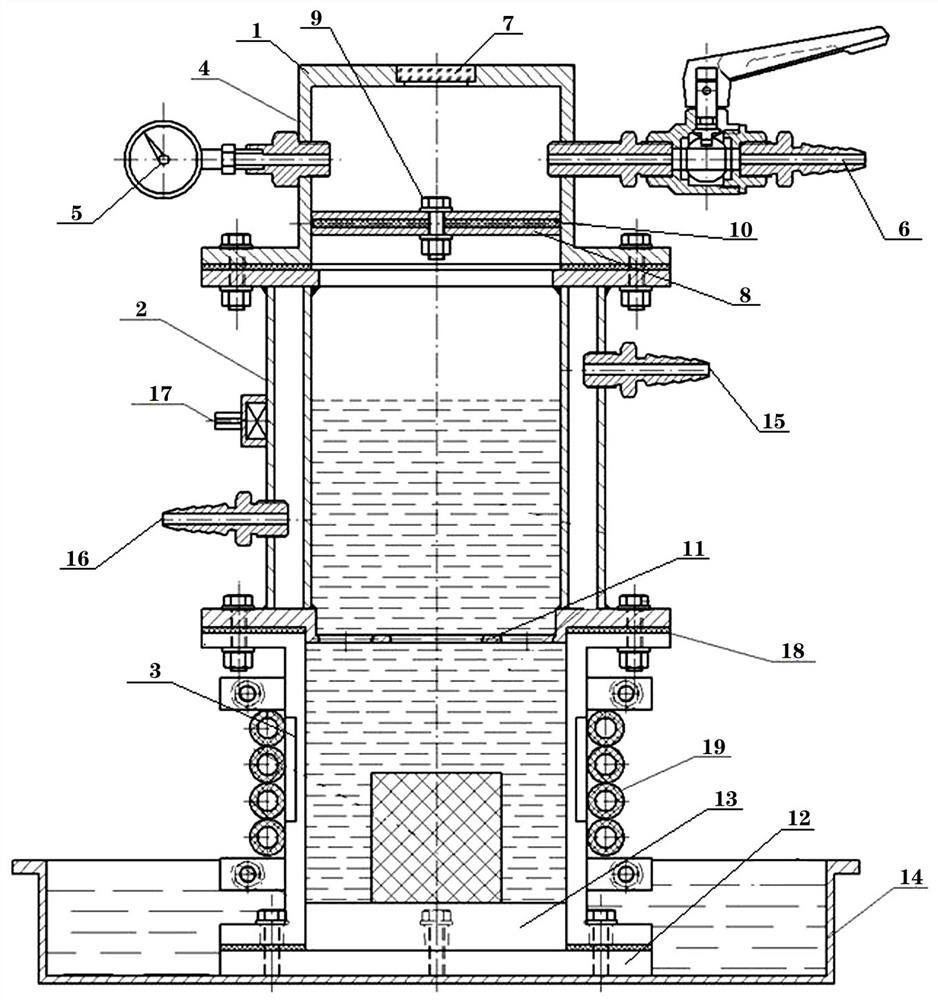

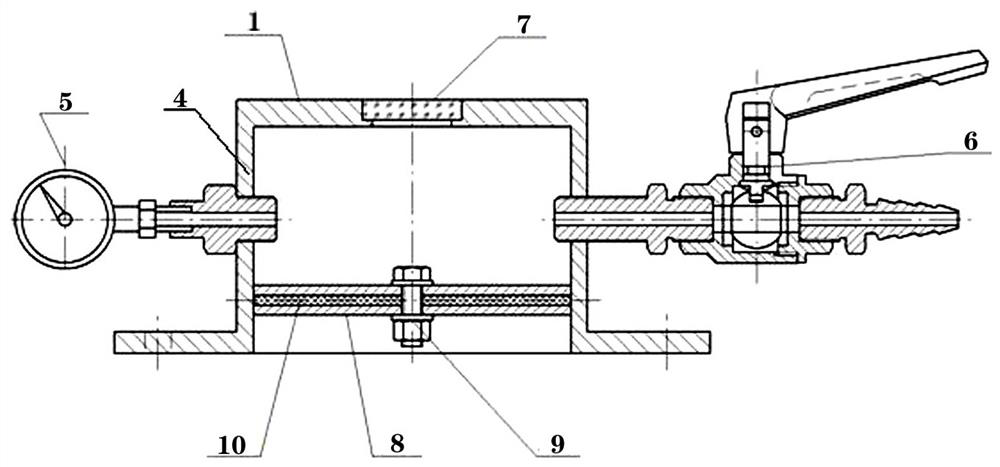

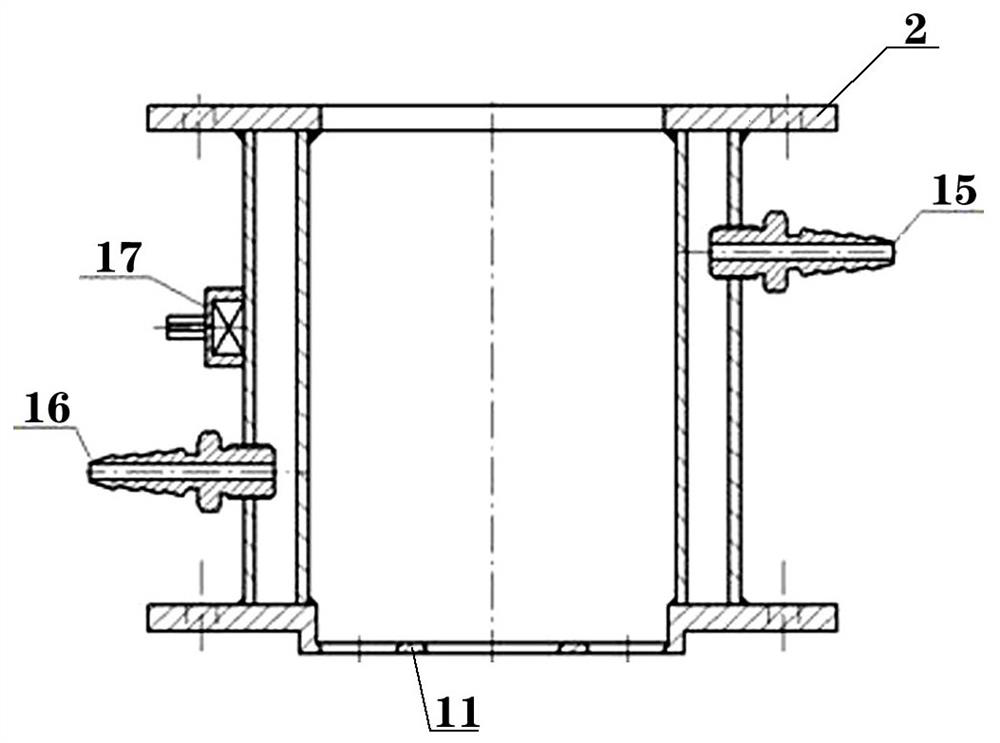

Novel processing device and processing technology for preparing grain through composite casting

PendingCN114195604AHigh densityQuality improvementNitroglycerine explosive compositionsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsExplosive AgentsEngineering

The processing device comprises an inflation pressurization assembly, a riser funnel and a grain forming mold, the inflation pressurization assembly is composed of an air storage tank, a pressure gauge and an air valve, an observation window is formed in the top of the air storage tank, the pressure gauge is arranged on the side wall of one side of the air storage tank, and the air valve is arranged on the side wall of the other side of the air storage tank. And an air valve is arranged on the side wall of the other symmetrical side. The device has the advantages that the safety degree is high in the slurry mixing process, the mixing uniformity is good, the grain density is high, the charging defects such as coarse crystals, shrinkage cavities, air holes and cracks in the grain forming process are avoided, the grain quality is good, the production efficiency is high, the application range is wide, grains with the diameters ranging from 50 mm to 500 mm can be manufactured, and the production cost is low. Fine, safe and efficient preparation of the high-solid-content and high-density fused cast explosive column is achieved, the process technical problem that the mixing safety of high-viscosity and high-energy fused cast explosives and the casting forming quality of the explosive column are affected is solved, and the charging requirement of a conventional efficient damaged ammunition warhead is met.

Owner:HENAN NORTHERN HONGYANG ELECTROMECHANICAL CO LTD

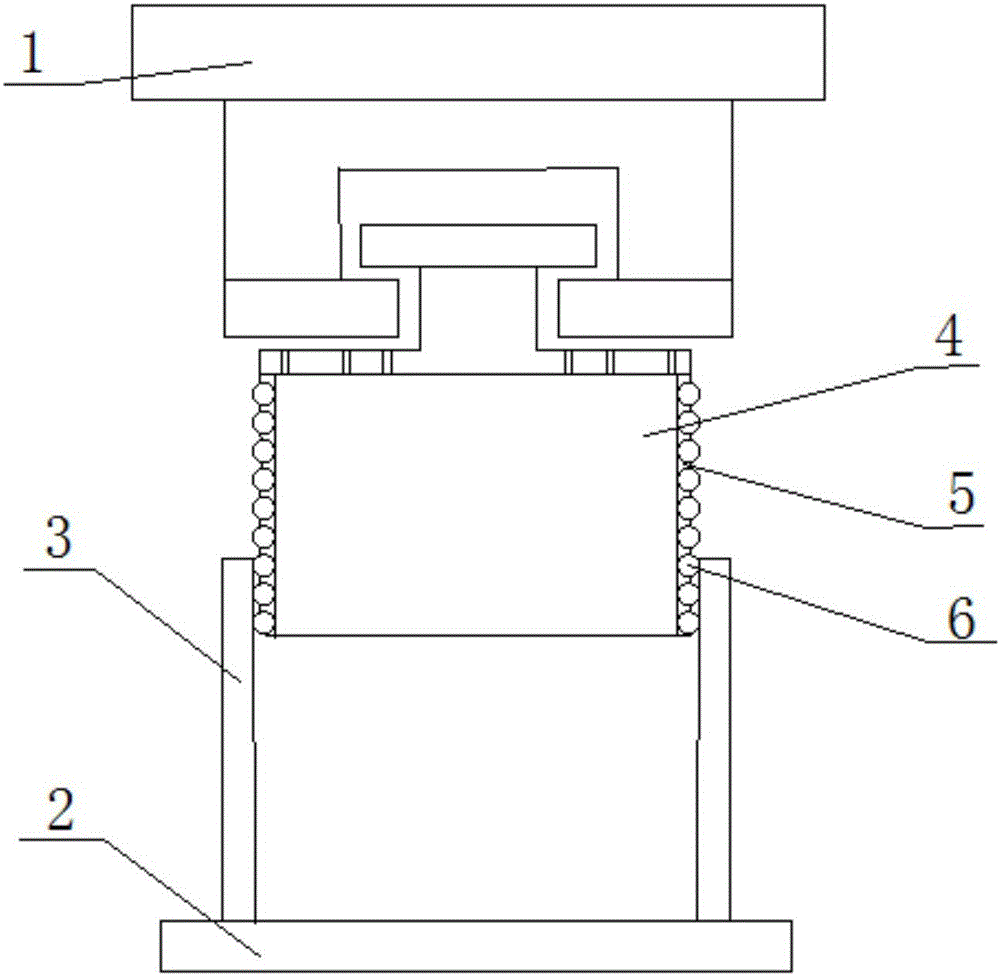

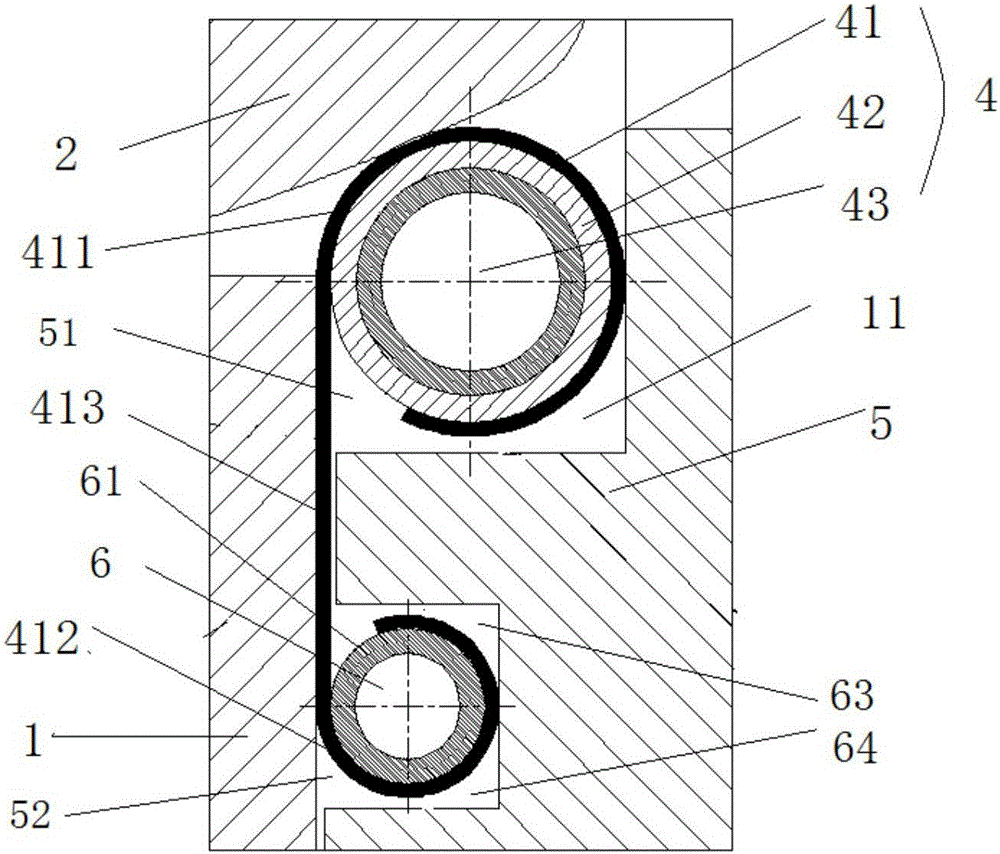

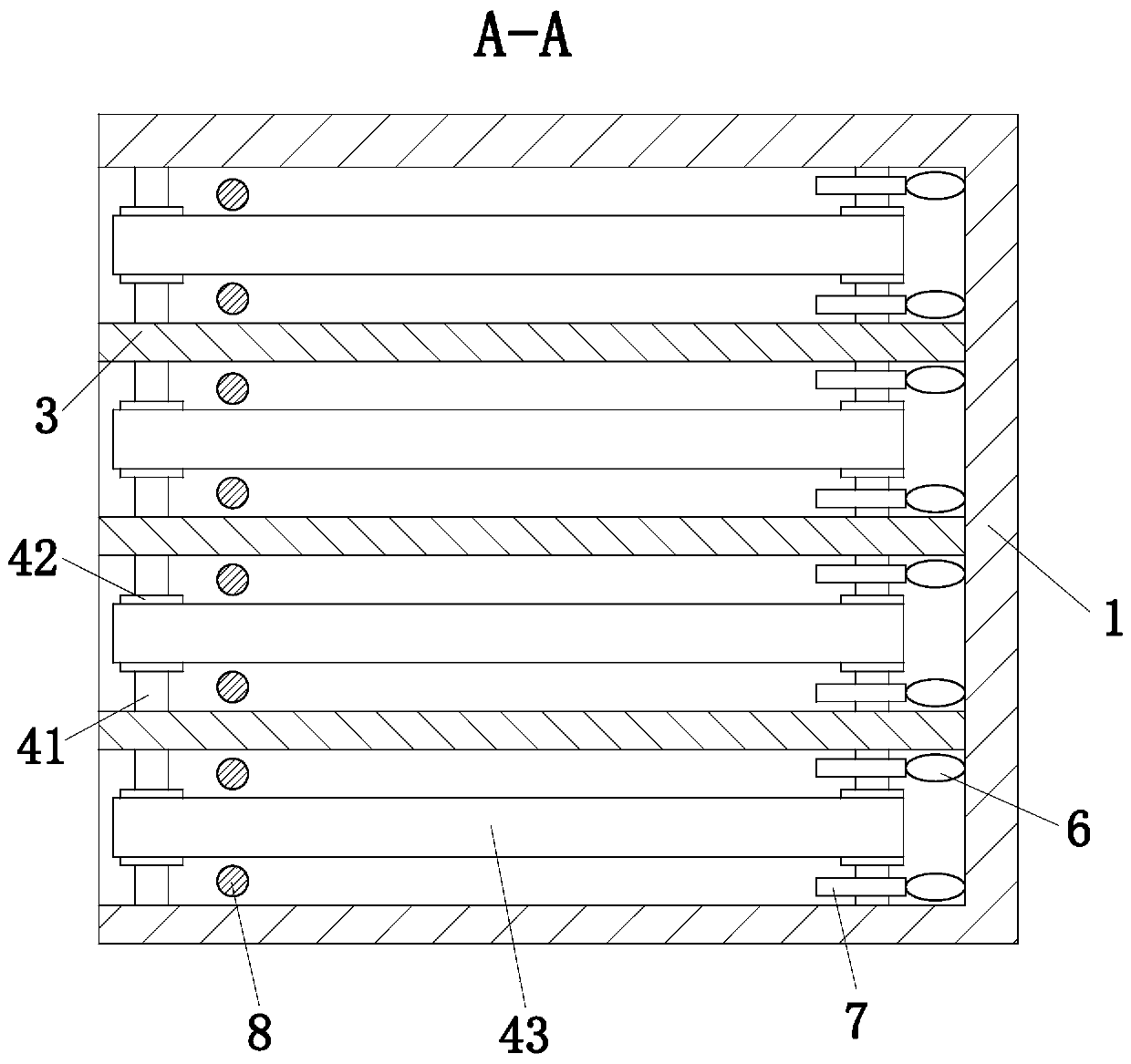

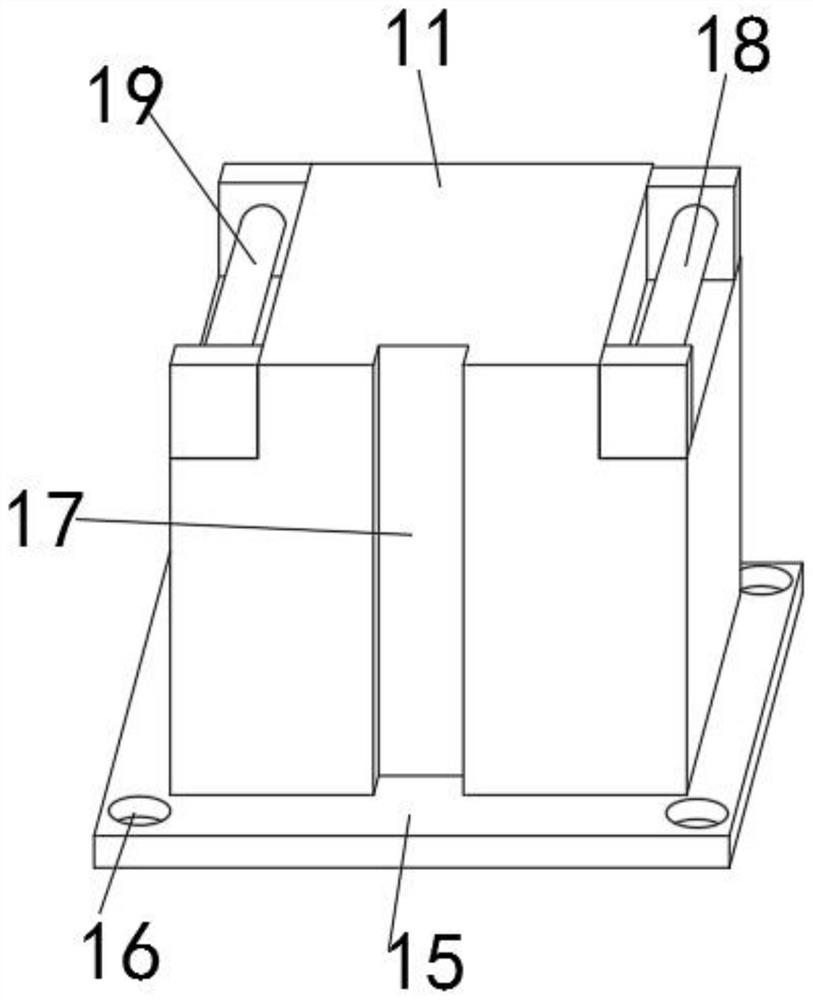

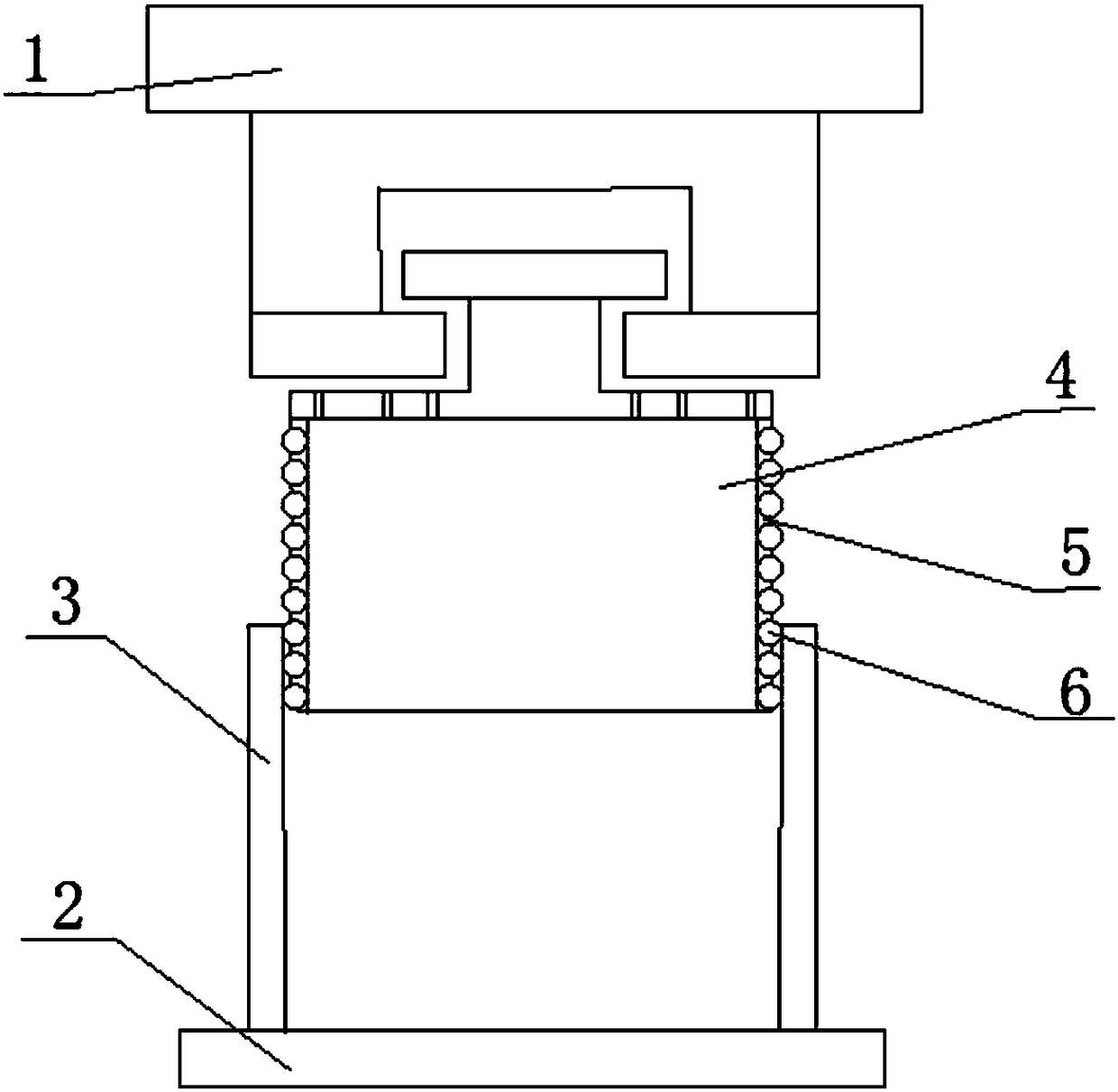

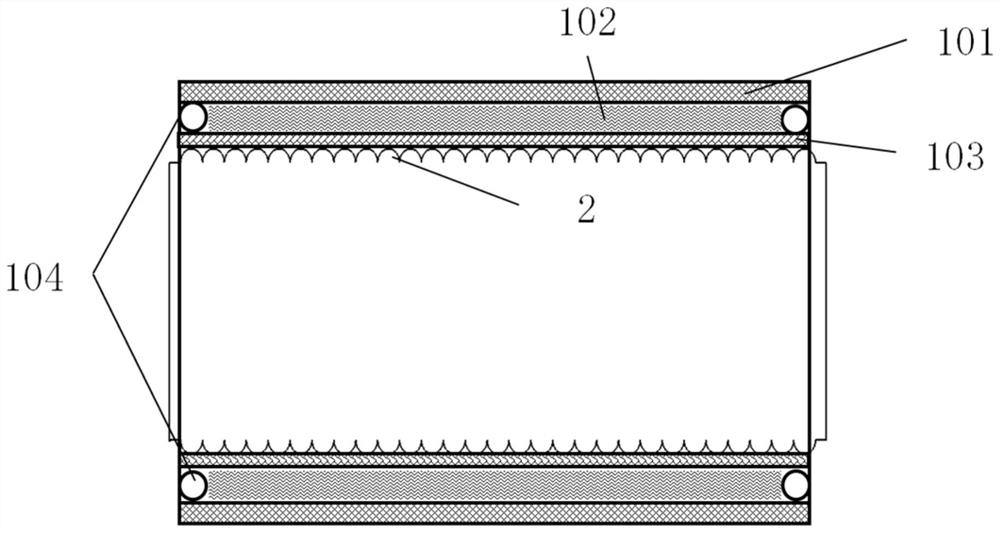

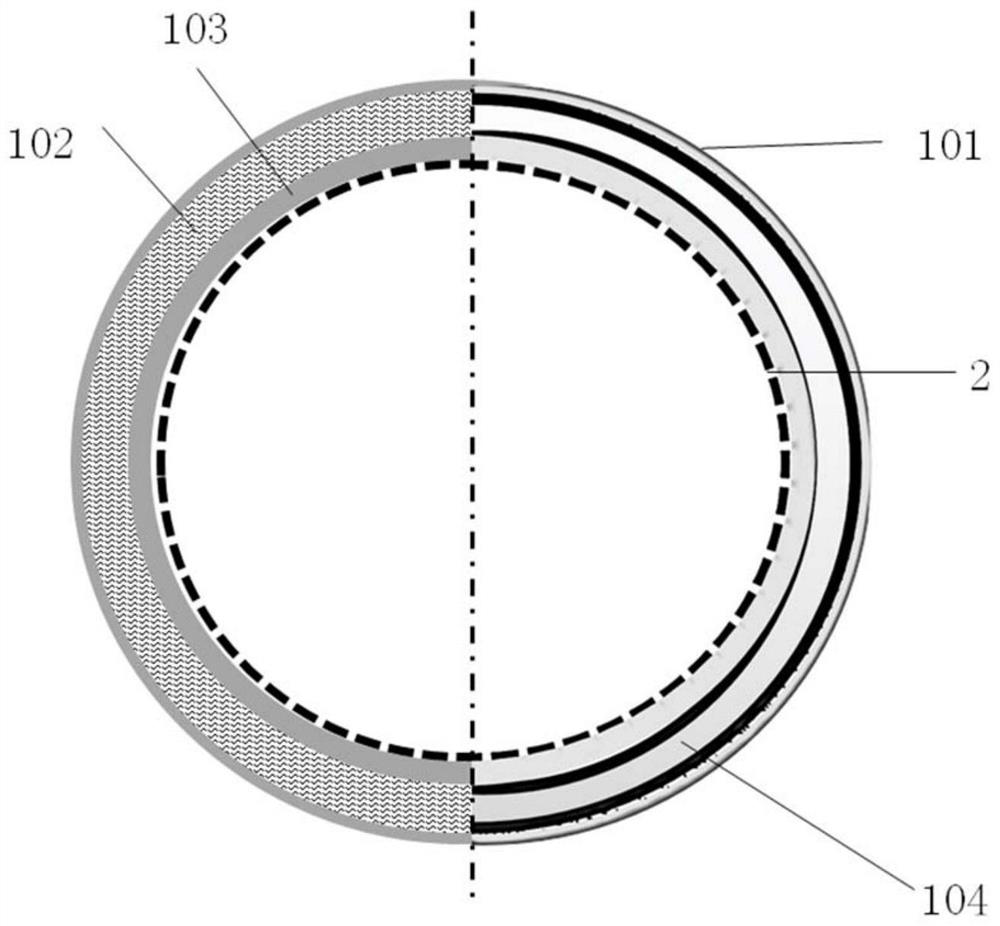

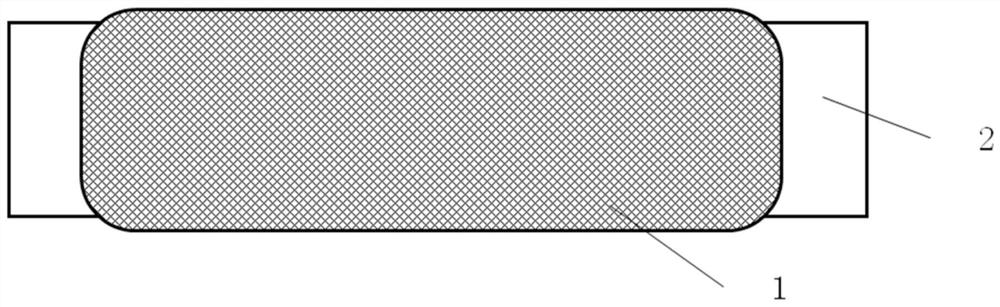

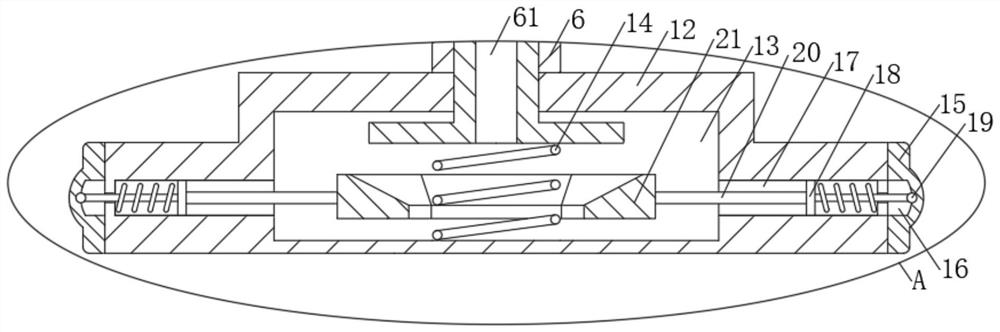

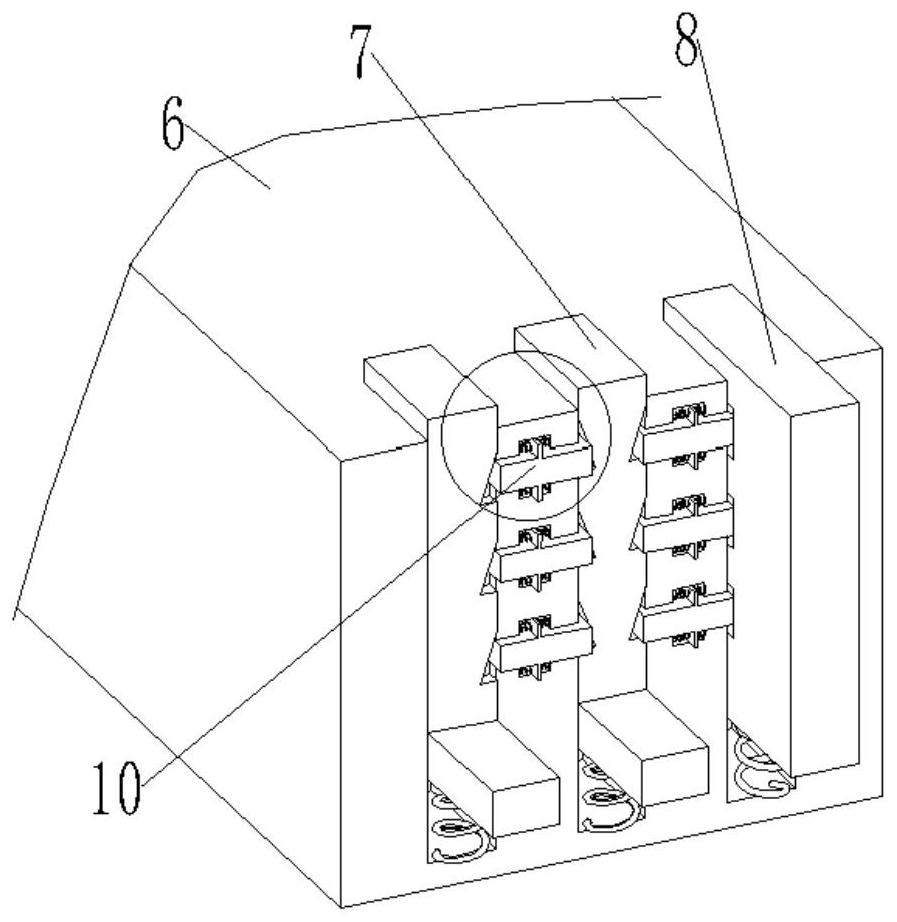

Mould device

The invention discloses a mould device. The mould device comprises an upper mould plate and a lower mould plate, and further comprises a lower mould cylinder, an upper mould cylinder and a copper sleeve, wherein the lower mould cylinder is fixedly connected with the lower mould plate; a first through hole is formed in the middle of the lower mould cylinder; the upper mould cylinder is fixedly connected with the upper mould plate and can slide in the first through hole; the copper sleeve detachably sleeves the outer side wall of the upper mould cylinder; a plurality of second through holes of which the axes are perpendicular to the axis of the copper sleeve are formed in the side wall of the copper sleeve; balls capable of rolling in the second through holes are arranged in all the second through holes; and the diameter of each ball is greater than the thickness of the side wall of the copper sleeve. The mould device provided by the invention has the advantages that when the upper mould cylinder slides in the lower mould cylinder, the friction between the balls, namely steel balls, and the upper mould cylinder, the friction between the steel balls and the lower mould cylinder, as well as the friction between the upper mould cylinder and the lower mould cylinder can be reduced because a plurality of the balls capable of rolling are arranged on the side wall of the copper sleeve; and when relatively serious abrasion is caused by the balls, only the balls need to be replaced, that is, the upper mould cylinder needs not be replaced, so that the maintenance efficiency is improved and the maintenance cost is reduced.

Owner:CHONGQING QILONG IND & TRADE CO LTD

Water-based ink printing press capable of changing printing area

ActiveCN112937092AIncrease temperatureImprove printing efficiencyRotary pressesOther printing apparatusElectric machineEngineering

The invention discloses a water-based ink printing press capable of changing printing area. The water-based ink printing press comprises a case body; the inner bottom wall of the case body is fixedly provided with a reference seat, and an automatic telescopic rod is fixedly installed in the reference seat; the telescopic end of the automatic telescopic rod is fixedly connected with a tool holding table; a driving motor is fixedly installed on the inner top wall of the case body; and the output end of the driving motor is fixedly connected with a rotating shaft. According to the water-based ink printing press capable of changing the printing area, in the rotating process of a printing mechanism, the power of the driving motor is controlled to increase to make the rotating speed increase, and accordingly, centrifugal force increases; print heads move outwards along base plane telescopic grooves under the action of the centrifugal force, and at this time, the centrifugal force is larger than the elastic force of the print heads to overcome the elastic force of springs, so that the printing area increases, so that larger to-be-printed matter can be conveniently printed, and on the contrary, if the power of the driving motor is reduced, the printing area is reduced; and the printing area is adjusted by the water-based ink printing press according to the specification of the to-be-printed matter, thus avoiding waste of electric energy.

Owner:浙江华众标签有限公司

Hard sealed butterfly valve

InactiveCN106151543AGuaranteed tightnessGuaranteed rigiditySpindle sealingsLift valveButterfly valve

The invention provides a hard sealed butterfly valve. A valve seat is ring-shaped, when the butterfly valve is closed, a disc extrudes and is attached to the valve seat, conditions that one end of the valve seat is clamped with the disc too tightly and the other end of the valve seat is clamped with the disc too loosely definitely occur if the disc cannot be tightly attached to the valve seat, and the valve seat is arranged in first accommodating space in a radially movable manner, so that at the moment, the valve seat on the side clamped too tightly moves far away from the disc in the radial direction and the valve seat on the side clamped too loosely moves close to the disc in the radial direction. The valve seat is enabled to move to the periphery of the disc accurately, so that the ring-shaped valve seat surrounds the circumference of the disc, and airtightness of the whole butterfly valve is guaranteed.

Owner:NEWAY VALVE SUZHOU

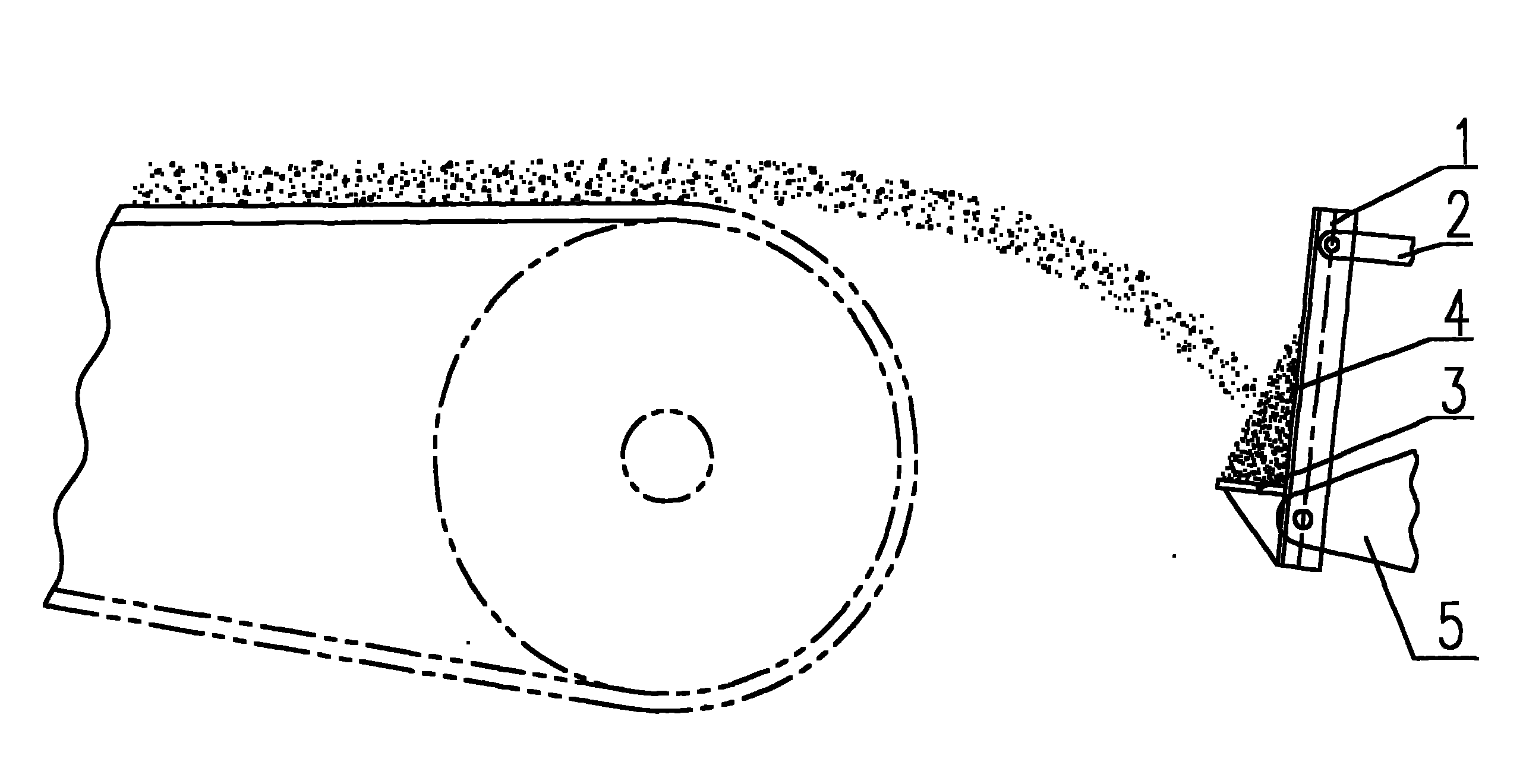

Wear-resisting device of receiving liner plate of band conveyor

InactiveCN102126609AAvoid violent frictionReduce wearConveyorsSupporting framesEngineeringMechanical engineering

Owner:TAIYUAN HEAVY IND

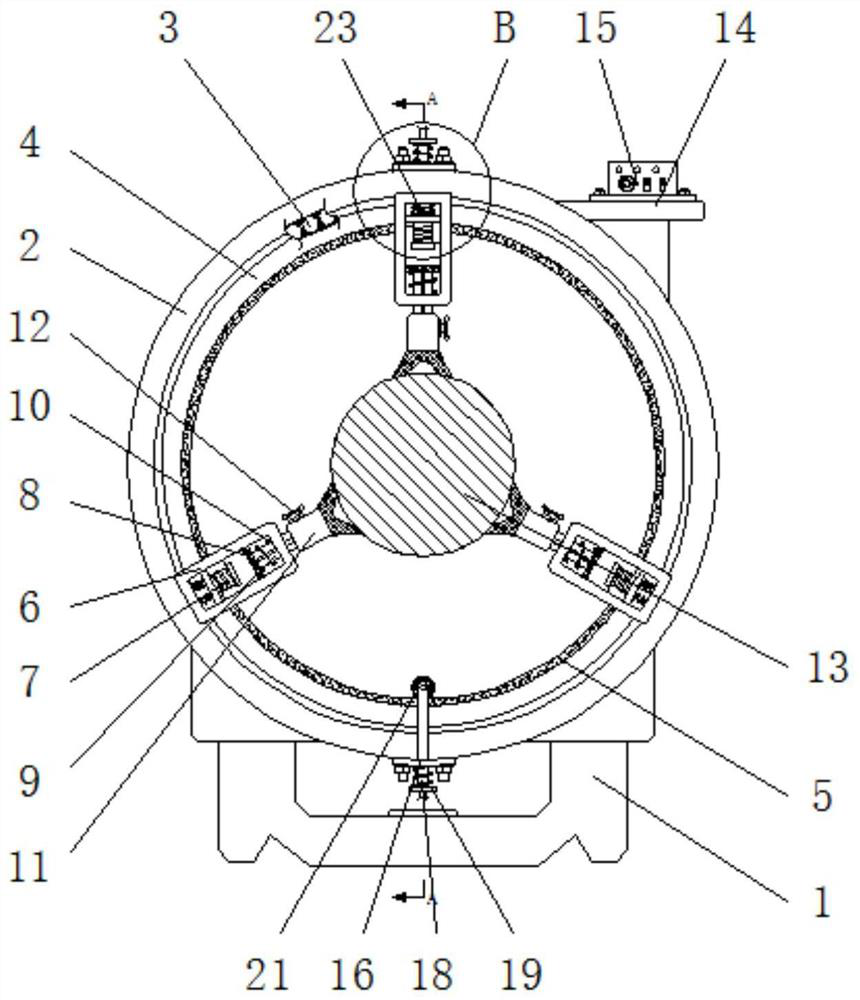

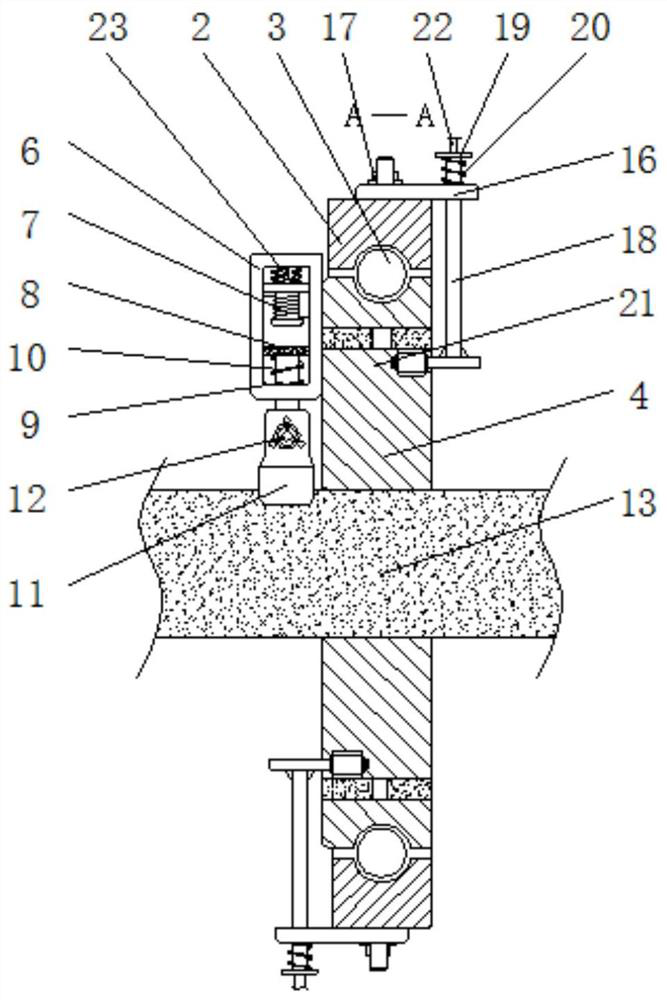

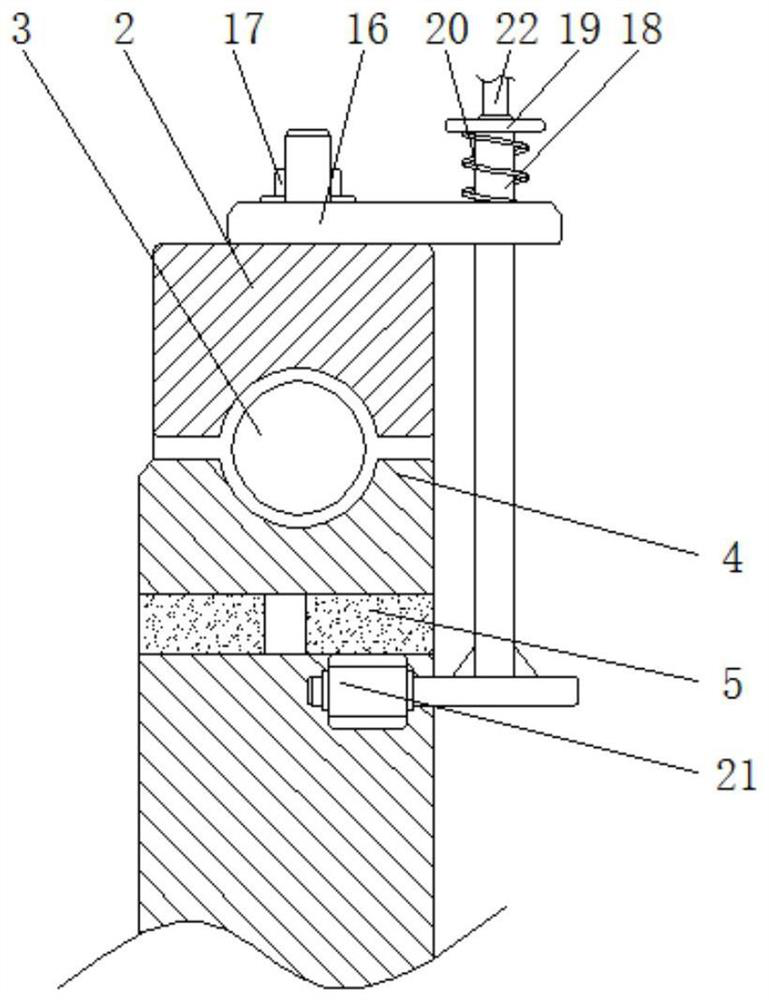

A steady frame for positioning in numerical control machining

ActiveCN109366206BEffectively fixedSolve the problem of circle jumpingLarge fixed membersNumerical controlEngineering

The invention relates to the technical field of intelligent numerical control equipment, and discloses a center frame for numerical control machining positioning. The center frame comprises a base; asupporting outer ring is fixedly installed at the top end of the base; the interior of the supporting outer ring is provided with a supporting ball and movably sleeved with a supporting inner ring through the supporting ball; and a conducting ring is fixedly installed in the inner cavity of the supporting inner ring. According to the center frame for numerical control machining positioning, by arranging three sets of electromagnets, when the center frame fixedly supports to-be-machined workpieces different in outer diameter, the magnitude and direction of the electric current of the center frame can be changed through an electric current controller only within the magnetic field intensity control range of the electromagnets, meanwhile, the problem that when an existing center frame fixedlysupports to-be-machined workpieces different in outer diameter, repeated positioning adjustment needs to be conducted on a threaded supporting claw of the center frame is solved, and the time, for clamping and positioning the to-be-machined workpieces different in outer diameter, of the center frame is effectively shortened.

Owner:浙江欧托电气有限公司

Steering rail capable of preventing violent friction for logistics transportation

PendingCN109230257ANot easy to damageAvoid violent frictionConveyorsConveyor partsLogistics managementEngineering

Owner:湖州中祺智能科技有限公司

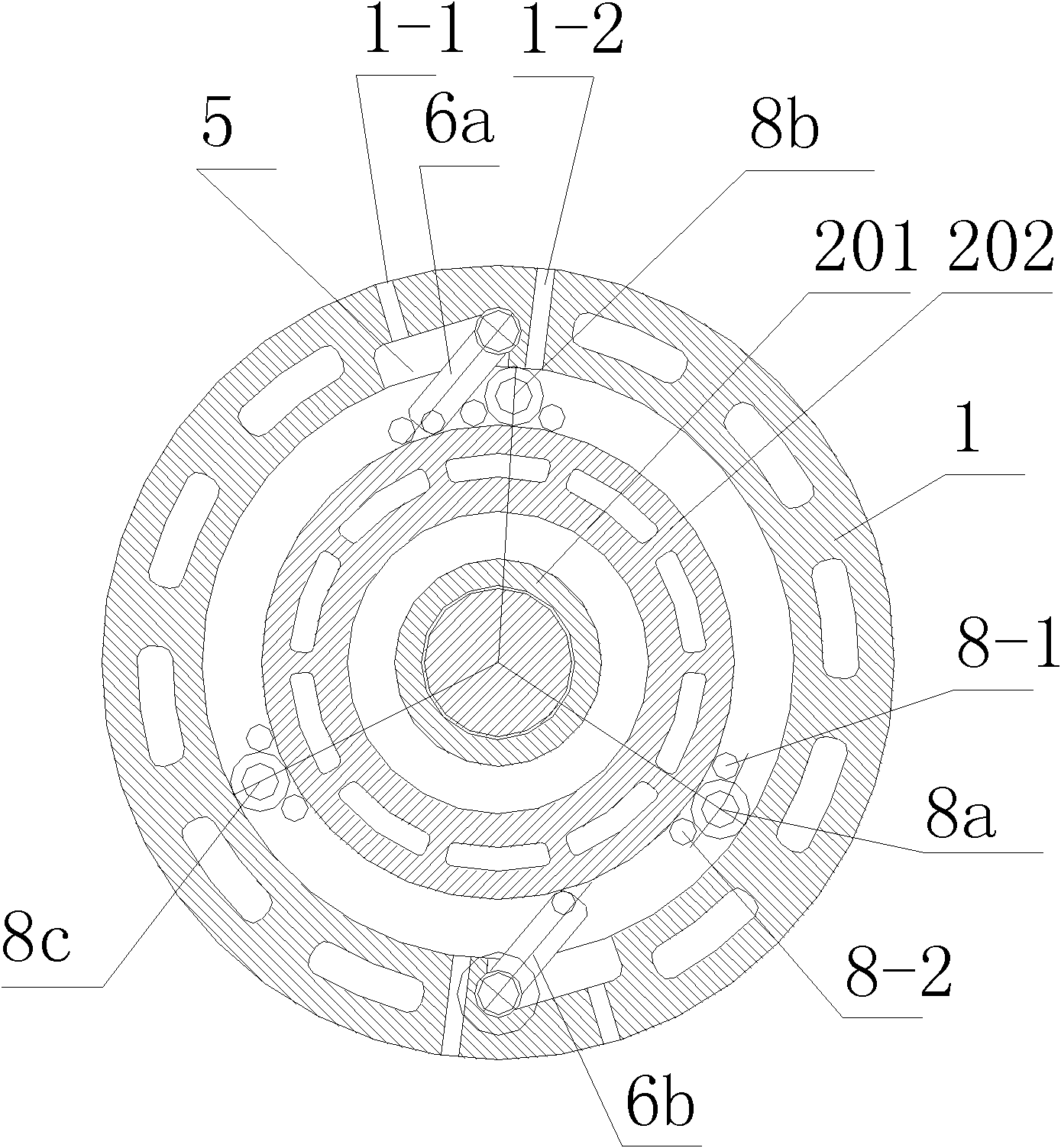

Star-spinning type rotation device with double sun wheels, engine and fluid machine

ActiveCN102678182BImprove efficiencyAvoid violent frictionInternal combustion piston enginesRotary piston pumpsRelative motionEngineering

The invention discloses a star-spinning type rotation device with double sun wheels, an engine and a fluid machine. A spin valve plate sun wheel is installed in the middle of a main sun wheel, and all pressure or parts of pressure are pressed on the spin valve plate sun wheel when spin valve plates are opened. Due to the facts that the spin valve plate sun wheel can be independent of the main sun wheel to rotate and the rotation of the main sun wheel is absorbed by bearings arranged between the spin valve plate sun wheel and the main sun wheel, severe friction produced by the relative motion between the valve plates and an outer cylinder surface of the main sun wheel is prevented, and the service life and efficiency of the star-spinning type rotation device are improved.

Owner:BEIJING ROSTAR TECH

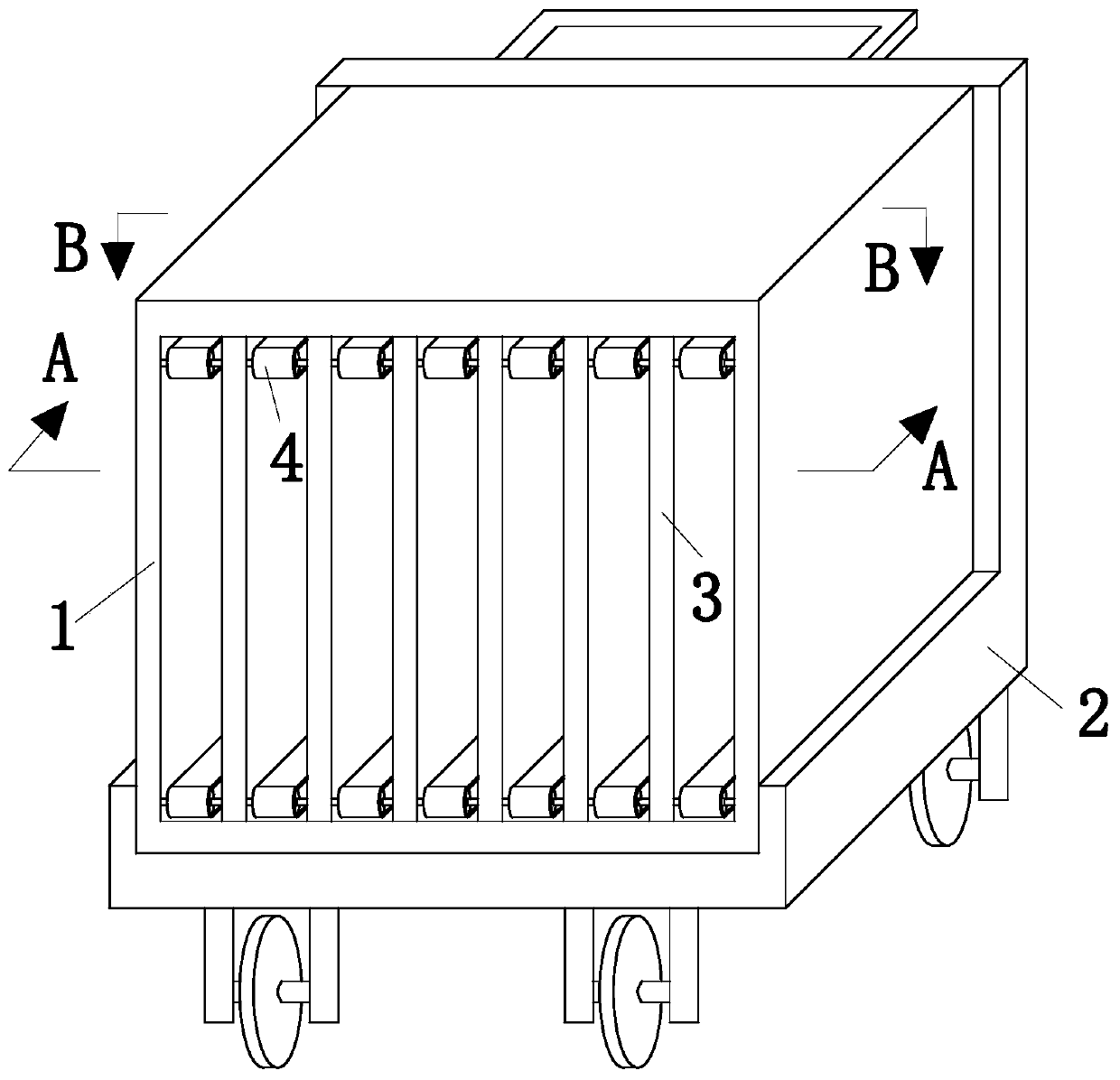

A pcb circuit board transportation platform

ActiveCN108974084BRealize transportationImplement bufferingCleaning using toolsHand carts with multiple axesEngineeringConveyor belt

The invention belongs to the technical field of printed circuit board manufacturing. Specifically, it is a PCB circuit board transportation platform, which includes a storage cabinet and a traveling device. The storage cabinet is installed on the traveling device; the storage cabinet is a cuboid with a cavity inside, and one end of the cuboid Openings are provided, and at least three partitions are vertically arranged inside the storage cabinet. The partitions divide the internal cavity of the cuboid into independent storage spaces. Transmission units are arranged horizontally between adjacent partitions at the top and bottom. The transmission units Used to store PCB circuit boards; the transmission unit includes a rotating shaft, a pulley and a conveyor belt. The number of pulleys is two, and the pulleys are installed horizontally between adjacent partitions through the rotating shafts; the conveyor belt is installed horizontally on the pulleys, and the PCB circuit board is installed vertically Placed between the upper and lower transmission units. The invention can realize the transportation of multiple circuit boards, and at the same time can buffer the vibration of the circuit board and realize the protection of the circuit board.

Owner:益阳市明正宏电子有限公司

An intelligent handling robot for wooden furniture processing

ActiveCN111923006BImprove stabilityAvoid shakingGripping headsControl engineeringStructural engineering

The invention discloses an intelligent handling robot for wooden furniture processing, which includes a lifting card frame, a moving base and a fixed card seat. On the side outer surface of the fixed card base, two sets of first hydraulic rods are fixedly installed between the lifting card frame and the mobile base on both sides close to the fixed card base. A hydraulic rod is movably connected, the inner side of one end of the mobile base is movably socketed to the second set of boards, and the inner side of the other end of the mobile base is movably socketed to the first set of boards; the invention is an intelligent handling robot for wooden furniture processing, so that its It has a synchronous lifting structure, which enables it to carry out furniture of different heights and different shapes, improving its scope of application, and at the same time avoids the shaking phenomenon of the intelligent handling robot for wooden furniture processing during handling and moving operations, and improves its stability.

Owner:安徽宏润工艺品有限公司

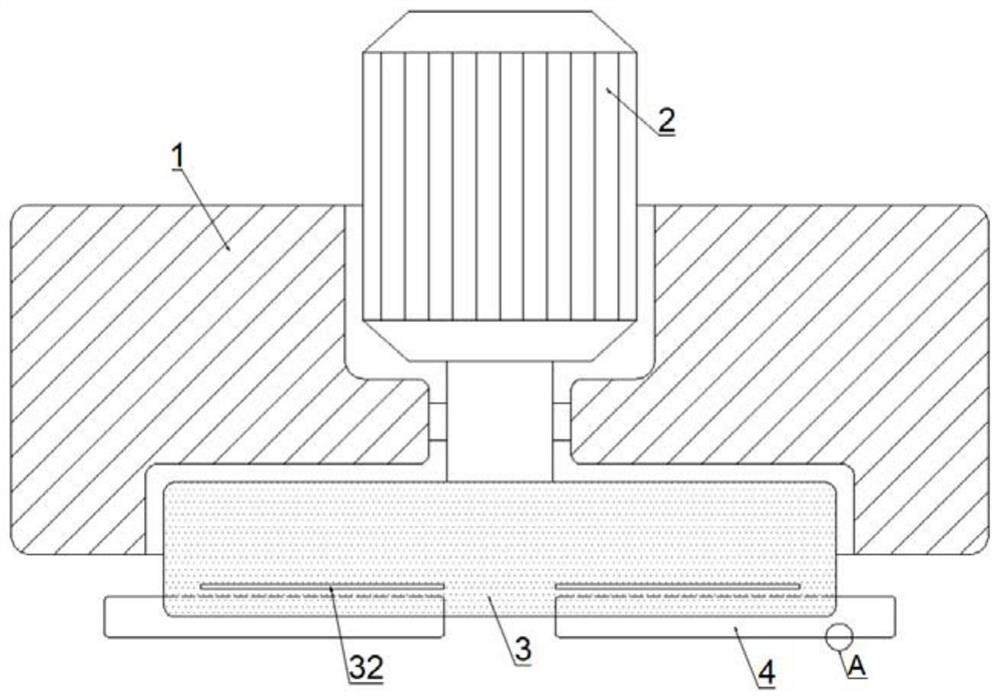

A mold device

ActiveCN105856617BImprove maintenance efficiencyAvoid violent frictionPressesSteel ballMaterials science

The invention discloses a mould device. The mould device comprises an upper mould plate and a lower mould plate, and further comprises a lower mould cylinder, an upper mould cylinder and a copper sleeve, wherein the lower mould cylinder is fixedly connected with the lower mould plate; a first through hole is formed in the middle of the lower mould cylinder; the upper mould cylinder is fixedly connected with the upper mould plate and can slide in the first through hole; the copper sleeve detachably sleeves the outer side wall of the upper mould cylinder; a plurality of second through holes of which the axes are perpendicular to the axis of the copper sleeve are formed in the side wall of the copper sleeve; balls capable of rolling in the second through holes are arranged in all the second through holes; and the diameter of each ball is greater than the thickness of the side wall of the copper sleeve. The mould device provided by the invention has the advantages that when the upper mould cylinder slides in the lower mould cylinder, the friction between the balls, namely steel balls, and the upper mould cylinder, the friction between the steel balls and the lower mould cylinder, as well as the friction between the upper mould cylinder and the lower mould cylinder can be reduced because a plurality of the balls capable of rolling are arranged on the side wall of the copper sleeve; and when relatively serious abrasion is caused by the balls, only the balls need to be replaced, that is, the upper mould cylinder needs not be replaced, so that the maintenance efficiency is improved and the maintenance cost is reduced.

Owner:CHONGQING QILONG IND & TRADE CO LTD

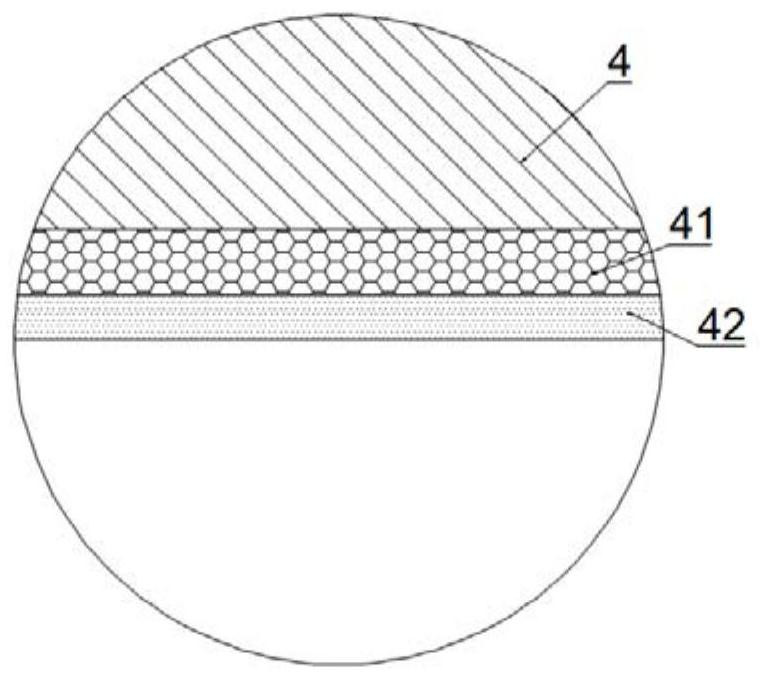

Heat preservation and exhaust corrugated pipe structure

PendingCN112746888AImprove insulation effectImprove shock absorptionExhaust apparatusSilencing apparatusThermodynamicsInsulation layer

The invention relates to a heat preservation and exhaust corrugated pipe structure which comprises a heat preservation outer pipe and a corrugated inner pipe, and the two ends of the heat preservation outer pipe are fixedly connected with the two ends of the corrugated inner pipe; the heat preservation outer pipe comprises an outer layer, a middle layer and an inner layer; and the inner layer wraps the outer surface of the corrugated inner pipe, the middle layer wraps the outer surface of the inner layer, the outer layer wraps the outer surface of the middle layer, and the outer layer, the middle layer and the inner layer are relatively fixed. Compared with the prior art, the structure and coating materials of an exhaust corrugated pipe are improved, a stainless steel woven belt at the outer layer provides durable heat preservation and a certain damping effect for the outermost layer, and a flexible basalt needled felt heat preservation layer at the middle layer provides good heat preservation performance and a radial damping effect; a basalt fiber woven belt at the inner layer provides a heat preservation and insulation function and ensures axial tensile elasticity; and the heat preservation effect of the corrugated pipe is improved on the premise that the damping effect is guaranteed, and the inner layer material and the outer layer material have good durability and are not prone to being damaged.

Owner:TONGJI UNIV

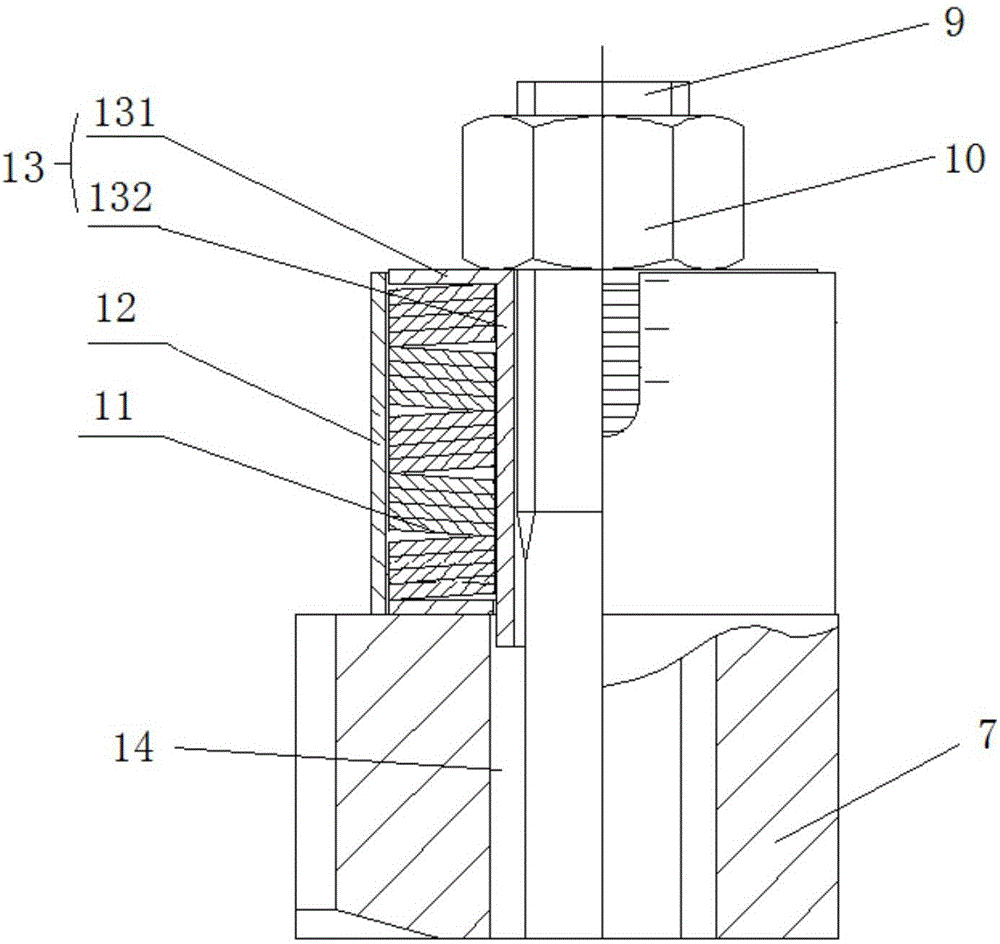

Flexible rotor based on active magnetic suspension bearing

InactiveCN111987935AImprove precision controlAvoid displacementShaftsMagnetic bearingsElectric machineryEngineering

The invention discloses a flexible rotor based on an active magnetic suspension bearing. The flexible rotor comprises an auxiliary supporting mechanism and a magnetic suspension bearing mechanism. Theauxiliary supporting mechanism comprises a positioning ring, clamping rings are arranged on the left side and the right side of the positioning ring, supporting rings are arranged at the ends, away from each other, of the two clamping rings, the two supporting rings are installed through a mounting mechanism, auxiliary bearings are arranged on the inner sides of the two supporting rings, and fixing mechanisms are arranged on the outer sides of the two auxiliary bearings. The magnetic suspension bearing mechanism comprises a connecting ring, and core bodies are distributed on the inner side face of the connecting ring in an array mode. An annular electric wire is wound on the side surface of the core body, and the inner end of the core body is provided with a mounting ring; according to the flexible rotor based on the active magnetic suspension bearing, the auxiliary bearings can be fixed, then coaxiality is achieved, high-precision control over the magnetic suspension bearing is achieved, violent friction between a high-speed rotor and the inner ring of the auxiliary bearings can be avoided, and scrapping of a high-speed magnetic suspension motor caused by heat generated by friction is prevented.

Owner:江苏联博精密科技股份有限公司

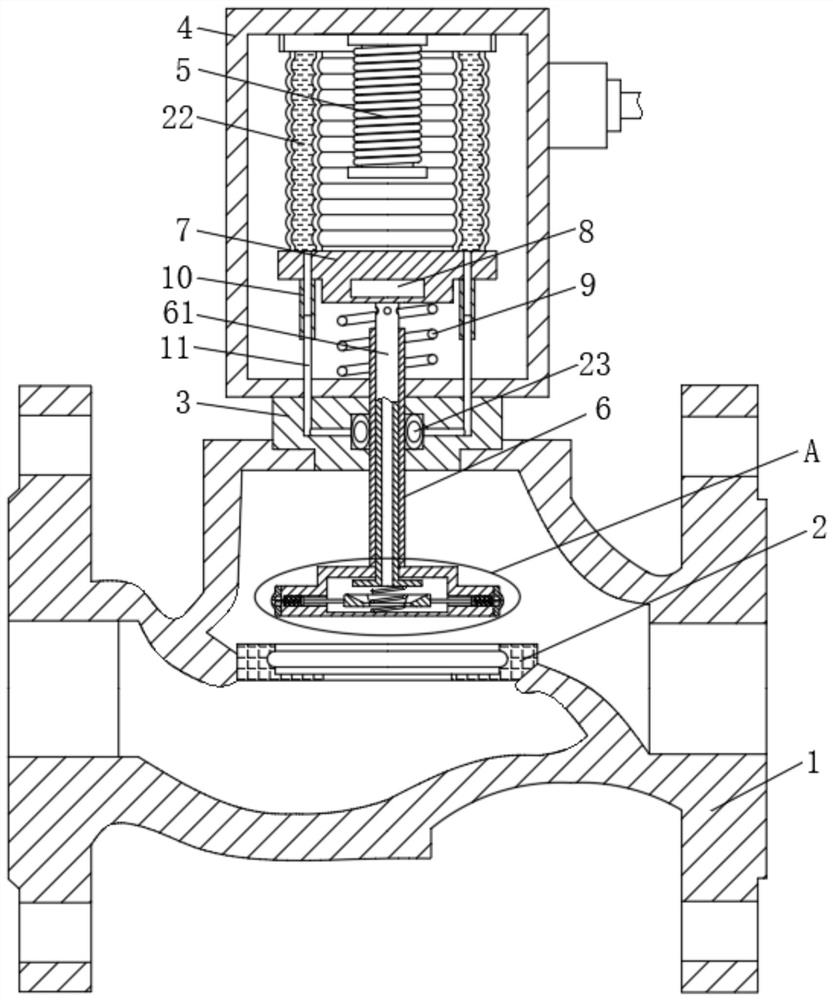

Multi-stage sealing refrigeration valve

PendingCN113803471AGuaranteed tightnessExtended service lifeSpindle sealingsOperating means/releasing devices for valvesPhysicsEngineering

The invention relates to the technical field of refrigeration valves, and discloses a multi-stage sealing refrigeration valve. The multi-stage sealing refrigeration valve comprises a valve body, a valve element base is fixedly installed inside the valve body, and a sealing base is fixedly connected to the upper end of the valve body. Through arrangement of a hollow pipe, a valve element shell and a rubber ring, when the refrigeration valve is not powered on, the valve element shell moves downwards, the rubber ring cannot make close contact with the valve element base in the process, severe friction between the rubber ring and the valve element base when the rubber ring is closed is avoided, the service life of the valve element and the valve element base is prolonged, when the valve element shell moves downwards to coincide with the valve element base, the hollow pipe continues to move downwards, a circular plate presses a wedge-shaped block downwards, the supporting plate can expand towards the outer side till the rubber ring tightly abuts against the inner side wall of the valve element base, meanwhile, air inside the hollow circular pipe can enter an annular cavity, the rubber ring can be expanded, the side face of the rubber ring can be completely attached to the inner side wall of the valve element base everywhere, and the sealing performance of the valve element is guaranteed.

Owner:曾俊

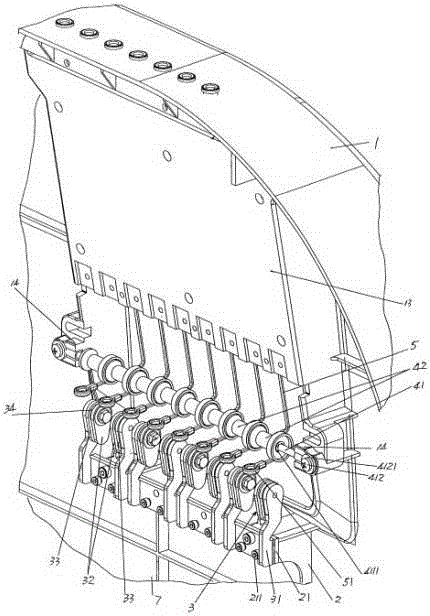

Positive Yarn Guide Mechanism of Computerized Flat Knitting Machine

The invention discloses an active type yarn guide mechanism of a computer flat knitting machine and belongs to the technical field of auxiliary components of computer flat knitting machines. The computer flat knitting machine comprises a bedside compartment which is arranged on the top of a machine frame of the computer flat knitting machine. The active type yarn guide mechanism comprises a sliding sleeve yarn guide device, a fixed plate base and a set of pulley yarn guide devices. The sliding sleeve yarn guide device is arranged on the bedside compartment and located below the bedside compartment in the height direction. The fixed plate base is fixed to the top of the machine frame. A yarn guide pulley base fixed plate is fixed to the fixed plate base and is correspondingly arranged below the sliding sleeve yarn guide device. The pulley yarn guide devices are arranged in the length direction of the yarn guide pulley base fixed plate at intervals. By the adoption of the active type yarn guide mechanism of the computer flat knitting machine, the yarn breakage rate is significantly lowered, it is ensured that yarn moves towards the knitting machine in a stable state, and the quality of a knitted object can be ensured.

Owner:JIANGSU JINLONG TECHNOLOGY CO LTD

Crane with double electric hoist adjusting mechanisms

InactiveCN112125149AGuaranteed uptimeEasy to useTrolley cranesTravelling gearWorking environmentGravity center

The invention discloses a crane with double electric hoist adjusting mechanisms. Balance auxiliary blocks are connected to the positions of rollers on electric hoist moving vehicles, so that when thegravity center shifts or has a trend of shifting in the advancing direction of a trolley during hoisting work, the gravity center between the double electric hoist moving vehicles can be balanced andcorrected, so that normal use of an electric hoist crane is guaranteed, and the service life of the electric hoist crane is prolonged. An automatic balance adjusting mechanism is arranged, when the gravity center shifts or has the trend of shifting in the direction perpendicular to the advancing direction of the trolley, the automatic balance adjusting mechanism can automatically perform balance adjustment on the gravity center of the electric hoist moving vehicles, then severe friction between trolley wheel rims and the side face of a rail is avoided, safe operation of the electric hoist moving vehicles is guaranteed, so that the safe operation of the working environment is guaranteed, and the working efficiency is improved.

Owner:新昌县七星街道盈捷机械厂

A sintering machine bellows end sealing device and its control method

ActiveCN110487086BReduce air leakage rateIncrease sintering rateFurnace safety devicesMaintainance of heating chambersHydraulic cylinderControl engineering

The invention provides a sintering machine air box end portion sealing device. The sintering machine air box end portion sealing device comprises a base mechanism, a counterweight four-connection-rodself-adjusting mechanism and a detection alarm mechanism, wherein the counterweight four-connection-rod self-adjusting mechanism comprises a sealing plate, transition plates, rotating parts, hydrauliccylinders and counterweight blocks, the detection alarm mechanism comprises air leakage sensors, a contact sensor, a second support and an alarm processor, and the alarm processor judges whether to issue a corresponding alarm or not and whether to control the hydraulic cylinders to act or not by analyzing feedback values of the air leakage sensors and the contact sensor. The invention further provides a control method for the sintering machine air box end portion sealing device. According to the sintering machine air box end portion sealing device and the control method thereof, the sensors collect working condition parameters of the sealing device and perform feedback to the alarm processor to perform analyzing, exceptional situations that the sealing plate cannot be restored or partialwear of the sealing plate leads to air leakage or continuous multiple trolleys are all collapsed and the like can be detected and disposed in time, the air leakage rate in the sintering production process can be greatly reduced, the sintering rate is increased and the sintering effect is improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Suspension apparatus of ship main engine

The invention relates to a suspension apparatus of a ship main engine. The suspension apparatus comprises wire ropes, and further comprises a suspension frame. A left end on the top of the suspension frame is connected with a first traction part through a first wire rope (111). A right end on the top of the suspension frame is connected with a second traction part through a second wire rope (211). A left end on the bottom of the suspension frame extends to a first suspension point (A) of a main engine (5) through a third wire rope (112). A right end on the bottom of the suspension frame extends to a fourth suspension point (D) of the main engine (5) through a fourth wire rope (212). A middle portion of the suspension frame is provided with space, wherein a middle wire rope passes through the middle portion of the suspension frame from top to bottom, and extends to a corresponding second suspension point (B) and a corresponding third suspension point (C) in the space. An upper end of the middle wire rope is connected with a third traction part. Compared to the prior art, the apparatus provided by the present invention has the following advantages that: the structure of the apparatus is simple; the pulley block is not required; the apparatus is easy to be used; the production cost of the apparatus is low; the suspension beam structure of the apparatus is solid and stable so as to provide longer service life.

Owner:ZHEJIANG ZHENGHE SHIPBUILDING

Integrally-formed memory foam bra without steel rings

InactiveCN108741262ASolve airtightnessGuaranteed breathabilityBrassieresHandkerchiefsEngineeringSilica gel

The invention provides an integrally-formed memory foam bra without steel rings and relates to the field of bras. The integrally-formed memory foam bra without steel rings comprises a closed-fit shellfabric, wherein cups are fixedly connected to the two sides of the front side of the closed-fit shell fabric, arc plastic plates are arranged in the cups, a first connection piece is fixedly connected to one side far from the central axis of the closed-fit shell fabric of the front side of each cup, and a first elastic rope is fixedly connected to one side close to the central axis of the closed-fit shell fabric of each first connection piece. The bra is provided with venting holes and through holes, so that external air can enter the back sides of the closed-fit shell fabric and the cups through the venting holes and the through holes when the bra is used; furthermore, breathability of the chest of a user is ensured when the bra is used; by means of arranging antiskid silica gel blocks,the antiskid silica gel blocks can contact the chest of the user, the chest of the user is prevented from directly contacting the cups, gaps are directly formed between the chest of the user and the cups, and the breathability of the bra is further improved.

Owner:湖州思凯家居科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com